Patents

Literature

2605results about "Solid electrolytic capacitors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

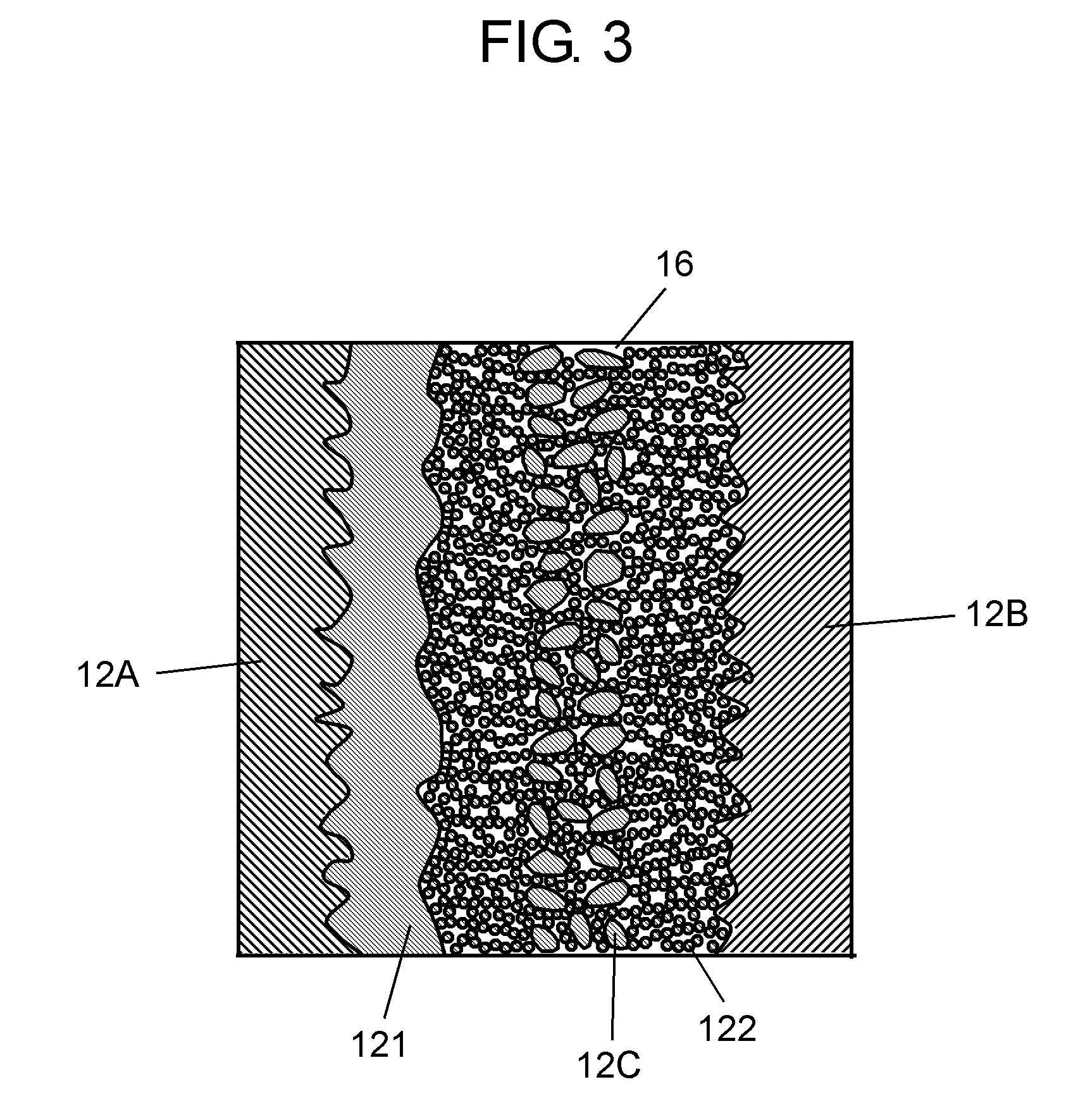

Electrolytic capacitors with a polymeric outer layer

ActiveUS6987663B2Reduce leakage currentLow ESRHybrid capacitor electrolytesSolid electrolytic capacitorsPolymer scienceElectrolysis

