Patents

Literature

72956 results about "Electrical resistance and conductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The electrical resistance of an object is a measure of its opposition to the flow of electric current. The inverse quantity is electrical conductance, and is the ease with which an electric current passes. Electrical resistance shares some conceptual parallels with the notion of mechanical friction. The SI unit of electrical resistance is the ohm (Ω), while electrical conductance is measured in siemens (S).

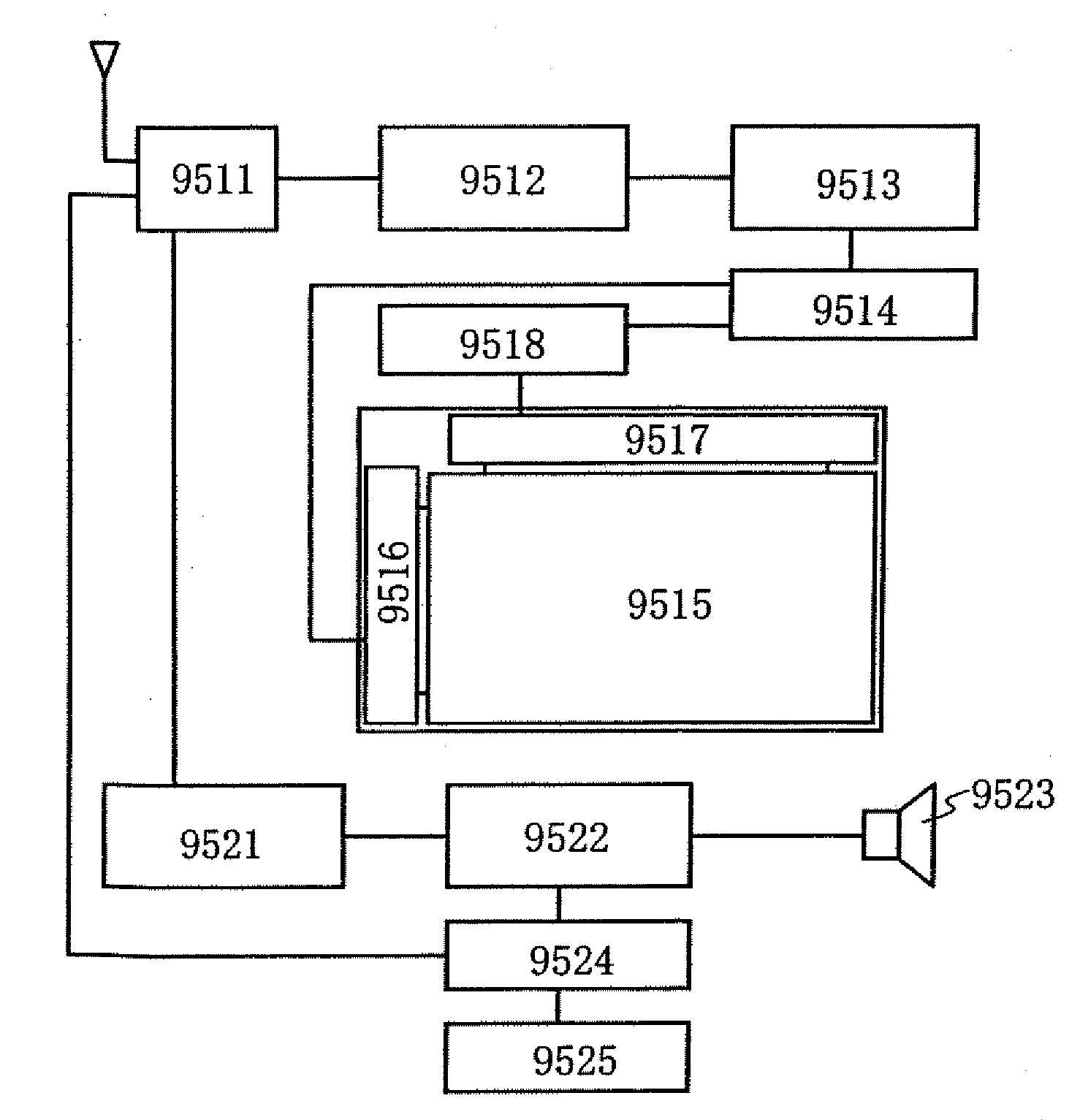

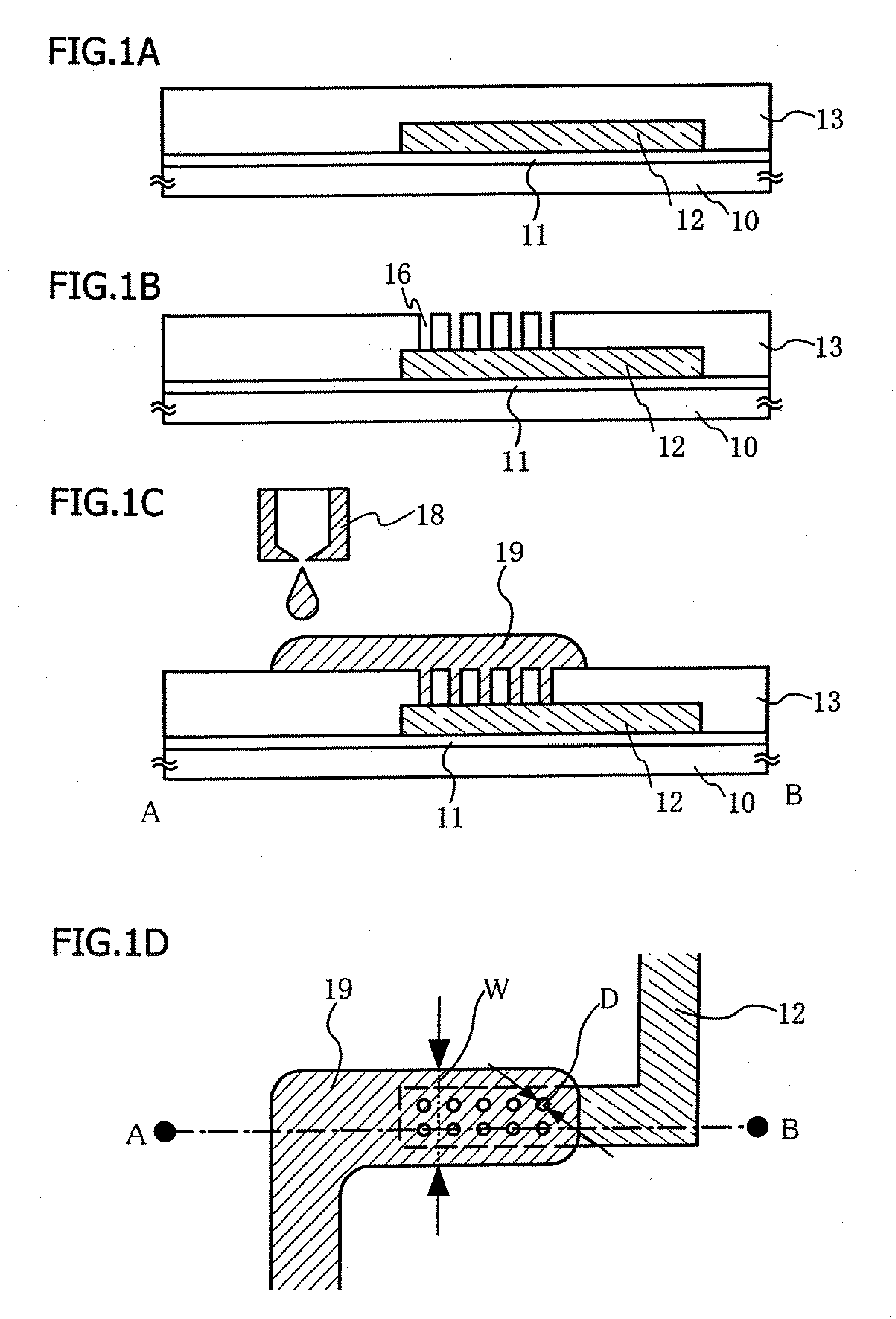

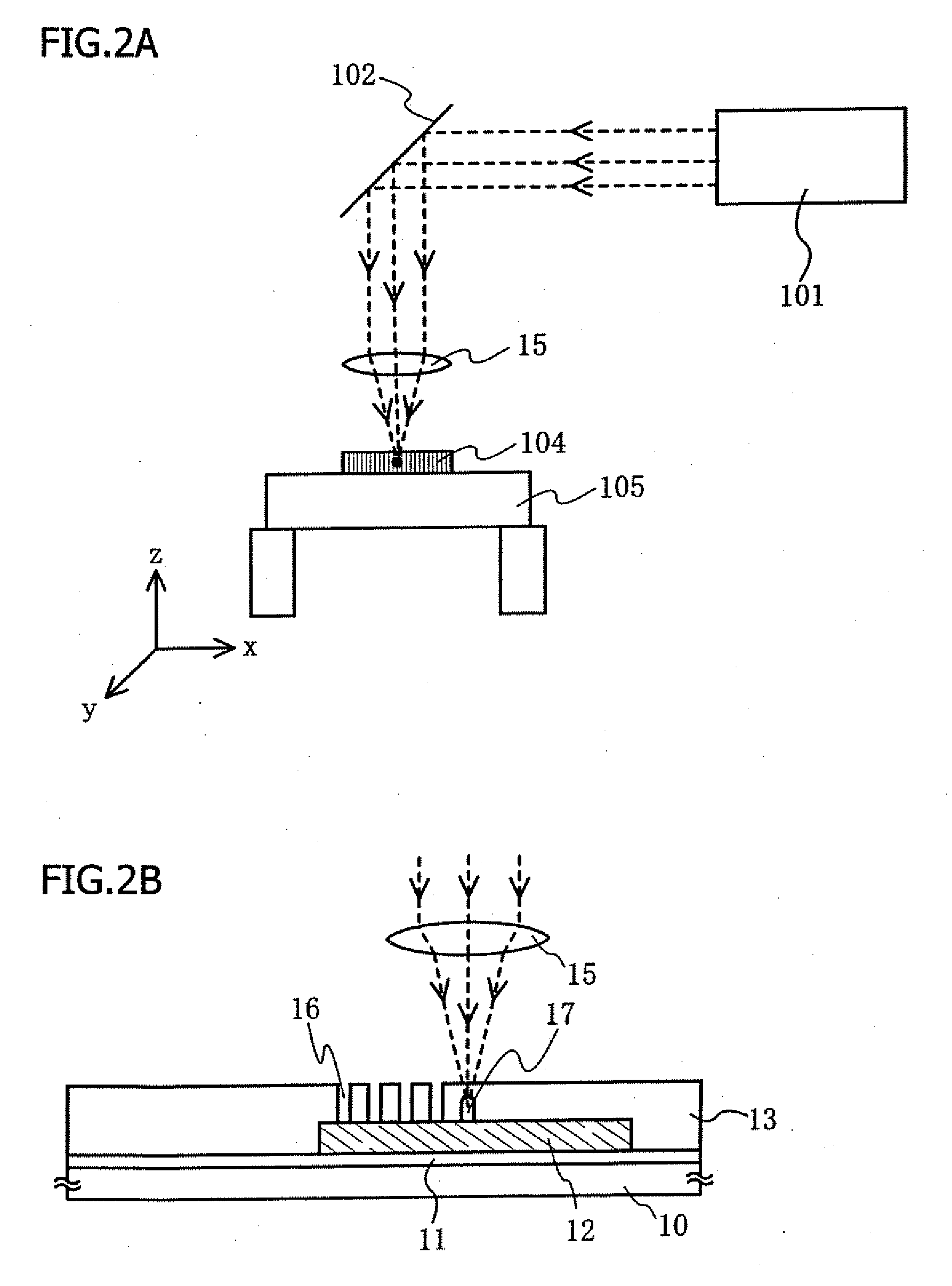

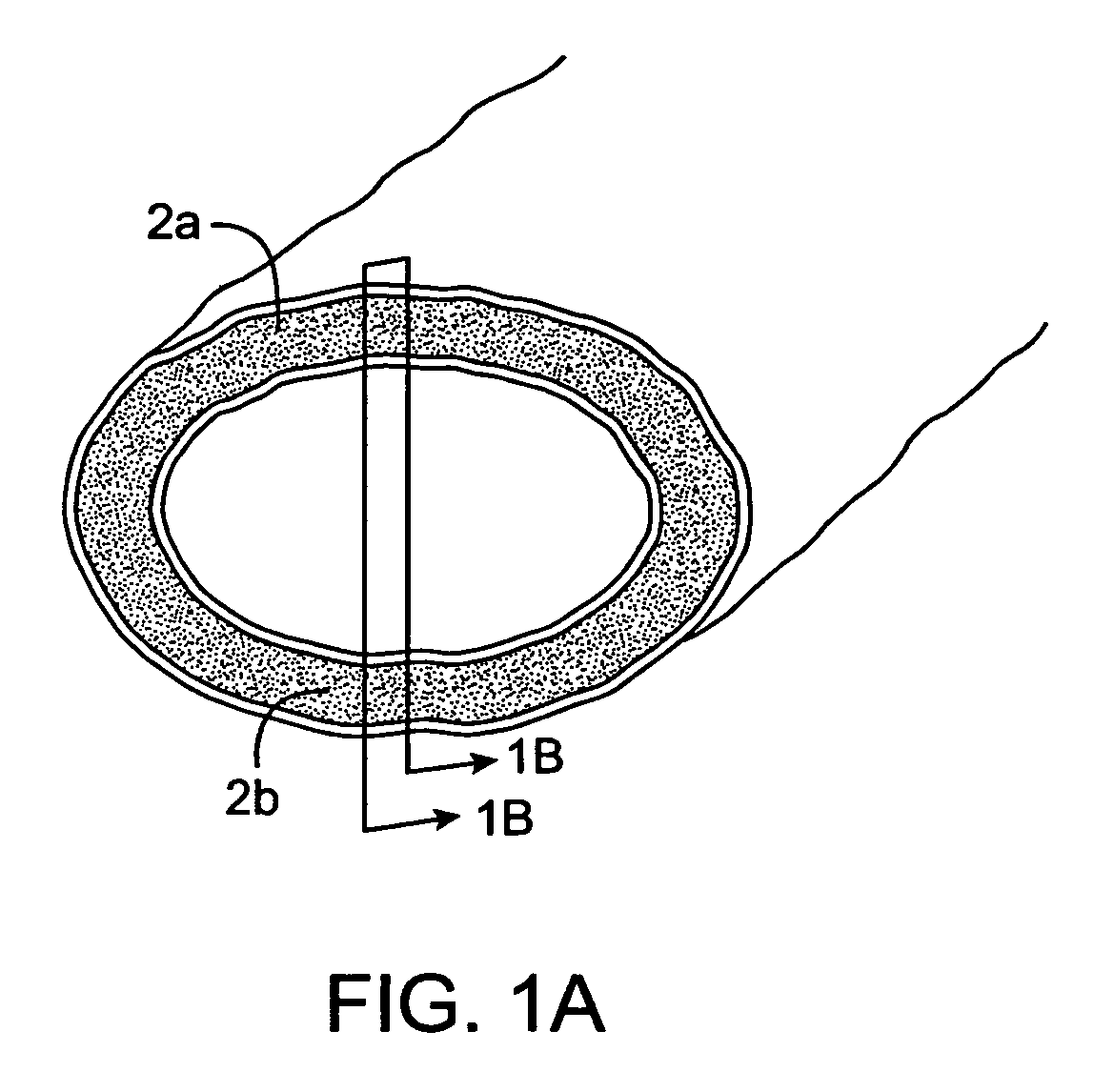

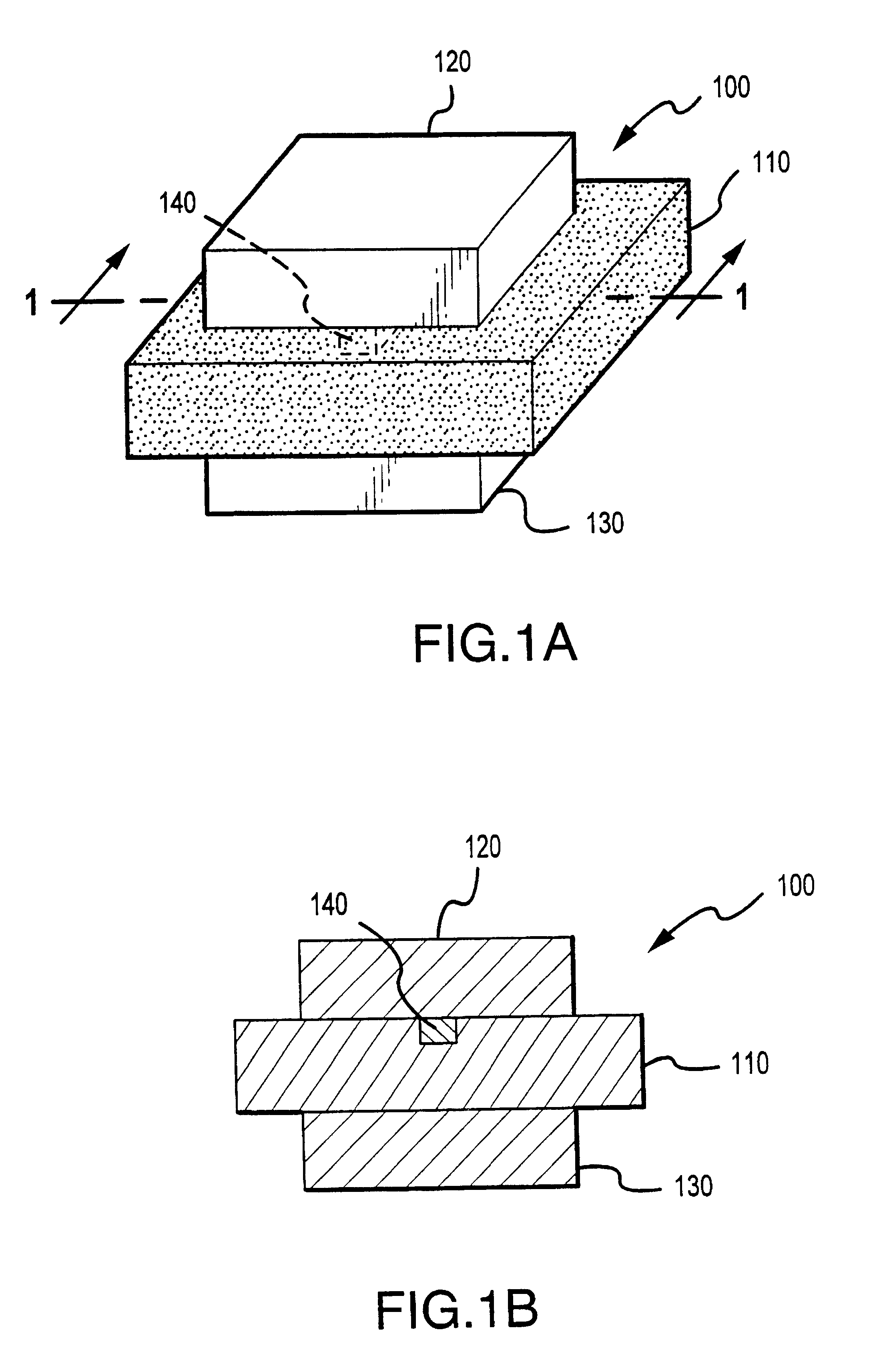

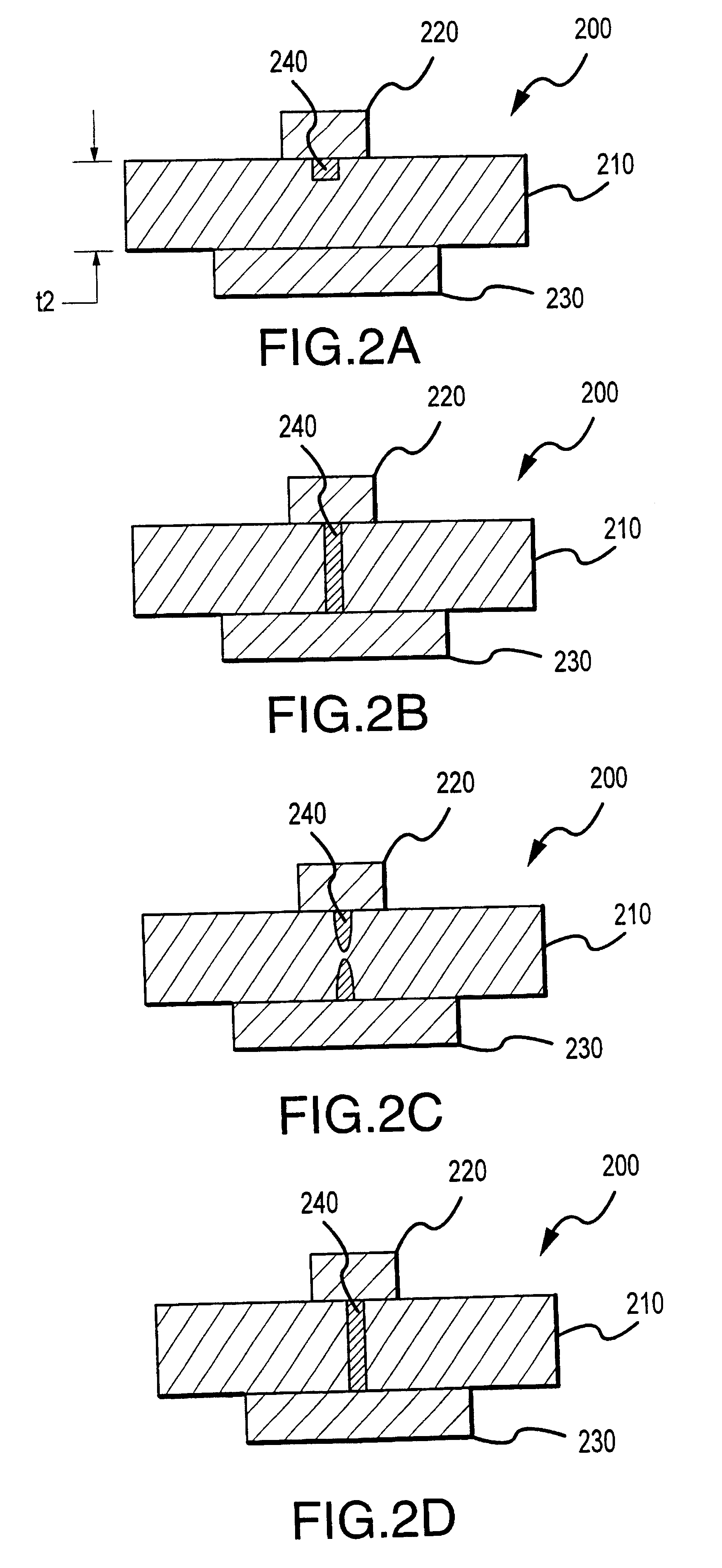

Semiconductor device and method for manufacturing the same, and electric device

InactiveUS20090073325A1Simple stepsHighly integratedTransistorTelevision system detailsElectrical resistance and conductanceLongest Diameter

It is an object of the present invention to simplify steps needed to process a wiring in forming a multilayer wiring. In addition, when a droplet discharging technique or a nanoimprint technique is used to form a wiring in a contact hole having a comparatively long diameter, the wiring in accordance with the shape of the contact hole is formed, and the wiring portion of the contact hole is likely to have a depression compared with other portions. A penetrating opening is formed by irradiating a light-transmitting insulating film with laser light having high intensity and a pulse high in repetition frequency. A plurality of openings having a minute contact area is provided instead of forming one penetrating opening having a large contact area to have an even thickness of a wiring by reducing a partial depression and also to ensure contact resistance.

