Patents

Literature

1026results about How to "Heat stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

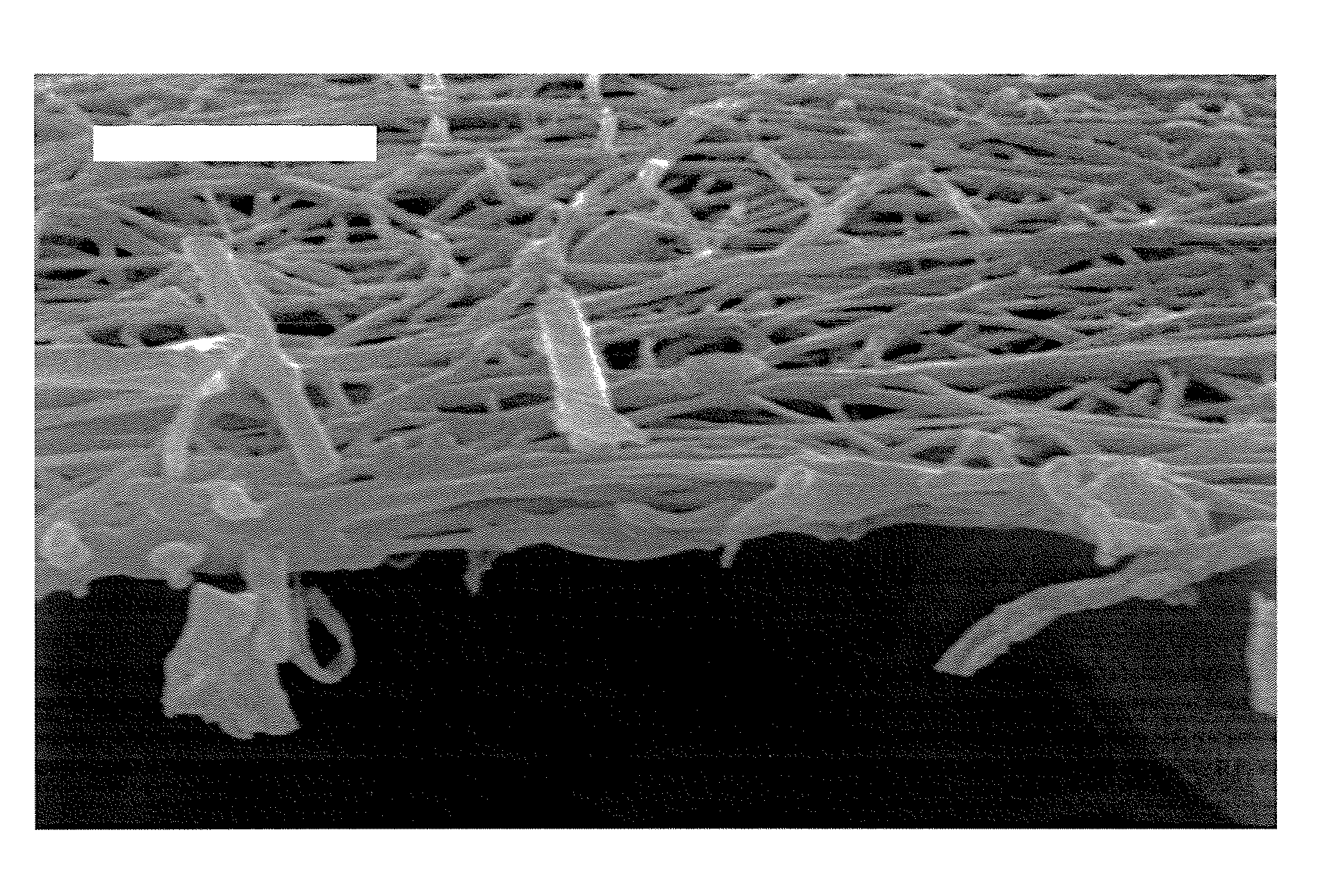

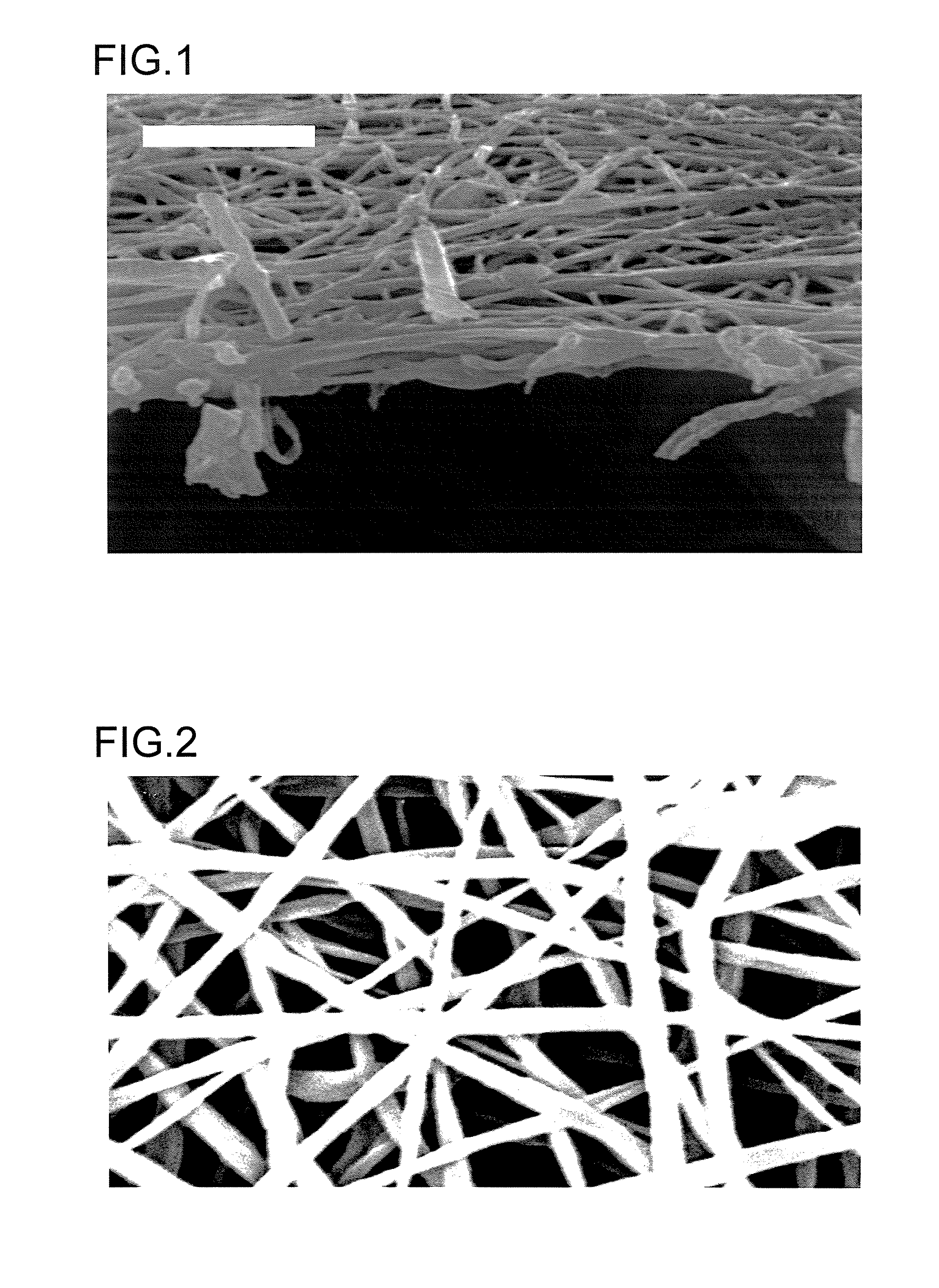

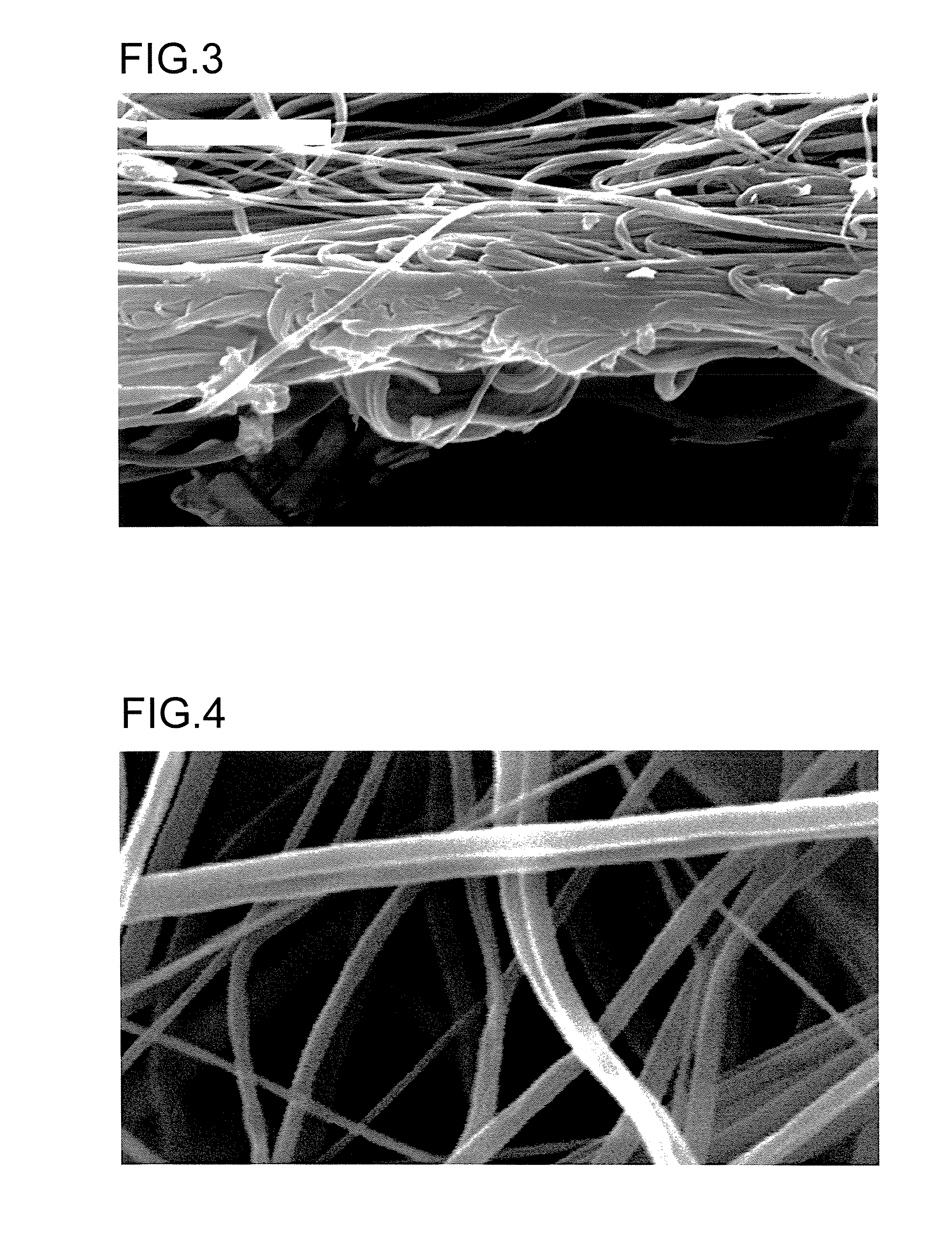

Fluoropolymer fine fiber

ActiveUS20090032475A1Advantageously employedHeat stableDispersed particle filtrationLiquid suspension thickening by filtrationPolymer scienceFiltration

A layer of fluoropolymer fine fiber can be made. The fine fiber can be made by electrospinning from a solvent or a solvent blend. The layers of the invention are useful in general filtration of fluid streams including gaseous and liquid streams. The fine fiber layers are also useful as hydrophobic filtration layers that can be used to separate water from a hydrocarbon stream.

Owner:DONALDSON CO INC

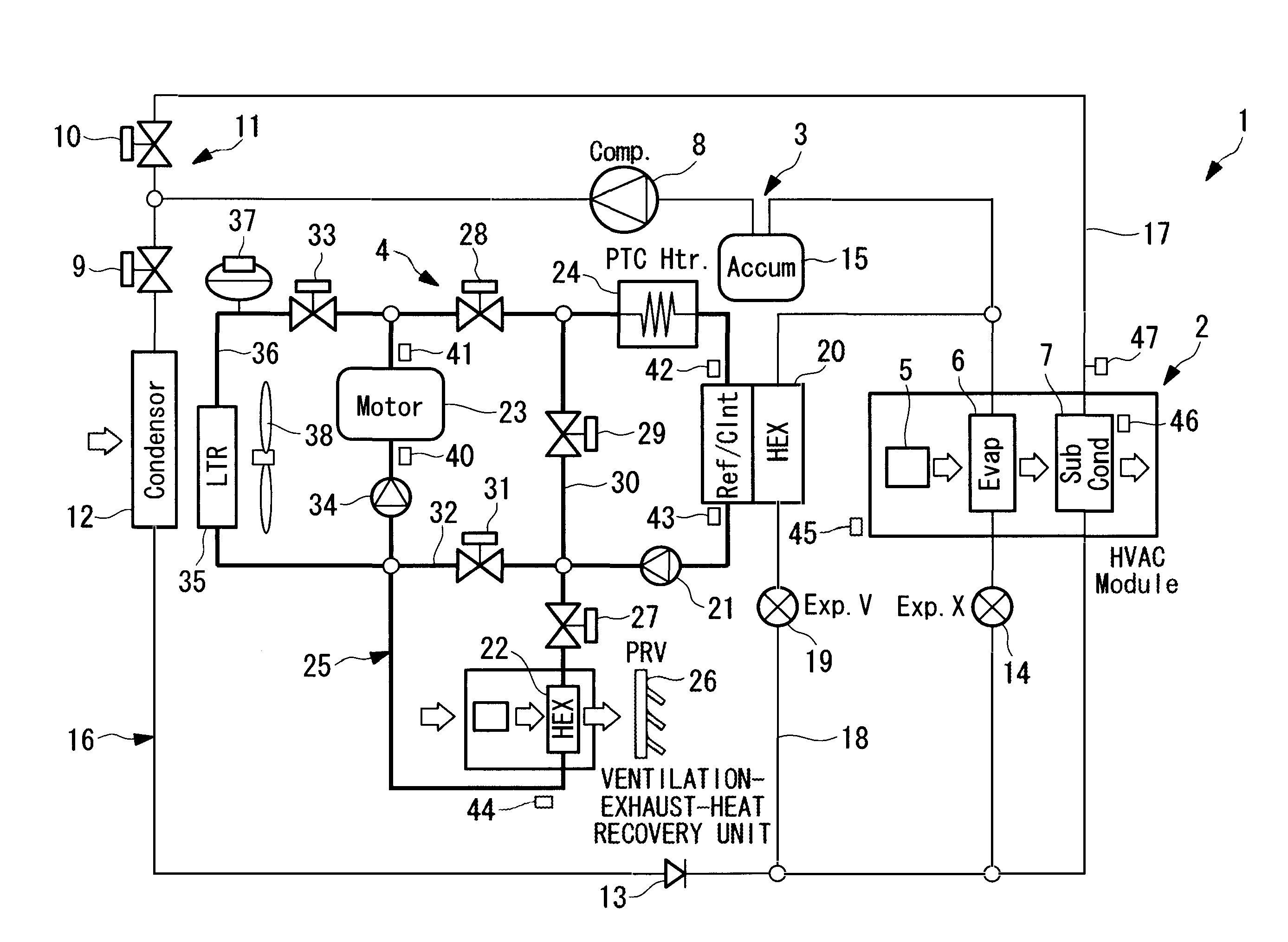

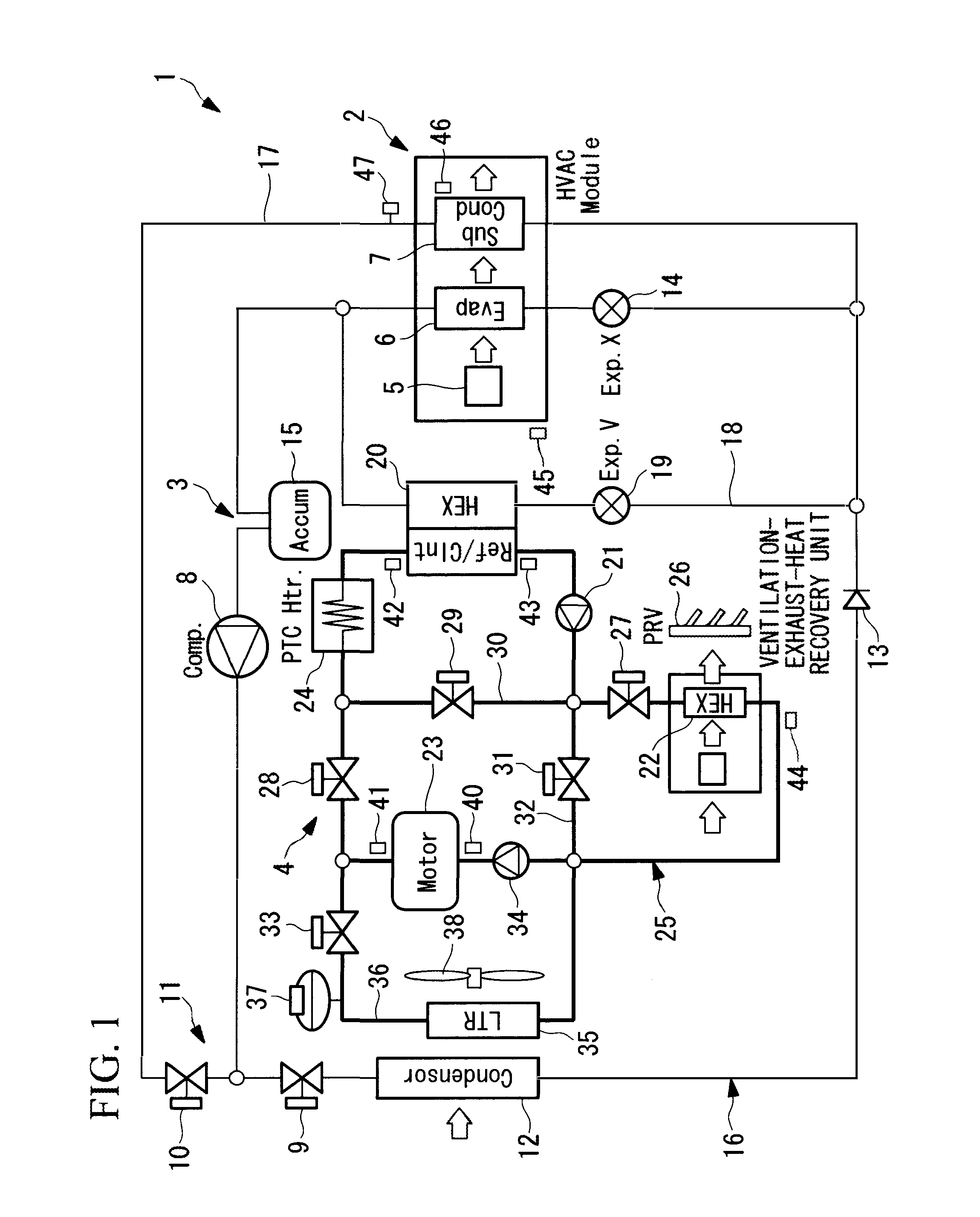

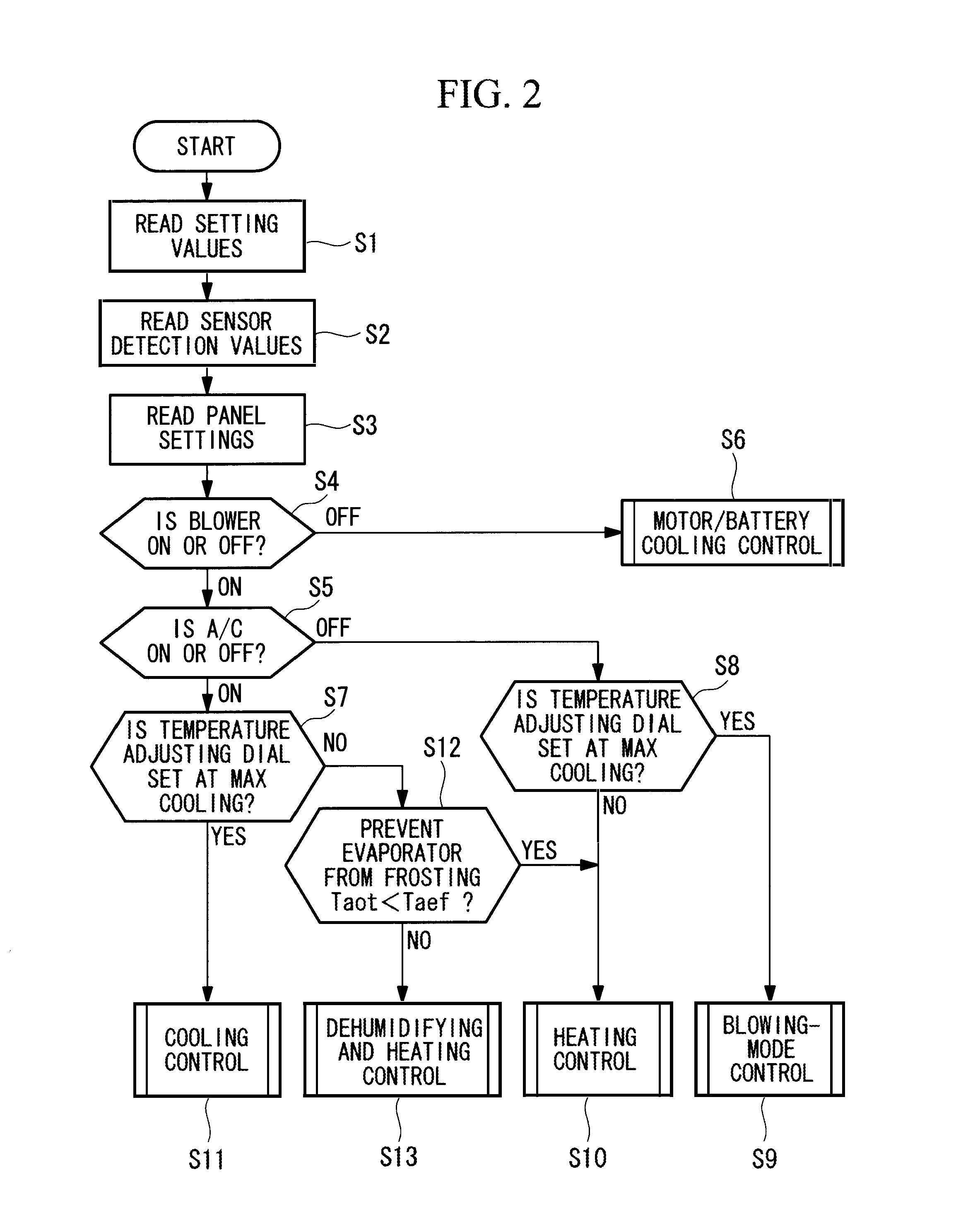

Vehicle air-conditioning system and operation control method therefor

ActiveUS20120205088A1Reduce usageHeat stableAir-treating devicesRailway heating/coolingEngineeringAir conditioning

A vehicle air-conditioning system includes: an HVAC unit that blows air whose temperature has been adjusted by a refrigerant evaporator and a second refrigerant condenser; a heat pump cycle in which a refrigerant compressor, a refrigerant circuit changeover section, a first refrigerant condenser, a first expansion valve, and the refrigerant evaporator are sequentially connected, in which a second expansion valve and a refrigerant / coolant heat exchanger are connected in parallel with the first expansion valve and the refrigerant evaporator, and in which the second refrigerant condenser is connected in parallel with the first refrigerant condenser; and a coolant cycle in which a coolant circulating pump, a ventilation-exhaust-heat recovery unit, a motor / battery, an electric heater, and the refrigerant / coolant heat exchanger are sequentially connected, and in which the ventilation-exhaust-heat recovery unit, the motor / battery, and the electric heater can be selectively used as a heat source.

Owner:MITSUBISHI HEAVY IND LTD

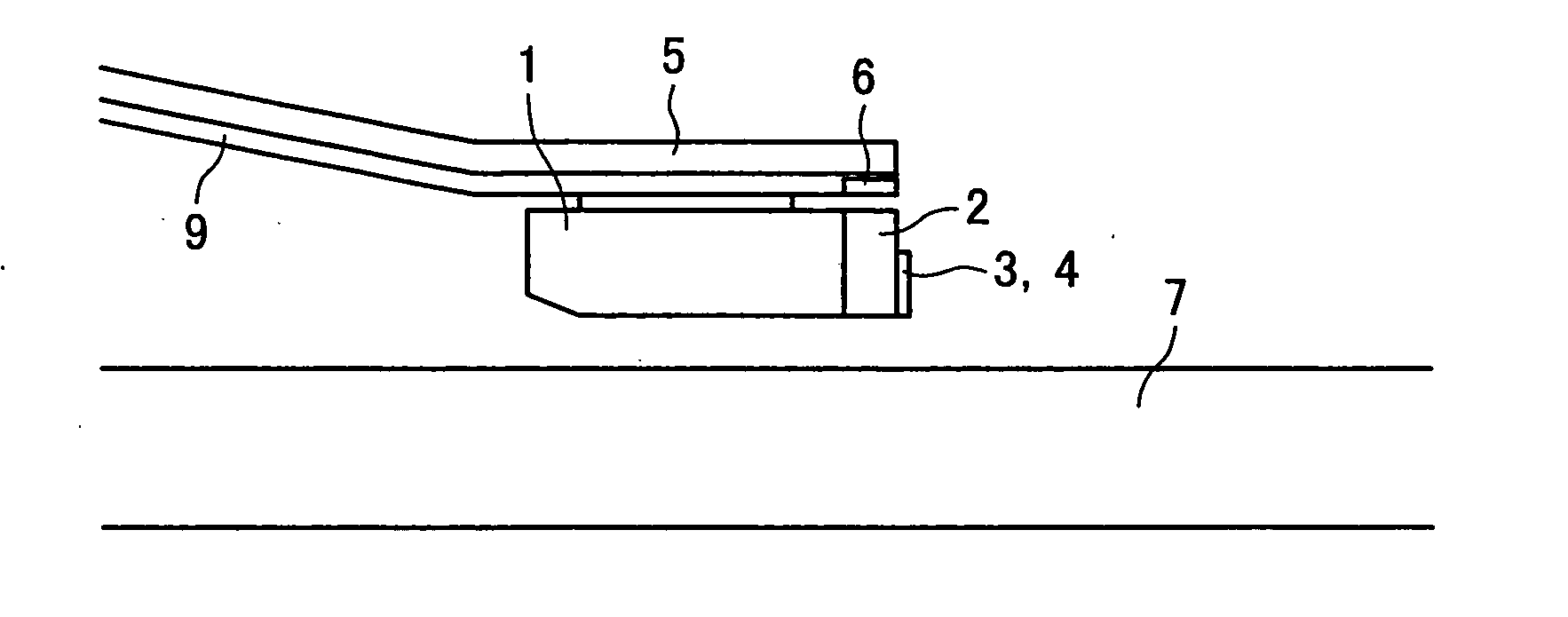

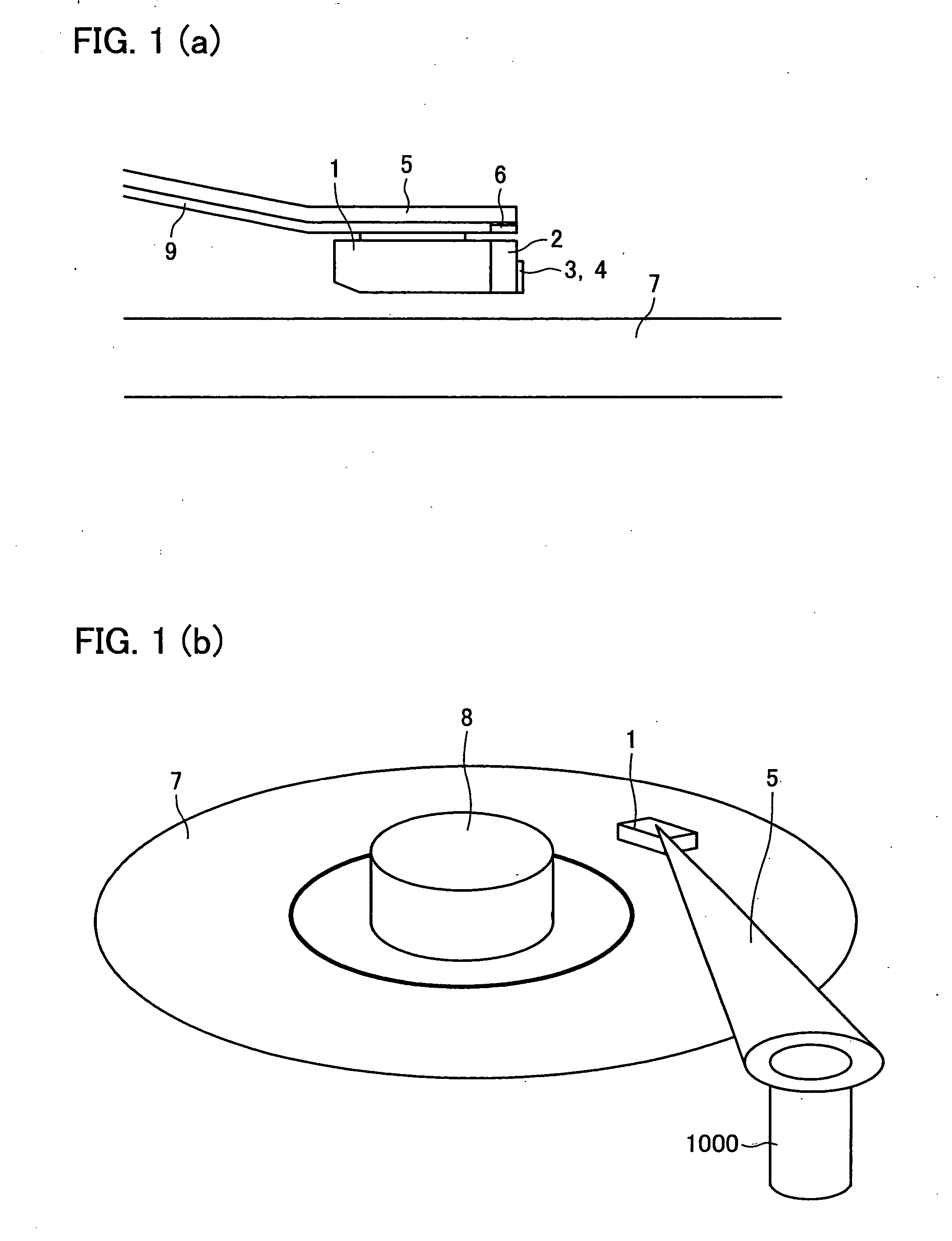

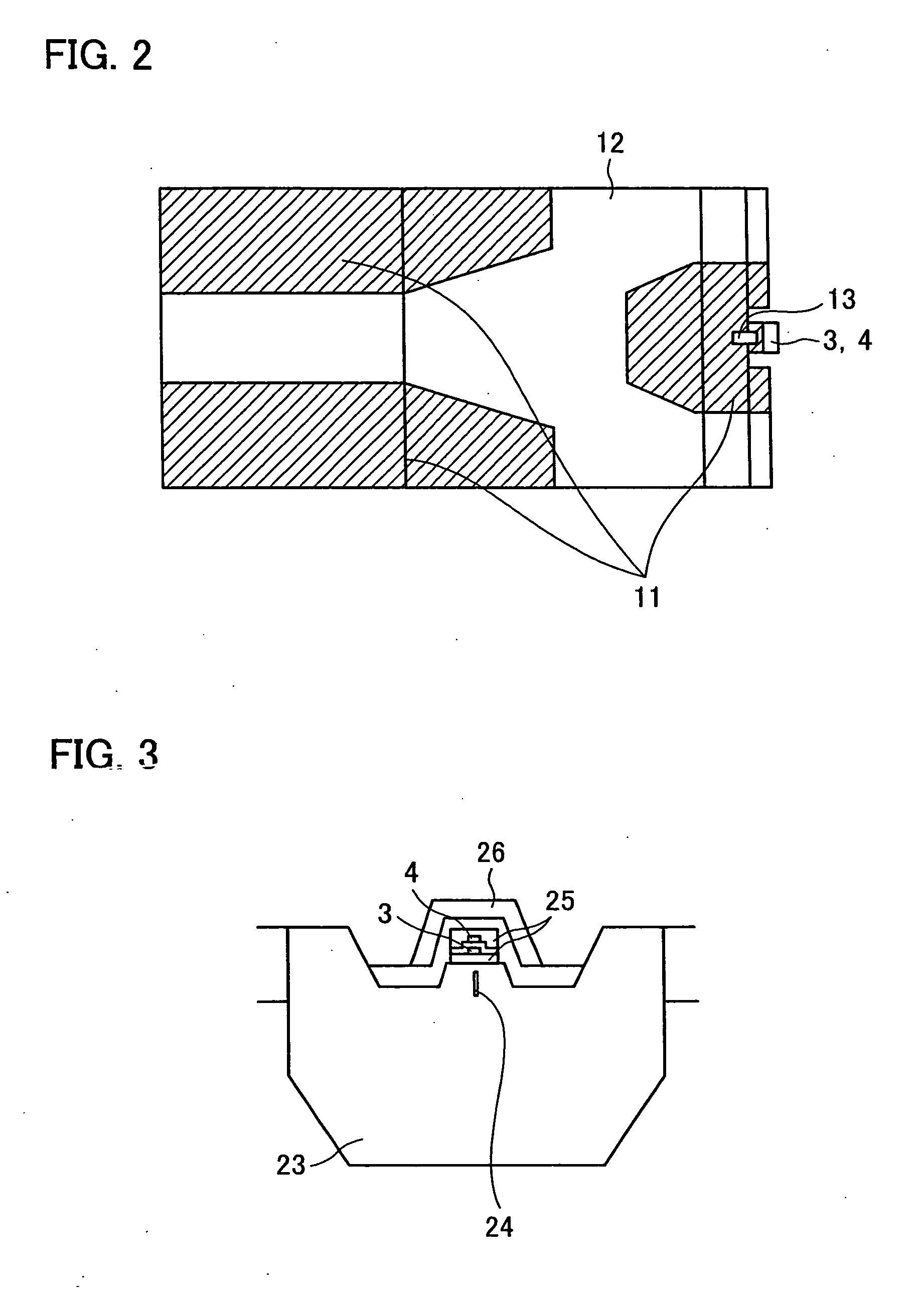

Read/write device, storage medium, driving method of read/write device, semiconductor laser life estimation method, program, program storage medium, and semiconductor laser

InactiveUS20050213436A1Shorten access timeDrive stabilityApparatus for flat record carriersHeads using thin filmsHeat-assisted magnetic recordingEstimation methods

In a read / write device for writing and reading a storage medium by way of a heat assisted magnetic recording / reproduction scheme, the read / write device including an elevated slider provided with a semiconductor laser, provided is a heat dissipation mechanism for dissipating heat generated in the elevated slider to an outside of a housing of the read / write device. Further, the storage medium has a second heatsink layer formed of an Al film having a thickness of 50 μm, a backing layer, a heat barrier layer, a first heatsink layer, a magnetic recording layer, and a protection film on a glass substrate. With this arrangement, in a read / write device which performs a heat assisted magnetic recording and reproduction by a semiconductor laser provided on the elevated slider, the occurrence of malfunction due to temperature rises in the storage medium is prevented.

