Patents

Literature

221423results about How to "Simple process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

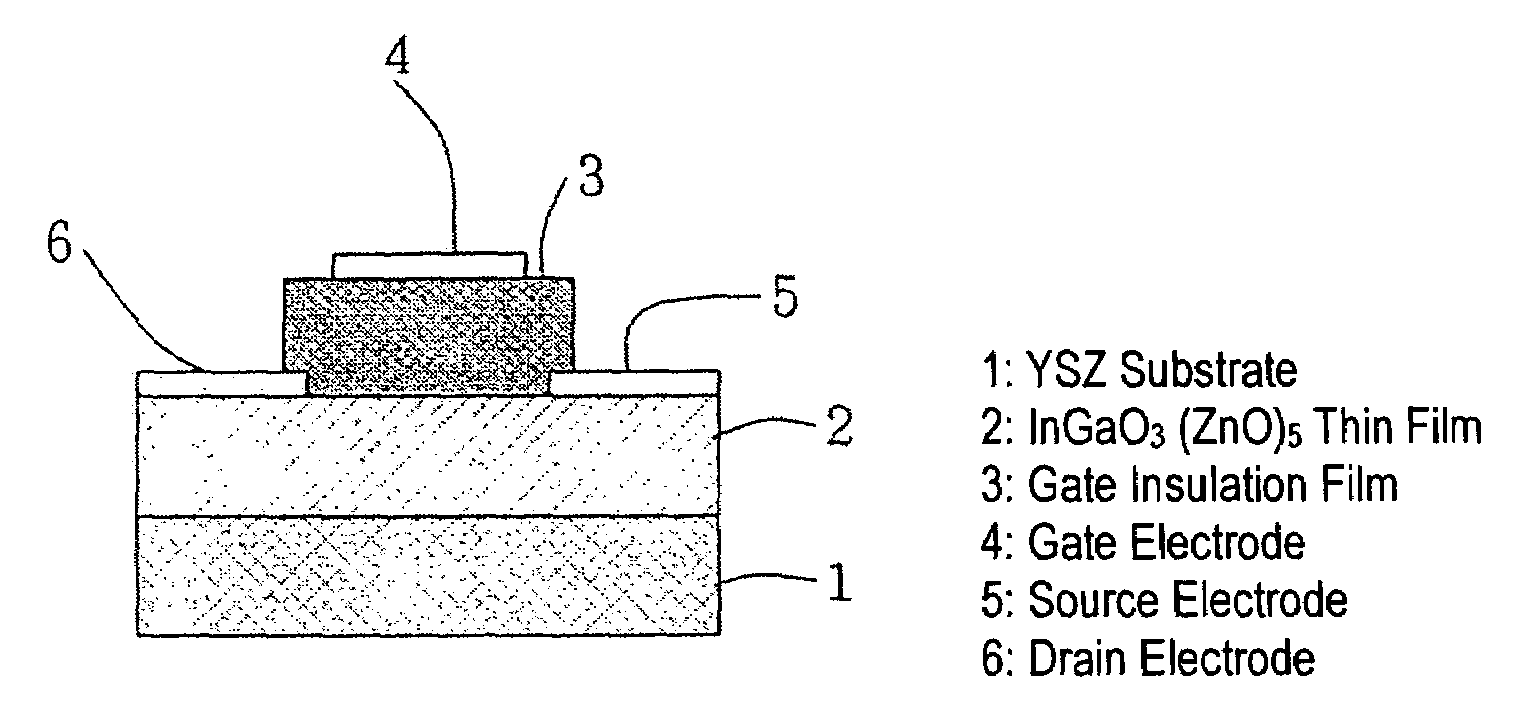

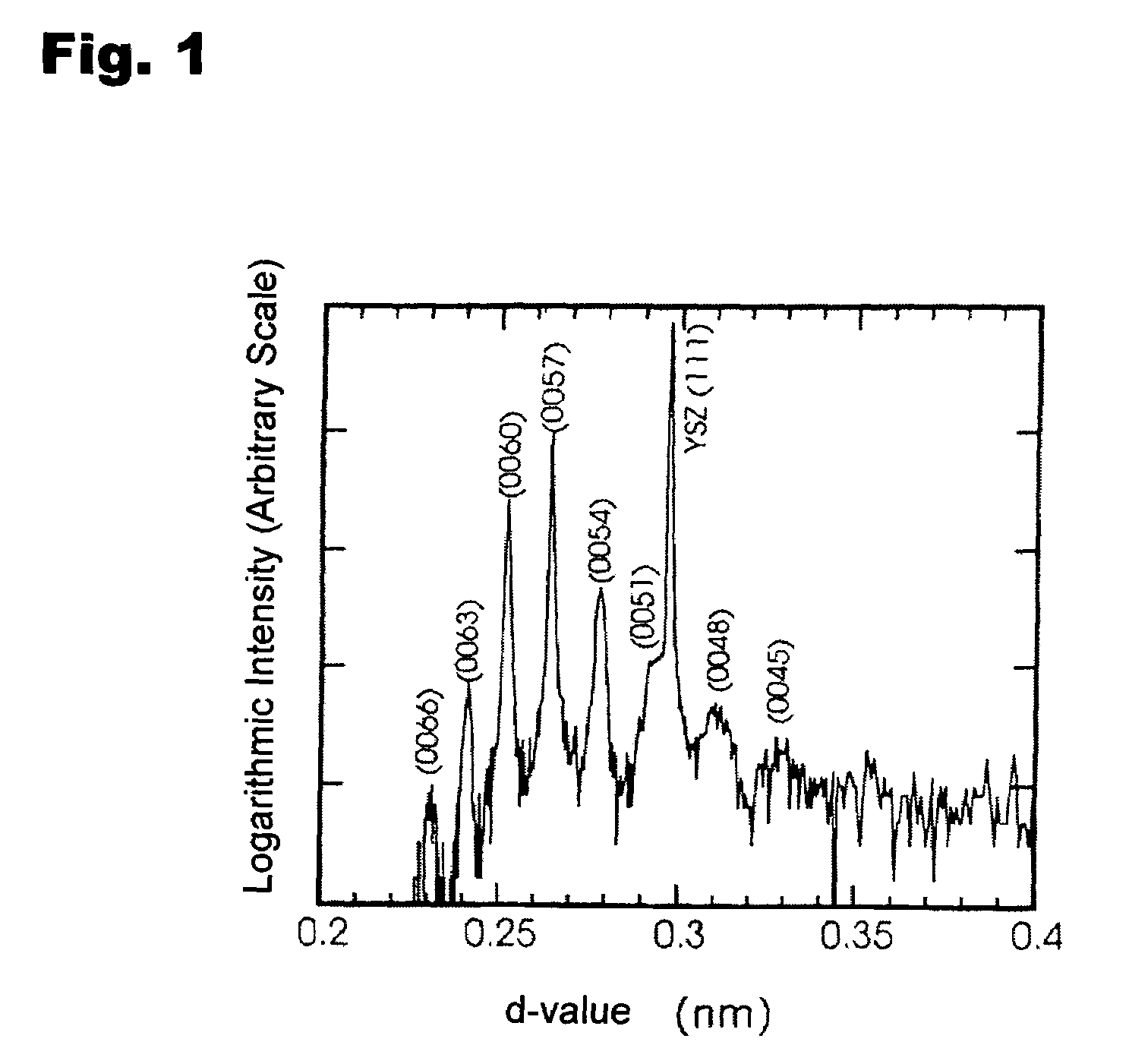

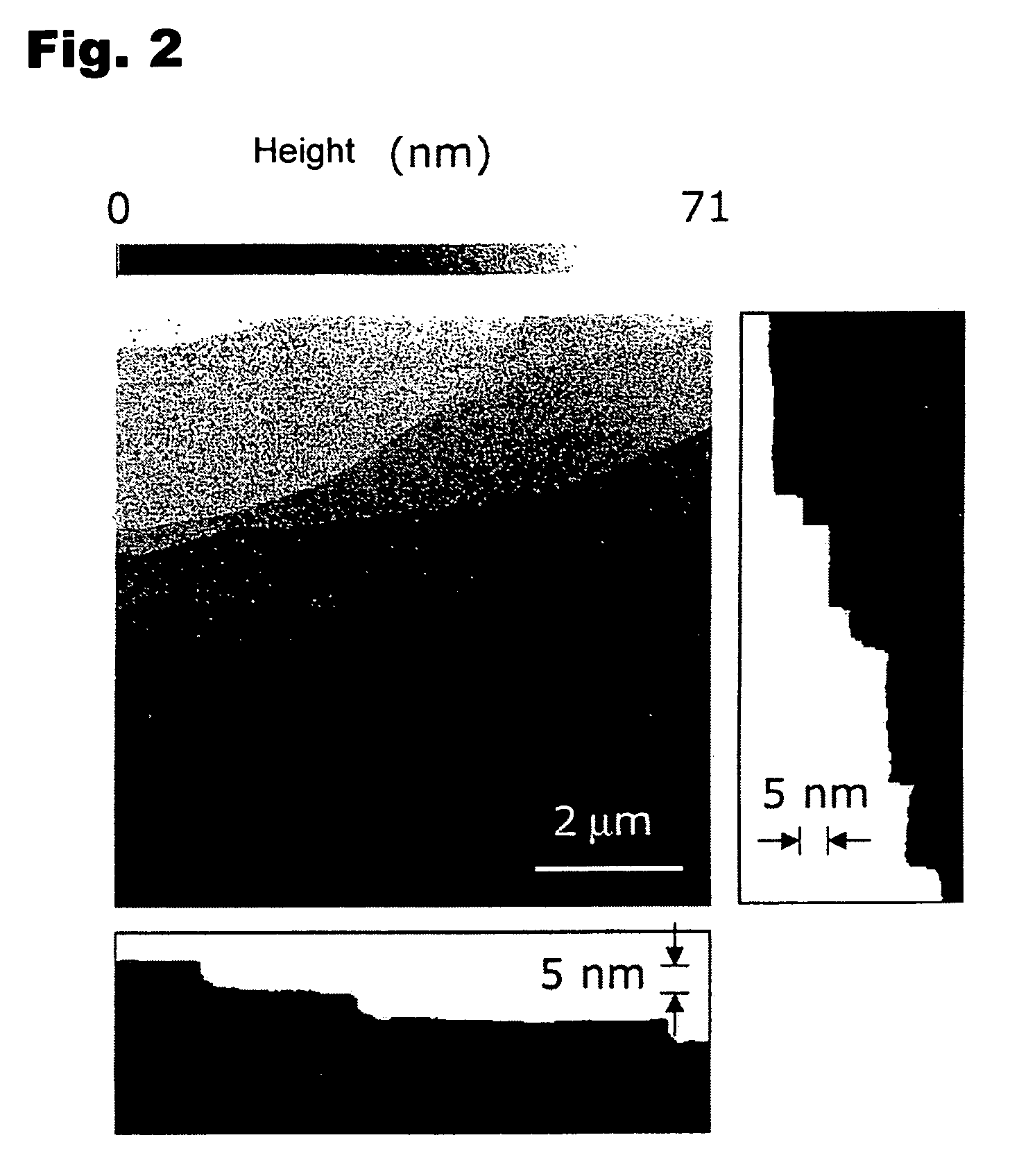

Natural-superlattice homologous single crystal thin film, method for preparation thereof, and device using said single crystal thin film

InactiveUS7061014B2Easy to controlSimple processTransistorPolycrystalline material growthSingle crystal substrateSingle crystal

Disclosed is a natural-superlattice homologous single-crystal thin film, which includes a complex oxide which is epitaxially grown on either one of a ZnO epitaxial thin film formed on a single-crystal substrate, the single-crystal substrate after disappearance of the ZnO epitaxial thin film and a ZnO single crystal. The complex oxide is expressed by the formula: M1M2O3 (ZnO)m, wherein M1 is at least one selected from the group consisting of Ga, Fe, Sc, In, Lu, Yb, Tm, Er, Ho and Y, M2 is at least one selected from the group consisting of Mn, Fe, Ga, In and Al, and m is a natural number of 1 or more. A natural-superlattice homologous single-crystal thin film formed by depositing the complex oxide and subjecting the obtained layered film to a thermal anneal treatment can be used in optimal devices, electronic devices and X-ray optical devices.

Owner:HOYA CORP +1

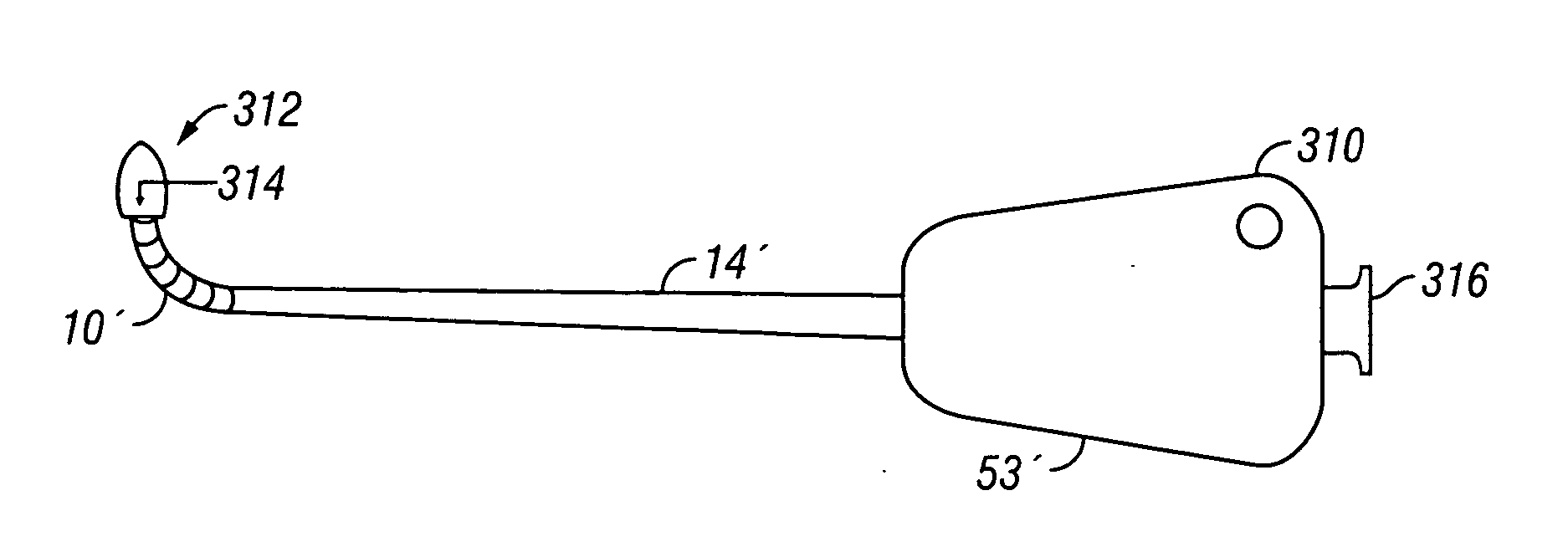

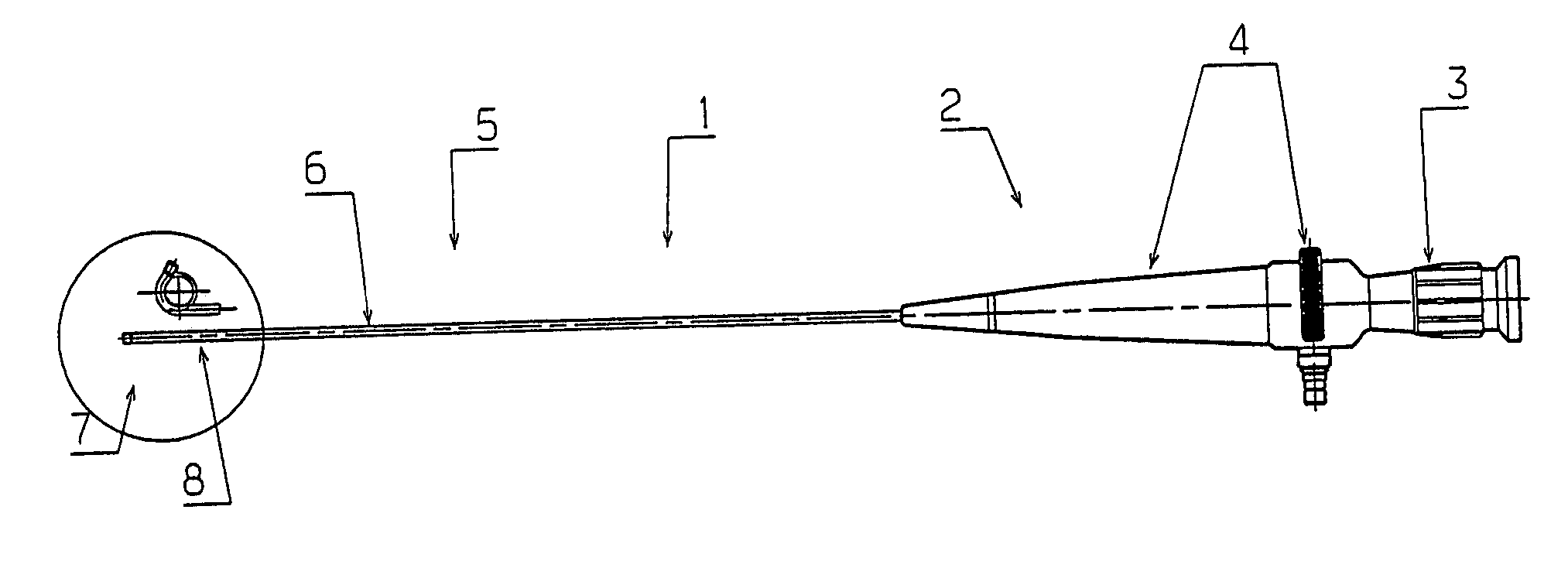

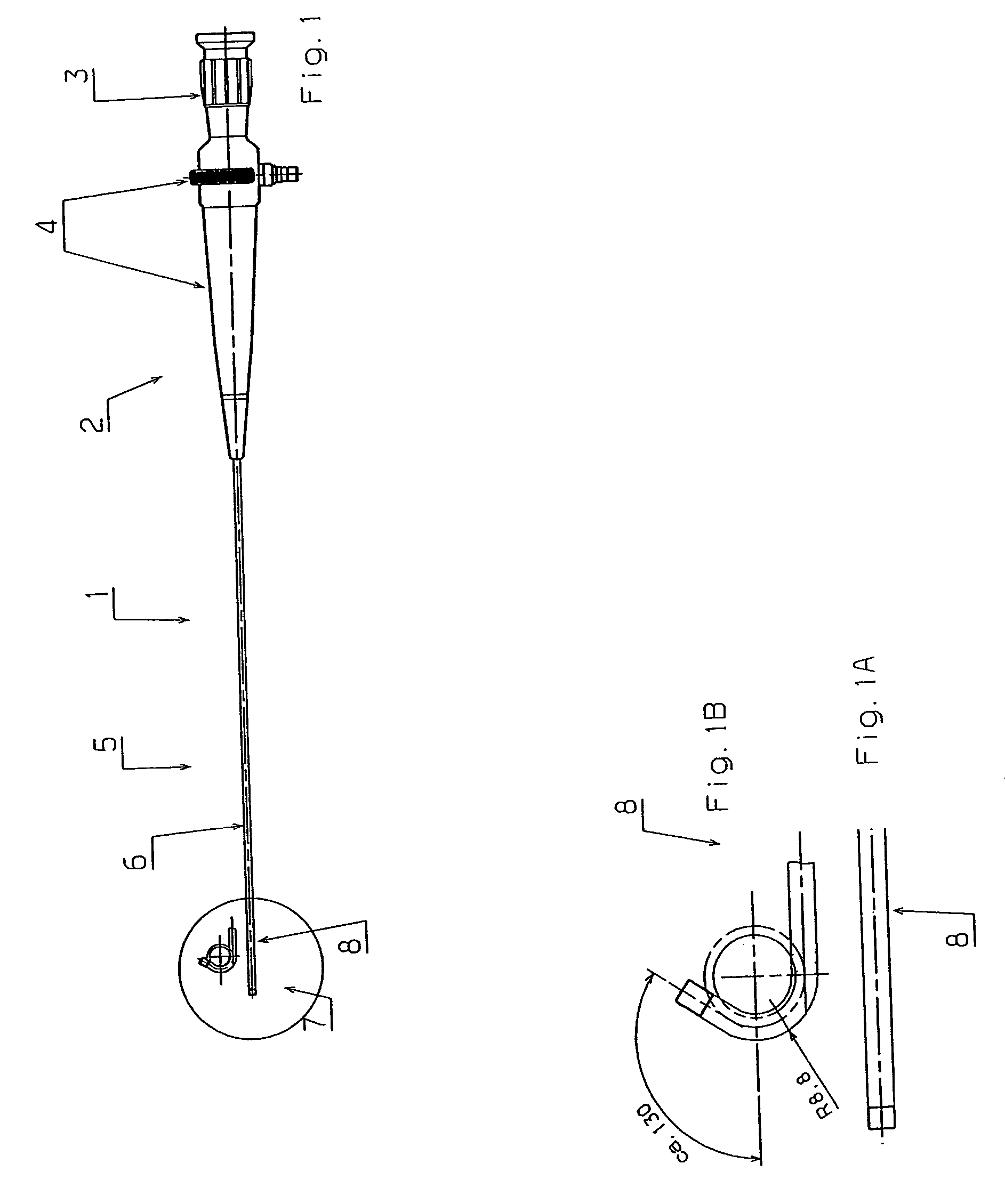

Articulate and swapable endoscope for a surgical robot

InactiveUS20060178556A1Simple processIncrease the areaEndoscopesSurgical manipulatorsSurgical robotEngineering

The present invention is directed to an articulate minimally invasive surgical endoscope with a flexible wrist having at least one degree of freedom. When used with a surgical robot having a plurality of robot arms, the endoscope can be used with any of the plurality of arms thereby allowing the use a universal arm design. The endoscope in accordance to the present invention is made more intuitive a to a user by attaching a reference frame used for controlling the at least one degree of freedom motion to the flexible wrist for wrist motion associated with the at least one degree of freedom. The endoscope in accordance to the present invention attenuates undesirable motion at its back / proximal end by acquiring the image of the object in association with the at least one degree of freedom based on a reference frame rotating around a point of rotation located proximal to the flexible wrist.

Owner:INTUITIVE SURGICAL OPERATIONS INC

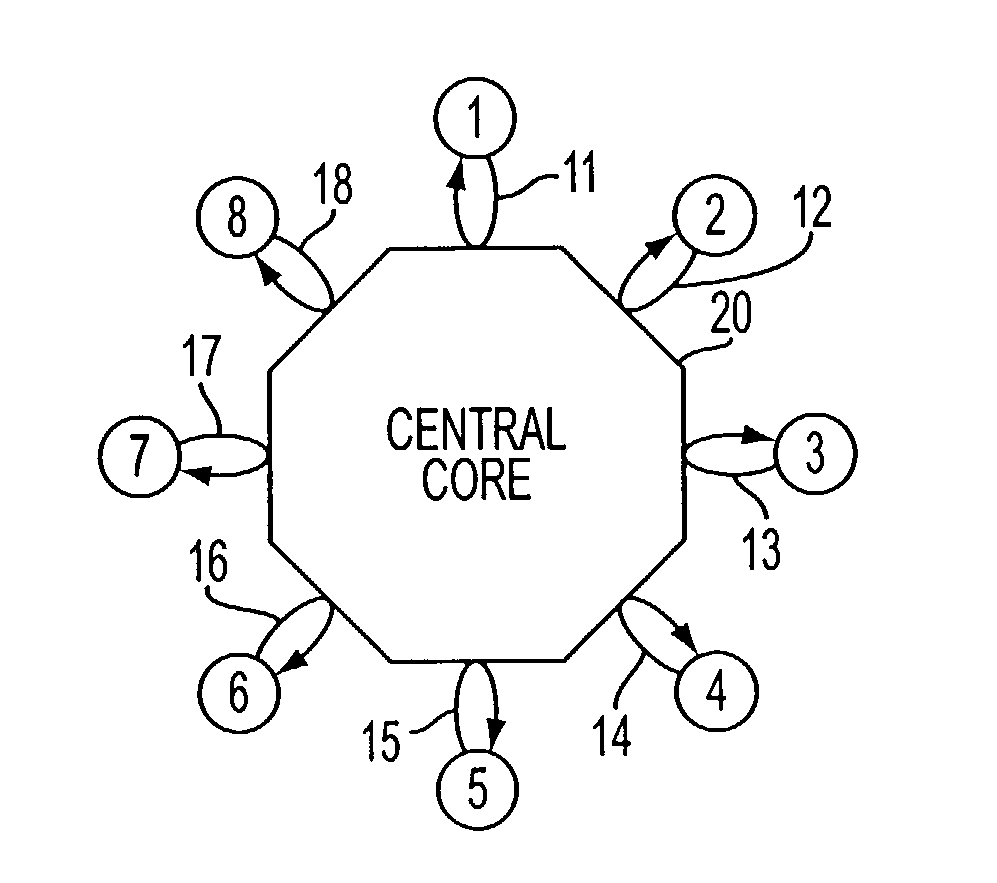

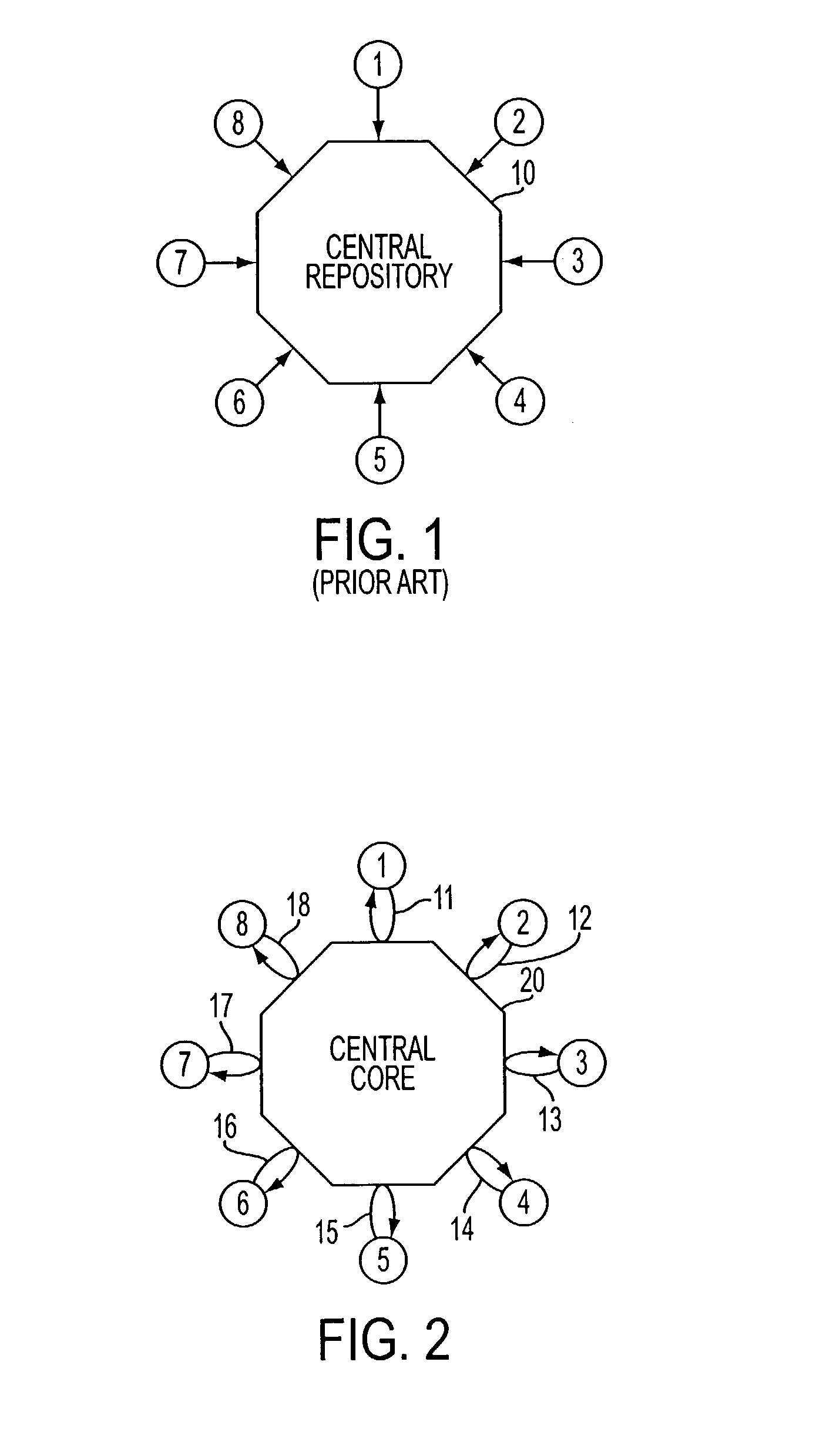

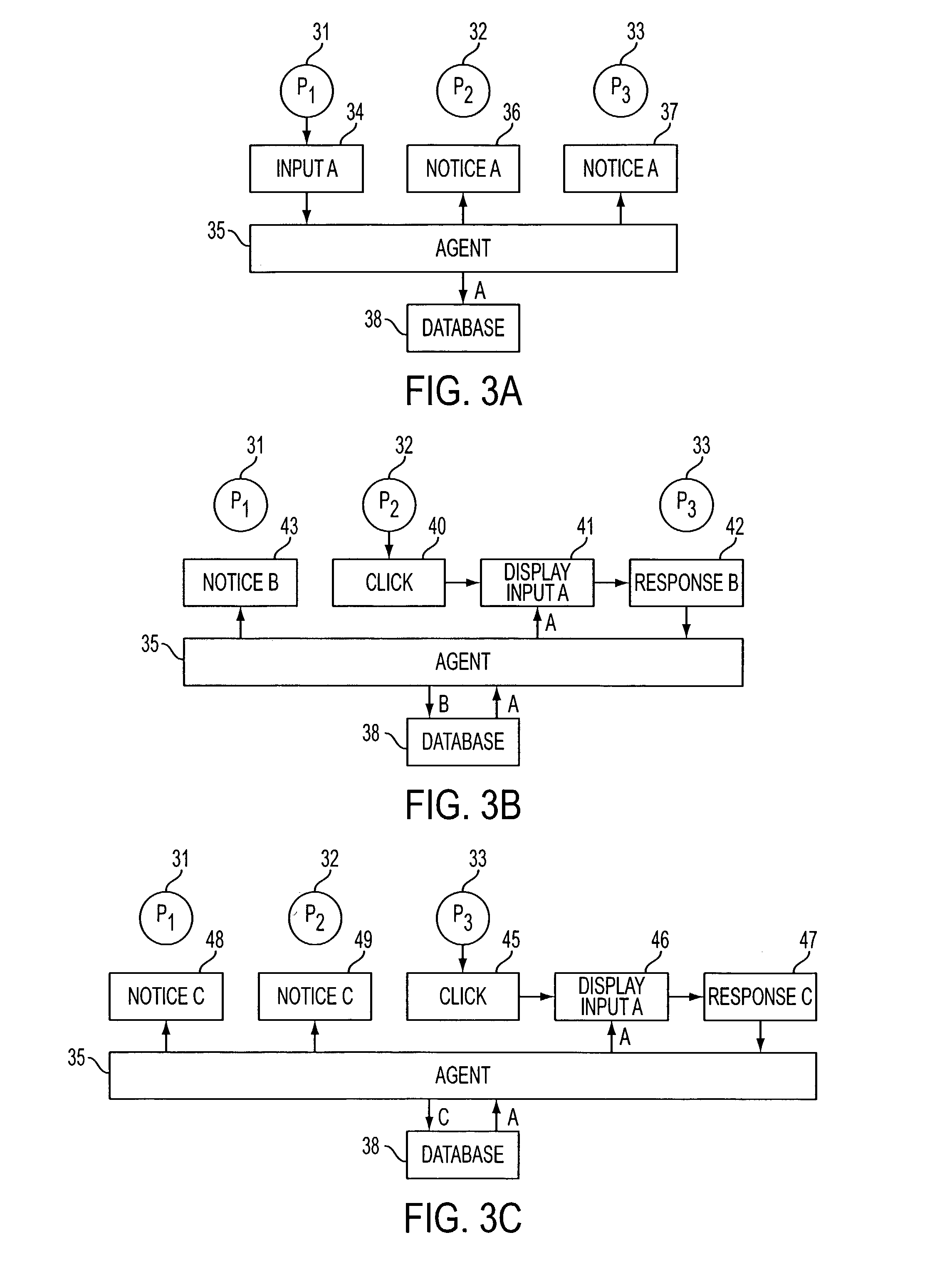

Centrifugal communication and collaboration method

InactiveUS8015495B2Improve abilitiesBetter, cheaper, and fasterOffice automationData switching networksTelecommunicationsBiological activation

A method of facilitating communications and collaboration of a group of plural remote participants comprises steps of receiving information over an information communications network from a first group participant; pushing, over the network to at least one other group participant, an access via an access channel; and allowing the other group participant to access at least some of the received information via said access channel in response to selective activation of the access channel by the other group participant.