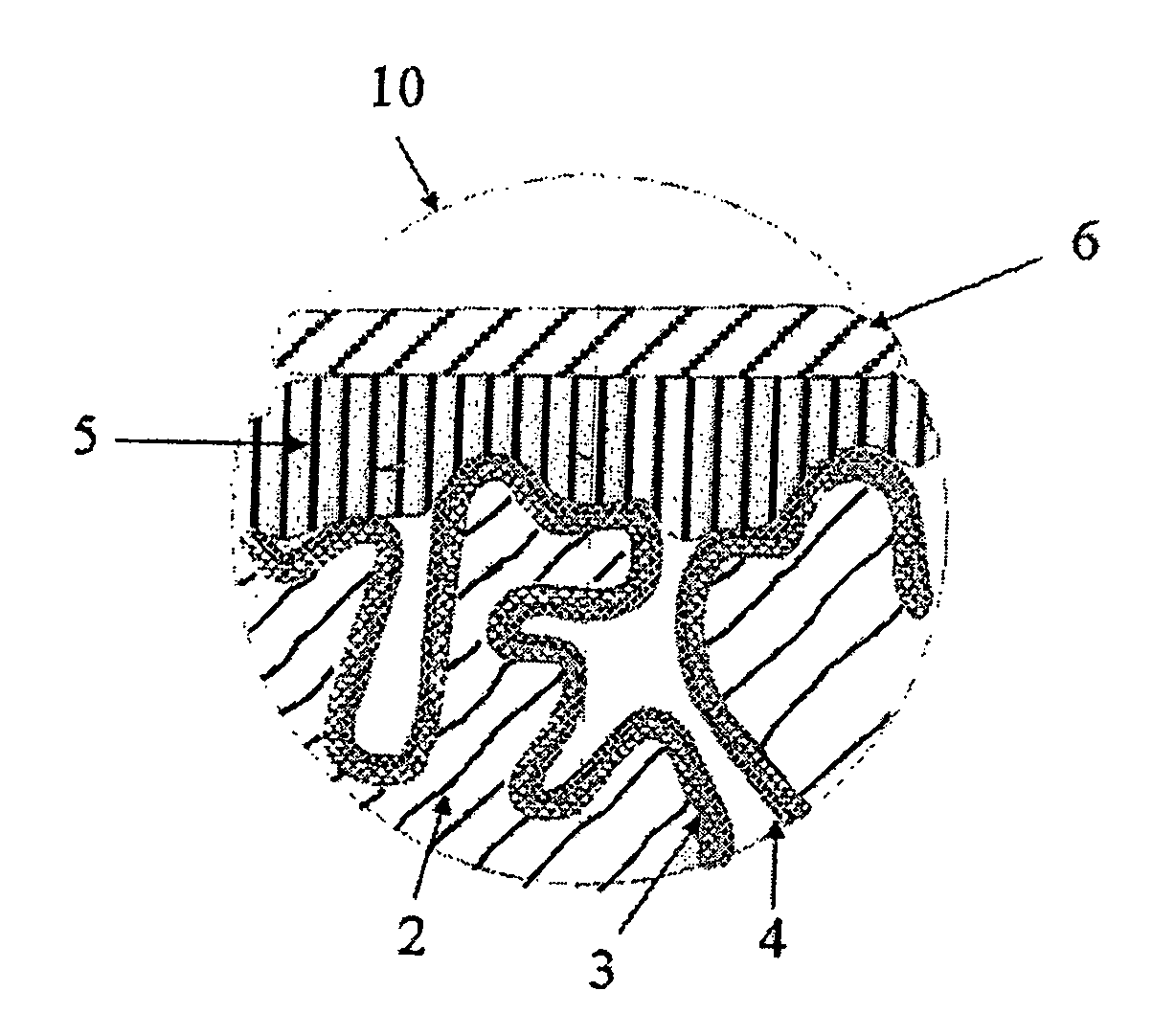

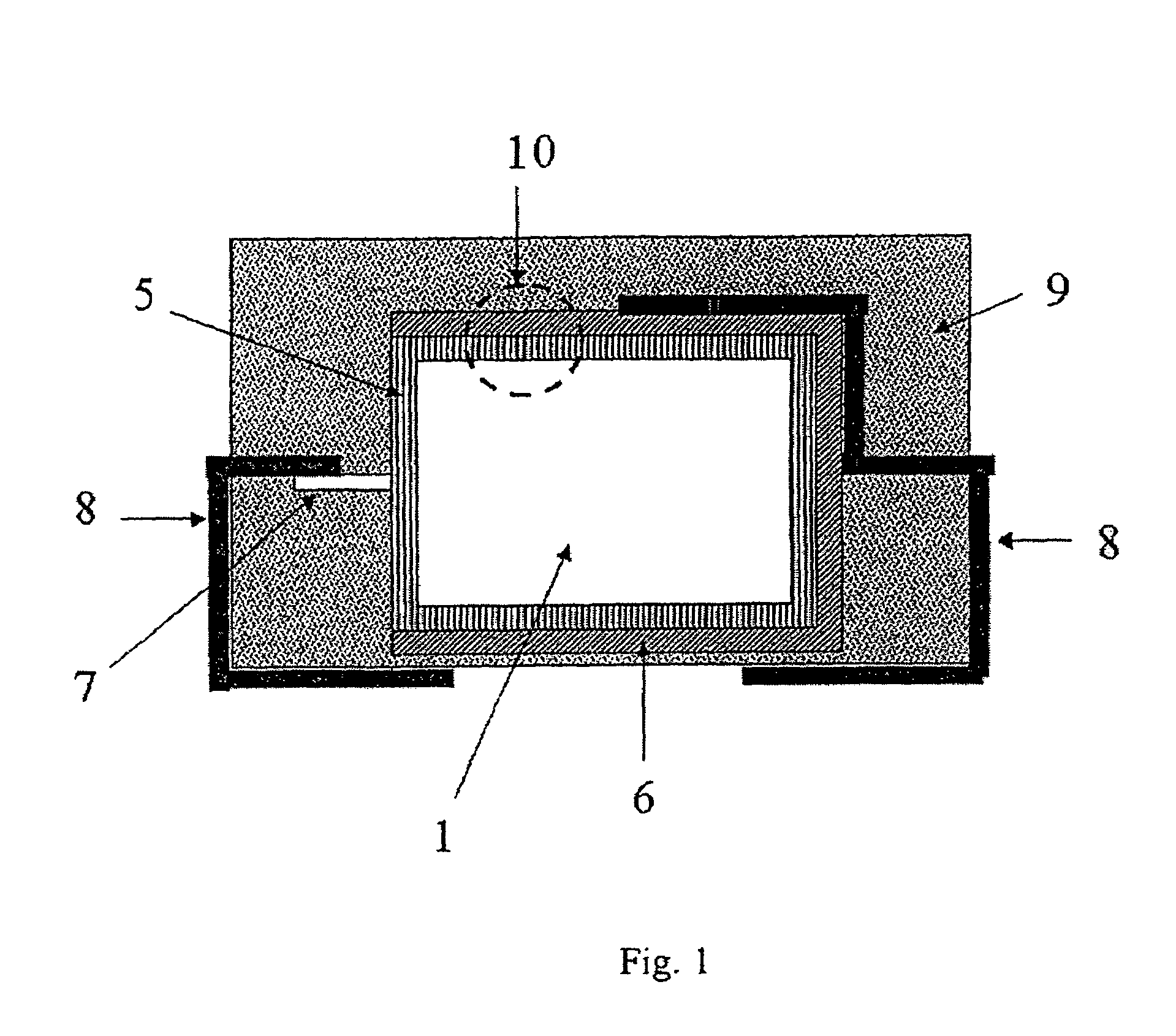

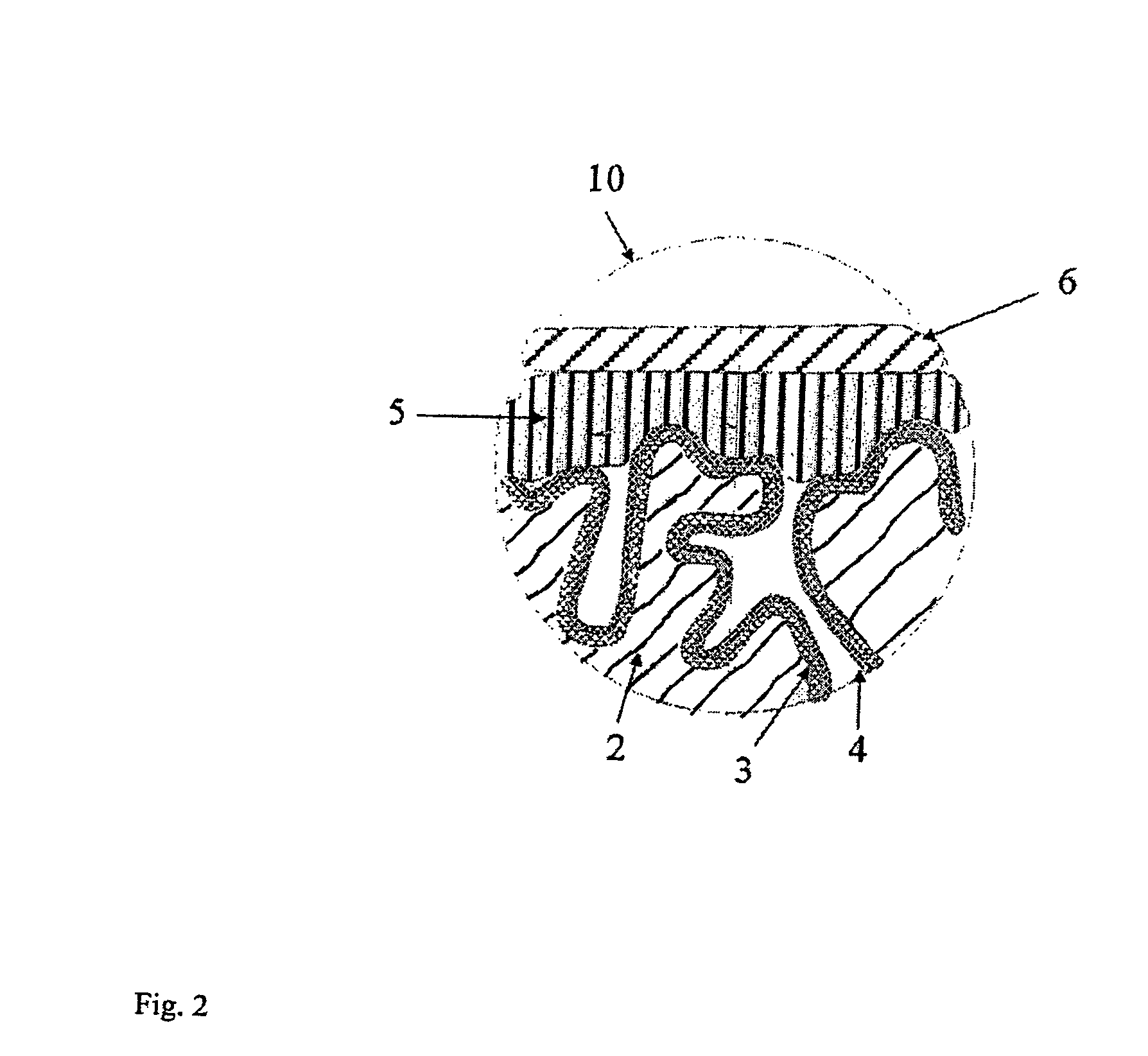

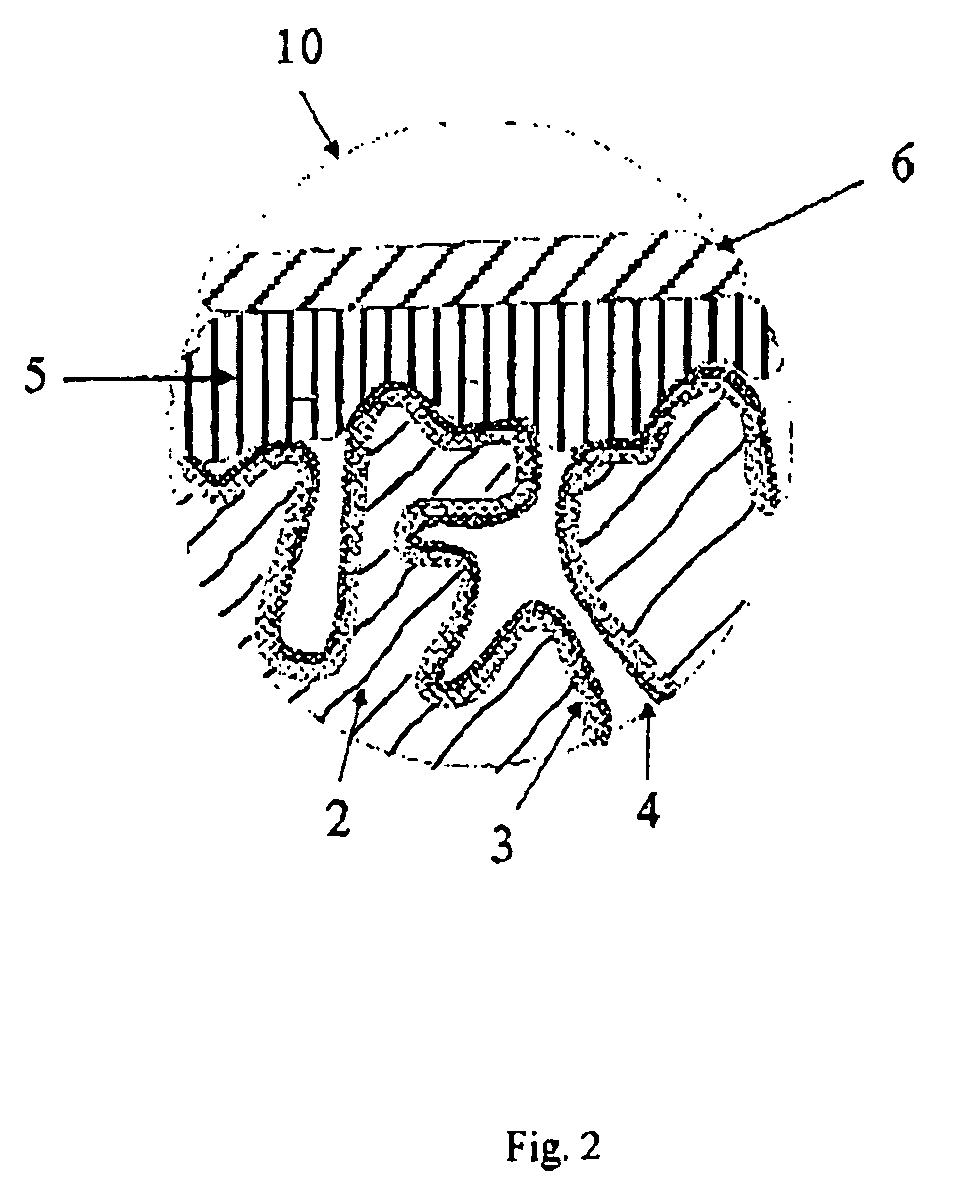

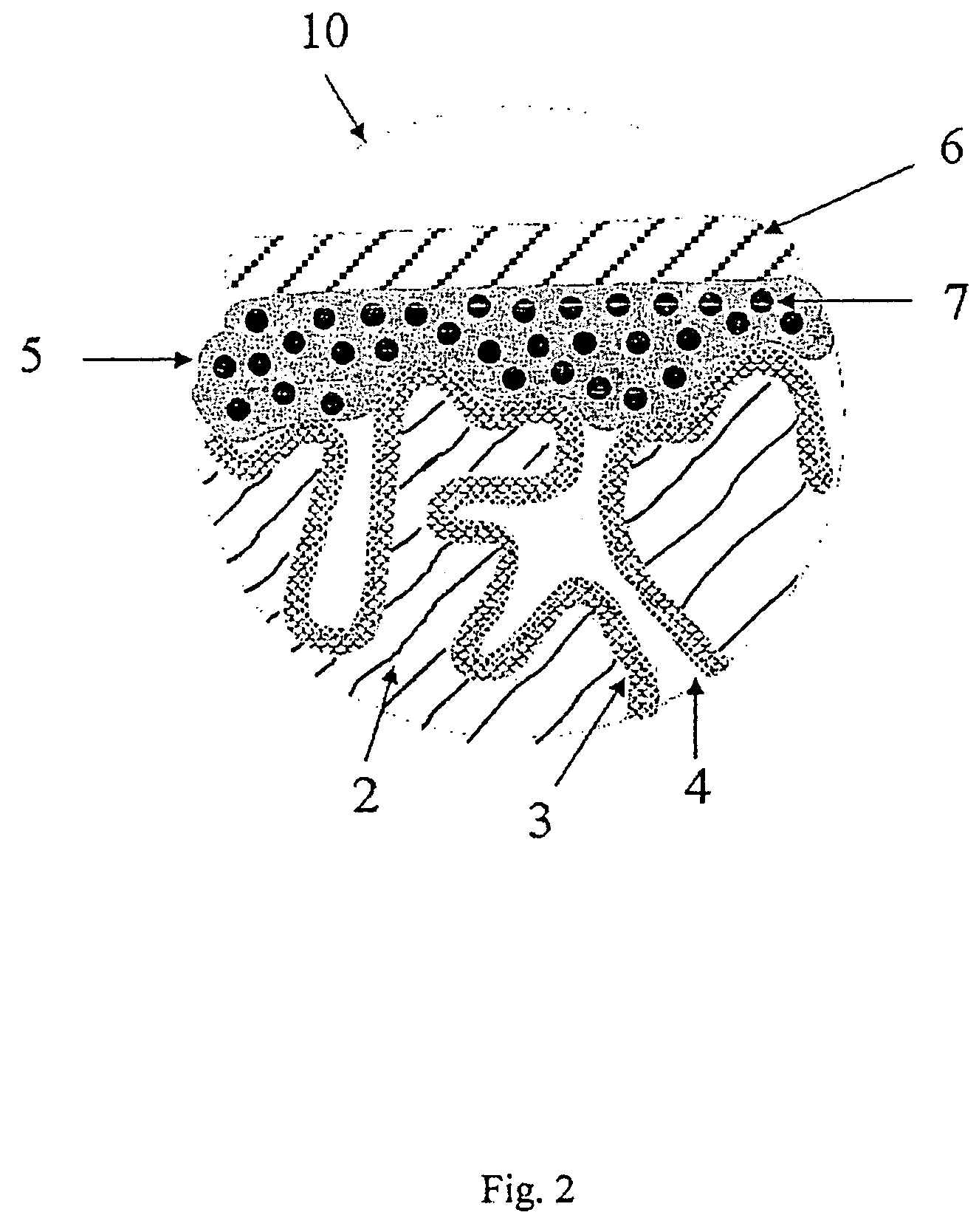

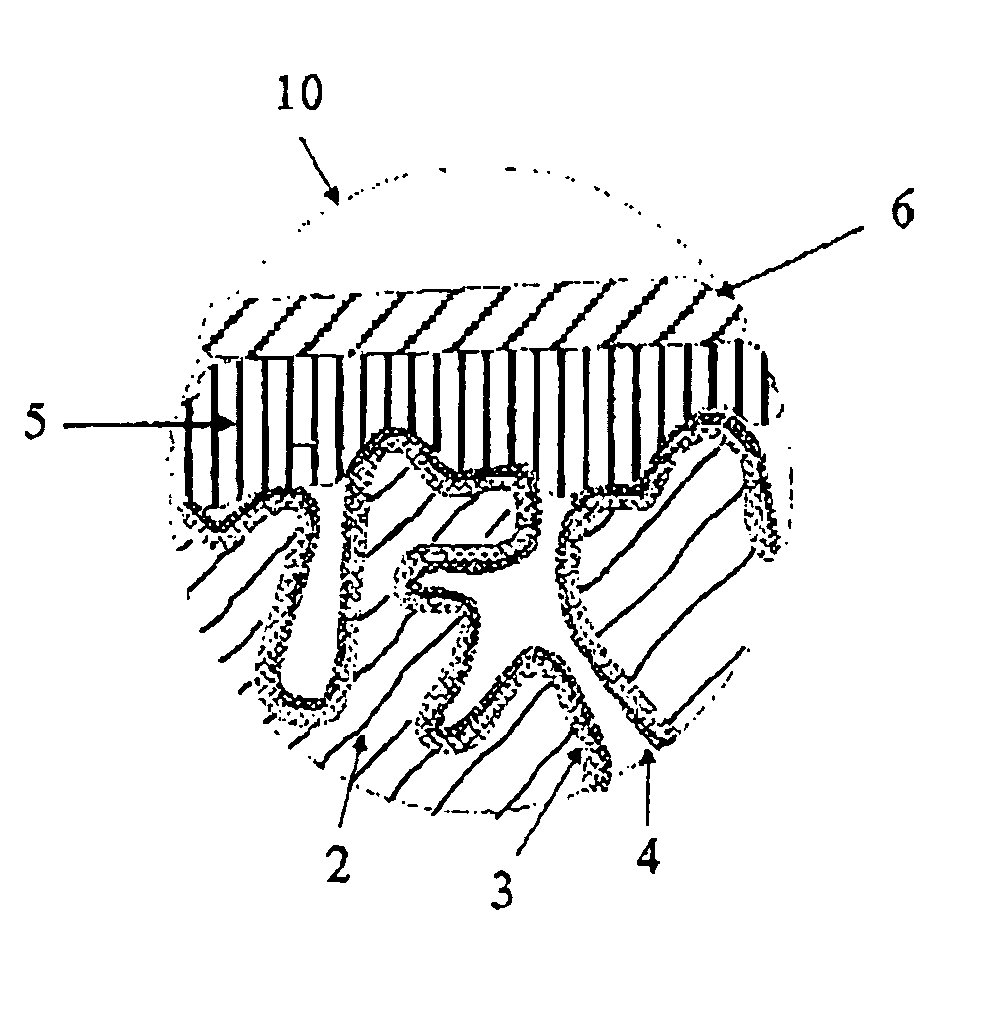

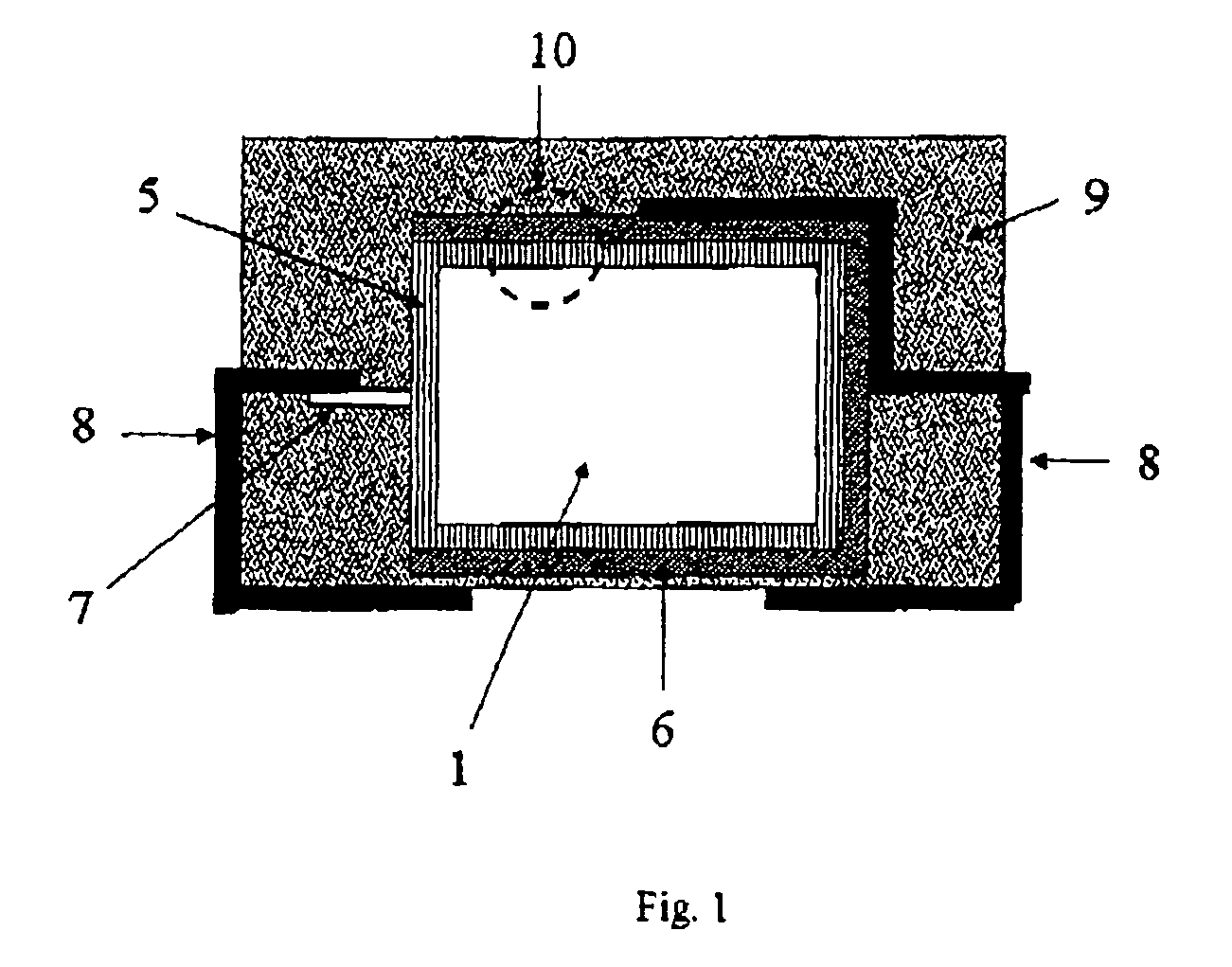

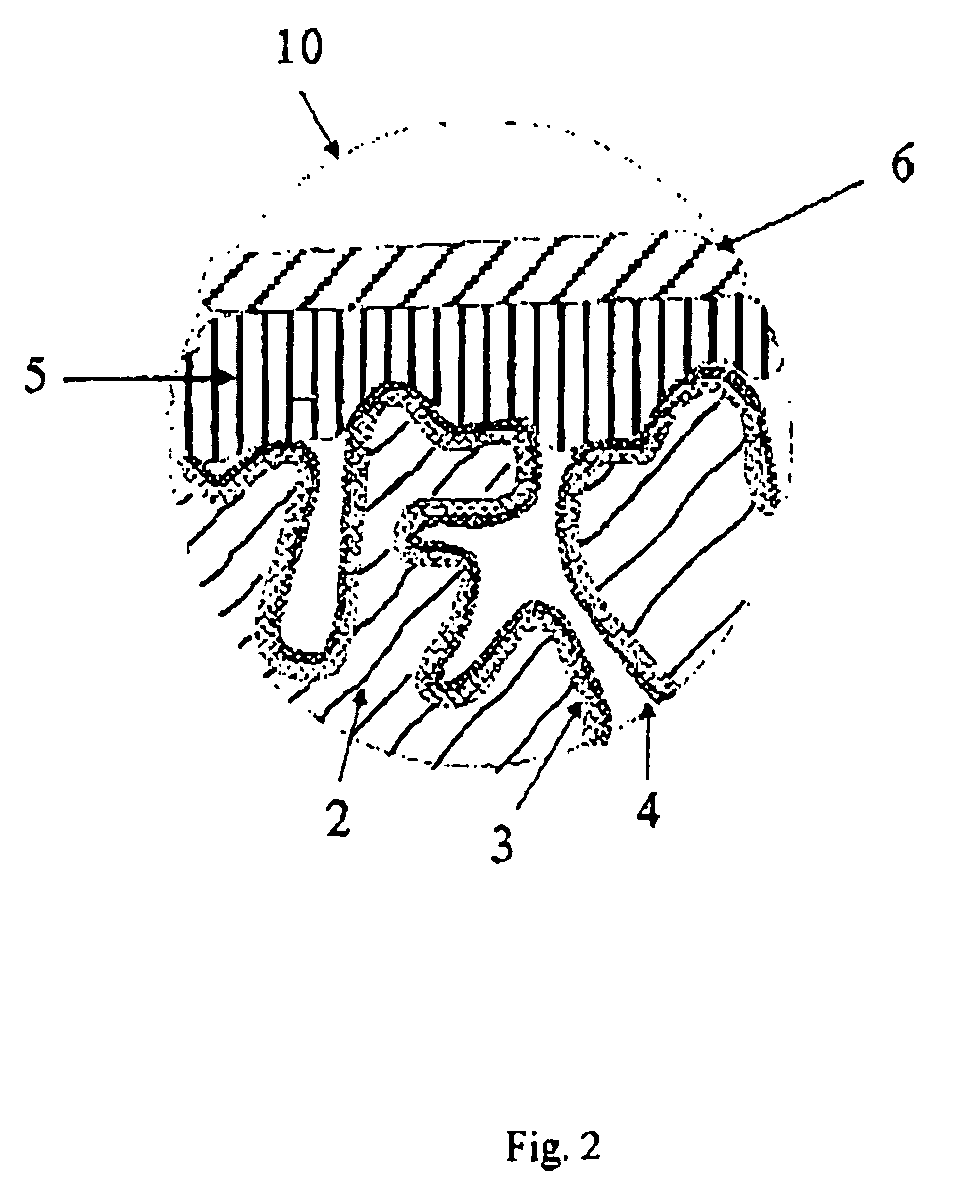

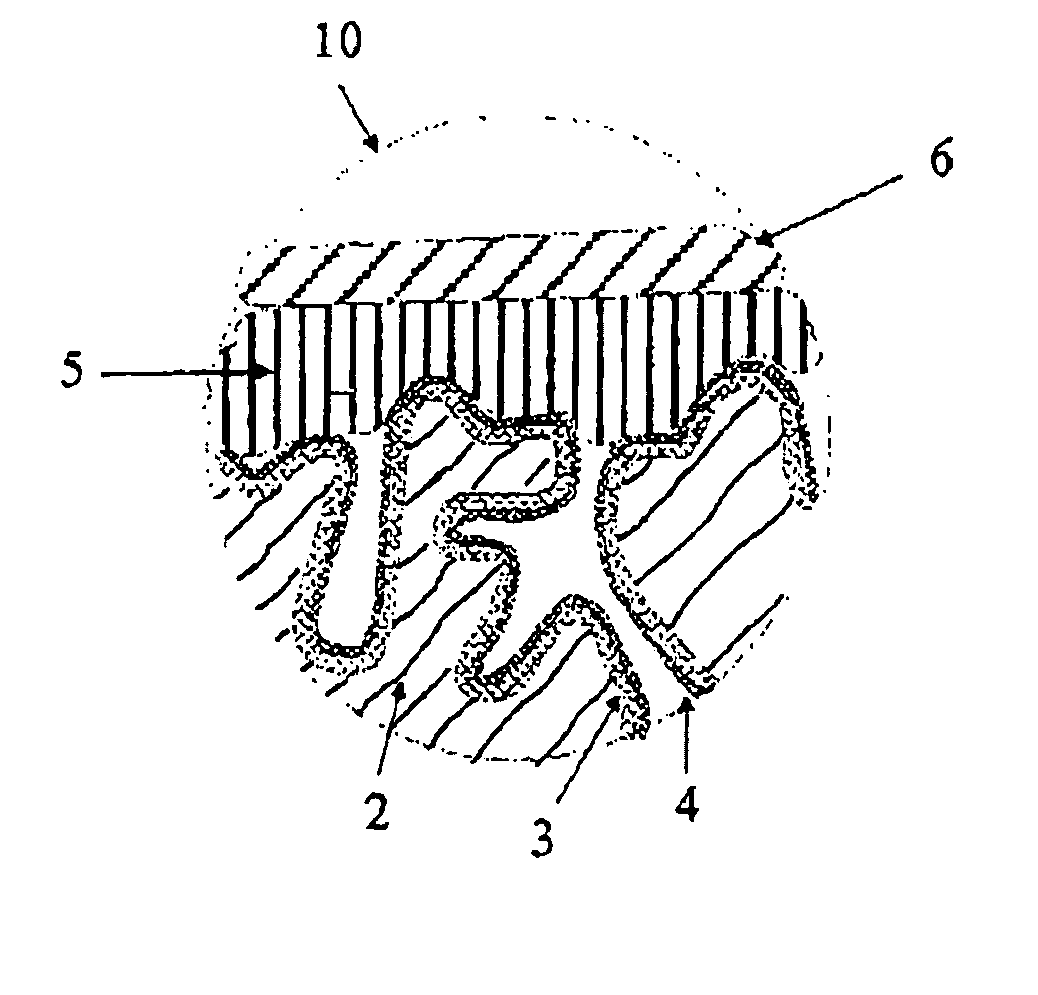

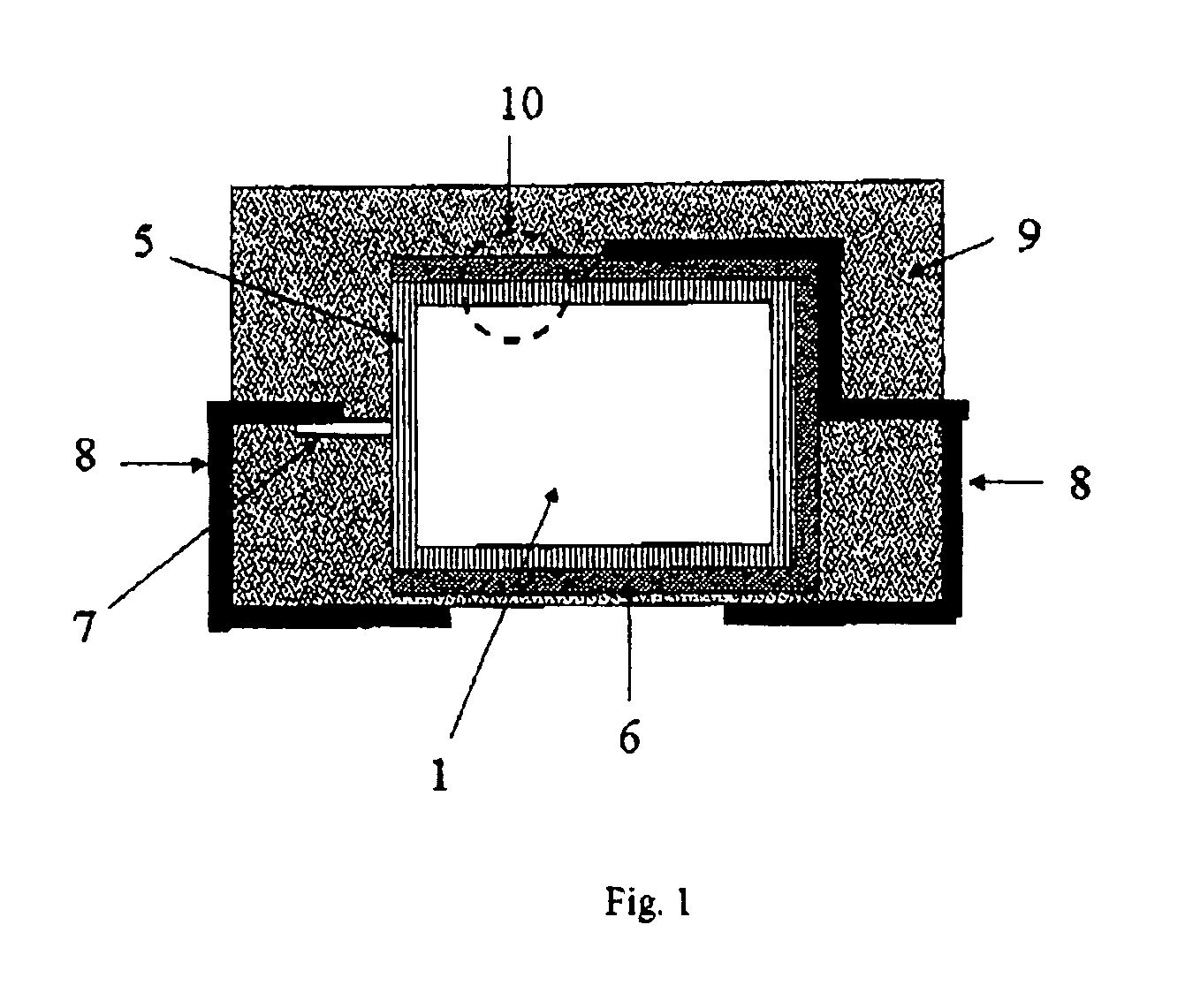

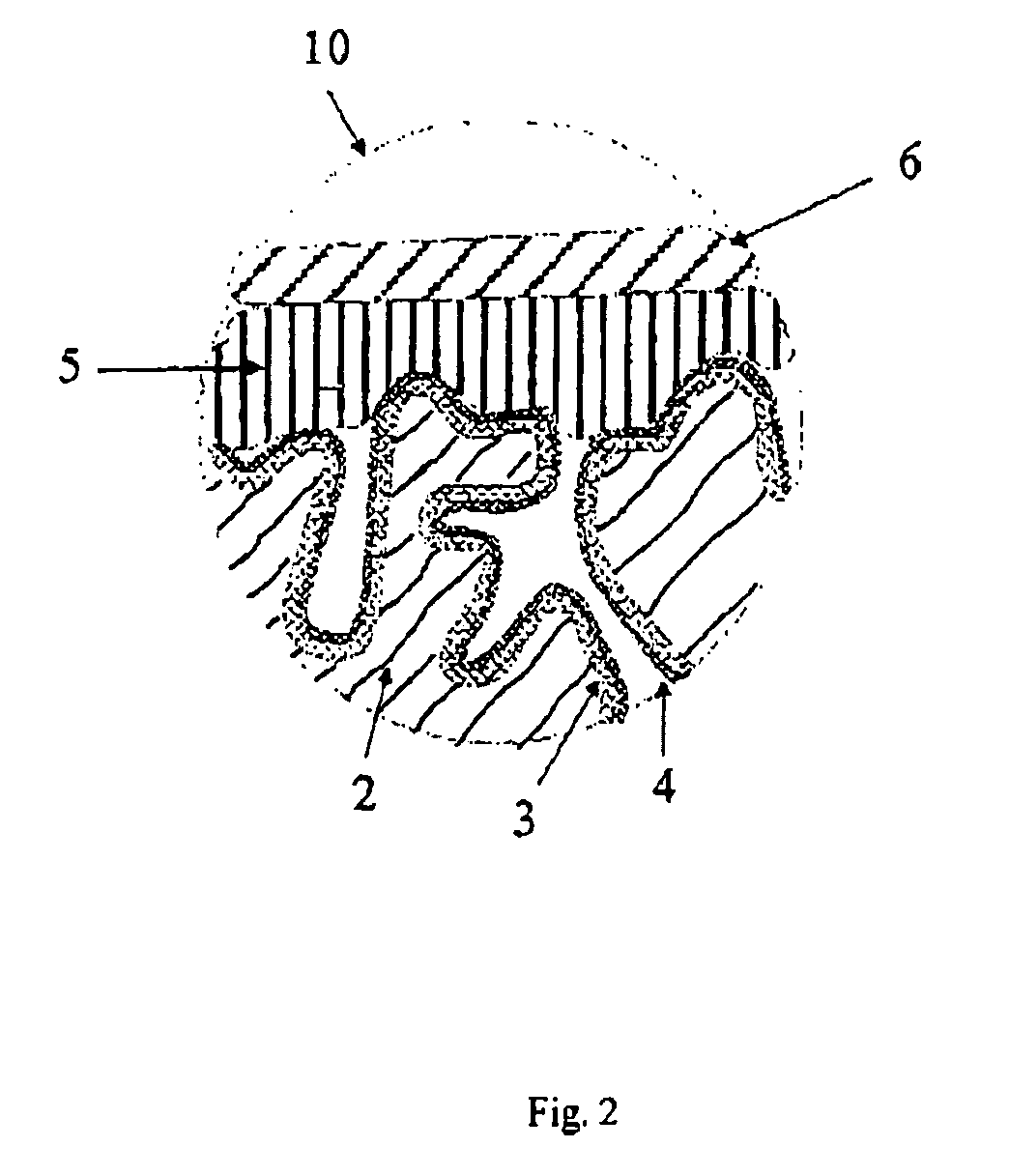

Electrolytic capacitors having low equivalent series resistance and low leakage current are described. The electrolytic capacitors include a solid electrolyte layer of a conductive material in particular a conductive polymer, and an outer layer that includes binders, polymeric anions and conductive polymers (e.g., polythiophenes). Also described is a method of preparing electrolytic capacitors that involves forming the conductive polymer of the solid electrolyte layer in situ by means of chemical oxidative polymerization or electrochemical polymerization. Electronic circuits that include the electrolytic capacitors are also described.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Solid electrolytic capacitor containing a conductive polymer

