Patents

Literature

2976 results about "Thermal load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal load is demand for heat energy. The heat may be needed for space heating, hot water heating, or some industrial process. The thermal load can be served by the boiler, by a generator from which waste heat can be recovered, or by surplus electricity.

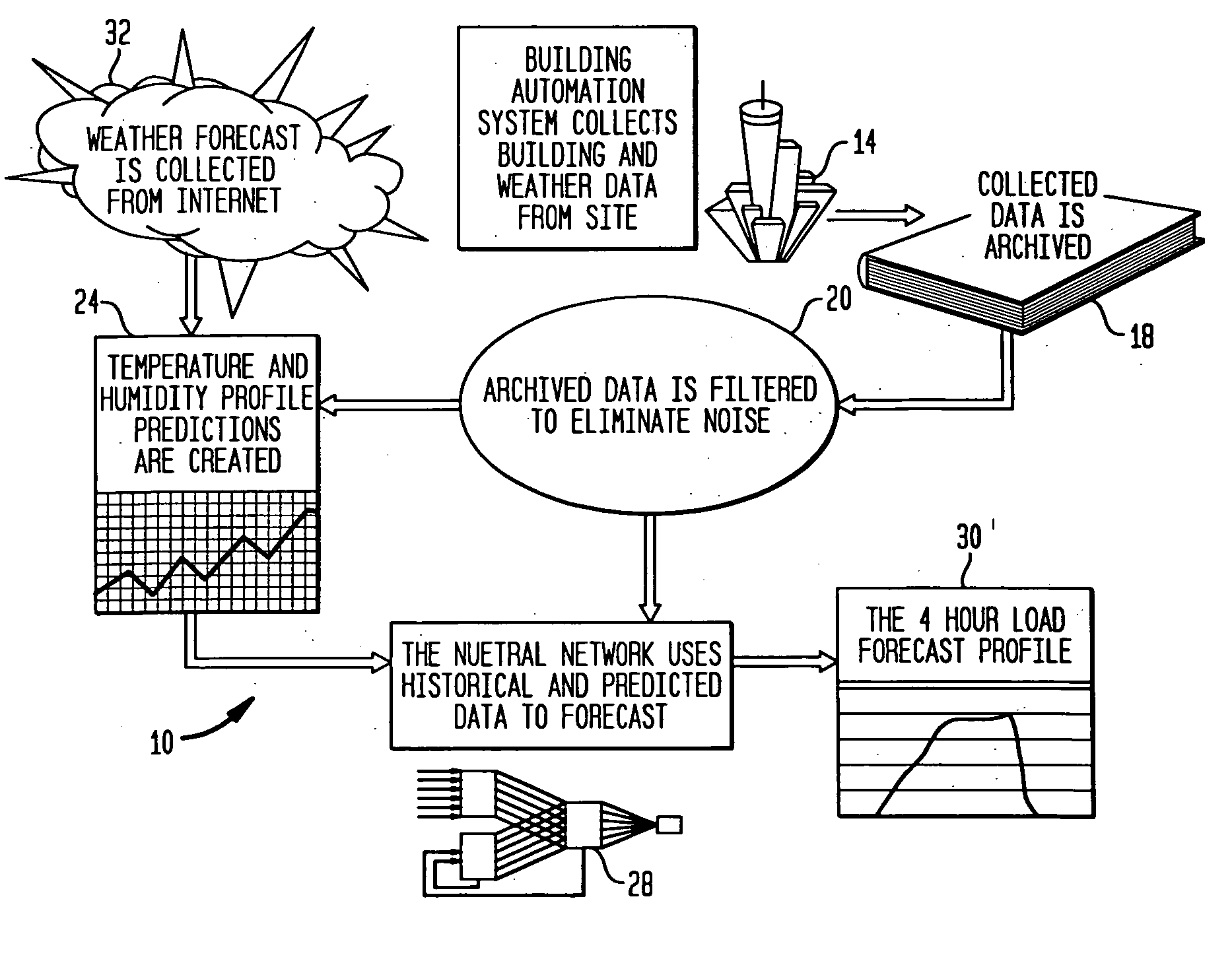

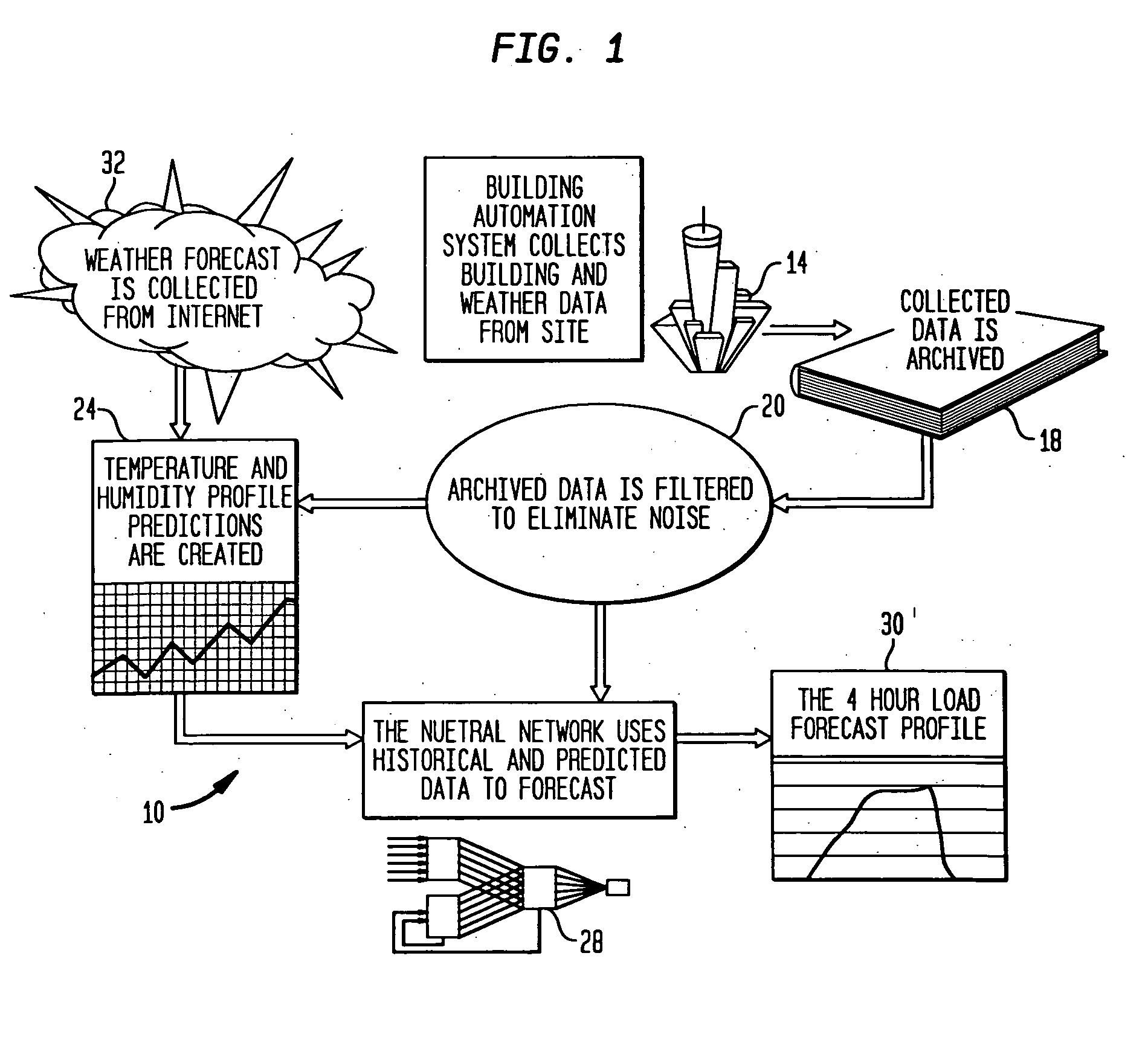

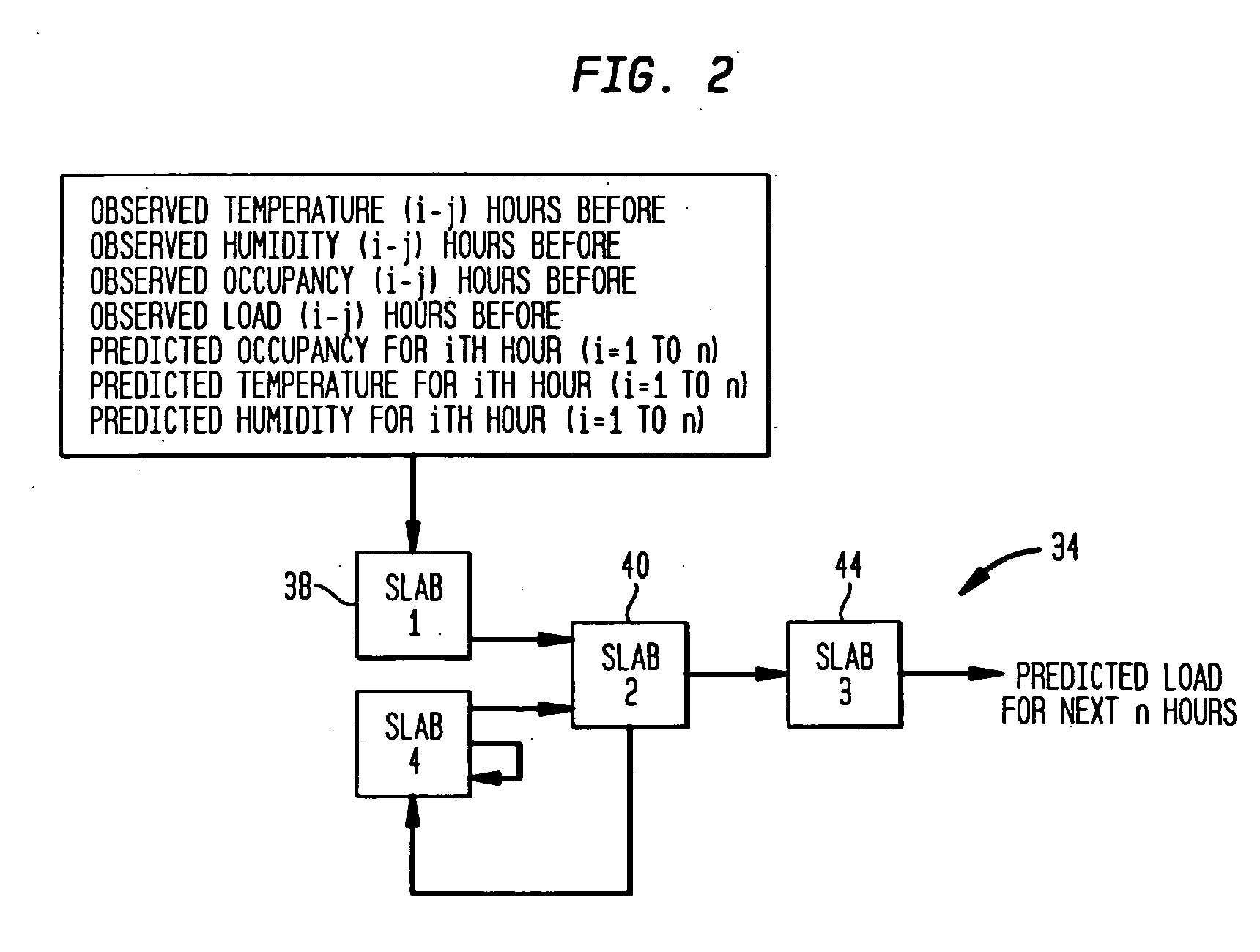

System and method for predicting building thermal loads

ActiveUS20050192915A1Error minimizationDigital computer detailsBiological neural network modelsNerve networkEngineering

A system for forecasting predicted thermal loads for a building comprises a thermal condition forecaster for forecasting weather conditions to be compensated by a building environmental control system and a thermal load predictor for modeling building environmental management system components to generate a predicted thermal load for a building for maintaining a set of environmental conditions. The thermal load predictor of the present invention is a neural network and, preferably, the neural network is a recurrent neural network that generates the predicted thermal load from short-term data. The recurrent neural network is trained by inputting building thermal mass data and building occupancy data for actual weather conditions and comparing the predicted thermal load generated by the recurrent neural network to the actual thermal load measured at the building. Training error is attributed to weights of the neurons processing the building thermal mass data and building occupancy data. Iteratively adjusting these weights to minimize the error optimizes the design of the recurrent neural network for these non-weather inputs.

Owner:SIEMENS IND INC

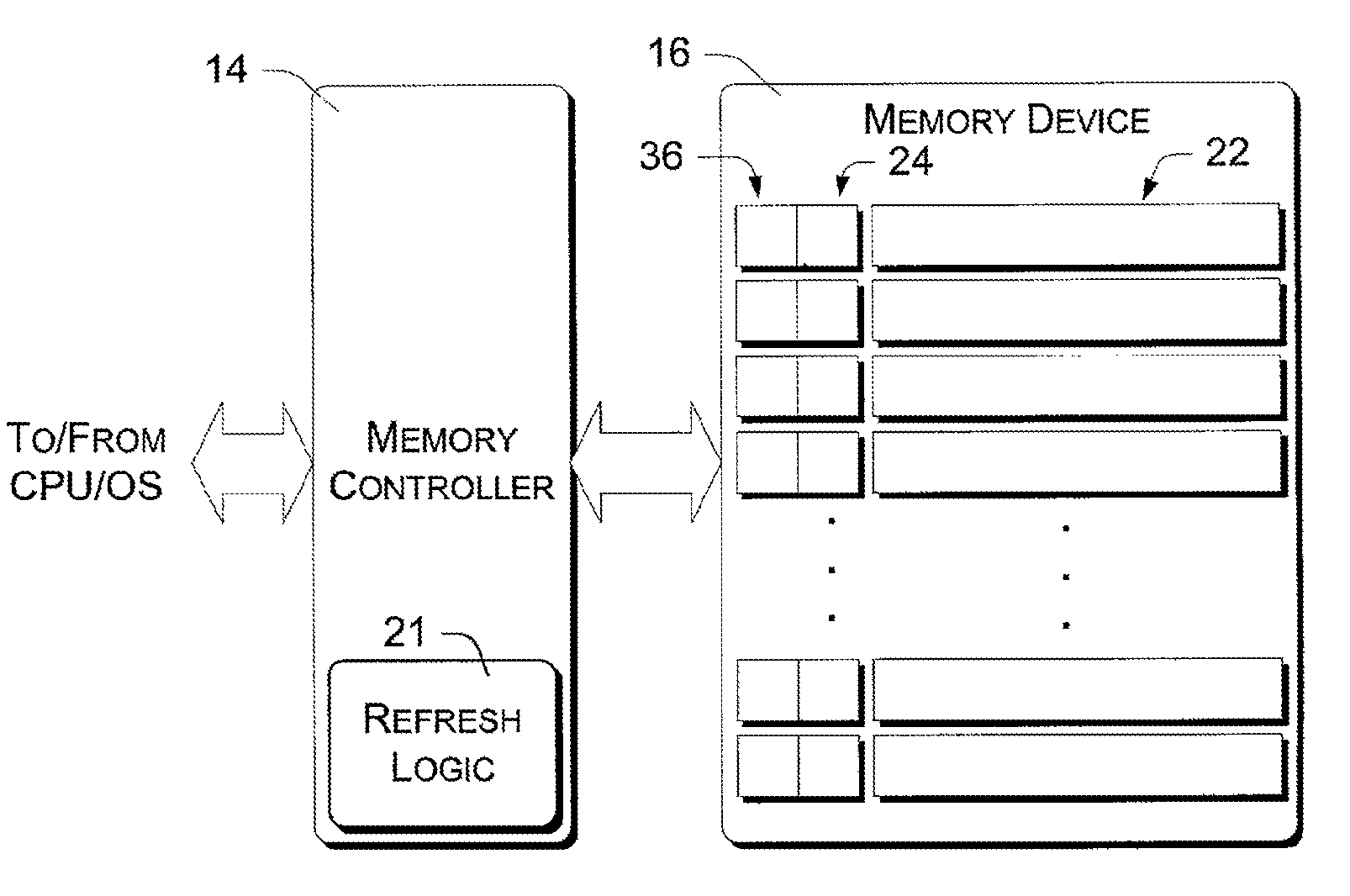

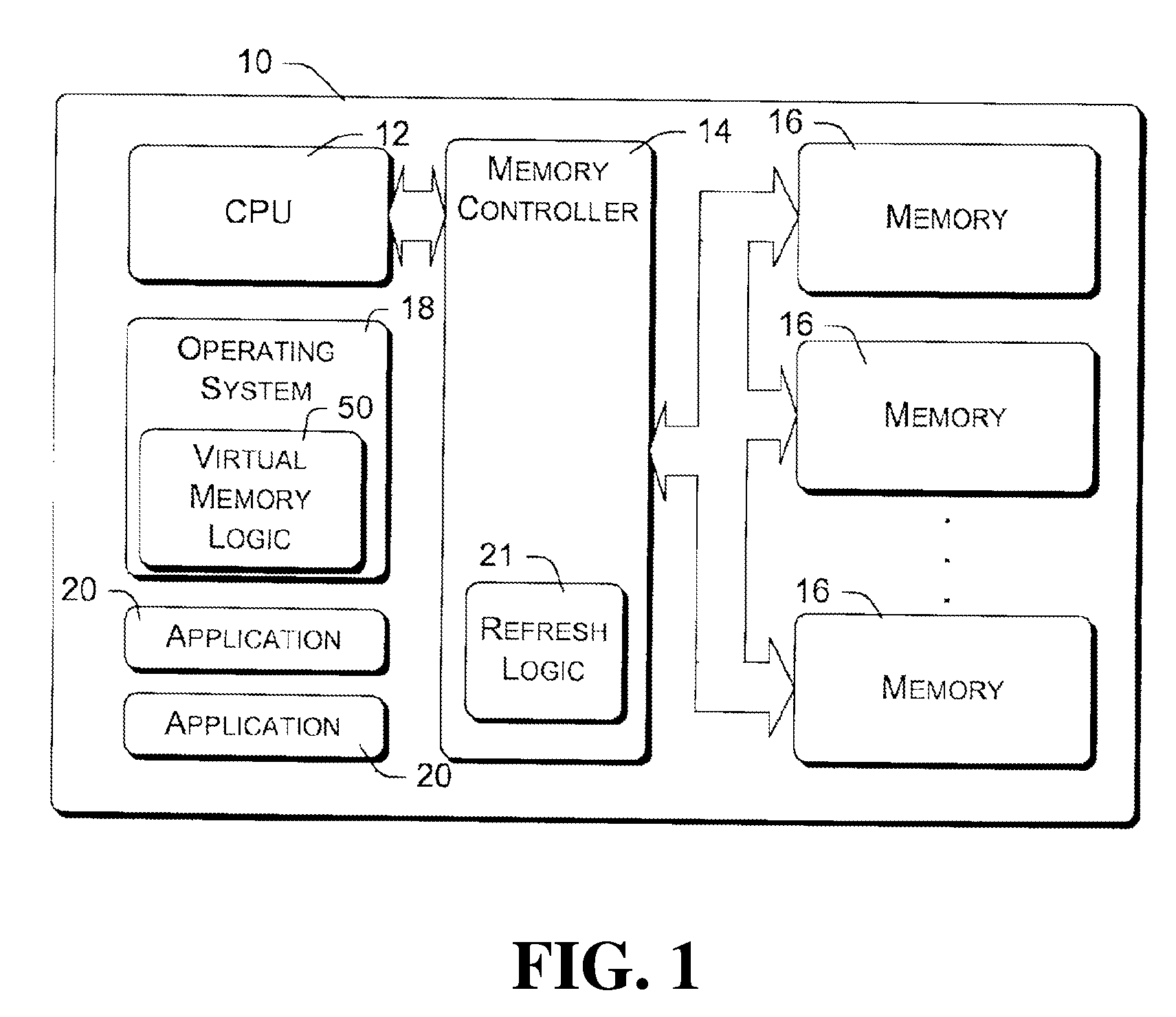

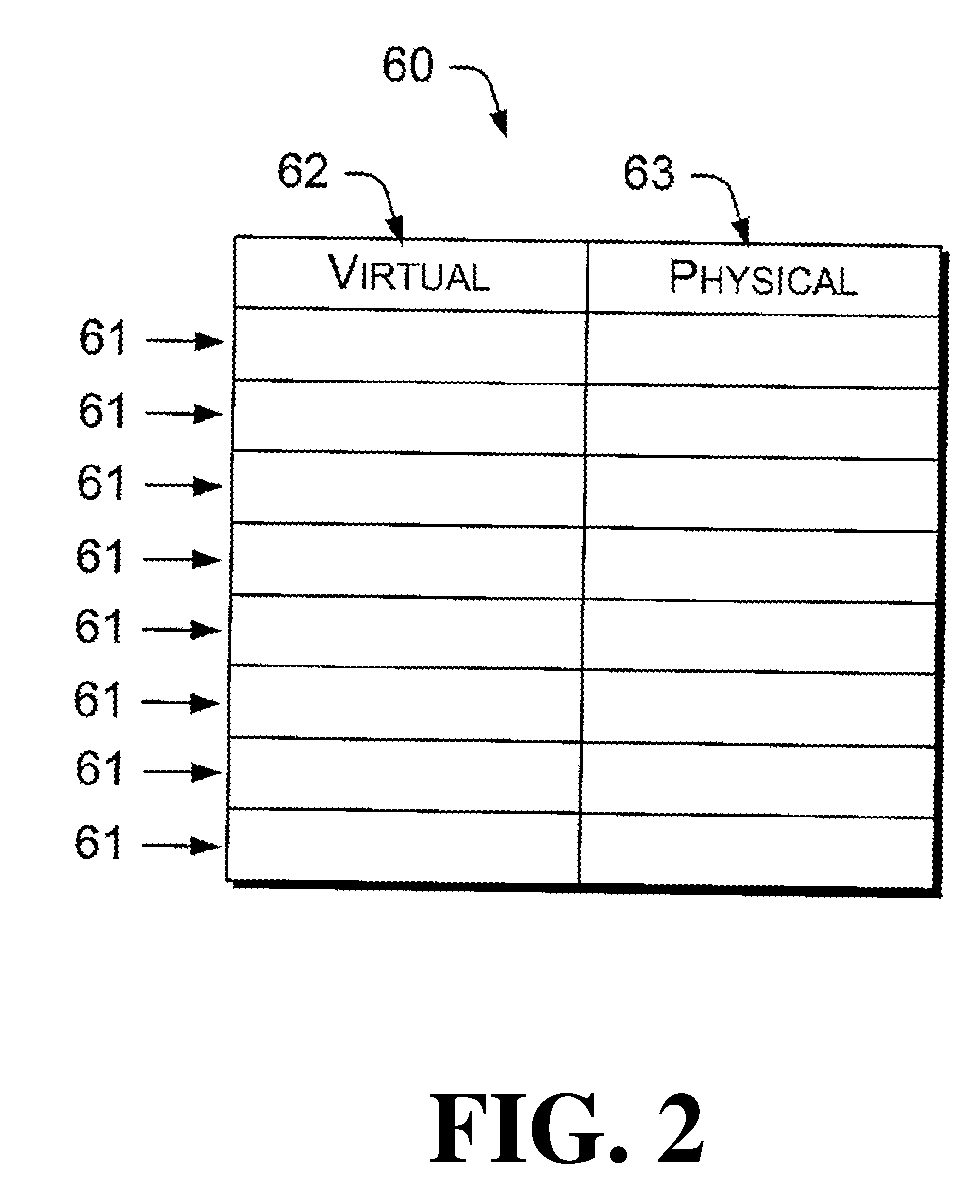

Redistribution of memory to reduce computer system power consumption

InactiveUS20070106860A1Limited amount of powerLowering thermal profileEnergy efficient ICTVolume/mass flow measurementDIMMPower mode

A method, apparatus and system are disclosed for redistributing memory allocation to portions of dynamic random access memory (DRAM) and dual in-line memory module (DIMM) devices that are underutilized, in order to balance memory usage more evenly amongst active devices so as to limit the amount of power and the thermal load consumed by an individual memory component. The disclosed method, apparatus and system are capable of identifying and tracking memory usage to minimize power consumption in a way that lessens the detrimental effects of “throttling” or reduced power modes for memory devices.

Owner:LENOVO GLOBAL TECH INT LTD

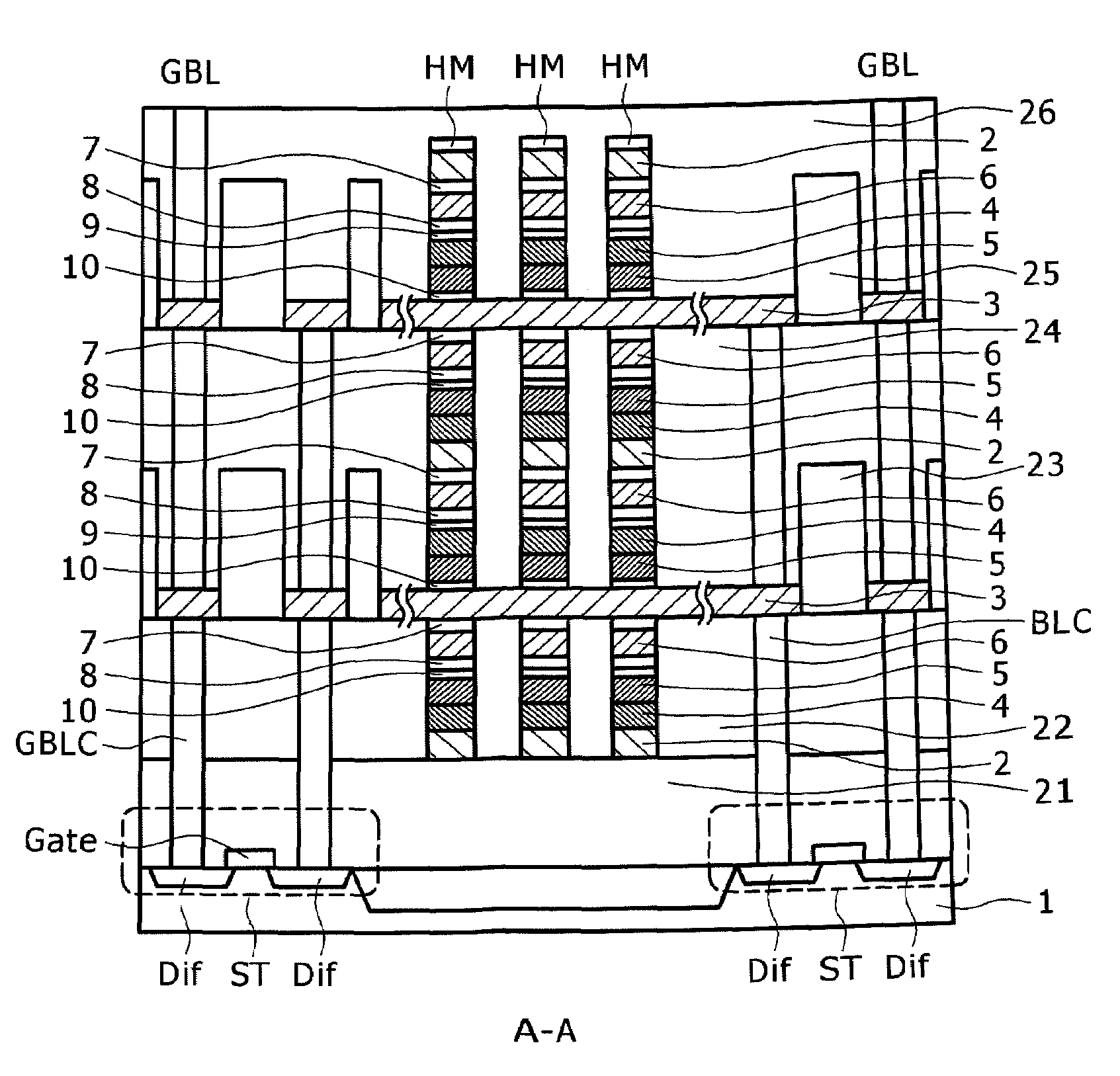

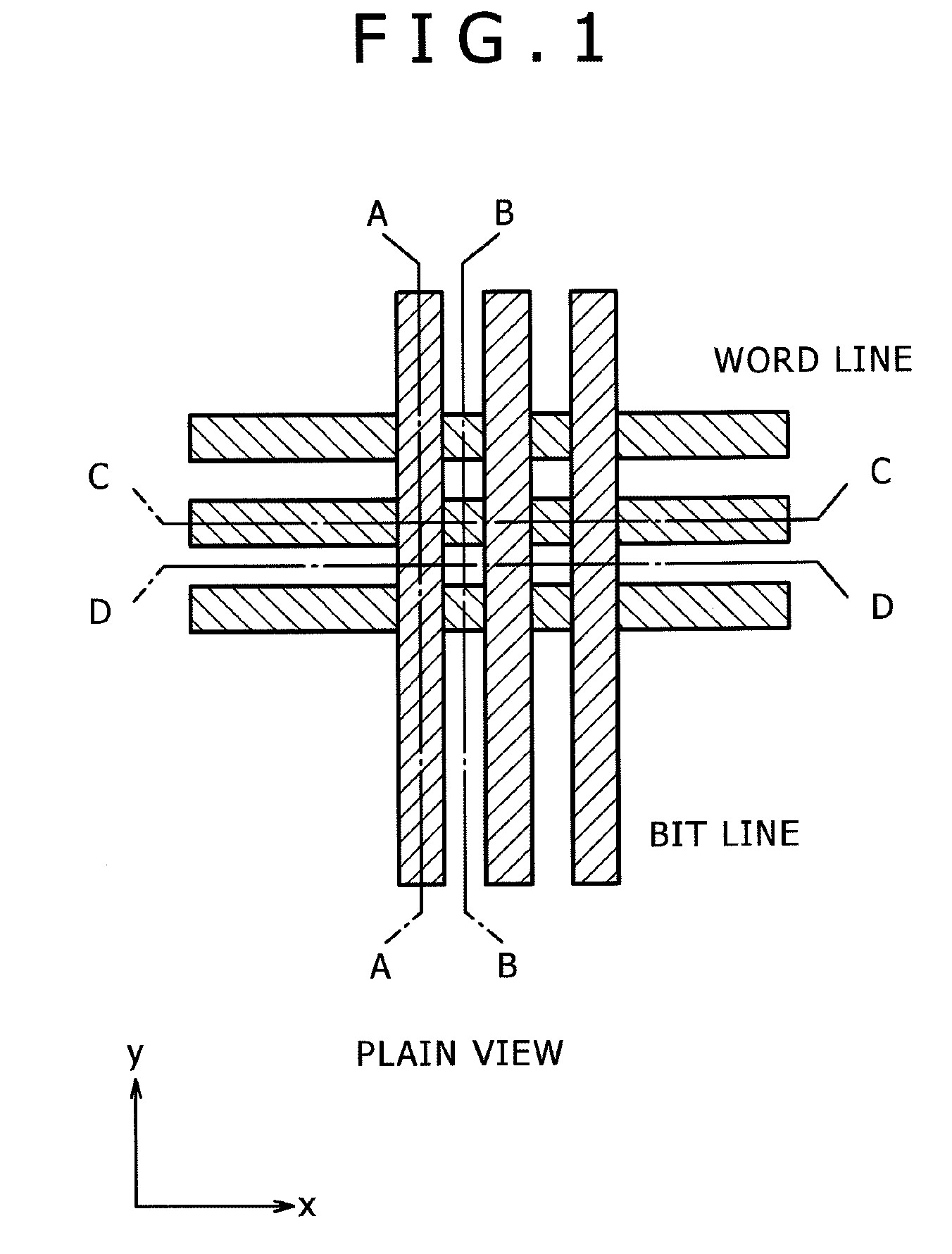

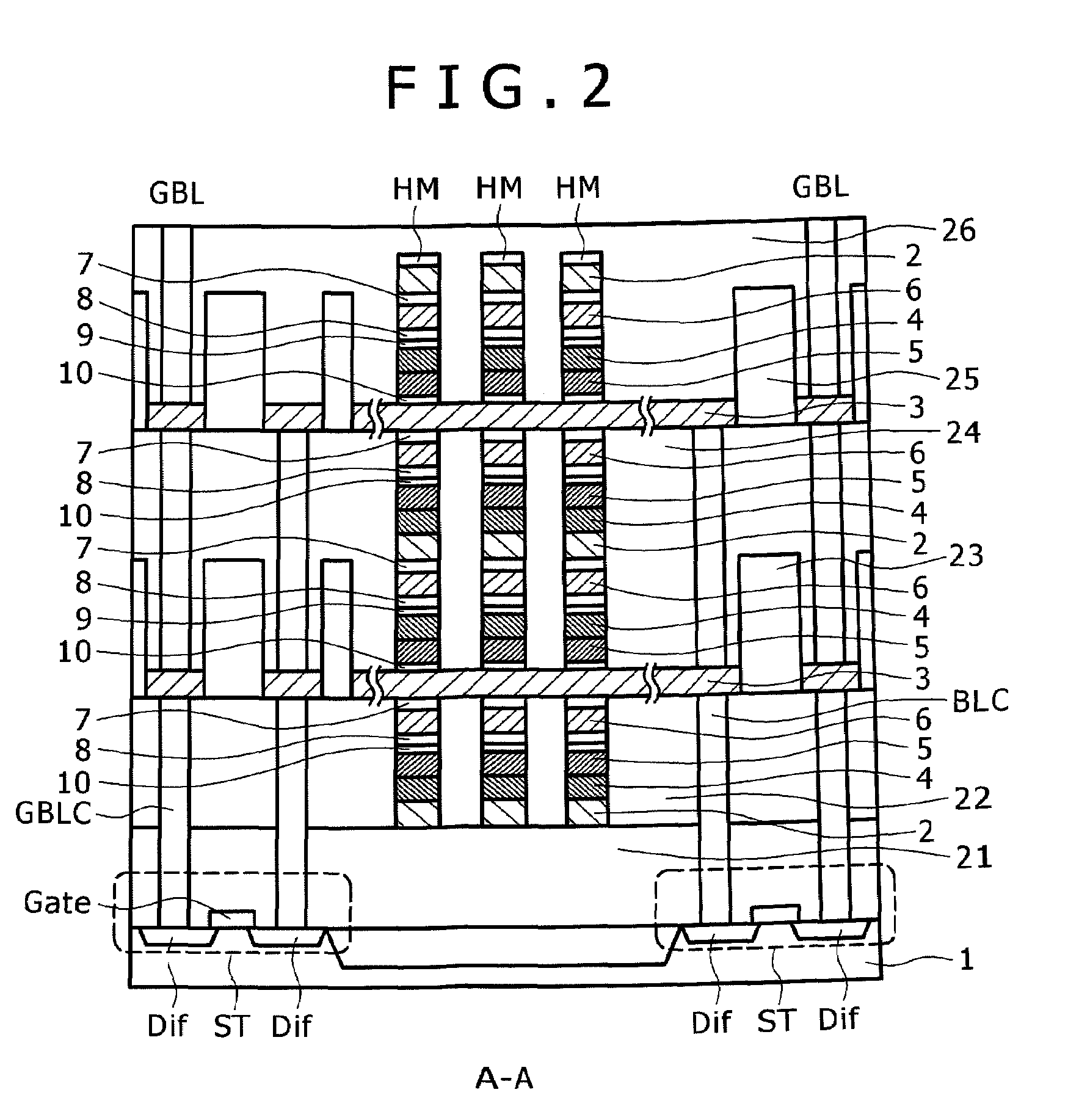

Semiconductor memory device and manufacturing method thereof

InactiveUS20090267047A1Large capacityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryDevice material

The present invention can promote the large capacity, high performance and high reliability of a semiconductor memory device by realizing high-performance of both the semiconductor device and a memory device when the semiconductor memory device is manufactured by stacking a memory device such as ReRAM or the phase change memory and the semiconductor device. After a polysilicon forming a selection device is deposited in an amorphous state at a low temperature, the crystallization of the polysilicon and the activation of impurities are briefly performed with heat treatment by laser annealing. When laser annealing is performed, the recording material located below the silicon subjected to the crystallization is completely covered with a metal film or with the metal film and an insulating film, thereby making it possible to suppress a temperature increase at the time of performing the annealing and to reduce the thermal load of the recording material.

Owner:HITACHI LTD

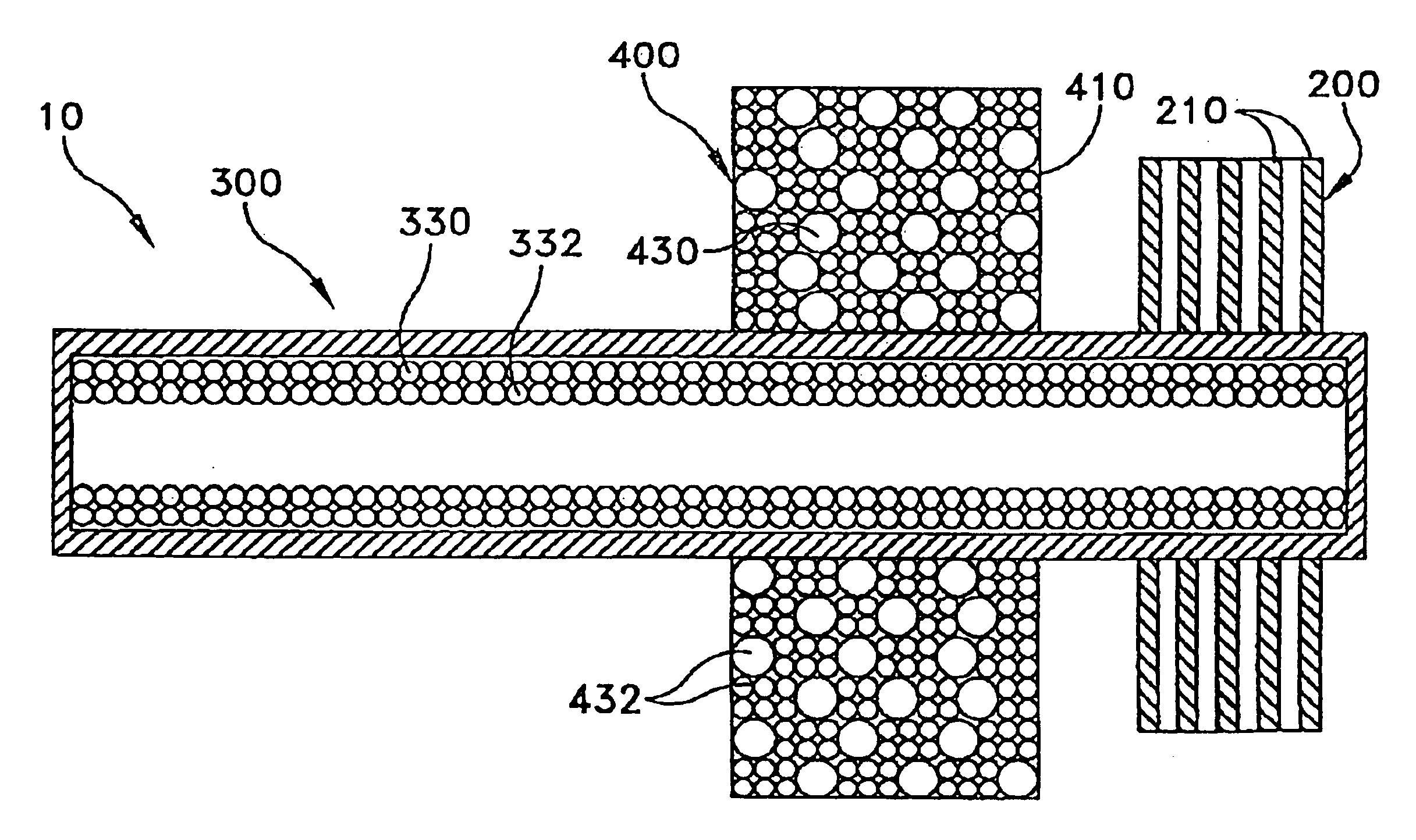

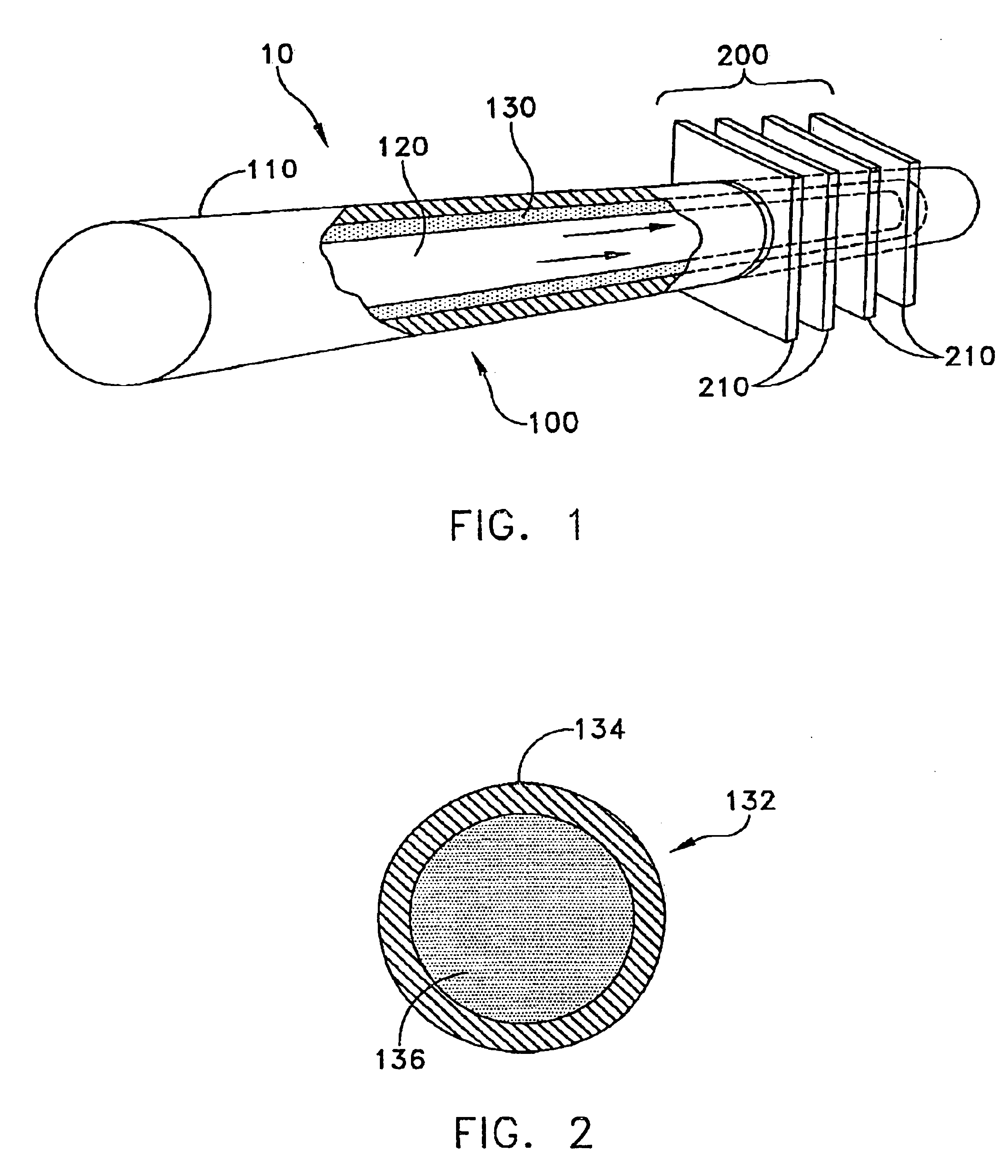

Heat pipe having a wick structure containing phase change materials

InactiveUS6889755B2Heat storage plantsSemiconductor/solid-state device detailsEngineeringPhase change

A wick for use in a heat pipe is provided incorporating particles of micro-encapsulated phase change material bonded together to form the wick. Use of a wick structure comprising micro-encapsulated PCM particles has the advantage of providing an additional heat absorber. This greatly enhances the ability of the heat pipe to absorb excess heat and may help to prevent damage to the heat pipe or heat generating component, such as an electronic device, especially at times of peak thermal loads.

