Patents

Literature

195932 results about "Control engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control engineering or control systems engineering is an engineering discipline that applies automatic control theory to design systems with desired behaviors in control environments. The discipline of controls overlaps and is usually taught along with electrical engineering at many institutions around the world.

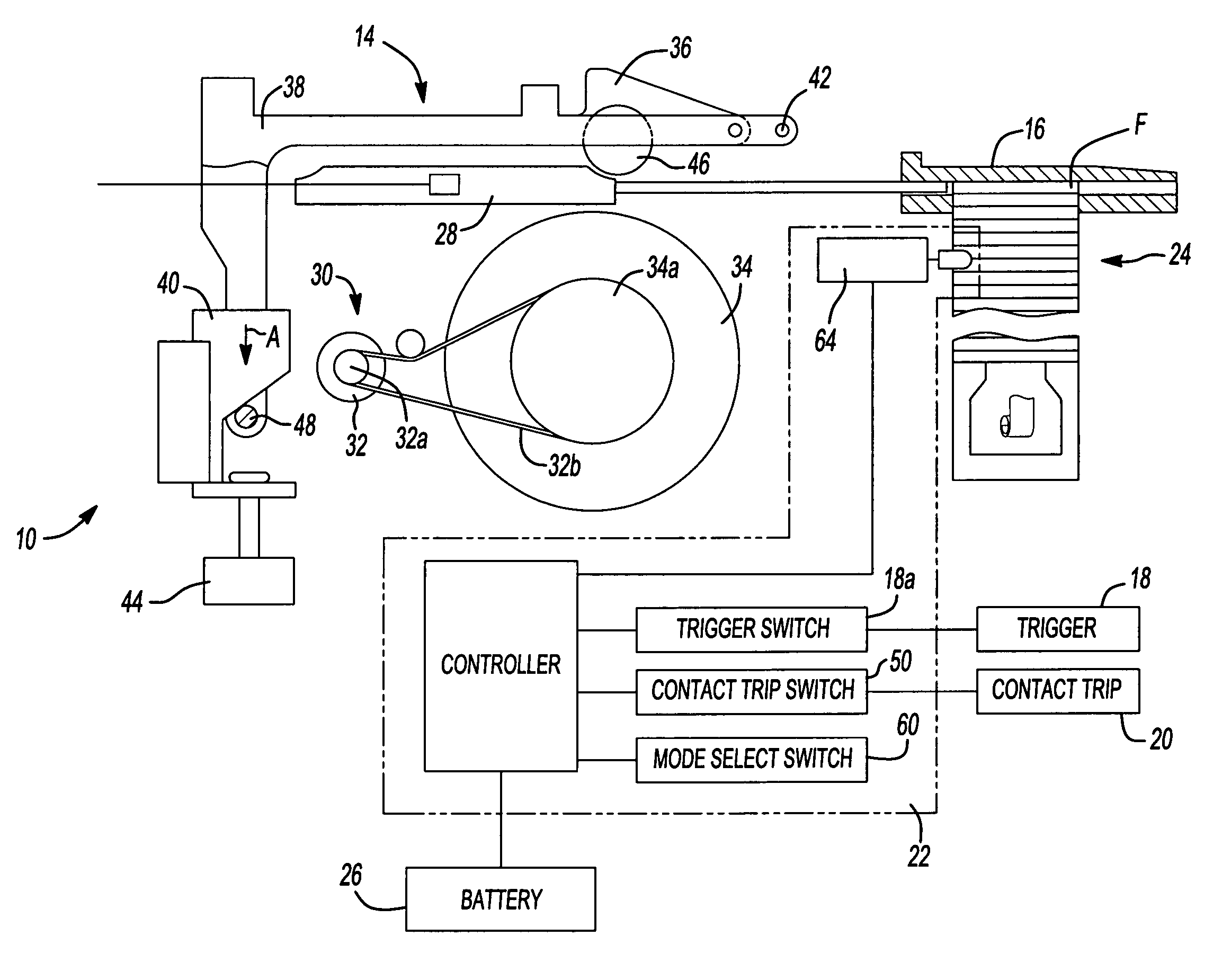

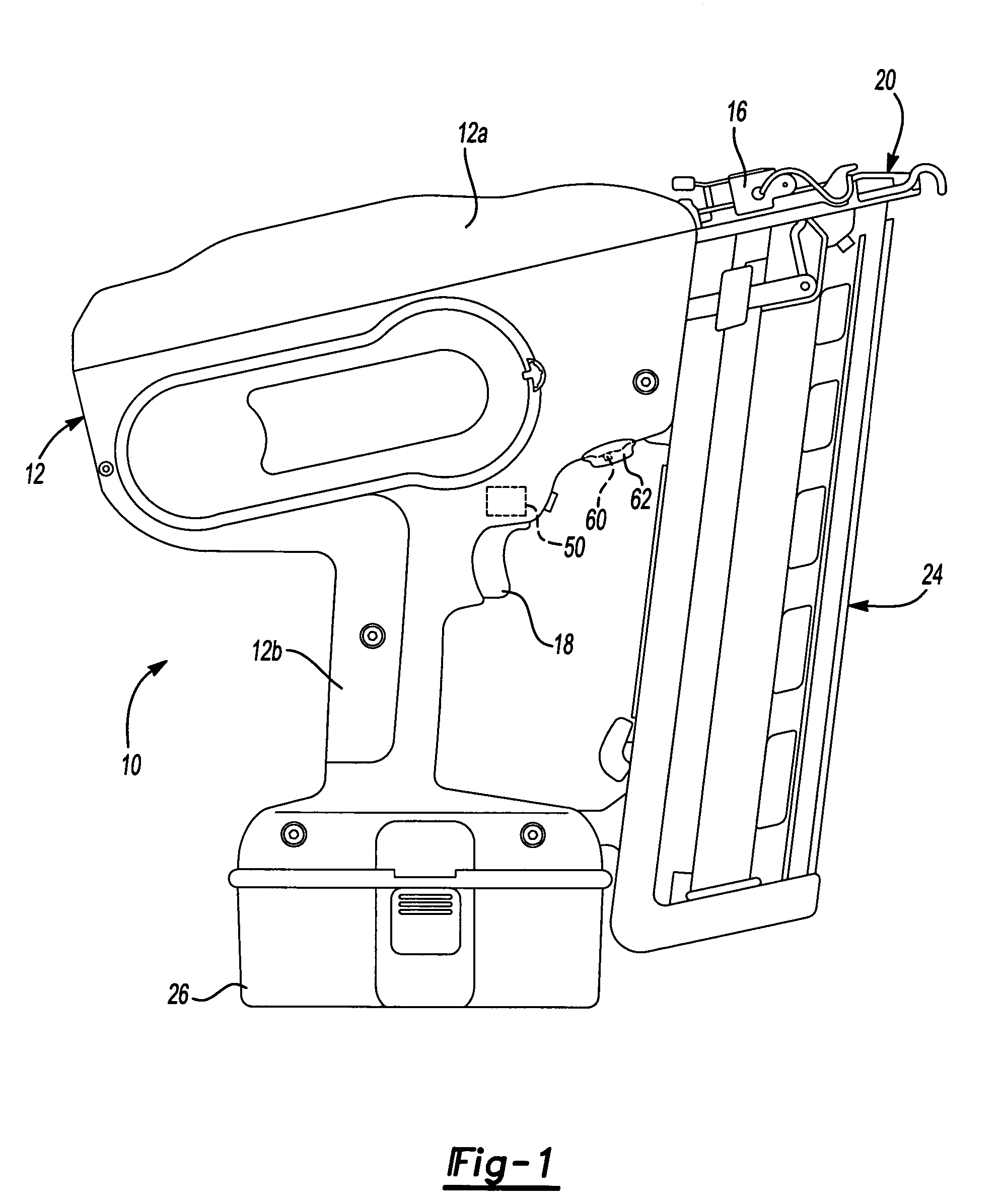

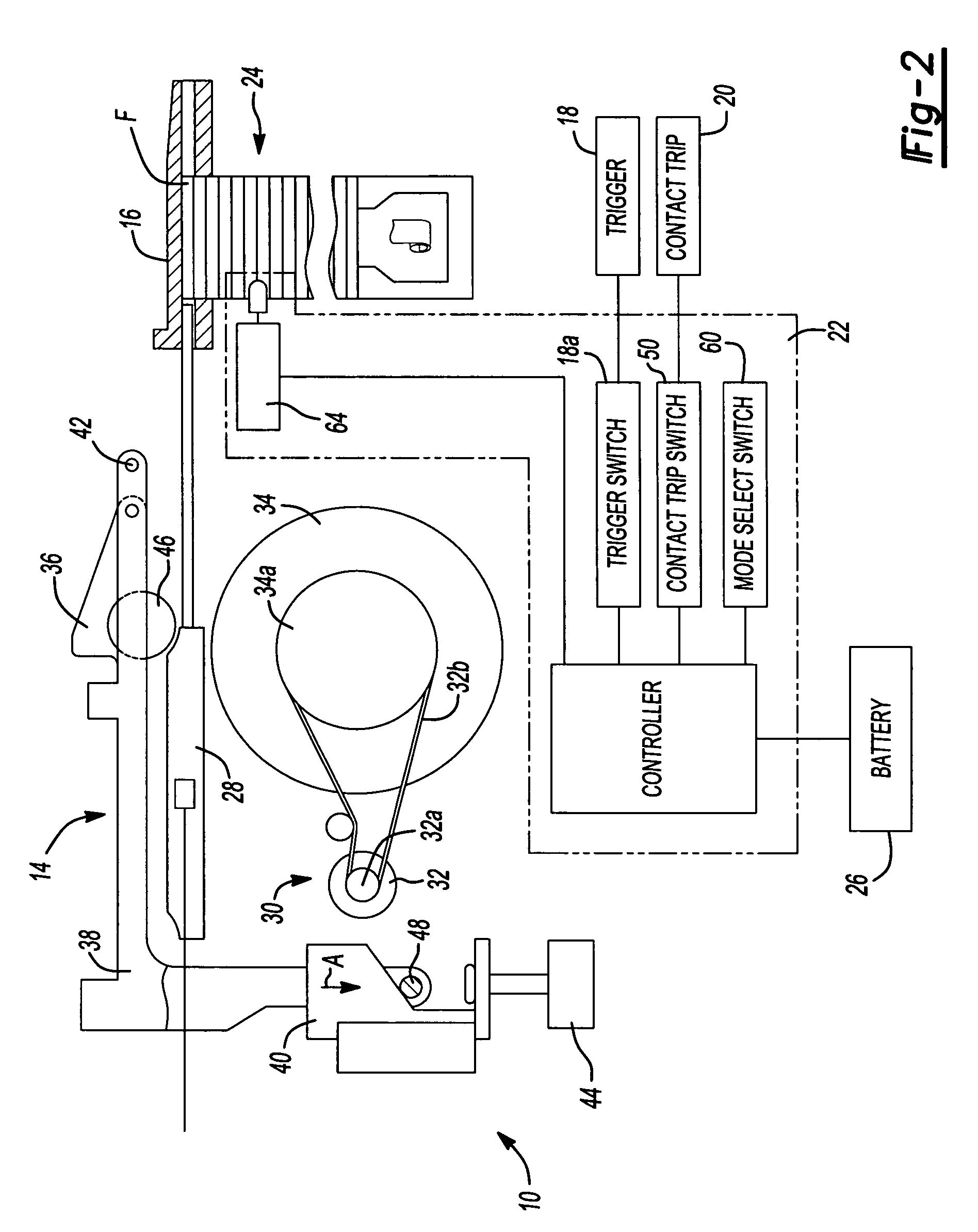

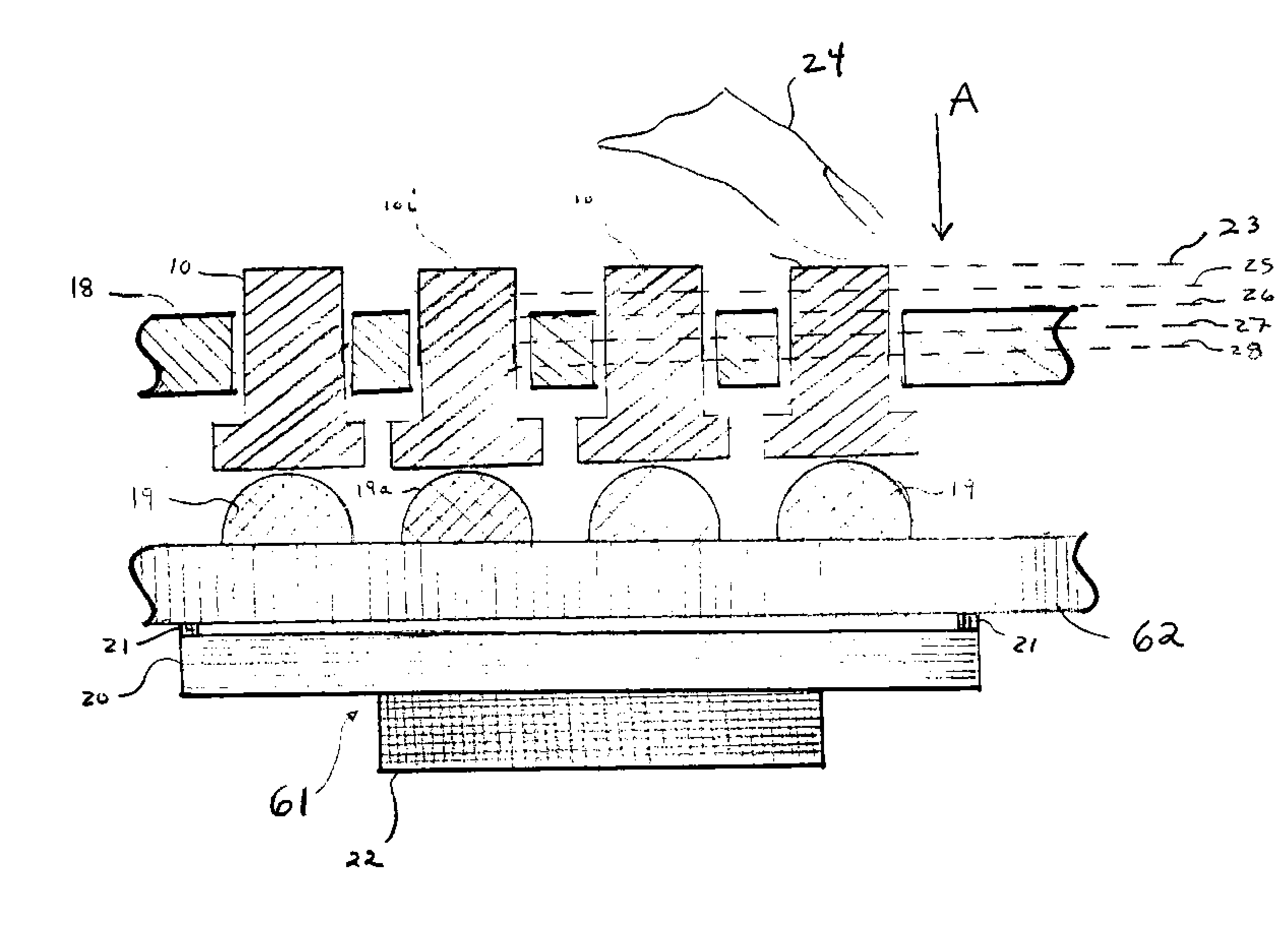

Method for controlling a power driver

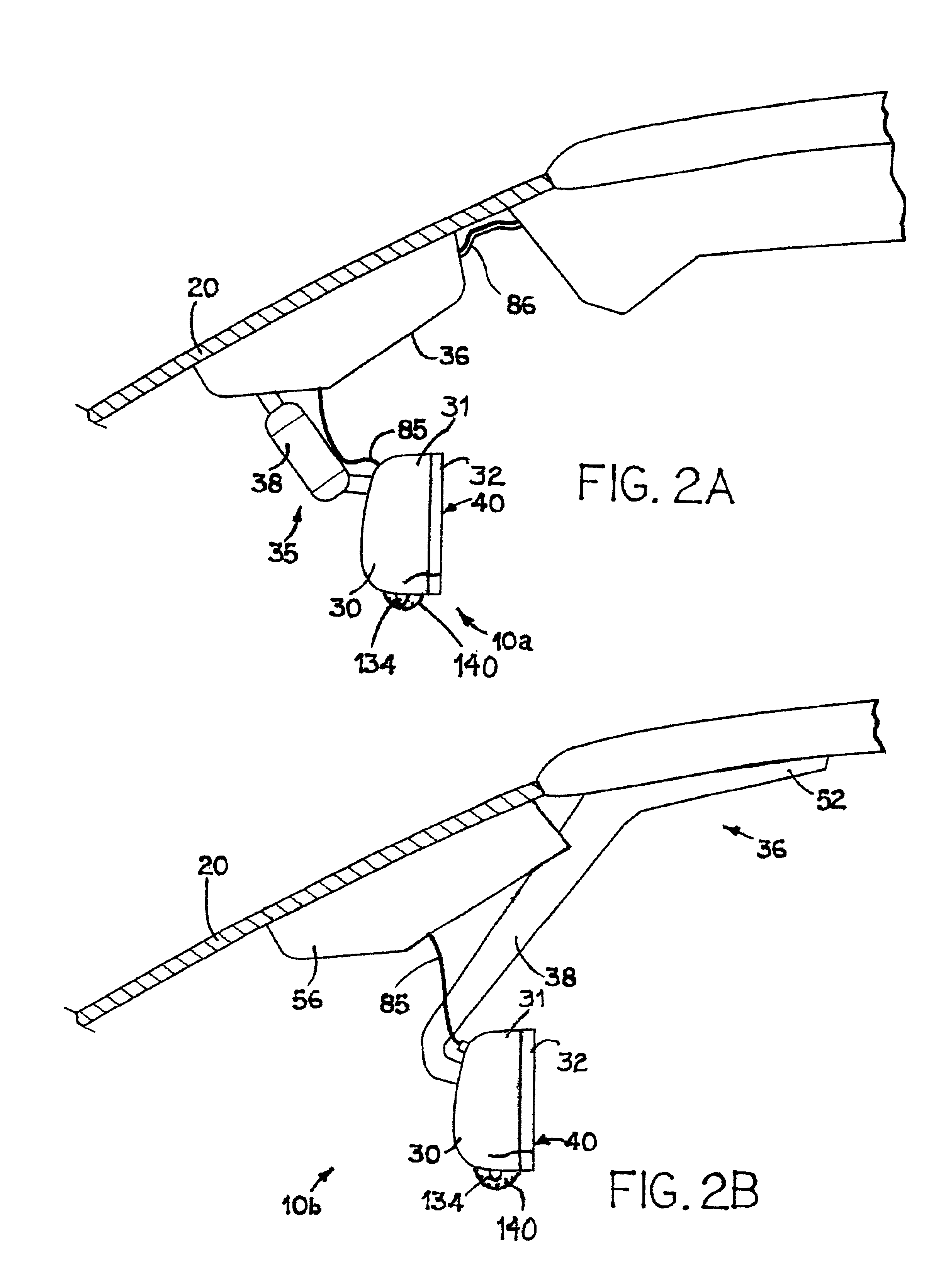

A driving tool having a driver, a power source, a sensor and a controller. The power source selectively provides an input to the driver to cause the driver to translate along an axis. The sensor senses a condition in the power source that is indicative of a level of kinetic energy of an element in the power source and generates a sensor signal in response thereto. The controller is coupled to the power source and the sensor and is responsive to the sensor signal for deactivating the power source to inhibit the power source from providing the input to the driver when the level of kinetic energy of the element in the power source is below a predetermined threshold. A method for operating a driving tool is also provided.

Owner:BLACK & DECKER INC

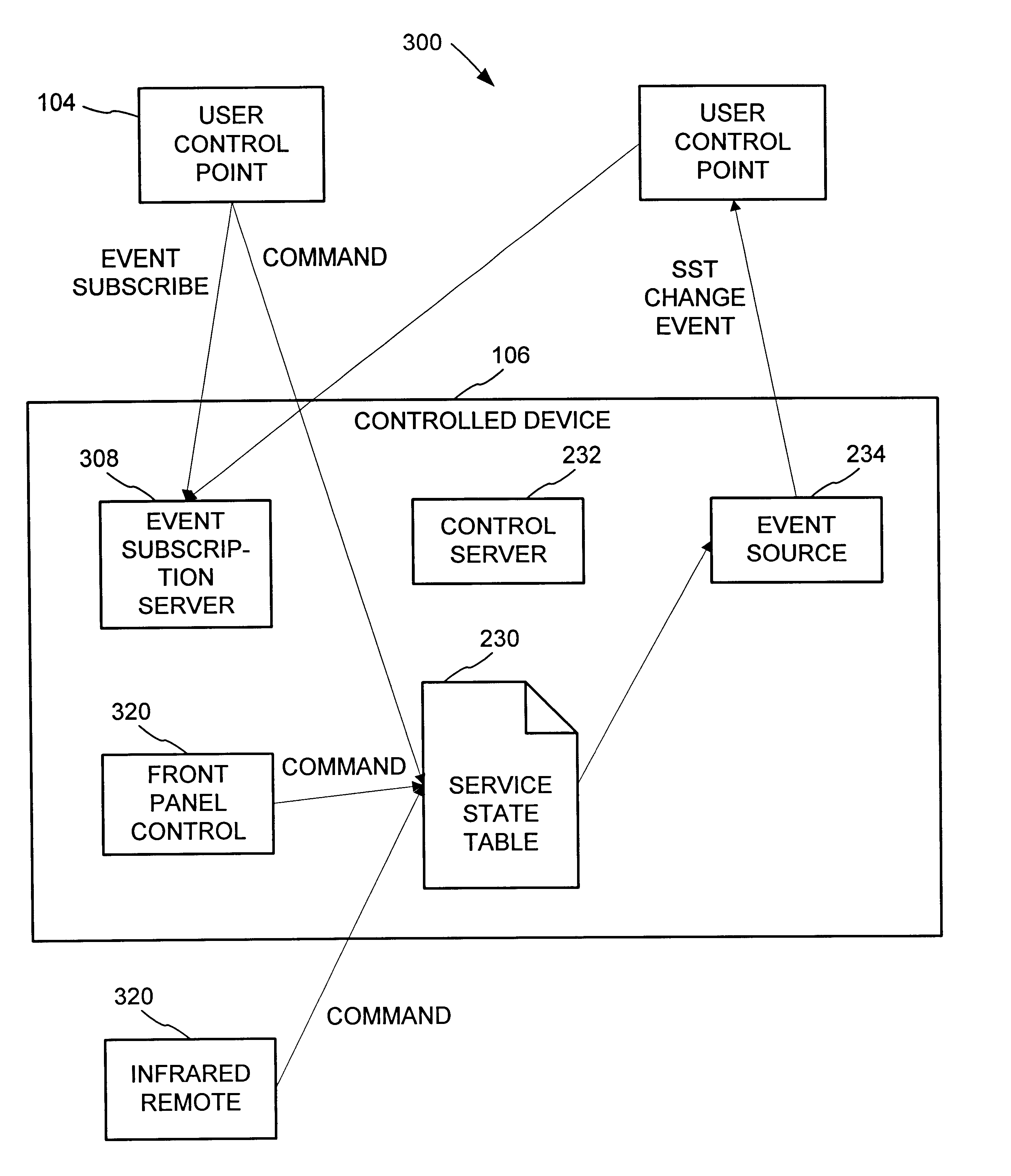

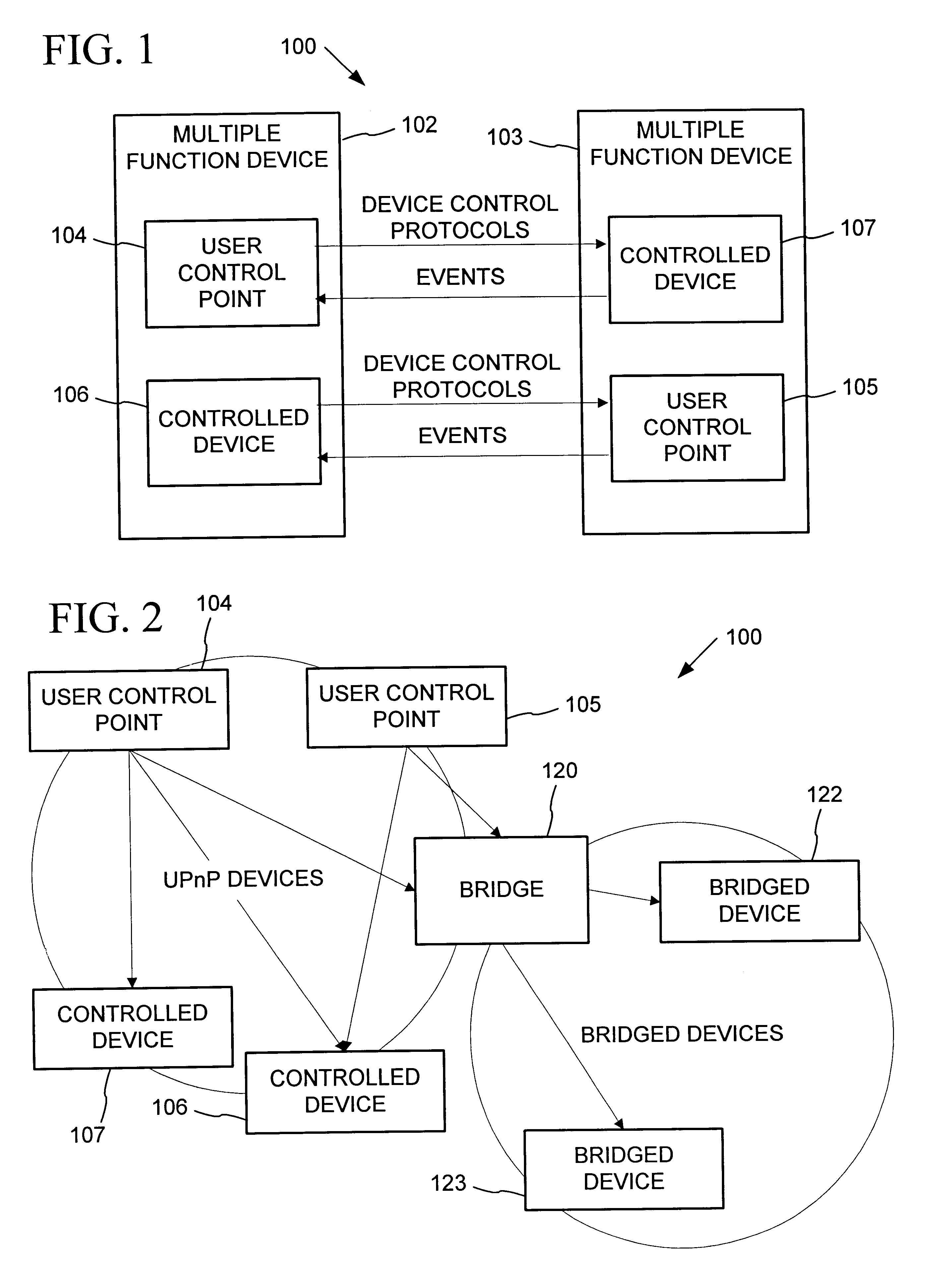

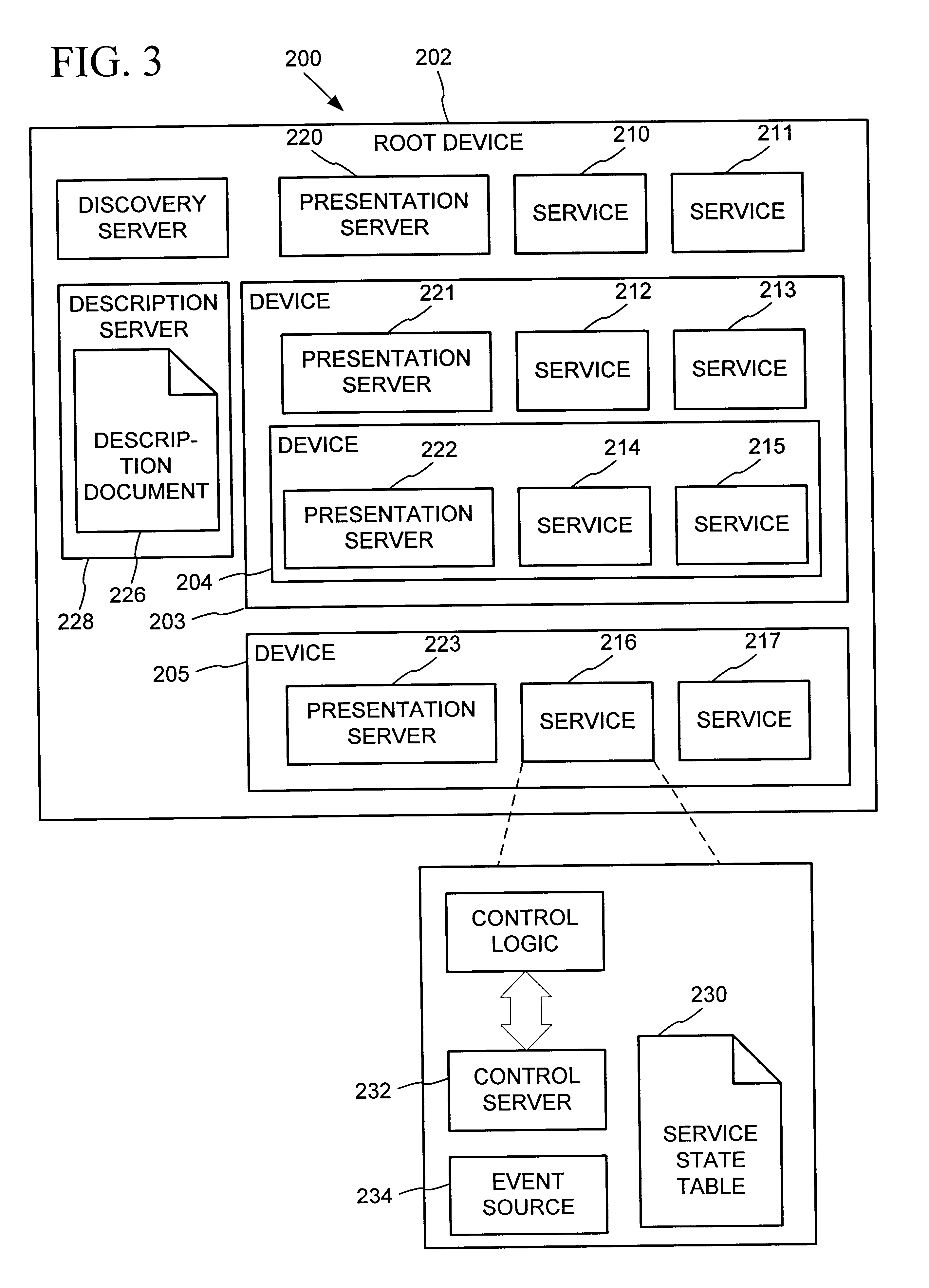

Synchronization of controlled device state using state table and eventing in data-driven remote device control model

InactiveUS6725281B1Falling in priceIncrease speedMultiple digital computer combinationsSecuring communicationEvent synchronizationEvent model

Controlled devices according to a device control model maintain a state table representative of their operational state. Devices providing a user control point interface for the controlled device obtain the state table of the controlled device, and may also obtain presentation data defining a remoted user interface of the controlled device and device control protocol data defining commands and data messaging protocol to effect control of the controlled device. These user control devices also subscribe to notifications of state table changes, which are distributed from the controlled device according to an eventing model. Accordingly, upon any change to the controlled device's operational state, the eventing model synchronizes the device's state as represented in the state table across all user control devices.

Owner:ROVI TECH CORP

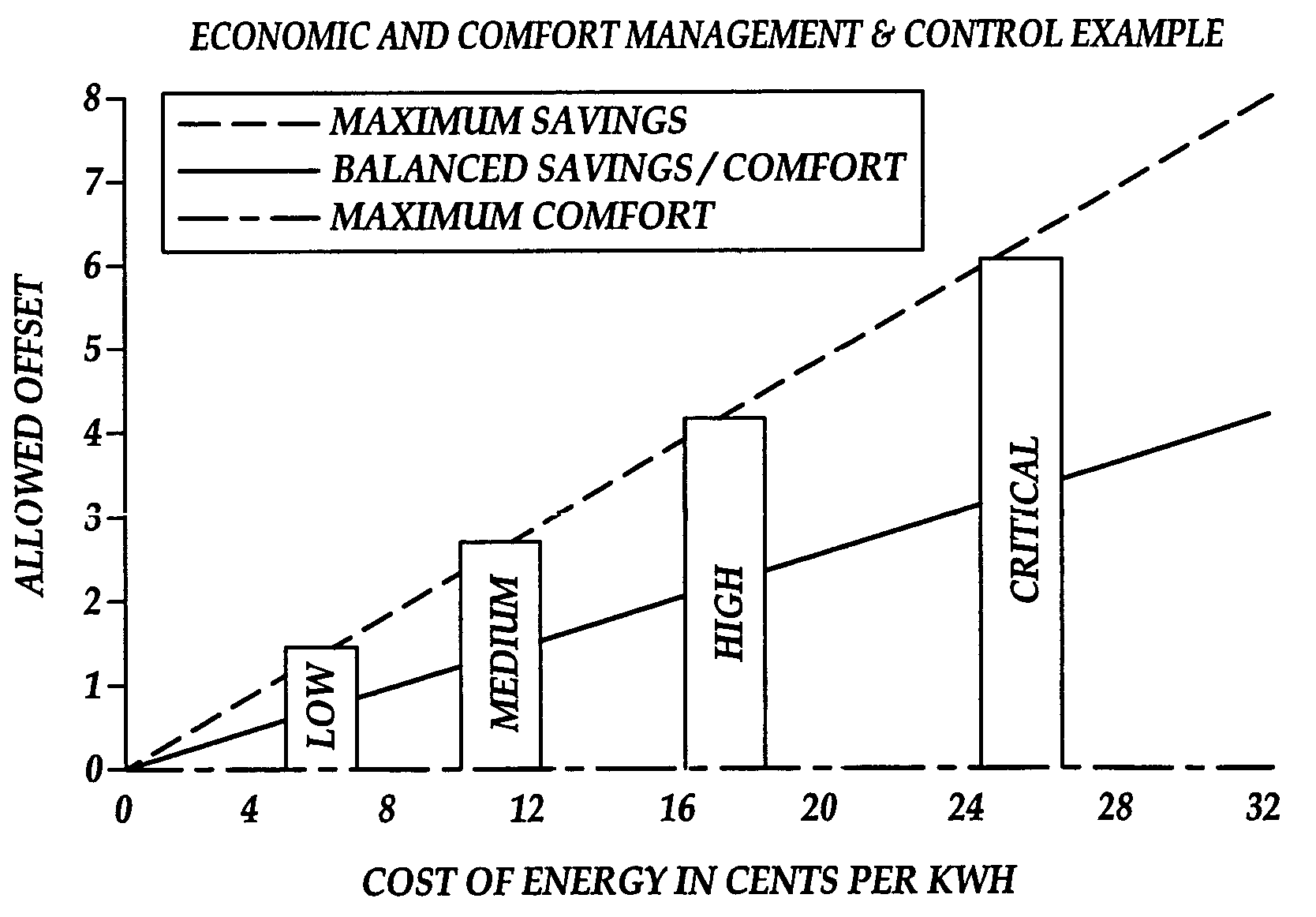

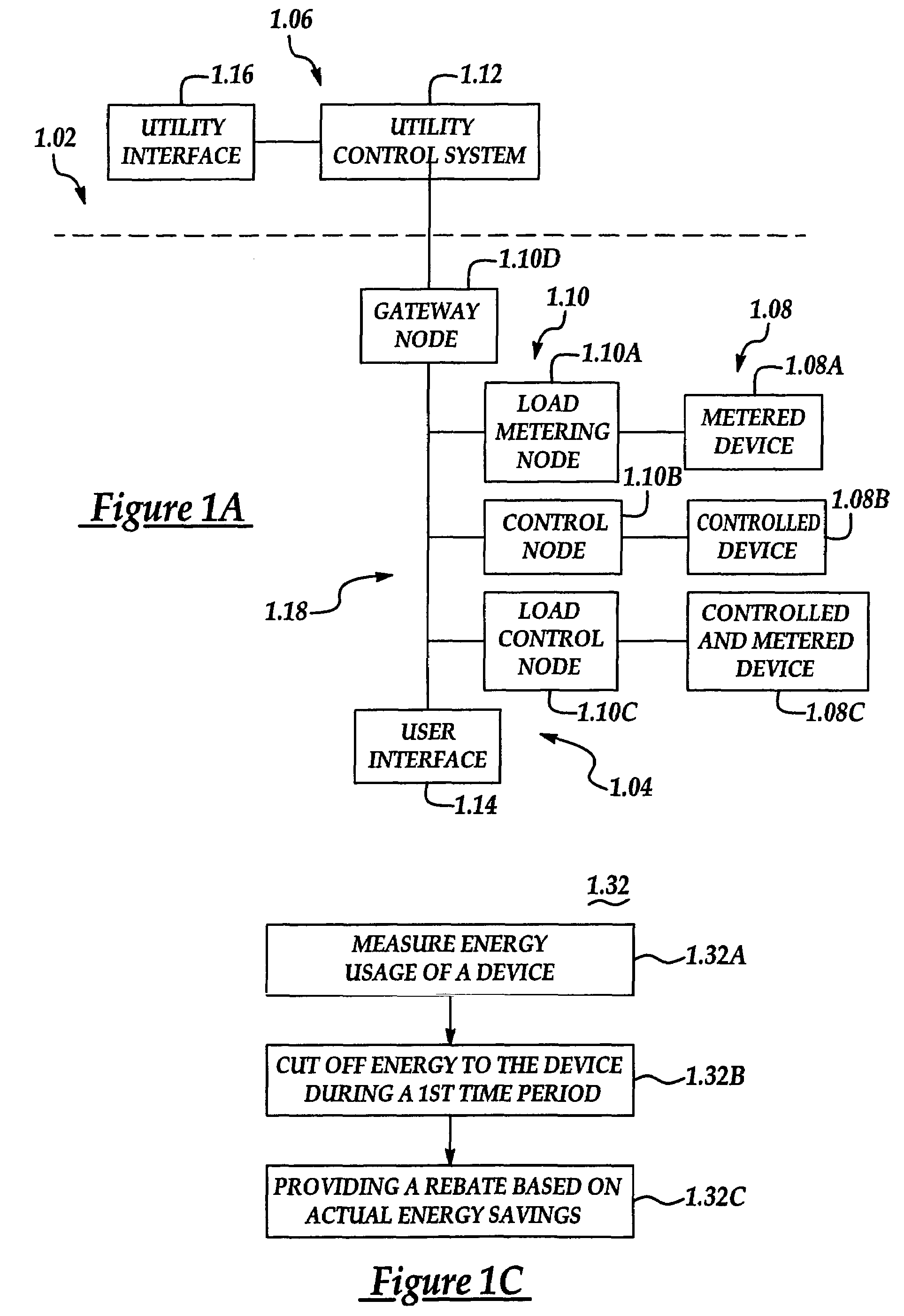

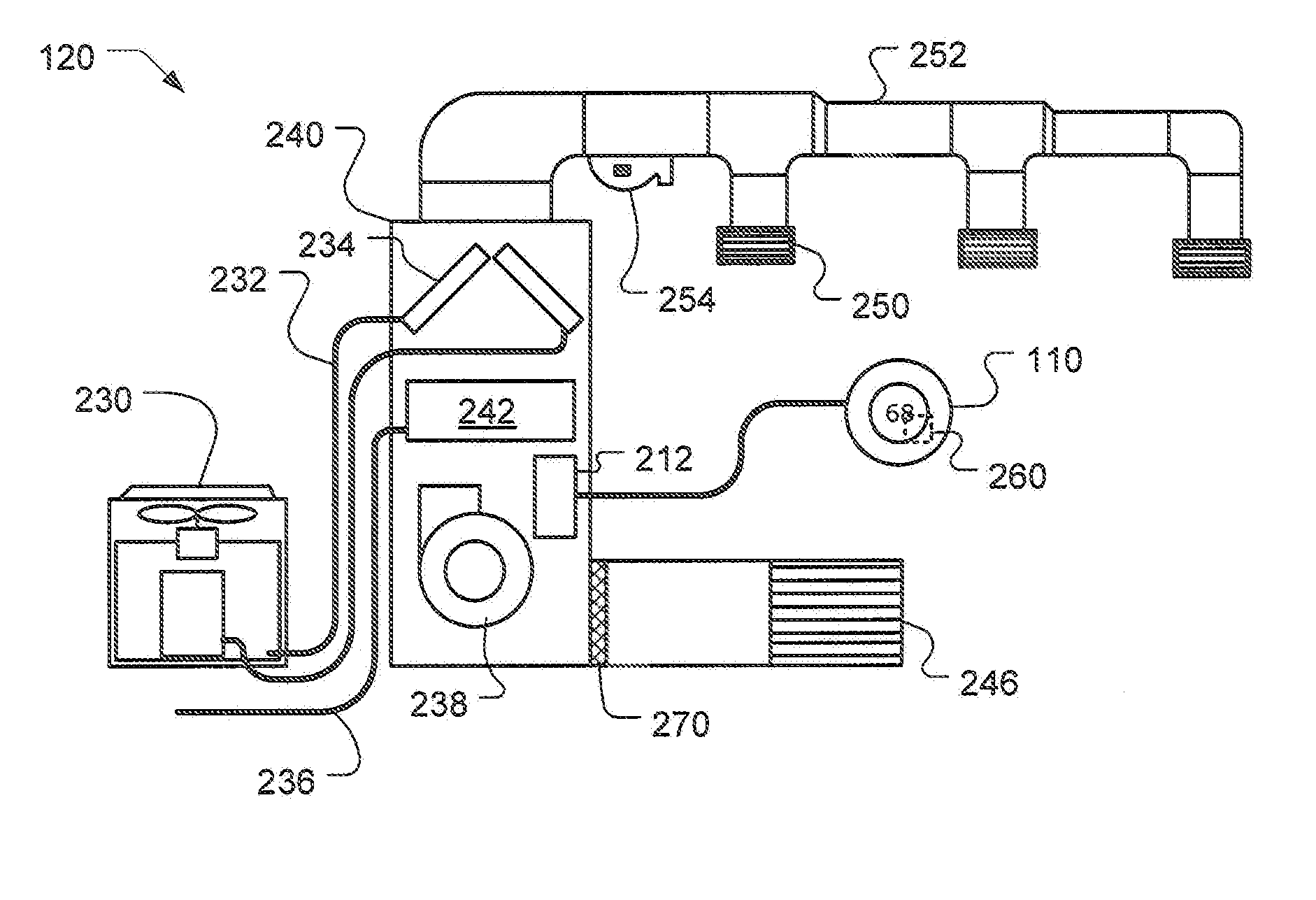

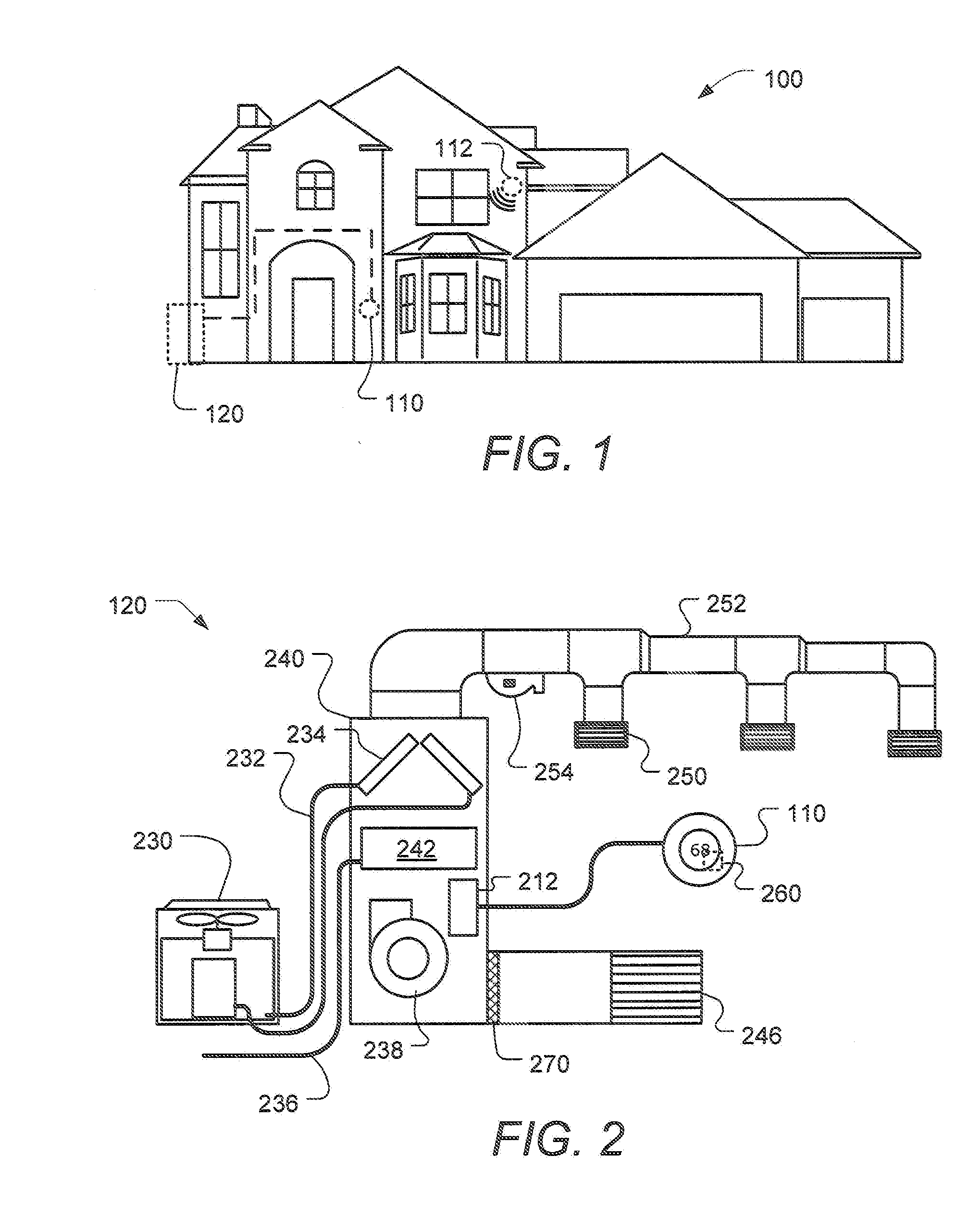

System and method of controlling an HVAC system

A system and method manage delivery of energy from a distribution network to one or more sites. Each site has at least one device coupled to the distribution network. The at least one device controllably consumes energy. The system includes a node and a control system. The node is coupled to the at least one device for sensing and controlling energy delivered to the device. A control system is coupled to the node and distribution network for delivery to the node at least one characteristic of the distribution network. The node controls the supply of energy to the device as a function of the at least one characteristic.