ActiveUS7515396B2Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

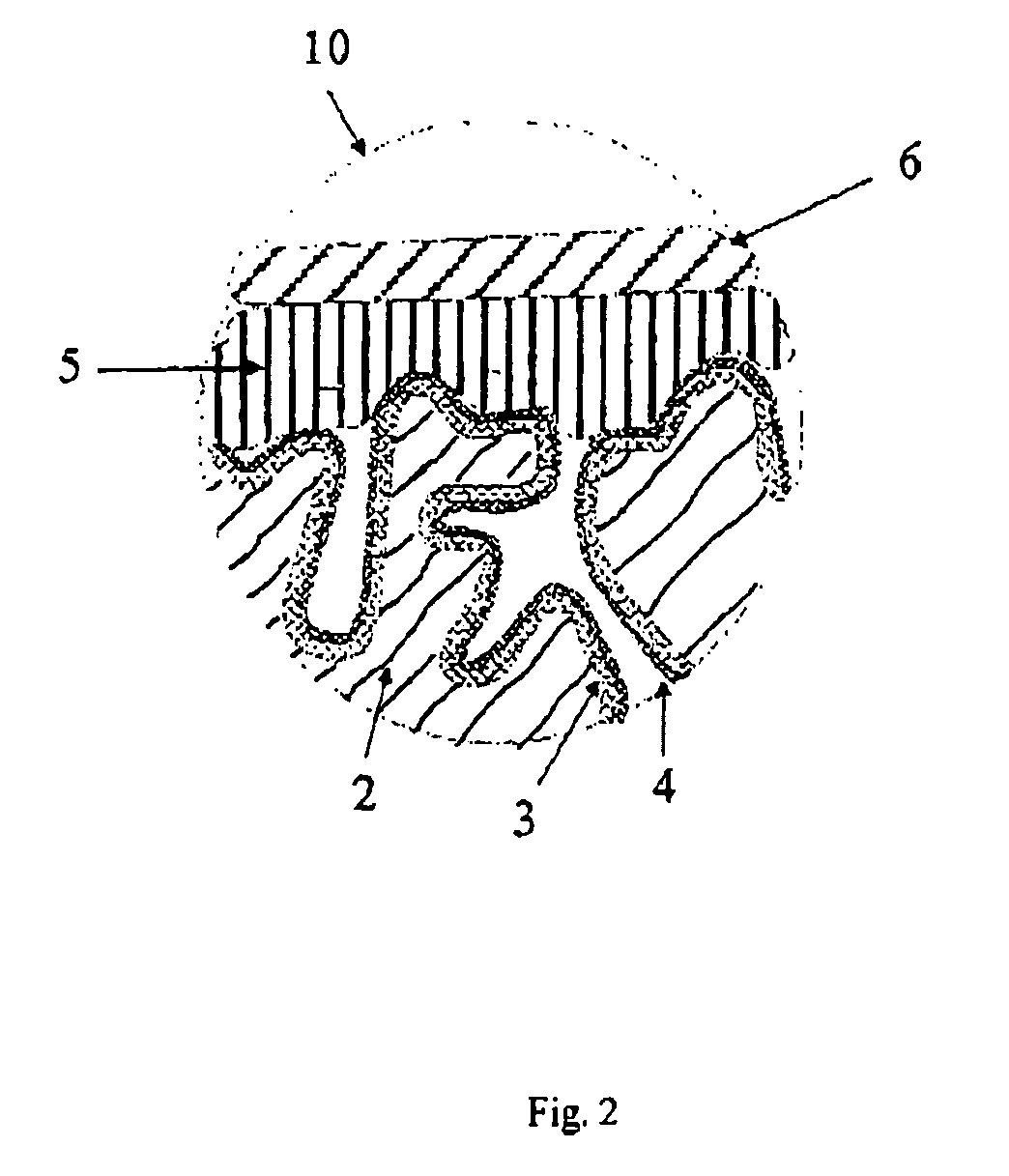

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

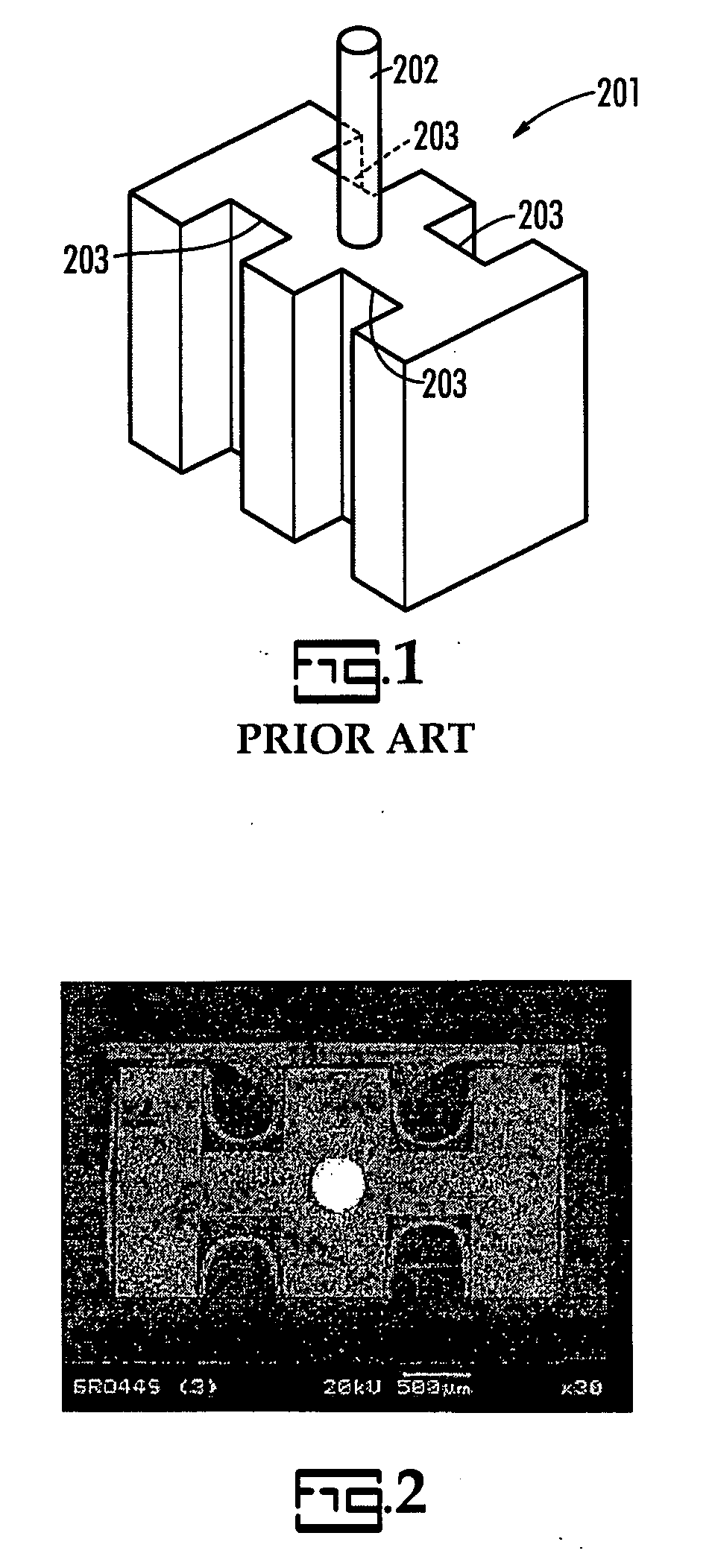

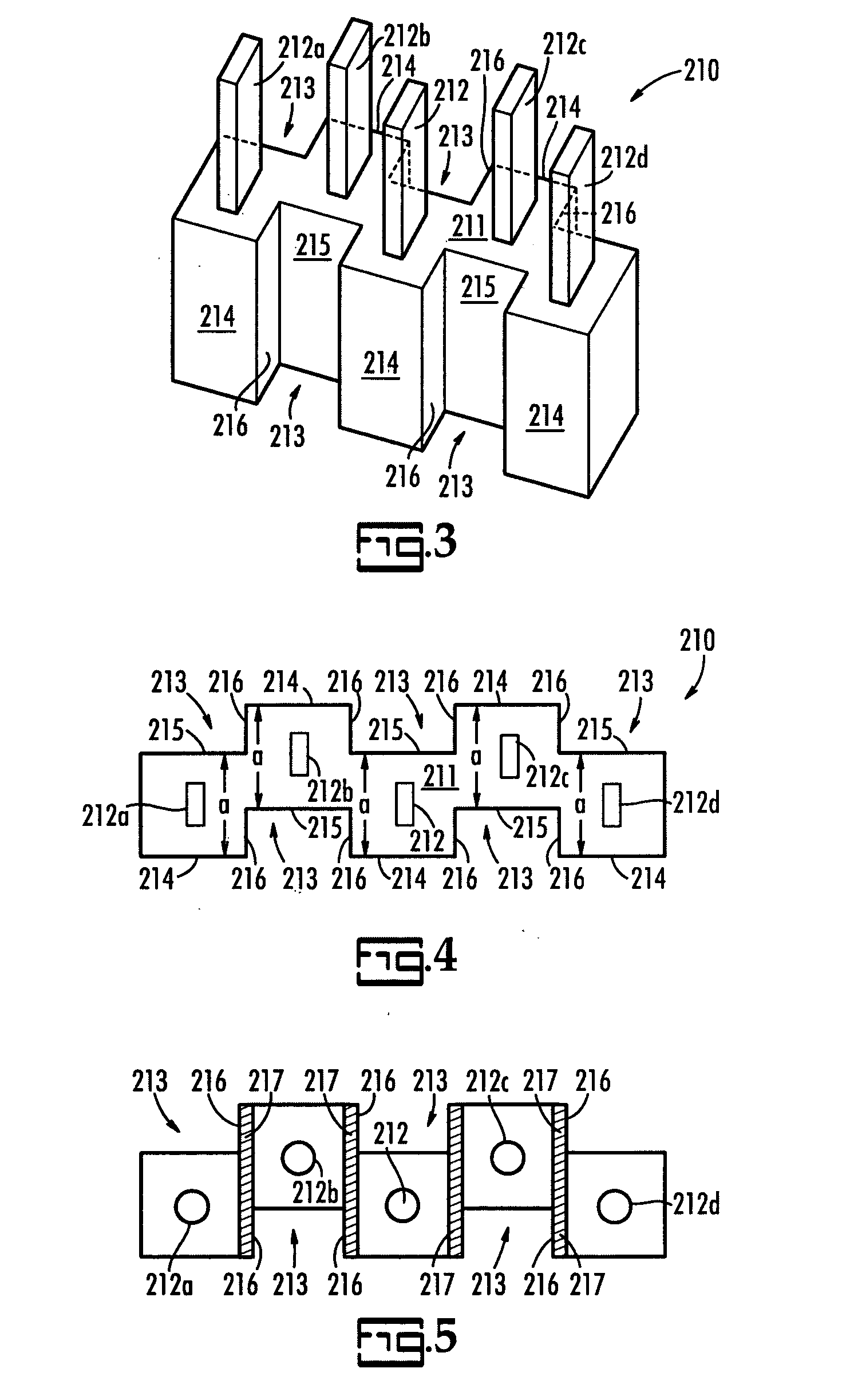

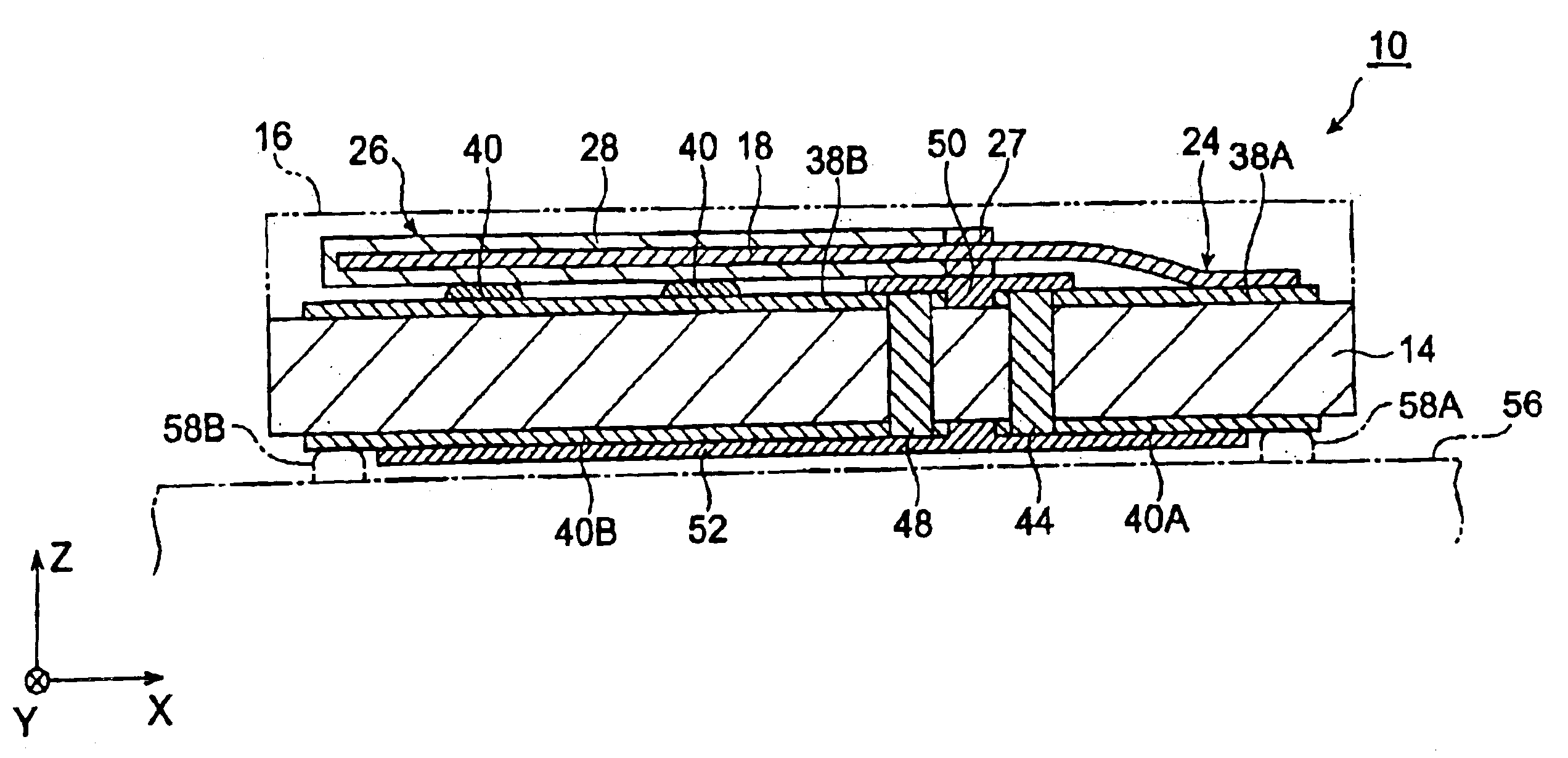

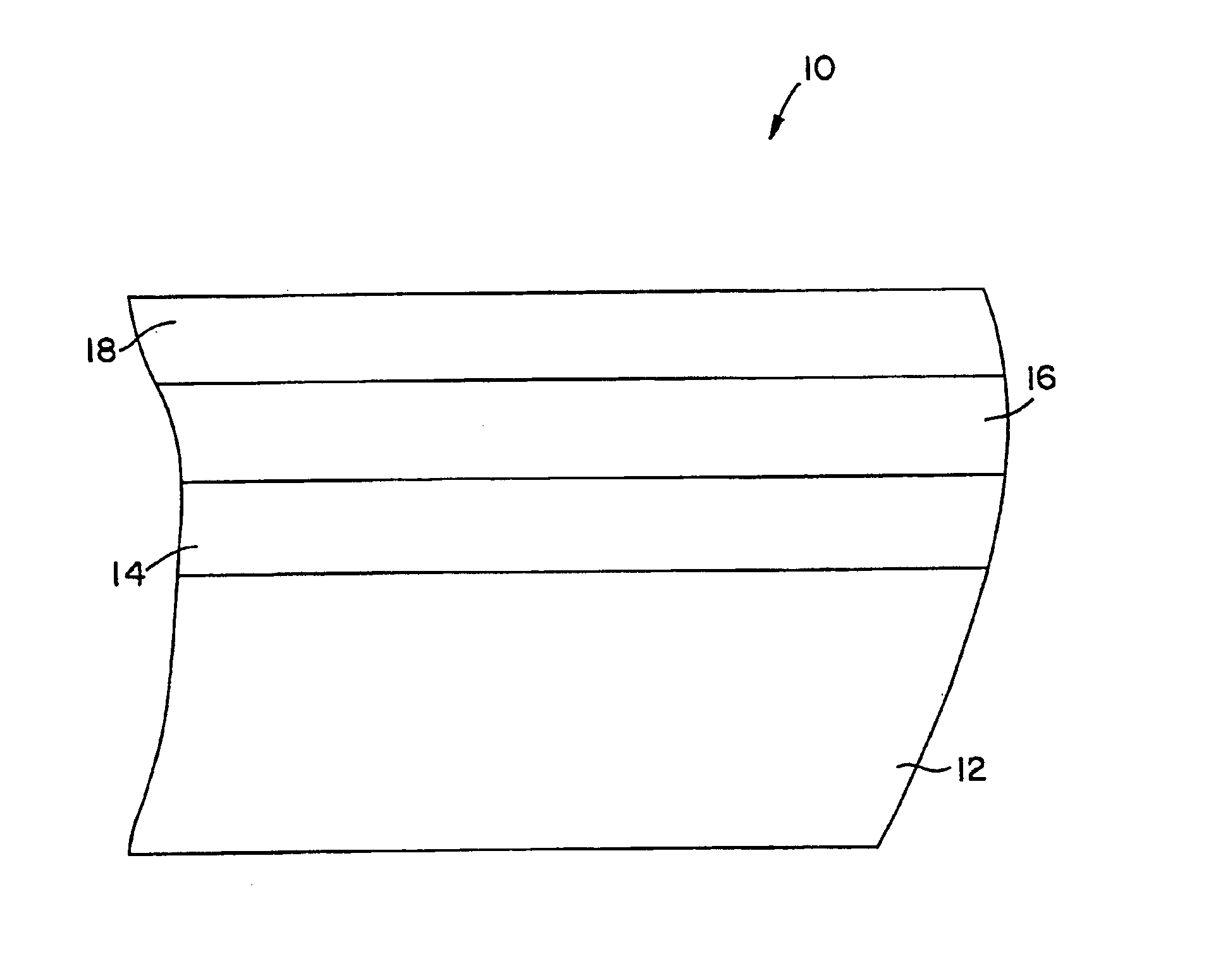

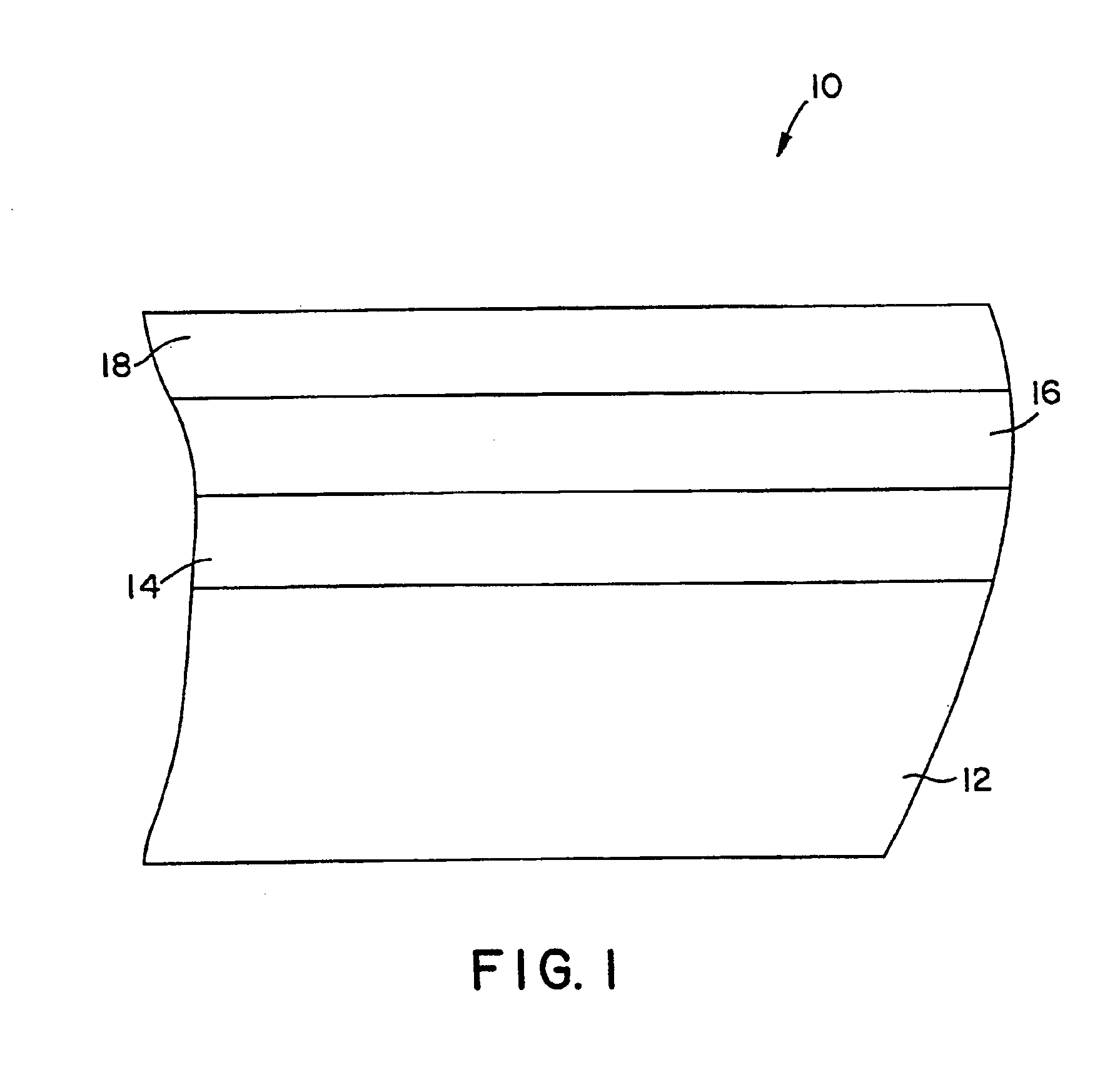

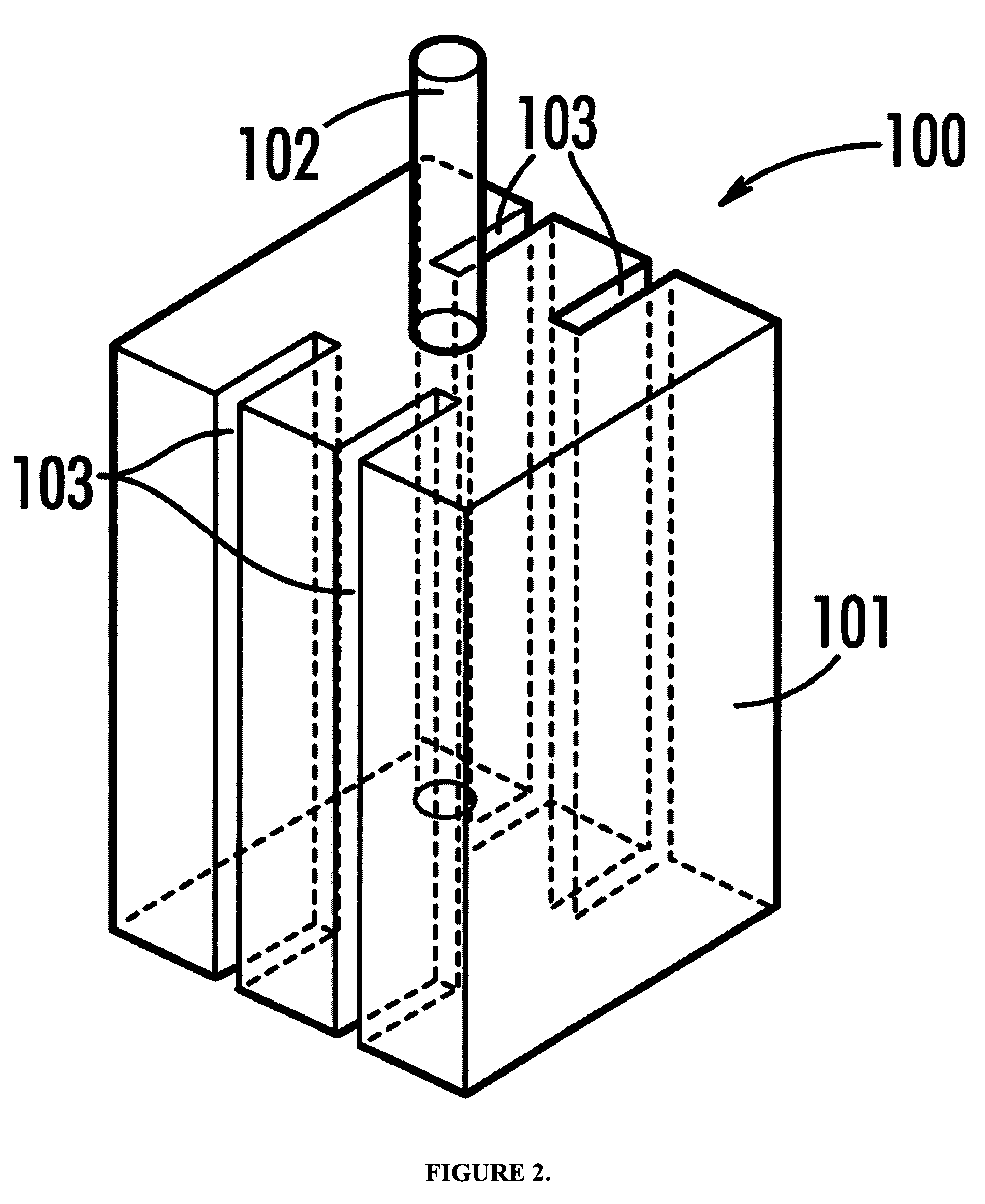

Fluted anode with minimal density gradients and capacitor comprising same

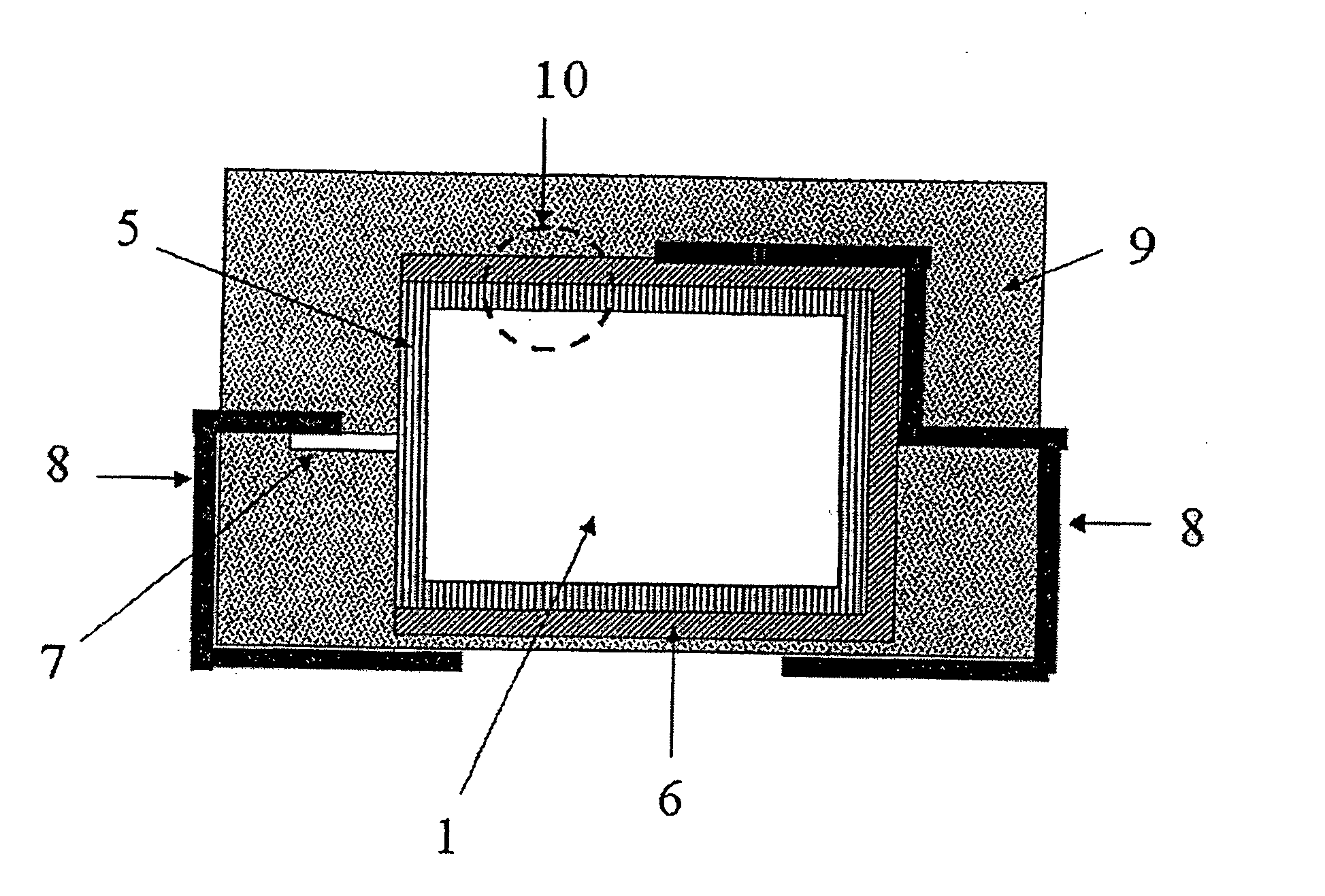

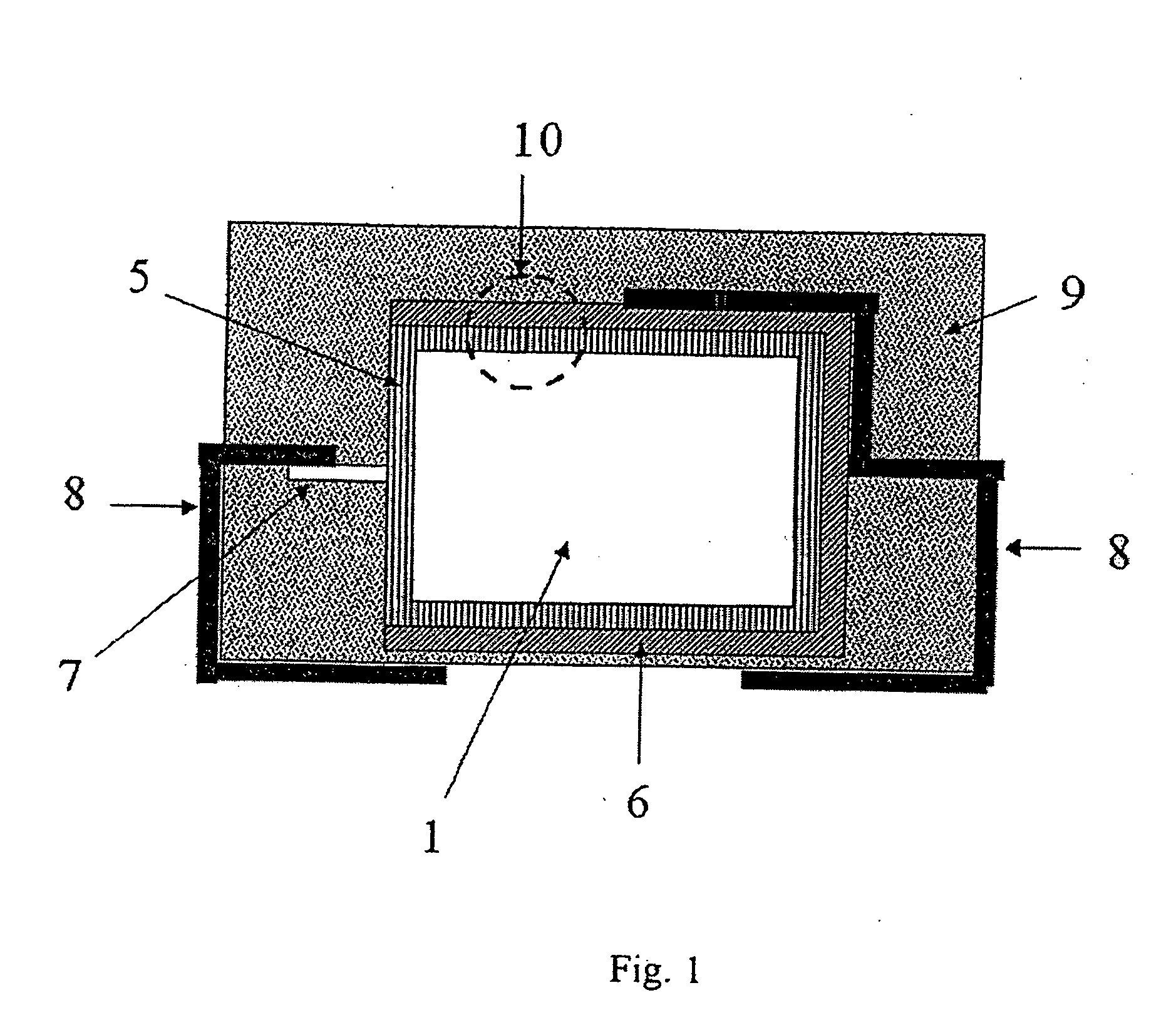

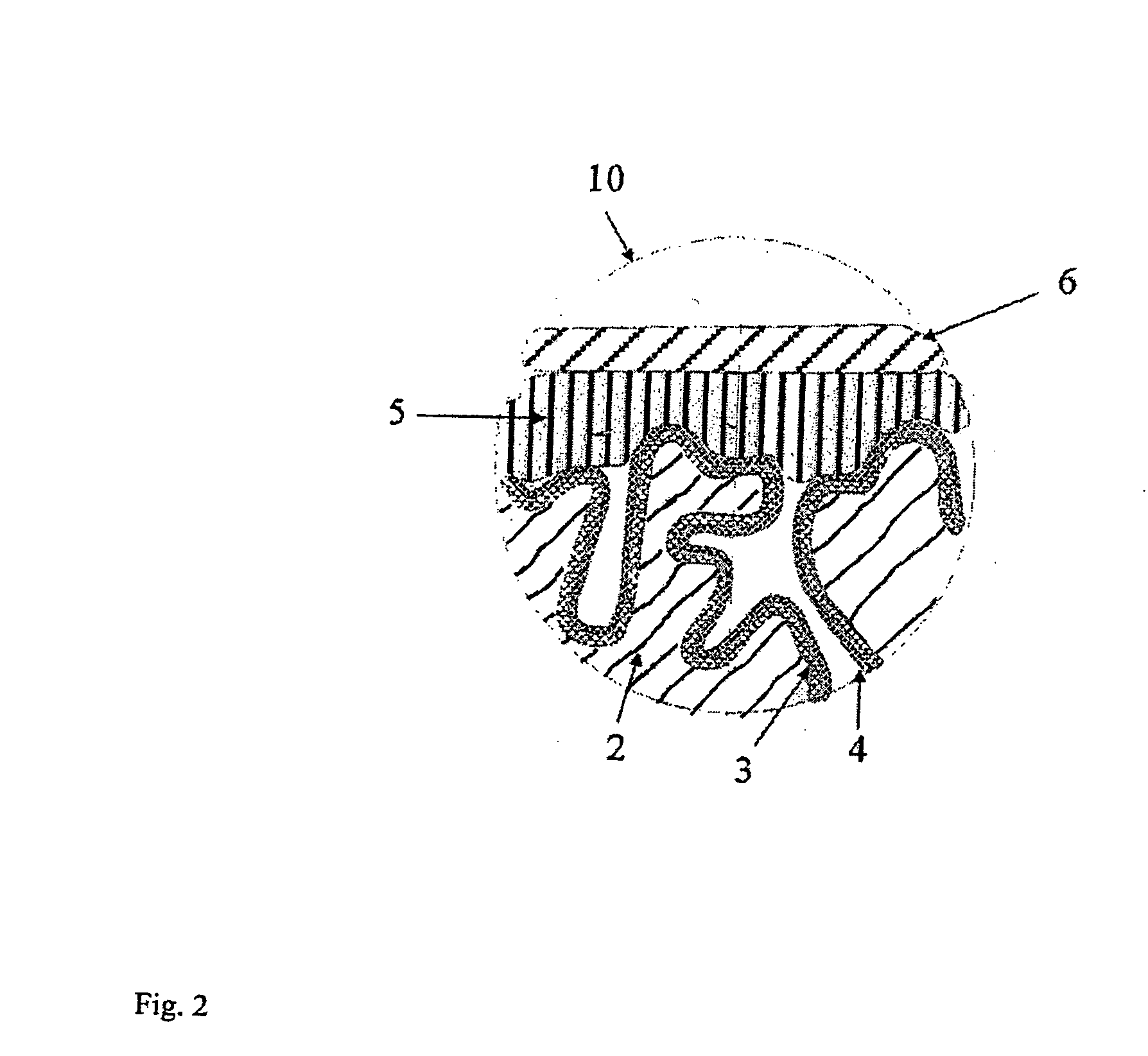

InactiveUS20050270725A1Improve consistencyImprove electrical performanceSolid electrolytic capacitorsLiquid electrolytic capacitorsCapacitorPhysics

Owner:KEMET ELECTRONICS CORP

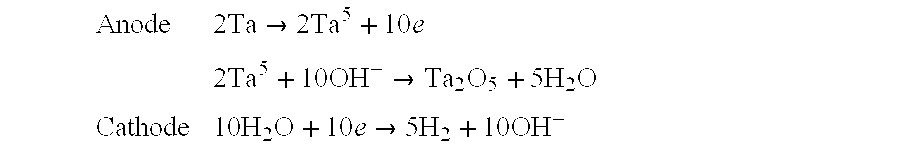

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS20070064376A1Lower equivalent series resistanceHigh nominal voltageSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisPhysical chemistry

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Fluted anode with minimal density gradients and capacitor comprising same

InactiveUS7116548B2Improve consistencyImprove electrical performanceSolid electrolytic capacitorsLiquid electrolytic capacitorsCapacitorPhysics

Owner:KEMET ELECTRONICS CORP

Solid electrolytic capacitor containing a conductive polymer

ActiveUS20080232037A1Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

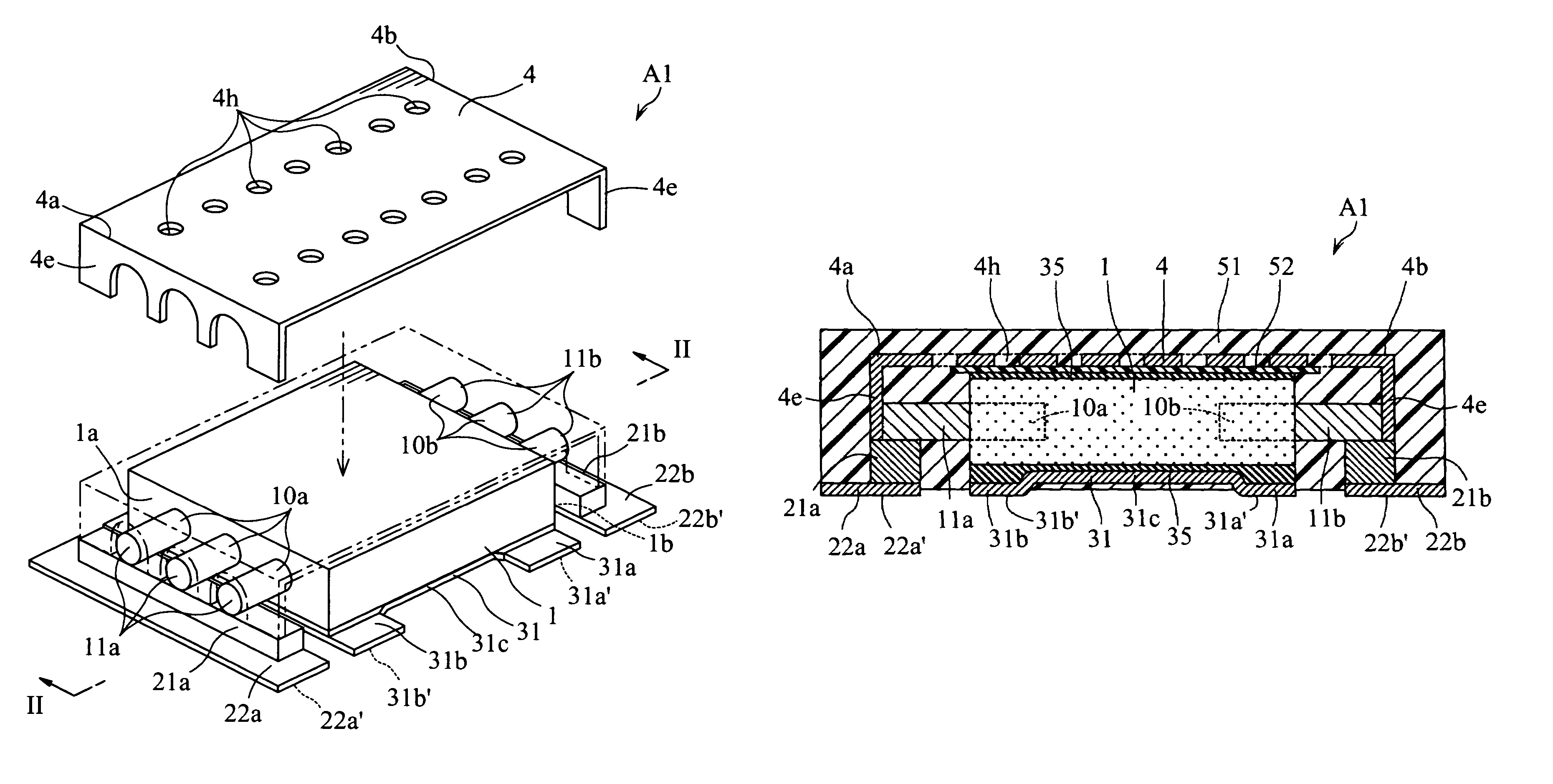

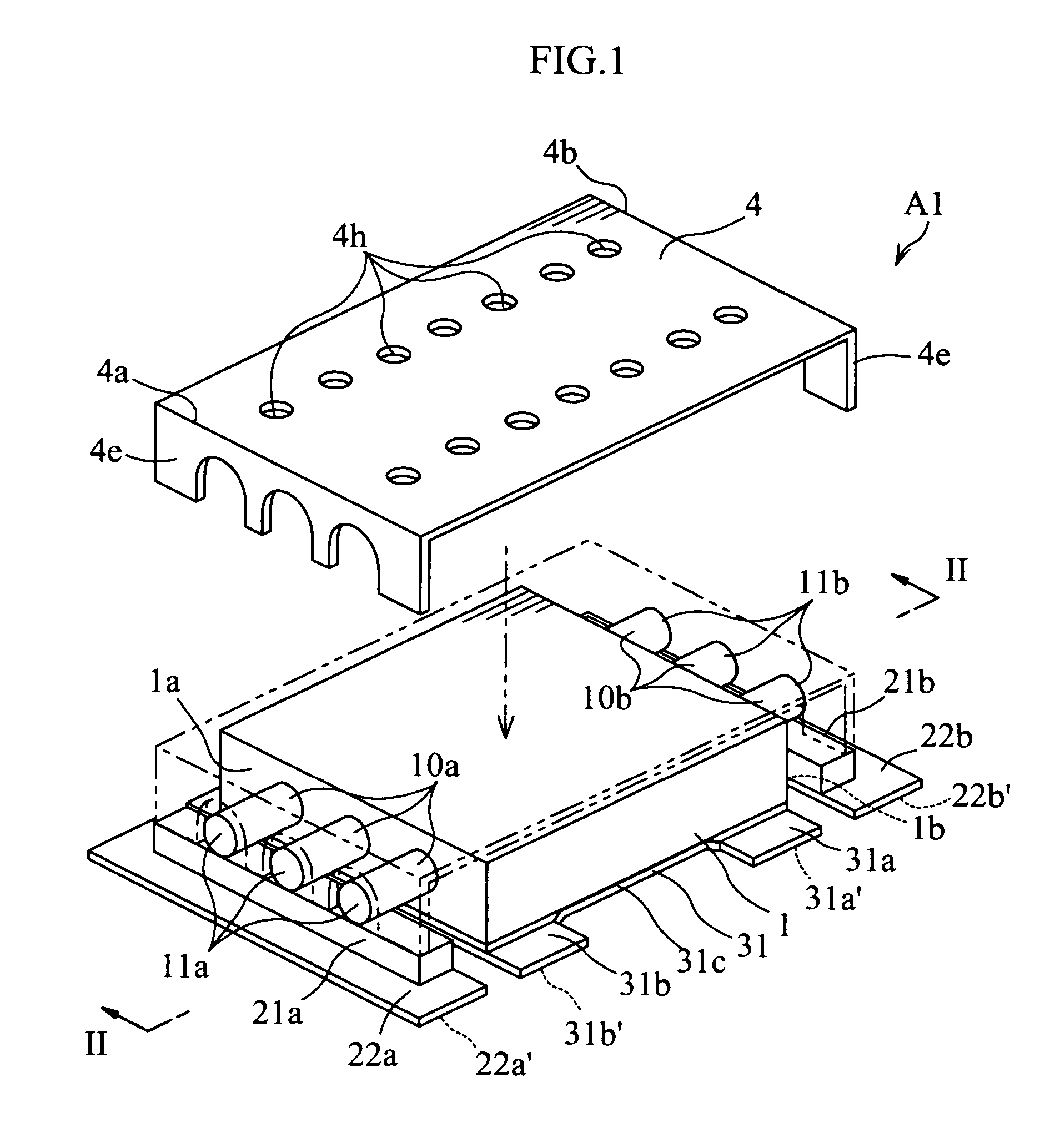

Method of manufacturing electrolytic capacitor and electrolytic capacitor

ActiveUS7497879B2Improve pressure resistanceSmall currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

ActiveUS7411779B2Lower equivalent series resistanceIncrease coverageHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisConductive polymer

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS8313538B2Solid electrolytic capacitorsLiquid electrolytic capacitorsPhysical chemistryCapacitor

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Sintered bodies based on niobium suboxide

Disclosed are sintered bodies that include: (a) 30 to 100 mol % of NbOx, wherein 0.5<x<1.5; and (b) 0 to 70 mol % of MgO. The sintered bodies may be used as inert apparatuses in the production of niobium suboxide powder or niobium suboxide anodes, or as chemically resistant components in chemical apparatuses.

