Bag lithium ion battery preparing method and battery thereby

A lithium-ion battery and bag-type technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of increased battery cost, increased battery process procedures, and difficulty in preparation, and achieves low production costs and low weight. The effect of lightness and large specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

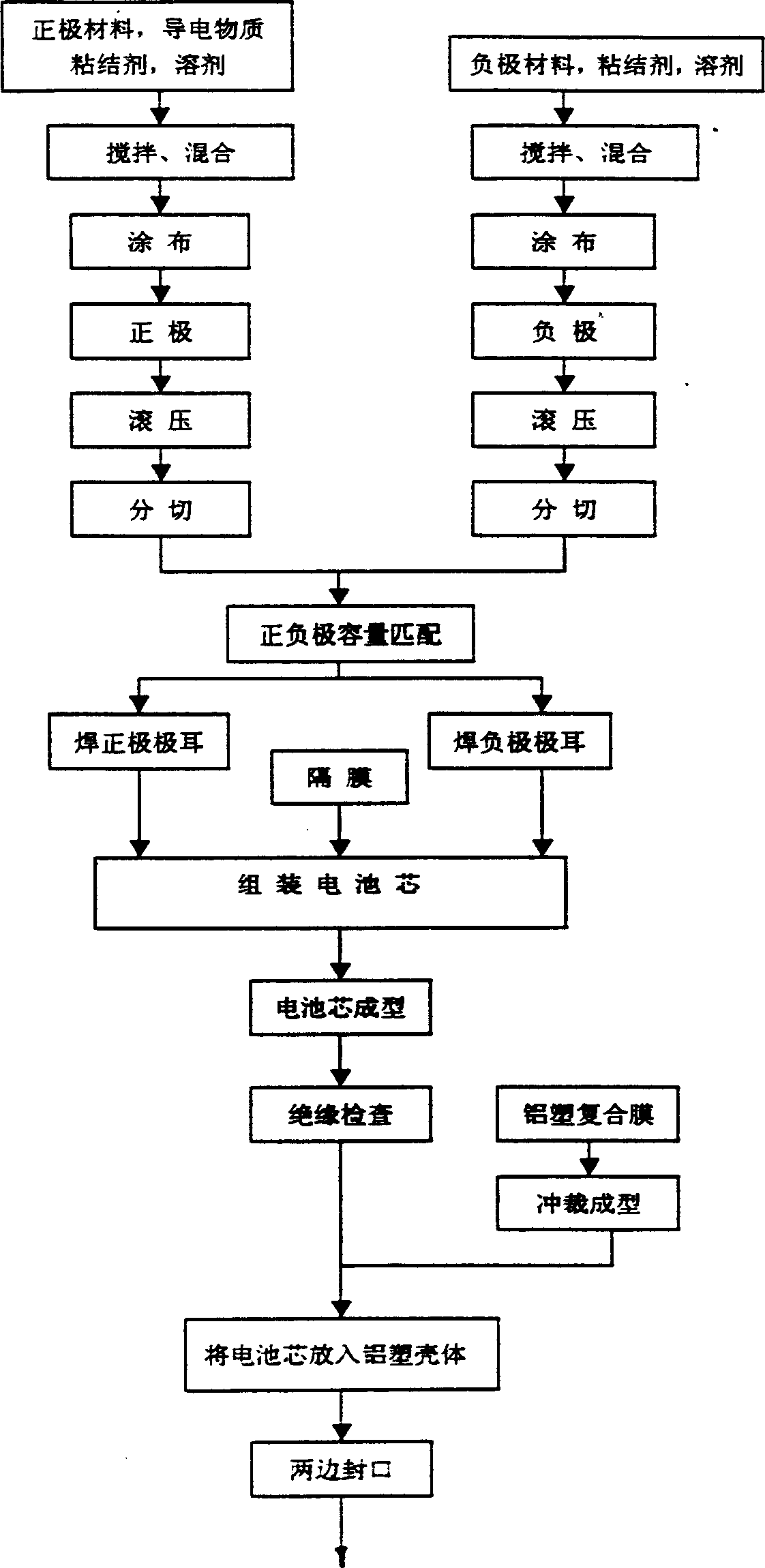

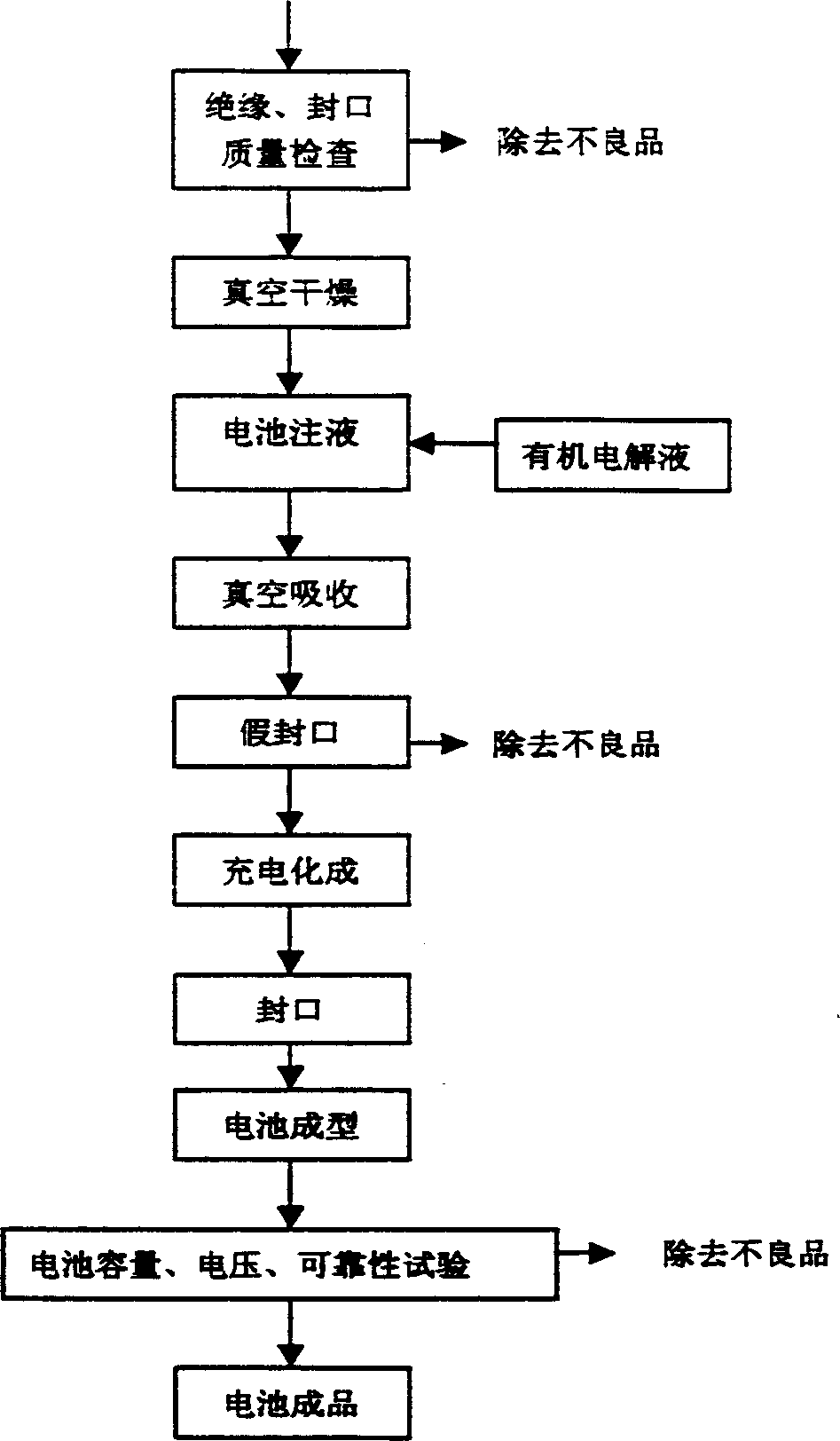

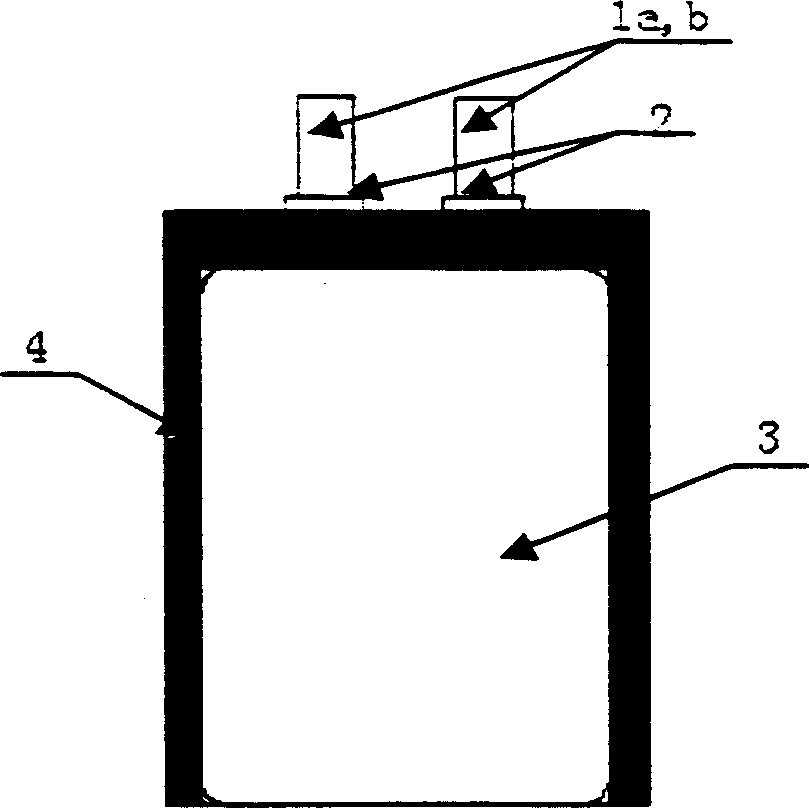

[0039] In this example, combined with Figure 1a , Figure 1b to Figure 7 shown.

[0040] Preparation of positive electrode: 89 parts (by weight) of LiCoO 2 1. After mixing 6 parts of conductive graphite evenly, add 5 parts of binder PVDF that has been dissolved by organic solvent nitrogen methyl pyrrolidone (NMP), use mechanical stirring