Owner:SAMPO IP

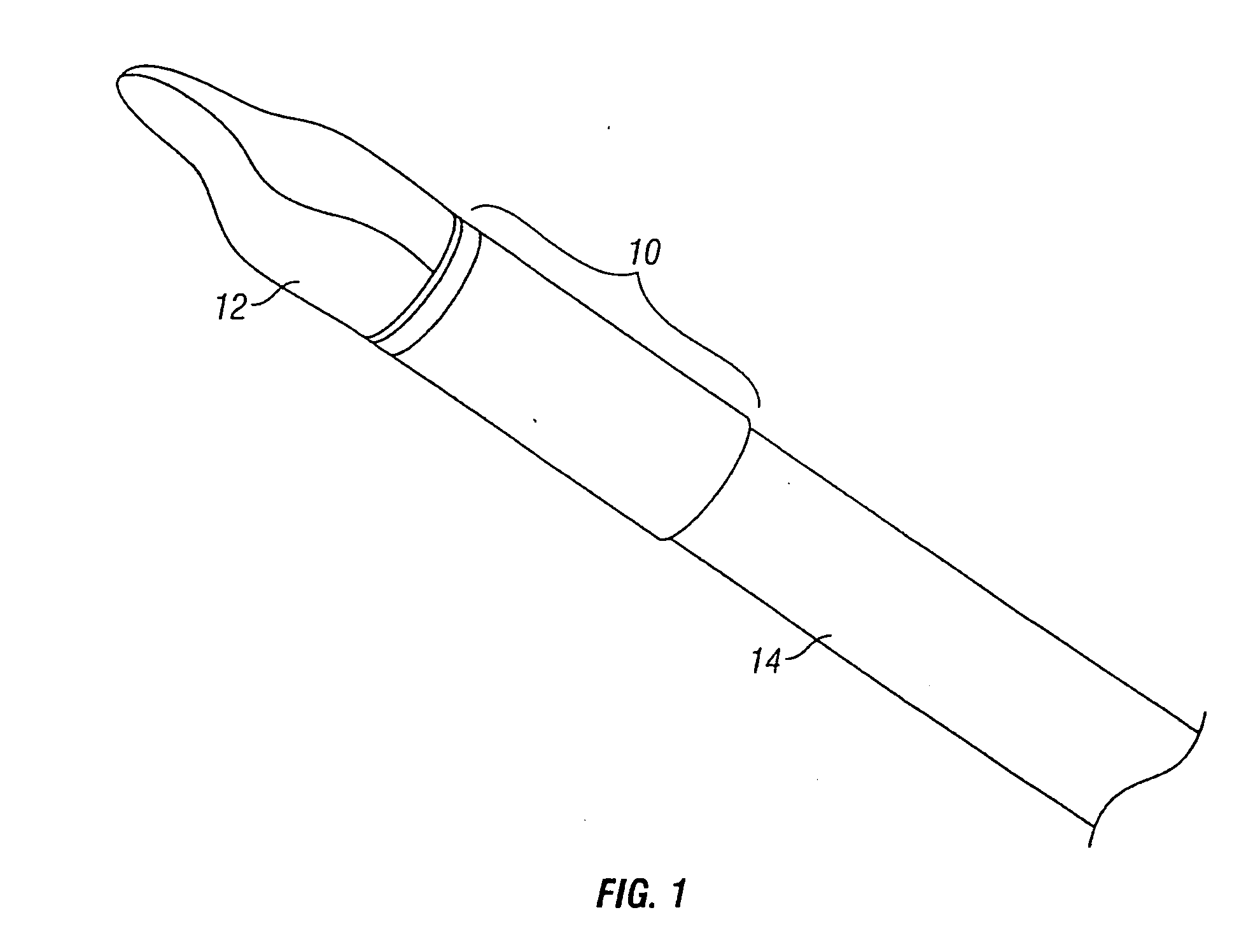

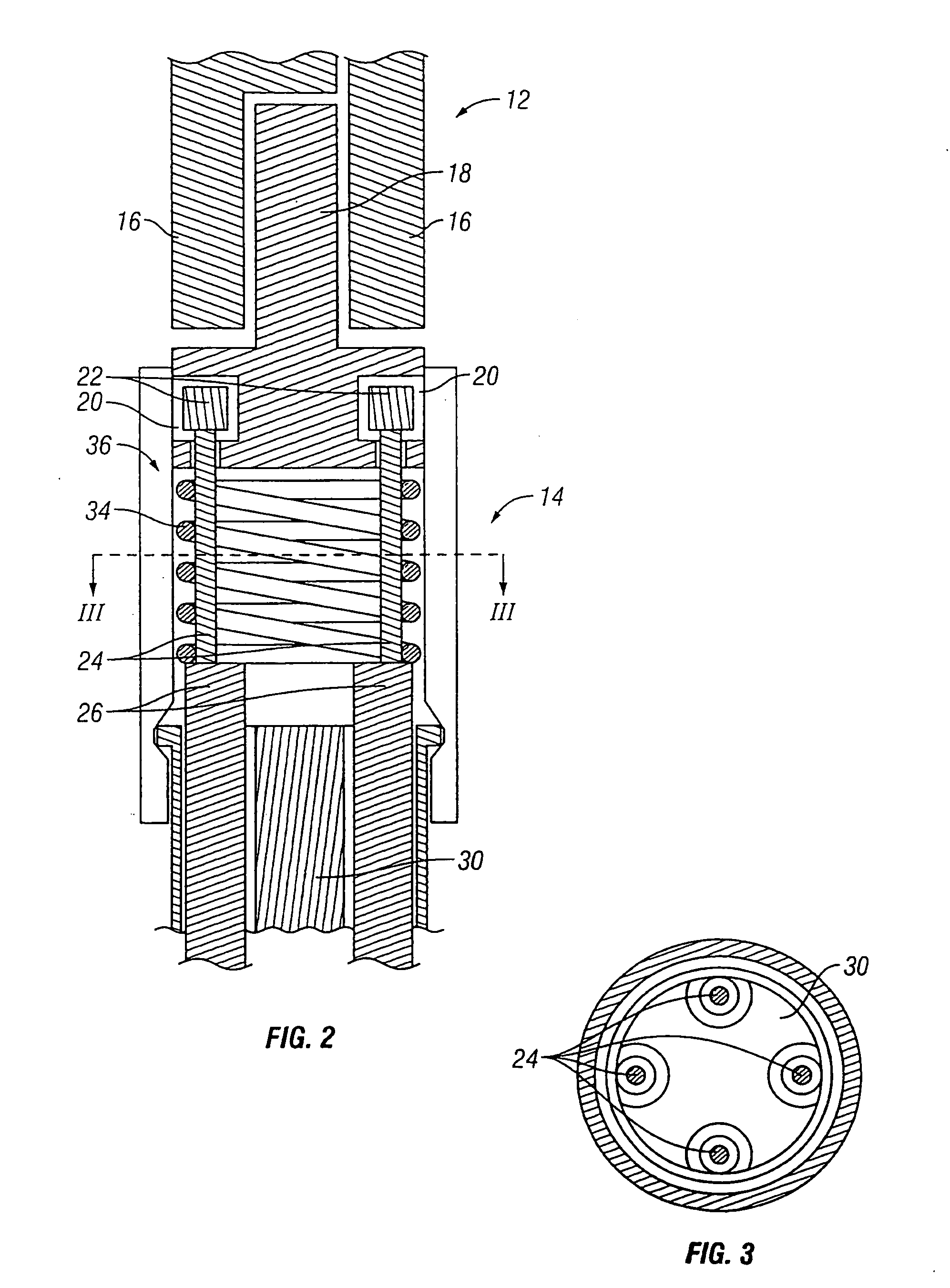

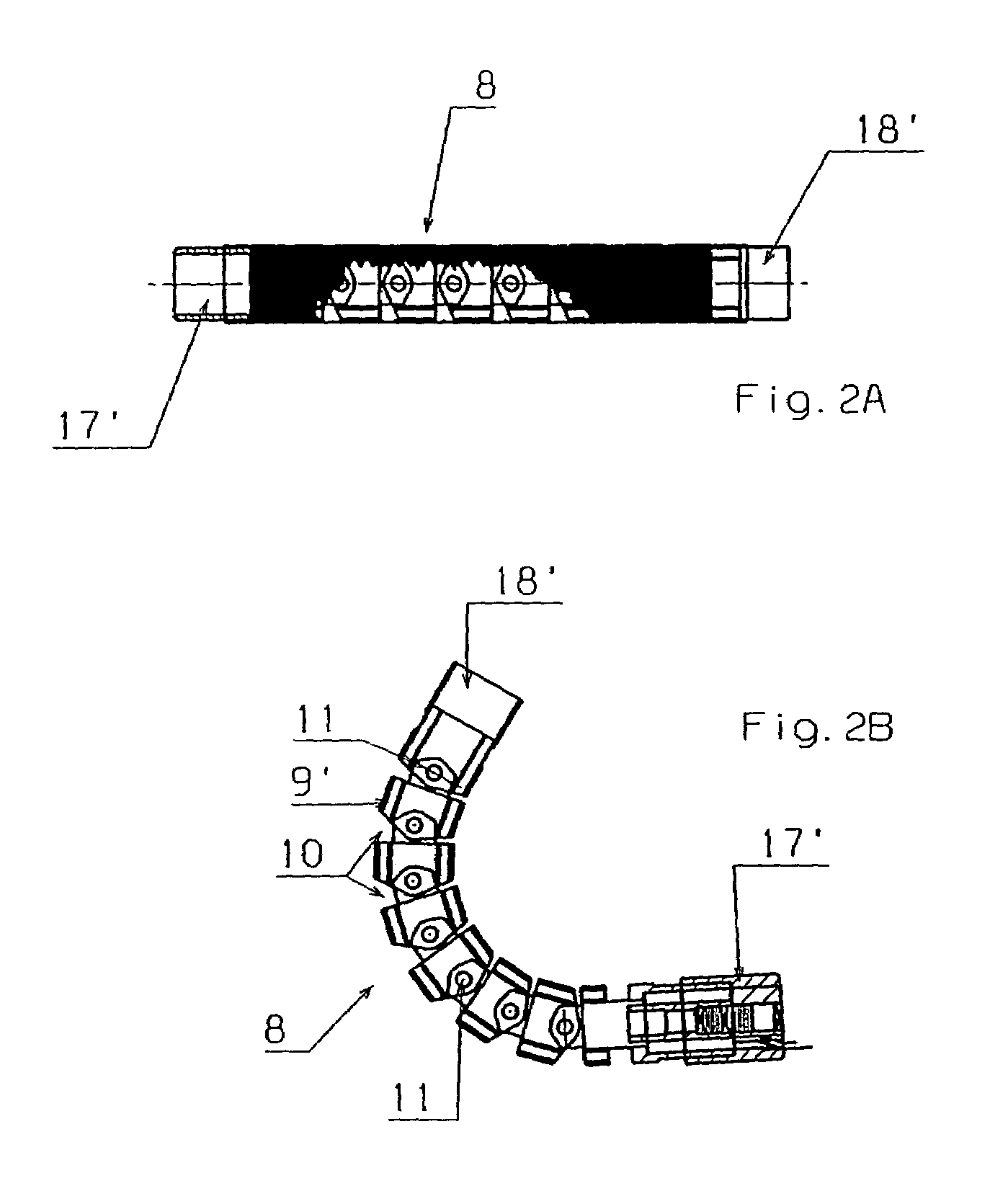

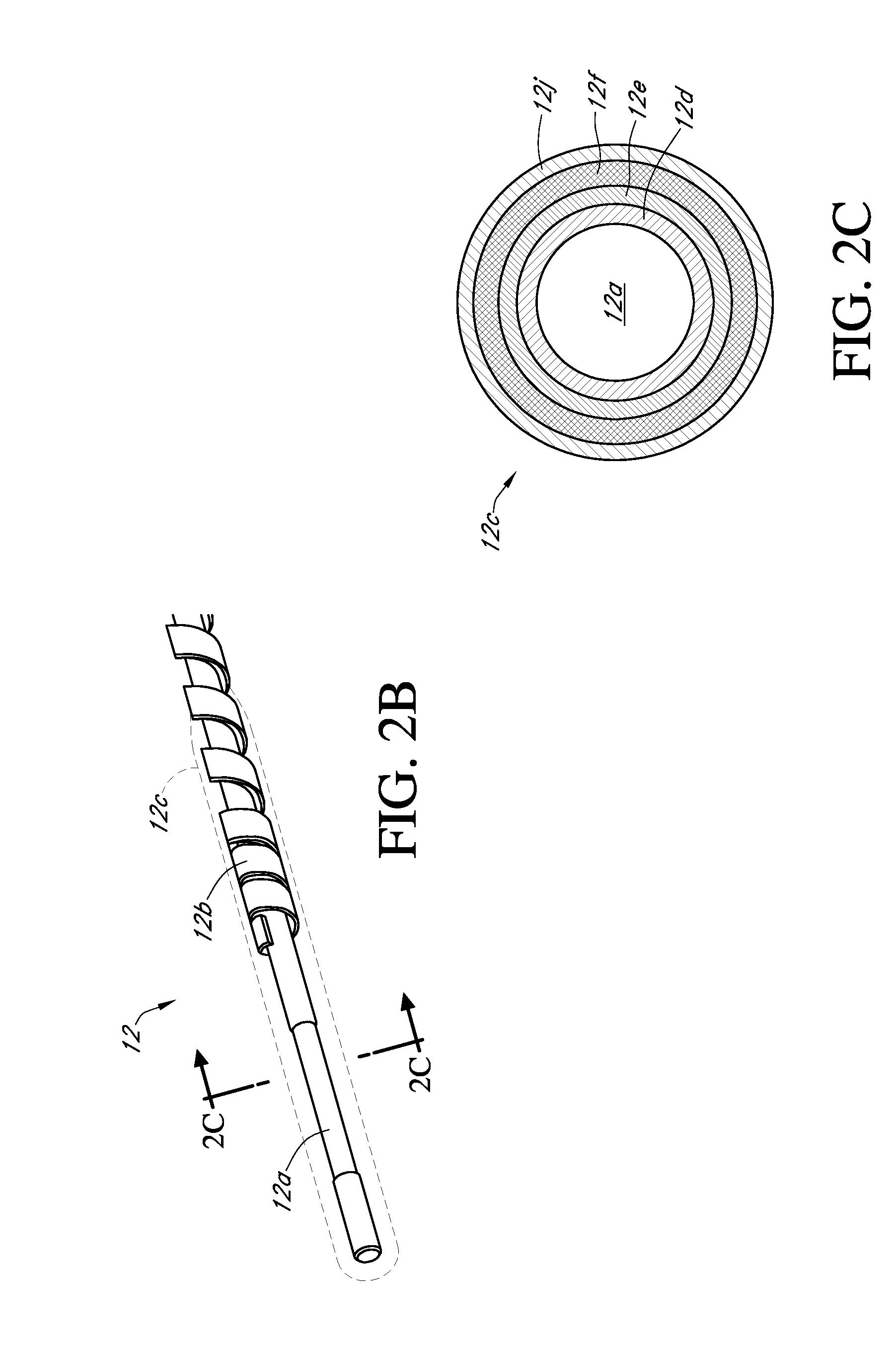

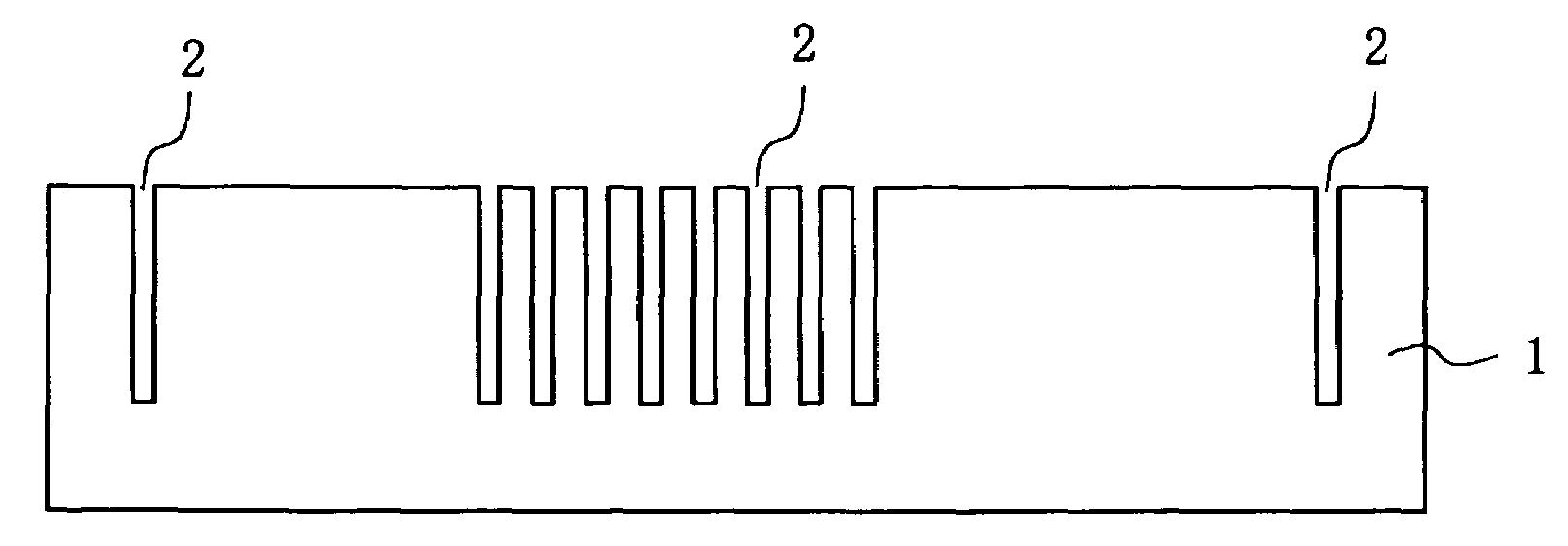

Bendable portion of an insertion tube of an endoscope and method of producing it

InactiveUS7766821B2Simple processSolve the complicated productionSurgeryEndoscopesEndoscopeBiomedical engineering

A bendable portion, which is arranged at the distal end of an insertion tube of an endoscope, comprises a plurality of tube segments, each of said tube segments having connecting means that cooperate with the connecting means of the adjacent tube segment, as well as control wires that can control the bending of the bendable portion. The respective connecting means of a tube segment are provided such that they axially protrude from the faces of the tube segment and are located within the mantle of the tube segment and such that they do not exceed the thickness of the mantle. The connecting means, which are provided on the respective faces of adjacent tube segments and which are located opposite each other, complement each other in the manner of a hinge-type connection.

Owner:HENKE SASS WOLF

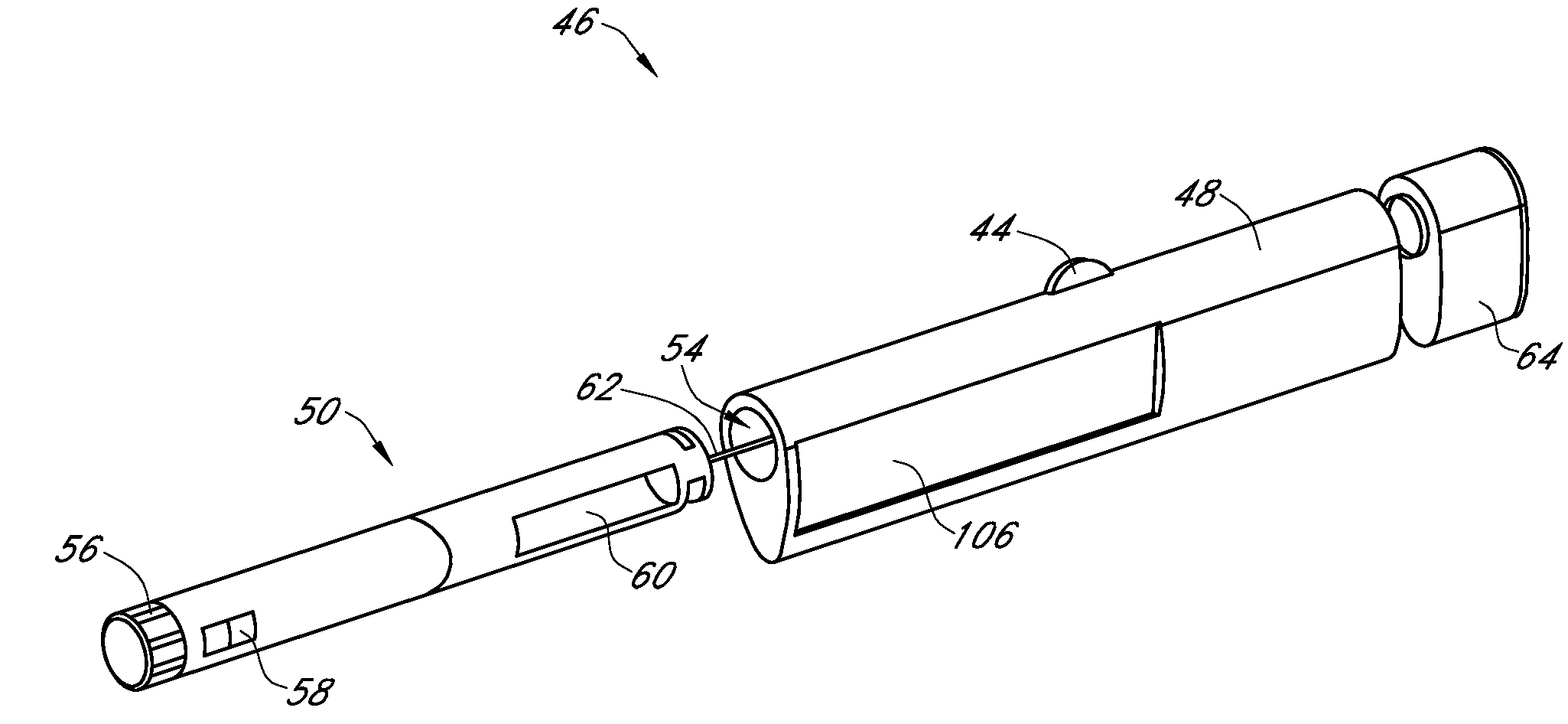

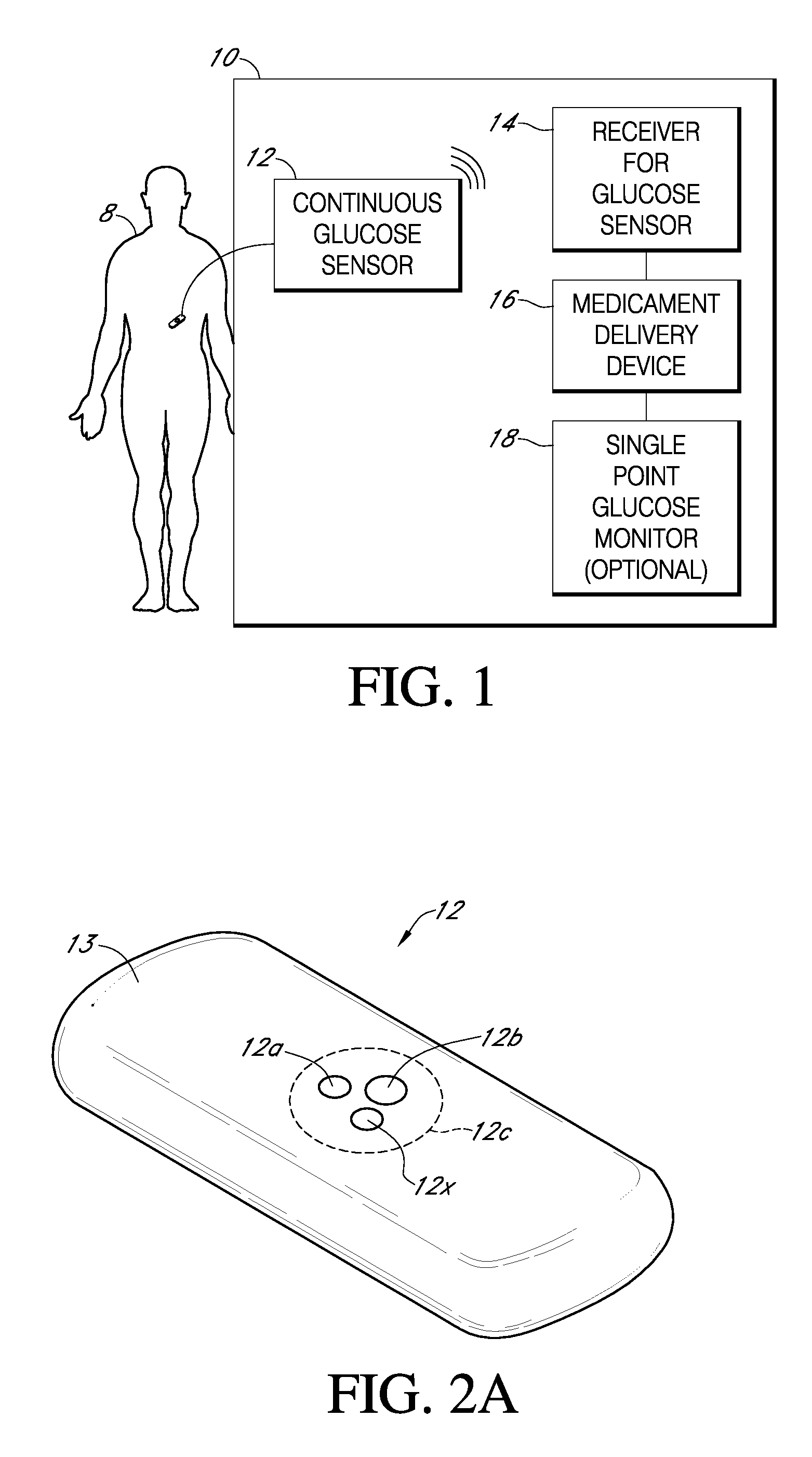

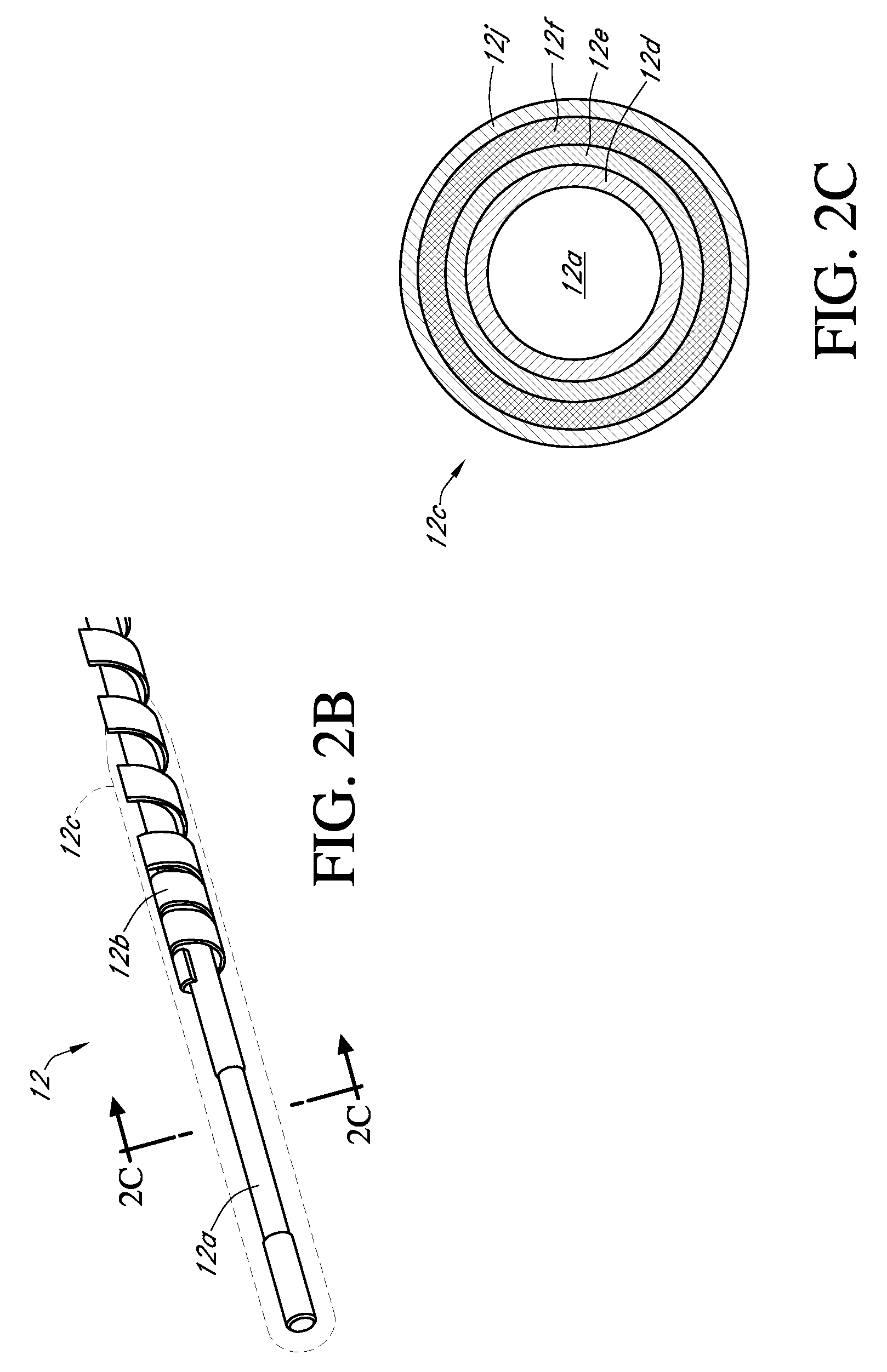

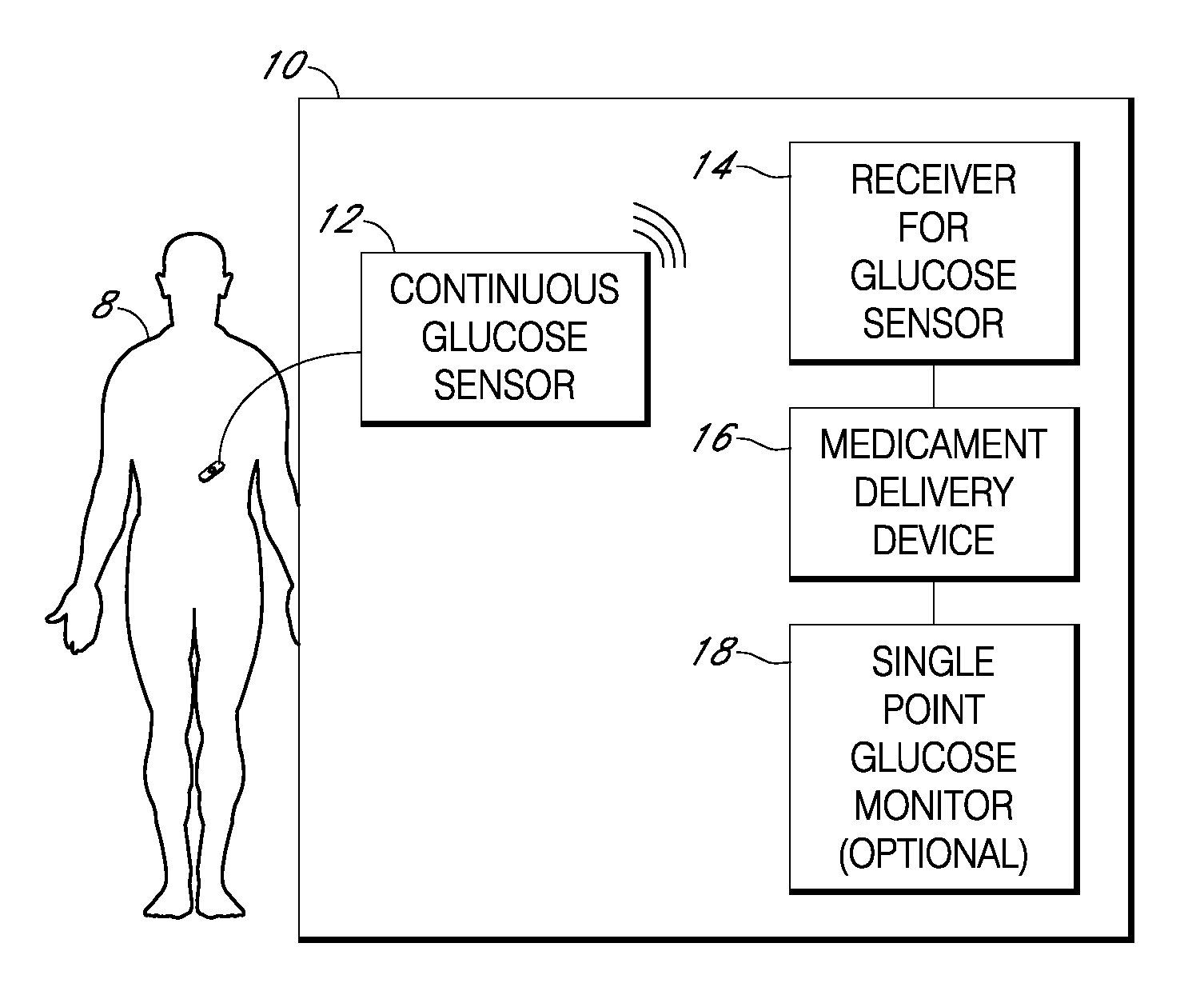

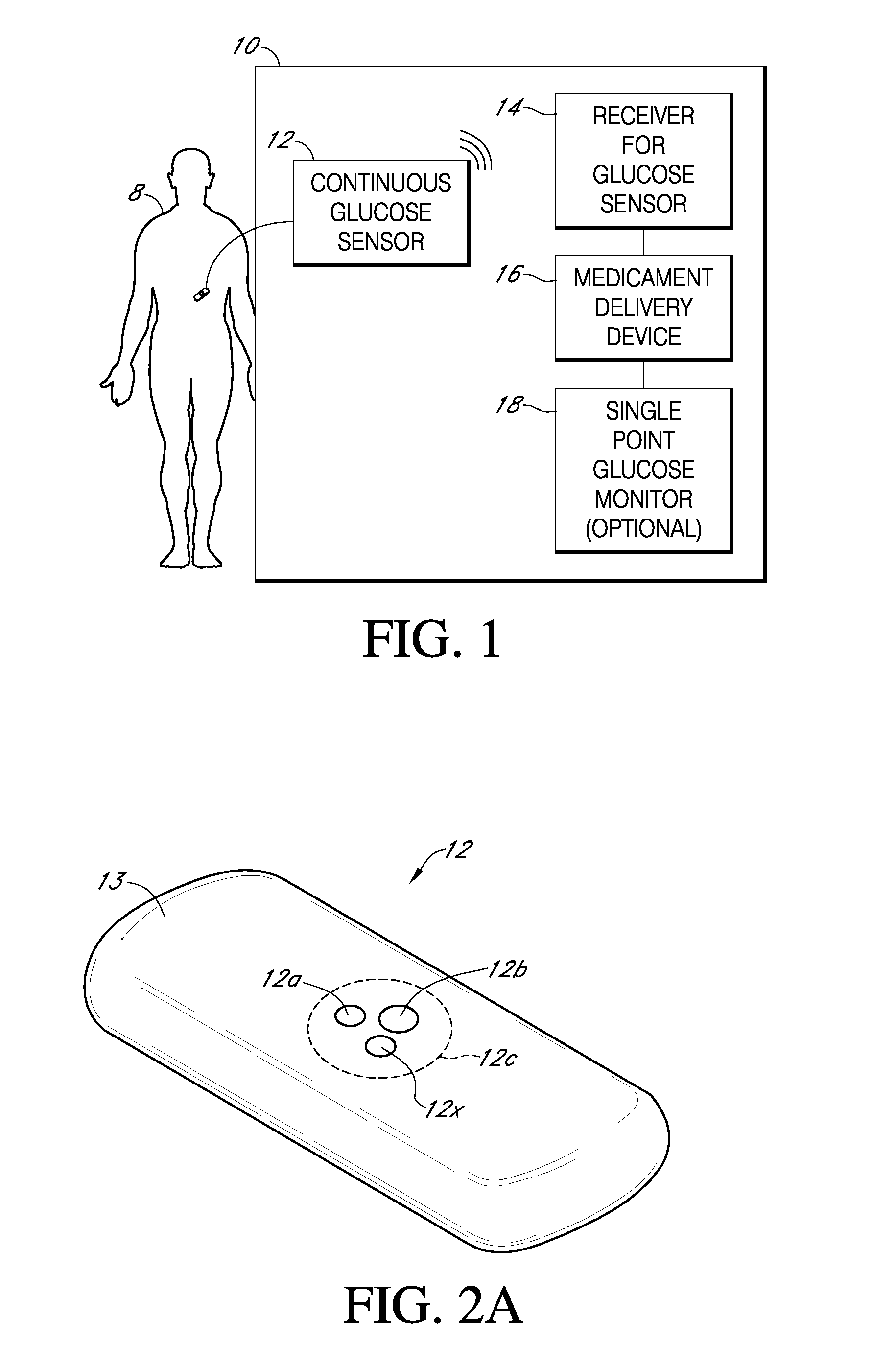

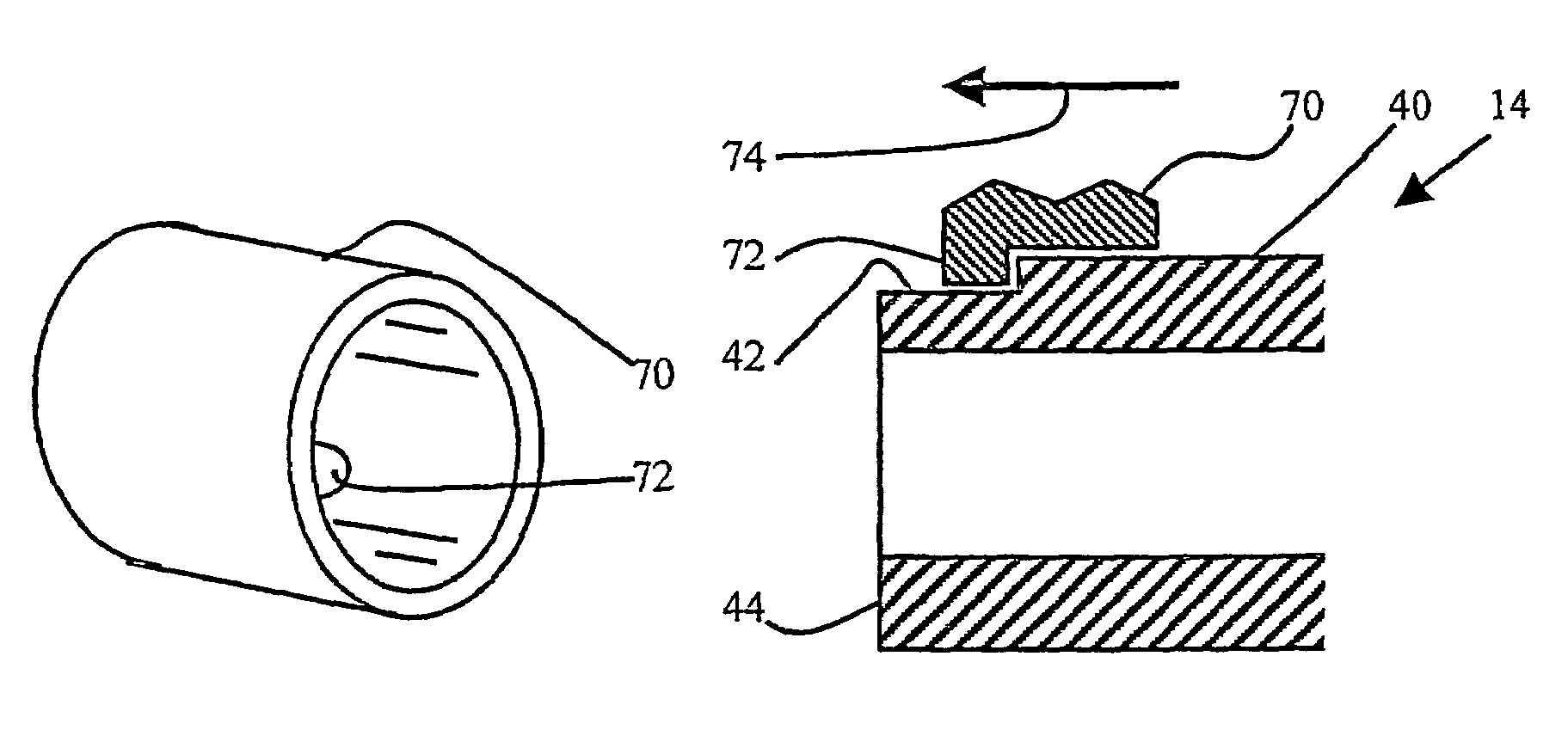

Integrated medicament delivery device for use with continuous analyte sensor

InactiveUS20080306434A1Reduce the burden onSimple processAmpoule syringes2D-image generationDiabetes mellitusMedication injection

An integrated system for the monitoring and treating diabetes is provided, including an integrated receiver / hand-held medicament injection pen, including electronics, for use with a continuous glucose sensor. In some embodiments, the receiver is configured to receive continuous glucose sensor data, to calculate a medicament therapy (e.g., via the integrated system electronics) and to automatically set a bolus dose of the integrated hand-held medicament injection pen, whereby the user can manually inject the bolus dose of medicament into the host. In some embodiments, the integrated receiver and hand-held medicament injection pen are integrally formed, while in other embodiments they are detachably connected and communicated via mutually engaging electrical contacts and / or via wireless communication.

Owner:DEXCOM

Integrated medicament delivery device for use with continuous analyte sensor

InactiveUS20080306444A1Ease burdenSimplify processAmpoule syringes2D-image generationDrug deliveryIntegrated systems

An integrated system for the monitoring and treating diabetes is provided, including an integrated receiver / hand-held medicament injection pen, including electronics, for use with a continuous glucose sensor. In some embodiments, the receiver is configured to receive continuous glucose sensor data, to calculate a medicament therapy (e.g., via the integrated system electronics) and to automatically set a bolus dose of the integrated hand-held medicament injection pen, whereby the user can manually inject the bolus dose of medicament into the host. In some embodiments, the integrated receiver and hand-held medicament injection pen are integrally formed, while in other embodiments they are detachably connected and communicated via mutually engaging electrical contacts and / or via wireless communication.

Owner:DEXCOM

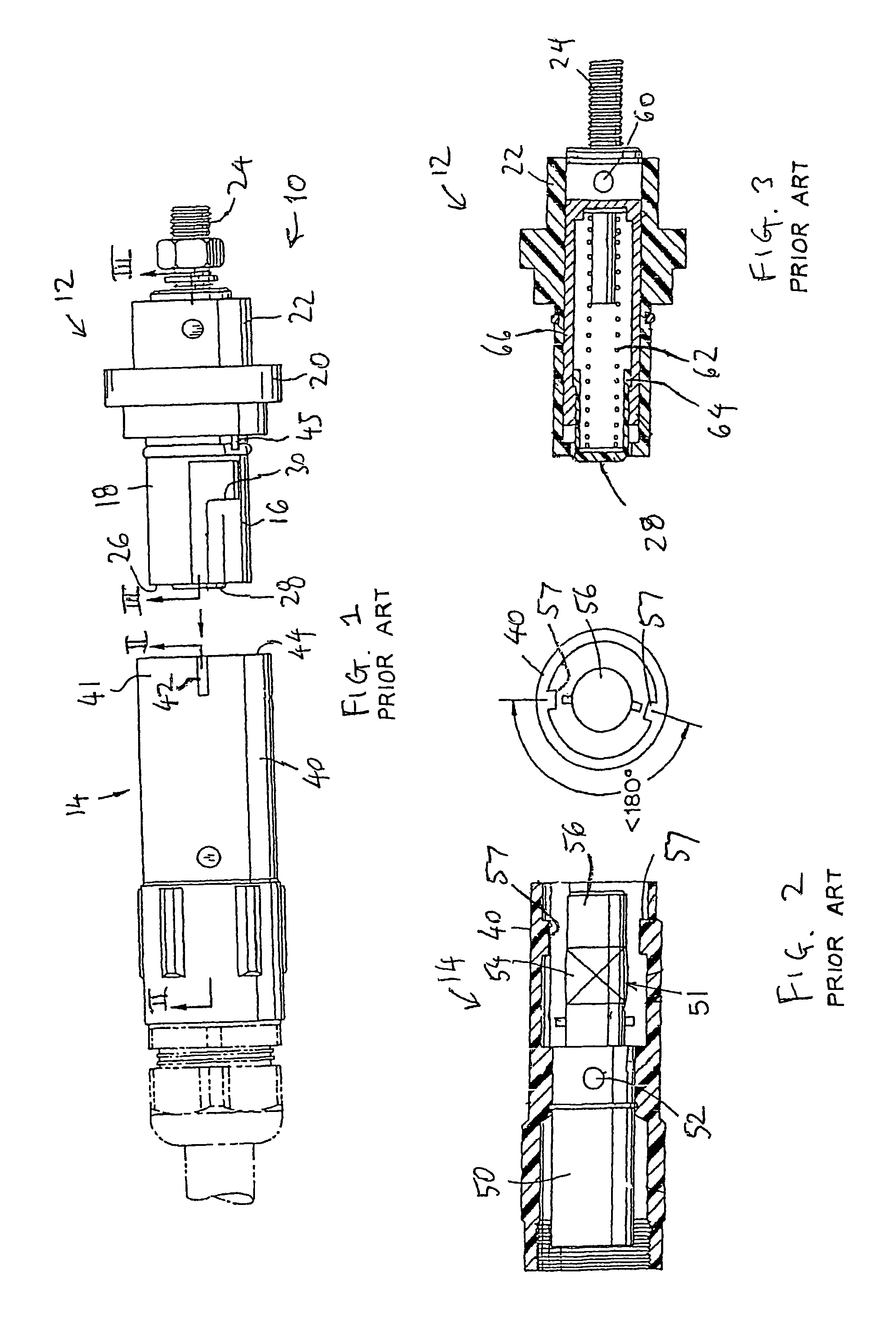

Electrical connector

ActiveUS7322859B2Avoid disconnectionPrevent rotationEngagement/disengagement of coupling partsOne pole connectionsCouplingLocking mechanism