Owner:THERMAL

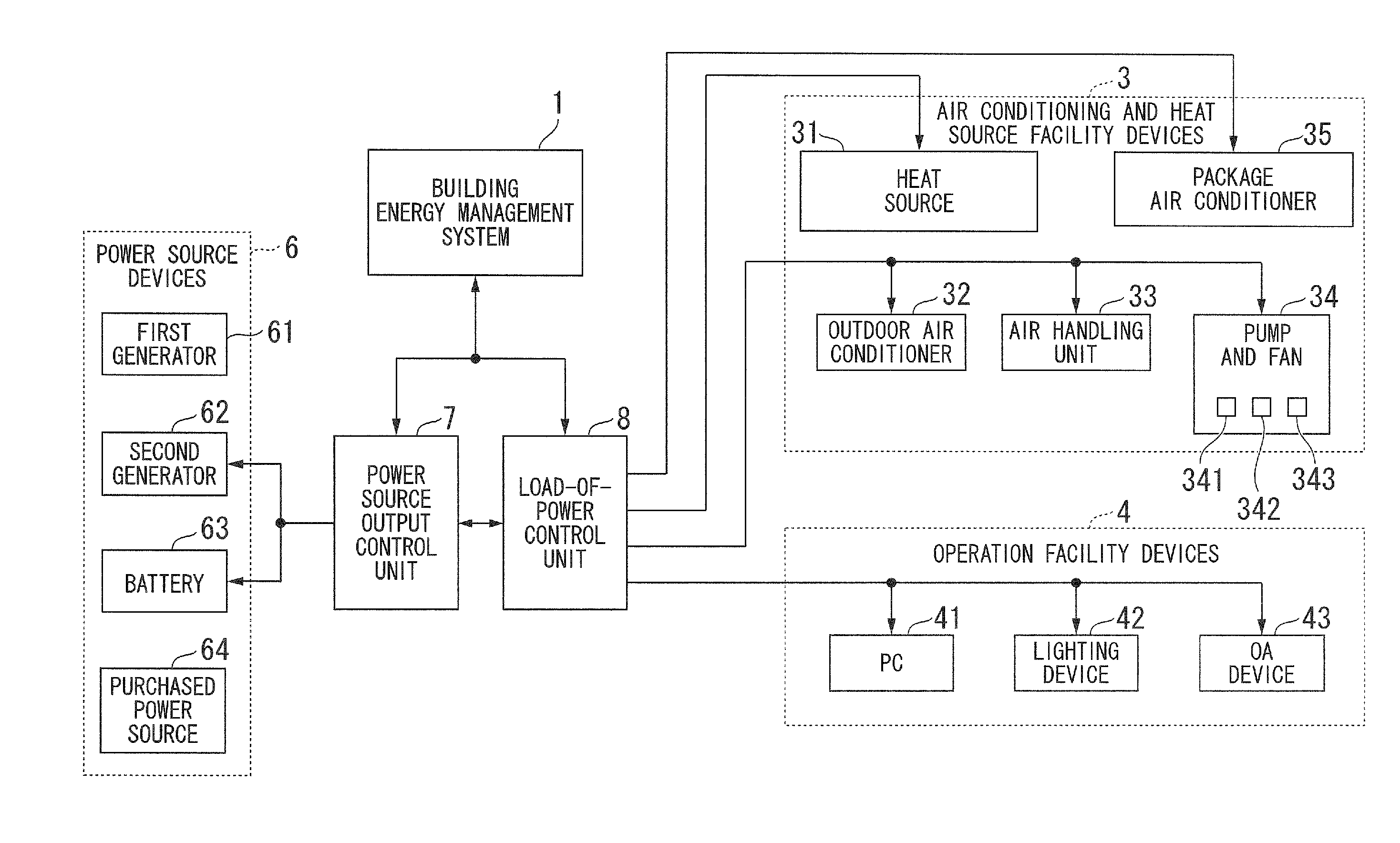

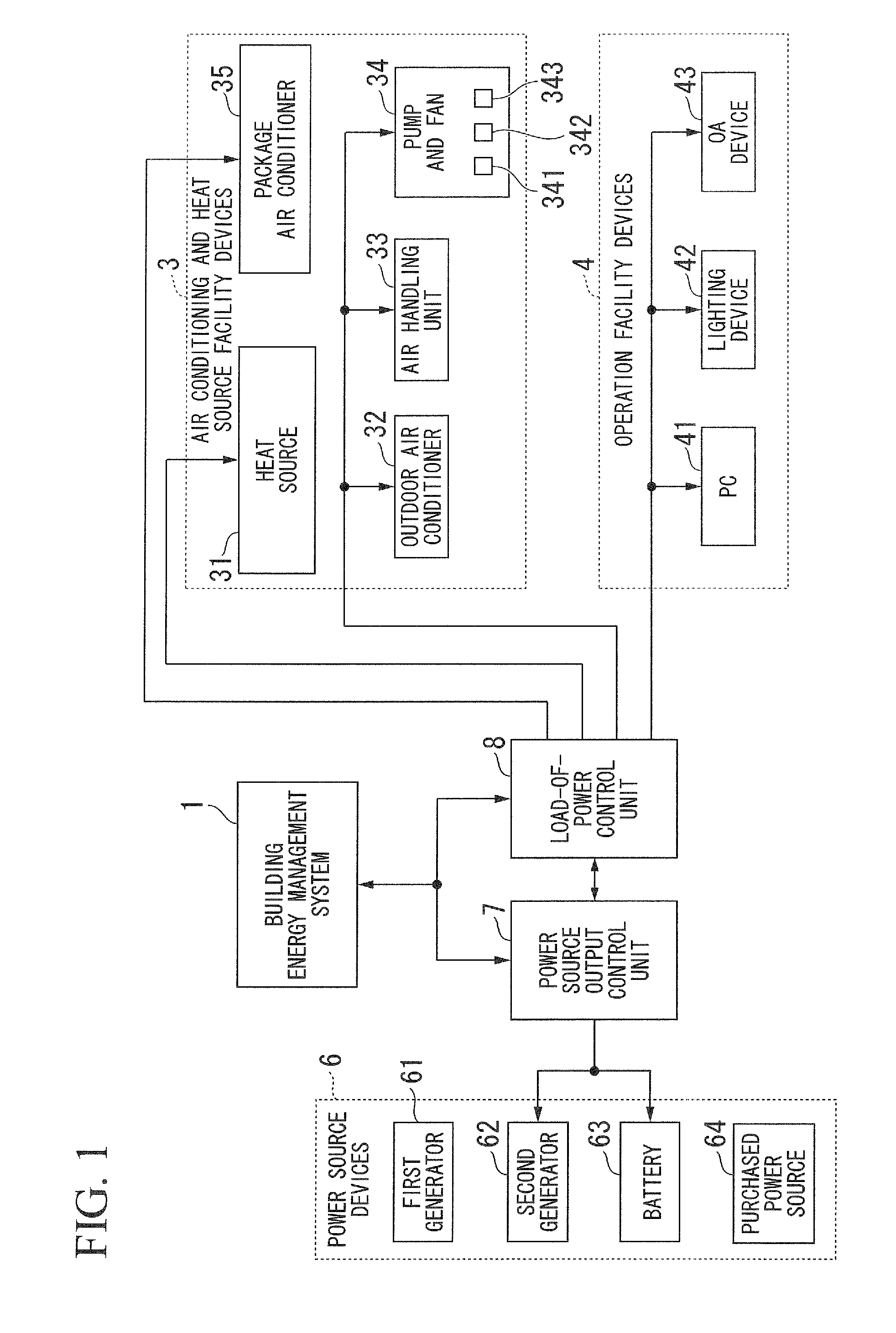

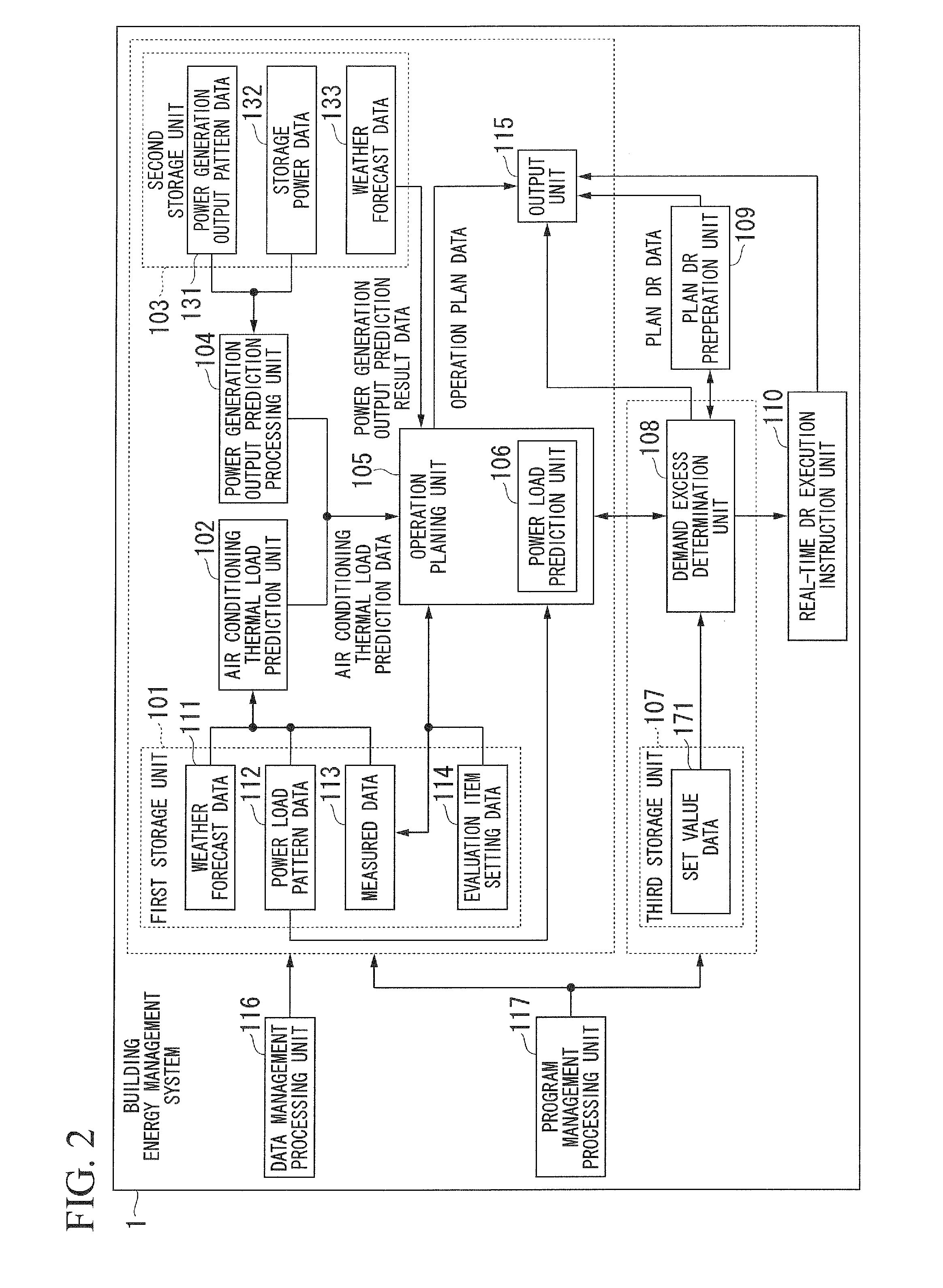

Operation Management Apparatus, Operation Management Method, and Operation Management Program

ActiveUS20120083927A1Possible to executeGeneration forecast in ac networkMechanical apparatusTime scheduleProgram planning

An operation management apparatus includes an air conditioning thermal load prediction unit configured to calculate an air conditioning thermal load predicted value indicating a predicted amount of heat required to adjust temperature to a pre-set temperature on a day-of-prediction, a power generation output prediction processing unit configured to calculate power generation output prediction data indicating a generated power obtained by a generator within the day-of-prediction, and an operation planning unit configured to prepare an air conditioning heat source operation plan, and determines a purchased power and the generated power using the power generation output prediction data to thereby prepare a power facility operation plan indicating a schedule of a power output from the purchased power source and the generator, so that the purchased power per predetermined time supplied from a purchased power source of a commercial power system becomes a target value.

Owner:THE SHIMIZU CONSTRUCTION CO LTD

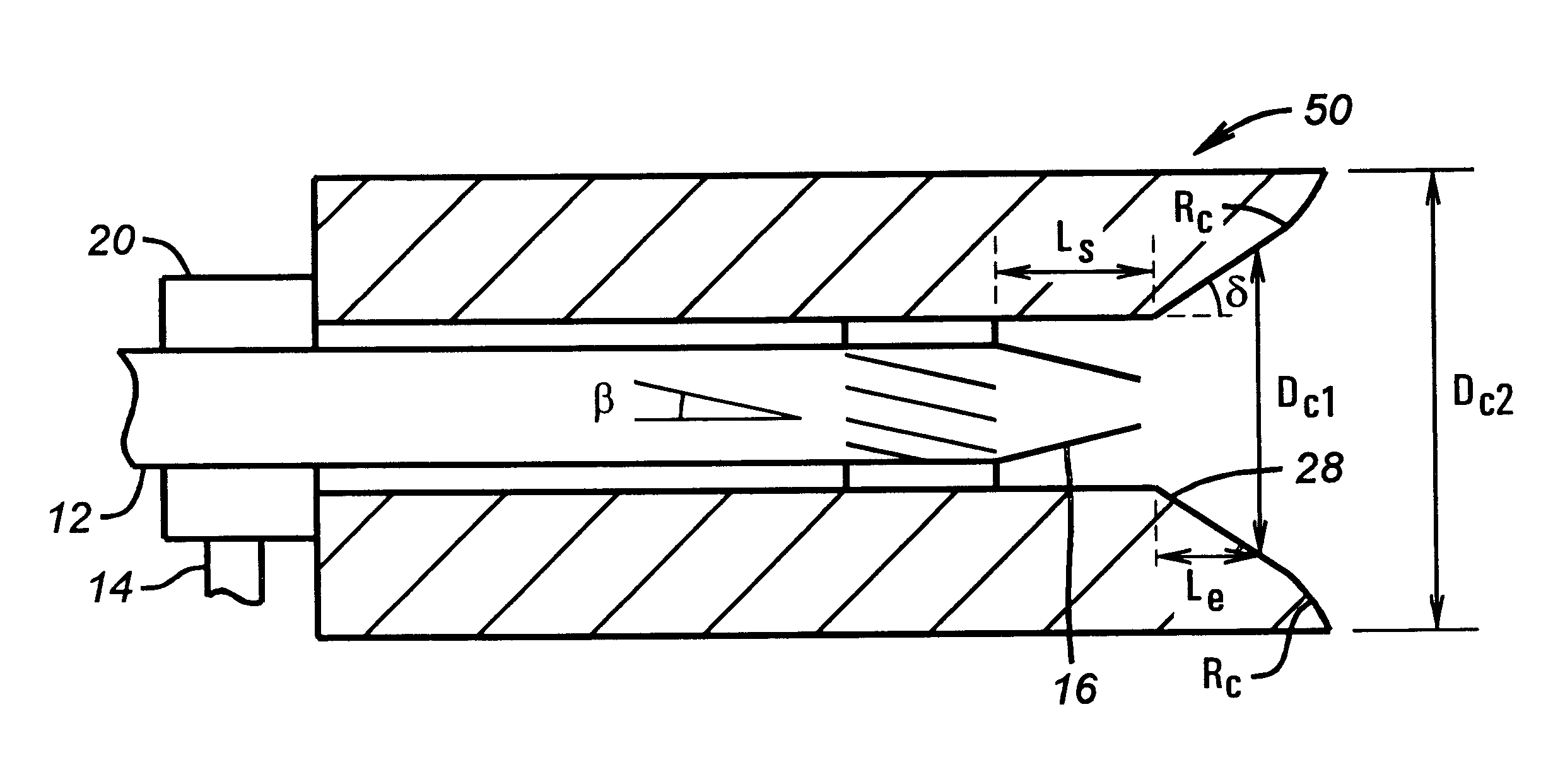

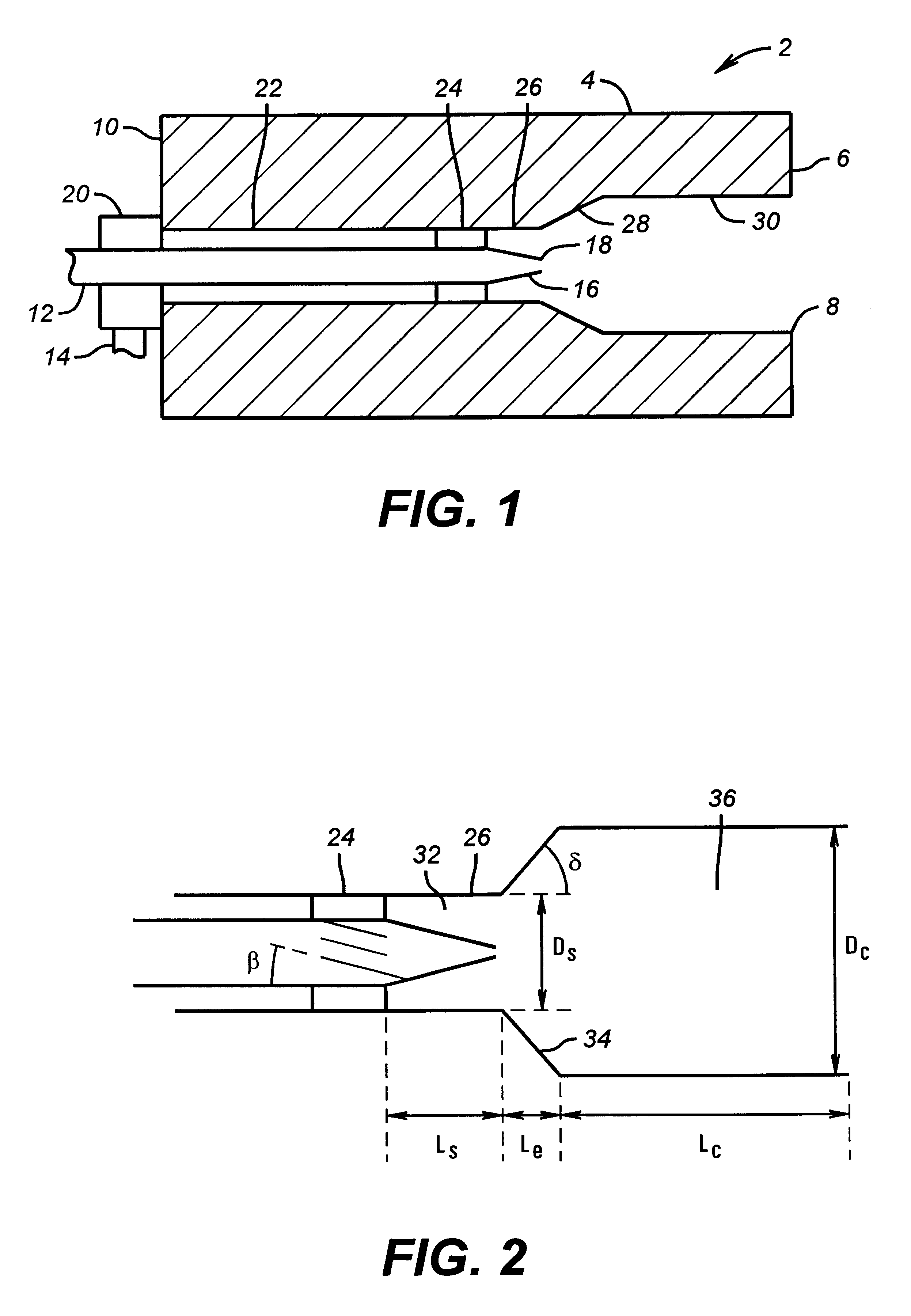

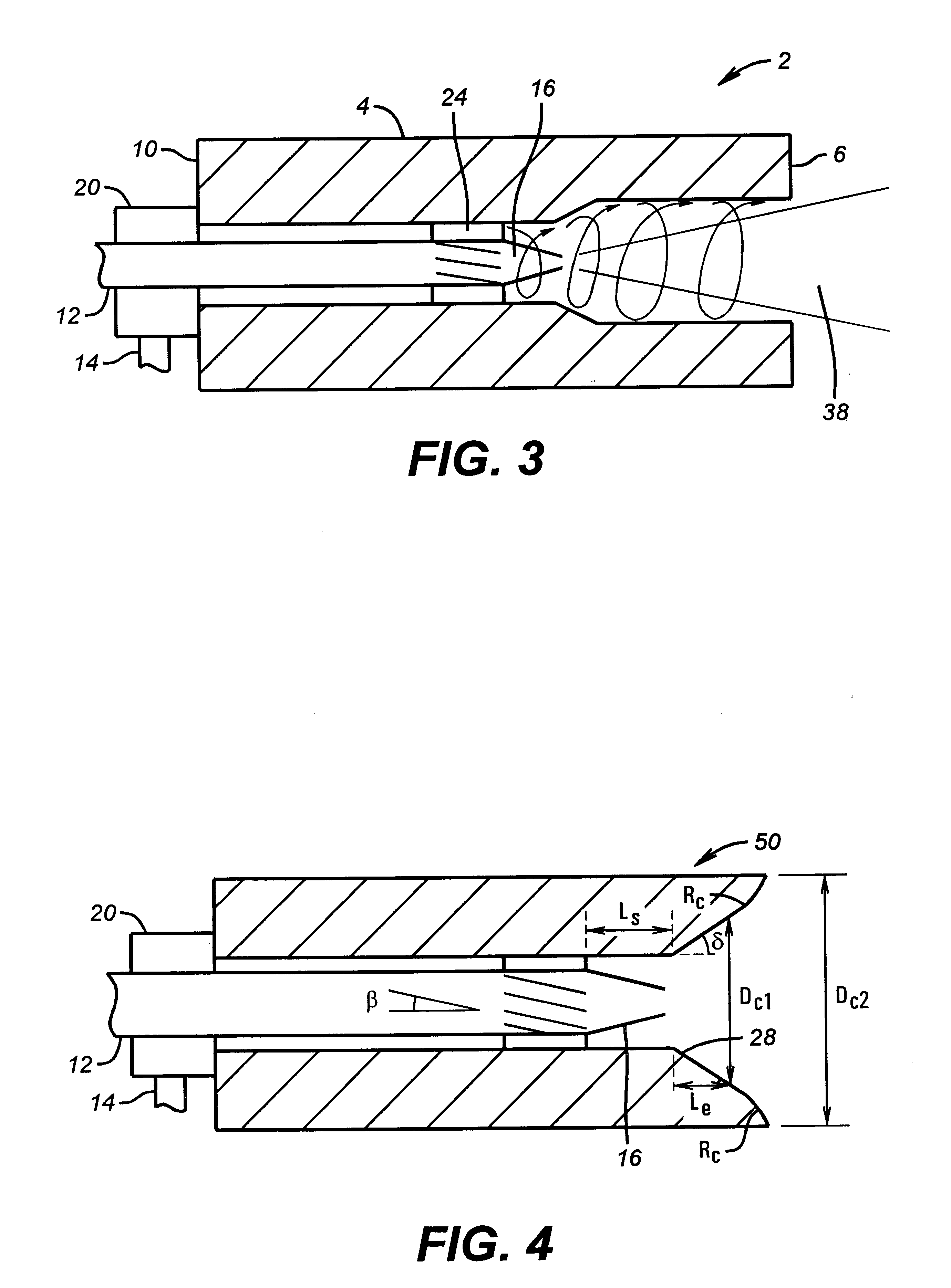

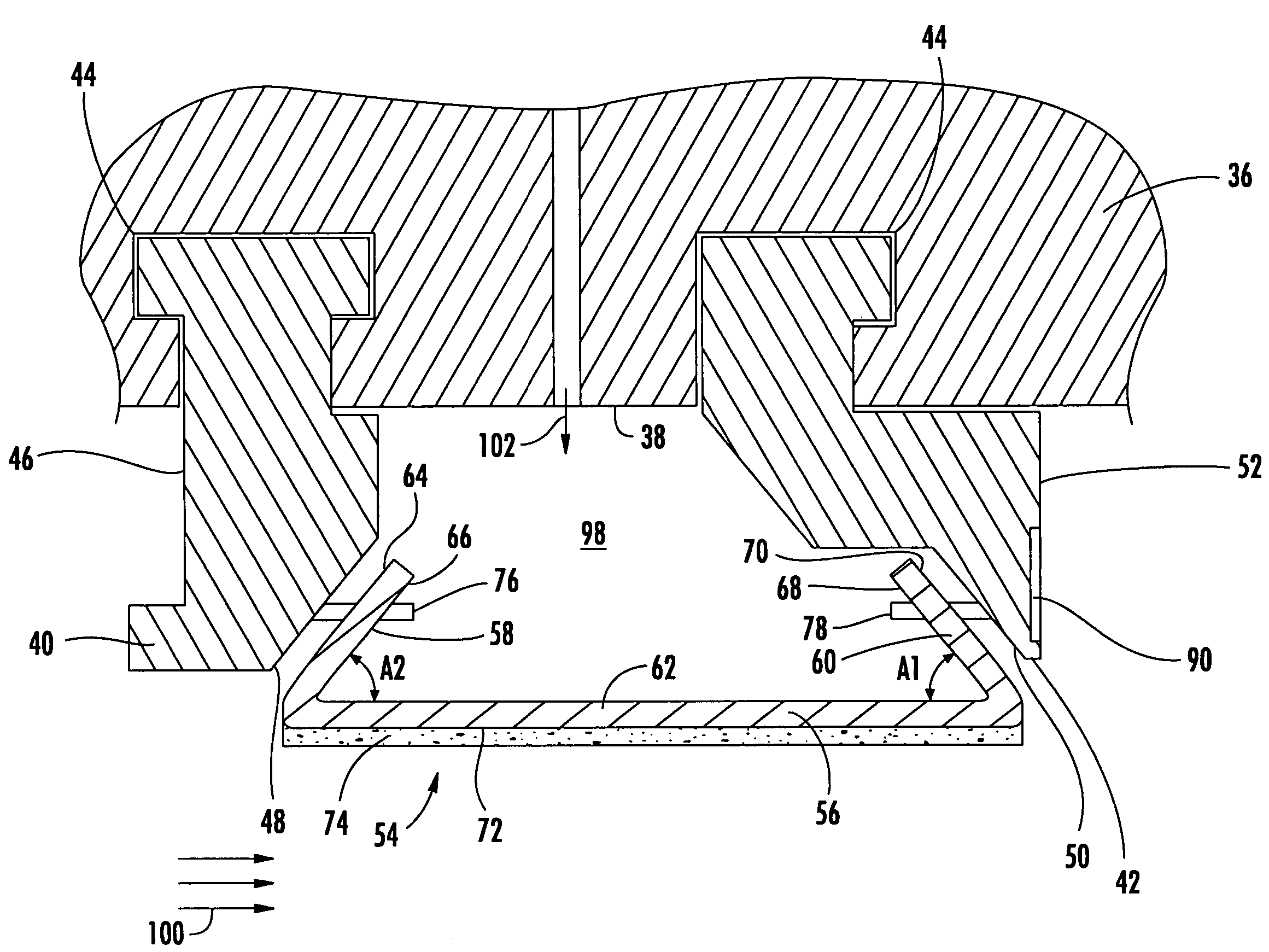

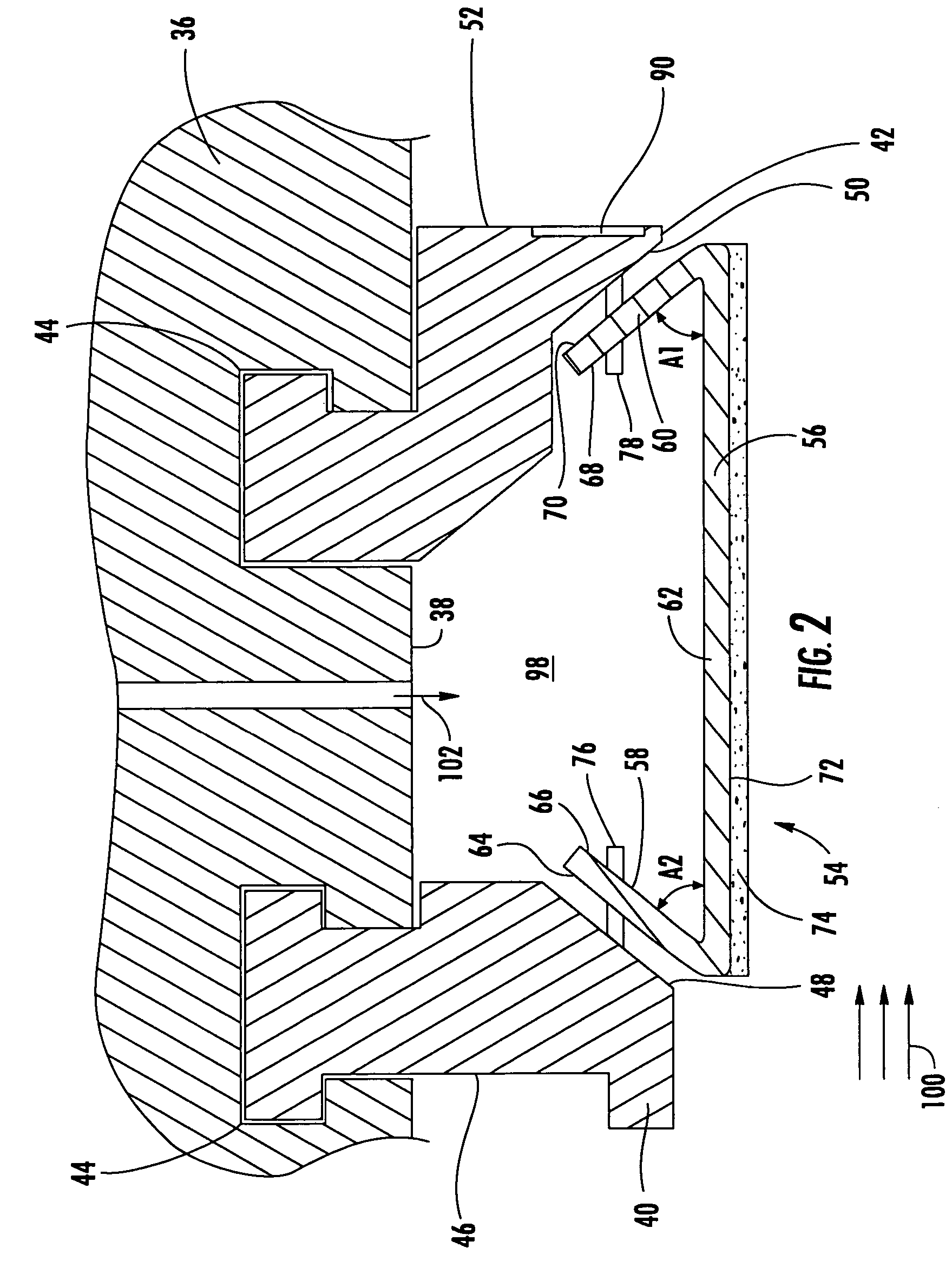

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

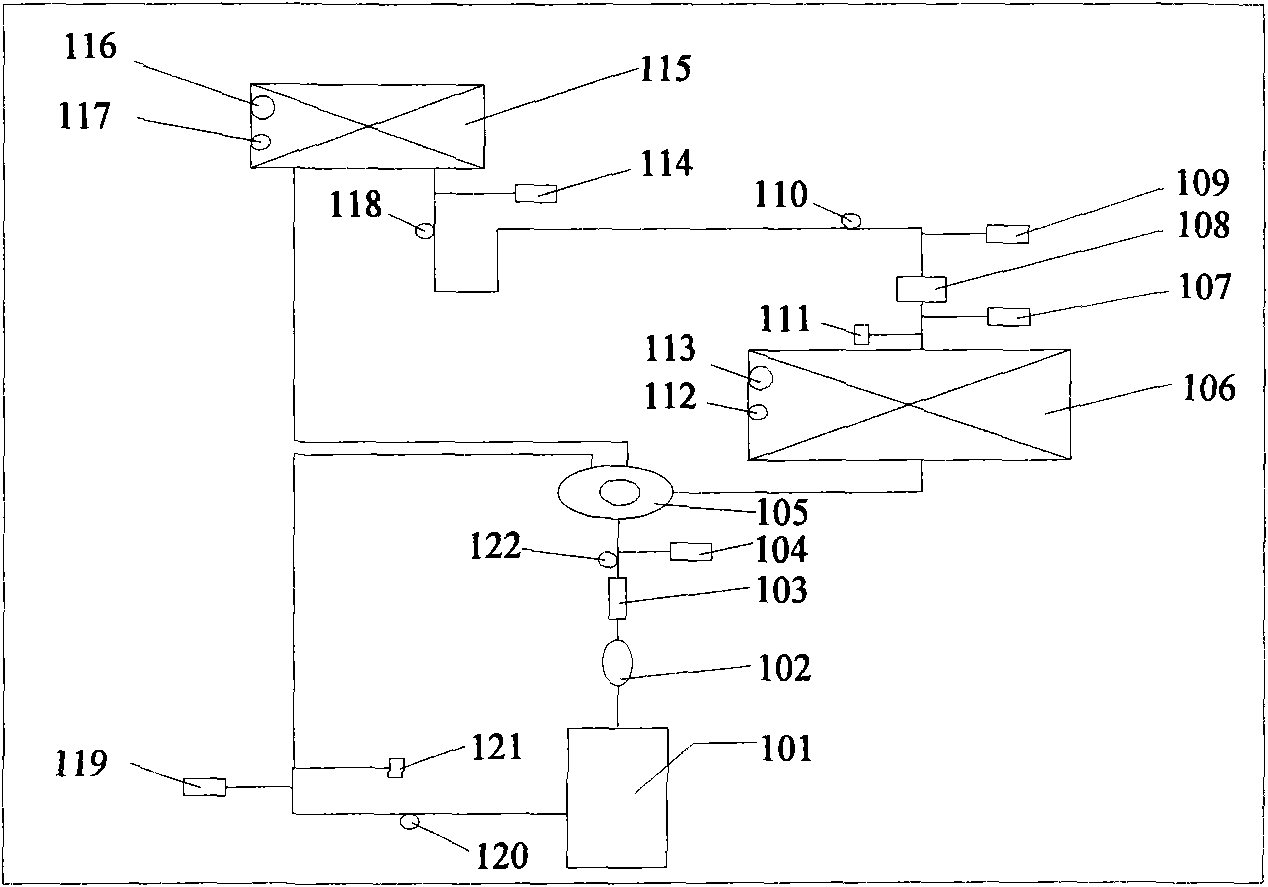

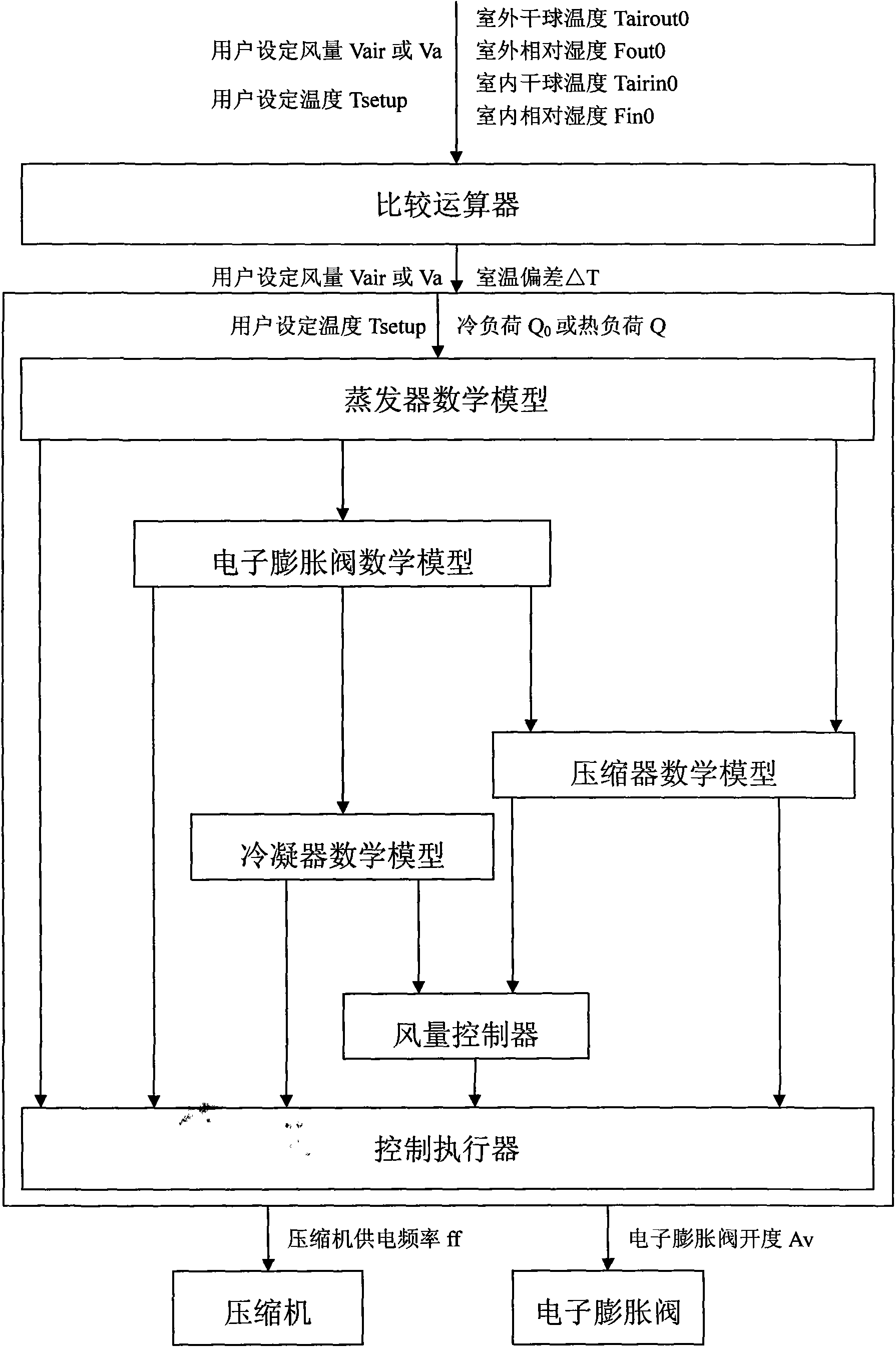

Variable frequency energy-saving control method for refrigeration system

ActiveCN101603751AGive full play to the heat exchange capacityReduce heat transfer temperature differenceSpace heating and ventilation safety systemsSpace heating and ventilation control systemsAir volumeOperating point

The invention belongs to the technical field of energy conservation, and relates to a variable frequency energy-saving control method for a refrigeration system. The control method comprises the steps of: determining the mass flow of a refrigerant according to the change or change trend of cooling load, then determining consumed power of a compressor which satisfies the flow, predicting the minimum condensation pressure which ensures that the thermal load of a condenser satisfies the cooling load and the power change of the compressor through an established energy-saving control mathematical model, and gradually adjusting the power frequency of the compressor to ensure that the rotating speed of the compressor reaches a predicted value; and adjusting the opening degree of an expansion valve to ensure that the condensation pressure reaches to be lowest, realizing the minimum pressure difference operation between the condenser and an evaporator, and ensuring that the operation energy consumption of the refrigeration system is lowest. The method solves the optimizing control problem of the compressor, the expansion valve and a fan in the system, utilizes the energy-saving control mathematical model to perform joint regulation on controllable factors (such as the rotating speed of the compressor, the opening degree of the expansion valve, and the air volume of an outdoor unit) of the operation of the system, ensures that the refrigeration system operates at a best operating point, and realizes the further energy conservation of the refrigeration system based on the variable frequency regulation.

