Patents

Literature

111 results about "Process composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process theory of composition The process theory of composition (hereafter referred to as "process") is a field of composition studies that focuses on writing as a process rather than a product.

Method and system for dry etching a metal nitride

InactiveUS20080230519A1Decorative surface effectsSemiconductor/solid-state device manufacturingTitanium nitrideProcess composition

A method and system of etching a metal nitride, such as titanium nitride, is described. The etching process comprises introducing a process composition having a halogen containing gas, such as Cl2, HBr, or BCl3, and a fluorocarbon gas having the chemical formula CxHyFz, where x and z are equal to unity or greater and y is equal to 0 or greater.

Owner:TOKYO ELECTRON LTD

Processing compositions and method of forming the same

ActiveUS20060110542A1Increased durabilityImprove conditionsPigmenting treatmentFouling preventionSilica particleAdditive ingredient

A method for processing compositions, compositions obtained by such a process and methods of use are disclosed for forming a detachable and renewable protective coating which is substantially transparent. The inventive process compositions are produced by making a highly concentrated dispersion of hydrophobically modified silica particles in the presence of an optional, yet preferable, disilazane derivative under high shear conditions. These process compositions are intended to be further diluted to final treatment compositions, optionally while adding other functional ingredients.

Owner:EVONIK OPERATIONS GMBH

Environmentally compatible processes compositions and materials treated thereby

InactiveUS20040170742A1Cause and induce damageAvoid premature germinationBiocideInorganic active ingredientsEnvironmental resistanceWorkspace

Environmentally friendly processes for prevention of qualitative deterioration and quantitative loss of plant matter and foodstuffs, during all stages of storage and handling, including pre- and post-harvest, pre- and post-planting, distribution and marketing involves the use of H2O2 compositions including Ag and at least one of Cu and Zn ions. The processes can also be used to prevent sprouting and rooting, and to promote fecundity of certain plant matter, and can also be used to eliminate or reduce quantities of harmful organisms and substances from soil, other growth media and substrates, equipment, materials water, workspaces and surfaces.

Owner:PIMI AGRO CLEANTECH

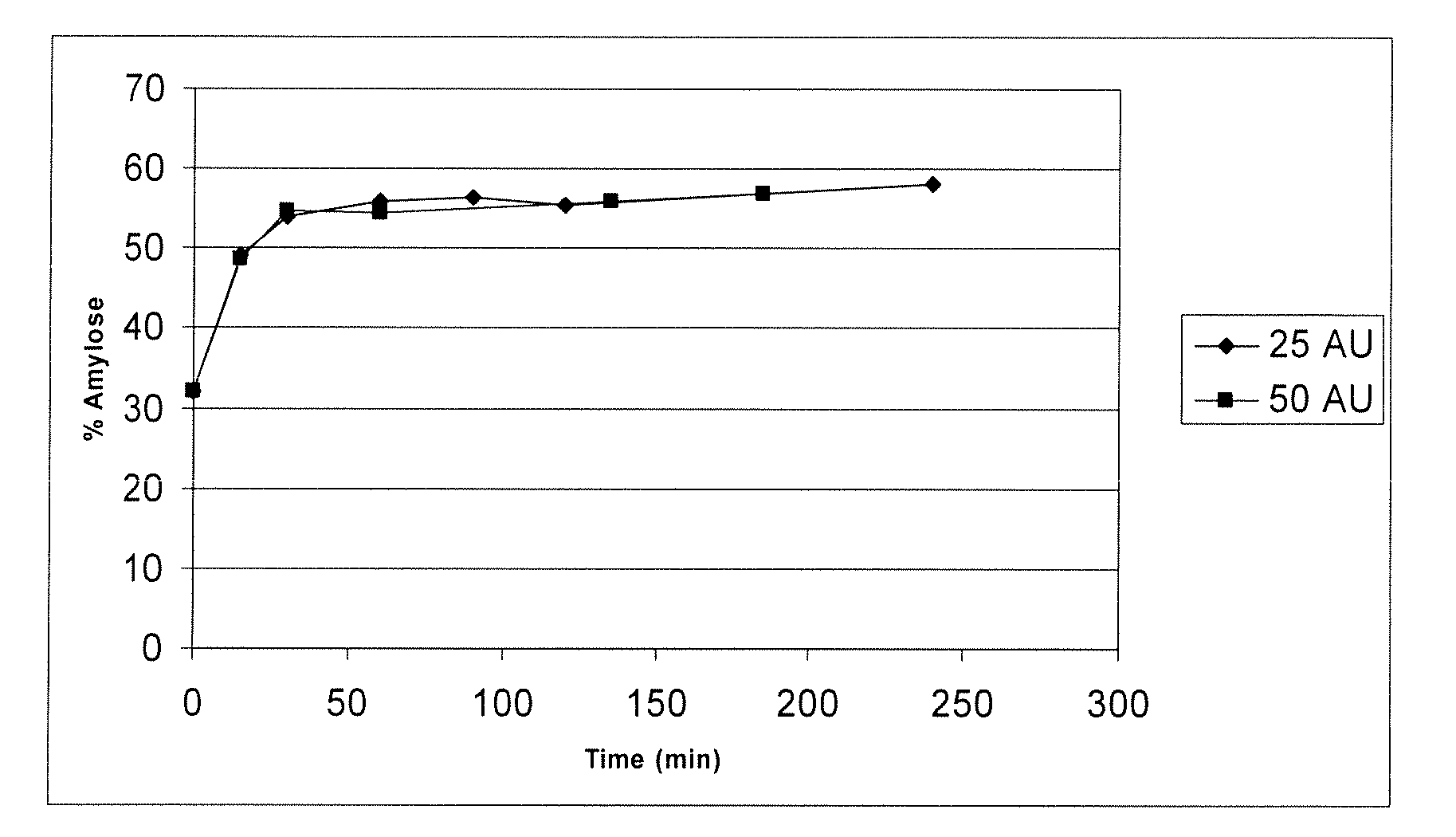

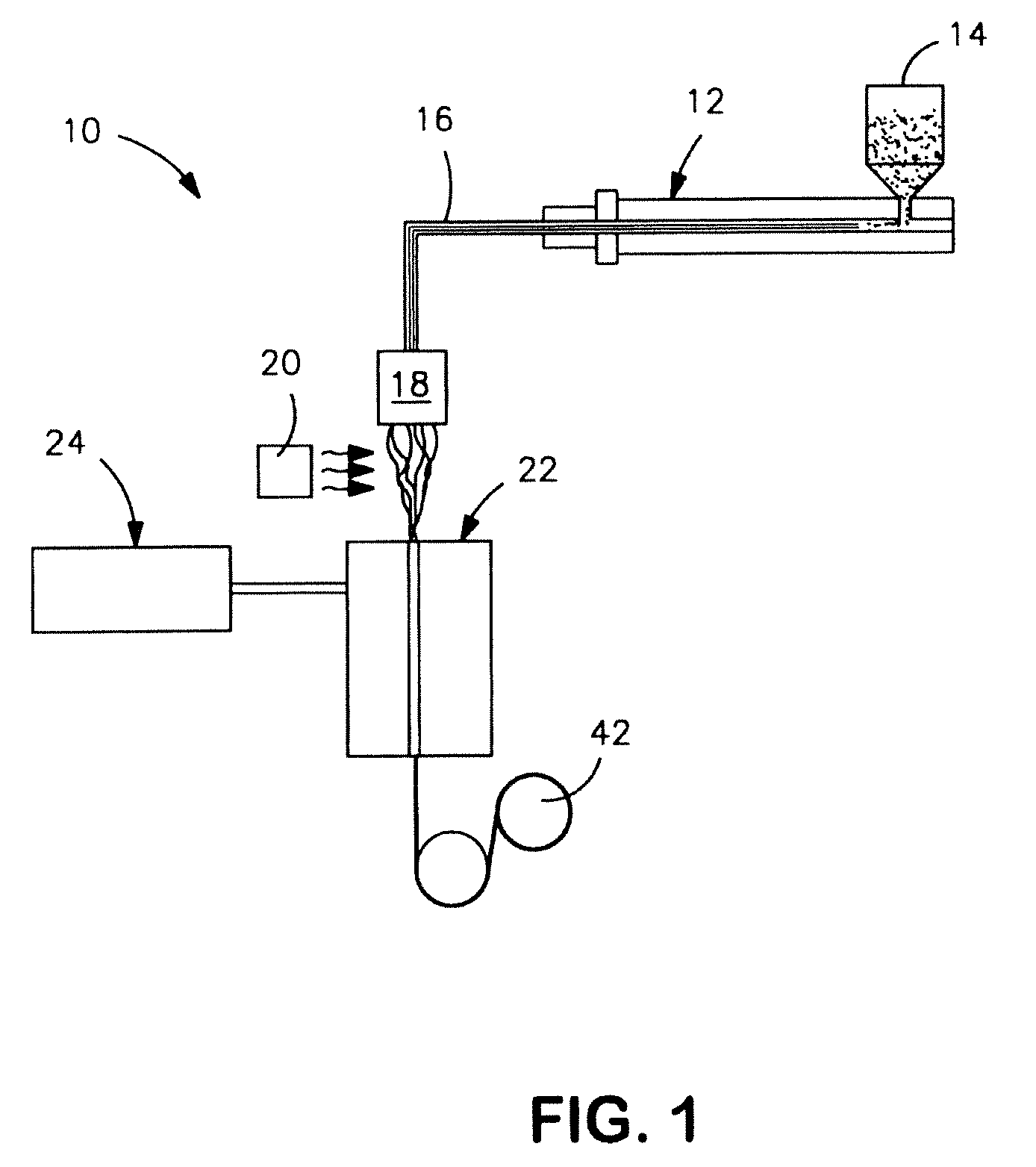

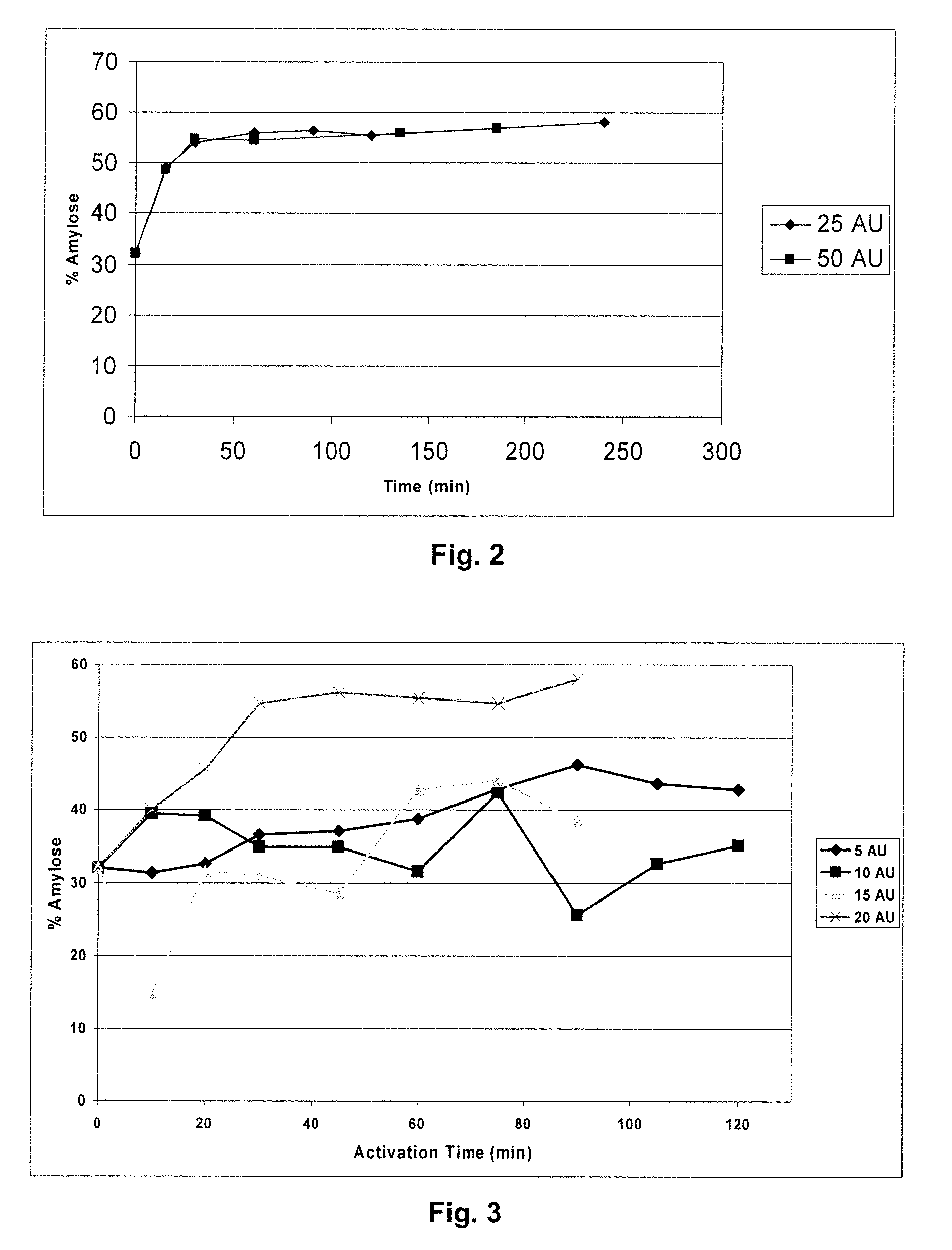

Thermoplastic Starch Formed from an Enzymatically Debranched Starch

A thermoplastic starch for use in a melt-processed composition (e.g., fiber, nonwoven web, etc.) is provided. The thermoplastic starch contains an enzymatically debranched starch and a plasticizer. By selectively controlling certain parameters of the enzymatic modification process (e.g., temperature, enzyme and starch concentrations, reaction time, isolation method, etc.), the present inventors have discovered that a native starch may be hydrolyzed in a highly efficient manner to form compositions having a comparably lower weight average molecular weight and viscosity, which are particularly suitable for use in the formation of thermoplastic starches for use in melt processing applications.

Owner:KIMBERLY-CLARK WORLDWIDE INC

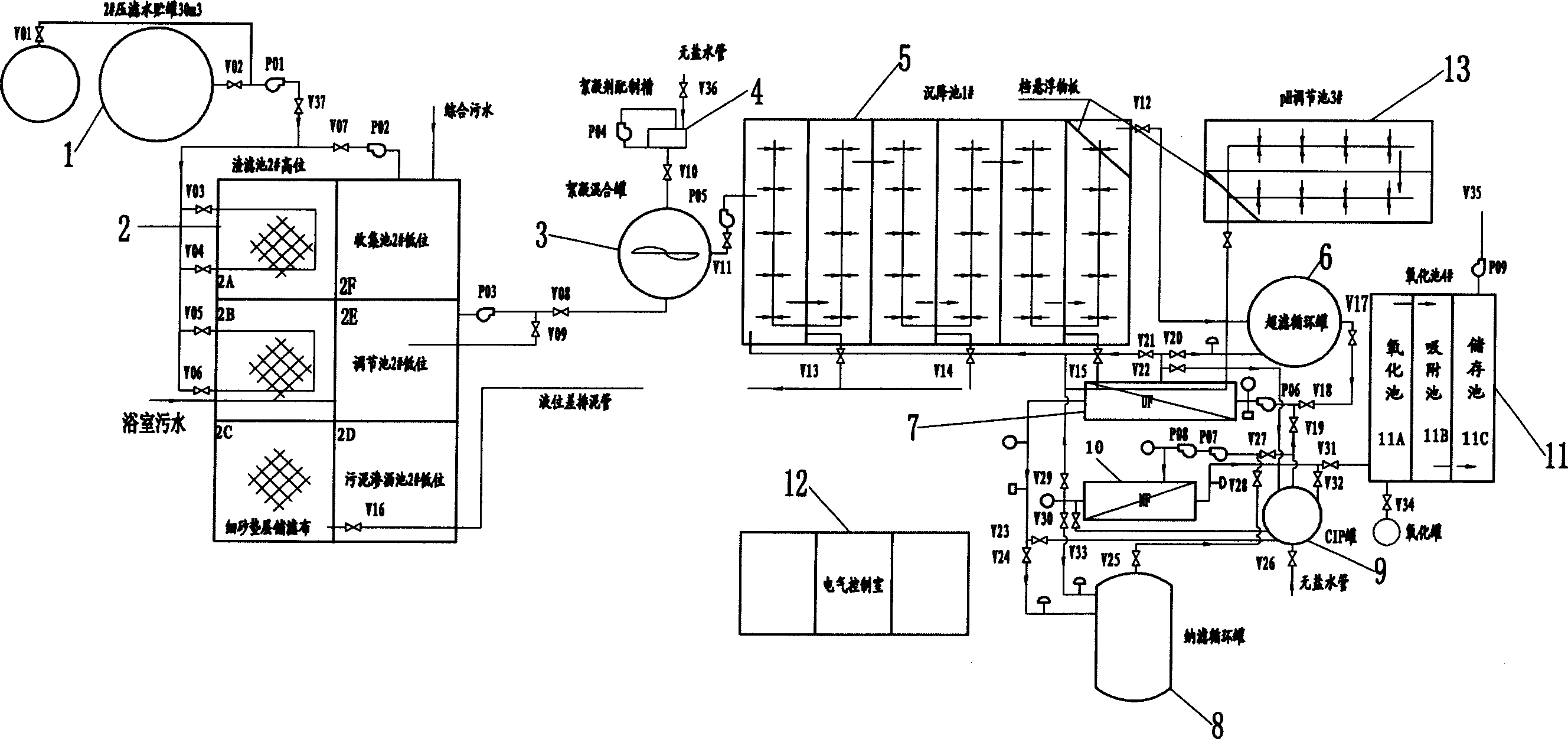

Nitrosobacterium-anaerobic ammonium oxidizing bacteria immobilization and middle-temperature sewage treatment process

InactiveCN101205099APromote proliferationIncrease concentrationTreatment with anaerobic digestion processesOn/in organic carrierNitrogen gasChemistry

The invention relates to a technique of nitrococcus and anaerobic ammonium-oxidation bacteria immobilization and mesothermal sewage treatment, which consists of nitrococcus immobilization technique and anaerobic ammonium-oxidation bacteria immobilization technique and combination of the two techniques is realized in an anaerobic baffled reactor under the condition of 20 to 25 DEG C. Concentration of nitrogen of the inlet sewage is below 100mg L<-1>; nitrite is produced during the middle part by nitrosoation reaction; the rest ammonia is carried out the anaerobic ammonium-oxidation reaction with the nitrite that the nitrogen is produced to get out of the system to ensure the nitrogen in the sewage be high efficiently removed in the mesothermal condition.The invention has the advantages that: (1) environment of vector is in favor of proliferation of biological cell, which can raise the concentration of microbiology which participate reaction to enhance reaction efficiency; (2) under the situation of no consumption of organic carbon source and acid-bases neutralizer as well as decrease of oxygen consumption, biological nitrogen removal can be realized and sewage treatment temperature is lowered to 20 to 25 DEG C, which has great energy-saving benefit.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

