Patents

Literature

15641 results about "Chemical formula" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chemical formula is a way of presenting information about the chemical proportions of atoms that constitute a particular chemical compound or molecule, using chemical element symbols, numbers, and sometimes also other symbols, such as parentheses, dashes, brackets, commas and plus (+) and minus (−) signs. These are limited to a single typographic line of symbols, which may include subscripts and superscripts. A chemical formula is not a chemical name, and it contains no words. Although a chemical formula may imply certain simple chemical structures, it is not the same as a full chemical structural formula. Chemical formulas can fully specify the structure of only the simplest of molecules and chemical substances, and are generally more limited in power than are chemical names and structural formulas.

Compound for organic optoelectronic device, organic light emitting diode including the same, and display including the organic light emitting diode

ActiveUS20140225088A1Extended life spanImprove efficiencyOrganic chemistrySolid-state devicesDisplay deviceLight-emitting diode

A compound for an organic optoelectronic device represented by Chemical Formula 1wherein, in Chemical Formula 1, variables A, Y1 to Y4, X1, m, R1 to R4, L1 to L3, n1 to n3, Ar1 and Ar2 are described in the specification.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Photoresist cross-linker and photoresist composition comprising the same

InactiveUS6368773B1Enhance the imageAdequate resultOrganic chemistryPhotosensitive materialsCarboxylic acidKetone

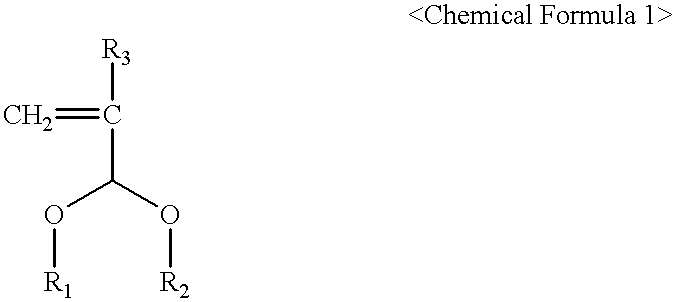

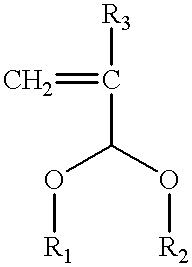

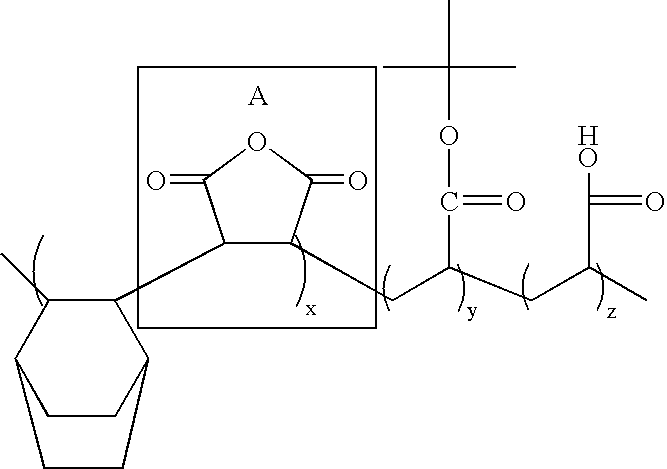

The present invention relates to a cross-linker for photoresist compositions which is suitable for a photolithography process using KrF (248 mn), ArF (193 mn), E-beam, ion beam or EUV light sources. Preferred cross-linkers, according to the present invention, comprise a copolymer of (i) a compound represented by following Chemical Formula 1 and / or (ii) one or more compound(s) selected from the group consisting of acrylic acid, methacrylic acid and maleic anhydride. ##STR1## wherein, R.sub.1 and R.sub.2 individually represent straight or branched C.sub.1-10 alkyl, straight or branched C.sub.1-10 ester, straight or branched C.sub.1-10 ketone, straight or branched C.sub.1-10 carboxylic acid, straight or branched C.sub.1-10 acetal, straight or branched C.sub.1-10 alkyl including at least one hydroxyl group, straight or branched C.sub.1-10 ester including at least one hydroxyl group, straight or branched C.sub.1-10 ketone including at least one hydroxyl group, straight or branched C.sub.1-10 carboxylic acid including at least one hydroxyl group, and straight or branched C.sub.1-10 acetal including at least one hydroxyl group; and R.sub.3 represents hydrogen or methyl.

Owner:HYUNDAI ELECTRONICS IND CO LTD

Polymers for photoresist and photoresist compositions using the same

InactiveUS6987155B2Improve the immunityExcellent etching resistance and adhesiveness and photosensitivityElectric discharge tubesPhotomechanical exposure apparatusResistX-ray

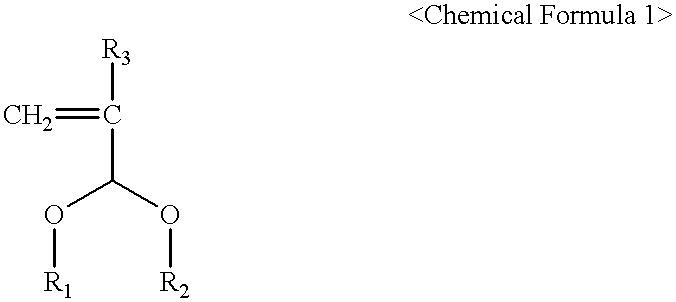

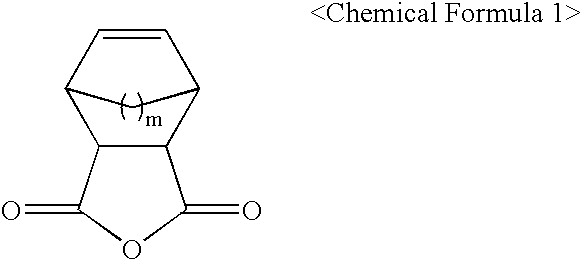

The present invention relates to photoresist monomers, polymers formed therefrom and photoresist compositions suitable for photolithography processes employing a DUV light source, such as KrF (249 nm) and ArF(193 nm); EUV; VUV; E-beam; ion-beam; and X-ray. Photoresist monomers of the present invention are represented by the following Chemical Formula 1: wherein, m is 1 or 2.Polymers of the present invention comprise repeating units derived from the comonomer of Chemical Formula 1, preferably together with monomers of the following Chemical Formula 2: wherein,R* is an acid-labile group, andl is 1 or 2.

Owner:HYUNDAI ELECTRONICS IND CO LTD

Metal-containing compound, its production method, metal-containing thin film, and its formation method

ActiveUS20100105936A1Appropriate thermal stabilityAppropriate volatilityGroup 3/13 organic compounds without C-metal linkagesGroup 4/14 organic compounds without C-metal linkagesLithiumHydrogen

Owner:TOSOH CORP +1

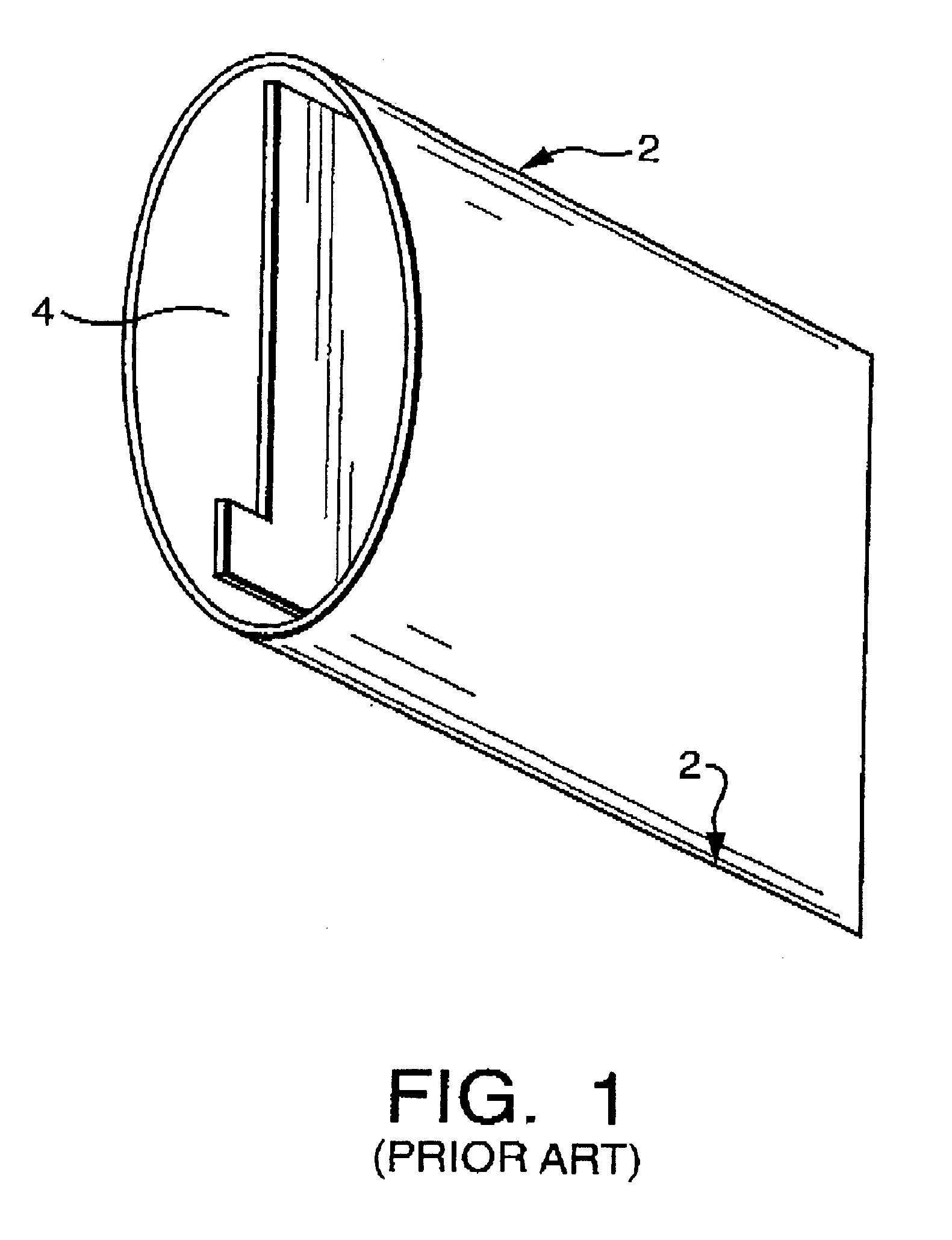

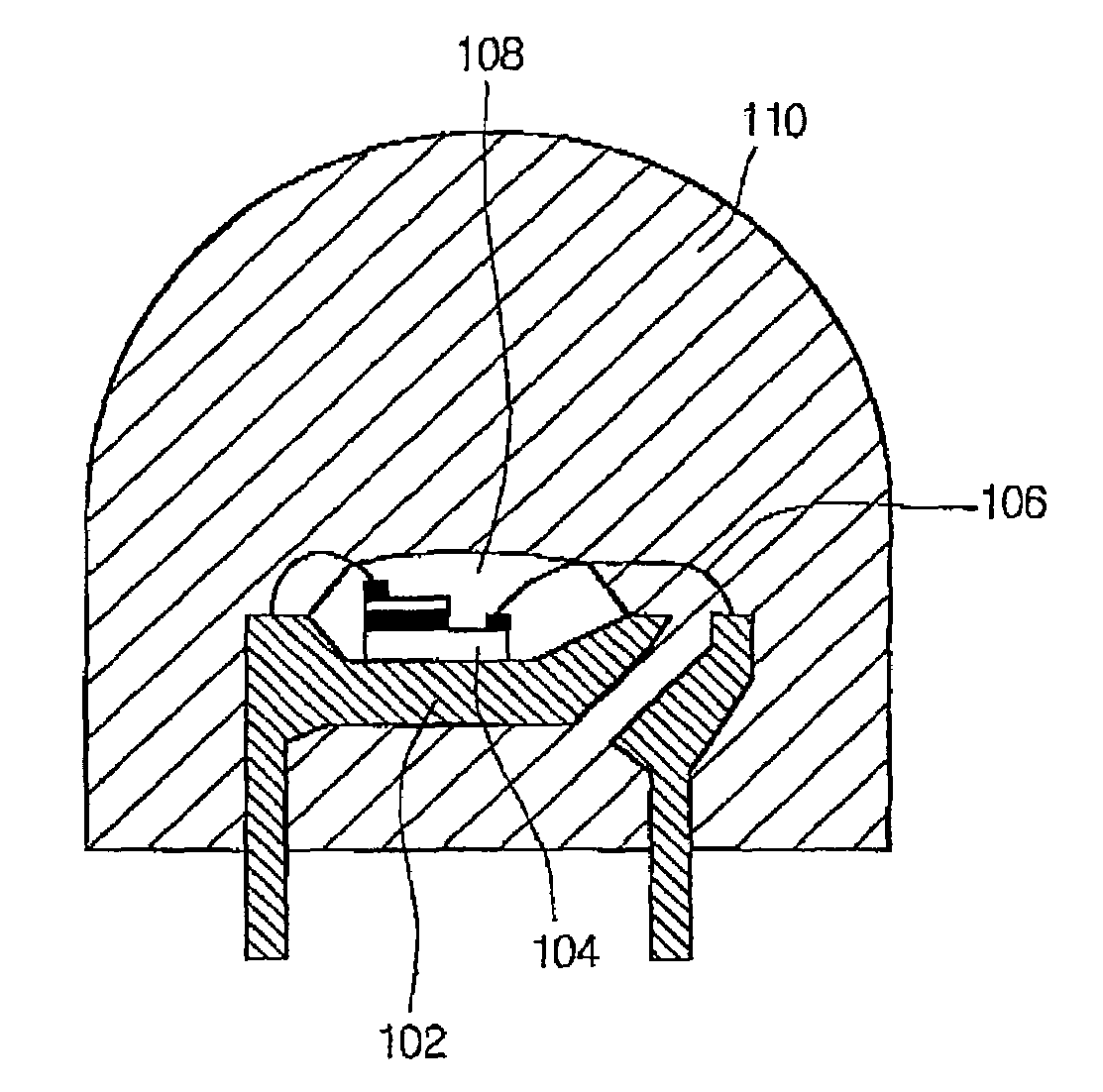

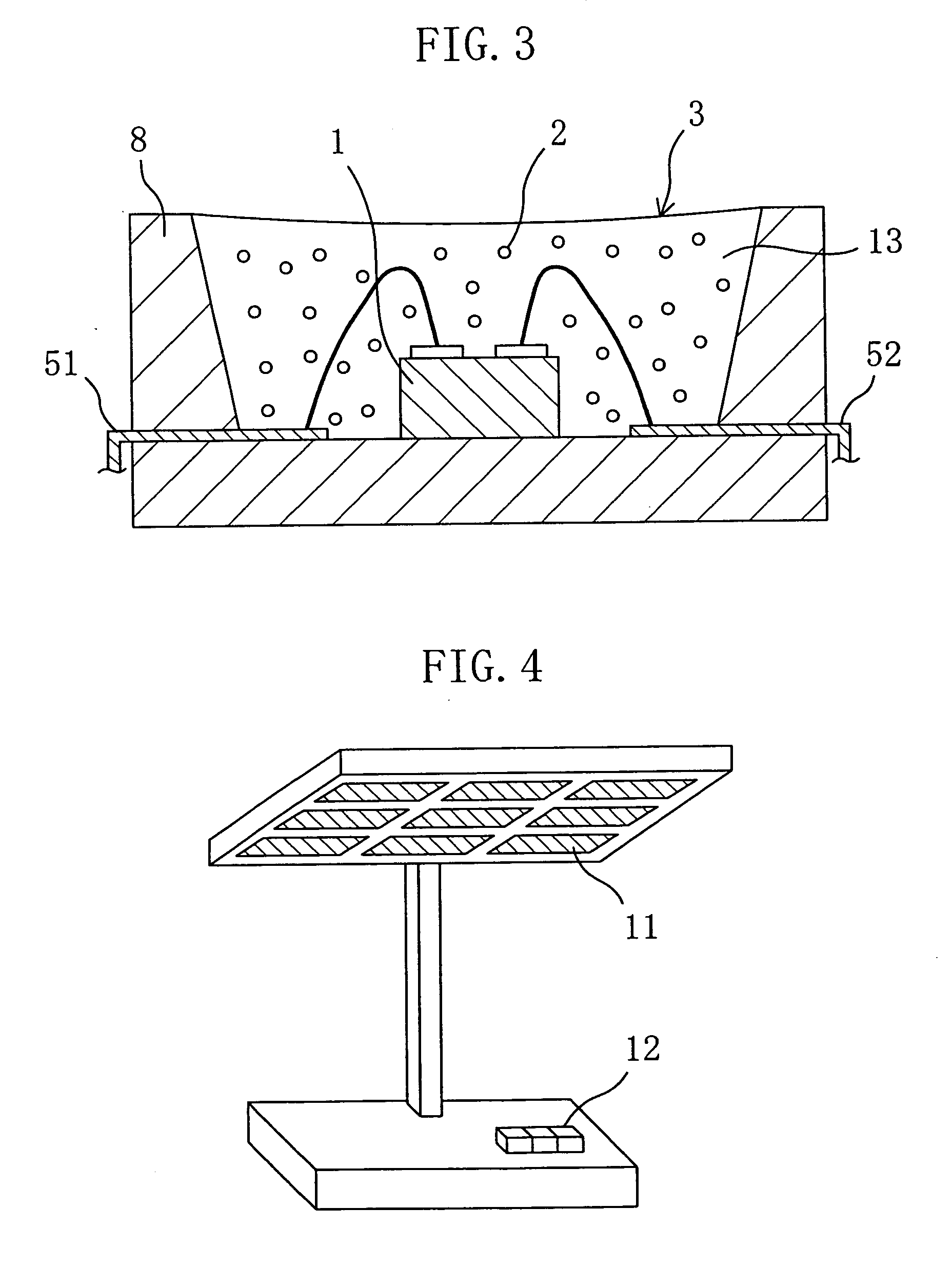

Light-emitting semiconductor device, light-emitting system and method for fabricating light-emitting semiconductor device

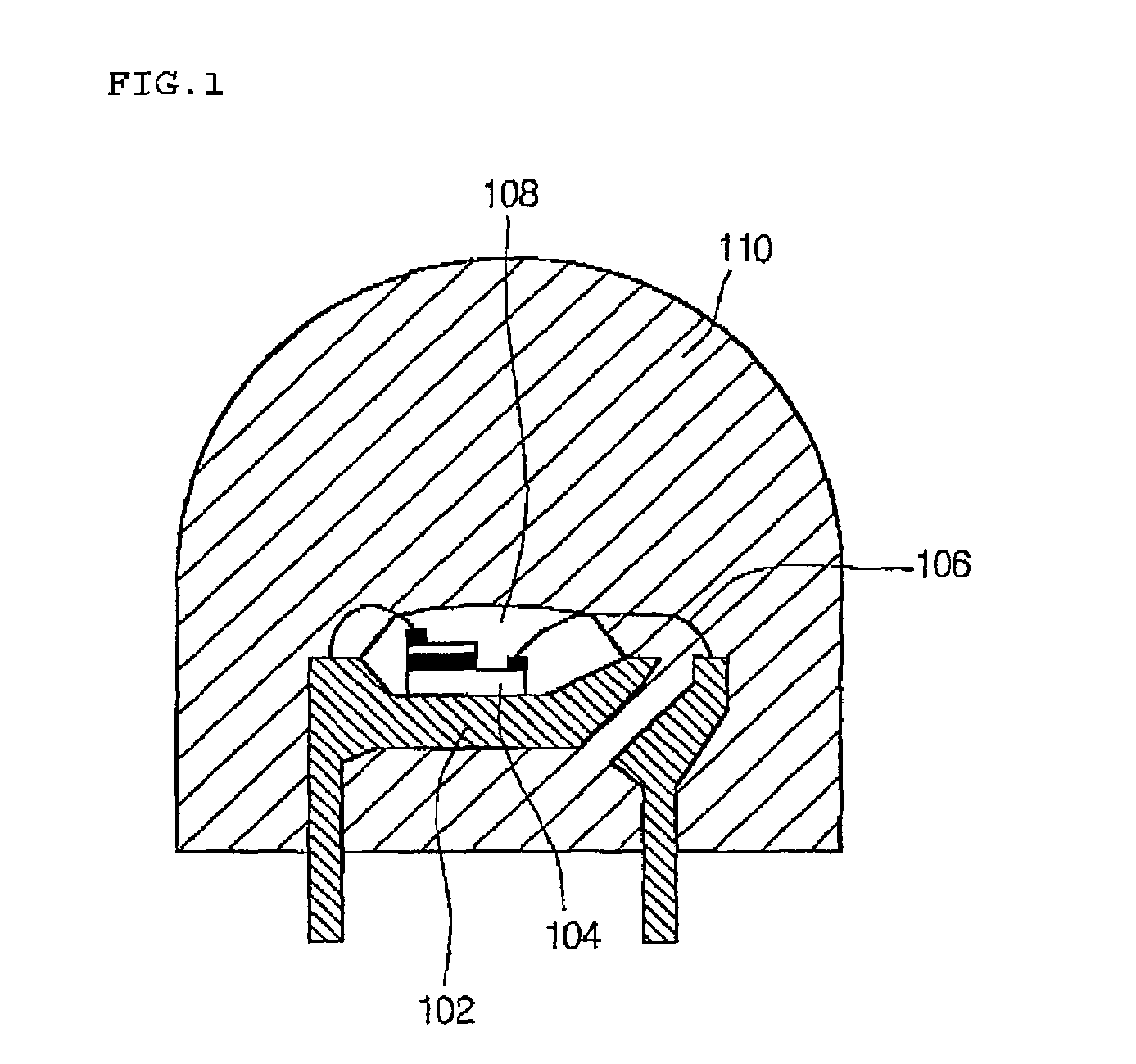

InactiveUS7023019B2Suppress color unevennessLittle color unevennessDischarge tube luminescnet screensPoint-like light sourceFluorescenceDevice material