Owner:H C STARCK GMBH

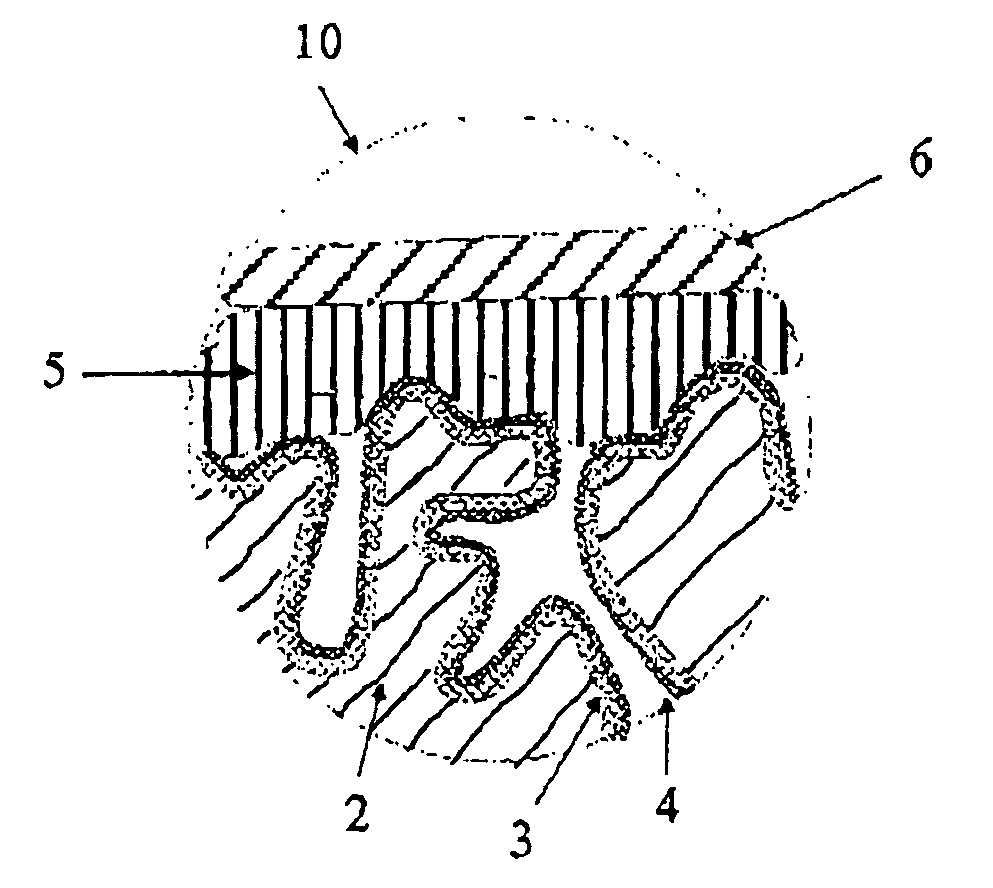

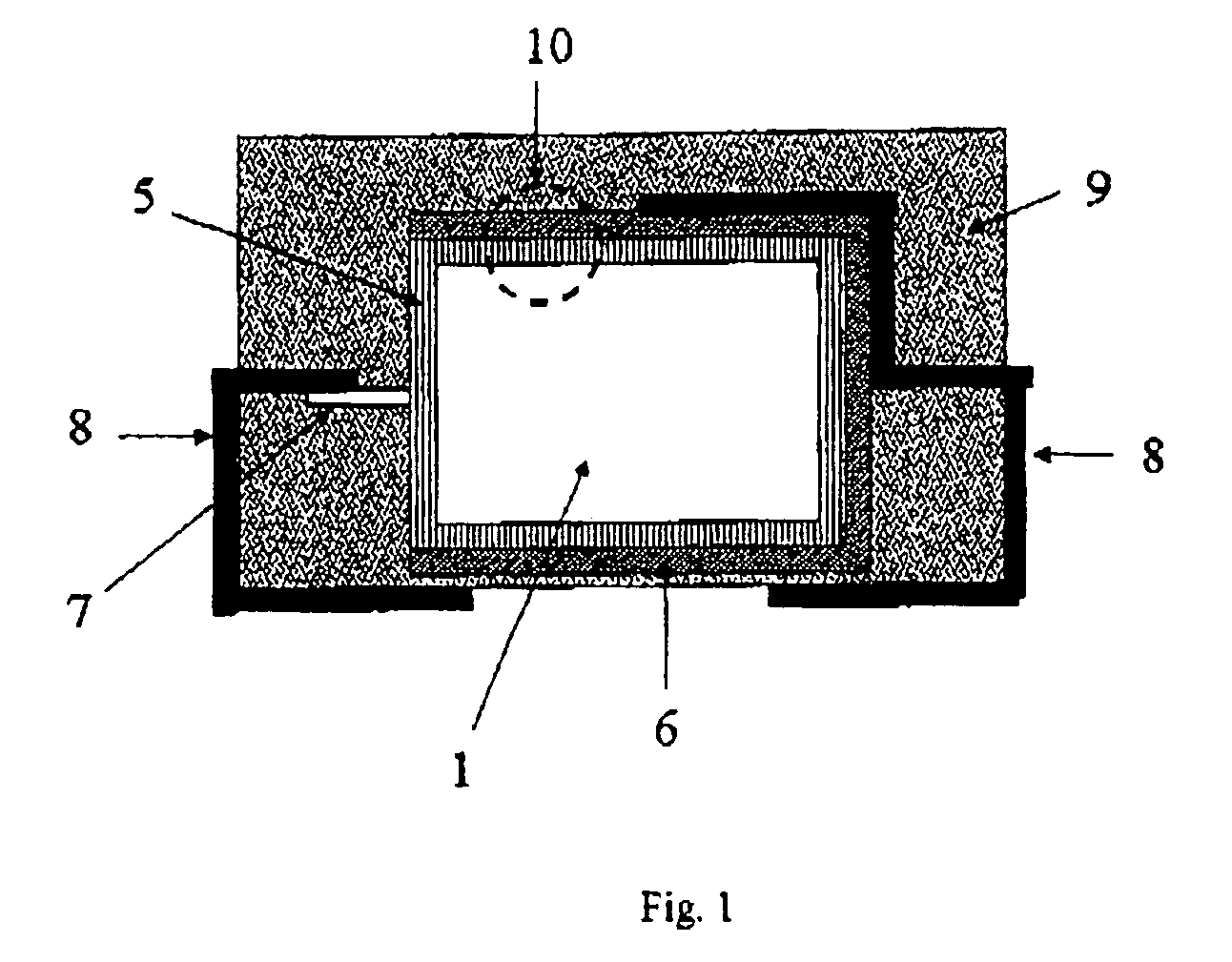

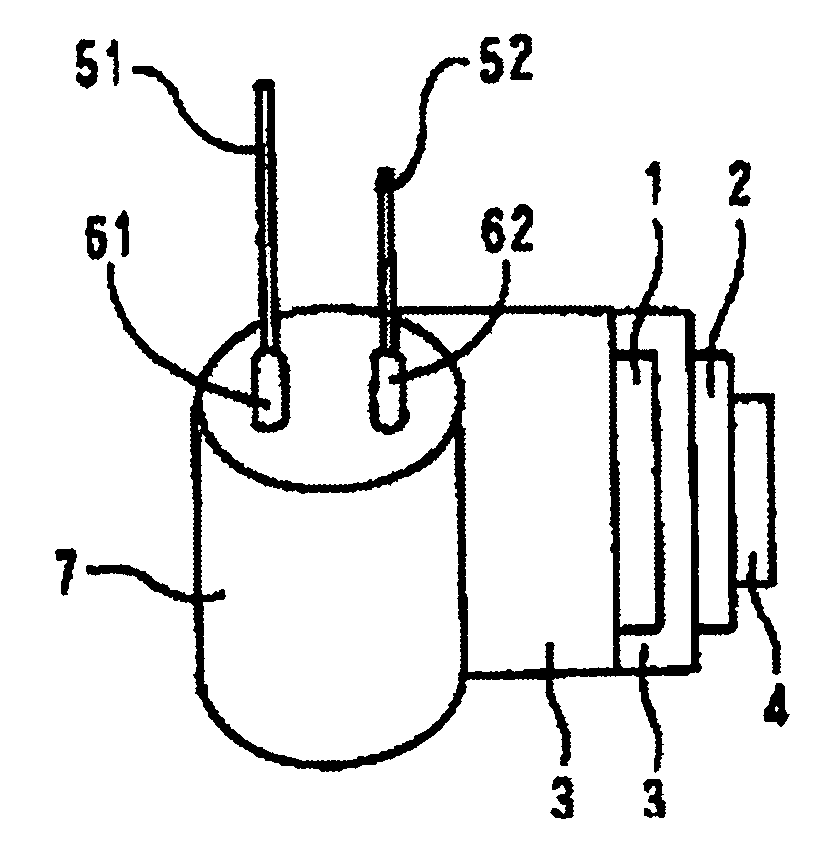

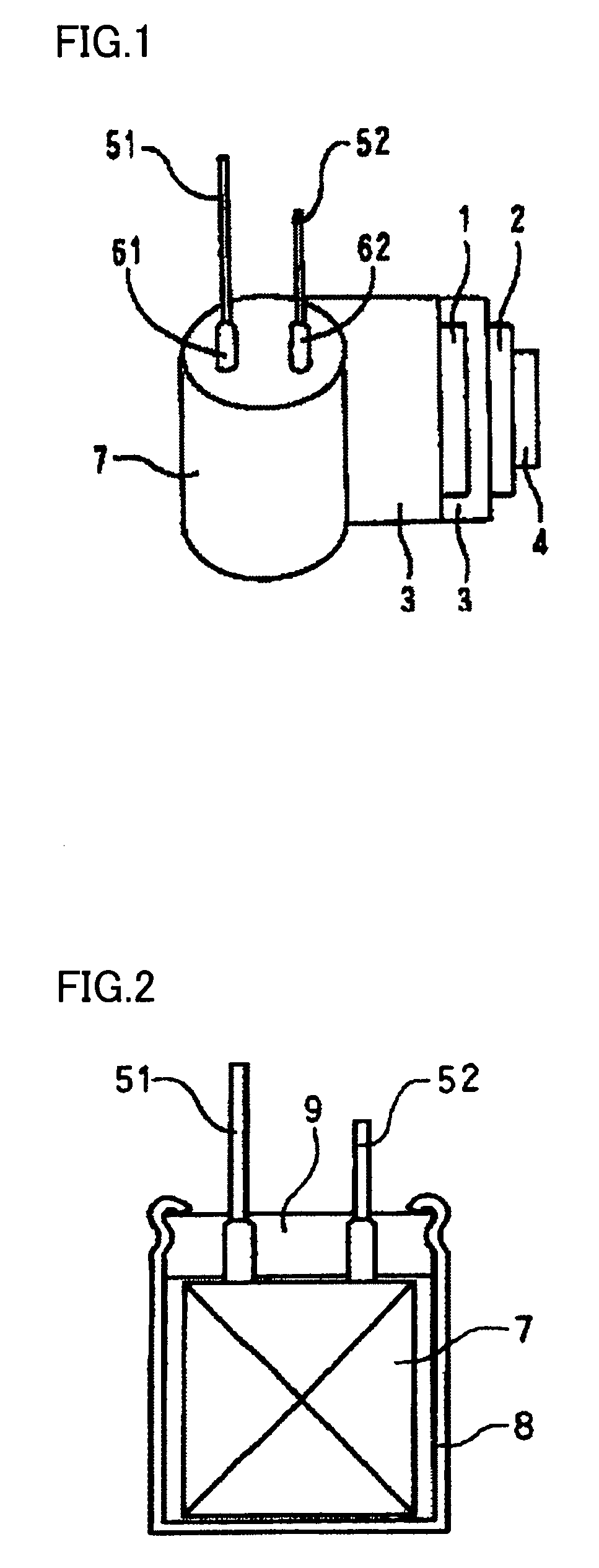

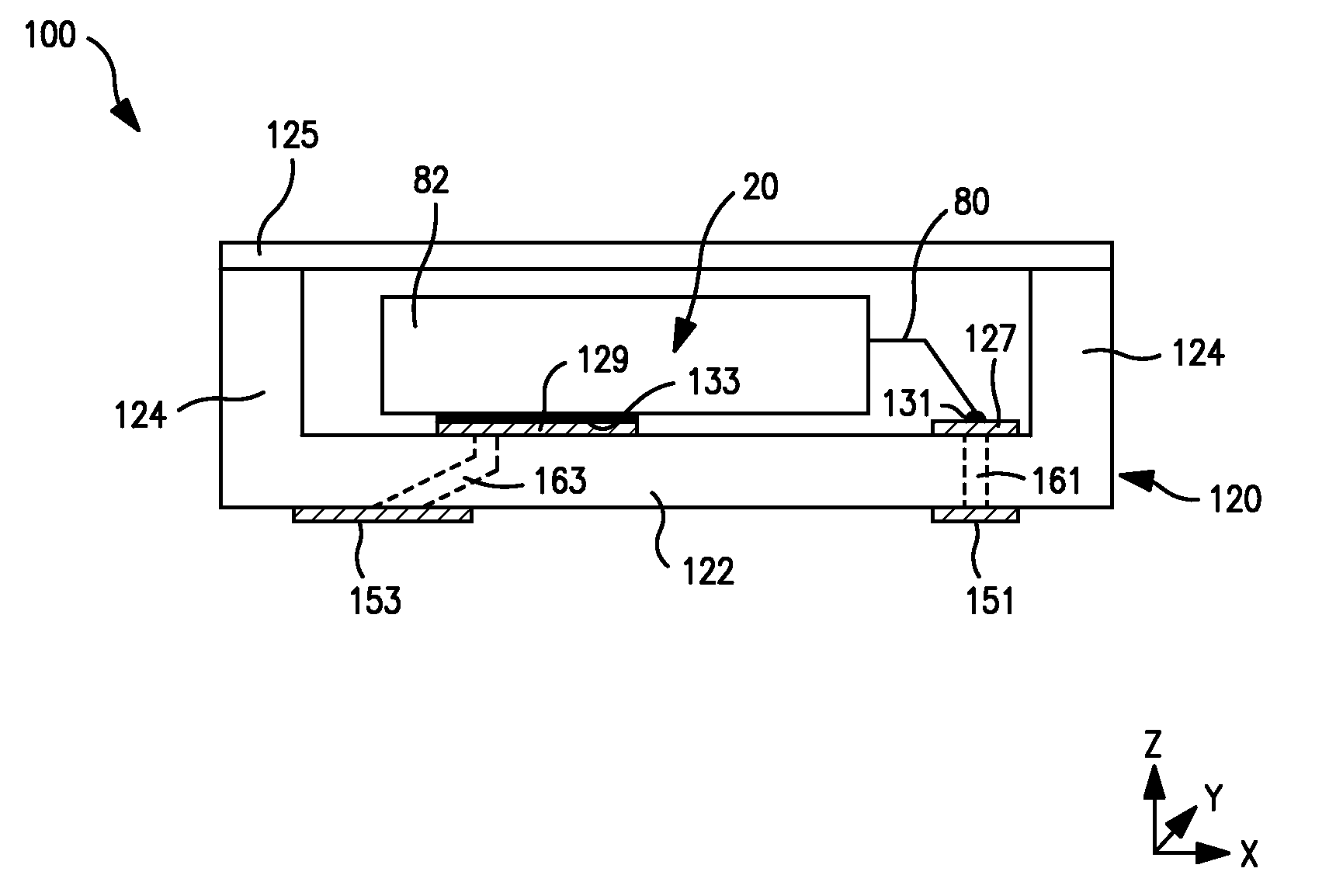

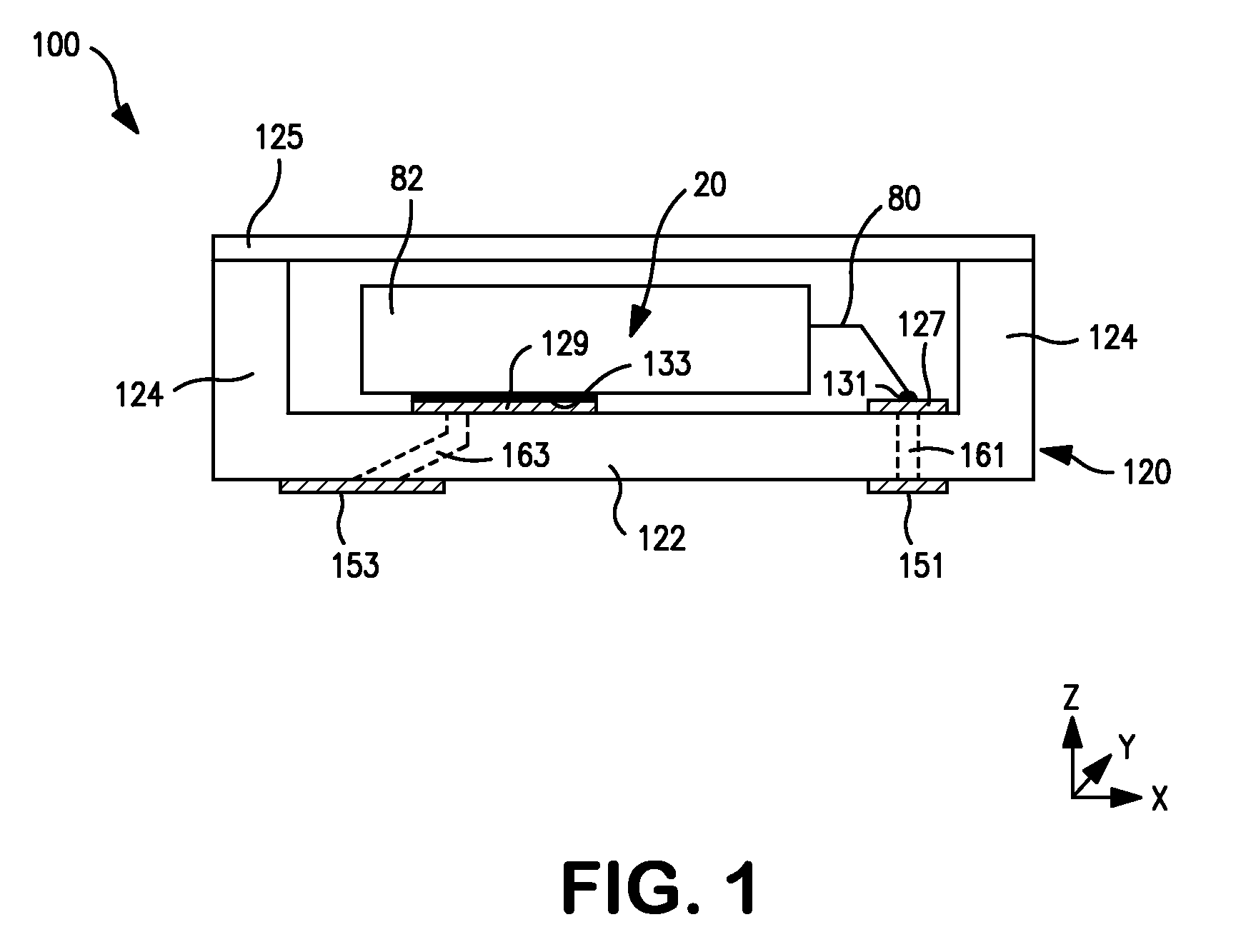

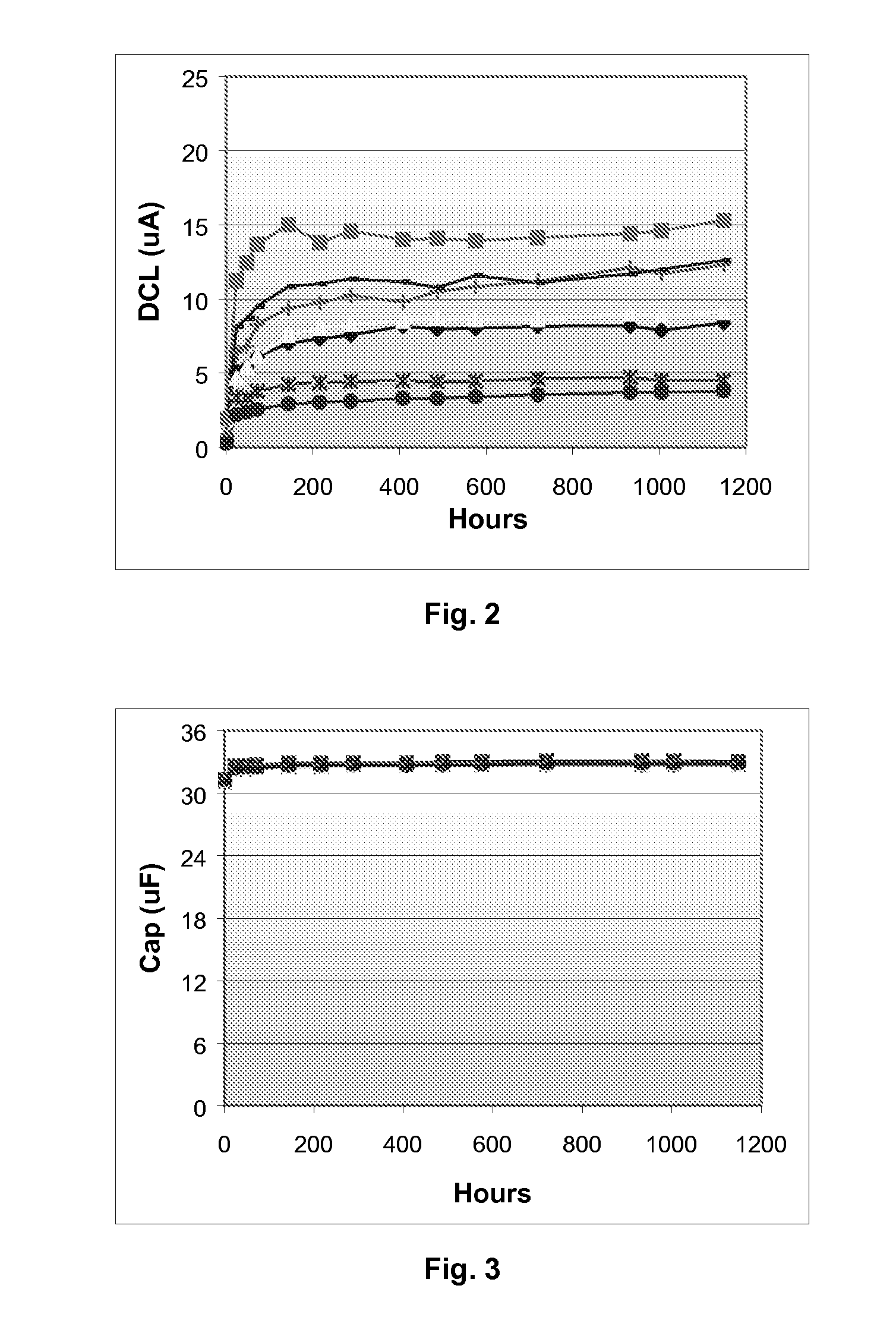

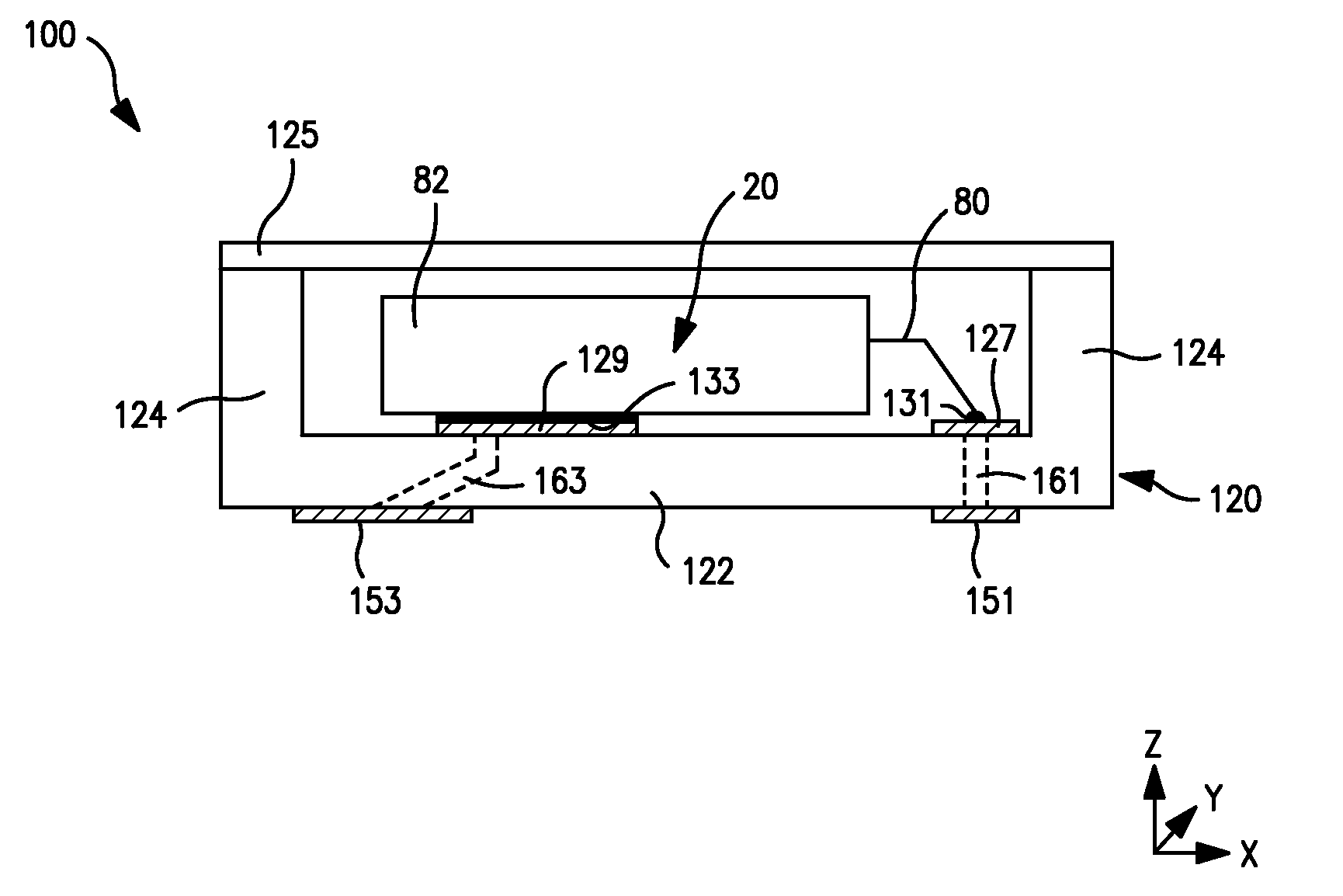

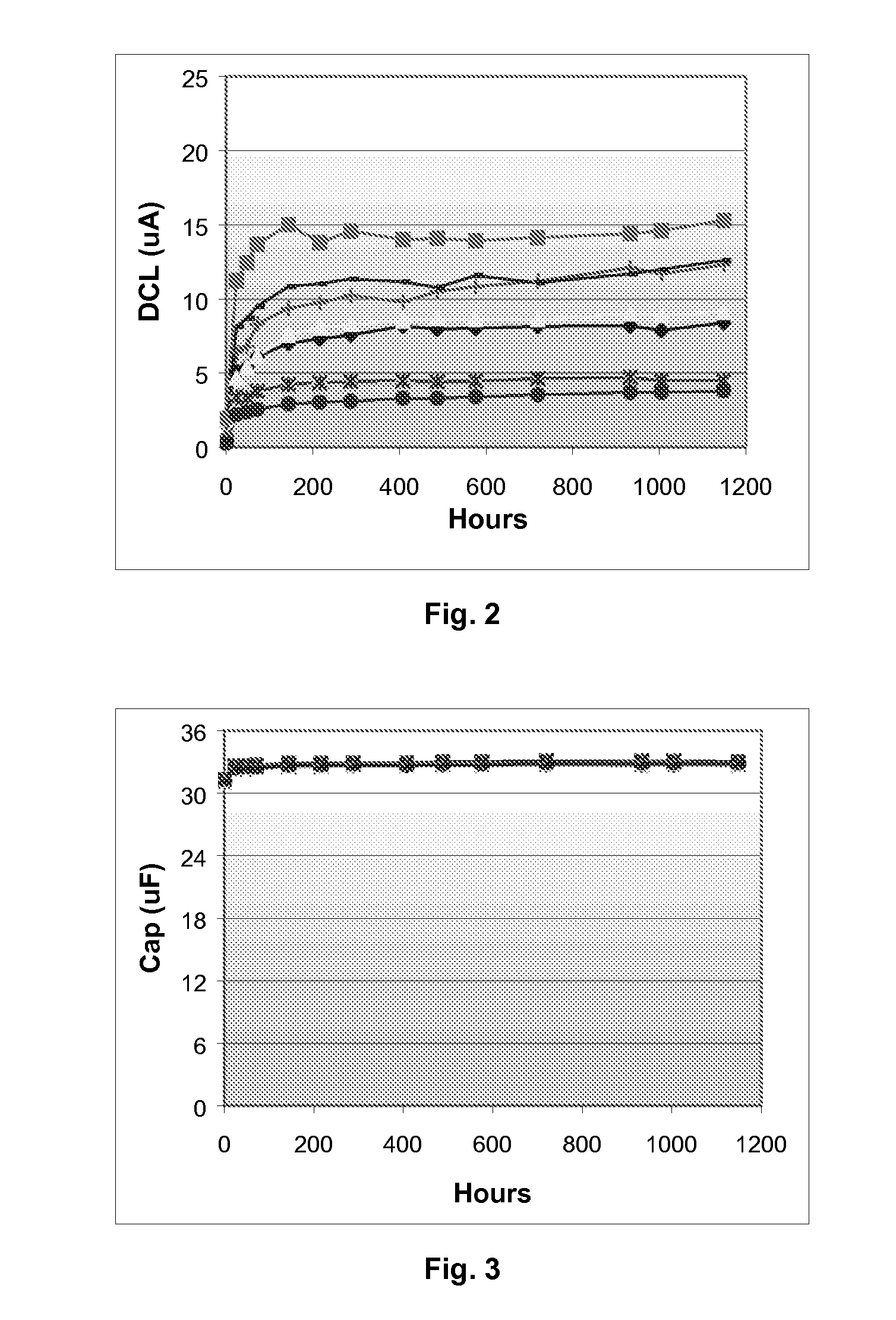

Hermetically Sealed Capacitor Assembly

ActiveUS20090244812A1Hybrid capacitor electrolytesSolid electrolytic capacitorsHermetic sealConductive polymer

A capacitor assembly that includes a conductive polymer electrolytic capacitor that is enclosed and hermetically sealed within a ceramic housing in the presence of an inert gas is provided. Without intending to be limited by theory, the present inventors believe that the ceramic housing is capable of limiting the amount of oxygen and moisture supplied to the conductive polymer of the capacitor. In this manner, the conductive polymer is less likely to oxidize in high temperature environments, thus increasing the thermal stability of the capacitor assembly.