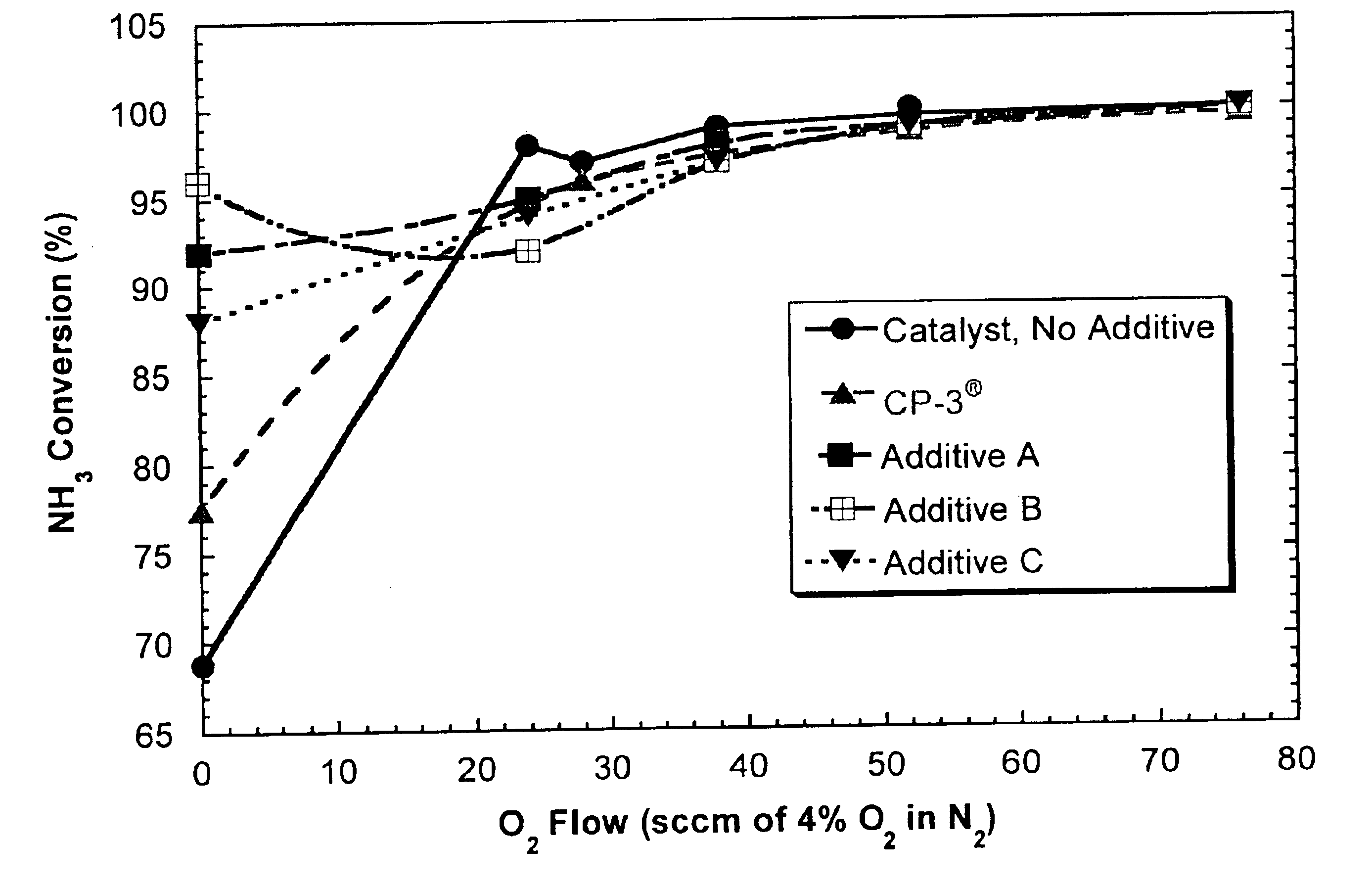

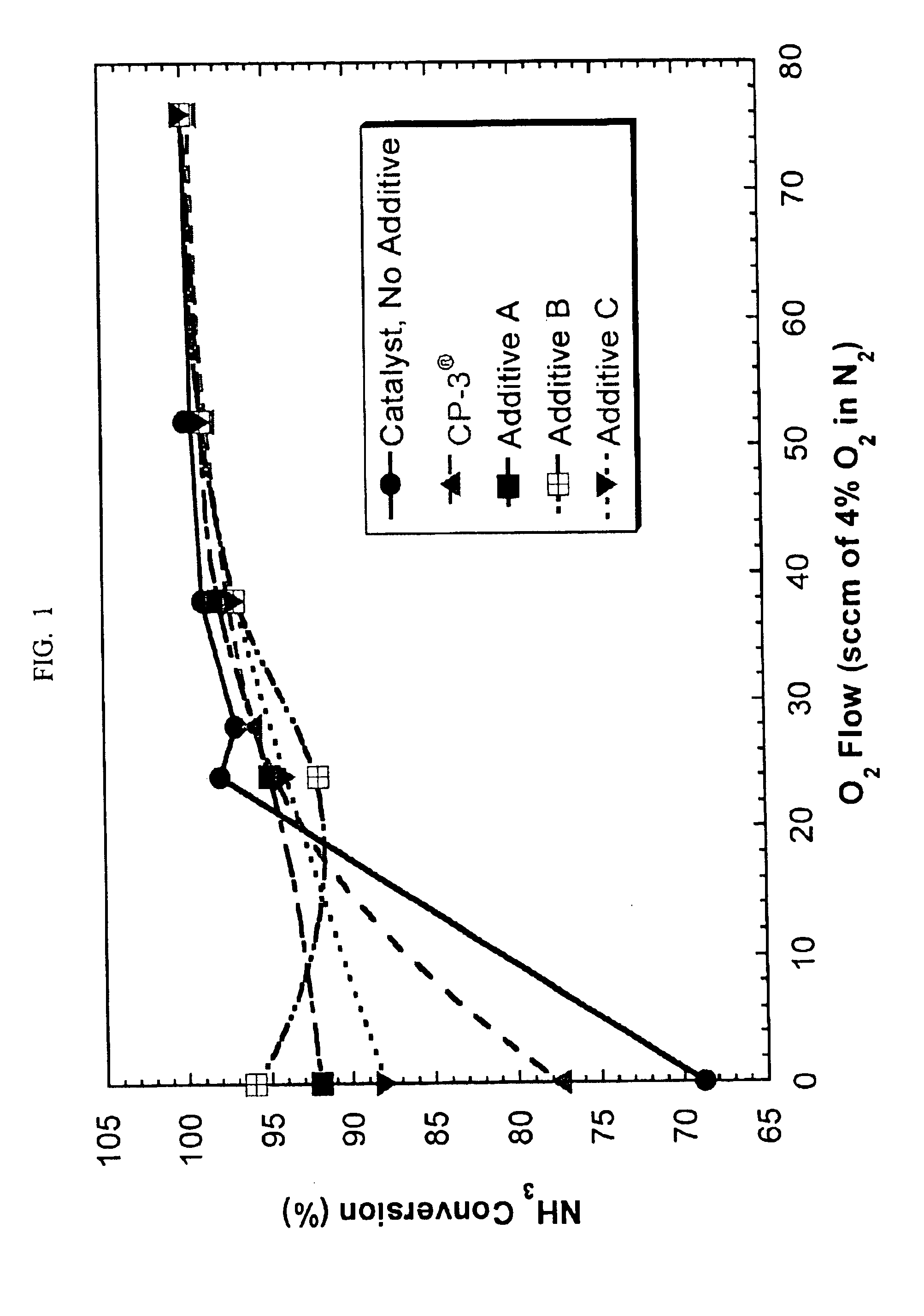

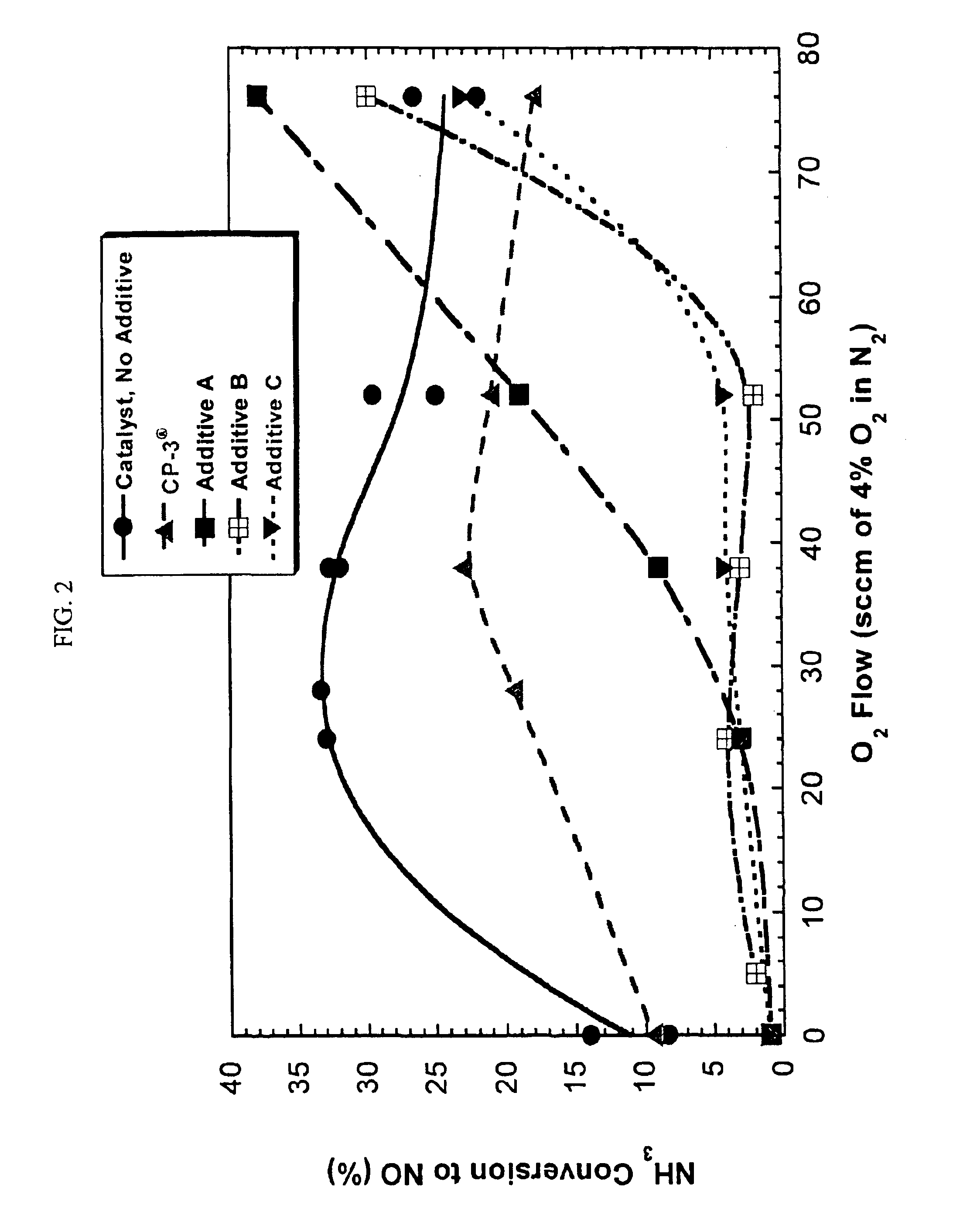

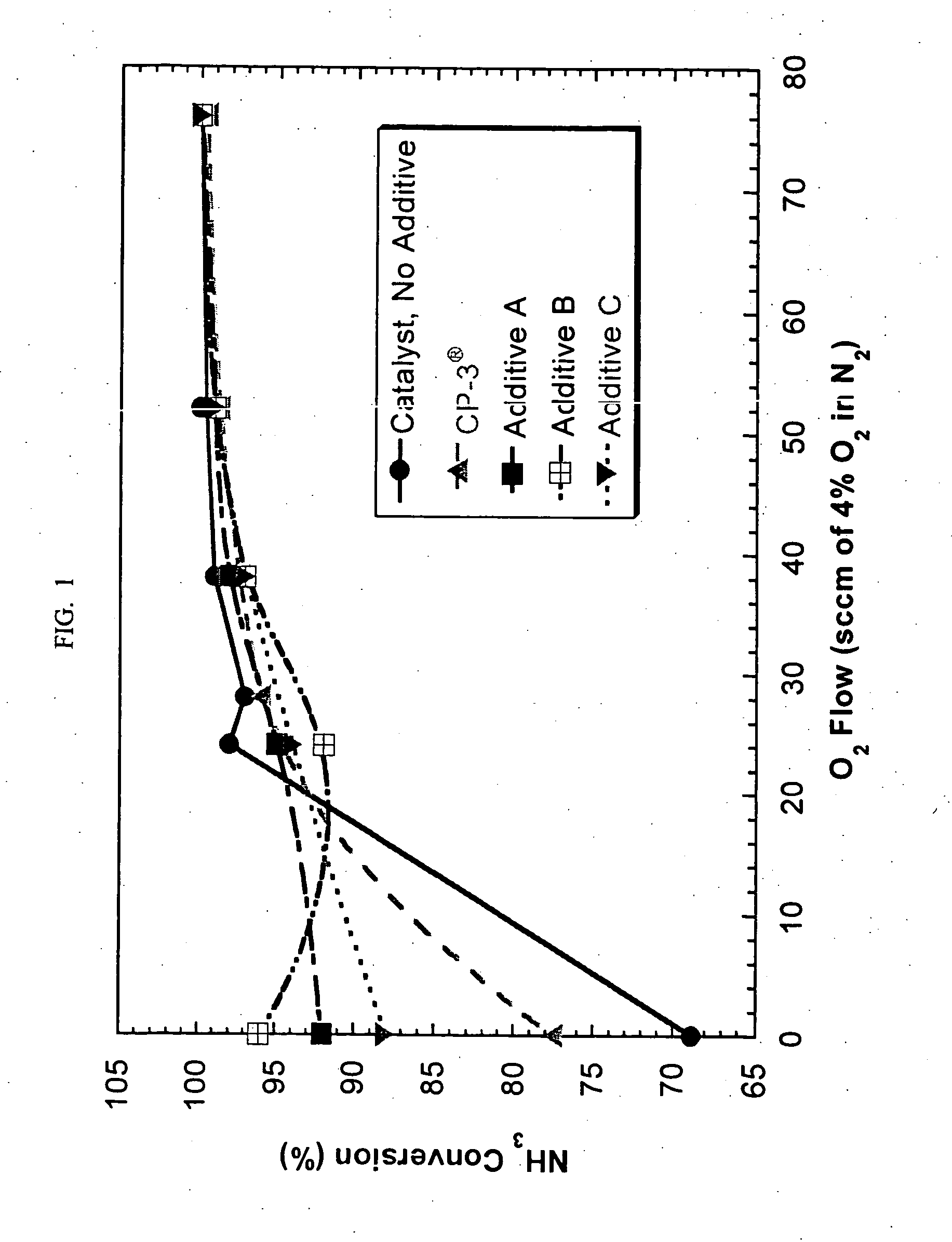

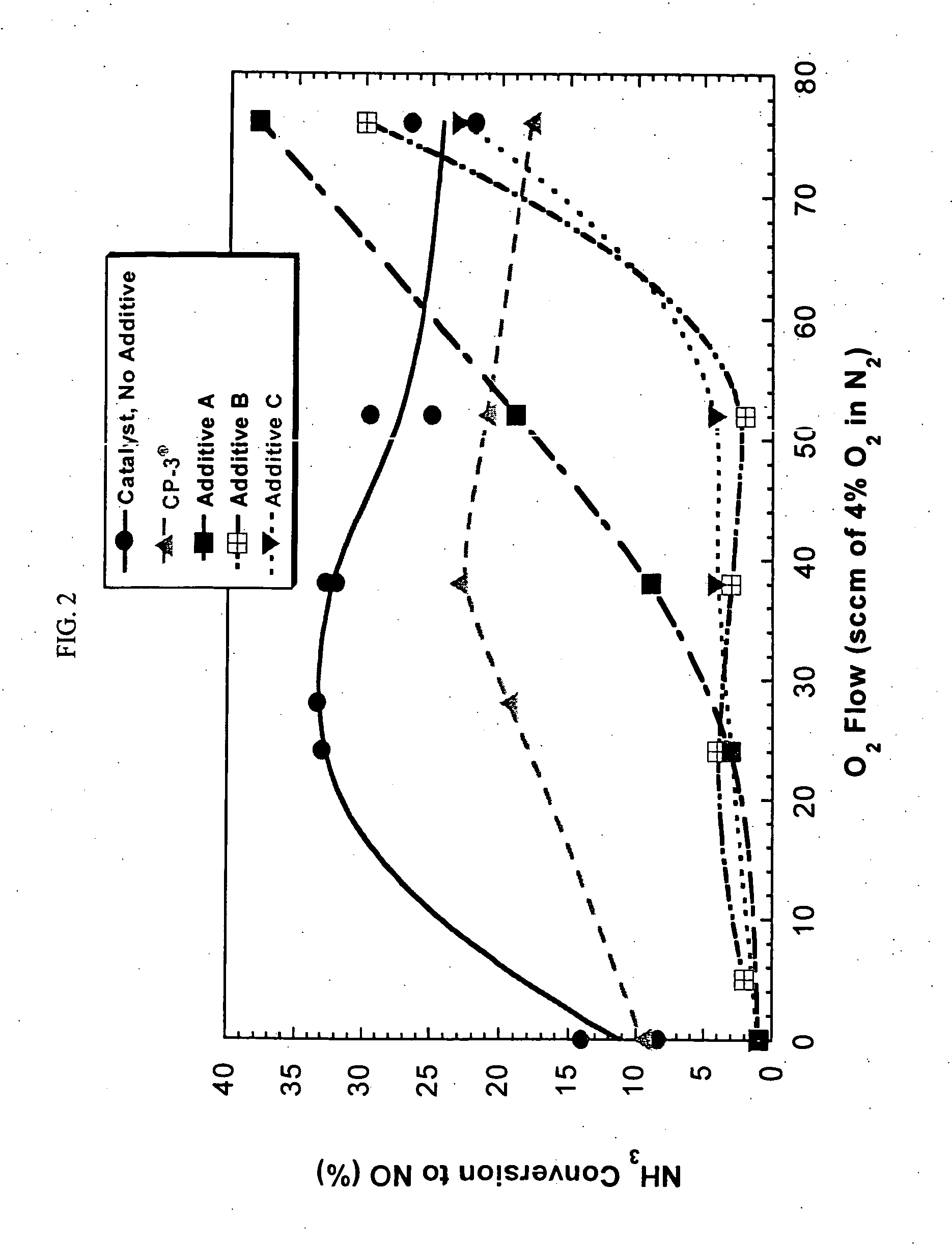

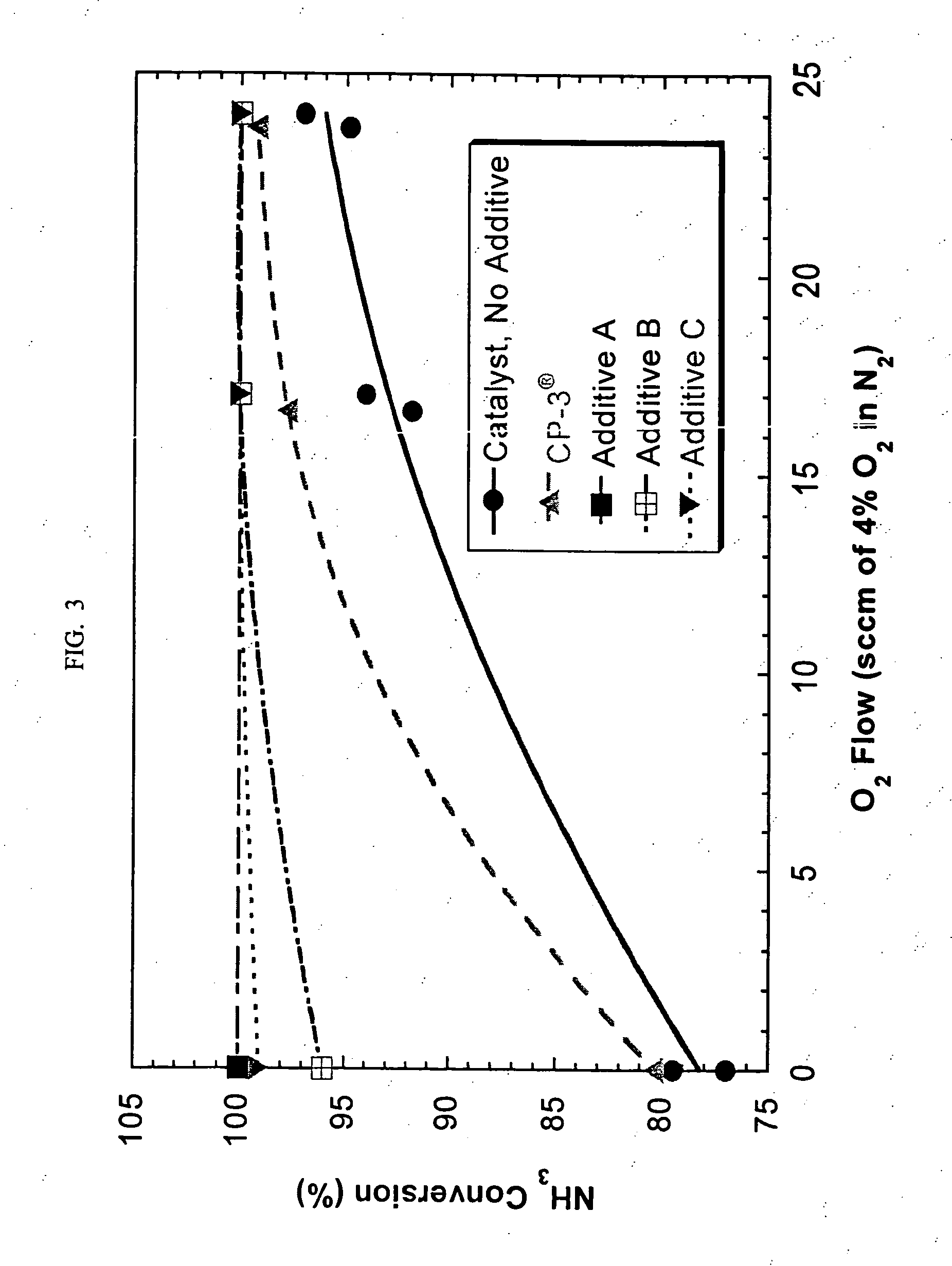

NOx reduction compositions for use in FCC processes

InactiveUS6881390B2Minimize conversionReduce contentCatalytic crackingNitrogen compoundsIridiumAlkaline earth metal

Compositions for reduction of gas phase reduced nitrogen species and NOx generated during a partial or incomplete combustion catalytic cracking process, preferably, a fluid catalytic cracking process, are disclosed. The compositions comprise (i) an acidic metal oxide containing substantially no zeolite, (ii) an alkali metal, alkaline earth metal, and mixtures thereof, (iii) an oxygen storage component, and (iv) a noble metal component, preferably rhodium or iridium, and mixtures thereof, are disclosed. Preferably, the compositions are used as separate additives particles circulated along with the circulating FCC catalyst inventory. Reduced emissions of gas phase reduced nitrogen species and NOx in an effluent off gas of a partial or incomplete combustion FCC regenerator provide for an overall NOx reduction as the effluent gas stream is passed from the FCC regenerator to a CO boiler, whereby as CO is oxidized to CO2 a lesser amount of the reduced nitrogen species is oxidized to NOx.

Owner:WR GRACE & CO CONN

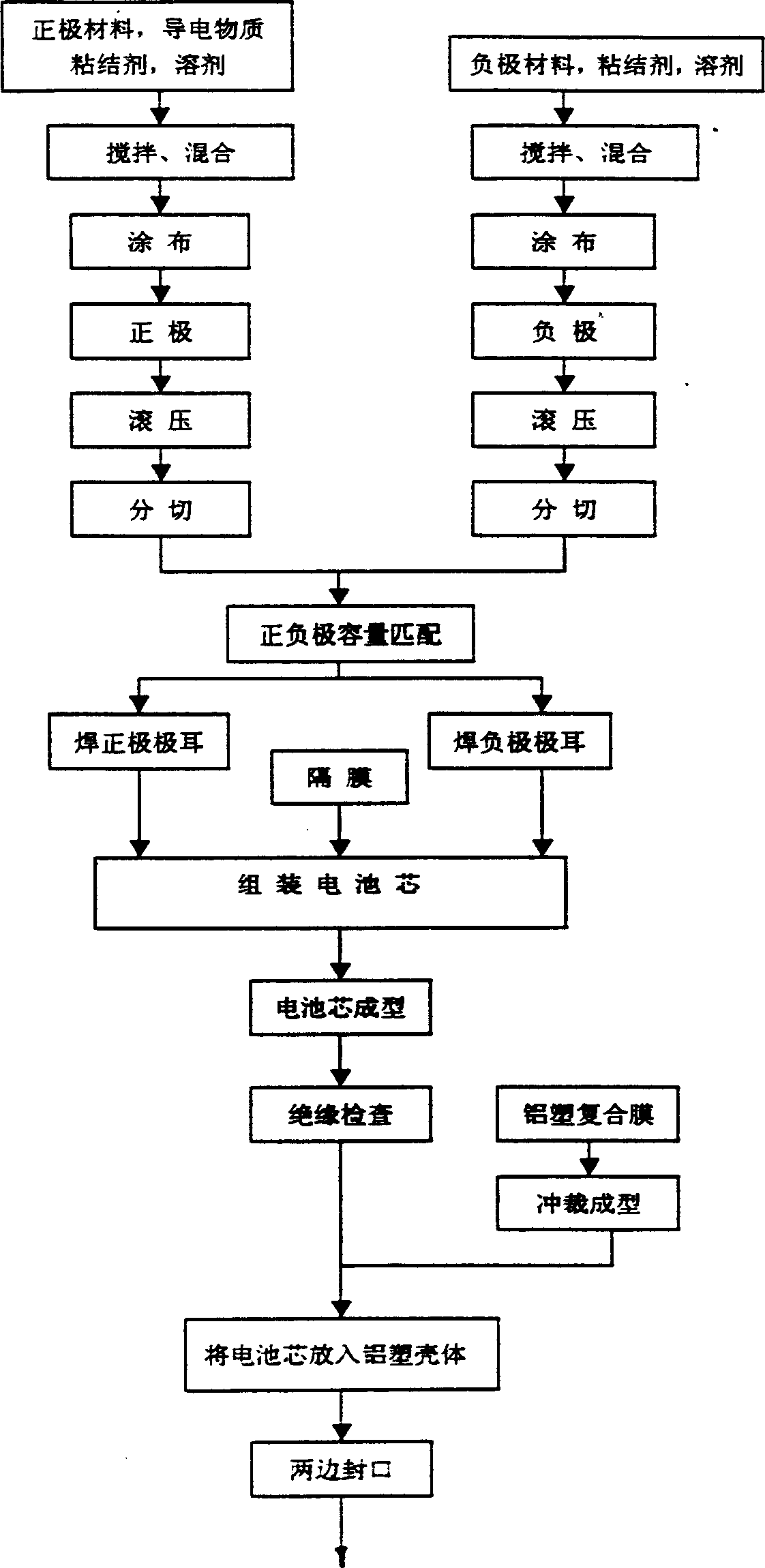

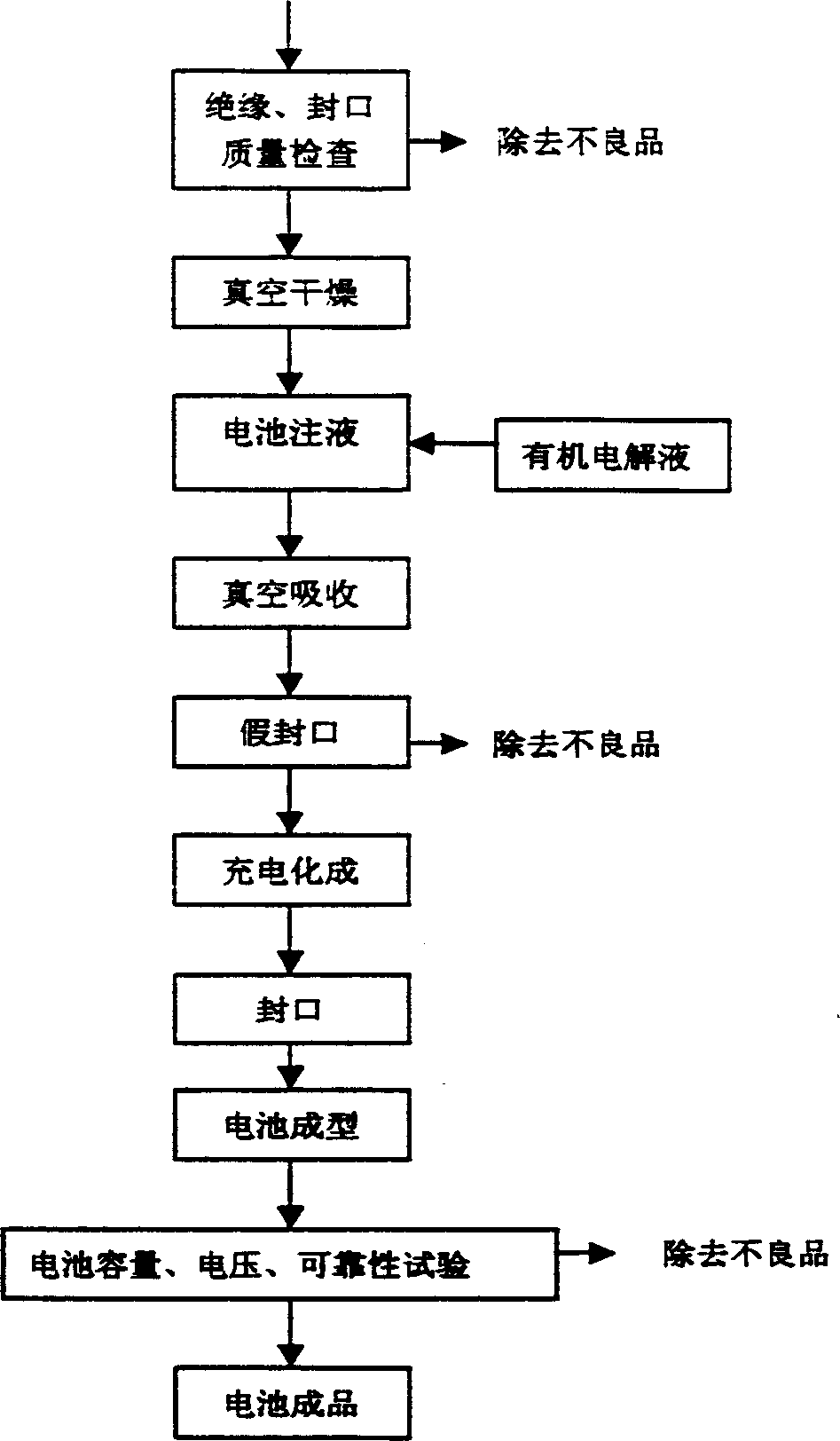

Bag lithium ion battery preparing method and battery thereby

InactiveCN1457113AVariable shapeAvoid deformationFinal product manufactureElectrolyte accumulators manufactureHigh densityPole piece

The battery is composed of the packaging bag made from aluminum-plastic complex film, positive and negative pole pieces, diaphragms, pole ears and electrolyte. The preparing method includes following technical procedures: forming the container for battery core, preparing and shaping positive and negative pole pieces, charging electrolyte, sealking etc. Under general environment, the method can manufacture batteries with different thickness and shapes in low cost and easy operations. The battery possesses the features of high density, lightweight, small size, large discharging current and good periodicity etc.