Owner:SEMICON ENERGY LAB CO LTD

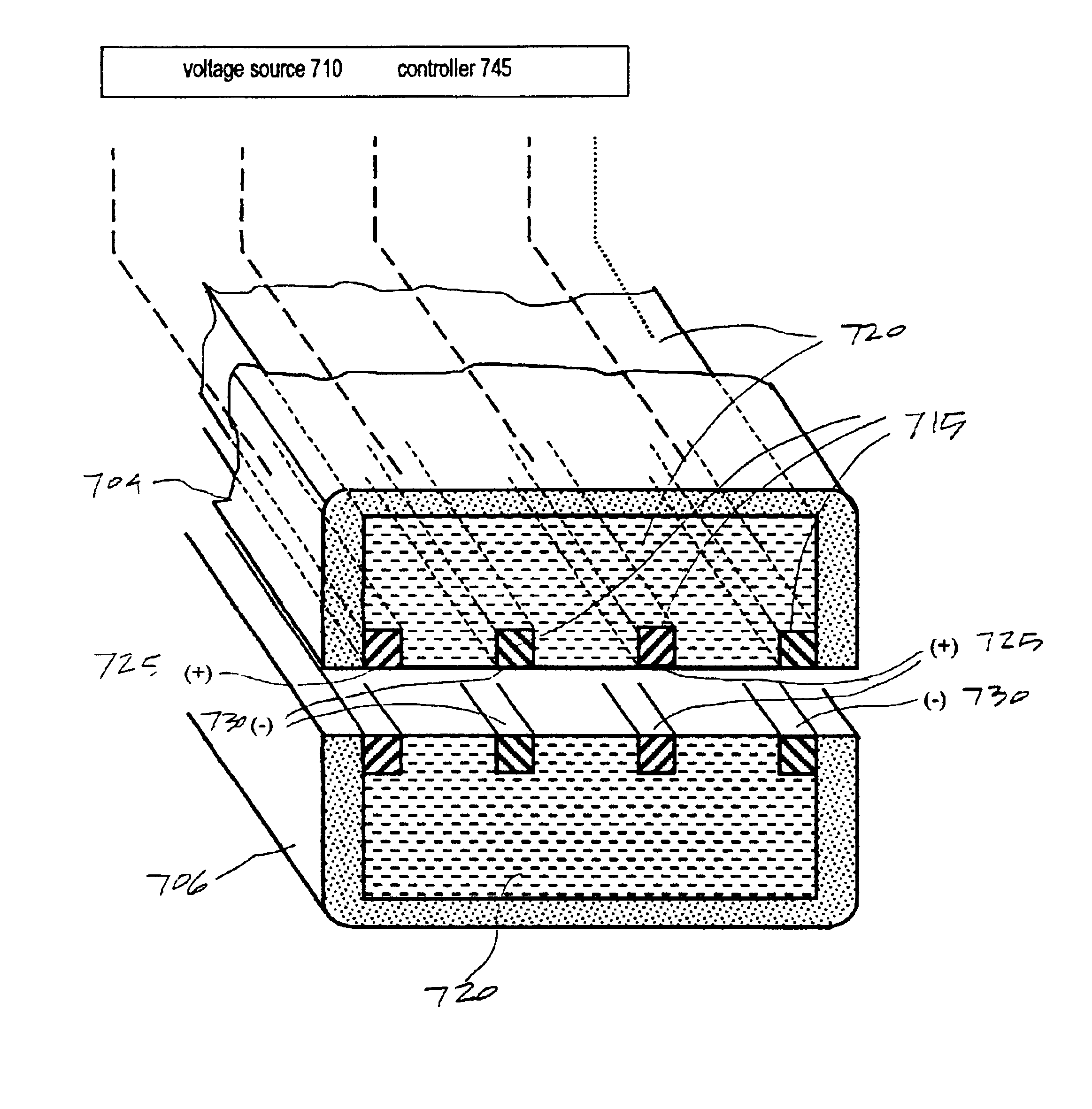

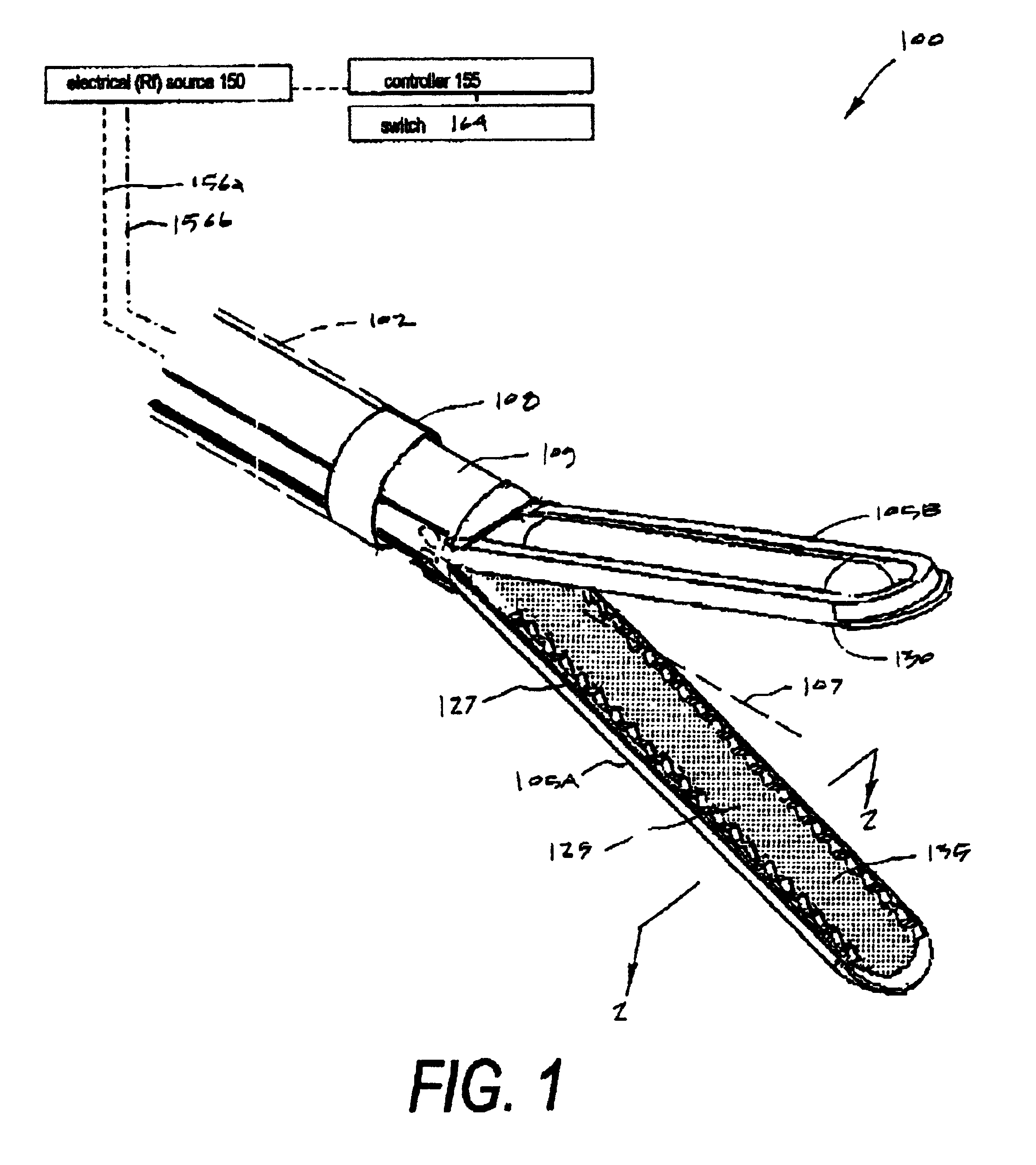

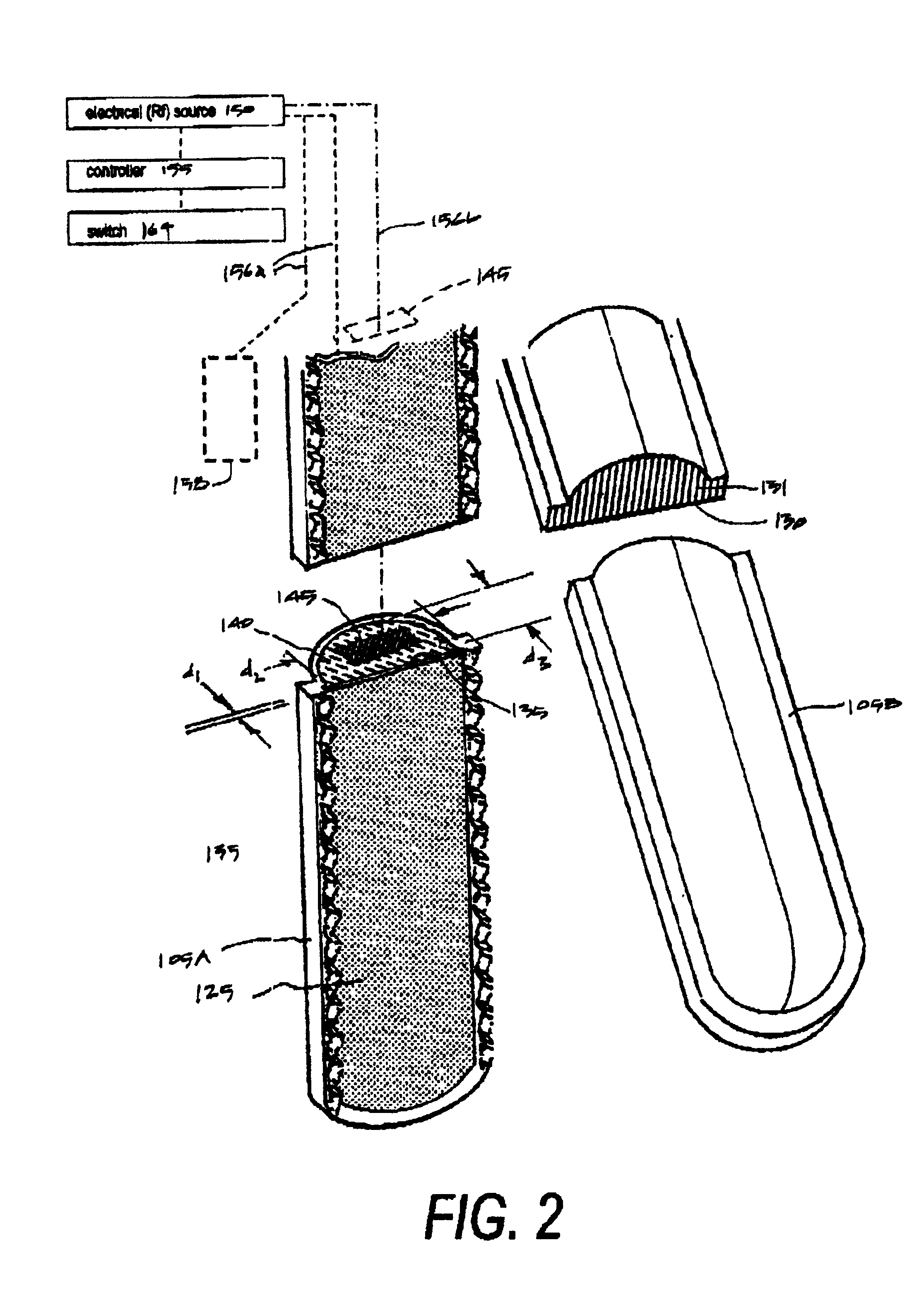

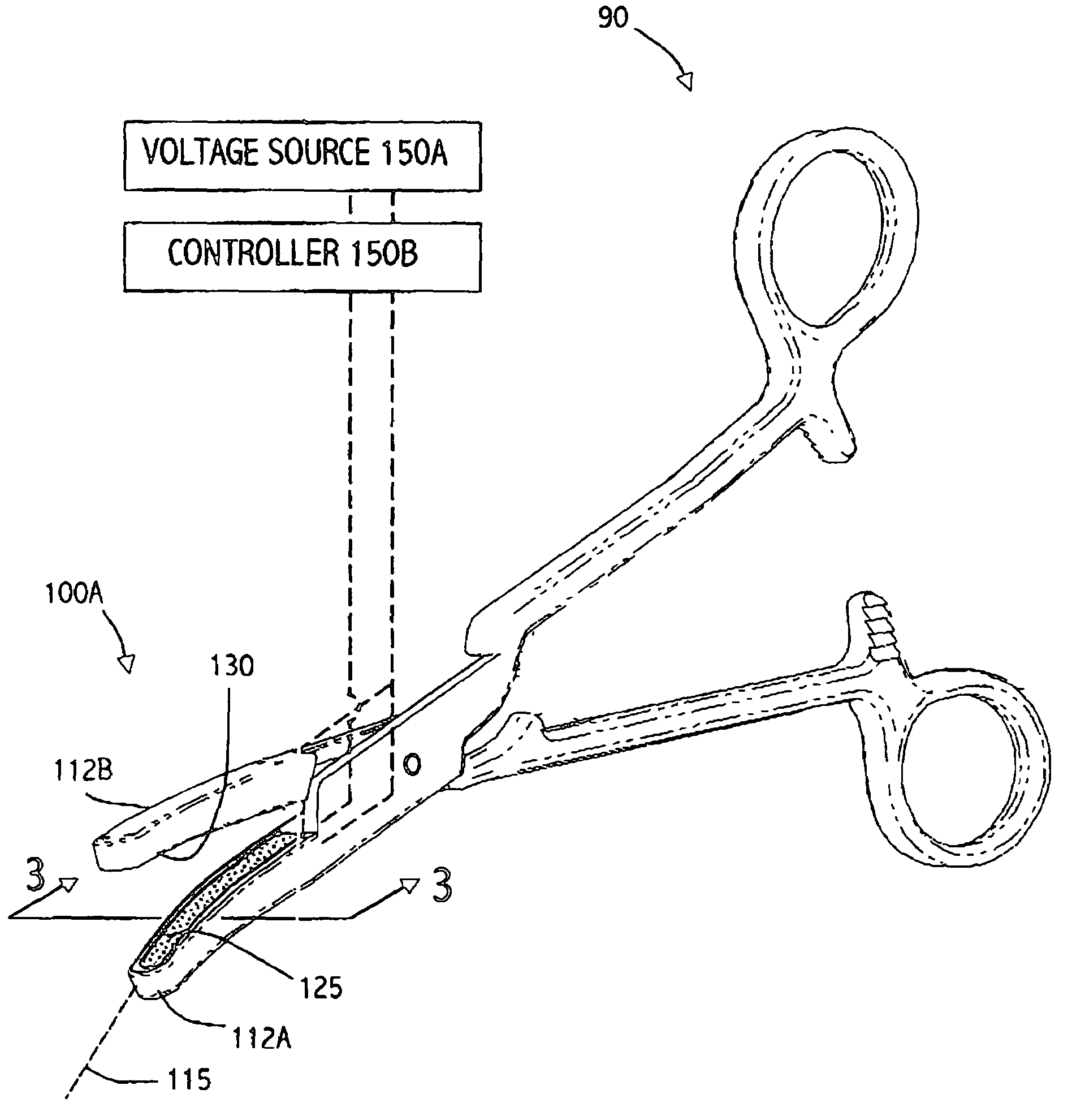

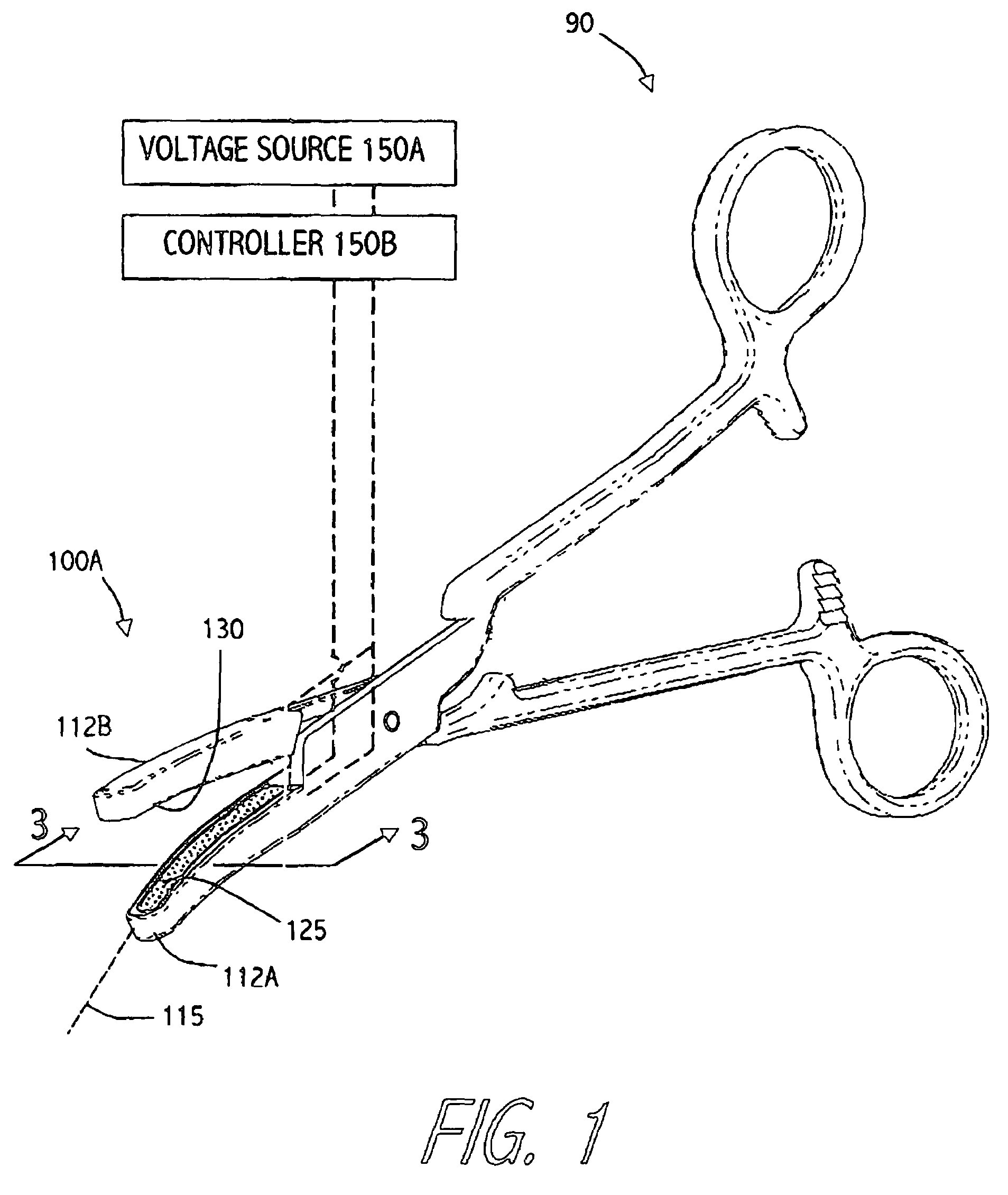

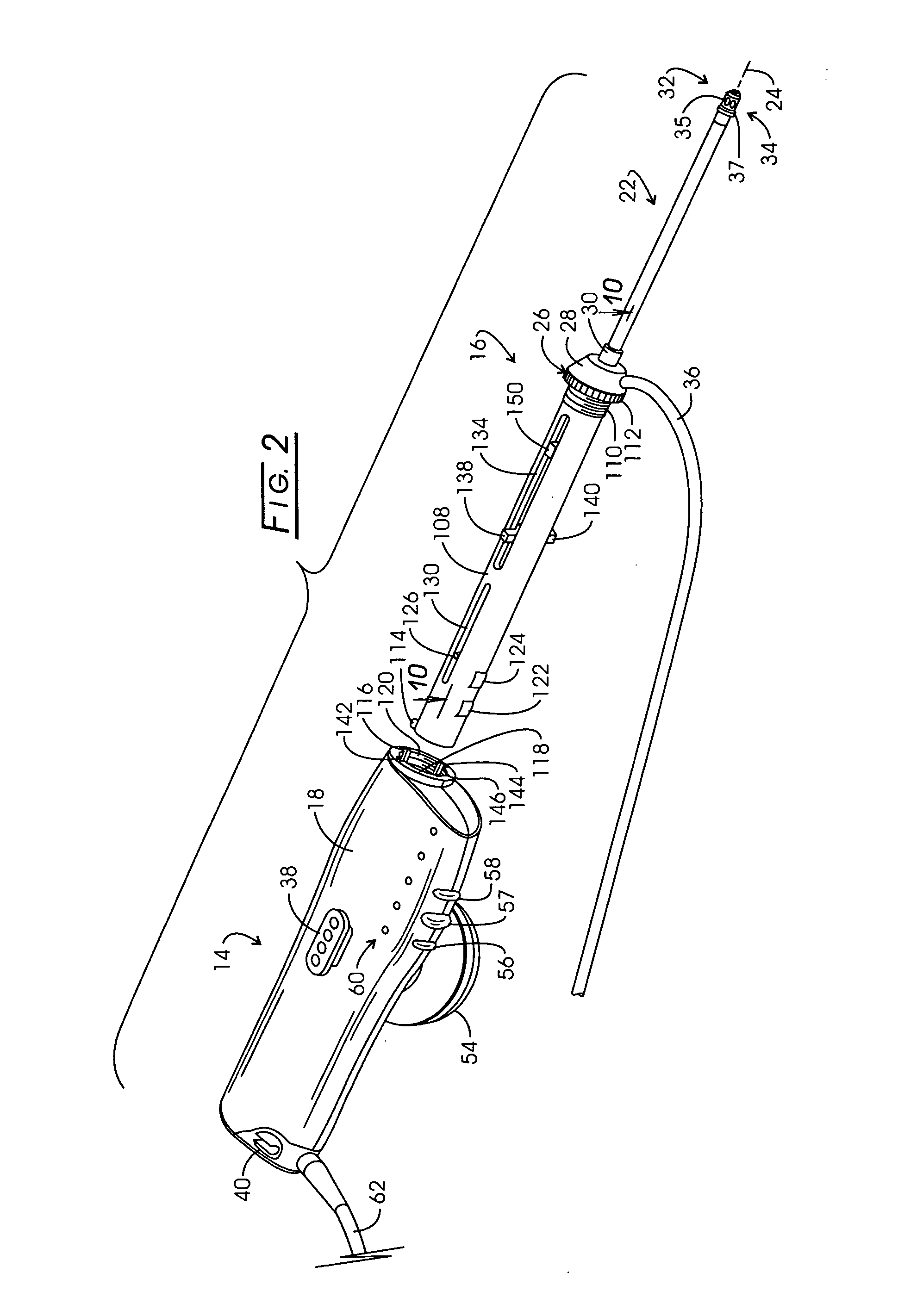

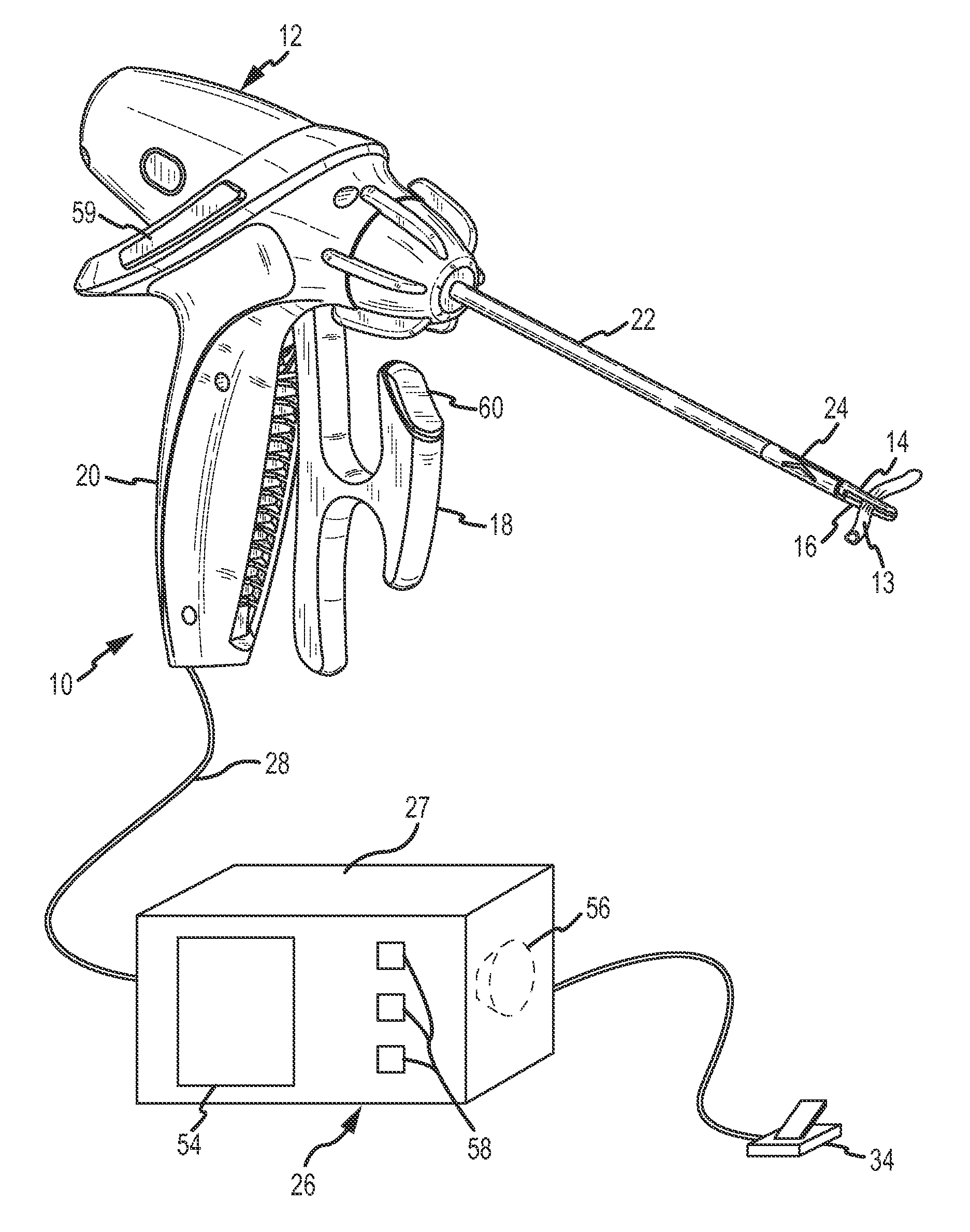

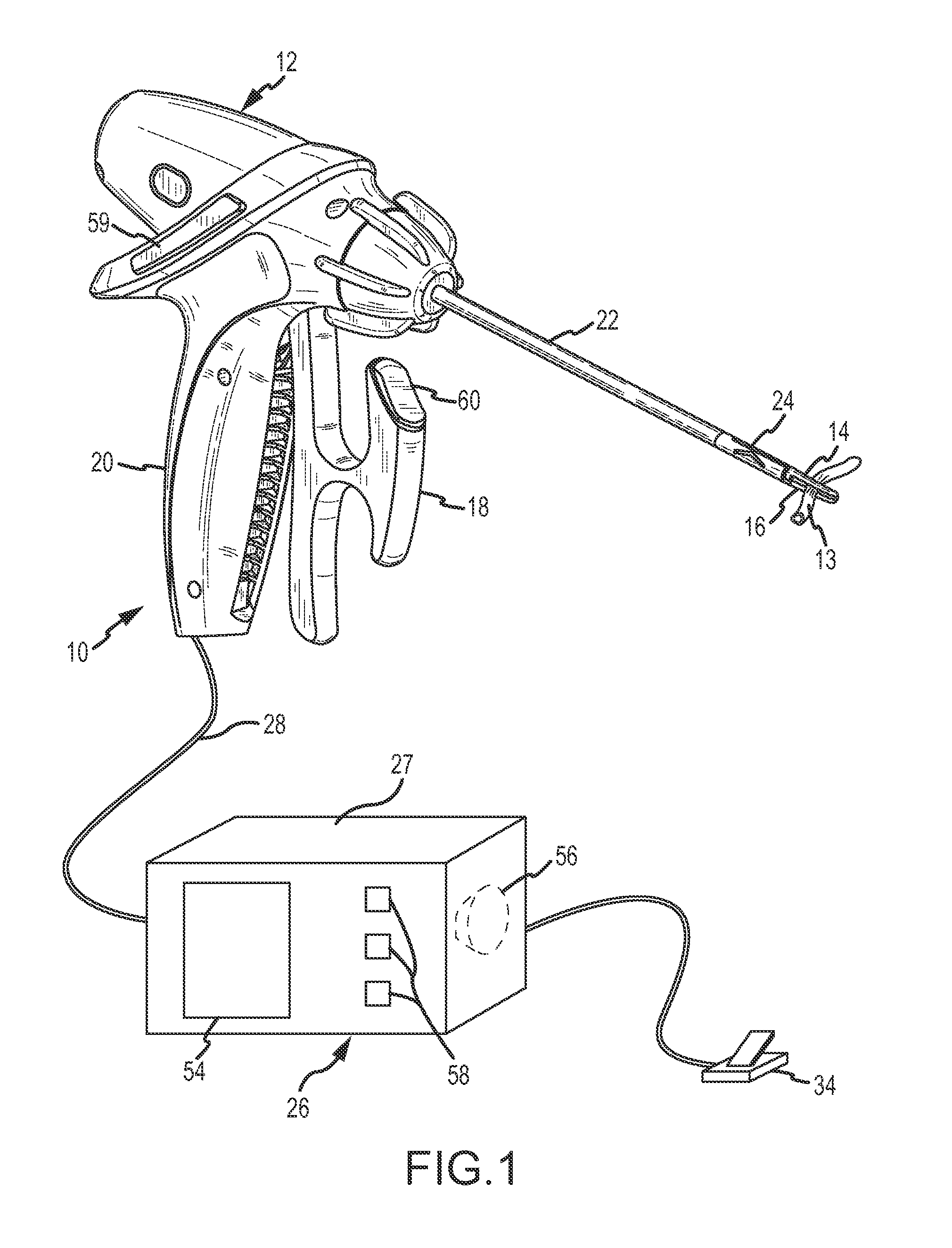

Electrosurgical instrument

InactiveUS6926716B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceVoltage source

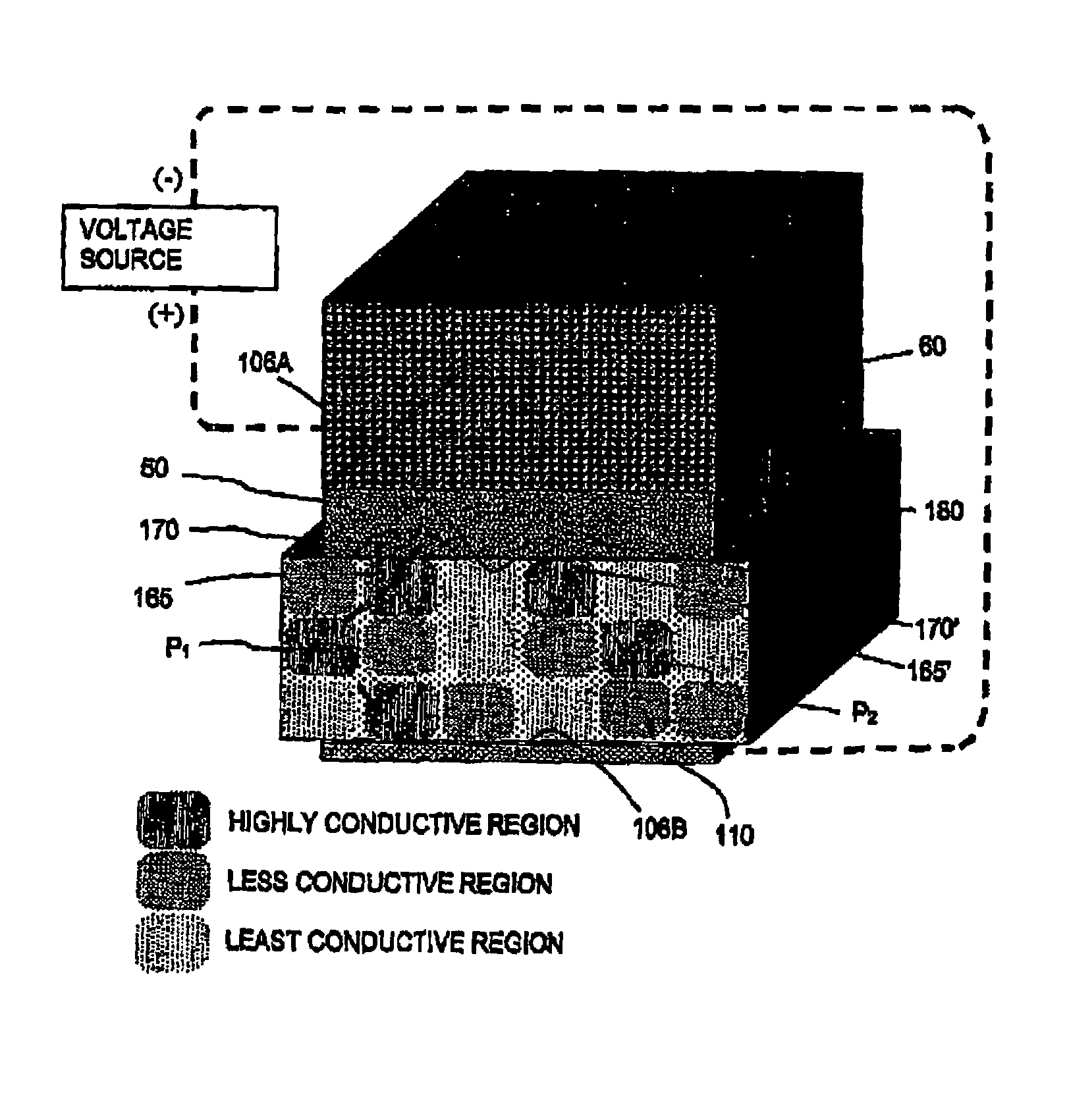

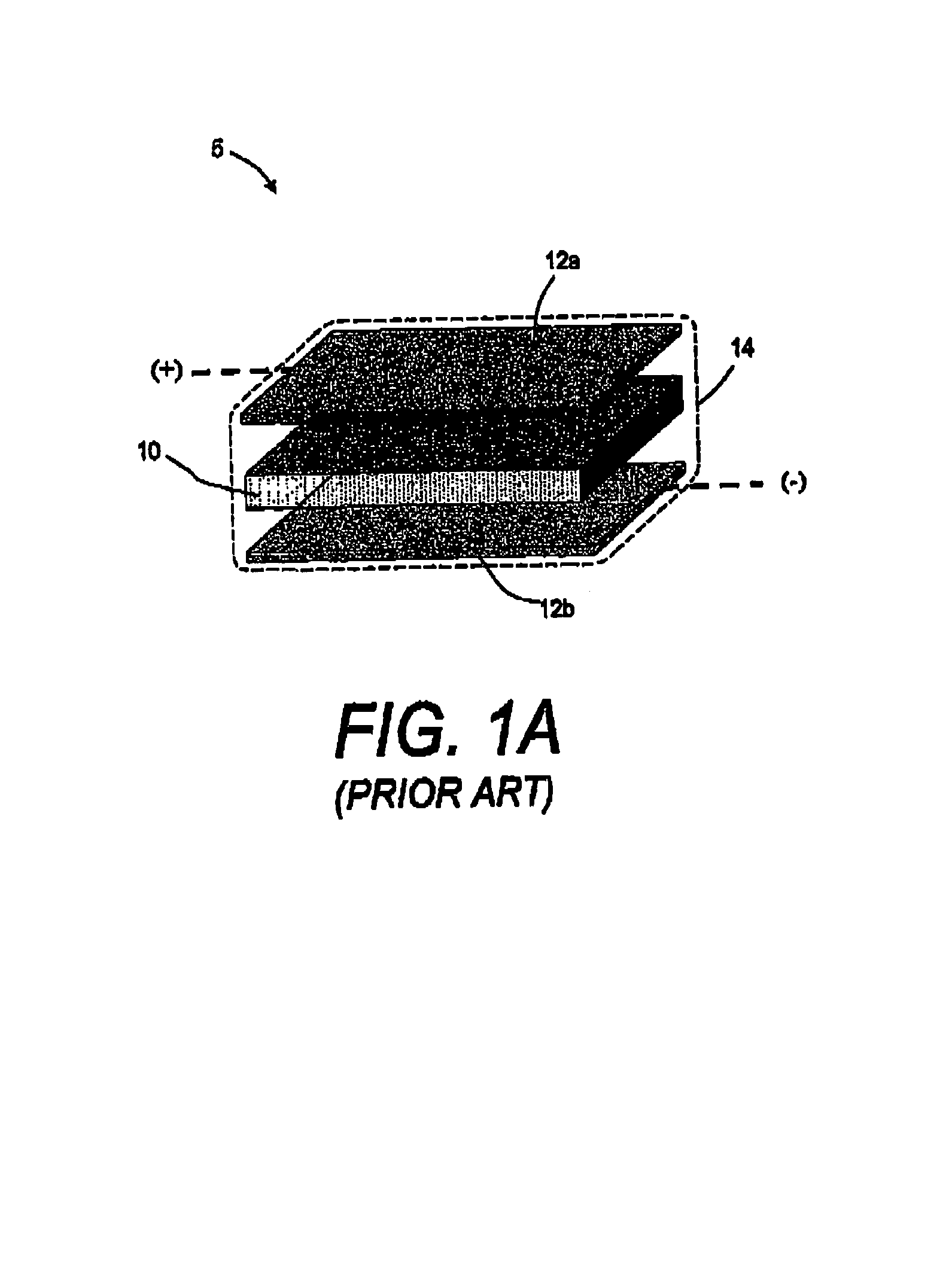

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines (i) a first surface conductive portion or a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material, and (ii) a second surface portion coupled to a fixed resistive material that coupled in series or parallel to a voltage source together with the first portion. In use, the engagement plane will apply active Rf energy to ohmically heat the captured tissue until the point in time that a controller senses an electrical parameter of the tissue such as impedance. Thereafter, the controller switches energy delivery to the second surface portion that is resistively heated to thereby apply energy to tissue by conductive heat transfer.

Owner:ETHICON ENDO SURGERY INC

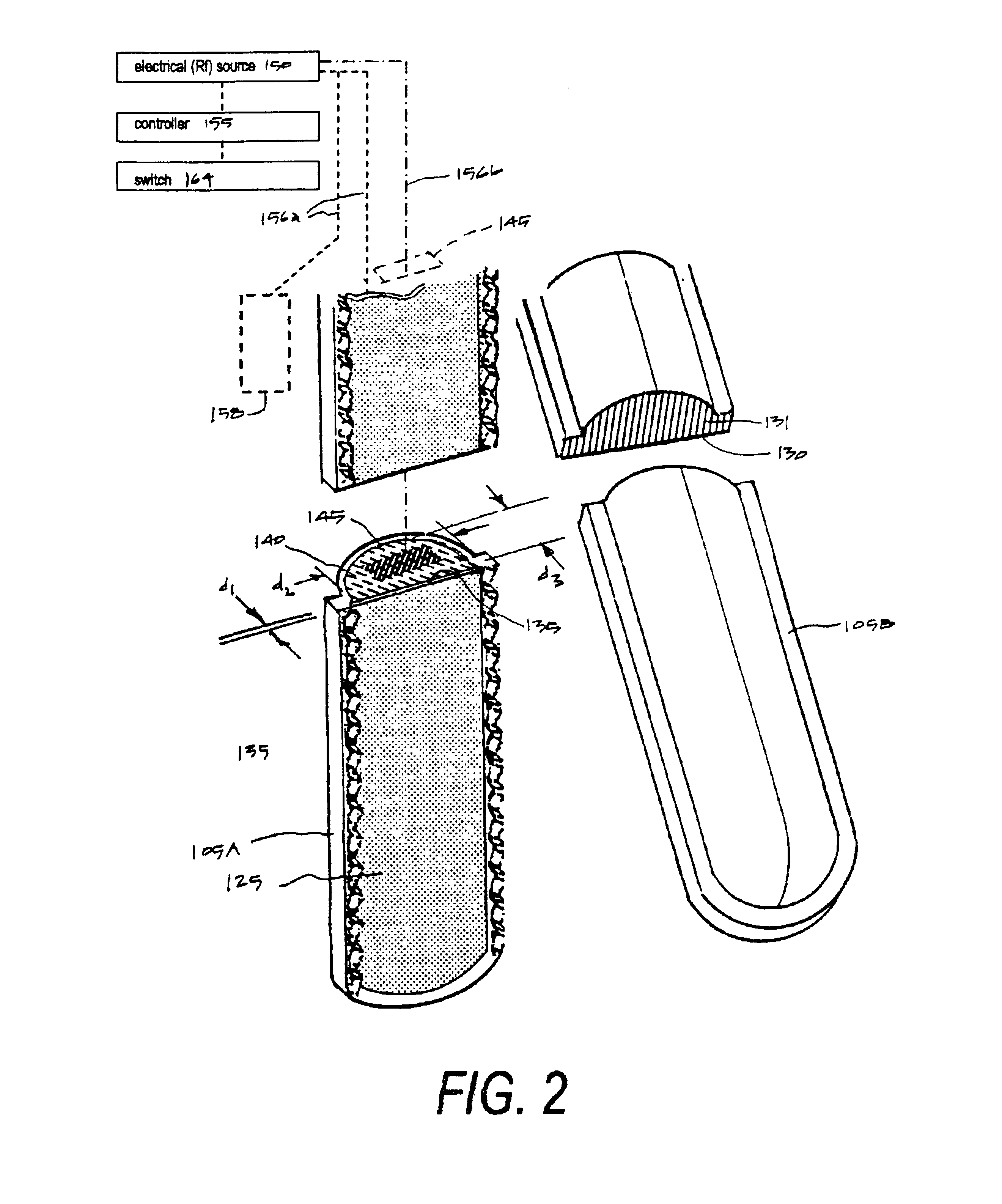

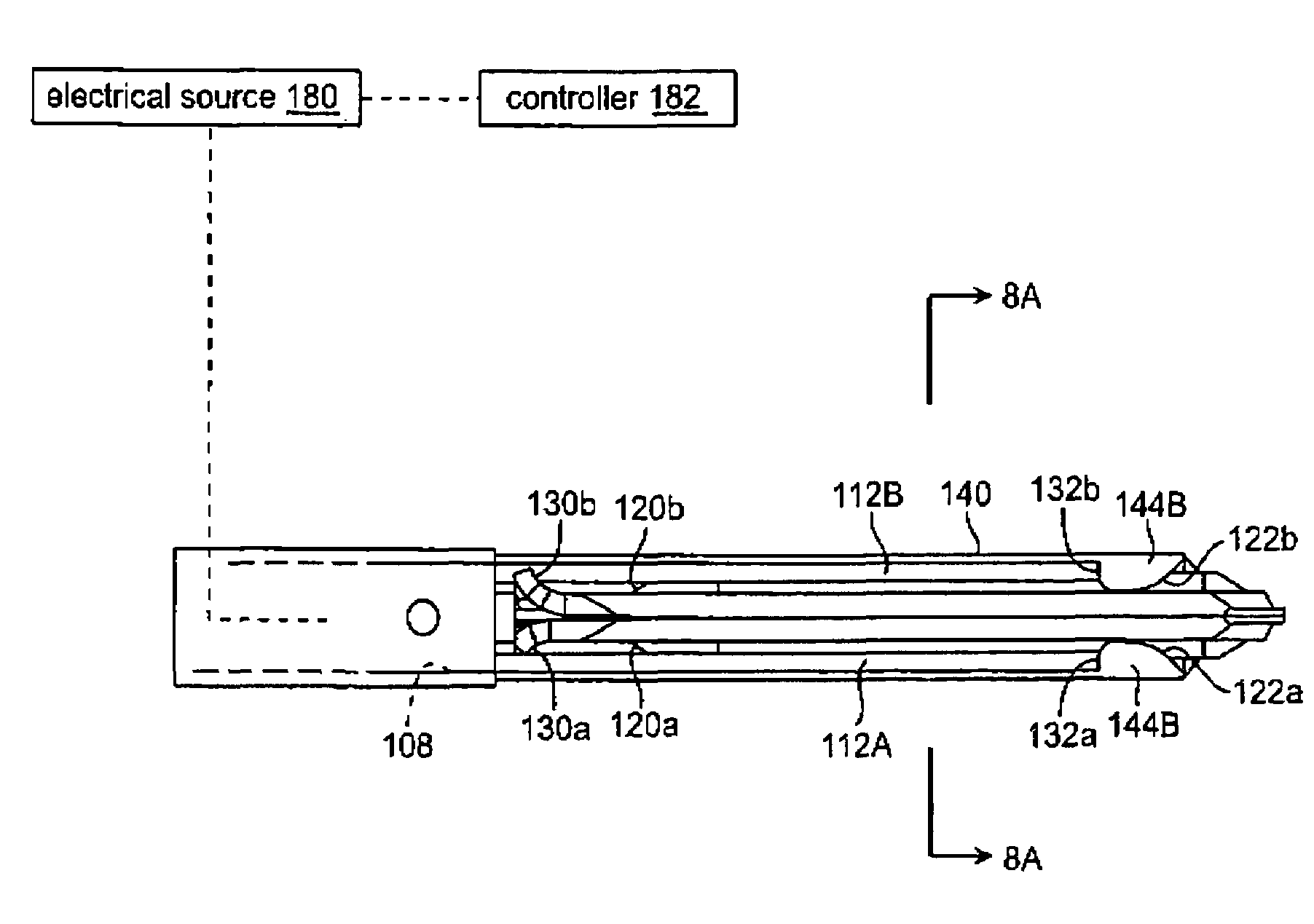

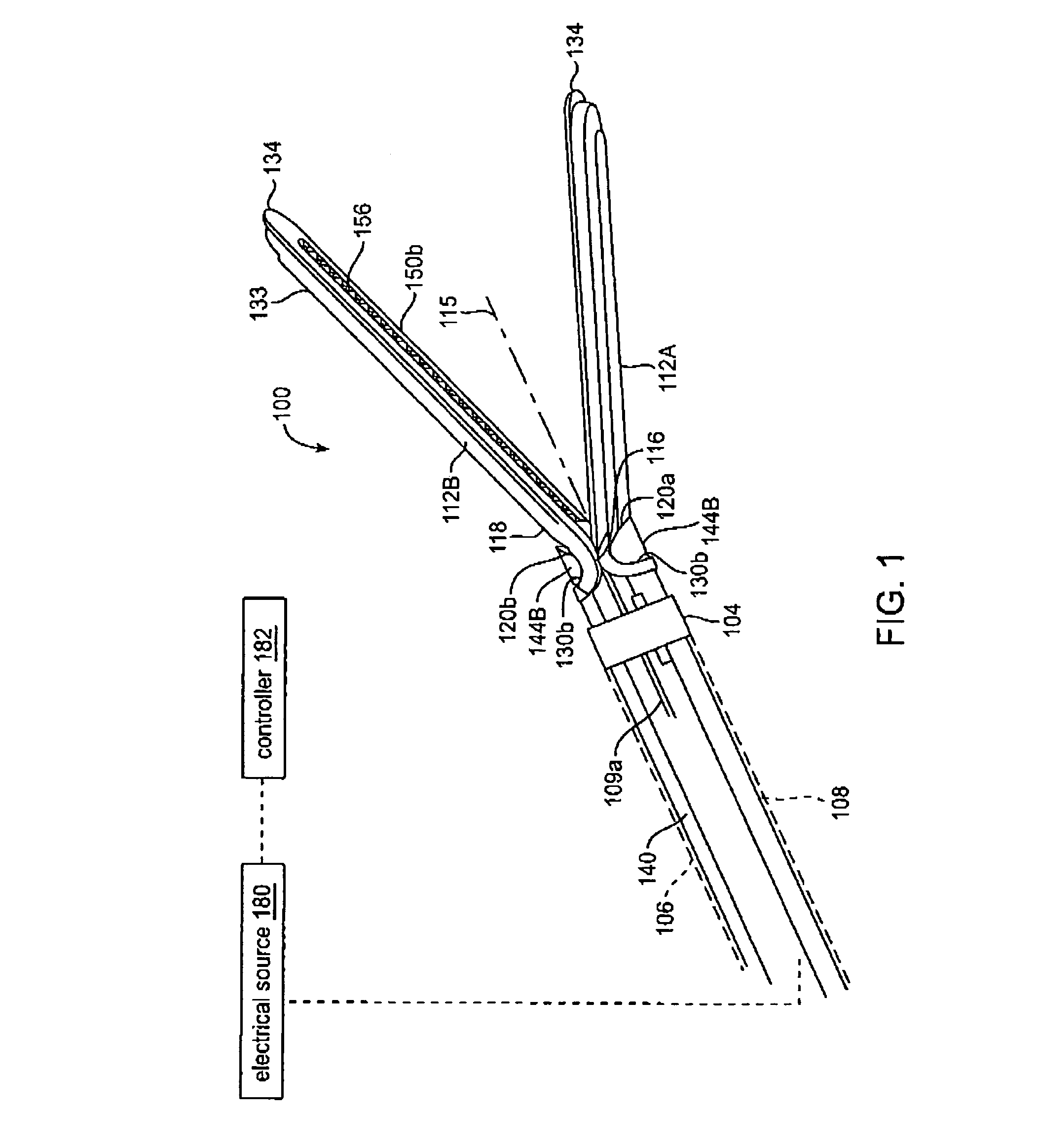

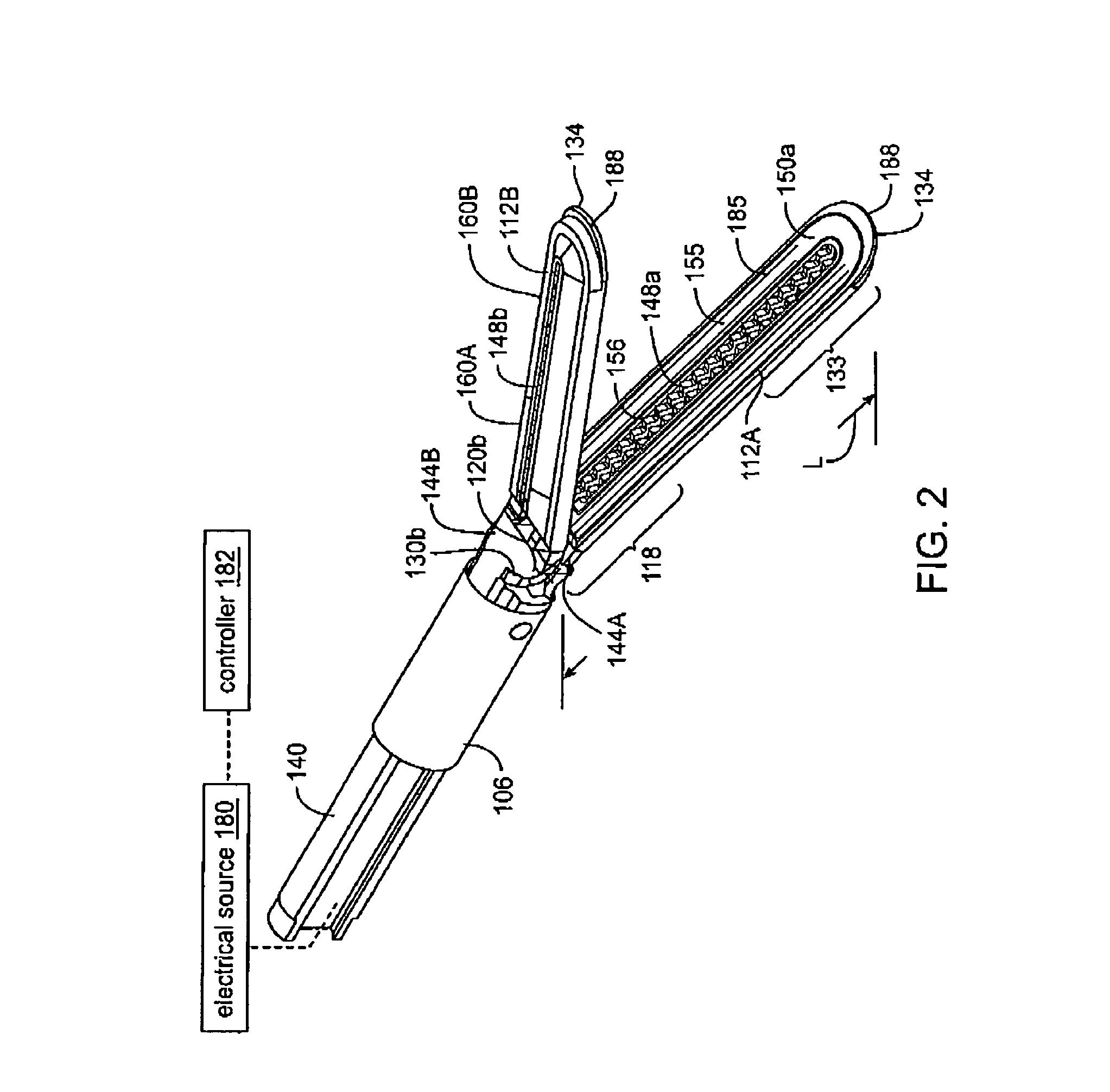

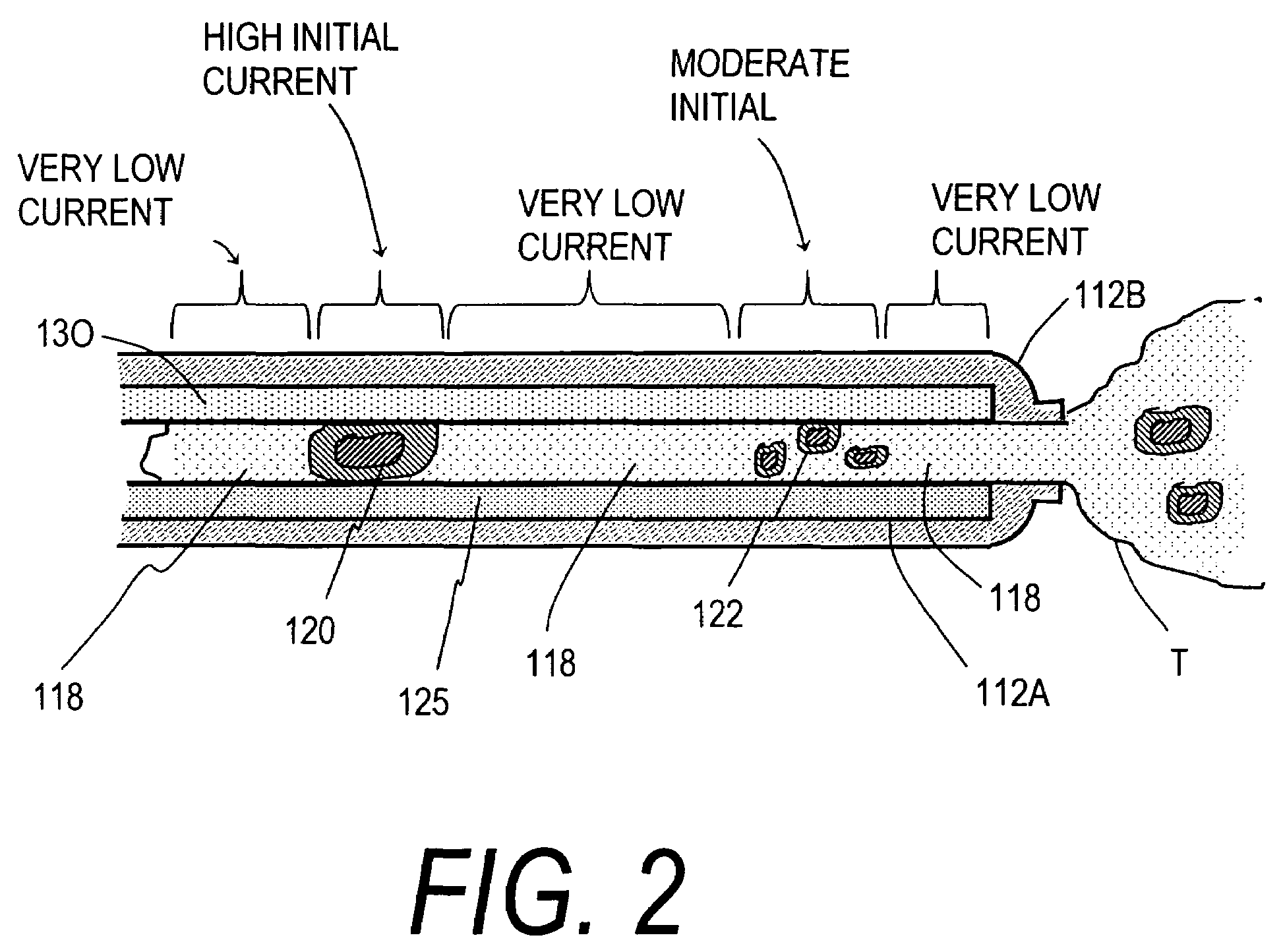

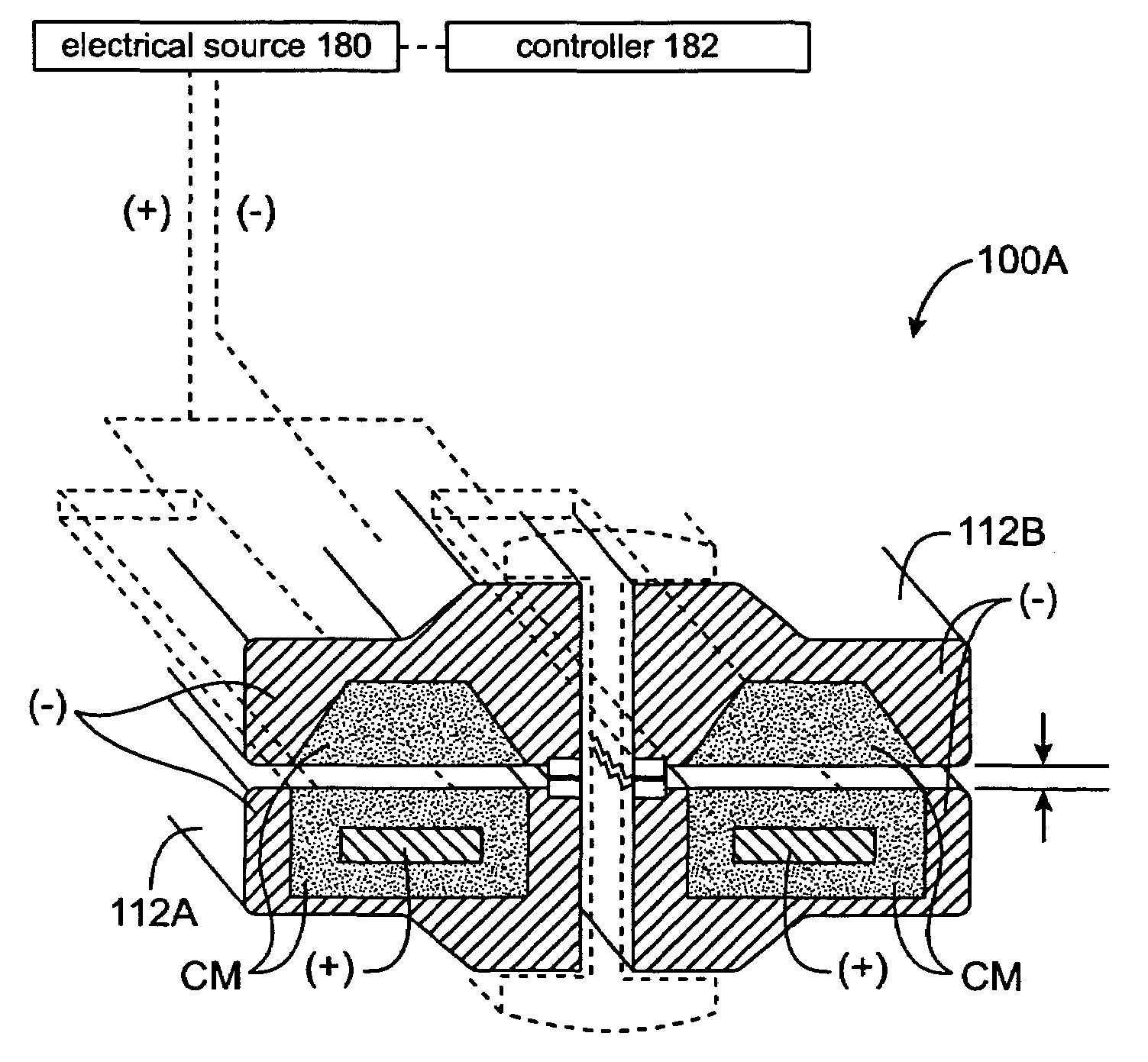

Electrosurgical jaw structure for controlled energy delivery

InactiveUS6929644B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingCoatingsThermal energyConductive materials