Owner:KYOCERA AVX COMPONENTS CORP

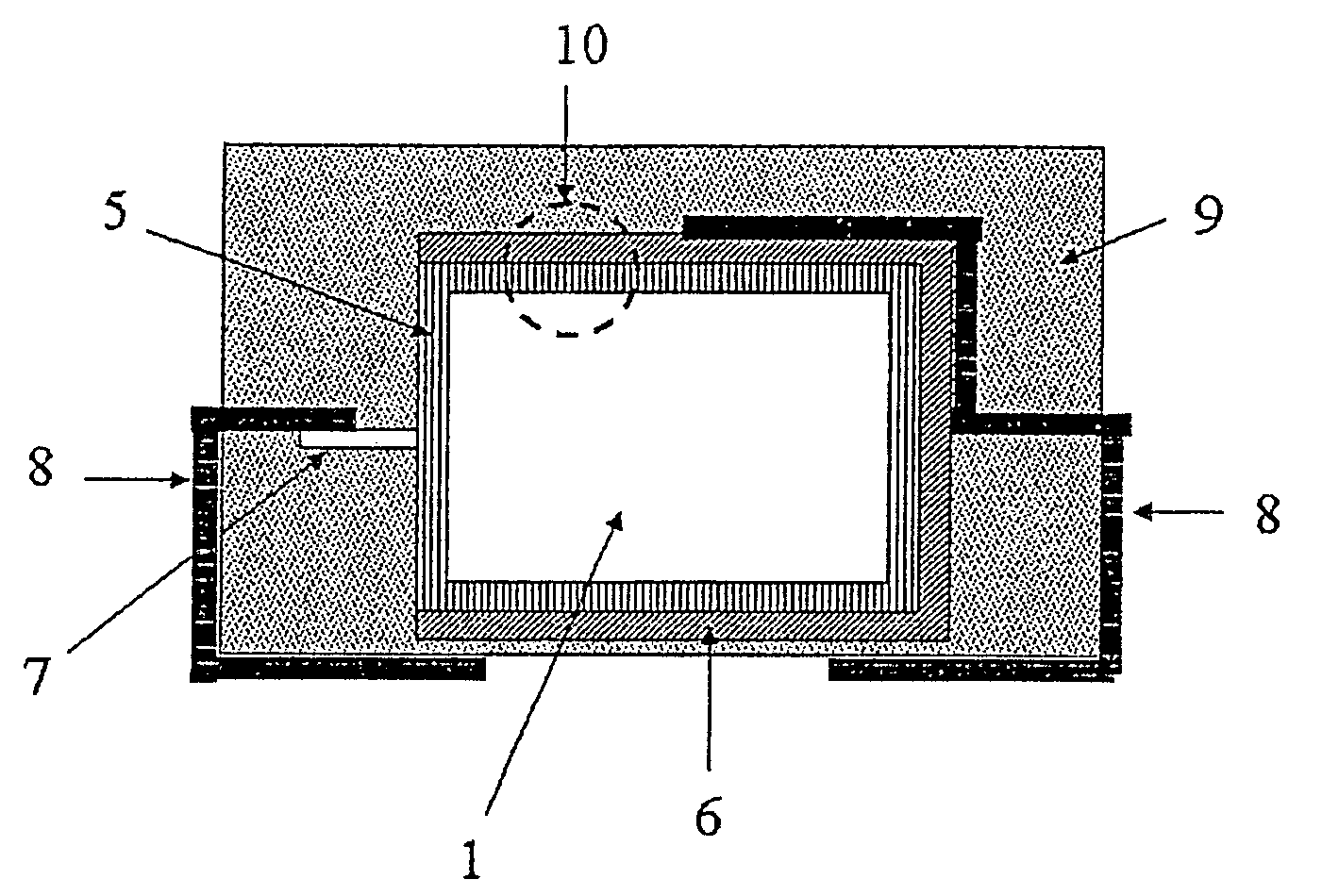

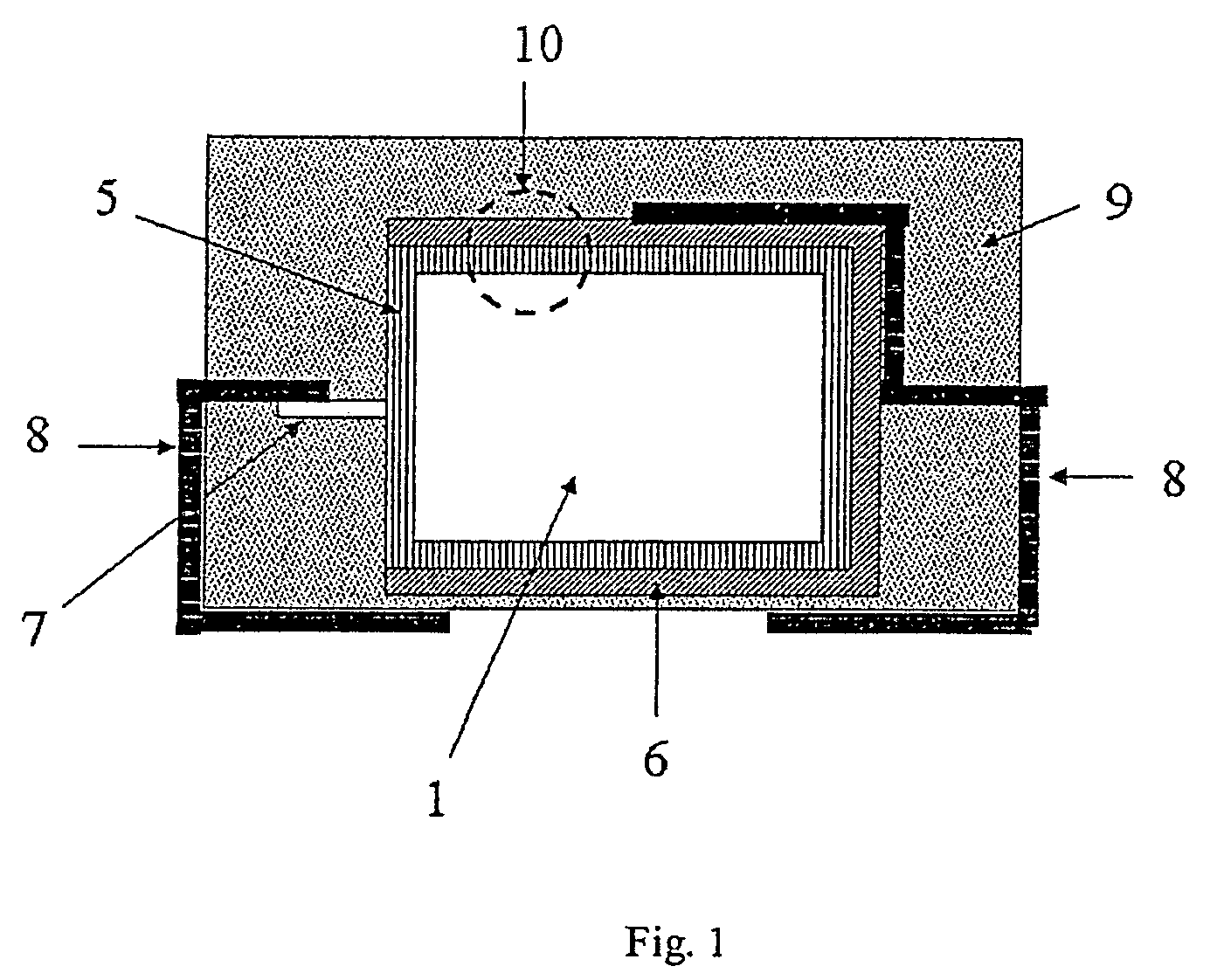

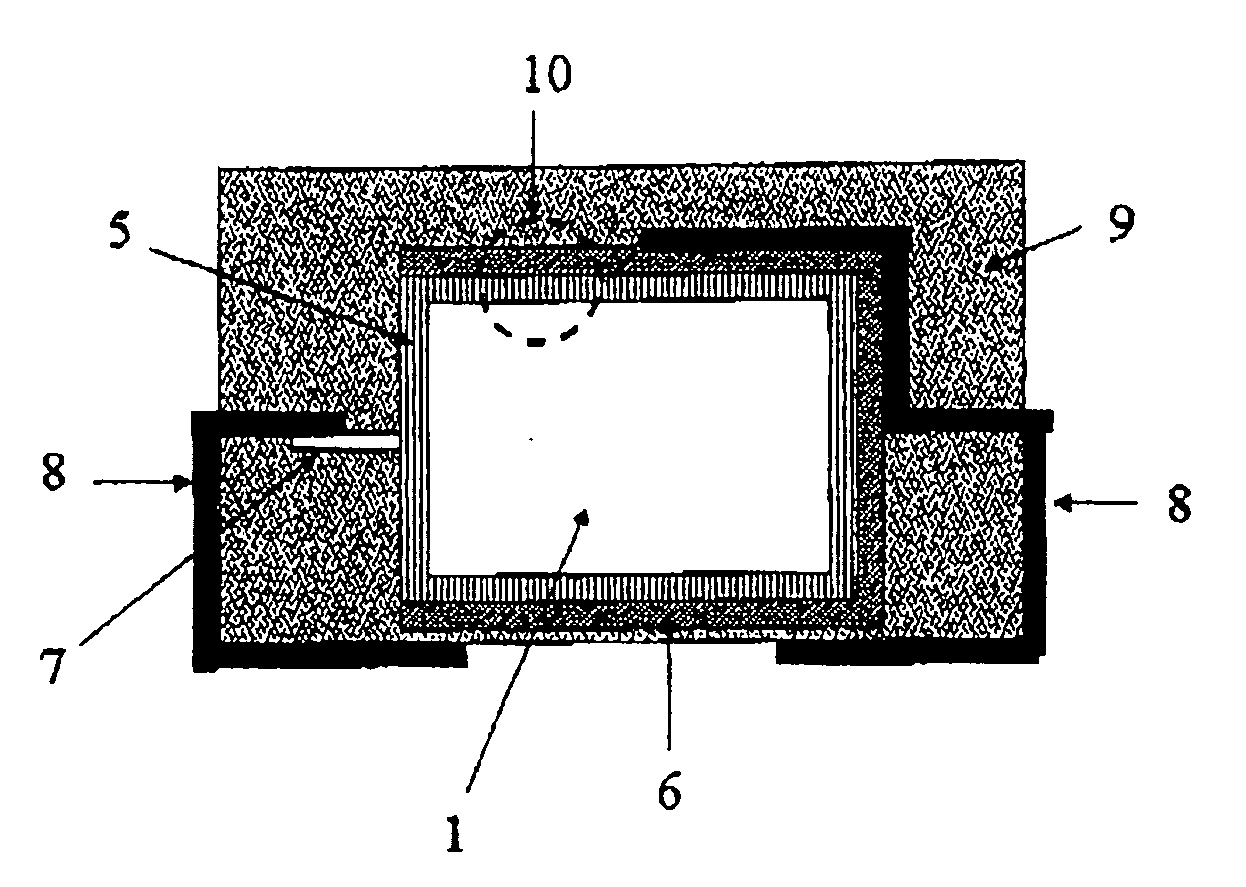

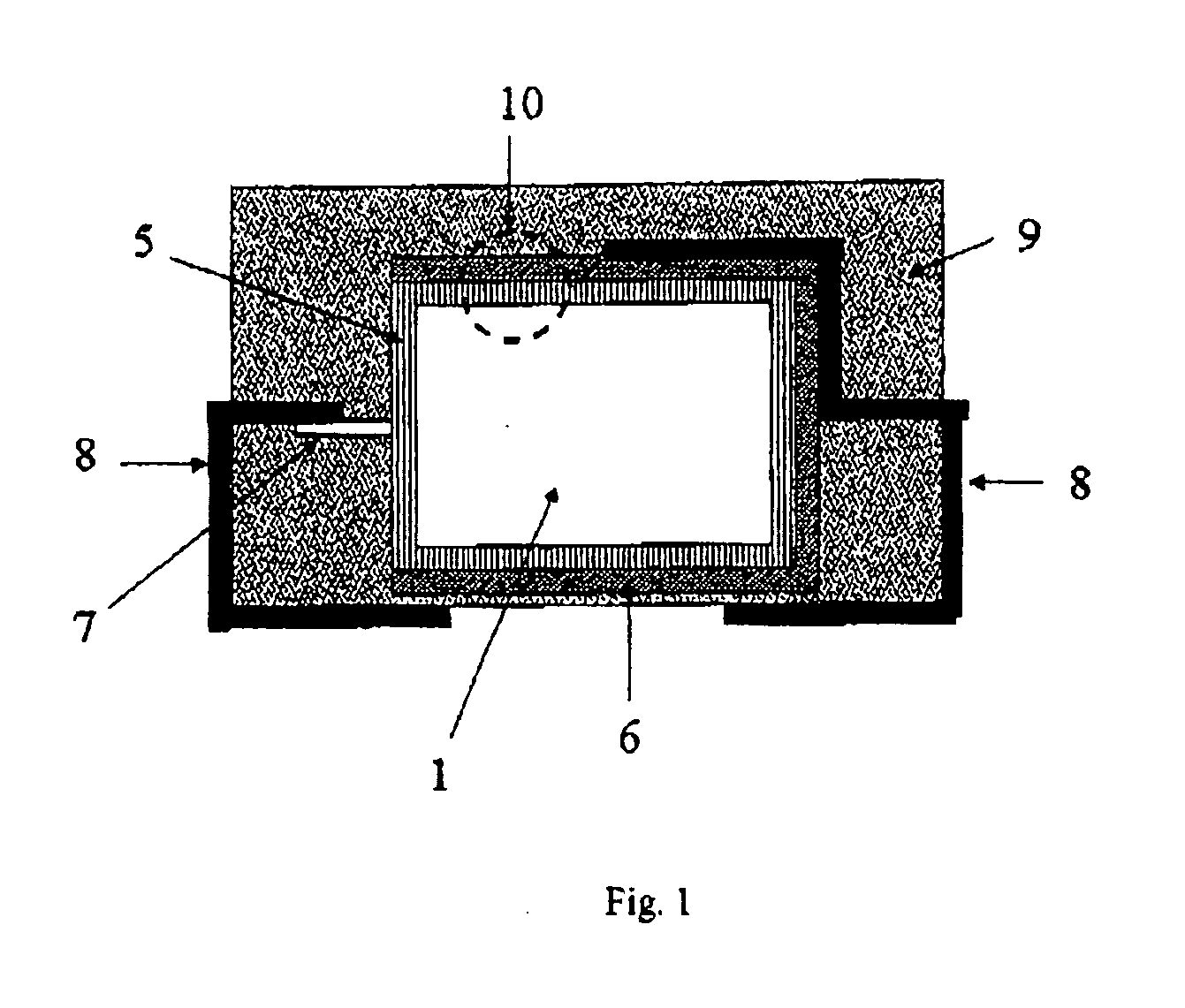

Electrolytic capacitor

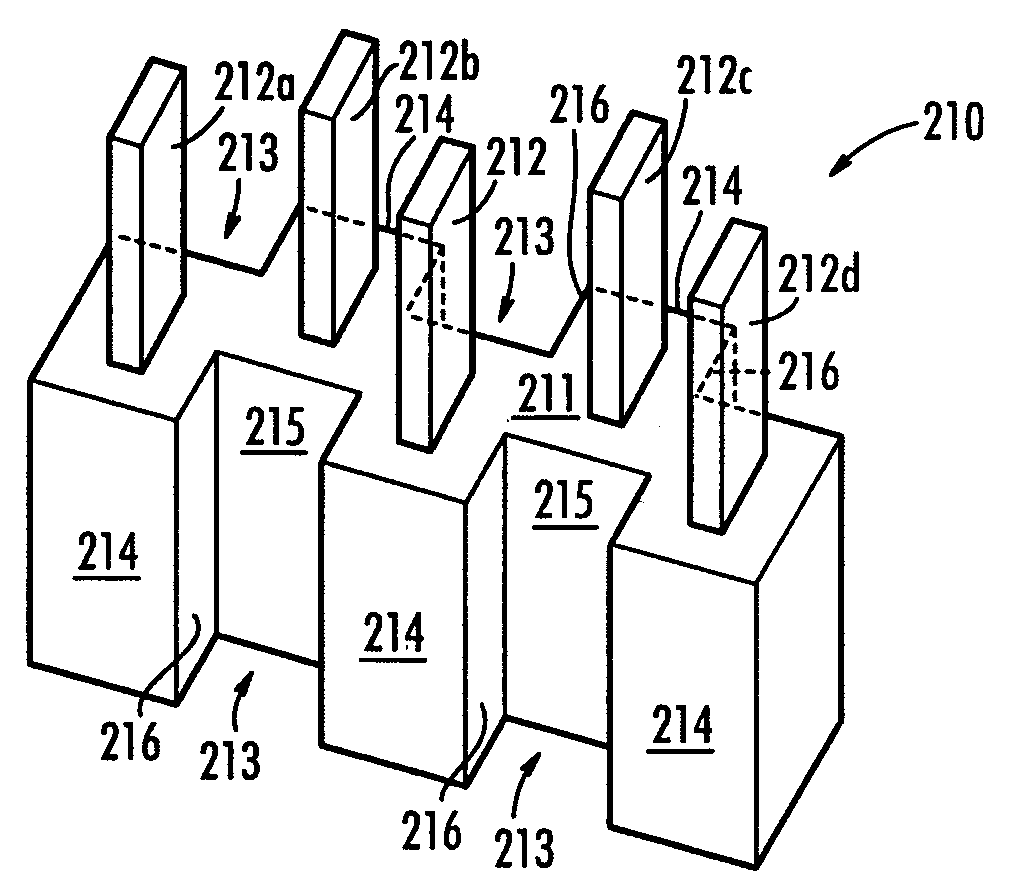

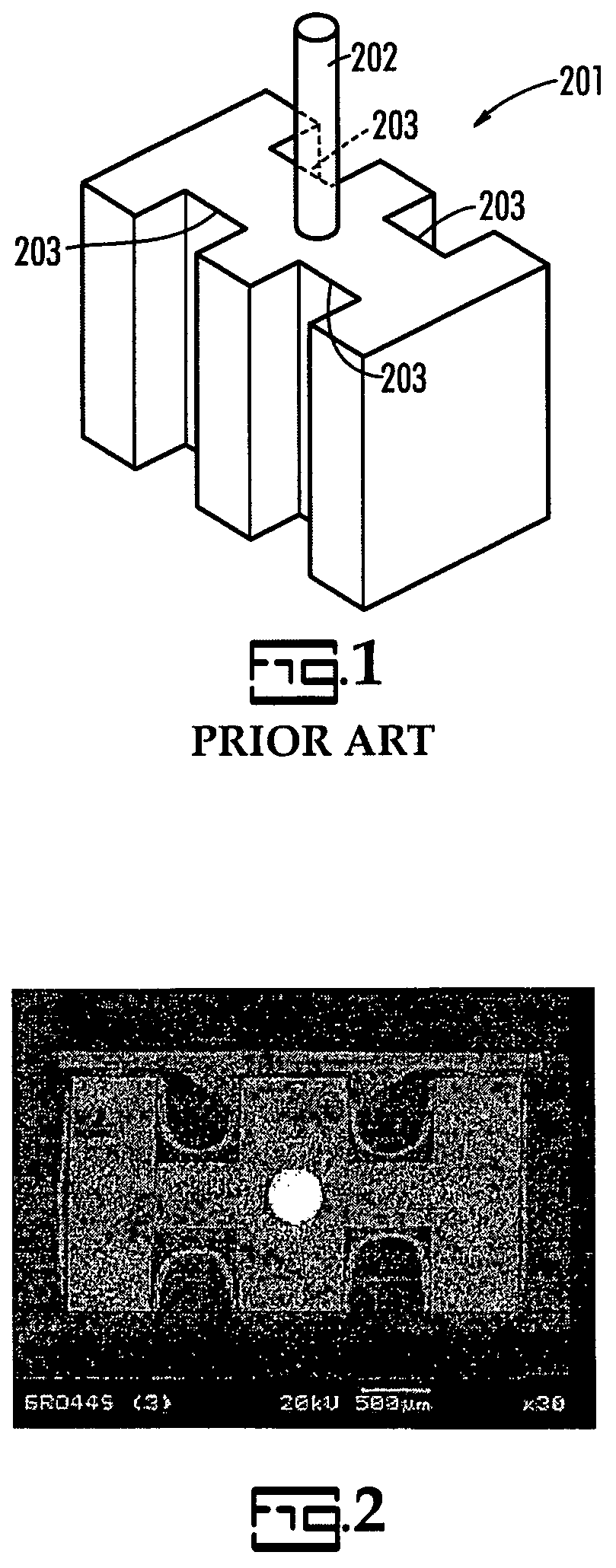

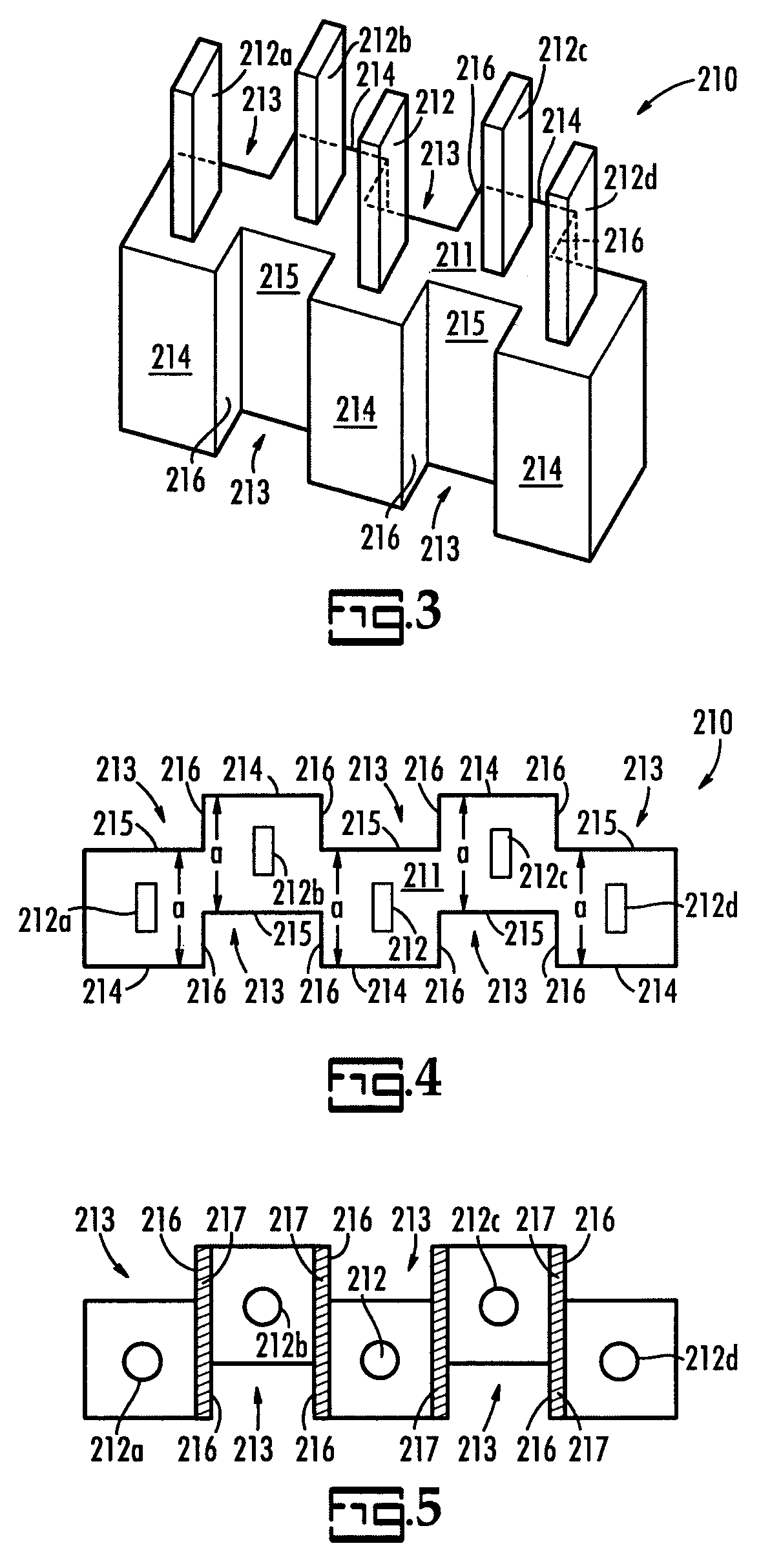

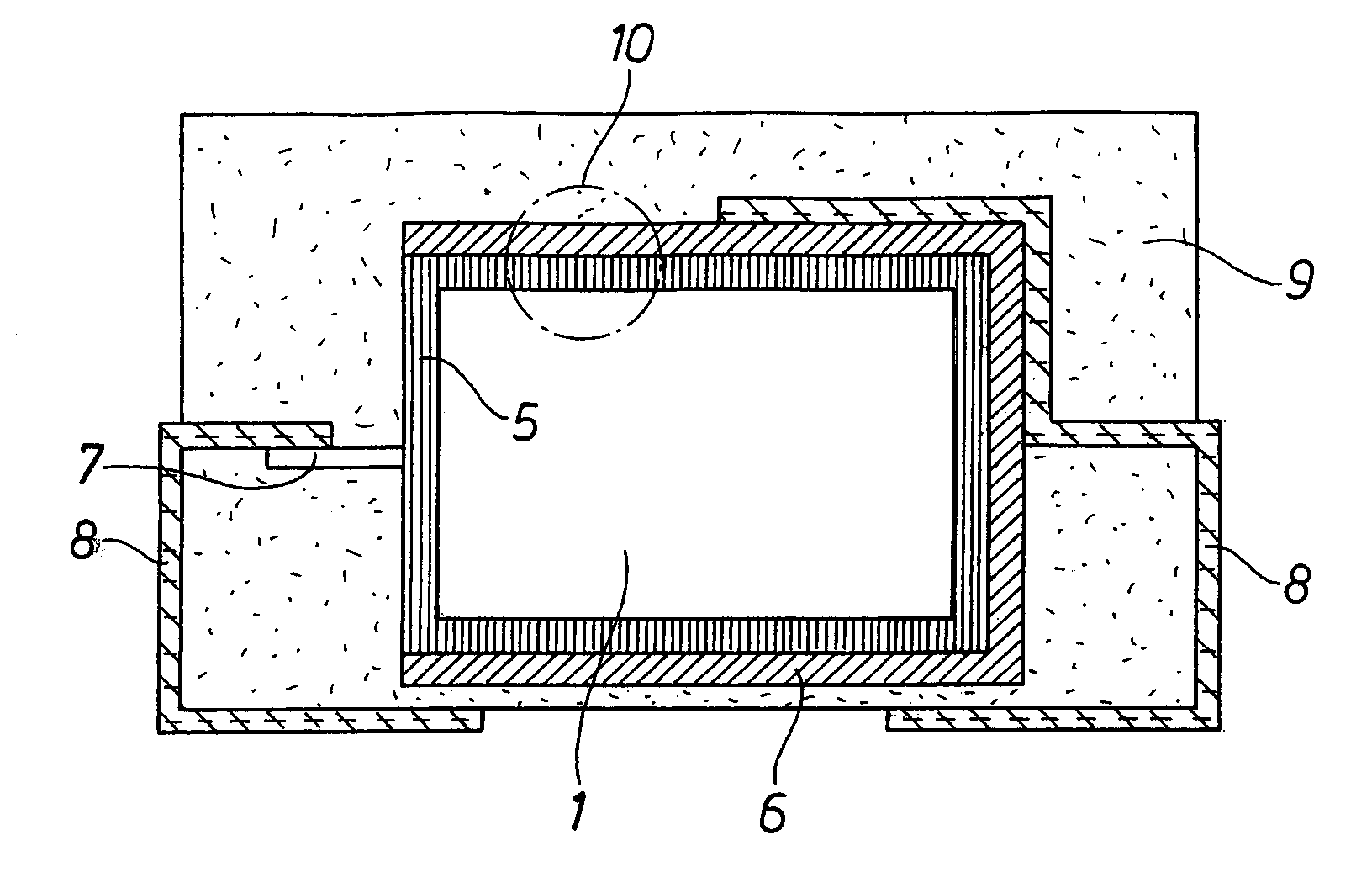

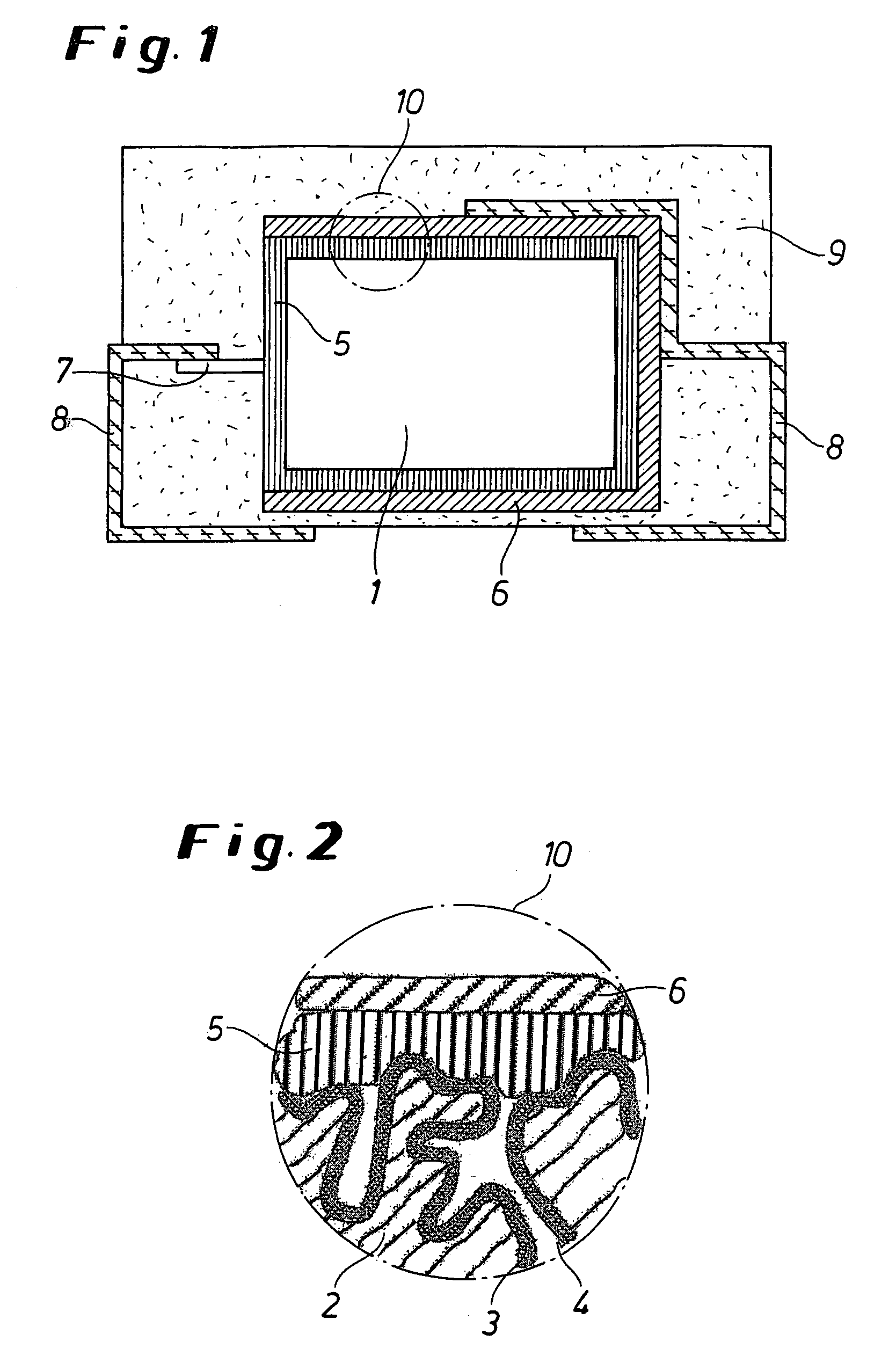

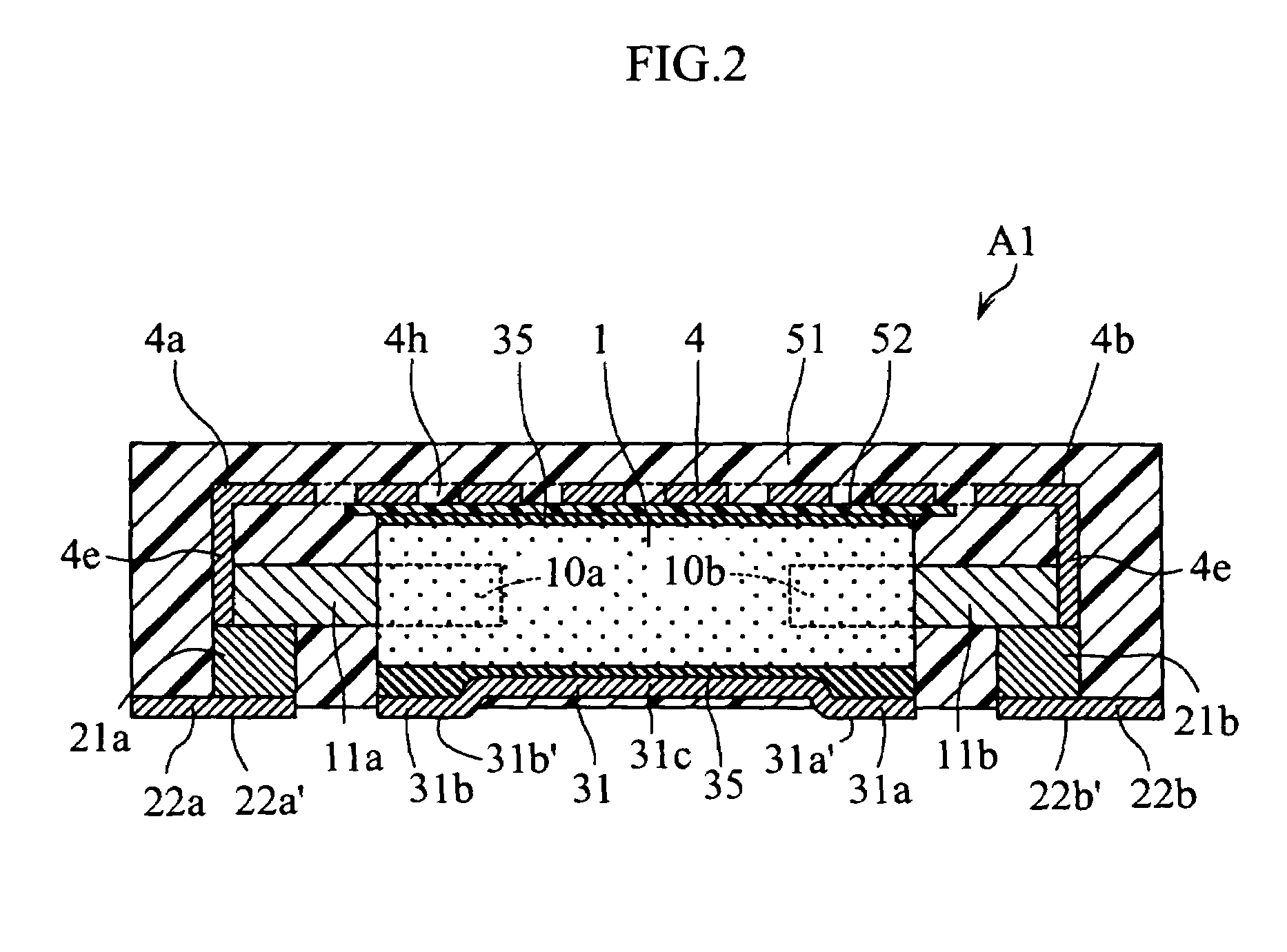

ActiveUS6870728B1ESL can be reduced more effectivelySolid electrolytic capacitorsLiquid electrolytic capacitorsEngineeringElectrolytic capacitor

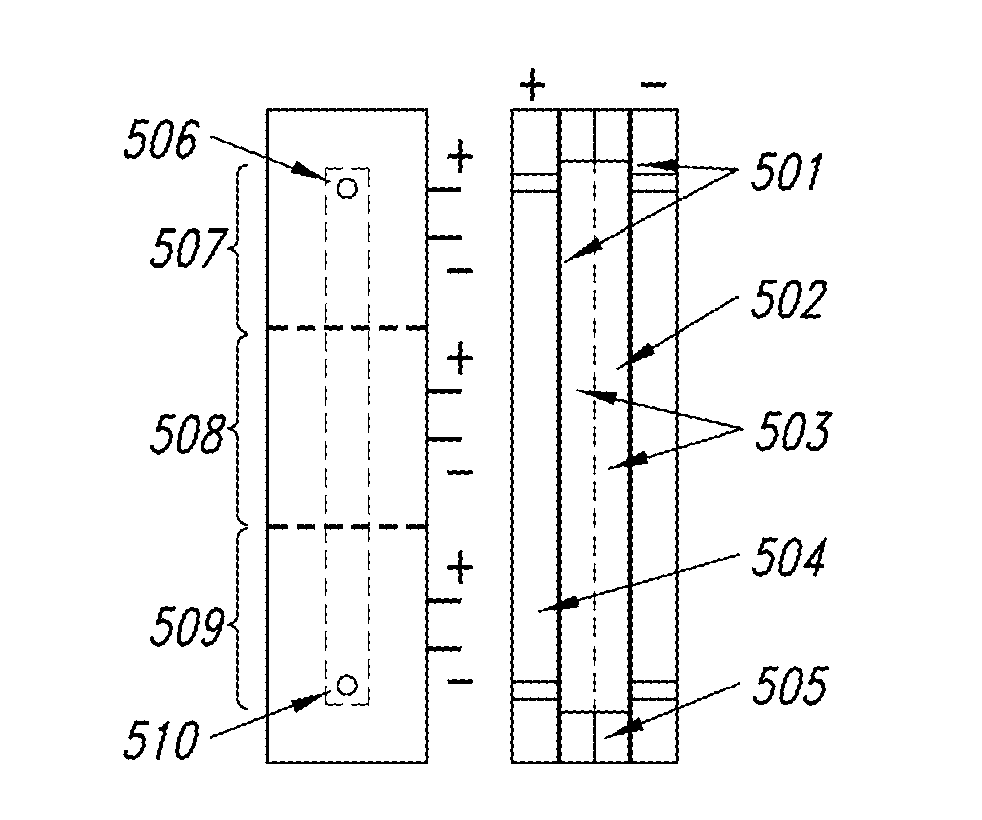

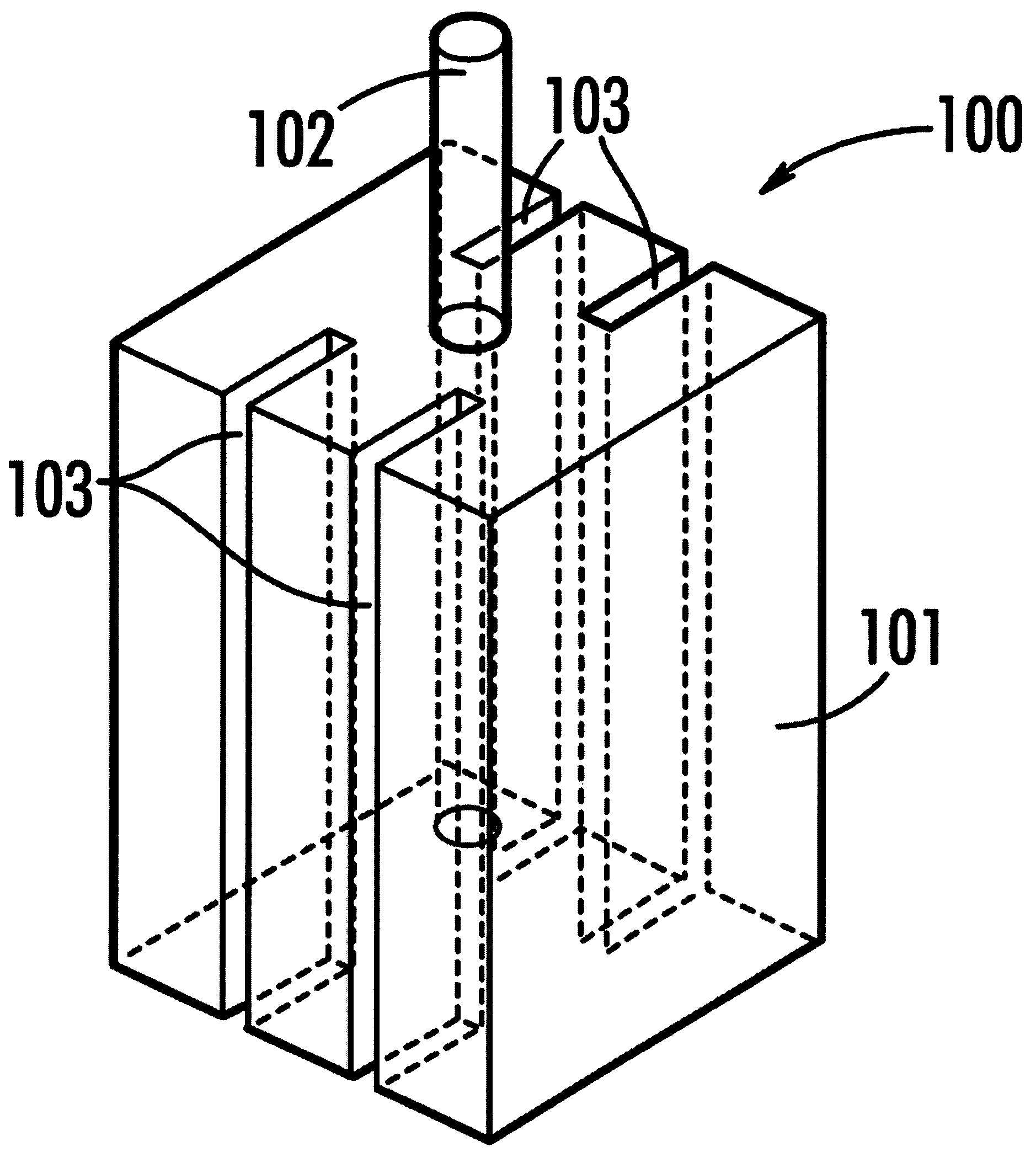

An electrolytic capacitor with a further lowered impedance is provided. In the electrolytic capacitor in accordance with the present invention, respective currents directed opposite from each other flow through anode and cathode vias extending along the thickness of a substrate. The anode vias are lopsidedly located in a marginal area of an anode electrode pattern, and thus are disposed significantly close to the cathode vias formed in a cathode electrode pattern disposed close to the anode electrode pattern. The cathode vias are lopsidedly located in a marginal area of the cathode electrode pattern, and thus are disposed significantly close to the anode vias. Since the anode and cathode vias are formed close to each other as such, this electrolytic capacitor achieves a lower ESL, thereby attaining an impedance lower than that of a conventional electrolytic capacitor.

Owner:MURATA MFG CO LTD

Process for the producing of electrolytic capacitors

InactiveUS7279015B2Hybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisPolymer science

Process for the production of electrolytic capacitors with low equivalent series resistance and low residual current, having a solid electrolyte formed from conducting polymers and an outer layer containing conducting polymers and a binder, electrolytic capacitors produced by the process and their use.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Electrolytic capacitors with a polymeric outer layer

ActiveUS20050111165A1Reduce leakage currentLow ESRHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisCompound (substance)

Electrolytic capacitors having low equivalent series resistance and low leakage current are described. The electrolytic capacitors include a solid electrolyte layer of a conductive material in particular a conductive polymer, and an outer layer that includes binders, polymeric anions and conductive polymers (e.g., polythiophenes). Also described is a method of preparing electrolytic capacitors that involves forming the conductive polymer of the solid electrolyte layer in situ by means of chemical oxidative polymerization or electrochemical polymerization. Electronic circuits that include the electrolytic capacitors are also described.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

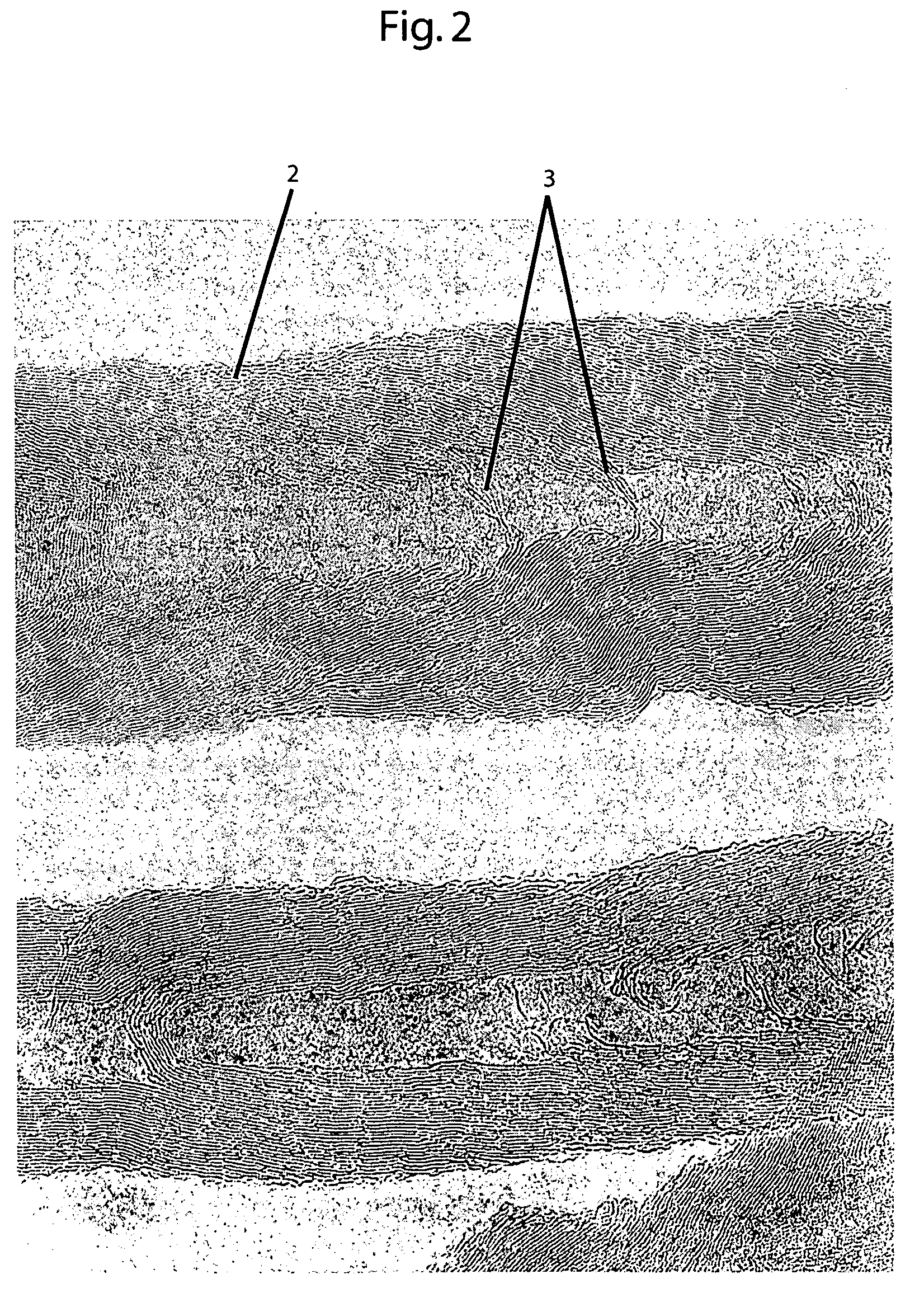

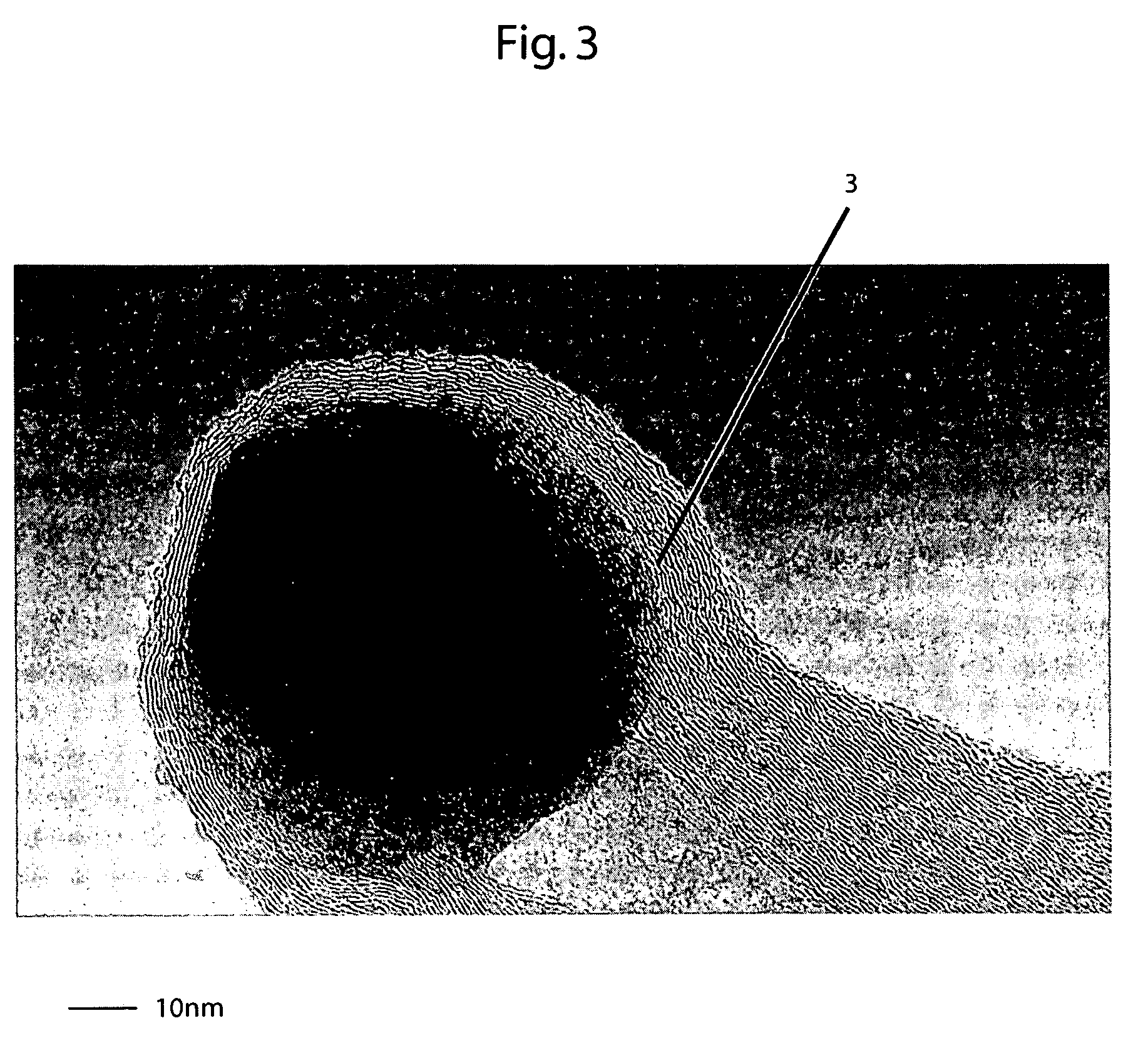

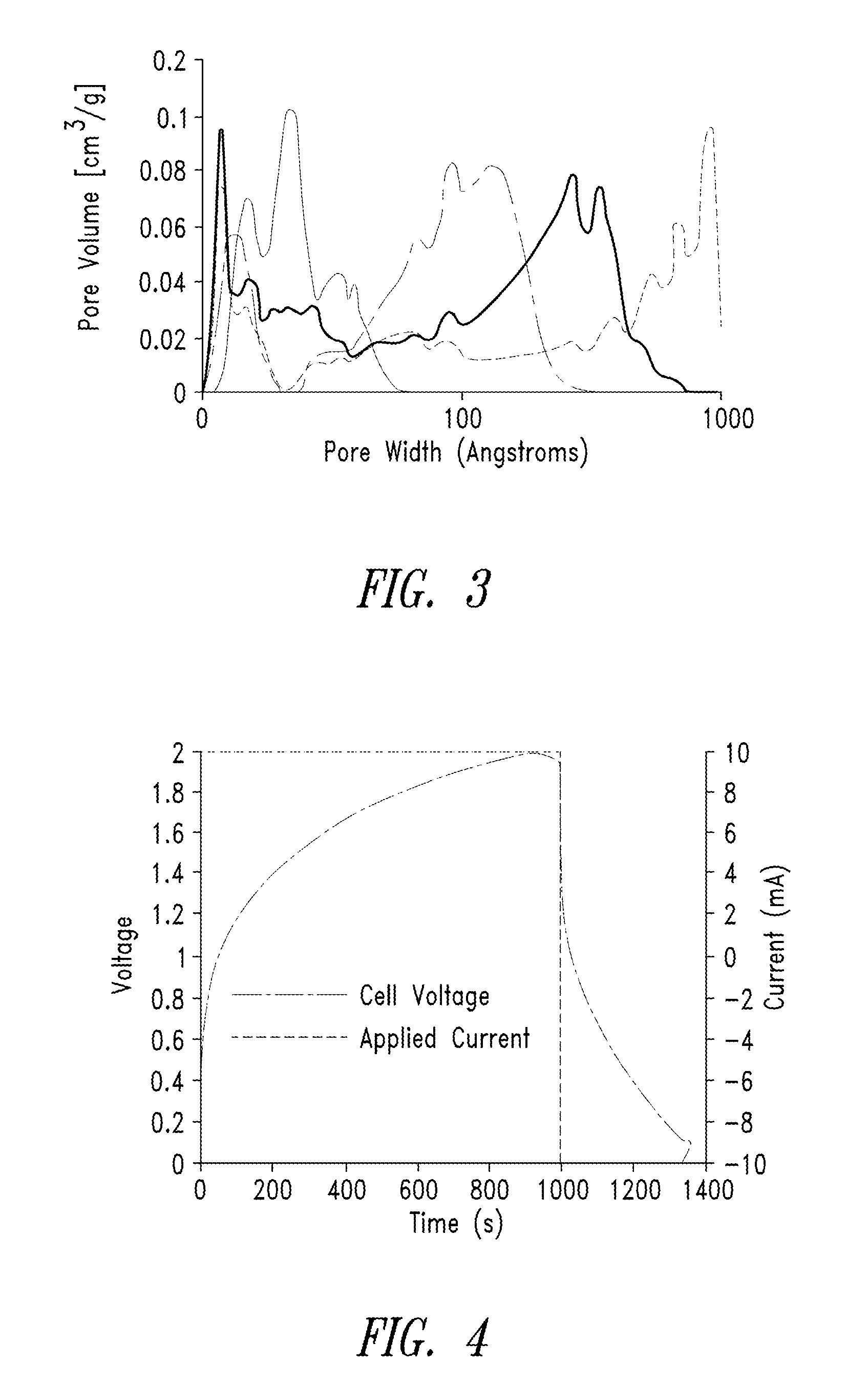

Negative electrode active material for an electricity storage device and method for manufacturing the same

InactiveUS20080220329A1Improve conductivityIncrease electrode densityMaterial nanotechnologyElectrode manufacturing processesElectricityCarbon composites

To provide a negative electrode active material for an electricity storage device, which has considerably enhanced low-temperature characteristic, increased energy density, and increased output power. A negative electrode active material is made of a carbon composite containing carbon particles as a core and a fibrous carbon having a graphene structure, which is formed on the surfaces and / or the inside of the carbon particles, wherein the carbon composite has a volume of all mesopores within 0.005 to 1.0 cm3 / g, and a volume of the mesopores each with a pore diameter ranging from 100 to 400 Å of not less than 25% of the volume of all mesopores.

