Patents

Literature

56results about "Rigid-tube cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

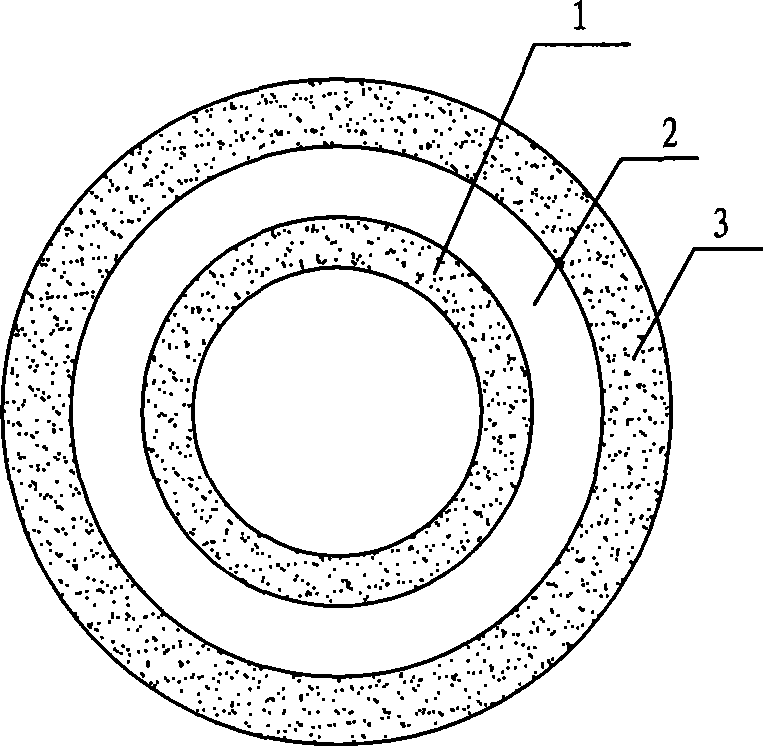

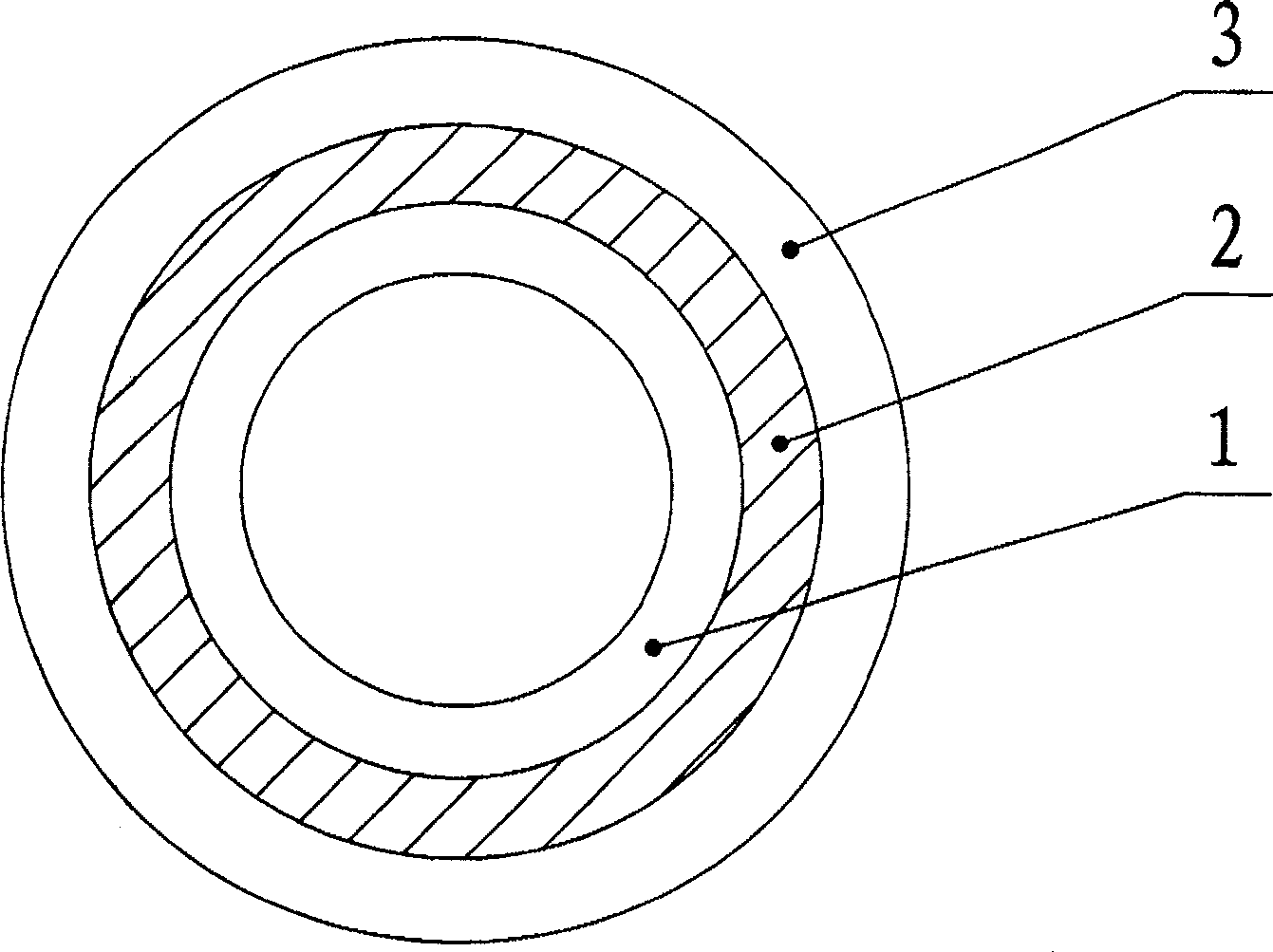

Composite insulating tube type bus and method for preparing the same

ActiveCN101339824AImprove insulation performanceImprove securityRigid-tube cablesManufacturing rigid-tube cablesState of artElectrical conductor

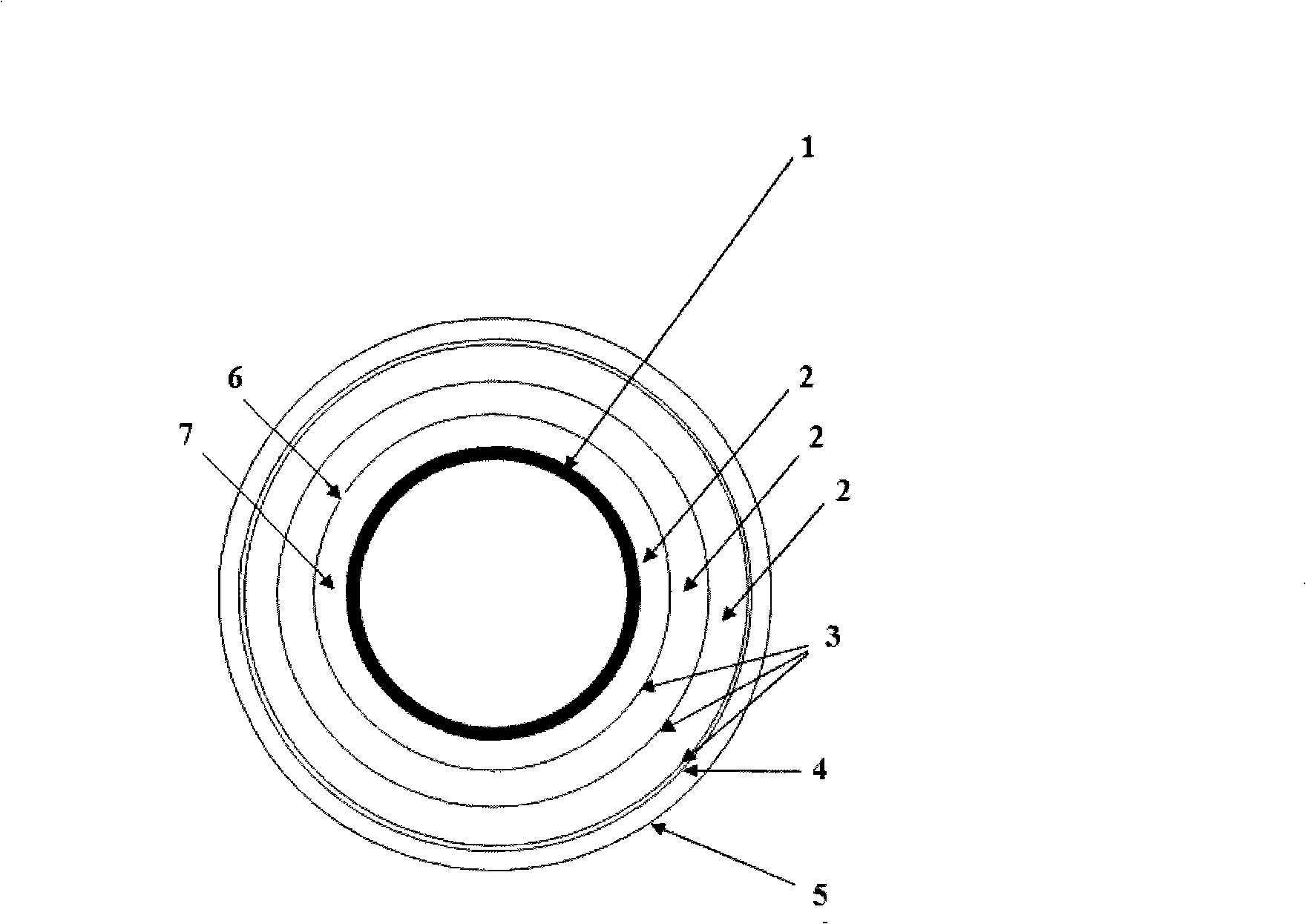

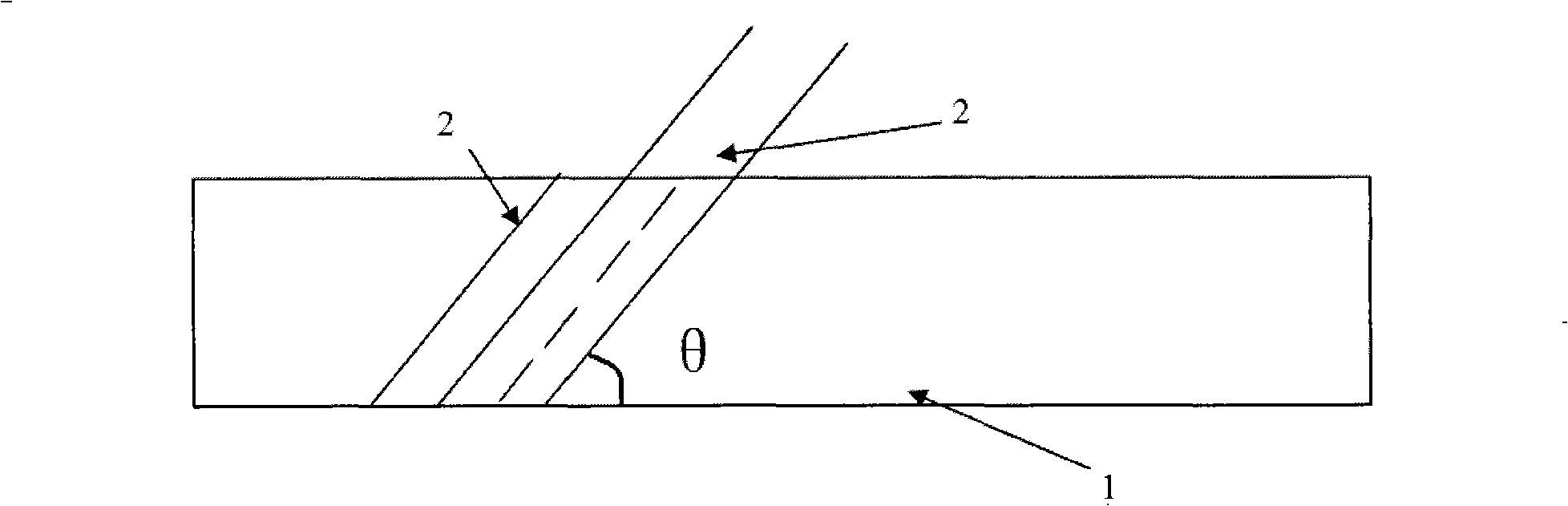

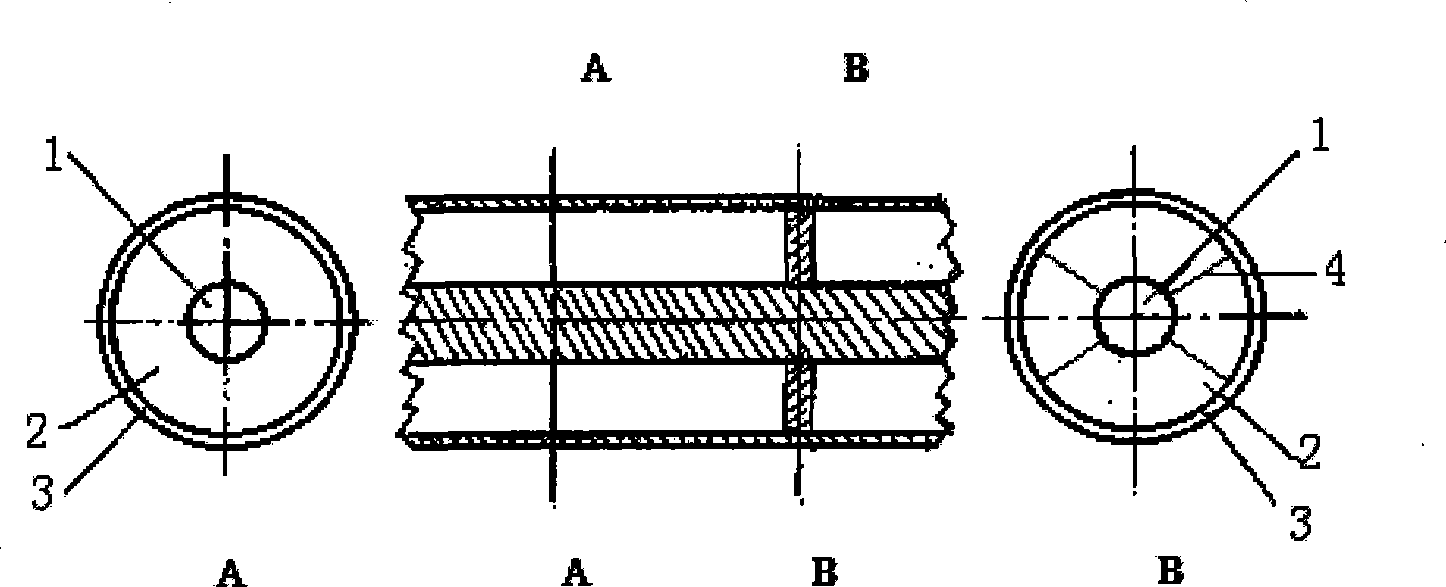

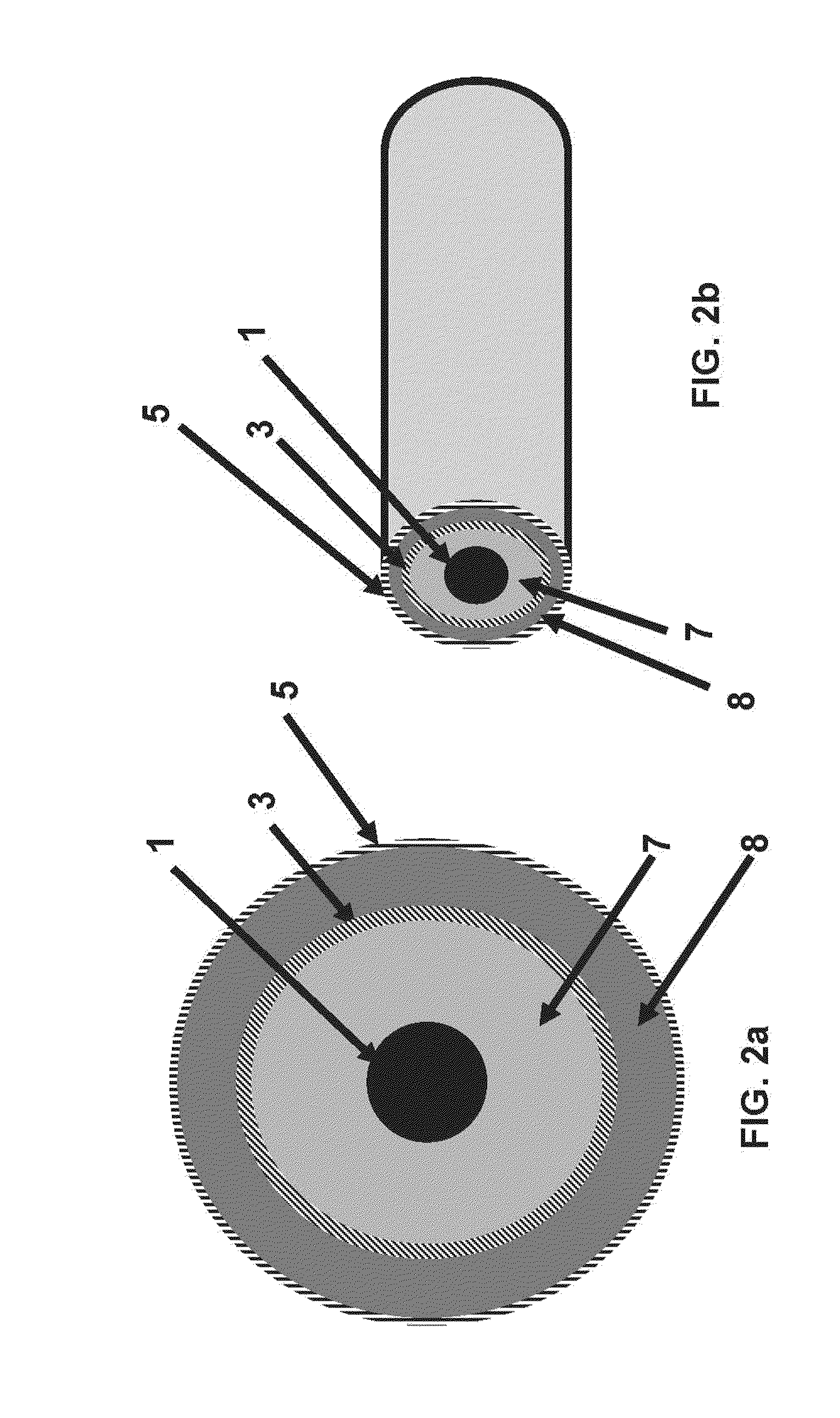

The invention discloses a compound insulating tube busbar and a preparation method thereof in the technical field of high voltage insulated conduction. The compound insulating tube busbar comprises a conductor tube, a compound insulating layer, a semiconductor electric strip layer, a shielding layer and a sleeve, wherein, the conductor tube is positioned on the innermost layer; a plurality of the compound insulating layers and the semiconductor electric strip layers are crosswise arranged at the external part of the semiconductor tube; a copper foil layer is arranged at the external part of the semiconductor electric strip layer and the sleeve is arranged at the external part of the copper foil layer. The preparation method of the invention adopts different properties of a solid buddle-free insulating film strip and insulating liquid to enwind and solidify the shaped insulating tube busbar on the surface of the tubular conductor, which causes the production procedure to be simple and the maintenance to be simple and convenient; compared with the prior art, the compound insulating tube busbar has better insulating property and longer service life, and can be applied to bitter environments.

Owner:SHANGHAI XIBANG ELECTRIC

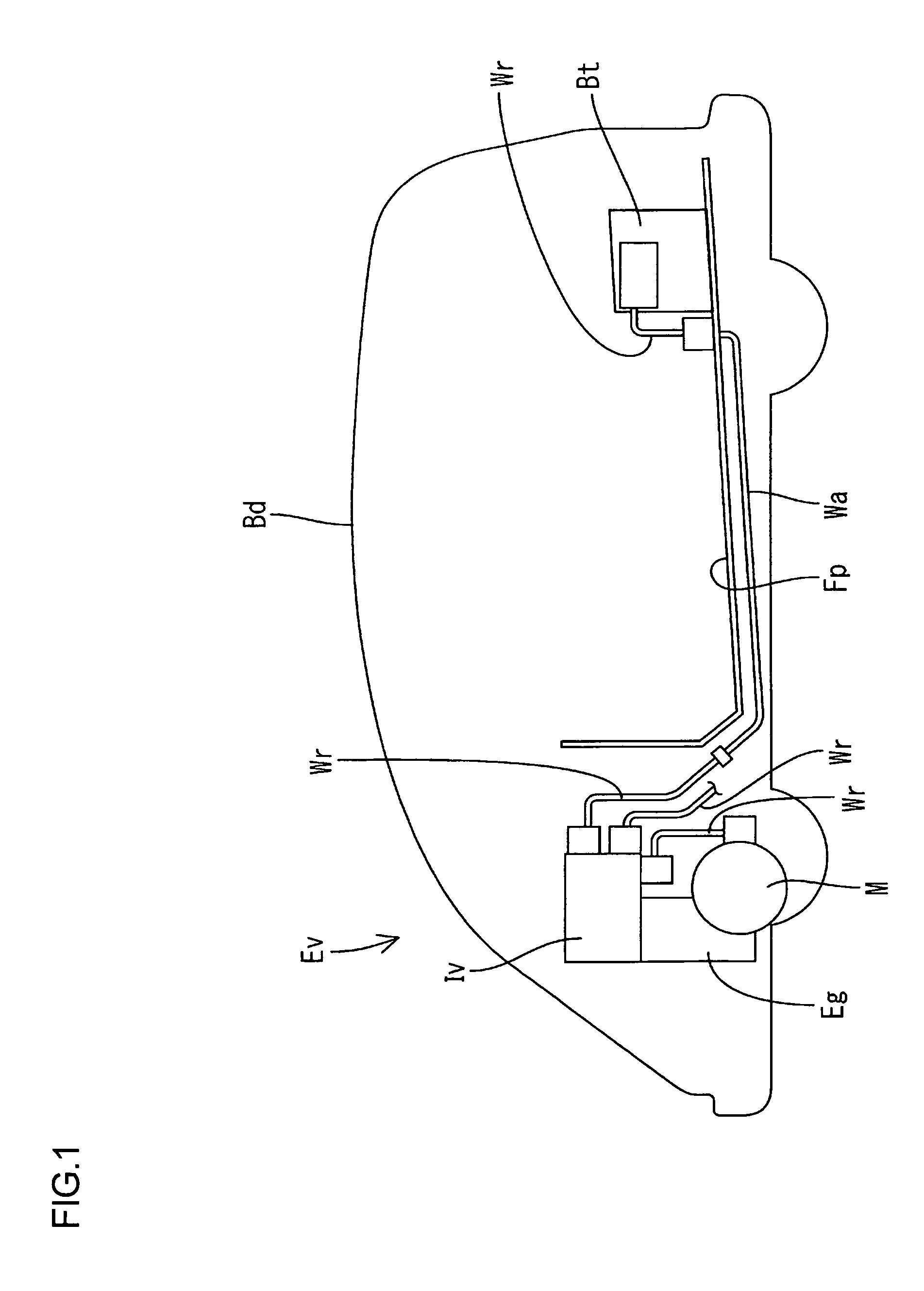

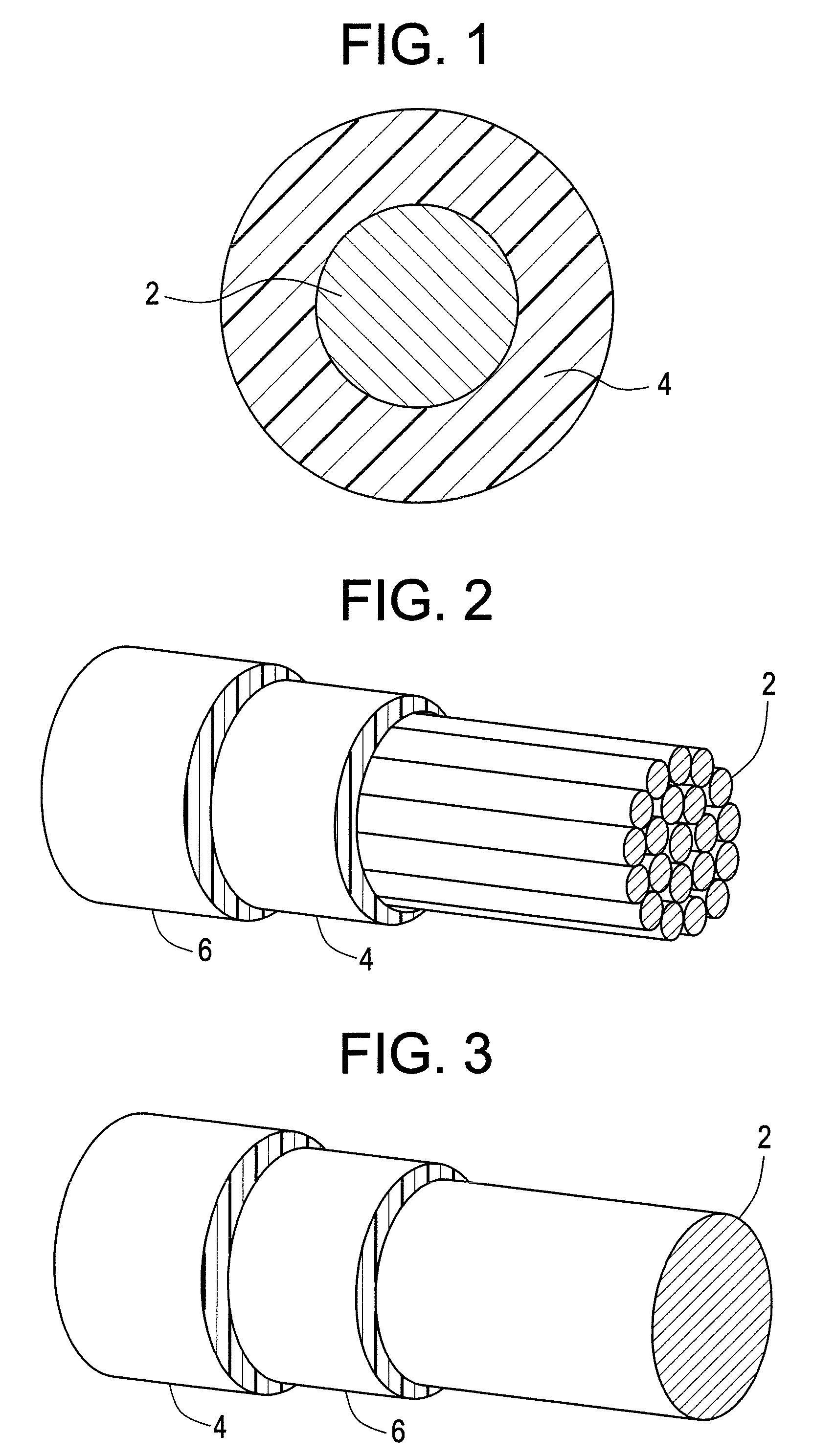

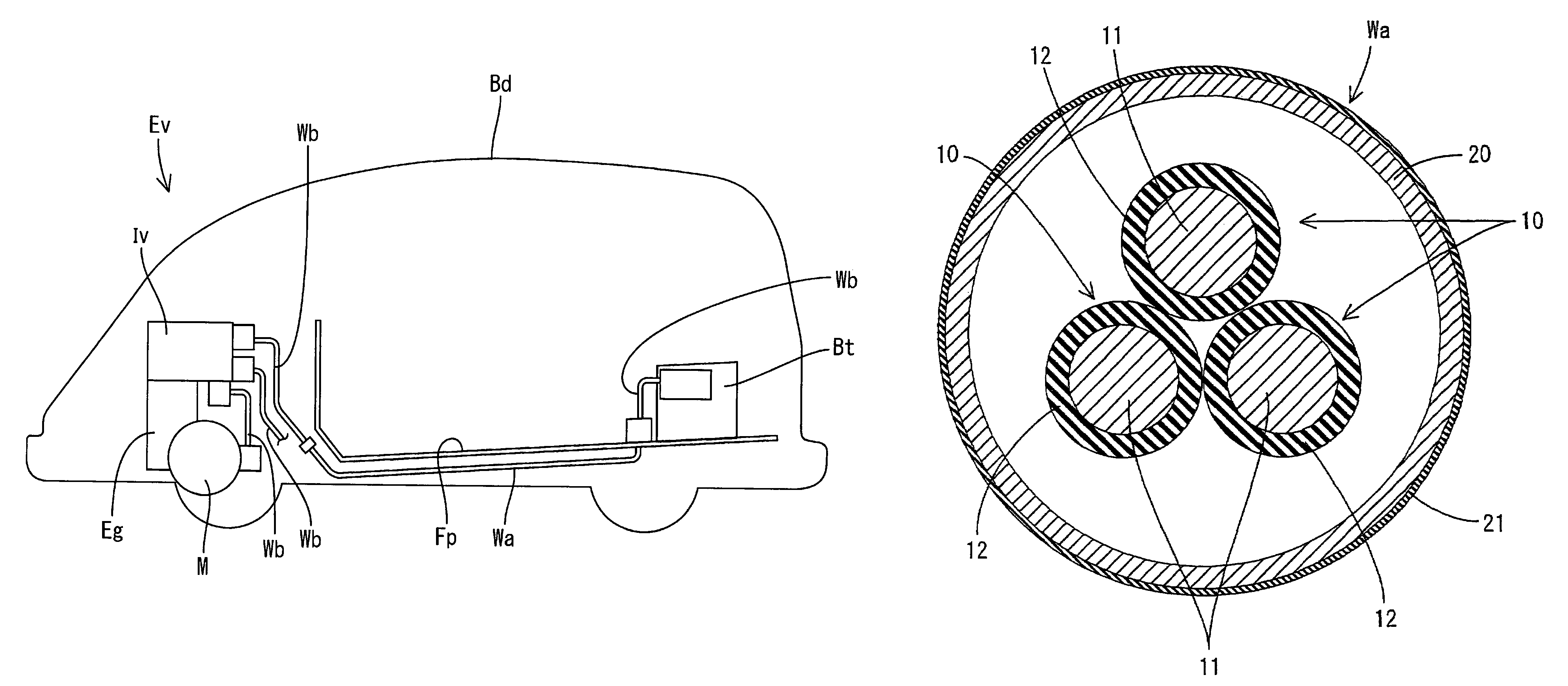

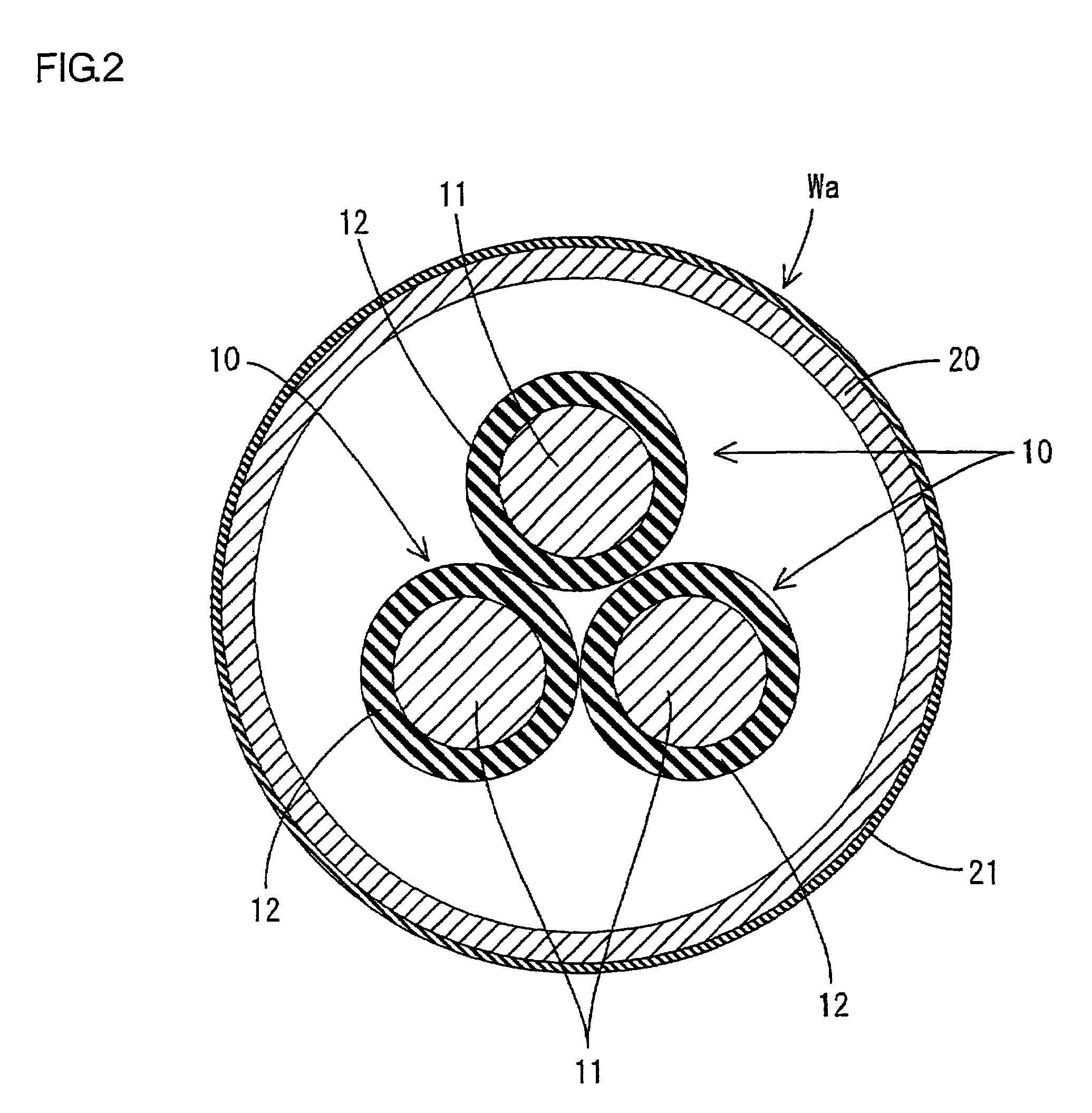

Shielded Conductor for Vehicle

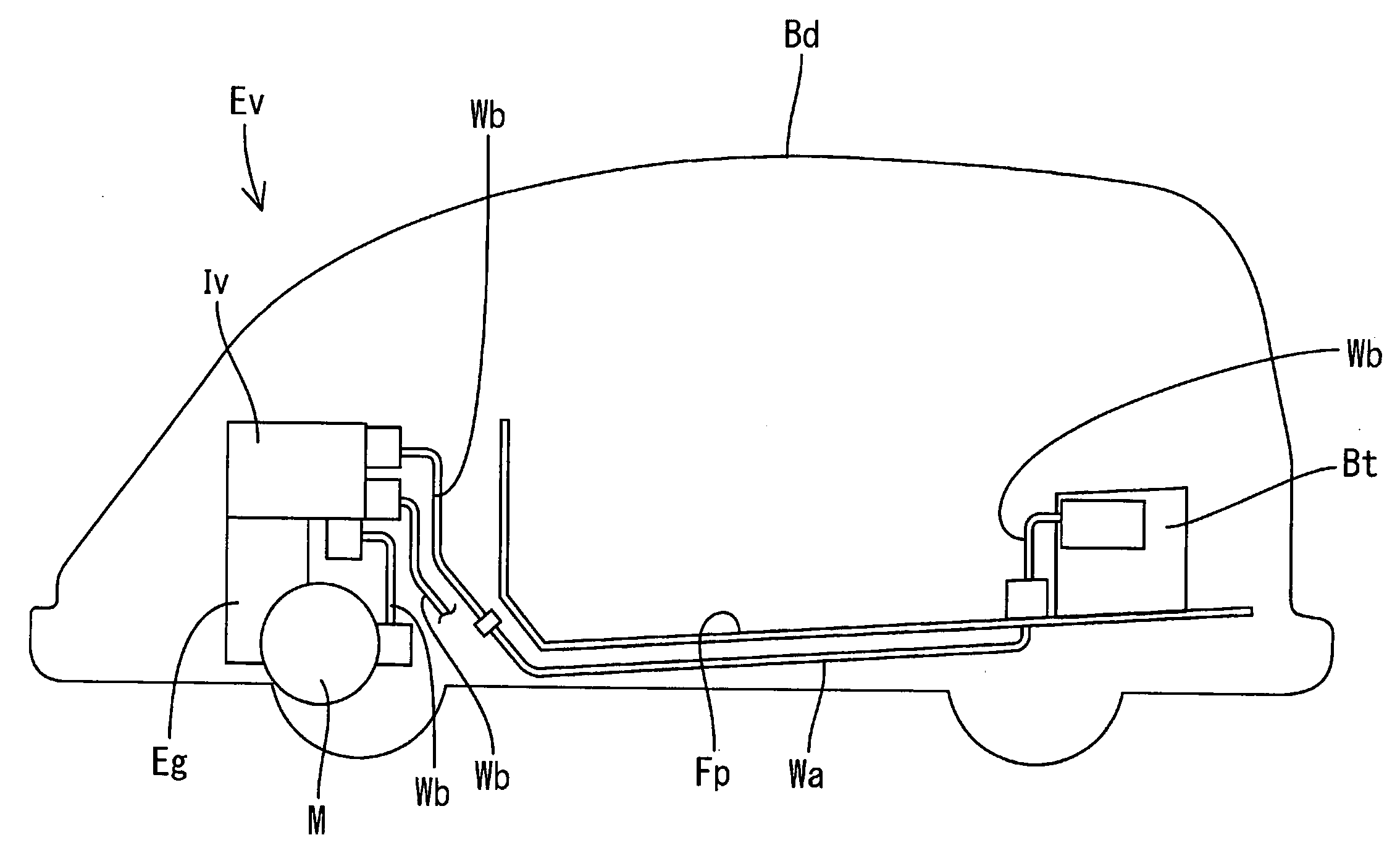

InactiveUS20090107694A1Improve shielding effectEasy to rustRigid-tube cablesPower cables with screens/conductive layersElectrical conductorMetal