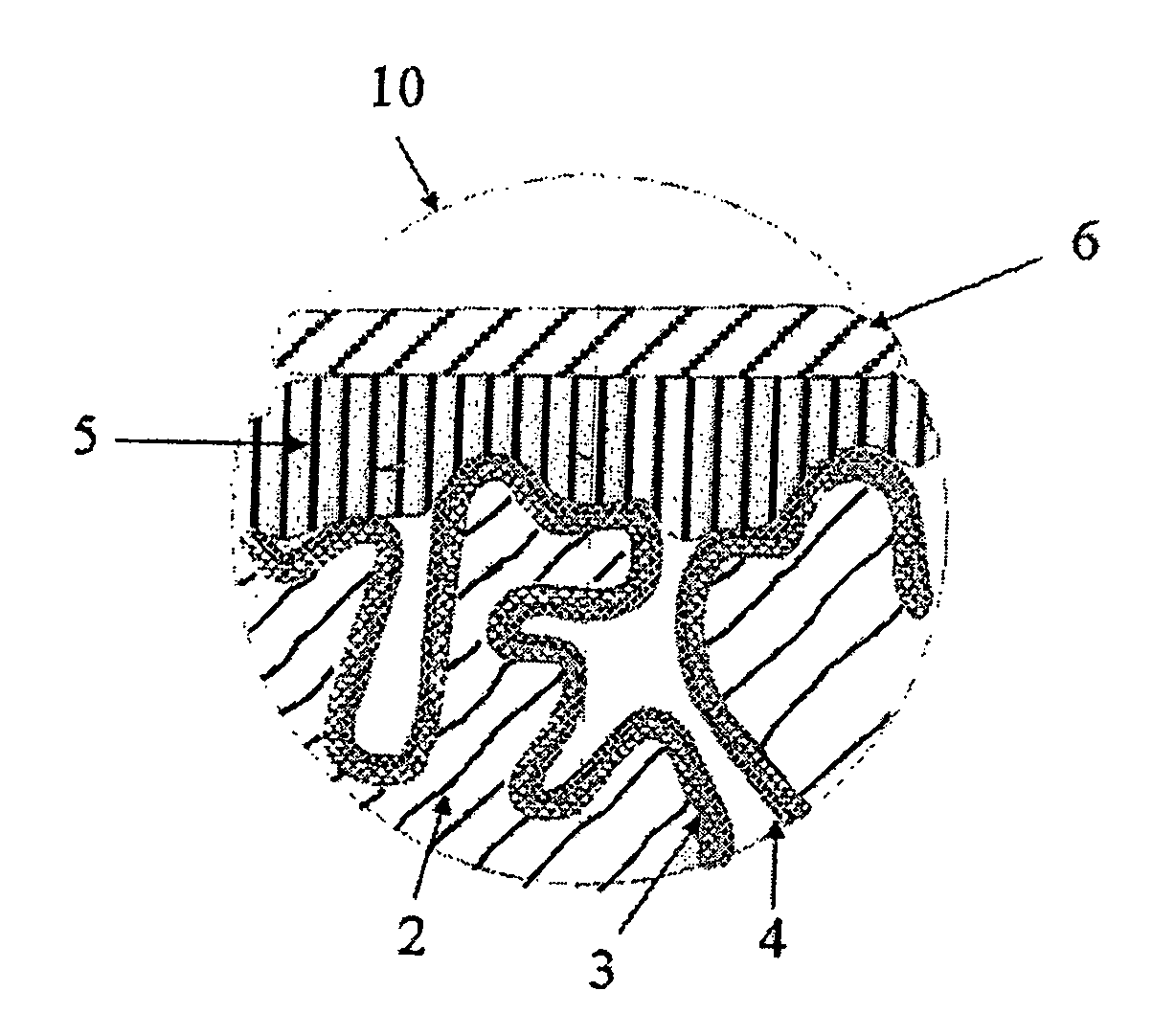

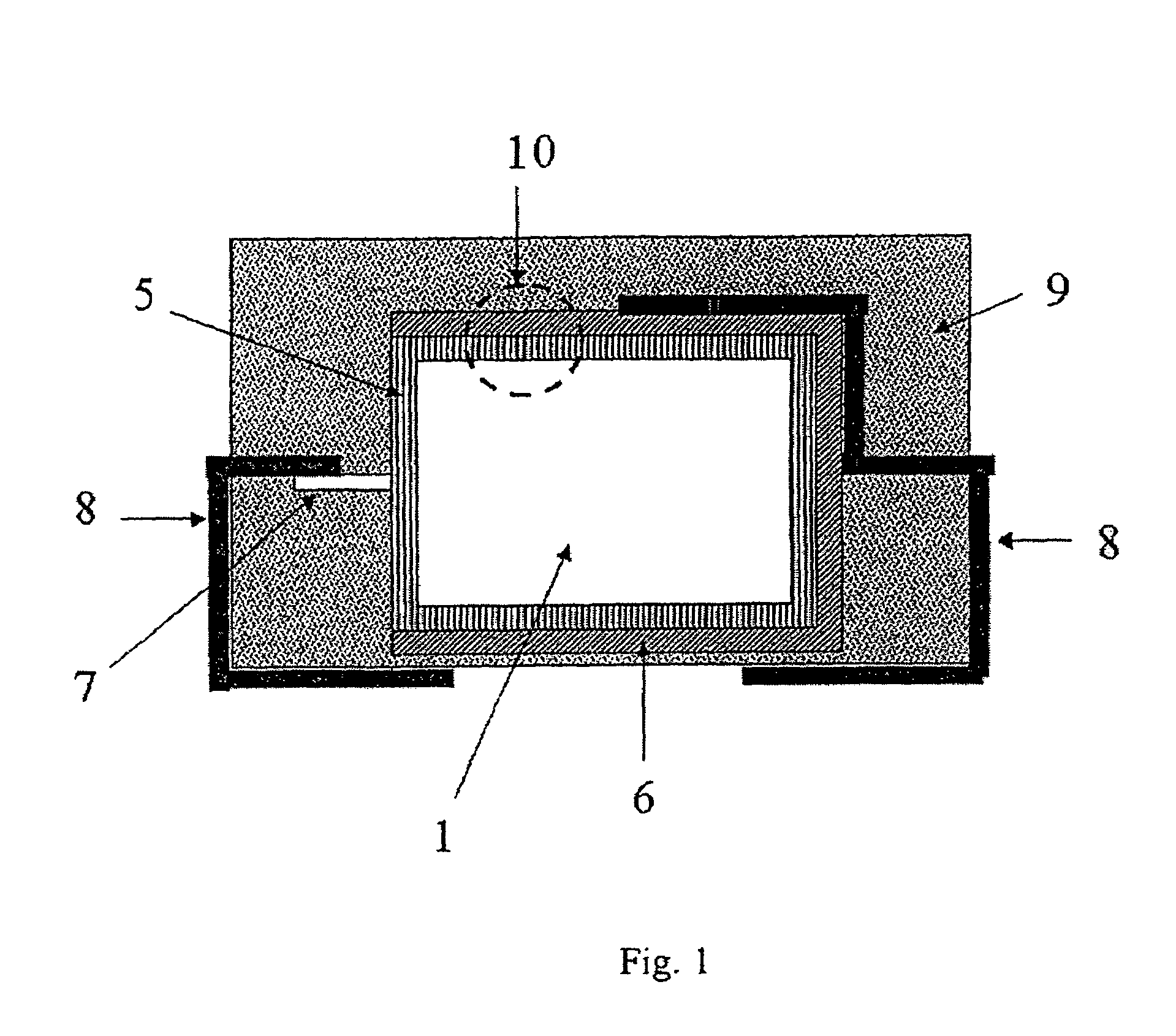

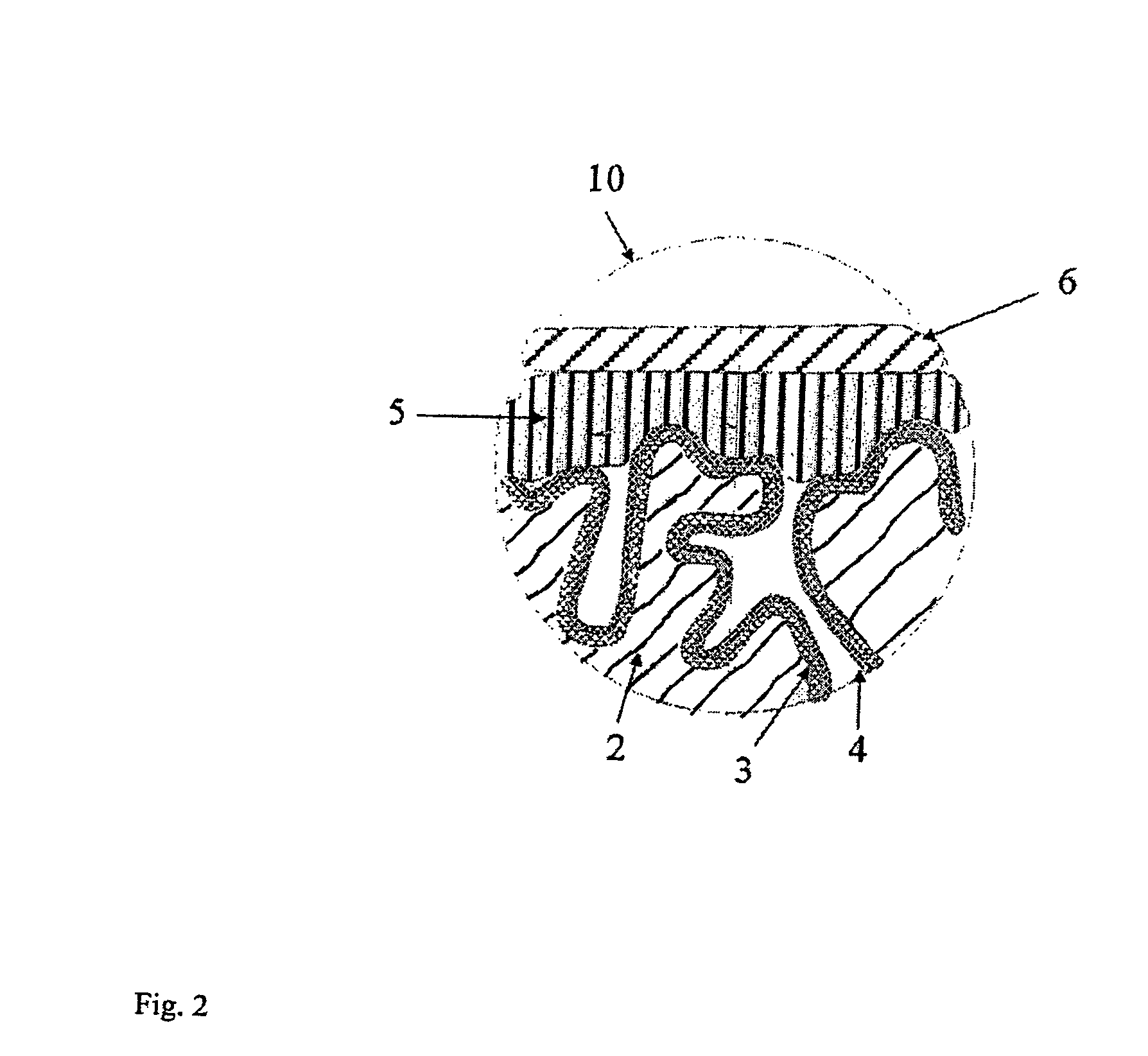

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines a surface conductive portion that overlies a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material. An interior of the jaw carries a conductive material or electrode that is coupled to an Rf source and controller. In an exemplary embodiment, the variably resistive matrix can comprise a positive temperature coefficient (PTC) material, such as a ceramic, that is engineered to exhibit a dramatically increasing resistance (i.e., several orders of magnitude) above a specific temperature of the material. In use, the engagement plane will apply active Rf energy to captured tissue until the point in time that the variably resistive matrix is heated to its selected switching range. Thereafter, current flow from the conductive electrode through the engagement surface will be terminated due to the exponential increase in the resistance of variably resistive matrix to provide instant and automatic reduction of Rf energy application. Further, the variably resistive matrix can effectively function as a resistive electrode to thereafter conduct thermal energy to the engaged tissue volume. Thus, the jaw structure can automatically modulate the application of energy to tissue between active Rf heating and passive conductive heating of captured tissue to maintain a target temperature level.

