Normalized steel for resistance welding petroleum case pipe with low yield ratio, resistance welding casing tube and its manufacturing method

A technology of oil casing and low yield ratio, which is applied in the direction of casing, drilling pipe, manufacturing tools, etc., and can solve problems such as difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0043] The molten steel after converter smelting and out-of-furnace refining is treated with Ca and continuously cast into billets. The continuous casting slab is heated at 1200-1250°C and then hot-rolled into a strip with a thickness of 10mm. The final rolling temperature is greater than 850°C. After rolling, the strip is cooled to 570°C by laminar flow and coiled into a coil. After shearing butt welding, coil forming, and ERW pipe making, the steel pipe is normalized at 880-1100°C and held for 40 minutes, and then the steel pipe is thermally straightened, and the heat straightening temperature is greater than 400°C. Finally, the steel pipe is cooled in the air and processed to obtain the low yield ratio electric resistance welded petroleum casing of the present invention.

[0044] See Table 2 for the chemical composition of the normalized steel used for resistance welding petroleum casing with low yield ratio in Examples 1-4 of the present invention.

[0045] The chemical c...

Embodiment 5

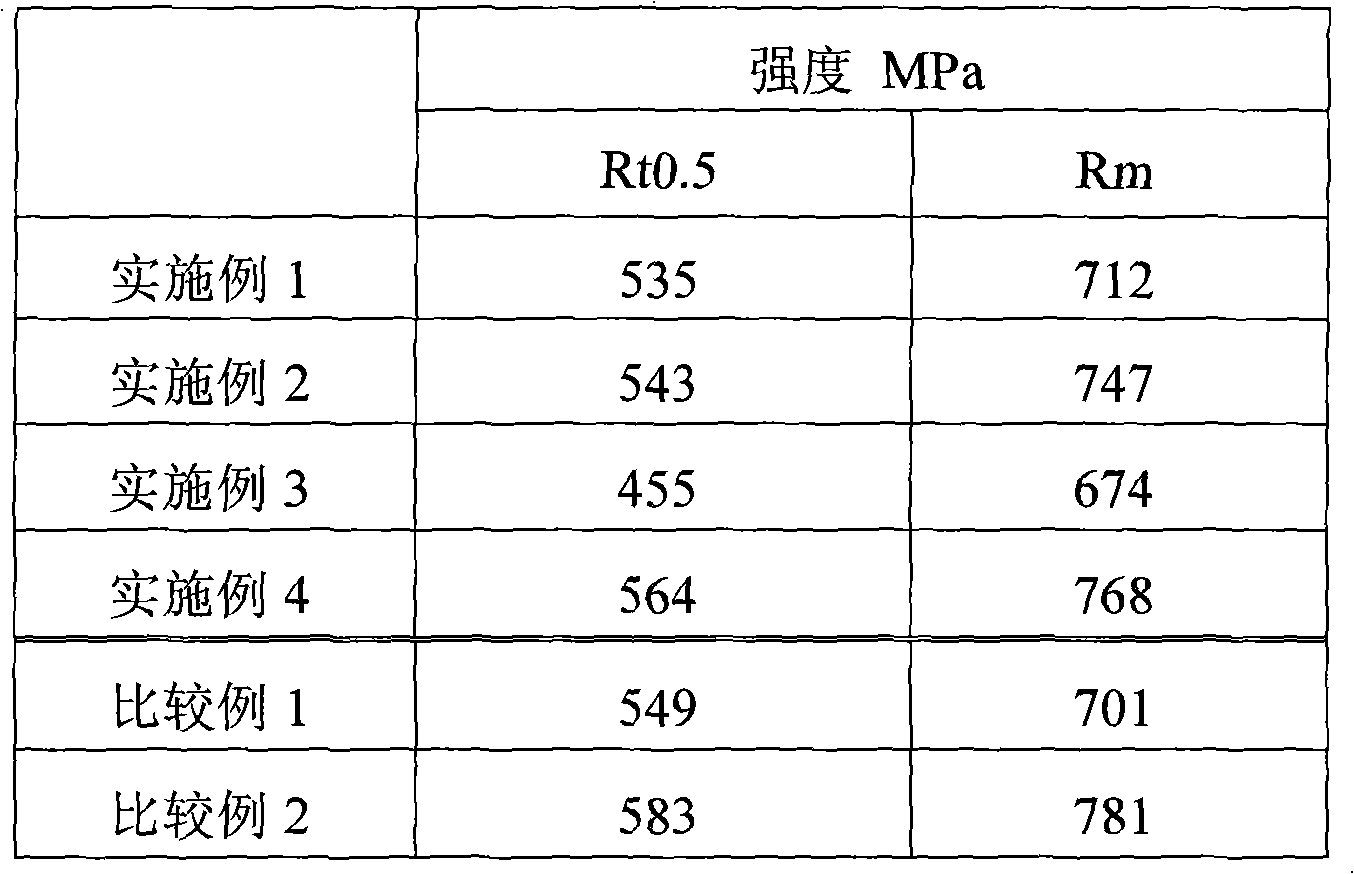

[0052] Carry out mechanical performance test to the hot-rolled coil in embodiment 1-4 and comparative example 1-2, its result is shown in table

