Patents

Literature

9864 results about "Electric drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

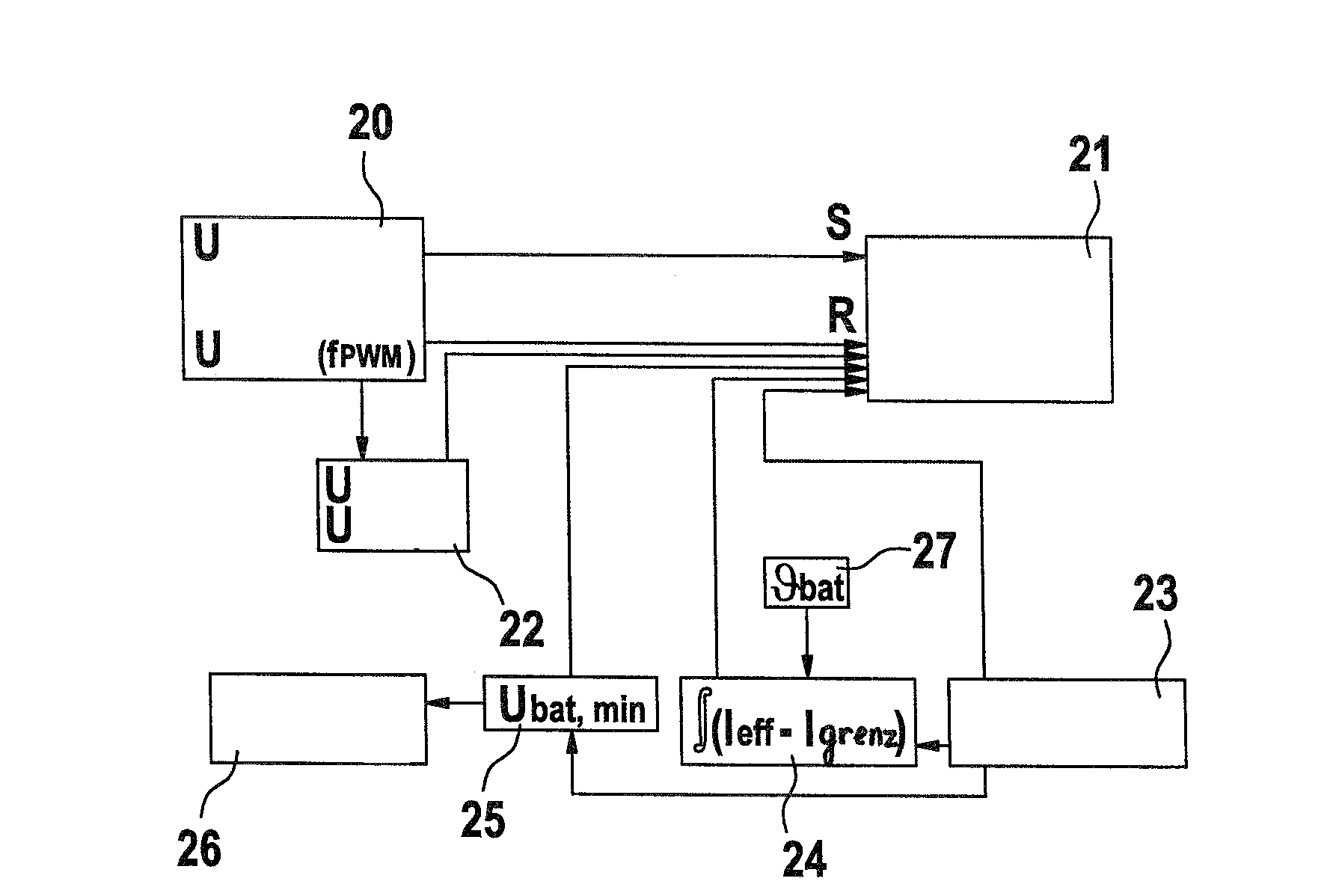

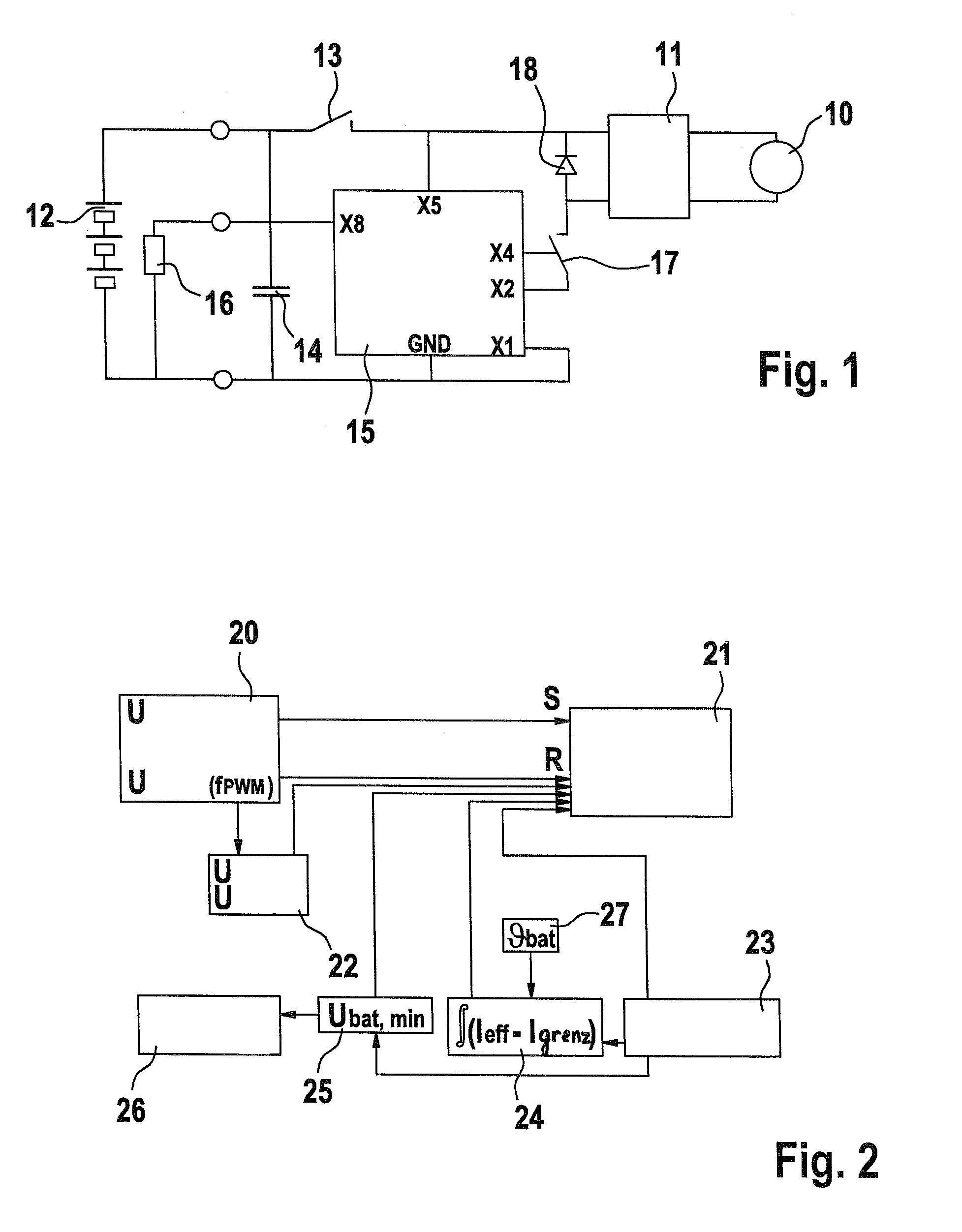

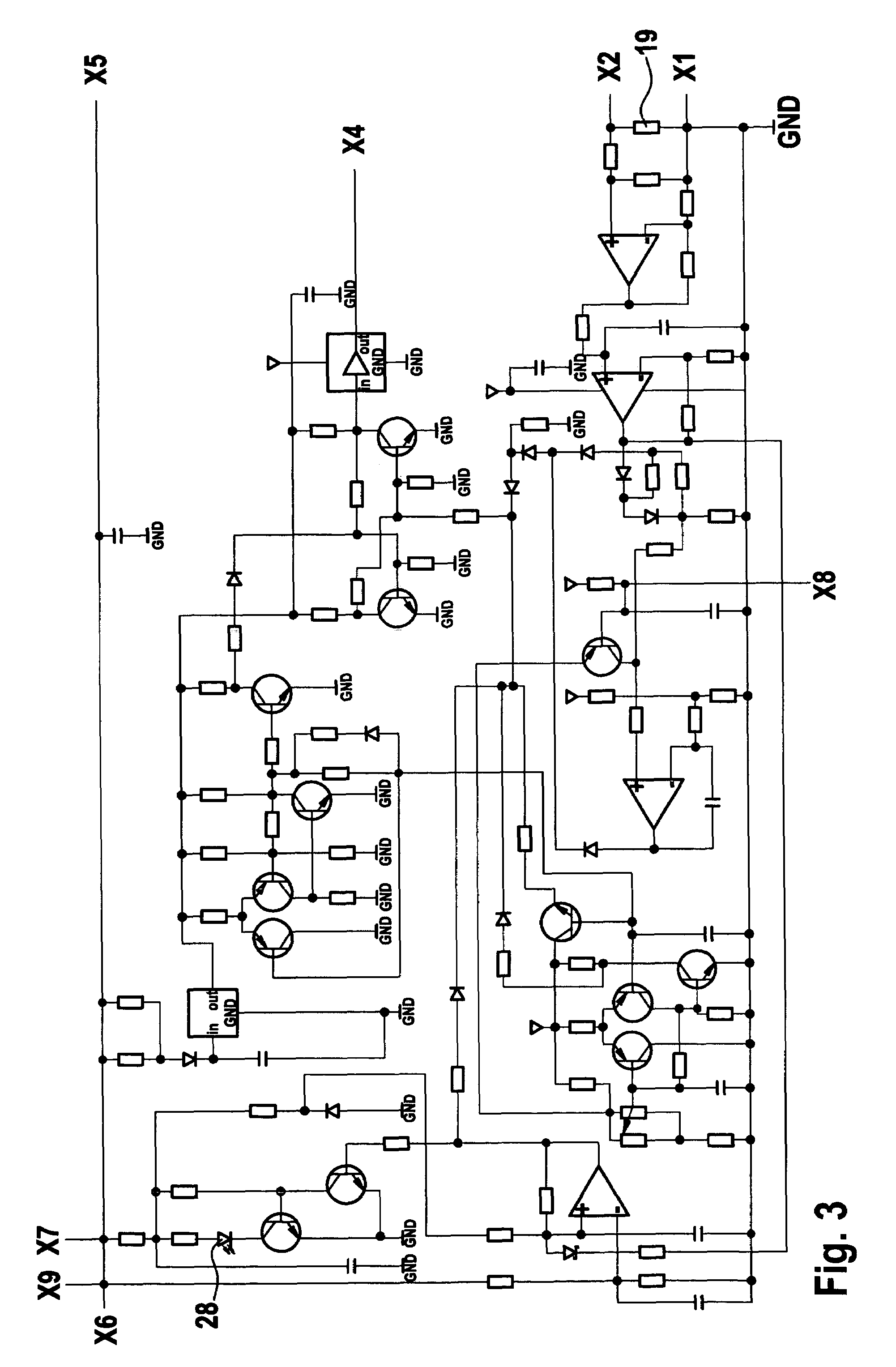

Method for operating a power tool

ActiveUS7336048B2Maintain good propertiesReduce widthTemperatue controlEmergency protective arrangements for automatic disconnectionMOSFETElectricity

In a method for operating a power tool with an energy accumulator, in particular a rechargeable energy accumulator, which supplies power to an electric drive motor, a clock frequency is generated by an electronic unit, with which a gate of a MOSFET—which supplies operating voltage to the drive motor—is switched on with each cycle, and a switching-off of the MOSFET is carried out within one cycle using different signals, as a function of operating parameters.

Owner:ROBERT BOSCH GMBH

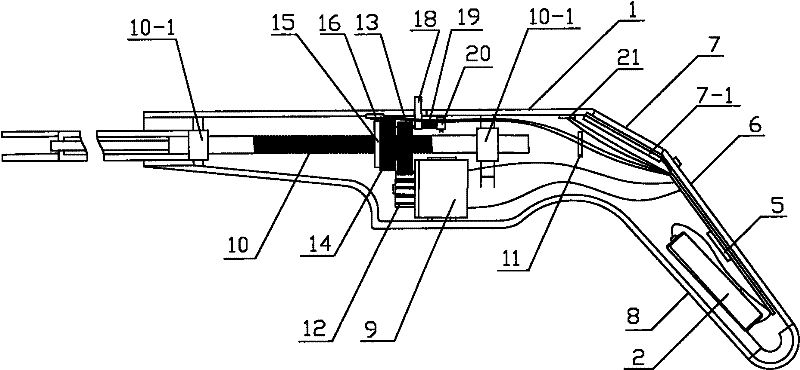

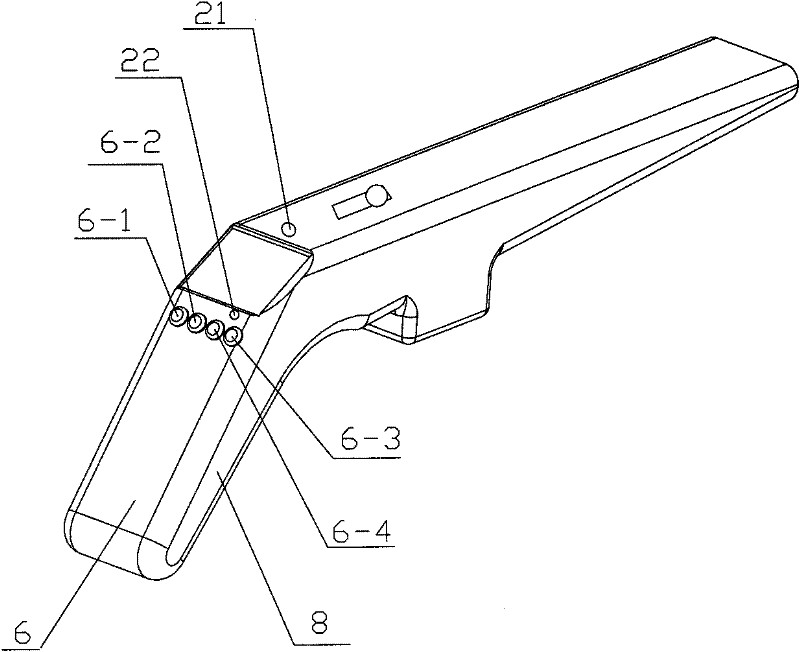

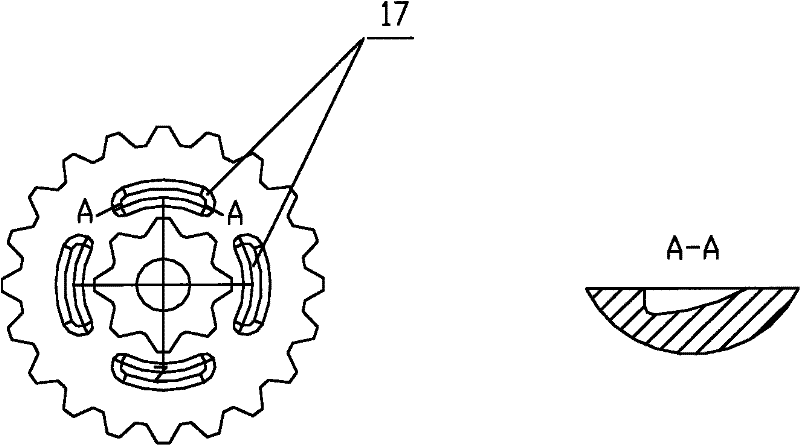

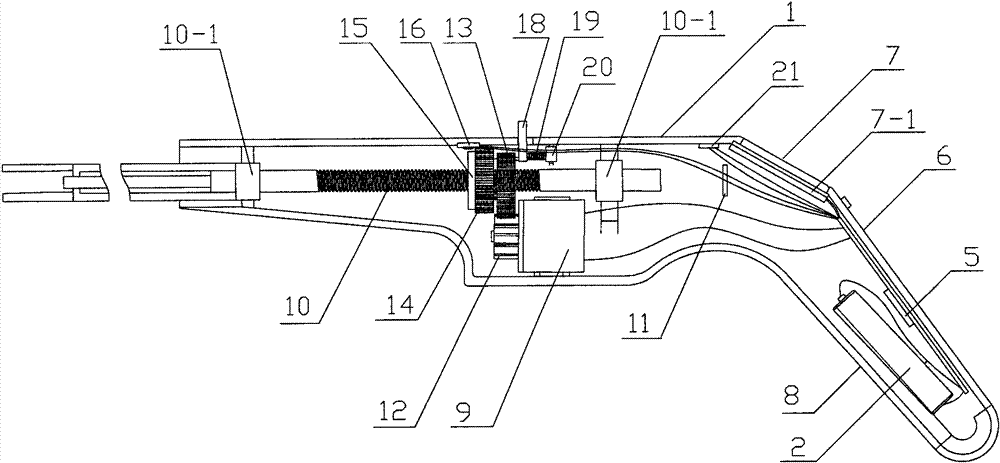

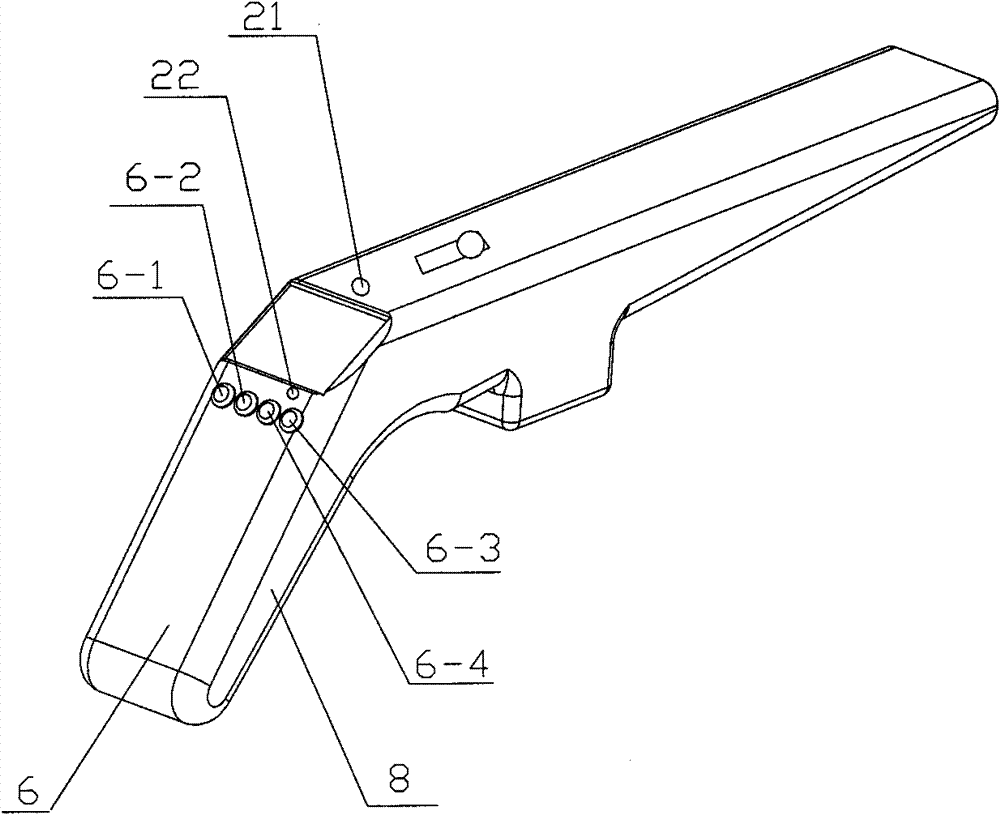

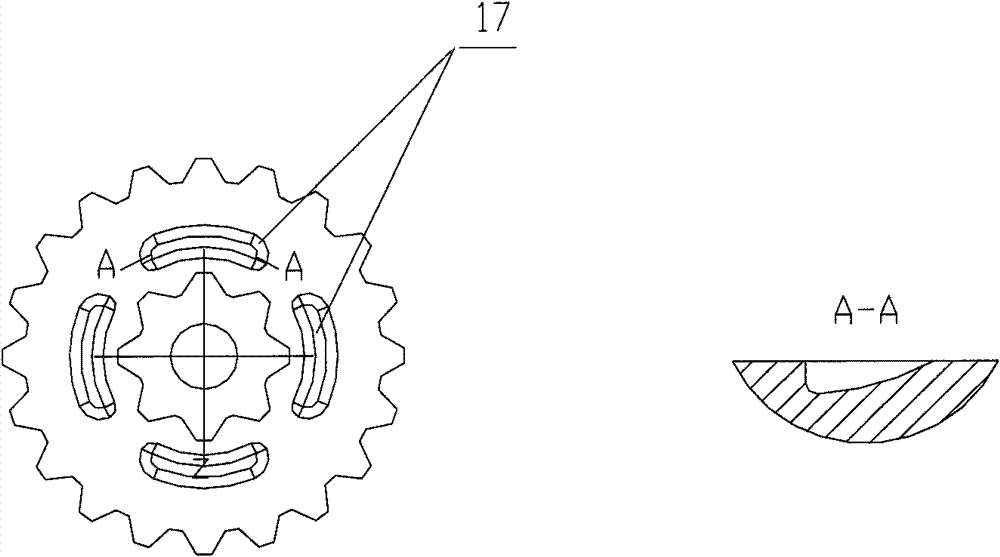

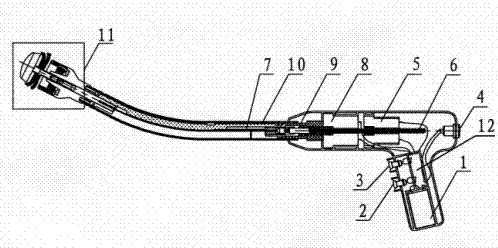

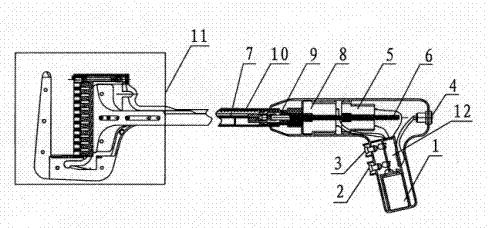

Numerically controlled surgical stapling apparatus

ActiveCN102228387AAccurate operationOperational securityNumerical controlSurgical staplesElectricityMemory chip

The invention relates to a numerically controlled surgical stapling apparatus comprising a clamping assembly, a housing and a main body assembly arranged in the housing. An electric driving device is arranged in the main body assembly. The stapling apparatus is characterized by further comprising a numerical control device which comprises a control board, a display screen and a sensing device, wherein at least one memory chip and a control chip are arranged on the control board; and the display screen is capable of displaying the values of operation parameters and clock information. The electric driving device is capable of receiving a signal produced by the numerical control device and drives a nail magazine to move toward a nail anvil until a predetermined closing gap, and further causes a suturing nail to reach a predetermined forming height after firing the suturing nail. The numerically controlled surgical stapling apparatus provided in the invention is capable of performing accurate and safe control on the transmission steps and the operation actions and also of clearly displaying the operation parameters so that a doctor can know the whole surgery process; therefore, human-machine conversation is made possible.

Owner:B J ZH F PANTHER MEDICAL EQUIP

Numerically controlled surgical stapling apparatus

ActiveCN102228387BAccurate operationOperational securitySurgical staplesNumerical controlMemory chipElectricity

The invention relates to a numerically controlled surgical stapling apparatus comprising a clamping assembly, a housing and a main body assembly arranged in the housing. An electric driving device is arranged in the main body assembly. The stapling apparatus is characterized by further comprising a numerical control device which comprises a control board, a display screen and a sensing device, wherein at least one memory chip and a control chip are arranged on the control board; and the display screen is capable of displaying the values of operation parameters and clock information. The electric driving device is capable of receiving a signal produced by the numerical control device and drives a nail magazine to move toward a nail anvil until a predetermined closing gap, and further causes a suturing nail to reach a predetermined forming height after firing the suturing nail. The numerically controlled surgical stapling apparatus provided in the invention is capable of performing accurate and safe control on the transmission steps and the operation actions and also of clearly displaying the operation parameters so that a doctor can know the whole surgery process; therefore, human-machine conversation is made possible.

Owner:B J ZH F PANTHER MEDICAL EQUIP

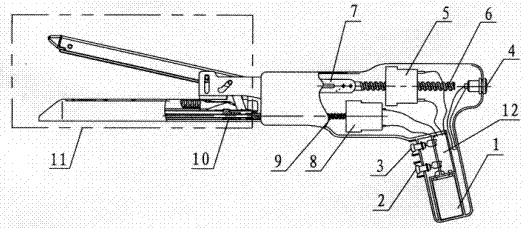

Electric anastomat for surgical department

InactiveCN102247182ARealize automatic operationEasy to operateSurgical staplesElectric driveSurgical department

The invention discloses an electric anastomat for a surgical department, comprising an osculating part and a driving device for driving an execution mechanism, wherein the osculating part is provided with a nail supporting seat, a nail bin and the execution mechanism; the driving device is an electric driving device which comprises a power supply, a control panel, a closed driving unit and a percussion driving unit; the closed driving unit consists of a closed motor and a closed driving mechanism; the input end of the closed driving mechanism is connected with the closed motor; the output end of the closed driving mechanism is connected with the execution mechanism of the osculating part; the percussion driving unit consists of a percussion motor and a percussion driving mechanism; the input end of the percussion driving mechanism is connected with the percussion motor; the output end of the percussion driving mechanism is connected with the execution mechanism of the osculating part; the closed motor and the percussion motor are respectively connected with the control panel through leads; and the control panel is connected with the power supply through a lead. According to the electric anastomat disclosed by the invention, the quality of an operation can be improved, the operation difficulty of doctors is reduced and the automatic operation can be realized.

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

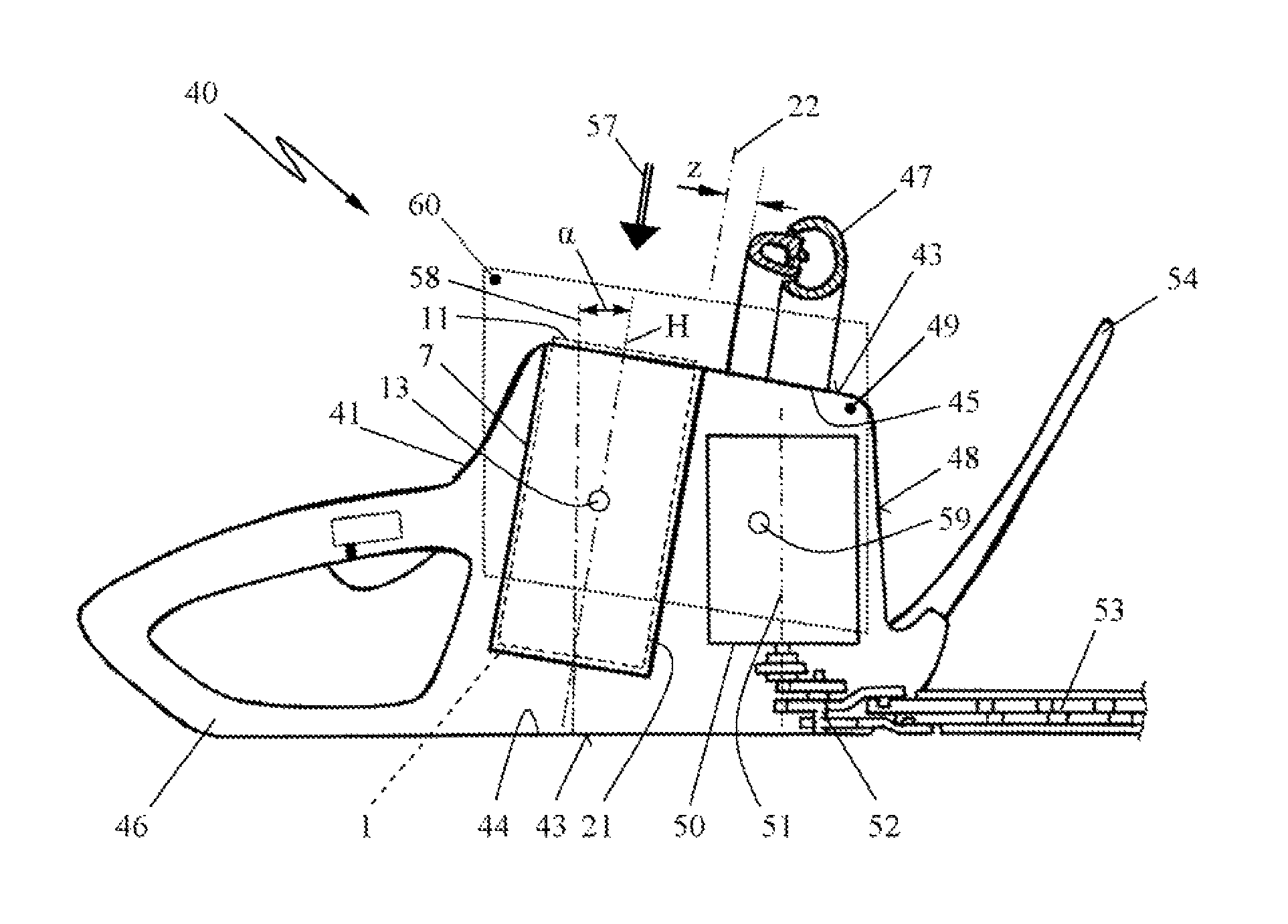

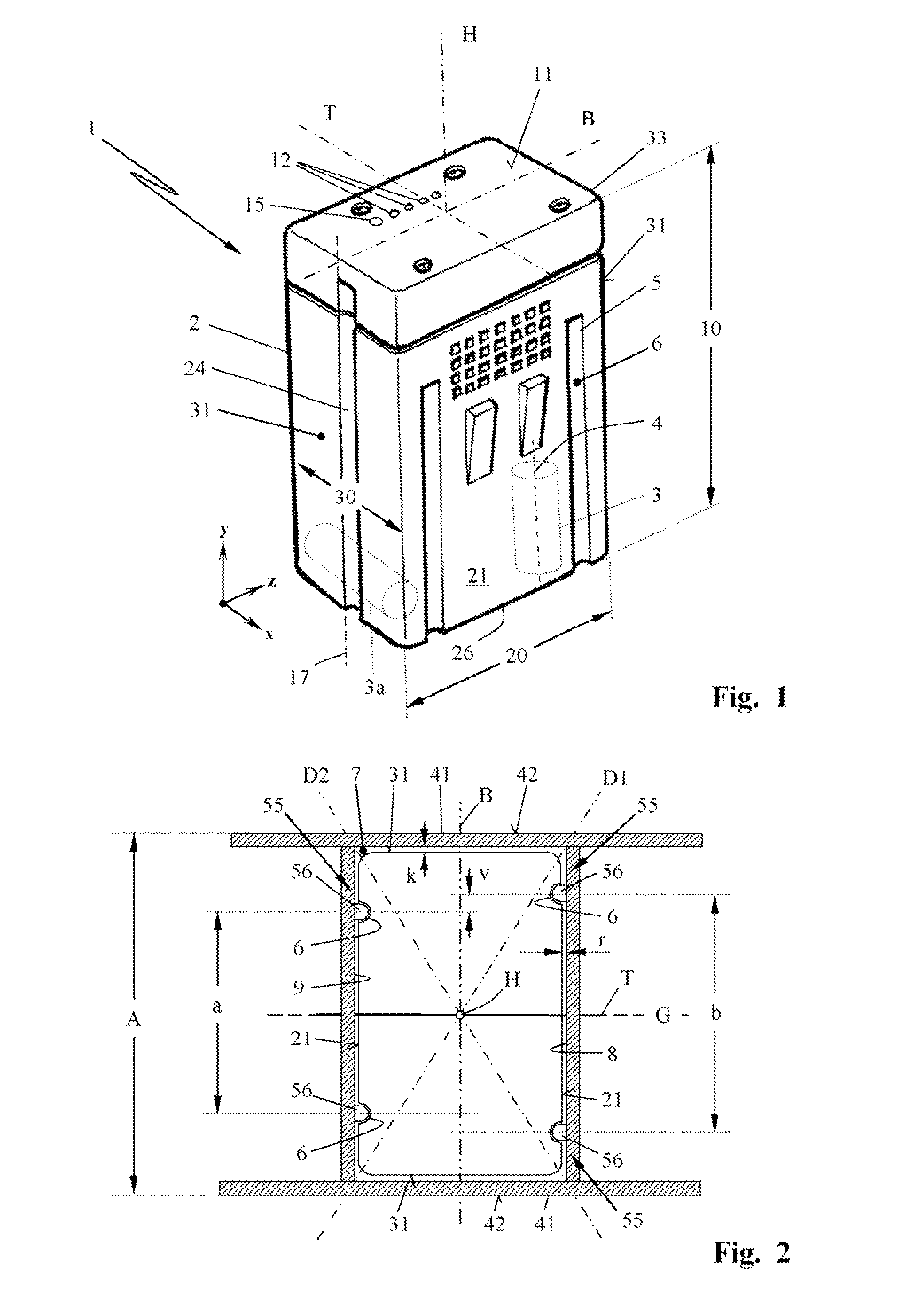

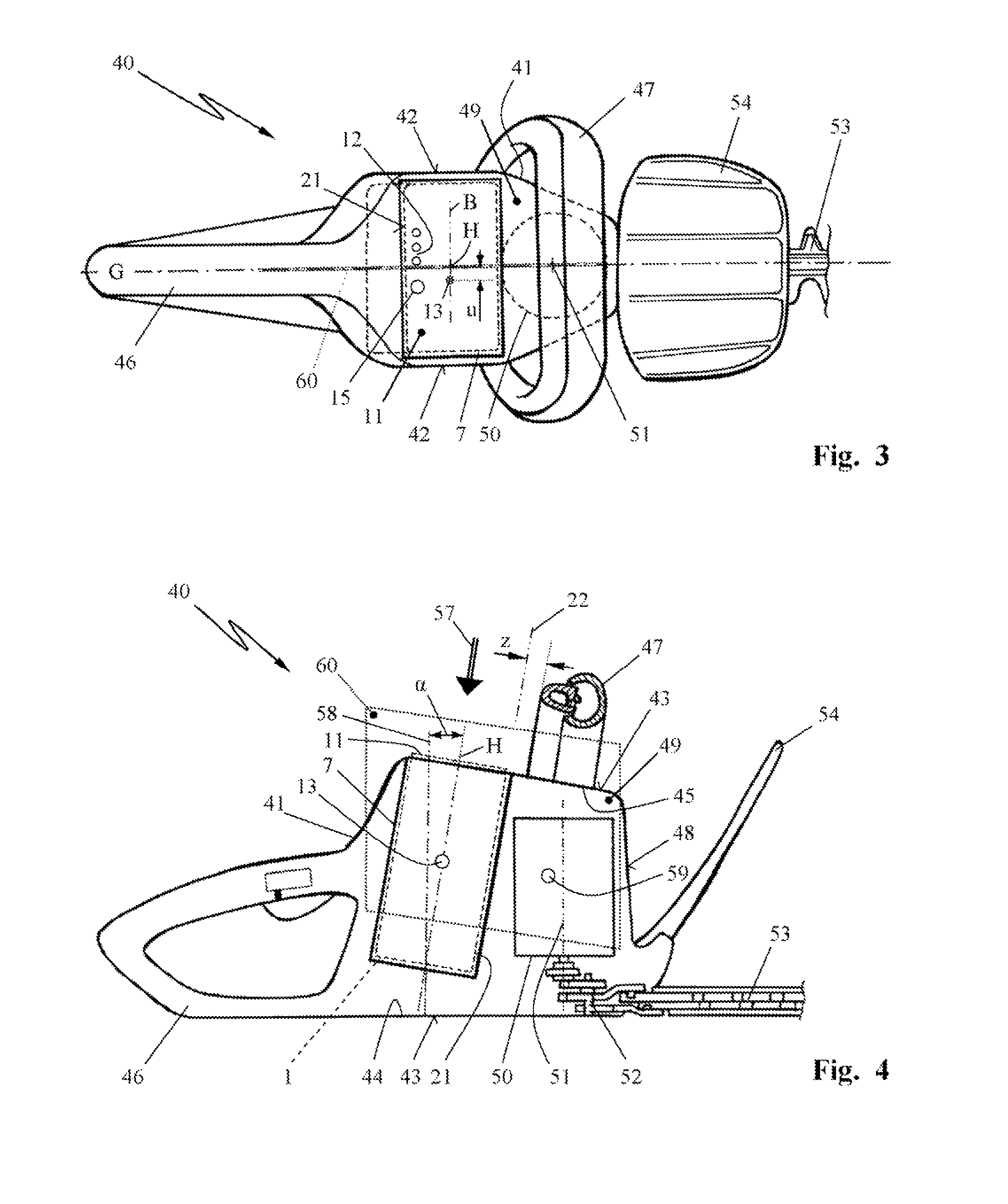

Electric power tool with battery pack

ActiveUS8869912B2Handling of the electric power tool is not impairShorten the lengthDrilling rodsConstructionsElectric driveEngineering

An electric power tool has a device housing with a rear grip extending in the longitudinal direction of the device housing. The device housing has first opposed housing sides and second opposed housing sides. An electric drive motor and its electronic control are arranged in the device housing. A battery pack compartment arranged in the device housing receives a battery pack that has a parallelepipedal shape and extends in a direction of a height axis, width axis and depth axis. The battery pack is arranged such that the width axis and the height axis extend transversely to the longitudinal axis of the device housing. The battery pack has narrow sides extending approximately parallel and at a minimal spacing relative to the first opposed housing sides, respectively. The battery pack has opposed end faces neighboring the second housing sides, respectively.