Owner:ITT MFG ENTERPRISES LLC

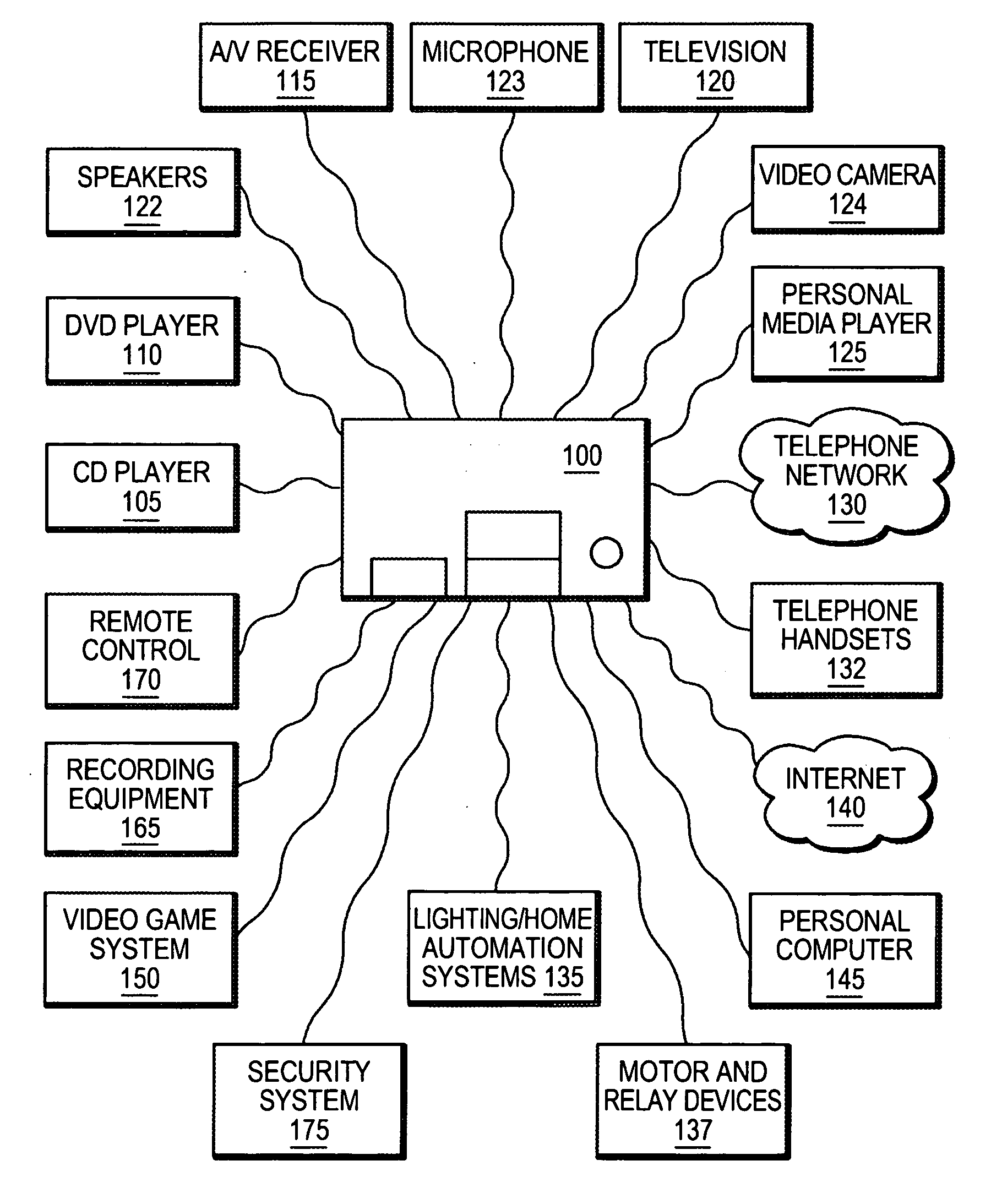

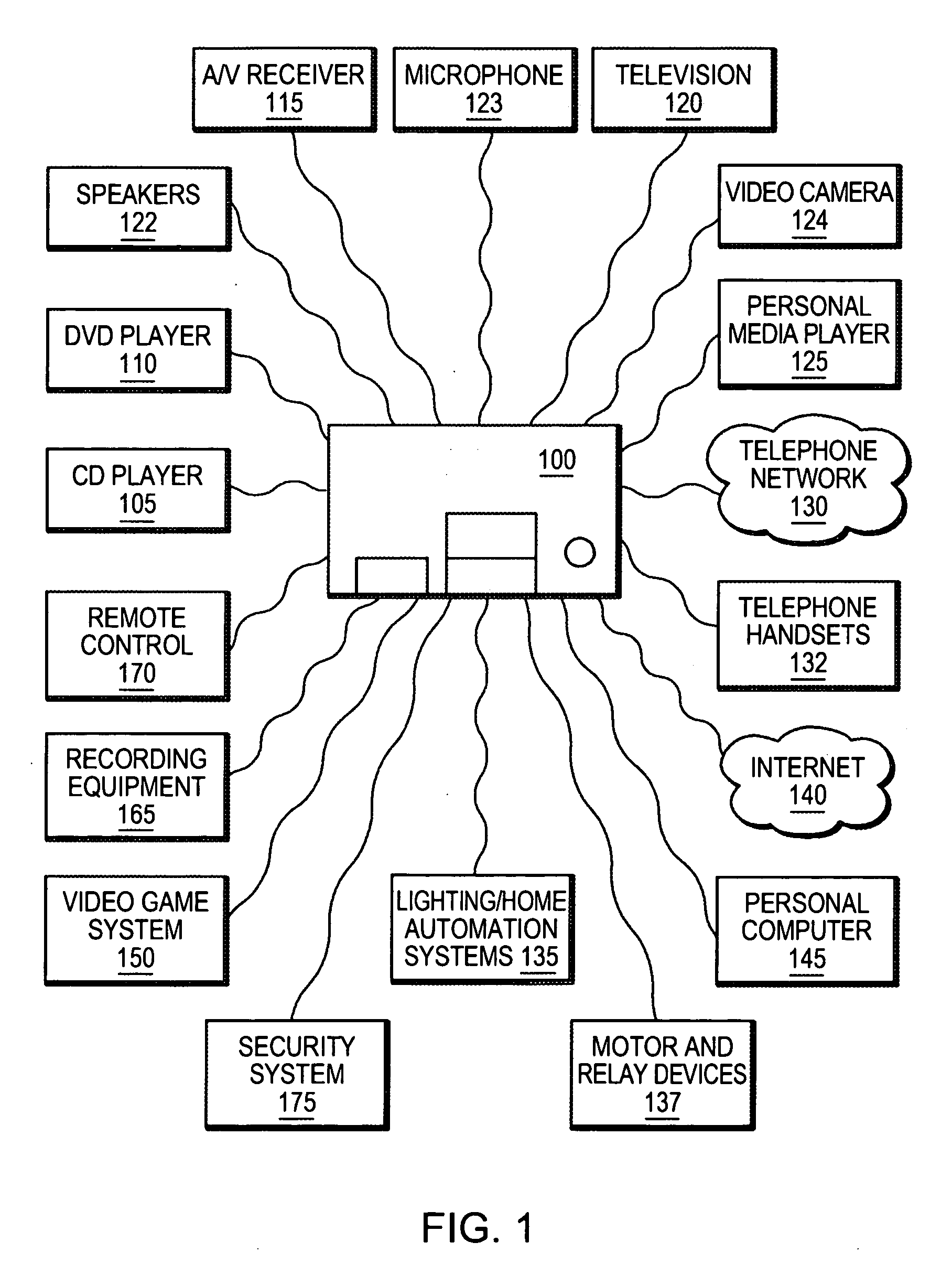

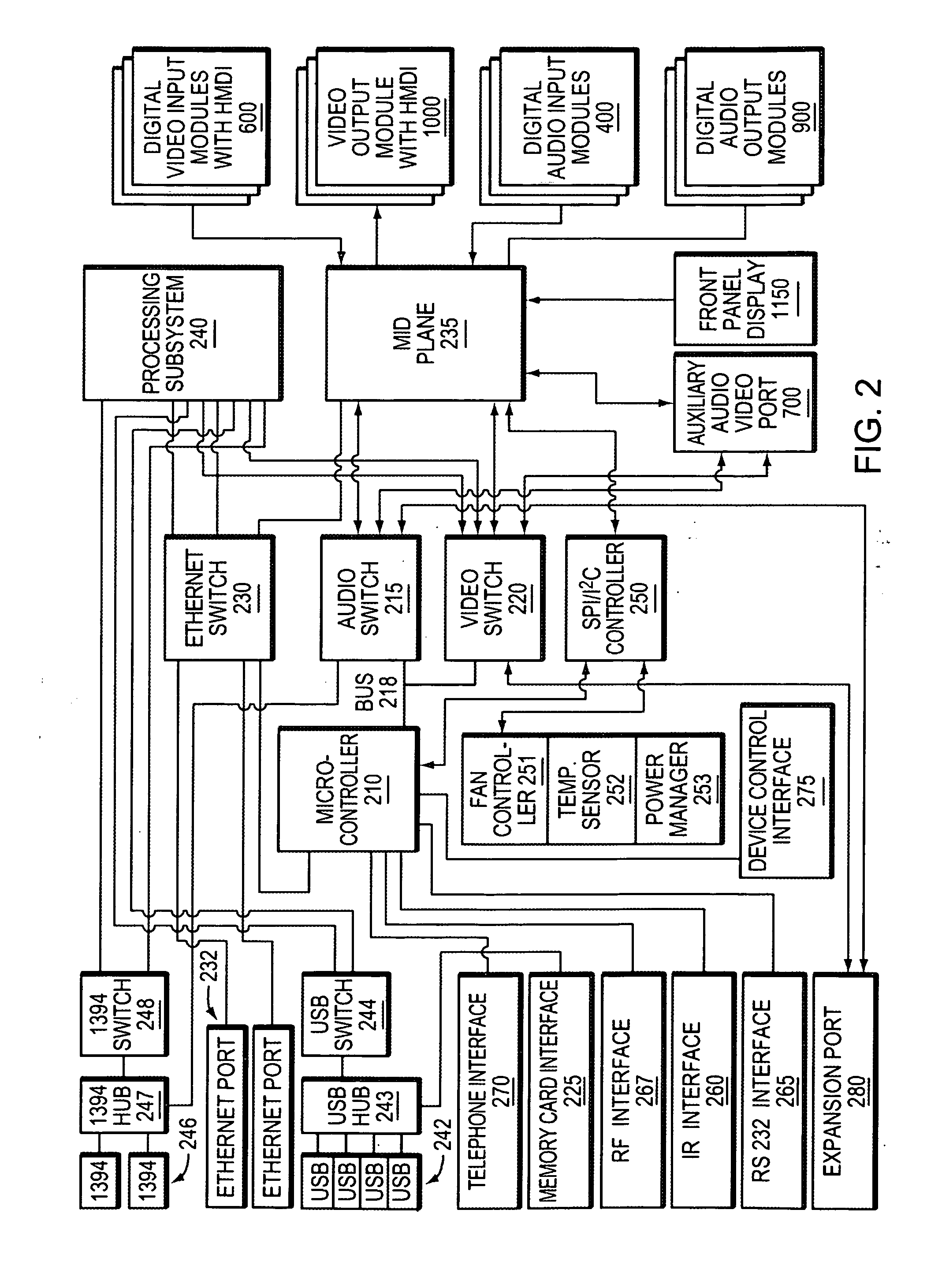

Programmable multimedia controller with programmable services

ActiveUS20070142022A1Easy to useEfficient modificationLink editingTransmission systemsControl systemProgrammable logic device

An integrated multimedia, entertainment, communications and control system. The system is based on a general purpose computer and is capable of interfacing with, controlling or managing a wide variety of audio, video, telecommunications, data communications or other devices. The system includes a programming environment for creating services or user experiences that may incorporate features or functionalities of several devices that are conventionally operated as separate, standalone devices.

Owner:SAVANT SYST INC

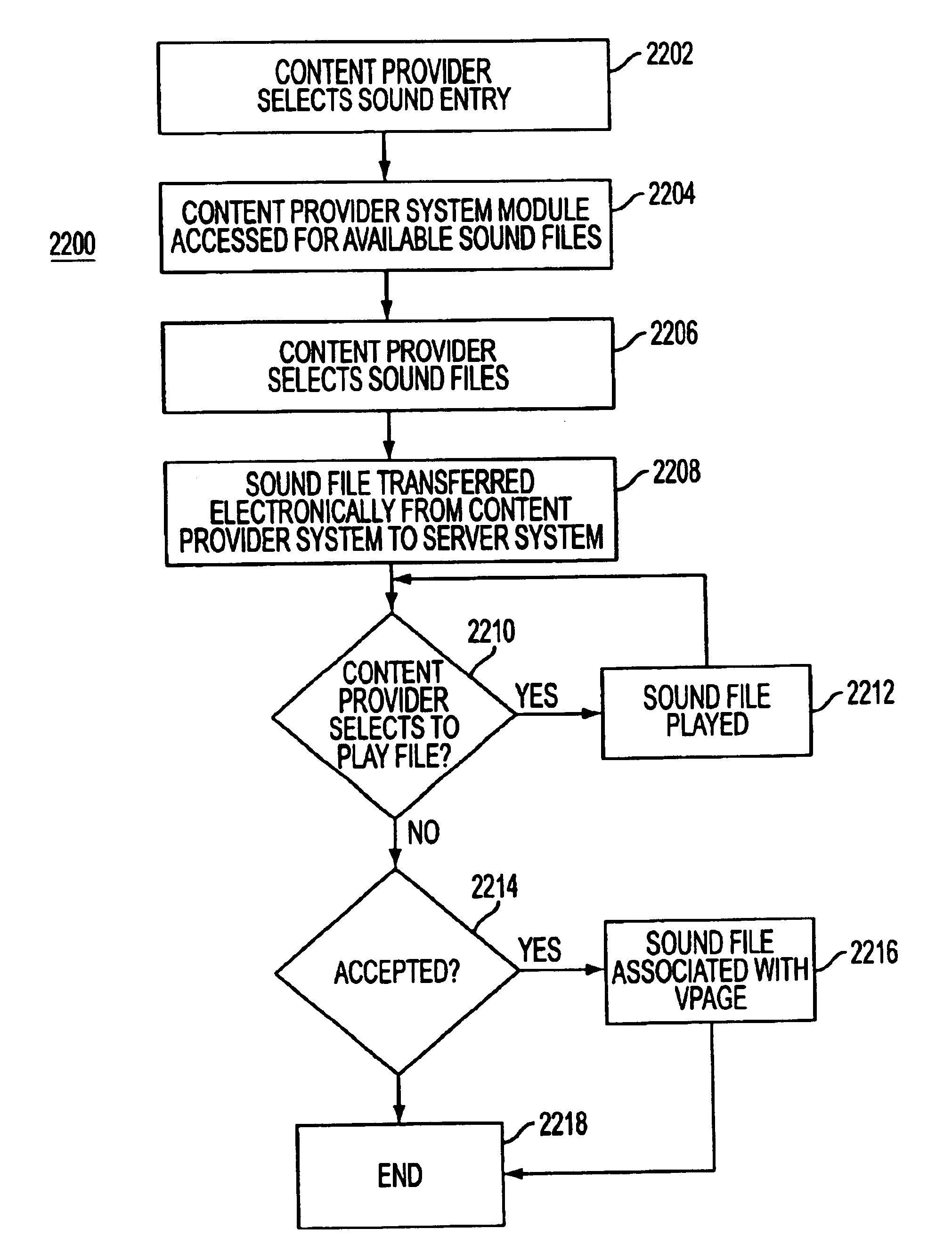

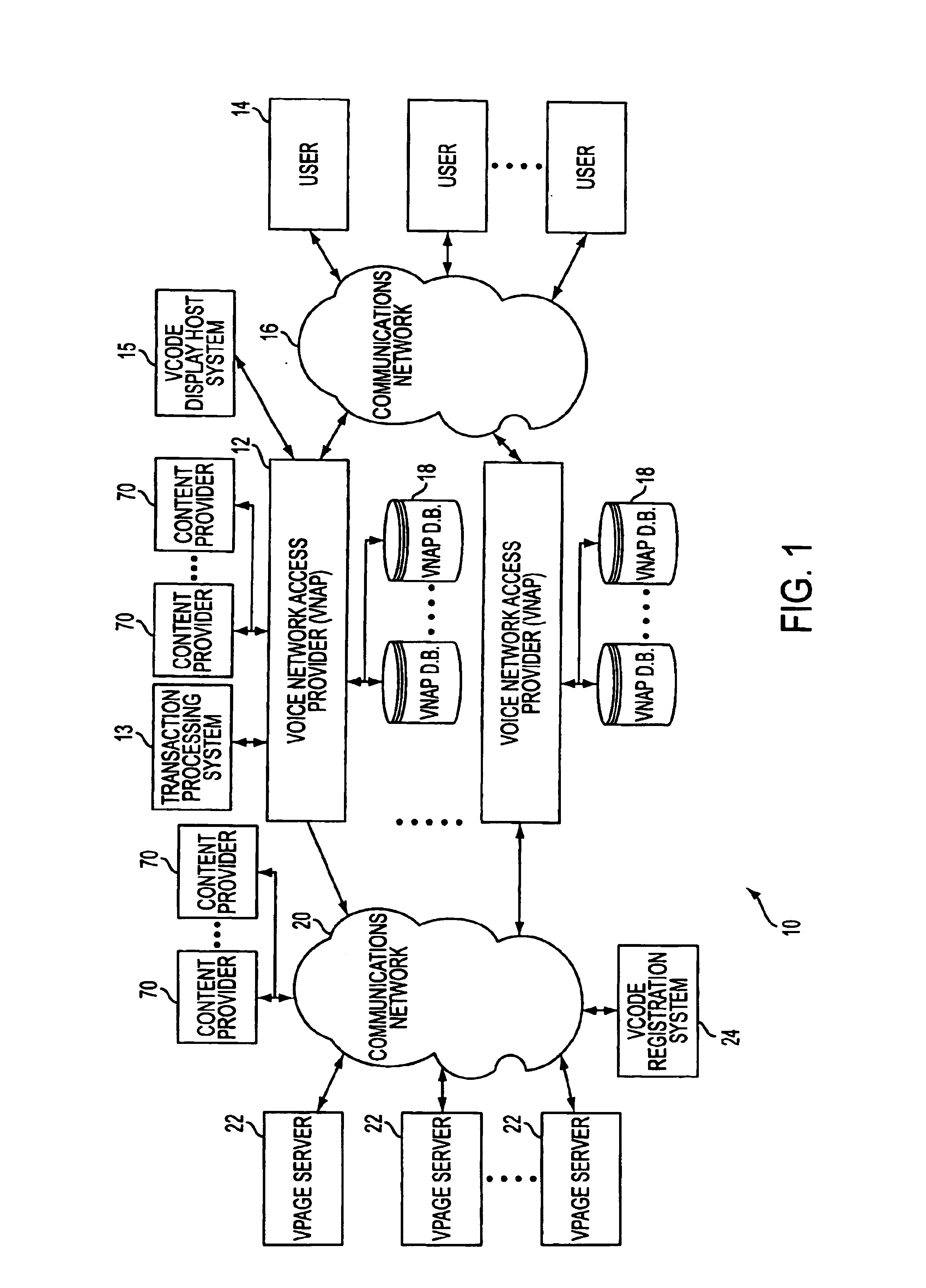

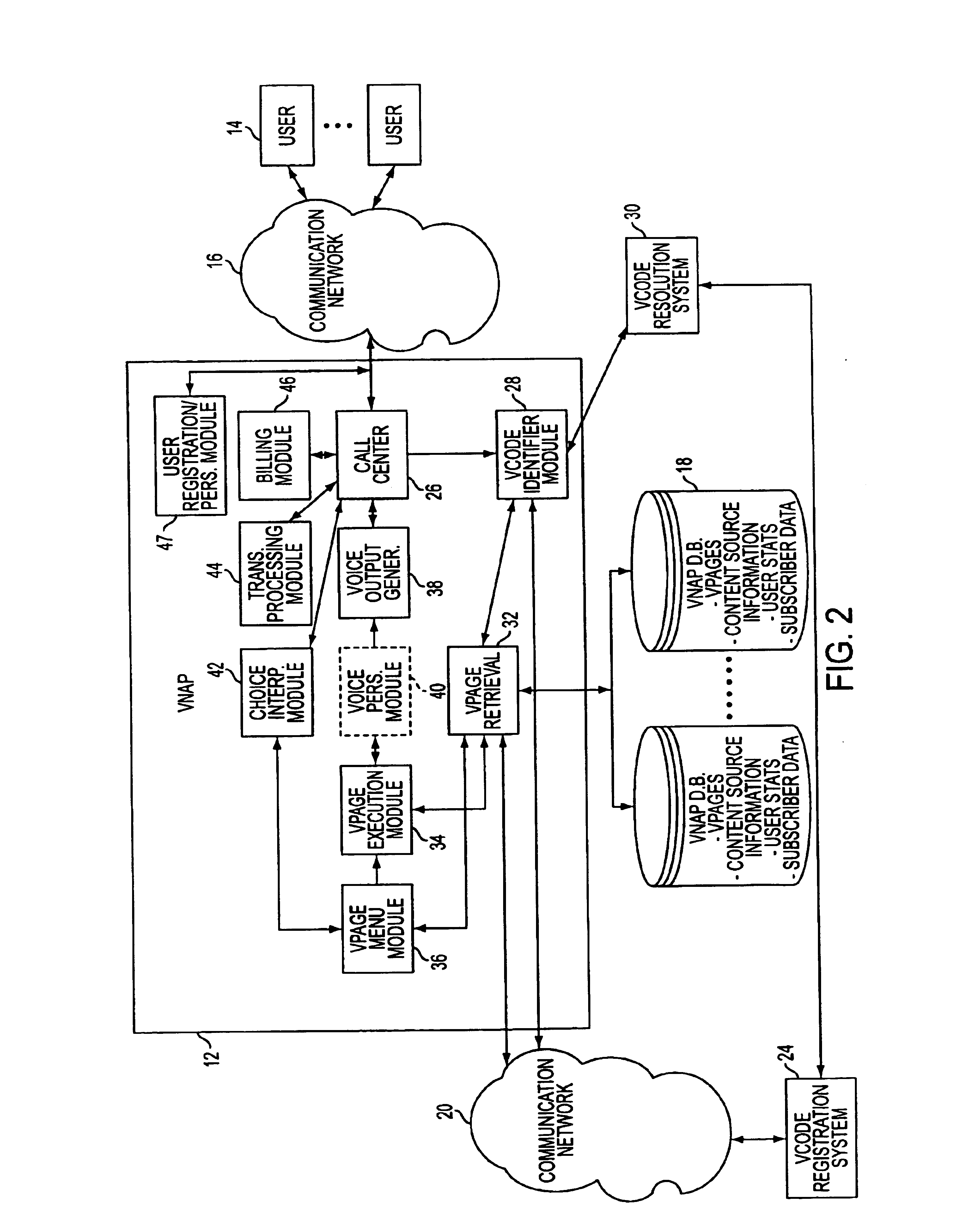

System and method for generating voice pages with included audio files for use in a voice page delivery system

InactiveUS6895084B1Require lotSimplify creationAutomatic call-answering/message-recording/conversation-recordingRecord information storageUser deviceSpeech sound

A content provider system for enabling content providers to create voice pages with audio files included for use in a network for voice page delivery through which subscribers request a voice page and a voice page server system delivers the voice page audibly to the subscriber. A content provider selects a voice page into which the audio file is to be incorporated, selects the audio file and the content provider system then transfers the audio file to a voice page server system which generates a voice page with the audio file included using XML-based tags designated for audio files. The audio files are uploaded from a number of user devices including a telephony device, a web-based system and a PDA.

Owner:GENESYS TELECOMMUNICATIONS LABORATORIES INC

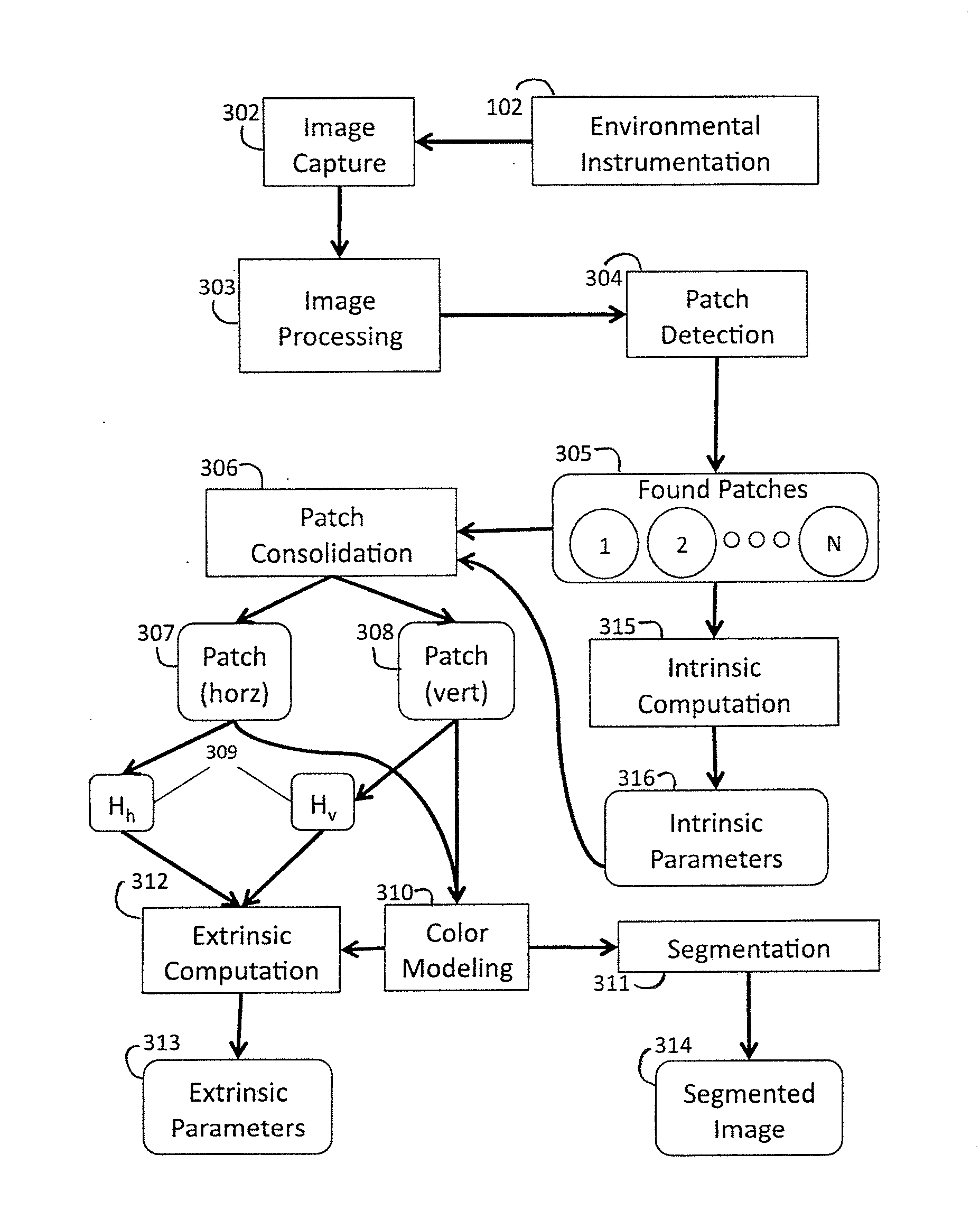

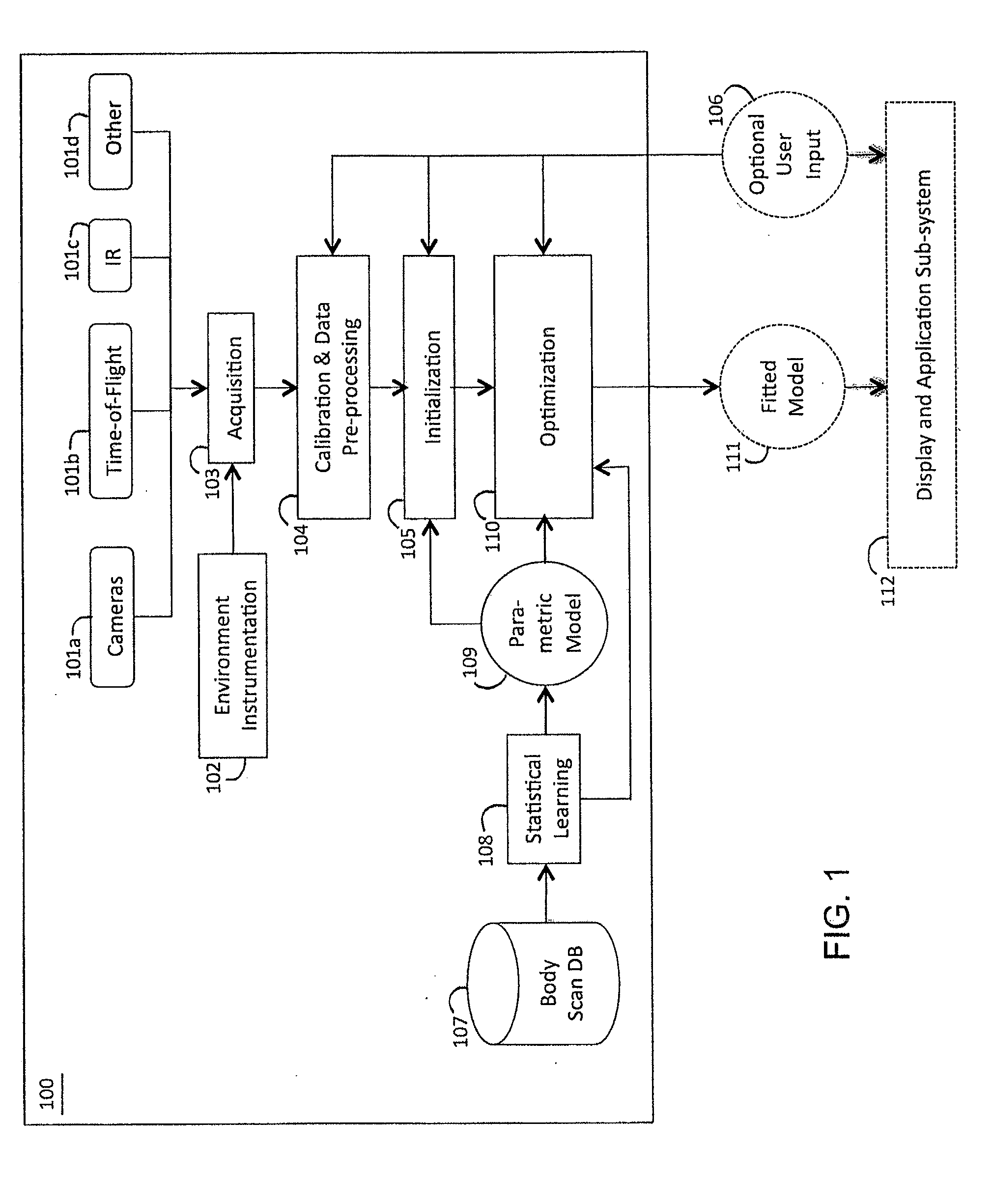

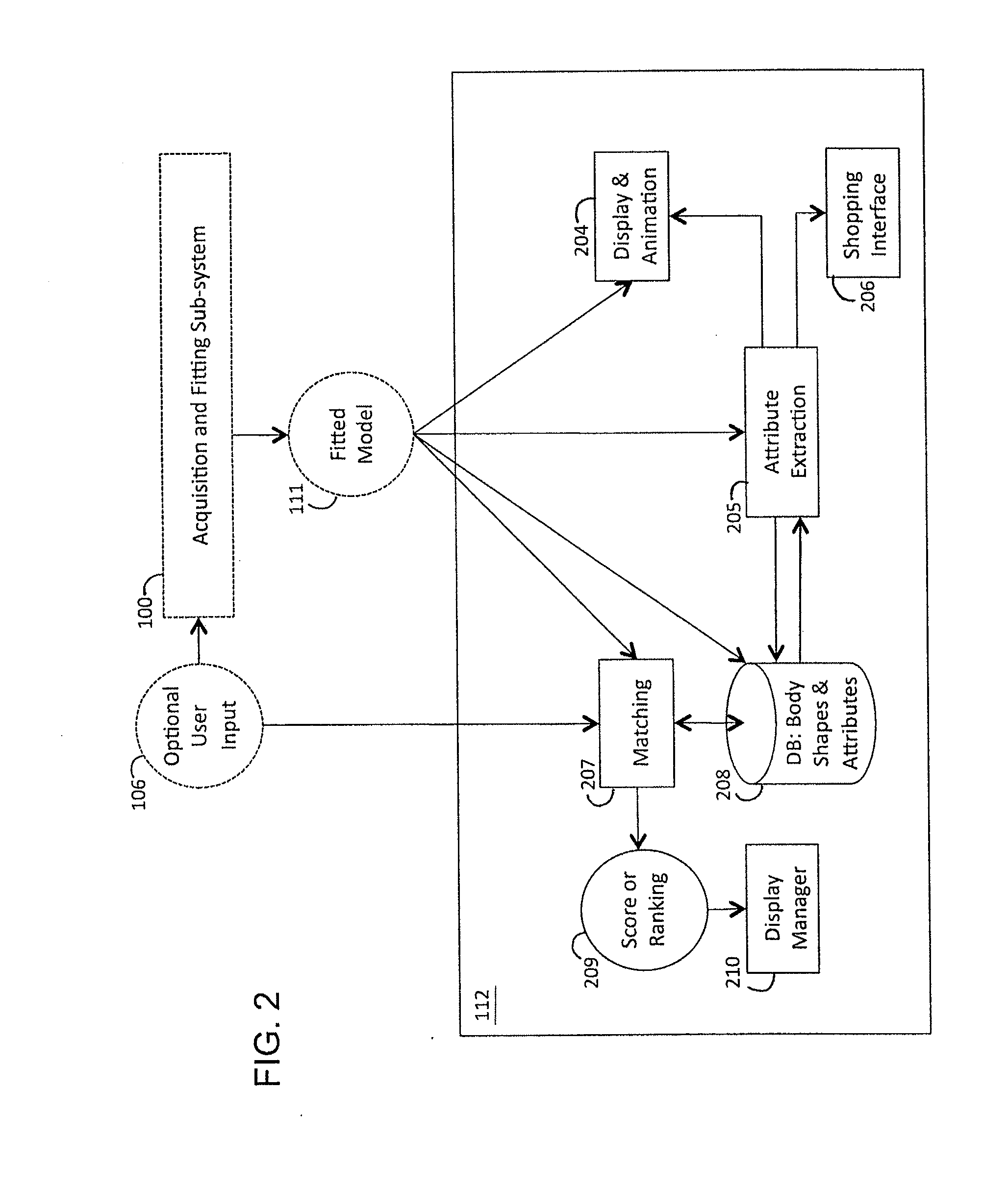

Method and apparatus for estimating body shape

ActiveUS20100111370A1Less-accurate measurementAccurate captureImage enhancementImage analysisBody shapeThe Internet

A system and method of estimating the body shape of an individual from input data such as images or range maps. The body may appear in one or more poses captured at different times and a consistent body shape is computed for all poses. The body may appear in minimal tight-fitting clothing or in normal clothing wherein the described method produces an estimate of the body shape under the clothing. Clothed or bare regions of the body are detected via image classification and the fitting method is adapted to treat each region differently. Body shapes are represented parametrically and are matched to other bodies based on shape similarity and other features. Standard measurements are extracted using parametric or non-parametric functions of body shape. The system components support many applications in body scanning, advertising, social networking, collaborative filtering and Internet clothing shopping.

Owner:BROWN UNIVERSITY

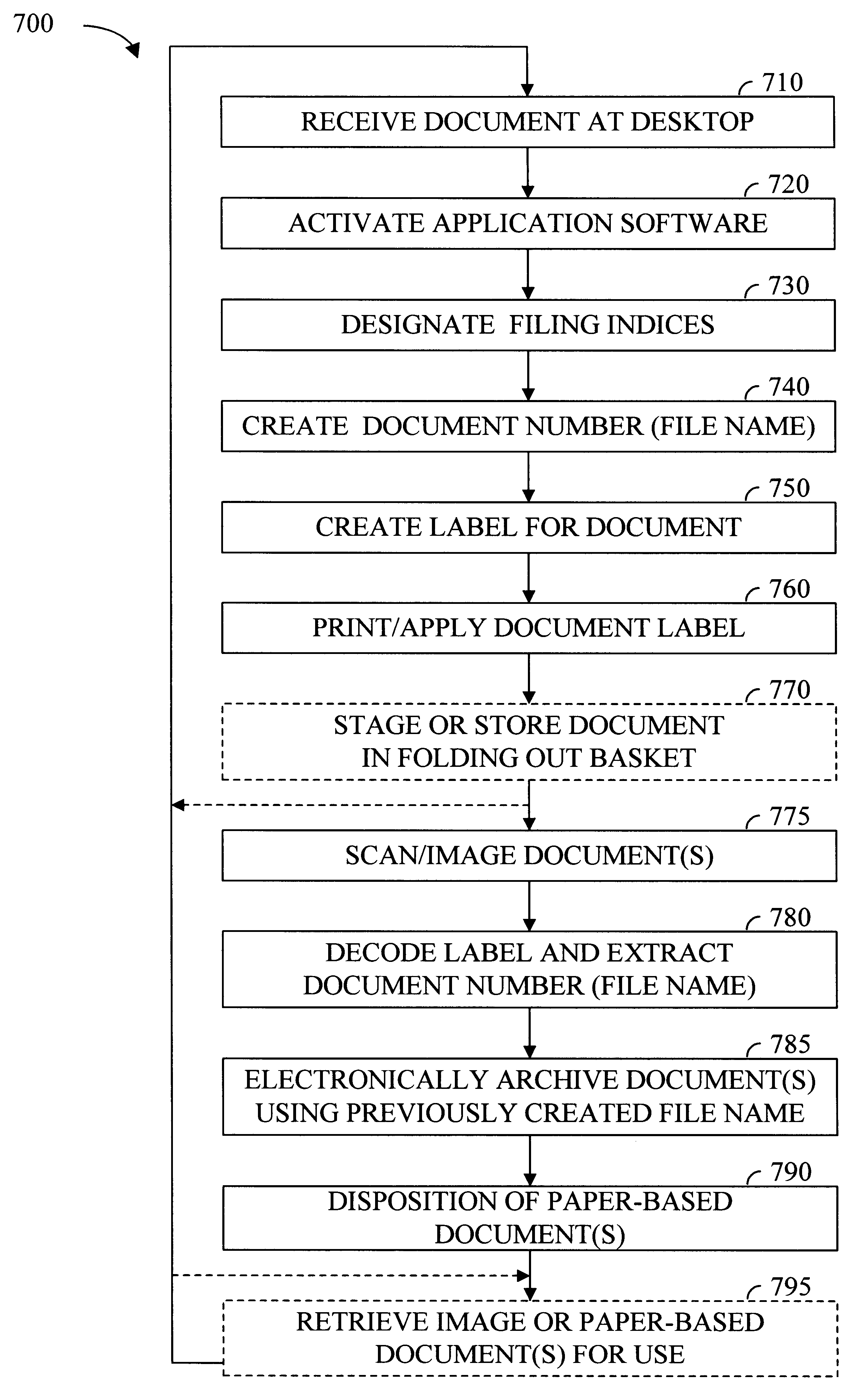

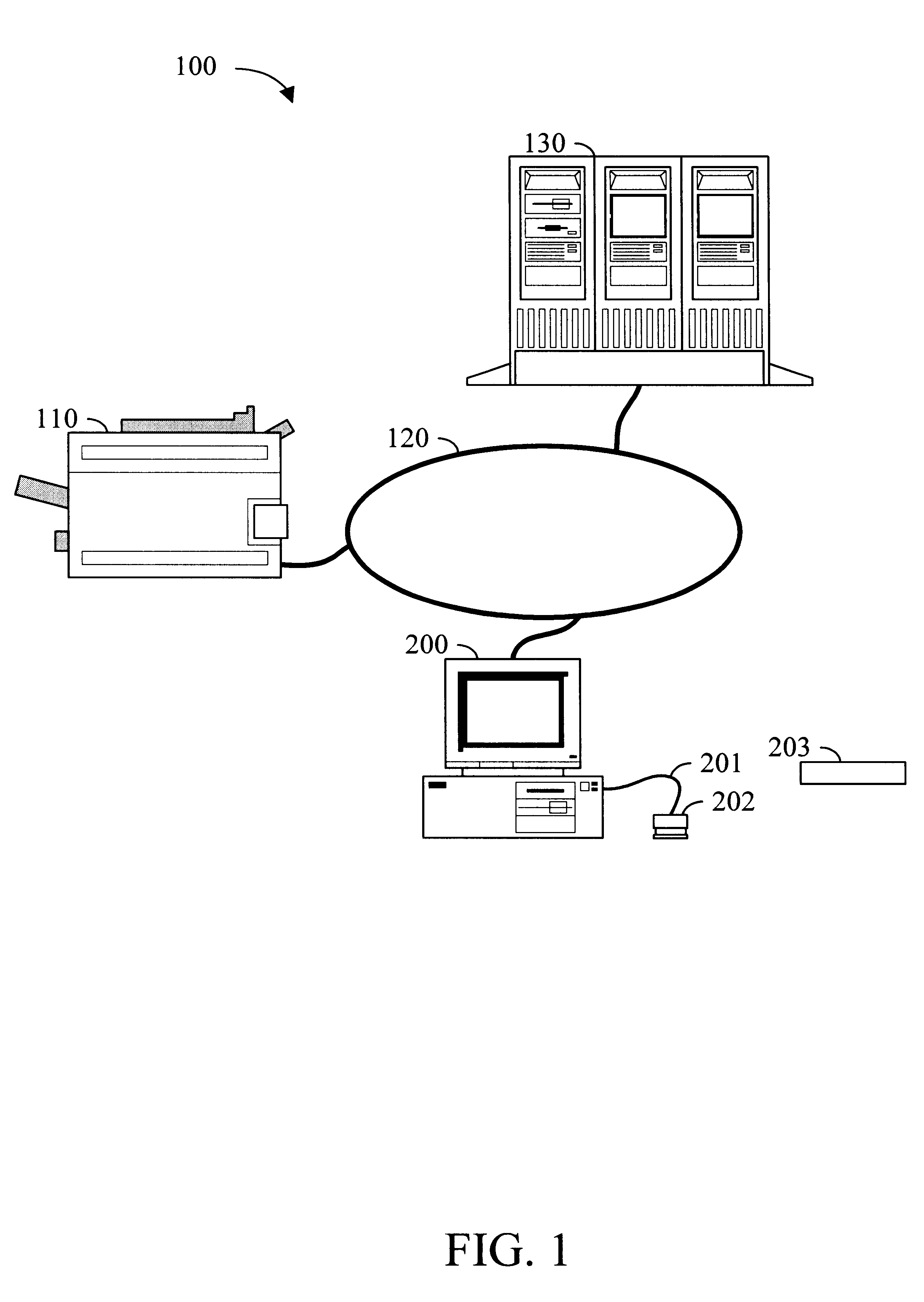

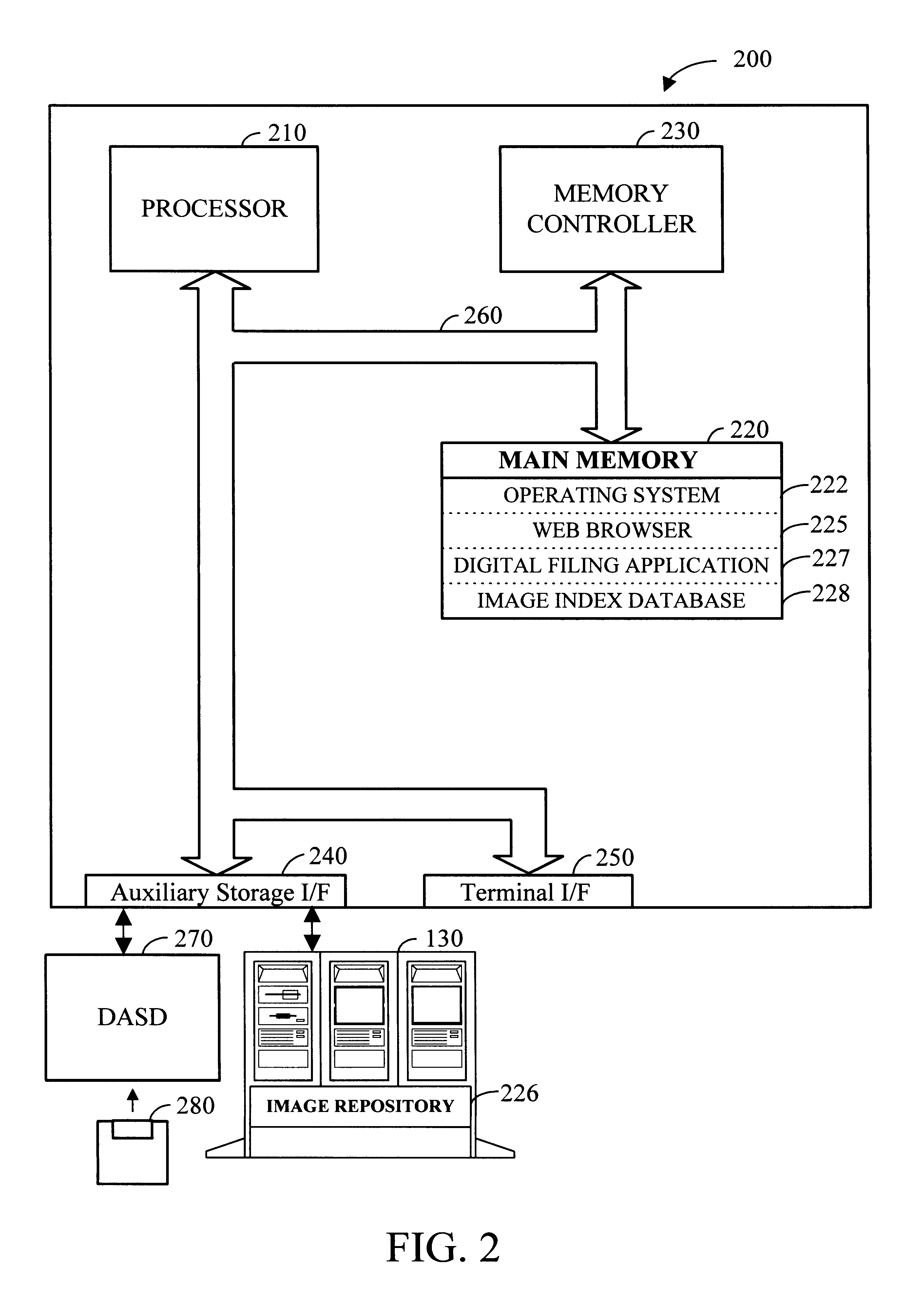

Apparatus and method for digital filing

InactiveUS6192165B1Easy and effective and imagingEasy and effective indexingData processing applicationsDigital computer detailsElectronic documentWeb browser

According to the preferred embodiments of the present invention, an apparatus and method for a digital filing system is disclosed. In this context, digital filing refers to the efficient management of paper-based information from its receipt at the desktop through an indexing, scanning, image storage and image retrieval process. The preferred embodiments of the present invention provide for easy and effective indexing, imaging, storing, retrieving and managing of paper-based documents, transforming them into electronic documents using a system which incorporates many existing office resources. The proposed system and method implements a desktop solution for digital filing, which can be made available to each worker. In one embodiment of the present invention, an individual has complete control over the electronic storage and retrieval of their documents from a standard desktop computer, using a standard web browser application. Uniquely, the digital filing system of the present invention also allows users to index and label documents prior to scanning / imaging by using a dedicated desktop labeling mechanism.

