Patents

Literature

12075 results about "Feedback control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

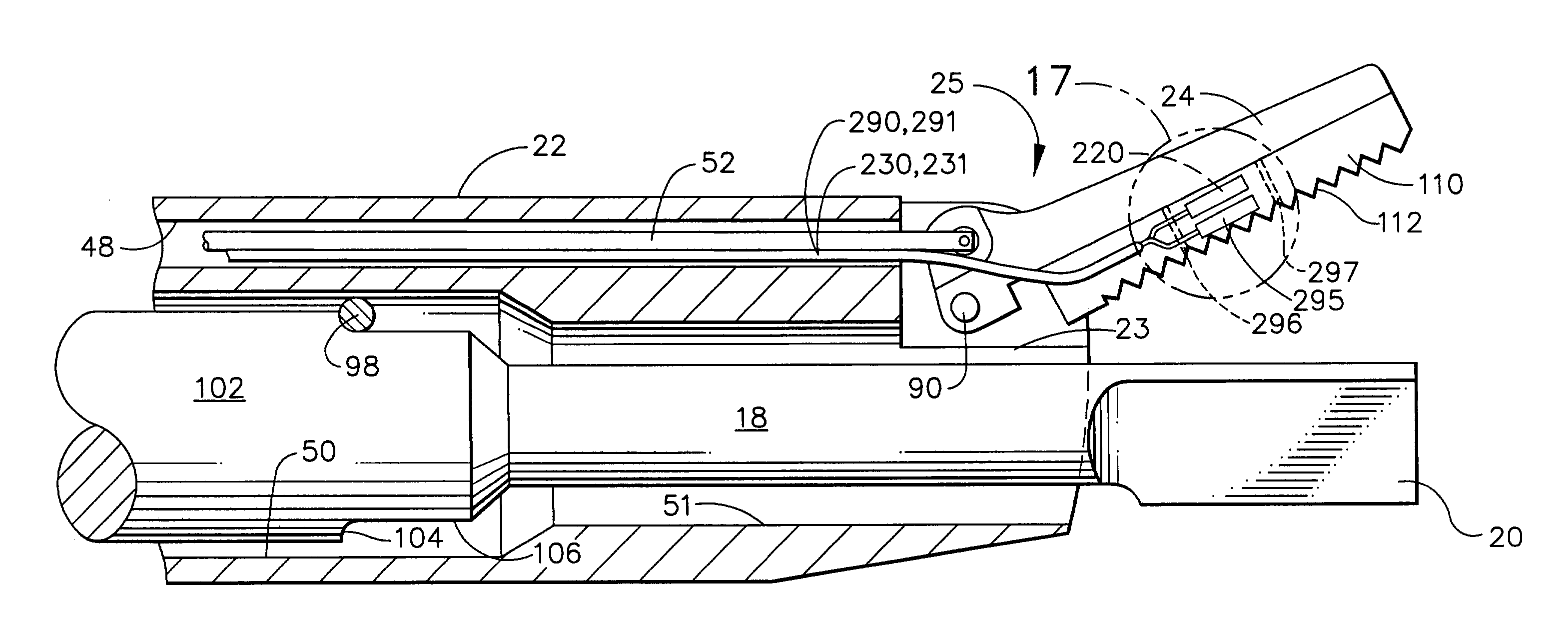

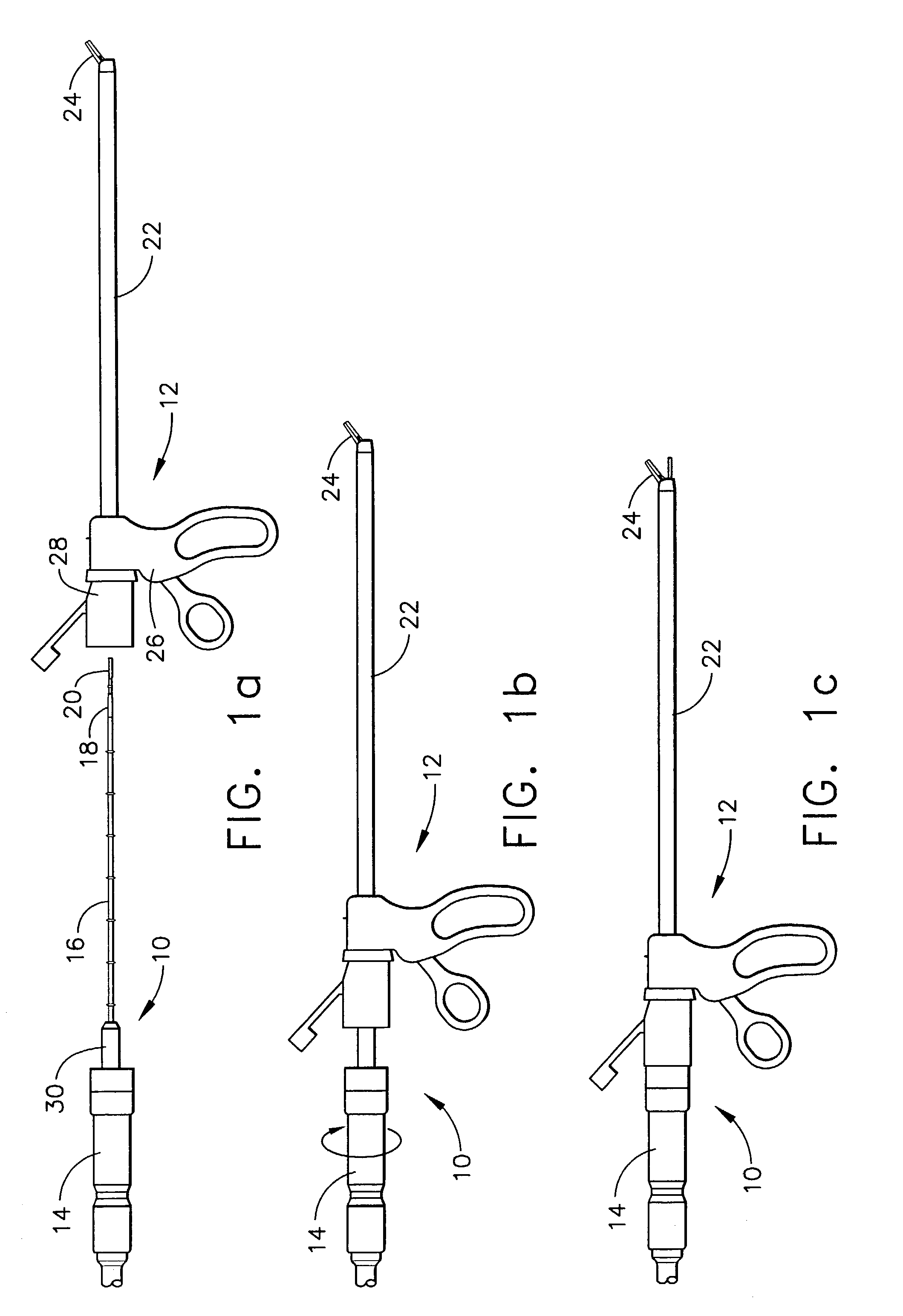

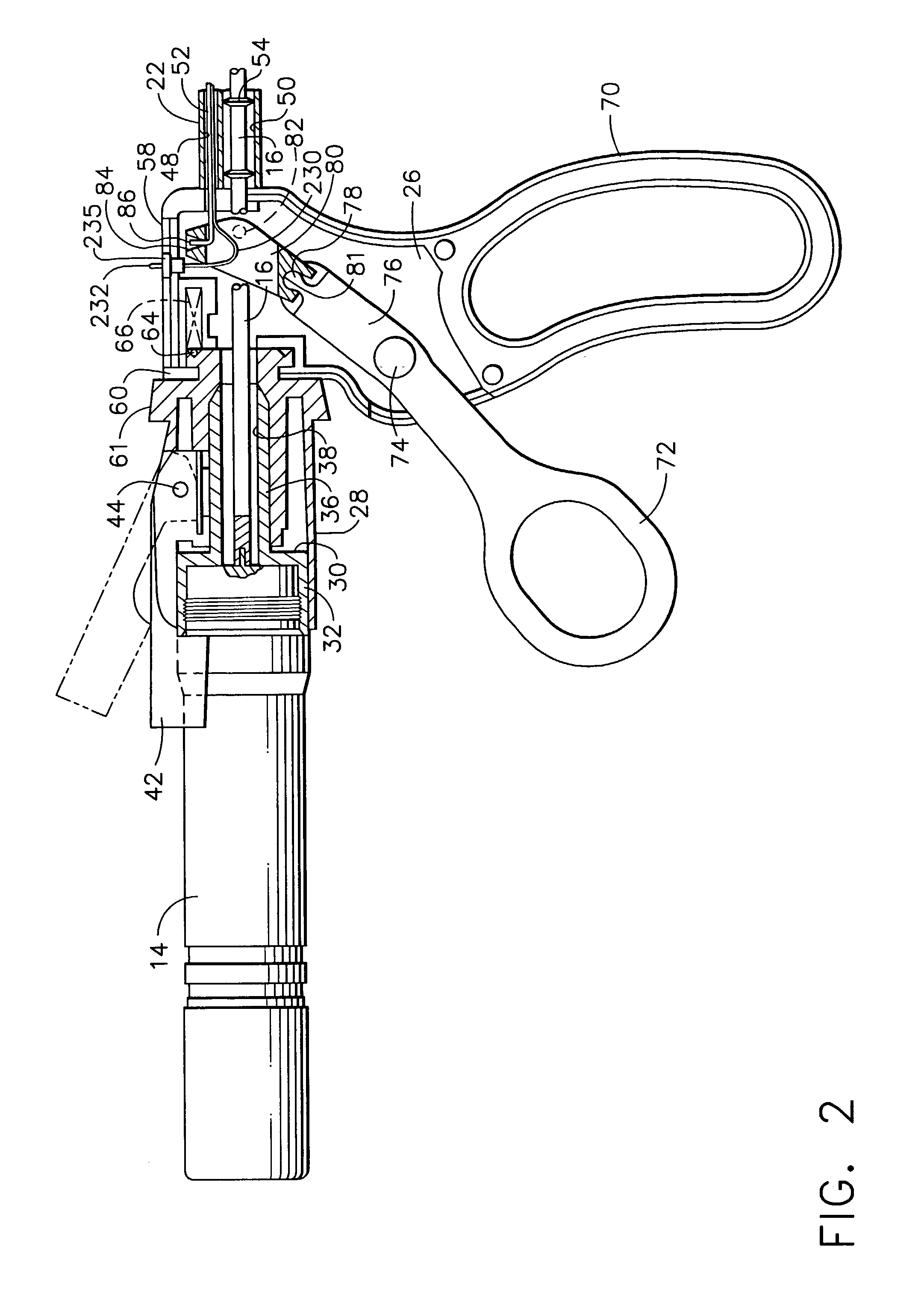

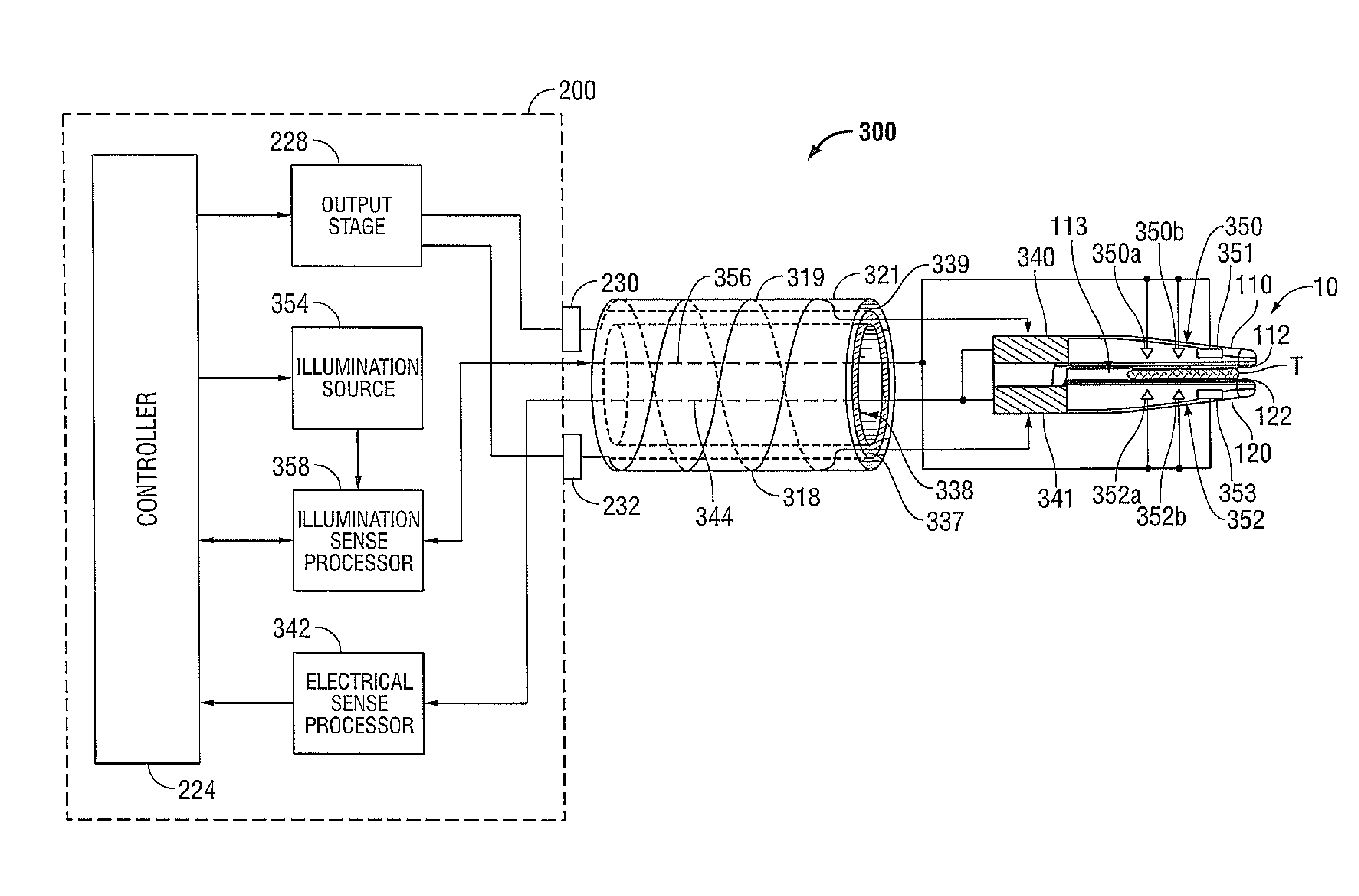

Feedback control in an ultrasonic surgical instrument for improved tissue effects

A temperature monitoring device and / or method which control the tissue temperature at the end-effector of a therapeutic ultrasonic cutting and coagulating instrument as the tissue is being heated with ultrasonic vibrations from the end-effector. One or more temperature sensors are located at the end-effector, preferably on a clamping member. The temperature sensors measure the temperature of the tissue engaged by the end-effector either directly or indirectly. An alternate method and apparatus provides an electrical tissue impedance measure in combination with an ultrasonic cutting and coagulating instrument to provide active feedback control of an ultrasonic generator.

Owner:ETHICON ENDO SURGERY INC

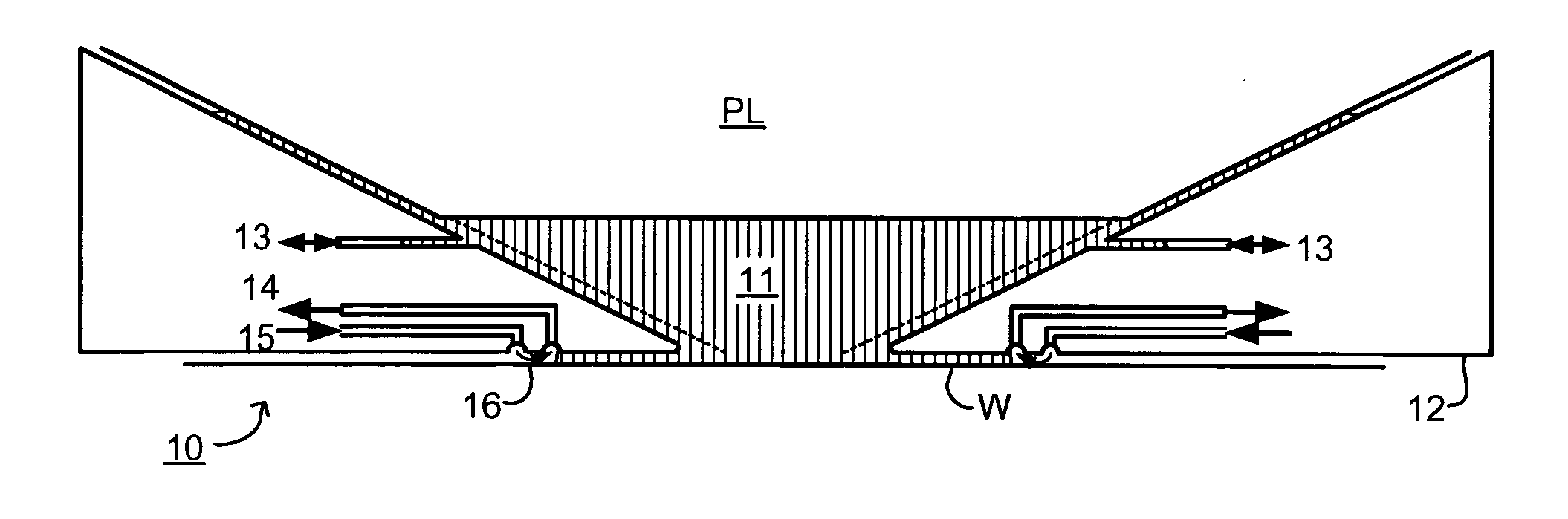

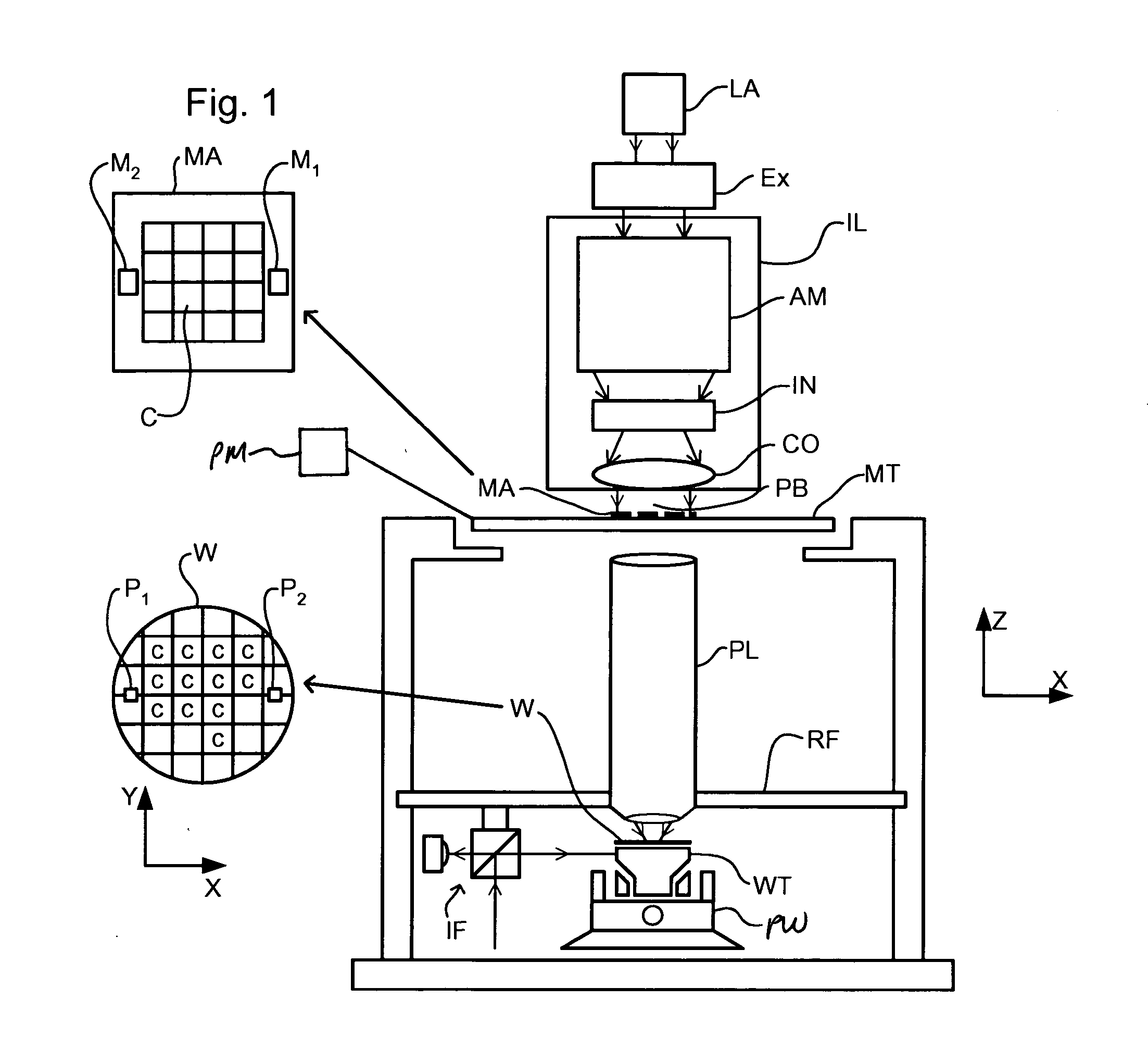

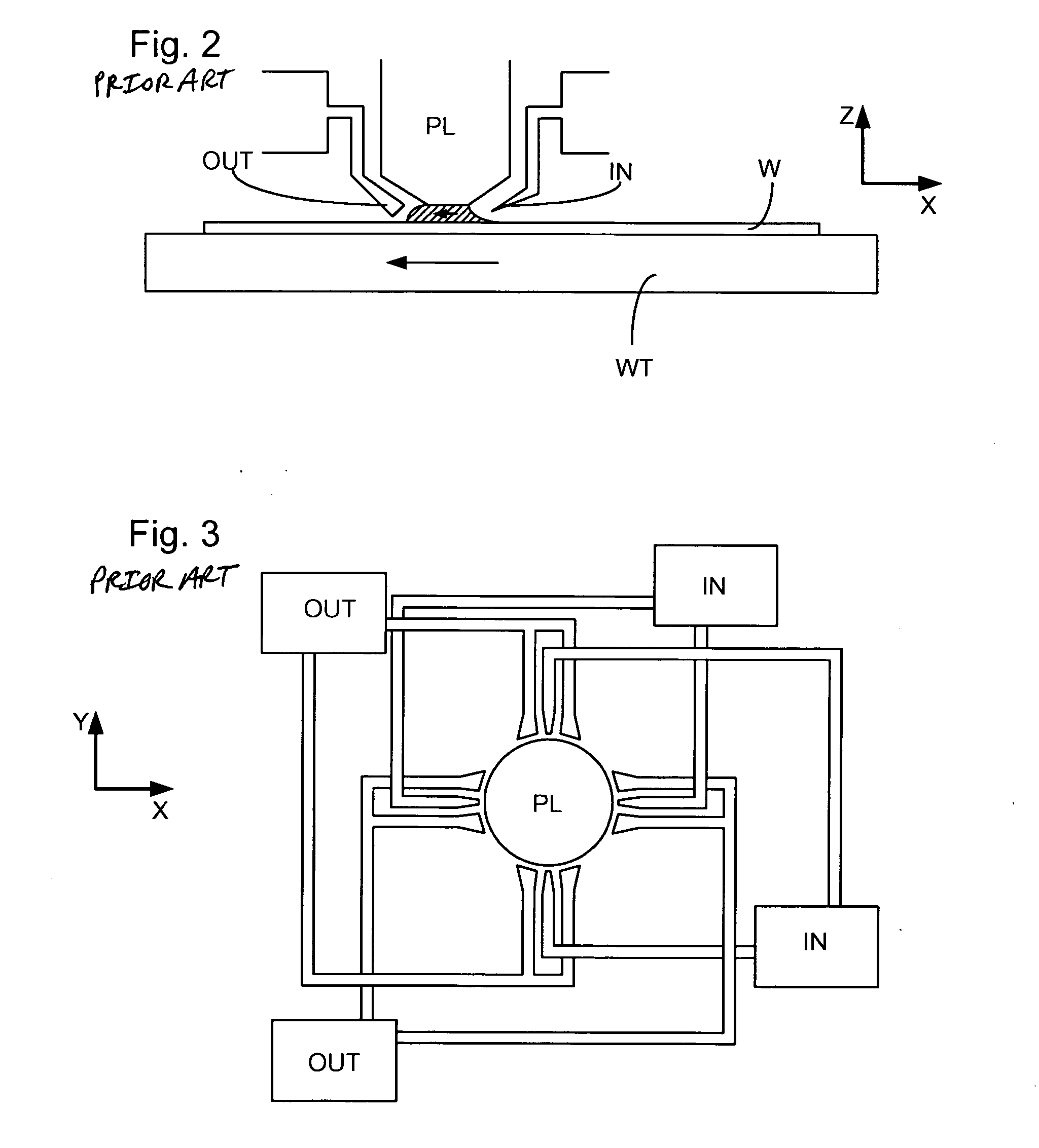

Lithographic apparatus and device manufacturing method

ActiveUS20050007569A1Reduce decreaseResidue reductionServomotor componentsSemiconductor/solid-state device manufacturingControl systemEngineering

In a lithographic apparatus, a localized area of the substrate surface under a projection system is immersed in liquid. The height of a liquid supply system above the surface of the substrate can be varied using actuators. A control system uses feedforward or feedback control with input of the surface height of the substrate to maintain the liquid supply system at a predetermined height above the surface of the substrate.

Owner:ASML NETHERLANDS BV

Electrosurgical generator

InactiveUS6923804B2Improving impedanceIncrease resistanceSurgical instruments for heatingSurgical instruments for aspiration of substancesResonant inverterConstant power

An electrosurgical generator which provides a constant power output particularly suited for cutting arc formation at an active electrode which exhibits a dynamic active surface area of varying geometry. Essentially constant power-based control is achieved through the utilization of a d.c. link voltage the level of which functions to establish the amplitude of the output of an RF resonant inverter. A dual loop feedback control is described wherein output power based control signals are slowly introduced at low gain, while link voltage based controls are comparatively rapidly applied. Enhanced development of a controlling d.c. link voltage is achieved through the utilization of an input network incorporating a power factor correction stage.

Owner:COVIDIEN AG

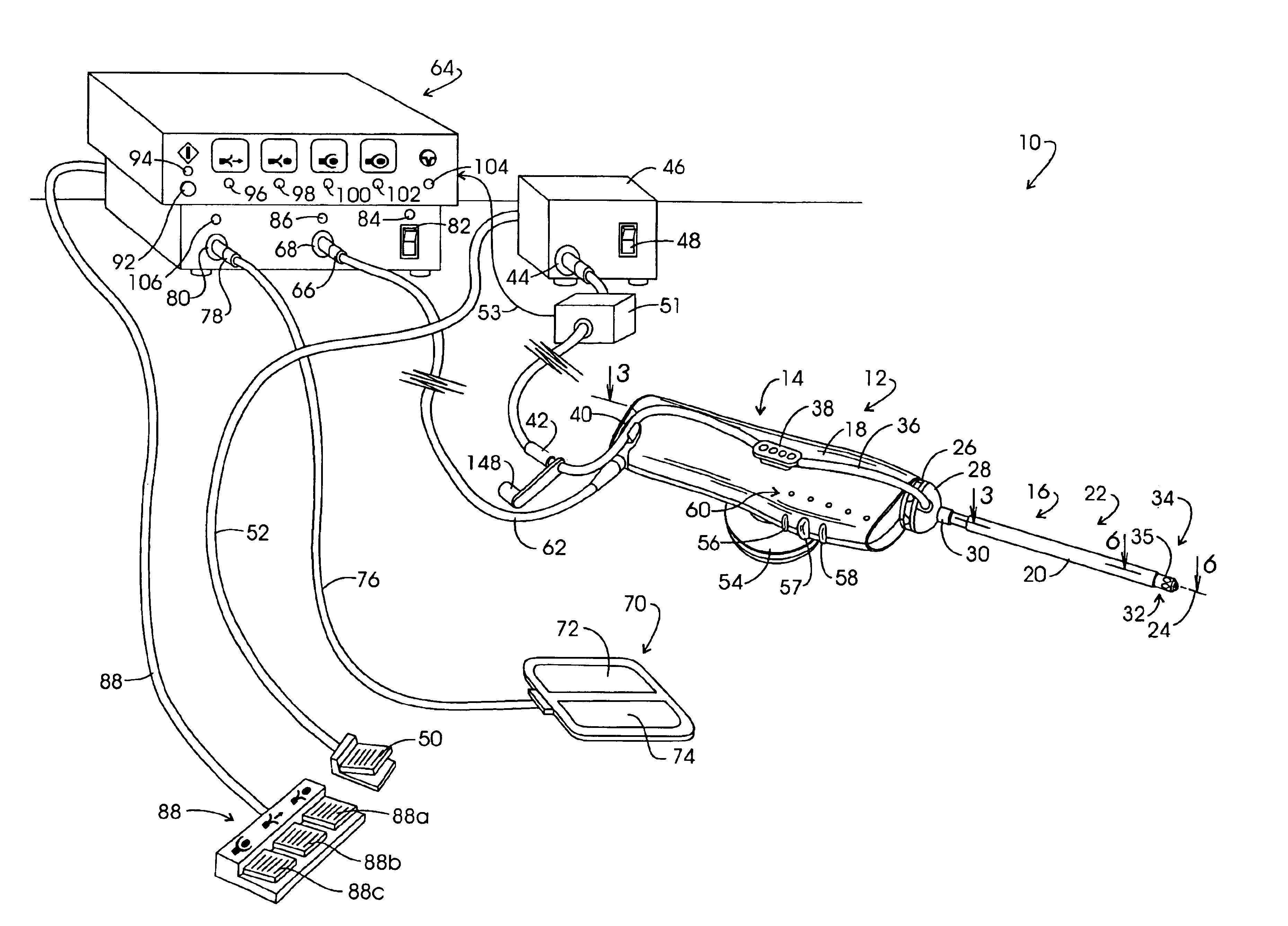

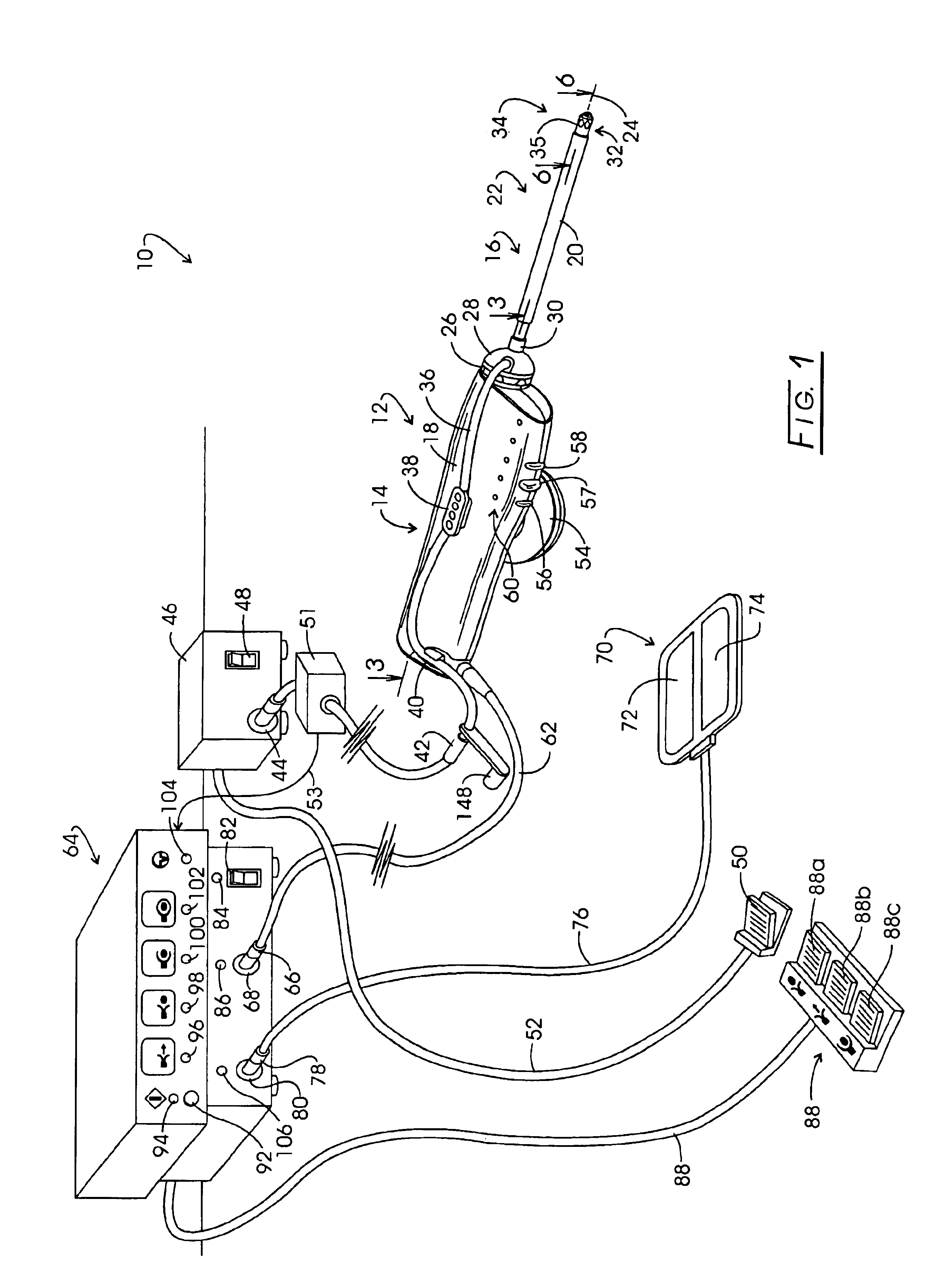

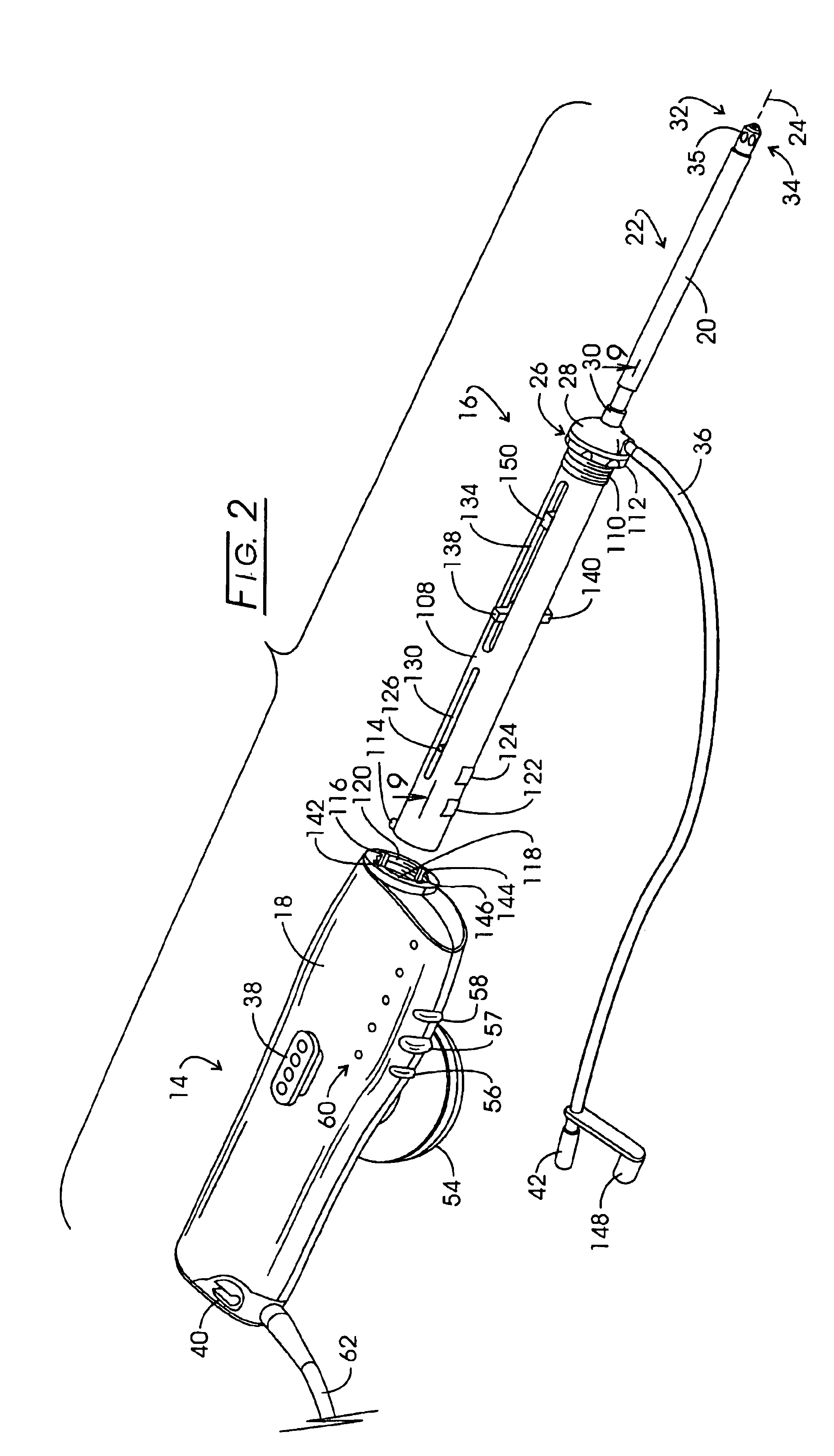

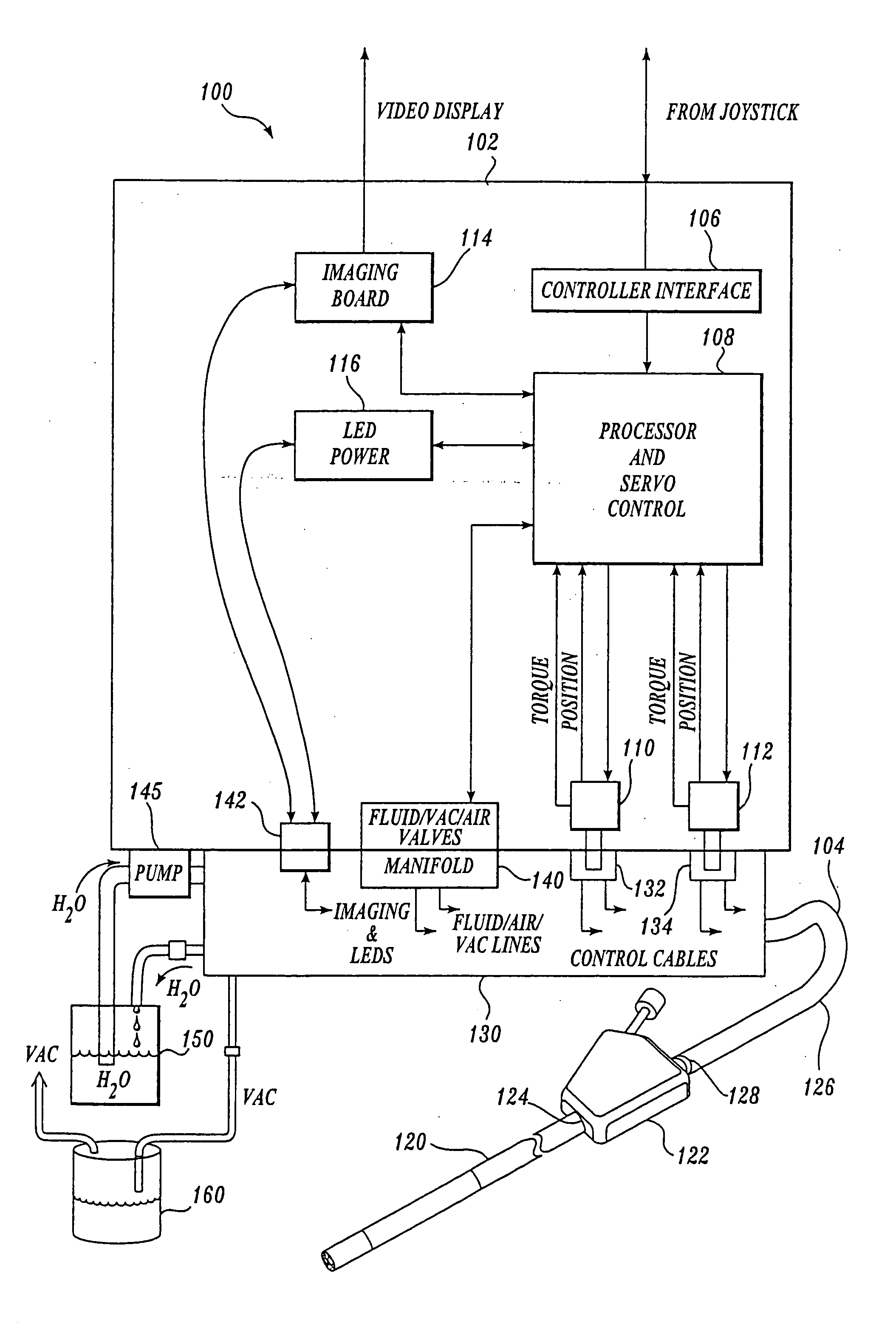

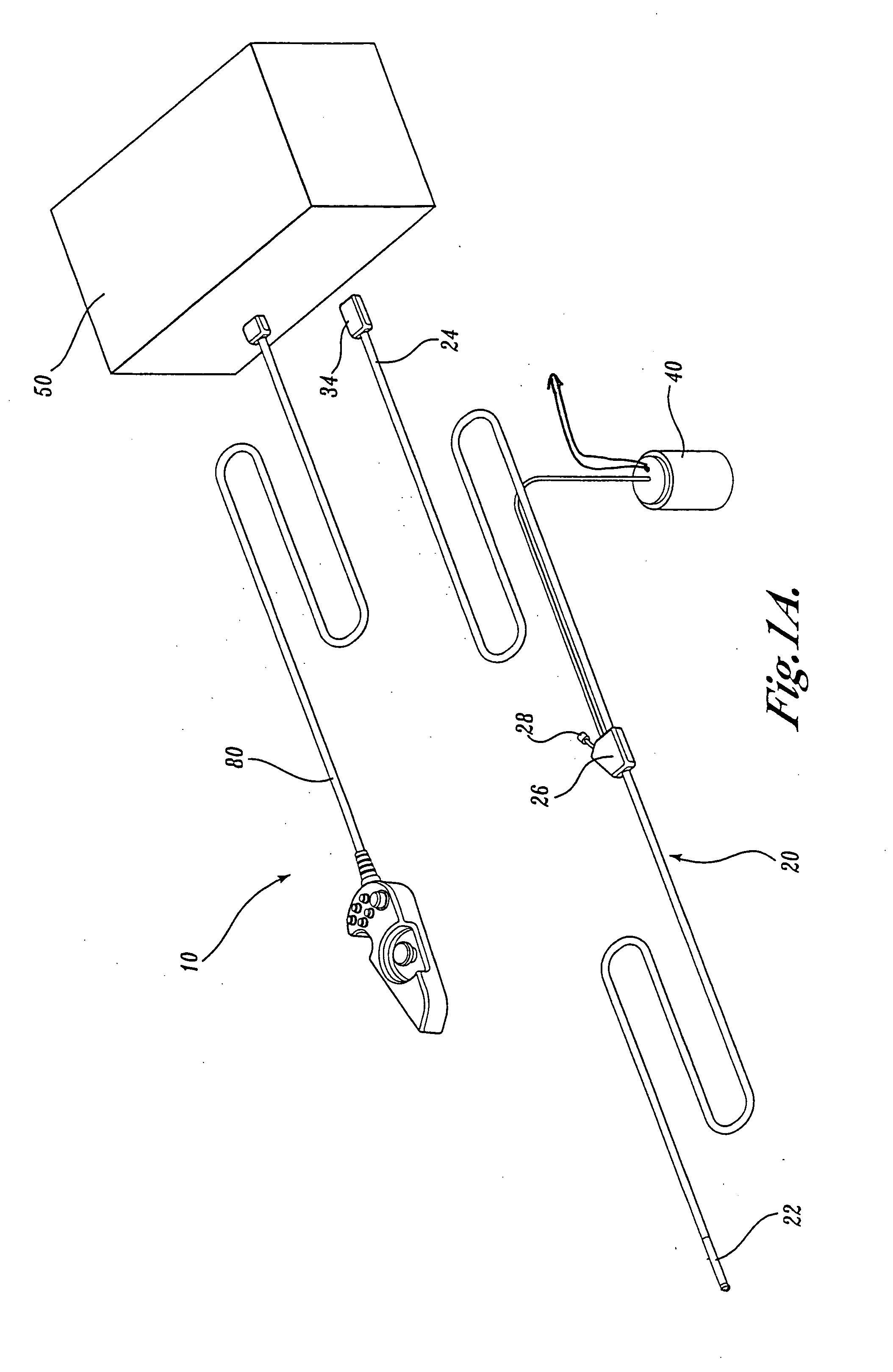

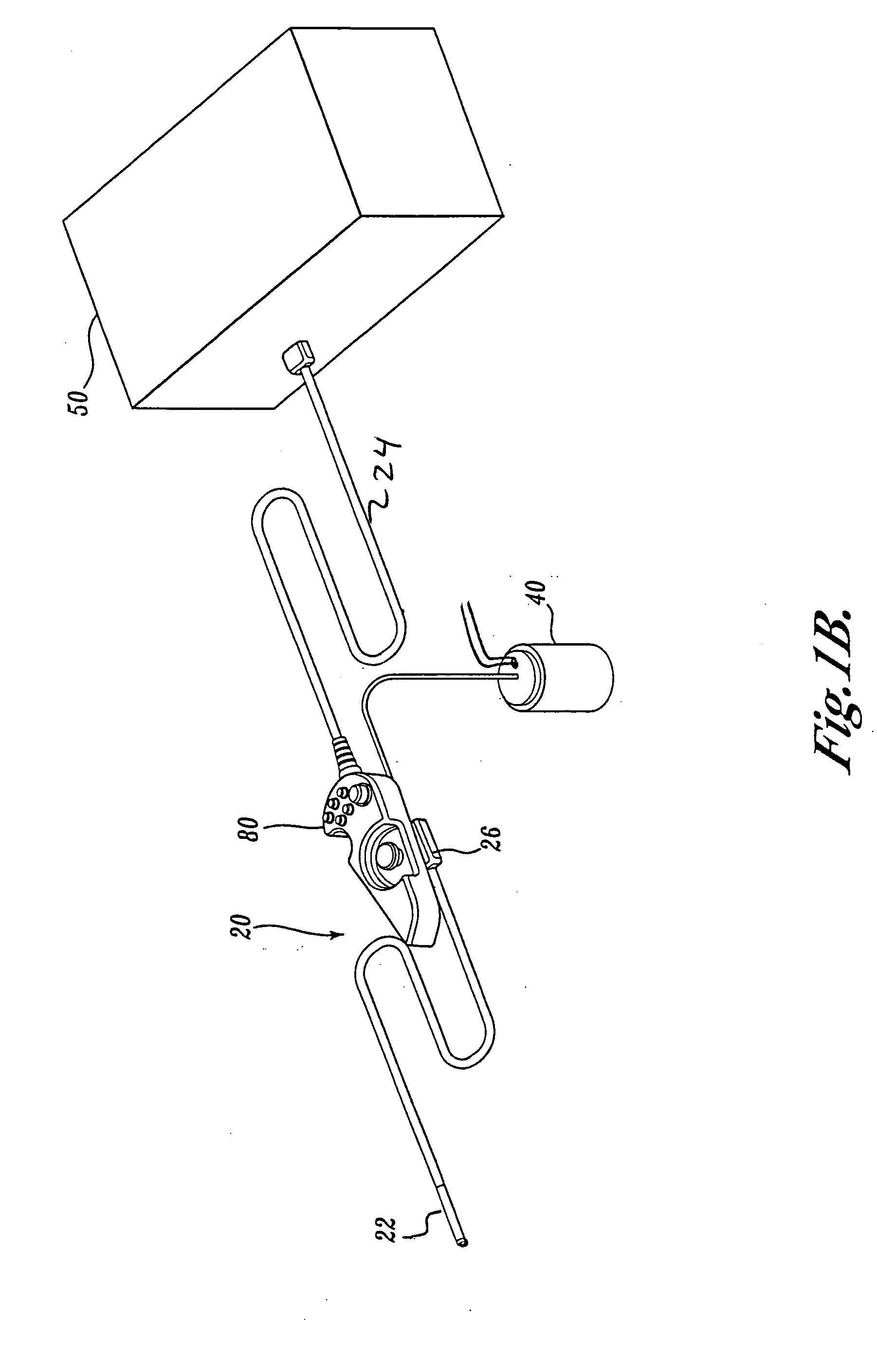

Force feedback control system for video endoscope

ActiveUS20050119527A1Reduce coefficient of frictionImprove device performanceSurgeryEndoscopesFluidicsControl system

A video endoscope system includes a reusable control cabinet and an endoscope that is connectable thereto. The endoscope may be used with a single patient and then disposed. The endoscope includes an illumination mechanism, an image sensor, and an elongate shaft having one or more lumens located therein. An articulation joint at the distal end of the endoscope allows the distal end to be oriented by the actuators in the control cabinet or actuators in a control handle of the endoscope. Fluidics, electrical, navigation, image, display and data entry controls are integrated into the system along with other accessories.