Owner:SUBARU CORP

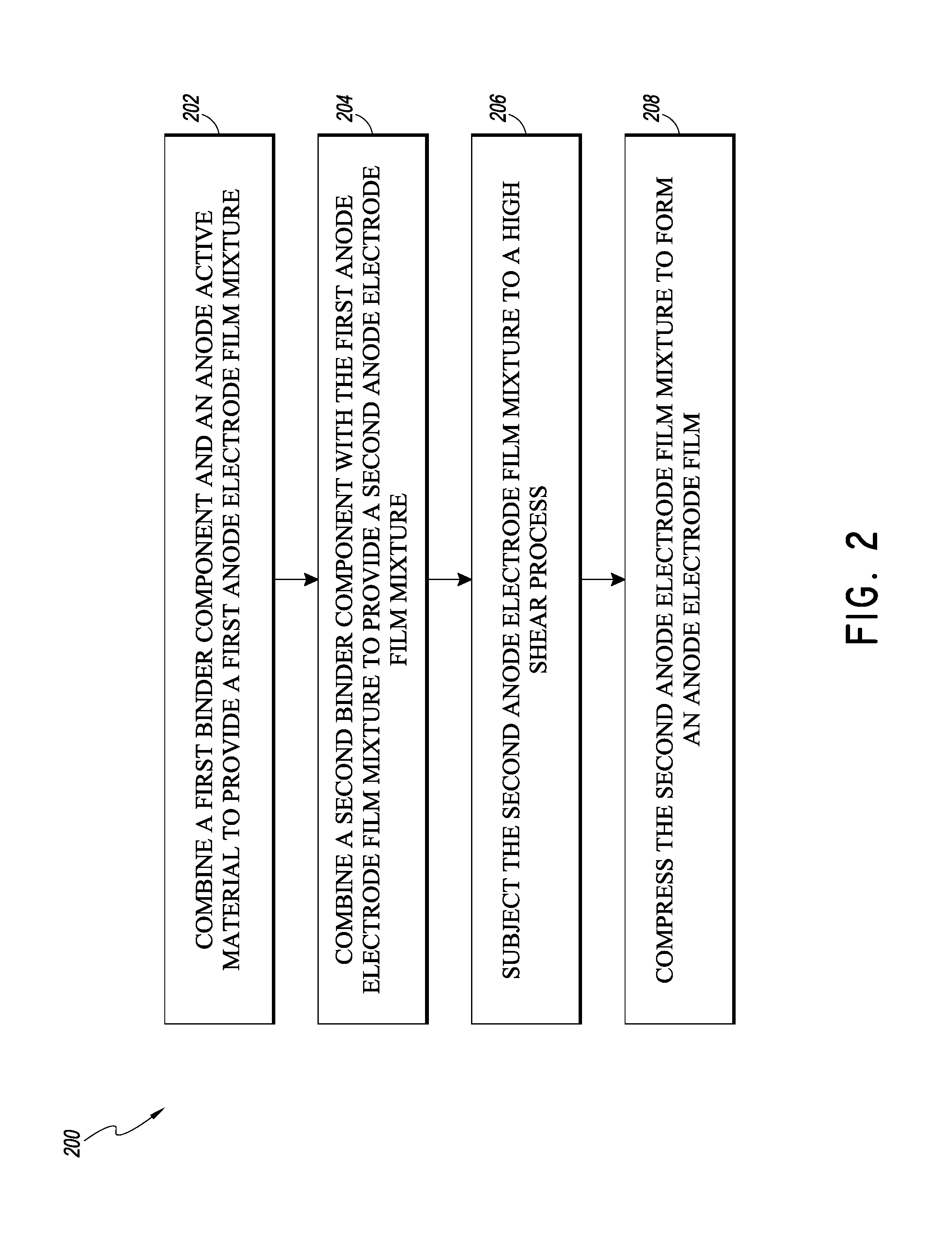

Dry energy storage device electrode and methods of making the same

ActiveUS20150303481A1Electrode rolling/calenderingSolid electrolytic capacitorsEthylene oxidePolyvinylidene difluoride

An energy storage device can include a cathode and an anode, where at least one of the cathode and the anode are made of a polytetrafluoroethylene (PTFE) composite binder material including PTFE and at least one of polyvinylidene fluoride (PVDF), a PVDF co-polymer, and poly(ethylene oxide) (PEO). The energy storage device can be a lithium ion battery, a lithium ion capacitor, and / or any other lithium based energy storage device. The PTFE composite binder material can have a ratio of about 1:1 of PTFE to a non-PTFE component, such a PVDF, PVDF co-polymer and / or PEO.

Owner:TESLA INC

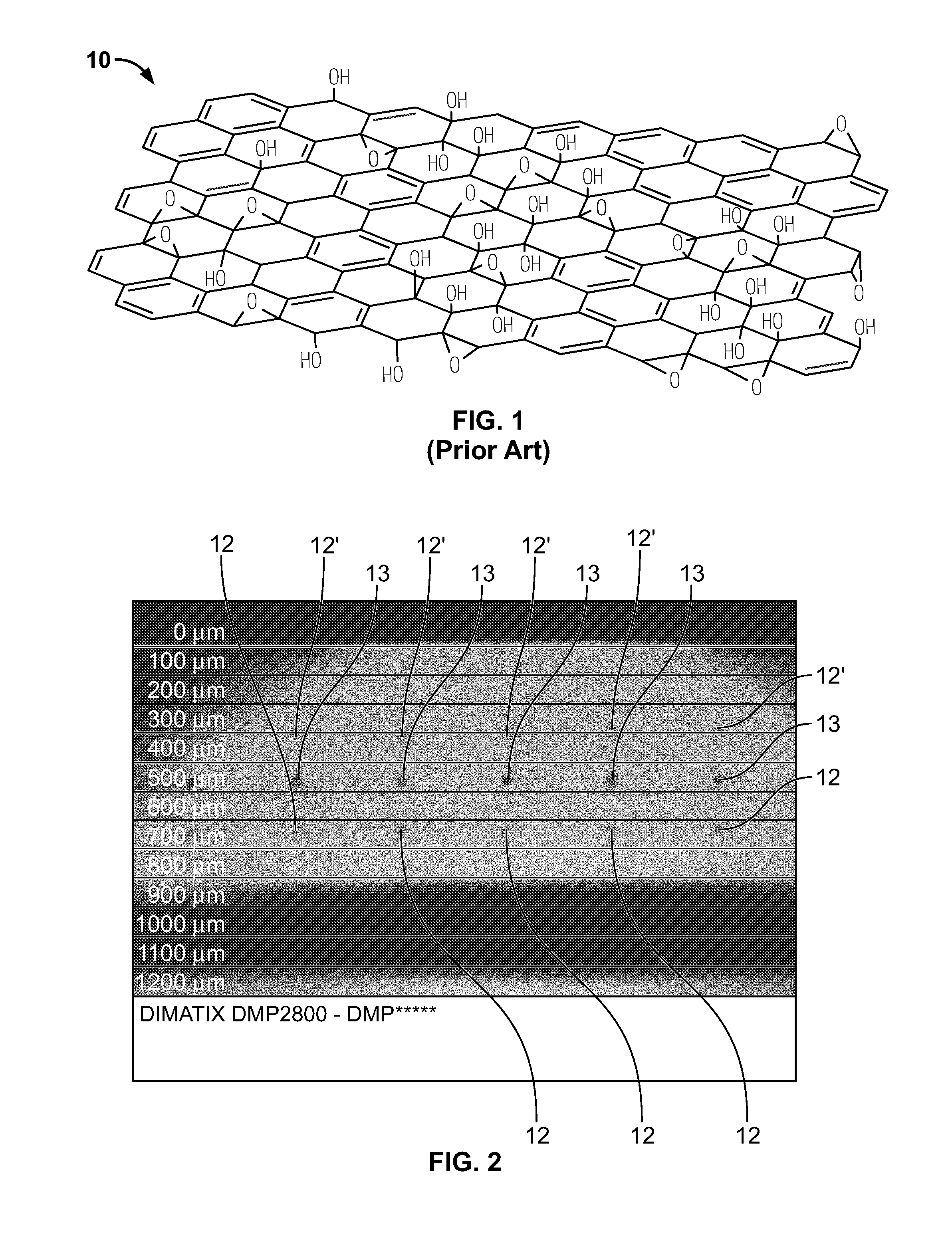

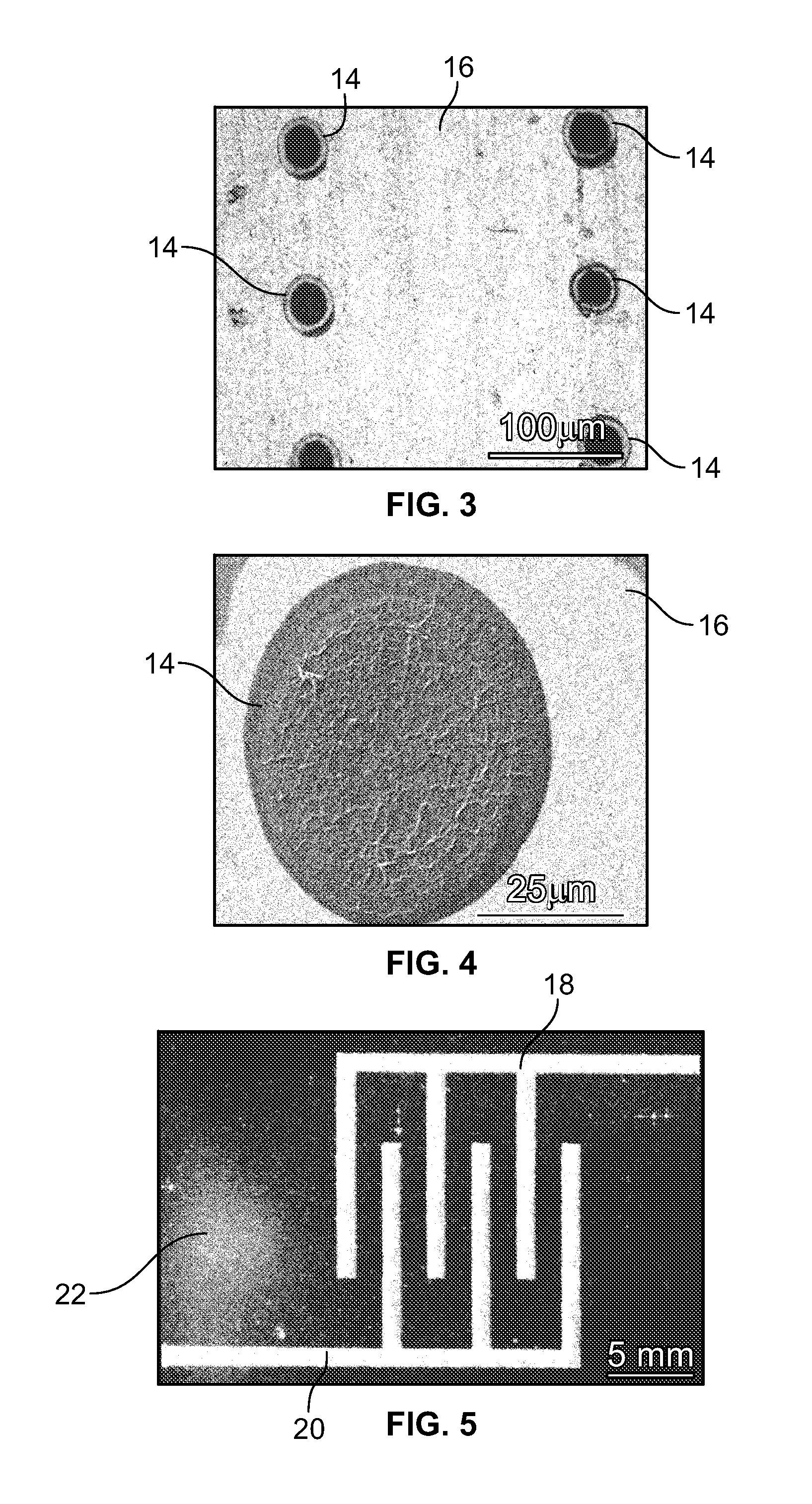

Inkjet-printed flexible electronic components from graphene oxide

InactiveUS20120170171A1Improve conductivityThermally degradedSolid electrolytic capacitorsHybrid capacitor electrodesCarbon nanotubeCharge separation

An electrical component includes an inkjet-printed graphene electrode. Graphene oxide flakes are deposited on a substrate in a graphene oxide ink using an inkjet printer. The deposited graphene oxide is thermally reduced to graphene. The electrical properties of the electrode are comparable to those of electrodes made using activated carbon, carbon nanotubes or graphene made by other methods. The electrical properties of the graphene electrodes may be tailored by adding nanoparticles of other materials to the ink to serve as conductivity enhancers, spacers, or to confer pseudocapacitance. Inkjet-printing can be used to make graphene electrodes of a desired thickness in preselected patterns. Inkjet printing can be used to make highly-transparent graphene electrodes. Inkjet-printed graphene electrodes may be used to fabricate double-layer capacitors that store energy by nanoscale charge separation at the electrode-electrolyte interface (i.e., “supercapacitors”).

Owner:STEVENS INSTITUTE OF TECHNOLOGY +1

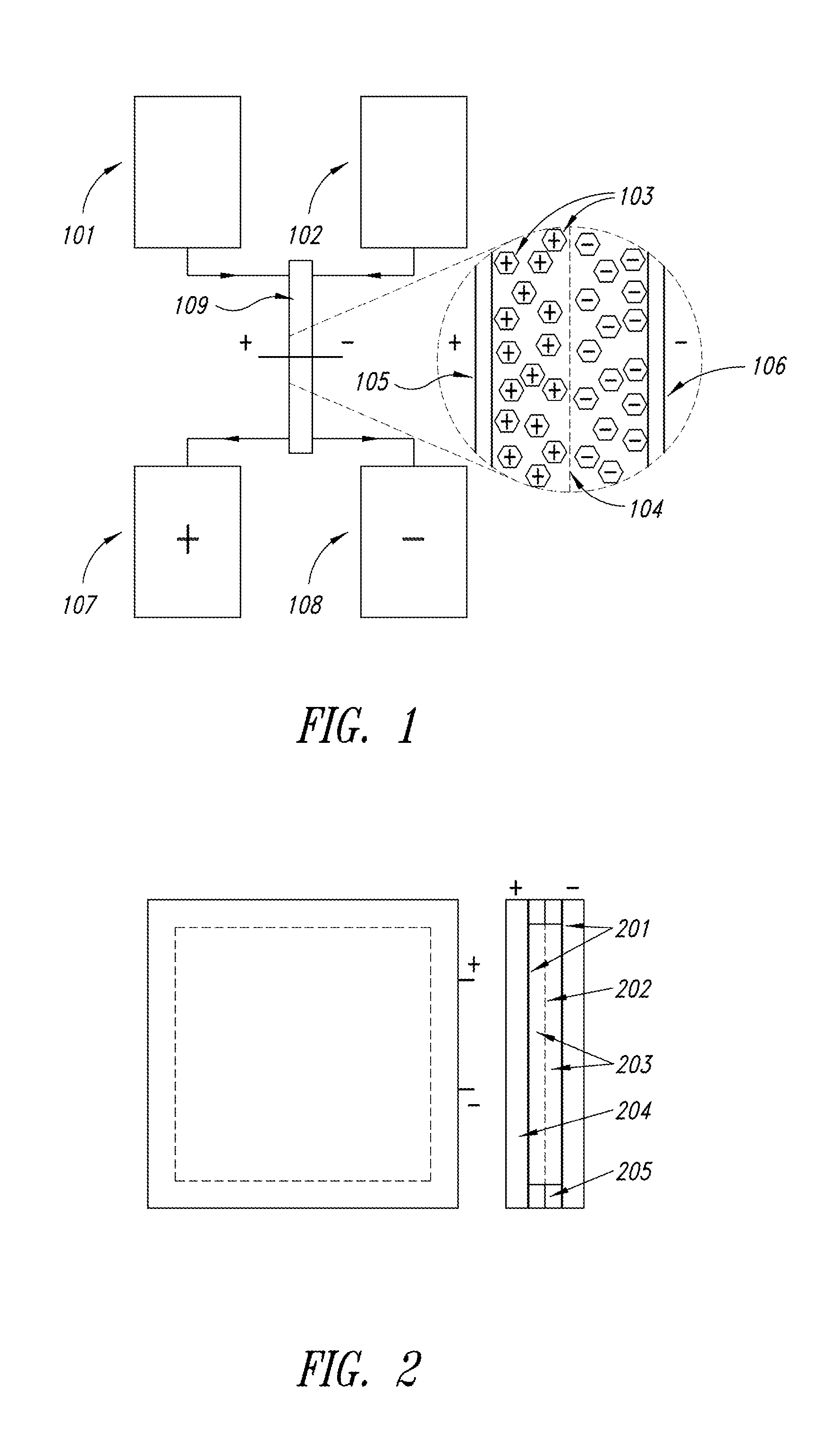

Flow ultracapacitor

The present application is generally directed towards electrochemical energy storage devices. The devices comprise electrode material suspended in an appropriate electrolyte. Such devices are capable of achieving economical $ / kWh(cycle) values and will enable much higher power and cycle life than currently used devices.

Owner:BASF AG

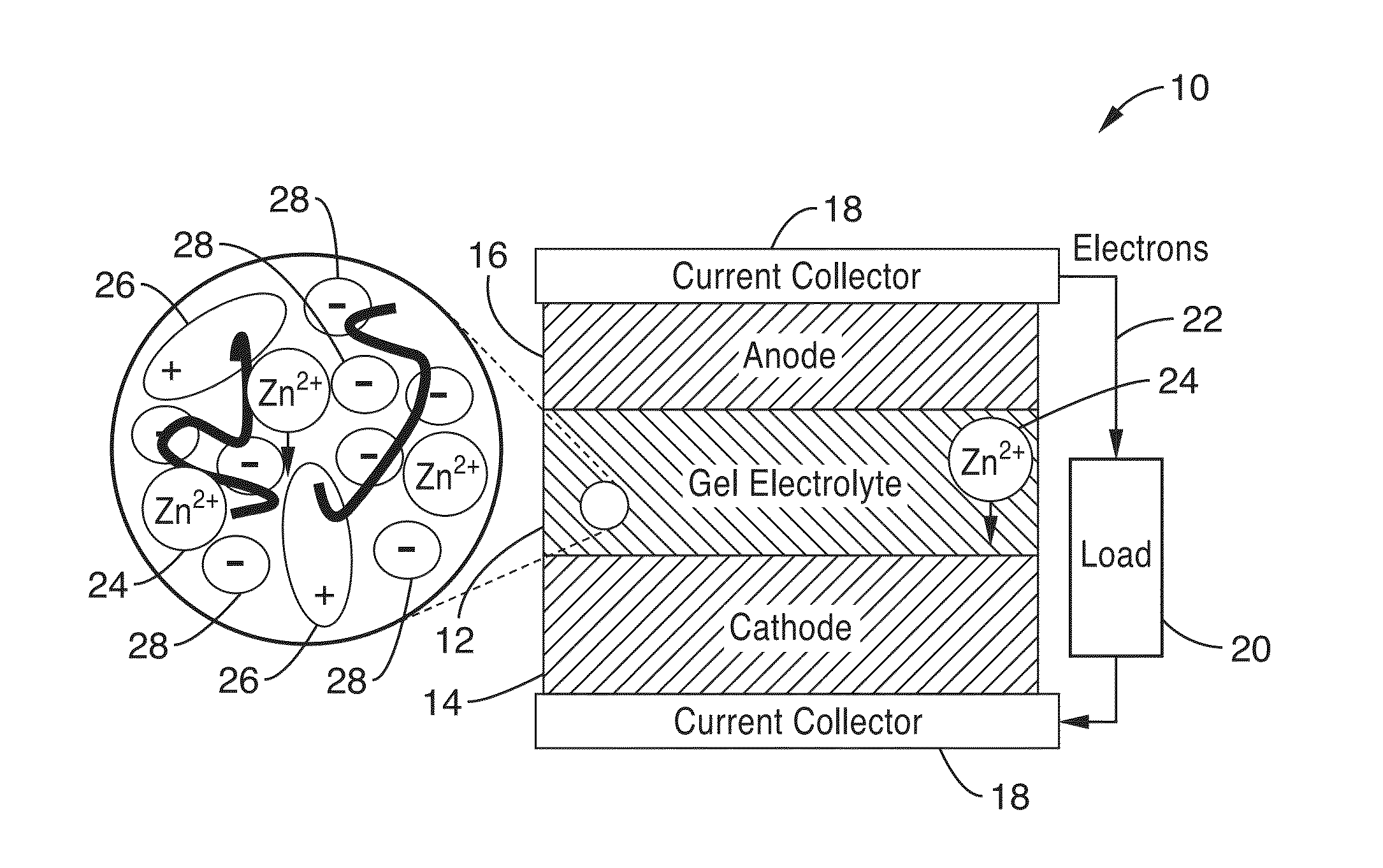

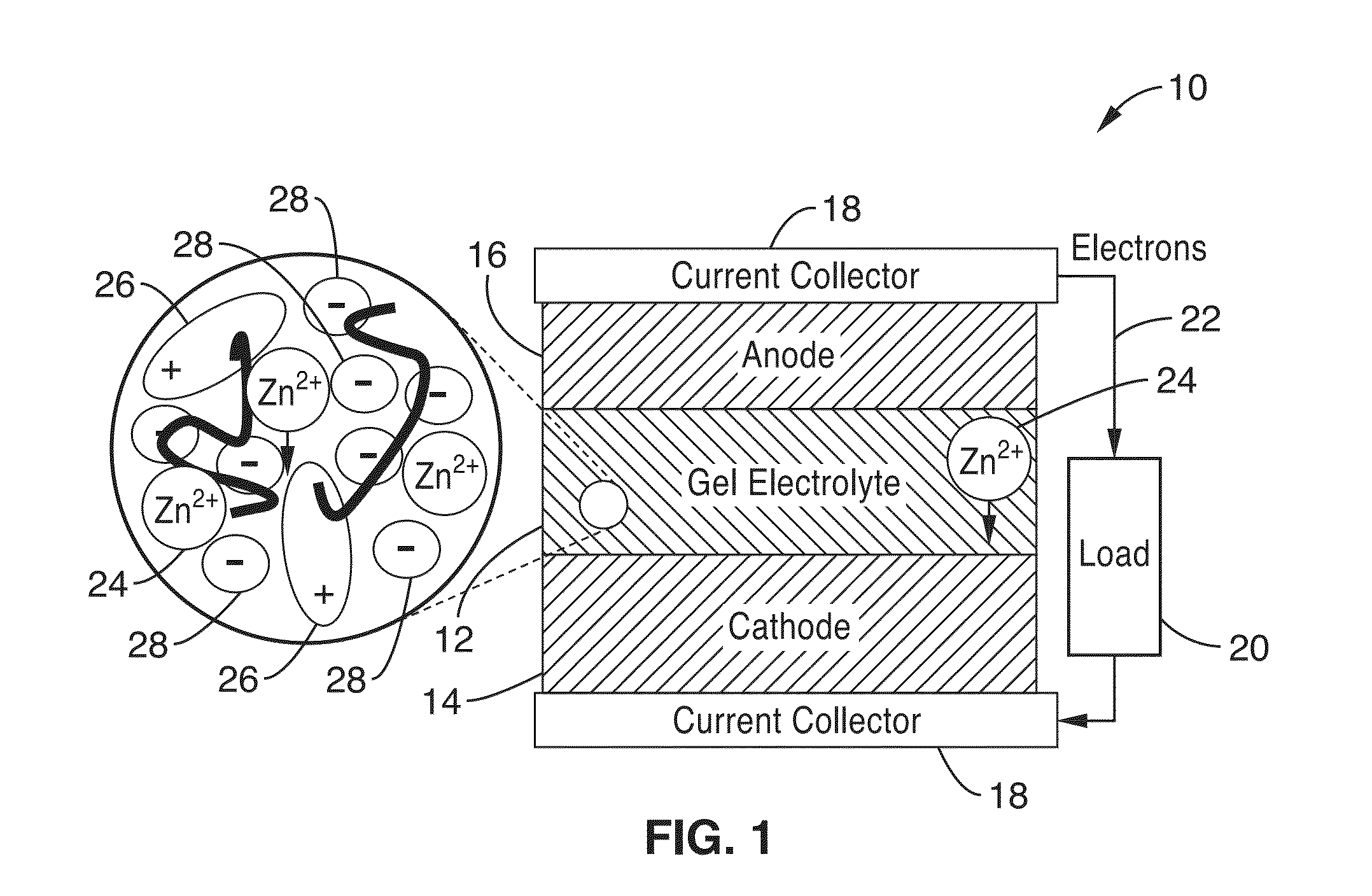

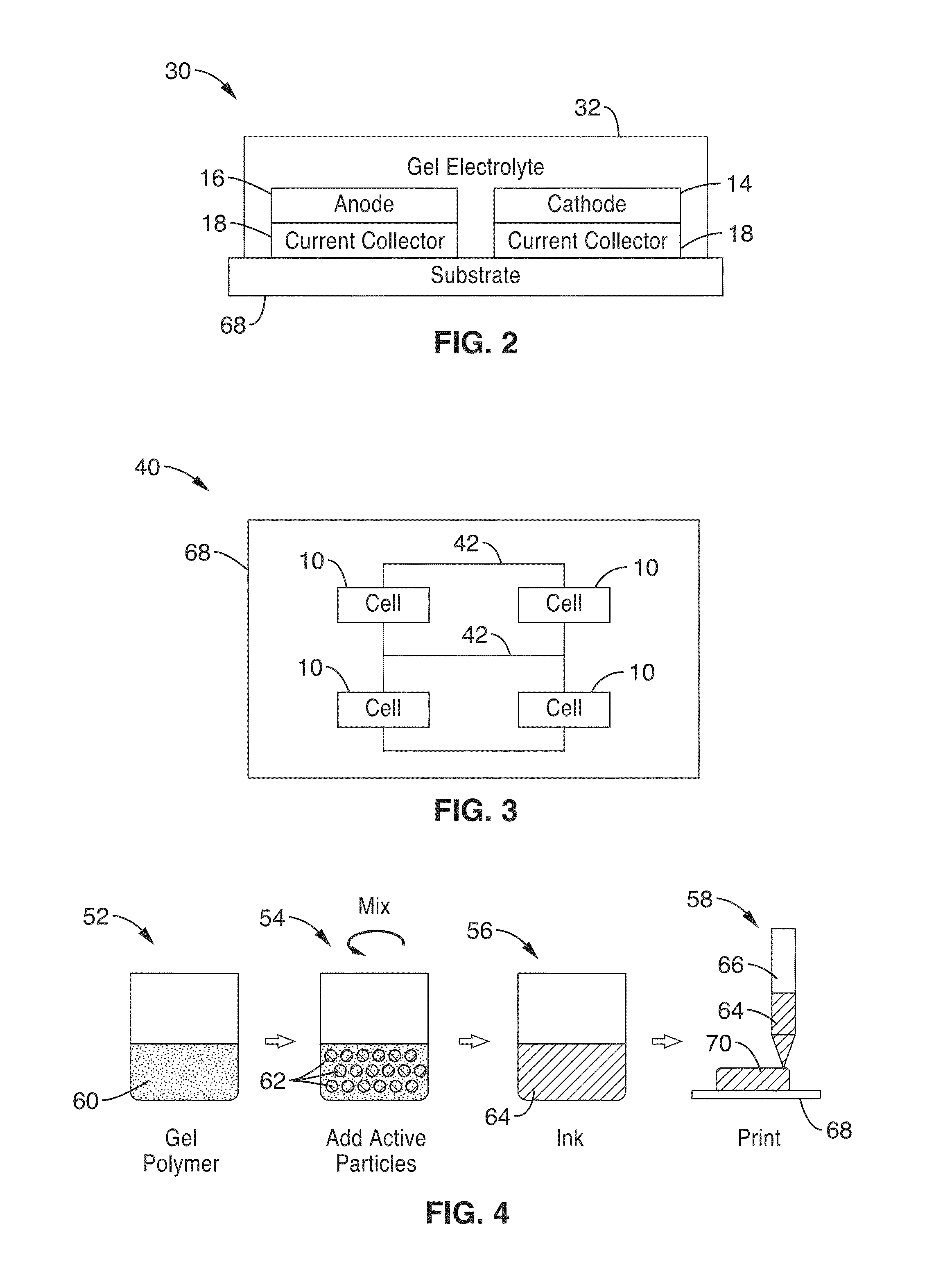

Ionic gel electrolyte, energy storage devices, and methods of manufacture thereof

ActiveUS20130280579A1Promote disseminationSolid electrolytic capacitorsLiquid electrolytic capacitorsPhysical separationElectrochemical cell

An electrochemical cell includes solid-state, printable anode layer, cathode layer and non-aqueous gel electrolyte layer coupled to the anode layer and cathode layer. The electrolyte layer provides physical separation between the anode layer and the cathode layer, and comprises a composition configured to provide ionic communication between the anode layer and cathode layer by facilitating transmission of multivalent ions between the anode layer and the cathode layer.

Owner:CCL LABEL INC +1

Process for the production of electrolyte capacitors

ActiveUS20080005878A1Lower equivalent series resistanceHeat stableCellsSolid electrolytic capacitorsElectrical resistance and conductanceElectrolysis

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Protective coating for electrolytic capacitors

InactiveUS6864147B1Low dissipation factorLow leakage currentSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingShellacElectrolysis

A solid electrolytic capacitor that comprises an anode that contains a valve-action metal (e.g., tantalum, niobium, and the like) and a dielectric film overlying the anode is provided. The capacitor also comprises a protective coating overlying the dielectric film, wherein the protective coating contains a relatively insulative, resinous material. For example, in one embodiment, the resinous material can be a drying oil, such as olive oil, linseed oil, tung oil, castor oil, soybean oil, shellac, and derivatives thereof. The capacitor also comprises a conductive polymer coating overlying the protective coating. As a result of the present invention, it has been discovered that a capacitor can be formed that can have a relatively low leakage current, dissipation factor, and equivalents series resistance.

