Patents

Literature

33008results about How to "Increase resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device including active layer made of zinc oxide with controlled orientations and manufacturing method thereof

InactiveUS20070187678A1Improve heat resistanceImprove propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesZincActive layer

A semiconductor device includes an oxide semiconductor thin film layer primarily including zinc oxide having at least one orientation other than (002) orientation. The zinc oxide may have a mixed orientation including (002) orientation and (101) orientation. Alternatively, the zinc oxide may have a mixed orientation including (100) orientation and (101) orientation.

Owner:KOICHI IND PROMOTION CENT +1

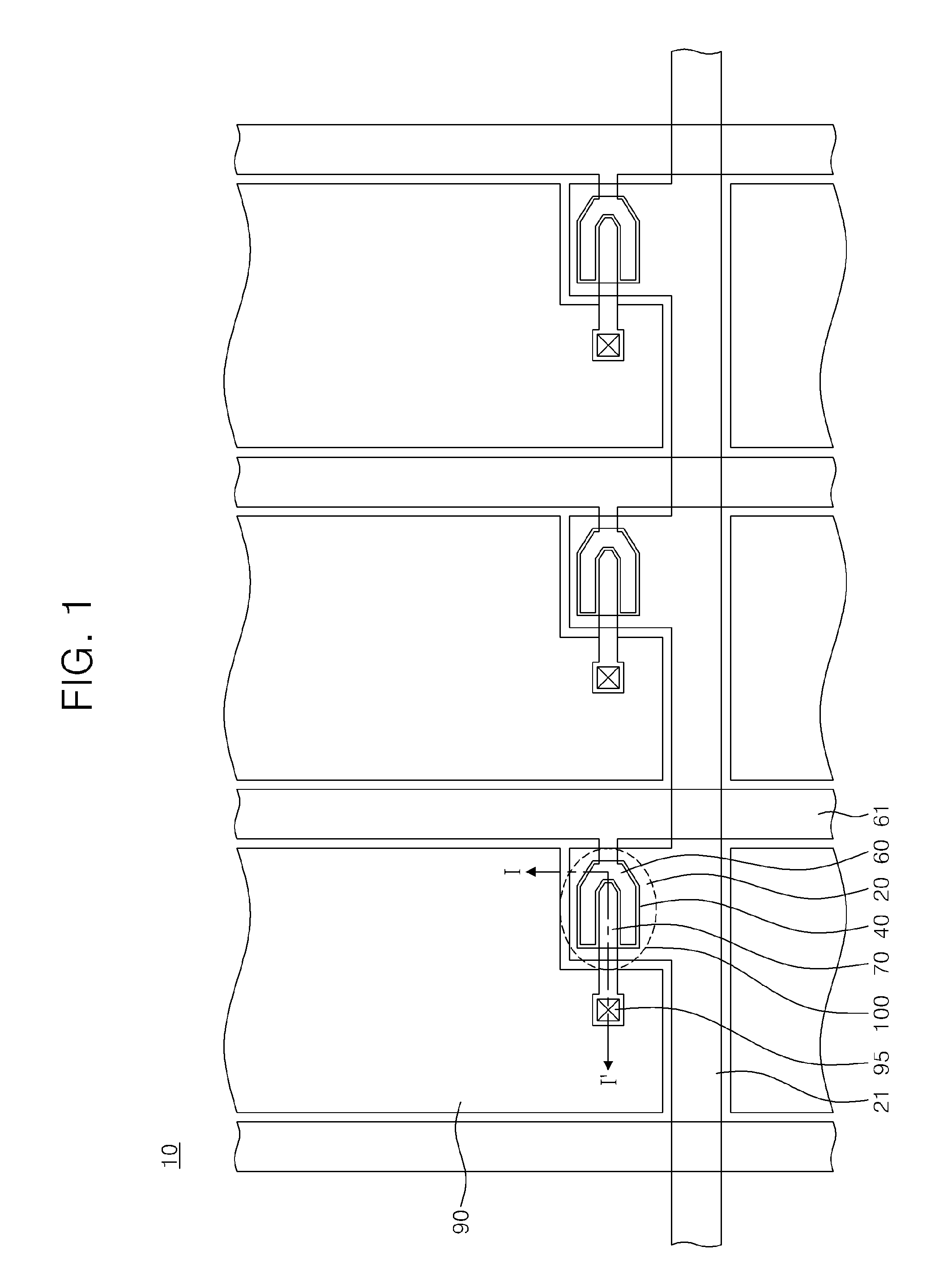

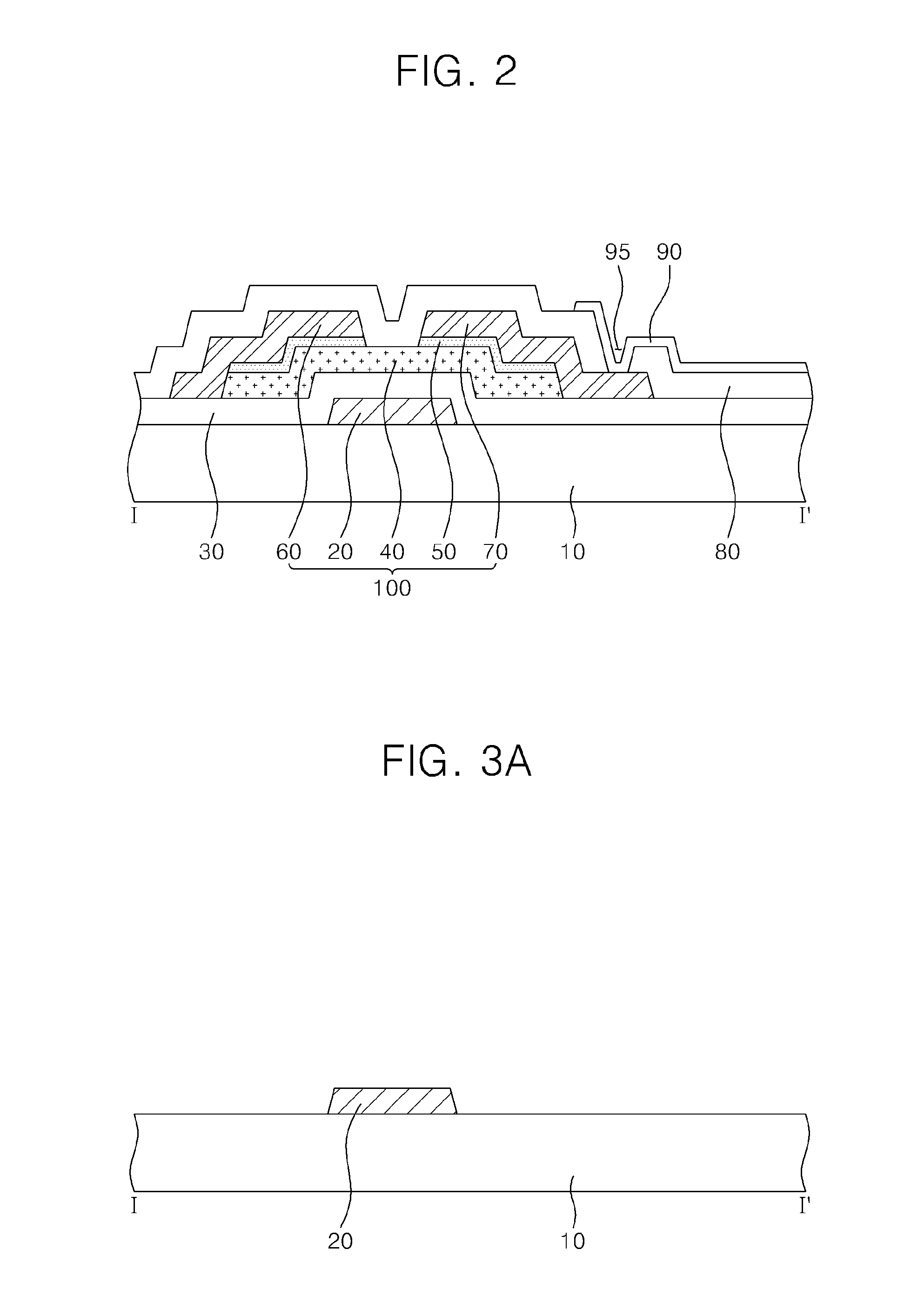

Thin film transitor substrate and method of manufacturing the same

InactiveUS20080258143A1Increases process time and leakage current and serial contact resistanceDegrading property of TFTTransistorSemiconductor/solid-state device manufacturingOxide semiconductorOxide

A method of manufacturing a thin film transistor (“TFT”) substrate includes forming a first conductive pattern group including a gate electrode on a substrate, forming a gate insulating layer on the first conductive pattern group, forming a semiconductor layer and an ohmic contact layer on the gate insulating layer by patterning an amorphous silicon layer and an oxide semiconductor layer, forming a second conductive pattern group including a source electrode and a drain electrode on the ohmic contact layer by patterning a data metal layer, forming a protection layer including a contact hole on the second conductive pattern group, and forming a pixel electrode on the contact hole of the protection layer. The TFT substrate including the ohmic contact layer formed of an oxide semiconductor is further provided.

Owner:SAMSUNG ELECTRONICS CO LTD

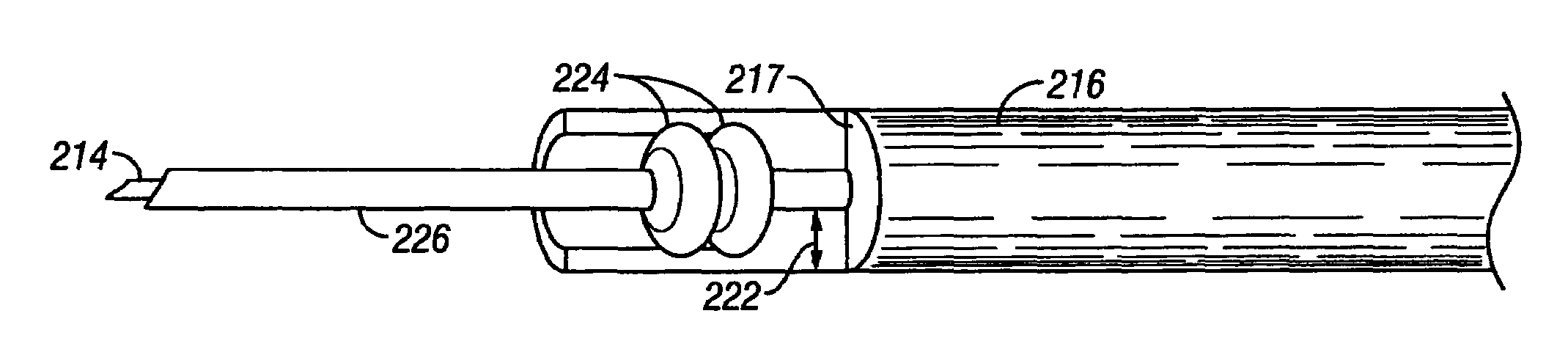

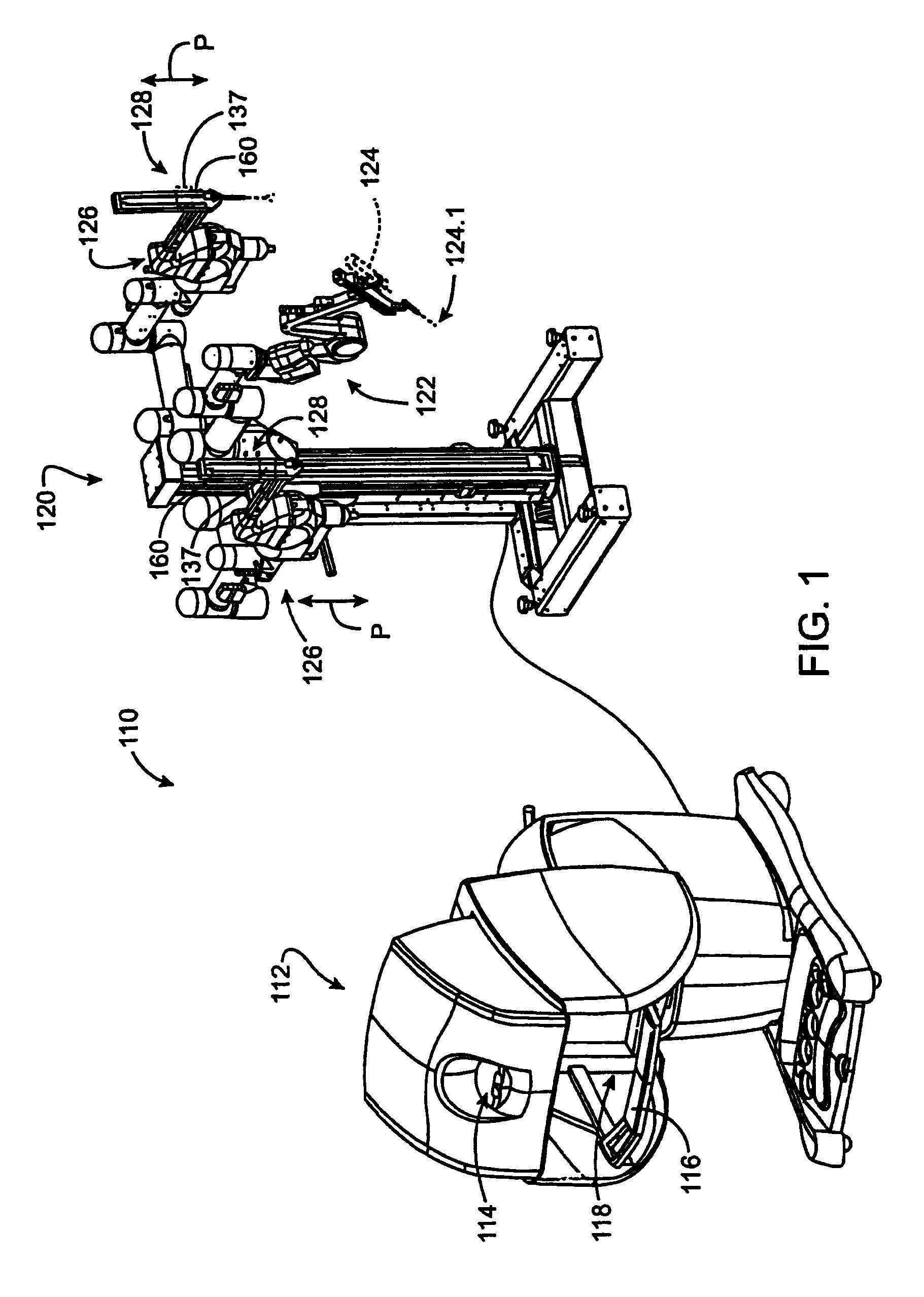

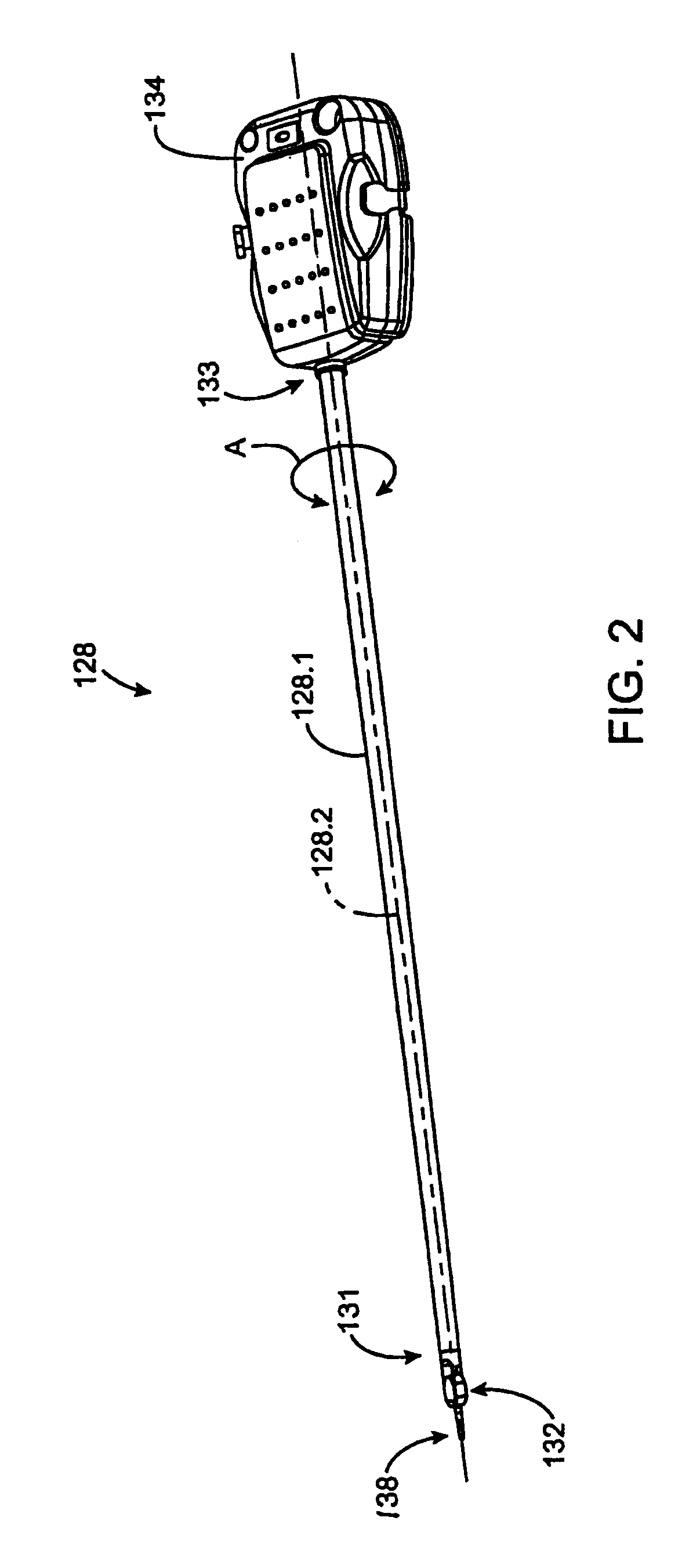

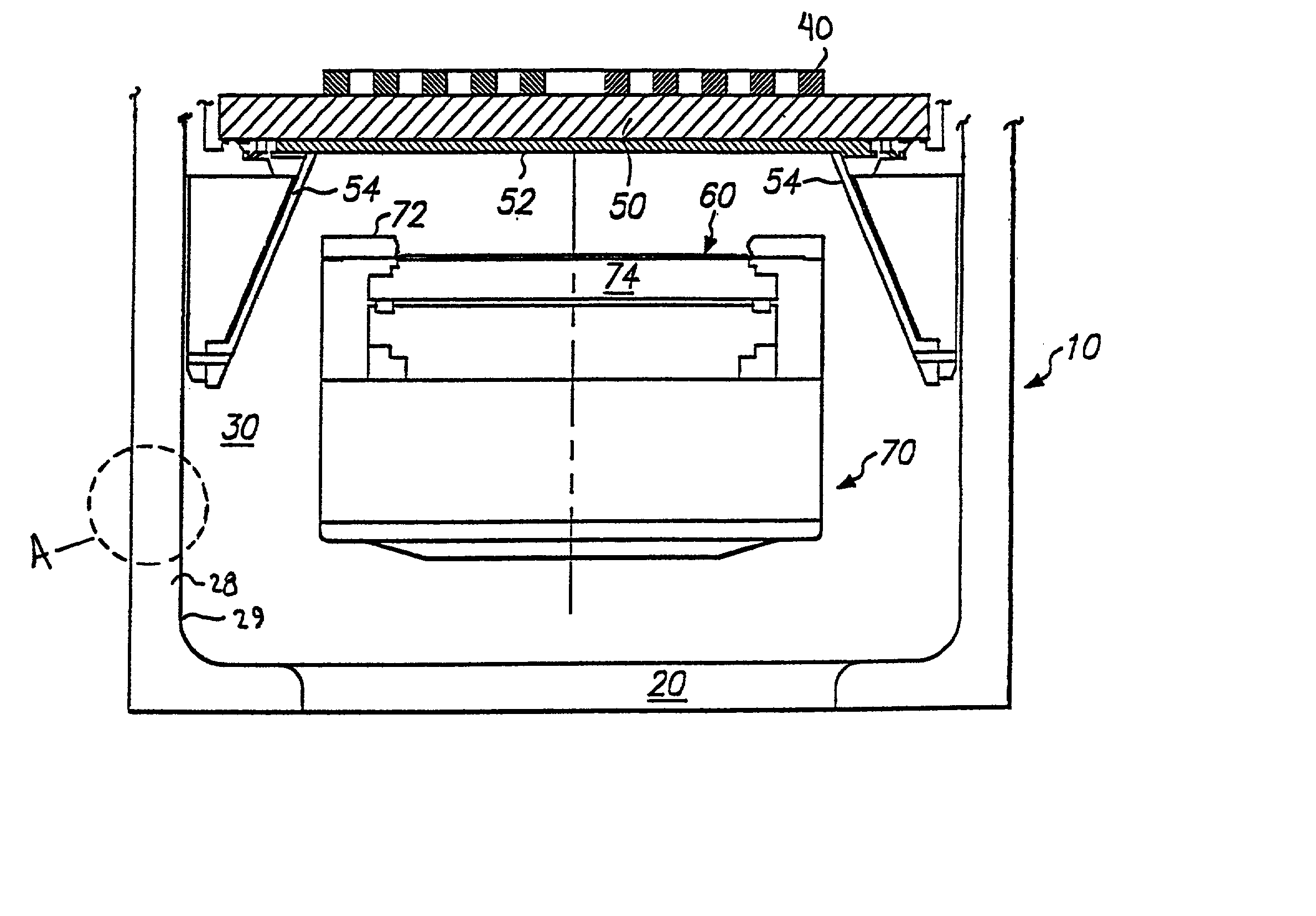

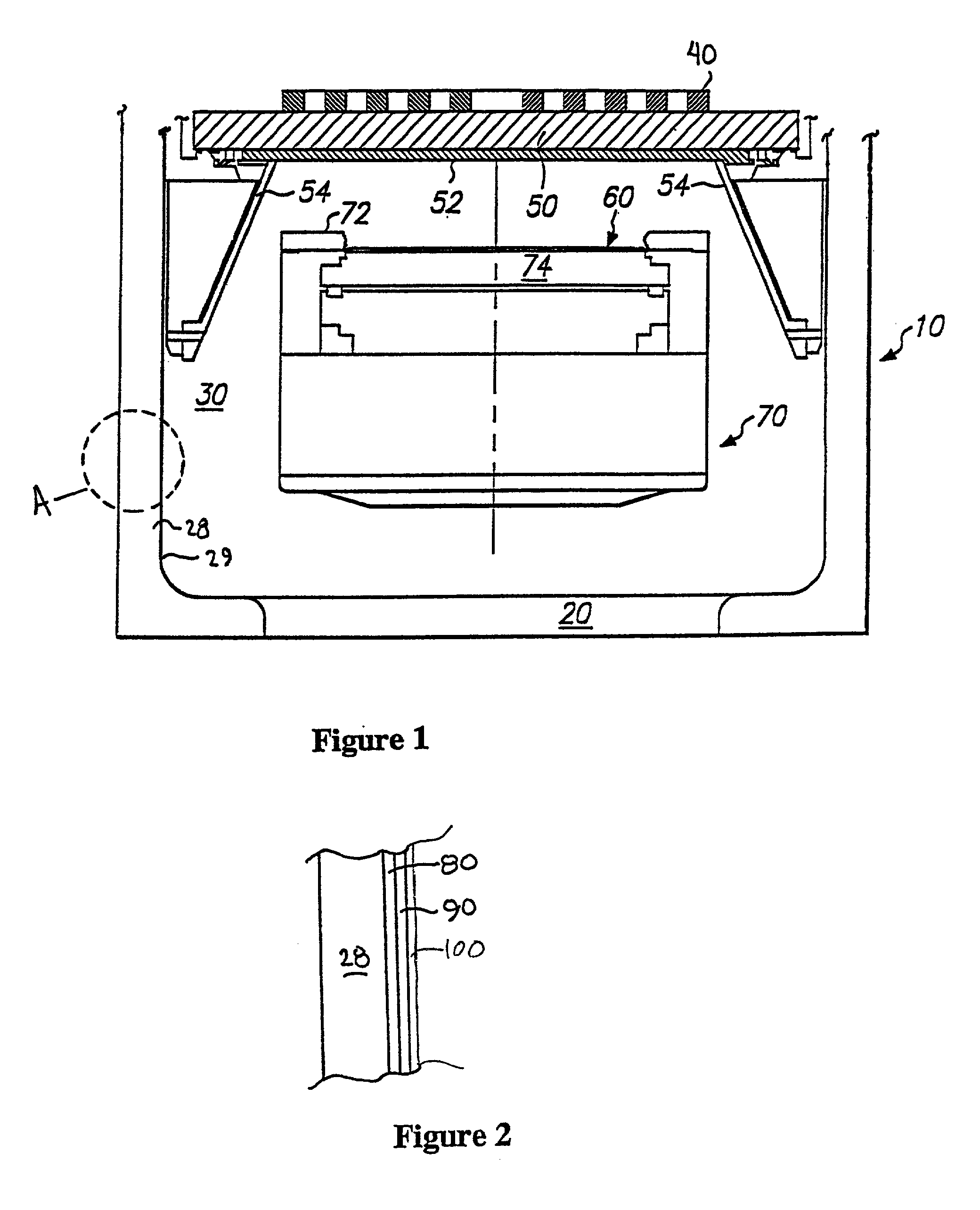

Surgical tool having electrocautery energy supply conductor with inhibited current leakage

InactiveUS7083615B2Low costEasy to manufactureDiagnosticsSurgical instruments for heatingCapacitanceElectrical conductor

The present invention provides improved electrosurgical instruments and systems having electrocautery energy supply conductors that provide inhibited current leakage and methods of performing a robotically controlled minimally invasive surgical procedure while preventing unintended capacitive coupling. A surgical instrument generally comprises an elongate shaft having a proximal end and a distal end and defining an internal longitudinally extending passage. An electrocautery end effector is coupled to or disposed at the distal end of the shaft. An interface or tool base is coupled to or disposed at the proximal end of the shaft and removably connectable to the robotic surgical system. Typically, an independent electrical conductor extends from the interface to the end effector to transmit electrical energy to tissue engaged by the end effector. A sealed insulation tube extends within the passage and over the conductor. A separation is maintained between the sealed insulation tube and the conductor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