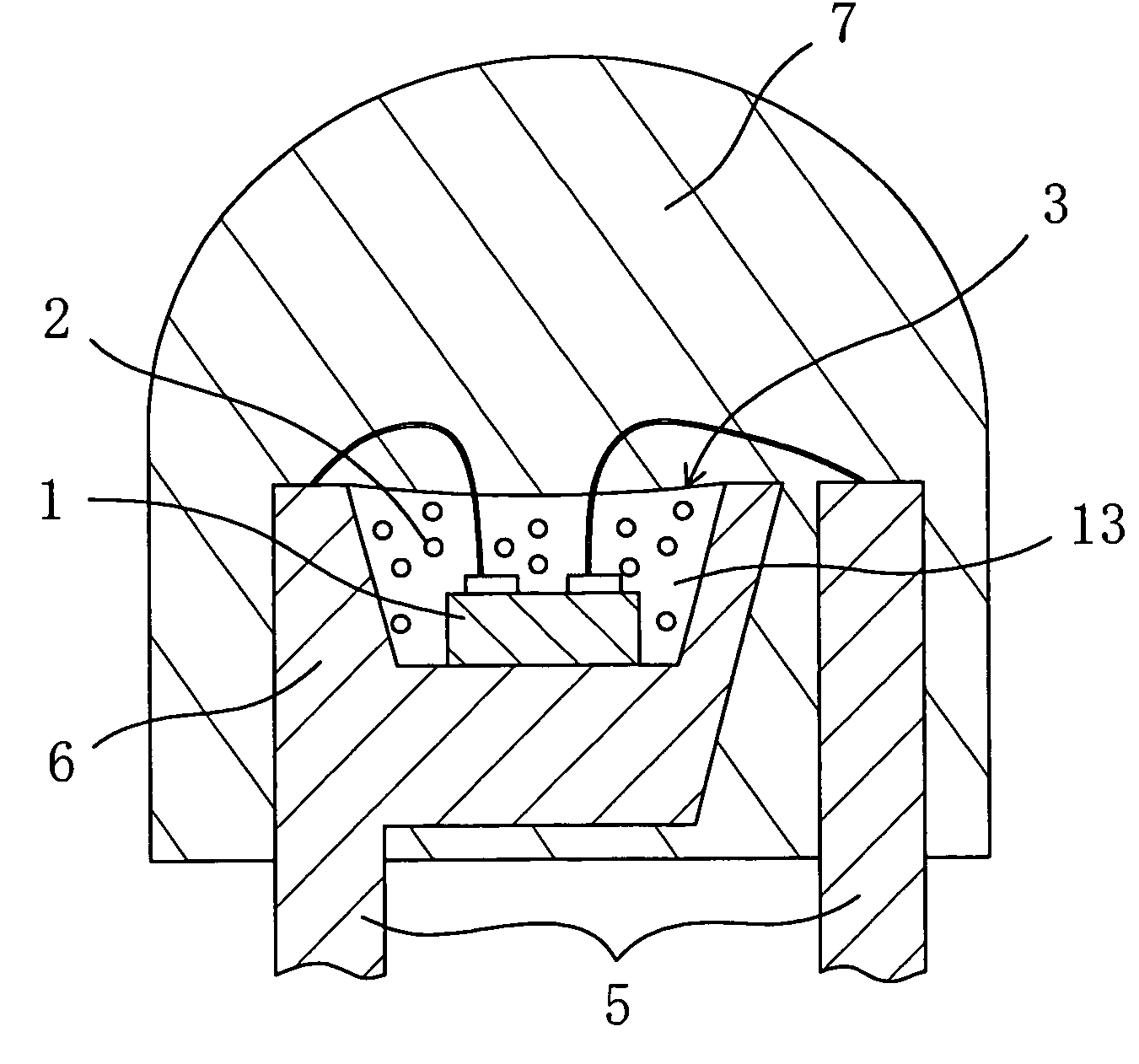

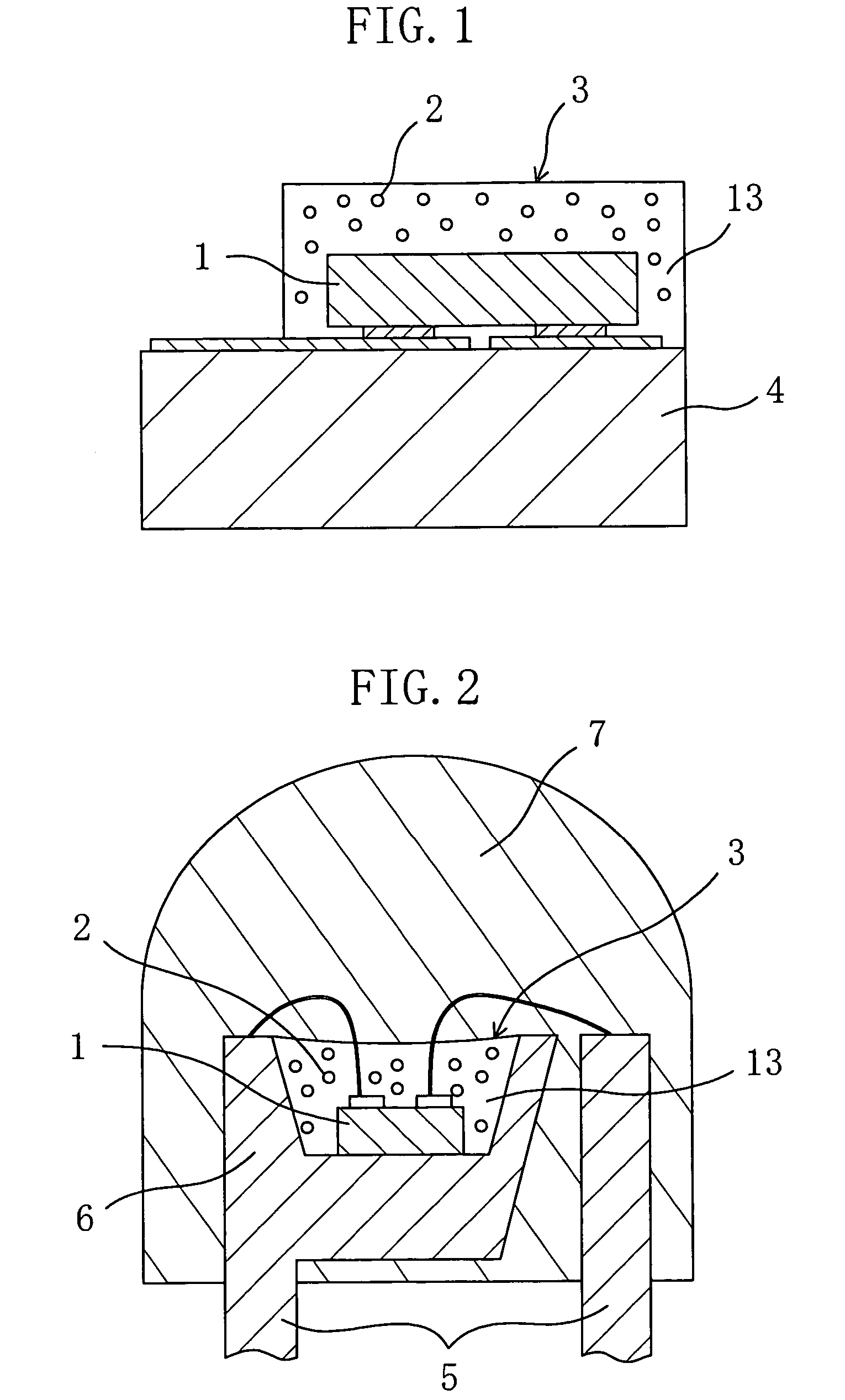

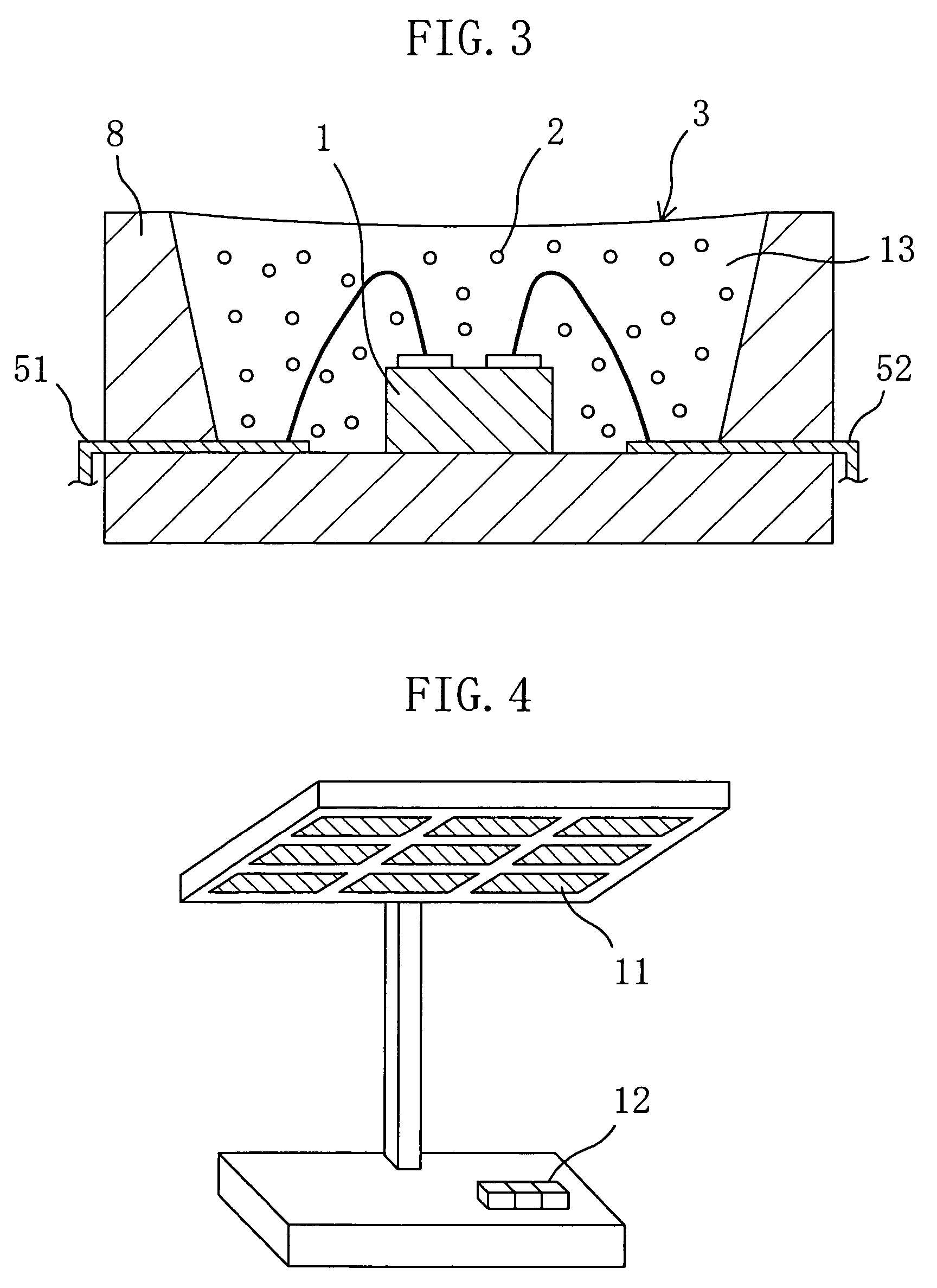

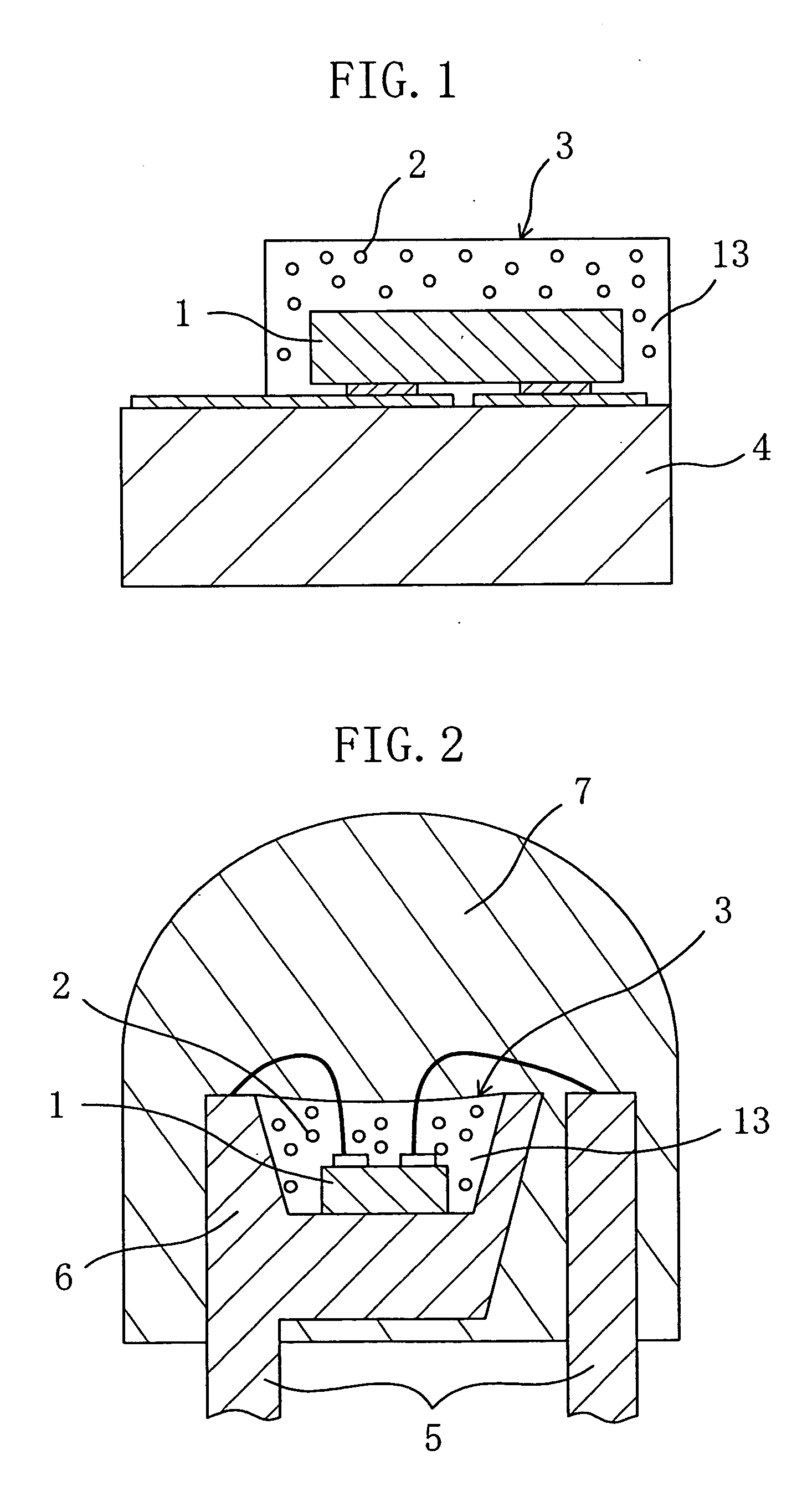

A chip-type light-emitting semiconductor device includes: a substrate 4 ; a blue LED 1 mounted on the substrate 4 ; and a luminescent layer 3 made of a mixture of yellow / yellowish phosphor particles 2 and a base material 13 (translucent resin). The yellow / yellowish phosphor particles 2 is a silicate phosphor which absorbs blue light emitted by the blue LED 1 to emit a fluorescence having a main emission peak in the wavelength range from 550 nm to 600 nm, inclusive, and which contains, as a main component, a compound expressed by the chemical formula: (Sr1-a1-b1-xBaa1Cab1Eux)2SiO4 (0<=a1<=0.3, 0<=b1<=0.8 and 0<x<1). The silicate phosphor particles disperse substantially evenly in the resin easily. As a result, excellent white light is obtained.

Owner:PANASONIC CORP

Method and system for dry etching a metal nitride

InactiveUS20080230519A1Decorative surface effectsSemiconductor/solid-state device manufacturingTitanium nitrideProcess composition

A method and system of etching a metal nitride, such as titanium nitride, is described. The etching process comprises introducing a process composition having a halogen containing gas, such as Cl2, HBr, or BCl3, and a fluorocarbon gas having the chemical formula CxHyFz, where x and z are equal to unity or greater and y is equal to 0 or greater.