Owner:SHARP KK

Process for the production of electrolyte capacitors

ActiveUS8058135B2Lower equivalent series resistanceHeat stableSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceElectrolysis

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

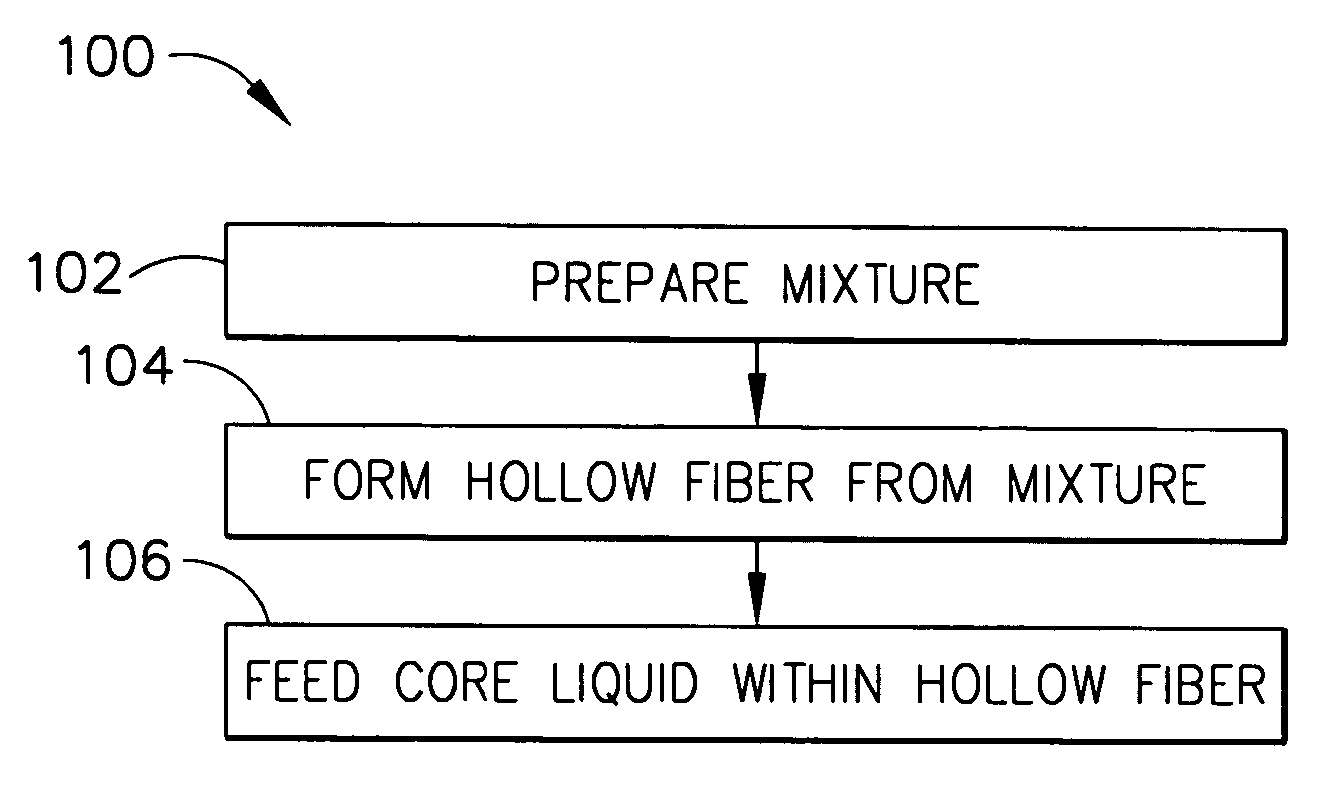

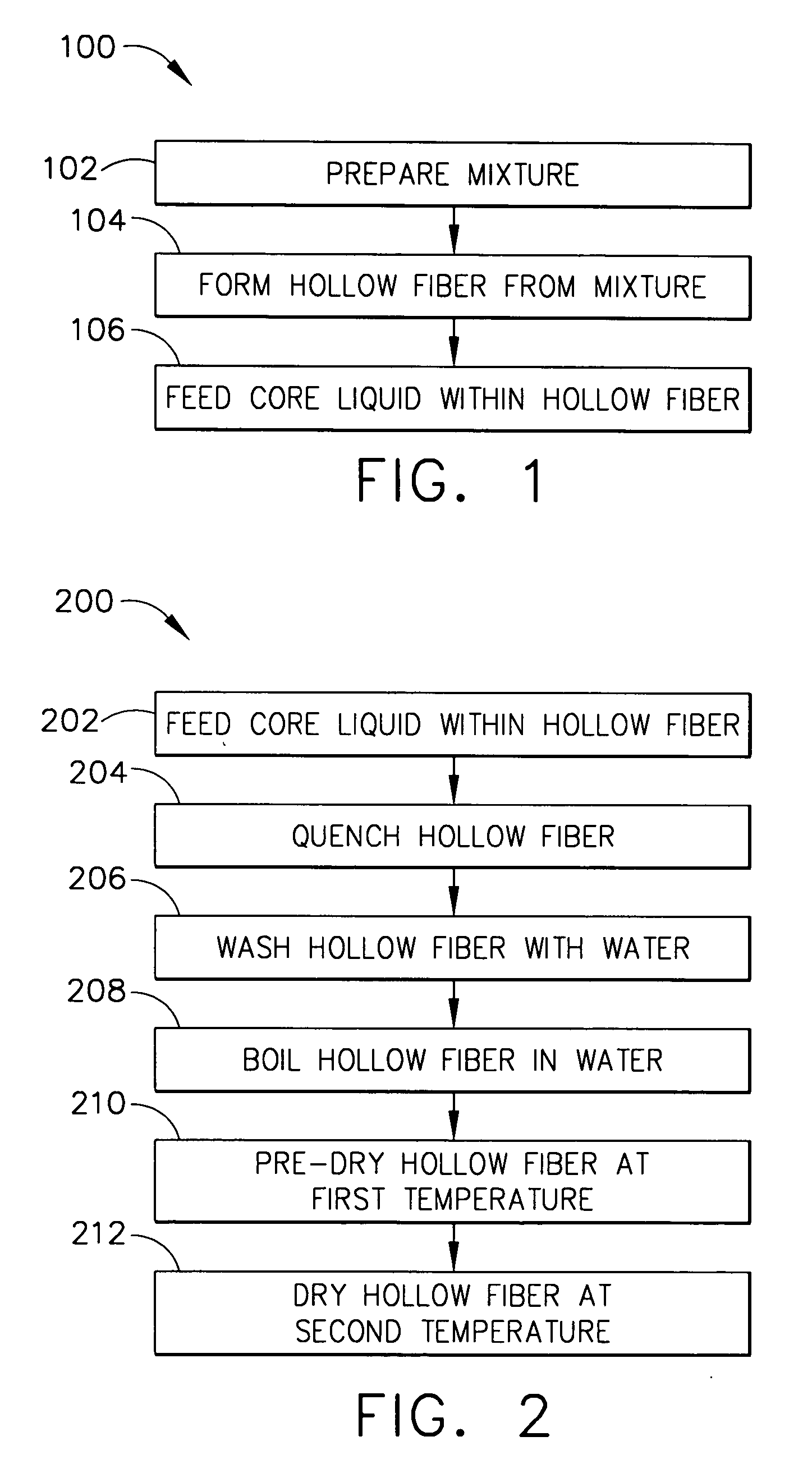

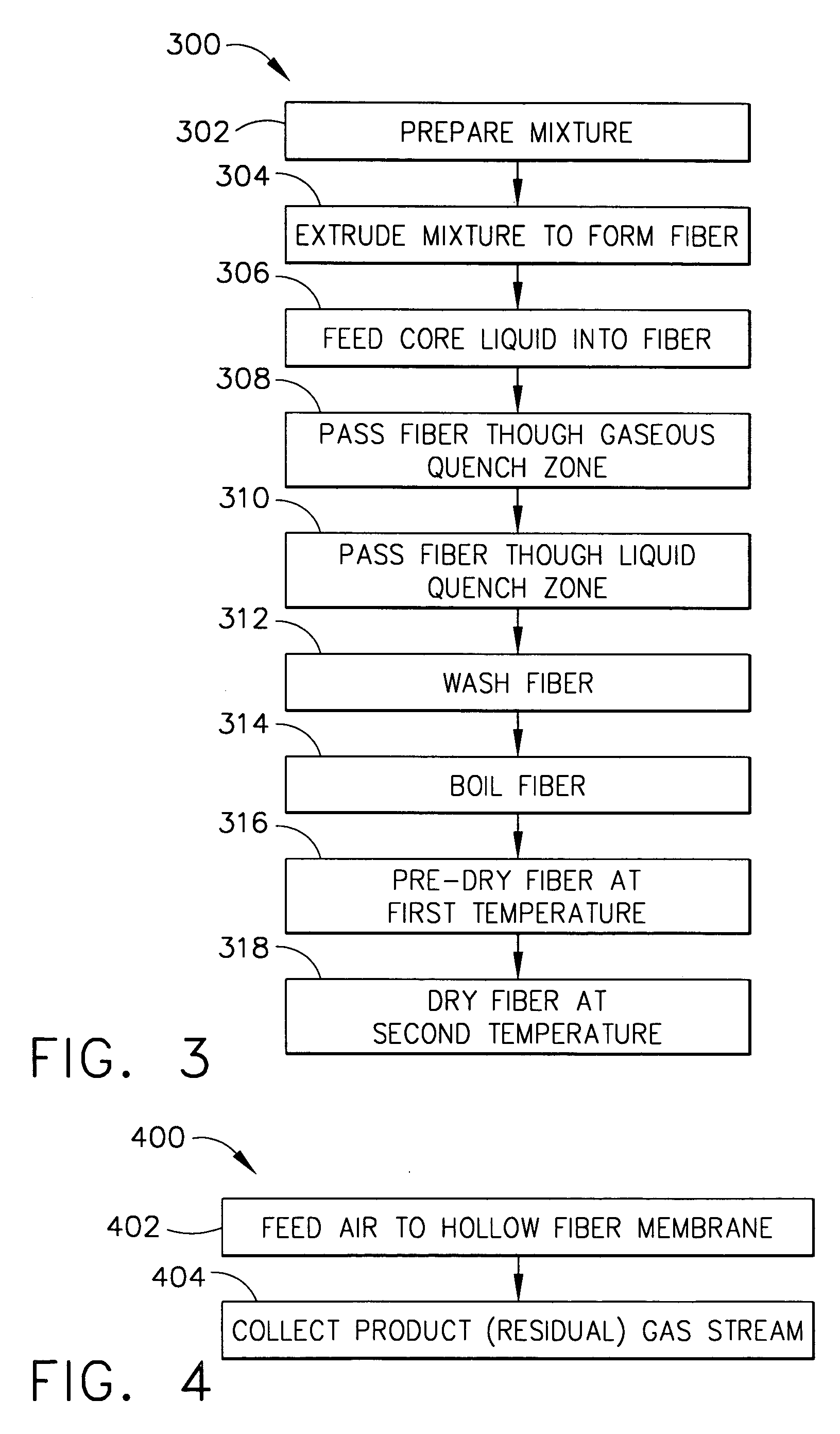

High temperature gas separation membrane suitable for OBIGGS applications

Gas separation membranes and methods for preparing such membranes. The gas separation membranes of the instant invention can separate oxygen and nitrogen in air to provide nitrogen enriched air (NEA), and are stable during exposure to temperatures of at least about 160° C. The gas separation membranes of the instant invention may be formed from polyetherimide by extruding a hollow fiber using a core liquid, quenching the extruded fiber in dry air to promote loss of solvent and non-solvent, and drying the fiber. Methods for separating bleed air fed directly from an aircraft precooler to a high temperature gas separation hollow fiber membrane, to provide NEA, are also disclosed.