Owner:BOSTON SCI SCIMED INC

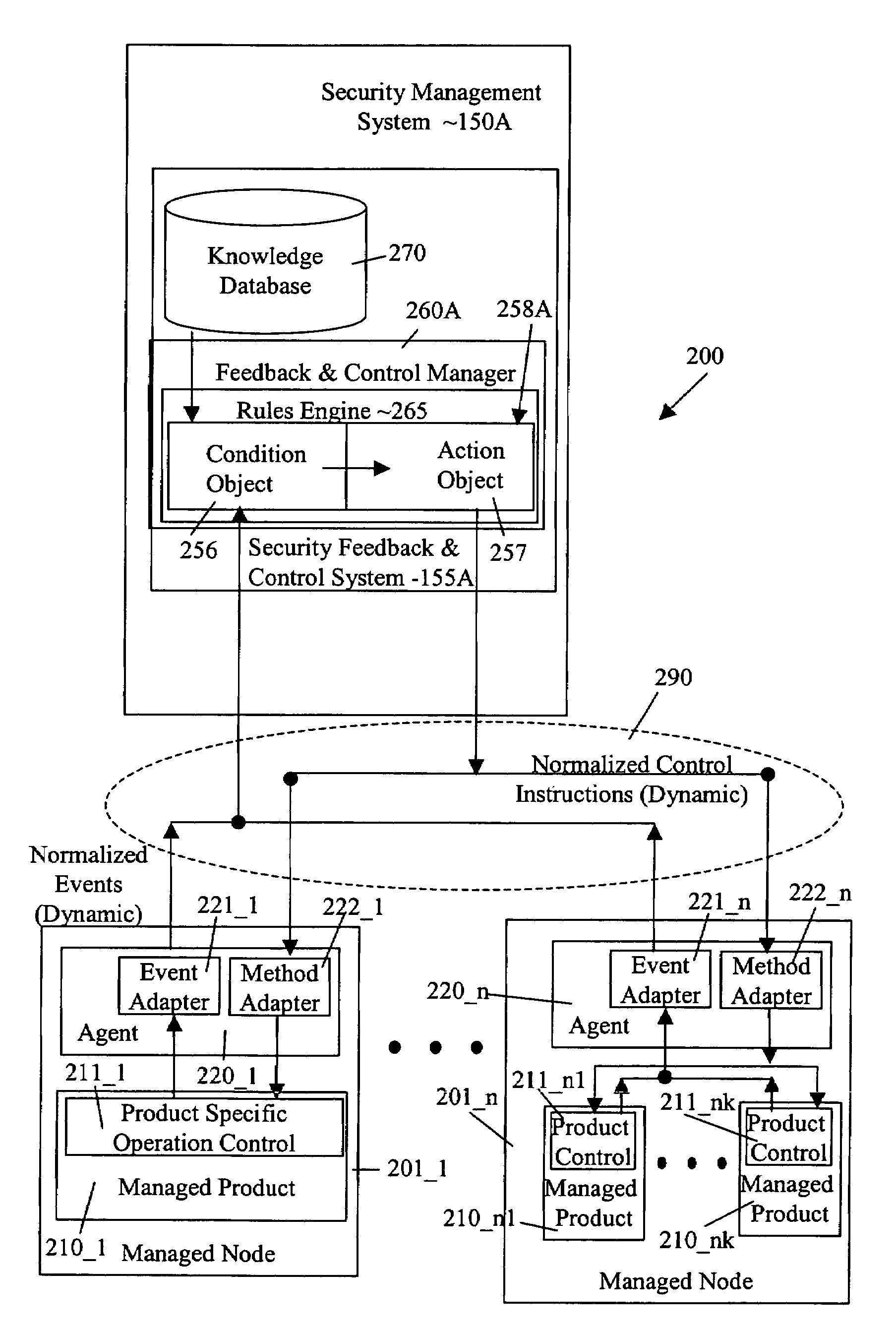

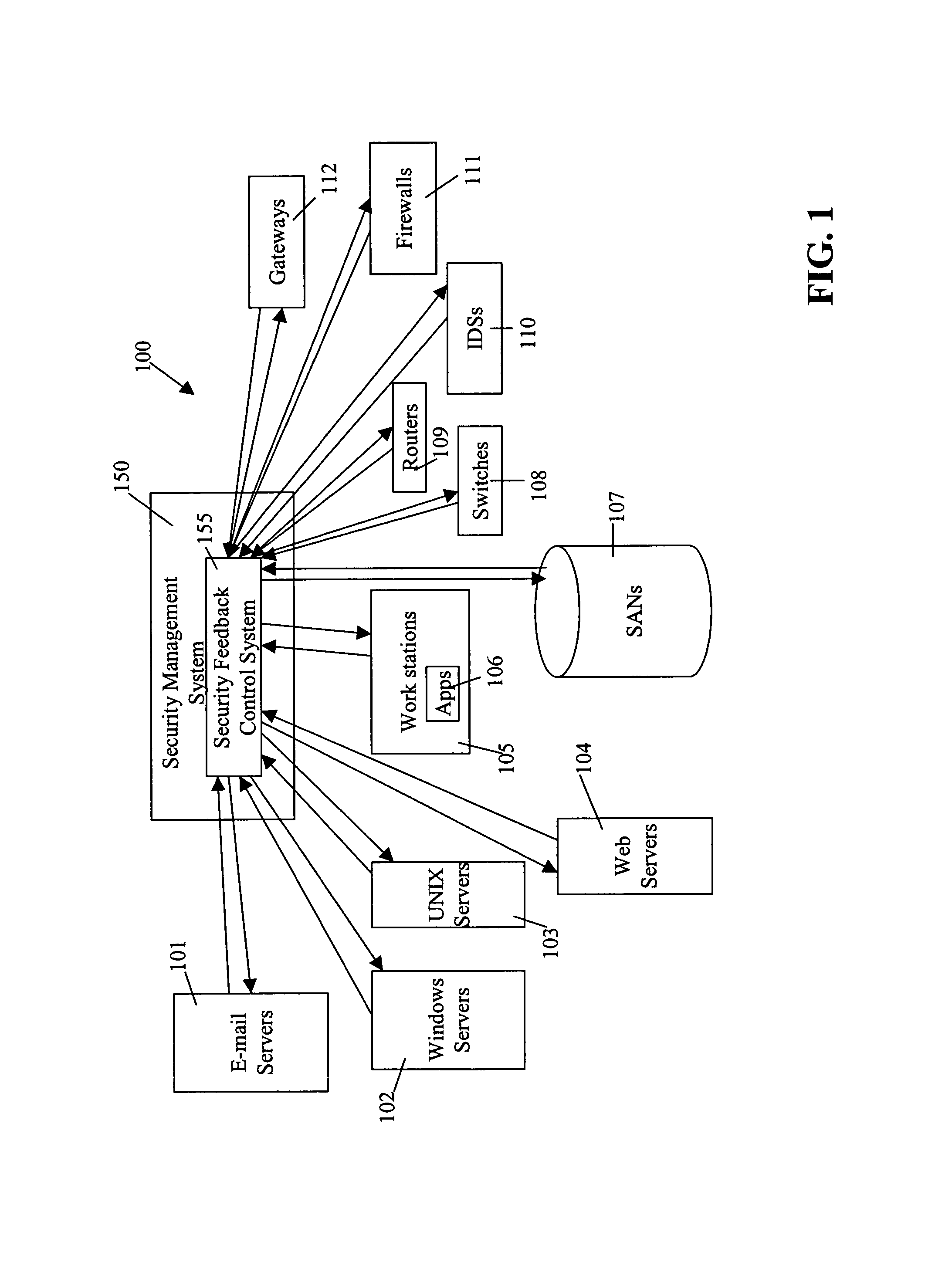

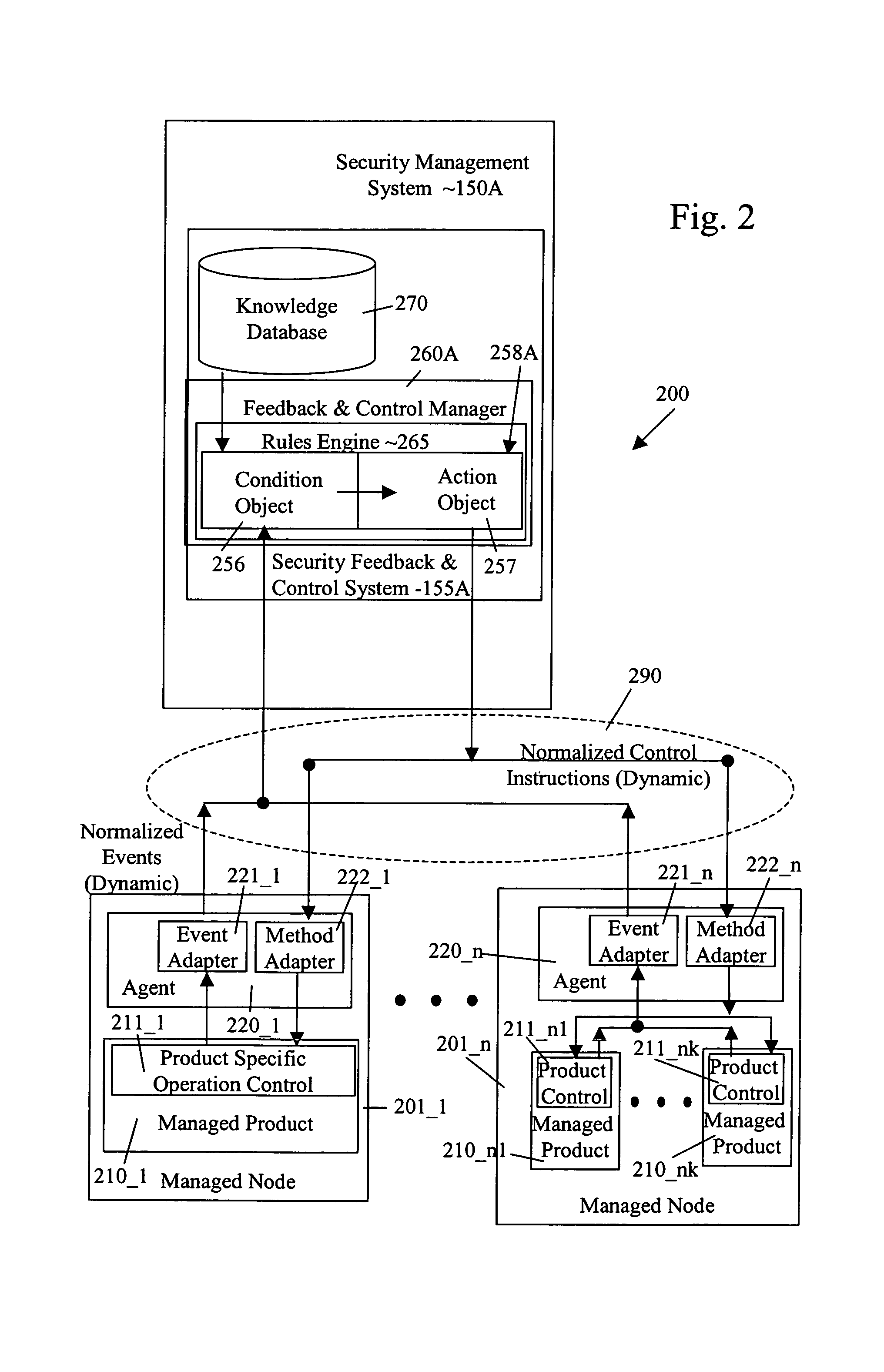

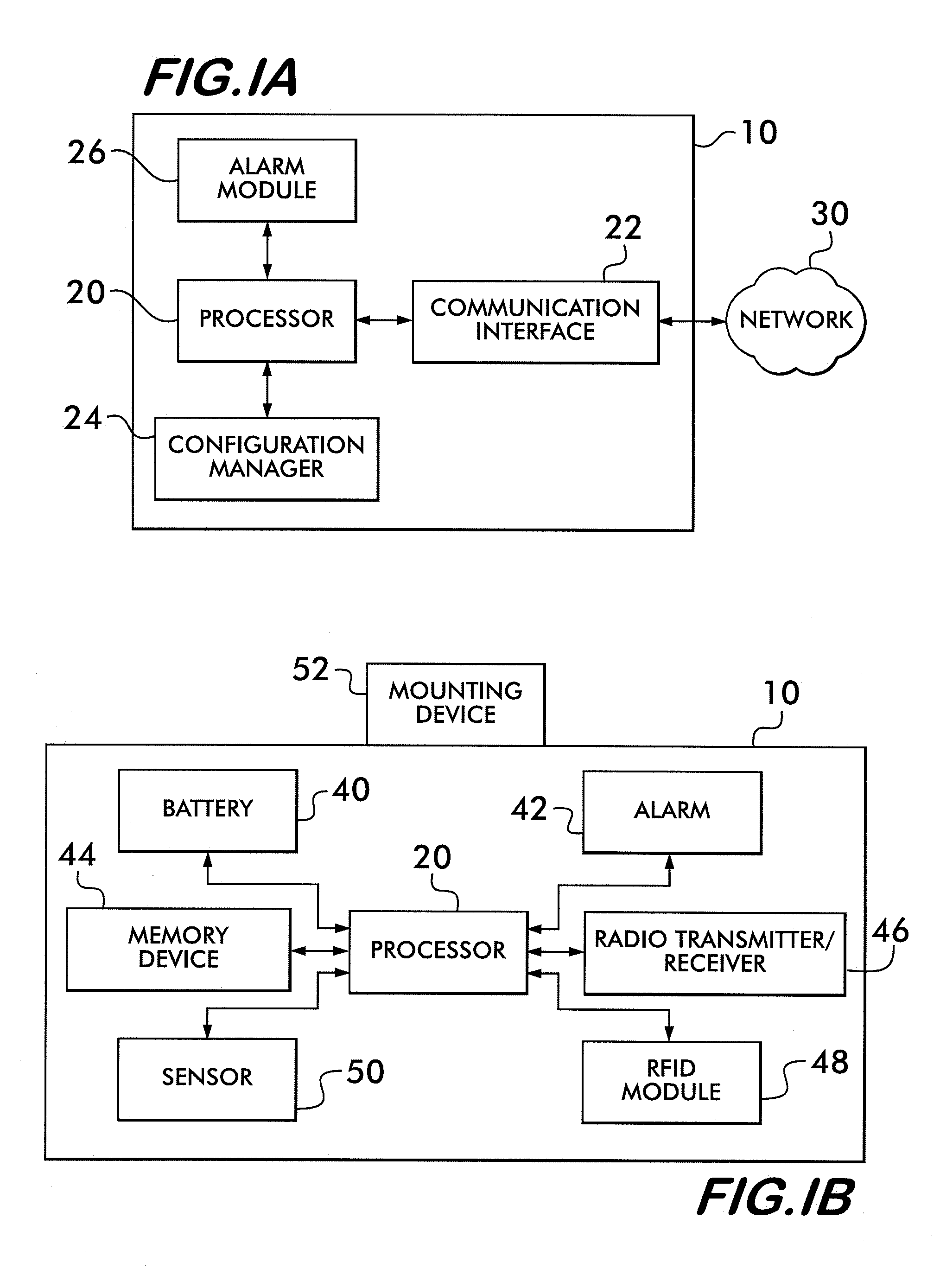

Security management system including feedback and control

InactiveUS7472422B1Memory loss protectionError detection/correctionPolicy decisionSafety management systems

A system uses automatic feedback and control to secure a network infrastructure by iterative convergence of the network's security structure to meet a security policy. Following initialization, a security feedback control system of the security management system makes dynamic adjustments to the system using bi-directional services that are controlled via policy decision components, without user intervention.

Owner:SYMANTEC CORP

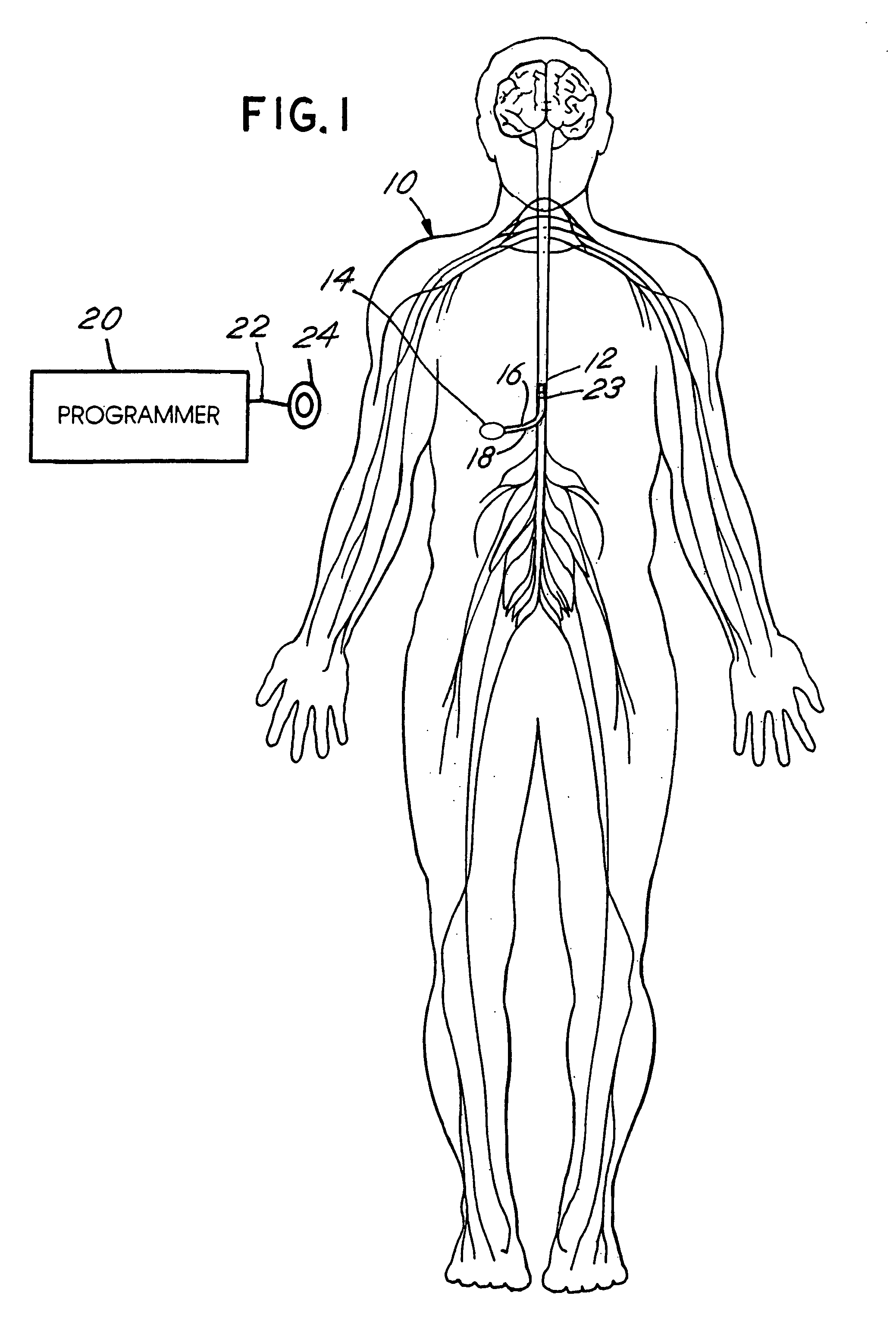

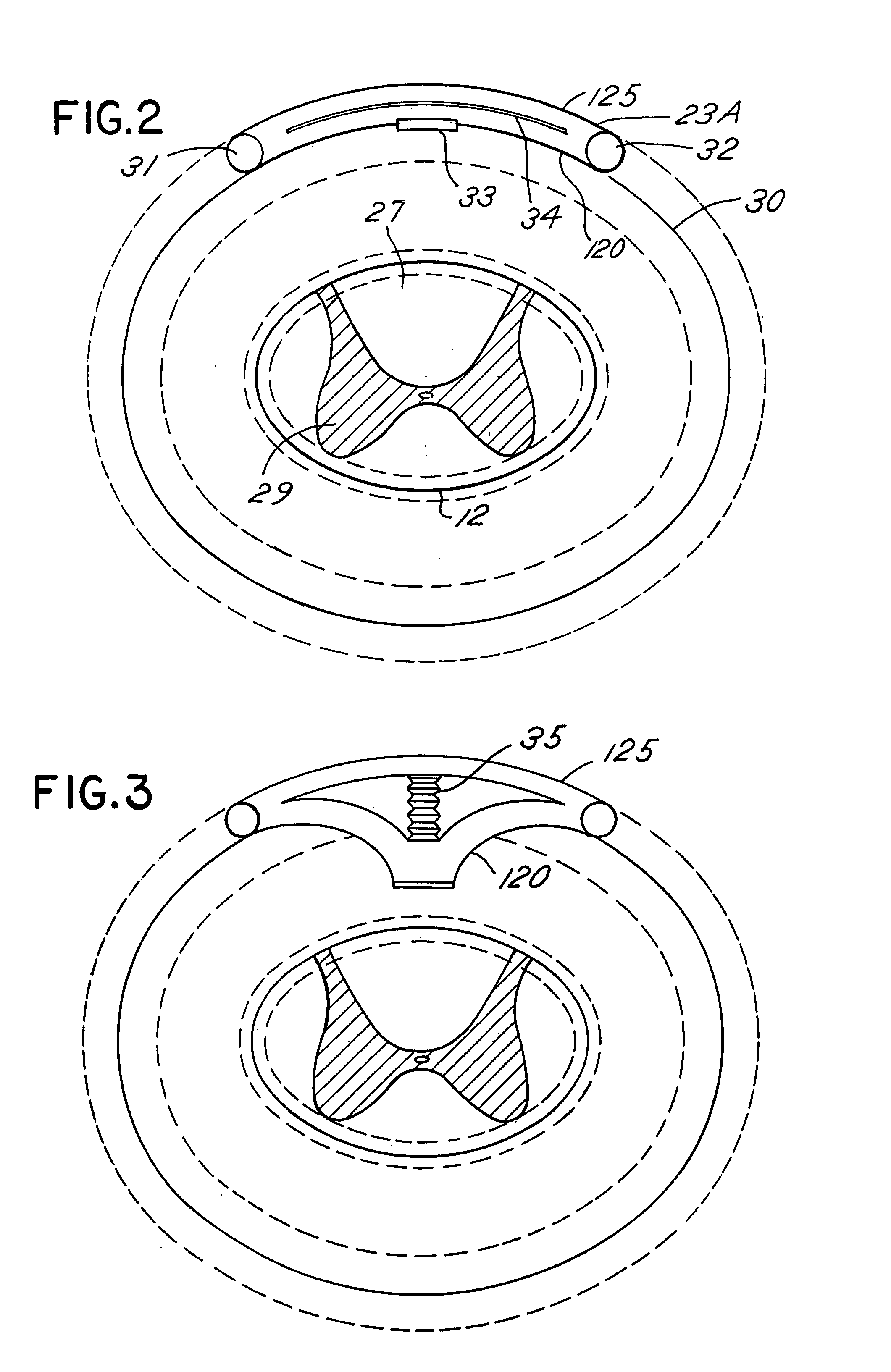

Techniques for positioning therapy delivery elements within a spinal cord or brain

Apparatus and techniques to address the problems associated with lead migration, patient movement or position, histological changes, neural plasticity or disease progression. Disclosed are techniques for implanting a lead having therapy delivery elements, such as electrodes or drug delivery ports, within a vertebral or cranial bone so as to maintain these elements in a fixed position relative to a desired treatment site. The therapy delivery elements may thereafter be adjusted in situ with a position control mechanism and / or a position controller to improve the desired treatment, such as_electrical stimulation and / or drug infusion to a precise target. The therapy delivery elements may be positioned laterally in any direction relative to the targeted treatment site or toward or away from the targeted treatment site. A control system maybe provided for open- or closed-loop feedback control of the position of the therapy delivery elements as well as other aspects of the treatment therapy.

Owner:MEDTRONIC INC

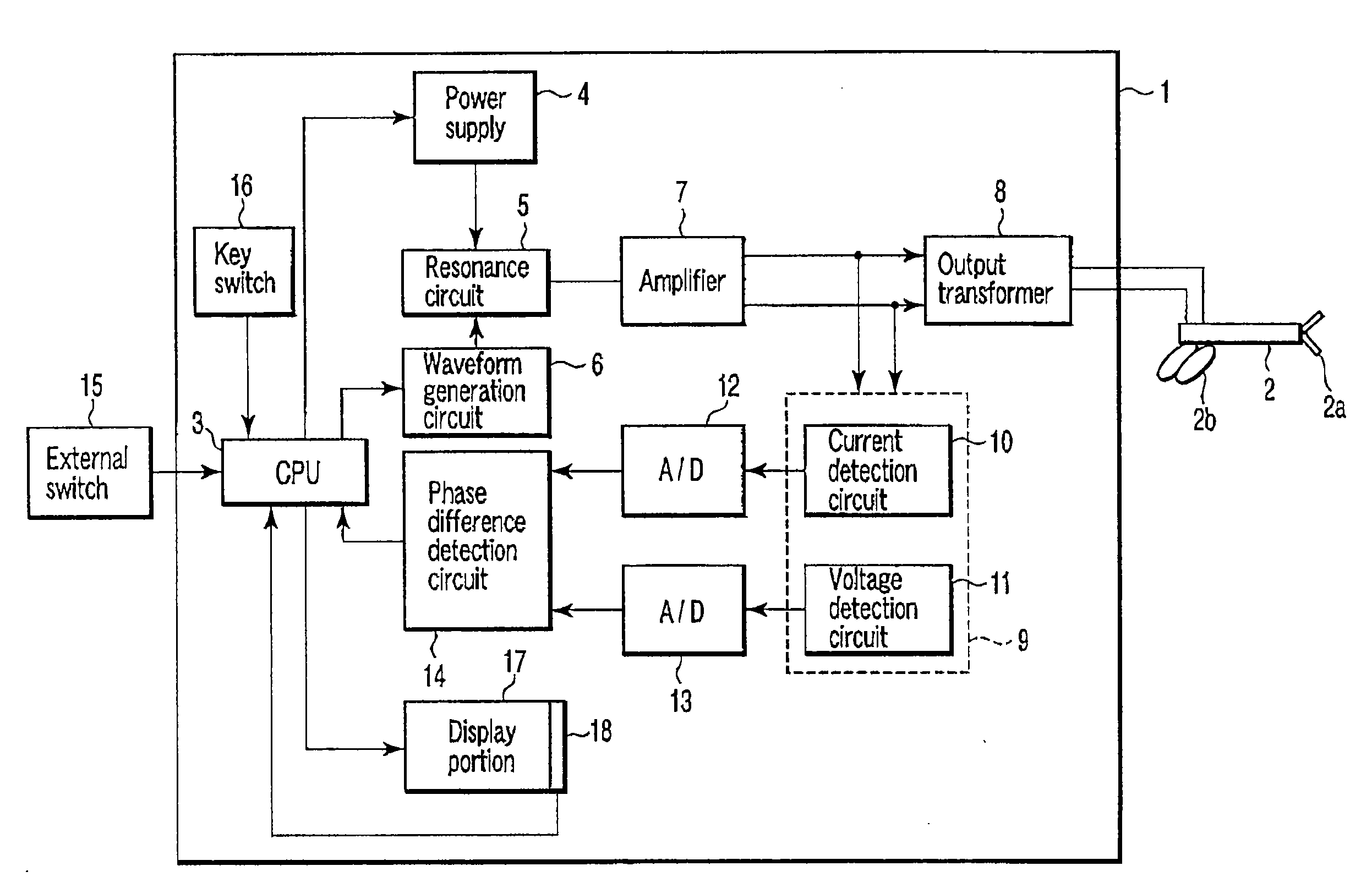

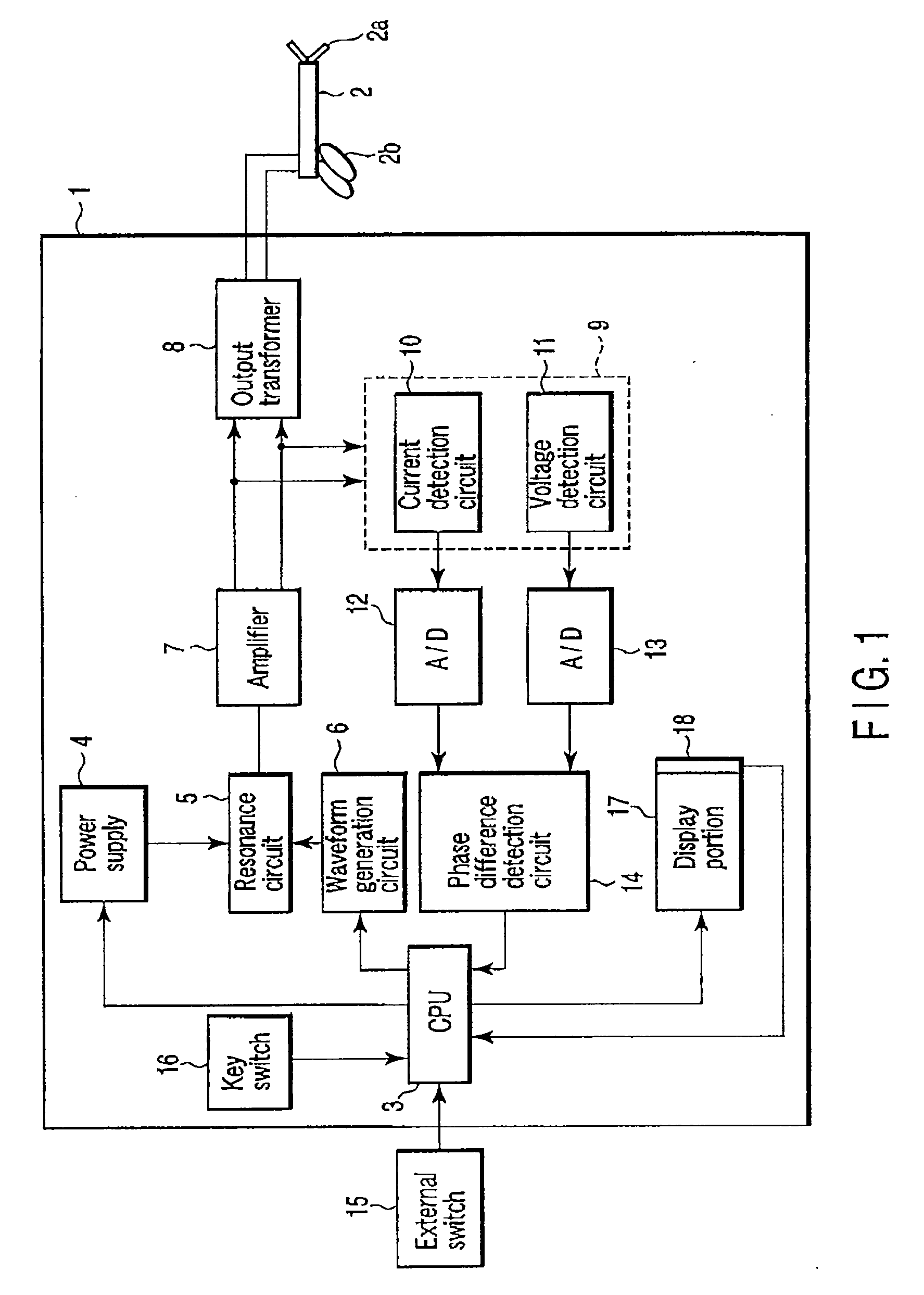

Electric processing system

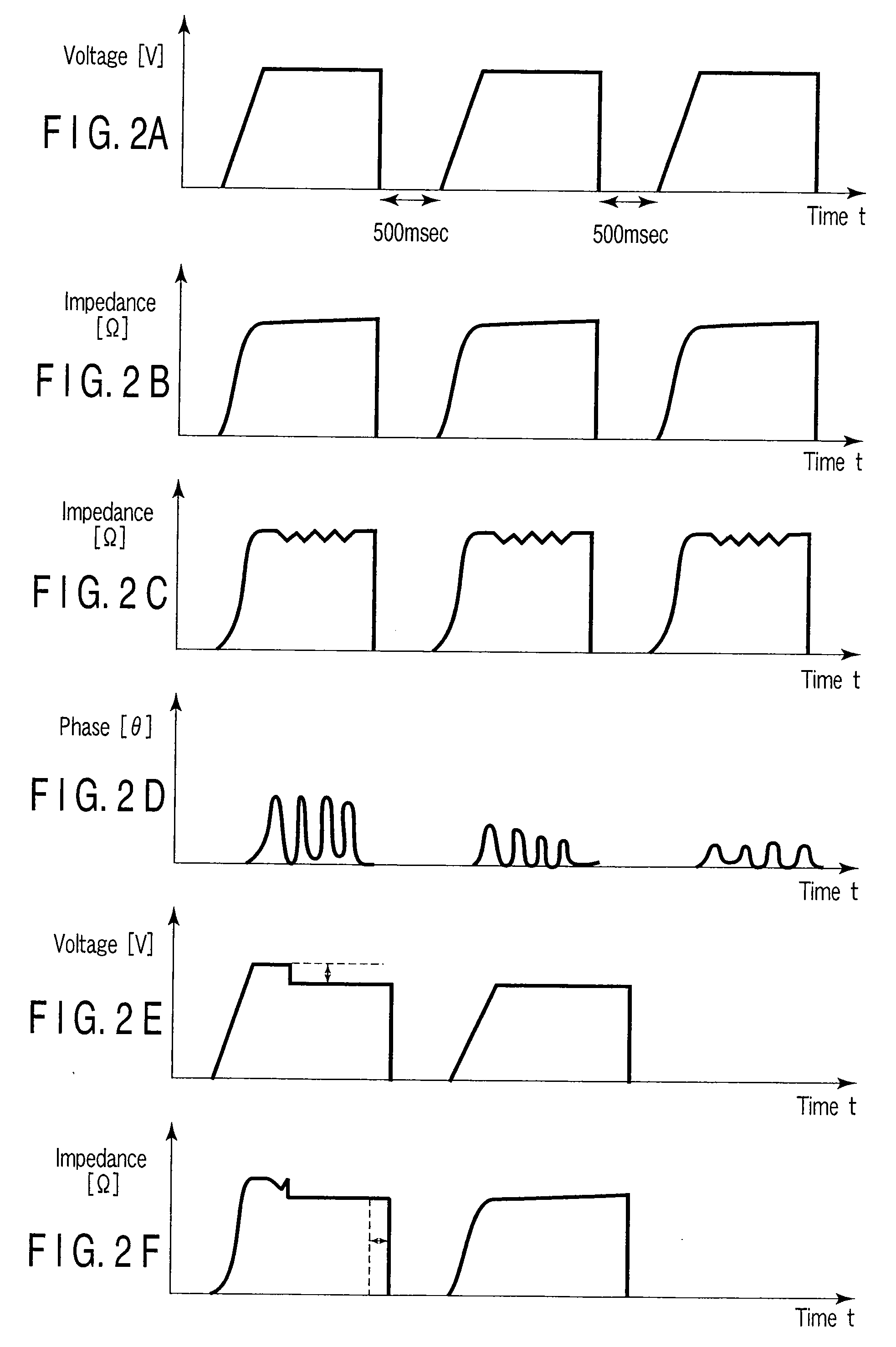

InactiveUS20080082098A1Quality improvementSimple processSurgical instrument detailsSurgical forcepsElectricityHigh frequency power

There is provided an electric processing system which sequentially monitors a phase difference of intermittently output high-frequency powers in the case of performing feedback control with respect to a high-frequency power applied to bipolar type sealing forceps, reduces the high-frequency power and prolongs an application time at the time of occurrence of abnormal discharge (a spark) at distal ends, thereby terminating the abnormal discharge (extinguishing the spark) to carry out sealing processing.