Owner:TOKYO ELECTRON LTD

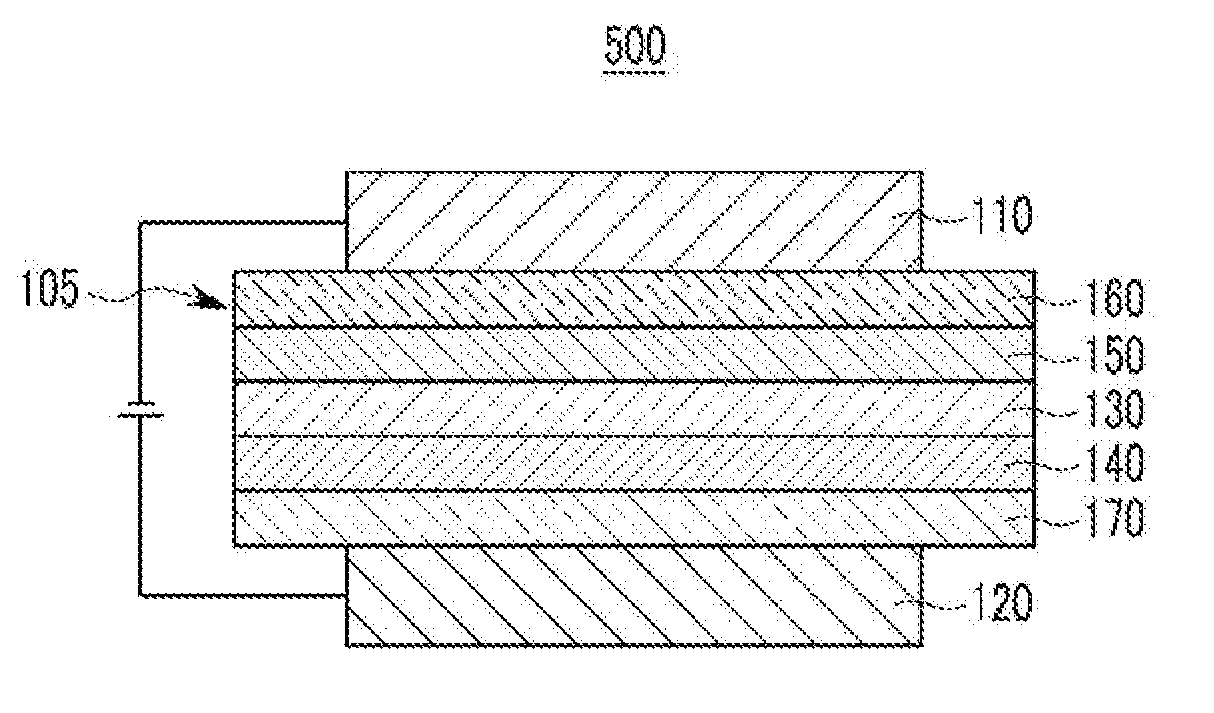

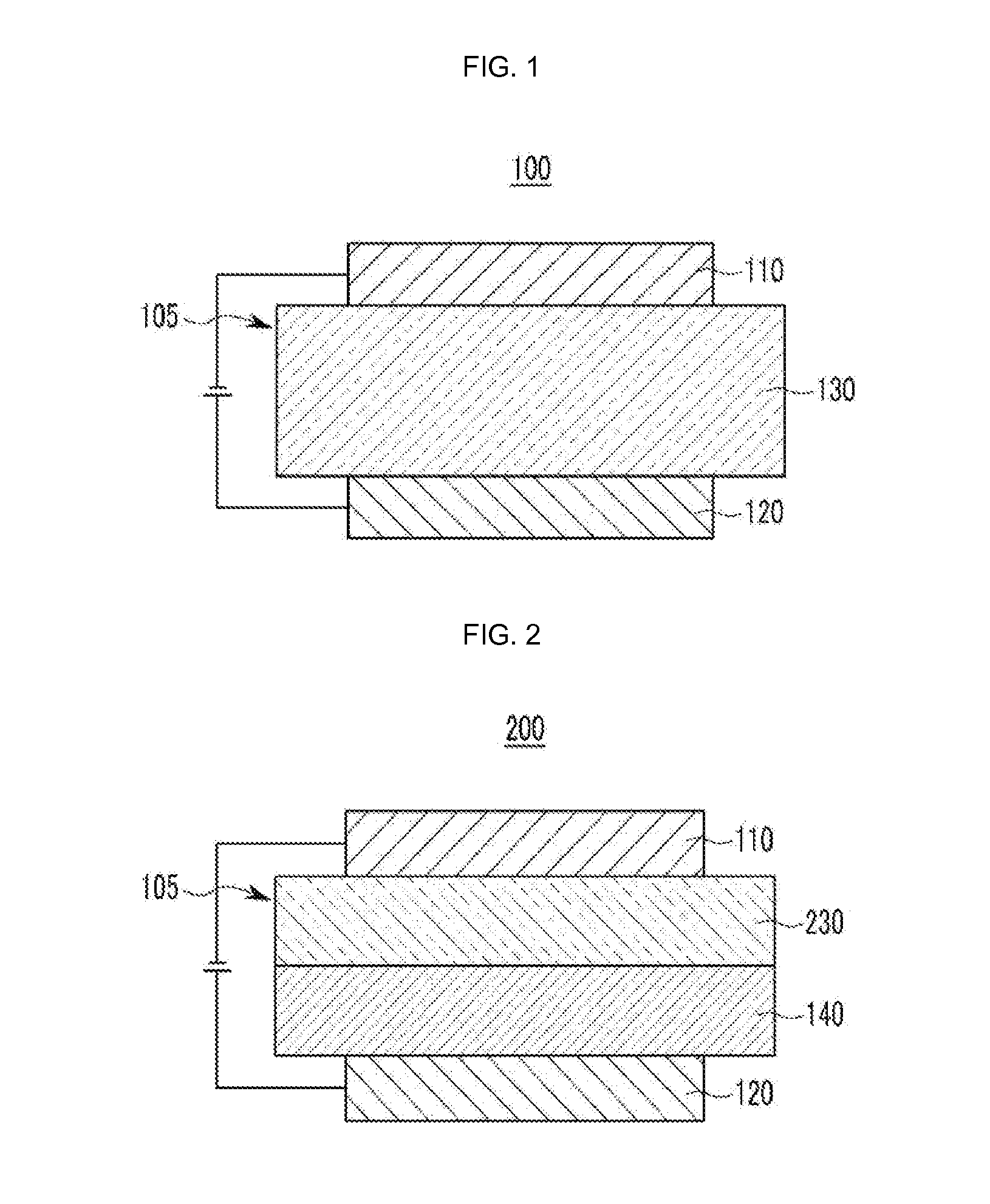

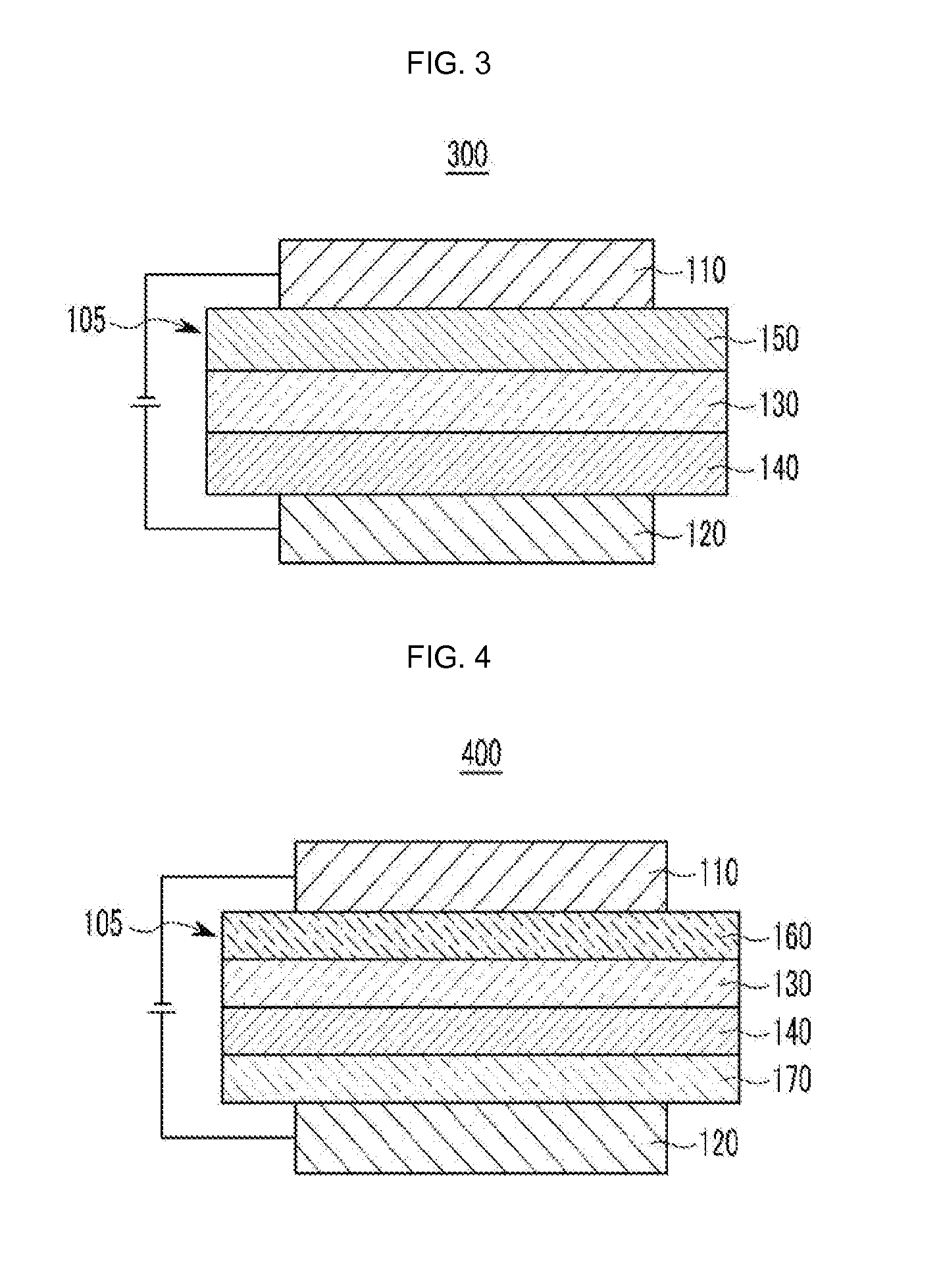

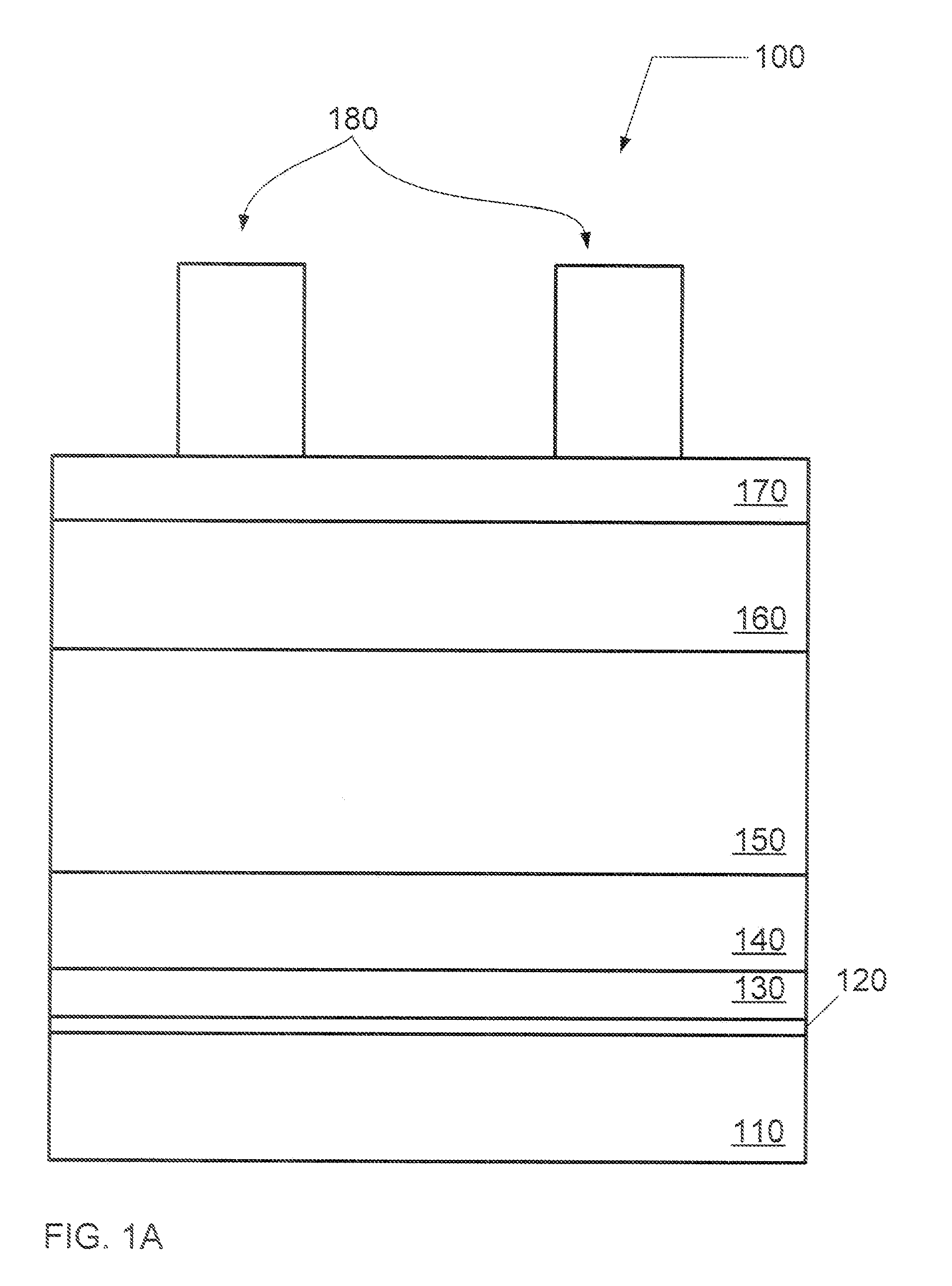

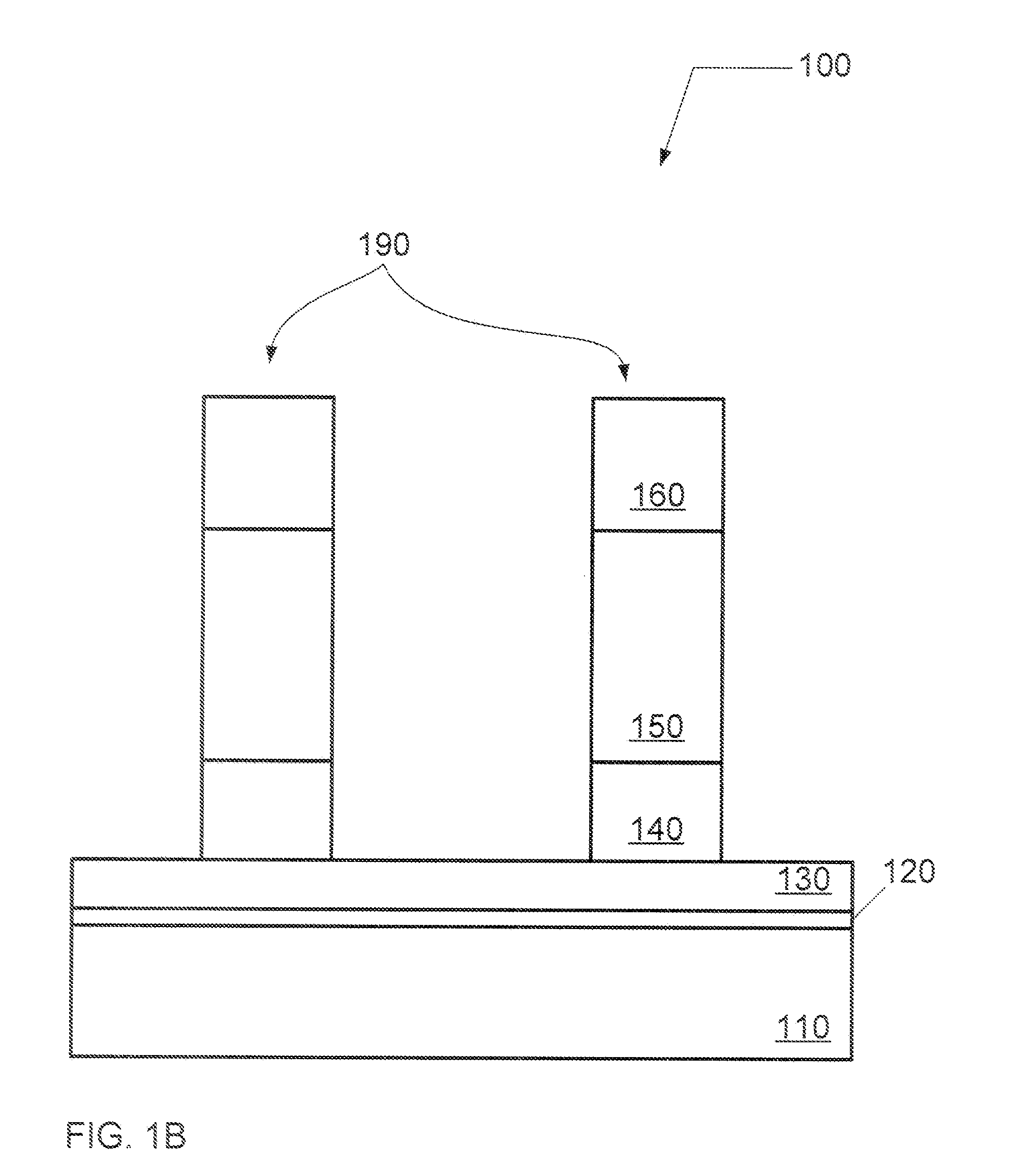

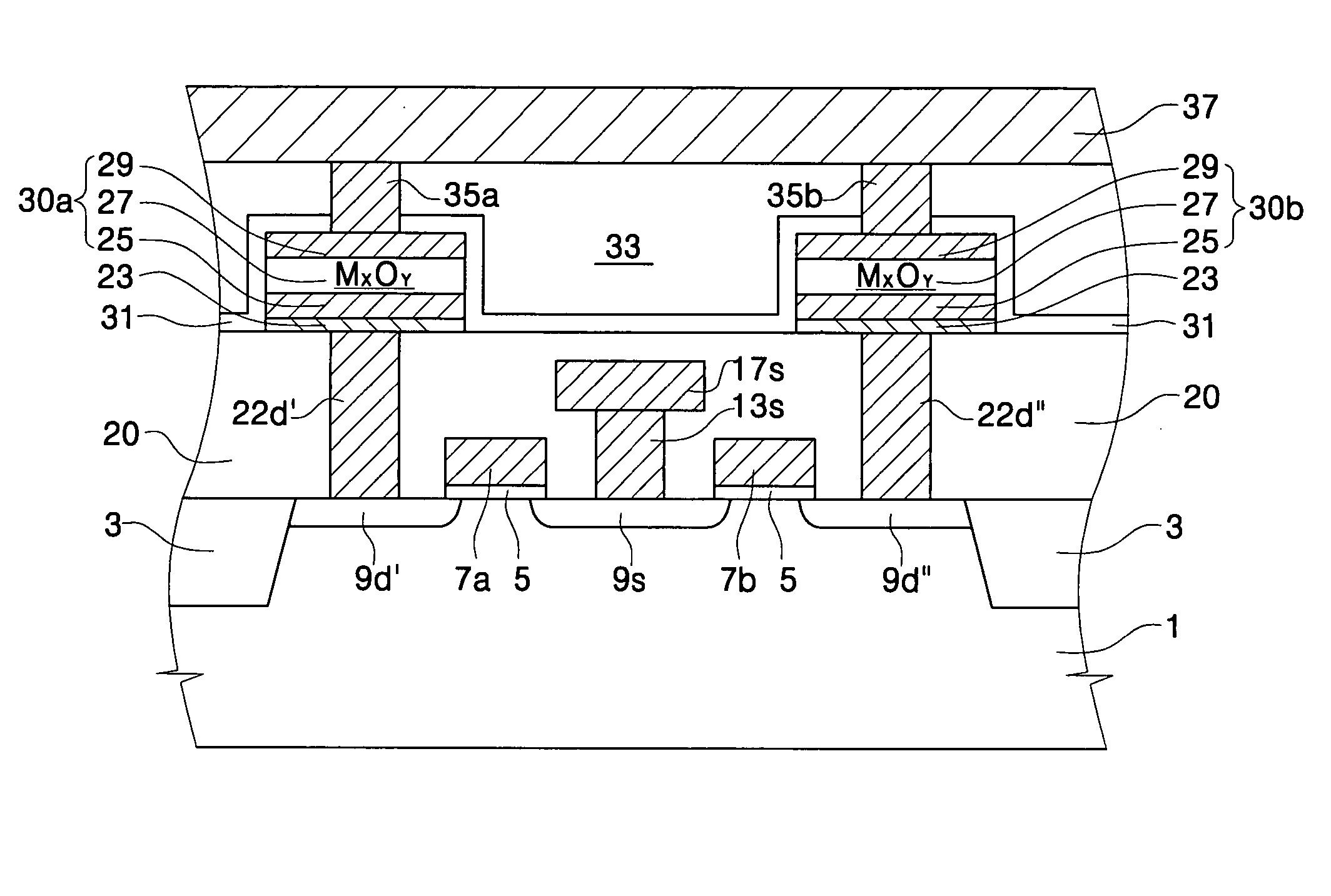

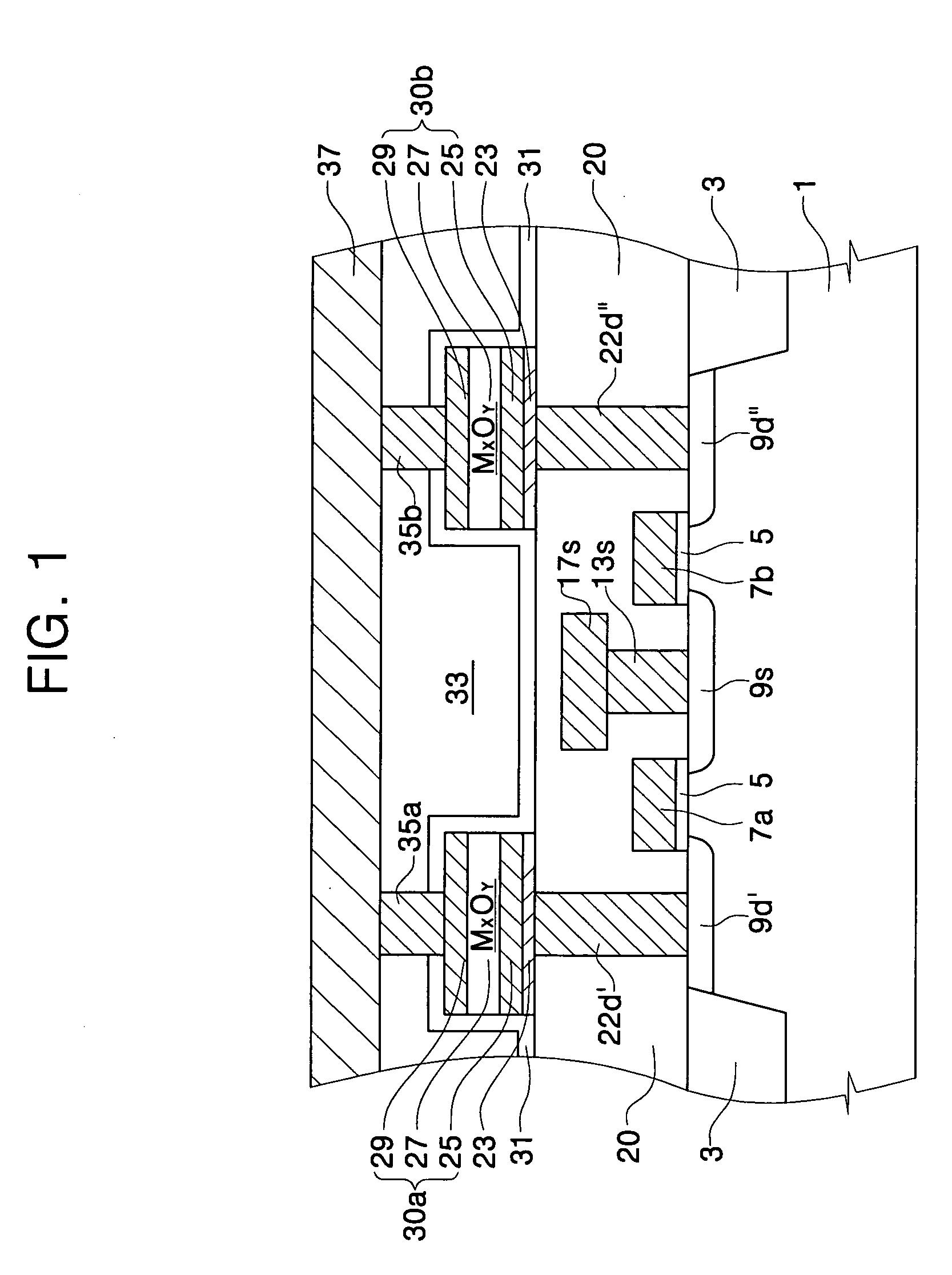

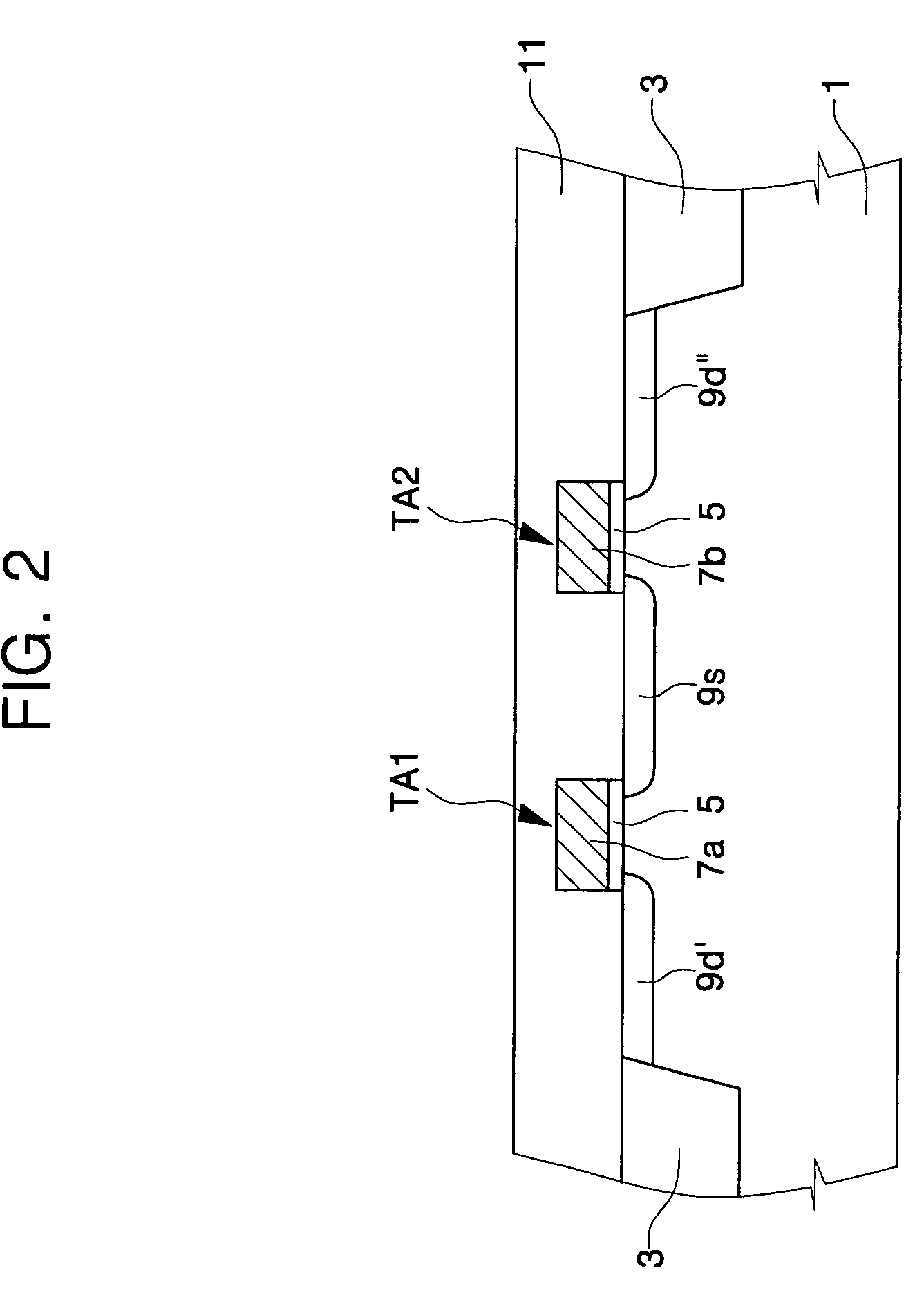

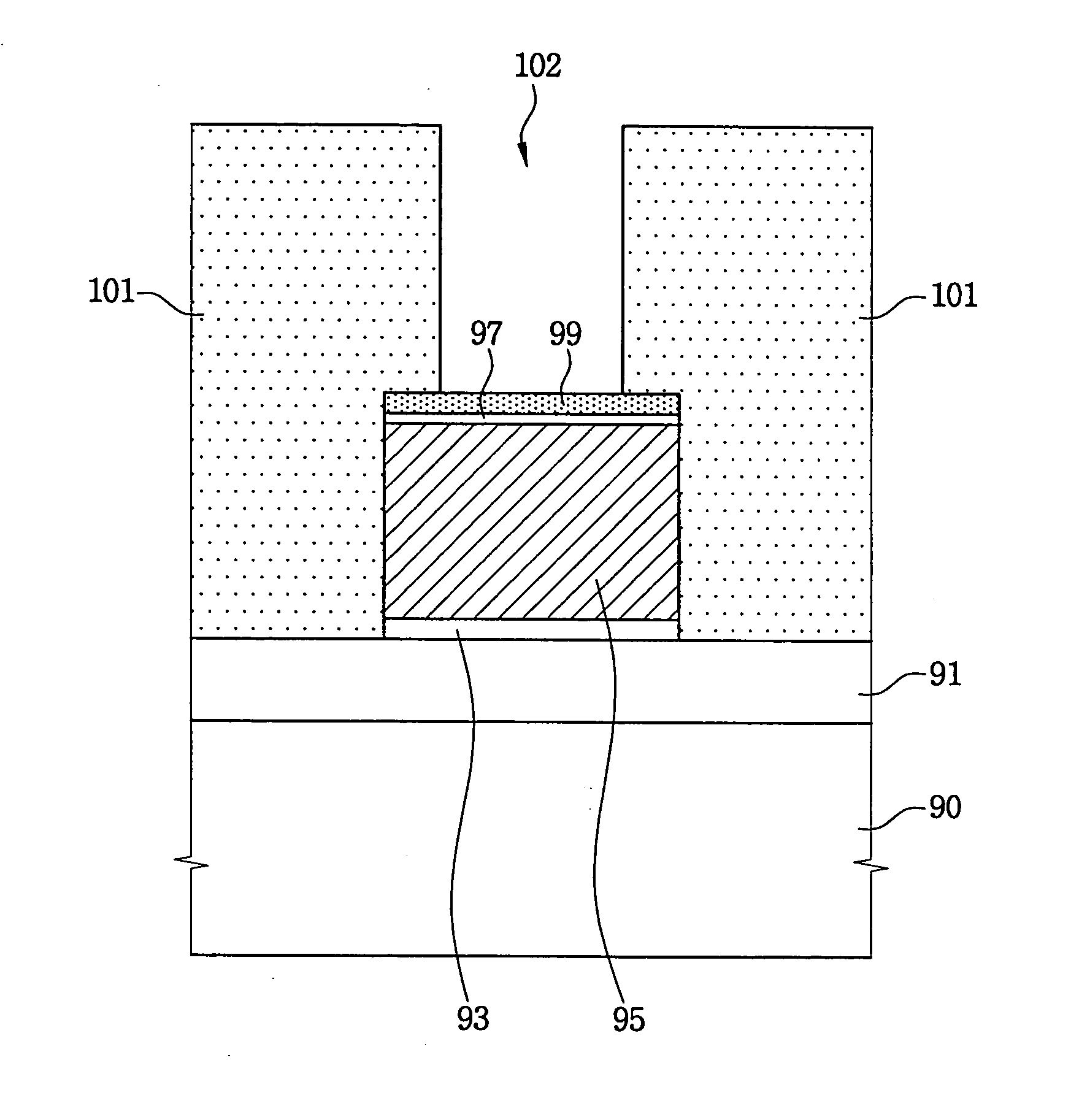

Non-volatile memory cells employing a transition metal oxide layer as a data storage material layer and methods of manufacturing the same

ActiveUS20060054950A1Solid-state devicesSemiconductor/solid-state device manufacturingOxygenStorage material

Non-volatile memory cells employing a transition metal oxide layer as a data storage material layer are provided. The non-volatile memory cells include a lower and upper electrodes overlapped with each other. A transition metal oxide layer pattern is provided between the lower and upper electrodes. The transition metal oxide layer pattern is represented by a chemical formula MxOy. In the chemical formula, the characters “M”, “O”, “x” and “y” indicate transition metal, oxygen, a transitional metal composition and an oxygen composition, respectively. The transition metal oxide layer pattern has excessive transition metal content in comparison to a stabilized transition metal oxide layer pattern. Methods of fabricating the non-volatile memory cells are also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

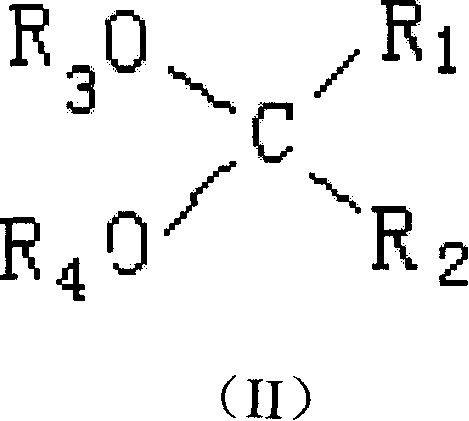

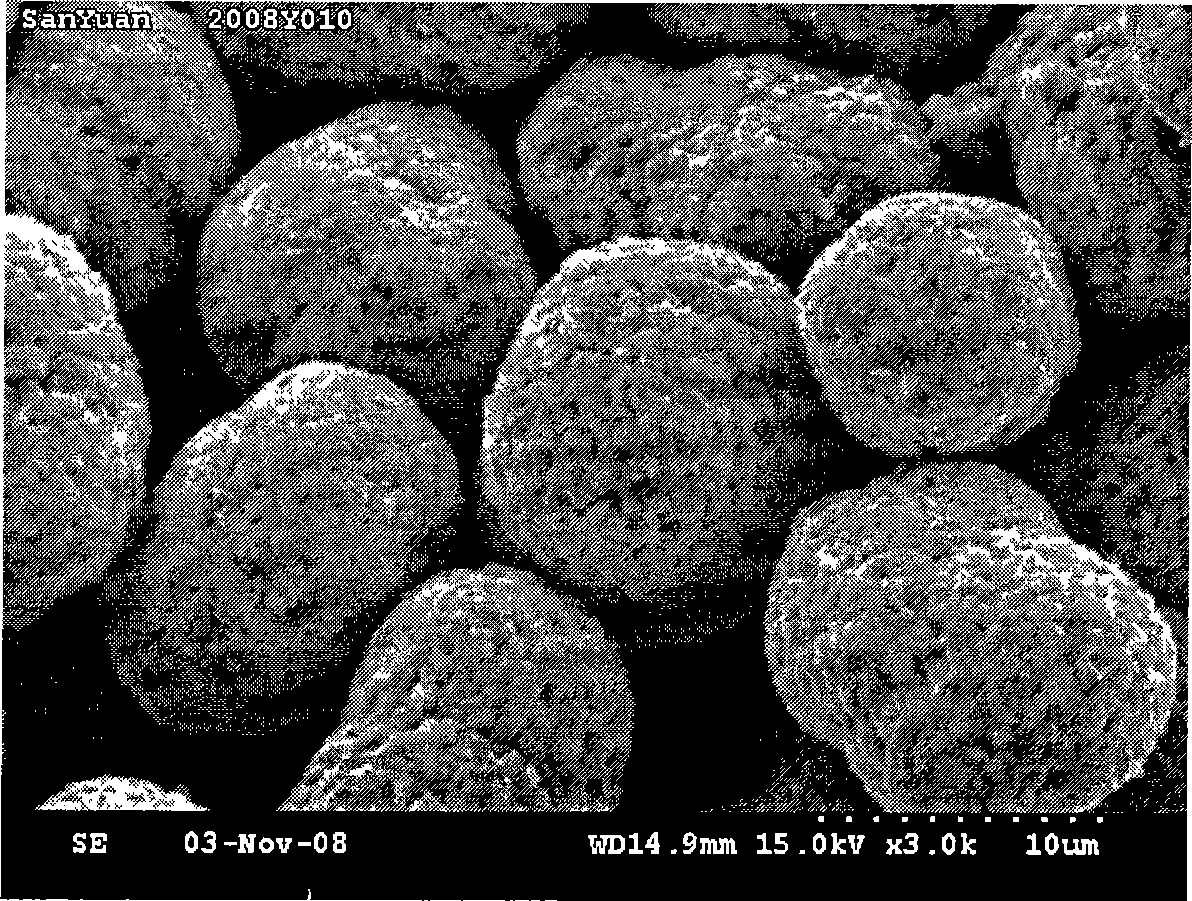

Adduct of magnesium halides, preparation method, and application

This invention provides a kind of magnesium halide adducts, whose general chemical formula is MgX2-mROH-nE-pH2O (I), wherein, X is Cl or Br; R is C1-C12 alkyl, C3-C10 cycloalkyl or C6-C10 aryl; E is dialkoxy hydrocarbon compound as shown in formula (II); m is 1-5; n is 0.005-1.0; p is 0-0.8. In formula (II), R1, R2, R3 and R4 are the same or different, and are H or C1-C10 linear or branched alkyl, C3-C10 cycloalkyl, C6-C10 aryl, C7-C10 alkylaryl or arylalkyl; two or more groups of R1 and R2 can bond into one or several fused rings; H is aryl or alkylaryl or H in benzene ring of arylalkyl can be substituted by halogen.

Owner:CHINA PETROLEUM & CHEM CORP +1

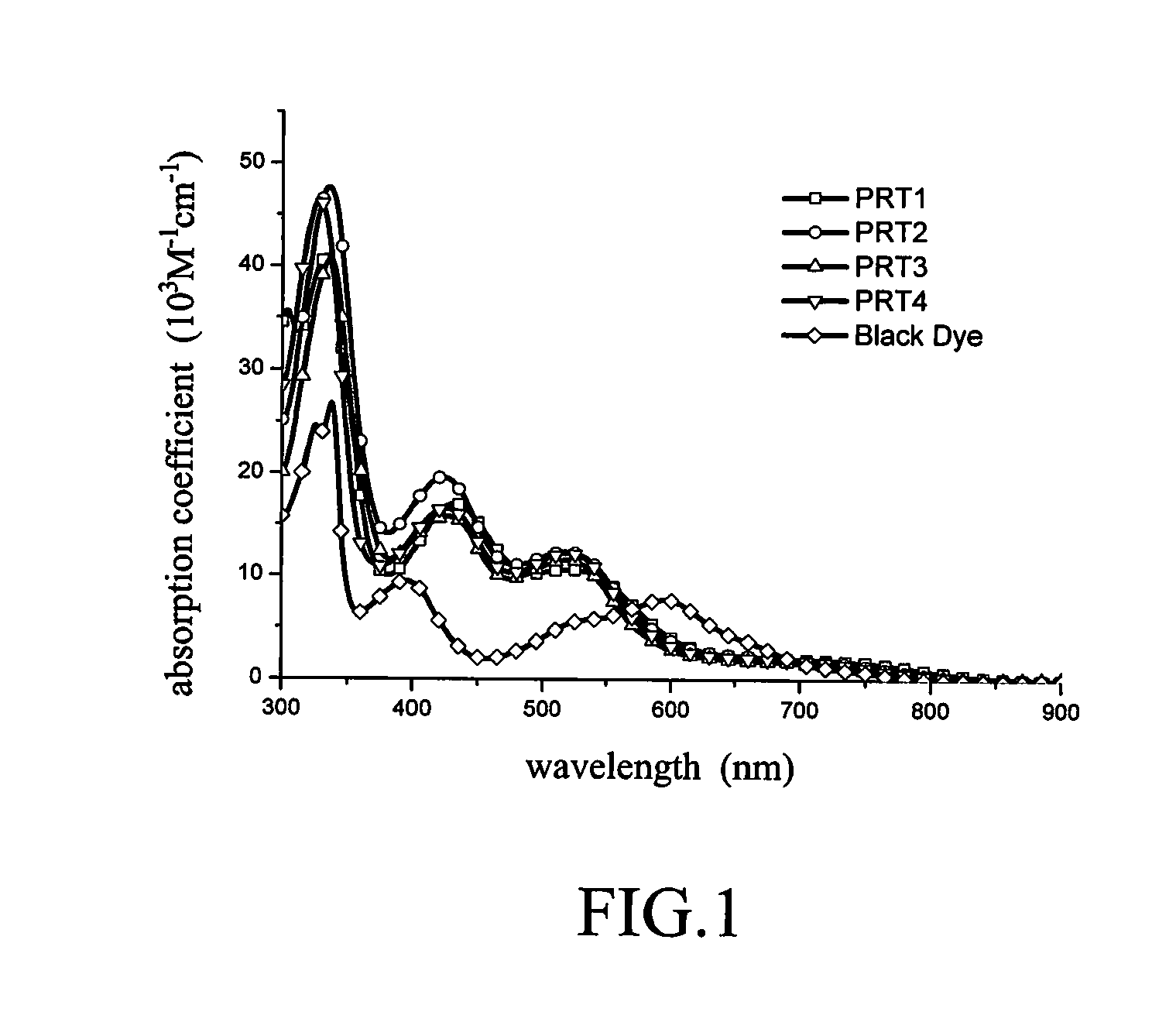

Panchromatic photosensitizers and dye-sensitized solar cell using the same

InactiveUS20100258175A1Improve photoelectric conversion efficiencyImprove response efficiencyRuthenium organic compoundsElectrolytic capacitorsPhosphoric acidCarboxylic acid

Panchromatic photosensitizers having a Formula of ML1L2X were synthesized, wherein M comprises ruthenium atom; X is a monodentate anion; L1 is heterocyclic bidentate ligand having one of formulae listed below:wherein G2 has one of formulae listed below:and L2 is a tridentate ligand having a formula listed below:The substituents R1, R2, R3, R4, R5, R6, R7 of L1 and L2 are the same or different, and represent alkyl, alkoxy, alkylthio, alkylamino, halogenated alkyl, phenyl or substituted phenyl group, carboxylic acid or counter anion thereof, sulfonic acid or counter anion thereof, phosphoric acid or counter anion thereof, amino-group, halogens, or hydrogen. The above-mentioned photosensitizers are suitable to use as sensitizers for fabrication of high efficiency dye-sensitized solar cell.

Owner:NATIONAL TSING HUA UNIVERSITY

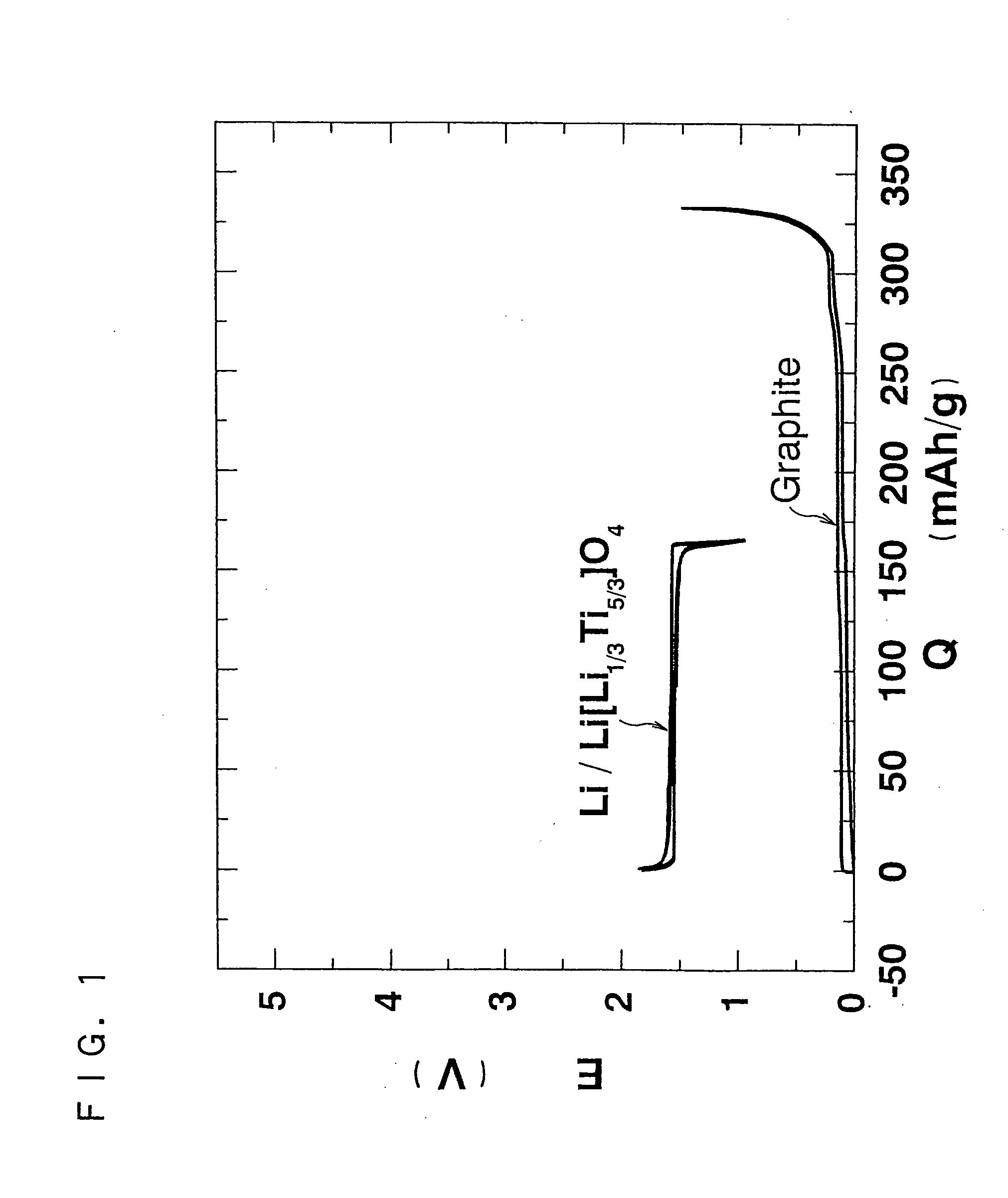

Non-aqueous electrolyte secondary battery

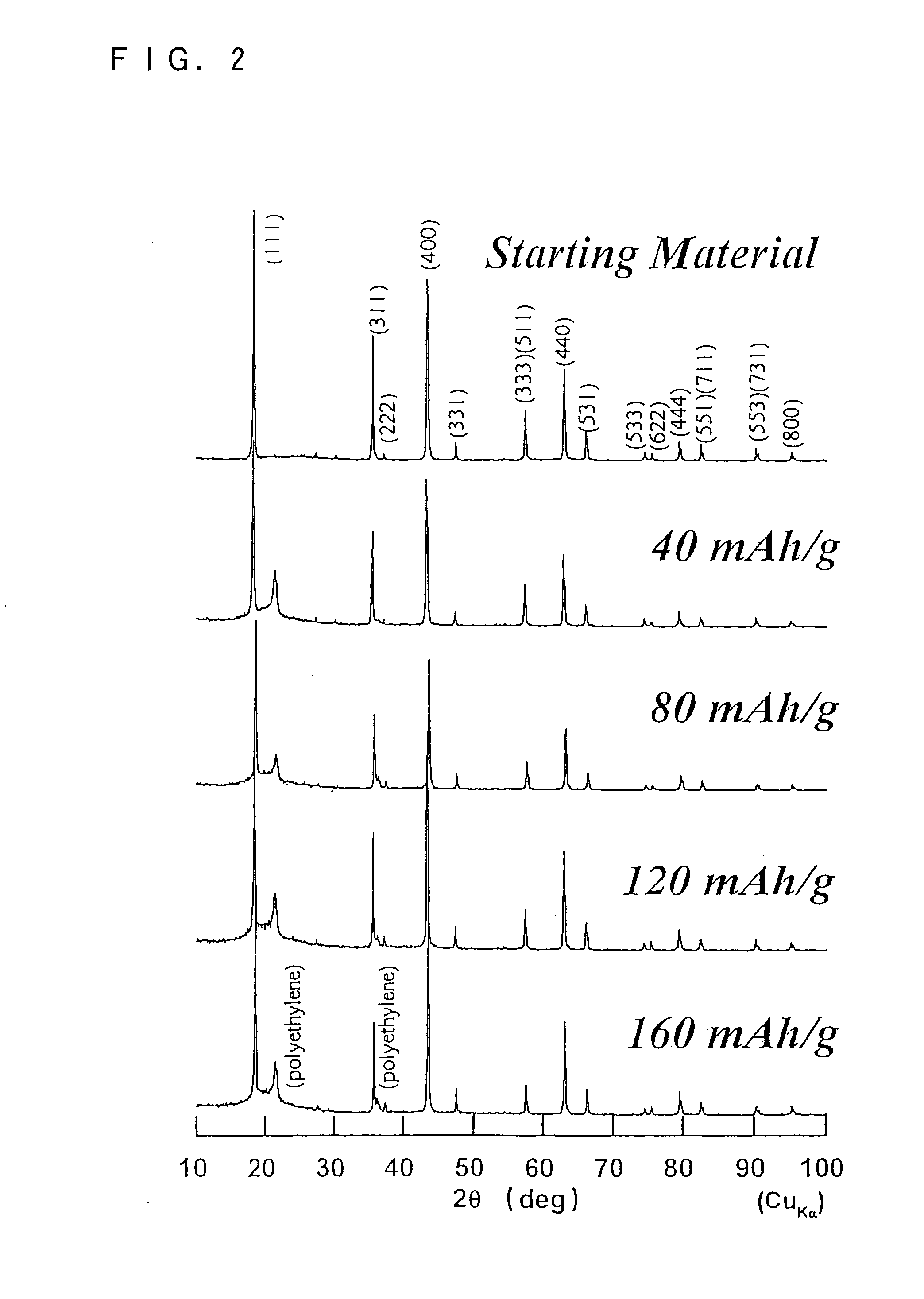

ActiveUS20050147889A1Reduce the possibilityIncrease resistanceFinal product manufactureElectrode carriers/collectorsHigh rateCobalt

As an alternative technique to lead-acid batteries, the present invention provides an inexpensive 2 V non-aqueous electrolyte secondary battery having excellent cycle life at a high rate by preventing volume change during charge and discharge. The non-aqueous electrolyte secondary battery uses: a positive electrode active material having a layered structure, being represented by chemical formula Li1±α[Me]O2, where 0≦α<0.2, and Me is a transition metal including Ni and at least one selected from the group consisting of Mn, Fe, Co, Ti and Cu, and including elemental nickel and elemental cobalt in substantially the same ratio; and a negative electrode active material including Li4Ti5O12(Li[Li1 / 3Ti5 / 3]O4).

Owner:OSAKA CITY UNIV +1

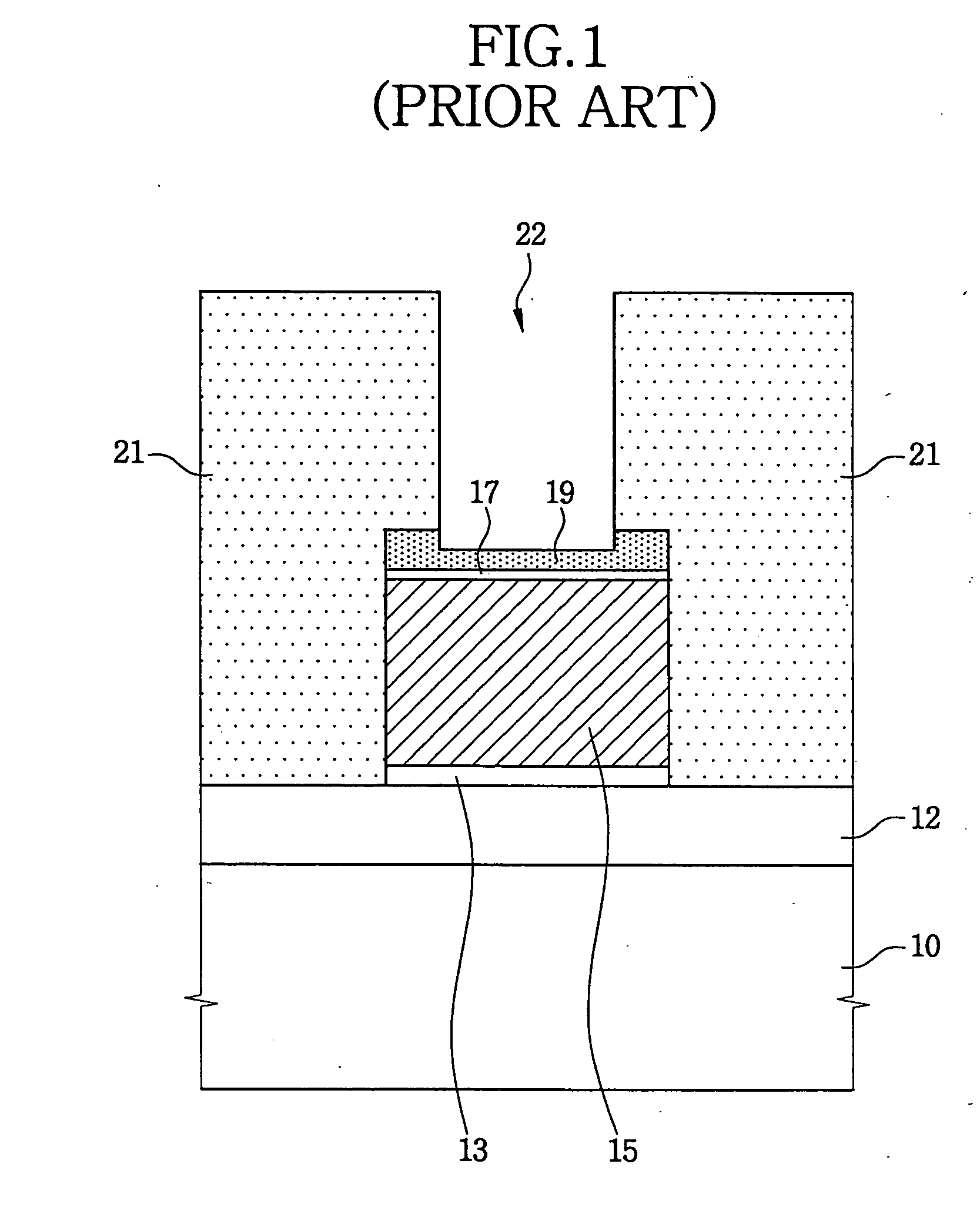

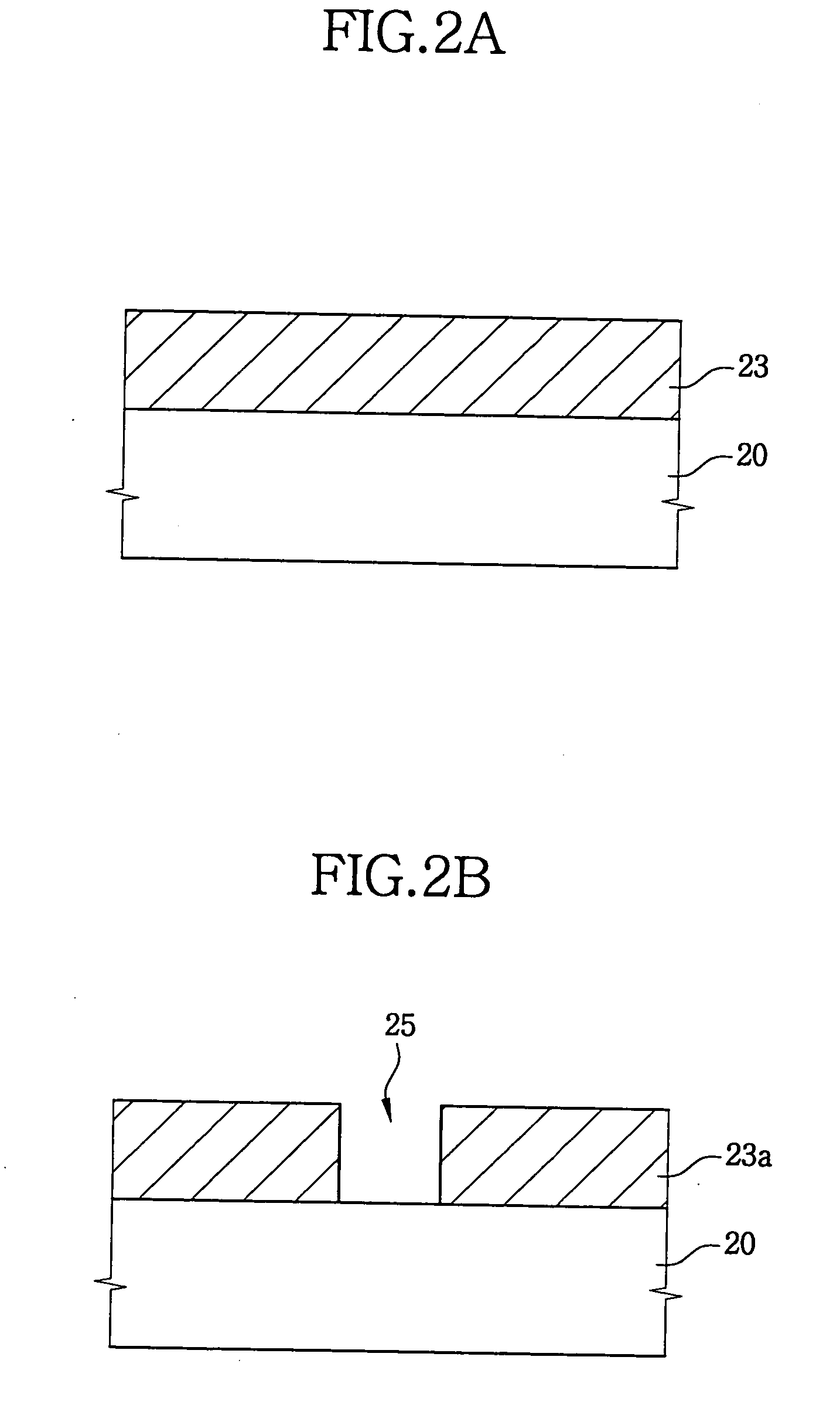

Method for forming a wiring of a semiconductor device, method for forming a metal layer of a semiconductor device and apparatus for performing the same

InactiveUS20050059240A1Good step coverageThe process parameters are simpleSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical reactionDevice material

In a method for forming a wiring of a semiconductor device using an atomic layer deposition, an insulating interlayer is formed on a substrate. Tantalum amine derivatives represented by a chemical formula Ta(NR1)(NR2R3)3 in which R1, R2 and R3 represent H or C1-C6 alkyl group are introduced onto the insulating interlayer. A portion of the tantalum amine derivatives is chemisorbed on the insulating interlayer. The rest of tantalum amine derivatives non-chemisorbed on the insulating interlayer is removed from the insulating interlayer. A reacting gas is introduced onto the insulating interlayer. A ligand in the tantalum amine derivatives chemisorbed on the insulating interlayer is removed from the tantalum amine derivatives by a chemical reaction between the reacting gas and the ligand to form a solid material including tantalum nitride. The solid material is accumulated on the insulating interlayer through repeating the above processes to form a wiring.