Owner:ANDREAS STIHL AG & CO KG

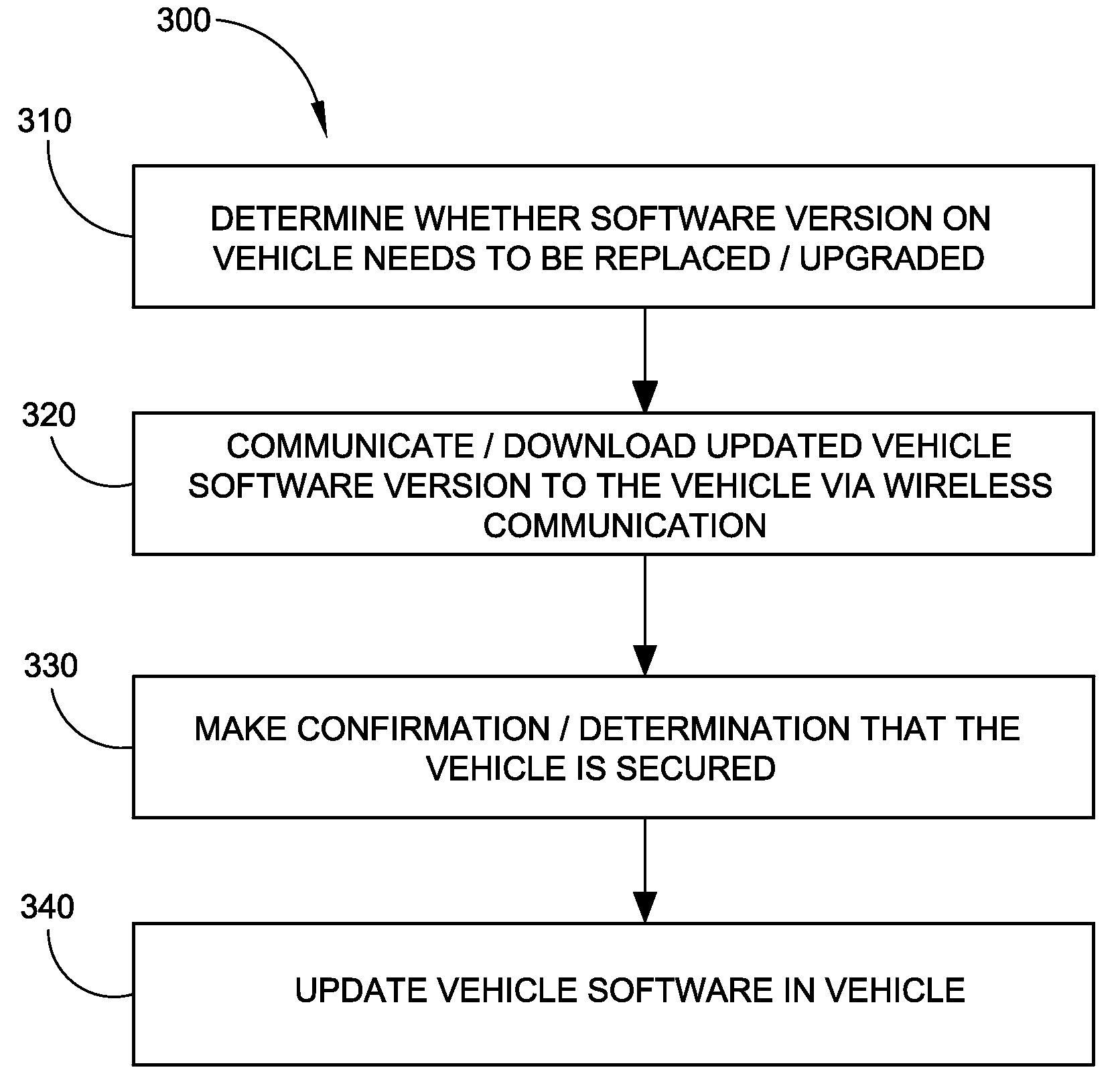

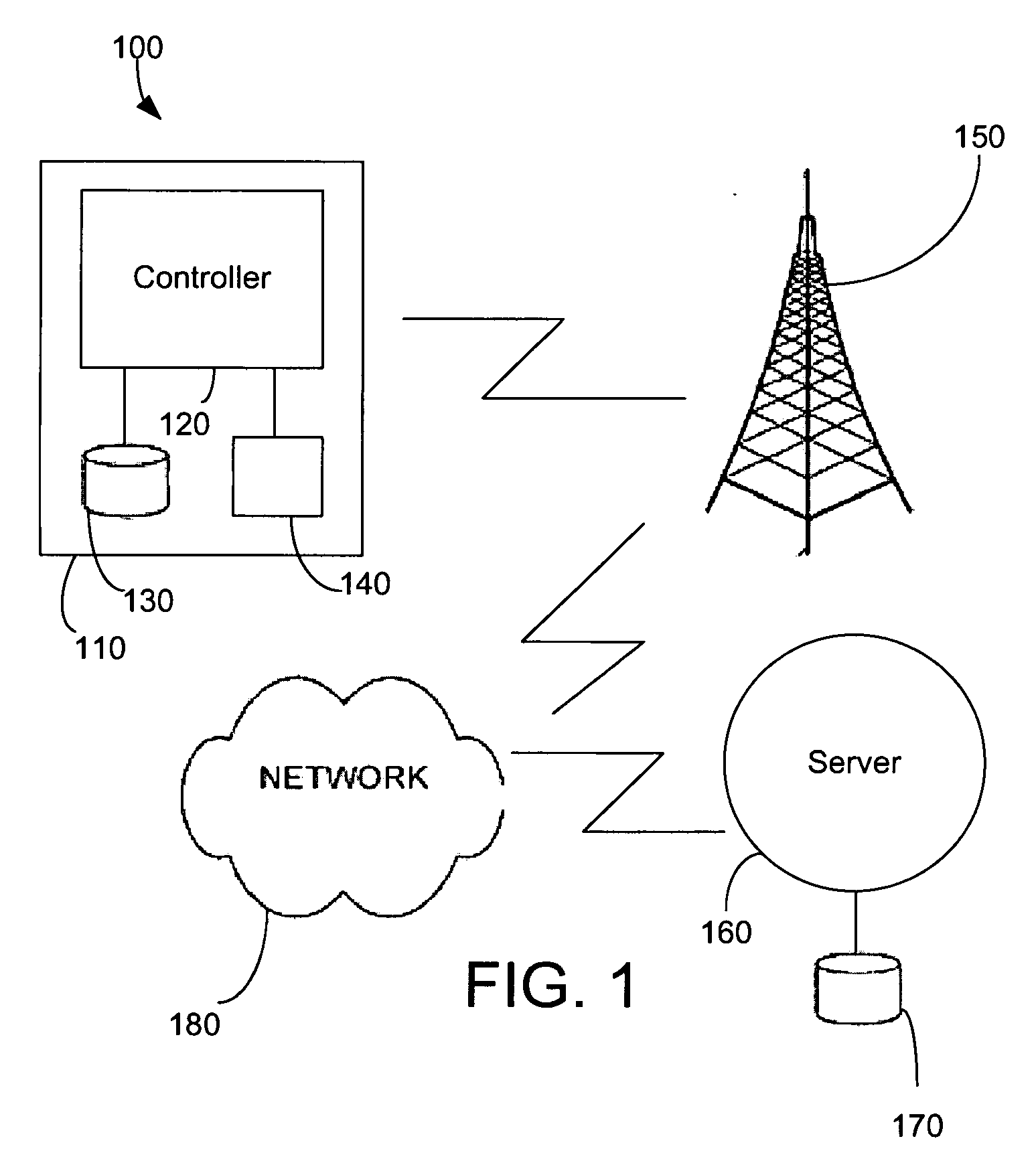

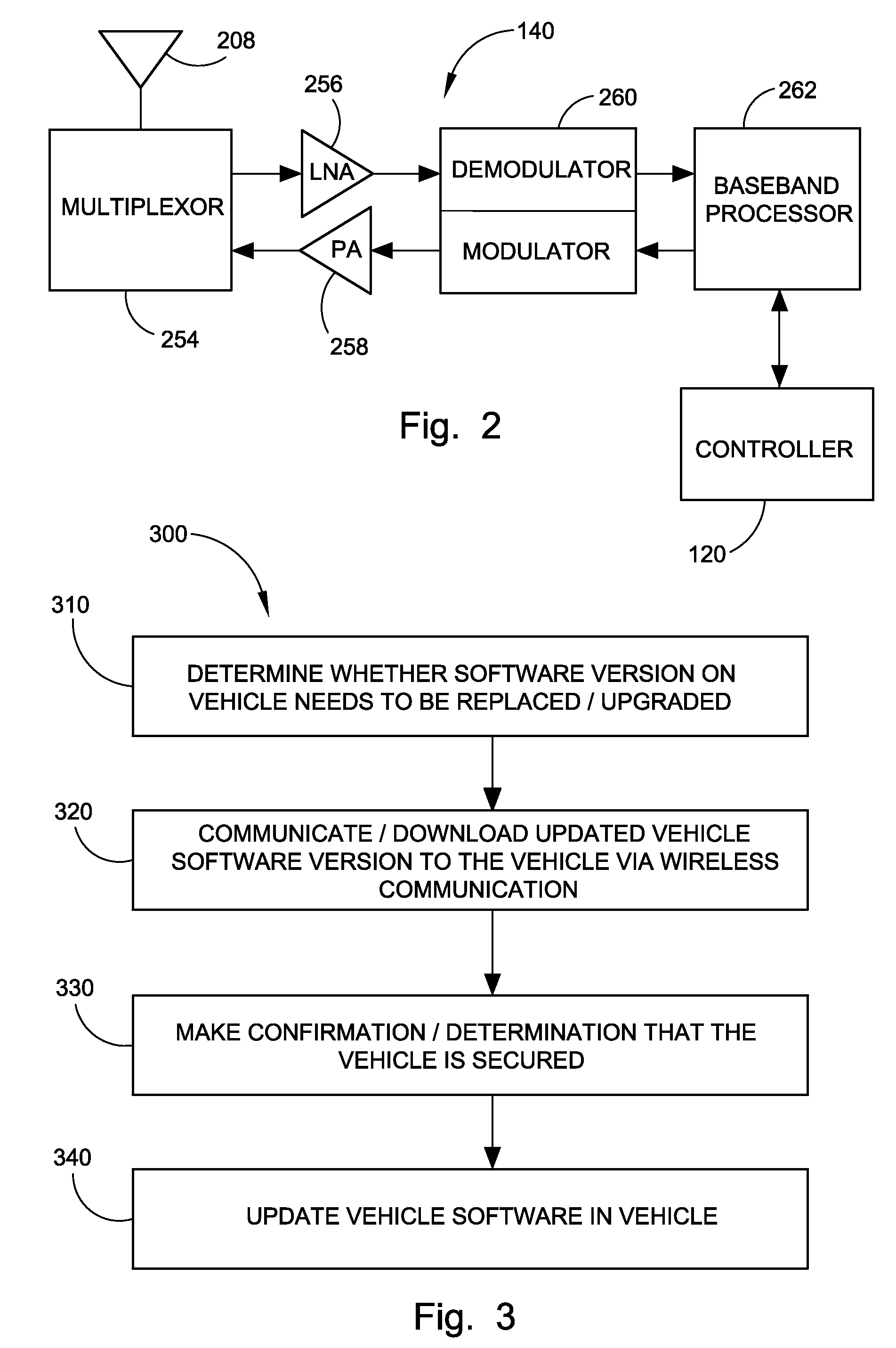

System and Method for Remotely Updating Control Software in a Vehicle With an Electric Drive System

InactiveUS20090300595A1Readily apparentSpecific program execution arrangementsMemory systemsElectric driveHeavy duty

A method of remotely updating control software in a heavy-duty vehicle having at least one programmed controller including securing the heavy-duty vehicle; determining that the vehicle is secured; establishing a wireless connection with the heavy-duty vehicle; downloading an updated control software; and updating the heavy-duty vehicle's control software with the updated control software in response to the determining that the vehicle is secured.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

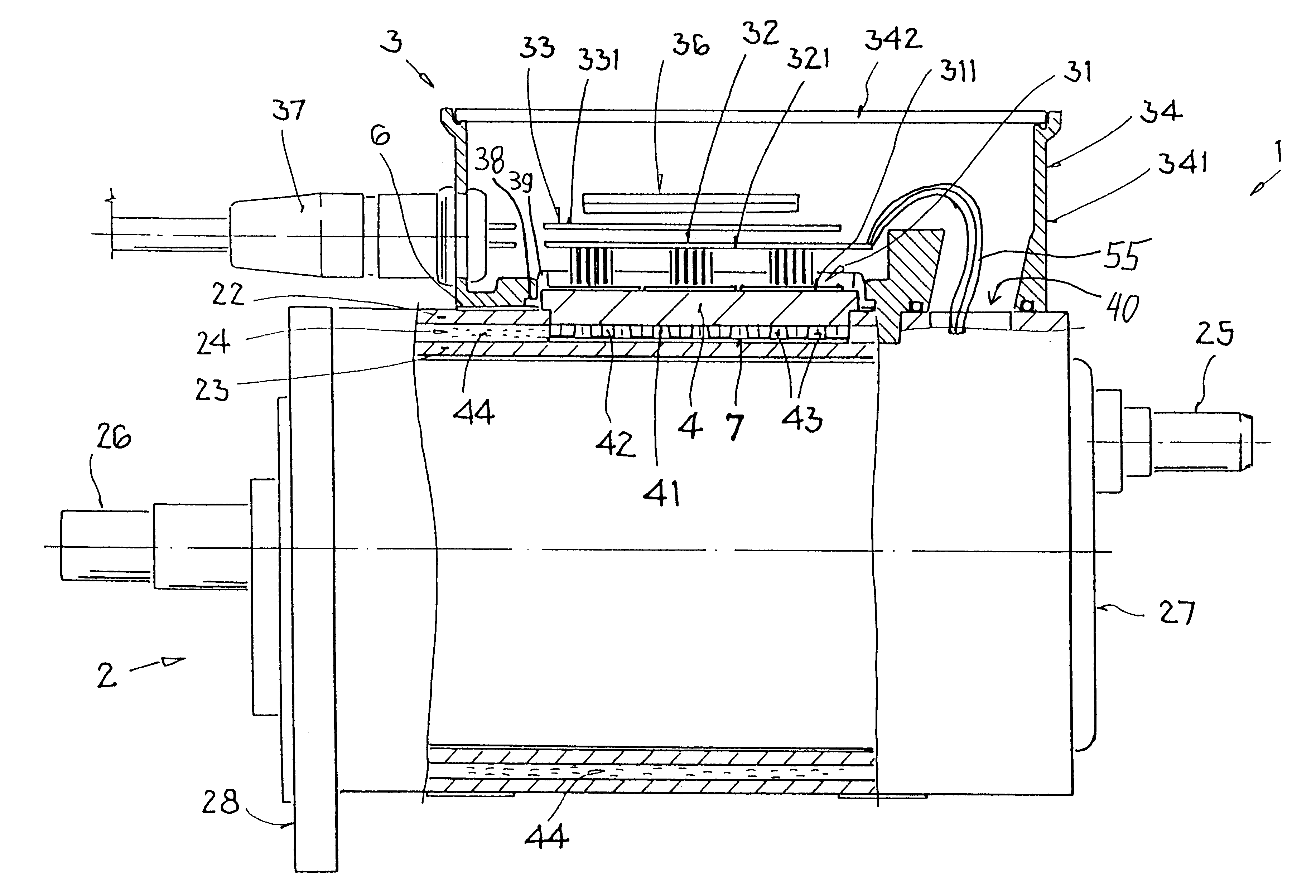

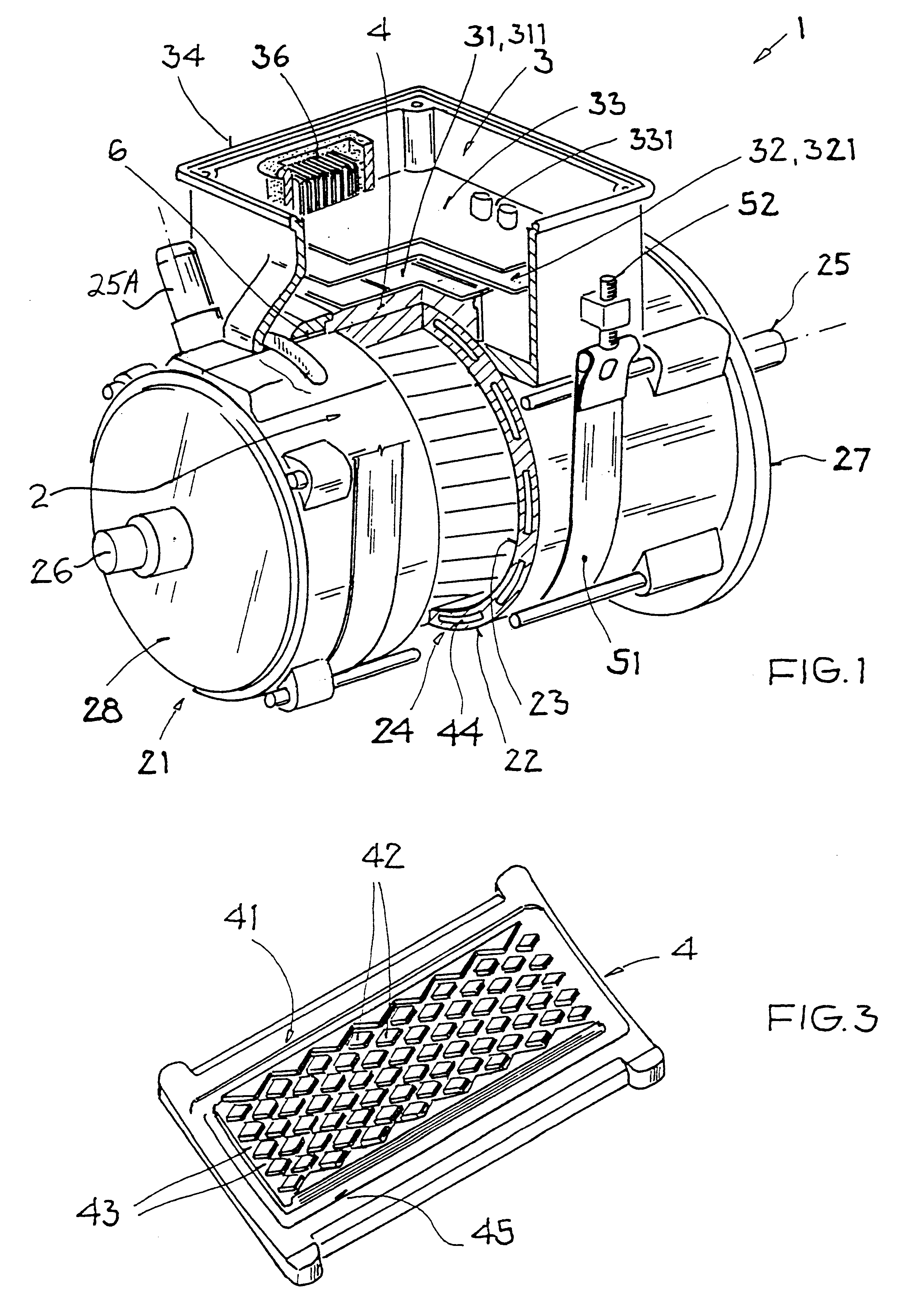

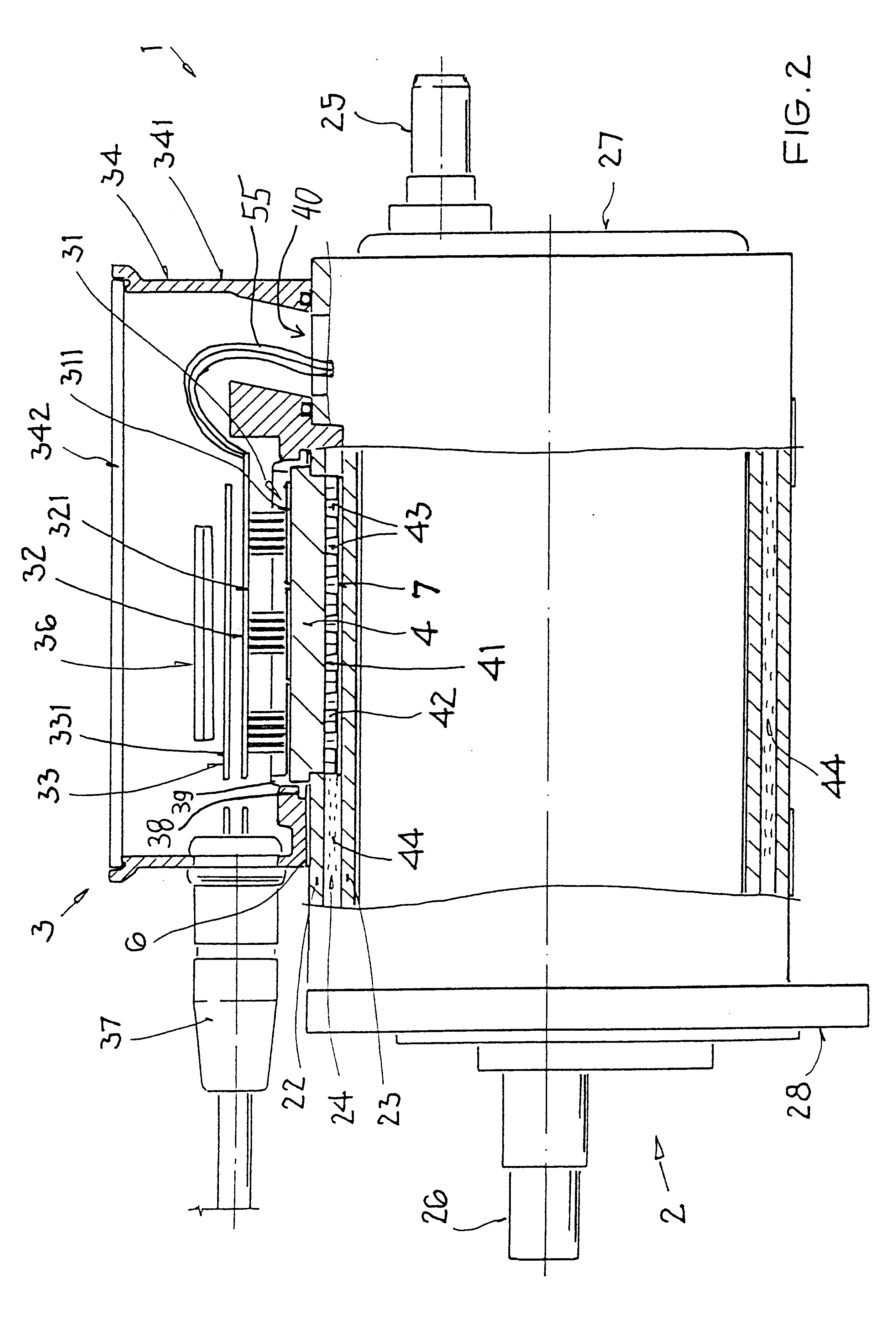

Integrated electric drive unit including an electric motor and an electronic control and monitoring module

InactiveUS6198183B1Small structural installation volumeReduce manufacturing costAssociation with control/drive circuitsMagnetic circuit rotating partsElectricityDouble wall

An electric drive unit includes an electronic control and monitoring module integrally connected to an electric motor. The housing of the electric motor has a double-walled construction to form a water jacket with cooling water passages therein. The electronic module includes at least one high power component that requires cooling. This component is mounted directly on a cooling insert that extends through a recess in the electronic module housing and is inserted in an opening provided in the outer wall of the motor housing. In this manner, the cooling insert is integrated into the water jacket of the motor housing and is directly cooled by the cooling water flowing in the cooling passages. A very compact and reliable construction is achieved, in which the electric motor and the electronic module share a common water cooling circuit. External water hoses and external electrical connections between the electric motor and the electronic module are avoided.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

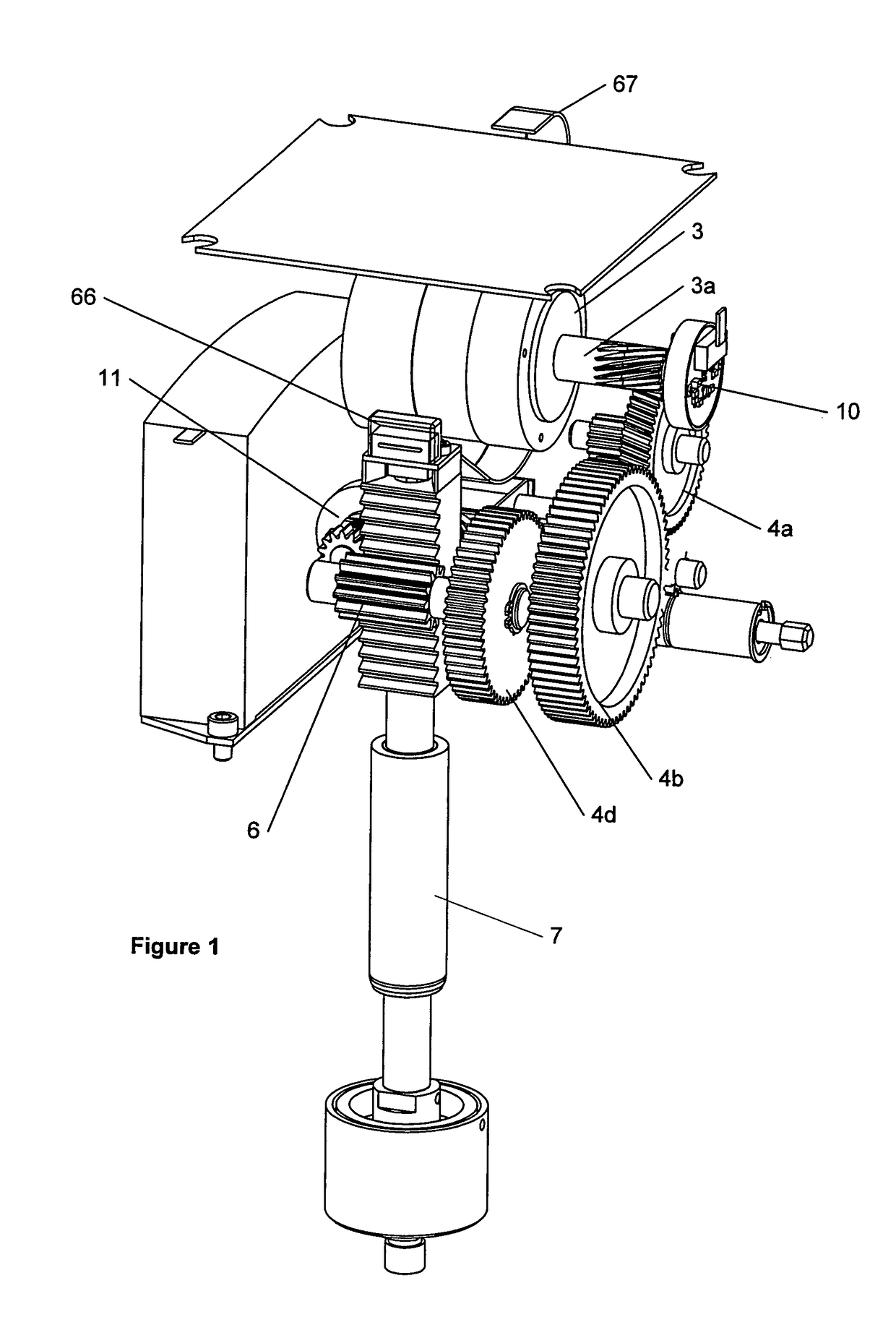

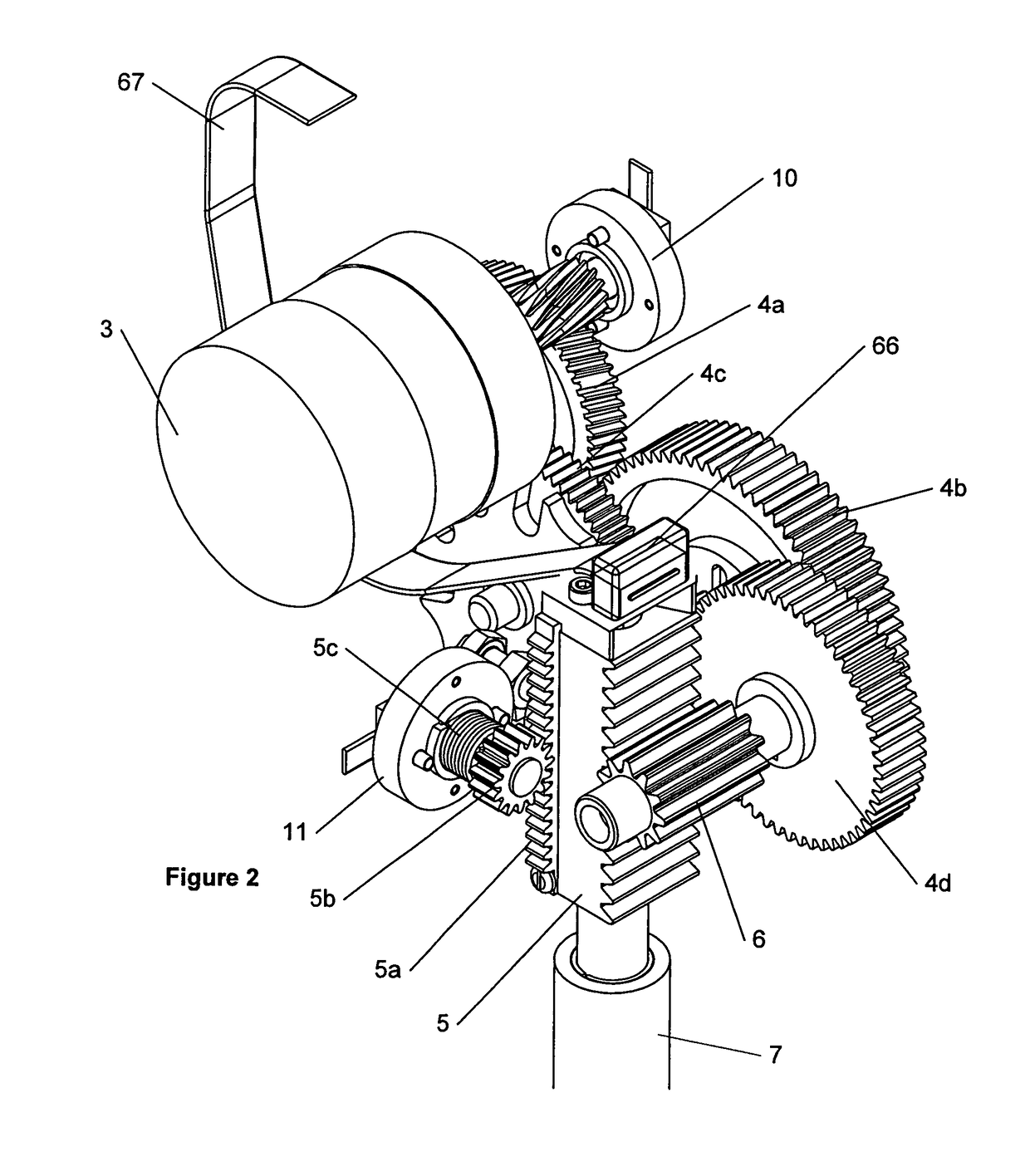

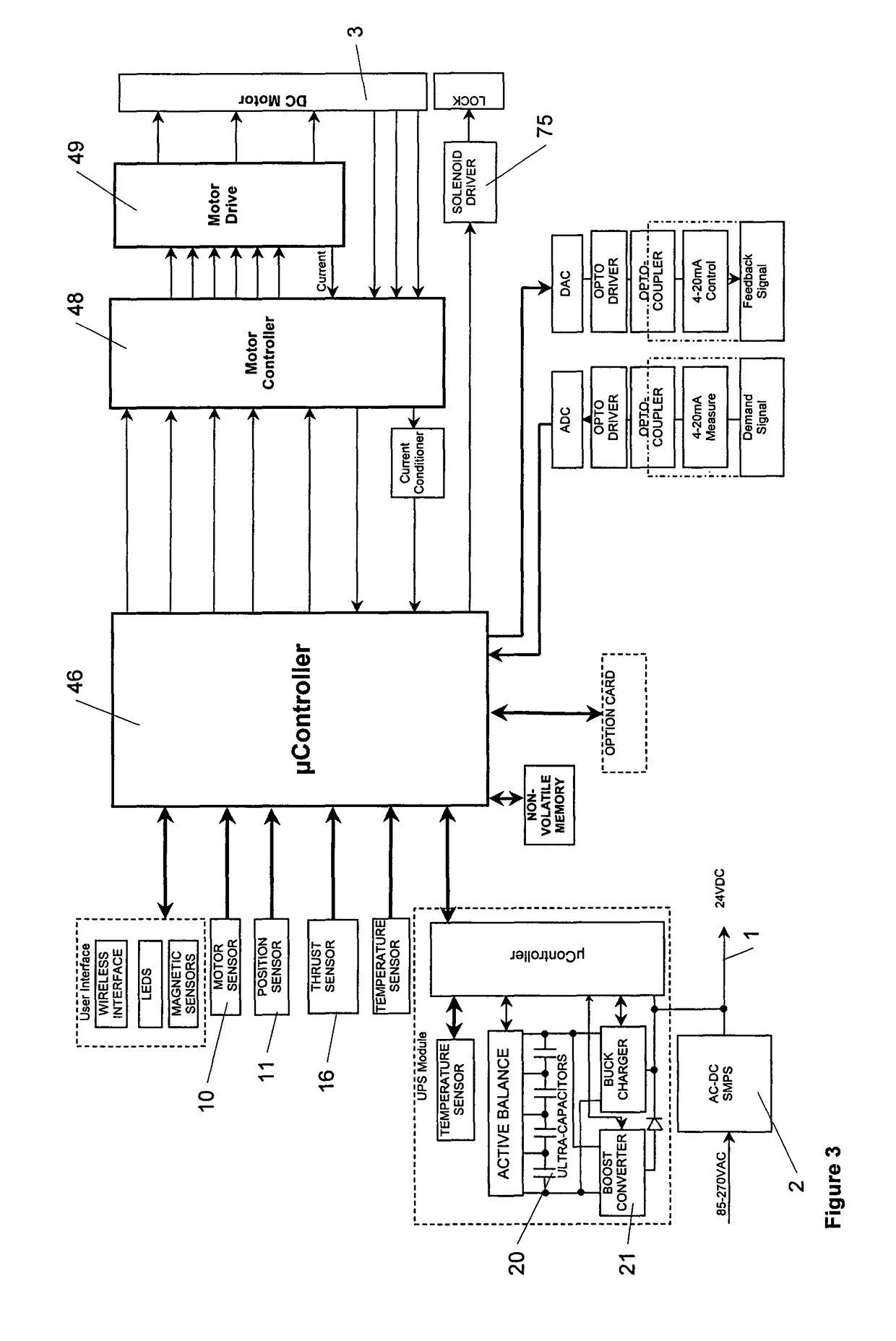

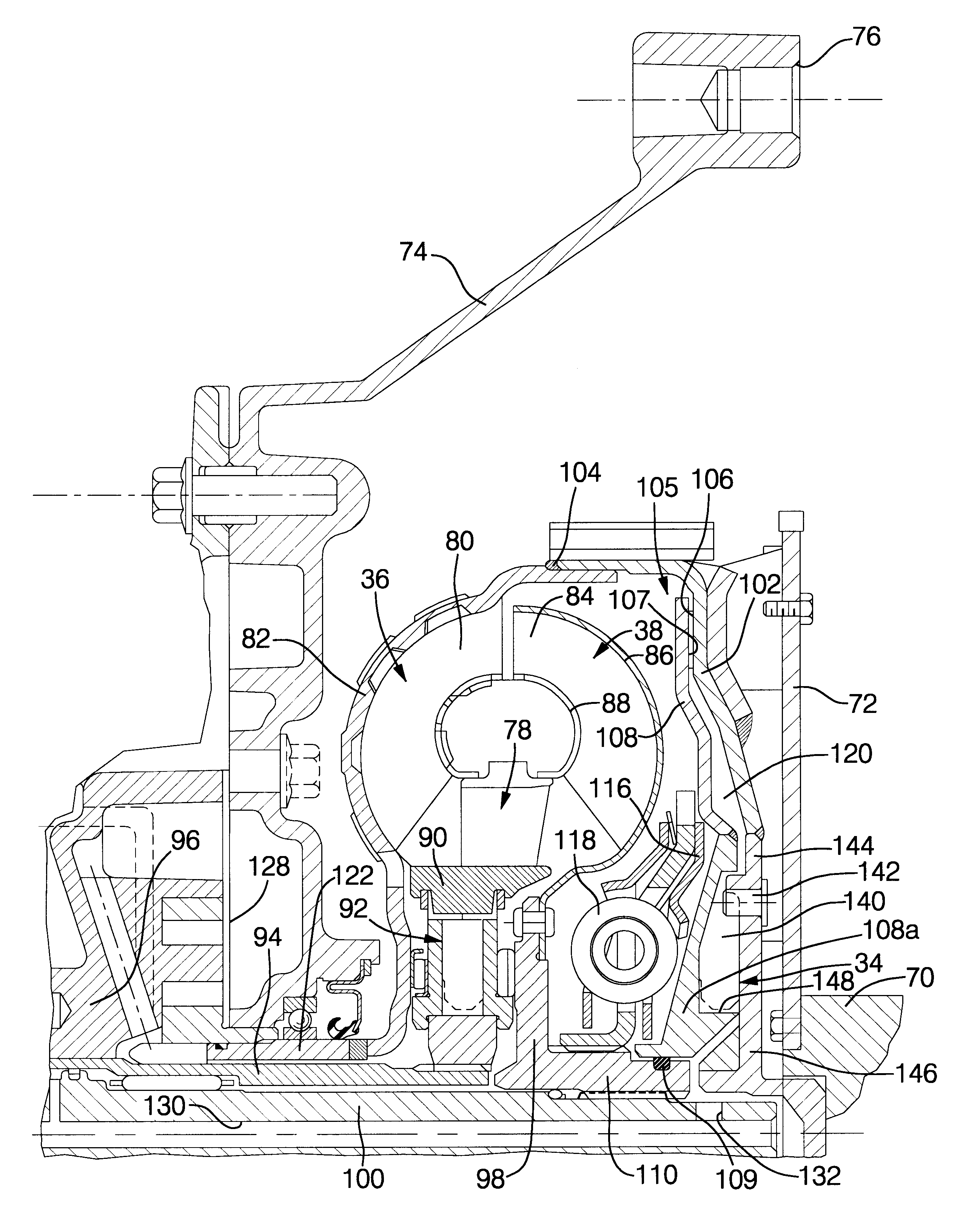

Valve actuators

ActiveUS8118276B2Low costImprove accuracySafety arrangmentsOperating means/releasing devices for valvesMotor speedValve actuator

A valve actuator having an electric drive motor with a motor shaft and having an output shaft linked to the motor shaft to drive movement of a valve, the actuator further having a control system arranged to provide a first closed loop control of the actuator output shaft and including a controller coupled to a first position sensor to sense the position of the actuator output shaft, and to a second position sensor to sense the position of the motor shaft and to enable determination of the speed of the motor shaft, the control system being configured to respond to sensed signals from the first and second sensors and adjust the motor speed / position accordingly.