Owner:OLYMPUS MEDICAL SYST CORP

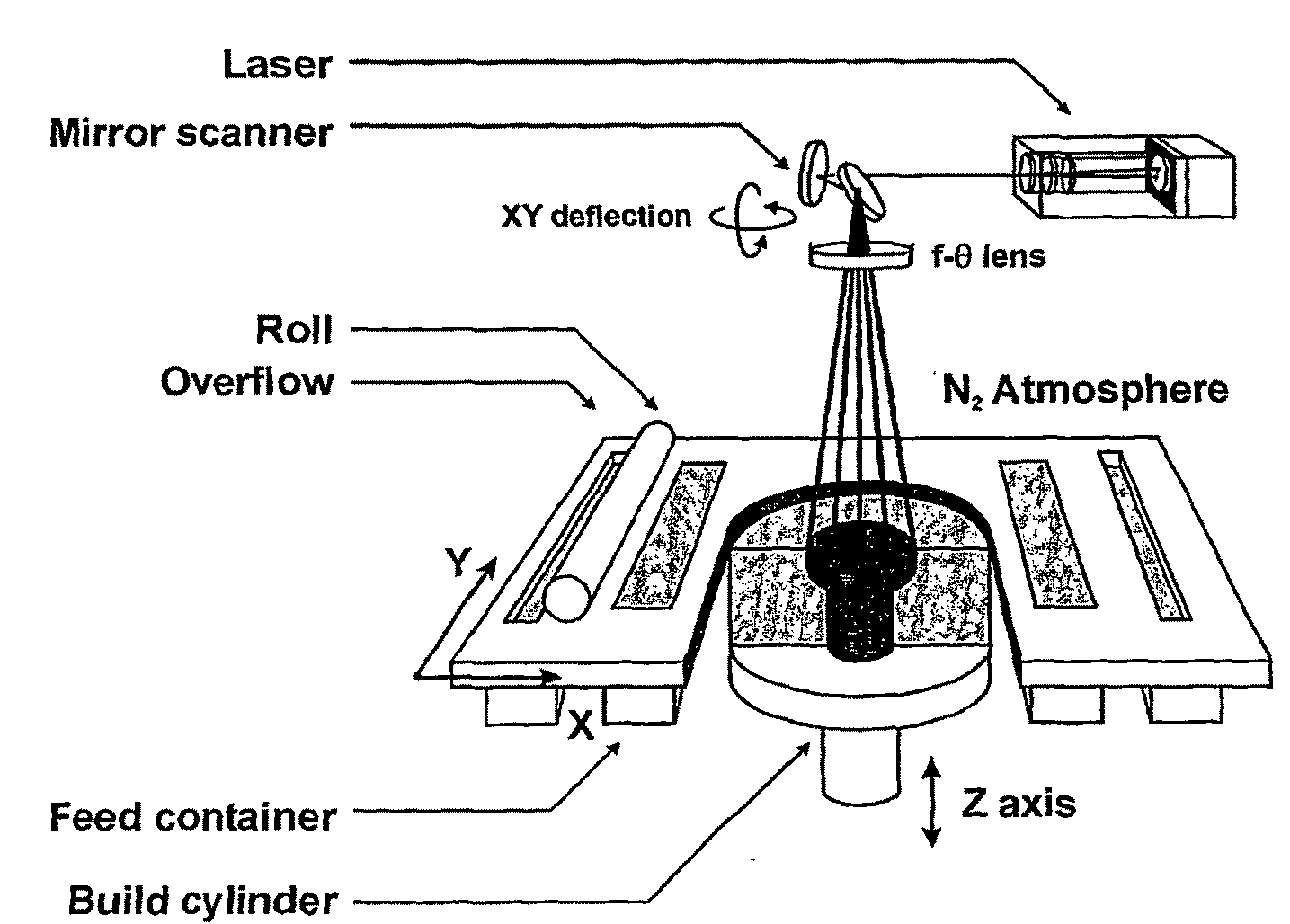

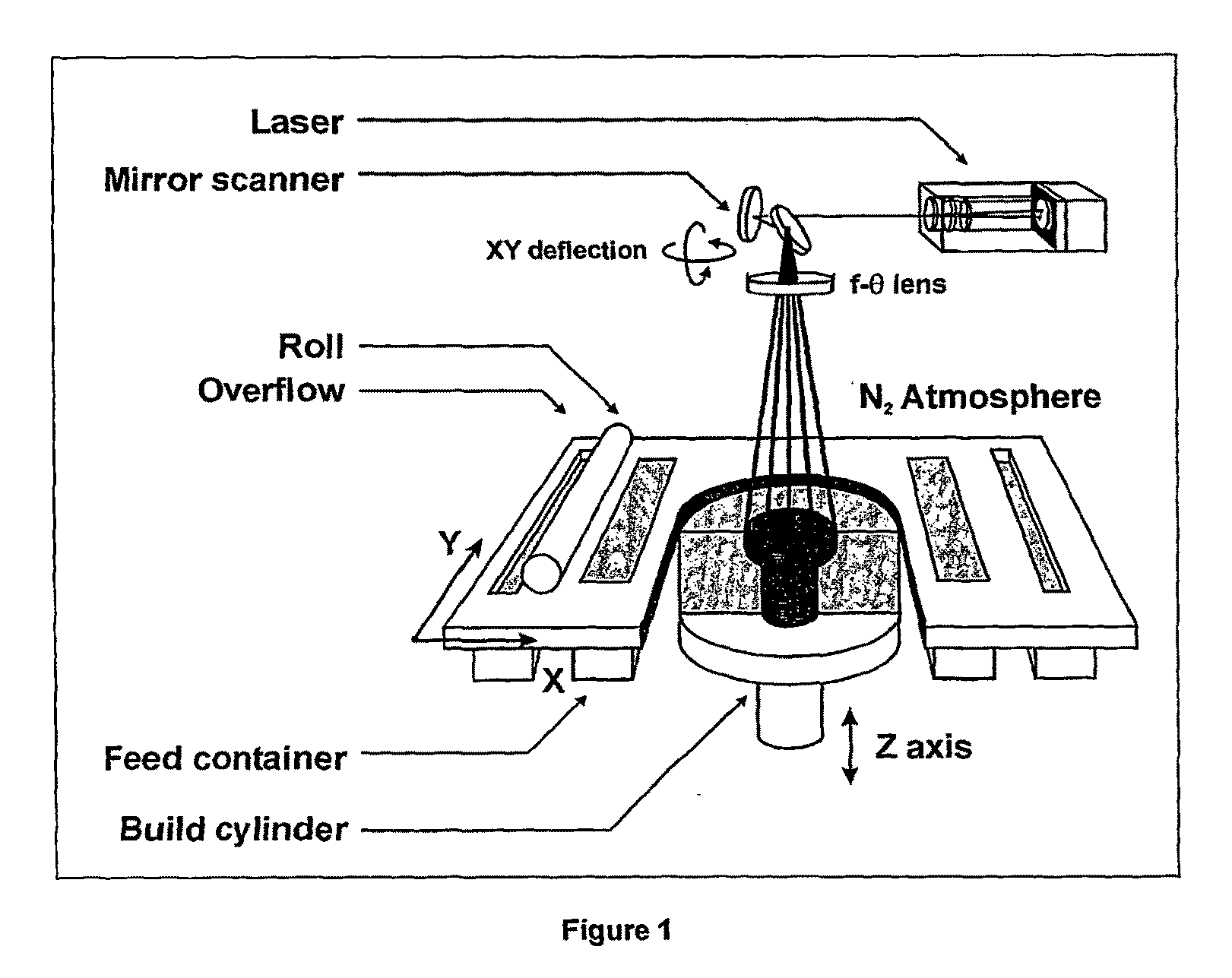

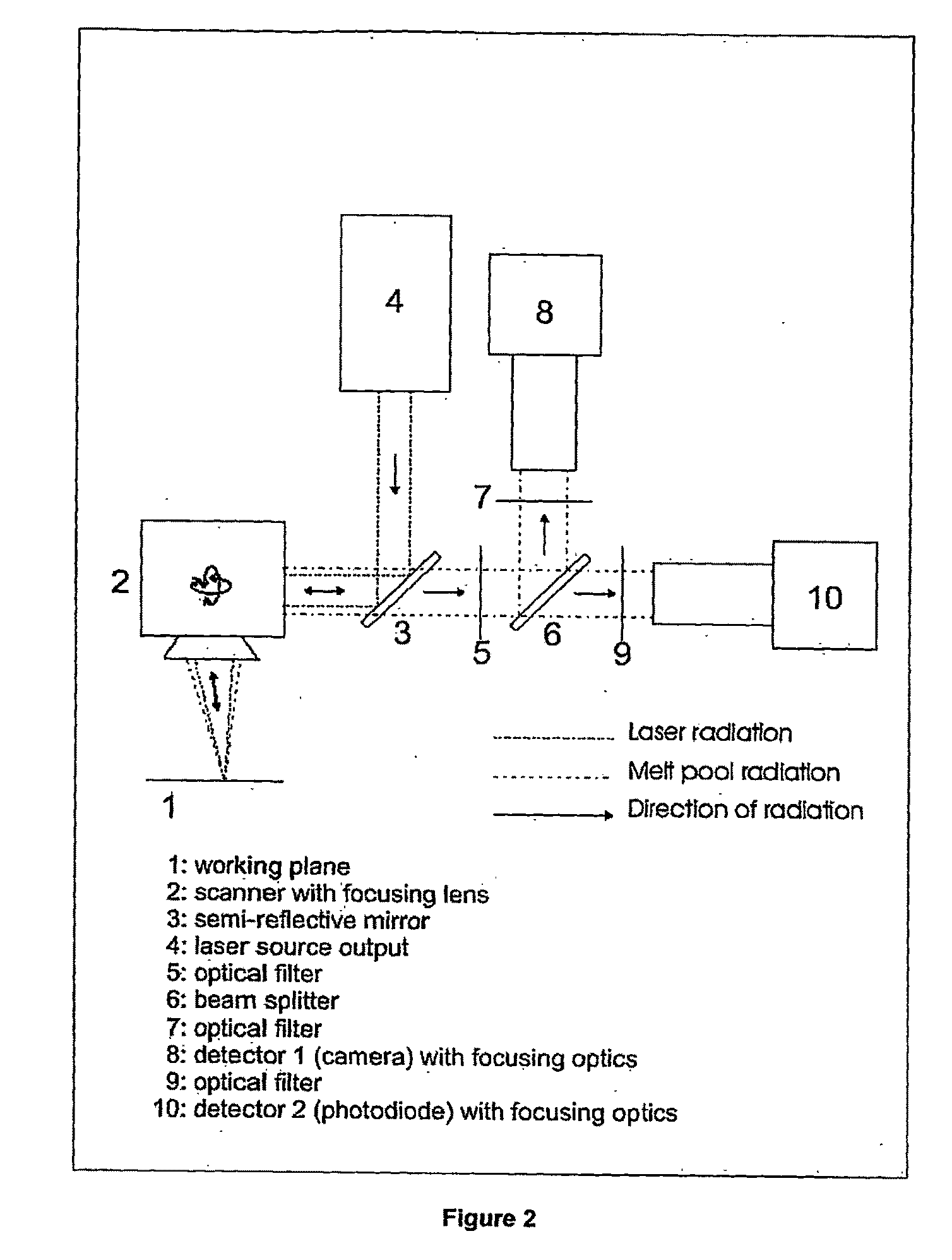

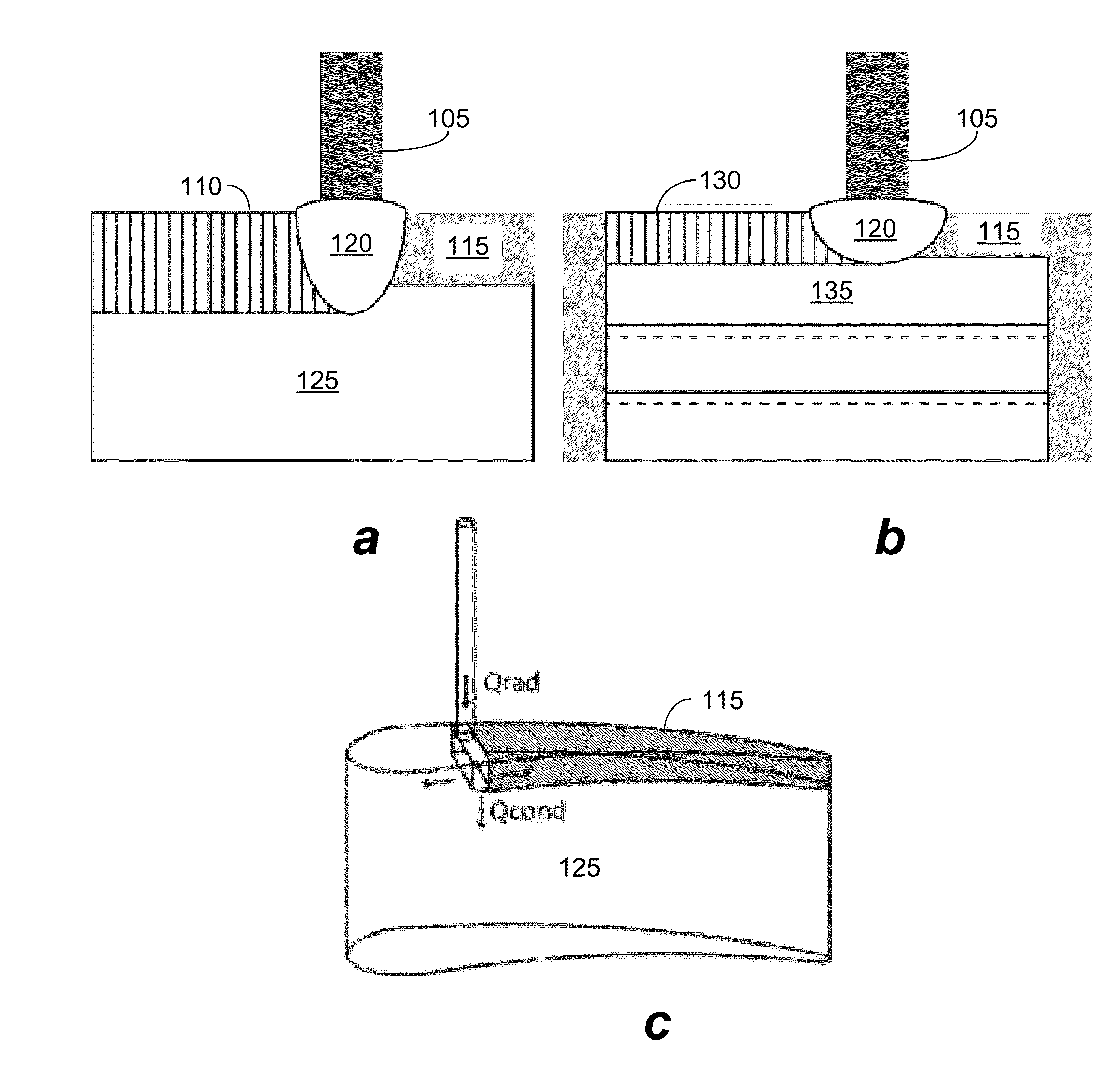

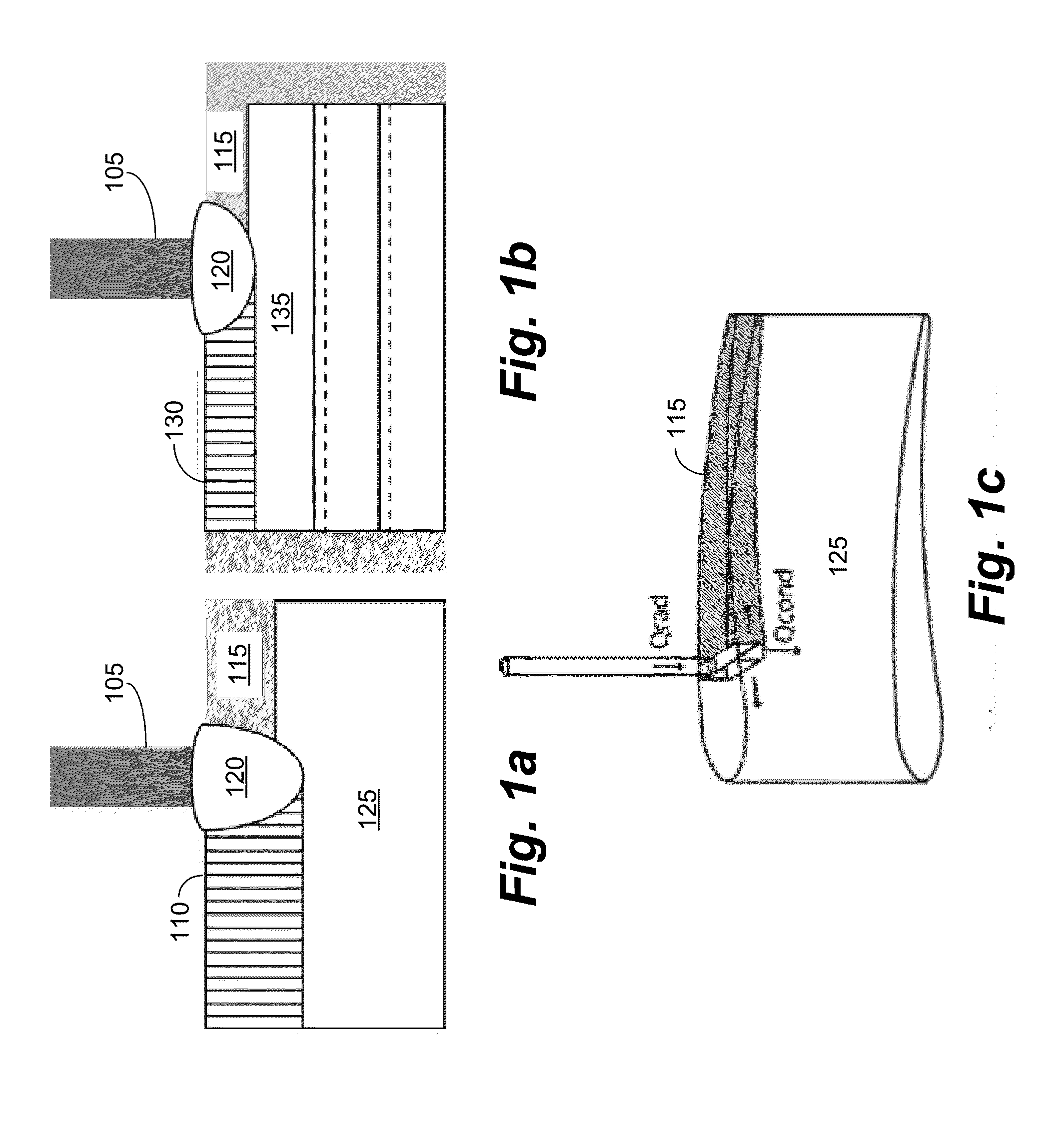

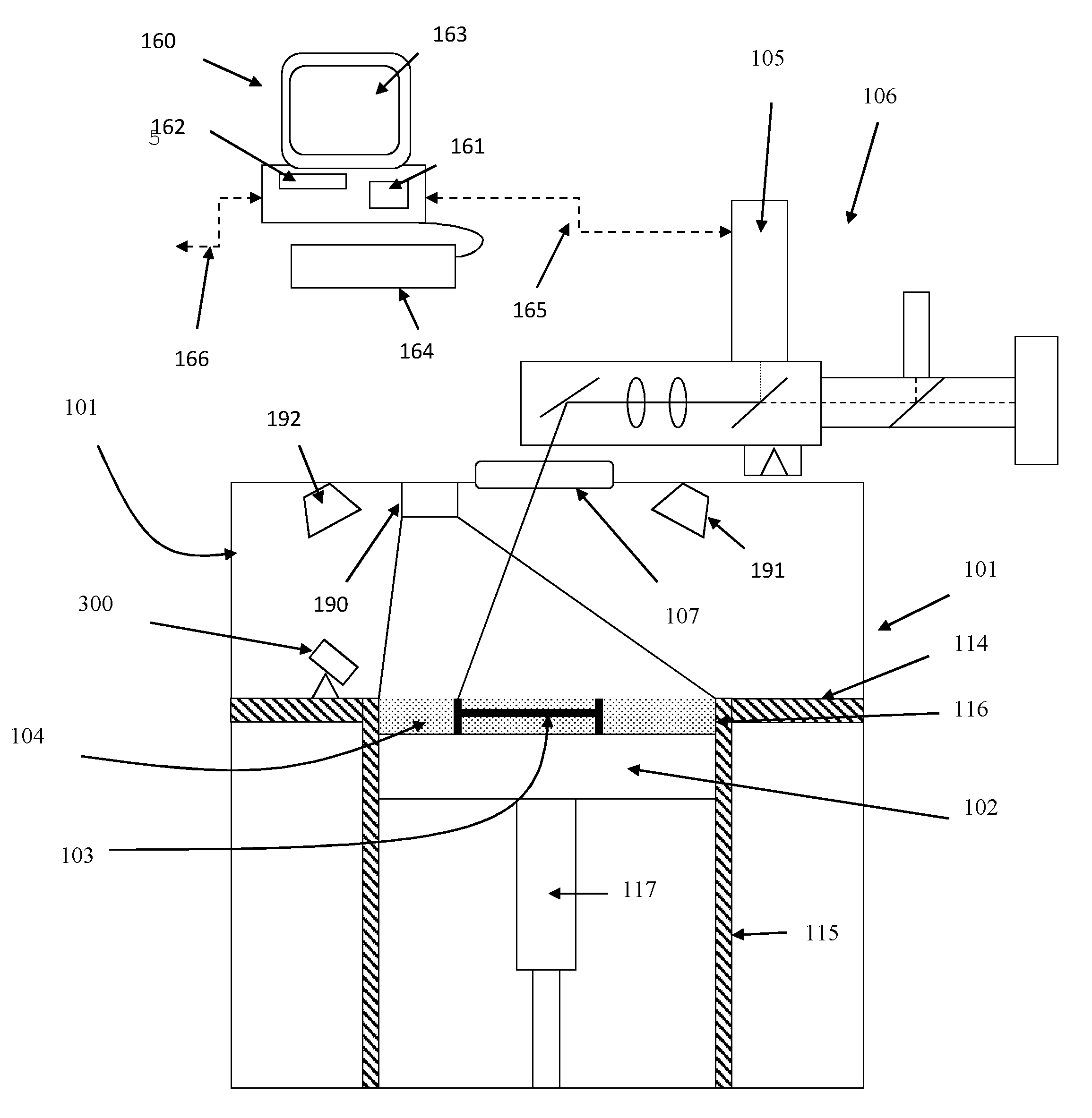

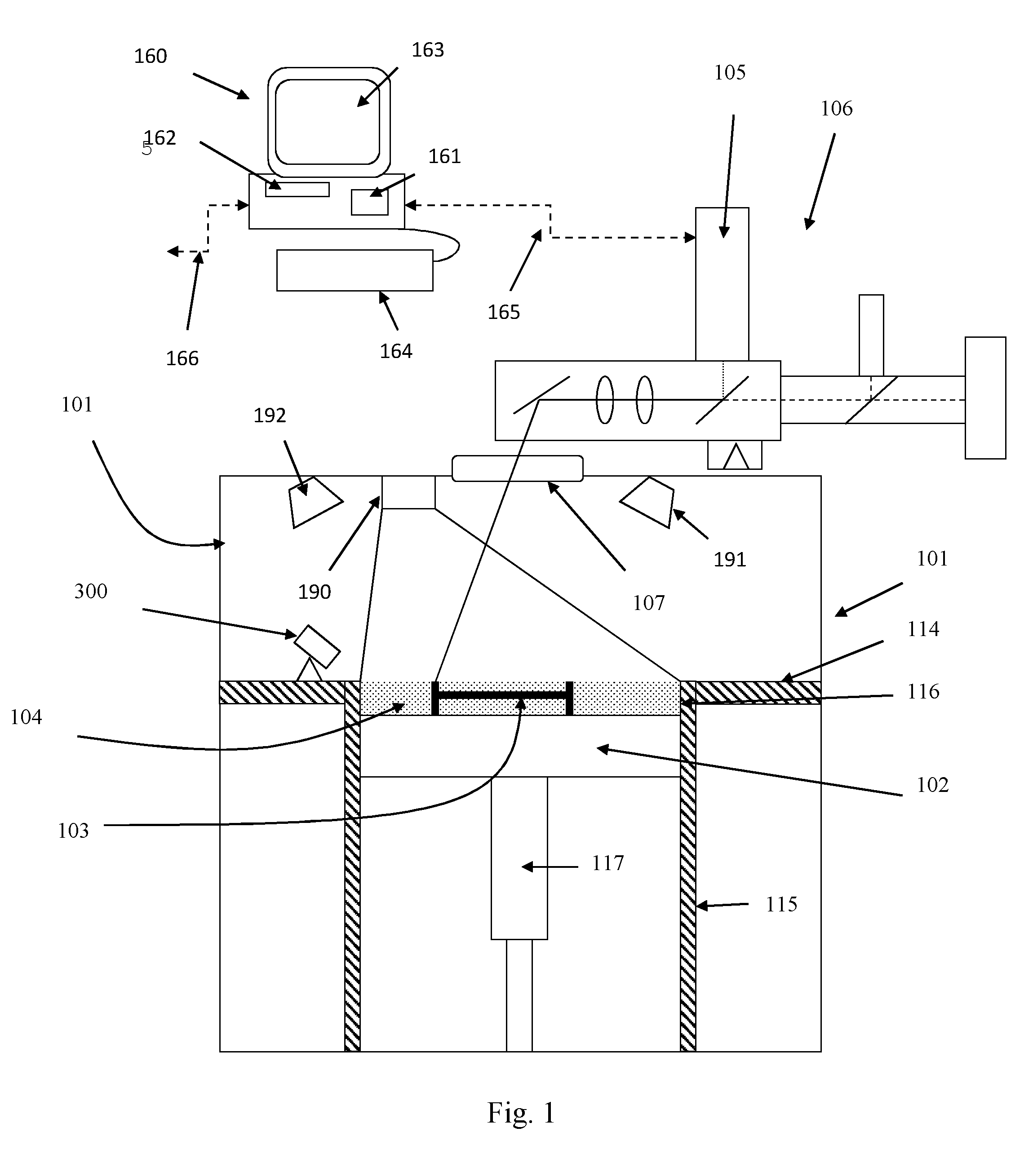

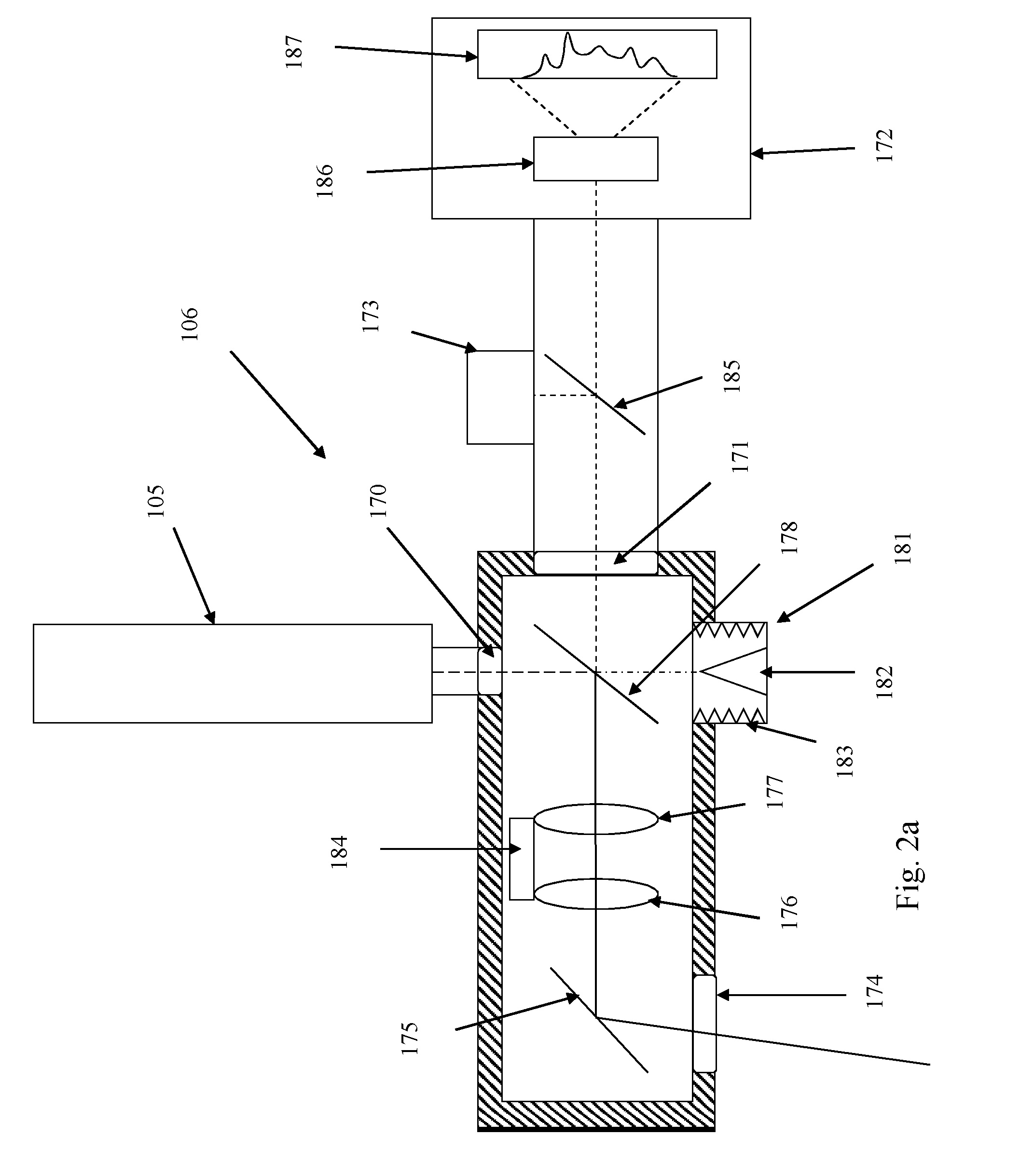

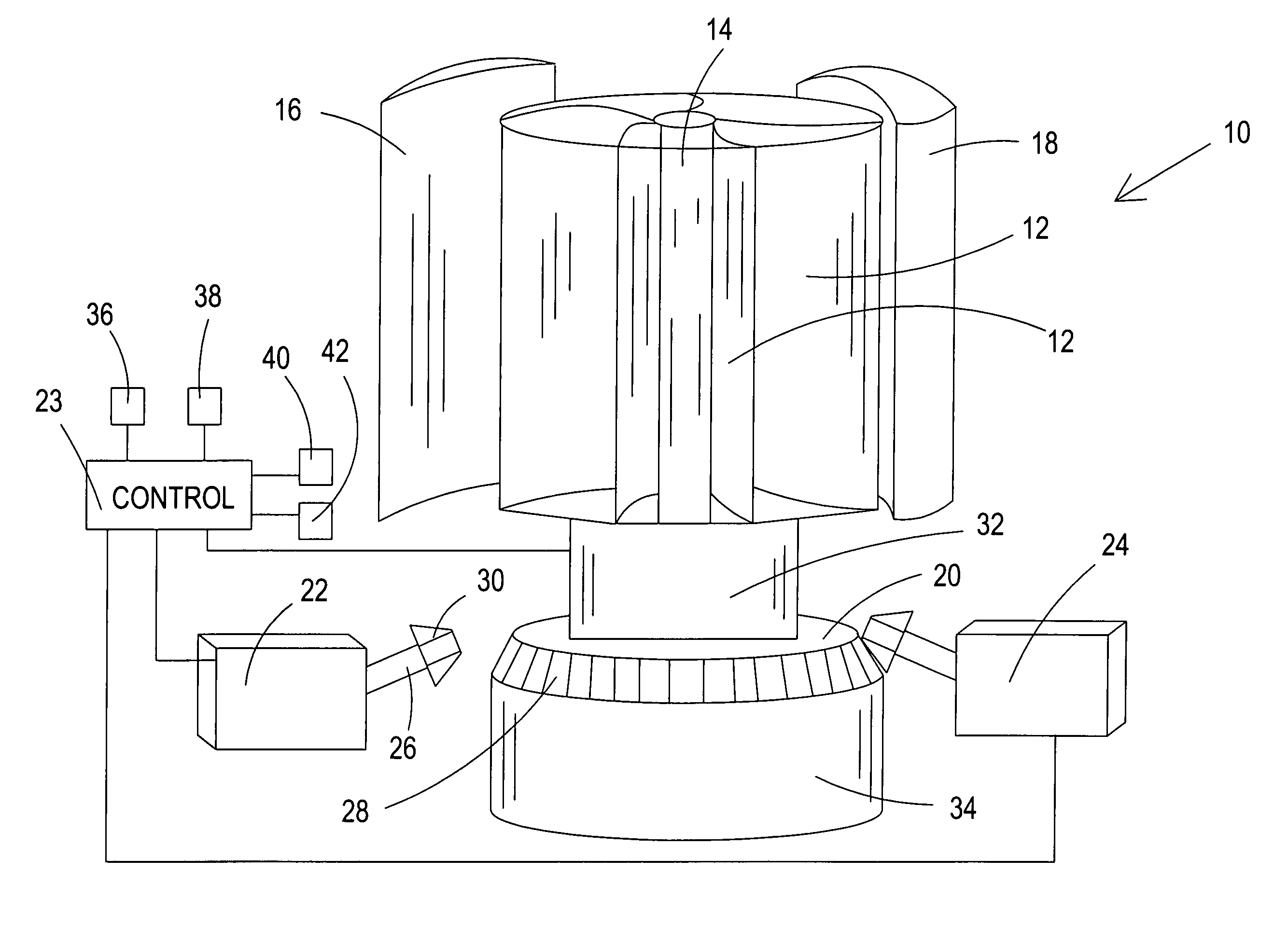

Procedure and apparatus for in-situ monitoring and feedback control of selective laser powder processing

InactiveUS20090206065A1Quality improvementReduce spectral distortionAdditive manufacturing apparatusIncreasing energy efficiencyControl systemFeedback controller

The present invention relates to a method and a device to monitor and control the Selective Laser Powder Processing. A Selective Laser Powder Processing device comprising a feedback controller to improve the stability of the Selective Laser Powder Processing process is presented. A signal reflecting a geometric quantity of the melt zone is used in the feedback controller to adjust the scanning parameters (e.g. laser power, laser spot size, scanning velocity, . . . ) of the laser beam (4) in order to maintain the geometric quantity of the melt zone at a constant level. The signal reflecting the geometric quantity of the melt zone can also be displayed in order to monitor the Selective Laser Powder Processing process. The present invention allows for the production of three-dimensional objects from powder material and improves the state of the art by compensating variations of the border conditions (e.g. local heat conduction rate) by a feedback control system based on a geometric quantity of the melt zone resulting in e.g. a lower amount of dross material when overhang planes are scanned.