Owner:ETHICON ENDO SURGERY INC

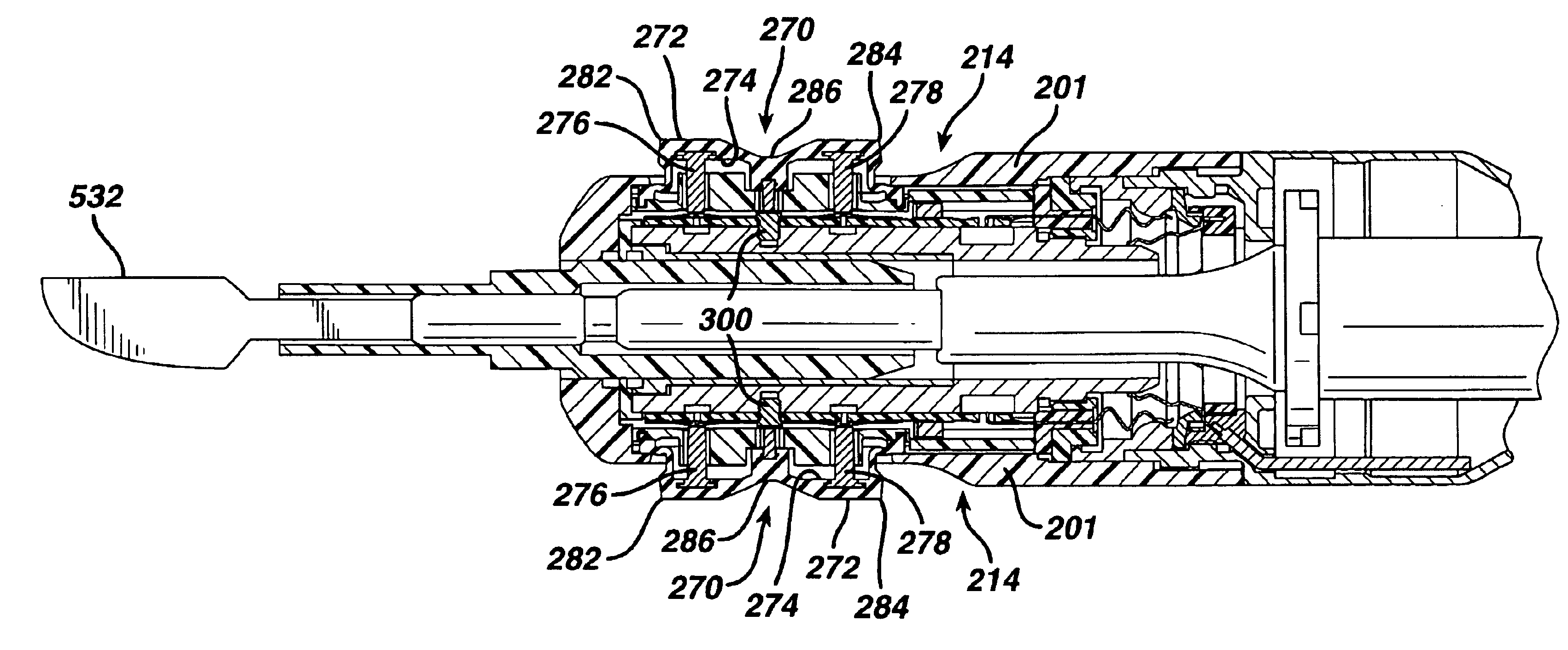

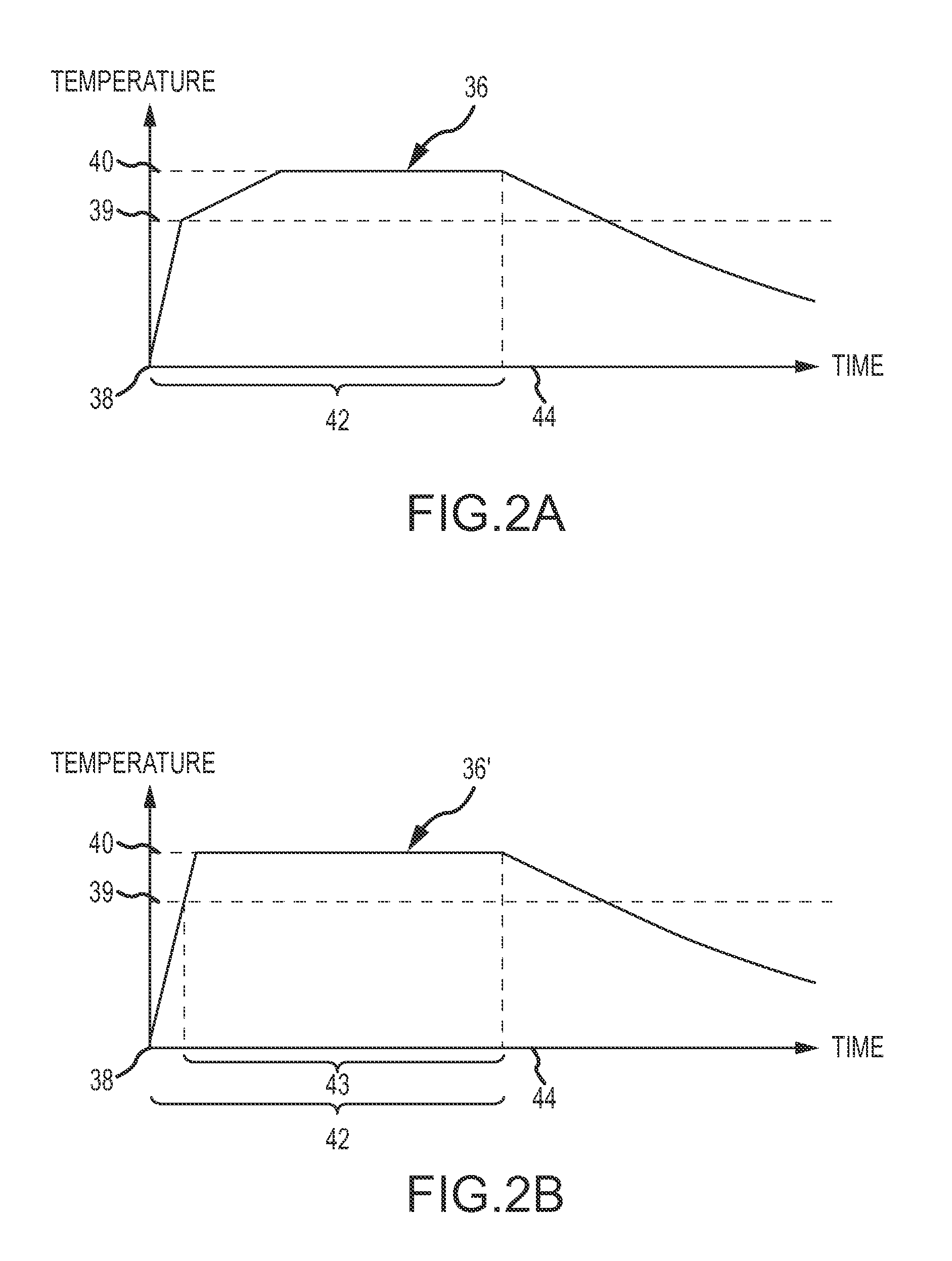

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

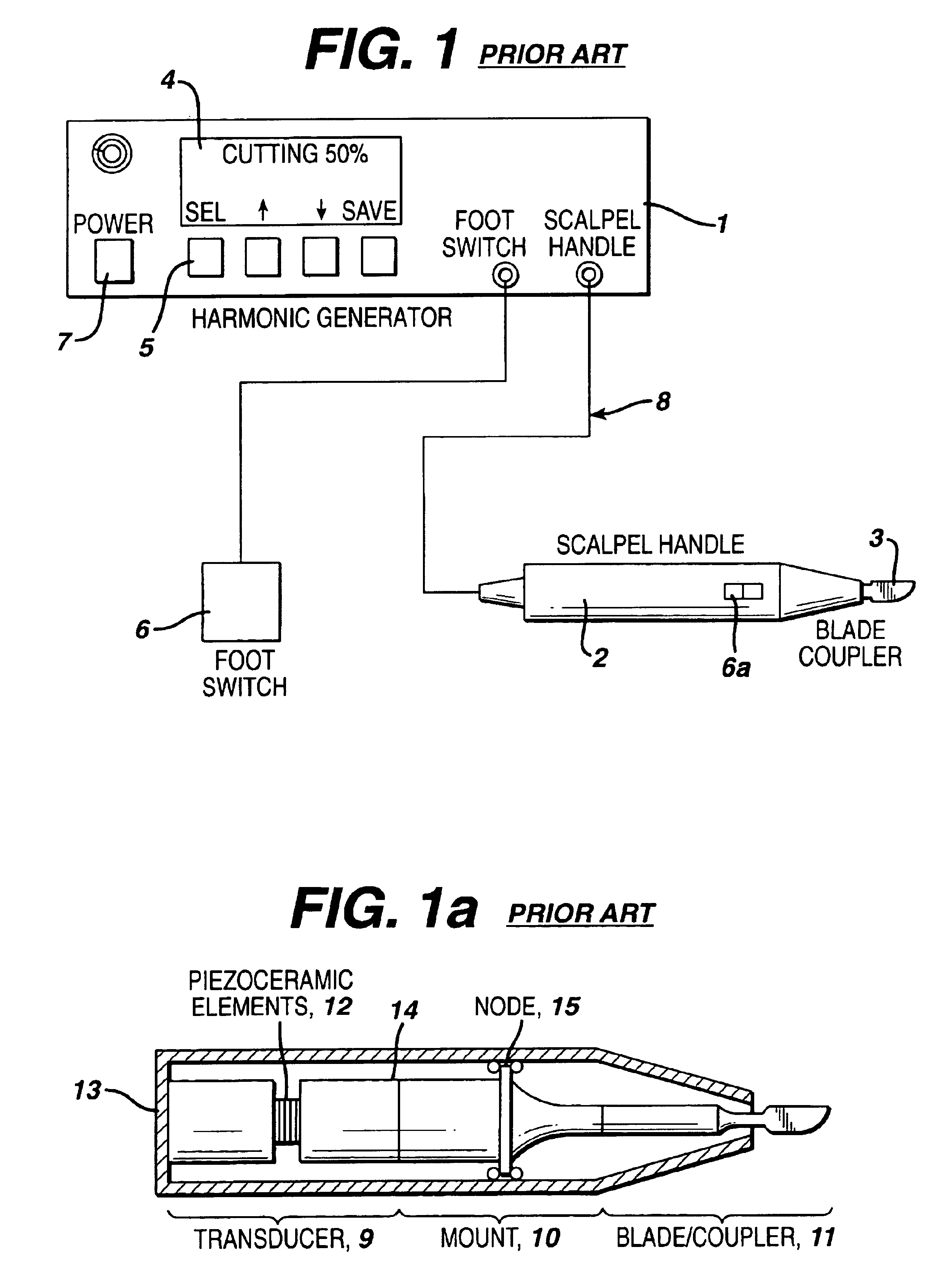

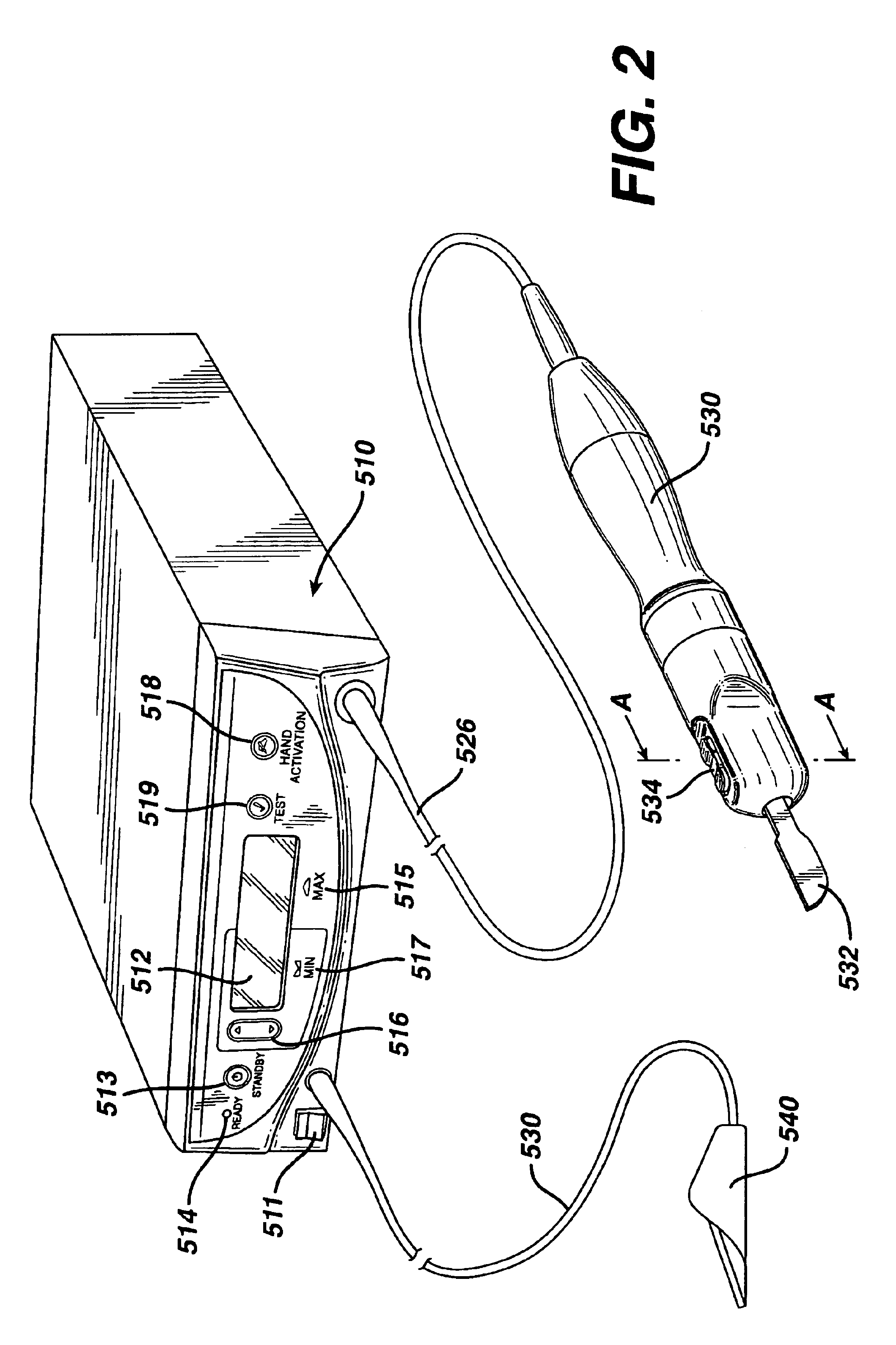

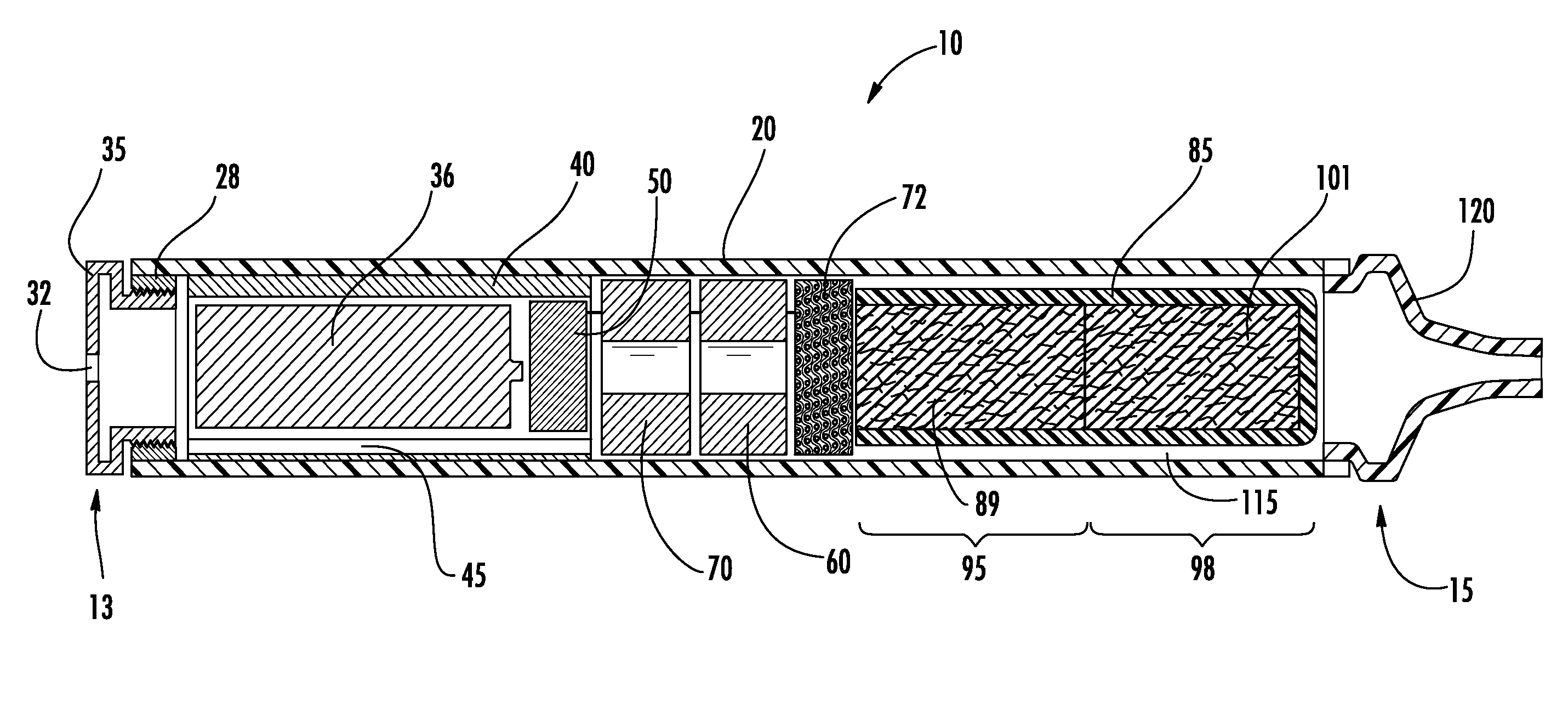

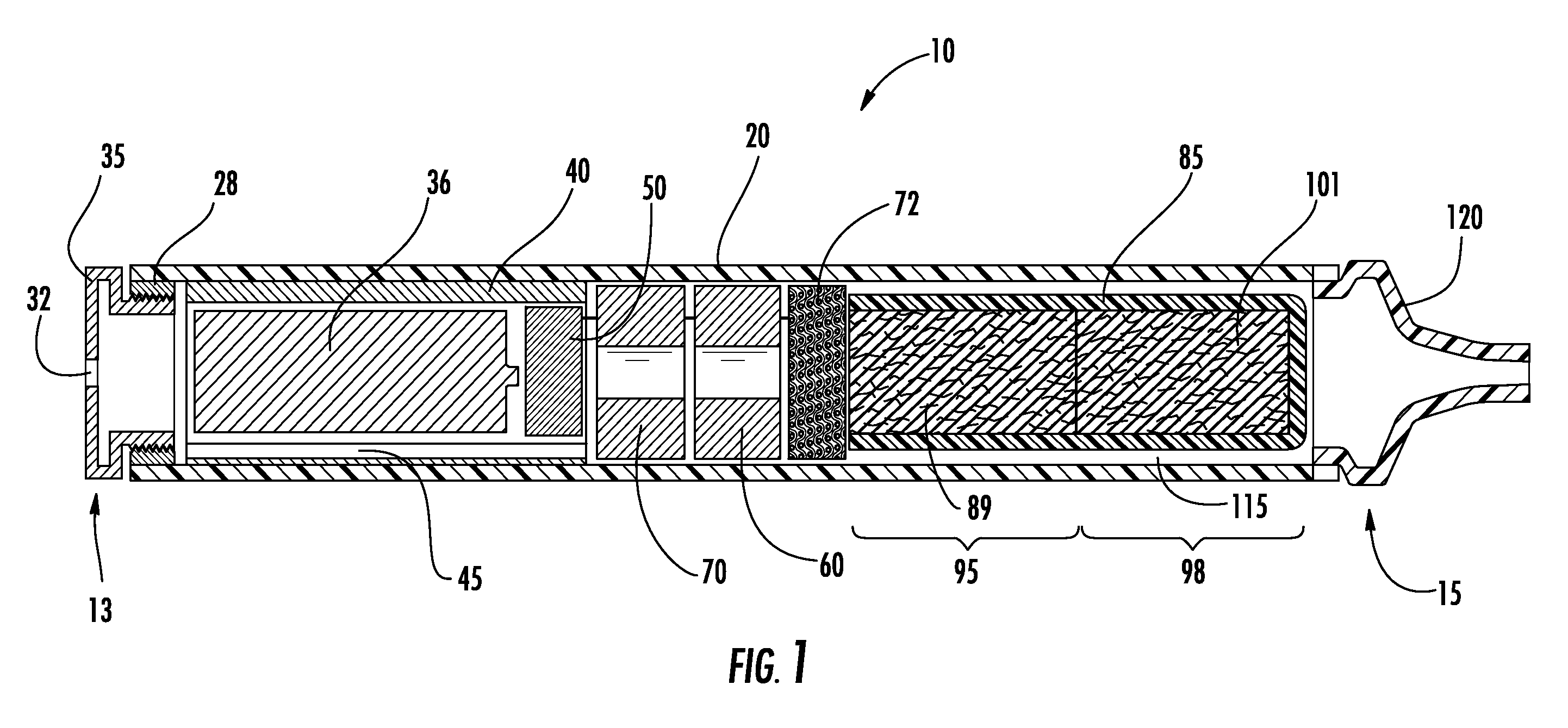

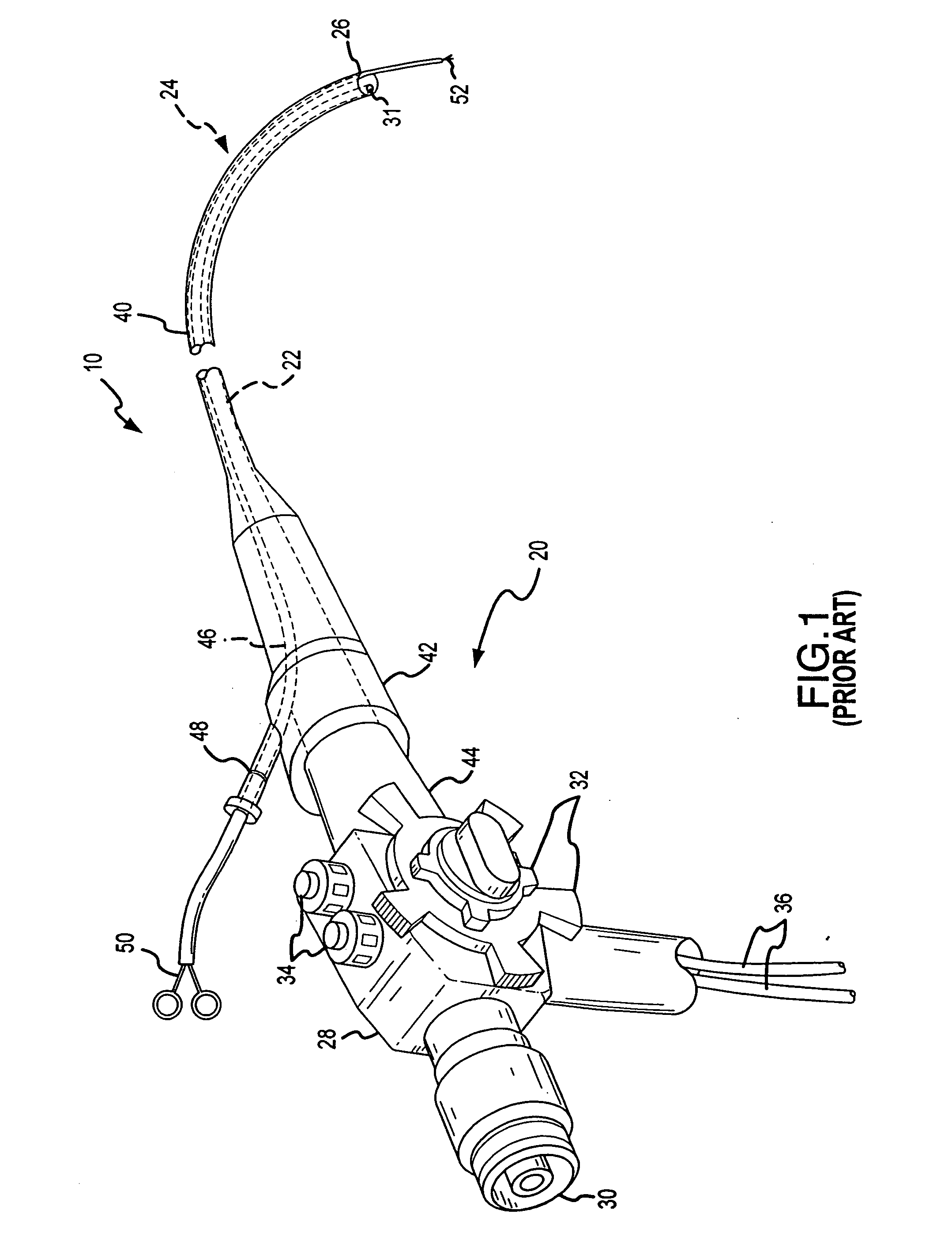

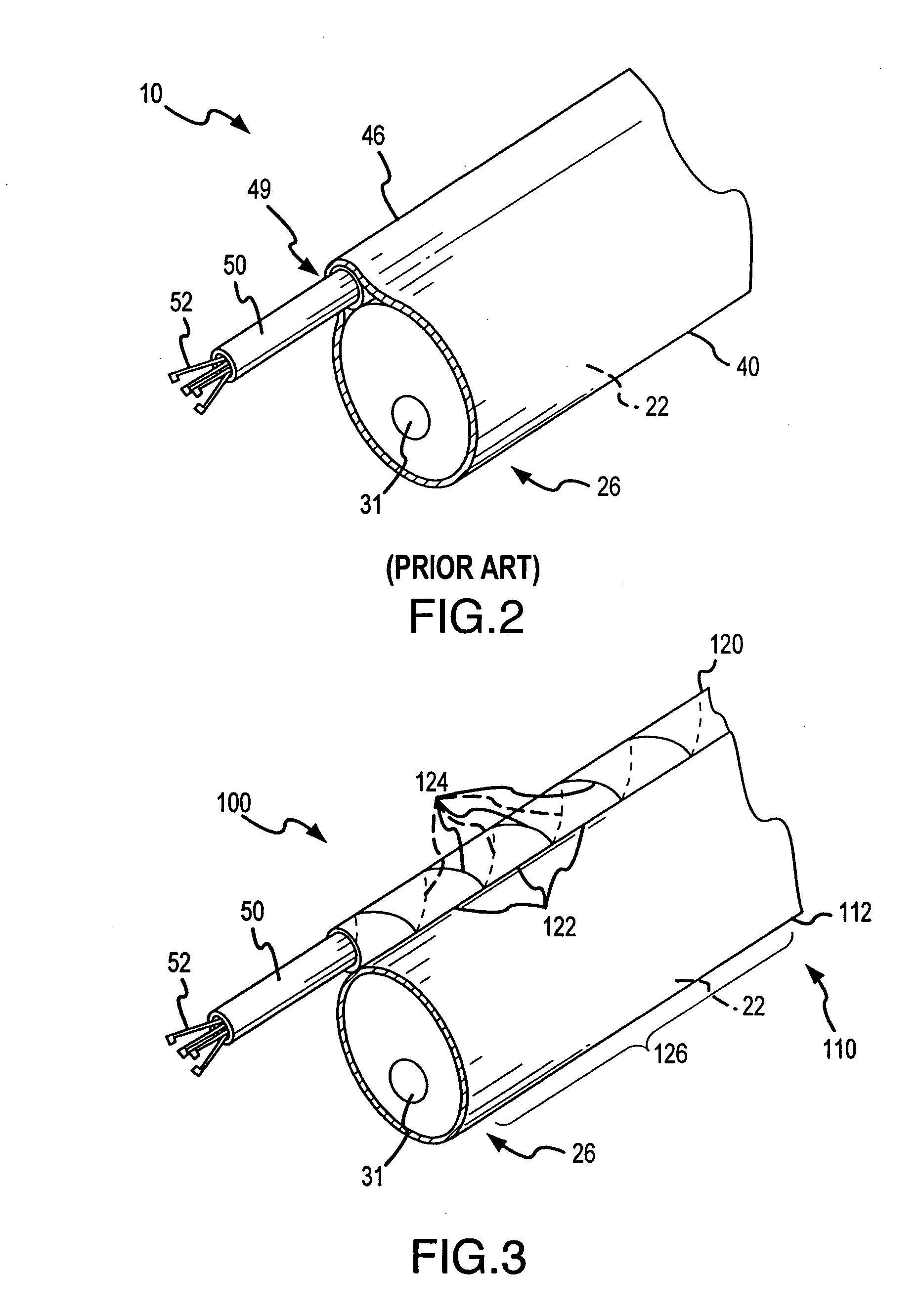

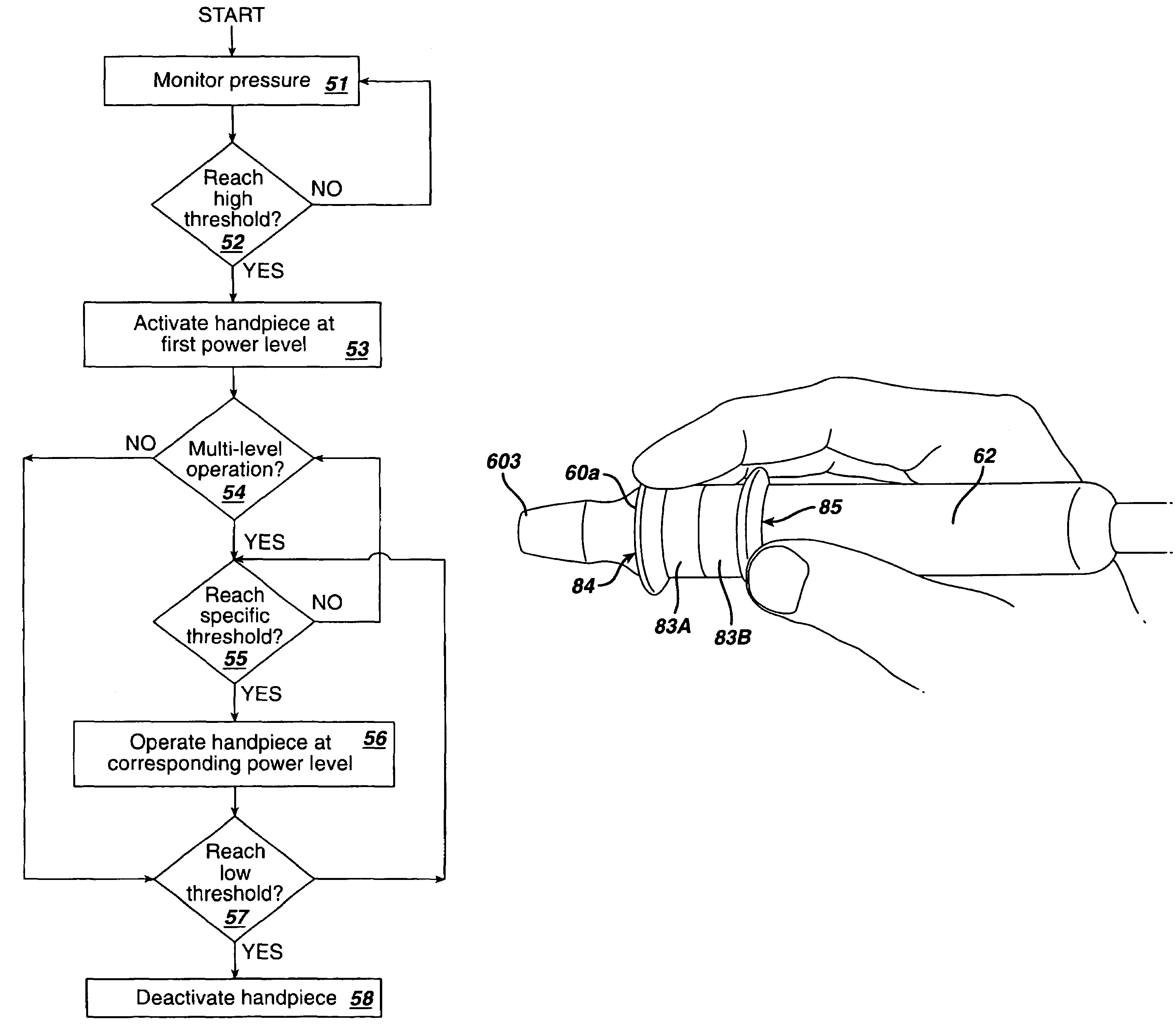

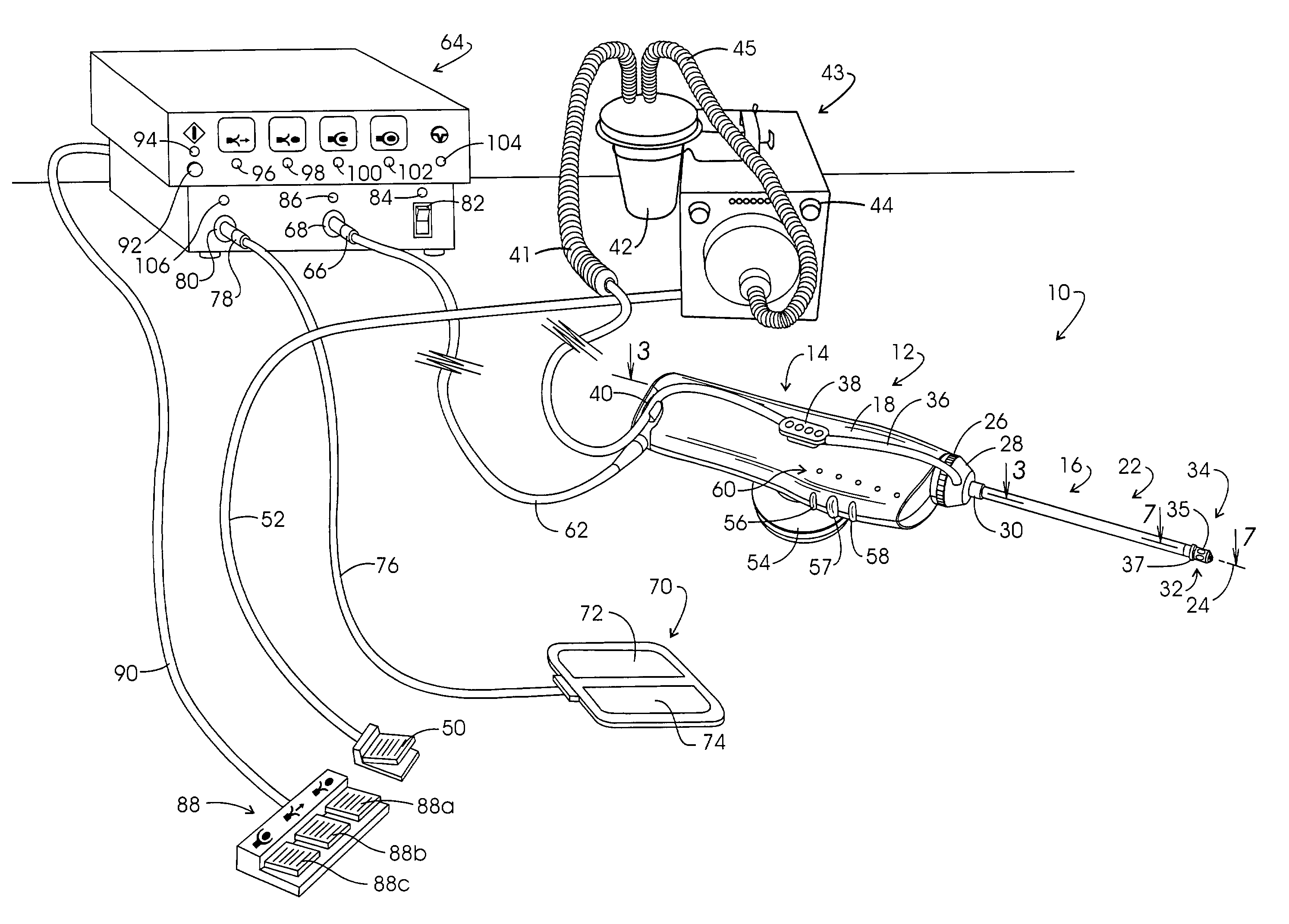

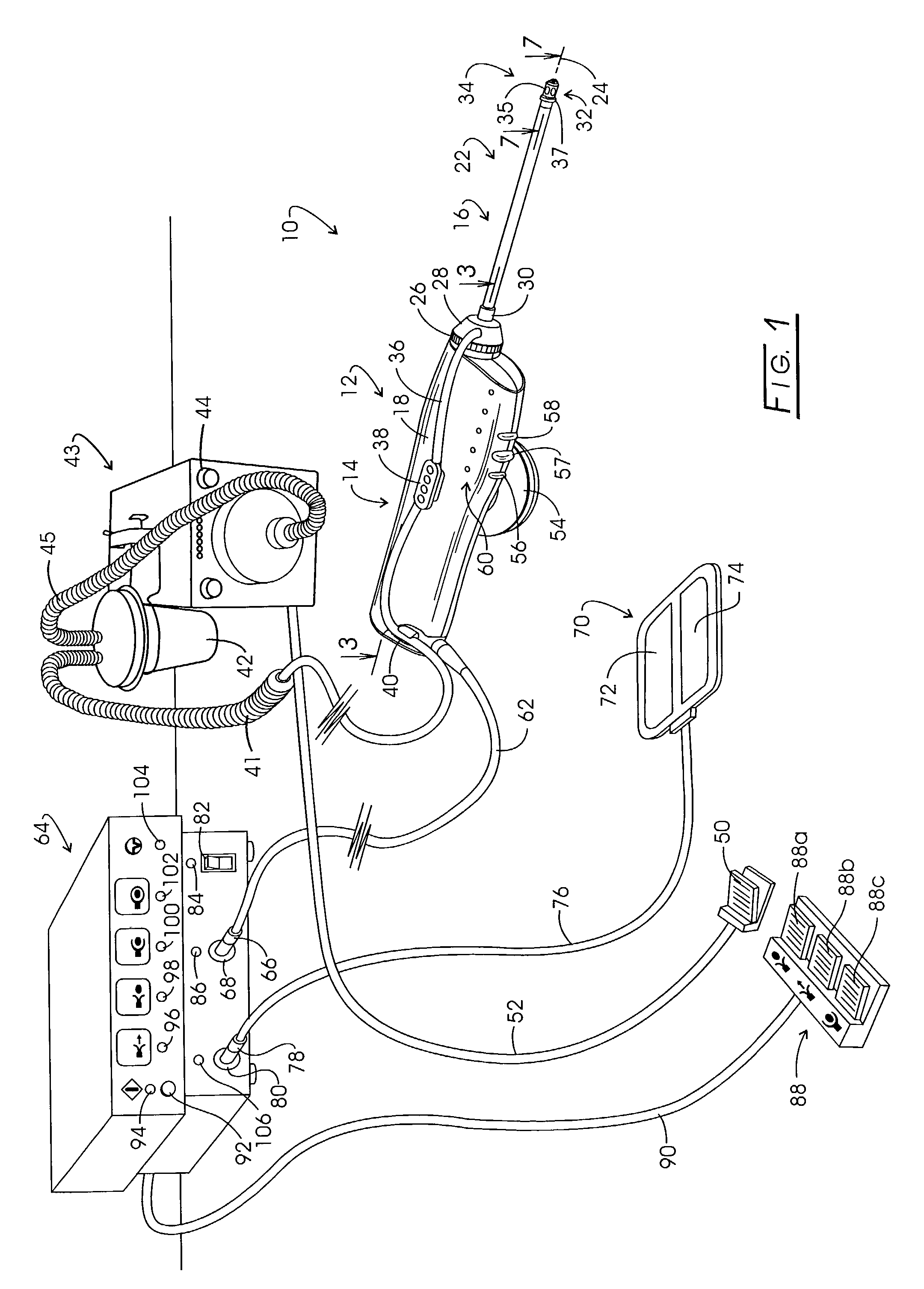

Finger operated switch for controlling a surgical handpiece

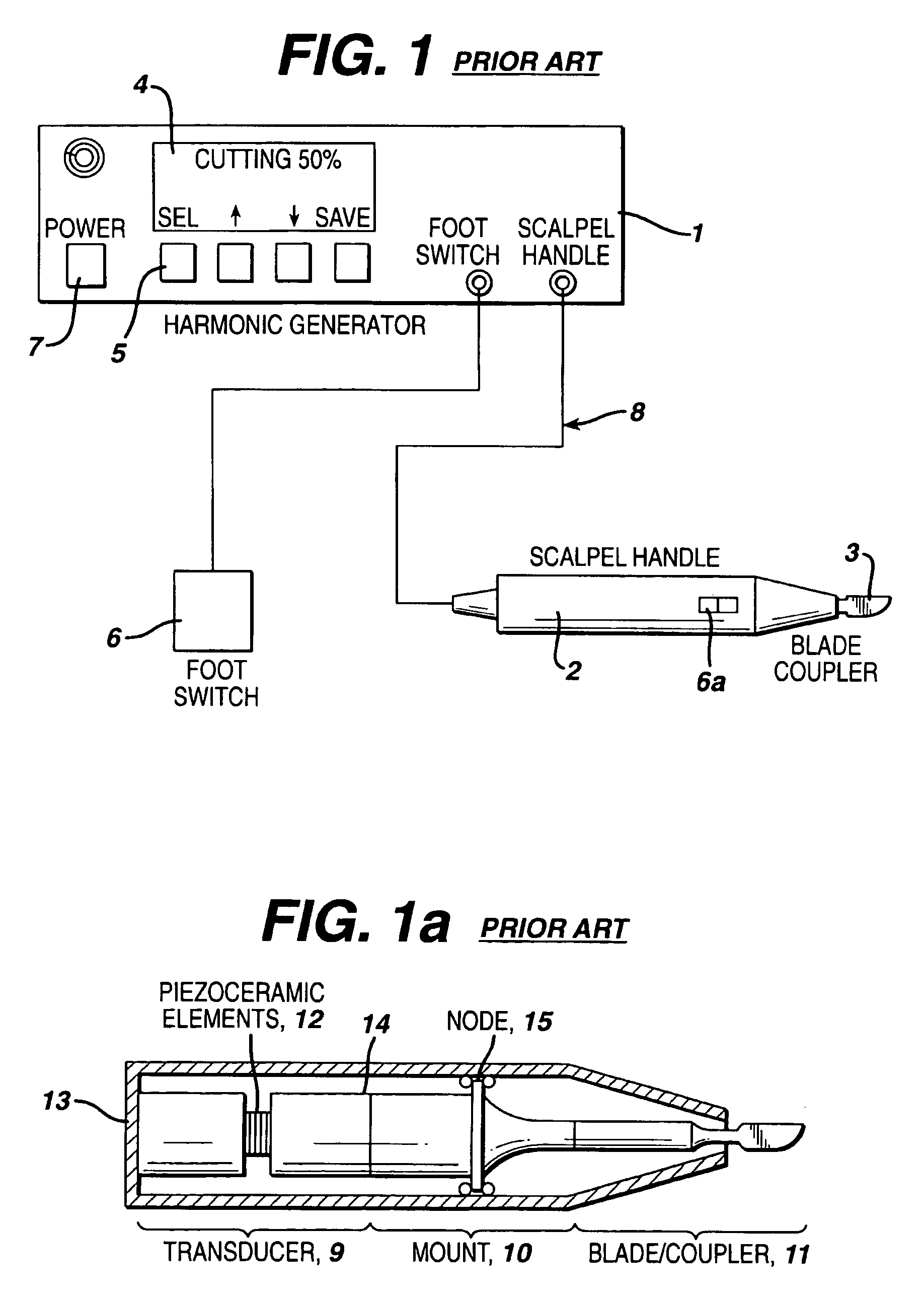

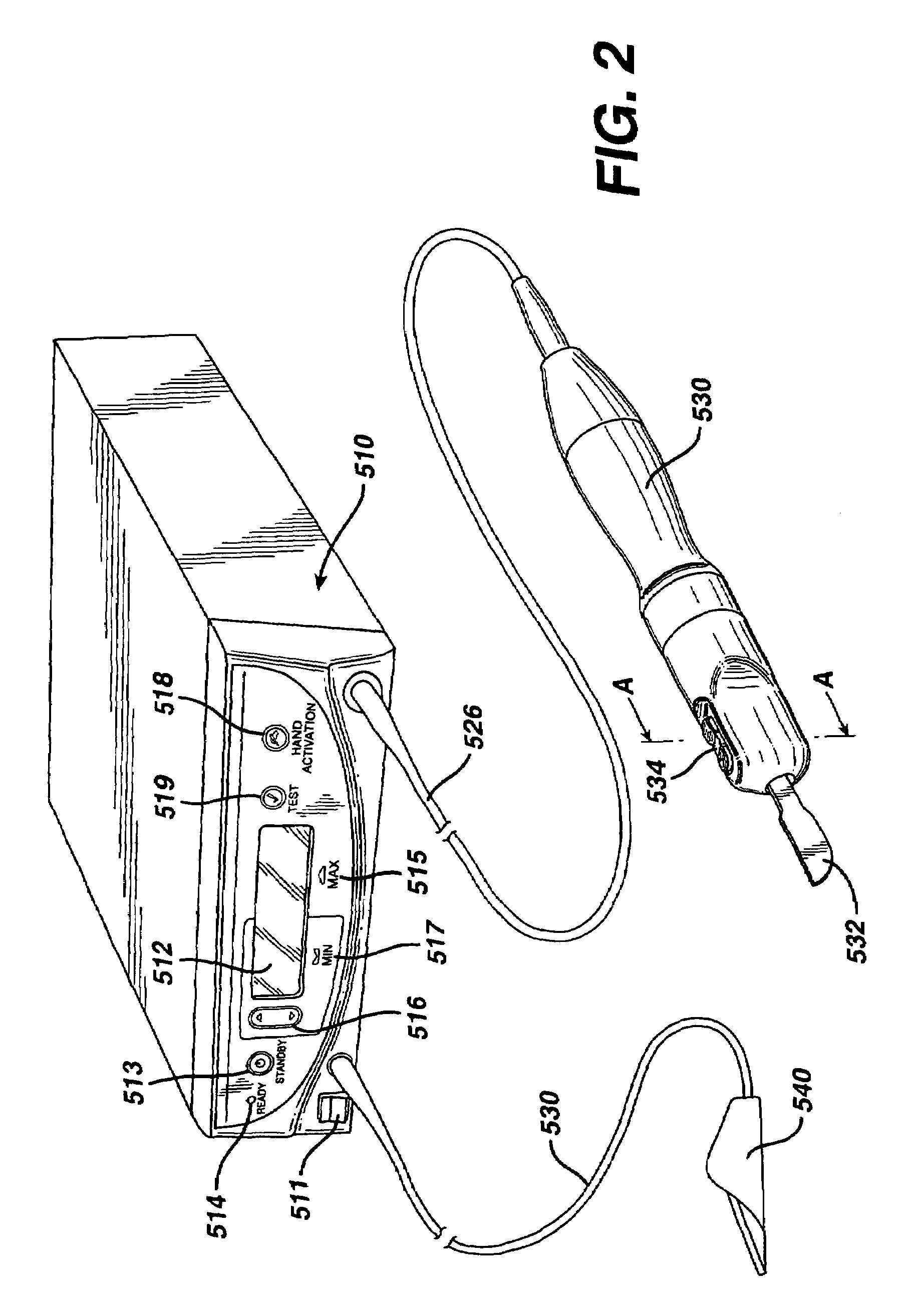

According to the invention, a finger-operated switch for activating and operating an ultrasonic surgical handpiece is provided. The power output of the surgical handpiece is responsive and proportional to the pressure applied to the finger-operated switch. The finger-operated switch includes, but not limited to, force sensitive resistors whose resistance is proportional to the force applied by the finger of the human operator of the surgical handpiece, force sensitive capacitors whose capacitance is proportional to the pressure, deflection or compression of the insulation layer between two electrodes or is proportional to the spacing between the two conductive layers, strain gauges mounted underneath or integral to the housing of the surgical handpiece such that the pressure applied thereto results in an output change in the strain gauges, magnets or ferromagnets encased or embedded in an elastomer with a sensor inside the surgical handpiece that detects the field strength of the magnet and monitors changes relative to the force applied to the handpiece housing, and piezo film or piezo ceramic whose charge or voltage is proportional to the force applied.

Owner:ETHICON ENDO SURGERY INC

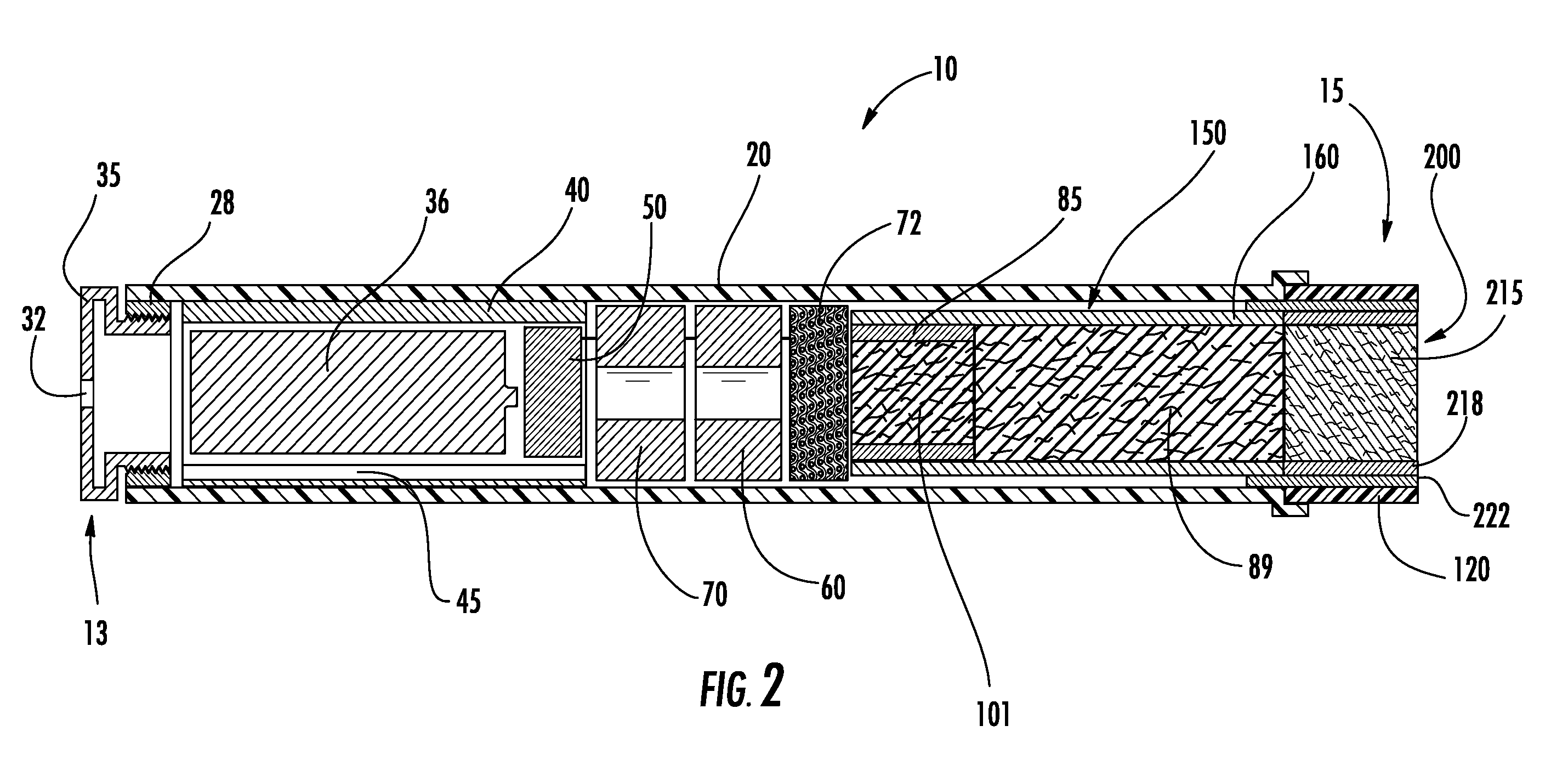

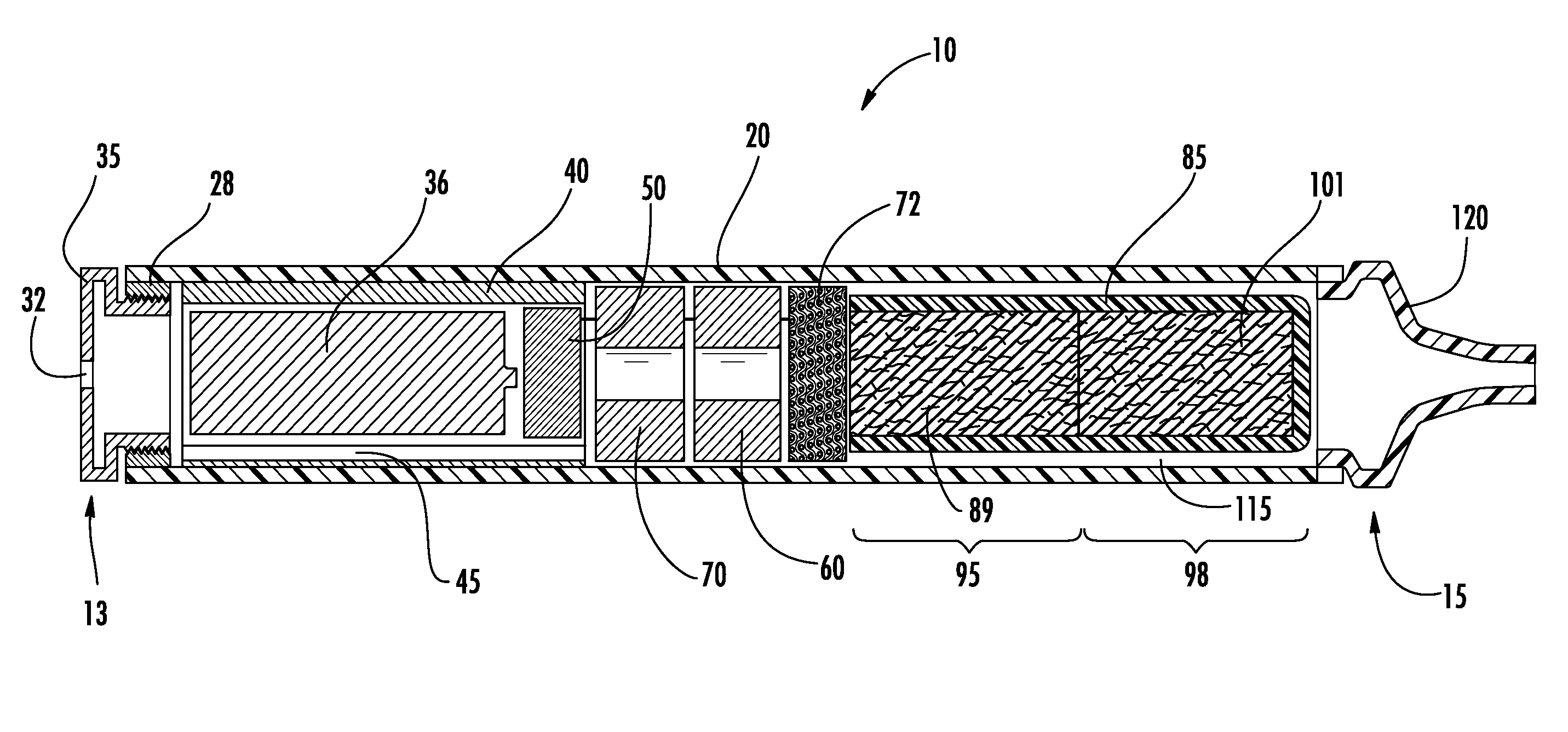

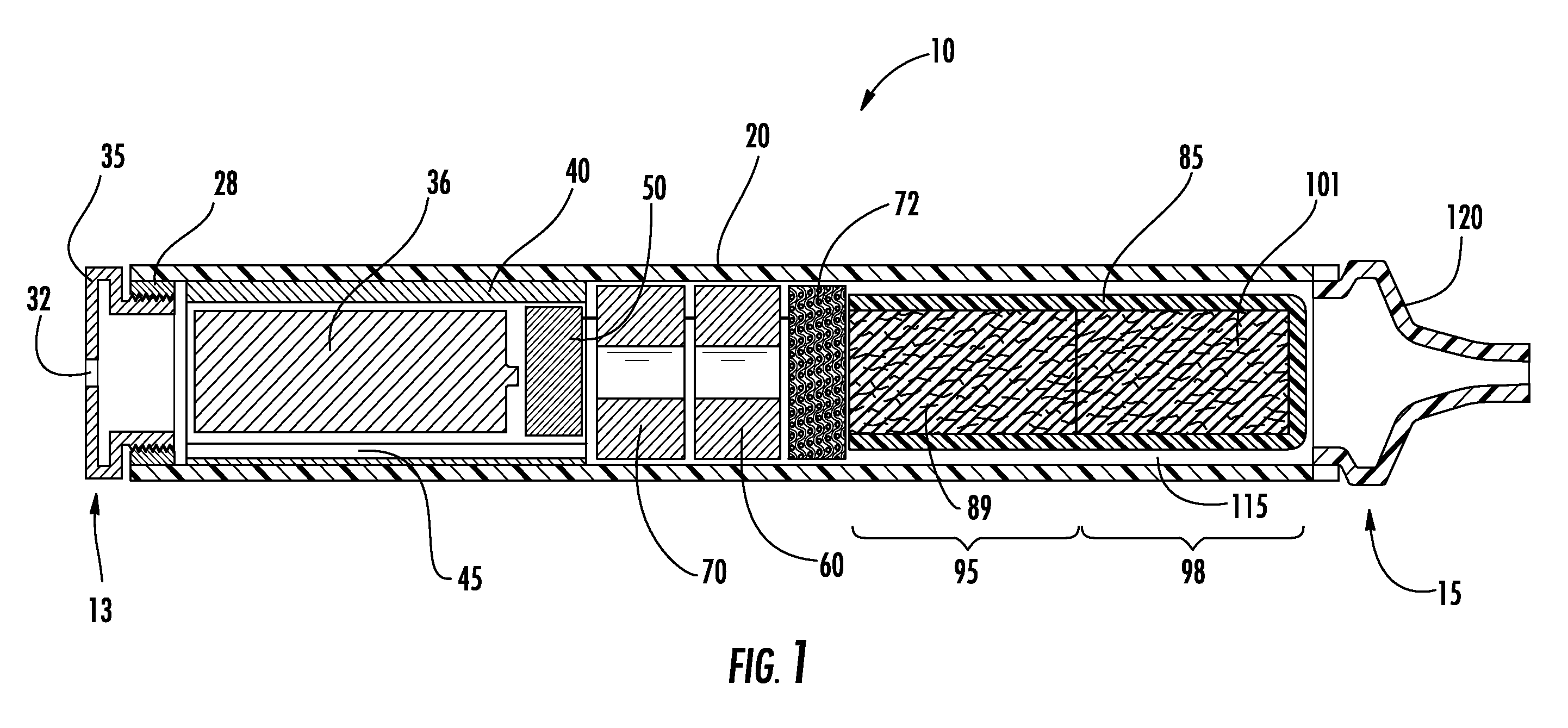

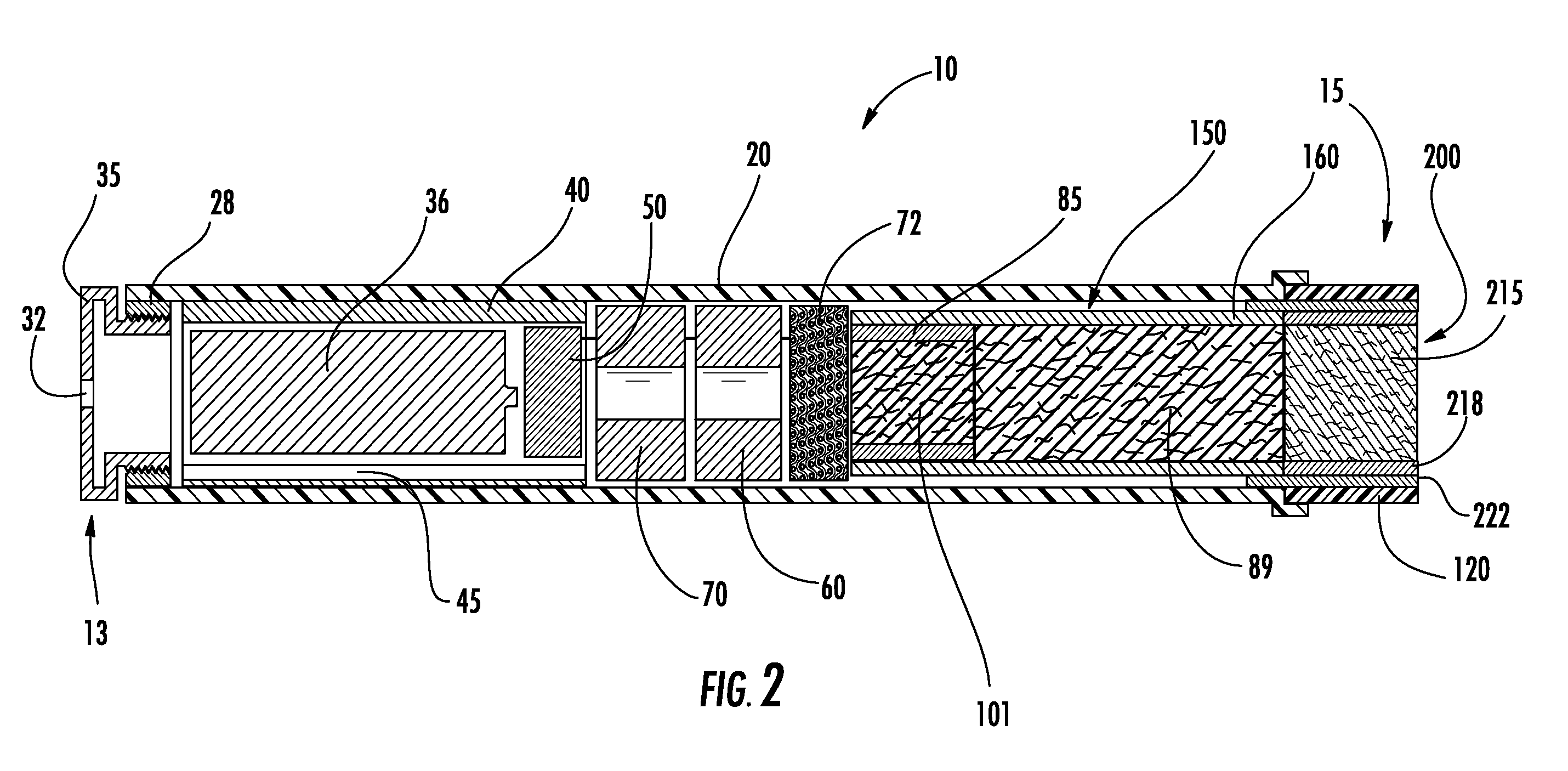

Tobacco-containing smoking article

ActiveUS7726320B2Tobacco preparationTobacco treatmentElectrical resistance and conductanceEngineering

A smoking article may include a cigarette incorporated within an electrically powered aerosol generating device that acts as a holder for that cigarette. The smoking article possesses at least one form of tobacco. The smoking article also possesses a mouth-end piece that is used by the smoker to inhale components of tobacco that are generated by the action of heat upon components of the cigarette. A representative smoking article possesses an outer housing incorporating a source of electrical power (e.g., a battery), a sensing mechanism for powering the device at least during periods of draw, and a heating device (e.g., at least one electrical resistance heating element) for forming a thermally generated aerosol that incorporates components of tobacco. During use, the cigarette is positioned within the device, and after use, the used cigarette is removed from the device and replaced with another cigarette.

Owner:RAI STRATEGIC HLDG INC

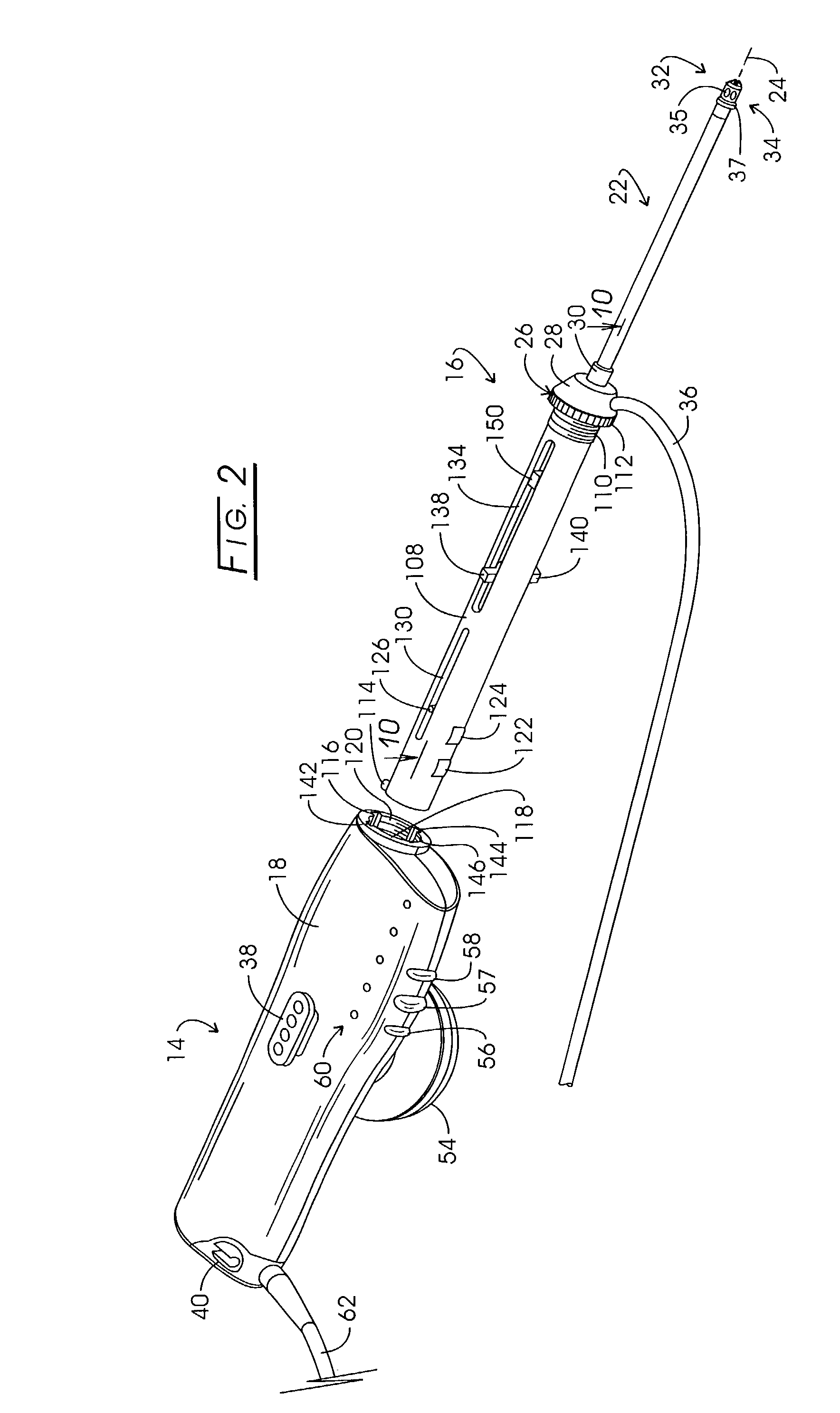

Electrosurgical probe and method of use

ActiveUS7169146B2Reduce the temperatureQuick changeSurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceVolumetric Mass Density

An electrosurgical instrument that allows precise modulation of active Rf density in an engaged tissue volume. The working end of the instrument has a tissue-contacting surface of a conductive-resistive matrix that is variably resistive depending on its temperature. The matrix comprises a positive temperature coefficient (PTC) polymeric material hat exhibits very large increases in resistivity as any local portion increases beyond a selected temperature. In a method of use, the polymeric PTC material senses the temperature of engaged tissue in a manner akin to pixel-by-pixel sensing and thereby changes its resistance in a corresponding pixel-by-pixel manner. The instrument further carries cooling means to cause accelerated thermal relaxation of the PTC matrix during use to make the engagement surface highly responsive to temperature changes that in turn alter the matrix between being electrically conductive and electrically resistive.