Owner:FUJIAN NANPING NANFU BATTERY

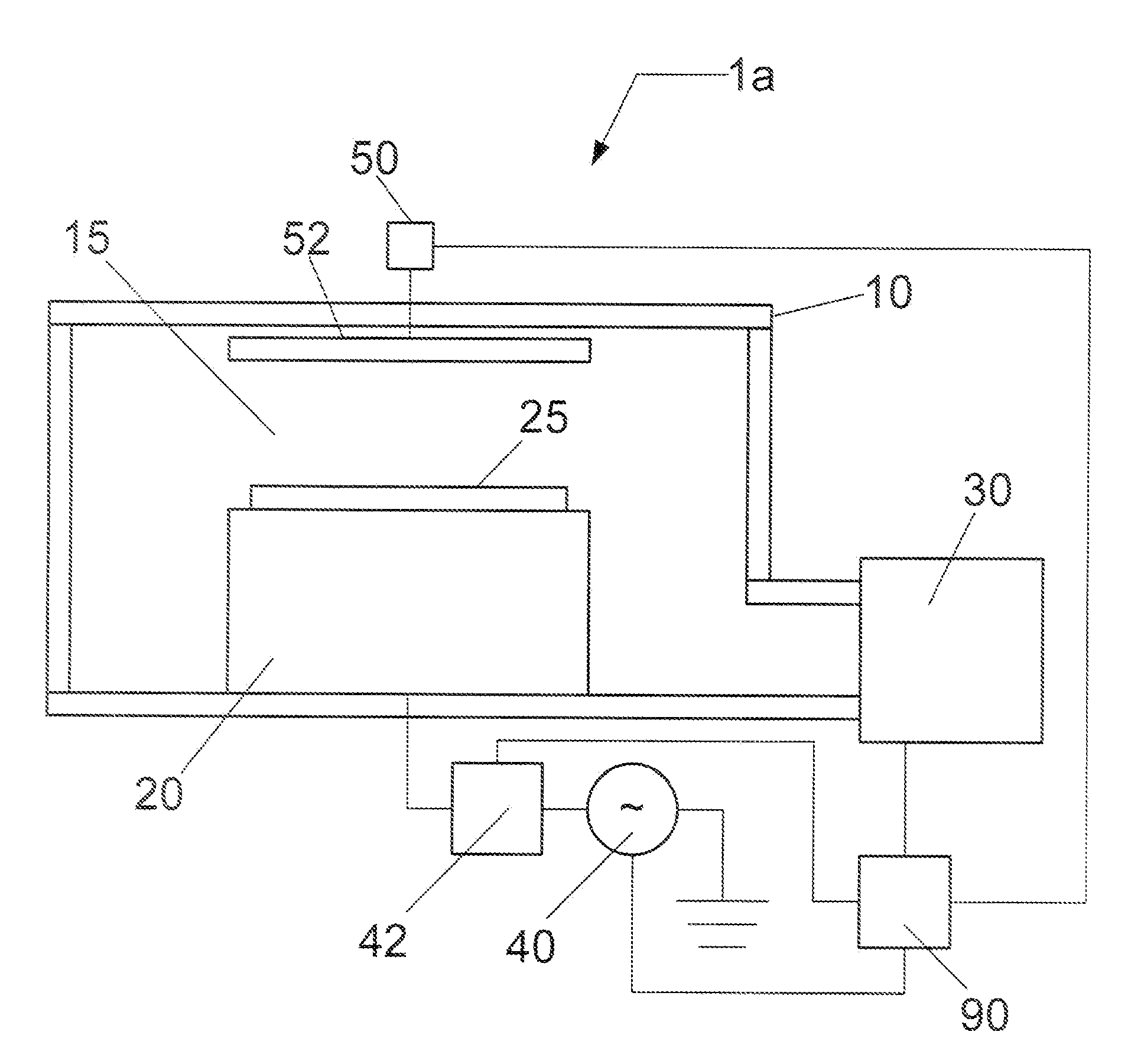

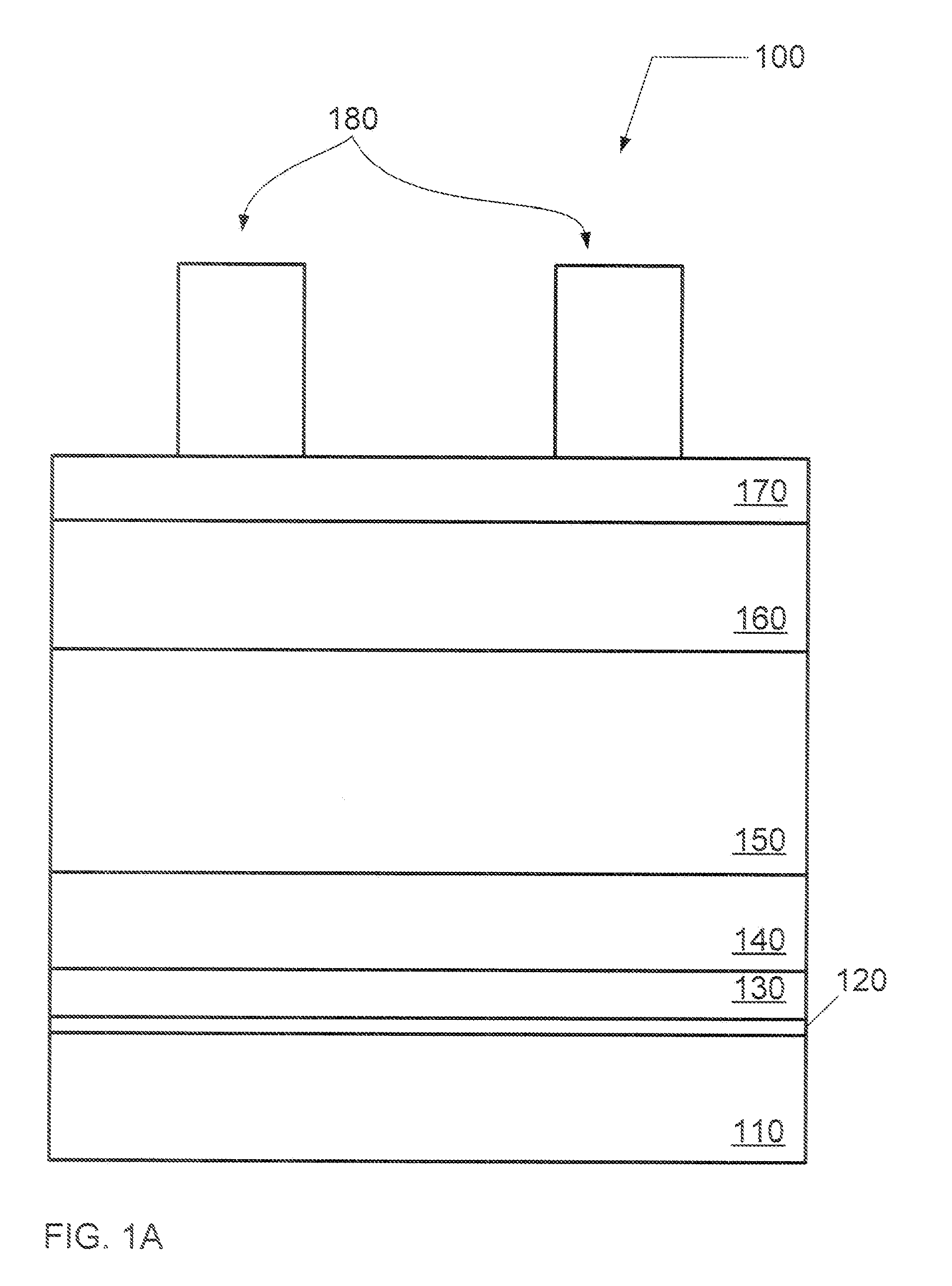

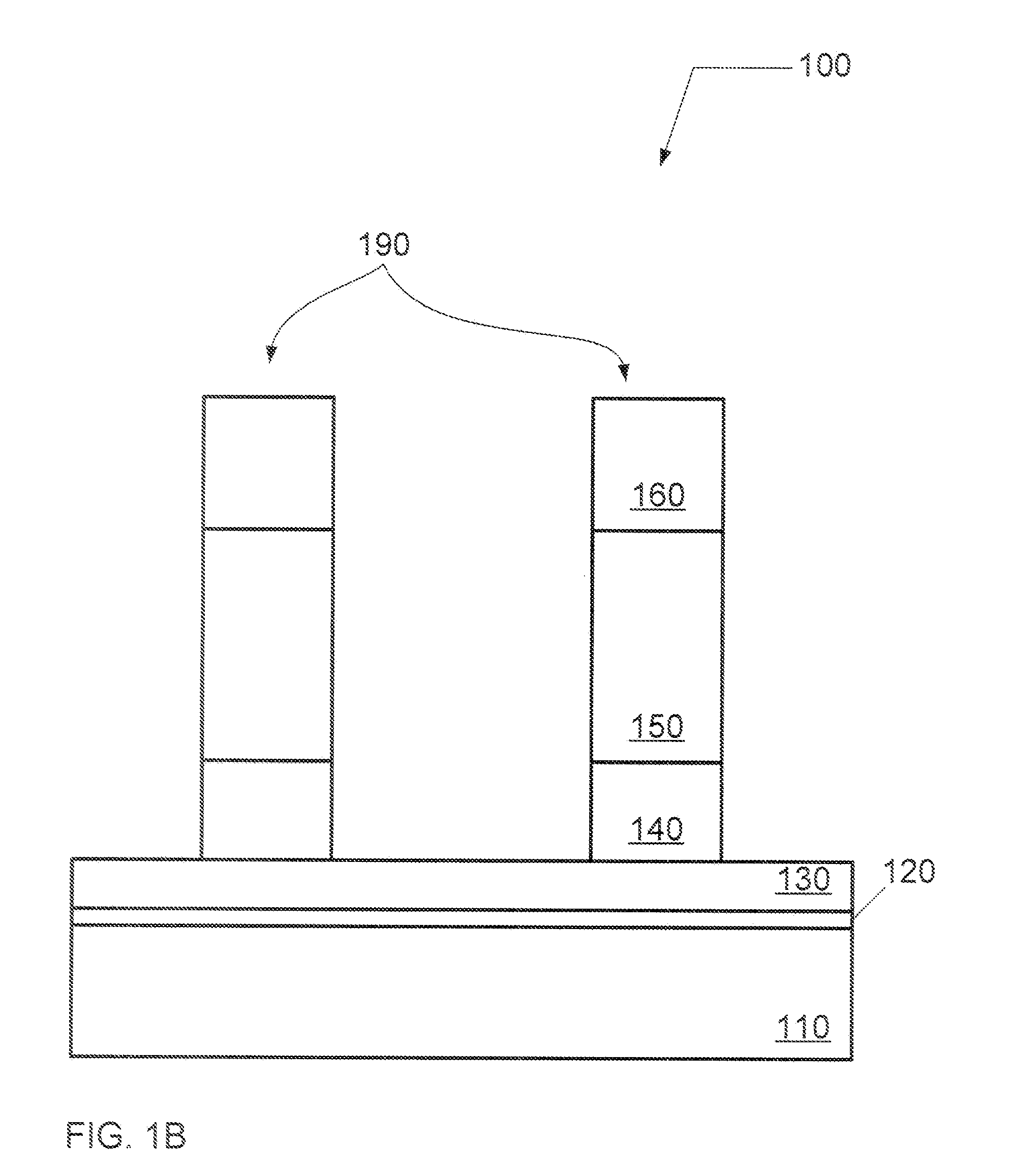

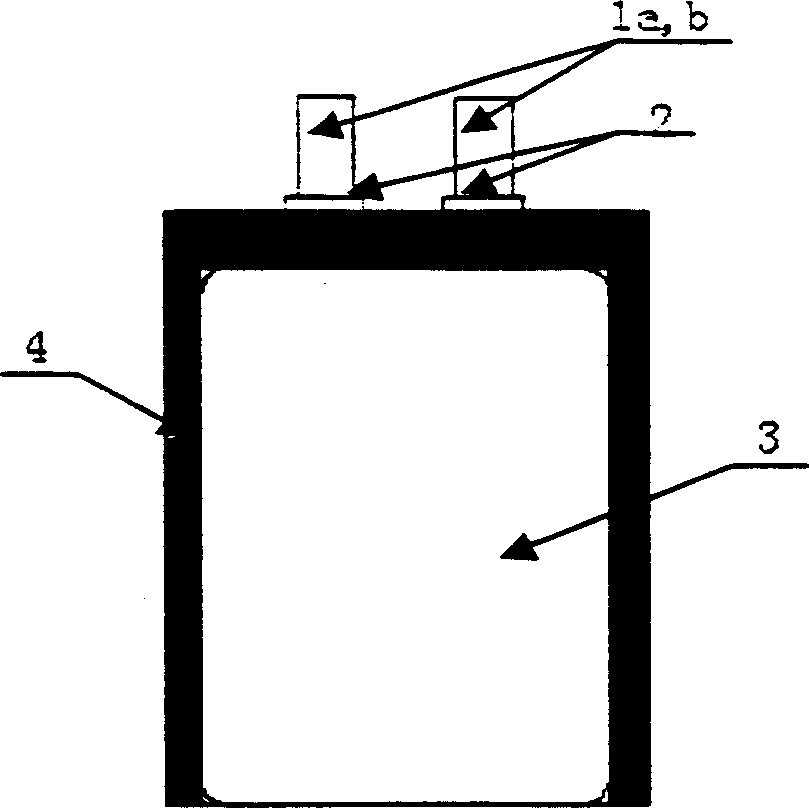

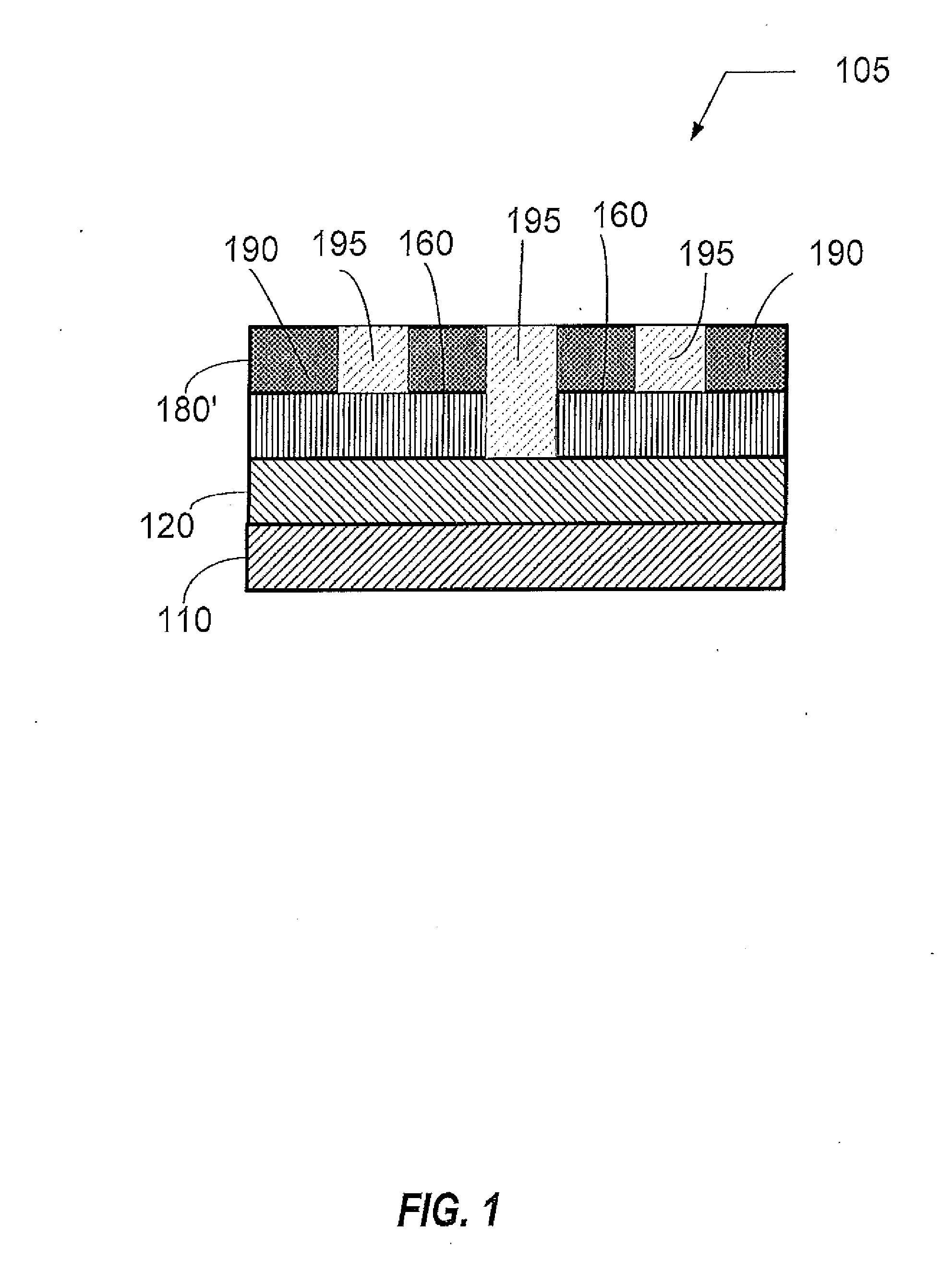

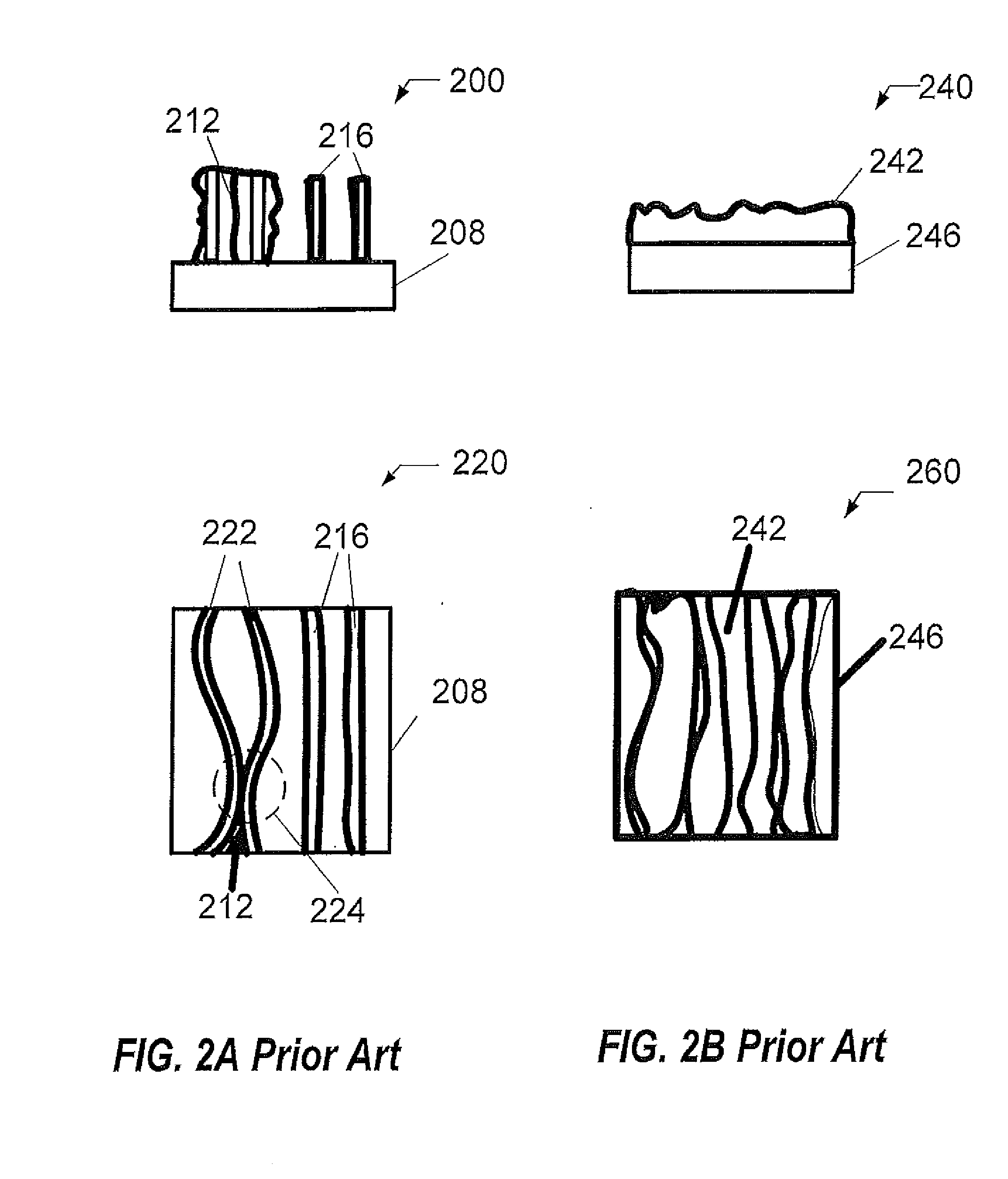

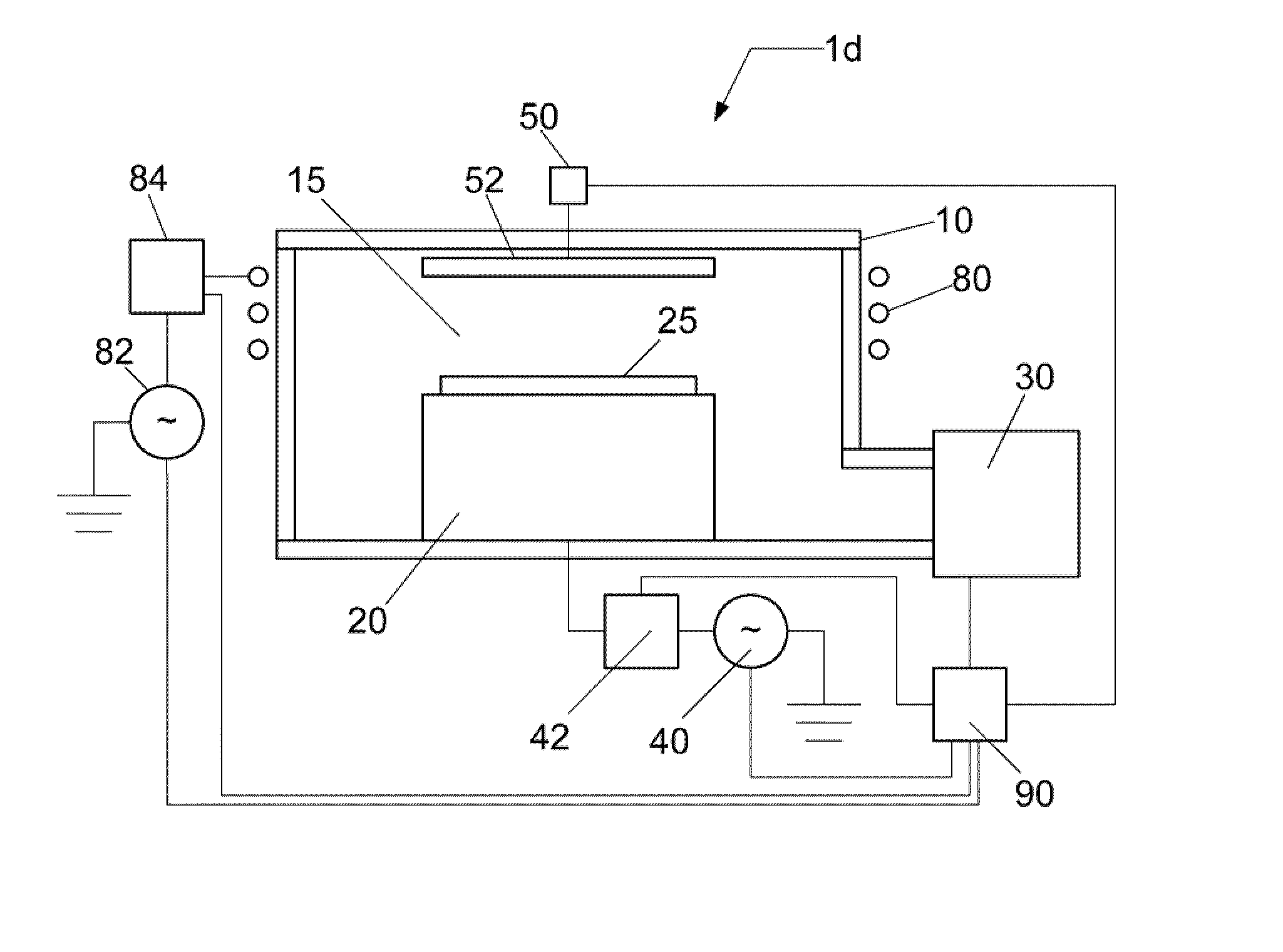

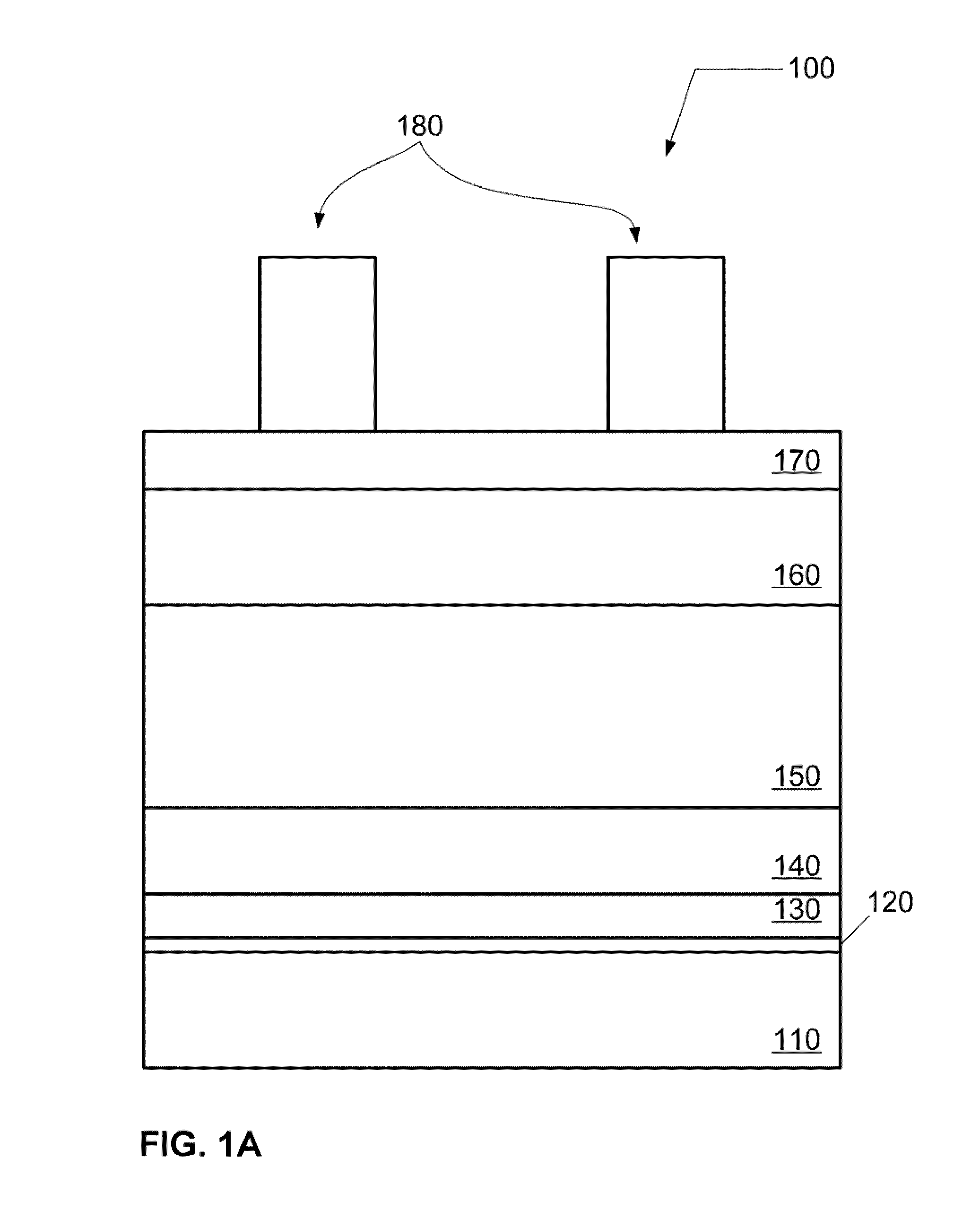

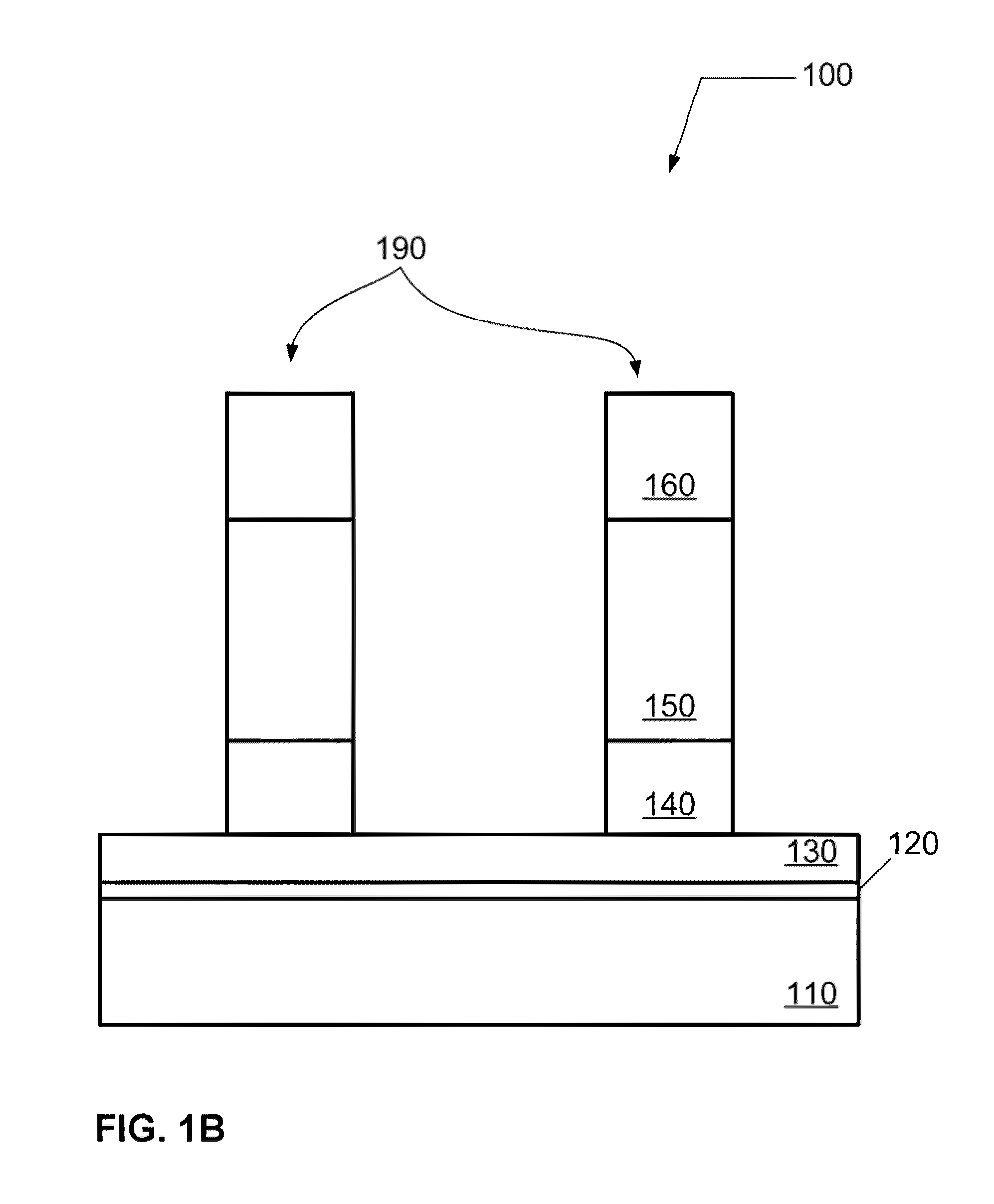

Etch process for reducing directed self assembly pattern defectivity using direct current positioning

ActiveUS20140370718A1Reducing directed self-assembly pattern defectivityReduce defectsPhotomechanical apparatusSemiconductor/solid-state device manufacturingProcess compositionElectron

A method for preparing a patterned directed self-assembly layer for reducing directed self-assembly pattern defectivity using direct current superpositioning is provided. A substrate having a block copolymer layer overlying a first intermediate layer, said block copolymer layer comprising a first phase-separated polymer defining a first pattern and a second phase-separated polymer defining a second pattern in said block copolymer layer is provided. A first plasma etching process using plasma formed of a first process composition to remove said second phase-separated polymer while leaving behind said first pattern of said first phase-separated polymer is performed. A second plasma etching process to transfer said first pattern into said first intermediate layer using plasma formed of a second process composition is performed. In an embodiment, said first phase-separated polymer is exposed to an electron beam preceding, during, or following said first plasma etching process, or preceding or during said second plasma etching process.

Owner:TOKYO ELECTRON LTD

Composition capable of being molten and processed and preparation method thereof