Owner:KRUTH JEAN PIERRE +1

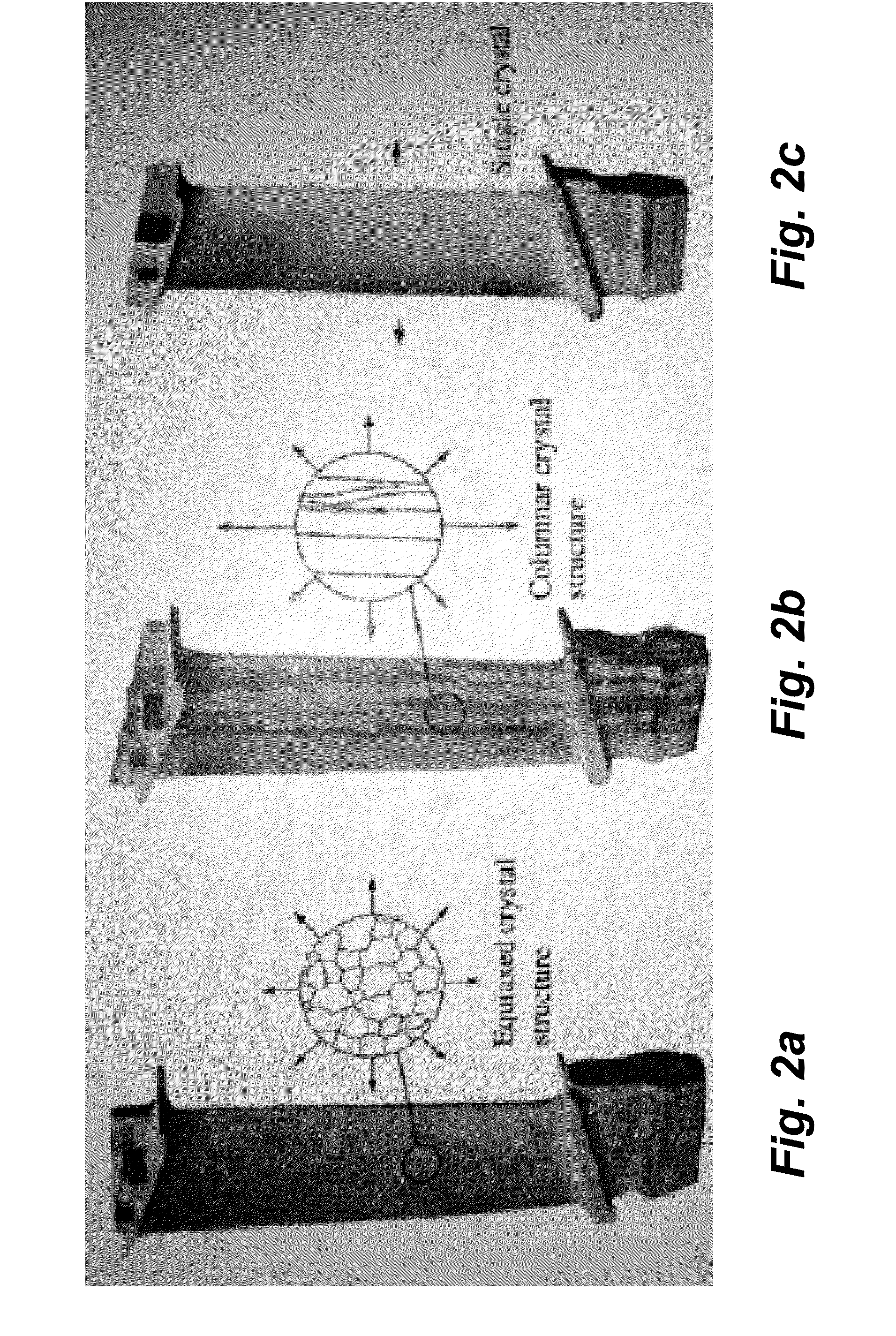

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

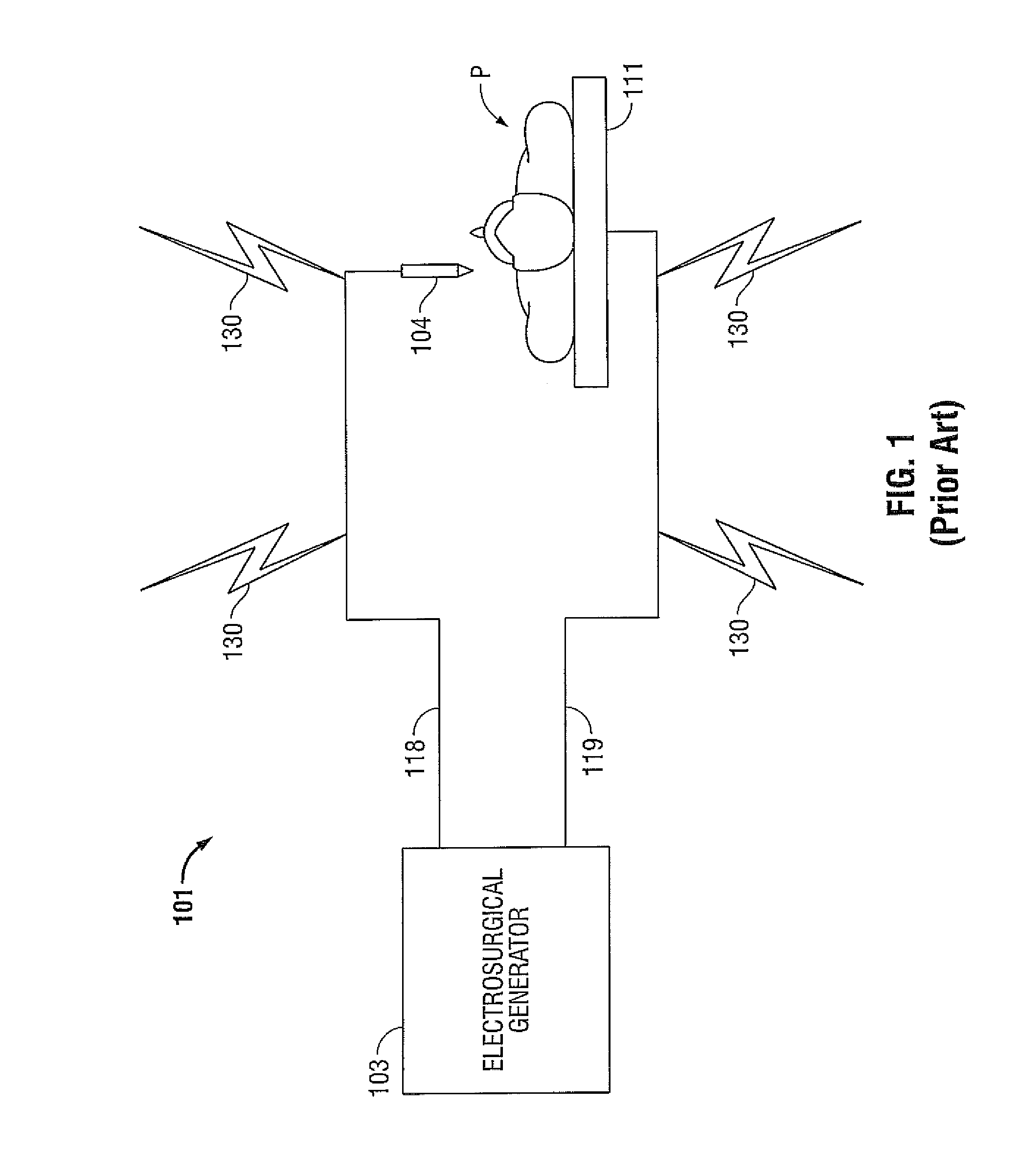

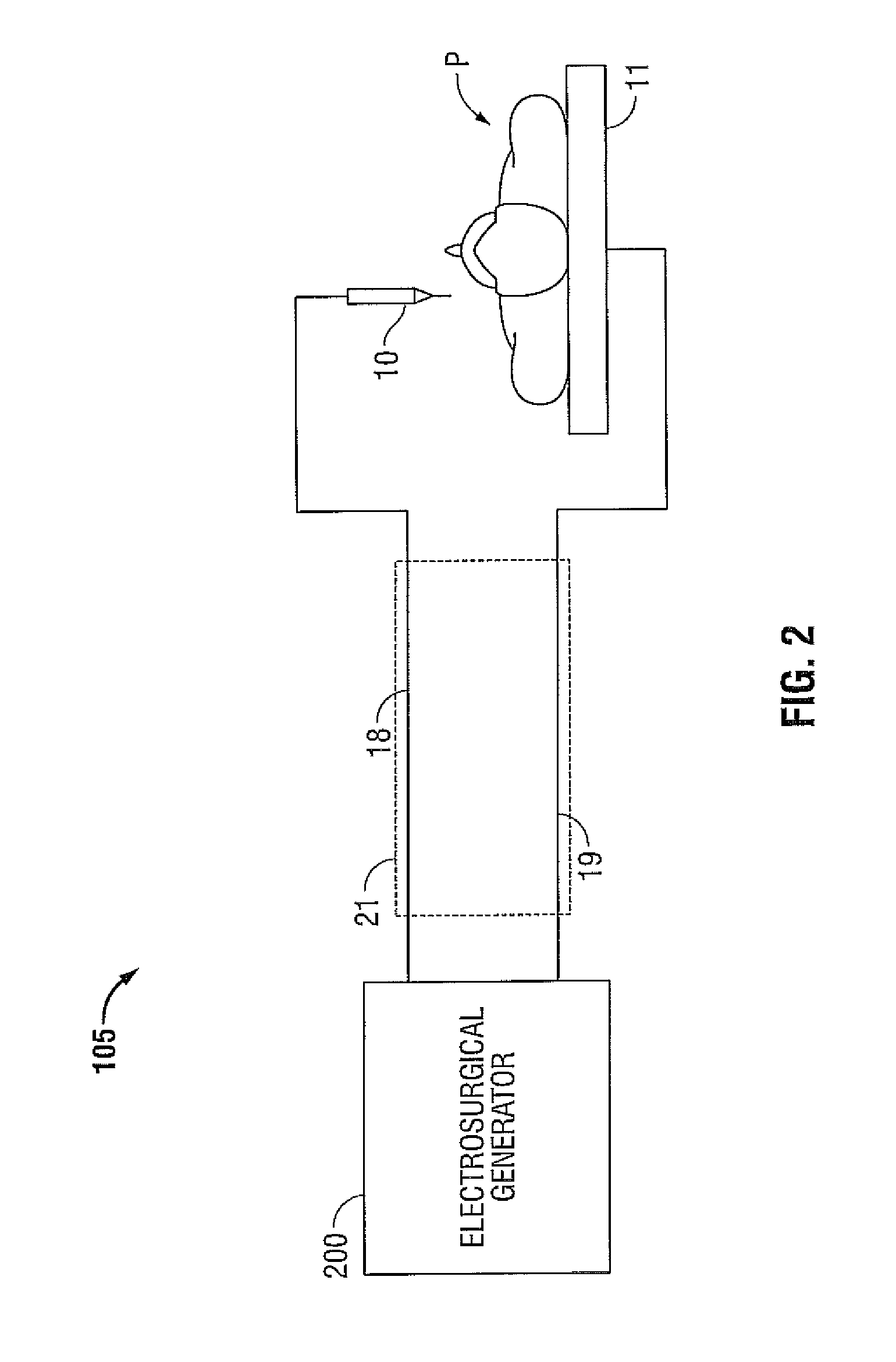

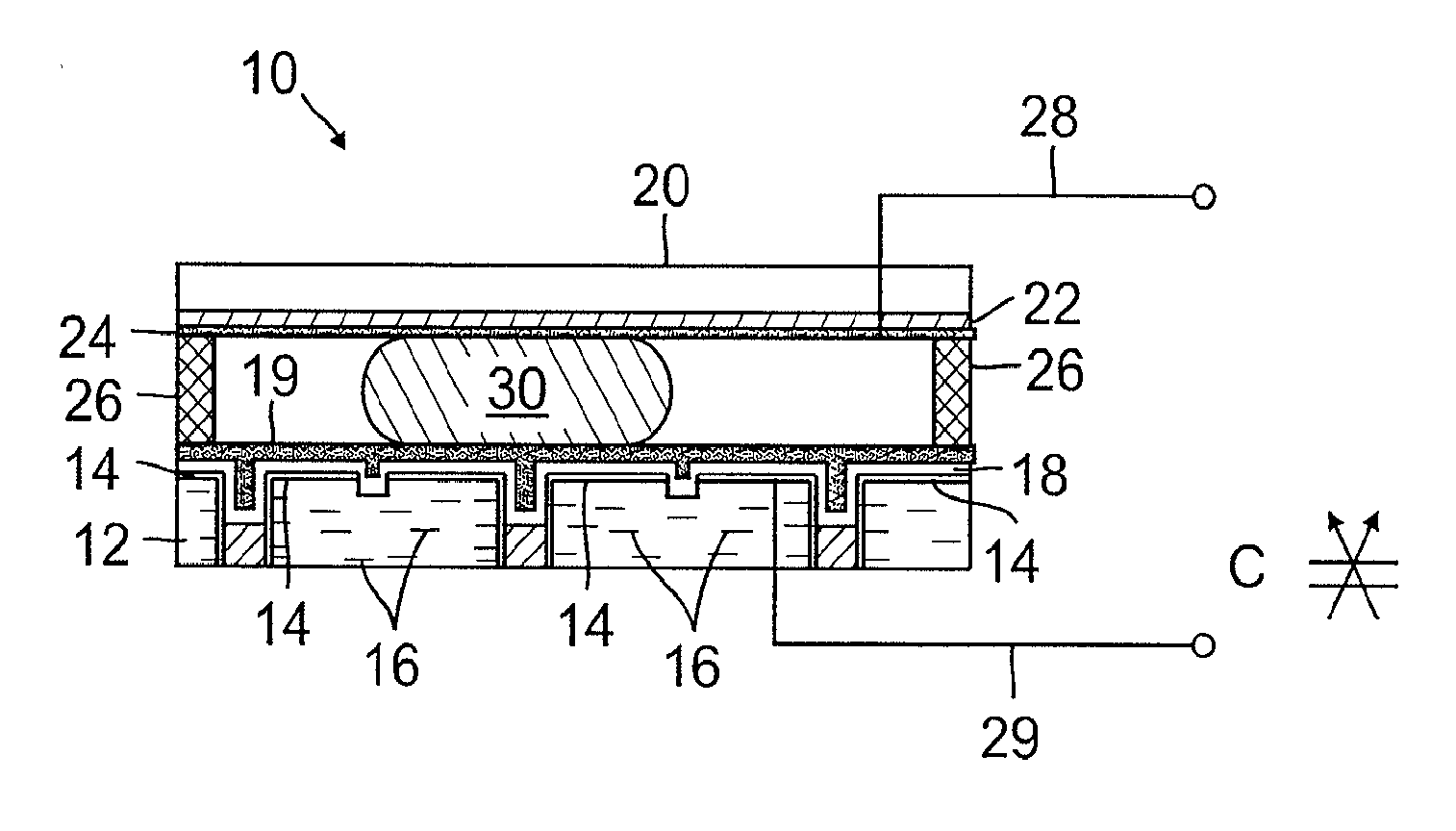

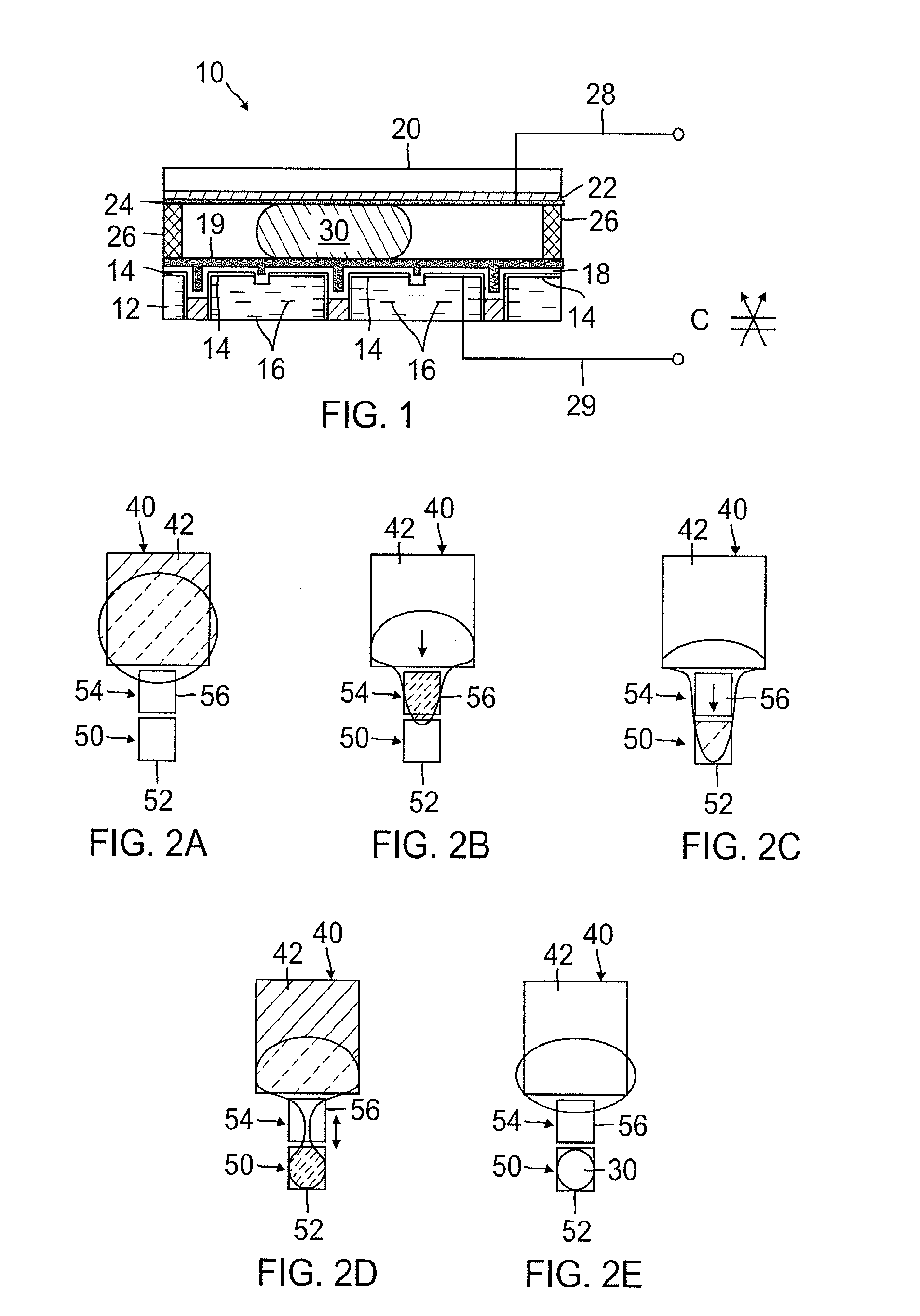

Electrosurgical apparatus with tissue site sensing and feedback control

InactiveUS9050089B2Maximize applicationReduce lossSurgical instruments for heatingFlexible cablesElectricityEngineering

An electrosurgical system and method for transmitting, monitoring, and controlling electrosurgical energy and tissue parameter quality at the tissue site. The electrosurgical system includes a generator adapted to generate electrosurgical energy for treating tissue. The generator includes one or more active output terminals which supply energy to the tissue. The active output terminals are operatively connected to one or more active leads. The generator also includes one or more return output terminal which returns energy from the tissue. The return output terminals are operatively connected to at least one return lead. The system also includes an electrosurgical instrument operatively connected to the one or more active leads and one or more return electrodes operatively connected to one or more return leads. The system further includes an electrosurgical cable including one or more active leads and one or more return leads. The one or more active leads and one or more return leads are wound in a double helix fashion such that the electrical field along the cable is mitigated along the length thereof.

Owner:TYCO HEALTHCARE GRP LP

Method and apparatus for real-time feedback control of electrical manipulation of droplets on chip

A device for generating droplets includes a substrate comprising a reservoir site configured to hold a liquid and including a first electrode, a droplet creation site including a second electrode, and droplet separation site disposed between the reservoir site and the droplet creation site and containing an electrode. The device includes control circuitry operatively coupled to the first, second, and third electrodes. The control circuitry is configured to measure the fluid volume on the electrodes and independently adjust an applied voltage to increase / decrease the quantity of fluid. The device can move fluid onto the creation site or back onto to the reservoir site. When the fluid volume is at the desired value or range, a driving voltage is delivered to the first and second electrodes to form a new droplet. The device may generate droplets having a uniform or user-defined size smaller than the electrode.

Owner:RGT UNIV OF CALIFORNIA

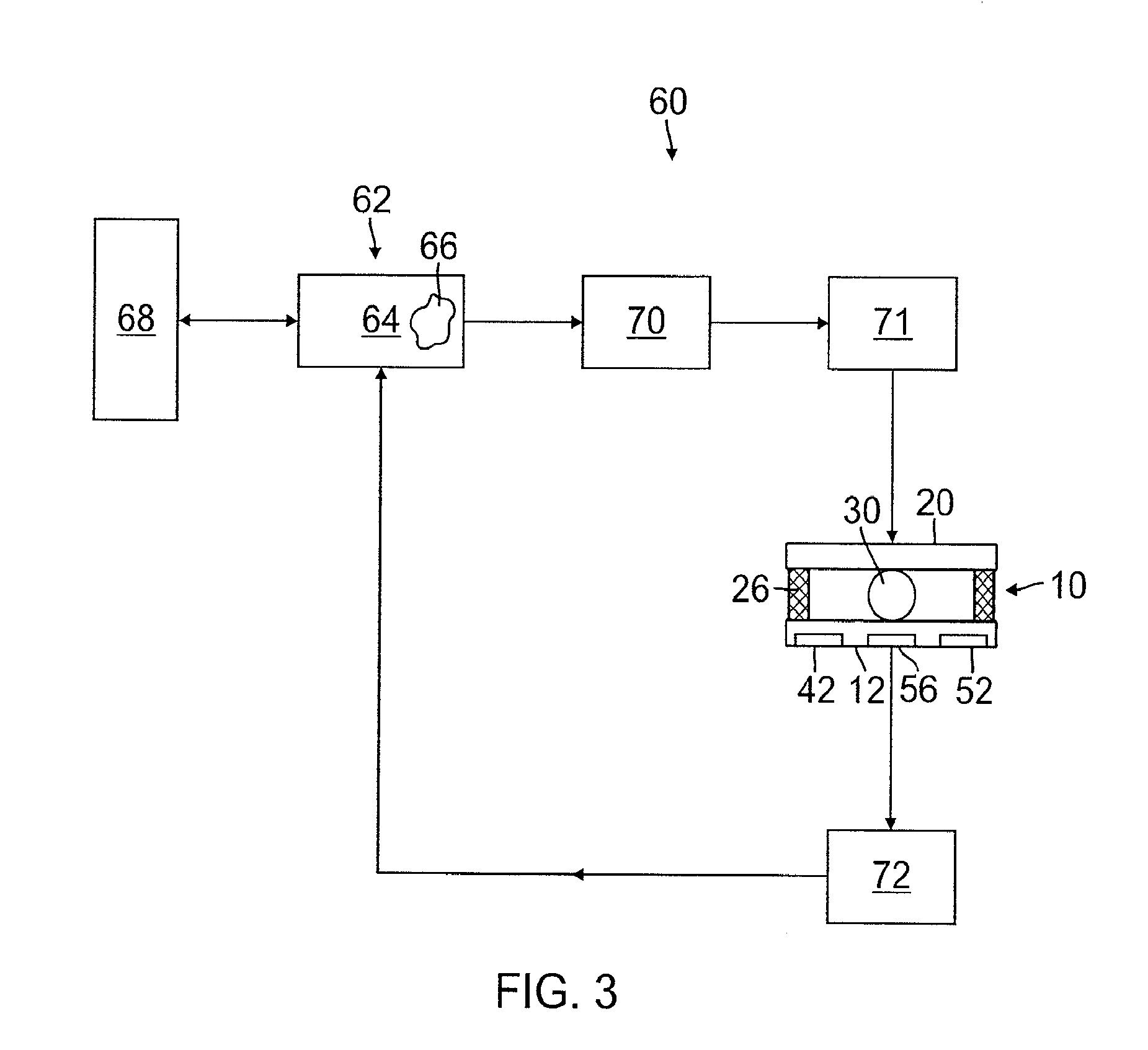

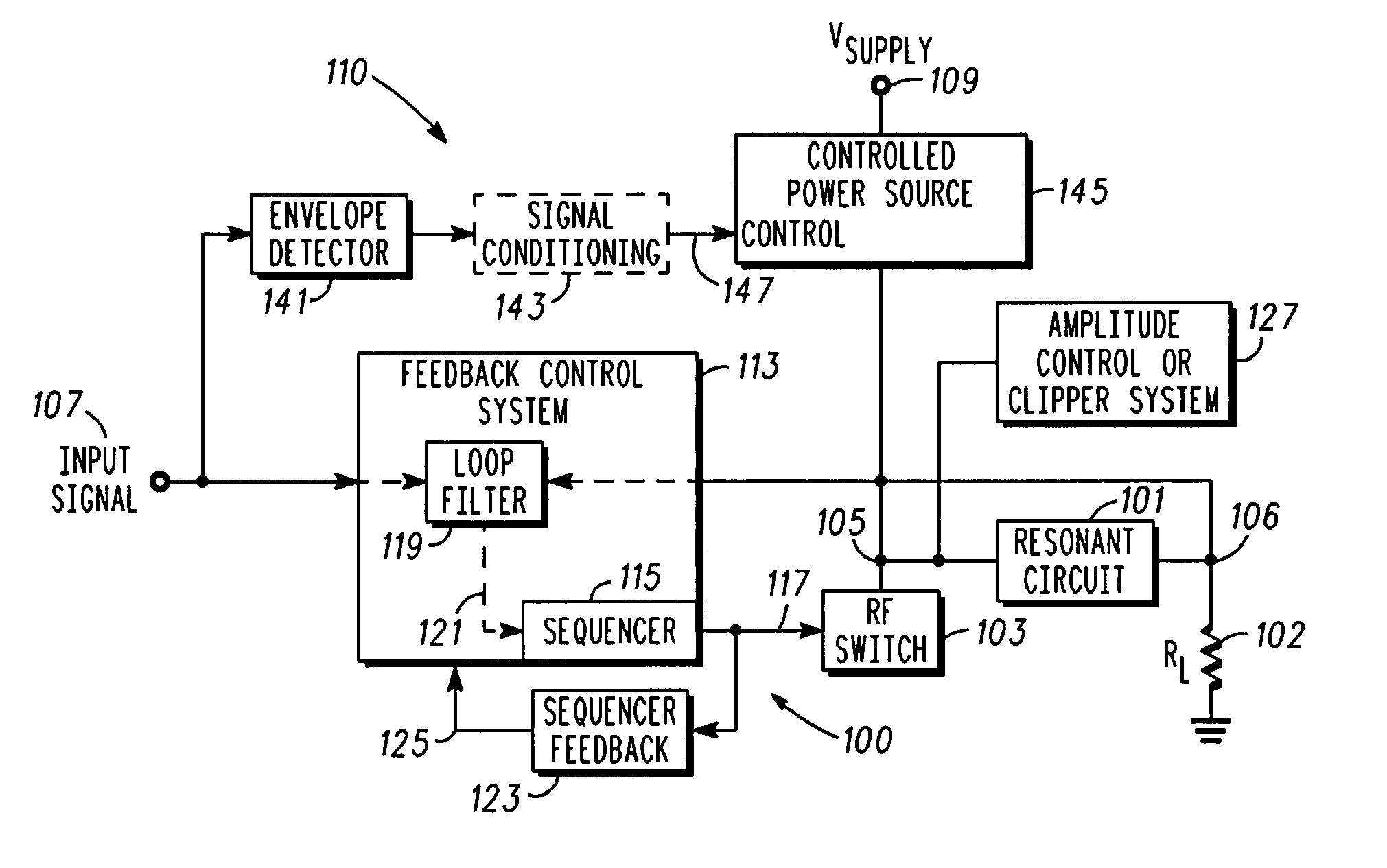

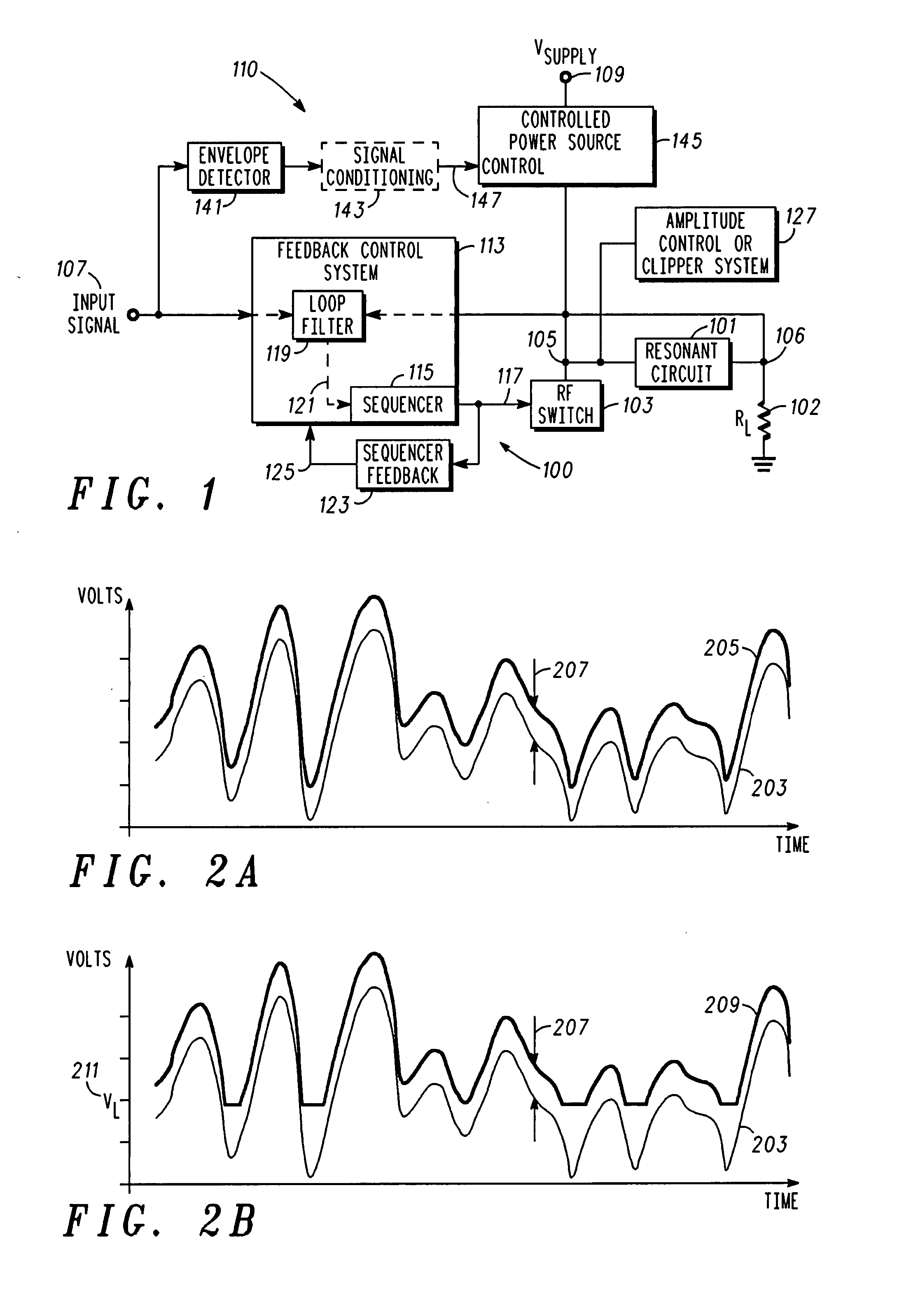

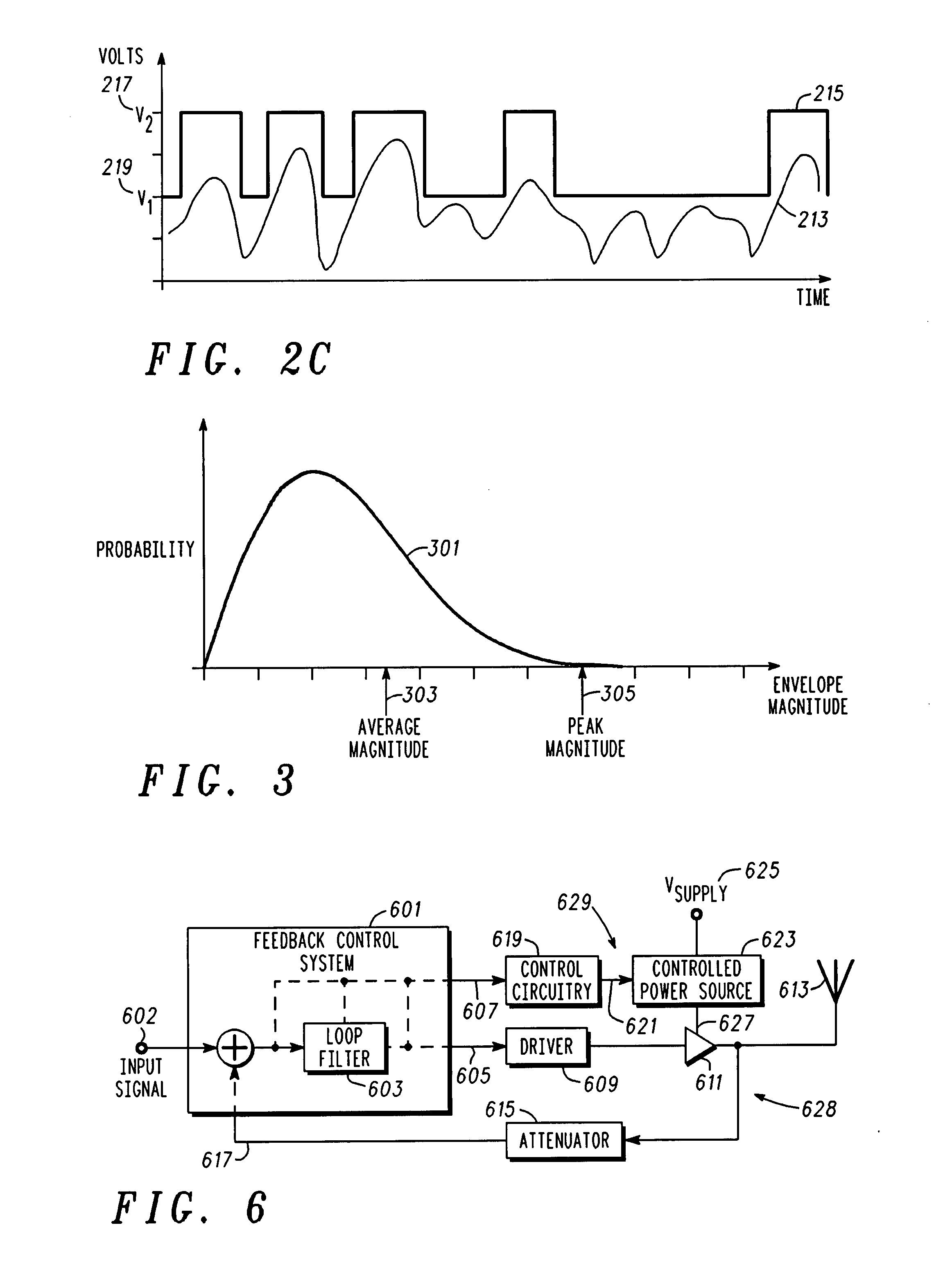

Radio frequency power amplifier and method using a controlled supply

A radio frequency power amplifier includes a feedback control system coupled to an input signal and a first feedback signal and configured to provide an output; a controlled supply configured to provide power that is controlled in accordance with a signal; and a radio frequency gain stage powered from the controlled supply, driven by the output from the feedback control system, and configured to provide an output signal at the radio frequency to a resonant load, where the first feedback signal corresponds to the output signal. Some embodiments include a sequencer in the feedback control system and others utilize an additional feedback loop to control the power provided by the controlled supply.

Owner:PWRF

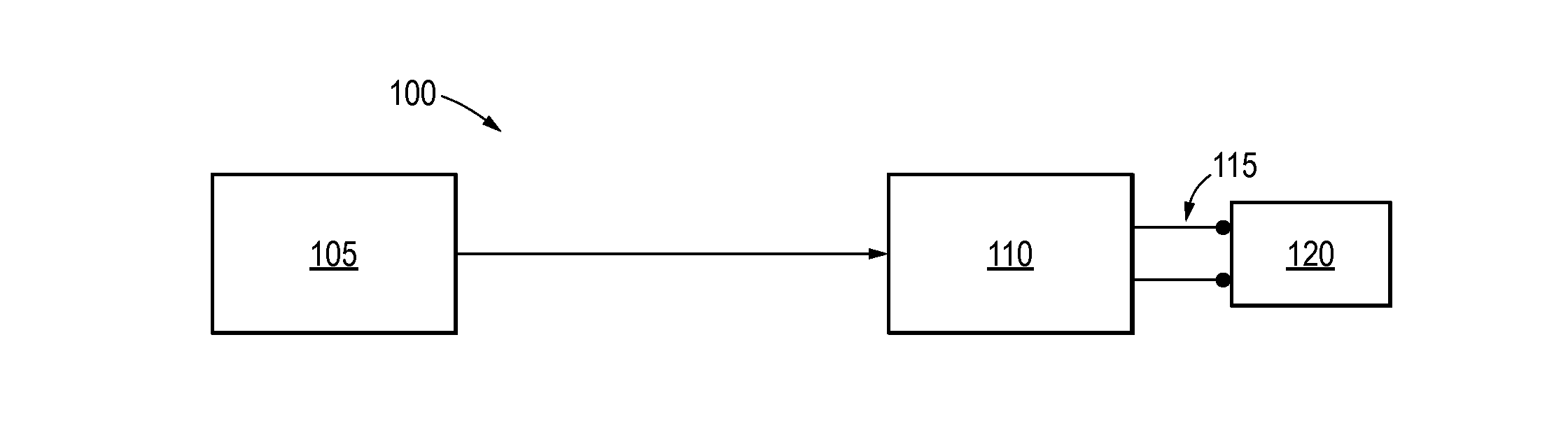

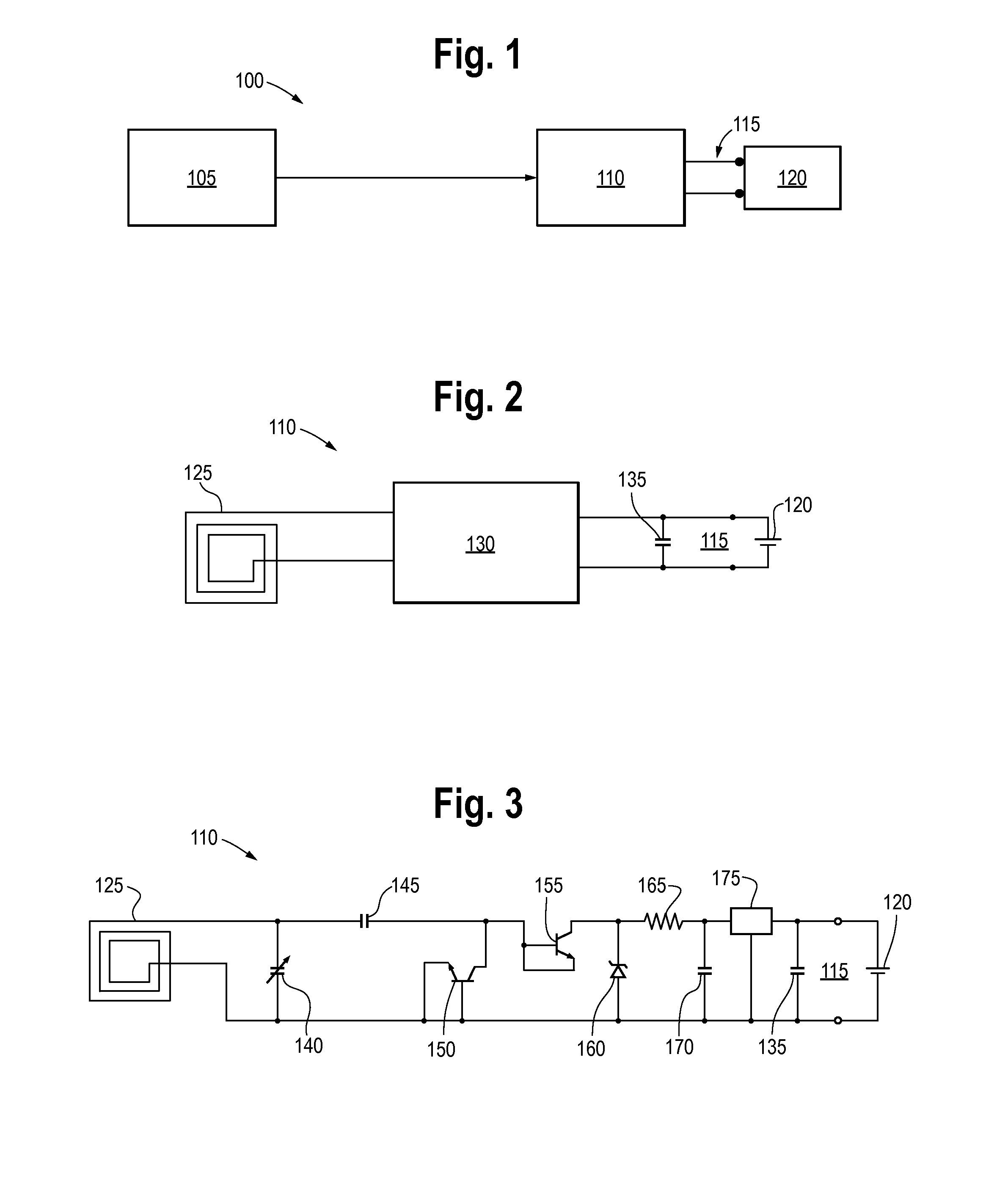

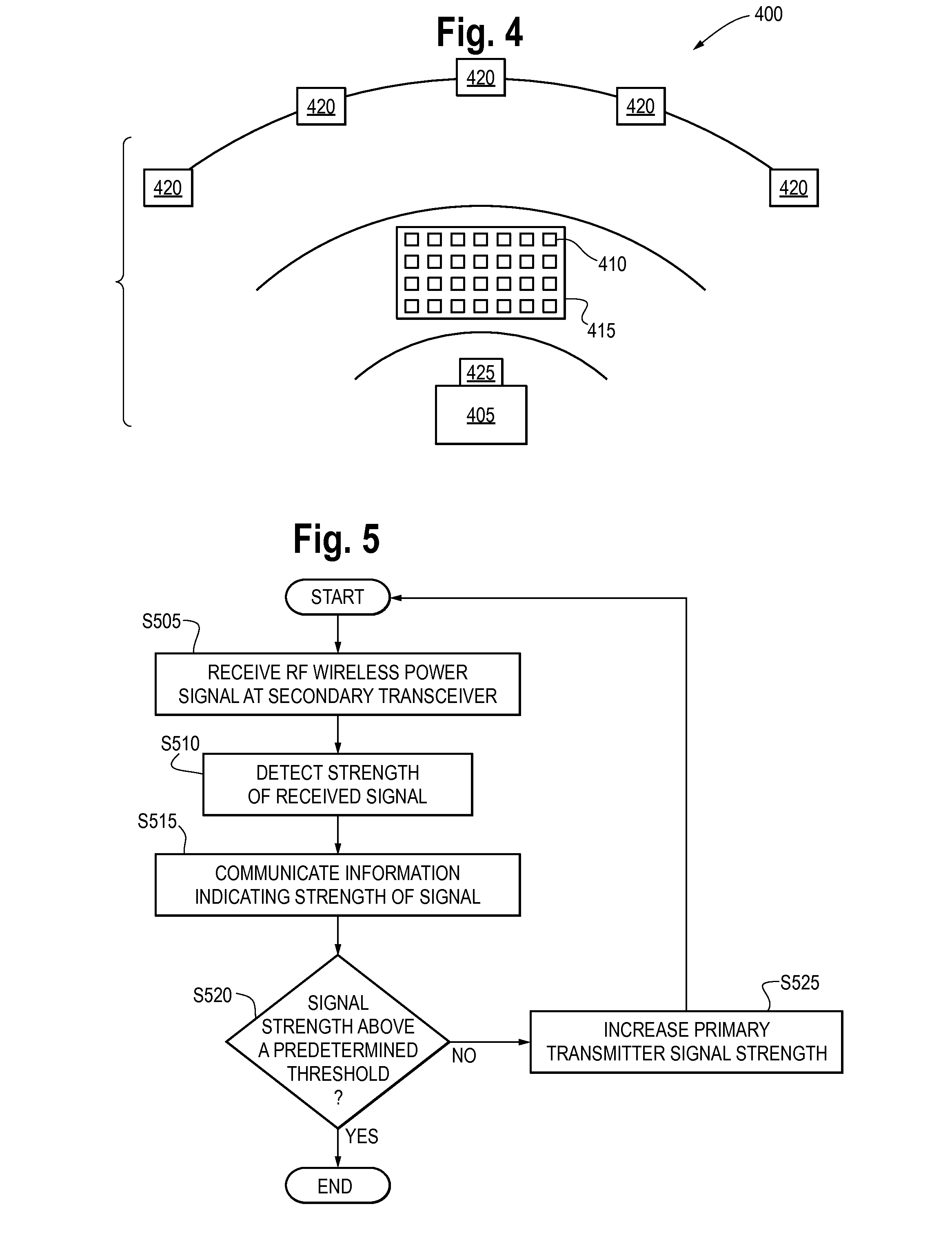

Wireless battery charging device, method and system

InactiveUS20130026982A1Simple and inexpensiveSimple and inexpensive systemElectromagnetic wave systemElectric powerBattery chargeEngineering

A battery charging device, method and system are disclosed for wirelessly charging a battery. A transmitter can transmit an RF wireless power signal to a battery charging device, and a receiver within the battery charging device can receive the RF wireless power signal. The battery charging device can thereafter transfer the received RF wireless power signal to a battery receiving portion to charge the battery. In an embodiment, the RF wireless power signal is transferred at a frequency of about 13.56 MHz to overcome wave shadowing. A battery recharging feedback control circuit can optionally be applied in combination with the battery charging device and can monitor a power quantity of the RF wireless power signal.