Owner:汉广中药科技(天津)有限公司

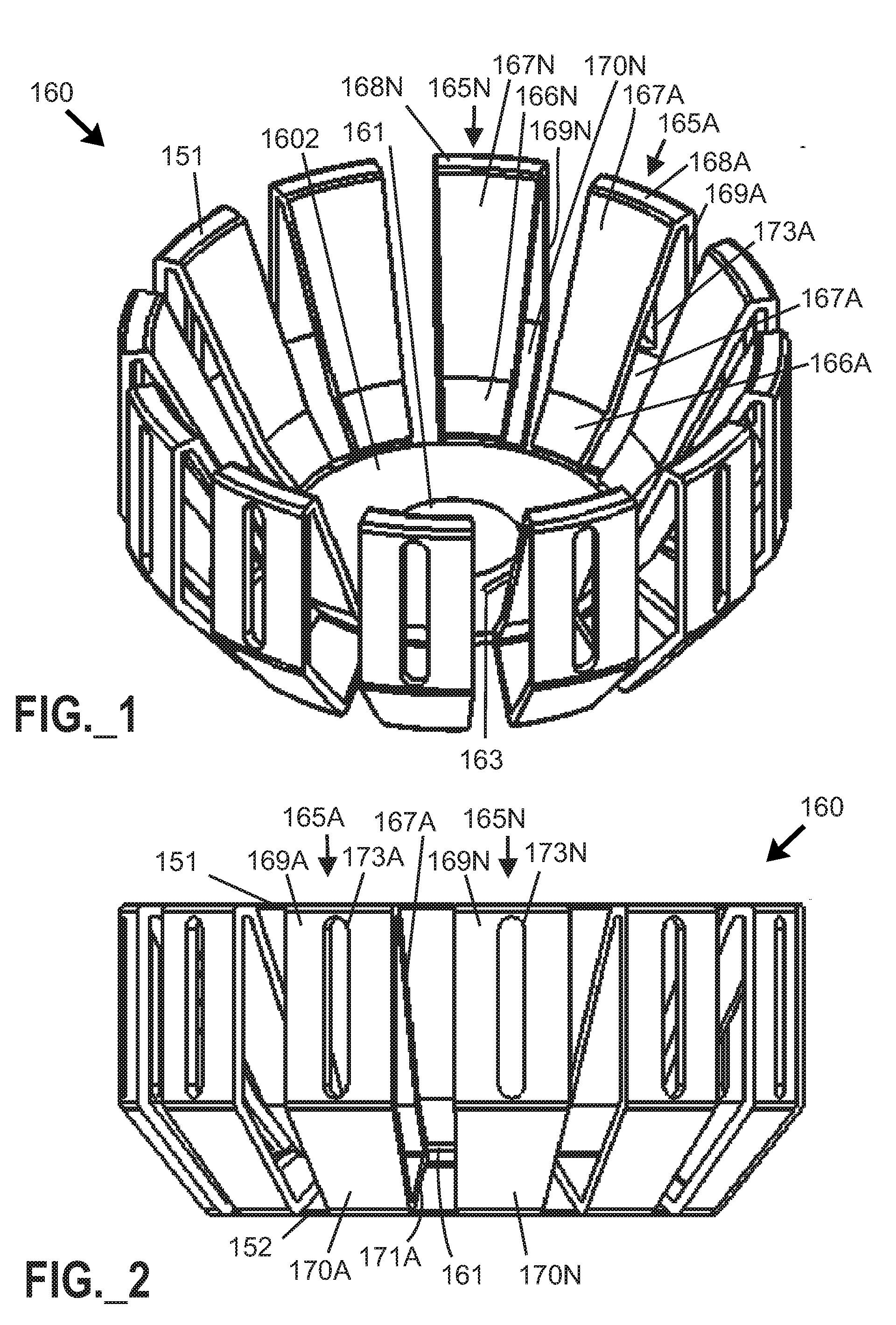

Solid state lighting device with improved heatsink

ActiveUS20100133578A1Point-like light sourceElectric circuit arrangementsDielectric layerAmbient air

A solid state lighting device includes a device-scale stamped heatsink with a base portion and multiple segments or sidewalls projecting outward from the base portion, and dissipates all steady state thermal load of a solid state emitter to an ambient air environment. The heatsink is in thermal communication with one or more solid state emitters, and may define a cup-like cavity containing a reflector. At least a portion of each one sidewall portion or segment extends in a direction non-parallel to the base portion. A dielectric layer and at least one electrical trace may be deposited over a metallic sheet to form a composite sheet, and the composite sheet may be processed by stamping and / or progressive die shaping to form a heatsink with integral circuitry. At least some segments of a heatsink may be arranged to structurally support a lens and / or reflector associated with a solid state lighting device.

Owner:IDEAL IND LIGHTING LLC

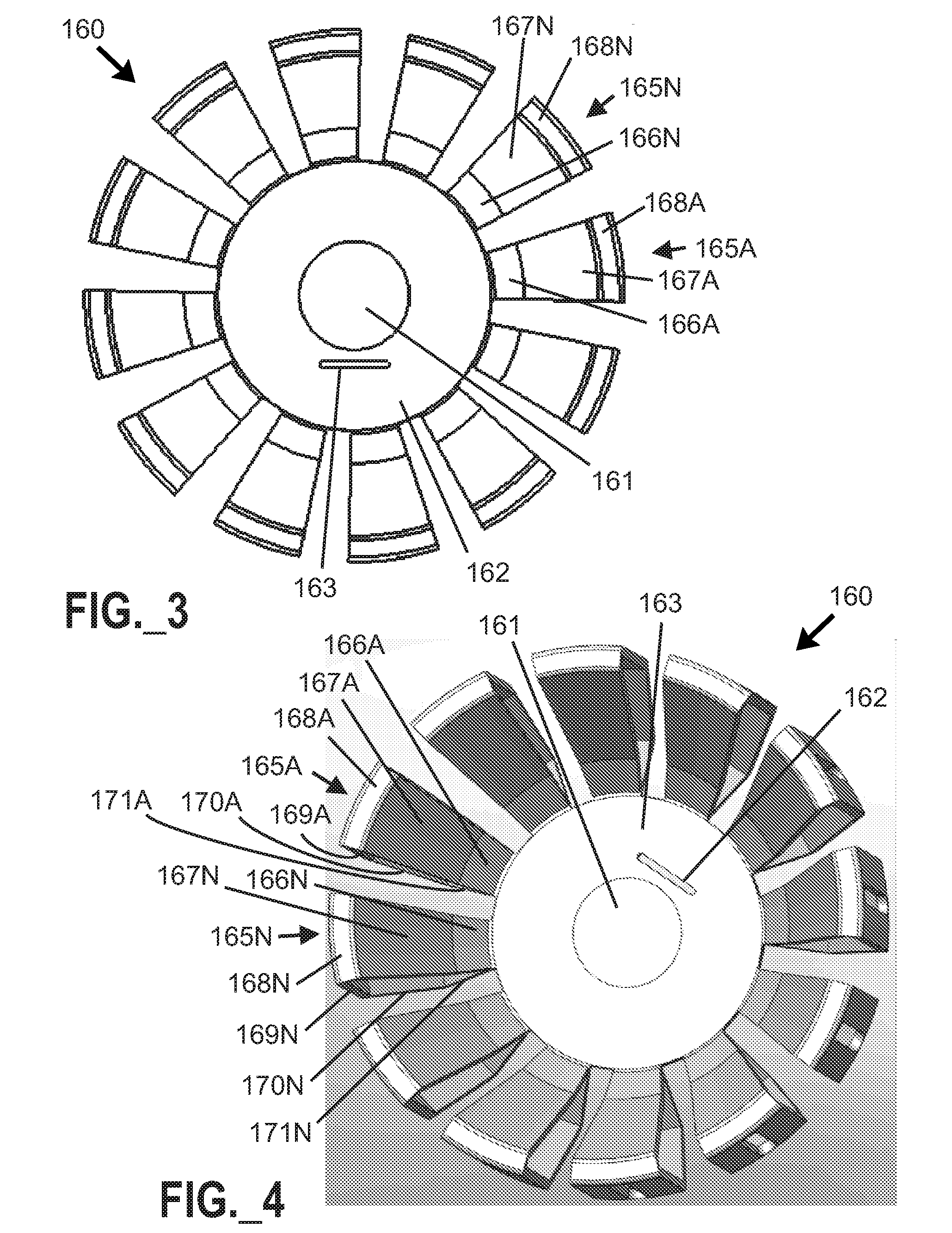

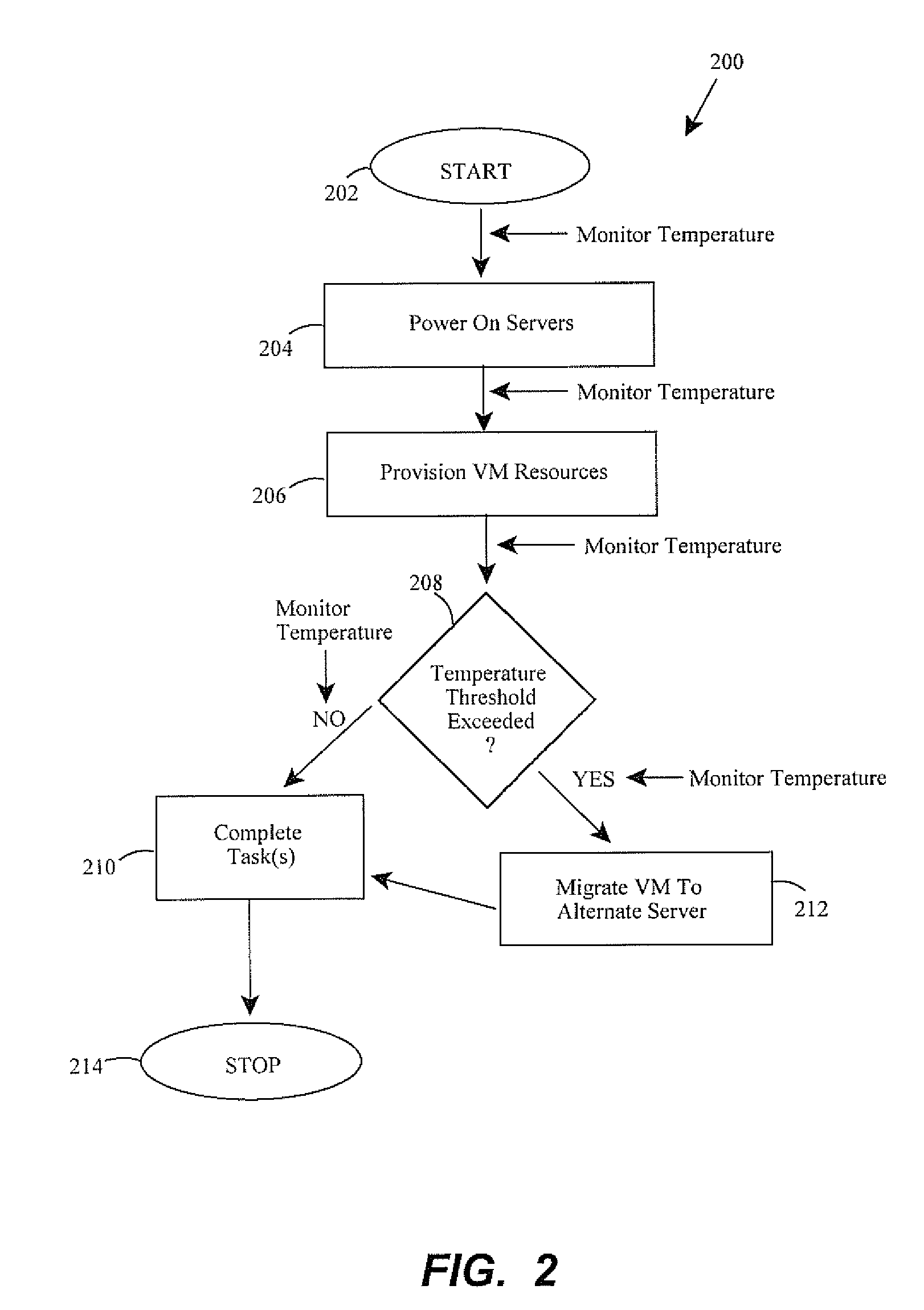

Dynamic thermal load balancing

ActiveUS20100217454A1Inhibit migrationImprove thermal efficiencyThermometer detailsTemperatue controlData centerComputerized system

A method for improving thermal efficiency in one or more data centers includes measuring a temperature at one or more computing devices having allocated thereto one or more computing workloads and determining whether the measured temperature exceeds a predetermined temperature threshold. If the predetermined temperature threshold is exceeded, sufficient computing workloads are migrated to one or more alternate computing devices to reduce the temperature at one or more of the computing devices to less than or equal to said predetermined temperature threshold. In accomplishing the method, there is provided a data orchestrator configured at least for receiving data concerning the measured temperature, determining whether the measured temperature exceeds the predetermined temperature threshold, and migrating one or more of the computing workloads to one or more alternate computing devices. Computer systems and computer programs available as a download or on a computer-readable medium for installation according to the invention are provided.

Owner:SUSE LLC

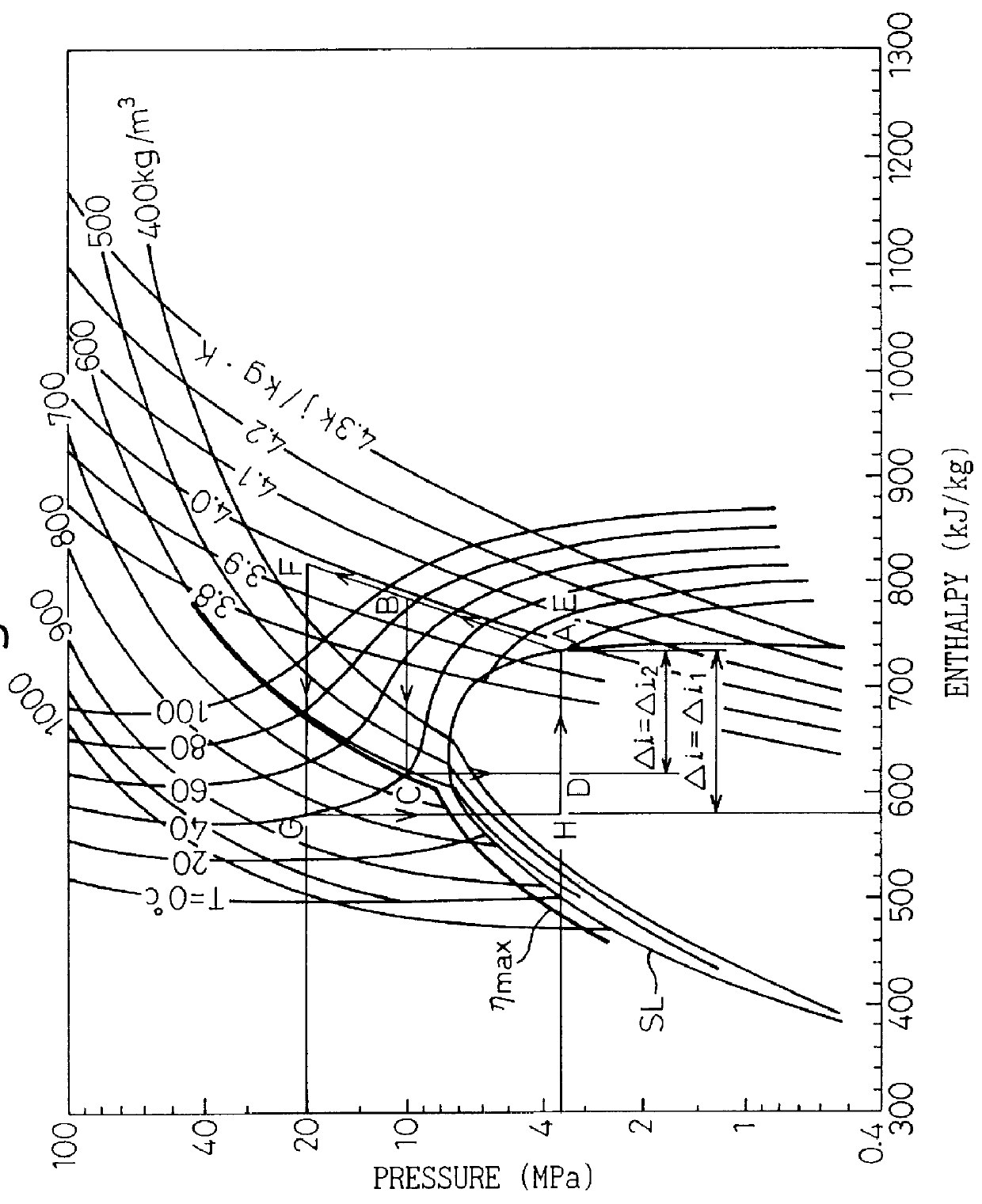

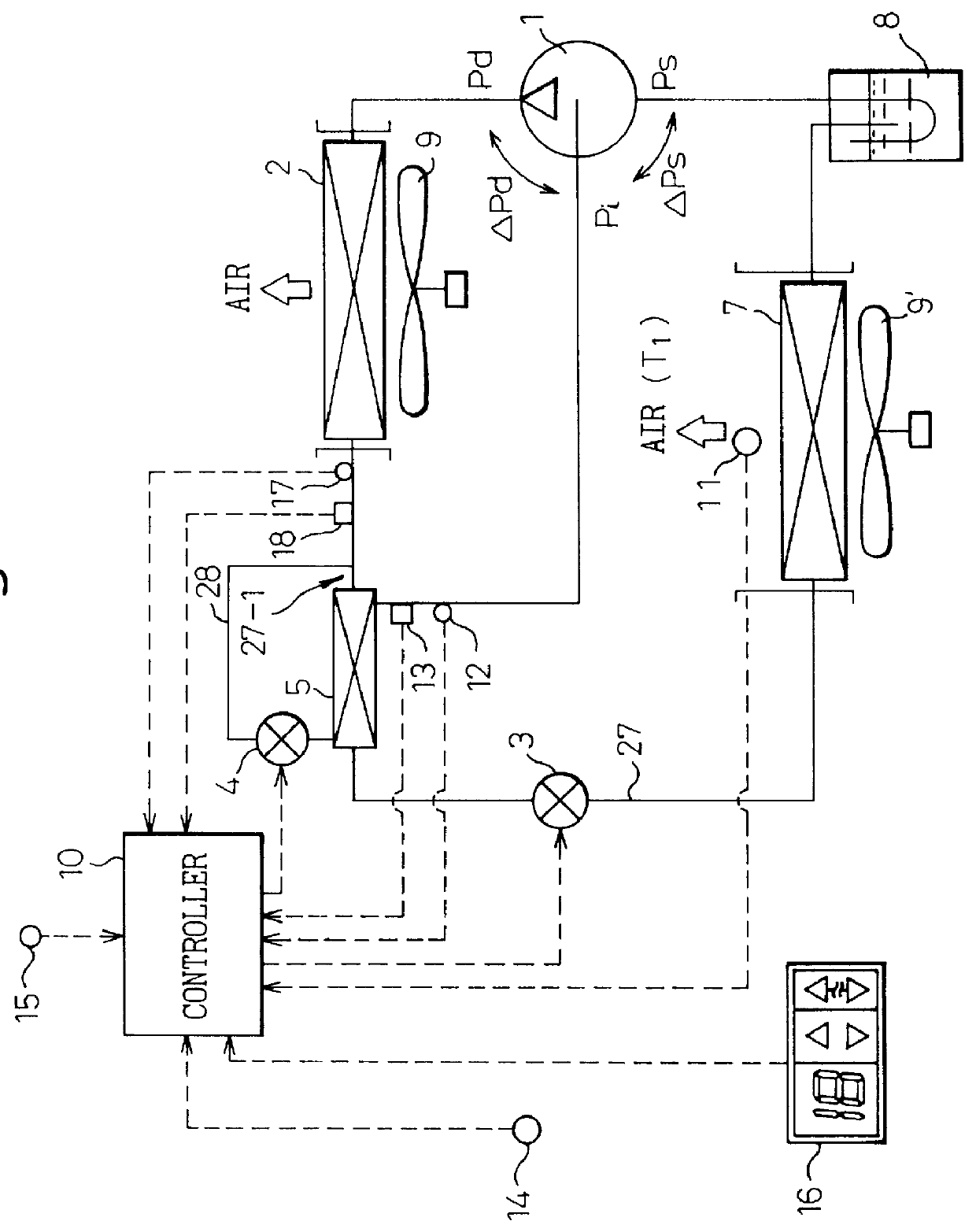

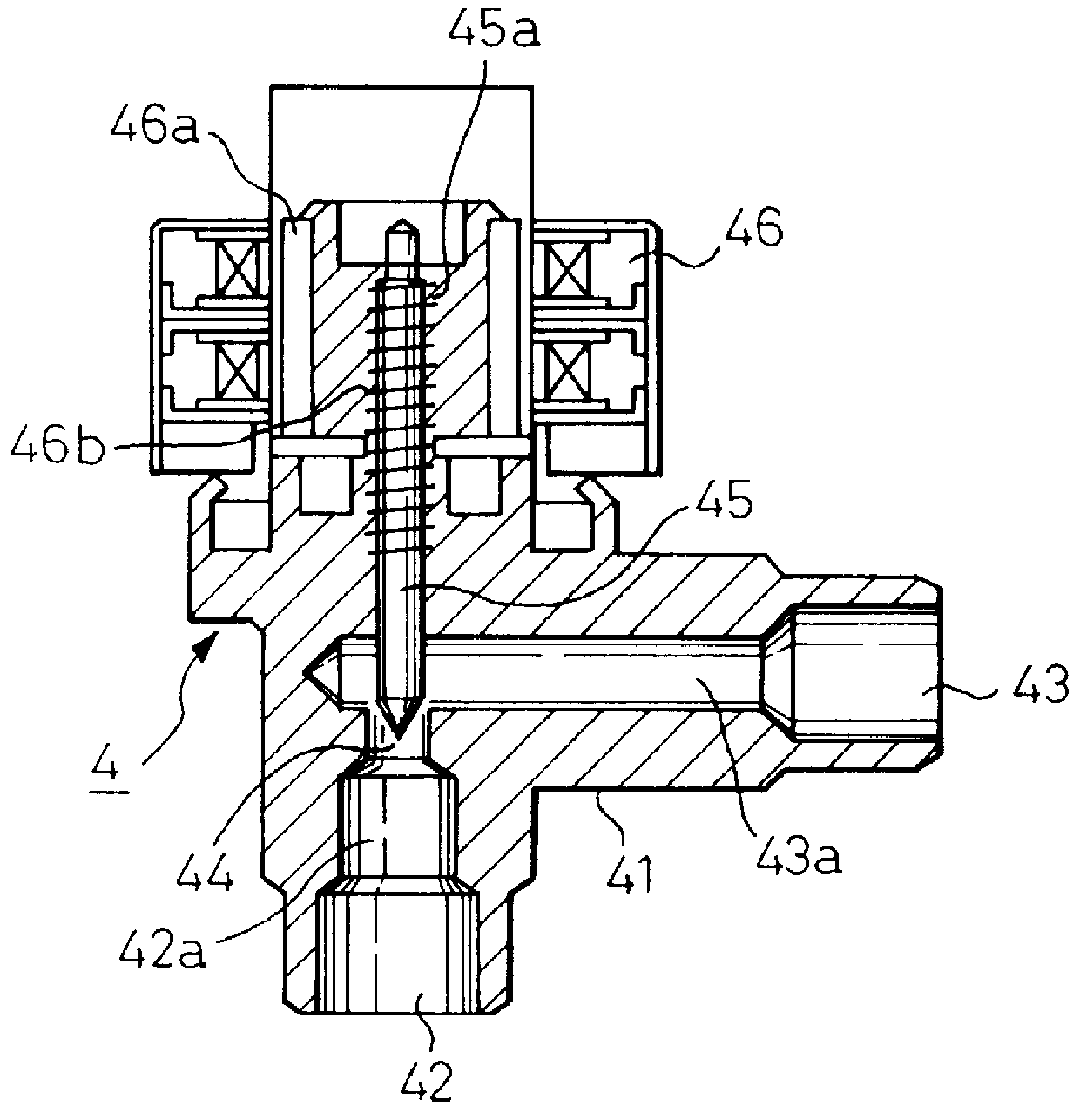

Vapor compression type refrigerating system

InactiveUS6044655AImprove the coefficient of performanceIncrease the differenceMechanical apparatusCompression machines with non-reversible cycleAutomobile air conditioningEngineering

A refrigerating system, using CO2 as a refrigerant, for an air conditioner for an automobile. A pressure at the outlet of the heat emitter 2 is controlled to a target value in accordance with the temperature of the refrigerant at the outlet of the heat emitter for obtaining an operation of the refrigerating system along the optimum control line eta max. A pressure reducer 4 and a cooler 5 are provided on a branched passageway 28 branched from a refrigerant recirculating passageway 27 for injection. The cooler 5 is for obtaining a heat exchange between a flow of the refrigerant on the branched passageway 28 after being cooled by the pressure reducer and a flow of the refrigerant on the main passageway 27, thereby cooling the refrigerant directed to the evaporator. In a second aspect of the invention, a means is provided for increasing a target value of the pressure at the pressure reducer when a thermal load of the refrigerating system is high. In a third aspect, a series of pressure reducers are arranged on the main recirculating passageway. The second stage pressure reducer is controlled so as to obtain a desired value of degree of super heating at the inlet of the compressor.

Owner:DENSO CORP +1

Estimating energy savings and carbon offsets for buildings in real-time

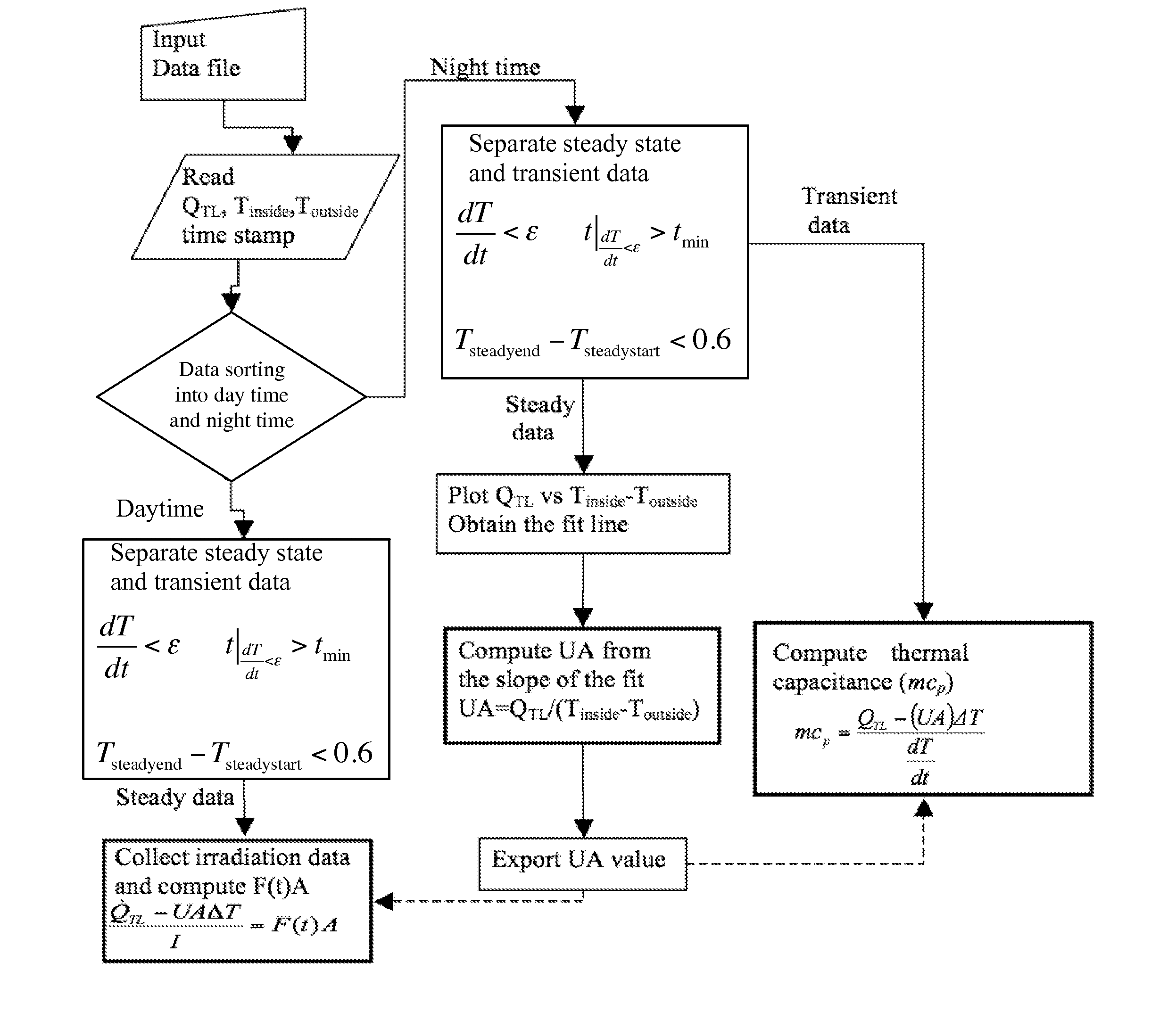

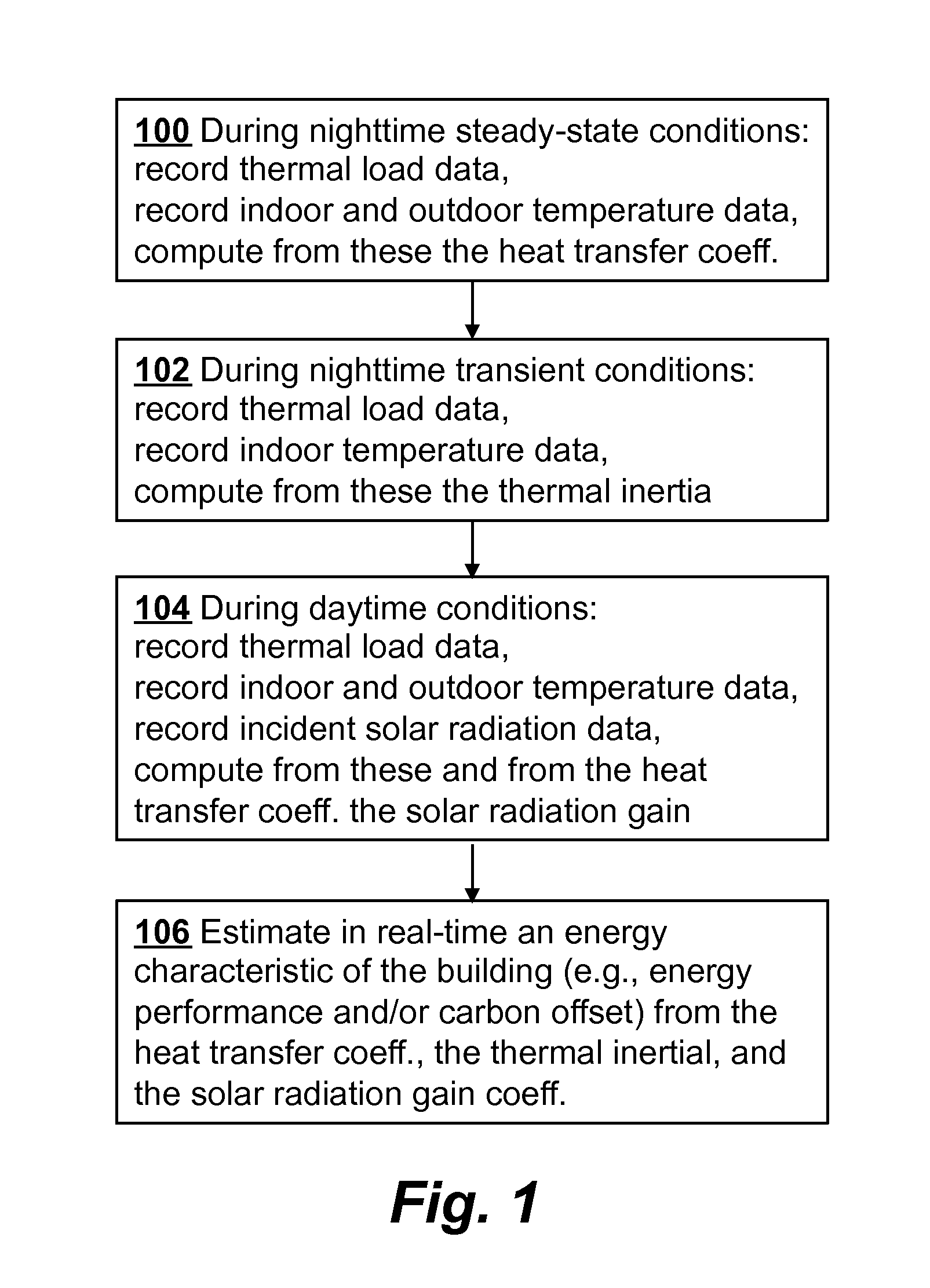

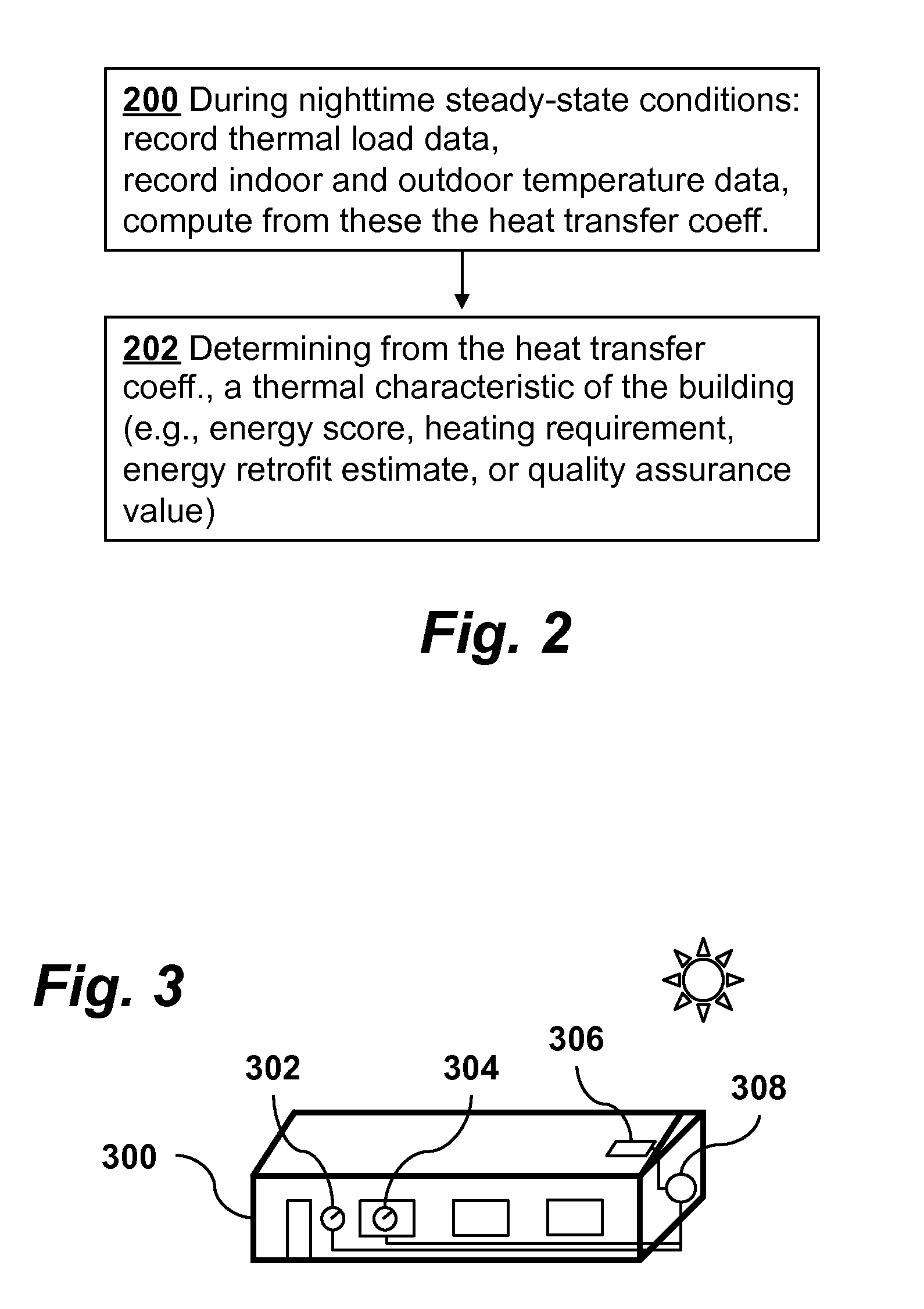

InactiveUS20130060471A1Easy to implementLow costDigital computer detailsSpecial data processing applicationsGain coefficientEngineering

Real-time monitoring of an energy characteristic of a building such as an energy performance of the building or a carbon offset of the building is performed by first computing a heat transfer coefficient of the building from nighttime steady-state thermal load data of the building and from nighttime steady-state indoor and outdoor temperature data of the building. A thermal inertia of the building is then computed from nighttime transient indoor temperature data of the building and nighttime transient thermal load data of the building. During daytime, a solar radiation gain coefficient is computed from daytime thermal load data, daytime indoor and outdoor temperature data, incident solar radiation data, and the heat transfer coefficient. The energy characteristic of the building is then estimated in real time from the heat transfer coefficient, the thermal inertia, and the solar radiation gain coefficient.