Owner:HONEYWELL INT INC

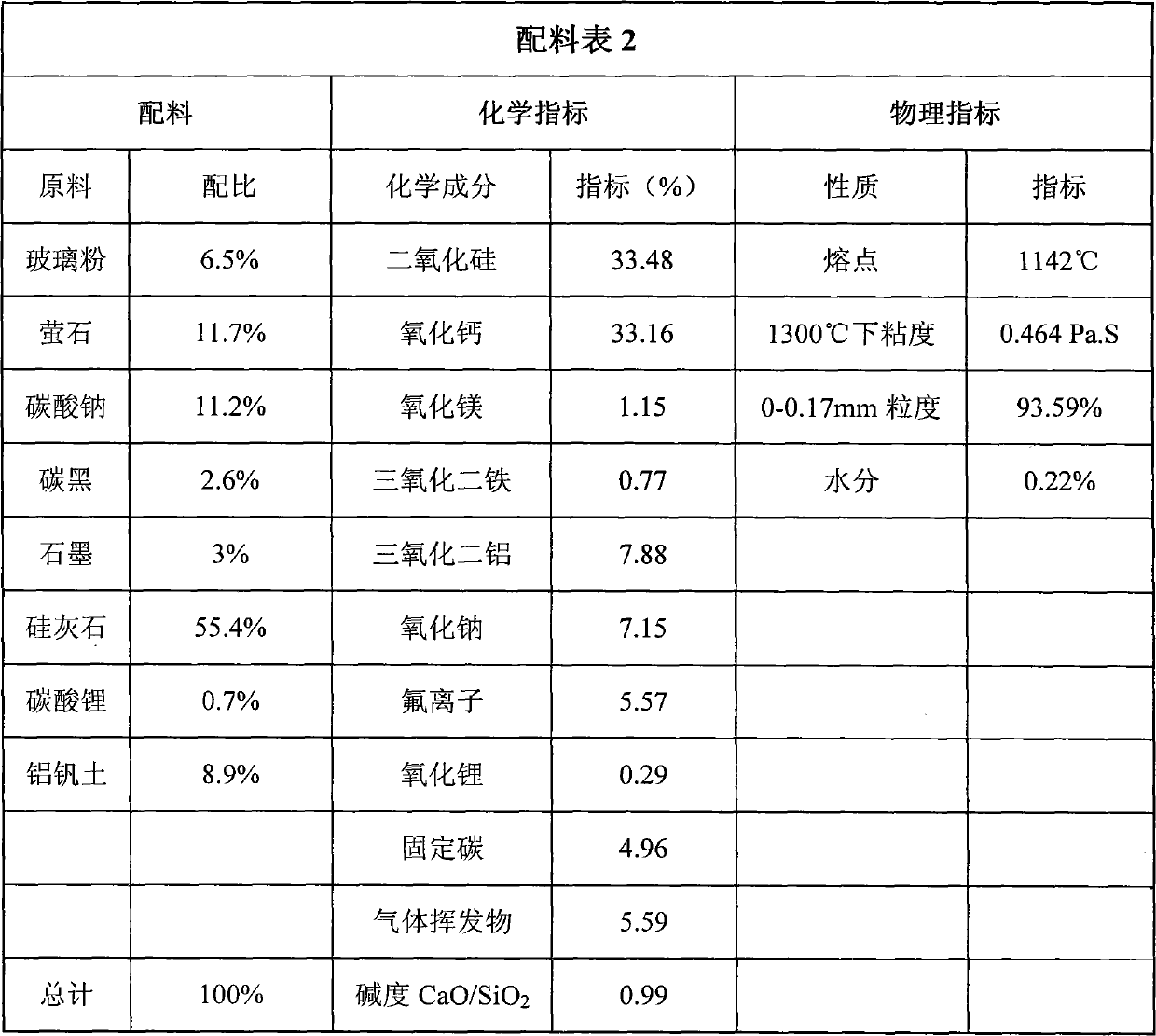

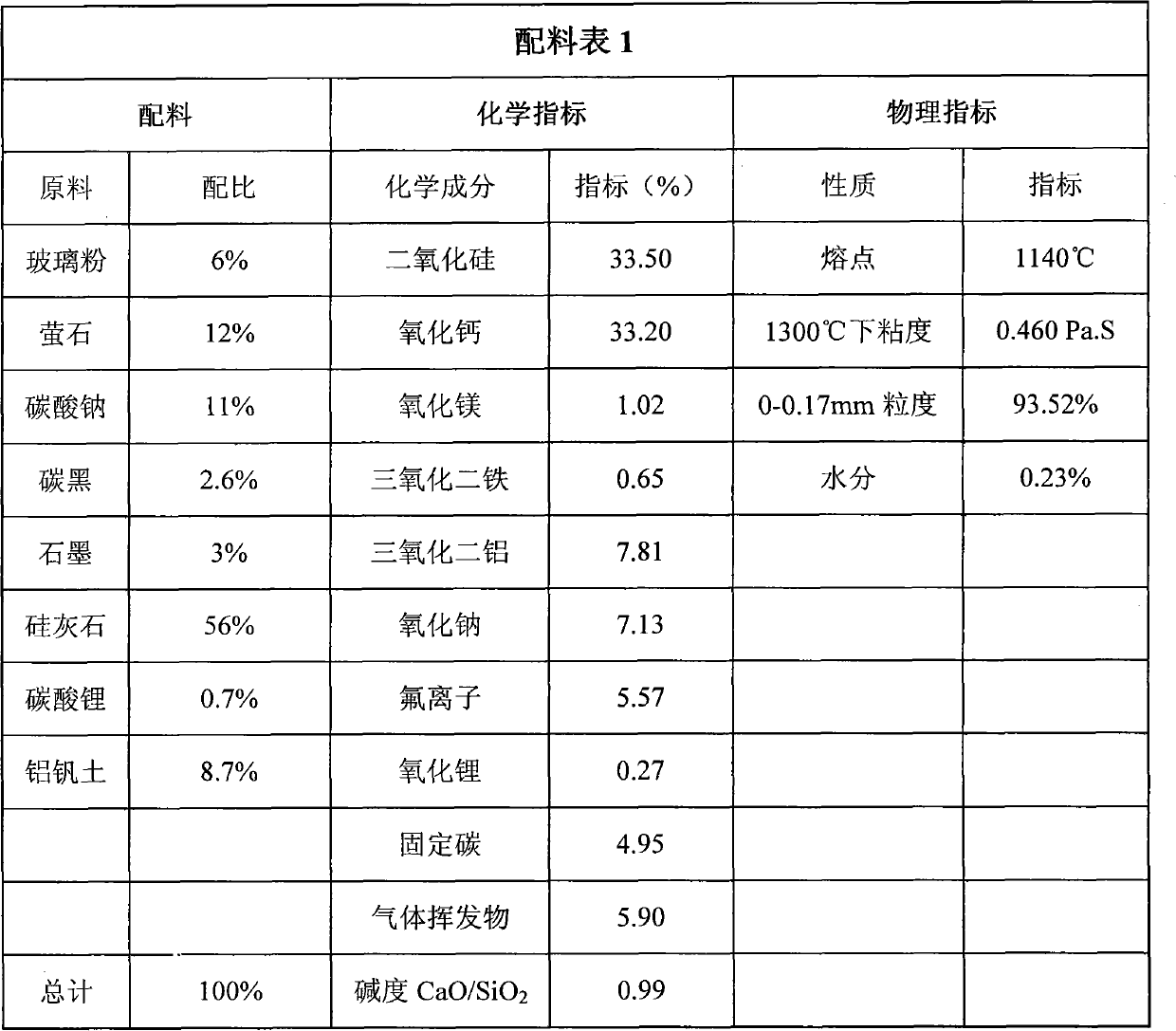

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

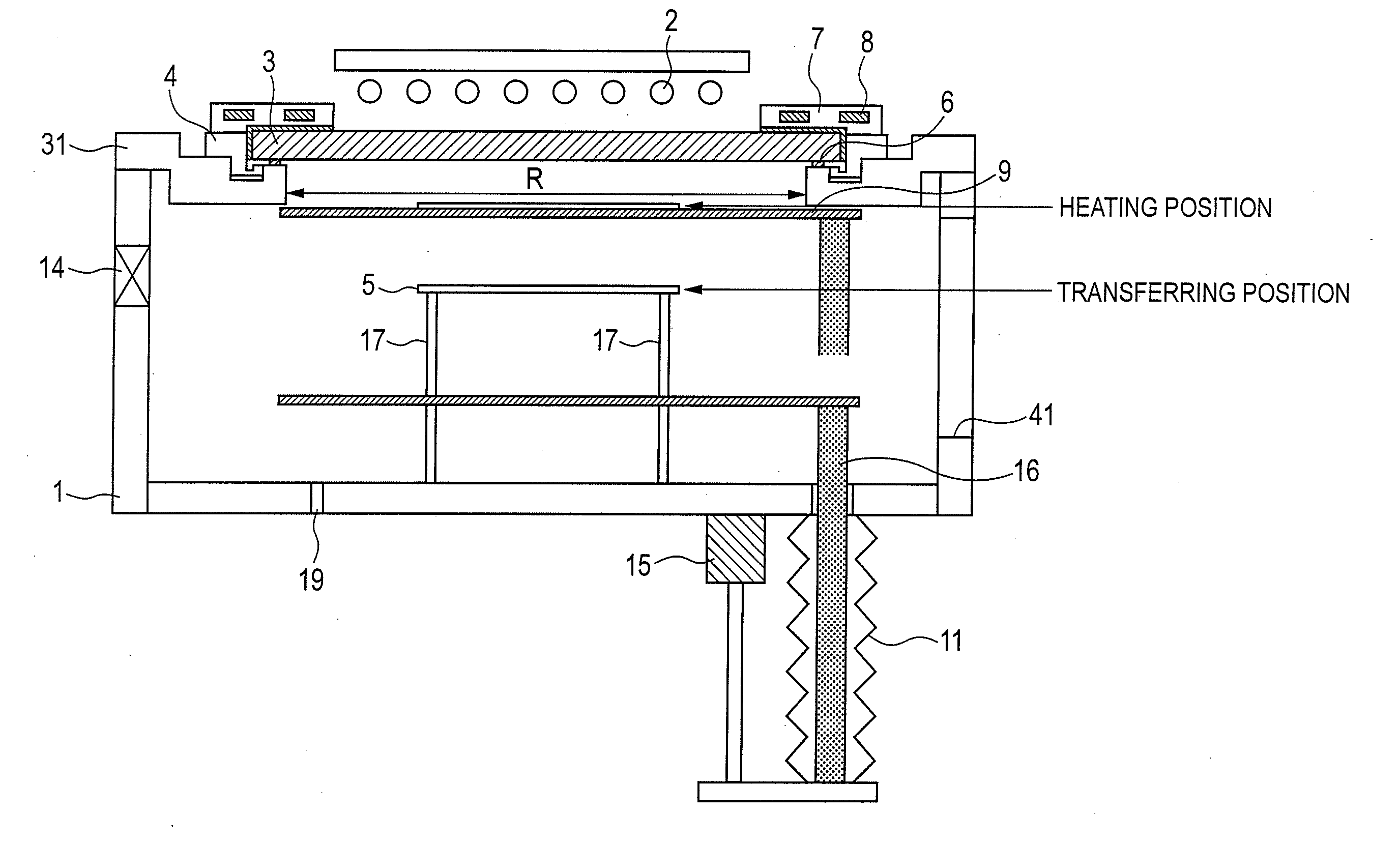

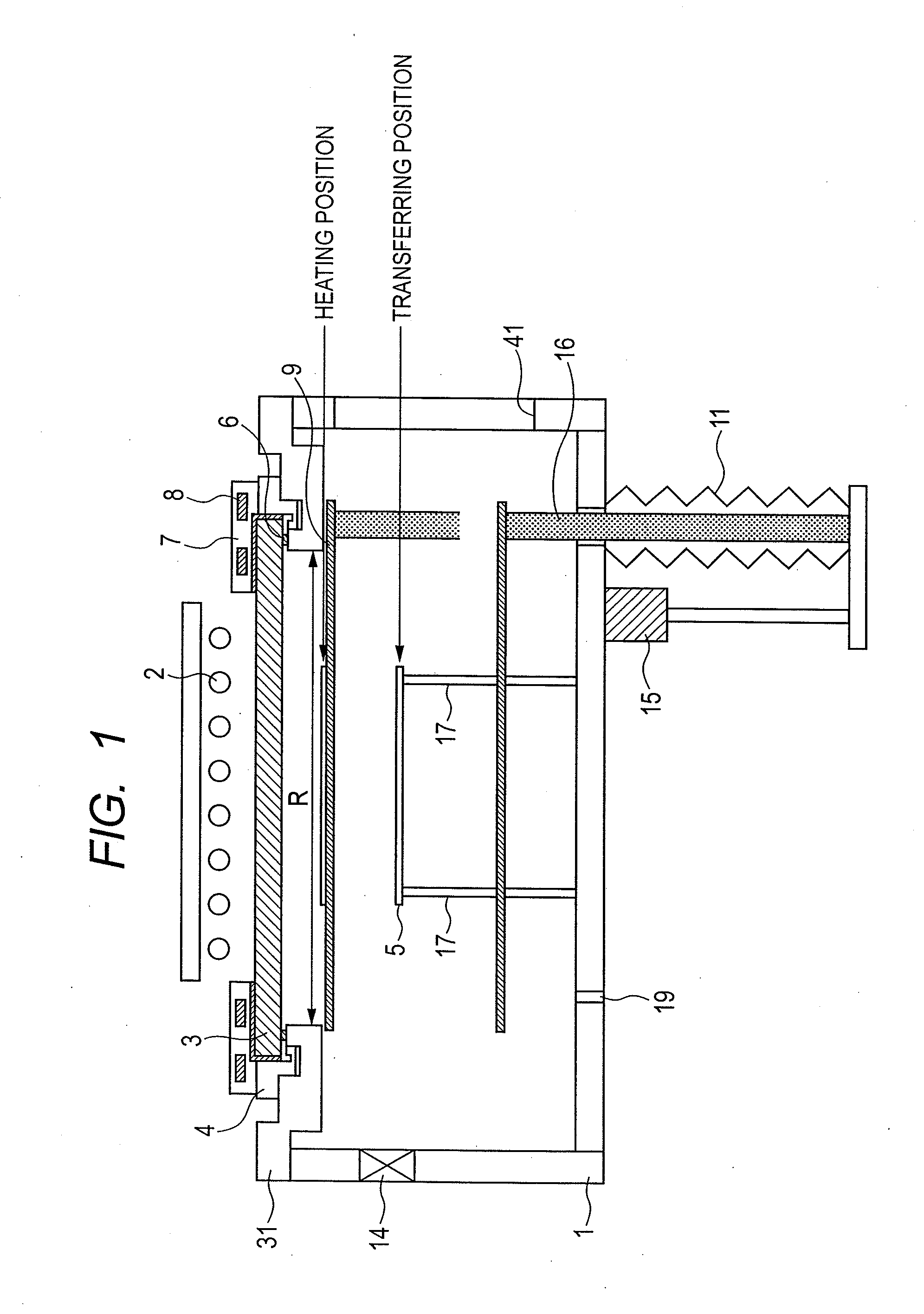

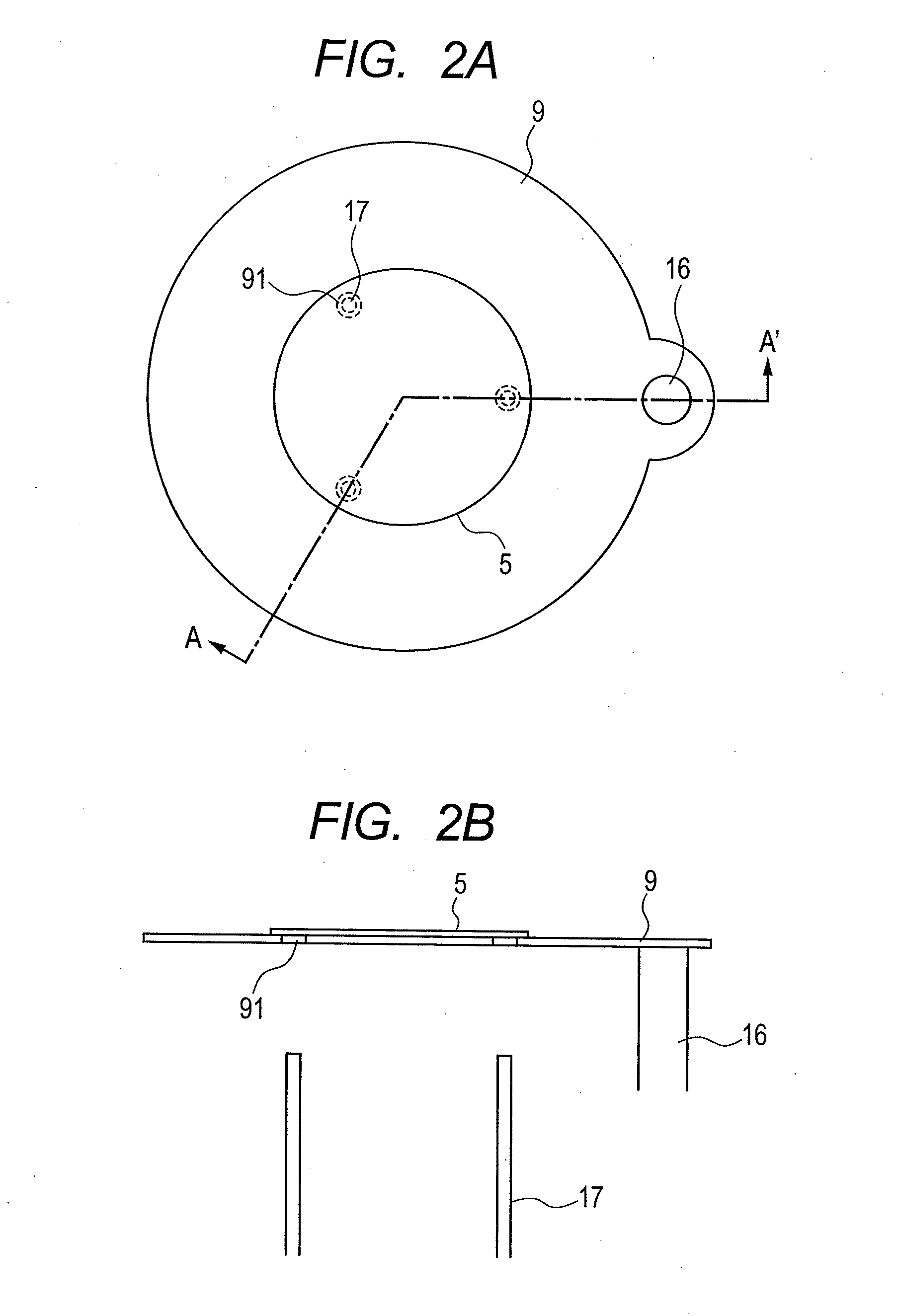

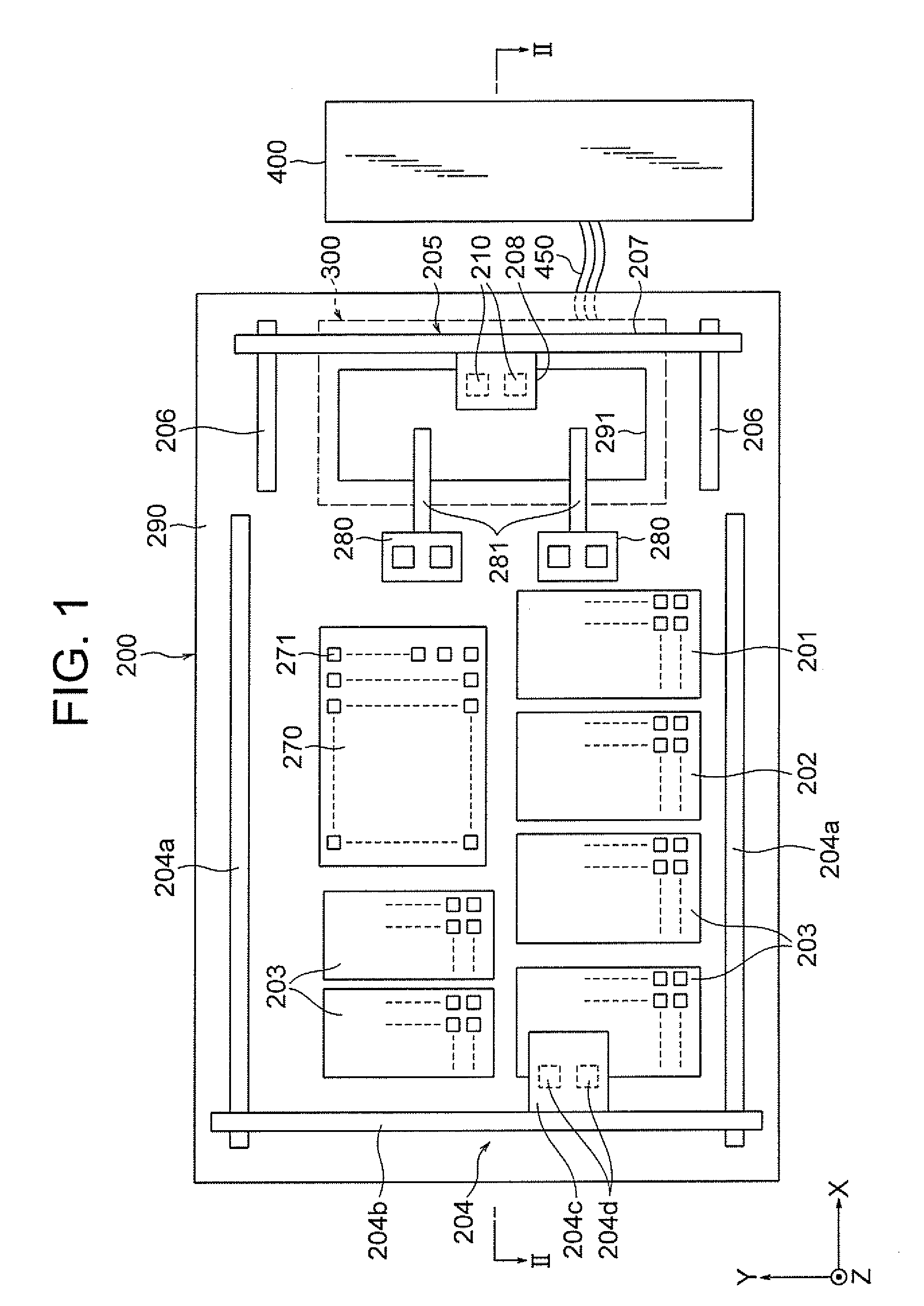

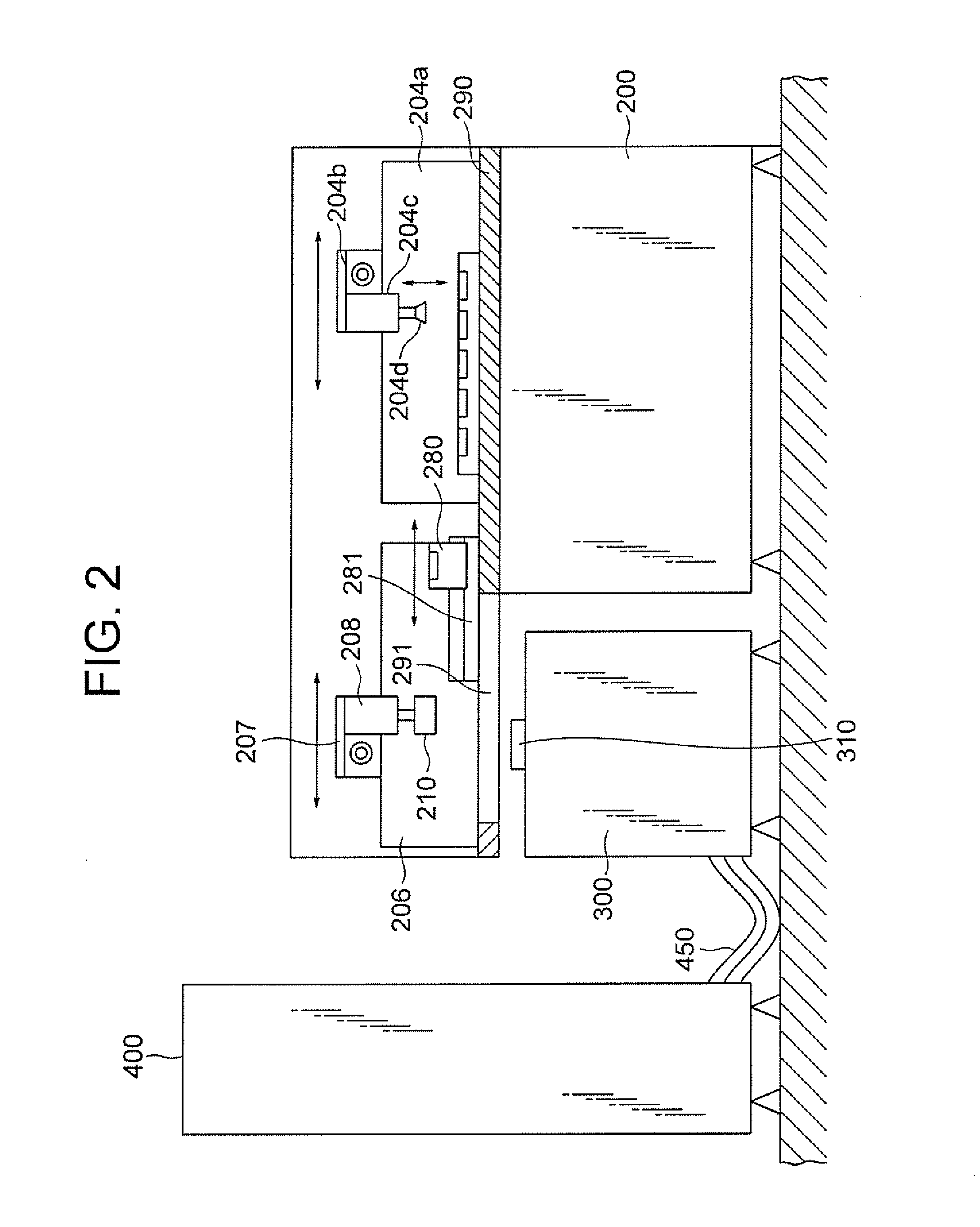

Vacuum heating and cooling apparatus

InactiveUS20110253037A1Heating fastIncrease vacuumCellsLiquid surface applicatorsAtmospheric airOptoelectronics

The vacuum heating and cooling apparatus can rapidly heat and cool only the substrate after film-forming treatment while maintaining high vacuum. The temperature rise of members in the chamber with time caused by accumulation of heat is suppressed, and the variation of temperature between substrates is decreased. In an embodiment, the heating and cooling apparatus for heating and cooling a substrate in a vacuum, includes: a vacuum chamber; a radiation energy source positioned at the vacuum chamber on an atmosphere side for emitting a heating light; an incidence part for causing the heating light from the radiation energy source to enter the vacuum chamber; a substrate-holding member for holding the substrate; and a substrate-transfer mechanism for transferring the substrate held by the substrate-holding member in a heating state to a heating position proximal to the radiation energy source, and transferring the substrate and the substrate-holding member in a non-heating state to a non-heating position distant from the radiation energy source, wherein the substrate-holding member has a plate shape for placing the substrate thereon and has an outer shape larger than that of the incidence part for causing the heating light to enter the vacuum chamber.

Owner:CANON ANELVA CORP

Ink jet ink composition and method for security marking

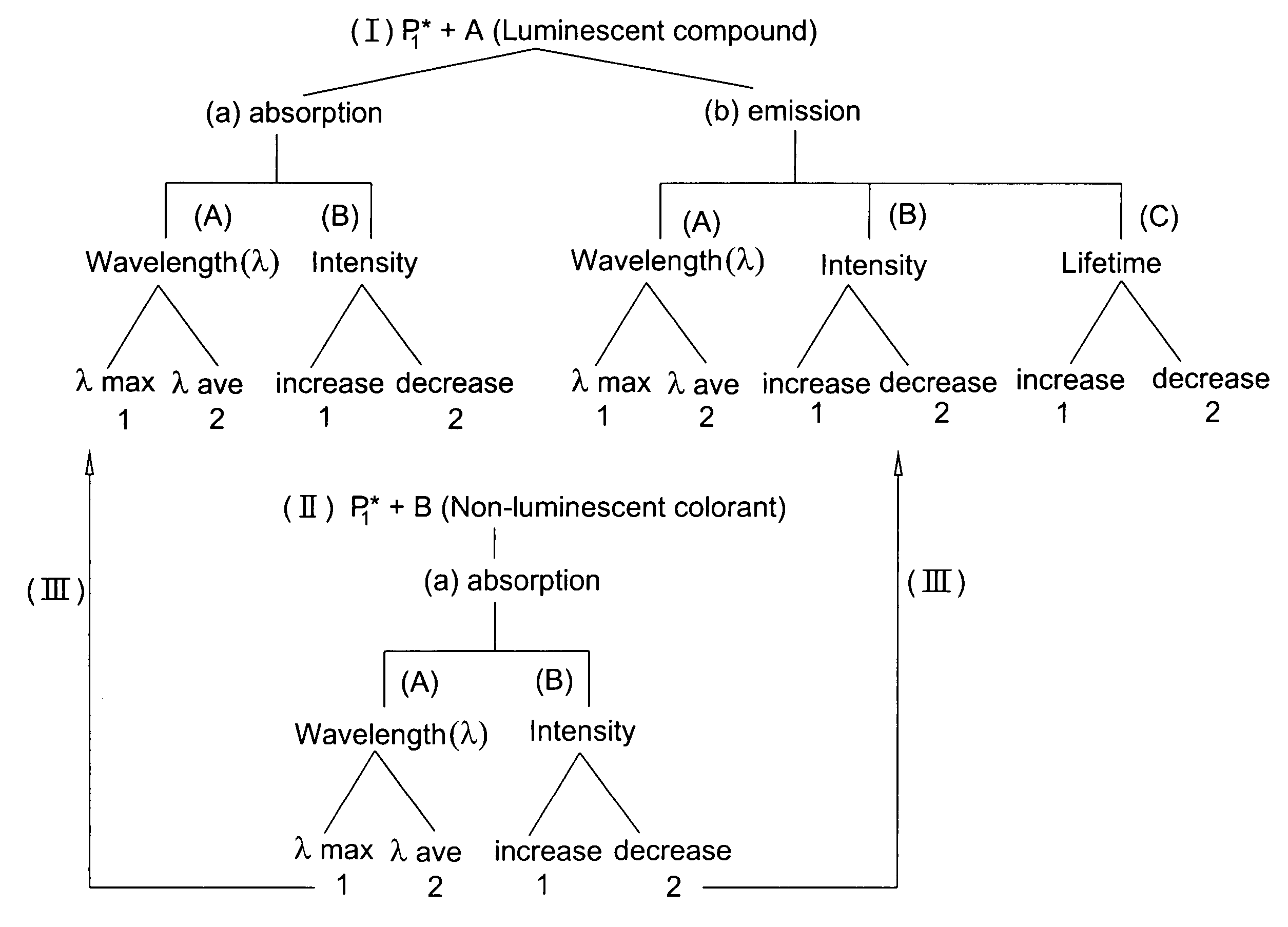

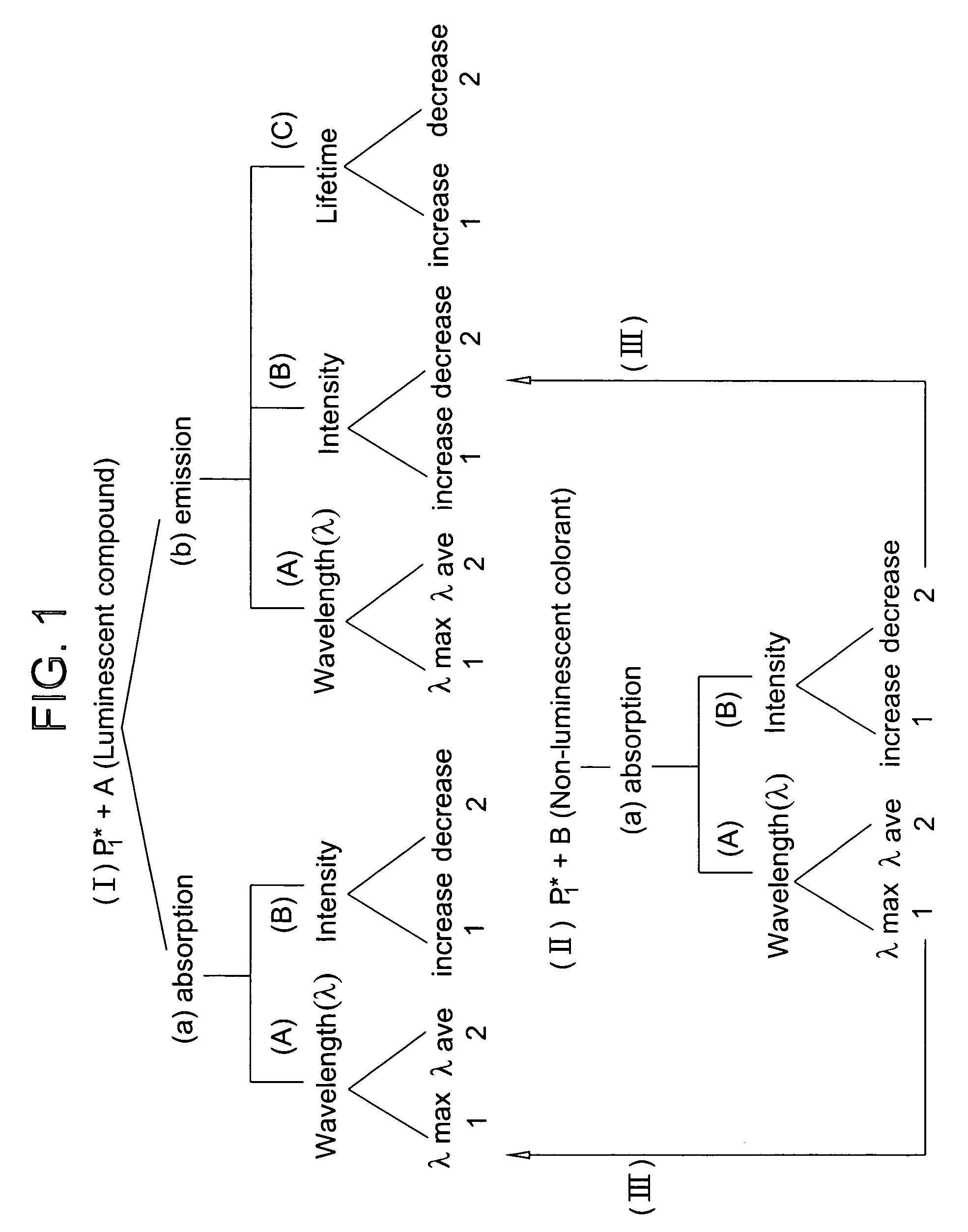

ActiveUS7147801B2Suitable for printingLuminescence quenchingNon-fibrous pulp additionLayered productsSolventLuminescence

Disclosed is an ink composition suitable for ink jet printing comprising a luminescent compound, a solvent, and an energy active compound, and optionally a non-luminescent colorant. The energy active compound, when exposed to energy, generates one or more active species that can react with the luminescent compound to alter one or more of the characteristics of the luminescent compound. The luminescent compound can be colored or colorless. Also disclosed is a method for marking substrates comprising providing a mark comprising a luminescent compound and an energy active compound. Further disclosed is a jet ink composition suitable for printing on substrates authentication or security marks which can be rendered unreadable. The luminescence of the mark is quenched and the visible color is changed when irradiated with a light.

Owner:VIDEOJET TECH INC

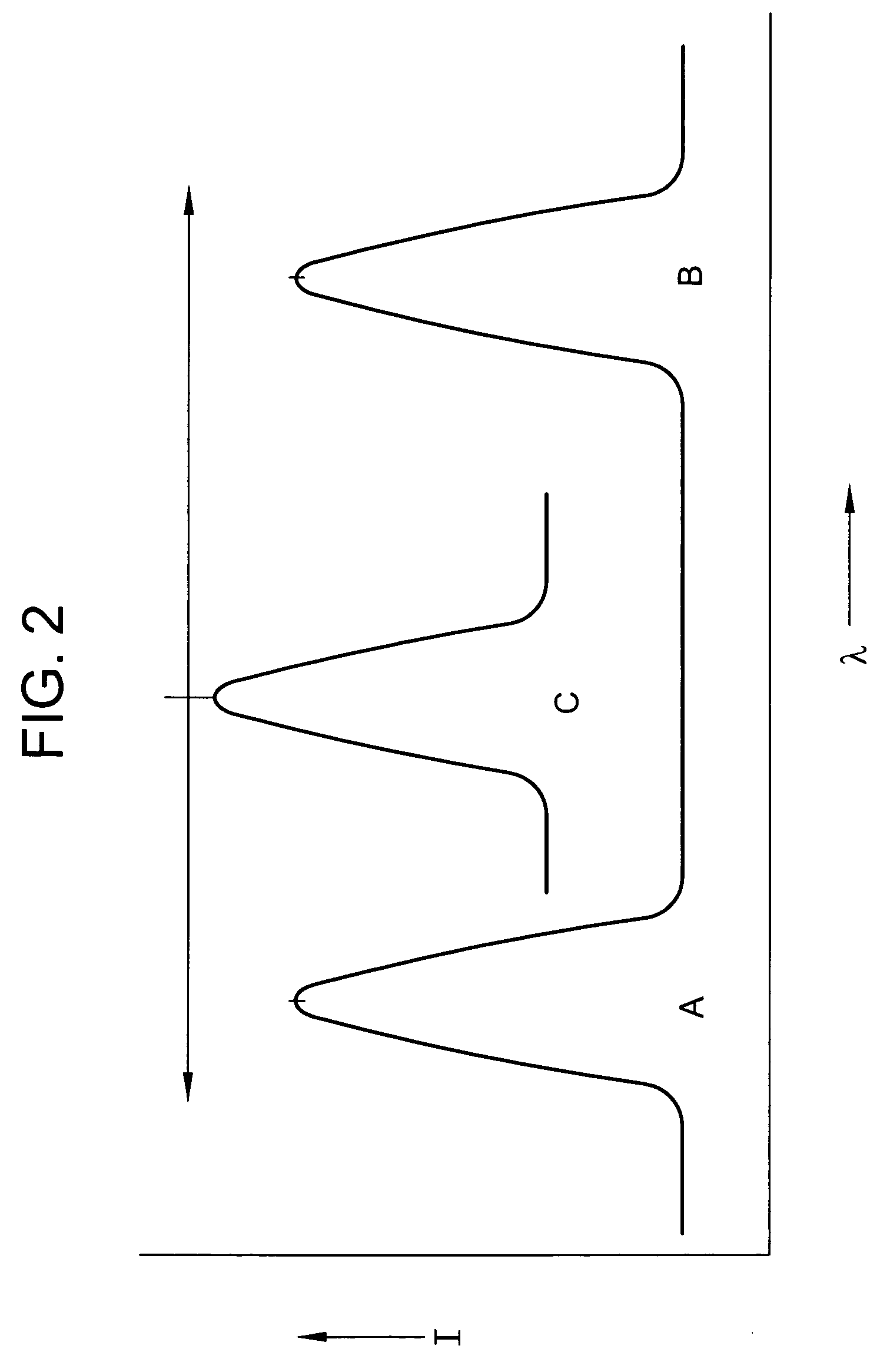

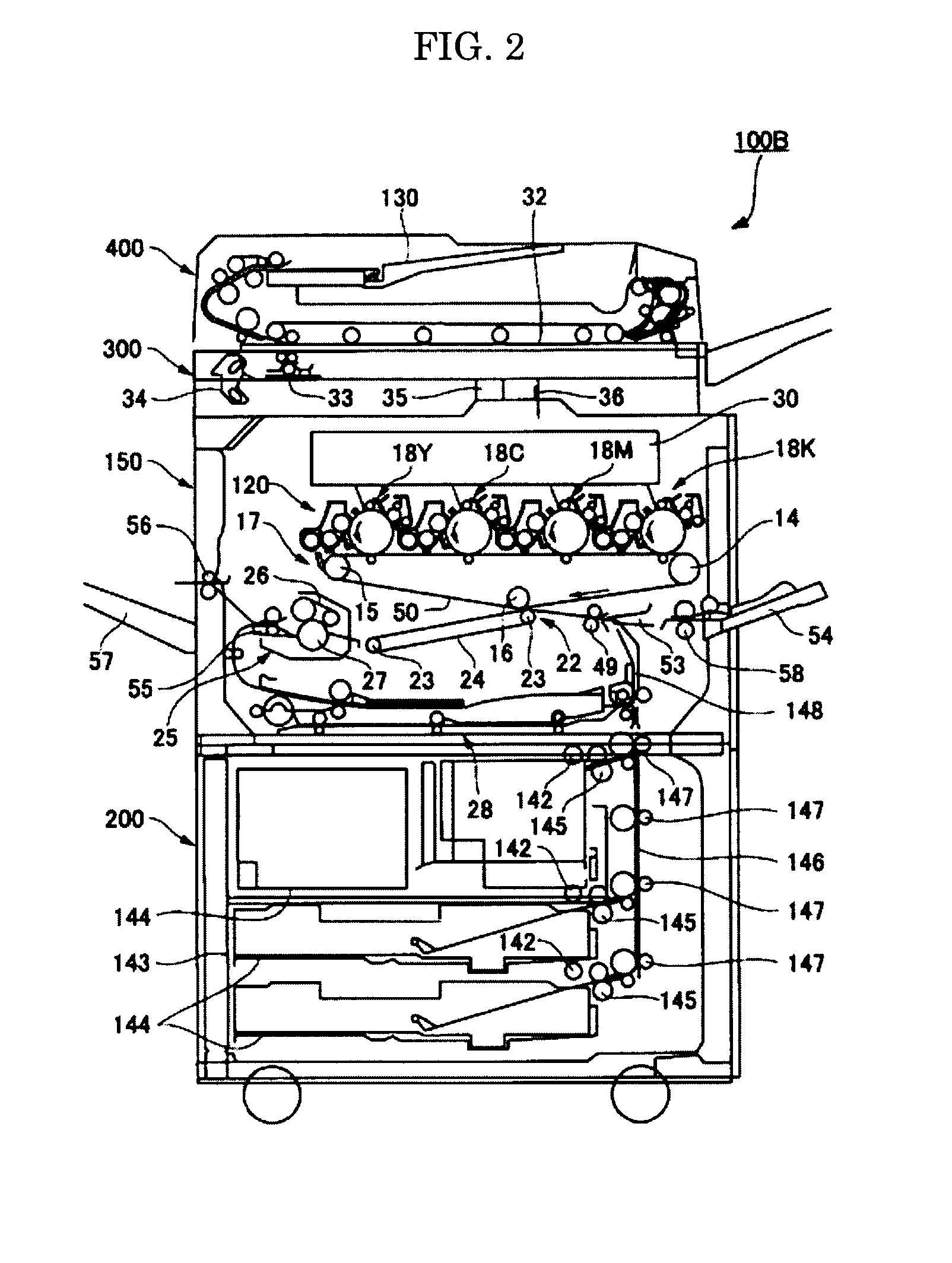

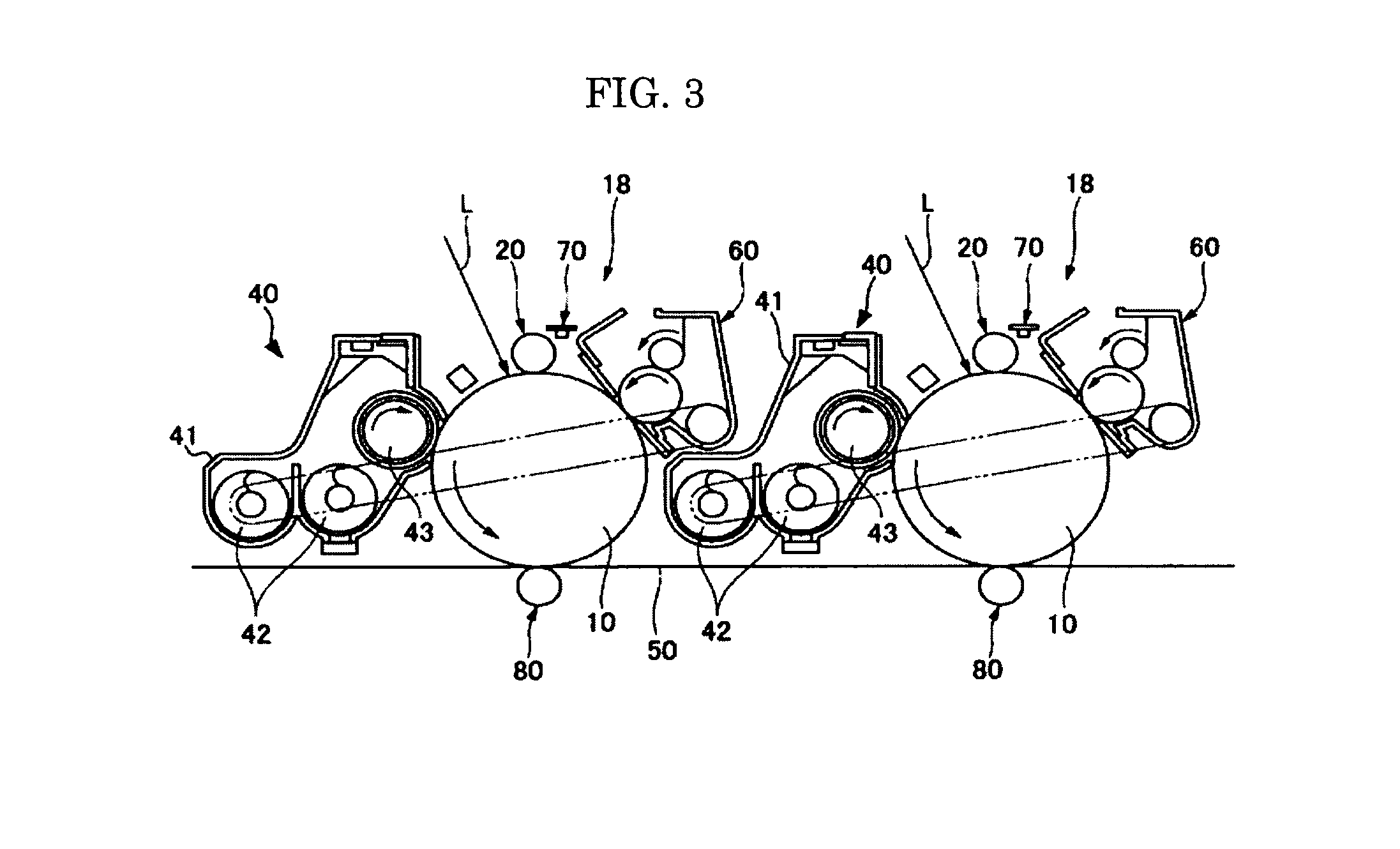

Toner for developing latent electrostatic images, developer, developer container housing developer therein, process cartridge, image forming apparatus and image forming method

InactiveUS20120052431A1Excellent low temperature fixing abilityDesirable offset resistanceElectrographic process apparatusDevelopersEngineeringTEMPERATURE ELEVATION

To provide a toner, containing: a crystalline polyester resin; and a non-crystalline polyester resin, wherein the crystalline polyester resin has a melting point of 60° C. to 80° C., and wherein the toner satisfies the relationship represented by the following formula: (W1−W1′) / W1<0.50, where W1 is a temperature width at a 1 / 3 height of a height of an endothermic peak of the crystalline polyester resin at the time of an initial temperature elevation on a DSC curve of the toner as measured by differential scanning calorimetry, and W1′ is a temperature width at a 1 / 3 height of a height of an endothermic peak of the crystalline polyester resin after the toner has been heated at 50° C. for 24 hours.