Owner:INVENSYS SYST INC

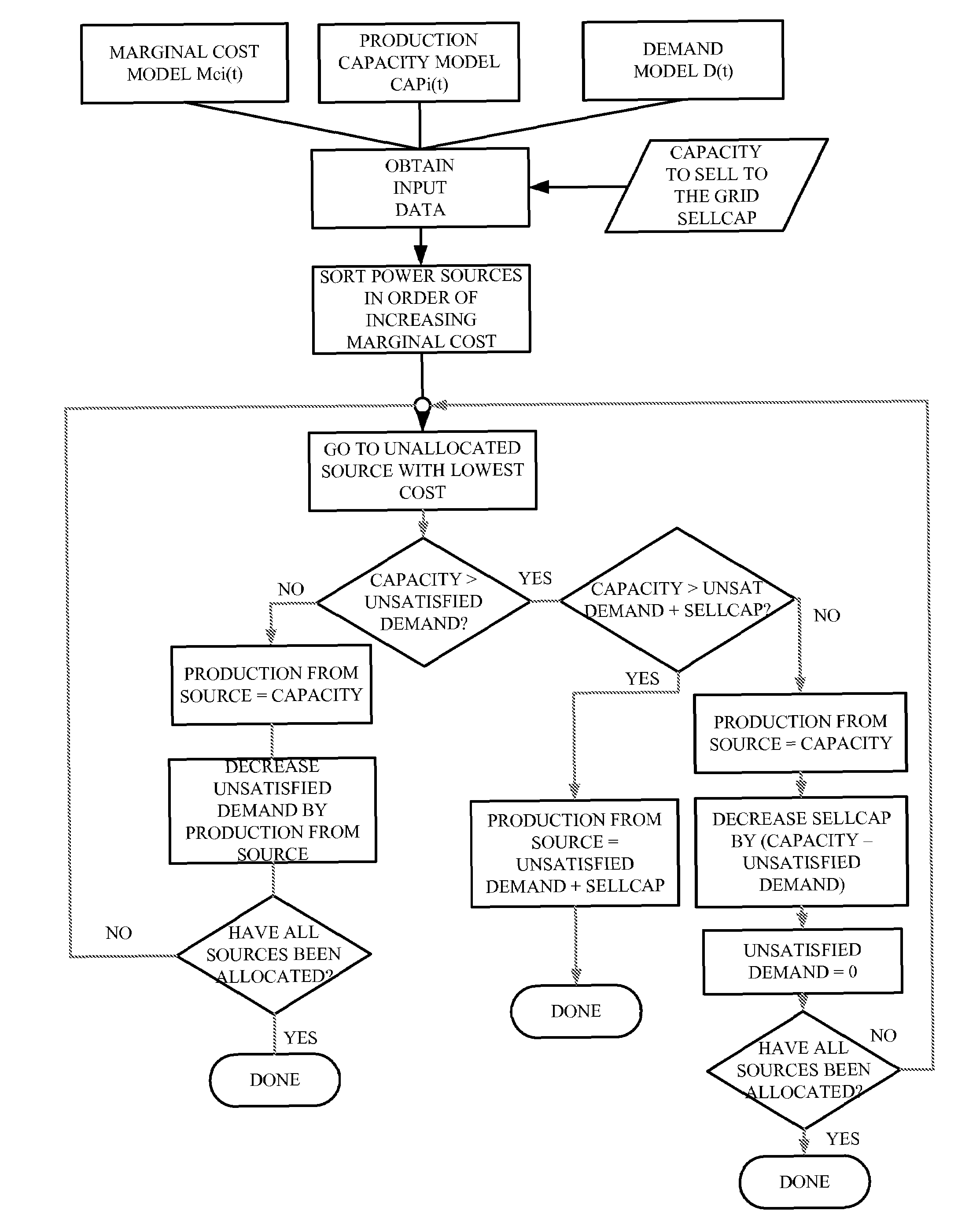

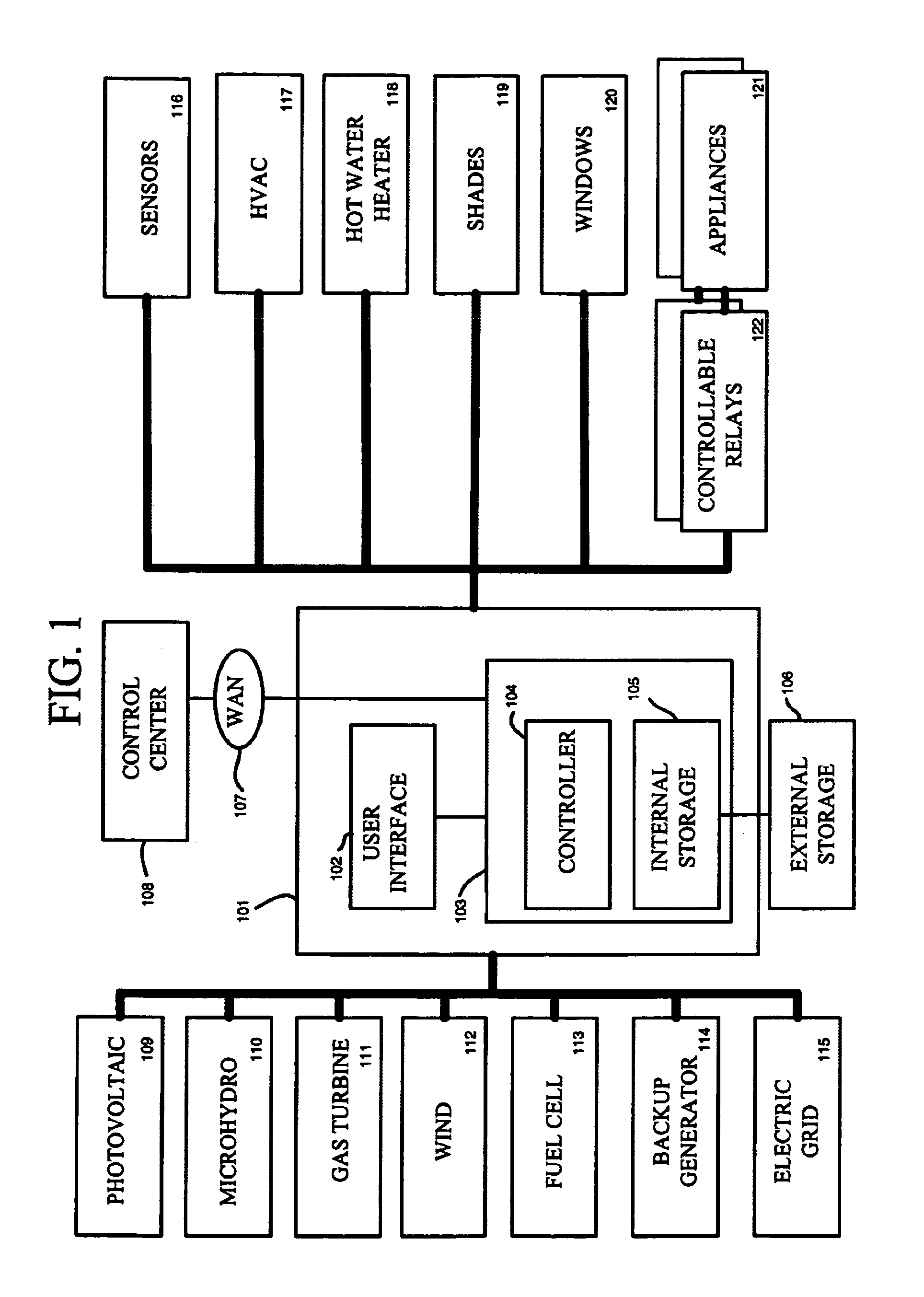

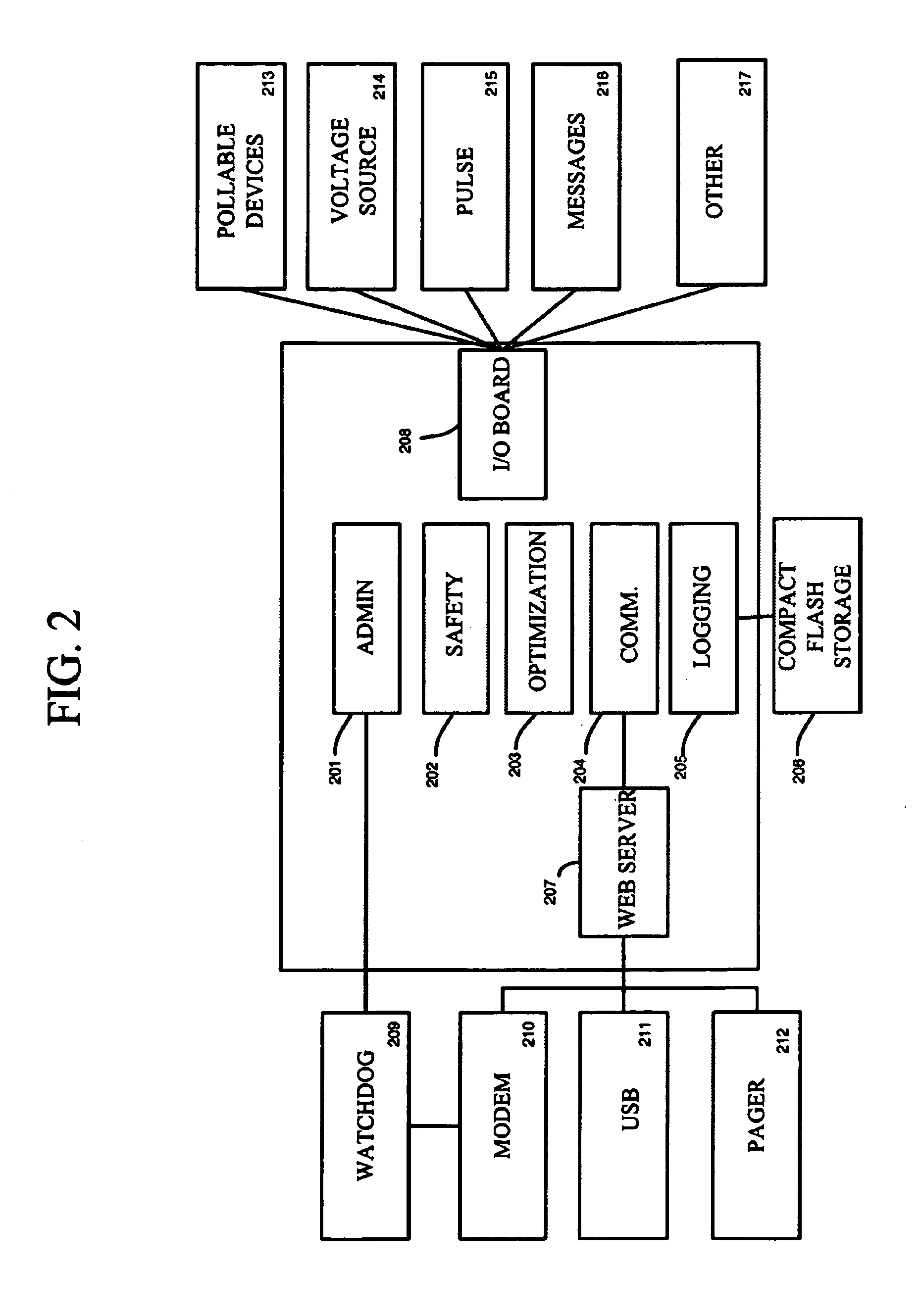

Optimized energy management system

Methods and systems are provided for optimizing the control of energy supply and demand. An energy control unit includes one or more algorithms for scheduling the control of energy consumption devices on the basis of variables relating to forecast energy supply and demand. Devices for which energy consumption can be scheduled or deferred are activated during periods of cheapest energy usage. Battery storage and alternative energy sources (e.g., photovoltaic cells) are activated to sell energy to the power grid during periods that are determined to correspond to favorable cost conditions.

Owner:GRIDPOINT

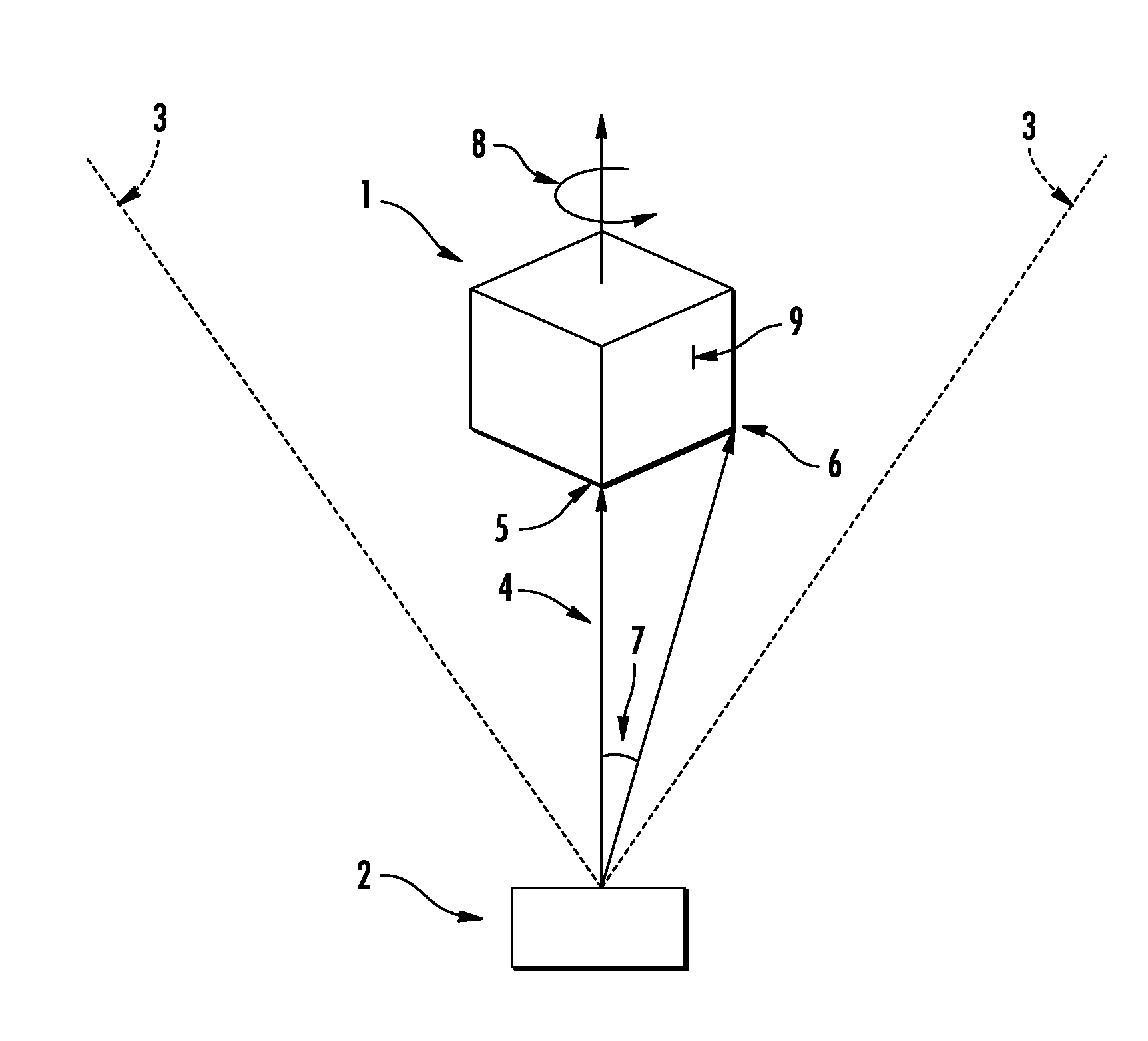

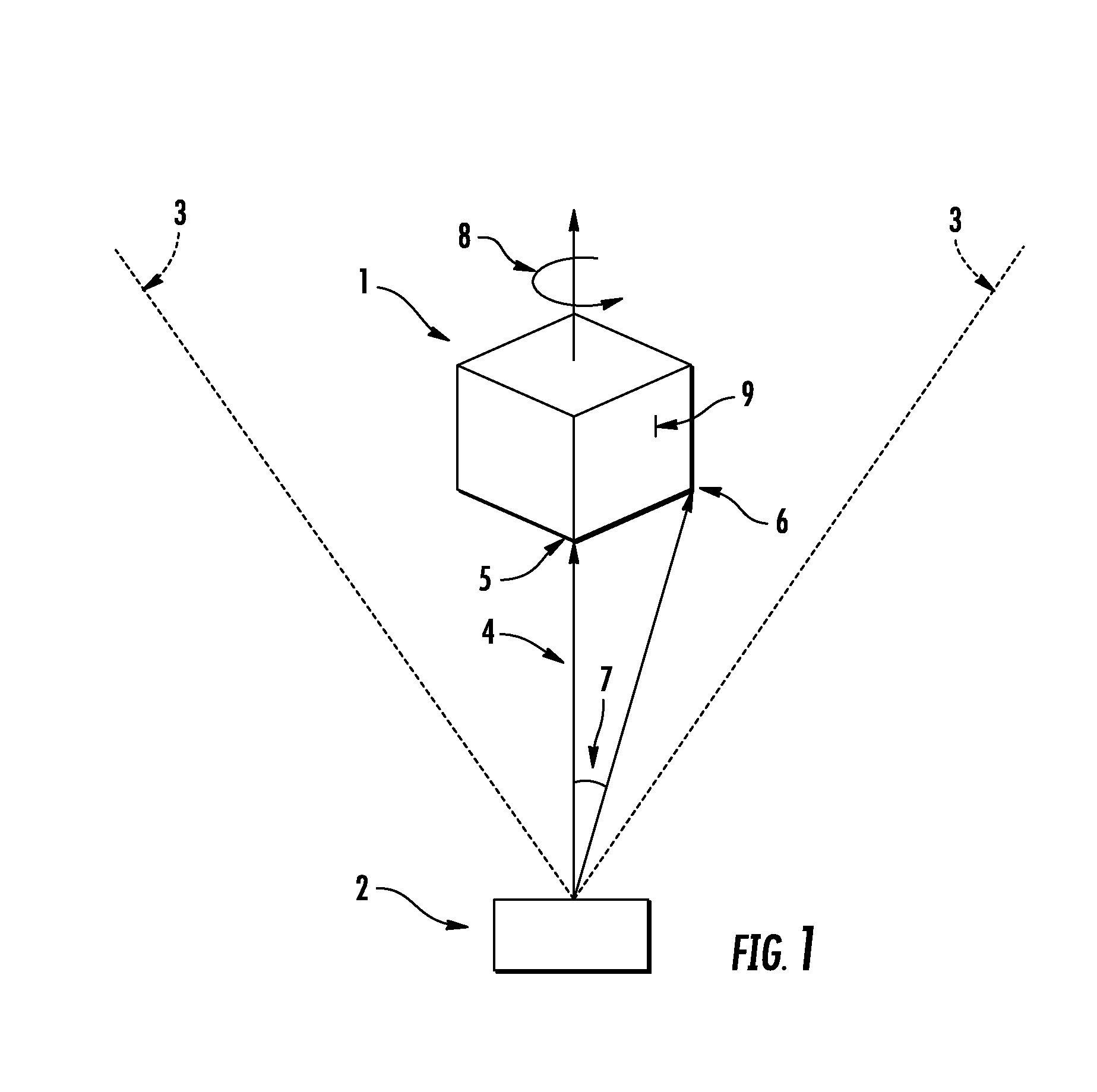

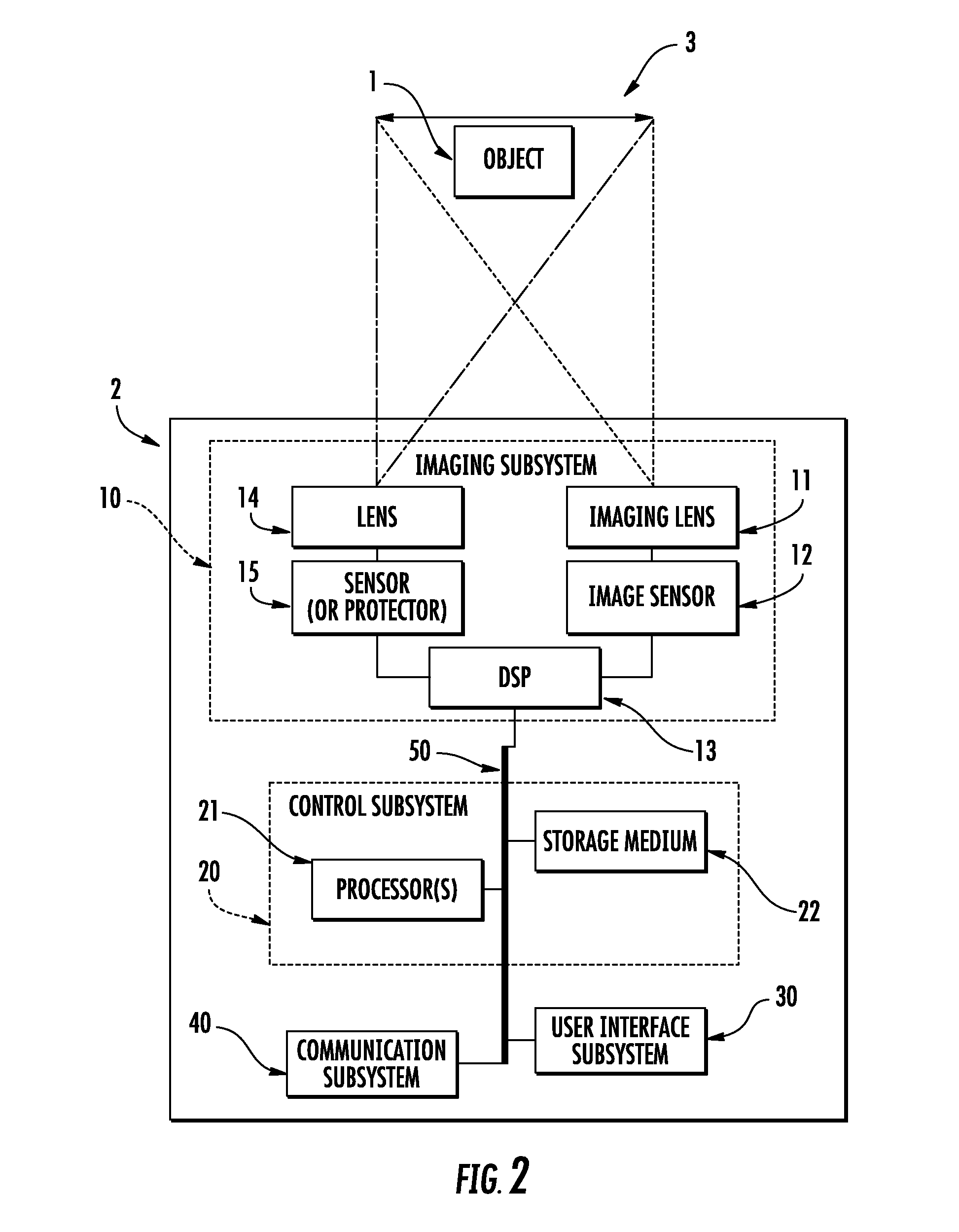

Handheld dimensioning system with measurement-conformance feedback

ActiveUS20160109219A1Color television detailsClosed circuit television systemsTechnical standardDimension measurement

A system and method for obtaining a dimension measurement that conforms to a conformance criteria is disclosed. The dimensioning system provides either (i) feedback to confirm that the measurement complies with the criteria or (ii) information on how the measurement geometry could be adjusted in order to provide a compliant measurement in a subsequent dimension measurement.

Owner:HAND HELD PRODS

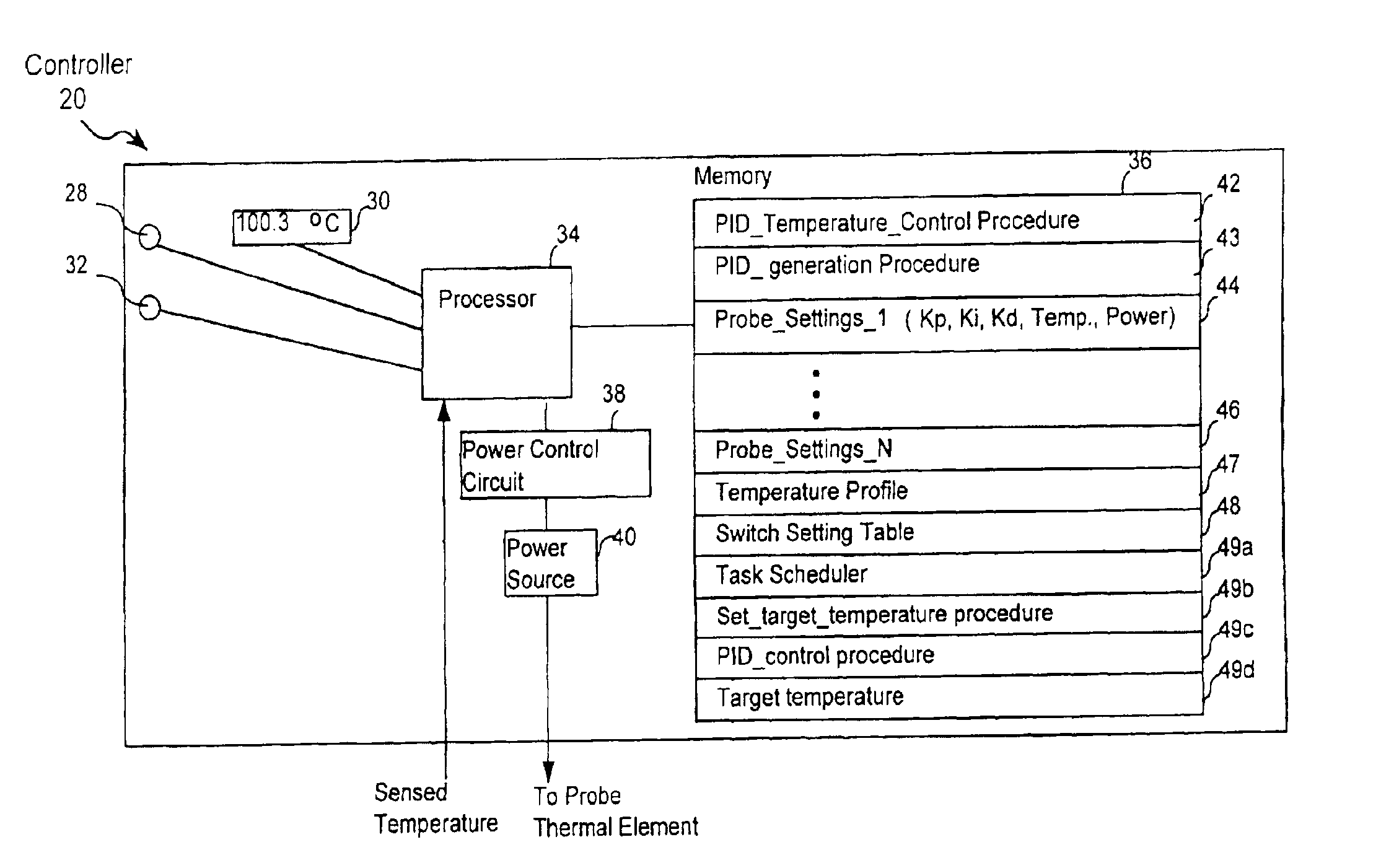

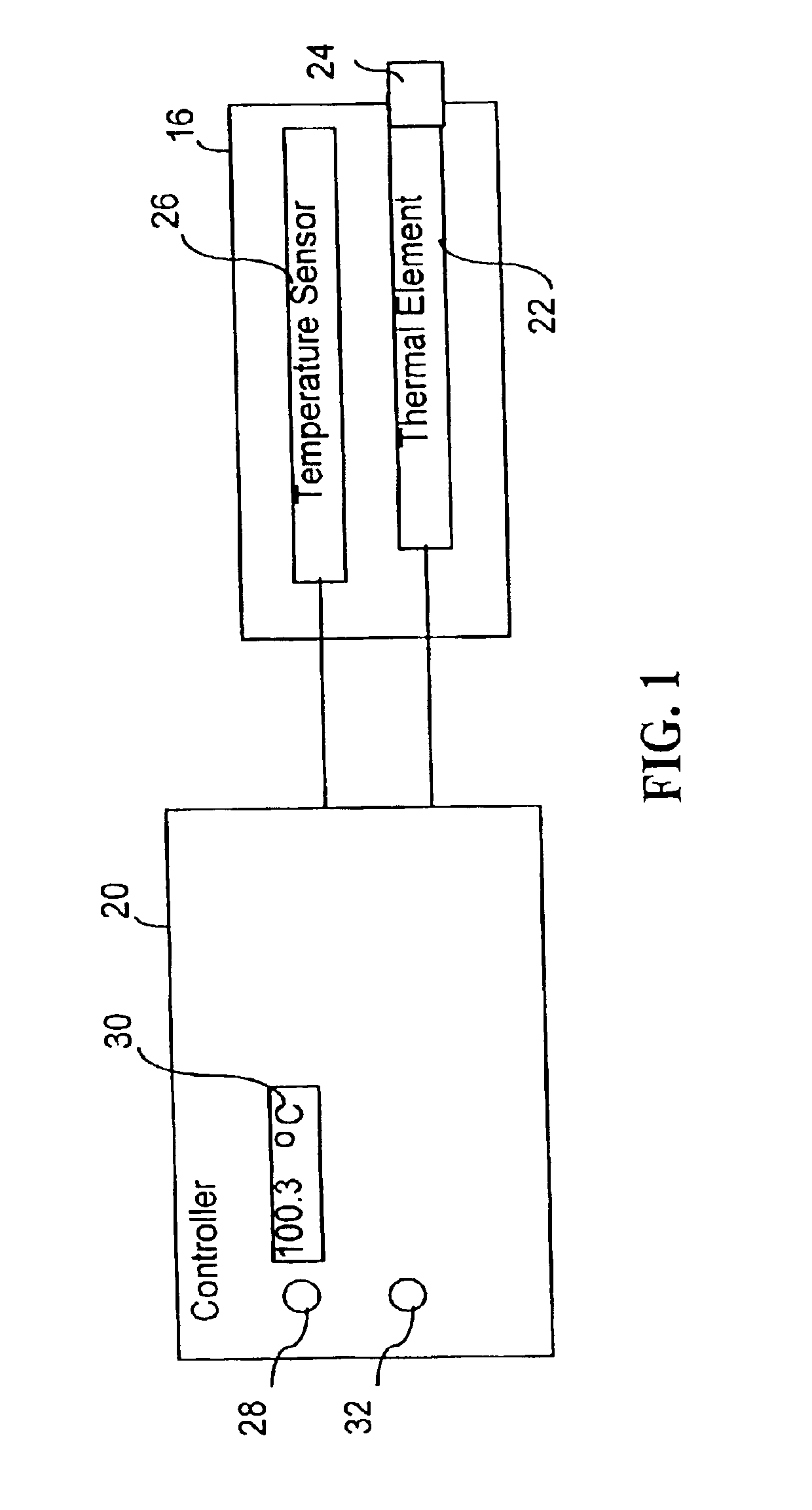

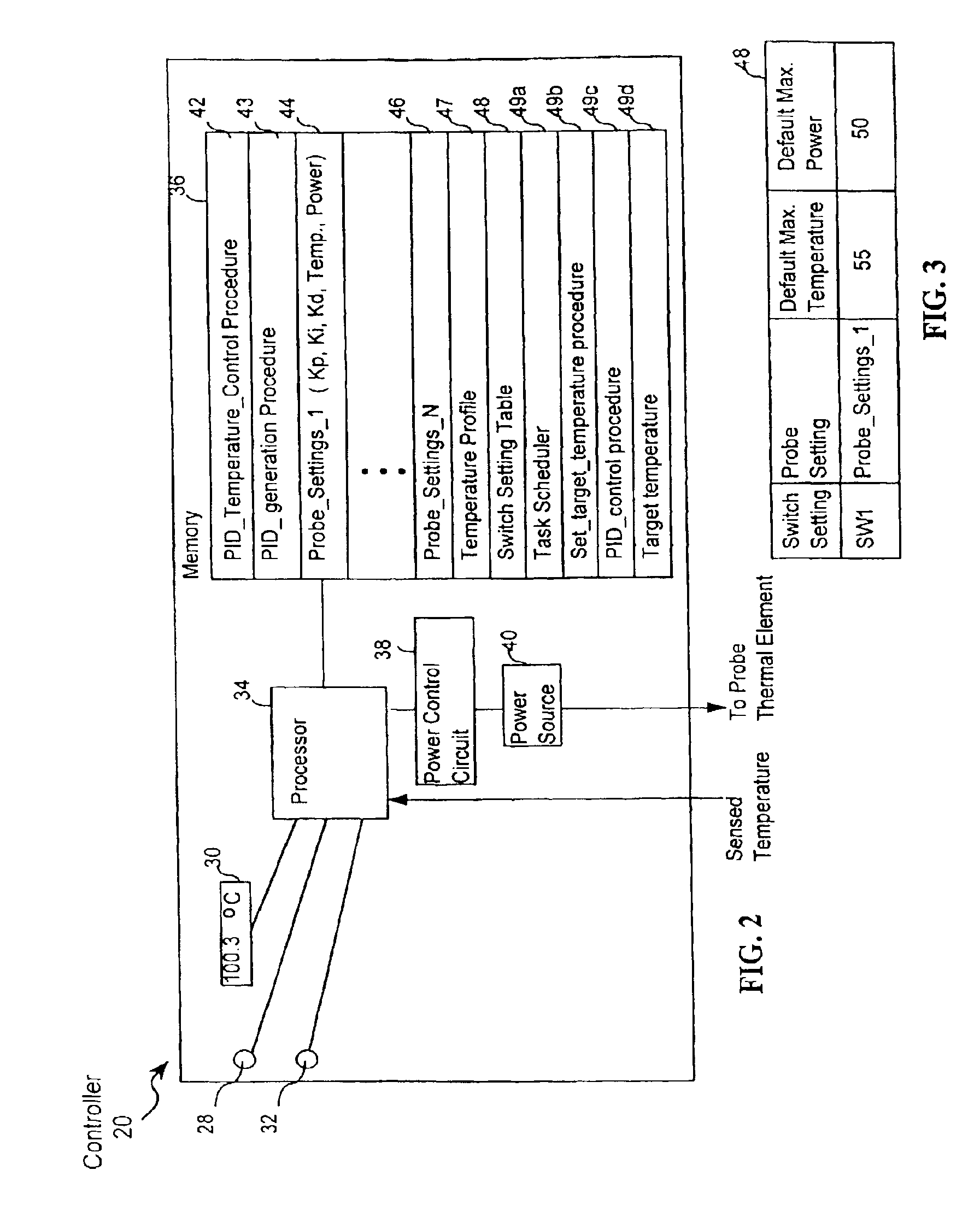

Method and apparatus for controlling a temperature-controlled probe

InactiveUS6939346B2Finer granularity of controlMinimize overshootThermometers using electric/magnetic elementsUsing electrical meansThermal energyMedicine

A thermal energy controller system useful in medical procedures includes a controller coupled to a probe, and a thermal element to vary probe temperature. The controller includes memory storing a non-continuous algorithm that permits user-selectable settings for various probe types such that controller operation is self-modifying in response to the selected probe setting. Probe output power Pout is constant in one mode to rapidly enable probe temperature to come within a threshold of a target temperature. The controller can then vary Pout dynamically using a proportional-integral-derivative (PID) algorithm Pout=Kp·P+Ki·I+Kd·D, where feedback loop coefficients Kp, Ki, Kd can vary dynamically depending upon magnitude of an error function e(t) representing the difference between a user-set desired target temperature and sensed probe temperature. Advantageously, target temperature can be rapidly attained without overshoot, allowing the probe system to be especially effective in arthroscopic tissue treatment.

Owner:ORATEC INTERVENTIONS

Vehicle rearview mirror assembly incorporating a communication system

InactiveUS6980092B2Easy to installMinimal additional wiringMirrorsSimultaneous aerial operationsCommunications systemControl system

A vehicle communication and control system is provided that may be more readily installed in a vehicle and that utilizes minimal additional wiring. According to some of the disclosed embodiments, the electrical components of the “brick” of a communication and control system are integrated into a rearview mirror assembly. Preferably, the microwave antenna for the GPS and the cellular telephone antenna are also integrated into the rearview mirror assembly. Various functions and features of the system are also disclosed.