Owner:ROTORK CONTROLS LTD

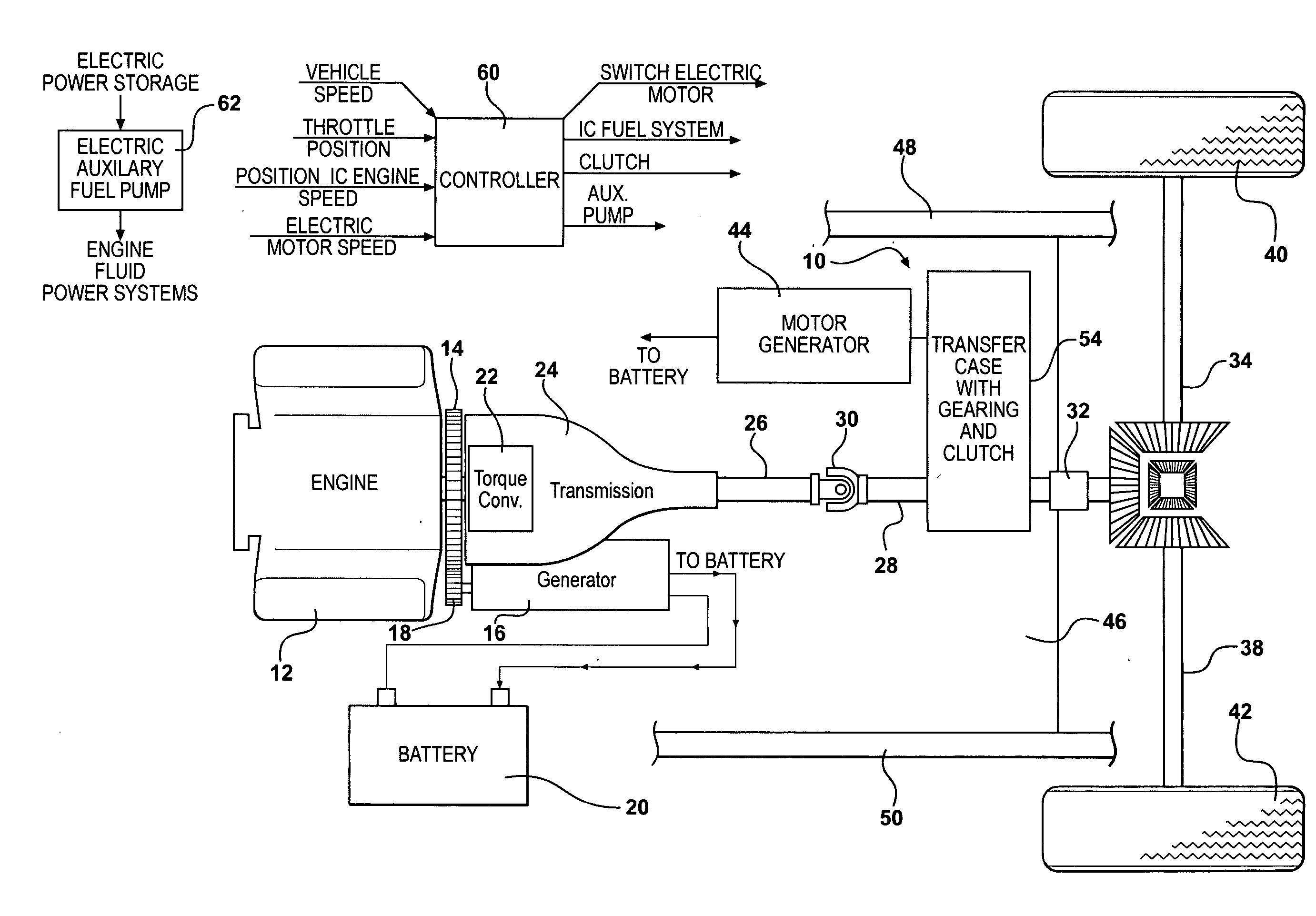

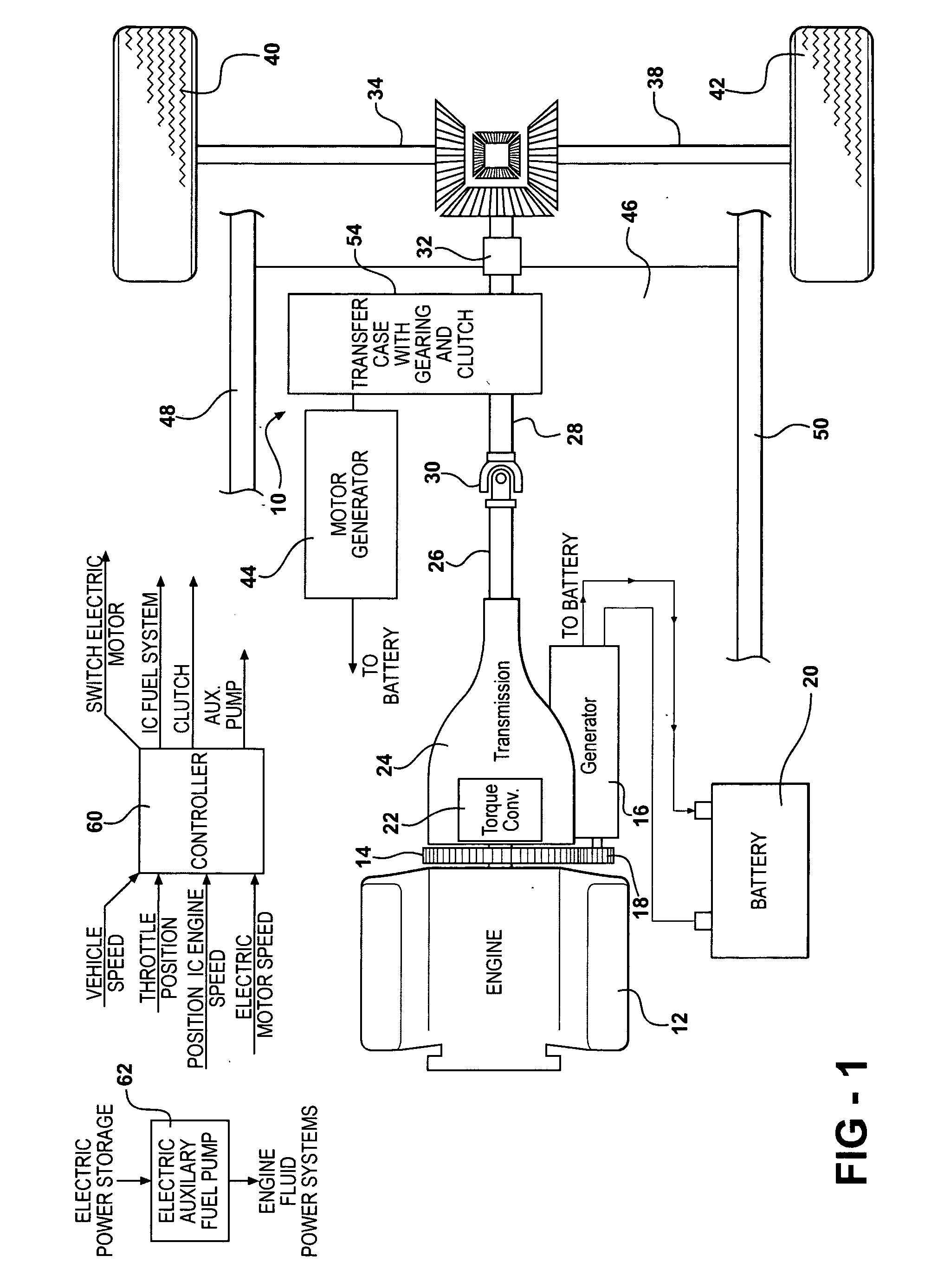

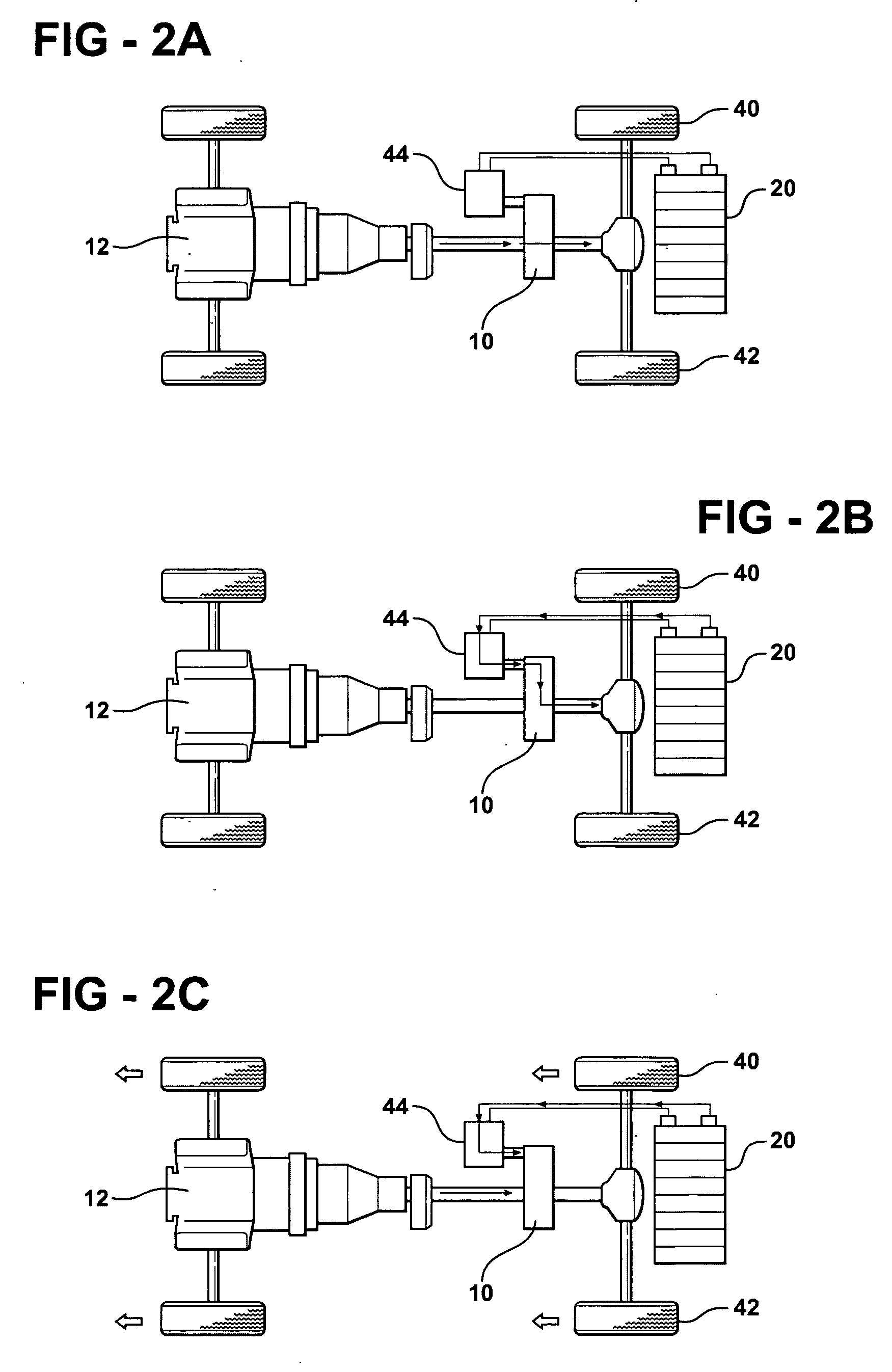

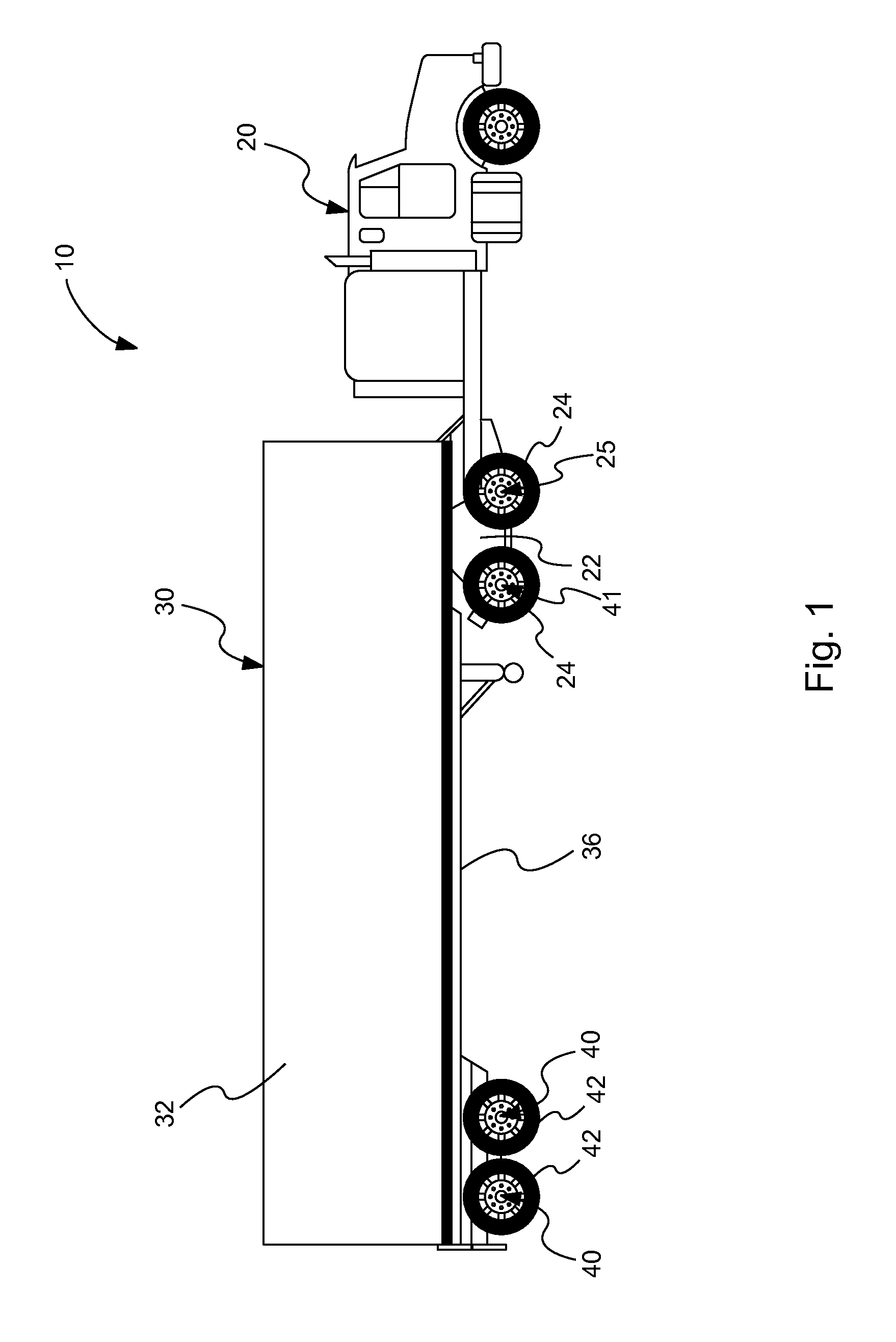

Hybrid vehicle formed by converting a conventional IC engine powered vehicle and method of such conversion

InactiveUS20060030450A1Reduce operating costsMaximize recoveryElectric propulsion mountingPropulsion using engine-driven generatorsElectricityCombustion

A method of converting a conventional internal combustion powered vehicle into a hybrid vehicle and apparatus for achieving that and modifying one of the serial elements of the drive train interconnecting the internal combustion to the driving wheels of the vehicle by providing an auxiliary power connection which allows the motor / generator to provide or remove mechanical power from the drive train during driving operation or regenerative braking. Generators switchingly connected to a vehicle battery and an electronic controller intercede the system relative to the operation of the vehicle and control the motor / generator switching the vehicle engine to apply an electric drive power to the vehicle at appropriate points in the vehicle operation and to drive the generator during braking of the vehicle to recharge the power source. The electric drive power elements are supported on a cross-member added to the vehicle.