Owner:RICOH KK

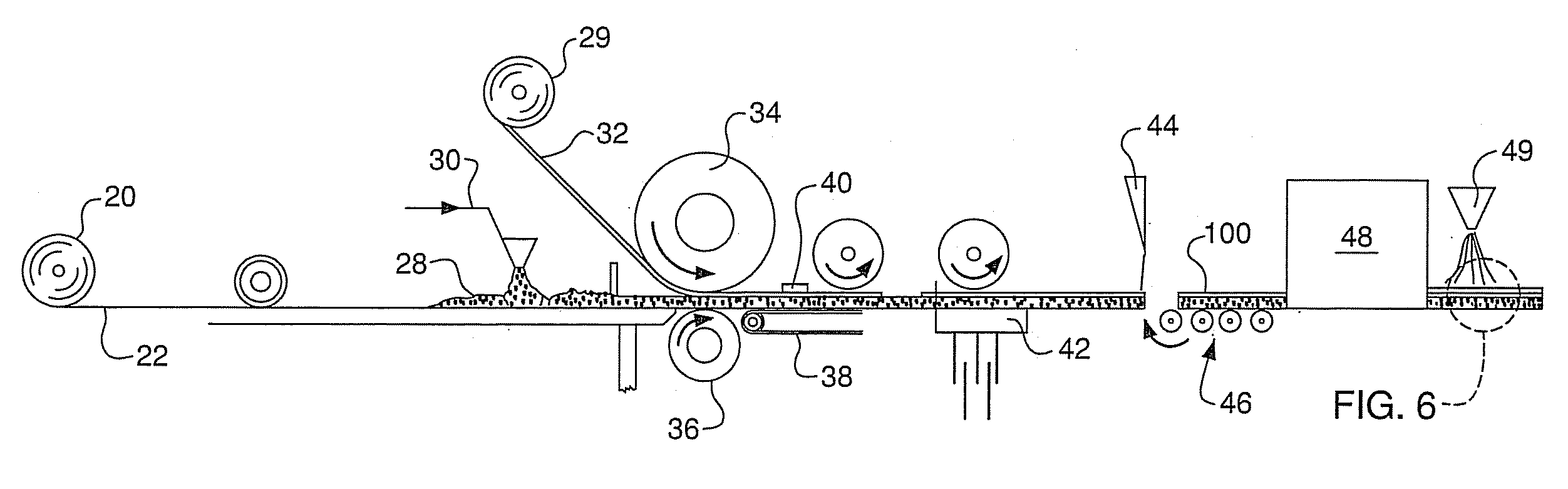

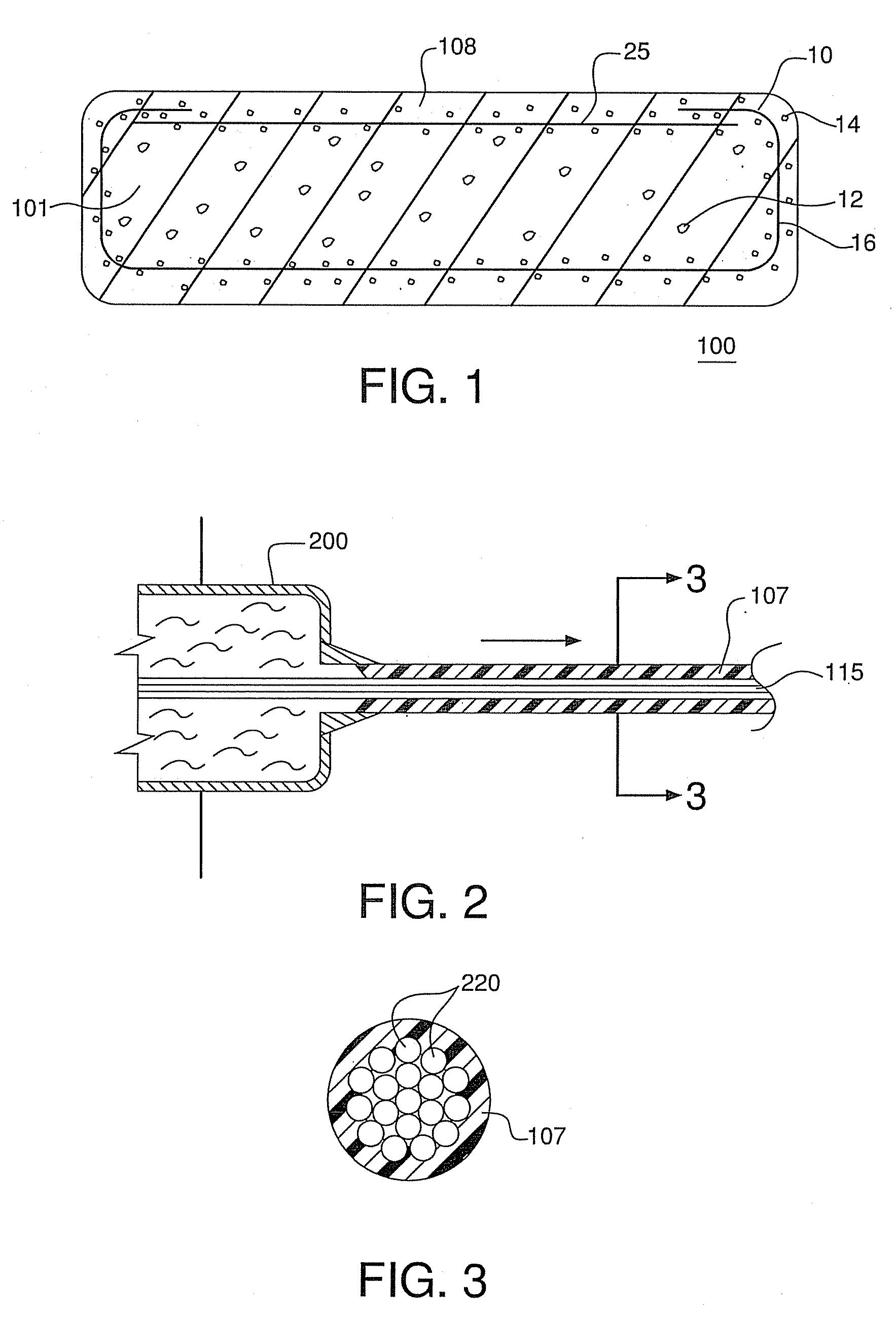

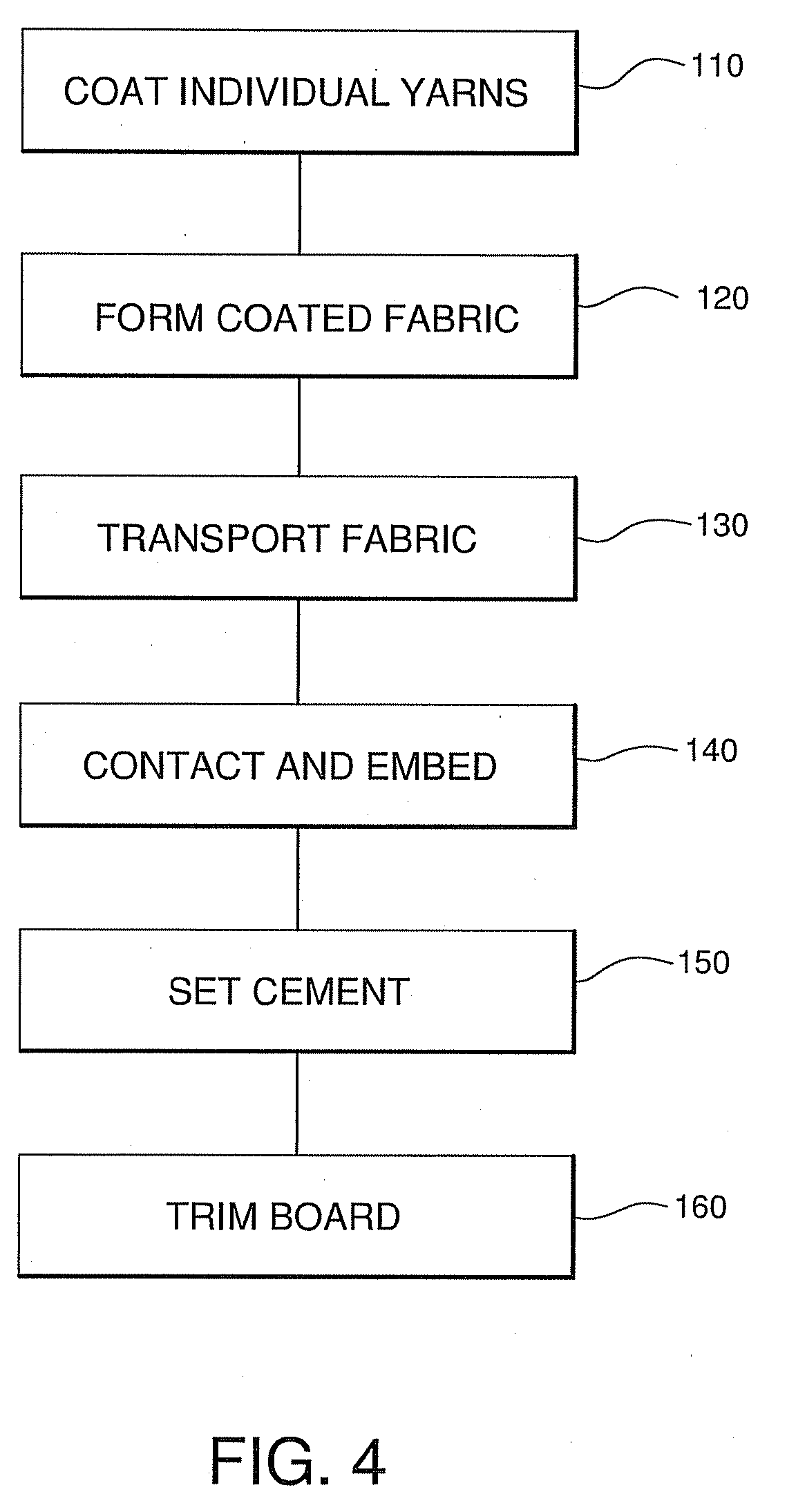

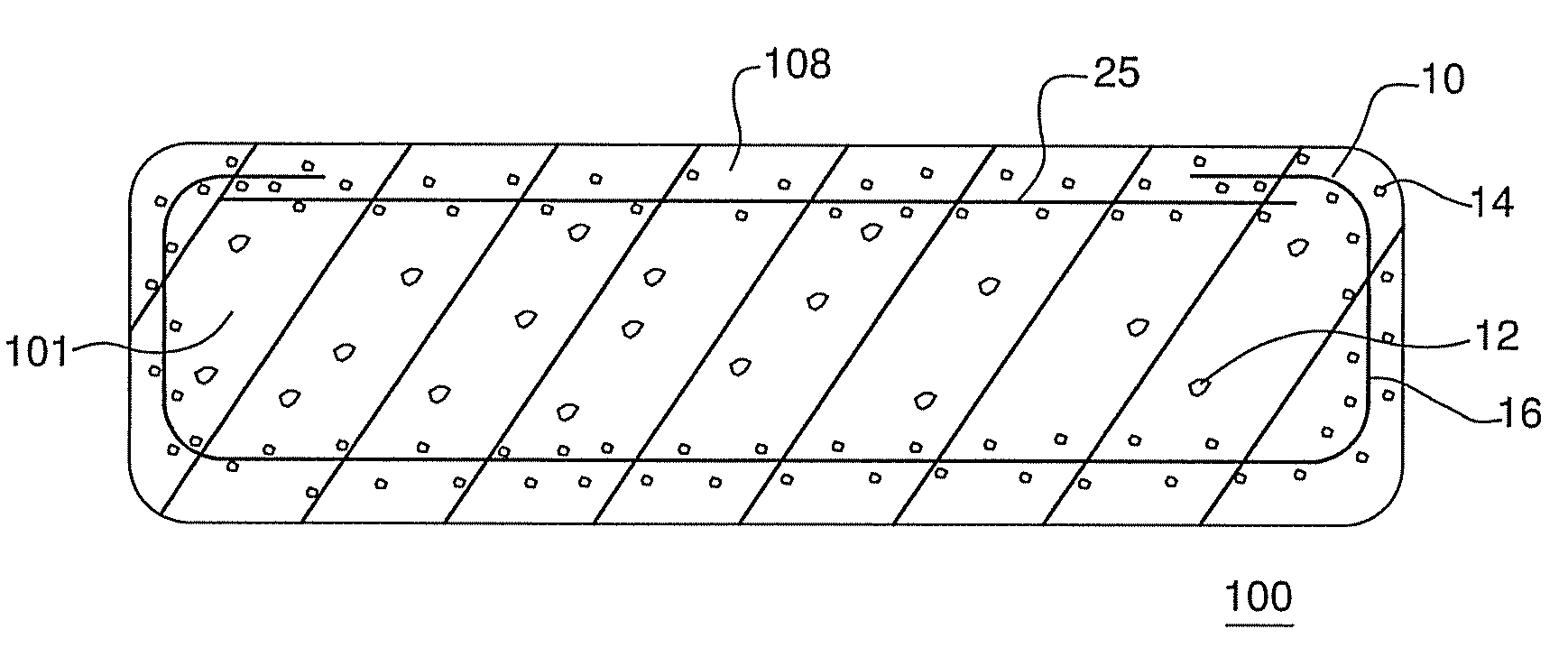

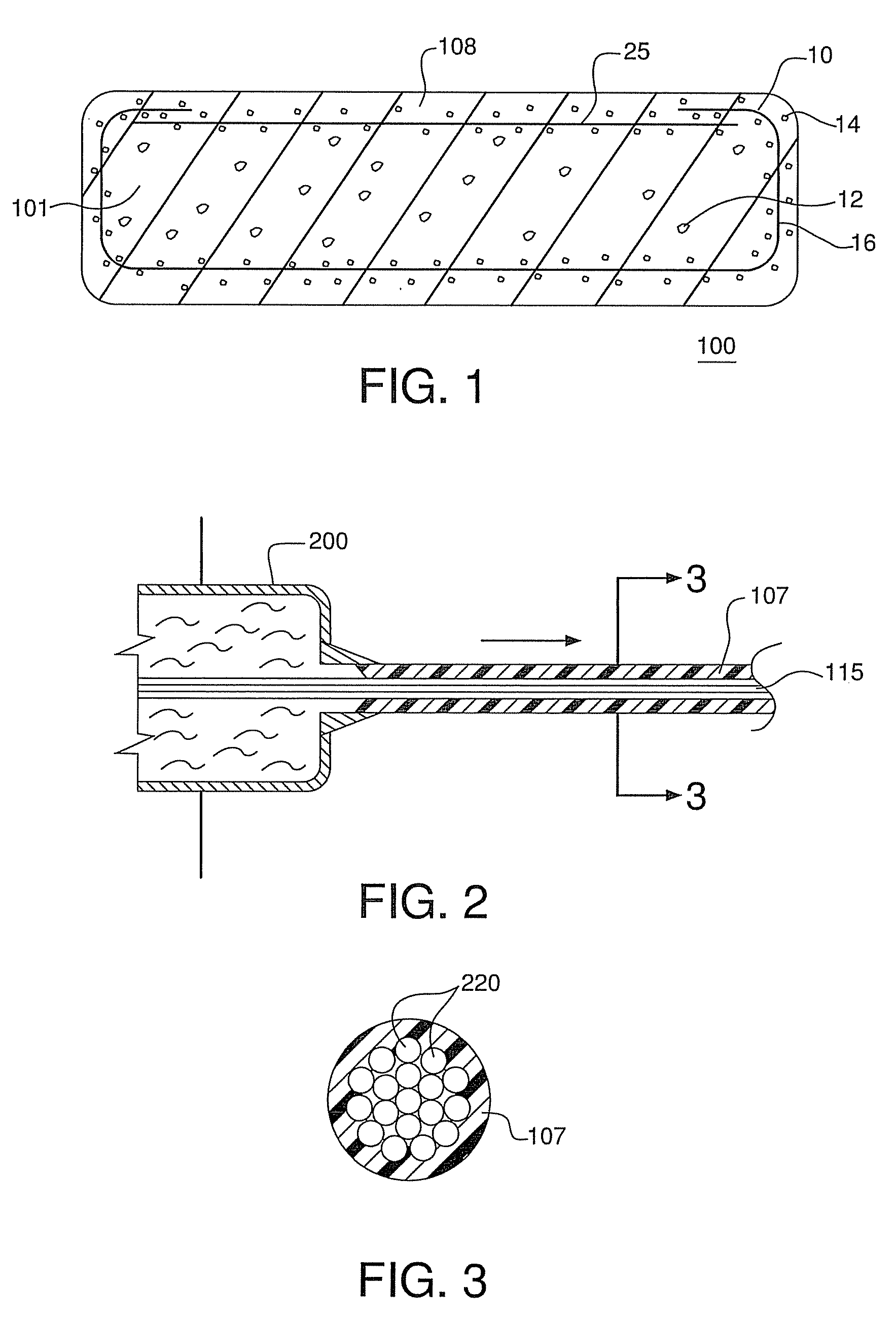

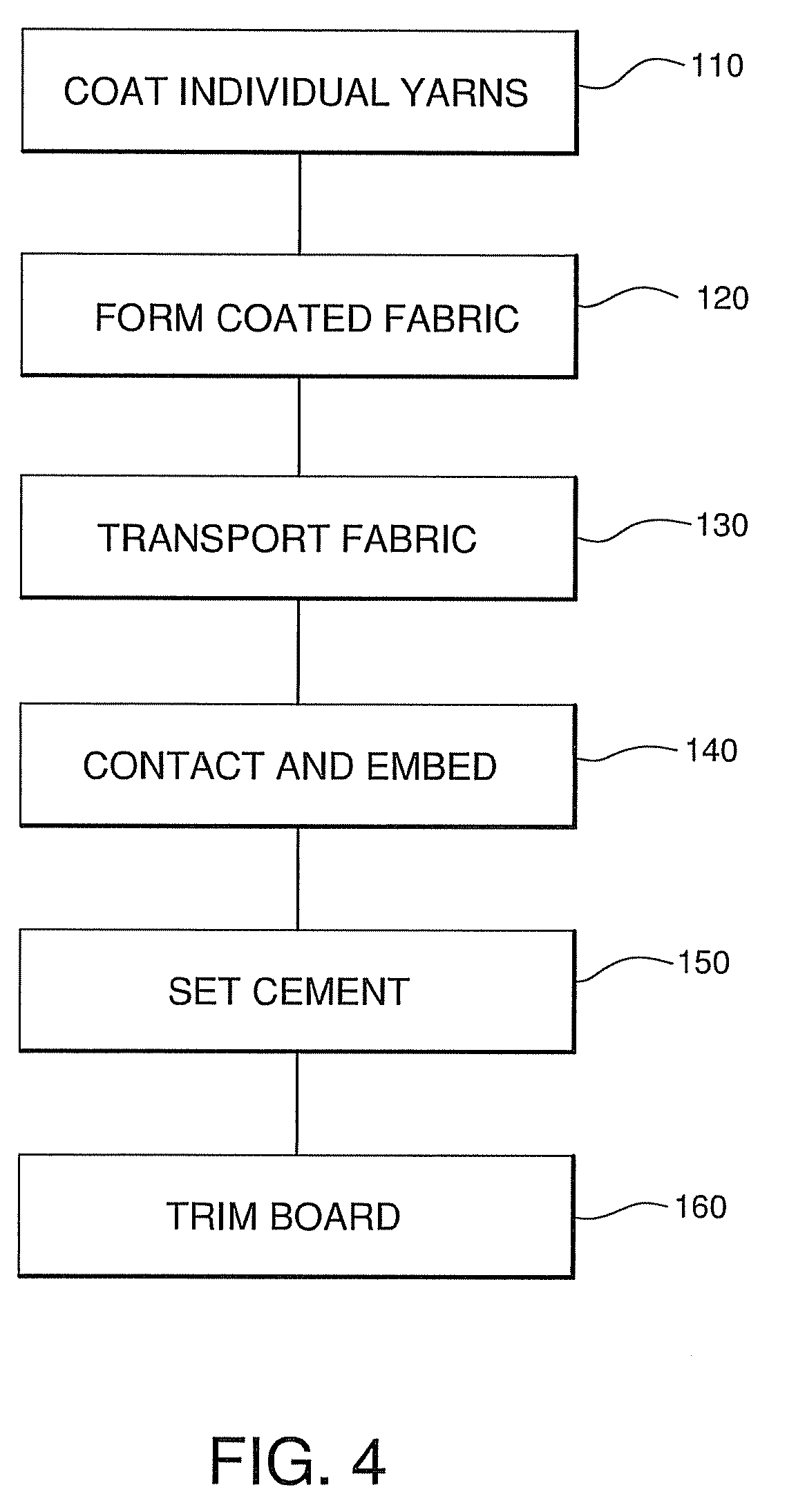

Polyolefin coated fabric reinforcement and cementitious boards reinforced with same

ActiveUS20100151757A1Increase line speedEasy to crackGlass making apparatusConstruction materialGlass fiberYarn

The present invention provides glass fiber fabric reinforcements, cement boards, and glass fiber coatings for such reinforcements. The glass fiber fabric reinforcement includes a glass fabric containing multiple yarns containing glass filaments and a polymeric coating disposed onto the multiple yarns to form a coated glass fabric. The polymeric coating comprises a polyolefin based copolymer composition whereby the glass fabric has a Gurley Stiffness measurement of about 100-3000 mg and an ASTM D 638 (2% Secant) modulus of compression of about 1-100 MPa. The reinforcement is sufficiently drapable and lacking in shape memory so as to be curved around the edge of a cement board during the manufacture of same.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Polyolefin coated fabric reinforcement and cementitious boards reinforced with same

The present invention provides glass fiber fabric reinforcements, cement boards, and glass fiber coatings for such reinforcements. The glass fiber fabric reinforcement includes a glass fabric containing multiple yarns containing glass filaments and a polymeric coating disposed onto the multiple yarns to form a coated glass fabric. The polymeric coating comprises a polyolefin based copolymer composition whereby the glass fabric has a Gurley Stiffness measurement of about 100-3000 mg and an ASTM D 638 (2% Secant) modulus of compression of about 1-100 MPa. The reinforcement is sufficiently drapable and lacking in shape memory so as to be curved around the edge of a cement board during the manufacture of same.

Owner:SAINT GOBAIN ADFORS CANADA LTD

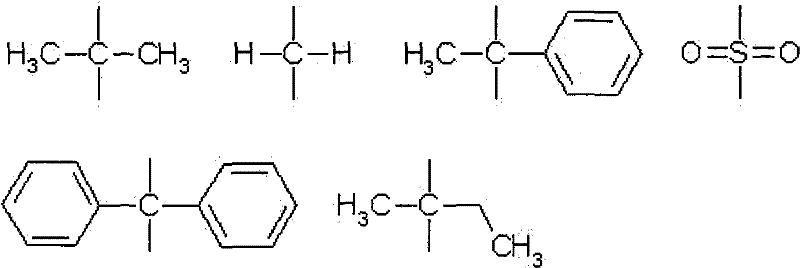

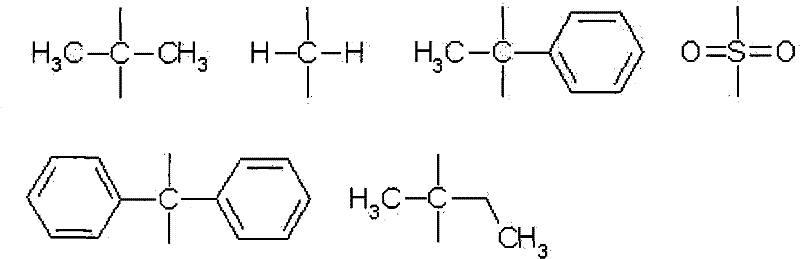

Resin composition as well as semi-solidified rubber sheet, laminating board and circuit board containing same

ActiveCN102206397AImprove flame retardant performanceImprove heat stabilitySynthetic resin layered productsGlass/slag layered productsCross-linkSheet film

The invention relates to a resin composition which mainly comprises epoxy resin, a hardening accelerator, a cross-linking agent and phosphorus-containing resin, wherein the phosphorus-containing resin is bisphenol phenolic resin or phenolic resin substituted by a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide or derivatives thereof. The resin composition can be applied to semi-solidified rubber sheets or insulating layers of circuit boards. In addition, the invention relates to a semi-solidified rubber sheet, a laminating board and a circuit board containing the resin composition.

Owner:ELITE MATERIAL

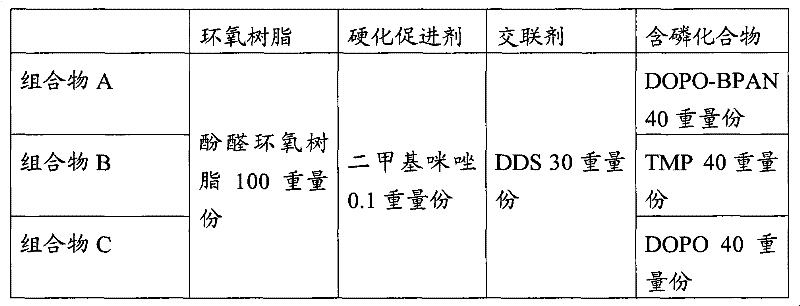

Contact pusher, contact arm, and electronic device test apparatus

InactiveUS20070200555A1Heat stableEasy to moveSemiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringElectronic equipment

A contact pusher (220a) attached to the front end of a contact arm (210) bringing an IC device (10) into contact with a contact part of a test head and pushing the IC device (10) is provided with a suction pad (240) for picking up and holding an IC device (10), a first press part (250) for pushing against a package (11) of an IC device (10), a second press part (260) for pushing against terminals (12) of the IC device (10), and a base part (230) for conducting heat to the first press part (250), the first press part (250) and the base part (230) contacting each other and the first press part (250) provided to be able to finely move relative to the base part (230).

Owner:ADVANTEST CORP

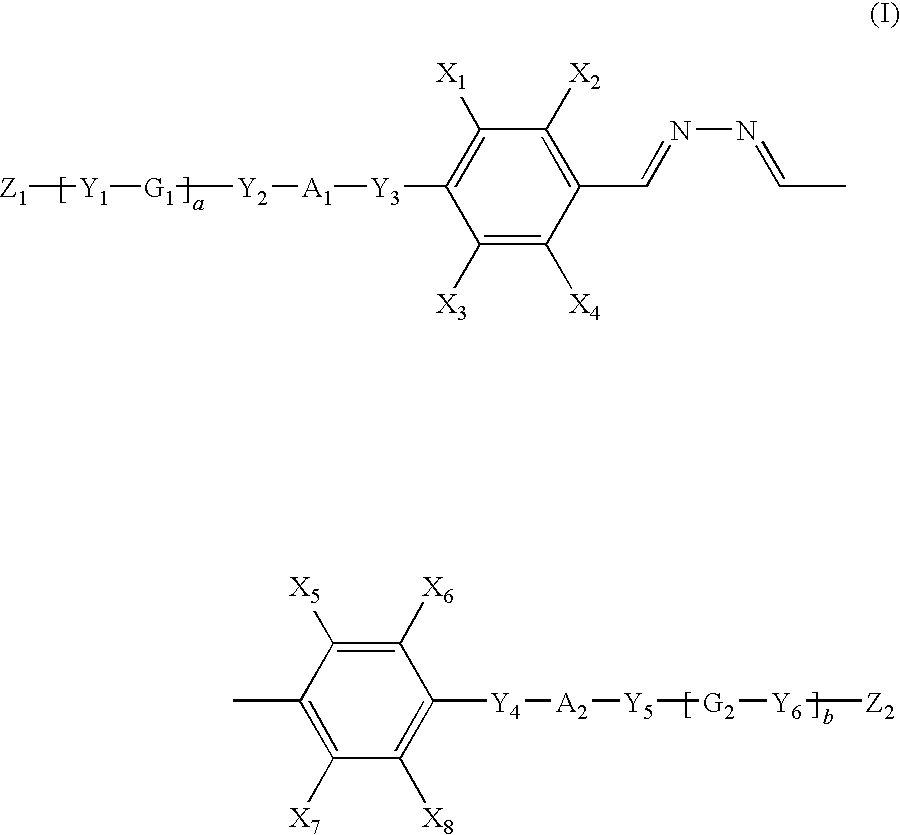

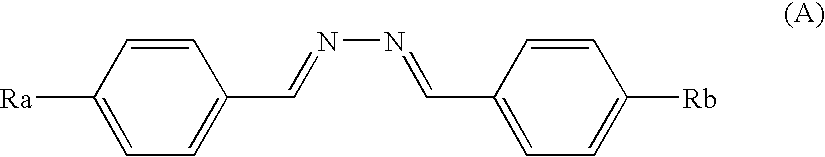

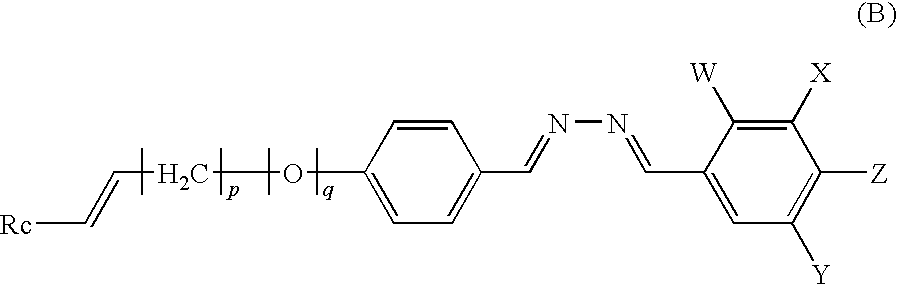

Polymerizable liquid crystal compound, polymerizable liquid crystal composition, liquid crystalline polymer, and optical anisotropic article

ActiveUS20100258764A1Low production costWide selectionLiquid crystal compositionsOrganic chemistryCrystallographyLiquid crystalline

A polymerizable liquid crystal compound shown by the following formula (I), a polymerizable liquid crystal composition that includes the polymerizable liquid crystal compound and a chiral compound polymerizable with the polymerizable liquid crystal compound, a liquid crystalline polymer obtained by polymerizing the polymerizable liquid crystal compound or the polymerizable liquid crystal composition, and an optical anisotropic article that includes the liquid crystalline polymer. The polymerizable liquid crystal compound shows a liquid crystal phase over a wider temperature range, is chemically stable, can be inexpensively produced, and has a wide selective reflection wavelength band Δλ (i.e., a large value Δn). The polymerizable liquid crystal composition includes the polymerizable liquid crystal compound, the liquid crystalline polymer is obtained by polymerizing the polymerizable liquid crystal compound or the polymerizable liquid crystal composition, and the optical anisotropic article includes the liquid crystalline polymer.wherein Y1 to Y6 represent —O—, —O—C(═O)—, —C(═O)—O—, or the like, G1 and G2 represent divalent aliphatic groups having 1 to 20 carbon atoms, Z1 and Z2 represent an alkenyl group having 2 to 10 carbon atoms or the like, A1 and A2 represent divalent organic groups A having 1 to 30 carbon atoms, X1 to X8 represent a hydrogen atom or the like, and a and b represent 0 or 1.

Owner:ZEON CORP

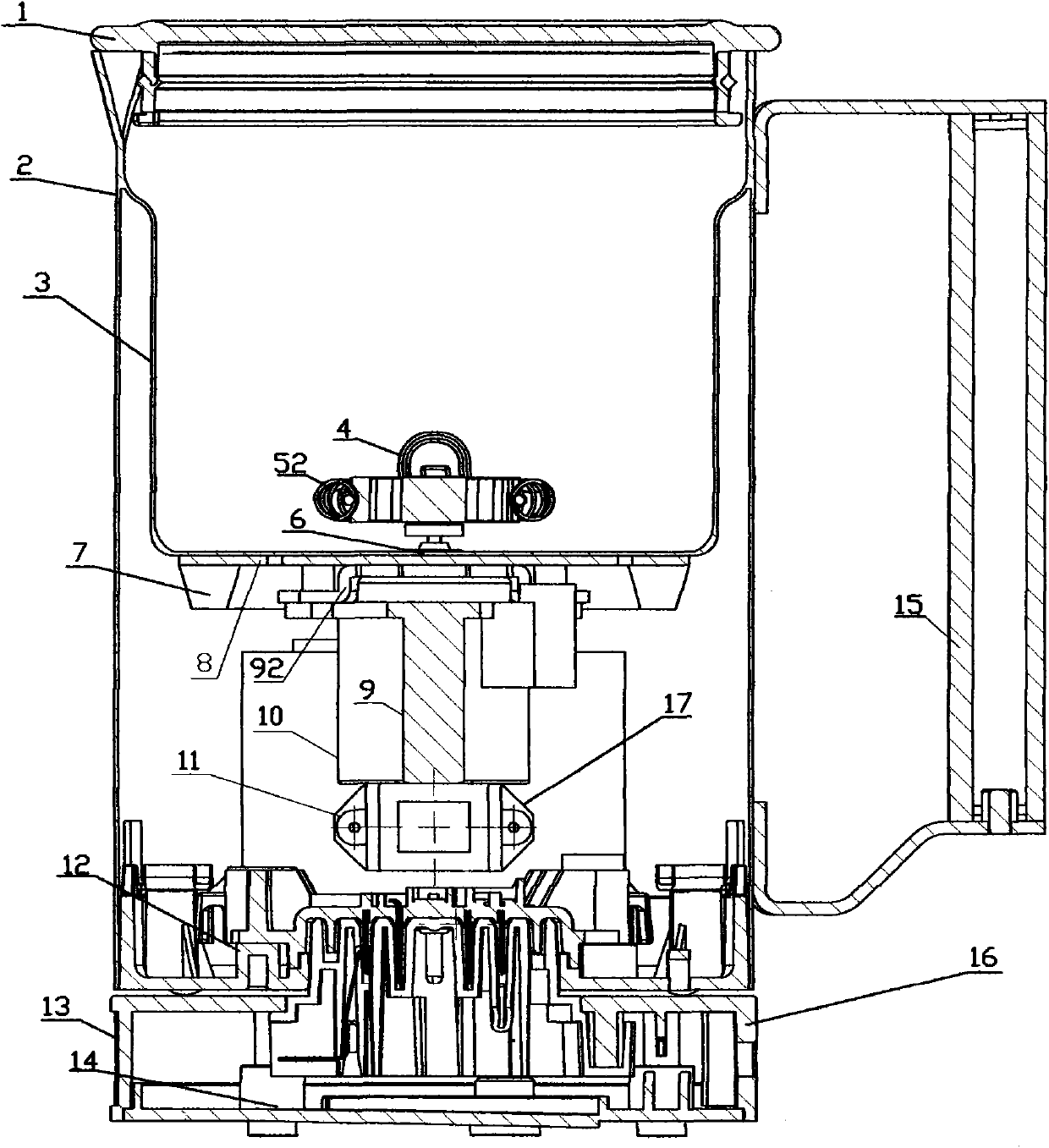

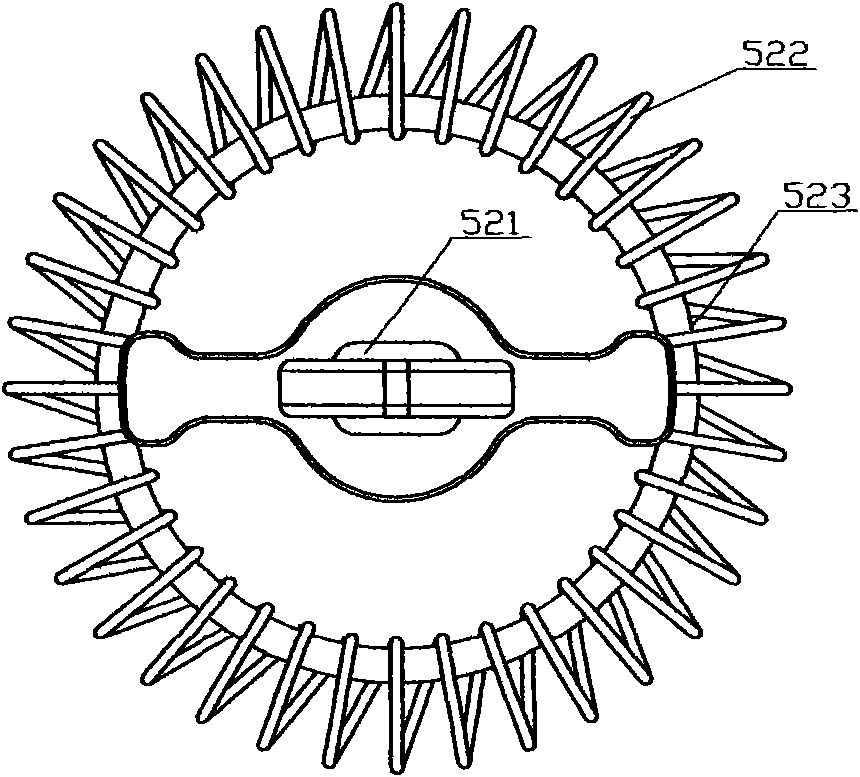

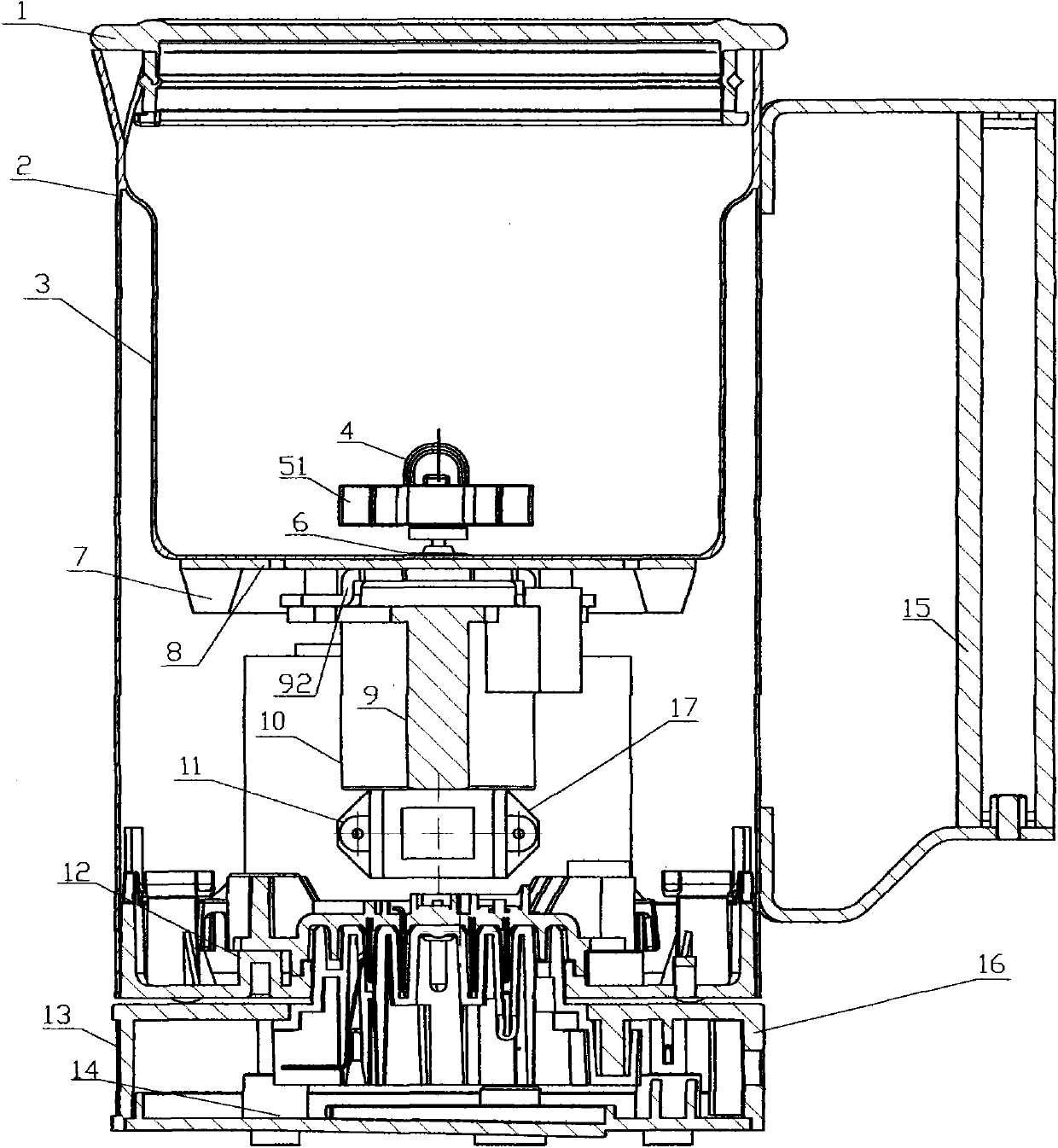

Milk foam machine directly driven by motor

ActiveCN101904700ASimple structureGood shaft seal performanceKitchen equipmentElectric machineLiquid state

Owner:GUANGDONG MASTER ELECTRICAL APPLIANCE CO LTD

Production technology of methyl naphthalenesulfonic acid-methyl aldehyde condensation compound

InactiveCN101386587ALow impurity contentHigh sulfonation efficiencyOrganic chemistryOrganic dyesMethyl aldehydeSulfate

The present invention provides a method for preparing a condensation compound of methylol naphthalene sulphonic acid formaldehyde. The method comprises the following steps that methylnaphthalene is adopted as the material, and is sulfonated with 104.5 percent of fuming sulfuric acid in advance; the sulfonated product is condensed with formaldehyde; and, finally the pH is adjusted to between 6 and 9 by liquid alkali, and thus the methylol naphthalene sulphonic acid formaldehyde condensation compound is obtained. The method does not need to add an azeotrope former, and does not need to add and distill of sulfonated bodies every time. The process is simplified, the manufacturing cost is saved, and the impurity content in the product is reduced. Additionally, the 104.5 percent of fuming acid is adopted to sulfonate. Not only the efficiency of methylnaphthalene sulfuration is improved, but also the total acidity of the condensation reaction process is reduced. The subsequent process completely adopts liquid alkali. No calcium sulfate calcium offscum is produced. Compared with the adoption of concentrated sulfuric acid, the quality of the product is equivalent in dispersancy, calcium and magnesium ions are not produced, and the product is stable in heat resistance.