Owner:AUTONETWORKS TECH LTD +2

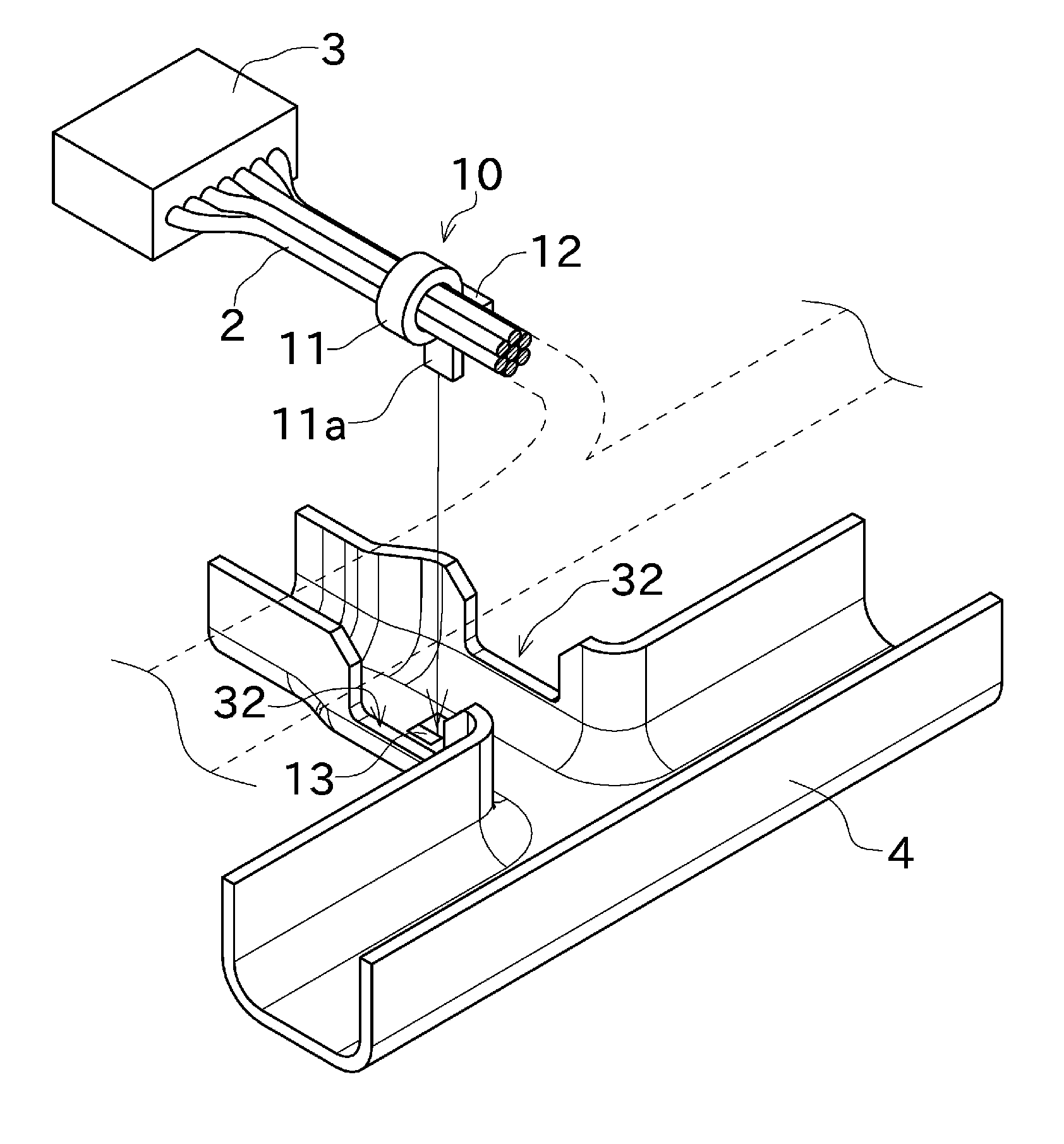

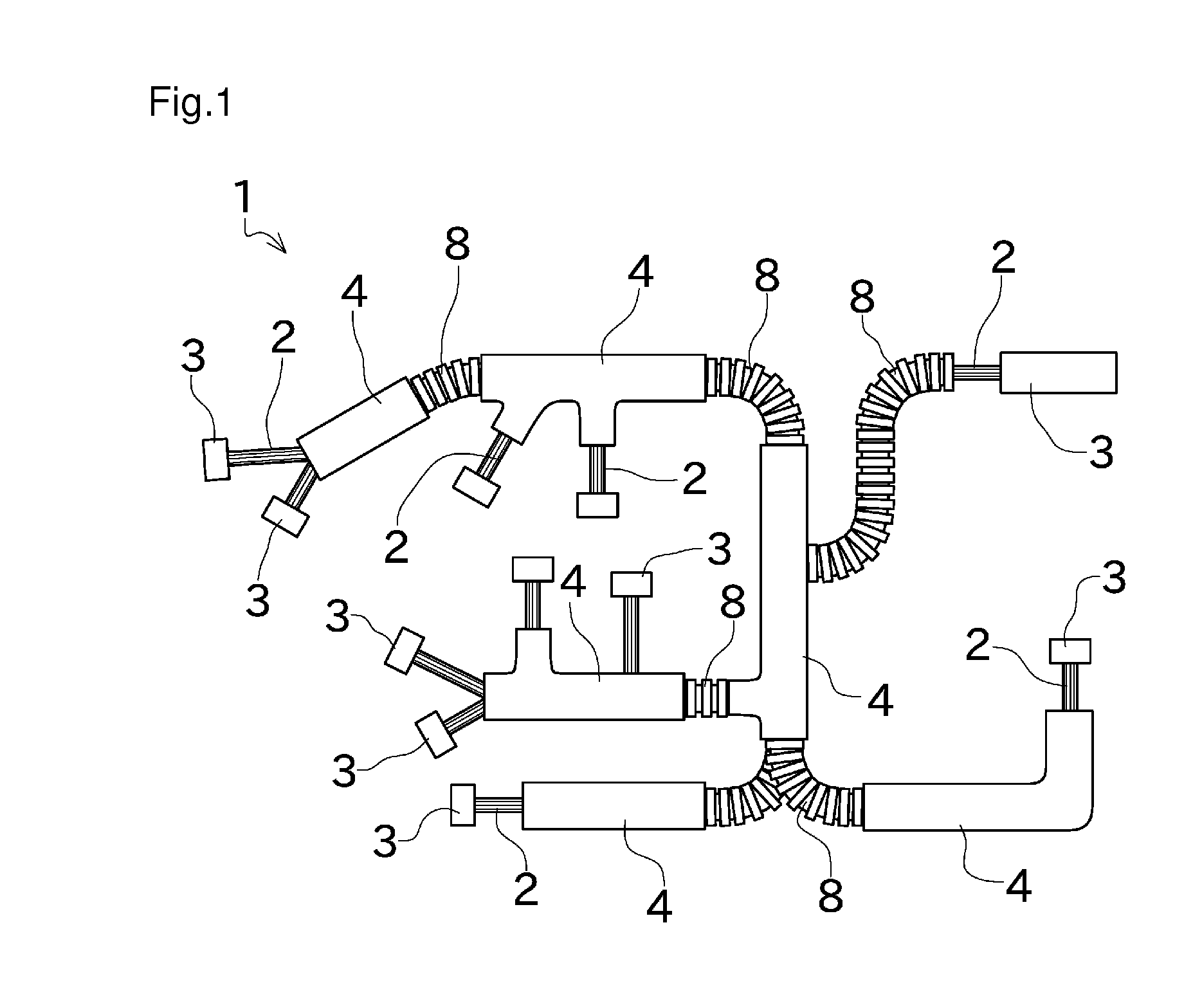

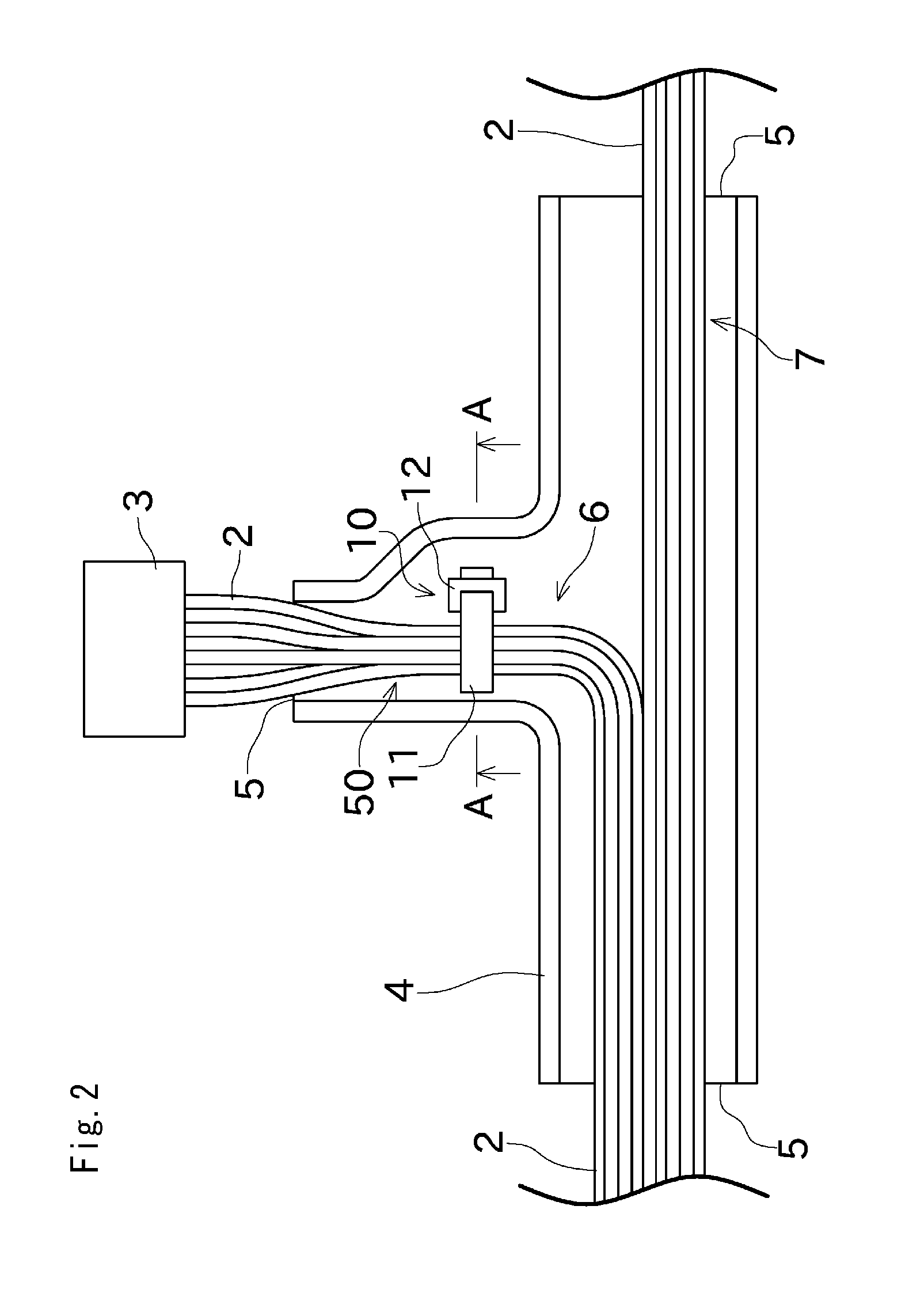

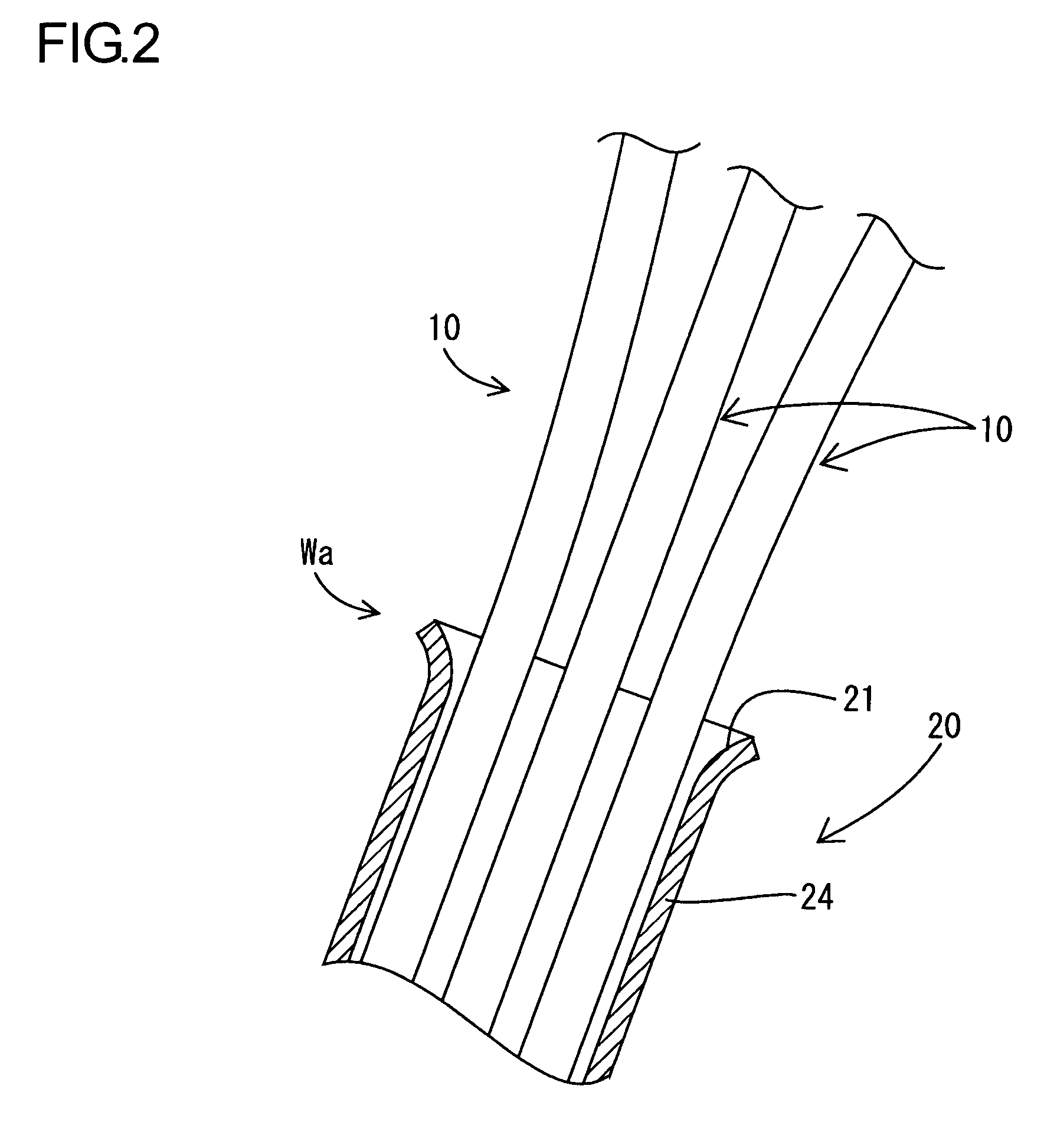

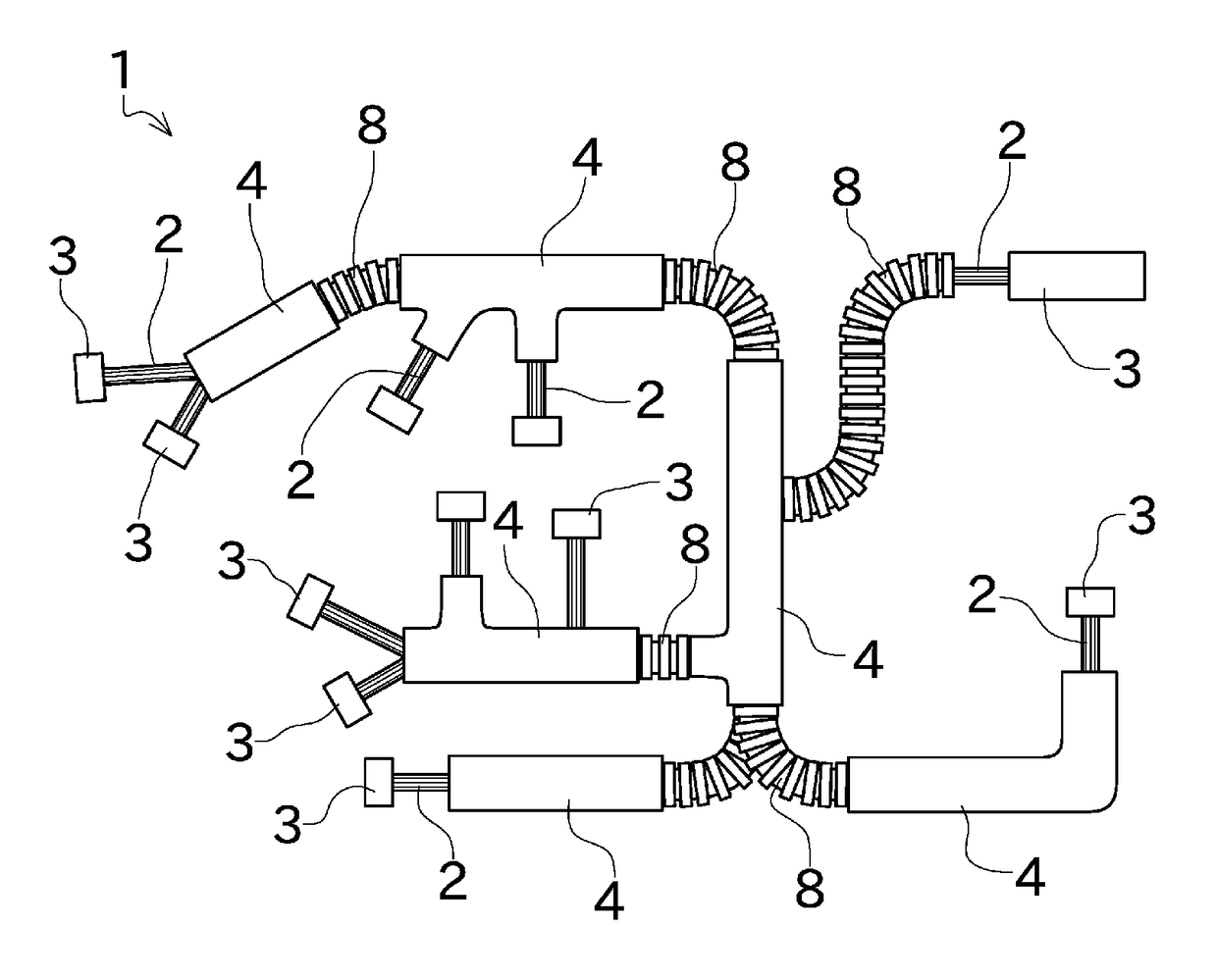

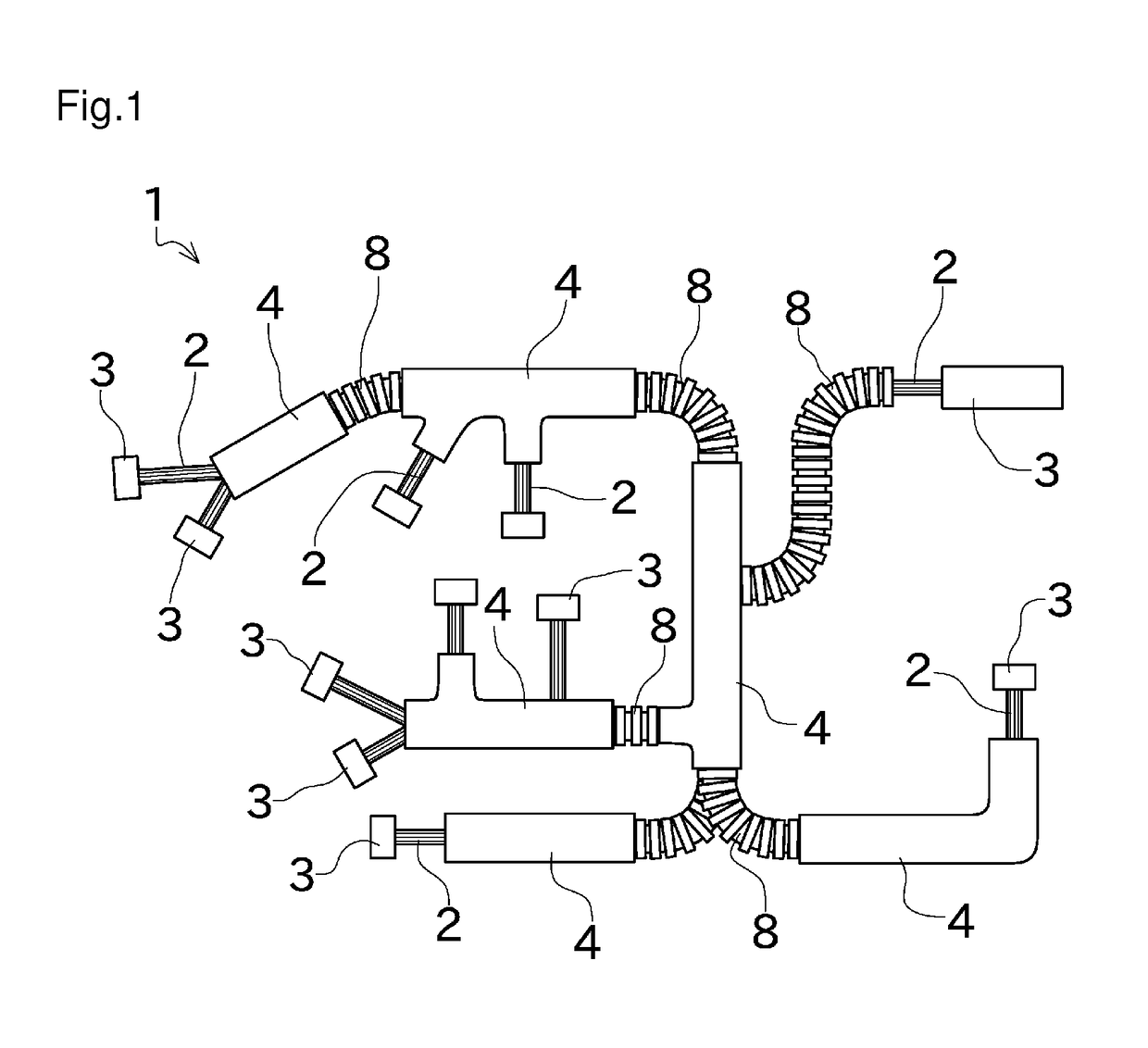

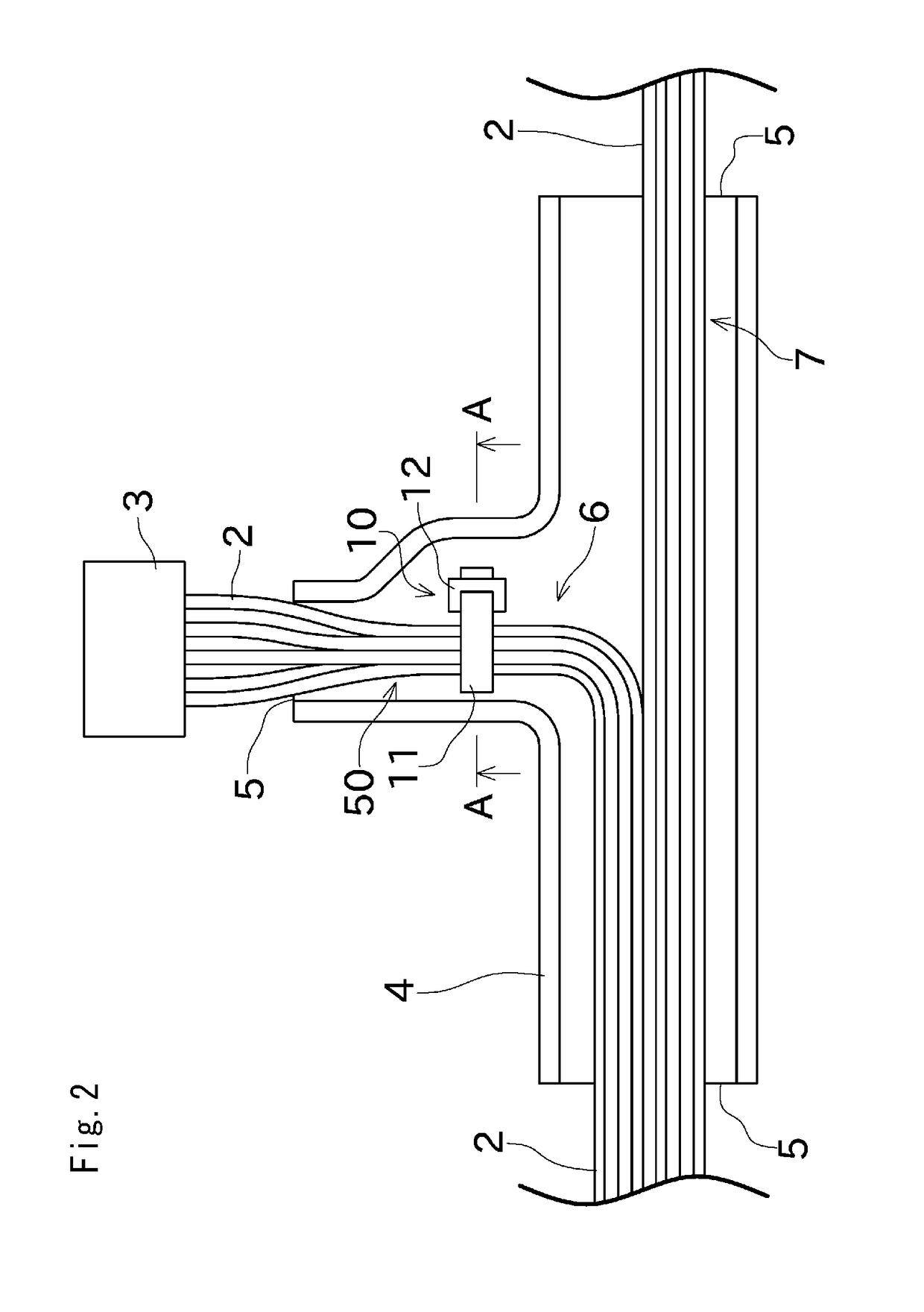

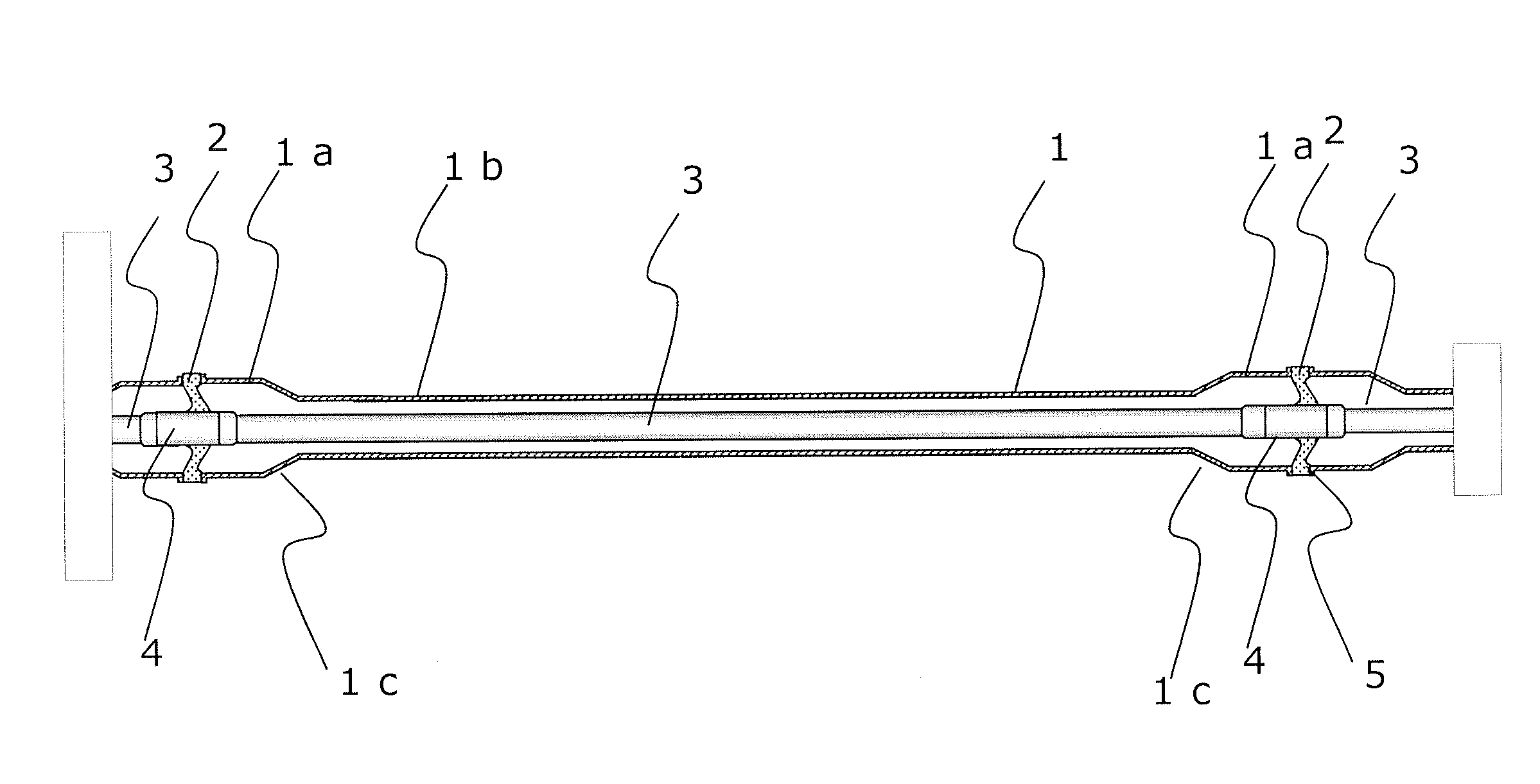

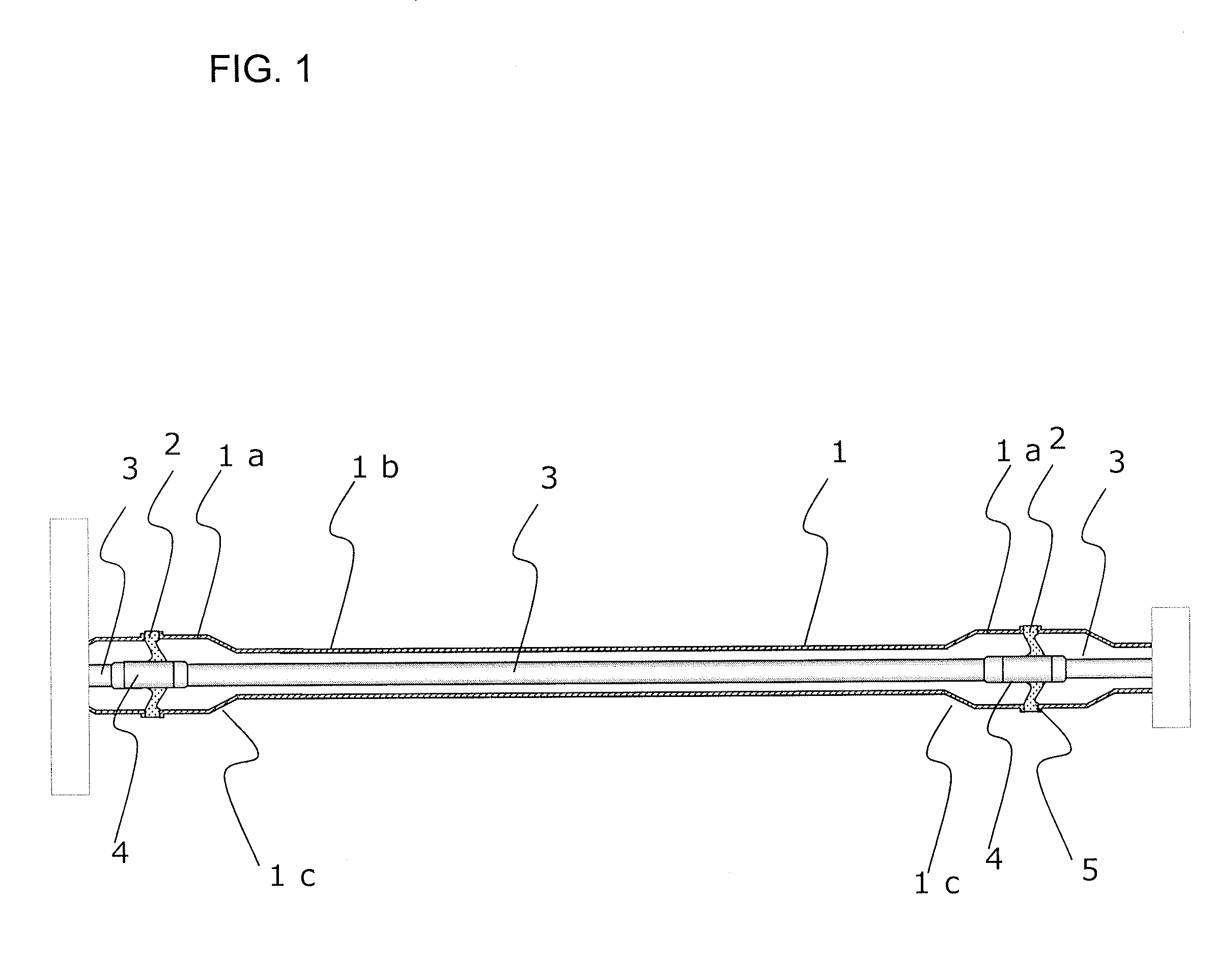

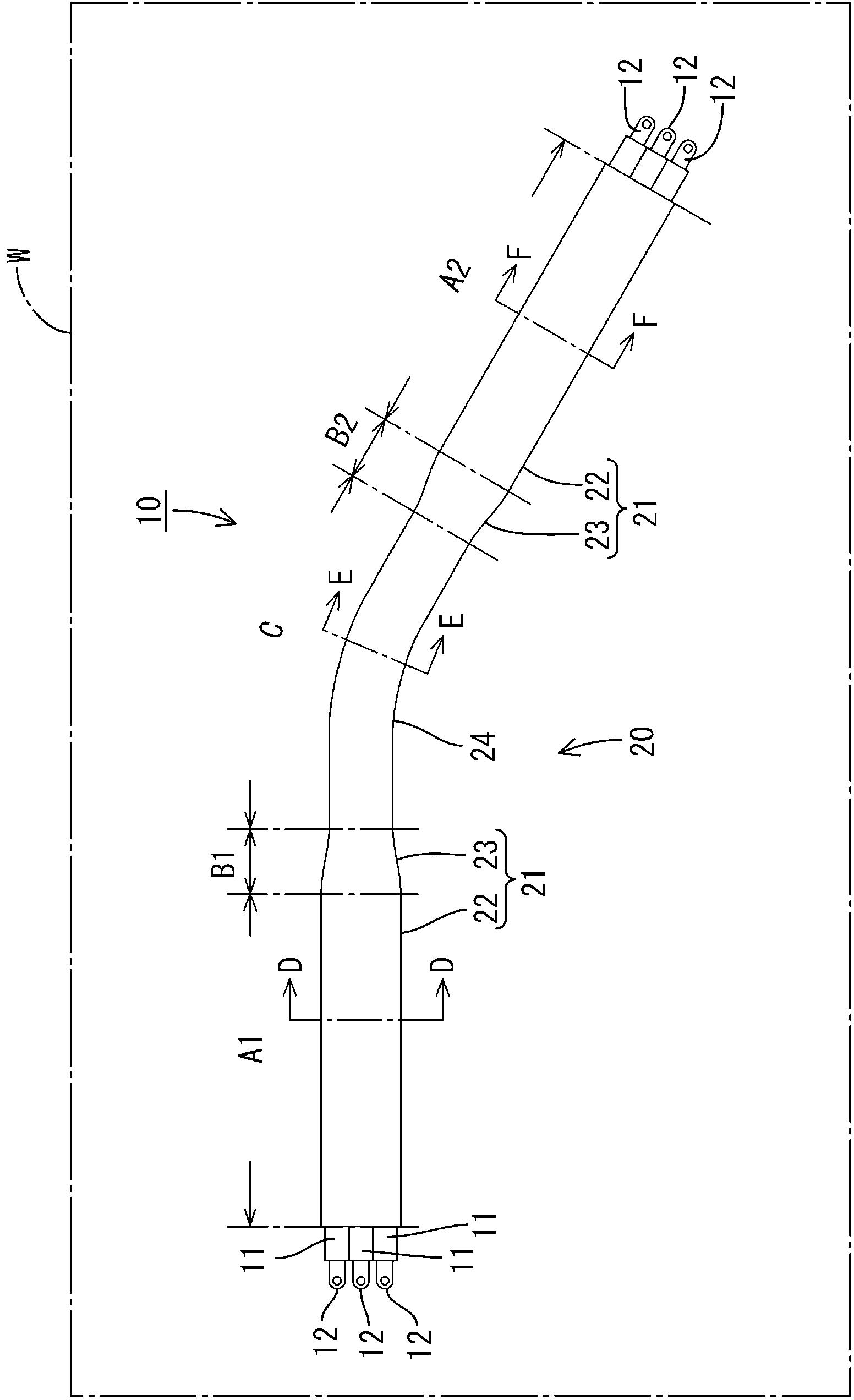

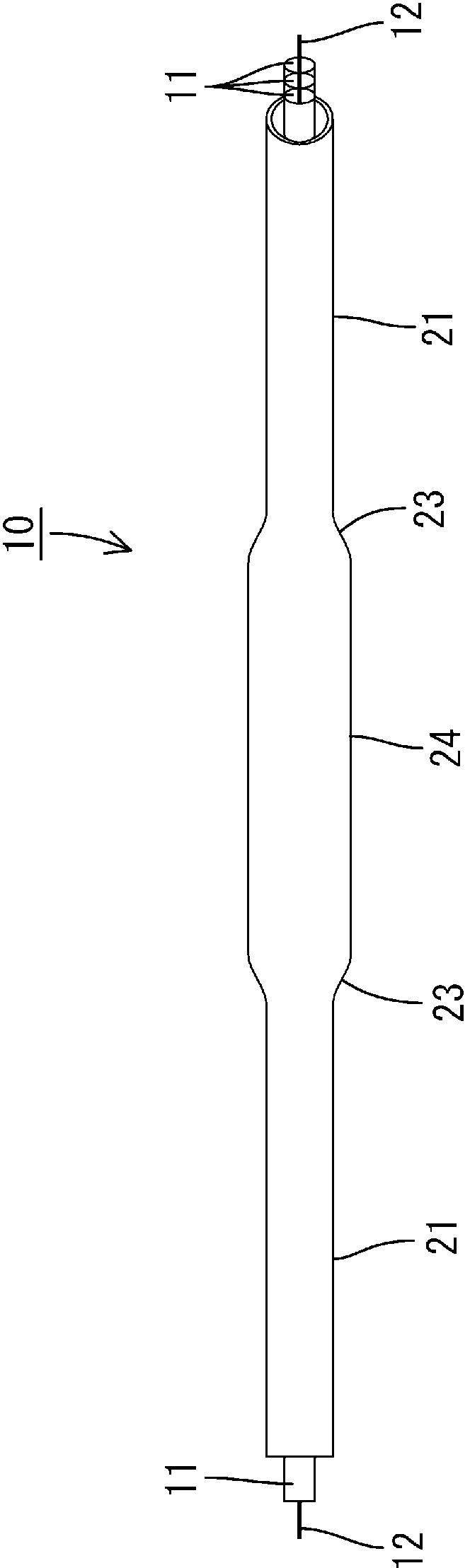

Wire harness and method for manufacturing wire harness

ActiveUS20150294768A1Efficient arrangementSuitable for installationLine/current collector detailsRigid-tube cablesDistal portionElectric wire

