Patents

Literature

3749results about How to "Prevent crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dosage Form with Impeded Abuse

InactiveUS20090004267A1Prevent crushingPrevent the subsequent abuseOrganic active ingredientsPowder deliveryWaxBreaking strength

A multiparticulate dosage form formulated to make misuse more difficult containing least one active substance with potential for misuse (A), at least one synthetic or natural polymer (C), optionally at least one natural, semi-synthetic or synthetic wax (D), at least one disintegrant (E) and optionally one or more additional physiologically compatible excipients (B), wherein the individual particles of the dosage form display a breaking strength of at least 500 N and a release of active substance of at least 75% after 45 minutes measured according to Ph.Eur. in the paddle mixer with sinker in 600 ml of aqueous buffer solution with a pH value of 1.2 at 37° C. and 75 rpm.

Owner:GRUNENTHAL GMBH

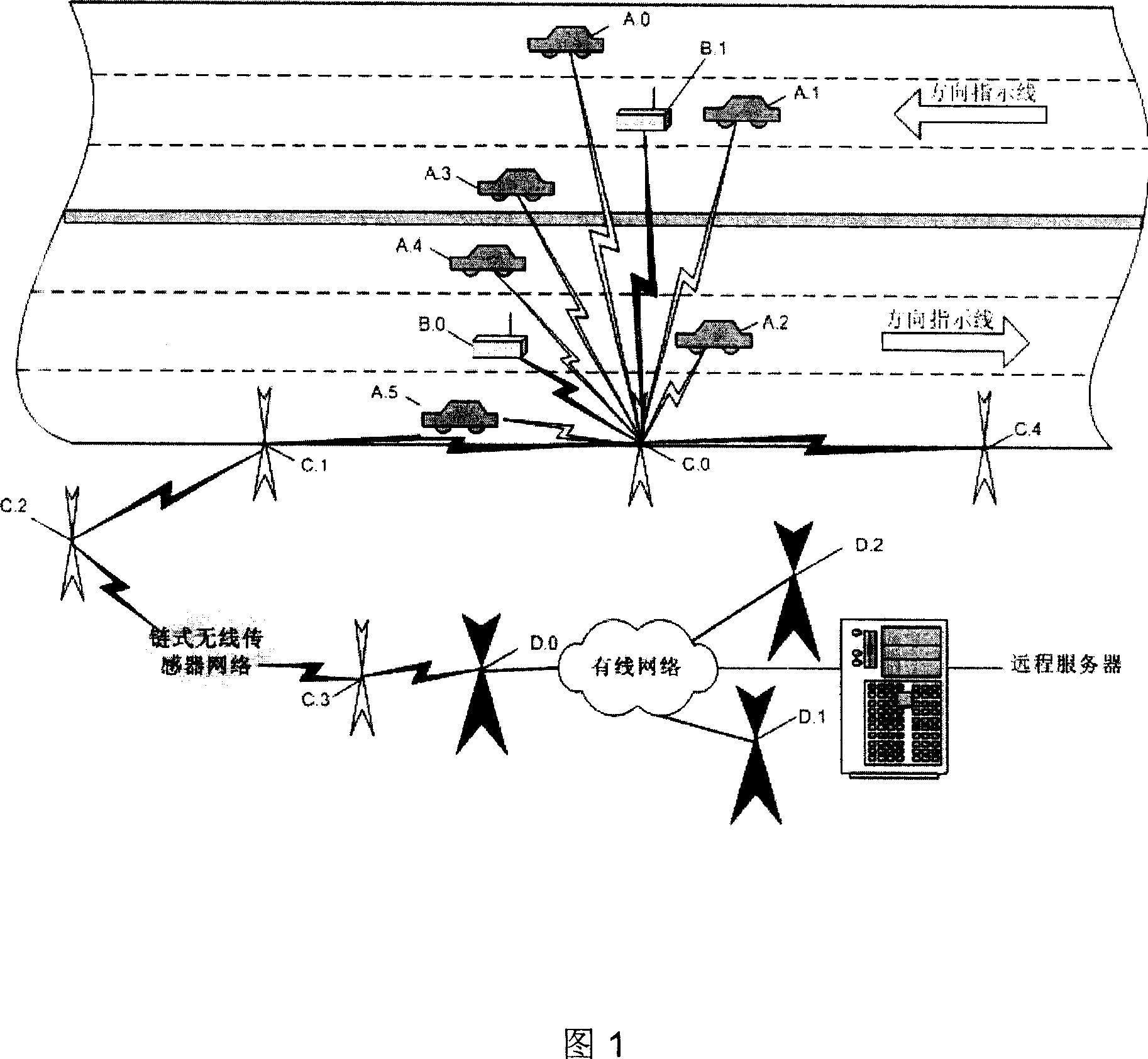

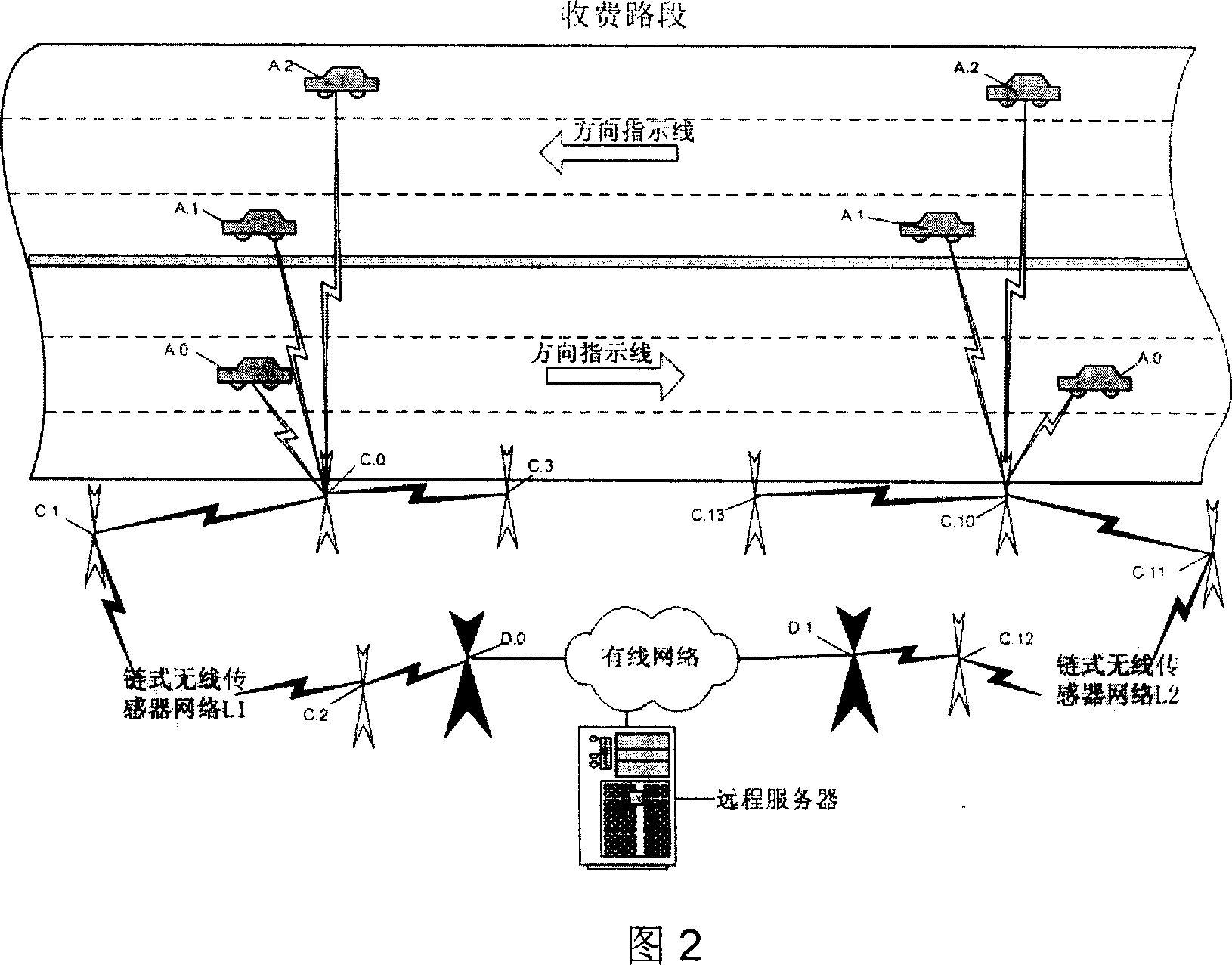

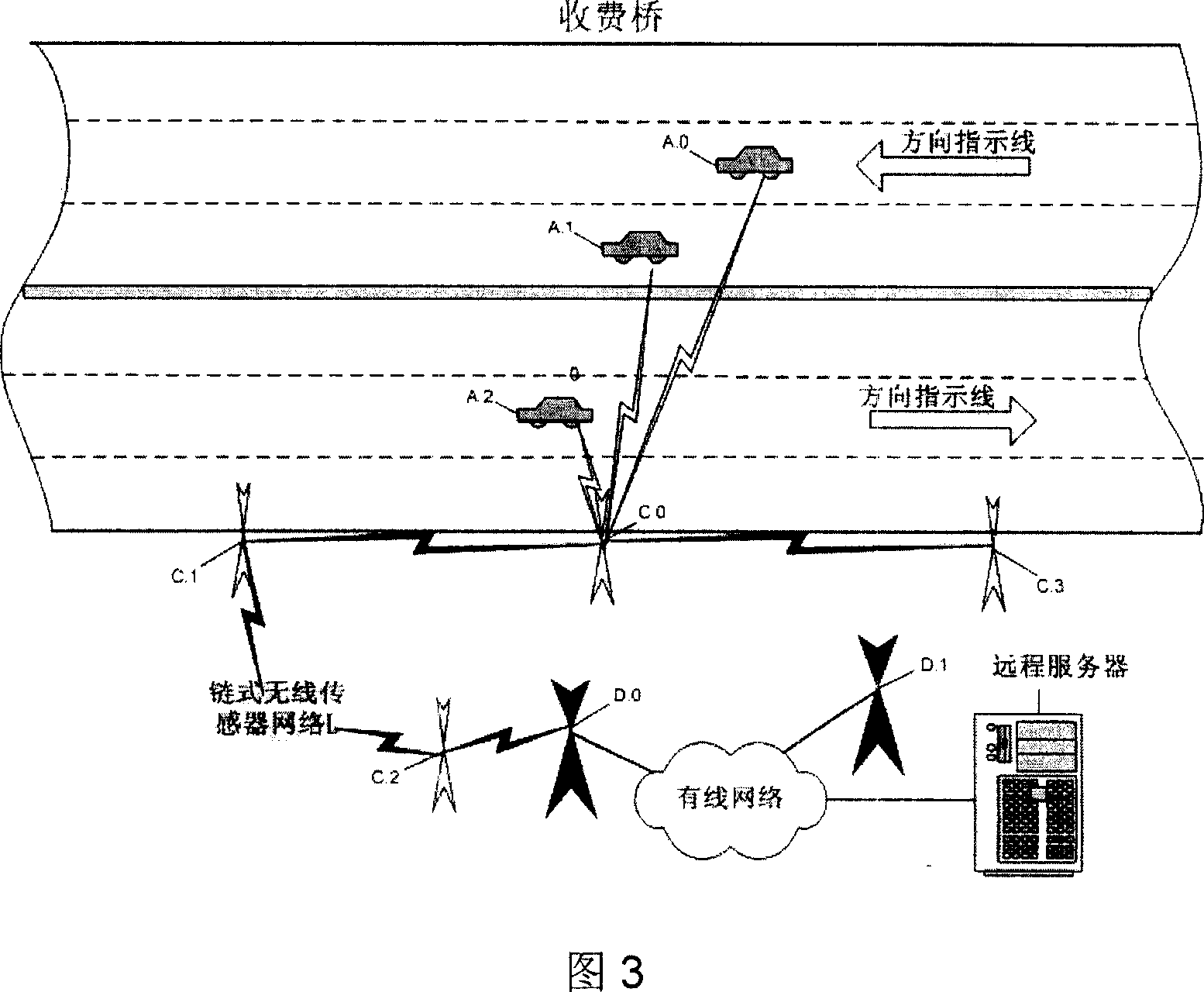

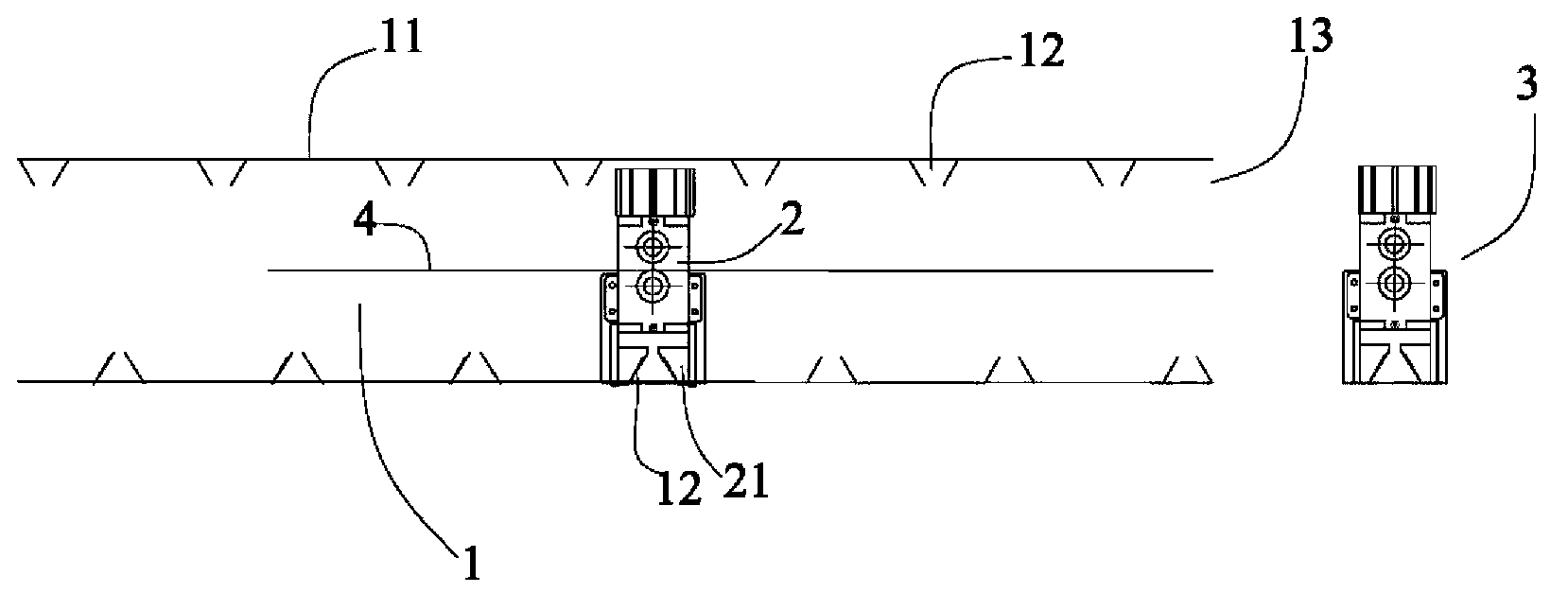

Road and vehicle managing system and method based on radio sensor network

InactiveCN101051418APrevent crushingAvoid damageRoad vehicles traffic controlStar/tree networksCable networkSensor node

The present invention relates to a road and vehicle management system based on wireless sensor network and its method. Said network