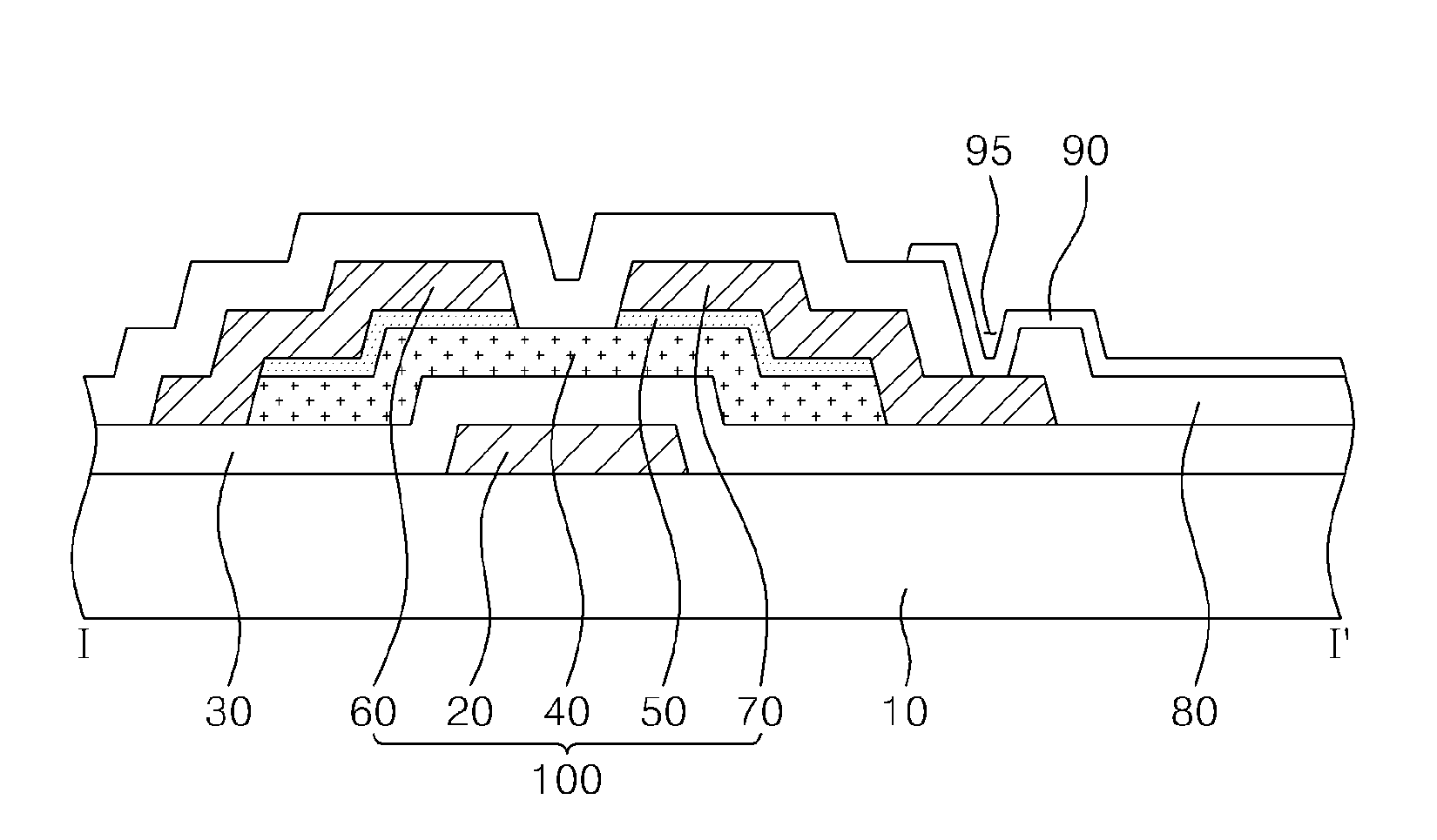

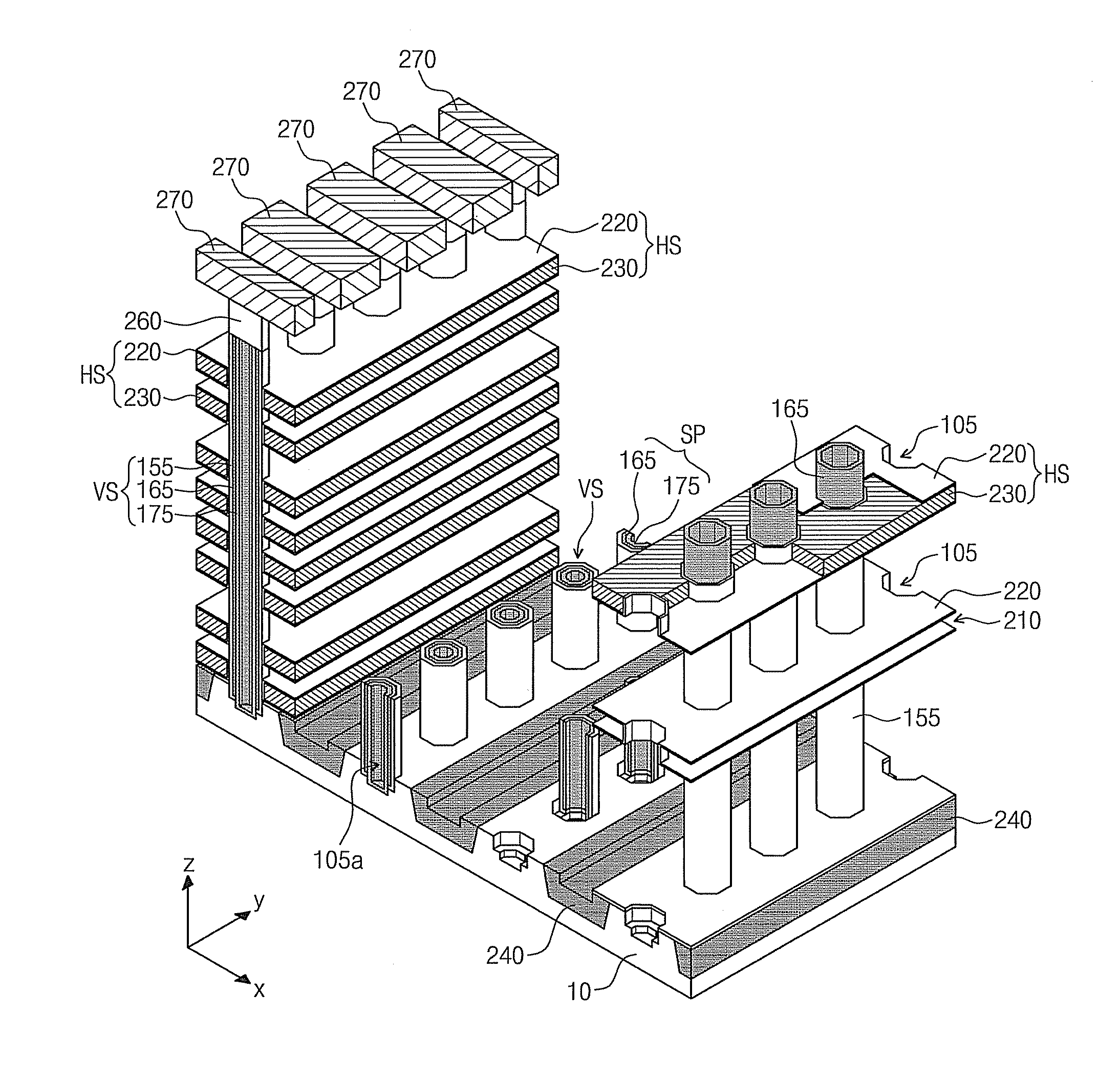

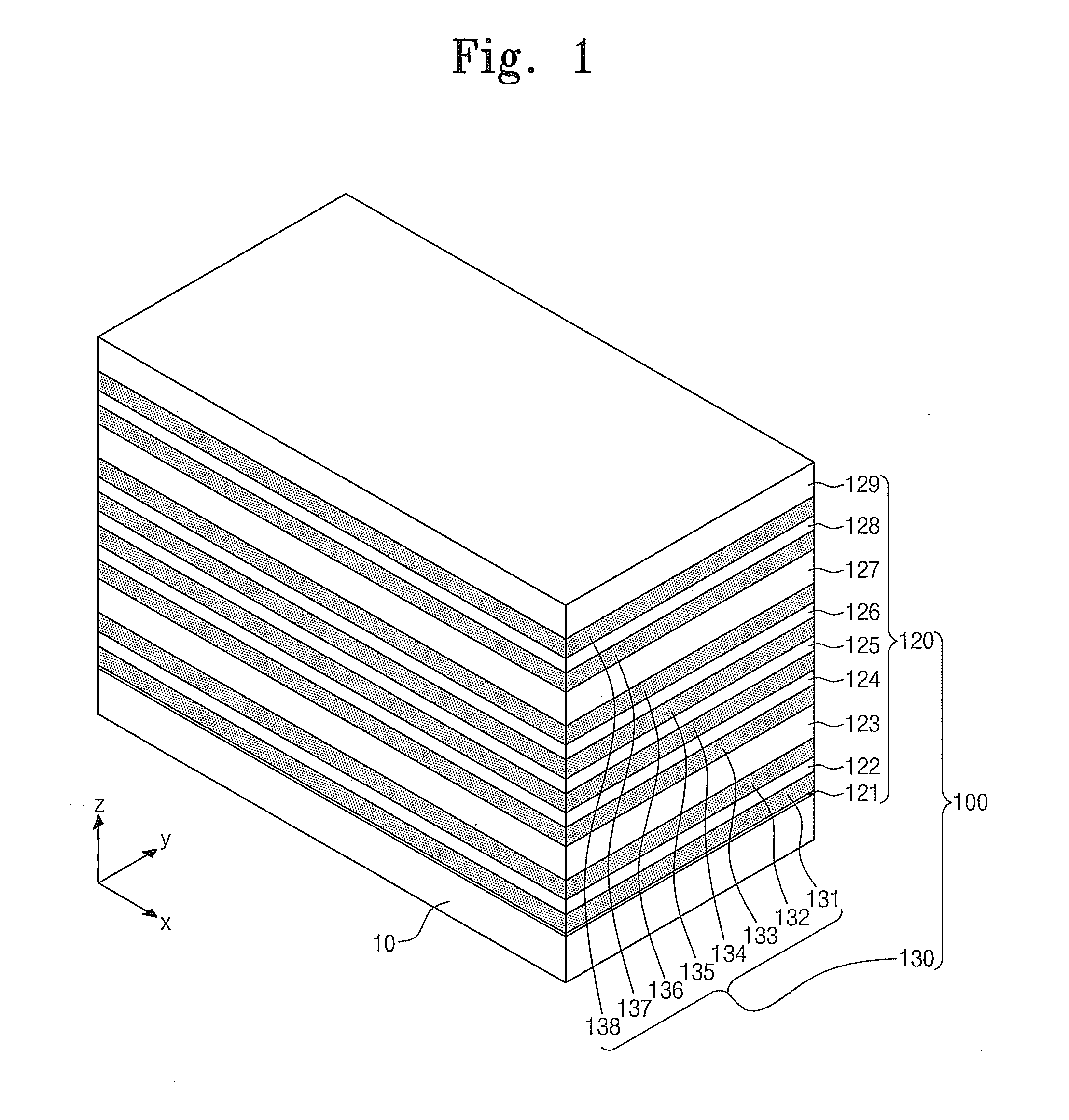

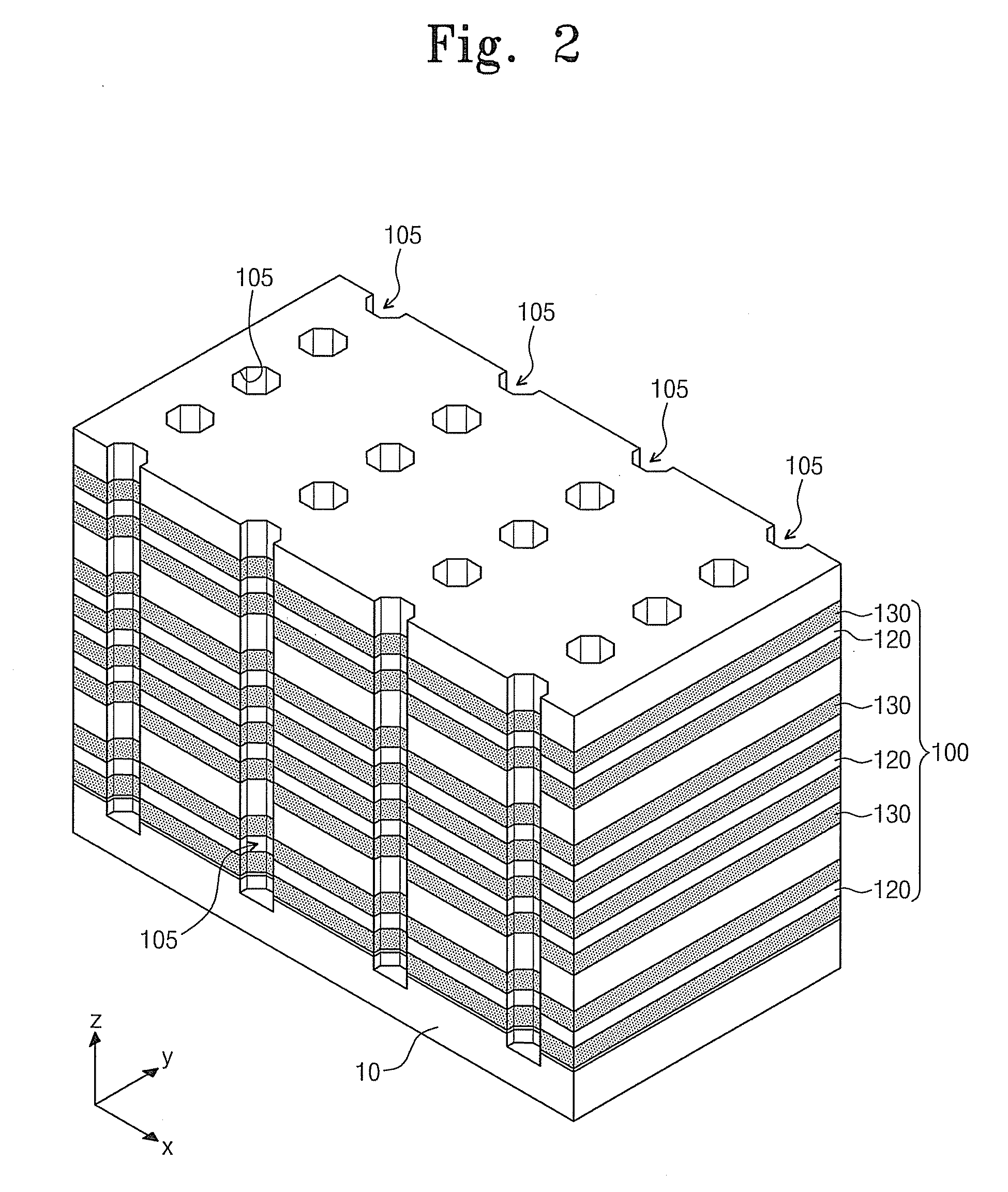

Three-Dimensional Semiconductor Memory Devices And Methods Of Fabricating The Same

ActiveUS20110233648A1Increasing the thicknessReduce resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Three-dimensional semiconductor memory devices and methods of fabricating the same. The three-dimensional semiconductor devices include an electrode structure with sequentially-stacked electrodes disposed on a substrate, semiconductor patterns penetrating the electrode structure, and memory elements including a first pattern and a second pattern interposed between the semiconductor patterns and the electrode structure, the first pattern vertically extending to cross the electrodes and the second pattern horizontally extending to cross the semiconductor patterns.

Owner:SAMSUNG ELECTRONICS CO LTD

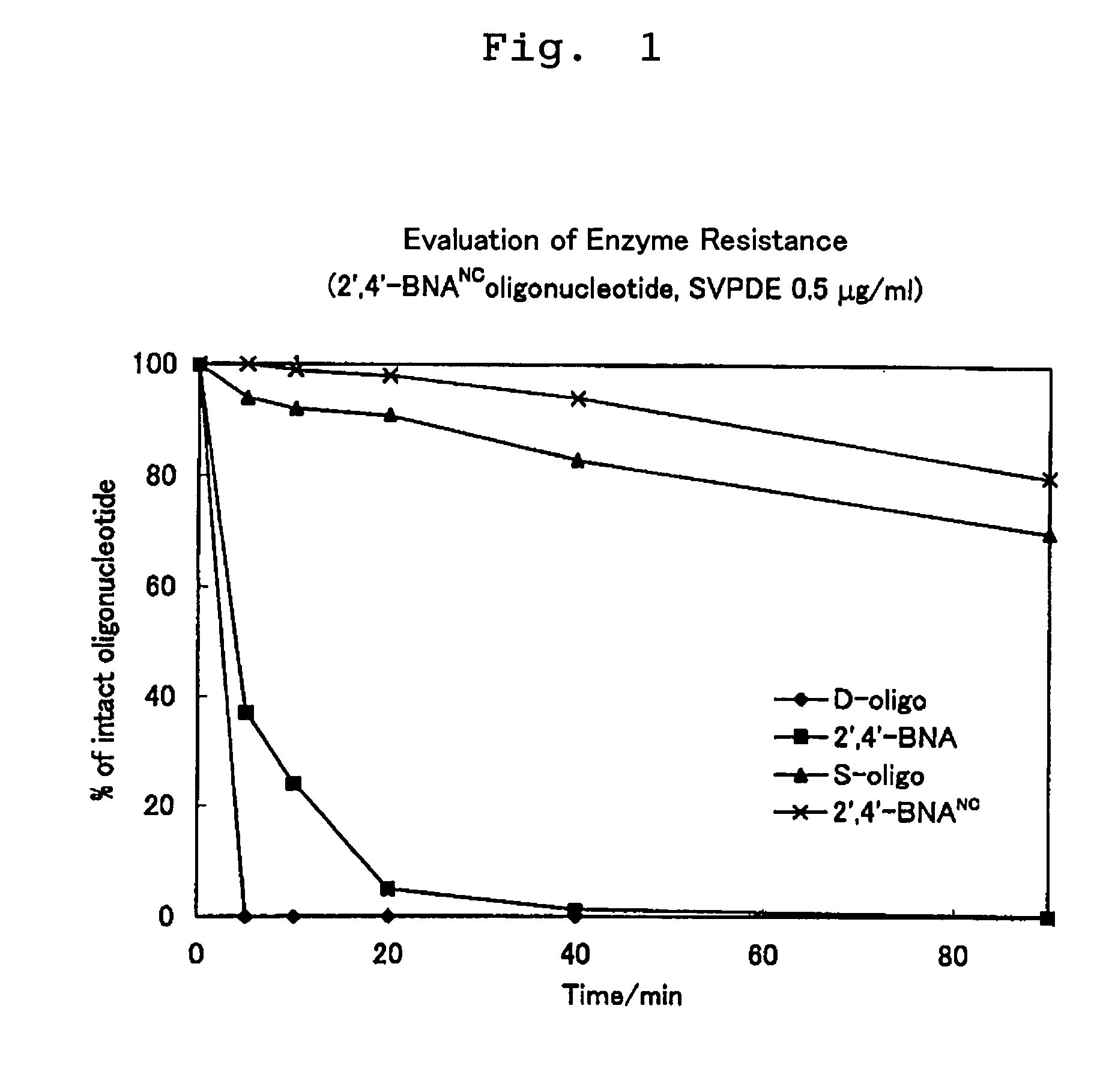

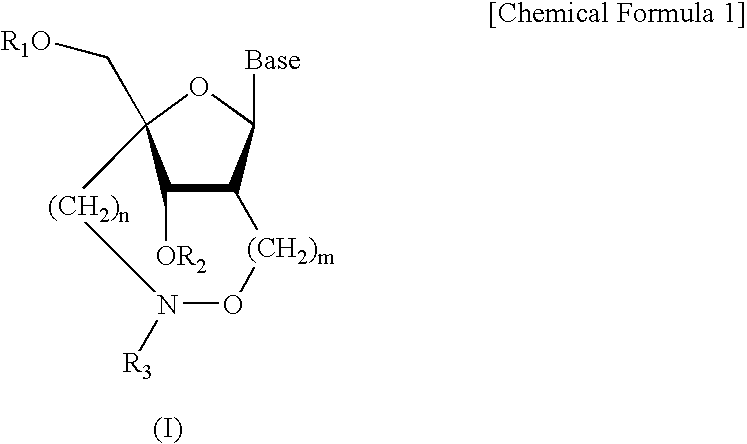

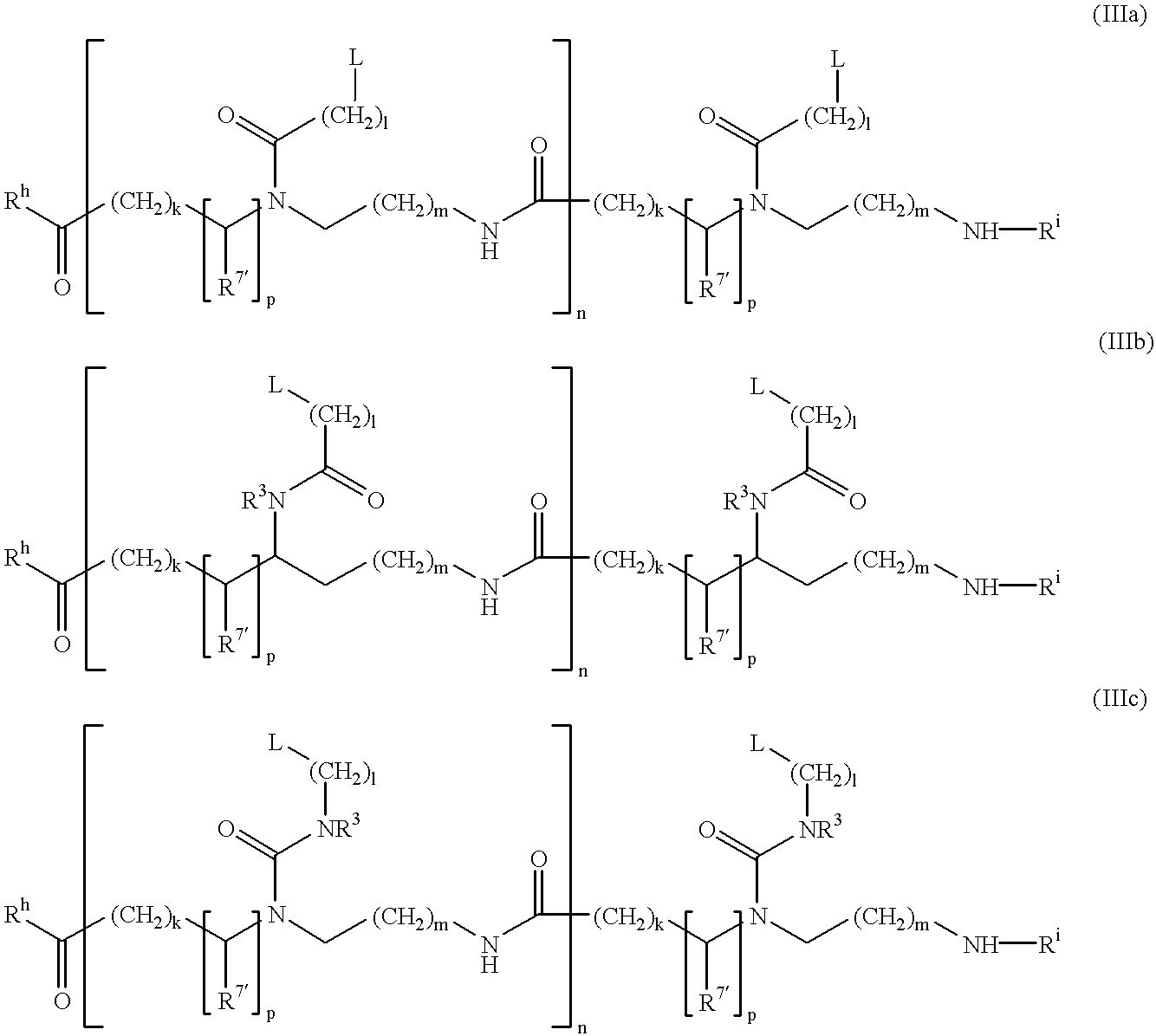

Artificial nucleic acids of n-o bond crosslinkage type

ActiveUS7427672B2High sensitivity analysisConfirmed its usefulnessBiocideSugar derivativesSingle strandDouble strand

Owner:RIKEN GENESIS

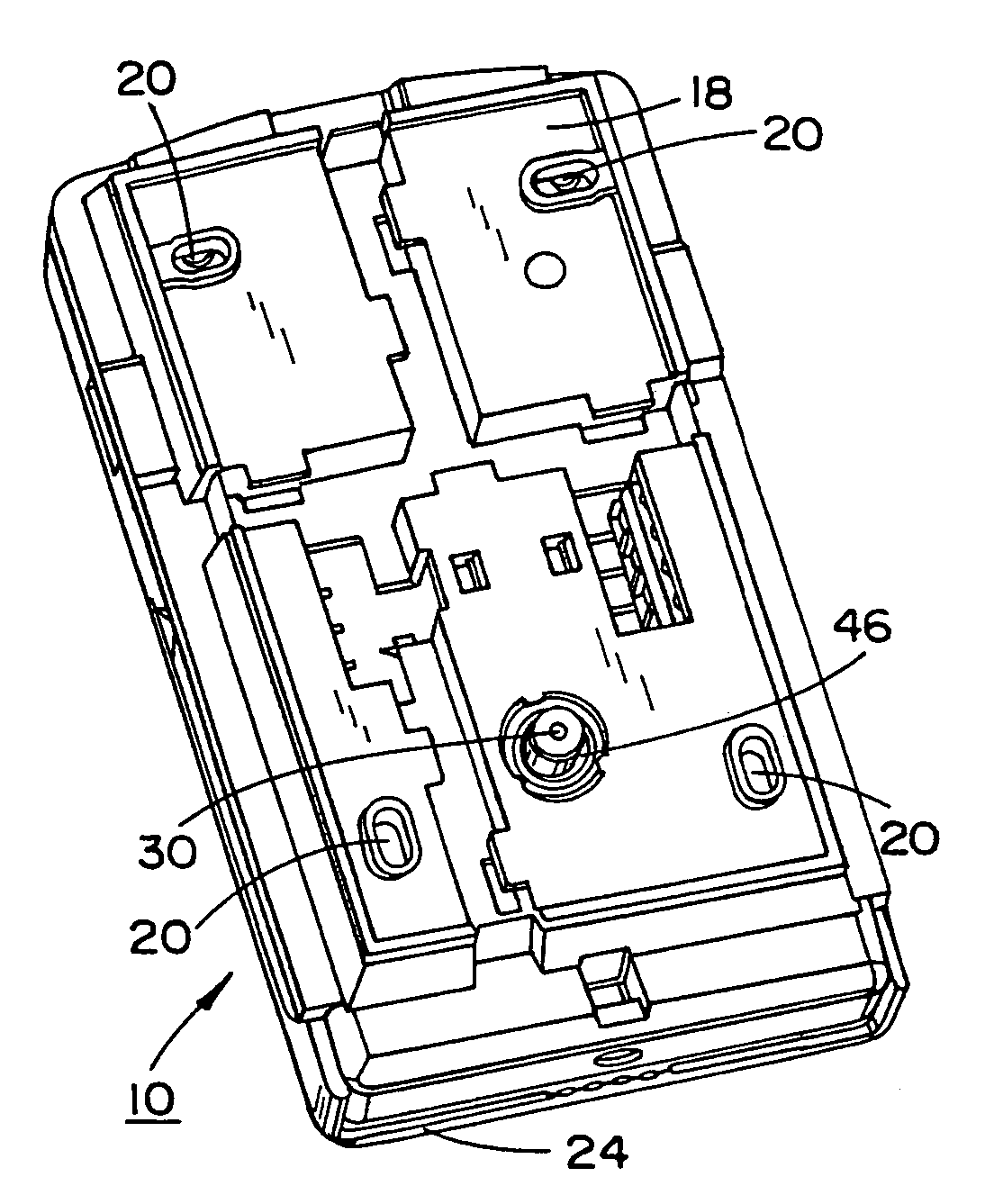

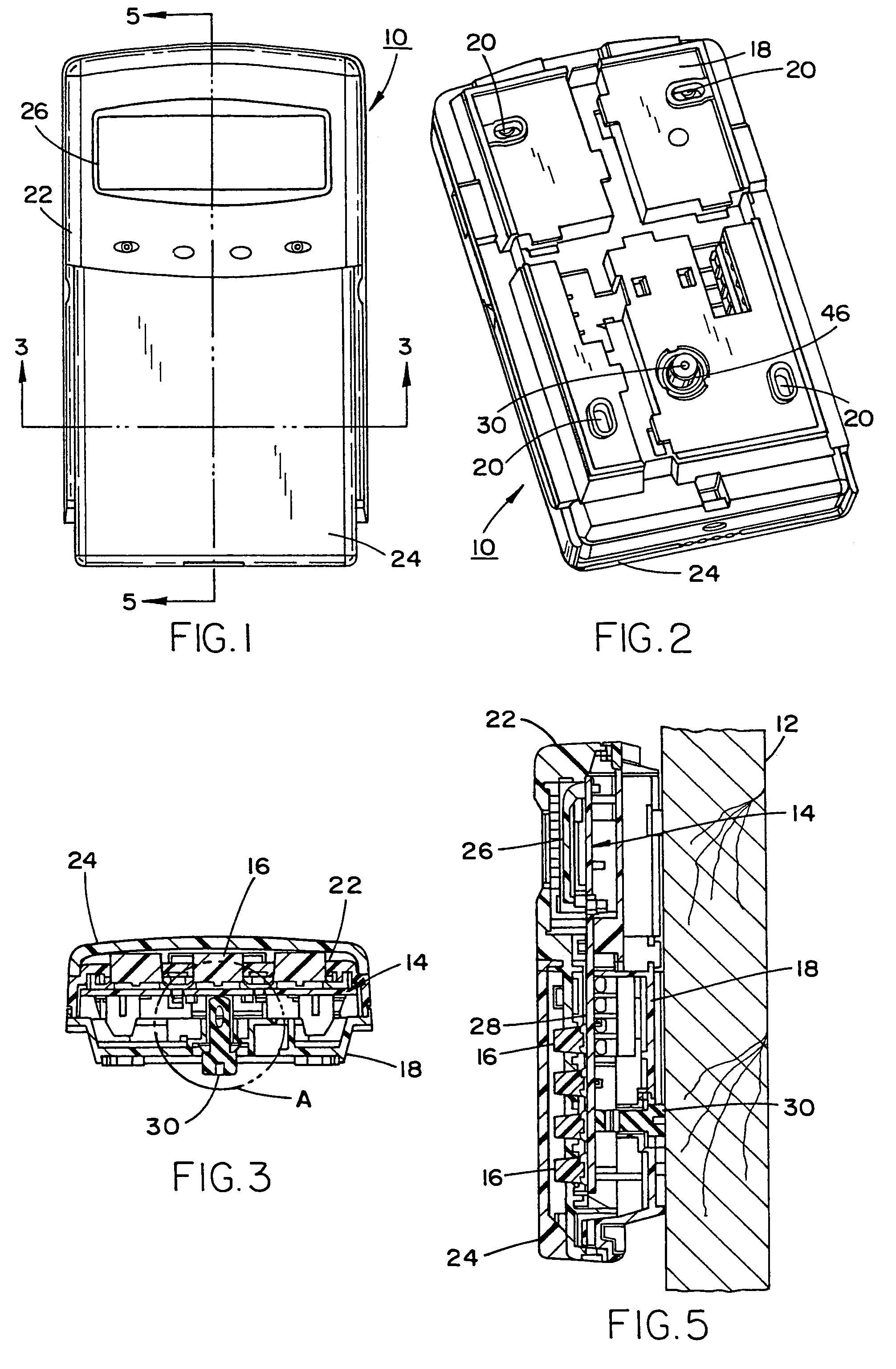

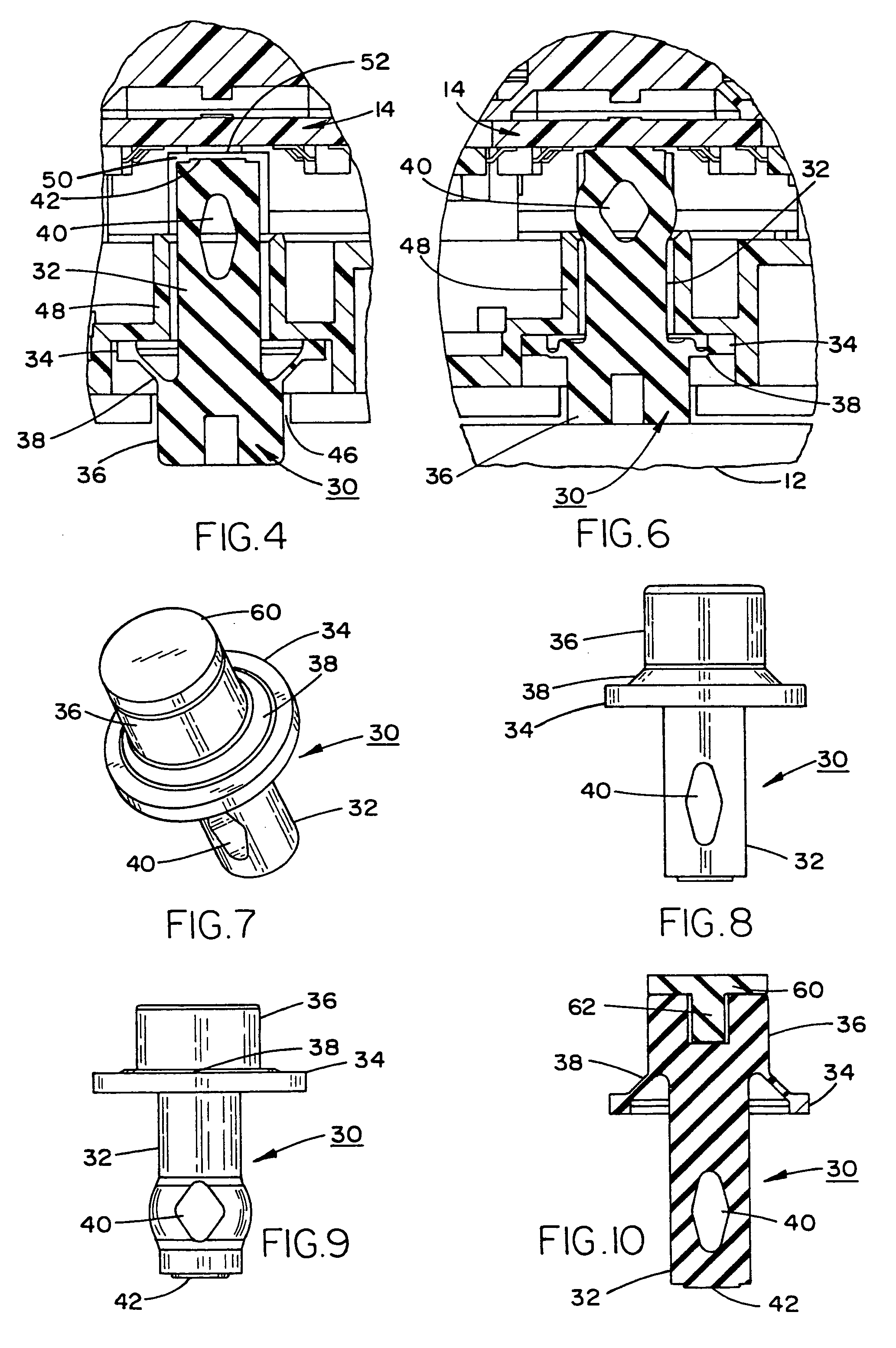

Conductive tamper switch for security devices

InactiveUS7388484B2Highly efficient and reliable in operationCost-effectively mountedInternal/peripheral component protectionRadio/inductive link selection arrangementsMonitoring siteFire alarm system

A tamper switch mechanism utilized in security interface devices such as keypad installations to render them tamper-resistant, wherein the devices are generally connected to burglar alarm and fire alarm systems. More particularly, provided is a conductive tamper switch which is installed in a security interface device, such as a keypad, which upon an unauthorized attempt to dislodge the device or keypad from a wall or surface on which it is mounted, will trigger an alarm or generate a warning signal at a monitoring site indicative that an effort at tampering with the device has been effected. Also disclosed is a method of providing the tamper switch mechanism in a security interface device, such as a keypad installation.

Owner:HONEYWELL INT INC

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

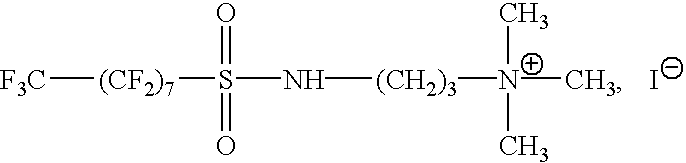

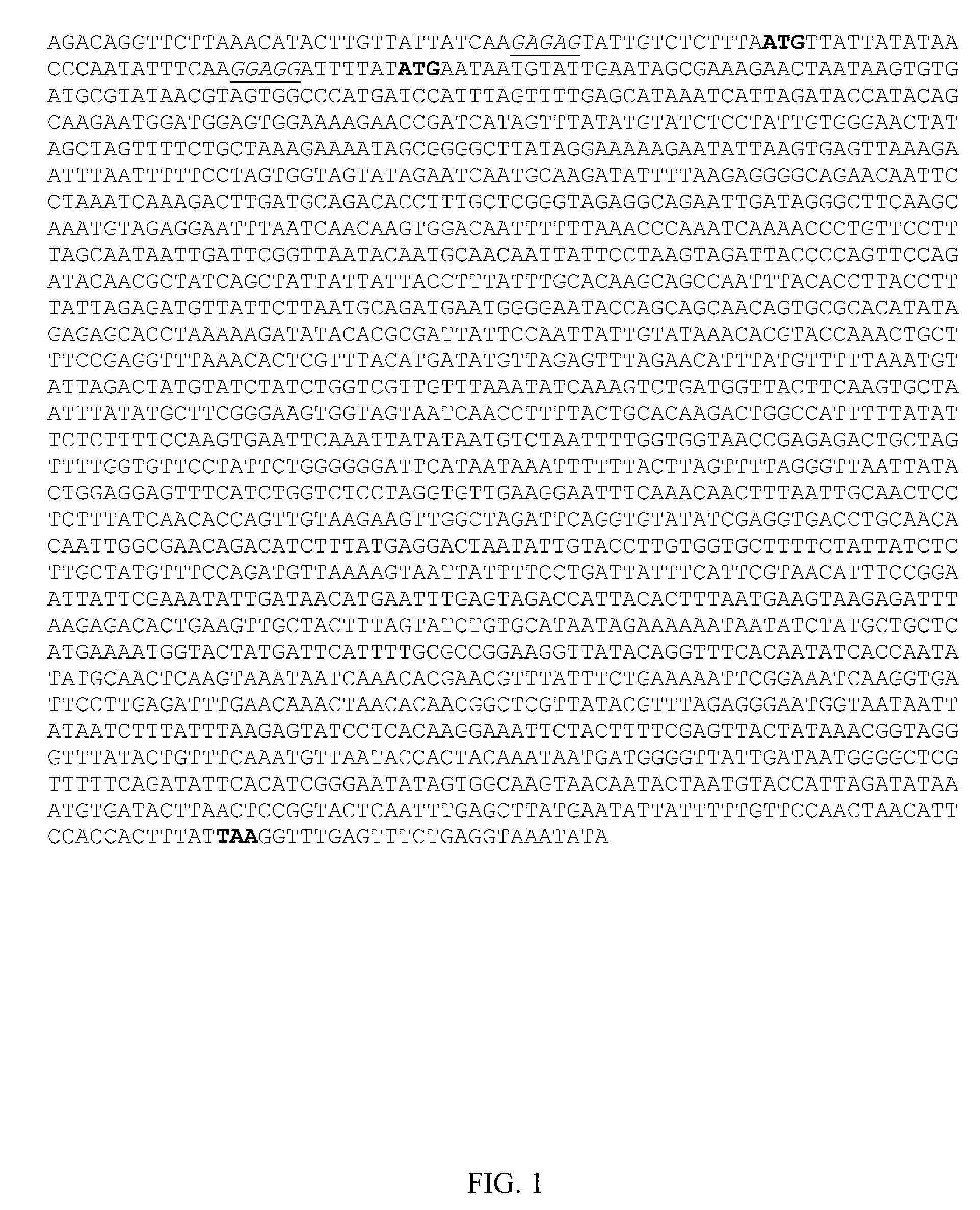

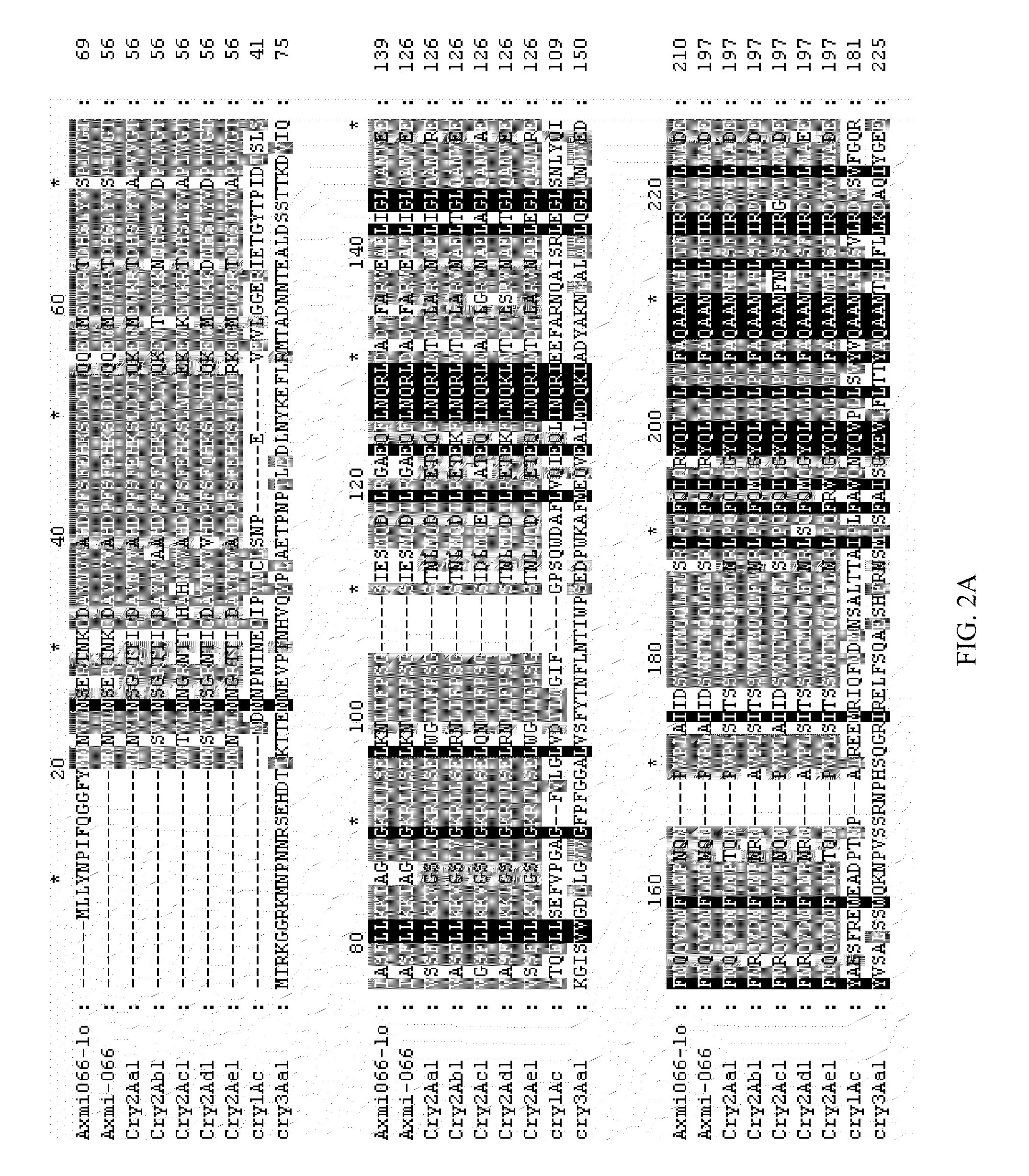

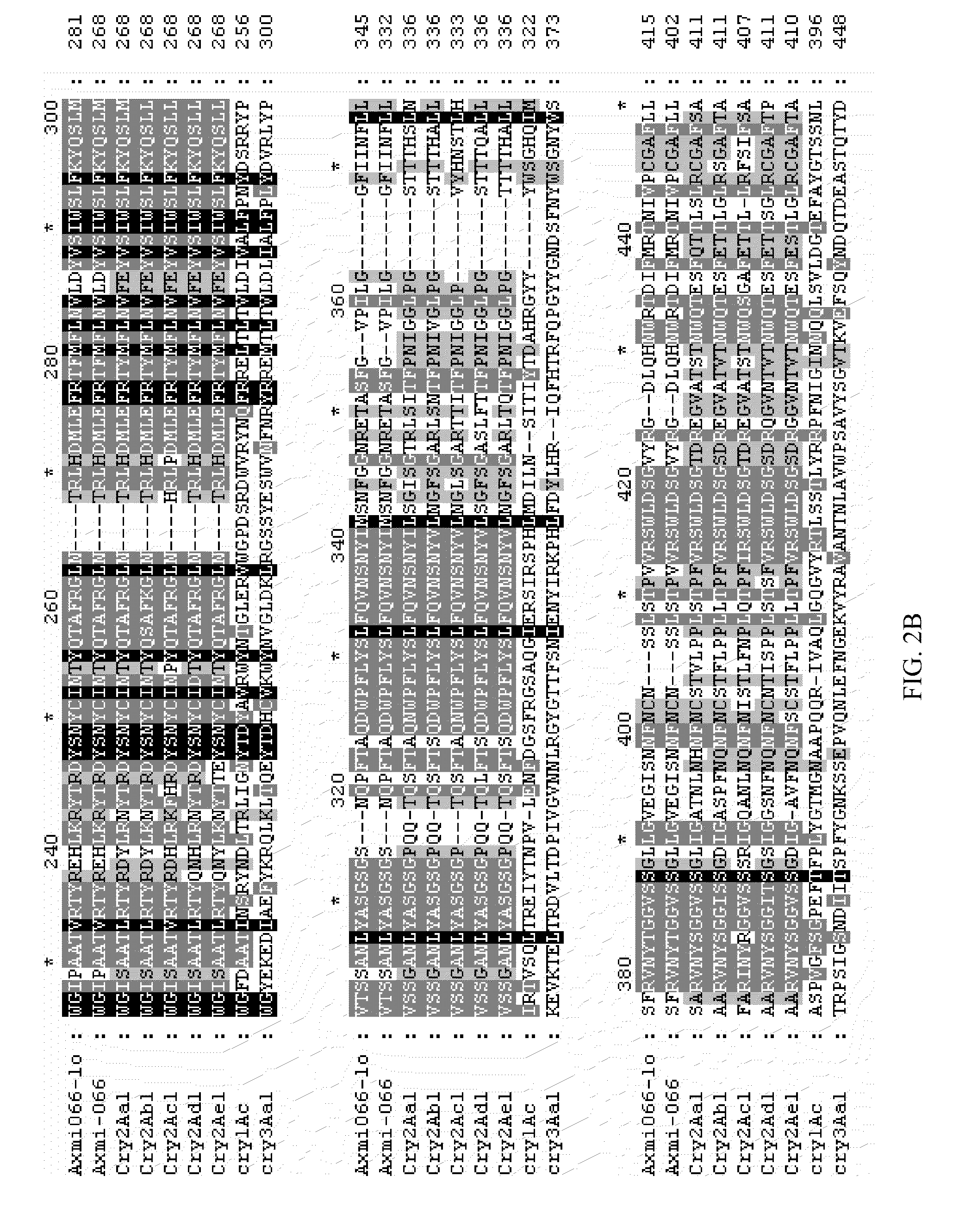

Axmi-066 and axmi-076: delta-endotoxin proteins and methods for their use

InactiveUS20090144852A1Increase productionIncrease resistanceBacteriaPeptide/protein ingredientsDelta endotoxinDNA construct

Compositions and methods for conferring pesticidal activity to bacteria, plants, plant cells, tissues and seeds are provided. Compositions comprising a coding sequence for pesticidal polypeptides are provided. The coding sequences can be used in DNA constructs or expression cassettes for transformation and expression in plants and bacteria. Compositions also comprise transformed bacteria, plants, plant cells, tissues, and seeds. In particular, isolated pesticidal nucleic acid molecules are provided. Additionally, amino acid sequences corresponding to the polynucleotides are encompassed. In particular, the present invention provides for isolated nucleic acid molecules comprising nucleotide sequences encoding the amino acid sequence shown in SEQ ID NO:5, 2, or 10, the nucleotide sequence set forth in SEQ ID NO:4, 1, 3, 4, 6, 9, or 11, or the nucleotide sequence deposited in a bacterial host as Accession No. B-50045, as well as variants and fragments thereof.