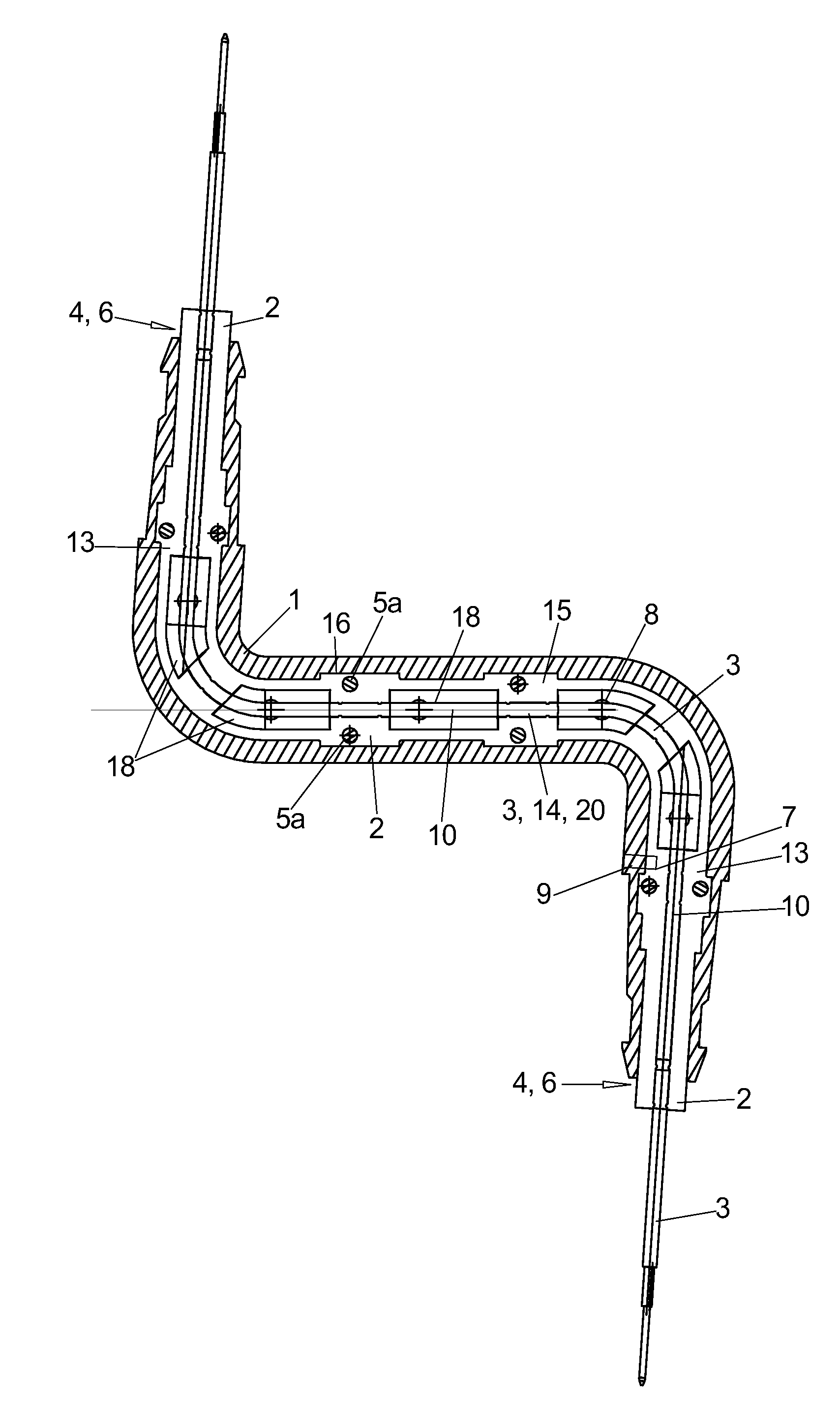

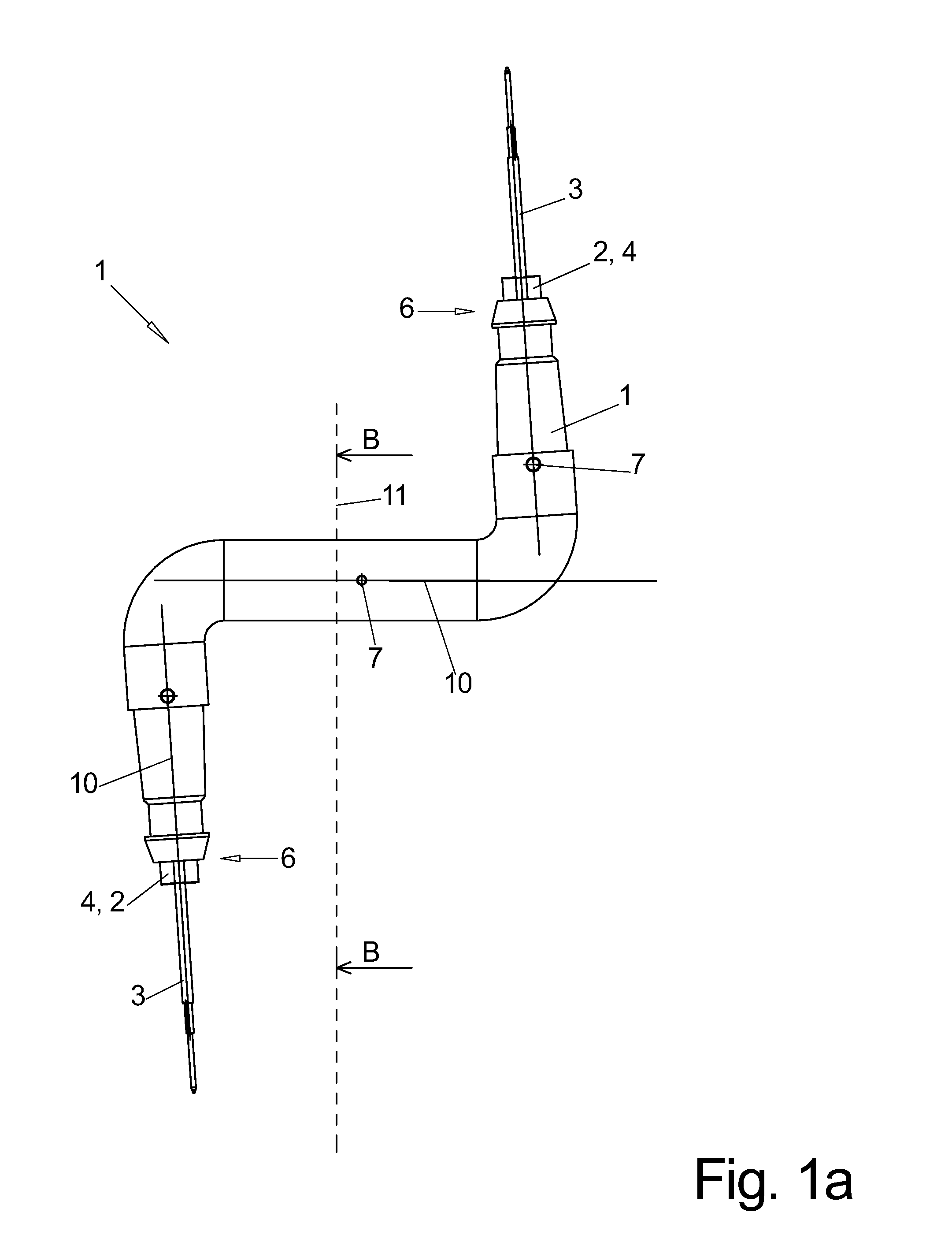

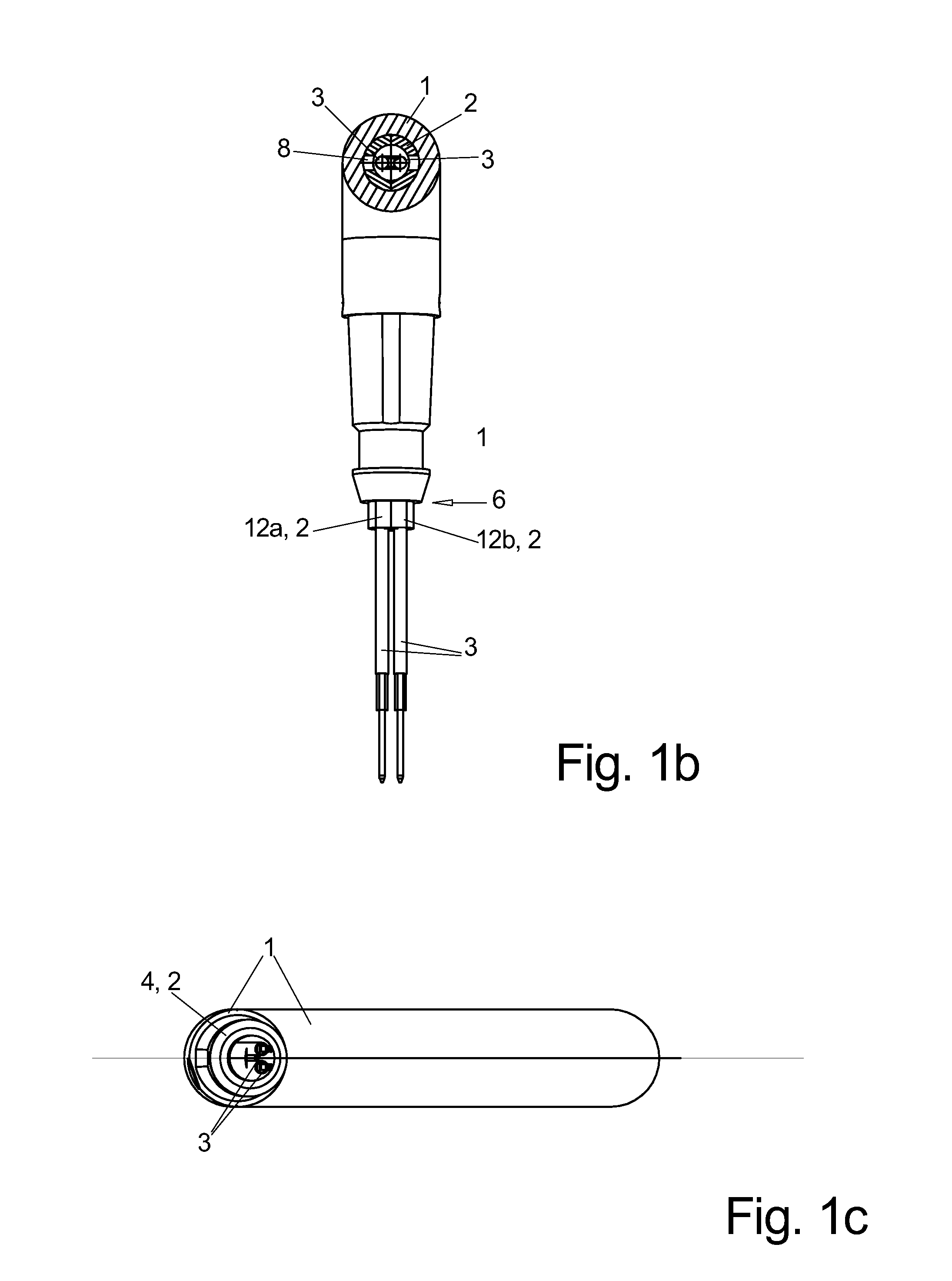

The invention of the present application provides a wire harness with an improved accuracy of the dimension, that can be manufactured with an easy operation. A protector (4) defines at least either one of a bending shape and a branching shape of a plurality of electric wires (2). A cable tie (10) is attached to the electric wires (2), and includes a distal portion (11a) to be attached to the protector (4). The protector (4) includes an engaging portion (13) engageable with the distal portion (11a). Positions of the electric wires (2) and the protector (4) relative to each other are settled by engagement of the distal portion (11 a) of the cable tie (10) attached to the electric wires (2) with the engaging portion (13).

Owner:FURUKAWA ELECTRIC CO LTD +1

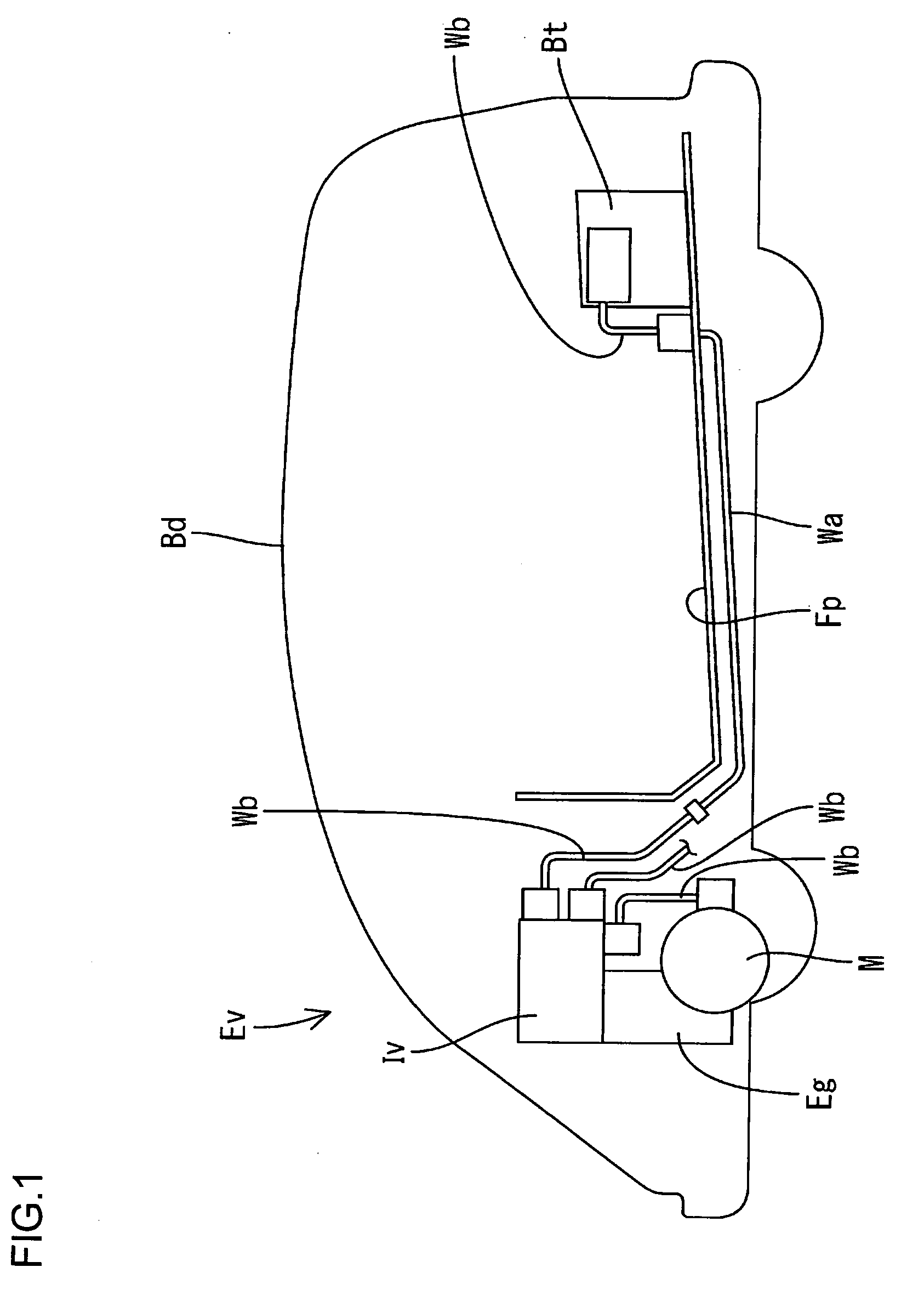

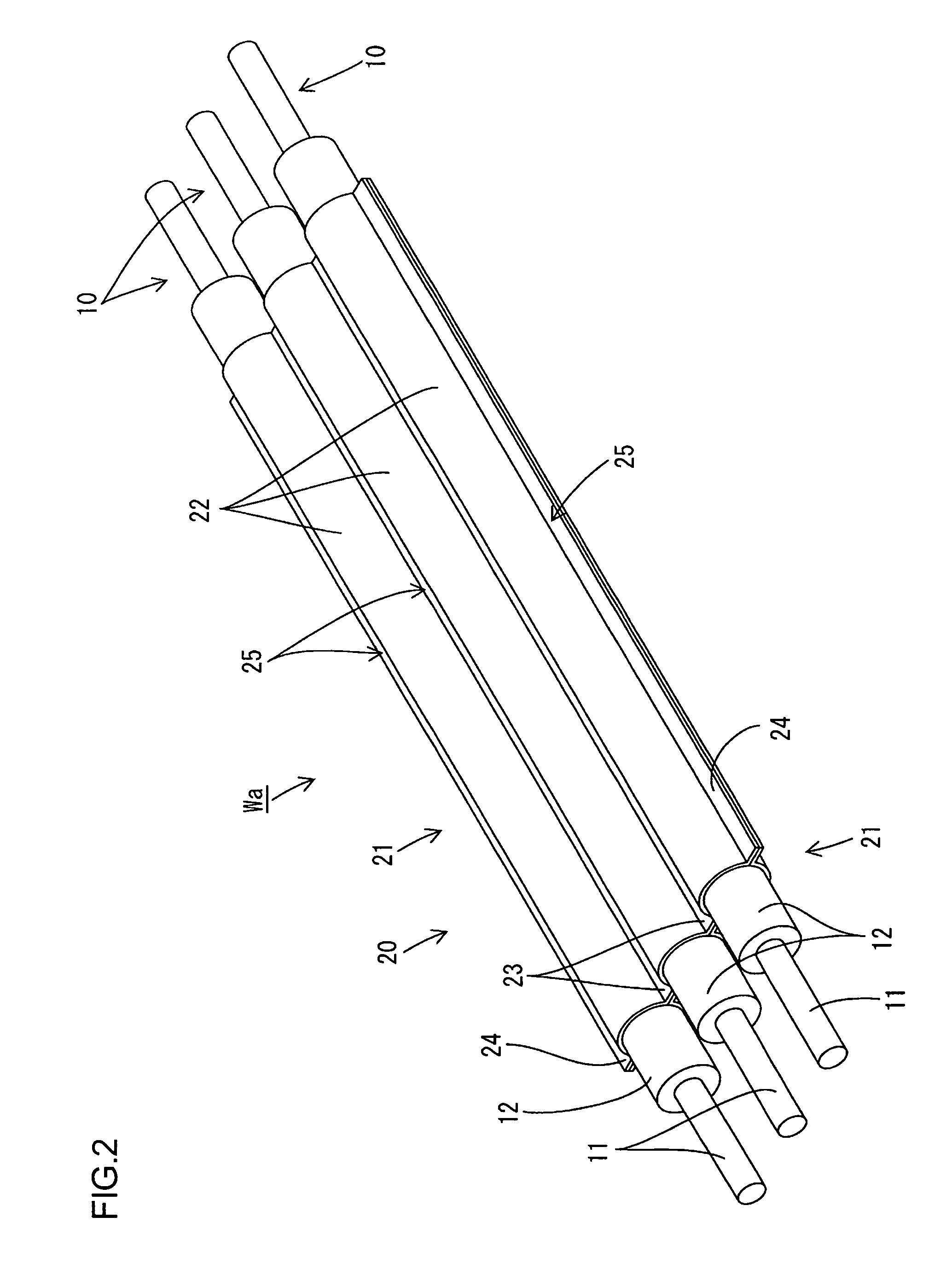

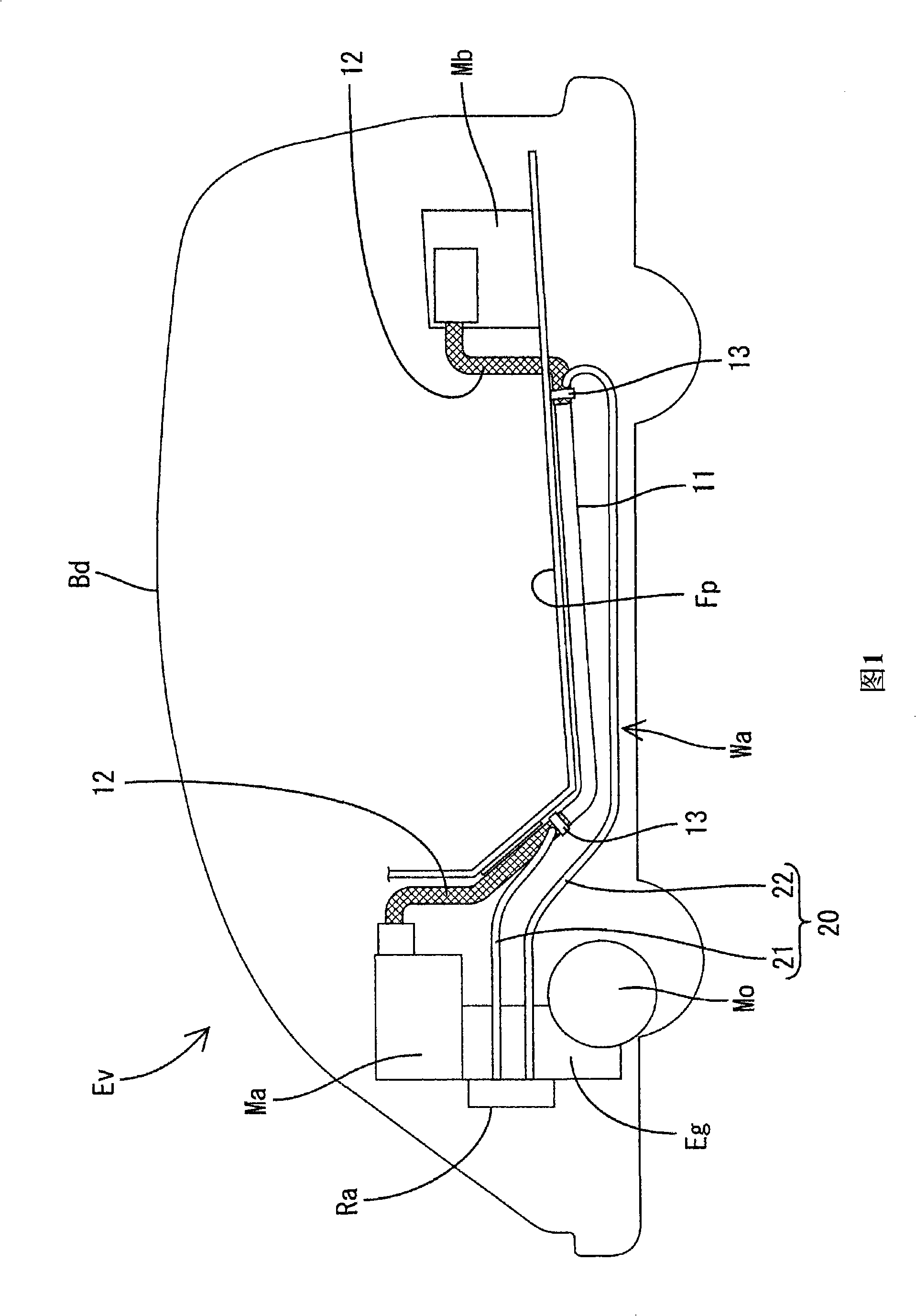

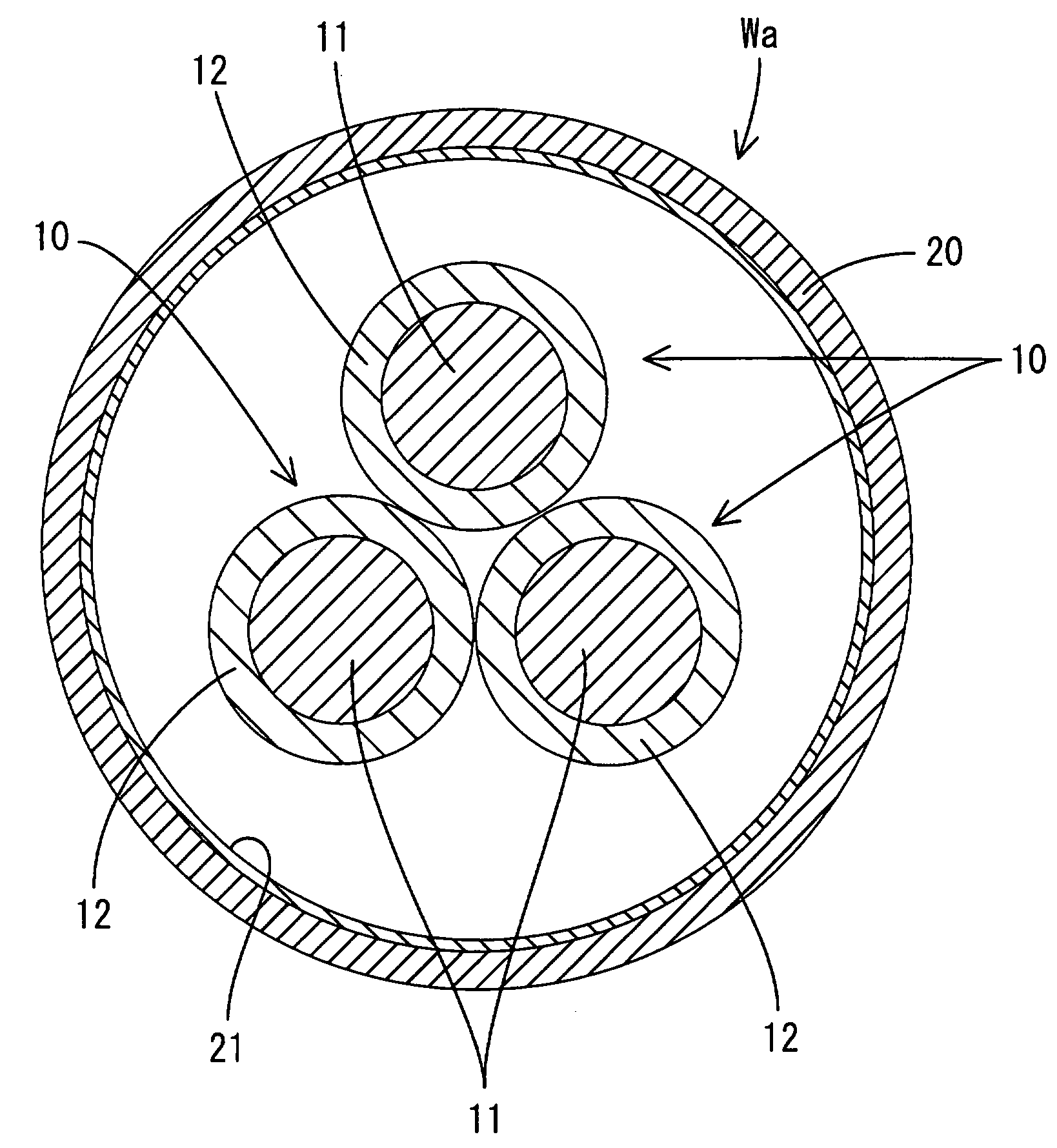

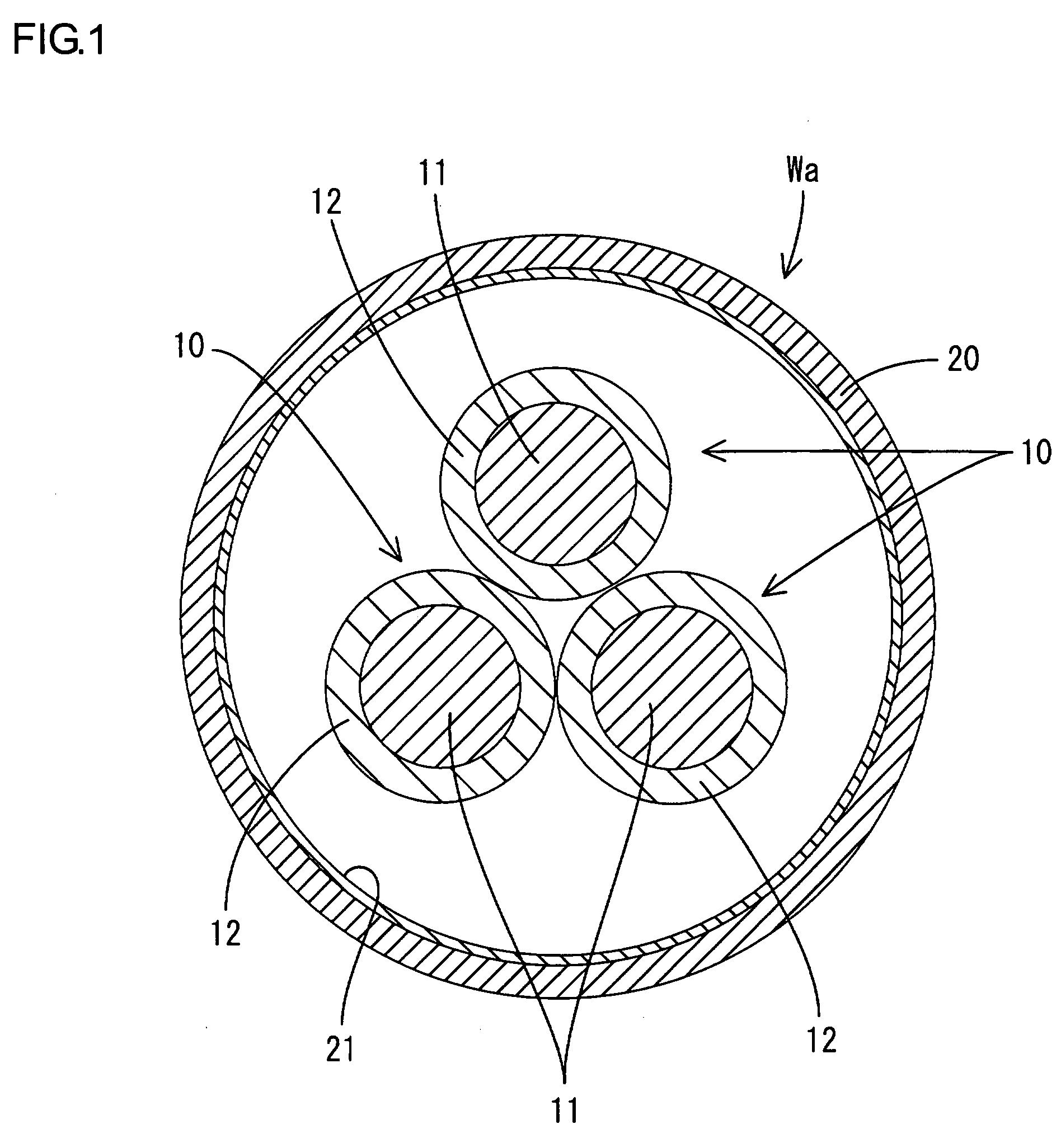

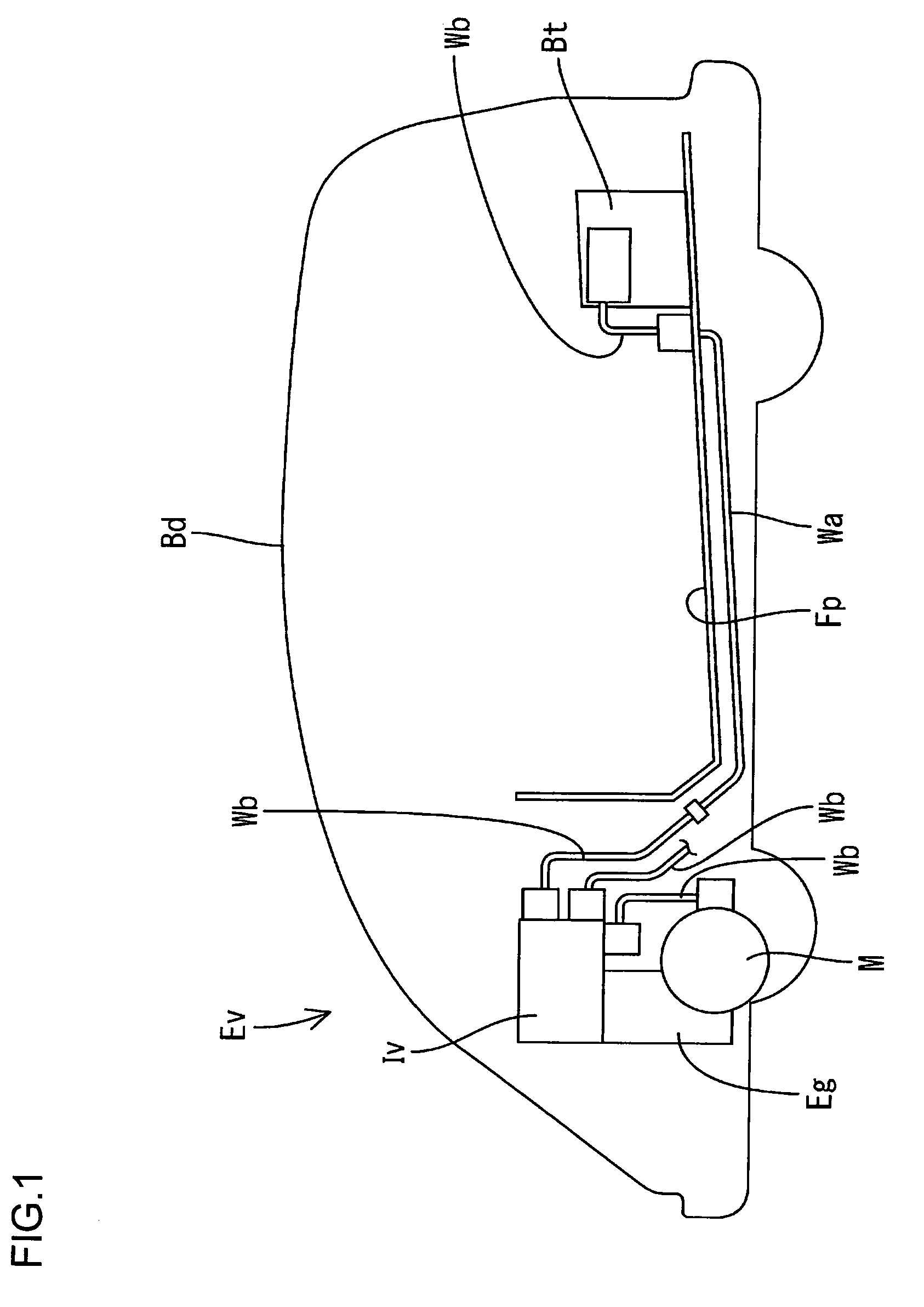

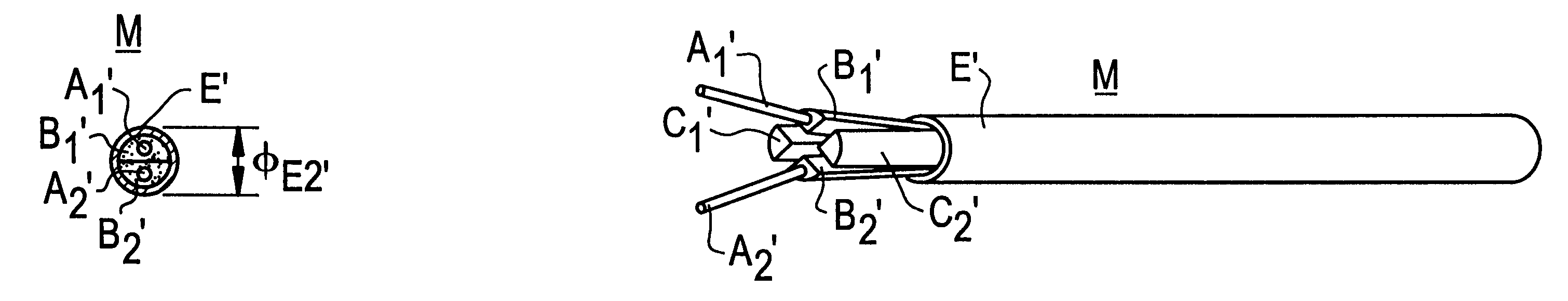

Shield conductor and shield conductor manufacturing method

InactiveUS8013249B2Improve performanceLow costLine/current collector detailsElectrically conductive connectionsElectrical conductorEngineering