Owner:SAMSUNG ELECTRONICS CO LTD

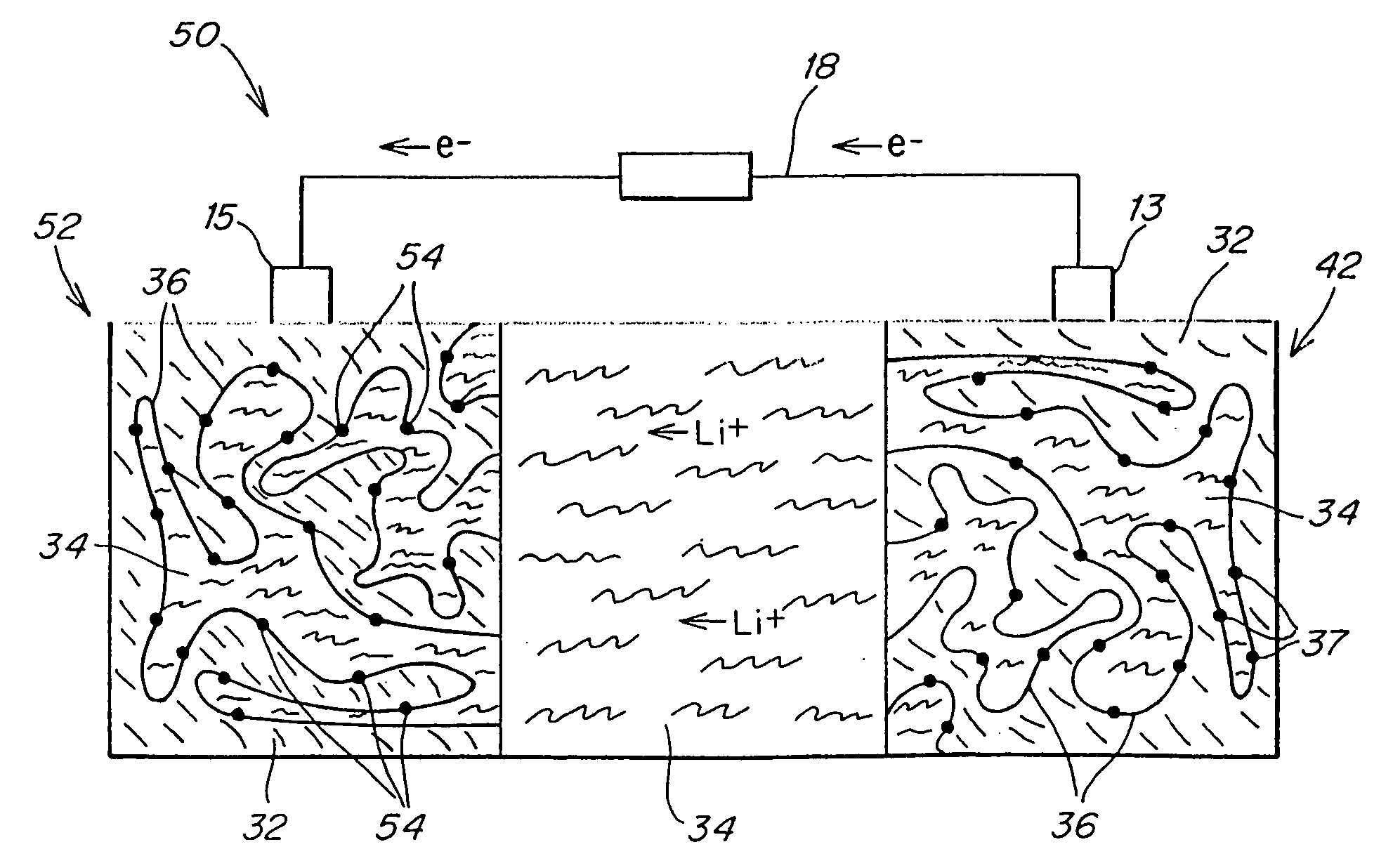

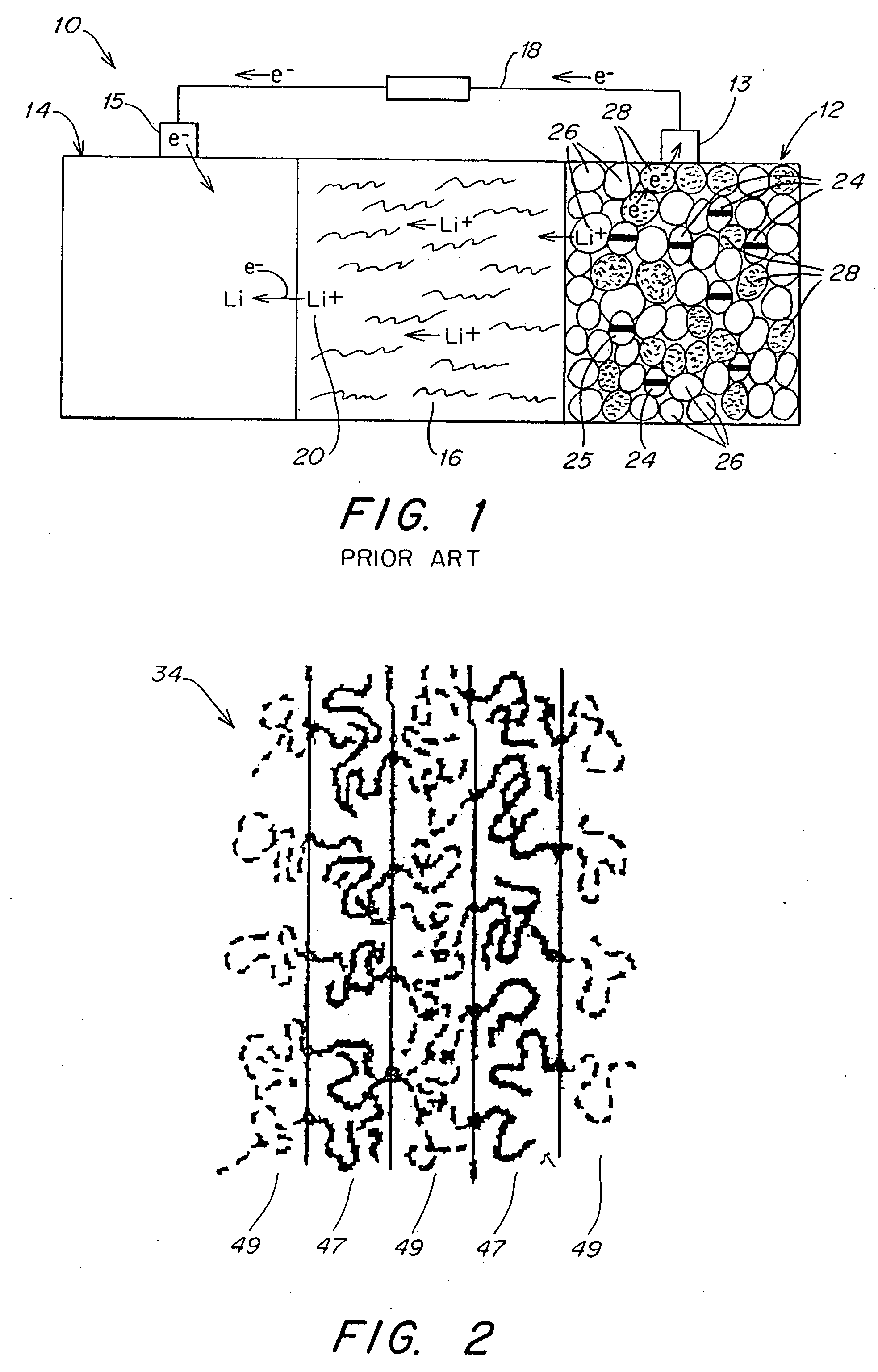

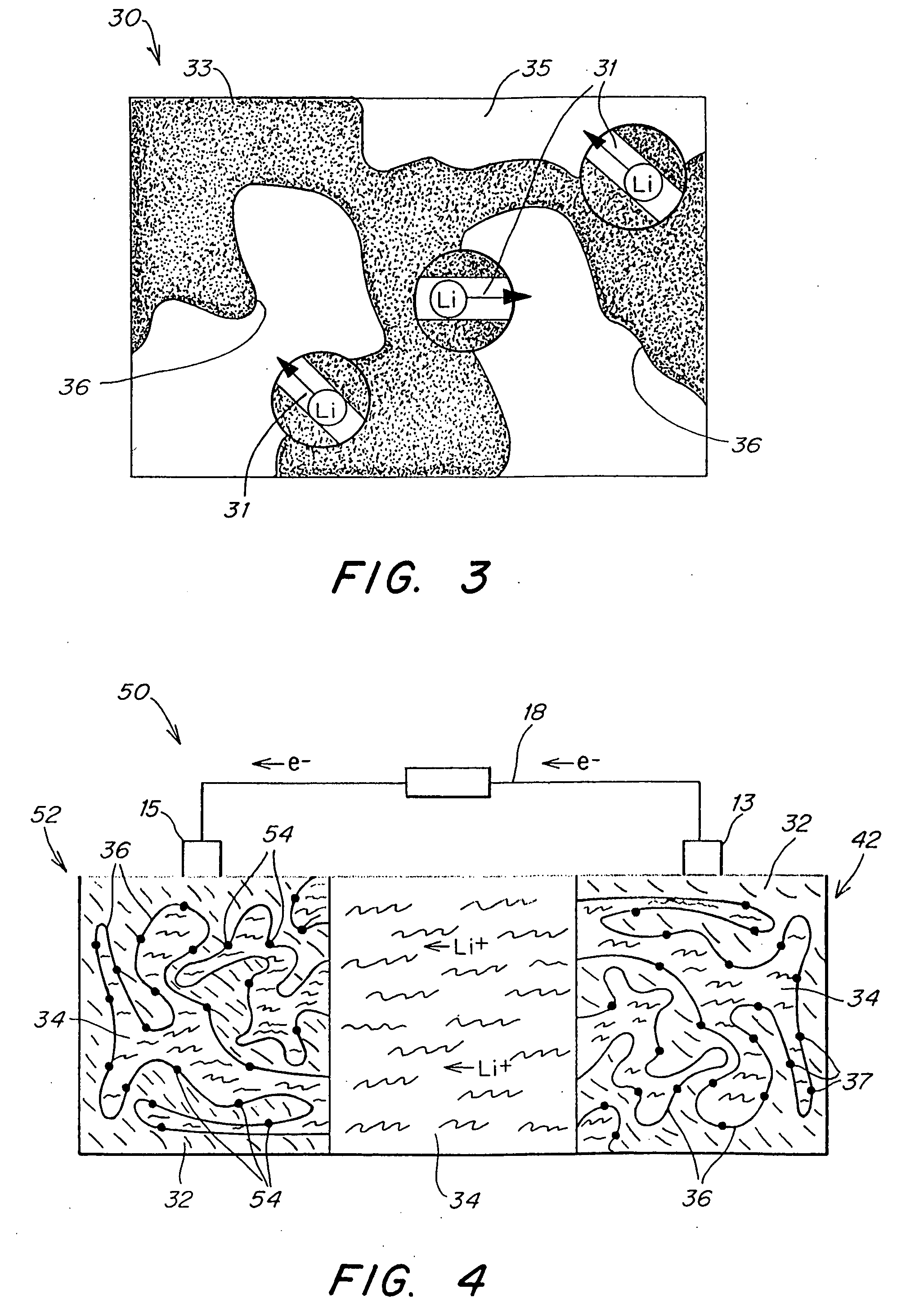

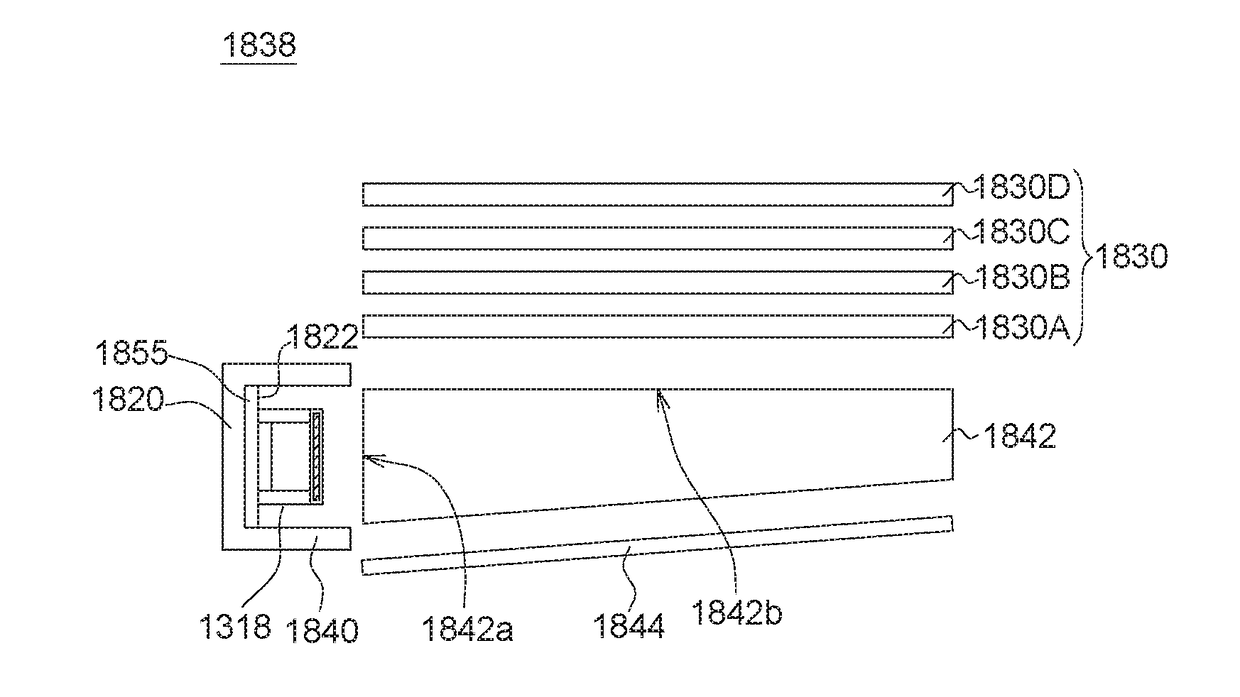

Polymer electrolyte, intercalation compounds and electrodes for batteries

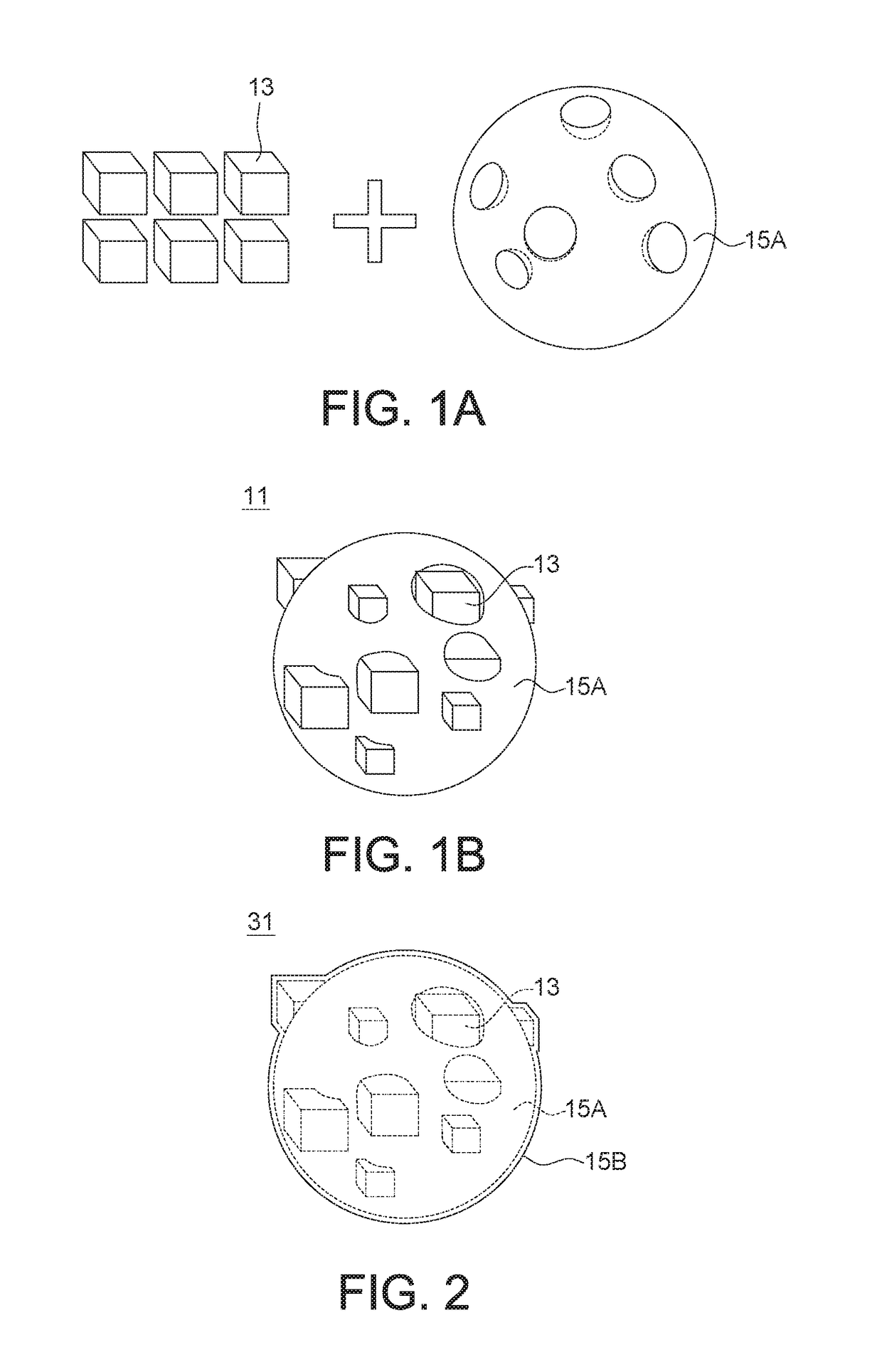

Solid battery components are provided. A block copolymeric electrolyte is non-crosslinked and non-glassy through the entire range of typical battery service temperatures, that is, through the entire range of at least from about 0° C. to about 70° C. The chains of which the copolymer is made each include at least one ionically-conductive block and at least one second block immiscible with the ionically-conductive block. The chains form an amorphous association and are arranged in an ordered nanostructure including a continuous matrix of amorphous ionically-conductive domains and amorphous second domains that are immiscible with the ionically-conductive domains. A compound is provided that has a formula of LixMyNzO2. M and N are each metal atoms or a main group elements, and x, y and z are each numbers from about 0 to about 1. y and z are chosen such that a formal charge on the MyNz portion of the compound is (4-x). In certain embodiments, these compounds are used in the cathodes of rechargeable batteries. The present invention also includes methods of predicting the potential utility of metal dichalgogenide compounds for use in lithium intercalation compounds. It also provides methods for processing lithium intercalation oxides with the structure and compositional homogeneity necessary to realize the increased formation energies of said compounds. An article is made of a dimensionally-stable, interpenetrating microstructure of a first phase including a first component and a second phase, immiscible with the first phase, including a second component. The first and second phases define interphase boundaries between them, and at least one particle is positioned between a first phase and a second phase at an interphase boundary. When the first and second phases are electronically-conductive and ionically-conductive polymers, respectively, and the particles are ion host particles, the arrangement is an electrode of a battery.

Owner:MASSACHUSETTS INST OF TECH

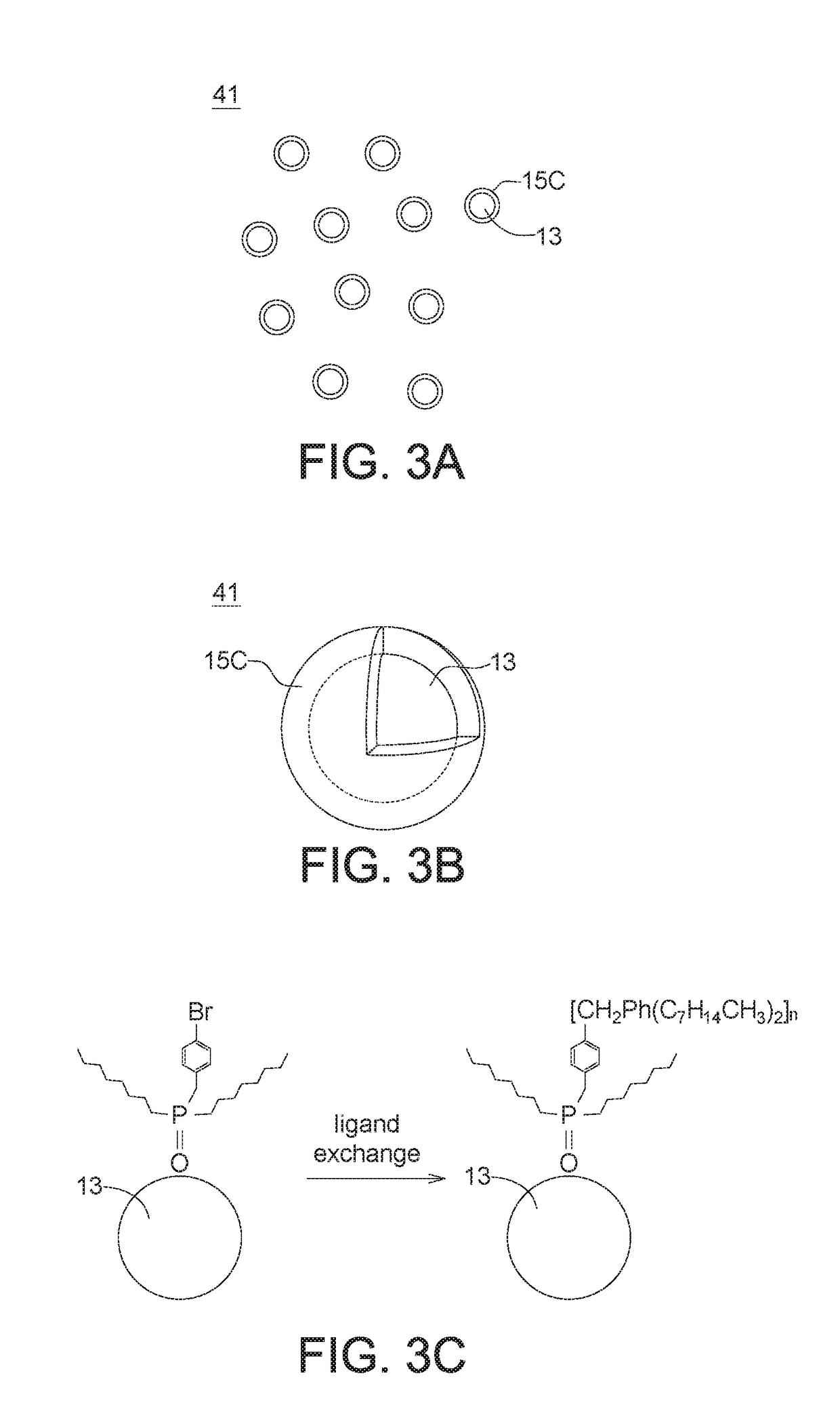

Quantum dot composite material and manufacturing method and application thereof

A quantum dot composite material and a manufacturing method and an application thereof are provided. The quantum dot composite material includes an all-inorganic perovskite quantum dot and a modification protection on a surface of the all-inorganic perovskite quantum dot. The all-inorganic perovskite quantum dot has a chemical formula of CsPb(ClaBr1-a-bIb)3, wherein 0≦a≦1, 0≦b≦1.

Owner:LEXTAR ELECTRONICS CORP

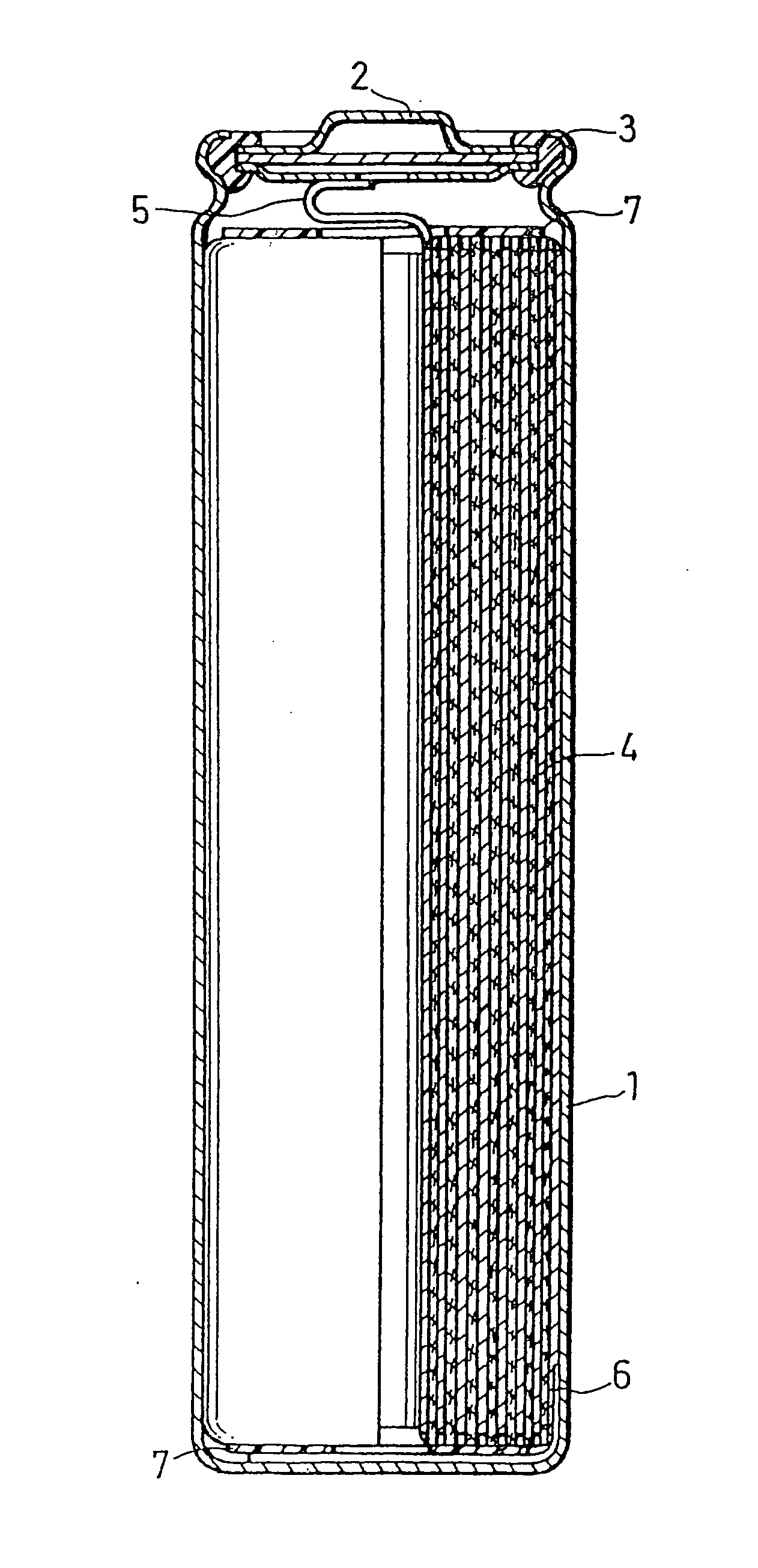

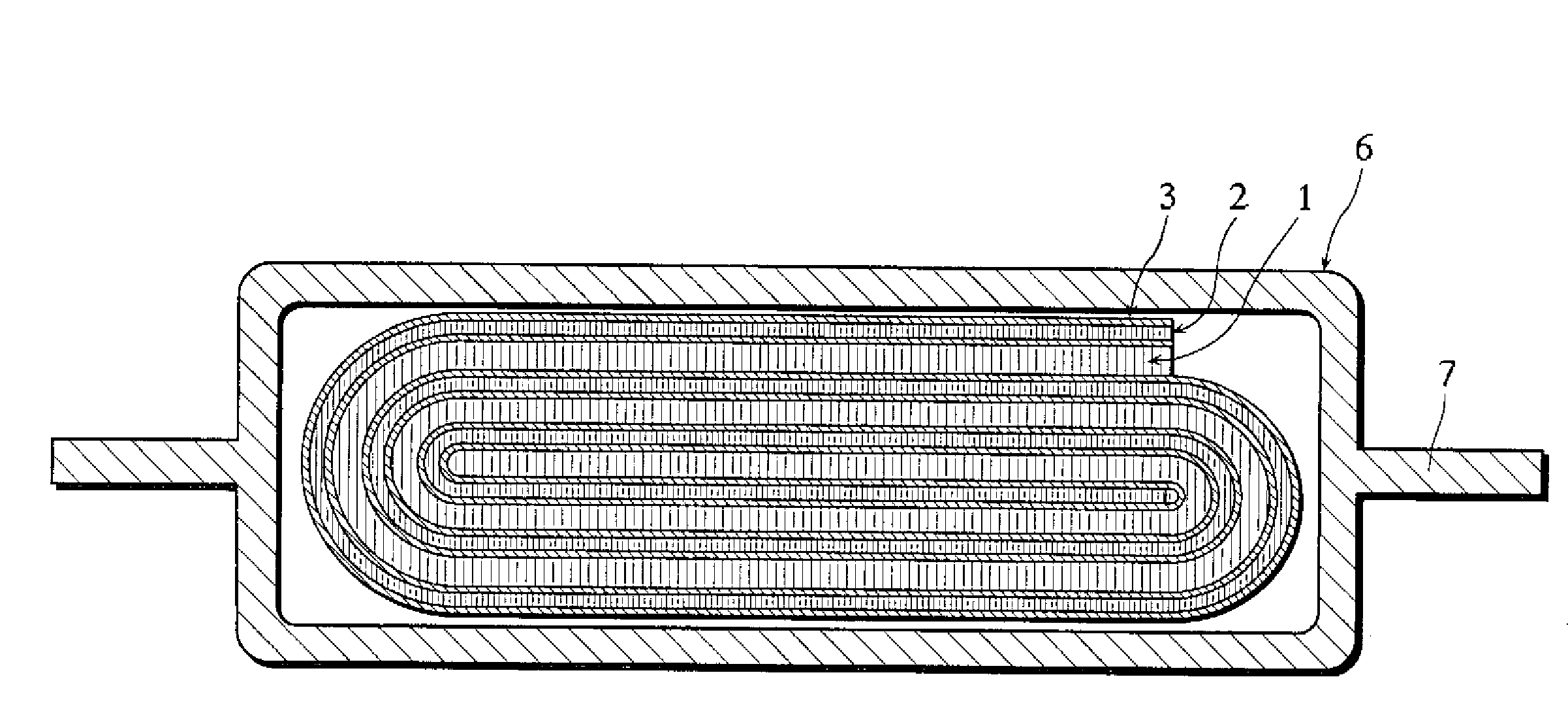

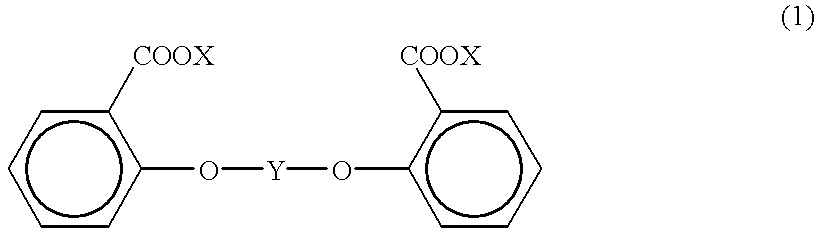

Lithium secondary battery and method of manufacturing the same

ActiveUS20080124631A1Avoid fracturesImprove cycle performanceElectrode carriers/collectorsNegative electrodesSilicon alloyMaterials science

A lithium secondary battery includes an electrode assembly having a positive electrode (1), a negative electrode (2) having a negative electrode current collector and a negative electrode active material layer formed on a surface of the negative electrode current collector and composed of a binder and negative electrode active material particles containing silicon and / or a silicon alloy, and a separator (3) interposed between the electrodes. The electrode assembly is impregnated with a non-aqueous electrolyte. The binder contains a polyimide resin represented by the following chemical formula (1):where R contains at least a benzene ring, and n is within the range of from 10 to 100,000, and the negative electrode active material particles have an average particle size of 5 μm or greater.