Owner:ATHENIX

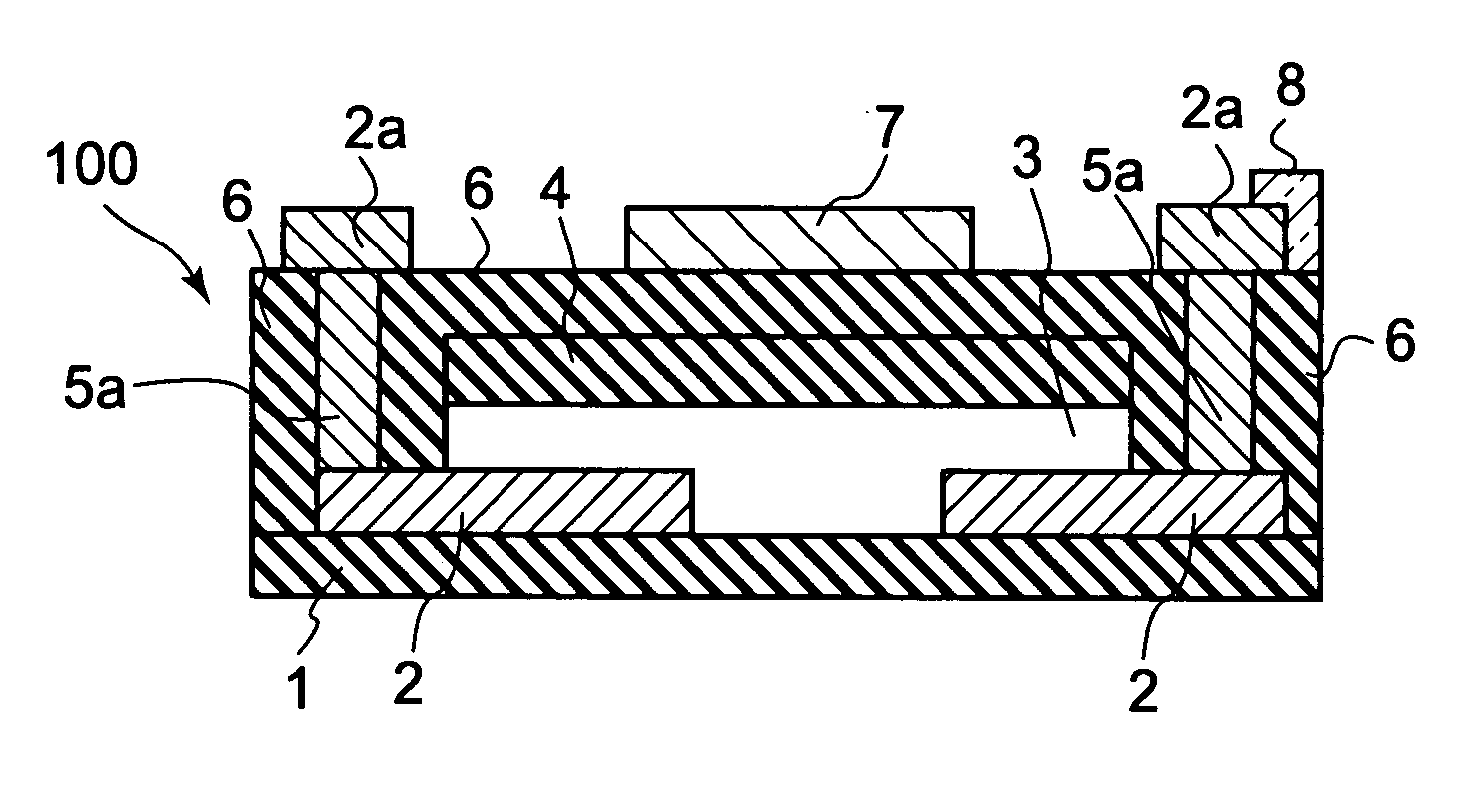

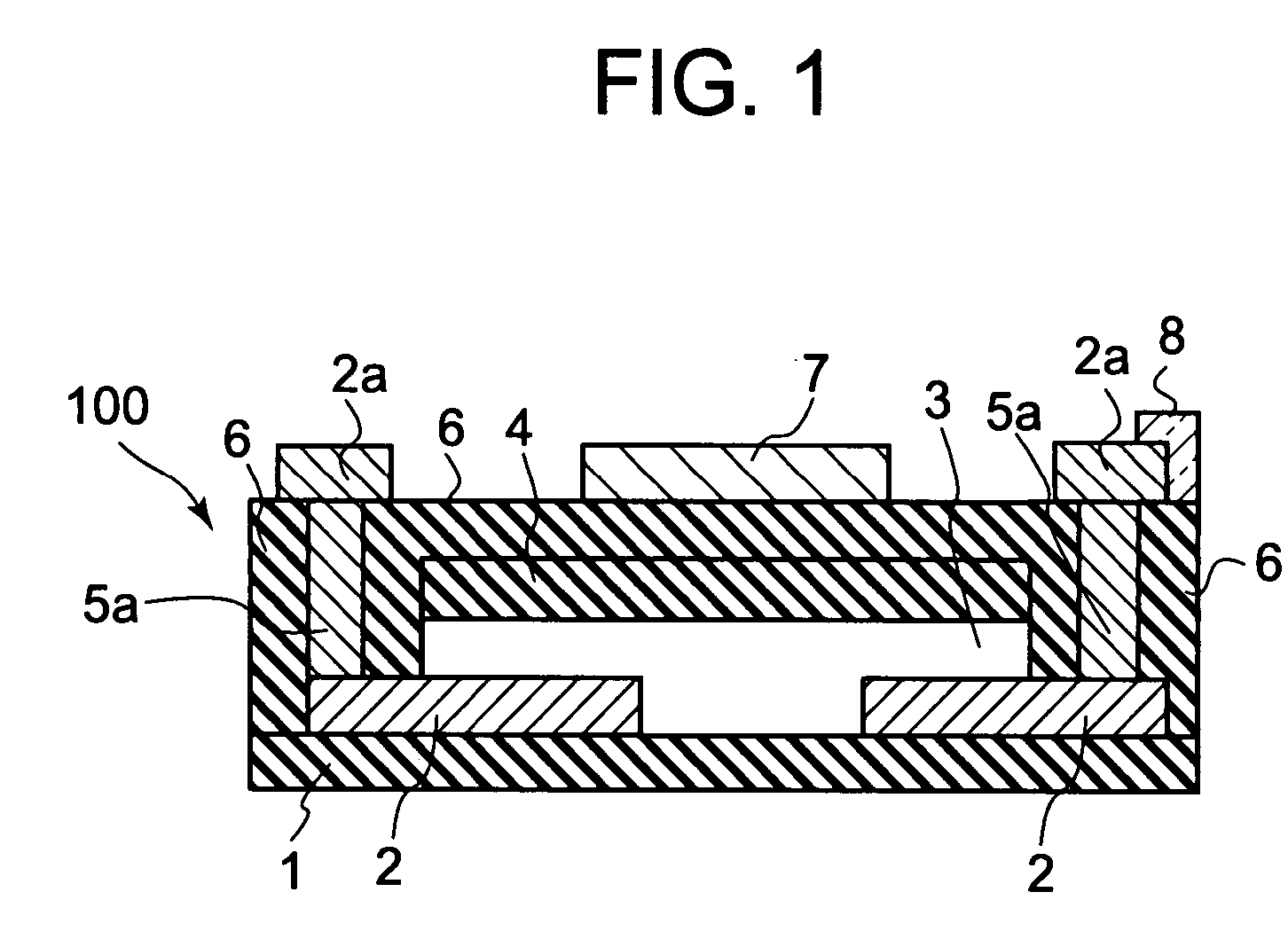

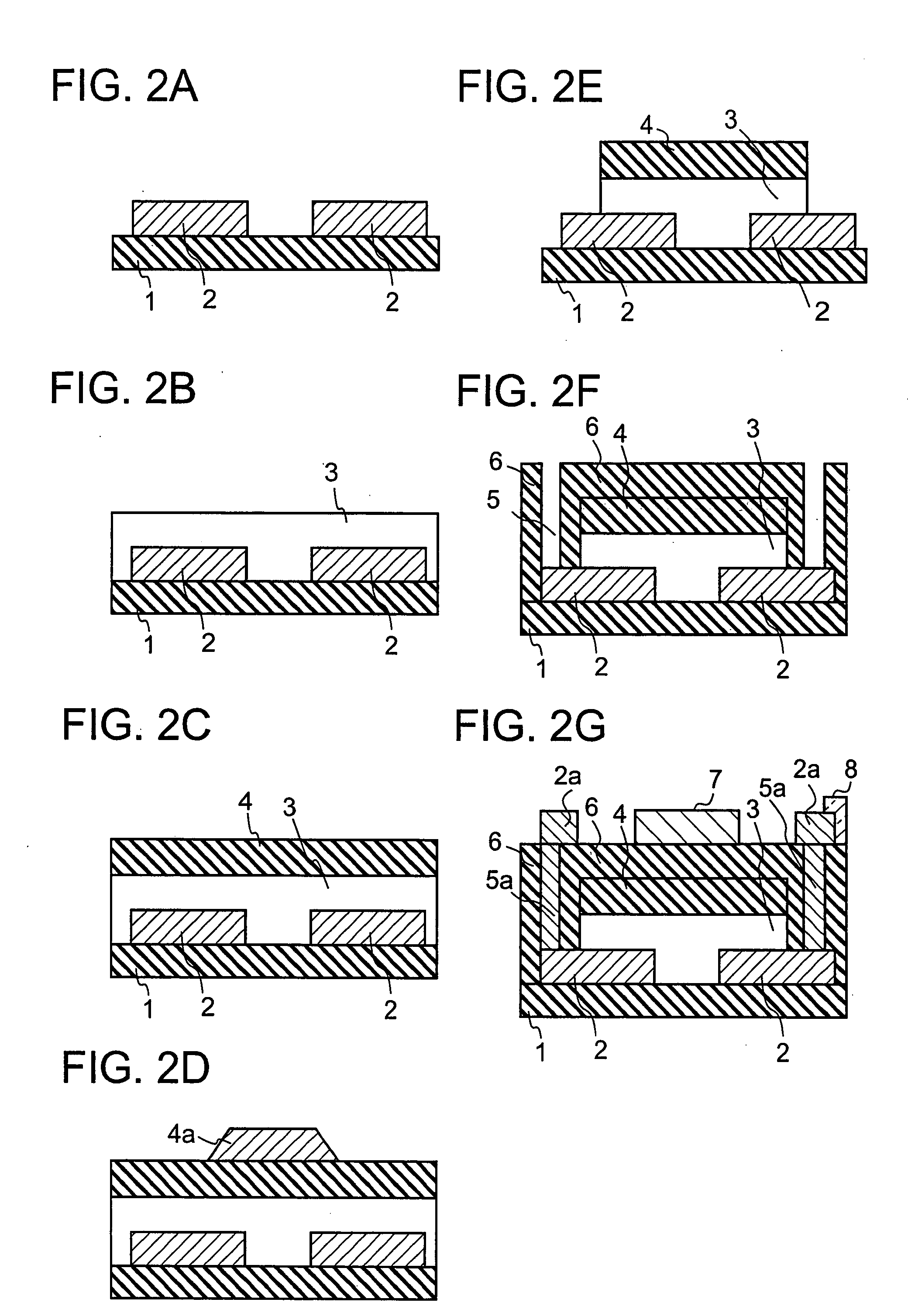

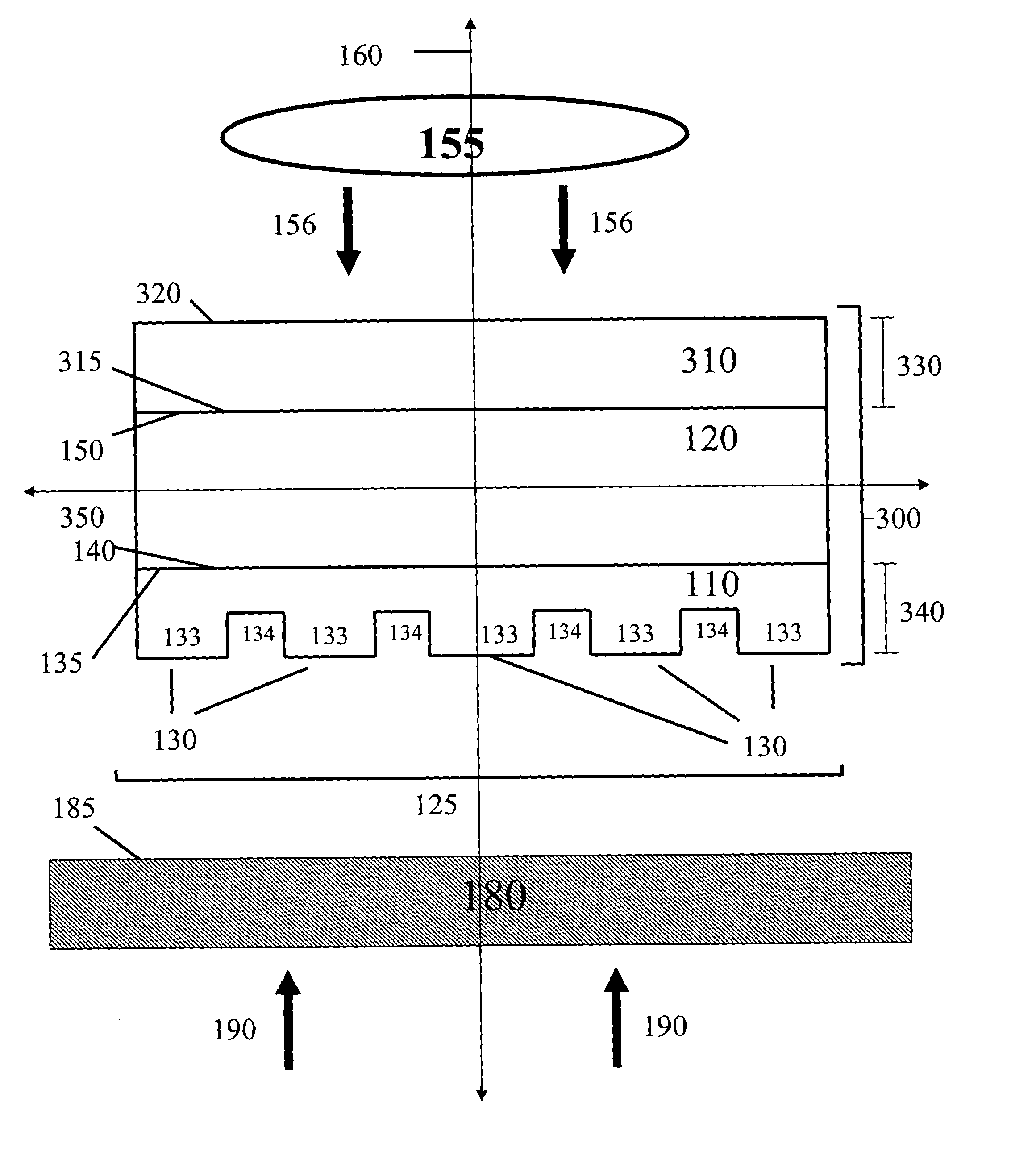

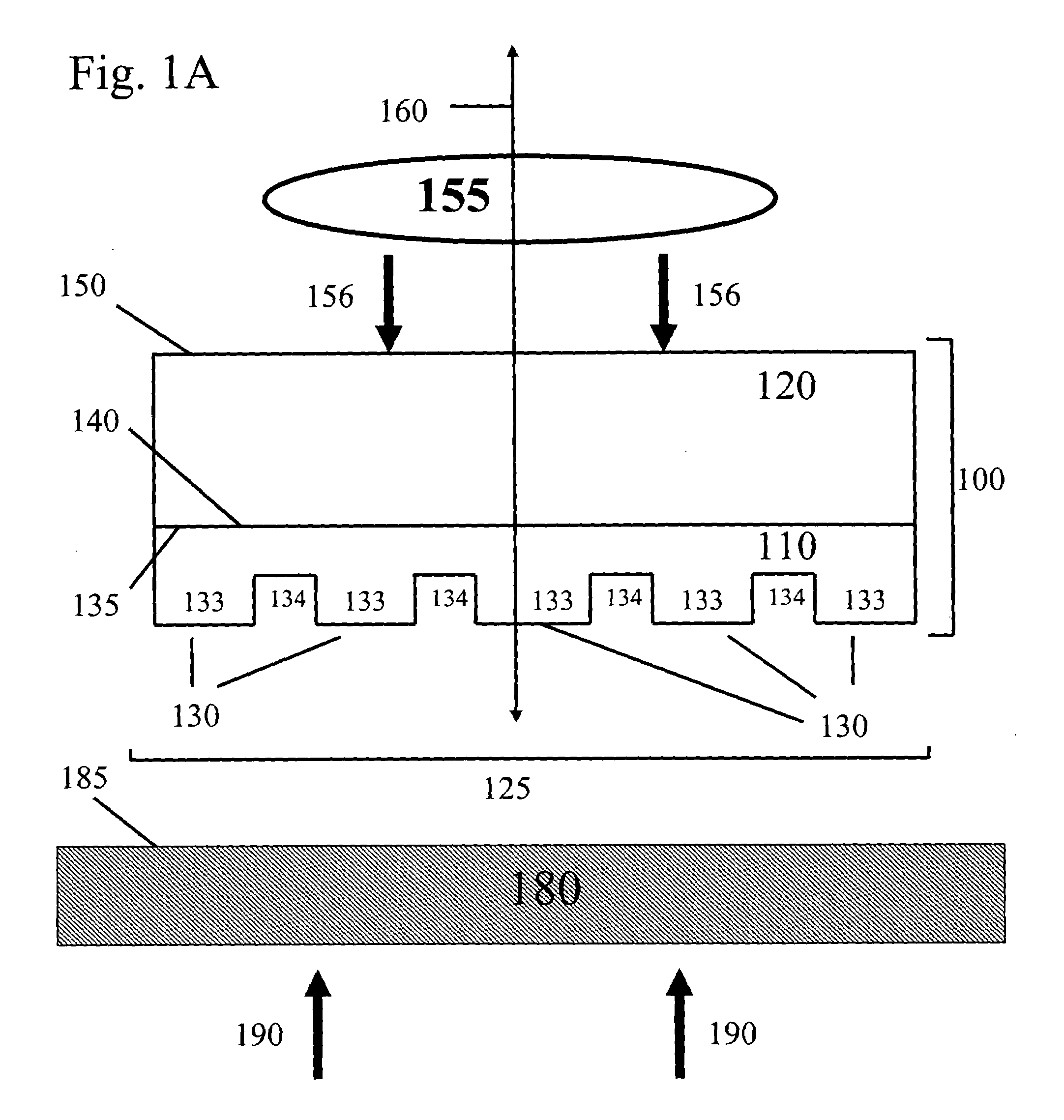

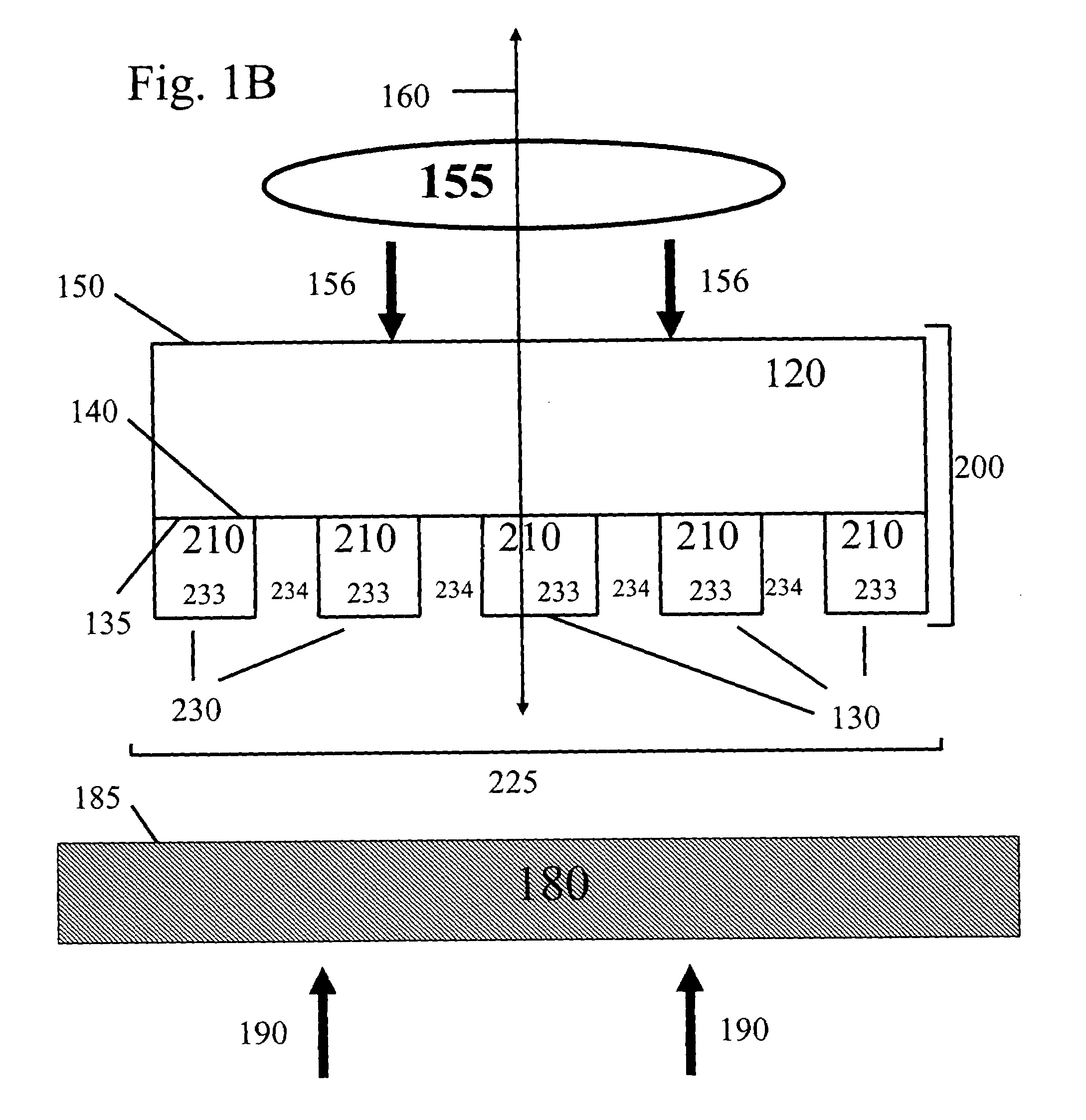

Composite patterning devices for soft lithography

ActiveUS7195733B2Improve fidelityIncrease resistanceMaterial nanotechnologyNanoinformaticsNano sizeYoung's modulus