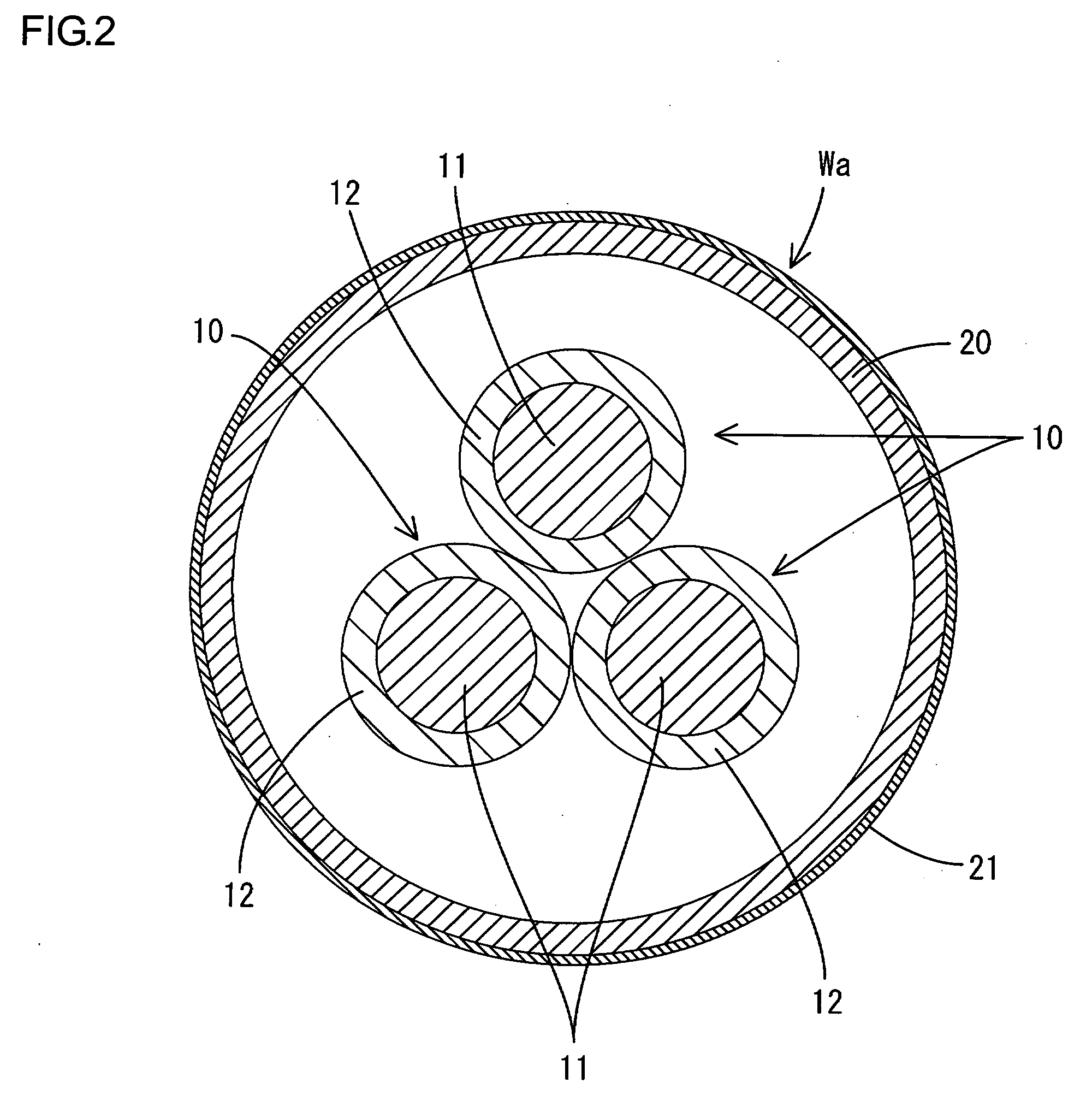

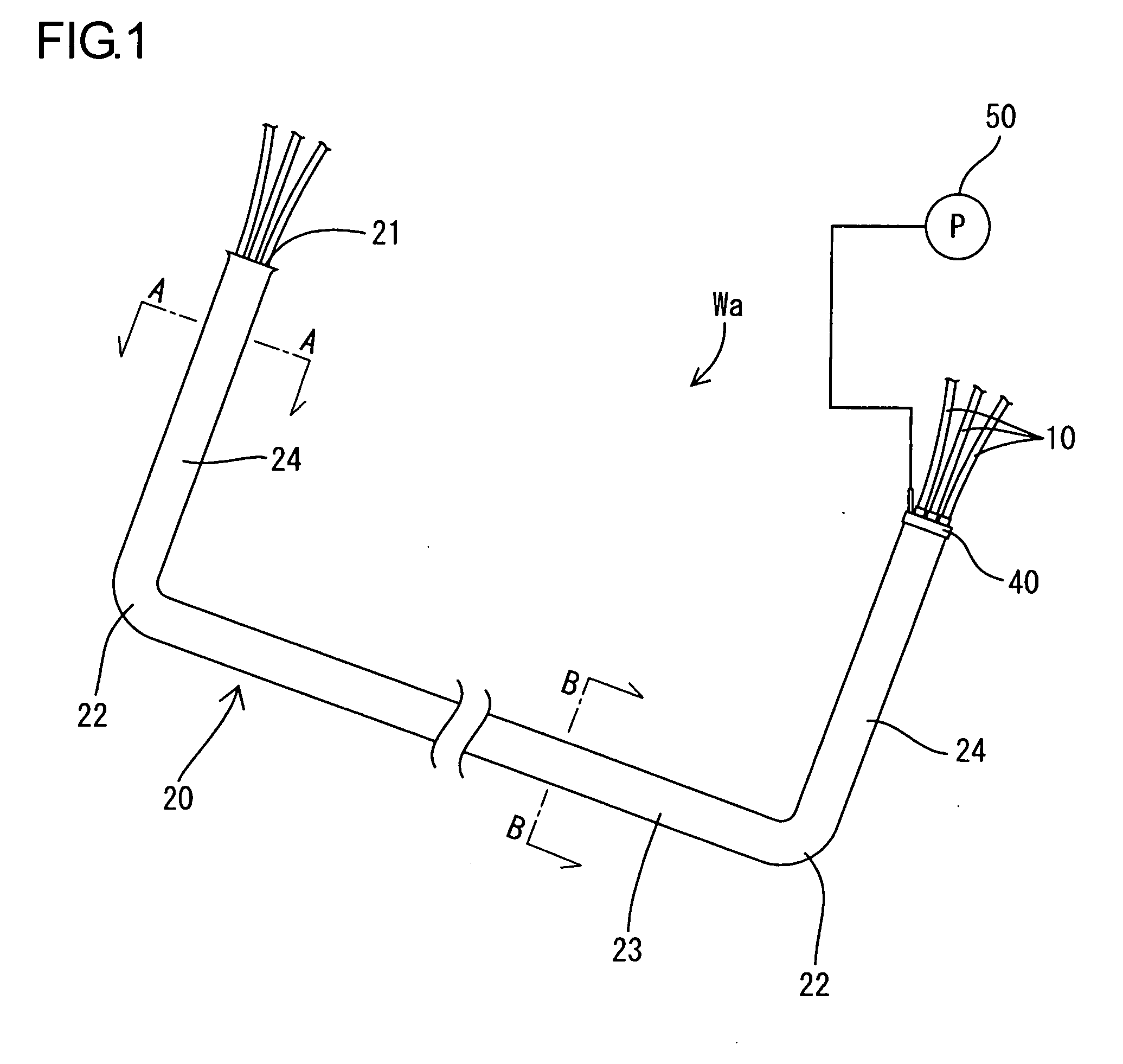

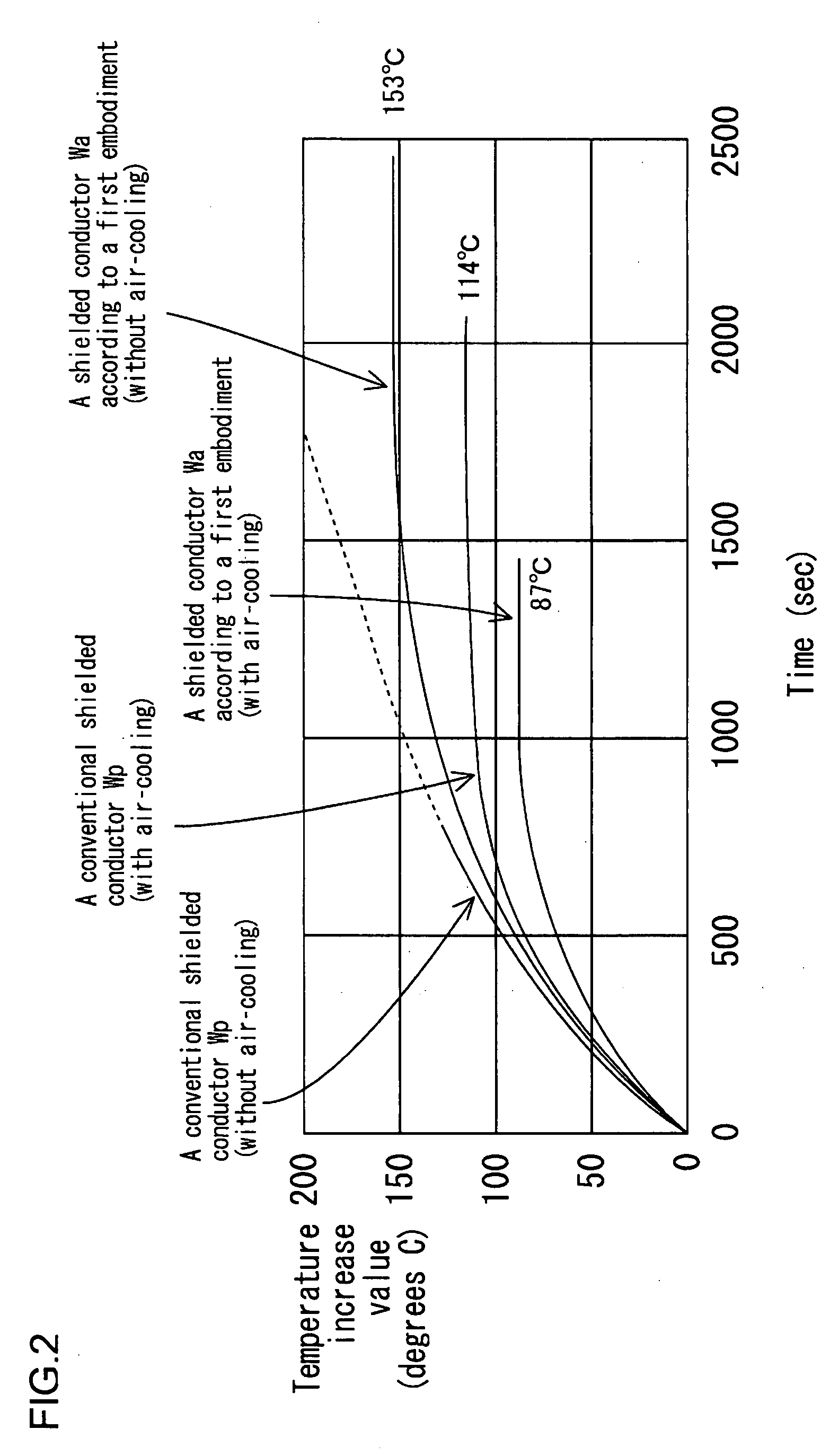

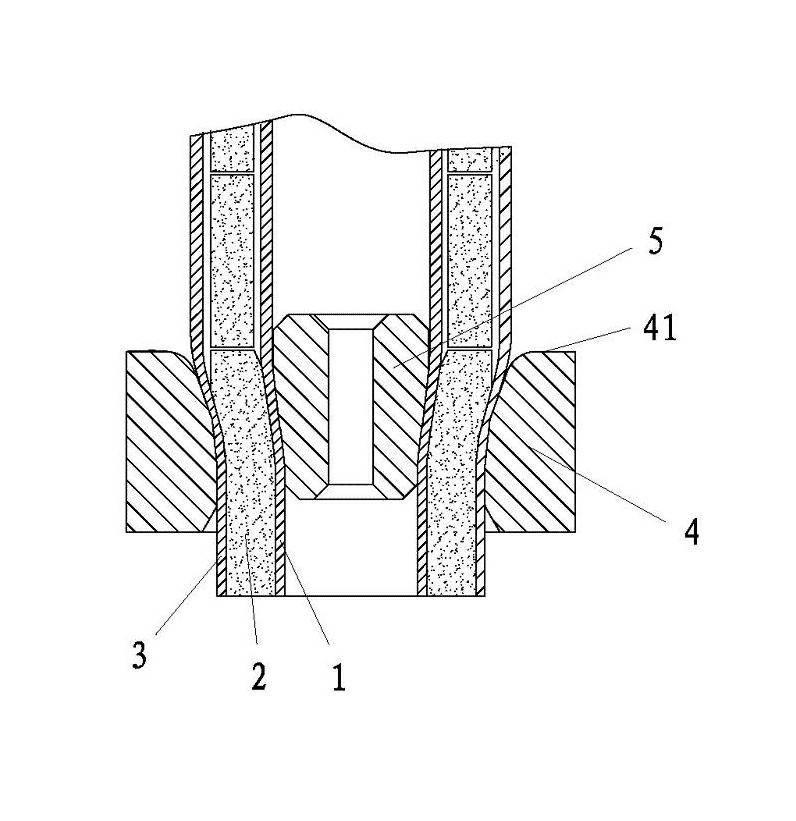

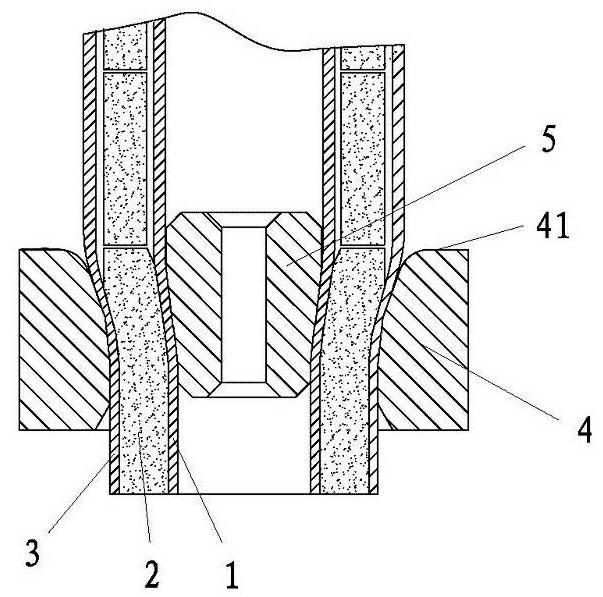

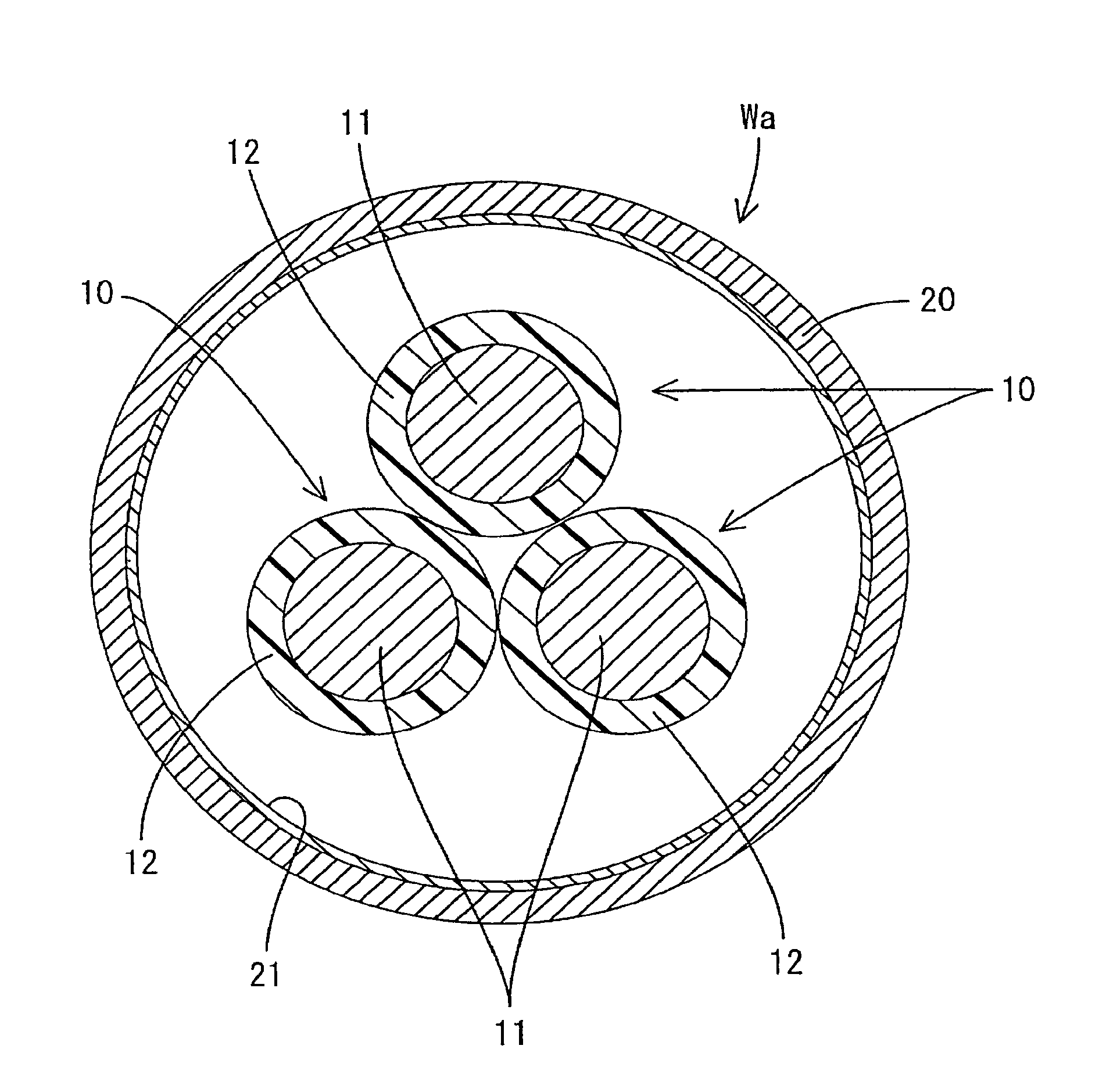

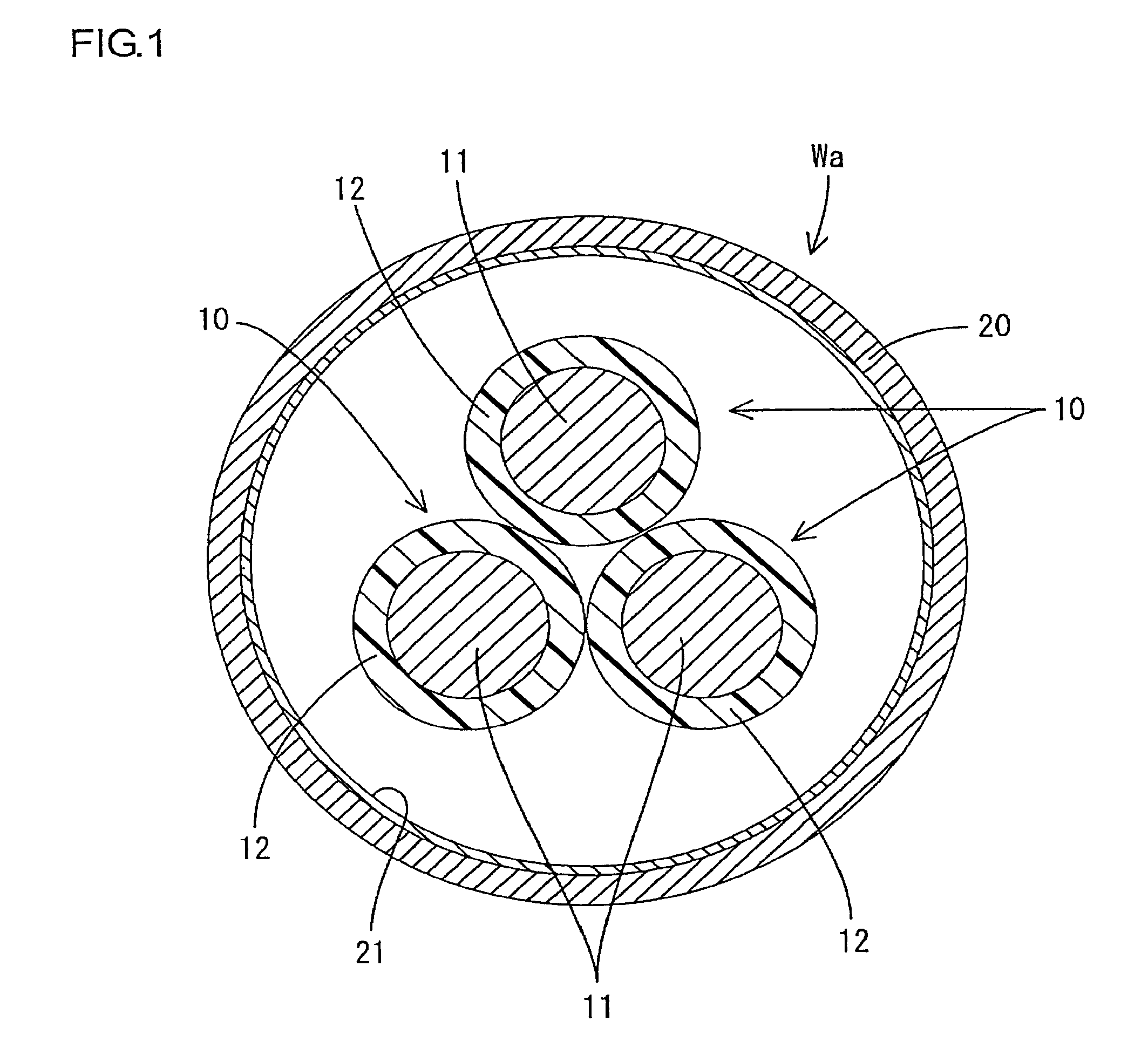

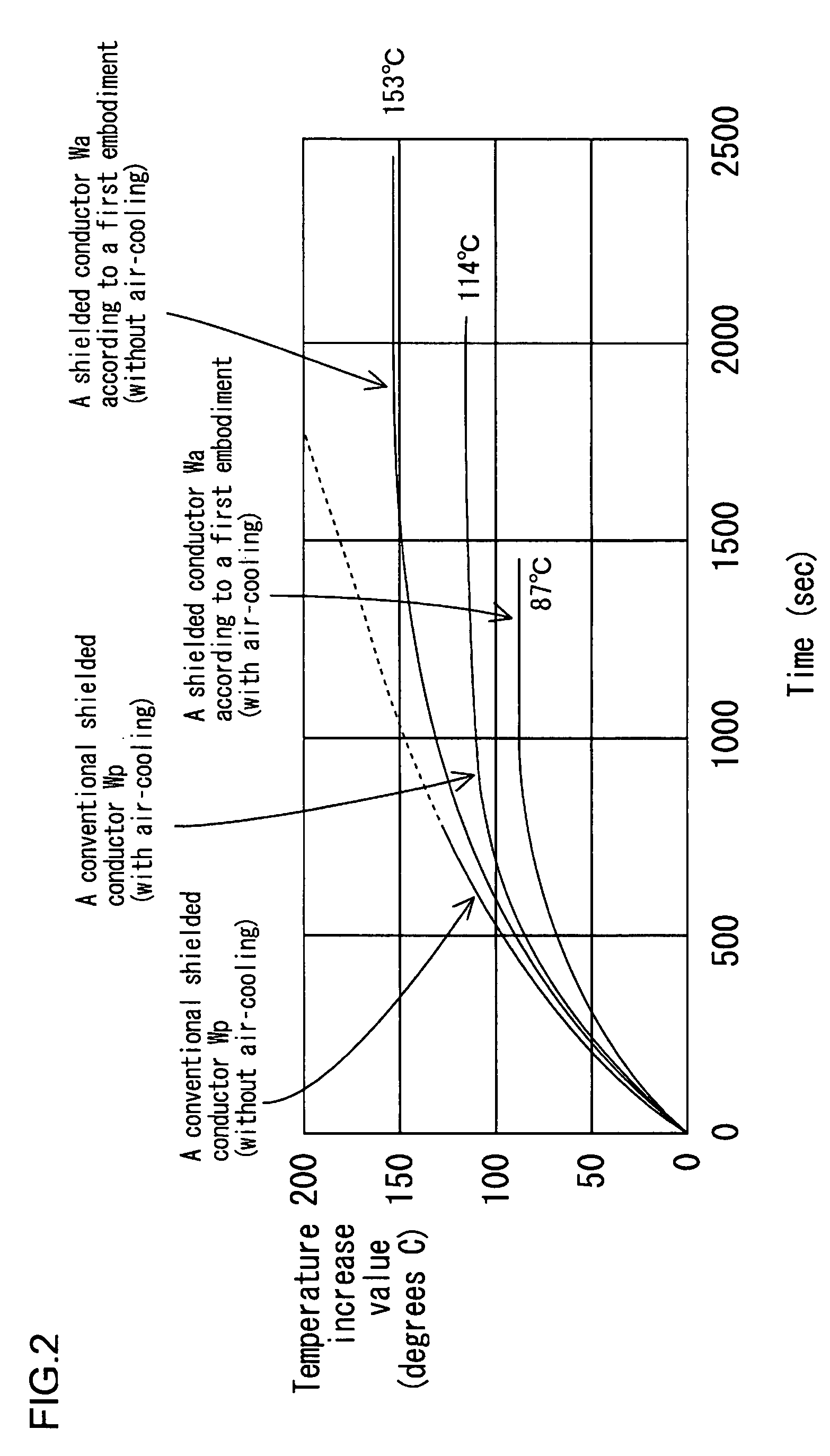

A shield conductor Wa comprises: a metallic pipe 20, a wire 10 to be inserted into the pipe 20, and a groove-like fitting member 22 provided in the pipe 20 as extending along the direction of axis of the wire 10, and at the same time, attached tightly to the circumference of the wire. With the inner surface of the groove-like fitting member 22 in the pipe 20 attached tightly to the circumference of the wire 10, the heat generated in the wire 10 is transmitted directly to the pipe 20, and then released to the air from the circumference of the pipe 20. This improves radiation performance of the shield conductor Wa.

Owner:AUTONETWORKS TECH LTD +2

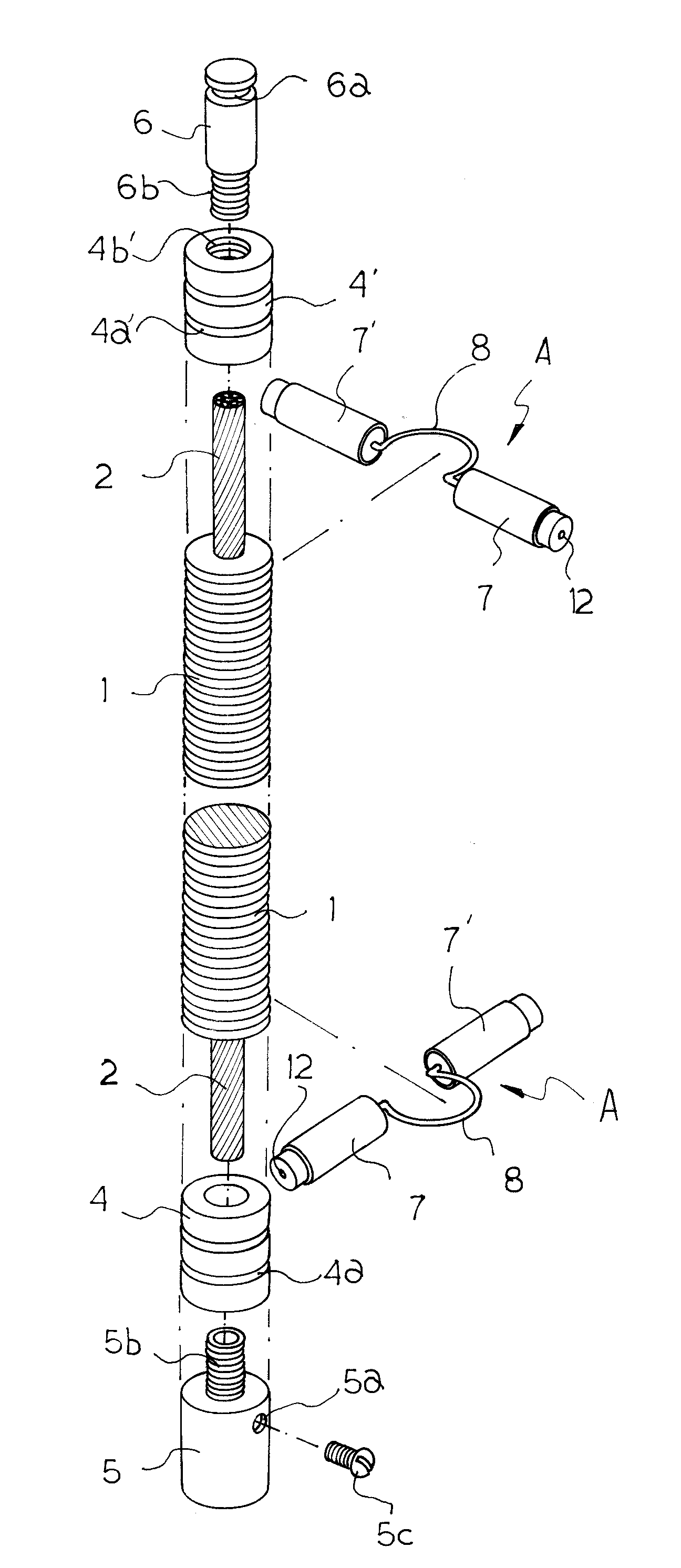

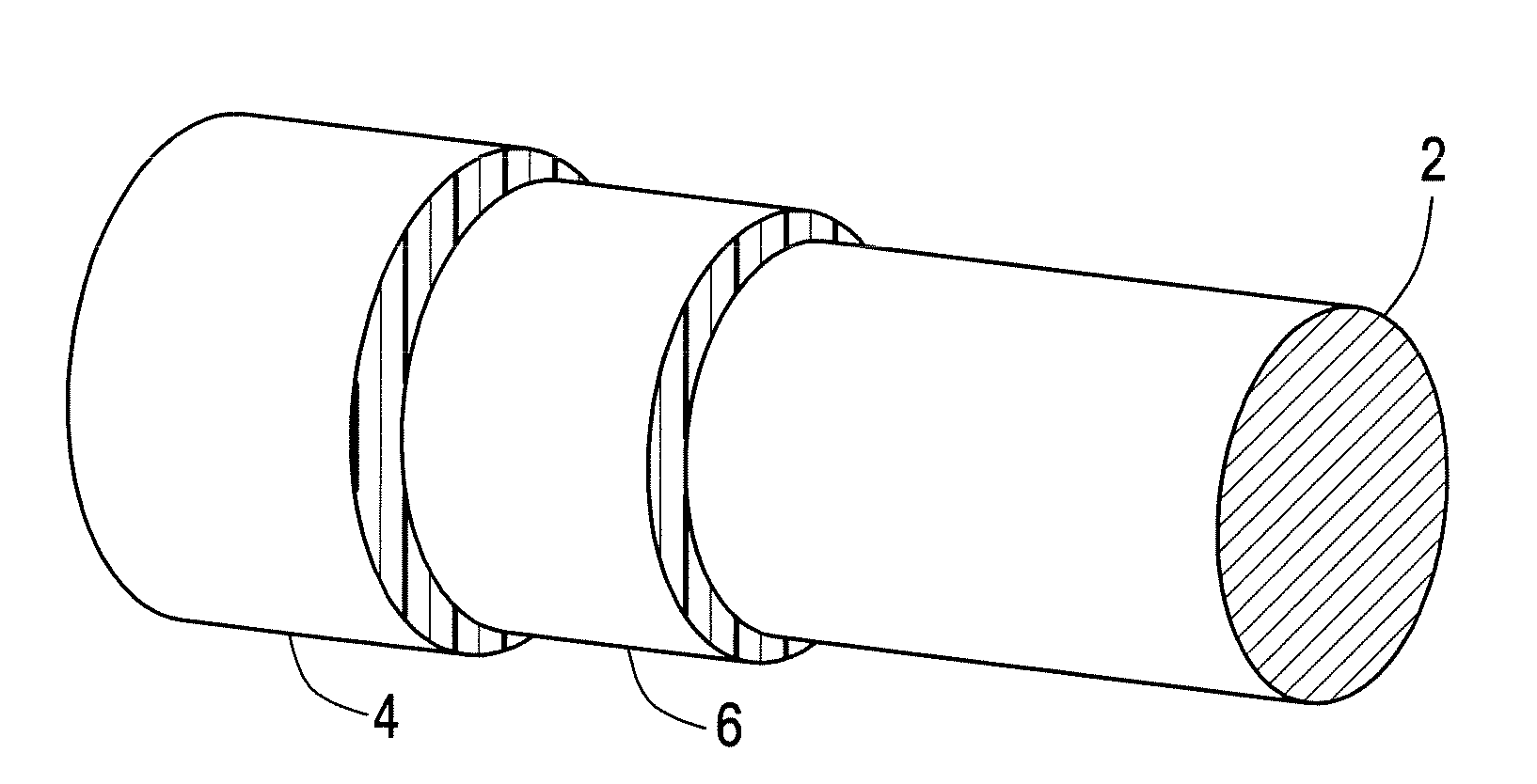

Grounding Wire Structure Having Stainless Steel Covering and Method of Manufacturing the Same

InactiveUS20080217041A1Prevent burstAvoid mistakesLine/current collector detailsRigid-tube cablesGraphiteGround line