Owner:ETHICON ENDO SURGERY INC

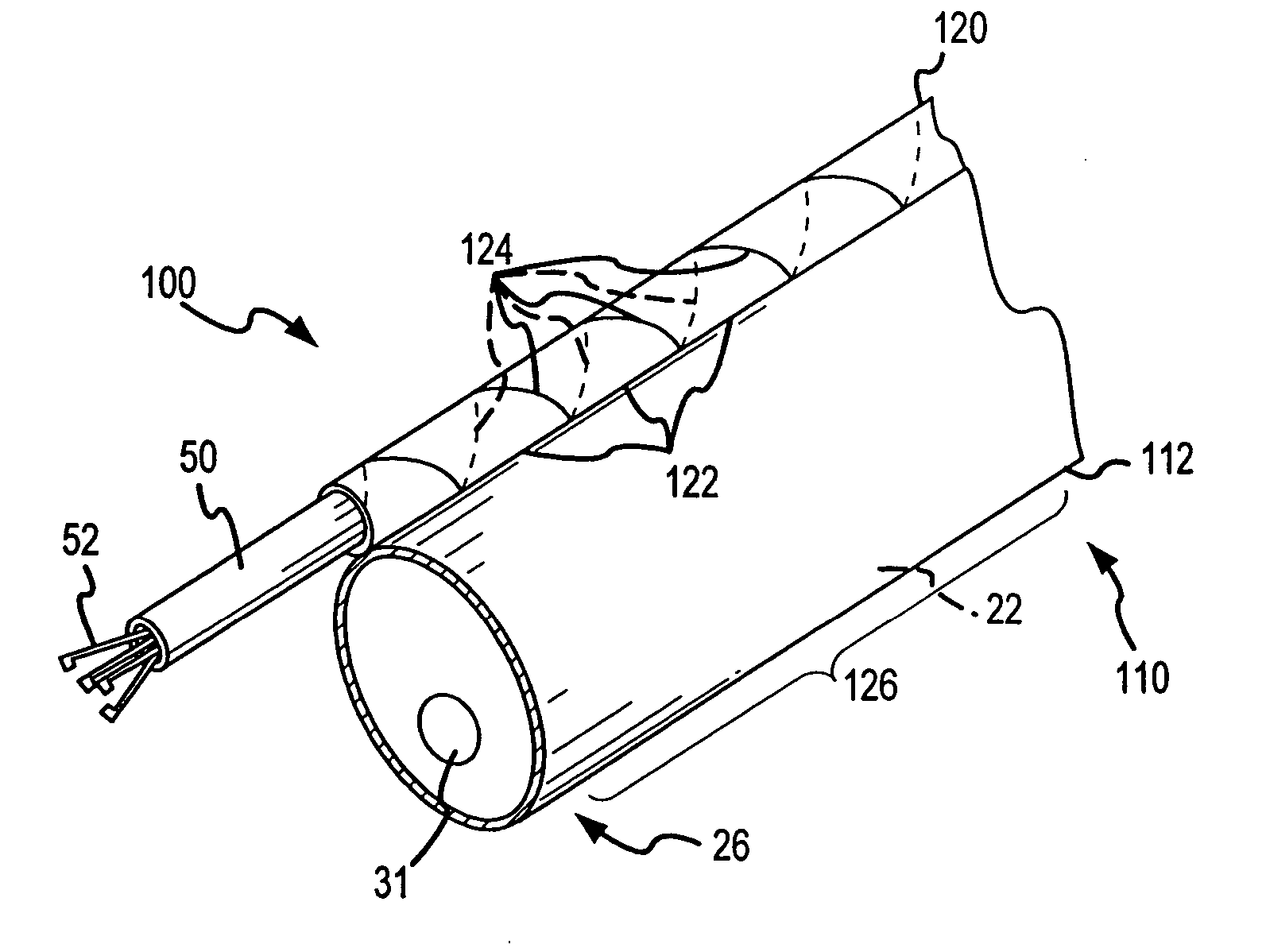

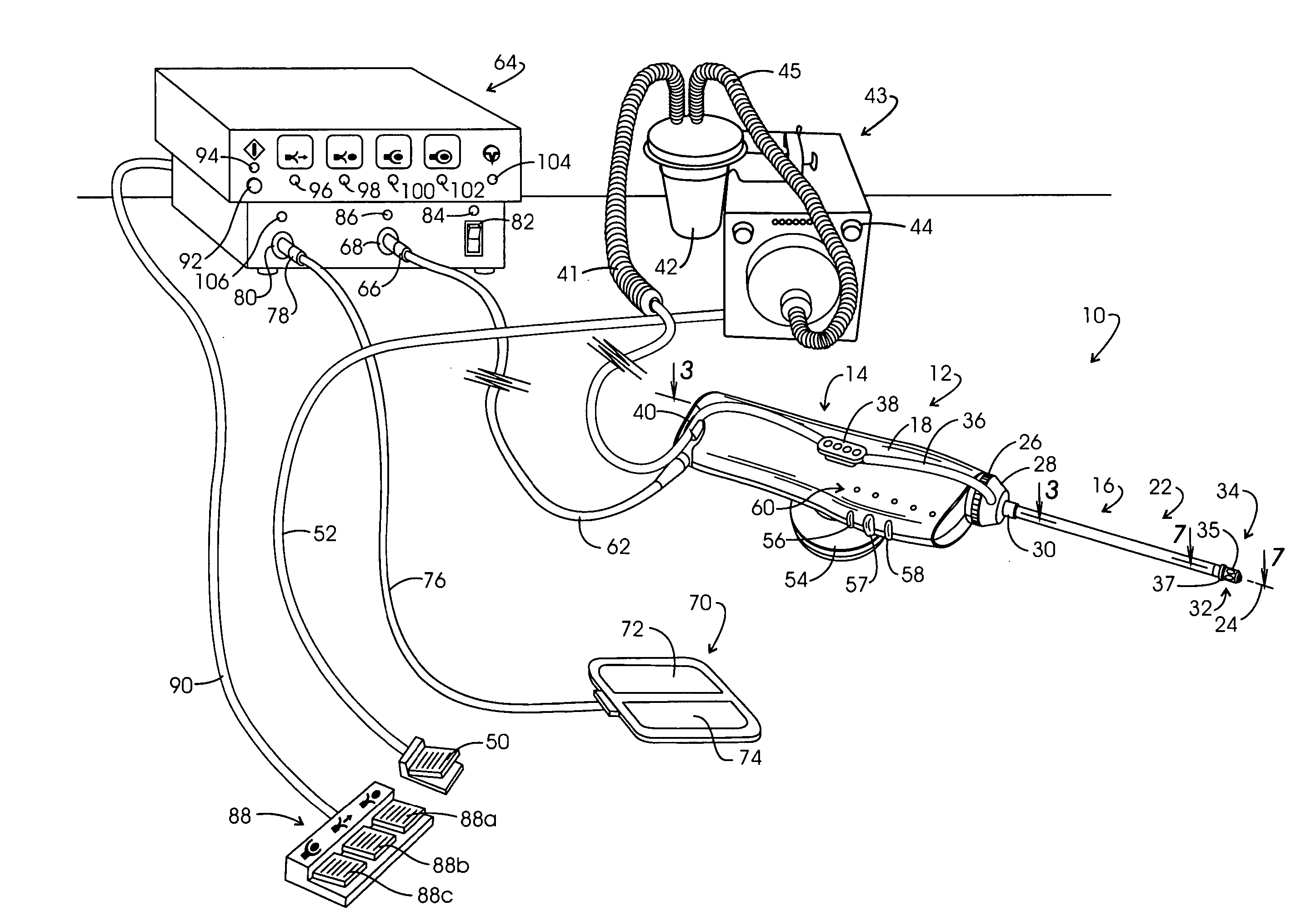

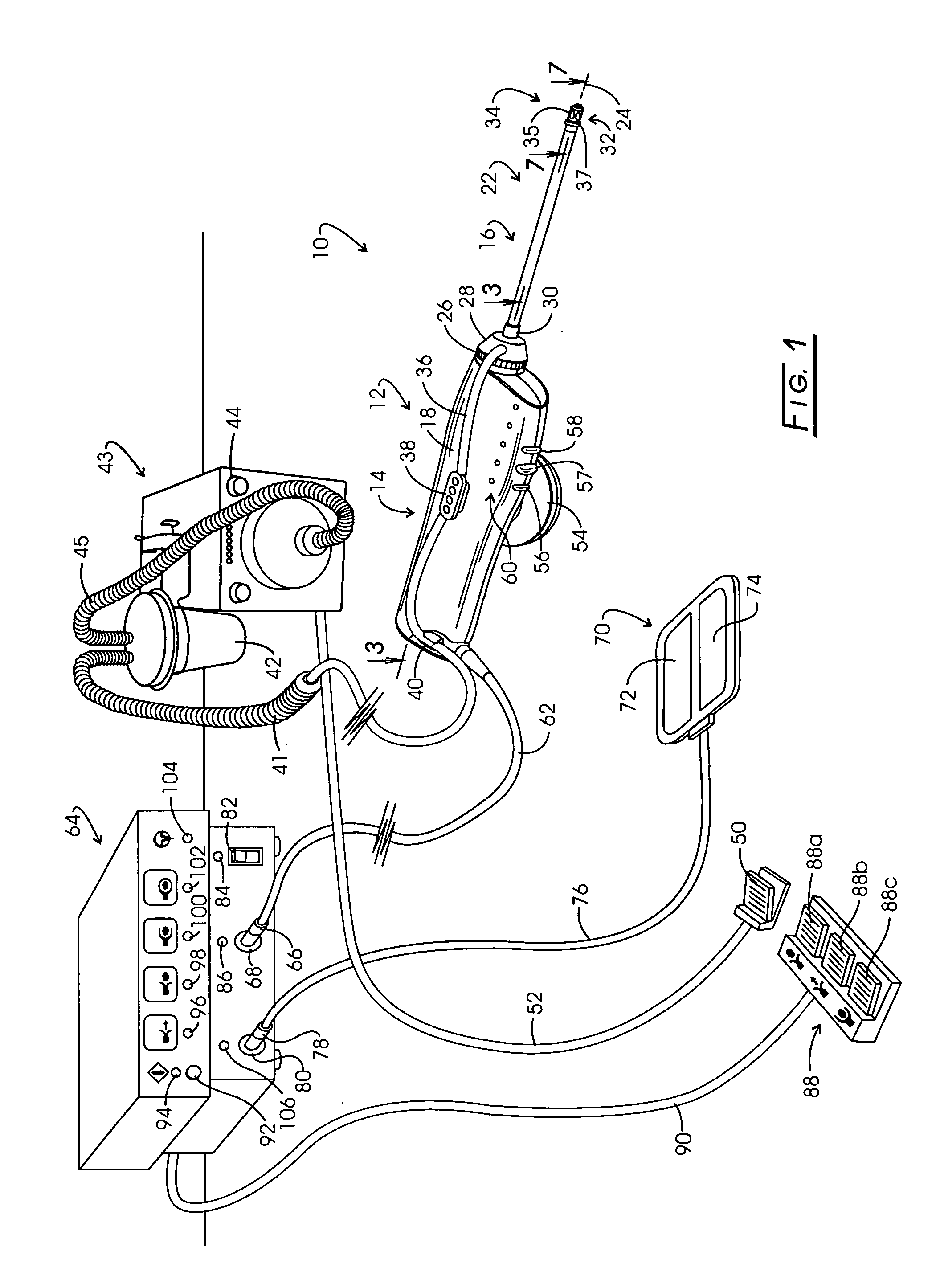

Endoscope assemblies having working channels with reduced bending and stretching resistance

InactiveUS20060079735A1Reduce bendingReduce stretch resistanceSurgeryVaccination/ovulation diagnosticsElectrical resistance and conductanceAxial force

Apparatus and methods for endoscope assemblies having working channels with reduced bending and stretching resistance are disclosed. In one embodiment, an endoscope assembly includes a sheath having a body portion adapted to at least partially encapsulate an endoscopic insertion tube, and a working channel attached to the body portion and extending along at least a portion of the body portion. The working channel includes a component for reducing the resistance of the assembly to bending and stretching. In alternate aspects, the working channel may include a cut, a gap, a sliding portion, or an expansion section. Endoscope assemblies having a working channel in accordance with the invention advantageously reduce the articulation and stretching resistance of the assembly during articulation of the endoscope assembly. Also, because the axial forces (tension and compression) within the working channel are reduced, the working channel can be fabricated out of a relatively hard, inelastic material, thereby reducing the friction within the working channel and improving the physician's ability to perform a medical procedure.

Owner:MARTONE STEPHEN +1

Finger operated switch for controlling a surgical handpiece

ActiveUS7883465B2Ultrasonic/sonic/infrasonic diagnosticsSurgical instrument detailsElastomerCapacitance

According to the invention, a finger-operated switch for activating and operating an ultrasonic surgical handpiece is provided. The power output of the surgical handpiece is responsive and proportional to the pressure applied to the finger-operated switch. The finger-operated switch includes, but not limited to, force sensitive resistors whose resistance is proportional to the force applied by the finger of the human operator of the surgical handpiece, force sensitive capacitors whose capacitance is proportional to the pressure, deflection or compression of the insulation layer between two electrodes or is proportional to the spacing between the two conductive layers, strain gauges mounted underneath or integral to the housing of the surgical handpiece such that the pressure applied thereto results in an output change in the strain gauges, magnets or ferromagnets encased or embedded in an elastomer with a sensor inside the surgical handpiece that detects the field strength of the magnet and monitors changes relative to the force applied to the handpiece housing, and piezo film or piezo ceramic whose charge or voltage is proportional to the force applied.

Owner:ETHICON ENDO SURGERY INC

Electrosurgery with infiltration anesthesia

InactiveUS20050267455A1Reliable formationAnaesthesiaSurgical instruments for heatingElectrical resistance and conductanceElectrosurgery

Method for carrying out the recovery of an intact volume of tissue wherein a delivery cannula tip is positioned in confronting adjacency with the volume of tissue to be recovered. The electrosurgical generator employed to form an arc at a capture component extending from the tip is configured having a resistance-power profile which permits recovery of the specimen without excessive thermal artifact while providing sufficient power to sustain a cutting arc. For the recovery procedure, a local anesthetic employing a diluent which exhibits a higher resistivity is utilized and the method for deploying the capture component involves an intermittent formation of a cutting arc with capture component actuation interspersed with pauses of duration effective to evacuate any accumulation or pockets of local anesthetic solution encountered by the cutting electrodes.

Owner:INTACT MEDICAL

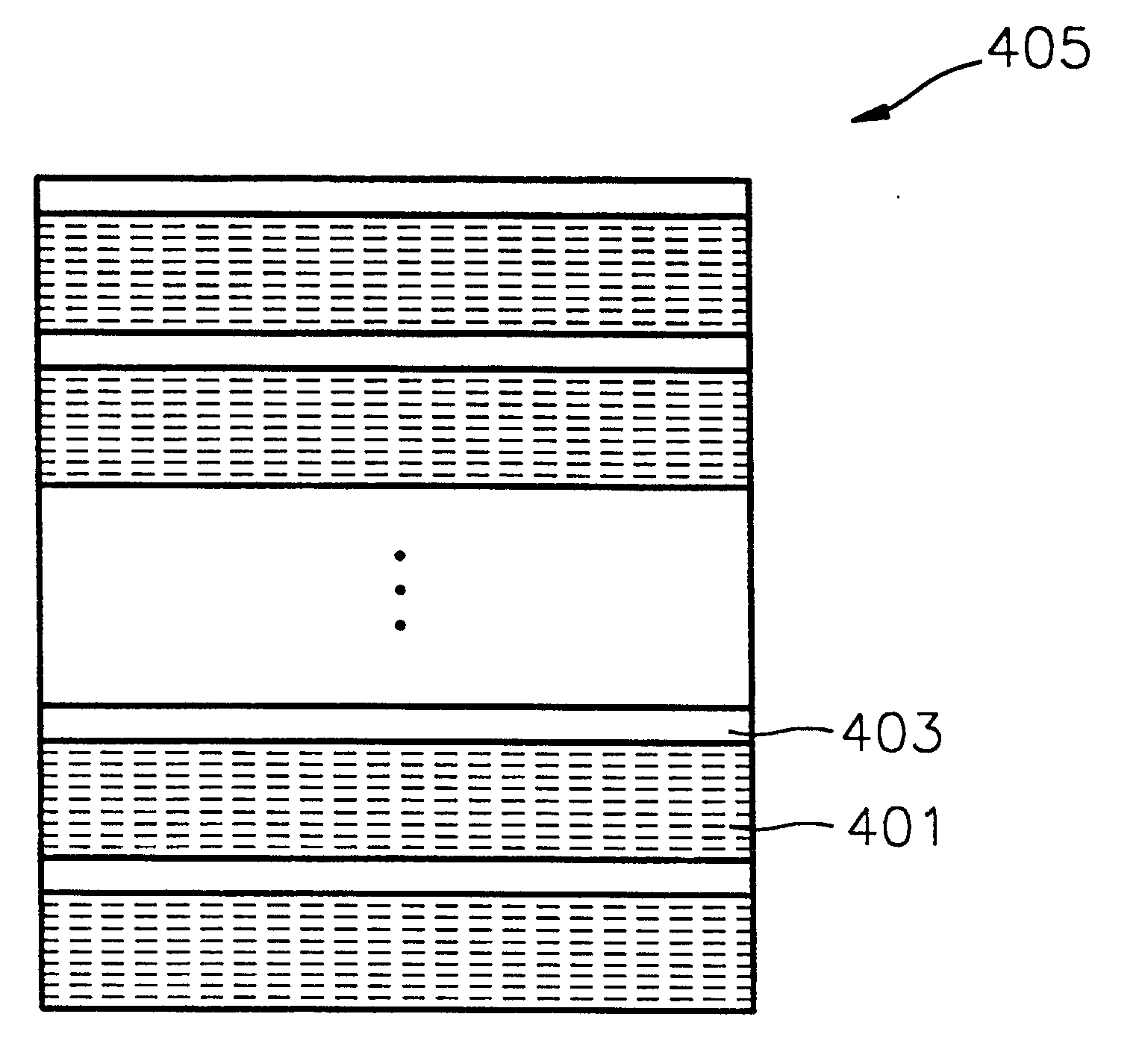

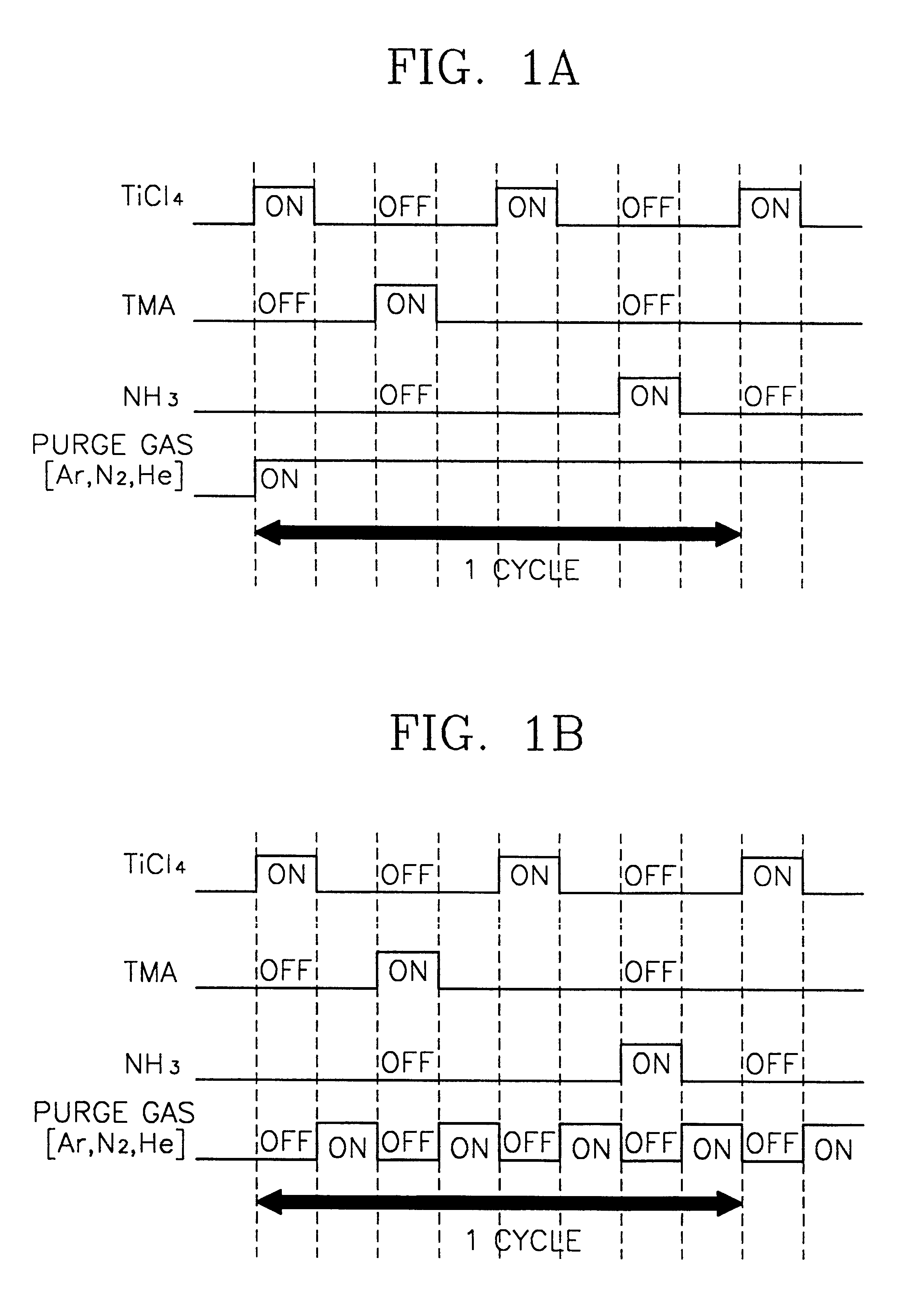

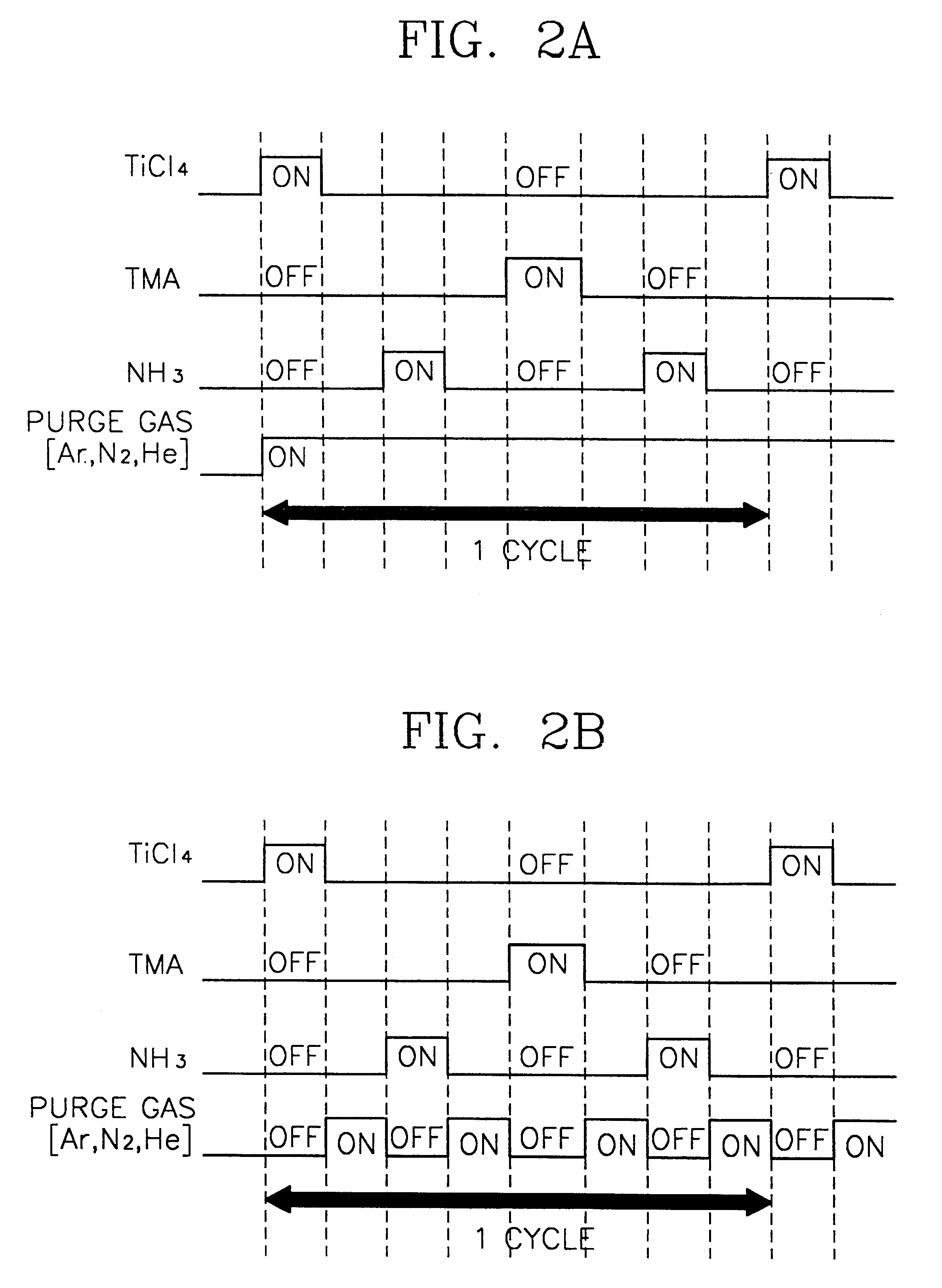

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

Tobacco-Containing Smoking Article

ActiveUS20080092912A1Tobacco preparationTobacco treatmentElectrical resistance and conductanceEngineering

A smoking article may include a cigarette incorporated within an electrically powered aerosol generating device that acts as a holder for that cigarette. The smoking article possesses at least one form of tobacco. The smoking article also possesses a mouth-end piece that is used by the smoker to inhale components of tobacco that are generated by the action of heat upon components of the cigarette. A representative smoking article possesses an outer housing incorporating a source of electrical power (e.g., a battery), a sensing mechanism for powering the device at least during periods of draw, and a heating device (e.g., at least one electrical resistance heating element) for forming a thermally generated aerosol that incorporates components of tobacco. During use, the cigarette is positioned within the device, and after use, the used cigarette is removed from the device and replaced with another cigarette.

Owner:RAI STRATEGIC HLDG INC

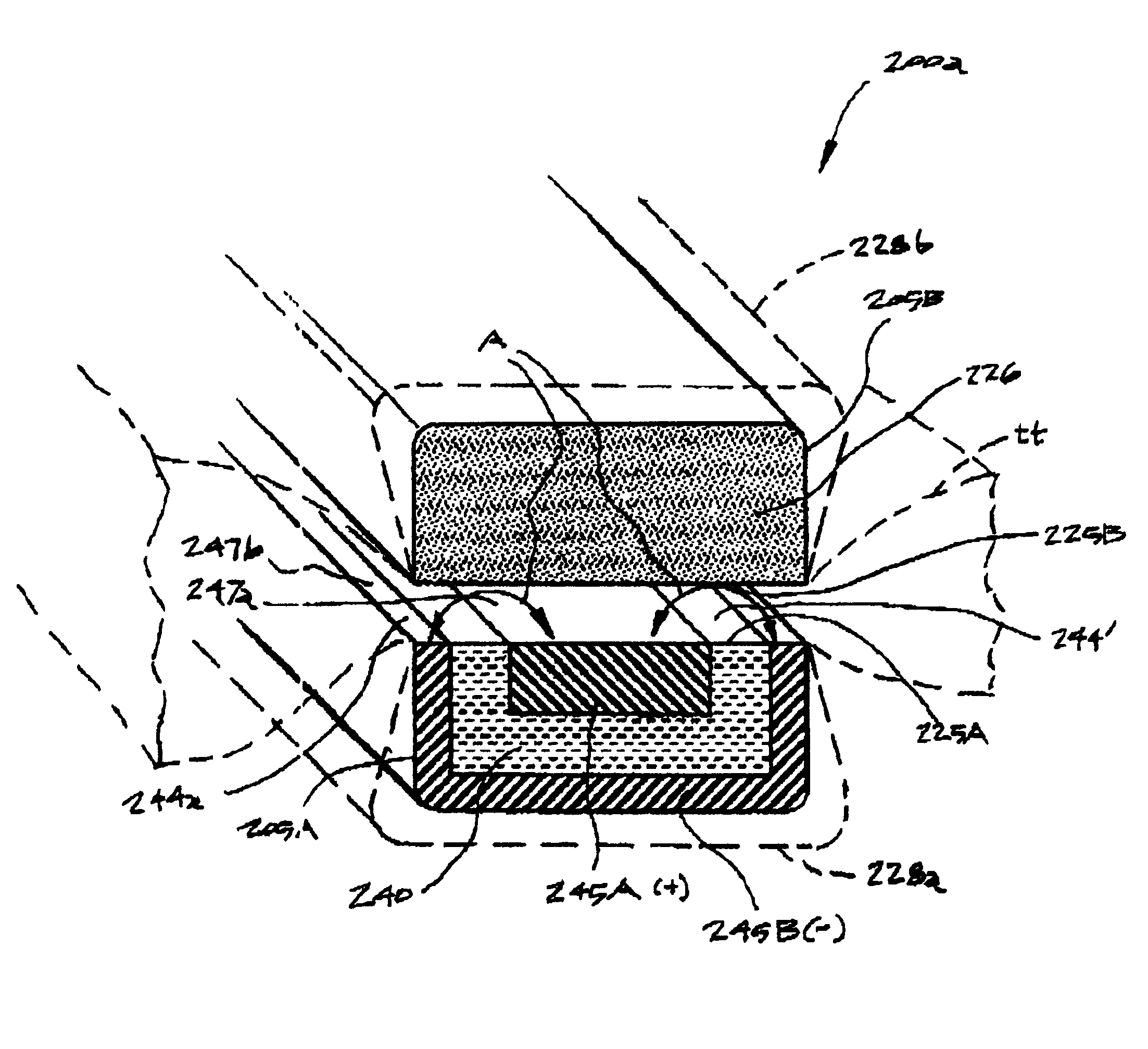

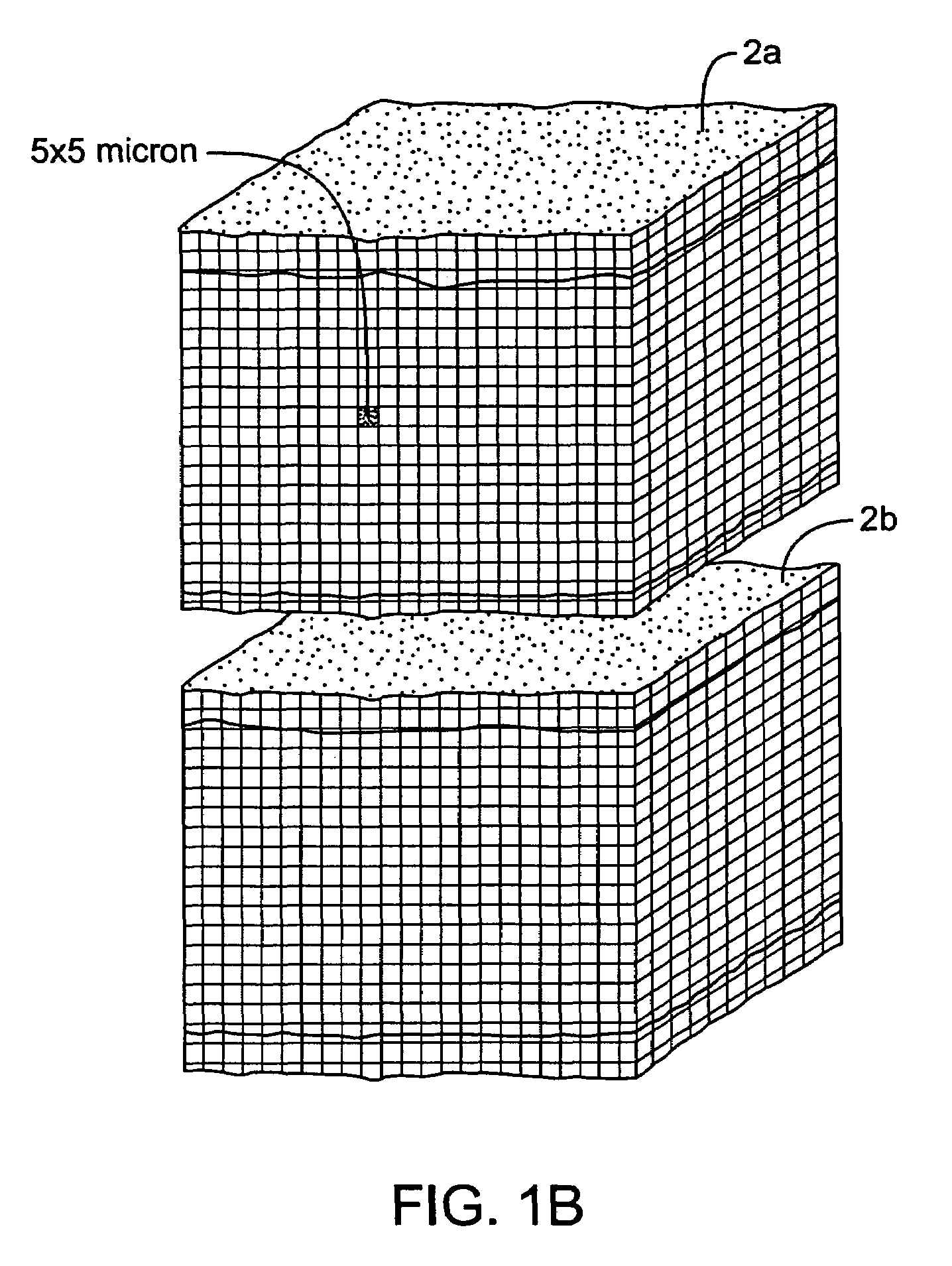

Electrosurgical instrument and method of use

InactiveUS7112201B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface. In another mode of operation, a conductive-resistive matrix can induce a “wave” of Rf energy density to sweep across the tissue to thereby weld tissue.

Owner:ETHICON ENDO SURGERY INC

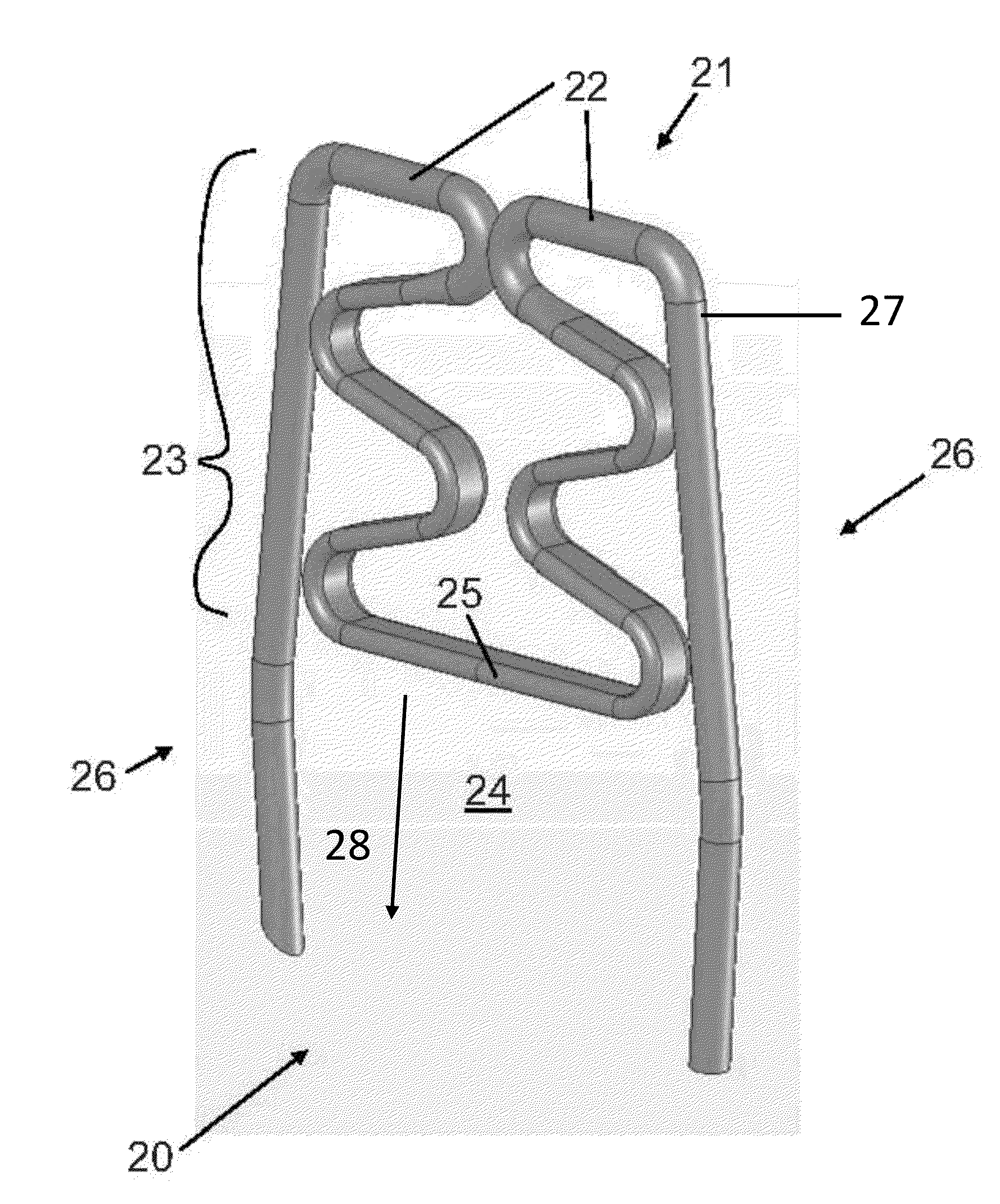

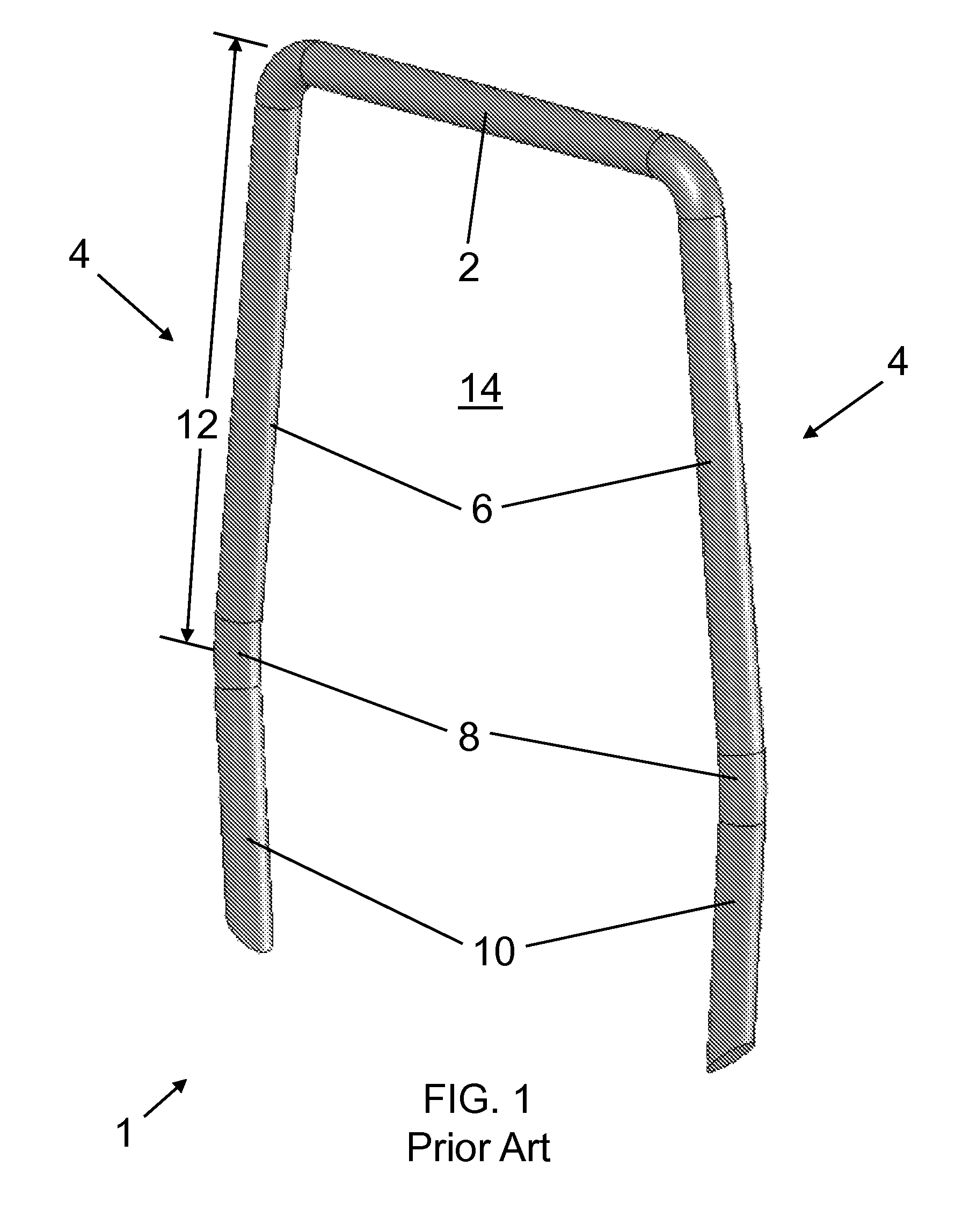

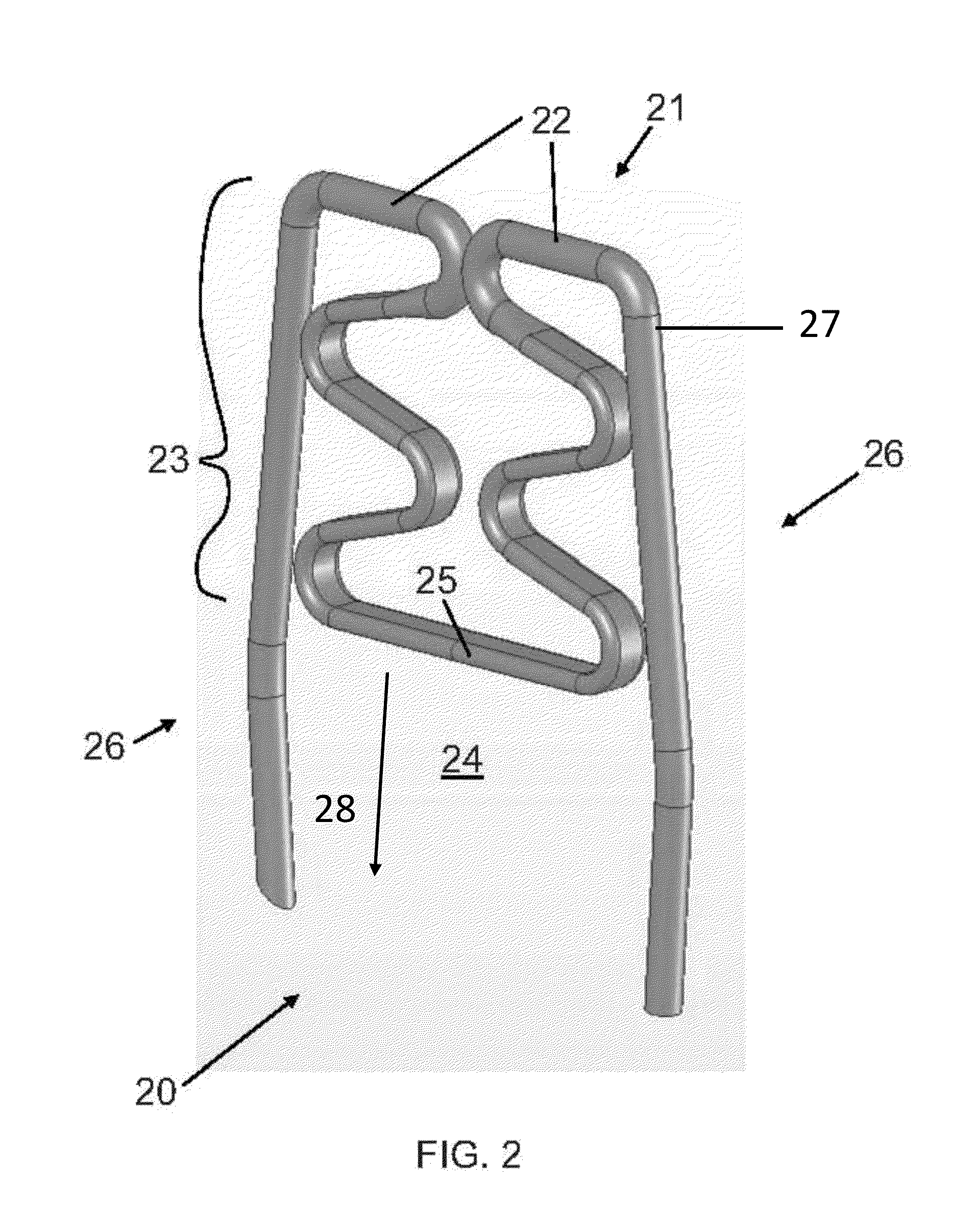

Adjustable compression staple and method for stapling with adjustable compression

ActiveUS8679154B2Suture equipmentsStapling toolsElectrical resistance and conductanceCompression device

A compression-self-adjusting staple includes a substantially U-shaped staple body and a compression device. The staple body has a bridge and two legs extending from the bridge at an angle thereto. Each of the legs has a base end integral with the bridge and a deformable distal end defining a stapling point shaped to pierce material to be stapled. The compression device is at least partly disposed between the legs and has a bias portion with a compression surface movably disposed between the legs and a compression resistor connected to the bridge and to the compression surface and formed to resist movement of the compression surface towards the bridge with a force.