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

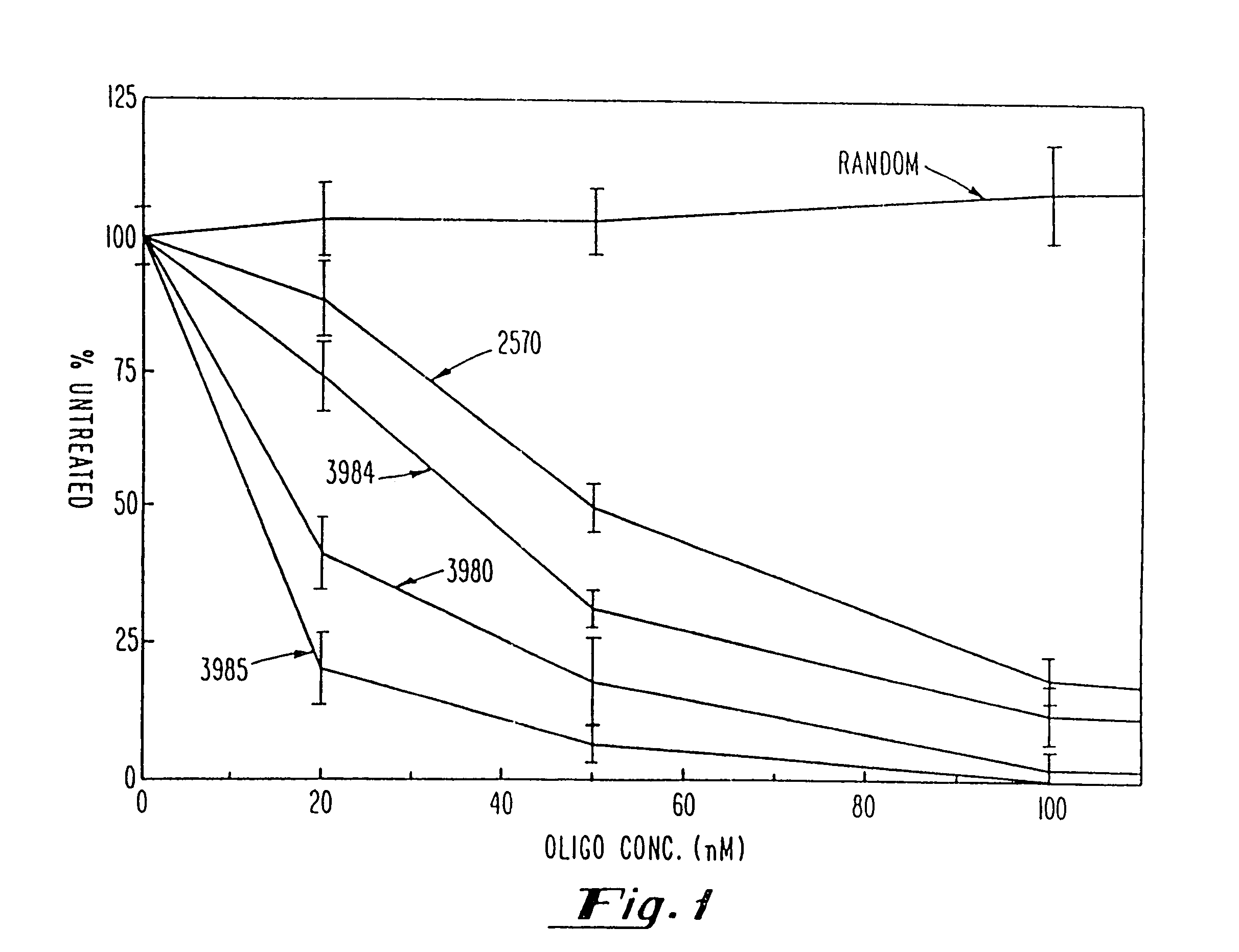

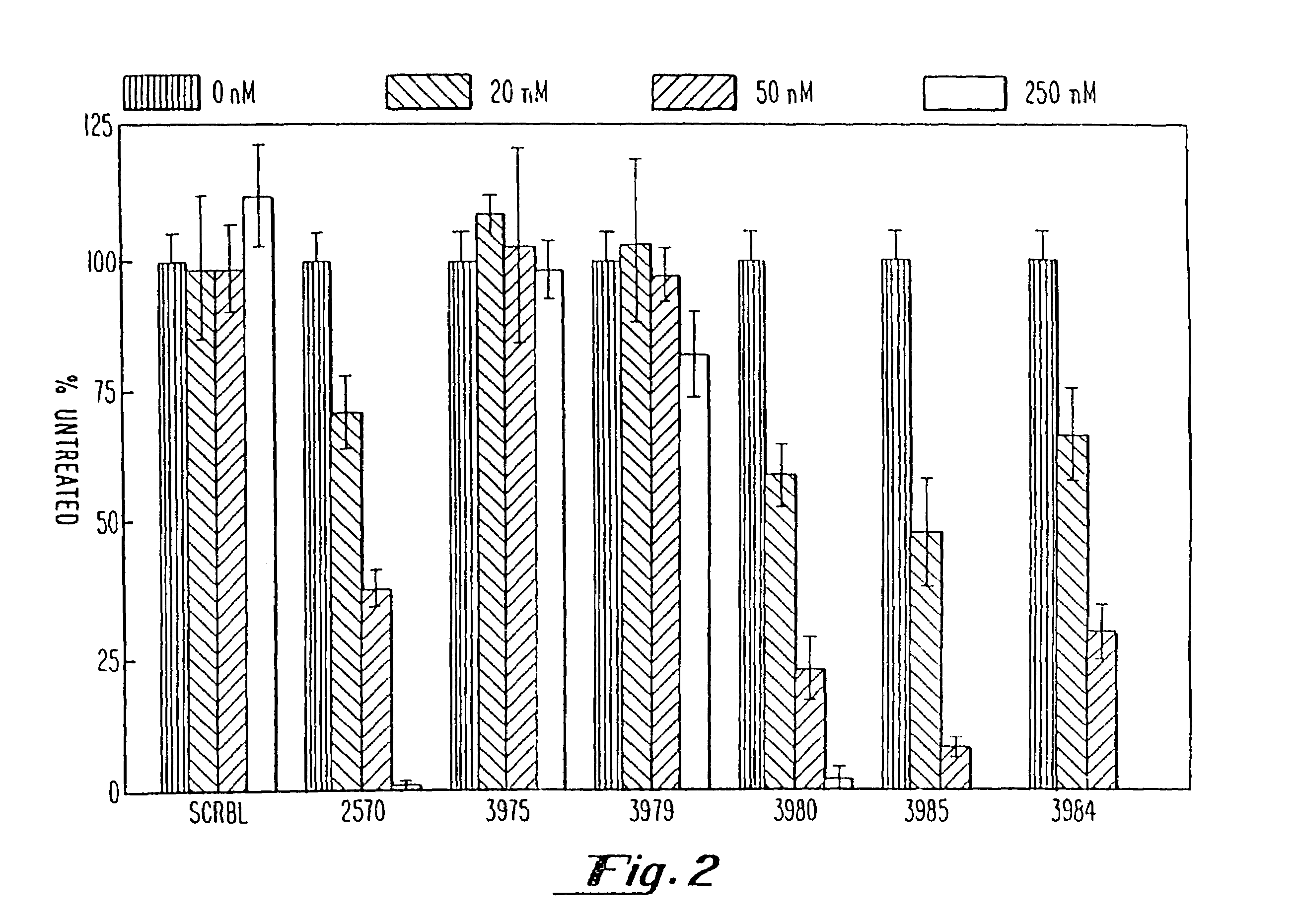

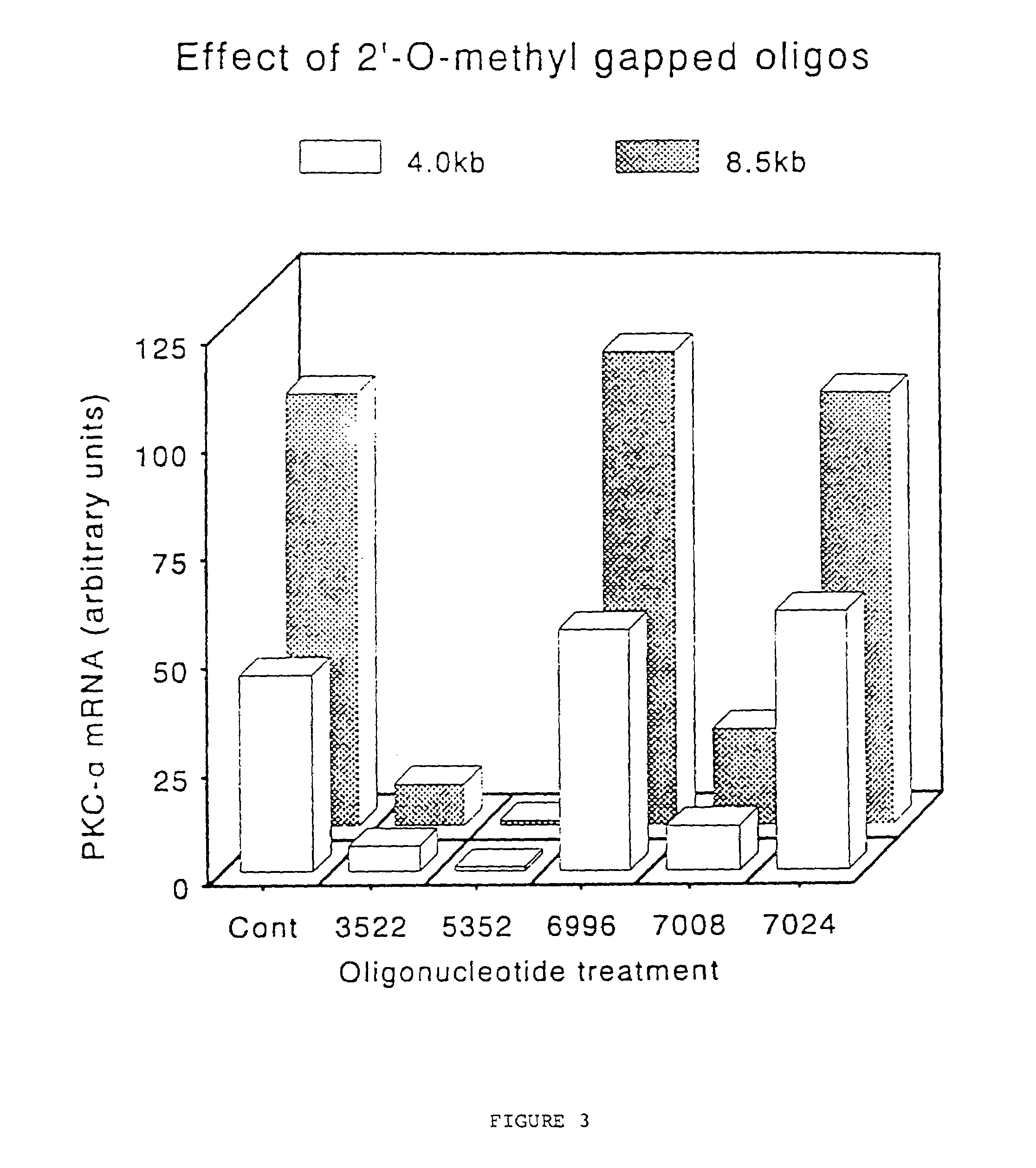

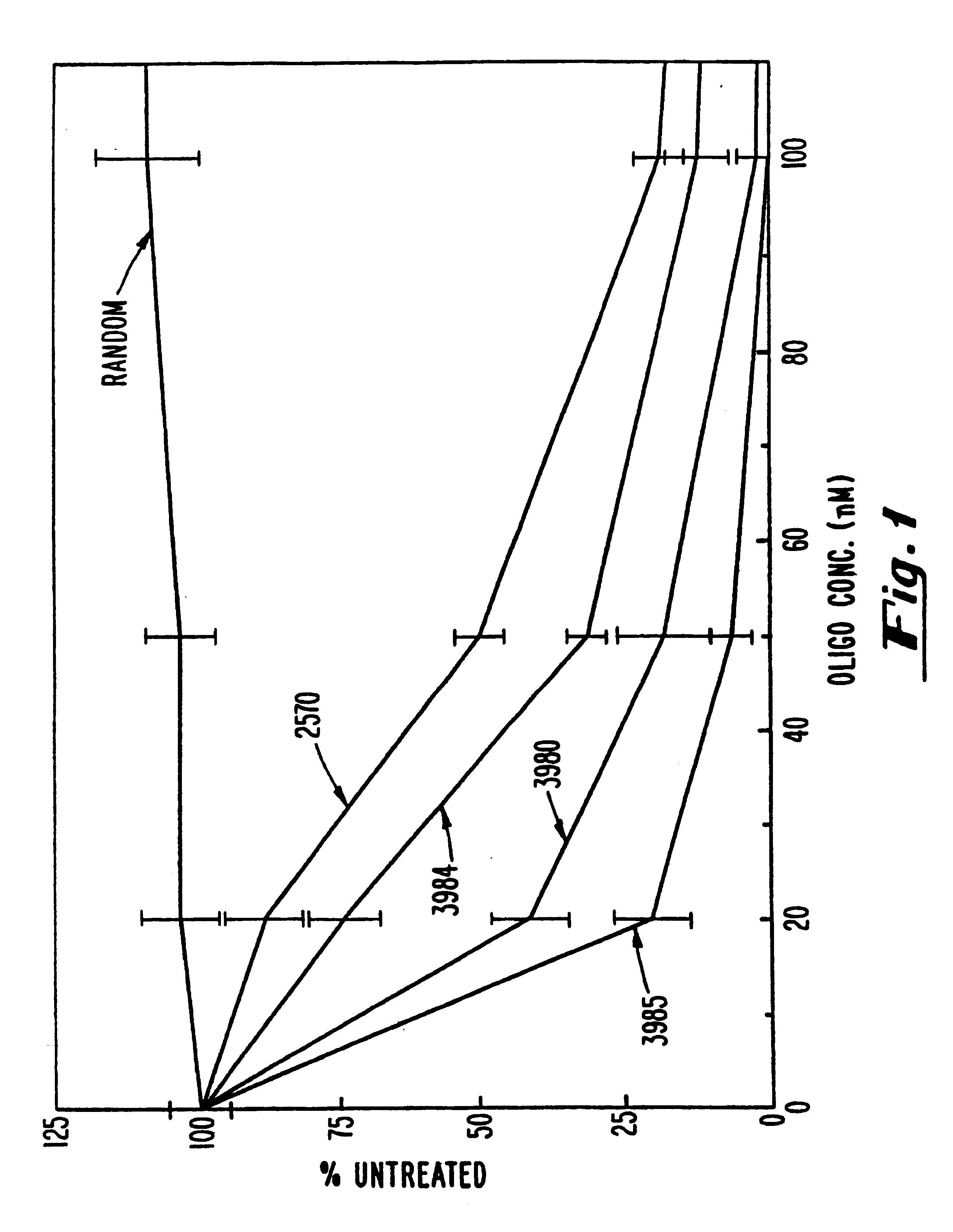

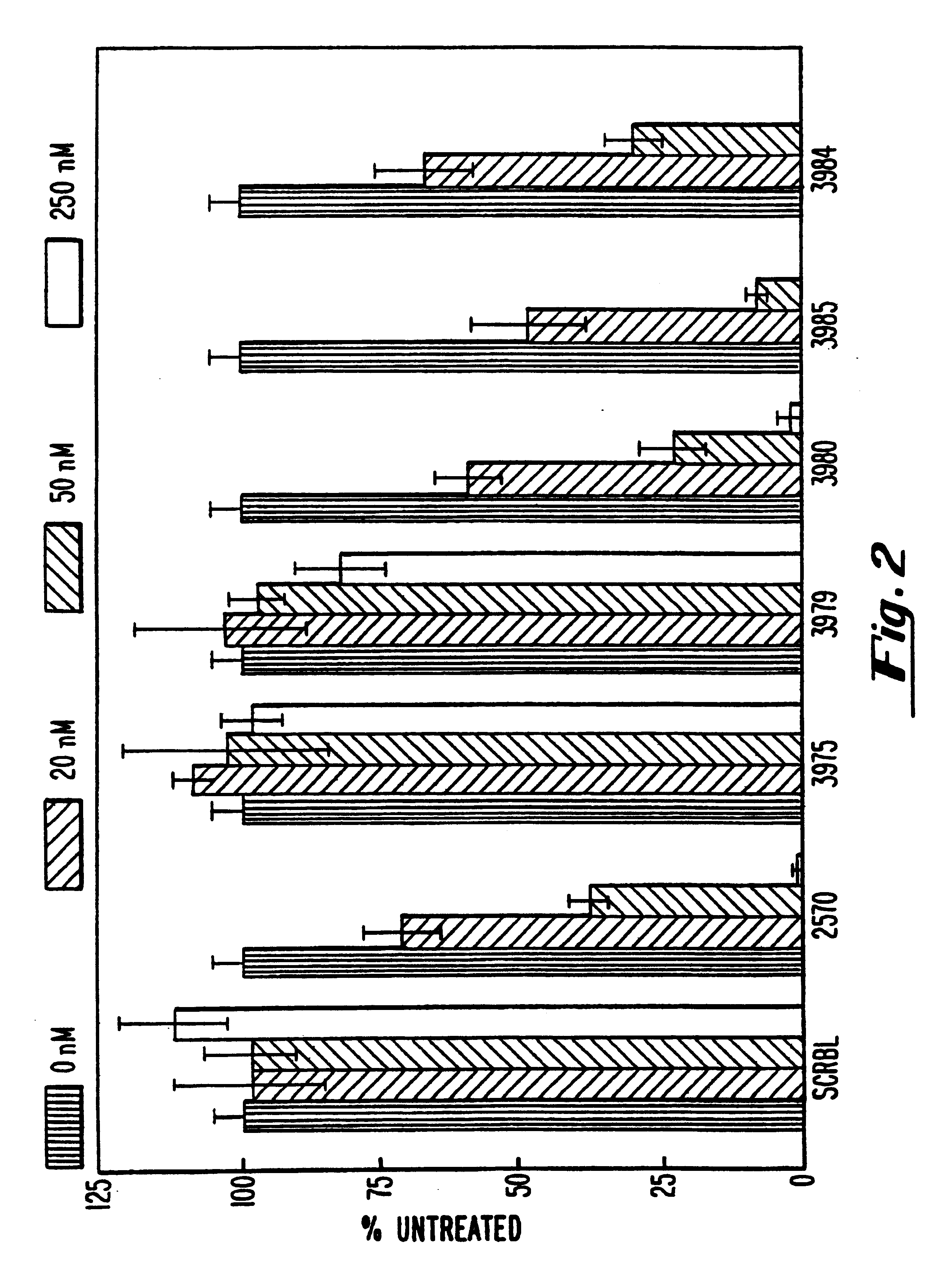

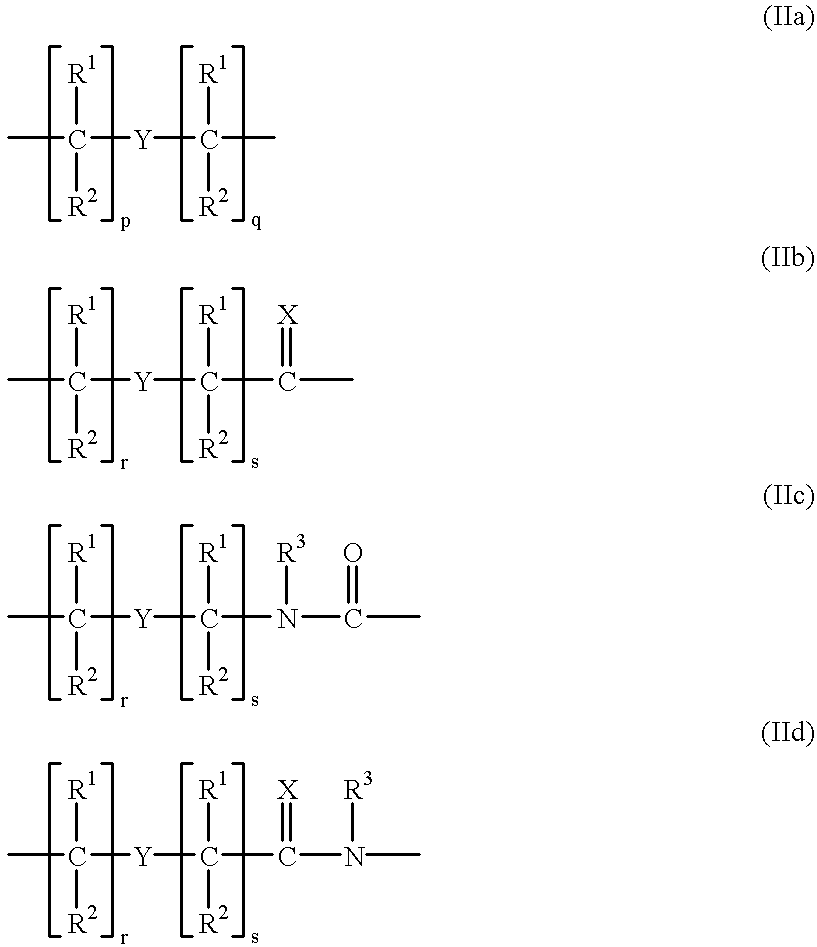

Gapped oligonucleotides

InactiveUS7015315B1Increased nuclease resistanceHigh binding affinityPeptide/protein ingredientsGenetic material ingredientsADAMTS ProteinsNuclease

Oligonucleotides and other macromolecules are provided which have increased nuclease resistance, substituent groups for increasing binding affinity to complementary strand, and subsequences of 2′-deoxy-erythro-pentofuranosyl nucleotides that activate RNase H. Such oligonucleotides and macromolecules are useful for diagnostics and other research purposes, for modulating the expression of a protein in organisms, and for the diagnosis, detection and treatment of other conditions susceptible to oligonucleotide therapeutics.

Owner:IONIS PHARMA INC

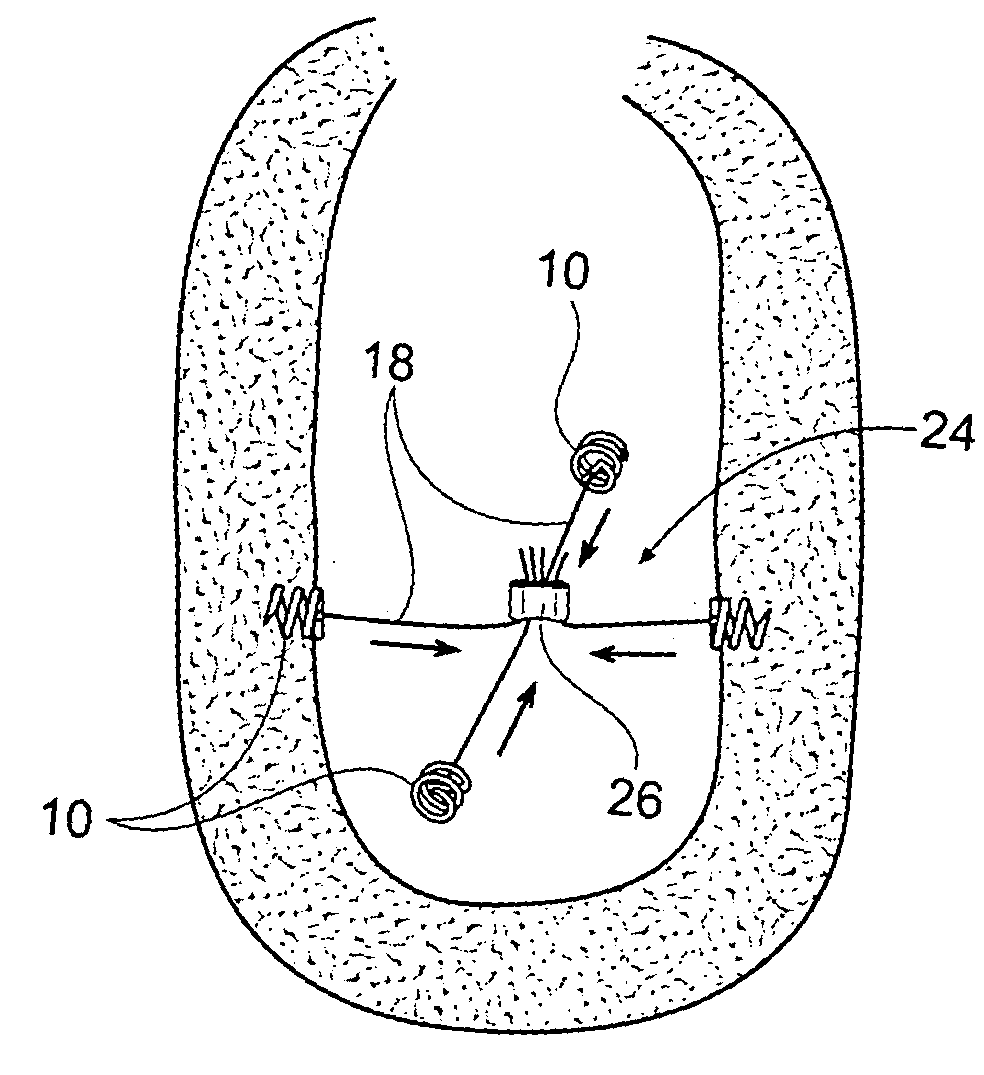

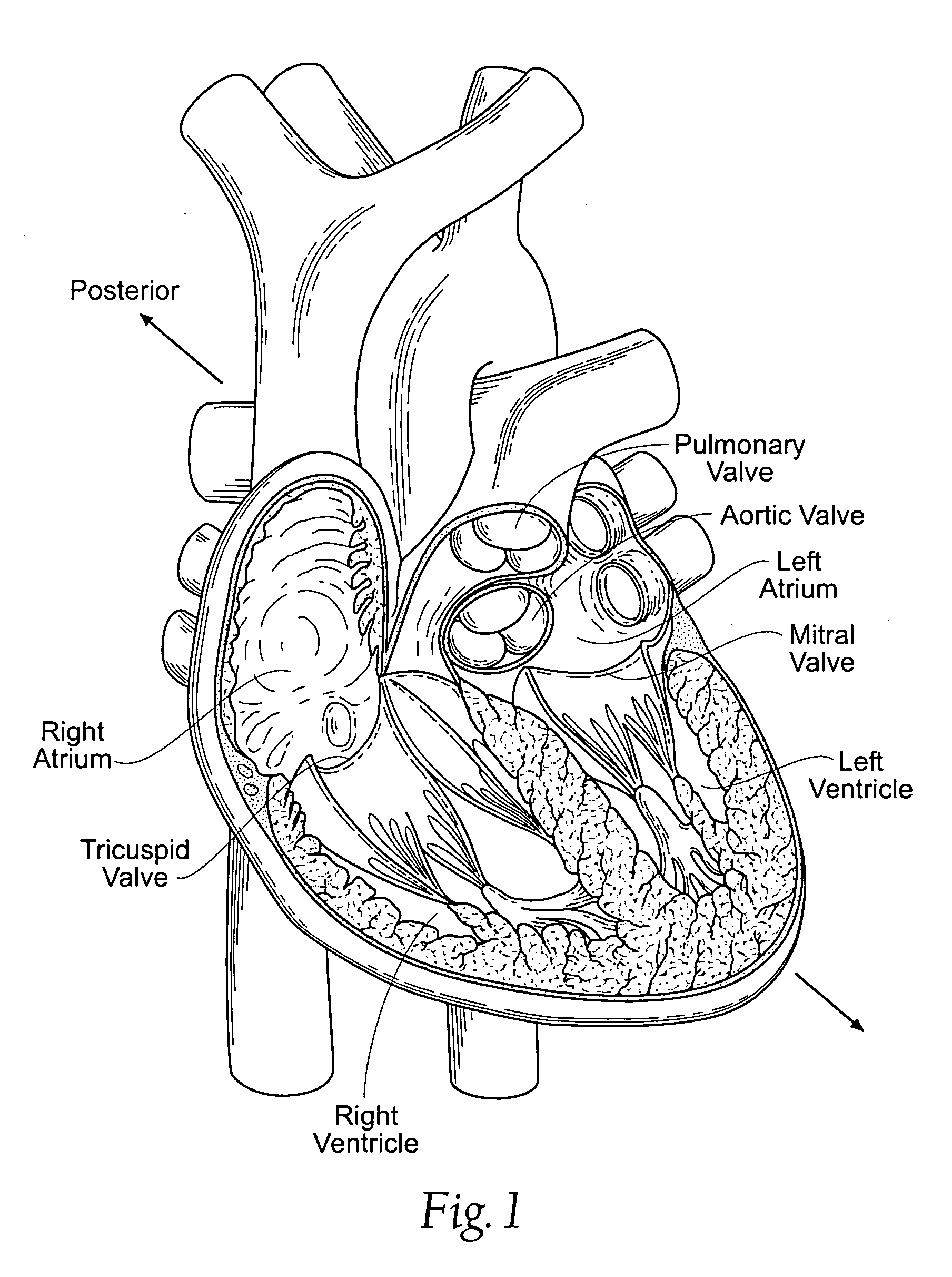

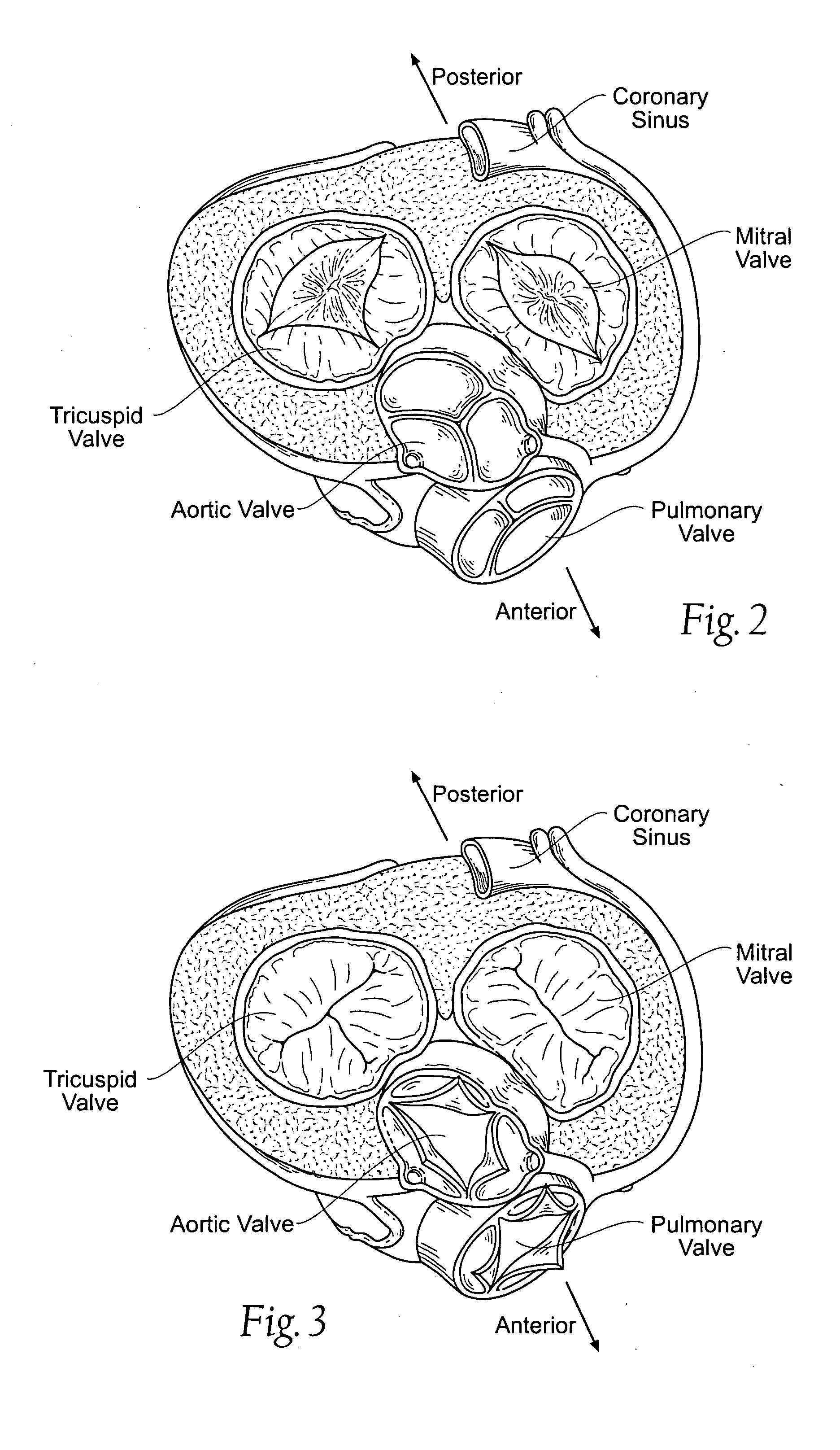

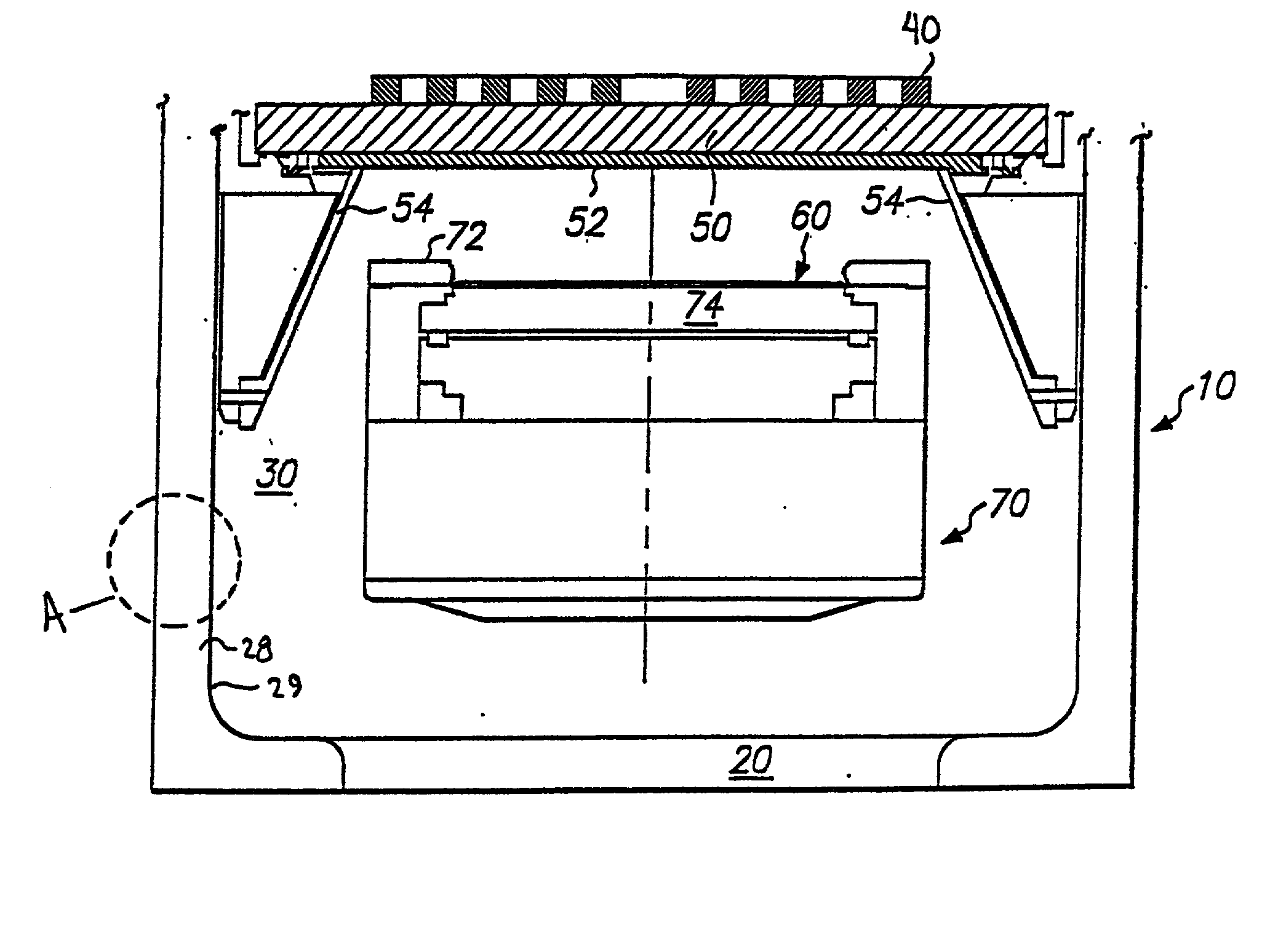

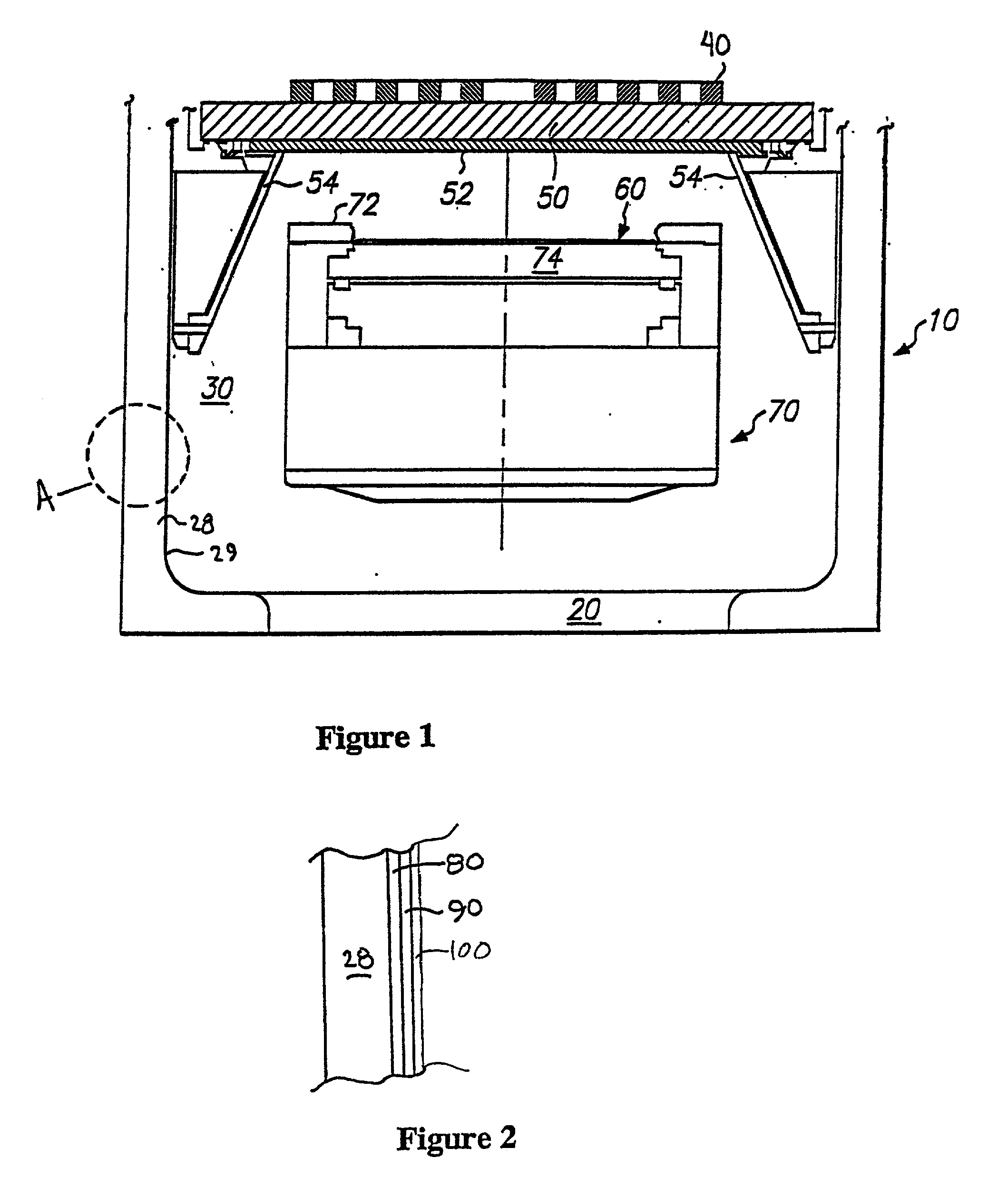

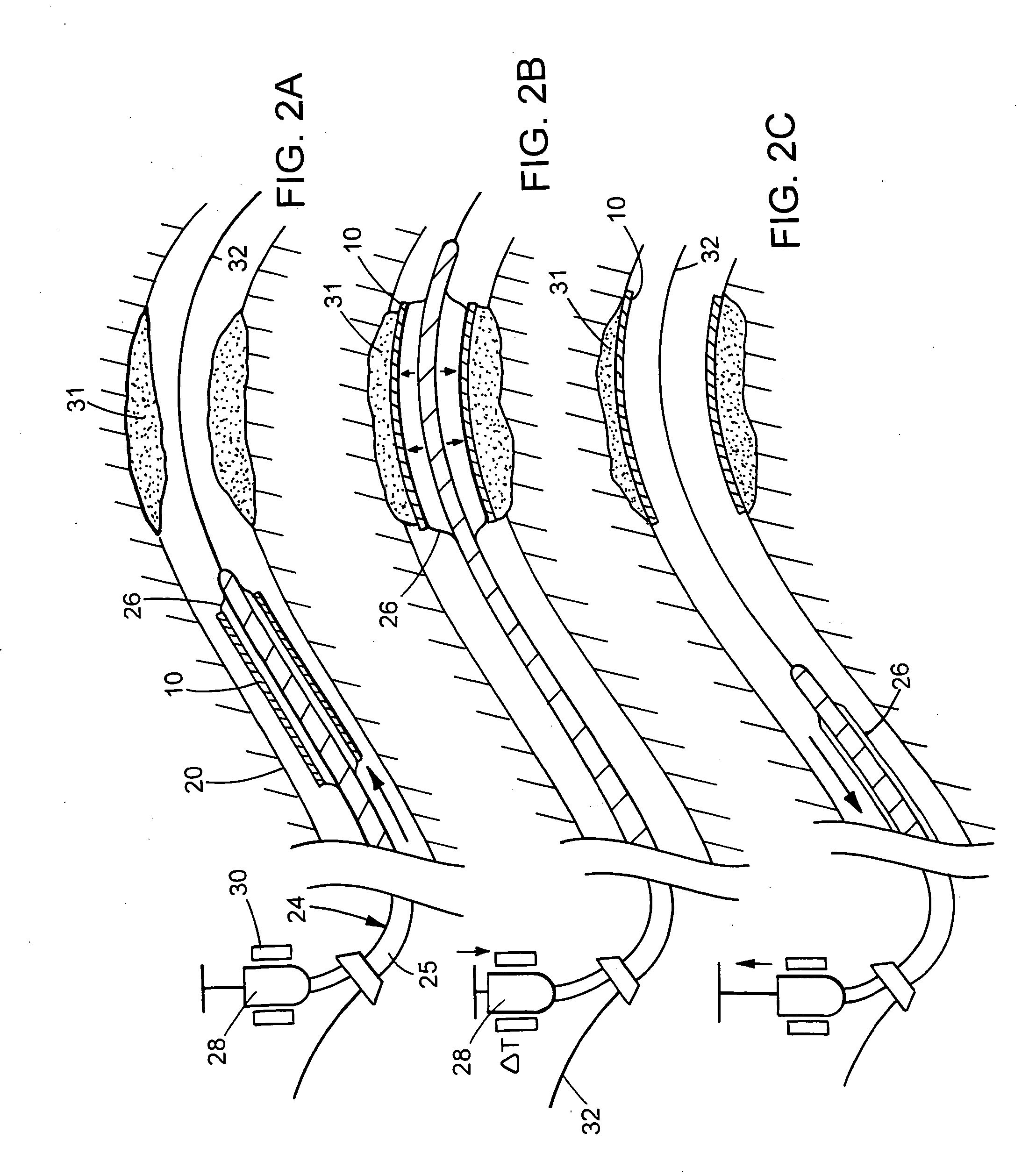

Devices, systems, and methods for supporting tissue and/or structures within a hollow body organ

InactiveUS20050177180A1Simple and cost-effective and less invasiveReduce tissue volumeSuture equipmentsAnnuloplasty ringsBody organsSurgical approach

Devices, systems and methods support tissue in a body organ for the purpose of restoring or maintaining native function of the organ. The devices, systems, and methods do not require invasive, open surgical approaches to be implemented, but, instead, lend themselves to catheter-based, intra-vascular and / or percutaneous techniques.