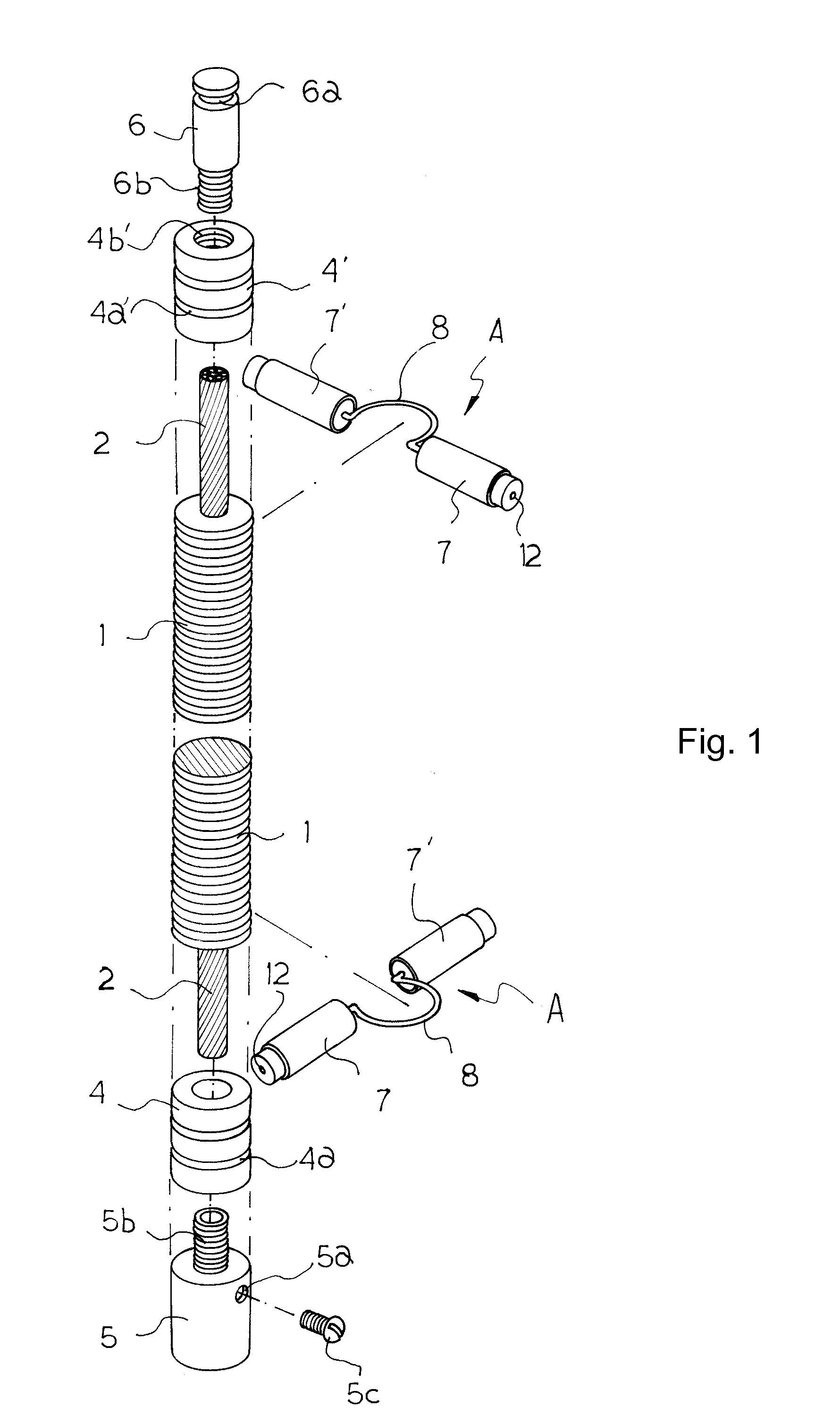

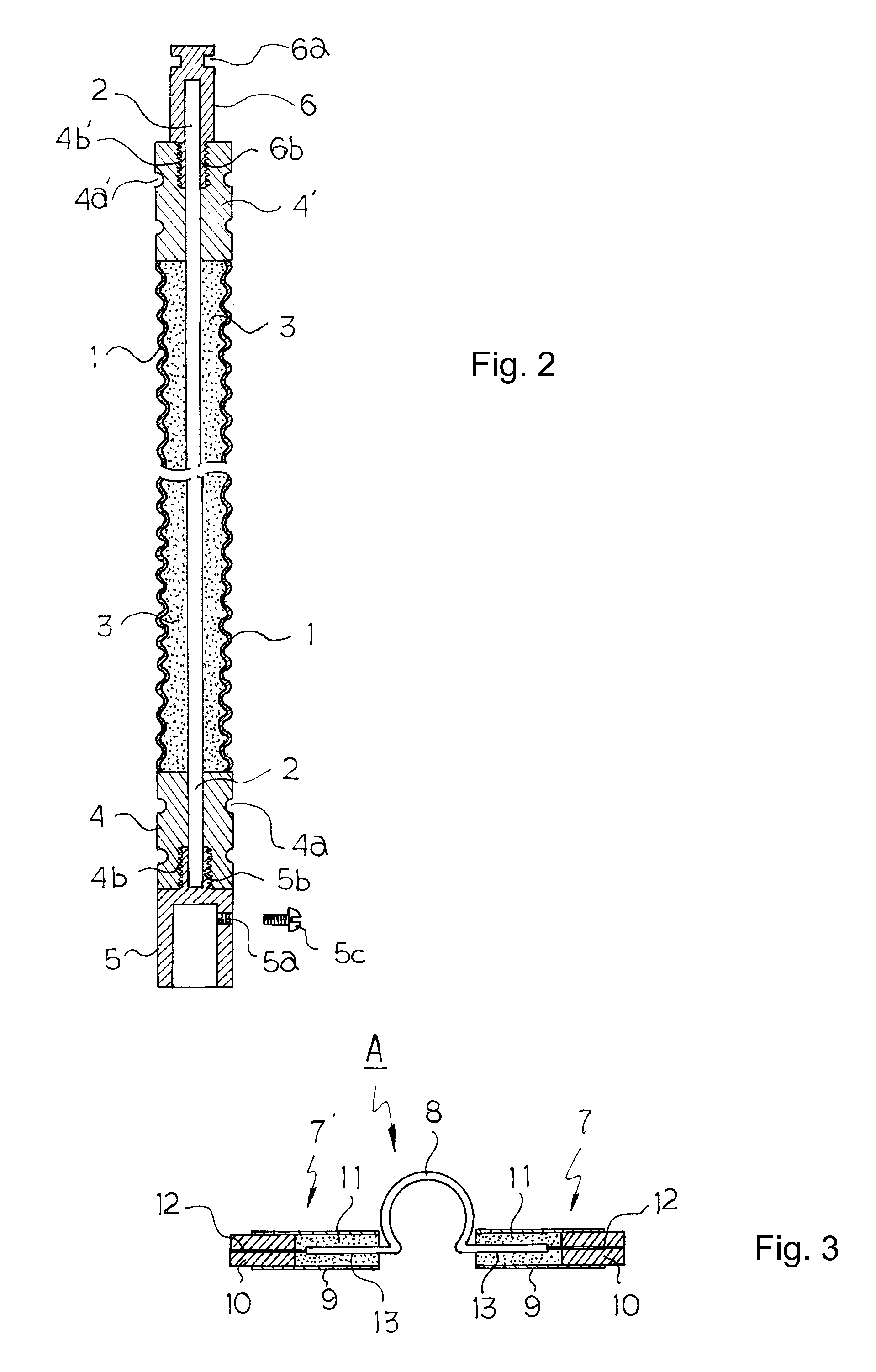

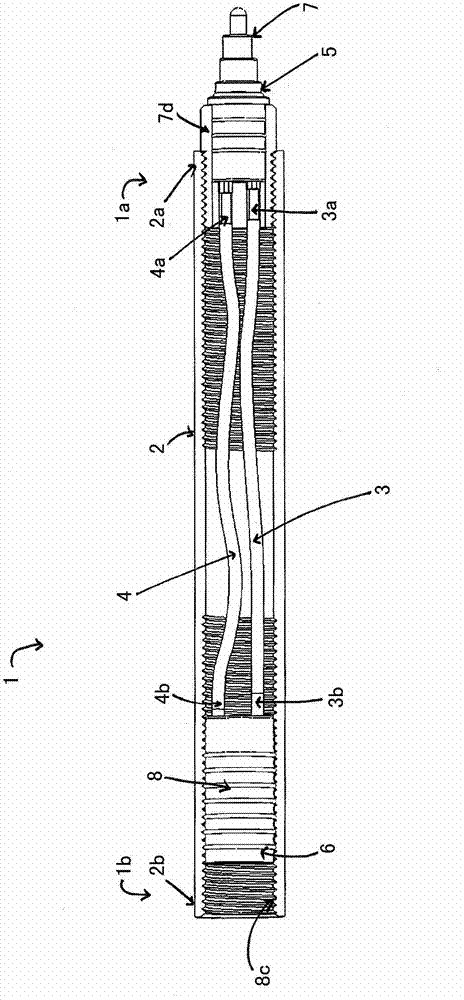

The present invention provides a grounding wire structure having a stainless steel covering and a method of manufacturing the grounding wire structure. In the present invention, first and second hollow connection frames (4) and (4′), each of which has a compressing groove (4a), (4a′) and an internal thread (4b), (4b′), are coupled to respective opposite ends of a stainless steel pipe (1), in which a grounding wire (2) is provided, and which is filled with graphite (3). Corrugated grooves are formed in the outer surface of the stainless steel pipe (1). A connection socket (5) is coupled to the internal thread (4b) of the first connection frame (4). A connection rod (6) is coupled to the internal thread (4b′) of the second connection frame (4′). Discharge tip assemblies (A), each of which has discharge tip bodies (7) and (7′) connected to each other through a connection pin (8), are fitted over the corrugated grooves of the stainless steel covering pipe (1).

Owner:KIM KUI YEUN

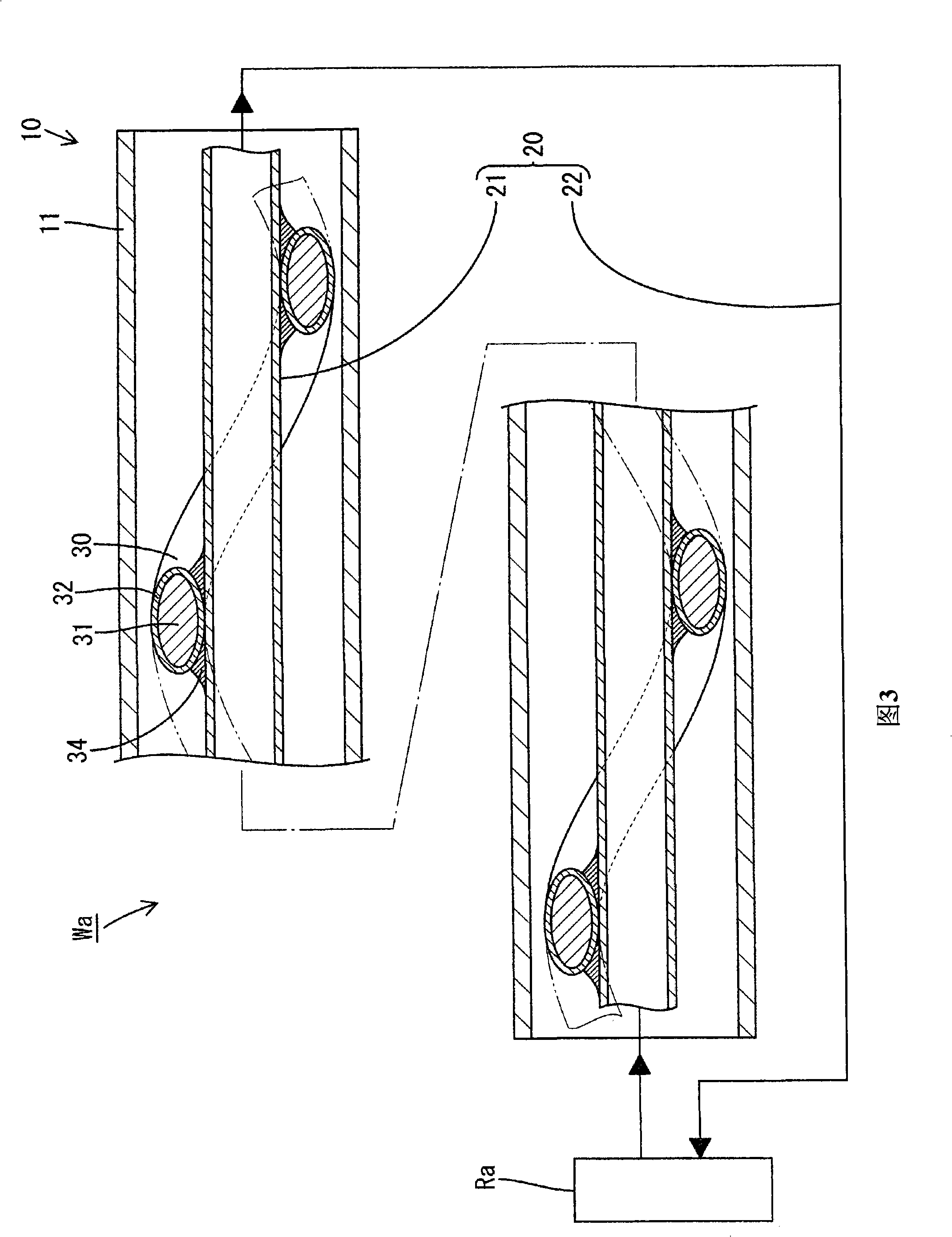

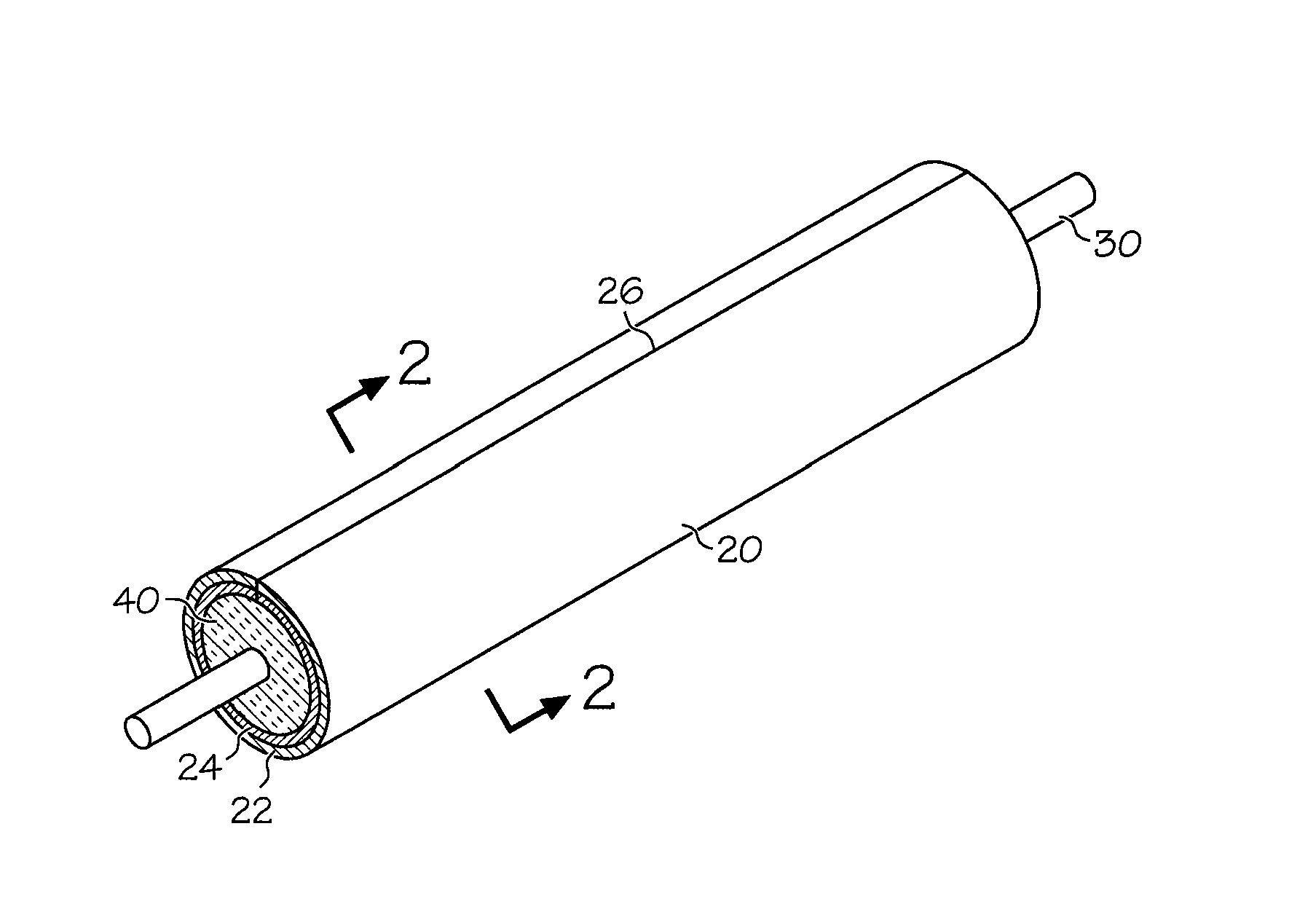

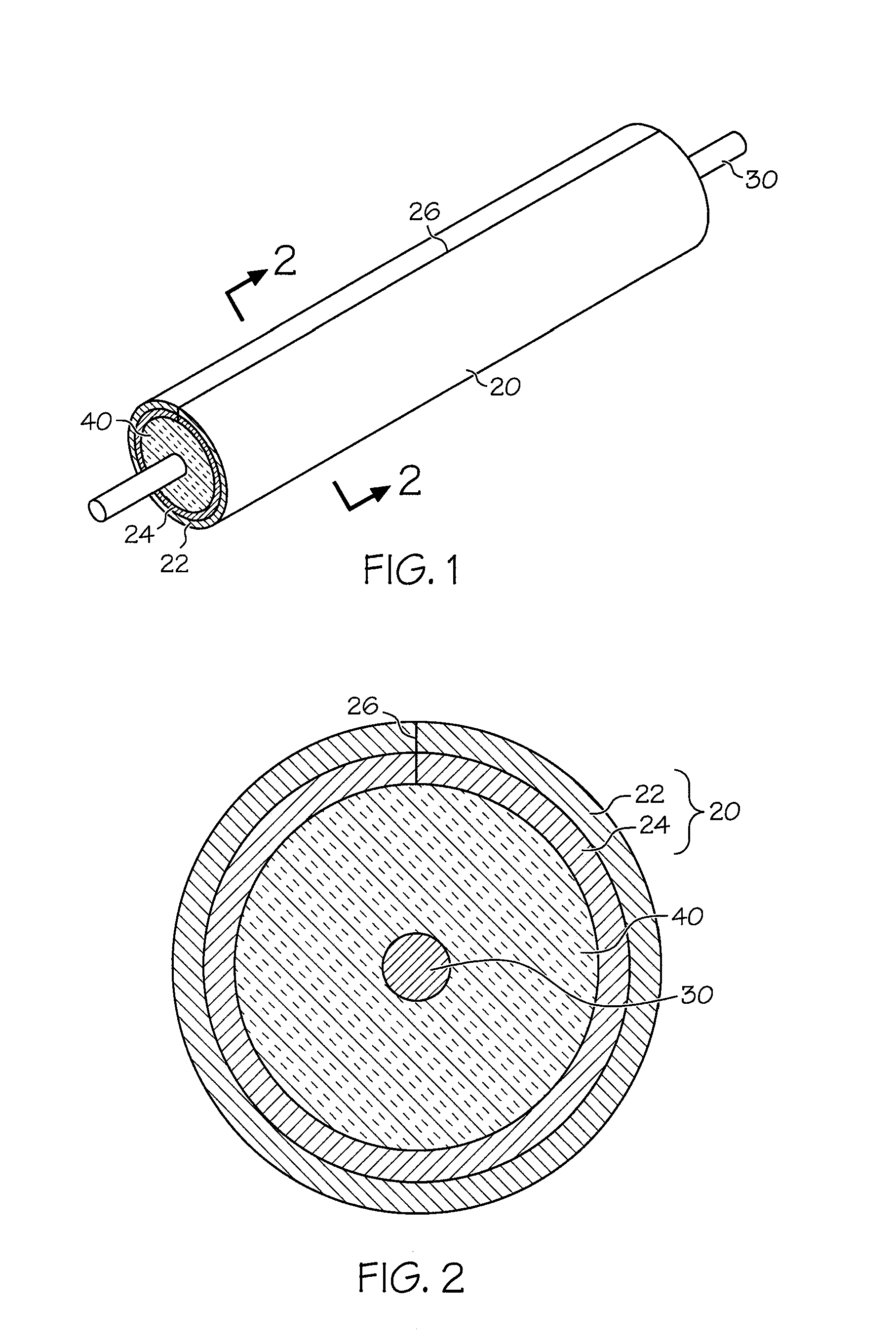

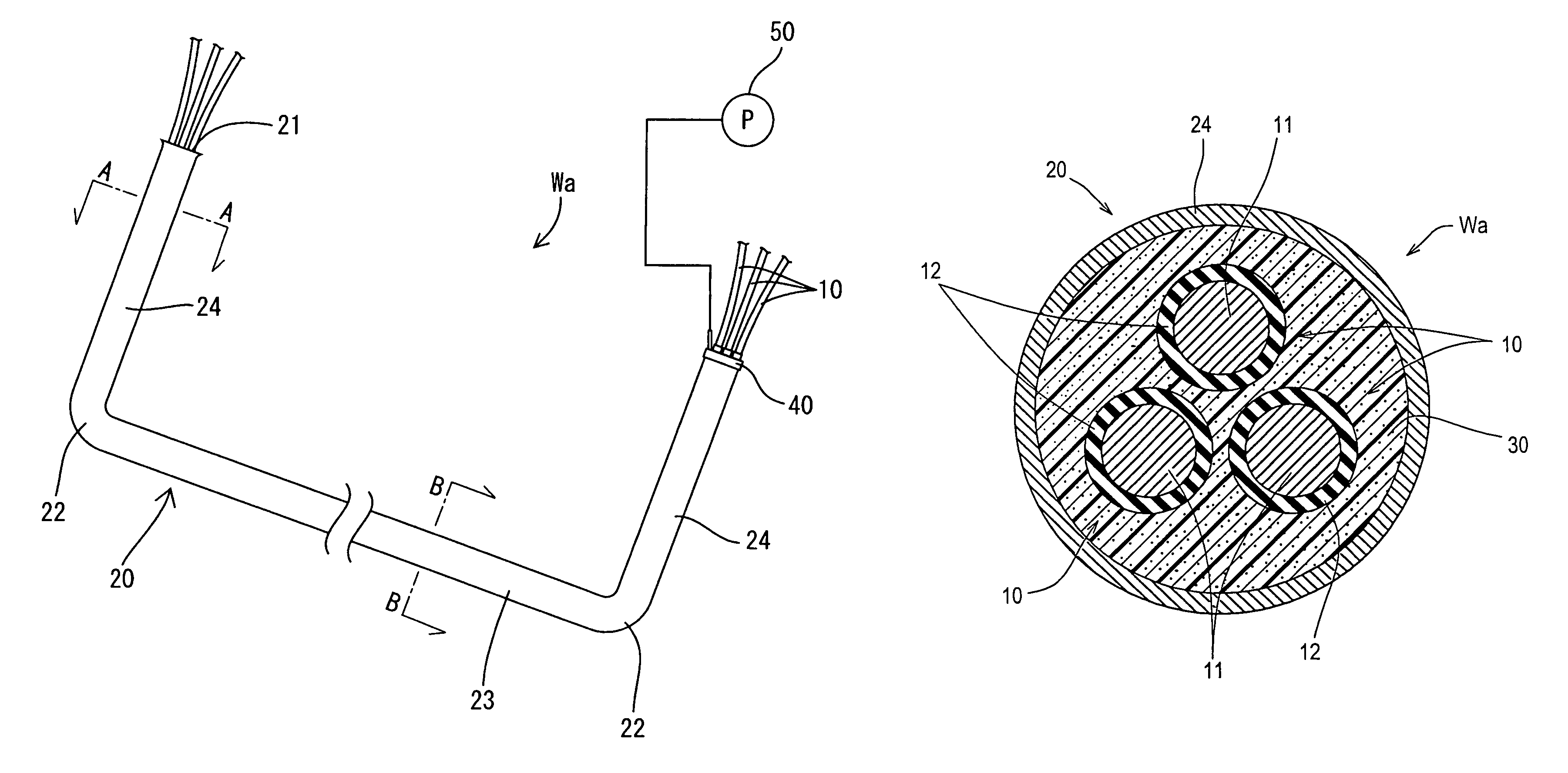

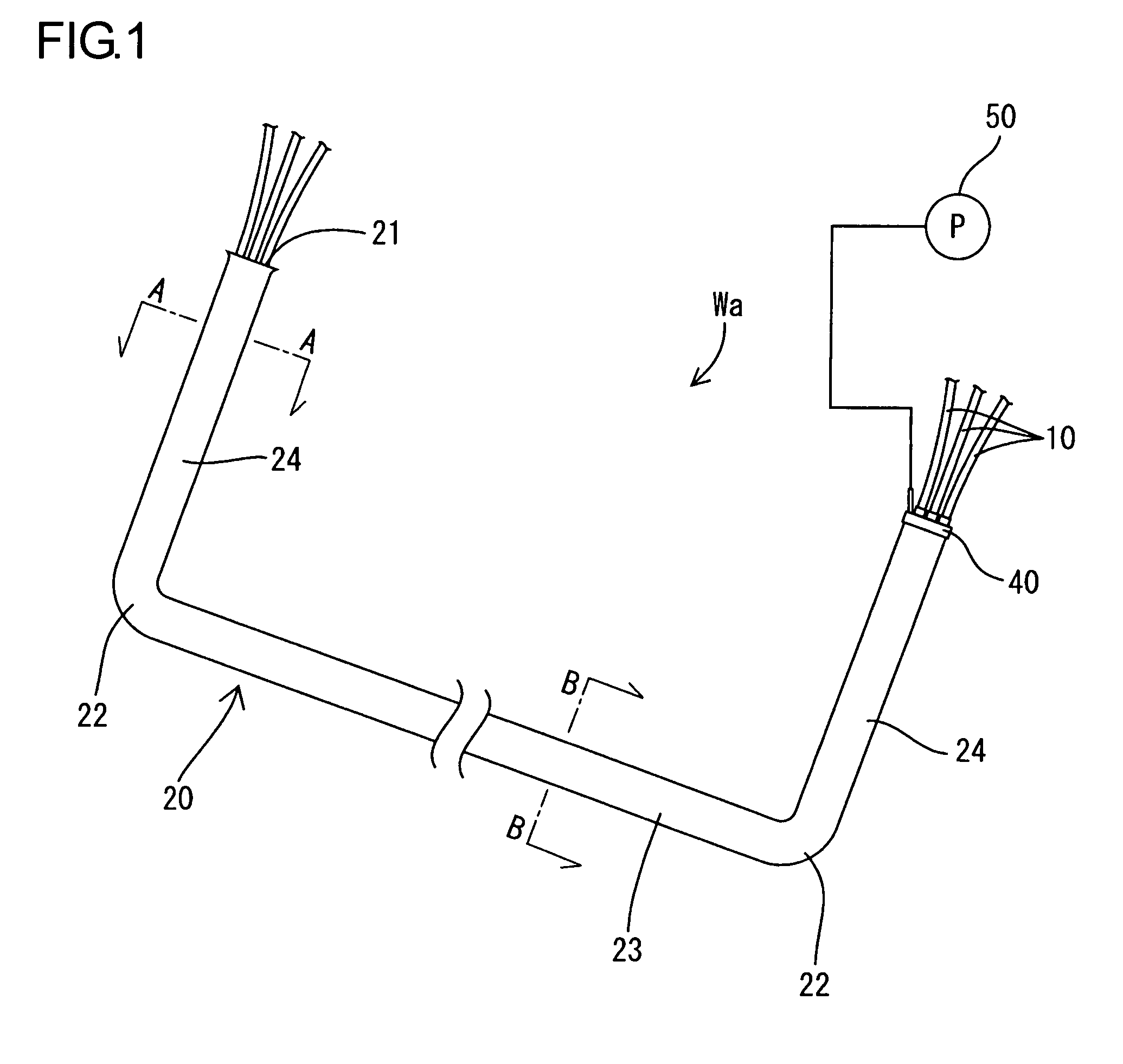

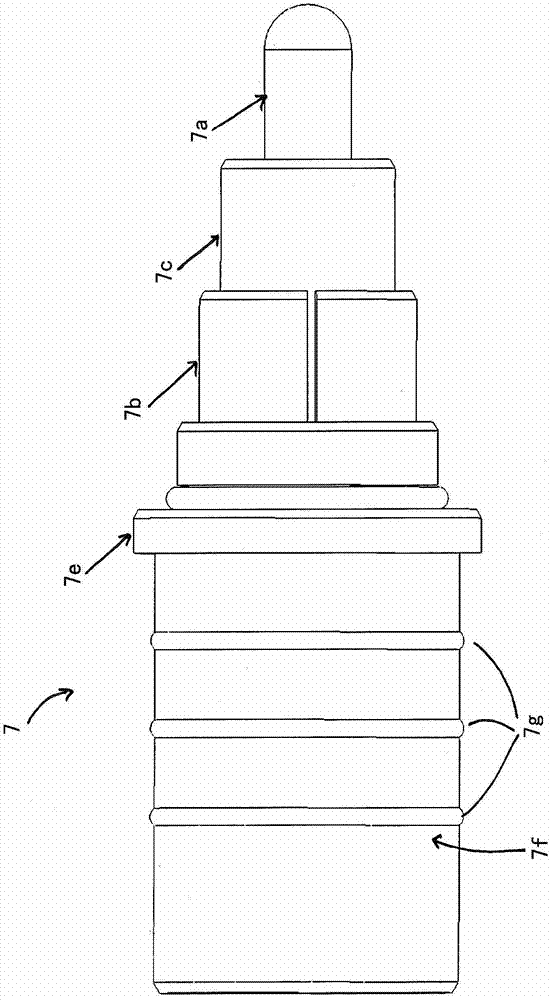

Shield Conductor and Method of Producing Thereof

InactiveUS20080156516A1Improve shielding effectImprove cooling effectLine/current collector detailsRigid-tube cablesElectrical conductorEngineering

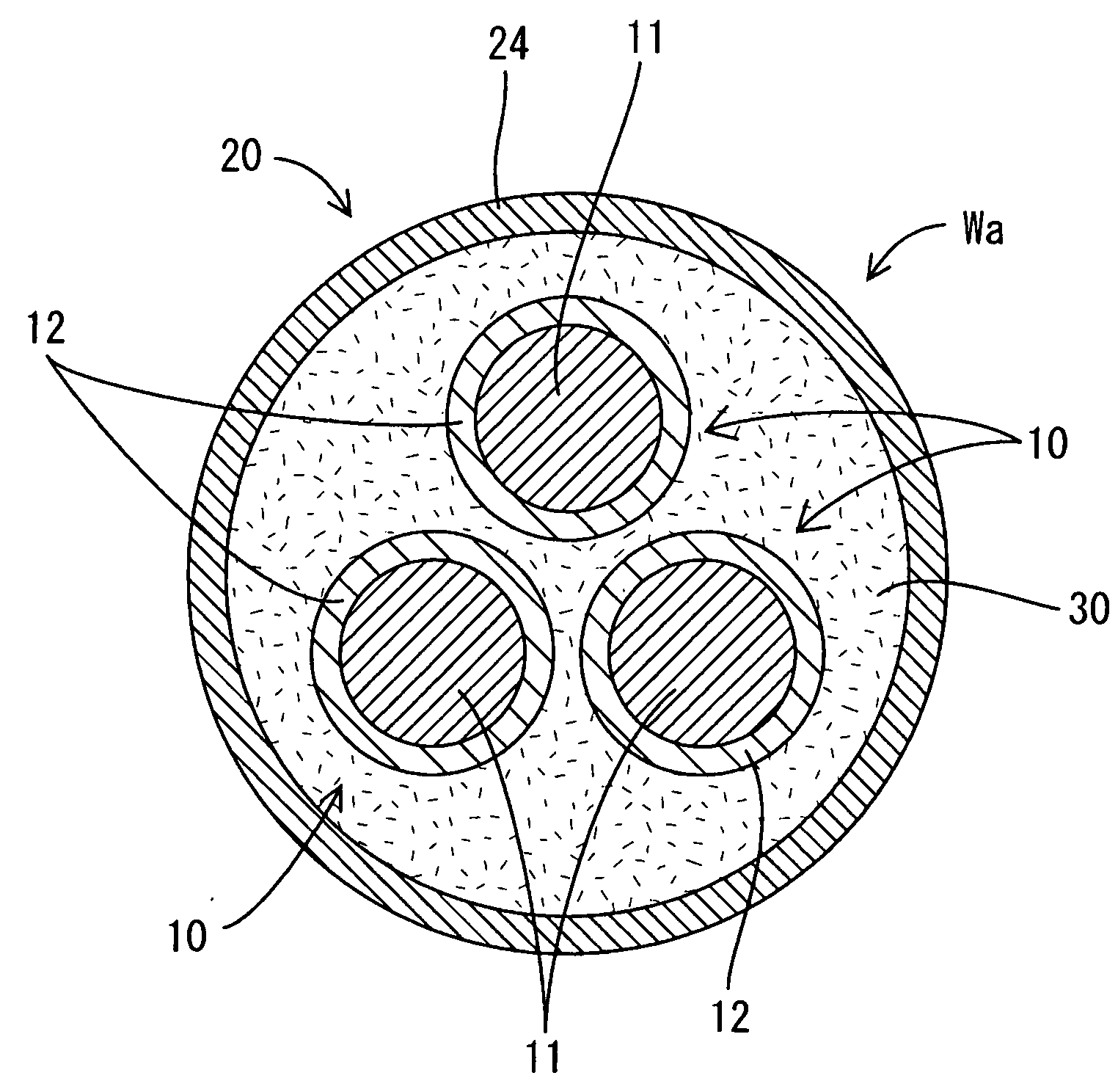

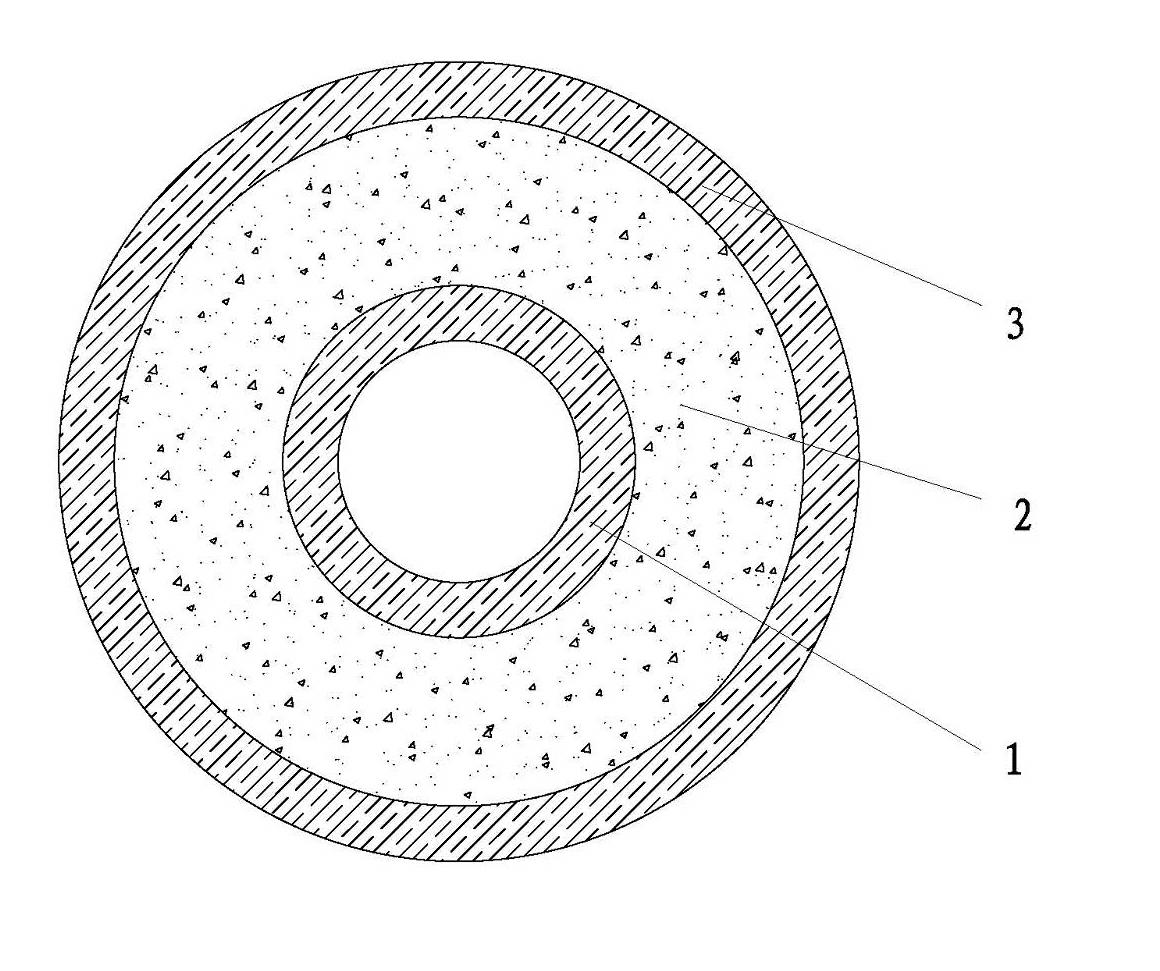

Since it is configured such that the gap between the pipe 20 and the electric wire 10 in the pipe 20 is filled with a filler 30 having a heat conductivity higher than that of air, the heat generated in the electric wire 10 is transferred to the filler 30, then from the filler 30 to the pipe 20, and is discharged from the outer periphery of the pipe 20 to the outside air. Since the filler 30 has a heat conductivity higher than that of air, the performance in discharging the heat generated in the electric wire 10 is superior compared with a case in which the filler 30 is not charged. Thus, heat dissipation in the shield conductor using a pipe is improved.