Owner:HYBRID ELECTRIC CONVERSION

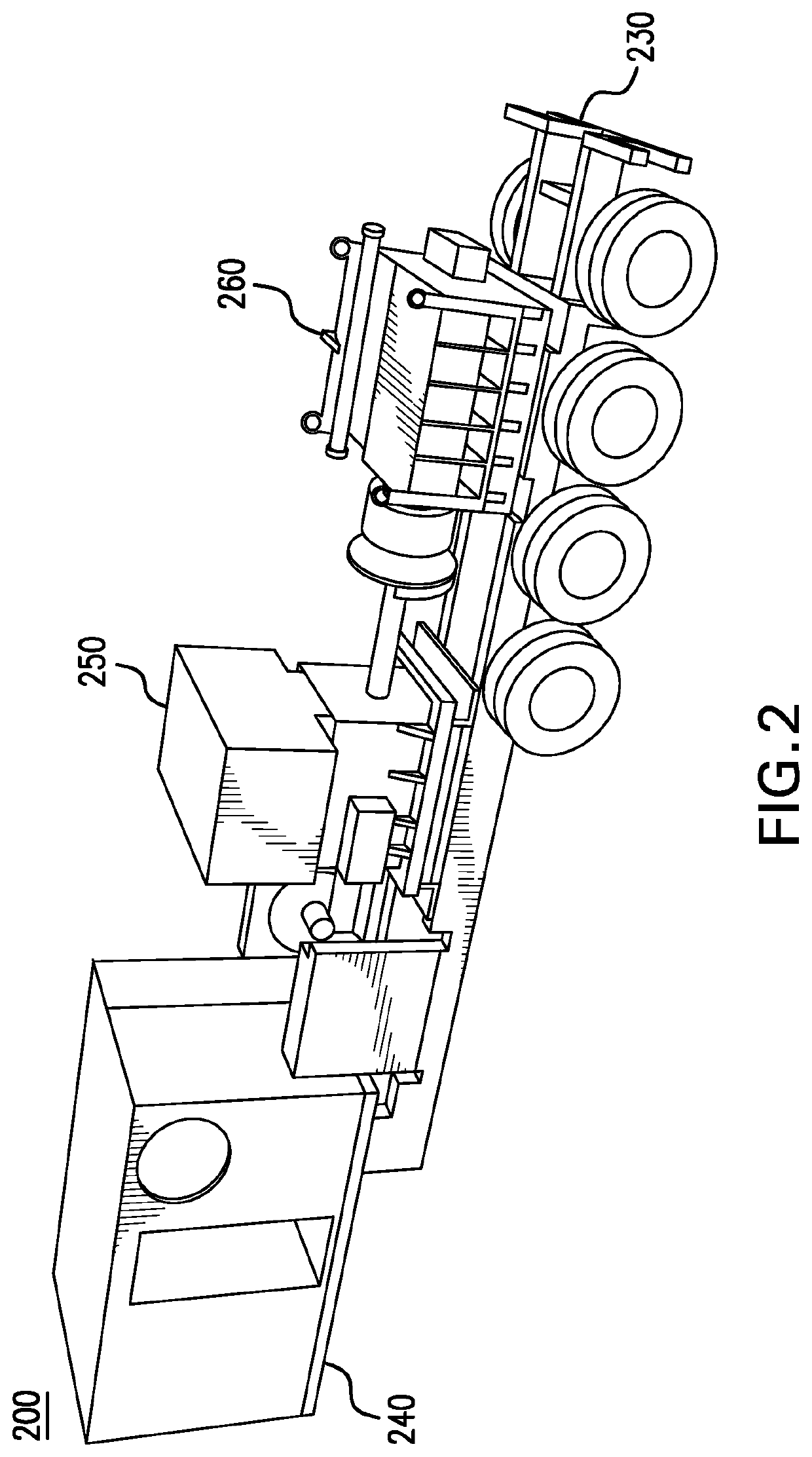

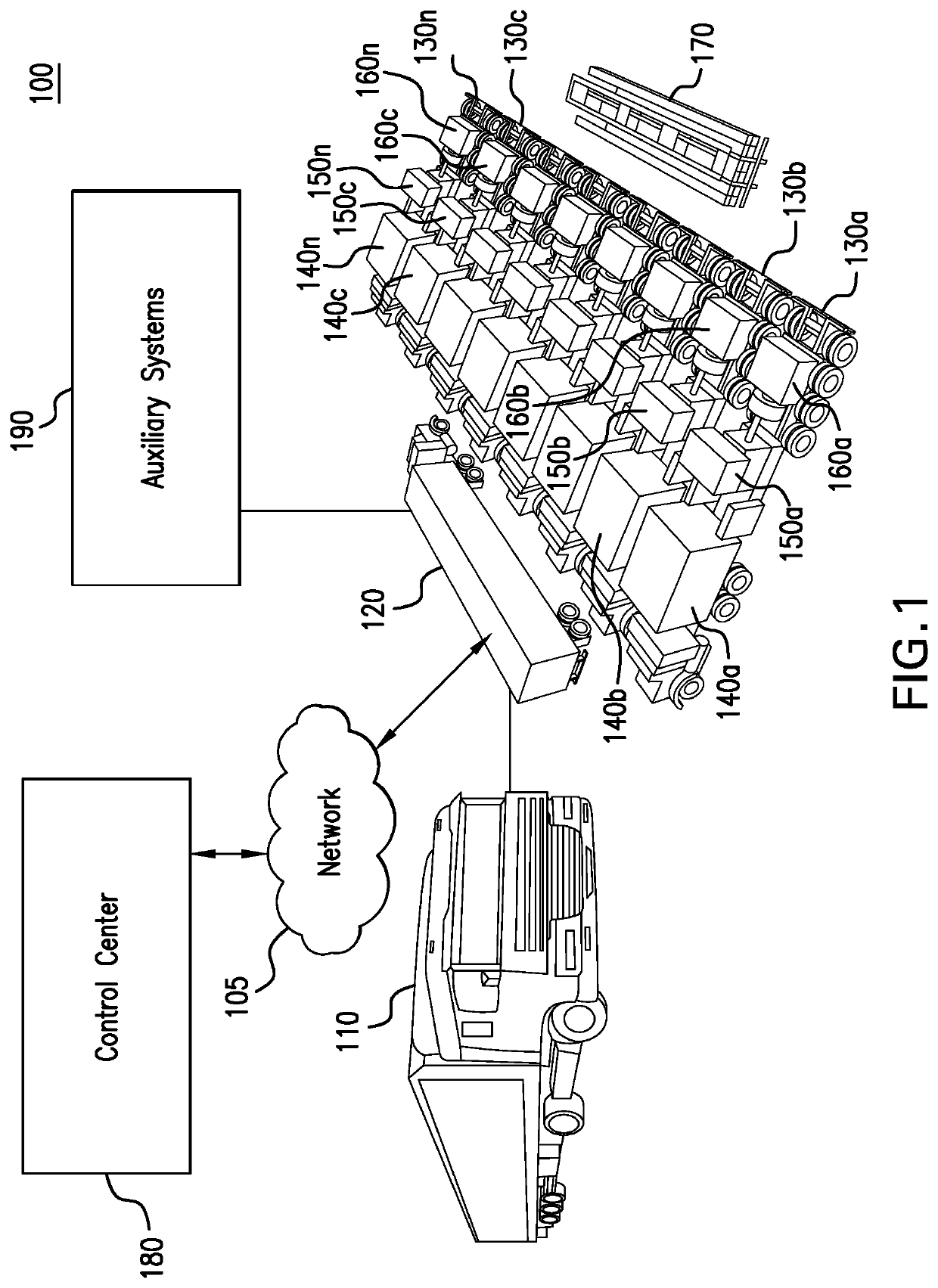

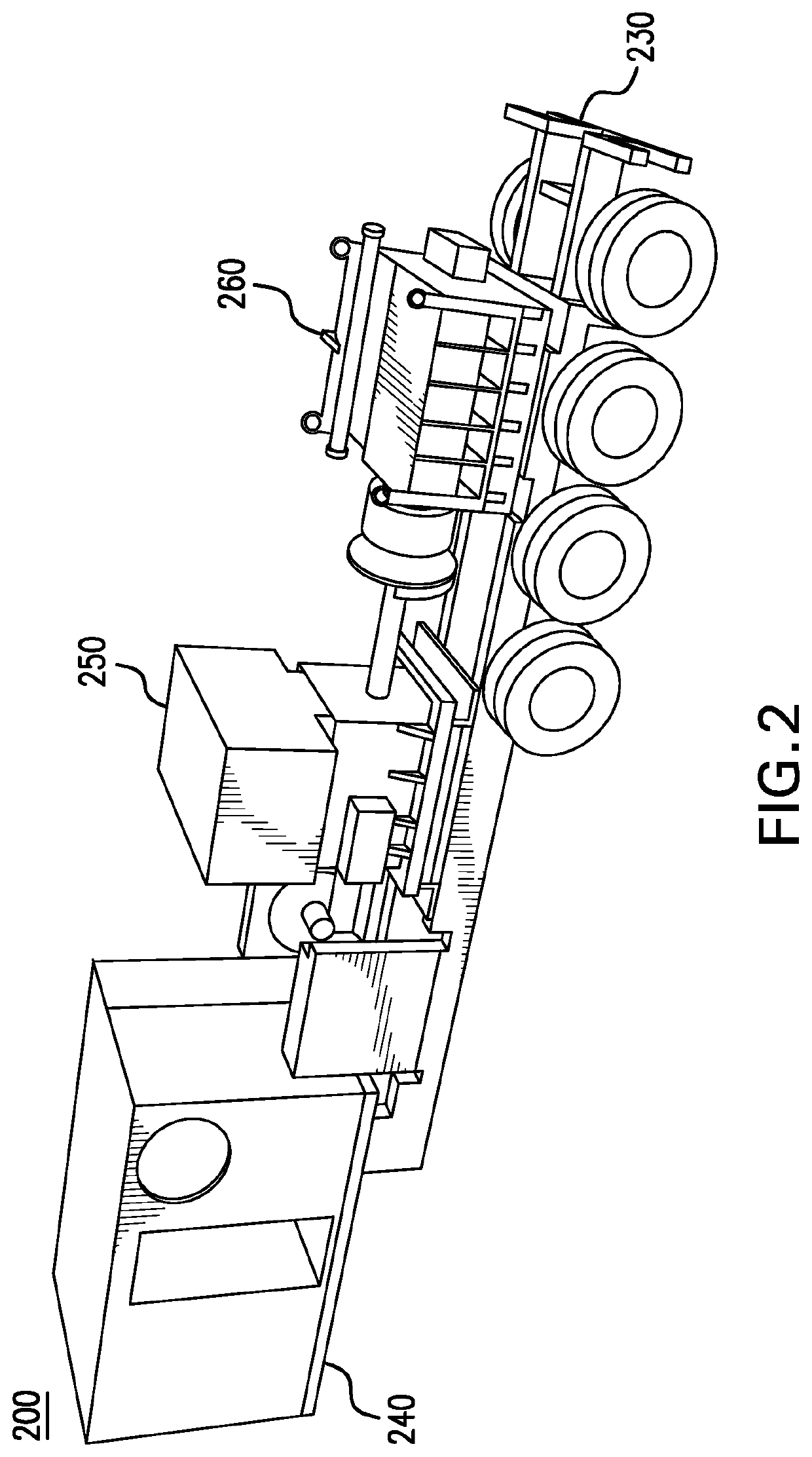

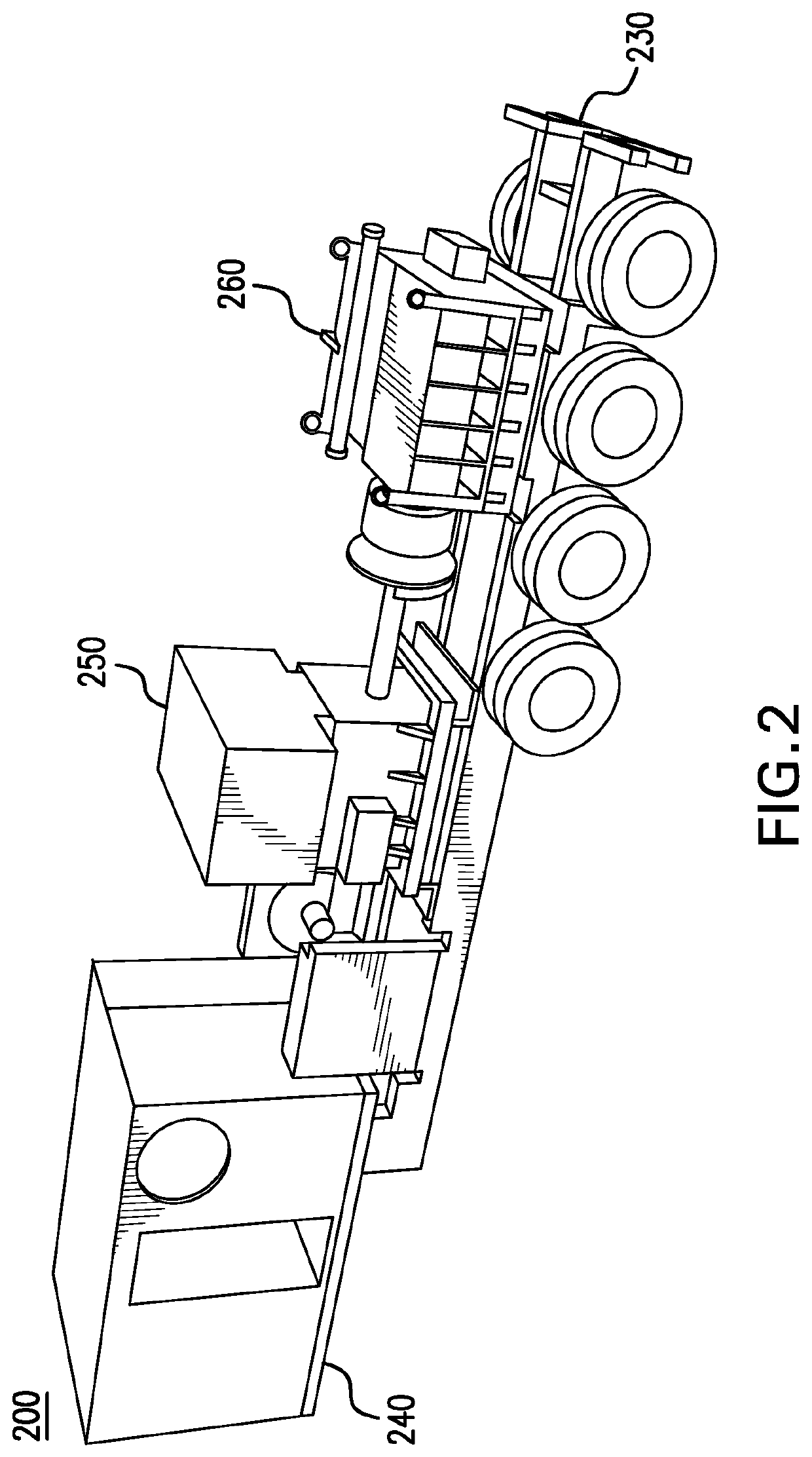

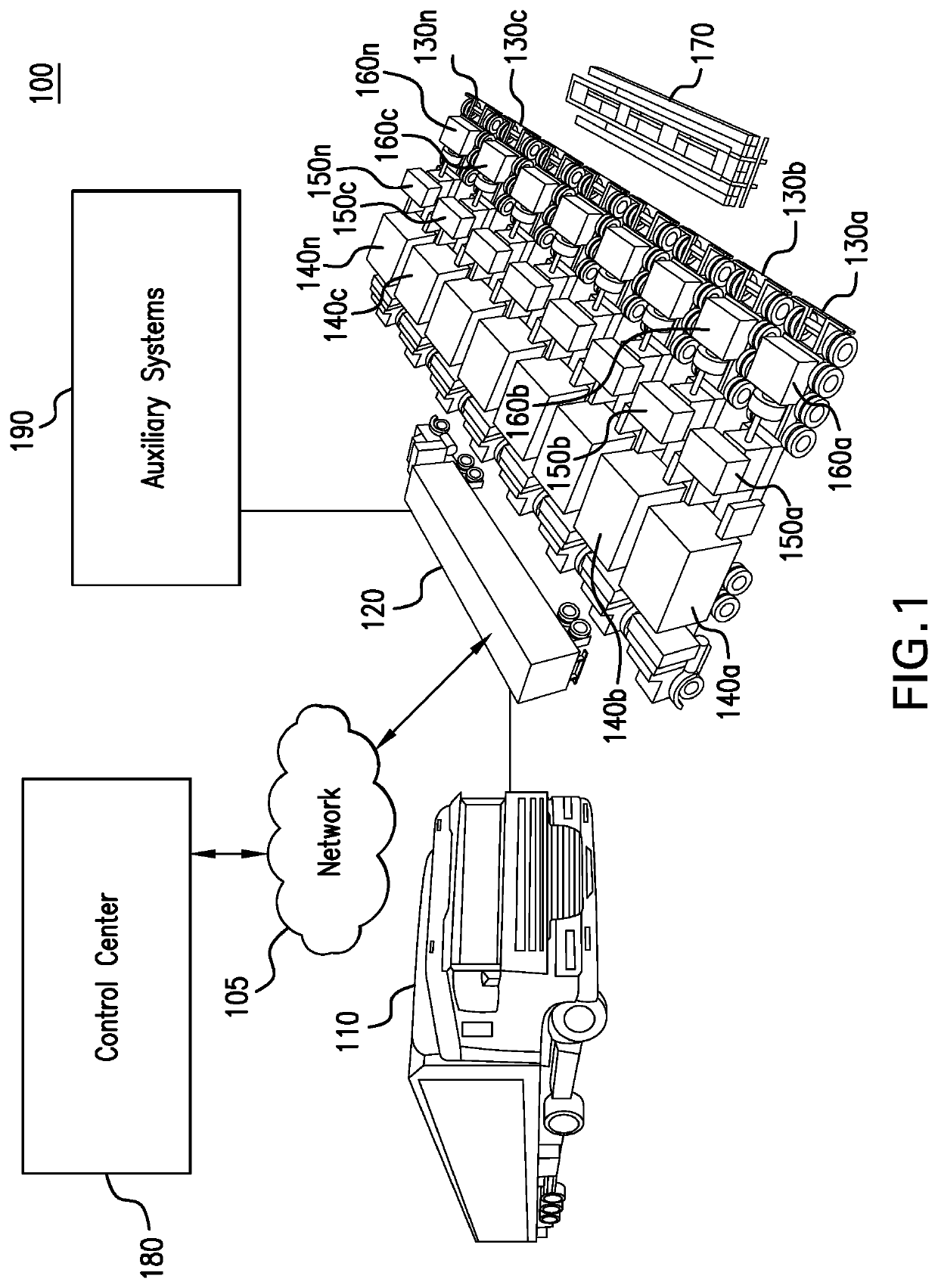

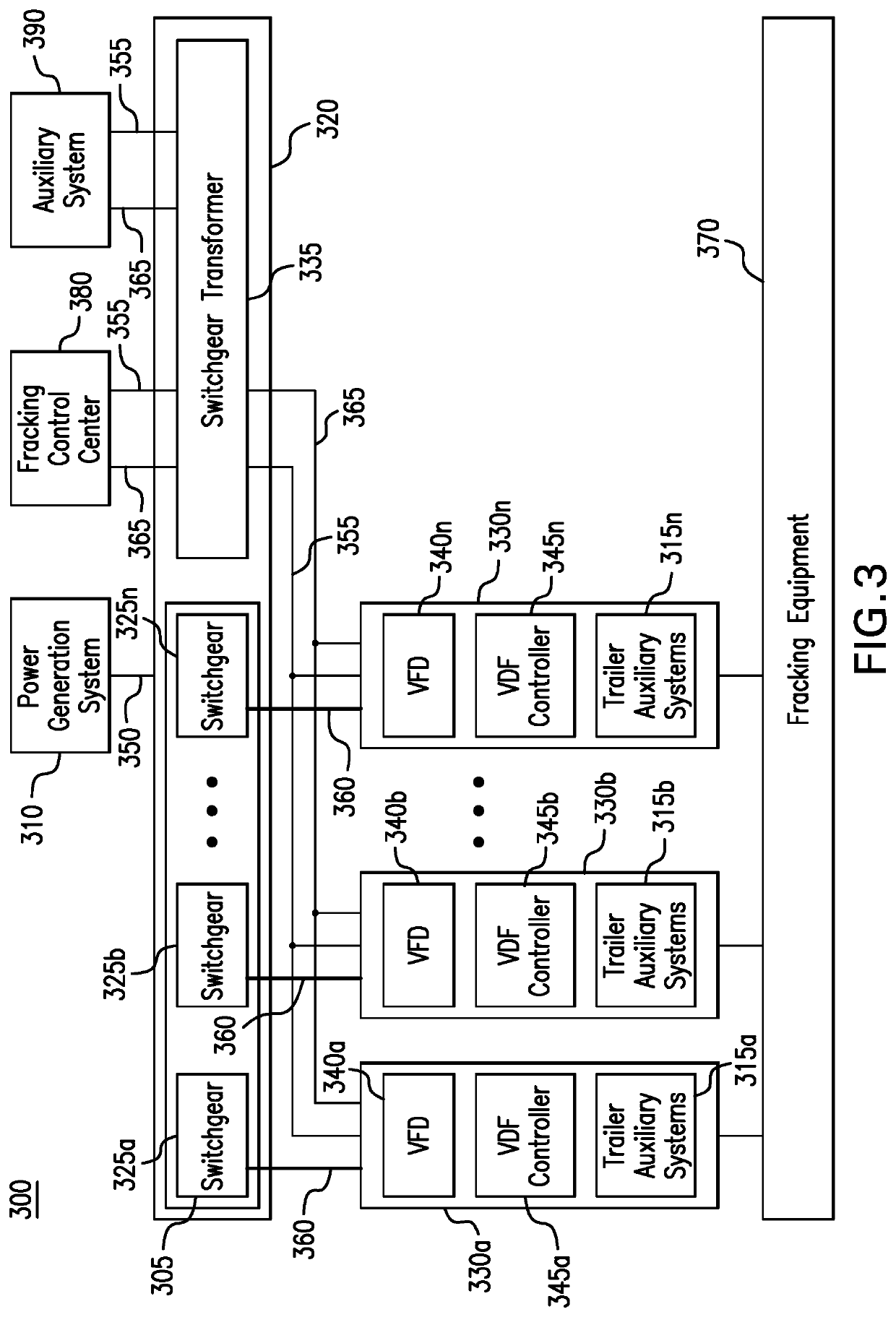

Power distribution trailer for an electric driven hydraulic fracking system

Owner:HALLIBURTON ENERGY SERVICES INC

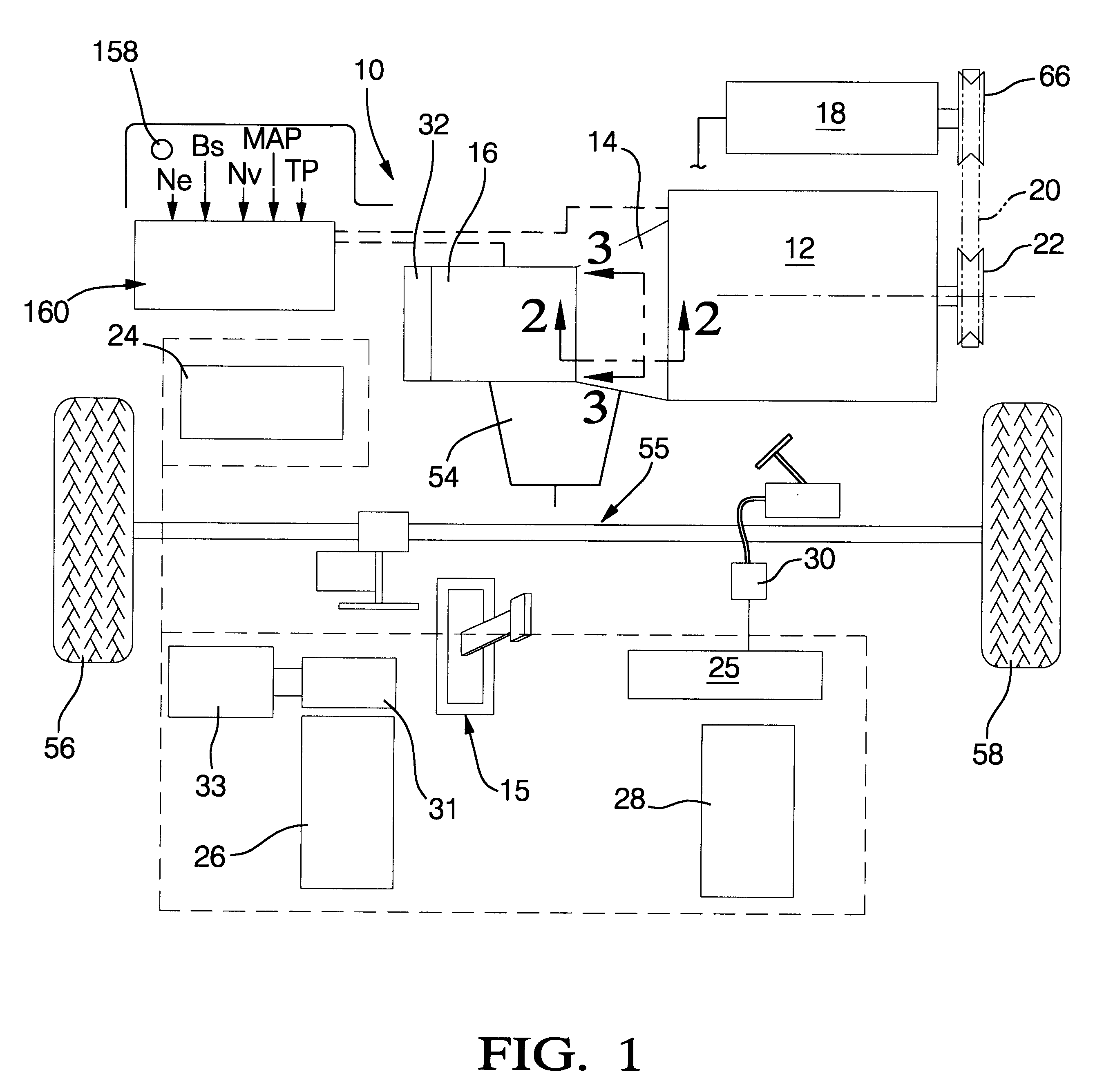

Hybrid electric drive and control method therefor

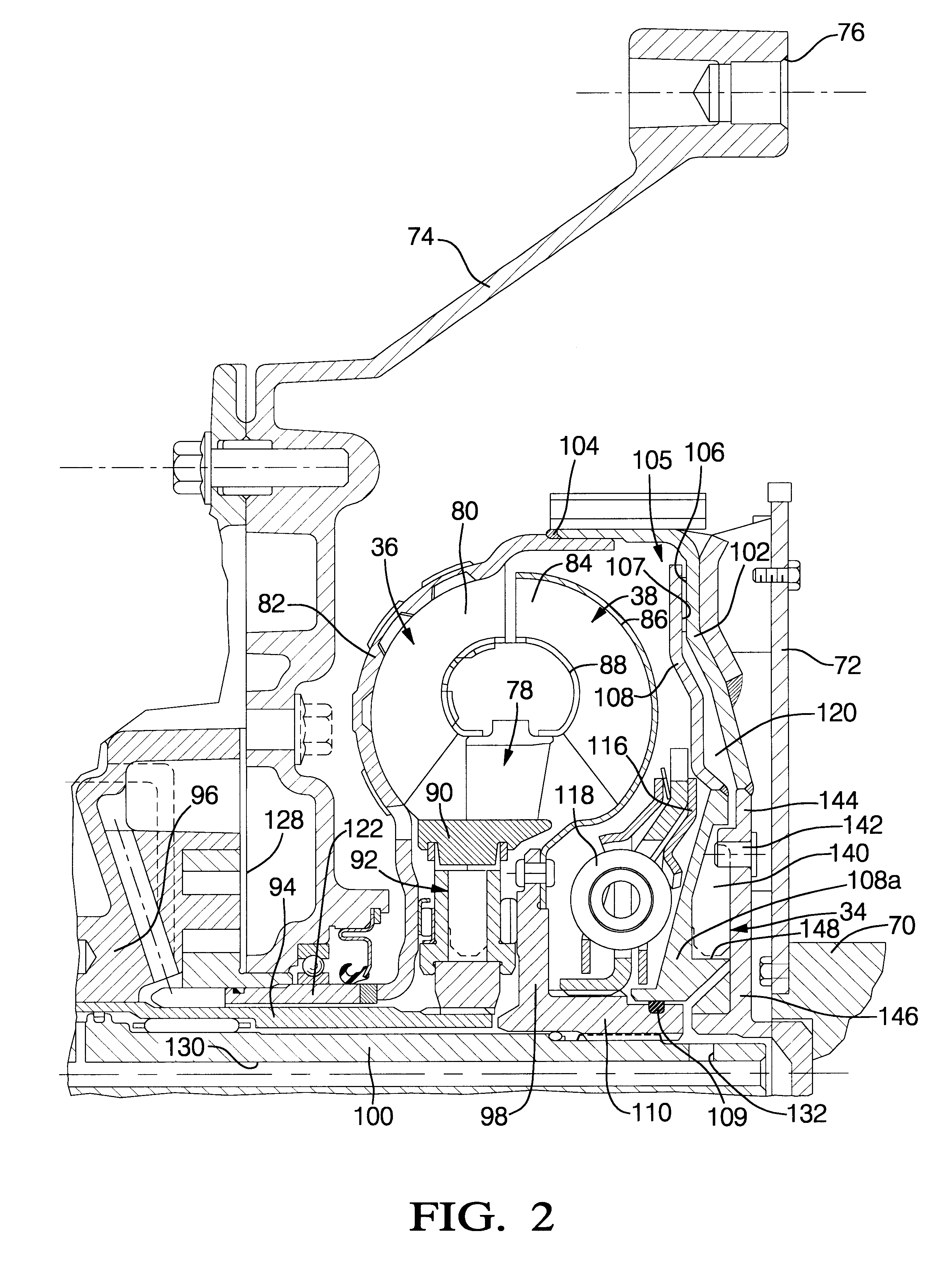

InactiveUS6376927B1Increase fuel consumptionImprove drivabilityInternal combustion piston enginesGearing controlHysteresisEngineering

A fuel management control method for a hybrid electric vehicle drive having an internal combustion engine and an electric motor arranged in parallel such that both can propel the vehicle; the system including an electric motor driven fuel pump and a programmable microprocessor; and wherein the method further includes monitoring vehicle speed and sensing braking pressure and directing signals of both vehicle speed and braking to the microprocessor and processing such inputs in accordance with an aggressive fuel management program including shut-off of fuel flow to the gas engine in response to vehicle braking at vehicle speeds above a predetermined maximum hysteresis speed and maintaining the fuel shut off during vehicle coasting above a predetermined speed while controlling the electric motor to provide regenerative braking or vehicle start during such fuel shut off modes of operation.

Owner:SATURN CORPORATION

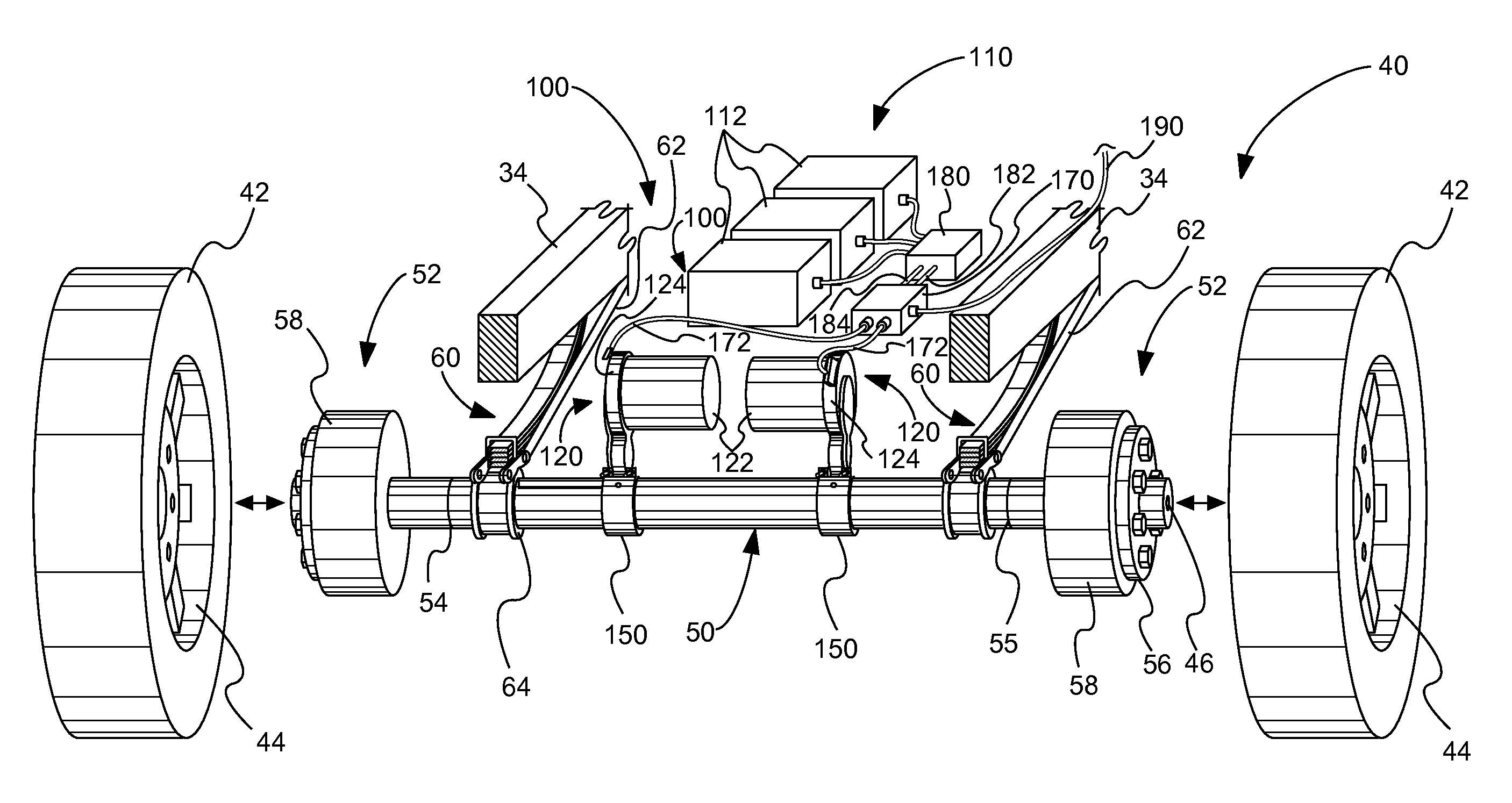

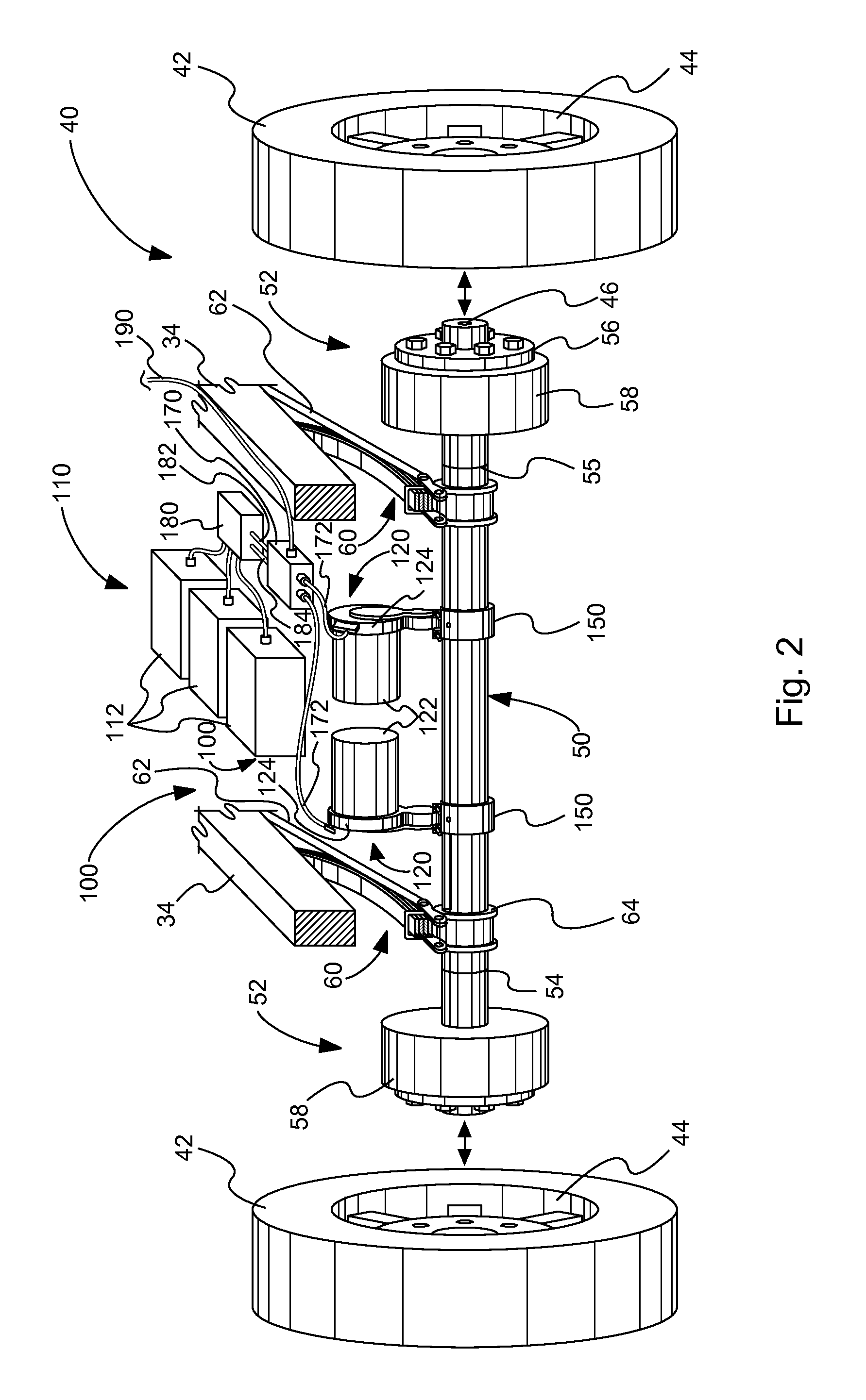

Electric drive system for passive vehicle

InactiveUS20110094807A1Inexpensive, compact, and light-weightEasy to modifyElectric devicesOperating modesElectric driveElectricity

One embodiment of an electric drive system includes first and second gear assemblies coupled to a hollow axle tube, and first and second electric motors respectively coupled to the first and second gear assemblies. Further, the electric drive system includes first and second drive axles positioned within the hollow axle tube. The first drive axle includes a first end portion coupled to a first wheel and a second end portion coupled to the first gear assembly. Similarly, the second drive axle includes a first end portion coupled to a second wheel spaced-apart from the first wheel and a second end portion coupled to the second gear assembly. Actuation of the first electric motor rotates the first drive axle and first wheel via the first gear assembly and actuation of the second electric motor rotates the second drive axle and second wheel via the second gear assembly.

Owner:ARES TRANSPORTATION TECH

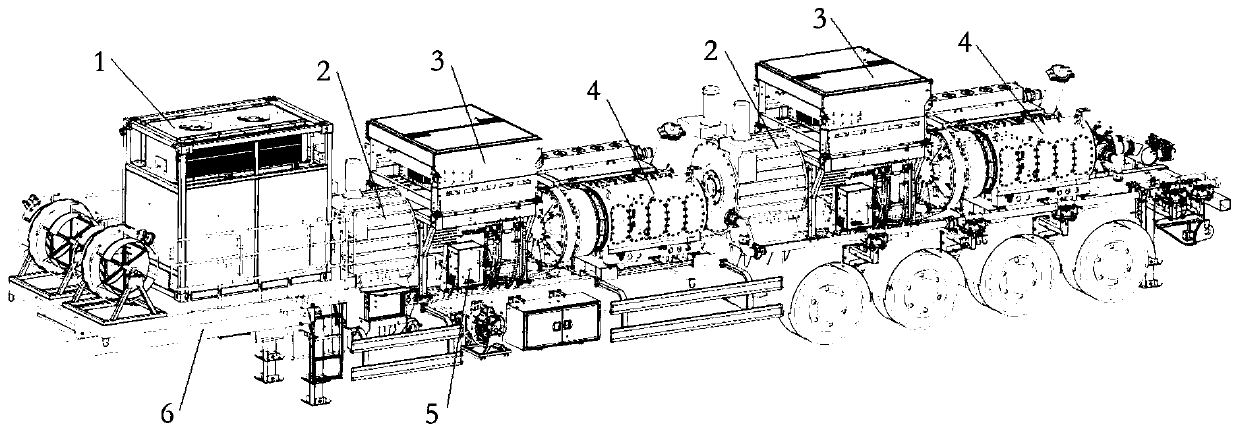

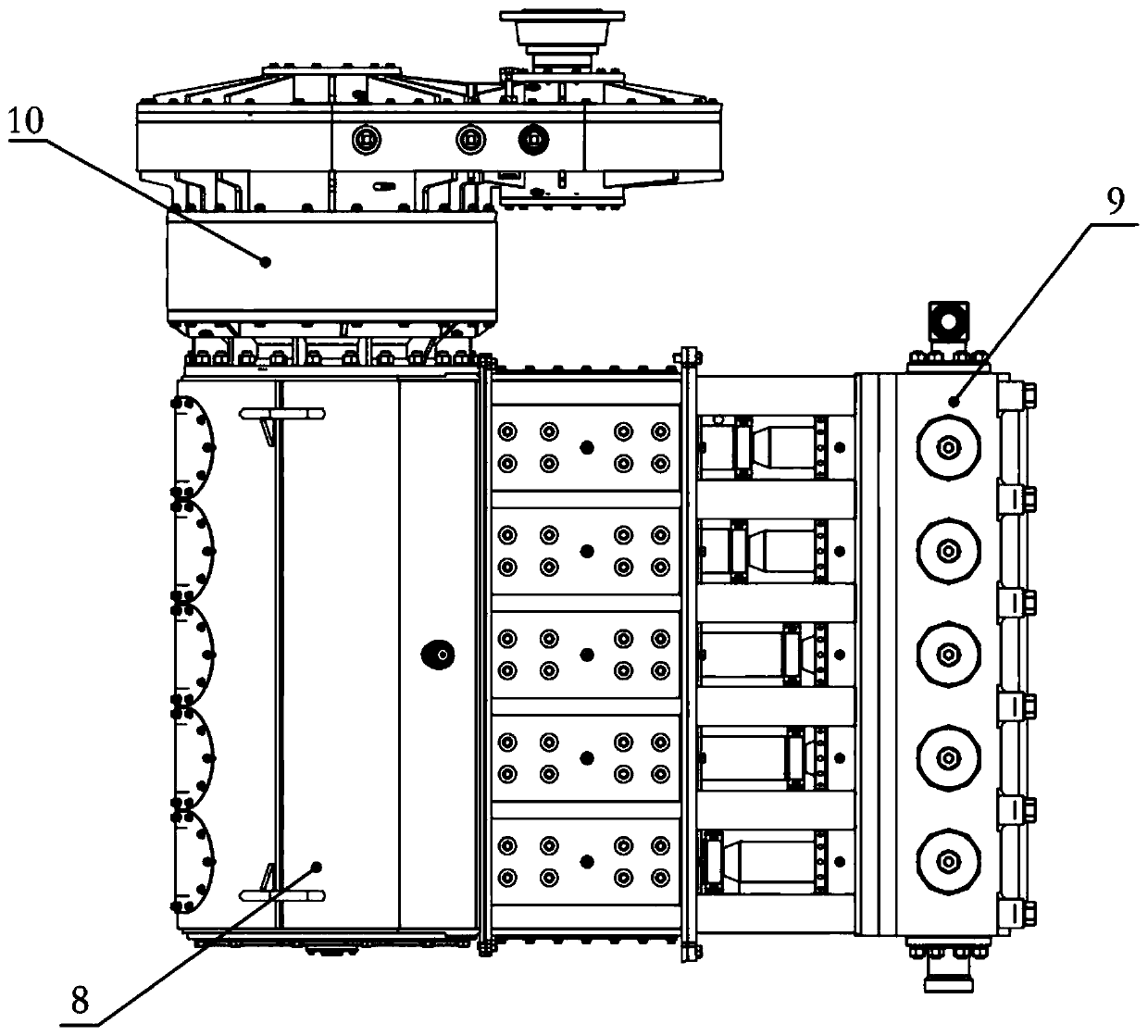

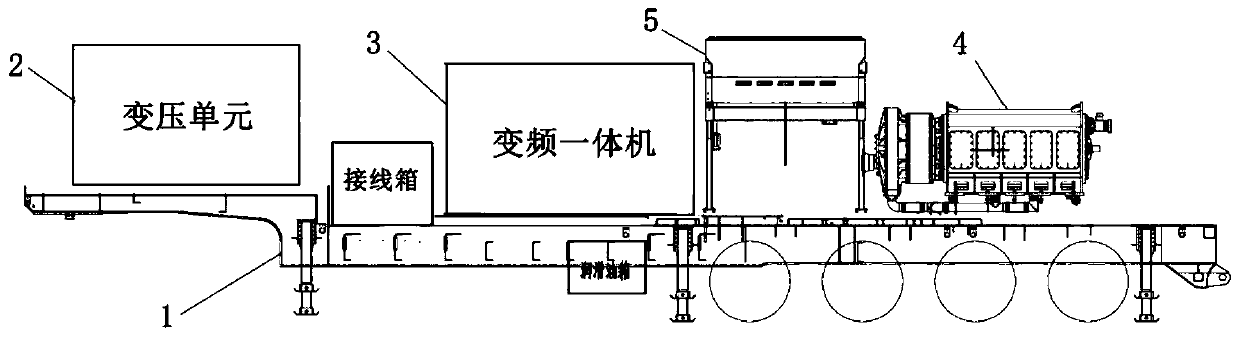

Electric drive fracturing semitrailer with dual engines and dual pumps

PendingCN109882144ARealized pump powerReduce investmentAssociation with control/drive circuitsPositive displacement pump componentsDrive shaftElectrical control

The invention discloses an electric drive fracturing semitrailer with dual engines and dual pumps. The electric drive fracturing semitrailer with the dual engines and the dual pumps comprises a semitrailer body, two plunger pumps, two radiators and an electrical control cabinet. The electric drive fracturing semitrailer with the dual engines and the dual pumps is characterized by further comprising two electromotorsand an inverter unit. The plunger pumps, the radiators, the electrical control cabinet, the electromotors and the inverter unit are integrated in the semitrailer body, the inverterunit is arranged on the gooseneck of the semitrailer body, the output end of the inverter unit individually drives the two electromotors, the other ends of the two electromotors are connected with theplunger pumps correspondingly, lubricating oil of the plunger pumps is cooled through the radiators, and local operation of the electric drive fracturing semitrailer with the dual engines and the dual pumps is realized through the electrical control cabinet. The electric drive fracturing semitrailer with the dual engine and the dual pump has the beneficial effects that the electromotors are adopted to drive the plunger pumps through a transmission shaft, the volume is small, and the economic efficiency, energy conservation and environment protection are achieved. The signal pump power of theplunder pumps is improved, design that the dual pumps are driven by the two electromotors is adopted by the whole fracturing device, the output power of the fracturing device is greatly improved, andthe using requirements are better met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

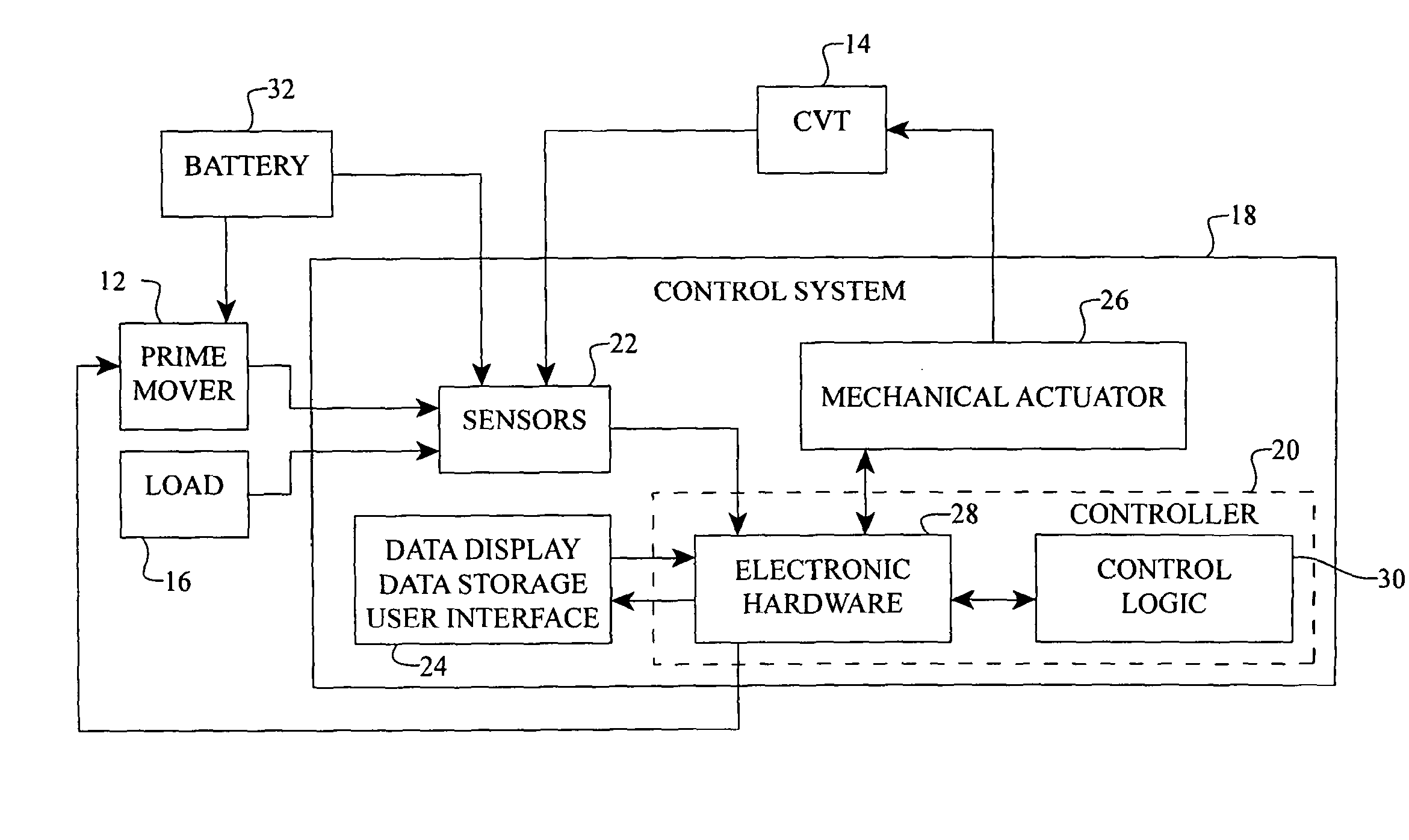

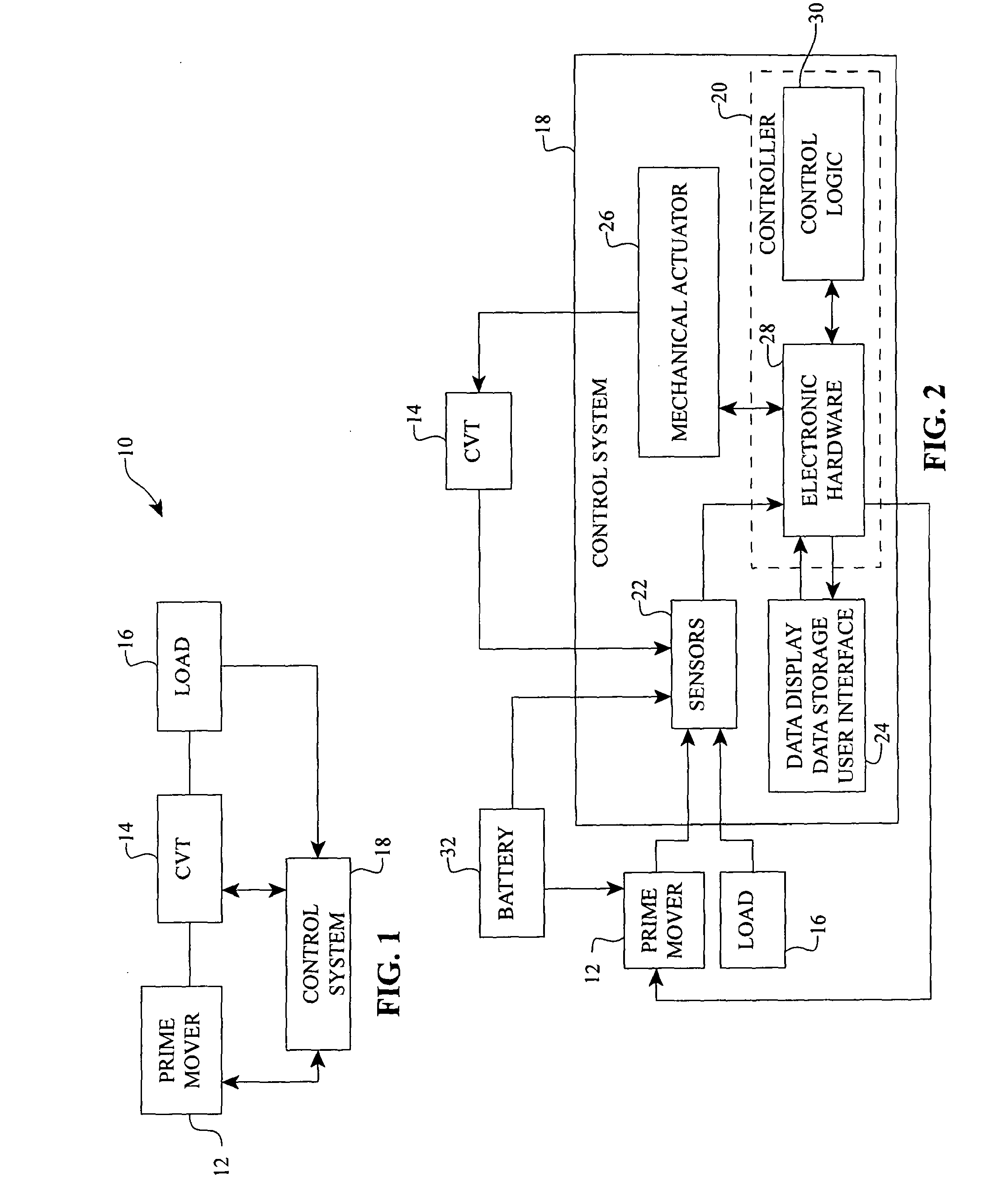

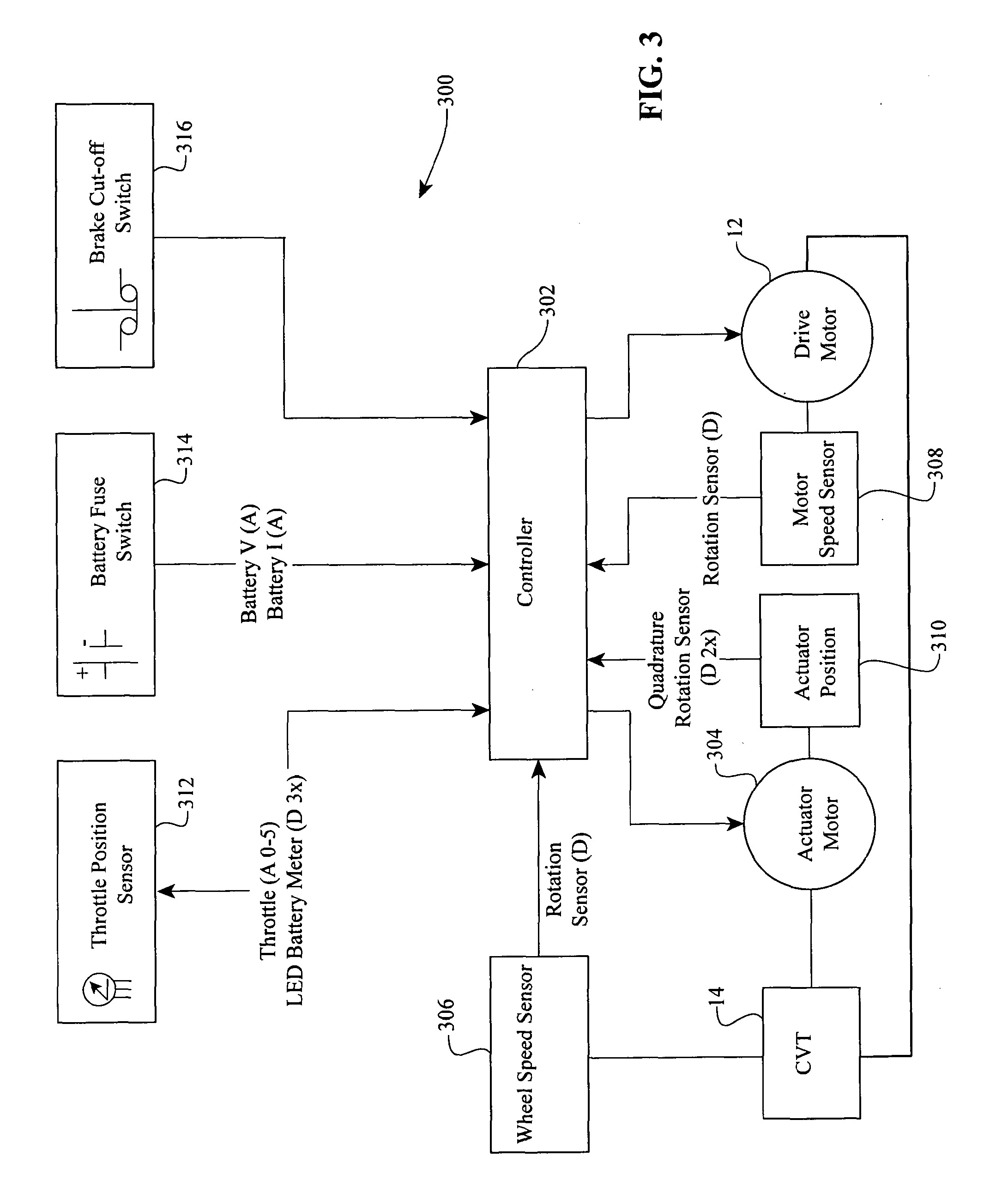

Systems and methods for control of transmission and/or prime mover

Disclosed here are inventive systems and methods for a powertrain of an electric vehicle (EV). In some embodiments, said powertrain includes a continuously variable transmission (CVT) coupled to an electric drive motor, wherein a control system is configured to control the CVT and / or the drive motor to optimize various efficiencies associated with the EV and / or its subsystems. In one specific embodiment, the control system is configured to operate the EV in an economy mode. Operating in said mode, the control system simultaneously manages the CVT and the drive motor to optimize the range of the EV. The control system can be configured to manage the current provided to the drive motor, as well as adjust a transmission speed ratio of the CVT. Other modes of operation are also disclosed. The control system can be configured to manage the power to the drive motor and adjust the transmission speed ratio of the CVT taking into account battery voltage, throttle position, and transmission speed ratio, for example.