Owner:IMAGETAG

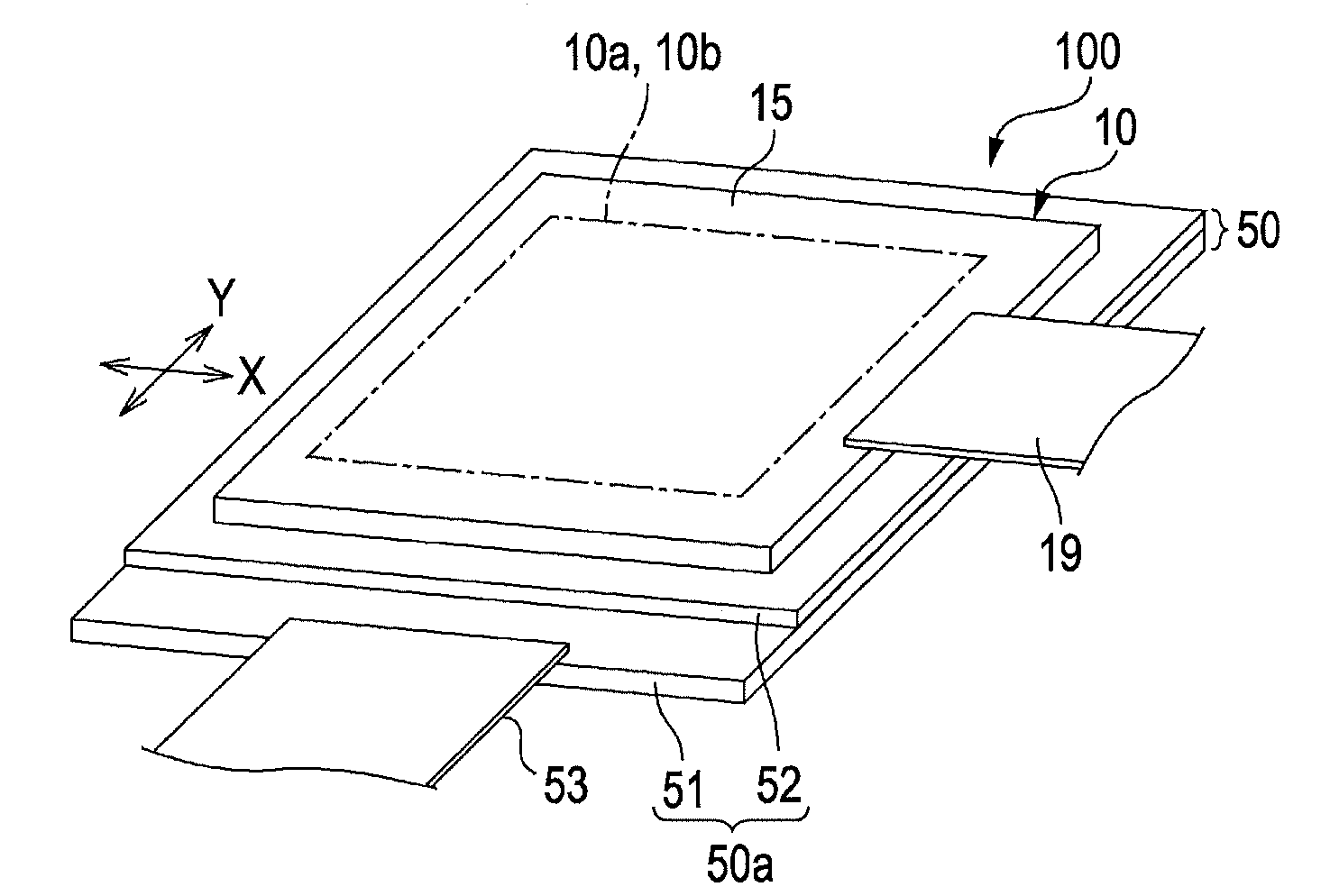

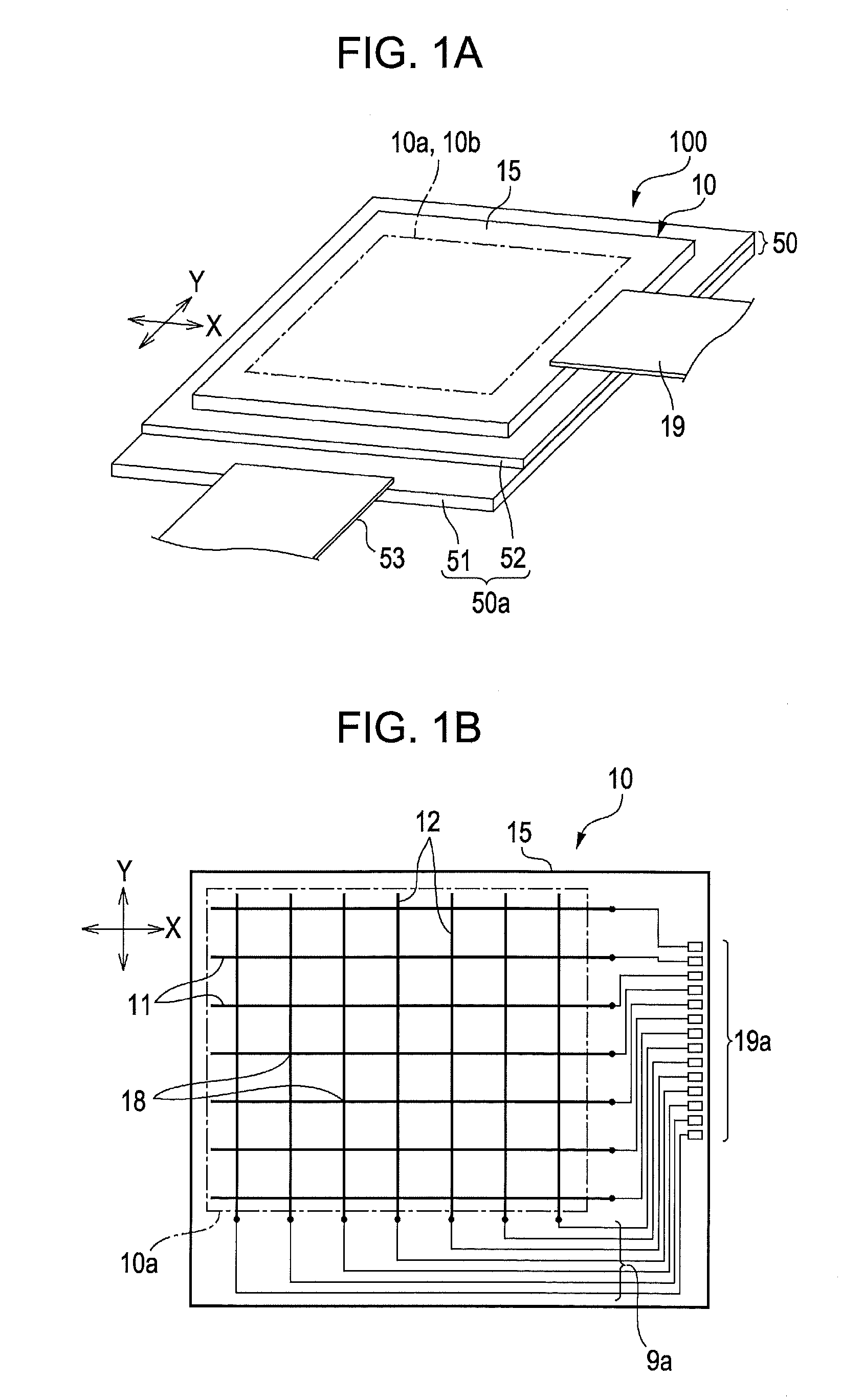

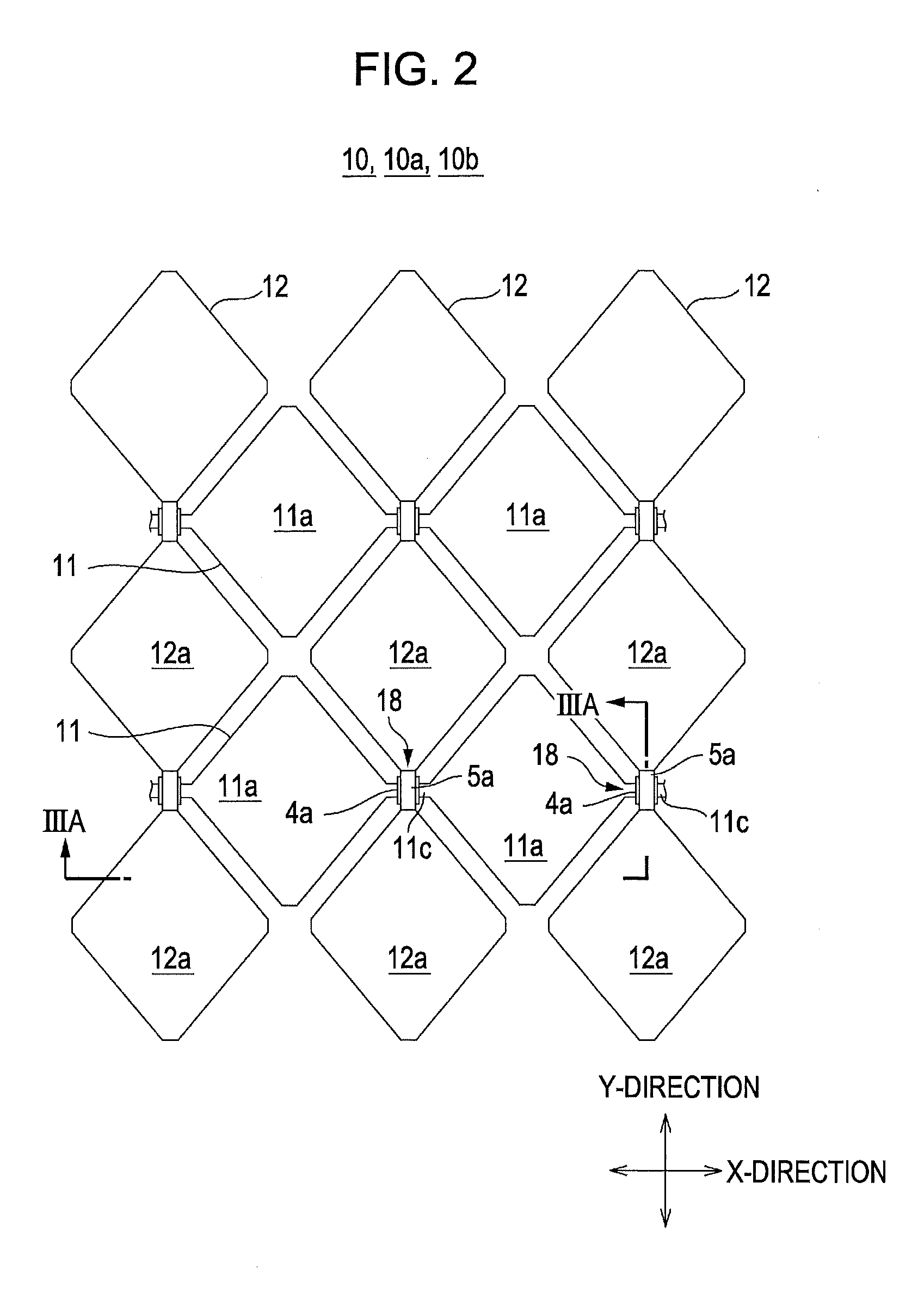

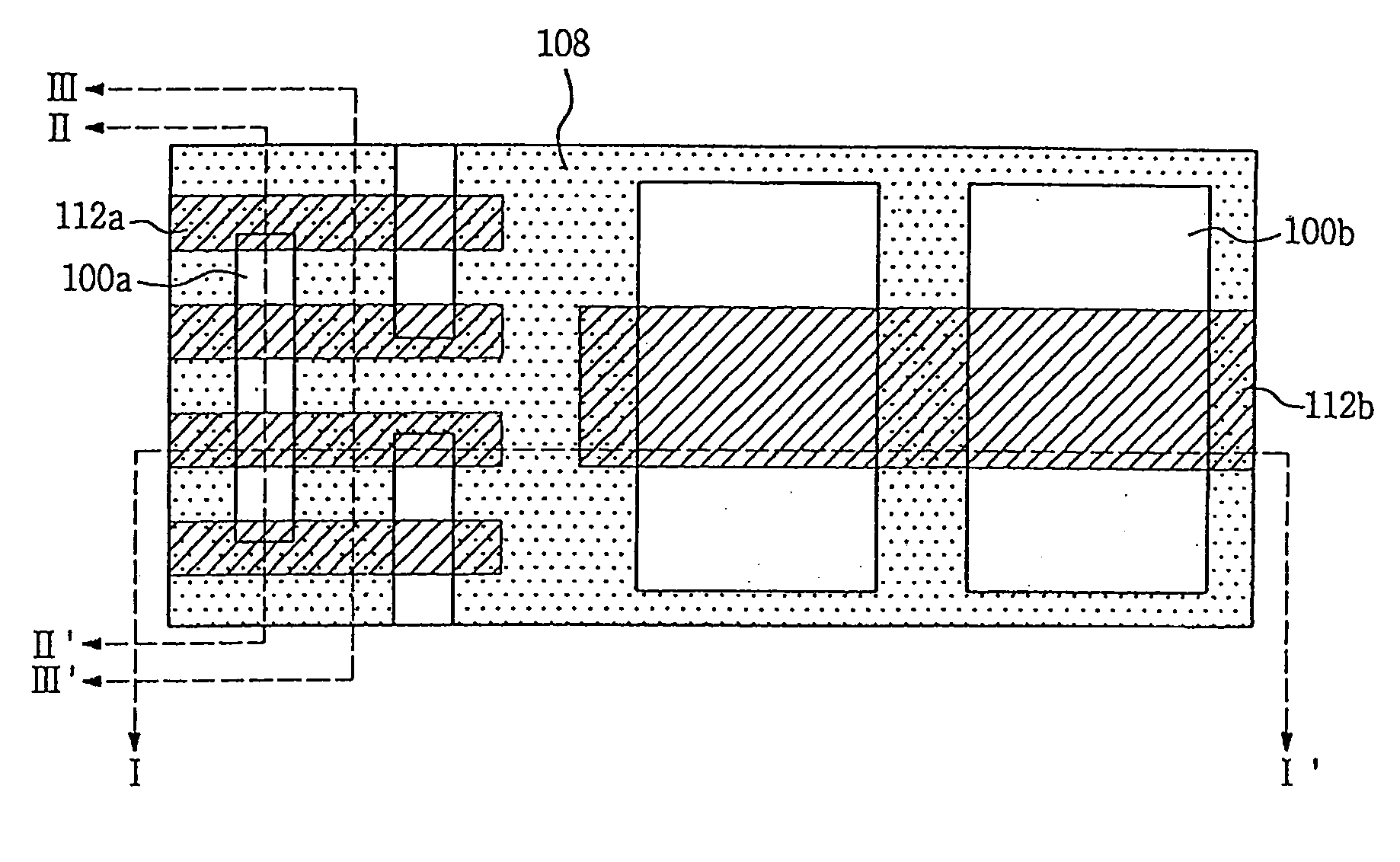

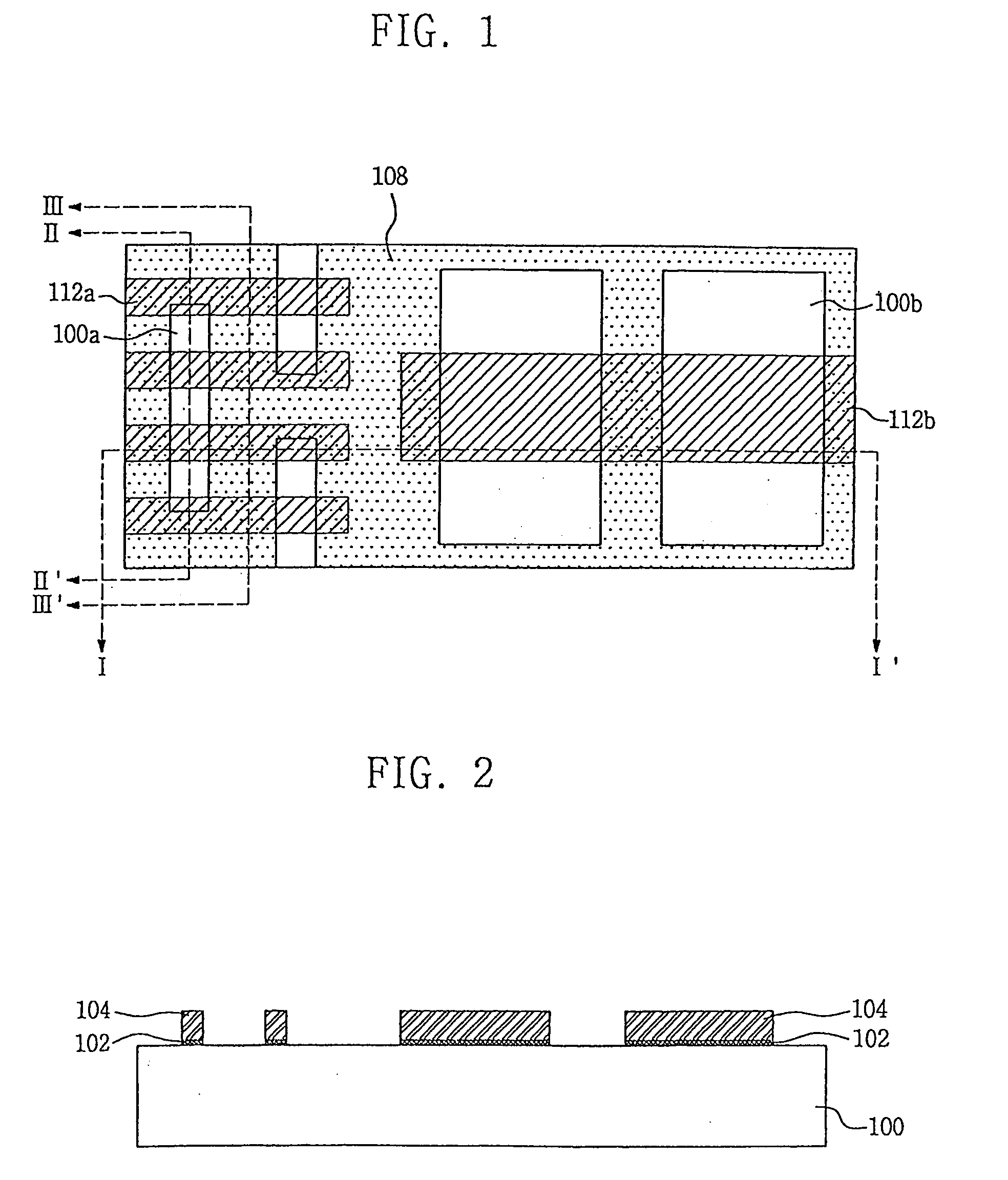

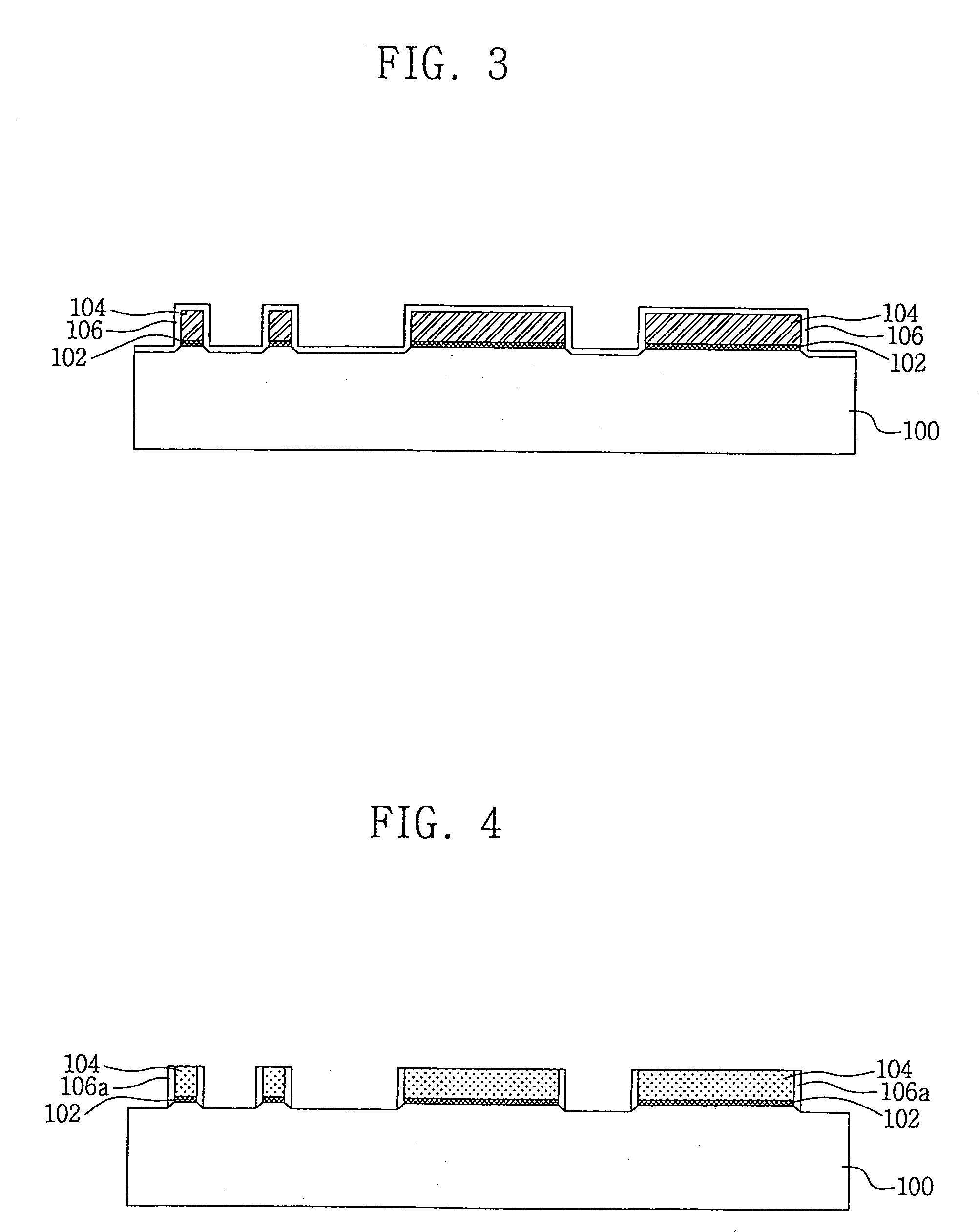

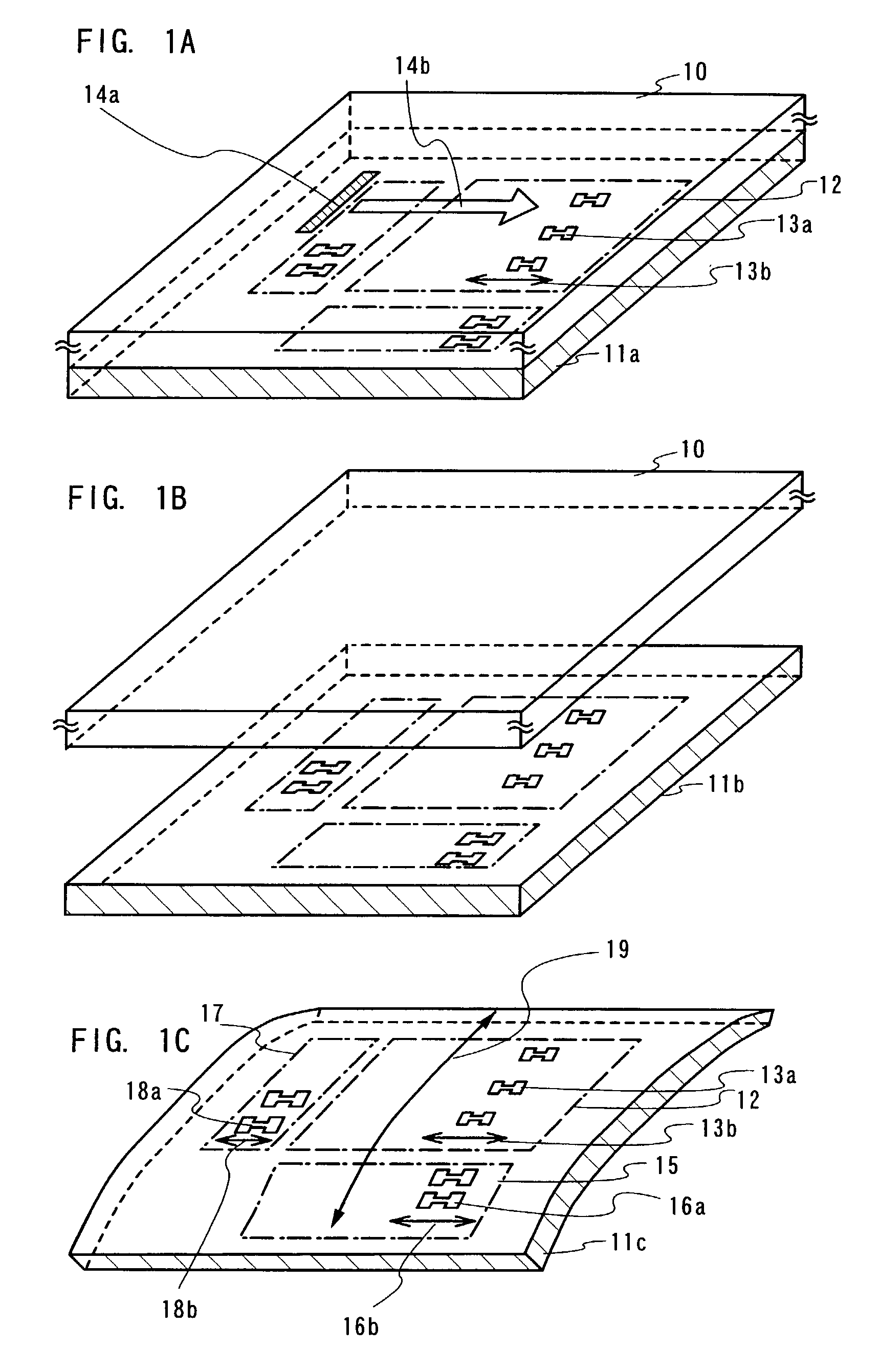

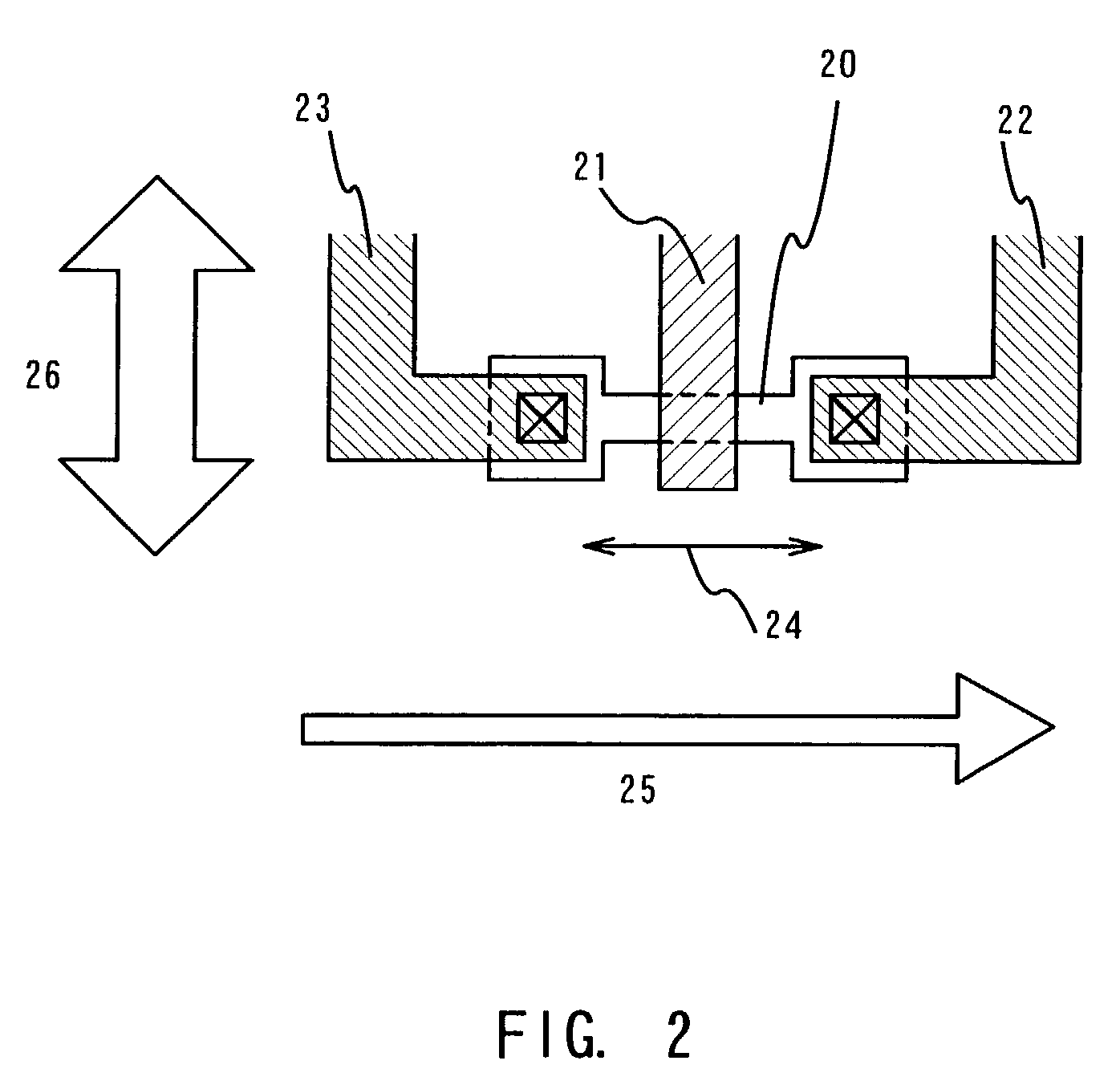

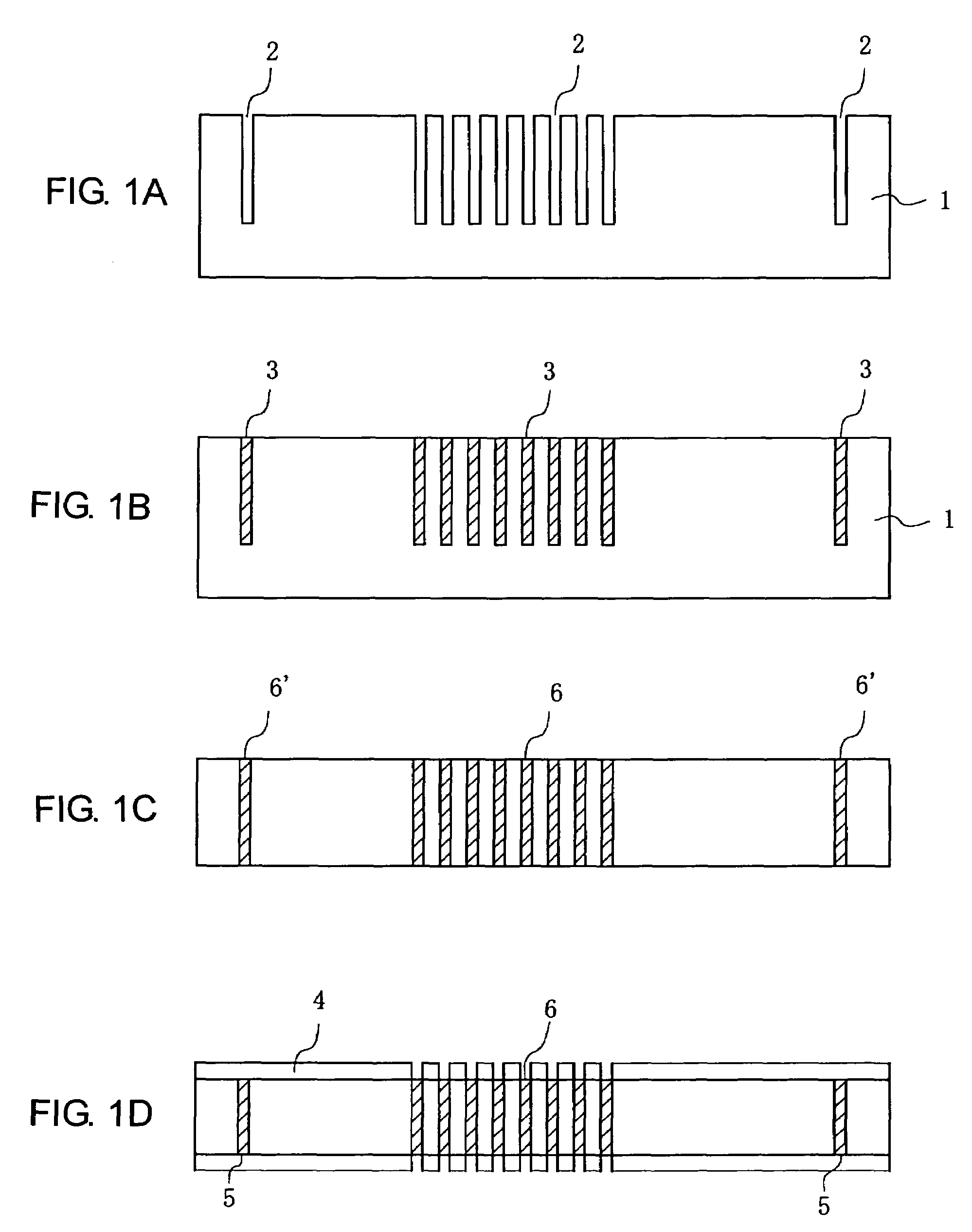

Capacitive input device

ActiveUS20080309635A1Reduce resistanceSimple processInput/output processes for data processingCapacitanceEngineering

A capacitive input device includes a translucent substrate; first translucent electrode lines, extending in a first direction; second translucent electrode lines, extending in a second direction intersecting with the first direction; interlayer insulating layers; and relay electrodes. The first translucent electrode lines intersect with the second translucent electrode lines at intersecting portions. Portions of one of each first translucent electrode line and each second translucent electrode line are connected to each other with the intersecting portions. Portions of the other are separated from each other with the intersecting portions. The translucent interlayer insulating layers overlie the first or second translucent electrode line portions connected to each other with the intersecting portions. The translucent relay electrodes overlie the interlayer insulating layers to electrically connect the first or second translucent electrode line portions, separated from each other with the intersecting portions, to each other.

Owner:JAPAN DISPLAY WEST

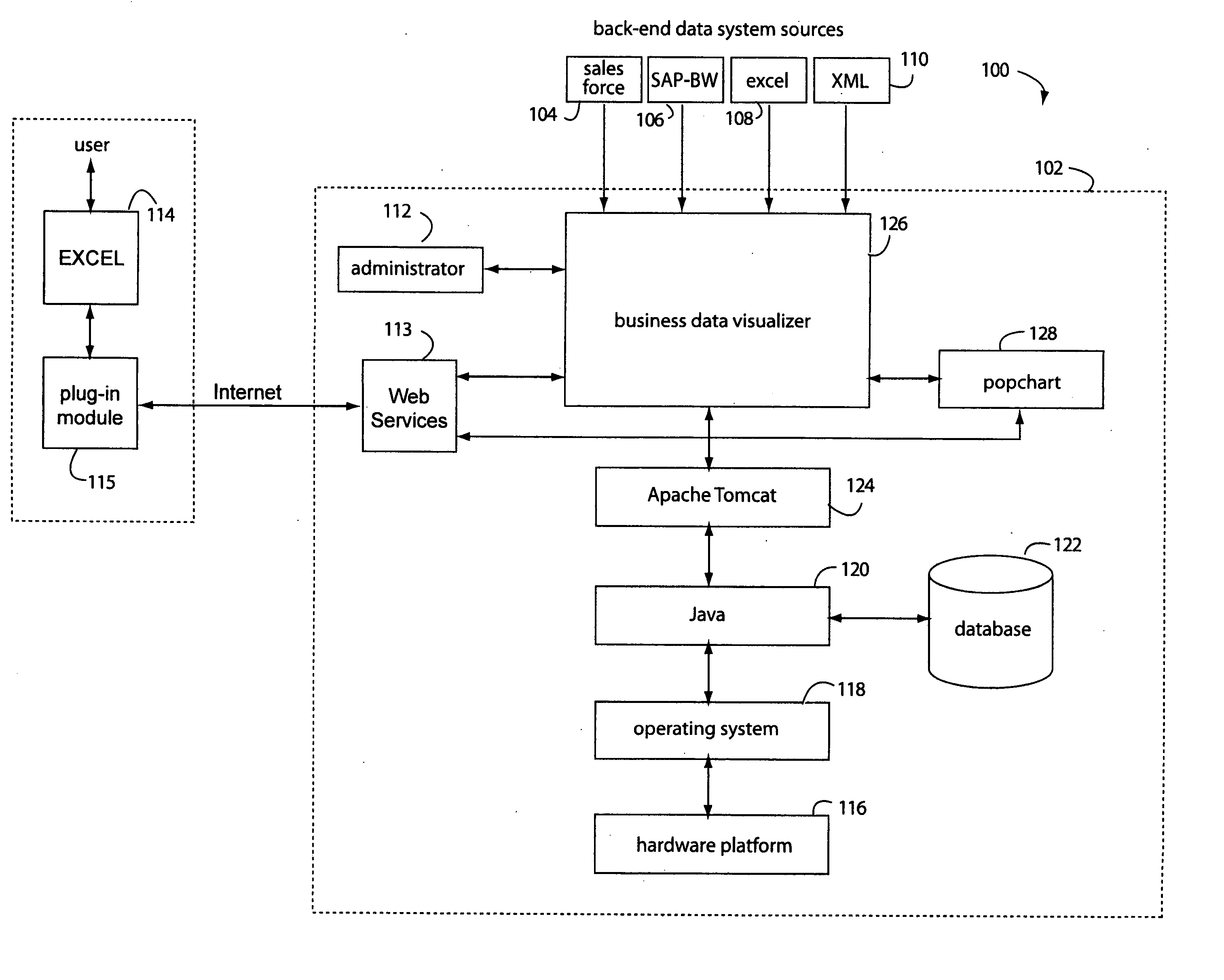

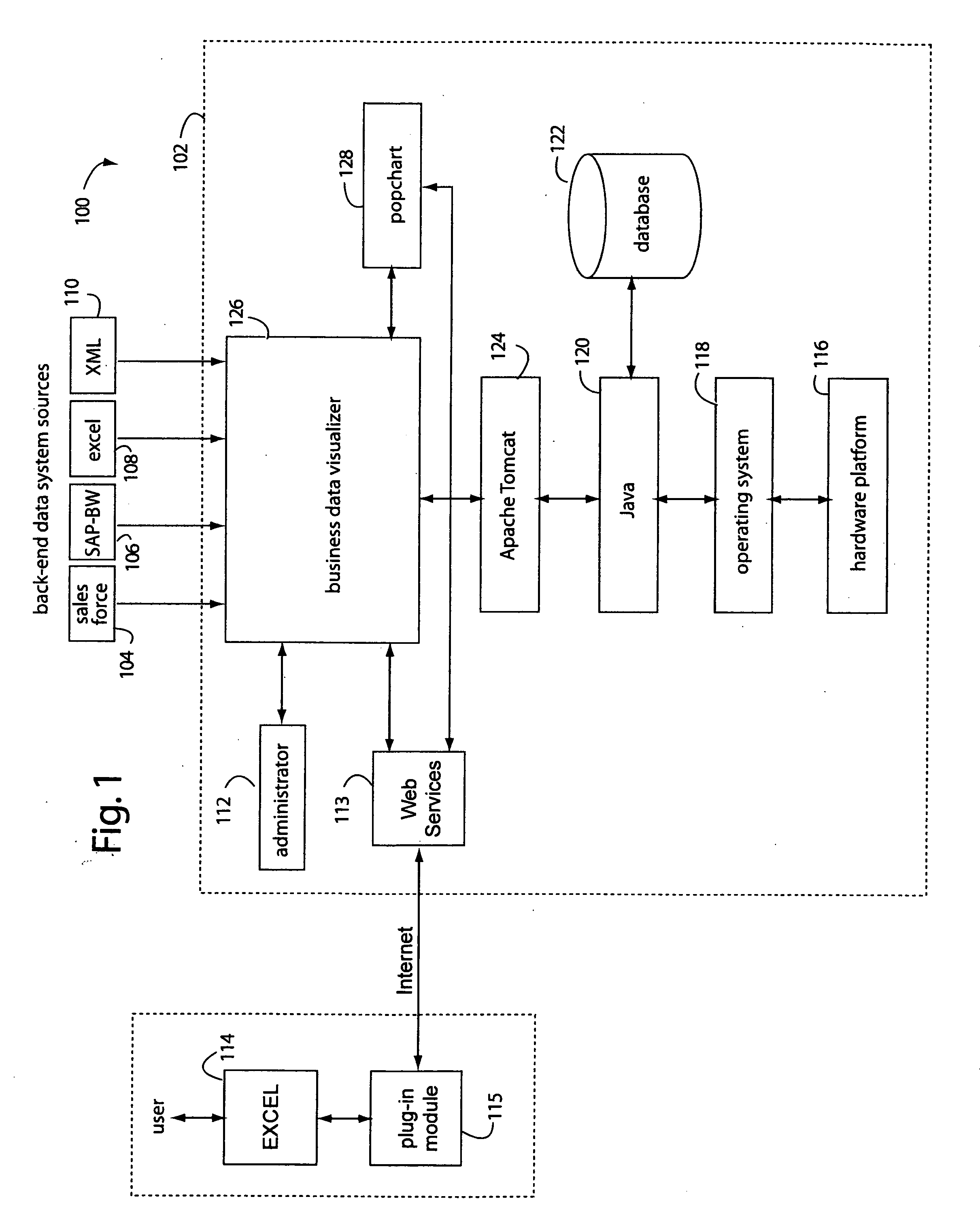

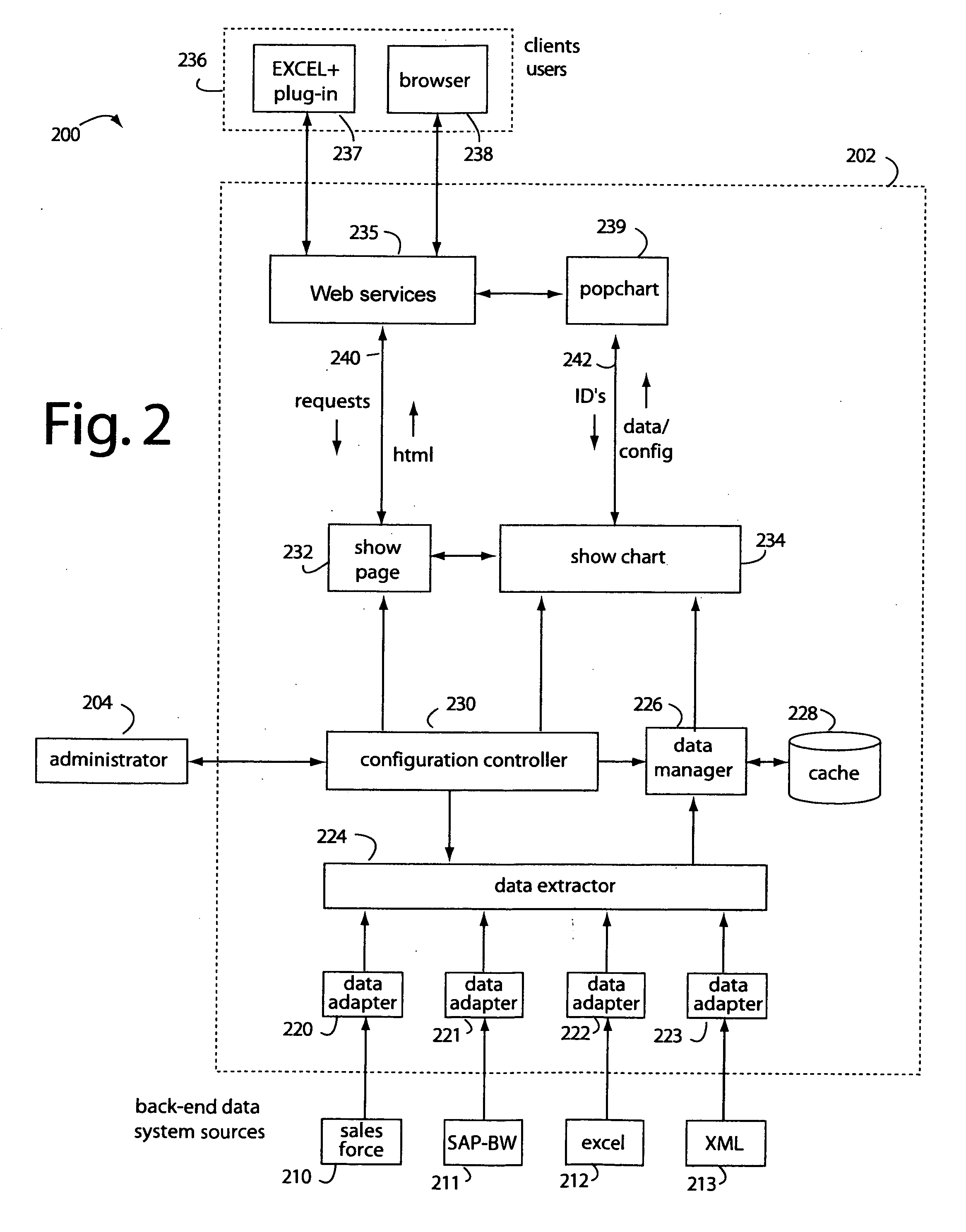

Spreadsheet user-interfaced business data visualization and publishing system

InactiveUS20060112123A1Improve strategic decisionFacilitate communicationDigital data processing detailsText processingDashboardData set

A spreadsheet user-interfaced web-based business data publishing system allows users to input and visualize field data and analytical results with interactive charts through a familiar MS-EXCEL user interface. A plug-in module associated with the user's browser and EXCEL application enables a background, web-services connection over the Internet to a management sub-system which extracts, transforms, and publishes data. Charts are customized using a WYSIWYG interface, and business dashboards are constructed through a simple drag-n-drop process. An account management system is included with access control to protect information security. The system is used for visualizing data managing reports, providing special tools to use SAP data, access Query Cubes in SAP BW, and standard and custom R / 3 reports. Once data has been extracted from SAP, it is transformed, merged with other data sources, and published as a dashboard or in a business portal. Its management and configuration functions are suited for enterprise reporting and sharing business data.