Owner:SANYO ELECTRIC CO LTD

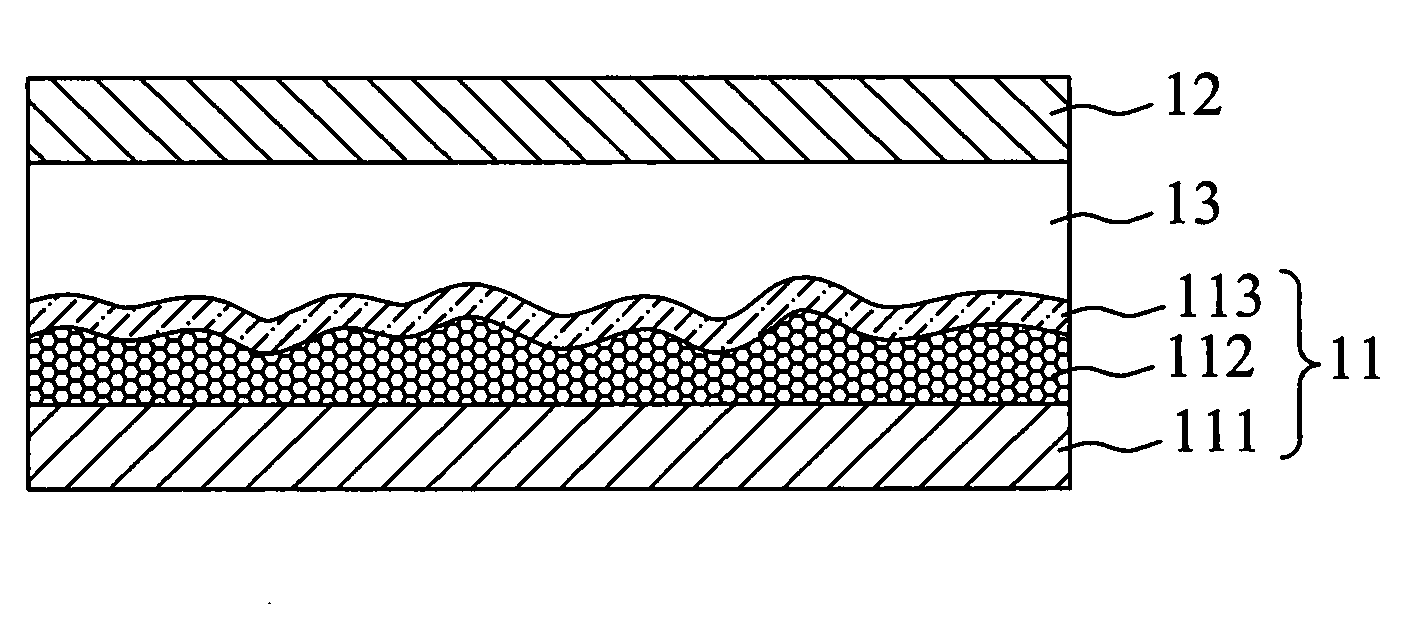

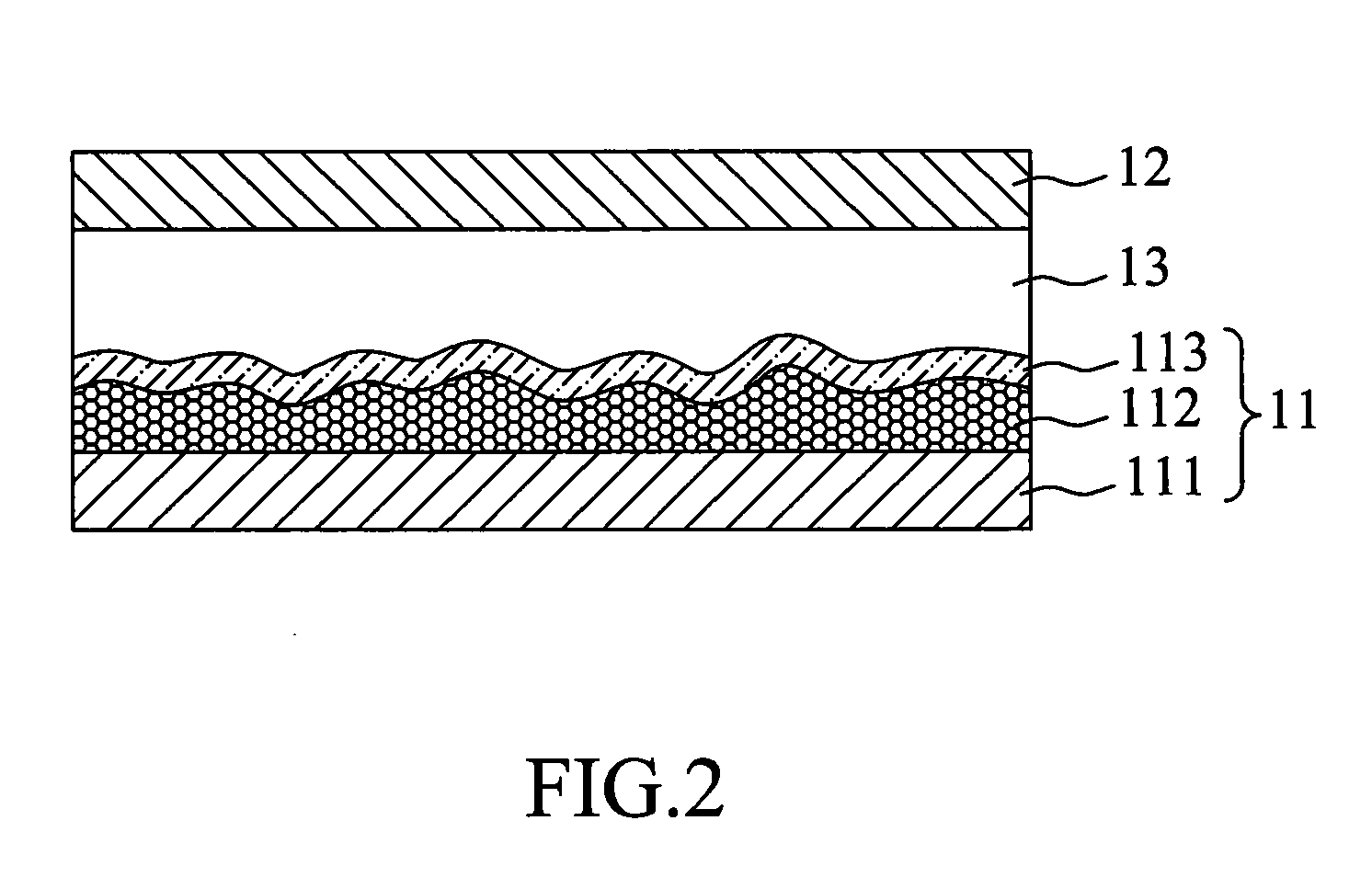

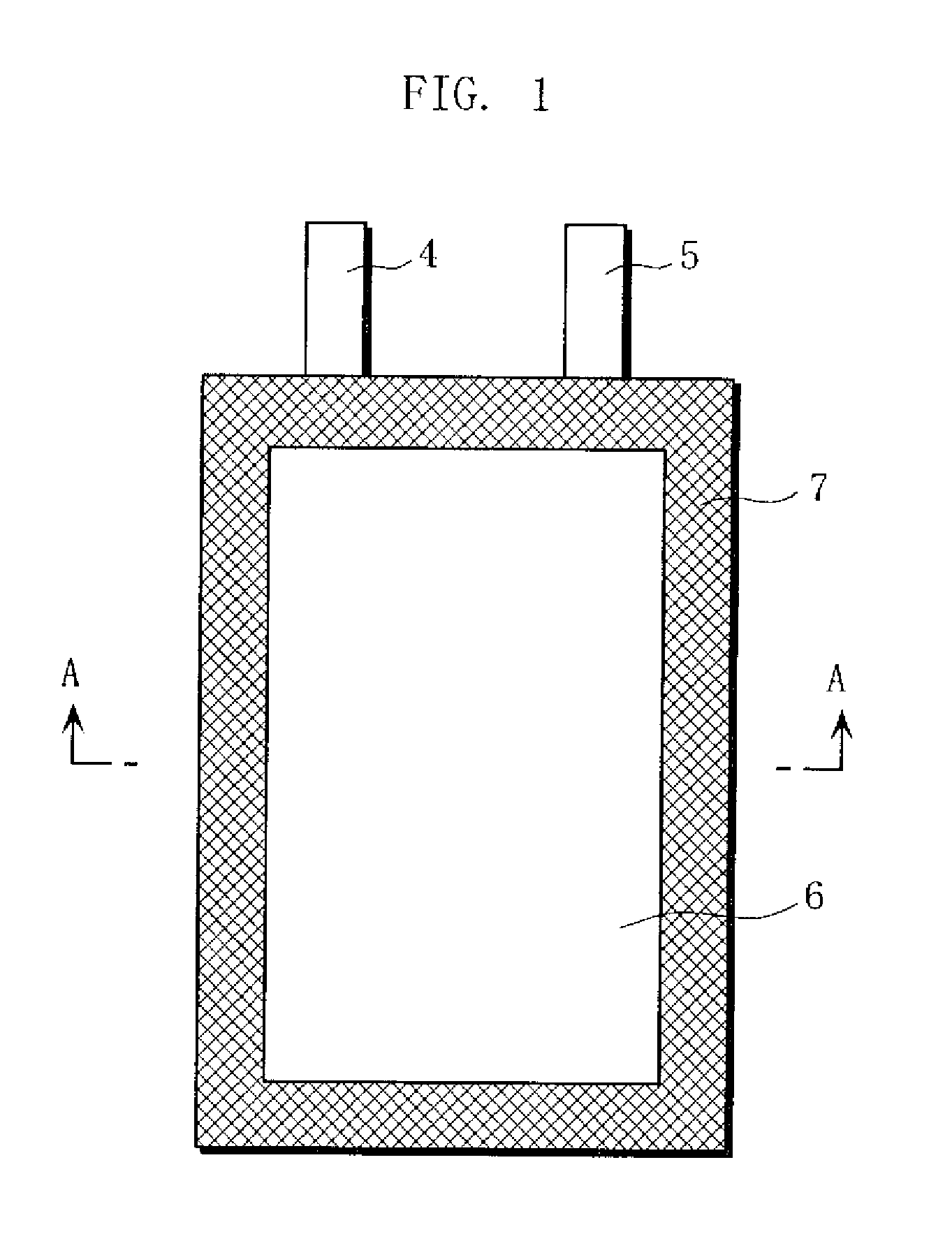

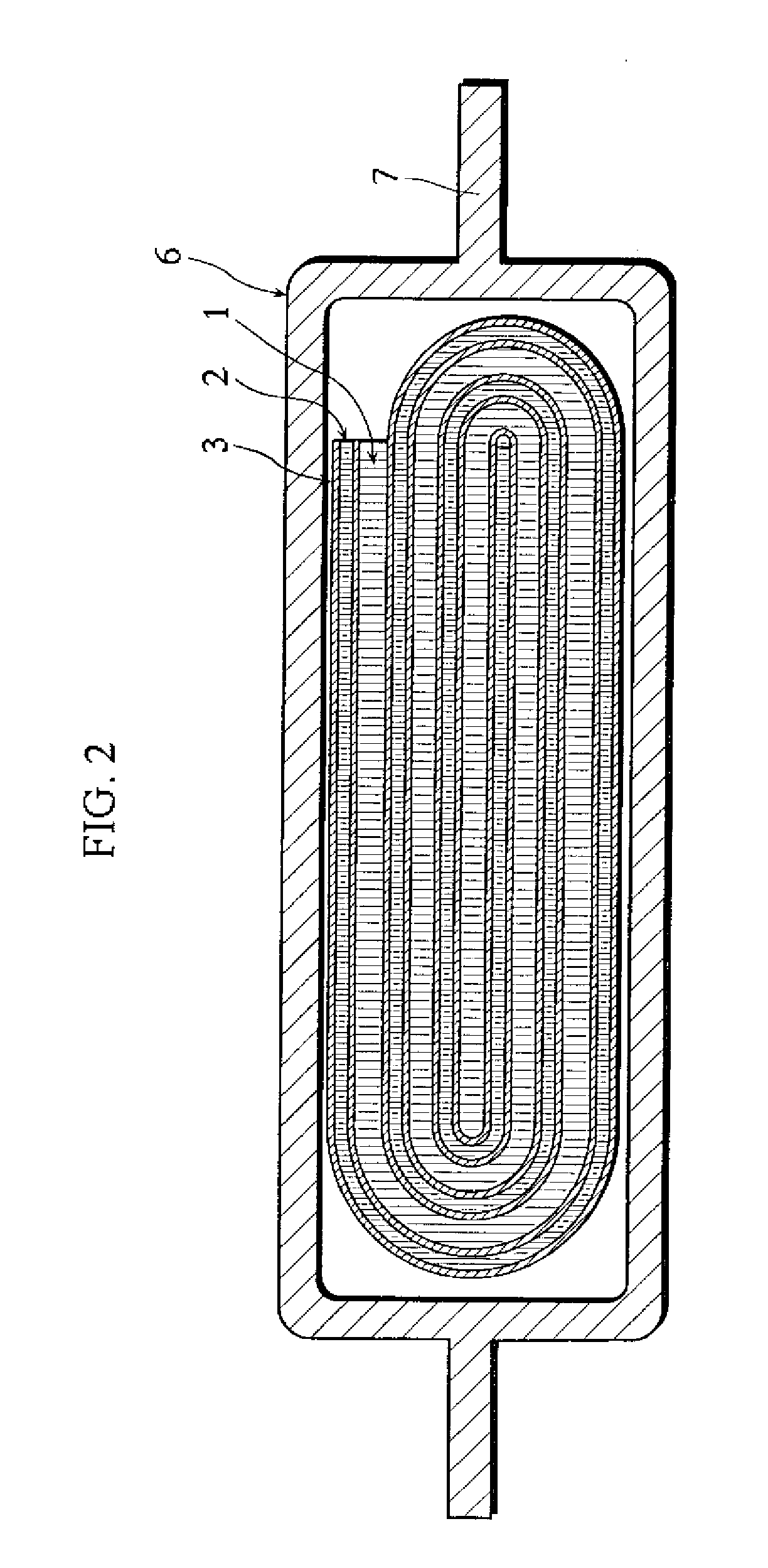

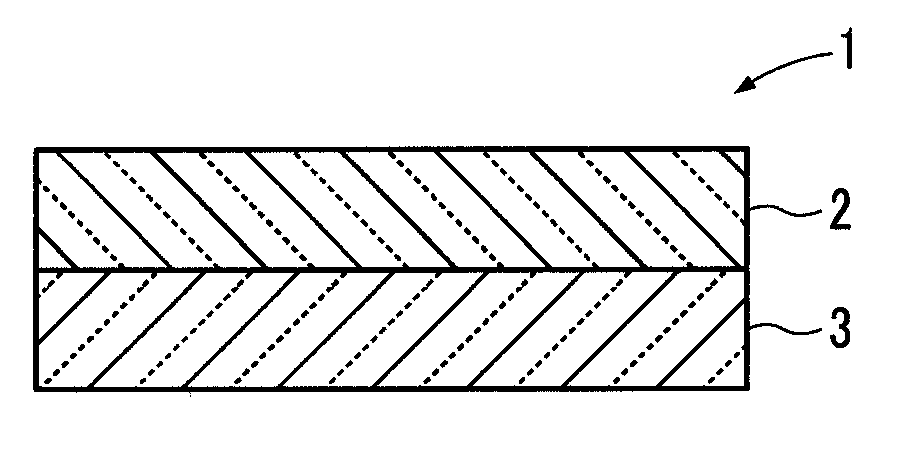

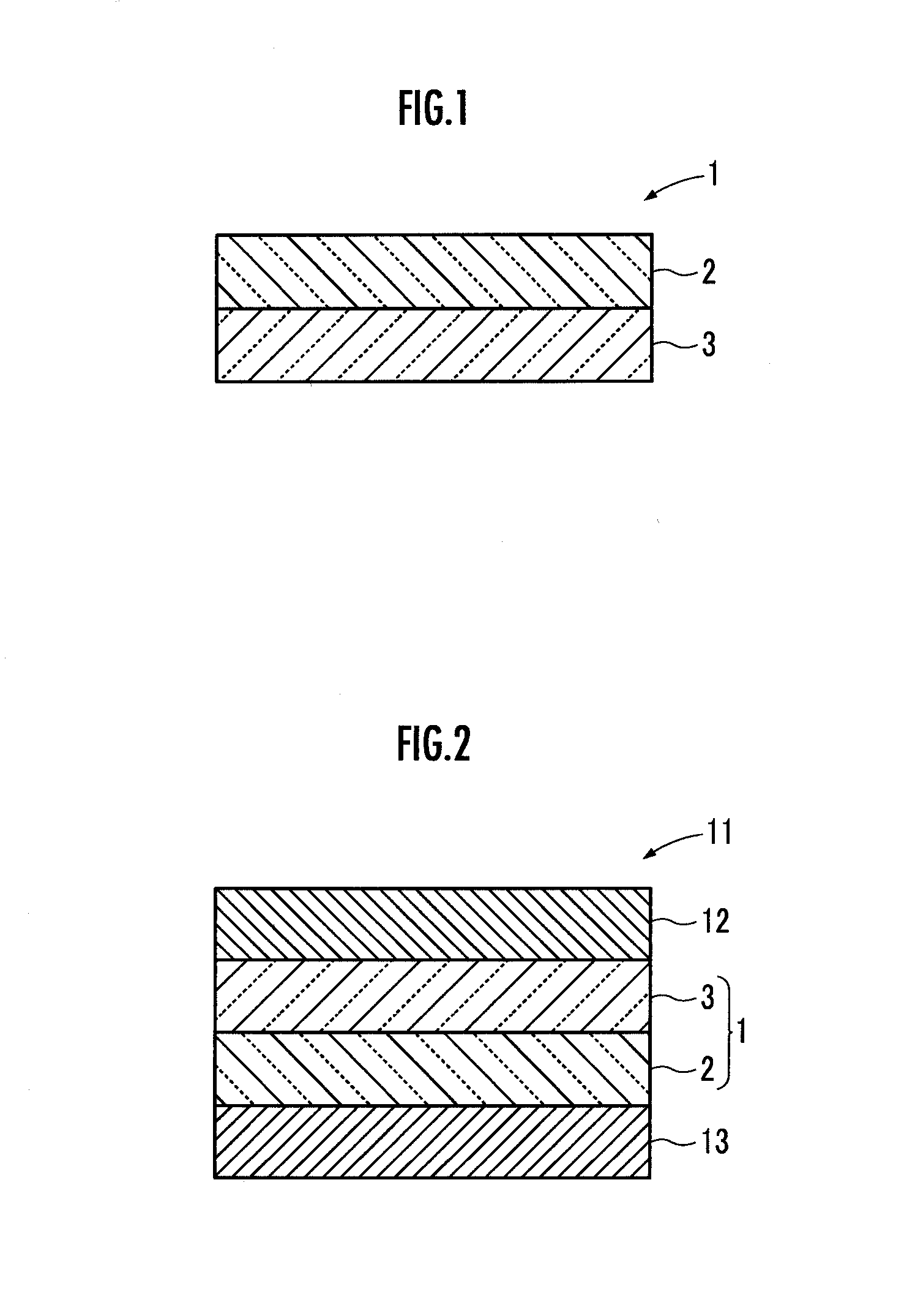

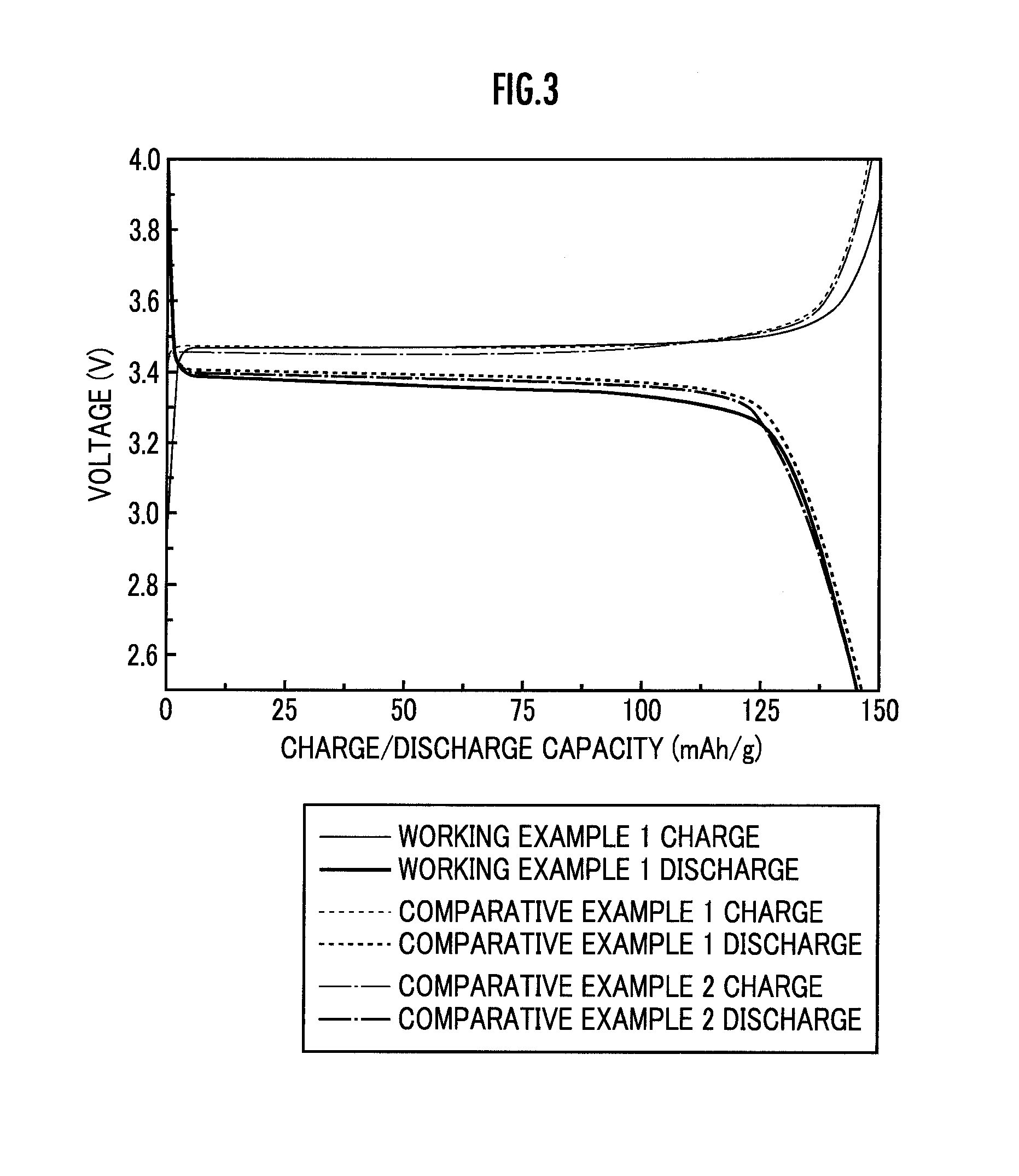

Lithium ion conductive composite electrolyte and lithium ion secondary battery using same

ActiveUS20130230778A1Improve cycle performancePrevent electrolyte leakageNon-aqueous electrolyte cellsSecondary cellsComposite electrolyteConductive polymer

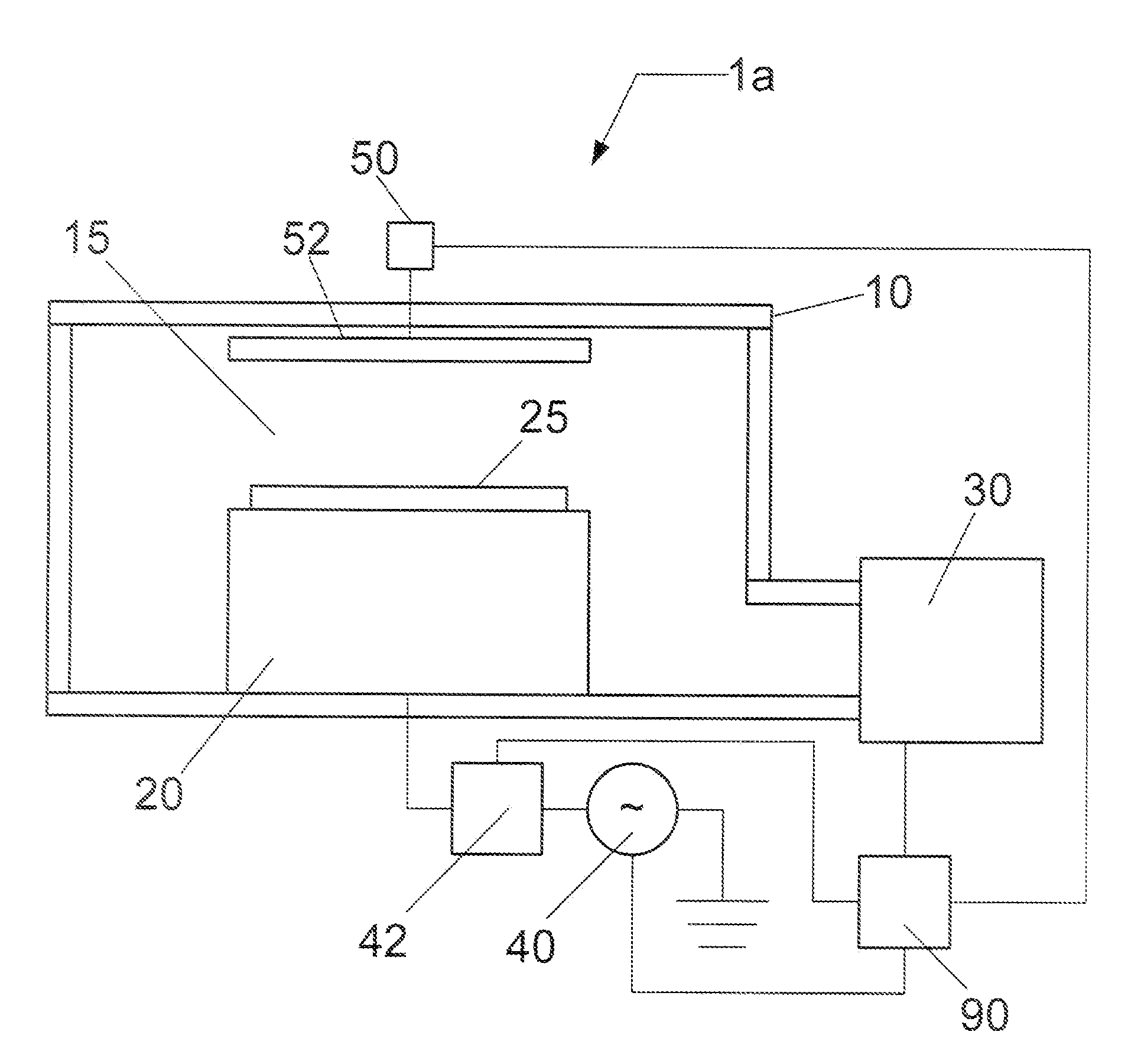

Provided is a lithium ion conductive composite electrolyte that can prevent leakage of electrolyte solution, and that have excellent cycle performance and lithium ion conductivity, and a lithium ion secondary battery. A lithium ion conductive composite electrolyte 1 is formed so that a lithium ion conductive polymer gel electrolyte is held in a porous body 2 formed from lithium ion conductive inorganic solid electrolyte particles and an organic polymer. The lithium ion conductive inorganic solid electrolyte particles are formed from a composite metal oxide that has a garnet structure, and is represented by the chemical formula Li7−yLa3−xAxZr2−yMyO12 (wherein 0≦x 3, 0≦y≦2, A is one of Y, Nd, Sm, and Gd, and M is Nb or Ta). A lithium ion secondary battery 11 includes the lithium ion conductive composite electrolyte 1 between a positive electrode 12 and a negative electrode 13.

Owner:HONDA MOTOR CO LTD

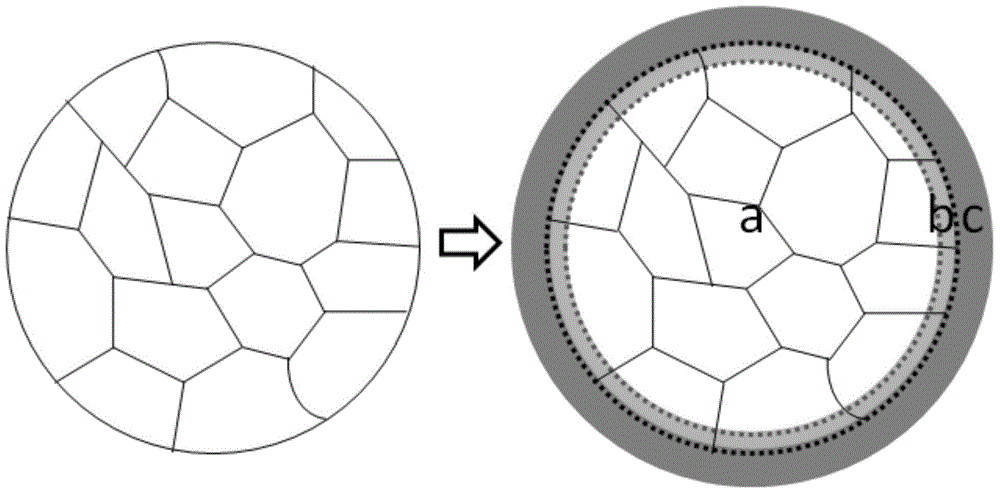

Anode material for nickel-base lithium ion battery and preparation method of anode material

ActiveCN104409700AEasy to operateSuitable for industrial productionCell electrodesSecondary cellsOptoelectronicsOxygen

The invention provides an anode material for a nickel-base lithium ion battery and a preparation method of the anode material. The anode material comprises an inner core, a doping layer and a cladding layer, wherein the chemical formula of the inner core is LiaNixCoyMzO2; the doping layer is another inner core containing M'; at least M' and oxygen elements are contained in the cladding layer; the anode material is of a core-shell structure, and comprises the inner core, the doping layer and the cladding layer from inside to outside. The anode material for the nickel-base lithium ion battery provided by the invention is little in lithium-nickel mixing, and the cycling stability of the material is obviously improved.

Owner:BTR NEW MATERIAL GRP CO LTD

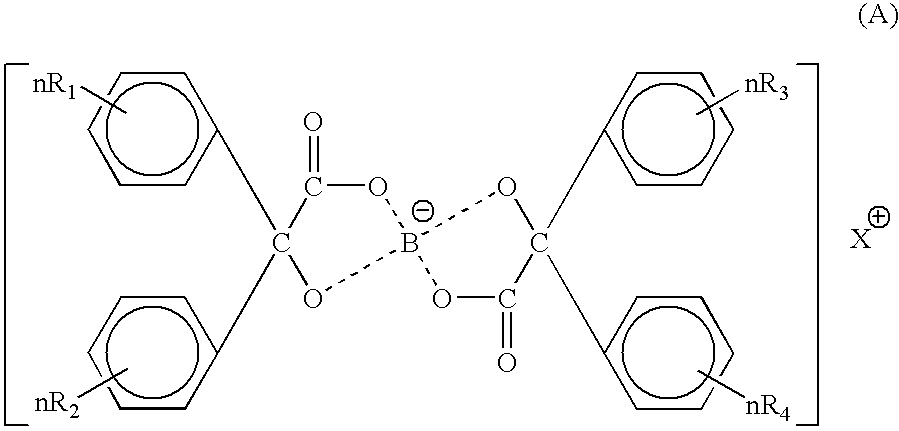

Toner and image forming method

InactiveUS20070207399A1Improve stabilityUniformly and efficiently chargingElectrographic process apparatusDevelopersImage transferLatent image

Toner for electrostatic charge development wherein no scumming occurs, and toner leakage caused by charge defect of the toner on a developing roller can be inhibited, and an excellent image stability is obtained is provided.The toner used for an image forming method having a latent electrostatic image forming step of forming a latent electrostatic image on a latent electrostatic image bearing member primarily charged, a developing step of developing the latent electrostatic image by each toner which multiple developing devices have to form a toner image on the latent electrostatic image bearing member, a transferring step of transferring the toner image with respective colors formed on the latent electrostatic image bearing member onto a recording material and a fixing step of fixing the toner image transferred onto the recording material, wherein the toner comprises a colorant and a resin and contains an organic boron compound represented by a following chemical formula (A) as a charge controlling agent, further the toner is treated with an inorganic fine particle and at least one of the inorganic particles is a magnesium silicate compound represented by a following general formula [2] is provided.wherein X is an alkali metal, R1, R2, R3 or R4 each represents a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, or a halogen atom.MgxSiyO(x+2y) [2]wherein x and y are integers.