The invention relates to a composition capable of being molten and processed and a preparation method thereof. The composition contains fine particle padding, low-density polyethylene, linear low-density polyethylene, dispersant and fluoropolymer, wherein the dispersant is macromolecule dispersant or high polymer dispersant, and is formed by one or the combination of saponated oligomerization dispersant, polyester dispersant containing substituted amine end groups, and polycarboxylates dispersant. The preparation method of the composition comprises the following steps: a, dehydrating the fine particle padding at more than 140 DEG C; b, modifying the surface of the fine particle padding by using the macromolecule dispersant or high polymer dispersant; c, uniformly mixing the fine particle padding, the low-density polyethylene and the linear low-density polyethylene; d, feeding mixture obtained by the step c into a screw extruder; e, adding fluoropolymer processing agent into a measurement section of the screw extruder; f, screw-extruding; and g, cutting. The molten and processed composition can be extruded and pulled into a ventilated membrane, and is applied to disposable diaper, feminine hygiene / panty liner and the like.

Owner:FUJIAN HENGAN HYGIENE MATERIAL

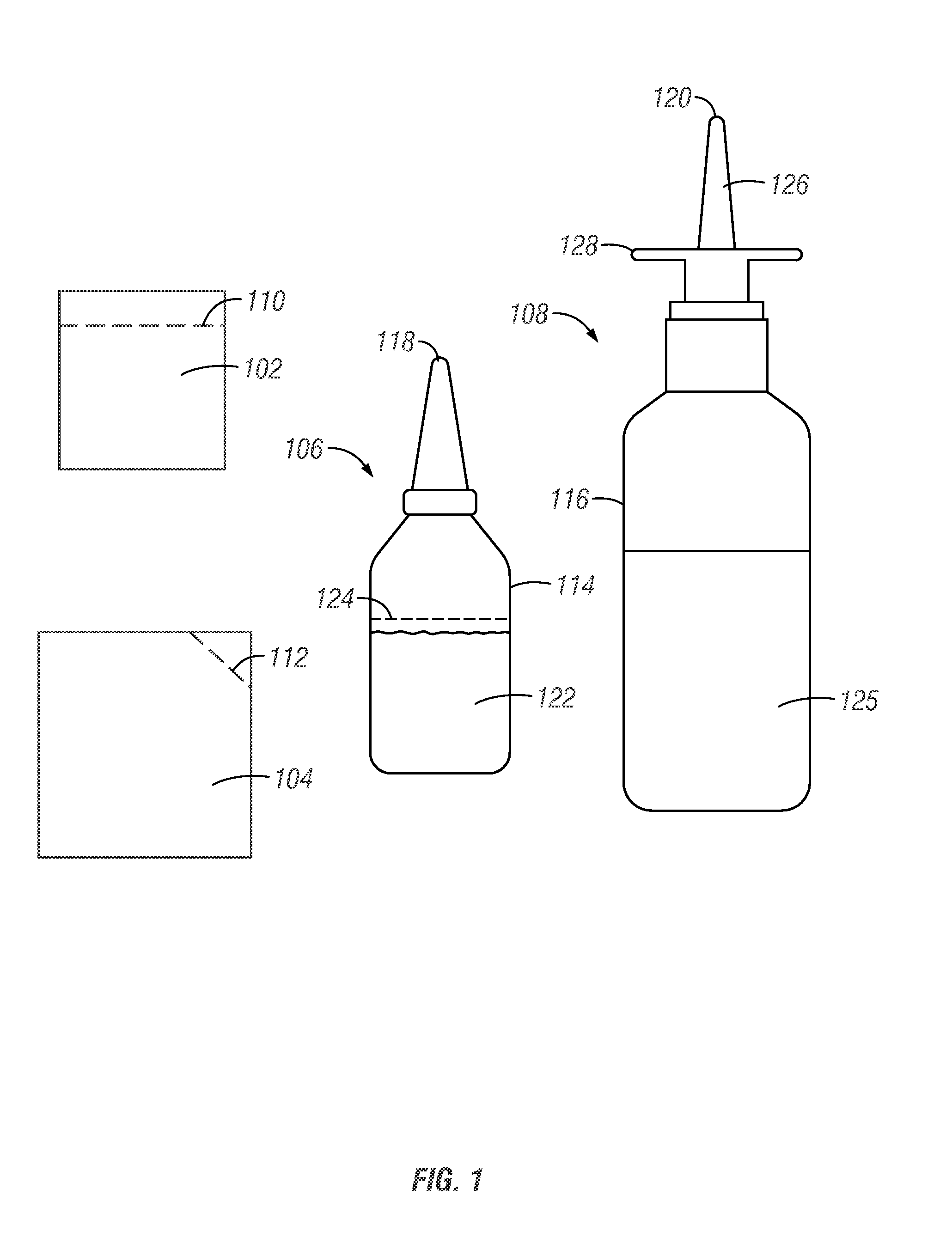

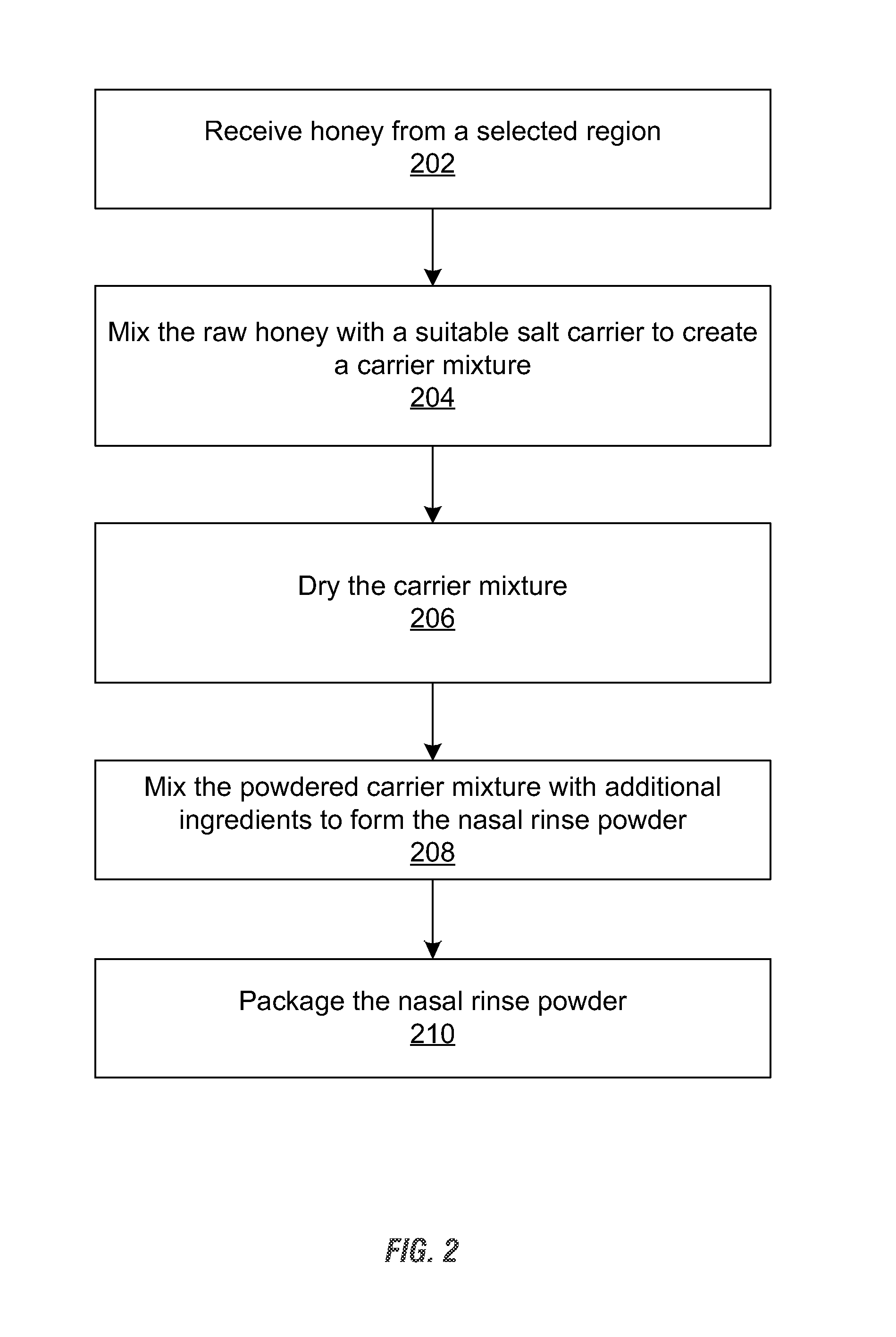

Honey nasal rinse

InactiveUS20140199266A1Improve antibacterial propertiesBiocideAnthropod material medical ingredientsParticulatesNasal cavity

Novel nasal rinse compositions are disclosed. The nasal rinse comprises a dried particulate composed of honey and a carrier. The composition may be a co-processed composition wherein the honey and carrier are combined while the honey is in liquid form and processed together to produce the dried particulate. Methods for producing the nasal rinse compositions are also provided, as well as methods of use of the nasal rinse compositions for the prevention or treatment of nasal infection, rhinitis, or sinusitis.