Owner:LIAO BATTERY SYST SHANGHAI

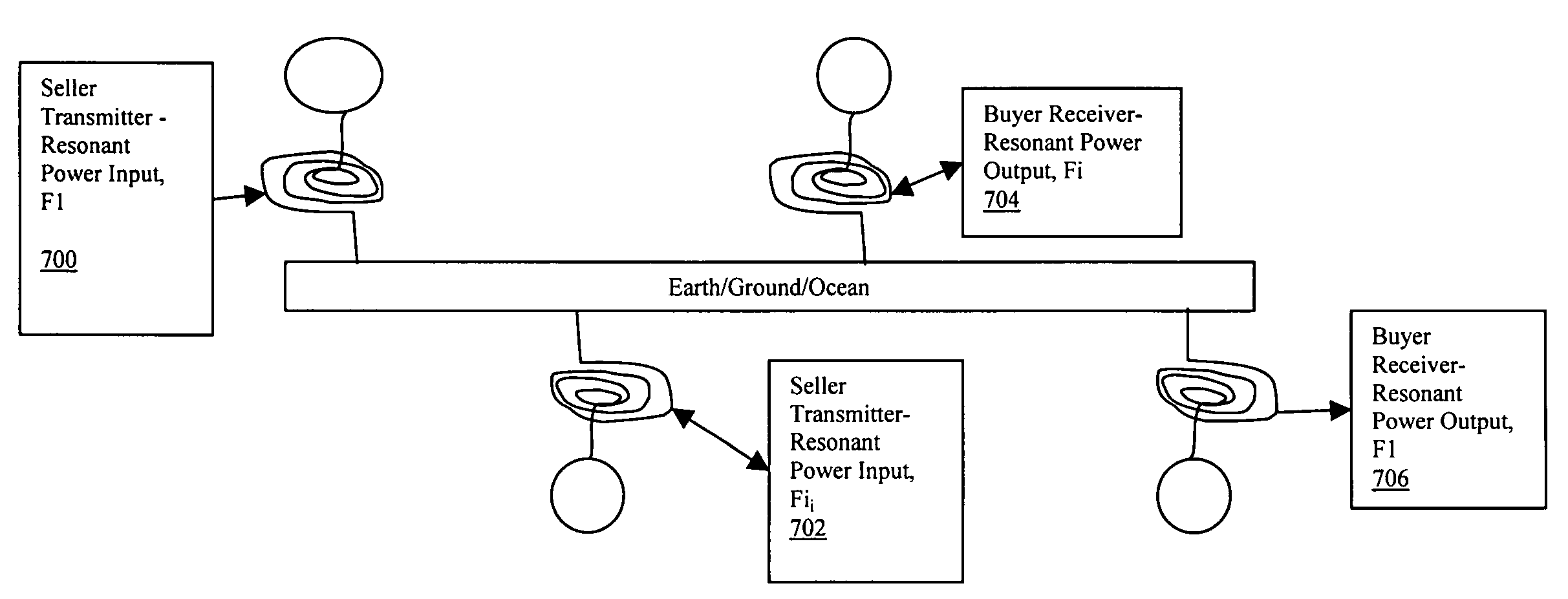

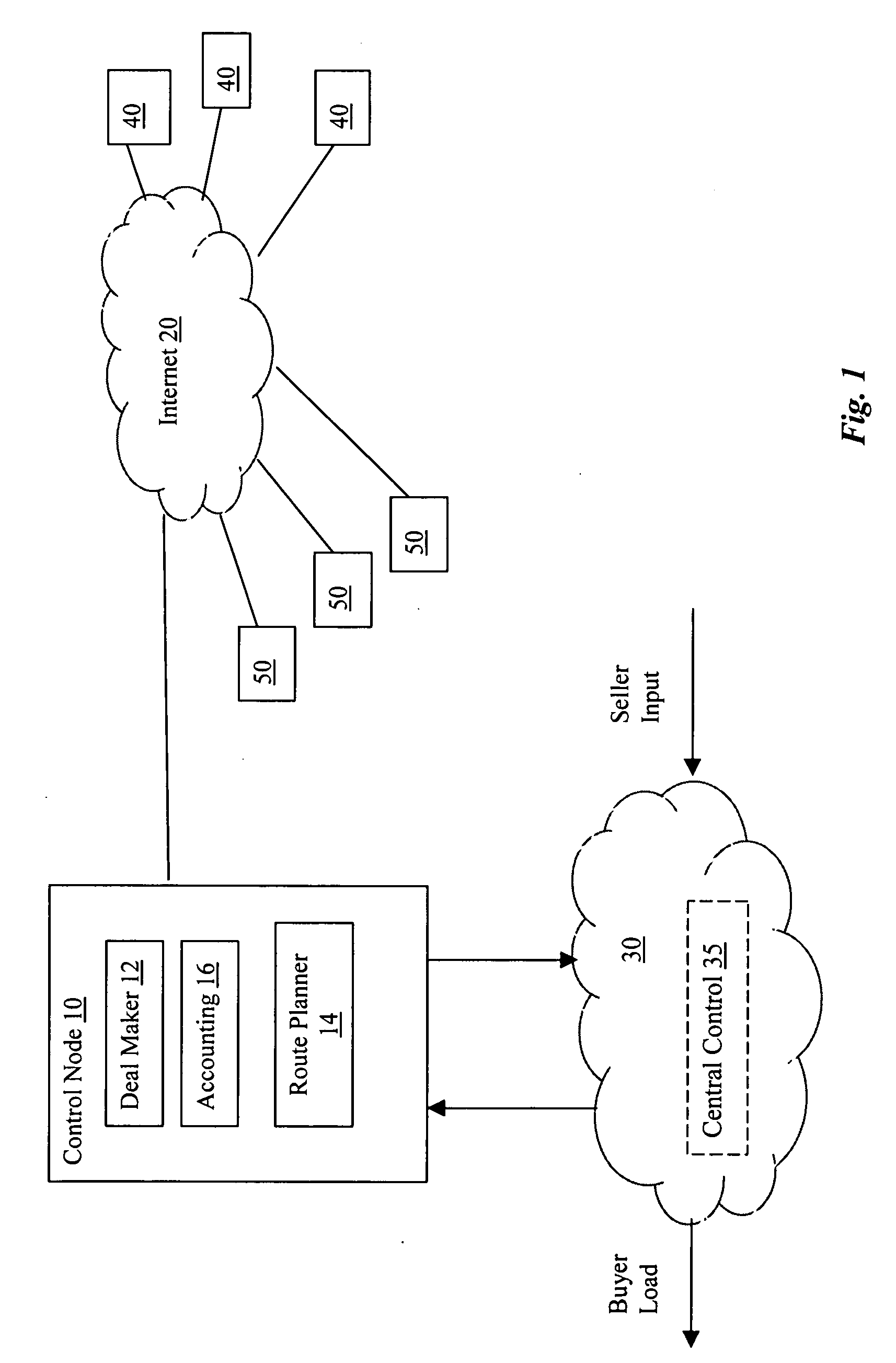

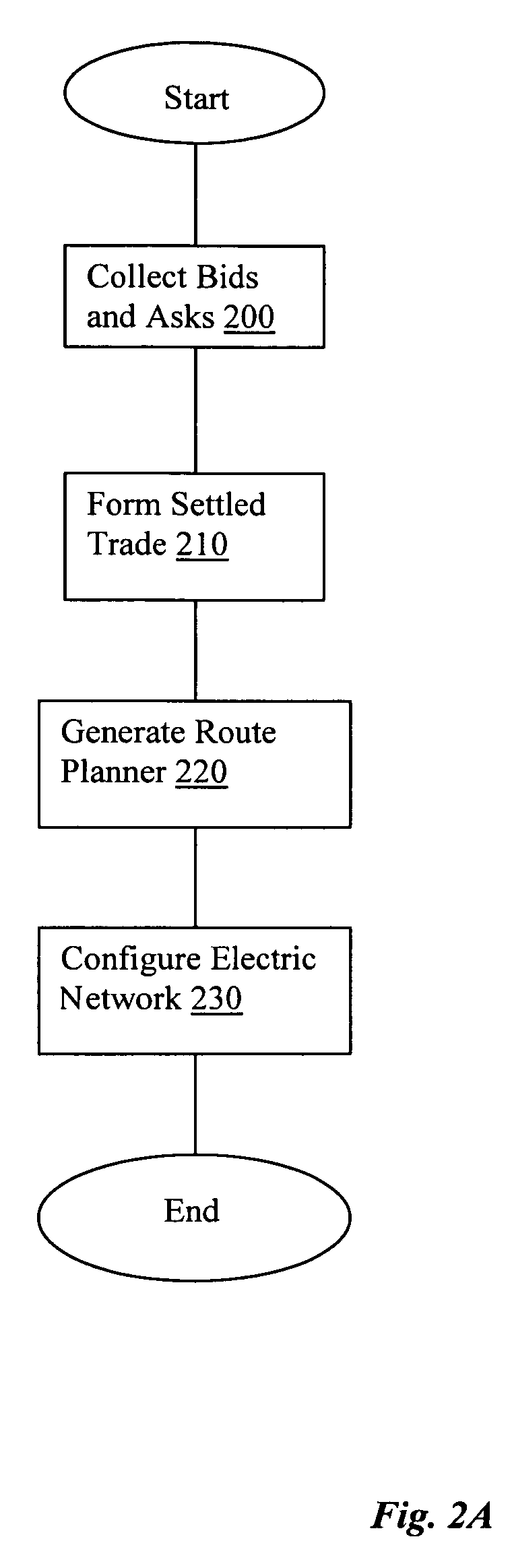

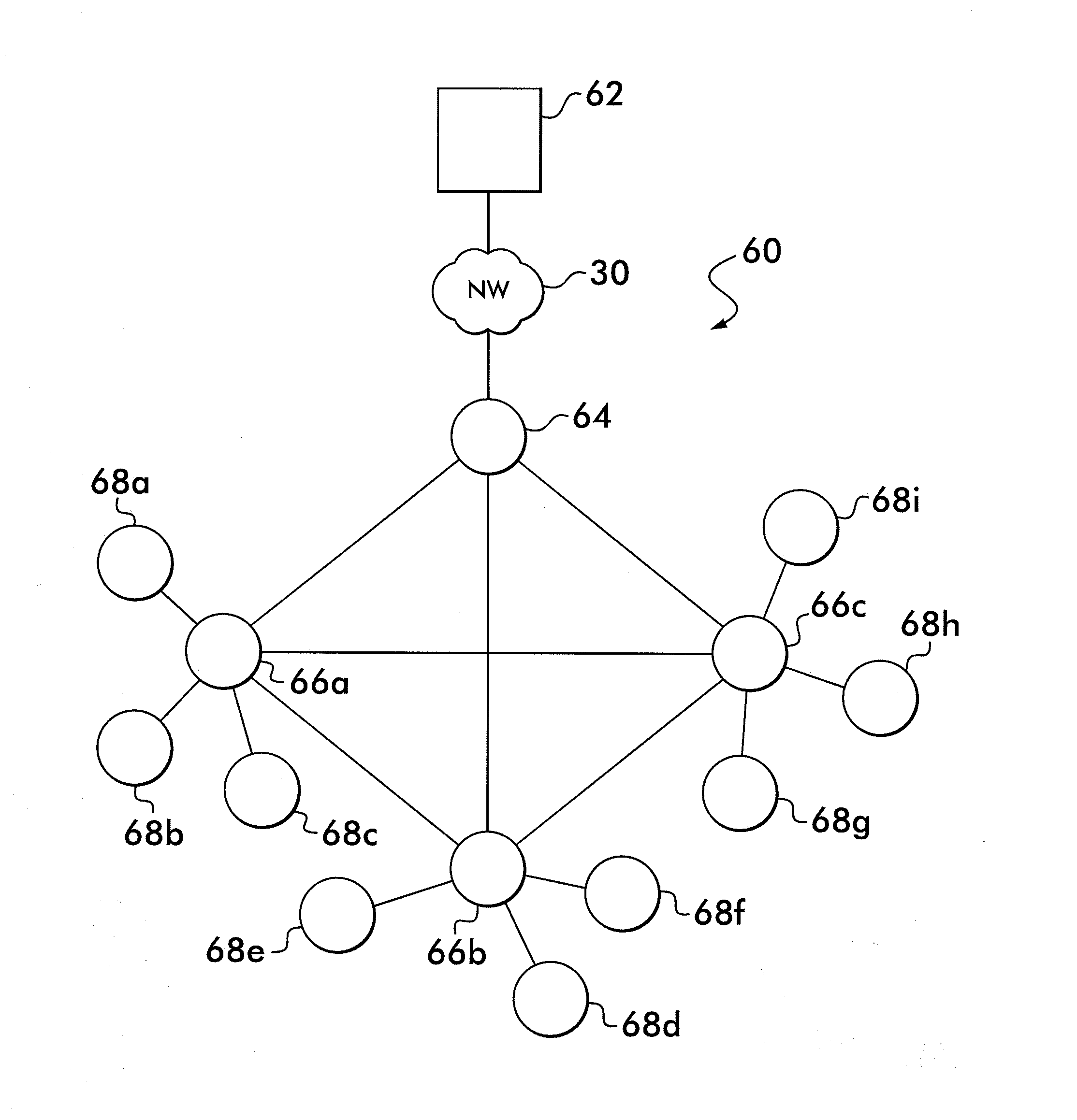

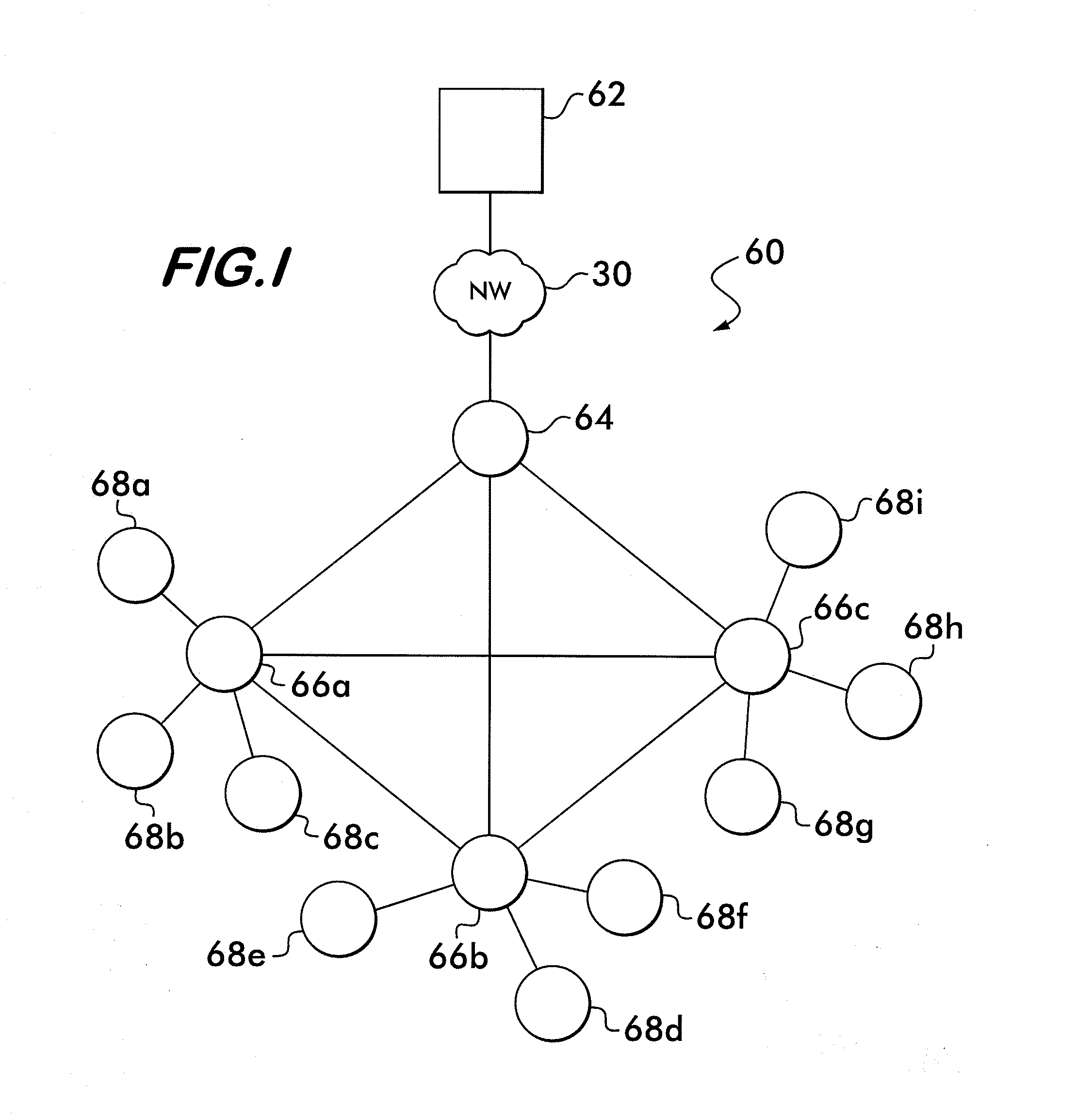

Intelligent Routing Of Electric Power

InactiveUS20080319893A1Facilitating online tradingCost-effectively manage their energy consumptionFinanceComputer controlElectric power systemDistribution system

A method and system for dynamically routing electric power in real time in accordance with parameters submitted by buyers and sellers of electric power using a feedback control scheme. A control node is arranged for receiving the parameters via a wide area network and to generate a route plan based on the parameters as well as current supply and demand in a network. The control node is also connected to the transmission and distribution systems to dynamically route electric power between matched buyers and sellers to effect the route plan.

Owner:GRID INNOVATIONS LLC +1

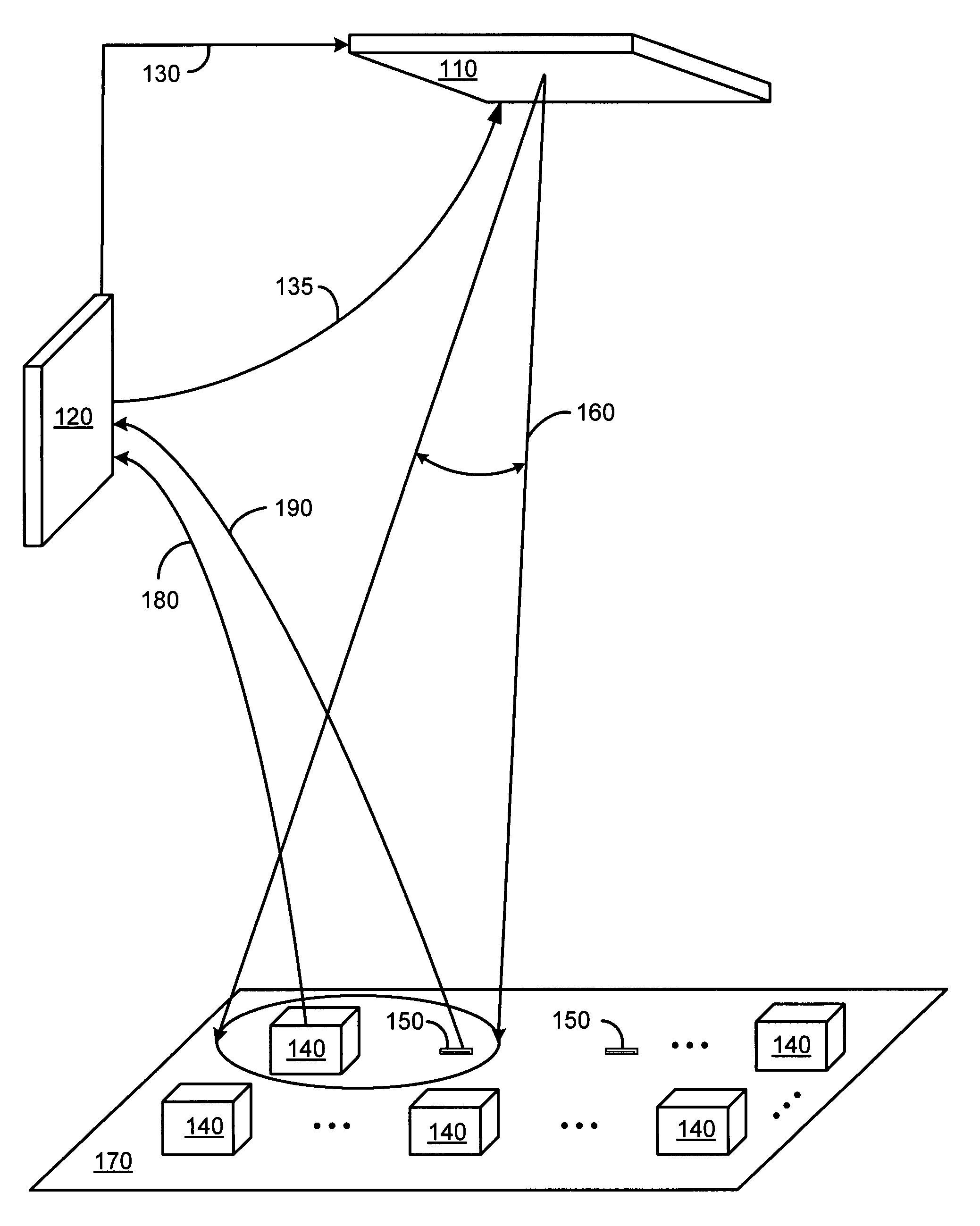

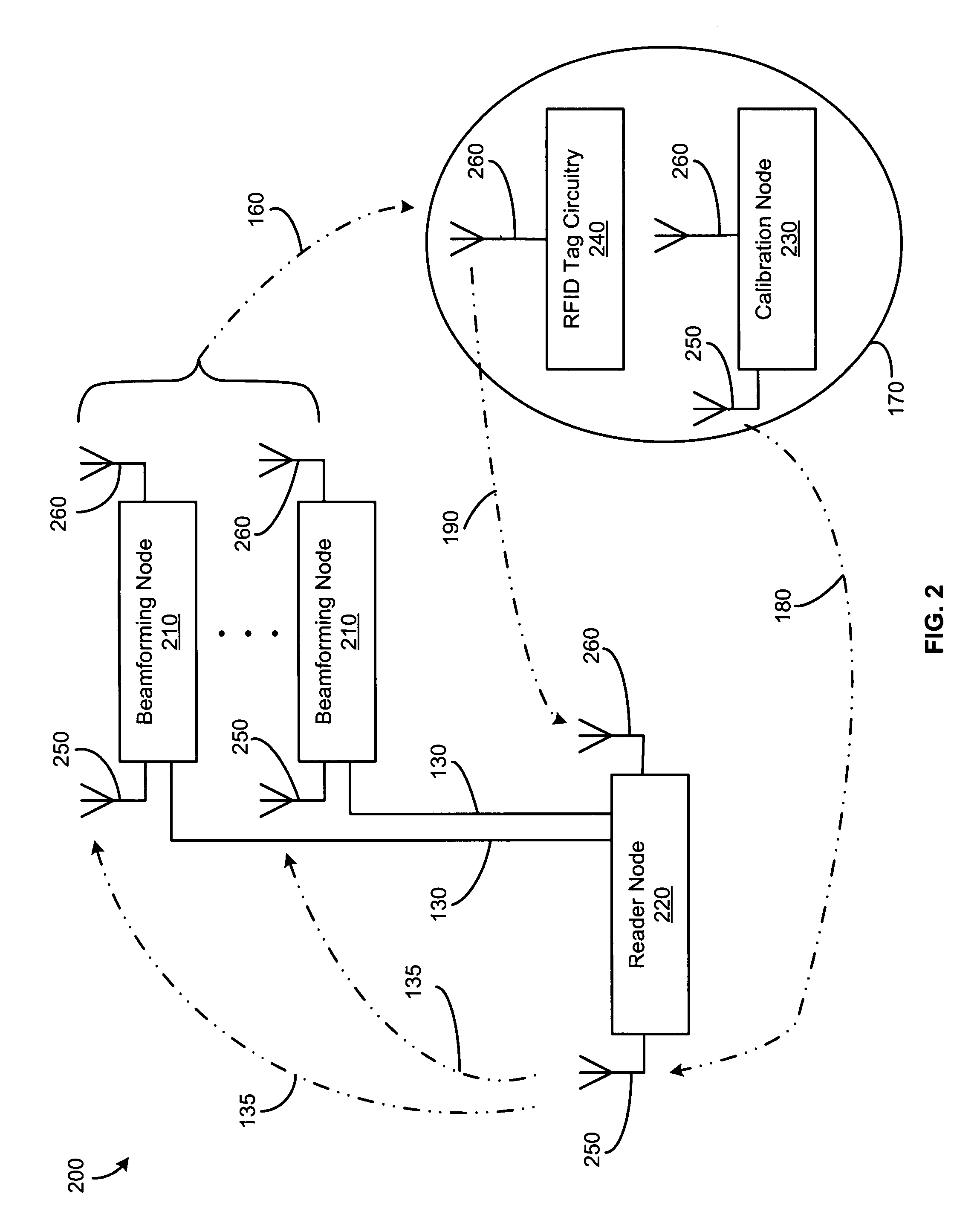

Systems and methods of beamforming in radio frequency identification applications

InactiveUS7652577B1Increased read rangeImprove reliabilitySensing record carriersBurglar alarm by hand-portable articles removalDistributed structureEngineering

Systems and methods for beamforming in radio frequency identification (RFID) applications are disclosed. A beamforming system uses a distributed architecture and techniques for antenna beamforming using a feedback control loop to direct radio frequency (RF) energy onto a specific region, referred to as an interrogation zone, which includes a calibration node where one or more RFID tags may be located. The distributed architecture of the beamforming system is resistant to fading and shadowing effects, providing accurate RFID reader operation even in environments with multi-path reflections or environmental changes, such as people moving around or changes in the location of equipment.

Owner:WIRAMA CORP +1

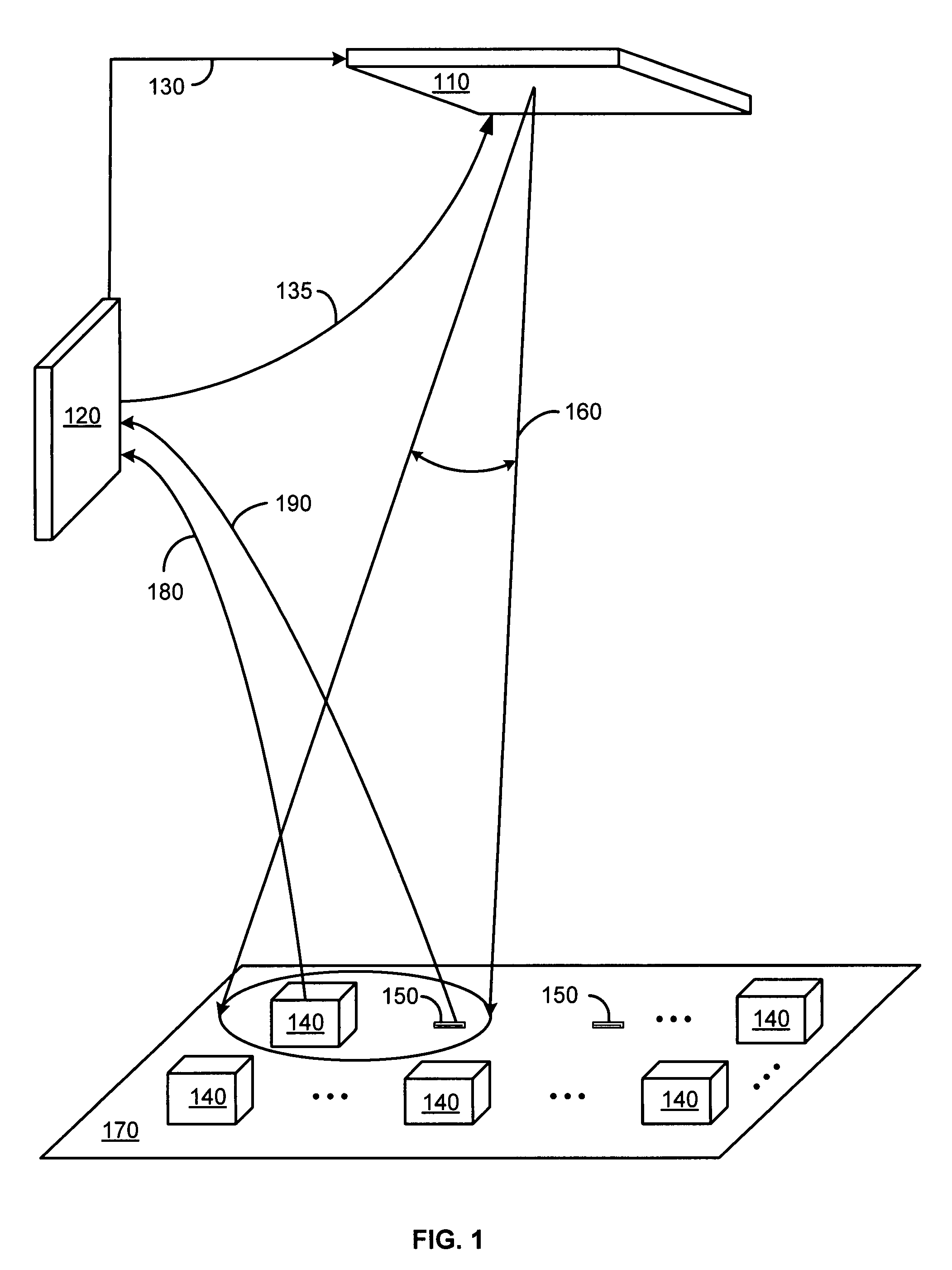

Calibration of Beamforming Nodes in a Configurable Monitoring Device System

InactiveUS20110080267A1Function increaseMultiplex system selection arrangementsTesting sensing arrangementsMonitoring systemEngineering

A system for radio frequency identification of a tag in an interrogation zone, includes a calibration node disposed in the interrogation zone to measure a signal strength of radio frequency identification signals from a beamforming system and provide signal data in accordance with the signal strength. A reader node is configured to receive the signal data and adjust the radio frequency identification signals generated by the beamforming system based upon the signal data. At least one of the calibration node, the reader node and the beamforming system is a configurable monitoring system. The calibration node, the reader node, and the beamforming system are coupled in a feedback control loop. The beamforming system includes a plurality of beamforming nodes. A signal of at least one beamforming node is optimized in accordance with the feedback control loop.

Owner:CHECKPOINT SYST INC

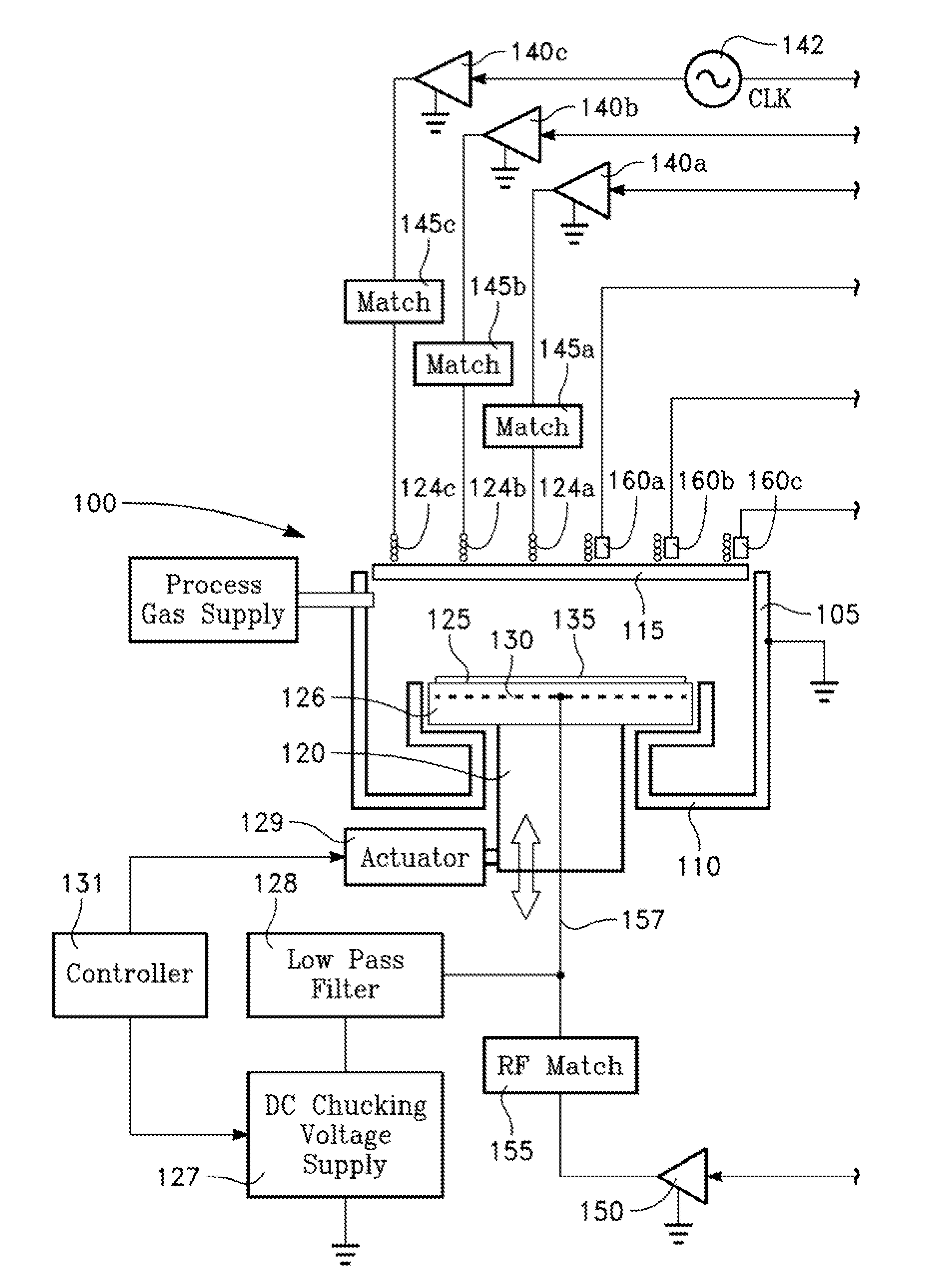

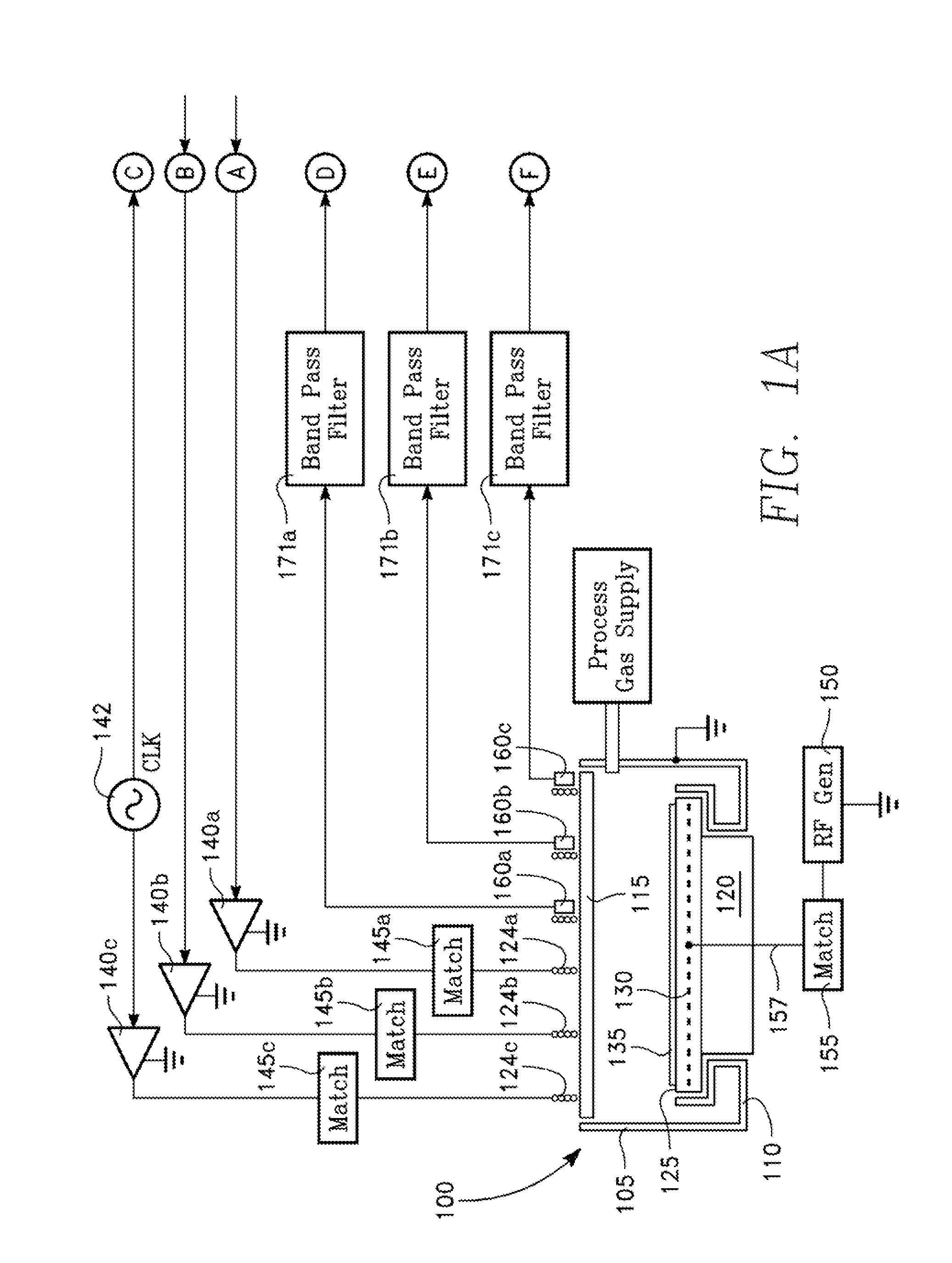

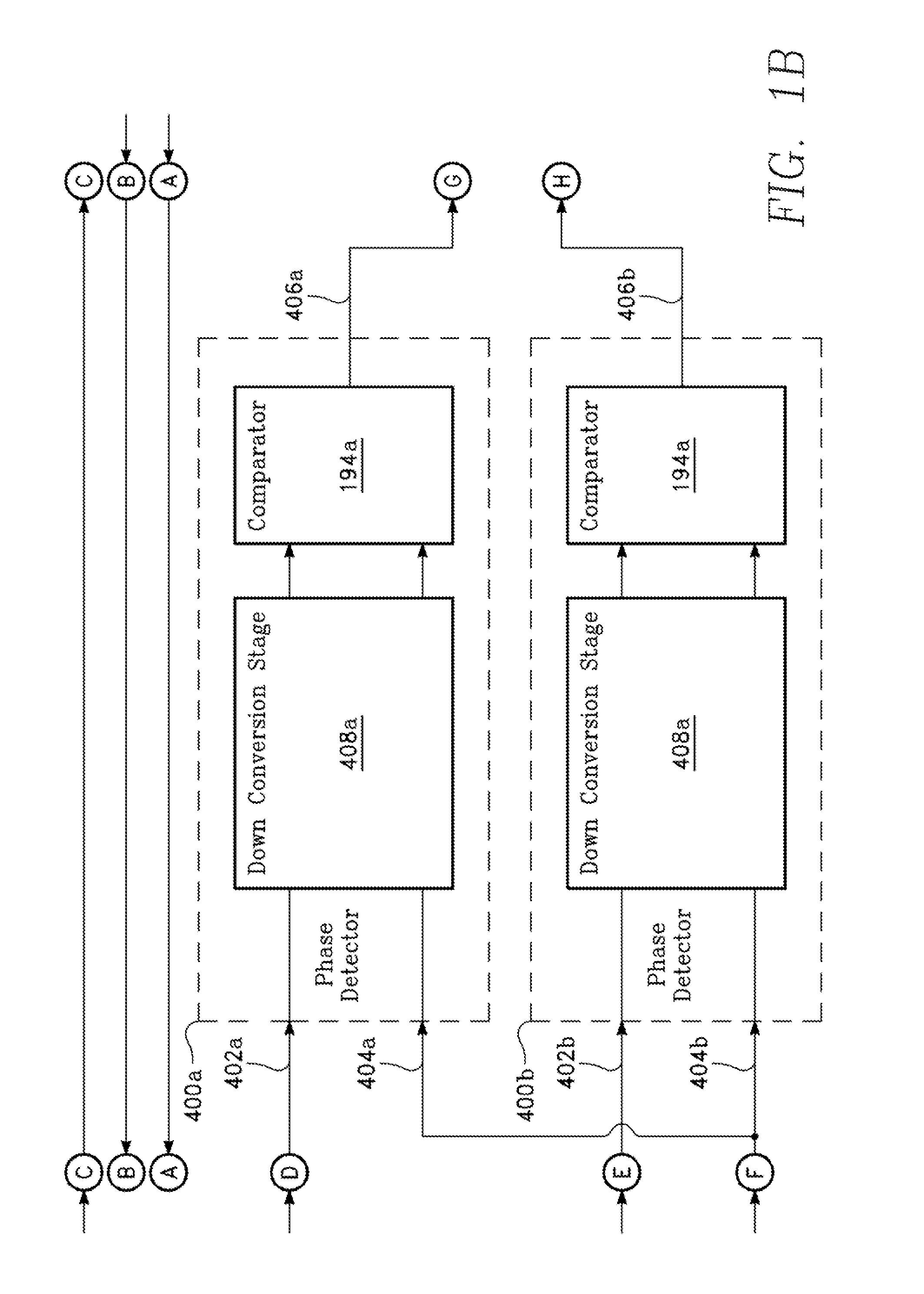

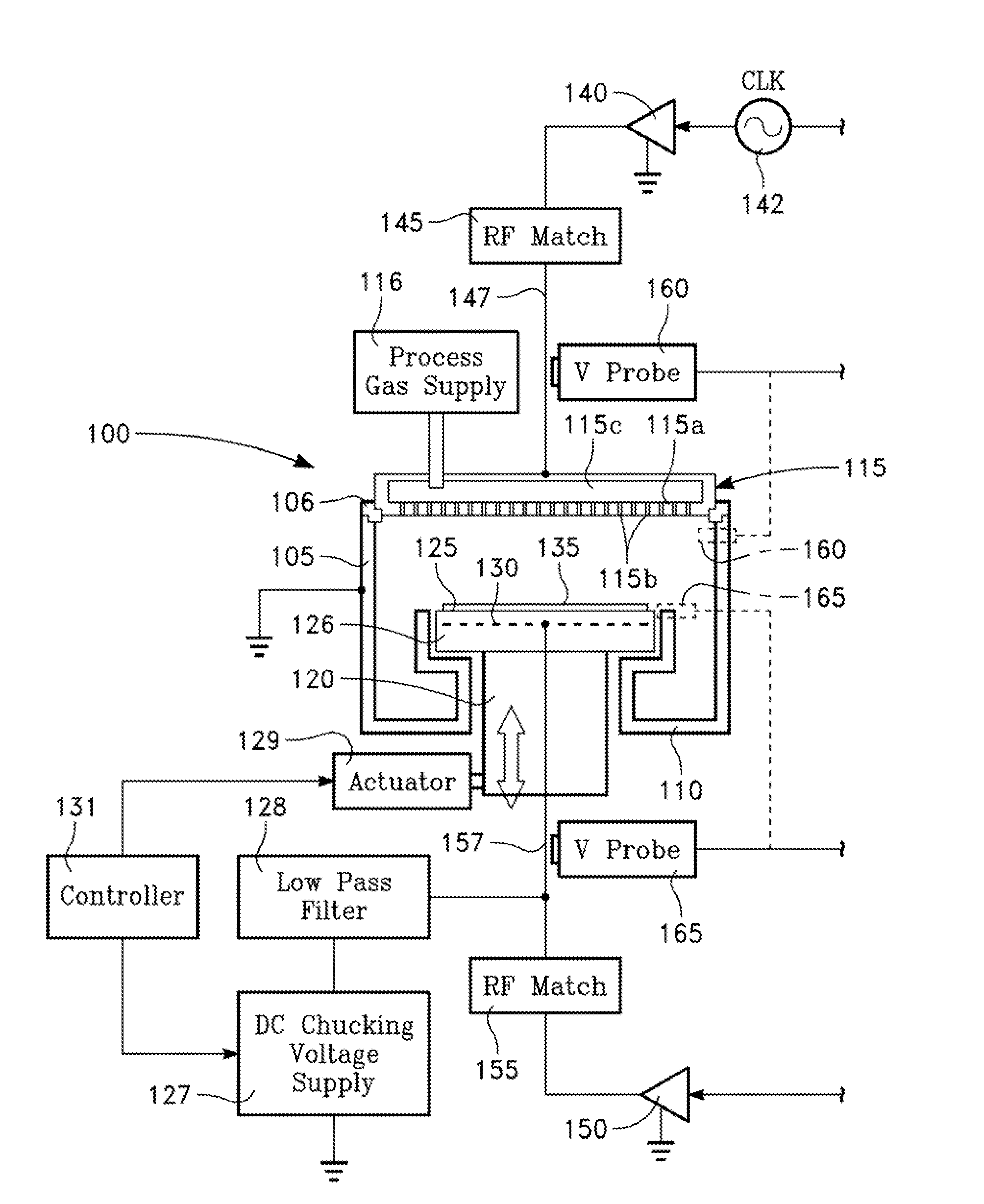

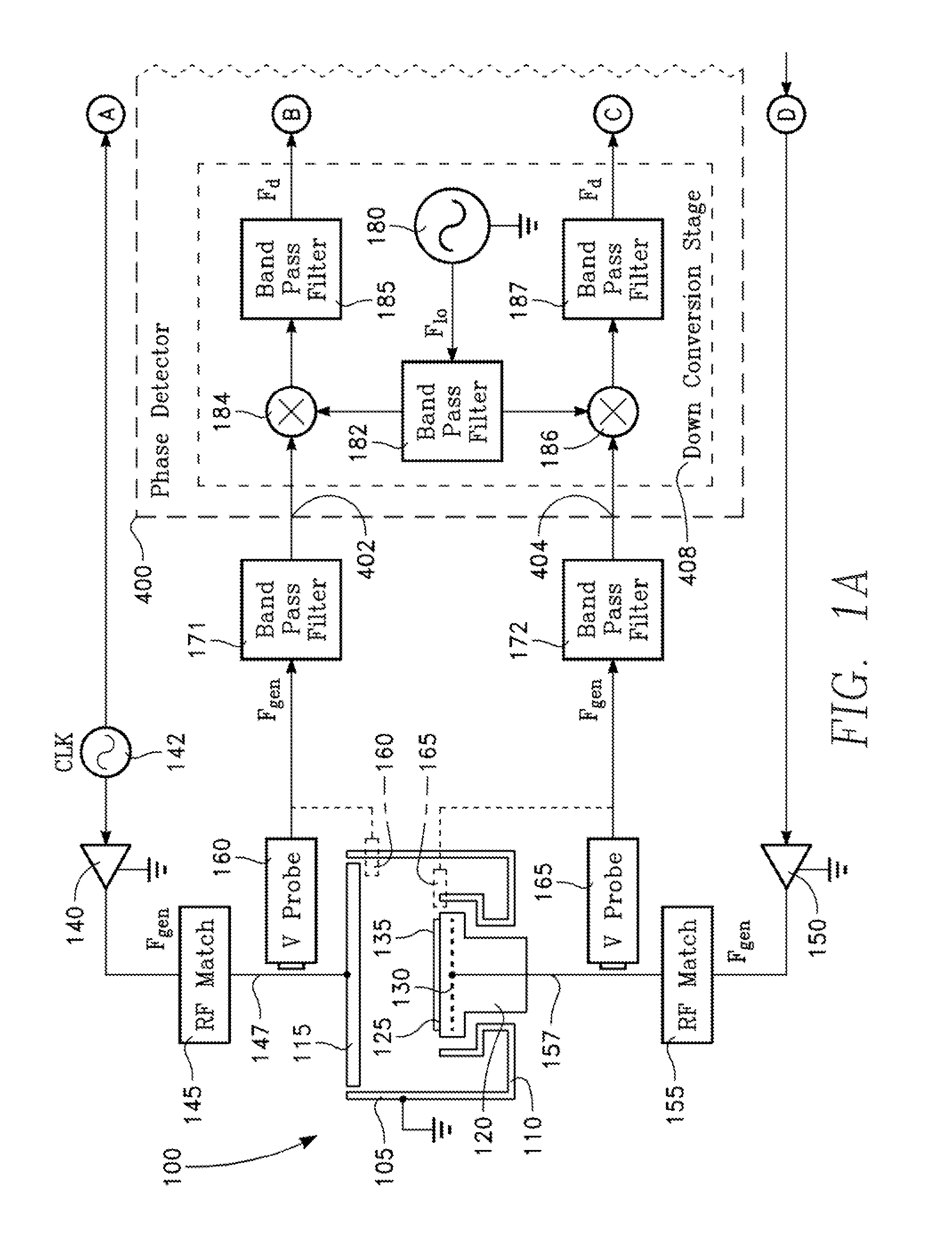

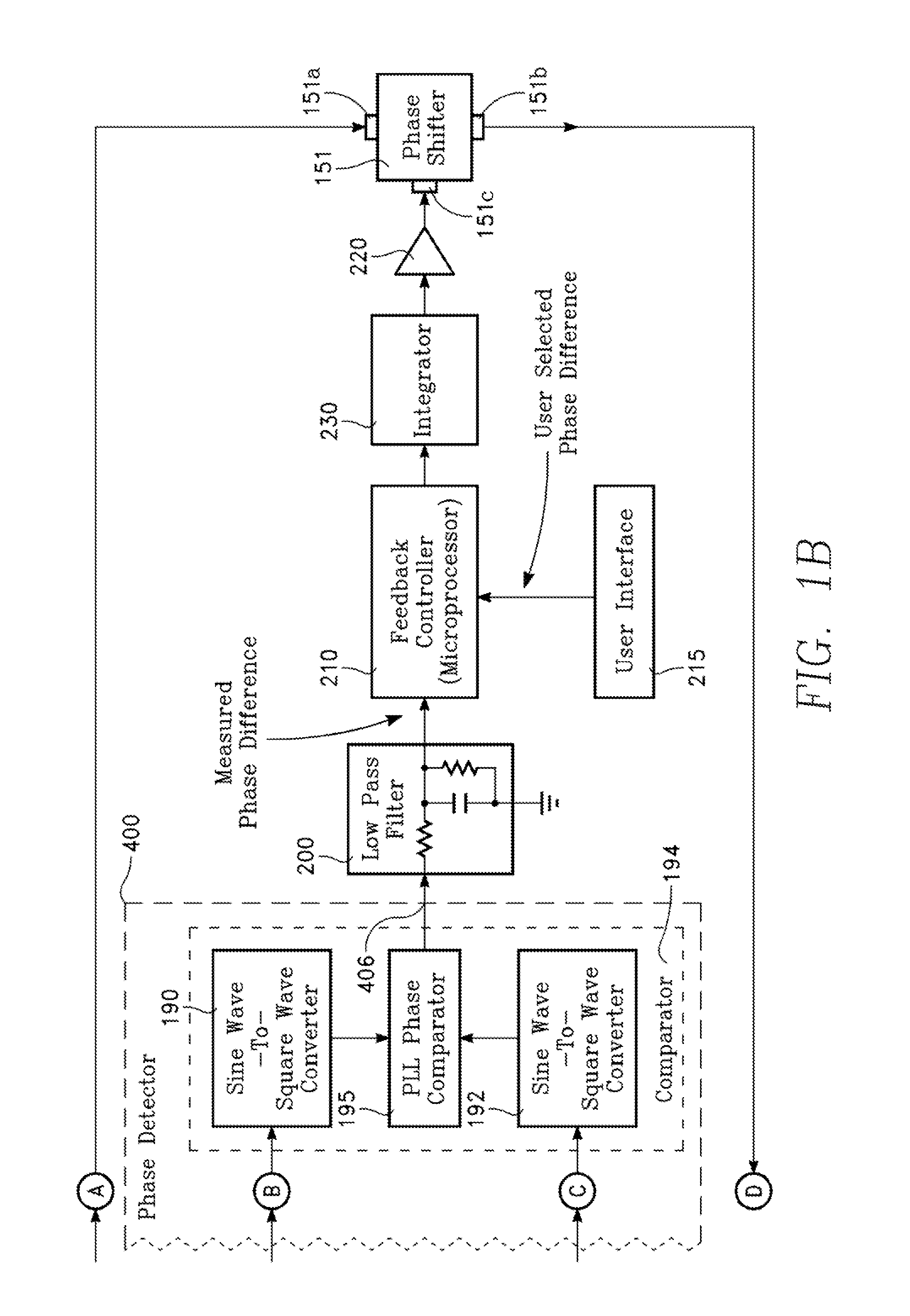

Independent control of RF phases of separate coils of an inductively coupled plasma reactor

ActiveUS20130284370A1Liquid surface applicatorsElectric discharge tubesPhysical chemistryEngineering

Plasma distribution is controlled in a plasma reactor by controlling the phase differences between different RF coil antennas, in accordance with a desired or user-selected phase difference, by a phase-lock feedback control loop.