Owner:CILAG GMBH INT

Electrosurgery with infiltration anesthesia

InactiveUS7004174B2AnaesthesiaVaccination/ovulation diagnosticsElectrical resistance and conductanceElectrosurgery

Method for carrying out the recovery of an intact volume of tissue wherein a delivery cannula tip is positioned in confronting adjacency with the volume of tissue to be recovered. The electrosurgical generator employed to form an arc at a capture component extending from the tip is configured having a resistance-power profile which permits recovery of the specimen without excessive thermal artifact while providing sufficient power to sustain a cutting arc. For the recovery procedure, a local anesthetic employing a diluent which exhibits a higher resistivity is utilized and the method for deploying the capture component involves an intermittent formation of a cutting arc with capture component actuation interspersed with pauses of duration effective to evacuate any accumulation or pockets of local anesthetic solution encountered by the cutting electrodes.

Owner:COVIDIEN AG

Surgical sealing surfaces and methods of use

ActiveUS7220951B2Fast transferHighly stable current-limitingDielectric heatingSurgical instruments for heatingOmni directionalSwitching time

Various embodiments provide compositions that exhibit positive temperature coefficient of resistance (PTCR) properties for use in thermal interactions with tissue—including thermal sensing and I2R current-limiting interactions. Embodiments also provide tissue-engaging surfaces having PTCR materials that provide very fast switching times between low resistance and high, current-limiting resistance. One embodiment provides a matrix for an electrosurgical energy delivery surface comprising a PTCR material and a heat exchange material disposed within an interior of the matrix. The PTCR material has a substantially conductive state and a substantially non-conductive state. The heat exchange material has a structure configured to have an omni-directional thermal diffusivity for exchanging heat with the PTCR material to cause rapid switching of the PTCR material between the conductive state and non-conductive state. Preferably, the structure comprises a graphite foam having an open cell configuration. The matrix can be carried by tissue contacting surfaces of various electrosurgical devices.

Owner:ETHICON ENDO SURGERY INC

Tissue fusion system and method of performing a functional verification test

InactiveUS8840609B2Reduce traumaProlong surgery timeSurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceOperational system

A jaw heating element of a handpiece of a thermal tissue operating system is tested on an ongoing basis by supplying a test heater power signal to the jaw heating element between individual thermal tissue operations. Voltage and current through the jaw heating element is sensed and the resistance of the jaw heating element is calculated. If the calculated resistance is outside a range of predetermined acceptable values, an error condition is indicated.

Owner:CONMED CORP

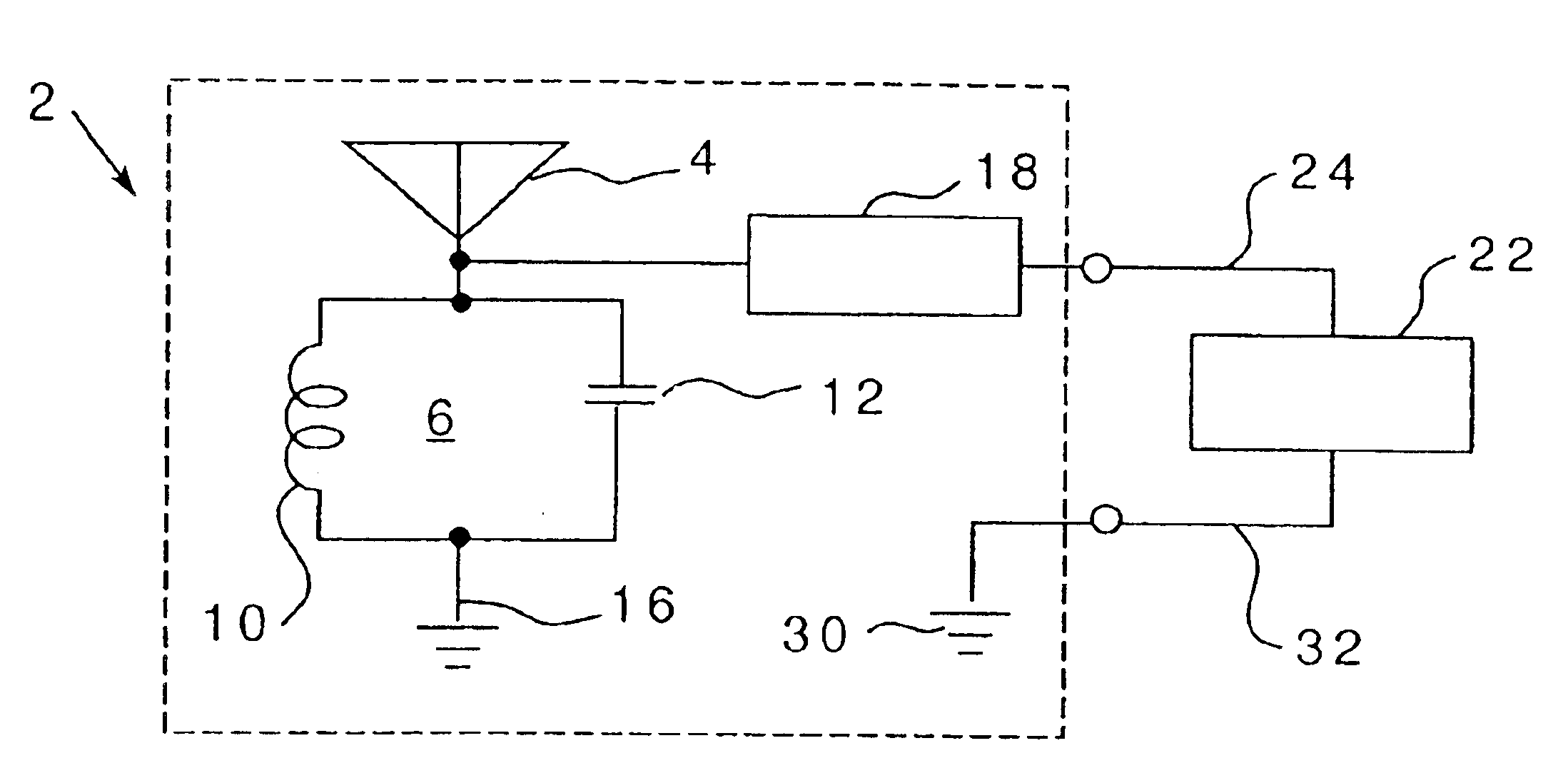

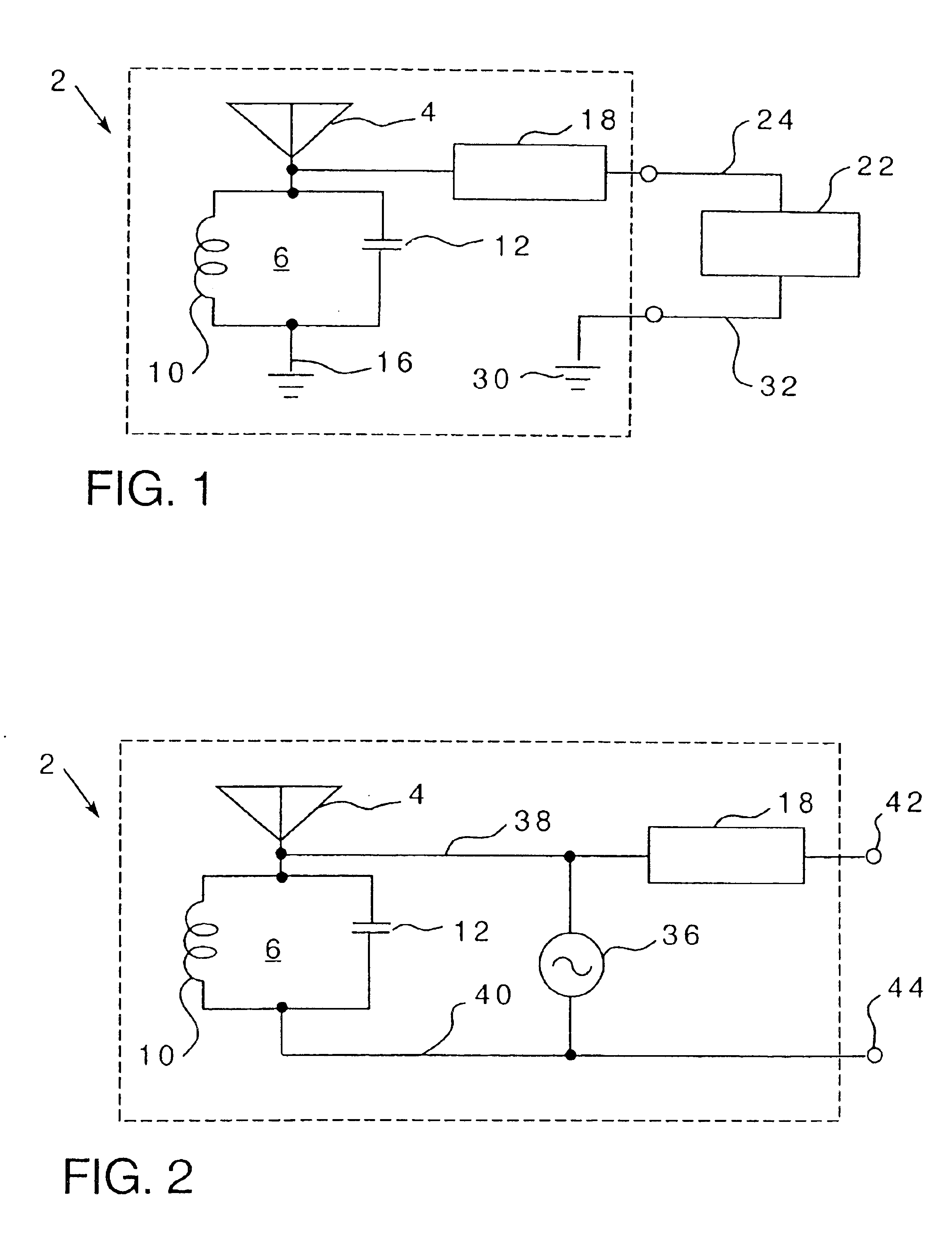

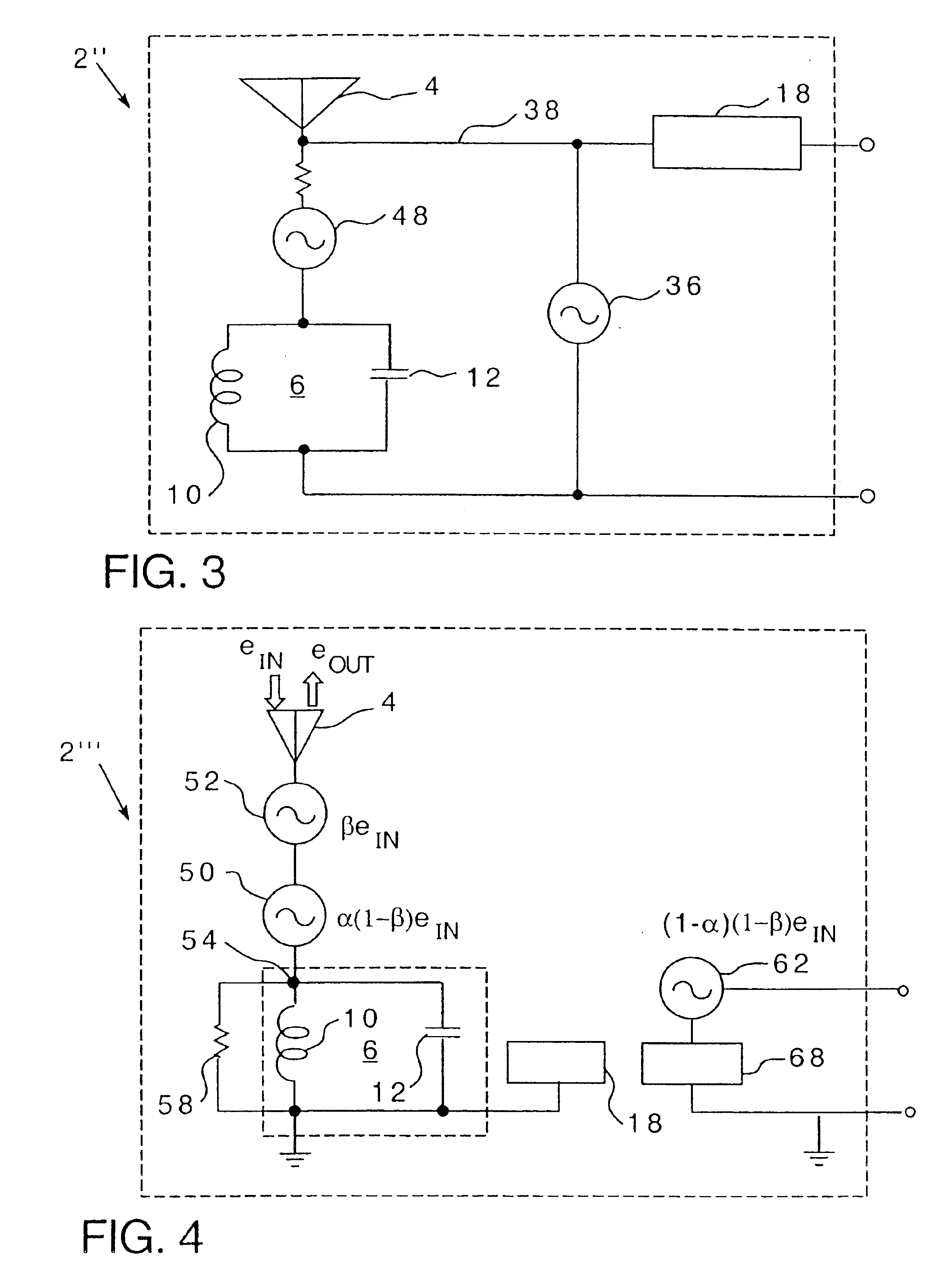

Energy harvesting circuits and associated methods

InactiveUS6856291B2Advantageously employedAntenna supports/mountingsAntenna feed intermediatesCapacitanceElectrical resistance and conductance

An inherently tuned antenna has a circuit for harvesting energy transmitted in space and includes portions that are structured to provide regenerative feedback into the antenna to produce an inherently tuned antenna which has an effective area substantially greater than its physical area. The inherently tuned antenna includes inherent distributive inductive, inherent distributive capacitive and inherent distributive resistive elements which cause the antenna to resonate responsive to receipt of energy at a particular frequency and to provide feedback to regenerate the antenna. The circuit may be provided on an integrated circuit chip. An associated method is provided.

Owner:PITTSBURGH UNIV OF

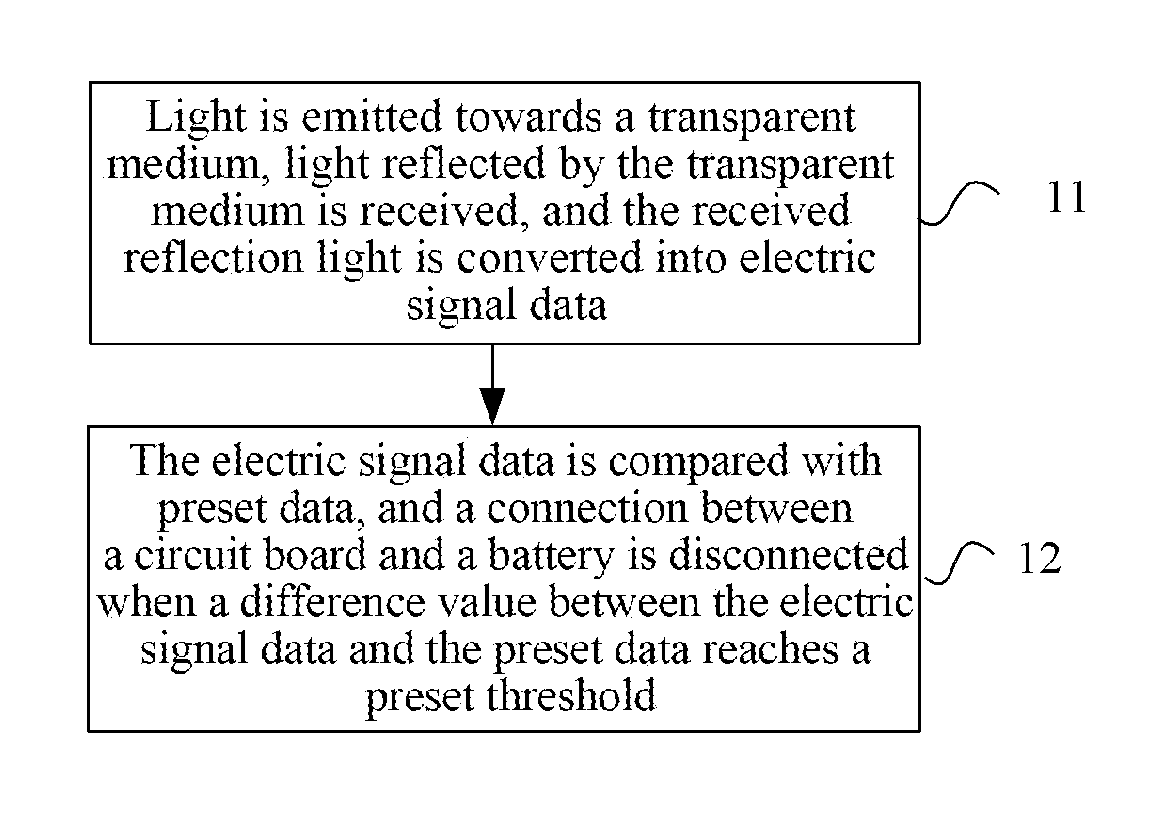

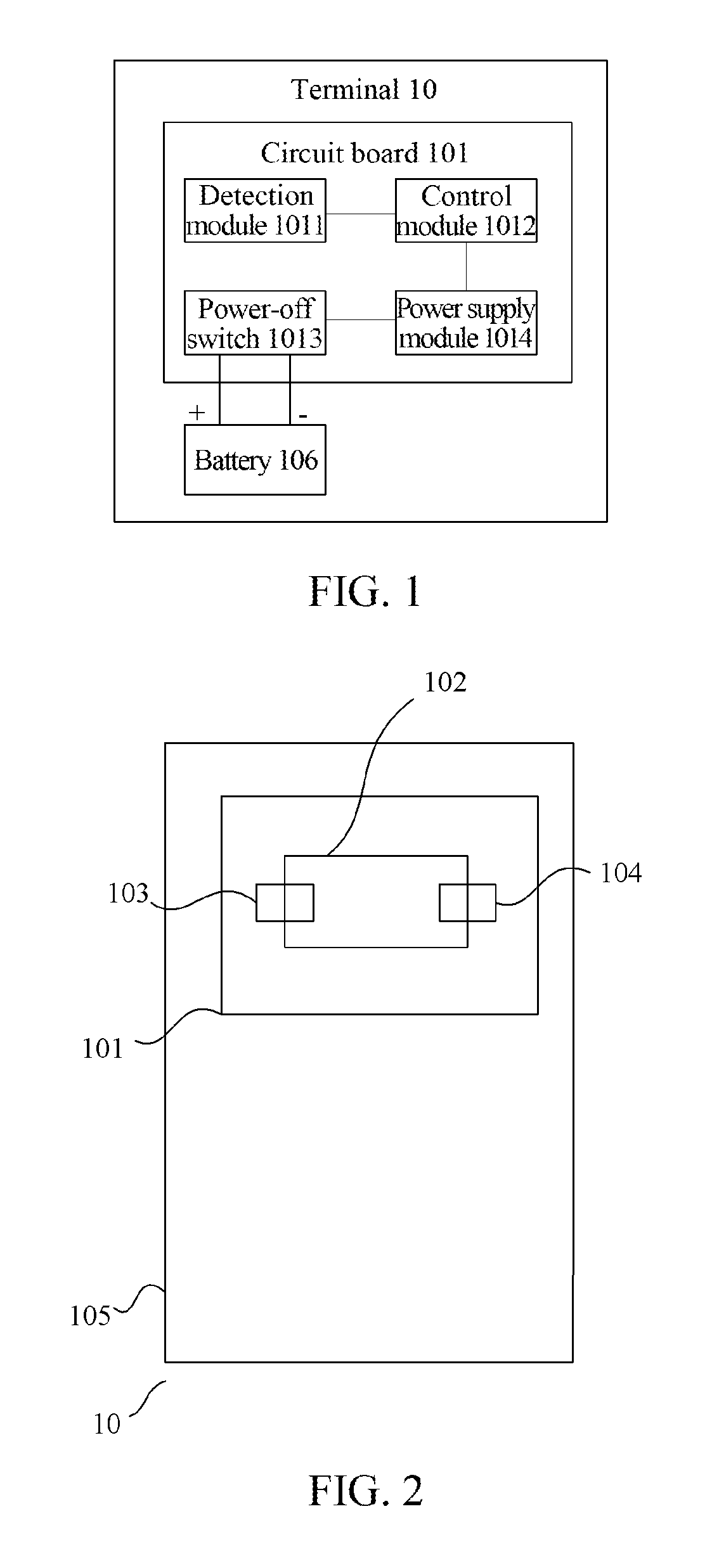

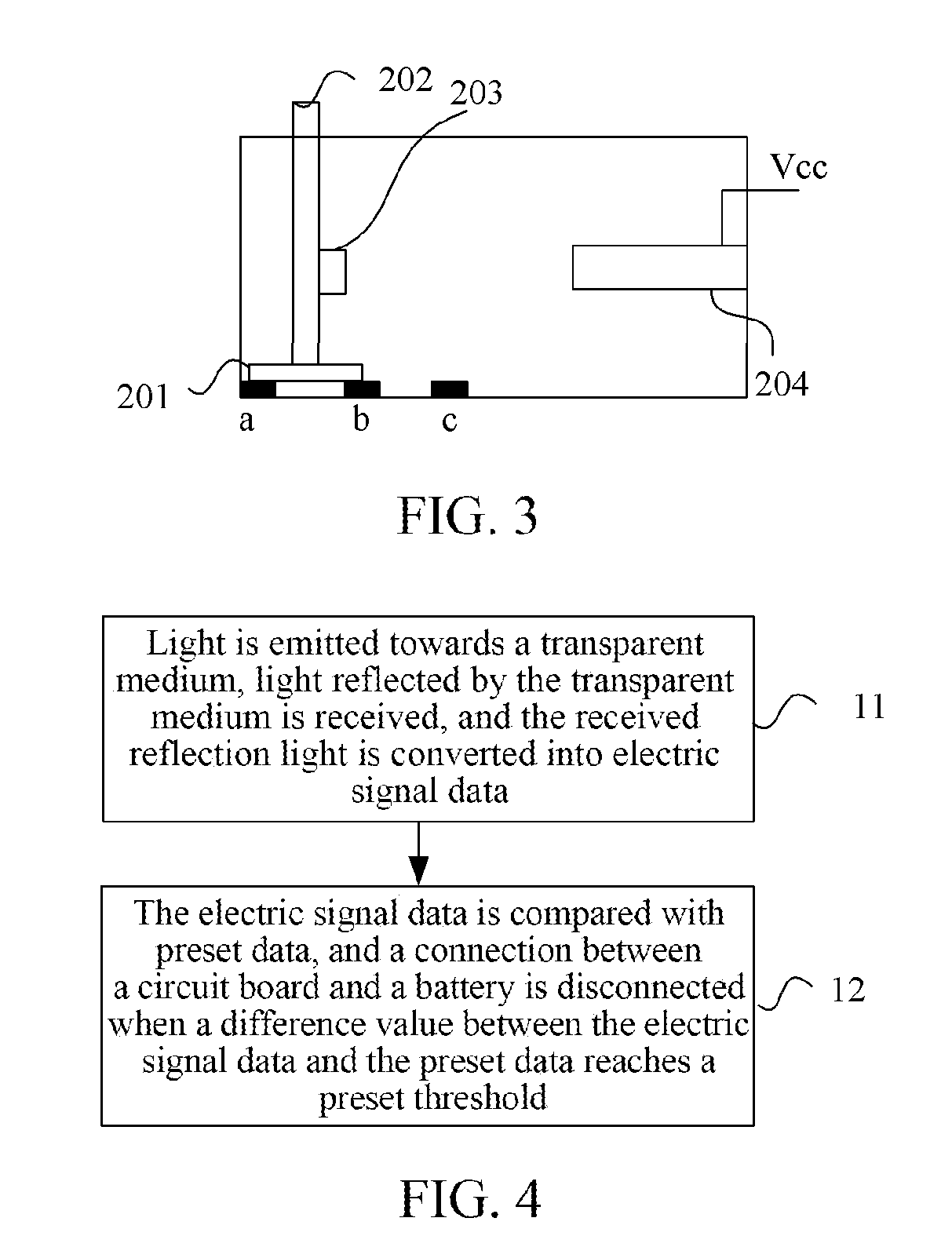

Terminal and electronic water-resistance method

ActiveUS9590433B2Avoid water damageDigital data processing detailsScattering properties measurementsElectricityElectrical resistance and conductance

A terminal and electrical water-resistance method, the terminal includes: a circuit board, a battery providing a power source for the circuit board, a housing provided with a transparent medium used for reflecting light; the circuit board includes: a detection module, configured to: emit light towards the transparent medium, receive the light reflected by the transparent medium to convert into electric signal data to send to a control module; the control module, configured to: receive the electric signal data to compare with preset data, trigger the power-off switch when a difference value between the electric signal data and the preset data reaches a preset threshold which is preset according to the light and the transparent medium, wherein, the preset data are electric signal data when the light is totally reflected by the transparent medium; a power-off switch configured to: disconnect a connection between the circuit board and the battery after triggering.

Owner:ZTE CORP

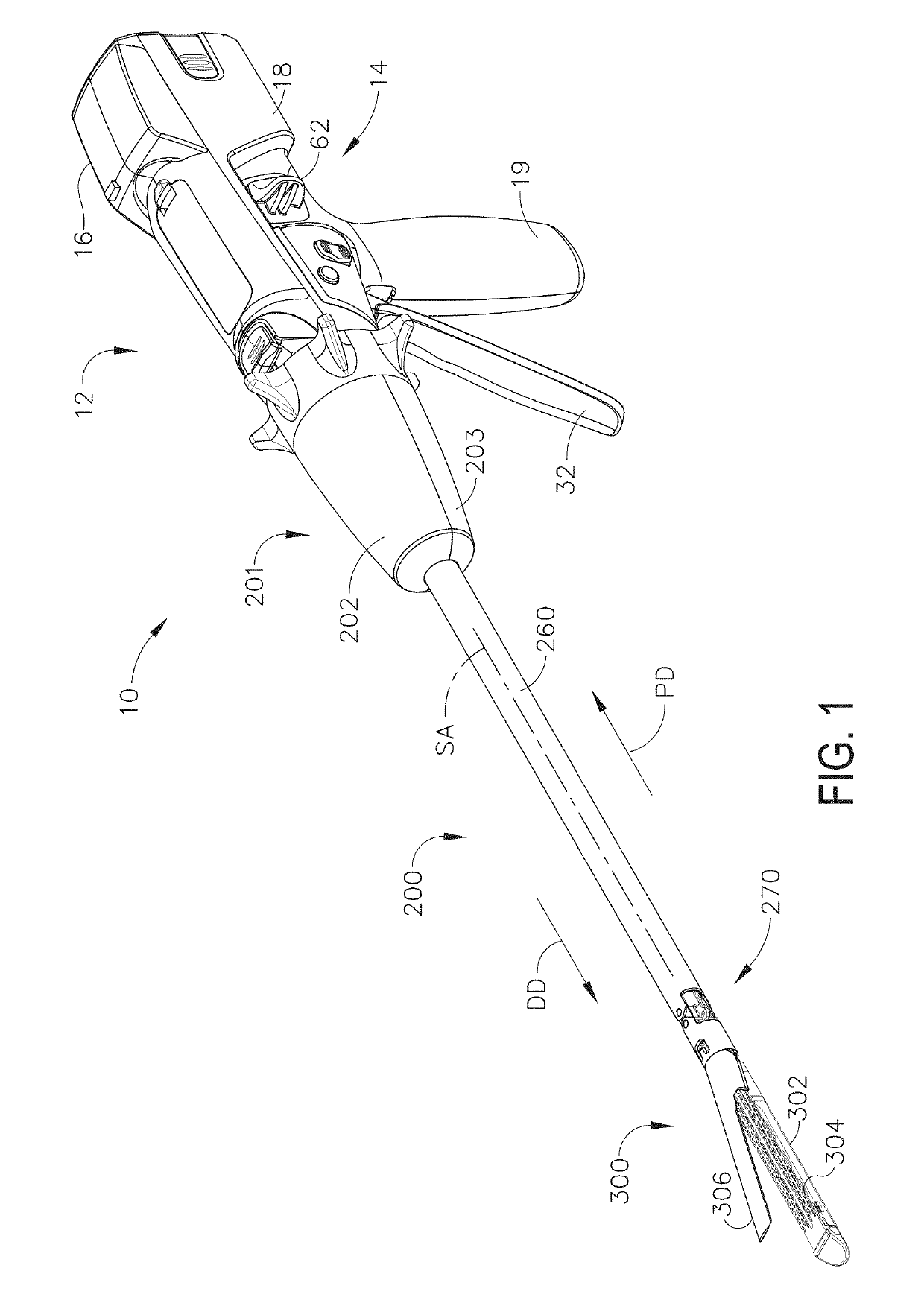

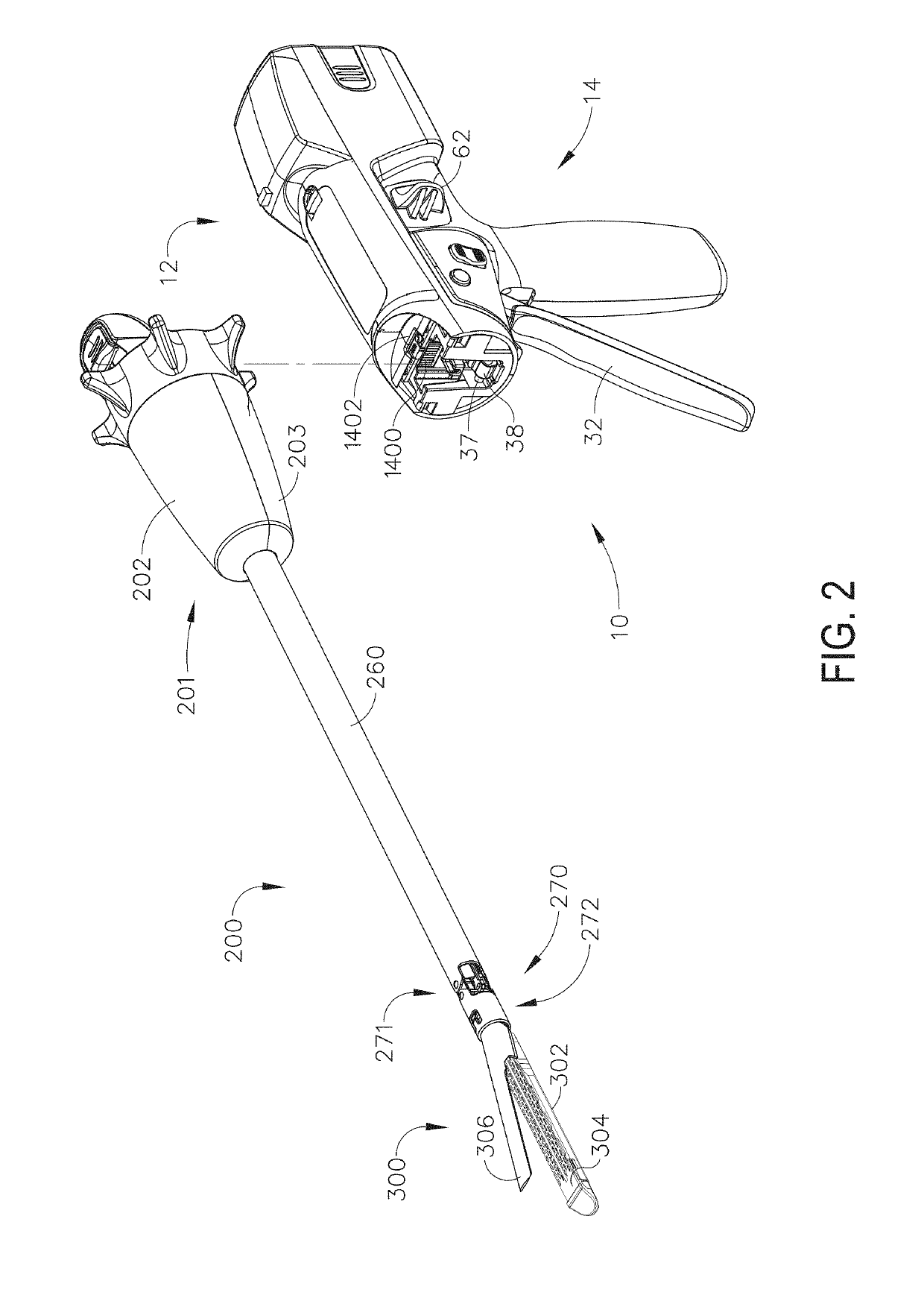

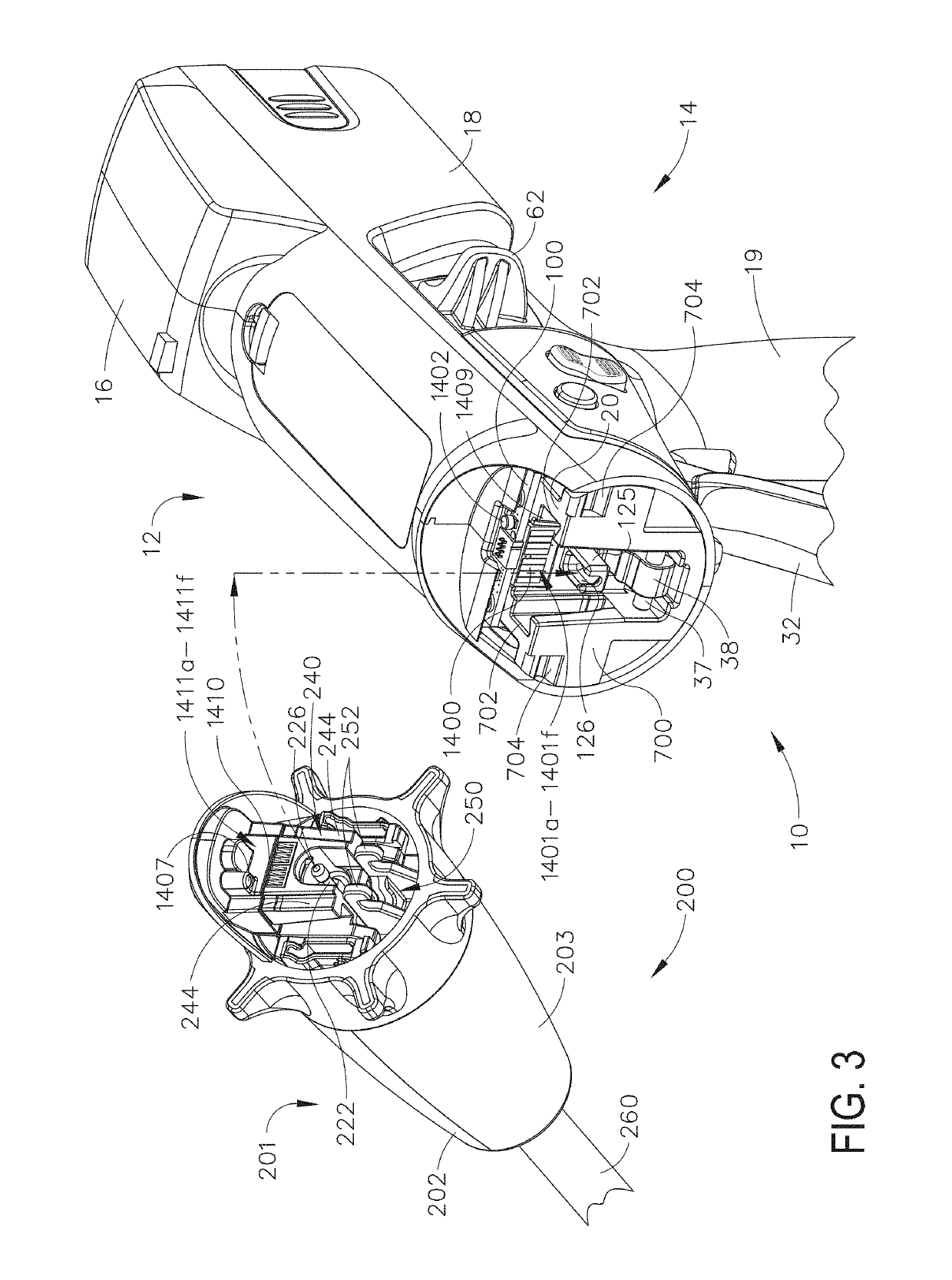

Surgical instrument with detection sensors

Aspects of the present disclosure are presented for a surgical instrument having one or more sensors at or a near an end effector and configured to aide in the detection of tissues and other materials and structures at a surgical site. The detections may then be used to aide in the placement of the end effector and to confirm which objects to operate on, or alternatively, to avoid. Examples of sensors include laser sensors used to employ Doppler shift principles to detect movement of objects at the surgical site, such as blood cells; resistance sensors to detect the presence of metal; monochromatic light sources that allow for different levels of absorption from different types of substances present at the surgical site, and near infrared spectrometers with small form factors.