Owner:SANTA CLARA UNIVERSITY

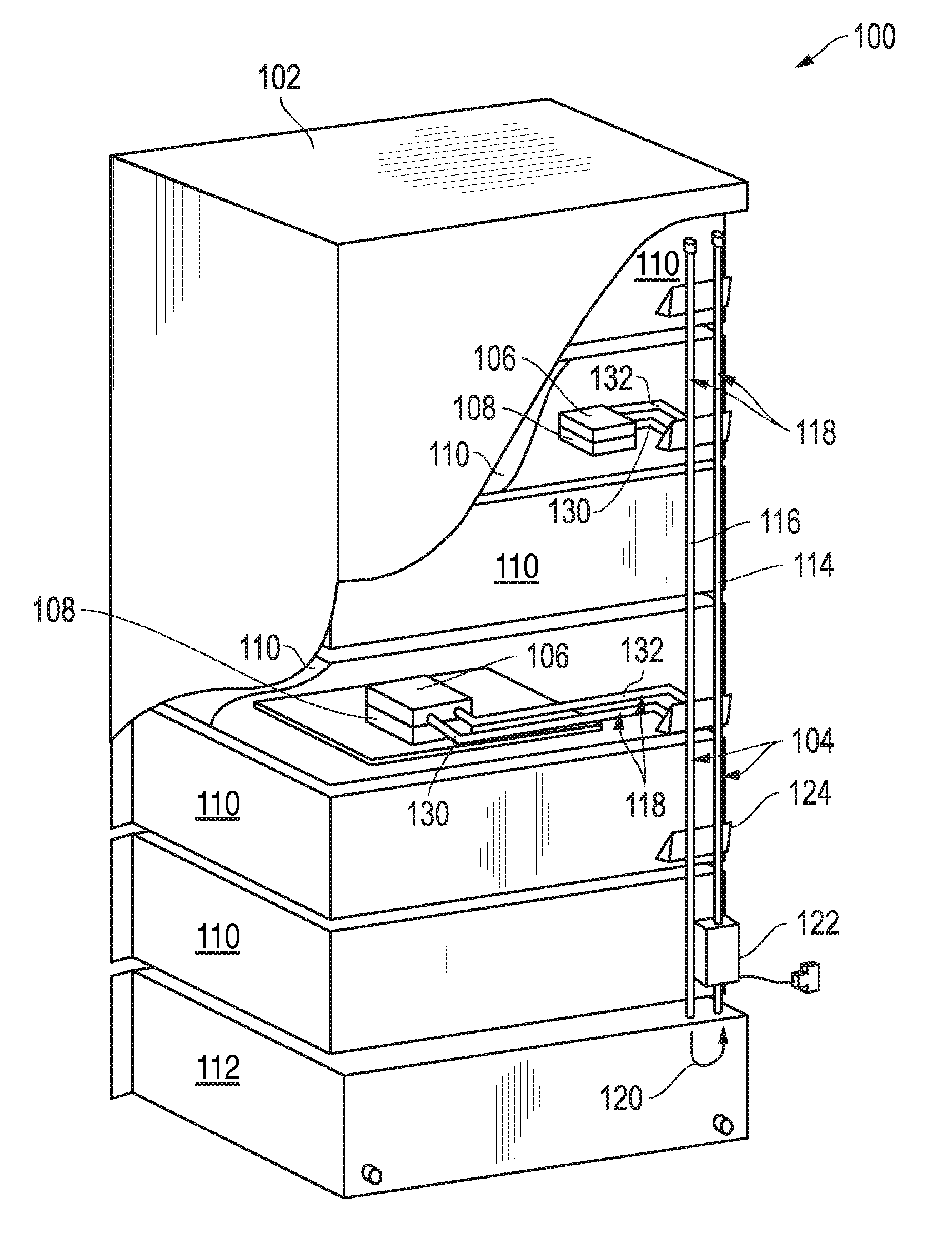

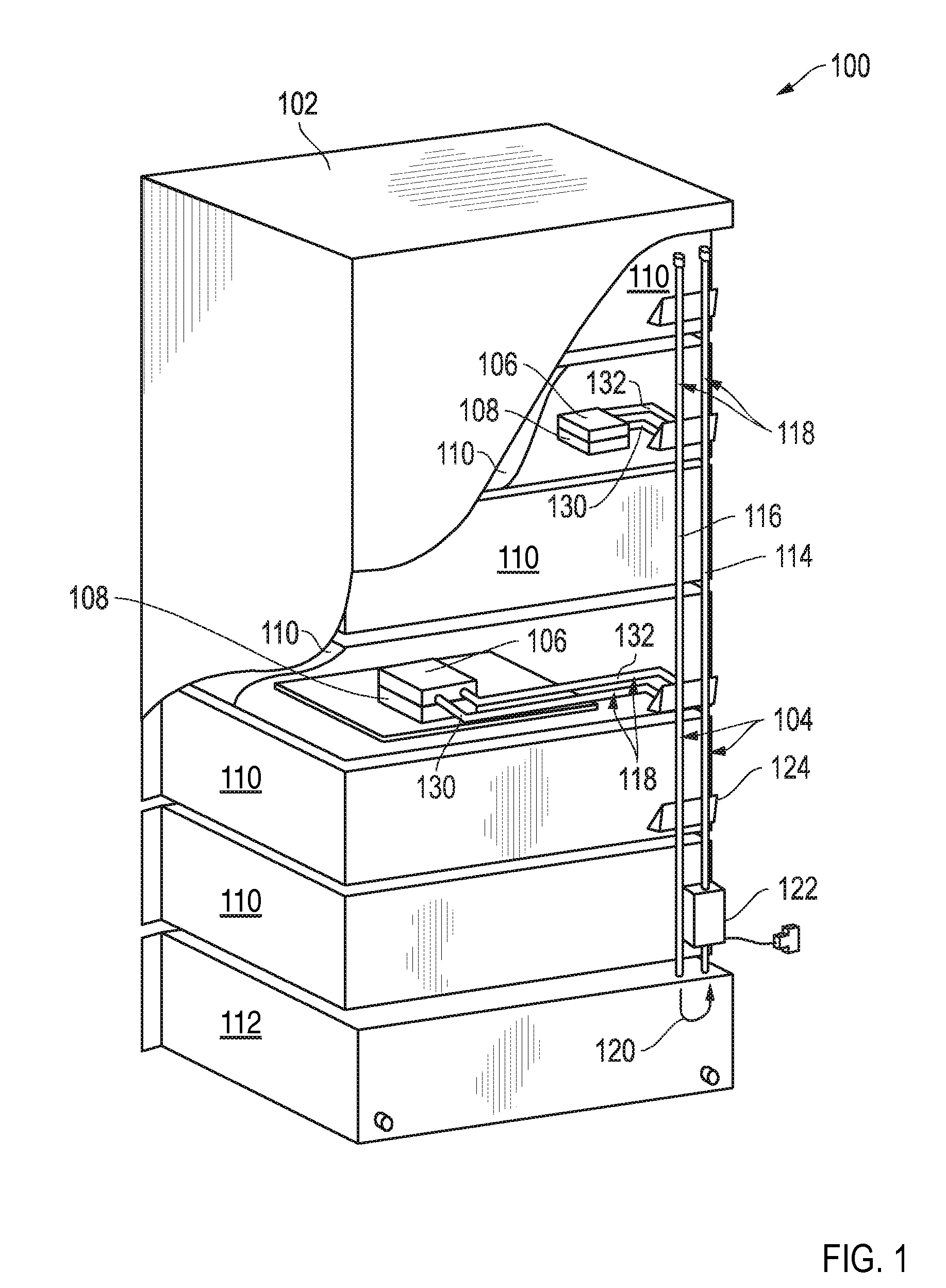

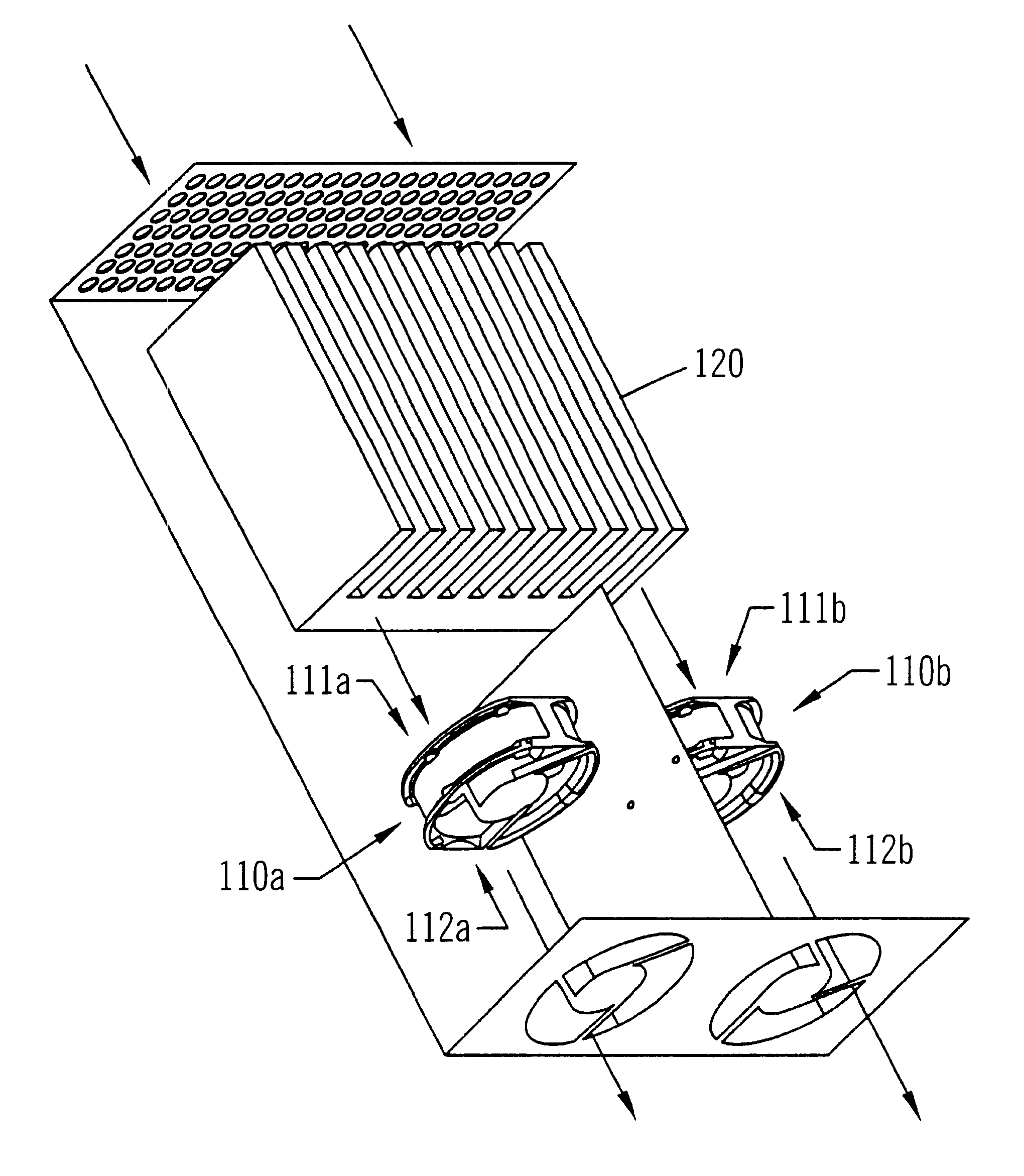

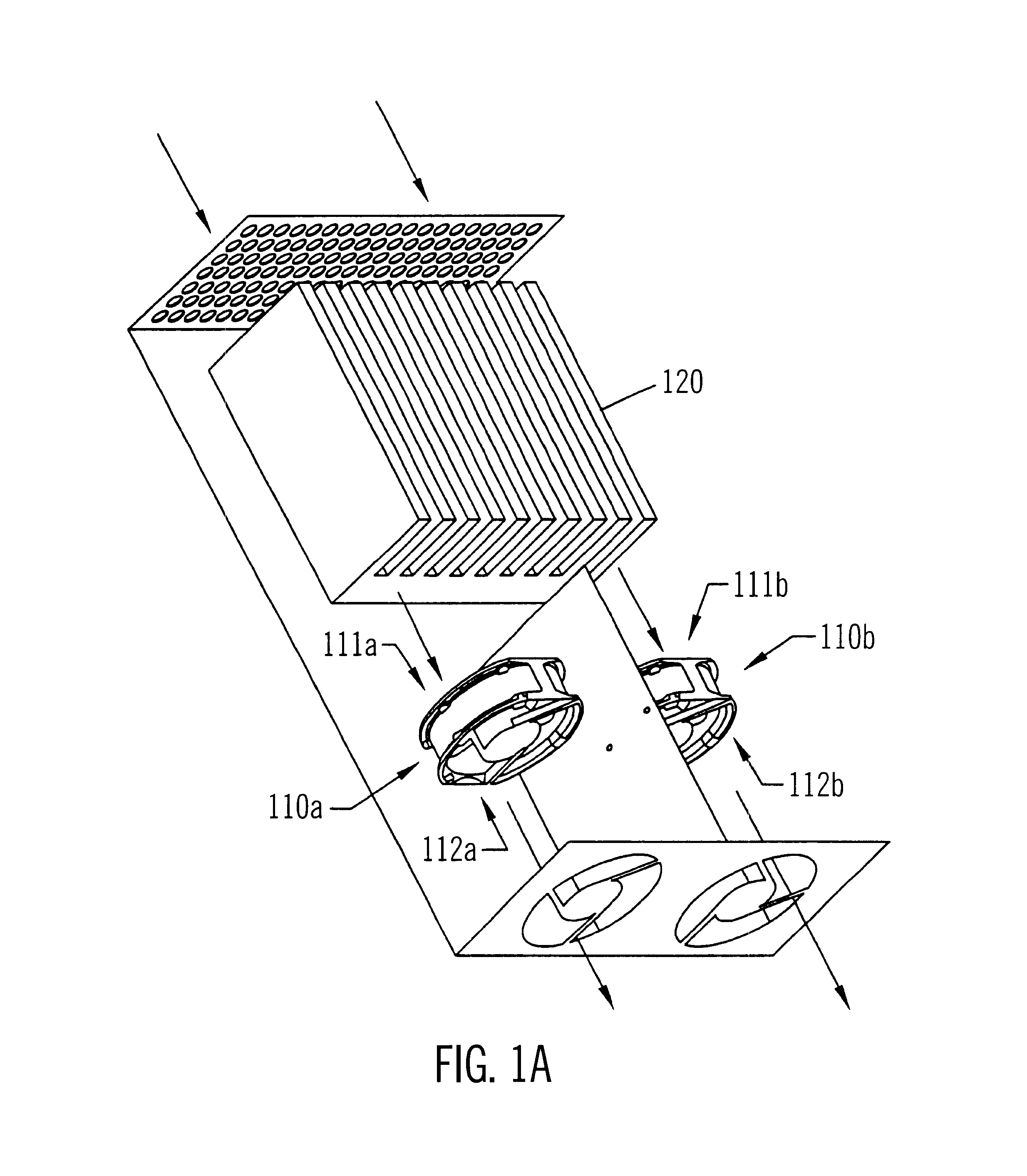

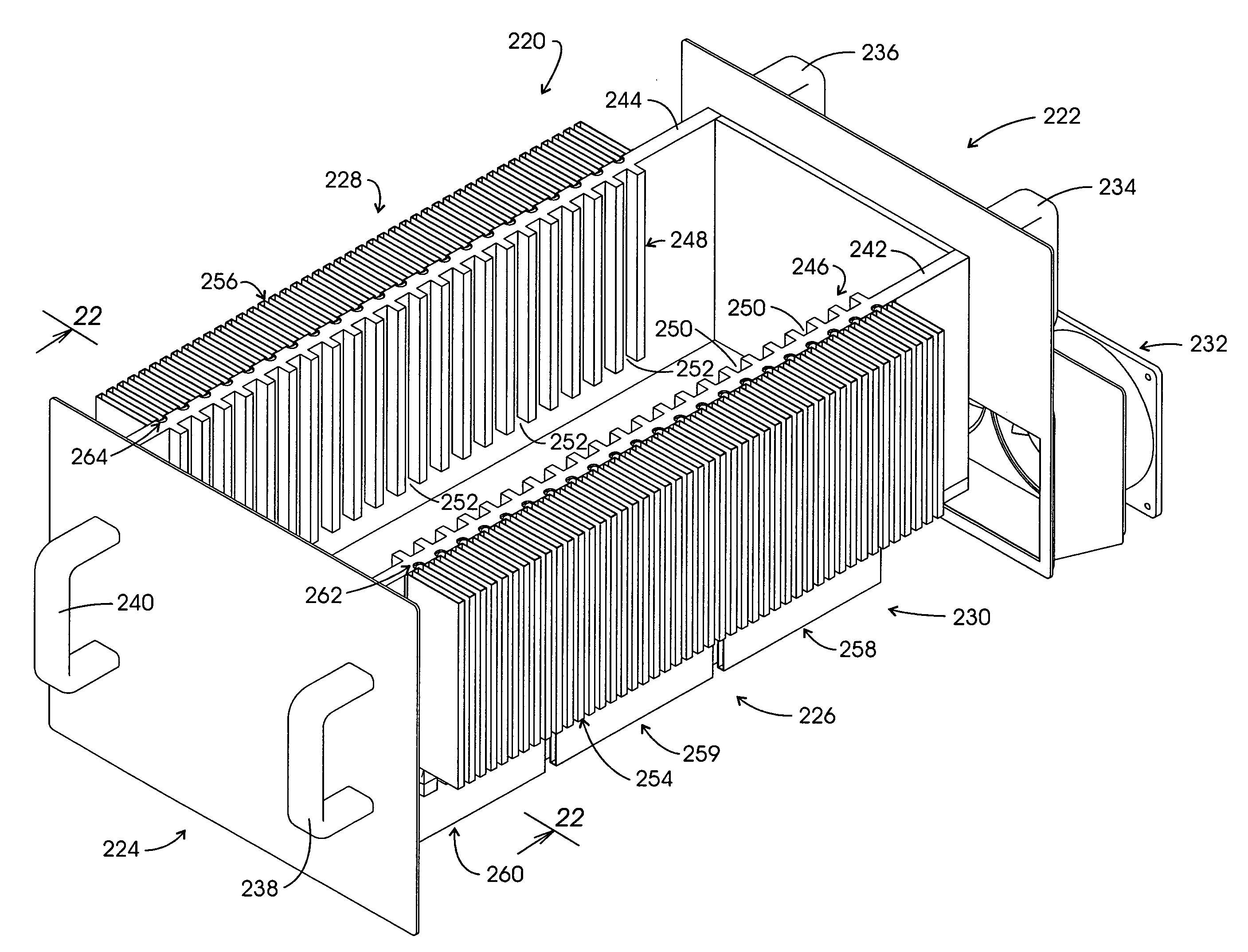

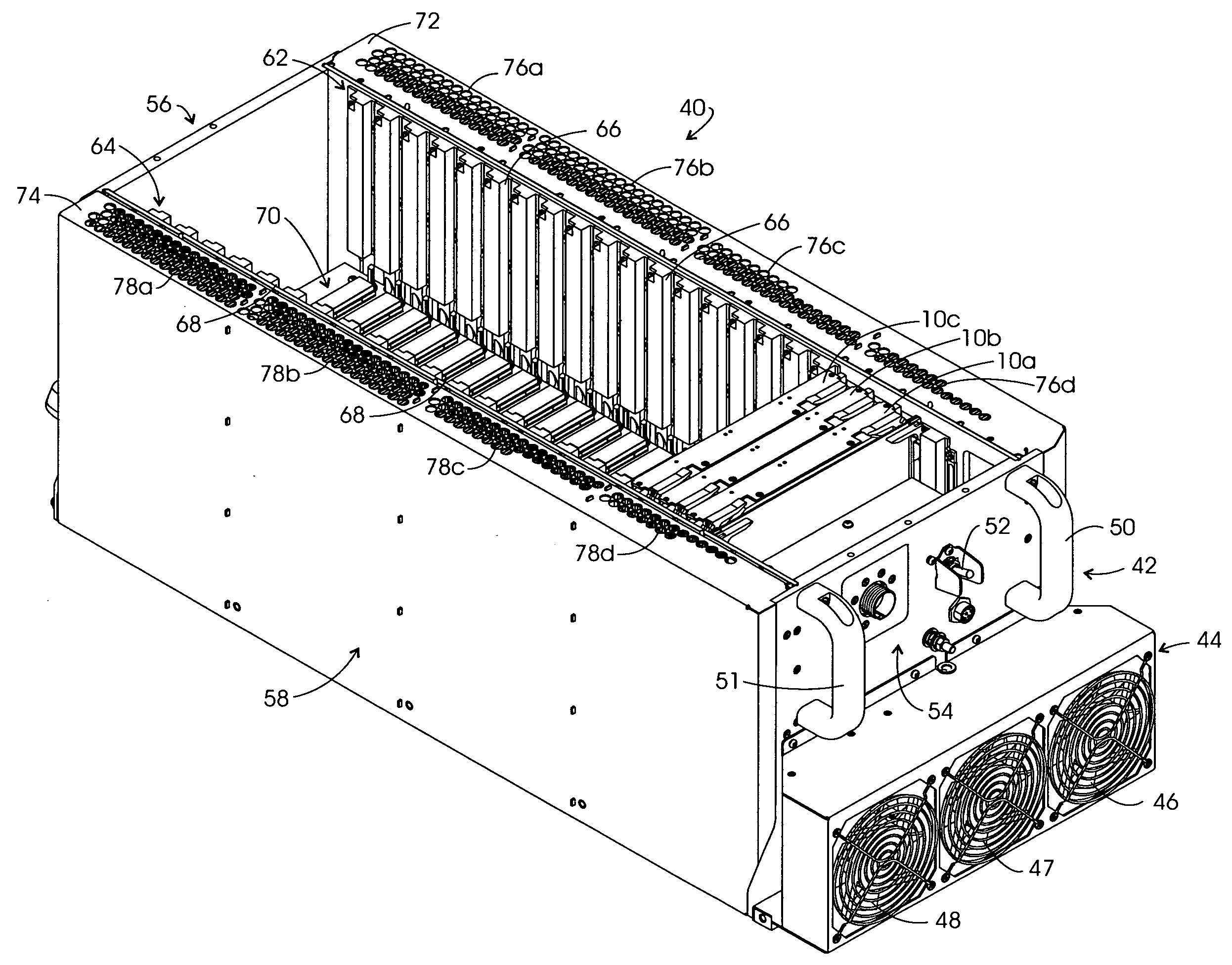

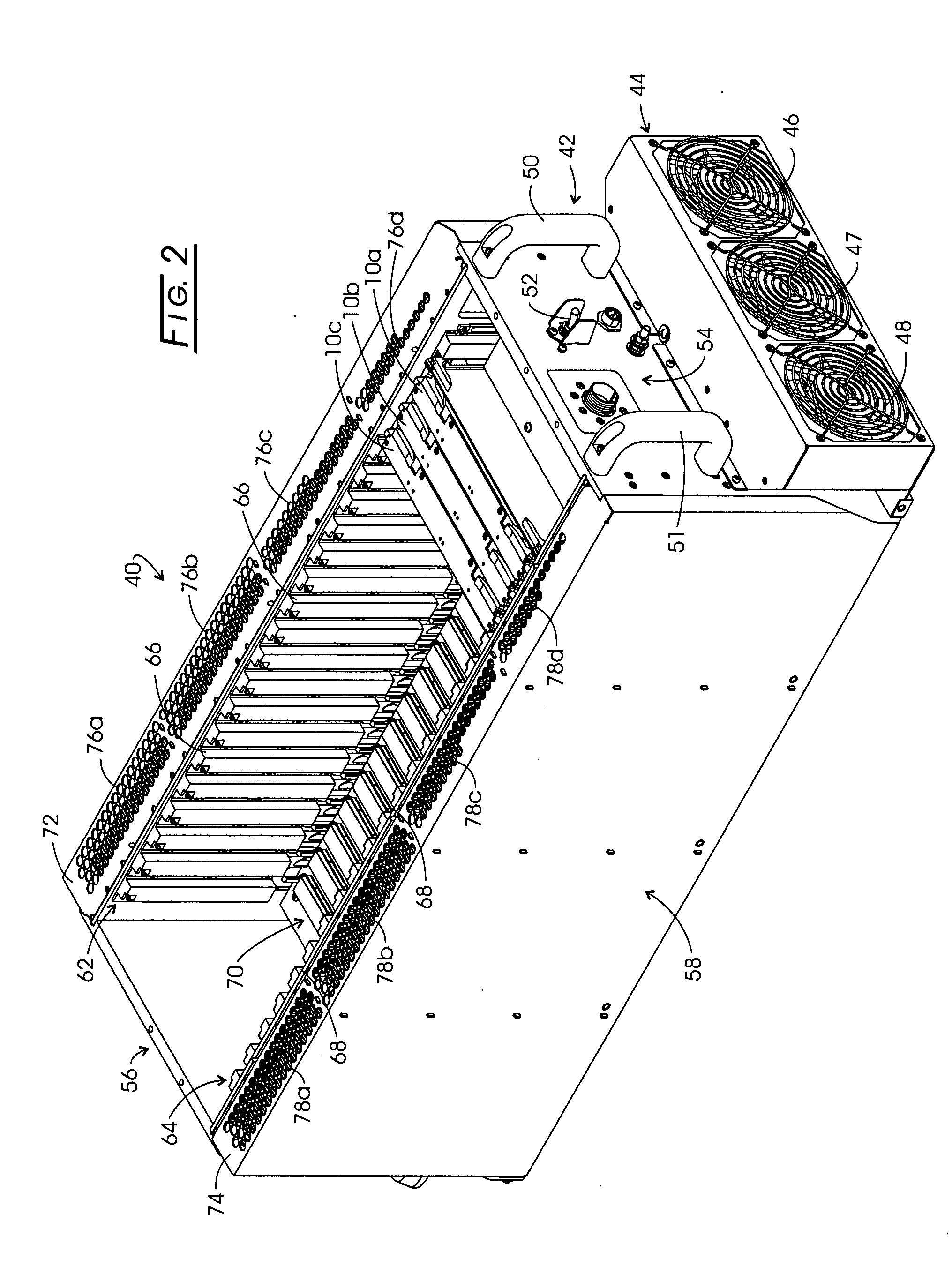

Heat Transfer Systems for Dissipating Thermal Loads From a Computer Rack

Heat transfer systems for dissipating thermal loads from a computer rack are disclosed that include: an expandable heat transfer bus extending along the rack, the expandable heat transfer bus capable of passing a thermal transport; one or more heat sinks connected to the expandable heat transfer bus, each heat sink capable of receiving the thermal transport from the bus and returning the thermal transport to the bus, and each heat sink capable of transferring into the thermal transport a thermal load from an electronic component inside a rack module mounted to the rack; and a heat exchanger connected to the expandable heat transfer bus capable of dissipating the thermal load of the thermal transport.

Owner:IBM CORP

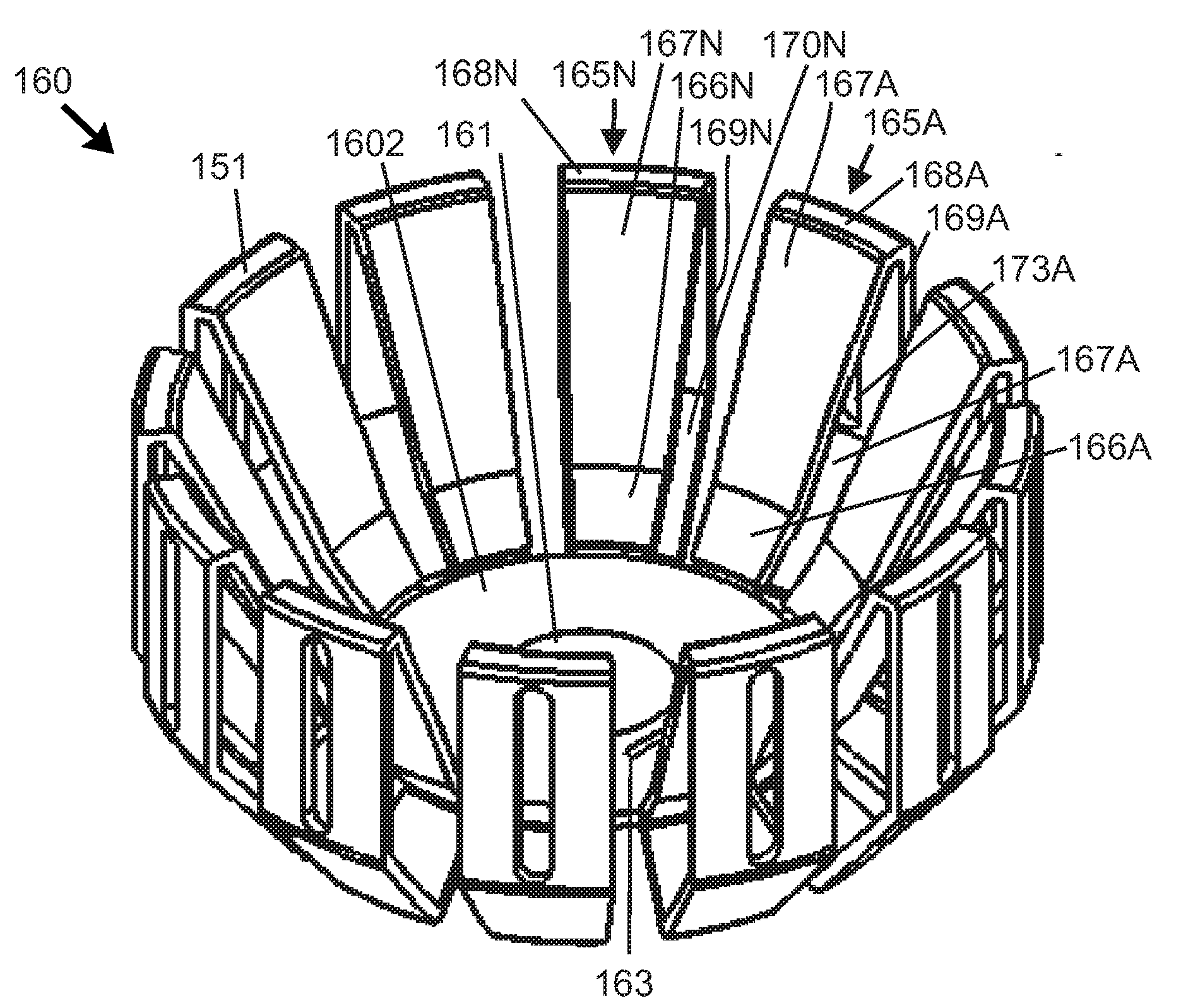

Ring seal system with reduced cooling requirements

Aspects of the invention are directed to systems for reducing the cooling requirements of a ring seal in a turbine engine. In one embodiment, the ring seal can be made of a ceramic material, such as a ceramic matrix composite. The ceramic ring seal can be connected to metal isolation rings by a plurality of pins. The hot gas face of the ring seal can be coated with a thermal insulating material. In another embodiment, the ring seal can be made of metal, but it can be operatively associated with a ceramic heat shield. The metal ring seal can carry the mechanical loads imposed during engine operation, and the heat shield can carry the thermal loads. By minimizing the amount of ring seal cooling, the ring seal systems according to aspects of the invention can result in improved engine performance and emissions.

Owner:SIEMENS ENERGY INC

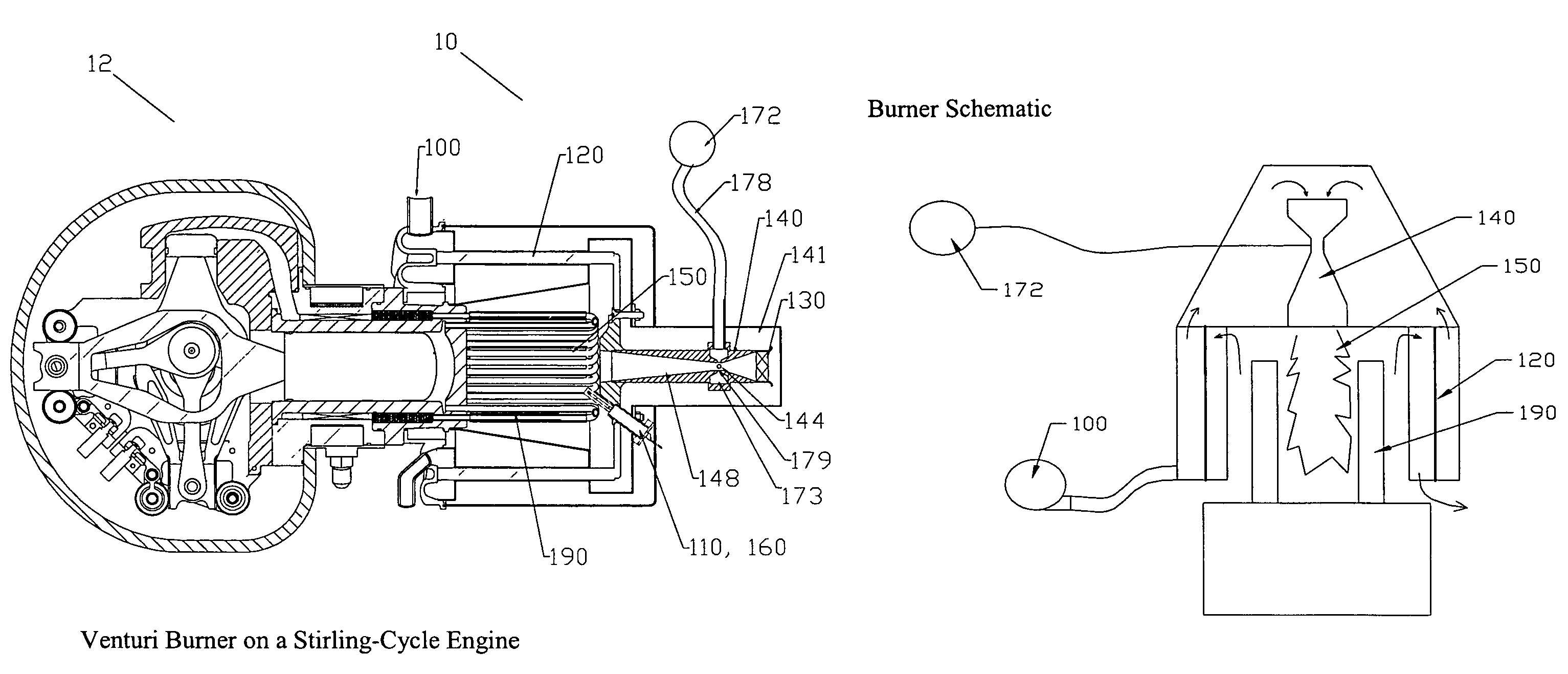

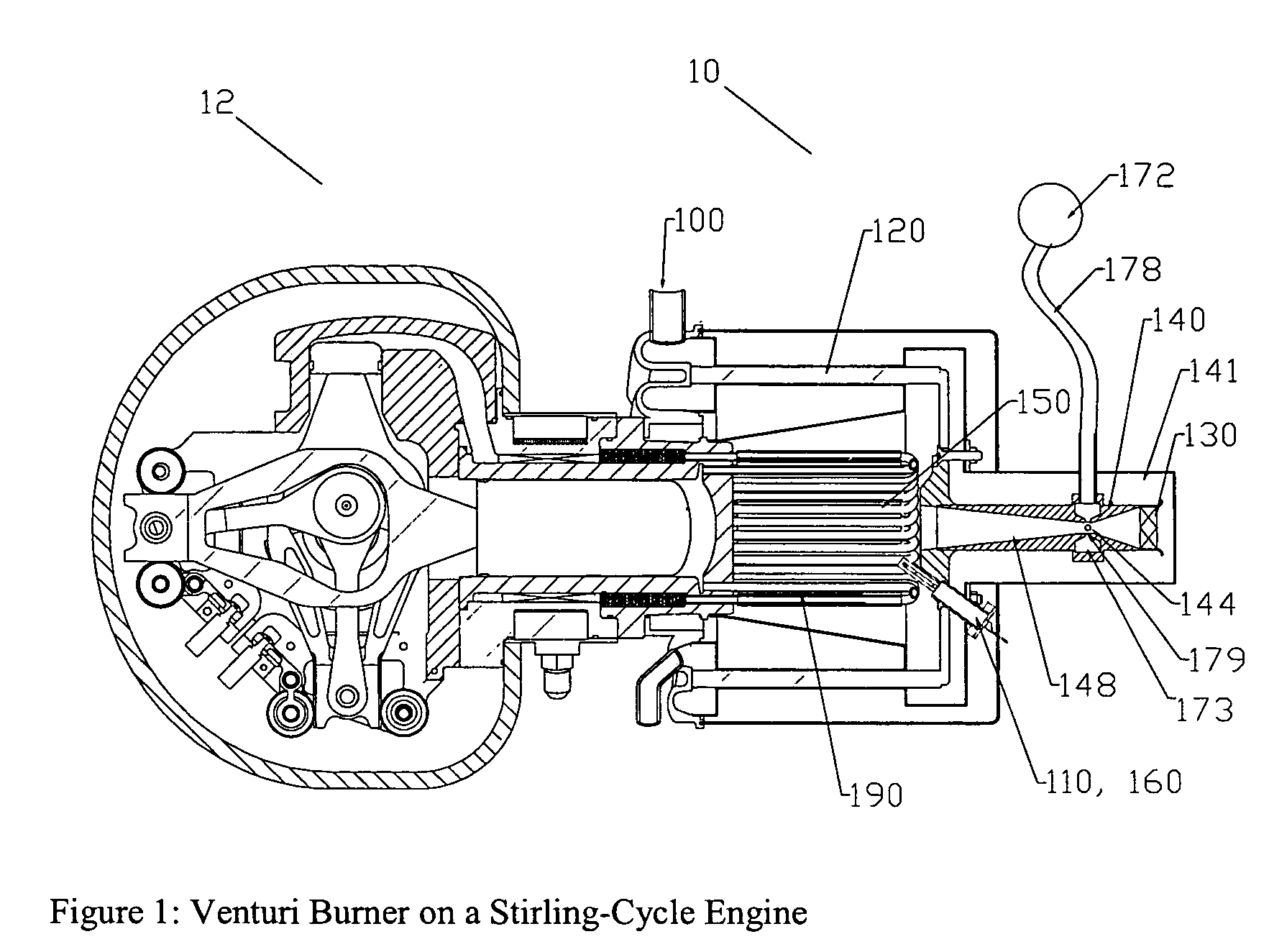

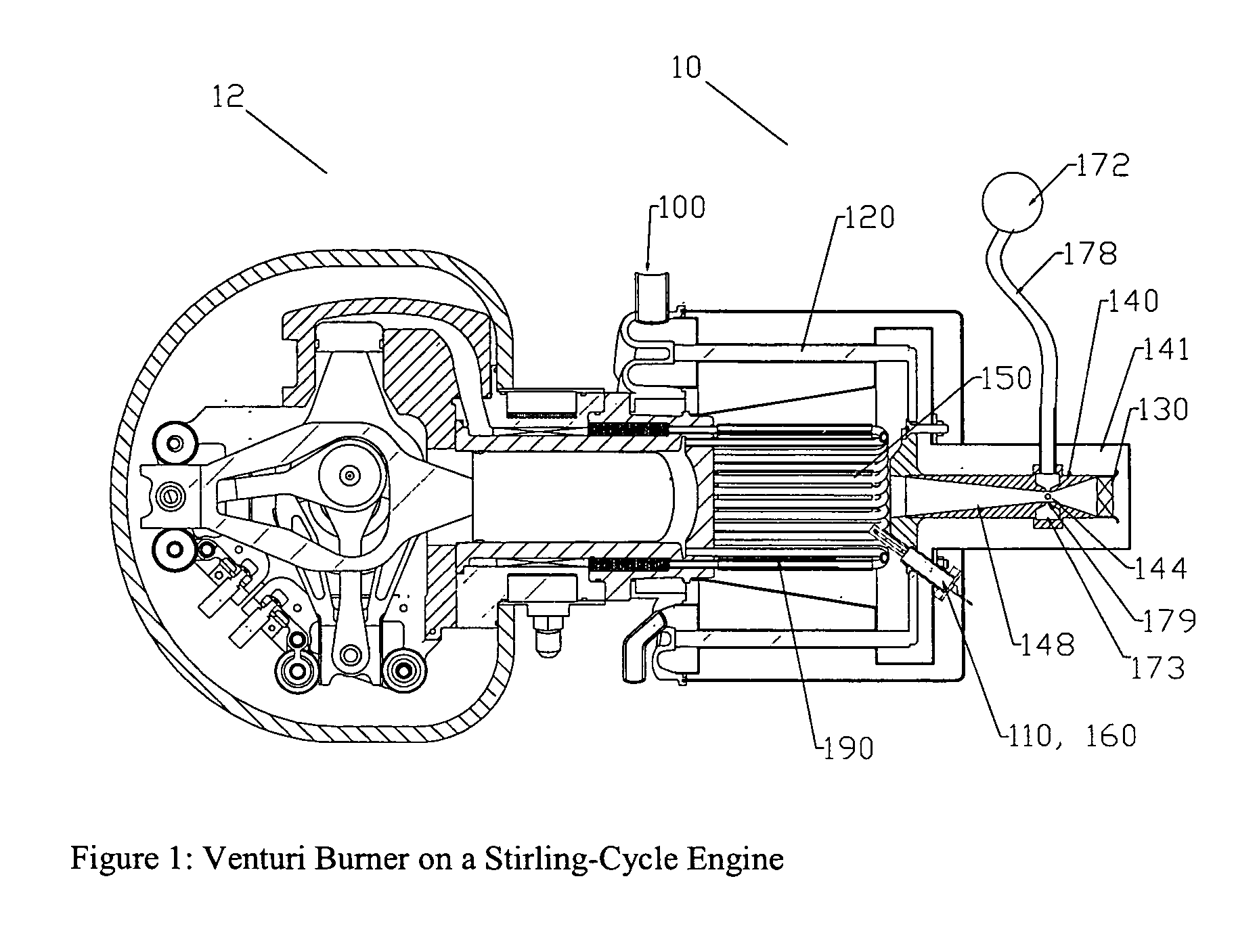

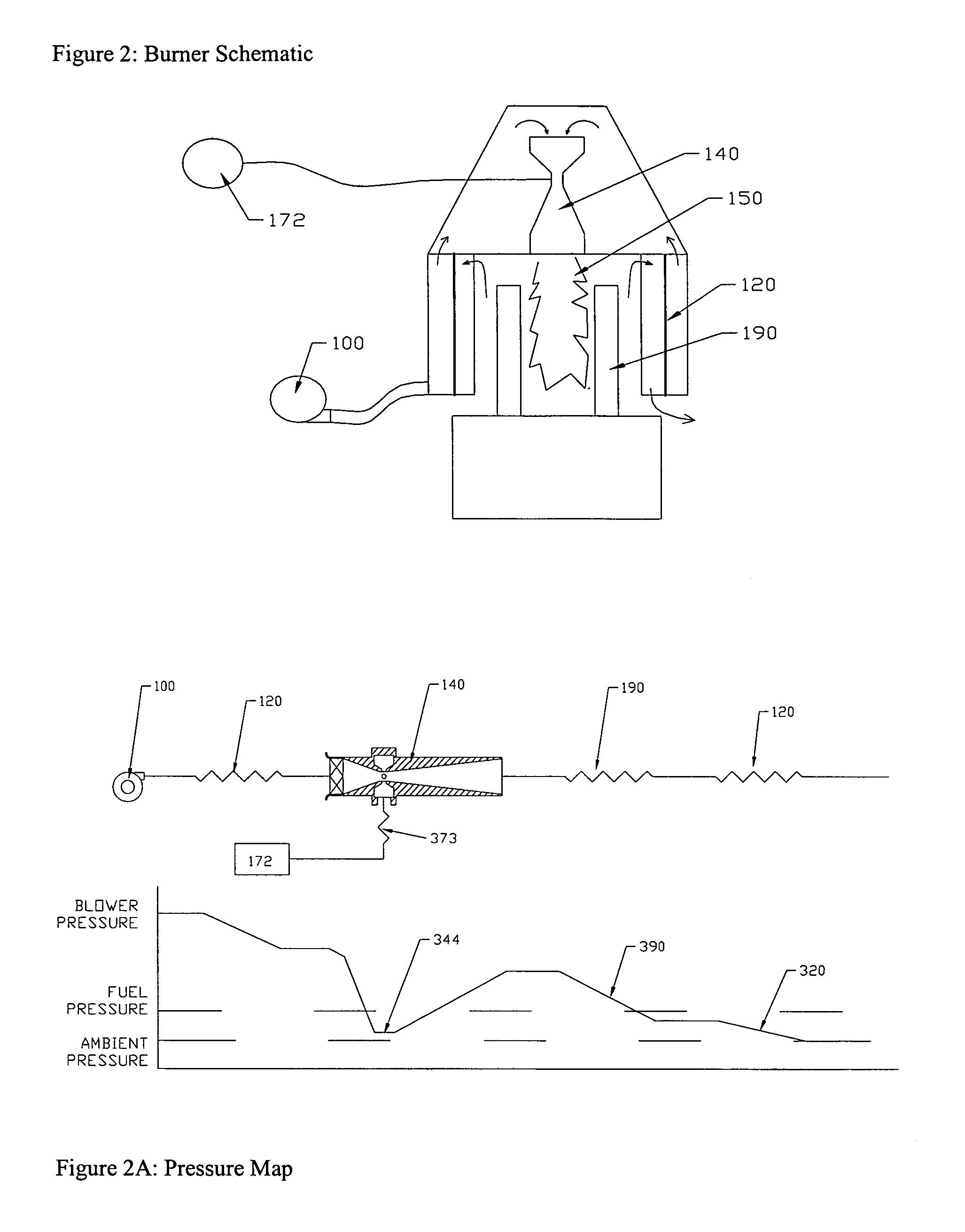

Gaseous fuel burner

ActiveUS7934926B2Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

Owner:NEW POWER CONCEPTS

Methods and apparatus for recirculating air in a controlled ventilated environment

InactiveUS20020072322A1Human health protectionMechanical apparatusEnvironmental engineeringContaminated air

<heading lvl="0">Abstract< / heading> Methods and apparatus for recirculating air in a controlled ventilated environment. In one example, recirculation of air from one or more rooms in a multiple room ventilated environment having a common source of supply air is controlled such that minimum ventilation and thermal load requirements for each room are satisfied independently, so as to facilitate a reduction in the amount of fresh outside air required for the environment. In another example, the controlled airflows in each room may be based additionally on respective air quality levels of the air drawn from each room. In one aspect, if contaminants are detected in one or more rooms of the ventilated environment, the amount of air recirculated from a contaminated room back to the environment may be controlled based on a detected level of the contaminant and a dilution ratio of any returned contaminated air to the total uncontaminated air supplied to the environment.