Owner:ZHEJIANG LONGSHENG GROUP +1

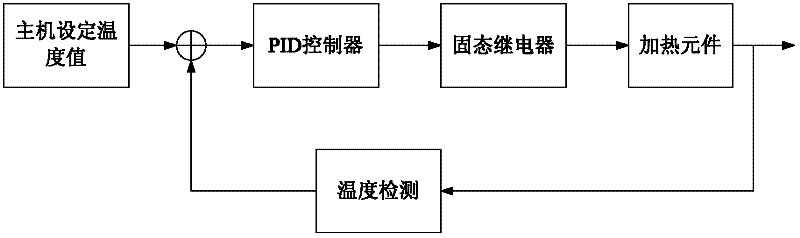

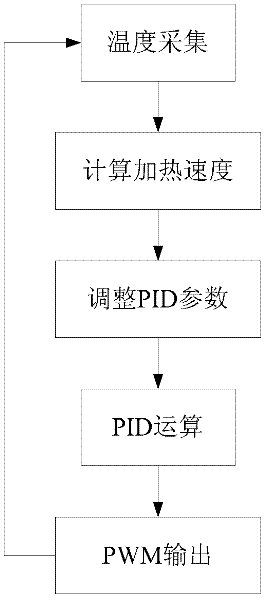

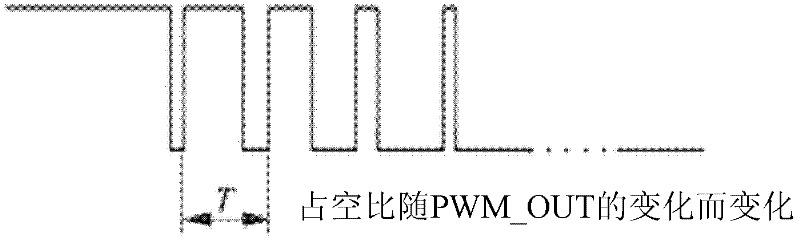

Self-adaptive PID (proportion integration differentiation) temperature control method

InactiveCN102650890AHeat stableNo overshootTemperatue controlAdaptive controlTemperature controlSilicon-controlled rectifier

The invention discloses a self-adaptive PID (proportion integration differentiation) temperature control method, which comprises the following steps of: step 1, collecting a temperature in real time; step 2, calculating a heating speed in real time; step 3, adjusting a PID parameter according to the real-time heating speed; step 4, carrying out PID arithmetic; and step 5, converting the result of the PID arithmetic into continuous control on a time quantum, and directly controlling the switching on and the switching off of the working current of a heater strip by using a bidirectional silicon controlled rectifier. The technical effects of the self-adaptive PID temperature control method lie in that the heating speed is calculated in a heating process; a control parameter is adjusted dynamically, so that the heating process is more stable; the algorithm is subjected to multiple tests on a plurality of different instruments at different ambient temperatures; results show that an appointed temperature can be stably achieved in a heating way; an overshoot phenomenon cannot appear in the heating process; and the precision meets a system requirement.

Owner:湖南迪斯生物技术股份有限公司

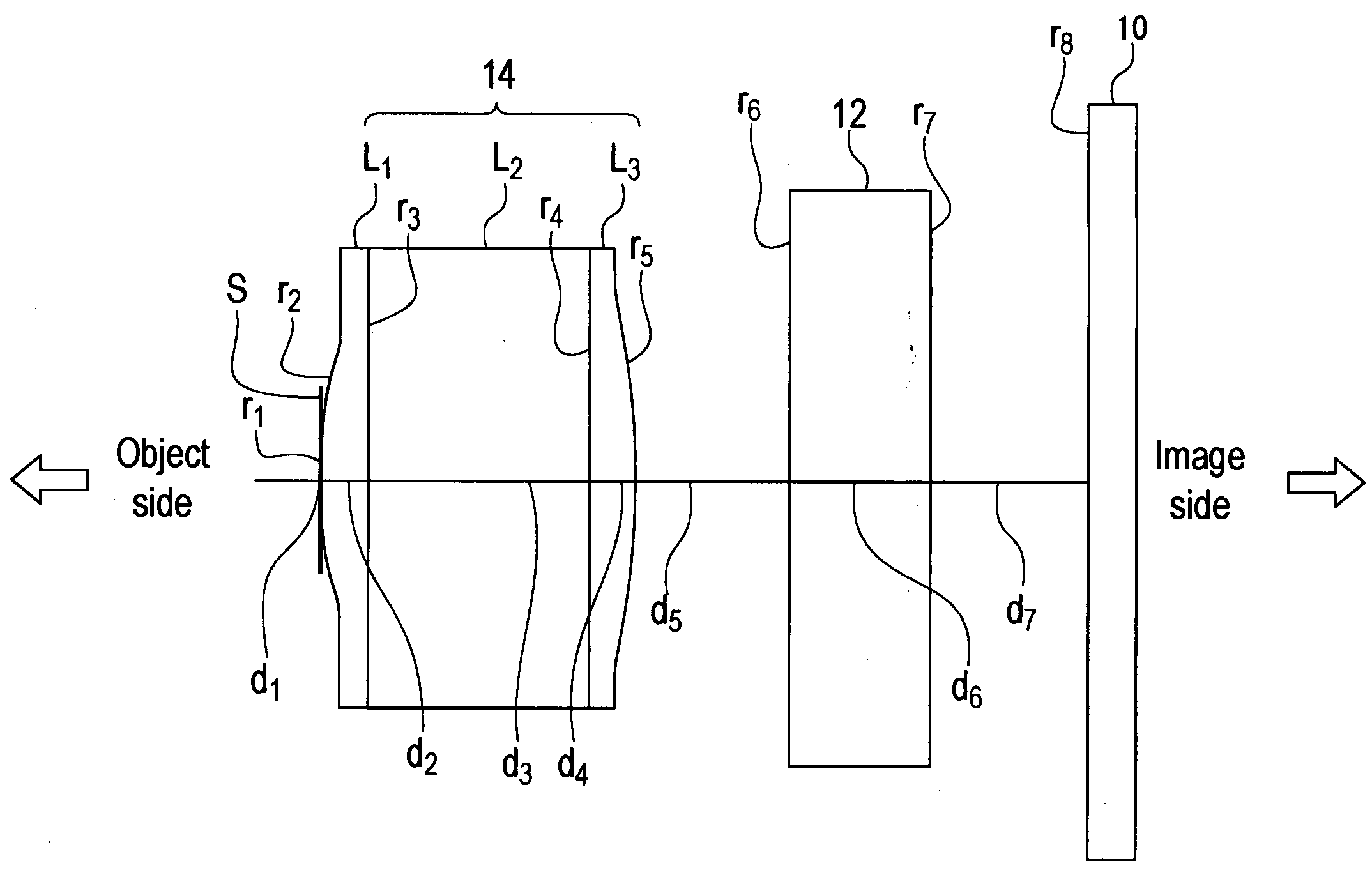

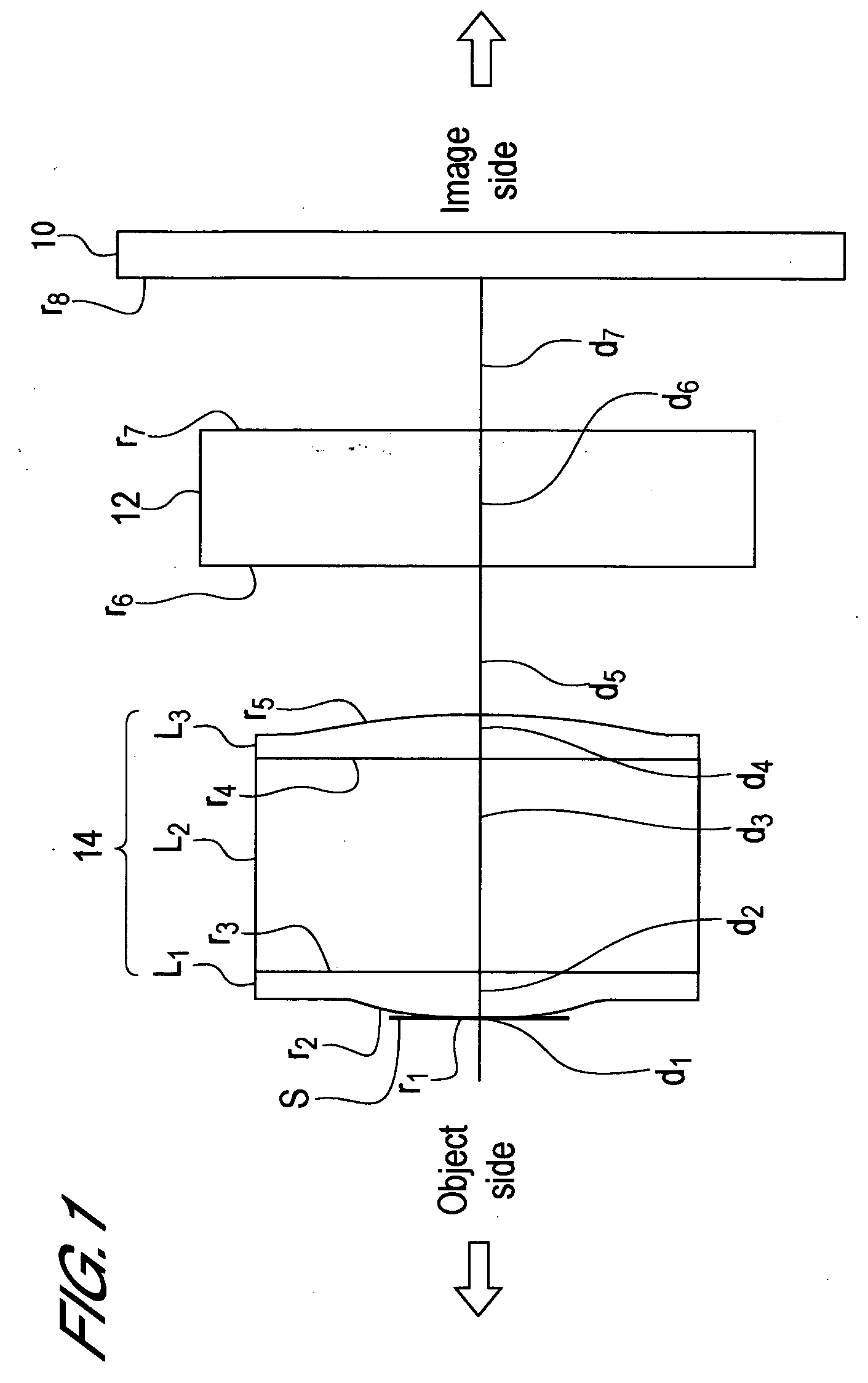

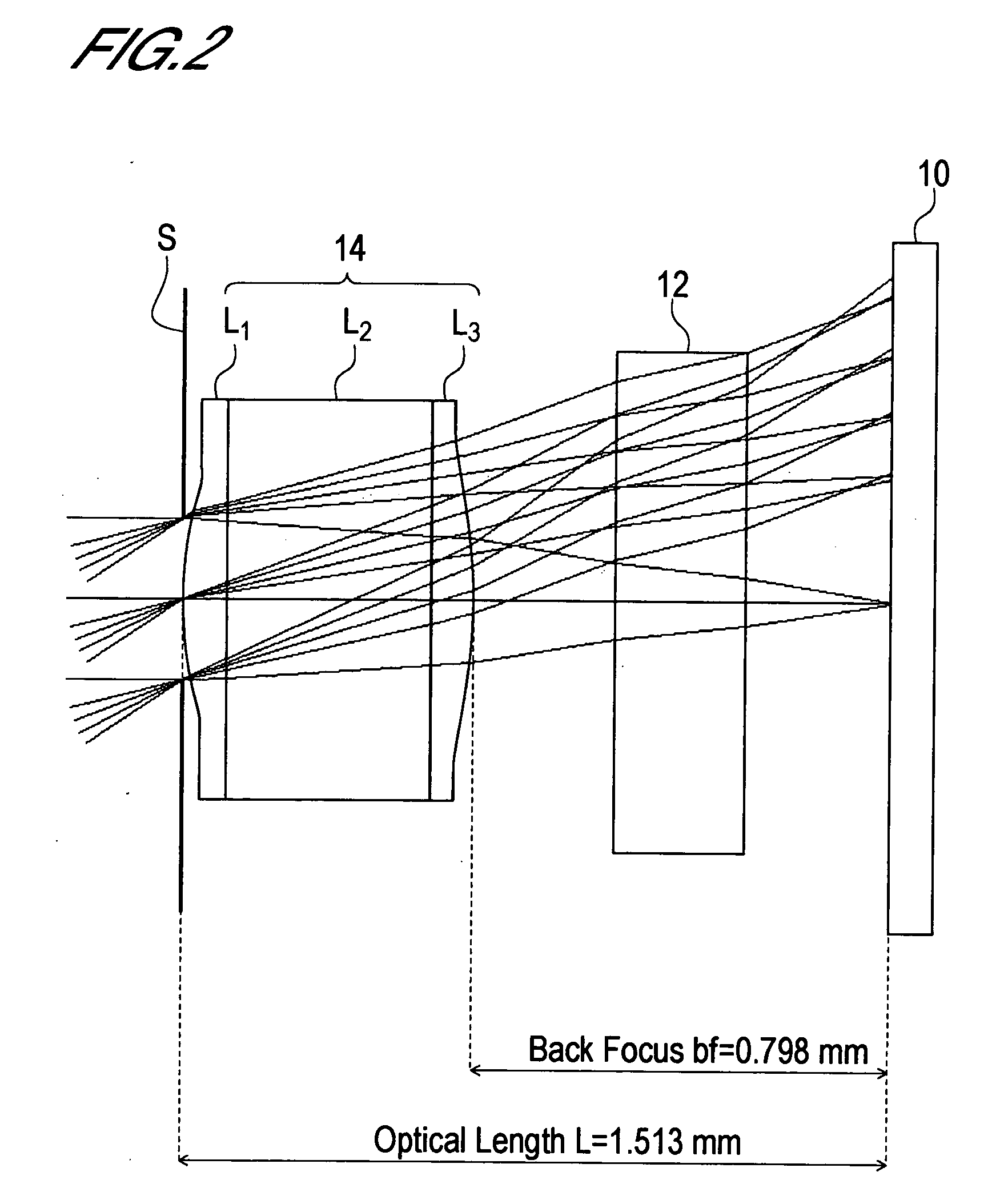

Imaging Lens

ActiveUS20090279188A1High melting pointGuaranteed Optical PerformanceOptical articlesLensCamera lensOptoelectronics

An imaging lens of which optical performance does not deteriorate even in a high temperature environment, various aberrations are well corrected, optical length is short, and back focus is sufficiently secured, comprising an aperture stop S and a junction type compound lens 14 having a positive refractive power, wherein the aperture stop and the junction type compound lens are arranged in this sequence from an object side to an image side. The junction type compound lens comprises a first lens L1, a second lens L2 and a third lens L3 arranged in this sequence from the object side to the image side. The first lens and the third lens are formed of a curable resin material, and the second lens is formed of an optical glass. The first lens and the second lens are directly bonded, and the second lens and the third lens are directly bonded. The object side face of the first lens and the image side face of the third lens are aspherical.

Owner:SEIKOH GIKEN +1

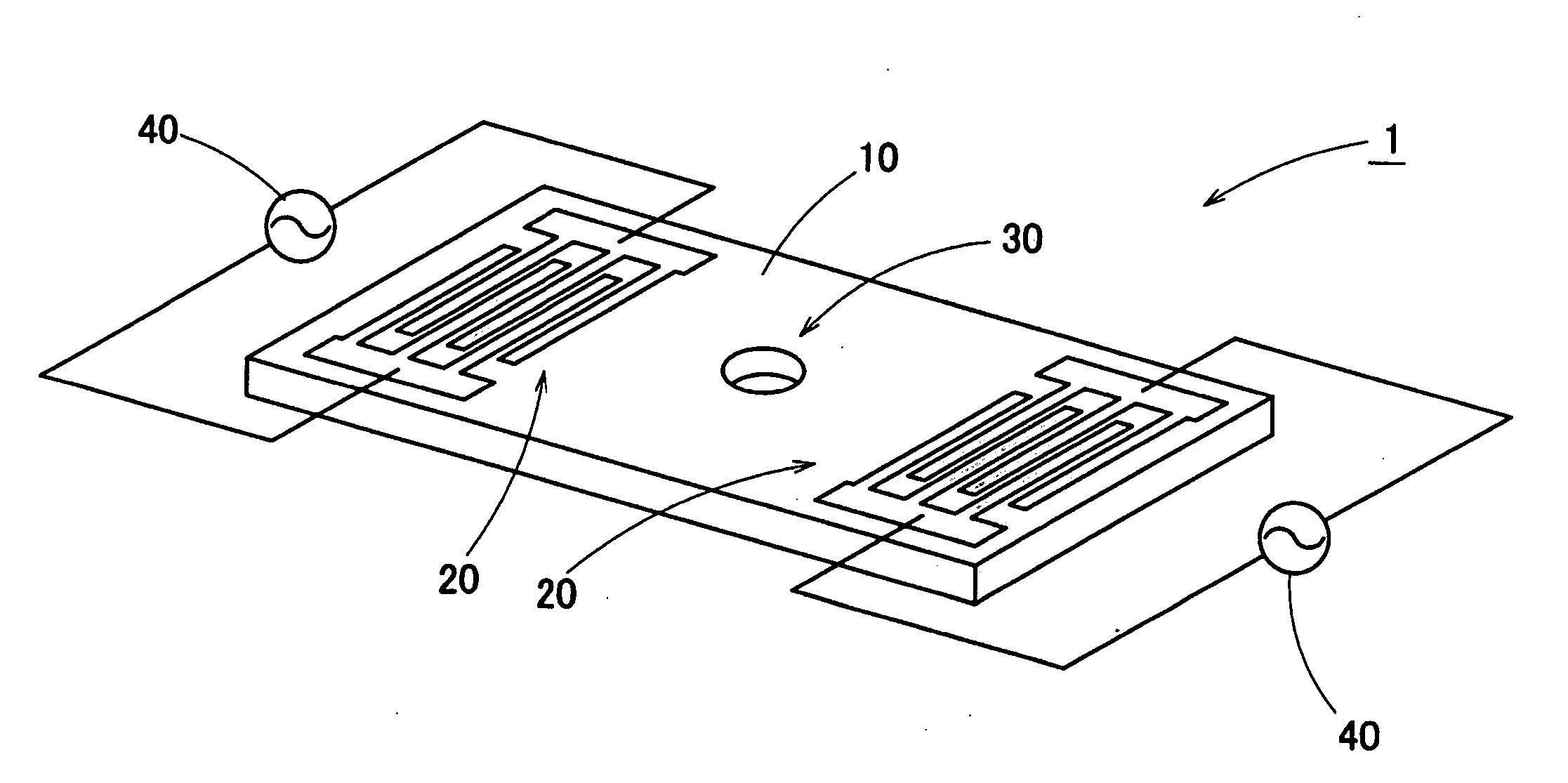

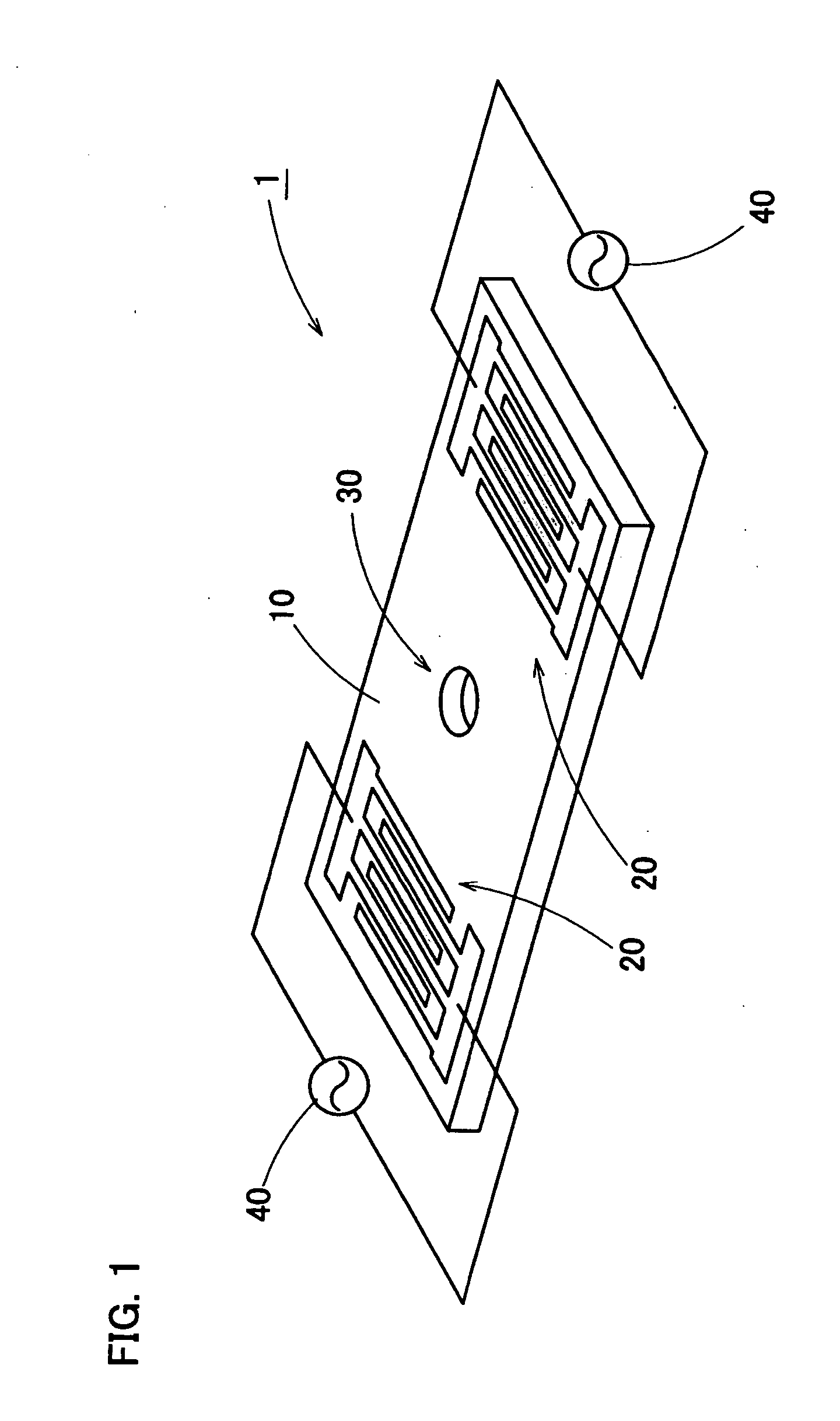

Heating apparatus using surface acoustic wave

InactiveUS20050083785A1Efficient methodShort timeUltrasound therapyTransducer detailsInterdigital transducerThermal reaction

The present invention provides new applications for surface acoustic waves. A heating apparatus with a surface acoustic wave generator is disclosed. In one embodiment of the invention, a heating apparatus comprise a surface acoustic wave generator having a piezoelectric substrate and inter-digital transducers (IDT) formed on the piezoelectric substrate, and a thermal reaction part is formed at the part of the piezoelectric substrate.

Owner:MEDICAL & BIOLOGICAL LAB CO LTD +1

Protein and calcium fortification system for clear and opaque beverages

InactiveUS20080063765A1Not cloudy appearanceAgreeable flavorMilk preparationMilk preservationMilk SerumWhey protein

A milk serum protein and calcium concentrate that is useful for fortifying acidic clear or opaque, carbonated or uncarbonated soft drinks without producing a cloudy appearance in clear drinks and with minimal effect upon the flavor of the beverage. Addition of liquid or melted fat or oil to drinks so fortified produces a beverage with a milk-like appearance.

Owner:CORNELL RES FOUNDATION INC

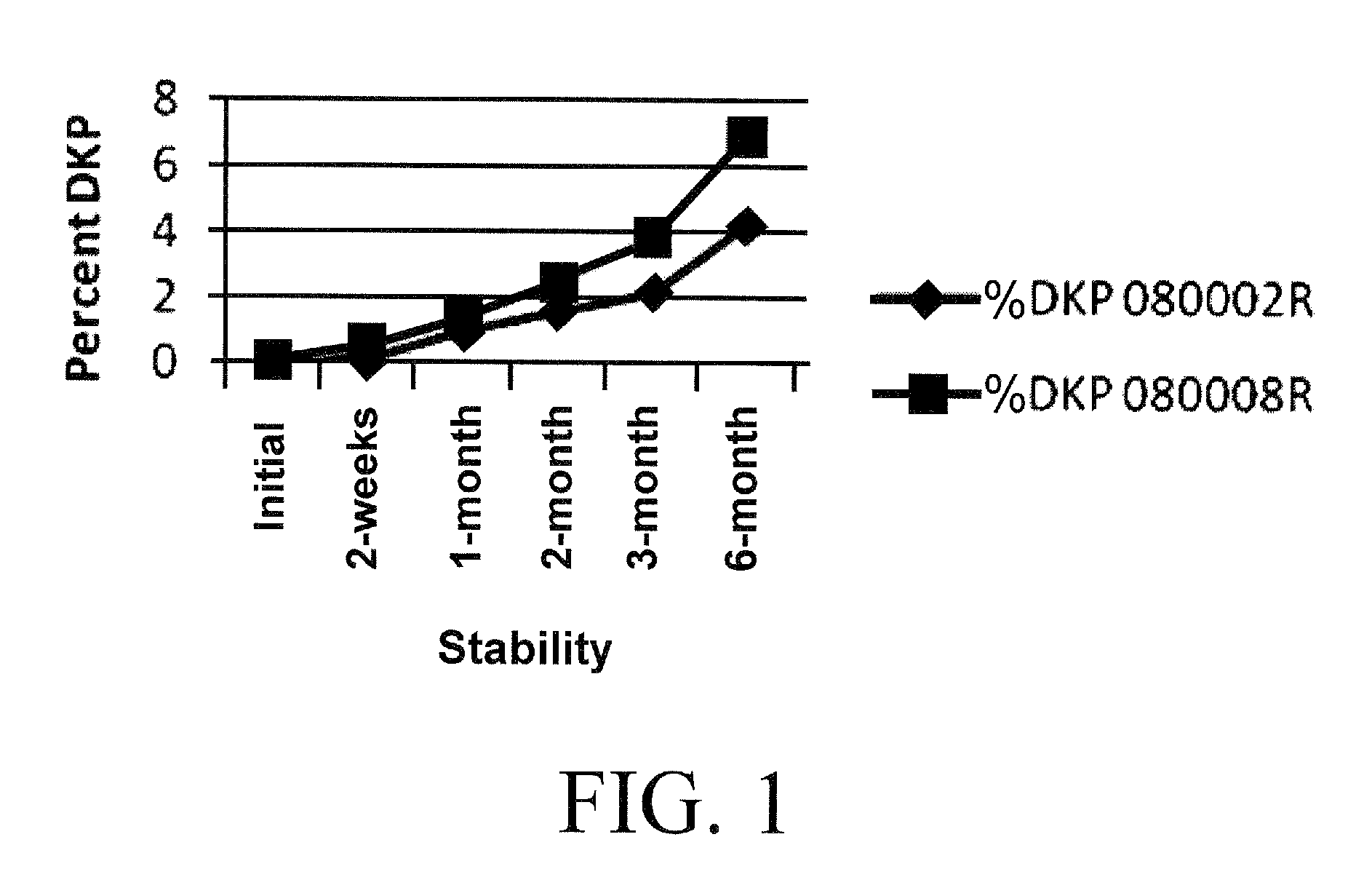

Stabilized Coating for Pharmaceutical Formulations

InactiveUS20100062062A1Improve stabilityEfficiently coat and stabilizeBiocidePharmaceutical non-active ingredientsPolyvinyl alcoholDiketopiperazines

A process is described for preparing stabilized tablet formulations for temperature and moisture sensitive active drugs. Water soluble polyvinyl alcohol is processed with drugs such as angiotensin converting enzyme (ACE) inhibitors and compressed into solid form once excess water is removed. Low dose polyvinyl alcohol ramipril tablets prepared by this process are stable under conditions of high humidity and heat for periods of at least up to six months with less than 8% hydrolysis of the prodrug to the active metabolite diketopiperazine (DKP).