Owner:GENTEX CORP

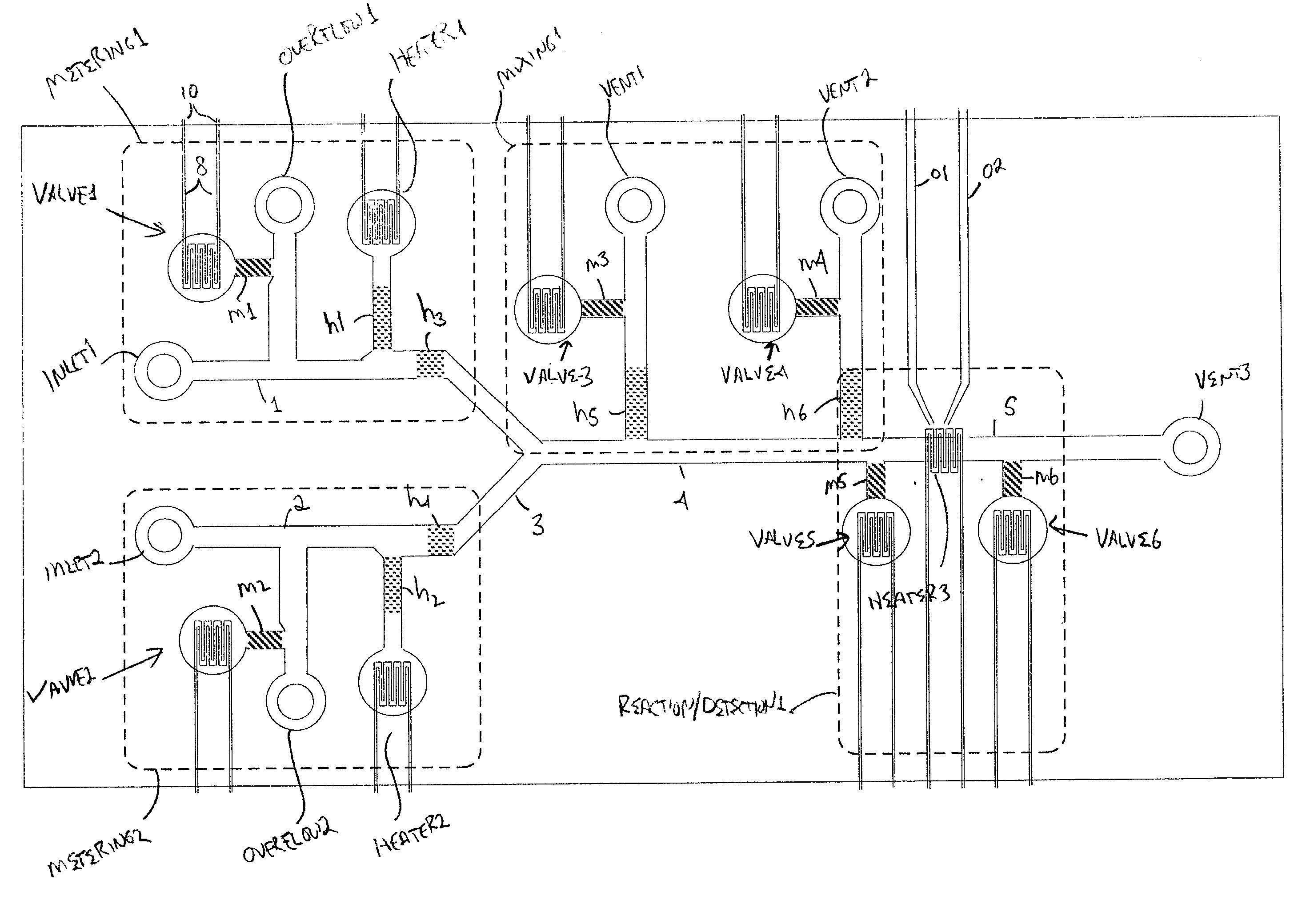

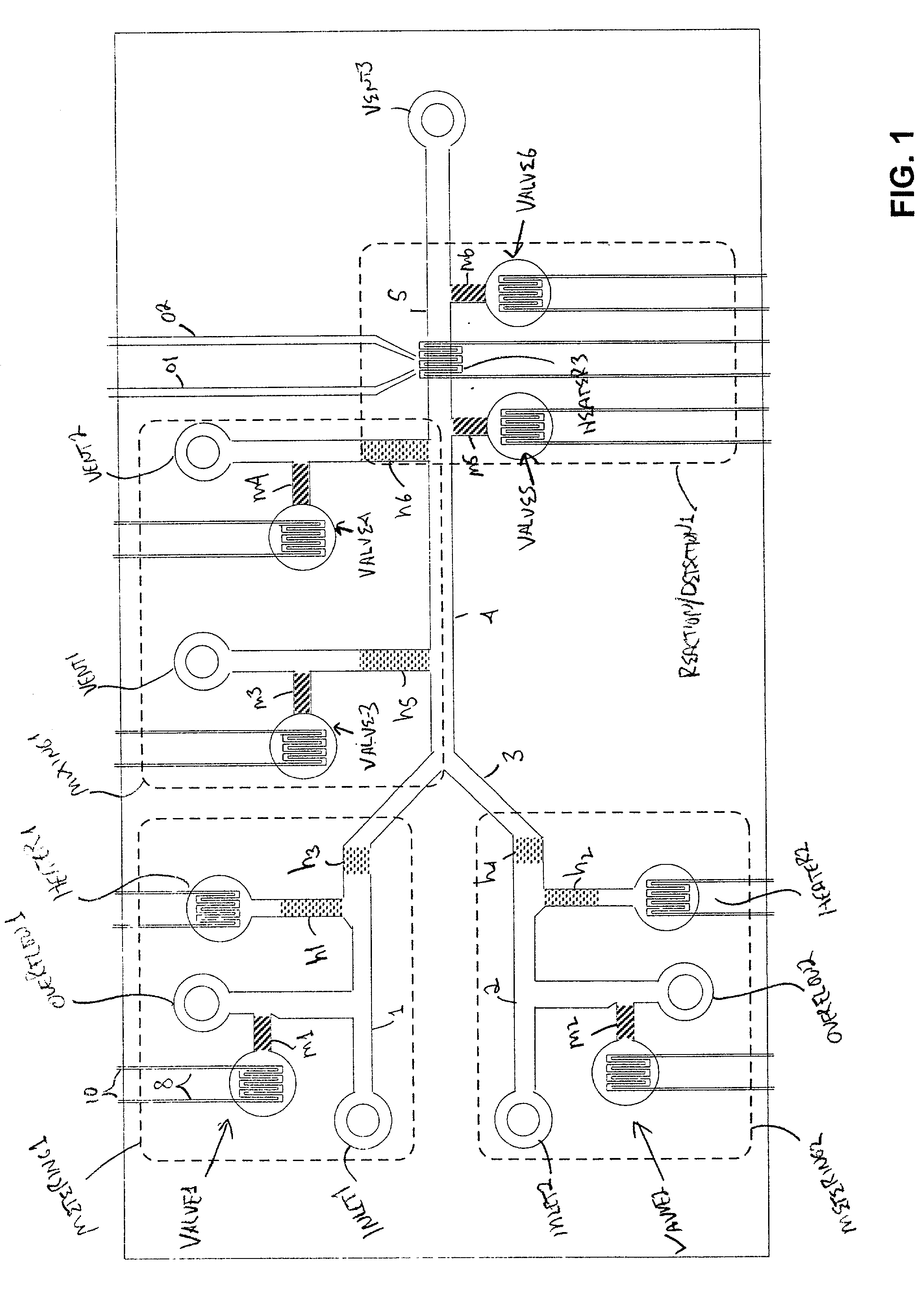

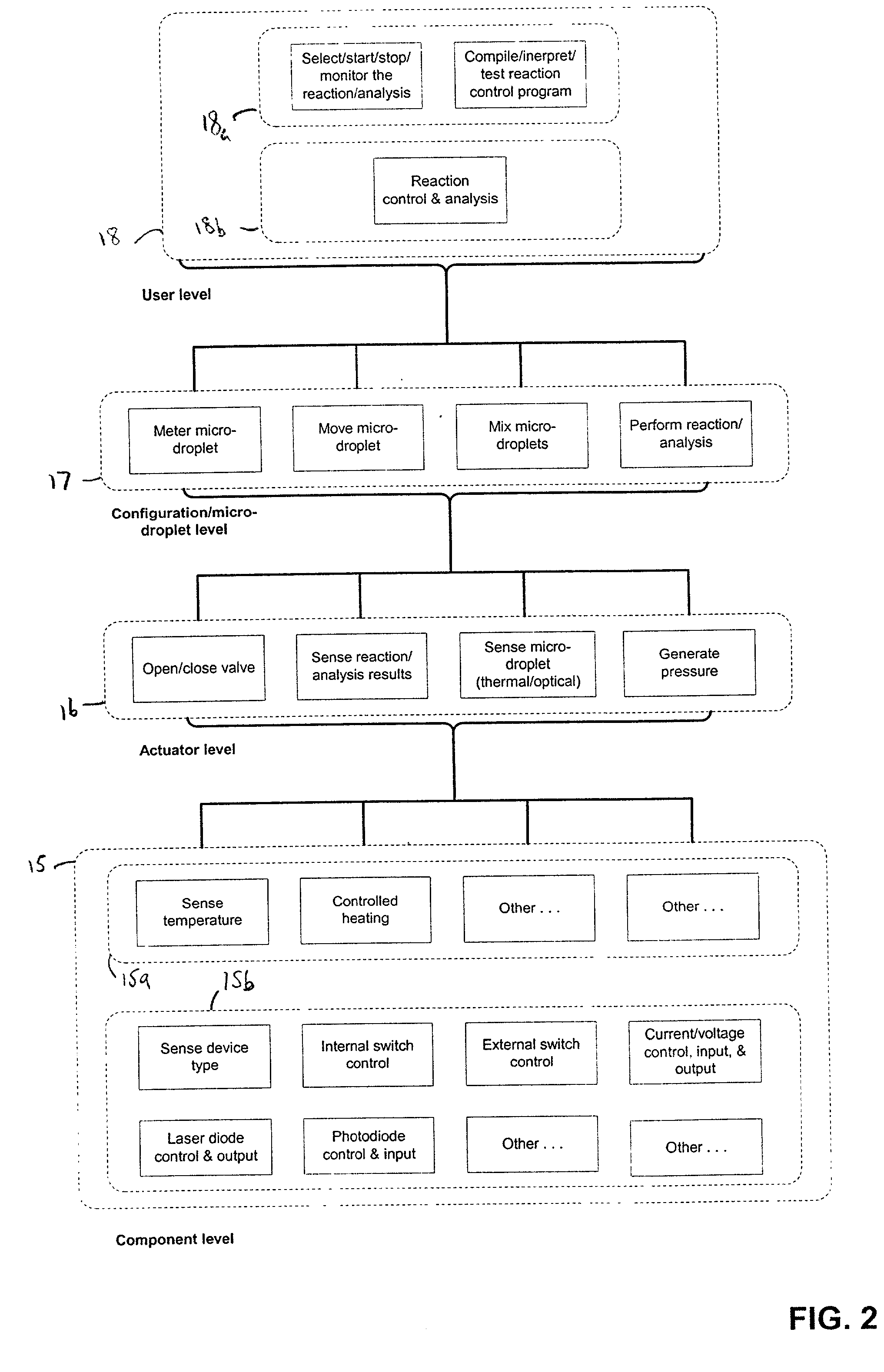

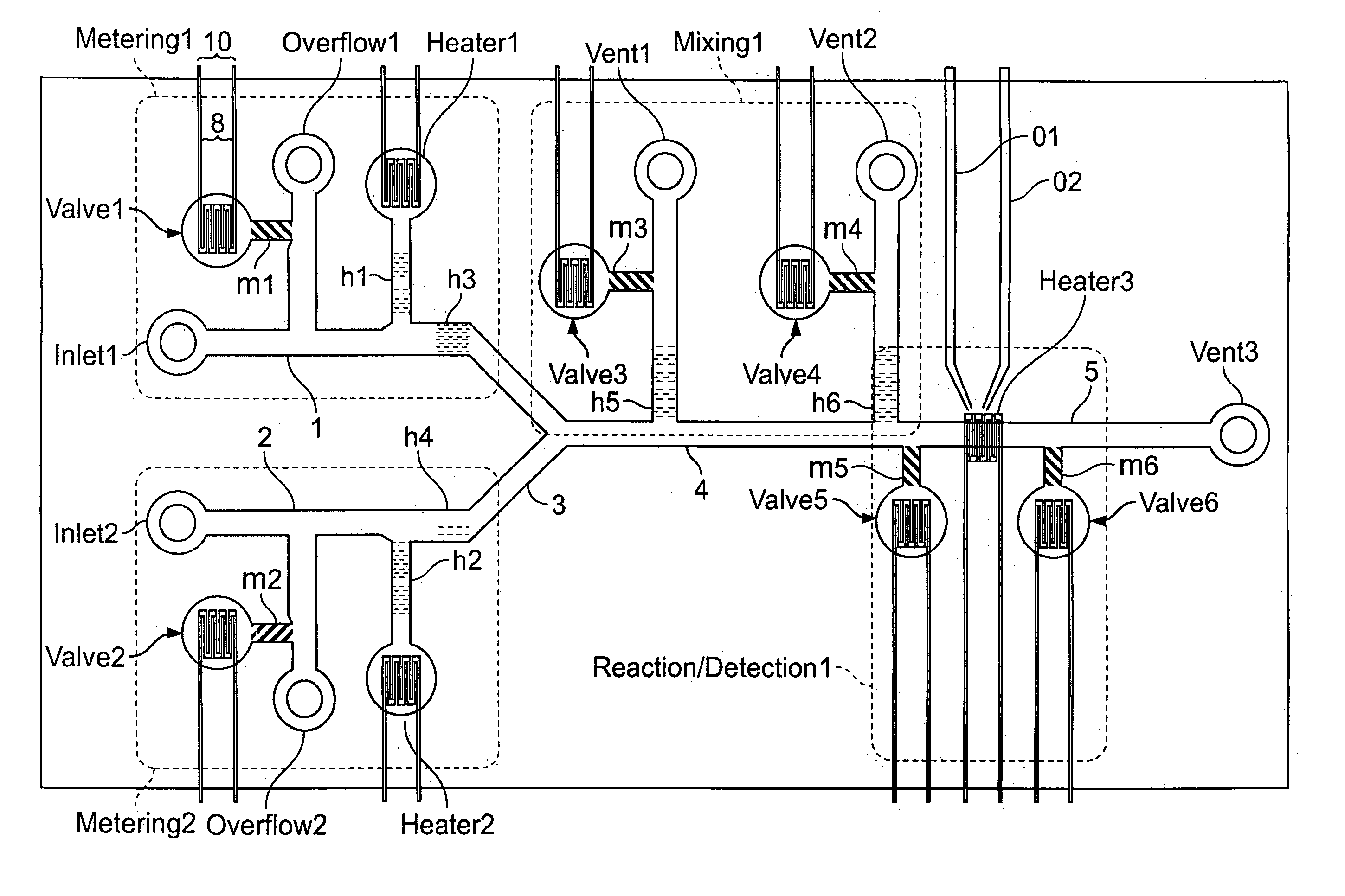

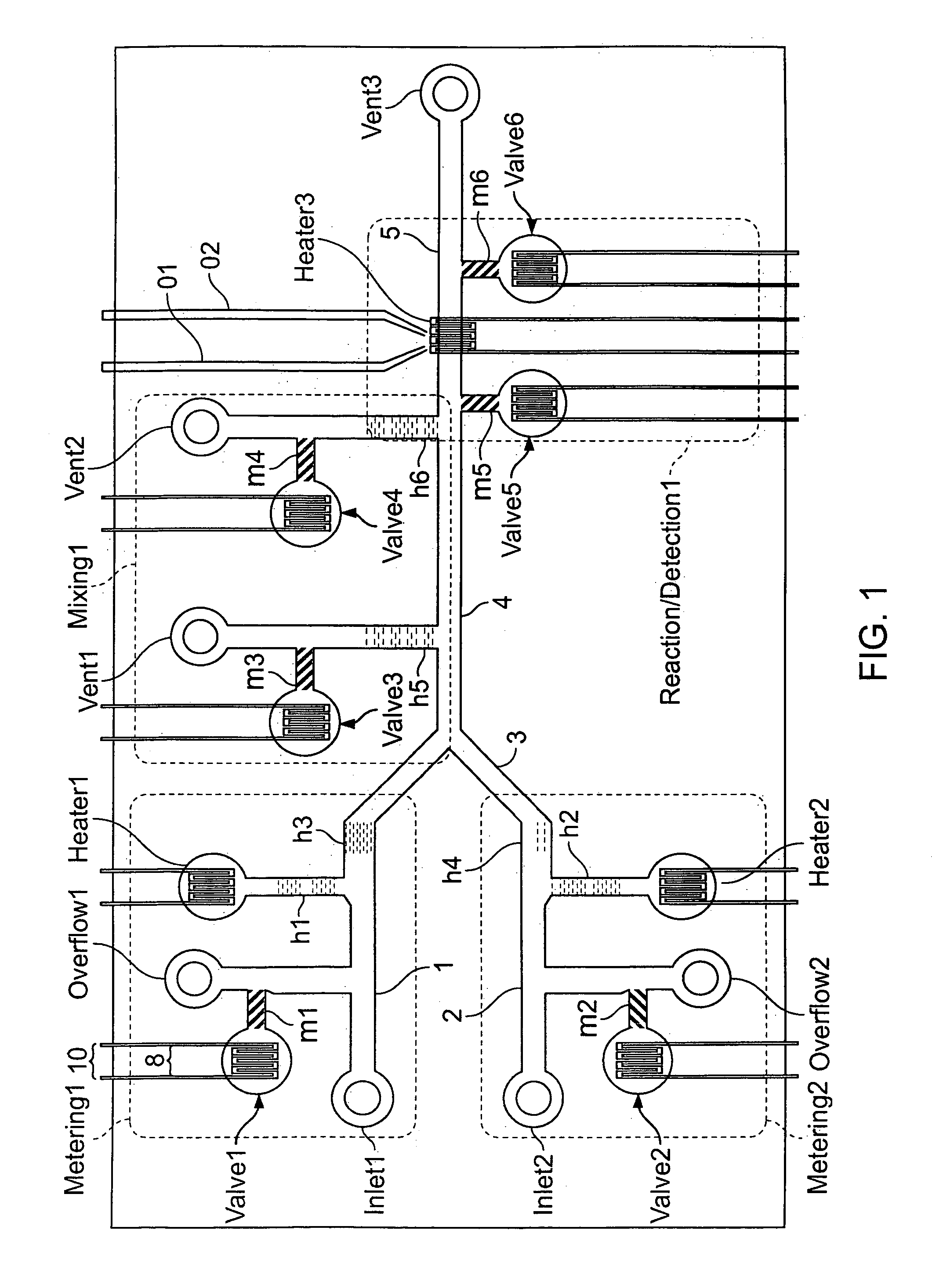

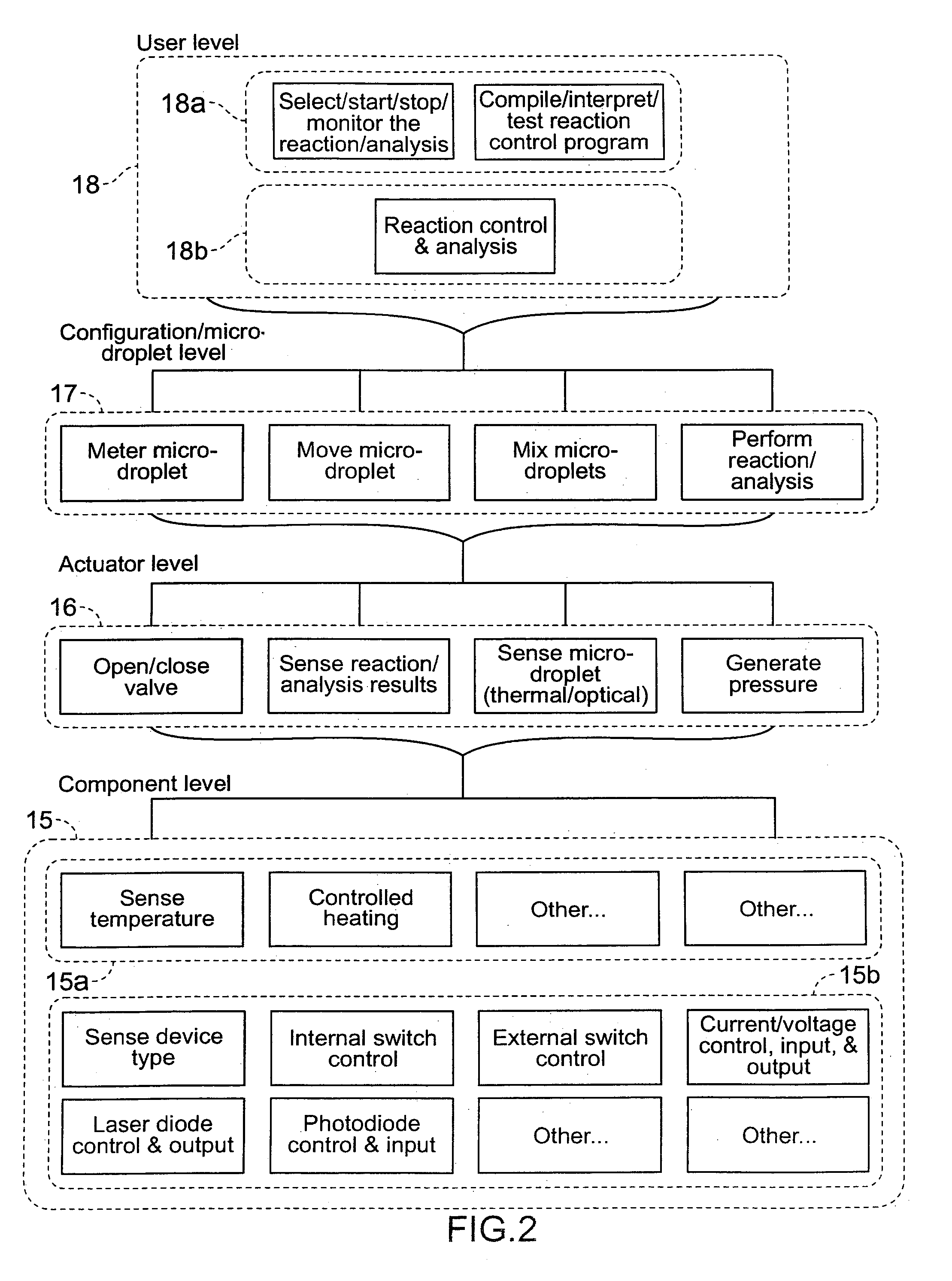

Methods and systems for control of microfluidic devices

InactiveUS20020143437A1Overcome deficienciesFixed microstructural devicesVolume/mass flow measurementControl systemLow voltage

The present invention provides control methods, control systems, and control software for microfluidic devices that operate by moving discrete micro-droplets through a sequence of determined configurations. Such microfluidic devices are preferably constructed in a hierarchical and modular fashion which is reflected in the preferred structure of the provided methods and systems. In particular, the methods are structured into low-level device component control functions, middle-level actuator control functions, and high-level micro-droplet control functions. Advantageously, a microfluidic device may thereby be instructed to perform an intended reaction or analysis by invoking micro-droplet control function that perform intuitive tasks like measuring, mixing, heating, and so forth. The systems are preferably programmable and capable of accommodating microfluidic devices controlled by low voltages and constructed in standardized configurations. Advantageously, a single control system can thereby control numerous different reactions in numerous different microfluidic devices simply by loading different easily understood micro-droplet programs.

Owner:HANDYLAB

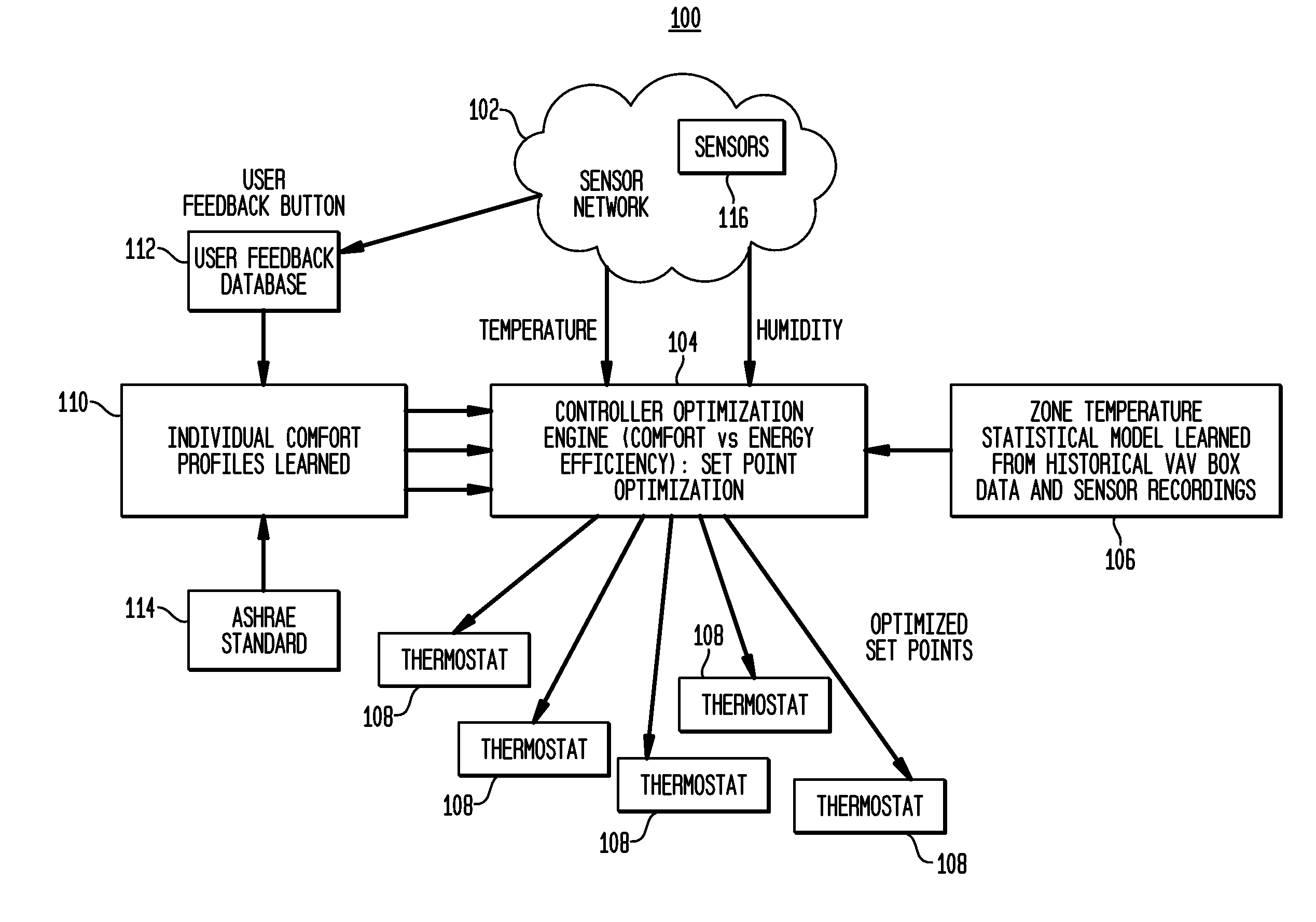

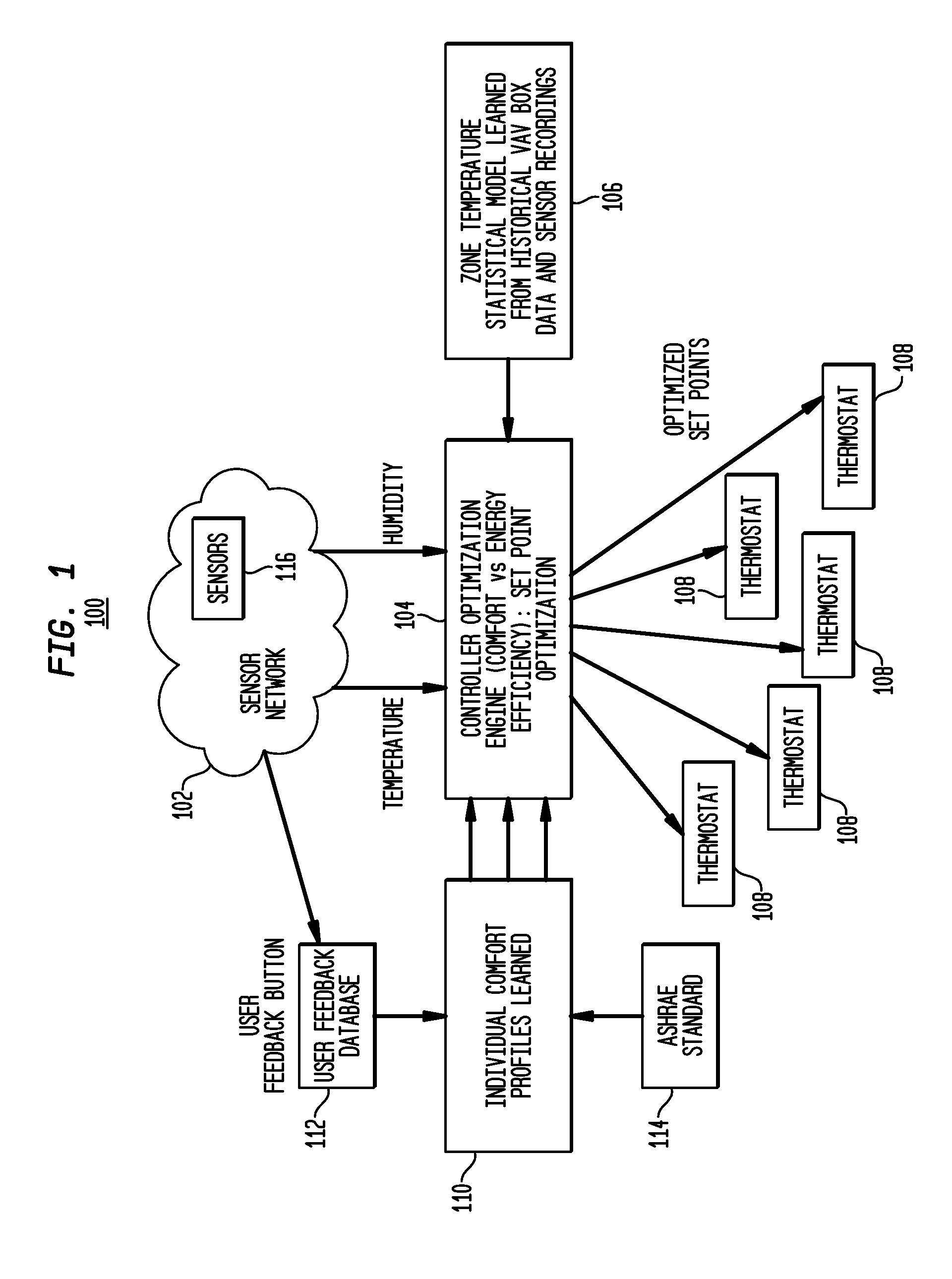

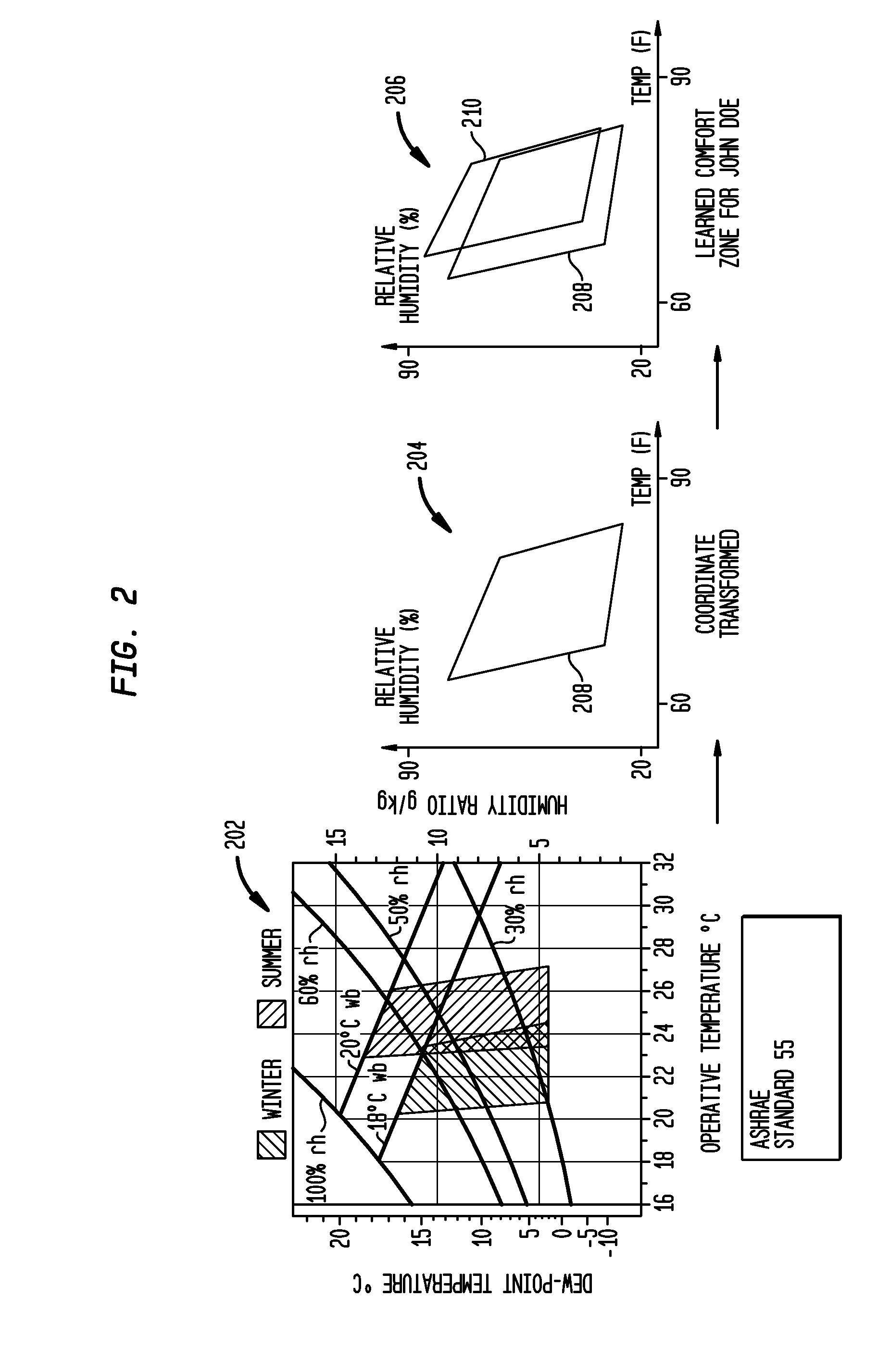

System and Method for Climate Control Set-Point Optimization Based On Individual Comfort

A system and method for calibrating a set-point for climate control includes a sensor network having a plurality of sensors configured to report a climate condition. A database is configured to receive reports from the sensors and generate one or more profiles reflecting at least one of historic climate control information and occupant preferences. A controller is configured to receive information from the profiles to generate a set-point based upon an optimization program. The optimization program is implemented to balance competing goals to generate the set-point for controlling climate control equipment in accordance with the set-point.

Owner:SIEMENS IND INC

Method and apparatus for providing tactile sensations

ActiveUS20030122779A1Input/output for user-computer interactionCathode-ray tube indicatorsTactile sensationTouchpad

Abstract of Disclosure Products and processes for providing tactile sensations to input devices or electronic devices are provided. Input devices include mechanical input devices (such as, for example, mechanical switches) and non-mechanical input devices (such as, for example, touchpads). Tactile feedback is provided by using an actuator or other means in communication with the input device or electronic device. A controller may be employed to receive signals from the input devices and control the actuator. Tactile feedback to an input device or electronic device may be provided in response to one or more events or situations. Such an event or situation may be any one designated. Examples of such events and situations include the level of pressure placed on an input device; the availability or lack of availability of a function associated with an input device; and the function, menu, or mode of operation associated with an input device s activation. A variety of feedback types and combinations may be selected.

Owner:IMMERSION CORPORATION

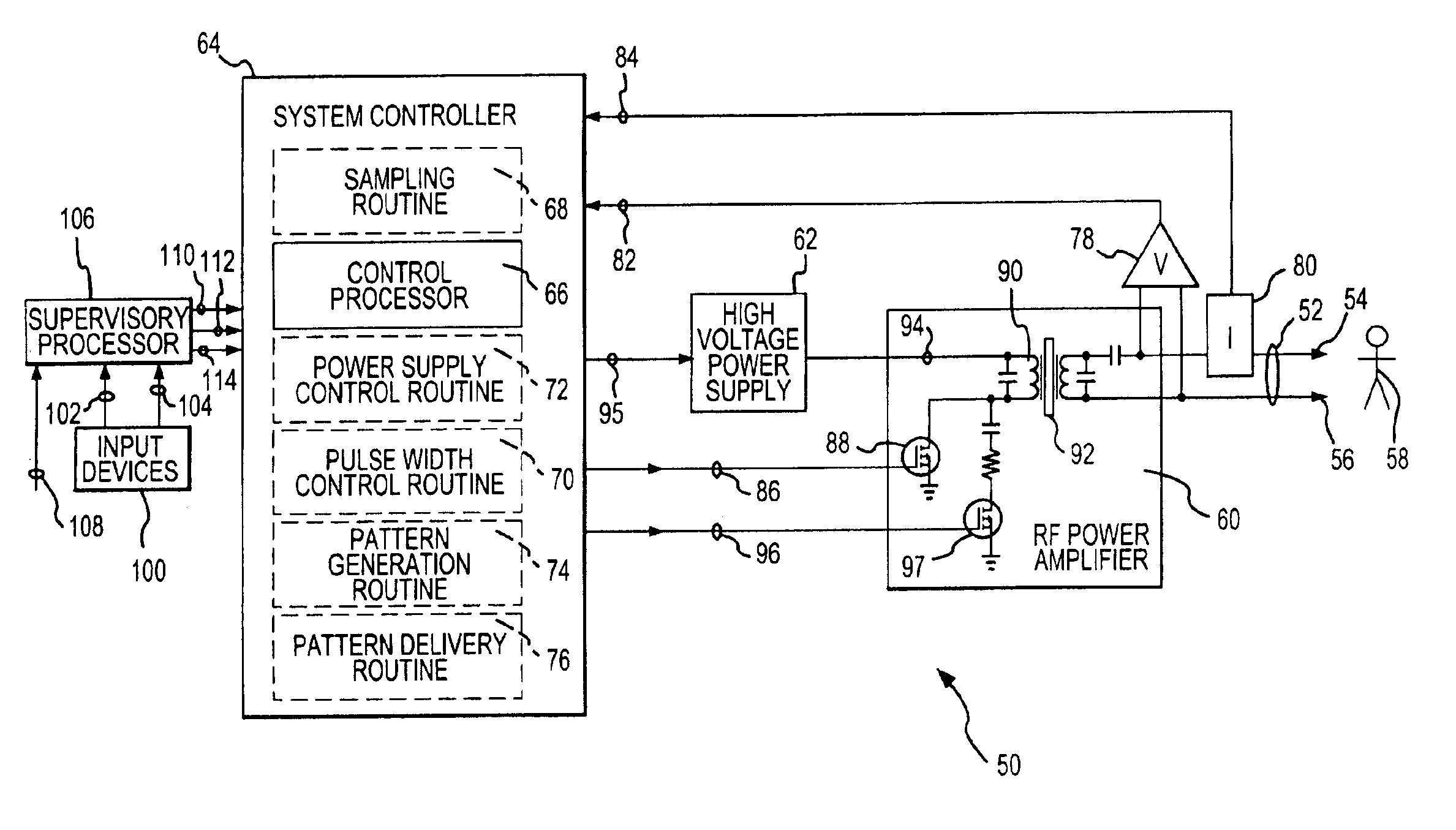

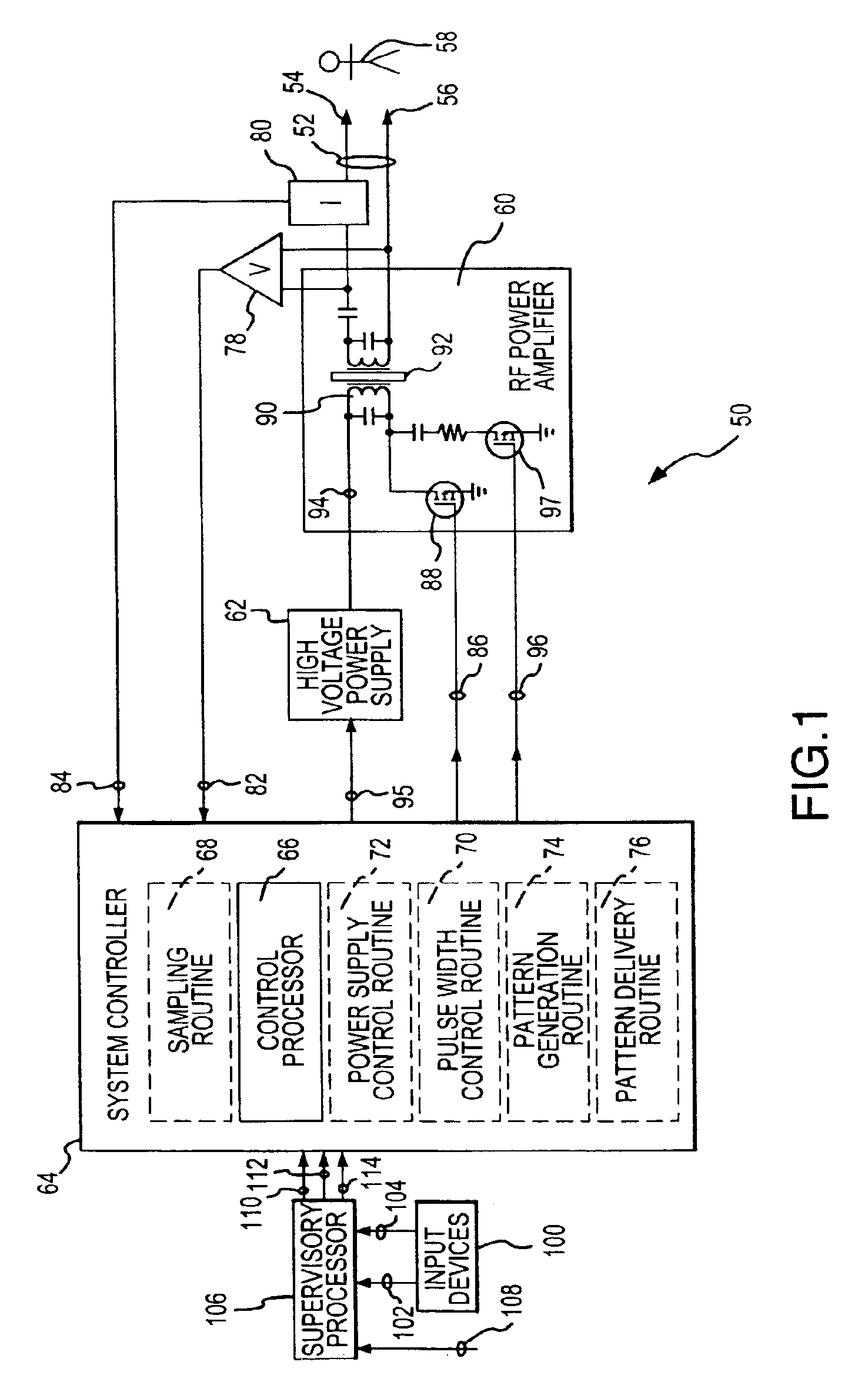

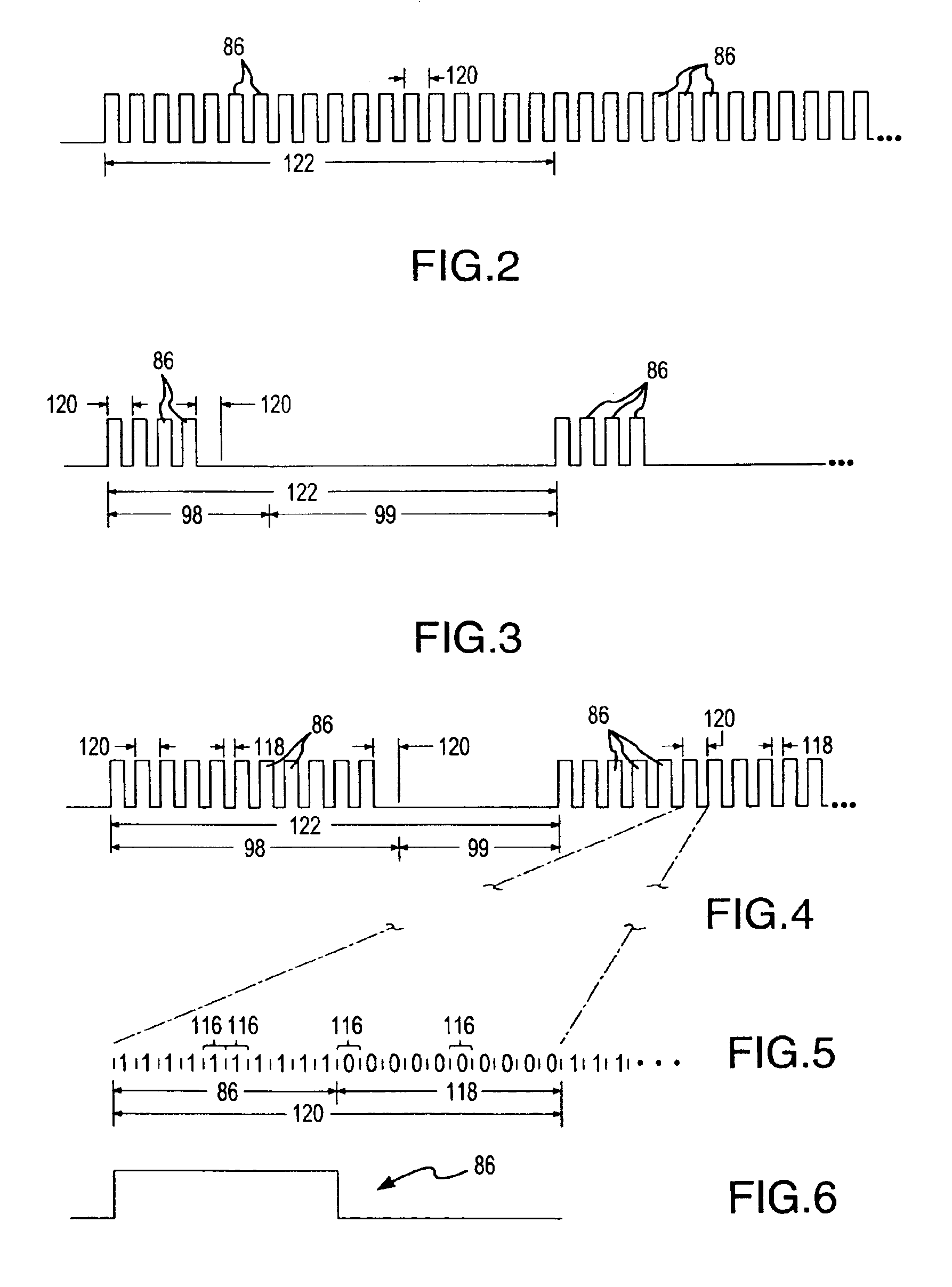

Electrosurgical generator and method with multiple semi-autonomously executable functions

InactiveUS6942660B2Compromising performanceCompromising safetySurgical instruments for heatingPattern generationOperation mode

Semi-autonomously executed routines accomplish the primary functions of electrosurgical energy delivery on a responsive basis for power control purposes and to adapt the delivered output waveform to perform new and better surgical procedures. The routines include and output voltage and output current sampling routine, a control routine for establishing the width of drive pulses used to create the output waveform, a pattern generation routine for establishing the pattern of drive pulses to be delivered in one mode cycle established by a selected mode of operation, a pattern delivery routine for repeatedly delivering sequences of the mode cycle pattern of drive pulses, and a power supply control routine for varying the voltage of the drive pulses in coordination with varying the width of the drive pulses.