Owner:RICOH KK

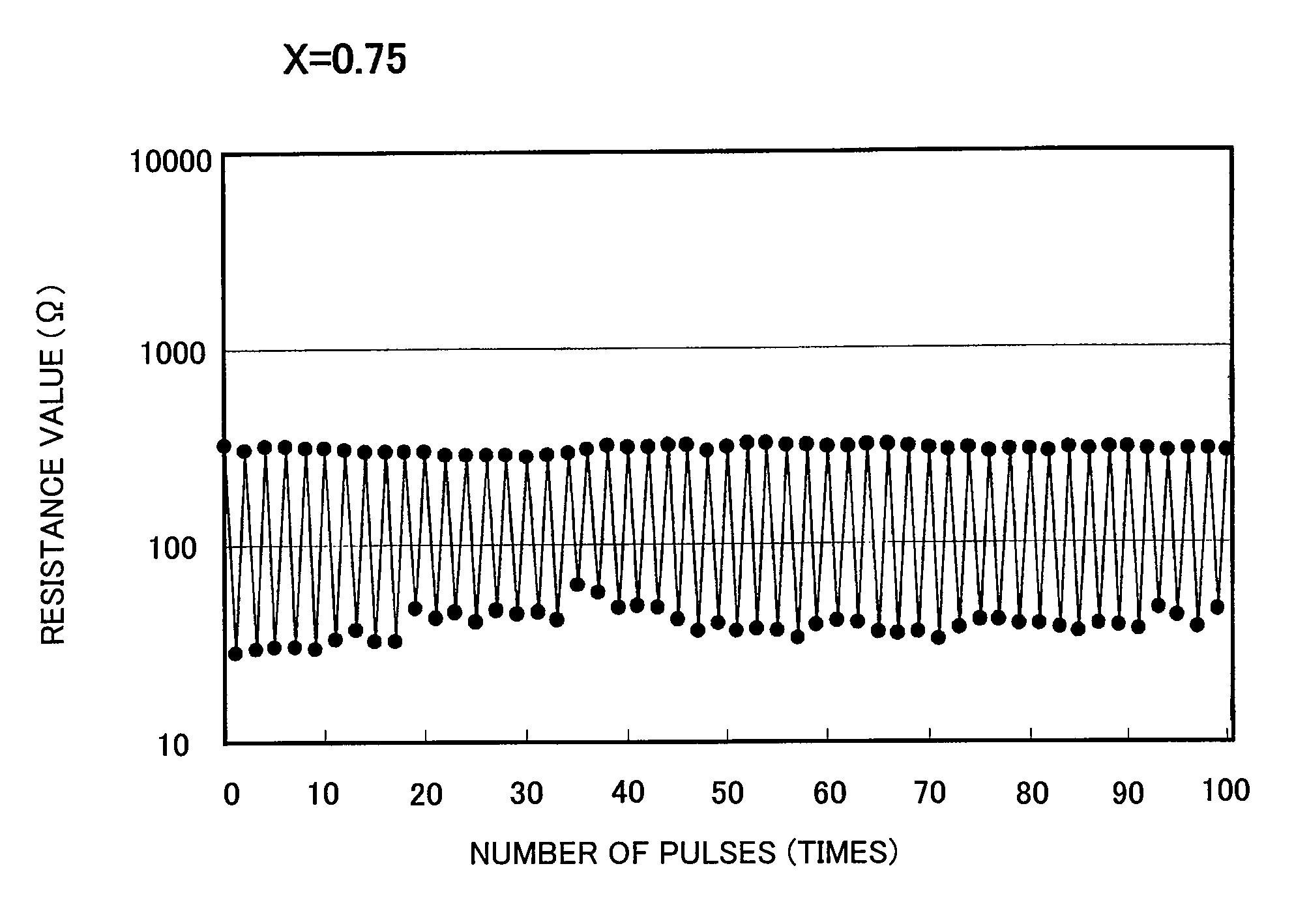

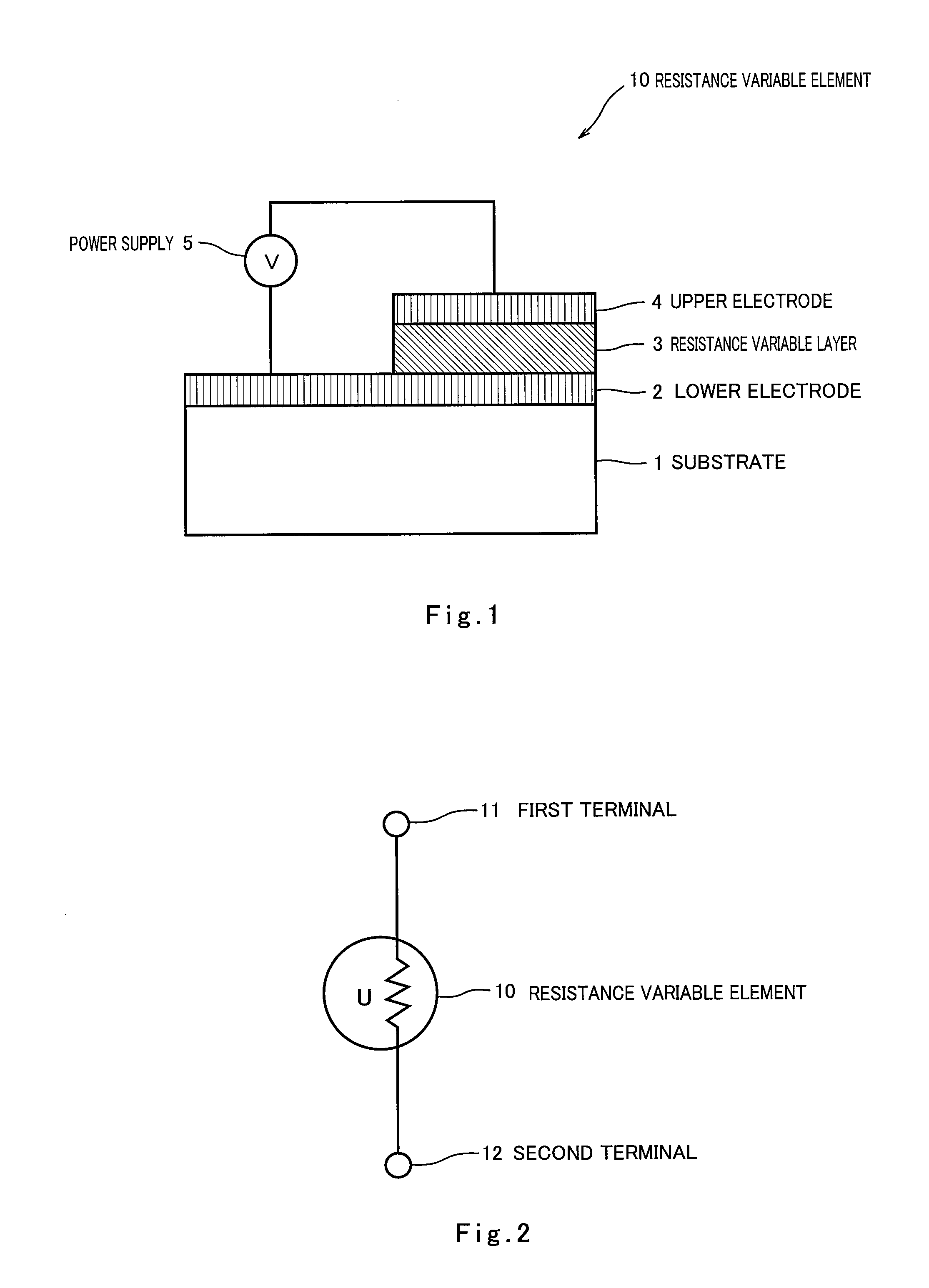

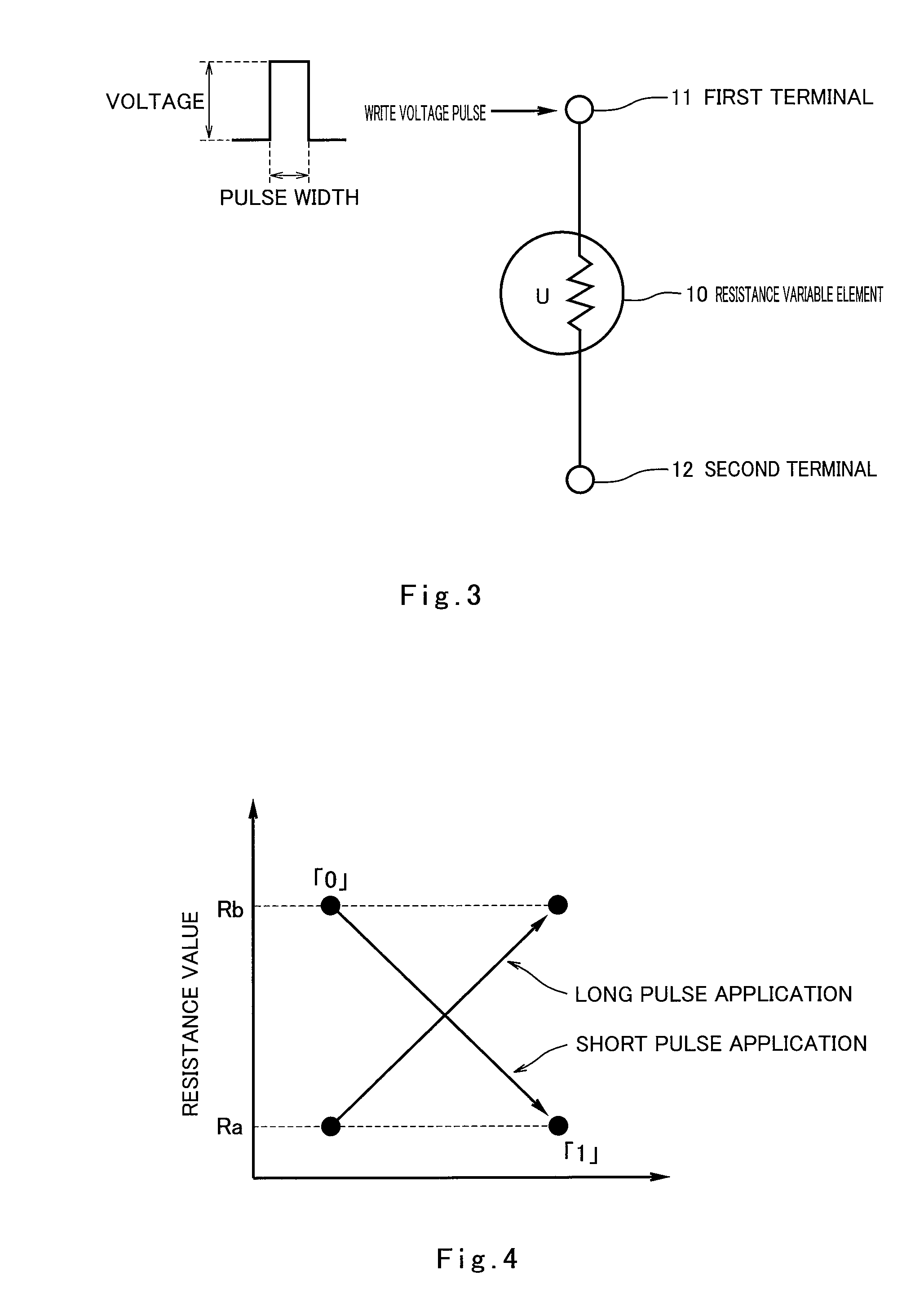

Resistance variable element and resistance variable memory apparatus

InactiveUS8018760B2Same polaritySolid-state devicesRead-only memoriesVoltage pulseElectrical polarity

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

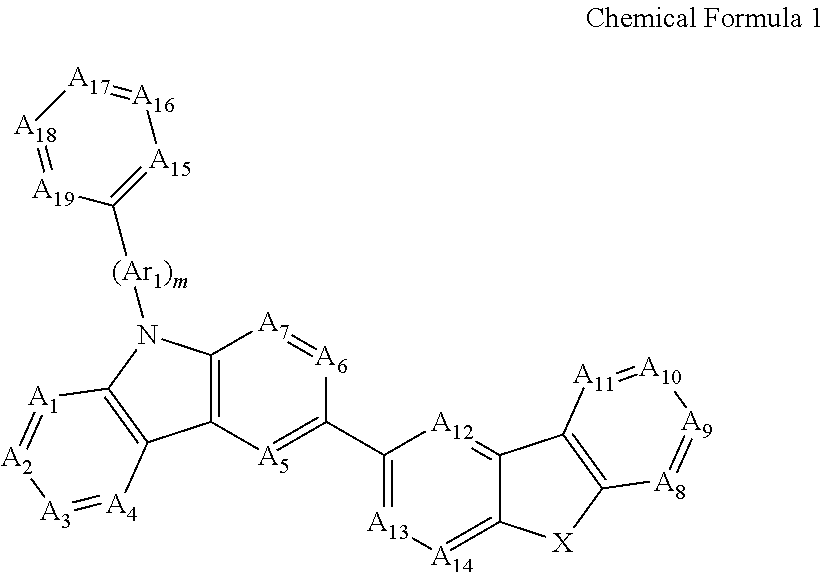

Novel organic electroluminescent compounds and organic electroluminescent device using the same

InactiveUS20100032658A1Improve luminous efficiencyImproved life propertyOrganic chemistrySolid-state devicesOrganic electroluminescenceMaterials science

Provided are novel organic electroluminescent compounds and organic electroluminescent devices comprising the same as electroluminescent material. Specifically, the organic electroluminescent compounds according to the invention are characterized in that they are represented by Chemical Formula (1):wherein, L is selected from the following structures.The organic electroluminescent compounds according to the invention exhibit high luminous efficiency in blue color and excellent life property as a material, so that an OLED having very good operation life can be prepared therefrom.

Owner:GRACEL DISPLAY INC

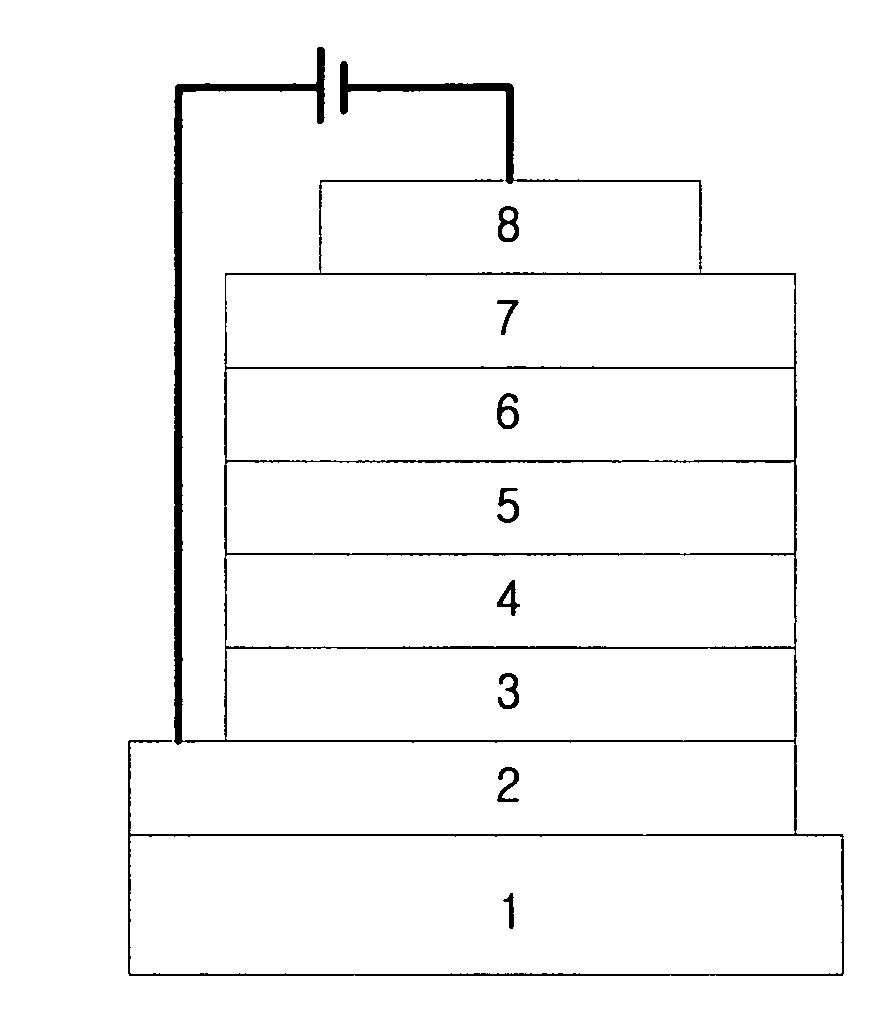

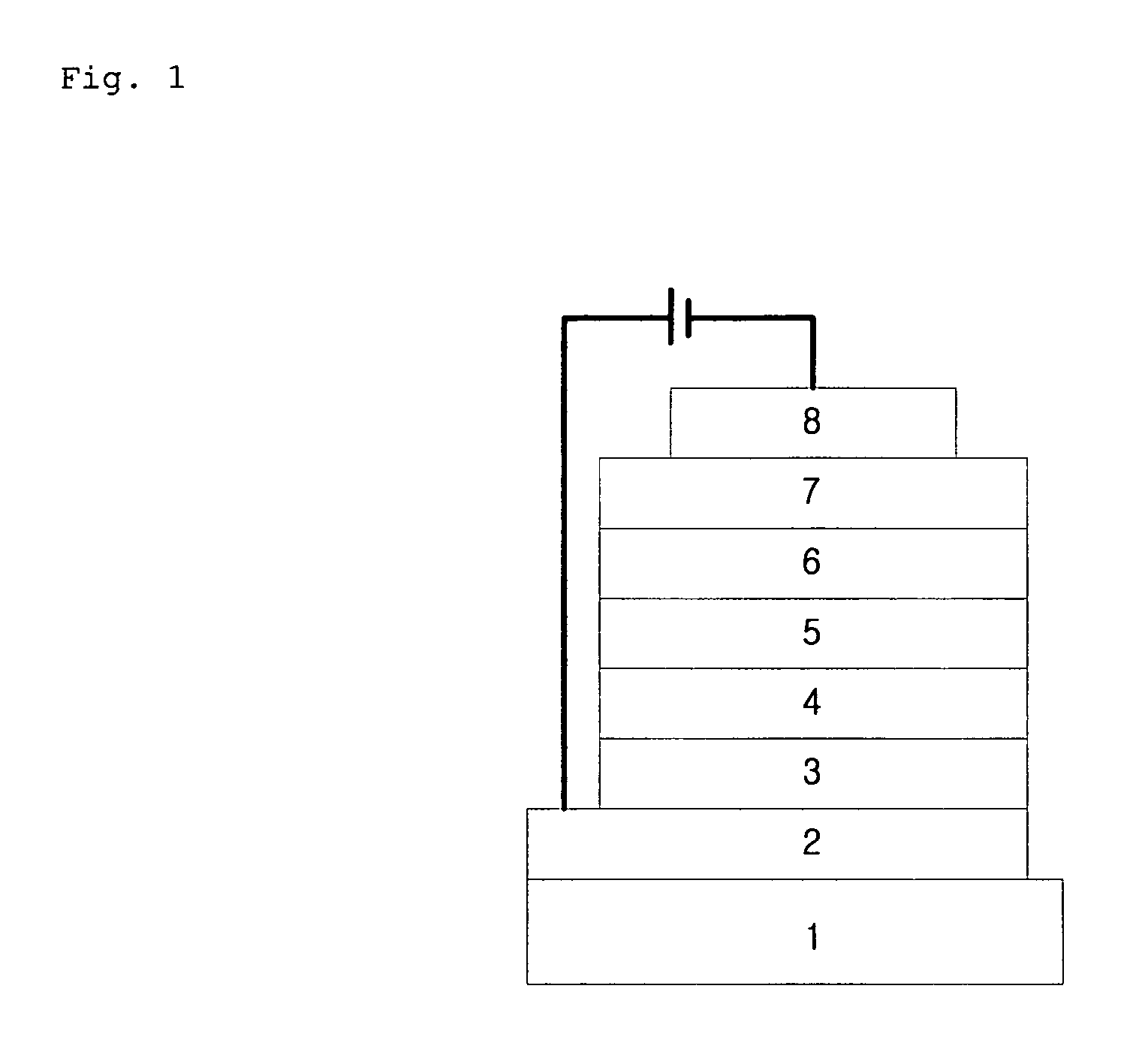

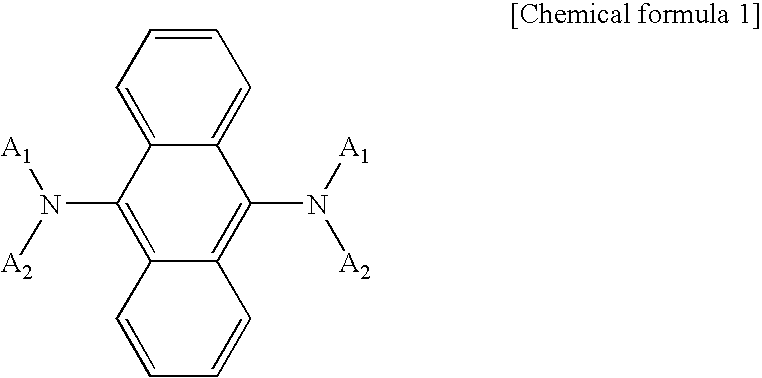

Organic electroluminescent device

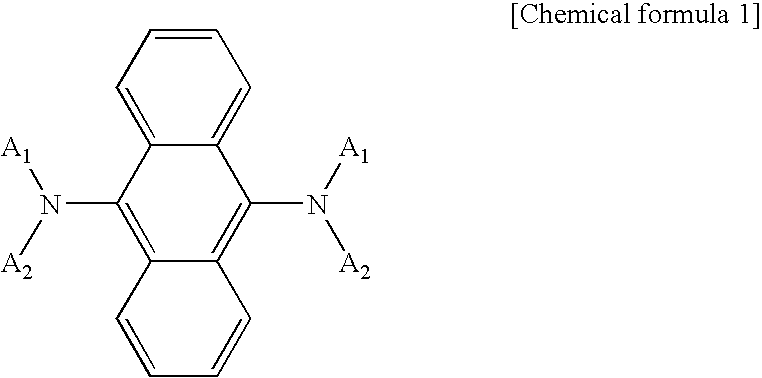

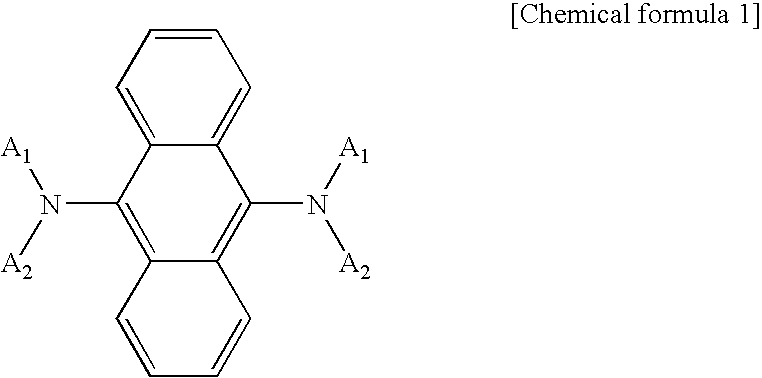

ActiveUS20040209118A1Discharge tube luminescnet screensElectroluminescent light sourcesDopantHydrogen

Disclosed is an organic electroluminescent device including a substrate, a first and second electrode formed on the substrate, and a light-emitting layer formed between the first electrode and the second electrode. The light-emitting layer includes a plurality of materials which is a green luminescent material using a following chemical formula as a dopant. In this case, at least one of A1 and A2 is selected from a substituted or non-substituted aromatic group, a heterocyclic group, an aliphatic group, and hydrogen.

Owner:LG DISPLAY CO LTD

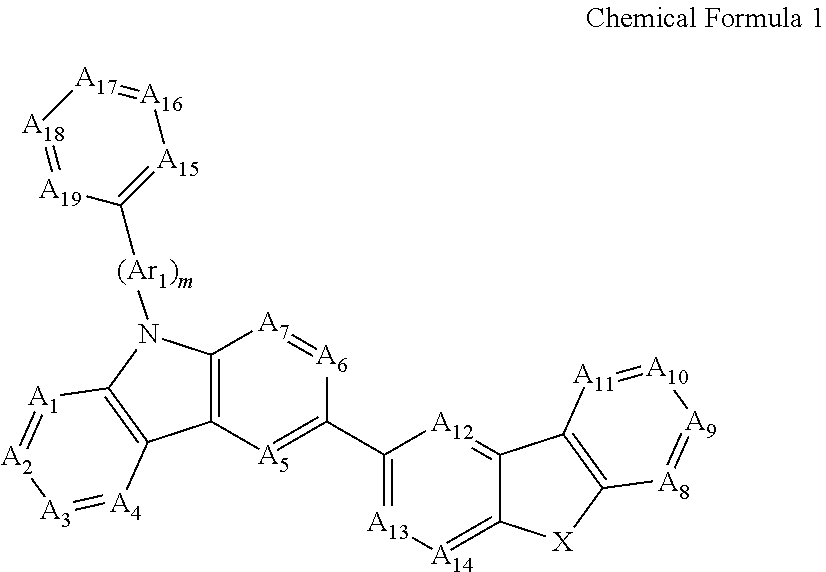

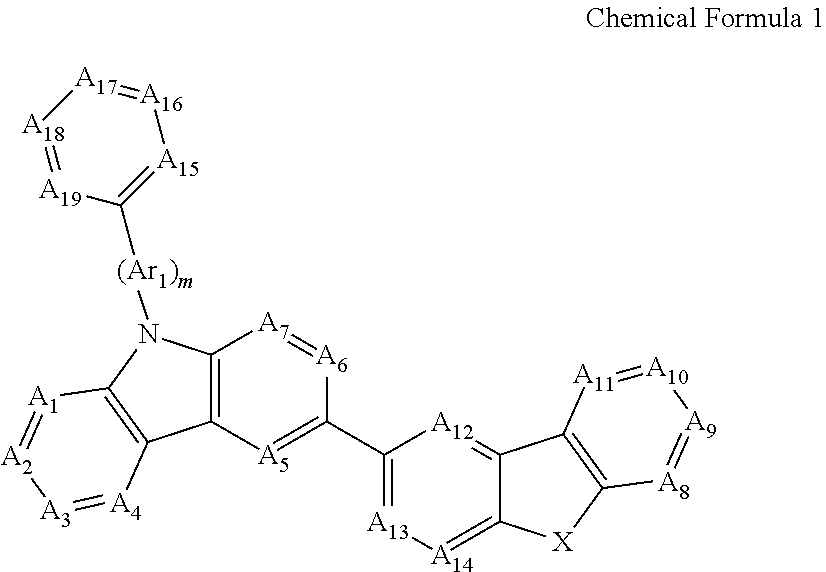

Novel organic electroluminescent compounds and organic electroluminescent device using the same

InactiveUS20120235123A1Improve luminous efficiencyExcellent life propertyGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsOrganic electroluminescenceMolecular physics

Provided are a novel organic electroluminescent compound and an organic electroluminescent device using the same. More particularly, the organic electroluminescent compound disclosed herein is represented by Chemical Formula 1:Since the organic electroluminescent compound disclosed herein exhibits good luminous efficiency and excellent life property, it may be used to manufacture OLED devices having very superior operation life.

Owner:ROHM & HAAS ELECTRONICS MATERIALS KOREA LTD

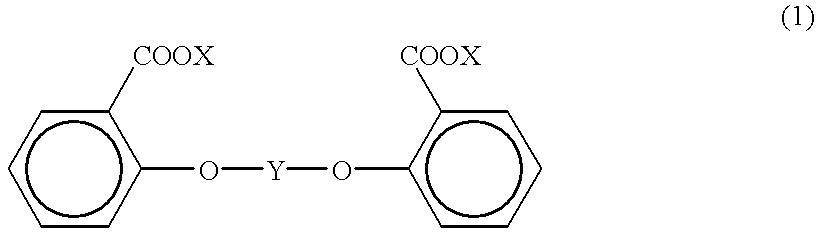

Process for producing aromatic polycarbonate

An aromatic polycarbonate and an active-hydrogen compound are subjected to the transesterification reaction in the presence of a transesterification catalyst under a reduced pressure condition followed by reaction with a salicylic acid ester derivative expressed by the following chemical formula (1),{wherein X is methyl or ethyl, and Y is a carbonyl group or a divalent functional group expressed by the following formula (2),(where Z is an alkylene group having a carbon number of 1 to 30, an arylene group having a carbon number of 6 to 30 or an aralkylene group having a carbon number of 7 to 30)}.An aromatic polycarbonate having a high molecular weight can be produced by this process.