Owner:FALLBROOK INTPROP COMPANY

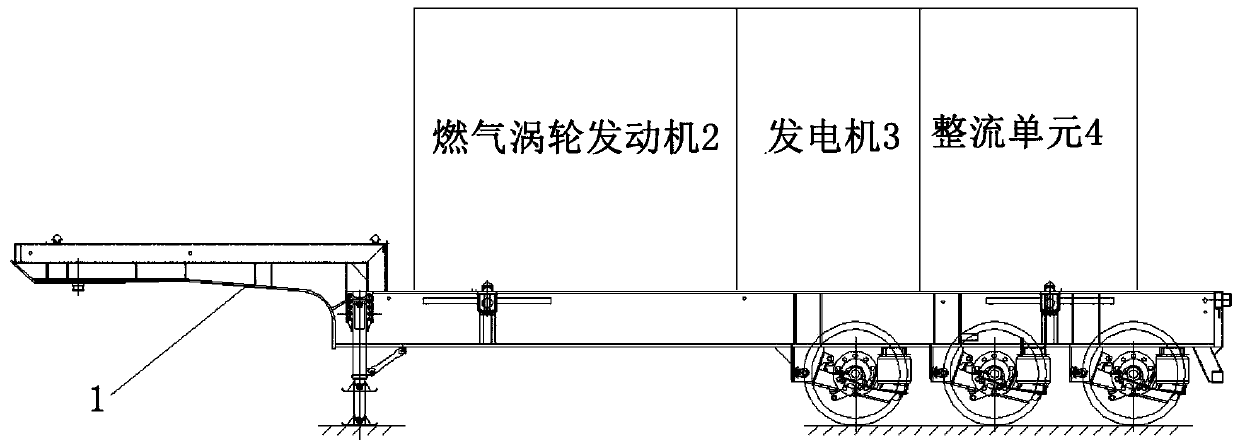

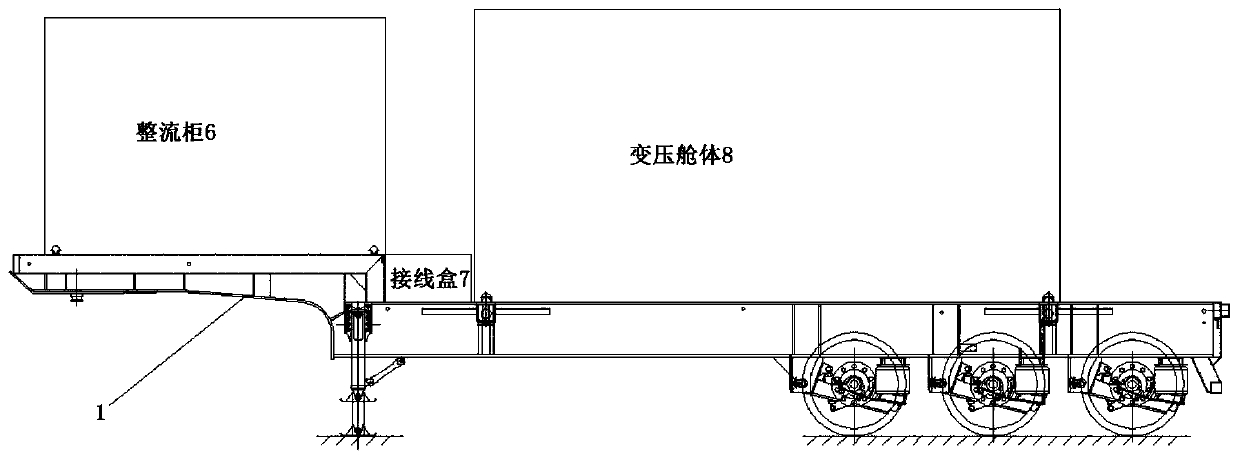

Power supply semi-trailer of electric drive fracturing equipment

PendingCN110118127AReduce wiringOptimize space layoutAssociation with control/drive circuitsGas turbine plantsElectricityTransformer

The invention discloses a power supply semi-trailer of electric drive fracturing equipment. The combination manner of a gas turbine engine, a power generator and a rectification unit is adopted, the power generator directly transmits the winding form and voltages needed by a rectification unit, conventional rectification transformer equipment is omitted, the rectification unit is connected with inversion units through common direct current buses, the common direct current buses can drive the multiple inversion units separately, and wiring of power supply circuits is reduced. The high-voltage inversion units are arranged on a gooseneck of the electric drive semi-trailer, and the space arrangement of the equipment is optimized. The whole power supply equipment is more compact in structure, small in occupied area and simple in wiring.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

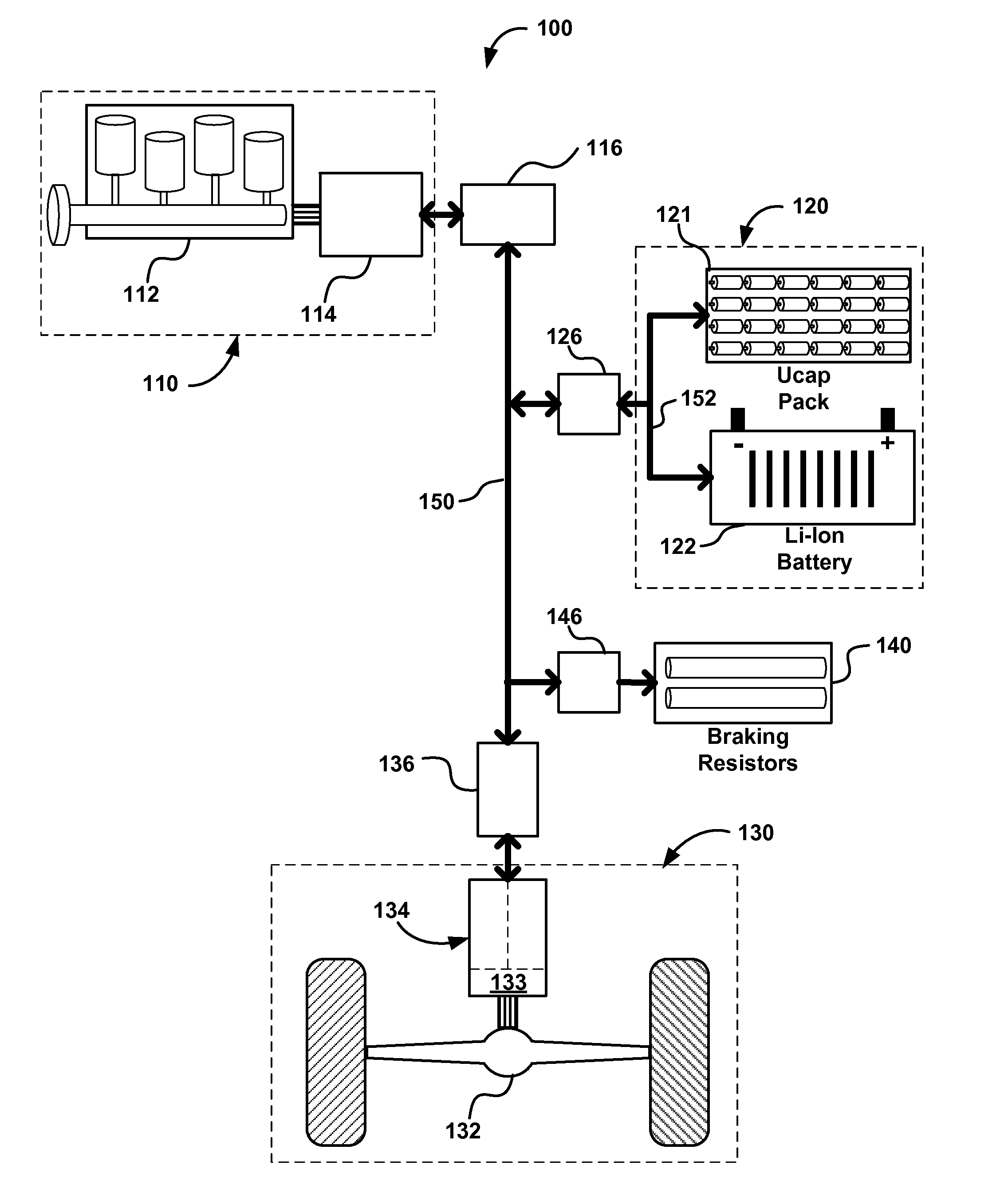

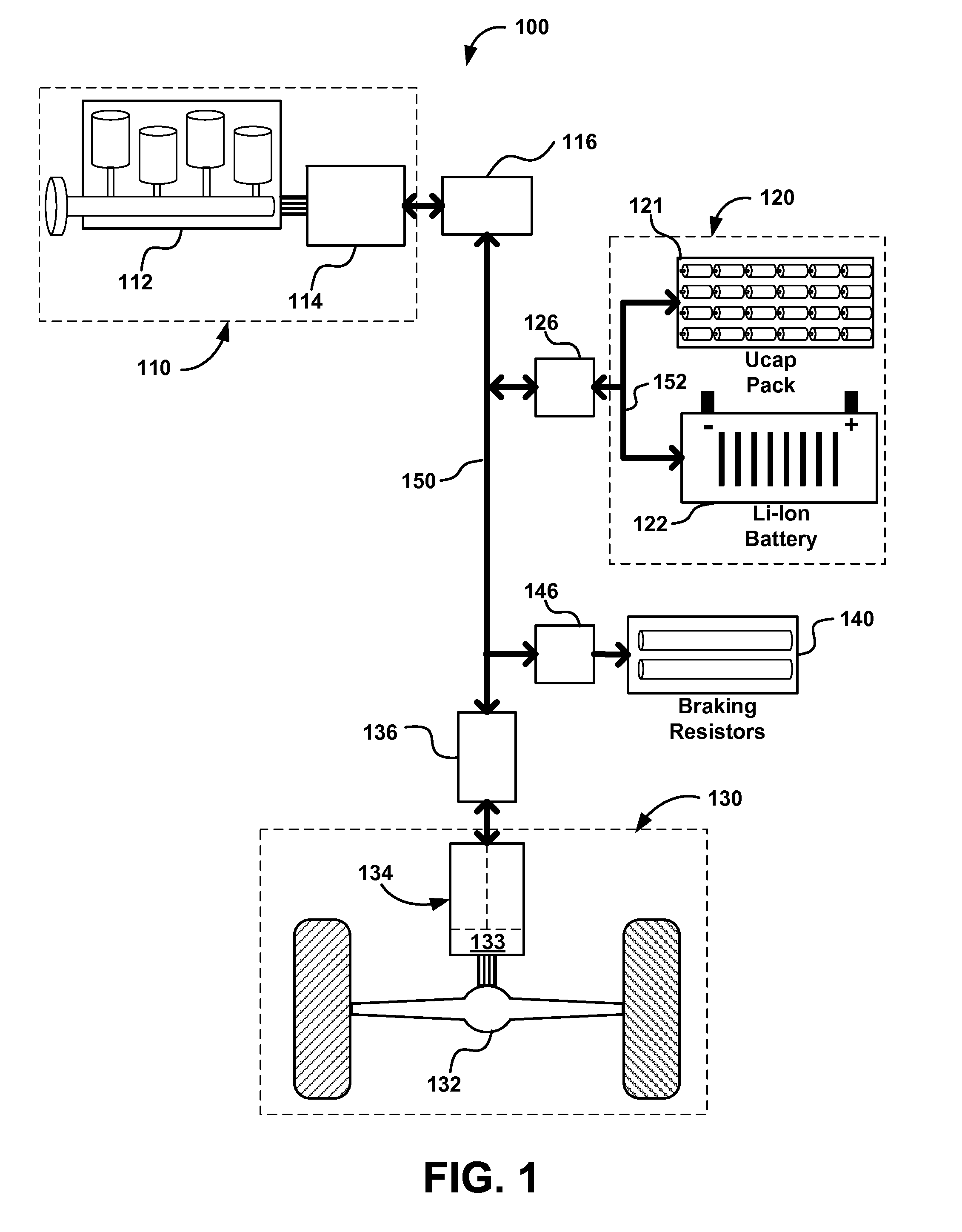

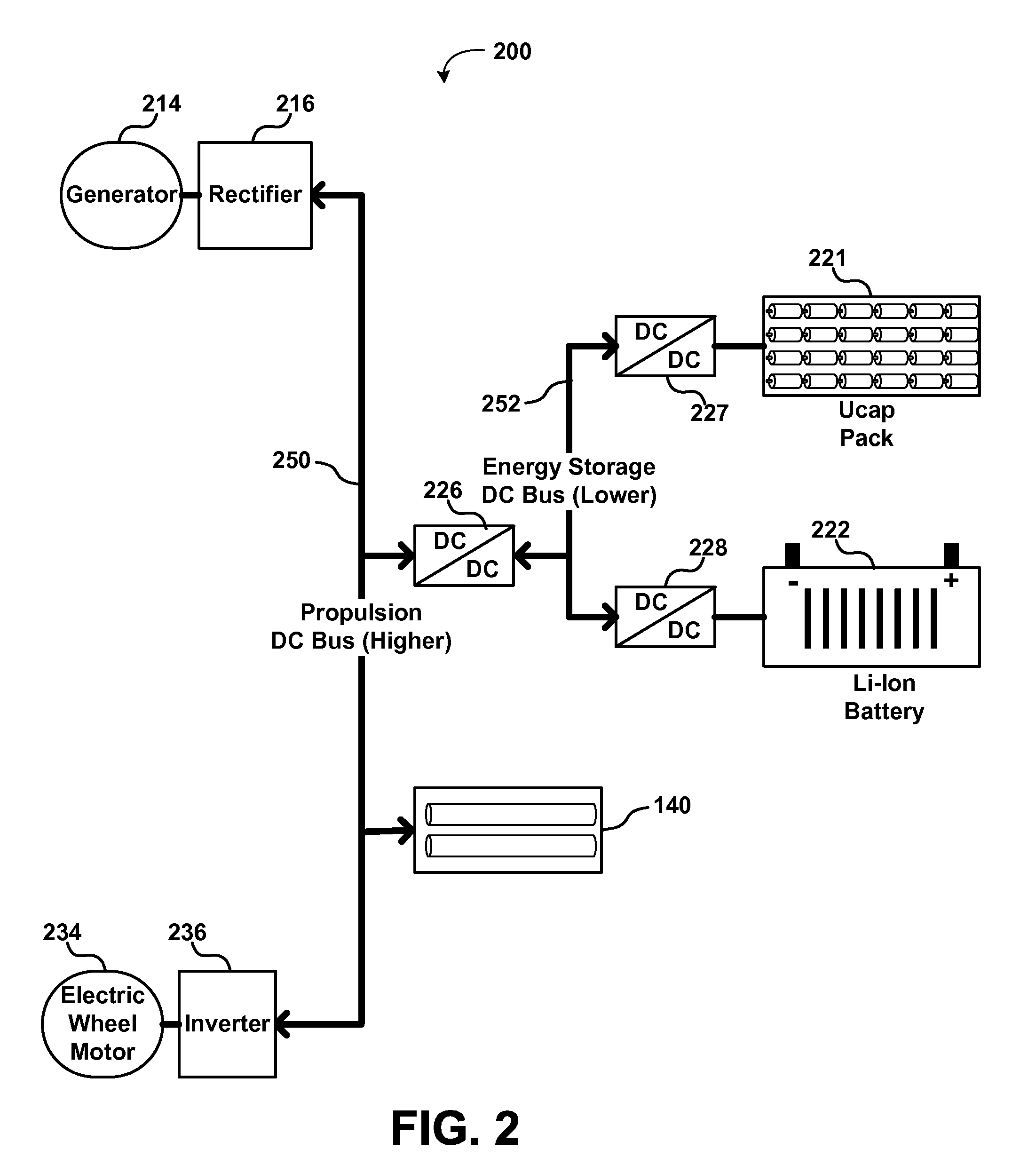

Propulsion Energy Storage Control System and Method of Control

InactiveUS20110100735A1Efficient and inexpensive and reliableElectrodynamic brake systemsPropulsion using engine-driven generatorsElectricityControl system

A propulsion energy storage control system and method of control interspersed between a heavy duty hybrid-electric drive system and its propulsion energy storage. The control system having an energy storage DC bus, electrical interfaces to the drive system and a plurality of propulsion energy storage subsystems, DC-to-DC converters at each interface, and a controller configured to operate each DC-to-DC converter independently such that power flow may charge, discharge, and shuttle between the plurality of propulsion energy storage subsystems.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

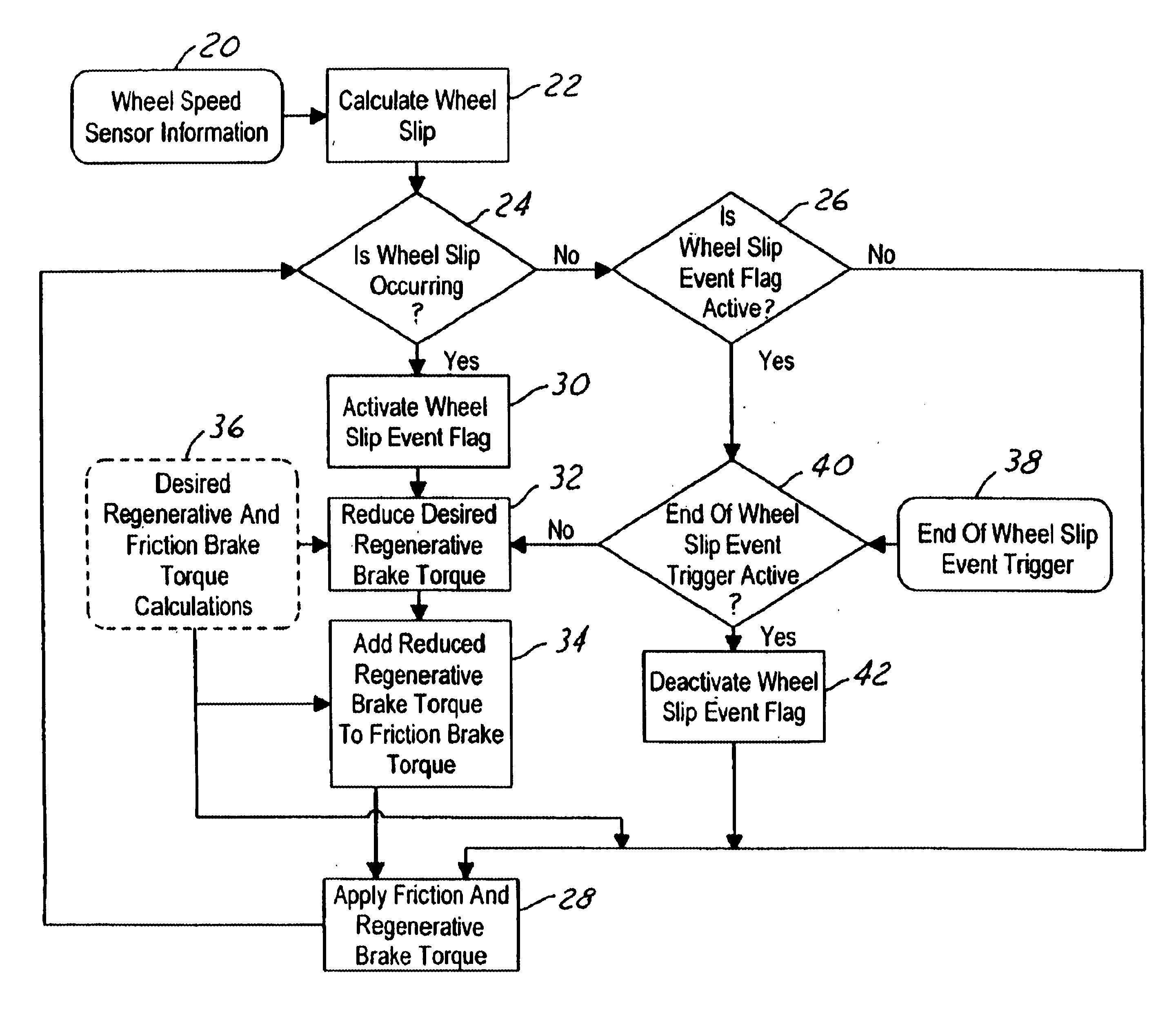

System and method for braking an electric drive vehicle on a low Mu surface

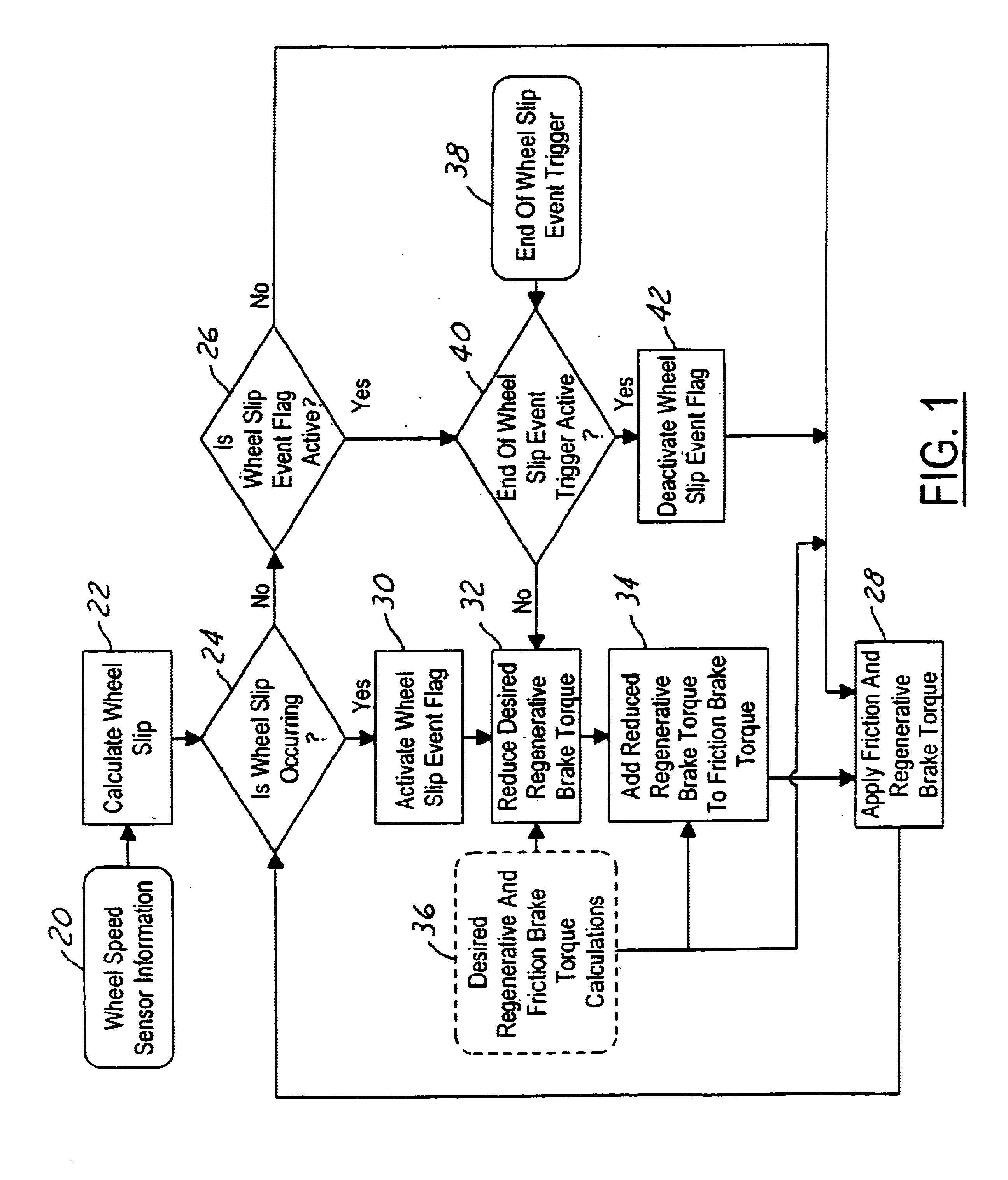

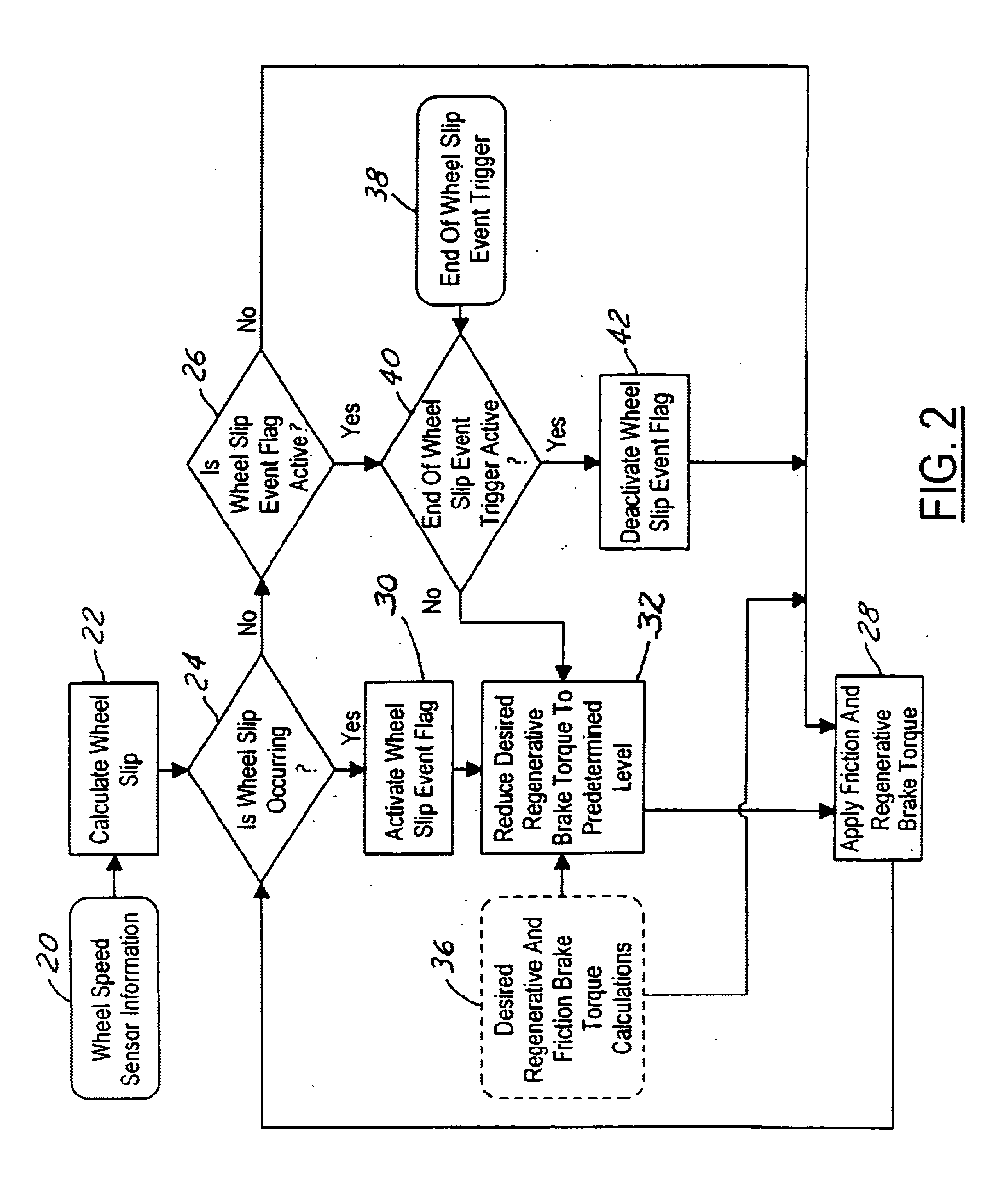

Strategies other than immediate elimination of regenerative braking (FIG. 2) are invoked when an incipient wheel lock-up is detected, the ABS becomes active, and / or incipient wheel slip is detected. The strategies include: reducing the regenerative braking torque as a function of the coefficient of friction of a surface on which the vehicle is traveling (FIG. 3); and adjusting regenerative braking in relation to the rate at which wheel slip is changing (FIG. 4). Some of the strategies may be applied on an individual wheel basis (FIG. 5), and some of the strategies may be applied in conjunction with operating friction brakes of the vehicle to apply at least some of the reduction in regenerative braking torque as friction brake torque (FIG. 1).