Owner:CILAG GMBH INT

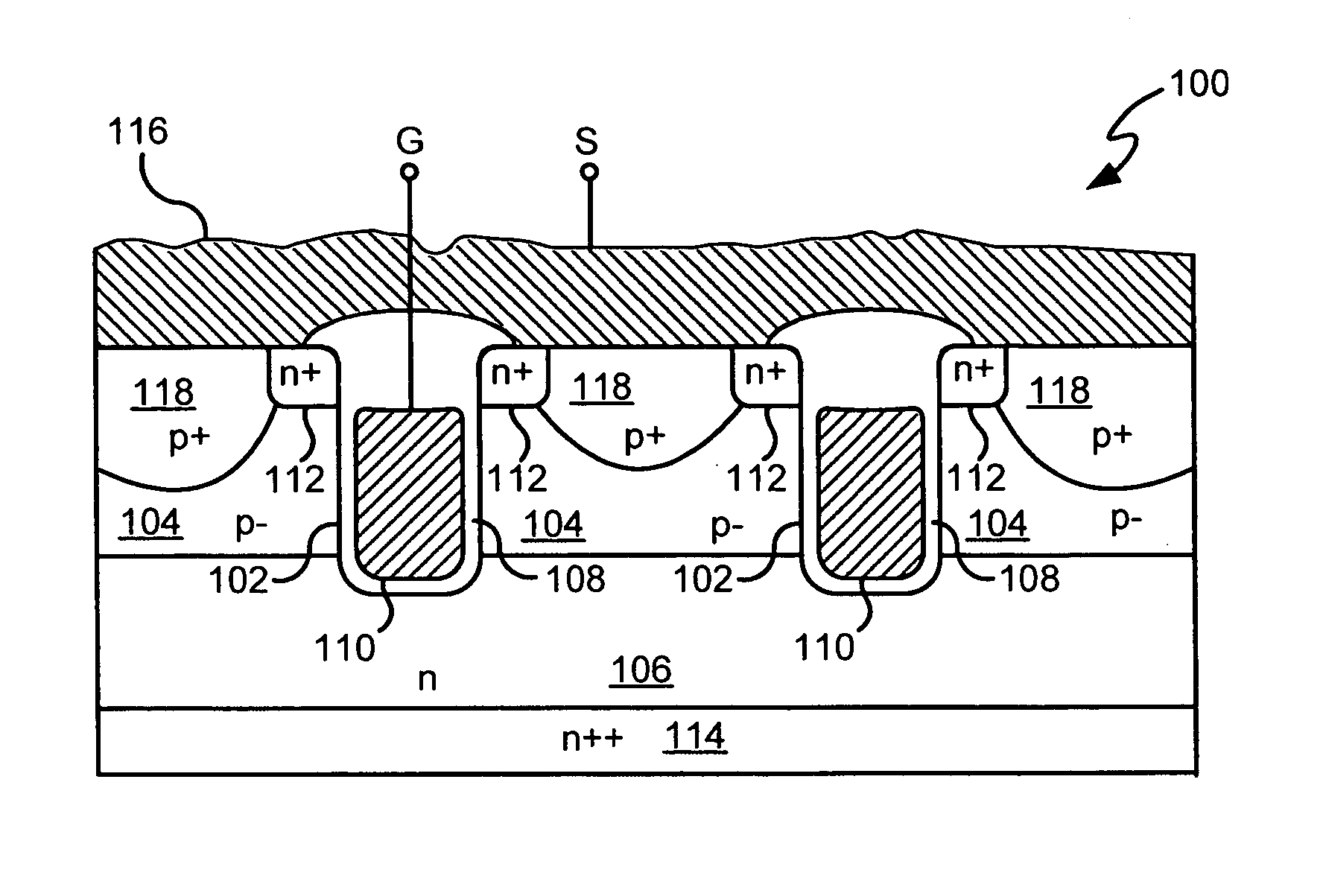

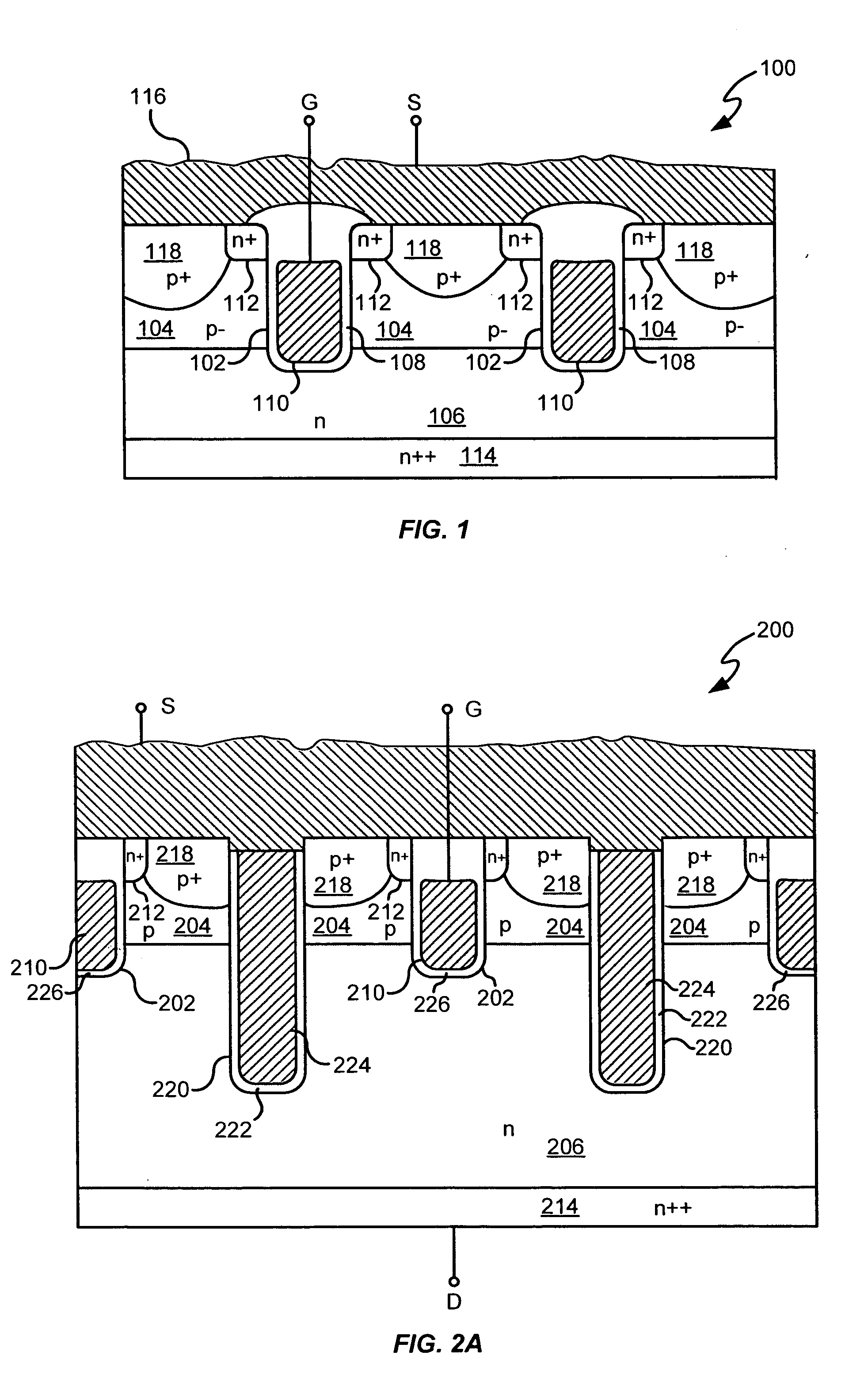

Power semiconductor devices and methods of manufacture

ActiveUS20050167742A1Improved voltage performanceFast switching speedEfficient power electronics conversionSemiconductor/solid-state device detailsEngineeringHigh voltage

Various embodiments for improved power devices as well as their methods of manufacture, packaging and circuitry incorporating the same for use in a wide variety of power electronic applications are disclosed. One aspect of the invention combines a number of charge balancing techniques and other techniques for reducing parasitic capacitance to arrive at different embodiments for power devices with improved voltage performance, higher switching speed, and lower on-resistance. Another aspect of the invention provides improved termination structures for low, medium and high voltage devices. Improved methods of fabrication for power devices are provided according to other aspects of the invention. Improvements to specific processing steps, such as formation of trenches, formation of dielectric layers inside trenches, formation of mesa structures and processes for reducing substrate thickness, among others, are presented. According to another aspect of the invention, charge balanced power devices incorporate temperature and current sensing elements such as diodes on the same die. Other aspects of the invention improve equivalent series resistance (ESR) for power devices, incorporate additional circuitry on the same chip as the power device and provide improvements to the packaging of charge balanced power devices.

Owner:SEMICON COMPONENTS IND LLC

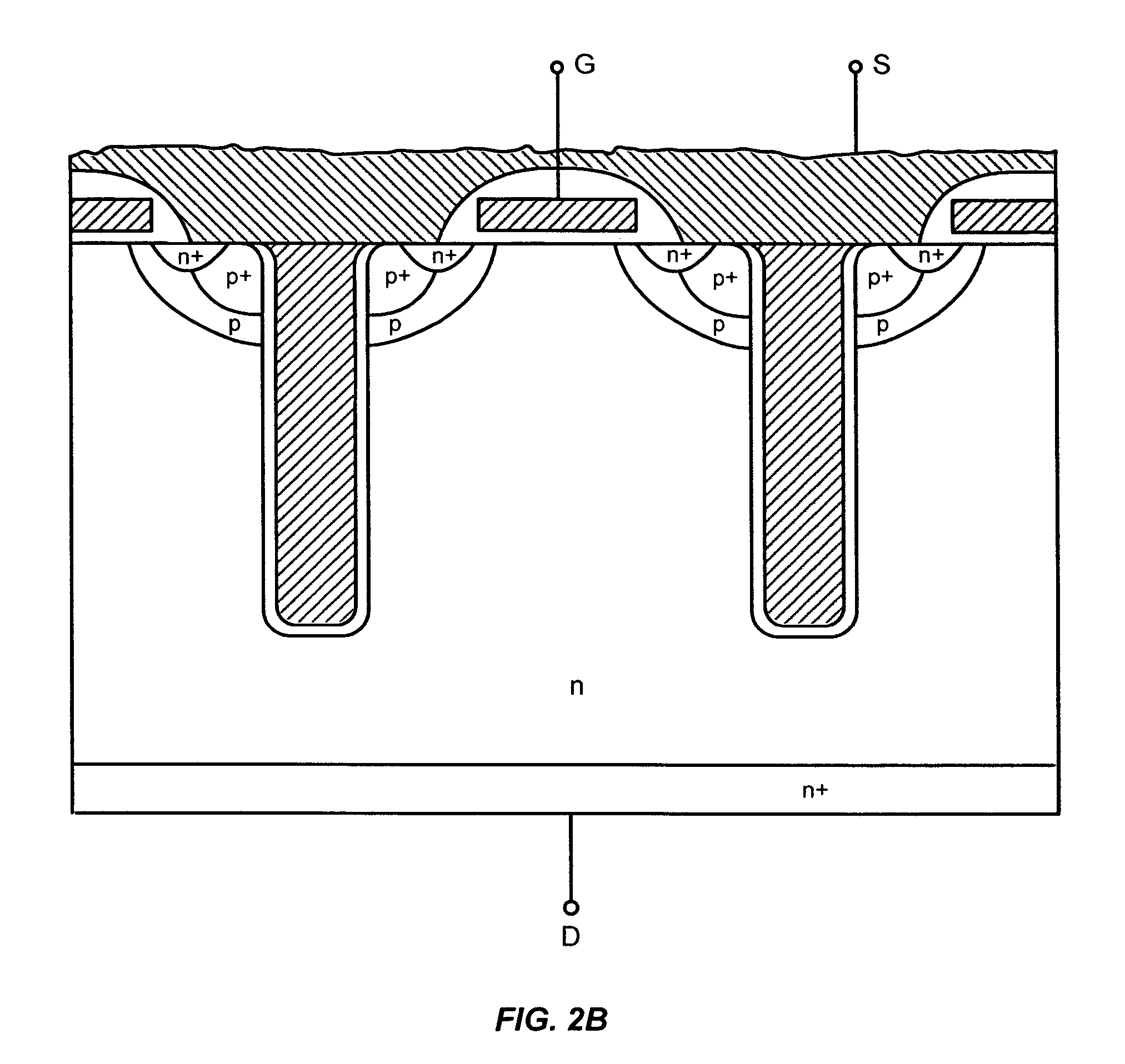

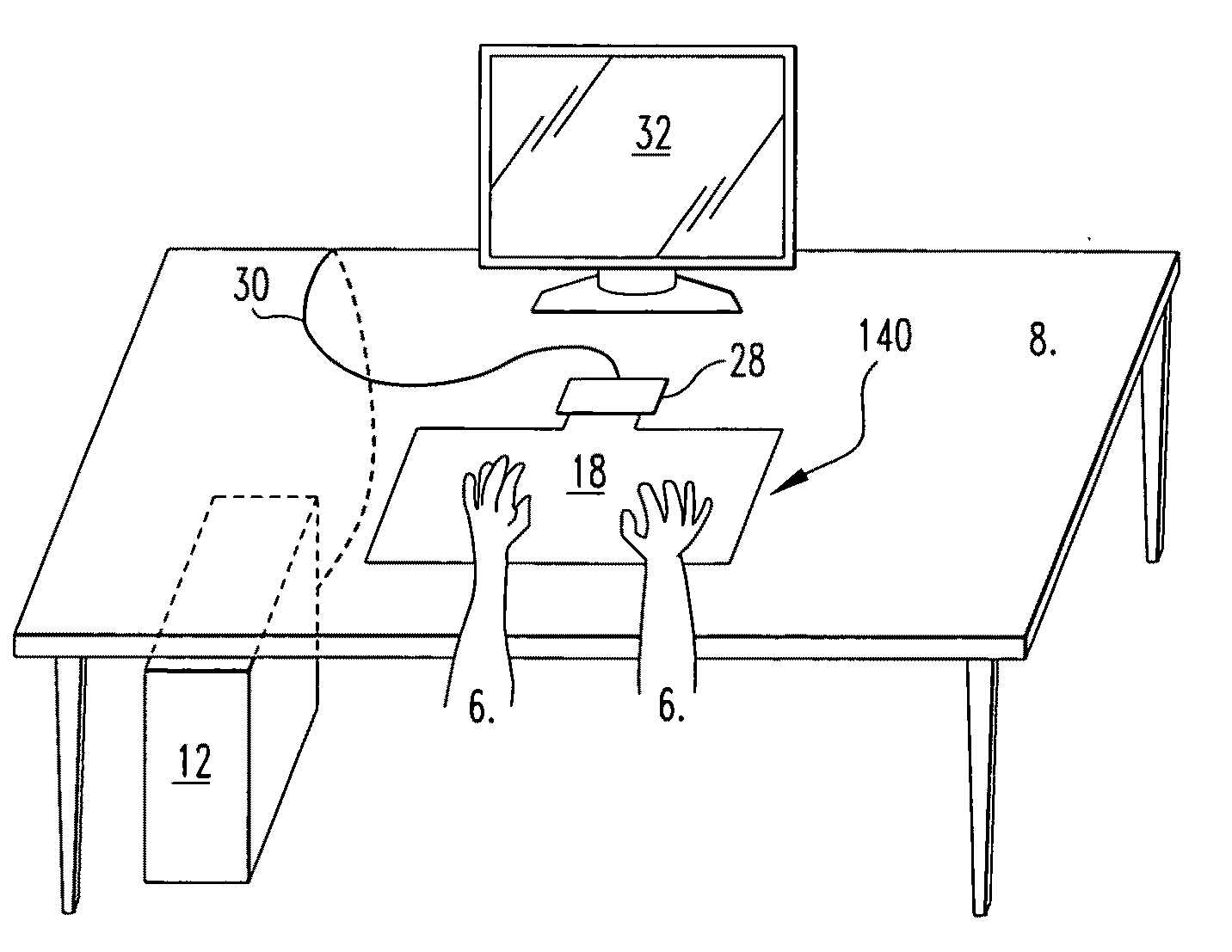

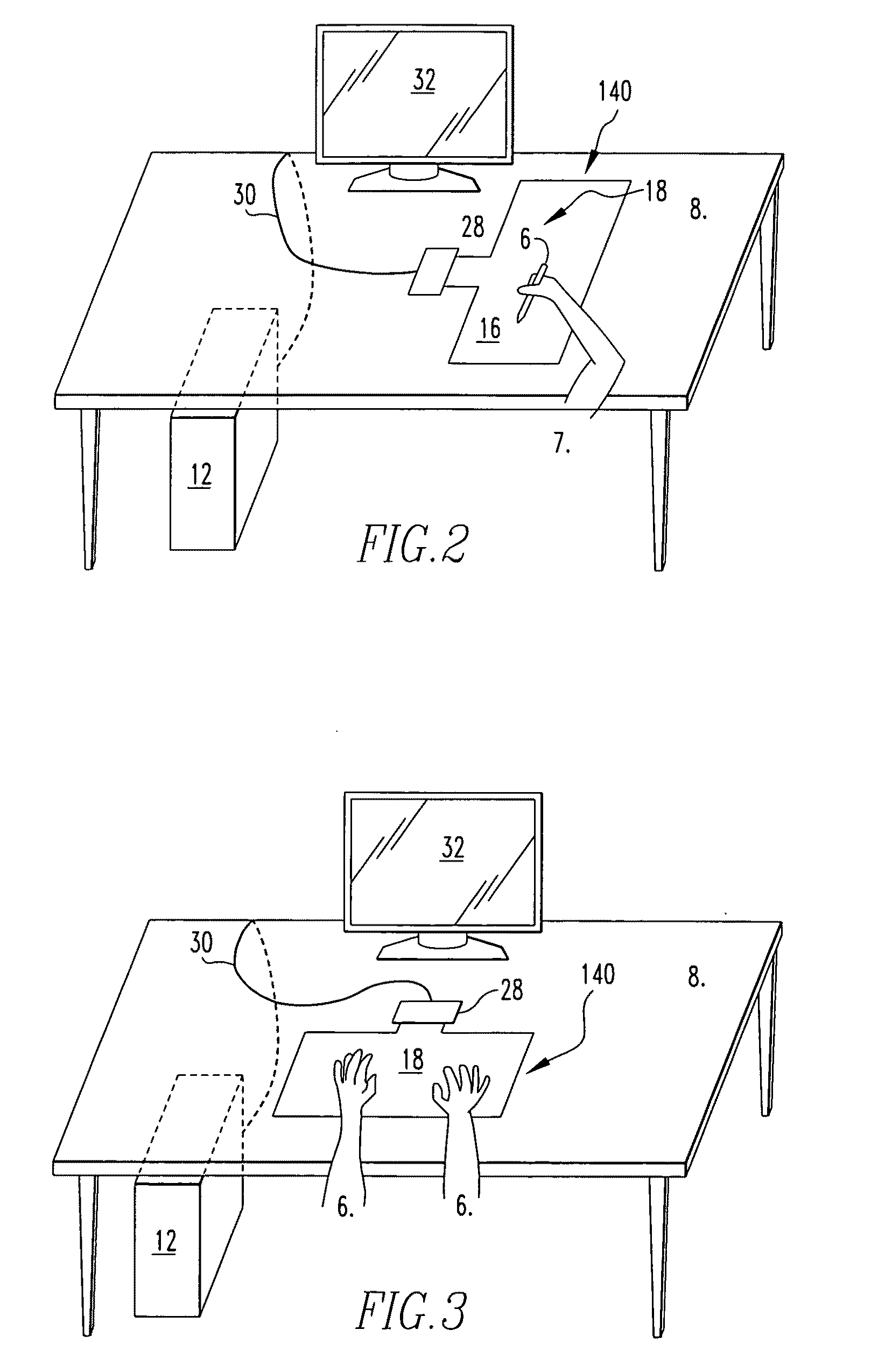

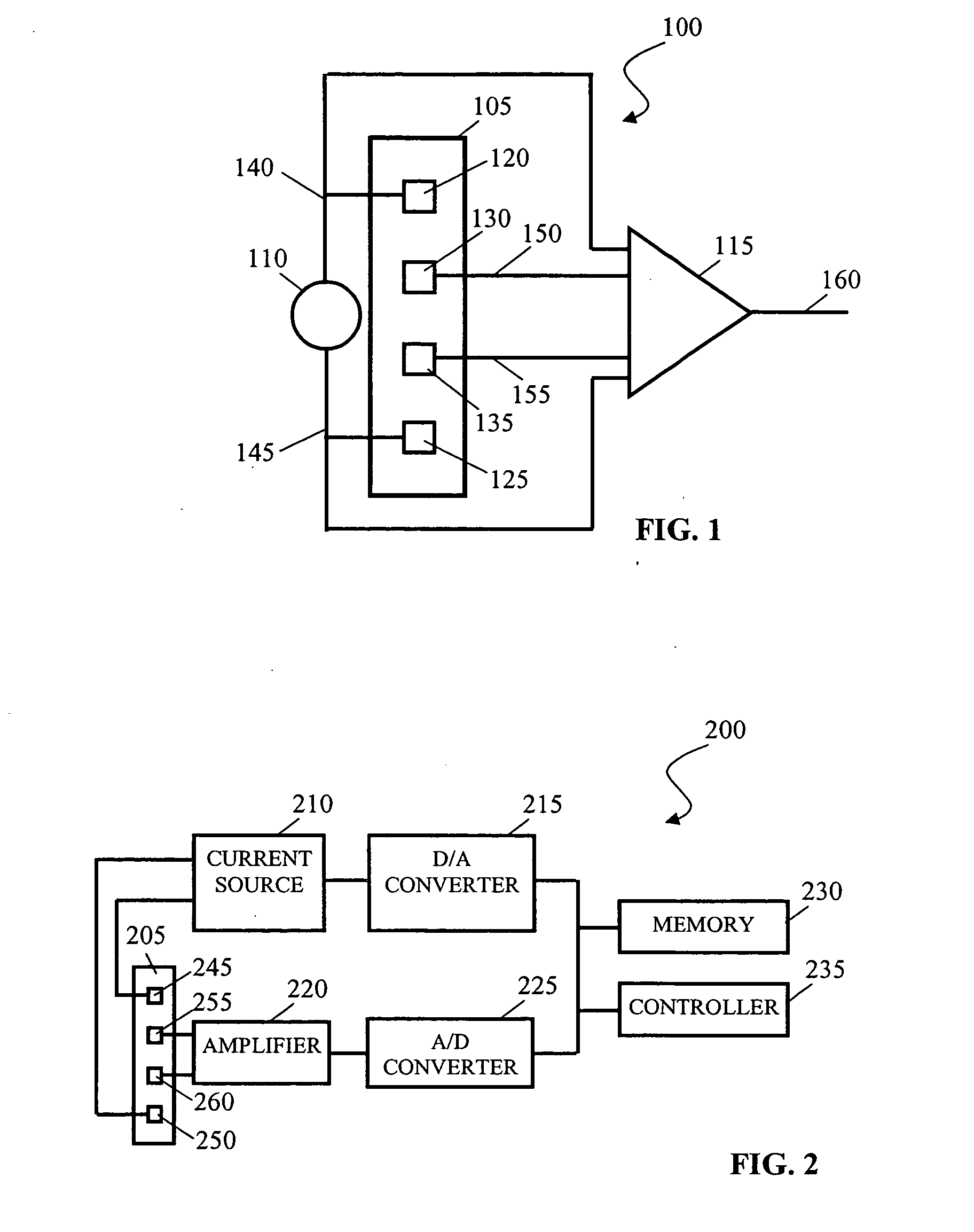

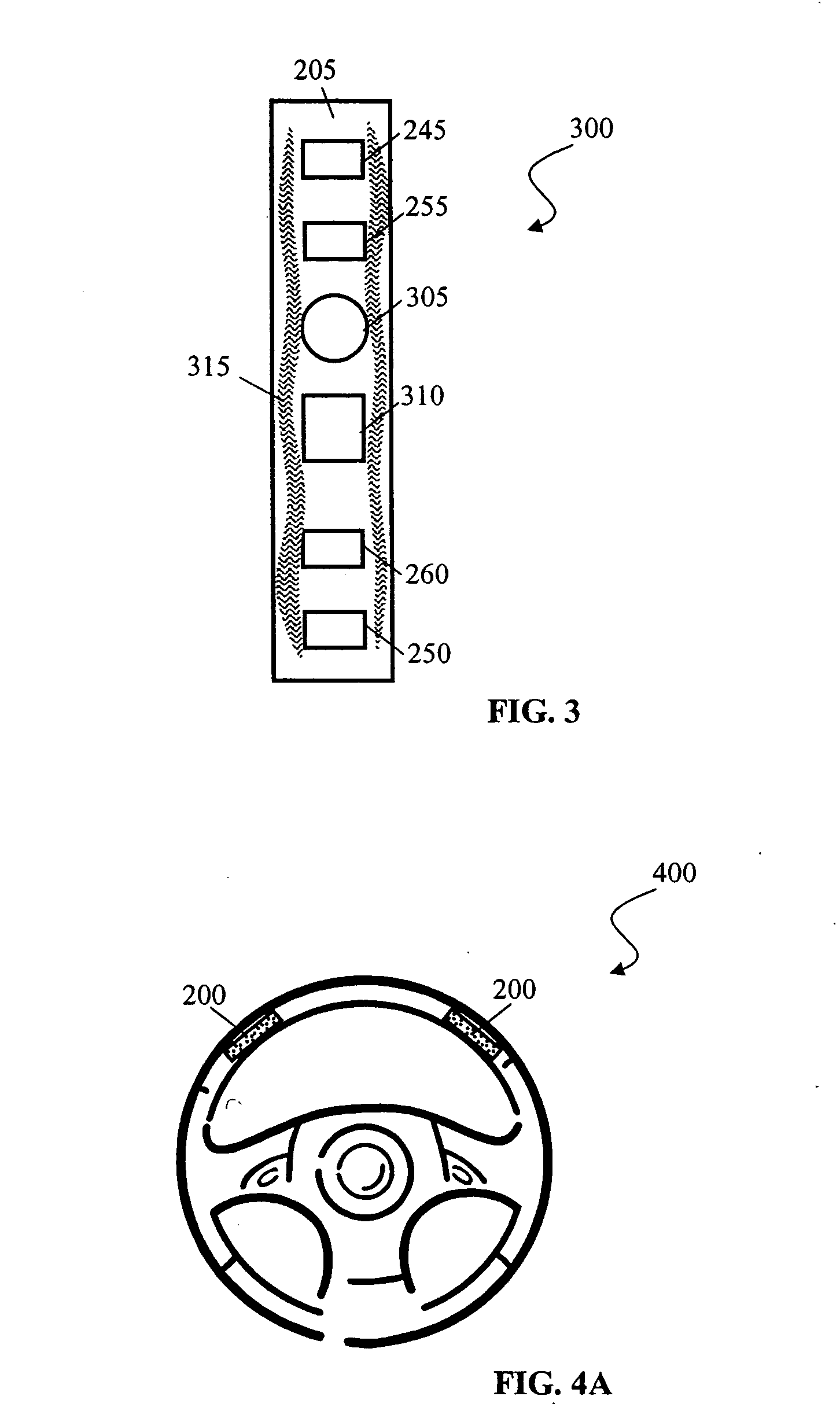

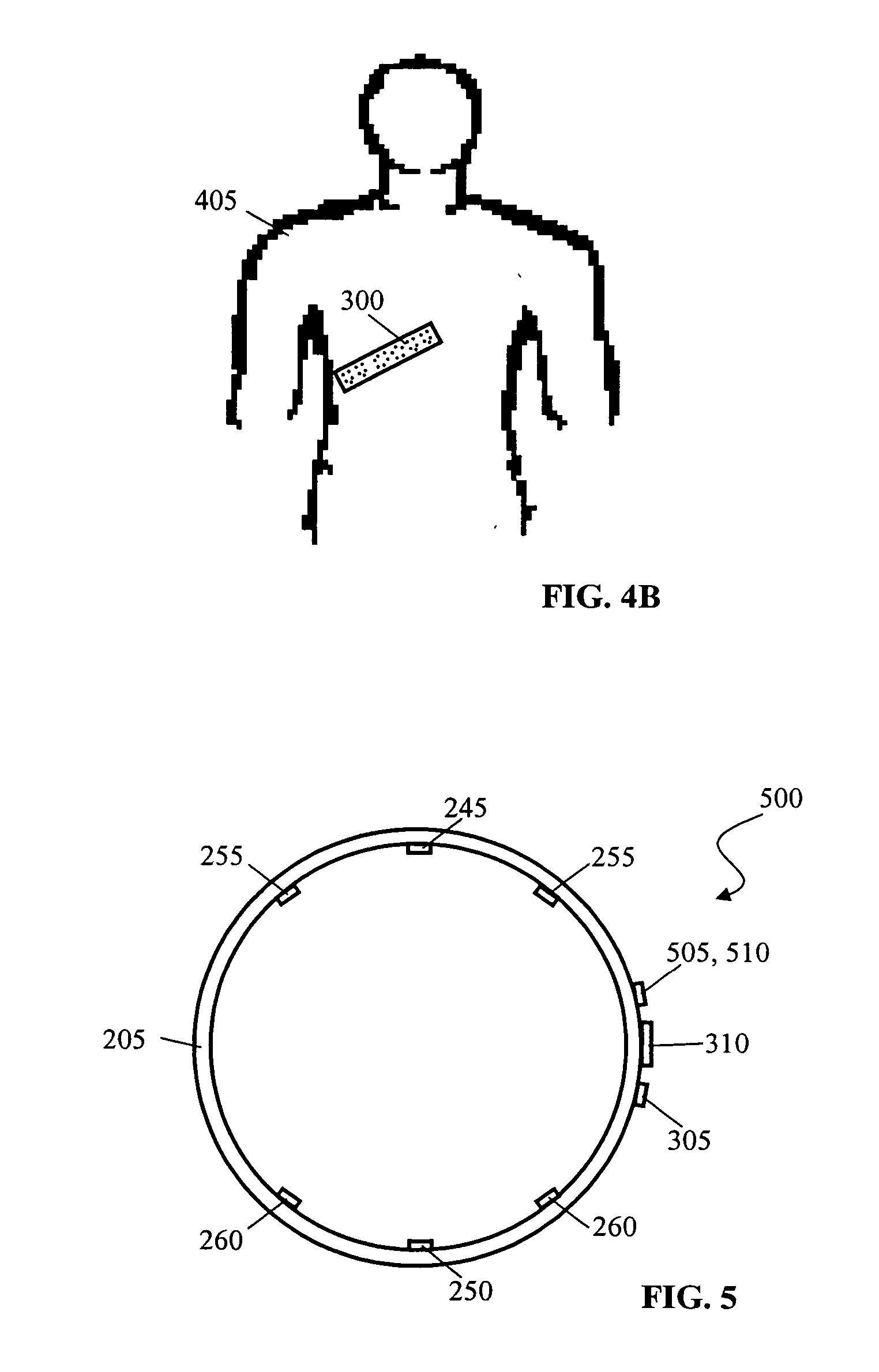

Method and apparatus for providing input to a processor, and a sensor pad

ActiveUS20090256817A1Easy to useInput/output processes for data processingSensor arrayElectrical resistance and conductance

An apparatus for providing input to a processor includes a sensor pad having a surface and a sensor array for sensing pressure at the surface and producing signals corresponding to the pressure at the surface. The sensor array having columns and rows of electrodes that are covered with resistive material which fills in the spaces between the electrodes and acts as a linear resistor between the electrodes and measures pressure on the pad surface between the electrodes. The apparatus includes an interface in contact with the sensor pad and in communication with the sensor array which couples to the processor to communicate the signals to the processor. A method for providing input to a processor includes the steps of sensing pressure with a sensor pad having a surface and a sensor array for sensing the pressure at the surface. There is the step of producing signals corresponding to the pressure at the surface with the sensor array. The sensor array having columns and rows of electrodes that are covered with resistive material which fills in the spaces between the electrodes and acts as a linear resistor between the electrodes and measures pressure on the pad surface between the electrodes. There is the step of communicating the signals to the processor with an interface in contact with the sensor pad and in communication with the sensor array which couples to the processor.

Owner:NEW YORK UNIV

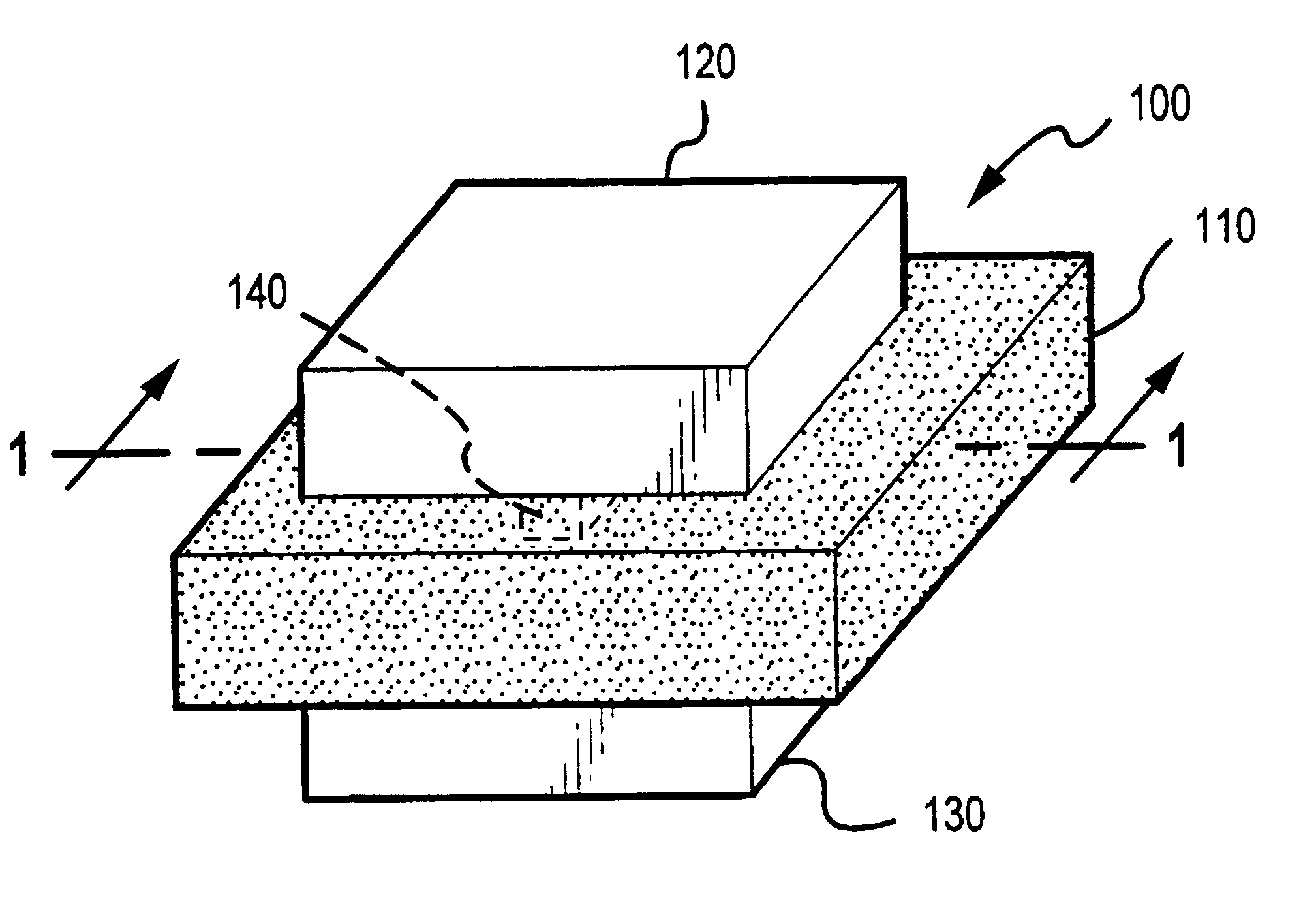

Programmable metallization cell structure and method of making same

InactiveUS6084796ASolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceElectrical conductor

A programmable metallization cell ("PMC") comprises a fast ion conductor such as a chalcogenide-metal ion and a plurality of electrodes (e.g., an anode and a cathode) disposed at the surface of the fast ion conductor and spaced a set distance apart from each other. Preferably, the fast ion conductor comprises a chalcogenide with Group IB or Group IIB metals, the anode comprises silver, and the cathode comprises aluminum or other conductor. When a voltage is applied to the anode and the cathode, a non-volatile metal dendrite grows from the cathode along the surface of the fast ion conductor towards the anode. The growth rate of the dendrite is a function of the applied voltage and time. The growth of the dendrite may be stopped by removing the voltage and the dendrite may be retracted by reversing the voltage polarity at the anode and cathode. Changes in the length of the dendrite affect the resistance and capacitance of the PMC. The PMC may be incorporated into a variety of technologies such as memory devices, programmable resistor / capacitor devices, optical devices, sensors, and the like. Electrodes additional to the cathode and anode can be provided to serve as outputs or additional outputs of the devices in sensing electrical characteristics which are dependent upon the extent of the dendrite.