Owner:AUTONETWORKS TECH LTD +2

Electric conductor for vehicle

InactiveCN101263756AMagnetic/electric field screeningRigid-tube cablesElectrical conductorWater flow

An electric conductor (Wa) for a vehicle has a protective pipe (11) formed of metal, a cooling pipe (20) allowing cooling water to flow through it and routed from the interior of the protective pipe (11) to the outside thereof, and an electric wire (30) routed along the cooling pipe (20) at least in the protective pipe (11). Heat generated in the wire (30) is transmitted in the protective pipe (11) to the cooling water flowing through the cooling pipe (20) and discharged in the outside of the protective pipe (11). Since the heat generated in the wire (30) is forcibly drawn by the cooling water, the electric conductor is superior in heat dissipation efficiency to the case where heat is dissipated from the outer circumferential surface of the protective pipe (11) to the atmosphere.

Owner:AUTONETWORKS TECH LTD +2

Heating element sheaths

The present invention is directed to a nickel-based alloy, such as INCOLOY or INCONEL, clad stainless steel sheath tubing material for heating elements. This clad material is designed to minimize the cost of heating elements generally constructed entirely of nickel-based alloys alone while providing necessary material requirements of weldability, hot strength, corrosion resistance, thermal shock resistance, and formability.

Owner:ENGINEERED MATERIALS SOLUTIONS

Distributive Conductor

InactiveUS20090095525A1Reduce the cross-sectional areaLow heat reflectivityRigid-tube cablesPower cables with screens/conductive layersElectrical conductorElectromagnetic shielding

A distributive conductor electromagnetically shields and protects an insulated wire 10 by inserting it into a pipe 20. Heat generated in the insulated wire 10 is absorbed into a low heat-reflective layer 21 of lower heat reflectivity, transferred to the pipe 20, and then dissipated from an outer circumferential wall of the pipe 20 to atmosphere.

Owner:AUTONETWORKS TECH LTD +2

High-temperature resistant and radiation-resistant inorganic insulating hollow cable as well as manufacturing method and mold thereof

ActiveCN102110495AGood electrical performanceImprove electrical performanceRigid-tube cablesManufacturing rigid-tube cablesAviationElectrical conductor

The invention relates to a high-temperature resistant and radiation-resistant inorganic insulating hollow cable as well as a manufacturing method and mold thereof, belonging to the technical field of power transmission cables and high-temperature winding lines. The high-temperature resistant and radiation-resistant inorganic insulatinghollow cable comprises a conductor, an insulating layer and a sheath layer, wherein the insulating layer is coated outside the conductor, and the sheath layer is coated outside the insulating layer. The conductor is a hollow metal tube; and the insulating layer is prepared from one or mixture of more of magnesium oxide, aluminum oxide or silicon dioxide with the purity above 99% and the grain size below 180 mum. The high-temperature resistant and radiation resistant inorganic insulating hollow cable provided by the invention has good electrical performance; the conductor is filled with a refrigerant so that the conductor can work for a long time at the temperature over 1000 DEG C; and the cable is suitable for the fields of nuclear stations, nuclear fusion devices, space flight and aviation and the like.

Owner:久盛电气股份有限公司

Shield conductor and method of producing thereof

InactiveUS7700879B2Improve performanceImprove conductivityLine/current collector detailsRigid-tube cablesElectrical conductorEngineering

An improved shield connector and a method of making the same include an electric wire having a conductor with an insulation coating and a metallic pipe. The electric wire is positioned in the metallic pipe. A filler is located inside the pipe, between the electric wire and the pipe, and the filler has a heat conductivity higher than that of air.

Owner:AUTONETWORKS TECH LTD +2

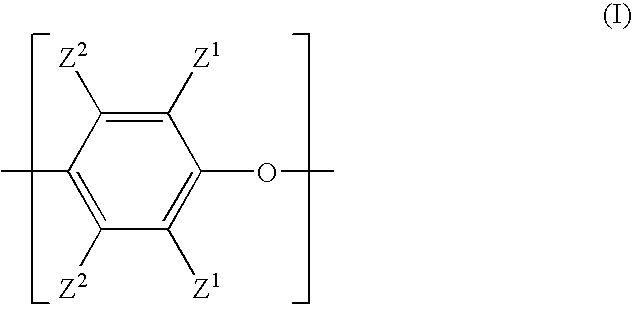

Flame retardant flexible thermoplastic composition, method of making, and articles thereof

A flexible thermoplastic composition includes among its components: (i) a poly(arylene ether); (iii) a polymeric compatibilizer; (iv) a polyolefin comprising a functional group; and (iv) magnesium dihydroxide. The flexible thermoplastic composition may be used for making electrical wires.

Owner:SHPP GLOBAL TECH BV

Wire harness and method for manufacturing wire harness

ActiveUS9672959B2Efficient arrangementSuitable for installationRigid-tube cablesManufacturing wire harnessesDistal portionEngineering

The invention of the present application provides a wire harness with an improved accuracy of the dimension, that can be manufactured with an easy operation. A protector (4) defines at least either one of a bending shape and a branching shape of a plurality of electric wires (2). A cable tie (10) is attached to the electric wires (2), and includes a distal portion (11a) to be attached to the protector (4). The protector (4) includes an engaging portion (13) engageable with the distal portion (11a). Positions of the electric wires (2) and the protector (4) relative to each other are settled by engagement of the distal portion (11a) of the cable tie (10) attached to the electric wires (2) with the engaging portion (13).

Owner:FURUKAWA ELECTRIC CO LTD +1

Pipeline accompanying-heat cable

InactiveCN101030459AImprove securityExtended service lifeRigid-tube cablesHeating element shapesFiberFriction effect

The invention is concerned with the grounding pole piping heating cable, relating to the field of carbon fiber heating cable with carbon fiber, carbon fiber insulation coating and outer insulation coating. The carbon fiber is inside of carbon fiber insulation coating which is in the outer insulation coating, and the outside of the latter is lubrication coating. For binding with carbon fiber heating cable or carbon fiber electric heating cable, piping will elongate for thermal expansion, and the lubricating oil film with small friction coefficient of the heating cable forms the oily sliding friction effect, and the glue of the adhesive tape cannot work with natural conglutination effect for the oil film to solve the problem of local or whole snap. This invention is with high safety factor and long service life.

Owner:钱生宏

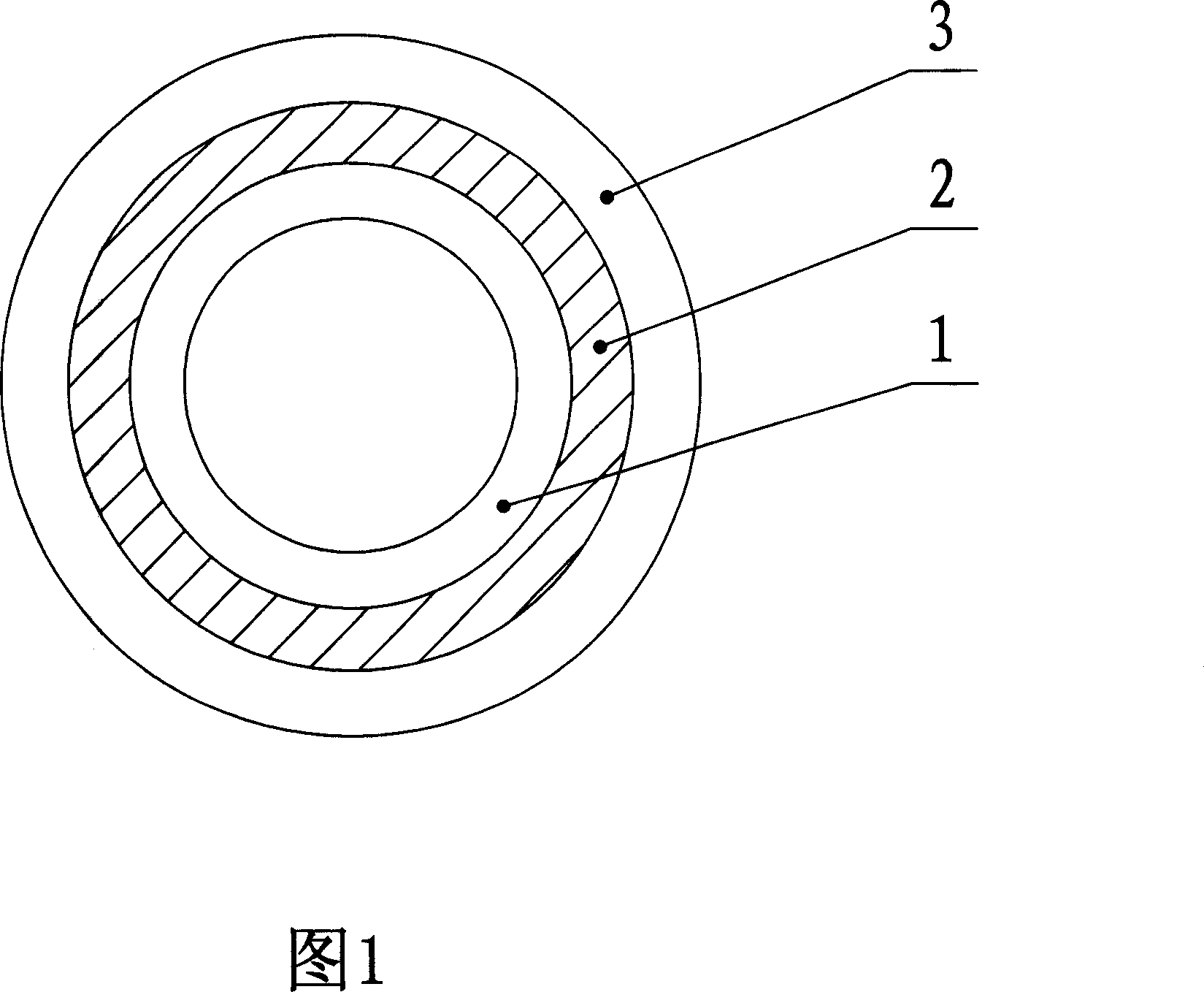

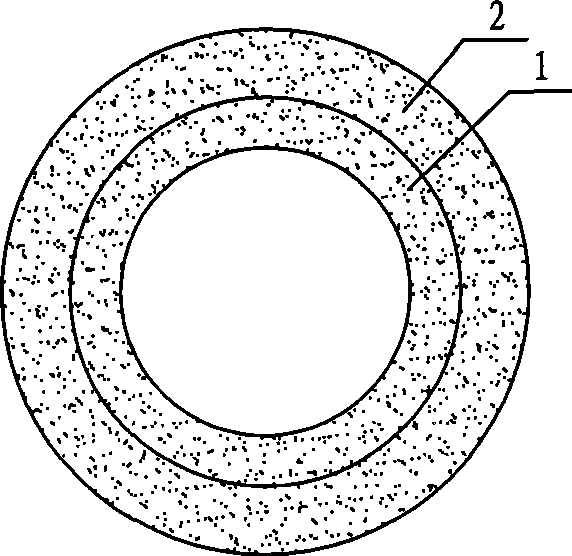

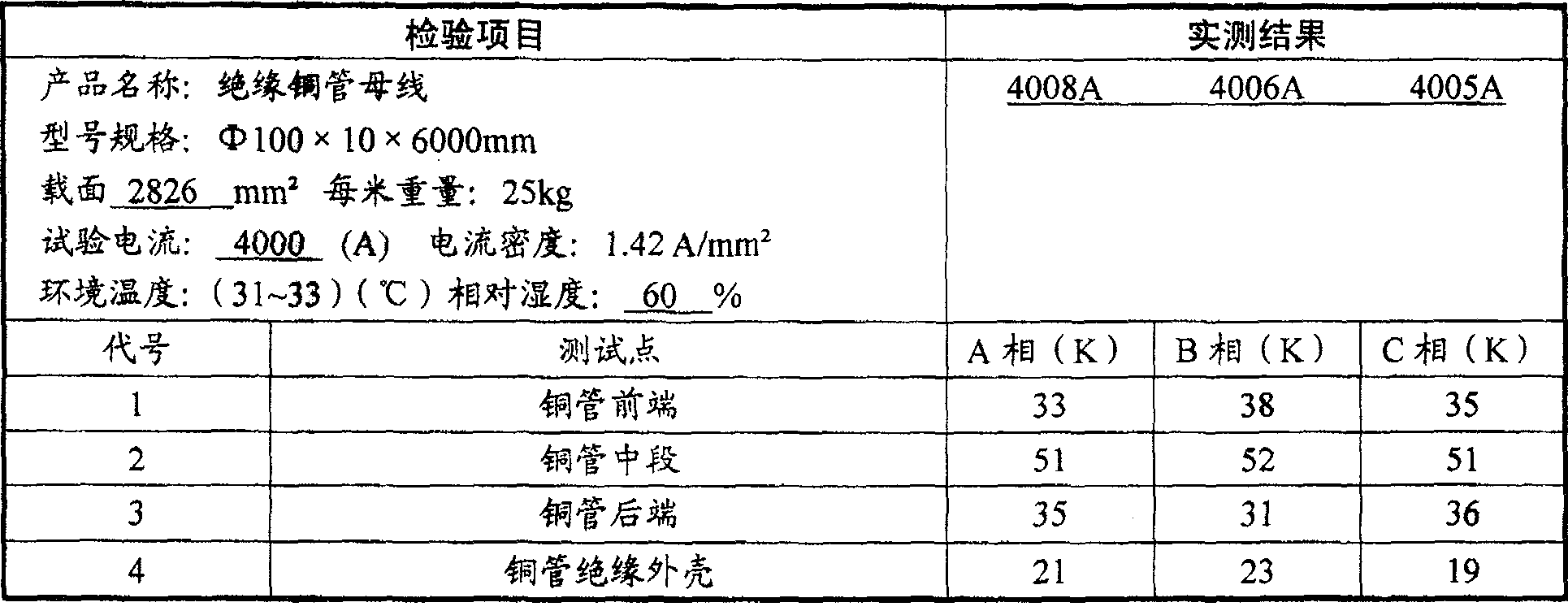

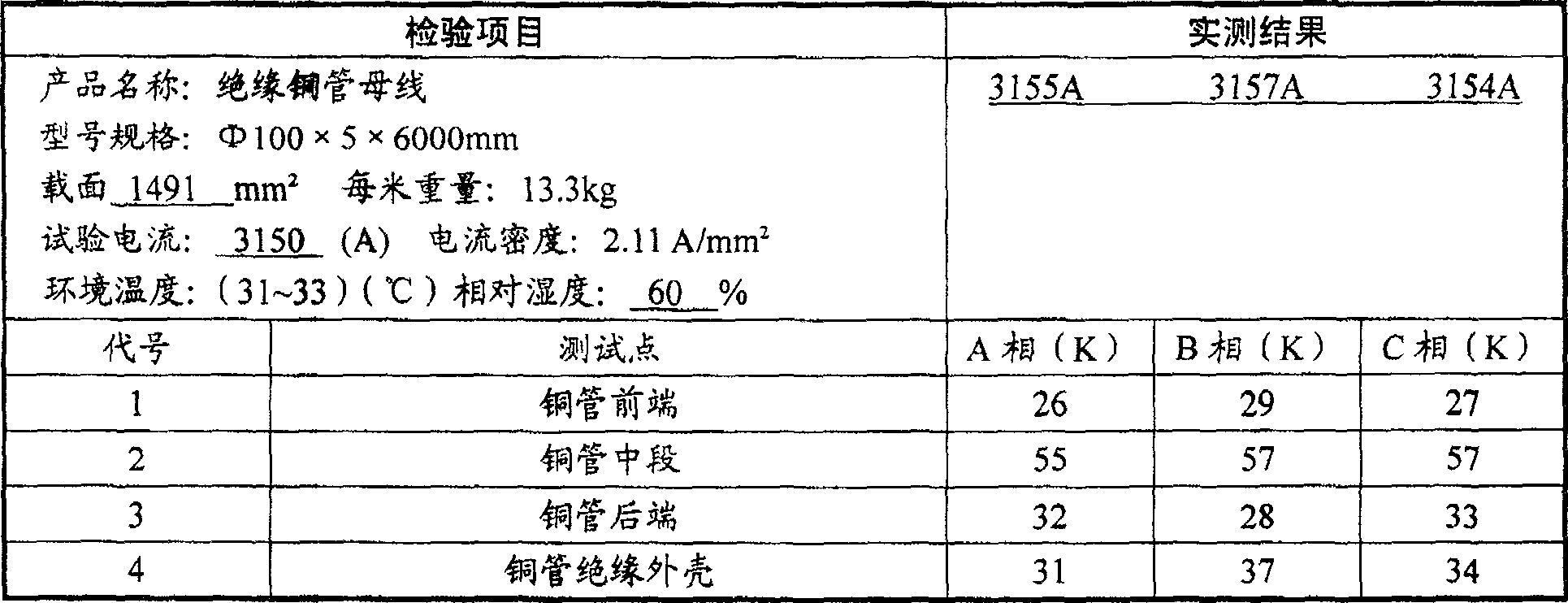

Insulation thin-wall copper pipe bus

ActiveCN101022043ALarge carrying capacityReduce weightRigid-tube cablesInsulated conductorsInsulation layerMetallic materials

This invention relates to insulation thin-wall copper pipe bus bar, in which, less than 4mm thickness of a copper wall is applied as the bus bar to the rated current of the bus bar under 8000A, and the current density can reach to 2.0(A / mm2) with 4mm thick of the wall of the bar and the current density can reach to 2.5(A / mm2) when the thickness is 3mm and the density can be 3.0(A / mm2) while the thickness of the bar is 2mm, then insulation process is done to the copper tube according to the voltage level of the bar, and the voltage level over 1KV needs shield process, potential of the surface of the insulation layer is zero and a metal protection shield layer is processed out of the insulation layer.

Owner:广东日昭电工有限公司

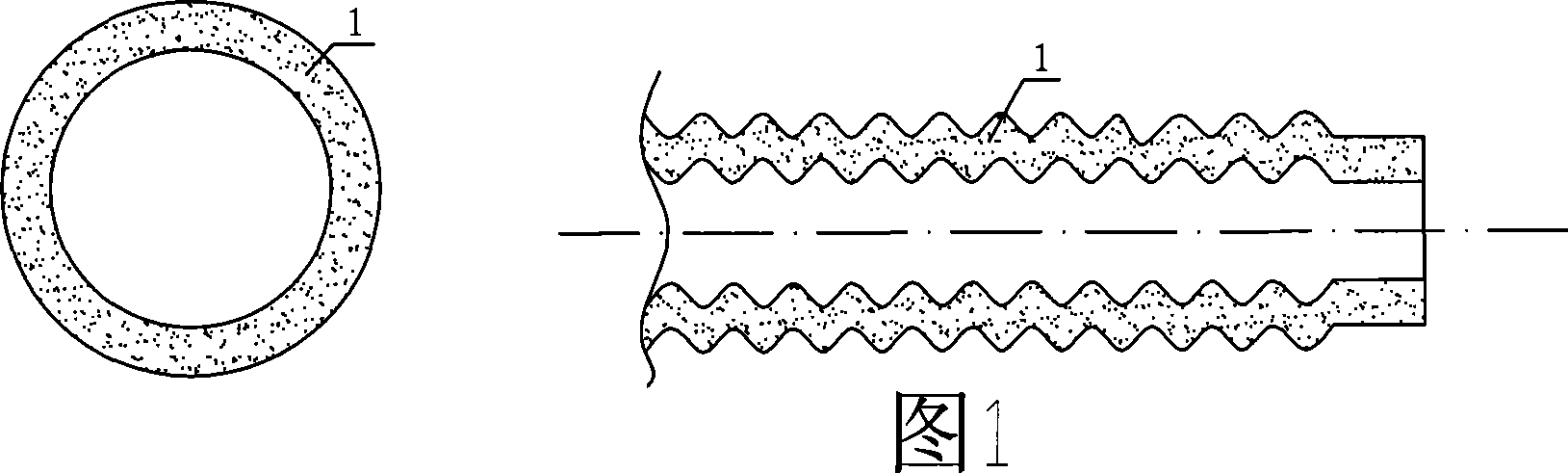

Conductive corrugated tube

InactiveCN101458974AWill not deform and breakPrevent crushingSingle tube conductorsRigid-tube cablesElectrical conductorEngineering

The invention provides a conductive corrugated pipe of corrugated pipe structure, which has the advantages of wires and cables as flexibility, and can be freely bended and released as wires and cables, has the advantages of hollow conductors as high current carrier amount, and is a multilayer conductive corrugated pipe capable of improving the effective section area of transmission current. The corrugated pipe should be added with a cable core before being applied in overhead lines, the corrugated pipe is made from copper or aluminum, the adjacent corrugated pipes are provided with an insulation layer therebetween. Additionally, the ratio current will not change when the temperature is lower than 4DEG C, the conductors of the corrugated pipe reduces some section area, the current is transmitted by the corrugated pipe, the temperature increase of the whole corrugated pipe conductor will be higher than former temperature increase, to fuse ice and snow.

Owner:罗志昭

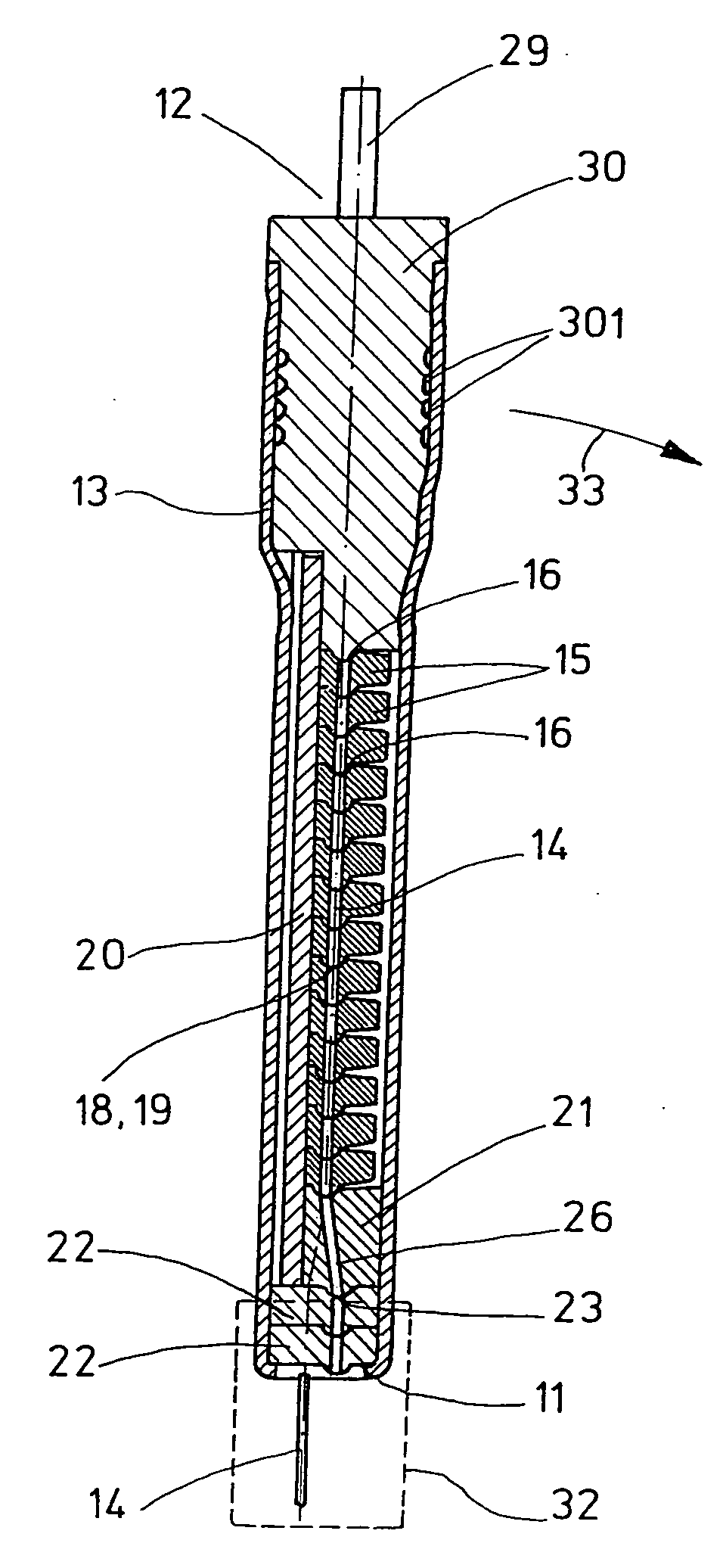

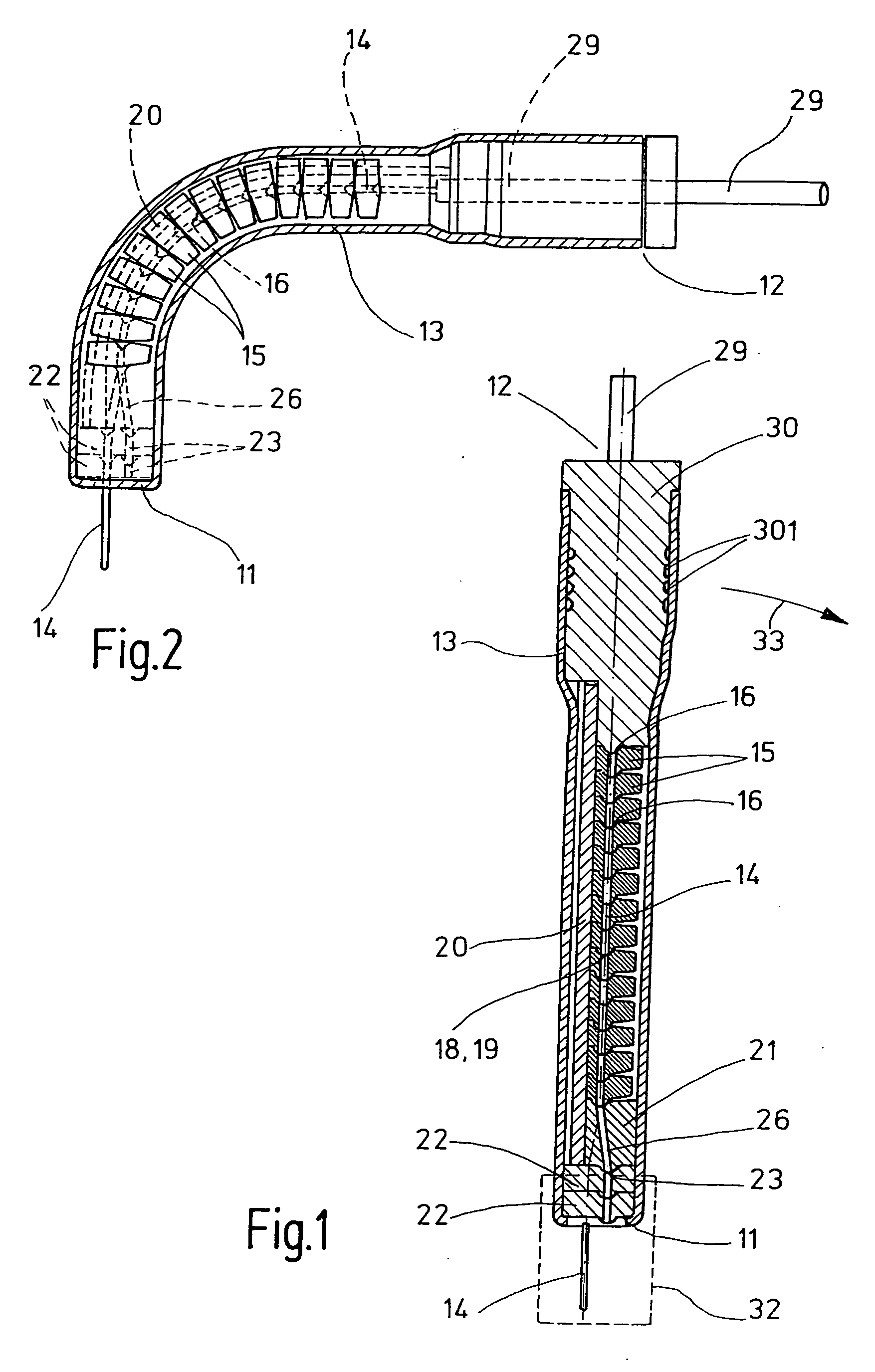

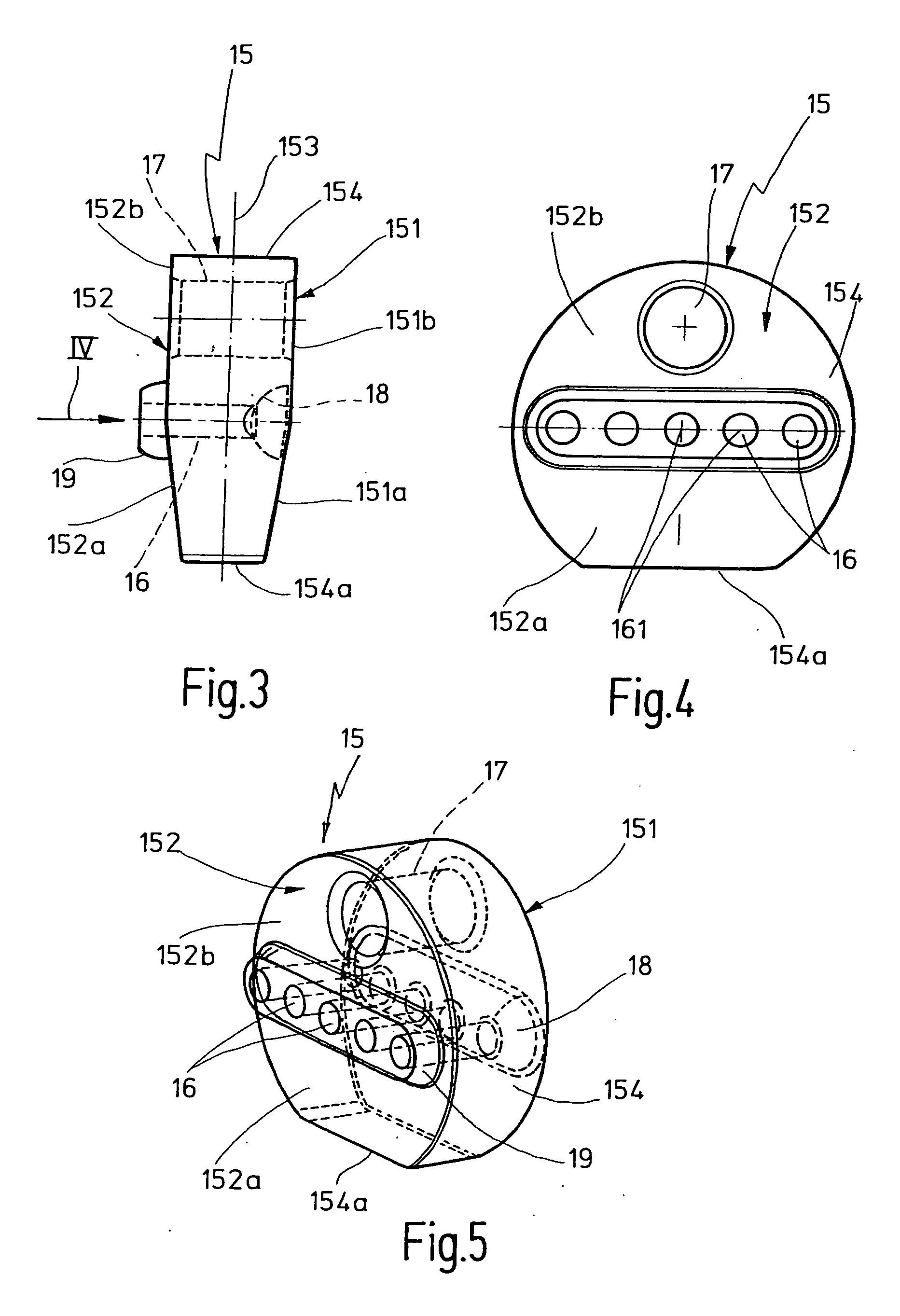

Connecting lead for a sensor

InactiveUS20060121800A1Expensive to manufactureSimple and inexpensive fashionRigid-tube cablesSoldered/welded conductive connectionsCombustionElectrical conductor

A connecting lead for a sensor, in particular for a sensor for determining a physical property of a measured gas, e.g. for determining the temperature or oxygen content in the exhaust gas of internal combustion engines, is described, said sensor comprising a sheathing tube, at least two electrical conductors extending in the sheathing tube, and an insulating arrangement that insulates the electrical conductors from one another and from the sheathing tube. To allow the use of unsheathed bare metal wires as electrical conductors, and avoid short circuits on the one hand between the metal wires and on the other hand between the metal wires and the sheathing tube, especially upon bending of the metal tube during installation, the insulating arrangement has a plurality of insulating elements, braced against one another, that have at least two through holes through each of which one electrical conductor is guided.