Owner:APTUS ENDOSYST

Cyclic azine derivatives, processes for producing these, and organic electroluminescent element containing these as component

ActiveUS20120214993A1Improve drivabilityAccelerate emissionsOrganic chemistryElectroluminescent light sourcesOrganic electroluminescenceOrganic compound

A cyclic azine compound represented by general formula (1):wherein each Ar1 represents an aromatic group, which is unsubstituted or substituted by a C1-4 alkyl group, a phenyl group or a pyridyl group; and A represents a group selected from those which are represented by general formulae (2) to (5), described in the description. The cyclic azine compound is useful for an organic compound layer of fluorescent or phosphorescent EL device.

Owner:TOSOH CORP +1

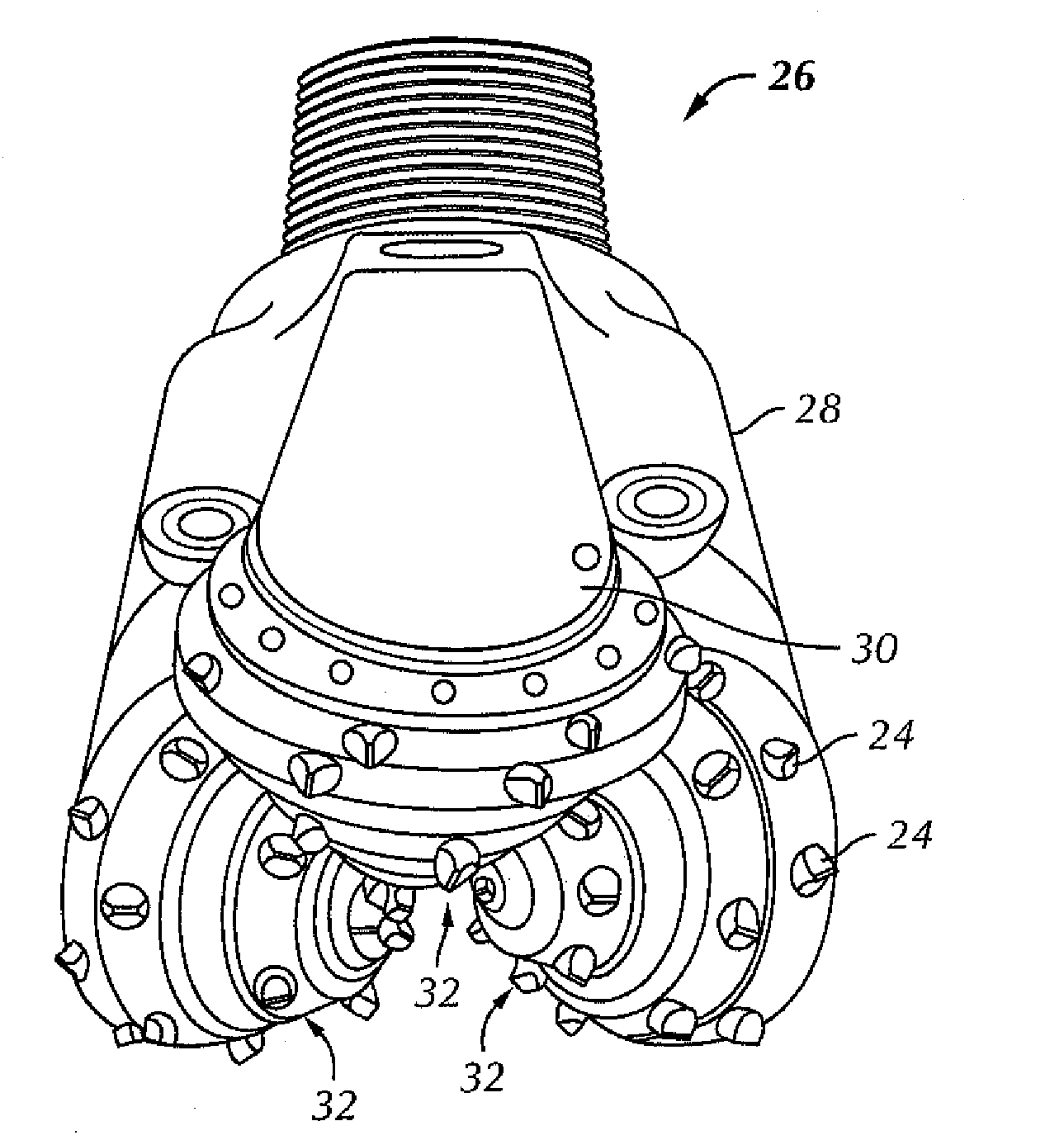

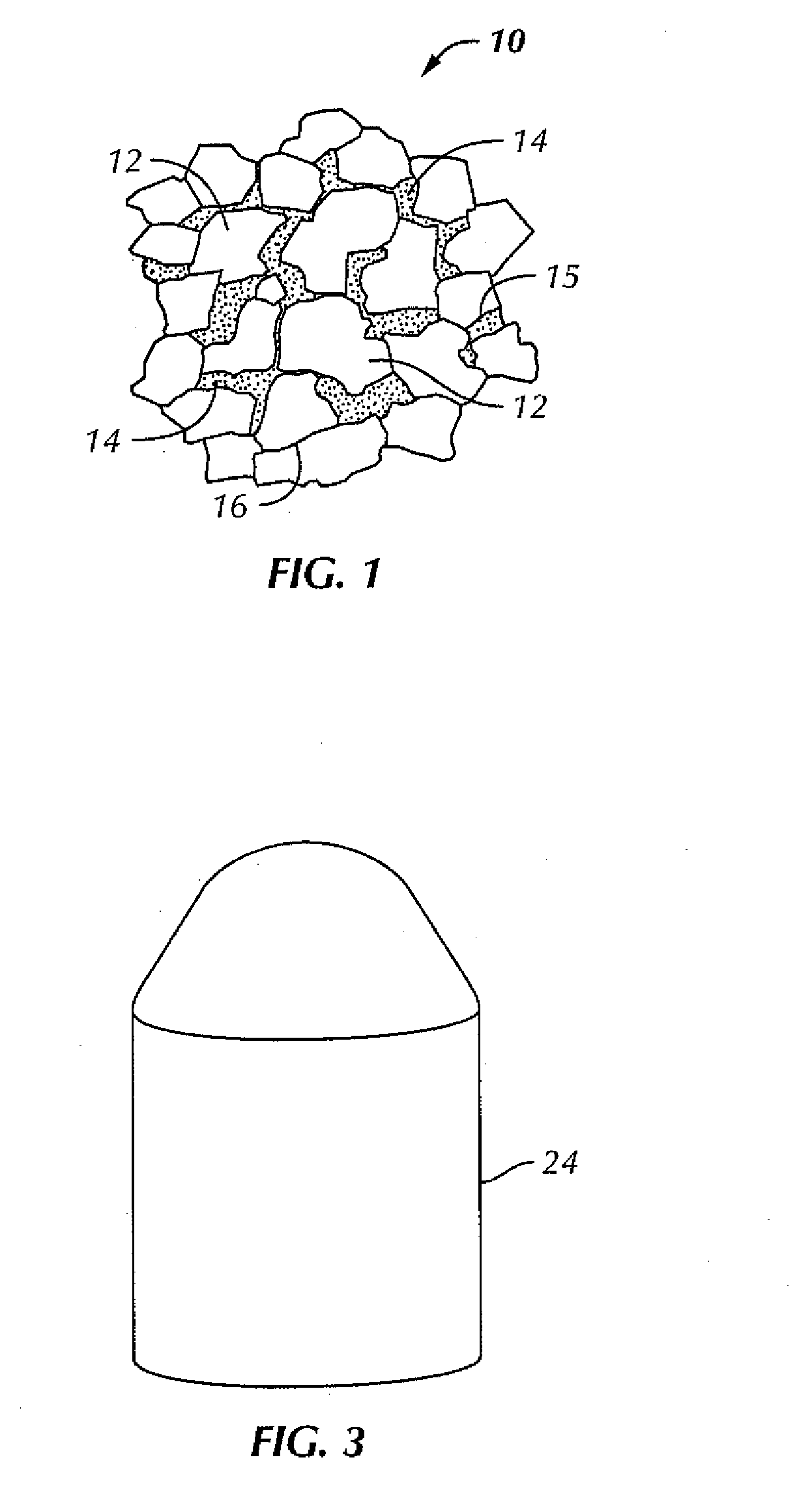

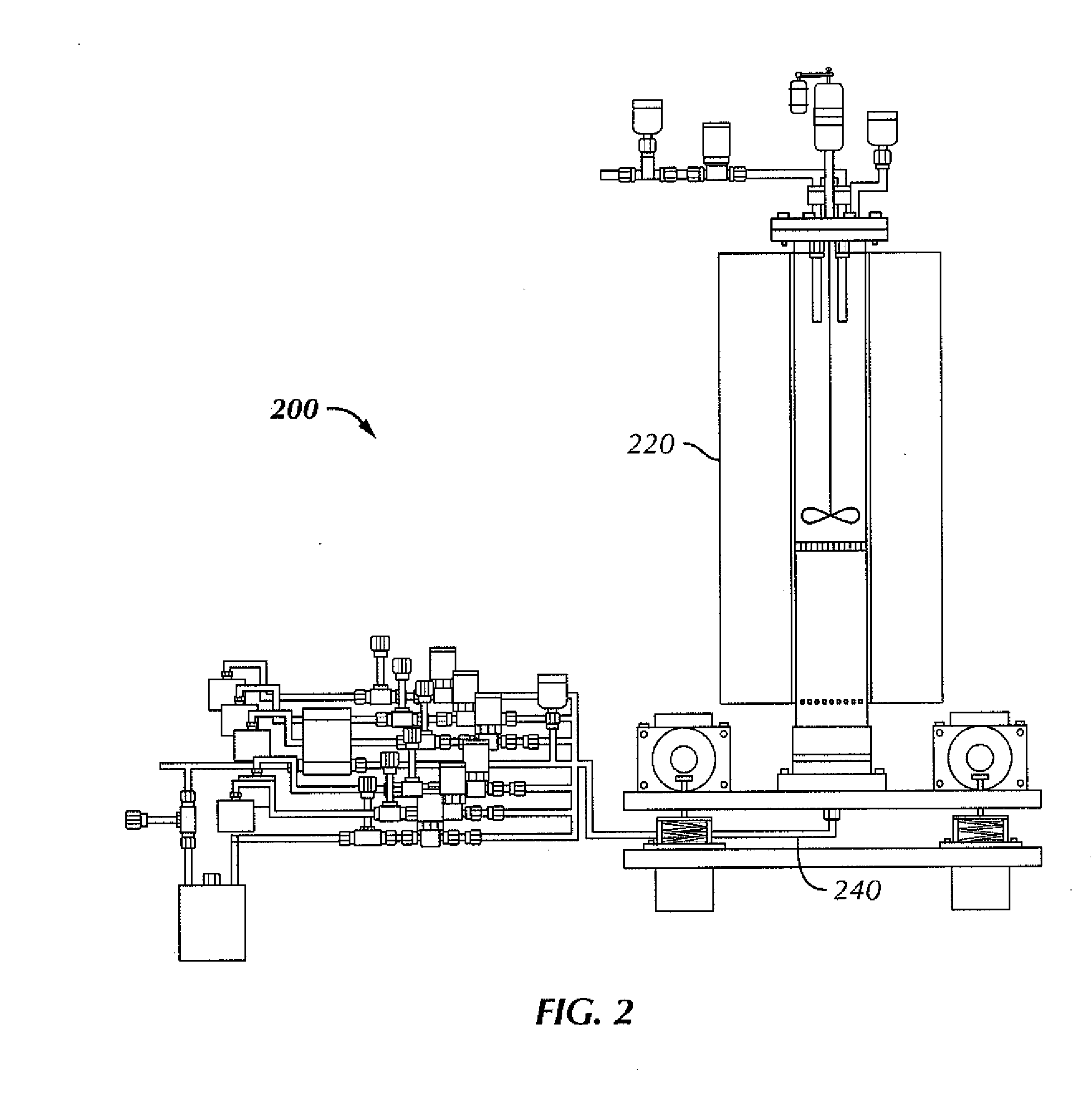

Nano-reinforced wc-co for improved properties

InactiveUS20080179104A1Increase resistanceImprove toughnessMaterial nanotechnologyDrill bitsCarbideNanometre

A drill bit that includes a bit body; and at least one cutting element for engaging the formation disposed on the bit body, the at least one cutting element comprising: a ductile phase; a plurality of carbide particles dispersed in the ductile phase; and a plurality of nanotubes integrated into the cutting element is disclosed.

Owner:SMITH INT INC

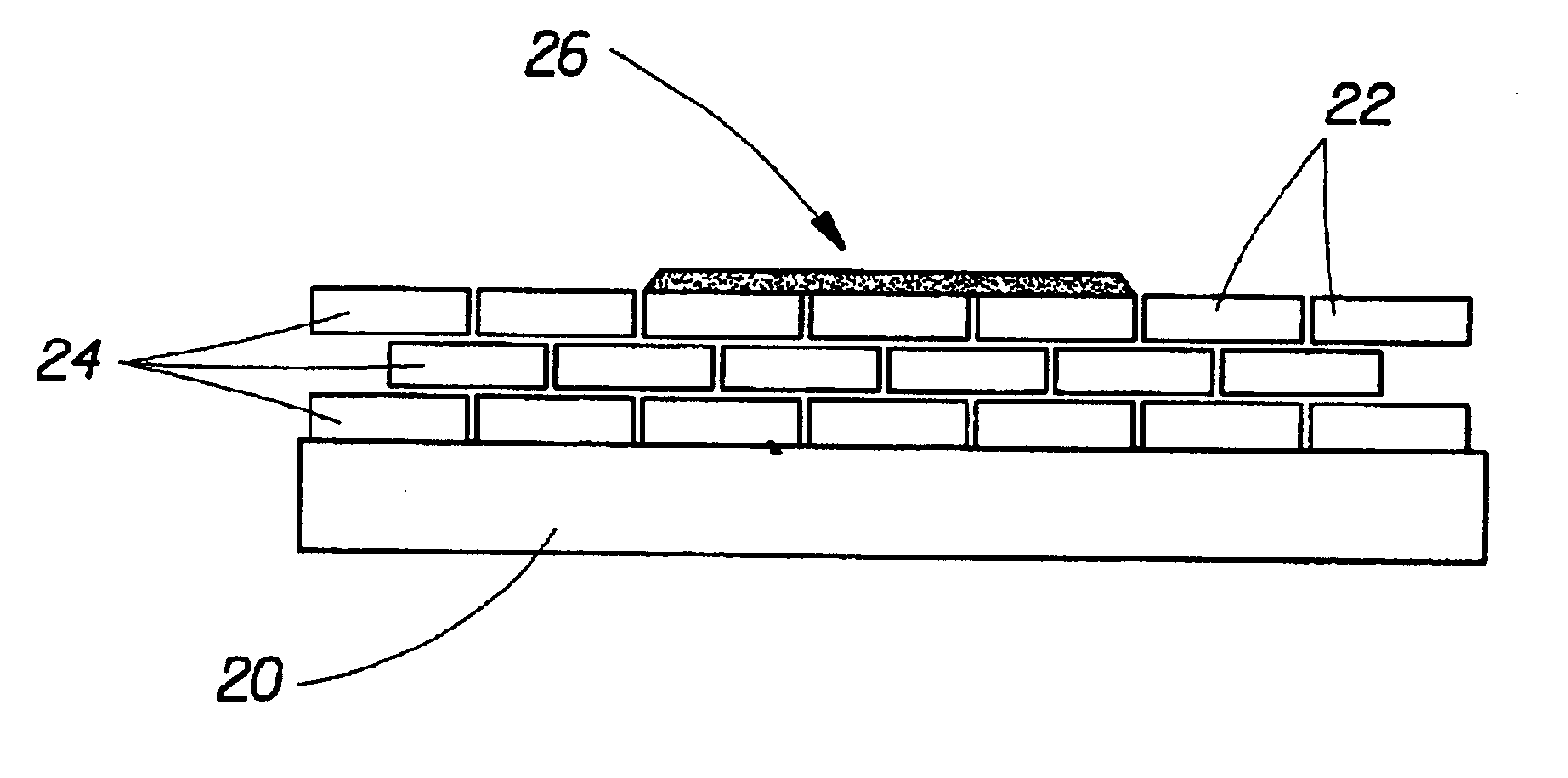

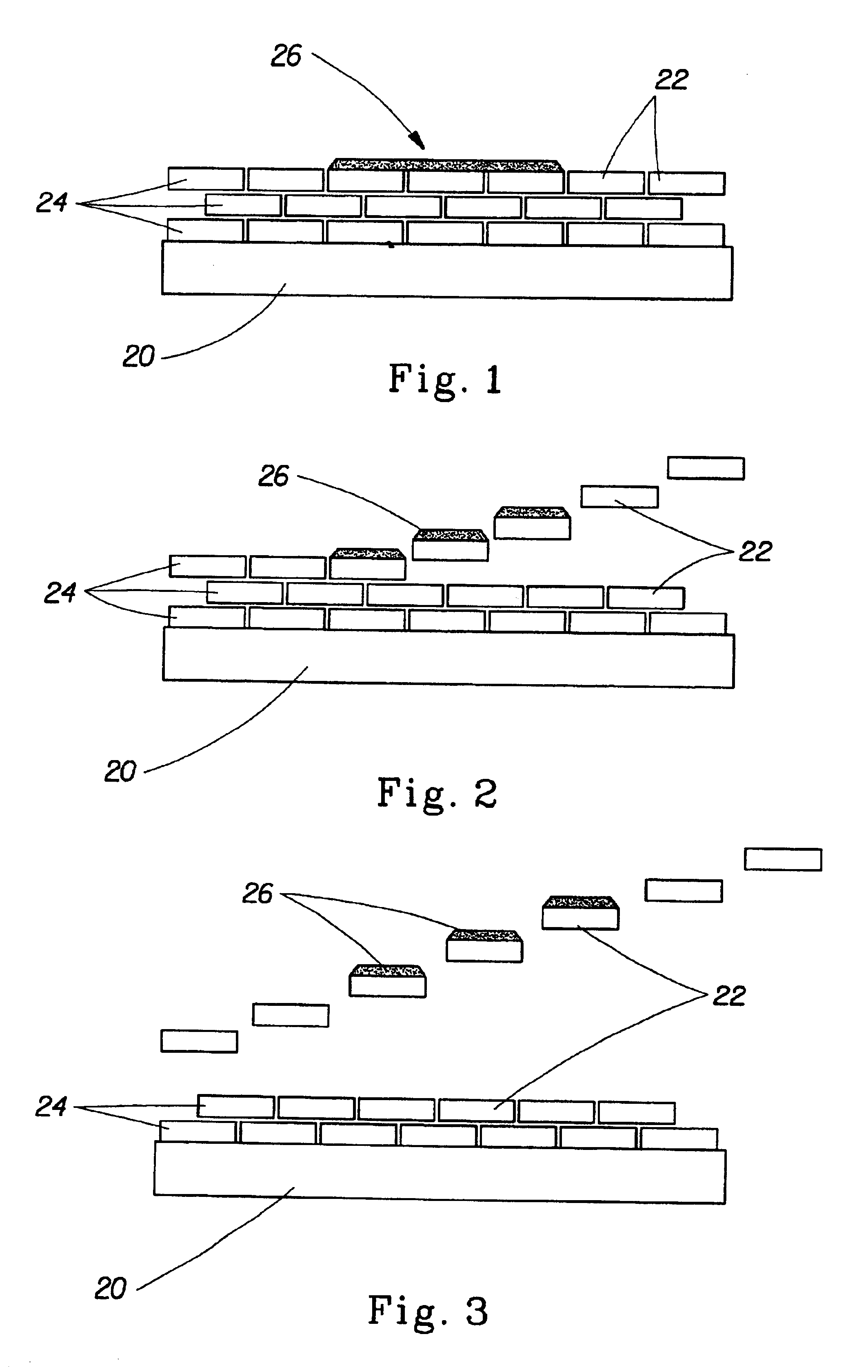

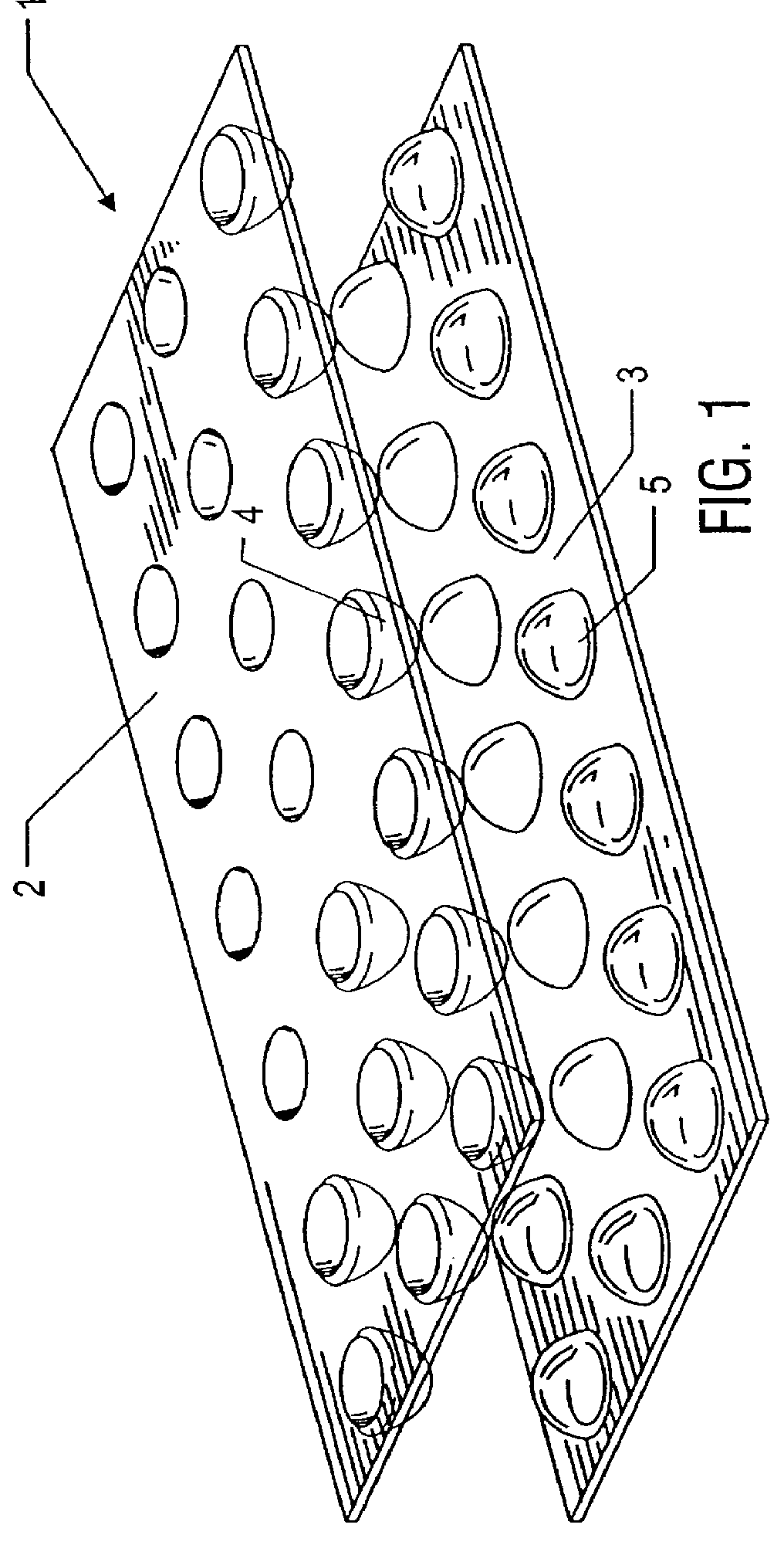

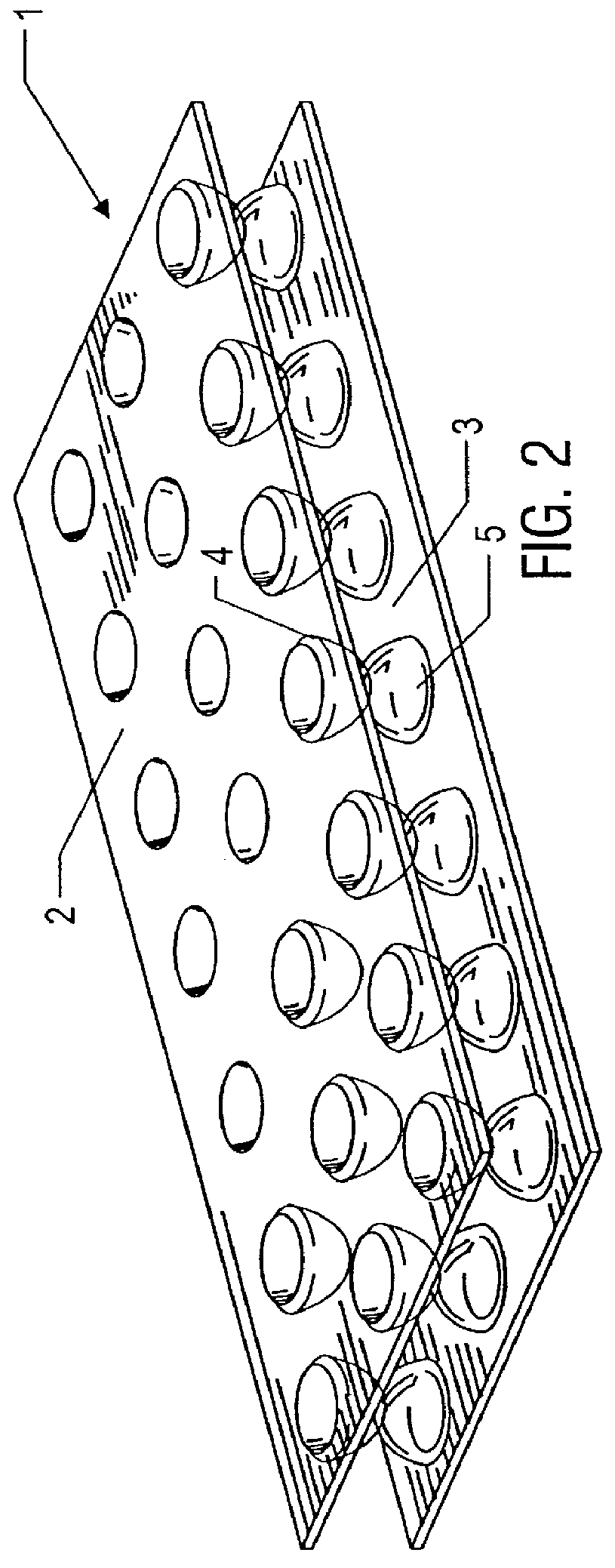

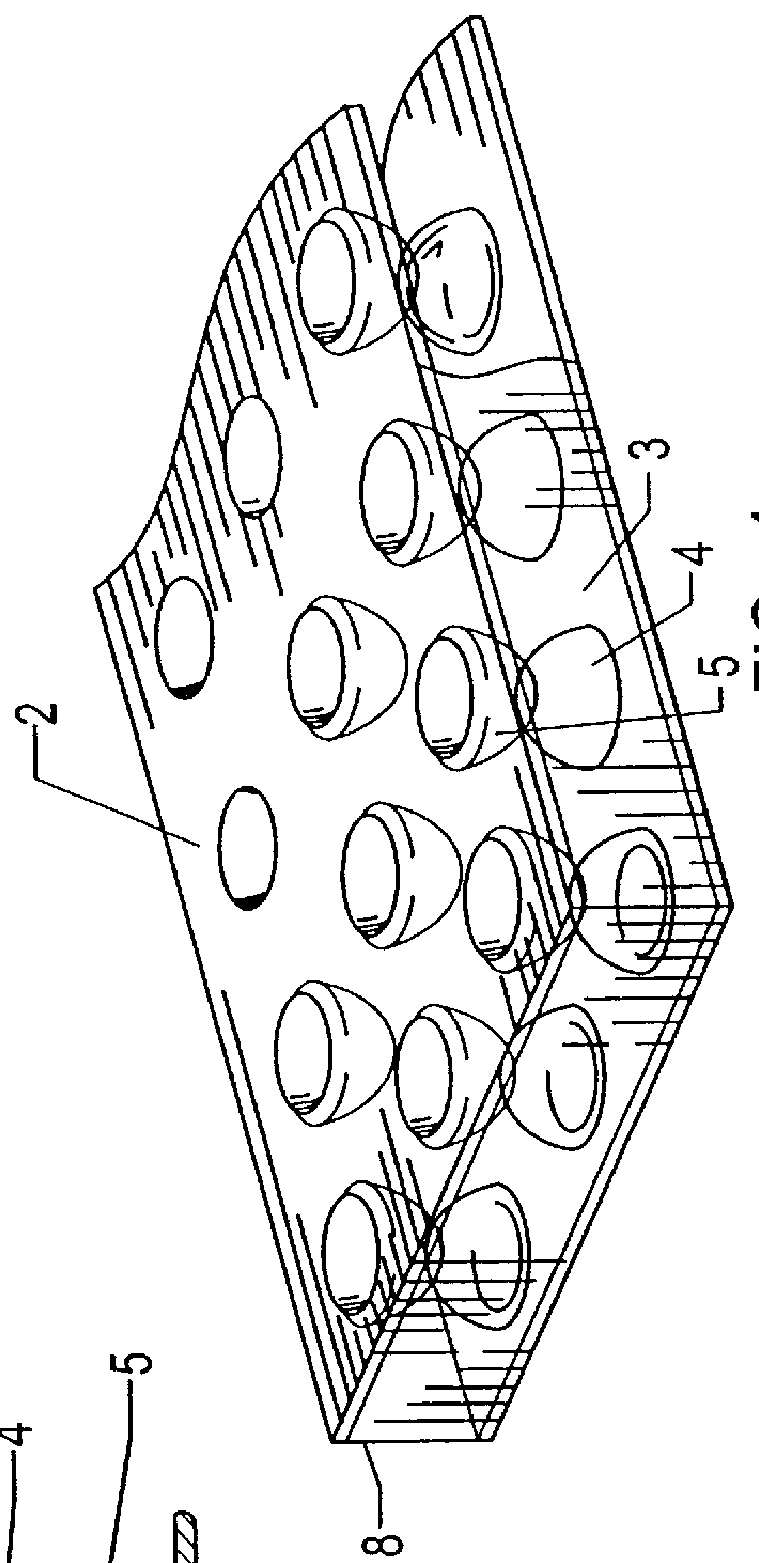

Shock absorbing component and construction method

InactiveUS6029962AImprove the immunityGood flexibilitySolesHollow wall articlesEngineeringMechanical engineering

Owner:SKYDEX TECH +2

Gapped 2' modified oligonucleotides

InactiveUS6326199B1High affinityAvoid degradationHydrolasesPeptide/protein ingredientsNucleotideNuclease

Oligonucleotides and other macromolecules are provided that have increased nuclease resistance, substituent groups for increasing binding affinity to complementary strand, and sub-sequences of 2'-deoxy-erythro-pentofuranosyl nucleotides that activate RNase H enzyme. Such oligonucleotides and macromolecules are useful for diagnostics and other research purposes, for modulating protein in organisms, and for the diagnosis, detection and treatment of other conditions susceptible to antisense therapeutics.