Owner:CONMED CORP

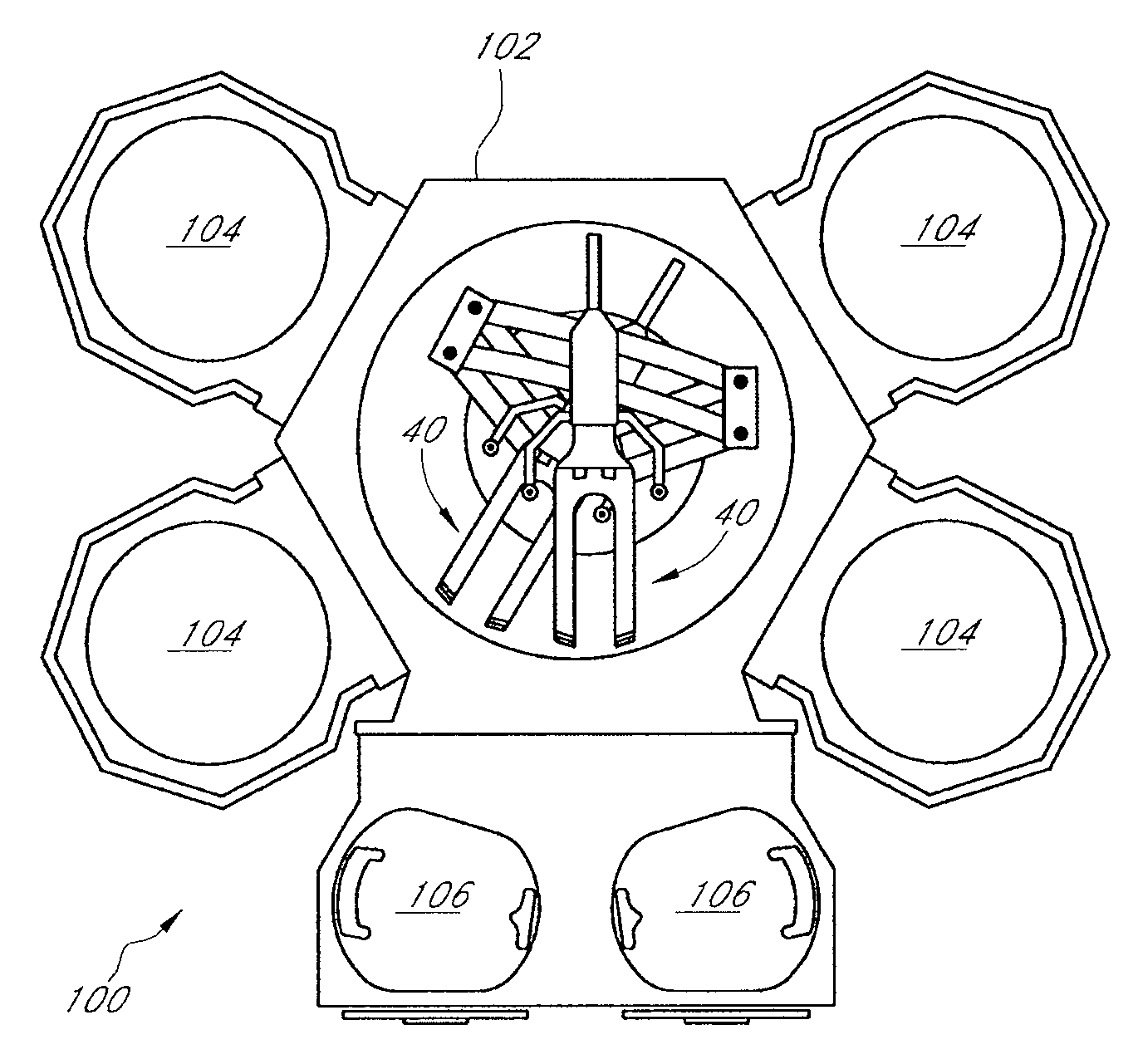

Position sensor system for substrate transfer robot

A substrate processing apparatus comprises a substrate handling chamber, a pair of position sensors, and a substrate transfer robot. Each of the sensors comprises an emitter configured to emit a beam of light, and a receiver configured to receive the light beam. The substrate transfer robot comprises an end effector and a robot actuator. The end effector is configured to hold a substrate such that the substrate has a same expected position with respect to the end effector every time the substrate is held. The robot actuator is configured to move the end effector within the handling chamber to transfer substrates among a plurality of substrate stations. An edge of a substrate held in the expected position by the end effector can partially block a light beam of one of the position sensors, while another end of the end effector partially blocks a light beam of the other position sensor.

Owner:ASM JAPAN

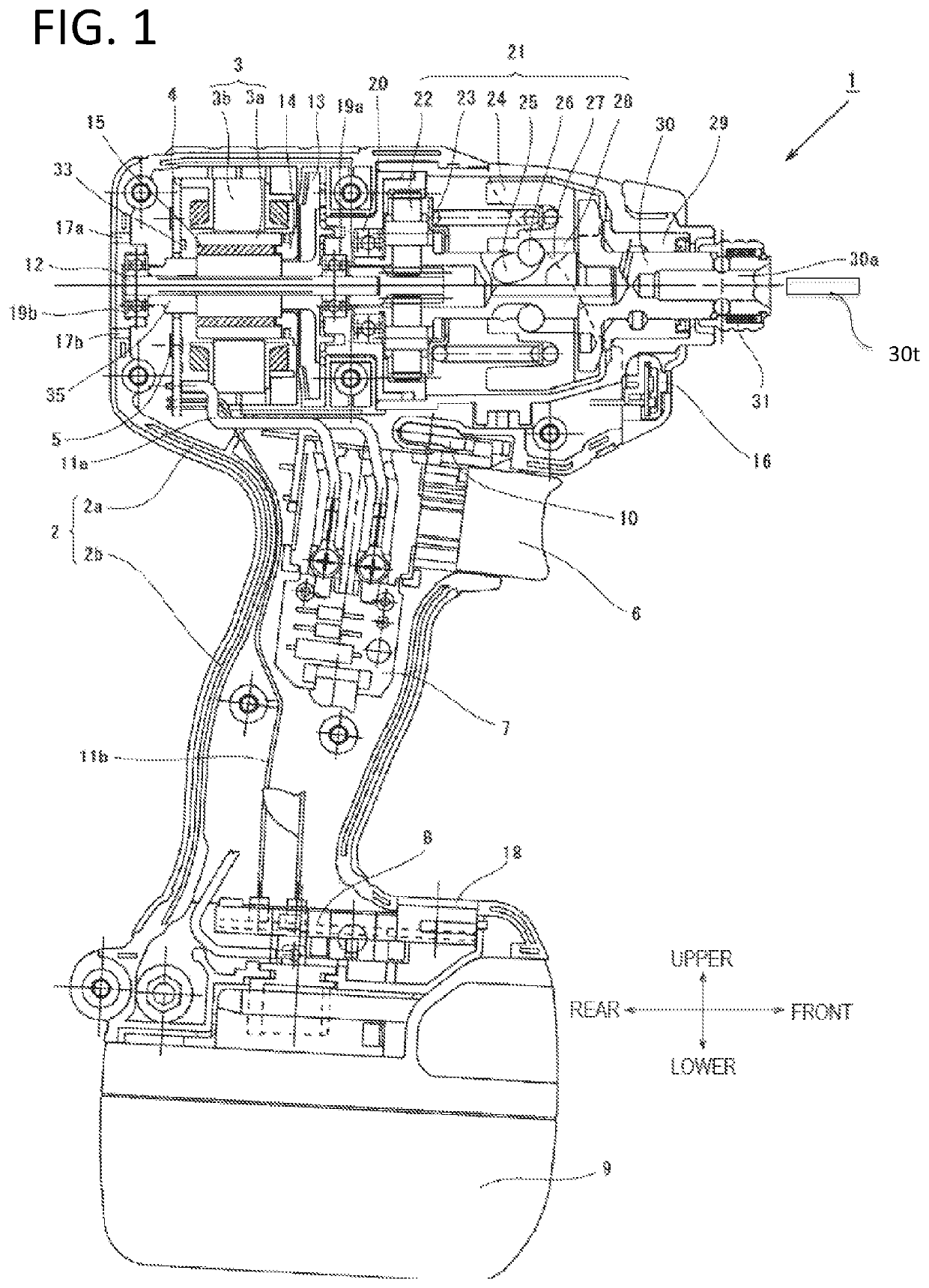

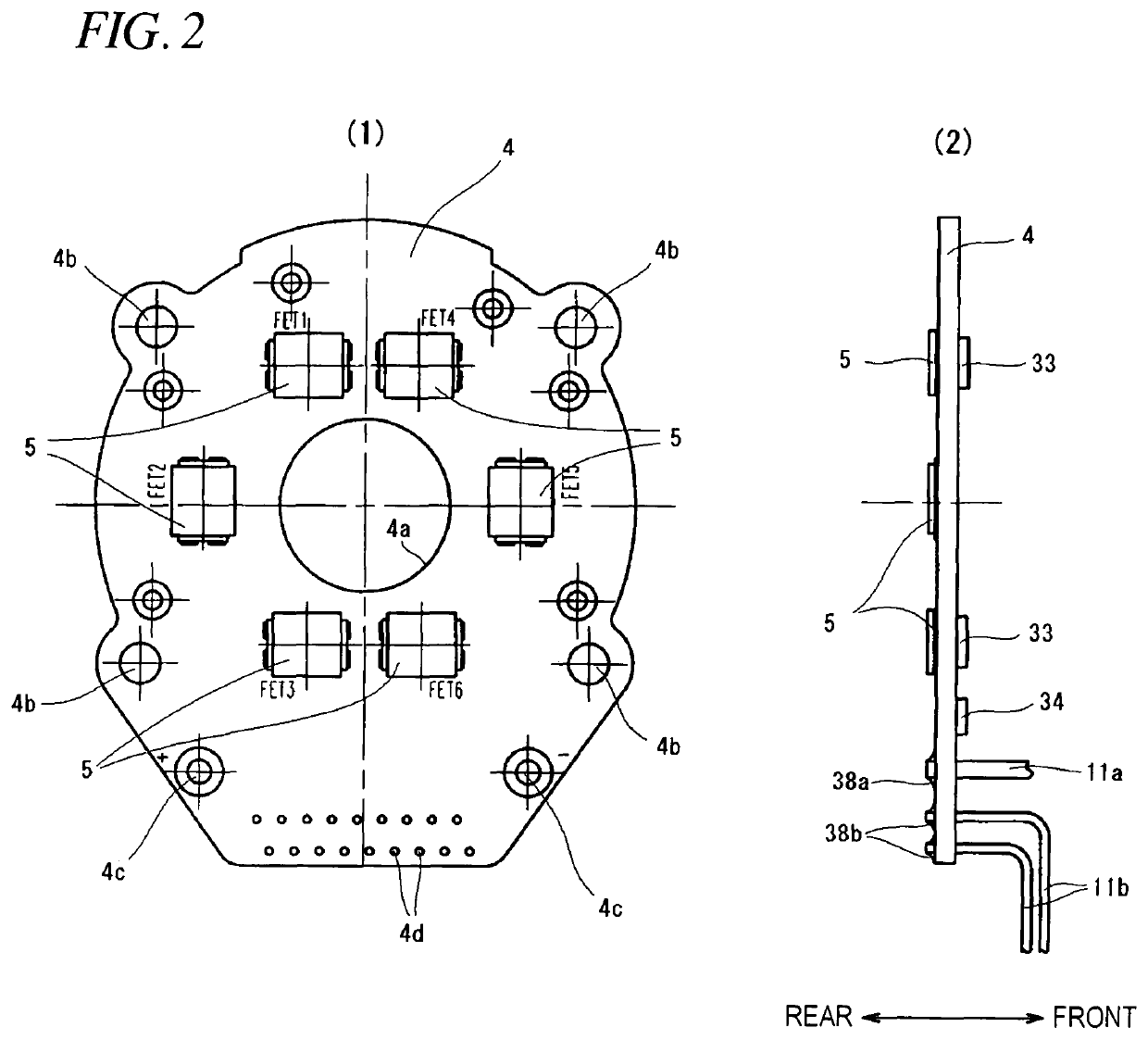

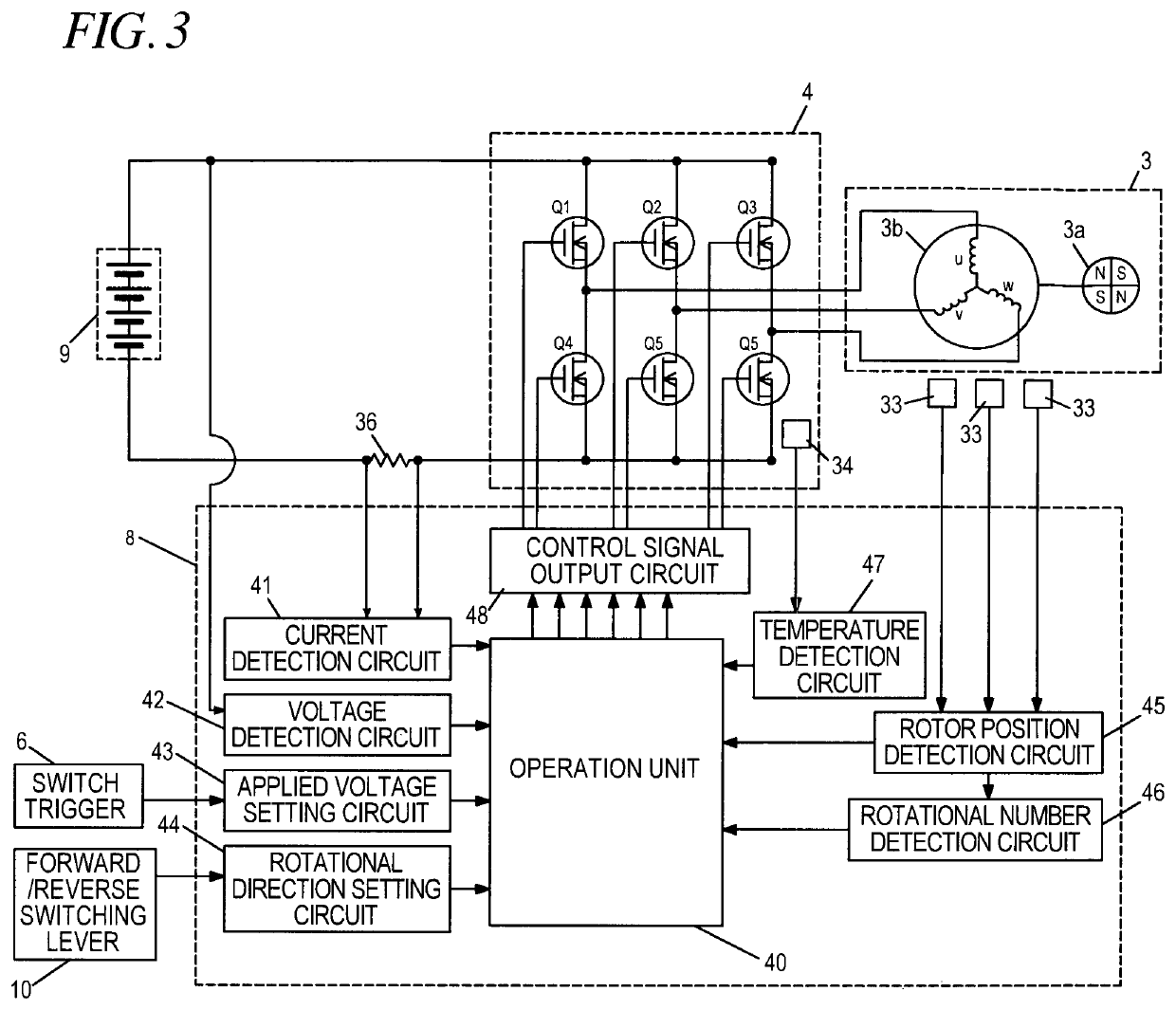

Impact tool and method of controlling impact tool

An impact tool includes: a motor; a trigger; a controller configured to control driving power supplied to the motor using a semiconductor switching element according to an operation of the trigger; a striking mechanism configured to drive a tip tool continuously or intermittently by rotation force of the motor, the striking mechanism including a hammer and an anvil. The controller drives the semiconductor switching element at a high duty ratio when the trigger is manipulated. The motor is driven so that the duty ratio is lowered before a first striking of the hammer on the anvil is performed and the first striking is performed at a low duty ratio lower than the high duty ratio.

Owner:KOKI HLDG CO LTD

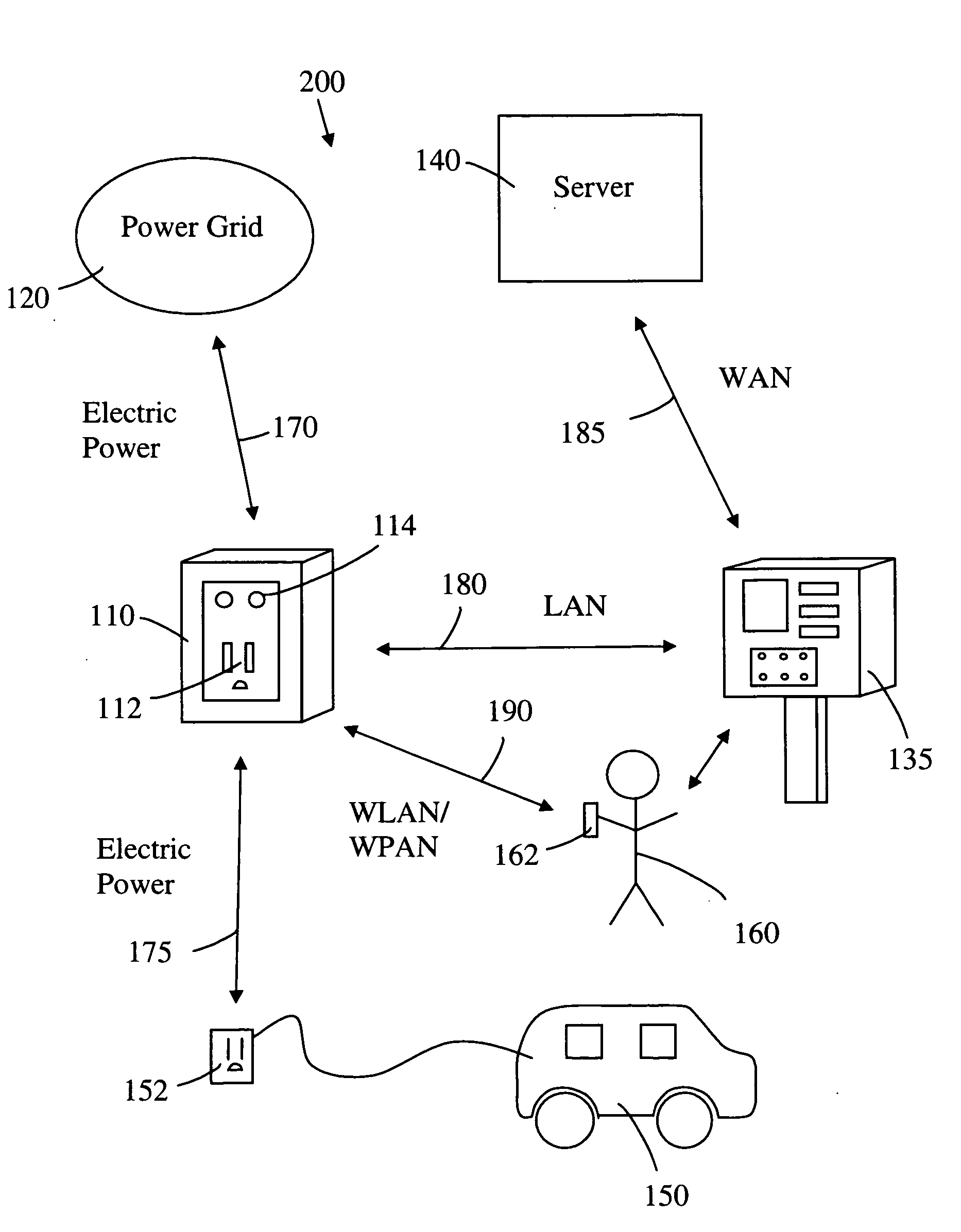

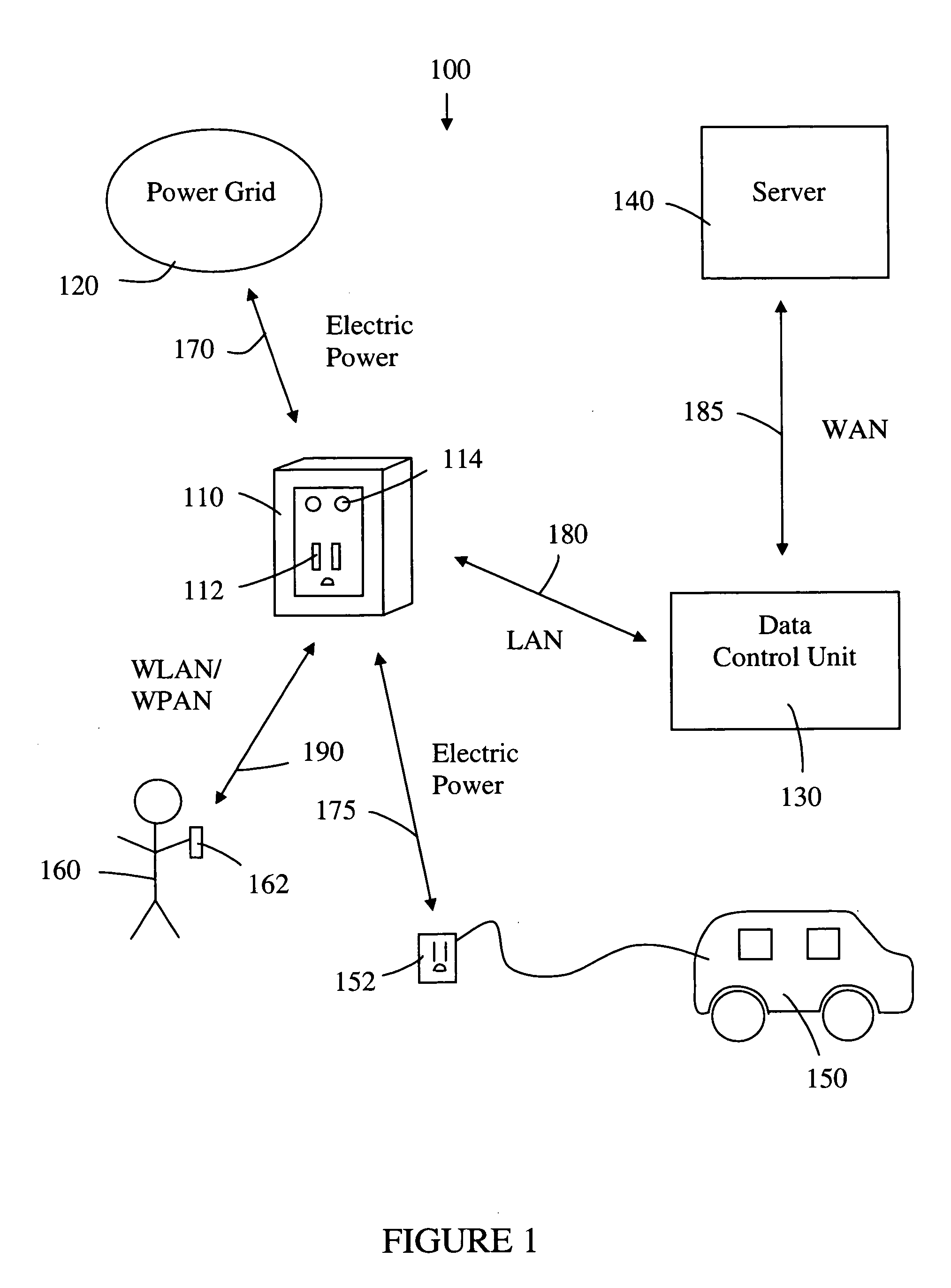

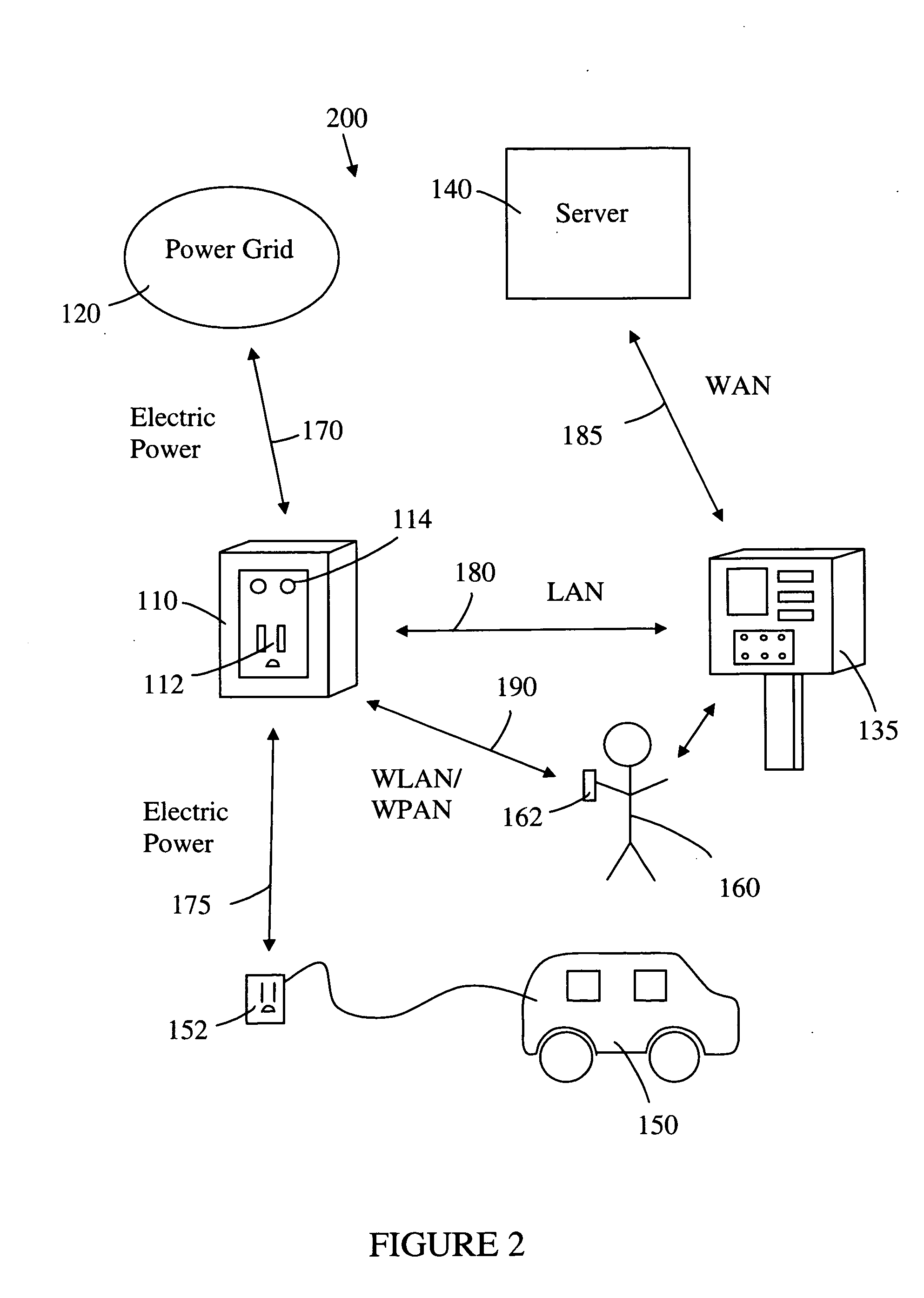

Network-controlled charging system for electric vehicles

ActiveUS20090174365A1Circuit authenticationTicket-issuing apparatusTransceiverTelecommunications link

A system for network-controlled charging of electric vehicles comprises charge transfer devices networked as follows: charge transfer devices and electric vehicle operators communicate via wireless communication links; charge transfer devices are connected by a local area network to a data control unit, which is connected to a server via a wide area network. The server stores consumer profiles and utility company power grid load data. A charge transfer devices comprises: an electrical receptacle for receiving an electrical connector for recharging an electric vehicle; an electric power line connecting the receptacle to a local power grid; a control device on the electric power line, for switching the receptacle on and off; a current measuring device on the electric power line, for measuring current flowing through the receptacle; a controller for operating the control device and monitoring the output from the current measuring device; a local area network transceiver connected to the controller, for connecting the controller to the data control unit; and a communication device connected to the controller, for wireless communication between the operator of the electric vehicle and the controller.

Owner:COULOMB TECHNOLOGIES

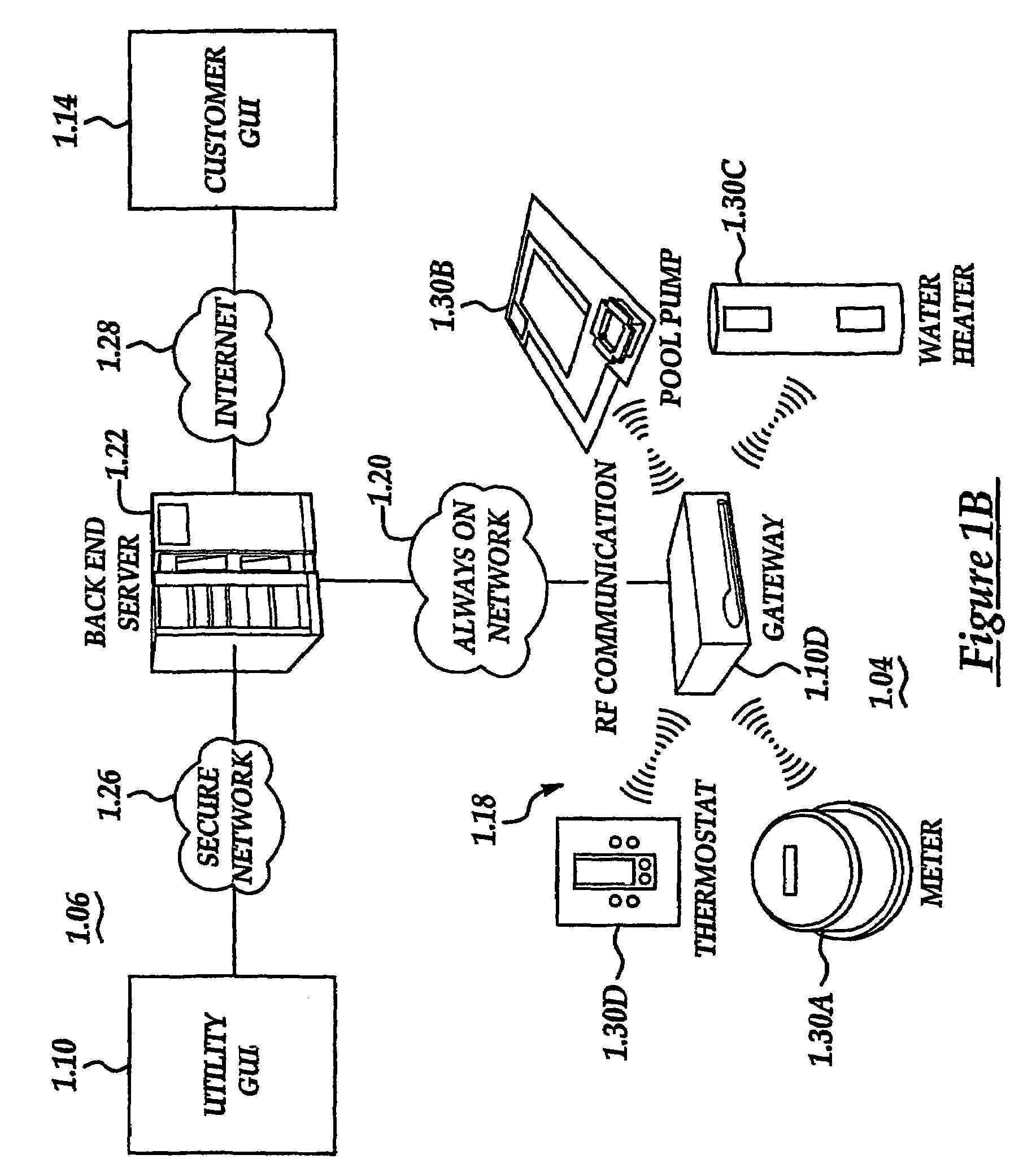

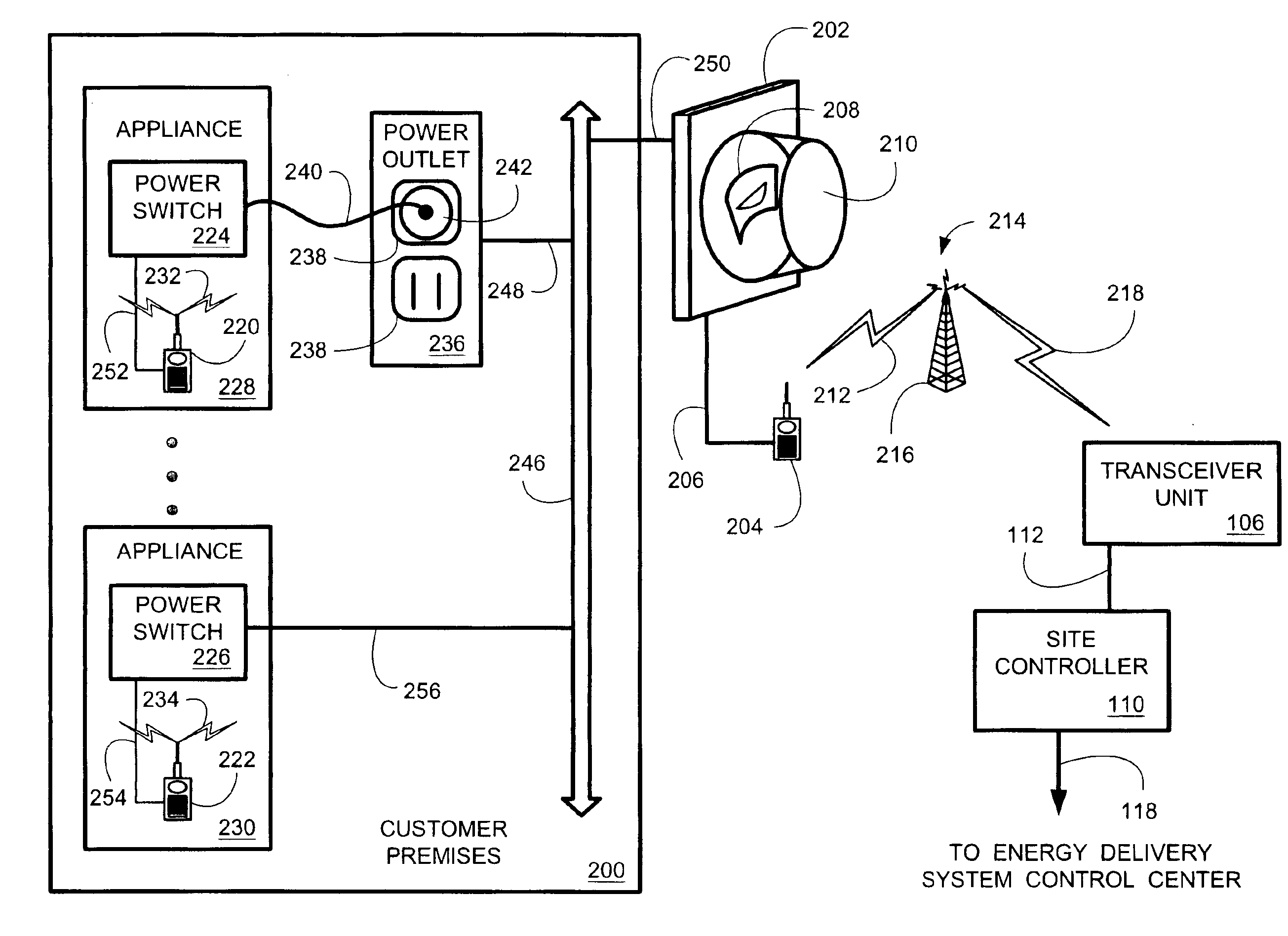

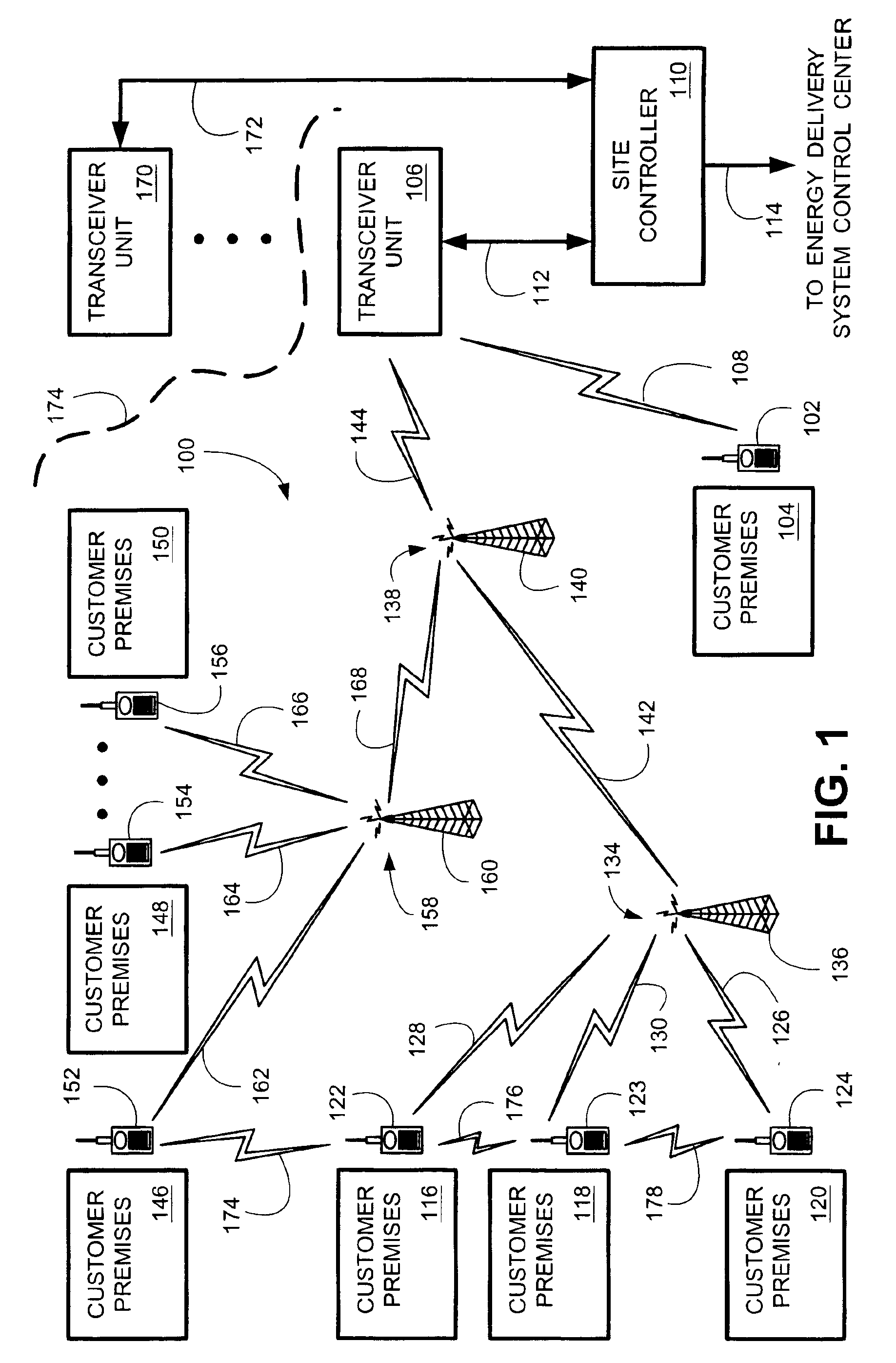

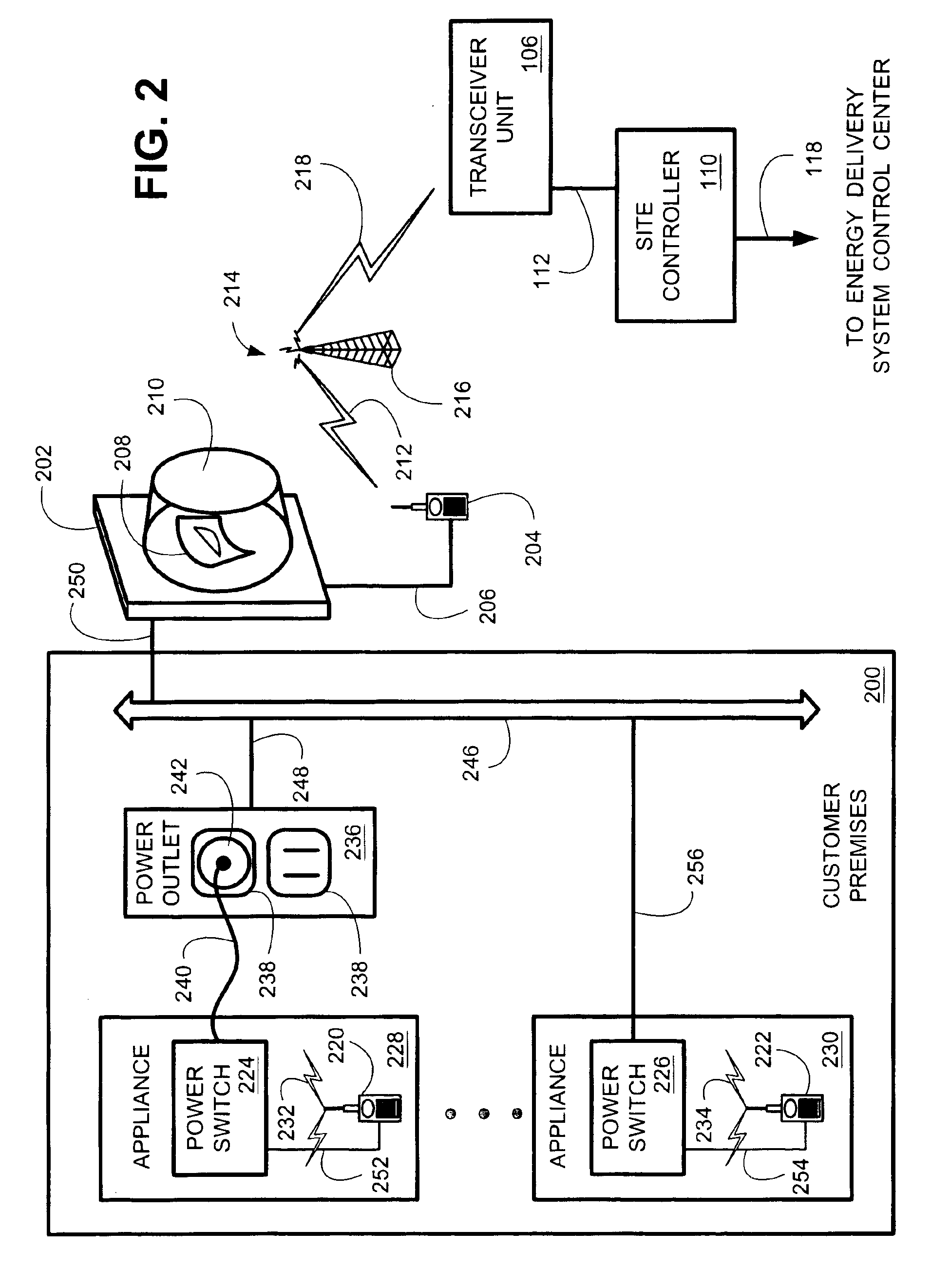

System and method for controlling power demand over an integrated wireless network

An intelligent network demand control system provides a system and method for controlling demand in an energy delivery system. Various embodiments of the intelligent network demand control system employs a transceiver network with a plurality transceivers coupled to meters and appliances residing at a plurality of customer premises. Control room operators instruct a customer premises (CP) energy management controller to implement a reduction in system demand. A demand reduction control signal is relayed out to a predefined group of transceivers to bring their respective controlled generators on line. The predefined transceivers, identified by their identification codes, are specified in the demand reduction control signal. The actual demand reduction is metered and relayed back to the CP energy management controller. In some embodiments, the total demand reduction is aggregated into a single number and then communicated to the operators.