Owner:ROBERT BOSCH GMBH

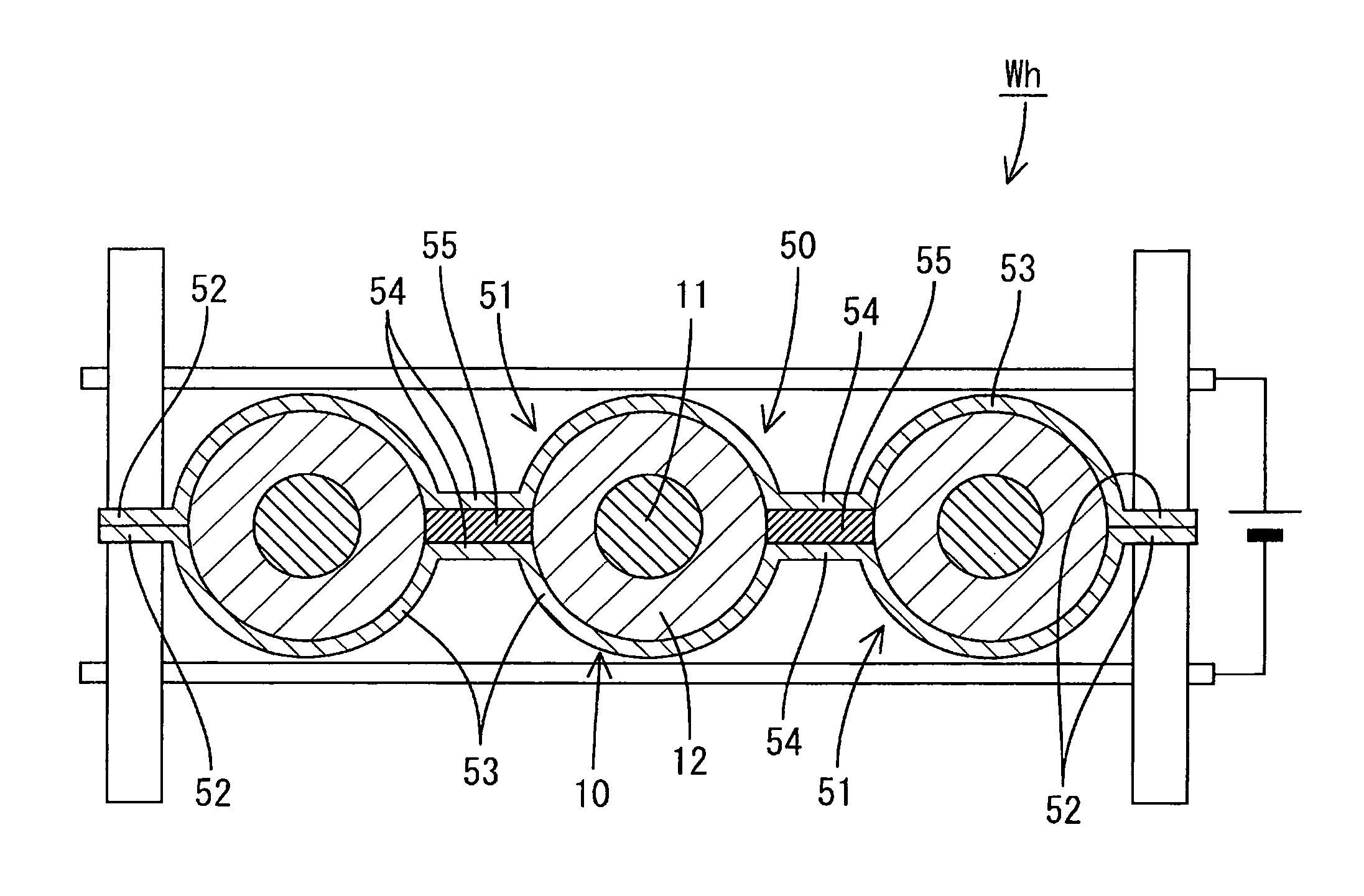

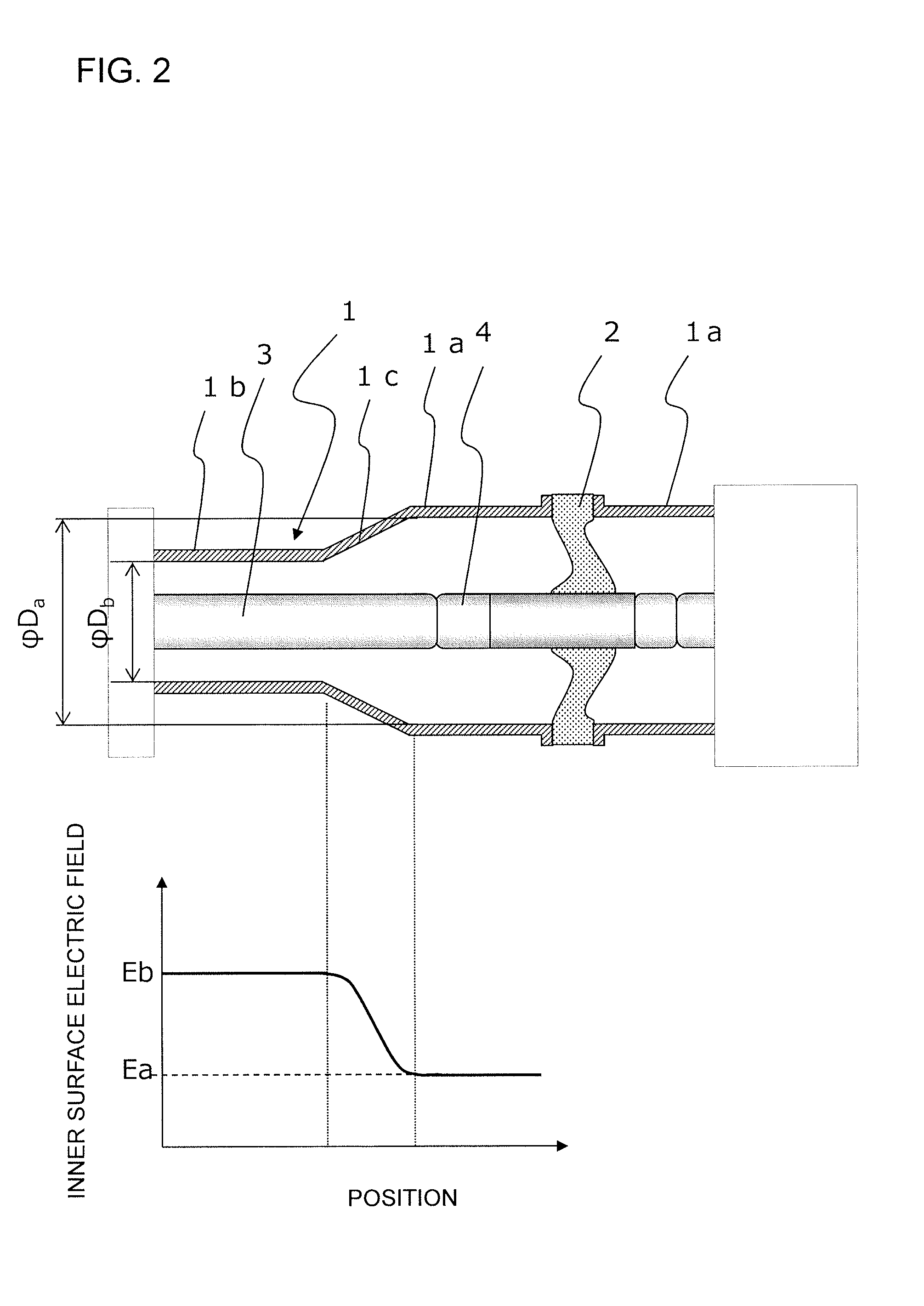

Gas Insulated Bus and Particle Removal Method for Gas Insulated Bus

ActiveUS20120281332A1Increase travel speedShorten operation timeCoaxial cables/analogue cablesSpraying power supplyElectrical conductorEngineering

The present invention is provided to satisfy insulation and conductivity performance requirements, to reduce the size of a gas insulated bus, and also to make conditioning for a particle more reliable. In a gas insulated bus having a conductor supported in a cylindrical metal container via an insulator, insulating gas being contained in the metal container, the metal container has an expanded diameter part formed over a given range in an area of the metal container in which the insulator is positioned and a reduced diameter part formed over the entire area of the metal container except for the expanded diameter part. Thus, when the temperature of the insulator increases during conduction, heat from the insulator is transferred to the metal container via a large space in the expanded diameter part and released to the air through a large outer surface of the expanded diameter part of the metal container.

Owner:HITACHI LTD

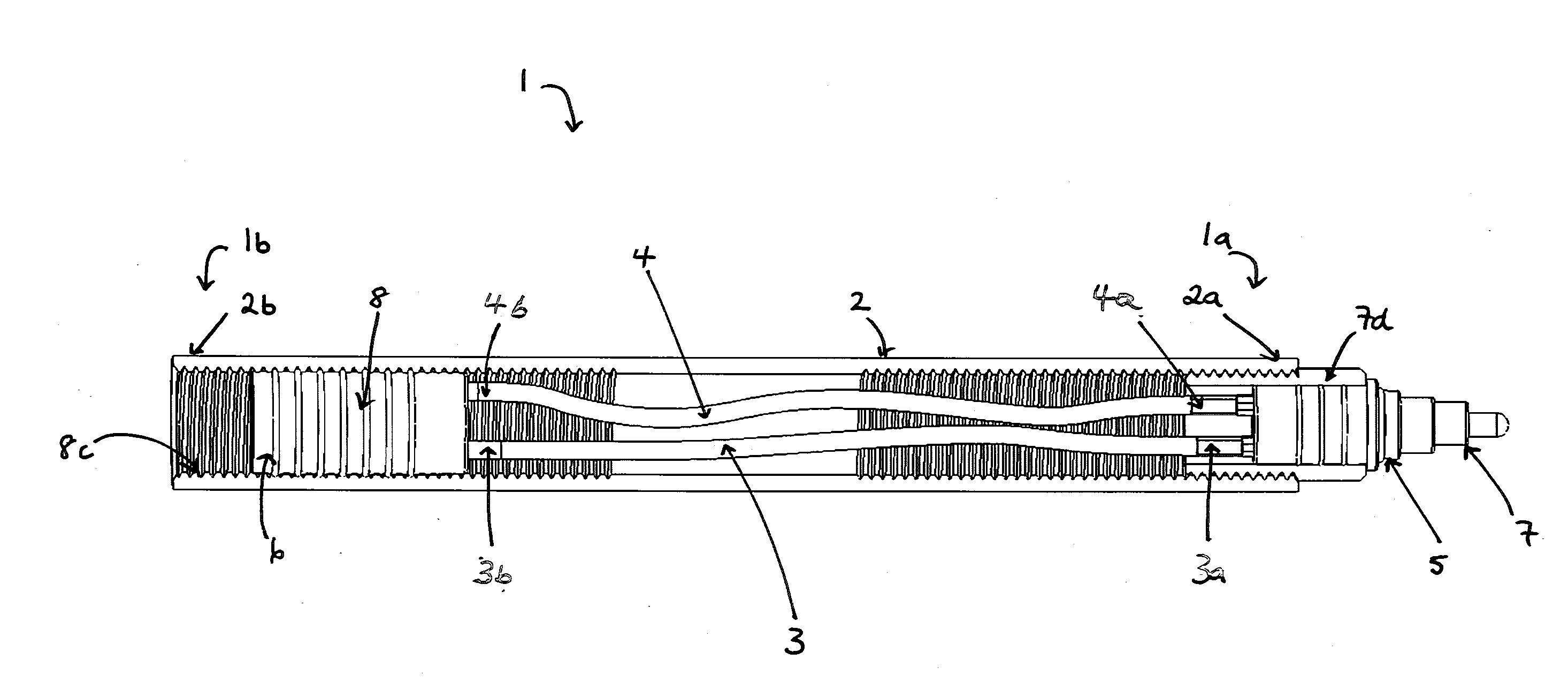

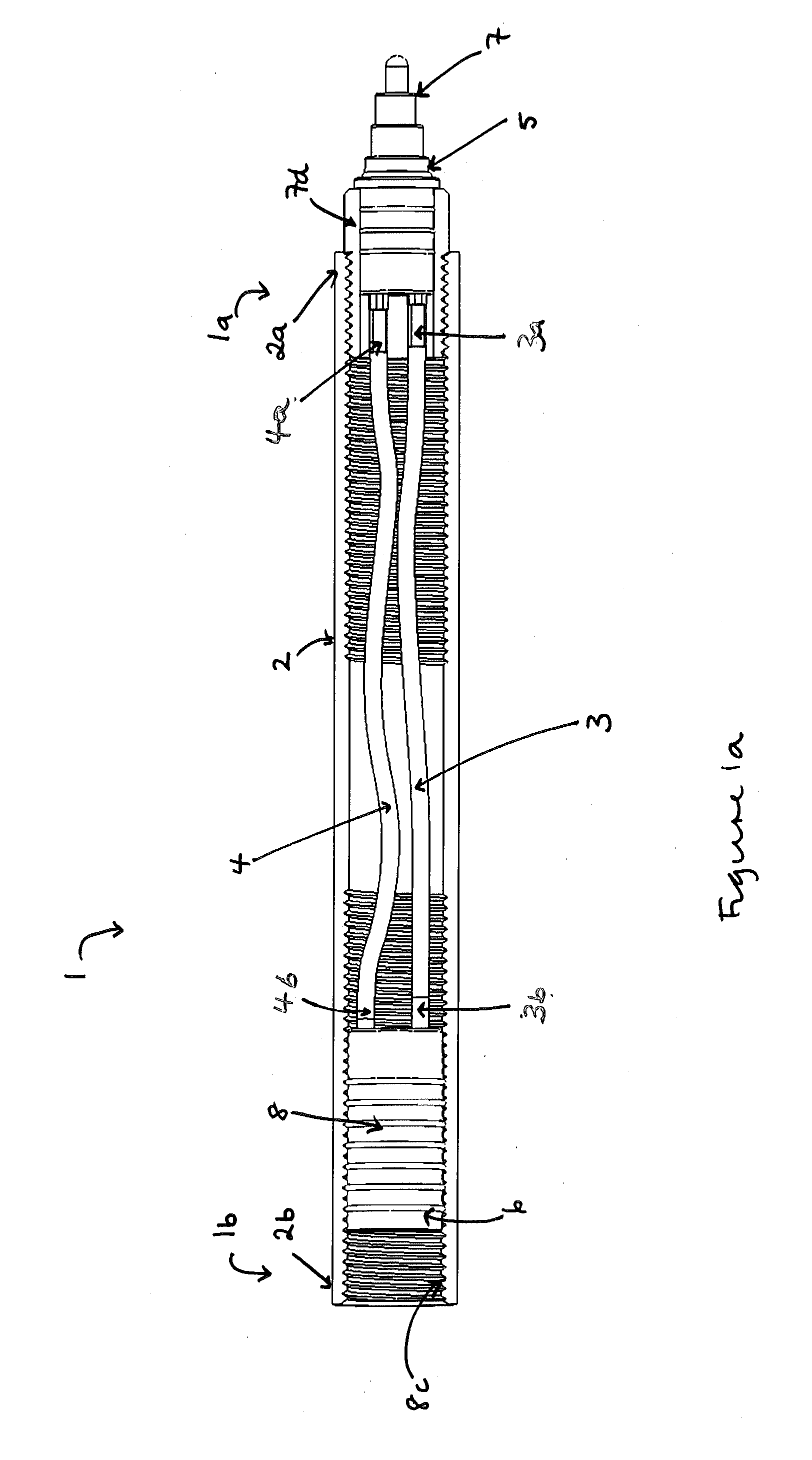

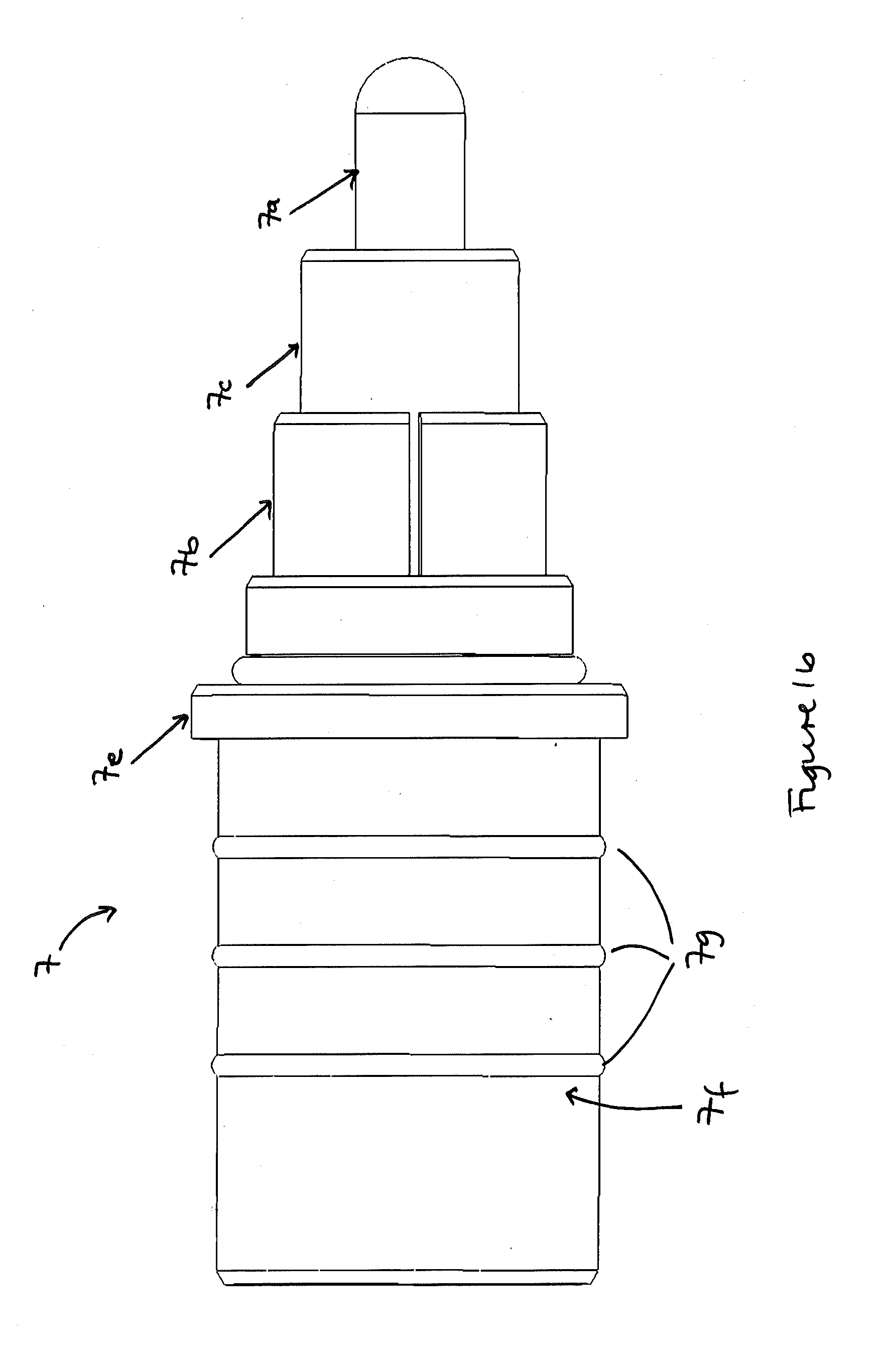

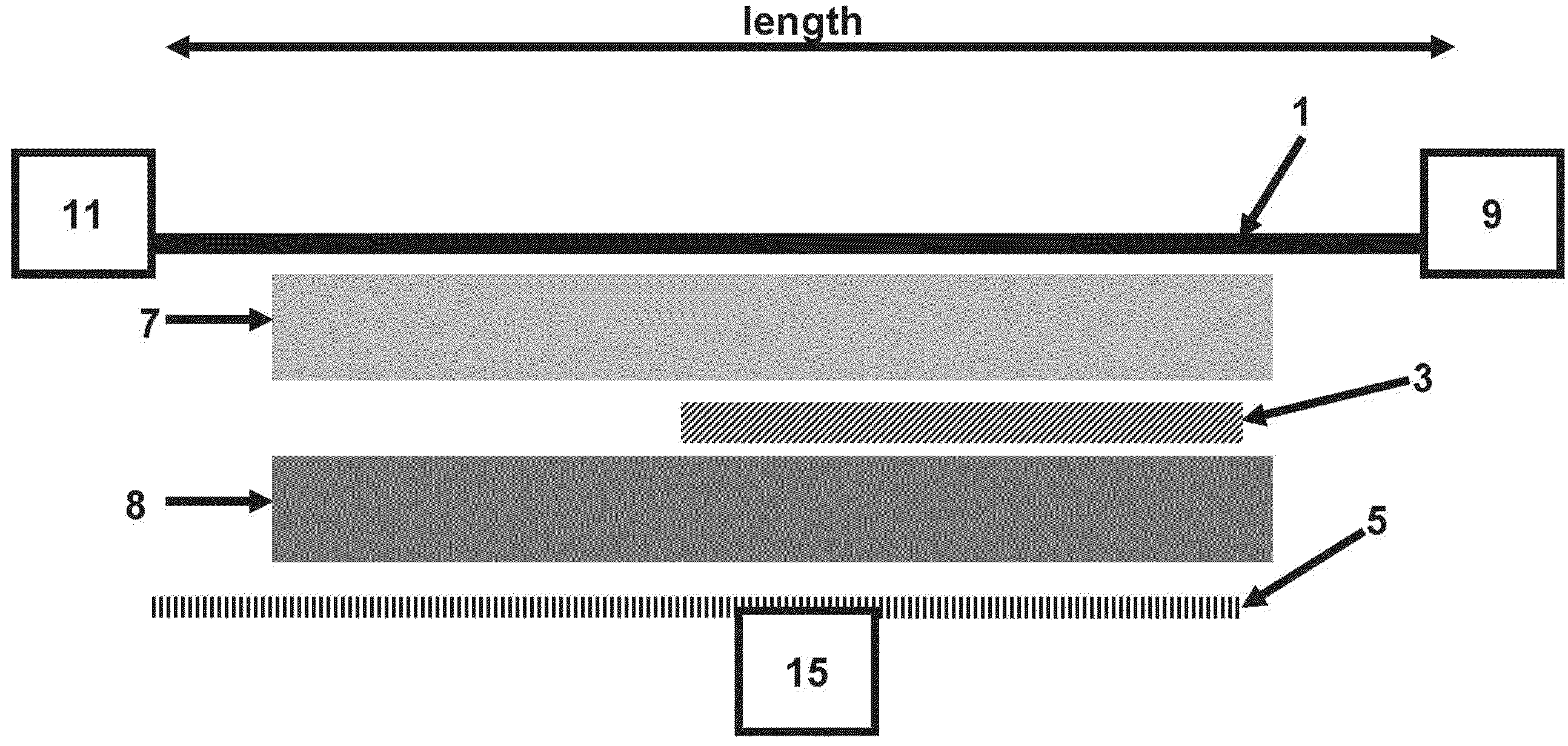

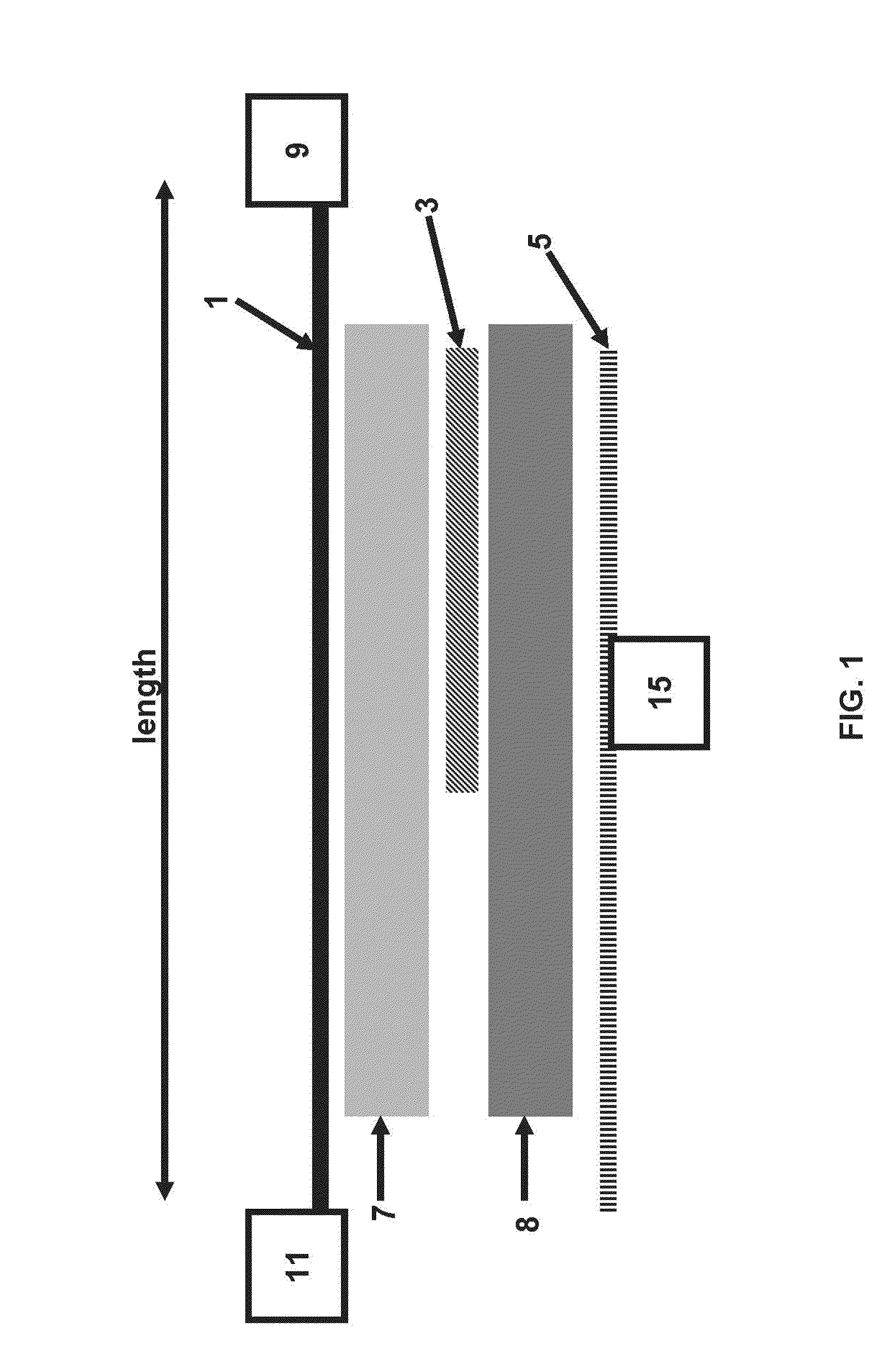

Low voltage rigid cable

A first aspect of the invention relates to a low voltage rigid cable comprising a substantially rigid housing, a live conductor arranged within the housing, a neutral conductor arranged within the housing, a first coupling means to couple the rigid cable with a first member, a second coupling means configured to couple the rigid cable with a second member and protection means to protect against electric shock. The protection means may comprise an earth conductor and insulating means configured to form an insulating barrier between the conductive parts of the rigid cable. In an embodiment of the invention, the housing may be configured to form an earth conductor. Further aspects of the invention relate to a rigid cable structure.

Owner:TP24

Power supply wire for high-frequency current

ActiveCN103106970AIncrease surface areaReduce skin effectRigid-tube cablesPower cables with screens/conductive layersElectrical conductorPower flow

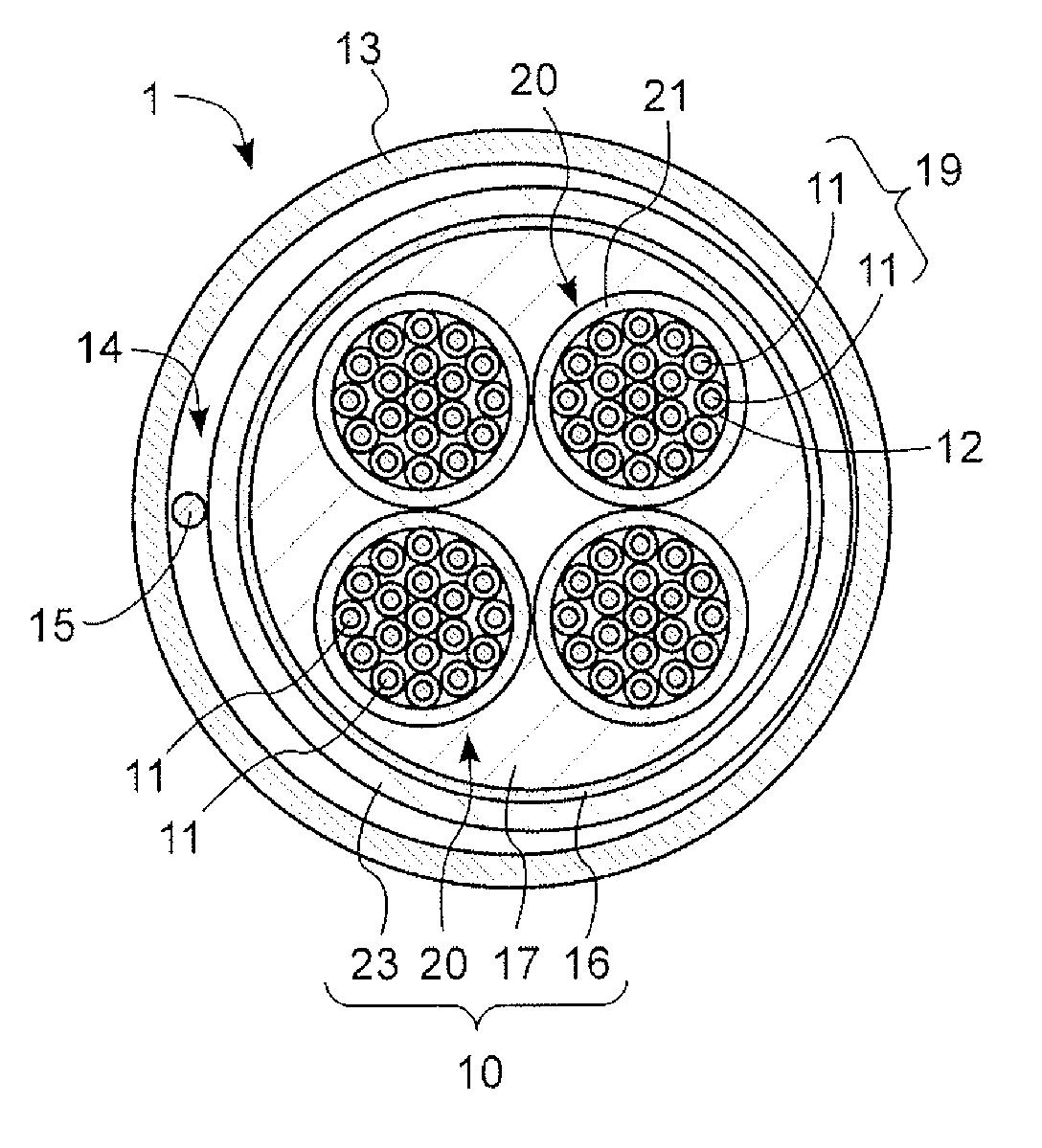

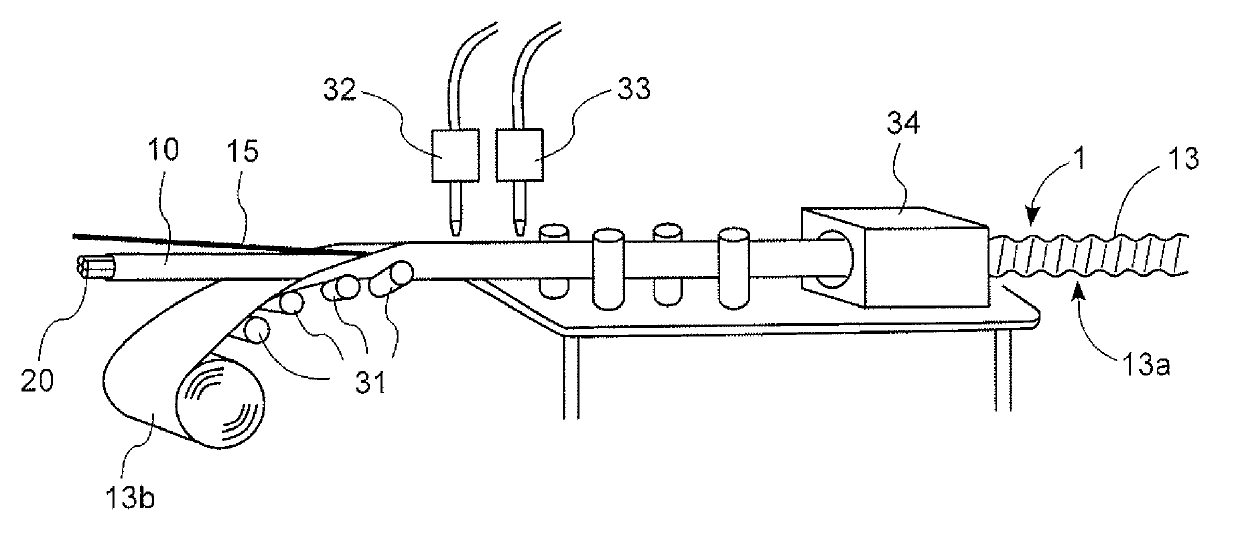

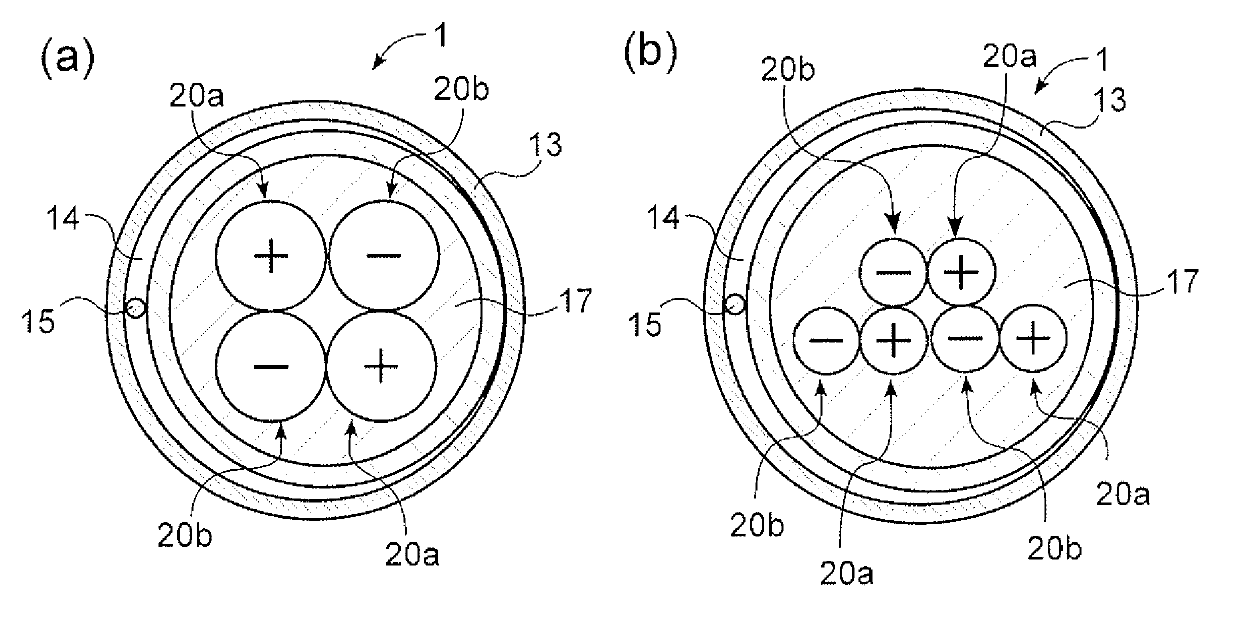

The invention provides a power supply wire for high-frequency current which reduces a supply loss of current affected by the skin effect and has a high degree of freedom in laying. The power supply wire for high-frequency current (1) comprises: a corrugated tube made of metal (13); a combined electric wire (10) disposed inside the corrugated tube (13) and including a plurality of unit electric wires (20) and a sheath material (23), each of the unit electric wires (20) being formed by bundling together a plurality of conductive wires (11) individually coated with insulating films (12), and the sheath material (23) covering the plurality of unit electric wires (20); and a gap (14) formed between the corrugated tube (13) and the combined electric wire (10).

Owner:KANZACC

Low voltage rigid cable

A first aspect of the invention relates to a low voltage rigid cable comprising a substantially rigid housing, a live conductor arranged within the housing, a neutral conductor arranged within the housing, a first coupling means to couple the rigid cable with a first member, a second coupling means configured to couple the rigid cable with a second member and protection means to protect against electric shock. The protection means may comprise an earth conductor and insulating means configured to form an insulating barrier between the conductive parts of the rigid cable. In an embodiment of the invention, the housing may be configured to form an earth conductor. Further aspects of the invention relate to a rigid cable structure.