Owner:TEIJIN LTD

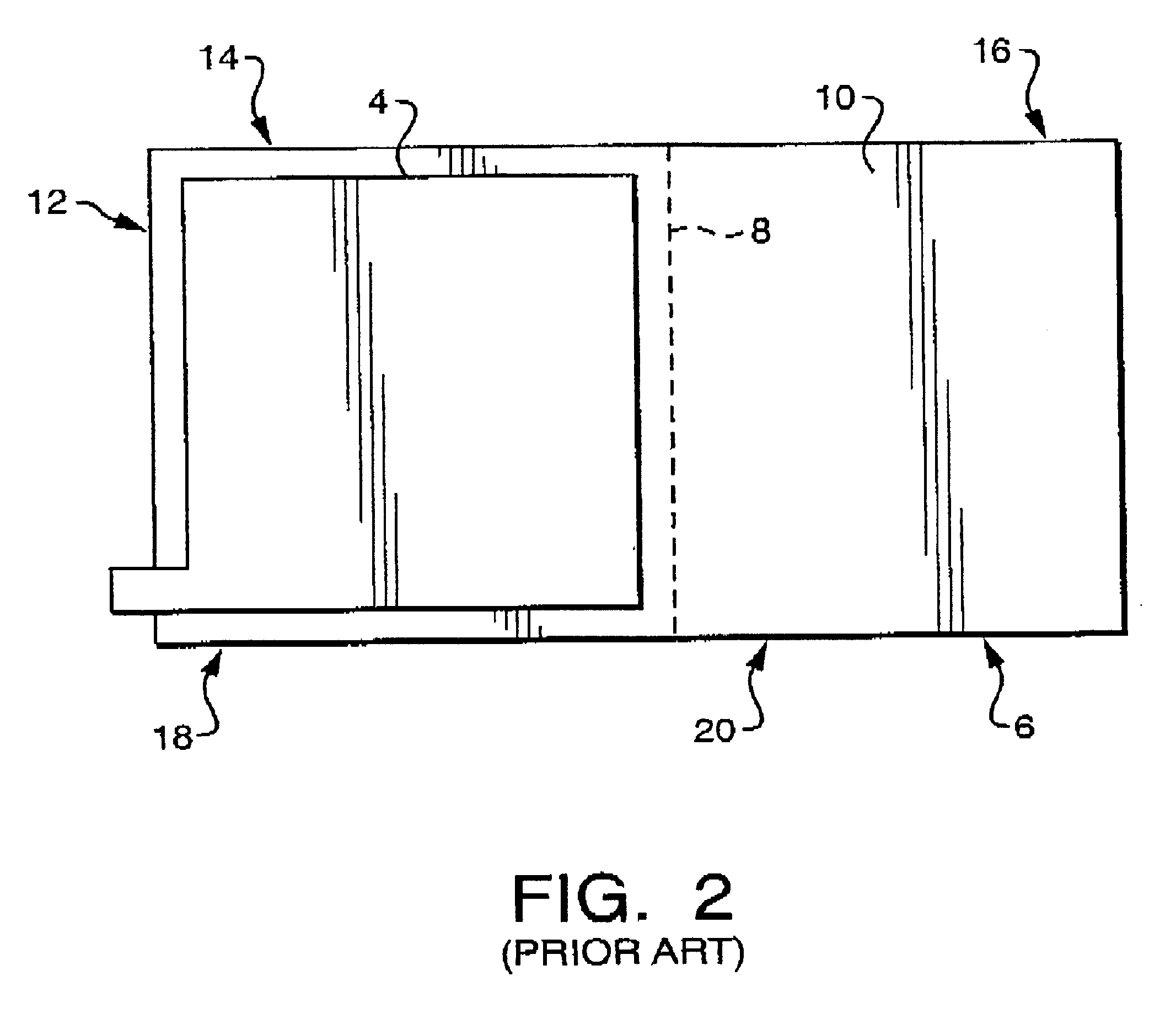

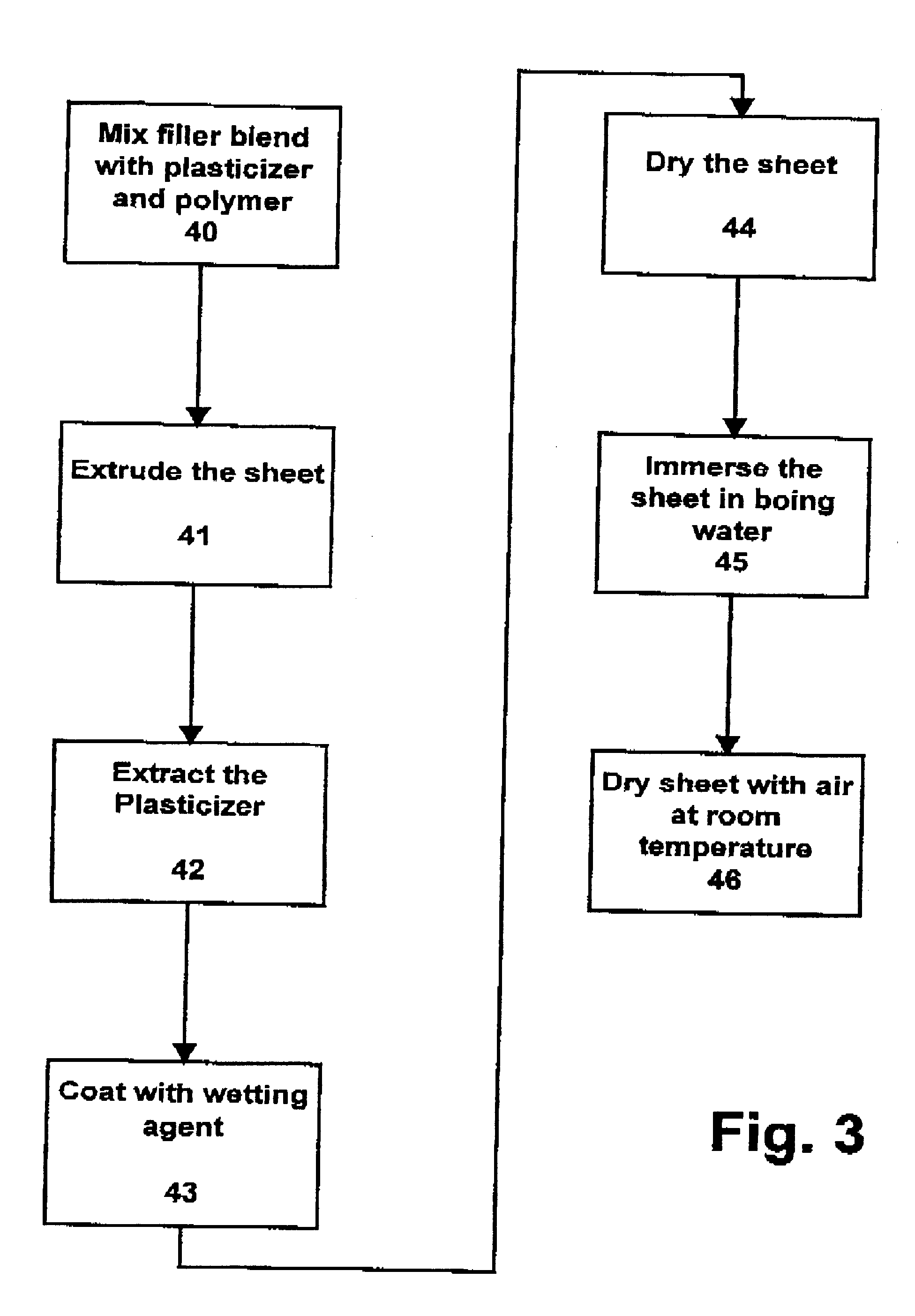

Microporous membrane battery separator for silver zinc batteries

InactiveUS6372379B1Improve cycle lifeExtended calendar lifeSilver accumulatorsCell component detailsPolyolefinFuel oil

A separator membrane for use in silver-zinc batteries is produced by extruding a blend of two fillers with the same chemical formula but different particle size. A polyolefine polymer and a plasticizer are blended and extruded to form a thin sheet of 1 to 10 mil thickness. The plasticizer is then extracted to leave submicron voids in the membrane. Plasticizers are added as processing aids, and can be either soluble or insoluble in water, and include petroleum oils, lubricating oils, fuel oils, and natural oils such as tall oils and linseed oils. The oil are then extracted from the membrane by conventional procedures such as single stage extraction using a suitable solvent. Commercially available wetting agents known to the art such as dodecylphenoxy polyethoxy ethanol and isooctyl phenyl polyethoxy ethanol are coated onto the sheet to improve wettability. The sheet is then dried, and boiled in distilled water for one minute or more, before being finally dried.

Owner:ZPOWER LLC

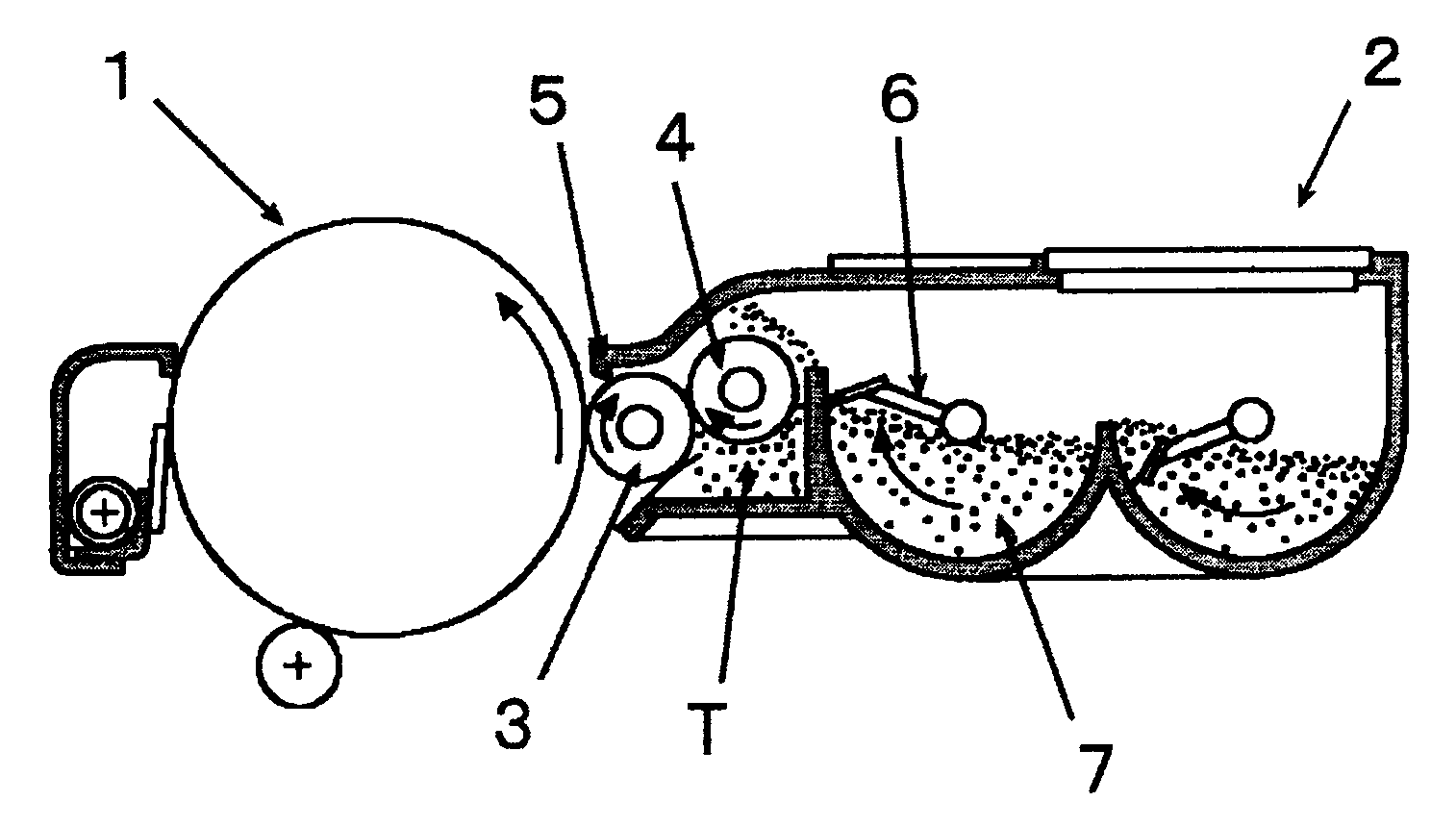

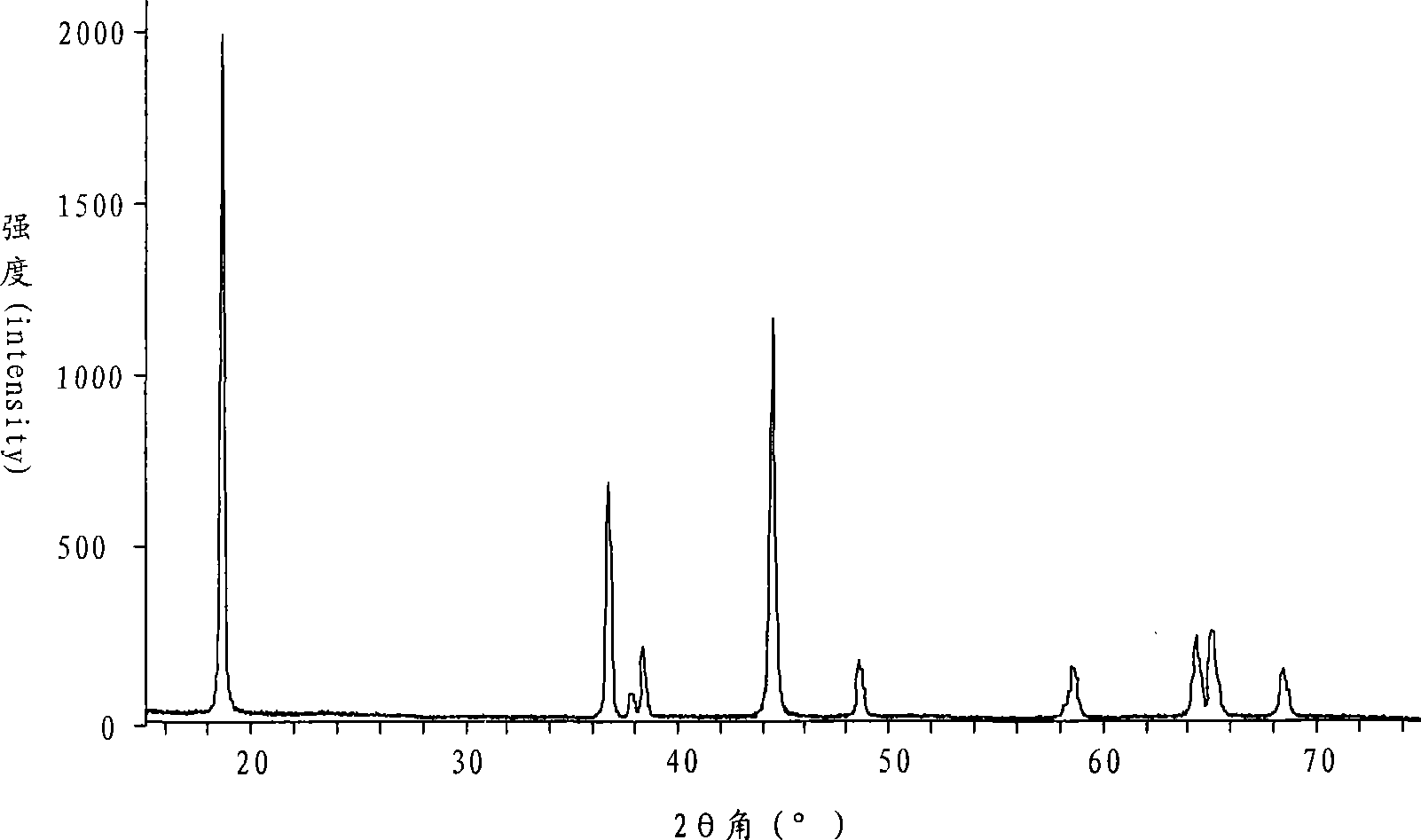

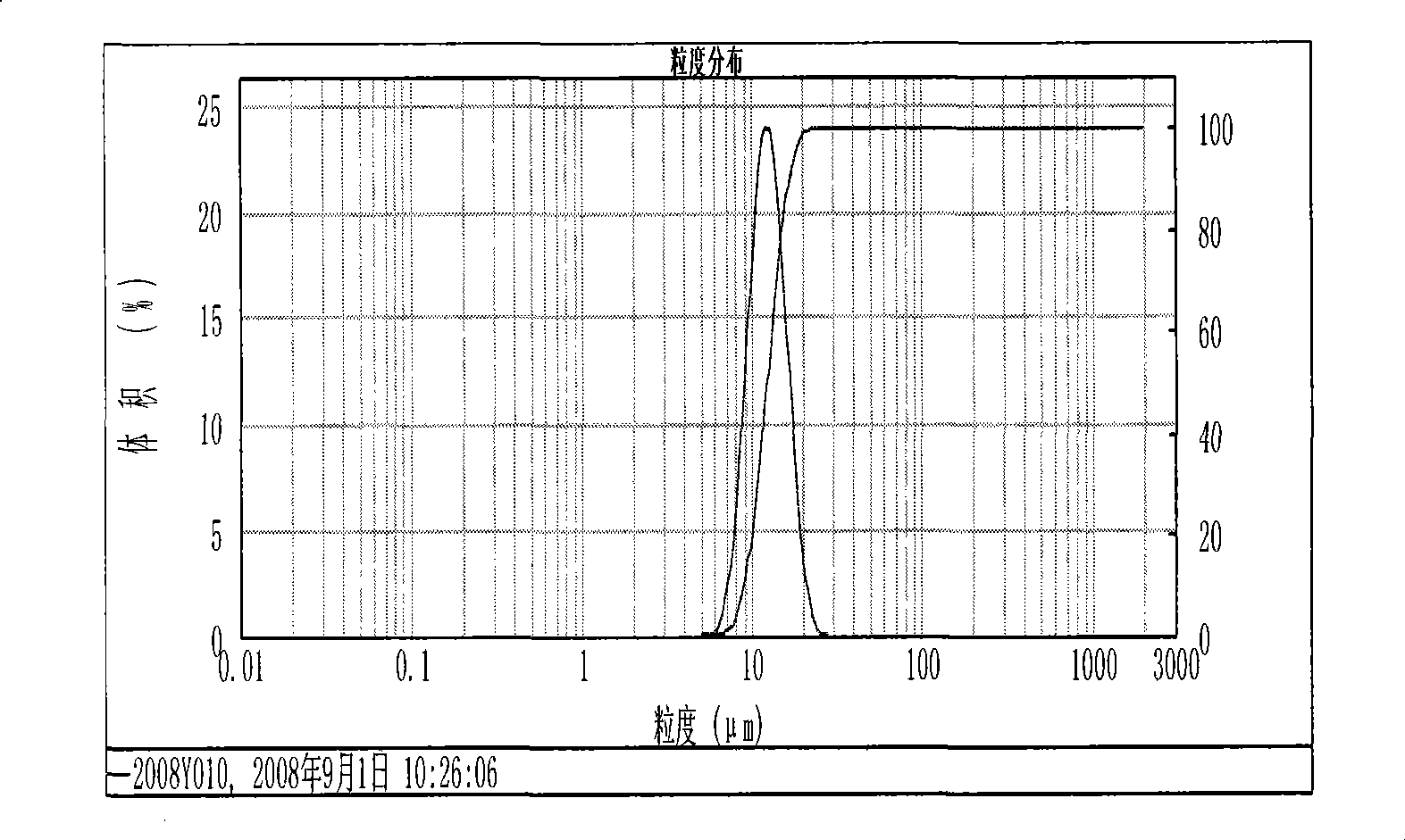

Multi-element composite positive pole material for lithium secondary battery and preparation thereof

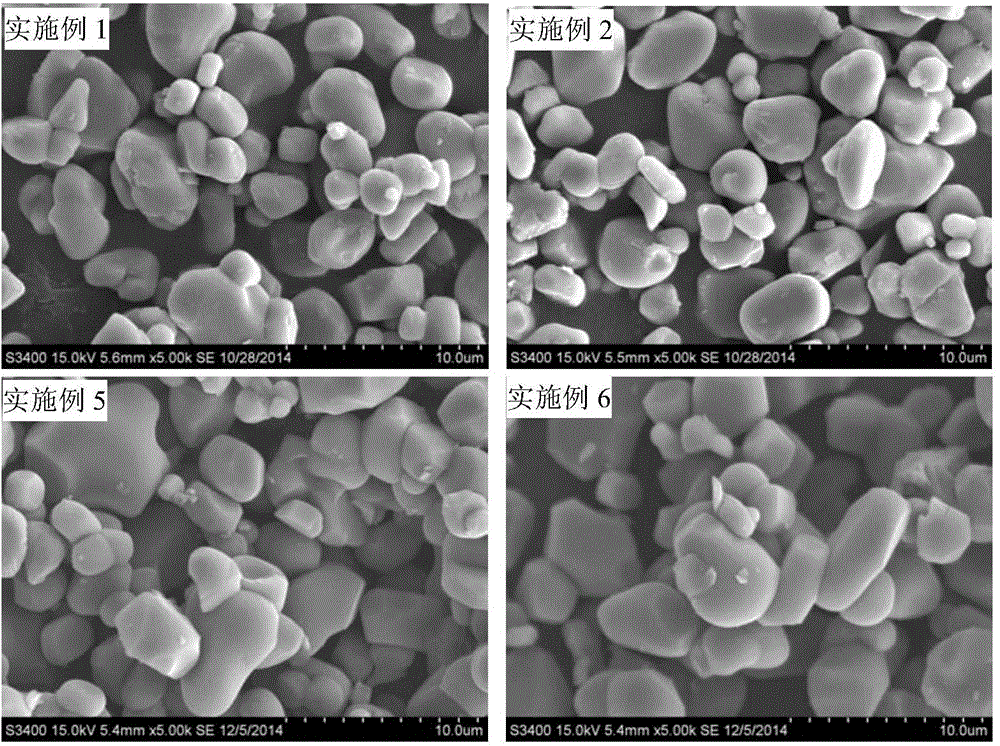

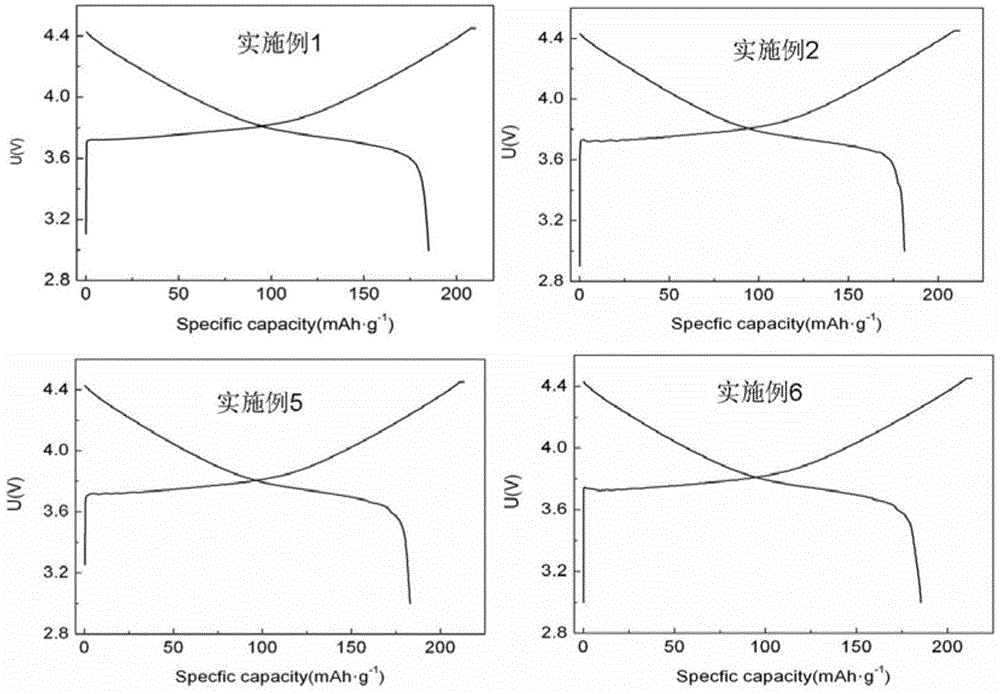

ActiveCN101478044AEnsure mixing uniformityAvoid destructionElectrode manufacturing processesSecondary cellsManganeseSpherical shaped

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

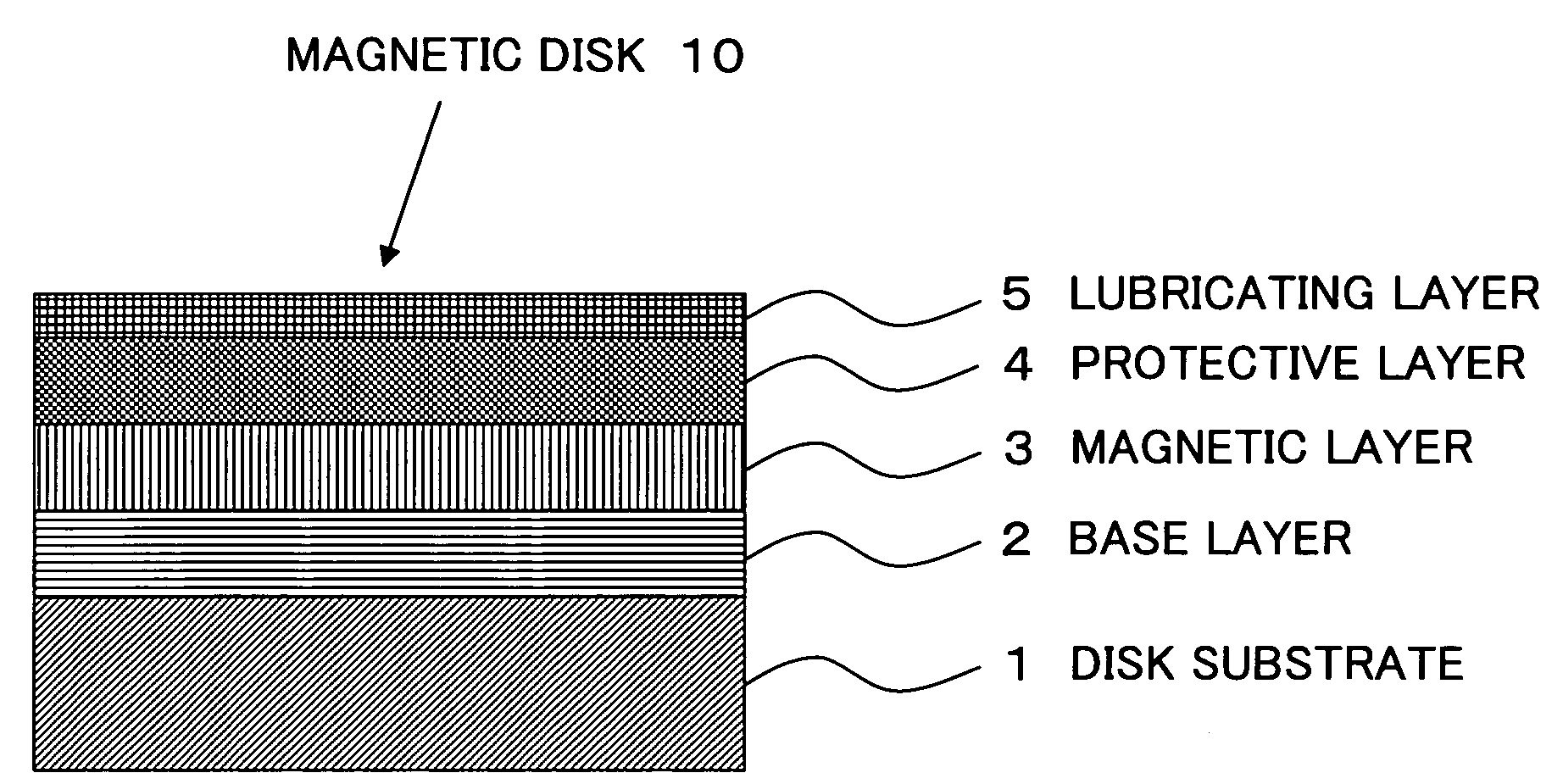

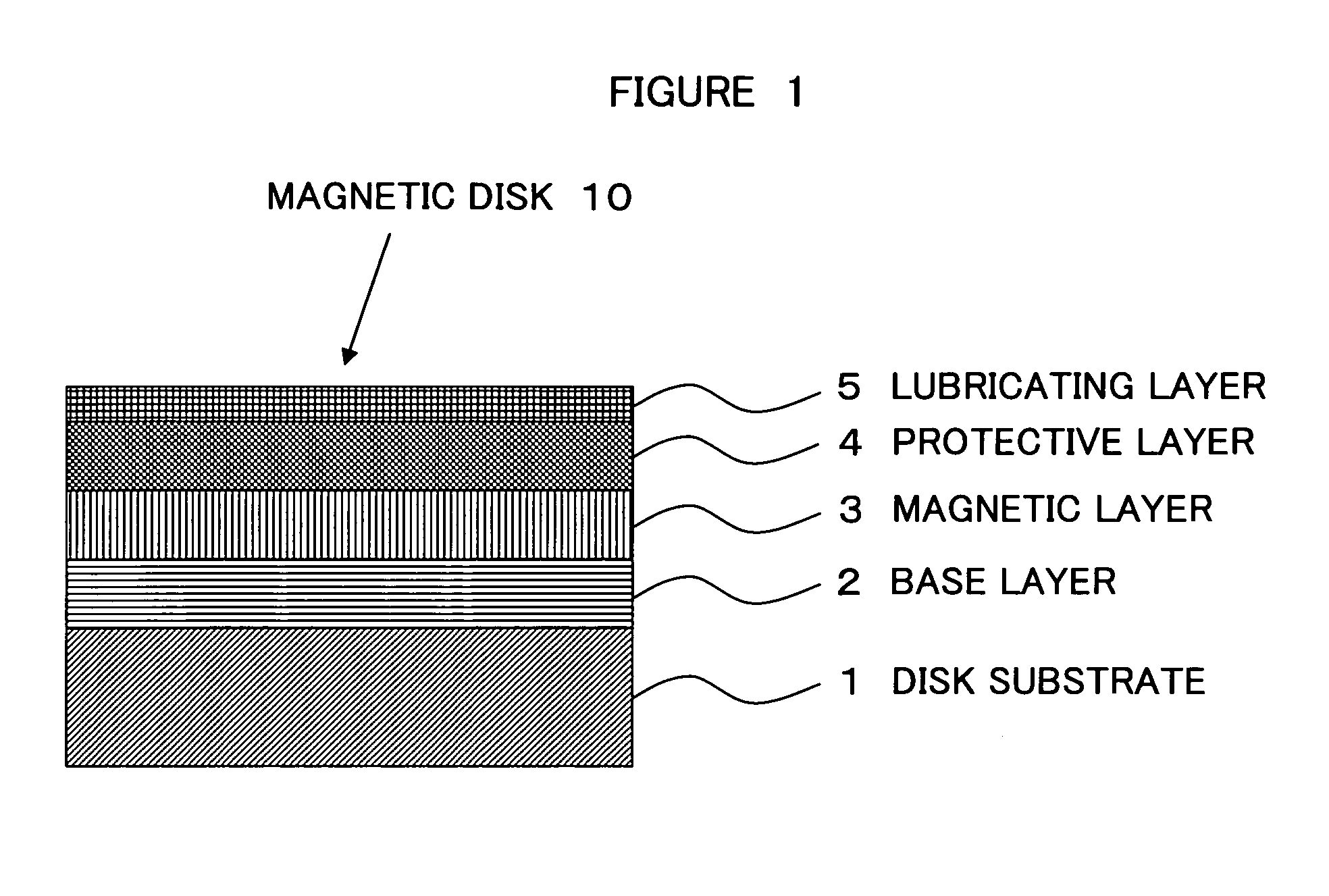

Magnetic disk and method of manufacturing same

Owner:WD MEDIA SINGAPORE PTE

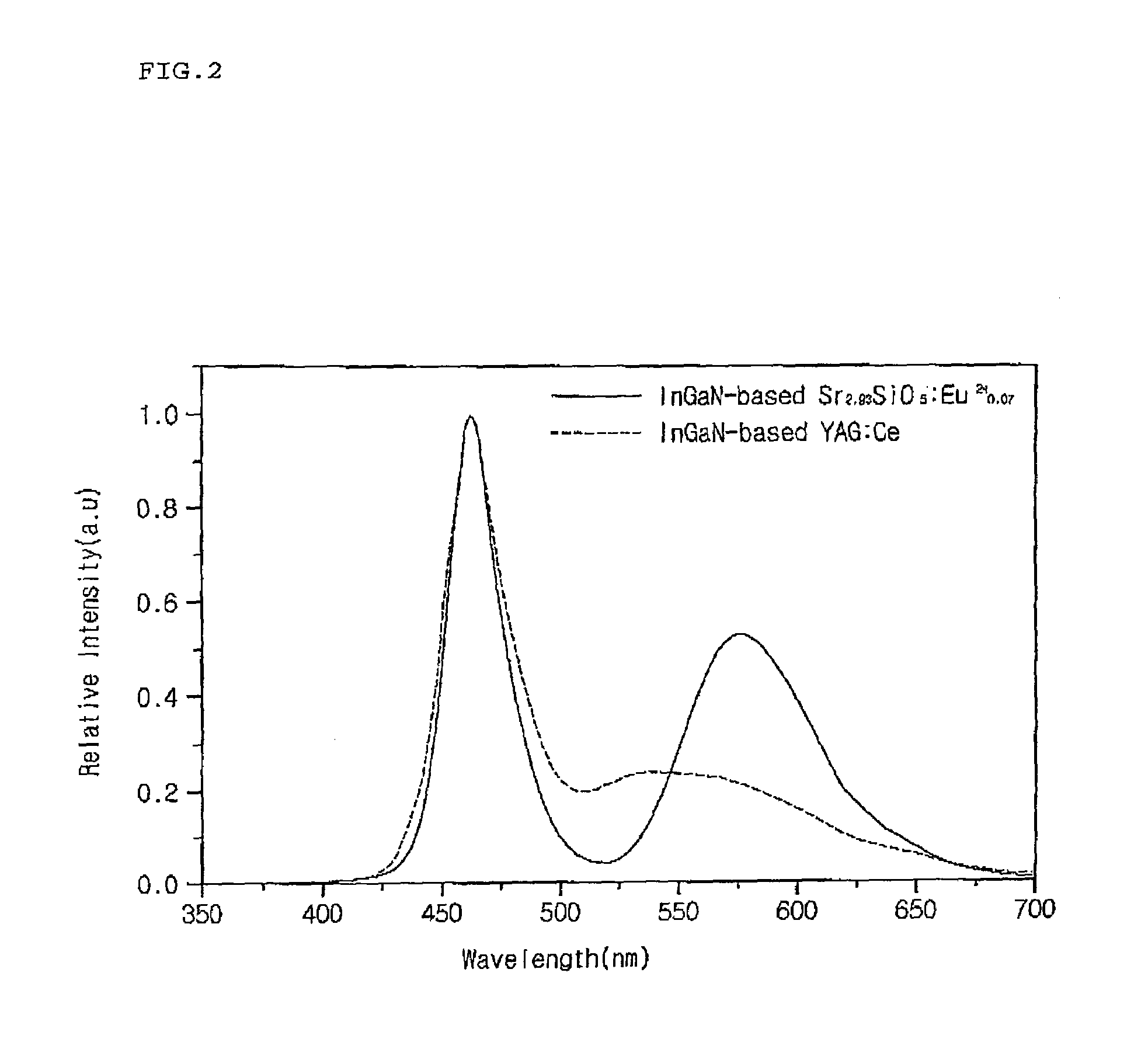

Strontium silicate-based phosphor, fabrication method thereof, and LED using the phosphor

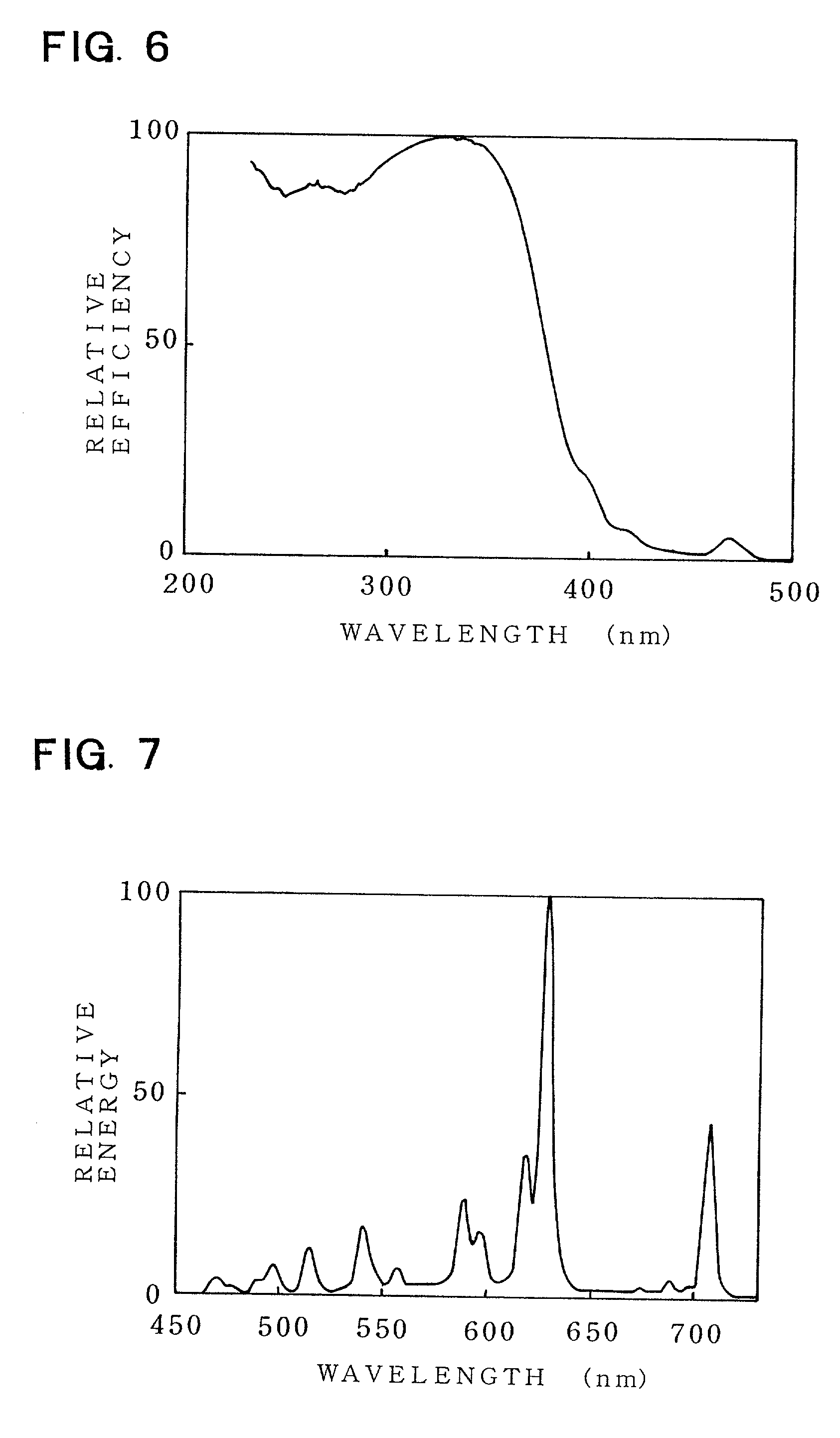

ActiveUS7045826B2Wide wavelength spectrumLuminous properties are stableSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorUltraviolet

A strontium silicate-based phosphor, a fabrication method thereof, and an LED using the strontium silicate-based phosphor are provided. The phosphor is applied to a long wavelength ultraviolet LED, an active luminous LCD, etc., to enable an improvement in the color purity and to enhance the luminous efficiency. The strontium silicate-based phosphor is expressed by a chemical formula: Sr3-xSiO5Eu2+x wherein x is 0<x≦1. The LED using the phosphor has a wide wavelength spectrum, shows a superior color purity characteristic, and can have a very high luminous efficiency as applied in the backlight source of an LED panel or an active luminous LCD.