Owner:IONIS PHARMA INC

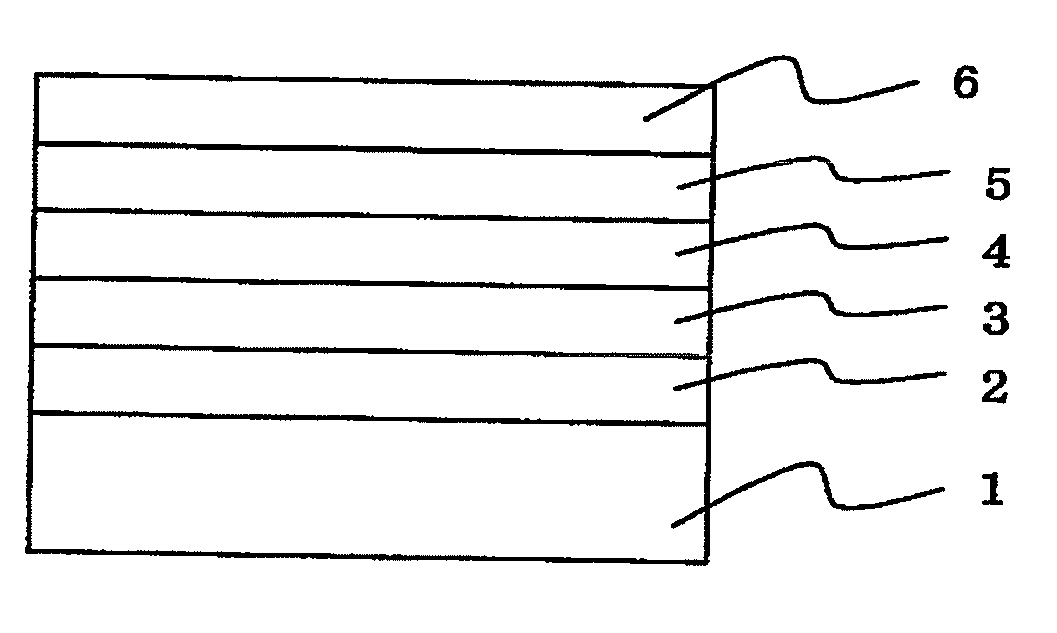

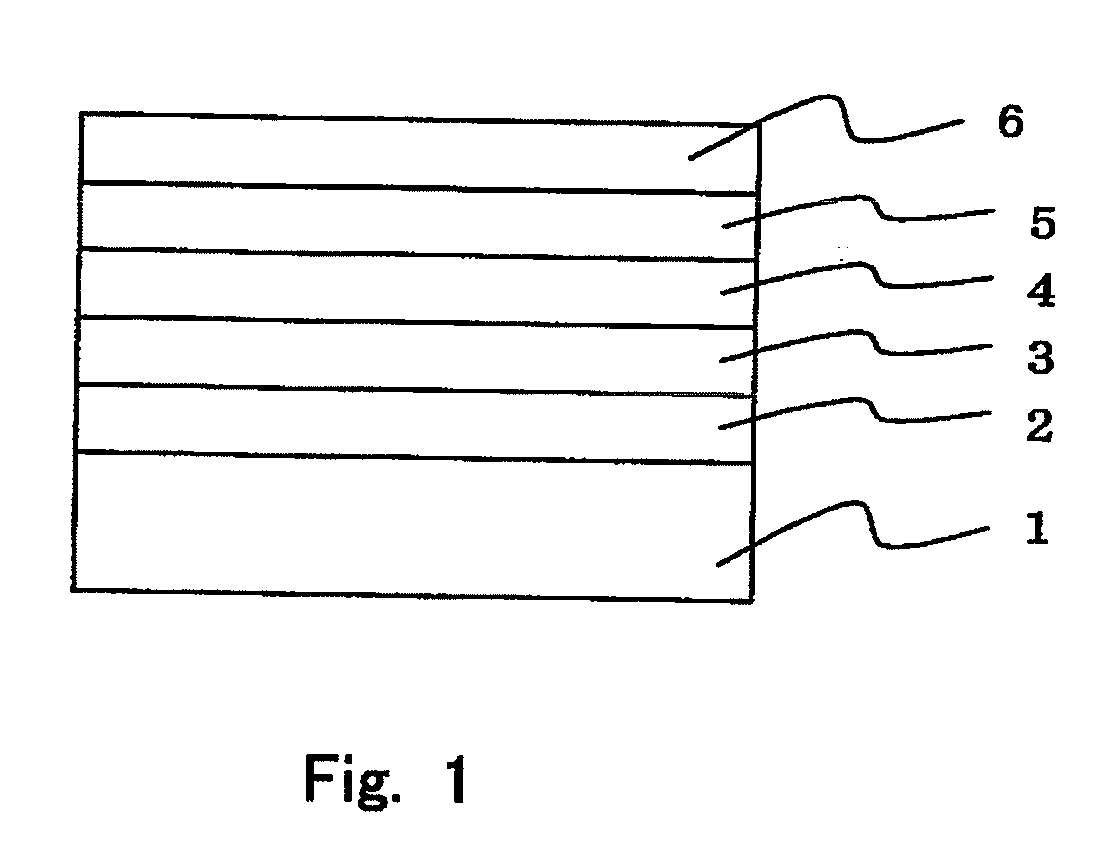

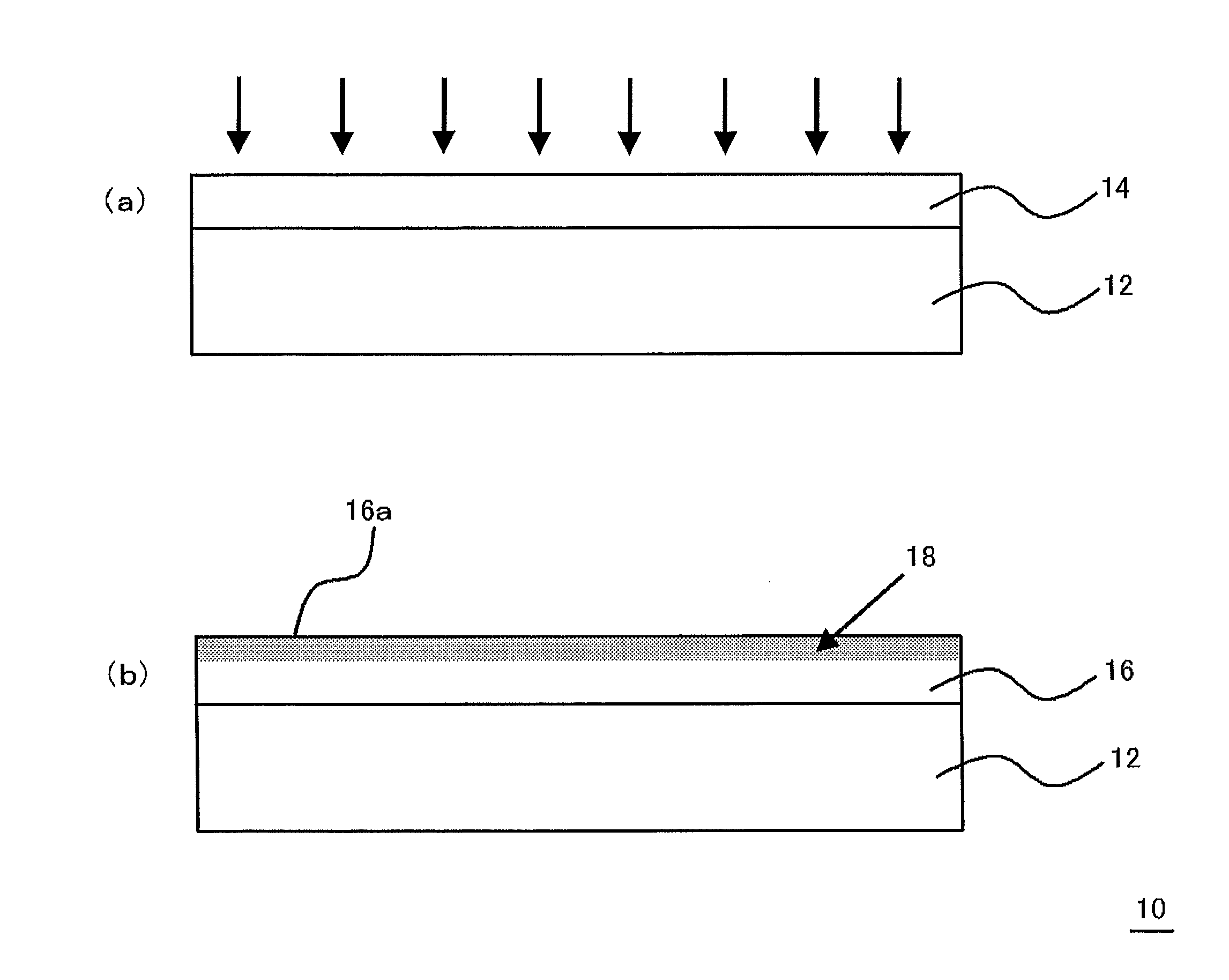

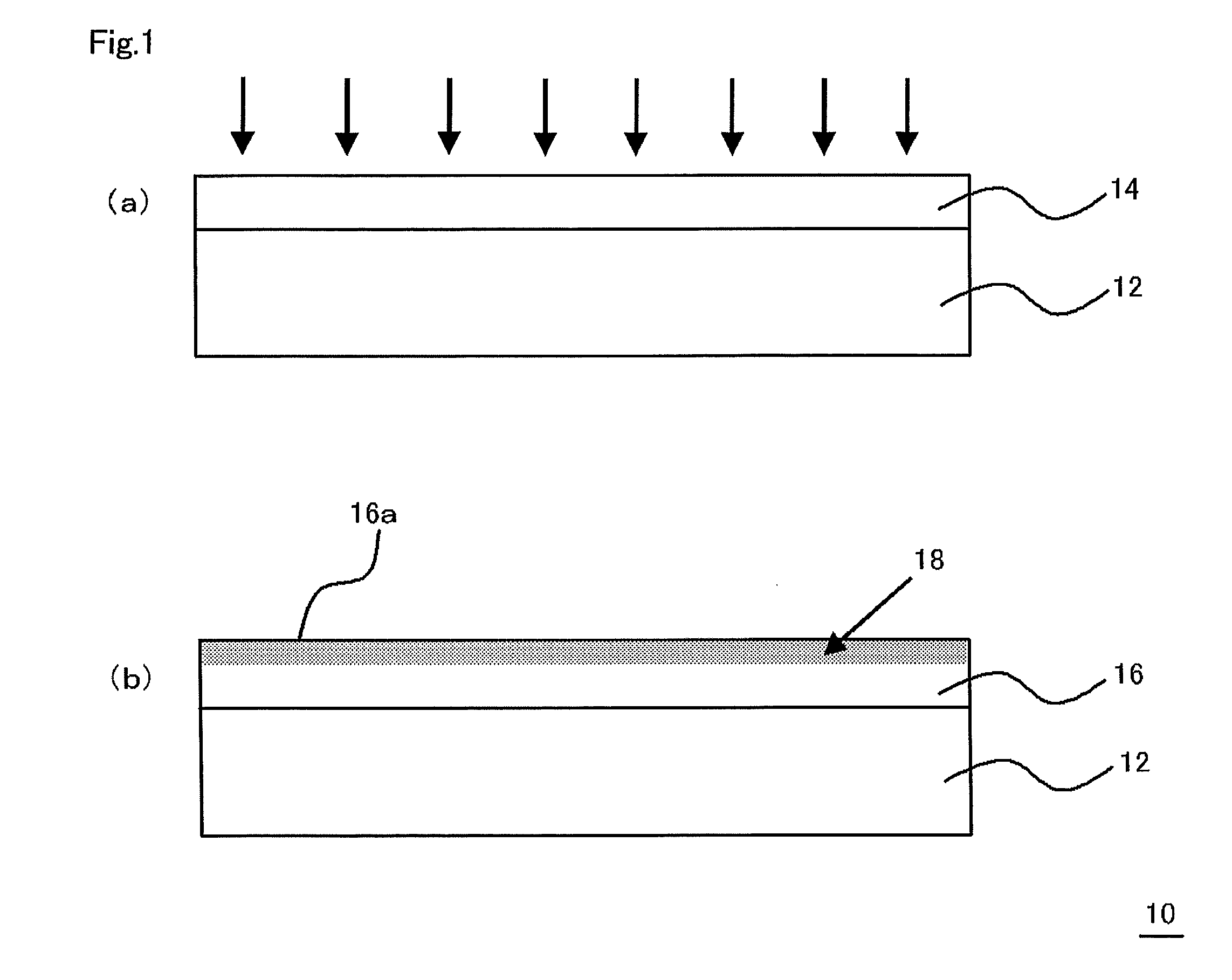

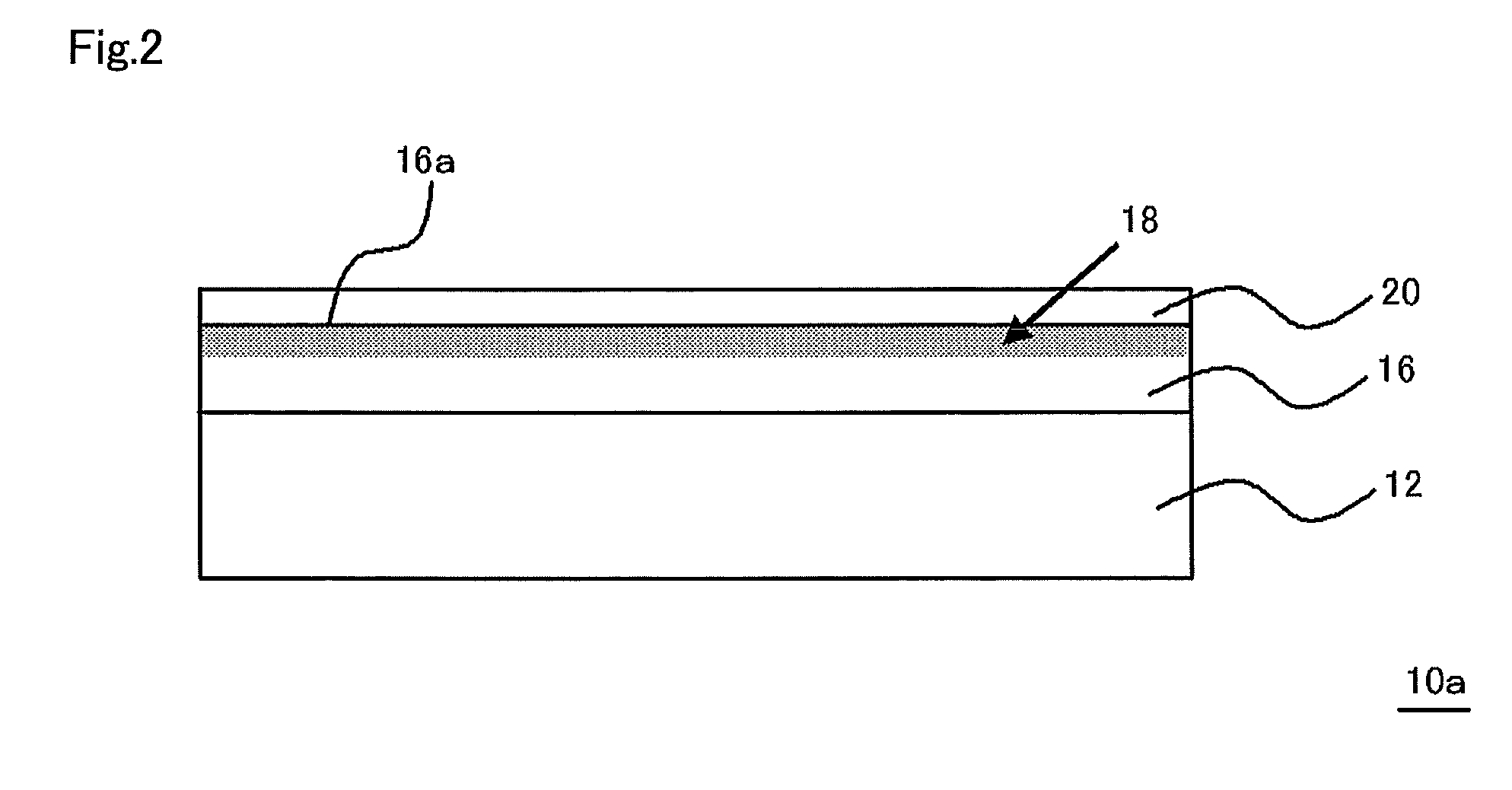

Multilayered material and method of producing the same

InactiveUS20120107607A1Reduce the impactIncrease production capacityRadiation applicationsPretreated surfacesWater vaporPolysilazane

A multilayered material is provided which includes a substrate and a silicon-containing film formed on the substrate, wherein the silicon-containing film has a nitrogen-rich area including silicon atoms and nitrogen atoms, or silicon atoms, nitrogen atoms, and an oxygen atoms and the nitrogen-rich area is formed by irradiating a polysilazane film formed on the substrate with an energy beam in an atmosphere not substantially including oxygen or water vapor and denaturing at least a part of the polysilazane film. A method of producing the multilayered material is also provided.

Owner:MITSUI CHEM INC

Coating composition for multiple hydrophilic applications

InactiveUS7008979B2Improve adhesionImprove the lubrication effectSurgerySynthetic resin layered productsColloidWear resistance

Owner:HYDROMER INC

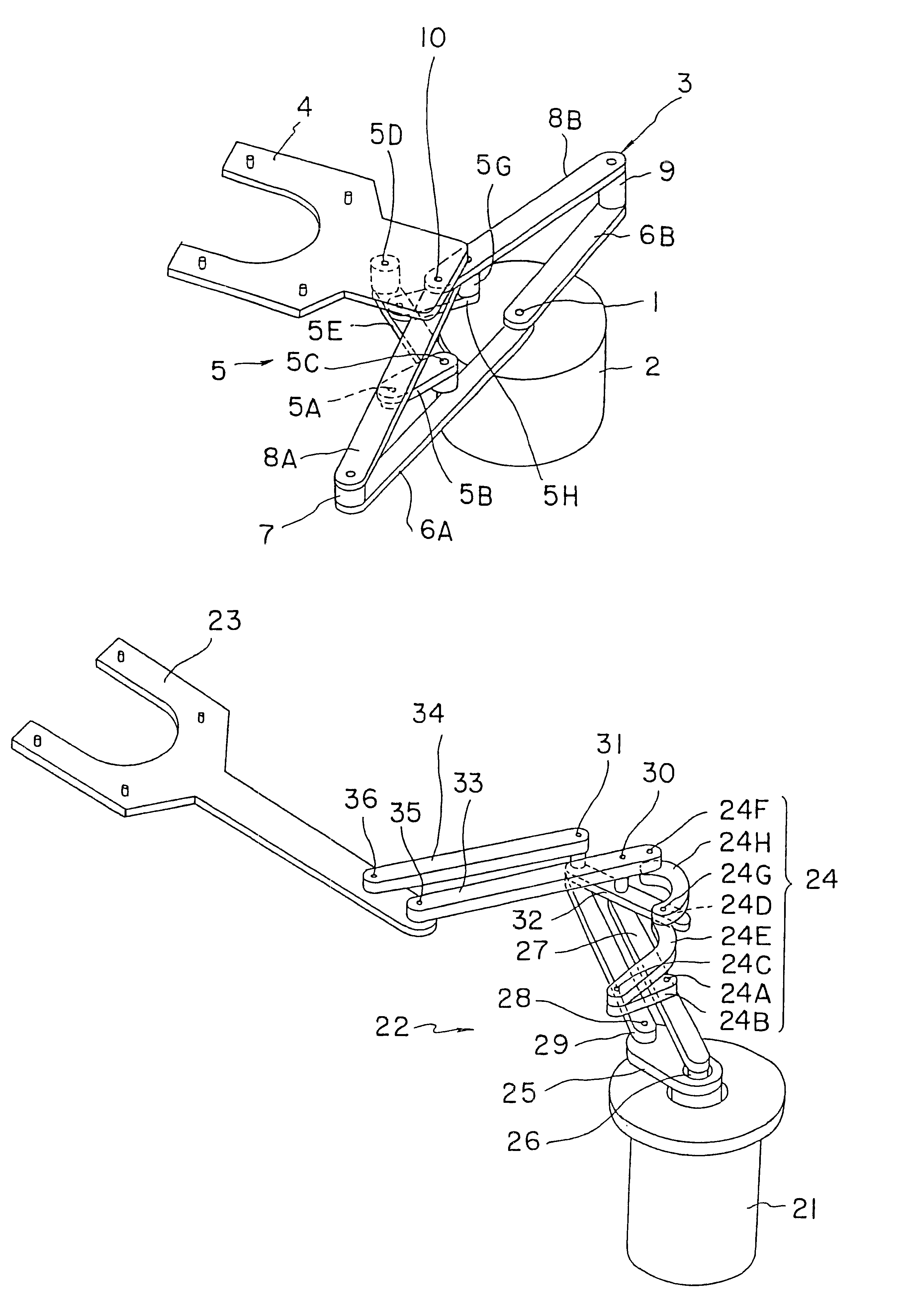

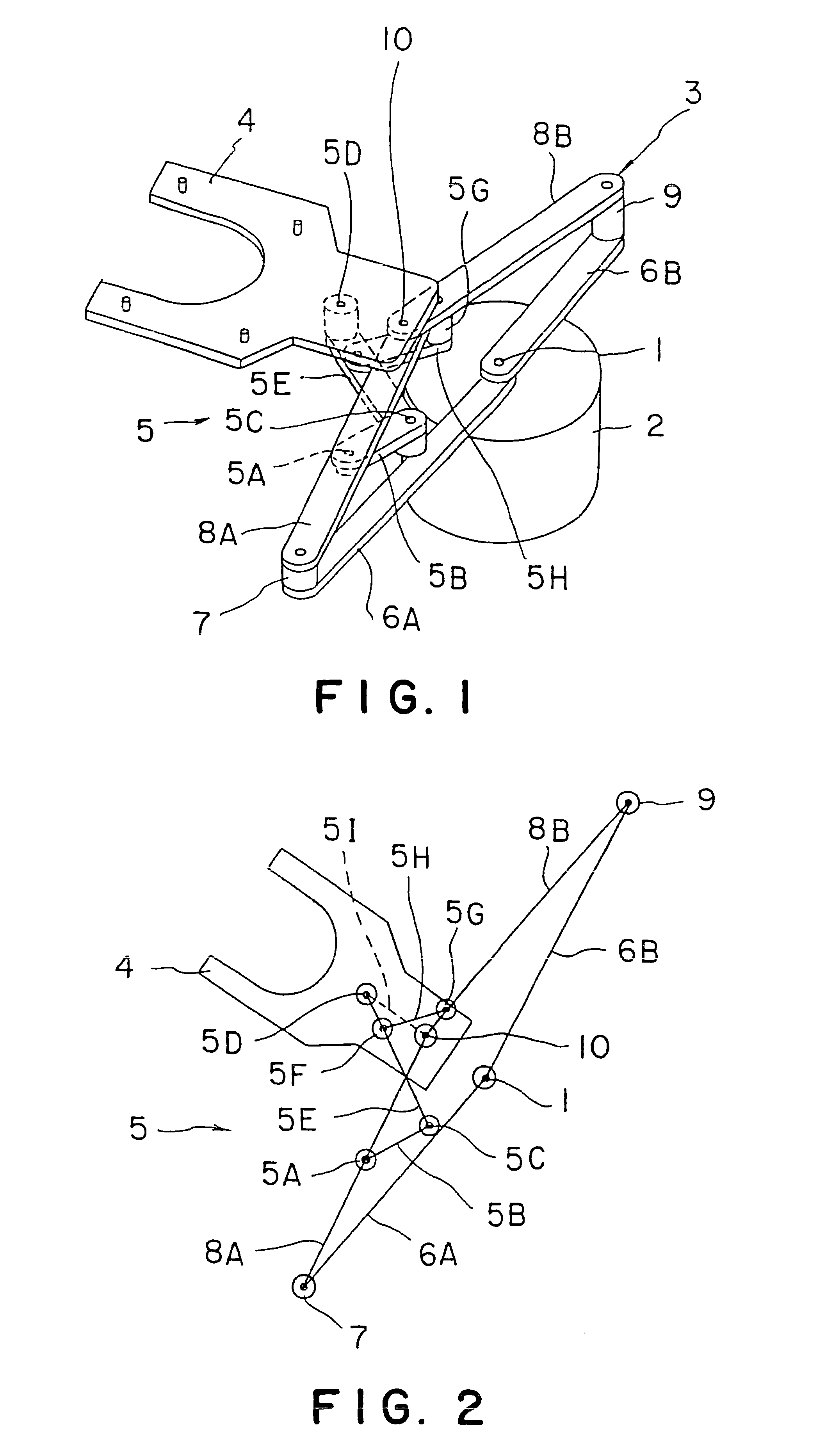

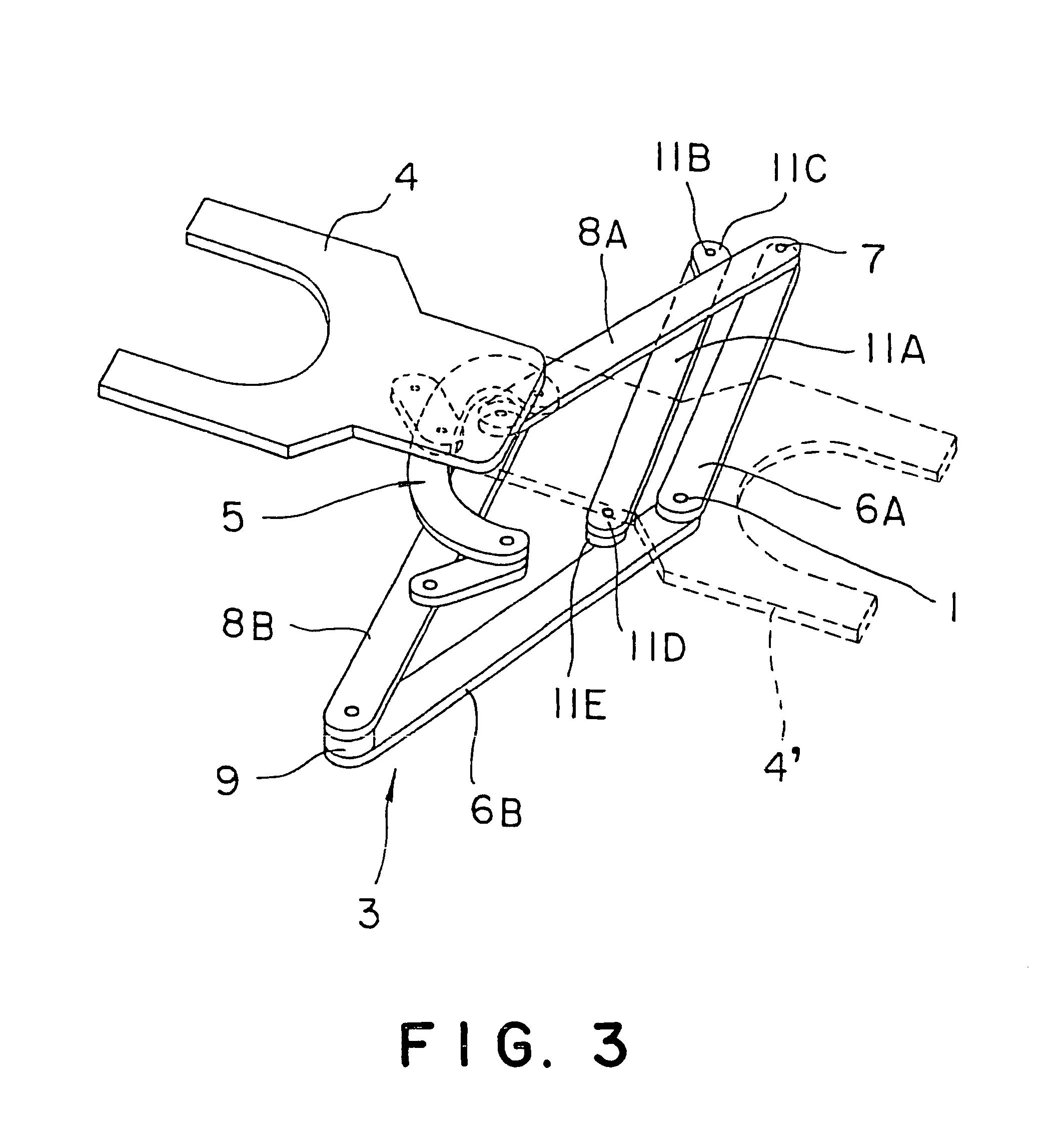

Conveyor system

InactiveUS6450757B1Increase resistanceAccurately and surely carrying a workpieceProgramme-controlled manipulatorMechanical apparatusMostly TrueHeat resistance

In most cases, a hot, corrosive atmosphere is created in, for example, a semiconductor wafer processing chamber. When an arm including belts, such as steel belts, is moved into such a semiconductor wafer processing chamber, the belts are exposed to the hot, corrosive atmosphere. Belts, such as steel belts, have limited heat resistance and corrosion resistance and the hot, corrosive atmosphere in the processing chamber shortens the life of the belts. A carrying device of the present invention has a frog leg type arm (3) and a wafer holder (4) connected to the frog leg type arm (3). The wafer holder (4) is pivotally connected to front end parts of a first front arm (8A) and a second front arm (8B) by coaxial joints (10). The wafer holder (4) is linked to the first front arm (8A) and the second front arm (8B) by a posture maintaining linkage (5) including two antiparallel linkages capable of controlling the turning of the wafer holder (4) relative to the first and the second front arms (8A, 8B).

Owner:TOKYO ELECTRON LTD

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

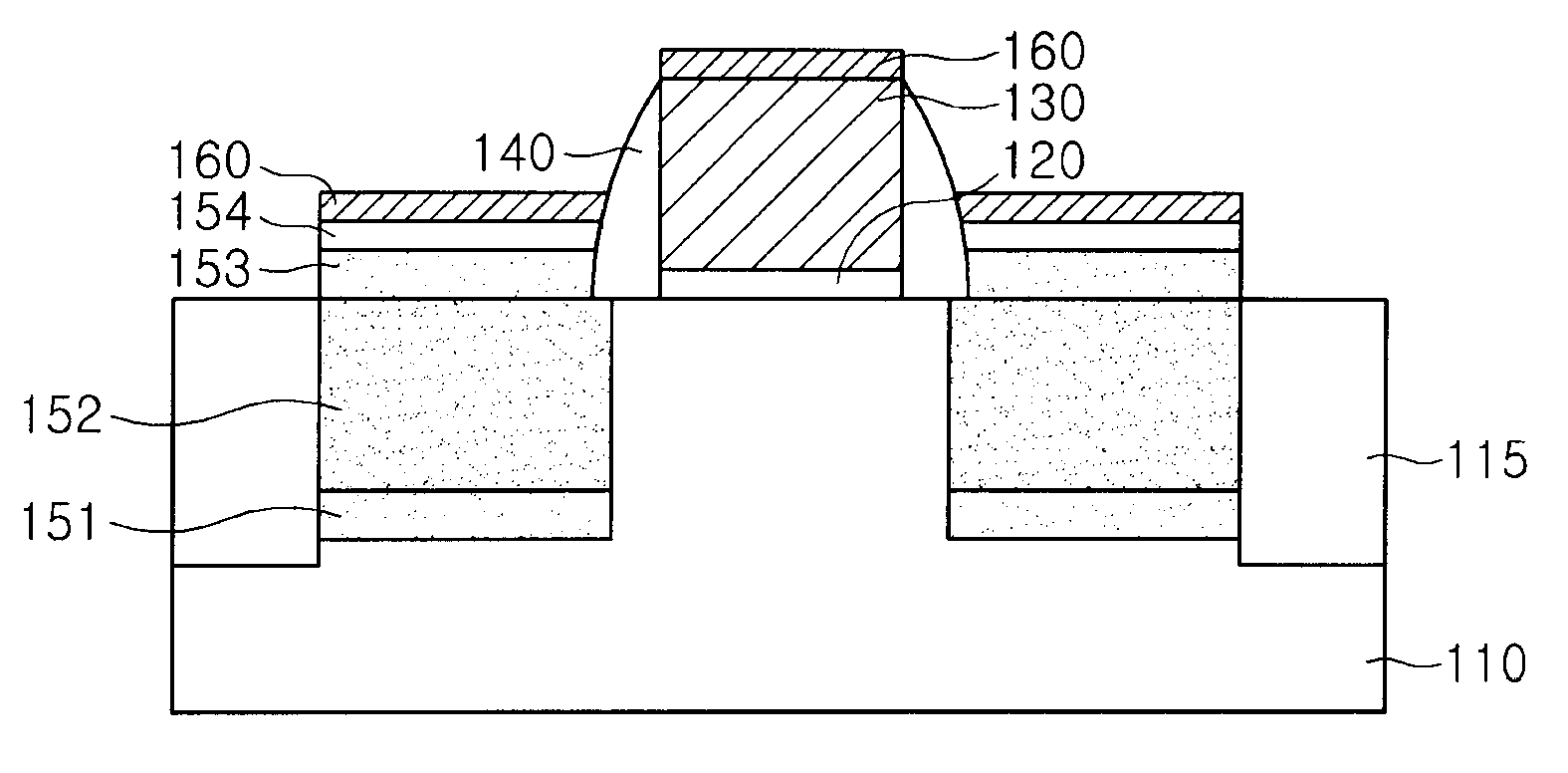

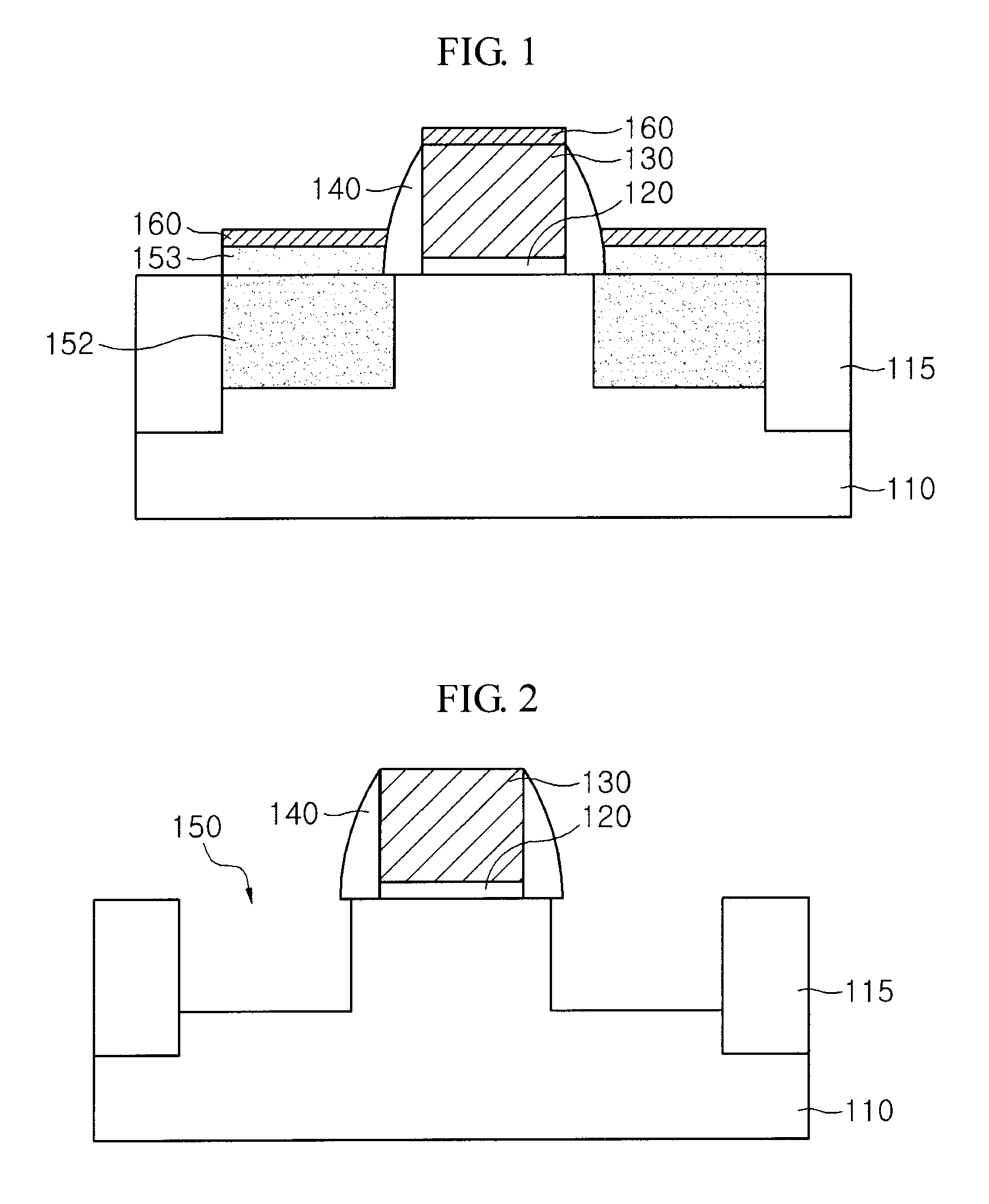

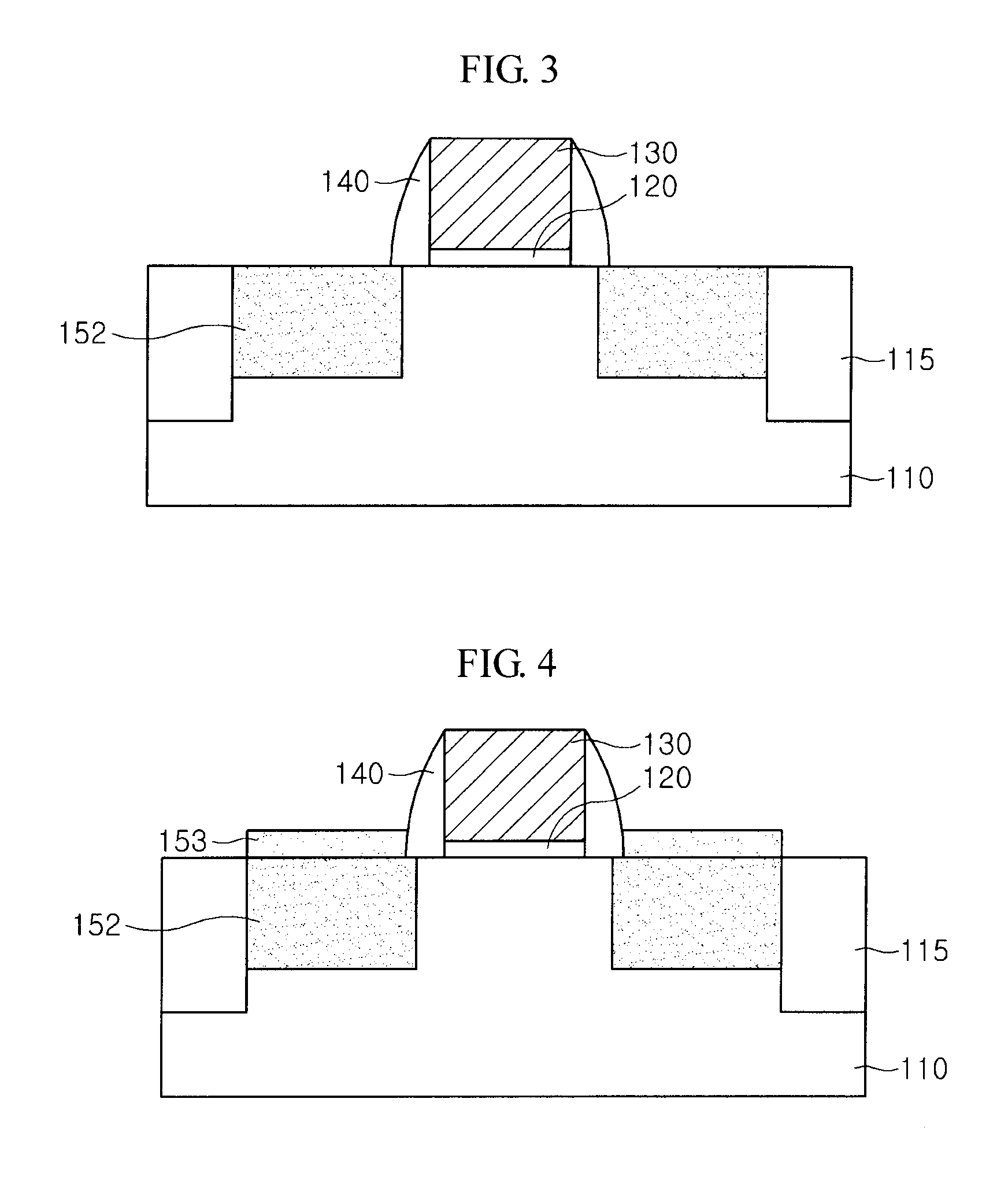

Transistor and method of fabricating the same

ActiveUS20090108308A1Improve performanceIncrease resistanceSolid-state devicesSemiconductor/solid-state device manufacturingSiliconTransistor

A transistor and a method of fabricating the same are provided. The transistor includes a SiGe epitaxial layer formed in a recess region of a substrate at both side of a gate electrode and a SiGe capping layer formed on the SiGe epitaxial layer. The transistor further includes a SiGe seed layer formed under the SiGe epitaxial layer and a silicon capping layer formed on the SiGe capping layer.