to form a uniform positive electrode slurry, and then apply it on such as Figure 7 The shown conductive base aluminum foil 11 is dried, rolled, and cut into a certain size positive electrode sheet. The pole piece thickness is 170μm.

[0041] Preparation of the negative electrode: 94 parts of the negative electrode material MCMB and 6 parts of the binder PVDF dissolved by the organic solvent nitrogen methyl pyrrolidone (NMP) were stirred in a stirring tank to form a uniform negative electrode slurry, and then coated on Figure 7 The shown conductive base copper foil 13 is dried, rolled, and cut to make a negative electrode sheet of a certa...

Embodiment 2

[0048] see Figure 1a , Figure 1b to Figure 7 As shown, 80 parts (by weight) of LiCoO 2 1. After 13 parts of conductive graphite are mixed evenly, 7 parts of binder PVDF dissolved by the organic solvent nitrogen methyl pyrrolidone (NMP) are added, mechanically stirred to form a uniform positive electrode slurry, and then coated on the conductive substrate aluminum foil 11 , after drying, rolling, and cutting into small positive pole pieces of a certain size, the tabs are left on the pole pieces. The pole piece thickness is 120μm.

[0049] Preparation of negative electrode: Stir 90 parts of negative electrode material graphite, 5 parts of conductive agent acetylene black and 5 parts of binder PVDF dissolved in organic solvent nitrogen methyl pyrrolidone (NMP) in a stirring tank to form a uniform negative electrode slurry material, and then coated on the conductive substrate copper foil 13, after drying, rolling, and cutting, a small negative electrode piece of a certain size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com