Owner:TP24

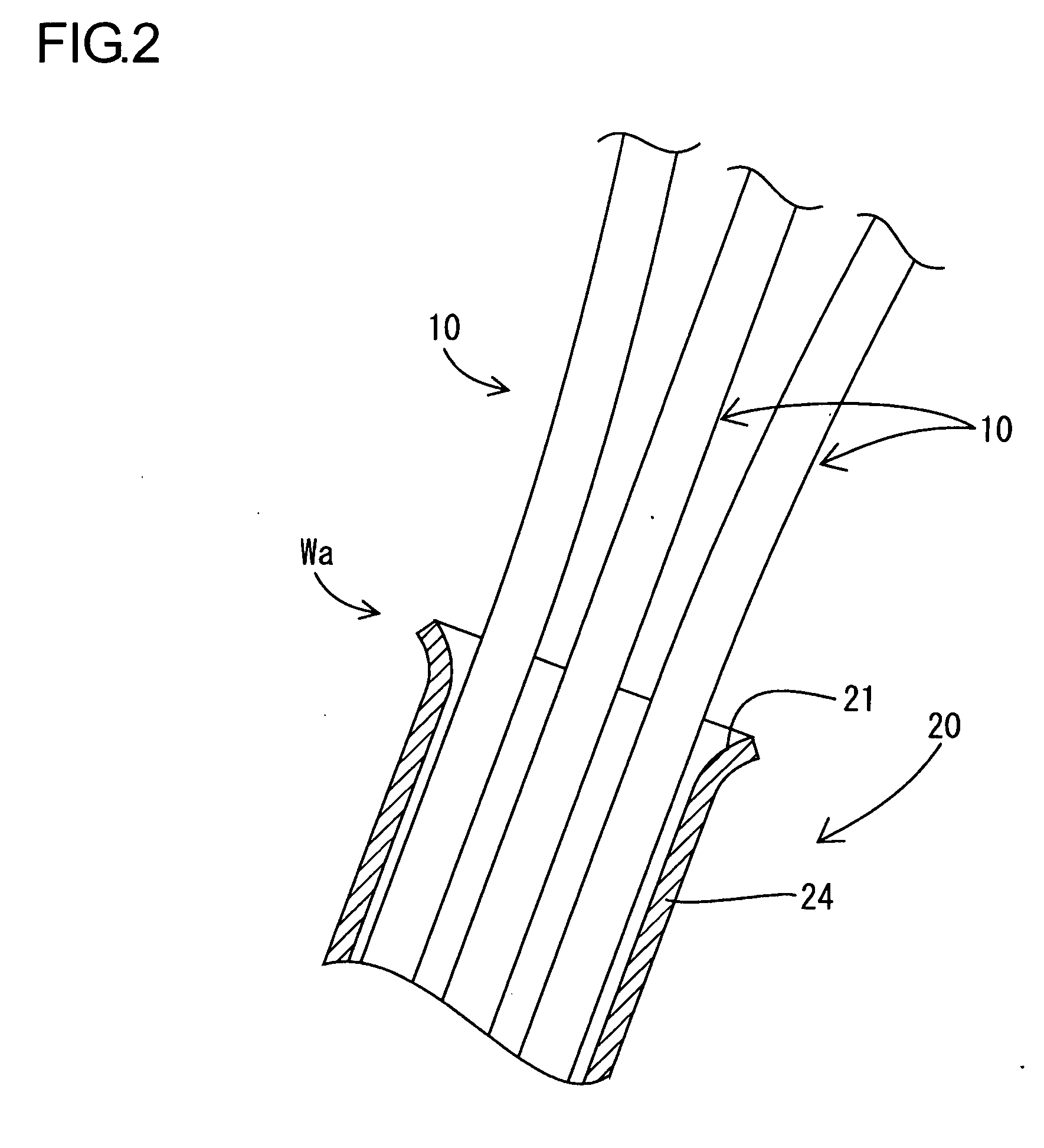

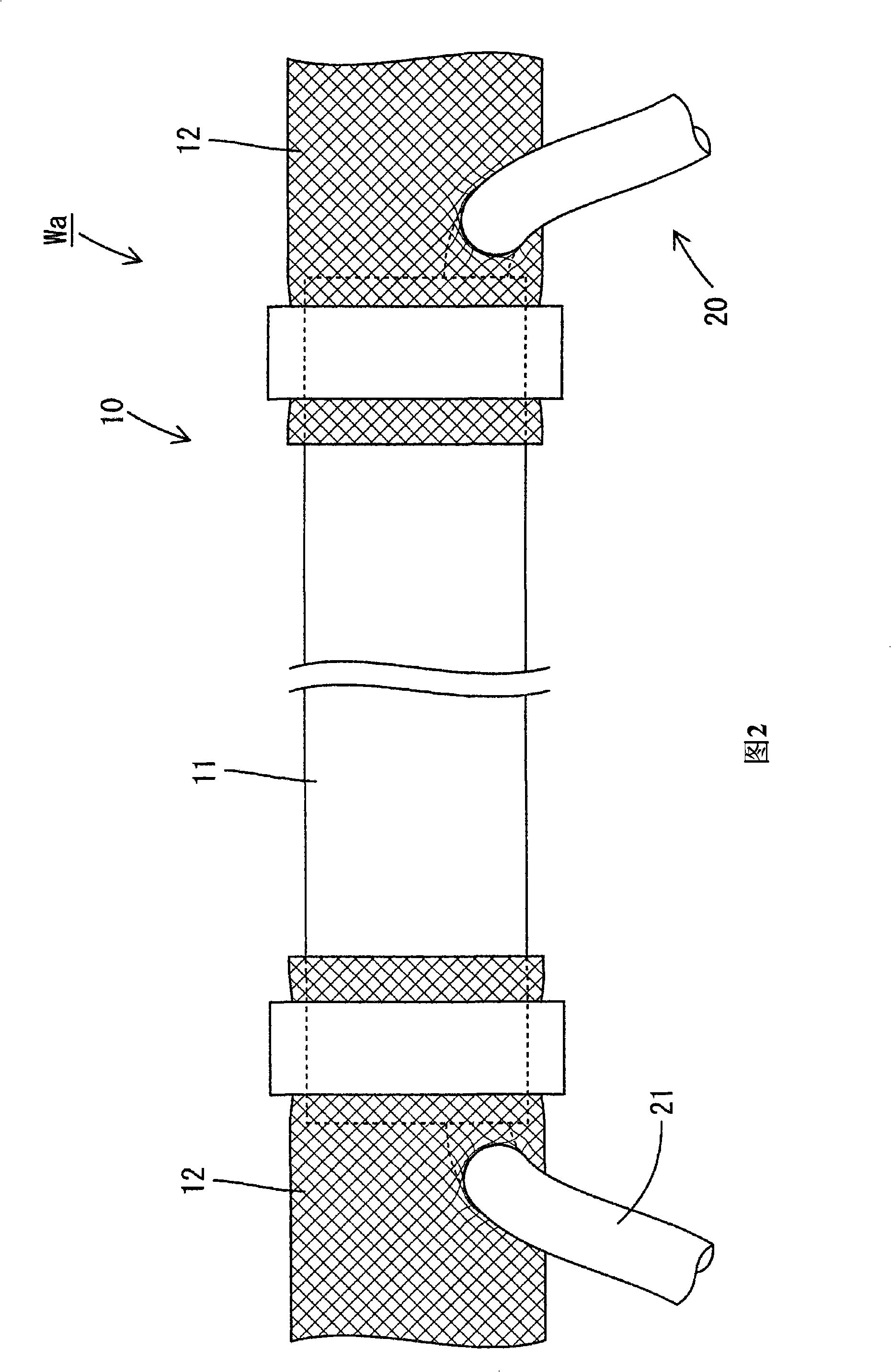

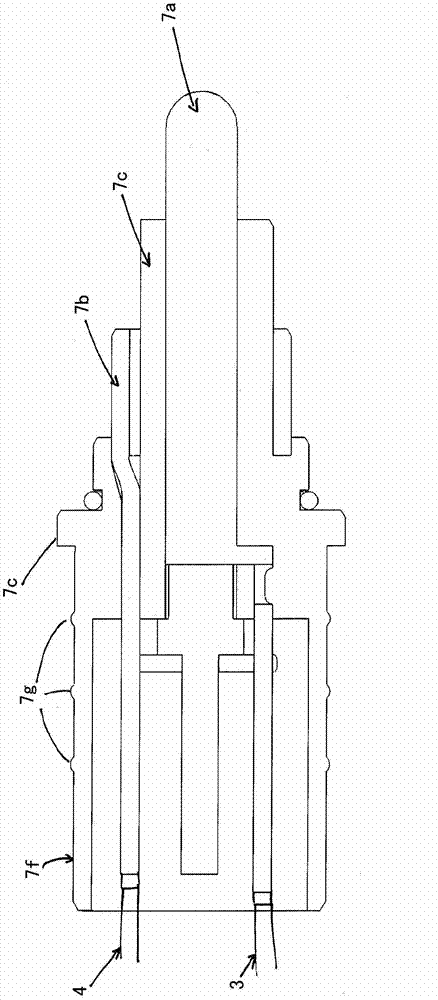

Shield conductor

InactiveCN103270557AEfficient use ofMagnetic/electric field screeningRigid-tube cablesElectrical conductorElectric wire

A shield conductor (10) is provided with: a metal pipe (20); electrical wires (11) running through said pipe (20); first irregularly shaped sections (21) that are provided in the pipe (20) and each have a first narrow section (21A) and a first wide section (21B) having different outside diameters; and a second irregularly shaped section (24) that is formed in the pipe (20) at a lengthwise position different from that of the first irregularly shaped sections (21) and has a second narrow section (24A) and a second wide section (24B) having different outside diameters. The first narrow section (21A) and the second narrow section (24A) are formed at different points along the circumference of the pipe, as are the first wide section (21B) and the second wide section (24B).

Owner:AUTONETWORKS TECH LTD +2

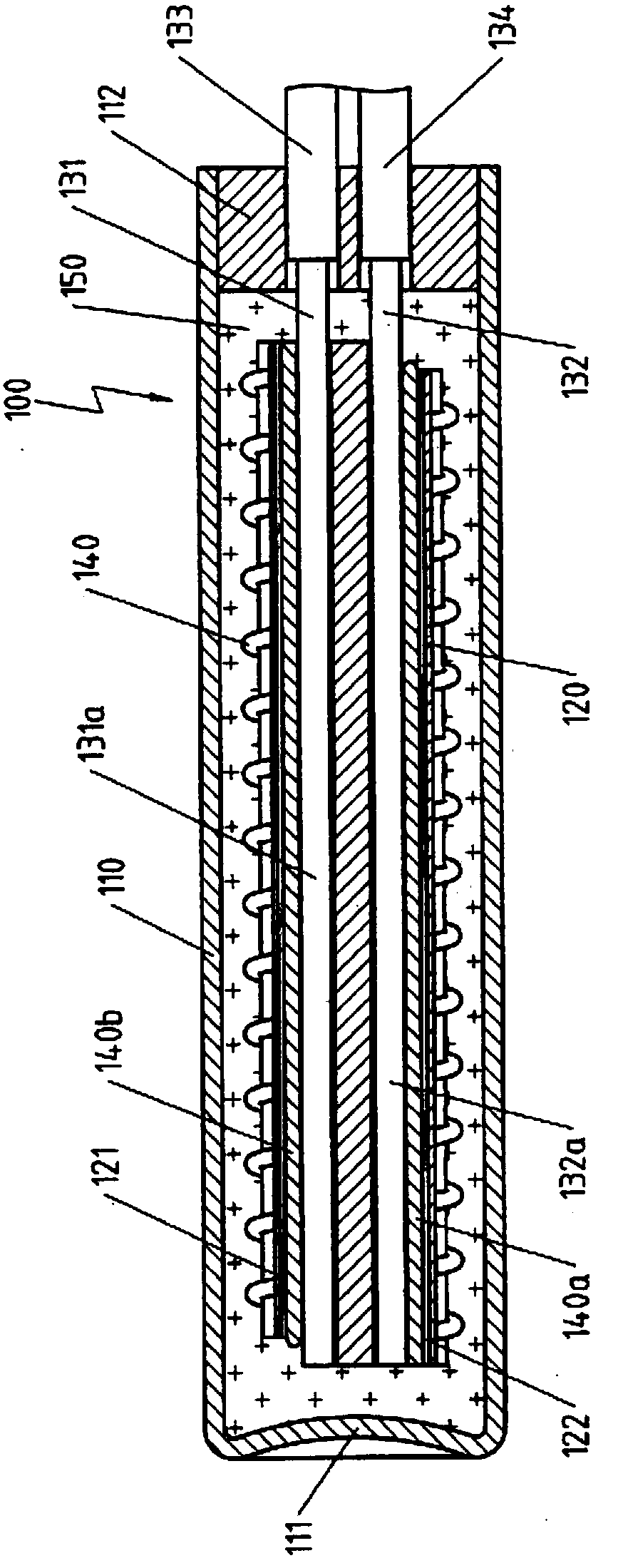

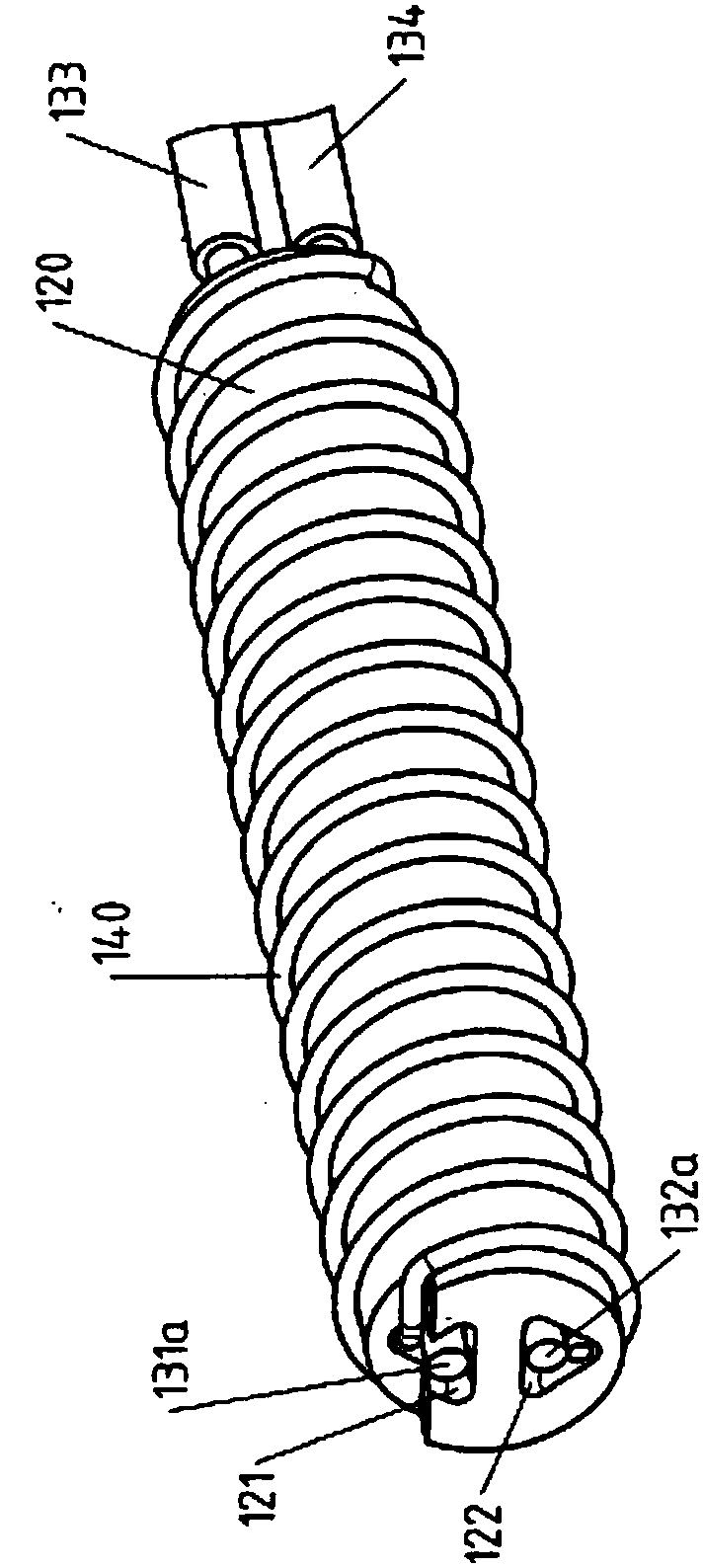

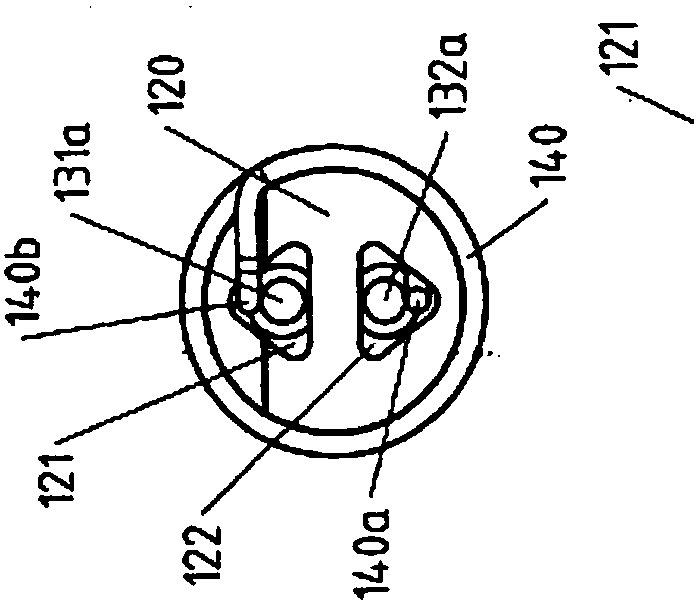

Electrical device with insulators

ActiveCN108633113AEasy to dripAvoid paddingRigid-tube cablesOhmic-resistance heating detailsElectrical conductorBiomedical engineering

An electrical device (100,200) is provided having a tubular metal sheath (110,210,250,260) and an insulator (120,160,220,251,261), the insulator (120,160,220,251,261) is arranged inside the tubular metal sheath (110,210,250,260), and at least one tunnel-shaped opening (121,122,161, 162,221,252,262) penetrates through the insulator (120,160,220,251,261), wherein at least one section (131a,132a,171a,172a) of the first electrical conductor (131,132,171,172,231) is arranged in the tunnel-shaped opening(121,122,161,162,221,252,262),wherein the cross section geometrical shape of the tunnel-shaped opening (121, 122, 161,162,221,252,262) deviates from a circle.

Owner:TUCKER & HELLINGE LTD

Vacuum power cable

InactiveCN101399097AExtend your lifeIncrease working voltageRigid-tube cablesPower cablesElectric power transmissionElectrical conductor

The invention relates to a vacuum power cable which belongs to the power transmission technology field. The vacuum power cable comprises a conducting core, an external layer sealing pipe and a middle insulation layer. The vacuum power cable is characterized in that the middle insulation layer is composed of vacuum and a solid insulation support. The solid insulation support of hub structure is arranged between the conducting core and the external layer sealing pipe in uniform segments to avoid the collision of the conducting core and the external layer sealing pipe. The vacuum is used as the main insulation. The vacuum height is higher than 1.33*10<-2>Pa. the cable has the characteristics of less consumed material, low cost, simple manufacturing, small capacity and large transmission capacity. No oxidation and electric aging problems happen to the insulation and conductors. The service life of the cable is prolonged greatly. The cable is suitable to be used as power cable of middle and high voltage grade.

Owner:SHANGHAI JIAO TONG UNIV

Distributive conductor

InactiveUS7750241B2Reduce reflectivityIncrease heat absorptionPlastic/resin/waxes insulatorsRigid-tube cablesElectrical conductorElectromagnetic shielding

Owner:AUTONETWORKS TECH LTD +2

Shielded conductor for vehicle

InactiveUS7700881B2Easy to rustImprove shielding effectPlastic/resin/waxes insulatorsRigid-tube cablesElectrical conductorMetallurgy

Owner:AUTONETWORKS TECH LTD +2

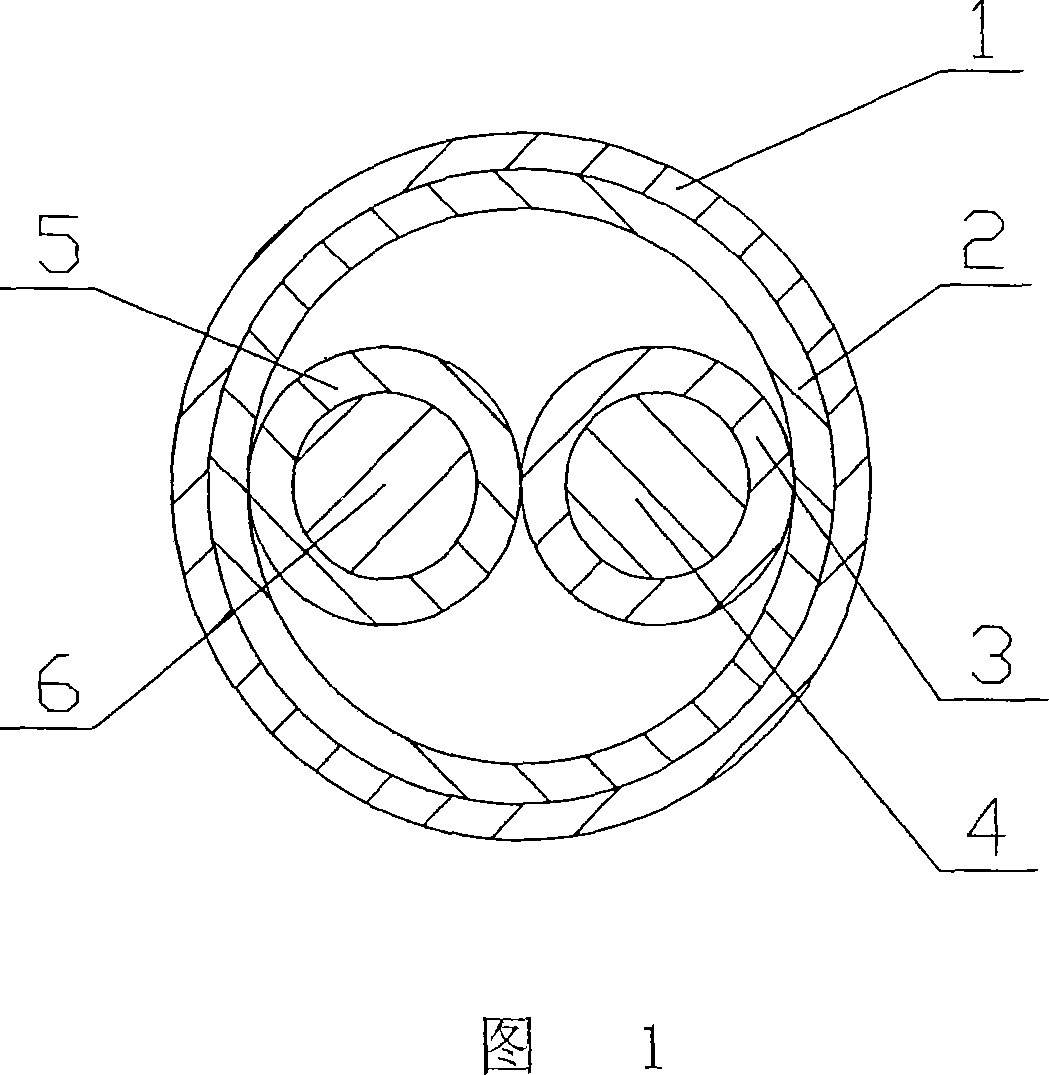

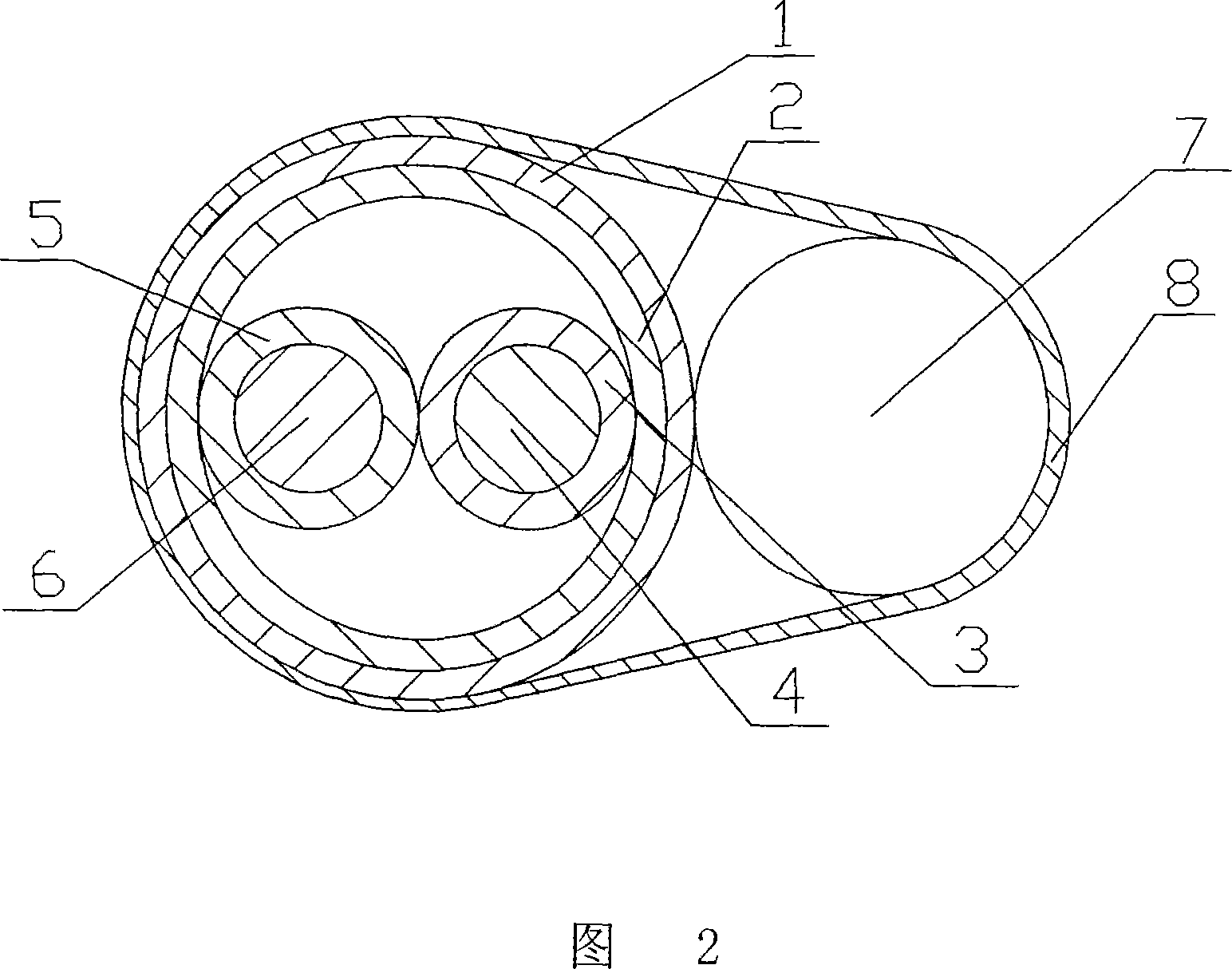

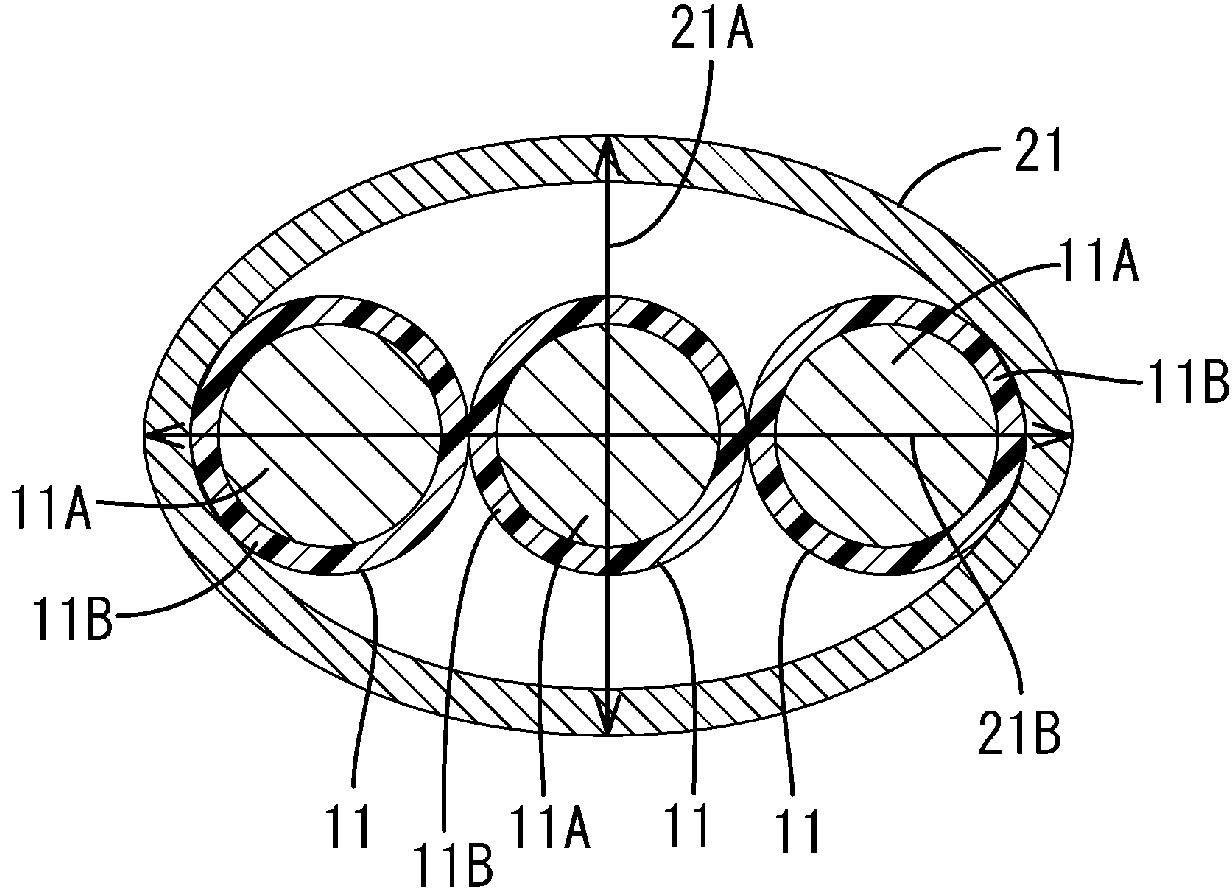

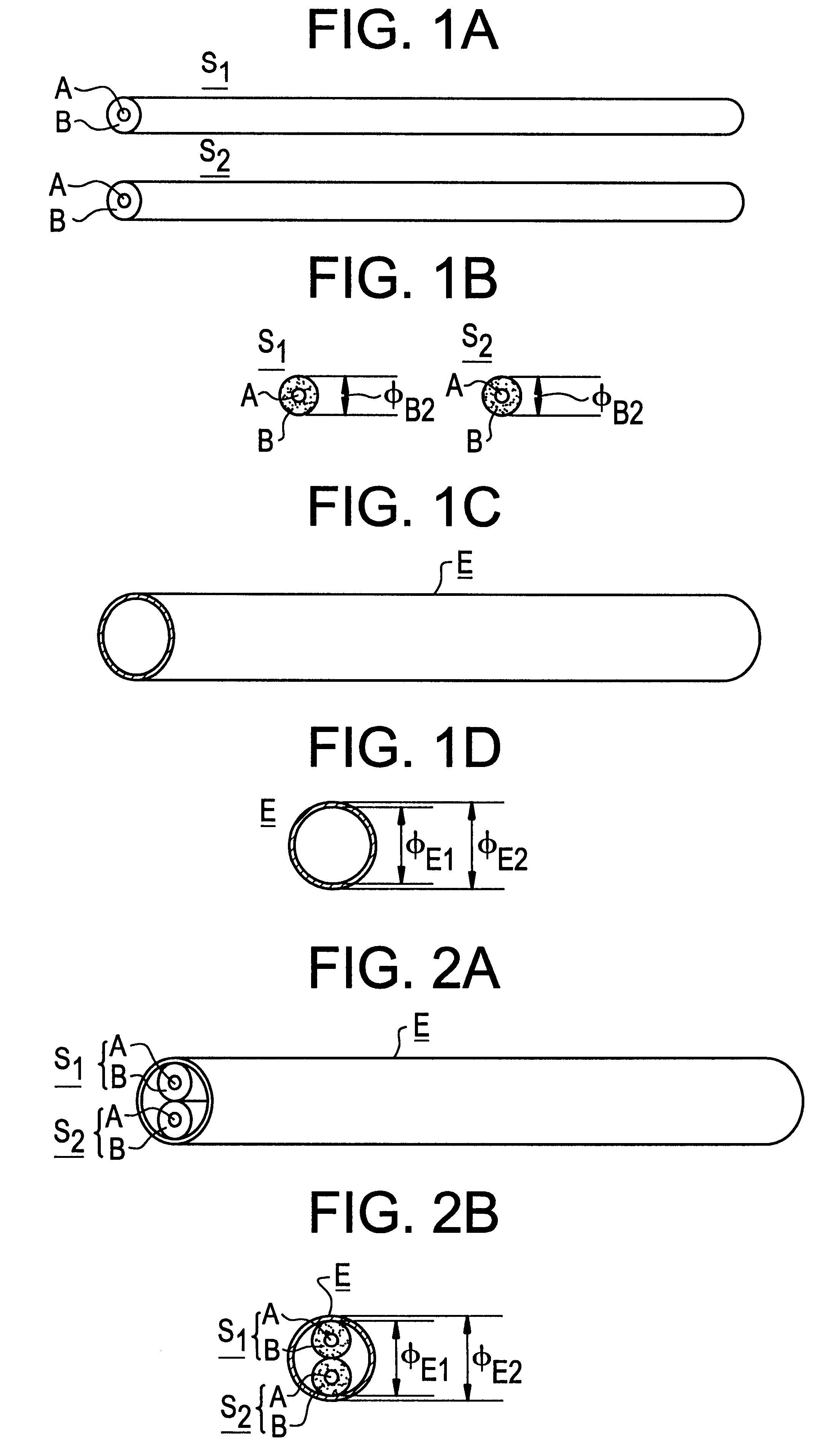

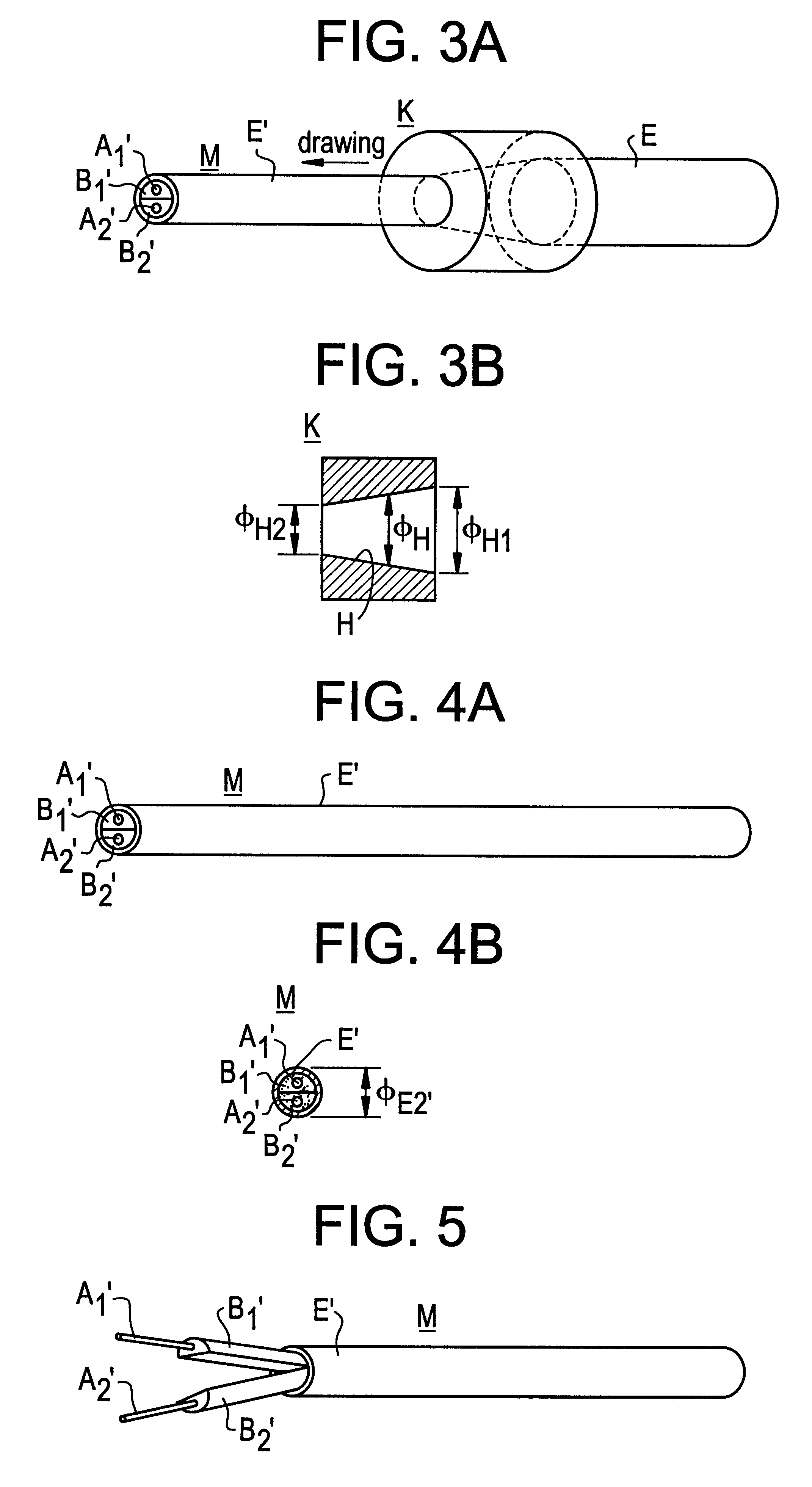

Shielded multiconductor cable and manufacturing method therefor

InactiveUS6337441B1Rigid-tube cablesPower cables with screens/conductive layersMulticore cableElectrical conductor

The present invention has a shielded multi-core cable manufacturing method which involves a step of drawing a cylindrical conductive pipe having inserted therein (a) two first cylindrical insulator rods in each of which a conductive core is embedded concentrically therewith, (b) two second cylindrical insulator rod, and / or (c) a cylindrical insulating tube thereby obtaining the shielded multi-core cable which has a construction in which (a) two first insulator rods each having embedded therein one of two conductive cores, (b) two second insulator rods and / or (c) second insulating tube, are held in cylindrical shielding conductive pipe.

Owner:KOAKKUS

Electromagnetic wrap

A device and method for altering the line reactance of a transmission line having a transmission line, a first floating conductor and a grounding (shielding) conductor. The first floating conductor is positioned between and electrically insulated from the transmission line and the grounding conductor. A source and a load are connected at opposite ends of the transmission line.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Injection molded element and production method

InactiveUS20140120347A1Simple and repeatable mannerOptimizationRigid-tube cablesCable fittingsElectrical conductorPlastic materials

Owner:DITTER PLASTIC

Insulation thin-wall copper pipe bus

ActiveCN100511493CLarge carrying capacityReduce weightRigid-tube cablesInsulated conductorsBusbarMetallic materials

The invention relates to an insulated thin-walled copper tube busbar. The busbar with a rated current of the insulated copper tube busbar below 8000A is suitable to use a copper tube with a wall thickness of less than 4mm as the busbar. Insulated copper pipe busbar with a wall thickness of 4mm copper pipe, the current density can reach 2.0 (A / mm2), the insulated copper pipe busbar wall thickness 3mm copper pipe, the current density can reach 2.5 (A / mm2), the insulated copper pipe busbar wall thickness 2mm copper tube, the current density can reach 3.0 (A / mm2), and then according to the voltage level of the bus, the copper tube is insulated and an insulating layer is added. The voltage level above 1kV needs to be shielded, and the surface potential of the insulating layer is zero. Make a metal protective shielding layer outside the insulating layer (the metal material is stainless steel, aluminum sheet, pipe, soft metal pipe).

Owner:广东日昭电工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com