Owner:KOREA RES INST OF CHEM TECH

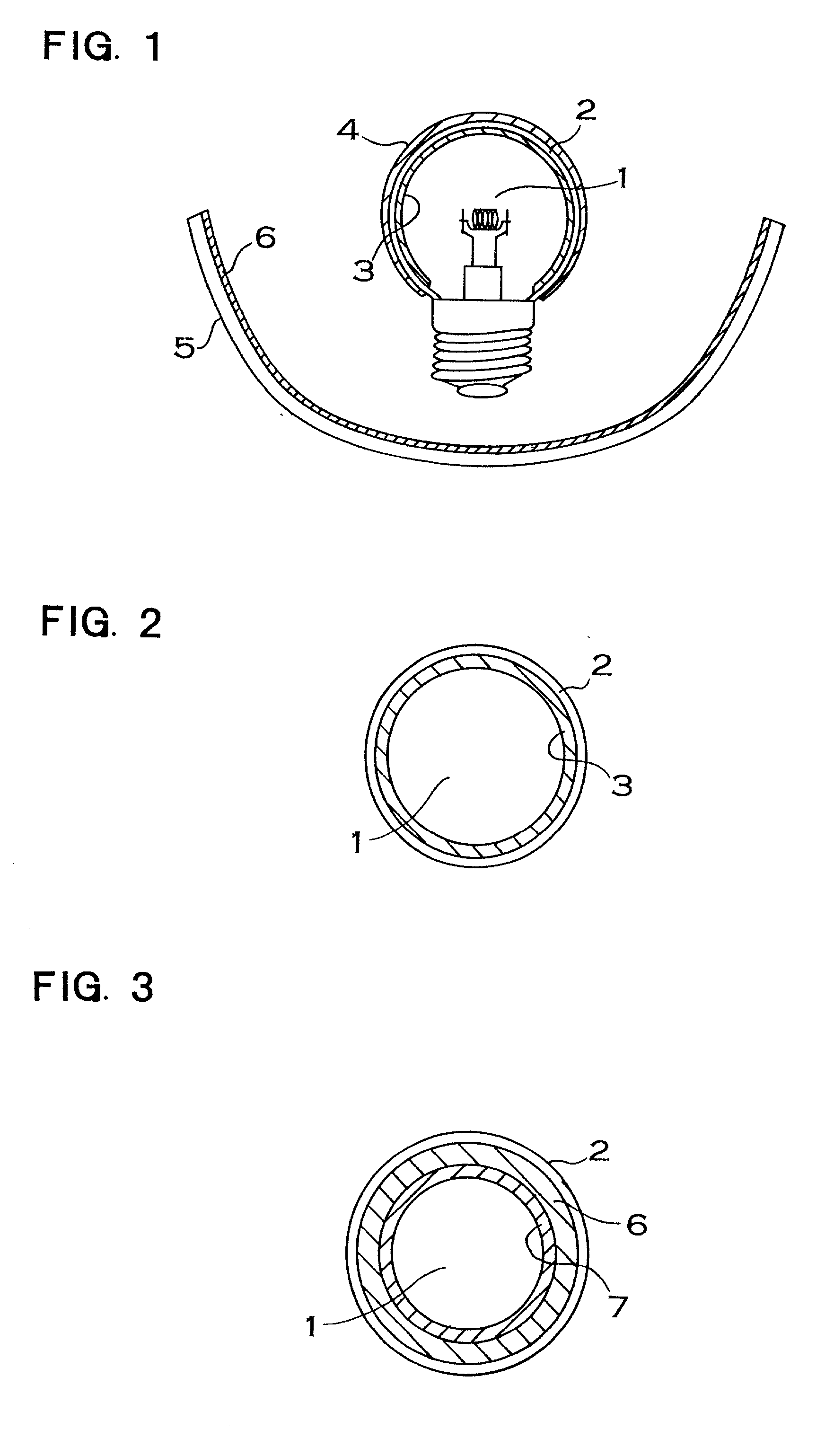

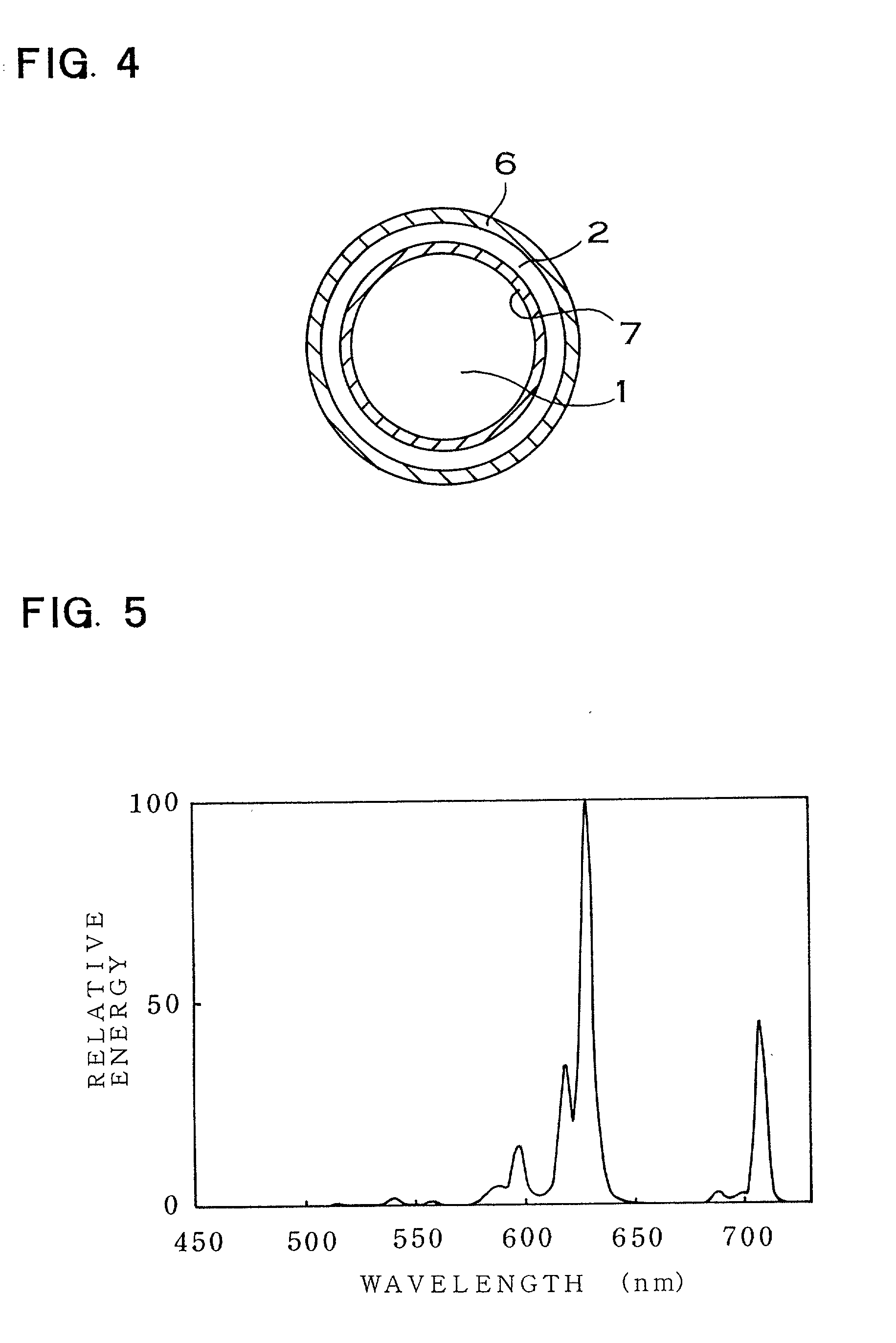

Red light emitting long afterglow photoluminescence phosphor and afterglow lamp thereof

InactiveUS20010043042A1Simple structureLow costDischarge tube luminescnet screensLamp detailsPhotoluminescenceRare earth

A red light emitting afterglow photoluminescence phosphor is a rare earth oxysulfide phosphor activated by Europium, which chemical formula is follows: Ln2O2S:Eux,My 0.00001<=x<=0.5 0.00001<=y<=0.3 wherein Ln is at least one selected from the group consisting of Y, La, Gd and Lu; M is a coactivator which is at least one selected from the group consisting of Mg, Ti, Nb, Ta and Gain the chemical formula.

Owner:NICHIA CORP

Light-emitting semiconductor device, light-emitting system and method for fabricating light-emitting semiconductor device

InactiveUS20050227569A1Excellent toneSuppresses reduction in luminous intensityDischarge tube luminescnet screensPoint-like light sourceFluorescenceDevice material

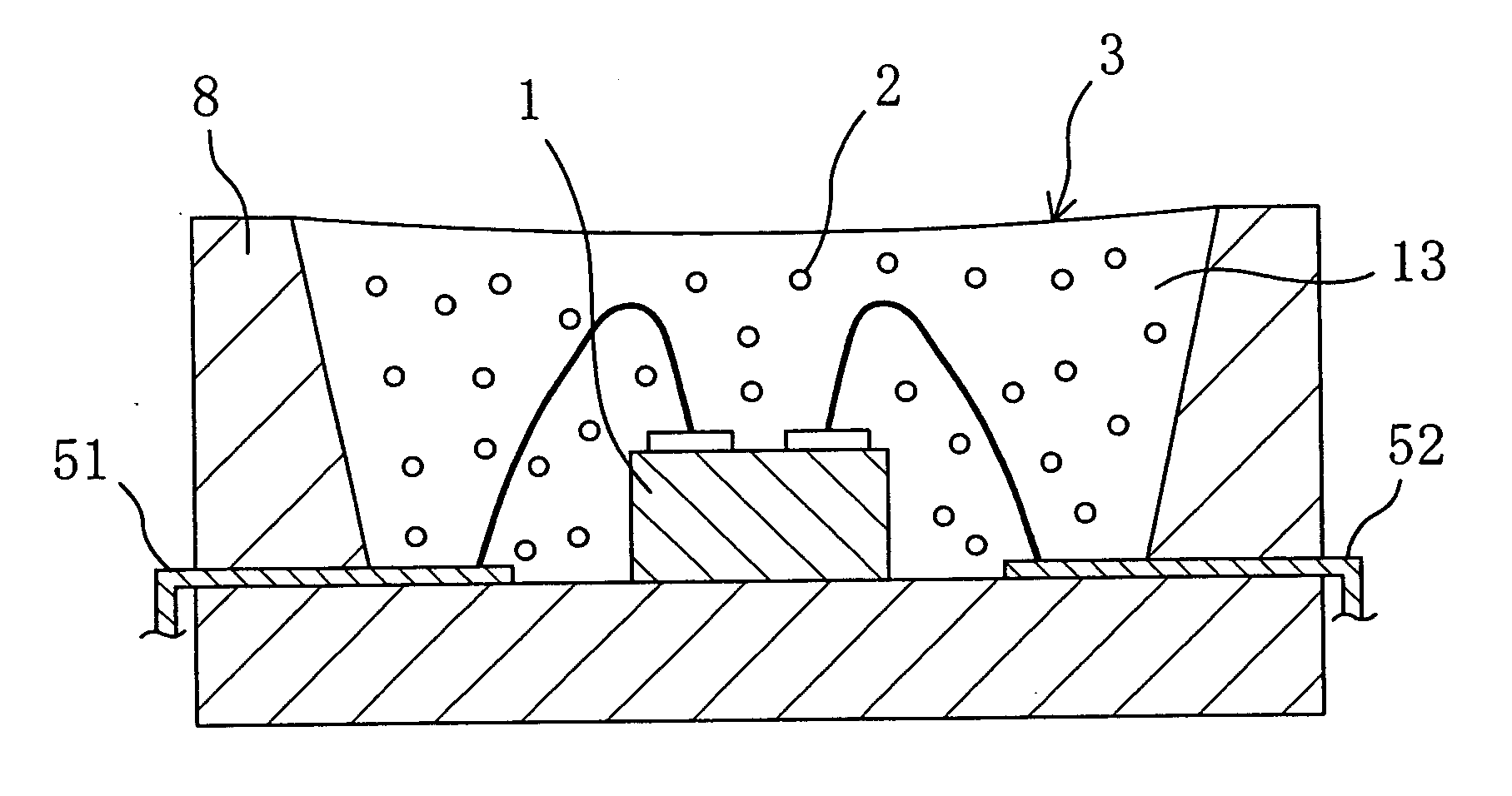

A chip-type light-emitting semiconductor device includes: a substrate 4; a blue LED 1 mounted on the substrate 4; and a luminescent layer 3 made of a mixture of yellow / yellowish phosphor particles 2 and a base material 13 (translucent resin). The yellow / yellowish phosphor particles 2 is a silicate phosphor which absorbs blue light emitted by the blue LED 1 to emit a fluorescence having a main emission peak in the wavelength range from 550 nm to 600 nm, inclusive, and which contains, as a main component, a compound expressed by the chemical formula: (Sr1-a1-b1-xBaa1Cab1Eux)2SiO4 (0≦a1≦0.3, 0≦b1≦0.8 and 0<x<1). The silicate phosphor particles disperse substantially evenly in the resin easily. As a result, excellent white light is obtained.

Owner:PANASONIC CORP

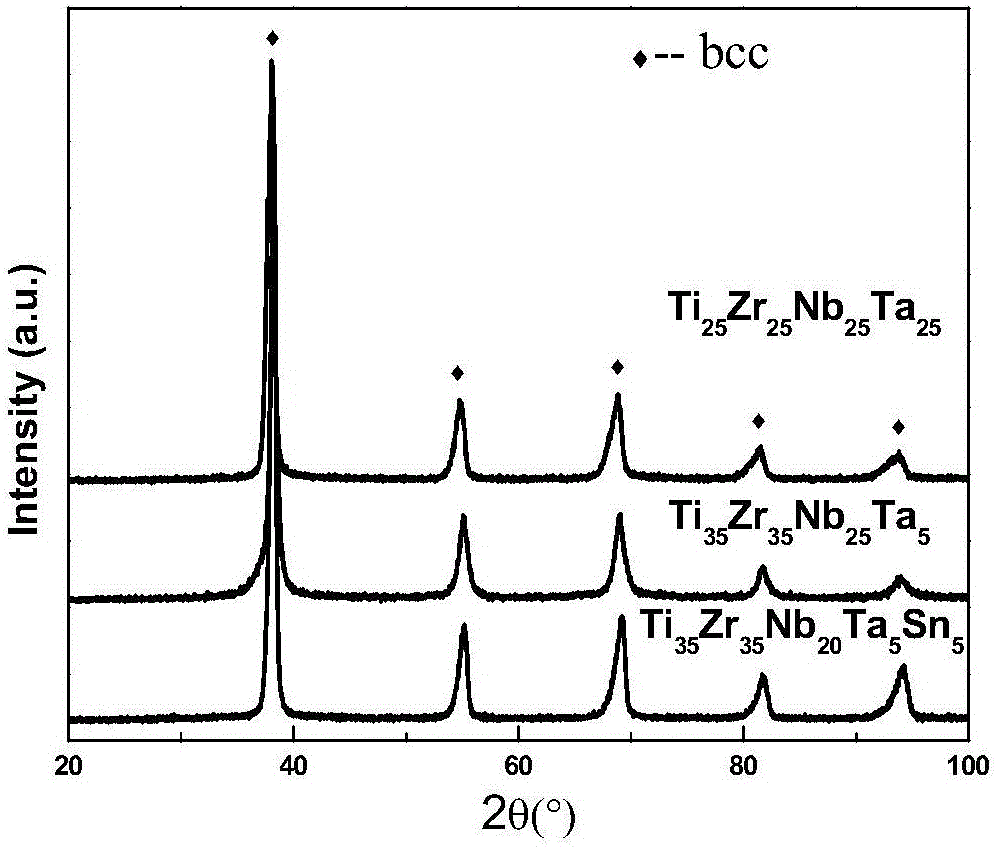

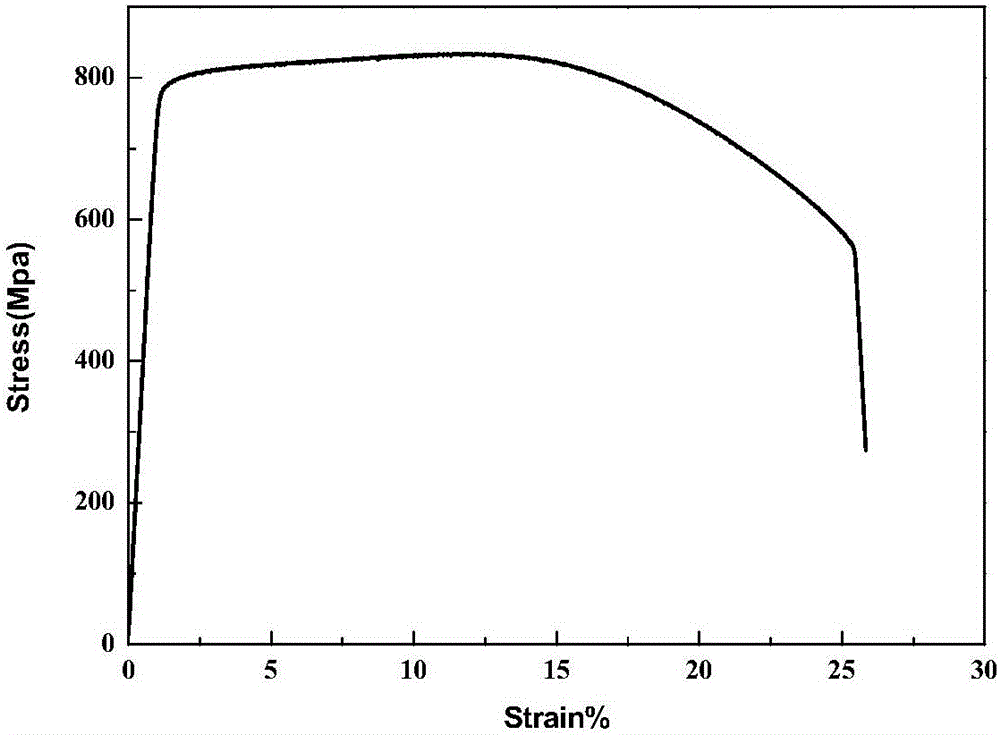

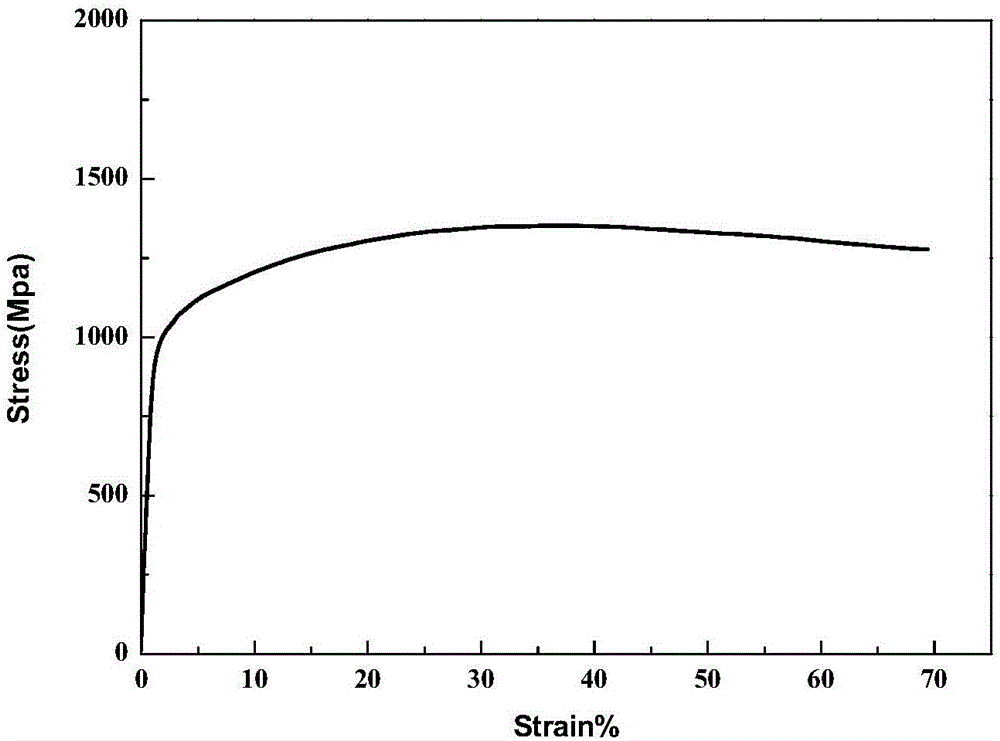

Biomedical TiZrNbTa high-entropy alloy and preparation method thereof

The invention discloses a biomedical TiZrNbTa high-entropy alloy and a preparation method thereof. The high-entropy alloy has a chemical formula of (TiaZrb)x(NbcTad)yMz; the atomic percents of all components are as follows: a not more than 35 at% and not less than 0, b not more than 35 at% and not less than 0, c not more than 35 at% and not less than 0, d not more than 35 at% and not less than 0, a+b=x, c+d=y, x not more than 70 at% and not less than 5, y not more than 70 at% and not less than 5, M is any one or more in V, Mo, Sn, W, Mn, Al, Fe, Co, Ni, Cu, Cr and Zn, z not more than 35 at% and not less than 0, and x+y+z=100. The alloy is higher in strength, excellent in plasticity and low in Young modulus; the components of the alloy is free of poison on human bodies, or are low-toxicity elements to satisfy the biomedical demands; and the high-entropy alloy is broad in application prospect in the aspect of biomedical materials.

Owner:UNIV OF SCI & TECH BEIJING

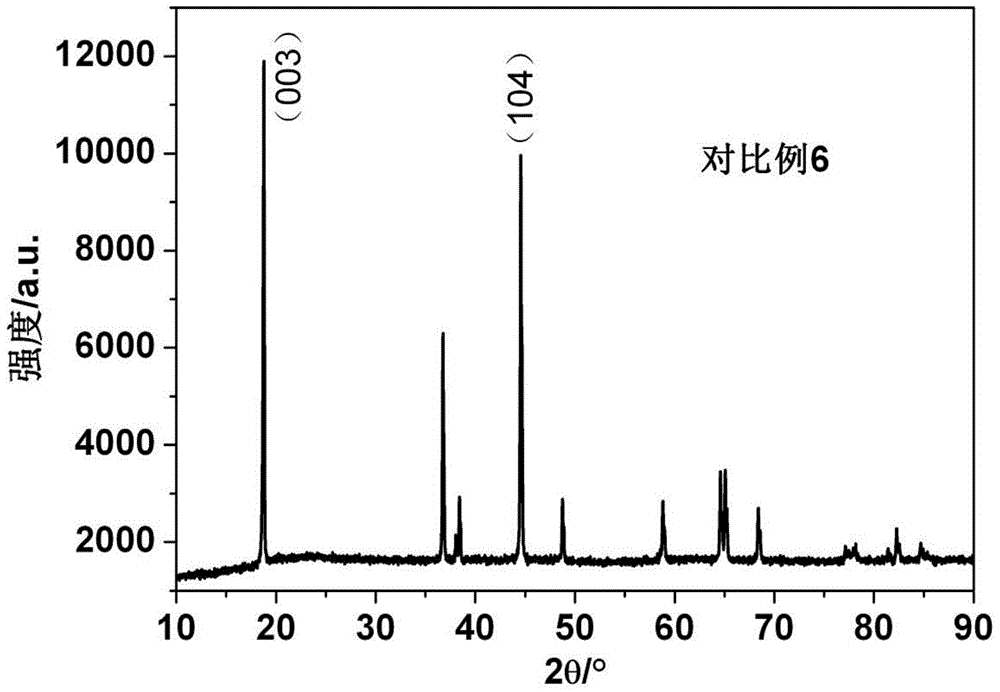

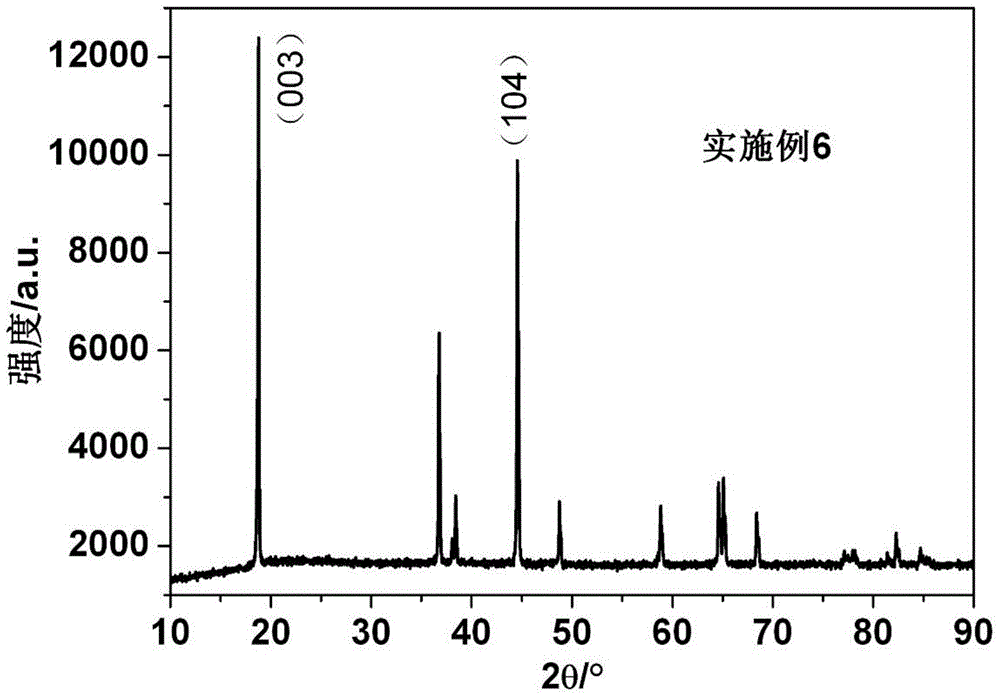

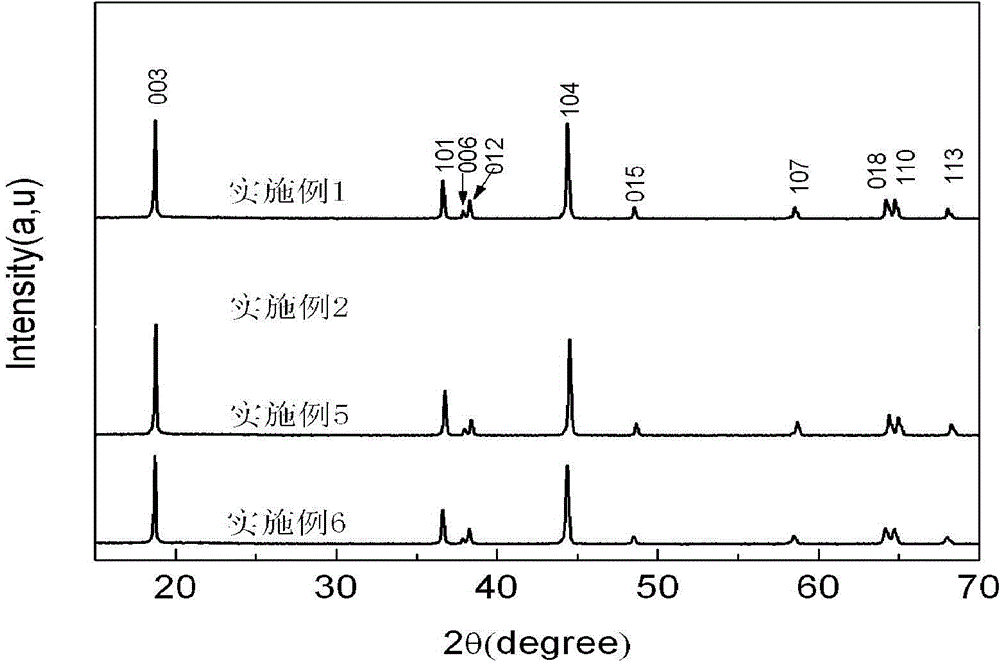

Monocrystal-like lithium battery ternary cathode material and preparation method thereof

The invention relates to a monocrystal-like lithium battery ternary cathode material and a preparation method thereof. The chemical formula of the cathode material is LiNi(1-x-y-z)CoxMnyMzO2, wherein x is larger than 0 and smaller than or equal to 0.65, y is larger than 0 and smaller than or equal to 0.3, z is larger than or equal to 0 and smaller than or equal to 0.05, and M is one or more of Mg, Ca, Ti, Zn, Cr, Fe, Zr, Co, Cu and Ru. The preparation method of the cathode material comprises the following steps of 1 precursor synthesizing; 2 material mixing, wherein a fluxing agent is added in the material mixing process; 3 sintering and the like. According to the method, the melting point of the material is lowered by adding the fluxing agent, therefore, precursors and lithium salts are in a molten environment, dispersion of metal ions is accelerated, and crystal grains start to grow and development at low temperature, break limitation of precursor aggregates after growing to a certain degree to be dispersed into monocrystal grains and finally grow into the cathode material with the monocrystal morphology; the sintering frequency and the sintering time in the existing monocrystal material synthesizing process are decreased, and then the production cost is reduced.

Owner:HENAN KELONG NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com