Owner:LANDISGYR TECH

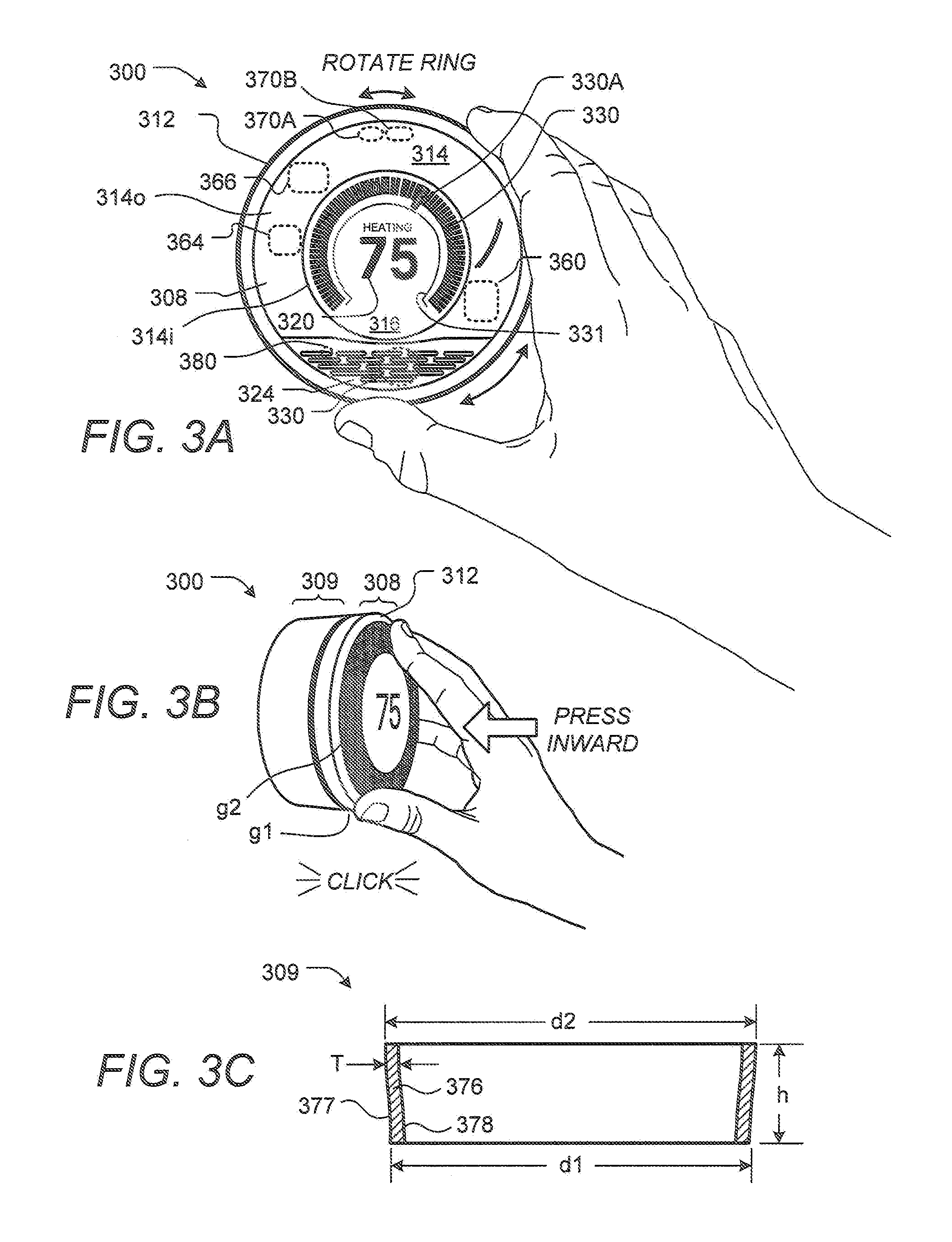

Thermostat graphical user interface

ActiveUS20120131504A1Easy to understandImprove understandingMechanical apparatusSpace heating and ventilation safety systemsGraphical user interfaceControl system

A thermostat for controlling an HVAC system is described, the thermostat having a user interface that is visually pleasing, approachable, and easy to use while also providing intuitive navigation within a menuing system. In a first mode of operation, an electronic display of the thermostat displays a population of tick marks arranged in an arcuate arrangement including a plurality of background tick marks, a setpoint tick mark representing a setpoint temperature, and an ambient temperature tick mark representing an ambient temperature, the setpoint temperature being dynamically changeable according to a tracked rotational input motion of a ring-shaped user interface component of the thermostat. In a second mode, the a plurality of user-selectable menu options is displayed in an arcuate arrangement along a menu option range area, and respective ones of the user-selectable menu options are selectively highlighted according to the tracked rotational input motion of the ring-shaped user interface component.

Owner:GOOGLE LLC

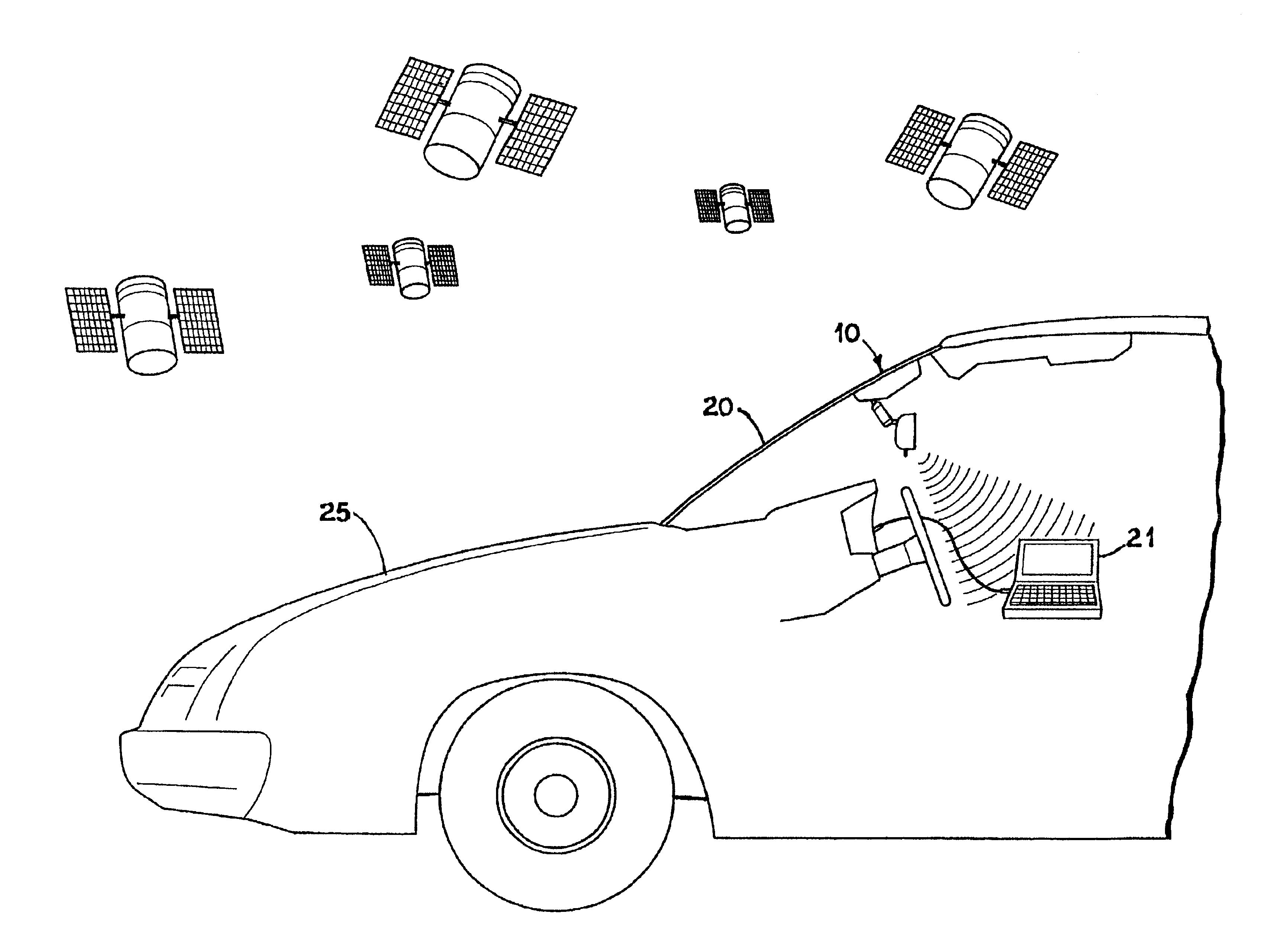

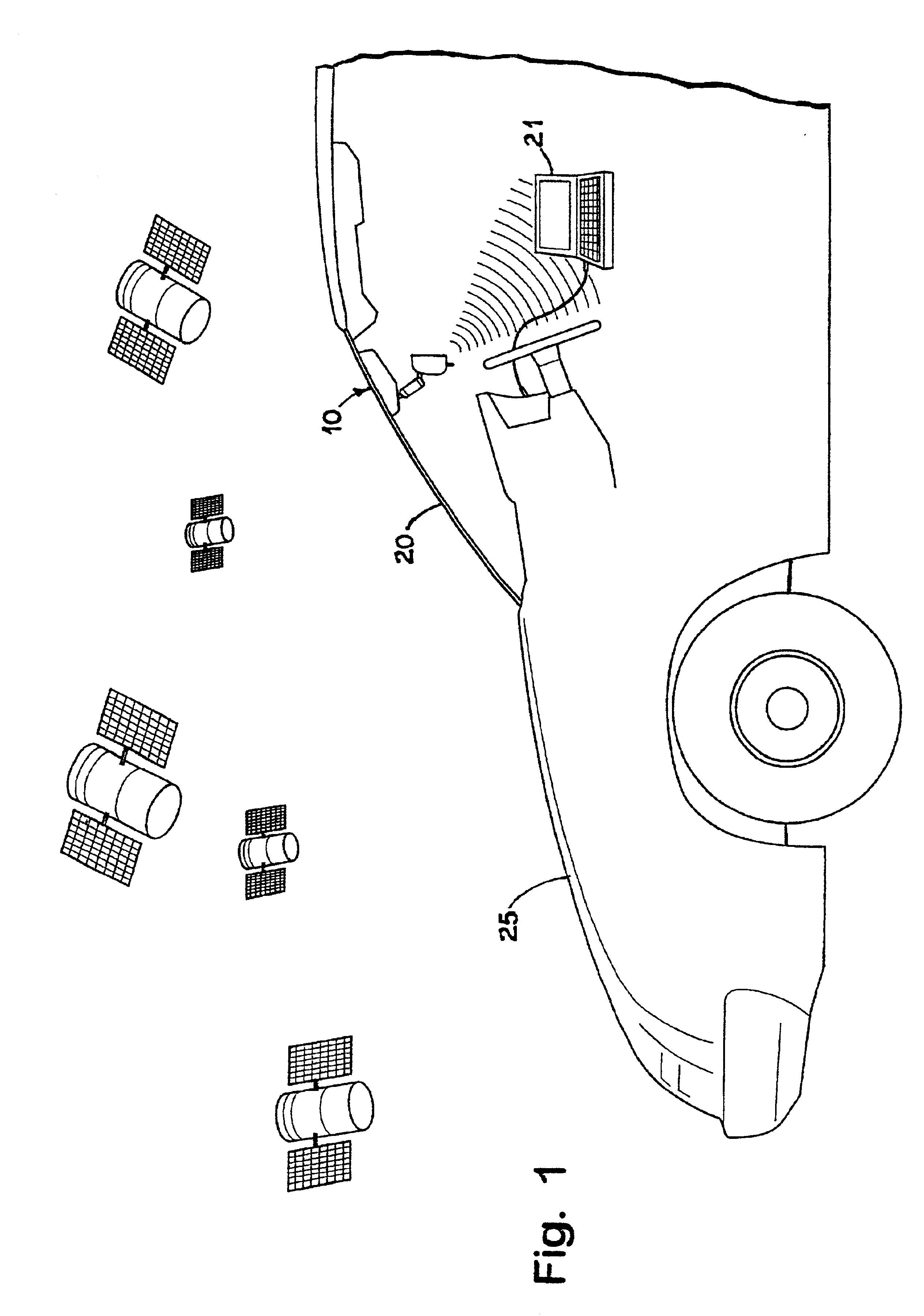

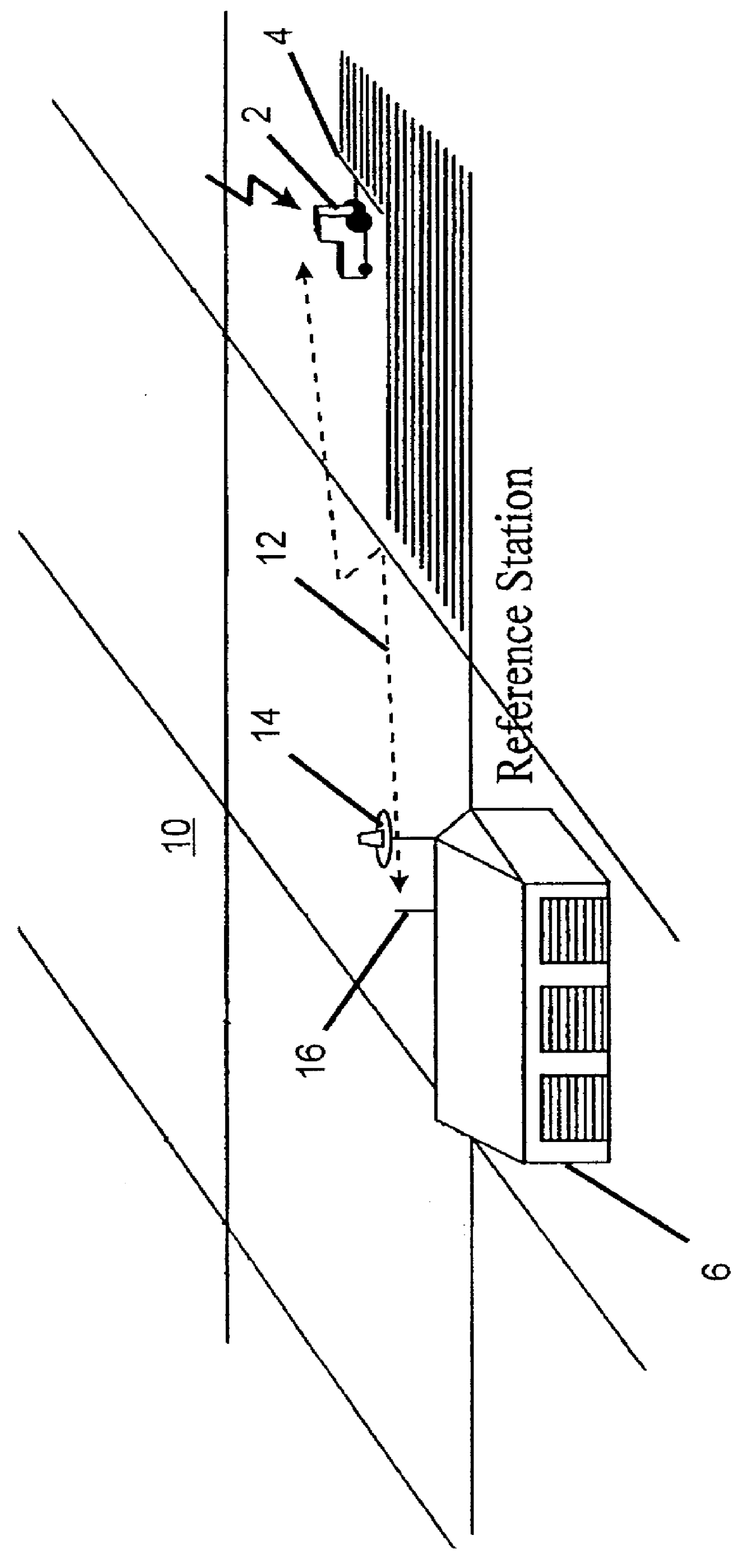

Method and system for automatic control of vehicles based on carrier phase differential GPS

InactiveUS6052647AImprove system stabilitySimple processDigital data processing detailsPosition fixationAutomatic train controlAutomatic control

Described is an automatic control system for land (and possible marine) vehicles based on carrier phase differential GPS (CPGPS). The system relies on CPGPS to determine vehicle position and attitude very precisely (position to within 1 cm and attitude to within 0.1 DEG ). A system incorporates a technique to calculate and compensate for antenna motion due to vehicle roll and pitch. One aspect of the system utilizes an intelligent vehicle controller that recognizes and adapts to changing conditions, such as vehicle speed, implements towed by the vehicle, soil conditions, and disturbance level. The system provides the capability to control the vehicle on various paths, including straight lines and arbitrary curves. Also described is a technique for initialization and vehicle control using only a single pseudolite.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

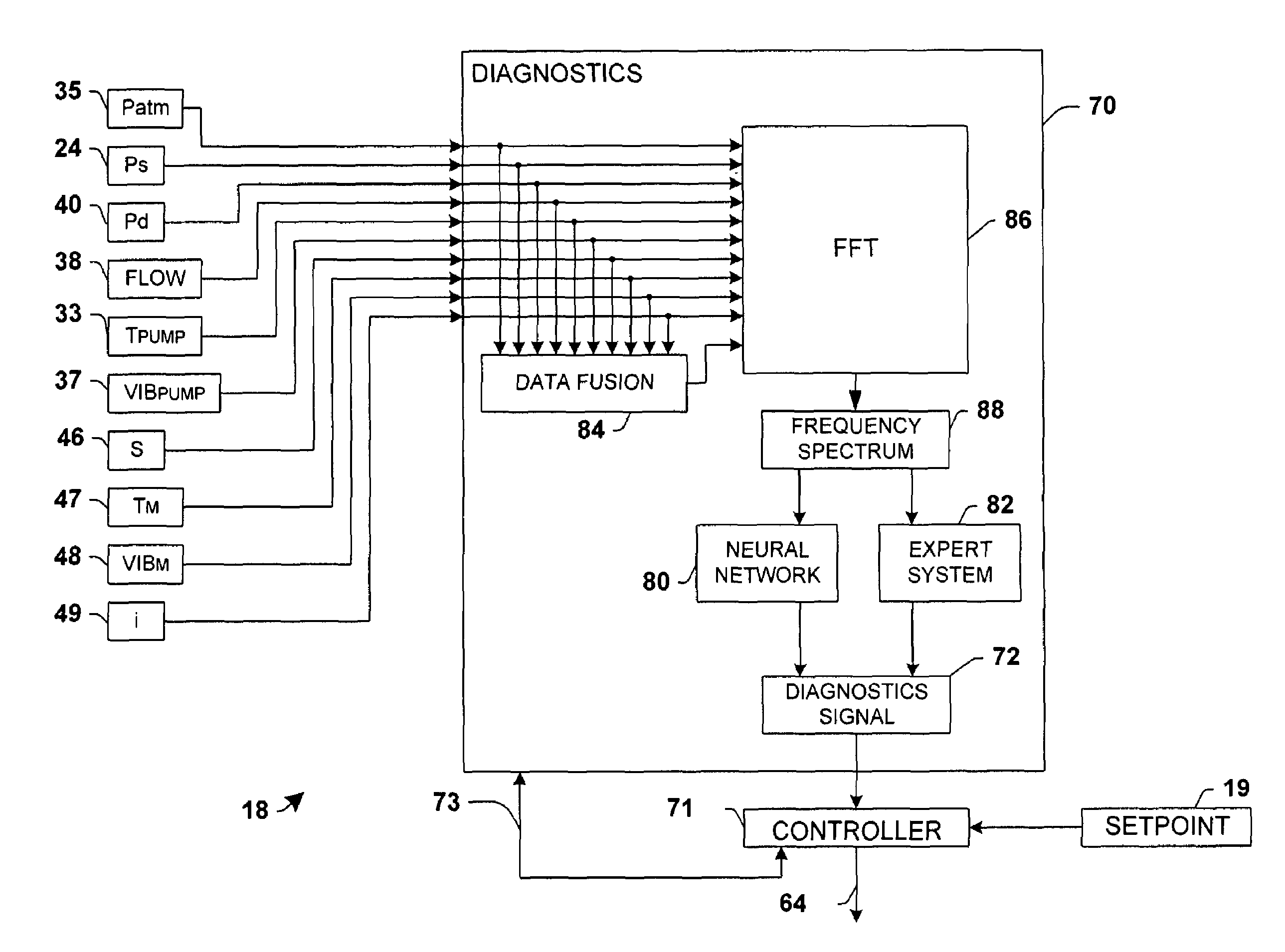

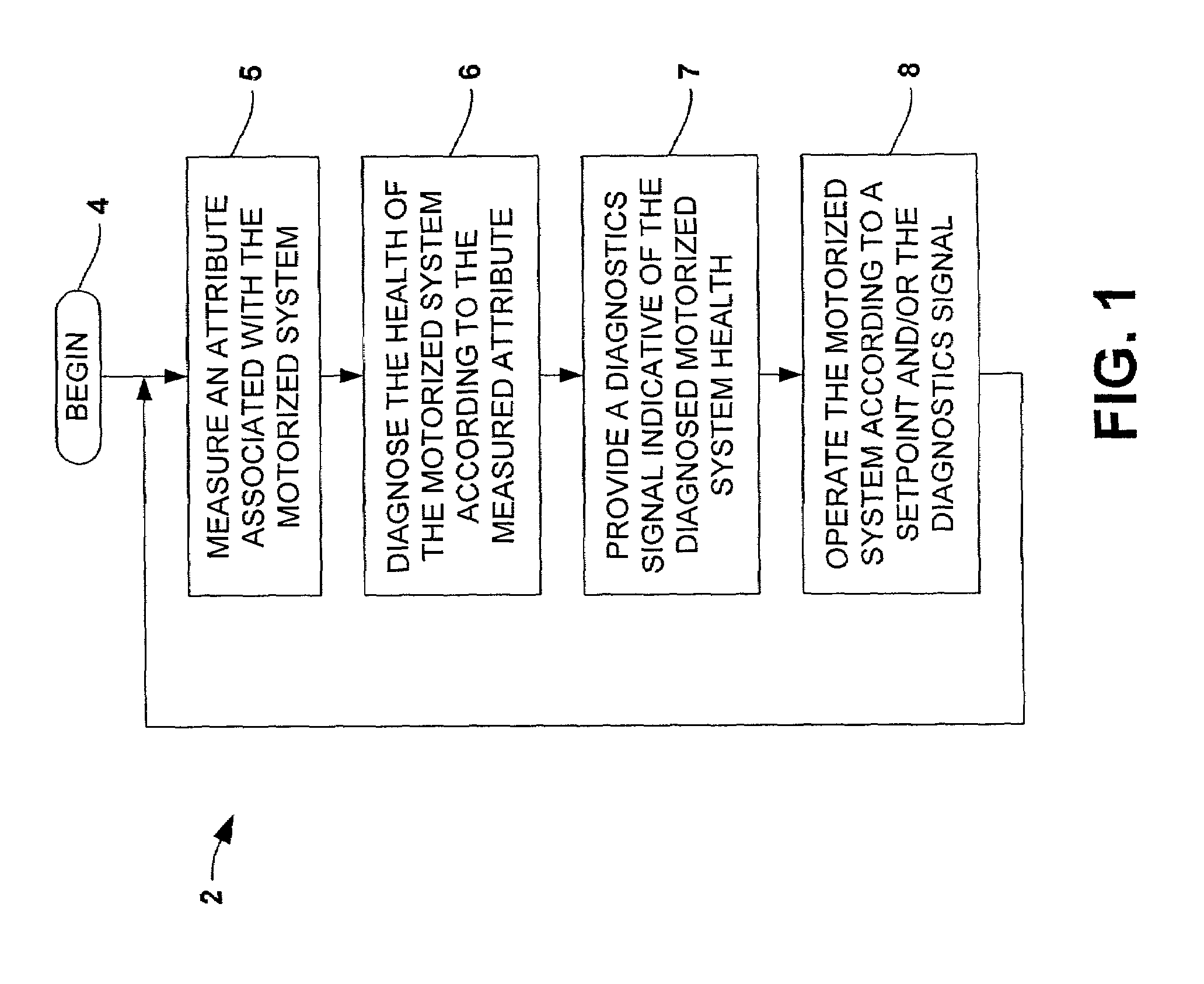

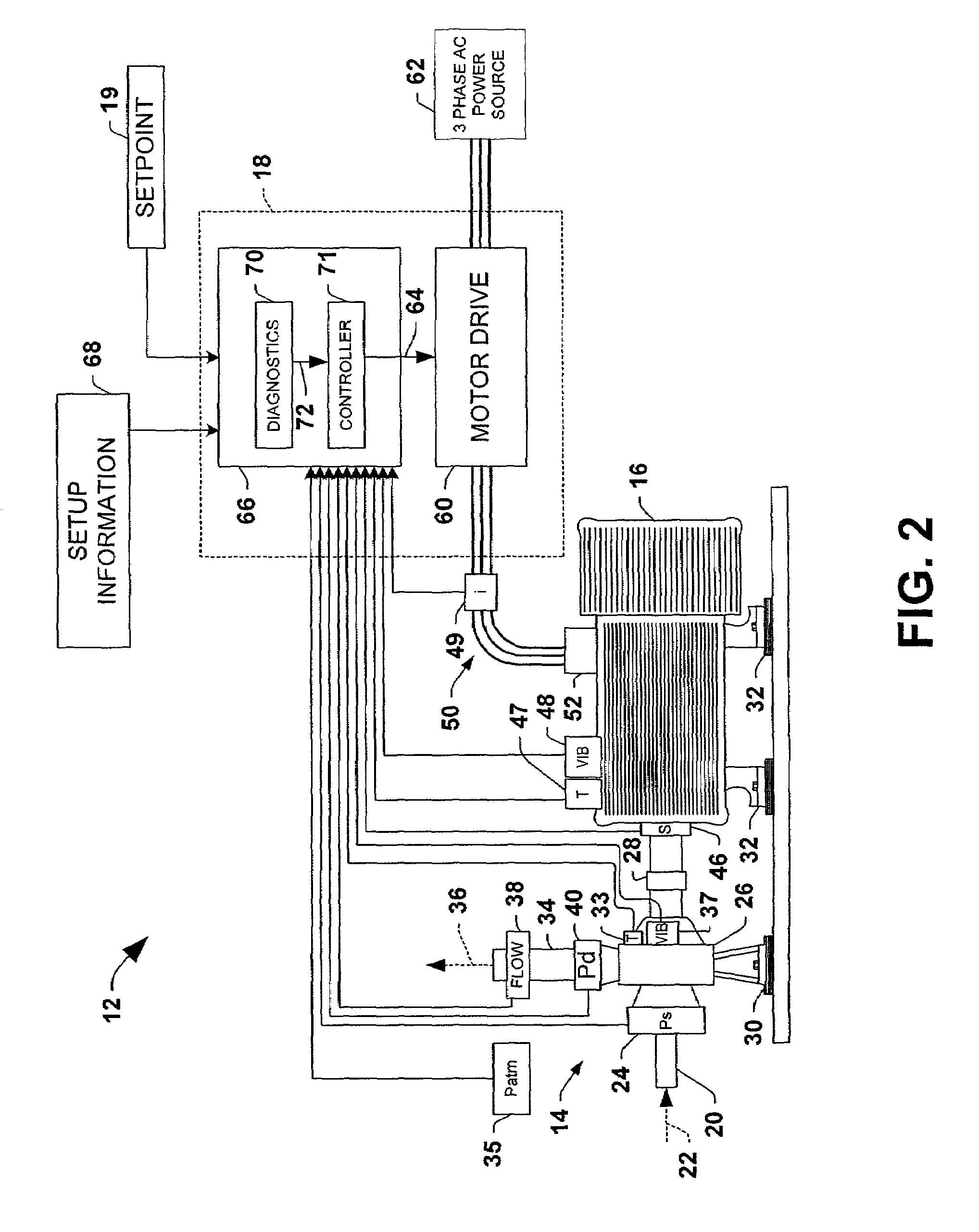

Motorized system integrated control and diagnostics using vibration, pressure, temperature, speed, and/or current analysis

InactiveUS7539549B1Condition be reduced and eliminatedAdvantageously employedPump componentsTesting/monitoring control systemsCurrent analysisDiagnostic system

Systems and methods are disclosed for controlling and diagnosing the health of a motorized system. The systems may comprise a diagnostics system and a controller, wherein the diagnostics system employs a neural network, an expert system, and / or a data fusion component in order to assess the health of the motorized system according to one or more attributes associated therewith. The controller may operate the motorized system in accordance with a setpoint and / or a diagnostics signal from the diagnostics system. Also disclosed are methodologies for controlling and diagnosing the health of a motorized system, comprising operating a motor in the motorized system in a controlled fashion, and diagnosing the health of the motorized system according to a measured attribute associated with the motorized system, wherein the motor may be operated according to a setpoint and / or the diagnostics signal.

Owner:ROCKWELL AUTOMATION TECH

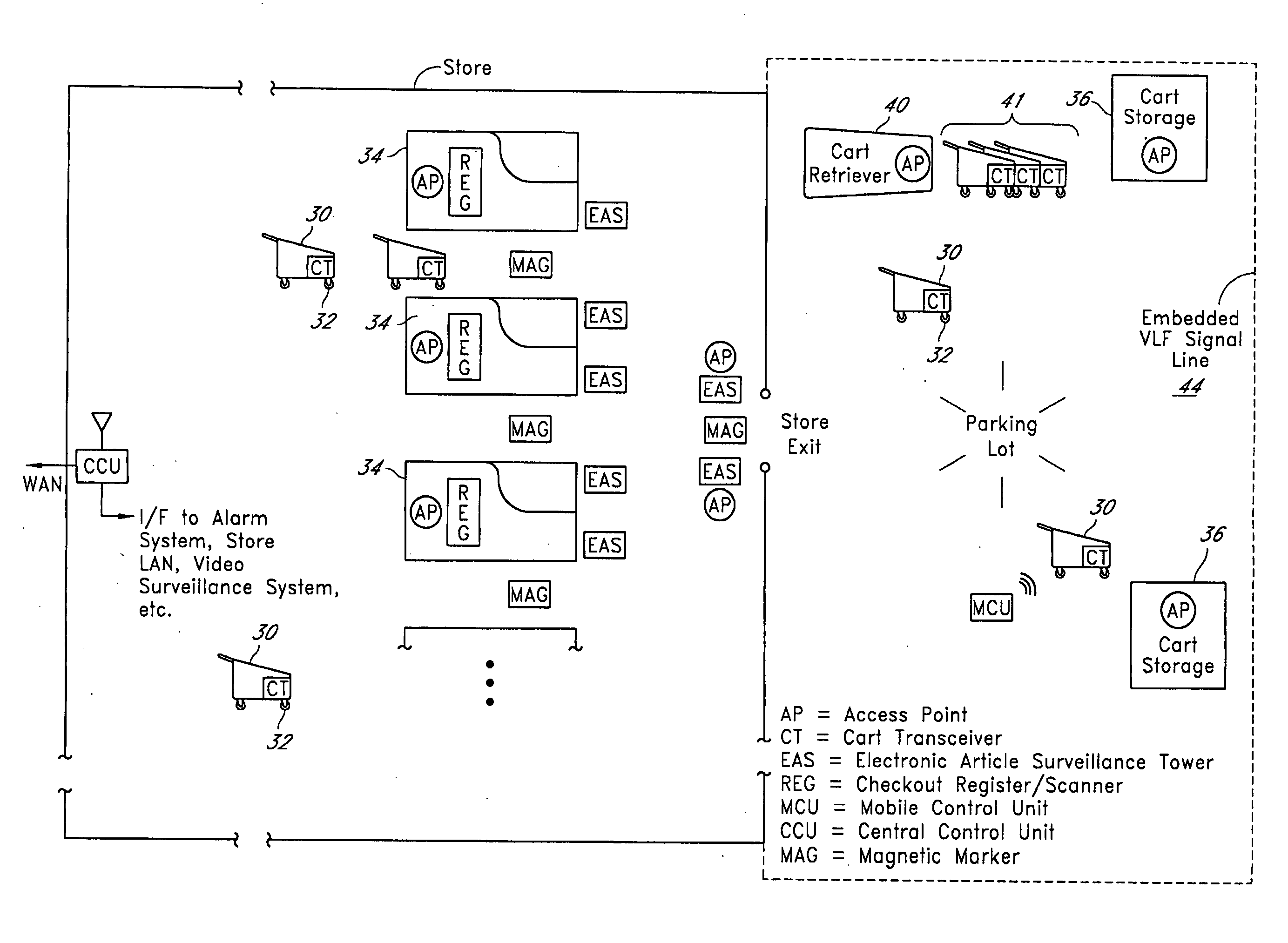

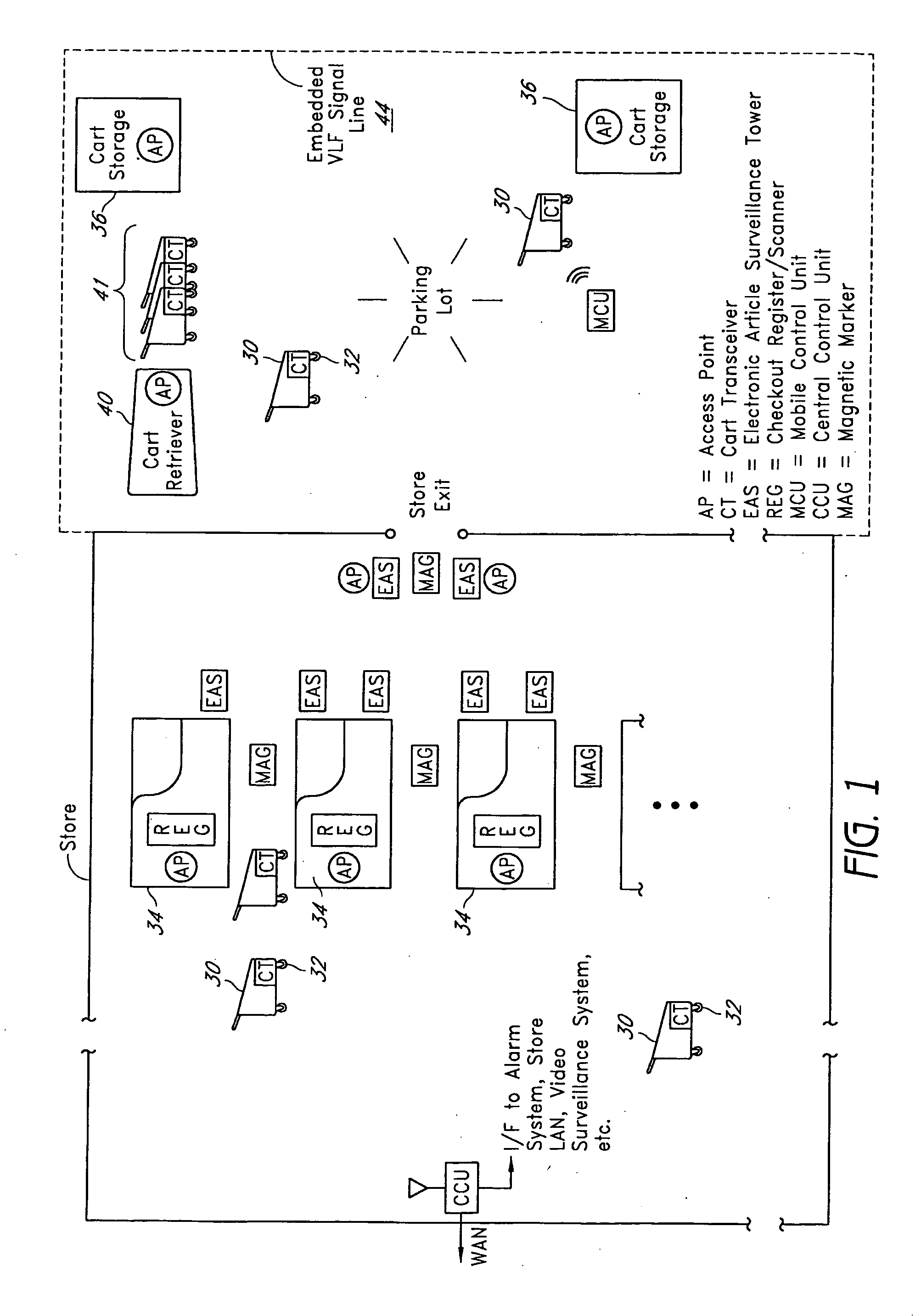

Two-way communication system for tracking locations and statuses of wheeled vehicles

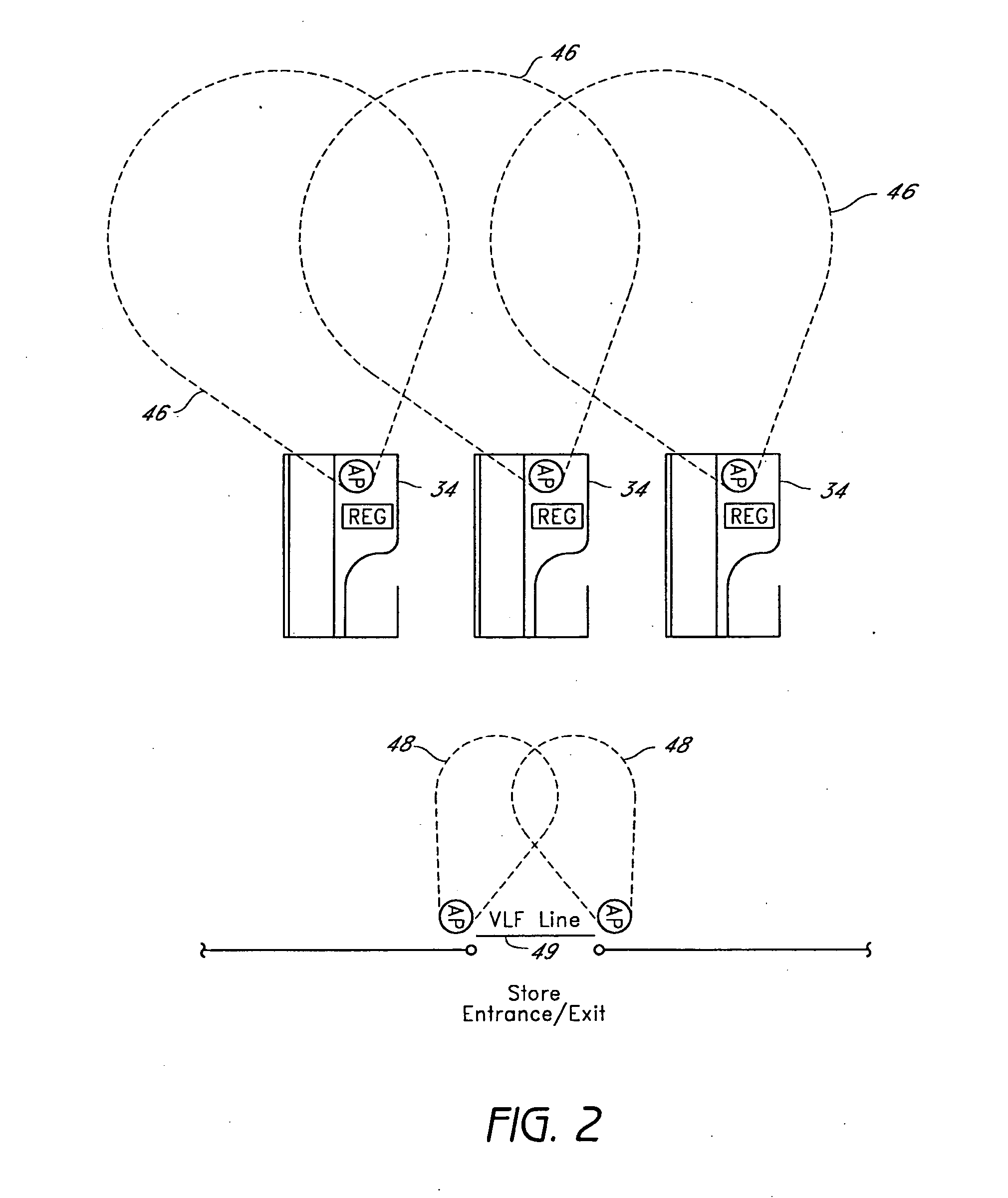

A vehicle tracking system includes a wheel containing sensor circuitry capable of sensing various types of conditions, such as wheel rotation, wheel vibration caused by skidding, and specific electromagnetic and / or magnetic signals indicative of particular wheel locations. The sensor circuitry is coupled to an RF transceiver, which may but need not be included within the wheel. The wheel may also include a brake mechanism. In one embodiment, the wheels are placed on shopping carts and are used to collect and monitor shopping cart status and location data via a wireless network. The collected data may be used for various purposes, such as locking the wheel of an exiting cart if the customer has not paid, estimating numbers of queued carts, stopping wheel skid events that occur during mechanized cart retrieval, store planning, and providing location-based messaging to customers.