Owner:APPLIED MATERIALS INC

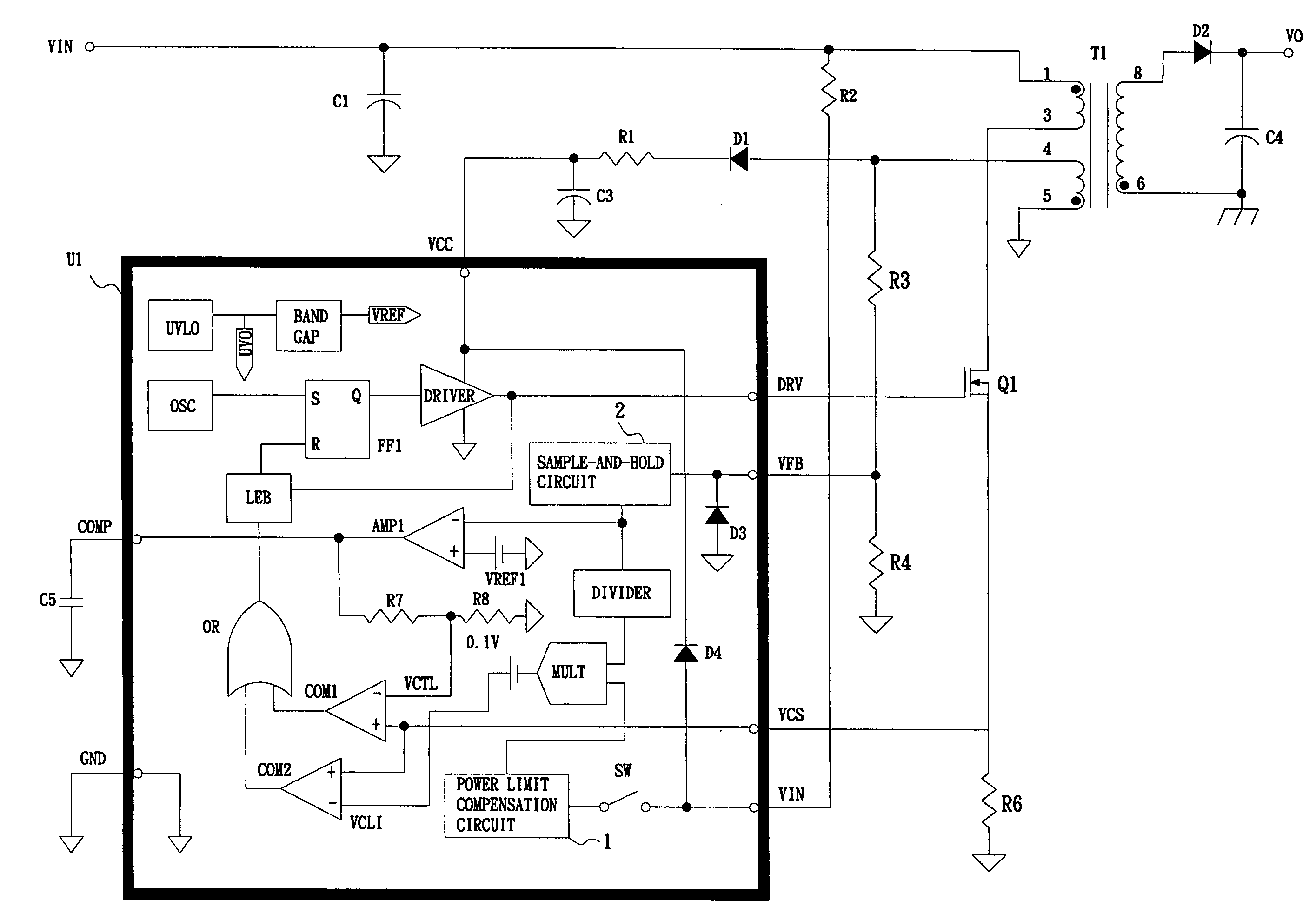

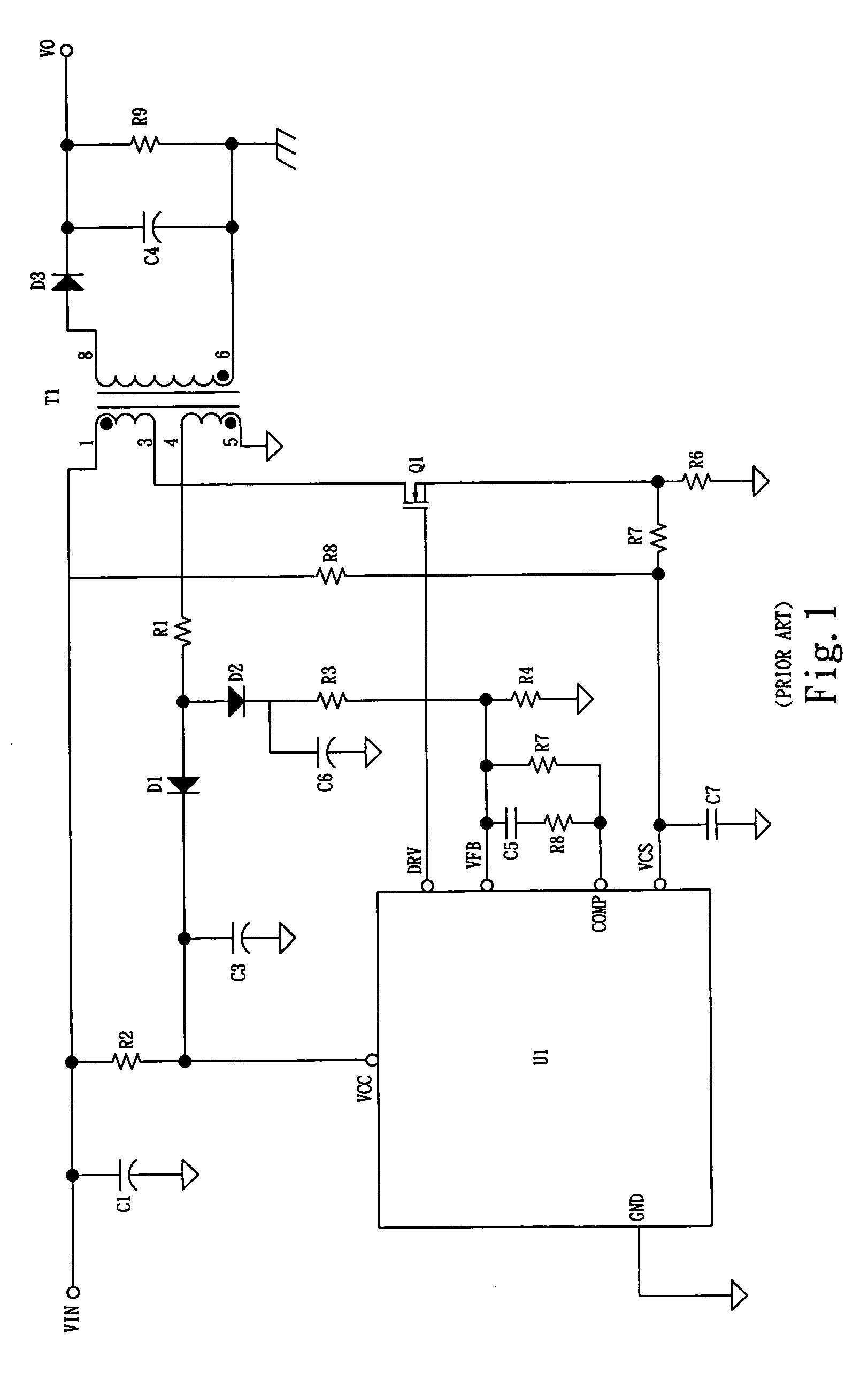

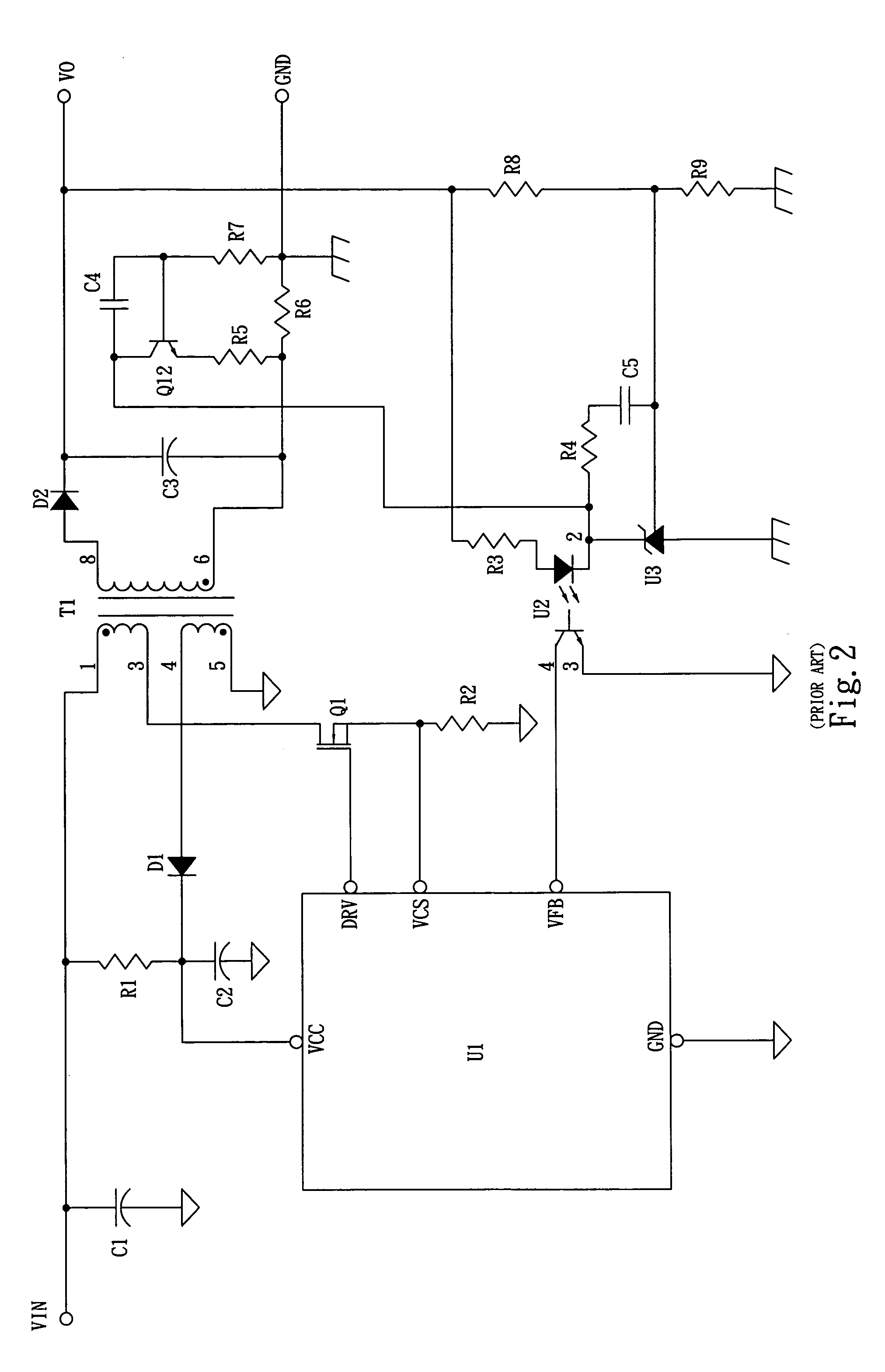

Primary-side feedback switching power supply

The present invention discloses a primary-side feedback switching power supply that uses a sample-and-hold circuit to obtain a corner voltage of a harmonic wave voltage while the primary-side auxiliary winding is operating at a discontinuous mode as a feedback control, and provides both voltage regulation and current limit functions. A stable voltage output is provided within the nominal input voltage and nominal output load, such that when the output reaches a current limit, the output voltage drops but the output current is controlled to remain unchanged, so as to provide an over-current protection.

Owner:NIKO SIMICONDUCTOR CO LTD

Additive manufacturing apparatus and method

ActiveUS20160236279A1Sufficient reflectivityAdditive manufacturing apparatusSpectrum investigationManufactured apparatusFeedback control

This invention concerns a laser solidification apparatus for building objects by layerwise solidification of powder material. The apparatus including a build chamber containing a build platform, a device for depositing layers of powder material on to the build platform, an optical unit for directing a laser beam to selectively solidify areas of each powder layer and a spectrometer for detecting characteristic radiation emitted by plasma formed during solidification of the powder by the laser beam. The invention also relates to a spectrometer for detecting characteristic radiation generated by interaction of the metal with the or a further laser beam. The spectra recorded using the spectrometer may be used for feedback control during the solidification process.

Owner:RENISHAW PLC

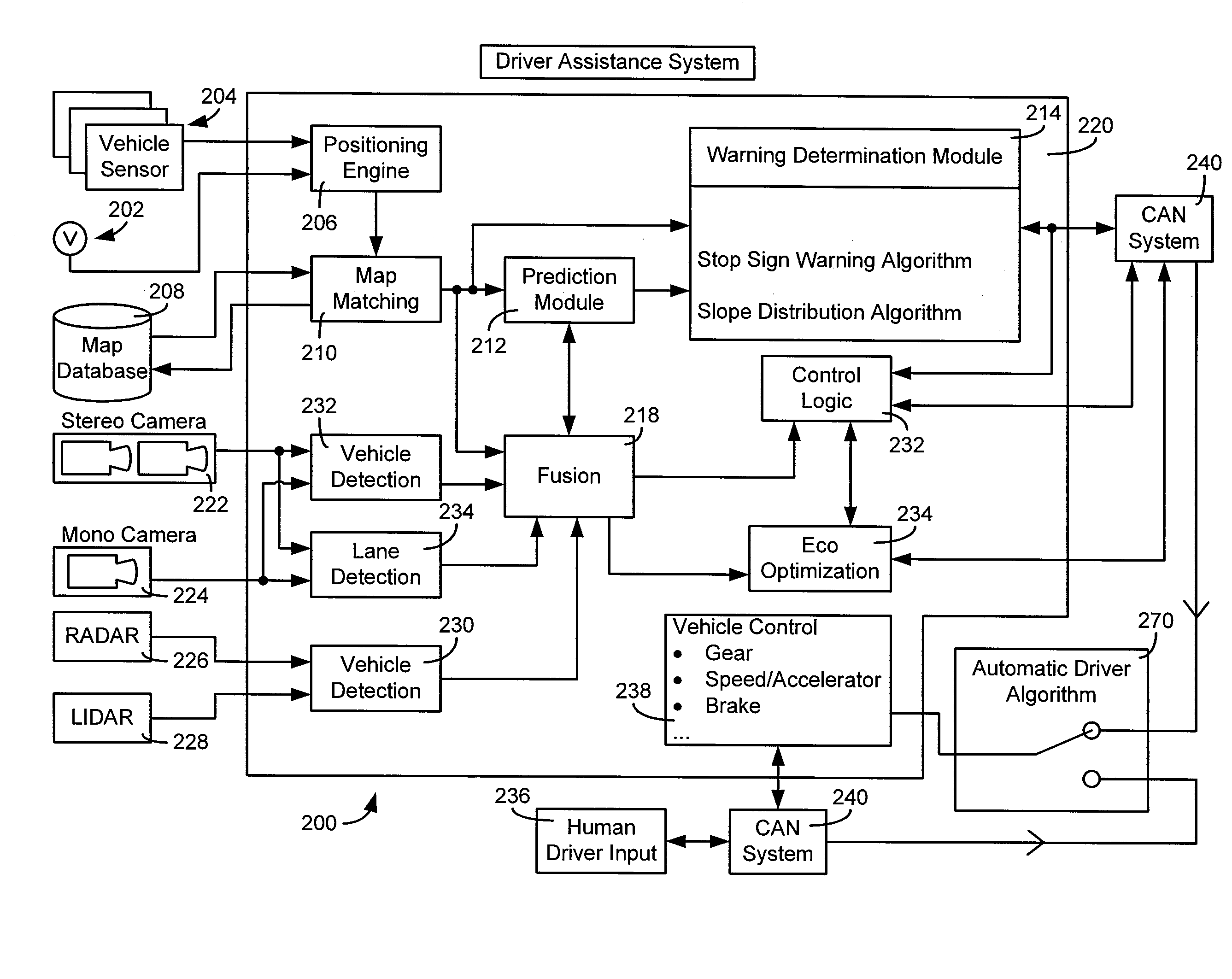

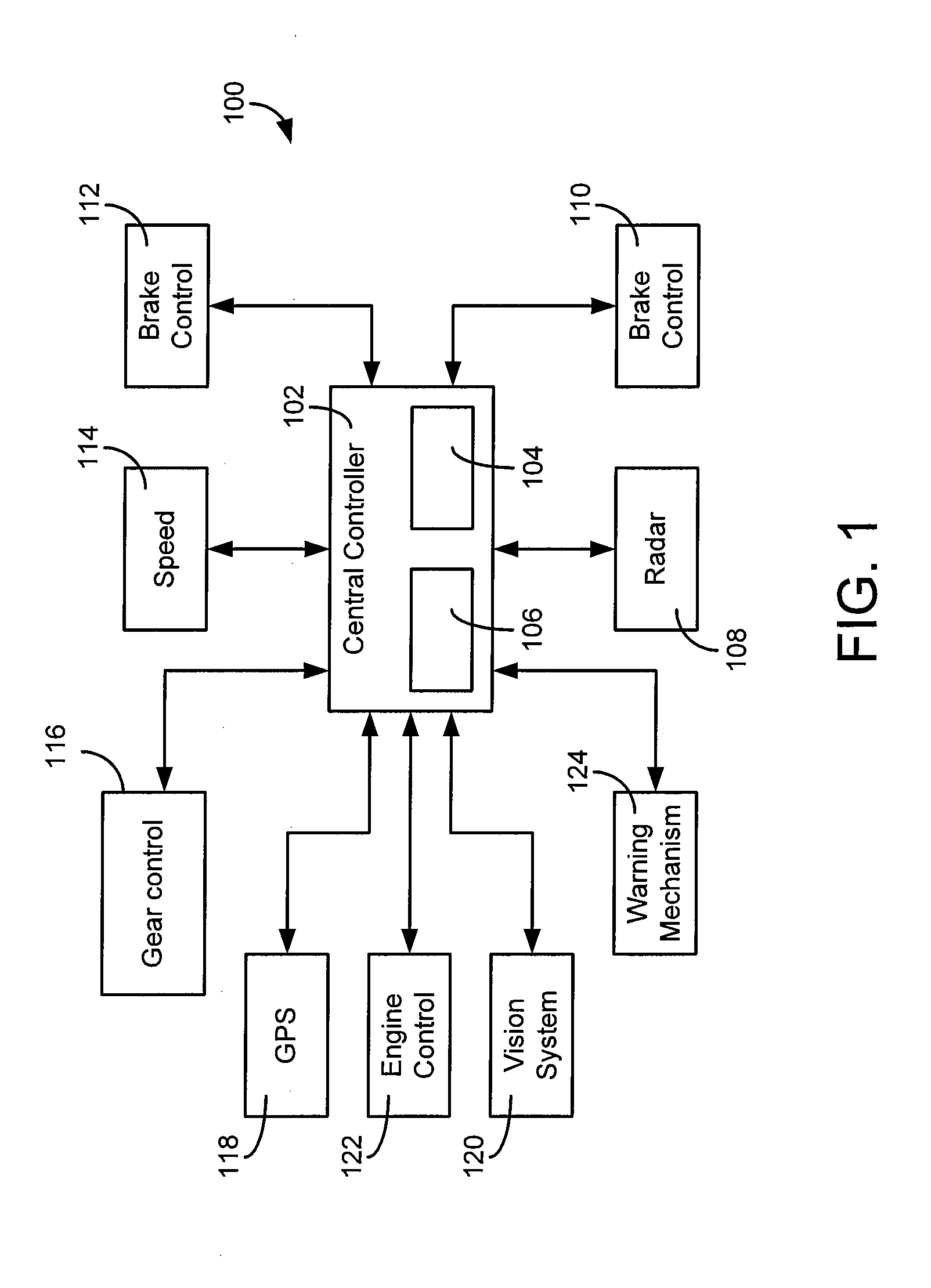

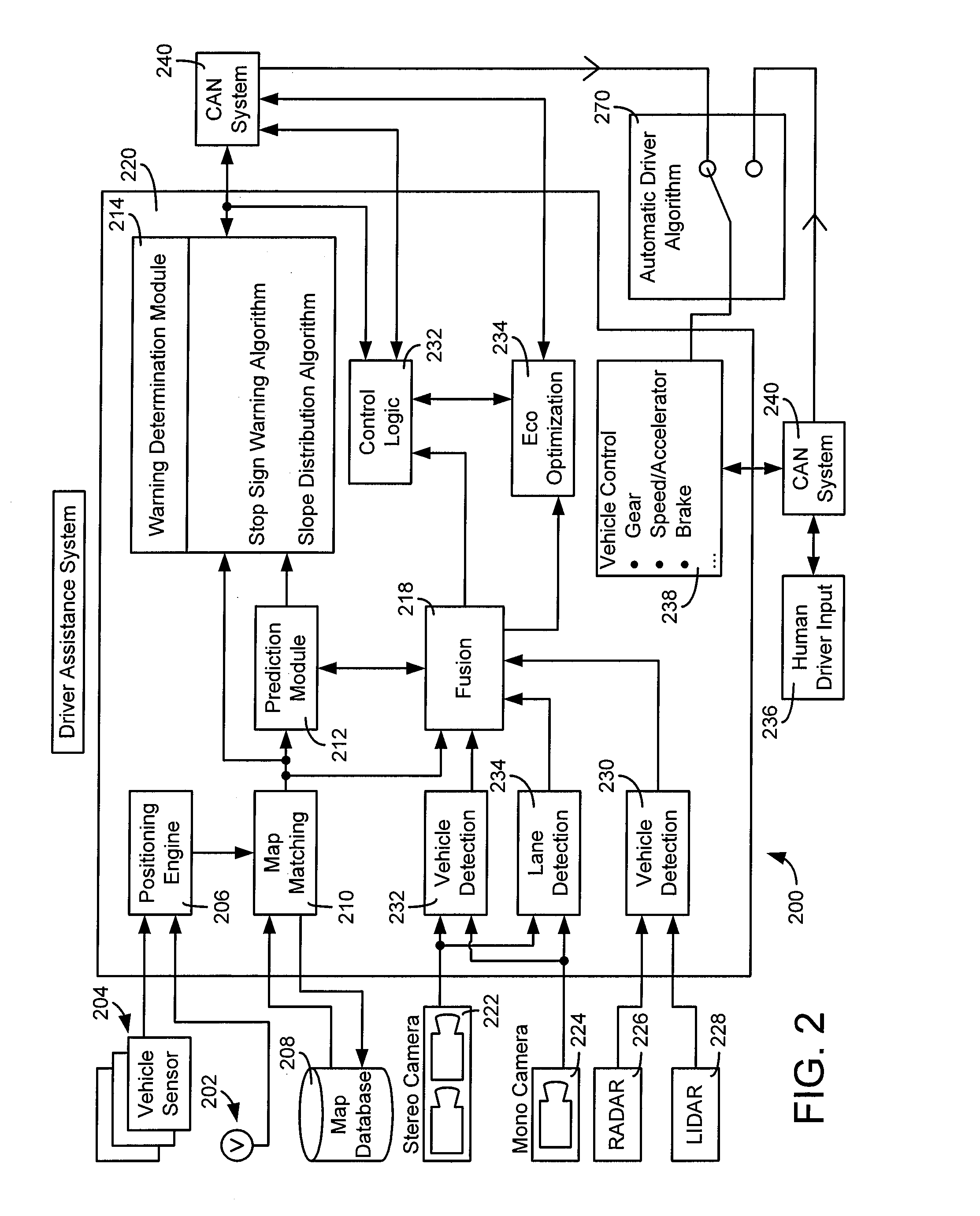

Driver assistance system

InactiveUS20120303222A1Instruments for road network navigationRoad vehicles traffic controlArea networkDriver/operator

A system and method of assisting a driver of a vehicle by providing driver and vehicle feedback control signals is disclosed. The system and method includes receiving location data of the vehicle from a GPS unit, receiving the location data of the vehicle and retrieving navigation characteristics relevant to the location data using a processing circuit, generating a most probable future path for the vehicle and determining a location of at least one navigation characteristic with respect to the most probable future path and the vehicle, generating vehicle data at least one vehicle sensor, and transmitting a control signal to a vehicle control area network to warn the driver of an upcoming navigation characteristic on the most probable path.

Owner:TK HLDG

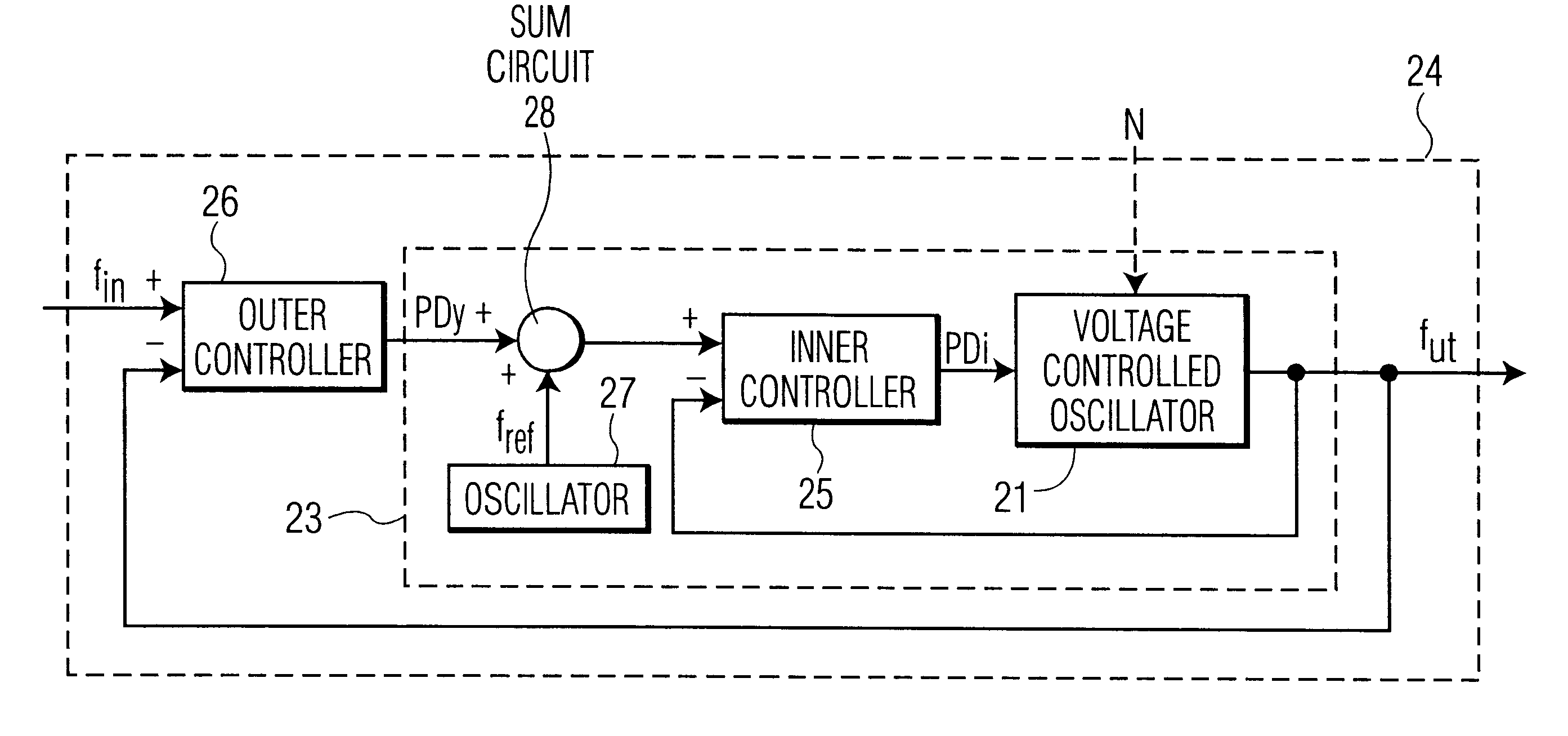

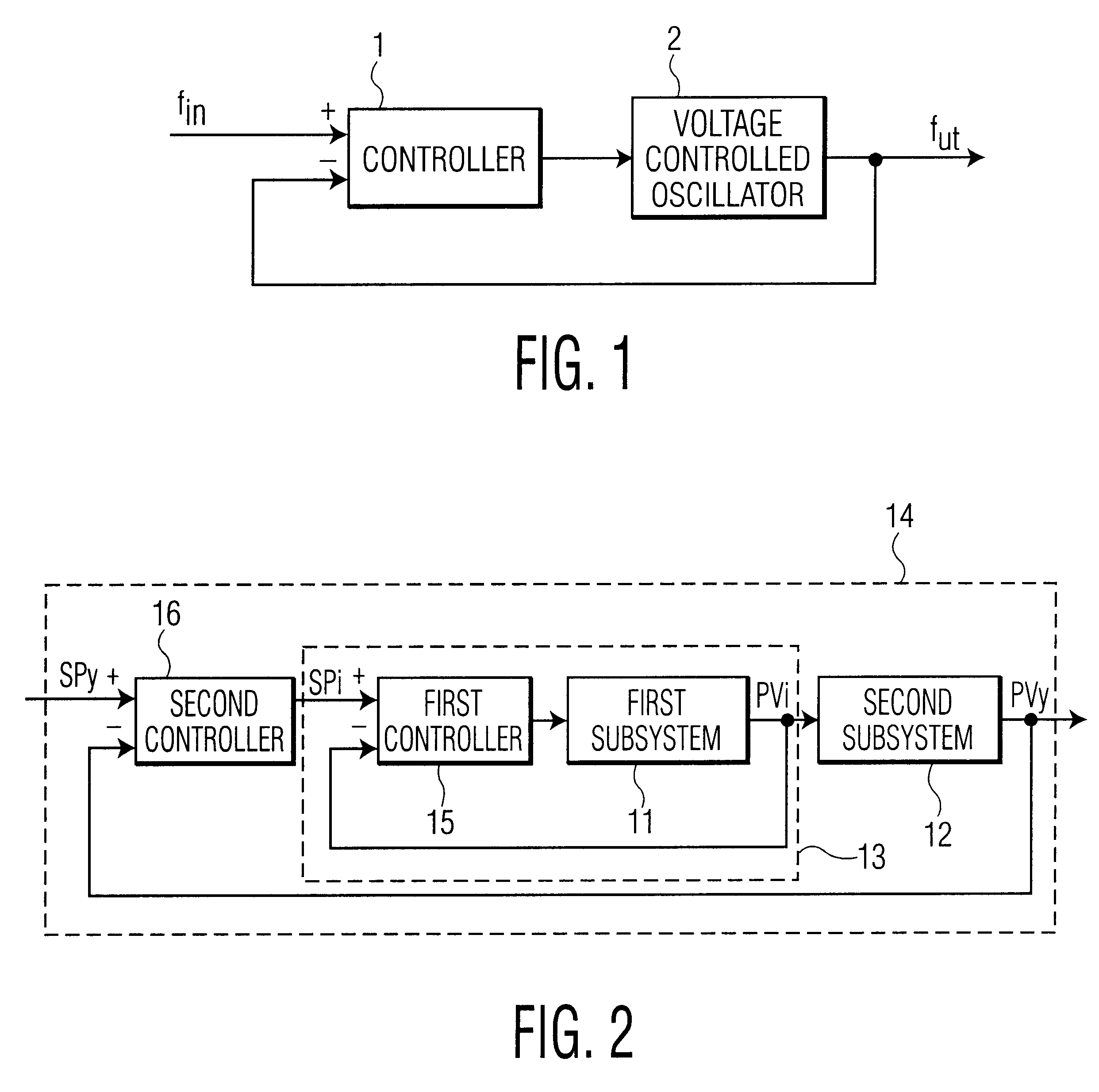

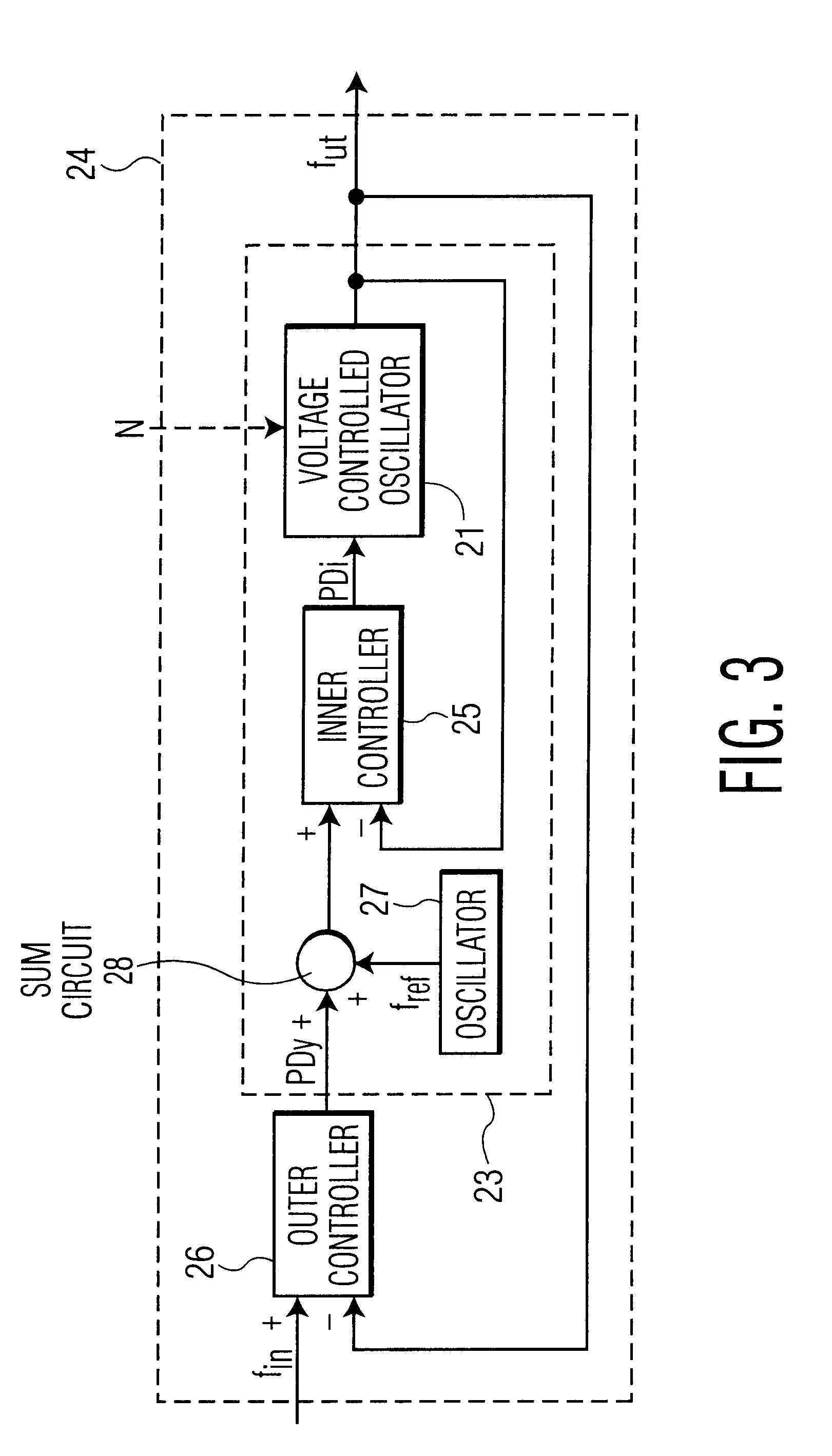

Phase locked loop control via inner and outer feedback control circuits

InactiveUS6384690B1Reduce inputGood frequencyPulse automatic controlNegative feedbackControl circuit

A phase locked loop includes at least one control circuit, where a voltage-controlled oscillator provides an output frequency which is arranged to strive to follow an input frequency. The phase locked loop also includes an outer, slow, negative feedback control circuit, having the input frequency as a setpoint, the output frequency as a process value and an outer output signal. The phase locked loop also includes an inner, fast, negative feedback control circuit, having the sum of a reference frequency from a stable oscillator and the outer output signal as a setpoint, the output frequency as the process value and an inner output signal for controlling the voltage controlled oscillator.

Owner:TELEFON AB LM ERICSSON (PUBL)

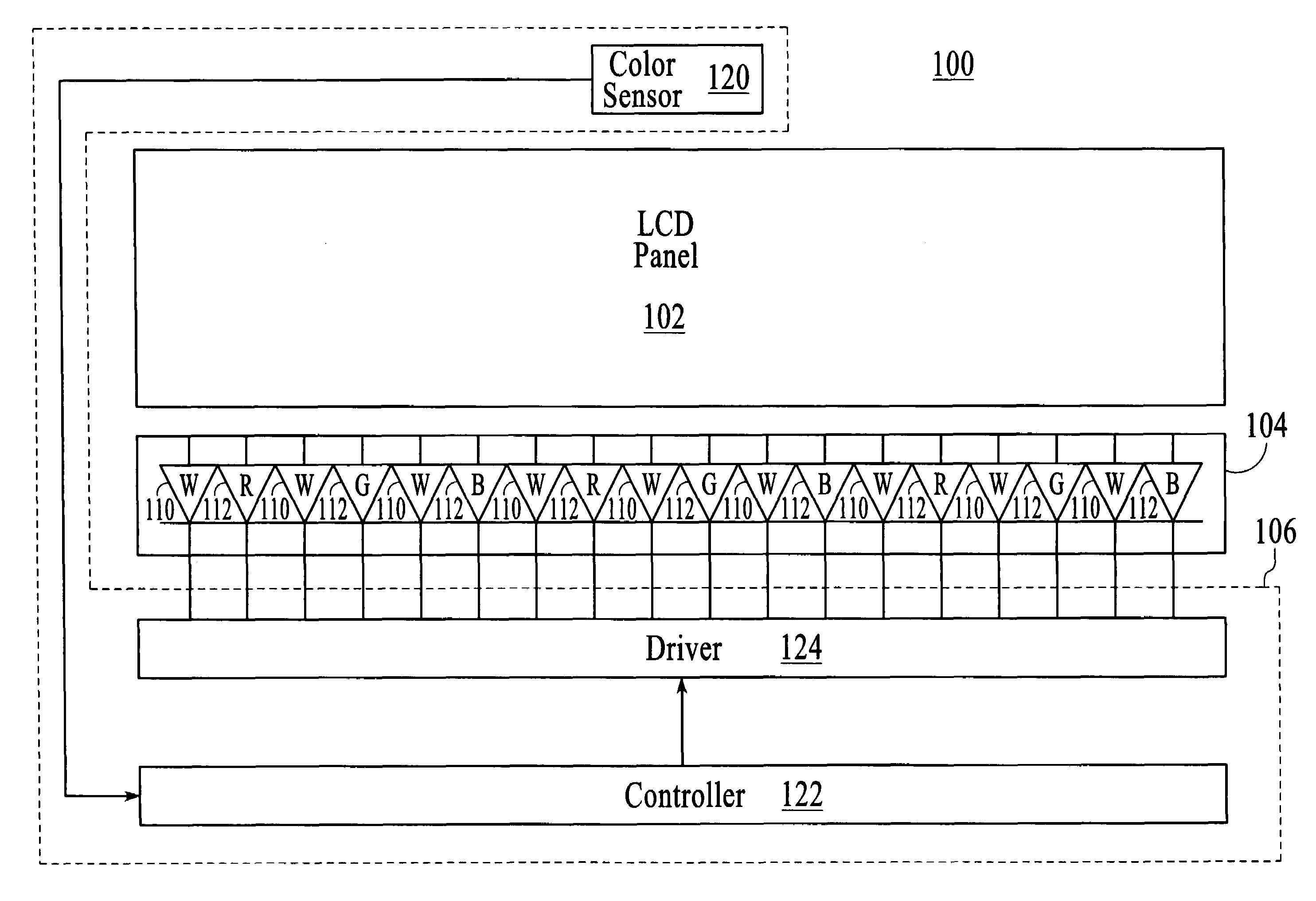

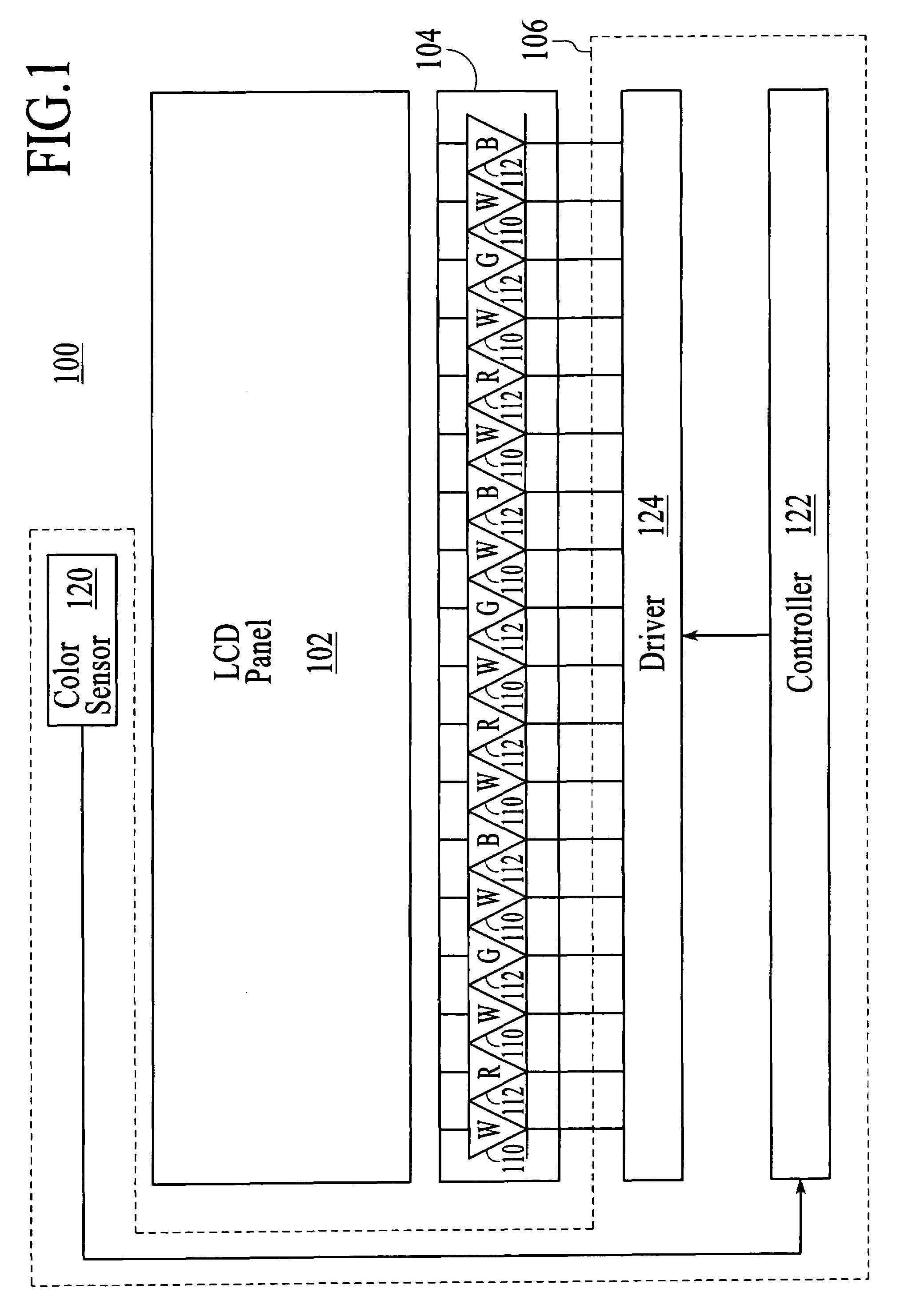

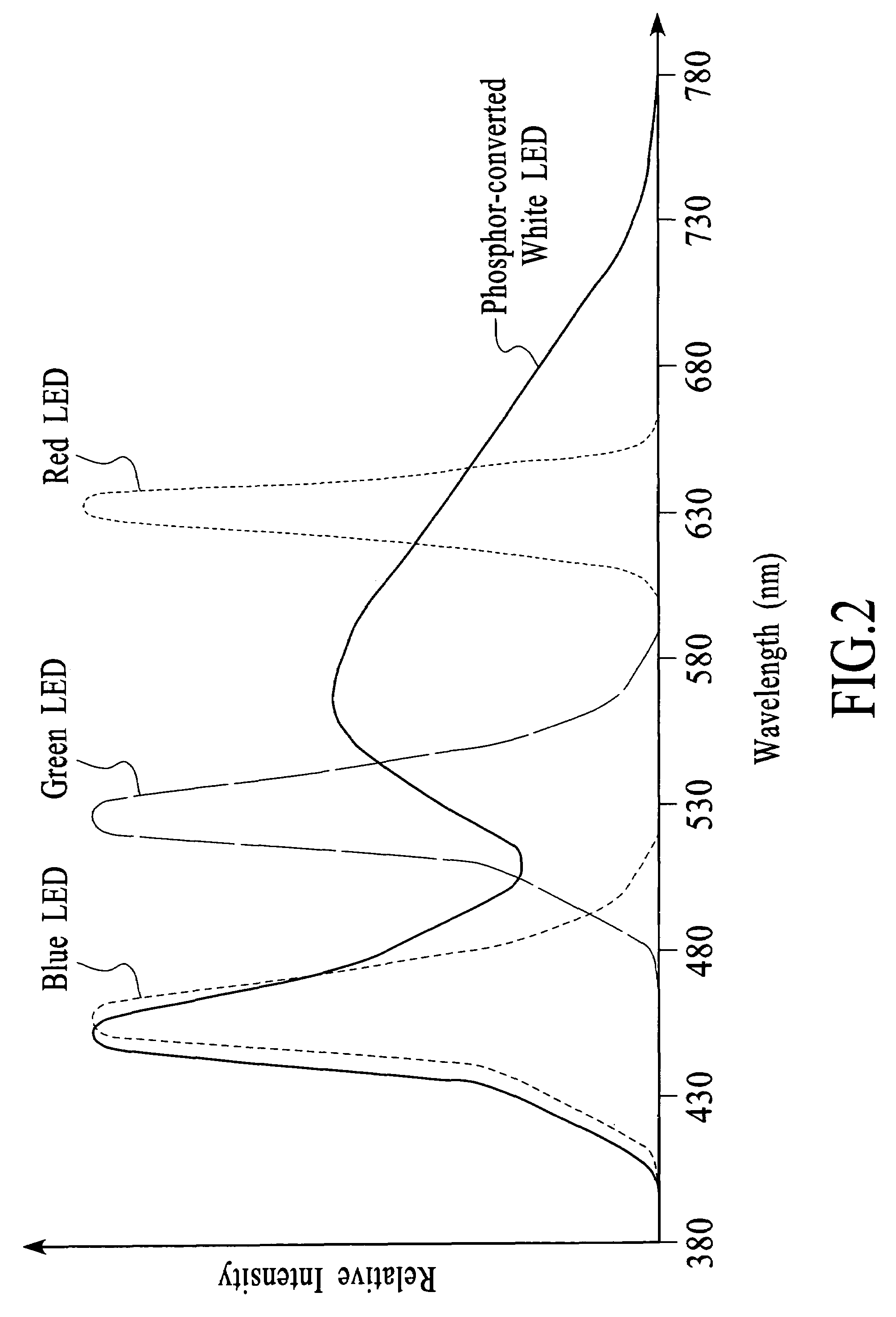

System and method for producing white light using LEDs

ActiveUS7009343B2High color rendering indexWide SPDStatic indicating devicesElectroluminescent light sourcesControl systemControl signal