Owner:MACNICA

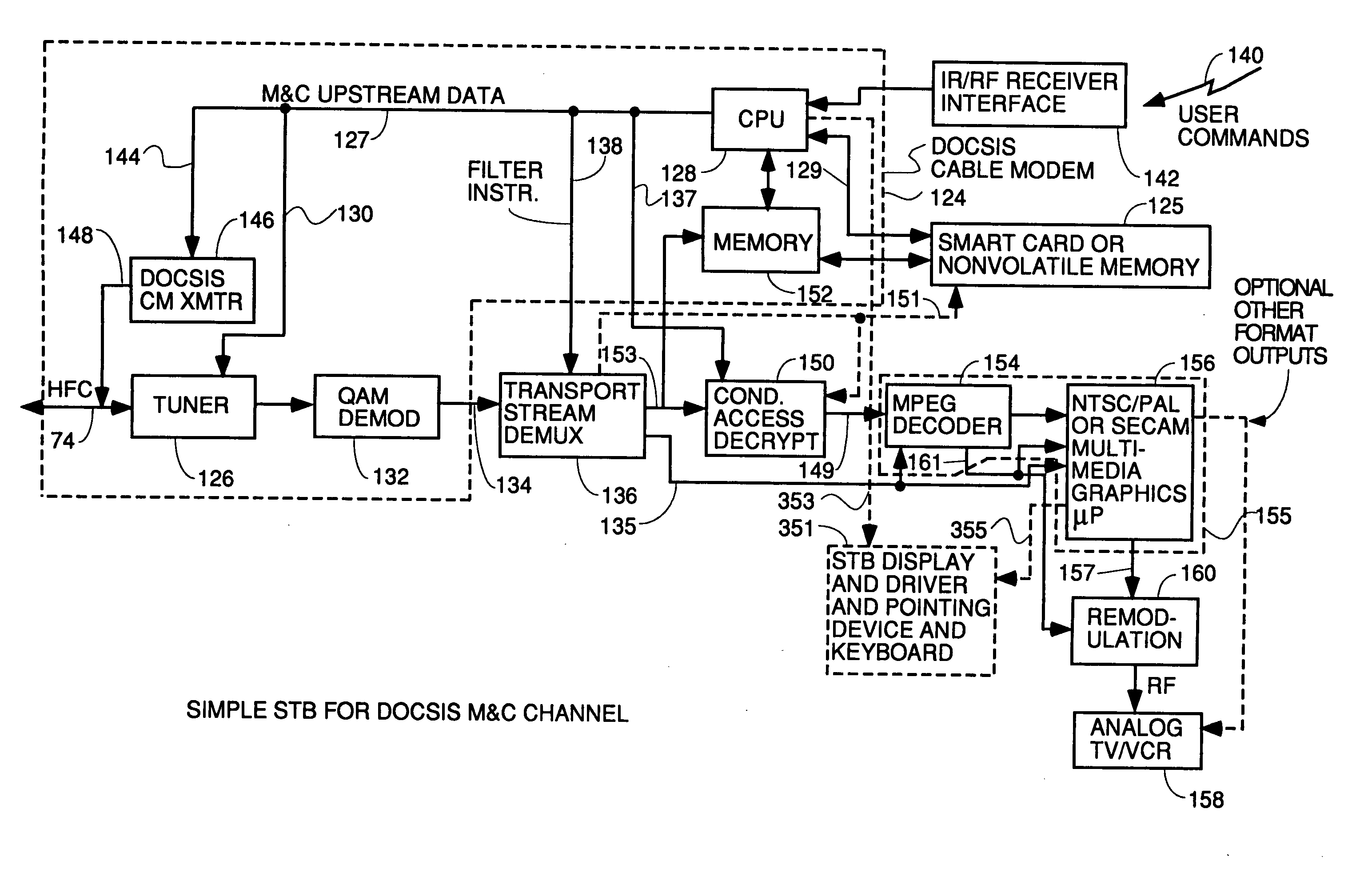

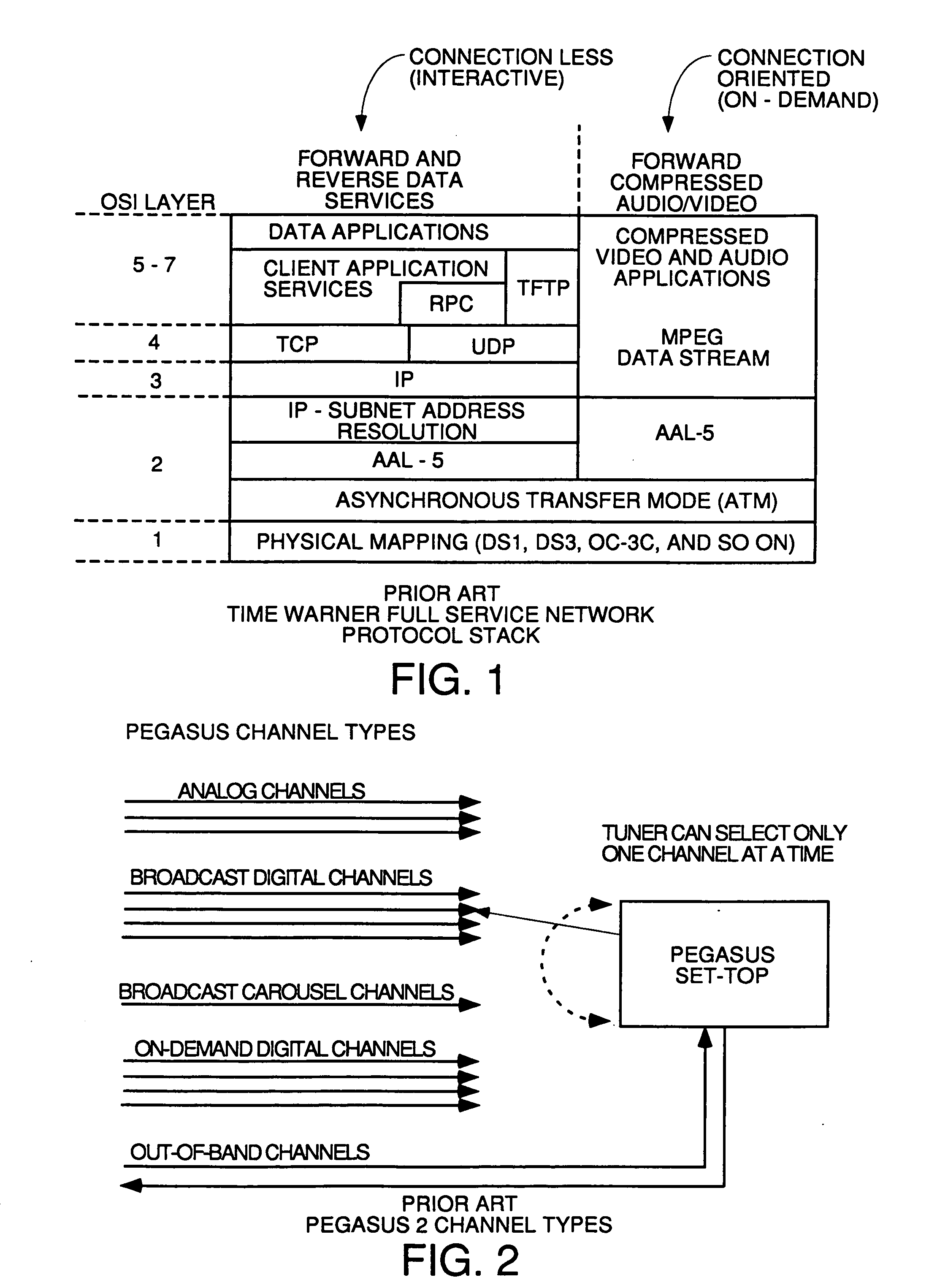

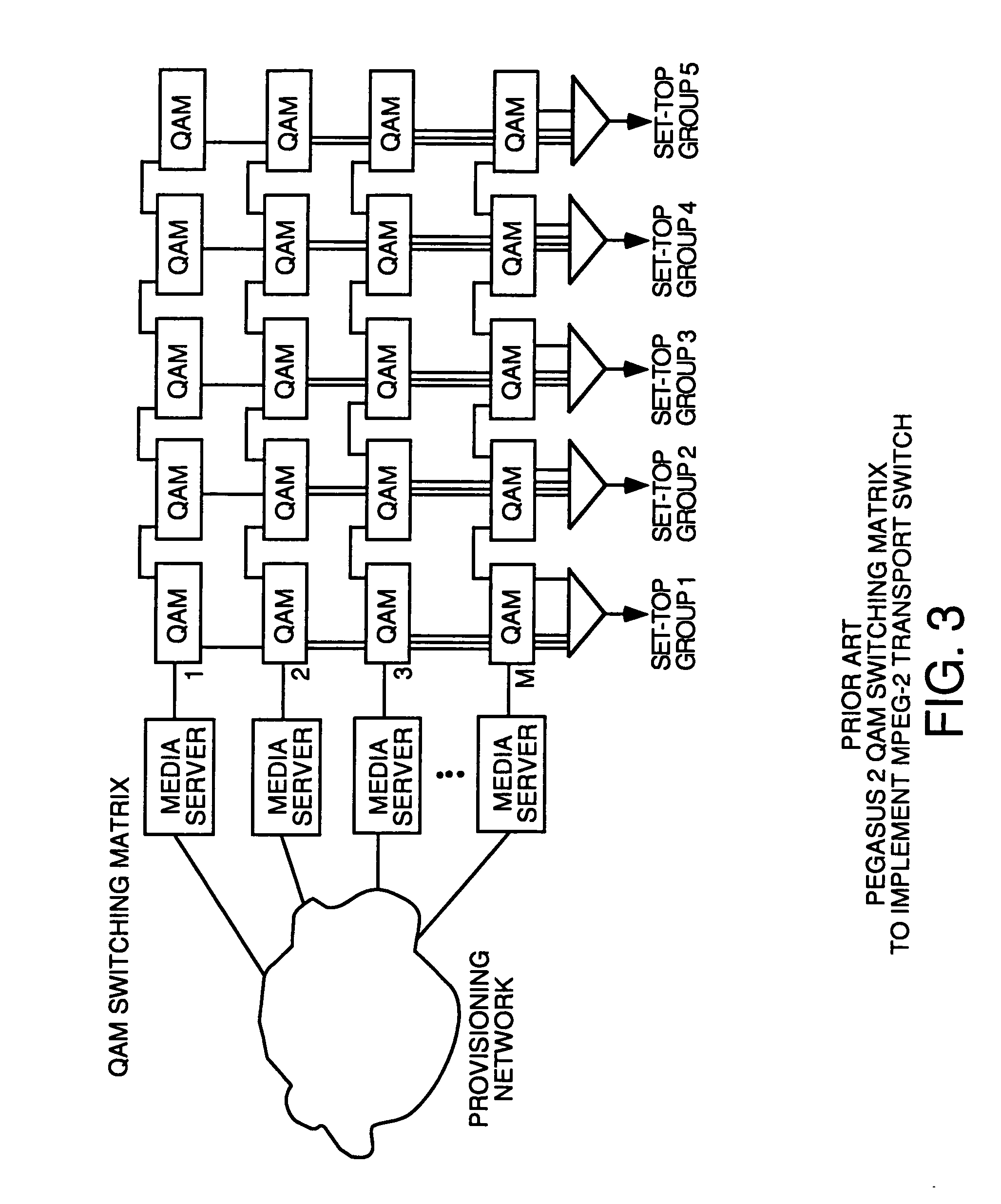

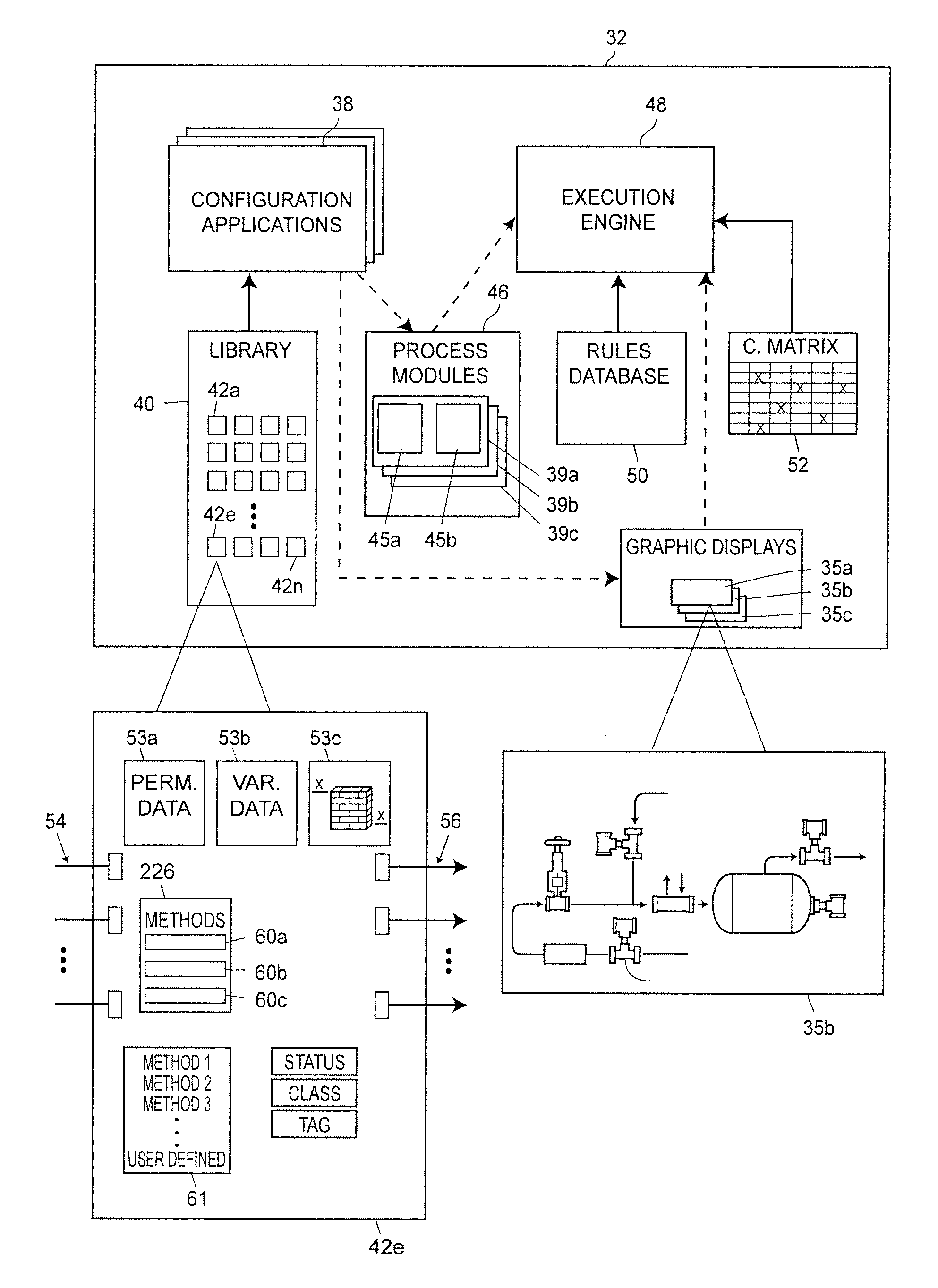

Thin DOCSIS in-band management for interactive HFC service delivery

InactiveUS20040181800A1Simple processLess-expensive to buildAnalogue secracy/subscription systemsTwo-way working systemsModem deviceConditional access

Circuitry and processes carried out thereby are disclosed for implementing simple single tuner set top box decoders which do not require a separate tuner for an out of band management and control channel. Removable smart card conditional access circuitry and replaceable modules having decoding circuitry for different compression schemes and encoding circuitry for different format television circuits is disclosed. An embodiment with a single tuner and a full DOCSIS compatible modem which can interface to personal computers, etc. is also disclosed to make the set top box a simple, inexpensive home gateway is also disclosed.

Owner:TERAYON COMM SYST

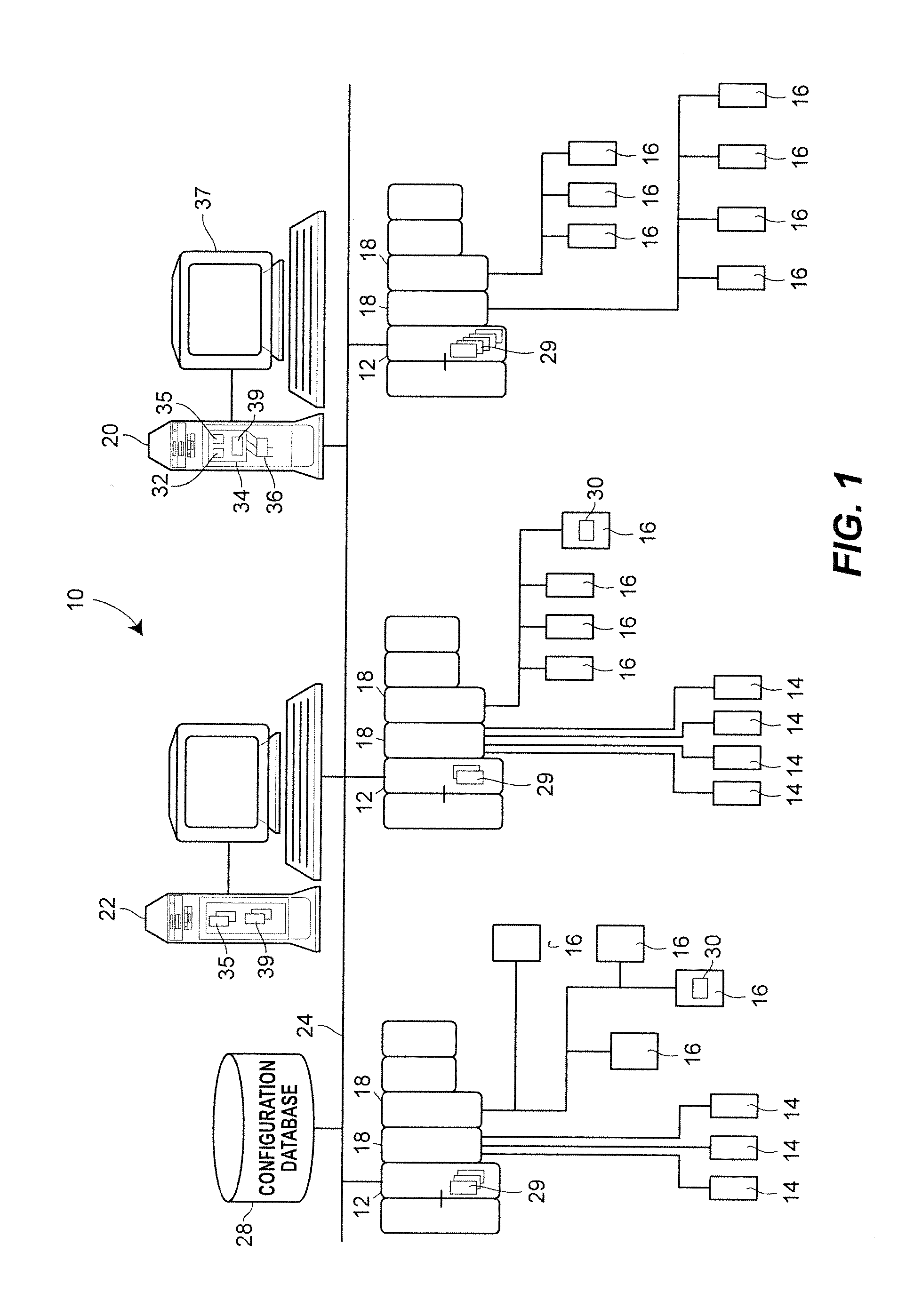

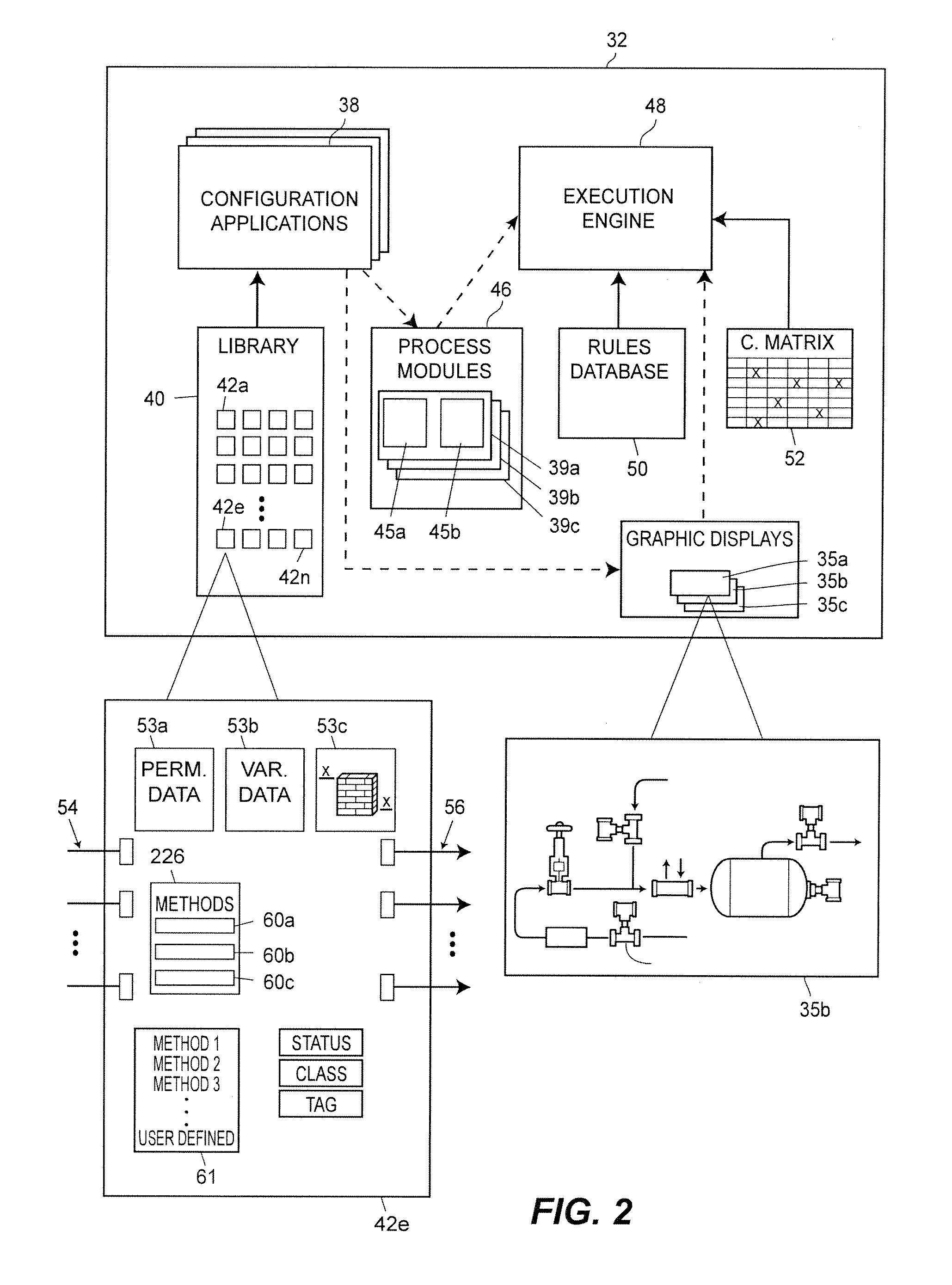

Dynamic User Interface for Configuring and Managing a Process Control System

ActiveUS20120029661A1Reduce the number of timesImprove convenienceElectric controllersIgnition automatic controlControl systemComputerized system

A process control management method in a computer system for configuring and supervising a process plant includes providing an interactive user interface to manage a plurality of objects in the process plant, where each of the plurality of objects corresponds to a physical or logical entity in the process plant, including generating a navigation pane to display a set of selectable items, each in the set of selectable items corresponding to a respective one of the plurality of objects, and generating a command pane to display a set of selectable controls, each in the set of selectable controls corresponding to a task to be performed on at least one of the plurality of objects in the process plant; receiving a selection of one of an item in the set of selectable items via the navigation panel and a control in the set of selectable controls via the command panel; determining an operational context based on the received selection, wherein the operational context corresponds to one of a range of actions applicable to the selection if the selection is an item selection, or a range of items to which the selection is applicable if the selection is a control selection; and adjusting one of the navigation pane or the command pane according to the operational context, including displaying a subset of selectable items in the navigational pane, wherein each in the subset of selectable items is within the range applicable to the selection, if the selection is a control selection, and displaying a subset of selectable controls in the command pane, wherein each in the subset of selectable controls is within the range applicable to the selection, if the selection is an item selection.

Owner:FISHER-ROSEMOUNT SYST INC

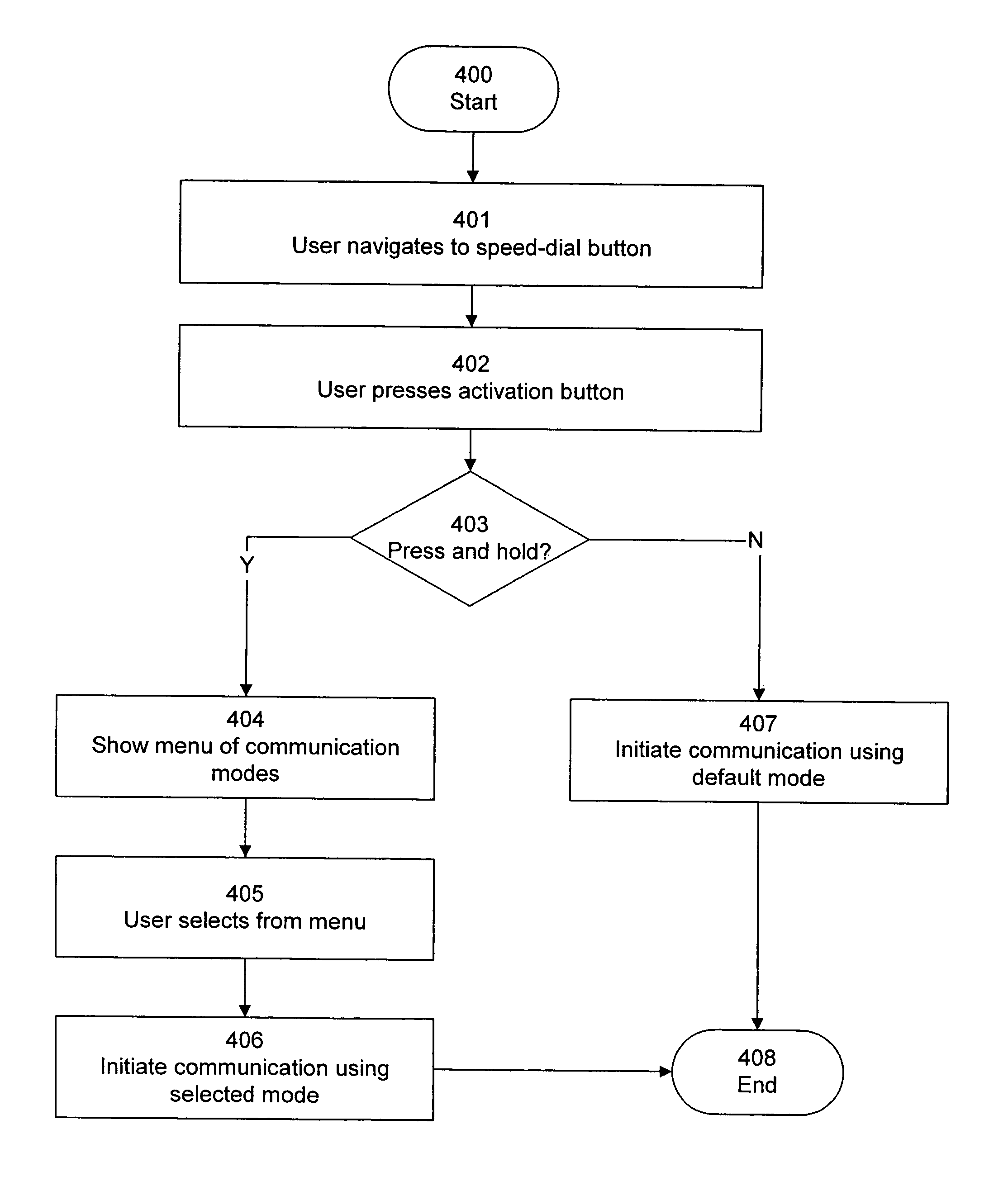

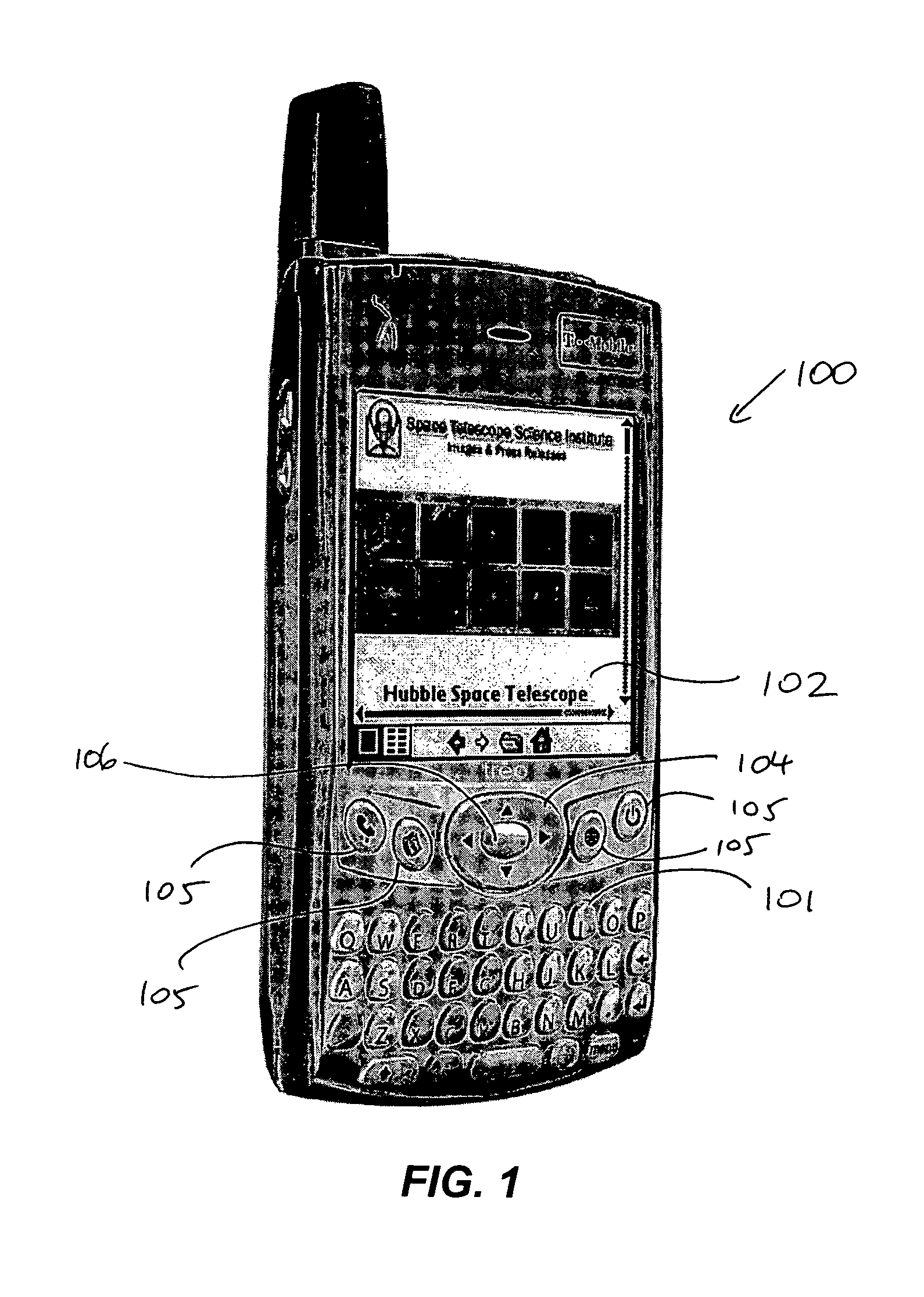

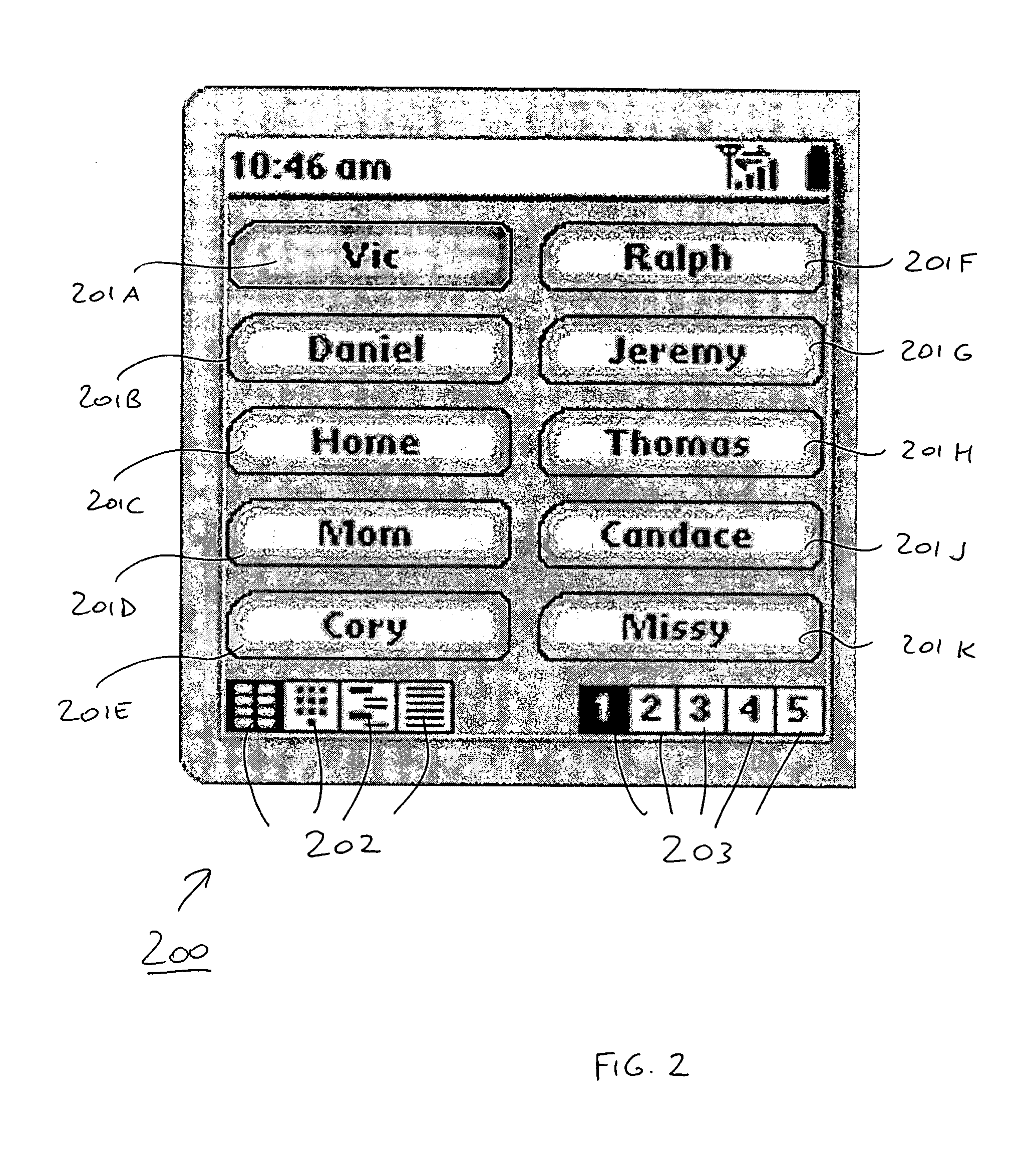

Communication device interface

ActiveUS7231229B1Easy to useSimple processCathode-ray tube indicatorsCalled number recording/indicationBiological activationContact number

In a communication device, user activation of a speed-dial button causes a context-sensitive menu to be displayed. The menu lists available options, or communication modes, for contacting the party associated with the speed-dial button. The user can select an item from the menu in order to initiate communication with the selected party using the communication mode associated with the menu item. In various aspects, the invention provides additional functionality for redialing previously called contact numbers, assigning speed-dial buttons to other commands and functions, and displaying presence information for contacts.