Owner:JUSUNG ENG

Carbonitride coated component of semiconductor processing equipment and method of manufacturing thereof

InactiveUS20020094378A1High purityIncrease resistanceCellsElectric discharge tubesCorrosion resistantMetallurgy

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a carbonitride containing surface and process for manufacture thereof.

Owner:LAM RES CORP

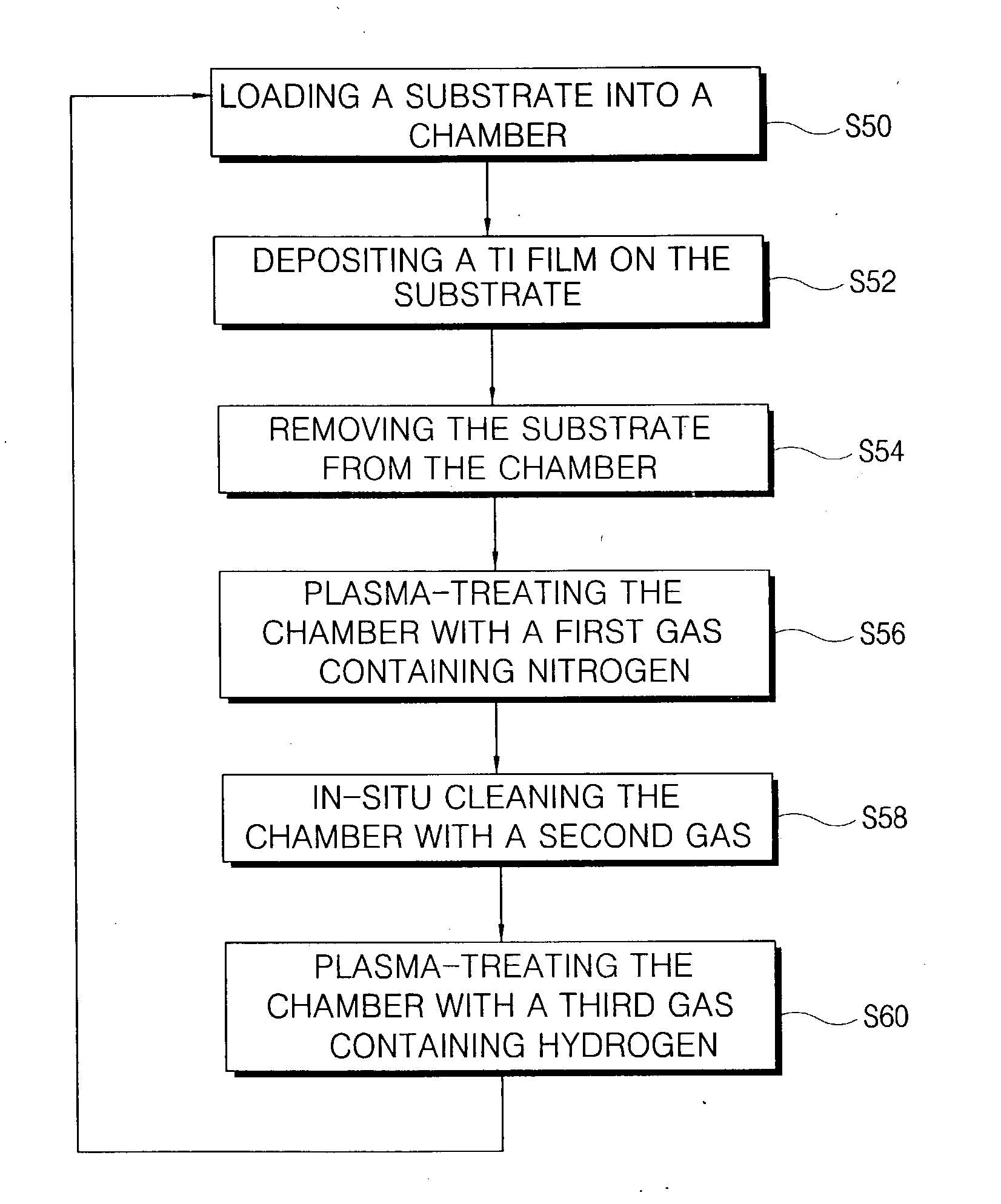

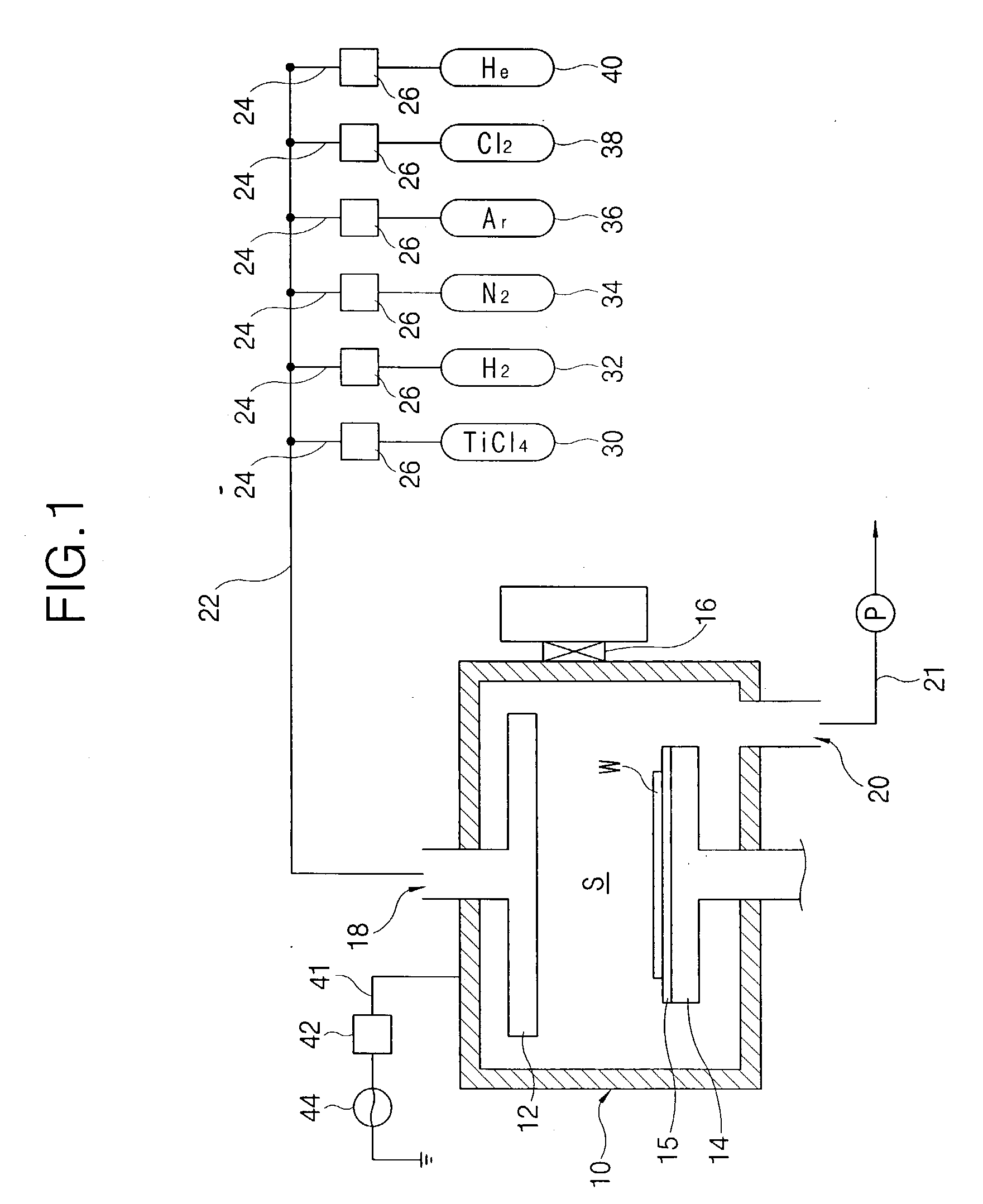

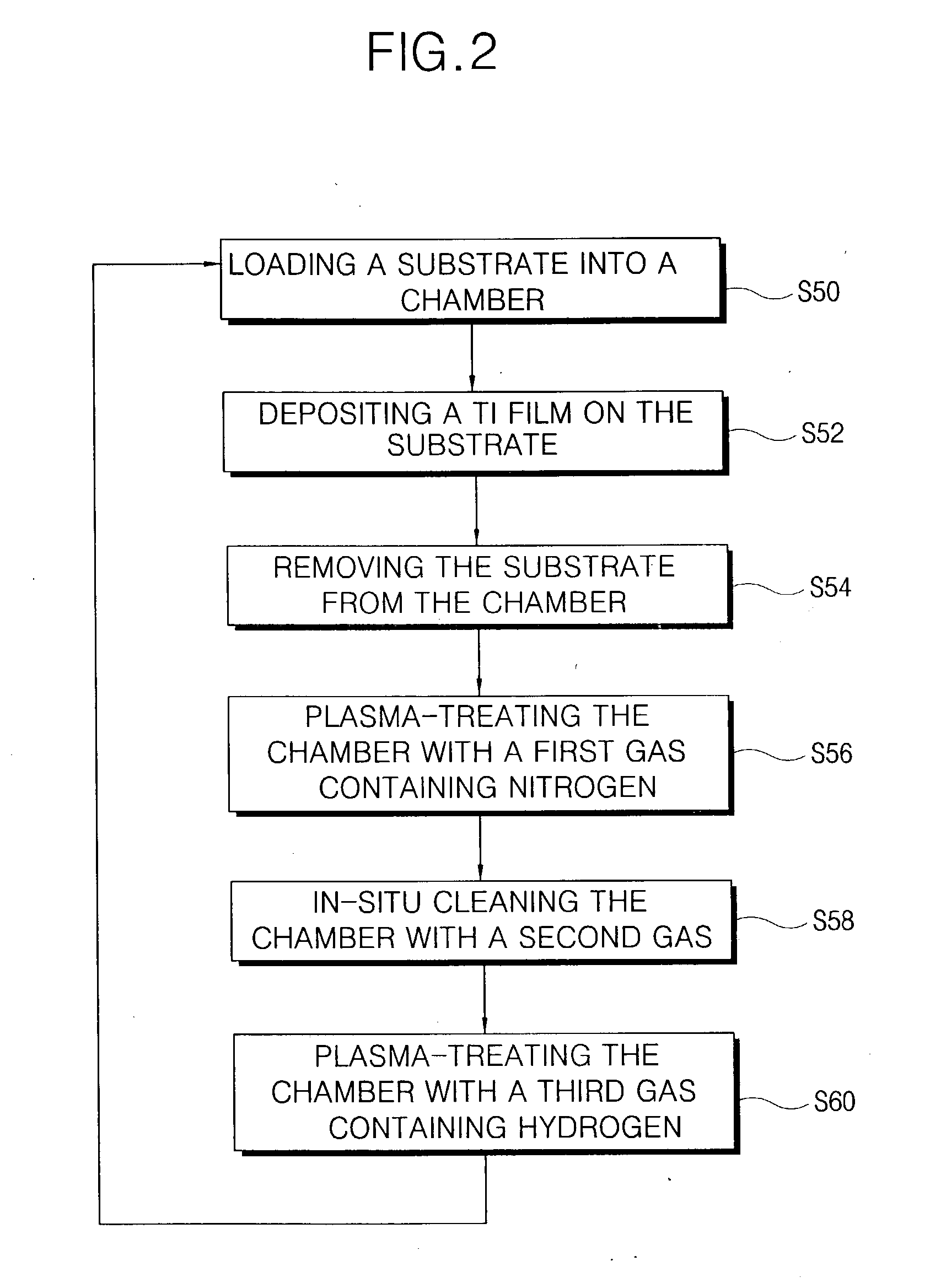

Method of cleaning a chemical vapor deposition chamber

InactiveUS20040013818A1Reduce the amount requiredIncrease resistanceHollow article cleaningElectrostatic cleaningHydrogenNitrogen

After a processing chamber is used to deposit a refractory metal film on a substrate, the chamber is plasma-treated with a gas including either nitrogen and / or hydrogen and in-situ cleaned. By plasma-treating the chamber with a gas including nitrogen, the refractory metal film that forms on interior surfaces of the chamber during substrate processing is nitrided. The nitrided refractory metal film can be removed from the chamber during the in-situ cleaning. By plasma-treating the chamber with a gas including hydrogen, reaction by-products generated in the chamber is diluted and removed. The chamber may be plasma-treated in a gas ambient including both nitrogen and hydrogen. Also, the plasma treatment may be performed before and after the in-situ cleaning.

Owner:SAMSUNG ELECTRONICS CO LTD

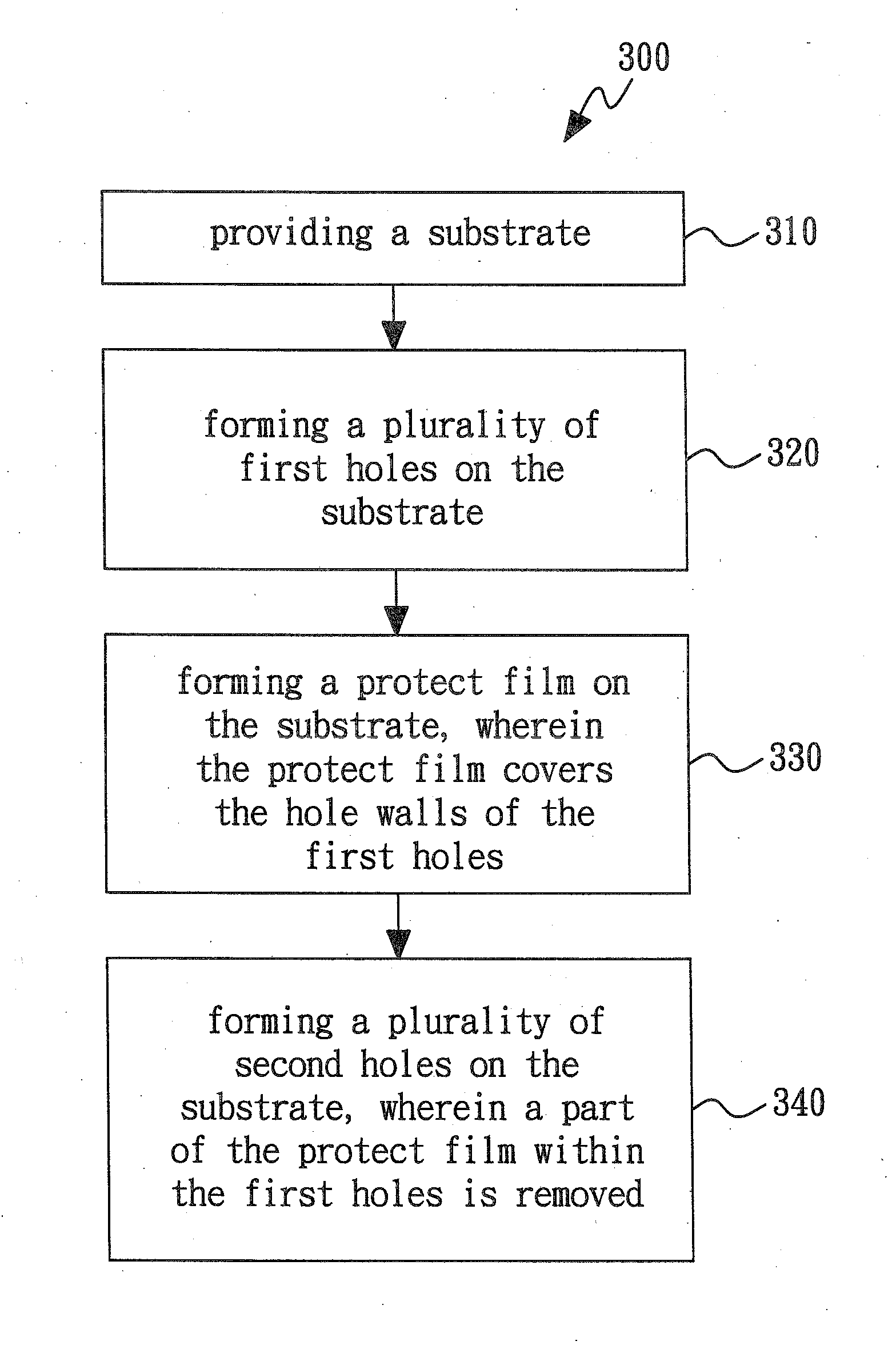

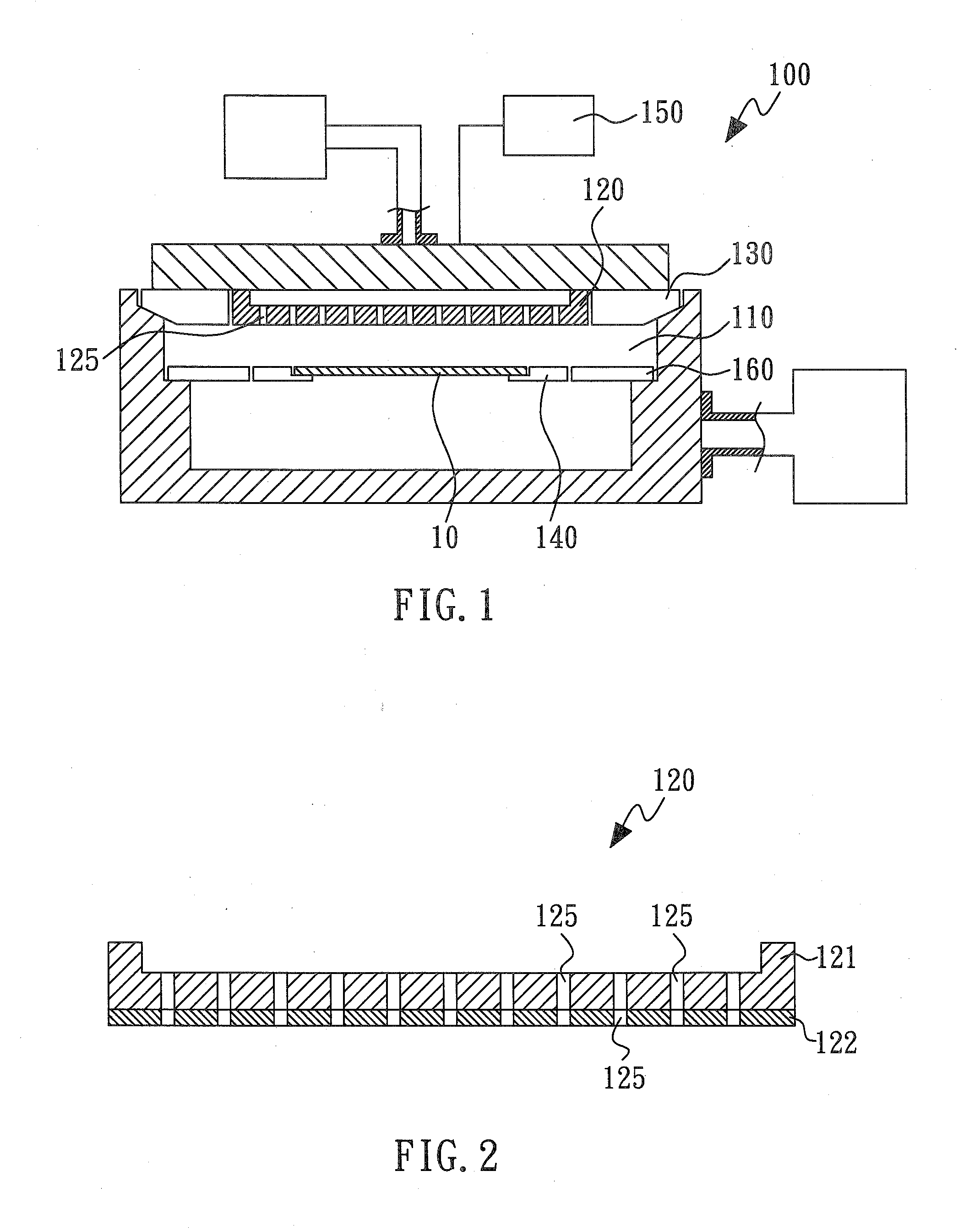

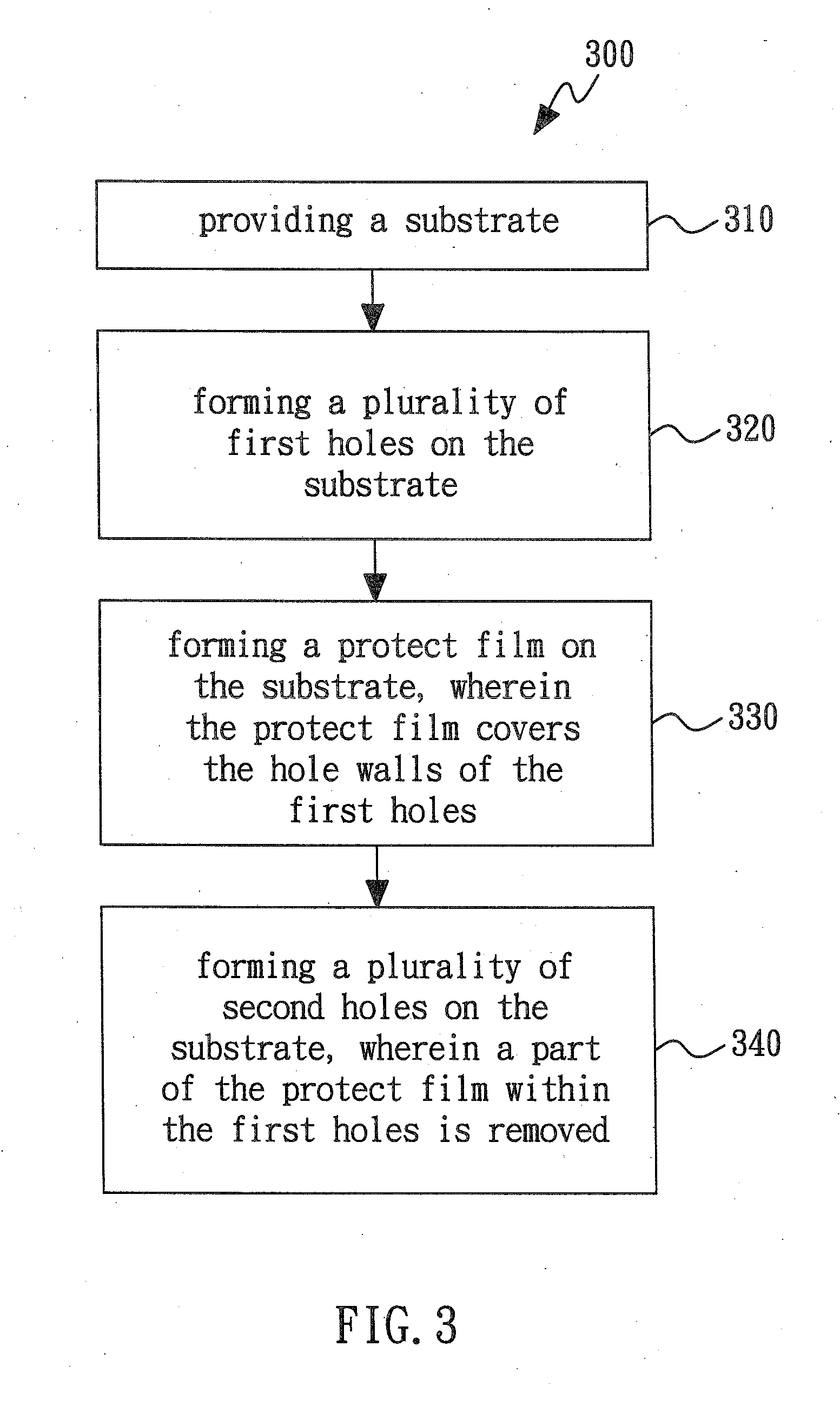

Method of Making Showerhead for Semiconductor Processing Apparatus

ActiveUS20110076401A1Low costReduce manufacturing costElectric discharge tubesPretreated surfacesTectorial membraneEngineering

A method of making a showerhead for a semiconductor processing apparatus is disclosed. In one embodiment, the method includes providing a substrate; forming first holes in the substrate; forming a protective film on the substrate, where the protective film covers sidewalls of the first holes; and forming second holes in the substrate, where a part of the protective film within the first holes is removed. In another embodiment, the method includes providing a substrate; forming islands on the substrate; forming a protective film on the substrate, where the protective film does not cover the tops of the islands; and forming holes in the islands.

Owner:HERMES EPITEK

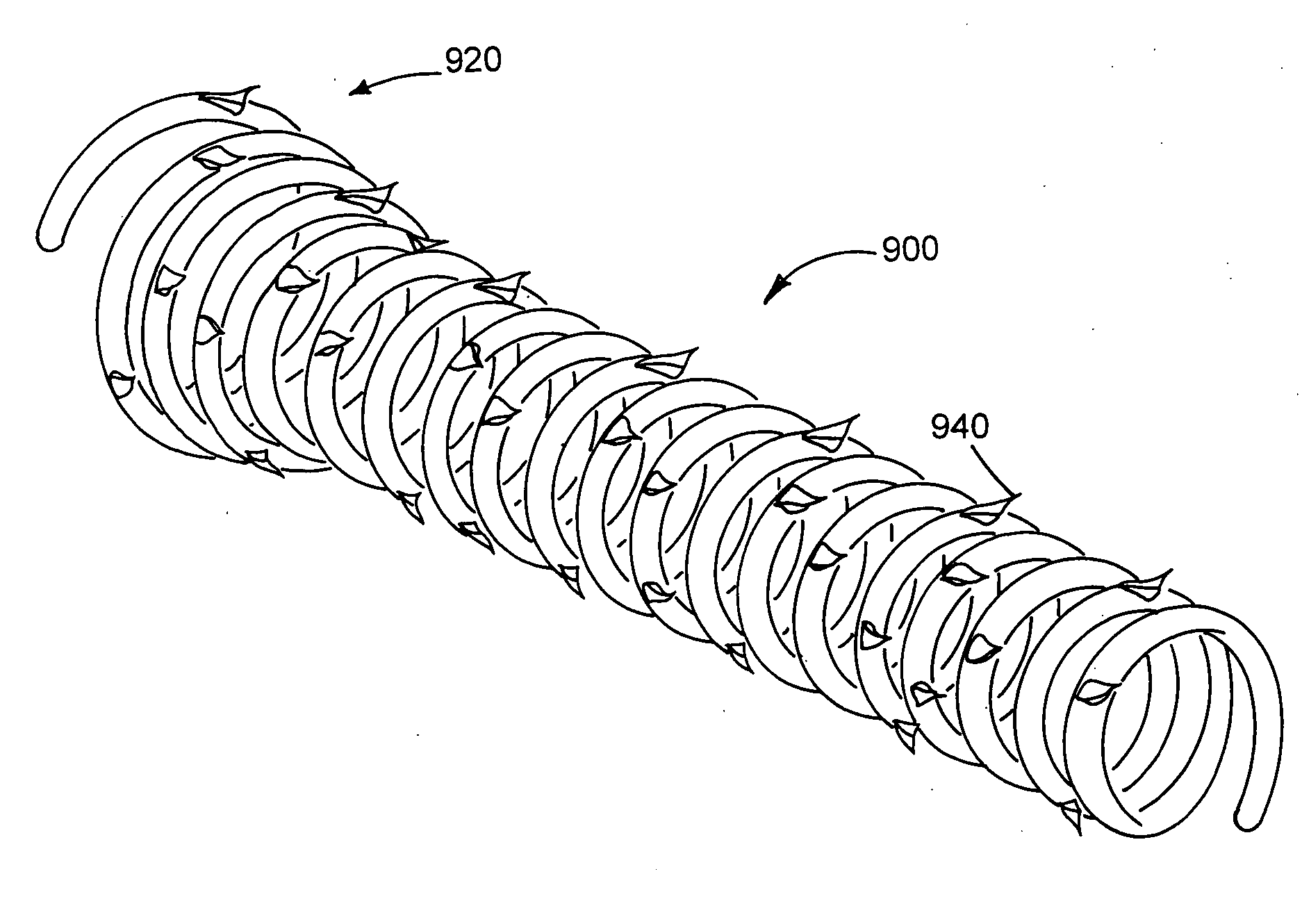

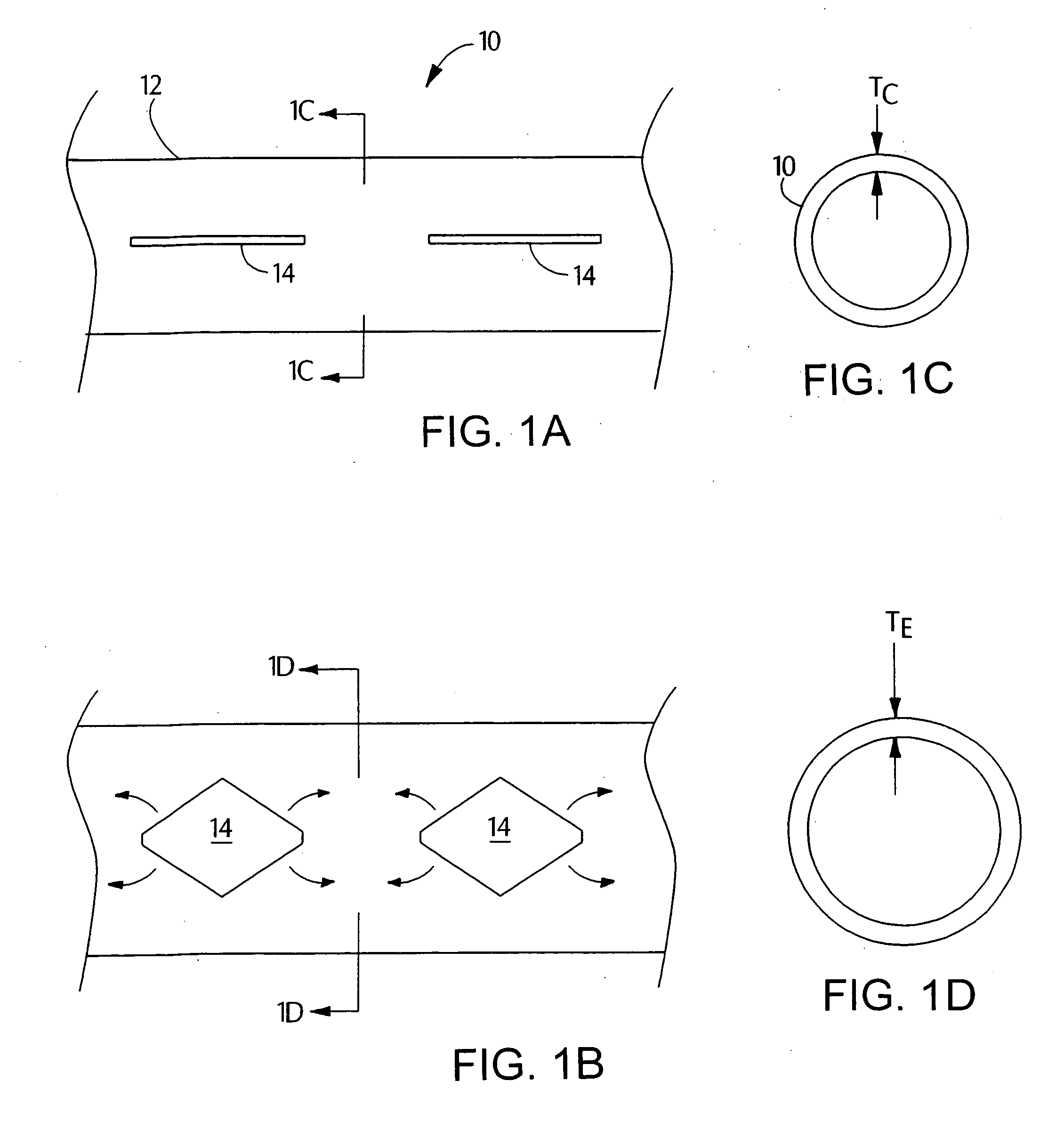

Implantable medical devices

InactiveUS20050010275A1Improve abilitiesIncrease resistanceStentsWound drainsInsertion stentBalloon catheter

A medical device includes a balloon catheter having an expandable member, e.g., an inflatable balloon, at its distal end and a stent or other endoprosthesis. The stent is, for example, an apertured tubular member formed of a polymer and is assembled about the balloon. The stent has an initial diameter for delivery into the body and can be expanded to a larger diameter by inflating the balloon.