Owner:AVAGO TECH INT SALES PTE LTD

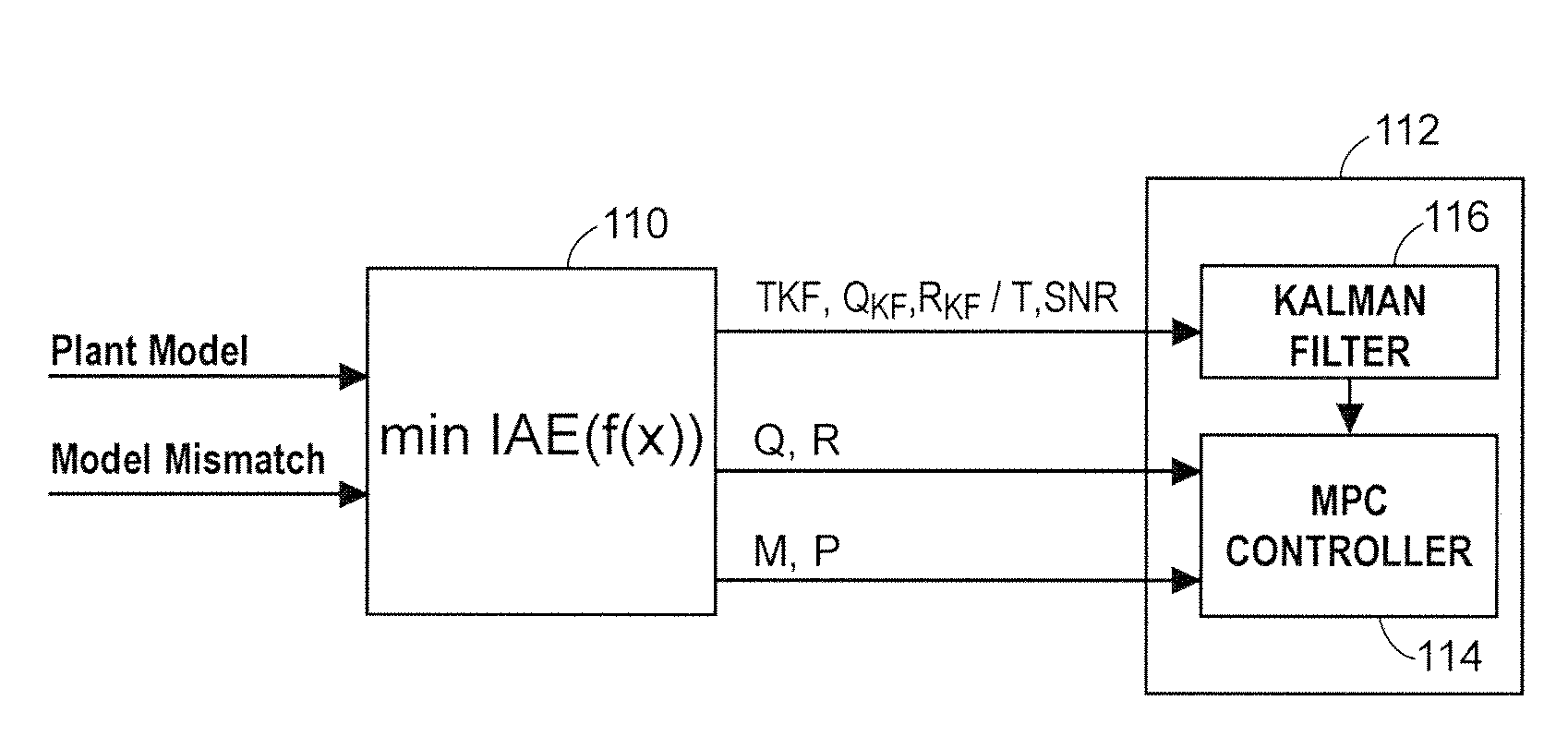

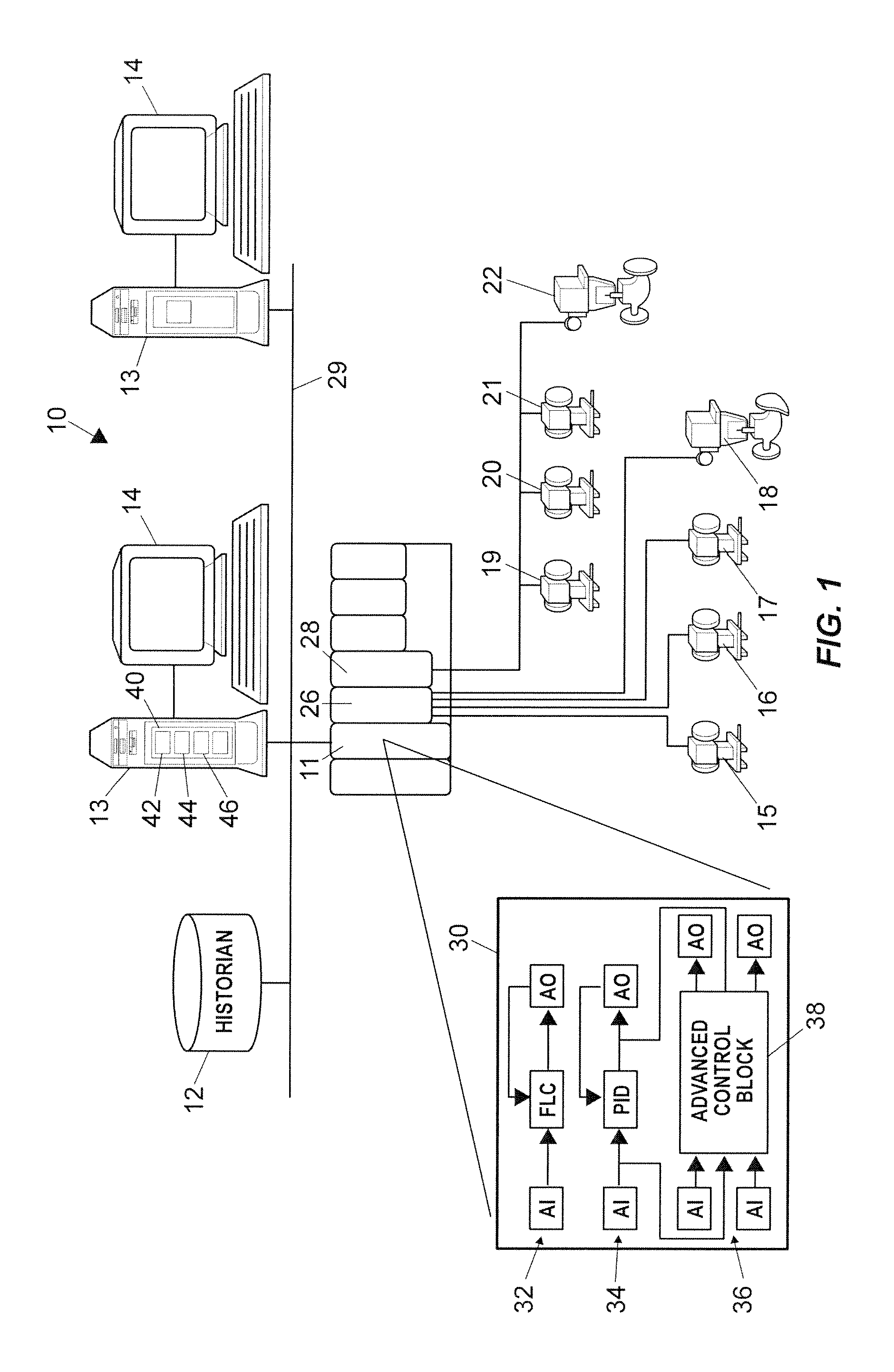

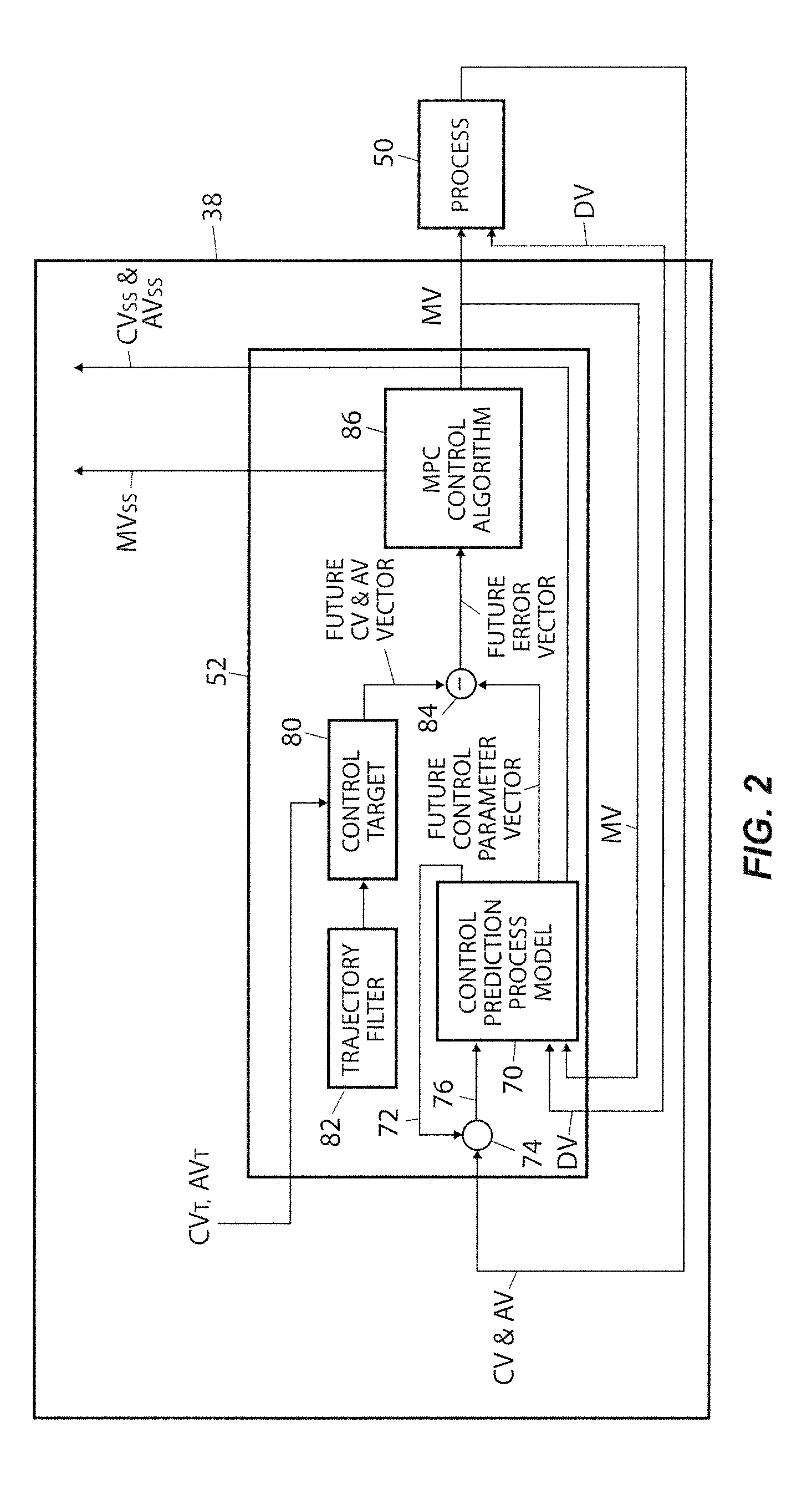

Robust adaptive model predictive controller with tuning to compensate for model mismatch

ActiveUS20090198350A1Improve immunityImprove performanceComputer controlSimulator controlClosed loopPredictive controller

An MPC adaptation and tuning technique integrates feedback control performance better than methods commonly used today in MPC type controllers, resulting in an MPC adaptation / tuning technique that performs better than traditional MPC techniques in the presence of process model mismatch. The MPC controller performance is enhanced by adding a controller adaptation / tuning unit to an MPC controller, which adaptation / tuning unit implements an optimization routine to determine the best or most optimal set of controller design and / or tuning parameters to use within the MPC controller during on-line process control in the presence of a specific amount of model mismatch or a range of model mismatch. The adaptation / tuning unit determines one or more MPC controller tuning and design parameters, including for example, an MPC form, penalty factors for either or both of an MPC controller and an observer and a controller model for use in the MPC controller, based on a previously determined process model and either a known or an expected process model mismatch or process model mismatch range. A closed loop adaptation cycle may be implemented by performing an autocorrelation analysis on the prediction error or the control error to determine when significant process model mismatch exists or to determine an increase or a decrease in process model mismatch over time.

Owner:FISHER-ROSEMOUNT SYST INC

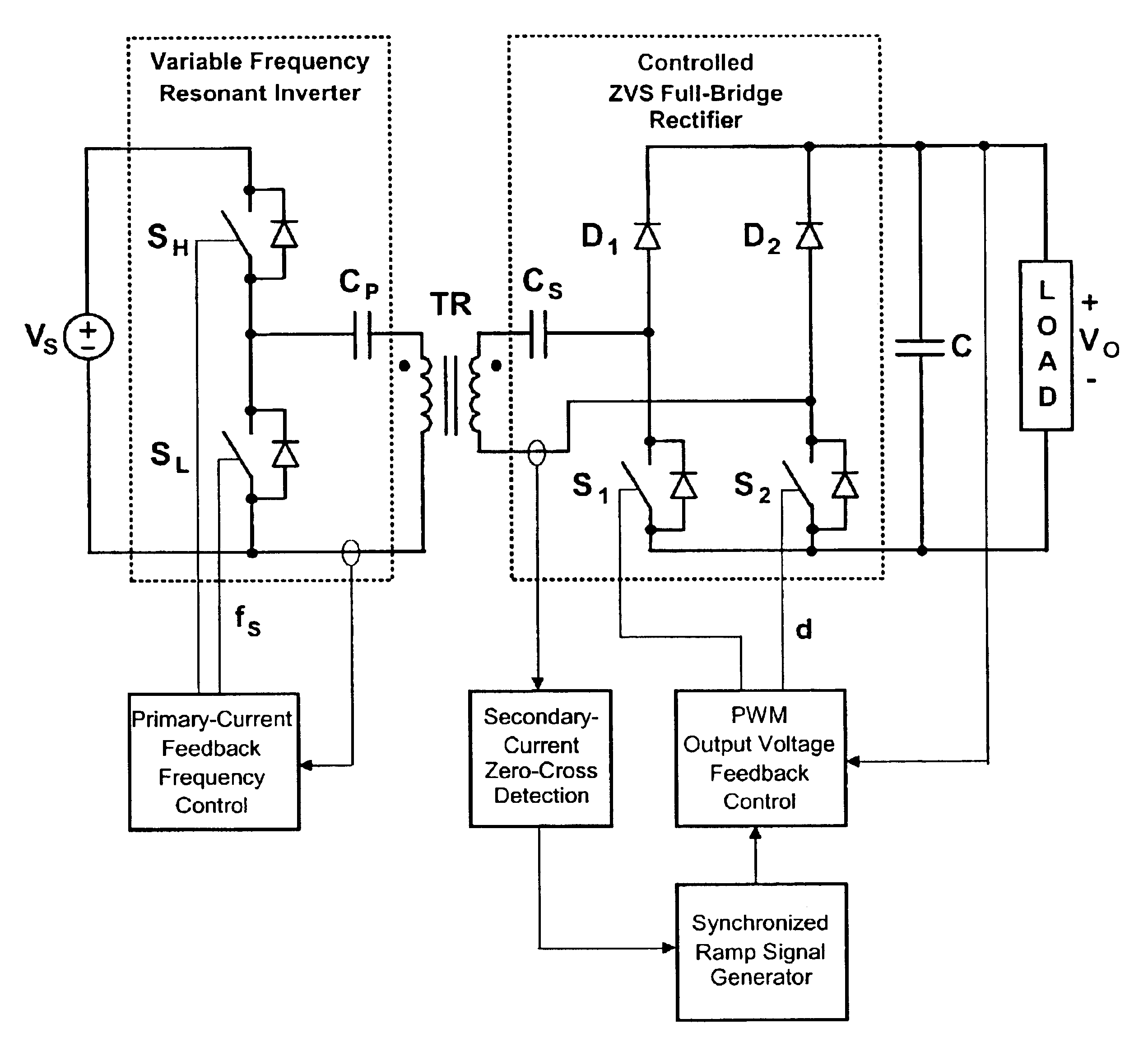

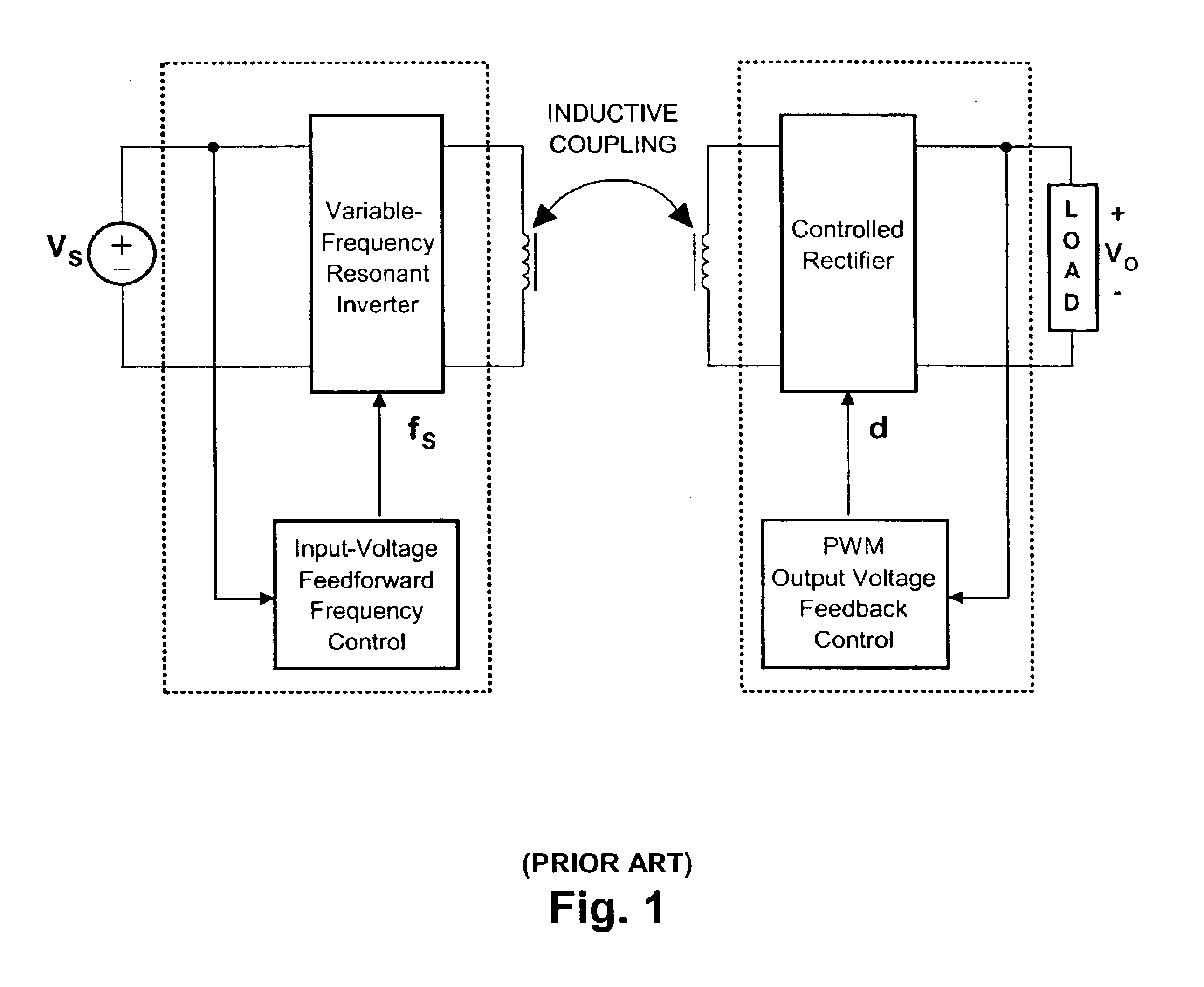

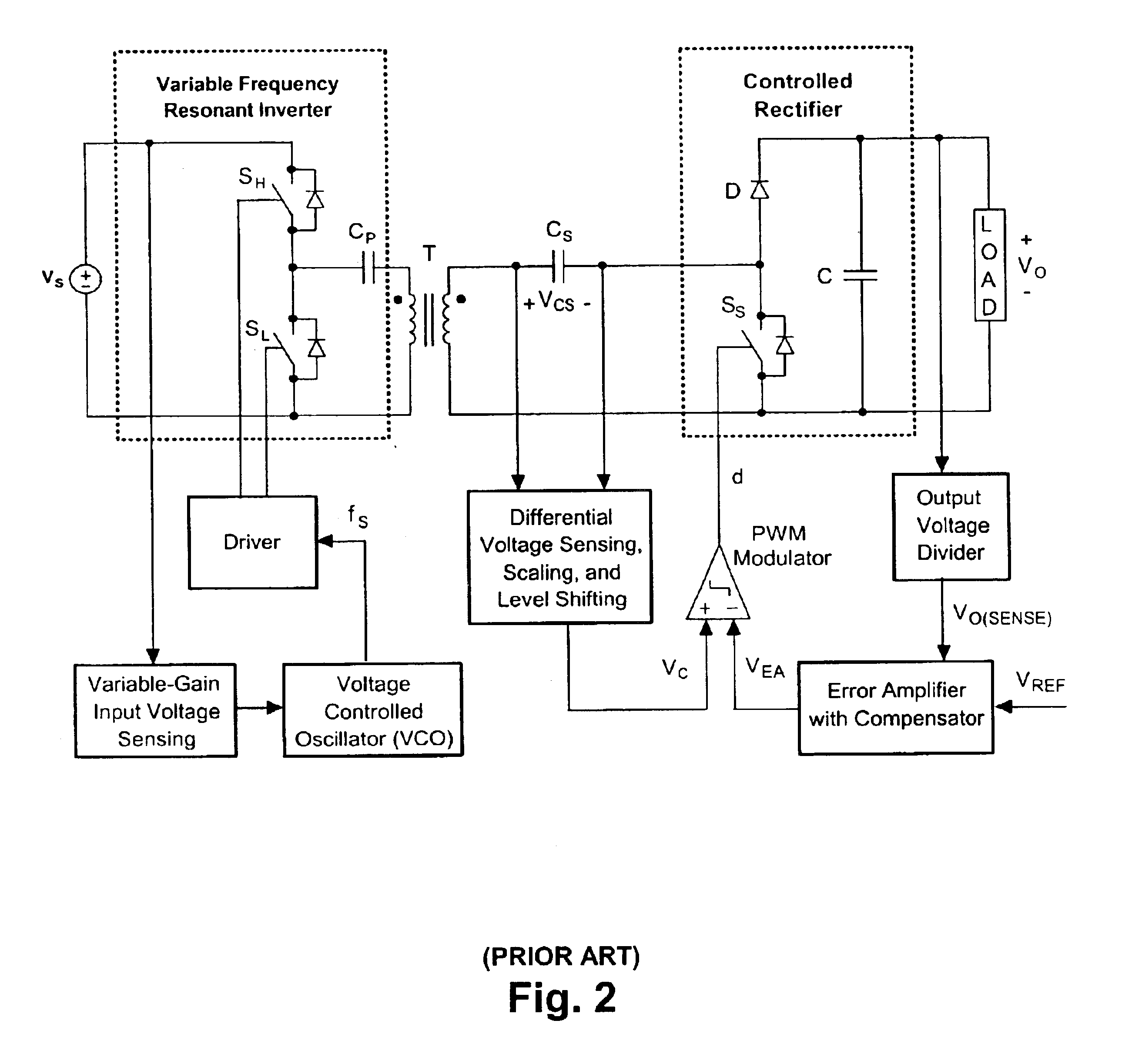

Contactless electrical energy transmission system having a primary side current feedback control and soft-switched secondary side rectifier

ActiveUS6934167B2Energy can transferEfficient power electronics conversionConversion with intermediate conversion to dcSwitching frequencyEngineering

A contactless electrical energy transmission system includes a transformer having a primary winding that is coupled to a power source through a primary resonant circuit and a secondary winding that is coupled to a load through a secondary resonant circuit. The primary and secondary resonant circuits are inductively coupled to each other. A primary control circuit detects current changes through the primary resonant circuit to control the switching frequency of a controllable switching device for maintaining a substantially constant energy transfer between the primary winding and secondary winding in response to at least one of a power source voltage change and a load change. As a result, excessive circulating energy of the CEET system is minimized providing a tight regulation of the output voltage over the entire load and input voltage ranges without any feedback connection between the primary side and the secondary side.

Owner:DELTA ELECTRONICS INC

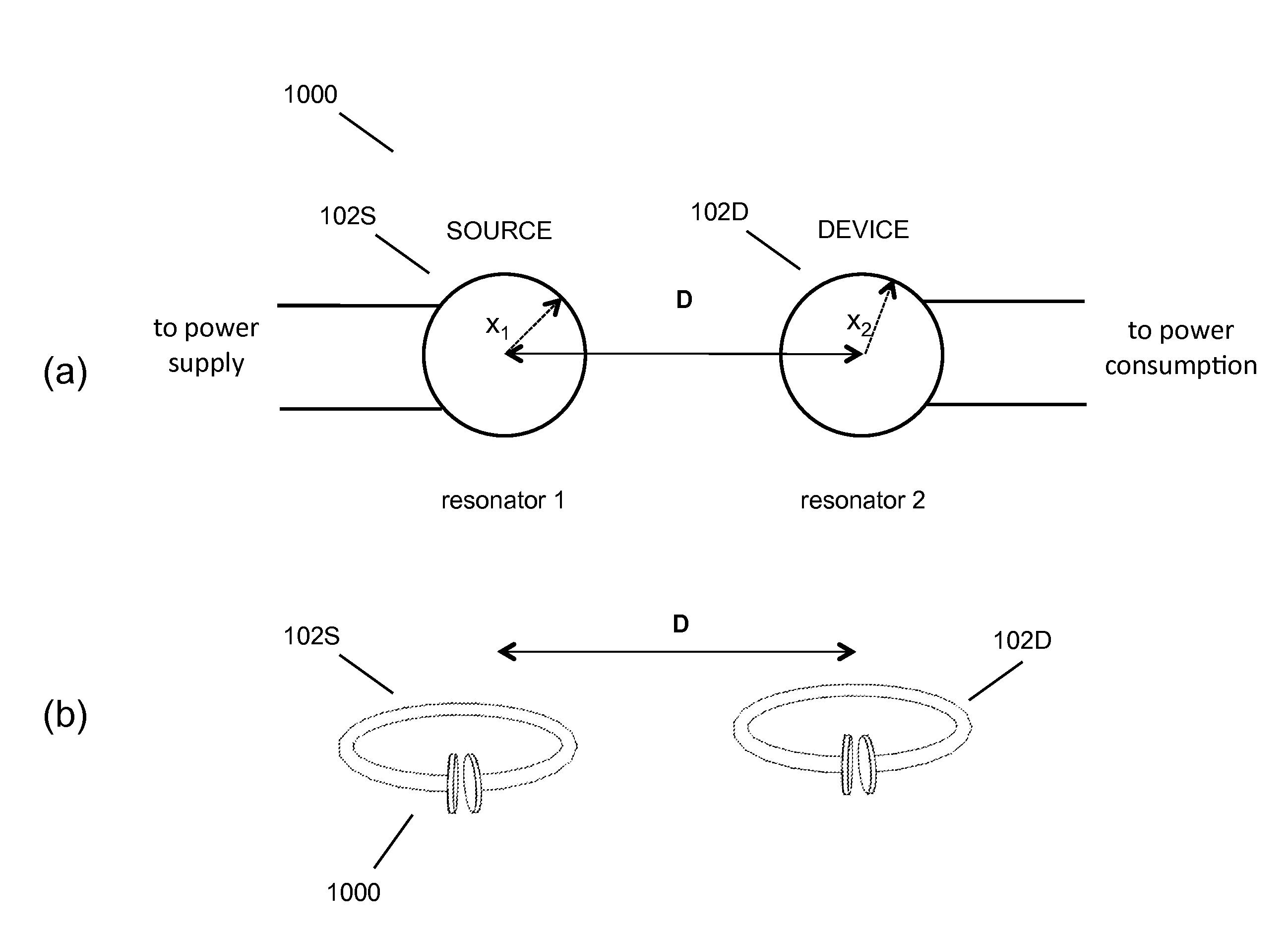

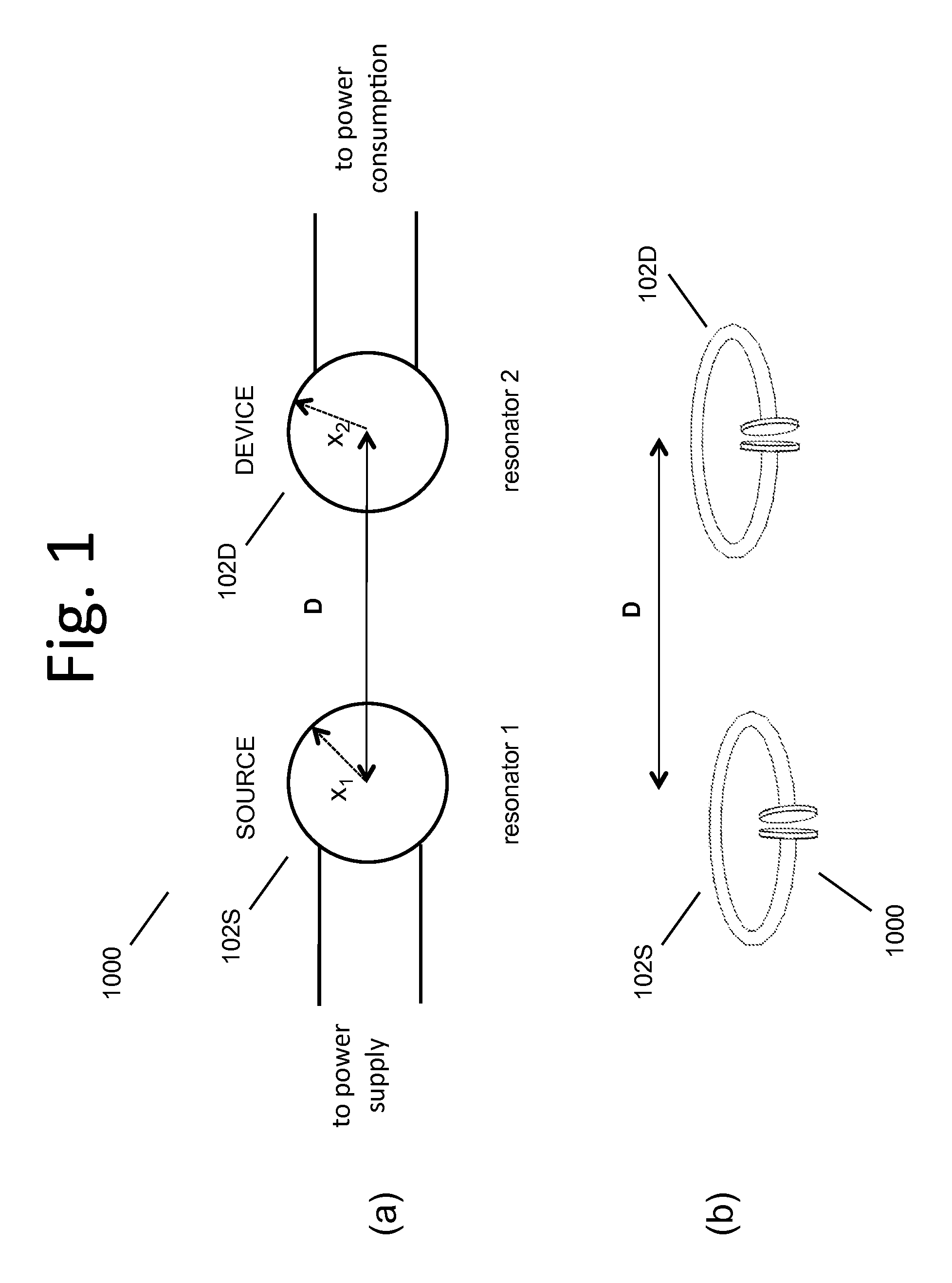

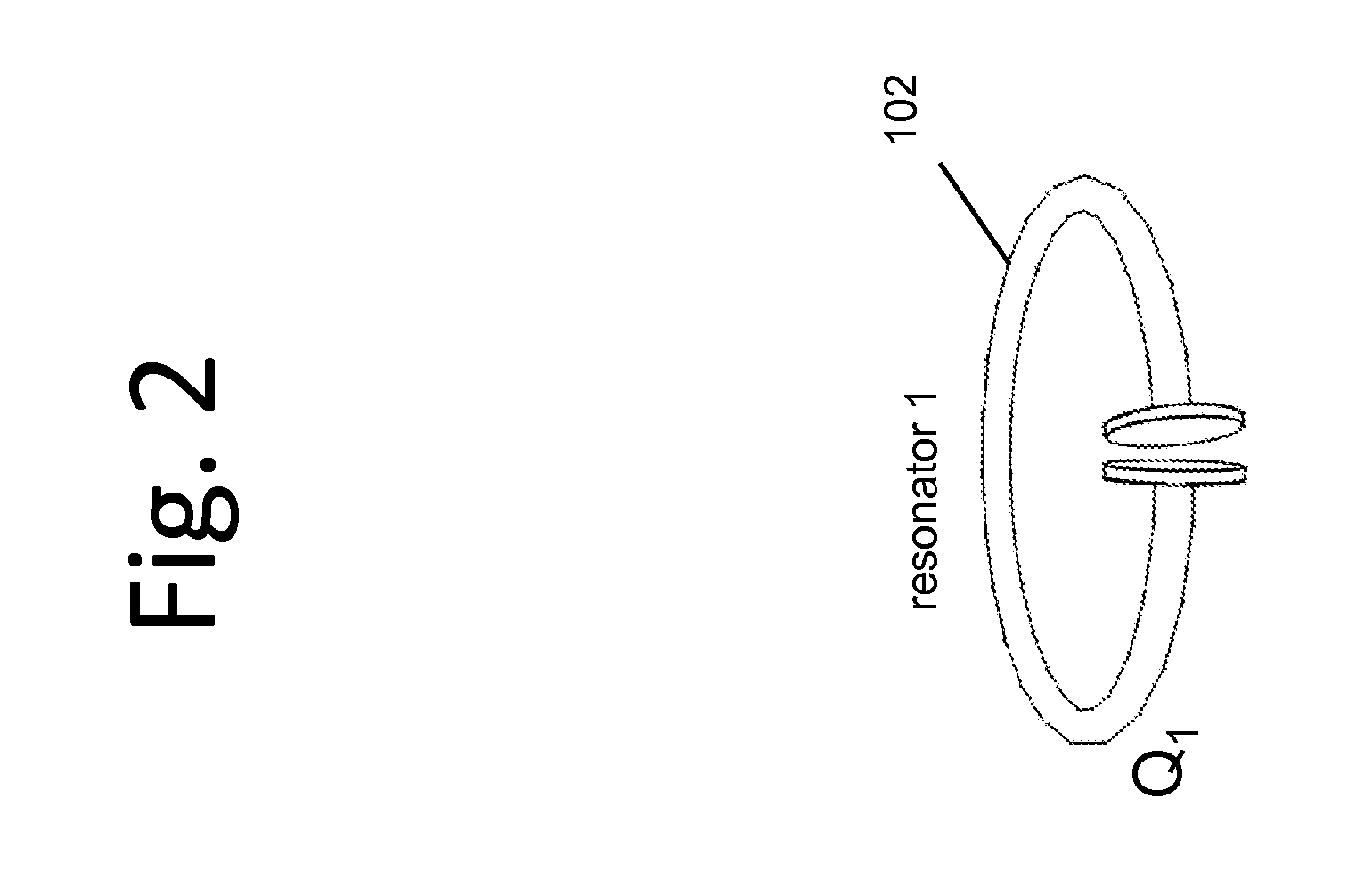

Wireless energy transfer with feedback control for lighting applications

ActiveUS20100201203A1Efficient deliveryEfficient energy transferLoop antennas with ferromagnetic coreMultiple-port networksEnergy transferElectricity

Described herein are improved configurations for a wireless lighting power transfer method including providing a source having a source resonator that includes a high-Q source magnetic resonator coupled to a power source, providing a device having a device resonator that includes a high-Q device magnetic resonator, distal from the source resonator, the device including a light emitting part electrically coupled to the device resonator, providing a signaling capability between the source and the device, signaling a state of the device to the source using the signaling capability, and energizing the source to generate an oscillating magnetic field according to the state of the device.

Owner:WITRICITY CORP

Two-phase operation of plasma chamber by phase locked loop

InactiveUS20130284369A1Liquid surface applicatorsElectric discharge tubesPhase differenceEngineering

Plasma distribution is controlled in a plasma reactor by controlling the phase difference between opposing RF electrodes, in accordance with a desired or user-selected phase difference, by a phase-lock feedback control loop.