Owner:PHOENIX CONTROLS

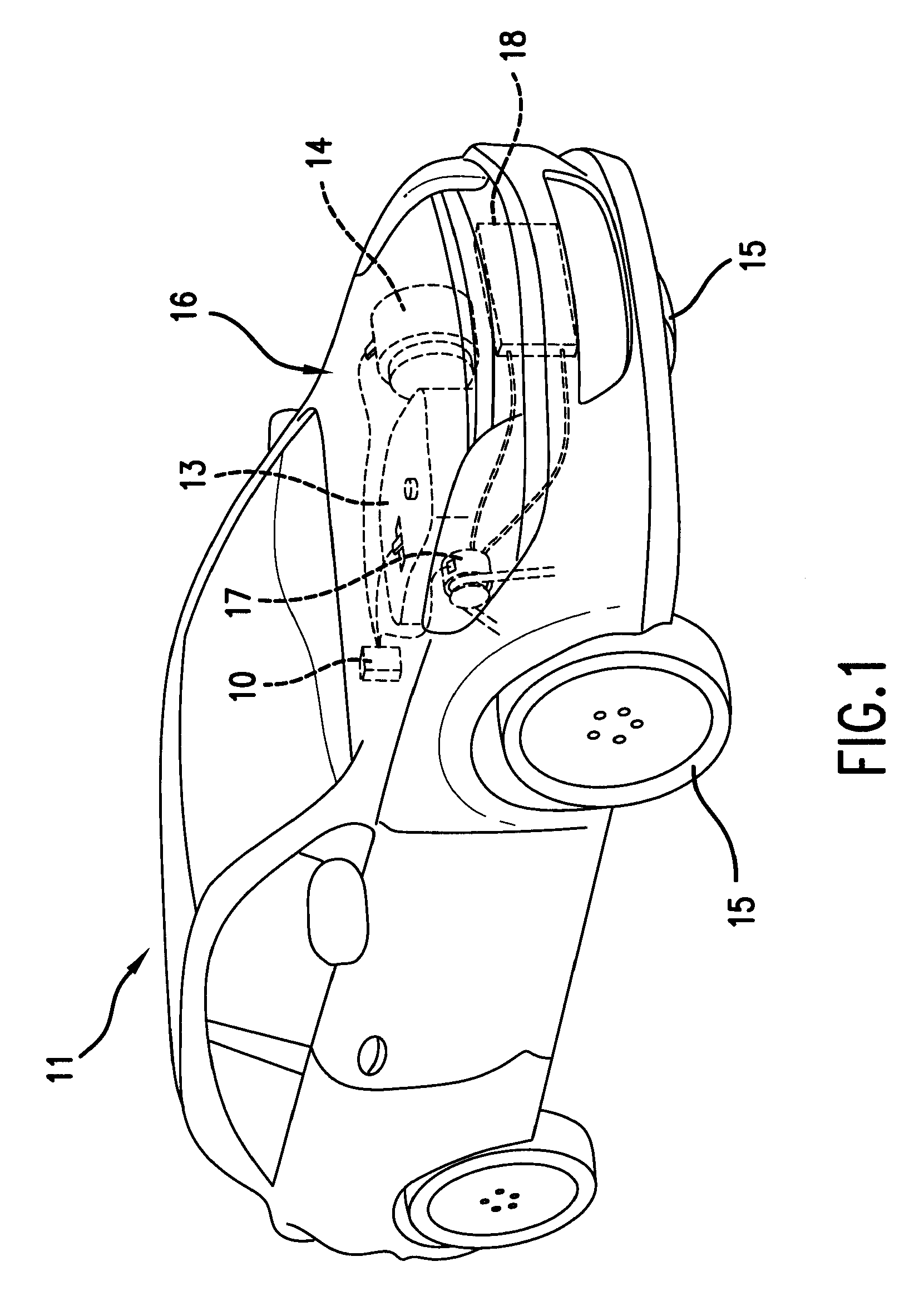

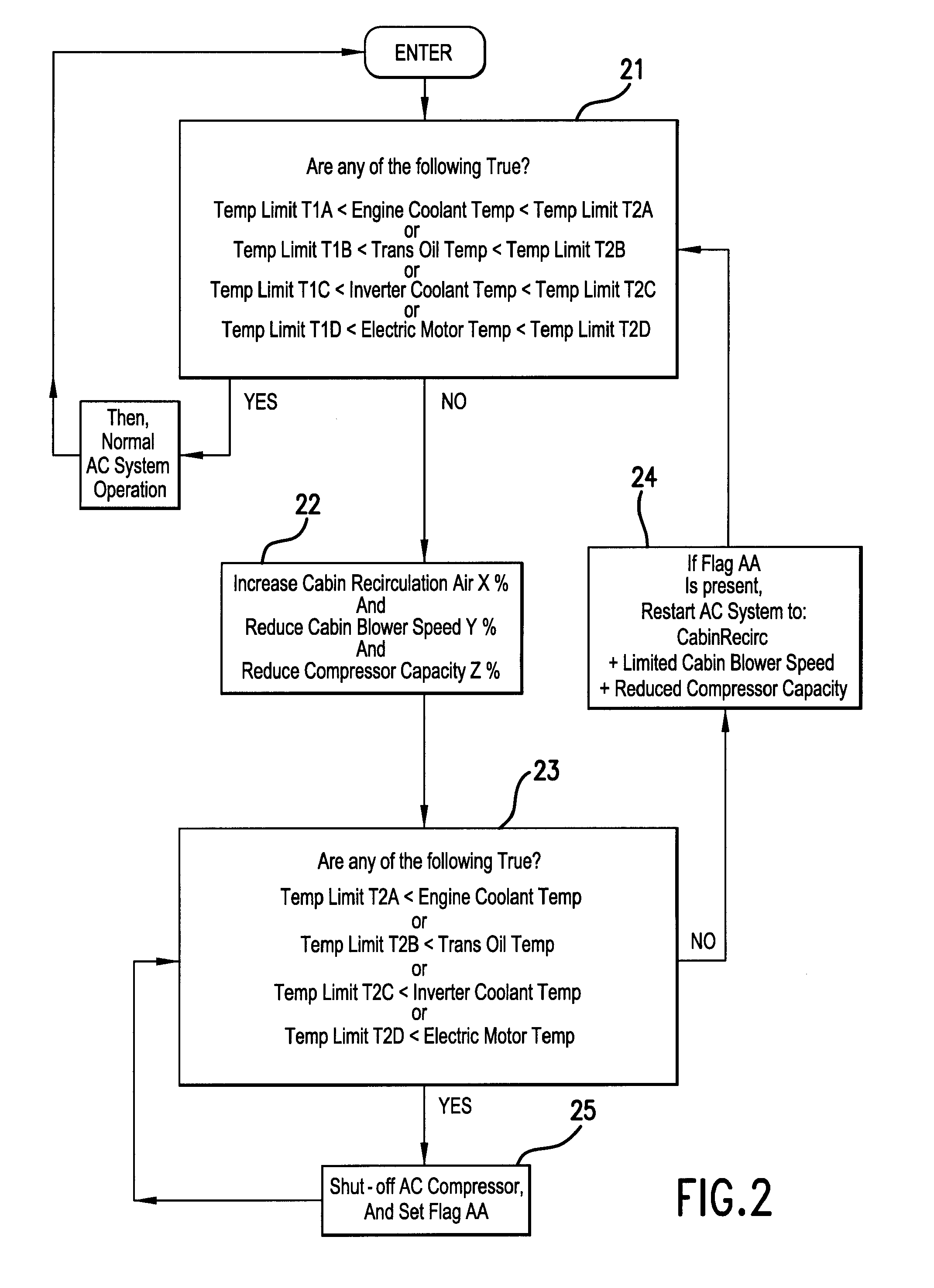

Methods of Optimizing Vehicular Air Conditioning Control Systems

InactiveUS20080034767A1Reduction in propulsion cooling system sizeReduce heat loadCompression machines with non-reversible cycleVehicle heating/cooling devicesElectric driveOperating temperature

Air conditioning system controls are optimized for an air conditioning system having a compressor in IC engine vehicles and in hybrid or fuel cell vehicles having electric drive motors by first determining the operating temperature of at least one of the following vehicle components: engine coolant and transmission oil for all types of vehicles, and for hybrid or fuel cell vehicles also determining the operating temperature of inverter coolant and the electric drive motors. At least one operating temperature is then compared to lower and upper temperature limits. If the operating temperature is outside of the temperature limits air conditioner heat load is reduced by at least one of the following steps: increasing cabin air recirculation, reducing cabin blower speed and reducing air conditioner compressor capacity. Subsequent to reducing air conditioner heat load, selected operating temperature or temperatures are monitored to determine if the operating temperature exceeds the upper temperature limit or limits. If the operating temperature or temperatures exceed the upper limit or limits the compressor is shut off.

Owner:GM GLOBAL TECH OPERATIONS LLC

Maintaining cooling efficiency during air mover failure

A method and apparatus may be employed for maintaining cooling efficiency during air mover failure. An electrical enclosure may include a heat-generating thermal load, multiple air movers configured to remove heat from the thermal load, and a backward-airflow reducing device configured to reduce the amount of air that can be drawn backwards through one of the air movers if that air mover fails. The backward-airflow reducing device may be a valve configured to open while the air mover if functioning and to close when the air mover is not functioning.

Owner:ORACLE INT CORP

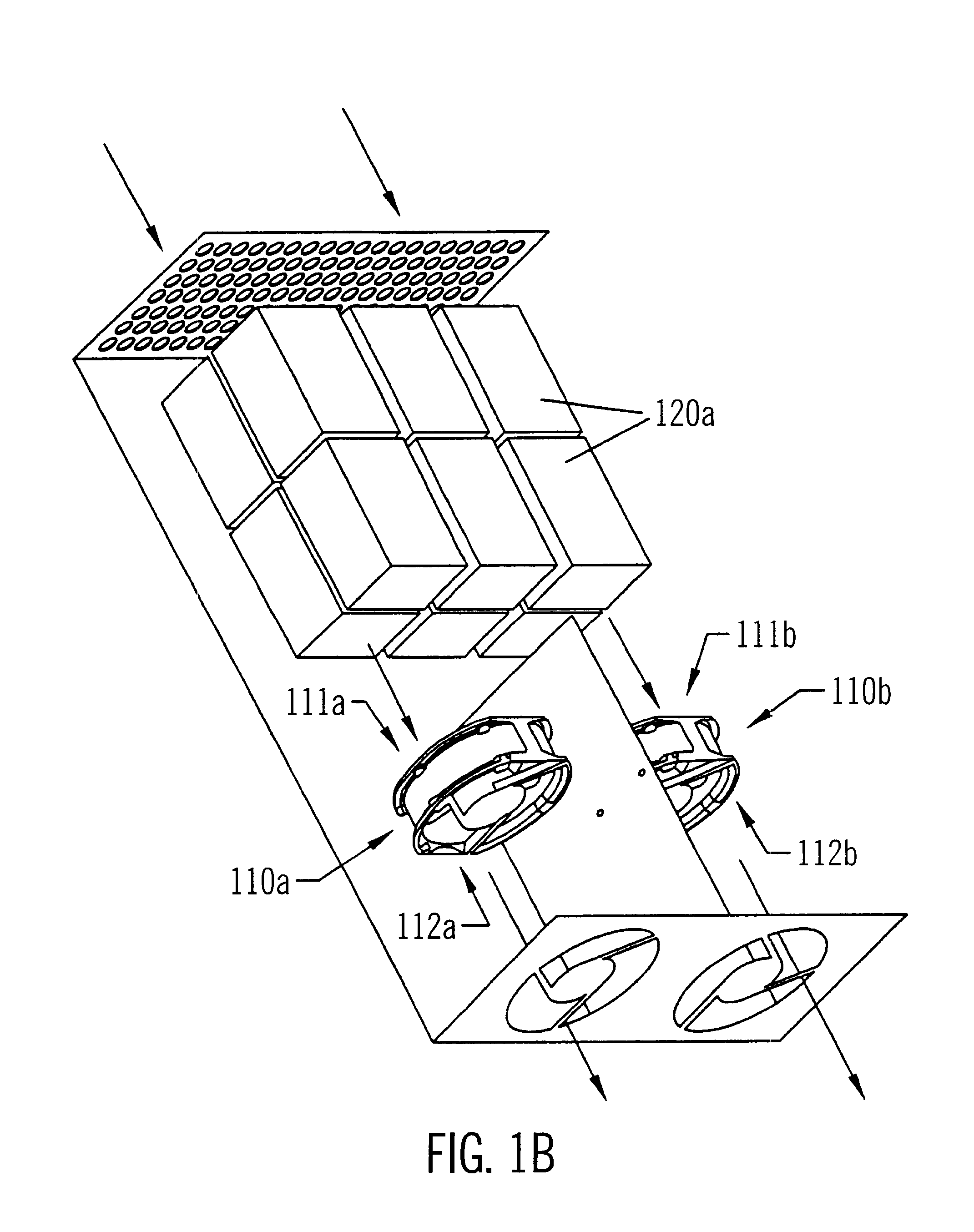

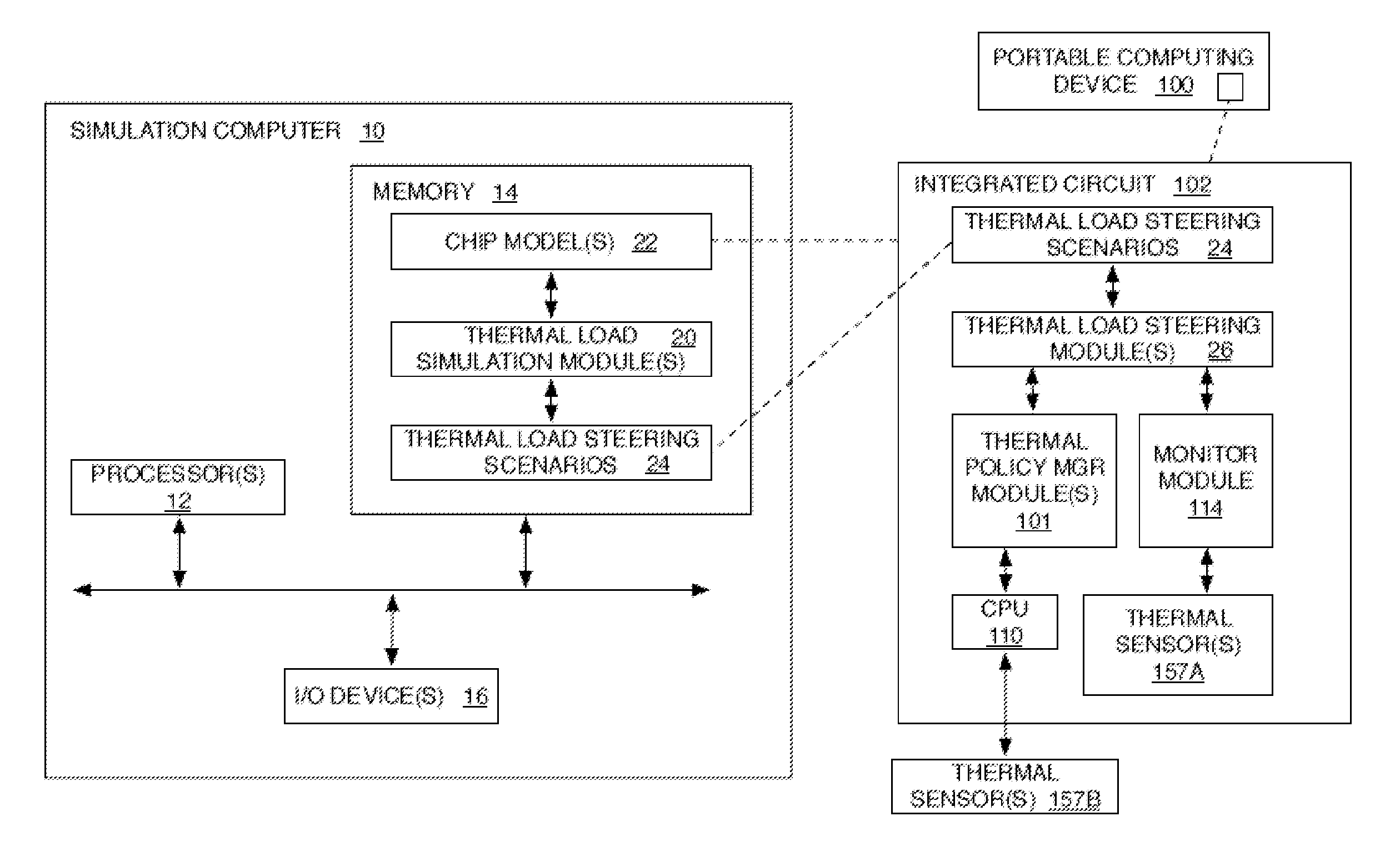

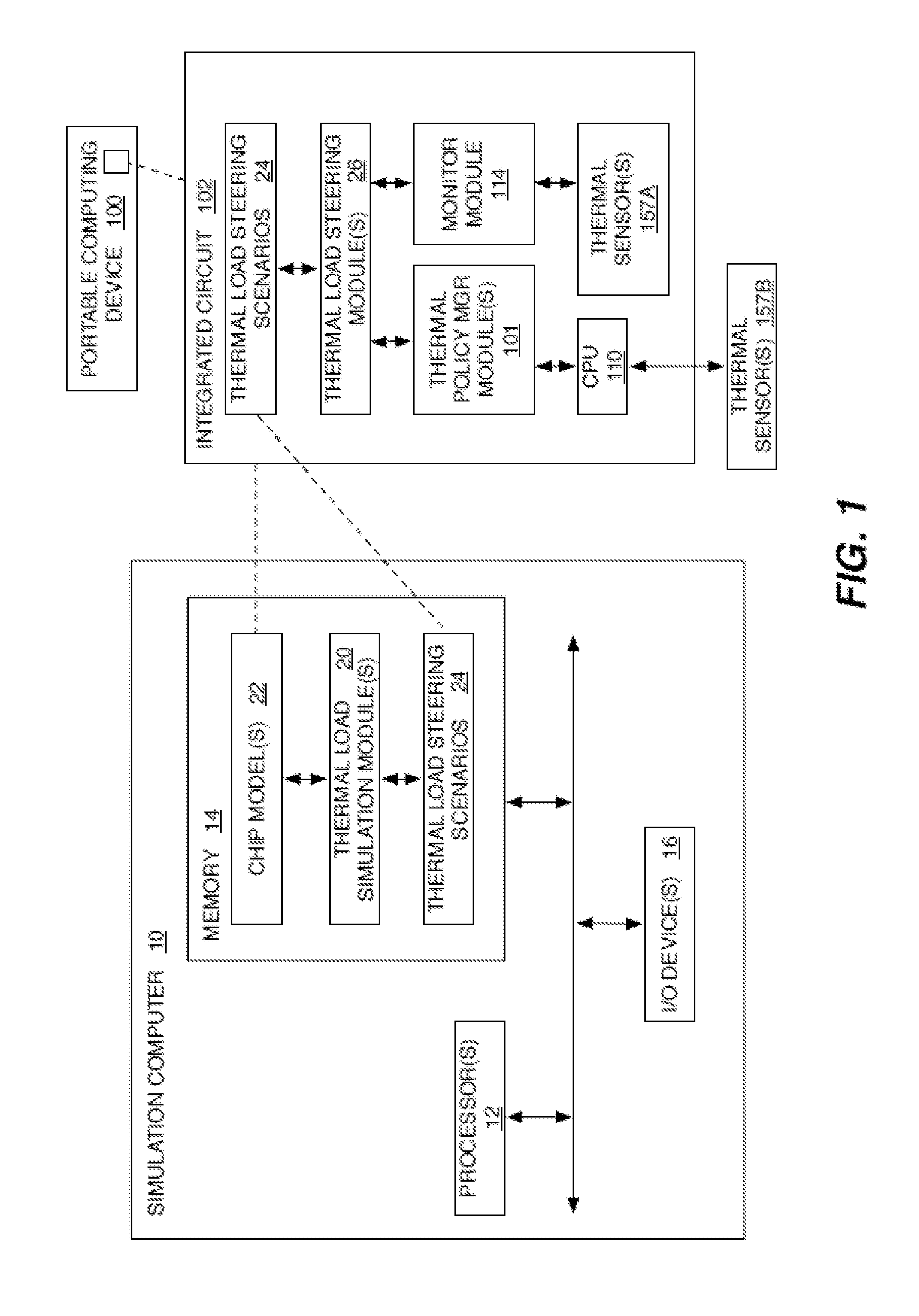

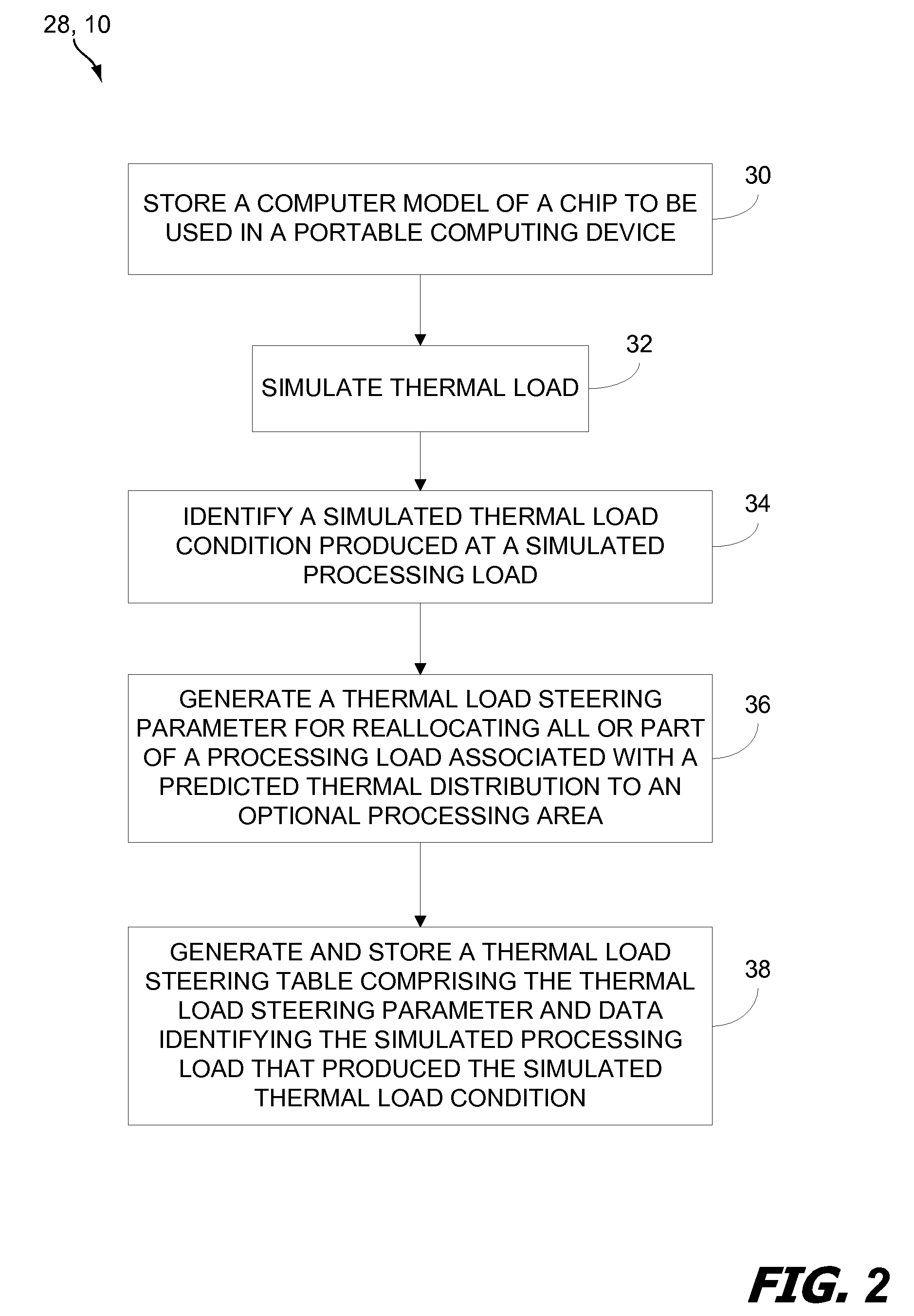

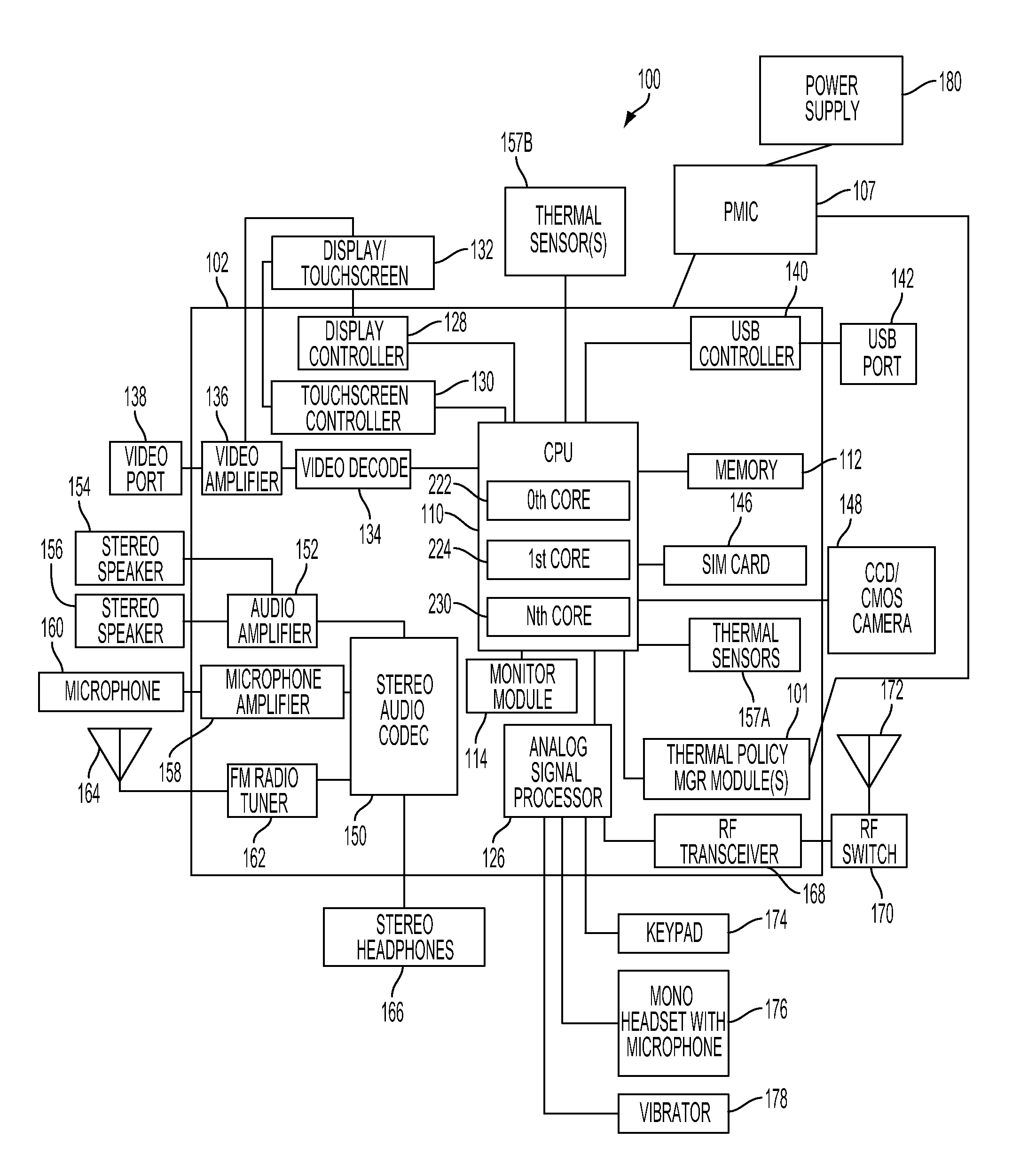

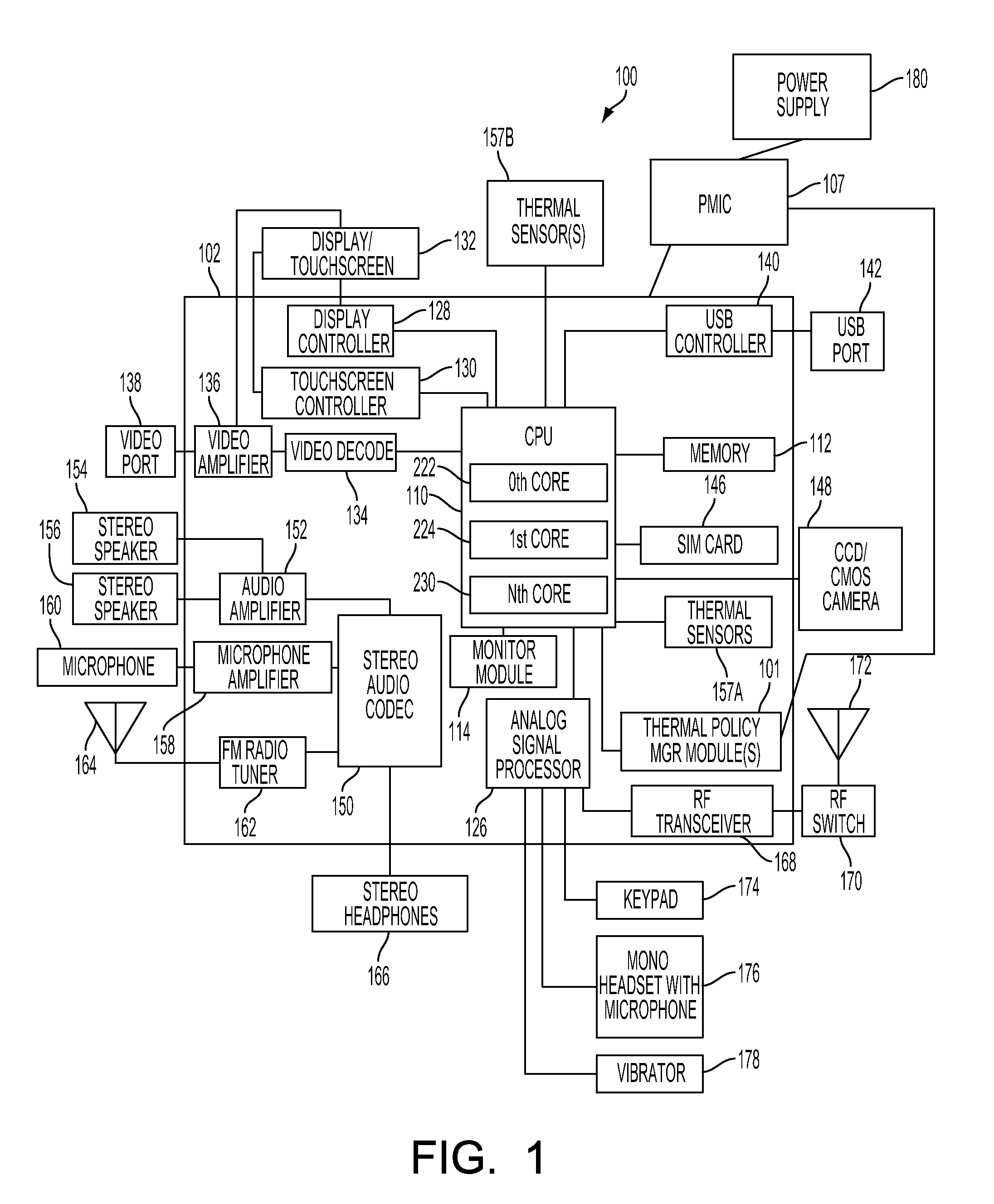

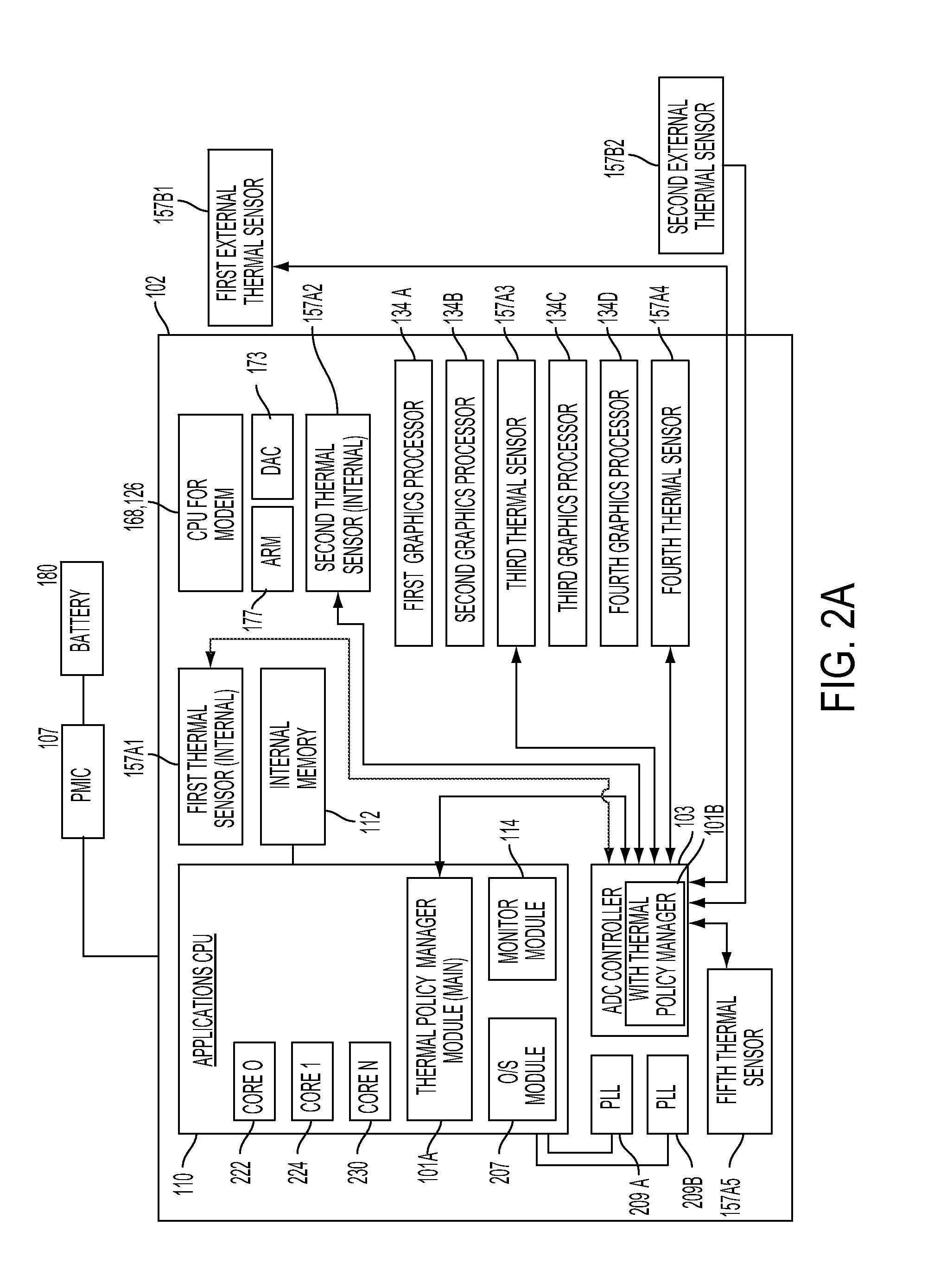

Method and system for thermal load management in a portable computing device

ActiveUS20120271481A1Reduce power densityLower quality of serviceEnergy efficient ICTDigital data processing detailsProcessingHeat energy

Methods and systems for leveraging temperature sensors in a portable computing device (“PCD”) are disclosed. The sensors may be placed within the PCD near known thermal energy producing components such as a central processing unit (“CPU”) core, graphical processing unit (“GPU”) core, power management integrated circuit (“PMIC”), power amplifier, etc. The signals generated by the sensors may be monitored and used to trigger drivers running on the processing units. The drivers are operable to cause the reallocation of processing loads associated with a given component's generation of thermal energy, as measured by the sensors. In some embodiments, the processing load reallocation is mapped according to parameters associated with pre-identified thermal load scenarios. In other embodiments, the reallocation occurs in real time, or near real time, according to thermal management solutions generated by a thermal management algorithm that may consider CPU and / or GPU performance specifications along with monitored sensor data.