Owner:GATEKEEPER SYST

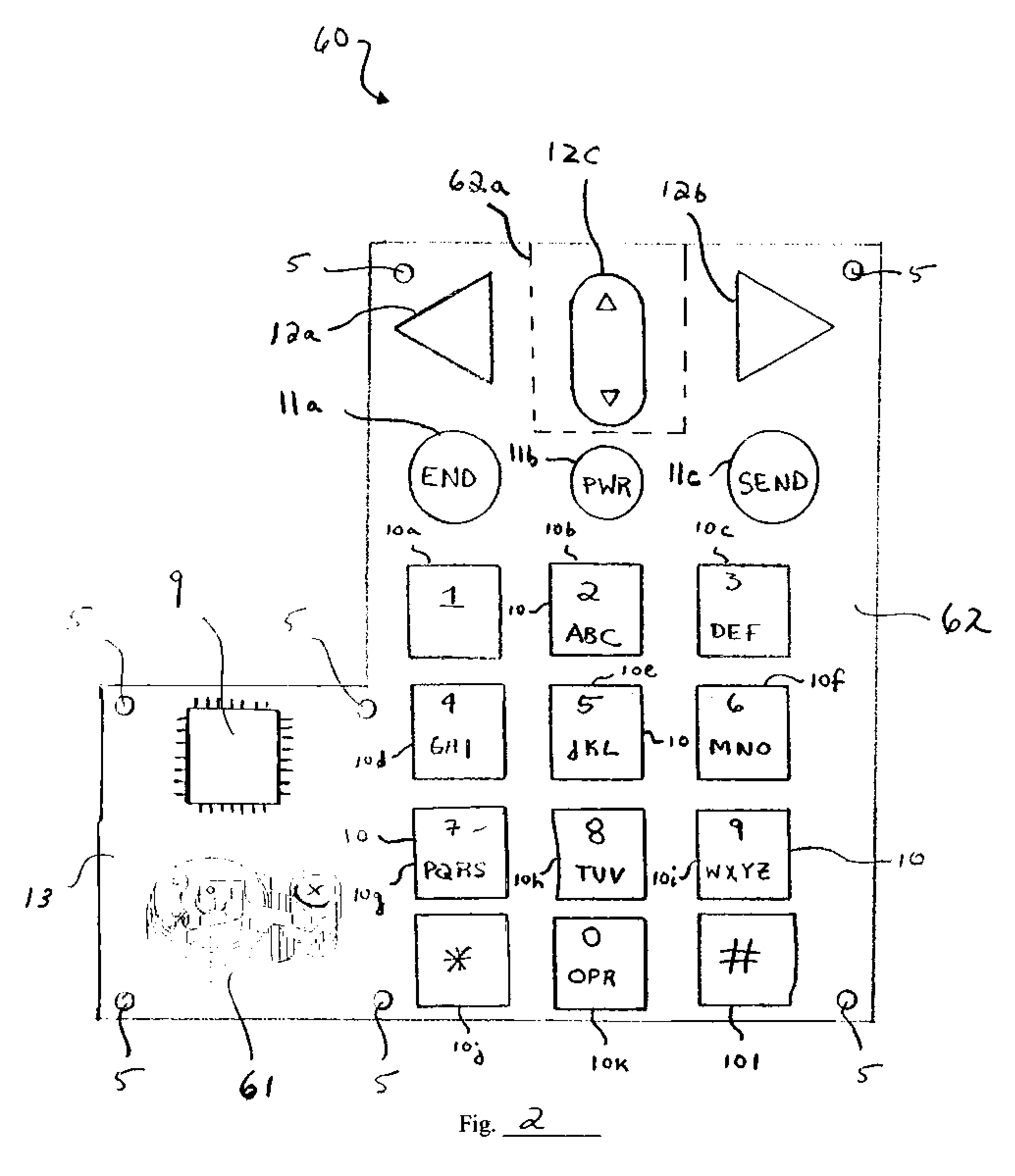

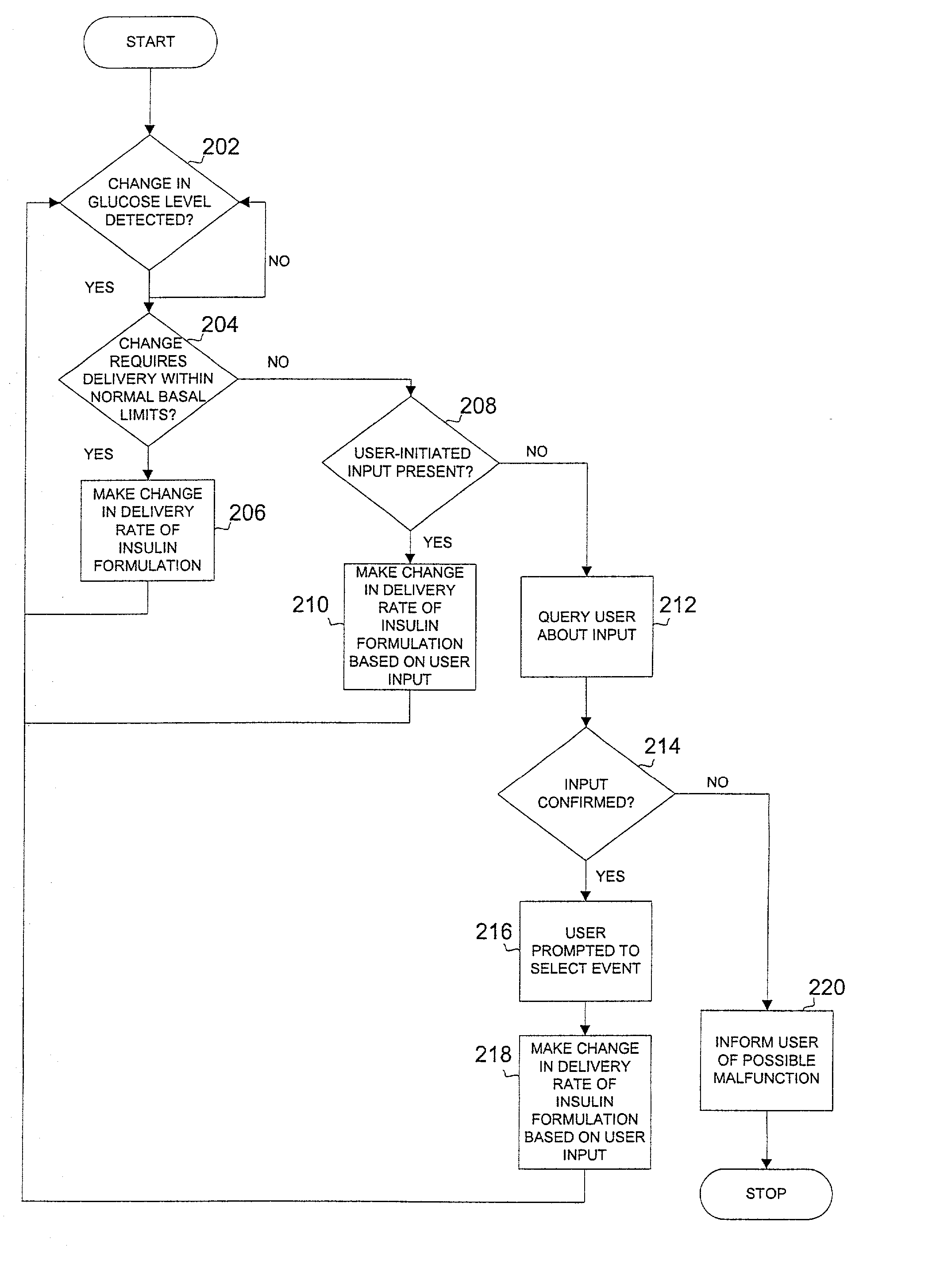

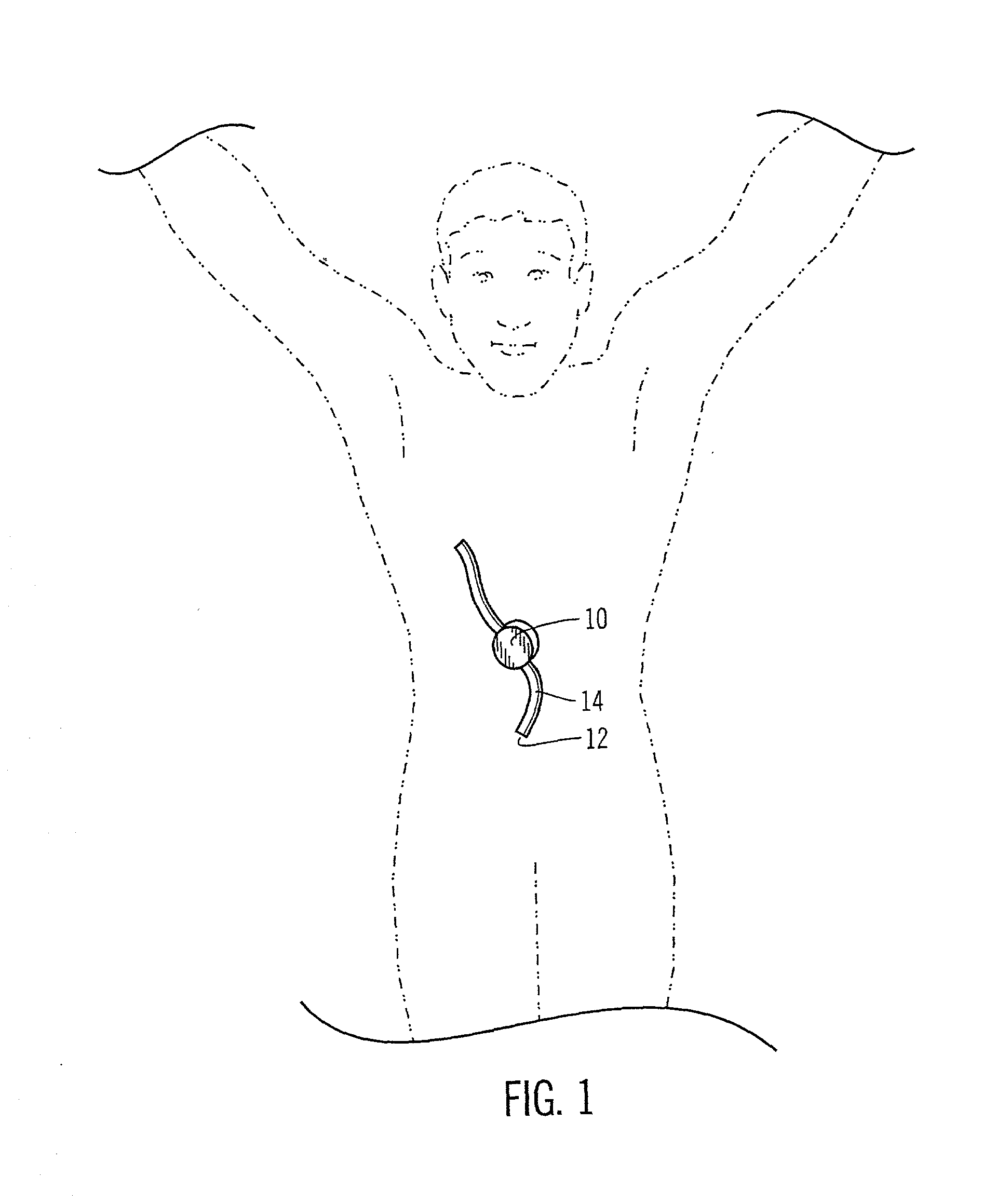

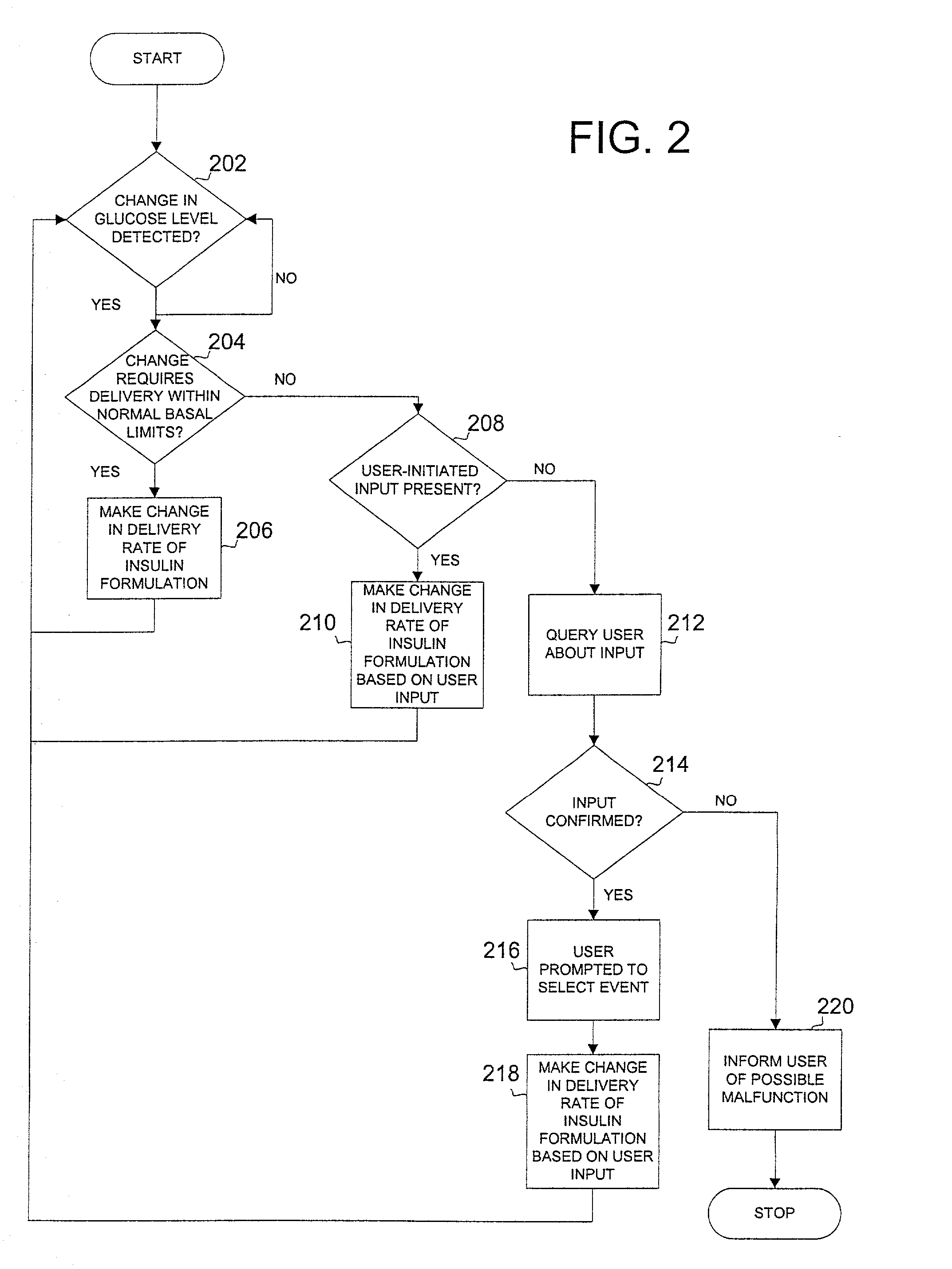

Safety limits for closed-loop infusion pump control

A system and process for providing safety limits on the delivery of an infusion formulation by an infusion pump system in response to a sensed biological state. The safety limits may comprise user-initiated event signals corresponding to events that may significantly affect the biological state. The safety limits may further comprise user-initiated event ranking signals for respective events which specify a degree, quantity, or measure for the respective event. The user-initiated event and event ranking signals may be communicated to a computing element associated with the infusion pump by an associated communication device having a user interface which comprises a plurality of user-selectable operators for entering information about the events and event rankings.

Owner:MEDTRONIC MIMIMED INC

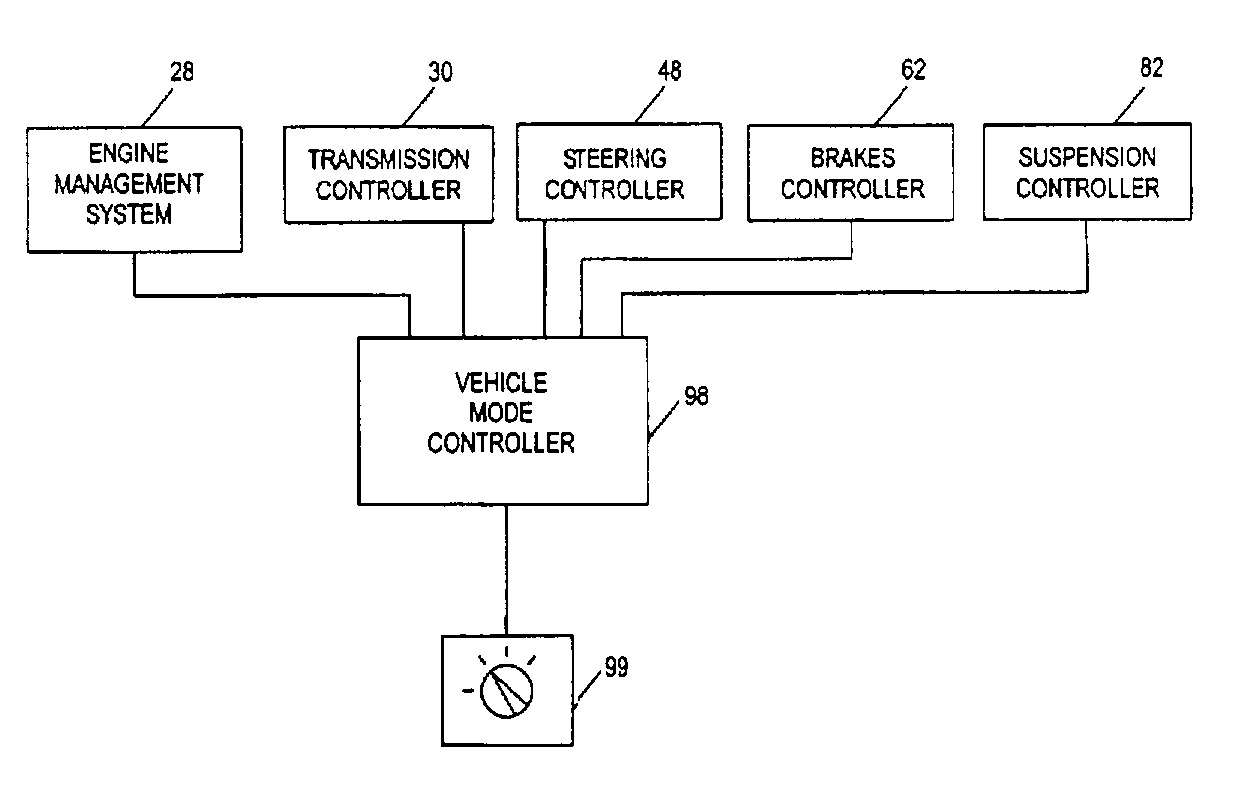

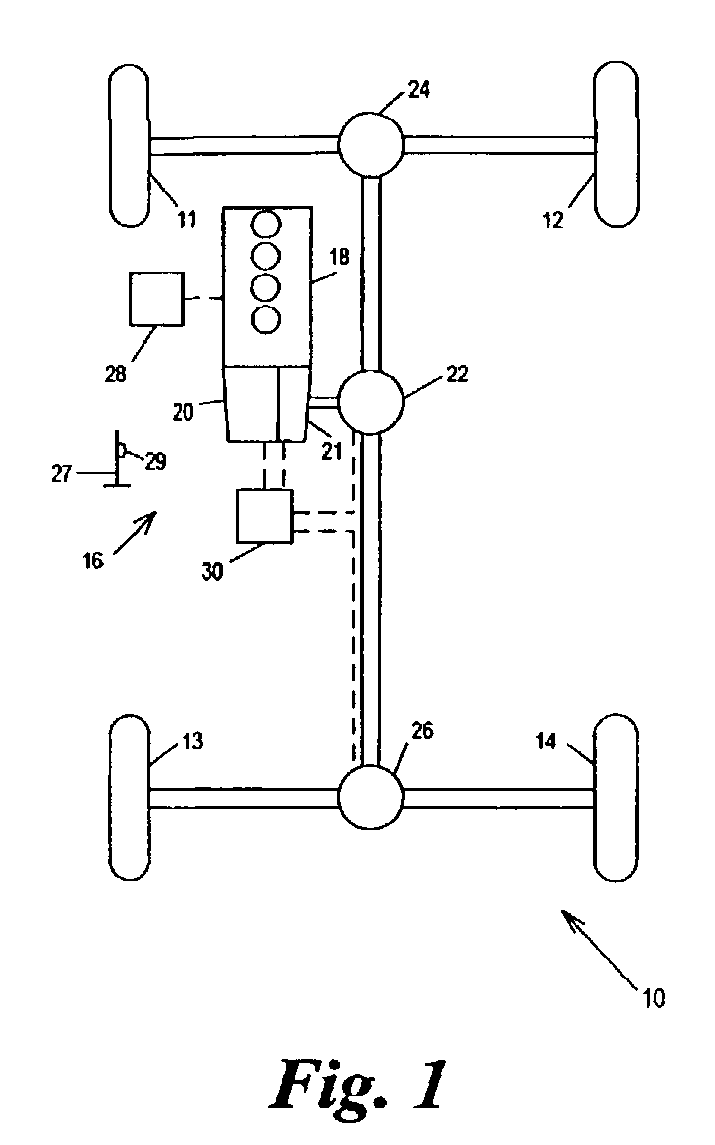

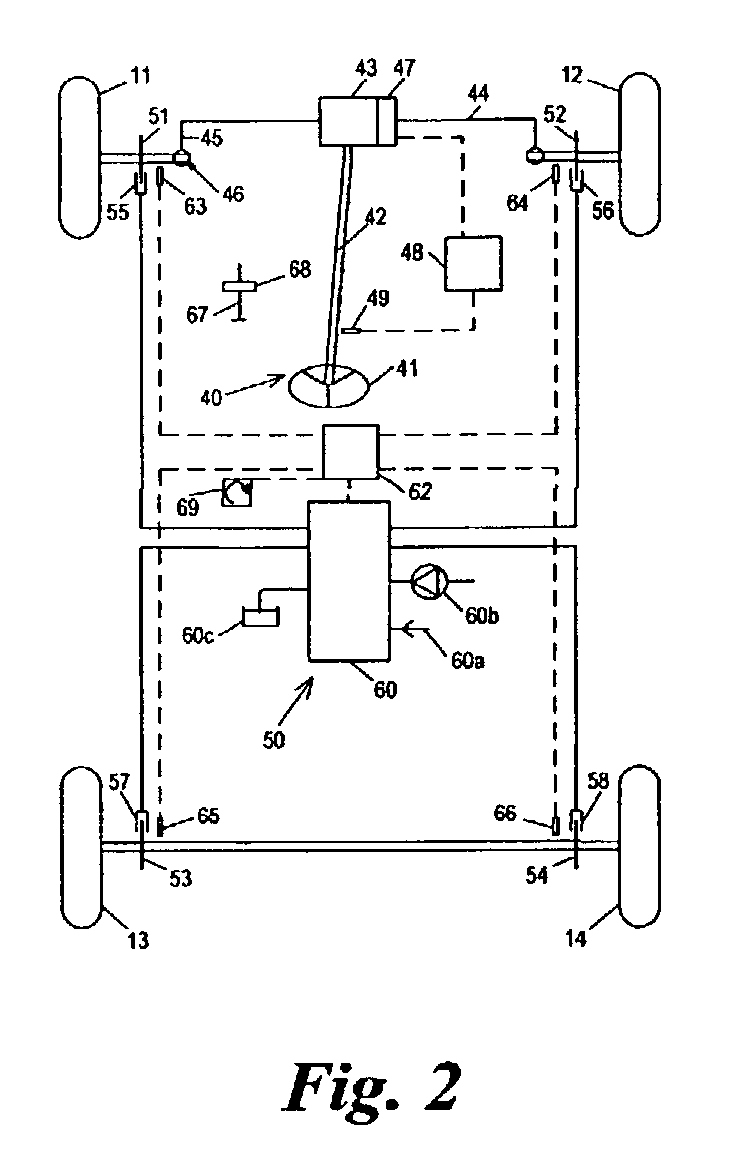

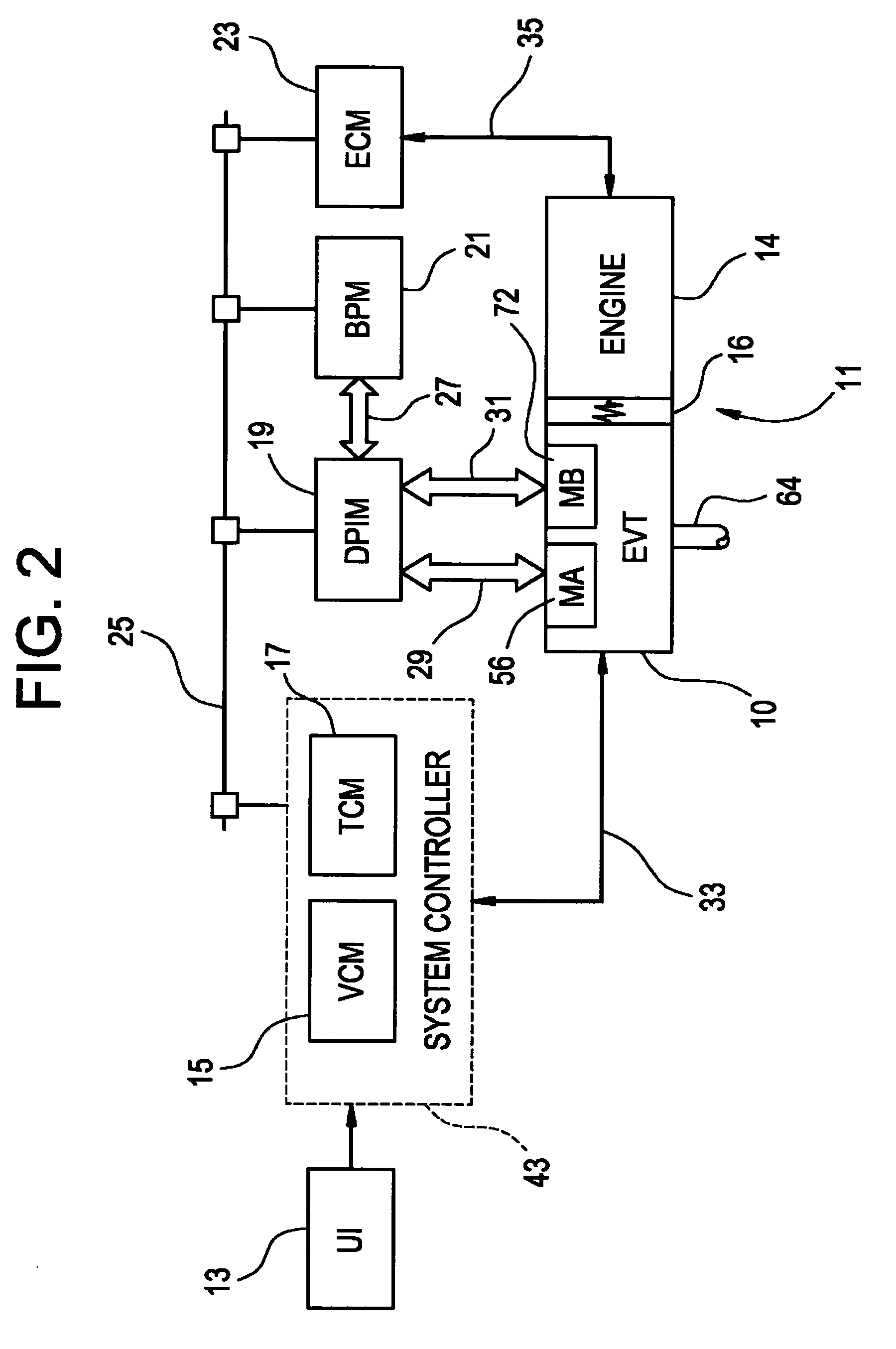

Vehicle control

ActiveUS7349776B2Improved vehicle controlEasy to controlBrake system interactionsDigital data processing detailsControl systemMode control

A vehicle control system has a plurality of subsystem controllers including an engine management system 28, a transmission controller 30, a steering controller 48, a brakes controller 62 and a suspension controller 82. These subsystem controllers are each operable in a plurality of subsystem modes, and are all connected to a vehicle mode controller 98 which controls the modes of operation of each of the subsystem controllers so as to provide a number of driving modes for the vehicle. Each of the modes corresponds to a particular driving condition or set of driving conditions, and in each mode each of the functions is set to the function in mode most appropriate to those conditions.

Owner:JAGUAR LAND ROVER LTD

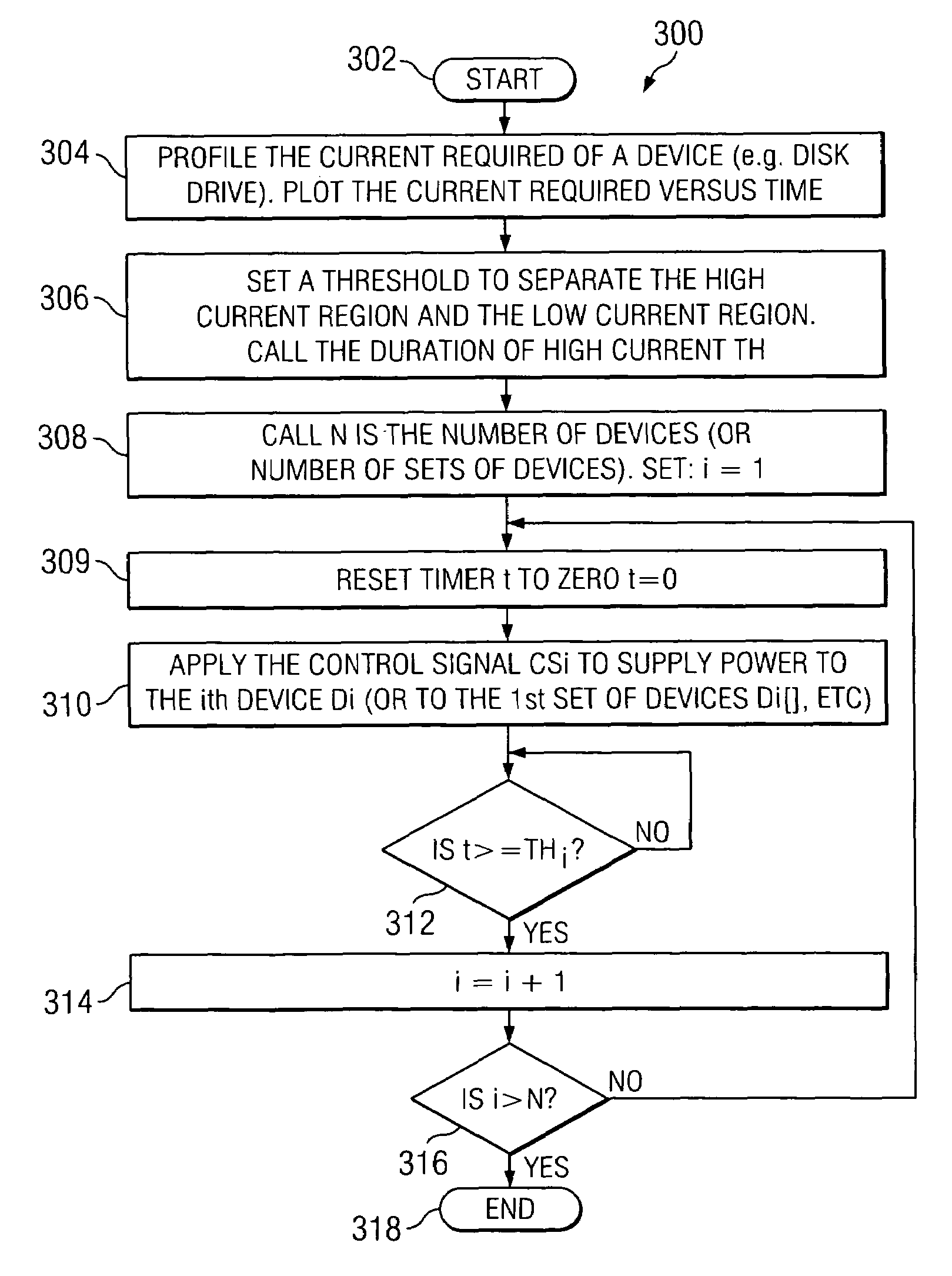

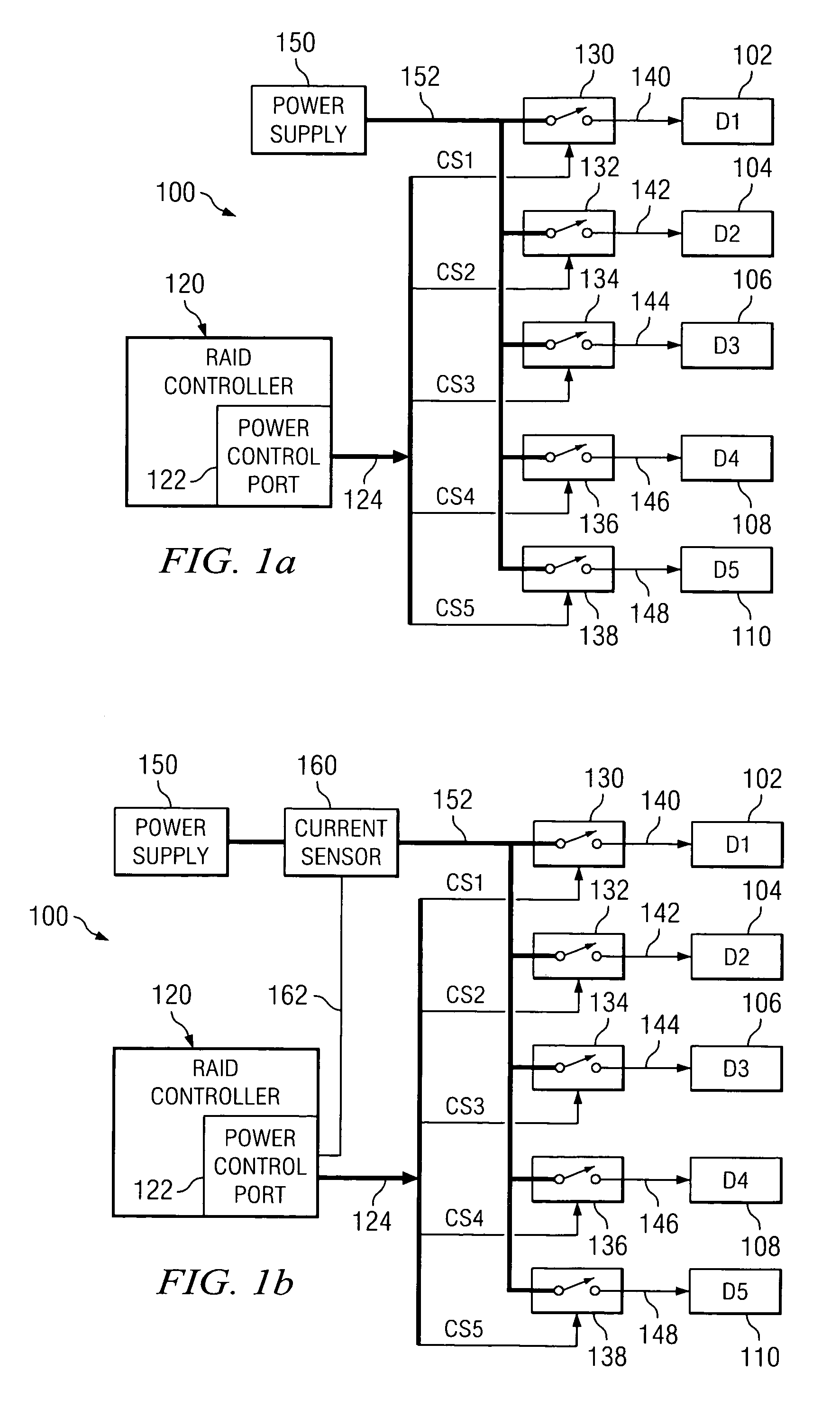

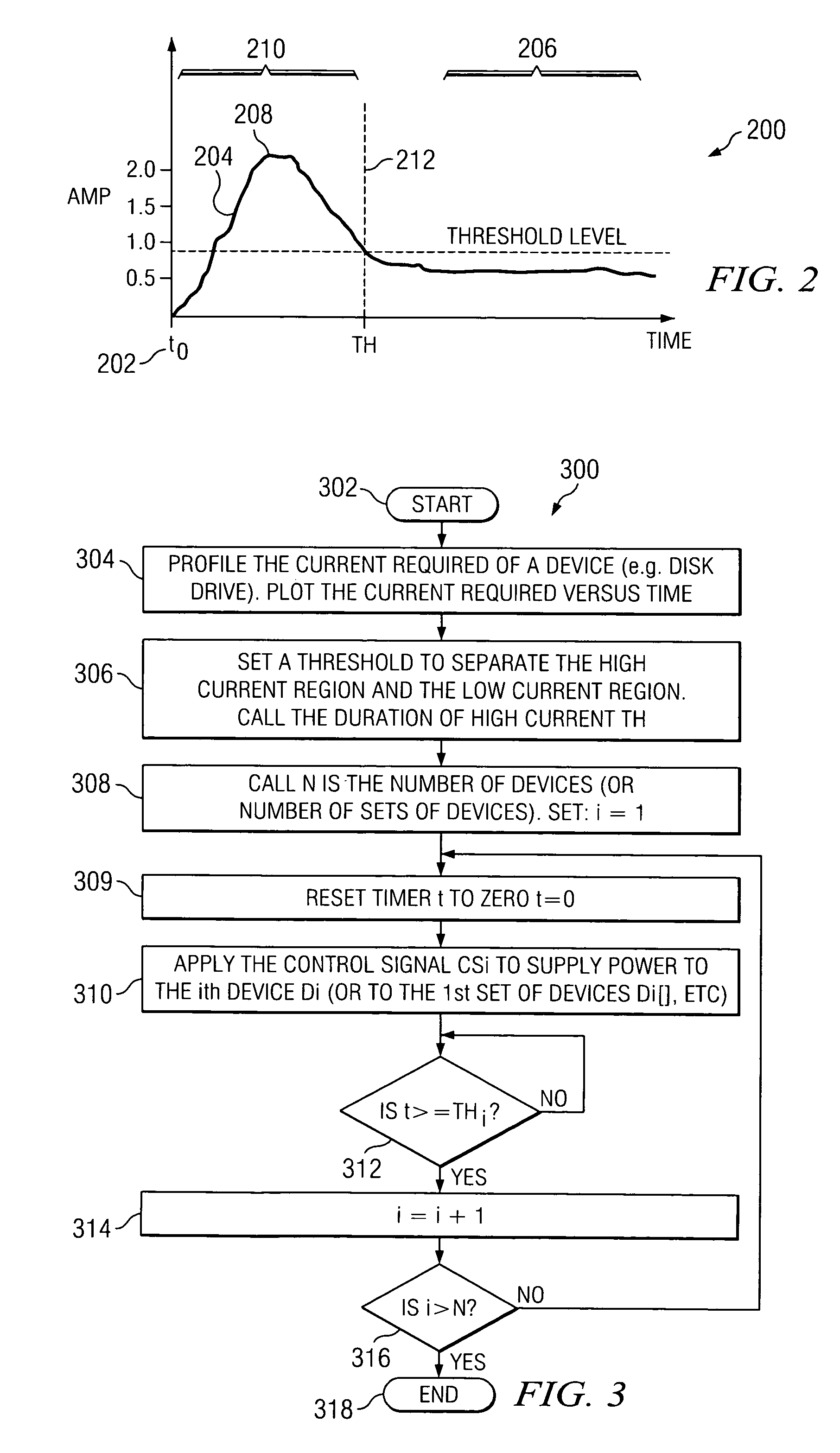

Method and apparatus for controlling power sequencing of a plurality of electrical/electronic devices

ActiveUS7370220B1Total current dropReduced Power RequirementsEnergy efficient ICTPower supply for data processingControl powerClosed loop

A method and apparatus for managing power sequencing in a data storage system. The turn-on or spin-up sequence for the media drives in an array of media drives is selectively controlled such that the overall rush current is reduced. The individual drive components are characterized to determine a power profile for each such component. A closed-loop process is then used to manage and reduce peak power requirements when starting up or spinning up an array of media drives using the drive profiles. The media drives can also be organized as a plurality of sets of drives, and a power profile for each set of drives is used to manage and reduce peak power requirements.