[0053] Table 4 The mechanical properties of hot-rolled coils of Examples 1-4 and Comparative Examples 1-2

[0054]

Embodiment 6

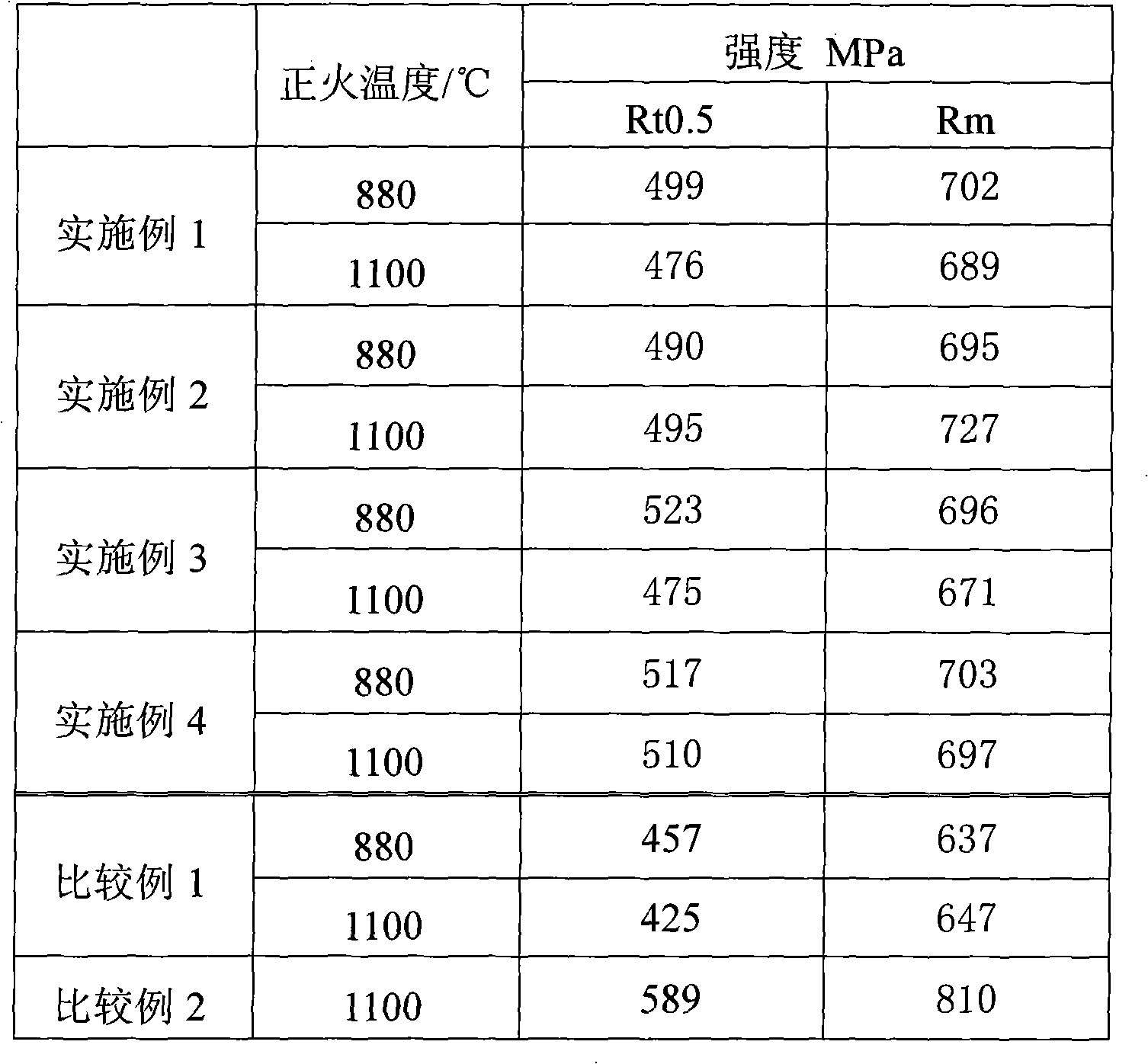

[0056] The mechanical property tests were carried out on the normalized heat-treated resistance welded petroleum casing obtained in Examples 1-4 and Comparative Examples 1-2, and the results are shown in Table 5.

[0057] The bushing mechanical property of table 5 embodiment 1-4 and comparative example 1-2

[0058]

[0059] Combining Table 2, Table 3 and Table 5, it can be concluded that the strength of the resistance welded petroleum casing obtained in Examples 1 to 4 all meets the requirements that the yield strength Rt0.5 is between 379 and 552 MPa, and the tensile strength Rm is greater than or equal to 655 MPa. Its yield strength is relatively low. The V content of Comparative Example 1 is slightly low, and the tensile strength of the material cannot meet the requirements, while the V content of Comparative Example 2 is too high, resulting in excessive strength of the material.

[0060] It can be seen from Table 4 and Table 5 that due to the normalizing heat treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com