Owner:QUALCOMM INC

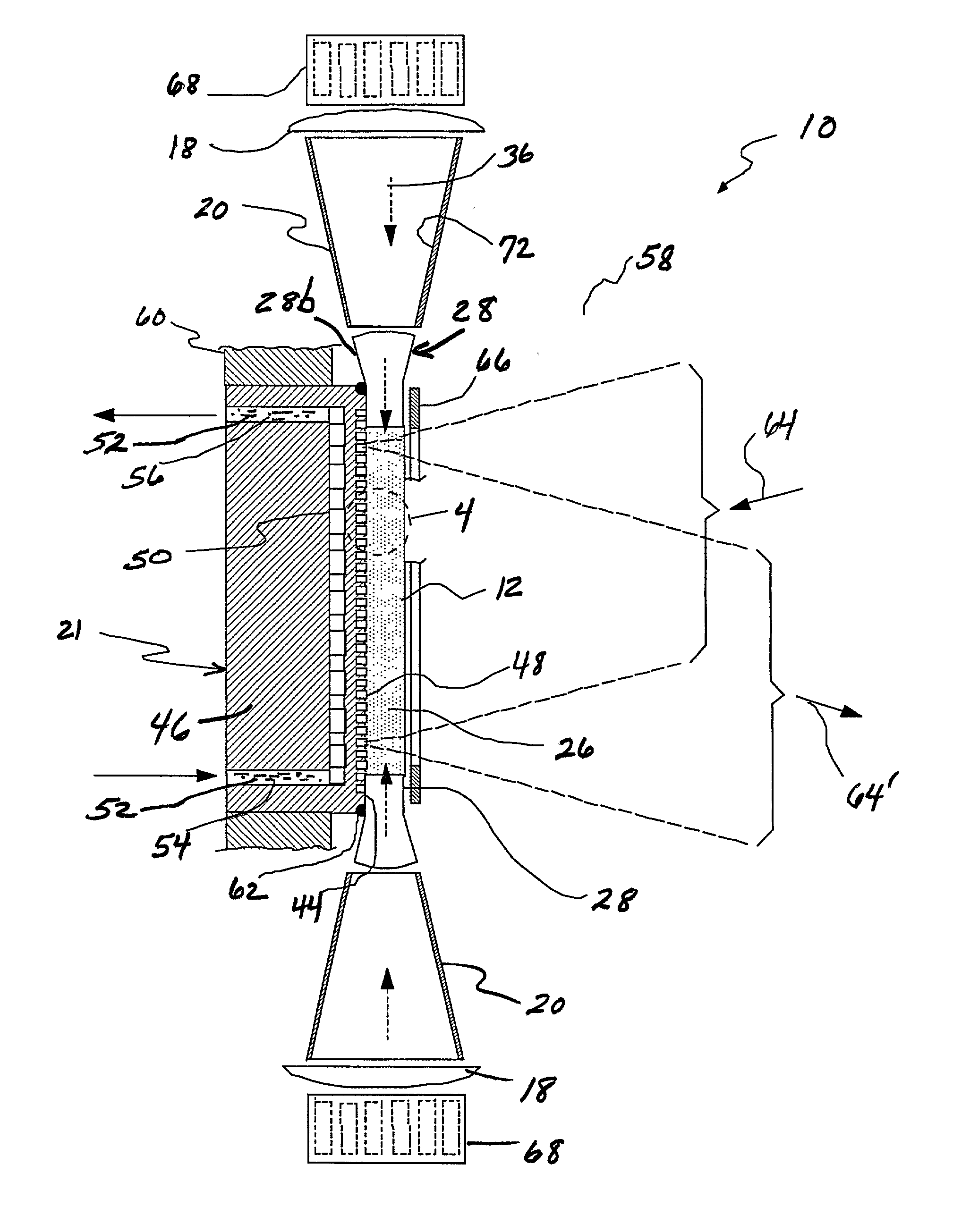

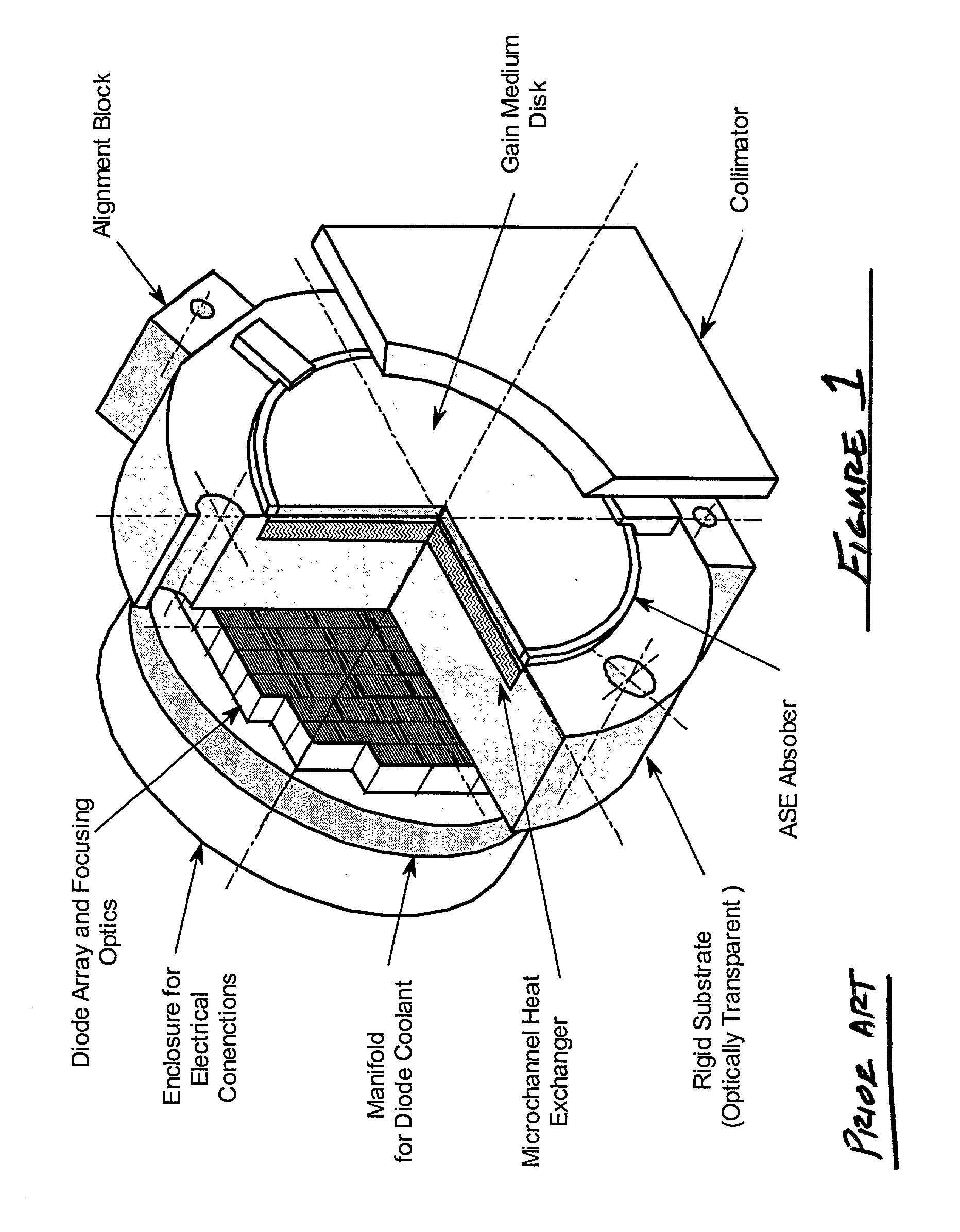

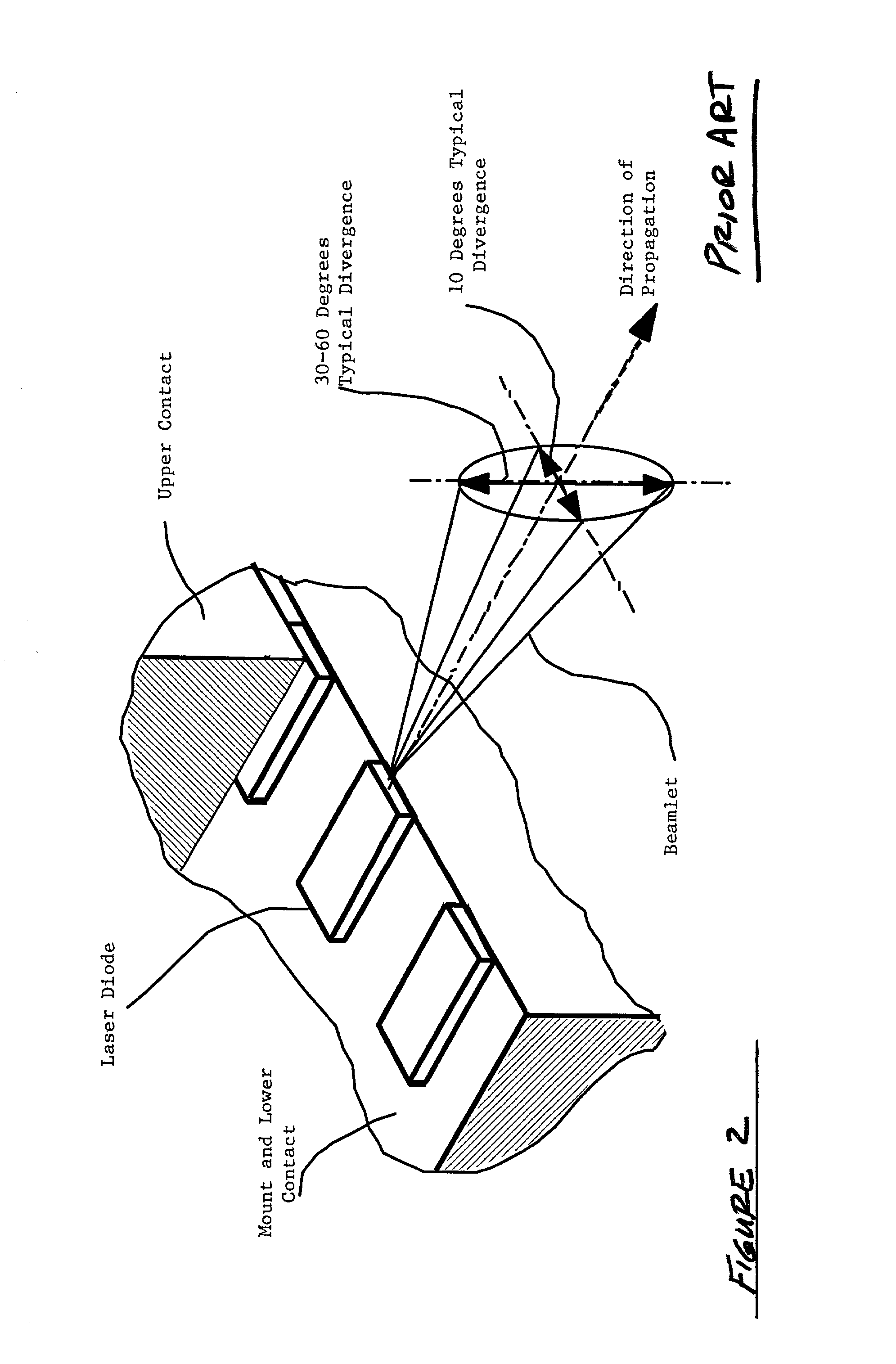

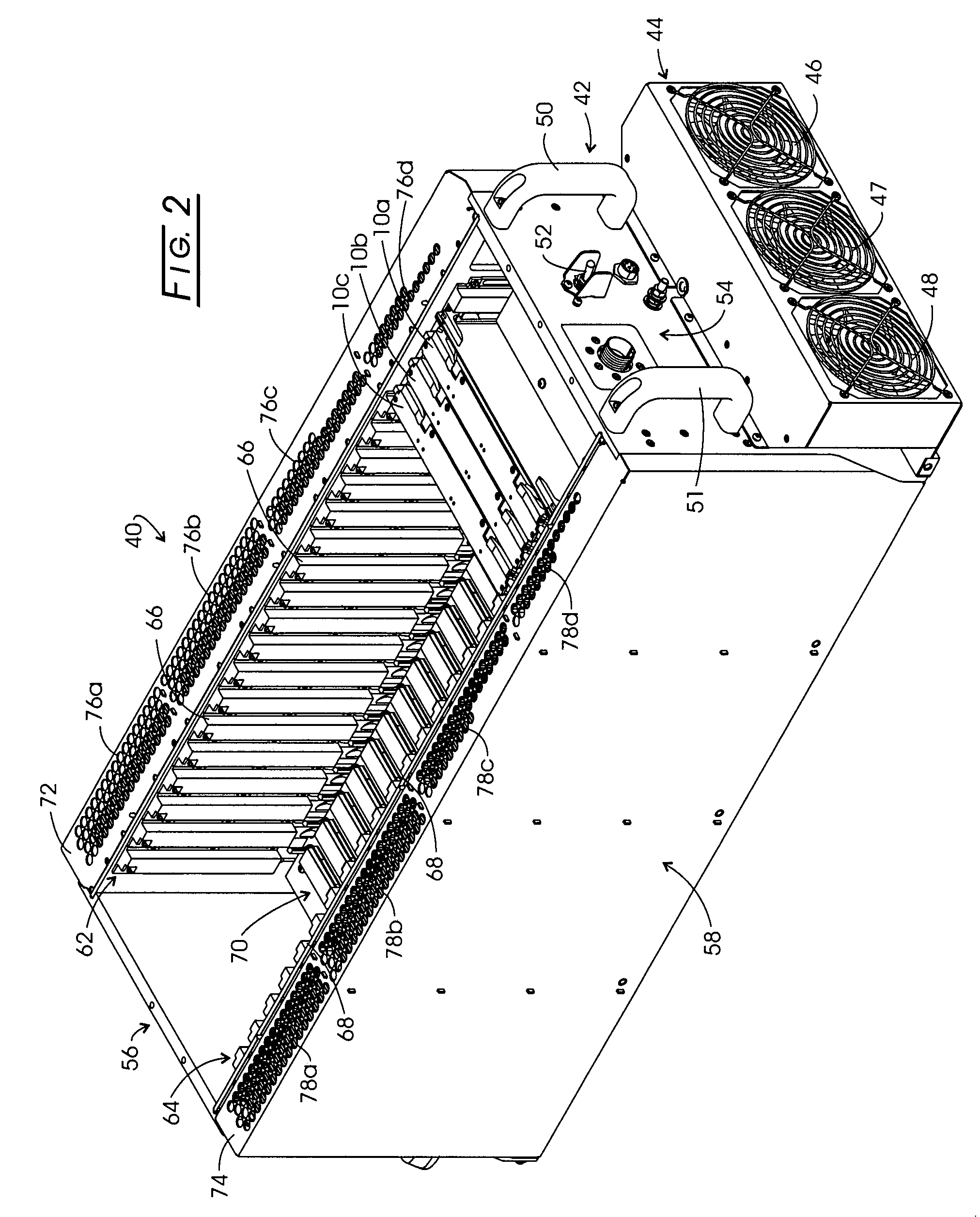

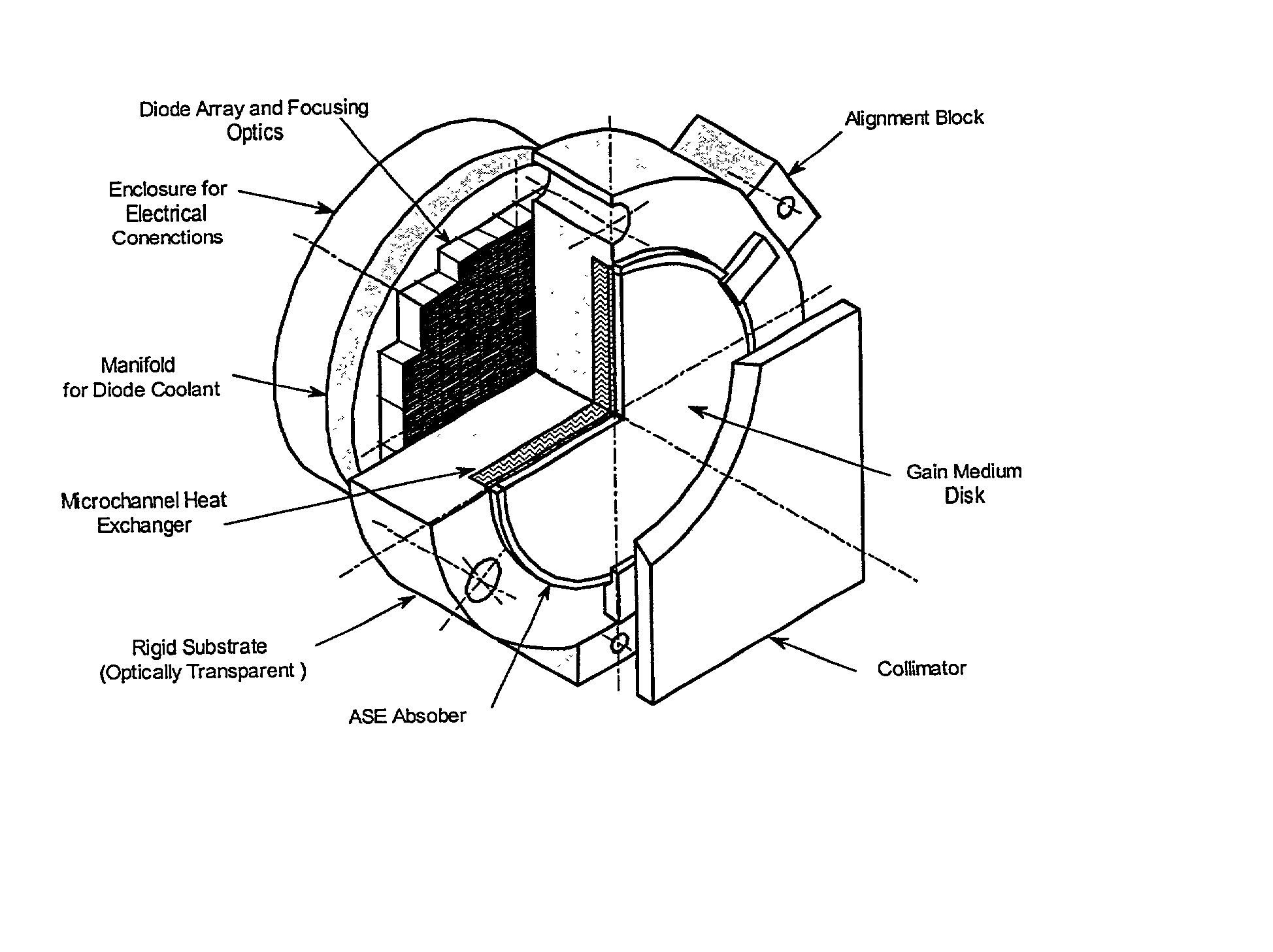

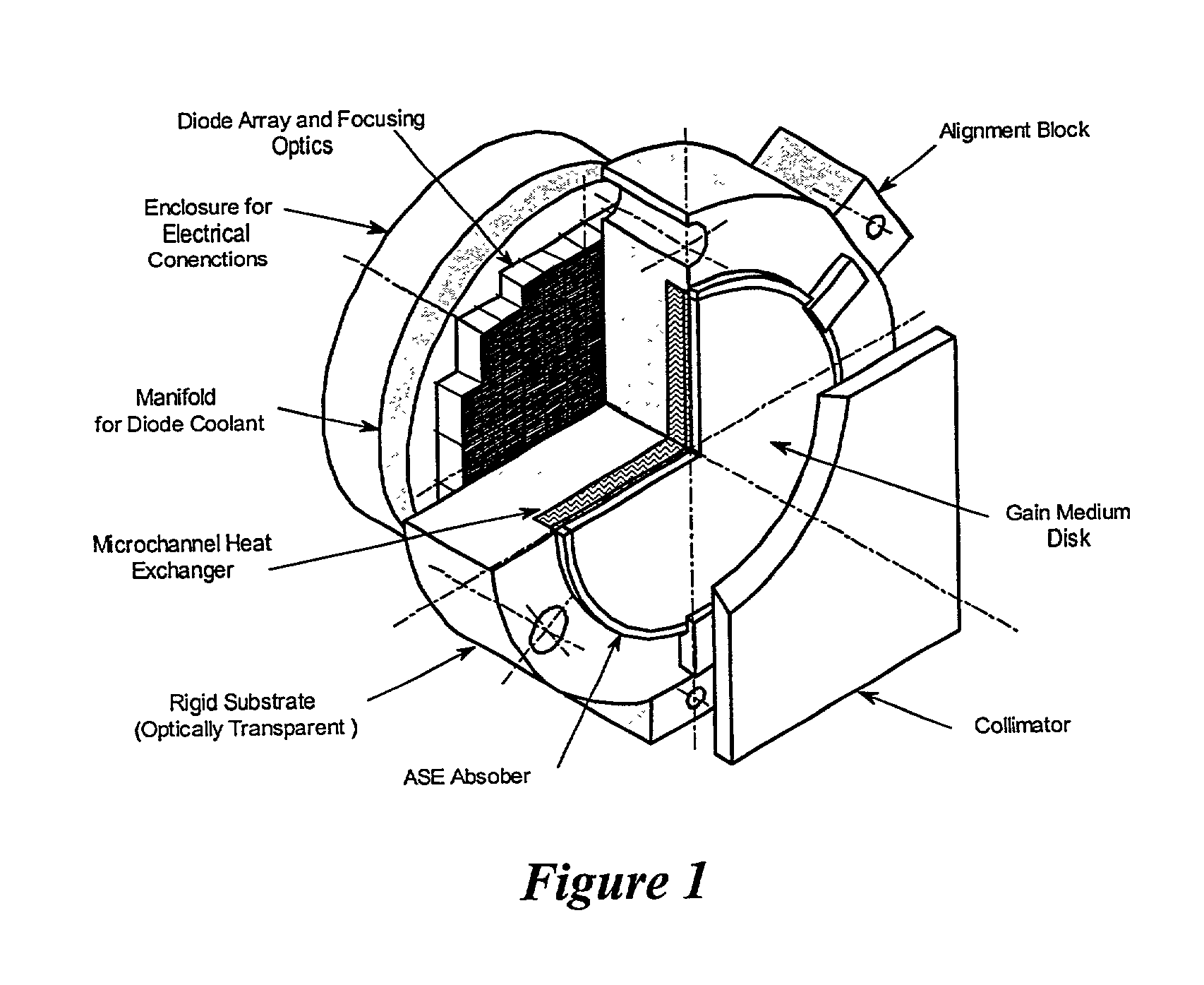

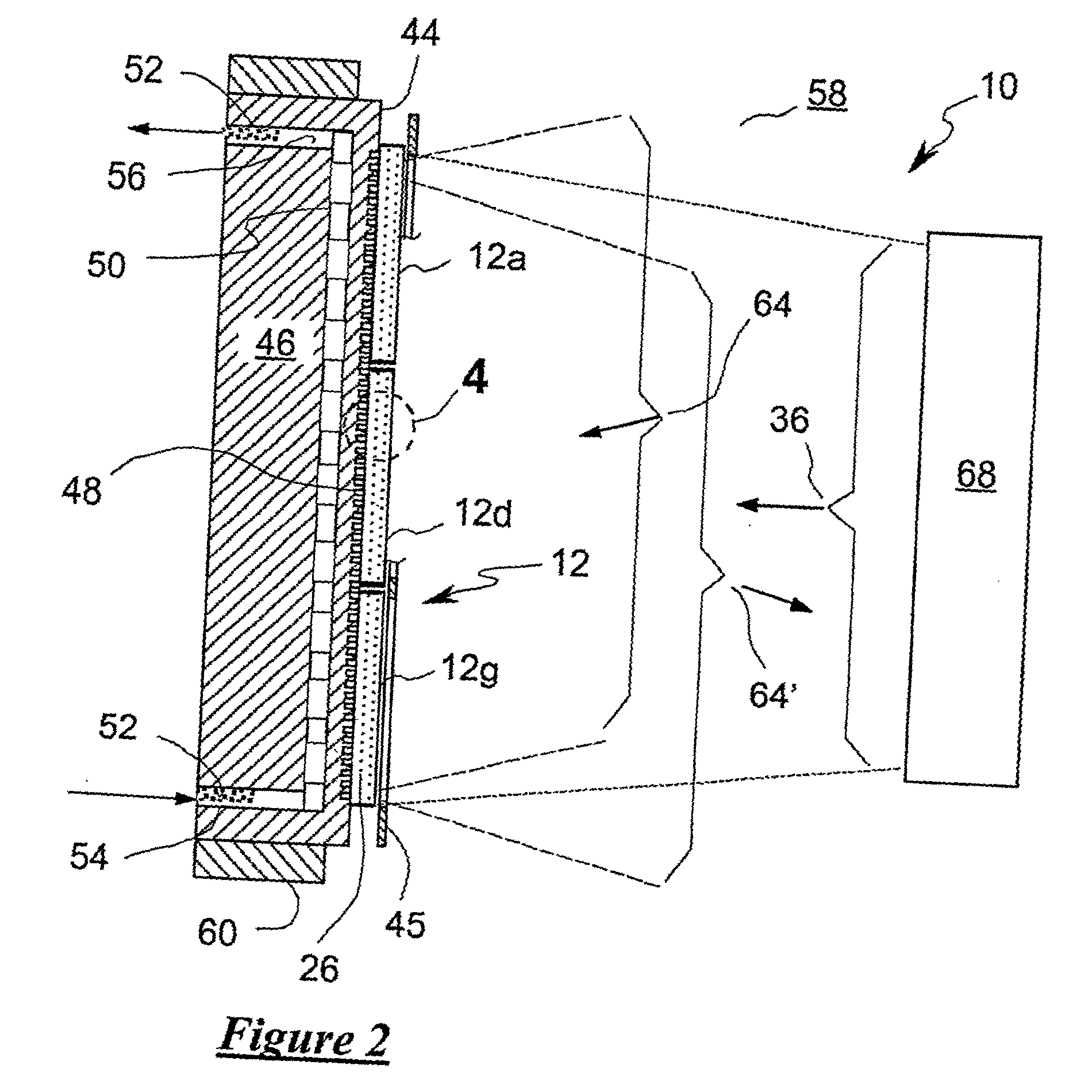

Side-pumped active mirror solid-state laser for high-average power

InactiveUS20020097769A1Active medium shape and constructionLaser cooling arrangementsSolid-state laser deviceOptical coating

Apparatus and method for achieving improved performance in a solid-state laser. The solid-state laser apparatus preferably uses a laser gain medium in the shape of a disk wherein optical pump radiation is injected into the peripheral edge of the disk. In the preferred embodiment the laser gain medium is provided with optical coatings for operation in the active mirror configuration. Furthermore, the laser gain medium is pressure-clamped to a rigid, cooled substrate, which allows it to maintain a prescribed shape even when experiencing significant thermal load. A cooling medium can be provided to a heat exchanger internal to the substrate and / or flowed through the passages on the substrate surface, thereby directly cooling the laser gain medium. Sources of optical pump radiation are placed around the perimeter of the gain medium. Tapered ducts may be disposed between the sources and the gain medium for the purpose of concentrating optical pump radiation. With the proper choice of laser gain medium doping, pump source divergence and geometry, a uniform laser gain is achieved across large portions of the gain medium.

Owner:THE BOEING CO

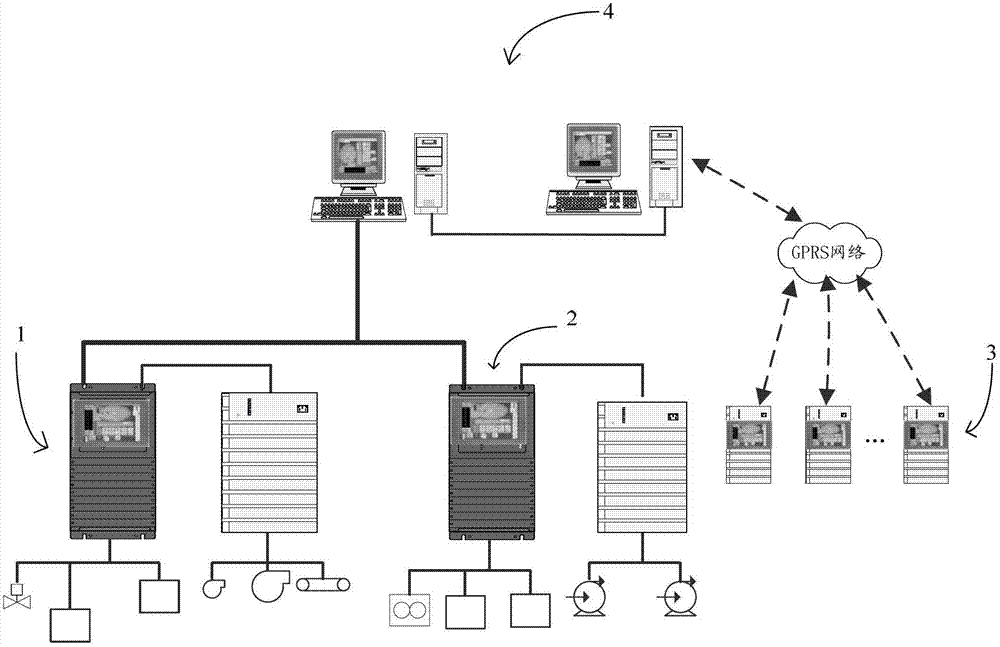

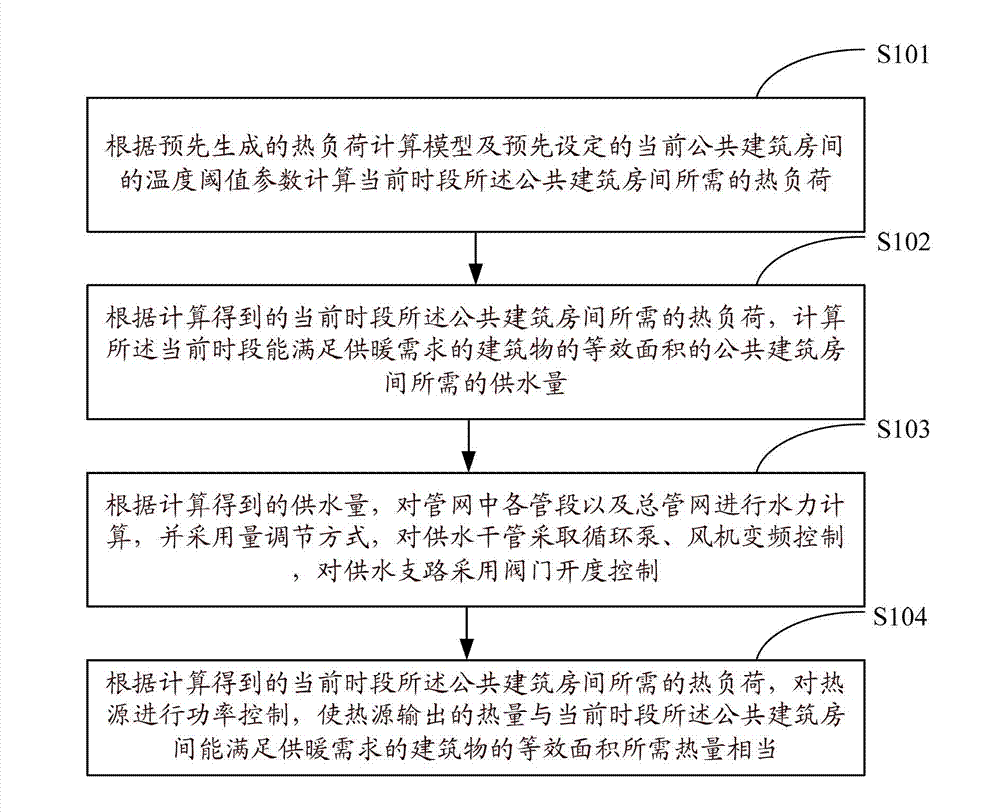

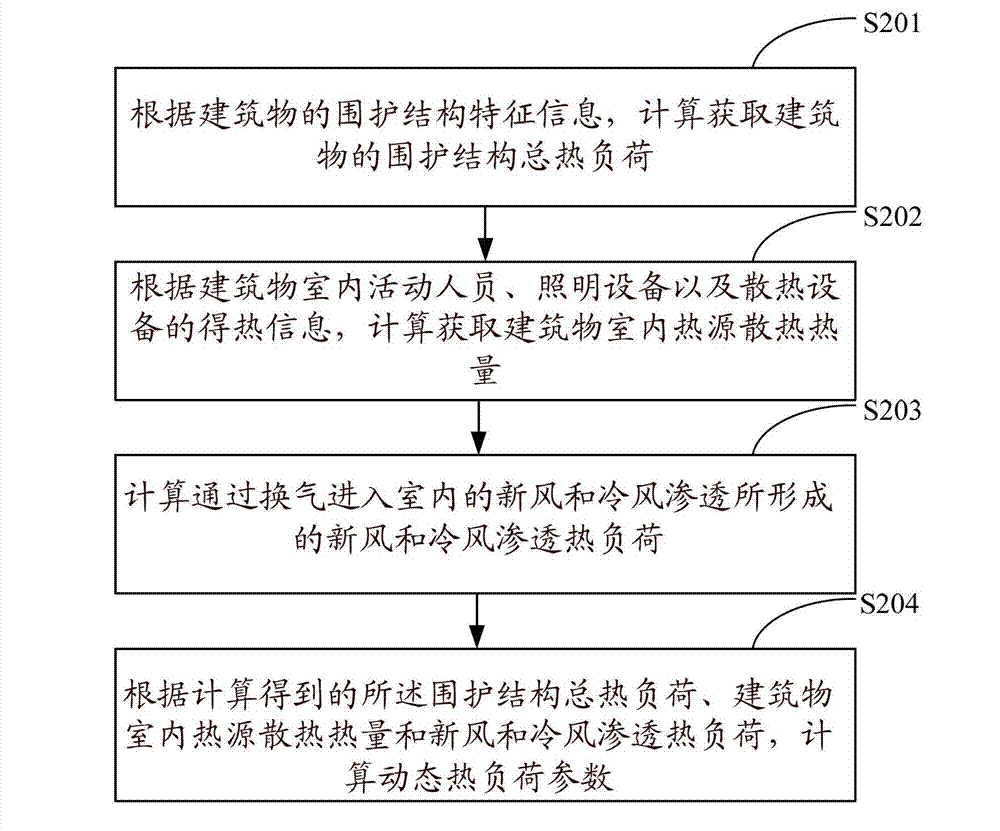

Centralized heating public building heat supply energy-saving control method

InactiveCN102865623AReduce wasteRealize time-division area controlLighting and heating apparatusSpace heating and ventilation detailsEngineeringCirculating pump

The invention relates to the technical field of heating and energy conservation and provides a centralized heating public building heat supply energy-saving control method. The method comprises the following steps of: calculating a thermal load required by a public building room in the current time period; calculating water supply quantity required by the public building room in an equivalent area of a building which meets the heating requirement in the current time period; calculating hydraulic power of each pipe section in a pipe network and the total pipe network, performing circulating pump and fan frequency variable control on a water supply main pipe by employing a quantity regulating mode, and performing valve opening control on a water supply branch; and controlling power of a heat source. According to the embodiment, the real-time thermal load required by the building is calculated according to the indoor and outdoor thermal disturbance, the heat waste is reduced, the hydraulic power of the distribution pipe network is reasonably calculated, the pipe section with a proper pipe diameter and a circulating pump with a proper lift are selected according to the calculation, the time and area control and on-demand heating of the thermal load can be realized, and the functions of supervising, calculating and controlling are truly integrated.

Owner:季涛

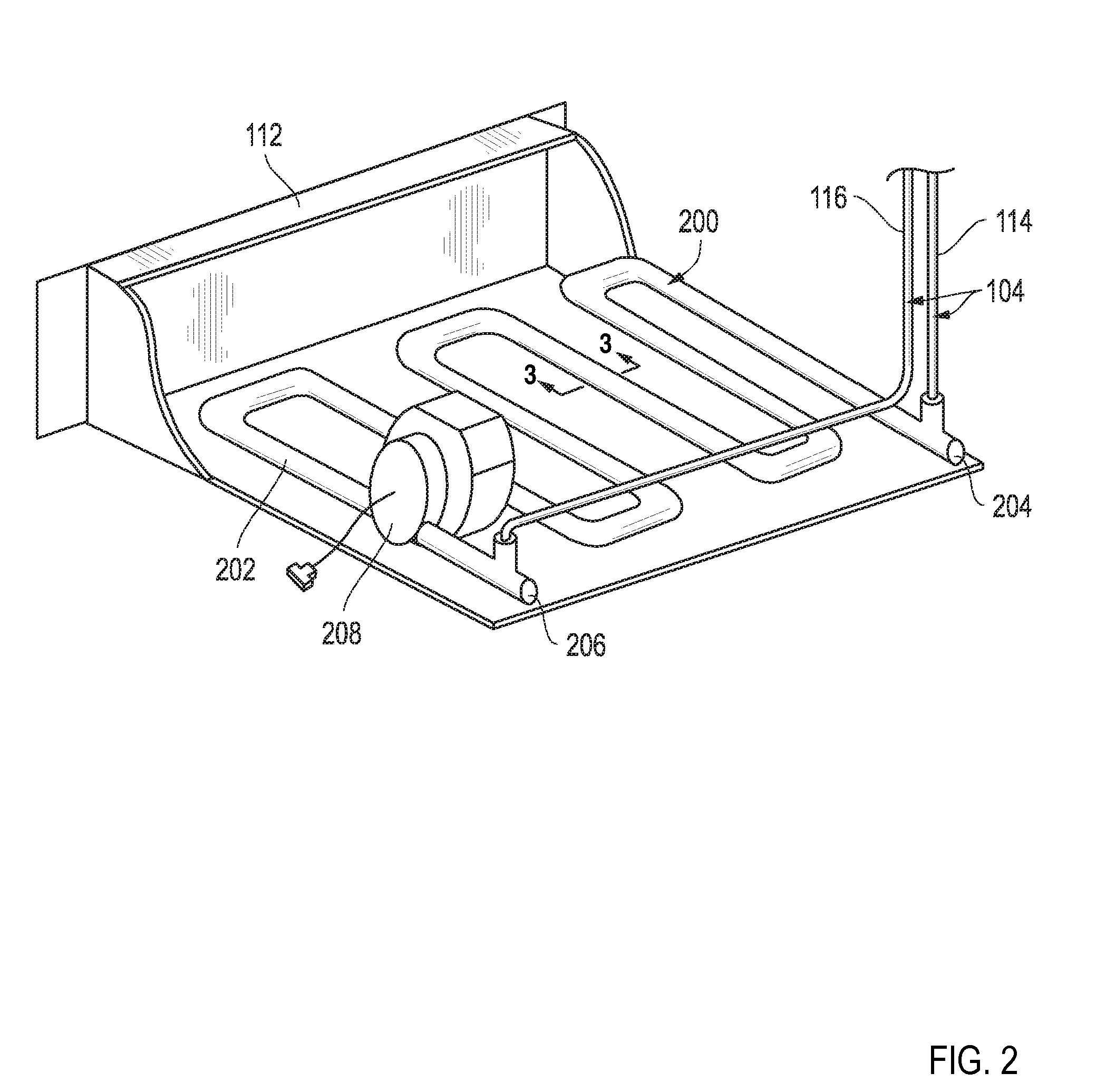

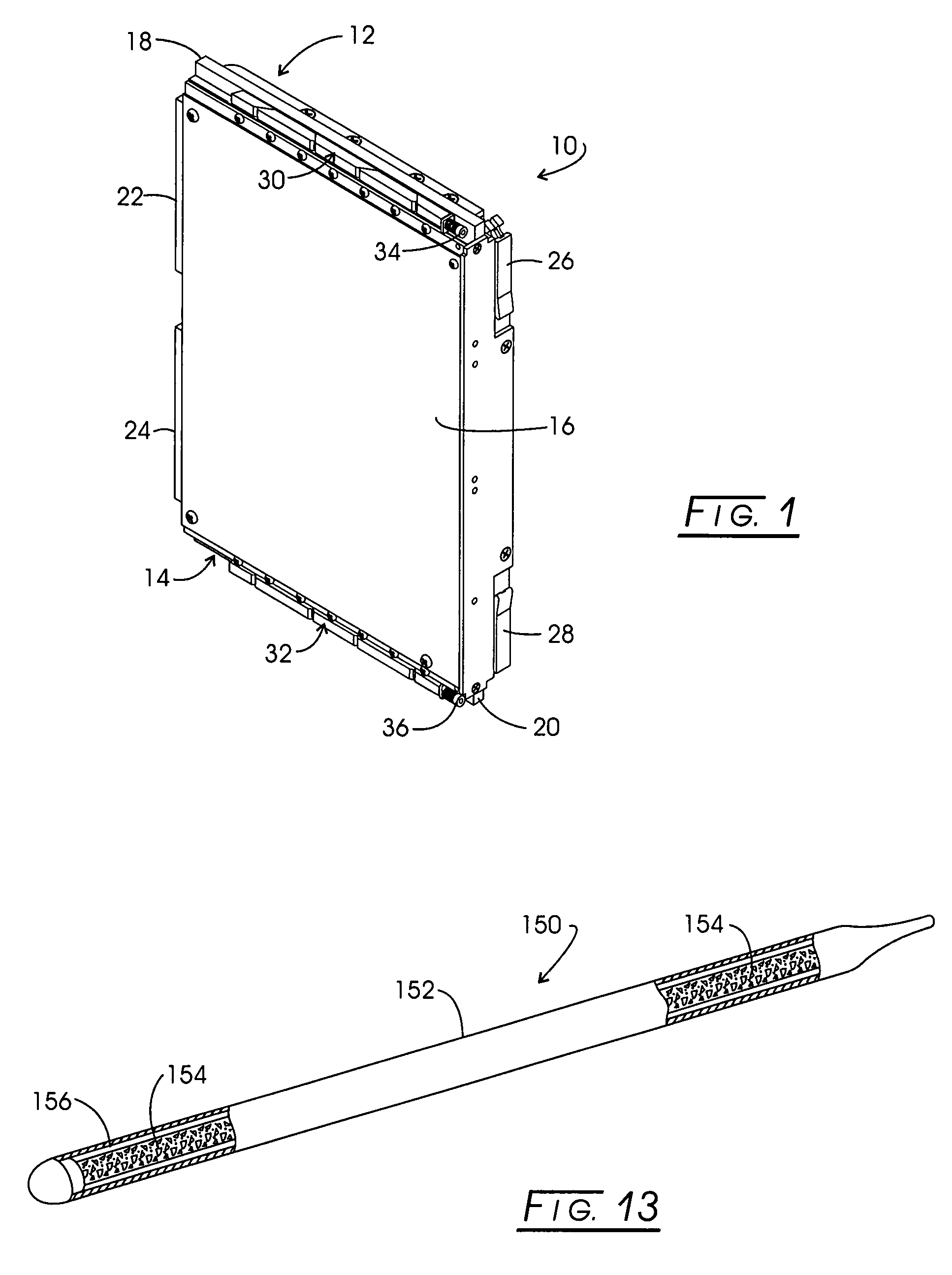

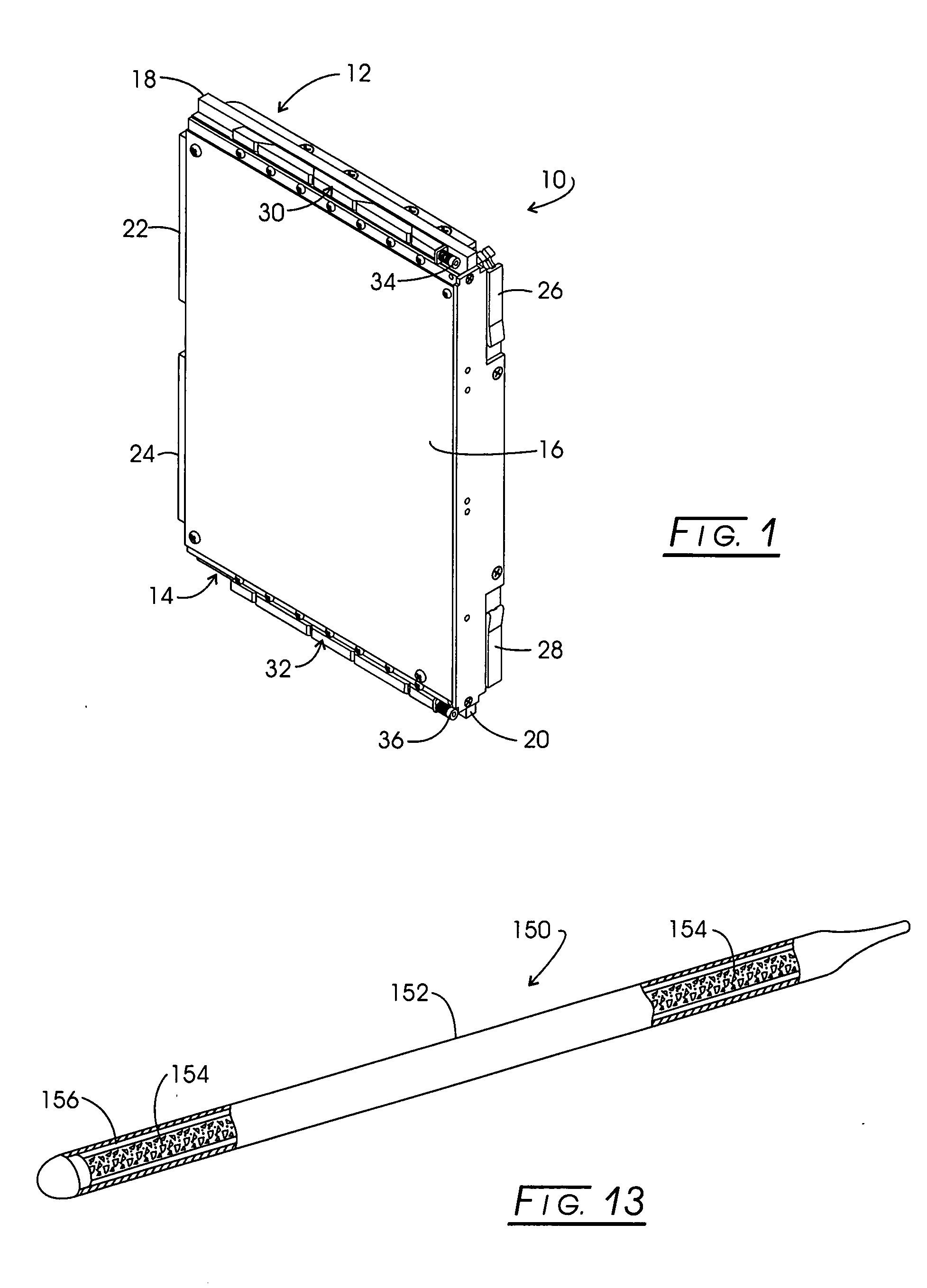

Method and system for dissipating thermal energy from conduction-cooled circuit card assemblies which employ remote heat sinks and heat pipe technology

InactiveUS7460367B2Maximum flexibilityIncrease the lengthDomestic cooling apparatusDigital data processing detailsThermal energyEngineering

Method and System for dissipating thermal energy from conduction-cooled circuit card assemblies in which thermal energy is directed into proximate heat sink assemblies and additionally is conveyed by heat pipes to one or more remote heat sink assemblies configured for the transfer of thermal energy to a flow of air and located within a chassis at a position remote from the system thermal load.