Owner:QUALCOMM INC

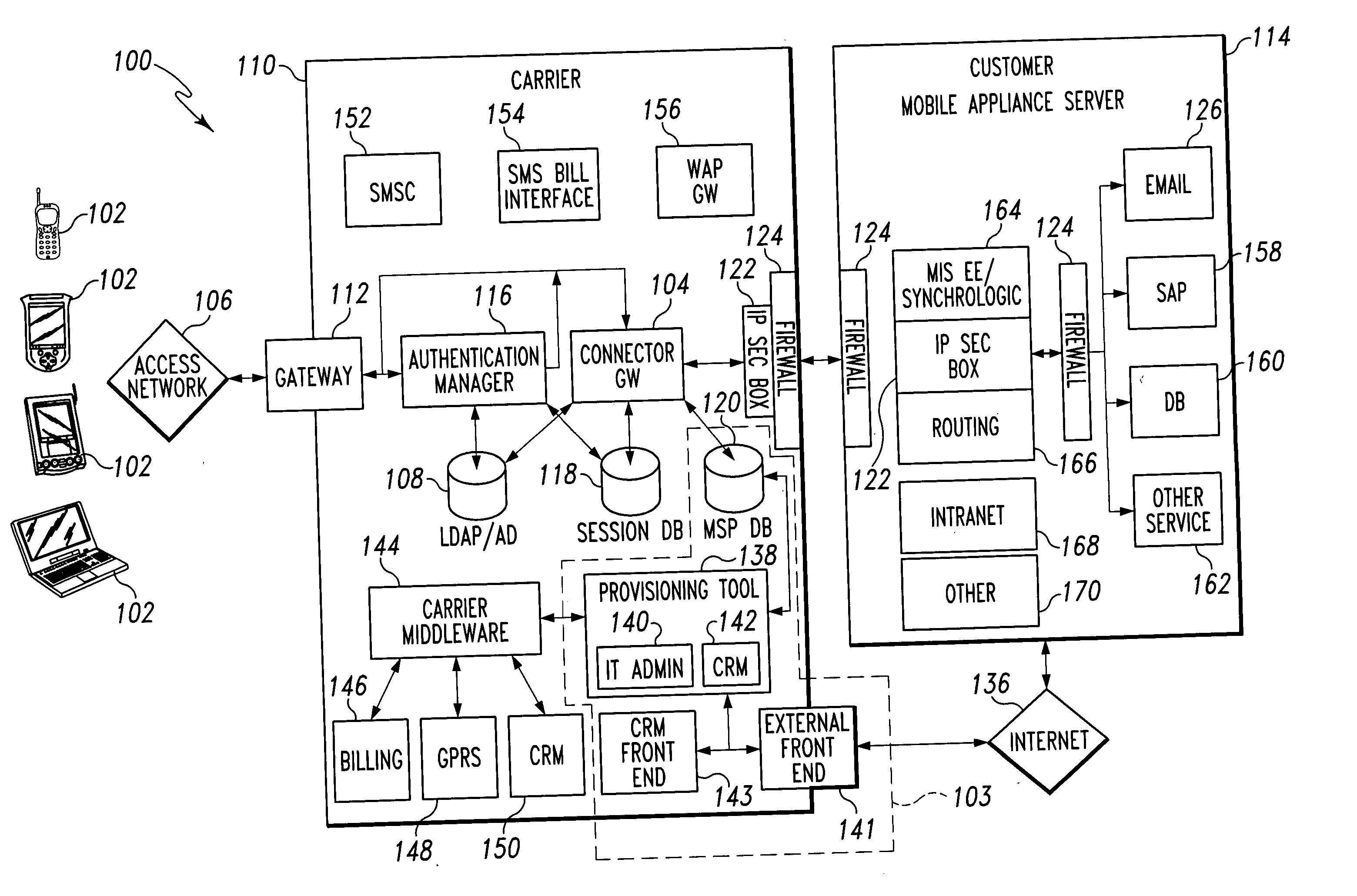

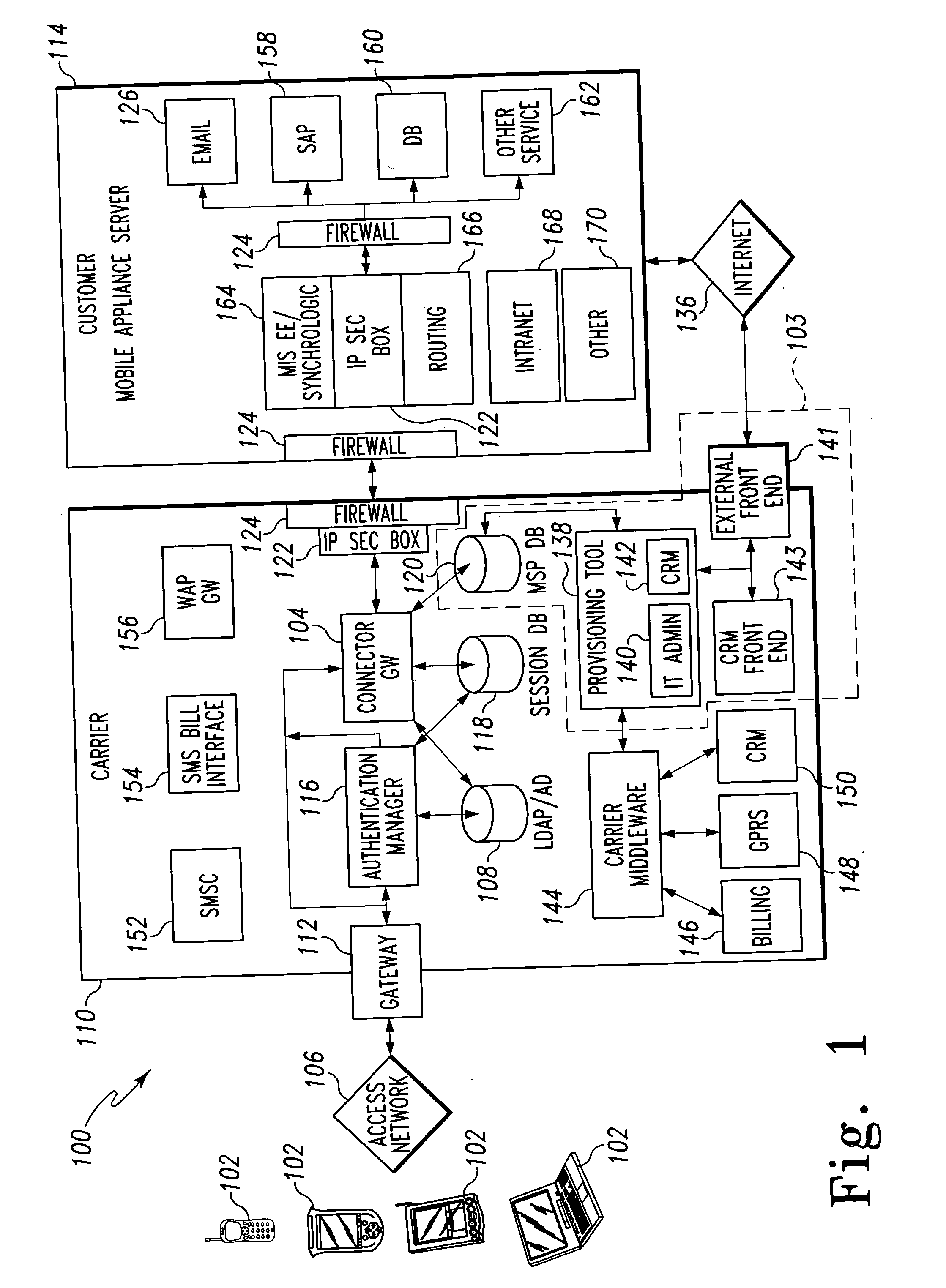

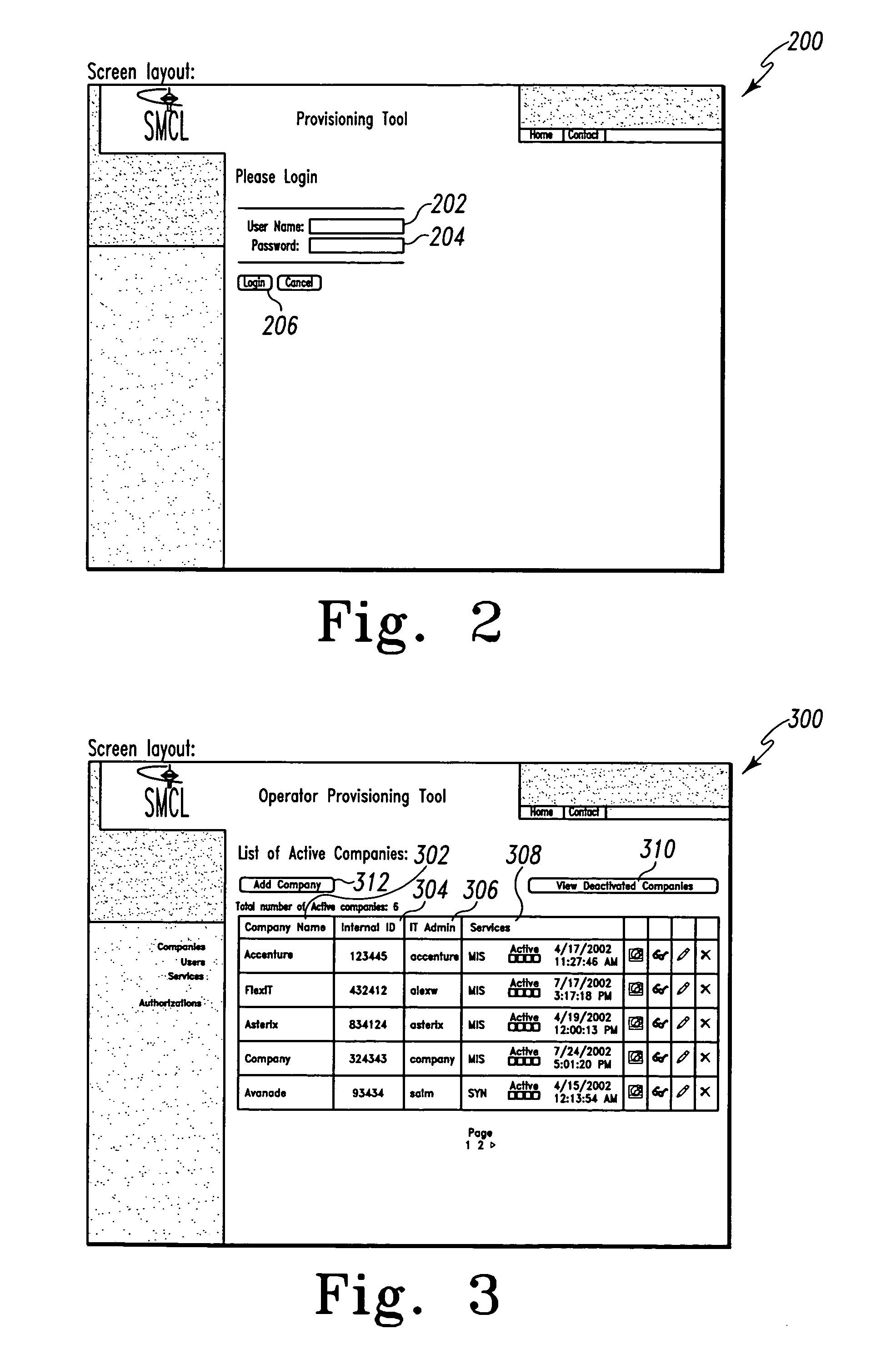

Mobile provisioning tool system

ActiveUS20050075115A1Simple processLimited accessUnauthorised/fraudulent call preventionEavesdropping prevention circuitsMobile businessWorkstation

A mobile provisioning tool system including a software provisioning tool application. The mobile provisioning tool system includes mobile devices capable of conducting wireless communication with wireless access points. A carrier network is connected with the wireless access points and a customer network that includes at least one business application. A provisioning tool application is located on a provisioning server. The provisioning tool application includes a CRM Rep component and an IT Admin component. A software provisioning tool application allows the provisioning workstation to automatically install mobile business services and configure network configuration settings on the mobile device.

Owner:ACCENTURE GLOBAL SERVICES LTD

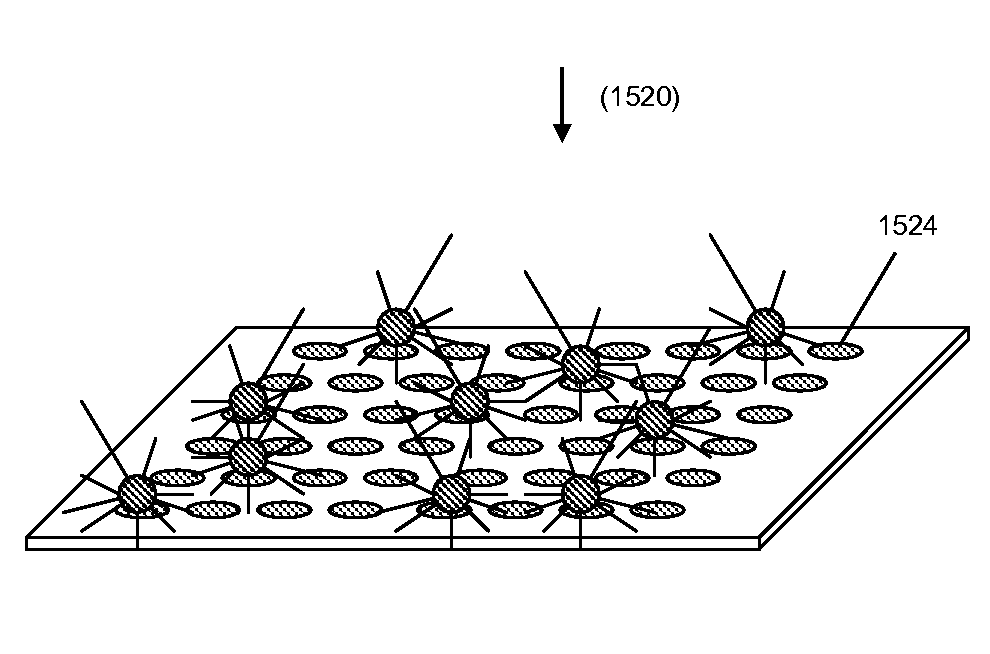

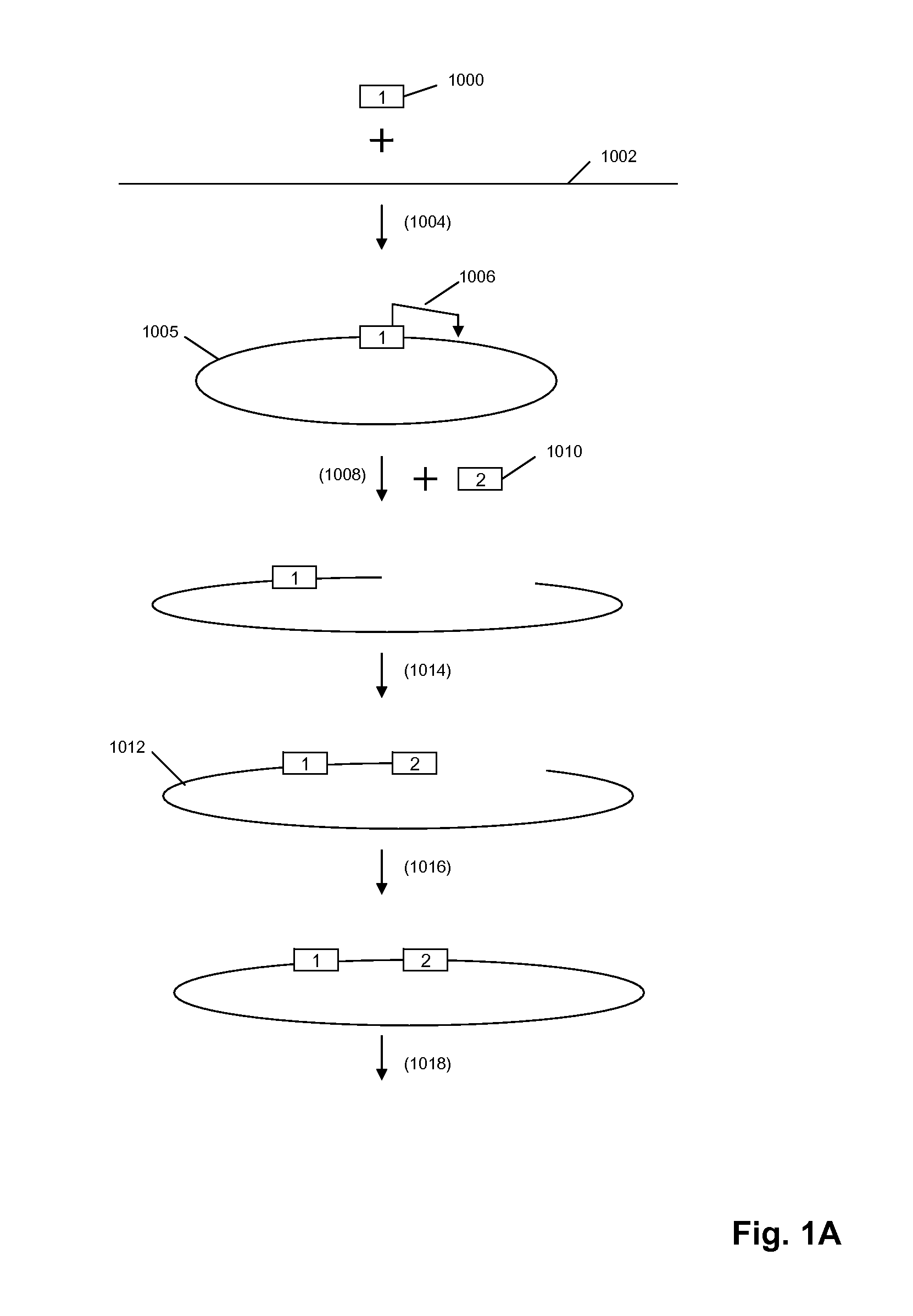

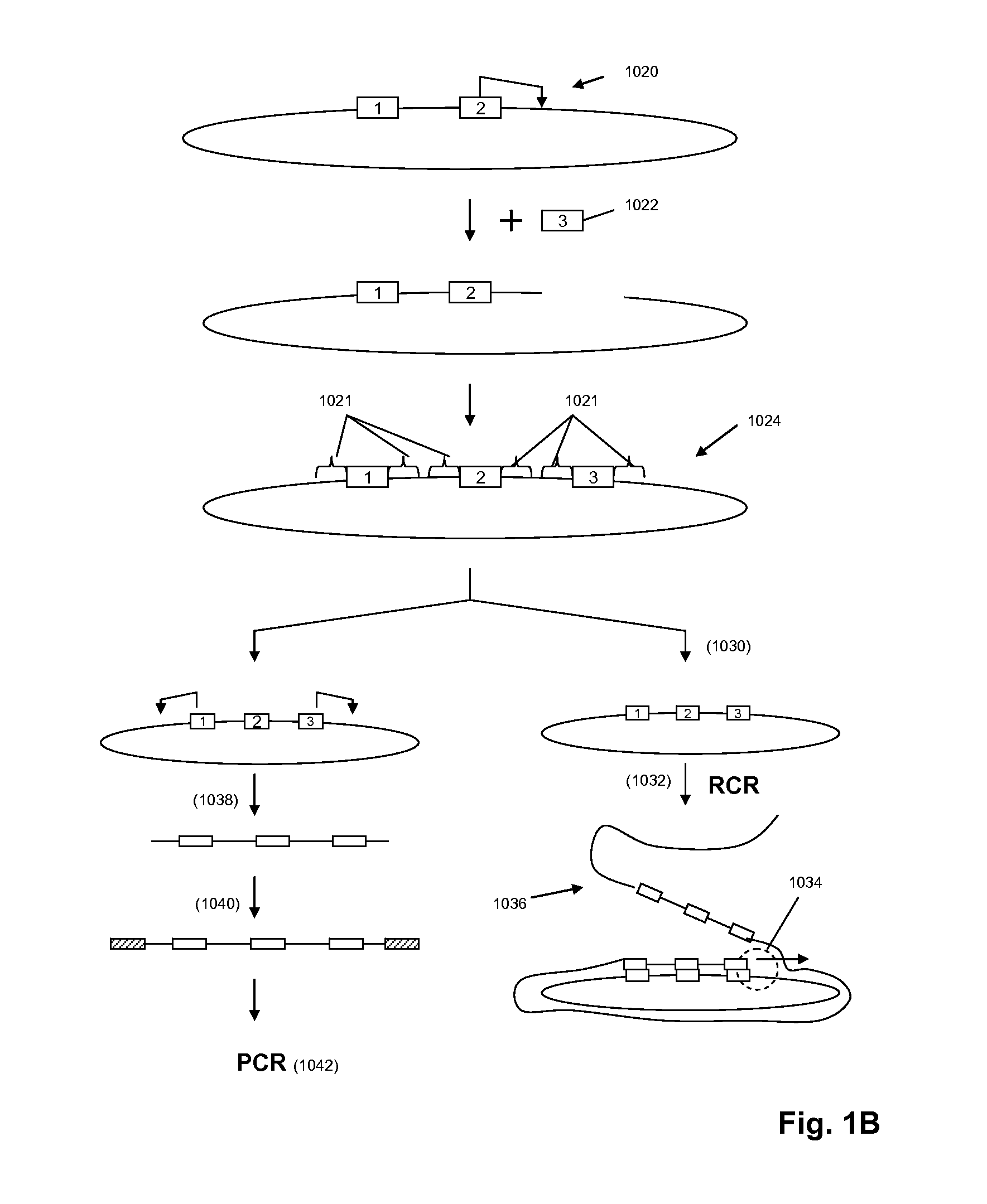

High throughput genome sequencing on DNA arrays

ActiveUS20090005252A1Simple processMicrobiological testing/measurementLibrary member identificationRe sequencingNucleotide

The present invention is directed to methods and compositions for acquiring nucleotide sequence information of target sequences using adaptors interspersed in target polynucleotides. The sequence information can be new, e.g. sequencing unknown nucleic acids, re-sequencing, or genotyping. The invention preferably includes methods for inserting a plurality of adaptors at spaced locations within a target polynucleotide or a fragment of a polynucleotide. Such adaptors may serve as platforms for interrogating adjacent sequences using various sequencing chemistries, such as those that identify nucleotides by primer extension, probe ligation, and the like. Encompassed in the invention are methods and compositions for the insertion of known adaptor sequences into target sequences, such that there is an interruption of contiguous target sequence with the adaptors. By sequencing both “upstream” and “downstream” of the adaptors, identification of entire target sequences may be accomplished.

Owner:COMPLETE GENOMICS INC

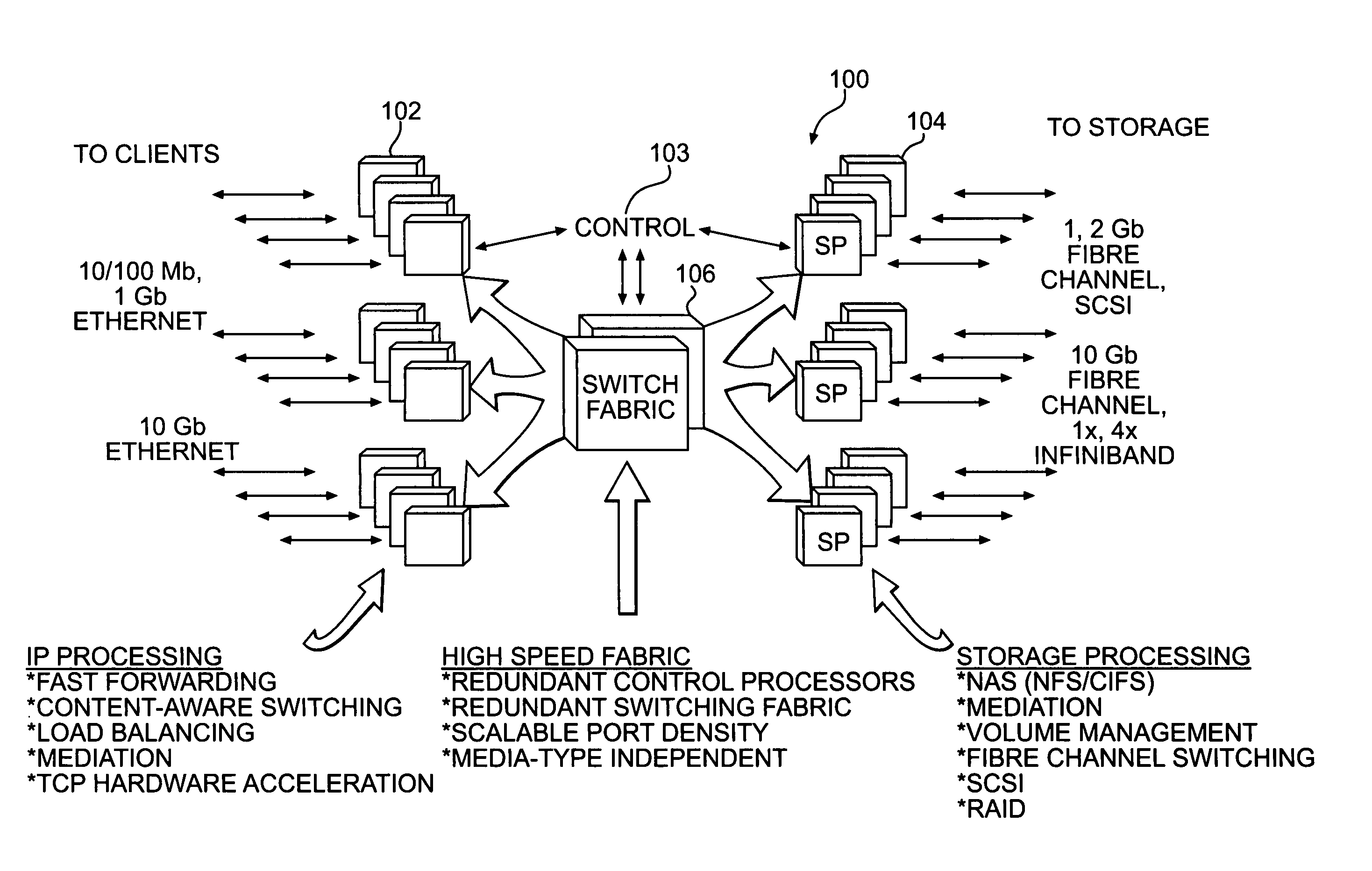

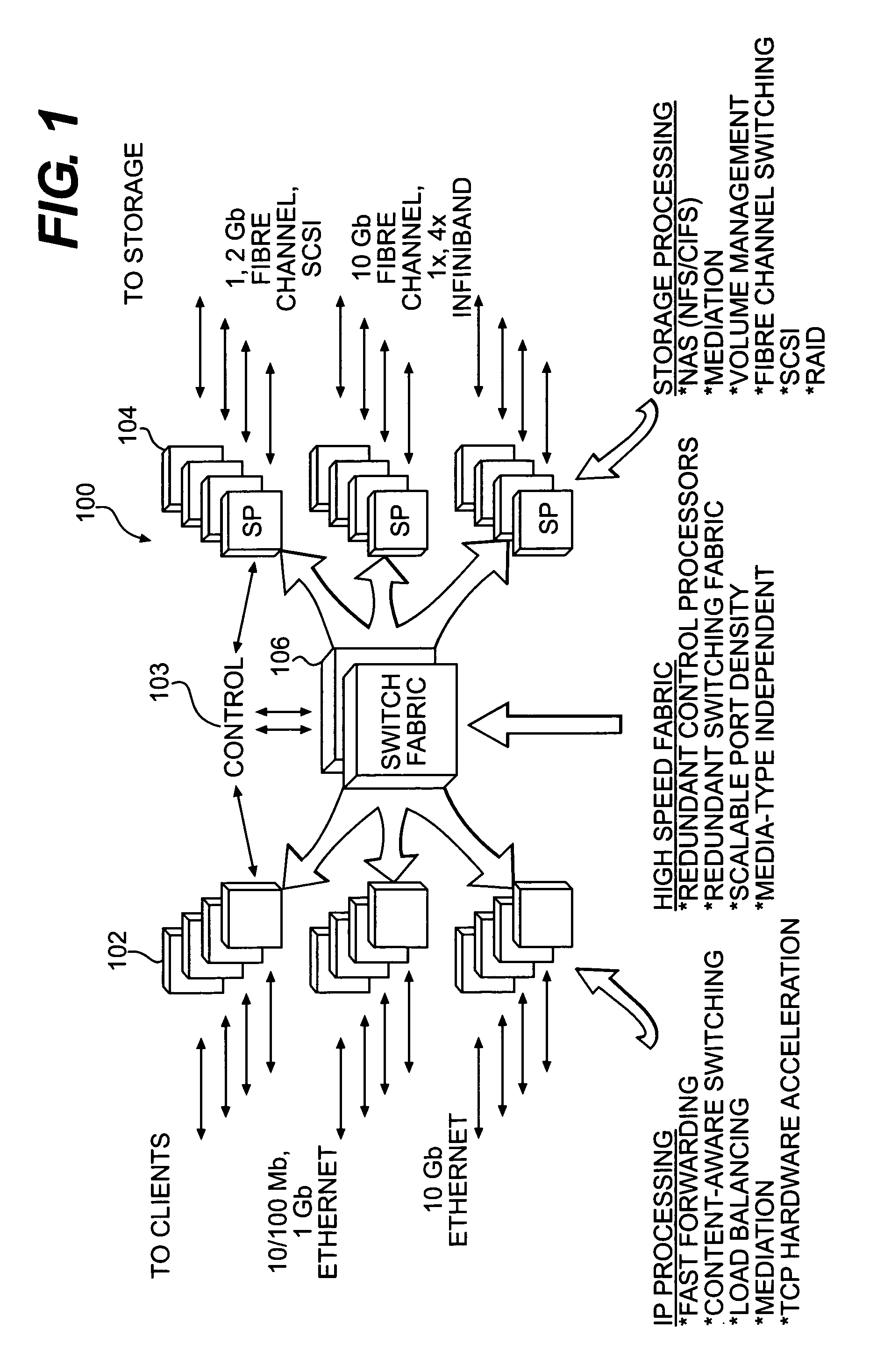

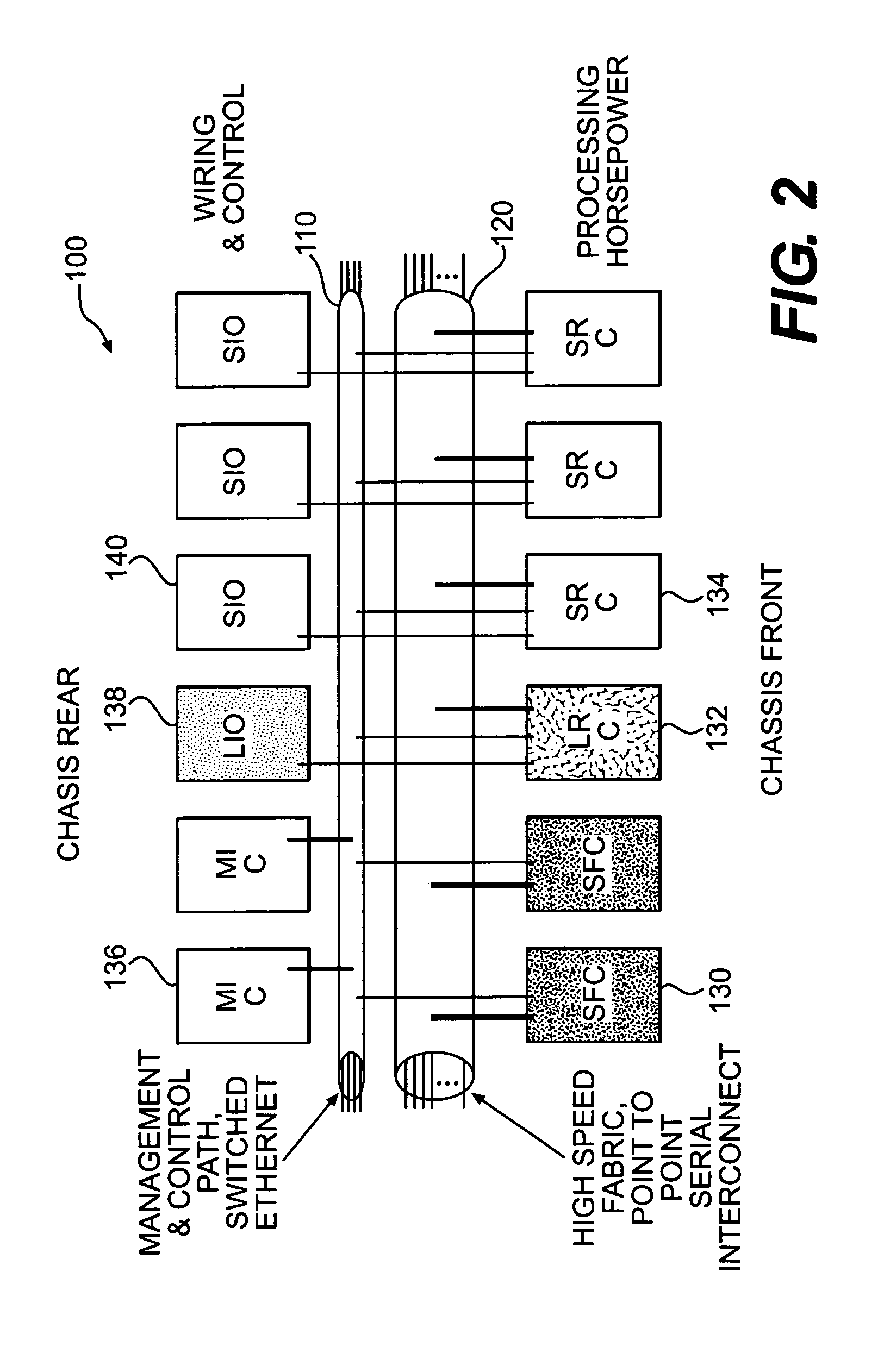

Switching system method for discovering and accessing SCSI devices in response to query

InactiveUS7089293B2Simple processRobust systemSpecial service provision for substationMultiplex system selection arrangementsStorage managementComputer engineering

Owner:ORACLE INT CORP

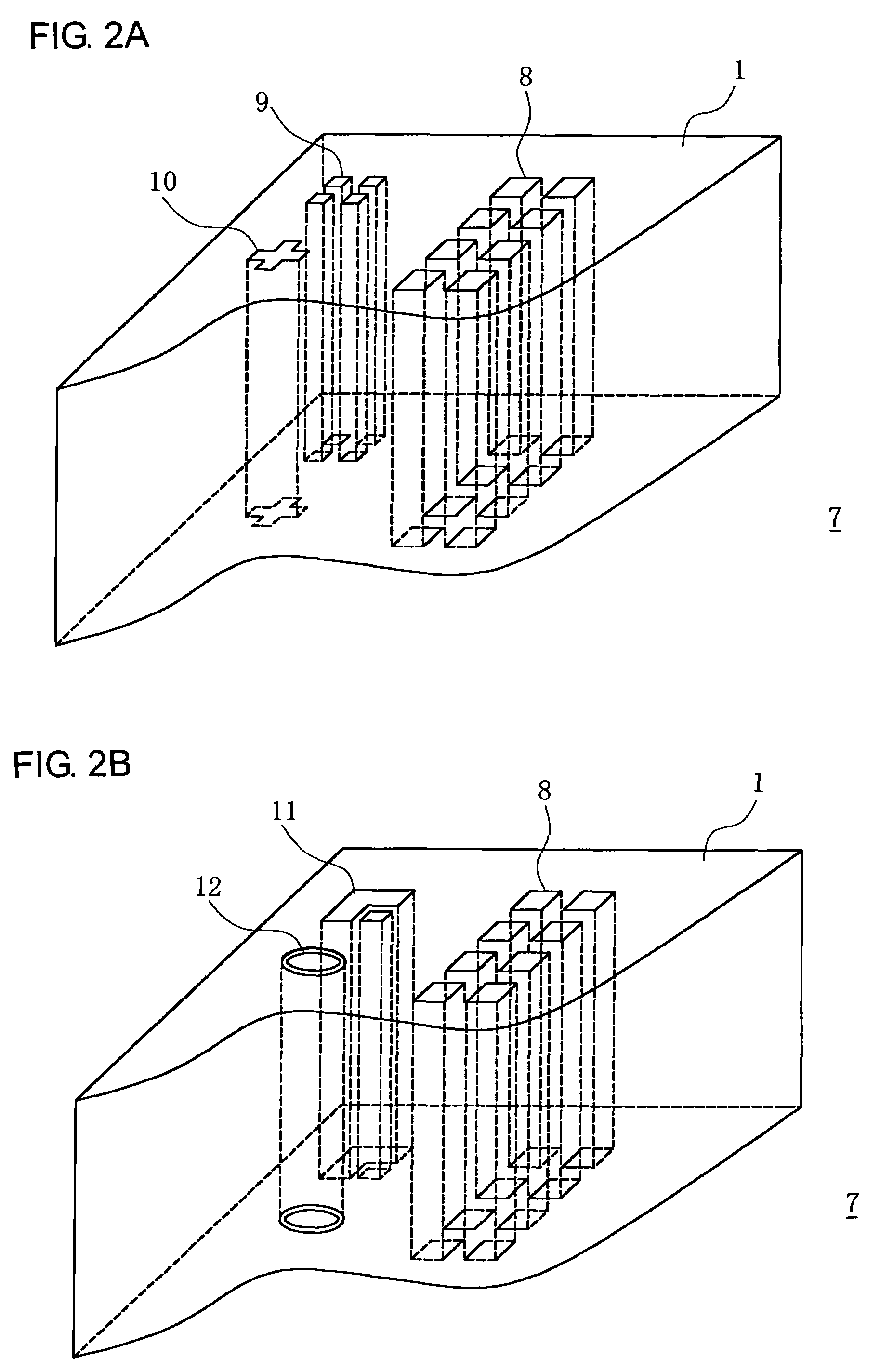

Method of forming fin field effect transistor

ActiveUS20050153490A1Prevent and substantially reduce leakage currentElectrode can be separatedTransistorSolid-state devicesInsulation layerDrain current

According to some embodiments, a fin type active region is formed under an exposure state of sidewalls on a semiconductor substrate. A gate insulation layer is formed on an upper part of the active region and on the sidewalls, and a device isolation film surrounds the active region to an upper height of the active region. The sidewalls are partially exposed by an opening part formed on the device isolation film. The opening part is filled with a conductive layer that partially covers the upper part of the active region, forming a gate electrode. Source and drain regions are on a portion of the active region where the gate electrode is not. The gate electrode may be easily separated and problems causable by etch by-product can be substantially reduced, and a leakage current of channel region and an electric field concentration onto an edge portion can be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

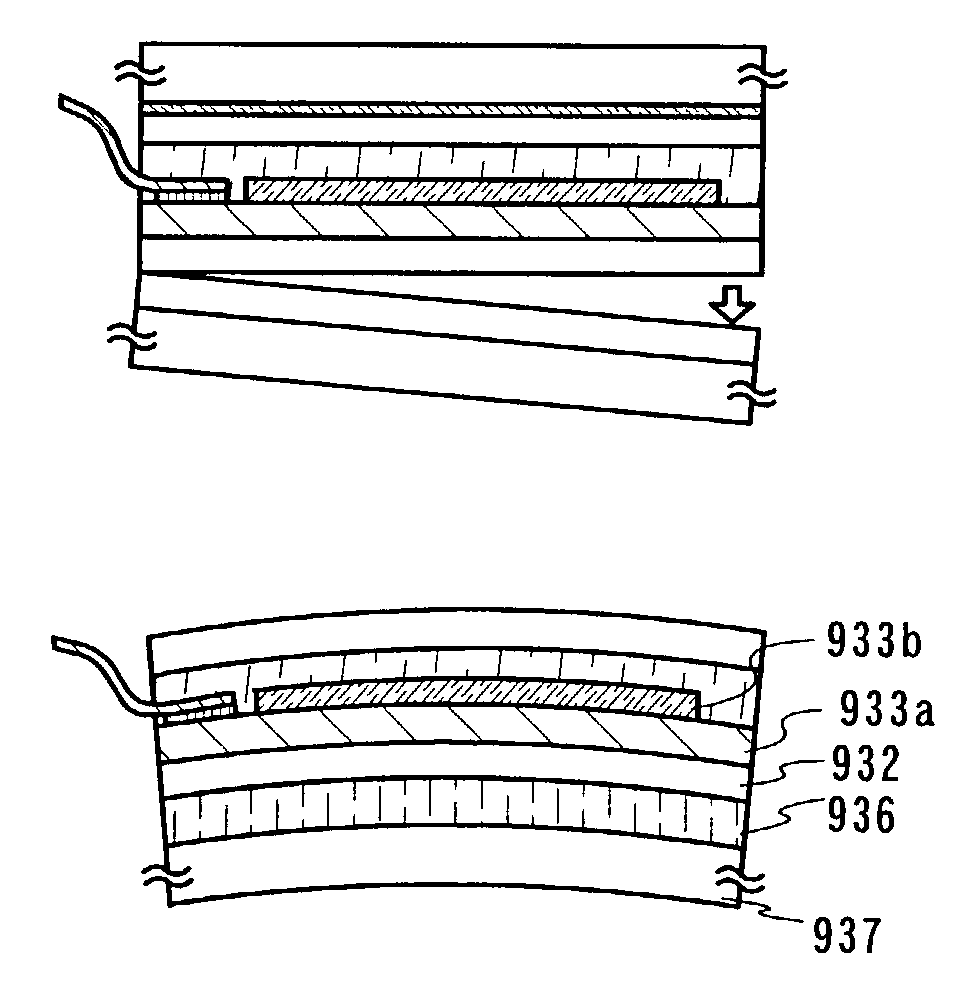

Vehicle, display device and manufacturing method for a semiconductor device

InactiveUS7335573B2Simple processBroad visionFinal product manufactureSemiconductor/solid-state device detailsDisplay deviceLight emitting device

To provide a semiconductor device in which a layer to be peeled is attached to a base having a curved surface, and a method of manufacturing the same, and more particularly, a display having a curved surface, and more specifically a light-emitting device having a light emitting element attached to a base with a curved surface. A layer to be peeled, which contains a light emitting element furnished to a substrate using a laminate of a first material layer which is a metallic layer or nitride layer, and a second material layer which is an oxide layer, is transferred onto a film, and then the film and the layer to be peeled are curved, to thereby produce a display having a curved surface.