Owner:LOST CREEK CONSULTING

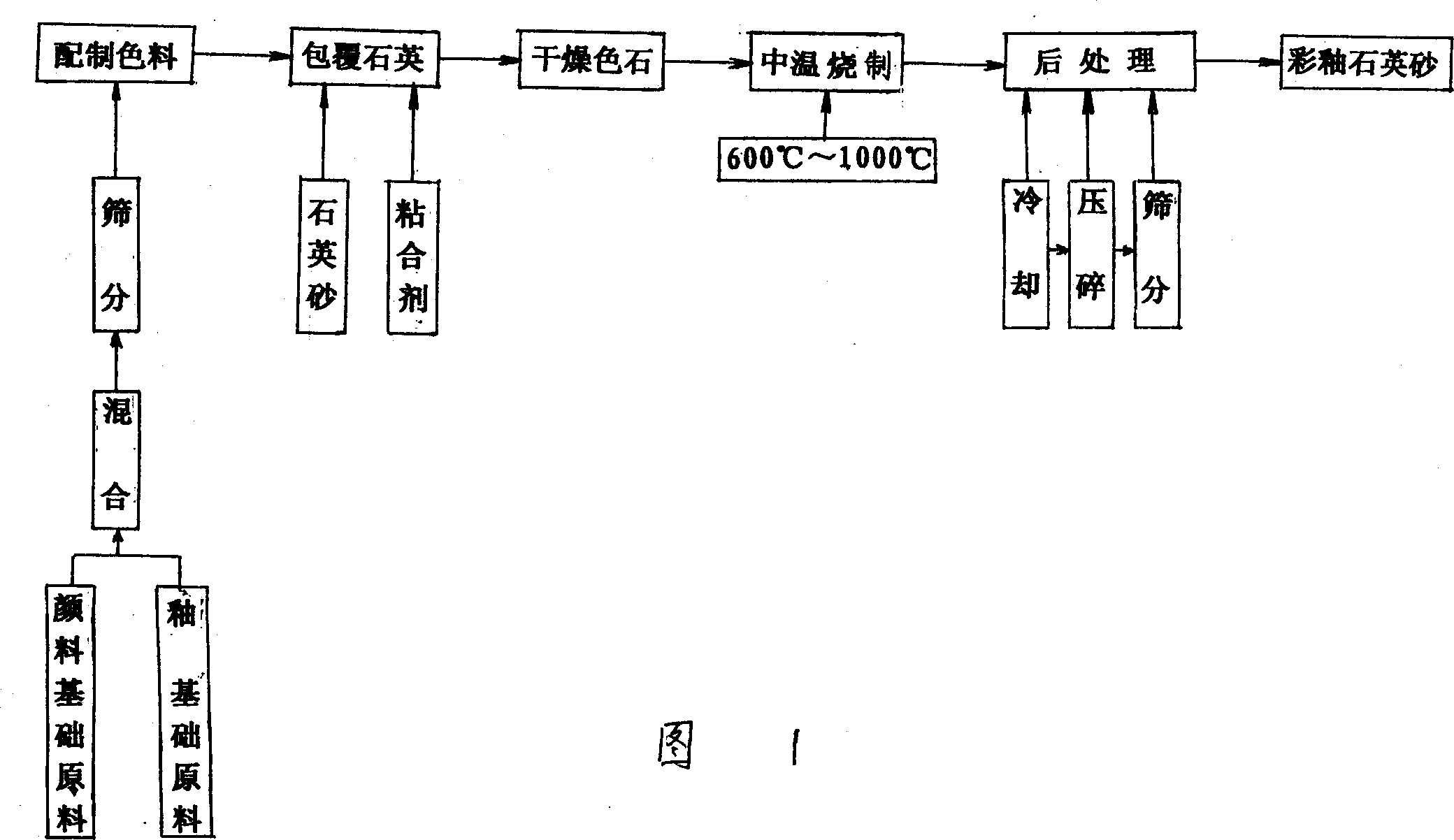

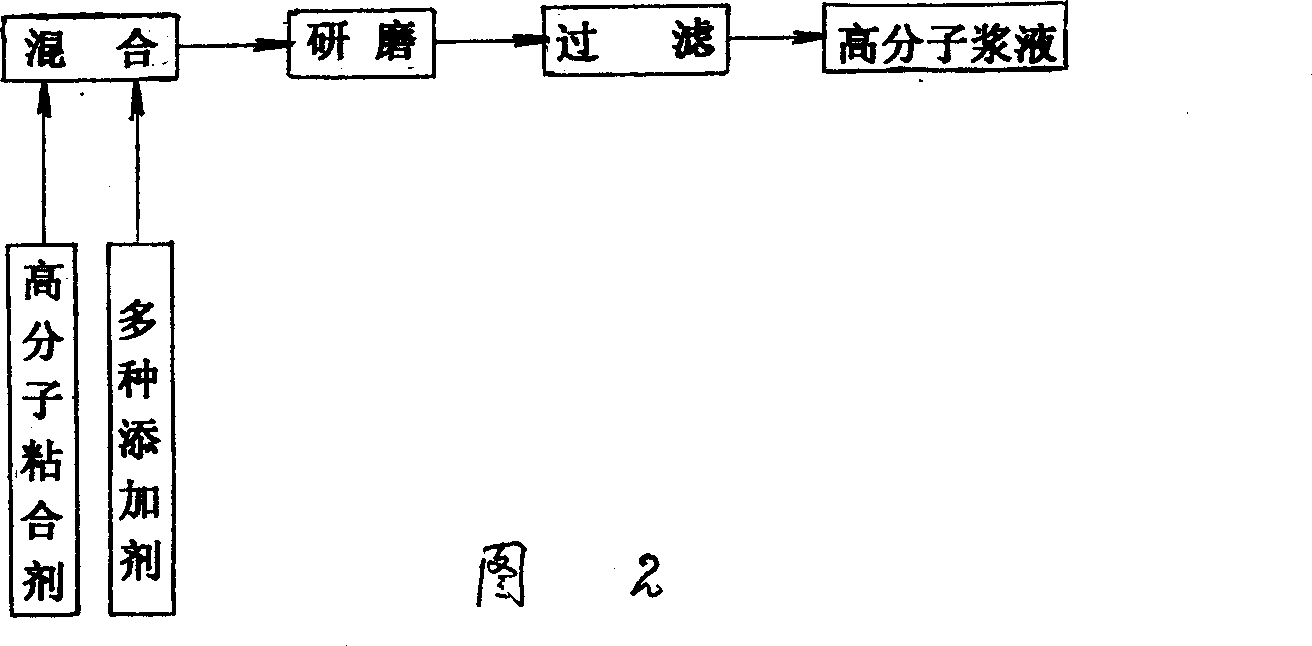

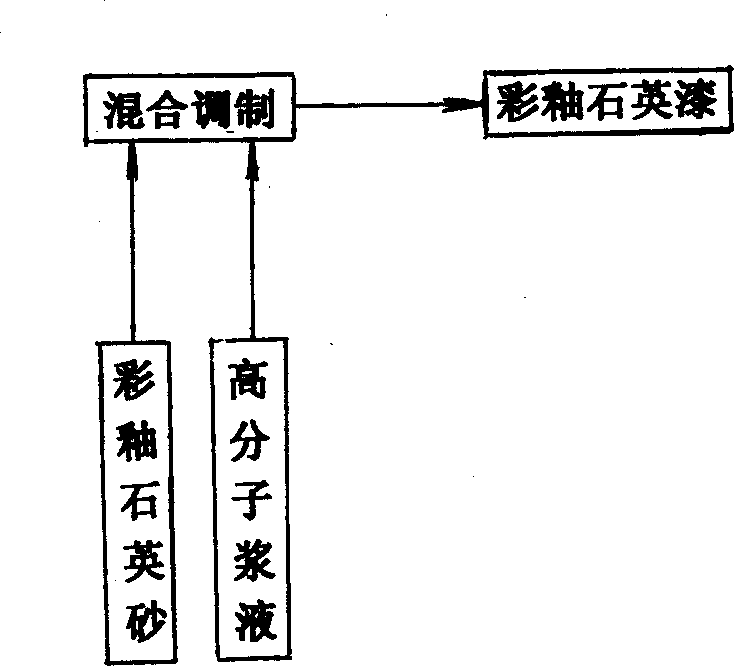

Production process of colar glaze guartz paint

The production process of color glaze quartz paint includes preparation of color glaze quartzite, preparation of polymer slurry and compounding of color glaze quartz paint. It features that during preparation of color glaze quartzite, using only two kinds of material for producing the inorganic basic pigment material and inorganic basic glaze material capable of produce the color quartzite material through mixing, sieving and middle temperature baking; and that the polymer slurry is compounded with several polymer adhesives and additives. The present invention has the advantages of simple process, easy operation, no toxicity, no environmental pollution and low cost and can produce excellent color glaze quartz paint with different required performance.

Owner:KEDA LUOKE NEW MATERIAL SICHUAN

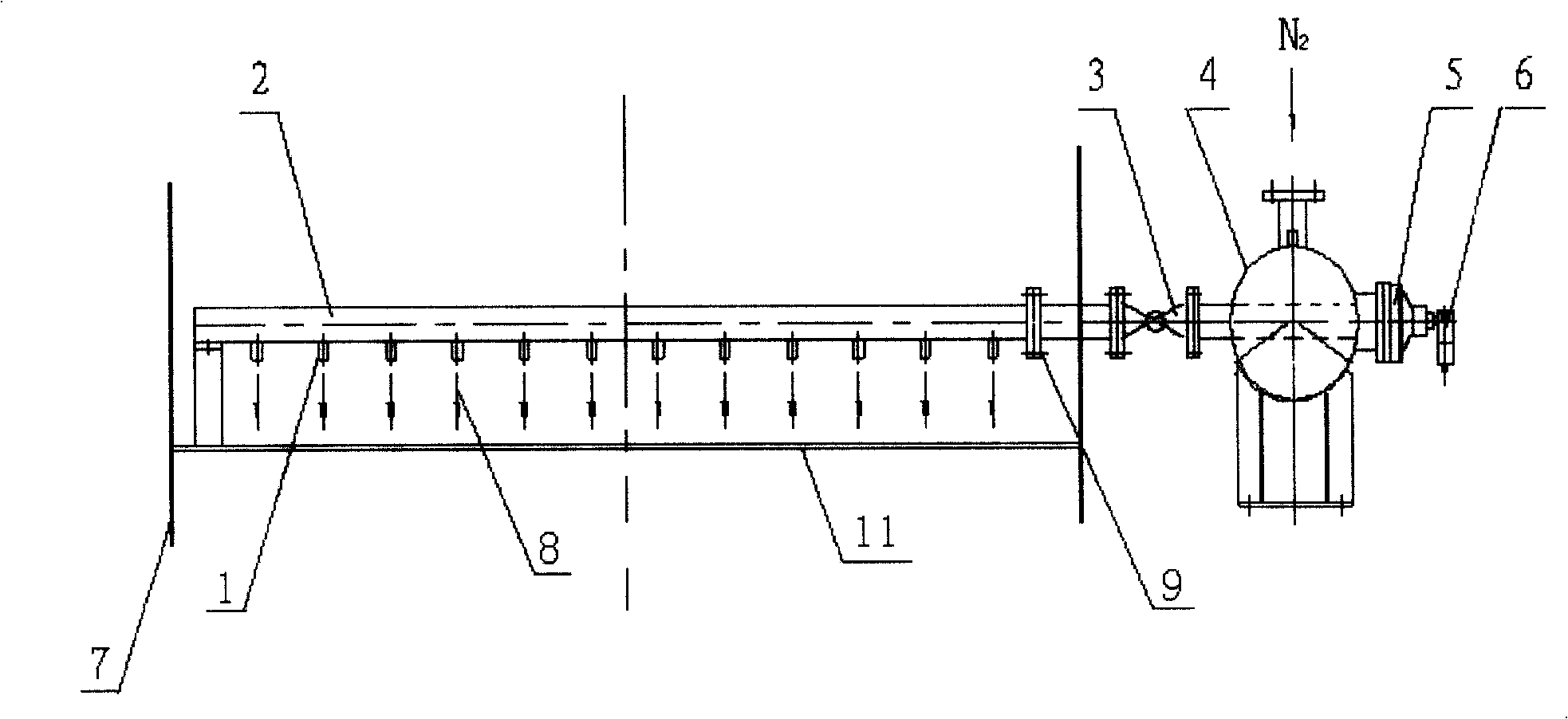

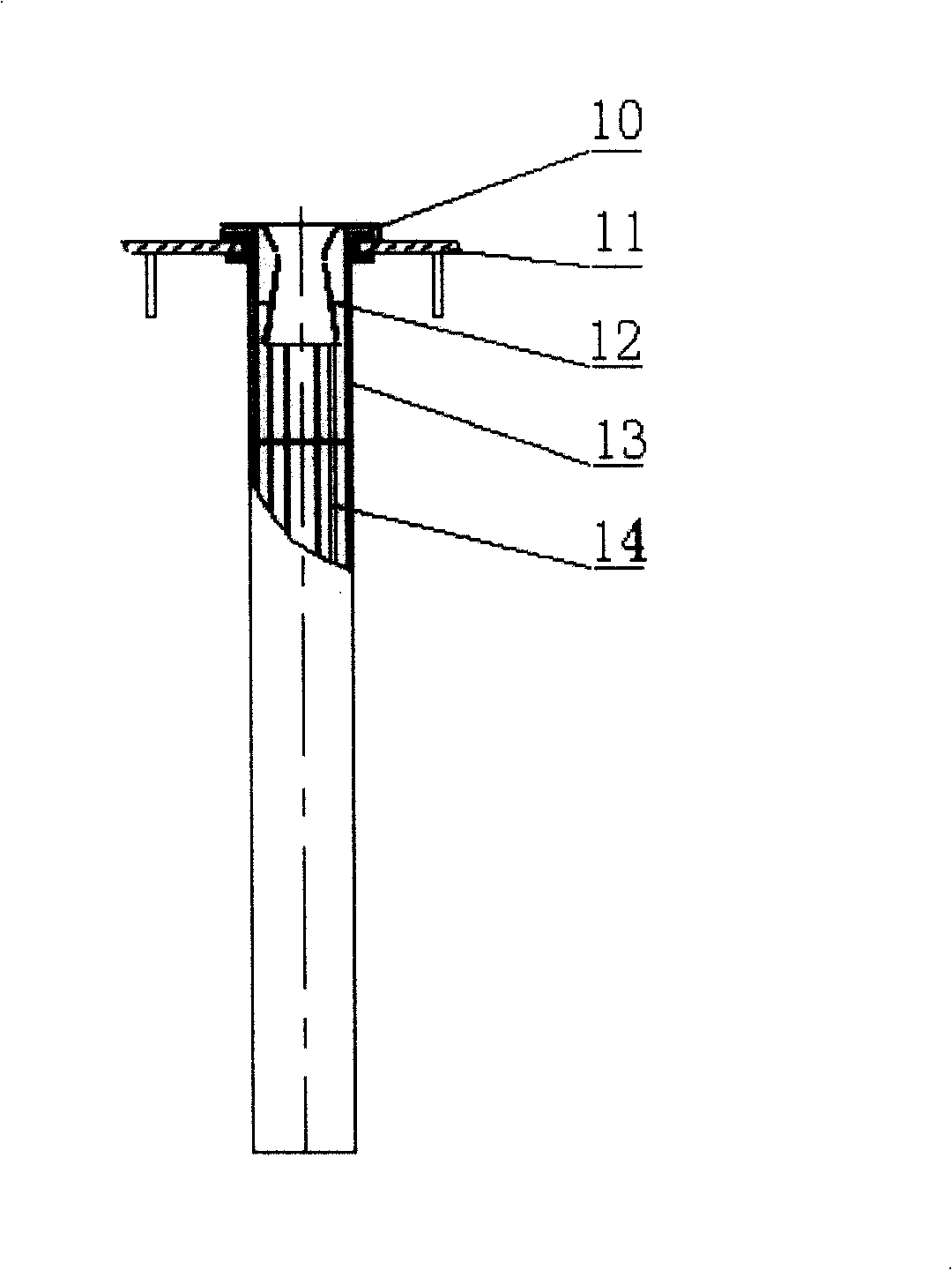

Blast furnace gas dust removing device and technique by dry method

ActiveCN101260322AEnsure safetyGet rid of dependenceChemical industryGas dust removalAutomatic controlProcess engineering

The invention relates to a blast furnace gas dry cloth-bag dust-removing device and technology, belonging to the metallurgy environmental protection dust removing technical field. The blast furnace gas dry cloth-bag dust-removing device and technology mainly comprise devices such as a dust-removing filtering device, an ash-clearing device, a dust-unloading and transporting device, an automatic control device, a gas dispersion device, and technologies such as large filtering wind speed, nitrogen or pure coal gas pulse current back-blowing and ash-clearing, pneumatic unloading and transporting ash and backup for nitrogen and pure coal gas, wherein, coal gas is filtered and purified by a filtering bag, the ash is back-blown by nitrogen or pure coal gas pulse current so as to control the resistance of the dust remover, thereby the filtering bag has the ideal dust removing effect, which is a dry dust-removing purification system having the advantages of high dust-removing efficiency, low dust content of the pure coal gas, low energy consumption of the dust-removing system, high heat efficiency of the pure coal gas and high automation degree; the filtering bag with over-long specification and a biserial pulse back-blowing system are adopted to meet the requirements of the dust-removing system upon a large filtering area and an excellent back-blowing efficiency; a crude gas bleeding valve group is increased to ensure that the coal gas with overproof temperature can not enter to a case of the dust remover, which protects the cloth-bag, controls effectively the high furnace roof pressure and operates the system more safer; the whole course waterless operation is realized so as to prevent the possibility of water containing coal gas dust to paste the filtering bag, thereby having the characteristics of less occupied area, short technology process, strong ability of clearing the ash, simple equipment and low labor intensity.