Owner:TRACEWELL SYST

High-average power active mirror solid-state laser with multiple subapertures

InactiveUS20020110164A1Precise positioningRelieve pressureActive medium materialActive medium shape and constructionOptical coatingHydrostatic pressure

An apparatus and method for achieving ultrahigh-power output from a solid-state laser. The solid-state laser of the subject invention uses multiple disk-shaped laser gain media (subapertures) placed adjacent to each other to fill an optical aperture of an AMA module. In one preferred embodiment each of the laser gain media is provided with optical coatings for operation in the active mirror configuration. Furthermore, each of the laser gain media is hydrostatic pressure-clamped to a rigid, cooled substrate, which allows it to maintain a prescribed shape even when experiencing significant thermal load. A cooling medium can be provided to a heat exchanger internal to the substrate and / or flowed through the passages on the substrate surface, thereby directly cooling the laser gain medium.

Owner:THE BOEING CO

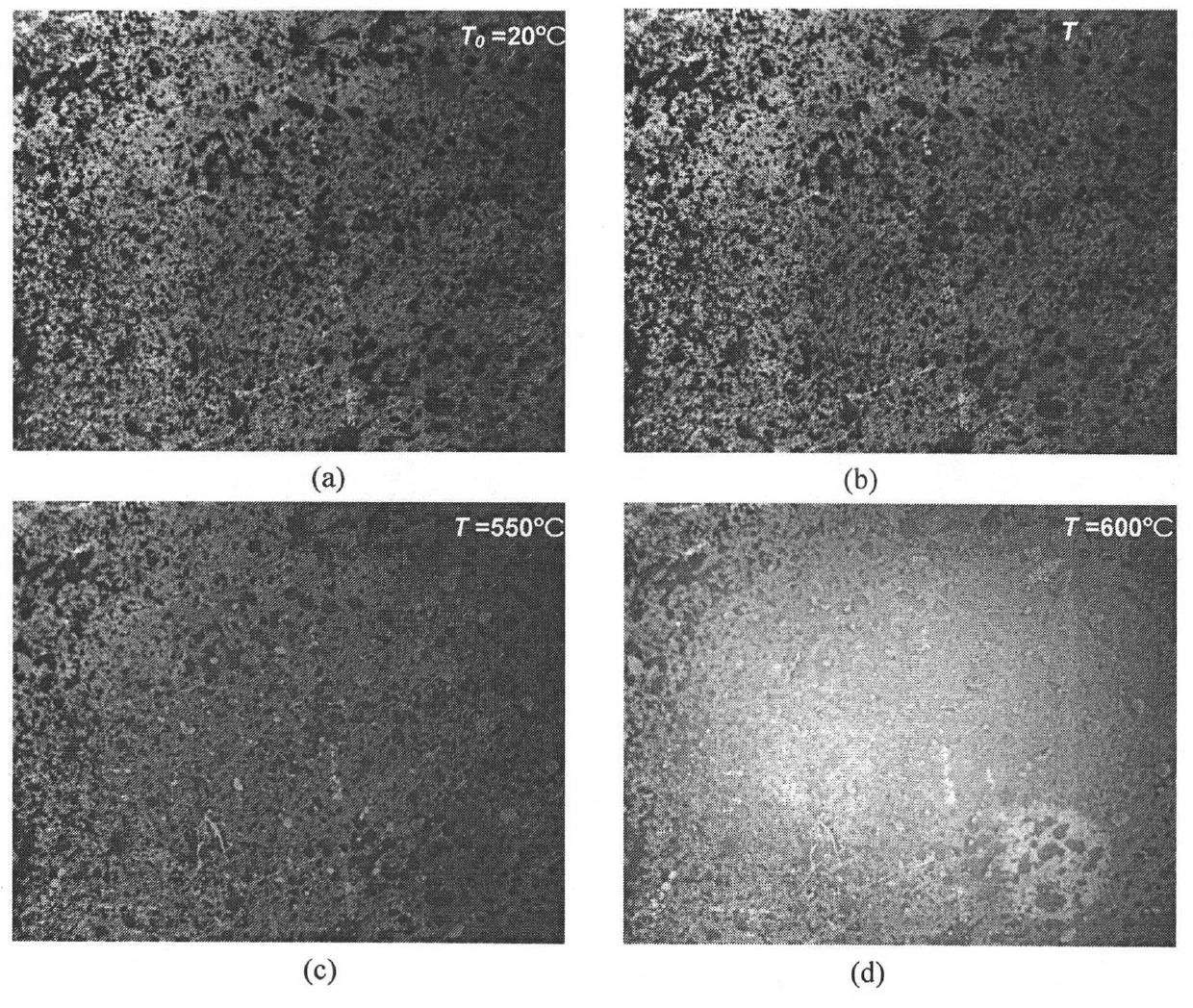

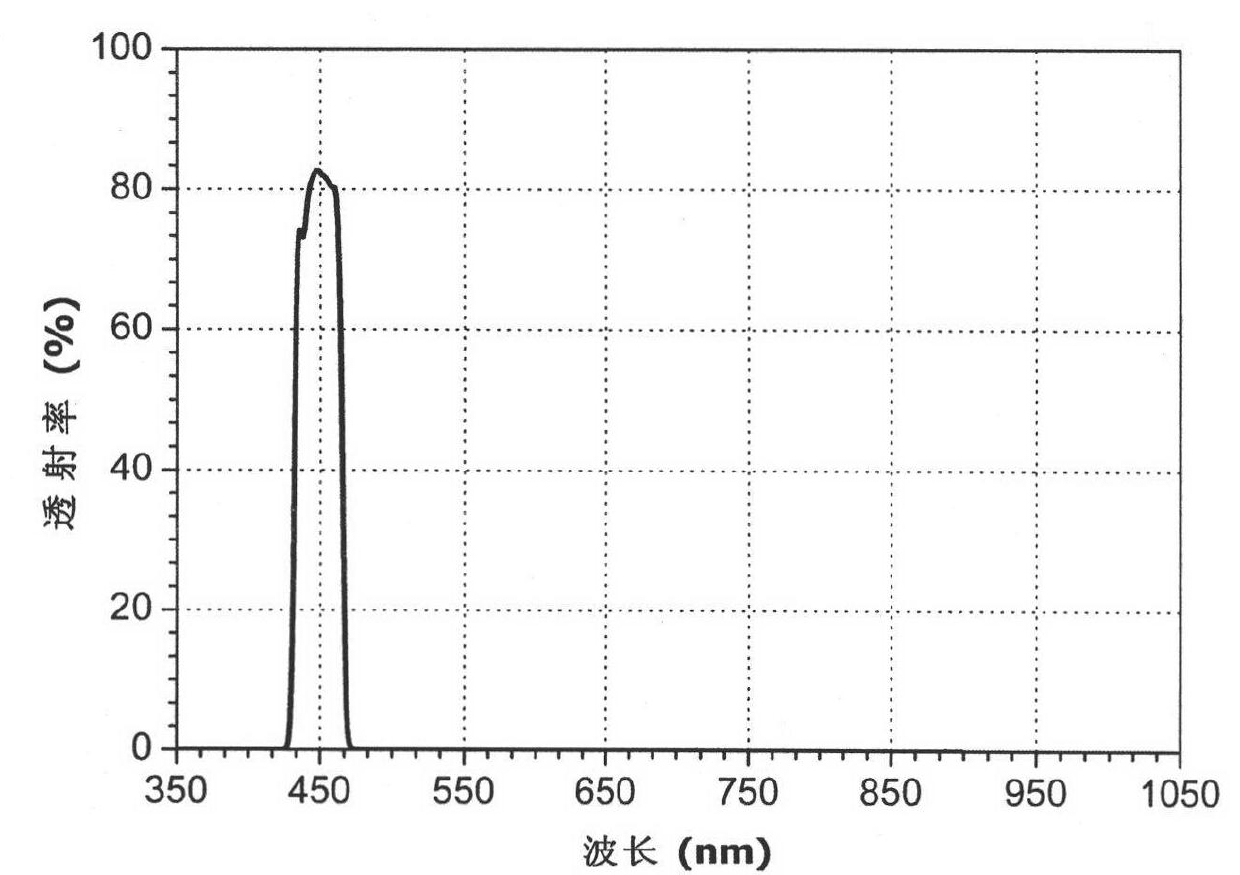

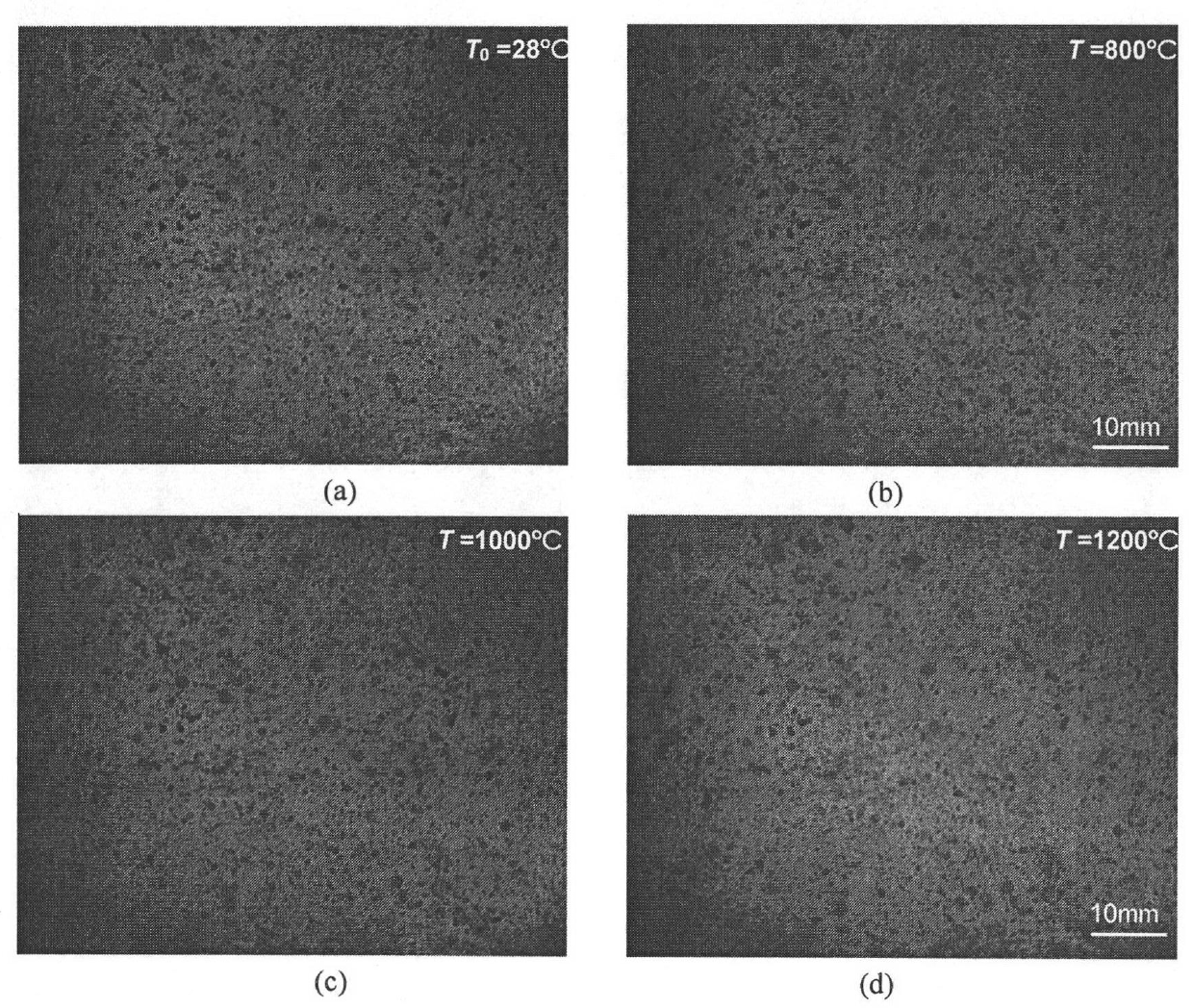

High-temperature three-dimensional digital image related measurement system and measurement method

The invention discloses a high-temperature three-dimensional digital image related measurement system and a high-temperature three-dimensional digital image related measurement method. The system comprises a digital camera, an imaging lens, band-pass optical filter, a monochromatic light source, a calibration board, a support system and a computer, wherein the support system consists of a triangular bracket, a guide rail and a translation stage; and the computer is used for acquiring a digital image and performing analysis processing. The measurement method comprises five steps. In the system, the band-pass optical filter is arranged in front of the imaging lens of the digital camera, so that the influence of the thermal radiation of a high-temperature object on the brightness enhancement of an acquired image of the camera can be reduced effectively. In the measurement, a measured object is lighted by adopting the monochromatic light source of which the lighting wavelength is positioned in a band-pass range of the band-pass optical filter. By using the system and the method, a brilliant image of the surface of the high-temperature object at the surface temperature of over 500 DEG C is acquired, wherein the image can be directly analyzed and processed by a three-dimensional digital image related method to acquire the three-dimensional morphology of the surface of the high-temperature object and a three-dimensional deformation field under the action of a thermal load. The system has a compact structure, is convenient to operate, and has a wide application range and high measurement precision.

Owner:BEIHANG UNIV

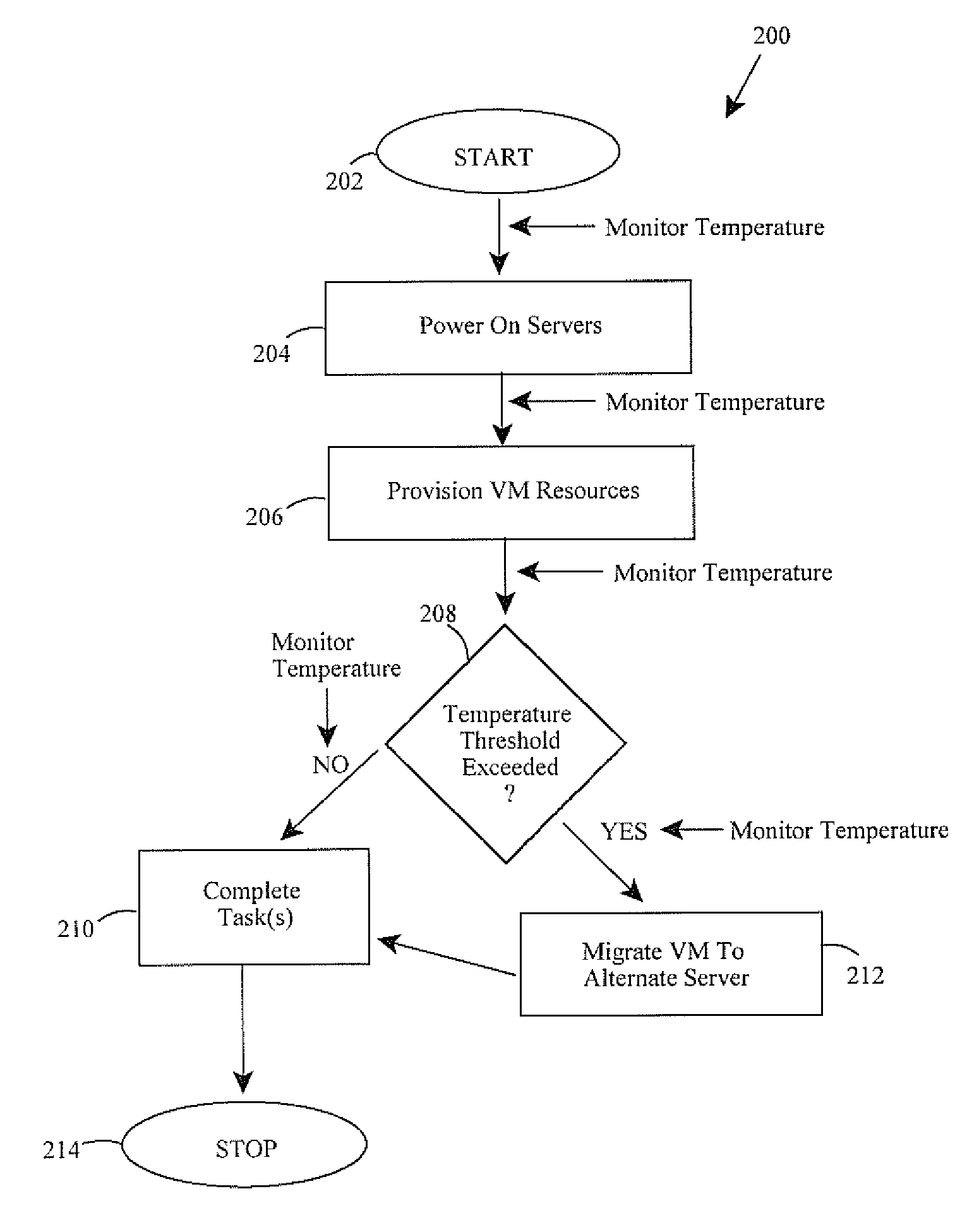

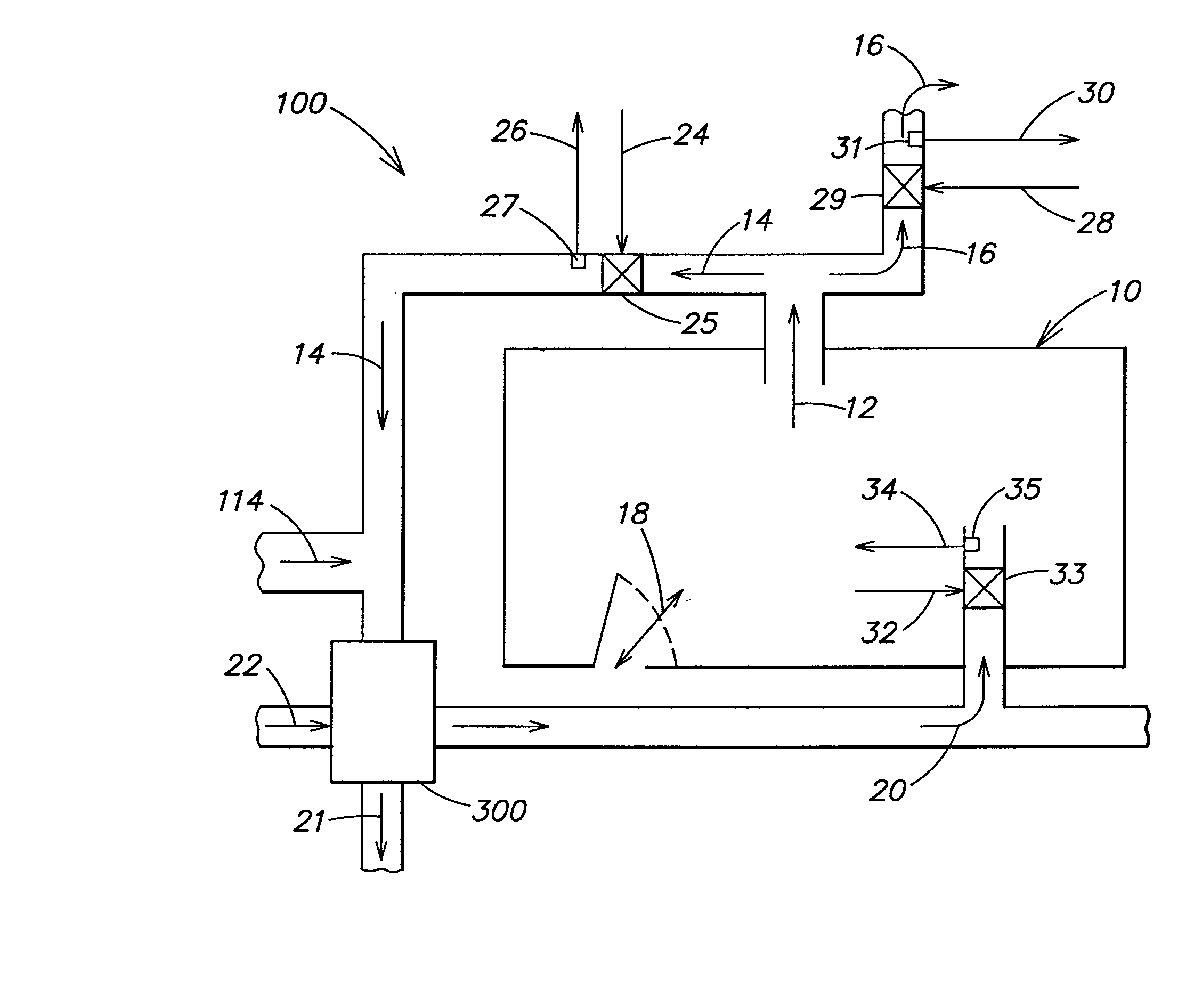

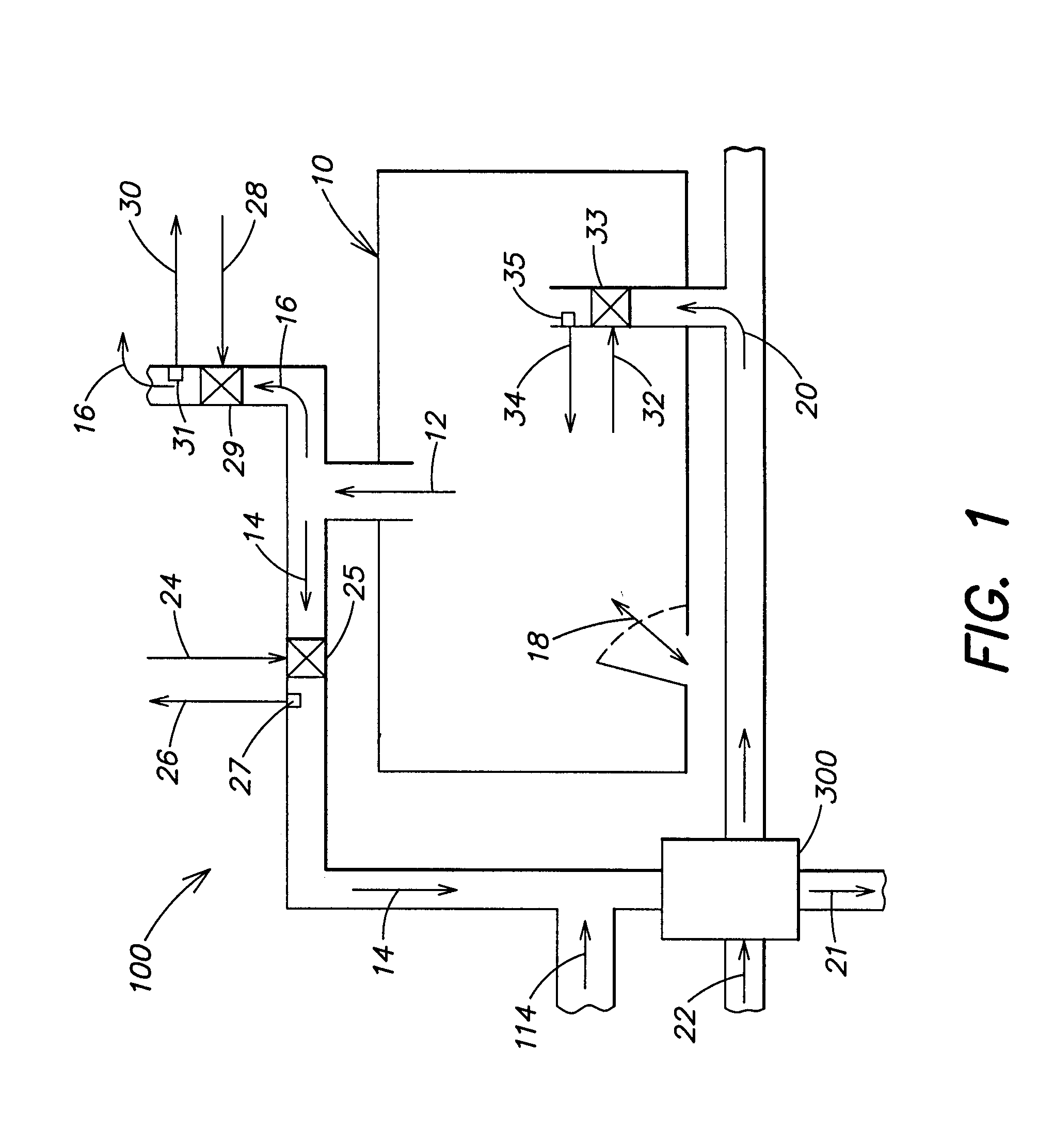

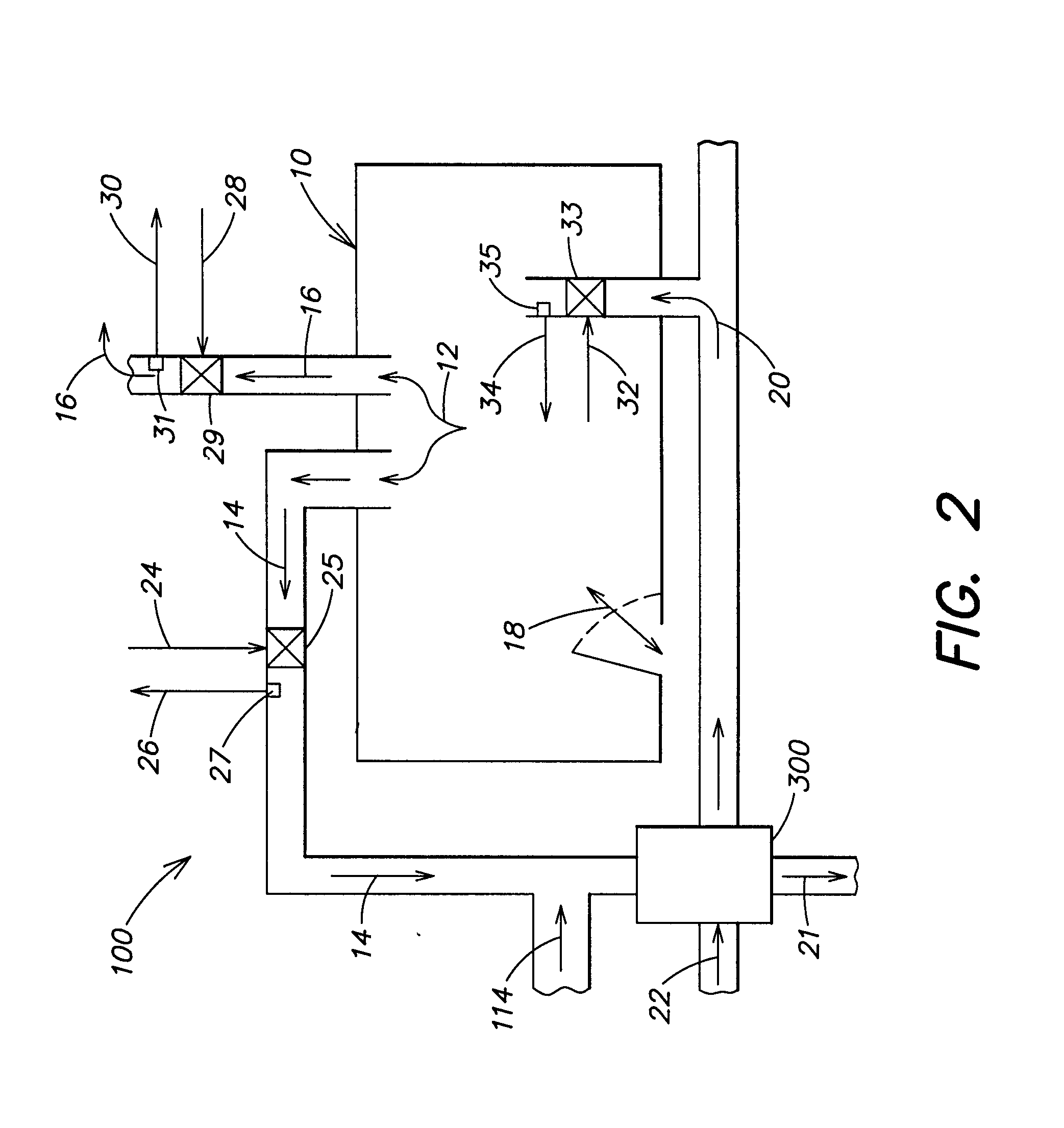

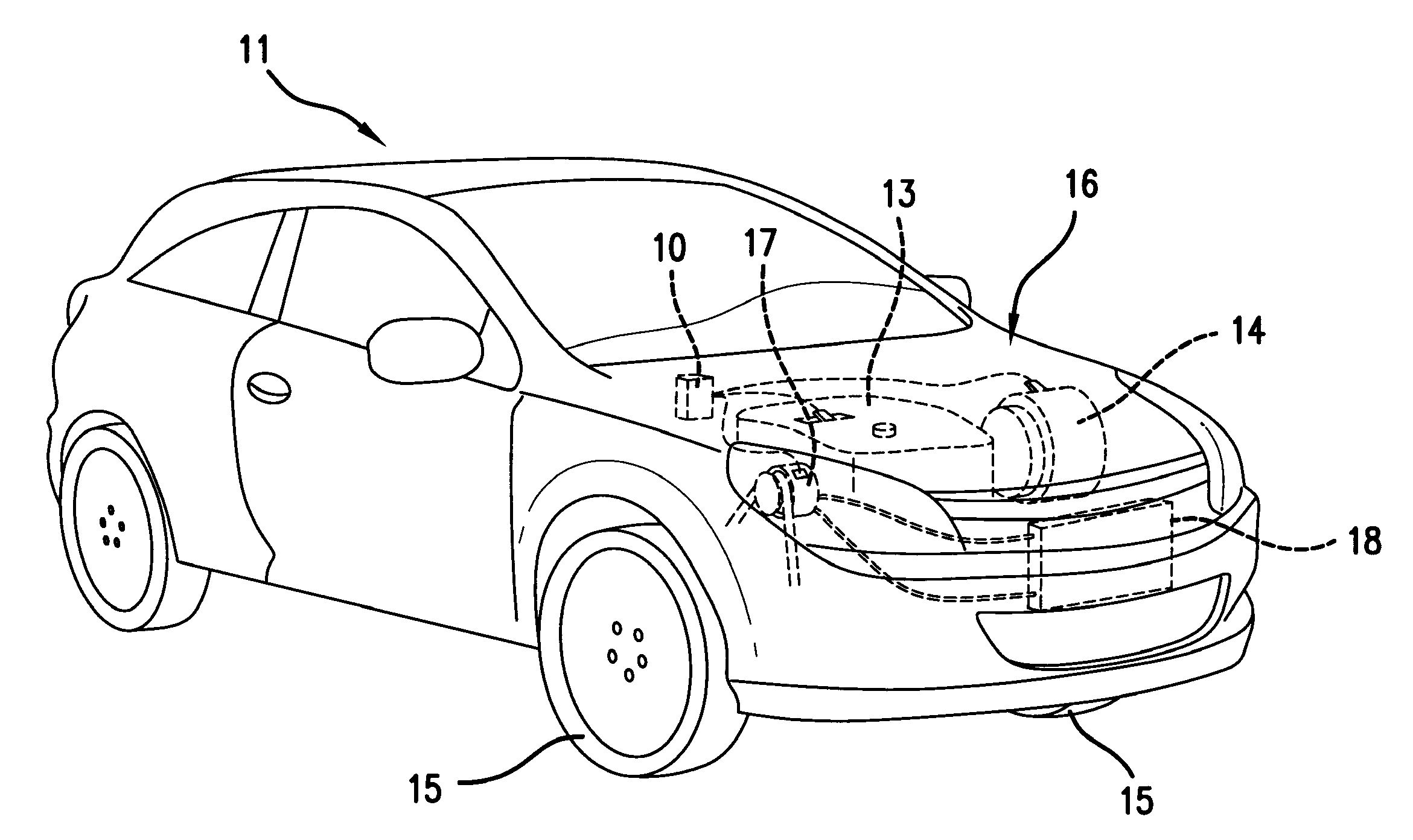

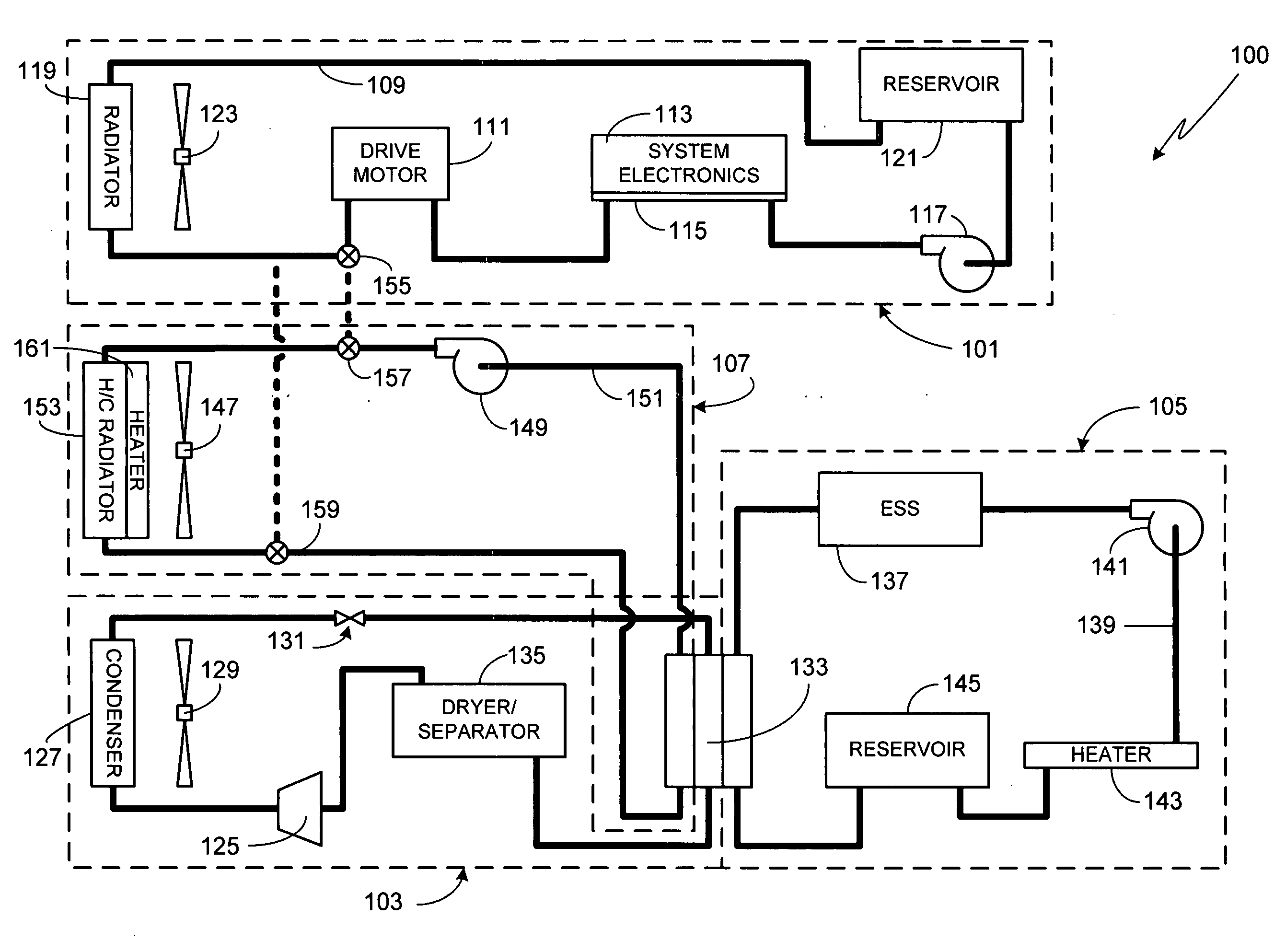

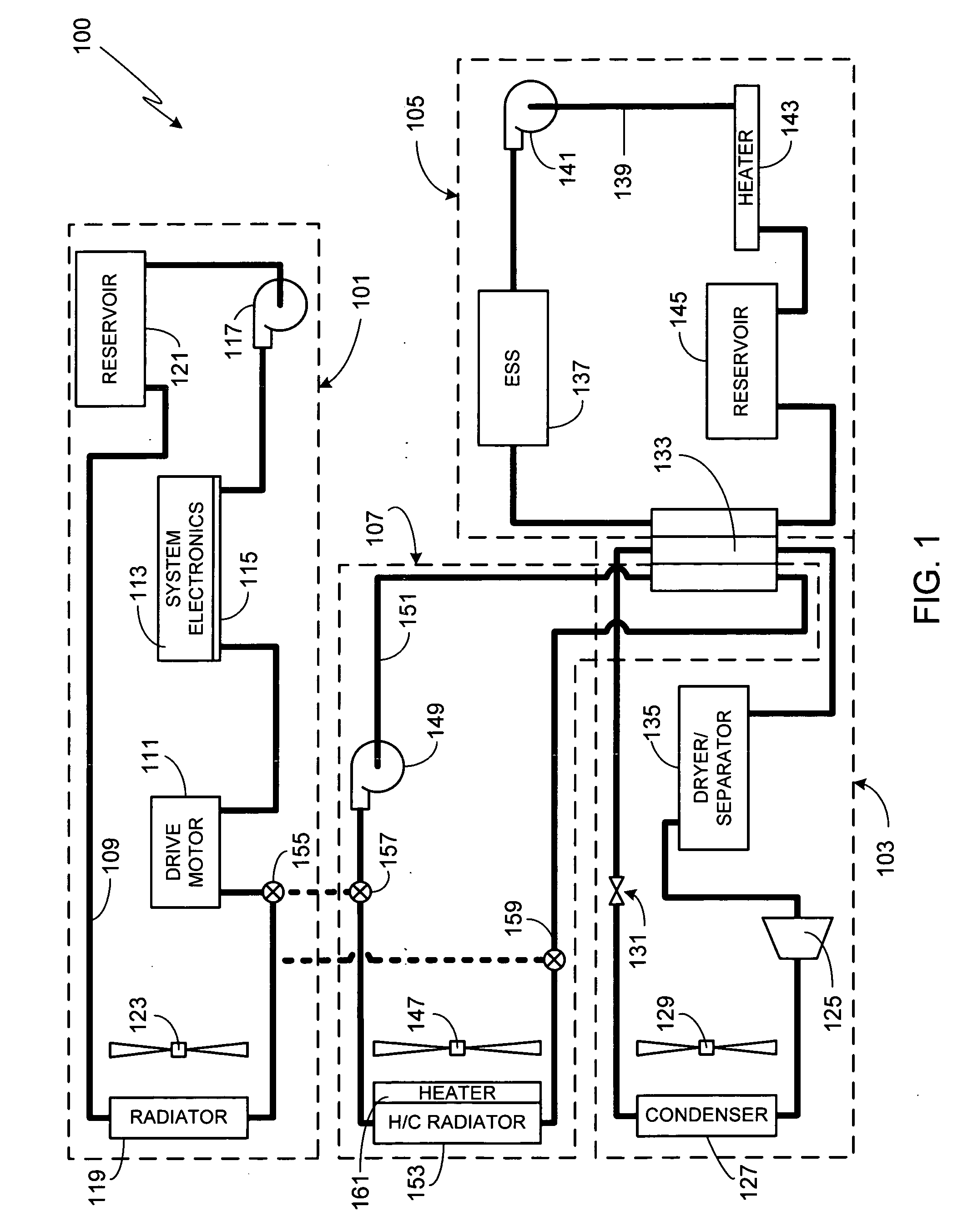

Electric vehicle thermal management system

ActiveUS20100025006A1Indirect heat exchangersPower to auxillary motorsDrive motorThermal management system

A method for managing thermal loads within an electric vehicle using an efficient thermal management system (100) that utilizes a single heat exchanger (133) is provided. A refrigeration subsystem (103) cools the heat exchanger (133). A first coolant loop (139) in thermal communication with the heat exchanger (133) is used to cool the energy storage system (137). A second coolant loop (151) corresponding to the HVAC subsystem (107) is also in thermal communication with the heat exchanger (133). Preferably a third coolant loop (109) corresponding to the drive motor cooling subsystem (101) is coupleable to the HVAC coolant loop (151), thus providing an efficient means of providing heat to the HVAC subsystem (107).