Owner:ORACLE INT CORP

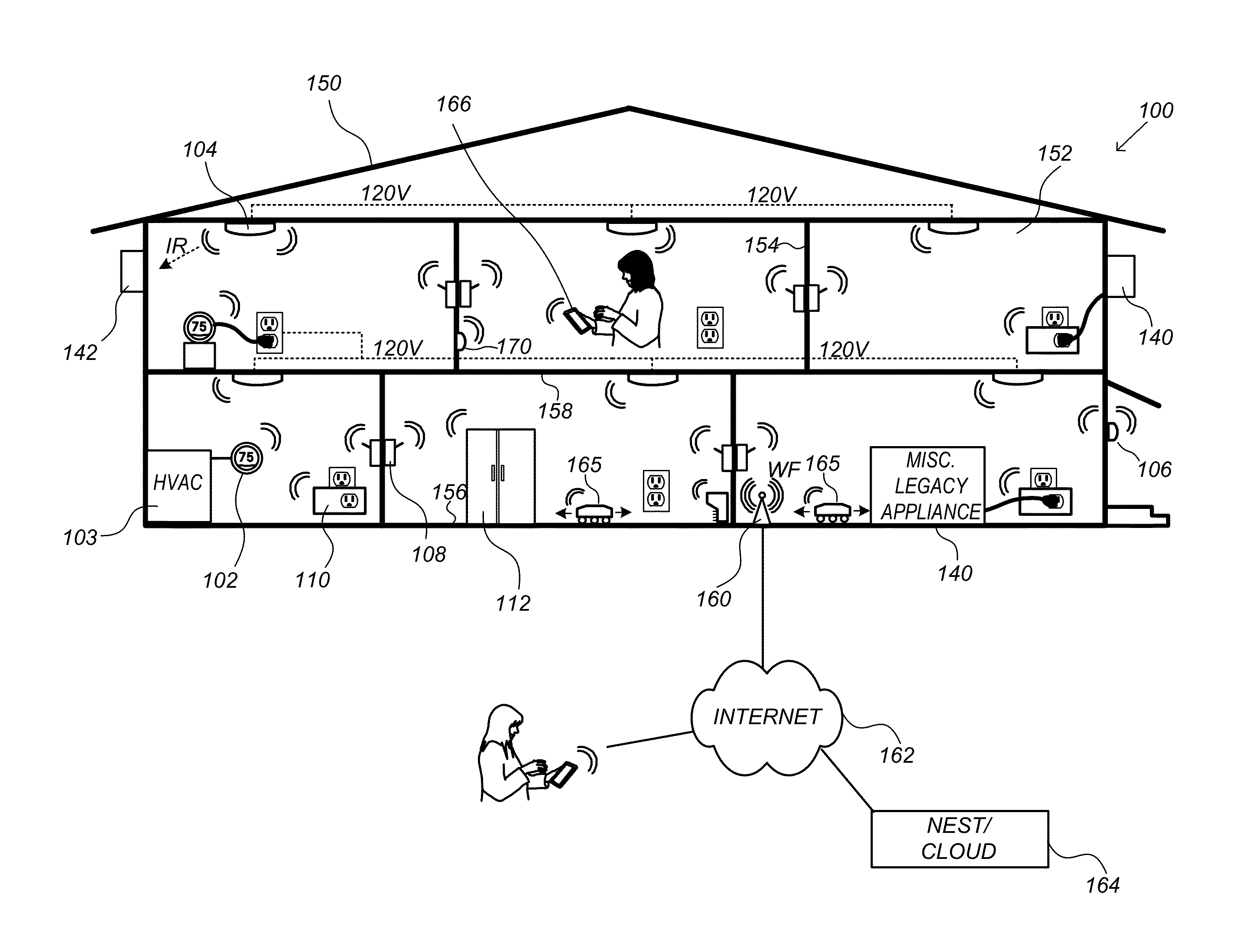

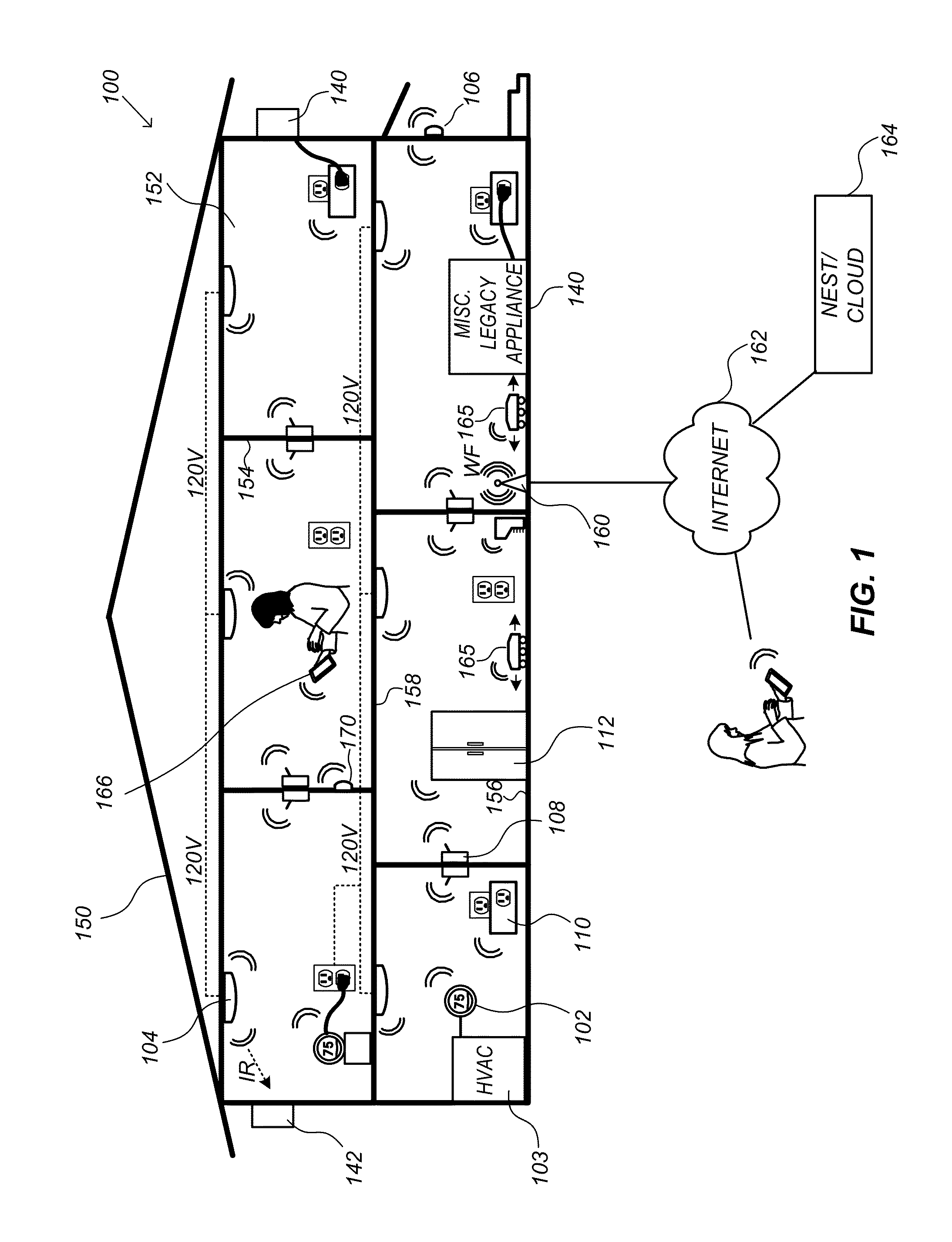

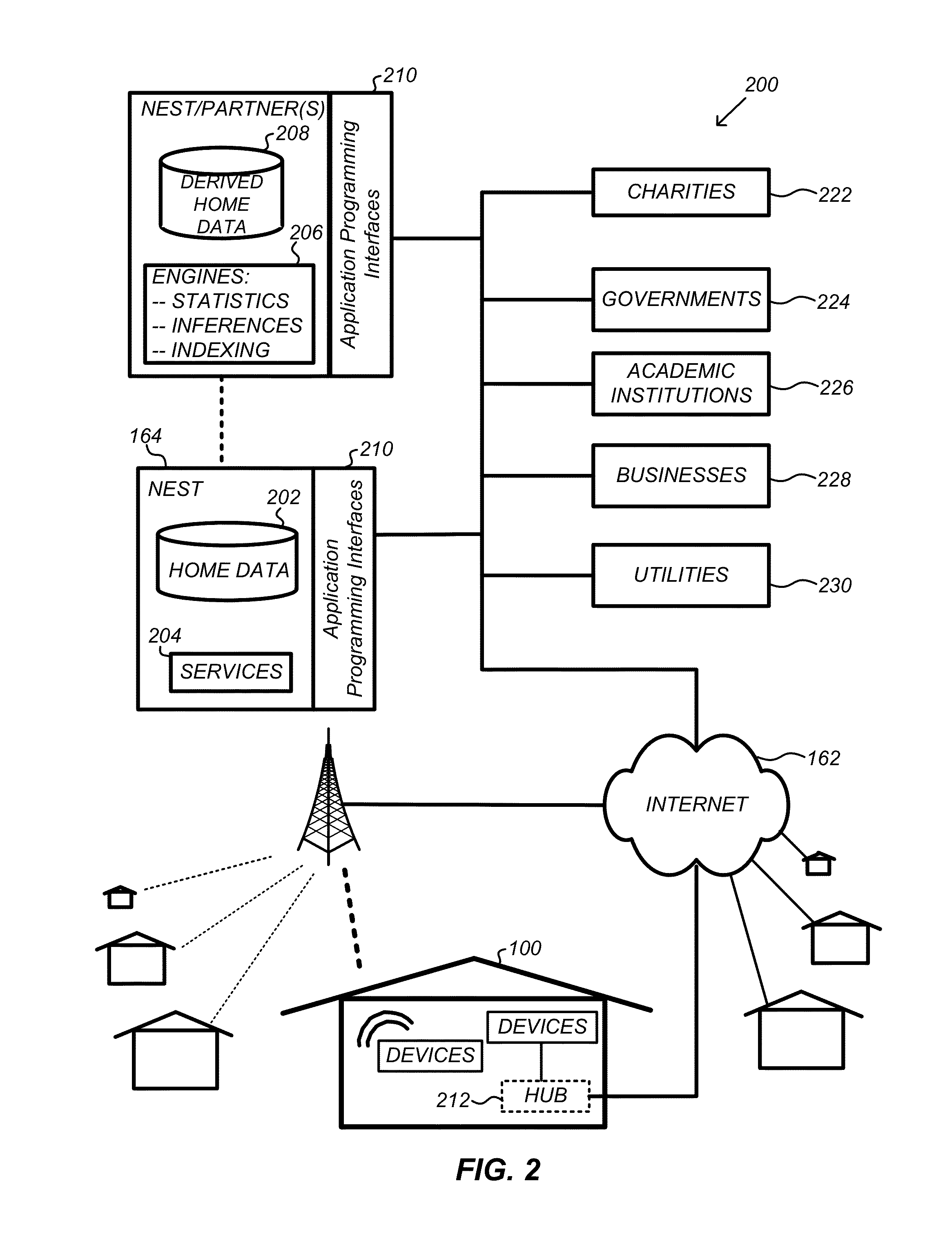

Smart-home control system providing HVAC system dependent responses to hazard detection events

Systems and methods for controlling a climate control system of a smart-home environment that includes a plurality of smart devices are provided. One method includes detecting, with a hazard detector of the smart devices, a level of carbon monoxide (CO) at the hazard detector that exceeds a threshold CO level at a location of the hazard detector, determining, by one of the smart devices, that the climate control system includes a combustion based heat source, and in response to the detecting and the determination, transmitting, by a system controller of the climate control system, a first signal to turn off at least one aspect of the climate control system.

Owner:GOOGLE LLC

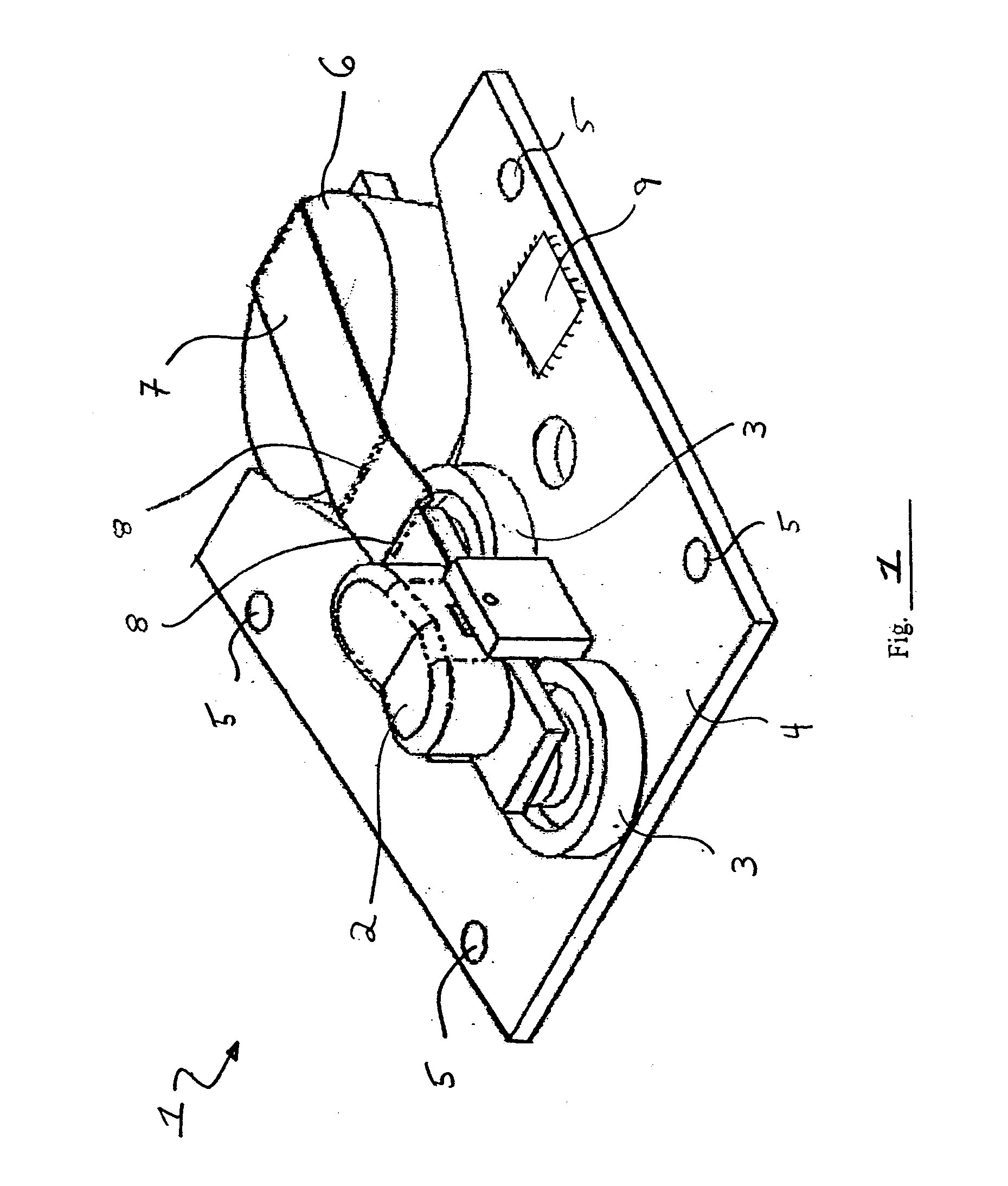

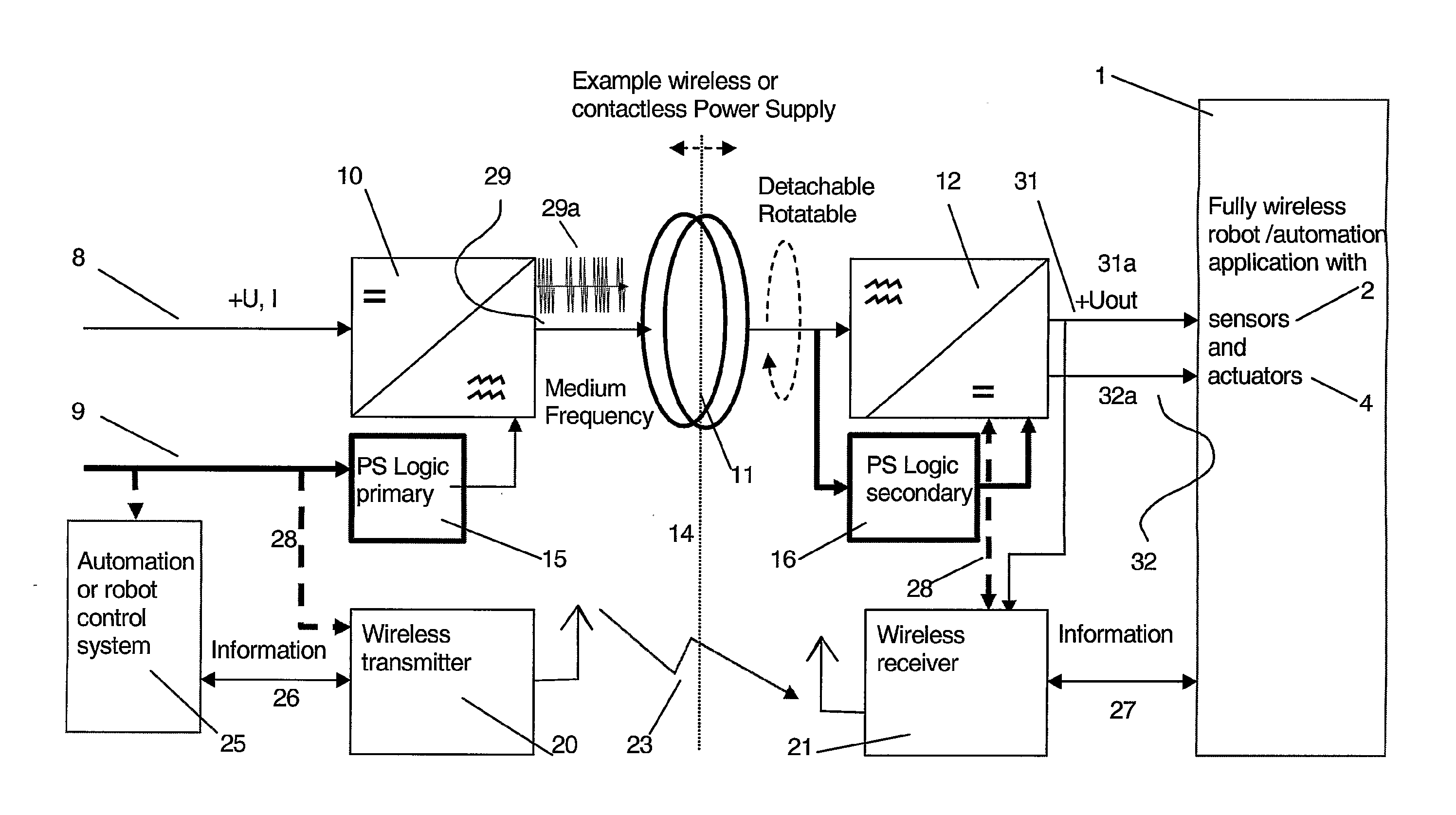

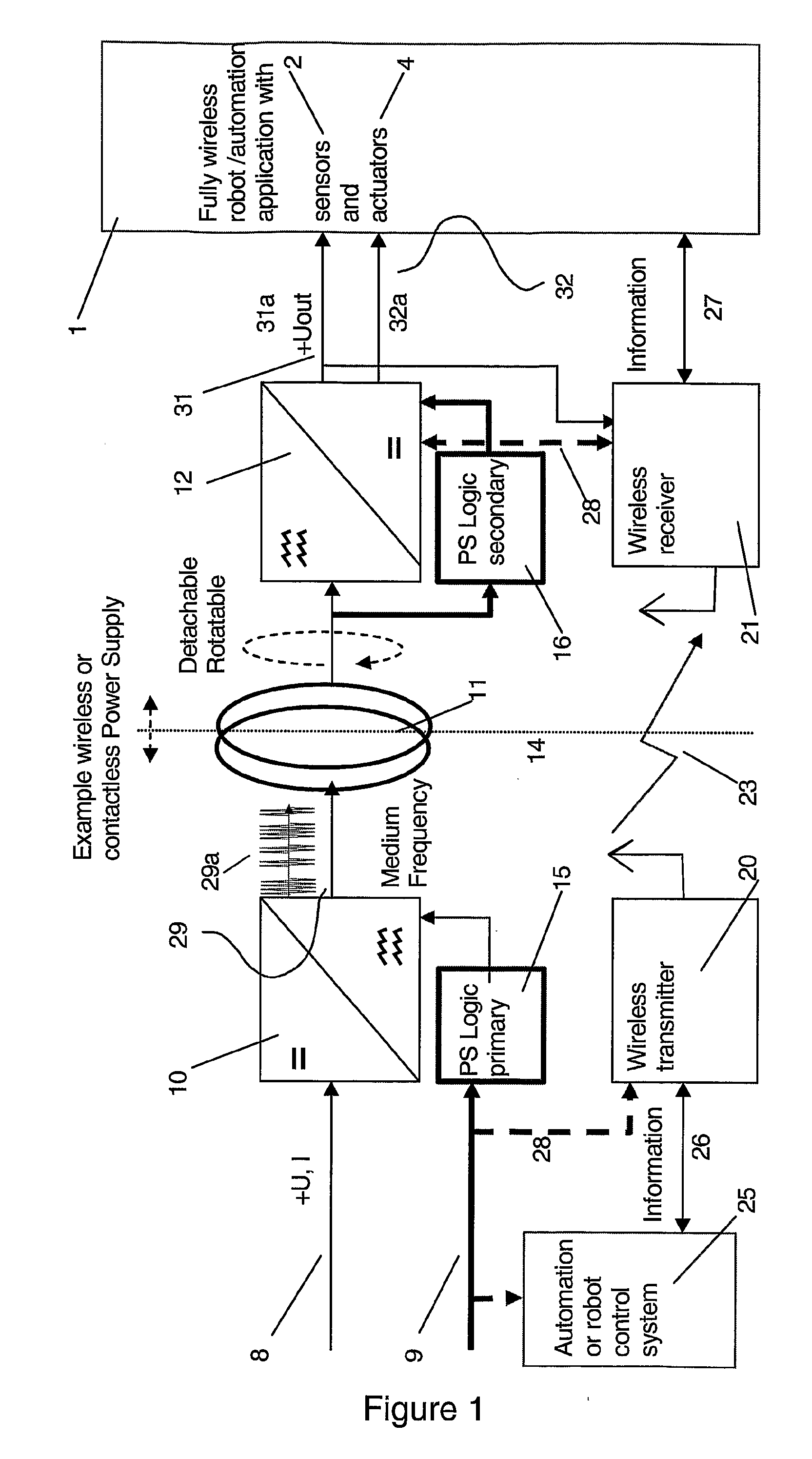

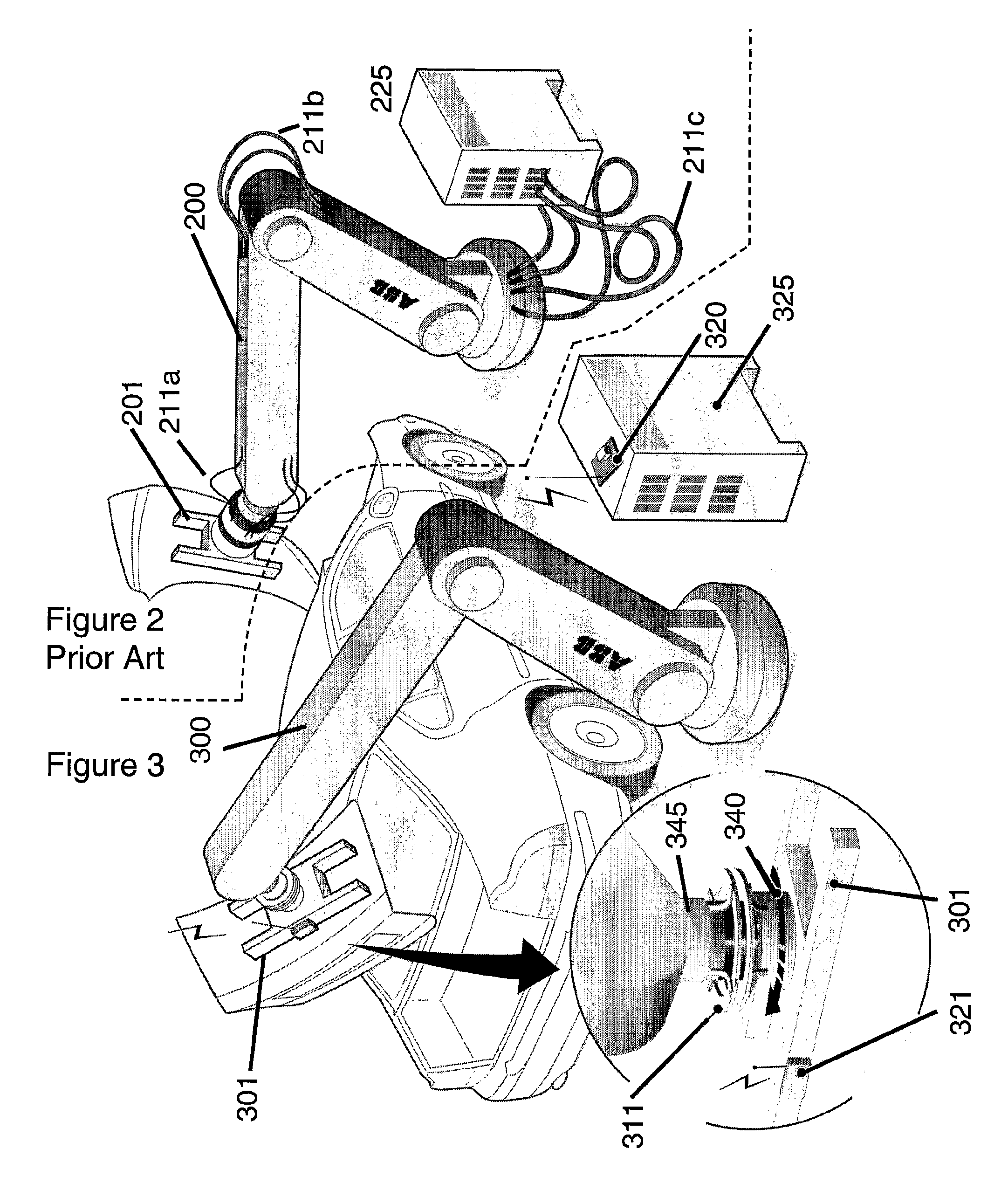

Tool for an Industrial Robot

InactiveUS20070276538A1Speeding up changeReduce downtimeSingle-phase induction motor startersProgramme-controlled manipulatorWireless controlIndustrial robotics

A robot or manipulator including a wireless power supply and a wireless communication device. One or more actuators on the robot tool may be wirelessly powered and wirelessly controlled. The robot tool may have one or more wireless communication members for transmission of data from sensors on the tool. The power supply includes a primary power supply member and secondary power supply member. Tool changes may be carried out automatically by the robot. In other aspects of the invention a method, a control system and a computer program for carrying out the method are described.

Owner:ABB RES LTD

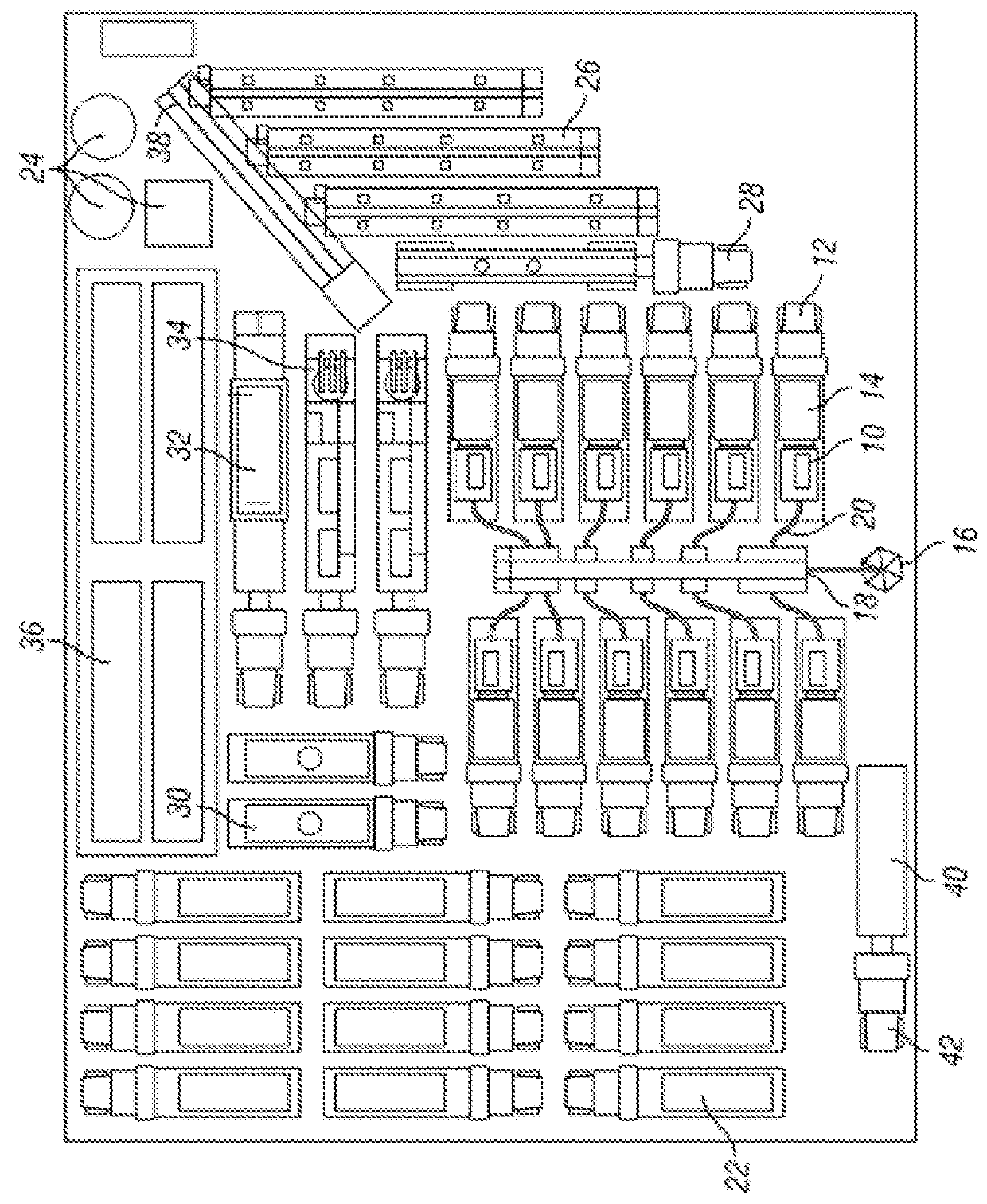

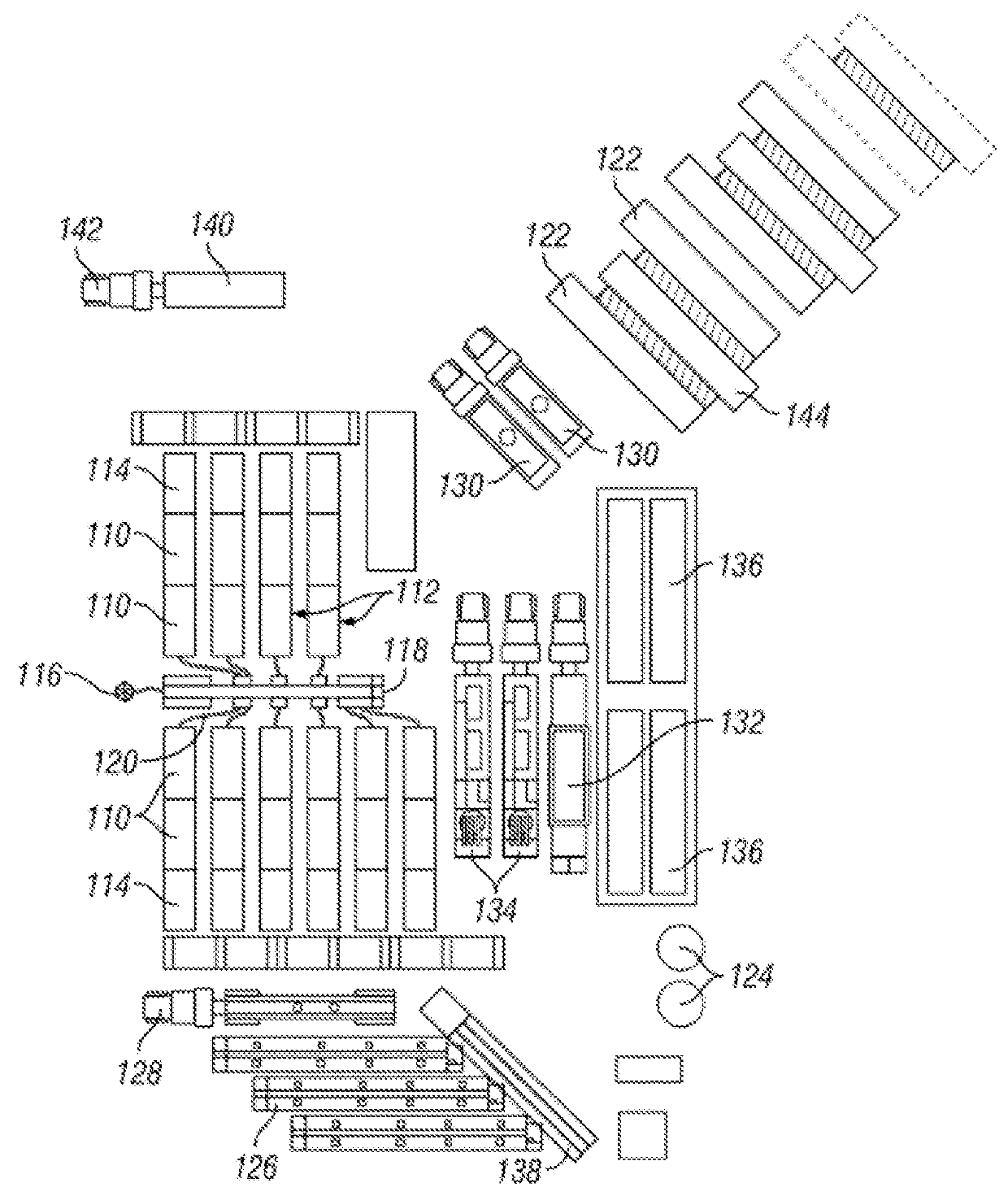

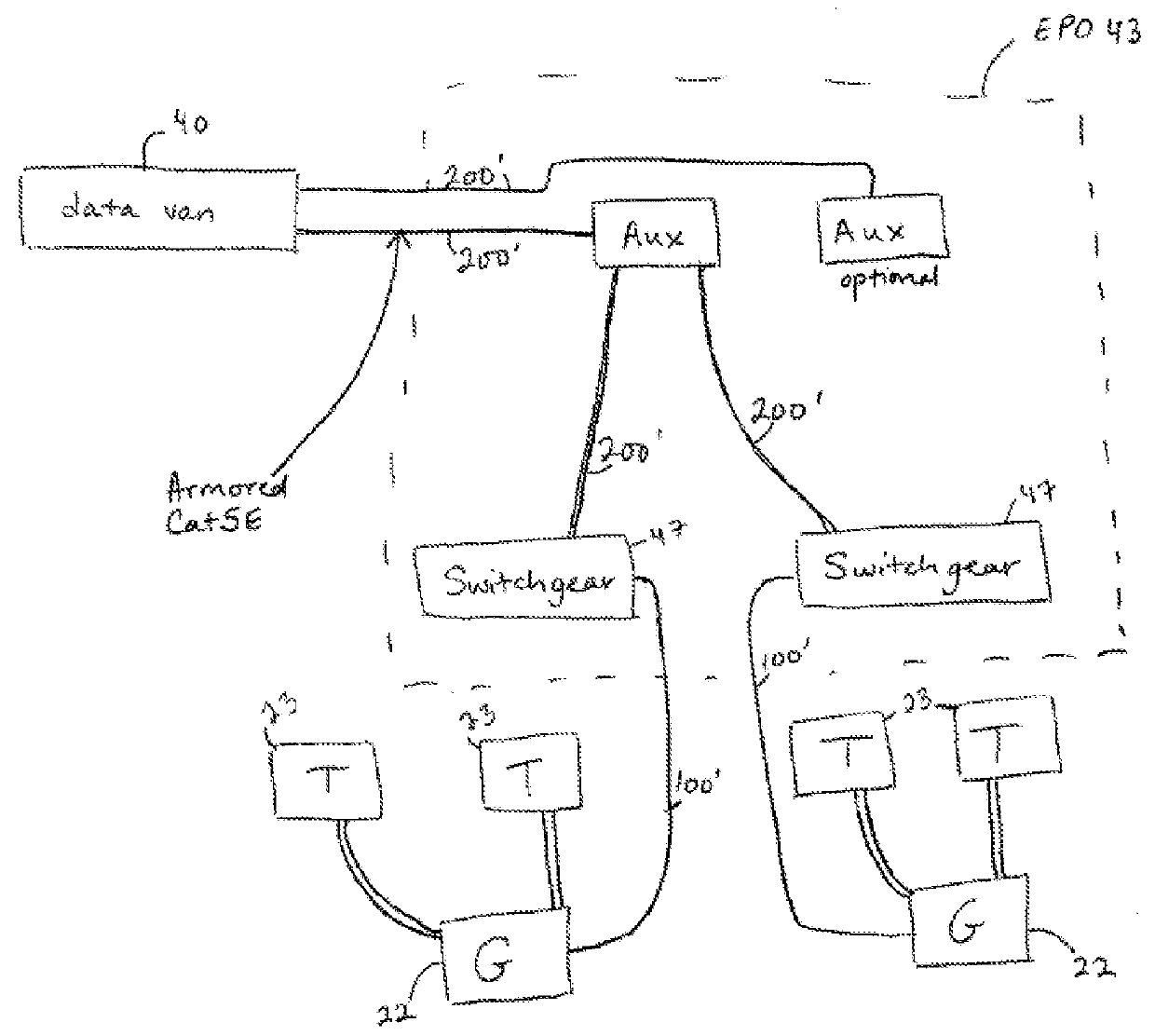

System for centralized monitoring and control of electric powered hydraulic fracturing fleet

A system and method are disclosed for centralized monitoring and control of a hydraulic fracturing operation. The system includes an electric powered fracturing fleet and a centralized control unit coupled to the electric powered fracturing fleet. The electric powered fracturing fleet can include a combination of one or more of: electric powered pumps, turbine generators, blenders, sand silos, chemical storage units, conveyor belts, manifold trailers, hydration units, variable frequency drives, switchgear, transformers, and compressors. The centralized control unit can be configured to monitor and / or control one or more operating characteristics of the electric powered fracturing fleet.