Owner:BAOTOU IRON & STEEL GRP

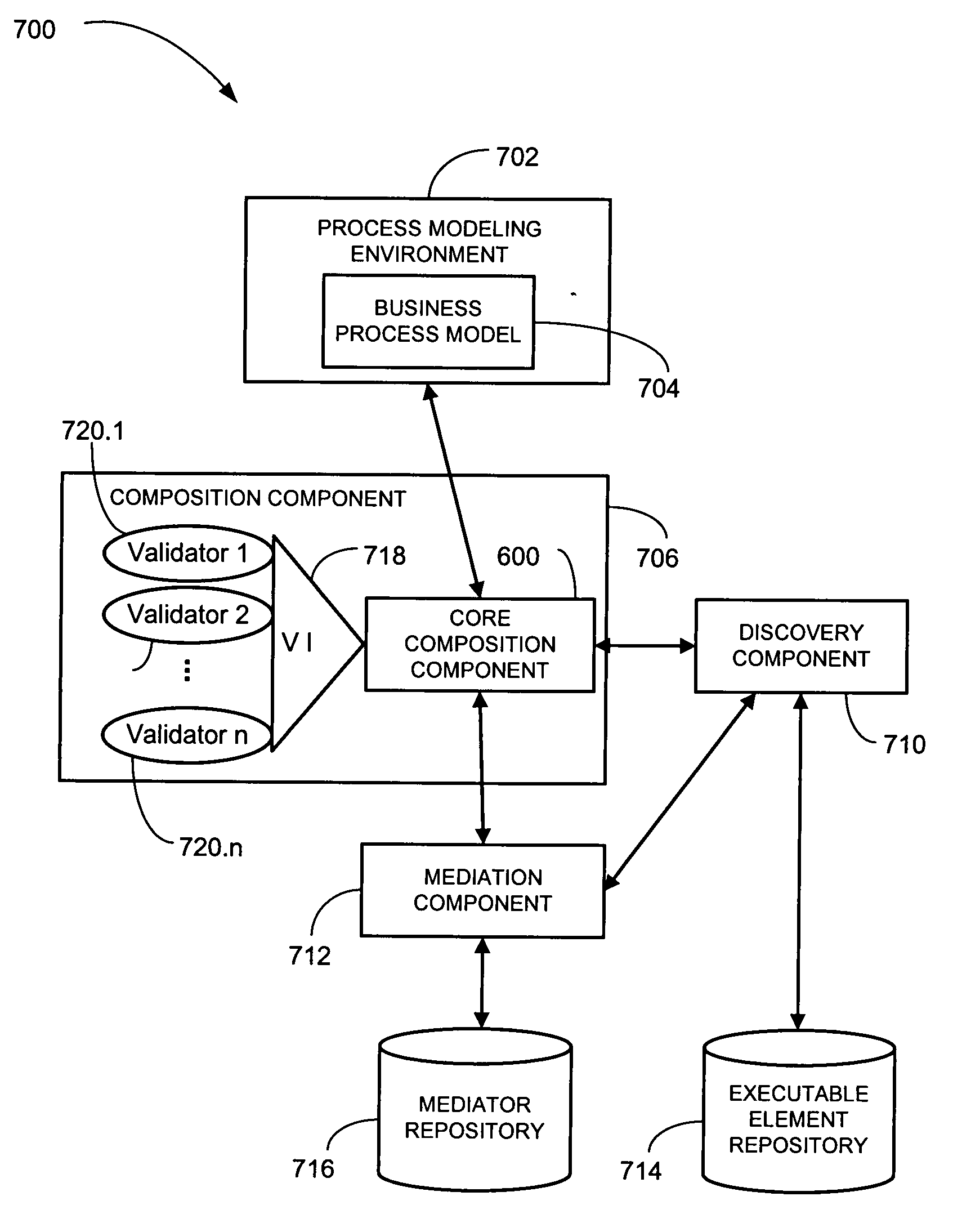

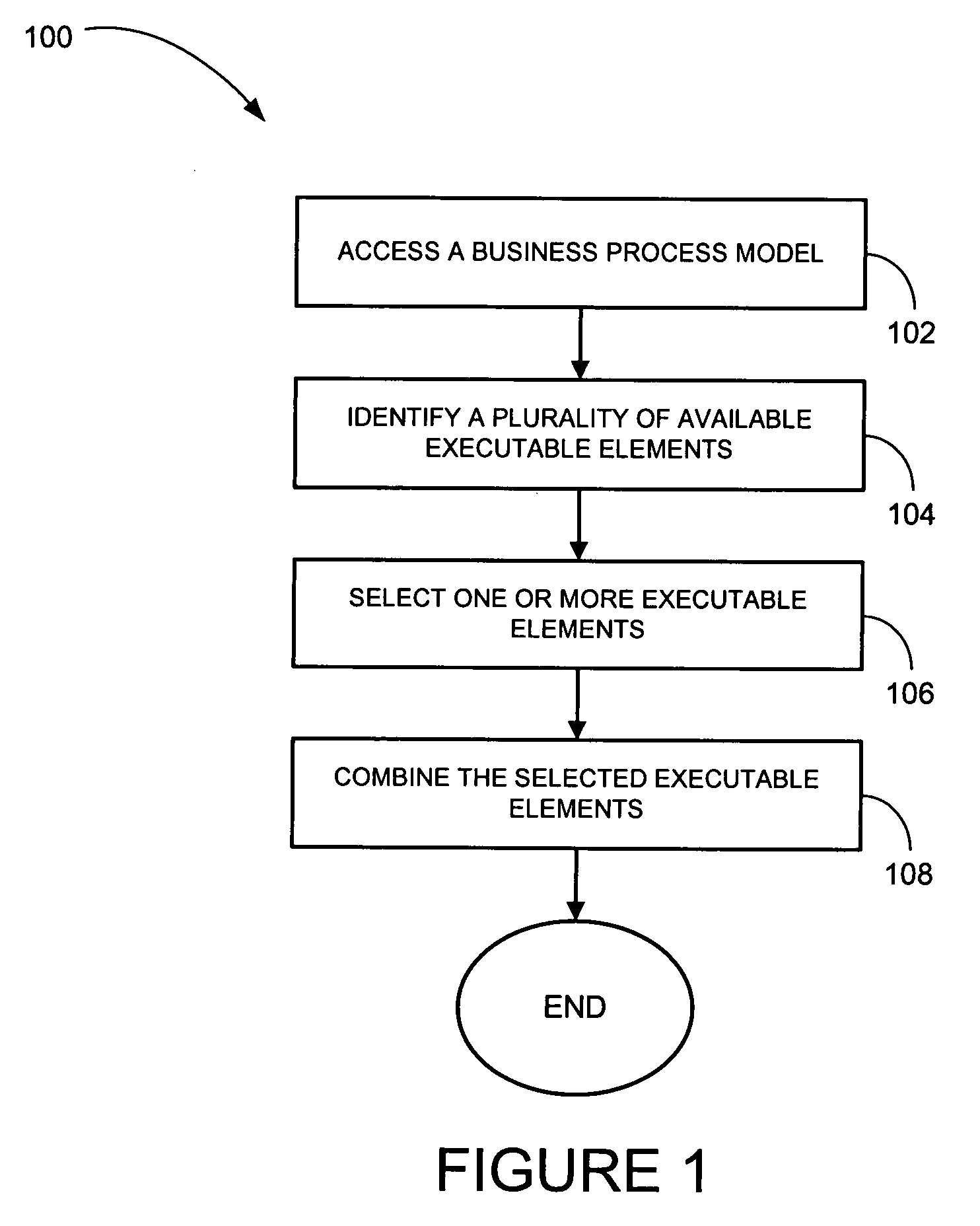

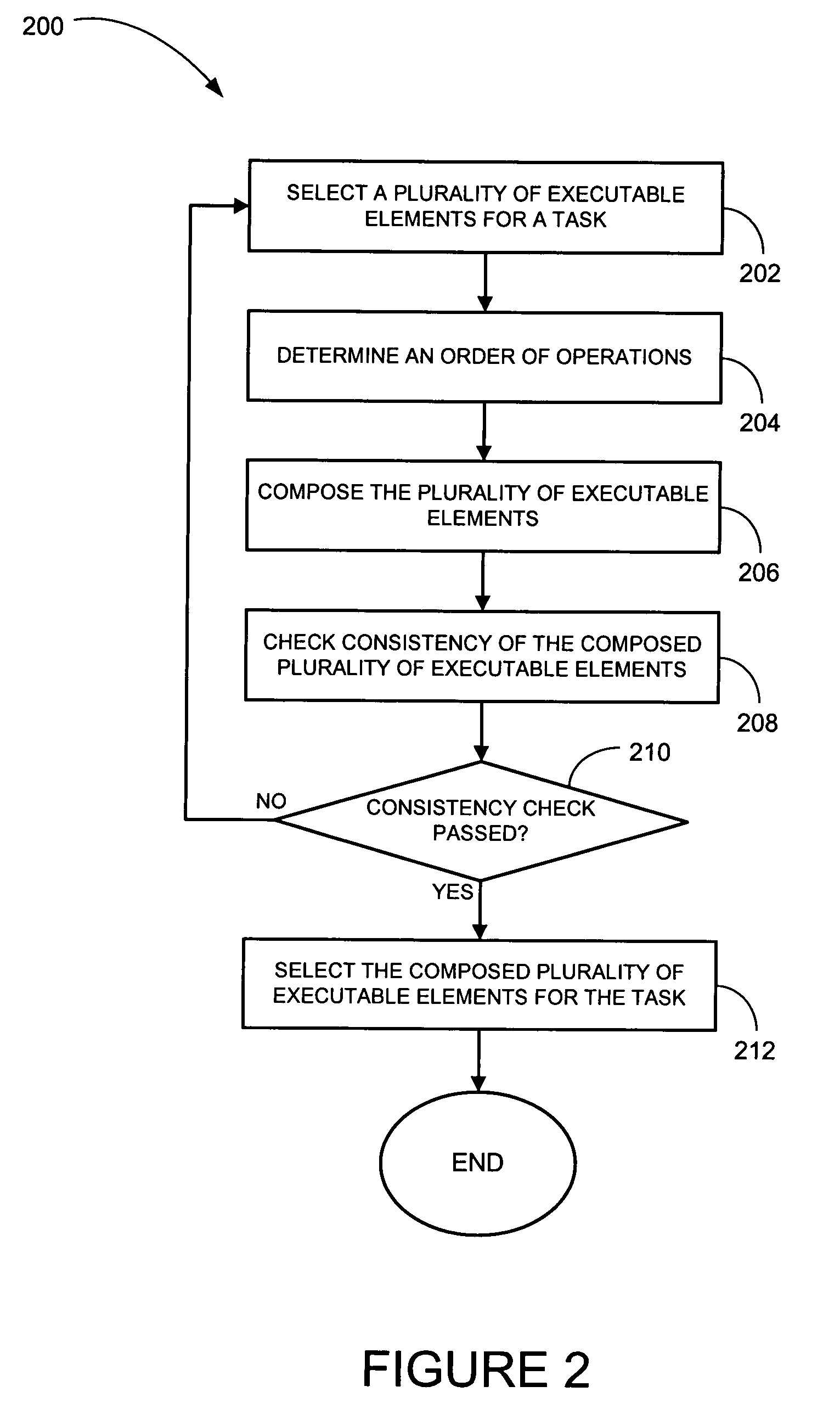

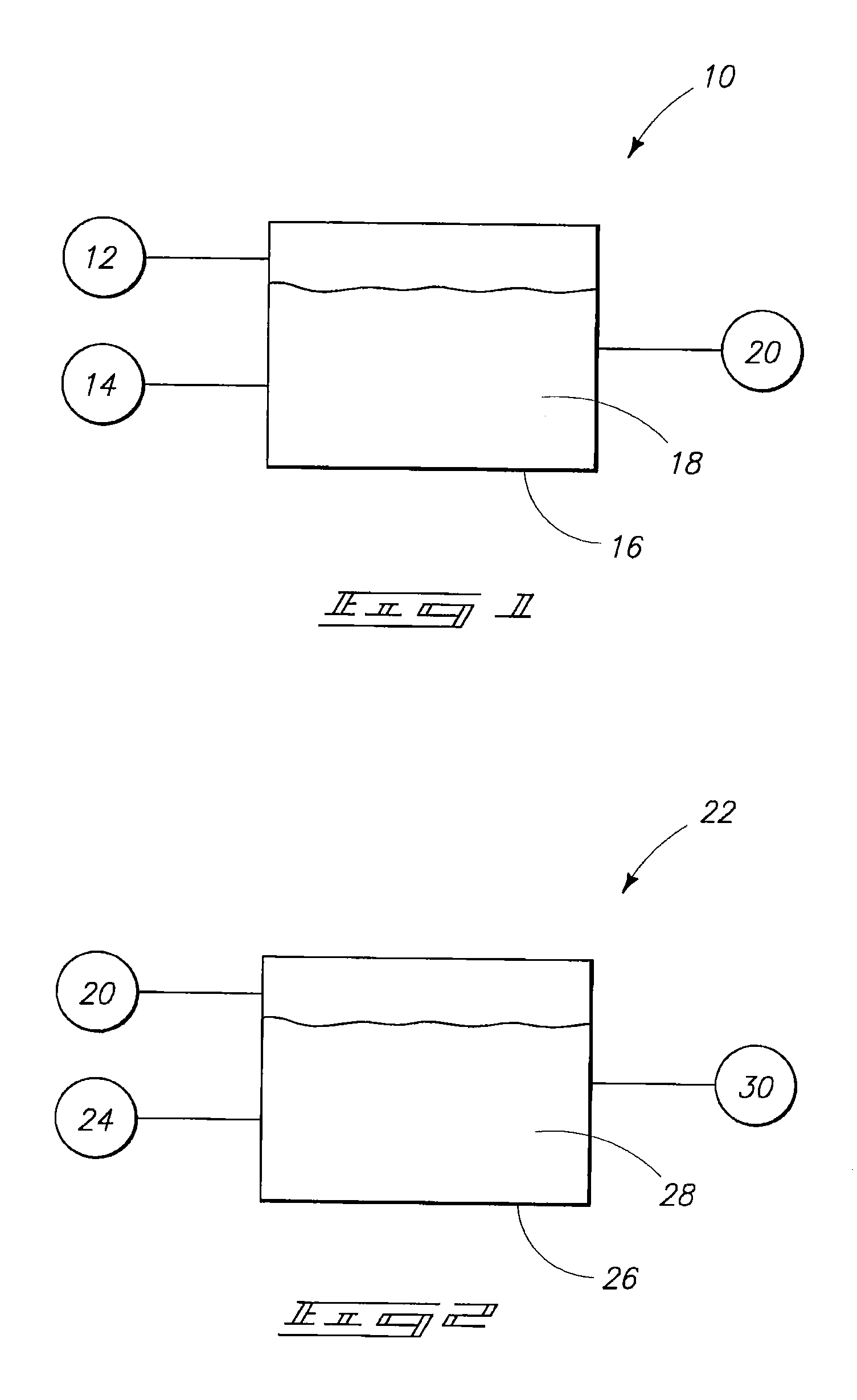

Method and system for process composition

A method and system for model composition. A business process model defined by a plurality of tasks may be accessed. A plurality of available executable elements capable of implementing the plurality of tasks may be identified. Each of the plurality of available executable elements may be capable of providing functionality to implement parts of the business process model. One or more executable elements may be selected among the plurality of available executable elements for each of the plurality of tasks. The selection may be based on functionality of an available executable element. The selected elements may be combined for the plurality of tasks to create an executable process for the business process model.

Owner:SAP AG

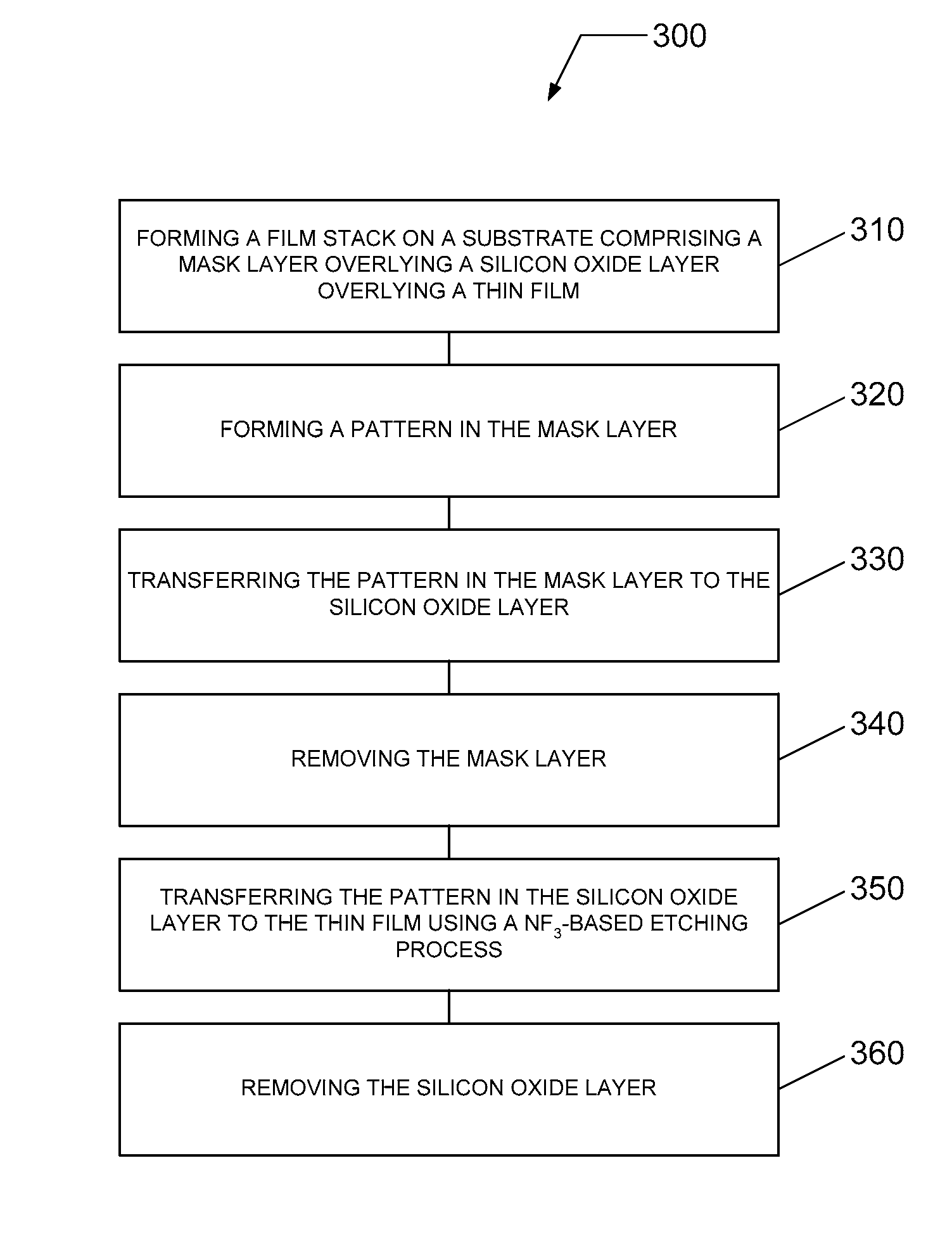

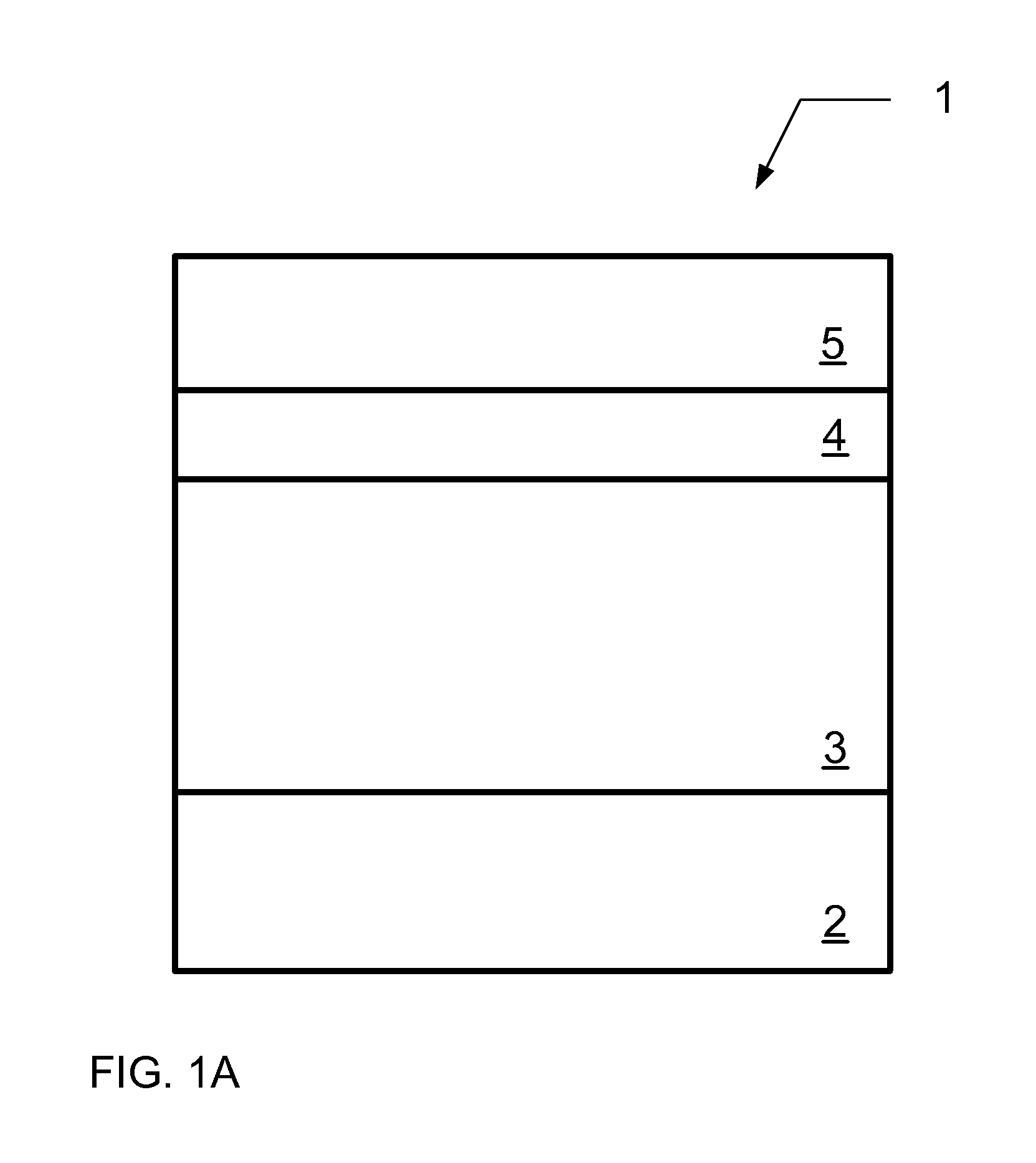

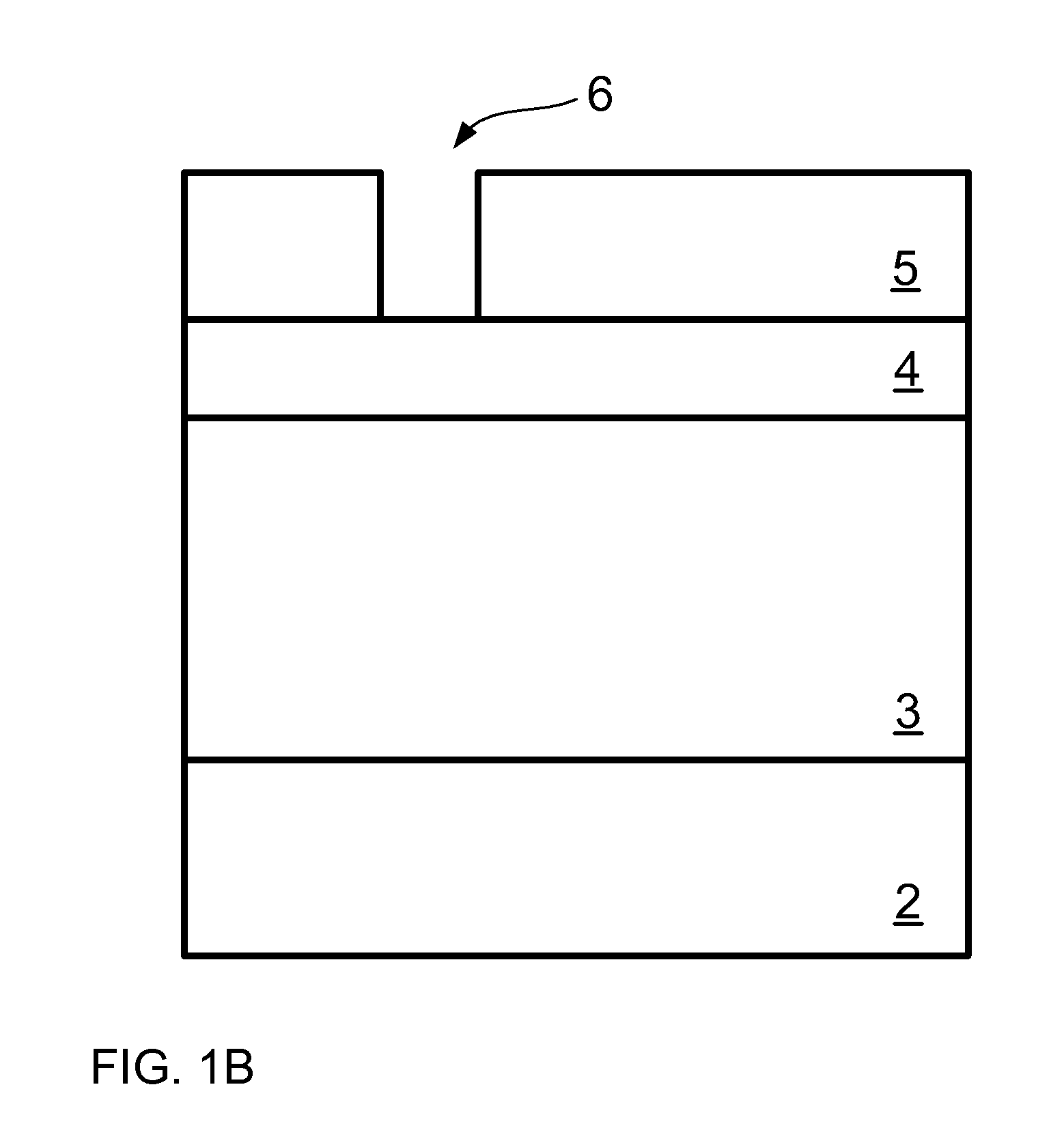

Method for metallizing a pattern in a dielectric film

A method of patterning a film stack is described. The method comprises preparing a film stack on a substrate, wherein the film stack comprises a SiCOH-containing layer formed on the substrate, a silicon oxide (SiOx) layer formed on the SiCOH-containing layer, and a mask layer formed on the silicon oxide layer. A pattern is created in the mask layer. Thereafter, the pattern in the mask layer is transferred to the silicon oxide layer using a first etching process, and then the mask layer is removed. The pattern in the silicon oxide layer is transferred to the SiCOH-containing layer using a second etching process formed from a process composition comprising NF3. Thereafter, the silicon oxide layer is removed using a third etching process.

Owner:TOKYO ELECTRON LTD

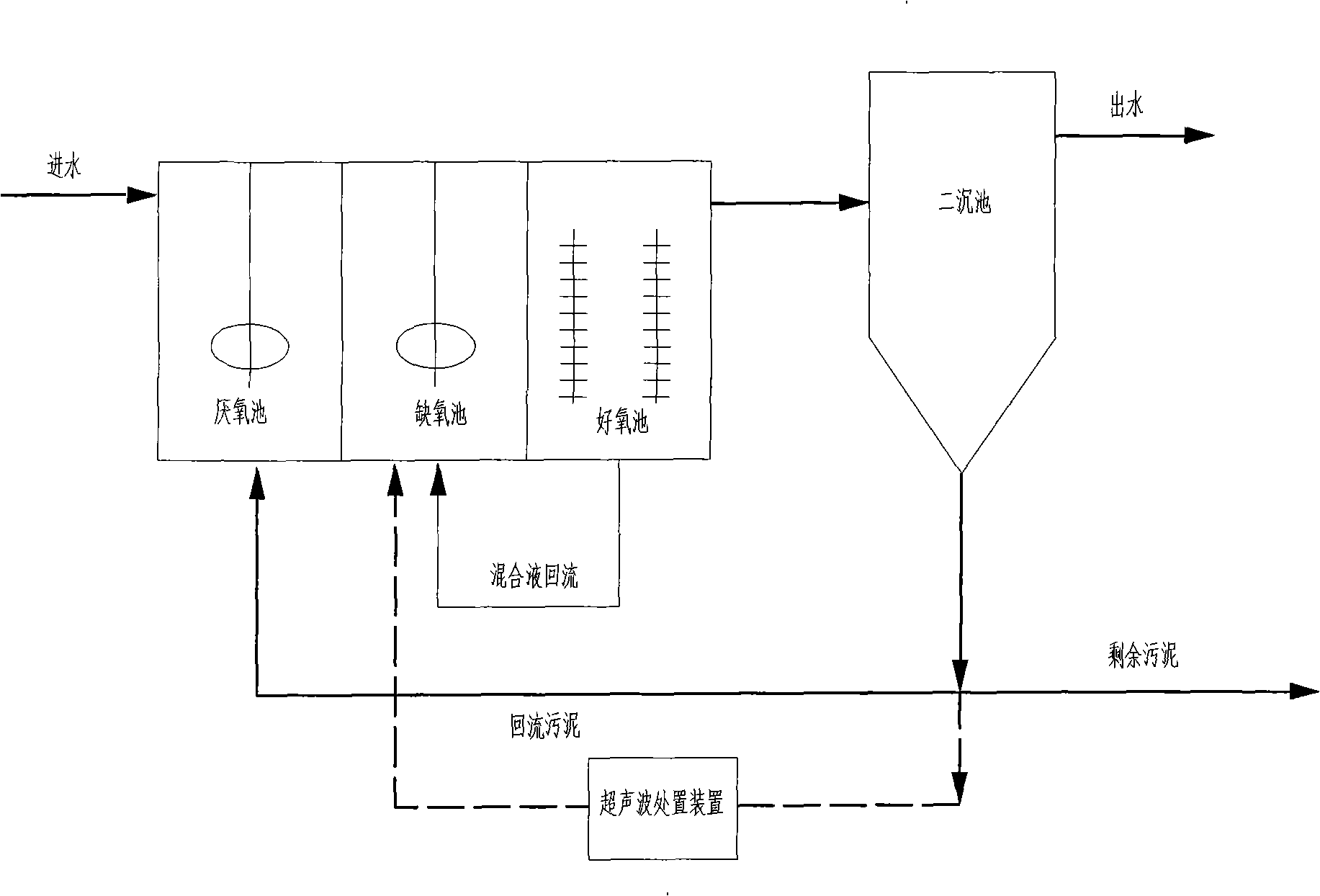

Improved process of activated sludge and biological film composite type A2/O

InactiveCN101348304AImprove the effect of nitrogen and phosphorus removalReduce the impactWater/sewage treatment with mechanical oscillationsTreatment with aerobic and anaerobic processesSolubilityActivated sludge

The invention relates to an improved process for activated sludge and biomembrane composite A<2>O. The improved process consists of three stages of processes, i.e. an anaerobic stage, an anoxic stage and an aerobic stage, and is characterized in that a ciliary biological packing material is added in an aerobic reactor; an ultrasonic treatment device is adopted to carry out cavitated decomposition for residual sludge inside a secondary settling tank so as to form organic substance with liquid solubility; moreover, the sludge is returned to the front end of an anoxic reactor. The improved process adopts the ciliary biological packing material to fix a great amount of nitrifying bacteria of long generation reproduction time, thereby improving the speed of nitration reaction and reducing the influence on nitrifying flora caused by sludge age change; the ultrasonic treatment device is adopted to treat residual sludge, thereby making use of efficient useful substances contained in the residual sludge; meanwhile, the improved process solves the problem of insufficient carbon source during A<2>O technological process, and maintains better denitrogenation and dephosphorization effects for an A<2>O technological system at the same time.