Owner:KYOCERA AVX COMPONENTS CORP

Process for the production of electrolyte capacitors

ActiveUS8058135B2Lower equivalent series resistanceHeat stableSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceElectrolysis

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Fluted anode with improved capacitance and capacitor comprising same

InactiveUS7154742B1Improve capacitance recoveryImprove uniformitySolid electrolytic capacitorsLiquid electrolytic capacitorsCapacitanceMetallurgy

Owner:KEMET ELECTRONICS CORP

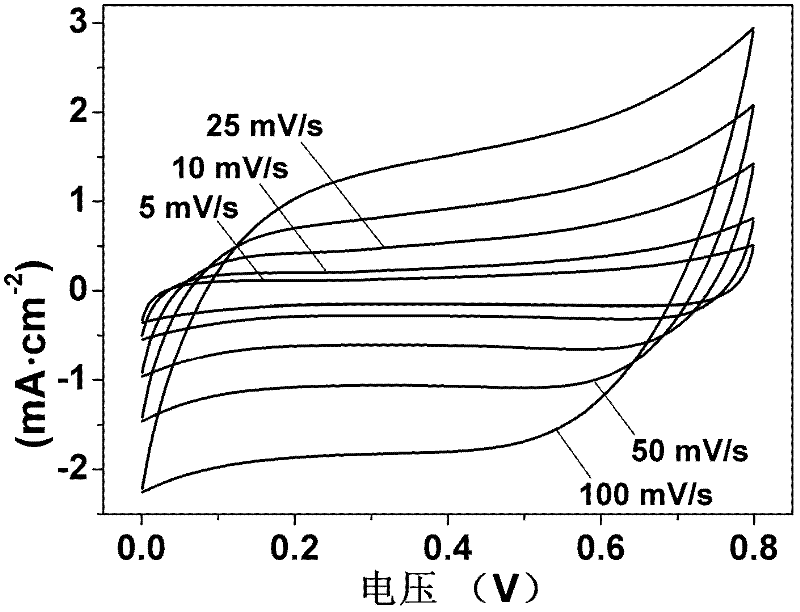

Preparation method of flexible super capacitor based on carbon cloth

InactiveCN102509635ASimple methodEasy to controlSolid electrolytic capacitorsSolid state electrolyteConductive polymer

The invention discloses a preparation method of a flexible super capacitor based on carbon cloth. The preparation method comprises the following steps of: firstly, growing carbon nanometer particles, carbon nanometer tubes, zinc oxides or tungsten oxide on the carbon cloth, or generating molybdenum dioxide on the carbon cloth; then, preparing manganese oxide or conductive polymers on the substances grown or generated on the carbon cloth for forming electrode materials; and finally, overlapping two electrode materials through solid electrolytes, separating the two electrode materials through a diaphragm and preparing the solid super capacitor. The flexible super capacitor prepared by the method provided by the invention has good electrochemical characteristics and the bending performance and has good application prospects in energy storage aspects.

Owner:HUAZHONG UNIV OF SCI & TECH

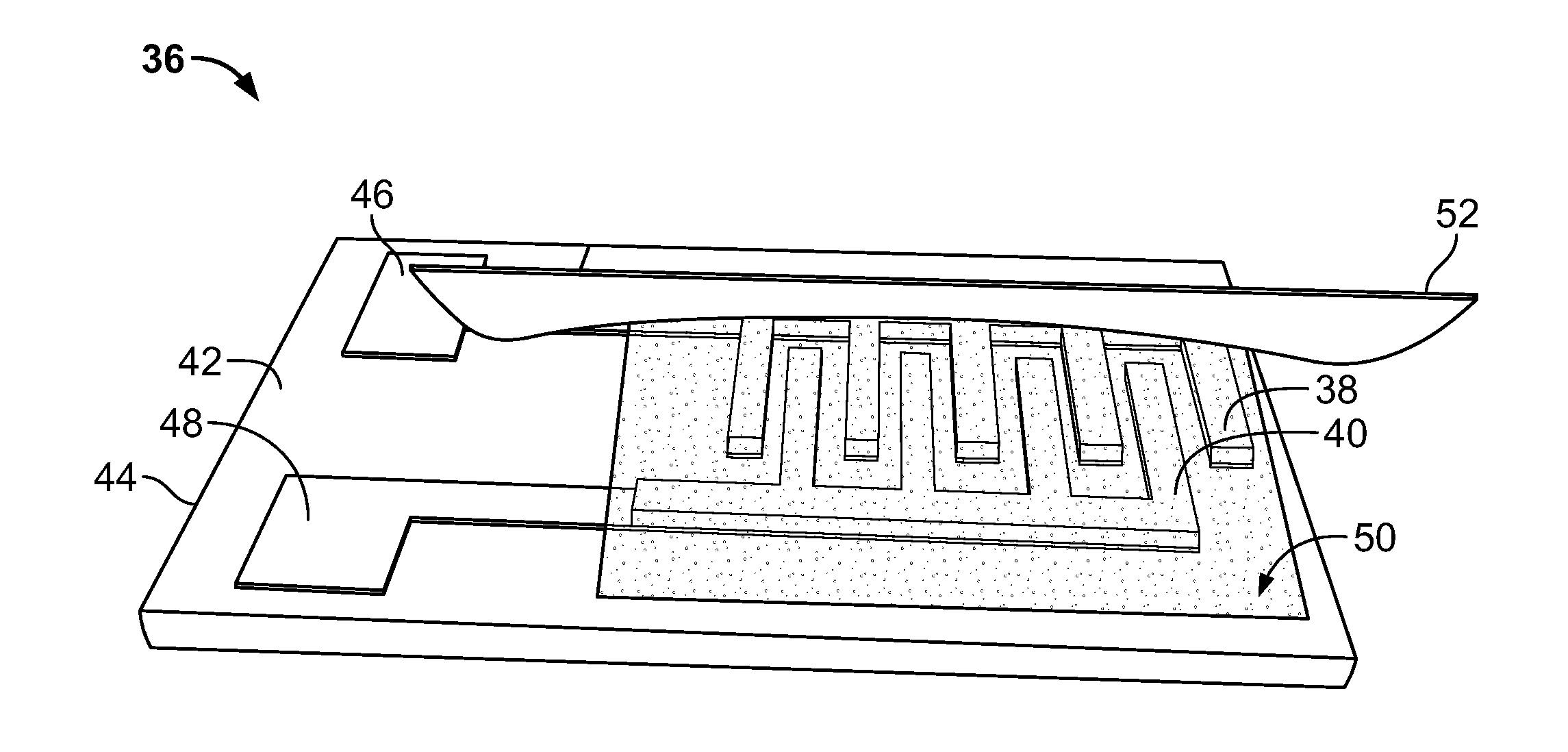

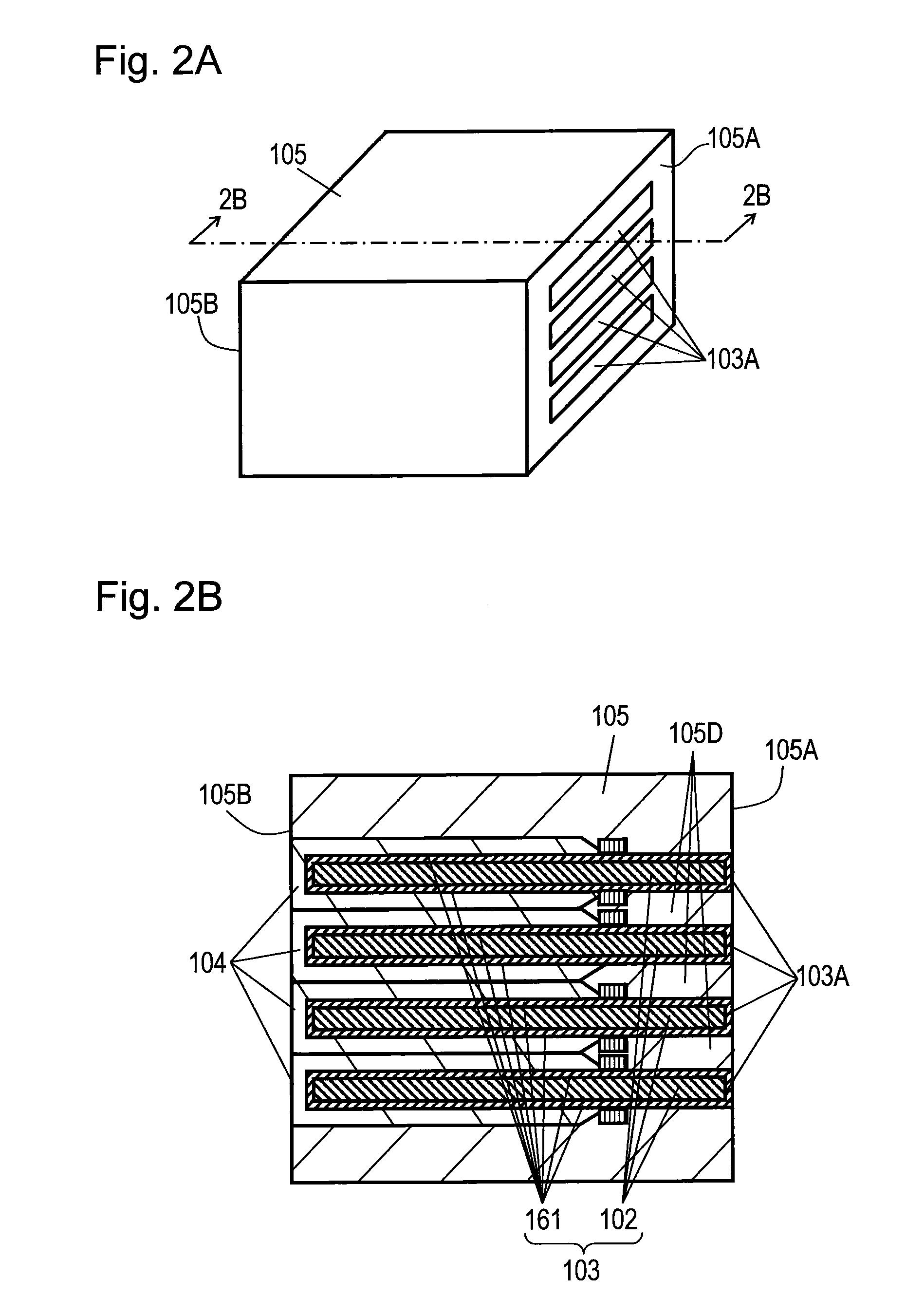

Hermetically sealed capacitor assembly

ActiveUS8094434B2Hybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisConductive polymer

A capacitor assembly that includes a conductive polymer electrolytic capacitor that is enclosed and hermetically sealed within a ceramic housing in the presence of an inert gas is provided. Without intending to be limited by theory, the present inventors believe that the ceramic housing is capable of limiting the amount of oxygen and moisture supplied to the conductive polymer of the capacitor. In this manner, the conductive polymer is less likely to oxidize in high temperature environments, thus increasing the thermal stability of the capacitor assembly.

Owner:KYOCERA AVX COMPONENTS CORP

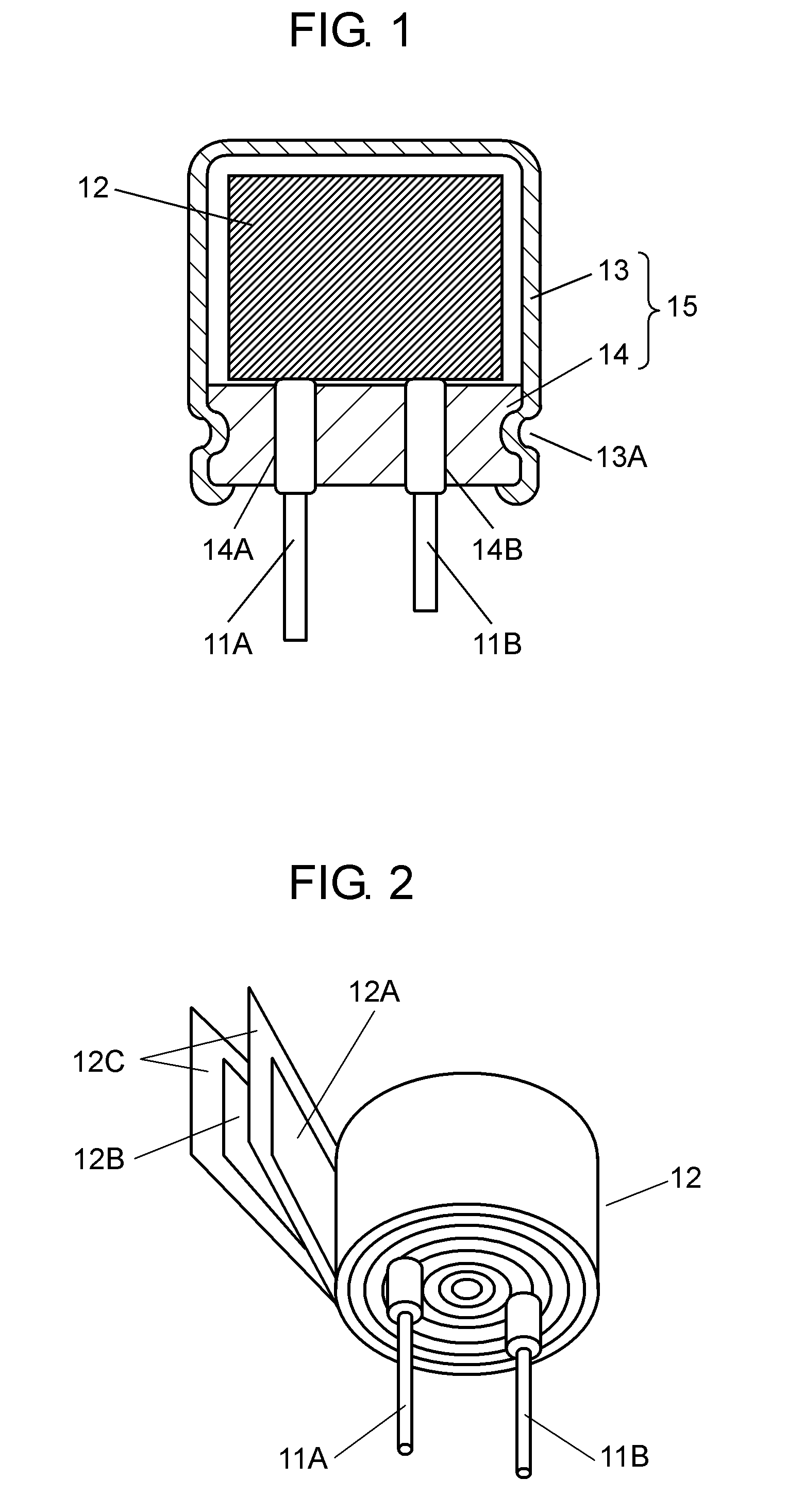

Solid electrolytic capacitor

ActiveUS20100165547A1Reduce in quantitySmall sizeSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisEdge surface

A capacitor element includes a positive electrode body made of valve metal, a dielectric oxide layer on the positive electrode body, a solid electrolytic layer made of conductive polymer on the dielectric oxide layer, and a negative electrode layer on the solid electrolytic layer. A solid electrolytic capacitor includes the capacitor element, a package made of insulating resin covering the capacitor element, a base electrode provided at an edge surface of the package and made of non-valve metal coupled with the positive electrode body, a diffusion layer for connecting the positive electrode body to the base electrode, an external electrode on the base electrode, and an external electrode connected to the negative electrode layer. The solid electrolytic capacitor reduces the number of components and processes to reduce its cost and to have a small size, and has a small equivalent series resistance and a small equivalent series inductance.

Owner:PANASONIC CORP

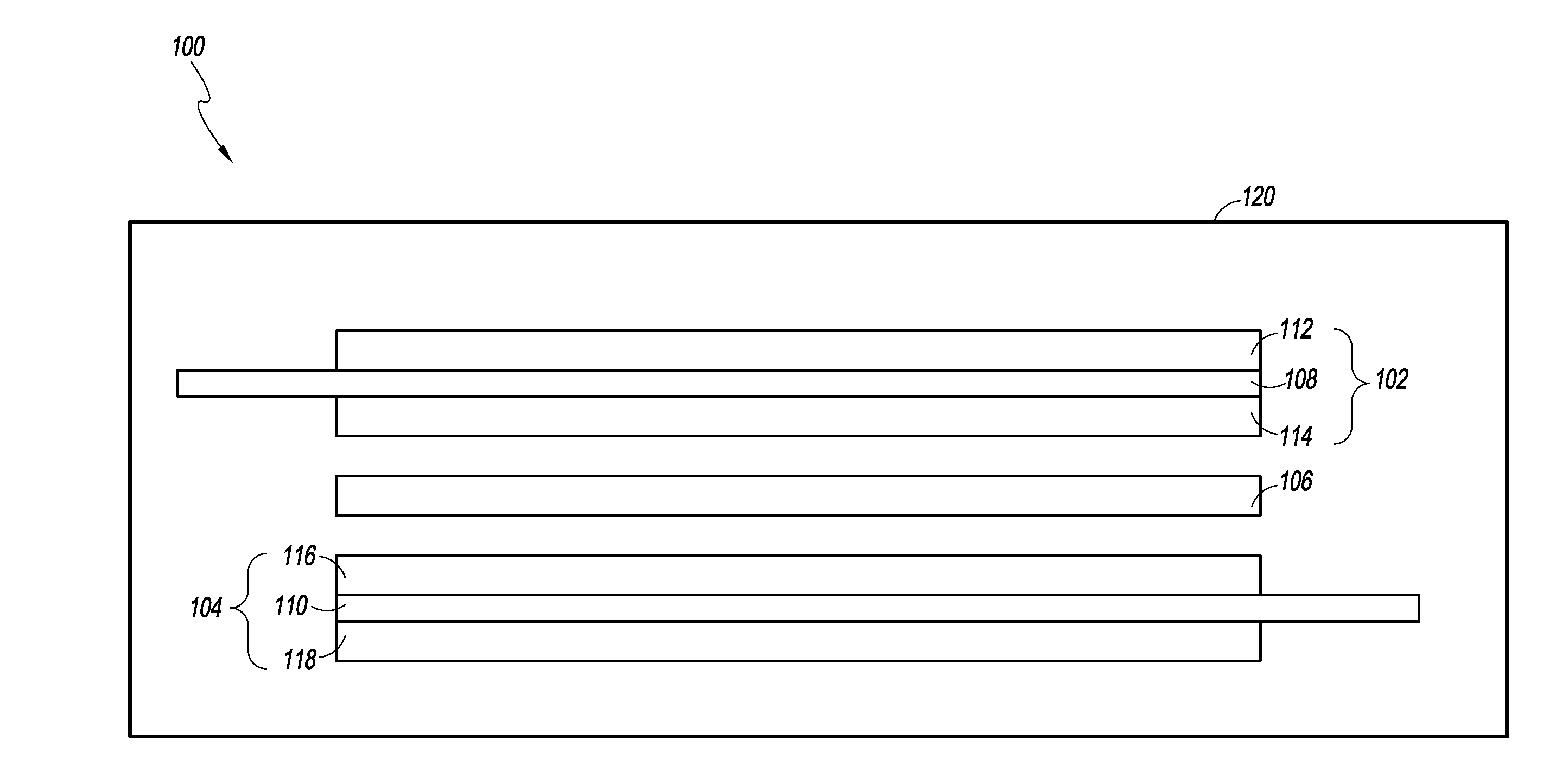

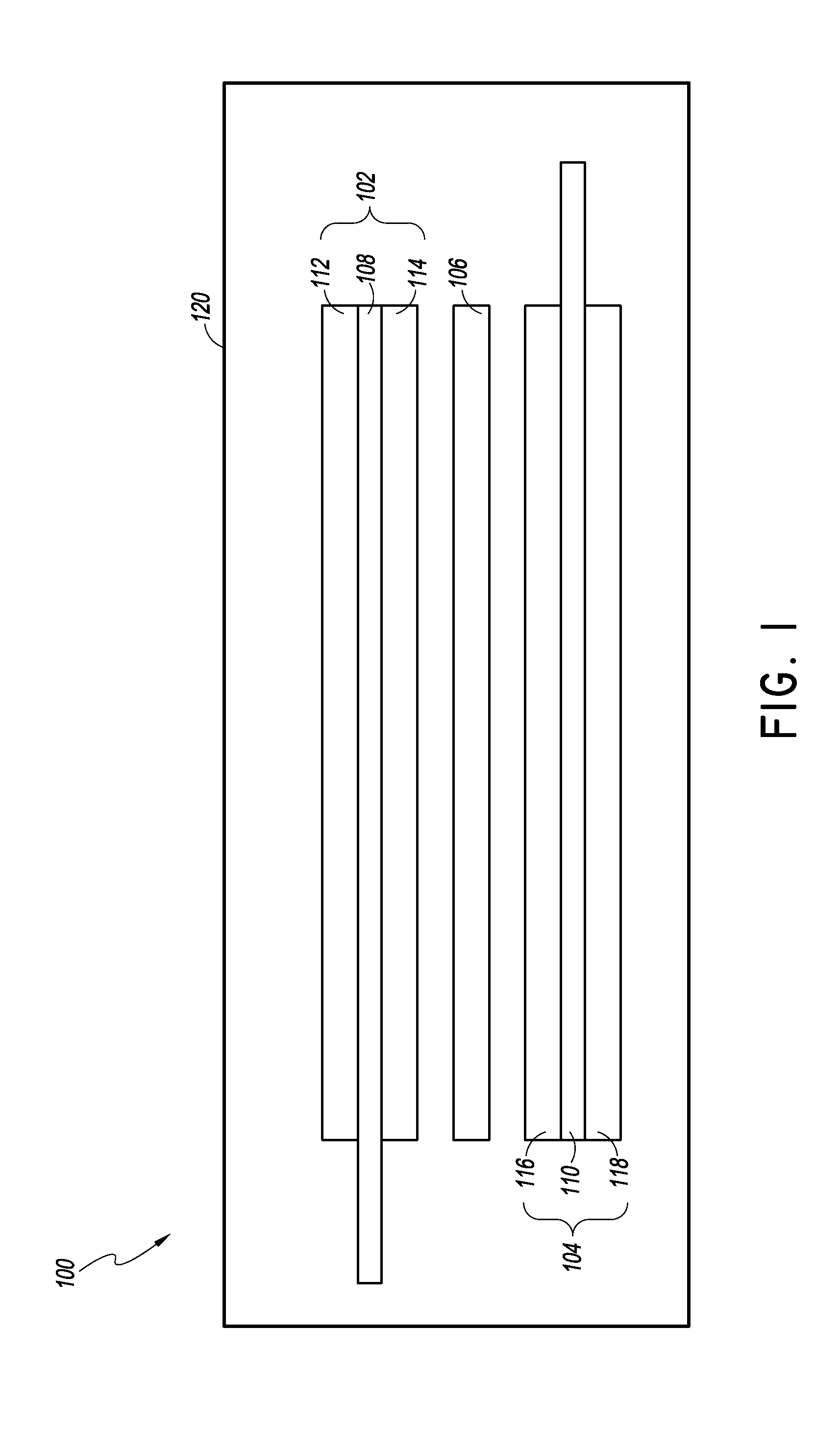

Electrolytic capacitor

ActiveUS20120300368A1Small sizeLarge capacitanceHybrid capacitor separatorsHybrid capacitor electrolytesElectrolysisDielectric layer

An electrolytic capacitor includes a capacitor element, an electrolyte solution with which the capacitor element is impregnated, and an outer package enclosing the capacitor element and the electrolyte solution. The capacitor element includes an anode foil having a dielectric layer on a surface thereof, a cathode foil, a separator disposed between the anode foil and the cathode foil, and a solid electrolyte layer in contact with the dielectric layer of the anode foil and the cathode foil. The electrolyte solution contains a low-volatile solvent that is at least one of polyalkylene glycol and a derivative of polyalkylene glycol.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

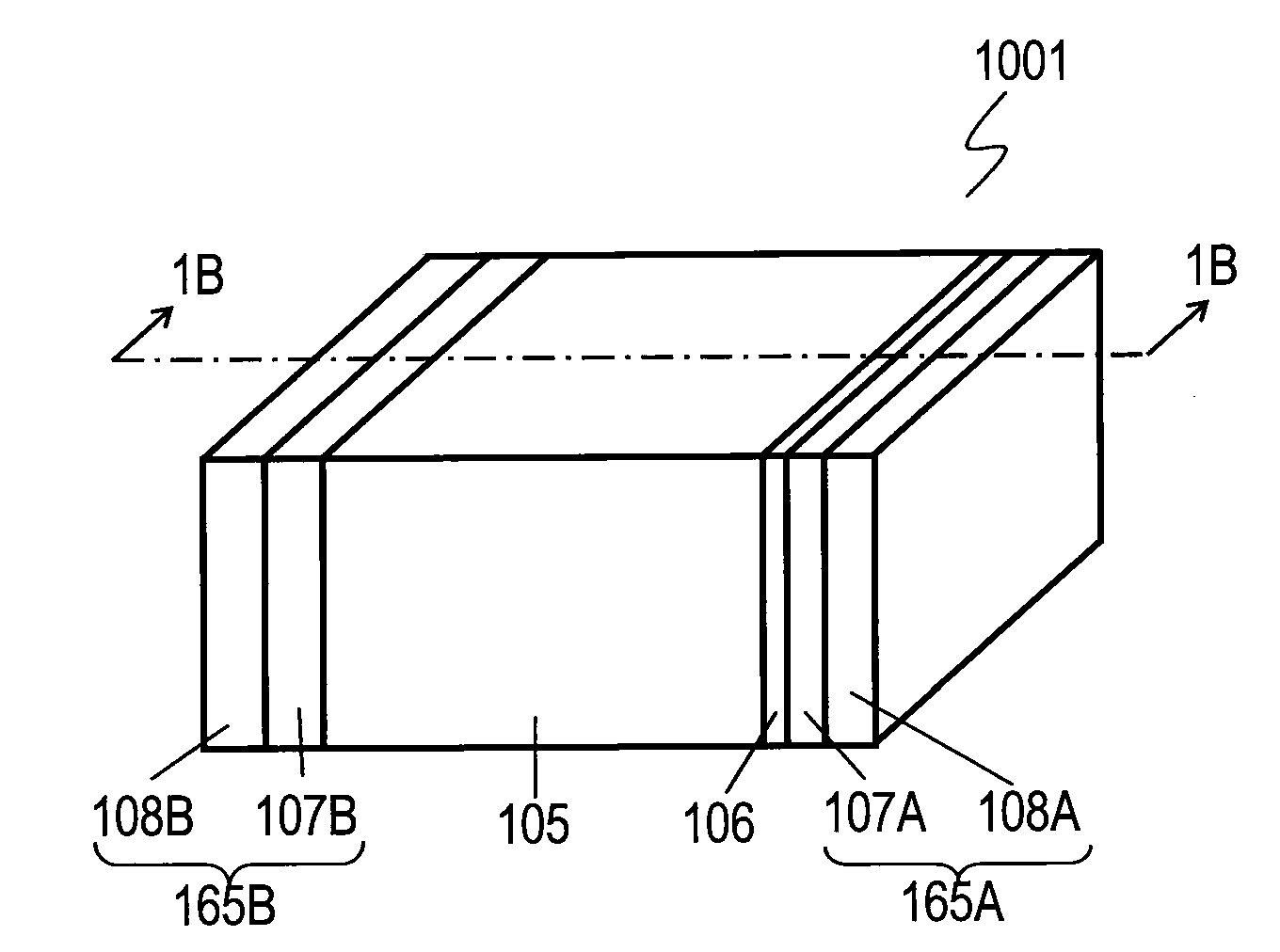

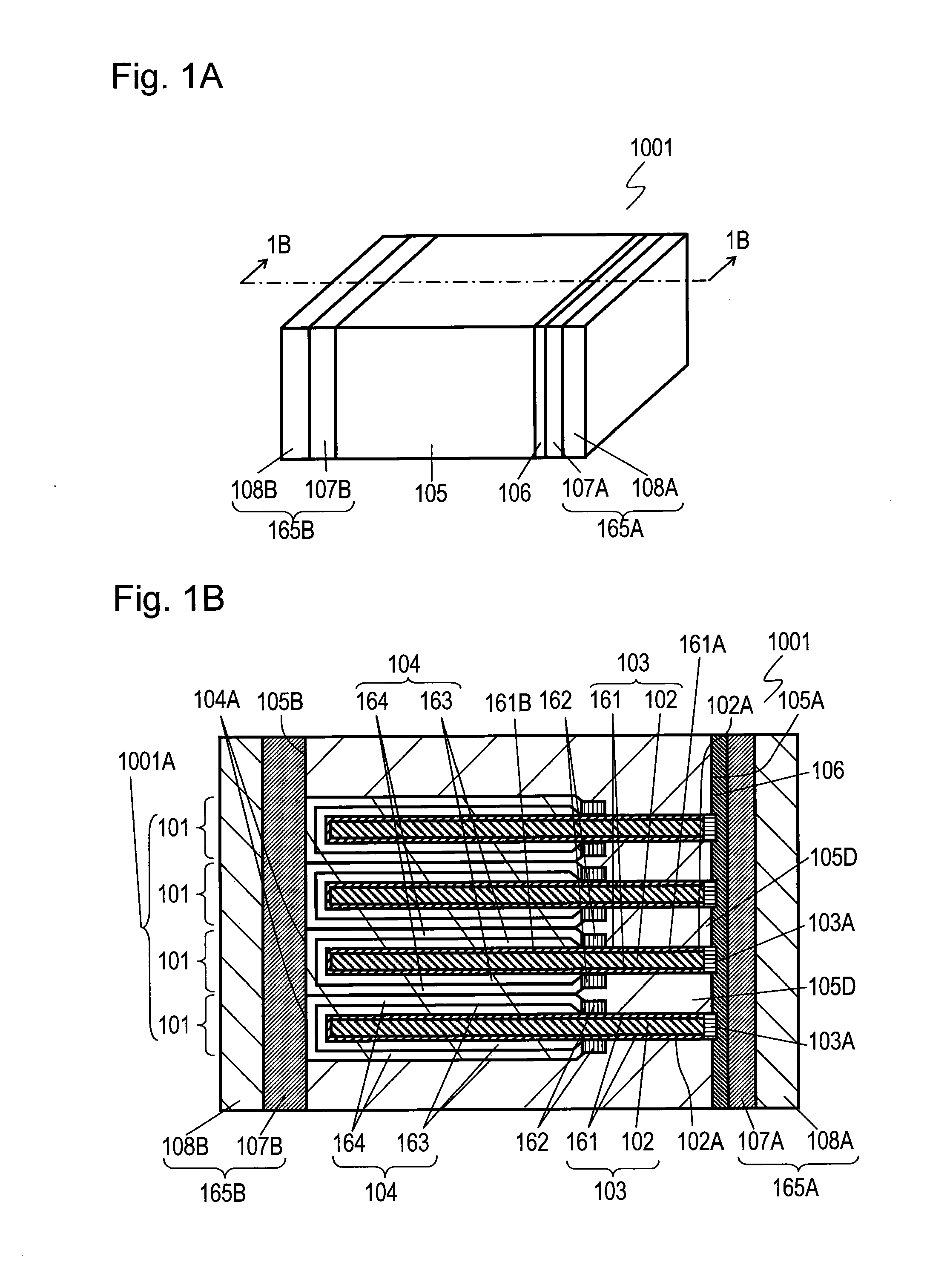

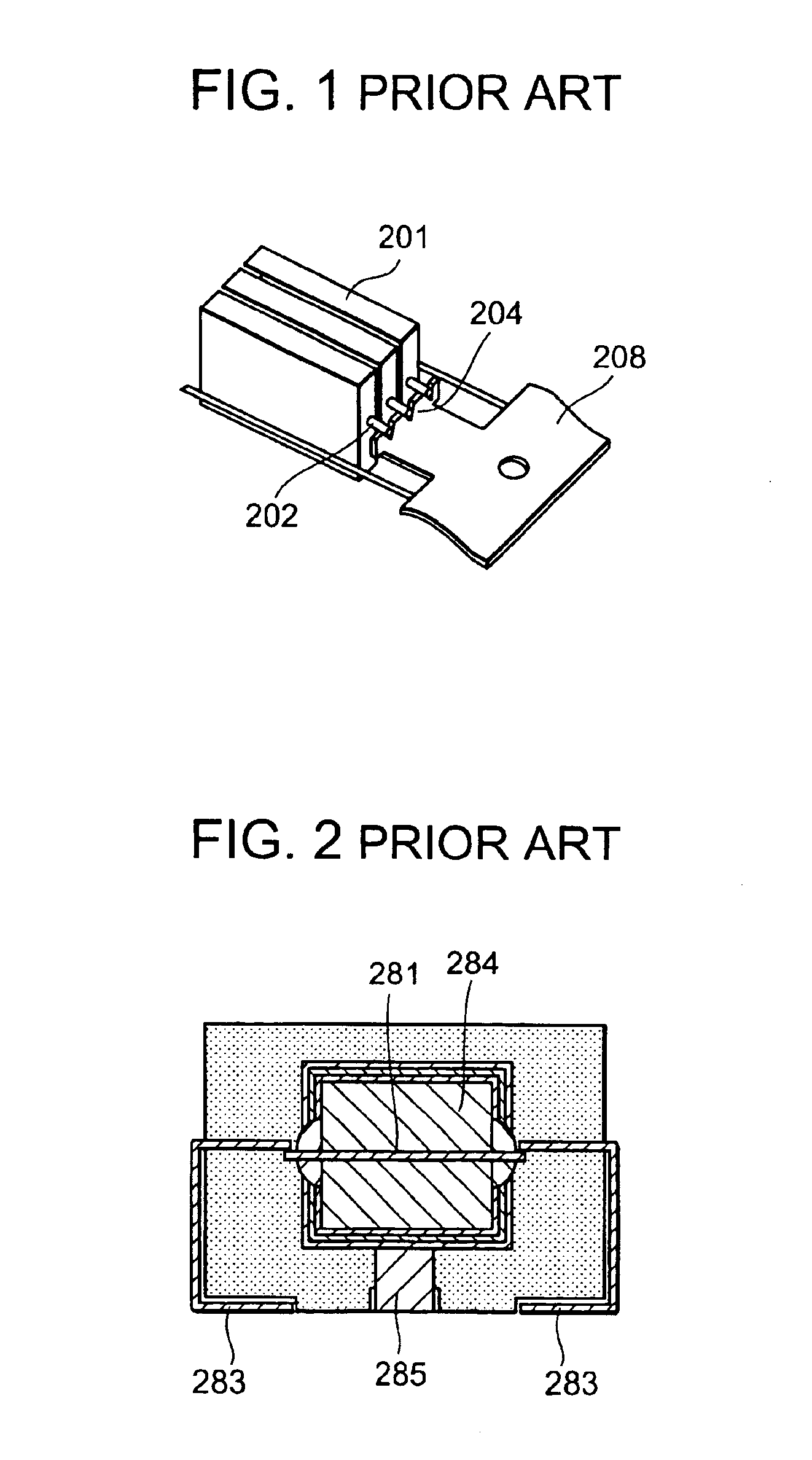

Solid electrolytic capacitor and electric circuit

InactiveUS7031141B2Large capacitanceLow ESRSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisOptoelectronics

A solid electrolytic capacitor includes a cathode including a solid electrolytic layer, an anode, and a dielectric layer provided between the cathode and the anode. The anode includes an anode body, an input anode terminal and an output anode terminal. A bypass current path for causing circuit current to detour around the anode body is formed between the input anode terminal and the output anode terminal.