Owner:US WELL SERVICS LLC

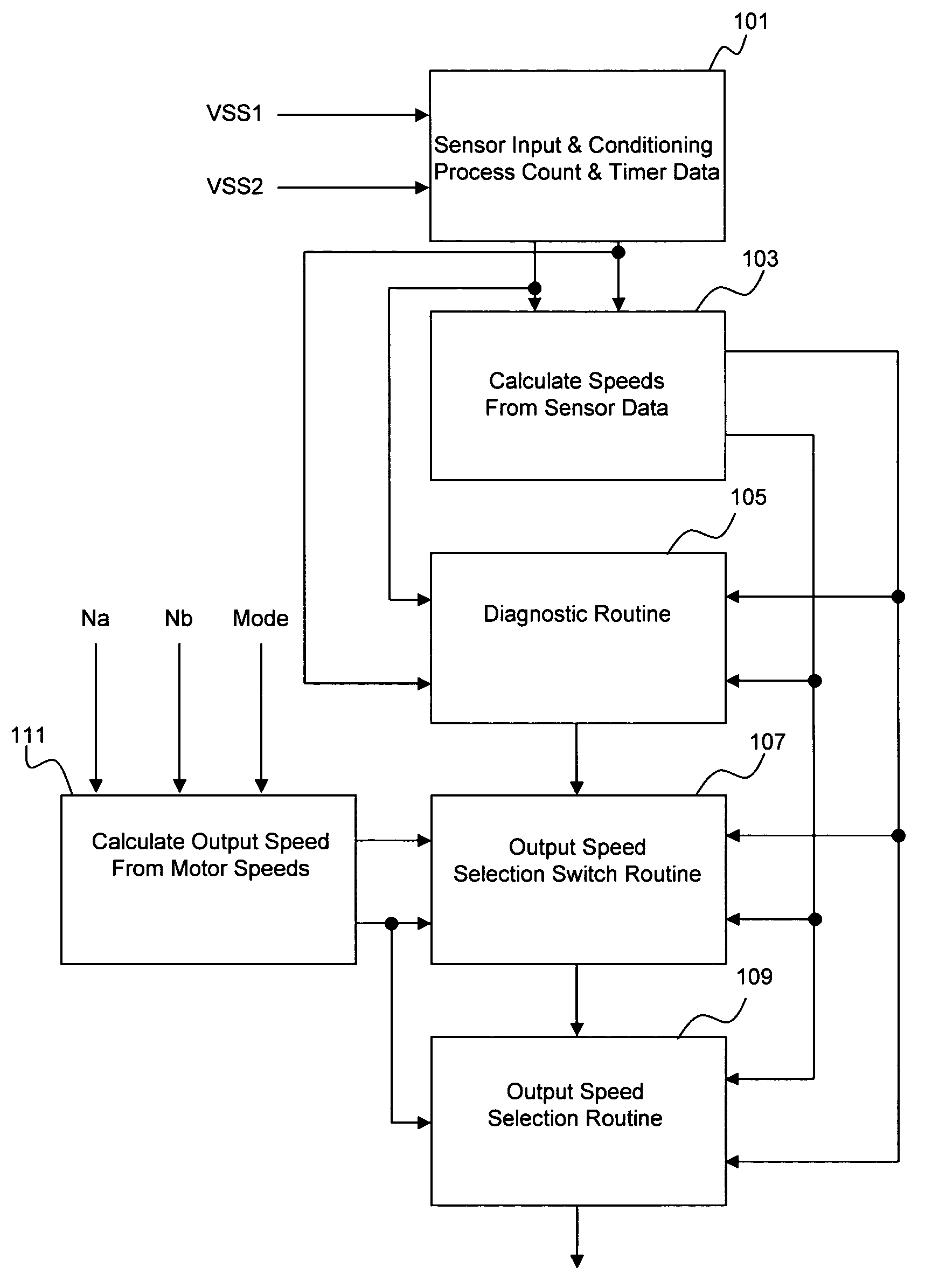

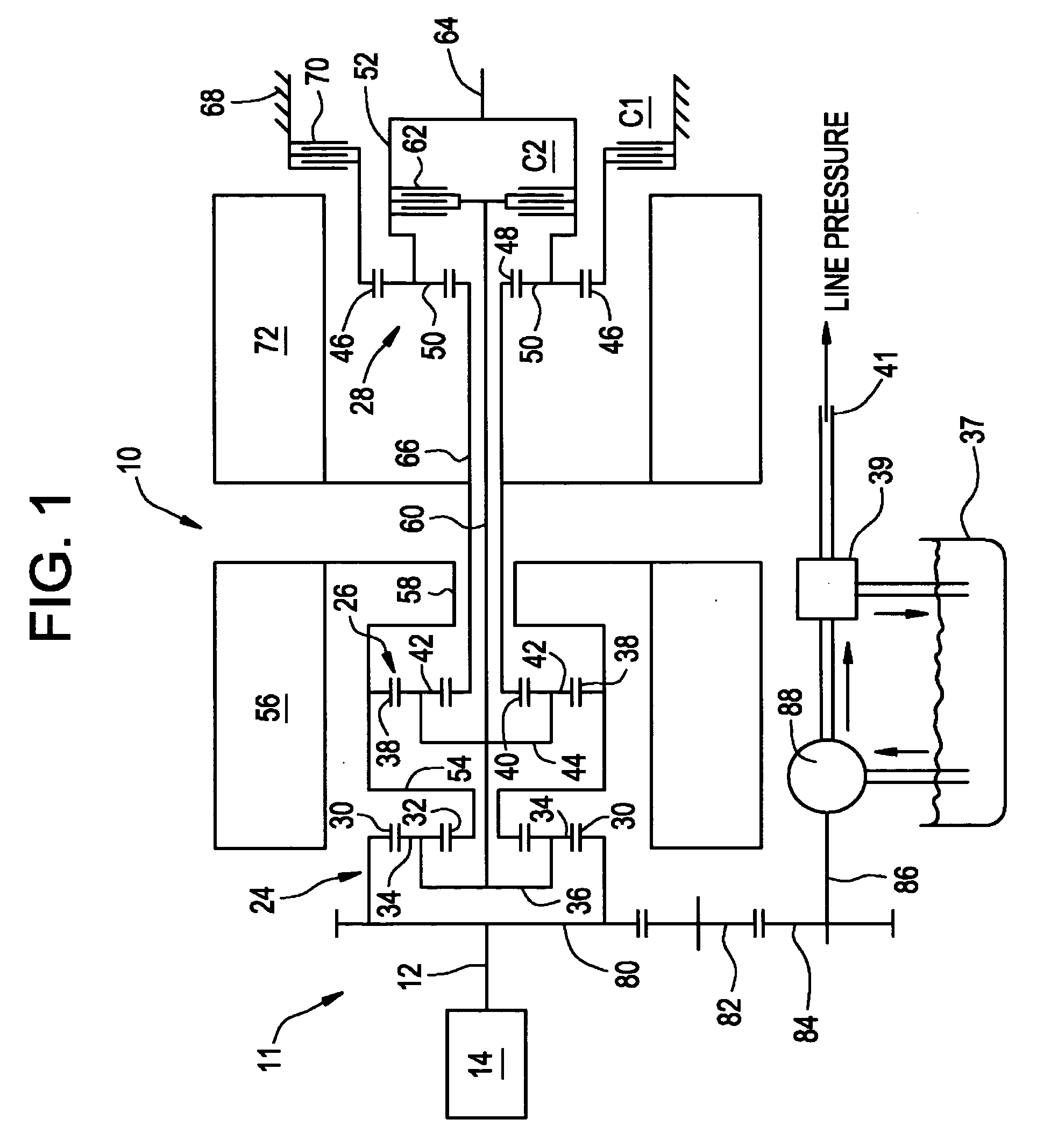

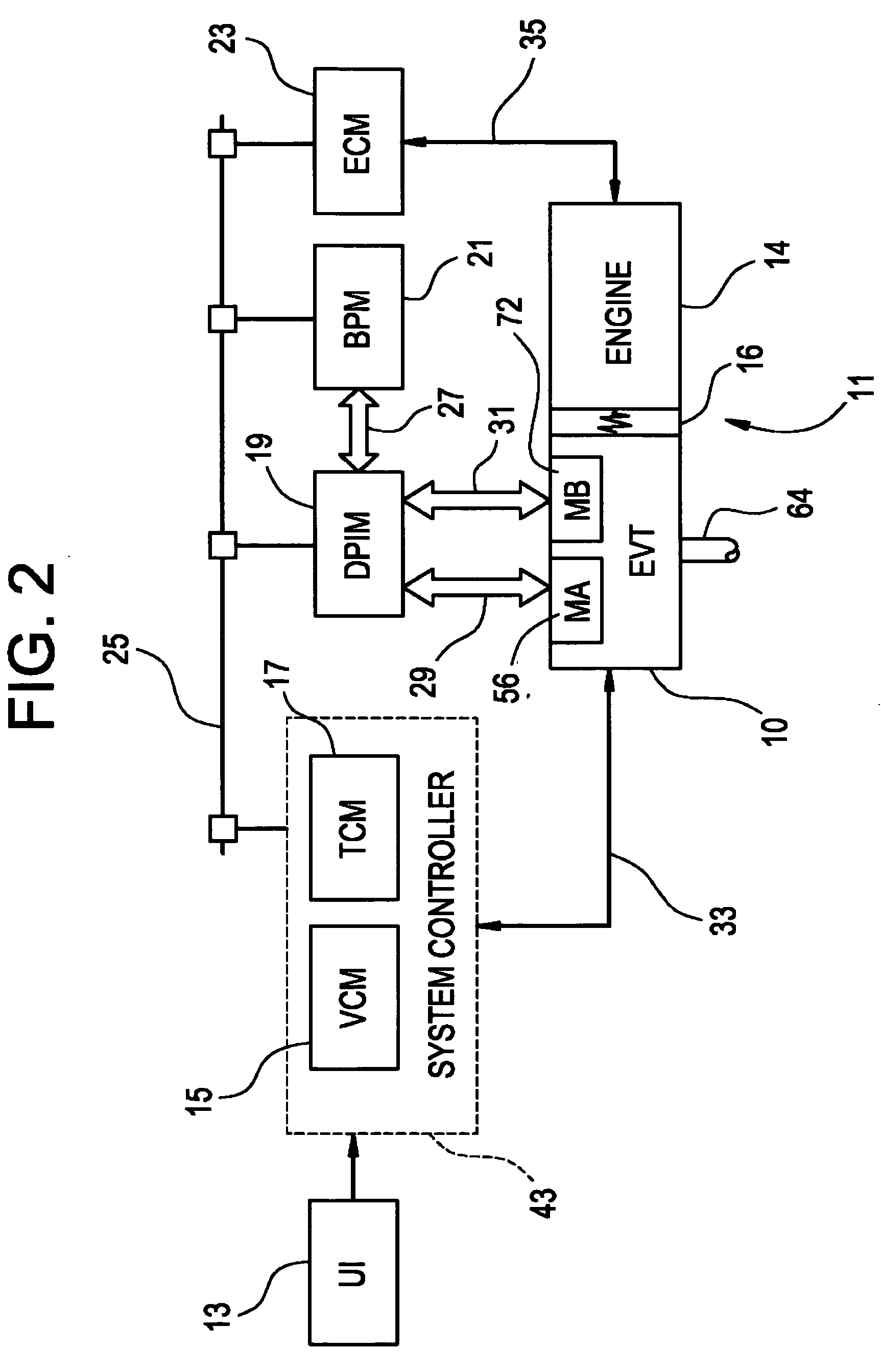

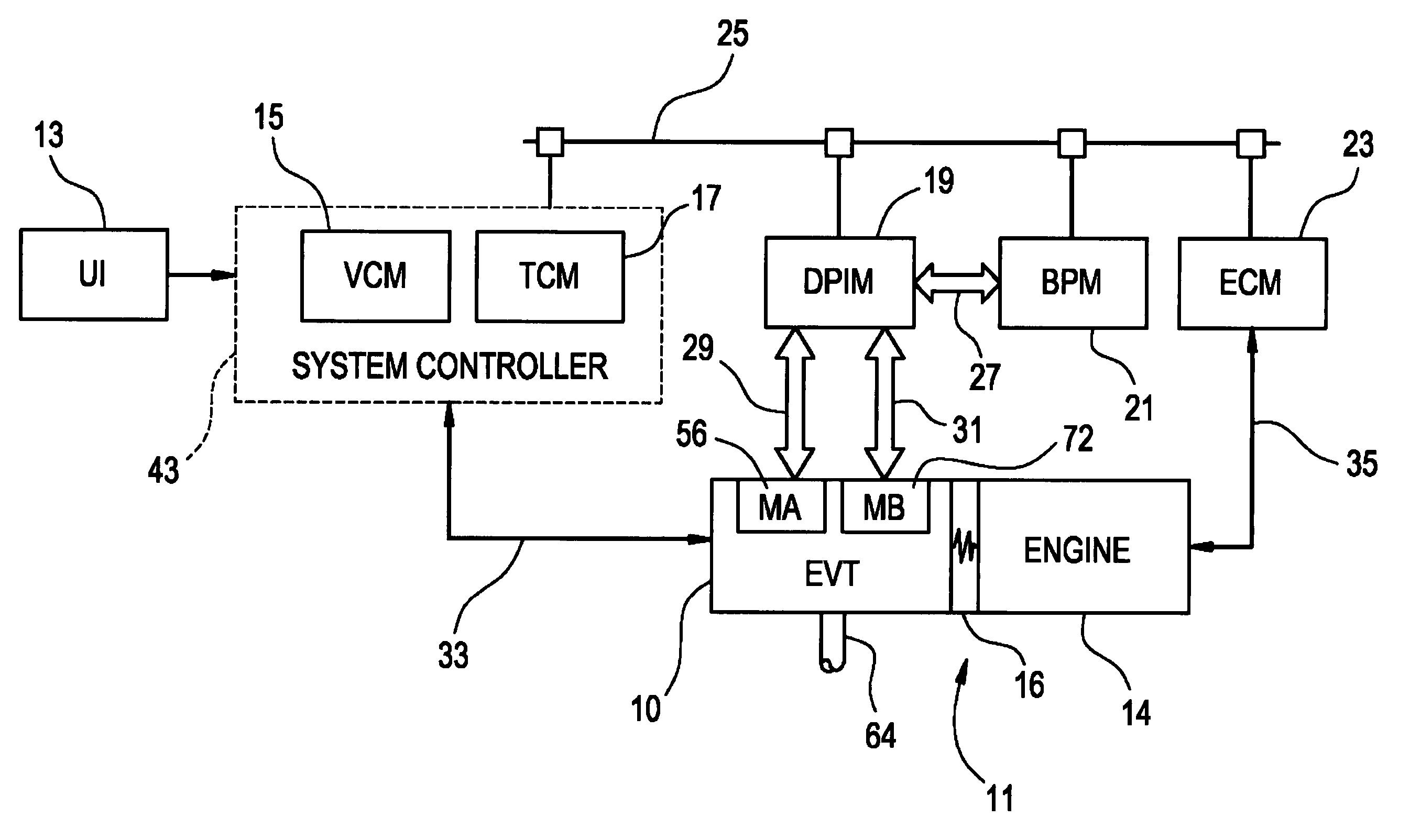

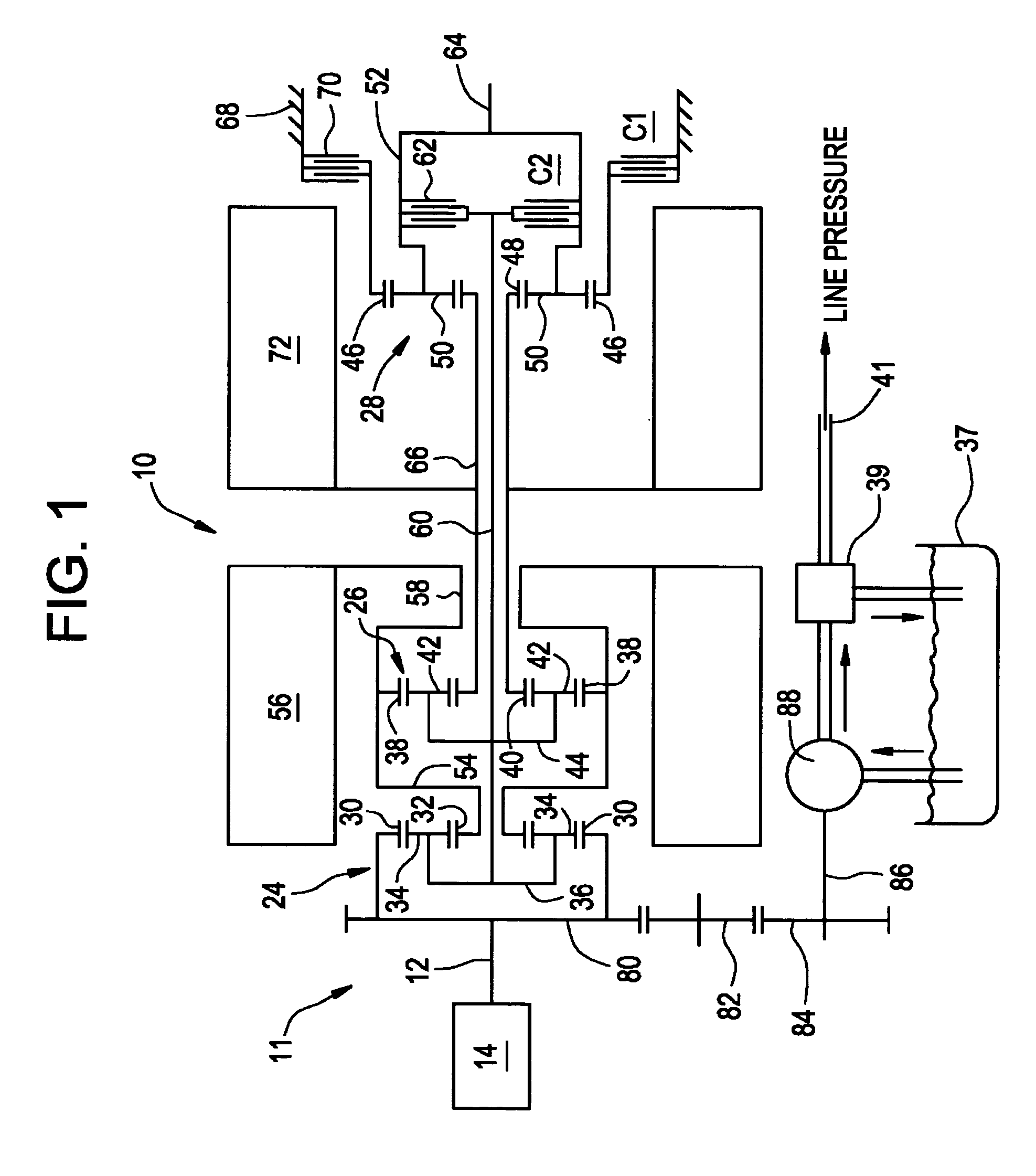

Hybrid transmission member speed determination, sensor diagnostics and fault recovery

ActiveUS20050080527A1Vehicle testingRegistering/indicating working of vehiclesVariatorHybrid powertrain

A hybrid powertrain has a transmission including a motor and a sensor for sensing rotation of the transmission output member. Motor speed signals are available from the motor controller. Speed signals representative of output speed are calculated from both the speed sensor and the motor speed in conjunction with known speed relationships between the motor and the output. A variety of in-range and dropped signal diagnostics is performed for the sensors and are used in the development of a set of software switches for selecting which of the speed sources is used as the output speed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Real-time operating parameter selection in a vehicular transmission

Preferred operating points for a vehicle powertrain including an engine and a transmission are determined in accordance with a comprehensive operational mapping of input and output conditions and corresponding aggregate system losses corresponding to engine and transmission losses. In a hybrid transmission application, additional losses from motors and batteries are aggregated into the system losses and battery constraints are considered in determining preferred operating points. Preferred operating points are provided in one or more sets of minimized data for on-vehicle implementation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Methods and systems for control of microfluidic devices

InactiveUS7010391B2Easy programmingSludge treatmentFixed microstructural devicesControl systemLow voltage

Owner:HANDYLAB

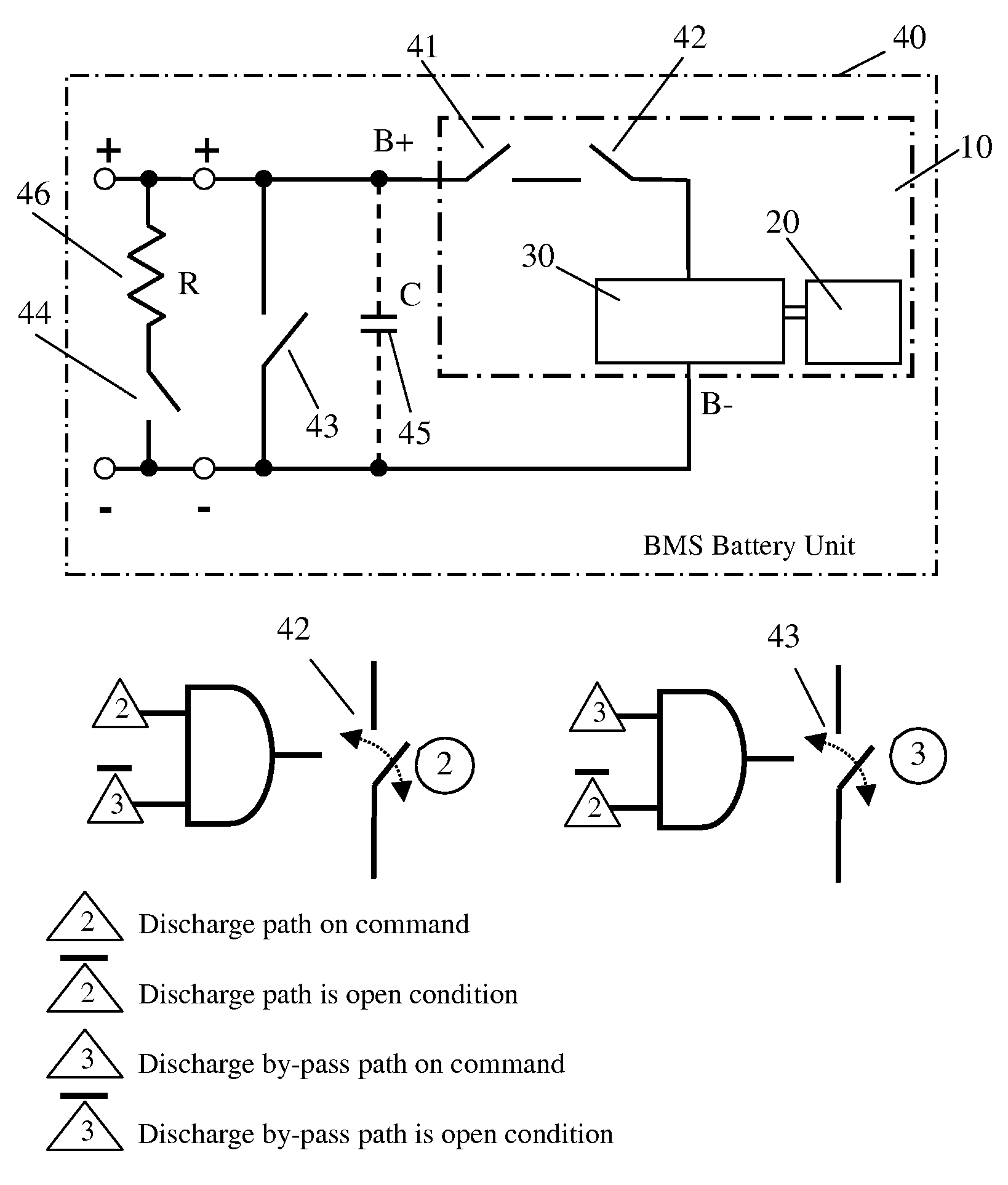

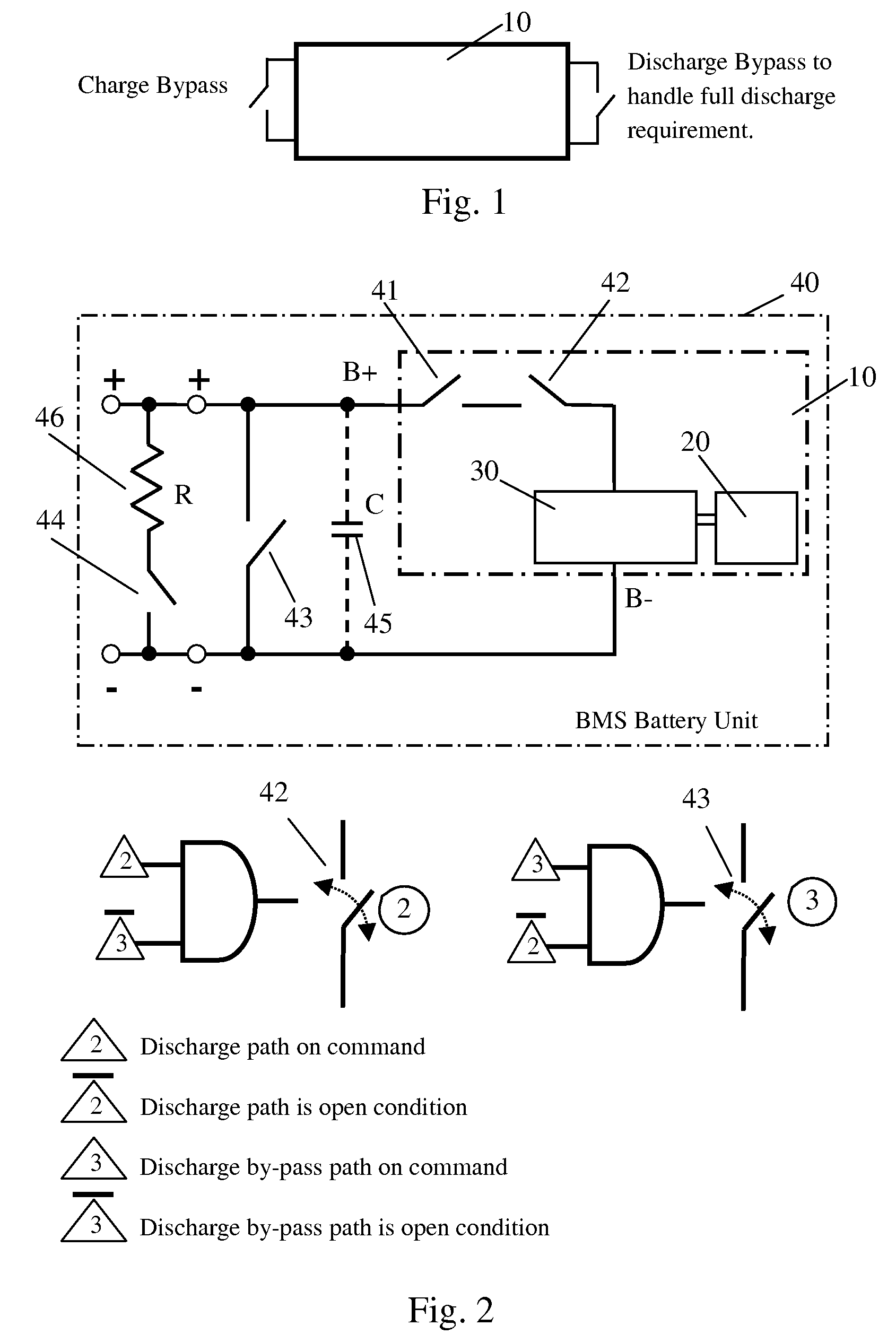

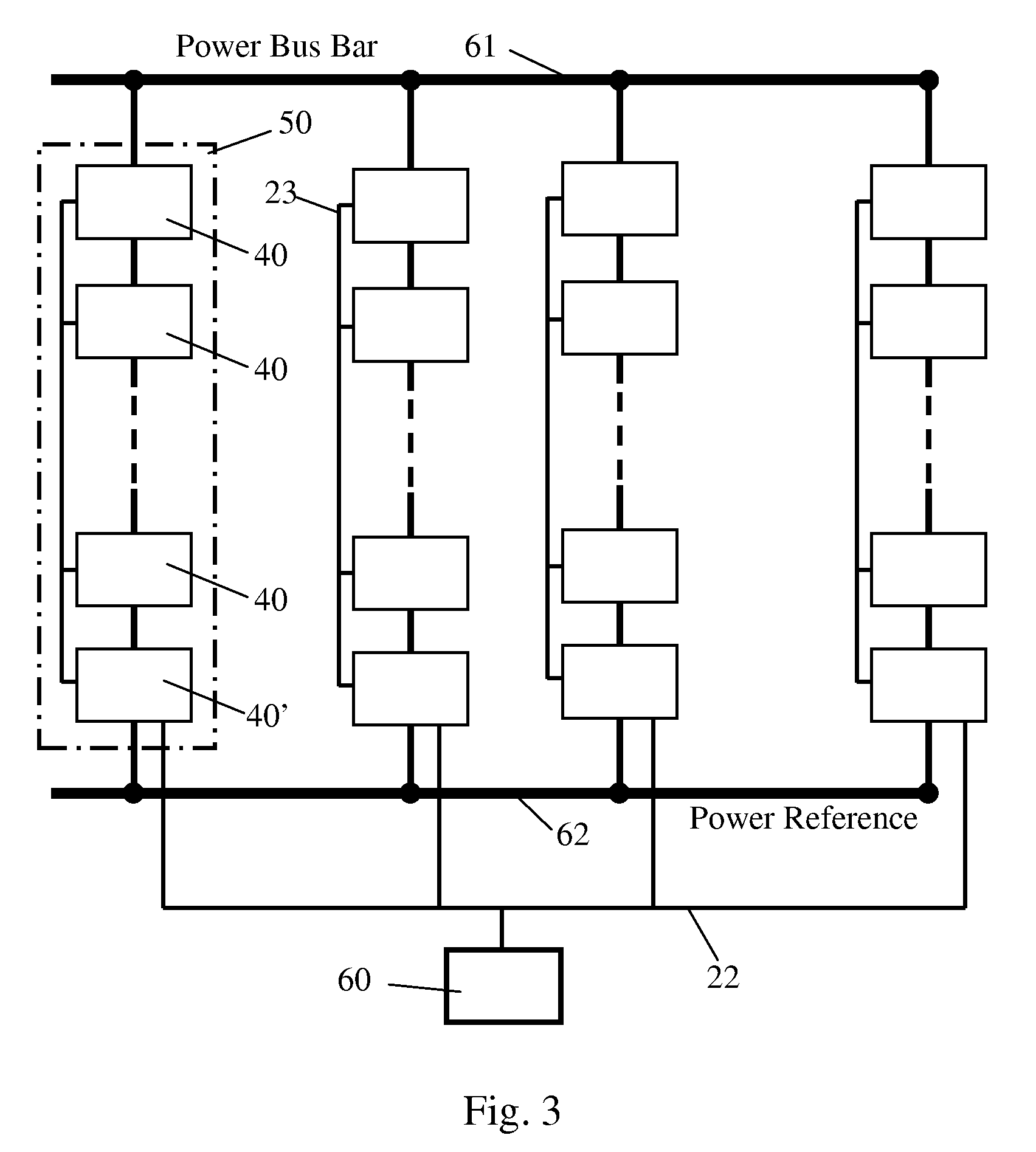

Distributed energy storage control system

InactiveUS20090066291A1Promote energy efficiencyHigh maintainabilityCharge equalisation circuitElectric powerAutomotive engineeringEngineering

A Distributed Energy Storage Control System (DESCS) comprised of one or a plurality of identical BMS (Battery Management System) battery unit (40), series-parallel system controller (60) and DESCS main controller (70). Each BMS battery unit (40) including a smart battery unit (10), a discharge bypass path control switch (43), a super capacitor (45), a charge bypass load (46) and charge bypass path control switch (44). This DESCS system substantially promotes the energy efficiency of battery, provides a large scale and complicated energy storage system with on-line repair or replacement of batteries, proceeds charge / discharge task uninterrupted during maintenance, and possesses high maintainability.

Owner:J TEK

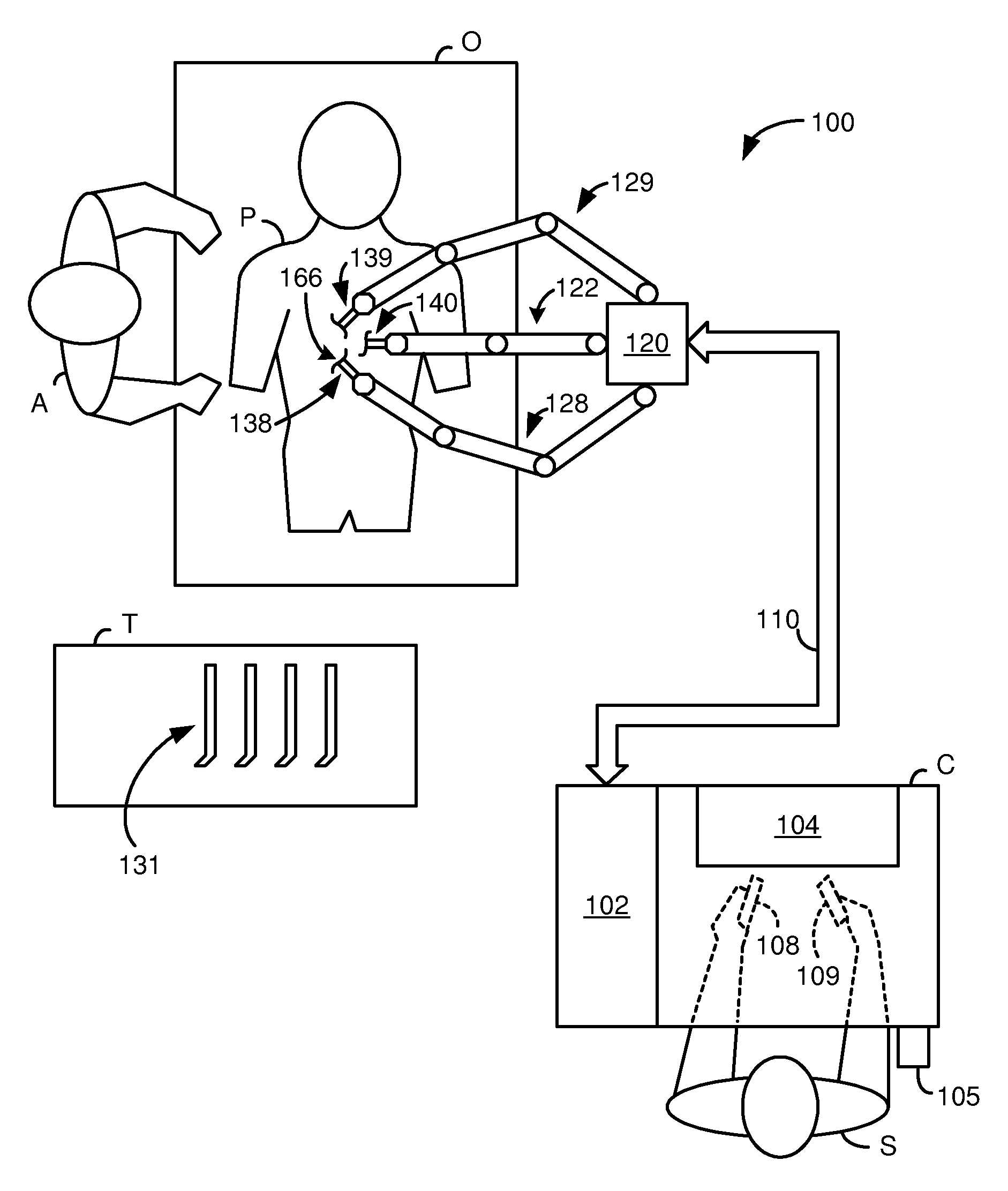

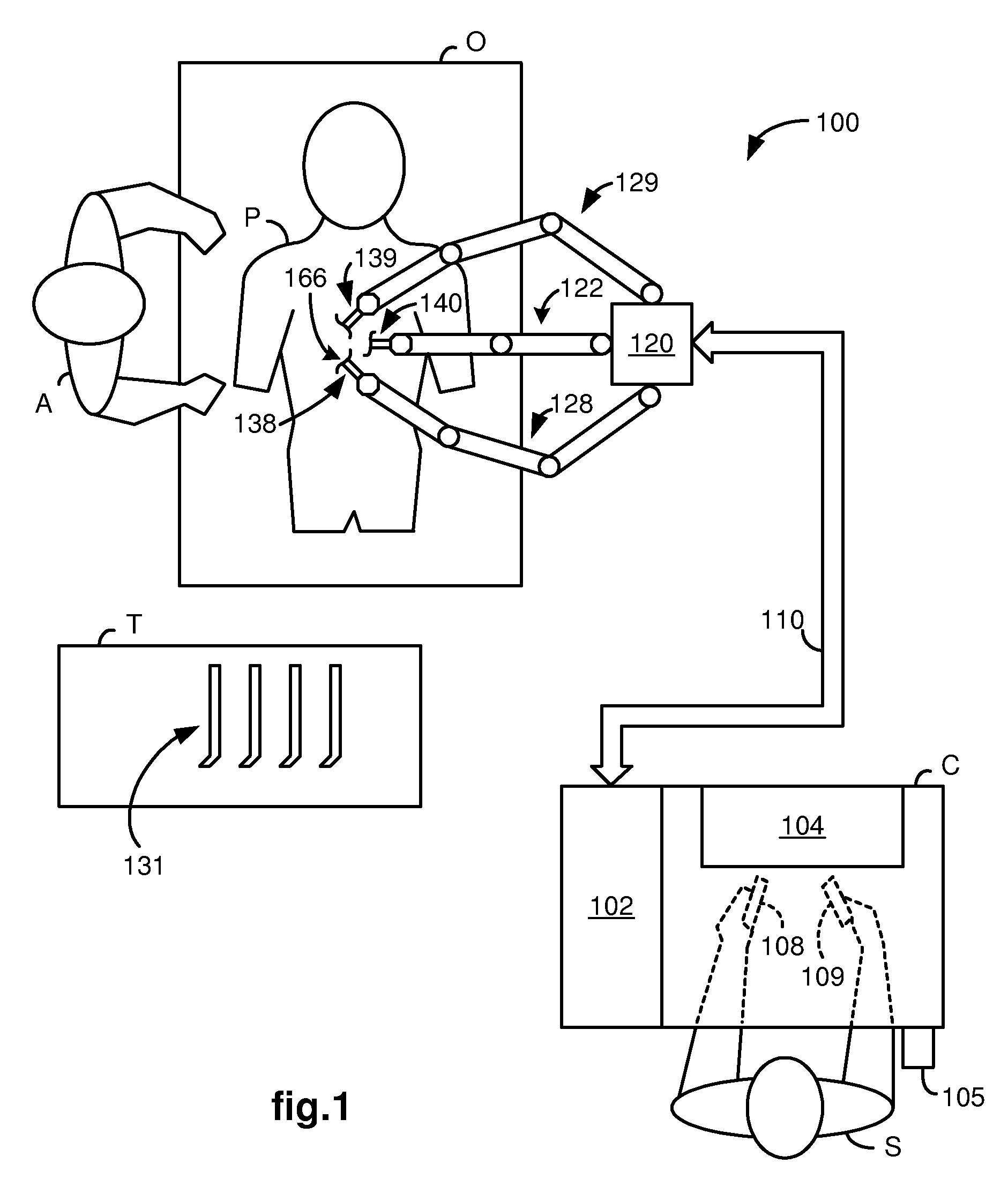

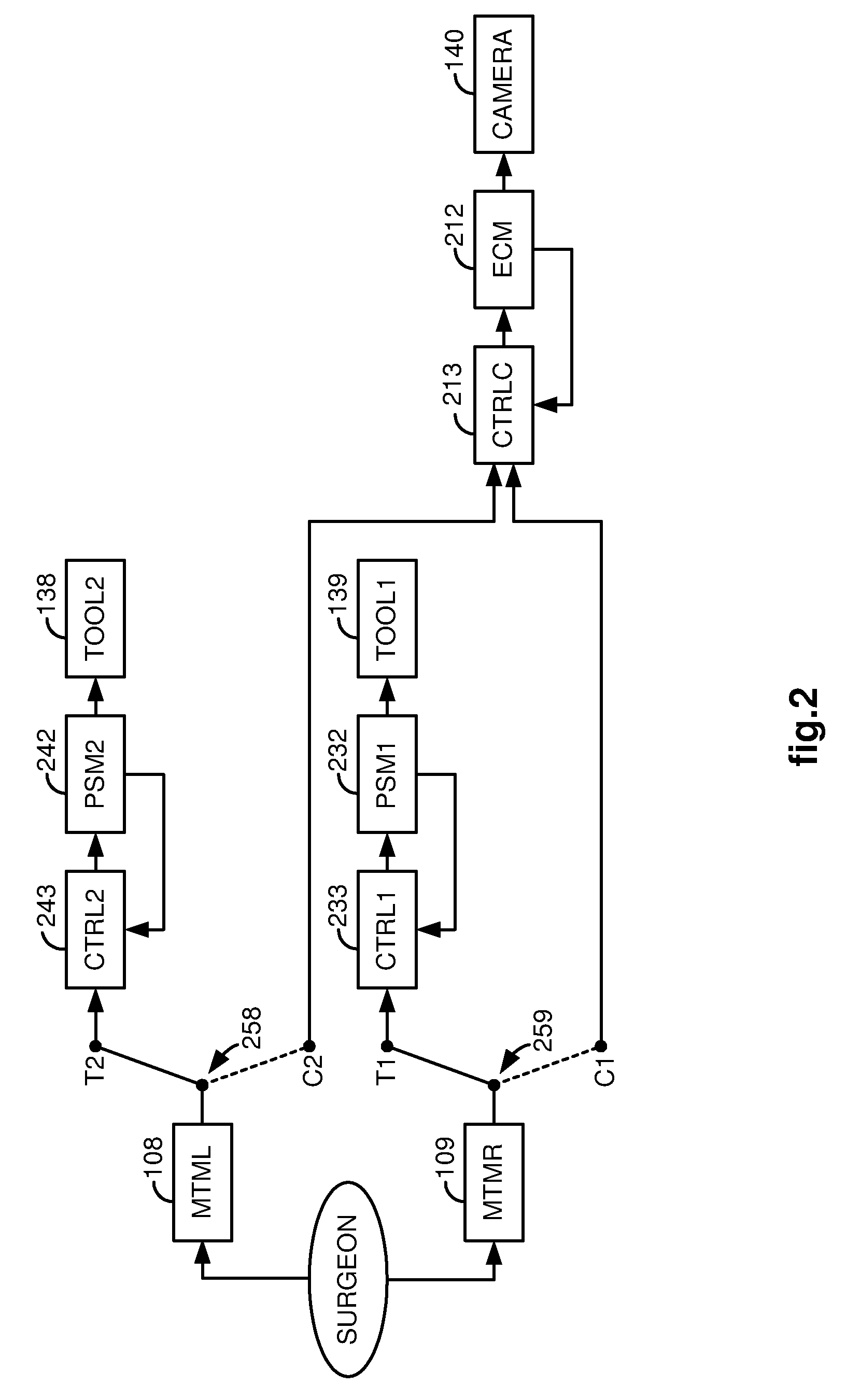

System and method for adjusting an image capturing device attribute using an unused degree-of-freedom of a master control device

ActiveUS8335590B2Sampled-variable control systemsProgramme-controlled manipulatorDevice PropertiesControl engineering

An image capturing device is robotically positioned and oriented in response to operator manipulation of a master control device. An unused degree-of-freedom of the master control device is used to adjust an attribute such as focusing of the image capturing device relative to a continually updated set-point. A deadband is provided to avoid inadvertent adjusting of the image capturing device attribute and haptic feedback is provided back to the master control device so that the operator is notified when adjusting of the attribute is initiated.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com