Owner:FORD GLOBAL TECH LLC

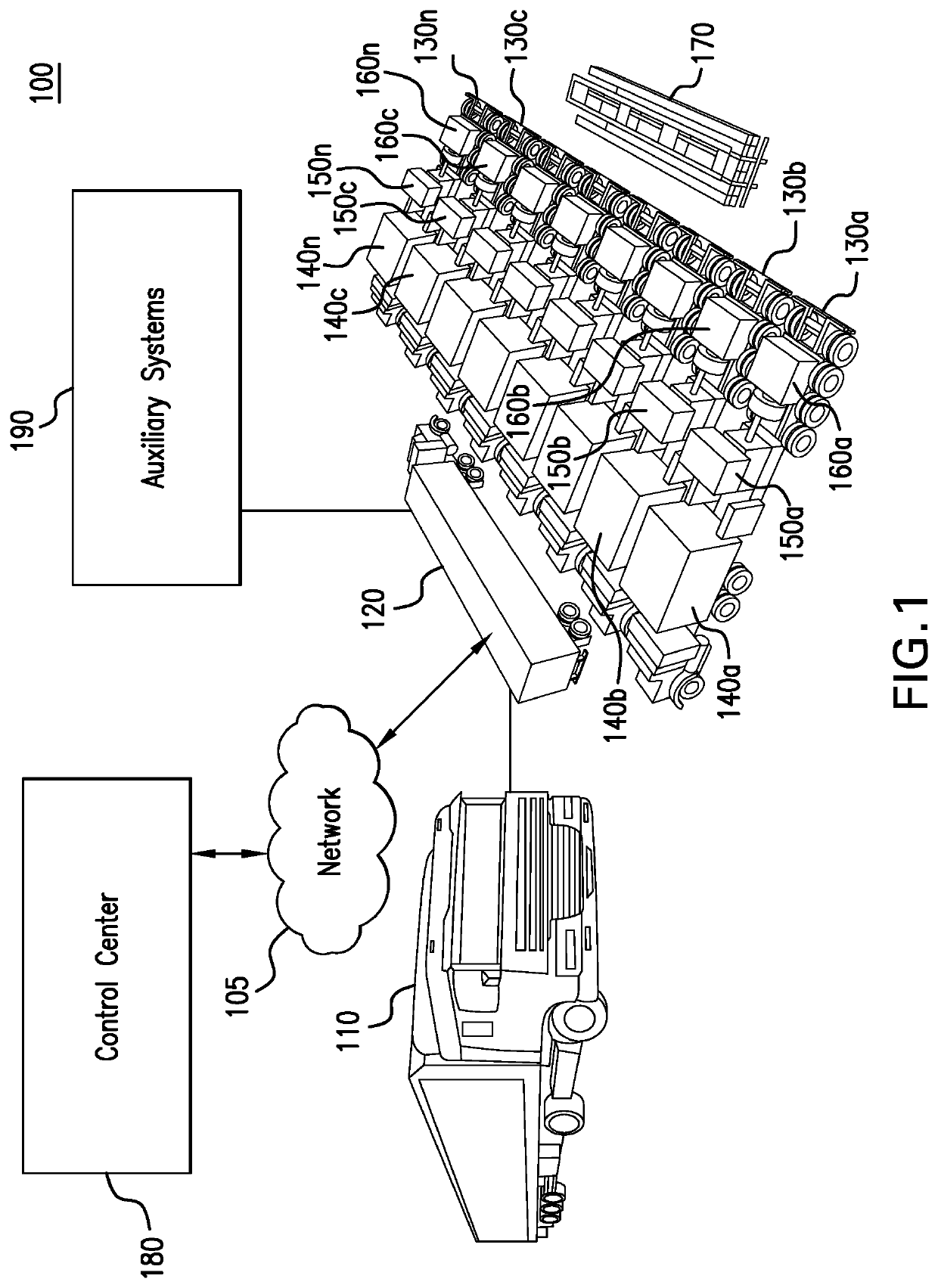

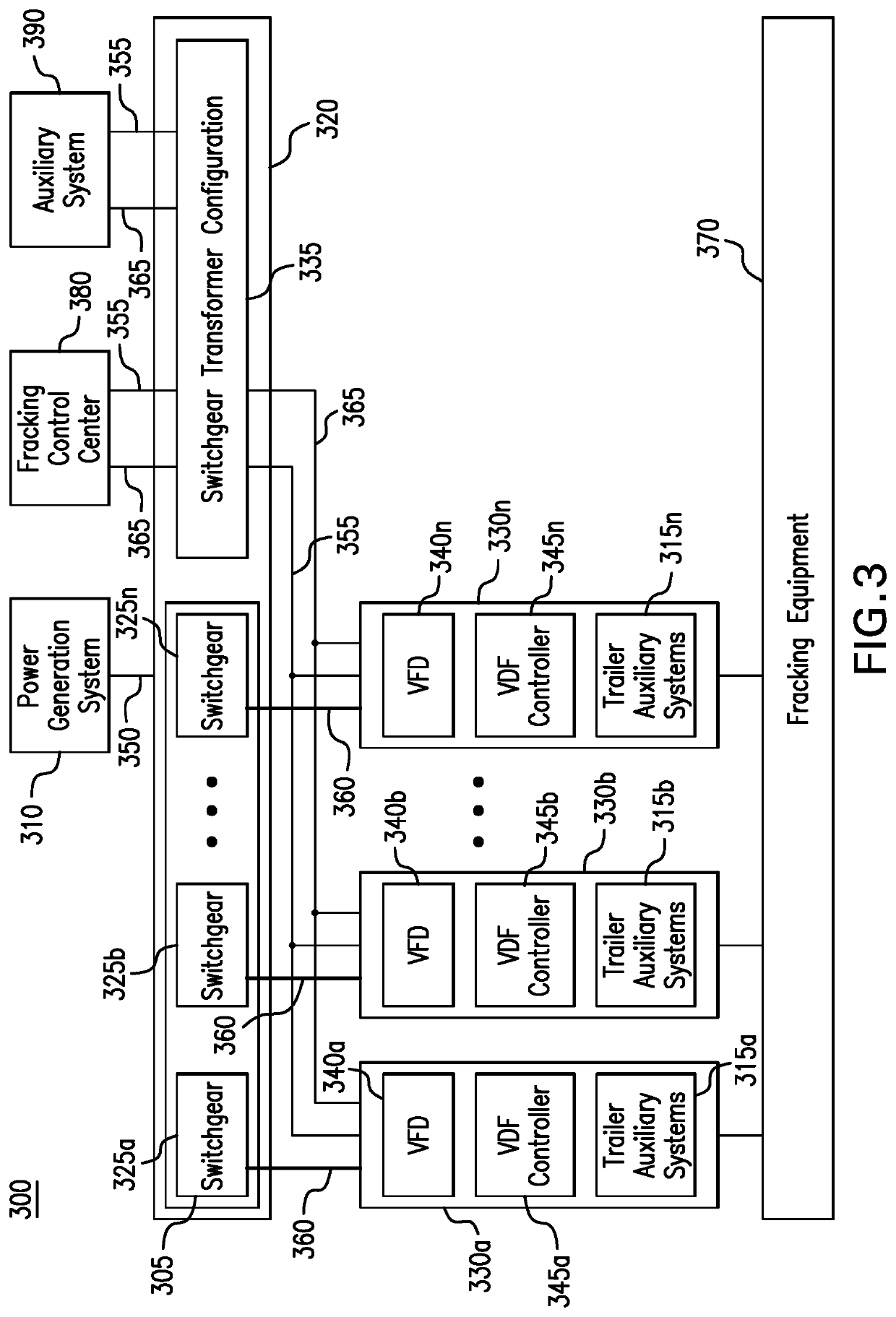

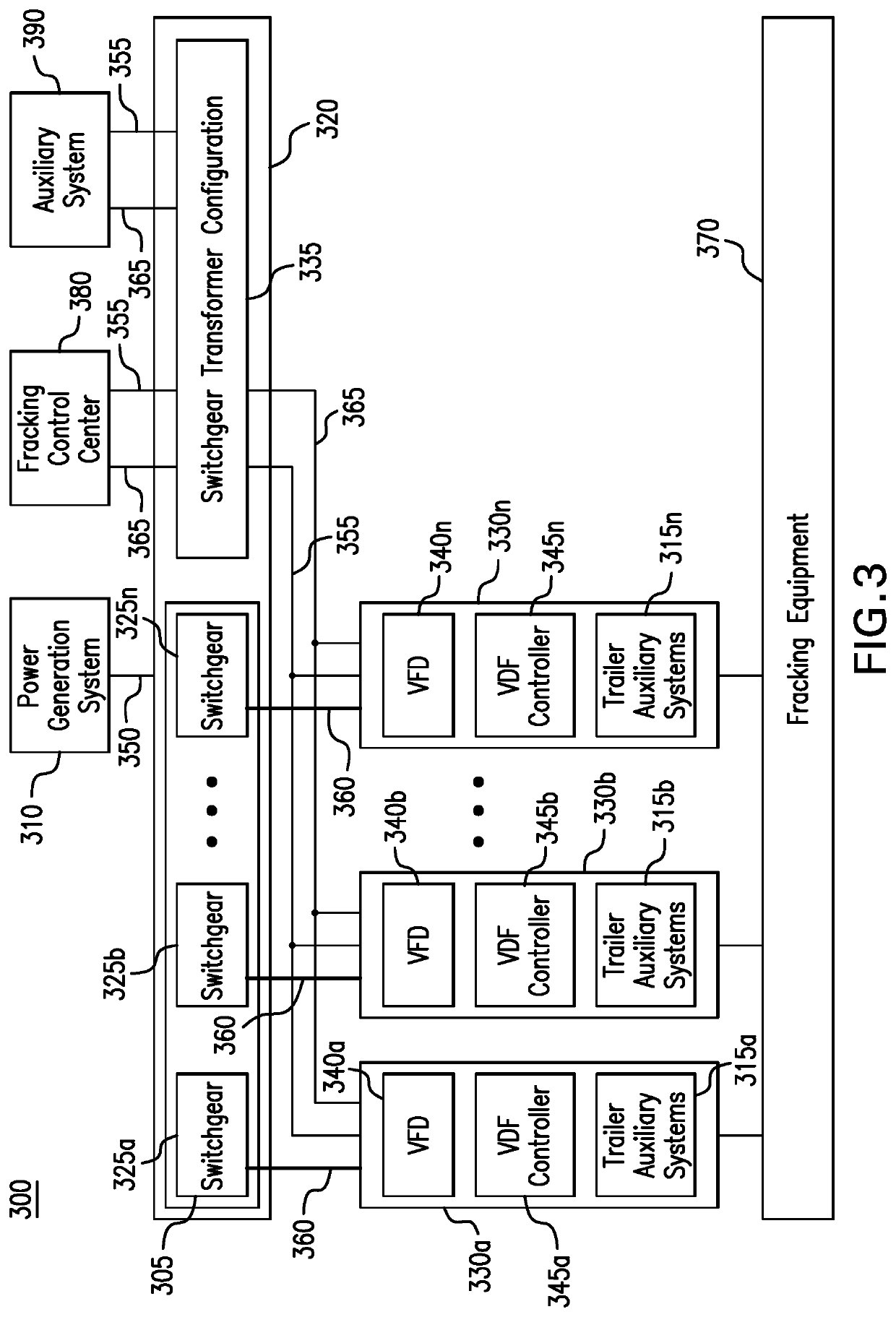

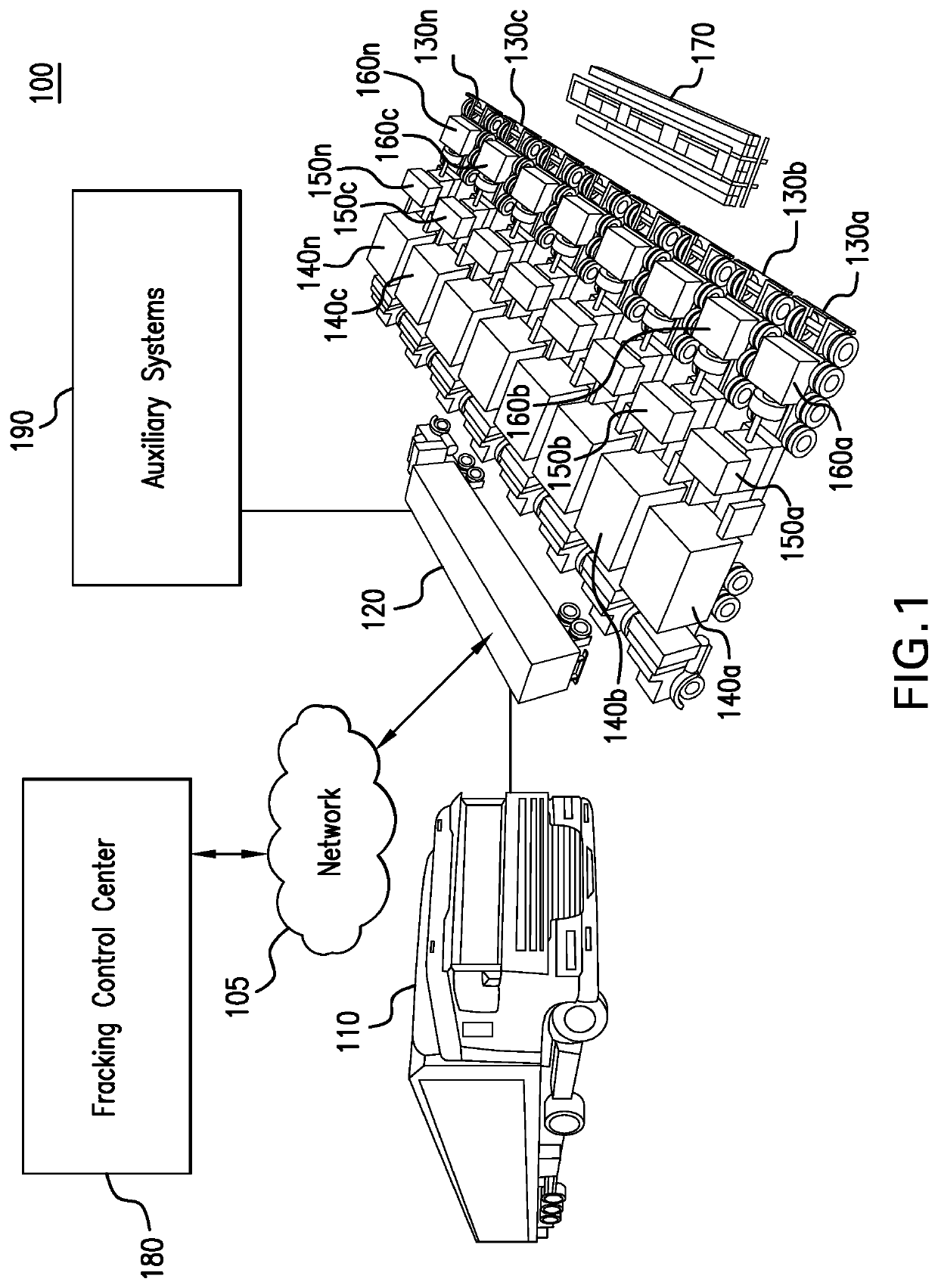

Parameter monitoring and control for an electric driven hydraulic fracking system

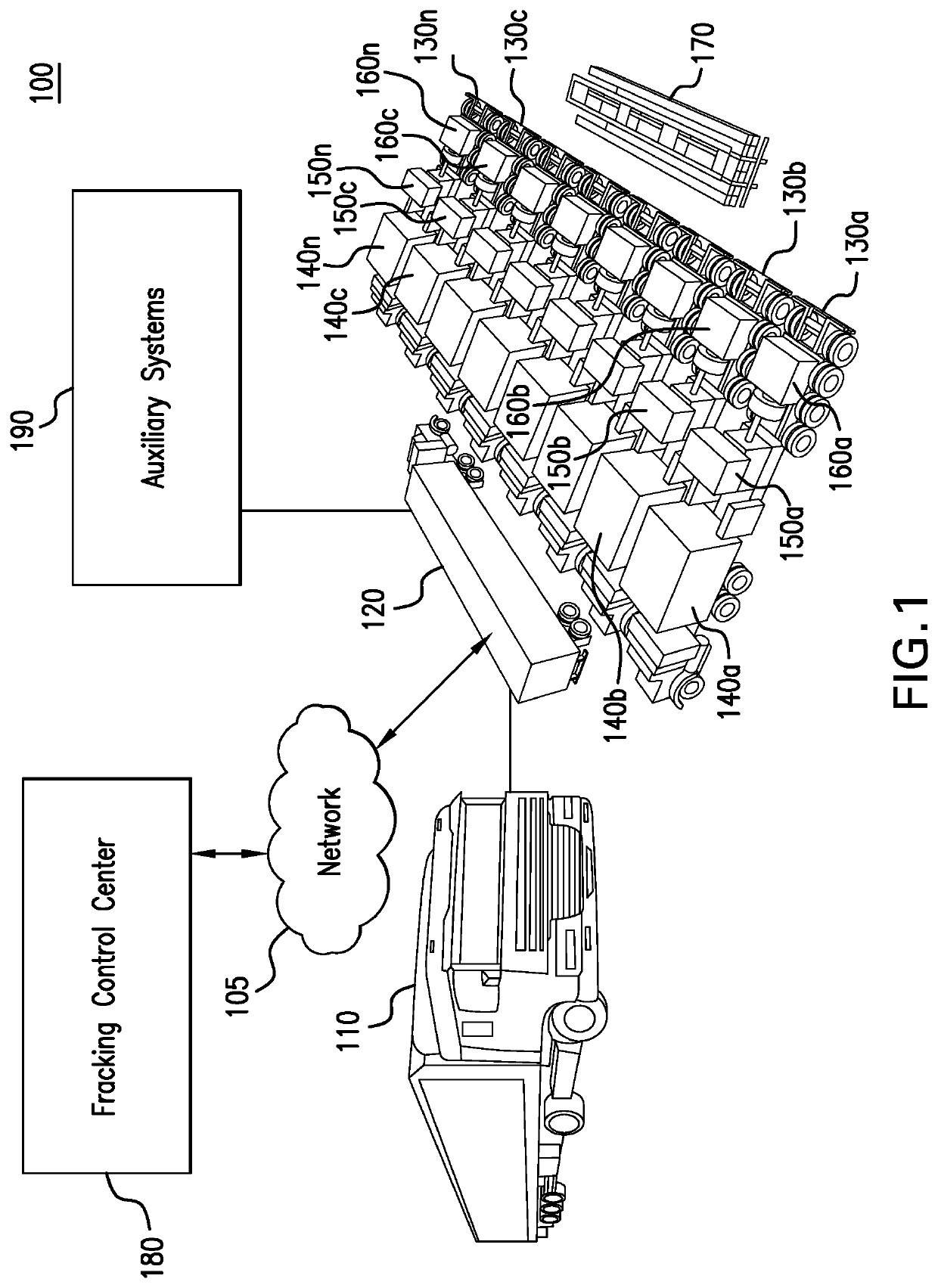

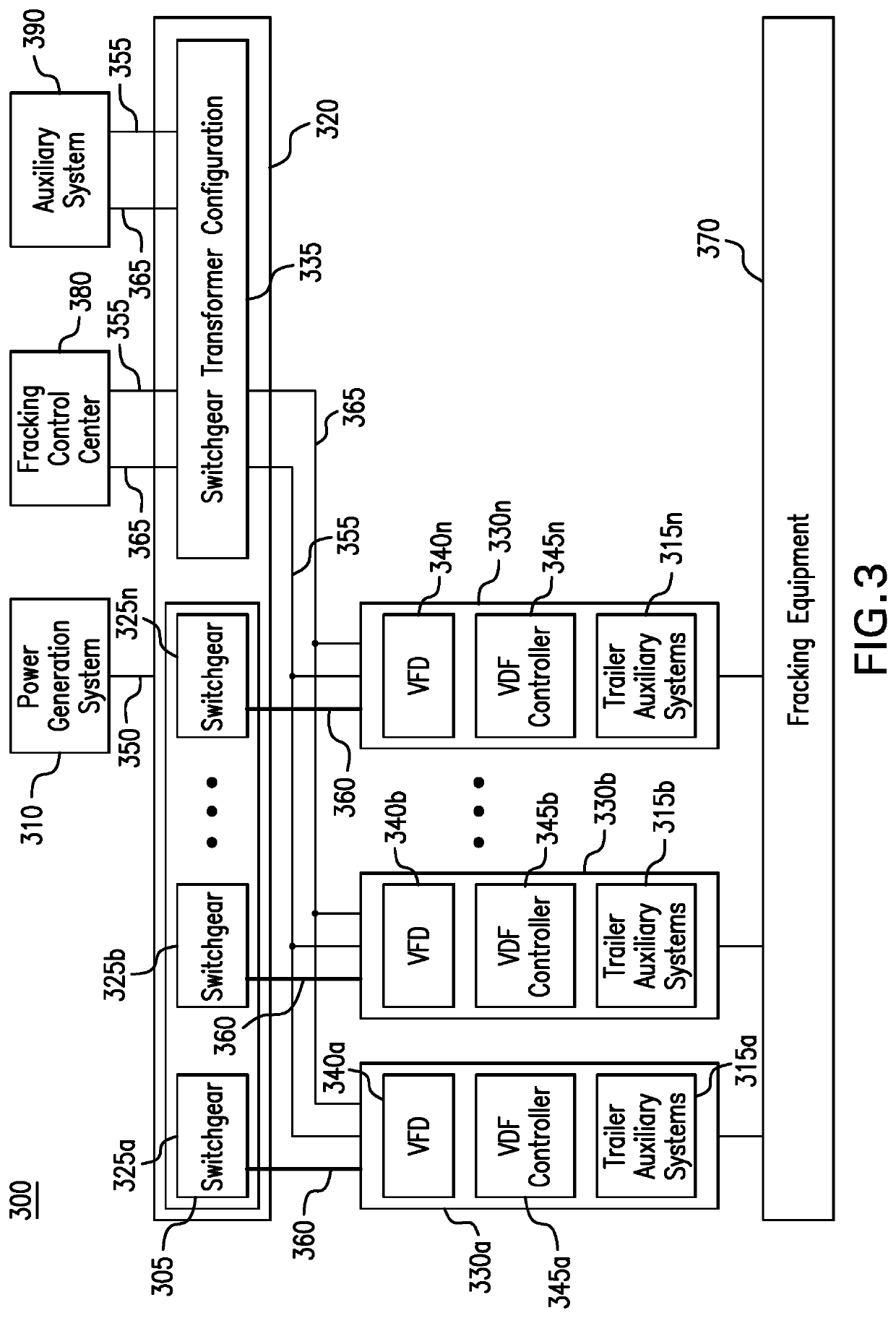

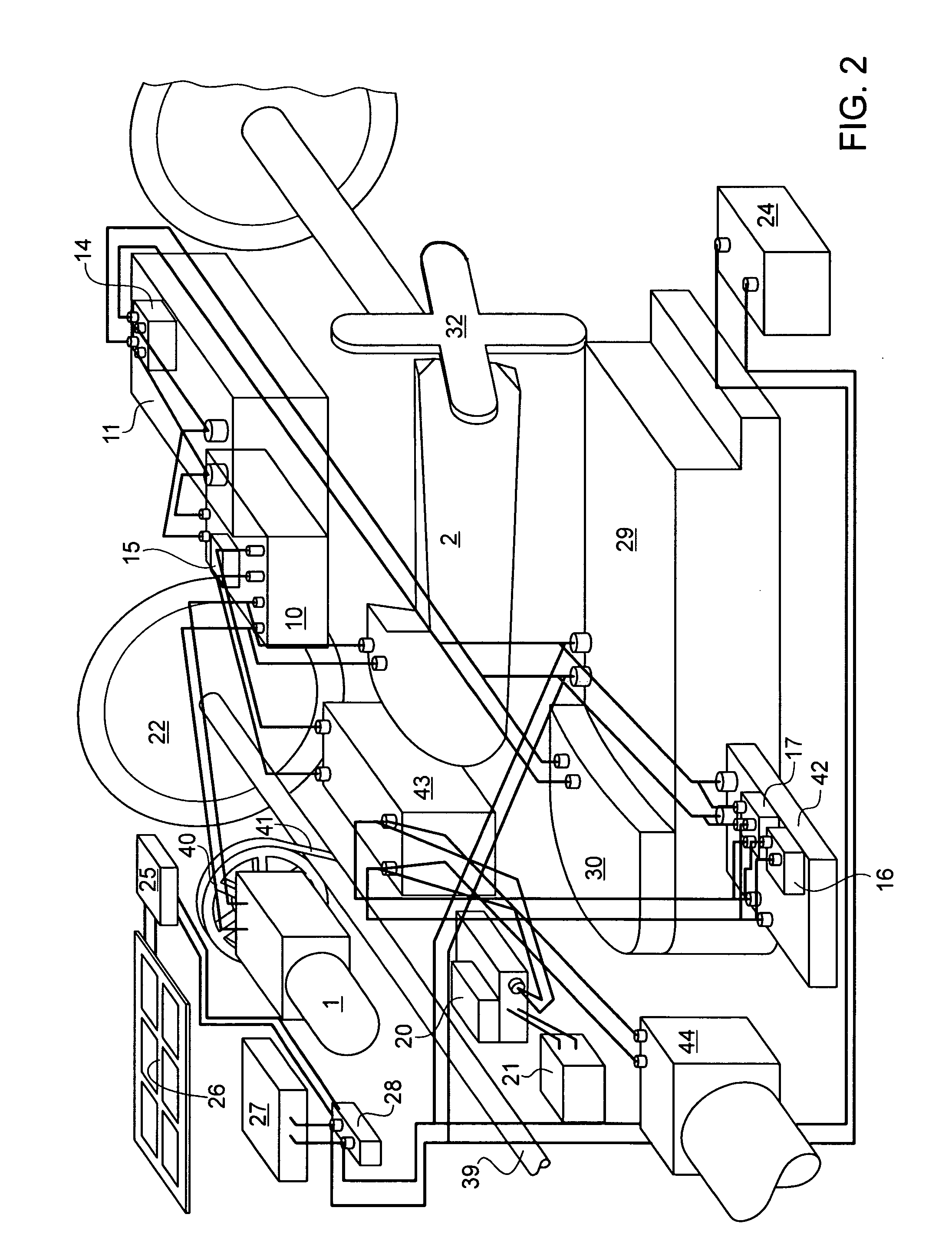

An electric driven hydraulic fracking system is disclosed. A pump configuration includes the single VFD, the single shaft electric motor, and the single hydraulic pump mounted on the single pump trailer. A controller associated with the single VFD and is mounted on the single pump trailer. The controller monitors operation parameters associated with an operation of the electric driven hydraulic fracking system as each component of the electric driven hydraulic fracking system operates to determine whether the operation parameters deviate beyond a corresponding operation parameter threshold. Each of the operation parameters provides an indicator as to an operation status of a corresponding component of the electric driven hydraulic fracking system. The controller initiates corrected actions when each operation parameter deviates beyond the corresponding operation threshold. Initiating the corrected actions when each operation parameter deviates beyond the corresponding operation threshold maintains the operation of the electric driven hydraulic fracking system.

Owner:HALLIBURTON ENERGY SERVICES INC

Parameter monitoring and control for an electric driven hydraulic fracking system

An electric driven hydraulic fracking system is disclosed. A pump configuration includes the single VFD, the single shaft electric motor, and the single hydraulic pump mounted on the single pump trailer. A controller associated with the single VFD and is mounted on the single pump trailer. The controller monitors operation parameters associated with an operation of the electric driven hydraulic fracking system as each component of the electric driven hydraulic fracking system operates to determine whether the operation parameters deviate beyond a corresponding operation parameter threshold. Each of the operation parameters provides an indicator as to an operation status of a corresponding component of the electric driven hydraulic fracking system. The controller initiates corrected actions when each operation parameter deviates beyond the corresponding operation threshold. Initiating the corrected actions when each operation parameter deviates beyond the corresponding operation threshold maintains the operation of the electric driven hydraulic fracking system.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