Owner:AETHOS PHARMA

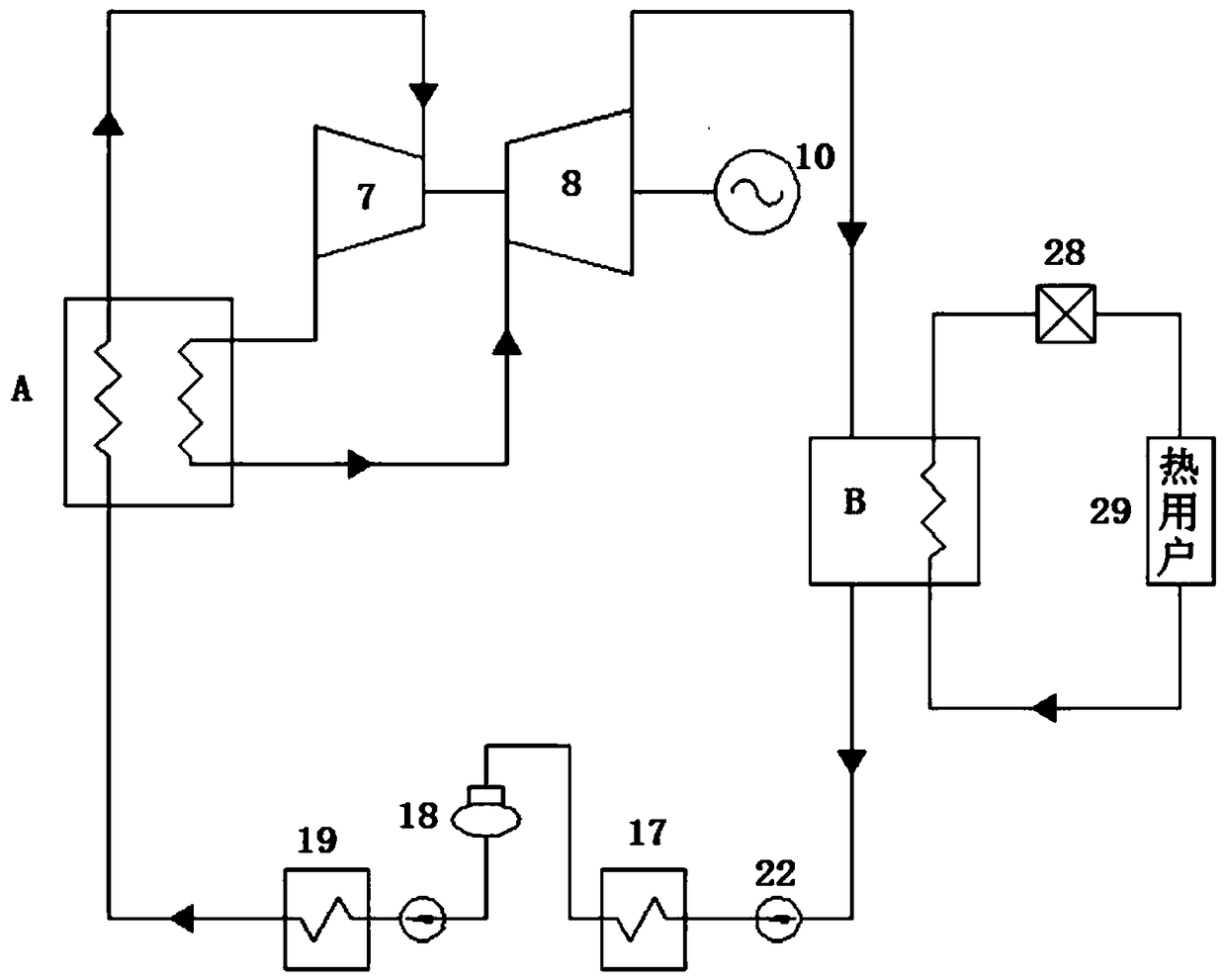

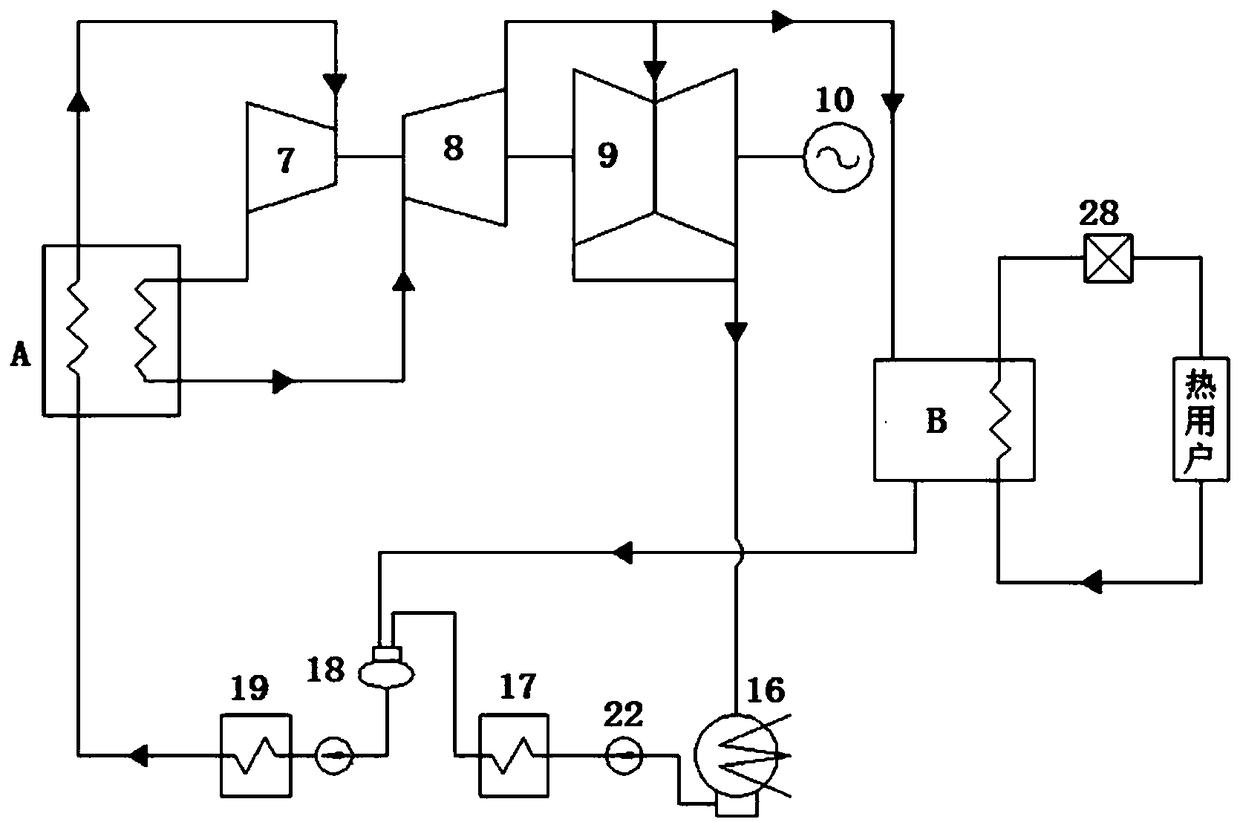

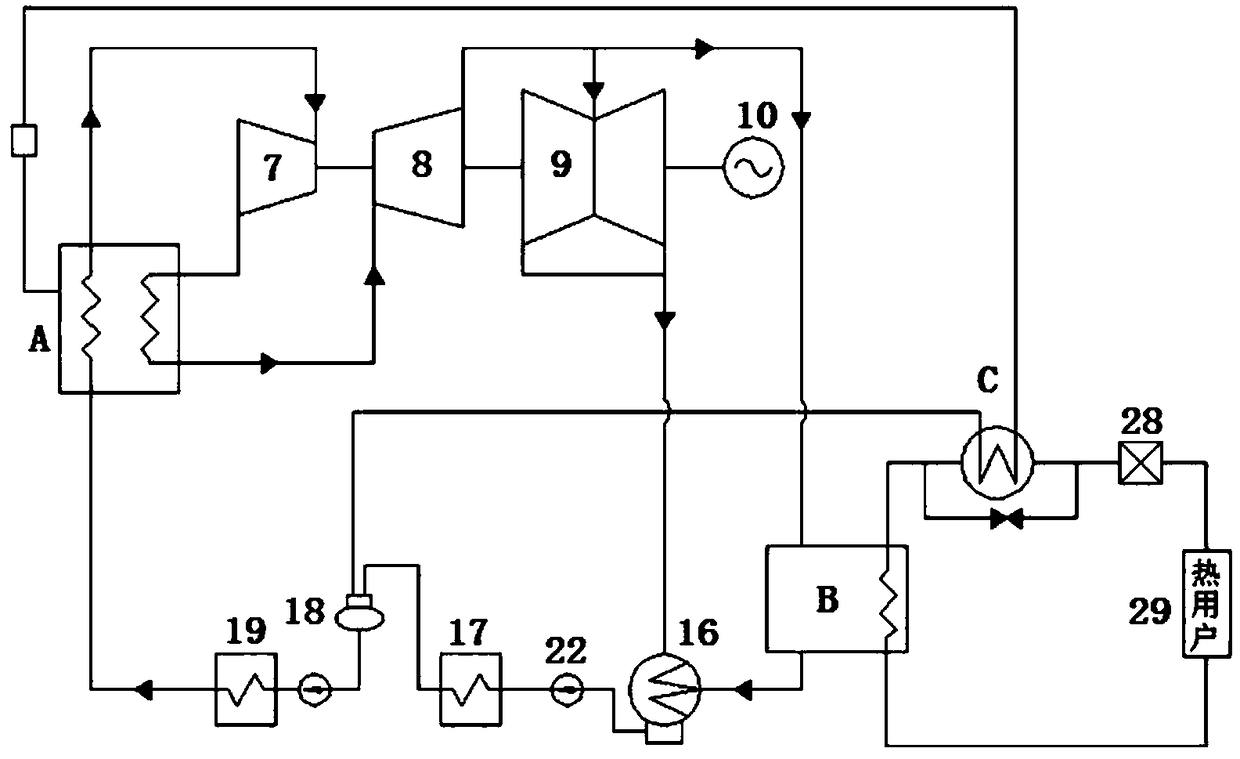

Thermodynamic system for improving heat supply unit electric output adjusting capacity

The invention relates to a thermodynamic system for improving heat supply unit electric output adjusting capacity. The thermodynamic system is characterized in that main steam or reheating section steam is subject to temperature and pressure reduction to directly serve as heat source steam for industrial heat users; an absorption heat pump 23 of a first-stage heat exchange device serves as a heatsource of a first-stage heat exchange station 25 in the heating period to supply heat to heat users 29 and supplies cold to the users in the non-heat supply period; a high-pressure electric boiler 24of a second-stage heat exchange device improves the boiler water feeding temperature, reduces heat absorbed by boiler fed water in an economizer 4, accordingly improves the boiler tail smoke discharging temperature, and guarantees normal running of an SCR denitration device 5; and according to a three-stage heat exchange device, exhaust steam of a turbine intermediate pressure cylinder 8 serves asheat source steam of a third-stage heat exchange station 27, the unit heat load is guaranteed, and the heat using requirement of the heat users 29 is met. The electric output adjusting capacity of the heat supply unit can be improved, it is guaranteed that the unit heat supply capacity is not decreased under the low load running working conditions, pyroelectric decoupling is achieved, and the electric output adjusting capacity of the heat supply unit is improved.

Owner:NORTHEAST DIANLI UNIVERSITY +2

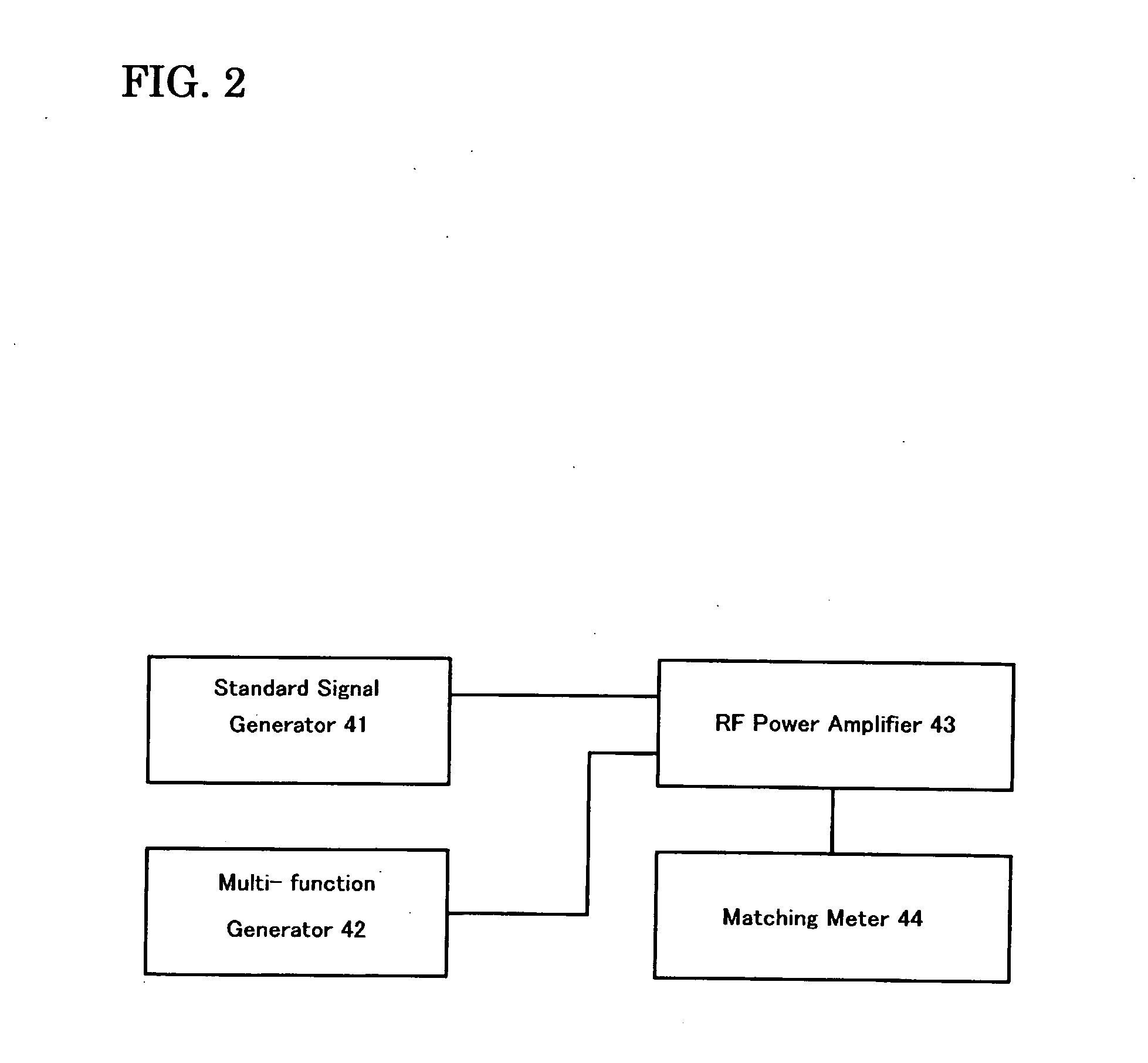

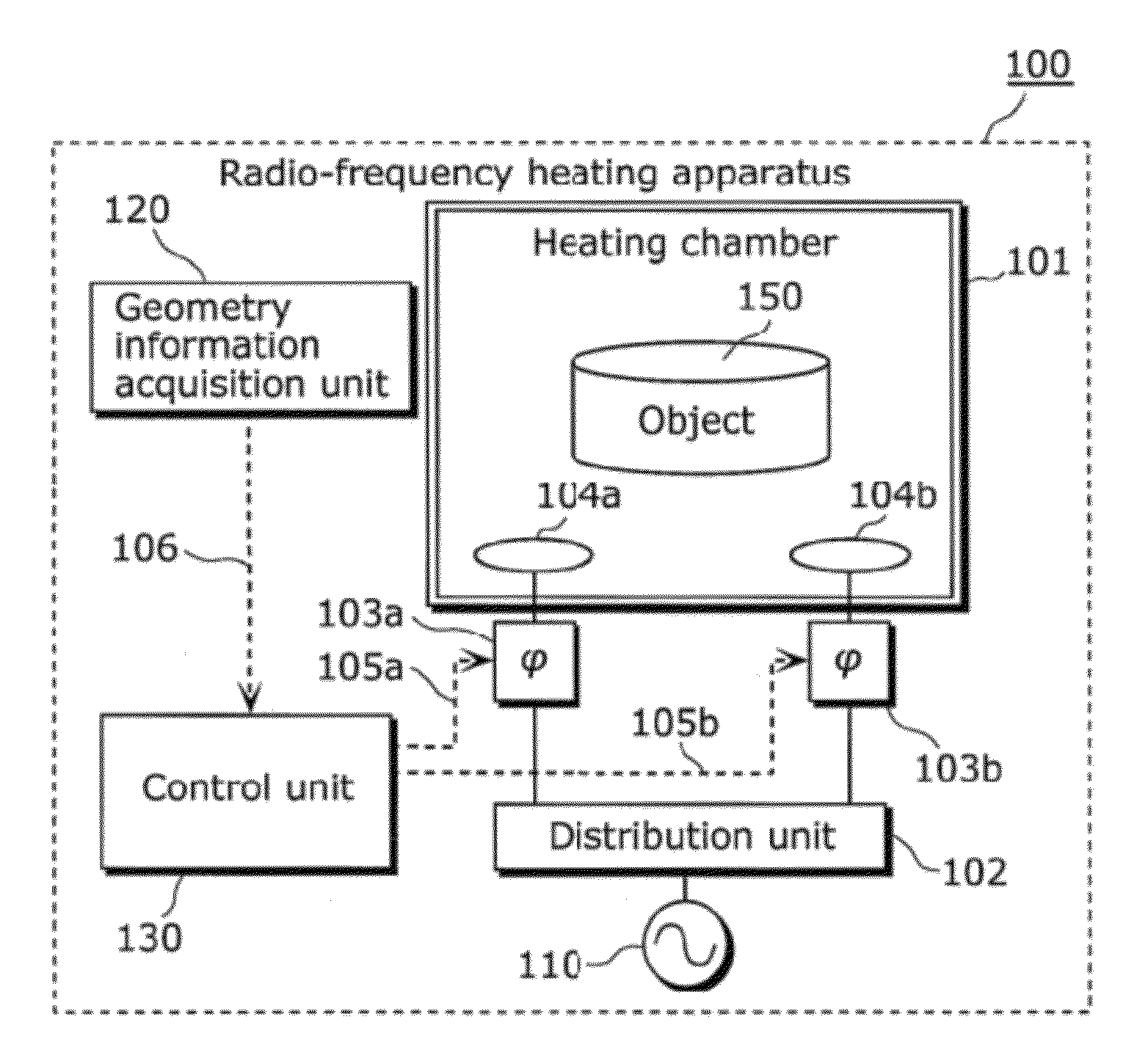

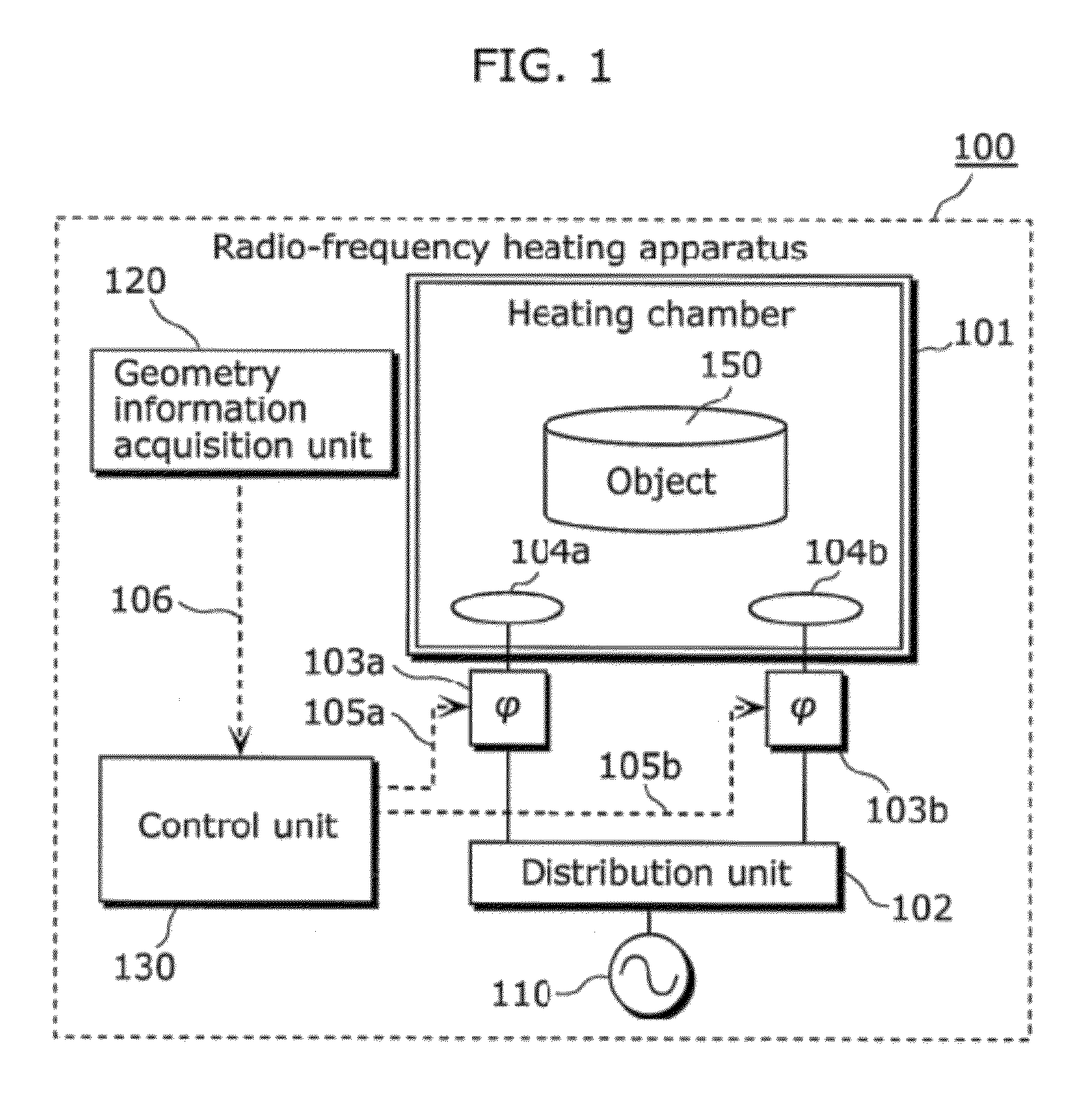

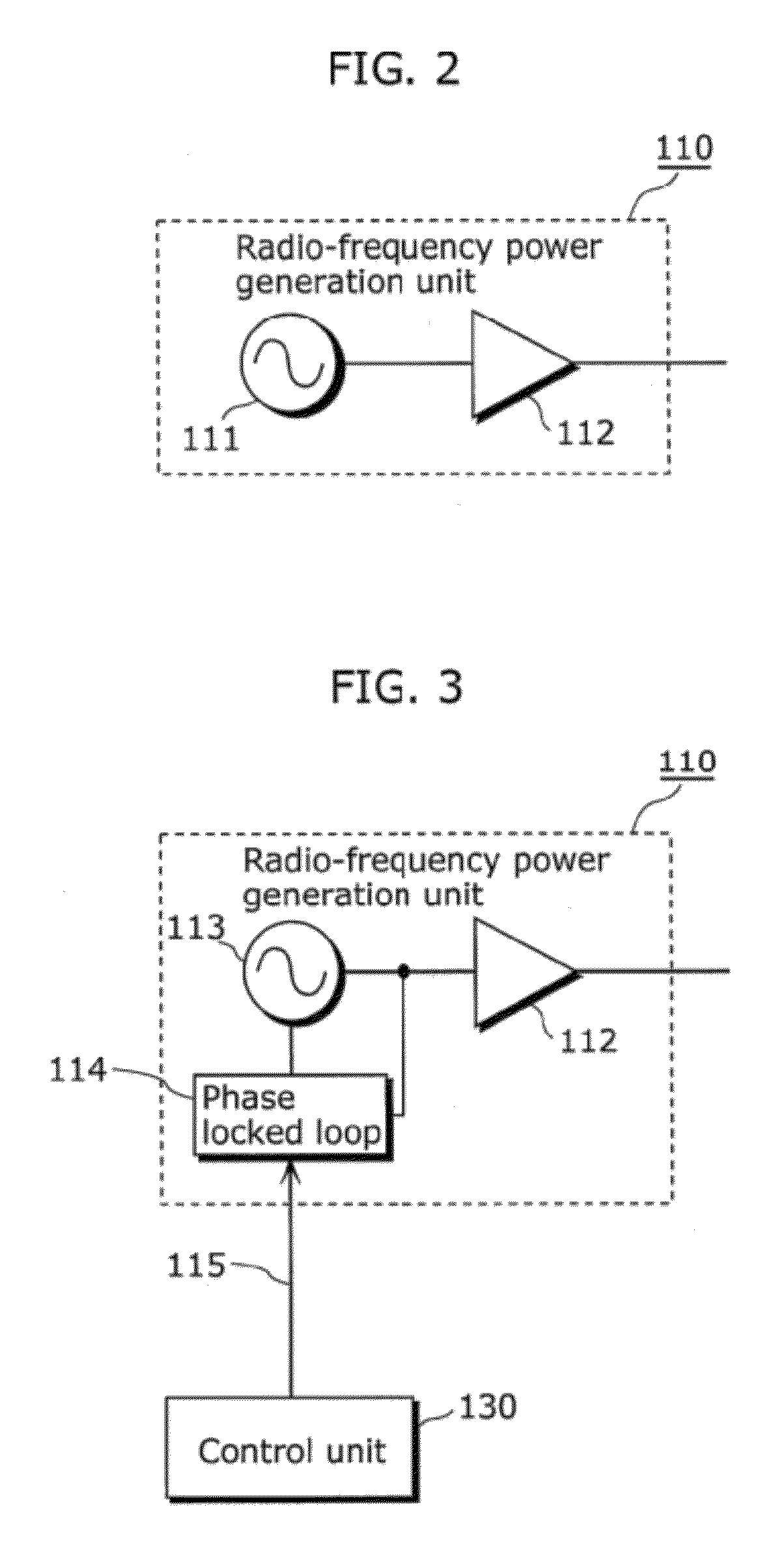

Radio-frequency heating apparatus and radio-frequency heating method

ActiveUS9398644B2Heat uniformly and efficientlyEfficient and uniform heatingMicrowave heatingInduction current sourcesRadio frequencyInformation acquisition