Owner:TESLA INC

Method and system for reducing thermal load by monitoring and controlling current flow in a portable computing device

ActiveUS20120272086A1Reduce heat loadEnergy efficient ICTHardware monitoringCurrent thresholdEngineering

A method and system for reducing thermal load by monitoring and controlling current flow in a portable computing device (“PCD”) are disclosed. The method includes monitoring a temperature of the PCD and determining if the temperature has reached a temperature threshold condition. This temperature threshold condition may be comprised within any one or more of a plurality of thermal policy states, in which each thermal policy state may dictate various thermal mitigation techniques. The thermal policy states may be associated with values that may indicate thermal loading of a PCD. If the temperature has reached the first threshold condition, then electrical current exiting a power supply device may be monitored. If it is determined that the electrical current has exceeded a current threshold condition, such as a maximum current, a hardware device corresponding to the electrical current may be selected for application of a thermal mitigation technique.

Owner:QUALCOMM INC

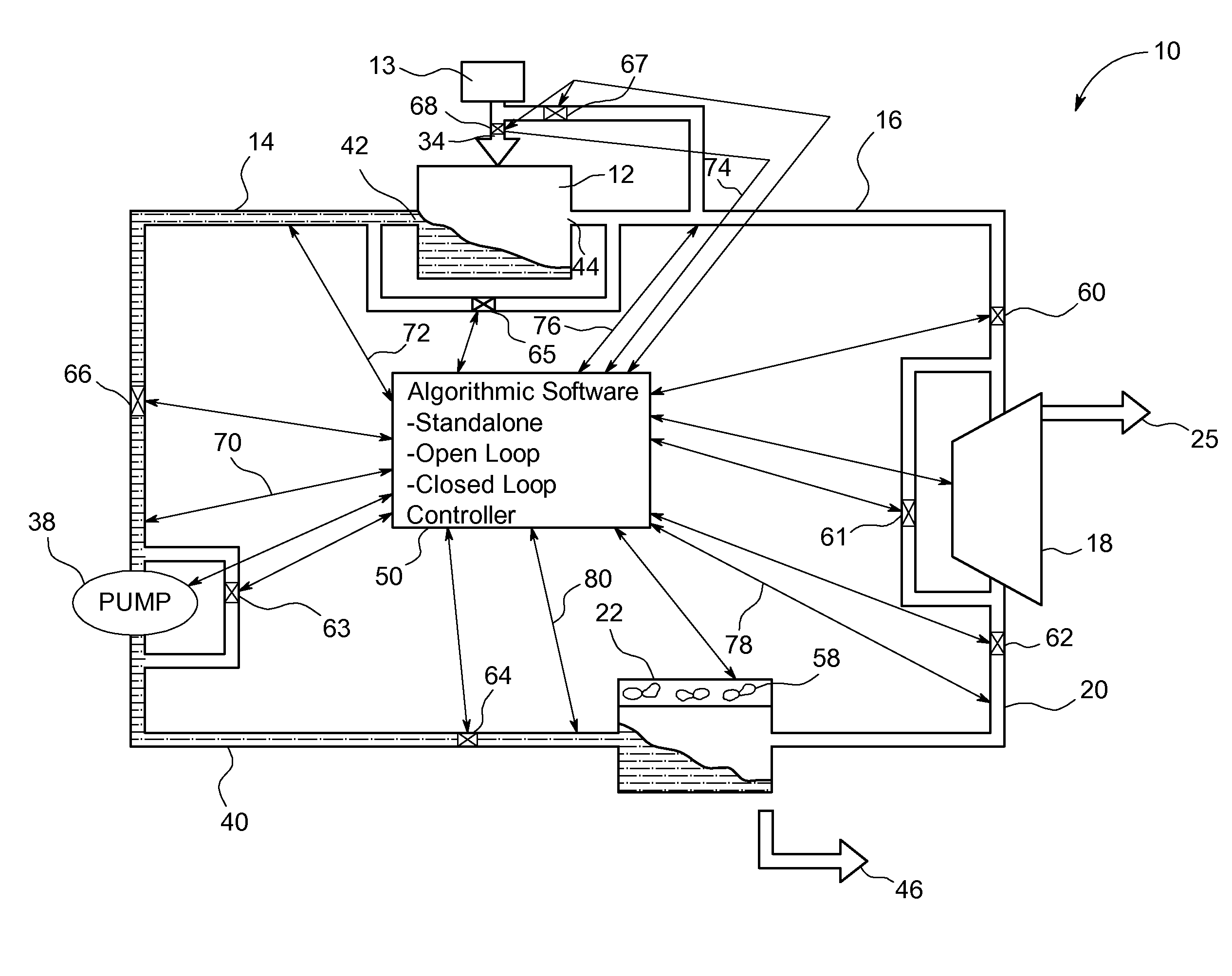

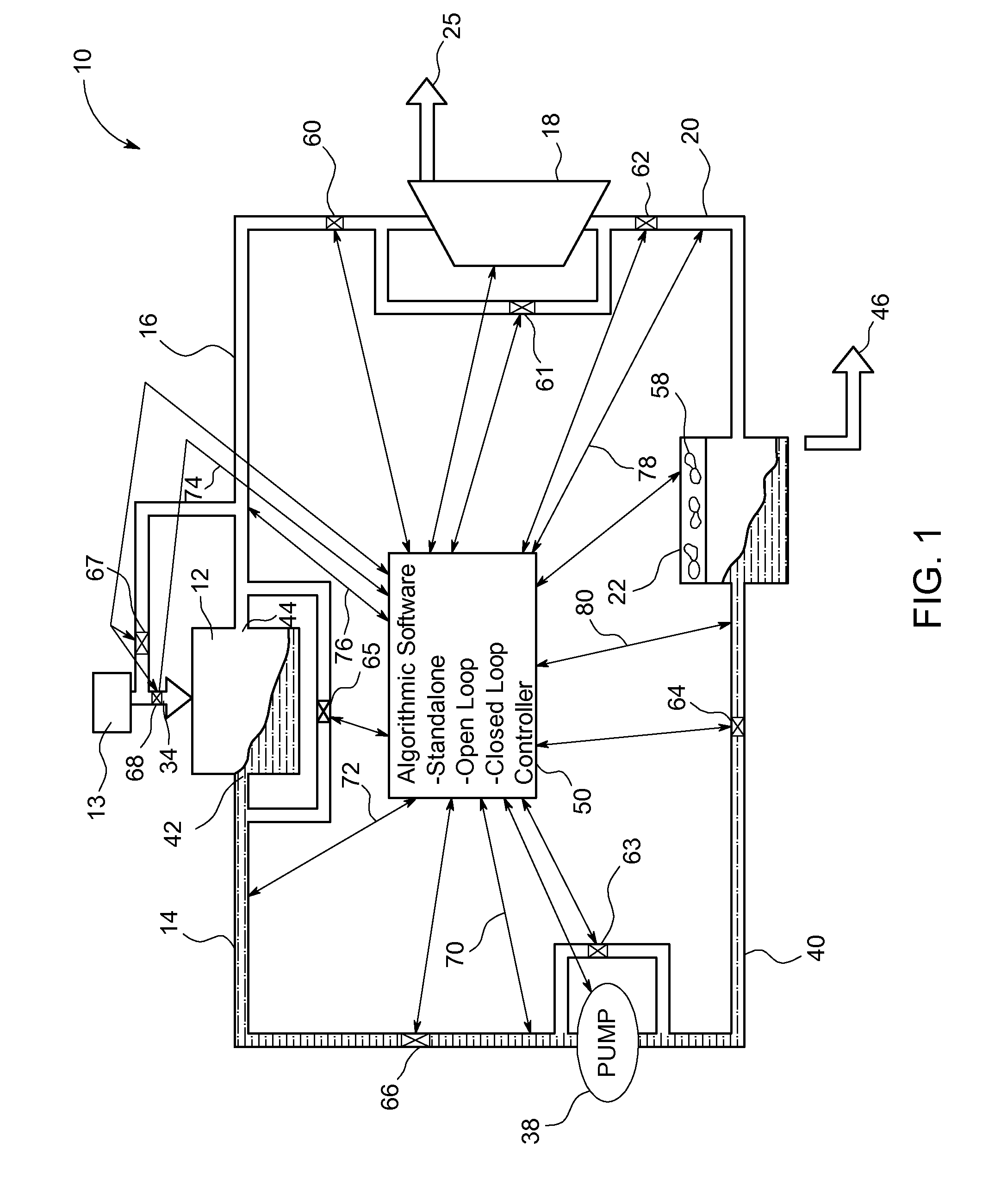

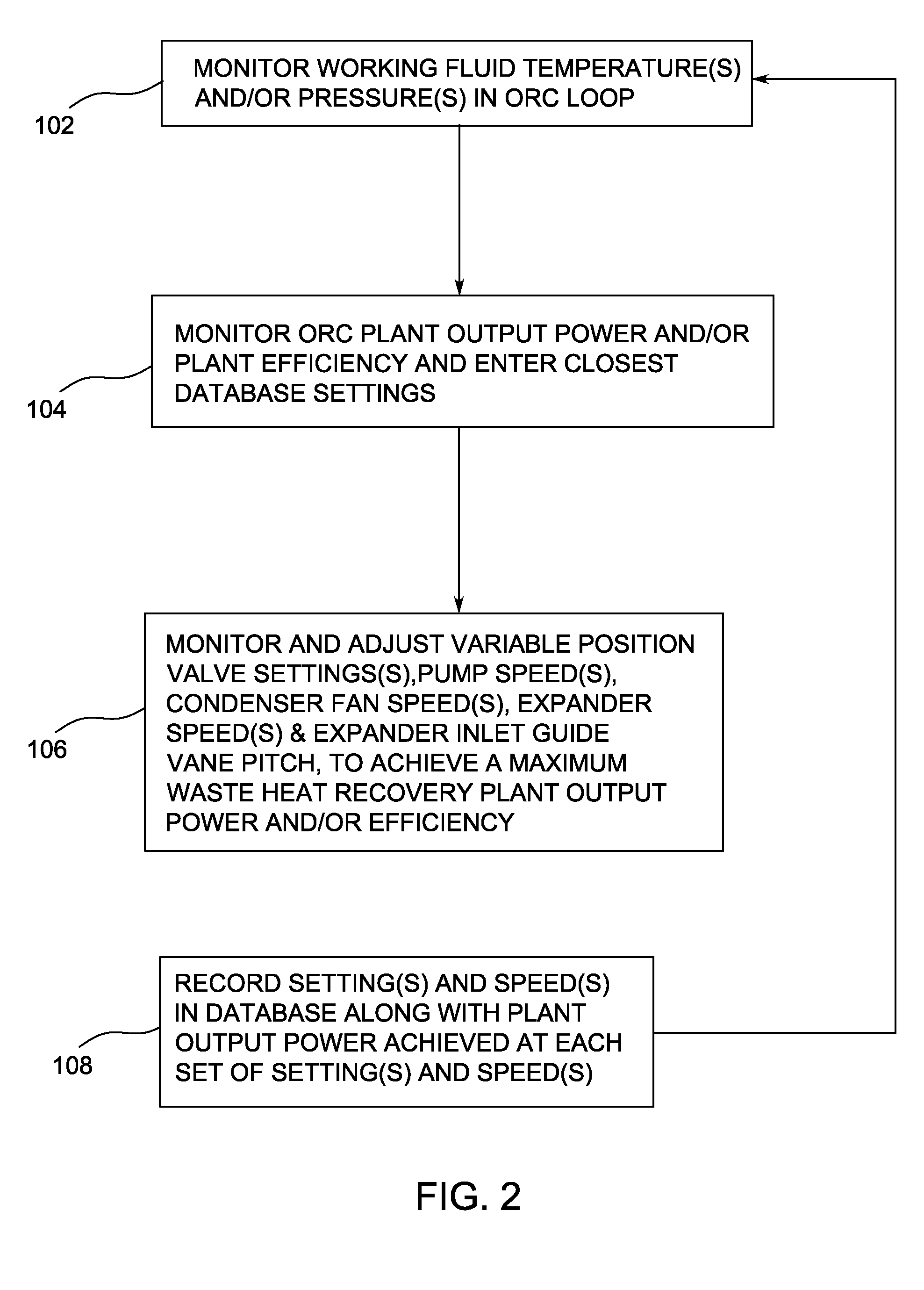

Auto optimizing control system for organic rankine cycle plants

InactiveUS20110203278A1Maximize efficiencyOutput maximizationWind motor controlPump componentsWorking fluidOrganic Rankine cycle

A waste heat recovery plant control system includes a programmable controller configured to generate expander speed control signals, expander inlet guide vane pitch control signals, fan speed control signals, pump speed control signals, and valve position control signals in response to an algorithmic optimization software to substantially maximize power output or efficiency of a waste heat recovery plant based on organic Rankine cycles, during mismatching temperature levels of external heat source(s), during changing heat loads coming from the heat sources, and during changing ambient conditions and working fluid properties. The waste heat recovery plant control system substantially maximizes power output or efficiency of the waste heat recovery plant during changing / mismatching heat loads coming from the external heat source(s) such as the changing amount of heat coming along with engine jacket water and its corresponding exhaust in response to changing engine power.

Owner:AI ALPINE US BIDCO INC

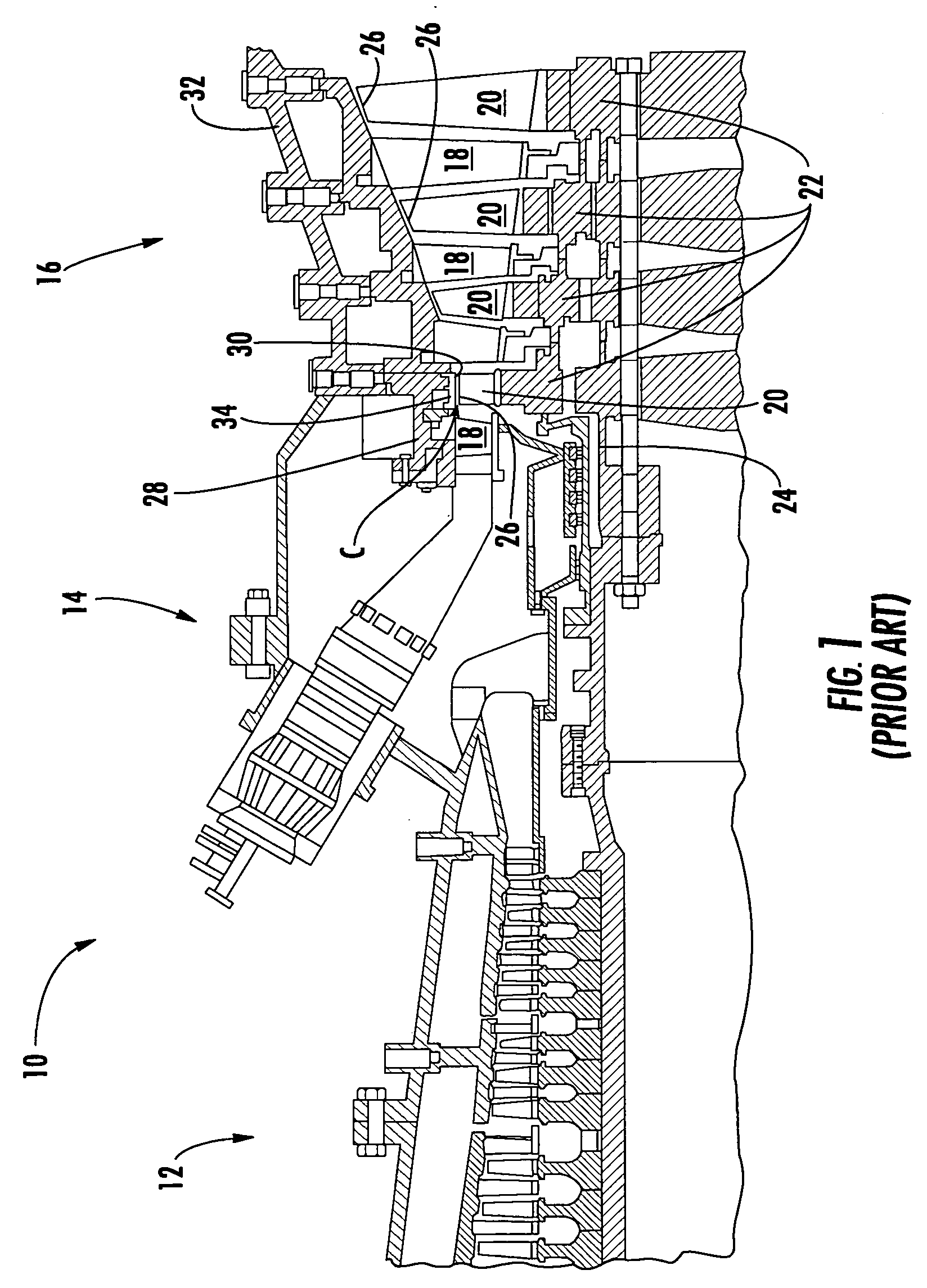

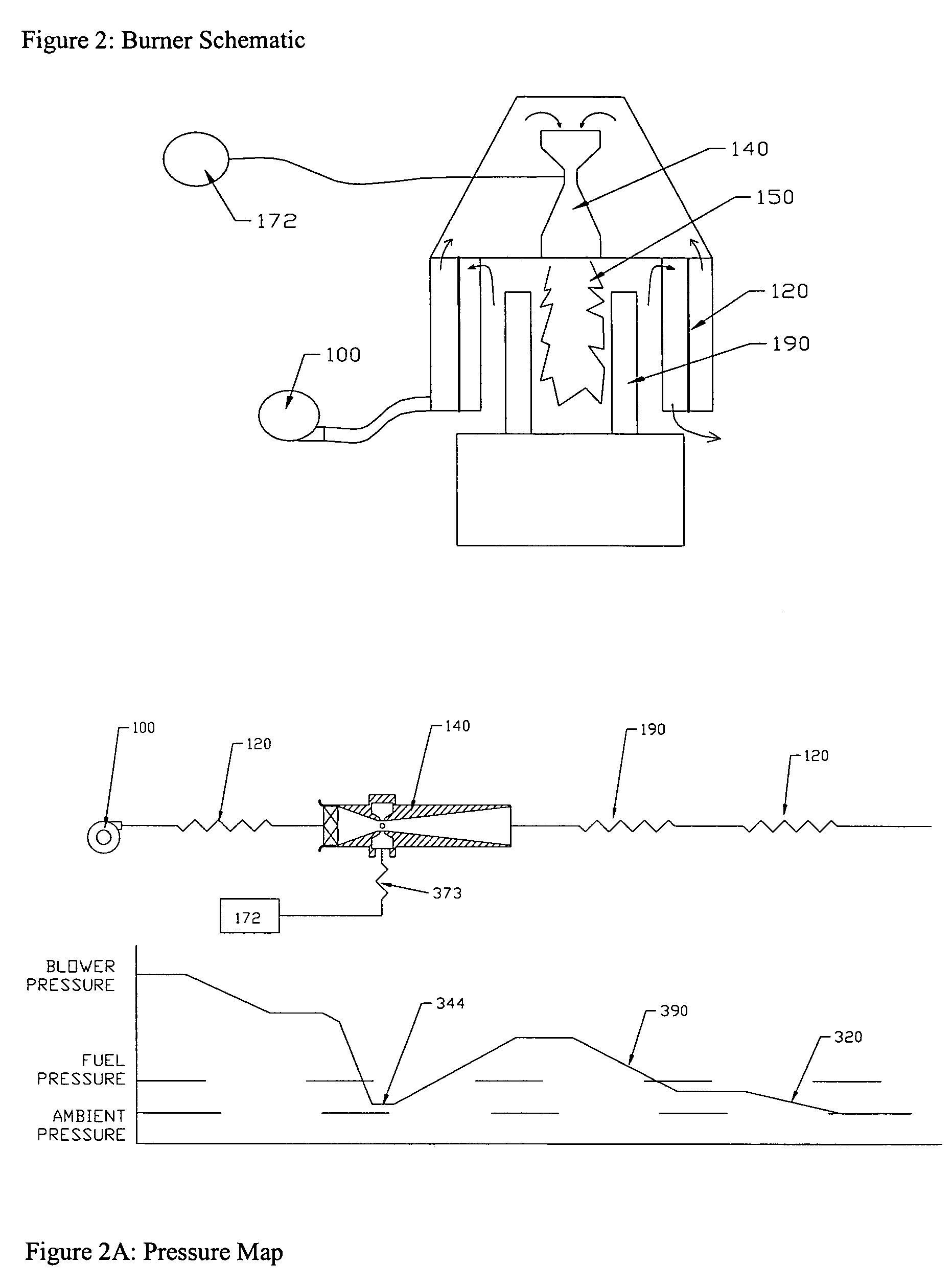

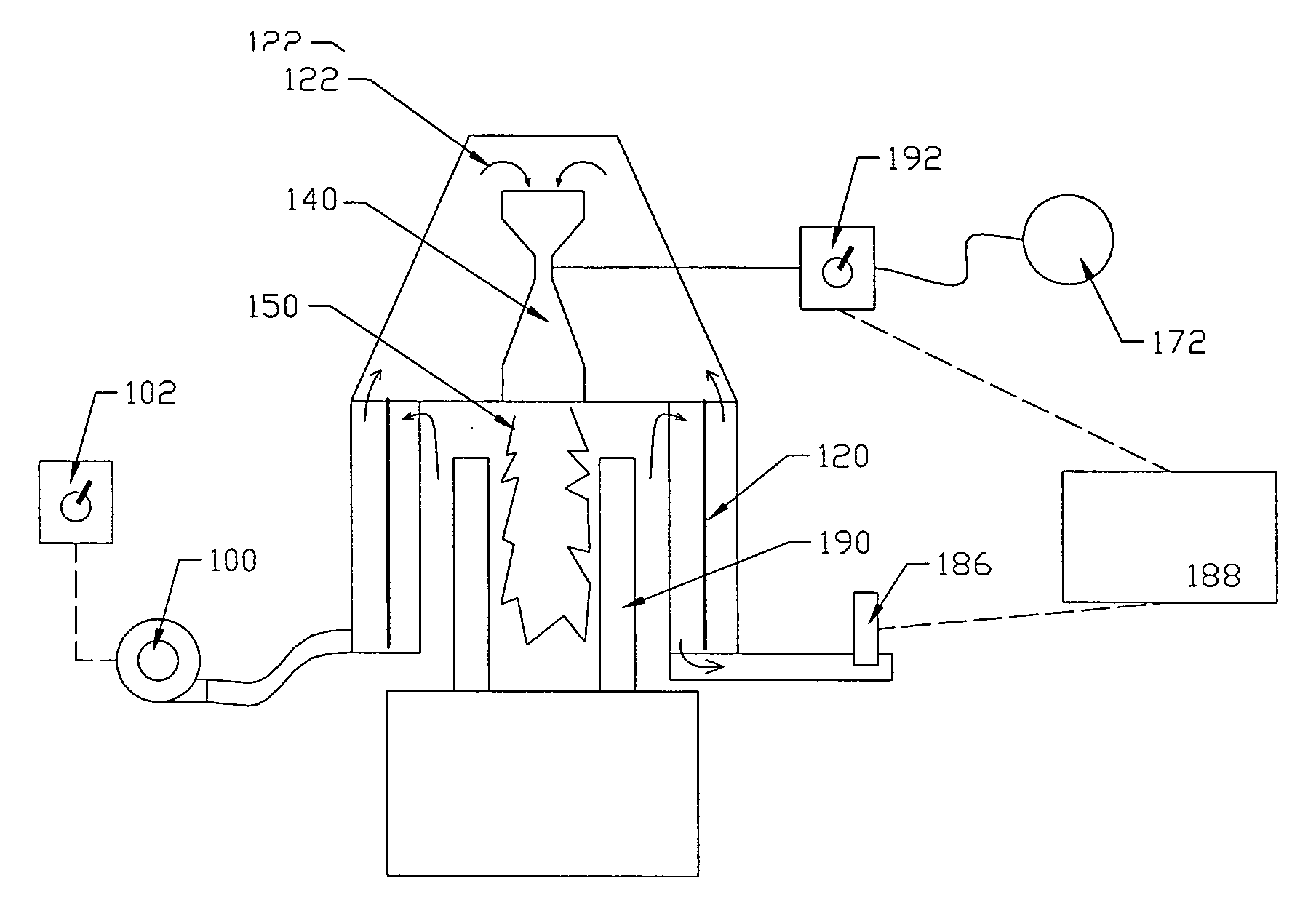

Gaseous fuel burner

ActiveUS20050250062A1Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

An ejector, such as a venturi, facilitates the delivery of gaseous fuel to the combustion chamber of a burner. A blower forces air through the ejector, and the air flow produces a suction that draws fuel from a fuel inlet to produce a fuel-air mixture. The amount of fuel drawn from the fuel inlet is a function of the air flow such that a substantially constant fuel-air ratio is obtained over a range of air flow rates and temperatures without the need for a separate high-pressure fuel pump. The fuel-air mixture may be provided to a combustion chamber for combustion. Air from the blower may be pre-heated prior to entering the ejector, for example, using a heat exchanger that recovers some of the heat from the combusted fuel-air mixture. Air flow through the ejector may be conditioned, for example, by a swirler, to produce a tangential air flow that can increase fuel flow by increasing air velocity across the fuel inlet and / or produce a swirl-stabilized flame in the combustion chamber. The combusted fuel-air mixture may be provided to a thermal load, such as an external combustion engine. Blower speed may be controlled manually or automatically to control power output. Fuel flow to the ejector can be controlled manually or automatically to control fuel-air ratio. The burner can be configured to operate with multiple fuel types, for example, using a fuel selector with fixed or variable restrictors.

Owner:NEW POWER CONCEPTS

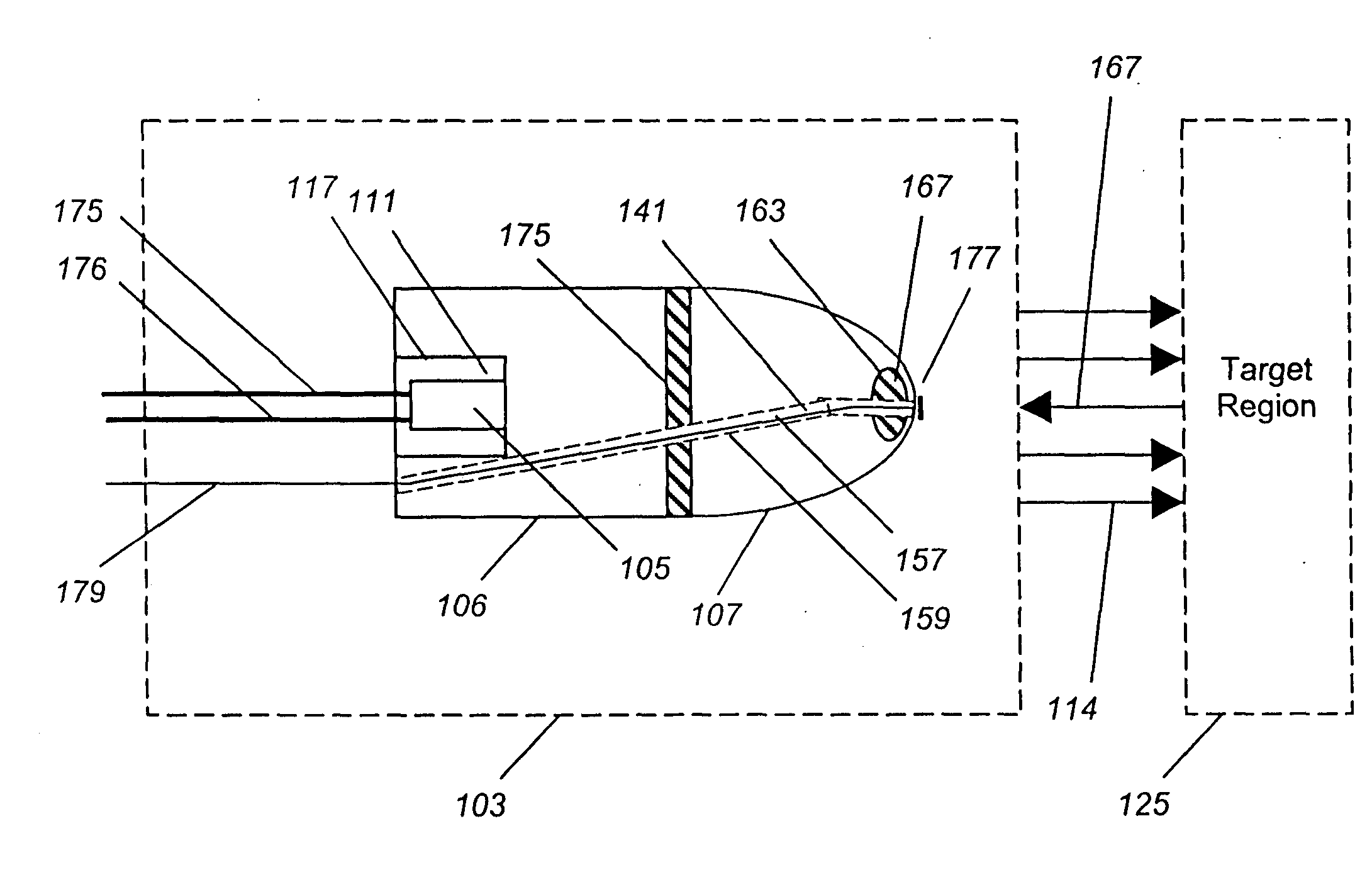

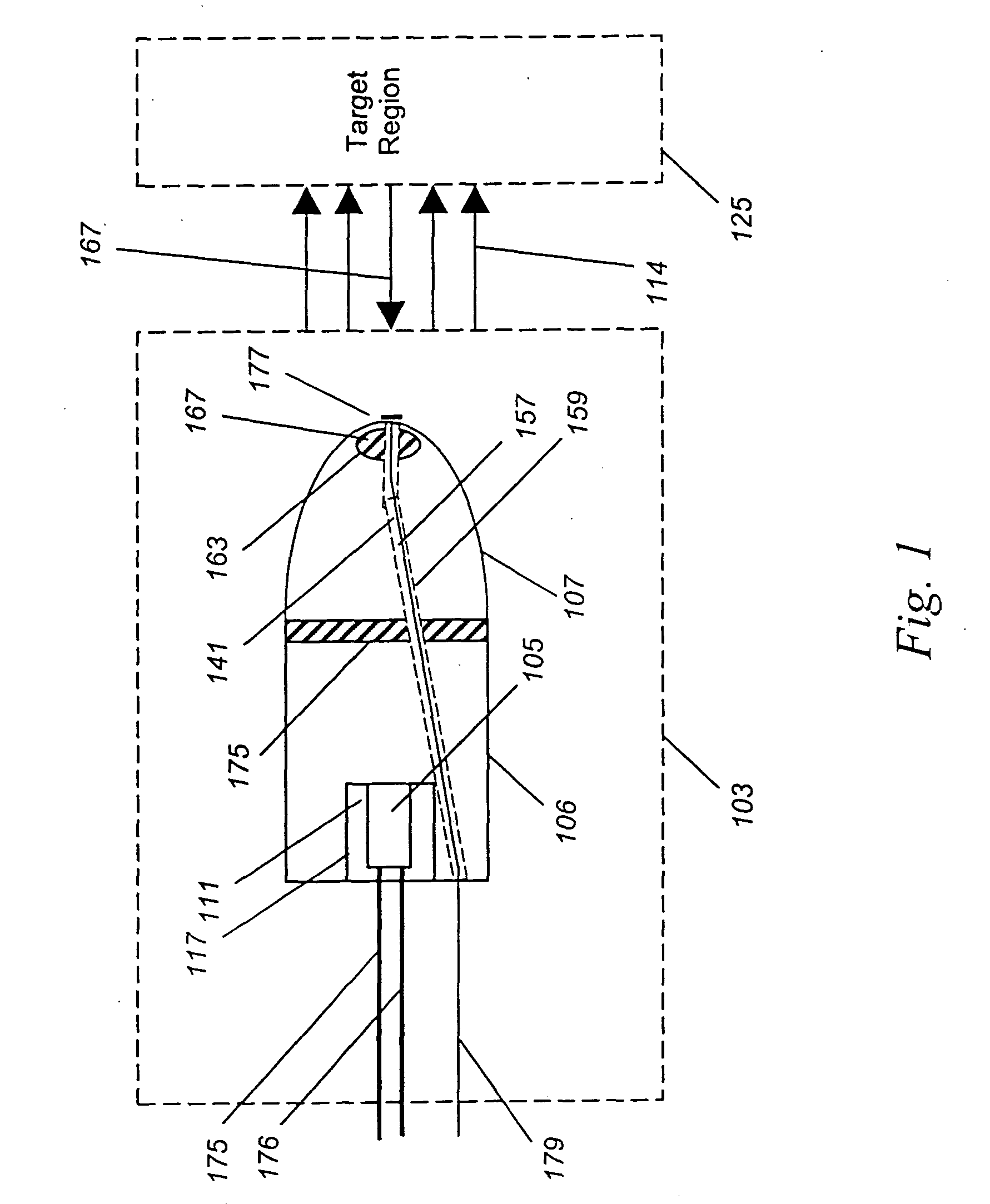

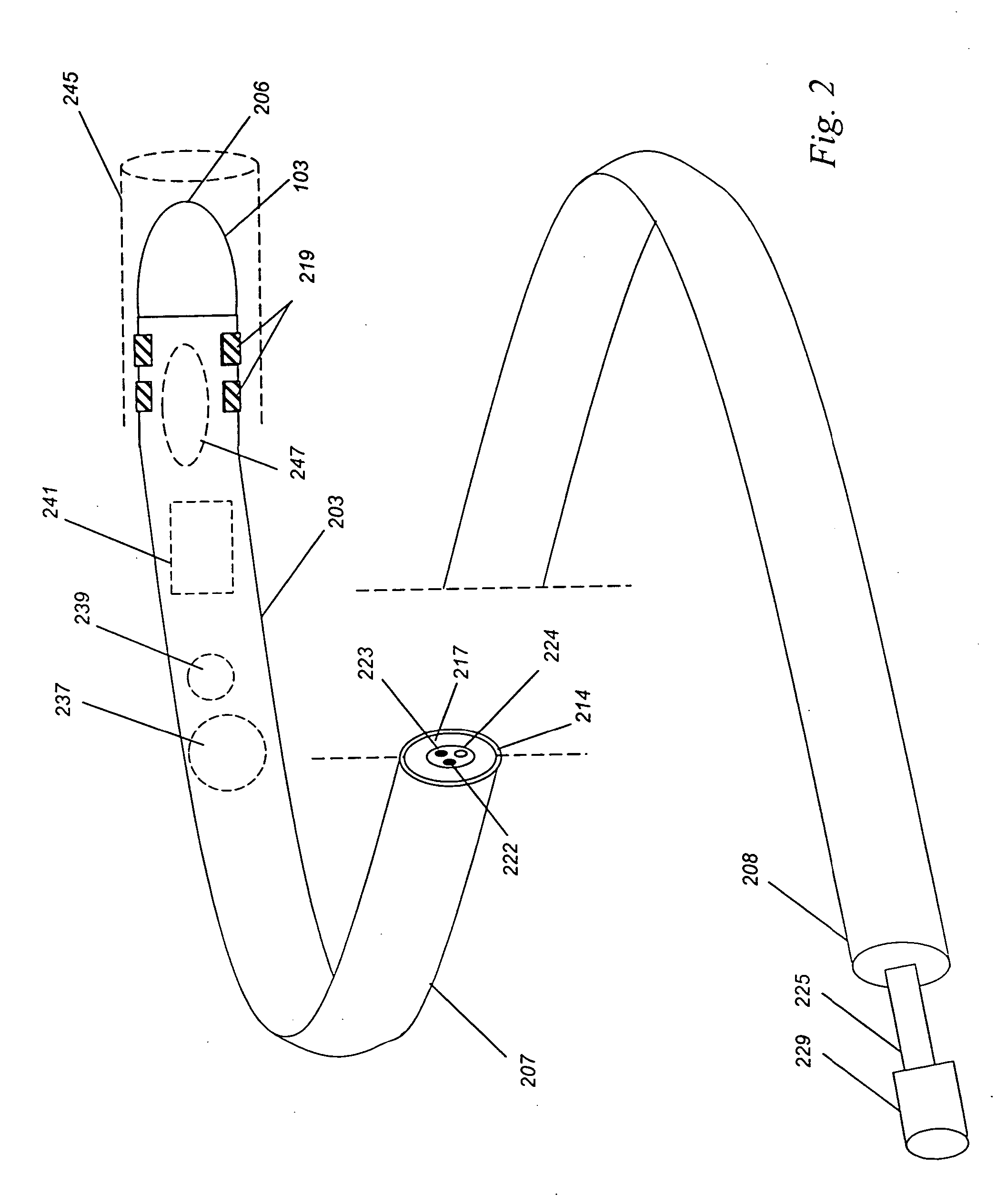

Spectroscopy illuminator with improved delivery efficiency for high optical density and reduced thermal load

InactiveUS20040039274A1Reduce deliveryReduce heatSurgeryDiagnostics using spectroscopyFluorescenceIn vivo

An improved illuminator for generating broadband light, and for delivering the light to a sample with an improved delivery efficiency, for higher optical density and / or reduced thermal transfer, than achieved with conventional halogen bulb sources. The illuminator enables spectroscopic analysis in thermally-sensitive or spatially-constrained environments. A phosphor-coated broadband white LED and integrated collimating optics produces a continuous, collimated broadband light beam from 400 nm to 700 nm, which is then transmitted through space to a sample region, such as a living tissue in vivo. A method and system for measuring oxigeneration of mucosal or subsurface tissue is also described.

Owner:J FITNESS LLC

Method and system for dissipating thermal energy from conduction-cooled circuit card assemblies which employ remote heat sinks and heat pipe technology

InactiveUS20080218980A1Increase the lengthMaximum flexibilityDomestic cooling apparatusDigital data processing detailsThermal energyEngineering

Method and System for dissipating thermal energy from conduction-cooled circuit card assemblies in which thermal energy is directed into proximate heat sink assemblies and additionally is conveyed by heat pipes to one or more remote heat sink assemblies configured for the transfer of thermal energy to a flow of air and located within a chassis at a position remote from the system thermal load.

Owner:TRACEWELL SYST

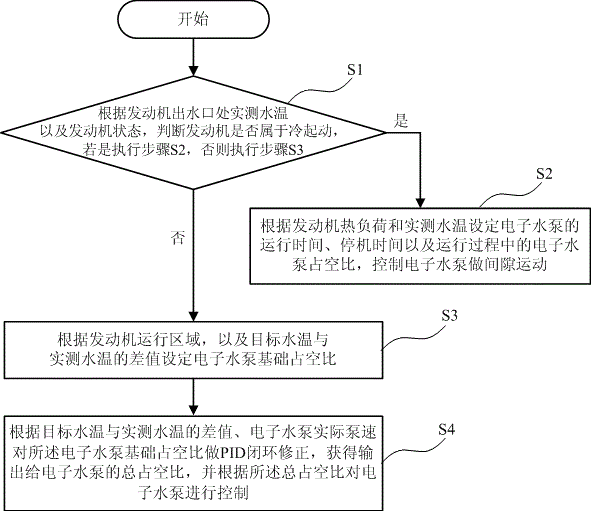

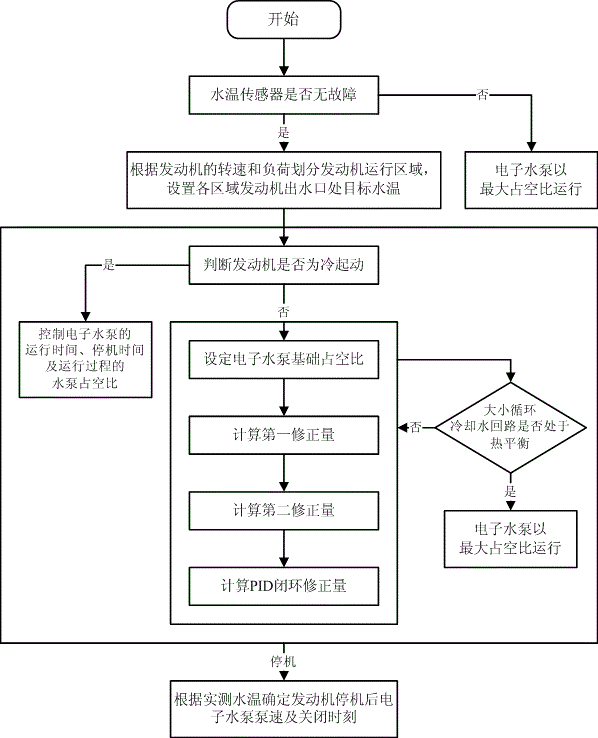

Method and device for controlling electronic water pump of water-cooling system of automobile engine

ActiveCN106246328ALower working temperatureEasy to controlCoolant flow controlMeasurement deviceIntermittent motionStop time

The invention provides a method and device for controlling an electronic water pump of a water-cooling system of an automobile engine. The method comprises the following steps: step S1, judging whether the engine is in a cold start state or not according to actually measured water temperature at a water outlet of the engine and the state of the engine, if the engine is in the cold start state, carrying out step S2, and if the engine is not in the cold start state, carrying out step S3; step S2, setting running time and stopping time of the electronic water pump according to the thermal load and the actually measured water temperature of the engine and duty ratio of the electronic water pump in a running process, and controlling the electronic water pump to carry out intermittent motion; step S3, setting a basic duty ratio of the electronic water pump according to a running region of the engine and difference between target water temperature and the actually measured water temperature; and step S4, carrying out PID closed-cycle correction on the basic duty ratio of the electronic water pump according to the difference between the target water temperature and the actually measured water temperature and actual pump speed of the electronic water pump to obtain total duty ratio output to the electronic water pump, and controlling the electronic water pump according to the total duty ratio. By the method and device for controlling the electronic water pump of the water-cooling system of the automobile engine, warming time can be shortened, and the water temperature control effect is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com