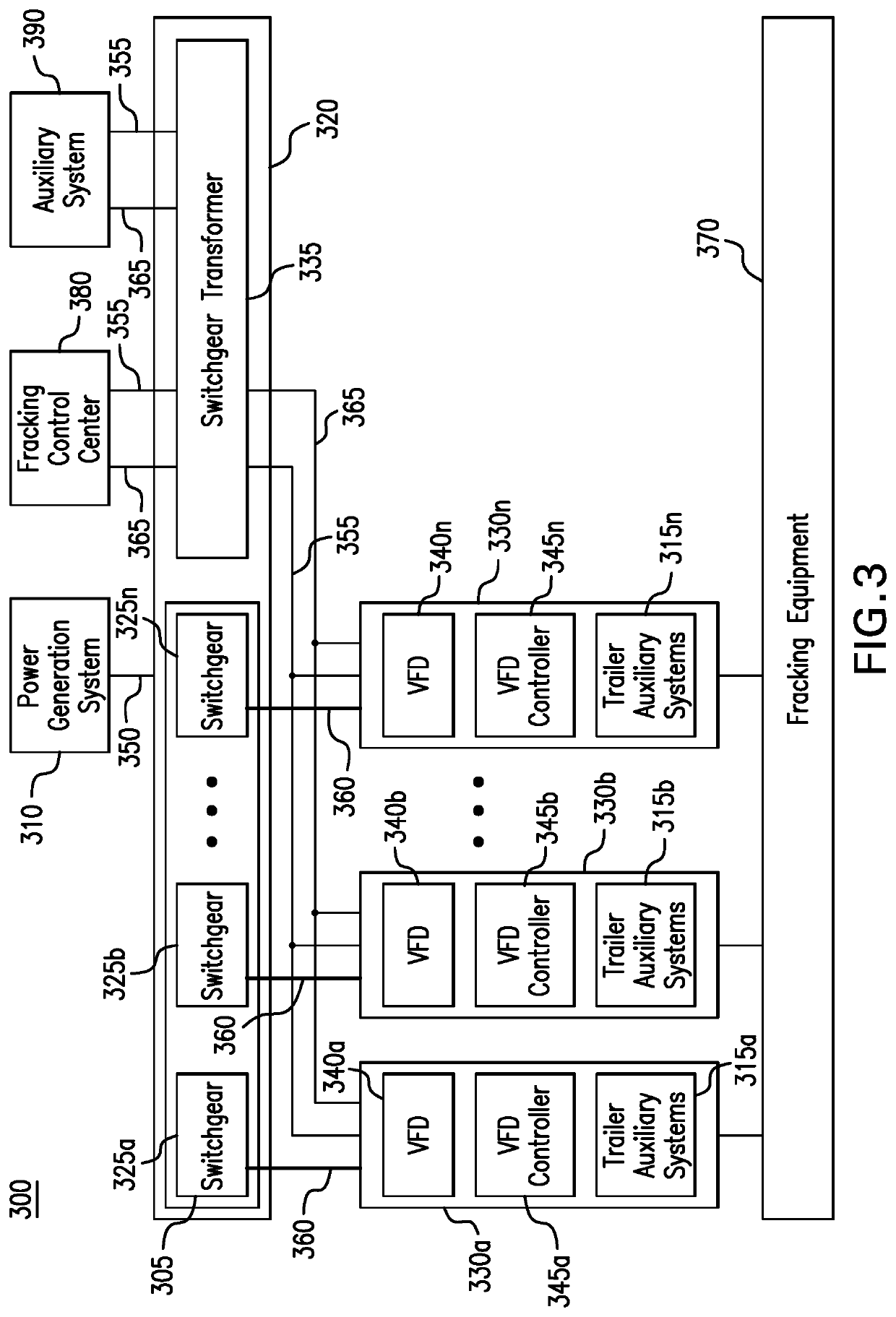

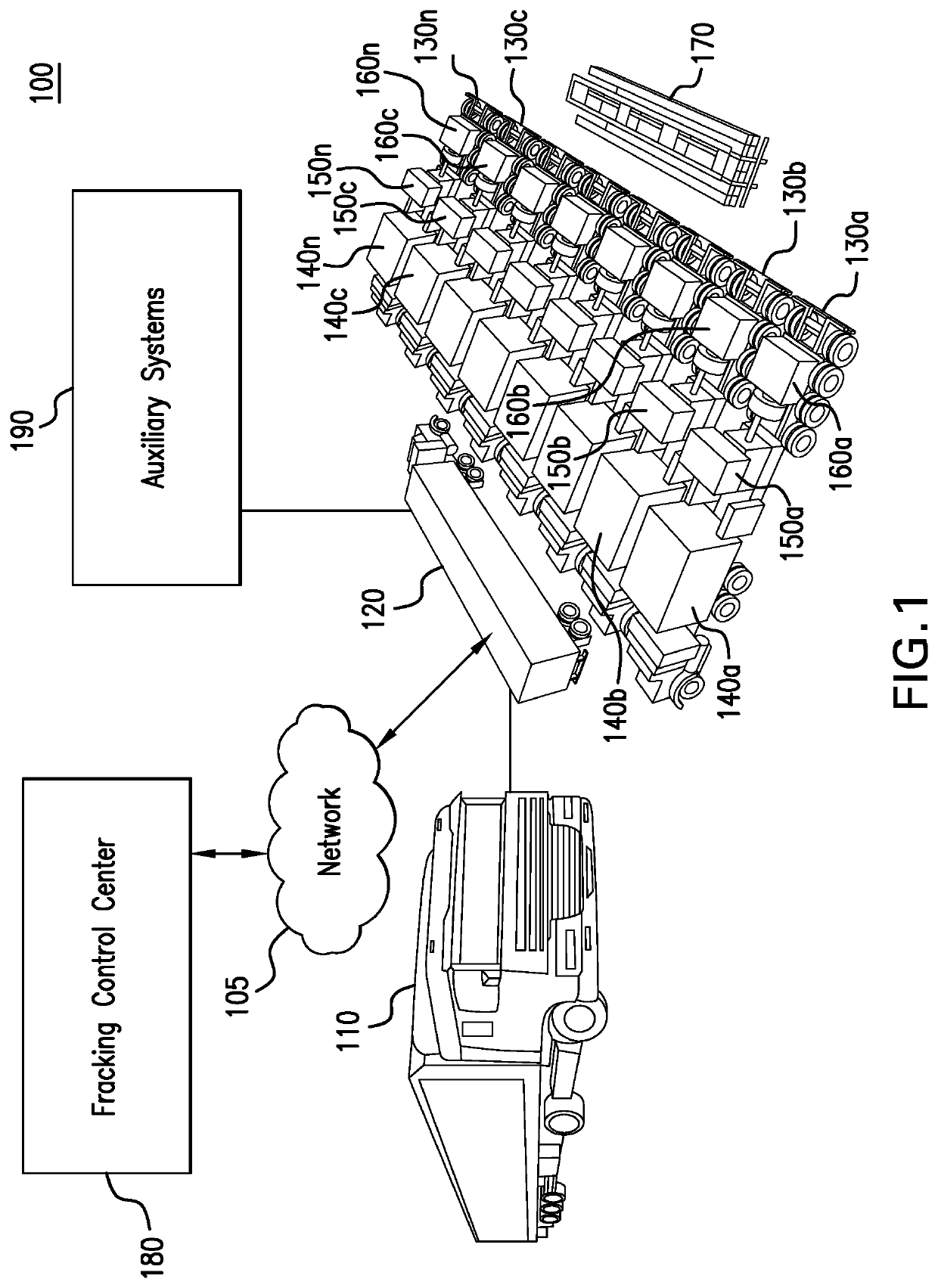

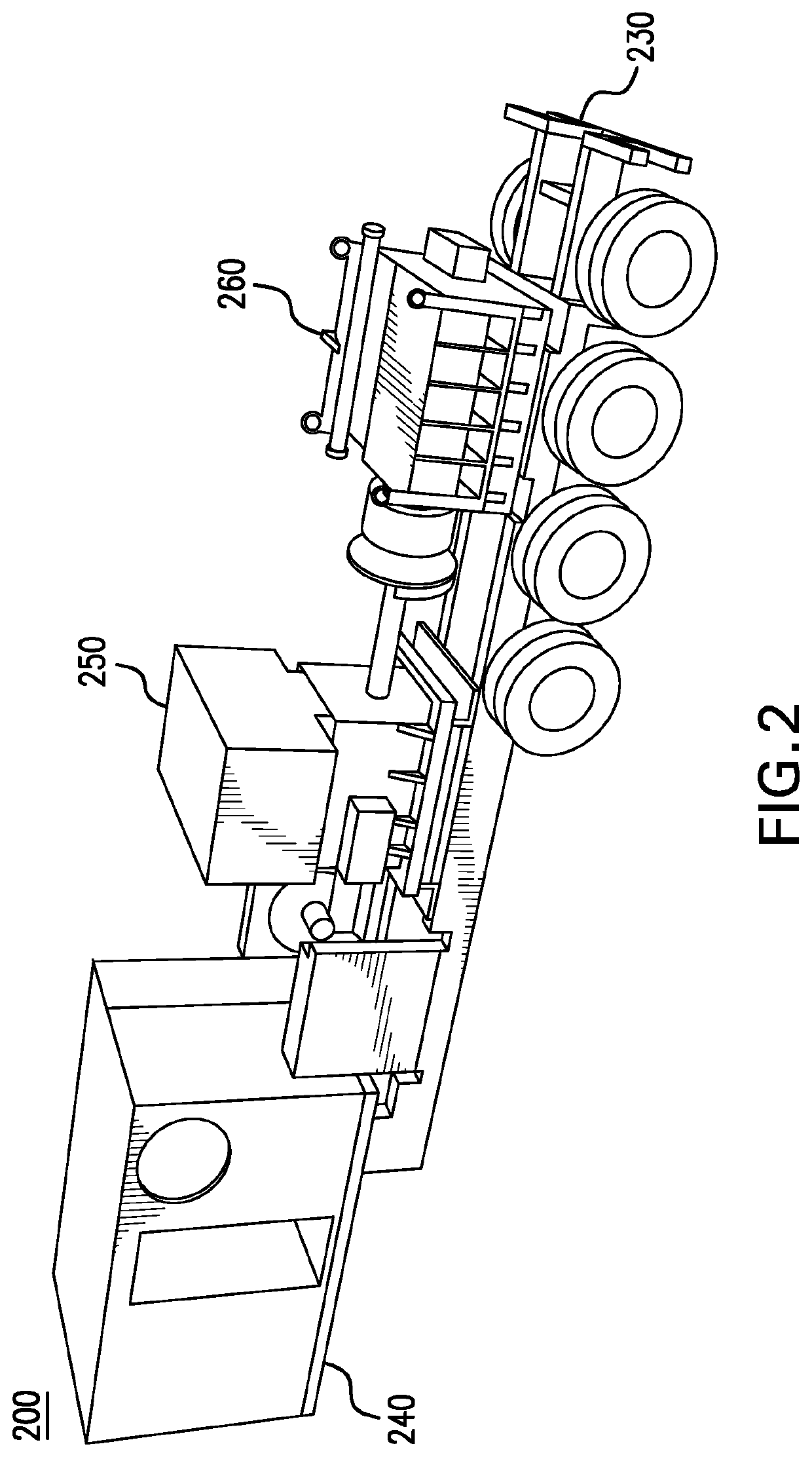

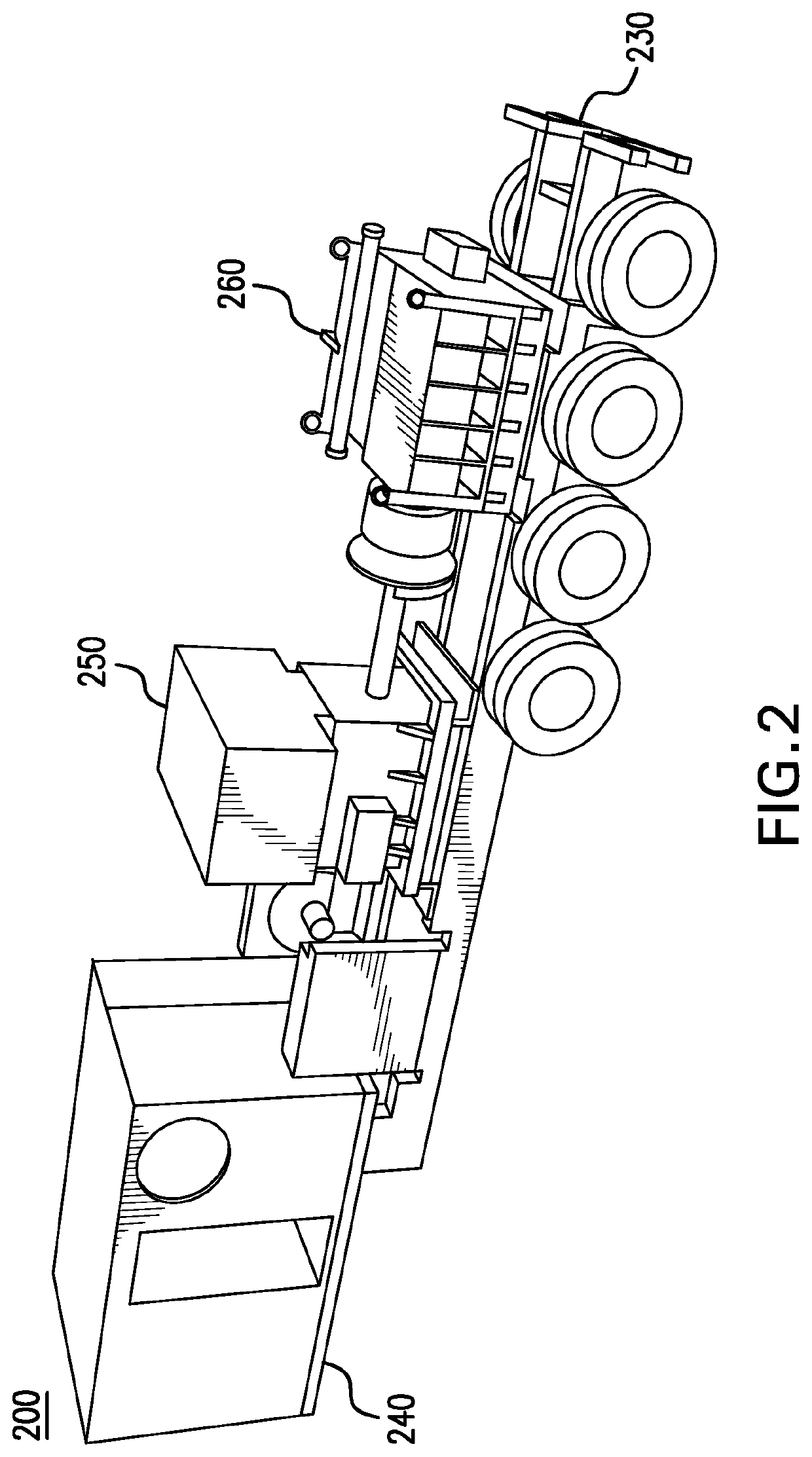

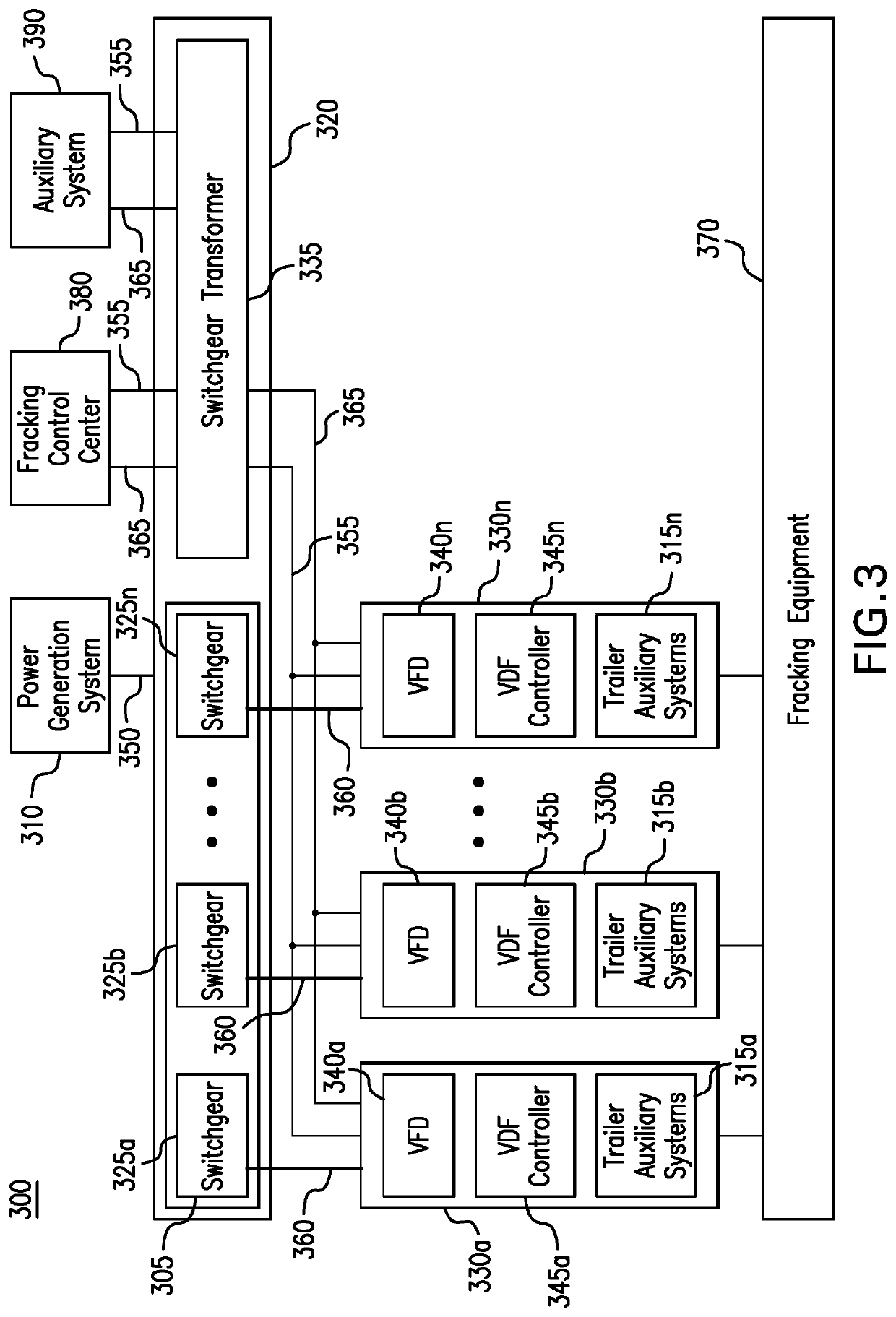

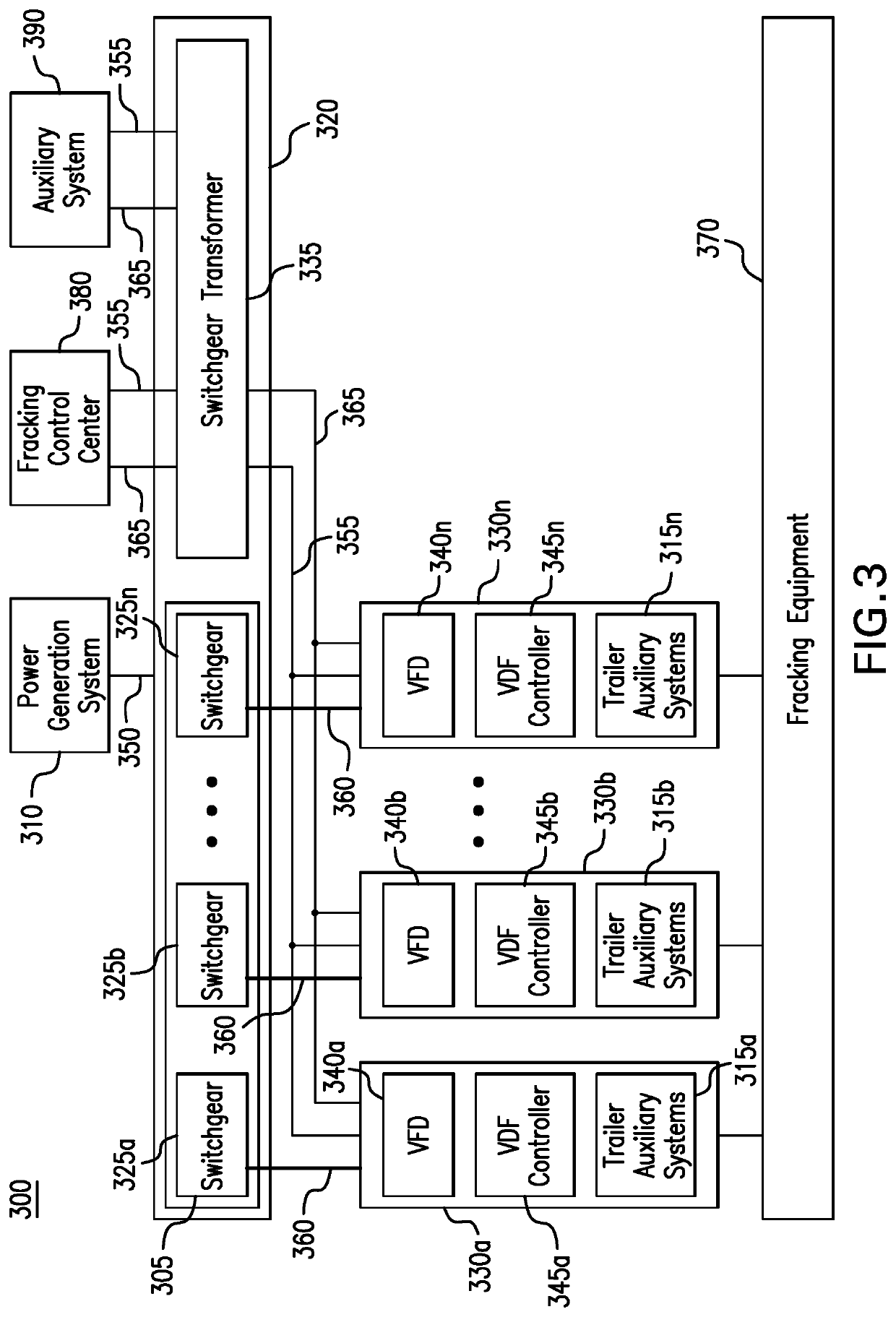

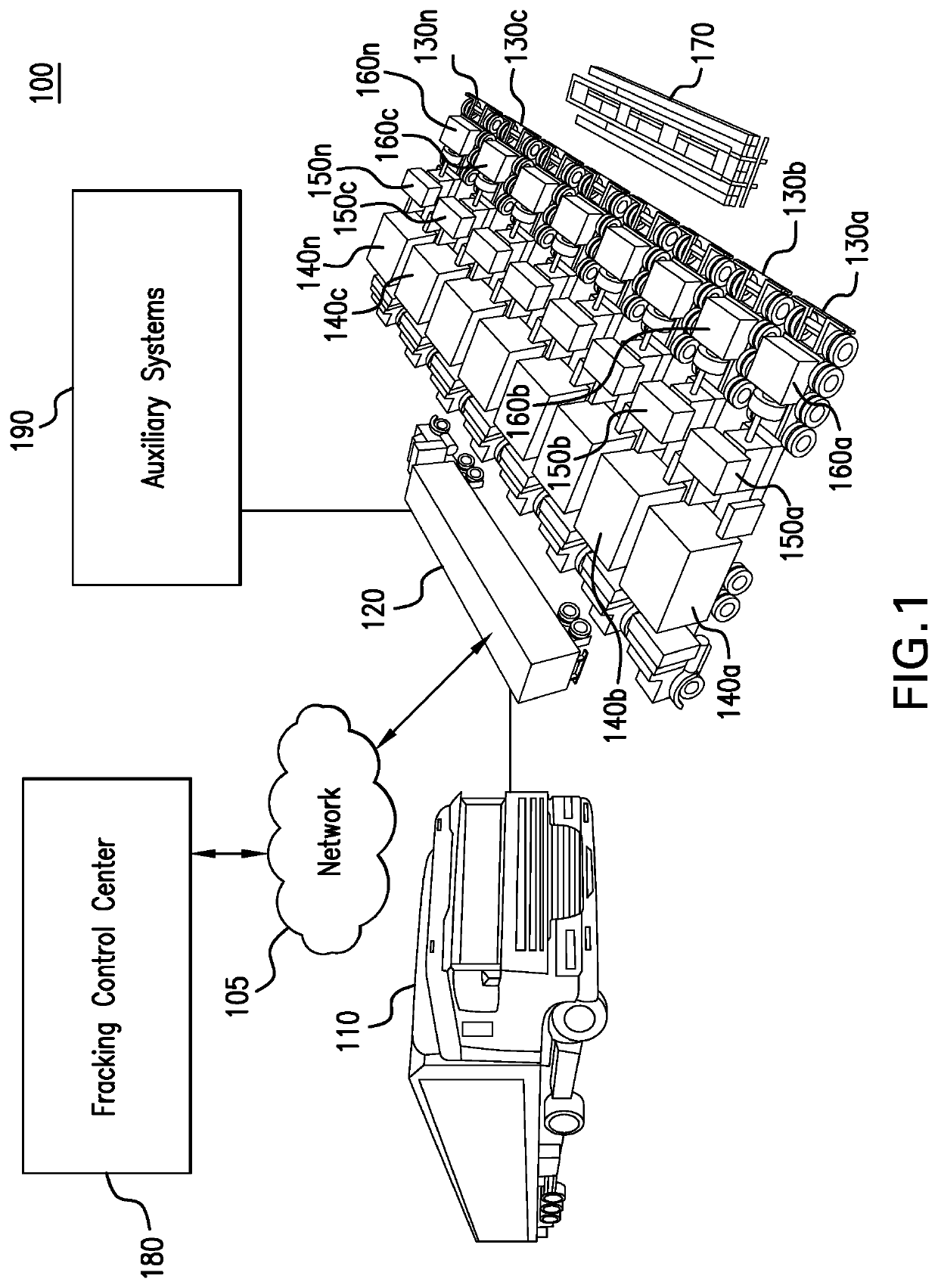

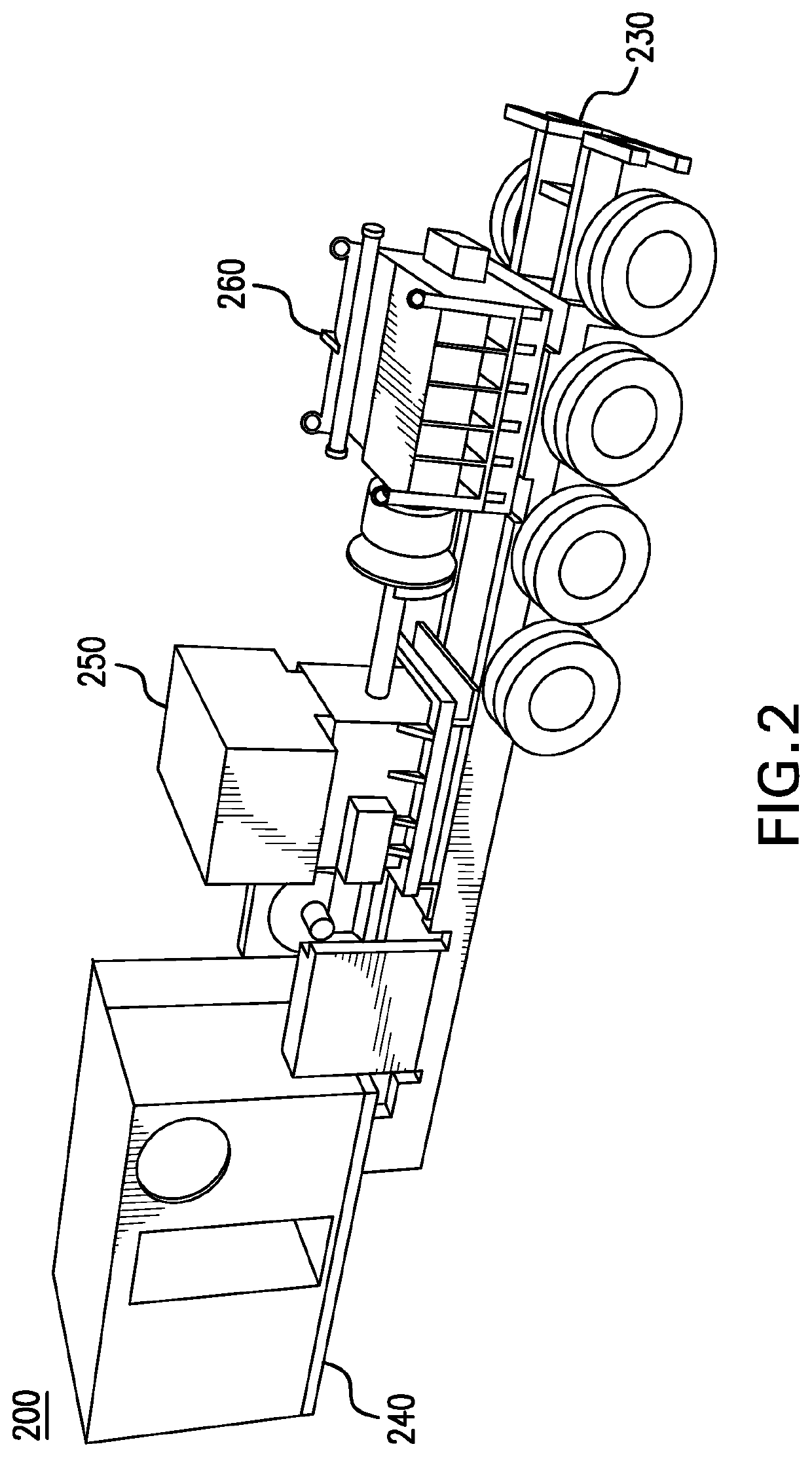

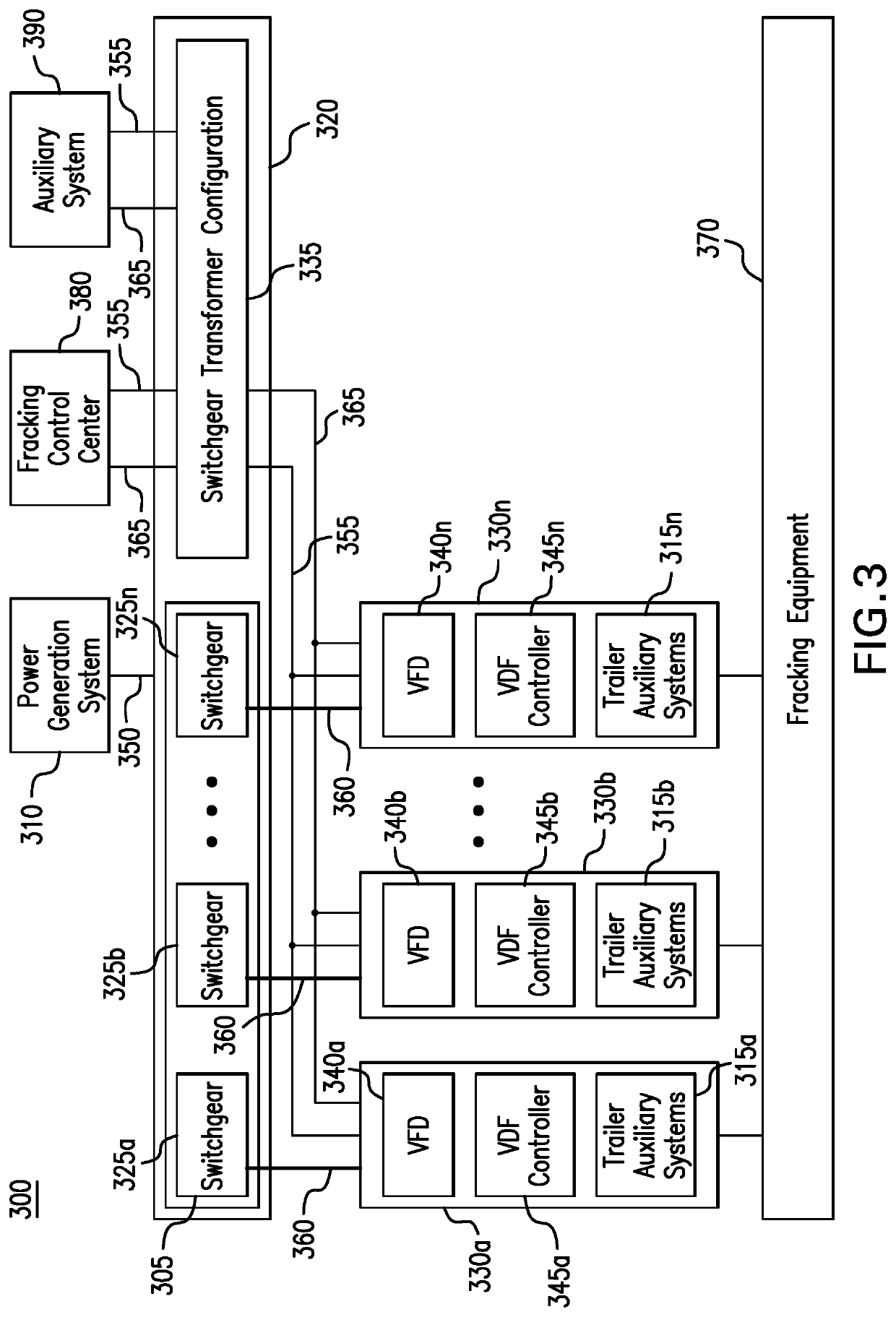

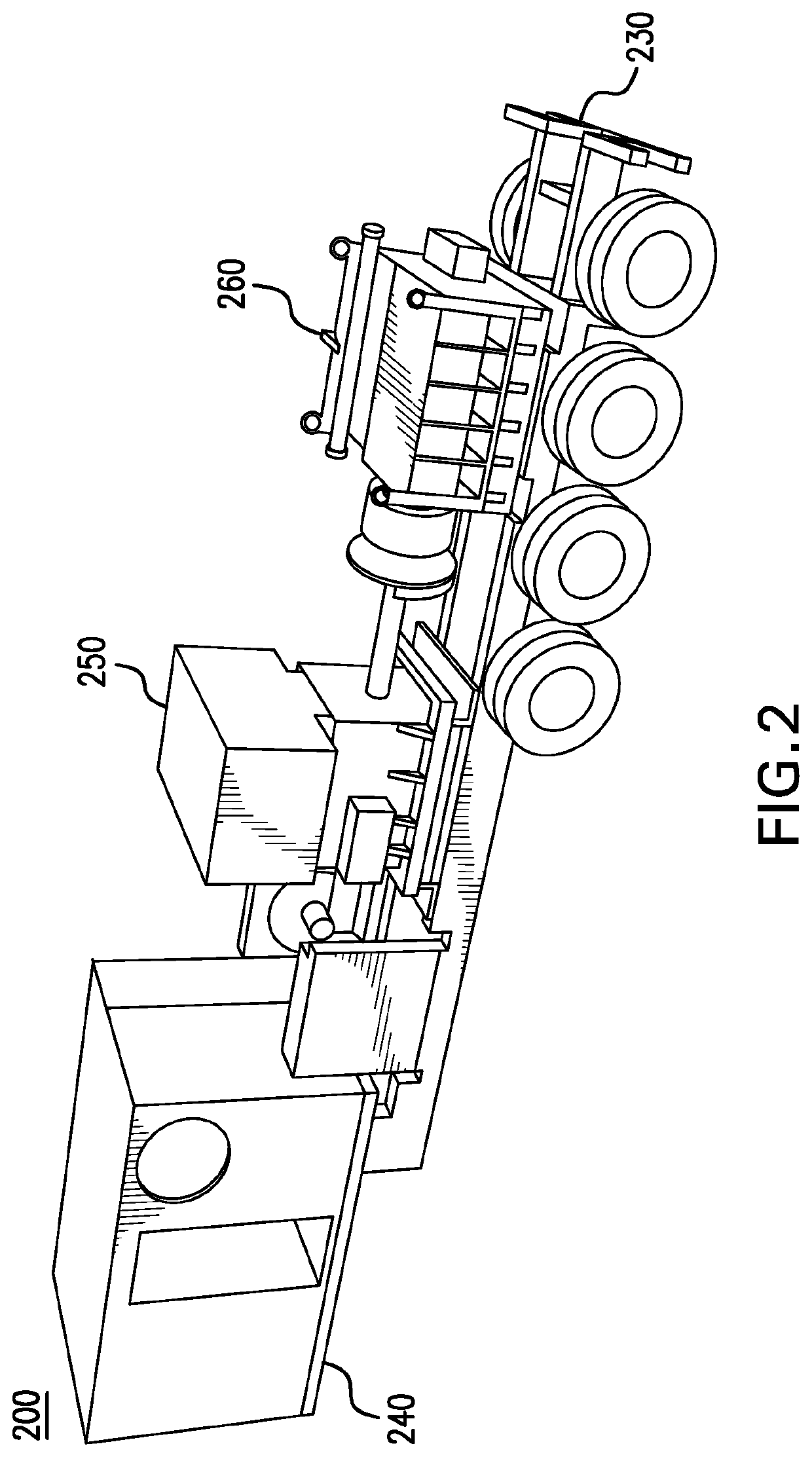

Variable frequency drive configuration for electric driven hydraulic fracking system

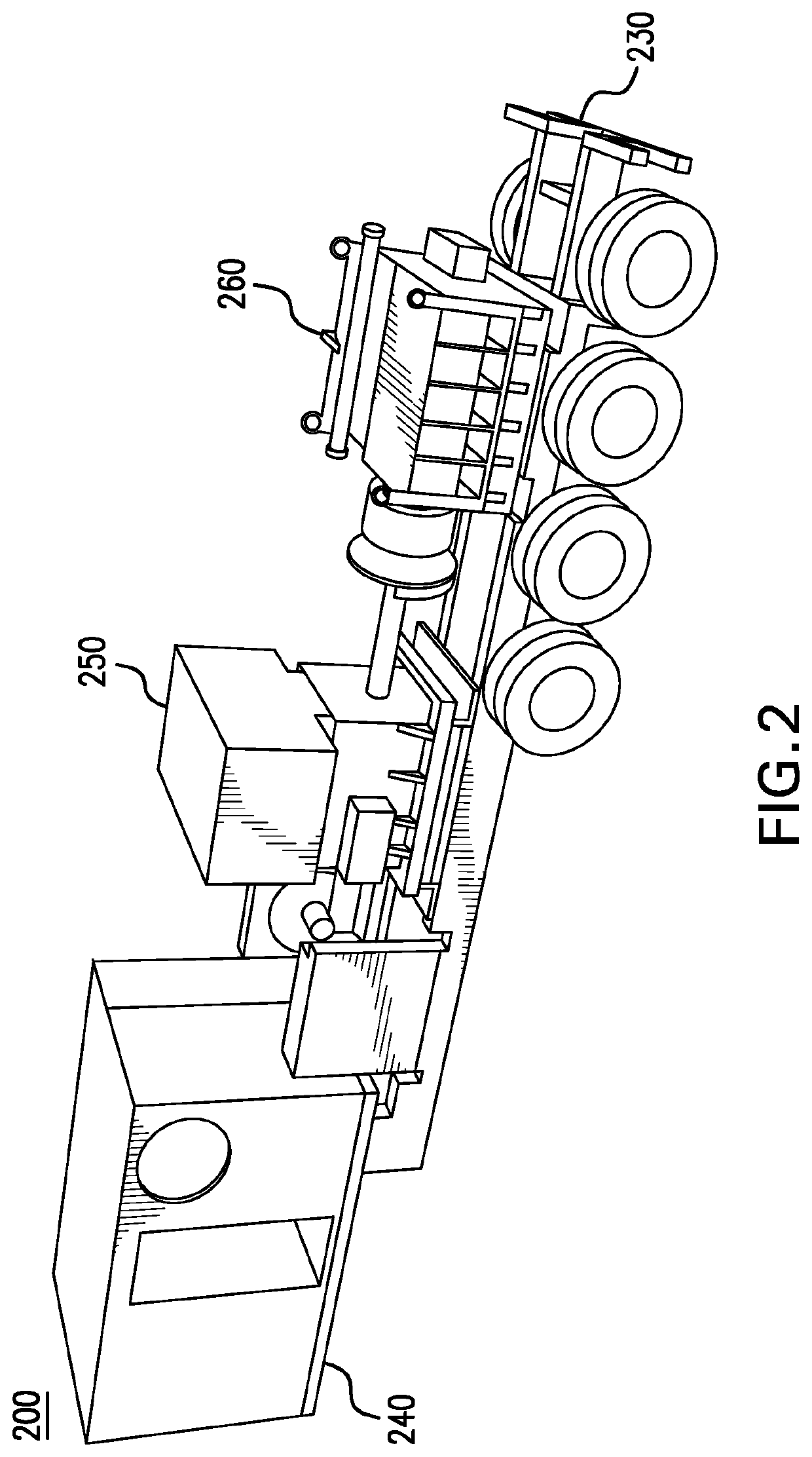

ActiveUS10753153B1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectric drive

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. A pump configuration includes a single VFD configuration, the single shaft electric motor, and the single shaft hydraulic pump mounted on the single pump trailer. The single VFD configuration converts the electric power at the power generation voltage level distributed from the power distribution trailer to a VFD voltage level and drives the single shaft electric motor to control the operation of the single shaft electric motor and the single hydraulic pump. The VFD voltage level is a voltage level that is required to drive the single shaft electric motor. The VFD configuration also controls operation of the auxiliary systems based on the electric power at the auxiliary voltage level.

Owner:HALLIBURTON ENERGY SERVICES INC

Power distribution trailer for an electric driven hydraulic fracking system

ActiveUS20200263527A1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. A power distribution trailer distributes the electric power generated by the power generation system at the power generation voltage level to the single VFD and converts the electric power at a power generation voltage level to a VFD voltage level and controls the operation of the single shaft electric motor and the single hydraulic pump. The power distribution trailer converts the electric power generated by the power generation system at the power generation level to an auxiliary voltage level that is less than the power generation voltage level. The power distribution trailer distributes the electric power at the auxiliary voltage level to the single VFD that controls an operation of the of the auxiliary systems.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

Electric driven hydraulic fracking system

ActiveUS10738580B1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. The single VFD converts the electric power of at least 13.8 kV to a VFD rated voltage level of at least 4160V and drives the single shaft electric motor at the VFD voltage level of up to 4160V to control the operation of the single shaft electric motor and the single hydraulic pump. The single shaft electric motor drives the single hydraulic pump with the rotation at the rated RPM level of at least 750 RPM. The single hydraulic pump continuously pumps the fracking media into the well at the HP level of at least 5000 HP. The single hydraulic pump operates on a continuous duty cycle to continuously pump the fracking media at the HP level of at least 5000 HP.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

Electric driven hydraulic fracking system

Owner:HALLIBURTON ENERGY SERVICES INC

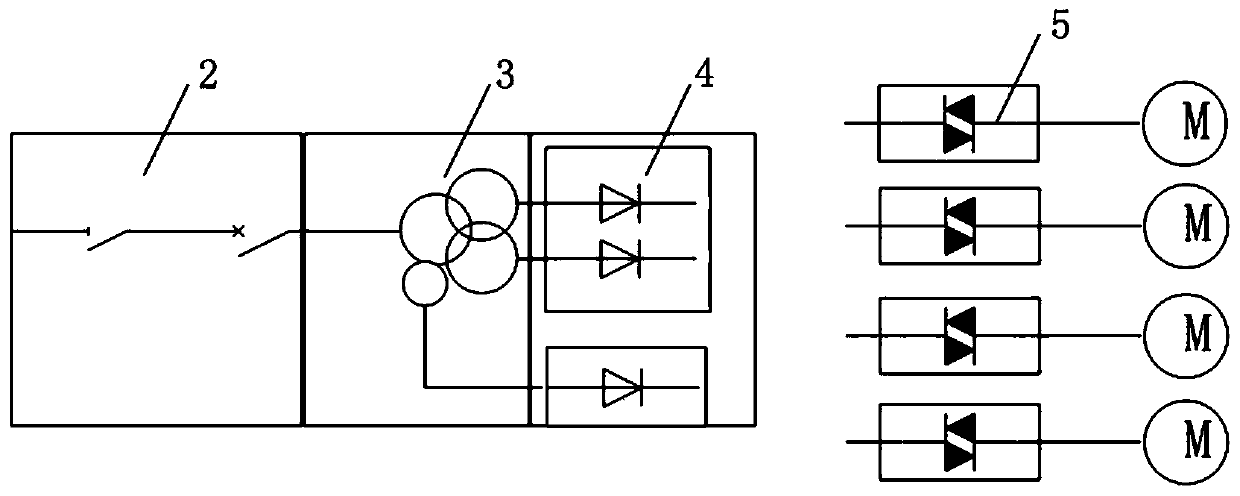

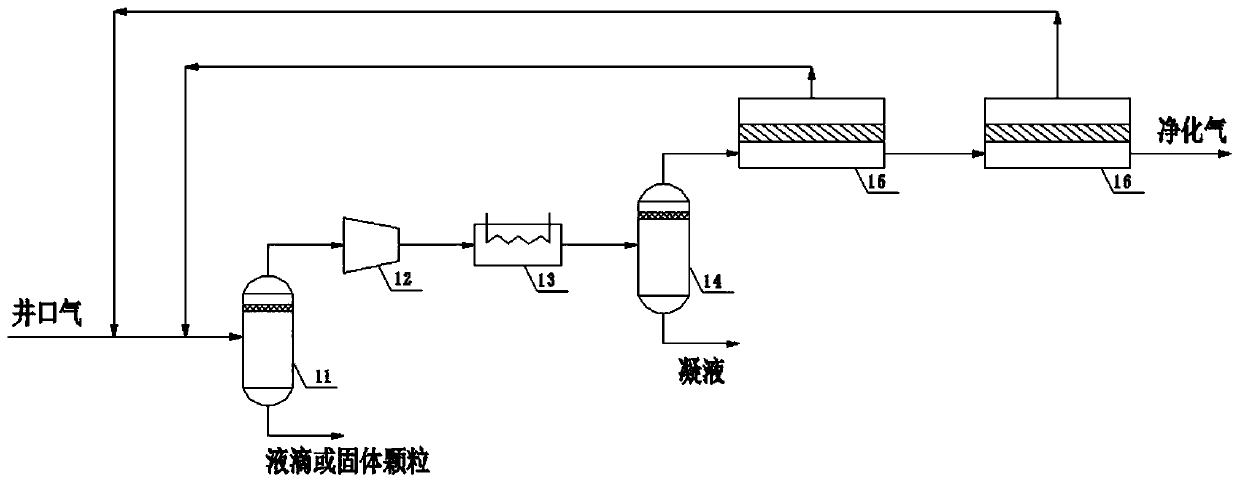

Electric driving fracturing type power supplying semitrailer

PendingCN110155193AReduce volumeCompact layoutAc-dc conversion without reversalSubstation/switching arrangement detailsTransformerLow voltage

The invention discloses an electric driving fracturing type power supplying semitrailer. The electric driving fracturing type power supplying semitrailer is characterized in that a high-voltage switch, a transformer and two rectifying unit sets are adopted to correspondingly drive a plurality of high-voltage converting units and a plurality of low-voltage converting units through common DC buses.The whole electric driving fracturing type power supplying semitrailer is small in size, compact in arrangement, and economic; the common high-voltage switch, the transformer and the rectifying unitsare adopted, so that the wiring of power supplying circuits can be reduced; the equipment quantity and investment output power can be decreased; and the use demand can be met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

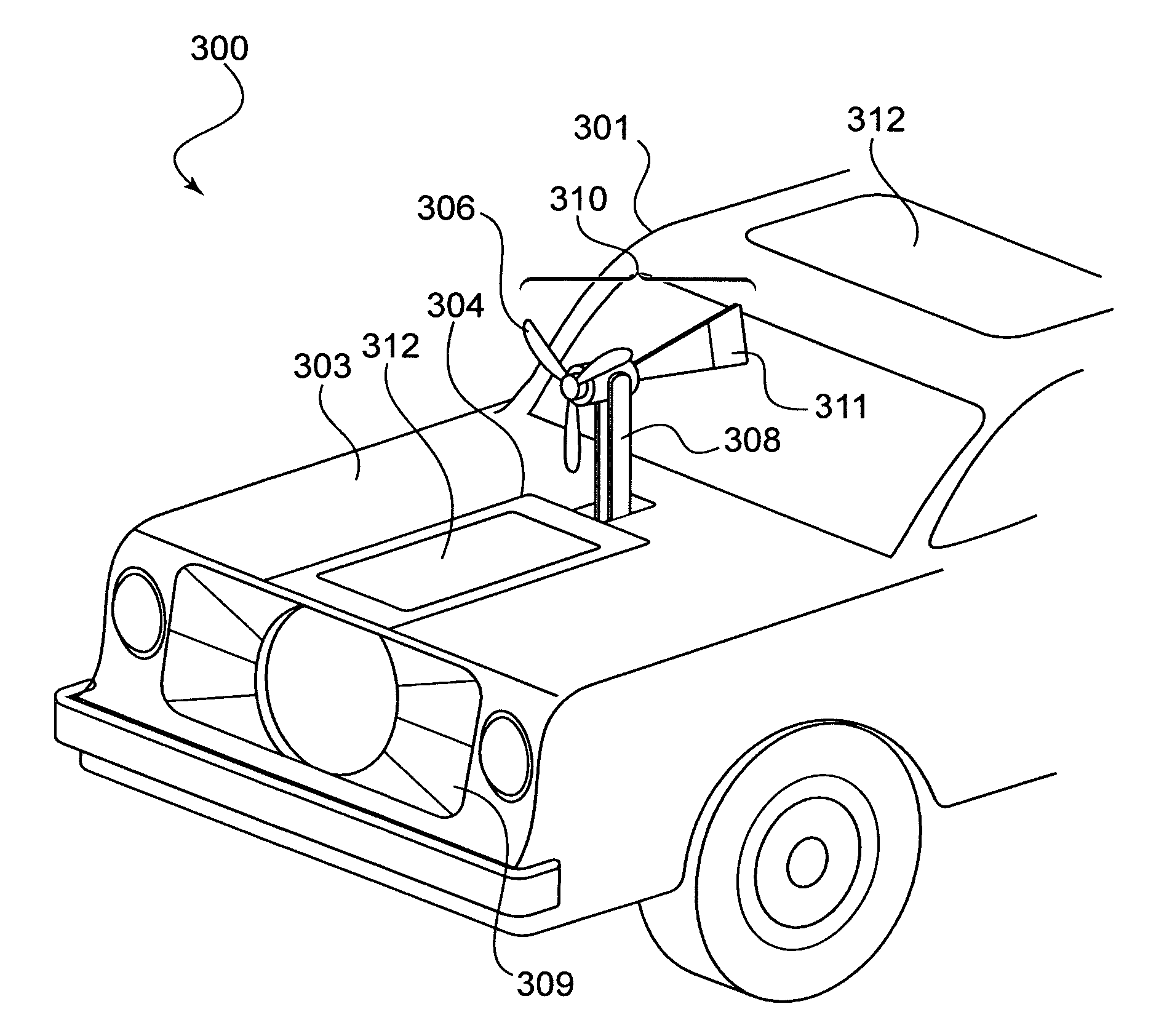

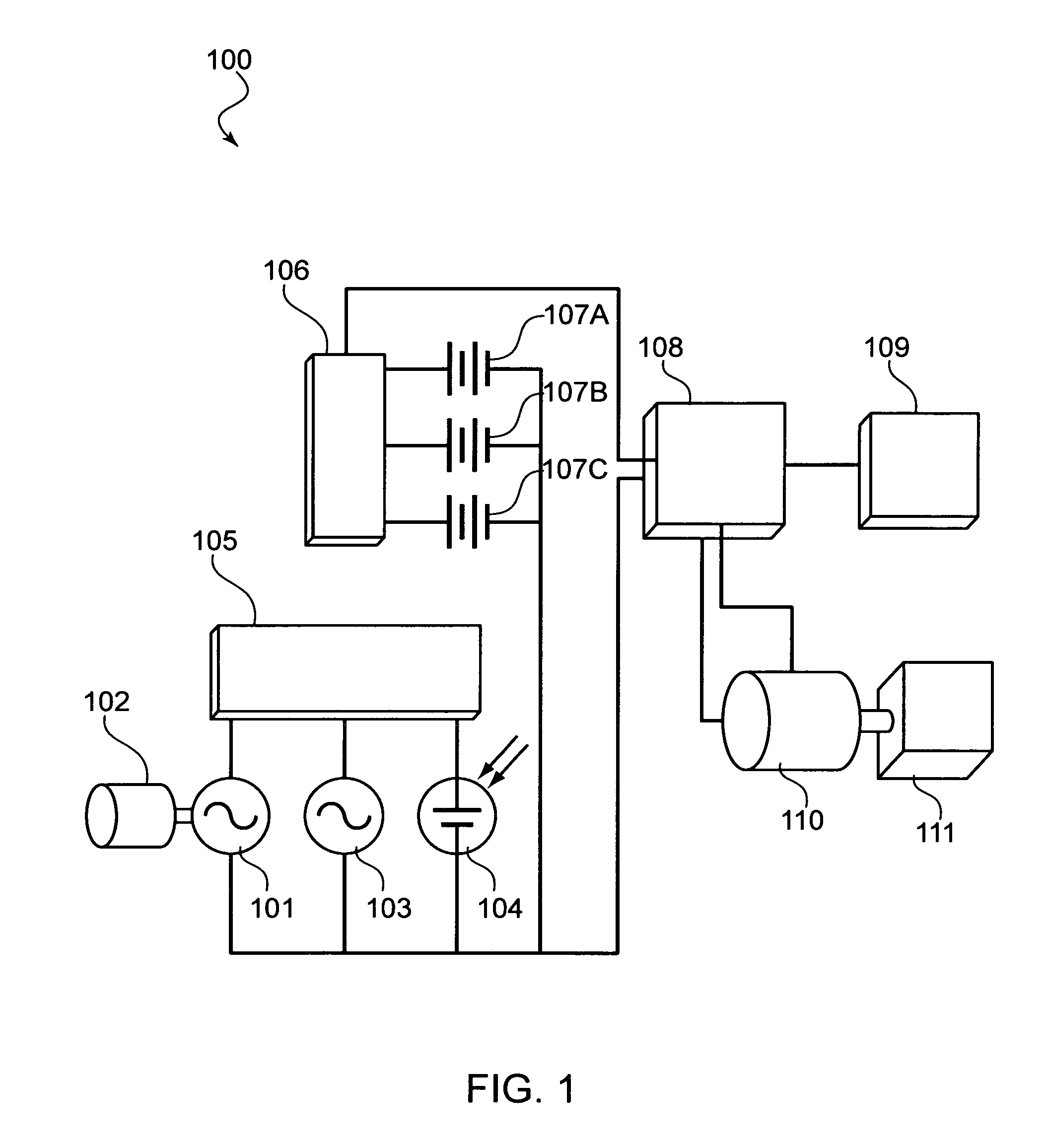

Power system for electric and hybrid vehicles

A power system for an electric vehicle, the power system comprising at least one power generating device selected from a group consisting of a solar panel, a wind turbine capable of producing electrical power, an auxiliary generator driven by an internal combustion engine, and a generator for producing electrical power mechanically connected to, and driven by the rotational force of an axle of a vehicle. The power system being further comprised of a charging device, a battery control device, at least one battery, a motor control device, an electric drive motor electrically connected to the motor control device, and a driver interface connected to the motor control device. The electric drive motor may be used to generate power through regenerative braking. The wind turbine may be raised outside the body of a vehicle while the vehicle is not in motion. The solar panel may be disposed outside the vehicle while remaining electrically connected to the charging device.