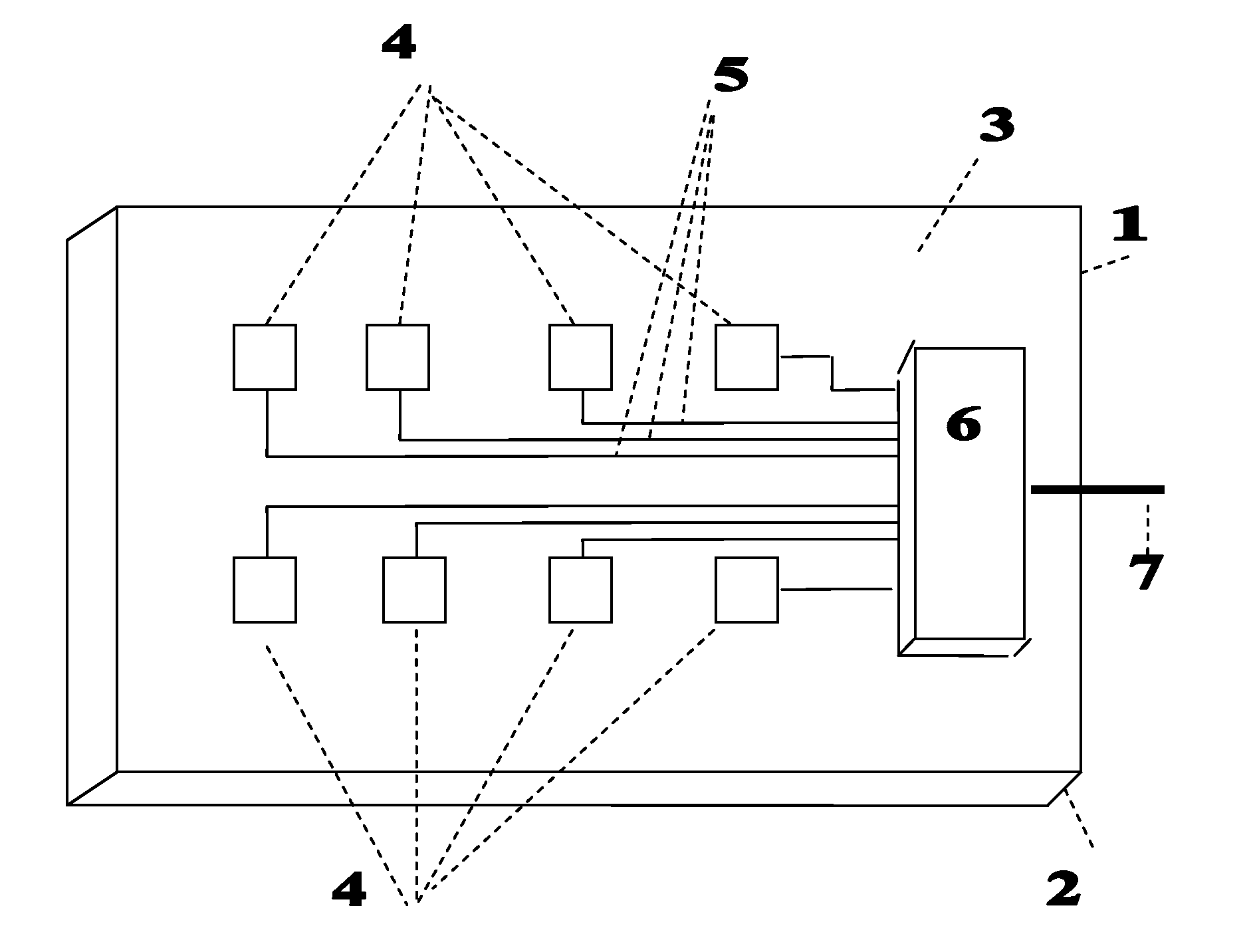

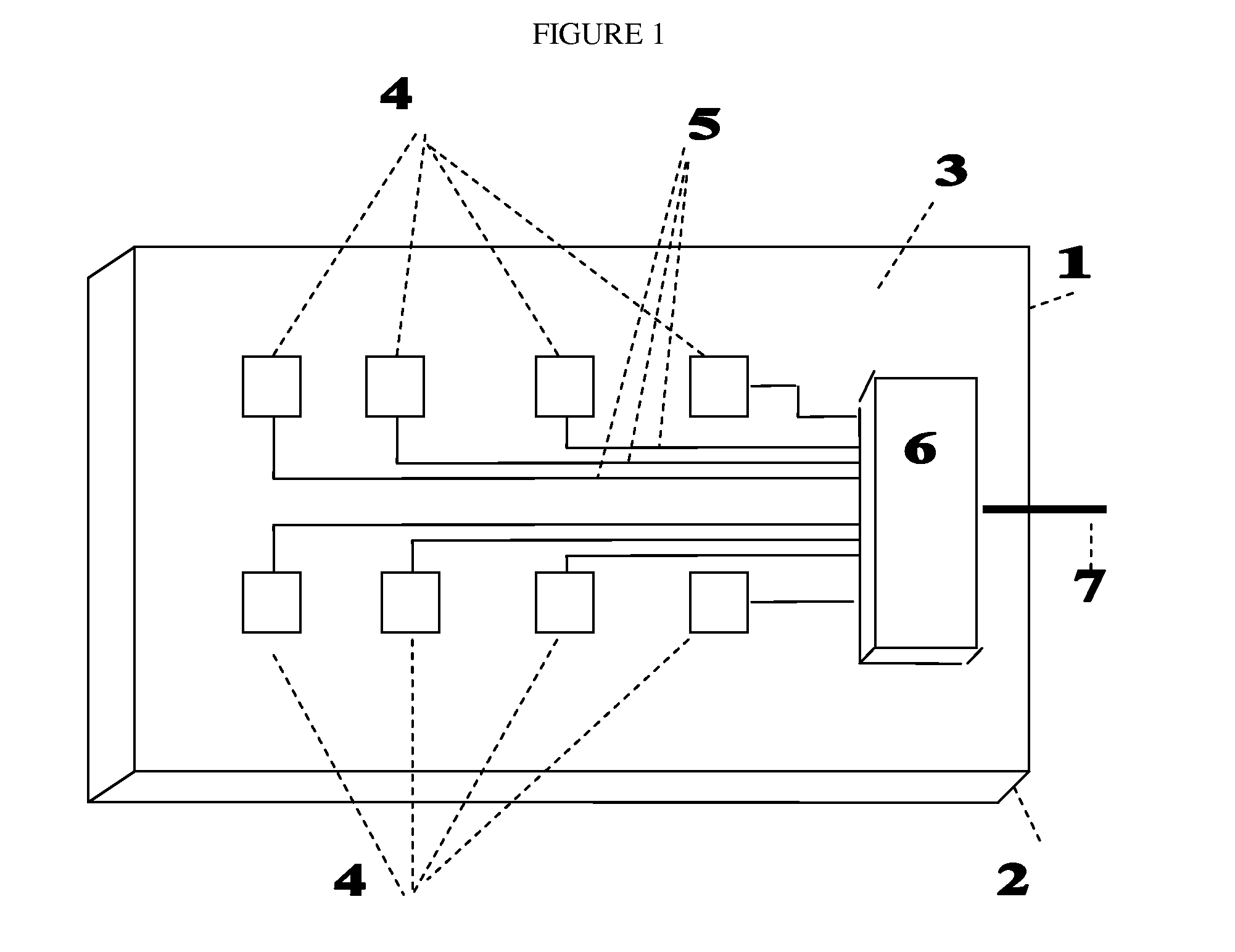

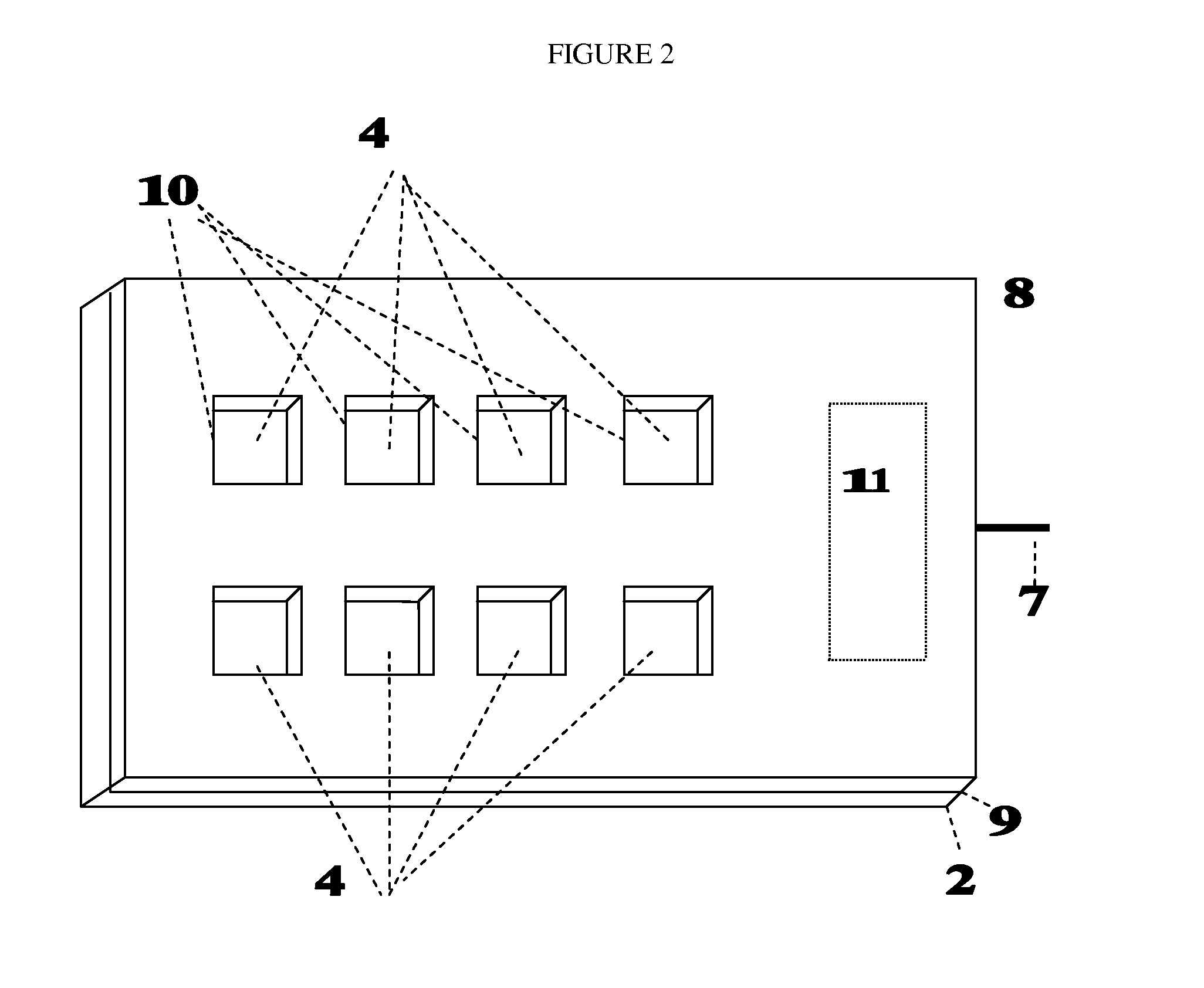

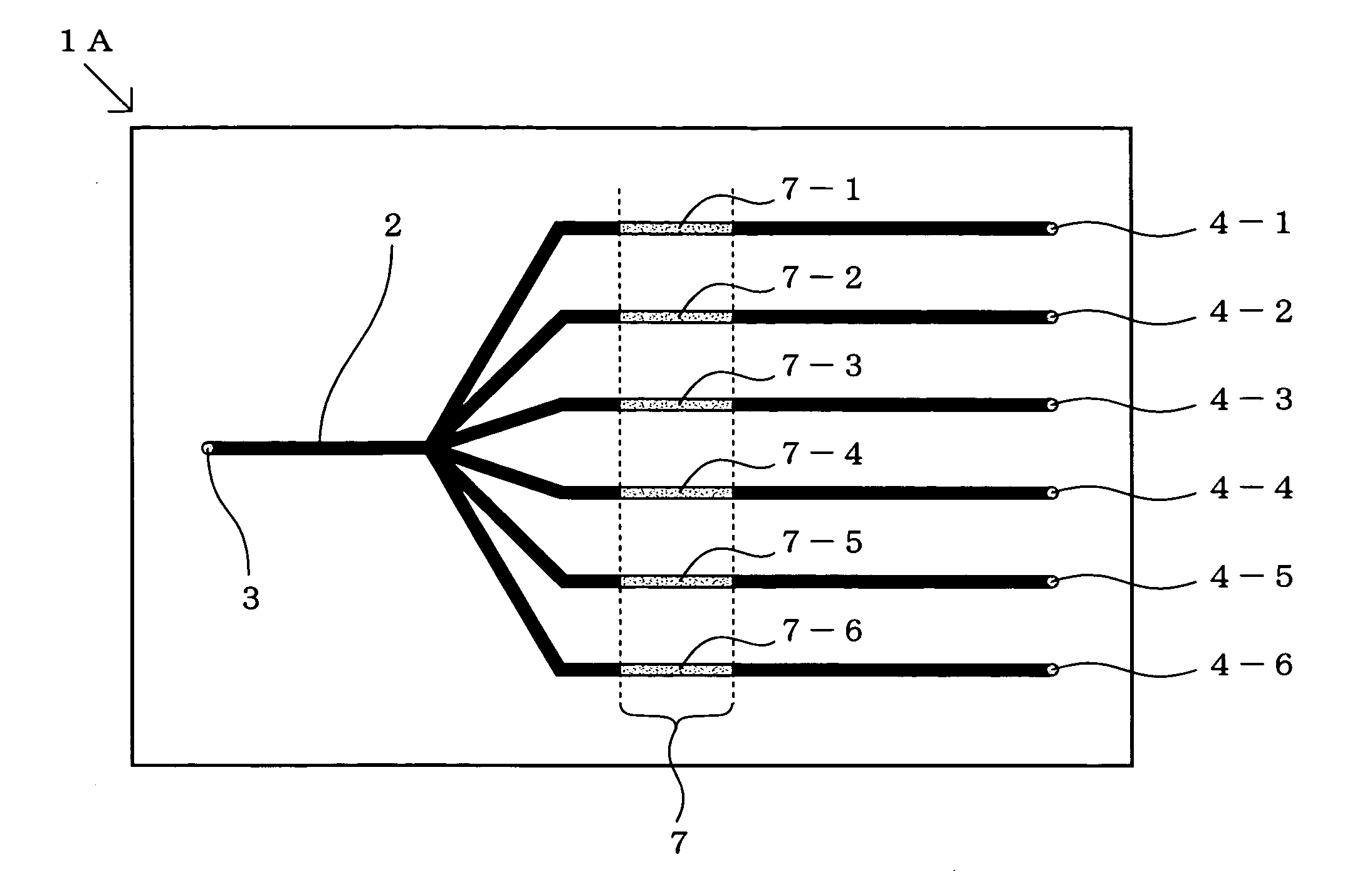

A radio-frequency heating apparatus includes a phase varying unit to vary the phase of radio-frequency power; and a plurality of antennas which are placed on the same plane in a heating chamber and radiate a plurality of radio-frequency waves. The radio-frequency waves have a predetermined phase difference caused by phase variation in the phase varying unit. A geometry information acquisition unit acquires the geometry of an object; and a control unit controls the phase varying unit so that the radio-frequency waves are in phase in a first mode, and the radio-frequency waves are in opposite phase in a second mode. The control unit switches between the first mode and the second mode based on the acquired geometry information.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Electrode arrays based on polyetherketoneketone

InactiveUS20110307042A1Exceptional resistance to solvent and waterImprove relationshipSpinal electrodesPrinted circuit assemblingMedical deviceMedical treatment

Laminated assemblies containing electrode-bearing layers comprised of polyetherketoneketone are useful in the fabrication of implantable medical devices.

Owner:OXFORD PERFORMANCE MATERIALS

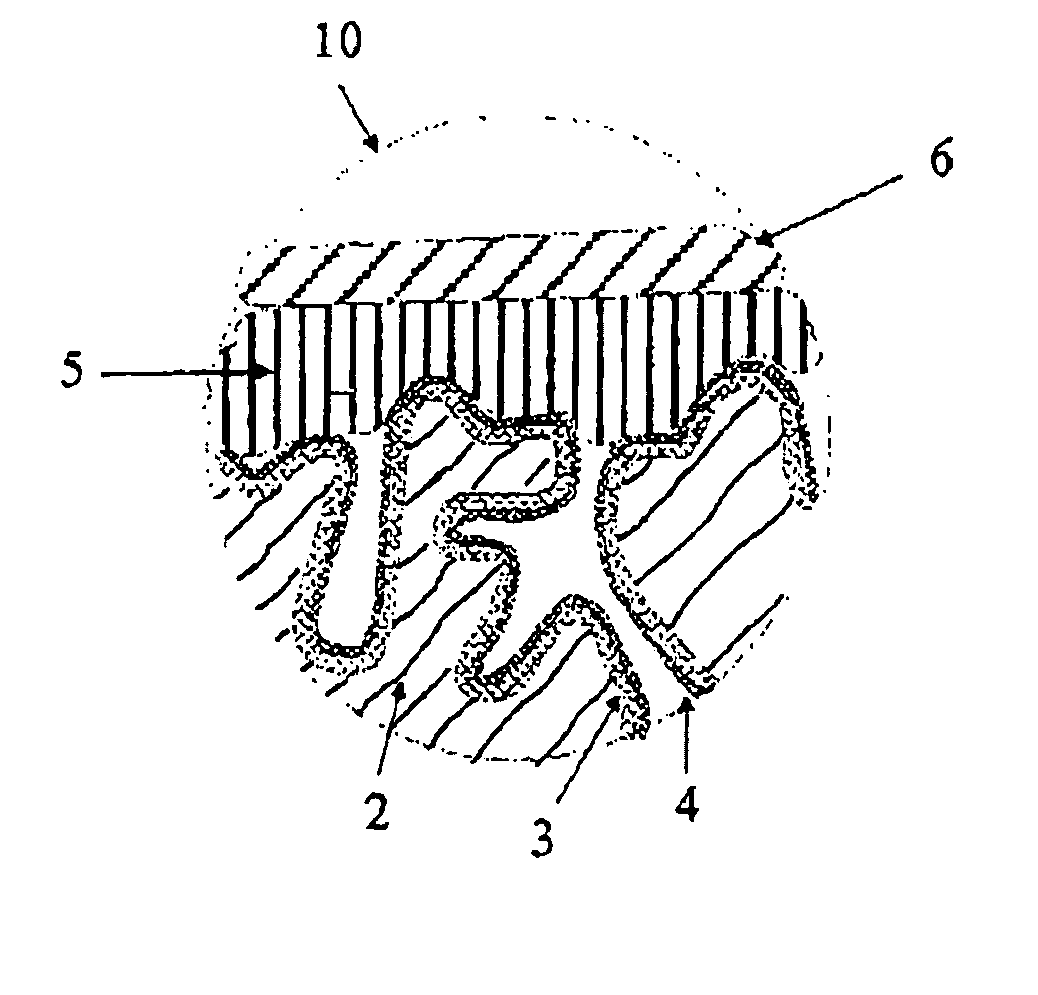

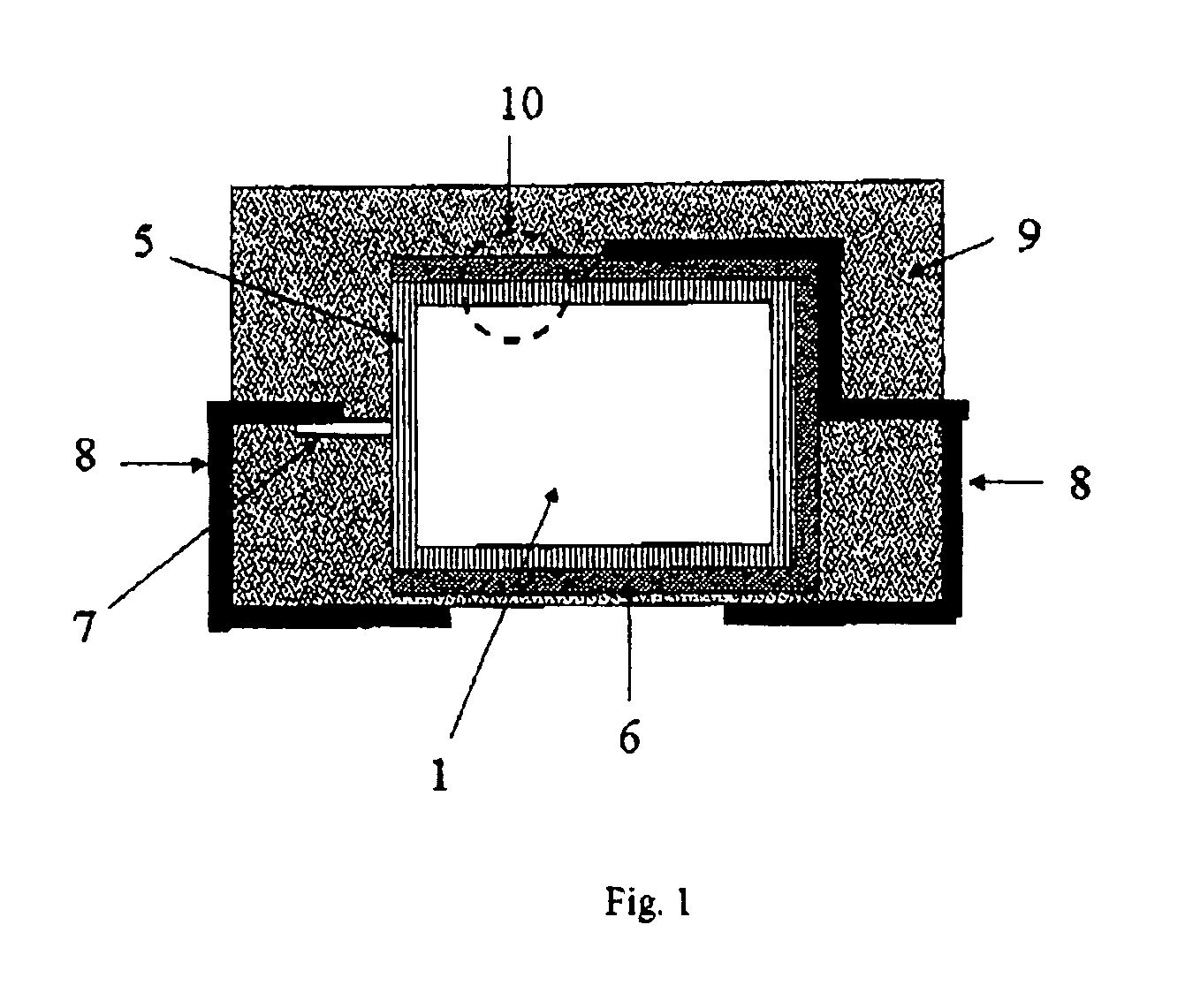

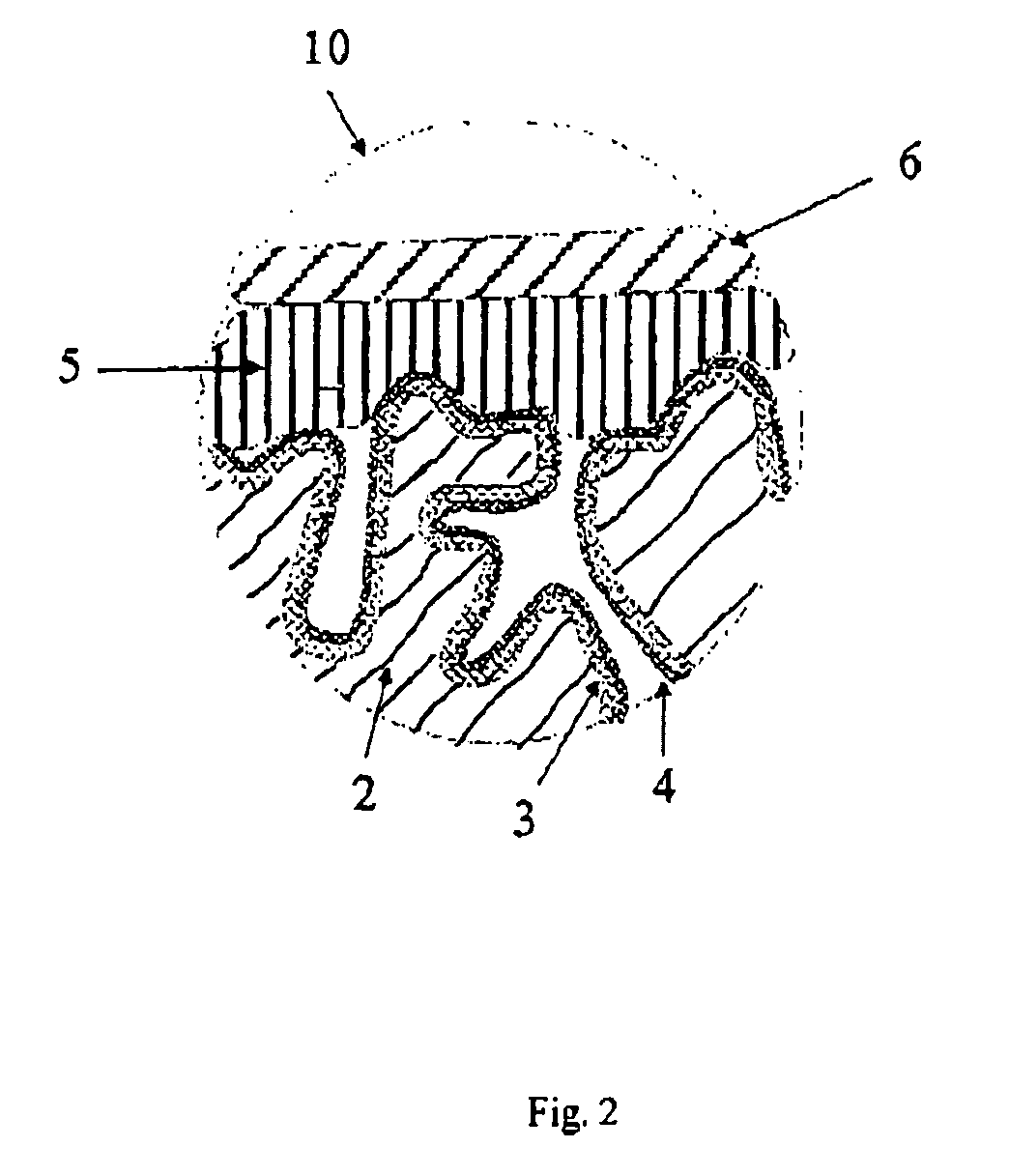

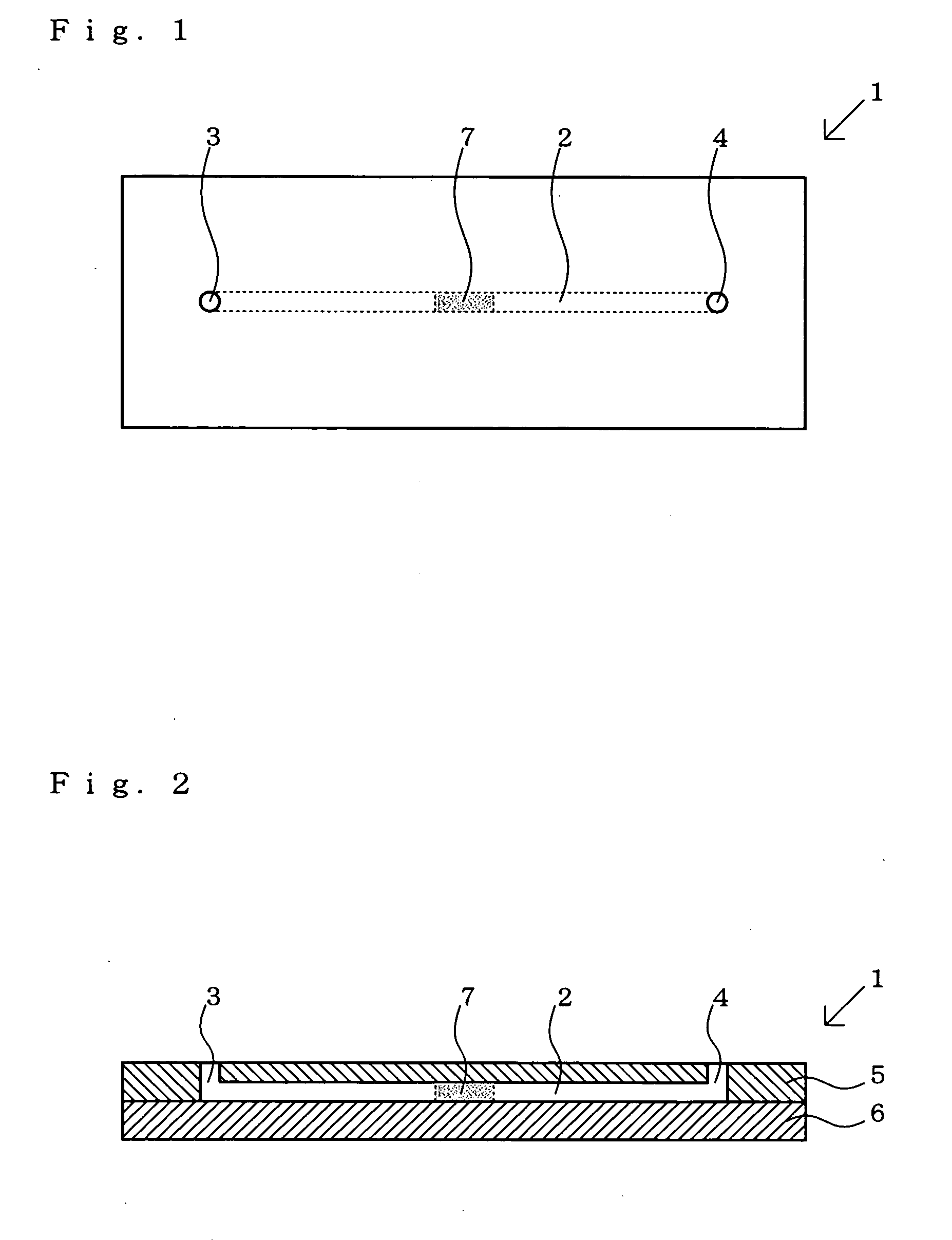

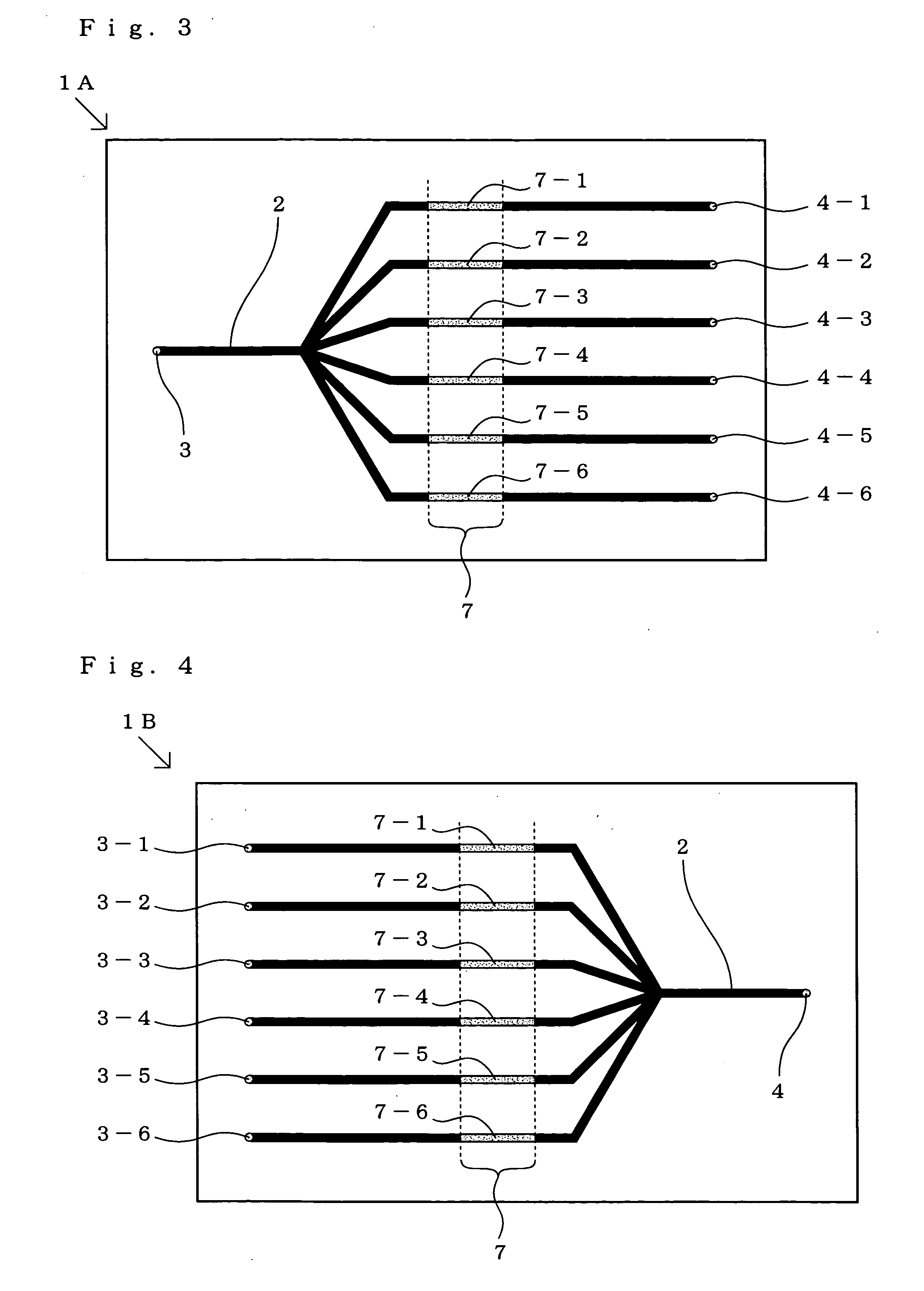

Kit, Device and Method For Analyzing Biological Substance

InactiveUS20080254997A1Simple and easyEasy to produceLibrary screeningLaboratory glasswaresImmunological substanceBiological substances

The invention provides an analytical device insusceptible to inactivation or other influences even when exposed to a thermal load or organic compounds contained in an adhesive in the process for manufacturing the same and, more over, allowing an immunological substance or the like to be readily immobilized at a site in the microchannel passage therein.The analytical kit is a combination of the analytical device and a reagent or reagents. The analytical device used in the analytical kit comprises a passage 2, 1 μm-5mm width and 1 μm-750 μm depth in cross-section formed therein and belongs to the category of the so-called microfluidic systems suited for analyzing very small amounts of liquid samples; thus, it is suited for analyzing biological substances. The analytical device 1 to be used in the analytical kit is prepared by forming a groove not wider than 5 mm on a first member 5 and / or second member 6, immobilizing a nucleic acid(s) at a part (capturing zone 7) of a place to become the channel 2 after joining the two members together and joining the two members together. The reagent(s) is (are) used after joining of the two members of the analytical device 1 and therefore will not be influenced by the fusion or adhesive.

Owner:NISSUI PHARMA

Solvent-resistant acrylic emulsion and preparation method thereof

InactiveCN108484811AStrong adhesionGood hardness and water resistanceSalt resistanceFunctional monomer

The invention discloses a solvent-resistant acrylic emulsion, belonging to the field of acrylic emulsions. The solvent-resistant acrylic emulsion comprises 180-260 parts of water, 50-60 parts of styrene, 40-50 parts of butyl acrylate, 0.5-5 parts of acrylic acid, 1-5 parts of an anionic emulsifier, 1-5 parts of a functional monomer, 0.2-1 part of an initiator, 0.1-0.5 part of an oxidant and 0.1-0.5 part of a reducing agent. The preparation method for the solvent-resistant acrylic emulsion comprises the following steps: 1) pre-emulsification; 2) polymerization; and 3) post-elimination. The solvent-resistant acrylic emulsion provided by the invention is improved in scrub resistance and solvent resistance while having the basic performance of good adhesion, hardness, water resistance, salt water resistance, salt spray resistance, scrub resistance and the like, so the application scope of the acrylic emulsion is broadened, the application properties of the coating are enhanced, the basic performance of the emulsion is substantively improved, and the cost performance of the emulsion is greatly improved.

Owner:佛山市顺德区巴德富实业有限公司

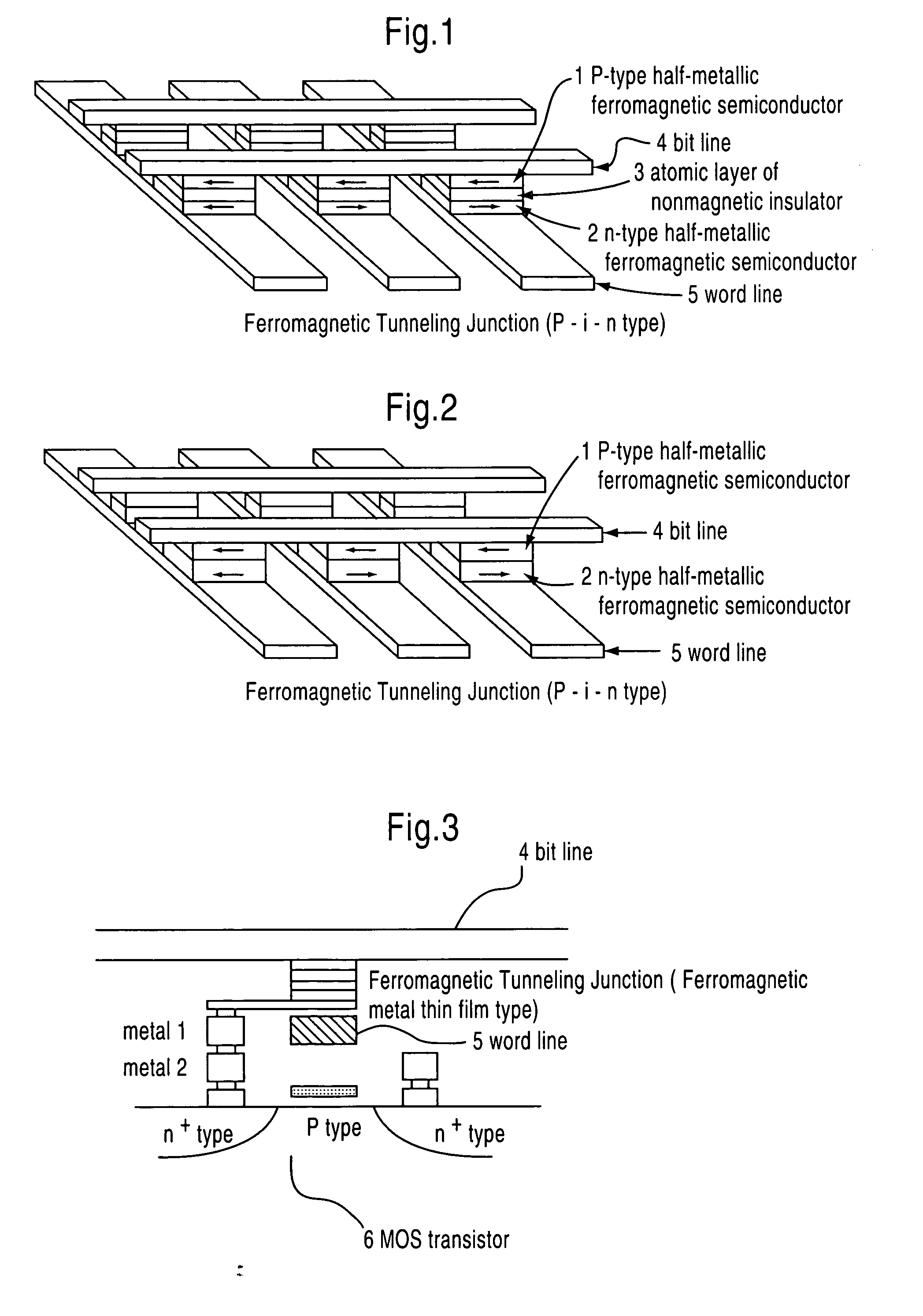

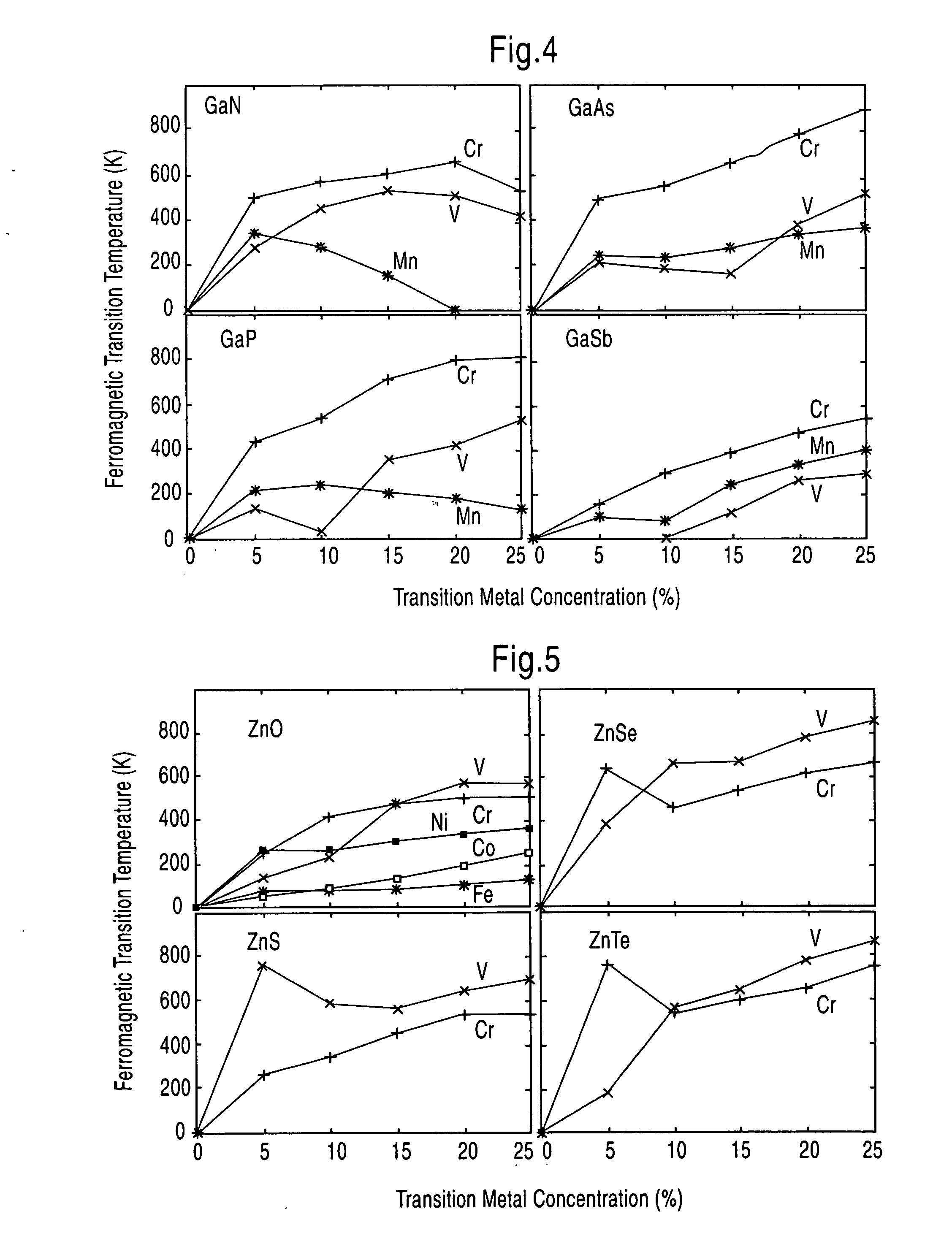

Magnetoresistive random-access memory device

InactiveUS20060177947A1Highly-integratedSimple structureTransistorMagnetic-field-controlled resistorsElectrical resistance and conductanceMagnetic reluctance

Disclosed is a new type of magnetoresistive random-access memory (MRAM) device using a magnetic semiconductor, which is capable of achieving high-integration and energy saving in a simplified structure without any MOS transistor, based on a rectification effect derived from a p-i-n type low-resistance tunneling-magnetoresistance-effect (low-resistance TMR) diode with a structure having a p-type half-metallic ferromagnetic semiconductor, an n-type half-metallic ferromagnetic semiconductor and at least one atomic layer of nonmagnetic insulator interposed therebetween, or a rectification effect derived from a p-n type low-resistance tunneling-magnetoresistance-effect (low-resistance TMR) diode with a structure devoid of the interposed atomic layer of nonmagnetic insulator.