Owner:ROHM CO LTD

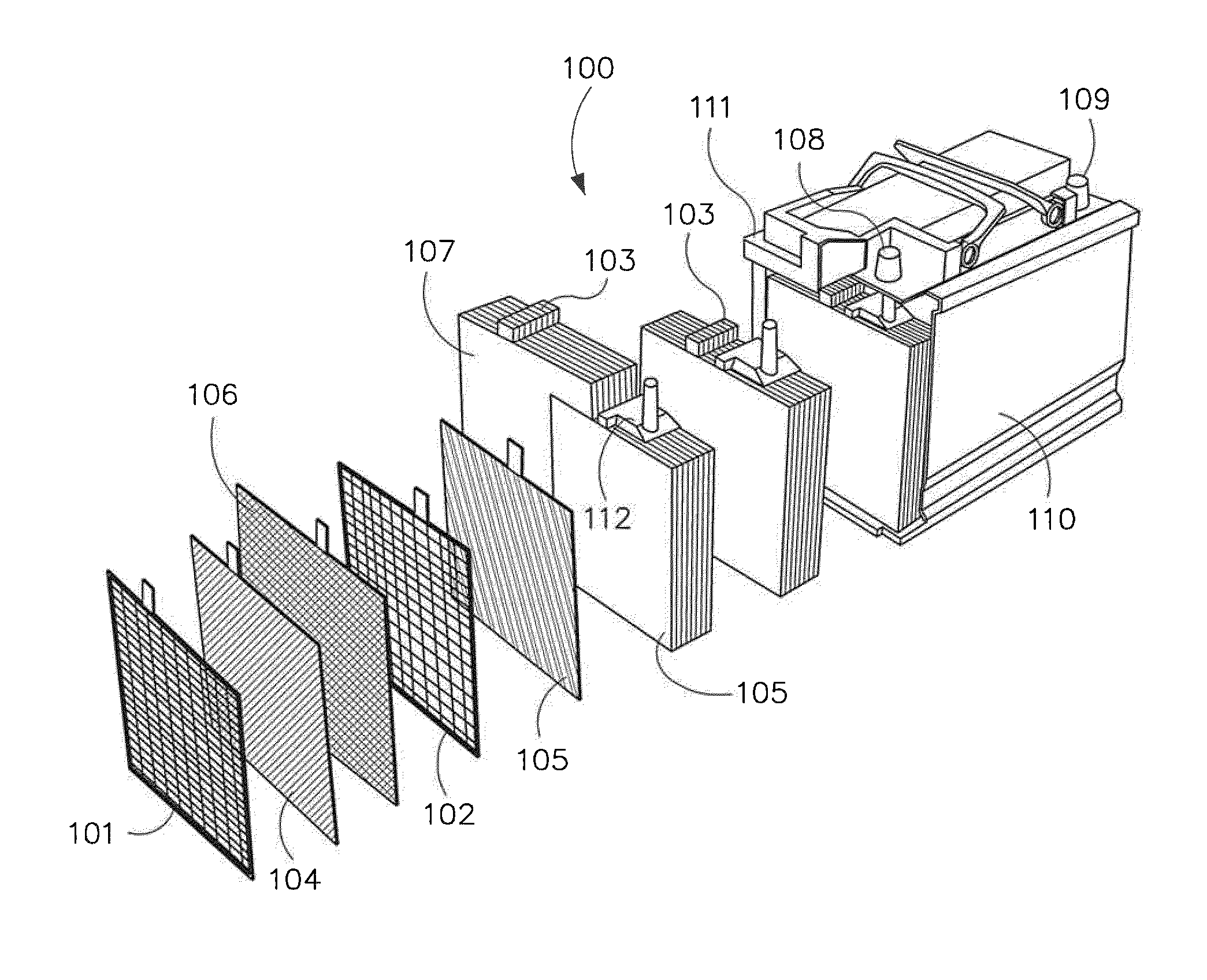

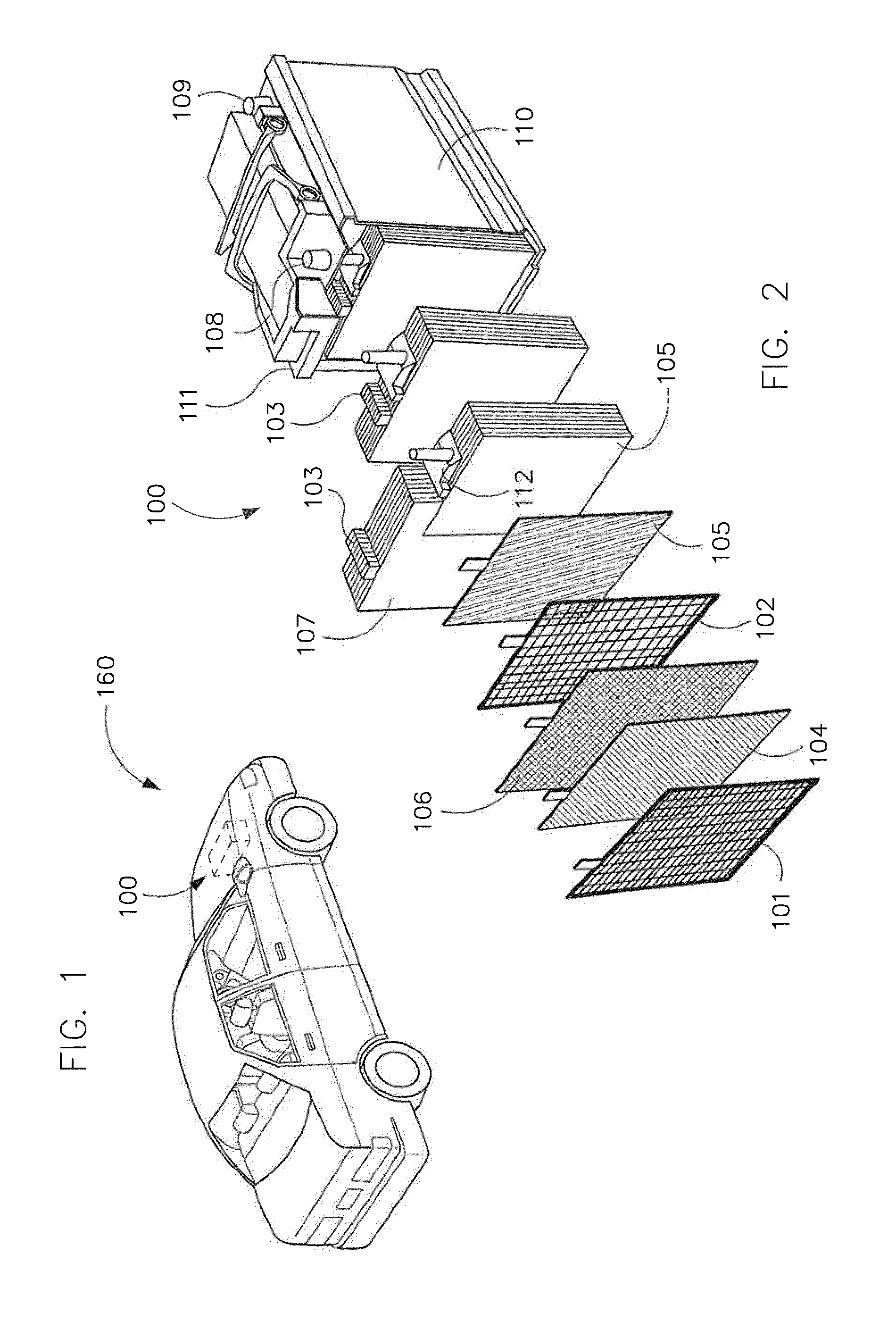

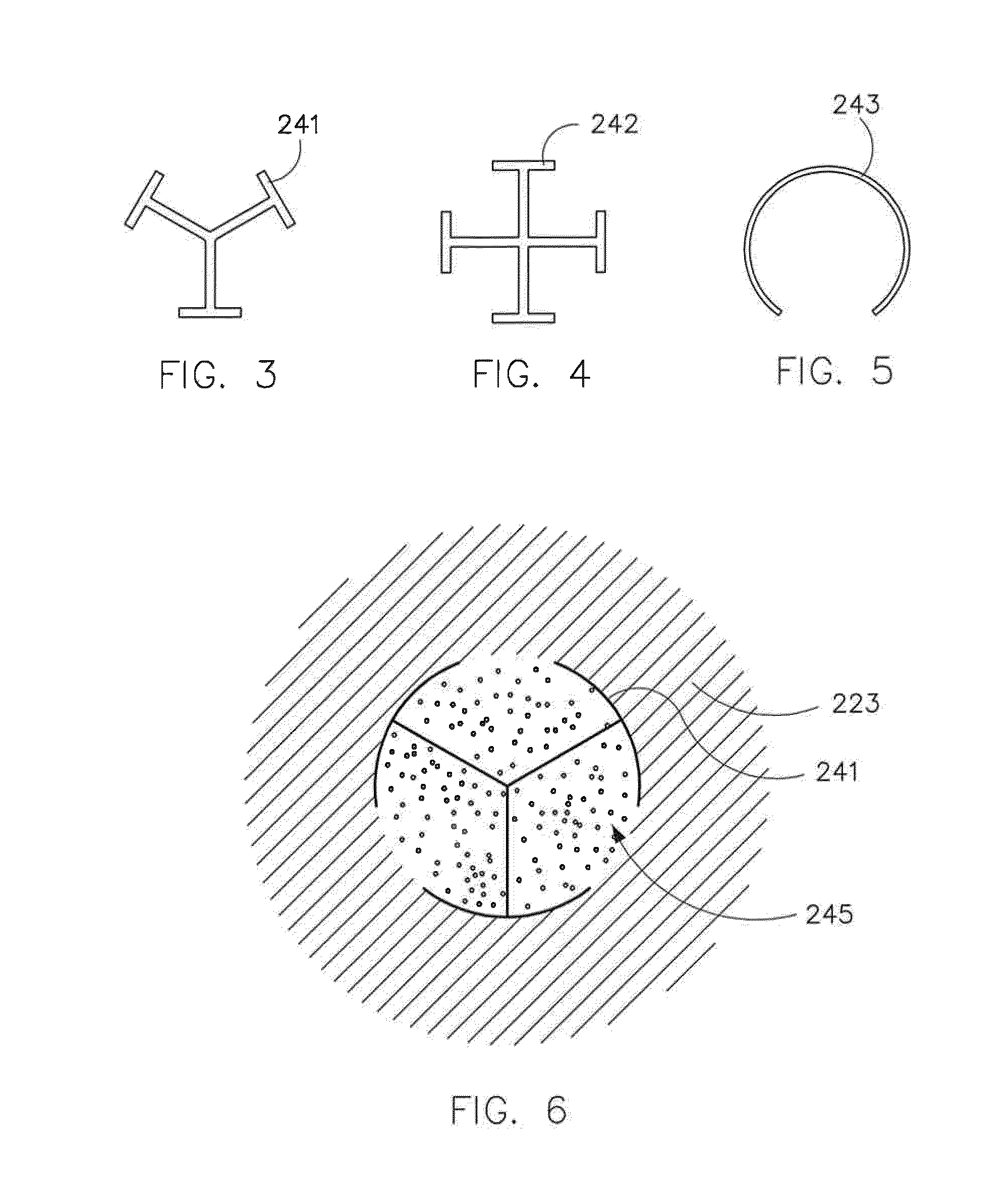

Electrical power storage devices

ActiveUS20110311876A1Large specific surface areaMaterial nanotechnologyNon-insulated conductorsElectrical batteryCarbon nanofiber

An electrical storage device includes high surface area fibers (e.g., shaped fibers and / or microfibers) coated with carbon (graphite, expanded graphite, activated carbon, carbon black, carbon nanofibers, CNT, or graphite coated CNT), electrolyte, and / or electrode active material (e.g., lead oxide) in electrodes. The electrodes are used to form electrical storage devices such as electrochemical batteries, electrochemical double layer capacitors, and asymmetrical capacitors.

Owner:JOHNSON CONTROLS AUTOBATTERIE GMBH & CO KGAA +1

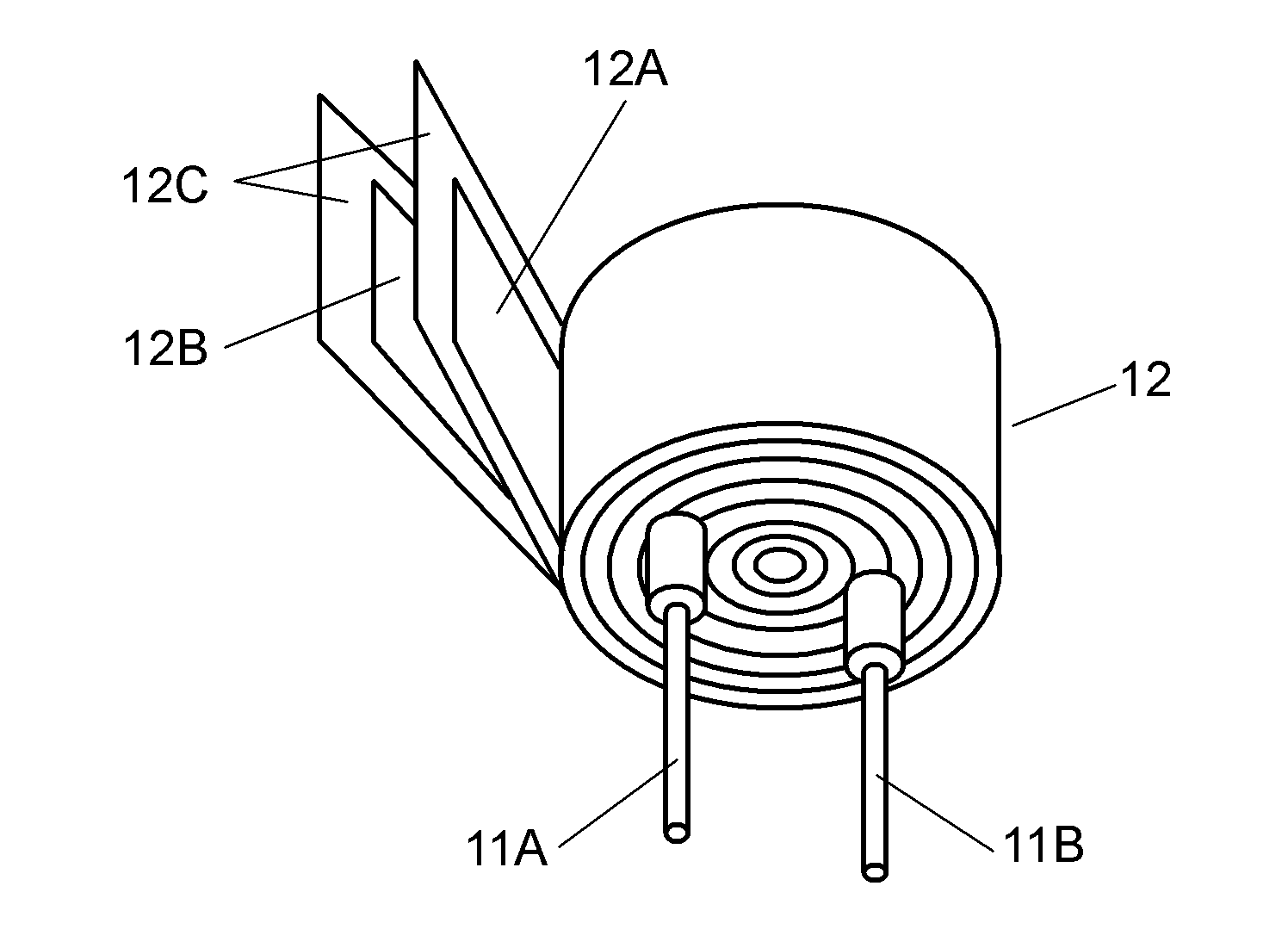

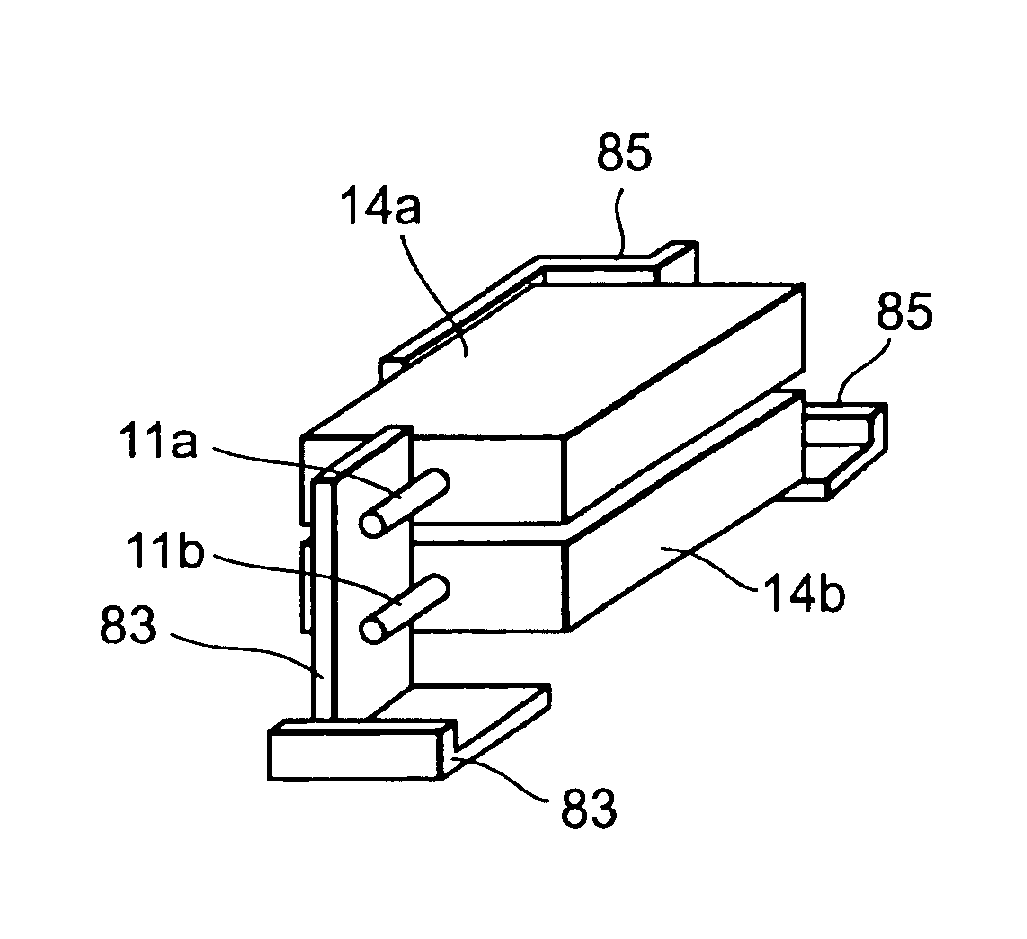

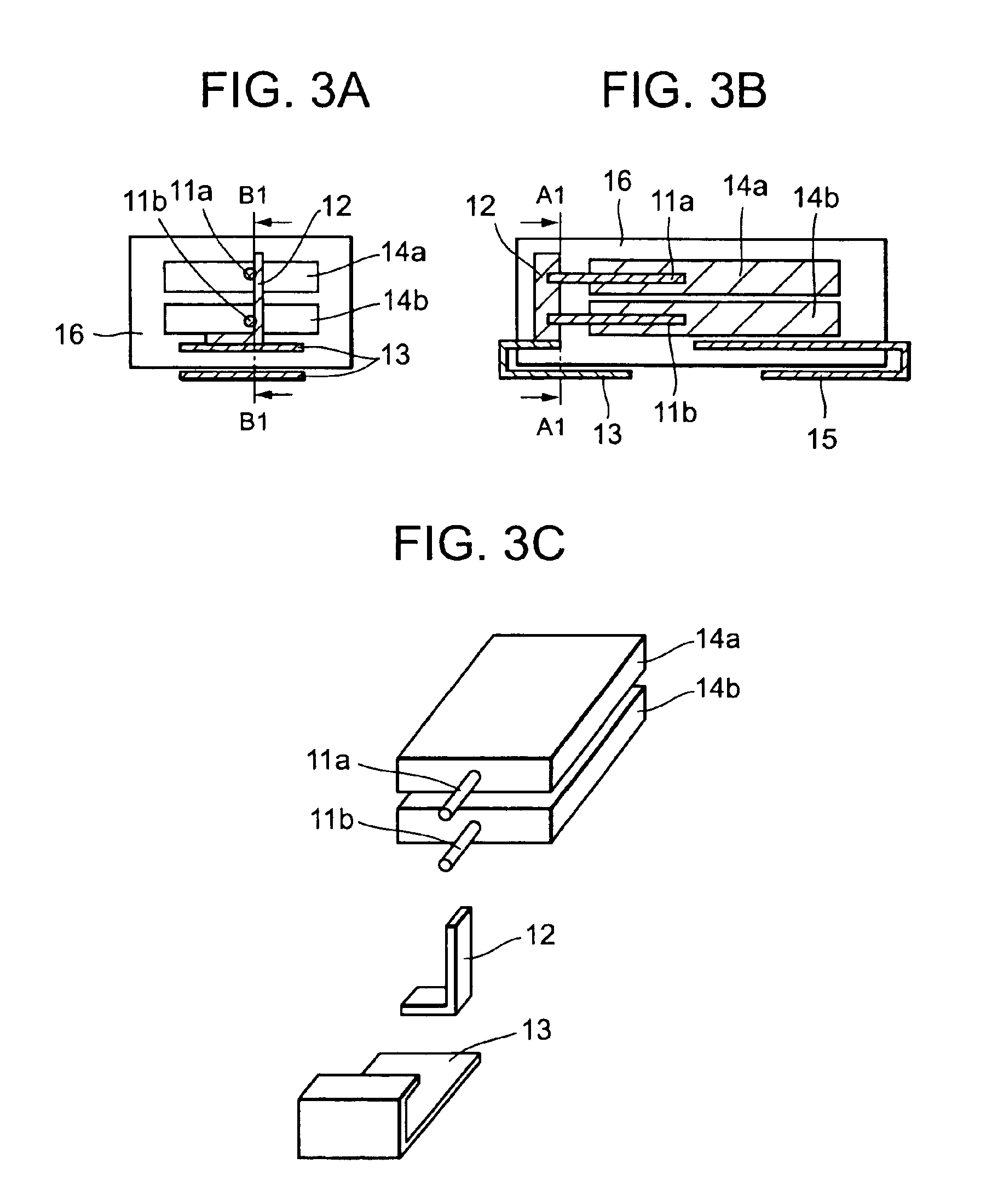

Solid electrolytic capacitor and method of manufacturing the same

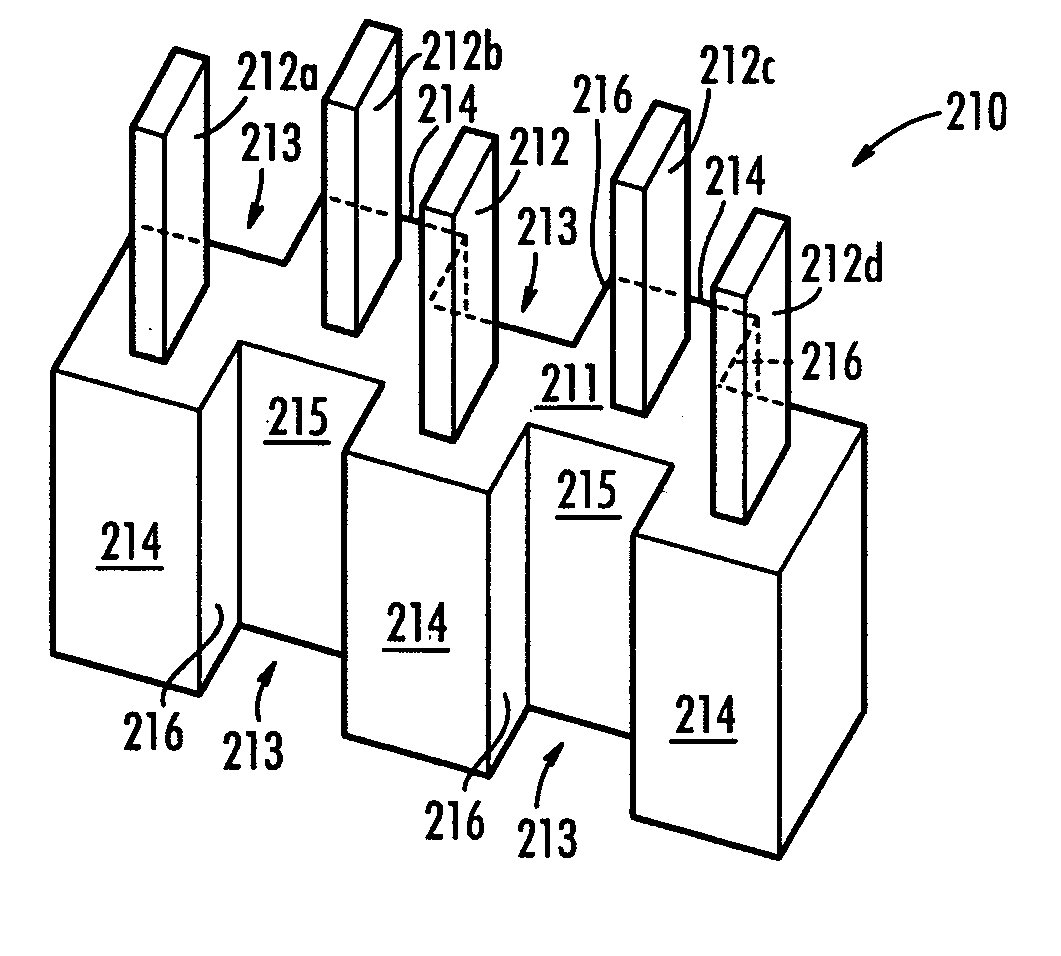

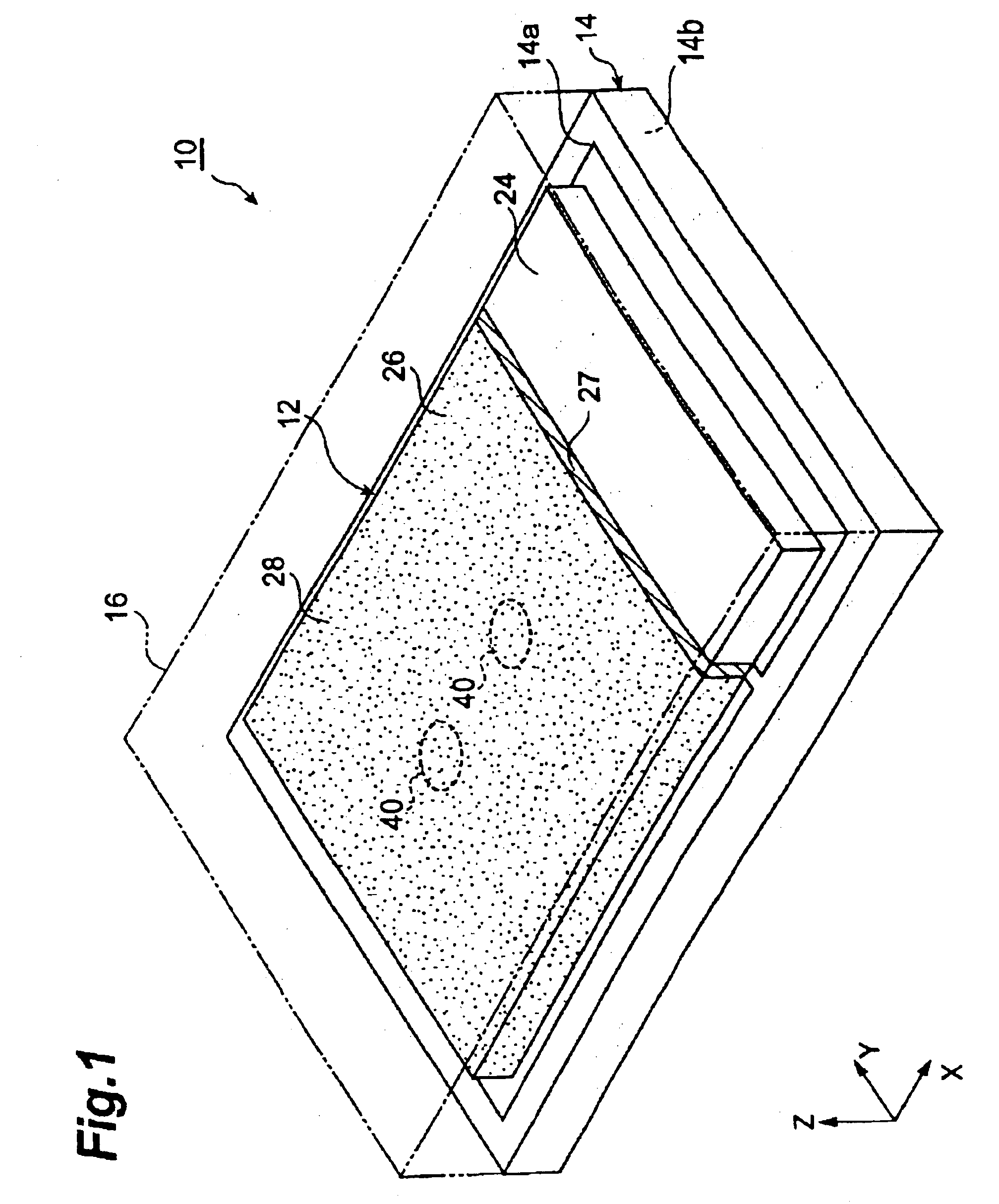

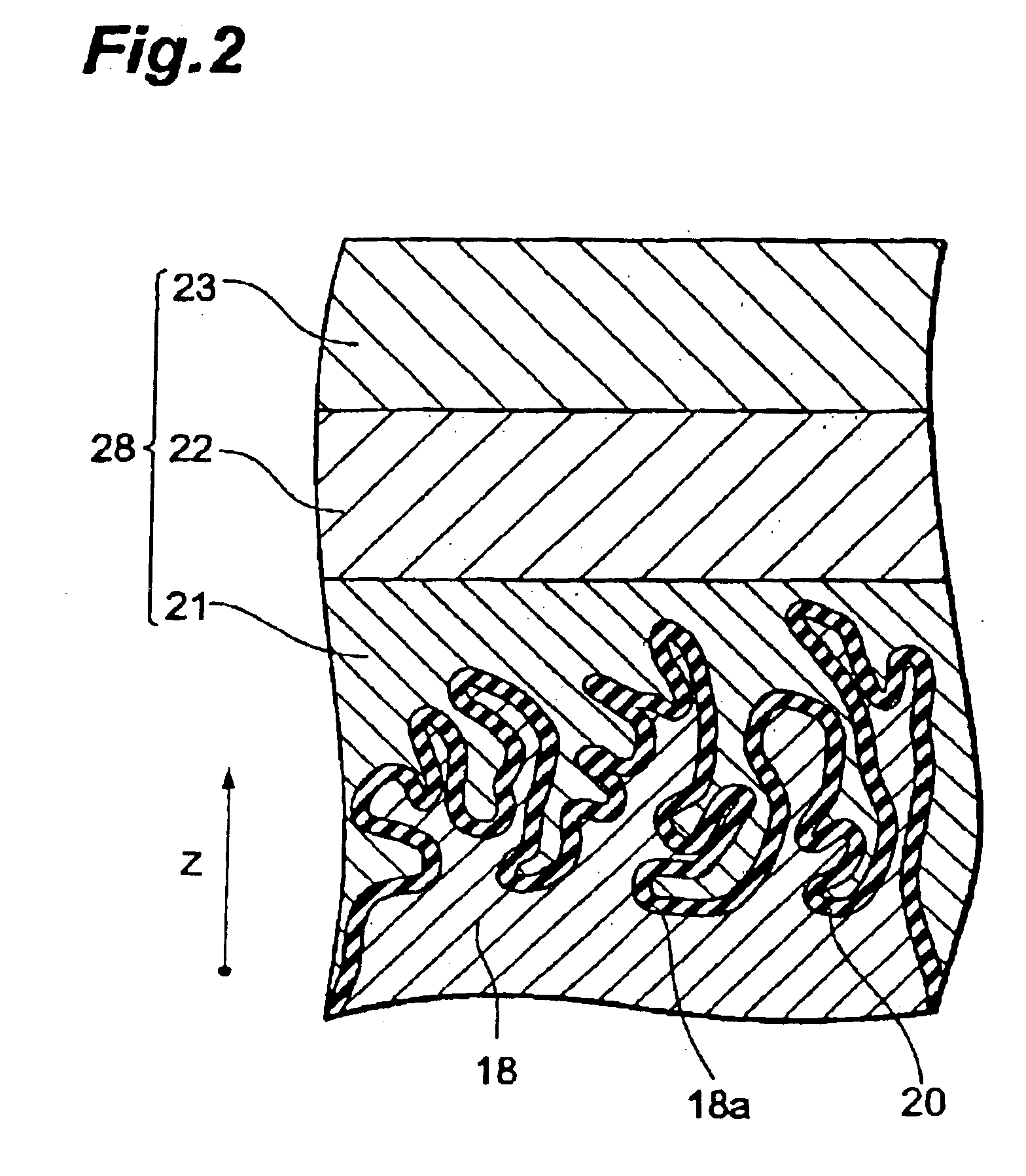

ActiveUS6912117B2Low ESRLarge capacitySolid electrolytic capacitorsLiquid electrolytic capacitorsNiobiumMetal

A solid electrolytic capacitor having at least two capacitor elements using a valve action metal, such as tantalum or niobium, and laminated in a direction perpendicular to a mounting surface of a substrate. The capacitor elements have a width parallel to the mounting surface of the substrate greater than a thickness perpendicular to the mounting surface of the substrate, and an anode terminal is connected with anode leads led out to at least one side of an anode body made of the valve action metal generally in parallel to the mounting surface of the substrate. A cathode layer on a dielectric oxide film of the anode body is connected to a cathode terminal and is coated with exterior coating resin with a part of the anode terminal and a part of the cathode terminal exposed.

Owner:TOKIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com