Owner:SUTHERLAND DANILO R

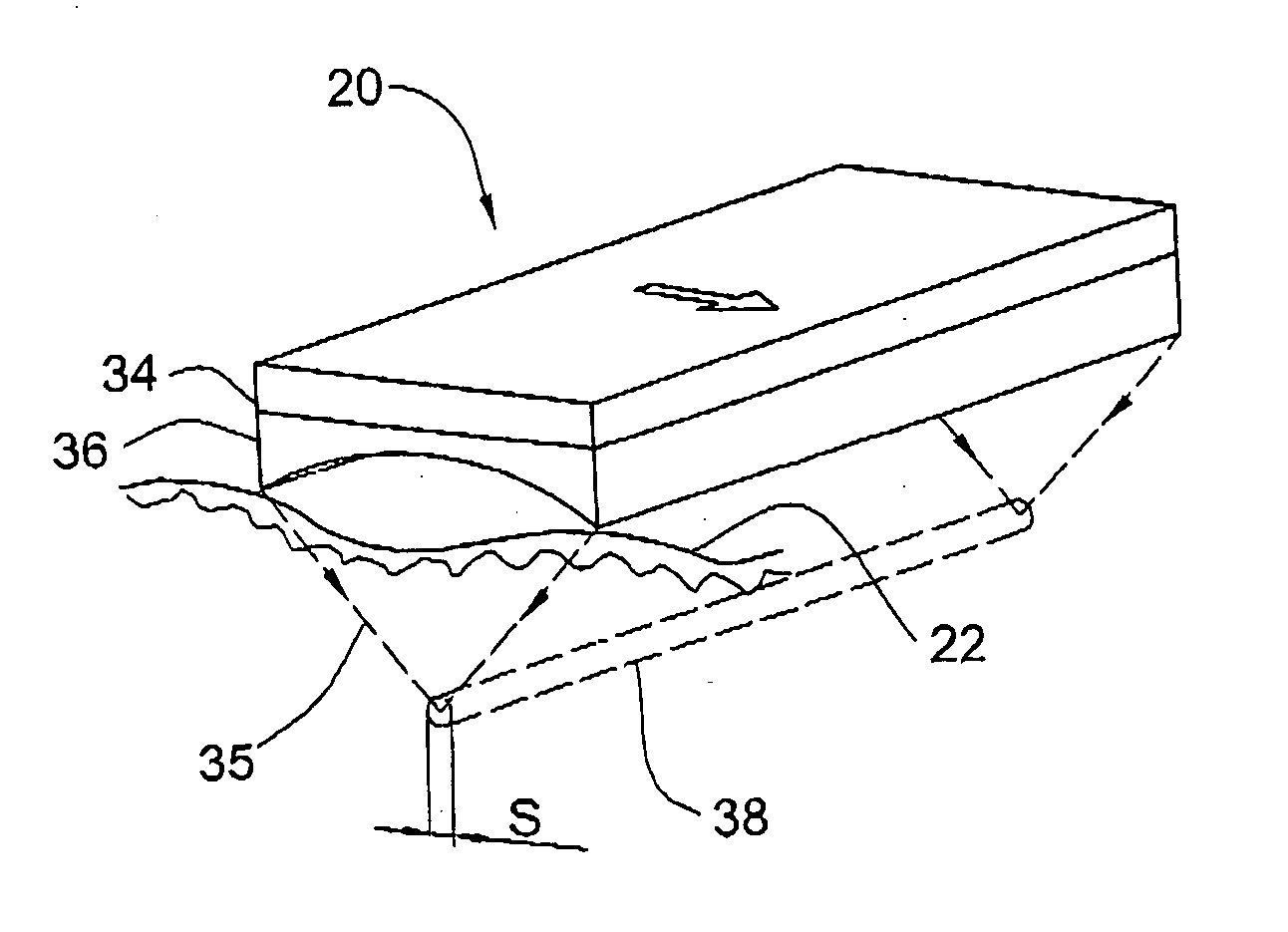

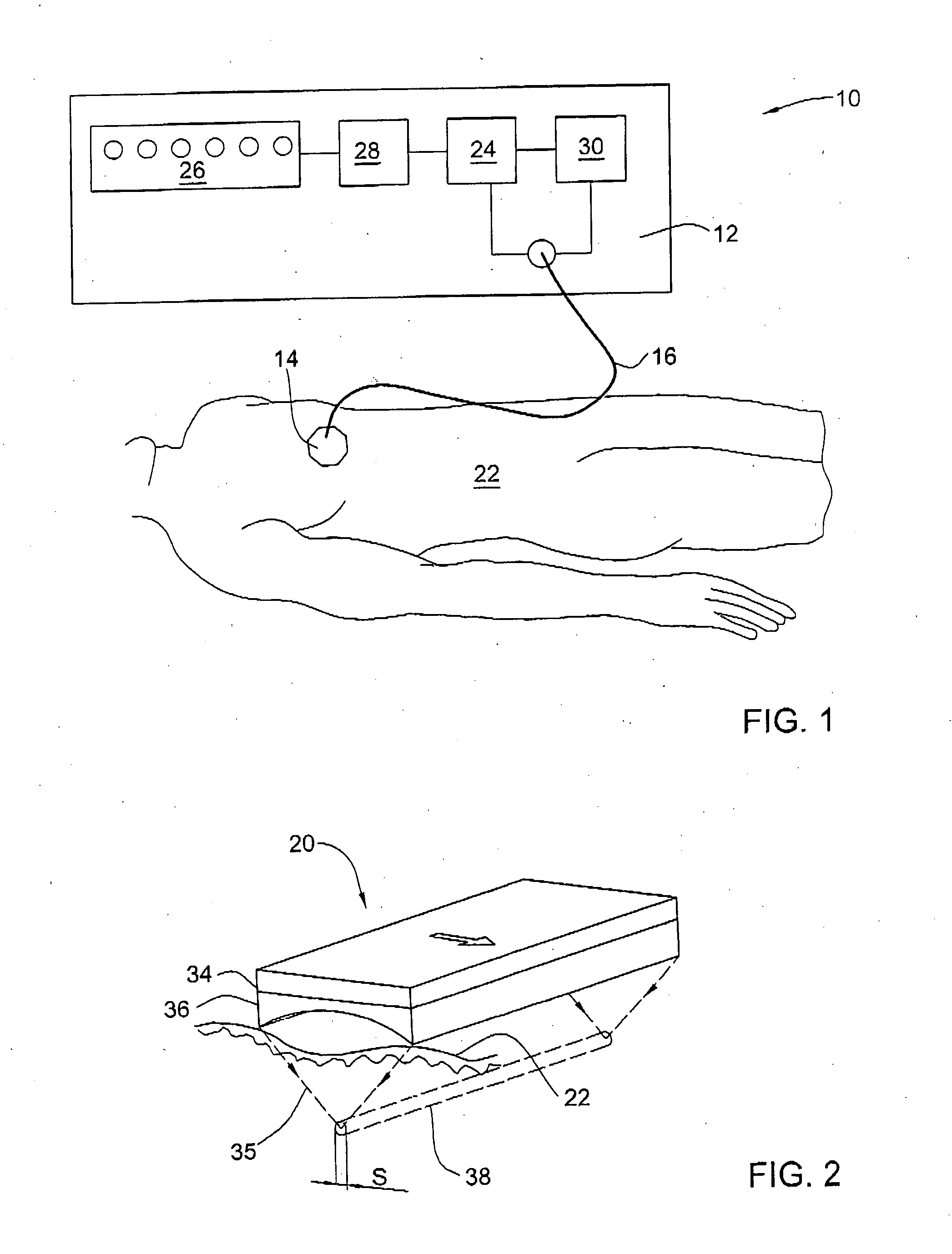

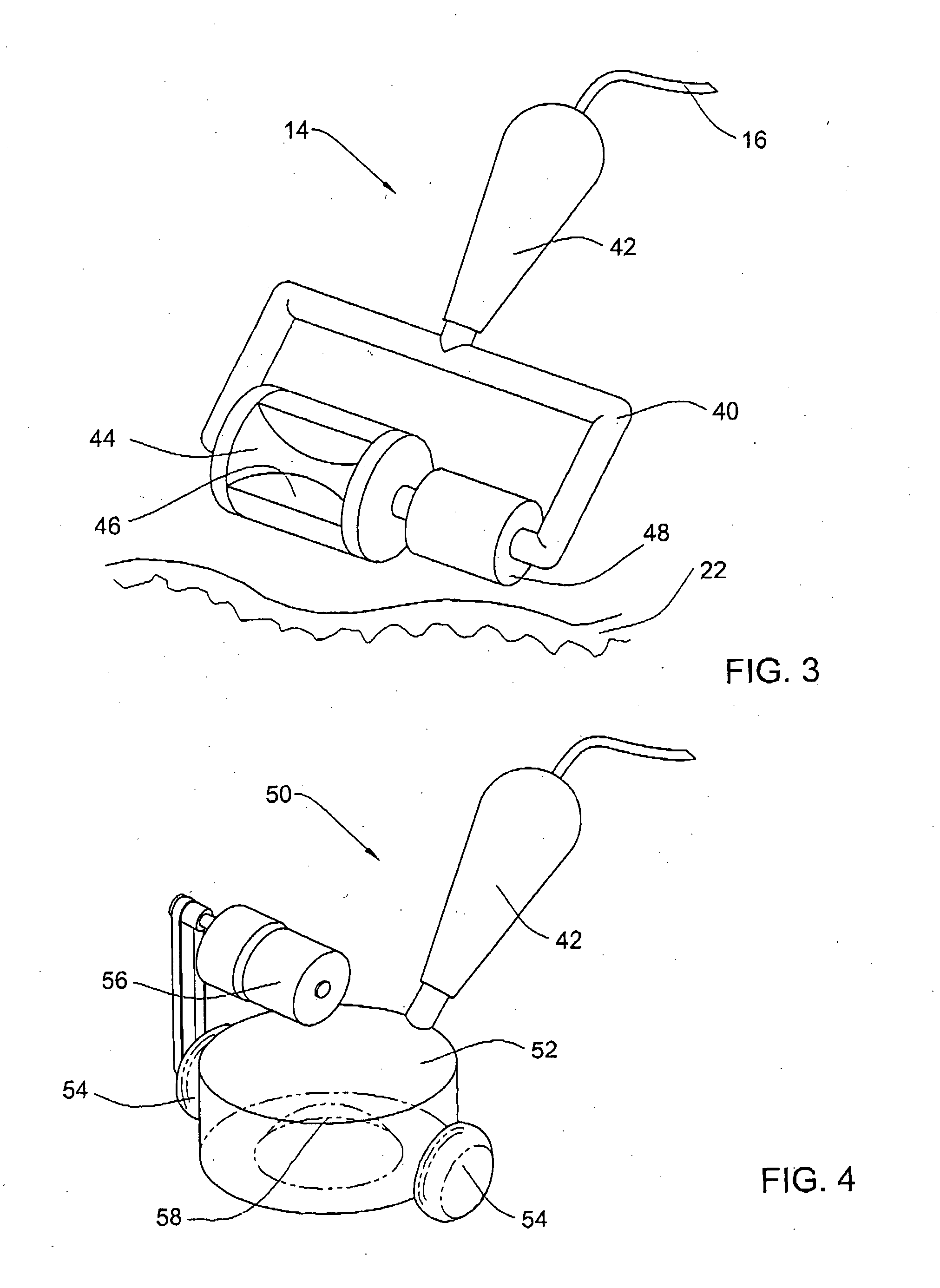

Method and device for sub-dermal tissue treatment

InactiveUS20050055018A1Avoid heat damageAvoid tissue damageUltrasound therapySurgical instruments for heatingCavitationHand held

System and method for non-invasive lysis of sub-dermal tissue by means of focused ultrasonic energy, the system comprising: a source of ultrasonic energy adapted to operate in continuous wave mode and to focus ultrasonic energy in a focal zone within the sub-dermal tissue, the ultrasonic energy being adapted to induce tissue cavitation in the focal zone; means for continuous displacement of the source over the skin surface; and means for determining a safe speed for the displacement, the safe speed allowing to avoid thermal tissue damage. The source of ultrasonic energy is accommodated in a hand-held applicator including a wheeled traction system powered by an electric drive.

Owner:SYNERON MEDICAL LTD

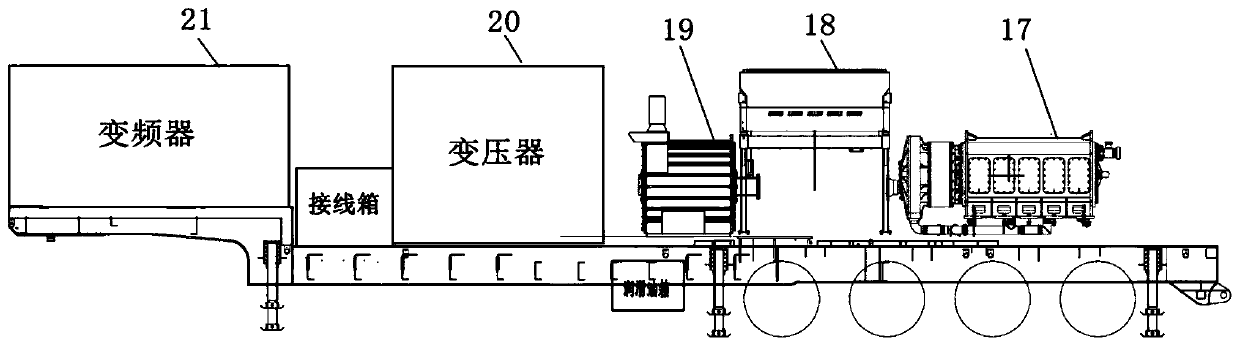

Electric drive fracturing semi-trailer of frequency conversion integrated machine

PendingCN110608030AOptimize layoutNo emission pollutionPositive displacement pump componentsFluid removalFrequency changerEngineering

The invention discloses an electric drive fracturing semi-trailer of a frequency conversion integrated machine. The optimization and integration of the traditional power supply semi-trailer and the fracturing semi-trailer realize the functions of power supply and fracturing of one semi-trailer without using the complete set of the power supply semi-trailer and the fracturing semi-trailer, the electric drive fracturing semi-trailer is more flexible in actual use, and the well field layout of oil and gas fields is greatly optimized; the transportation is convenient; only a set of high-voltage cables can be connected with the high-voltage power supply to reach a working state, and the wiring installation is faster; compared with diesel-driven fracturing, and the noise of the electric drive fracturing is low without exhaust emission pollution; the driving source is power, which has lower cost than the diesel; the electric drive fracturing semi-trailer adopts an integrated design of a motorand a frequency converter (namely, the frequency conversion integrated machine), the space occupied by the electric motor and the inverter in the prior art is reduced effectively, so the installing part of the electric drive fracturing semi-trailer has smaller volume and the transportation is more convenient, and can also provide space guarantee for installing other equipment on the semi-trailerbody.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

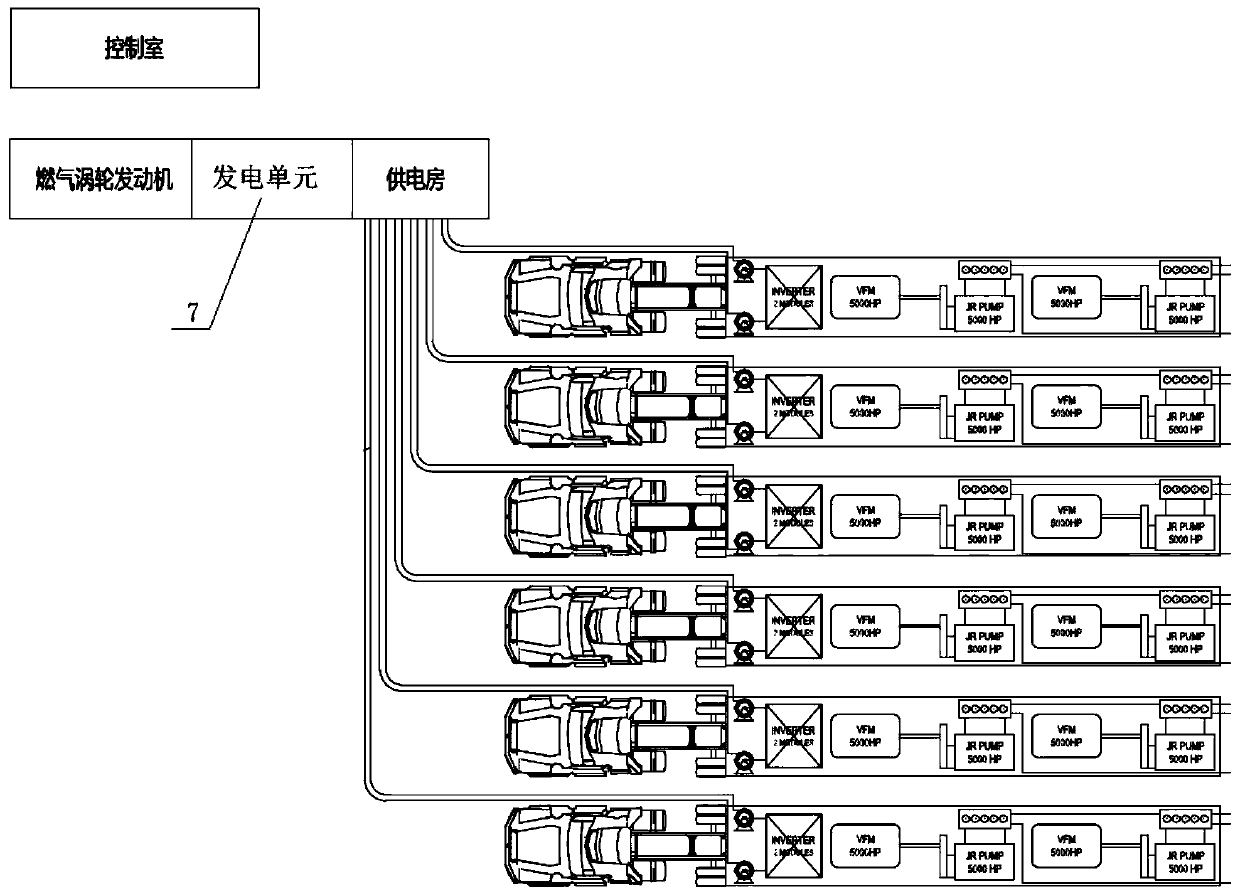

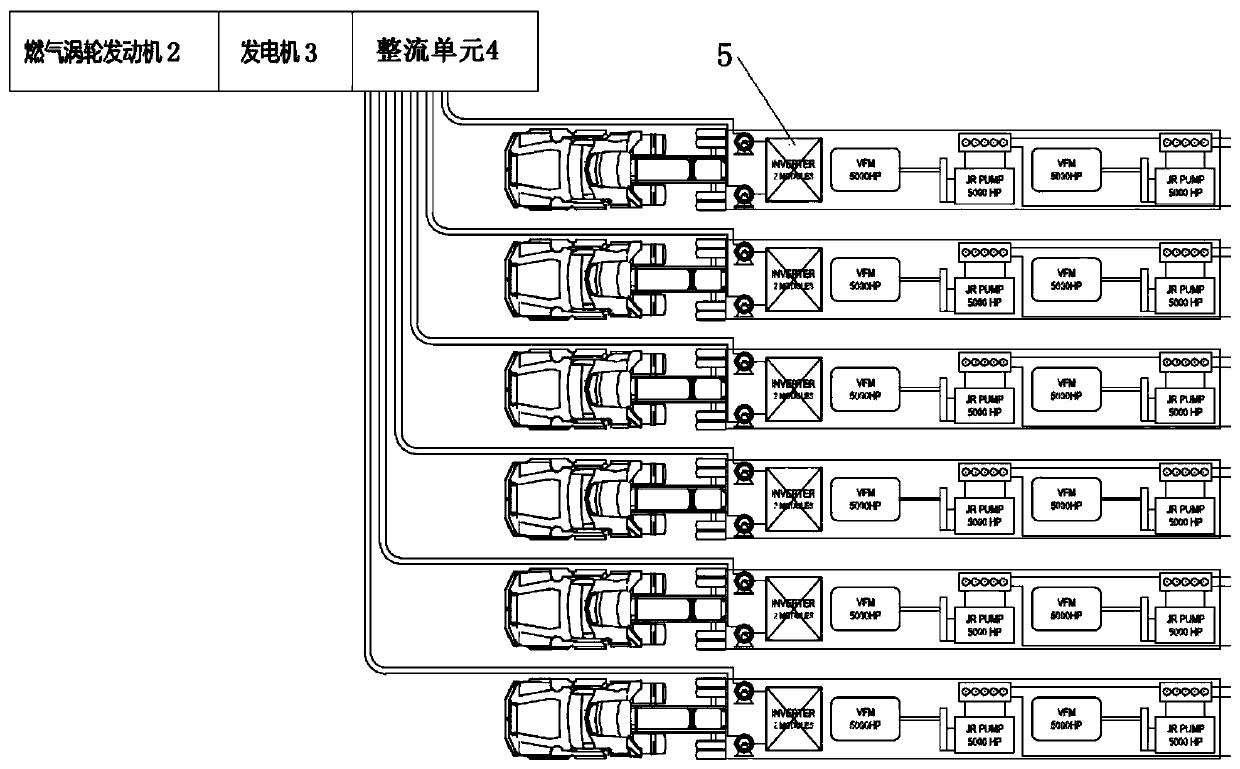

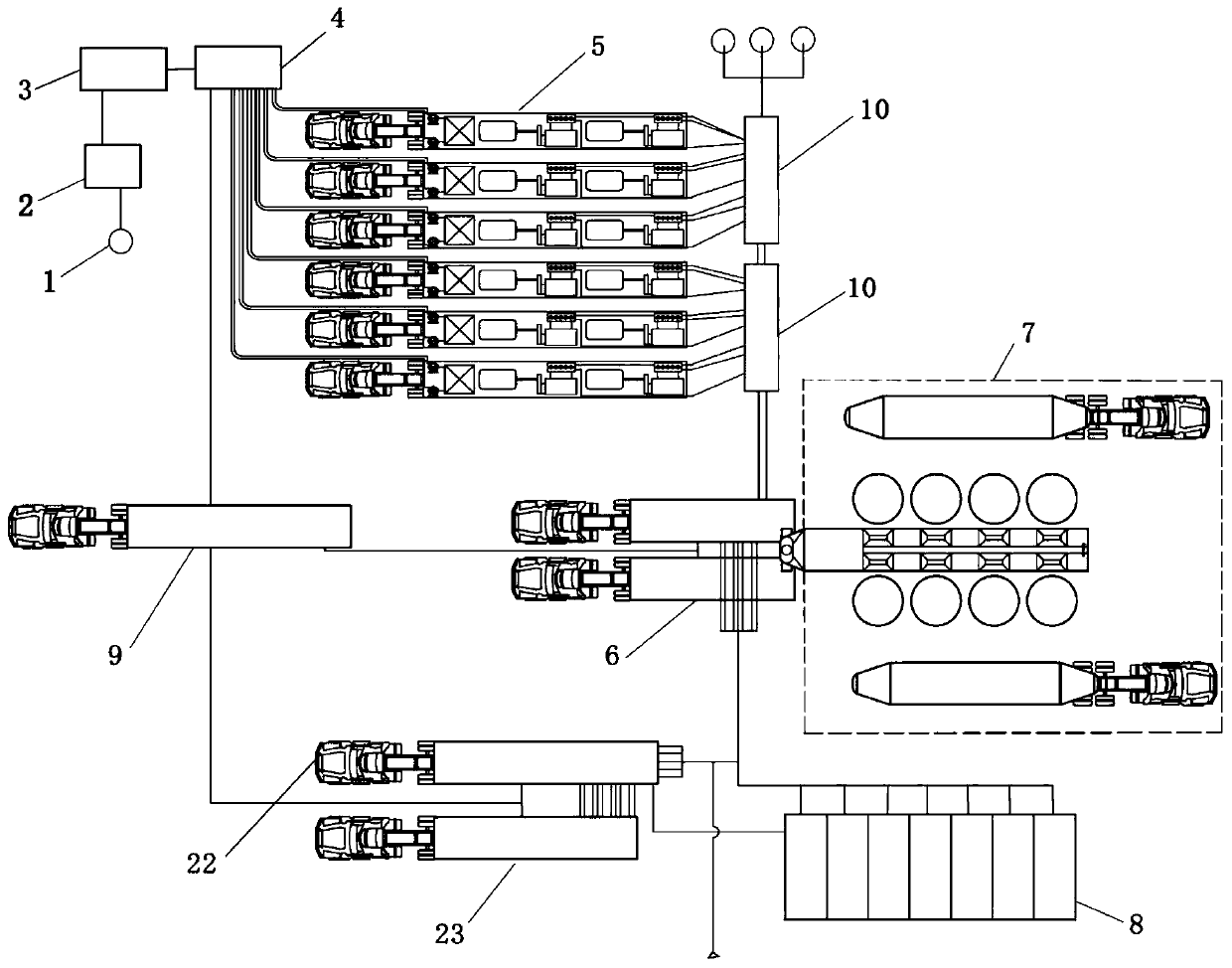

Fracturing well site layout system

PendingCN110821464ASimple structureFlexible useFluid removalAc network circuit arrangementsThermodynamicsElectric drive

The invention discloses a fracturing well site layout system. The fracturing well site layout system comprises a gas source, a processing device, a power supply system, a power distribution system, anelectric drive fracturing device, an electric drive sand mixing device, a sand supply device, a liquid supply device, an instrument device and a high-low pressure manifold, wherein the gas source provides fuel needed by power generation for the power supply system after being processed by the processing device; the power supply system drives the electric drive fracturing device and the electric drive sand mixing device through the power distribution system; the sand supply device provides fracturing sand needed by mixing for the electric drive sand mixing device; the liquid supply device provides needed liquid for the electric drive sand mixing device; the output end of the electric drive sand mixing device is connected with the electric drive fracturing device through the high-low pressure manifold; the electric drive fracturing device communicates with a well mouth through the high-low pressure manifold; and the instrument device is used for remotely controlling the electric drive fracturing device and the electric drive sand mixing device. The fracturing well site layout system has the beneficial effects that the occupied area is smaller, the output power of the single electricdrive fracturing device is larger, wiring of the whole well site layout is simpler, the wiring time is shorter, and application is more flexible.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

Variable frequency drive configuration for electric driven hydraulic fracking system

ActiveUS20200263498A1Non-enclosed substationsCharge equalisation circuitHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. A pump configuration includes a single VFD configuration, the single shaft electric motor, and the single shaft hydraulic pump mounted on the single pump trailer. The single VFD configuration converts the electric power at the power generation voltage level distributed from the power distribution trailer to a VFD voltage level and drives the single shaft electric motor to control the operation of the single shaft electric motor and the single hydraulic pump. The VFD voltage level is a voltage level that is required to drive the single shaft electric motor. The VFD configuration also controls operation of the auxiliary systems based on the electric power at the auxiliary voltage level.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

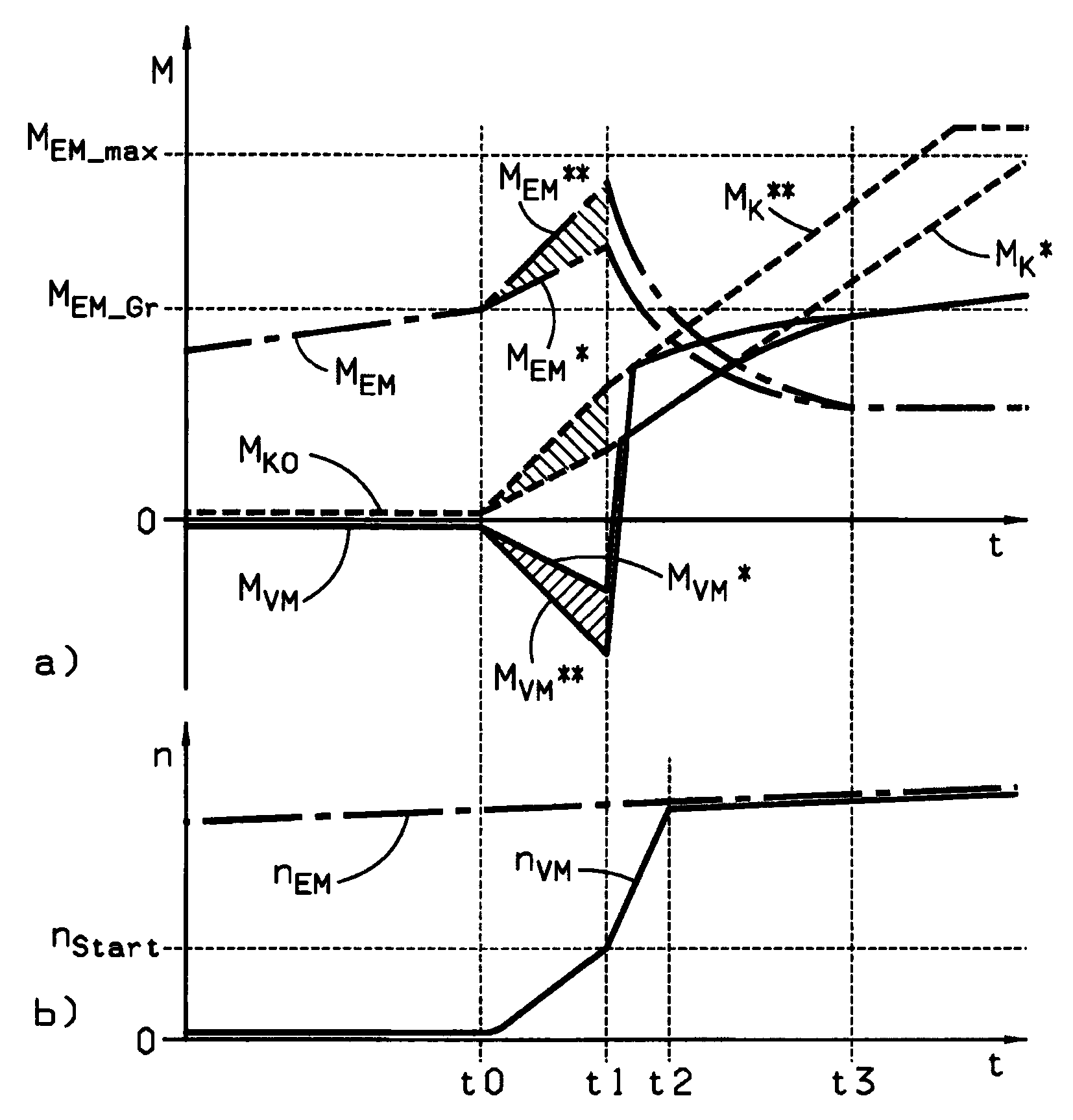

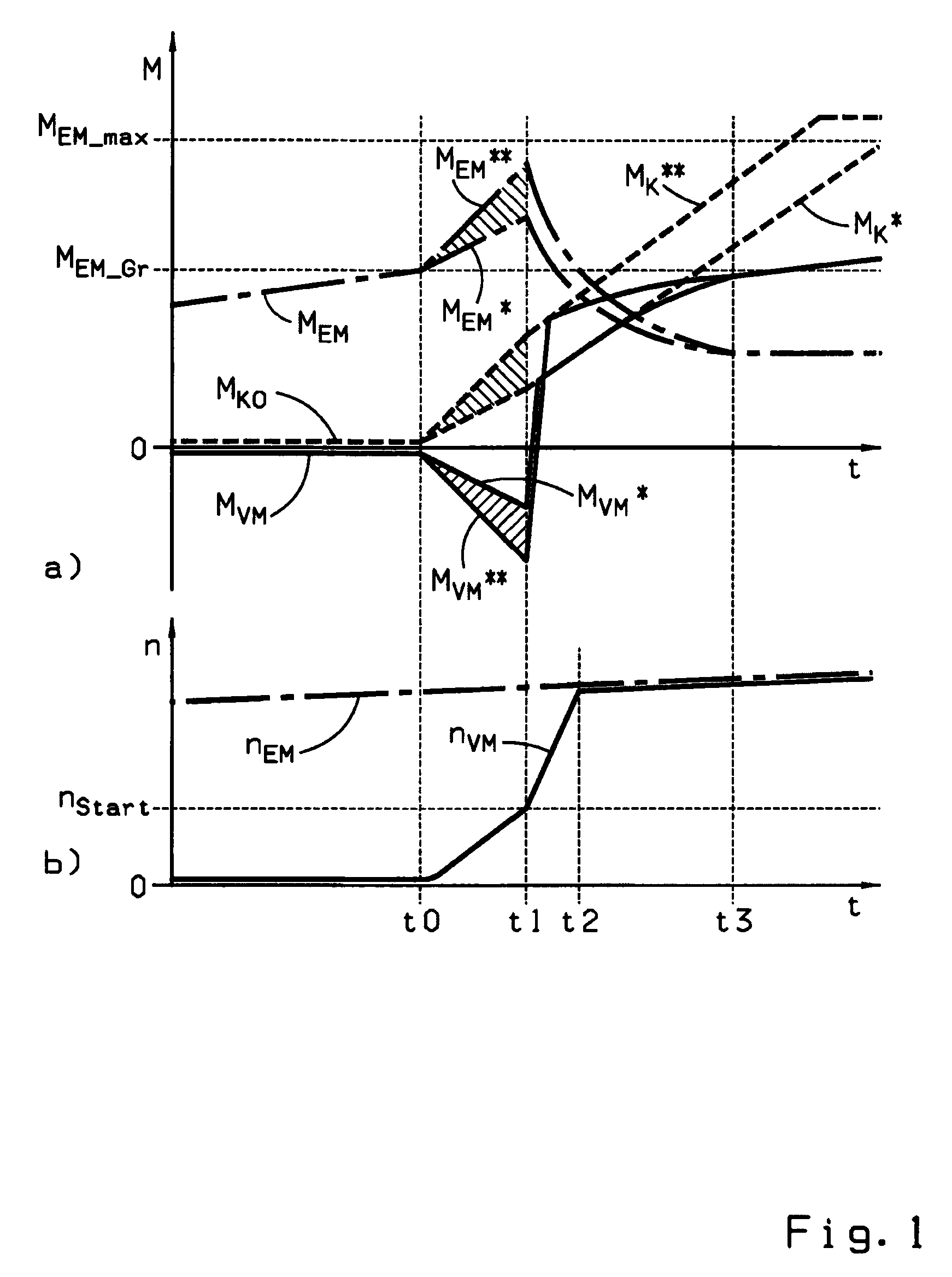

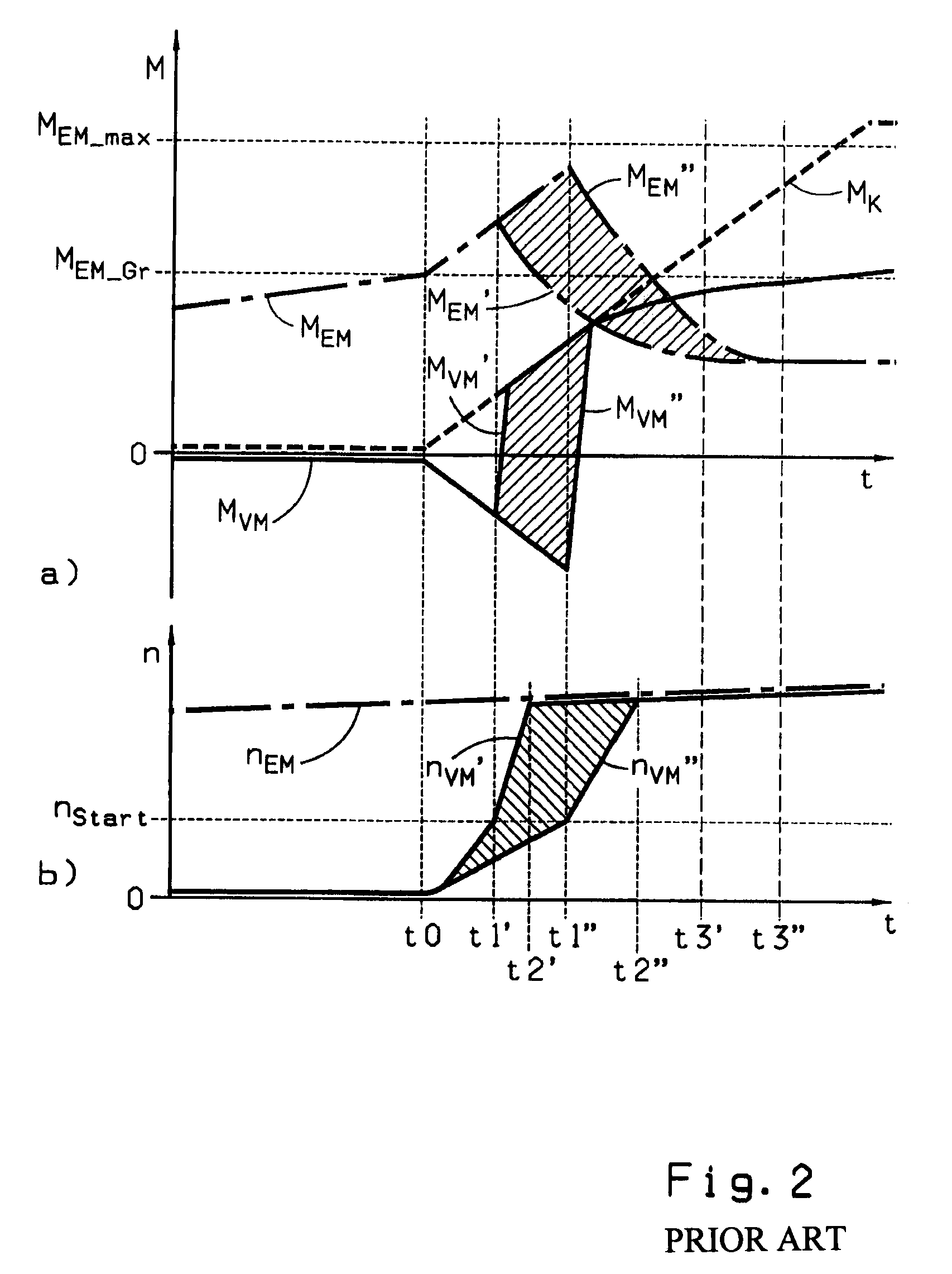

Method to control a hybrid drive train

InactiveUS20090312144A1Prevent fallingFunction increaseInternal combustion piston enginesDigital data processing detailsClutchElectric drive

A method of controlling a hybrid drive train of a vehicle having, in series, an internal combustion engine, a clutch, an electric motor and a transmission with an output connected to the drive axle. During traction operation, the vehicle changes from an electric driving mode into a combination driving mode or a combustion engine driving mode, in that the clutch is engaged and the combustion engine torque is temporarily increased. The method includes regulating engagement of the clutch at least until reaching a starting rotational speed of the combustion engine such that the acceleration of the combustion engine occurs according to a predetermined progression of rotational speed and that the torque of the combustion engine is increased by the same amount as the transferable torque of the clutch is increased by the engagement process.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com