Owner:UNIV OF CONNECTICUT +2

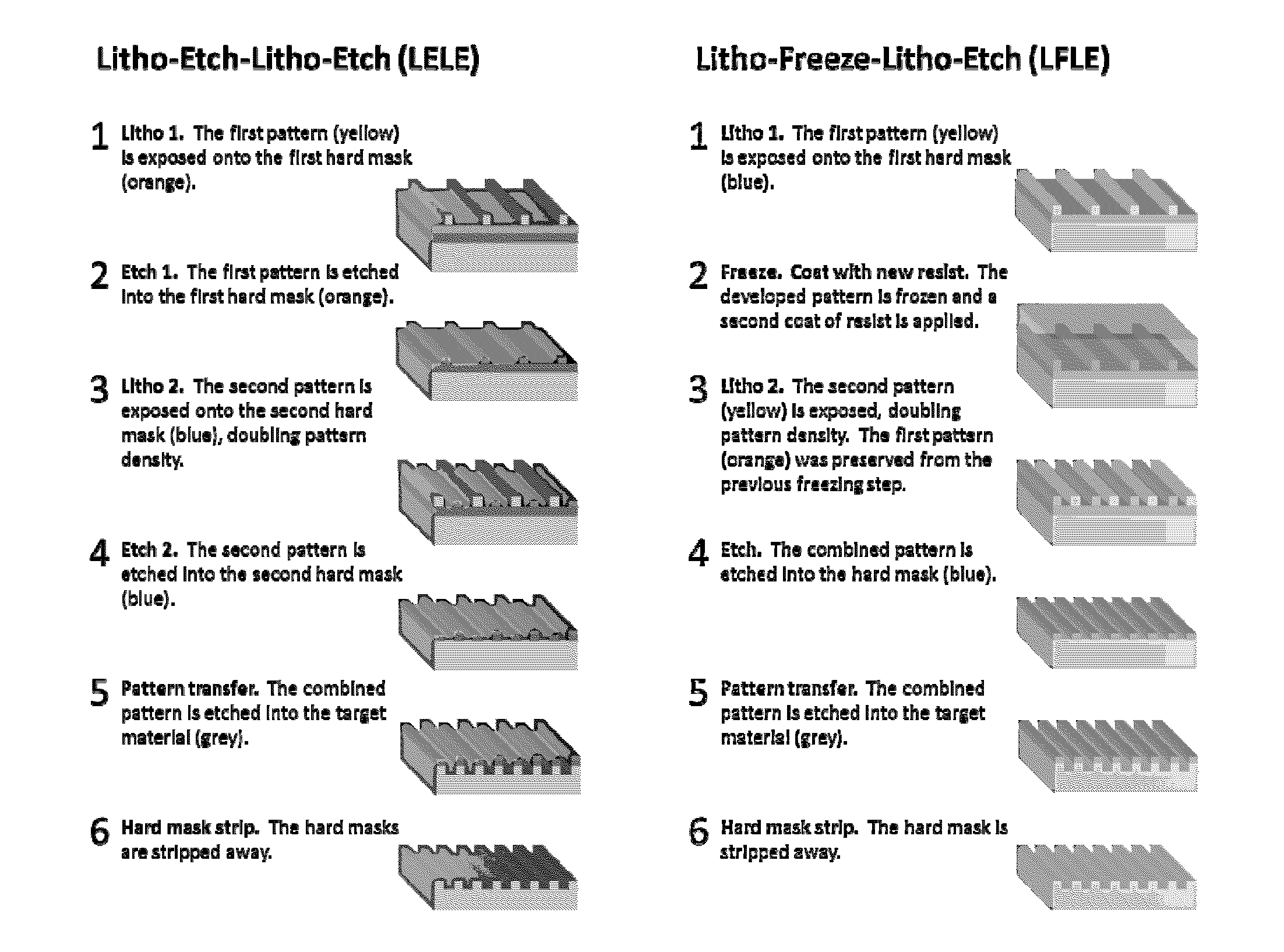

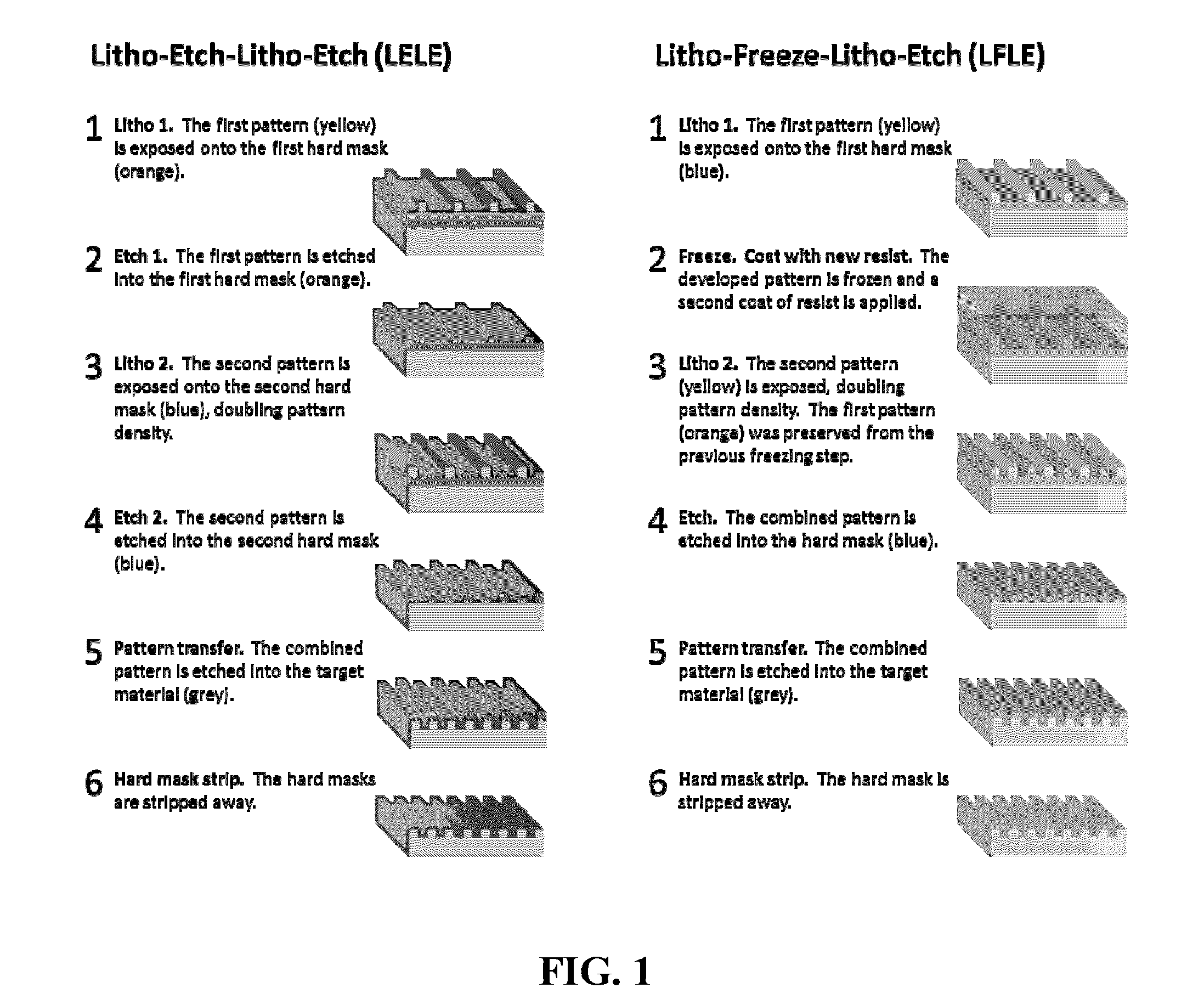

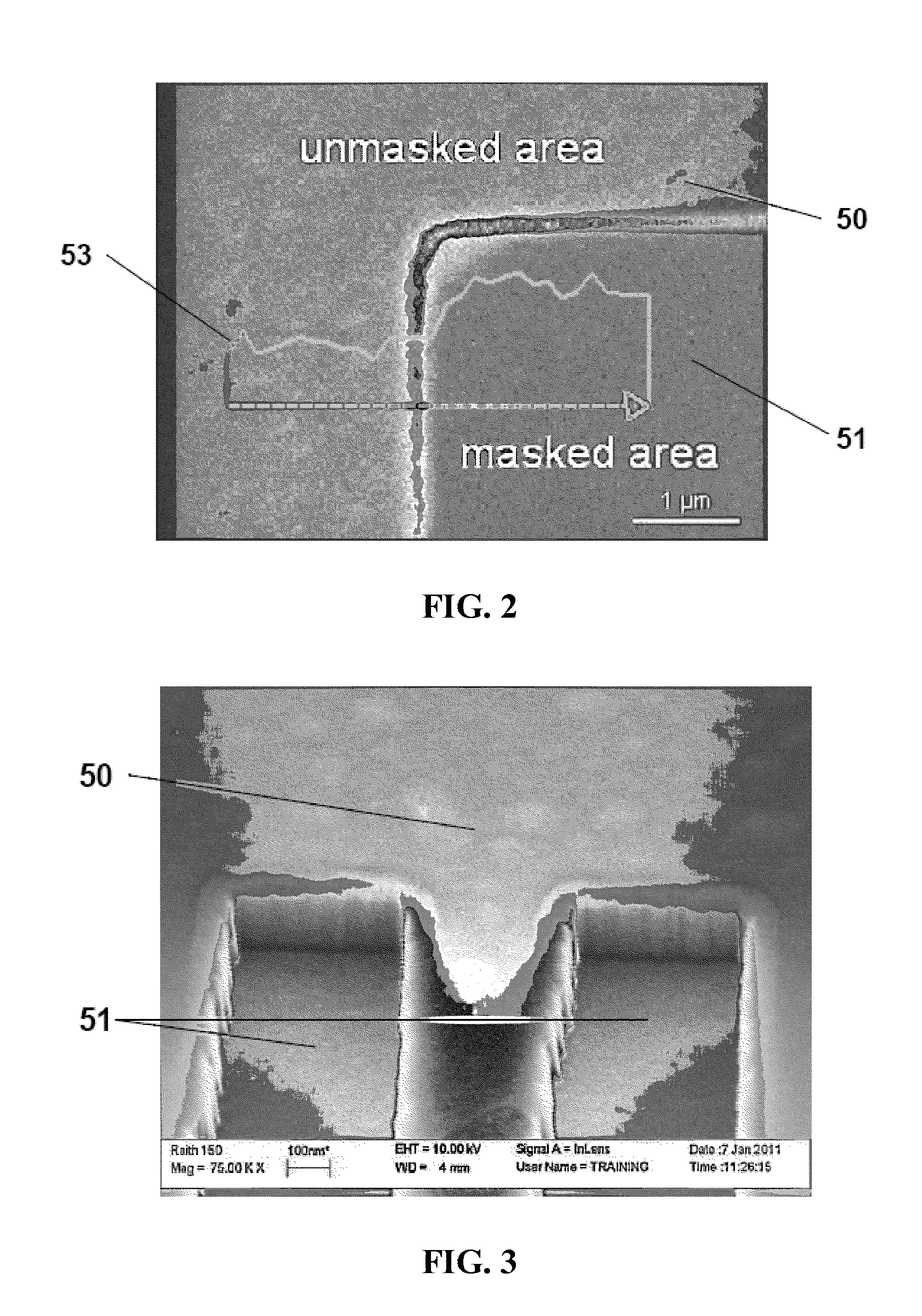

Sequential Infiltration Synthesis for Enhancing Multiple-Patterning Lithography

ActiveUS20130256265A1Reduce in quantityImprove throughputDecorative surface effectsPhotomechanical apparatusPhotoresistMultiple patterning lithography

Simplified methods of multiple-patterning photolithography using sequential infiltration synthesis to modify the photoresist such that it withstands plasma etching better than unmodified resist and replaces one or more hard masks and / or a freezing step in MPL processes including litho-etch-litho-etch photolithography or litho-freeze-litho-etch photolithography.

Owner:UCHICAGO ARGONNE LLC

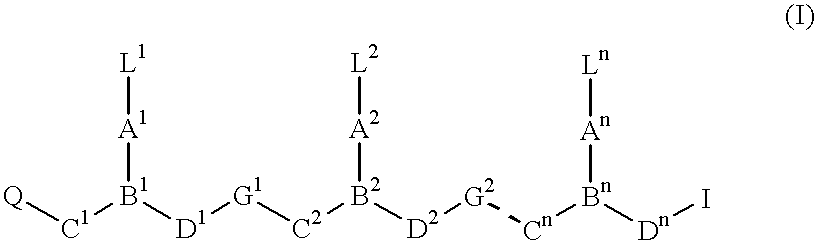

PNA-DNA-PNA chimeric macromolecules

InactiveUS6277603B1Increase resistanceHigh affinitySugar derivativesPeptide/protein ingredientsBiological bodyResearch purpose

Macromolecules are provided that have increased nuclease resistance, increasing binding affinity to a complementary strand, and that activate RNase H enzyme. The macromolecules have the structure PNA-DNA-PNA where the DNA portion is composed of subunits of 2'-deoxy-erythro-pento-furanosyl nucleotides and the PNA portions are composed of subunits of peptide nucleic acids. Such macromolecules are useful for diagnostics and other research purposes, for modulating protein in organisms, and for the diagnosis, detection and treatment of other conditions susceptible to therapeutics.

Owner:IONIS PHARMA INC

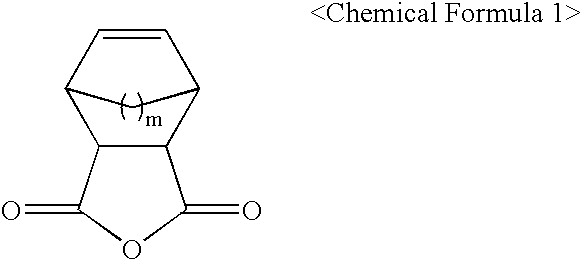

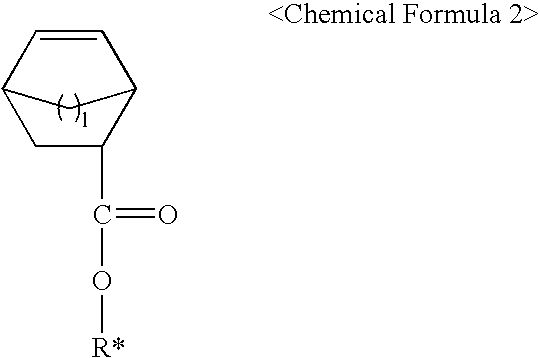

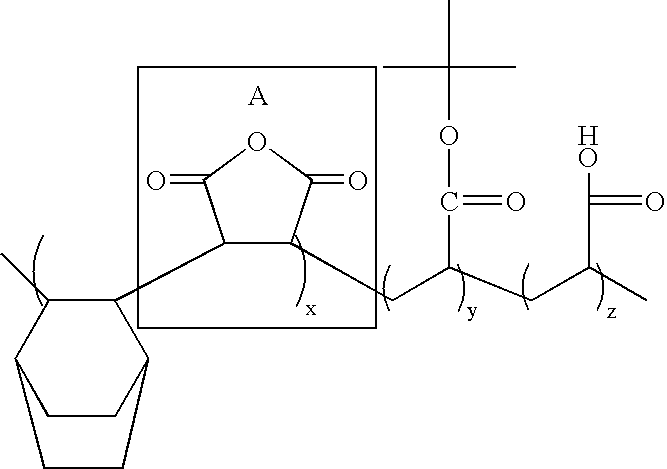

Polymers for photoresist and photoresist compositions using the same

InactiveUS6987155B2Improve the immunityExcellent etching resistance and adhesiveness and photosensitivityElectric discharge tubesPhotomechanical exposure apparatusResistX-ray

The present invention relates to photoresist monomers, polymers formed therefrom and photoresist compositions suitable for photolithography processes employing a DUV light source, such as KrF (249 nm) and ArF(193 nm); EUV; VUV; E-beam; ion-beam; and X-ray. Photoresist monomers of the present invention are represented by the following Chemical Formula 1: wherein, m is 1 or 2.Polymers of the present invention comprise repeating units derived from the comonomer of Chemical Formula 1, preferably together with monomers of the following Chemical Formula 2: wherein,R* is an acid-labile group, andl is 1 or 2.

Owner:HYUNDAI ELECTRONICS IND CO LTD

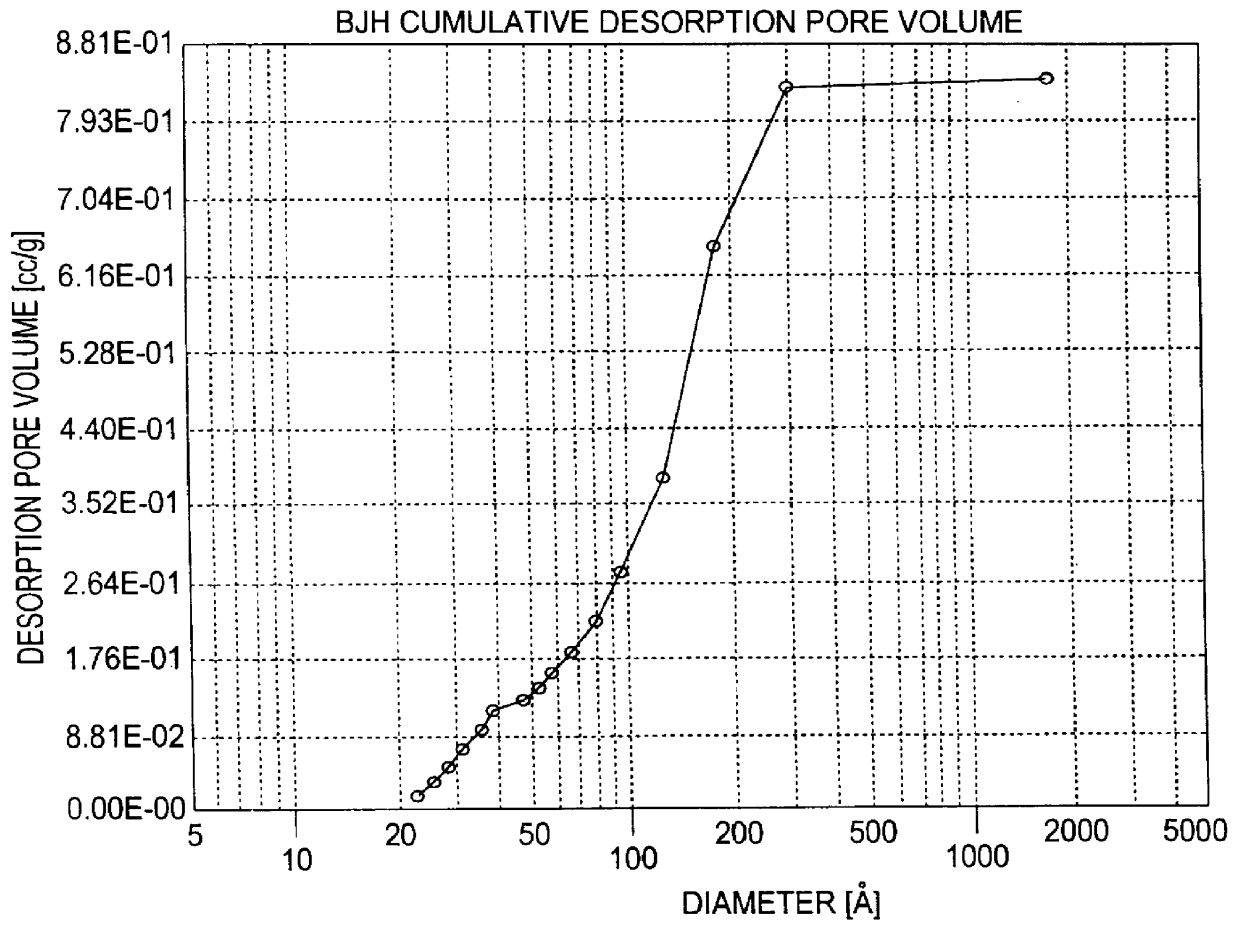

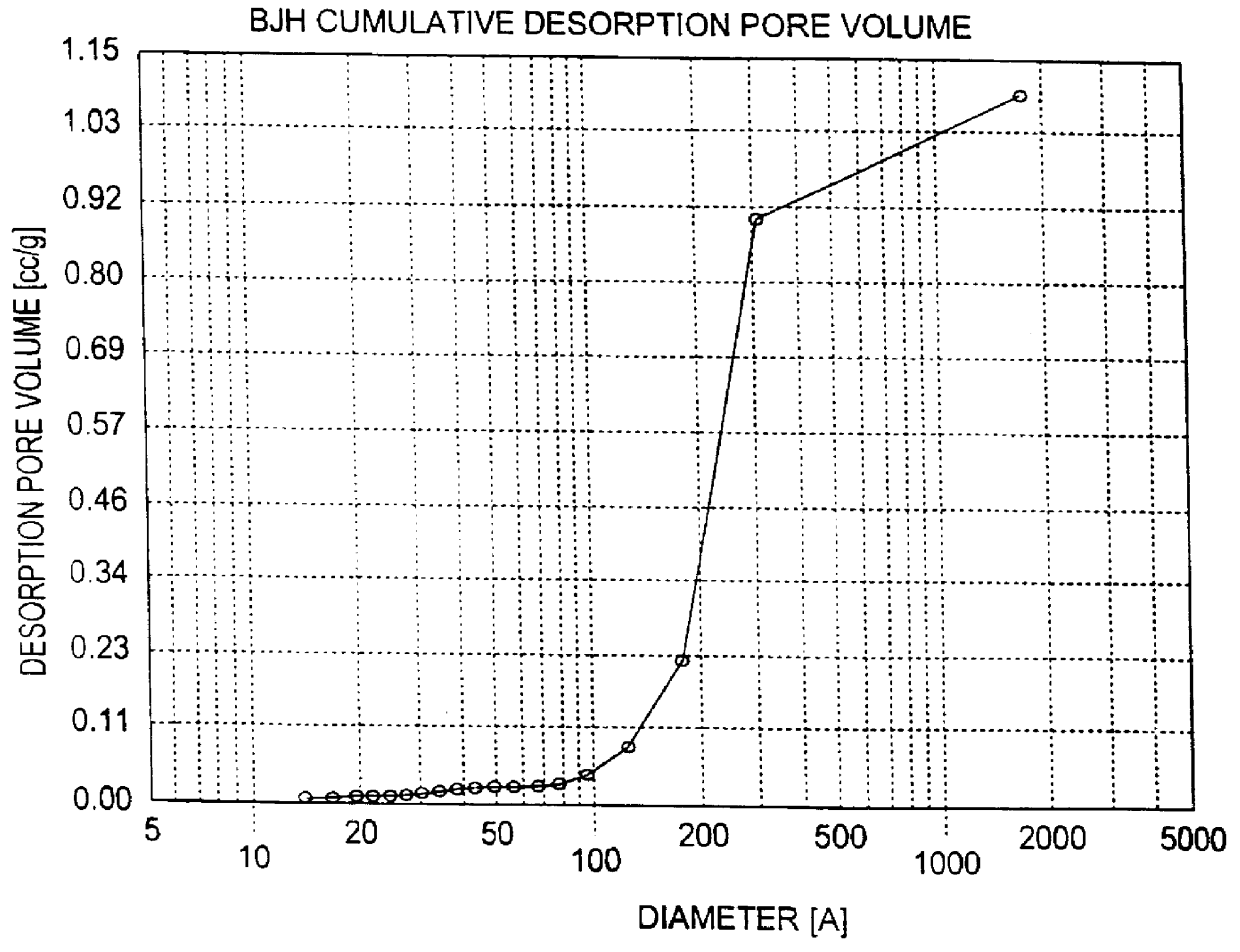

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

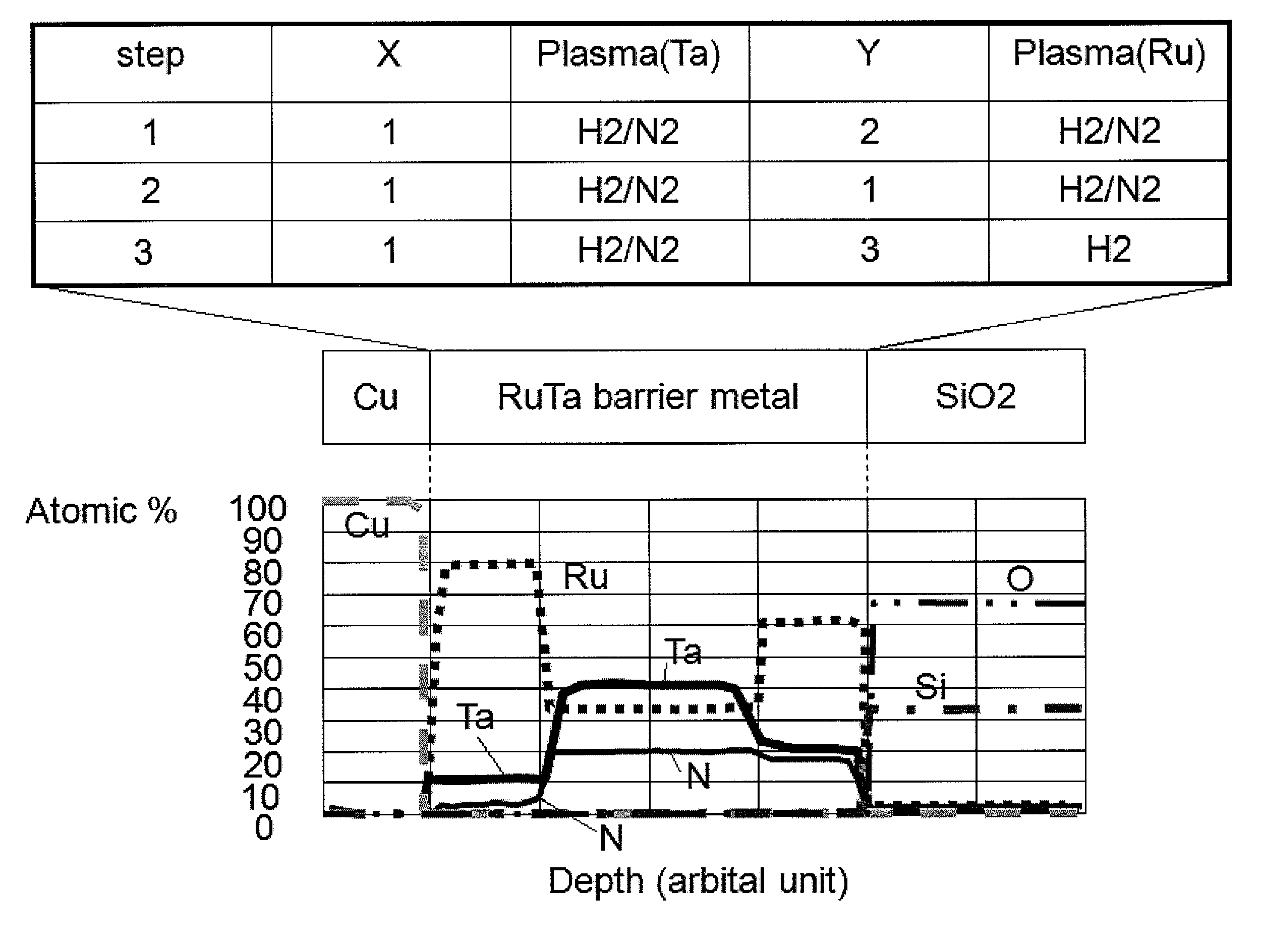

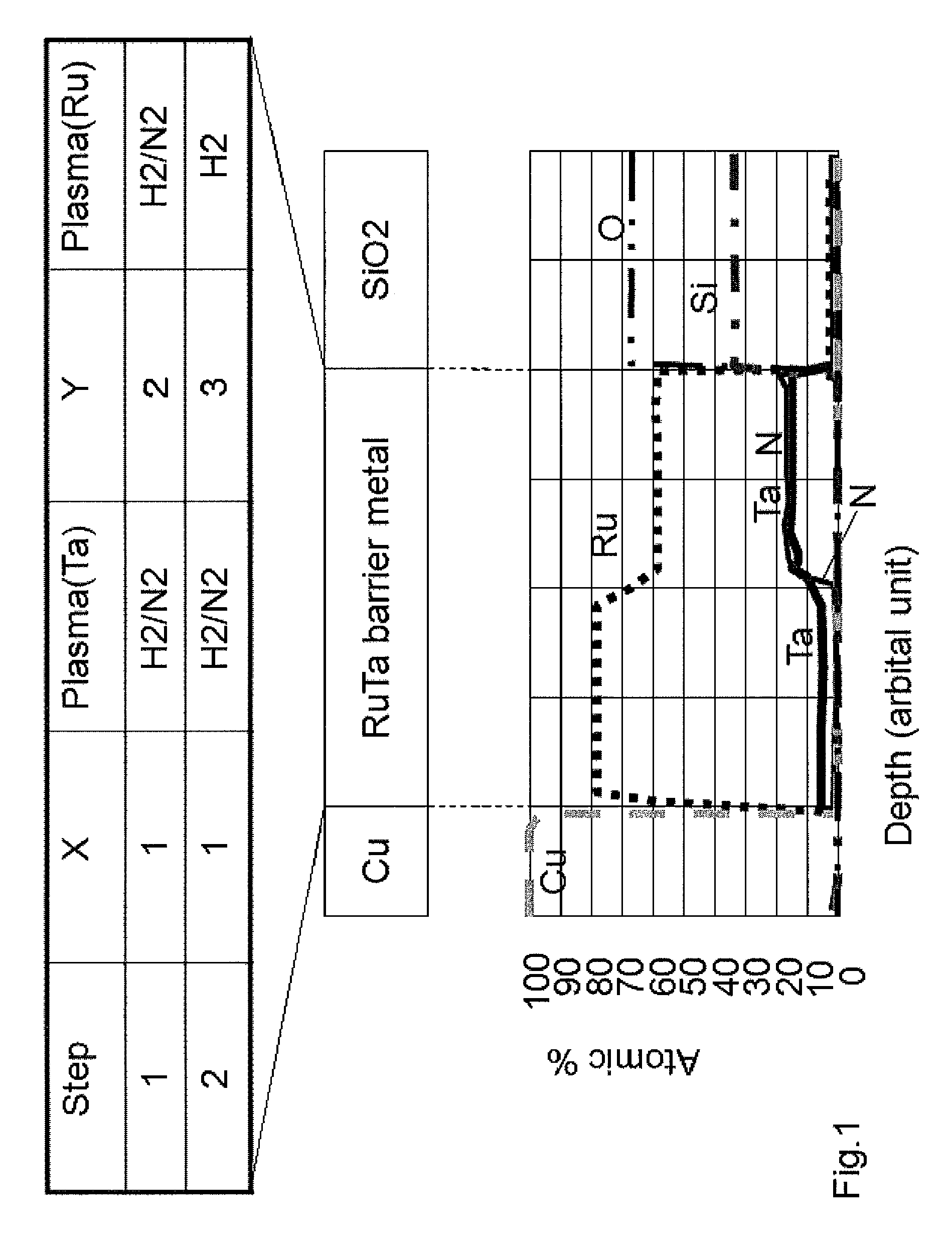

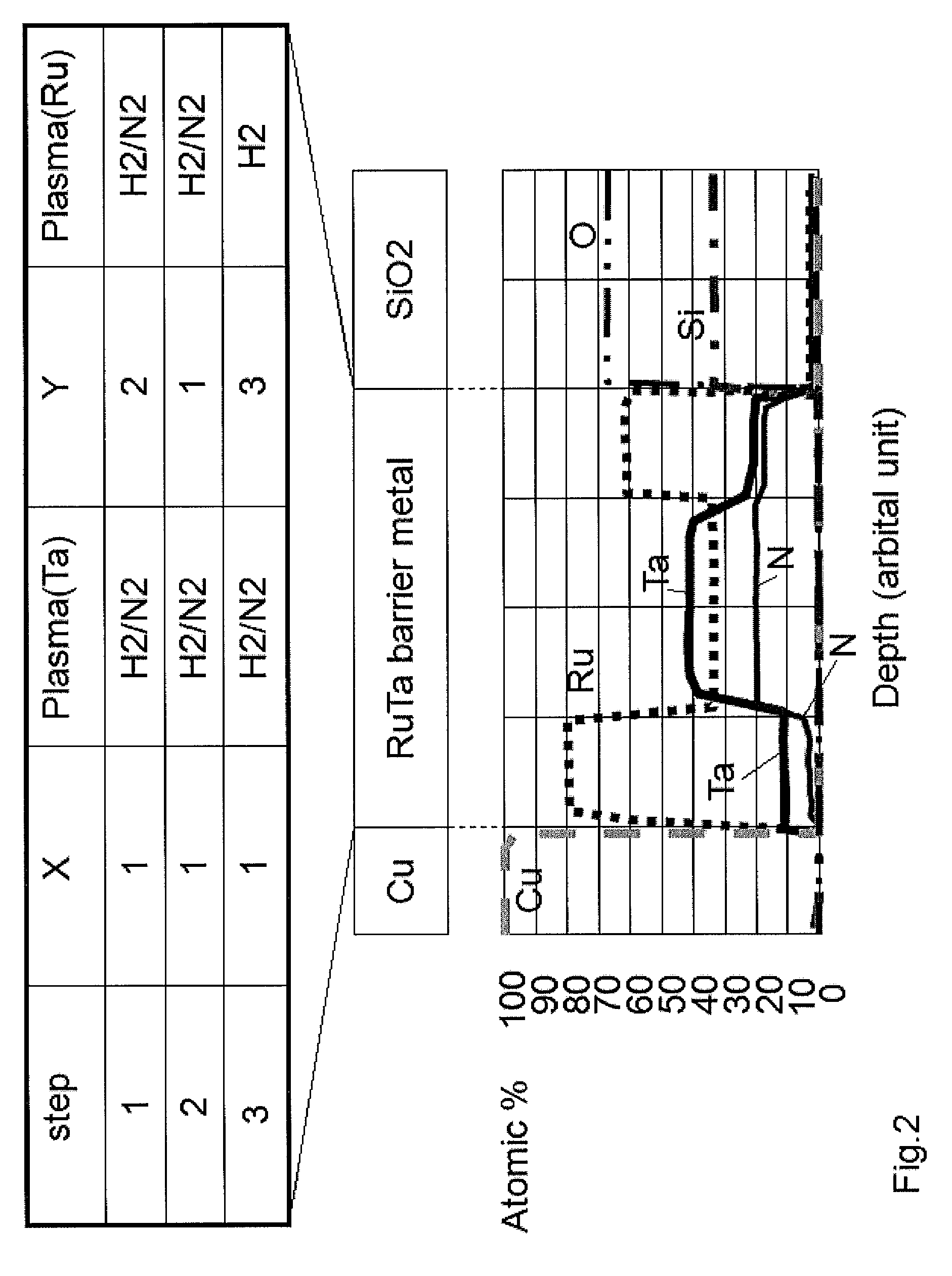

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com