Owner:APPLIED MATERIALS INC

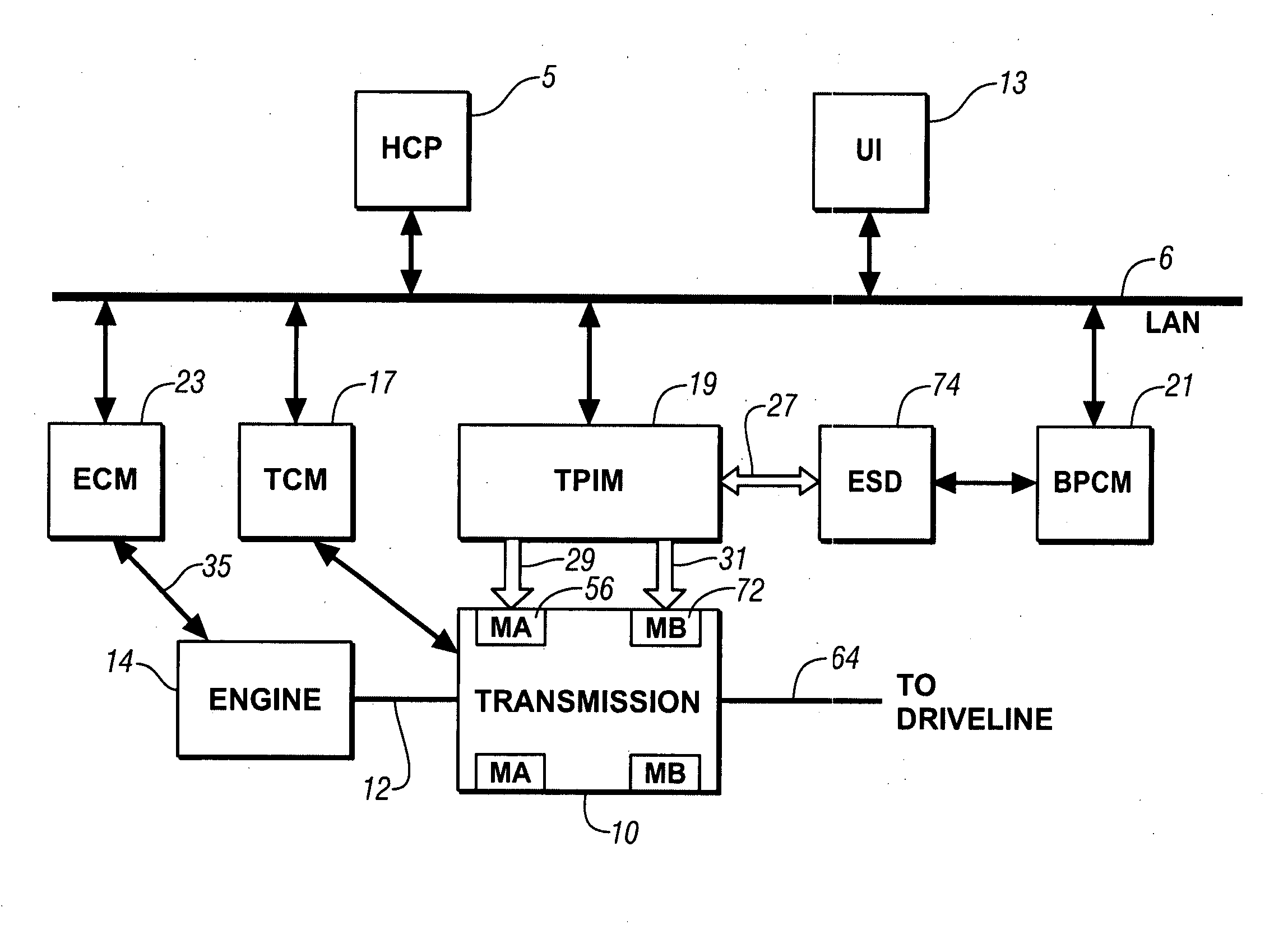

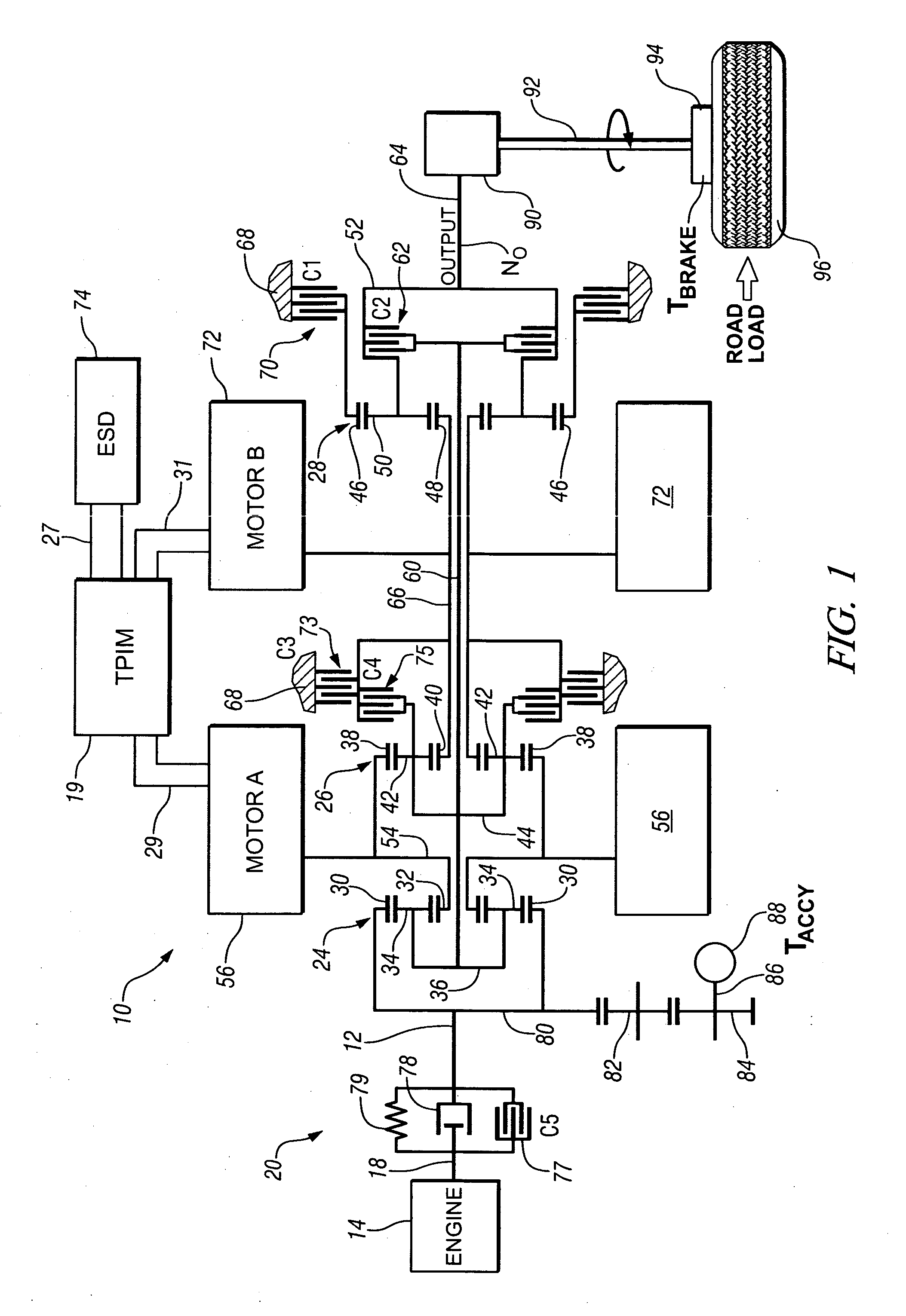

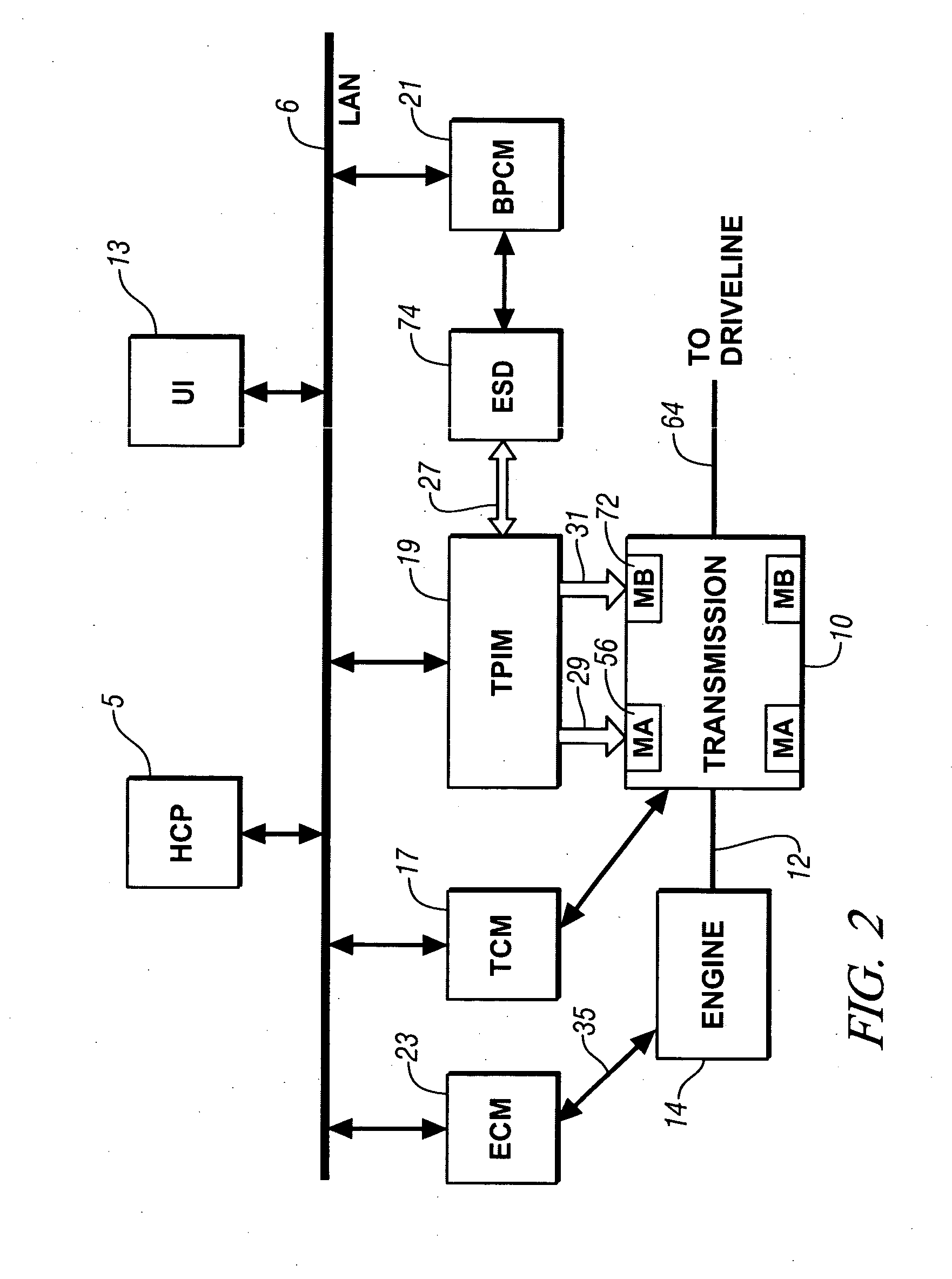

Driveline lash estimation and clunk management using multivariable active driveline damping

ActiveUS20070225888A1Minimize impactHybrid vehiclesDigital data processing detailsDrivetrainEngineering

Driveline lash and clunk are controlled in a powertrain system having multiple torque-generative and torque control devices using a multivariable feedback control approach to provide active driveline damping. Control parameters used by a state estimator are different, depending on whether the driveline lash is taken up or is currently slack. When the estimated driveline axle torque is not substantially zero, the nominal parameters for transmission mode or gear are used in the state estimator. When the estimated axle torque is substantially zero, the parameters are switched to neutral parameters, the lash estimator indicates neutral lash state, and angle of lash is tracked until it accumulates an expected amount of lash in the driveline. During a lash transition time, active damping controls the driveline component speeds so that the effect of lash take-up is minimized. After lash take-up occurs, desired axle torque is used by the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

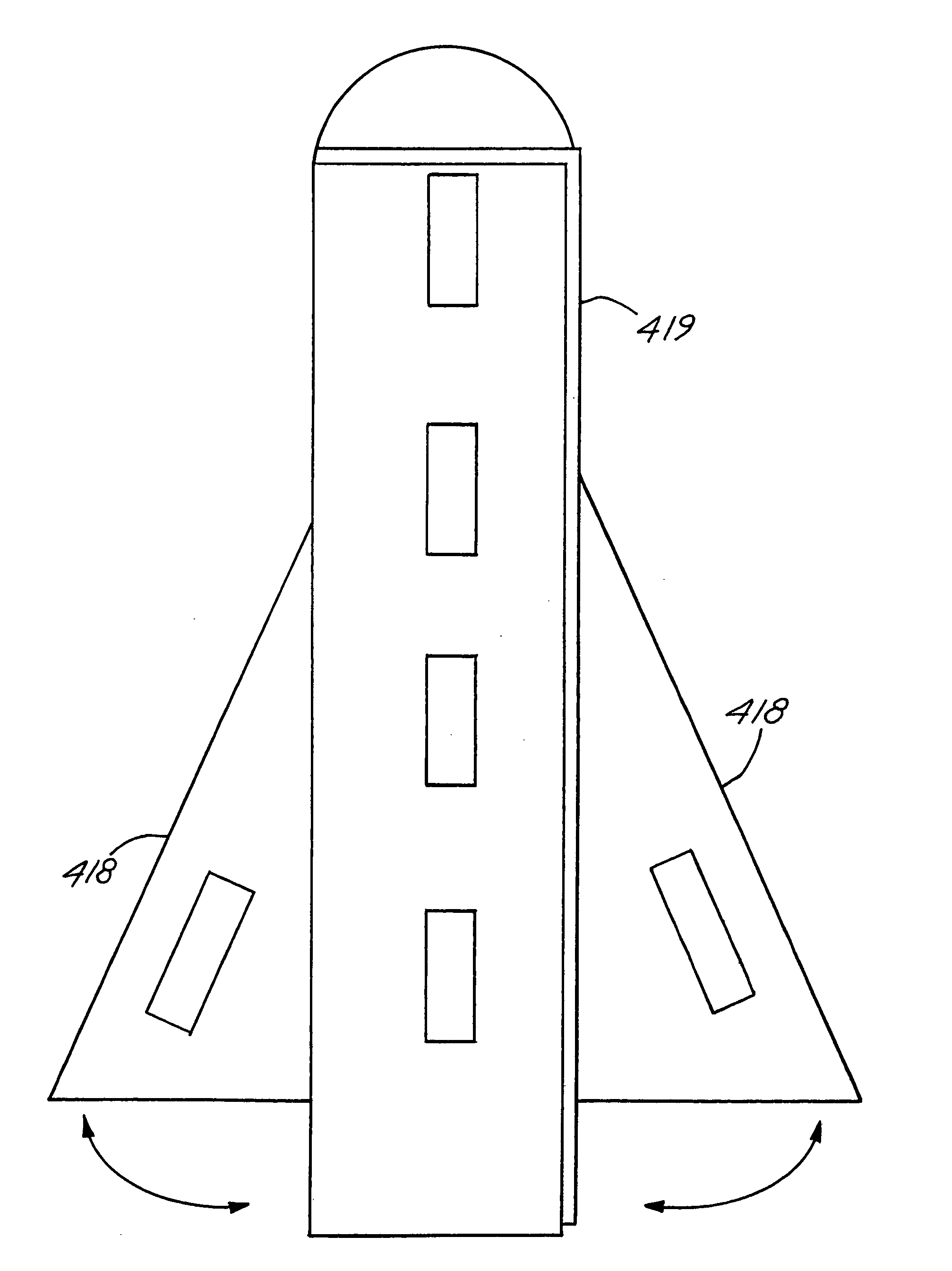

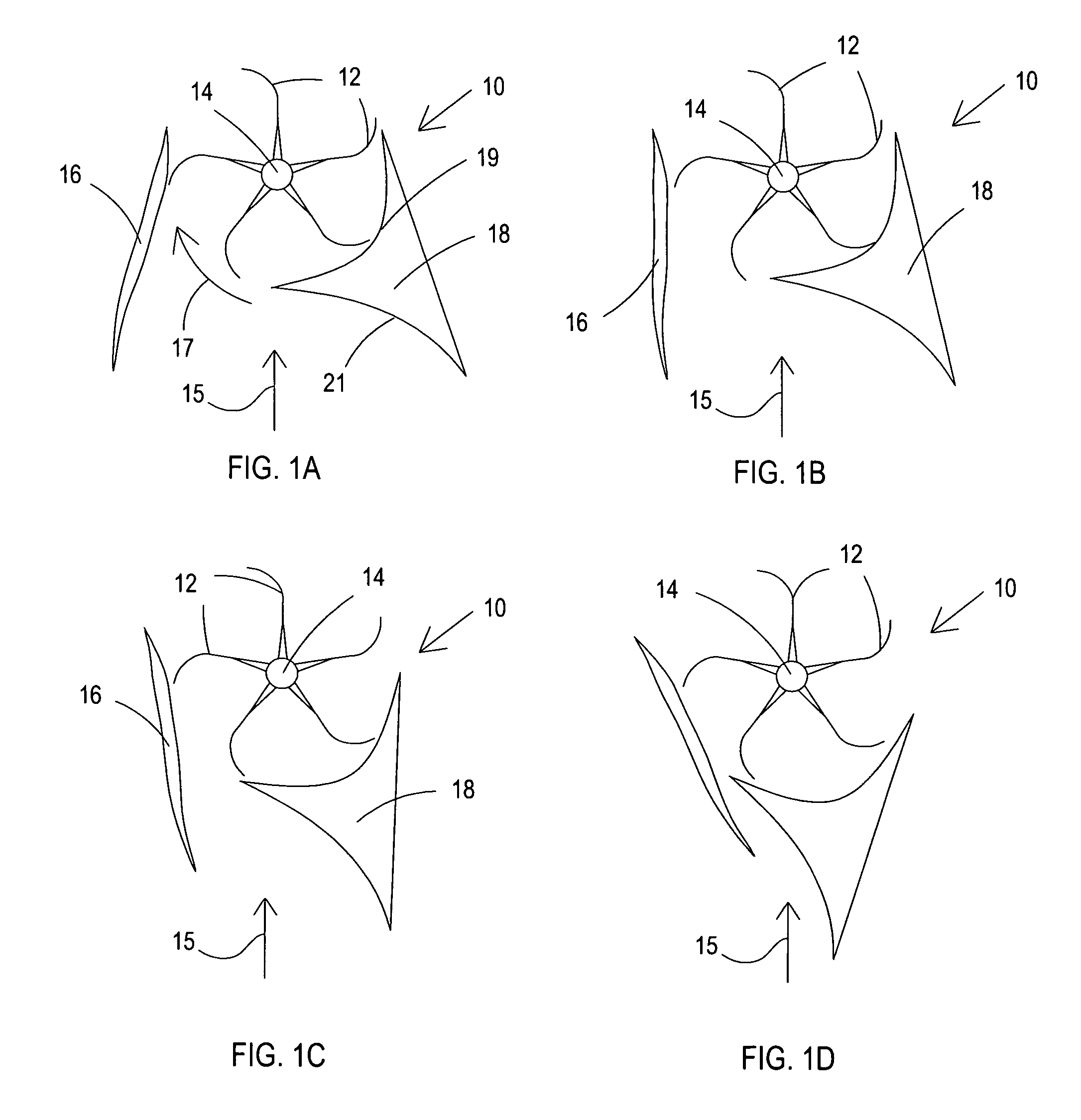

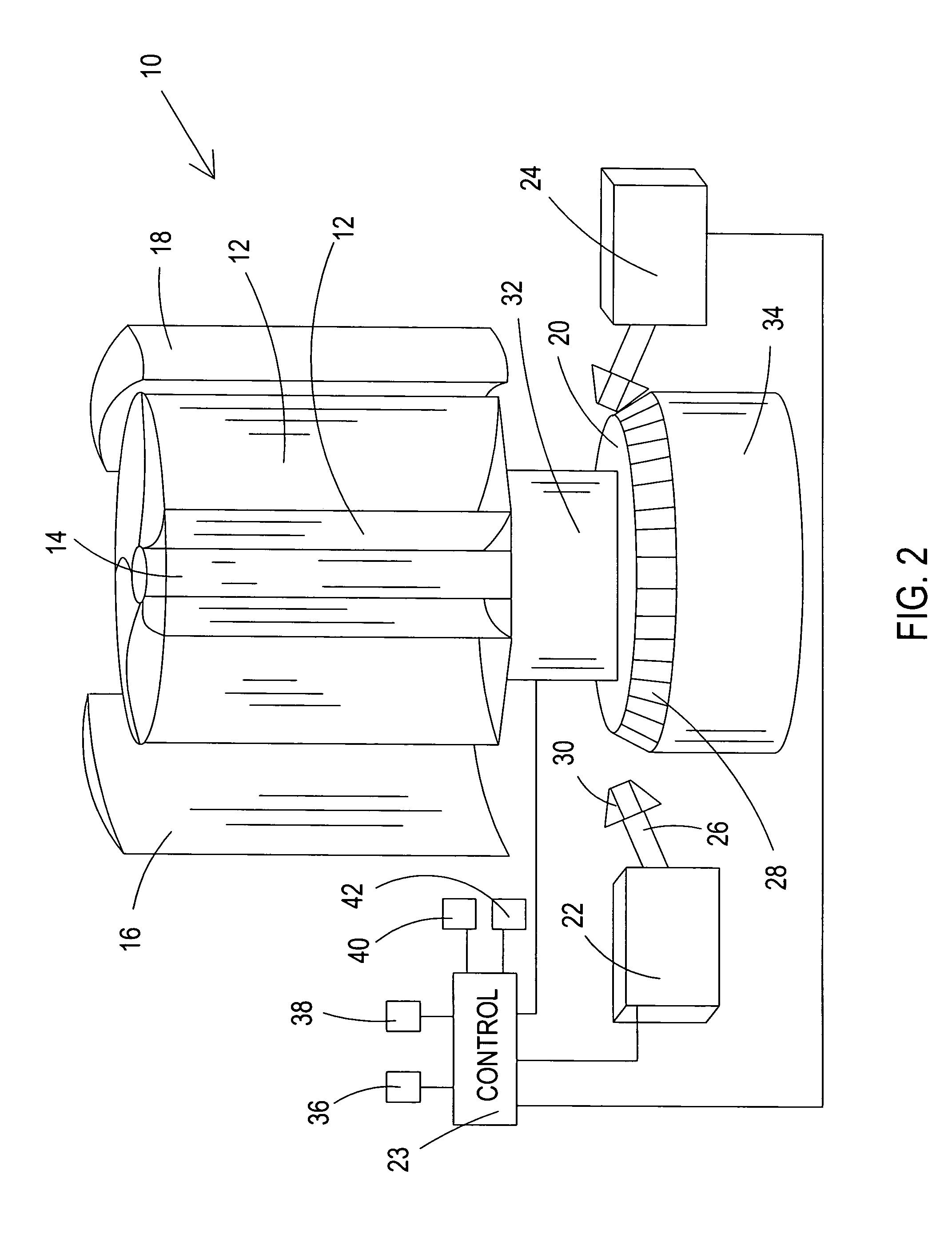

Wind dam electric generator and method

InactiveUS6984899B1Constant windmill shaft rotational speedWind motor controlEngine fuctionsAir volumeEngineering

A vertical axis windmill is provided wherein the amount of wind directed to blades in the power producing part of rotation and the mechanical load of multiple generators is controlled by a feedback control to maintain a relatively constant rotational frequency of the shaft of the windmill. In a preferred embodiment, two wind foils extend radially outwardly from the blades to thereby provide a scoop capable of pulling in more air than would normally be received by the blades. The wind foils then direct the wind flow to the power producing part of rotation of the blades for maximum power output, when necessary. The wind foils can close to control the wind flow to the blades. The generating capacity of a plurality of generators is also controlled in response to shaft rotation to maintain substantially constant shaft rotation.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

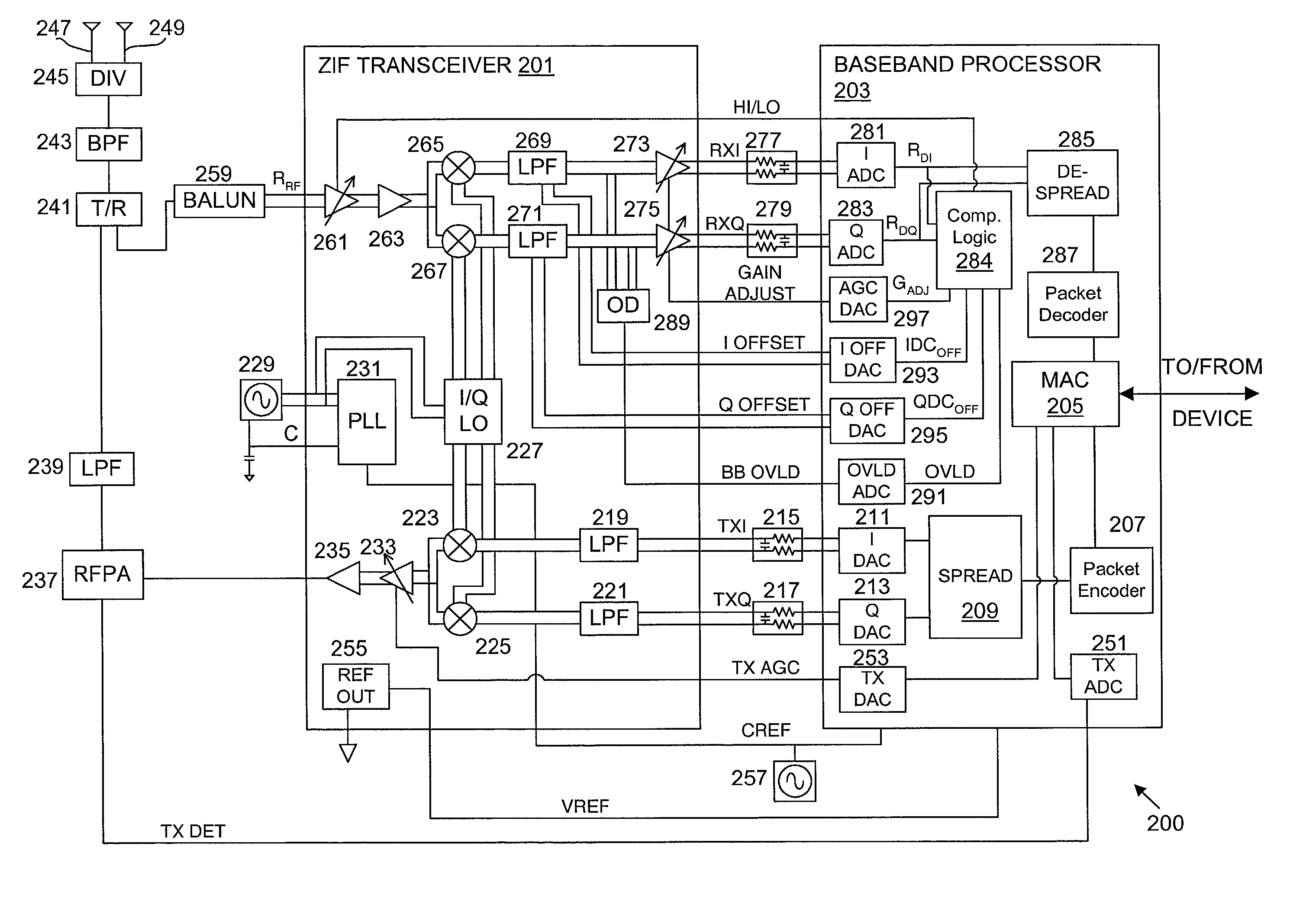

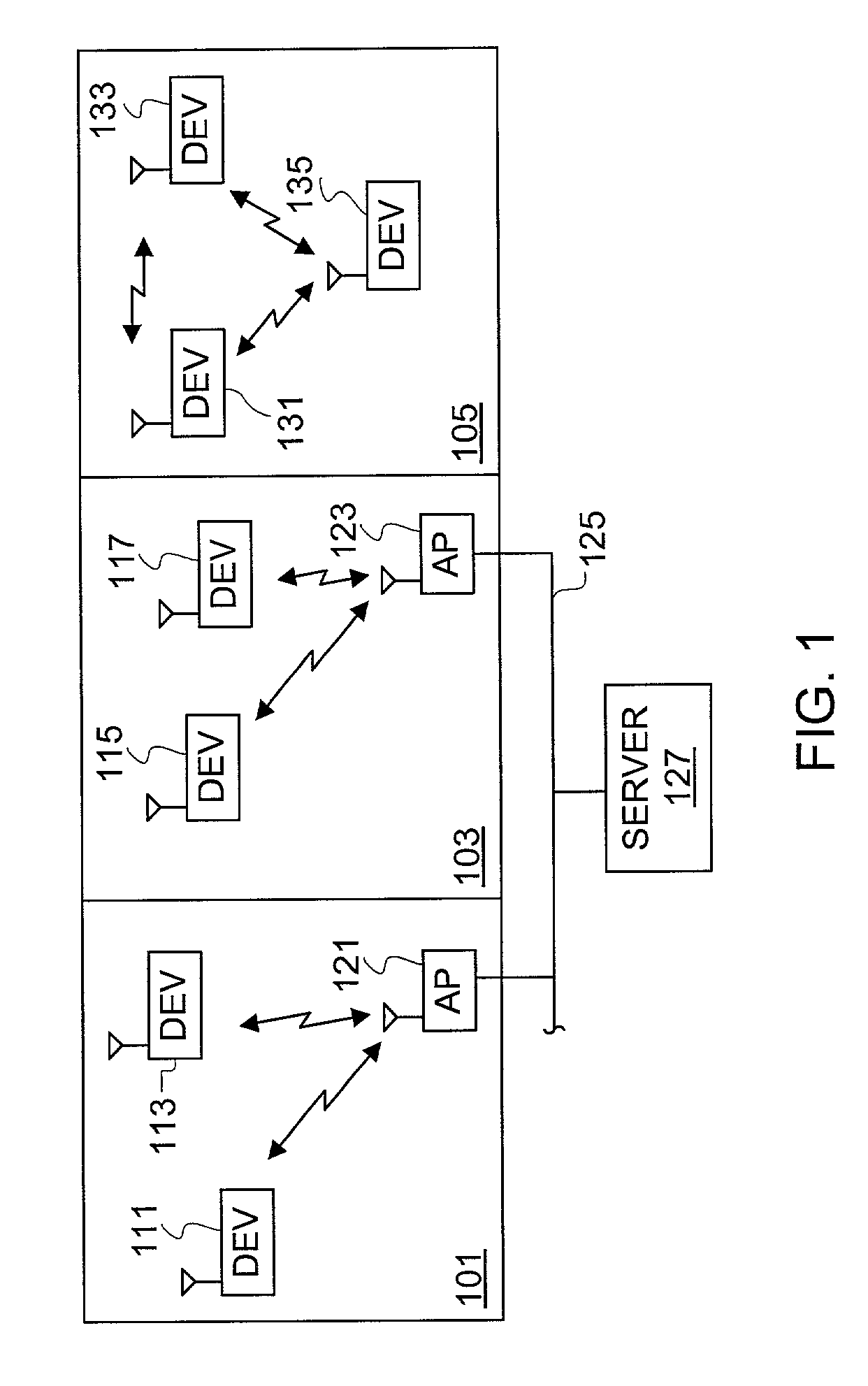

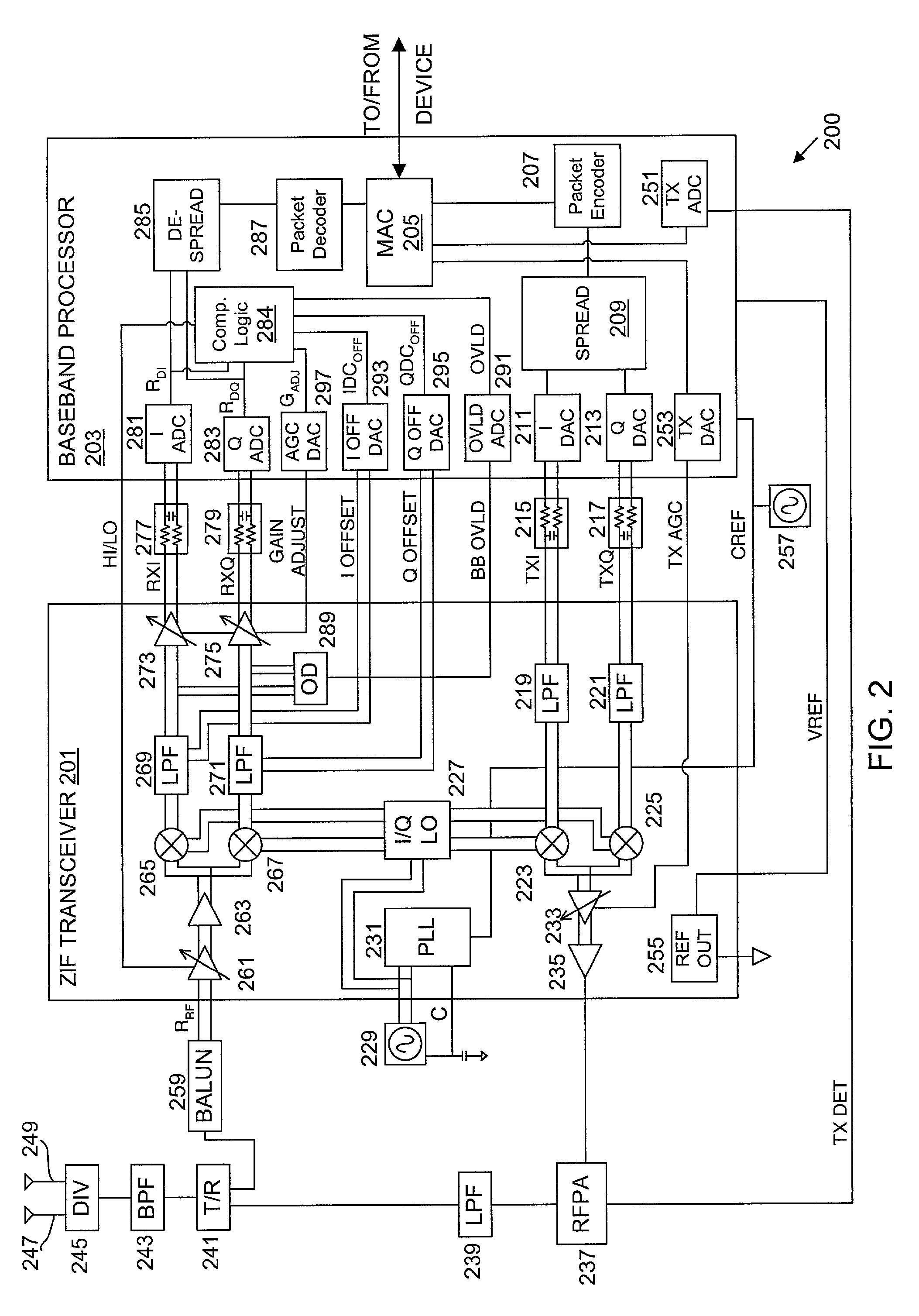

Packet acquisition and channel tracking for a wireless communication device configured in a zero intermediate frequency architecture

A method of controlling operation of a wireless device configured in a zero intermediate frequency architecture including a DC loop and a gain loop. The method includes processing energy in a wireless medium to generate a corresponding receive signal, monitoring the receive signal via a predetermined measurement window, detecting a changed condition in the channel, holding the gain feedback control loop at a constant gain level, and operating the DC loop in an attempt to search a stable DC value for the receive signal while the gain loop is held constant. A first case is DC saturation, where the gain is held constant until DC is controlled. A second case is clear channel assessment, where a prior stored gain setting is applied to the gain loop after detecting the end of the packet. A third case is preparation for receiving an expected acknowledgement packet after transmitting a packet, where again a prior stored gain setting is applied to the gain loop and DC is searched.

Owner:INTELLECTUAL VENTURES I LLC

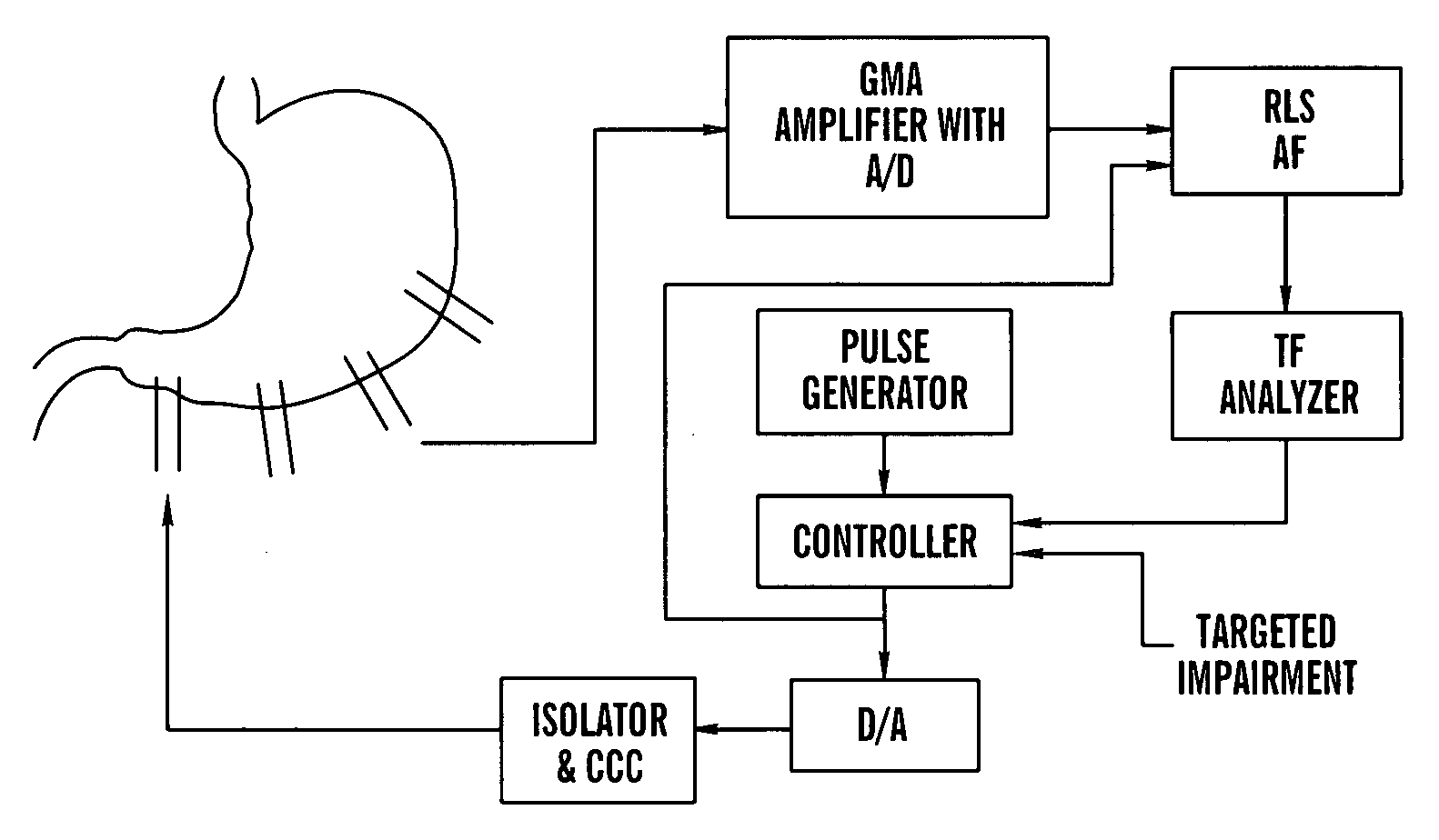

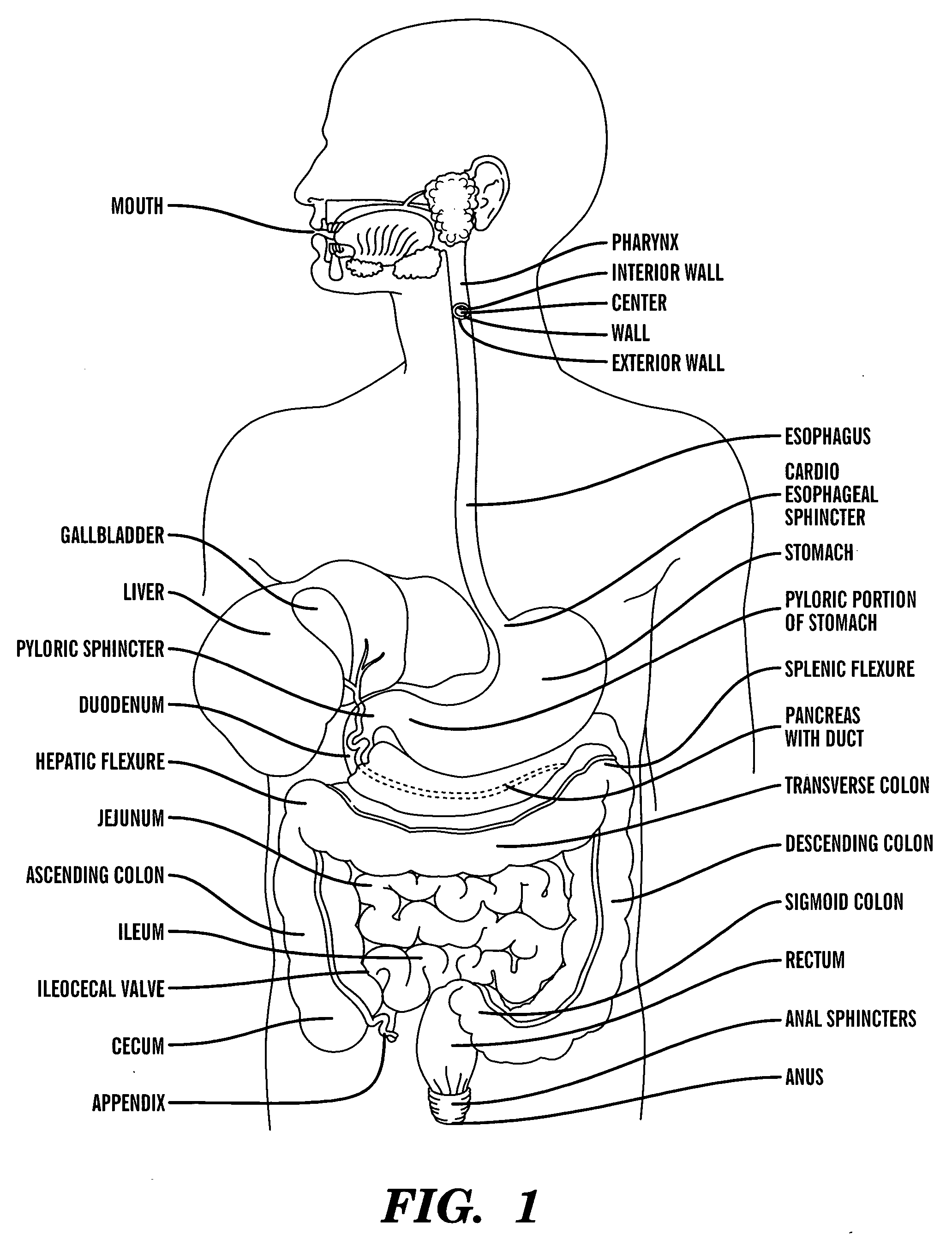

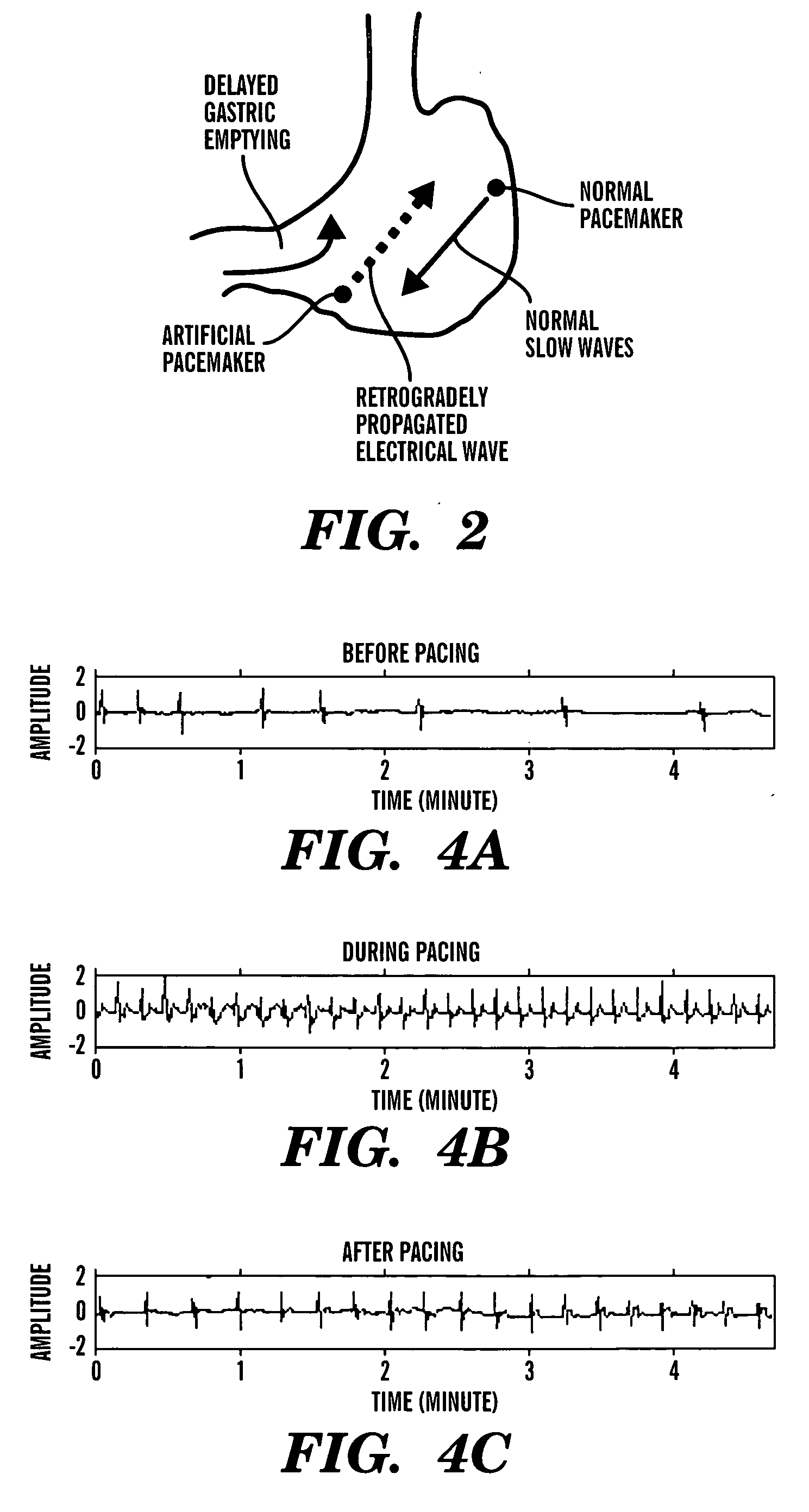

Gastrointestinal electrical stimulation

The present invention is directed to a method of regulating gastrointestinal action in a subject using a stimulatory electrode and a sensor to provide retrograde feedback control of electrical stimulation to the GI tract. The invention is further directed to a method for reducing weight in a subject, again using a stimulatory electrode and a sensor to provide retrograde feedback control of electrical stimulation to the stomach. The invention is further directed to a method of providing electrical field stimulation to a gastrointestinal organ, as well as a method of providing an electrical potential gradient in a gastrointestinal organ. Further provided is a method of stimulating the vagus nerve of a subject. Additionally provided is a method of placing a device in the gastrointestinal tract or wall of a subject from the exterior of the subject, using a needle to insert the device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com