Owner:AXON TECH +1

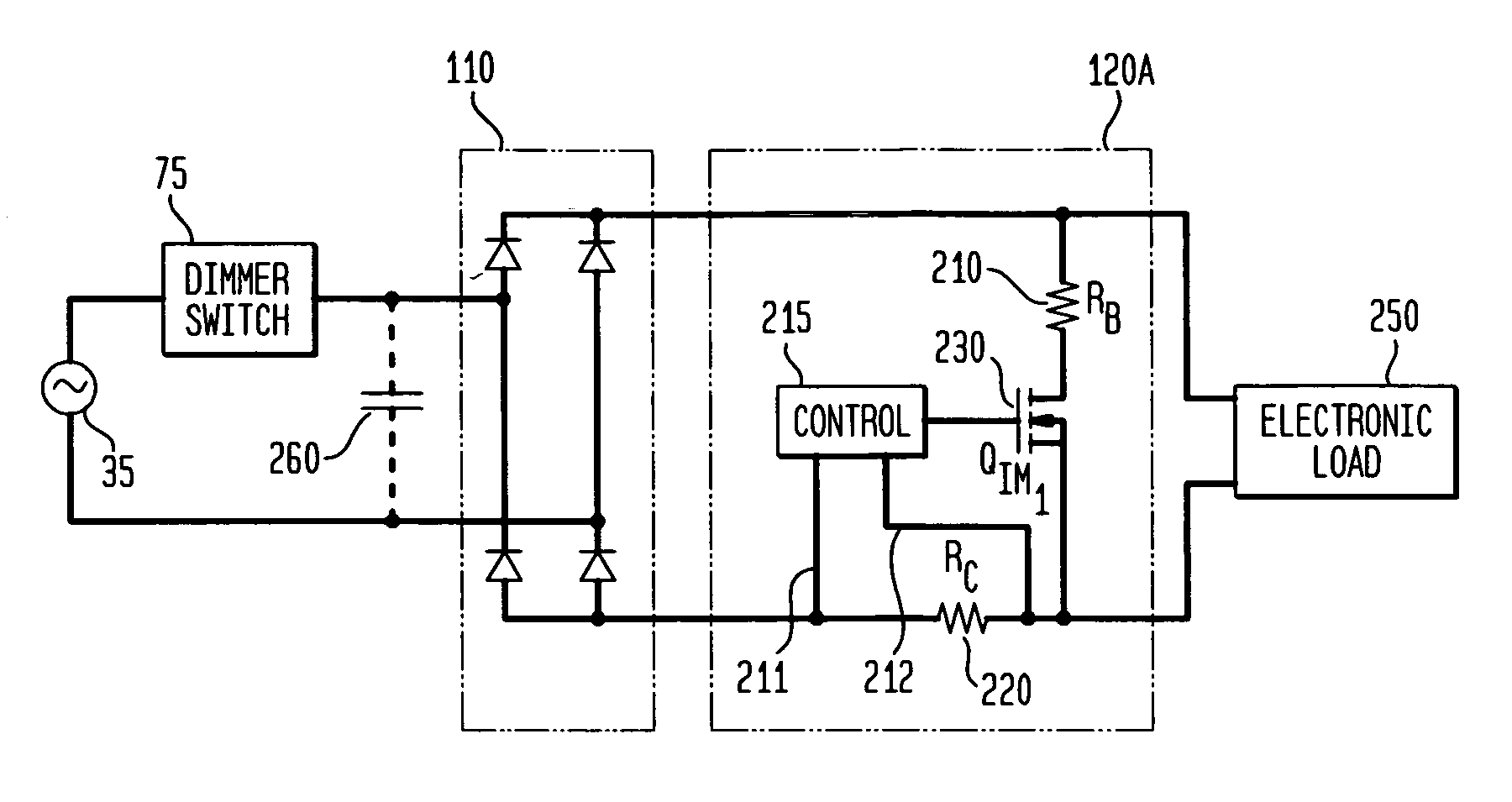

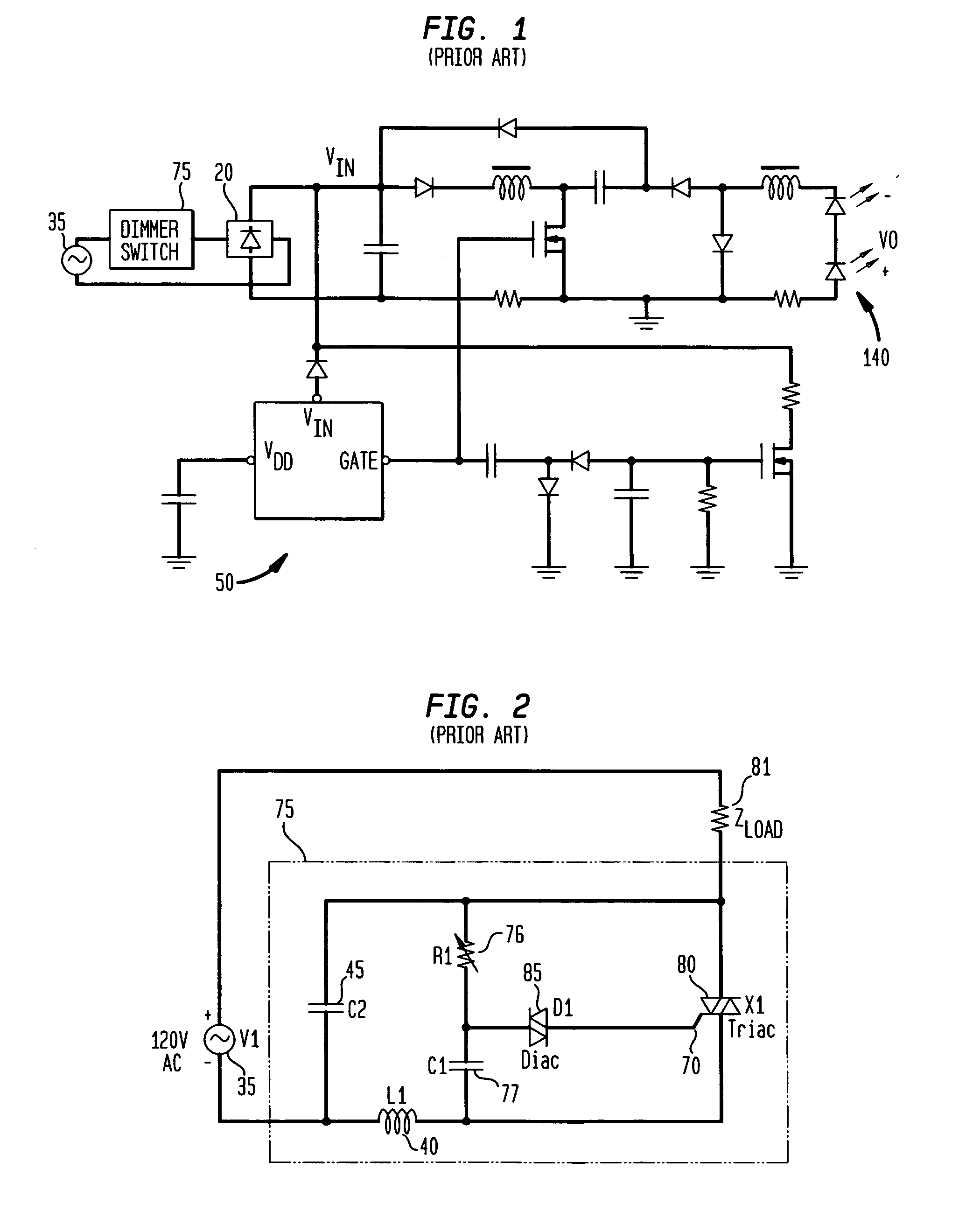

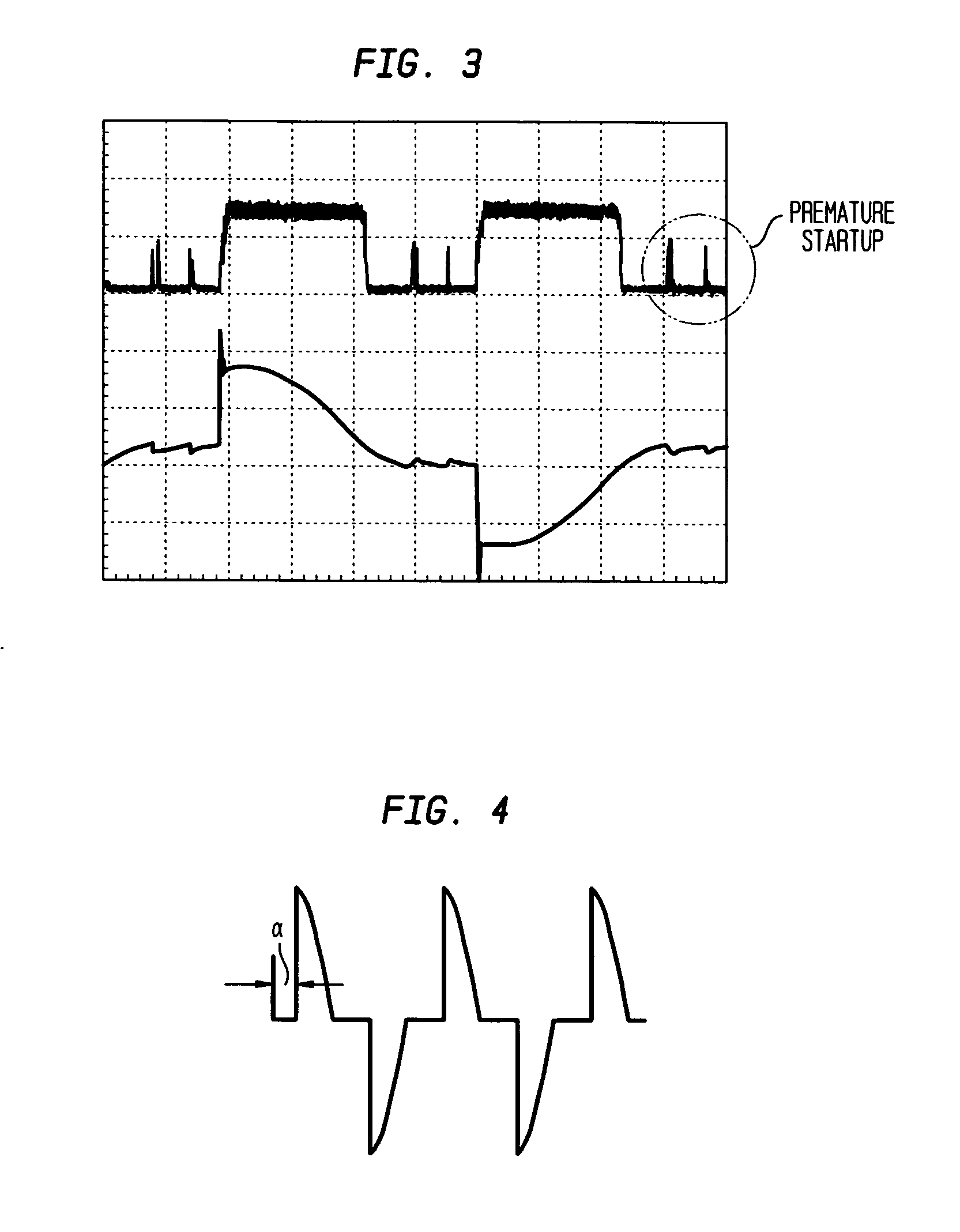

Impedance matching circuit for current regulation of solid state lighting

ActiveUS20070182347A1Low component requirementsElectrical apparatusElectroluminescent light sourcesSilicon-controlled rectifierElectrical resistance and conductance

Exemplary embodiments provide an impedance matching circuit for providing variable power from a dimmer switch having a triac to a switching power supply couplable to solid-state lighting. An exemplary impedance matching circuit includes a first resistor coupled to receive a first current from the switching power supply; a second resistor; and a transistor coupled in series to the second resistor, with the transistor responsive to a gate voltage to modulate a second current through the second resistor in response to a detected level of the first current through the first resistor.

Owner:CHEMTRON RES

Electrolytic capacitors with a polymeric outer layer

ActiveUS6987663B2Reduce leakage currentLow ESRHybrid capacitor electrolytesSolid electrolytic capacitorsPolymer scienceElectrolysis

Electrolytic capacitors having low equivalent series resistance and low leakage current are described. The electrolytic capacitors include a solid electrolyte layer of a conductive material in particular a conductive polymer, and an outer layer that includes binders, polymeric anions and conductive polymers (e.g., polythiophenes). Also described is a method of preparing electrolytic capacitors that involves forming the conductive polymer of the solid electrolyte layer in situ by means of chemical oxidative polymerization or electrochemical polymerization. Electronic circuits that include the electrolytic capacitors are also described.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Hydration monitoring

InactiveUS20050070778A1Inhibition of mobilityData processing applicationsNutrition controlElectrical resistance and conductanceMonitoring system

Systems and techniques for monitoring hydration. In one implementation, a method includes measuring an electrical impedance of a region of a subject to generate an impedance measurement result, and wirelessly transmitting the data to a remote apparatus. The probe with which impedance is measured may in the form of a patch adhesively secured to the subject.

Owner:PHILOMETRON

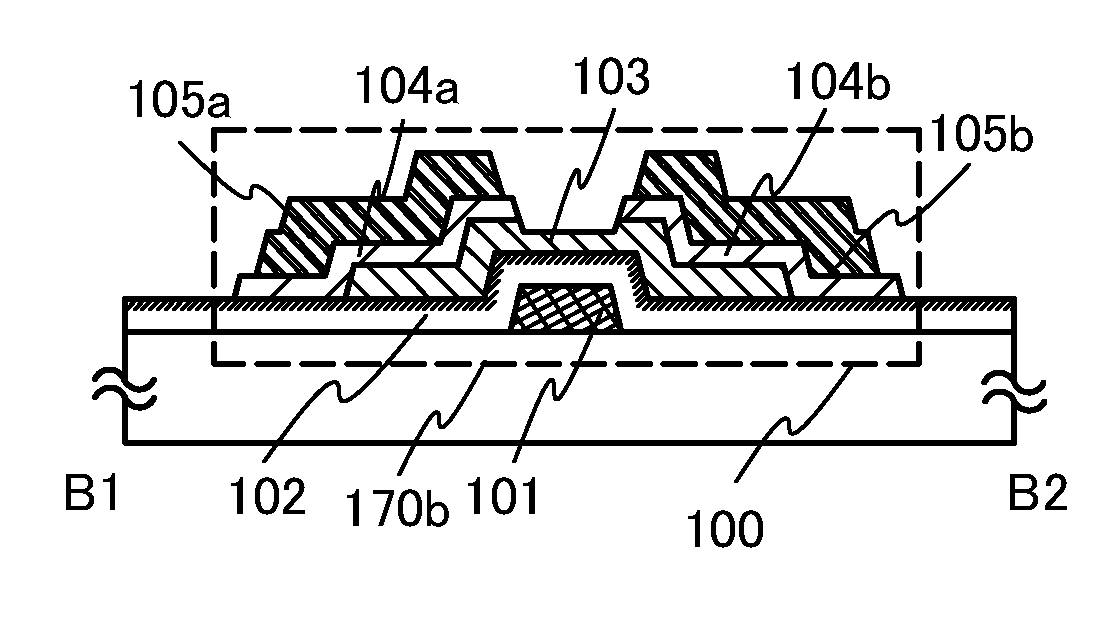

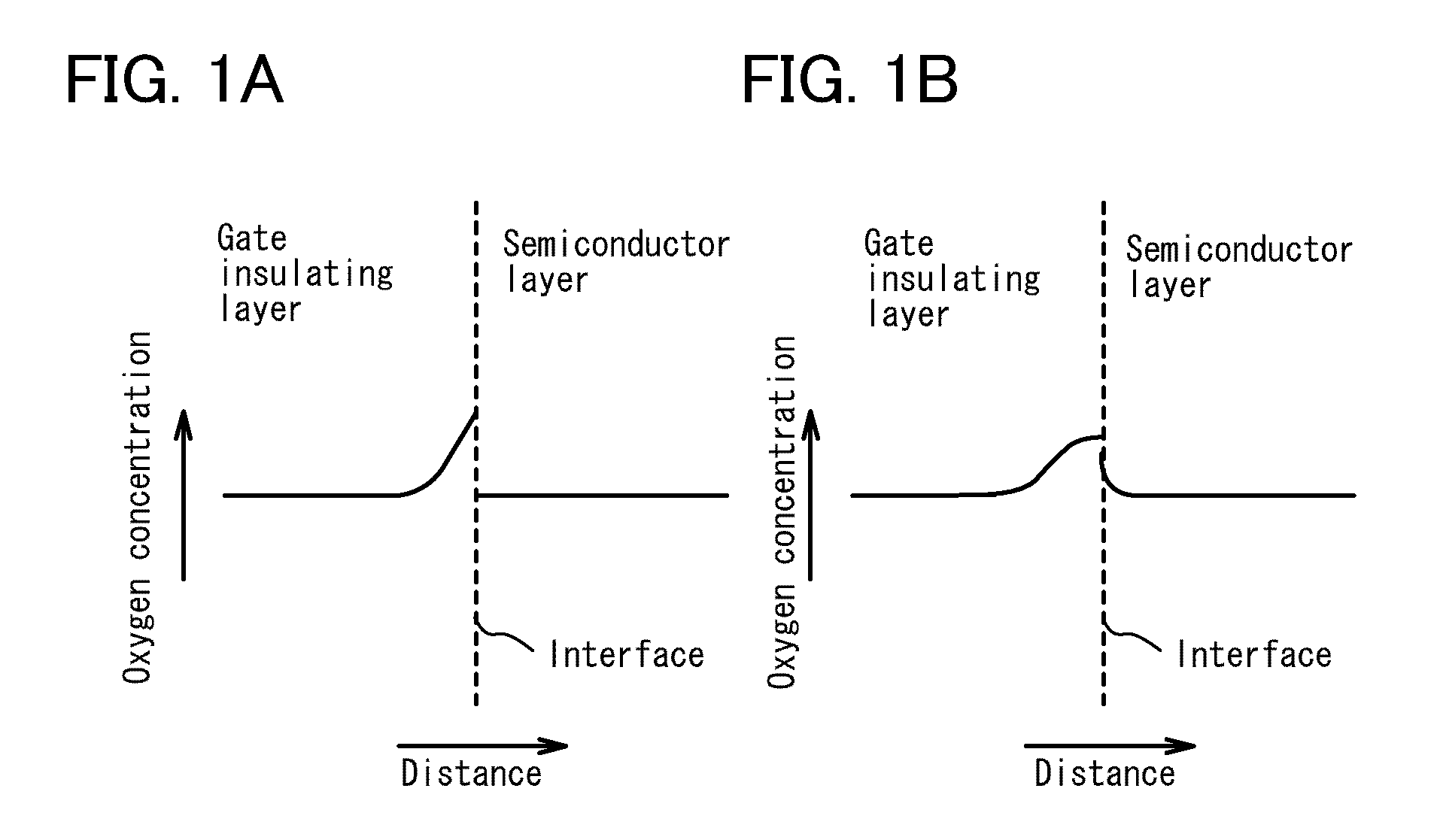

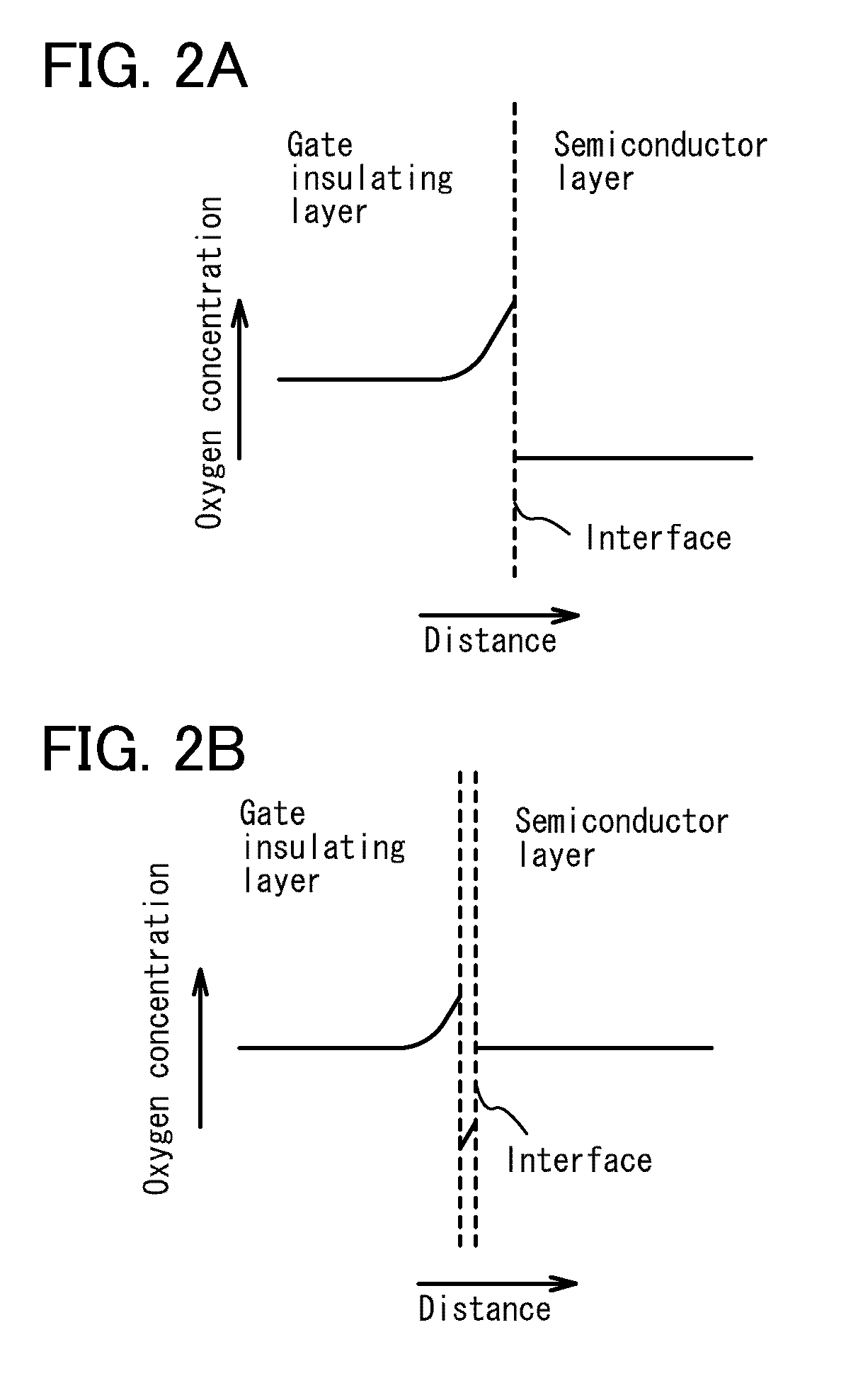

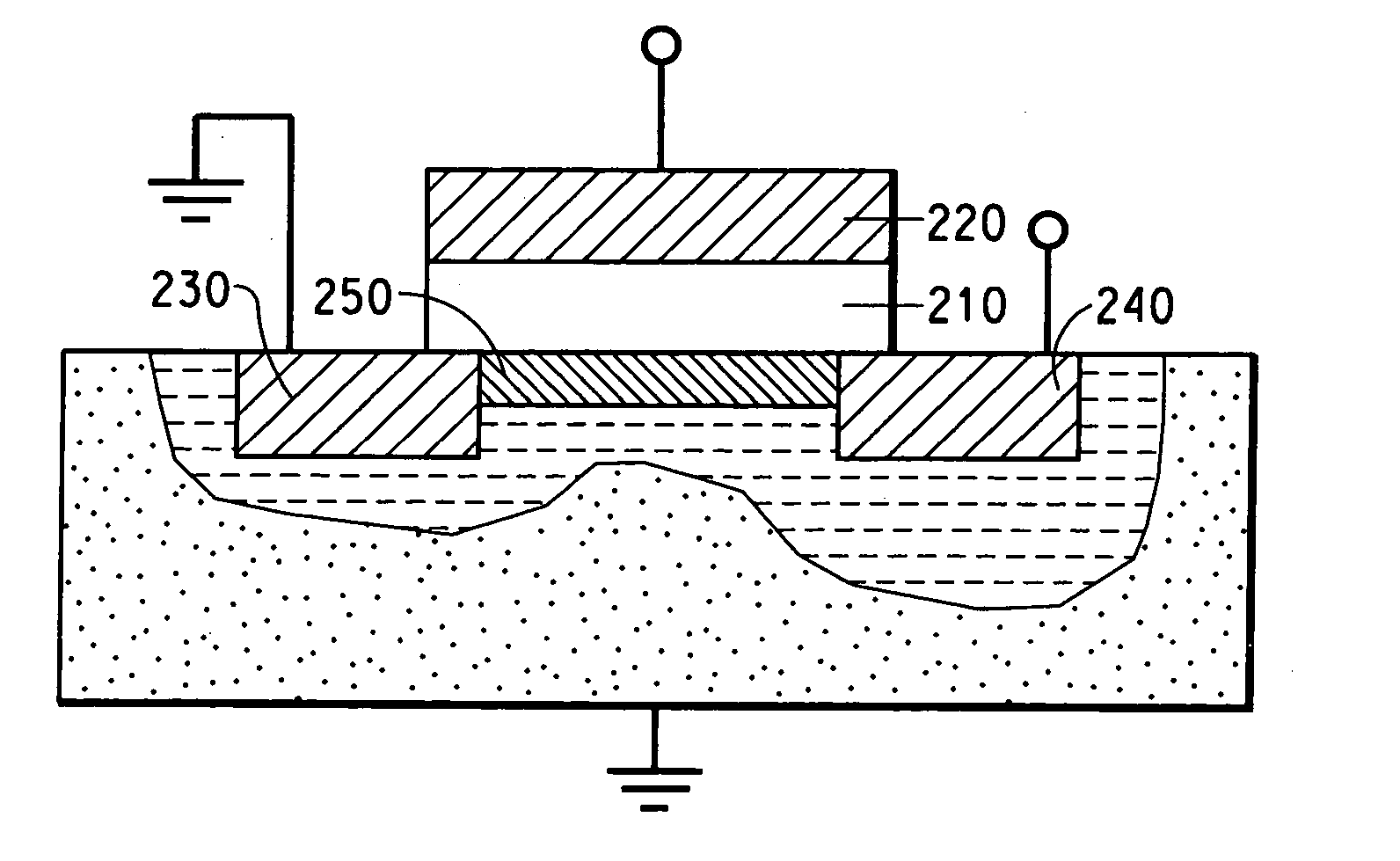

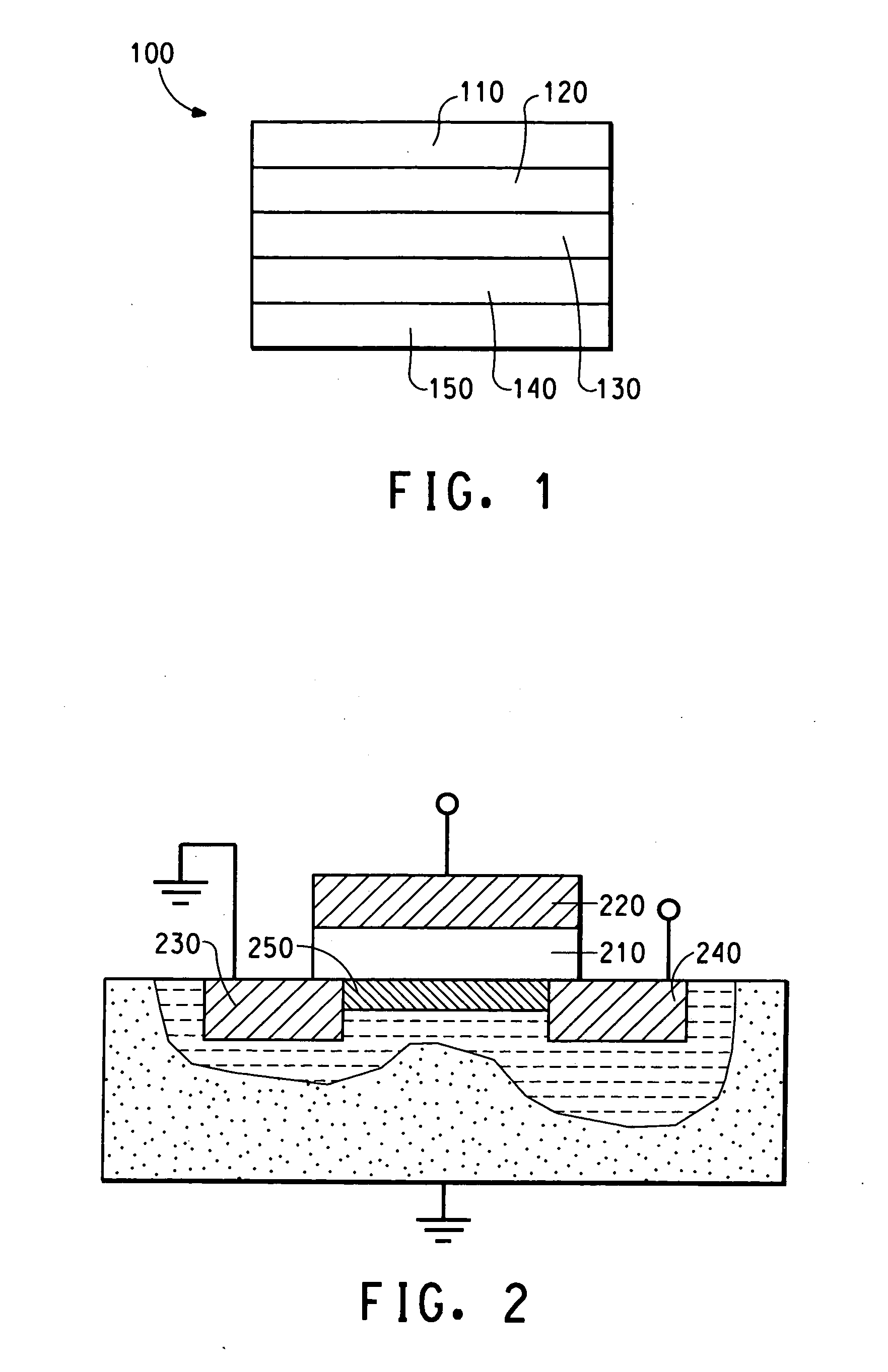

Semiconductor device and method for manufacturing the same

ActiveUS20100051949A1Small currentHigh on-off ratioTransistorStatic indicating devicesMetallic materialsOxygen deficient

A thin film transistor structure in which a source electrode and a drain electrode formed from a metal material are in direct contact with an oxide semiconductor film may lead to high contact resistance. One cause of high contact resistance is that a Schottky junction is formed at a contact plane between the source and drain electrodes and the oxide semiconductor film. An oxygen-deficient oxide semiconductor layer which includes crystal grains with a size of 1 nm to 10 nm and has a higher carrier concentration than the oxide semiconductor film serving as a channel formation region is provided between the oxide semiconductor film and the source and drain electrodes.

Owner:SEMICON ENERGY LAB CO LTD

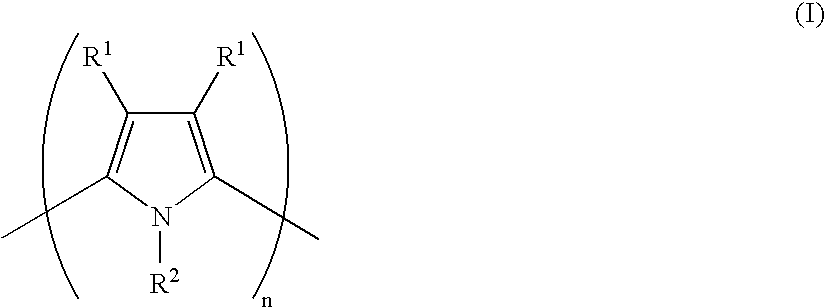

Water dispersible polypyrroles made with polymeric acid colloids for electronics applications

InactiveUS20050205860A1Material nanotechnologyHybrid capacitor electrolytesWater dispersiblePolypyrrole

Compositions are provided comprising aqueous dispersions of at least one polypyrrole and at least one colloid-forming polymeric acids at methods of making such compositions. The new compositions are useful in electronic devices including organic electronic devices such as organic light emitting diode displays, memory storage, electromagnetic shielding, electrochromic displays,and thin film transistors, field effect resistance devices.

Owner:EI DU PONT DE NEMOURS & CO

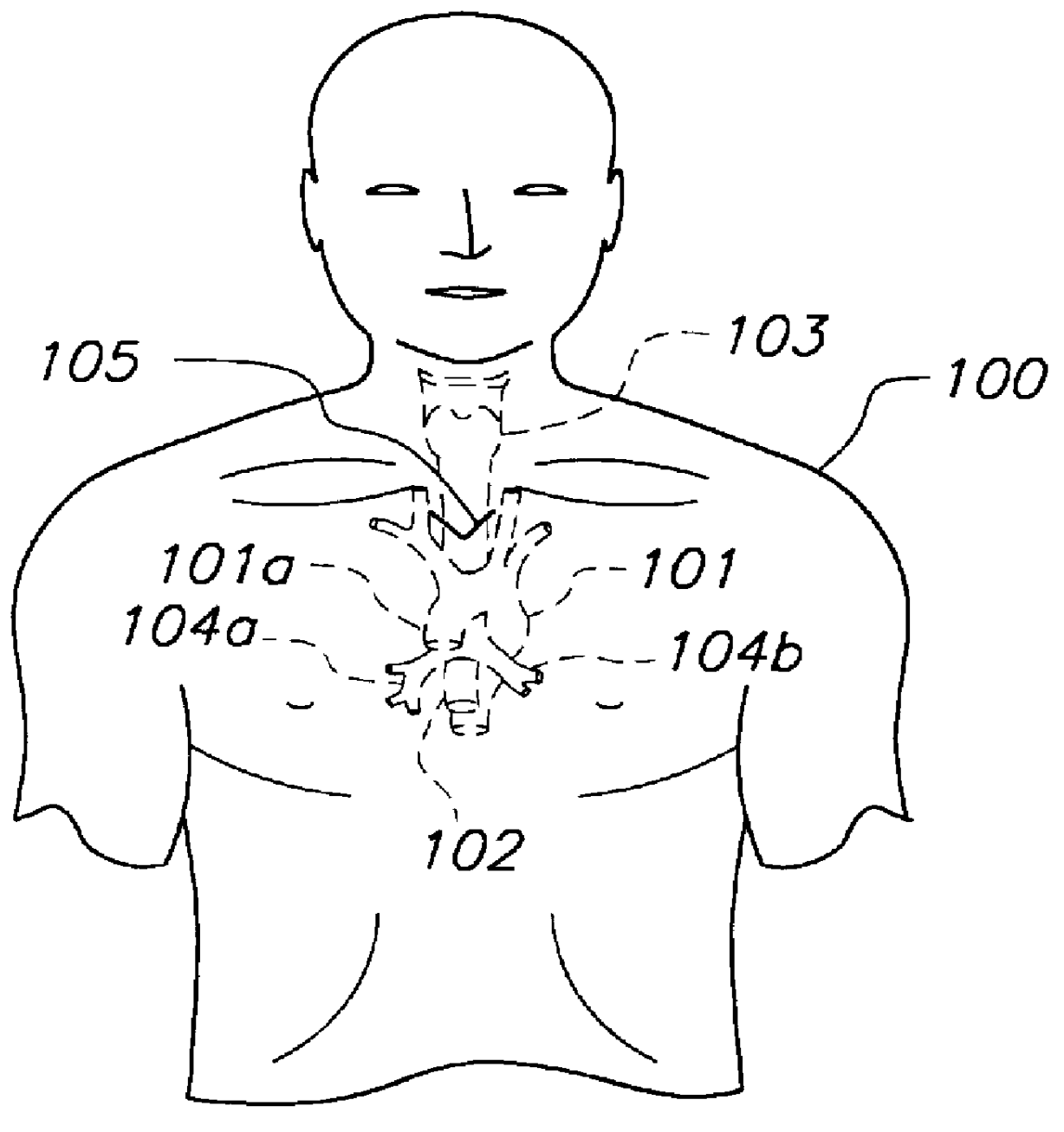

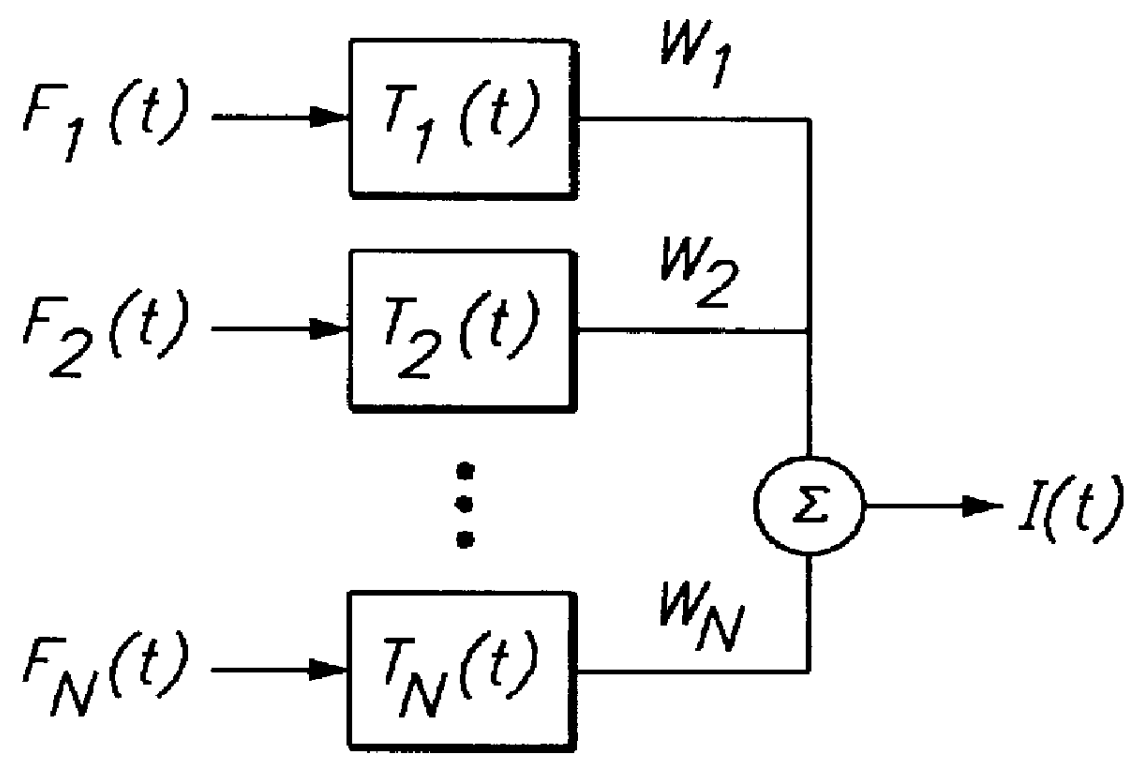

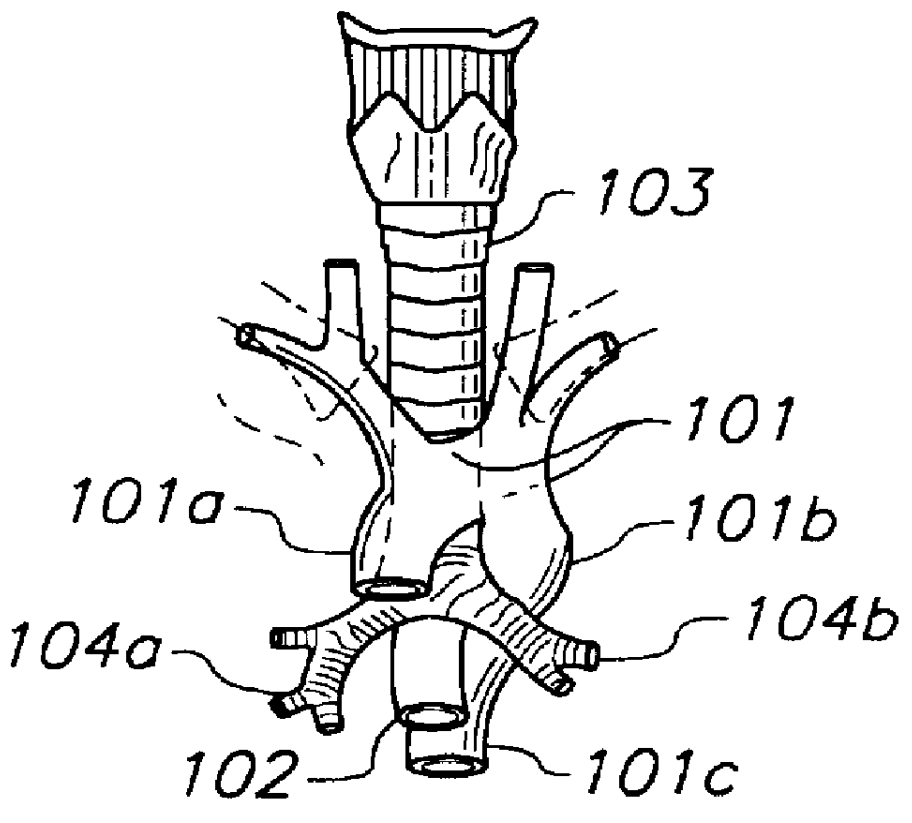

Apparatus and methods of bioelectrical impedance analysis of blood flow

InactiveUS6095987AAccurately and non-invasively and continuously measuring cardiac outputCatheterSensorsBioelectrical impedance analysisCardiac pacemaker electrode

Apparatus and methods are provided for monitoring cardiac output using bioelectrical impedance techniques in which first and second electrodes are placed in the trachea and / or bronchus in the vicinity of the ascending aorta, while an excitation current is injected into the thorax via first and second current electrodes, so that bioelectrical impedance measurements based on the voltage drop sensed by the first and second electrodes reflect voltage changes induced primarily by blood flow dynamics, rather than respiratory or non-cardiac related physiological effects. Additional sense electrodes may be provided, either internally, or externally, for which bioelectrical impedance values may be obtained. Methods are provided for computing cardiac output from bioelectrical impedance values. Apparatus and methods are also provided so that the measured cardiac output may be used to control administration of intravenous fluids to an organism or to optimize a heart rate controlled by a pacemaker.

Owner:ECOM MED

Programmable sub-surface aggregating metallization structure and method of making same

InactiveUS6418049B1Low costHighly manufacturableNanoinformaticsSolid-state devicesCapacitanceElectrical conductor

A programmable sub-surface aggregating metallization sructure ("PSAM") includes an ion conductor such as a chalcogenide-glass which includes metal ions and at least two electrodes disposed at opposing surfaces of the ion conductor. Preferably, the ion conductor includes a chalcogenide material with Group IB or Group IIB metals. One of the two electrodes is preferably configured as a cathode and the other as an anode. When a voltage is applied between the anode and cathode, a metal dendrite grows from the cathode through the ion conductor towards the anode. The growth rate of the dendrite may be stopped by removing the voltage or the dendrite may be retracted back towards the cathode by reversing the voltage polarity at the anode and cathode. When a voltage is applied for a sufficient length of time, a continuous metal dendrite grows through the ion conductor and connects the electrodes, thereby shorting the device. The continuous metal dendrite then can be broken by applying another voltage. The break in the metal dendrite can be reclosed by applying yet another voltage. Changes in the length of the dendrite or the presence of a break in the dendrite affect the resistance, capacitance, and impedance of the PSAM.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com