Owner:JAPAN SCI & TECH CORP

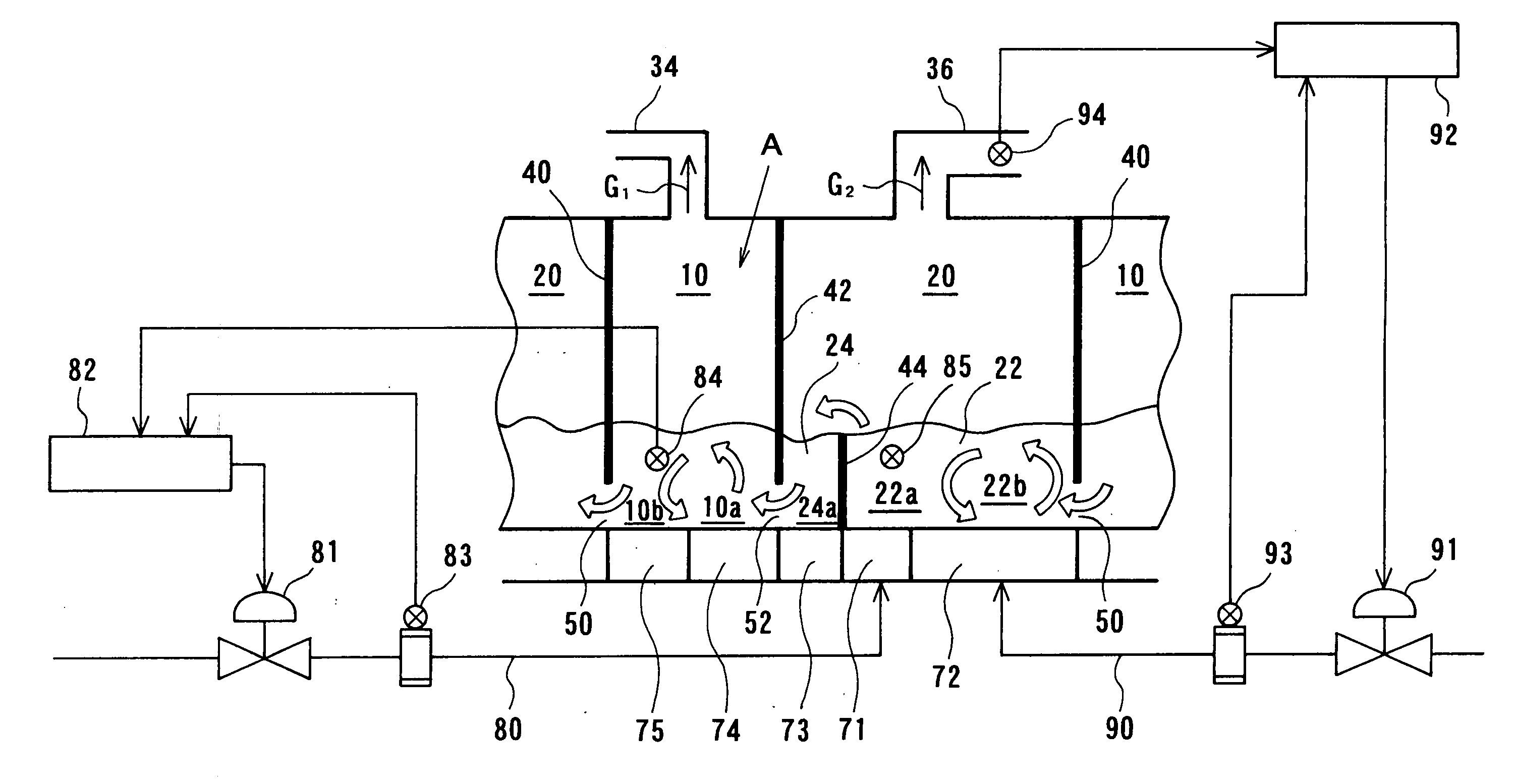

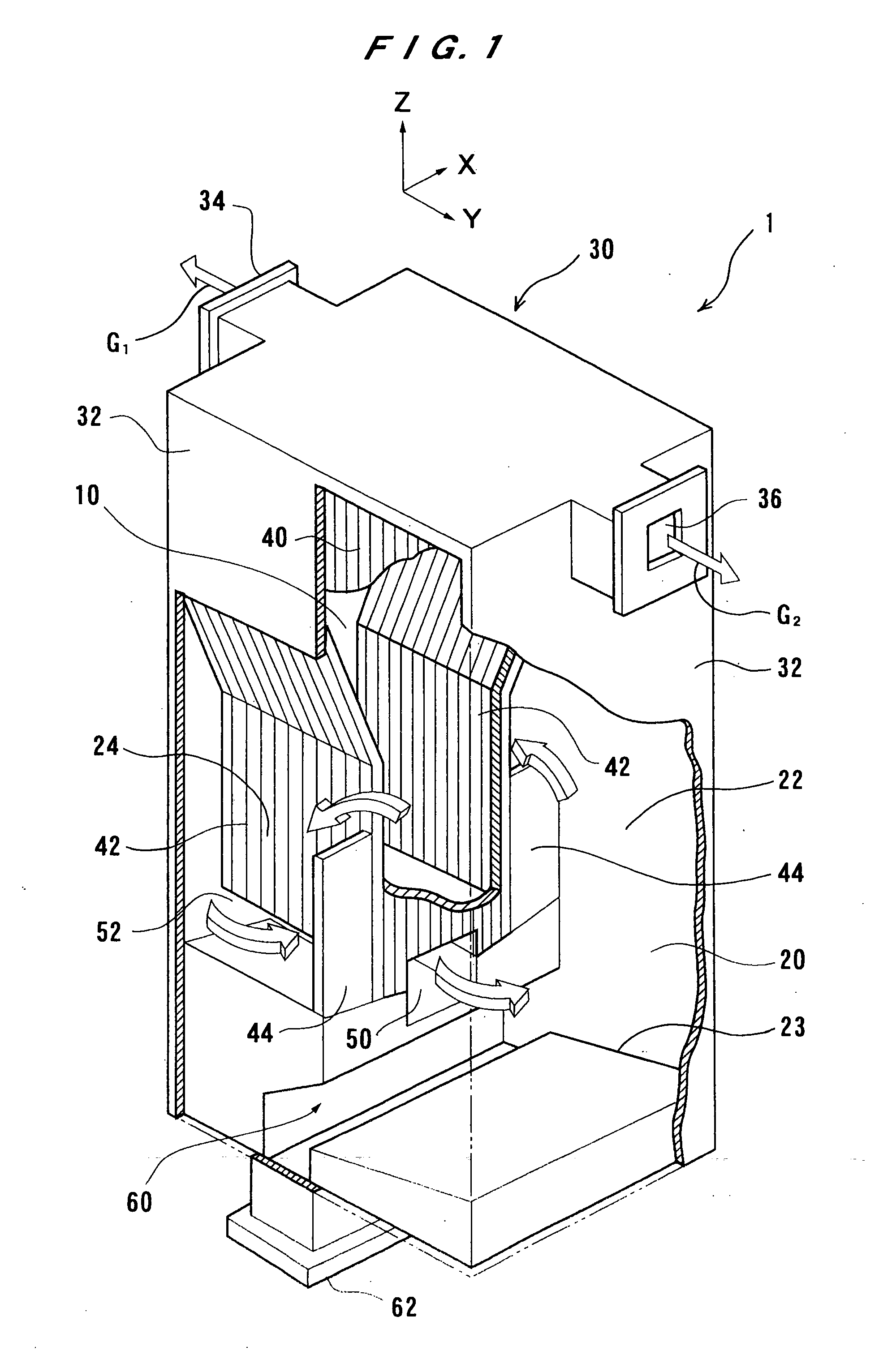

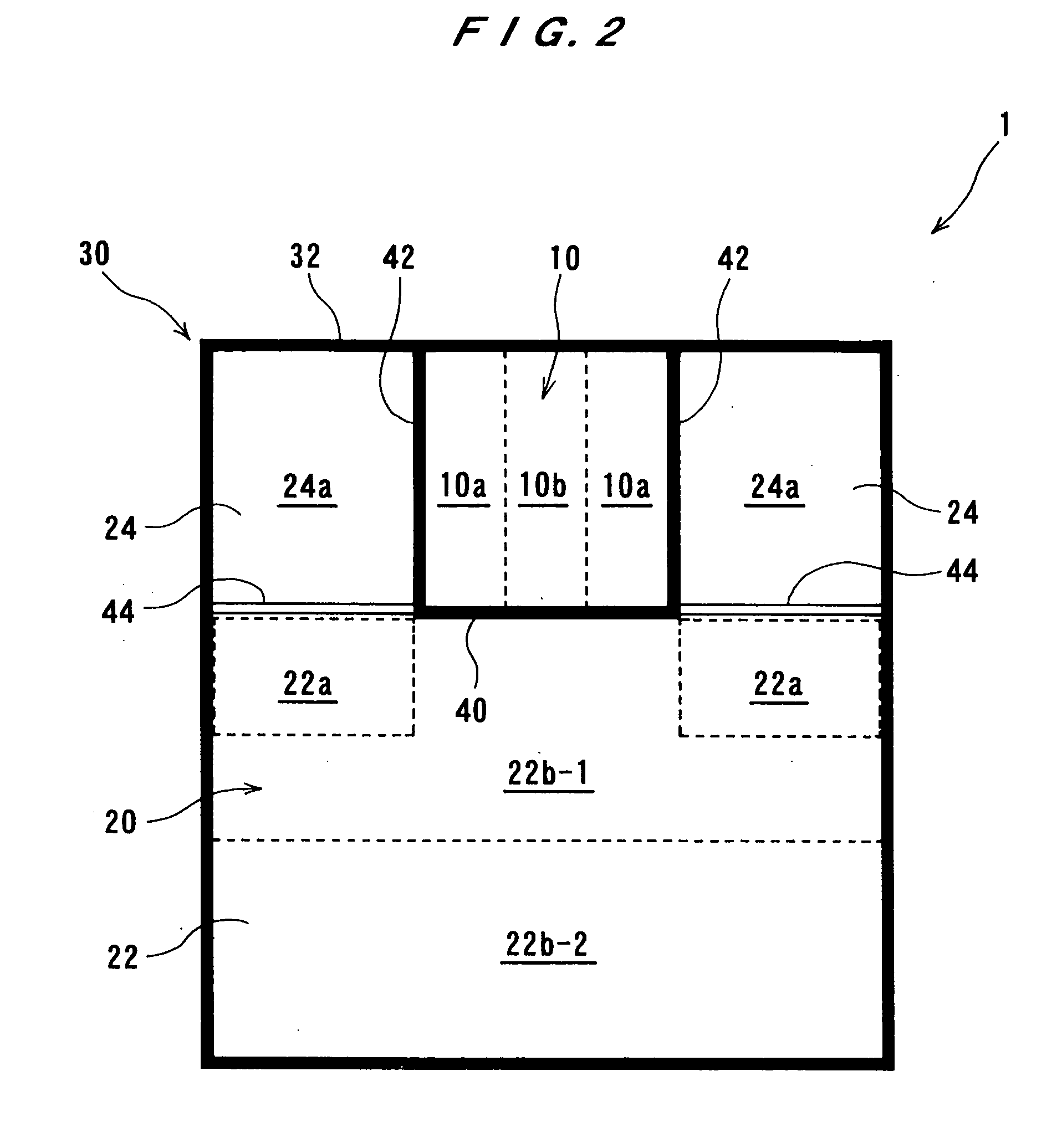

Fluidized-bed gasification furnace

InactiveUS20070014704A1Easy to controlHeat stableWaste based fuelCrucible furnacesProcess engineeringCombustion chamber

A fluidized-bed gasification furnace has a gasification chamber for fluidizing a fluidized medium therein and pyrolyzing a material in the fluidized medium to produce a pyrolysis gas and a pyrolysis residue. The fluidized-bed gasification furnace also has a combustion chamber having a combustion portion for fluidizing a fluidized medium therein and combusting the pyrolysis residue to heat the fluidized medium and a settling portion disposed adjacent to the combustion portion and the gasification chamber for settling the heated fluidized medium therein. The fluidized-bed gasification furnace includes a first passage for introducing the pyrolysis residue from the gasification chamber to the combustion chamber together with the fluidized medium, a second passage for introducing the heated fluidized medium in the combustion chamber from the settling portion of the combustion chamber to the gasification chamber, and a first diffusion device for supplying a fluidizing gas to a first region in the combustion portion adjacent to the settling portion of the combustion chamber to move the fluidized medium from the combustion portion to the settling portion. The fluidized-bed gasification furnace also includes a circulation controller operable to adjust a flow rate of the fluidizing gas supplied from the first diffusion device to control a circulation amount of the fluidized medium.

Owner:EBARA CORP

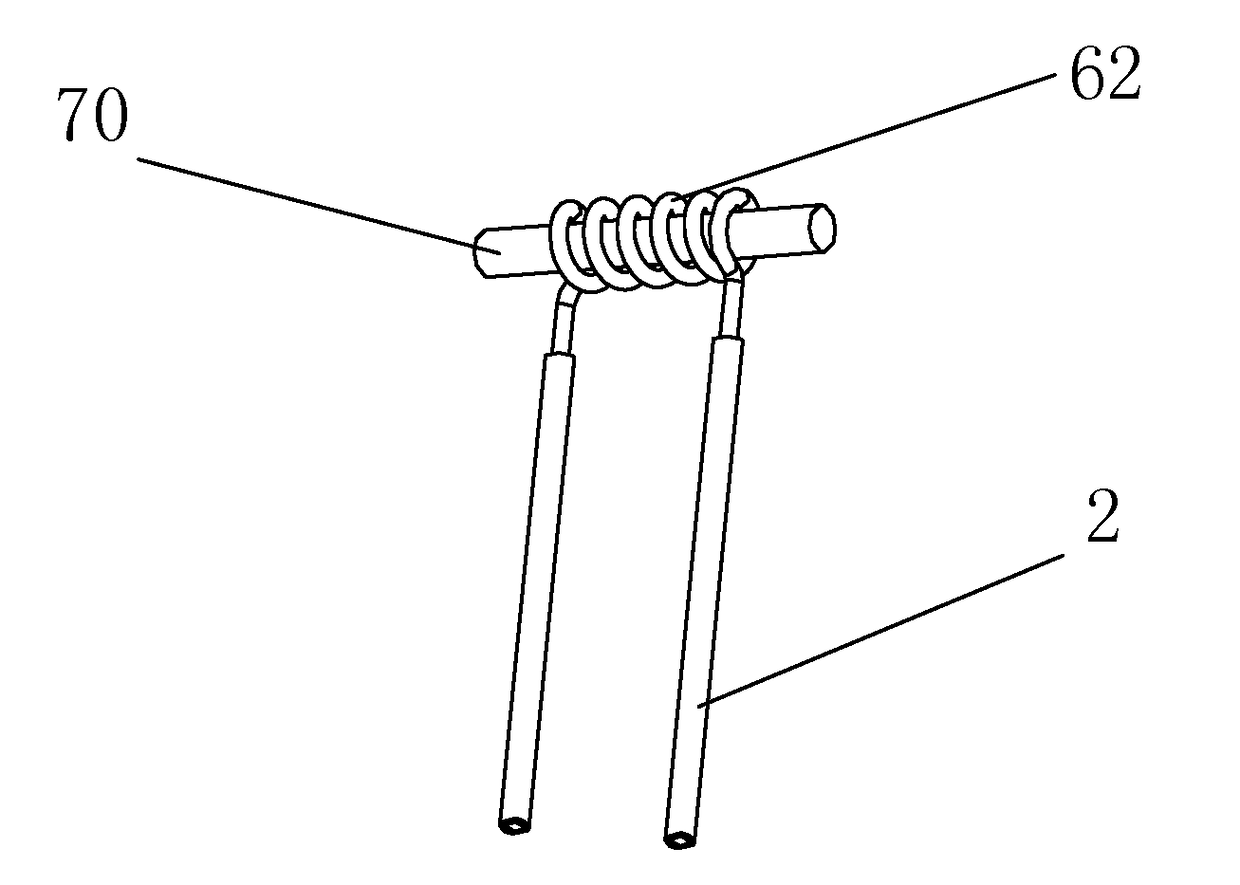

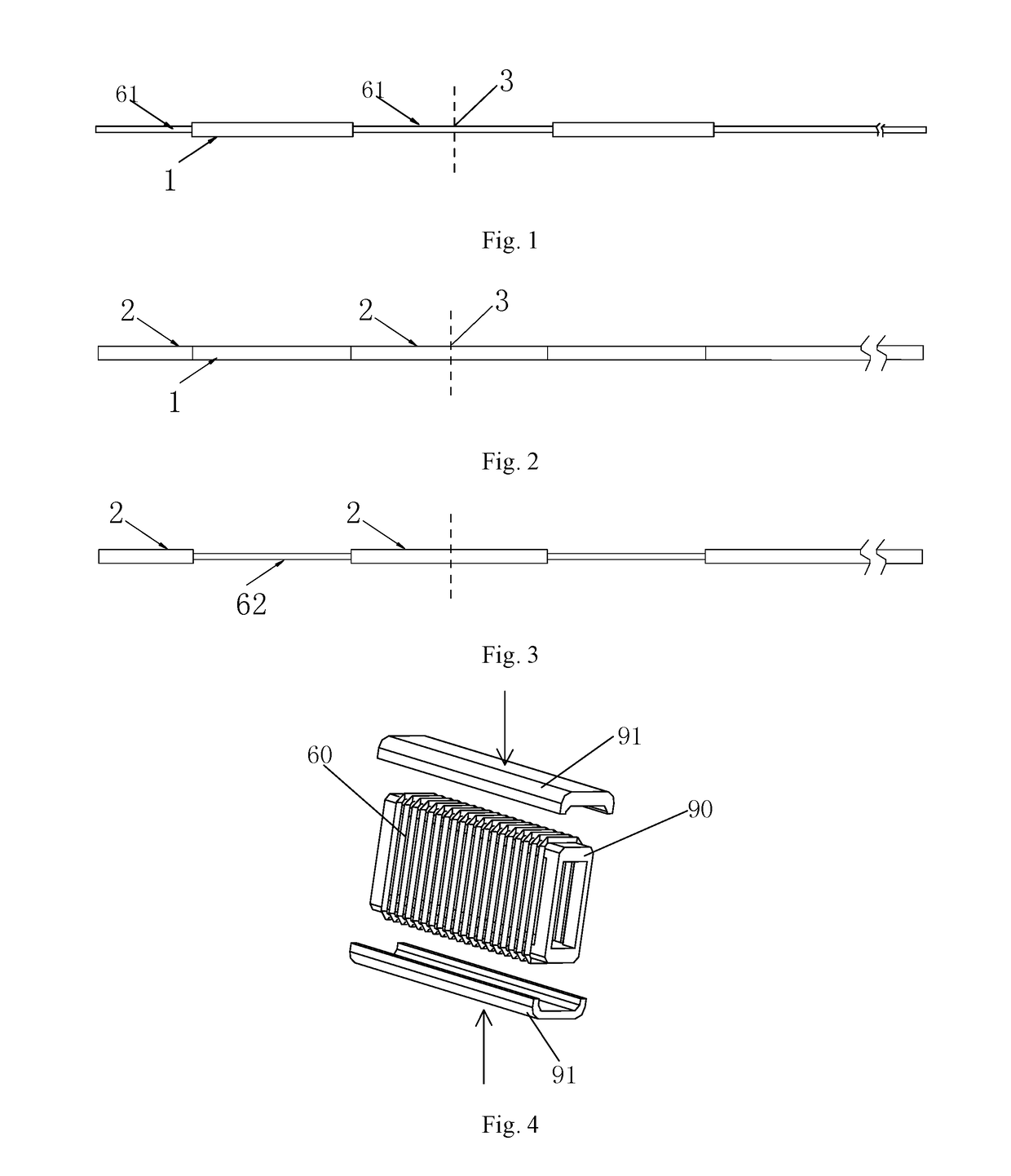

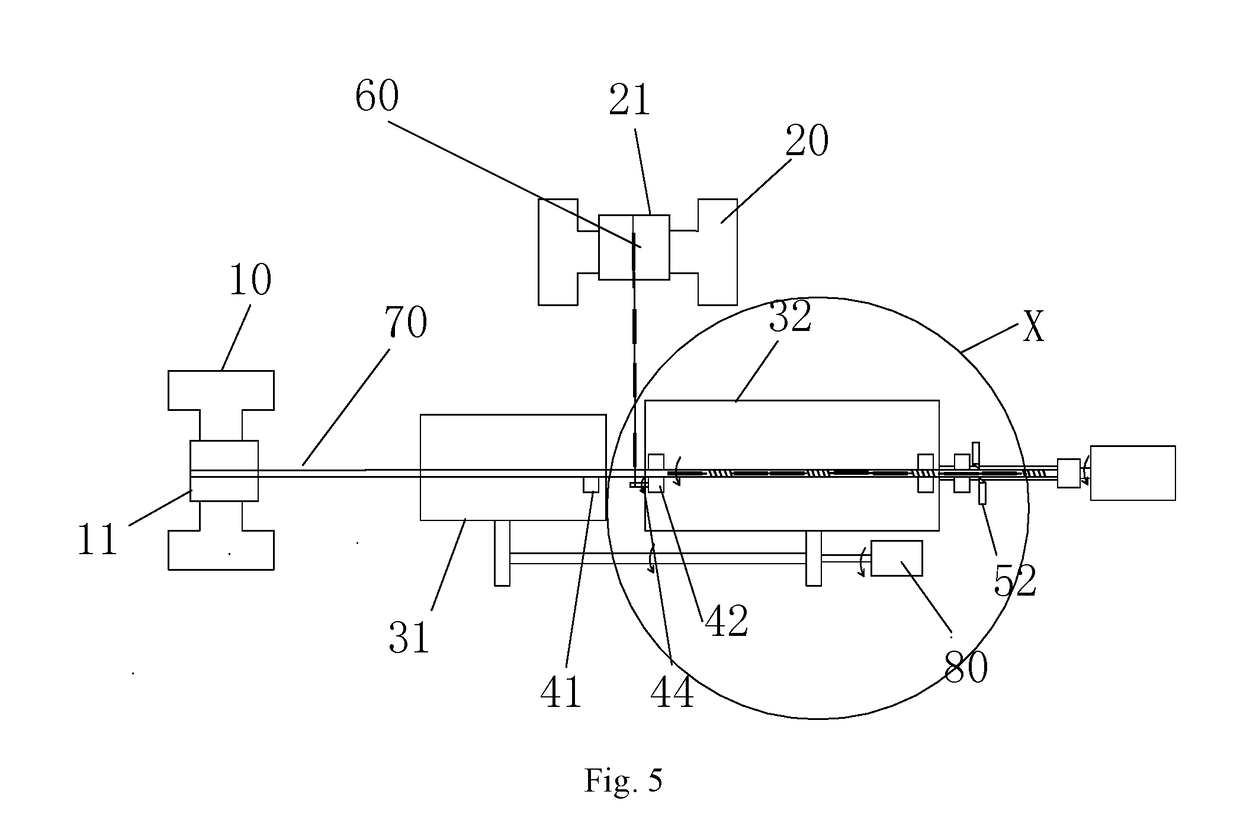

Forming method for heating element of electronic cigarette and manufacturing method for atomization assembly

InactiveUS20170224021A1Efficient manufacturing methodIncrease productivityTobacco devicesHeating element shapesElectrical resistance and conductanceEngineering

A forming method for a heating element of an electronic cigarette and a manufacturing method for an atomization assembly are provided, the forming method comprises coiling a heating wire into a heating coil, dividing the heating coil into sections including a plurality of heating sections and connecting sections; providing a deposition preventing layer on an external surface of the heating section; electroplating the heating coil, coating outer peripheral faces of all of the connecting sections of the heating coil with coatings having an electrical resistivity lower than that of the heating wire; removing the deposition preventing layer; and cutting the heating coil electroplated. The present application makes the manufacturing process of the heating element and the atomization assembly continues automatically, the production efficiency is improved, the resistance of the heating element or atomization assembly manufactured is more stable, and the product quality is higher.

Owner:HUIZHOU KIMREE TECH

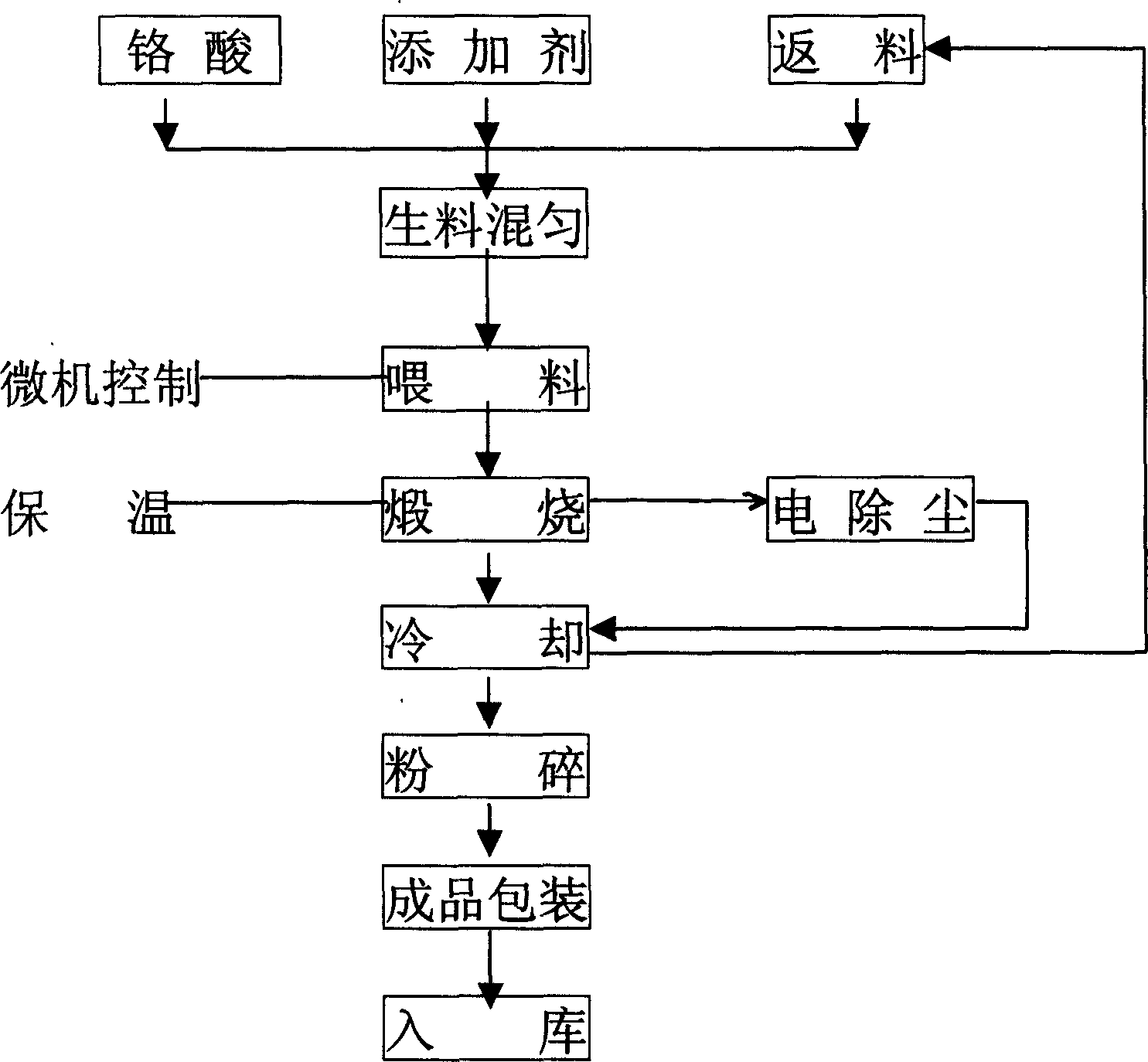

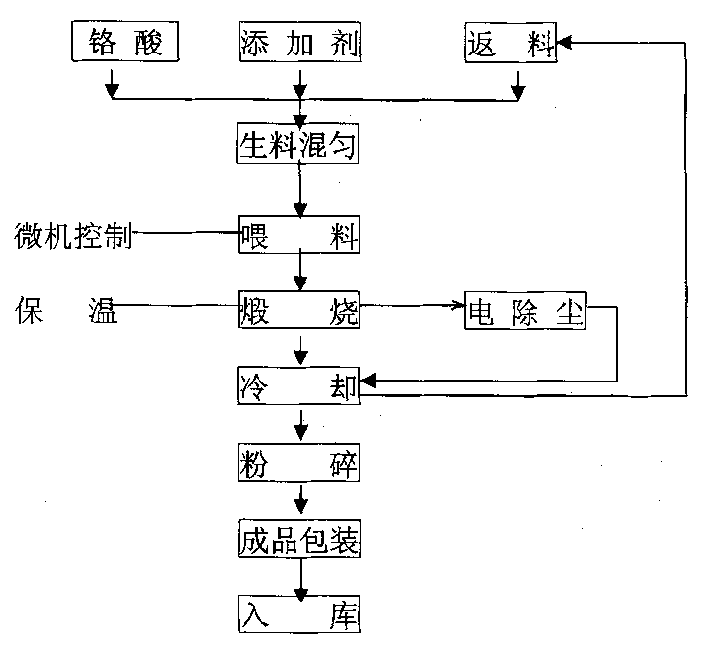

Method of producing dichromium trioxide using chromic acid thermal decomposition continuous method

InactiveCN1459419AHigh thermal efficiencyReduce consumptionChromium trioxideLiquid gasComputer control

A process for preparing Cr2O3 by continuous thermodecomposition of chromic acid includes such steps as proportionally mixing chromic acid, coarse Cr2O3 as returning charge and additive chosen from boric acid (preferable), ammonium chloride, starch and saw dust; after uniformly mixing under a computer control, parallel-flow combustion of the said mixture and liquefied gas as fuel in an insulated rotary furnace, thermodecomposition reaction to generate Cr2O3, keeping the temp. for a certain time, cooling and pulverizing to obtain the product. The unpulverized material is used as the said returning charge.

Owner:民乐县化工厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com