Owner:SEMICON ENERGY LAB CO LTD

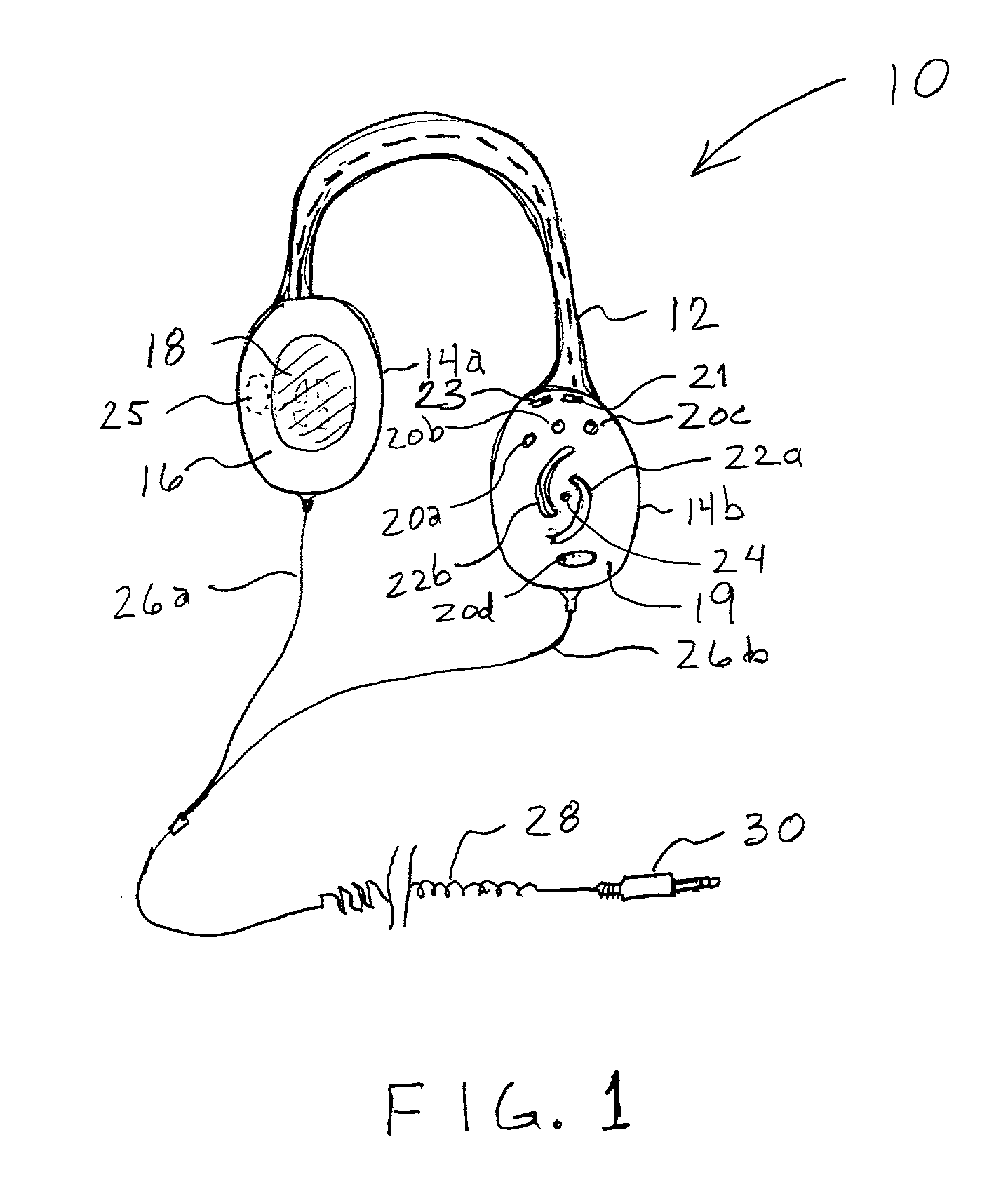

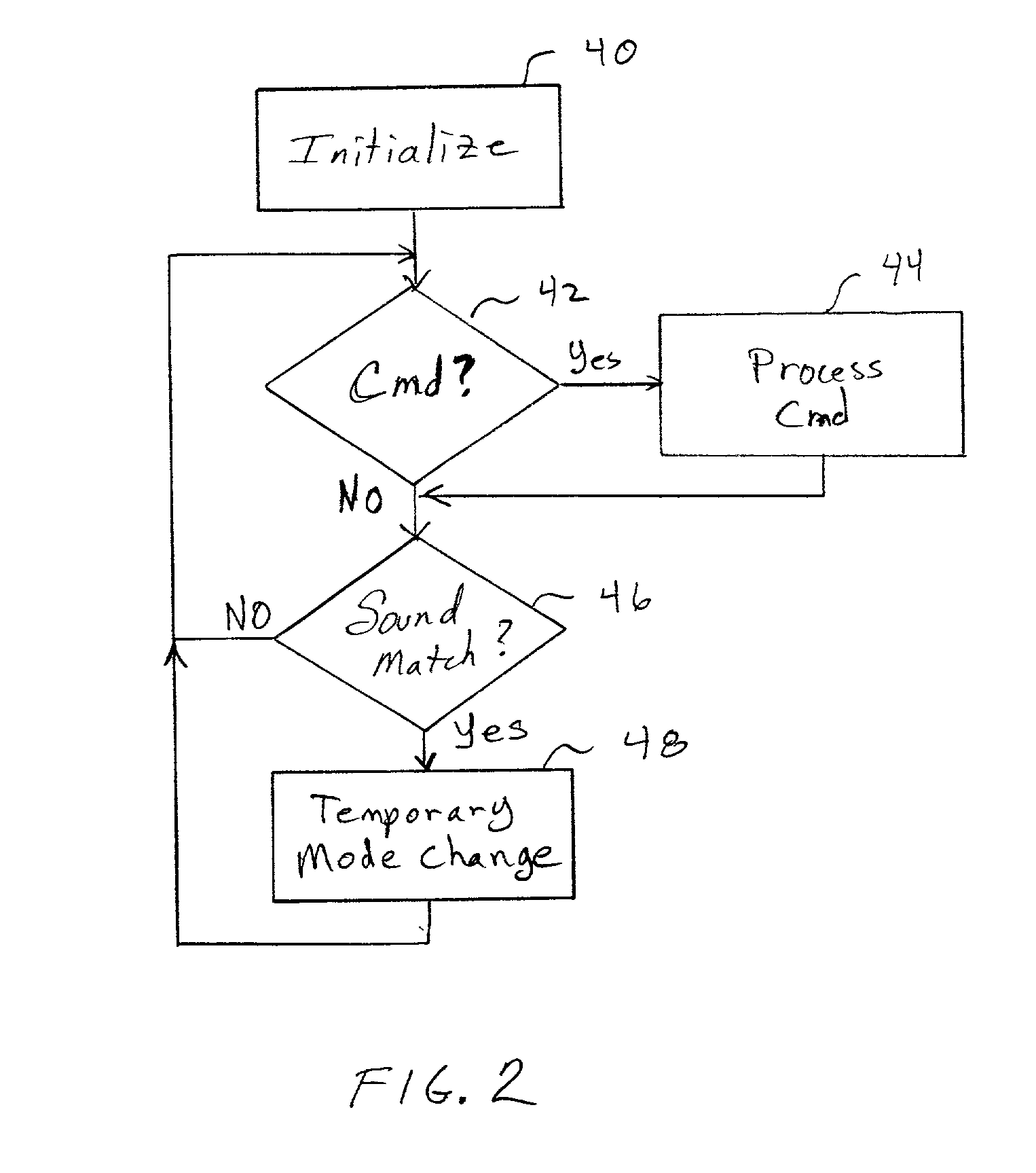

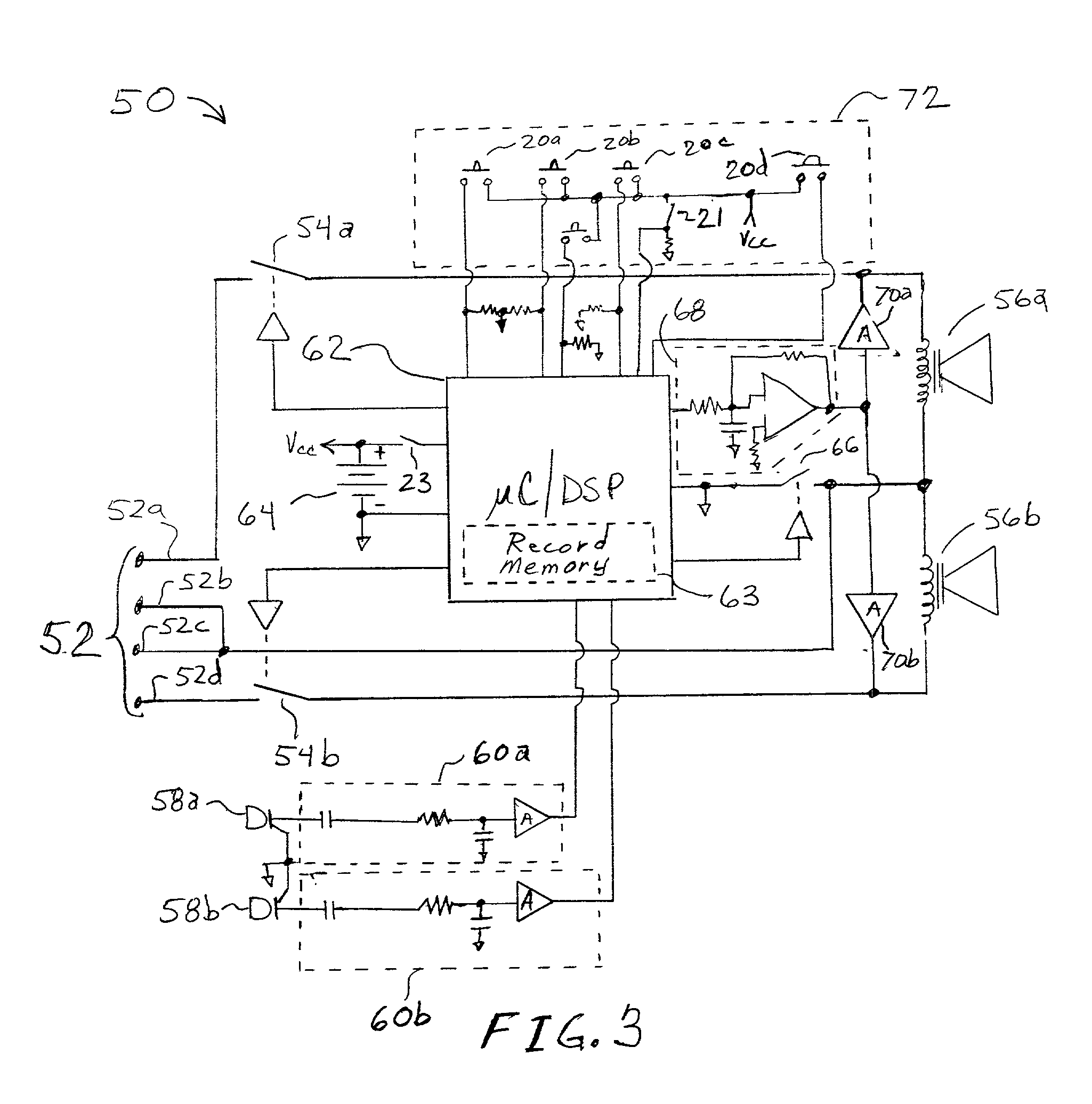

System and method for selective control of acoustic isolation in headsets

InactiveUS20010046304A1Improve abilitiesReduced isolationHeadphones for stereophonic communicationBroadcast circuit arrangementsMicrophoneEngineering

An apparatus and method for providing controlled acoustic isolation within various forms of headsets. The invention provides manual and automatic mechanisms for changing the amount of acoustic isolation provided by the headsets. Sounds in the environment that the user wishes to be made aware of can be programmed into a set of stored sound selection characteristics. In response to correlation of the stored sound characteristics with sounds in the external environment the headset decreases acoustic isolation by coupling signals from one or more external microphones to the audio conversion elements within the earpieces. Alternatively, the apparatus can respond to sounds to be blocked by increasing acoustic isolation. A manual control may be activated by the user to decrease acoustic isolation at their discretion.

Owner:RAST RODGER H

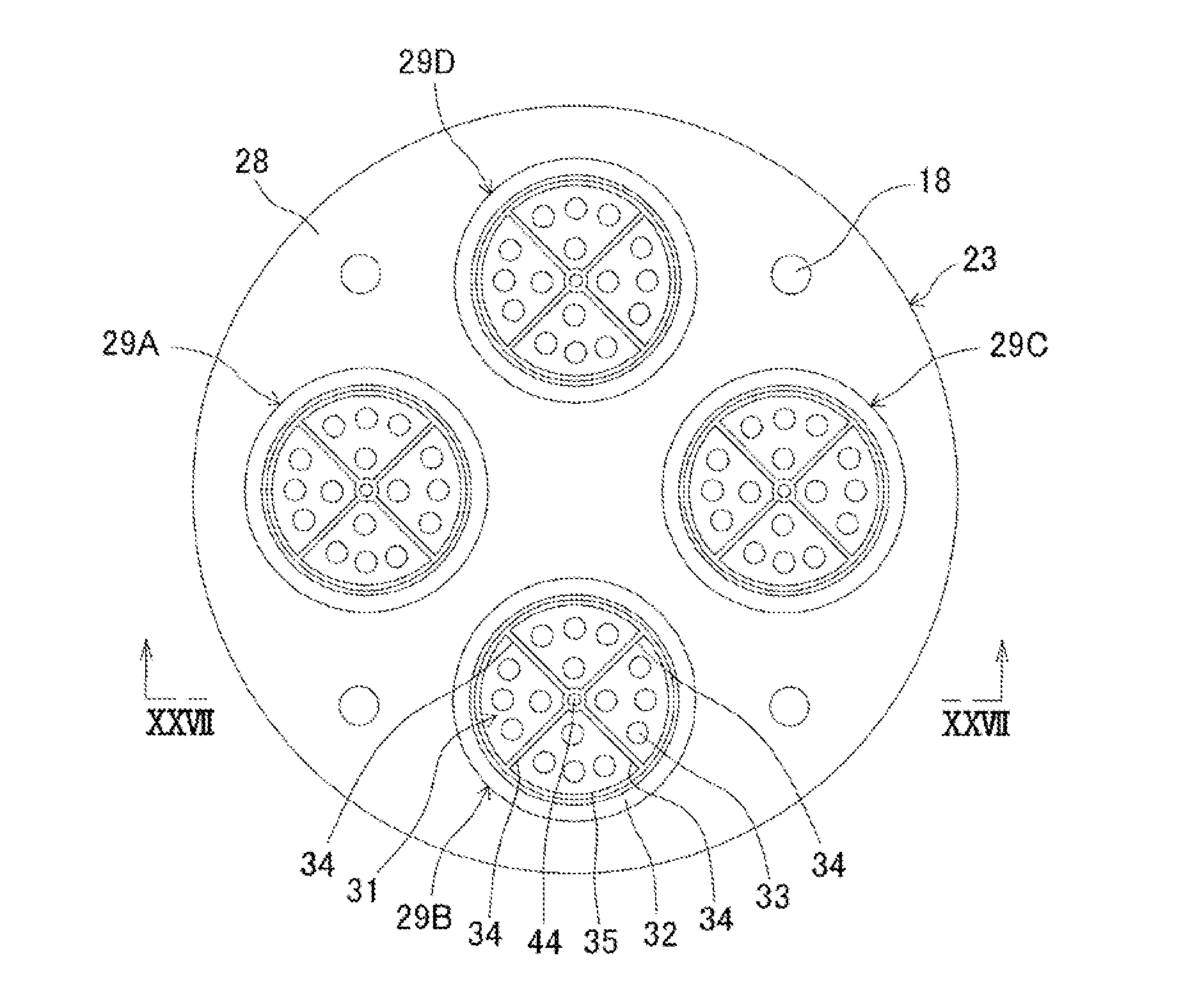

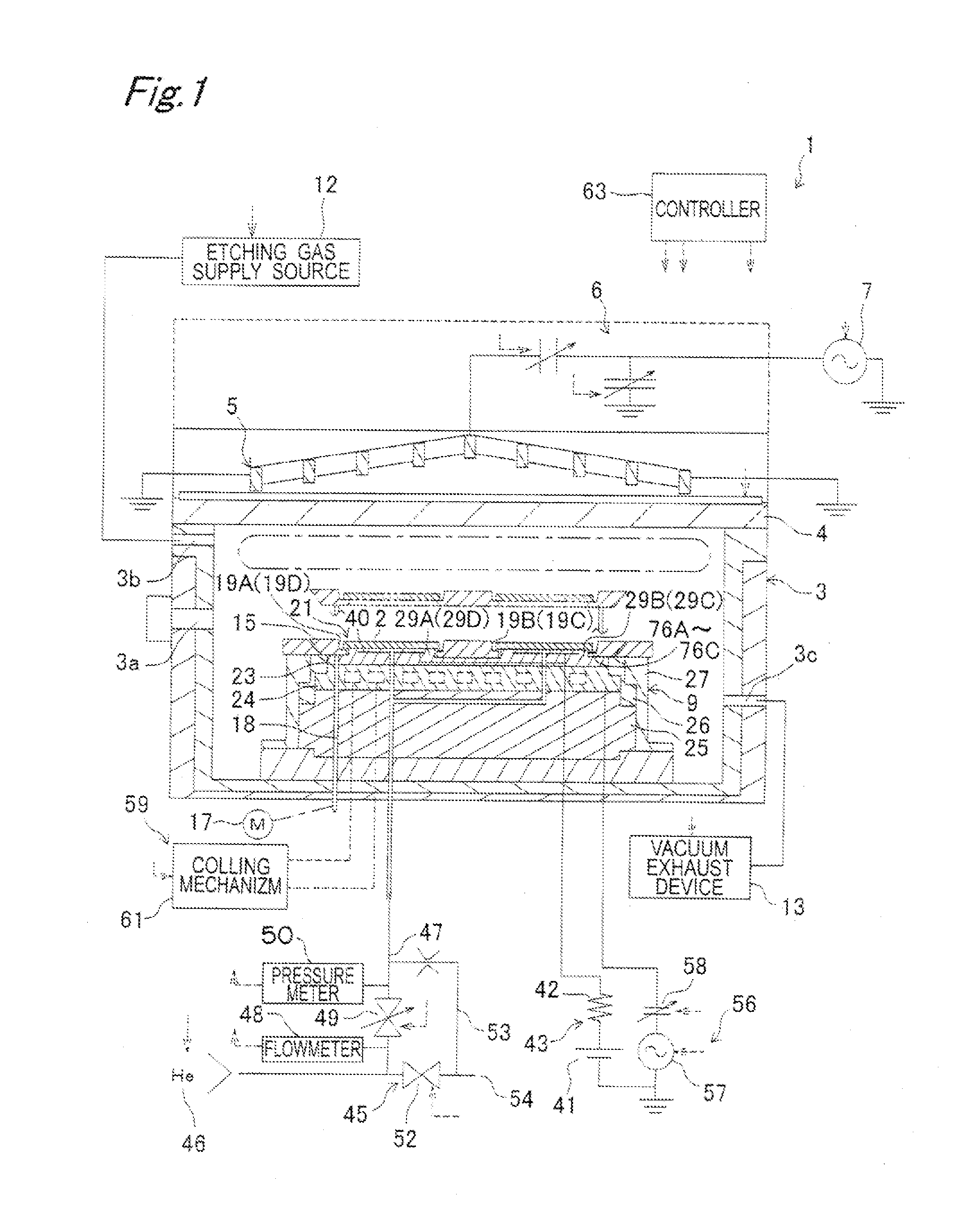

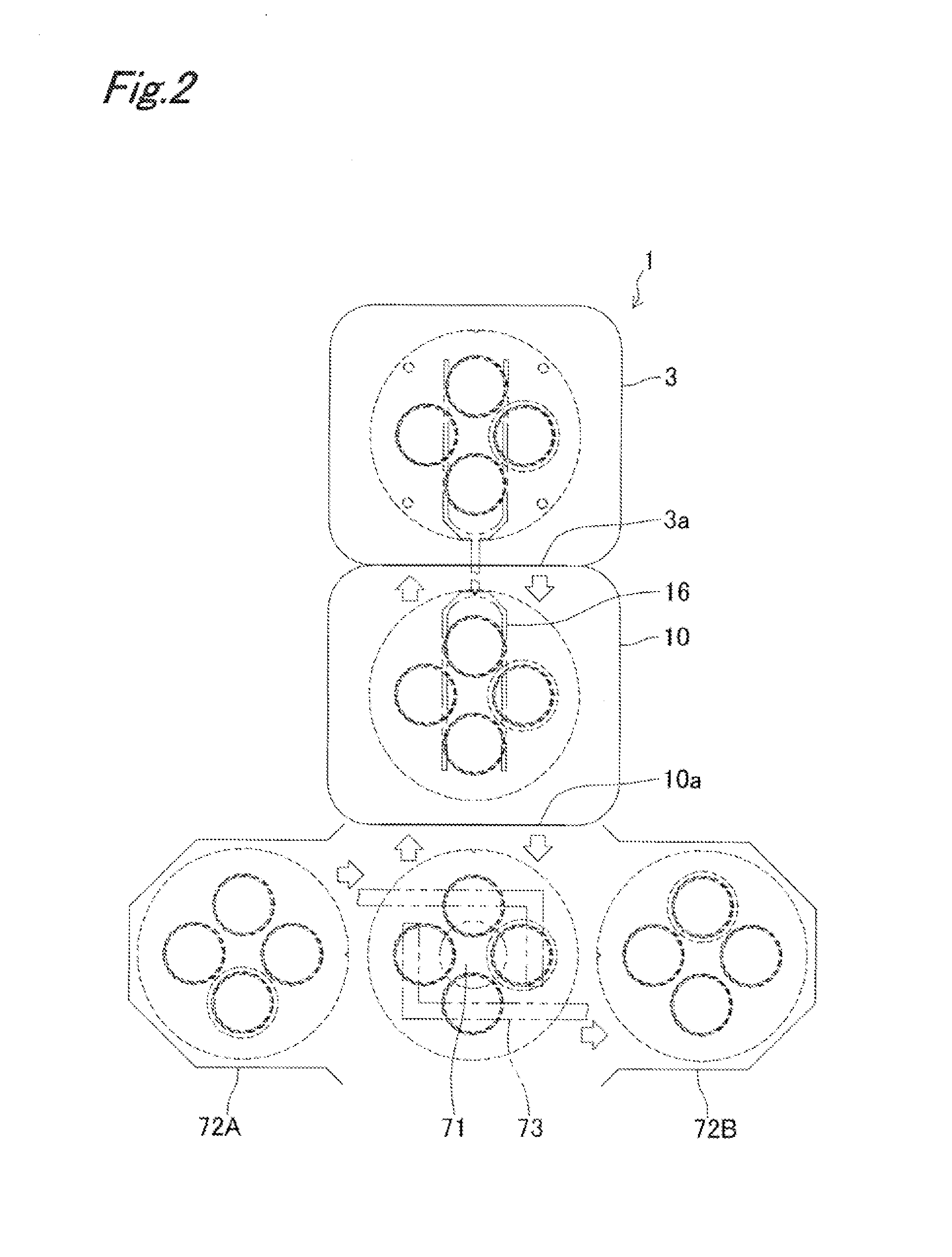

Plasma processing apparatus and plasma processing method

InactiveUS20120006489A1Heat suppressionIncrease of the substrate (Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric plateEngineering

Substrates are contained in substrate containing holes which penetrate a tray in the thickness direction. A dielectric plate in a chamber is provided with a tray supporting surface which supports the lower surface of the tray and substrate placing sections which protrude upward, and has an electrostatic chuck electrode therein. The substrate supporting section which supports the substrate contained in the substrate containing holes is provided with a plurality of protruding sections formed at intervals in the circumferential direction of the substrate containing holes. The substrates are supported in point-contact mode by means of the protruding sections.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Attapulgite argil powder with air purifying function

ActiveCN102173743BImprove adhesionImprove plasticityDispersed particle separationDeodrantsFiberHazardous substance

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

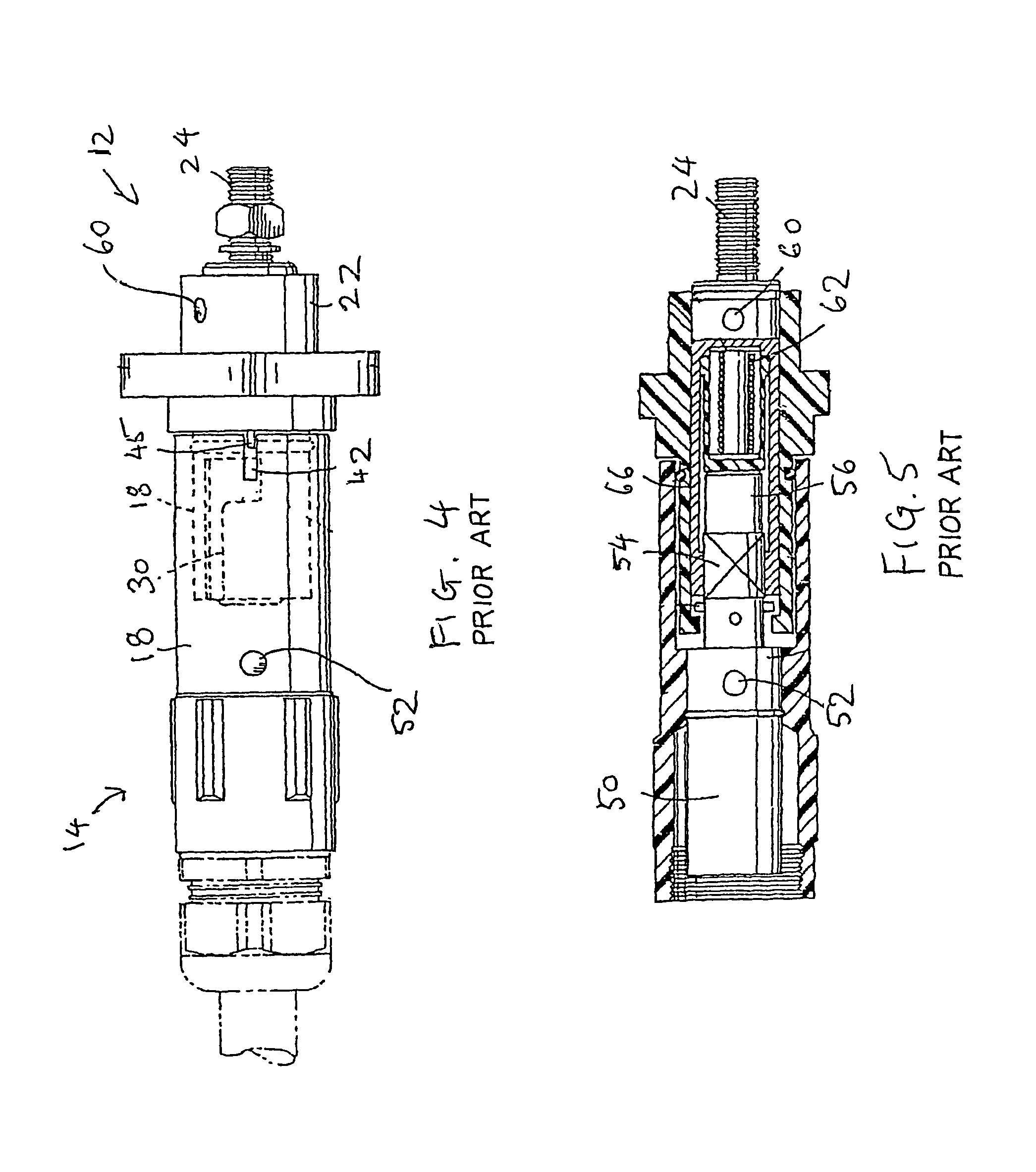

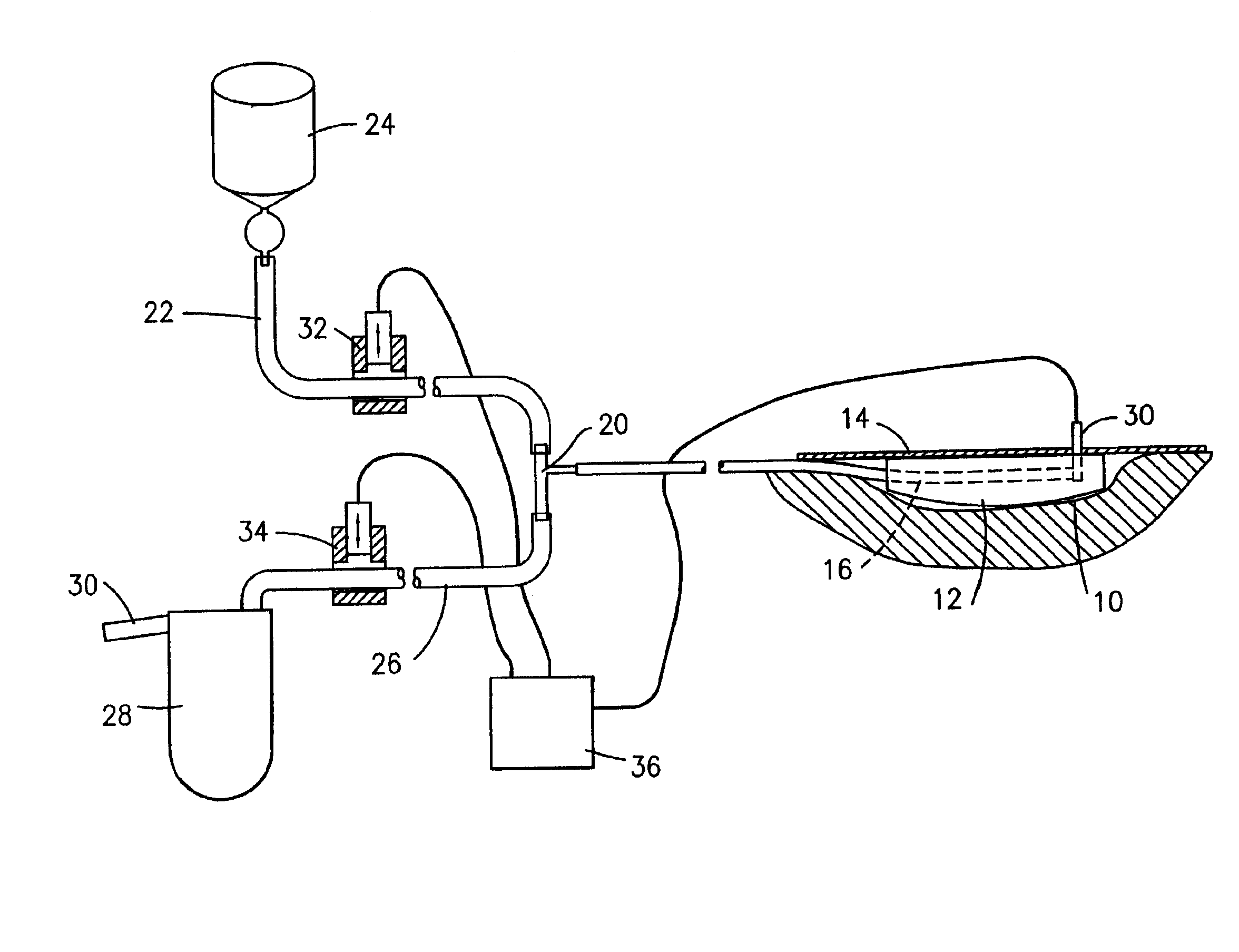

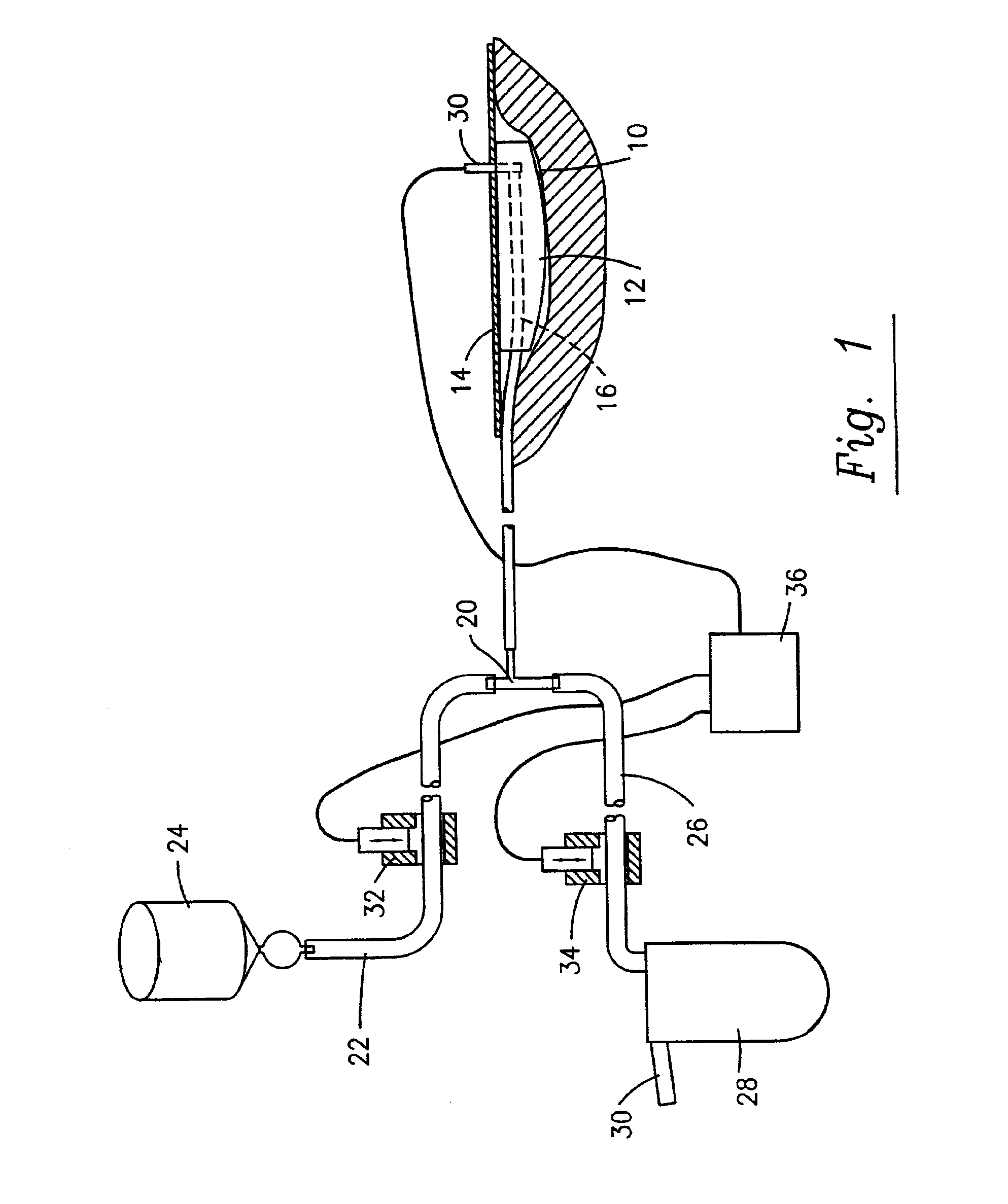

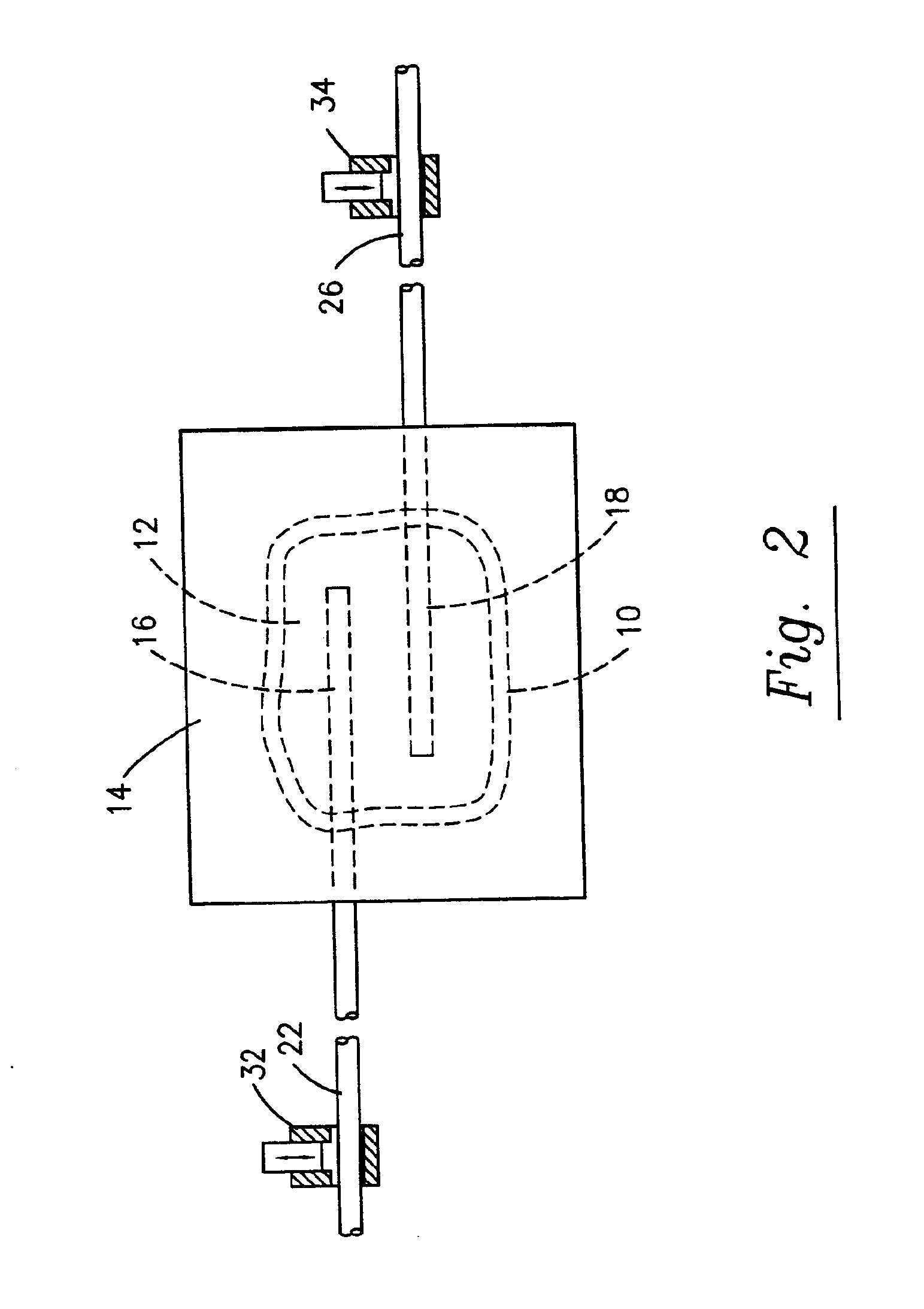

Process and device for application of active substances to a wound surface

InactiveUS7077832B2Enhances wound healing processHigh effectivenessWound drainsMedical devicesBiomedical engineeringWound surface

For application of active substances to a wound surface a porous padding (12) is provided upon the wound (10), which is sealingly covered over with a foil (14). A fluid active substance is introduced into the padding (12) via a supply line (22) and is then suctioned out of the padding (12) via a removal line (26). Closure mechanisms (32, 34) control the introduction of the active substance and the suctioning off of the active substance in the manner, that the active substance after being introduced remains for a predetermined dwell time in the padding (12), before it is suctioned off. After the suctioning off the vacuum in the padding (12) is maintained for a certain time period, before renewed introduction of the active substance. The opening of the closure mechanisms (32, 34) are temporally controlled to occur slowly.