Owner:中钢集团武汉安全环保研究院有限公司

Environment-friendly type flame-retardant rubber floor and production method thereof

ActiveCN101230159ANo corrosionImprove flame retardant performanceFlat articlesAntimony trioxideStearic acid

The invention relates to raw material of environmental protection type flame retardant rubber floor, which is mainly composed of rubber, aluminum hydroxide (magnesium), reinforcing filler, sulfur, zinc oxide, stearic acid, accelerator, antioxidant, diantimony trioxide, phosphorus flame retardant, molybdenum compound, borate, and pigment. The production process is mainly composed of plasticization settlement, mixing settlement, remixing softening, malleating and sulphuration, etc., coarse material includes a plurality of highly effective environmental protection flame retardant, and traditional harmful flame retardant and heavy metal elements are stopped to be used. The product has the advantages of low smoke, low toxicity, low corrosion, good flame-resistant performance, strong tensile strength, and good anti-slip and elastic performance, etc., thus being suitable to be widely used in the public places such as trains, ships, hospitals, organizations, schools and entertainment place, etc. with high fire protection requirements.

Owner:安徽省金越亨通交通装备有限公司

Composition containing a compound capable of establishing hydrogen bonds, and cosmetic treatment process

ActiveUS20100028277A1High strengthImprove staminaBiocideOrganic active ingredientsHydrogenChemical compound

Composition containing, in a cosmetically or dermatologically acceptable medium, a compound that may be obtained by reaction between:an oil bearing at least one nucleophilic and / or electrophilic reactive function, anda junction group capable of establishing hydrogen bonds with one or more partner junction groups, the junction group bearing at least one reactive function capable of reacting with the reactive function borne by the oil, and also comprising at least one unit of formula (I) or (II):

Owner:LOREAL SA

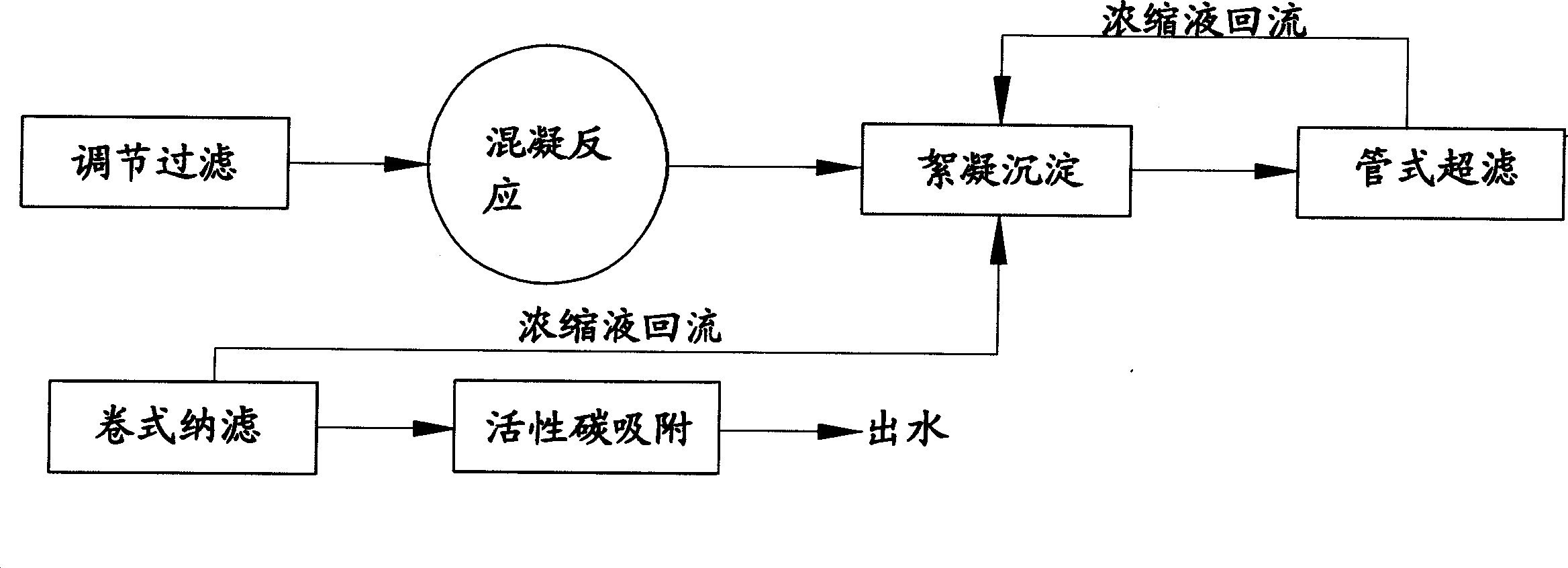

Dye waste water treatment method based on membrane technology

ActiveCN1827535AOvercoming processingOvercome costsUltrafiltrationWater/sewage treatment bu osmosis/dialysisWater basedFiltration

The present invention discloses a method for treatment of dye waste water based on membrane technique, mainly comprising the part of fore treatment of dye waste water and the part of membrane filtration-seperation system. Fore treatment of dye waste water consists of techniques such as exhaust conditioning, flocculating setting and clarifying. Membrane filtration-seperation system consists of techniques such as hyperfiltration circulation and Na-filtration circulation. The invention is a new treatment of dye waste water based on membrane technique, characterized in that the CODCr and PH of the dye waste water is adjusted in the equalizing tank before it enters the membrane filtration-seperation system. Afterwards, the waste water is uniformly mixed in the flocculation retort and then deposits in the flocculation precipitating tank. The clarified solution is disposed by the treatment of hyperfiltration, the hyperfiltration dislysate is disposed by the treatment of Na-filtration, the Na-filtration dislysate is absorbed by the activated carbon, and as a result the water let meets the sewage discharge standard of two-level GB8978-96. The method is especially suitable for treatment of waste water of azo-dyes which is difficult to meet the discharge standard by the conventional waste treatment.

Owner:SANDA FILM SCI & TECH XIAMEN

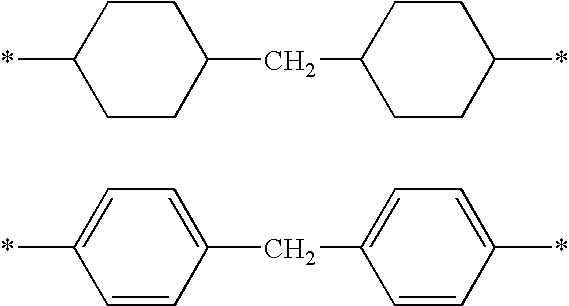

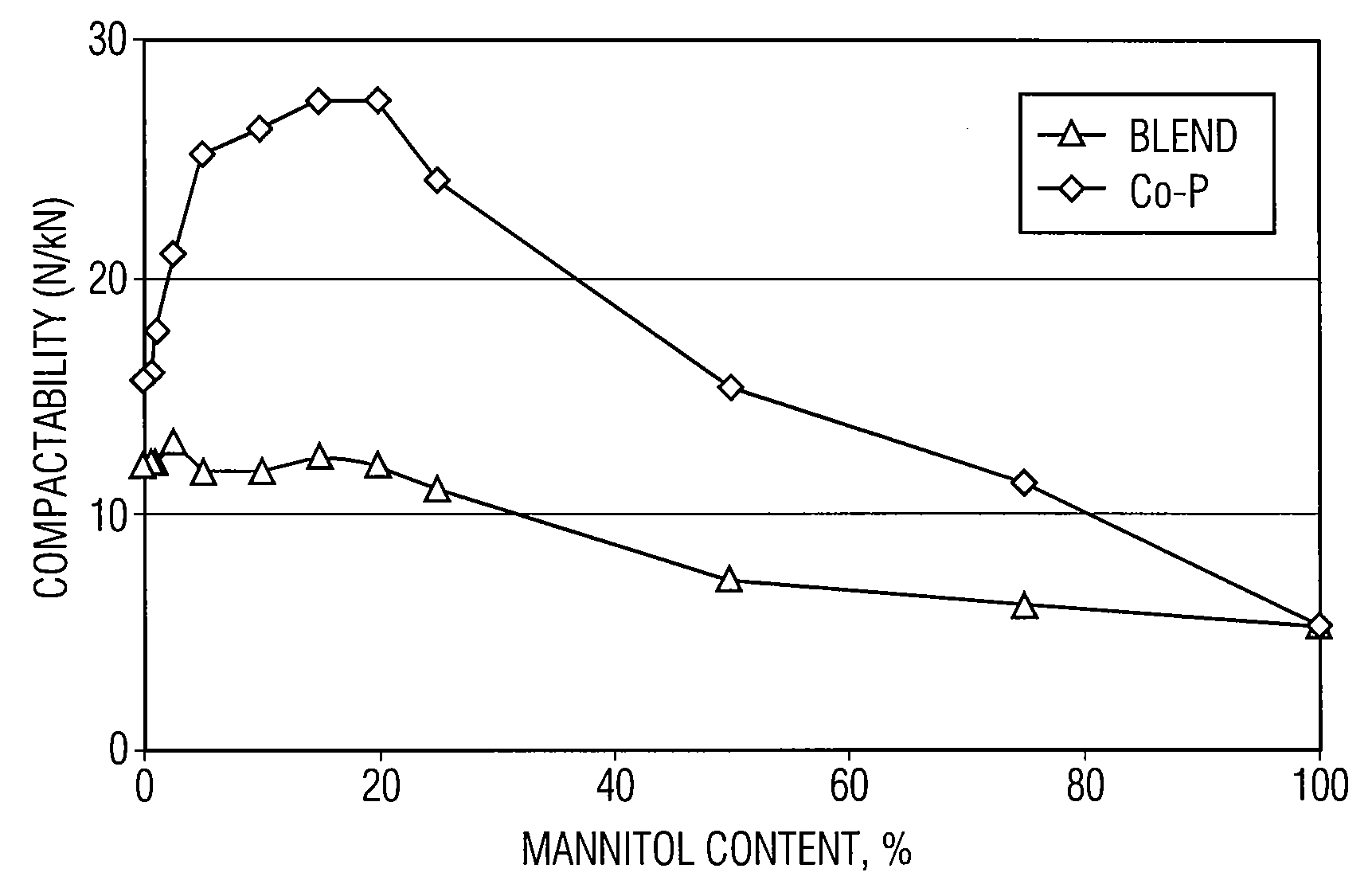

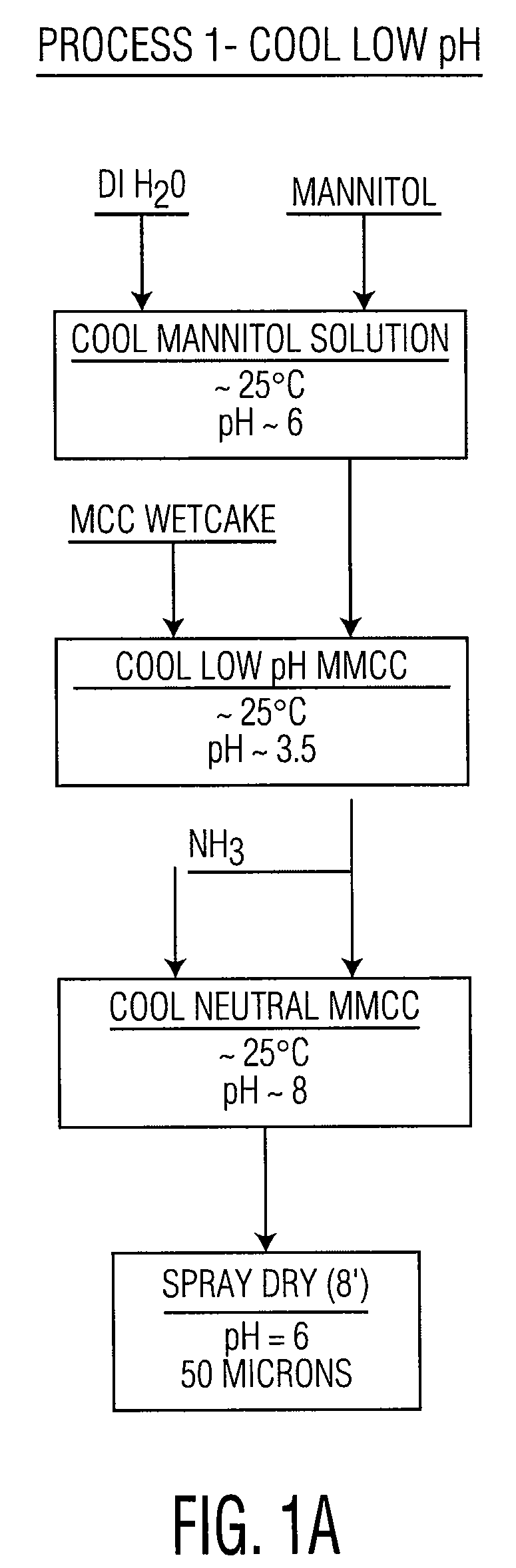

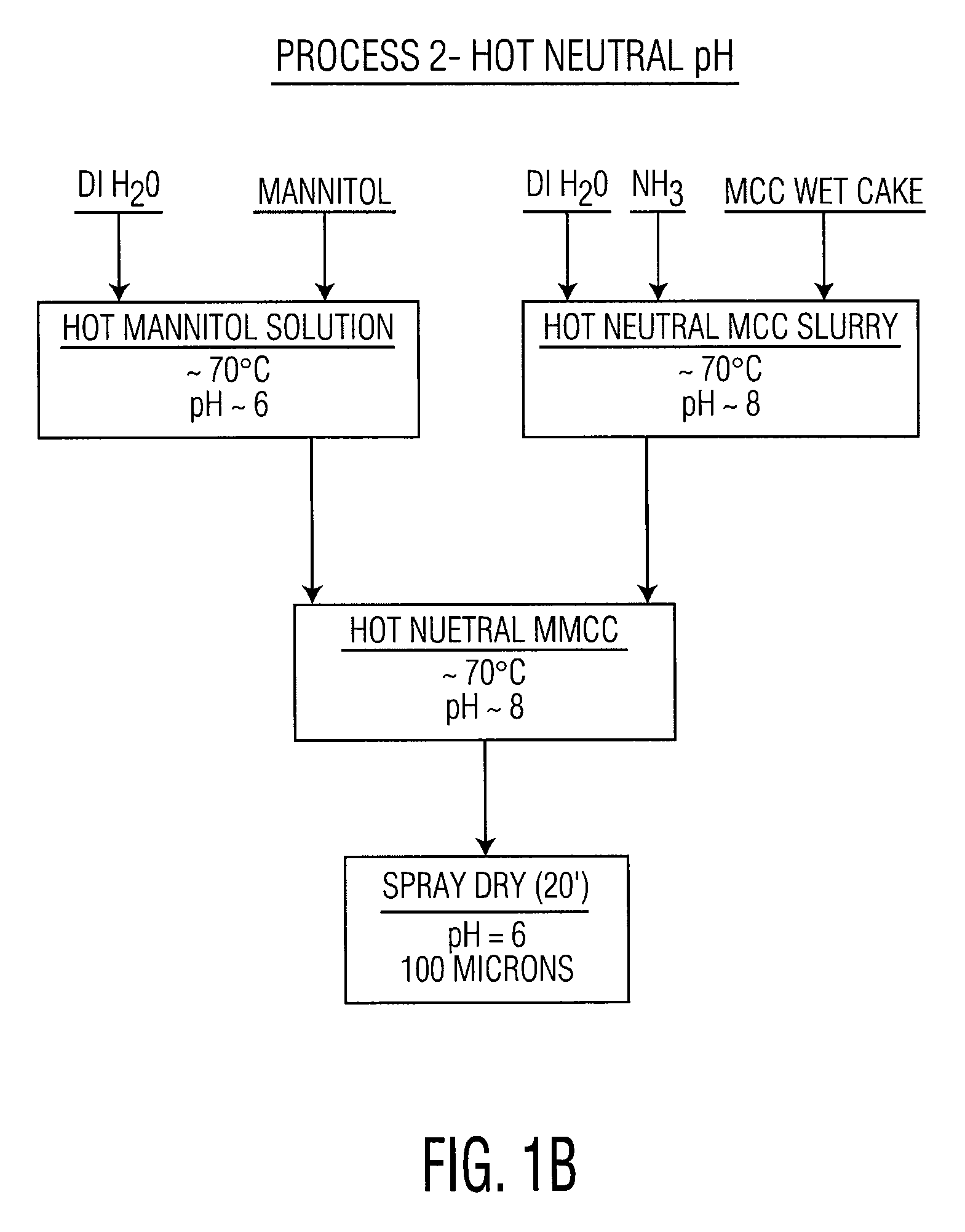

Co-processed microcrystalline cellulose and sugar alcohol as an excipient for tablet formulations

ActiveUS20080131505A1Improve the compaction effectWood working apparatusPill deliveryParticulatesMANNITOL/SORBITOL

Owner:DUPONT NUTRITION USA INC

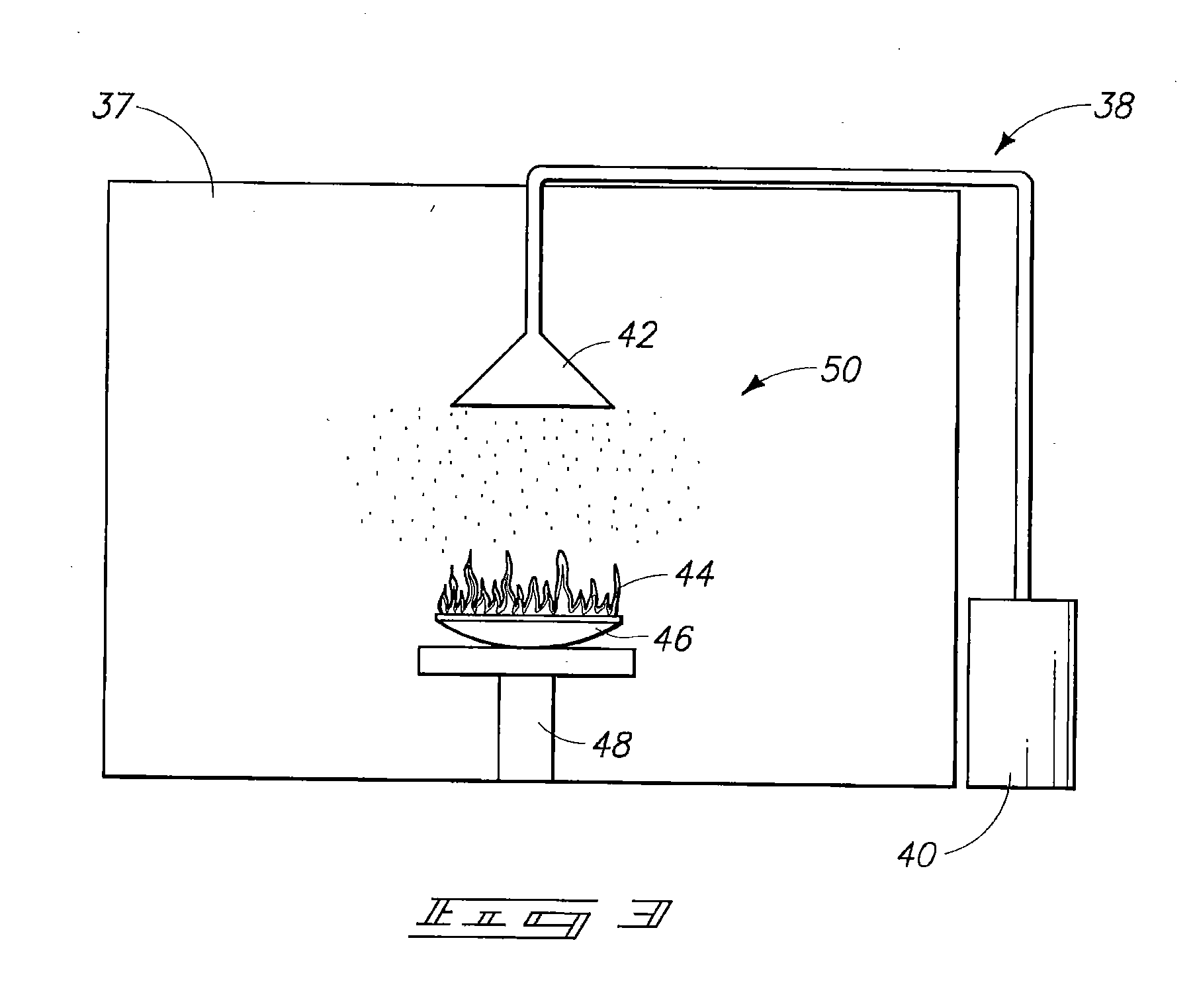

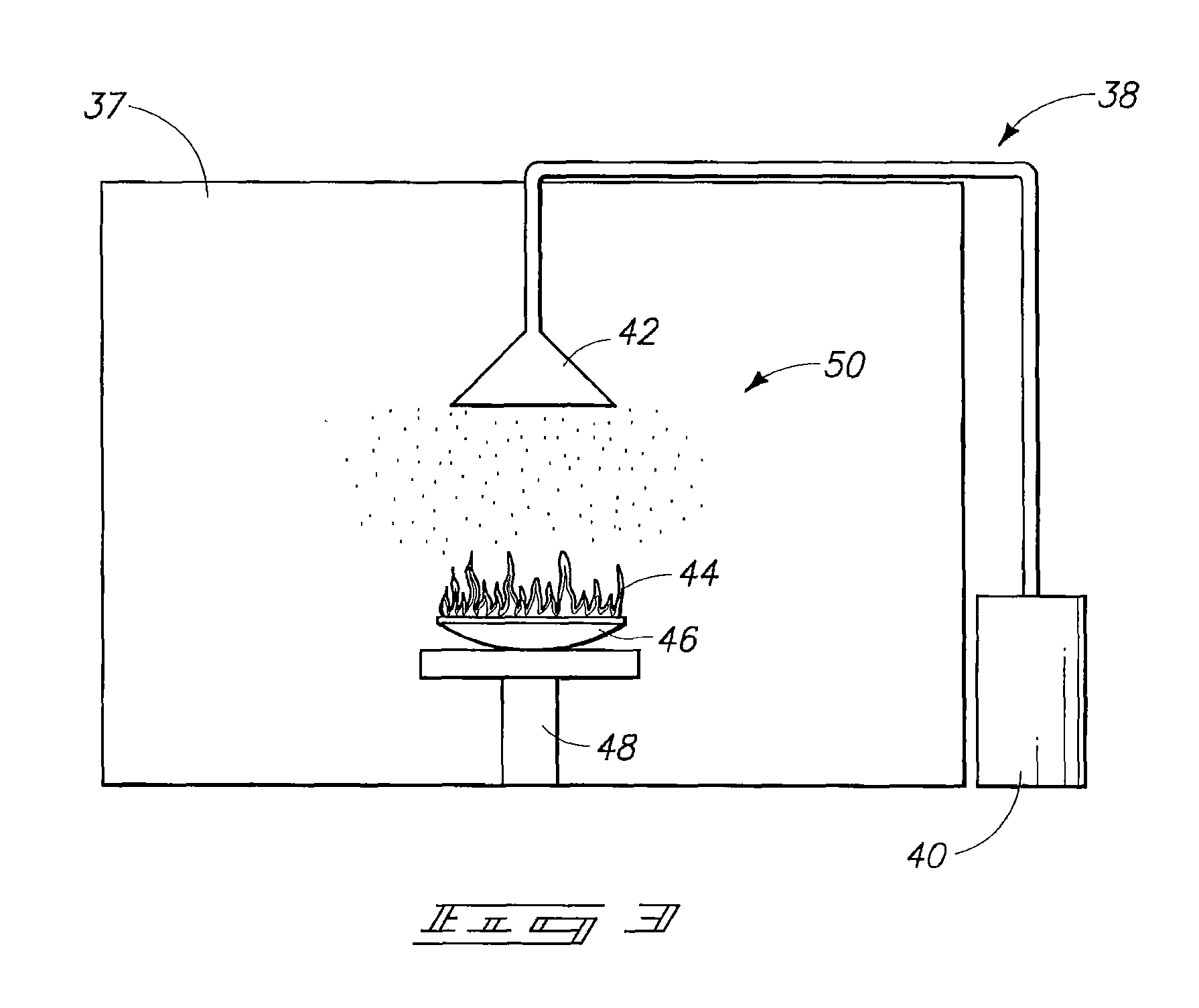

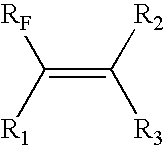

Compositions, Combustion Prevention Compositions, Methods for Preventing and/or Extinguishing Combustion, Combustion Prevention Systems, and Production Processes

ActiveUS20070152200A1Preparation by hydrogen halide split-offOther chemical processesCombustionProcess composition

Compositions comprising are provided wherein RF is a fluorine containing moiety comprising (CF3)2CFCH2(CF3)CH—, (CF3)2CFCH2((CF3)2CF)CH—, (CF3)2CFCH2((CF3)2CH)CH—, (CF3)2CHCH2((CF3)2CF)CH—, ((CF3)2CFCH2)2CH—, (CF3)2CFCH2CF—, (CF3)2CF—, (CF3)2CH—, CF3—, or CnF2n+1—, n being an integer from 2 to 20; R1 is F or H; R2 comprises (CF3)2CF—, (CF3)2CH—, CF3—, F, or H; and R3 comprises (CF3)2CF—, (CF3)2CH—, CF3—, F, or H, such compositions can produced according to processes, and utilized to prevent combustion utilizing systems.