Owner:KCI MEDICAL RESOURCES

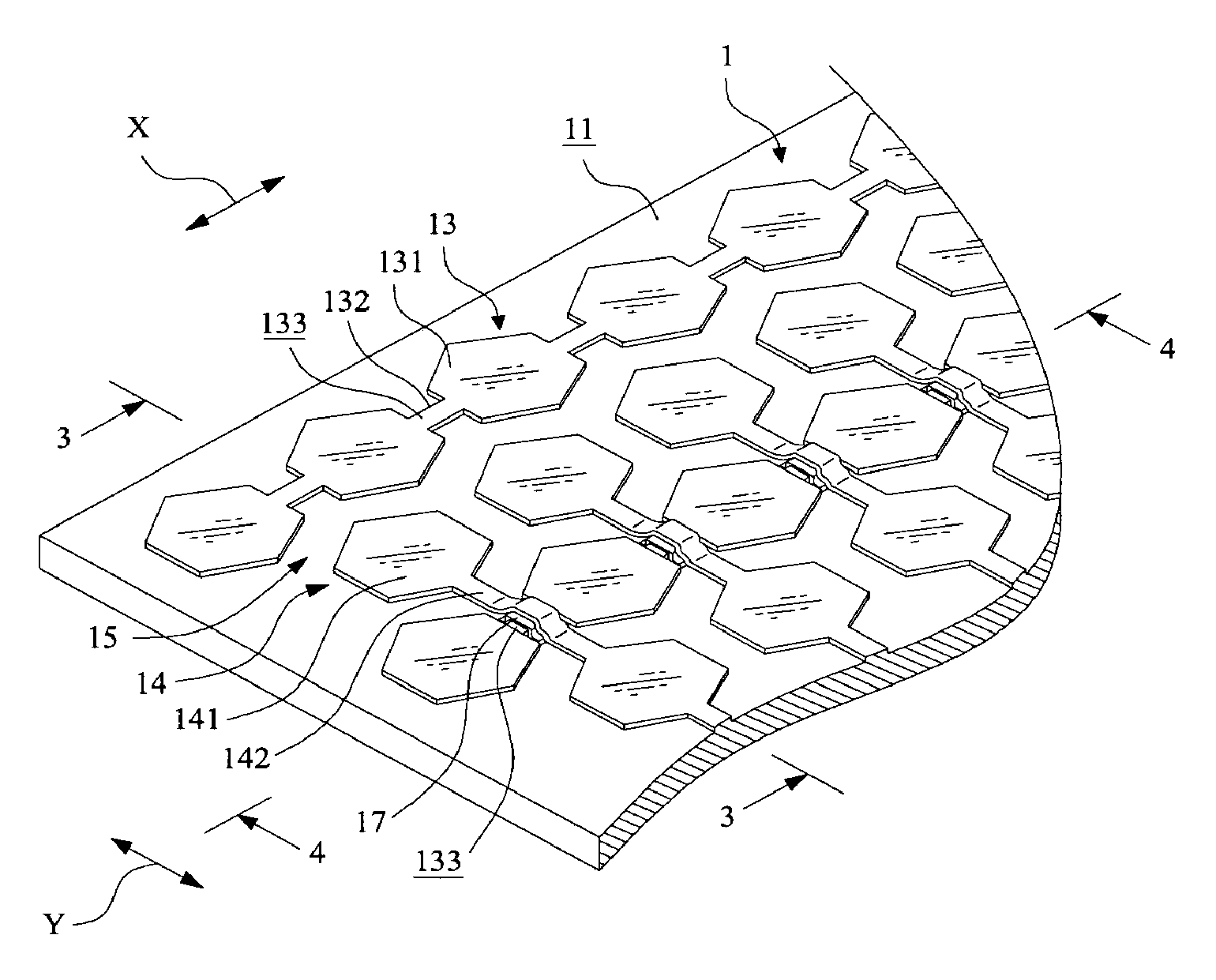

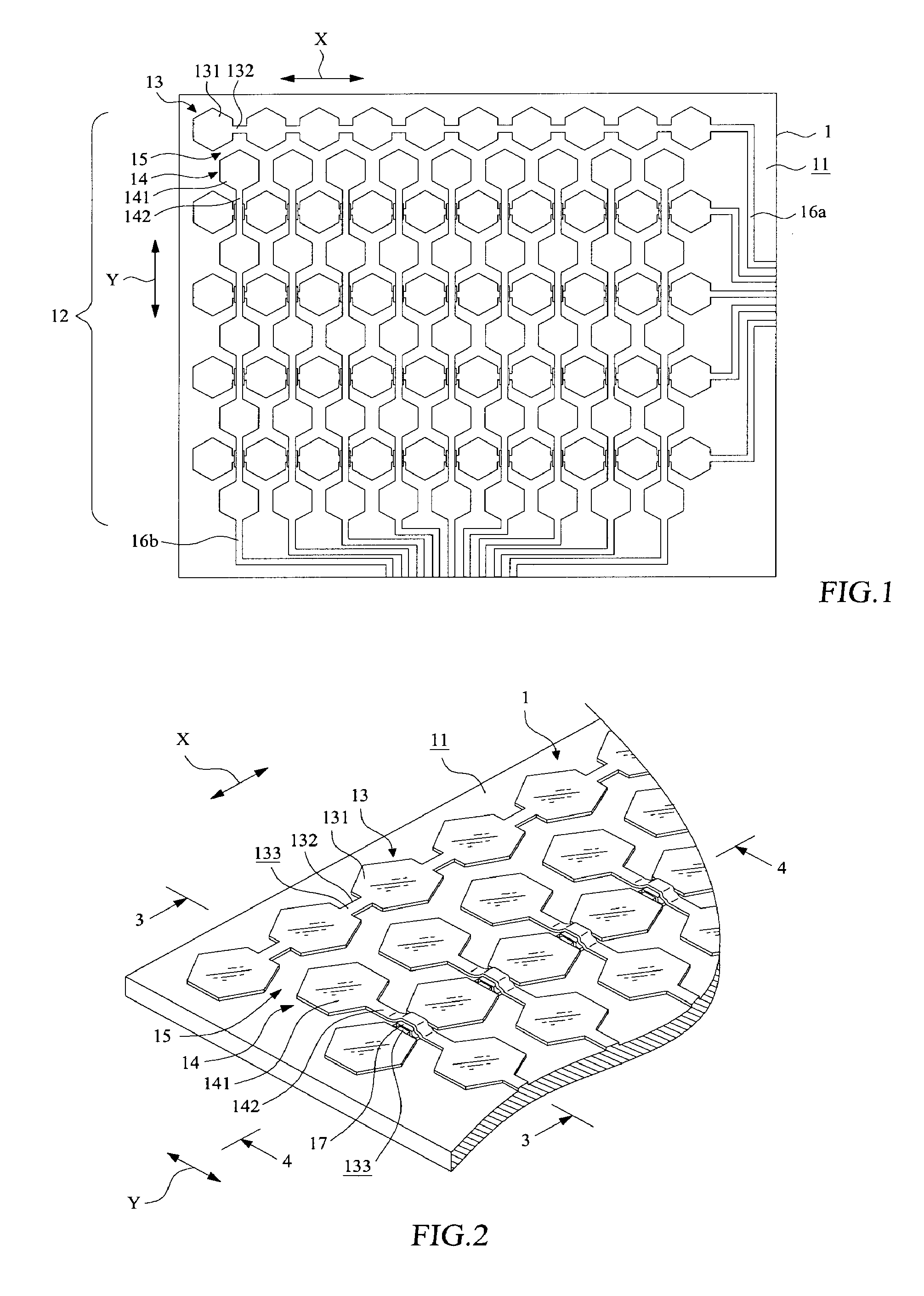

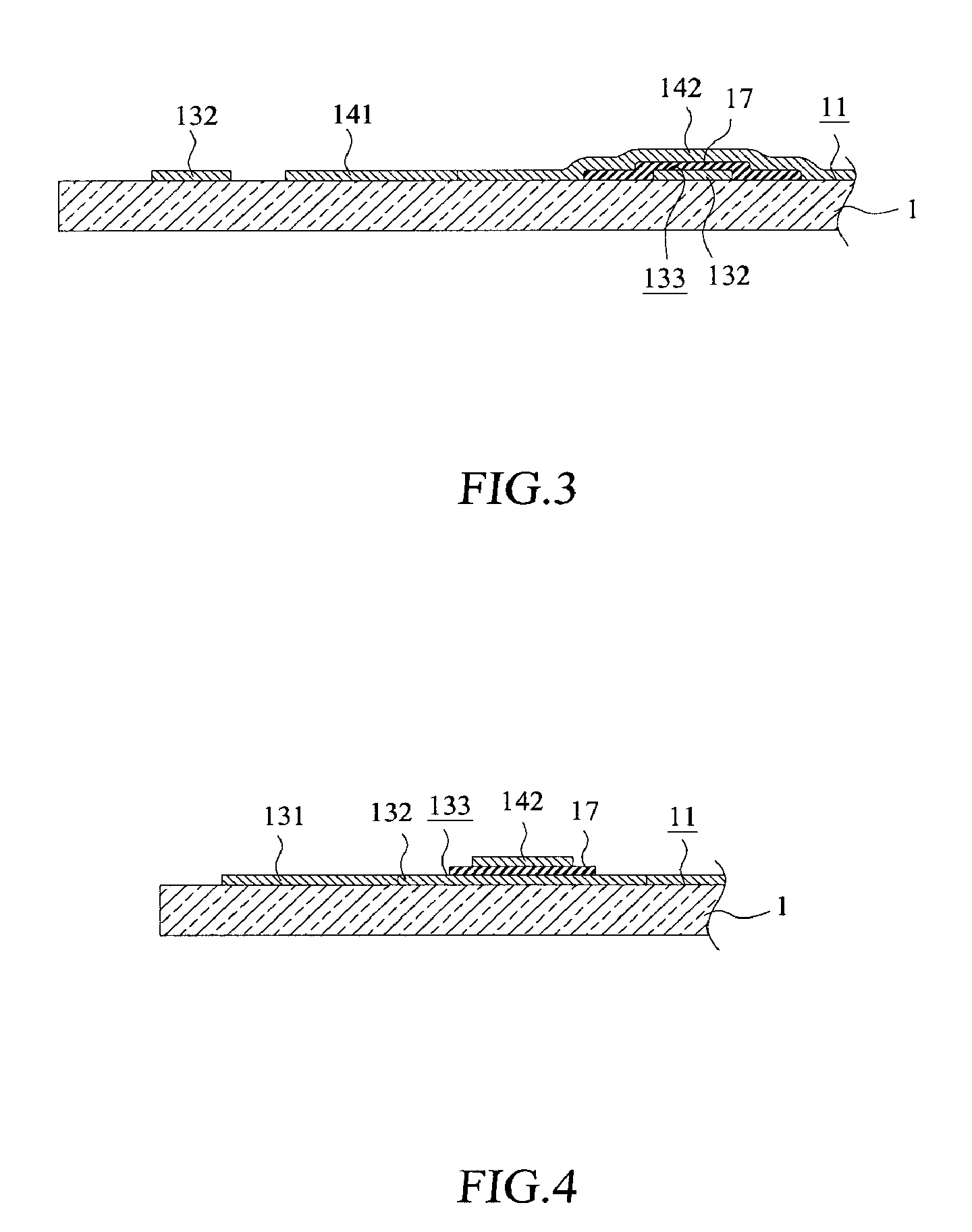

Conductor pattern structure of capacitive touch panel

ActiveUS20080264699A1Simple structureReduce the thickness of the structureTransmission systemsResistance/reactance/impedenceElectrical conductorEngineering

Disclosed is a conductor pattern structure of a capacitive touch panel. First-axis conductor assemblies and second-axis conductor assemblies are formed on a surface of a substrate. Each first-axis conductor assembly includes a plurality of first-axis conductor cells that are interconnected by first-axis conduction lines. An insulation layer is formed on a surface of each first-axis conduction line. Each second-axis conductor assembly includes a plurality of second-axis conductor cells that are interconnected by second-axis conduction lines. Each second-axis conduction line extends across the insulation layer of the associated first-axis conduction line.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

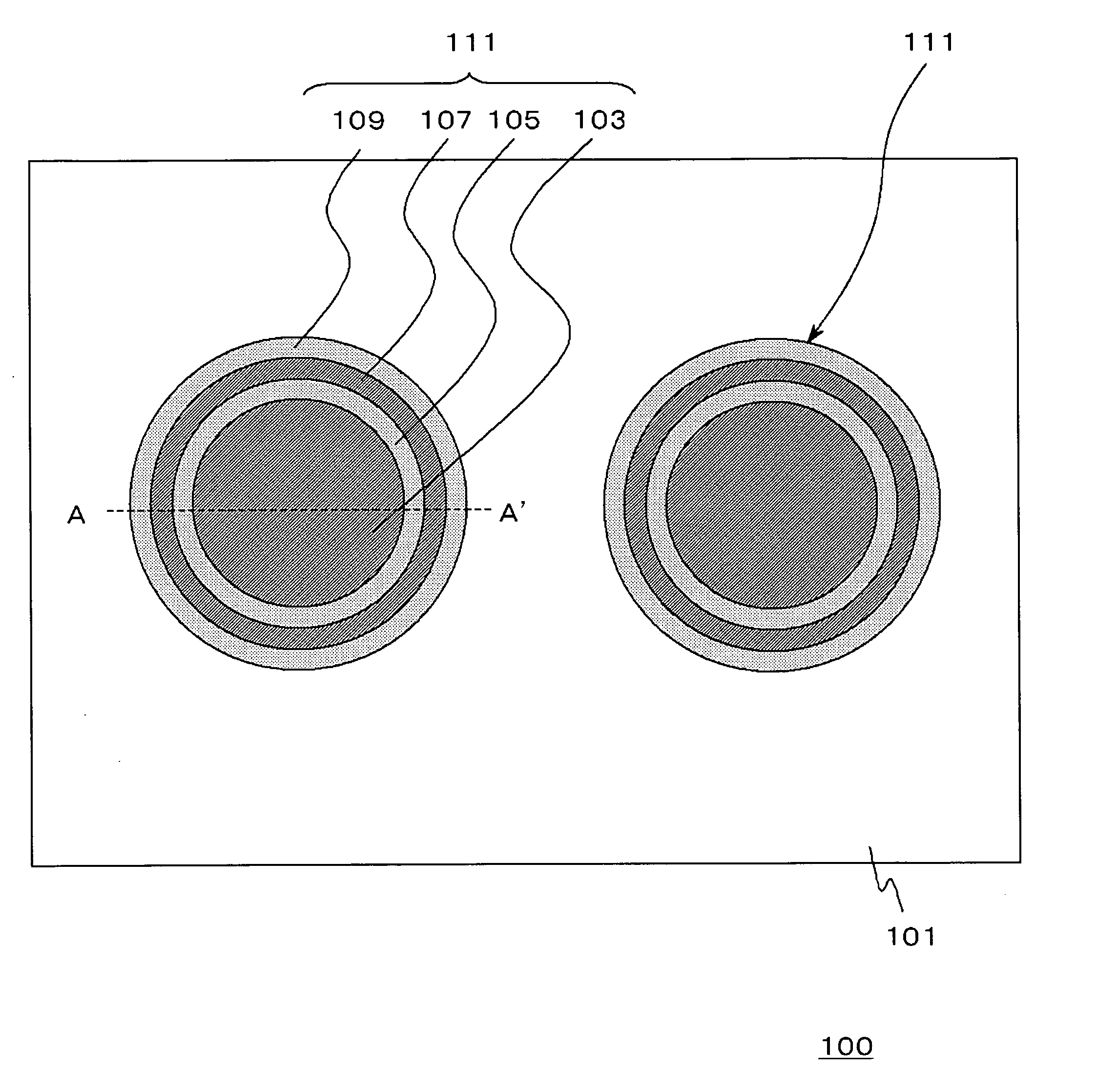

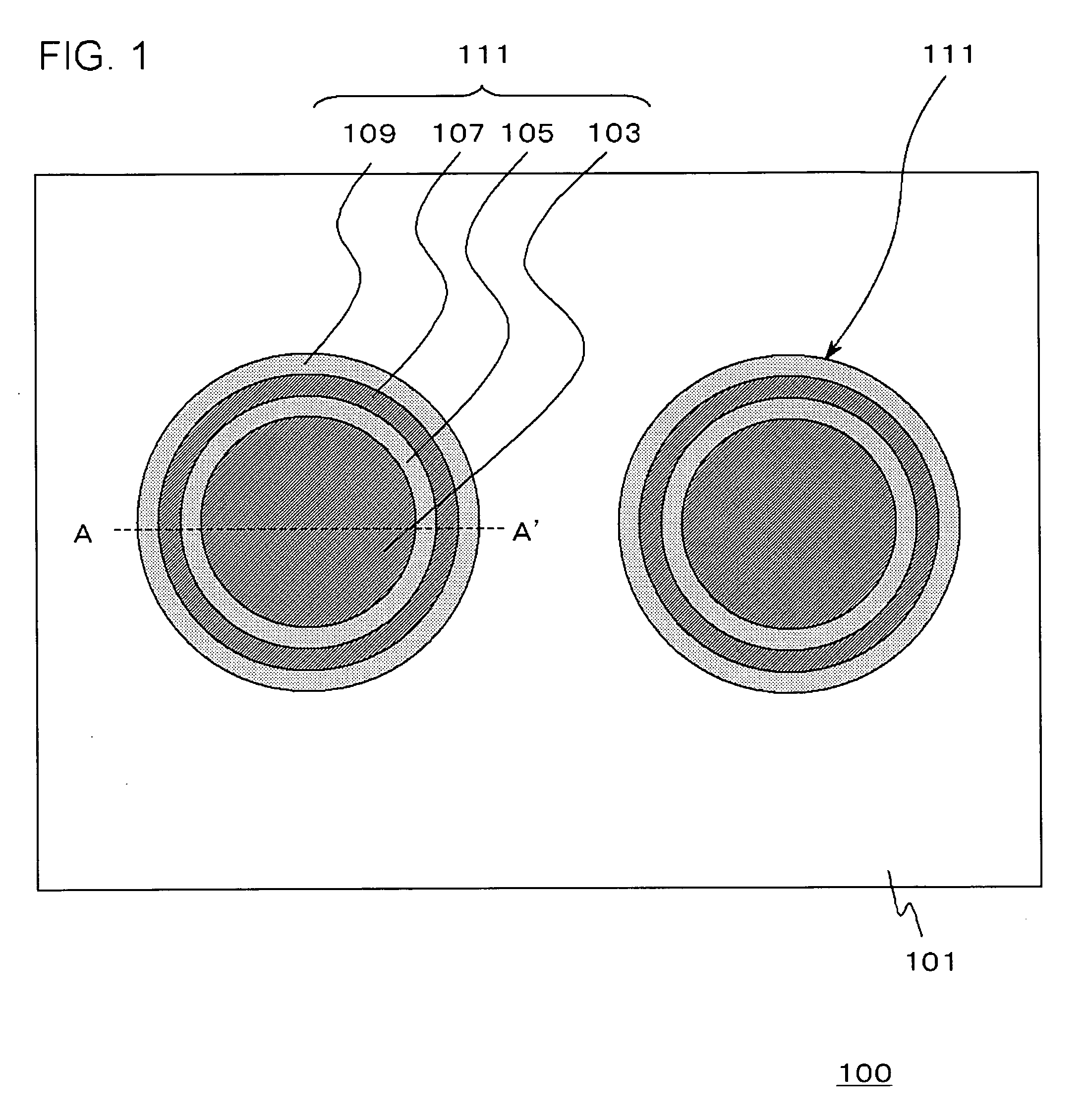

Chip and multi-chip semiconductor device using thereof and method for manufacturing same

InactiveUS7122912B2Improve alignment accuracyReduce the overall diameterSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:RENESAS ELECTRONICS CORP

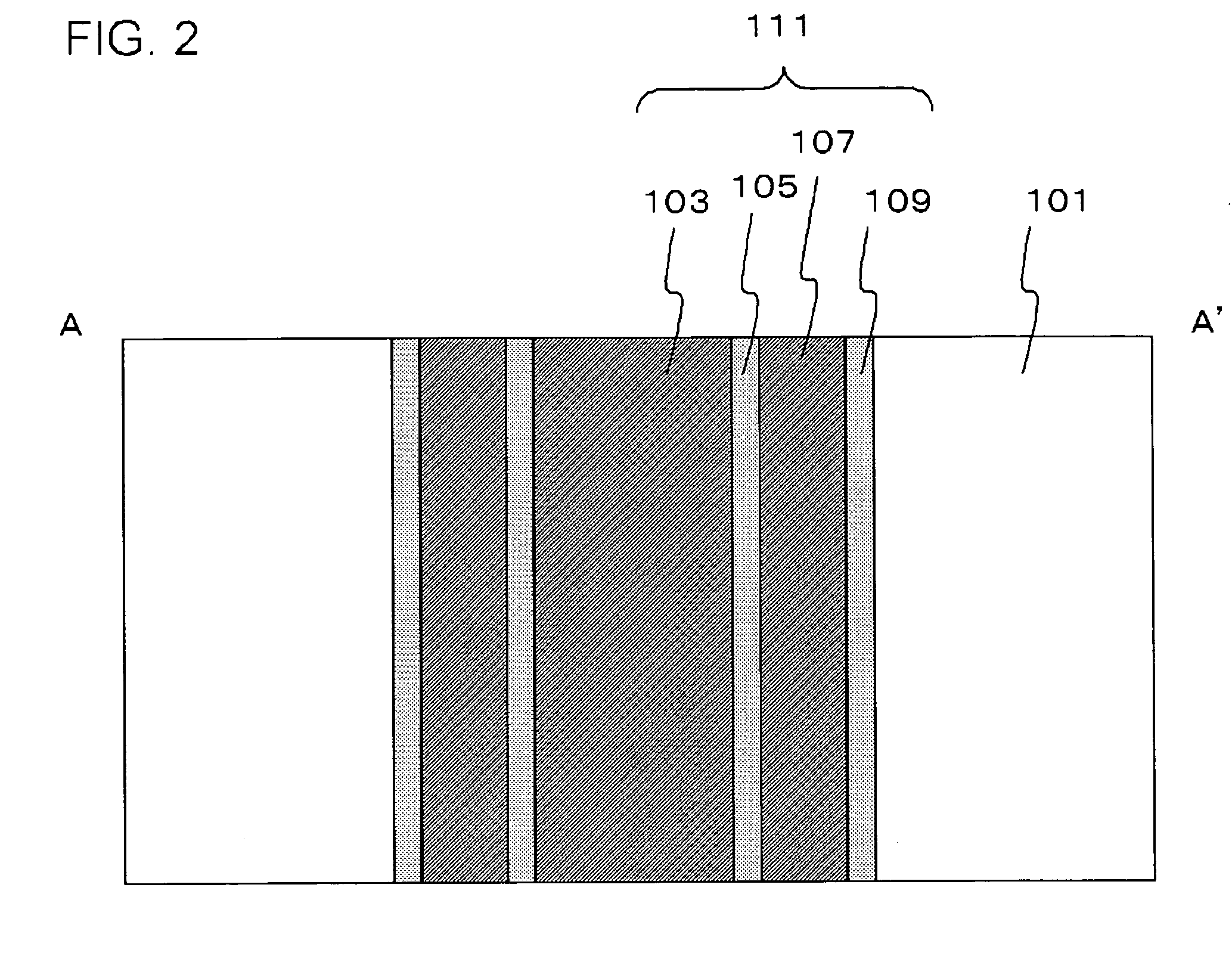

Semiconductor device and method for manufacturing the same

ActiveUS20060001174A1Stable productionSimple processSemiconductor/solid-state device detailsSolid-state devicesSecondary layerEngineering

A semiconductor device 100 is provided with a multiplex through plug 111 that fills an opening extending through the silicon substrate 101. The multiplex through plugs 111 comprises a column-shaped and solid first through electrode 103, a first insulating film 105 that covers the cylindrical face of the first through electrode 103, a second through electrode 107 that covers the cylindrical face of the first insulating film 105 and a second insulating film 109 that covers the cylindrical face of the second through electrode 107, and these have a common central axis. The upper cross sections of the first insulating film 105, the second through electrode 107 and the second insulating film 109 are annular-shaped.

Owner:TESSERA ADVANCED TECH

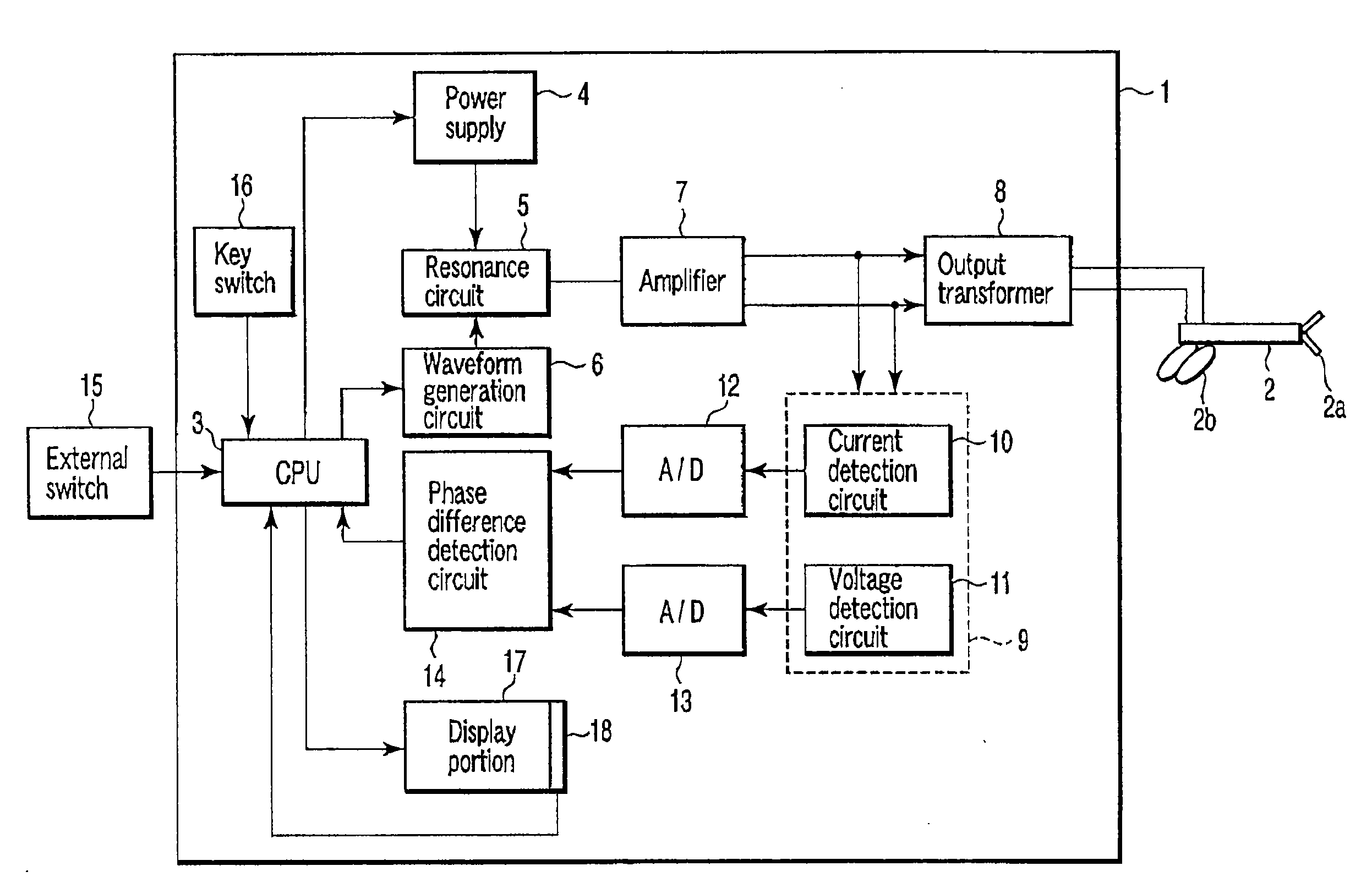

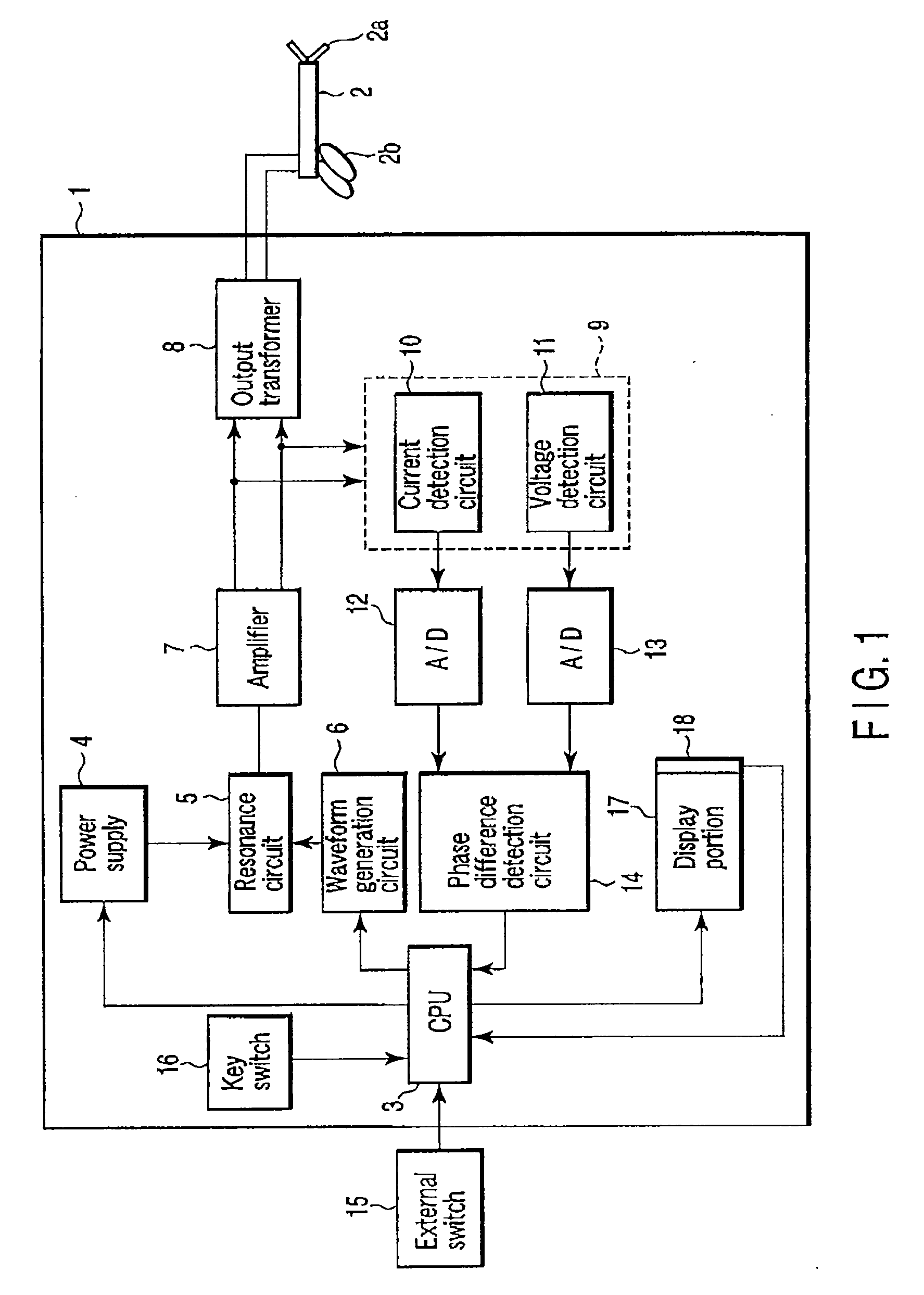

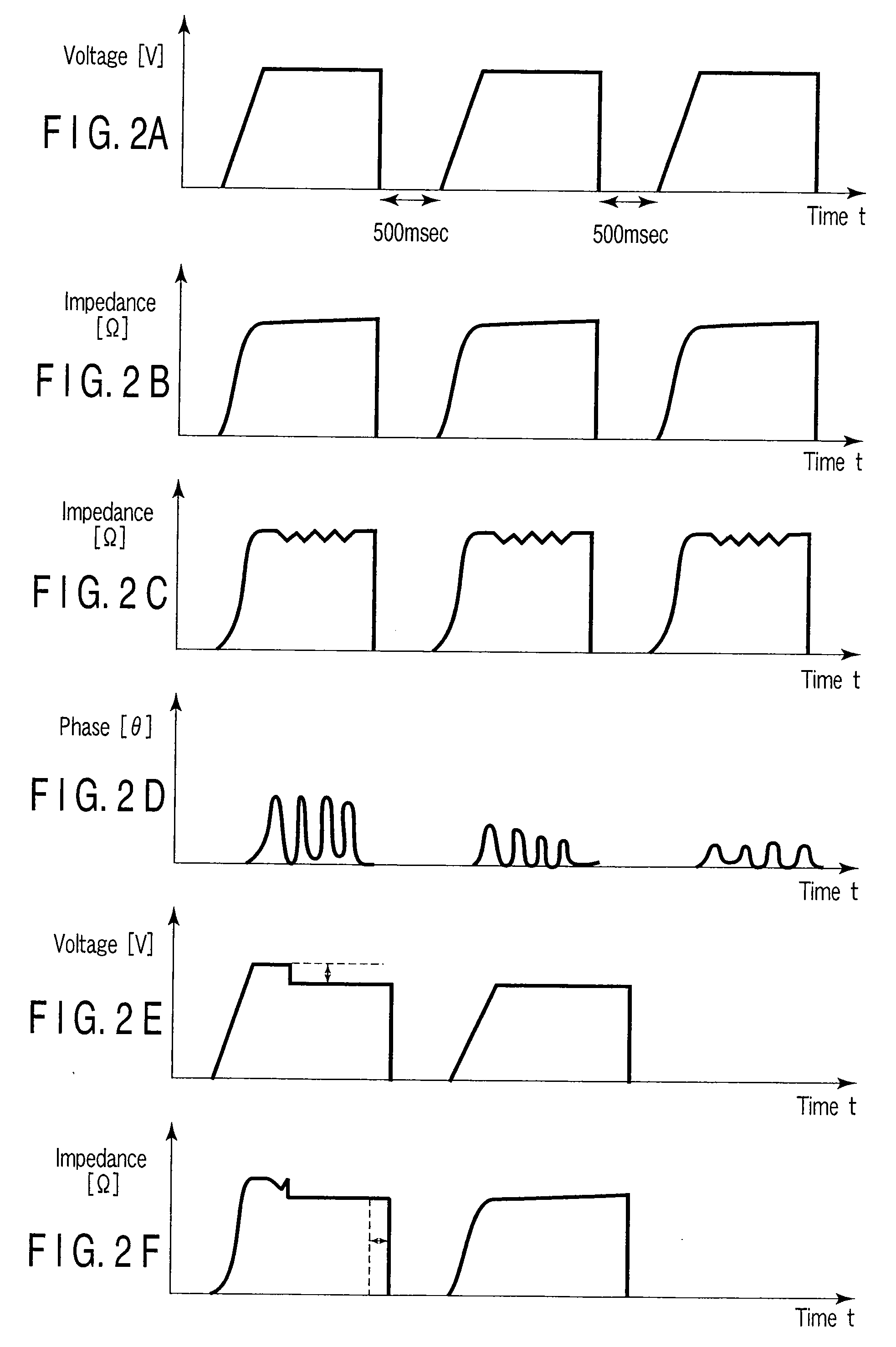

Electric processing system

InactiveUS20080082098A1Quality improvementSimple processSurgical instrument detailsSurgical forcepsElectricityHigh frequency power

There is provided an electric processing system which sequentially monitors a phase difference of intermittently output high-frequency powers in the case of performing feedback control with respect to a high-frequency power applied to bipolar type sealing forceps, reduces the high-frequency power and prolongs an application time at the time of occurrence of abnormal discharge (a spark) at distal ends, thereby terminating the abnormal discharge (extinguishing the spark) to carry out sealing processing.

Owner:OLYMPUS MEDICAL SYST CORP

Derivative seeds

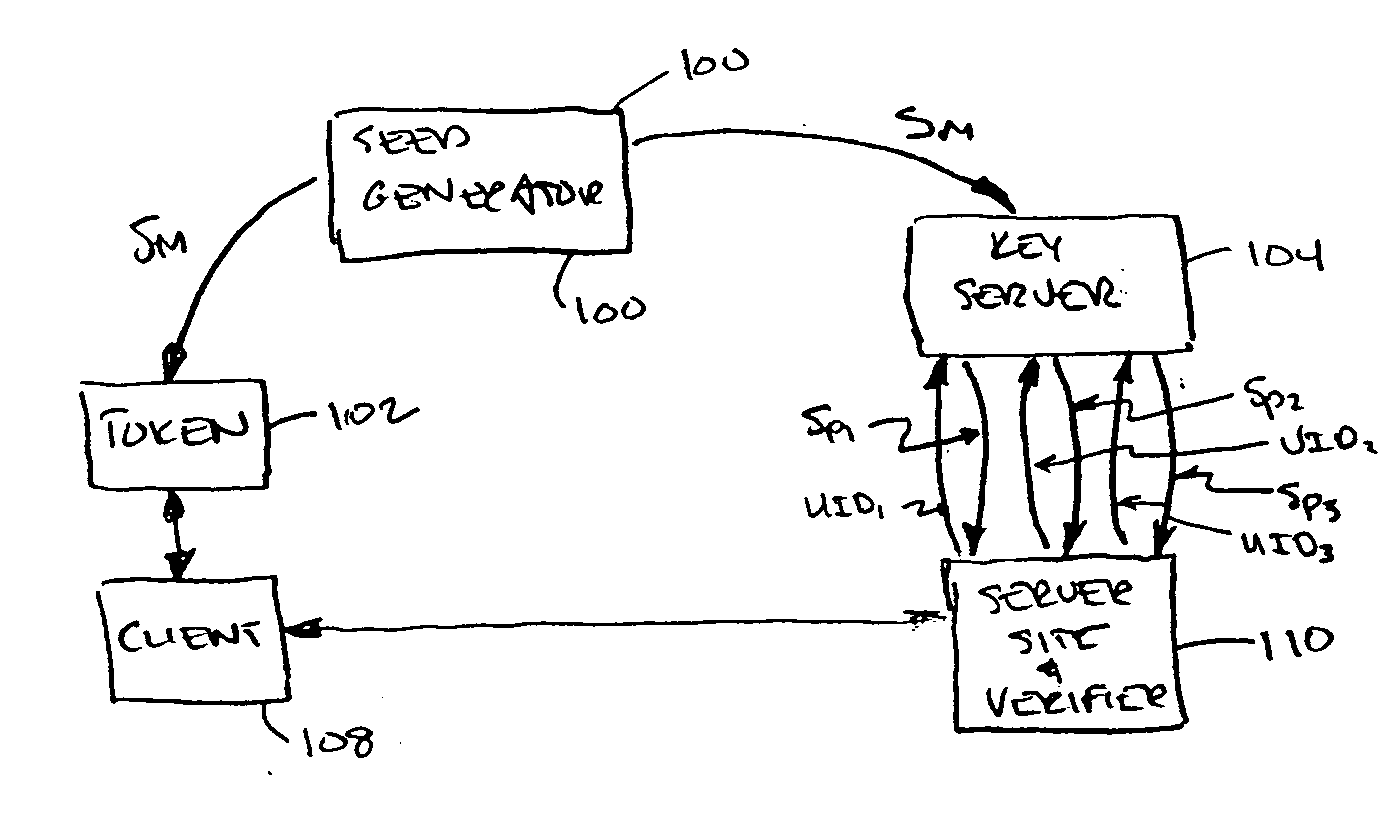

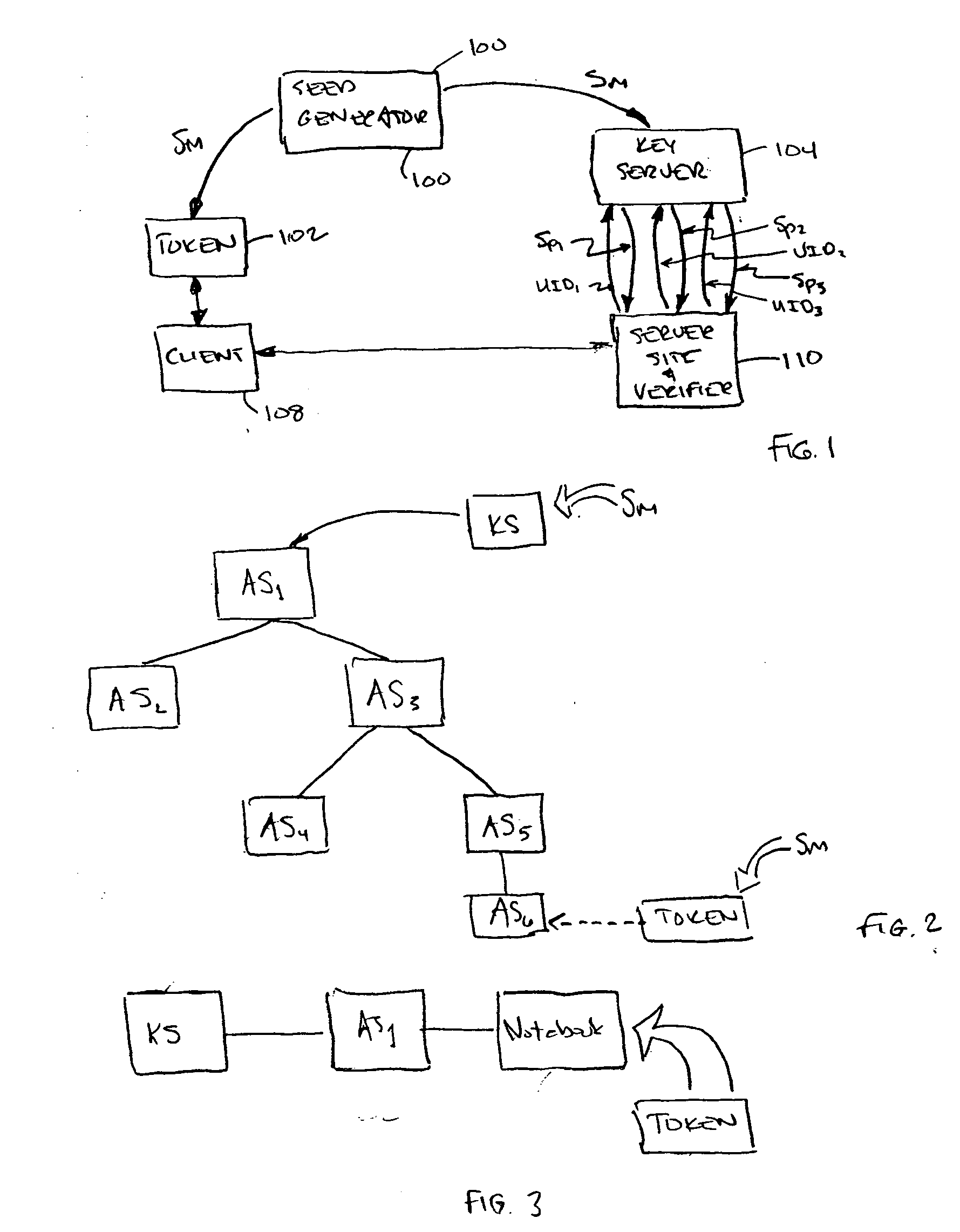

ActiveUS20070174614A1Simplify the distribution processImprove securityDigital data processing detailsUser identity/authority verificationUnique identifierComputer science

A method of generating authentication seeds for a plurality of users, the method involving: based on a single master seed, generating a plurality of derivative seeds, each one for a corresponding different one of a plurality of users; and distributing the plurality of derivative seeds to a verifier for use in individually authenticating each of the plurality of users to that verifier, wherein generating each one of the plurality of derivative seeds involves mathematically combining the master seed and a unique identifier identifying the corresponding user.

Owner:EMC IP HLDG CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com