Owner:THE CHEMOURS CO FC LLC

Combined multi-stage filter core and its making method

InactiveCN1390622AHigh filtration precisionExtended service lifeFiltration separationChemical treatmentComposite filter

A multi-stage composite filter core is prepared from the chemically processed composition through pulverizing, chemically processing, stirring, cold pressing, drying and hot die pressing. It is a hollow cylinder with 3 coaxial layers, which have 5-10 meshes, 10-30 meshes and 30-50 meshes from outside to inside. Its advantages are high precision and long service life.

Owner:欢乐海(北京)科技有限公司

Method for preparing PVA (polyvinyl alcohol) assisted dispersant for manufacturing polyvinyl chloride by using suspension method

ActiveCN102311516ASolve the problem of insoluble in waterSolve the problem of fragmentationPolyvinyl chlorideProcess composition

The invention discloses a method for preparing a PVA (polyvinyl alcohol) assisted dispersant for manufacturing polyvinyl chloride by using a suspension method. The method comprises a process for preparing a copolymer solution through copolymerization of binary or multielement monomers, and an alkali or acid catalytic alcoholysis process; the polymerization degree of the prepared PVA assisted dispersant is 200-400, and the alcoholysis degree of the PVA assisted dispersant is 33-55mol%; and the assisted dispersant is totally soluble in water, and is used for the suspension polymerization of chloroethylene. The PVA assisted dispersant prepared by the method is exclusively used for the suspension polymerization process of chloroethylene; and the method disclosed by the invention is environmental-friendly and economic in cost, the performance of the obtained product is good, and a problem that a low-alcoholysis-degree assisted dispersant is not completely soluble in water is solved.

Owner:TIANJIN SUNNYMER +1

NOx reduction compositions for use in FCC processes

InactiveUS20050042158A1Minimize conversionReduce contentCatalytic crackingNitrogen compoundsIridiumAlkaline earth metal

Compositions for reduction of gas phase reduced nitrogen species and NOx generated during a partial or incomplete combustion catalytic cracking process, preferably, a fluid catalytic cracking process, are disclosed. The compositions comprise (i) an acidic metal oxide containing substantially no zeolite, (ii) an alkali metal, alkaline earth metal, and mixtures thereof, (iii) an oxygen storage component, and (iv) a noble metal component, preferably rhodium or iridium, and mixtures thereof, are disclosed. Preferably, the compositions are used as separate additives particles circulated along with the circulating FCC catalyst inventory. Reduced emissions of gas phase reduced nitrogen species and NOx in an effluent off gas of a partial or incomplete combustion FCC regenerator provide for an overall NOx reduction as the effluent gas stream is passed from the FCC regenerator to a CO boiler, whereby as CO is oxidized to CO2 a lesser amount of the reduced nitrogen species is oxidized to NOx.

Owner:WR GRACE & CO CONN

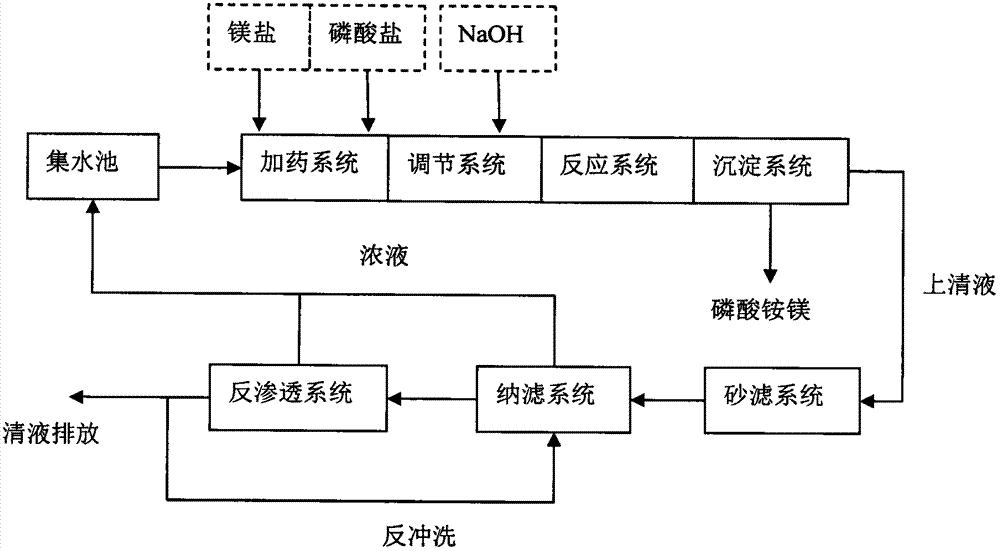

Method for treating ammonia nitrogen in wastewater by using integrated process

InactiveCN102964003AGuaranteed emission standardsZero emissionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRetention timeMagnesium salt

The invention relates to a method for treating ammonia nitrogen in wastewater by using an integrated process, and the method comprises a magnesium ammonium phosphate chemical precipitation process and a membrane treatment process and comprises the processing steps of collecting water, dosing, adjusting the pH (potential of Hydrogen) value, reacting, precipitating and filtering. The method has the technical characteristics that magnesium salt and phosphate are added during the dosing; a NaOH solution is added to regulate the pH to 8.5-10 during the adjustment; during the reaction, the wastewater retention time is greater than or equal to 30 minutes, the ammonia ion in the wastewater is fully reacted to generate magnesium ammonium phosphate precipitates and heavy metal ion is converted into hydroxide precipitates; the precipitation time is greater than or equal to 6 hours to realize solid-liquid separation during the precipitation; and the supernatant liquid enters a membrane treatment system, the reverse osmosis clear water can be directly discharged and the concentrated water returns to a water collecting tank or is subjected to nanofiltration. The method has the advantages that ammonia nitrogen-containing wastewater with various concentrations can be treated; heating is not needed in the treatment process; the ammonia nitrogen content in the effluent can meet the national first grade effluent standard; and the content of other pollutants such as heavy metals and the like in the effluent can be used for achieving the effluent standard. The method is suitable for treating low-biodegradability ammonia nitrogen-containing wastewater and the ammonia nitrogen-containing wastewater of factories without heat resources.

Owner:CECEP L&T ENVIRONMENTAL TECH

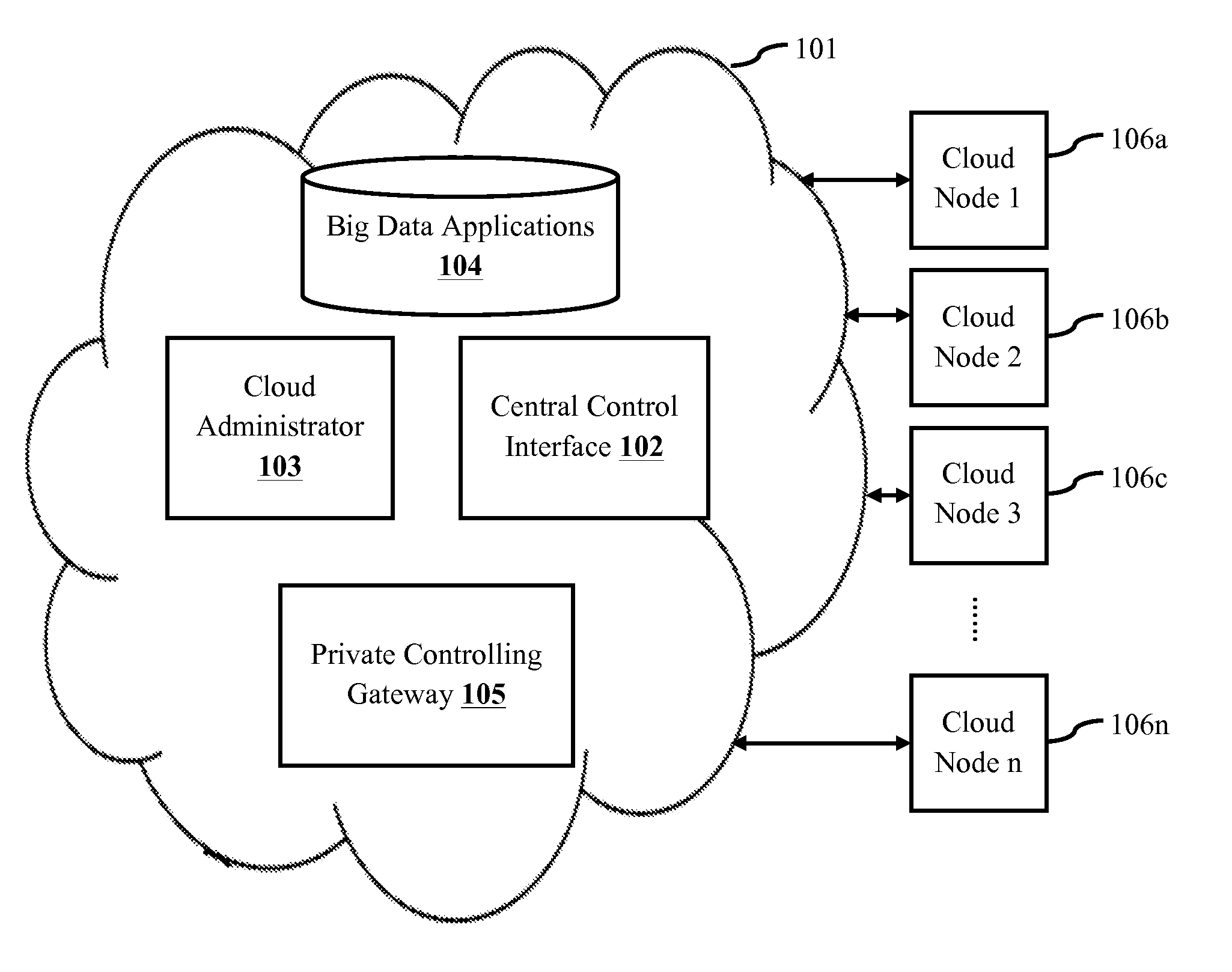

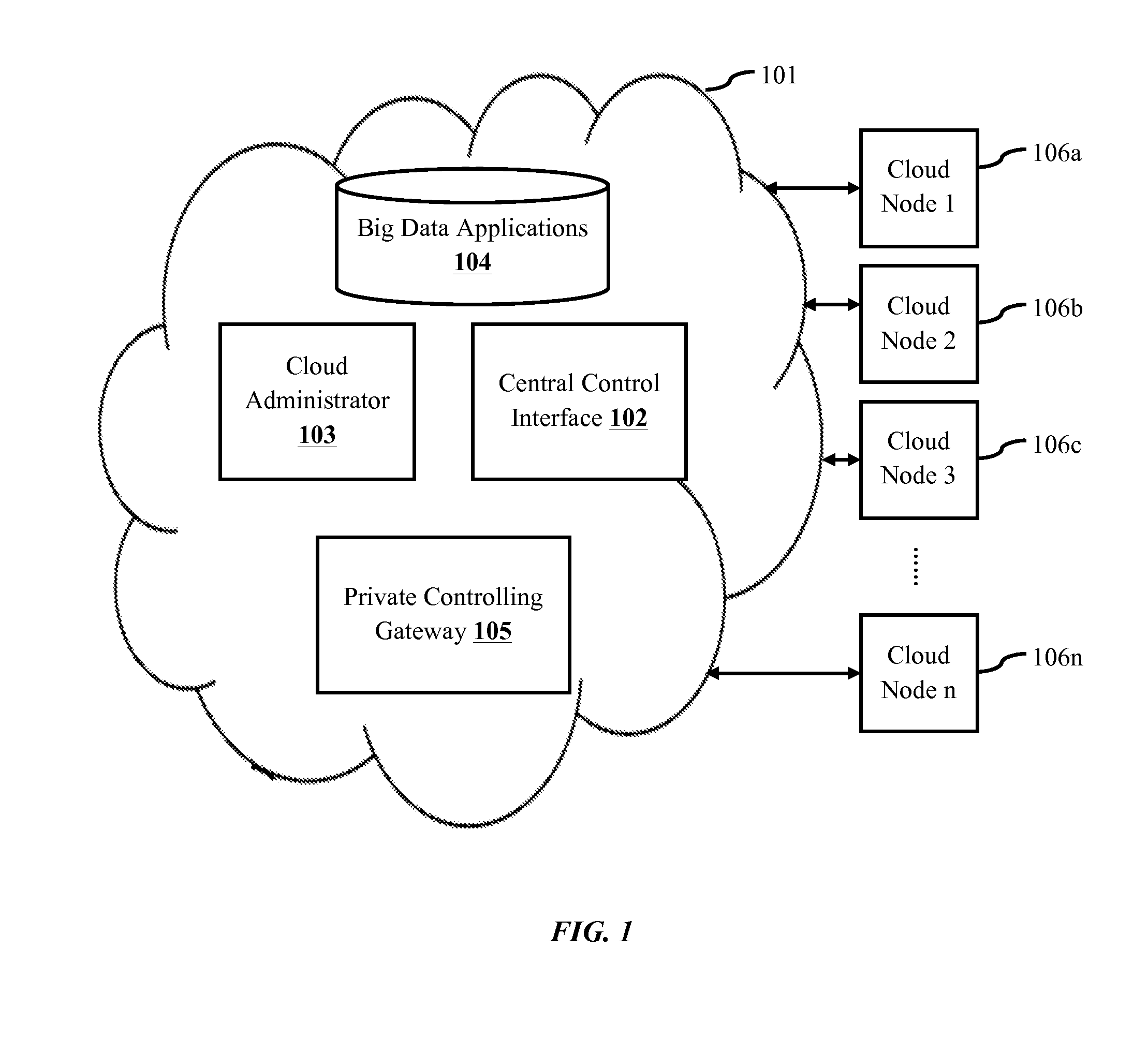

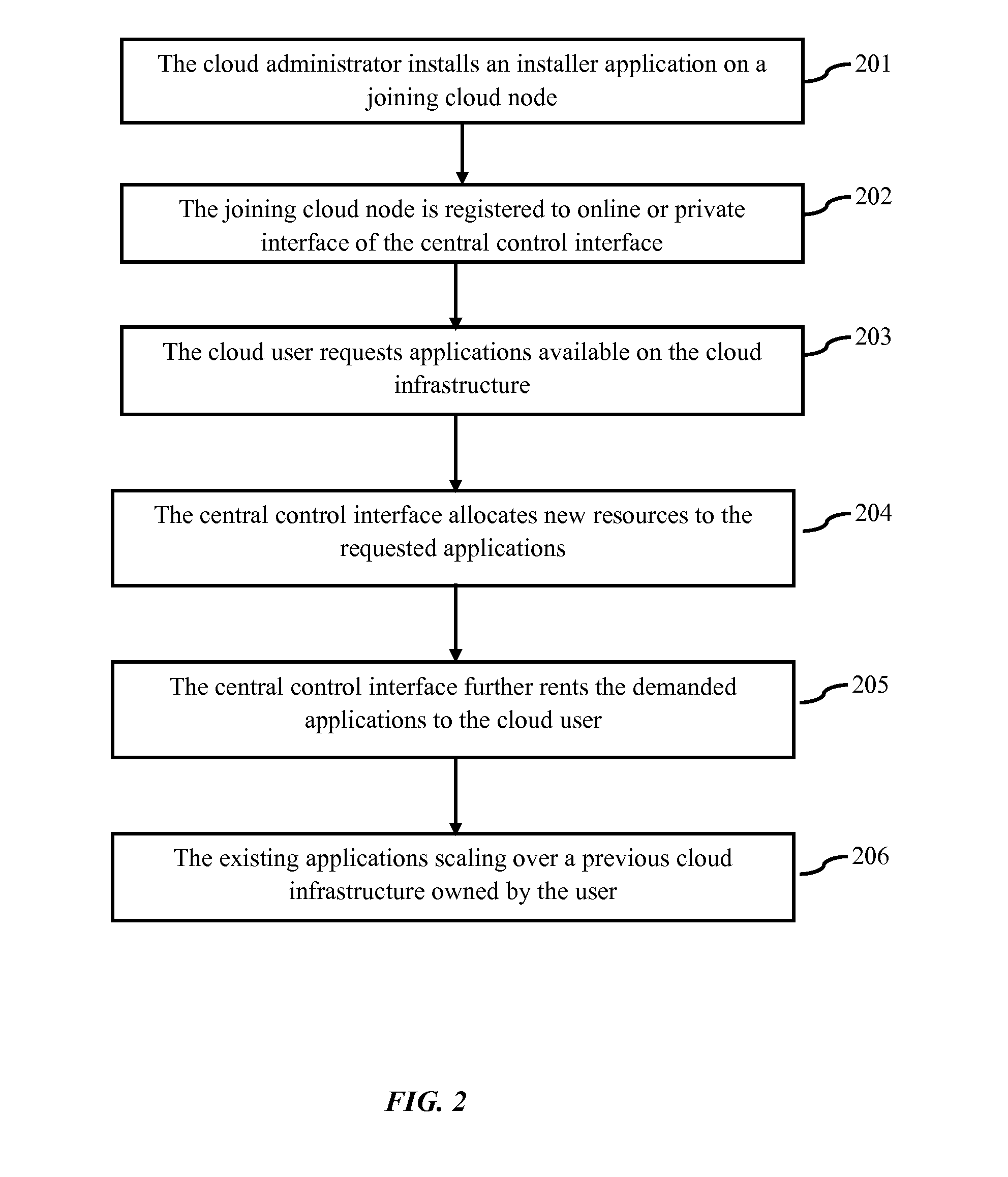

System and method providing marketplace for big data applications

InactiveUS20150089626A1Multiple digital computer combinationsBuying/selling/leasing transactionsData setCloud user

The embodiments herein disclose a system and method for providing a marketplace for Big Data applications. The system facilitates a repository of applications, data sets, process compositions and extension modules received from the various vendors. The assets provided by the marketplace are deployed upon receiving the requests on public and private clouds. The marketplace comprises the algorithms, data sets and software systems to generate, share and save the insights for a plurality of cloud users. The system provides Big Data applications on demand from the cloud users and installs the requested application on a dedicated platform adopted for online Big Data processing.

Owner:KORANGY FRED

Compositions, combustion prevention compositions, methods for preventing and/or extinguishing combustion, combustion prevention systems, and production processes

ActiveUS8148584B2Preparation by hydrogen halide split-offOther chemical processesCombustionProcess composition

Compositions comprisingare provided wherein RF is a fluorine containing moiety comprising (CF3)2CFCH2(CF3)CH—, (CF3)2CFCH2((CF3)2CF)CH—, (CF3)2CFCH2((CF3)2CH)CH—, (CF3)2CHCH2((CF3)2CF)CH—, ((CF3)2CFCH2)2CH—, (CF3)2CFCH2CF—, (CF3)2CF—, (CF3)2CH—, CF3—, or CnF2n+1—, n being an integer from 2 to 20; R1 is F or H; R2 comprises (CF3)2CF—, (CF3)2CH—, CF3—, F, or H; and R3 comprises (CF3)2CF—, (CF3)2CH—, CF3—, F, or H, such compositions can produced according to processes, and utilized to prevent combustion utilizing systems.

Owner:THE CHEMOURS CO FC LLC

Reduced NOx combustion promoter for use in FCC processes

InactiveUS6902665B2Promoting CO combustionAvoiding significant NOx formationCatalytic crackingMolecular sieve catalystsCombustionAlkaline earth metal

Compositions comprising a component containing (i) an acidic oxide support, (ii) an alkali metal and / or alkaline earth metal or mixtures thereof, (iii) a transition metal oxide having oxygen storage capability, and (iv) palladium promote CO combustion in FCC processes while minimizing the formation of NOx. The acidic oxide support preferably contains silica alumina. Ceria is the preferred oxygen storage oxide.

Owner:WR GRACE & CO CONN

Method for etching metal nitride with high selectivity to other materials

ActiveUS20100206841A2Decorative surface effectsSemiconductor/solid-state device manufacturingHalogenTitanium nitride

A method and system of etching a metal nitride, such as titanium nitride is described. The etching process comprises introducing a process composition having a halogen containing gas, such as Cl2, HBr, or BCl3, and a hydrocarbon gas having the chemical formula CxHy, where x and y are equal to unity or greater.

Owner:TOKYO ELECTRON LTD

Instant roux

InactiveUS20060034997A1Function increaseHigh opacityFood preparationProcess compositionFood products

This invention relates to an instant roux comprising co-processed modified starch and flour and fat. In addition, the invention relates to the process for providing such “ready-for-use” compositions and the improved food products prepared from the co-processed compositions.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Three dimensional printing compositions and processes

InactiveUS20180134911A13D object support structuresDomestic articlesPolymer scienceProcess composition

Compositions suitable for three dimensional printing technology and methods for producing three dimensional printed articles and building materials are provided. The compositions are optimized for dimensional stability during and following various printing processes. In this manner, the compositions and articles printed or produced therefrom minimize any shrinkage or expansion following drying or curing of the printed or finished article and can be used to form accurate molds of digitally designed articles.

Owner:RAPID PATTERN LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com