system includes the following several portions: vehicle-mounted mobile node, roadbed monitoring sensor node embedded in ground base, roadside fixed sensor node, monitoring base station and server. Besides, said invention also provides the concrete function and action of above-mentioned every portion, and also provides the working principle of said system and its concrete operation method.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

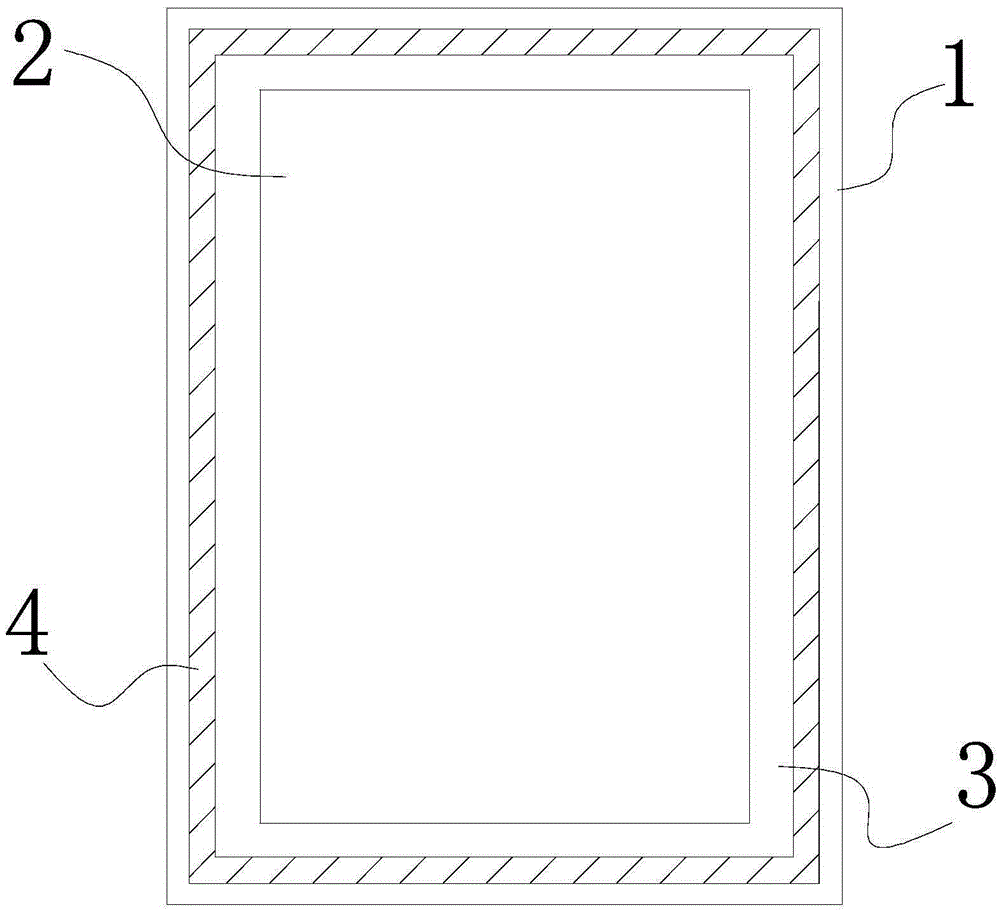

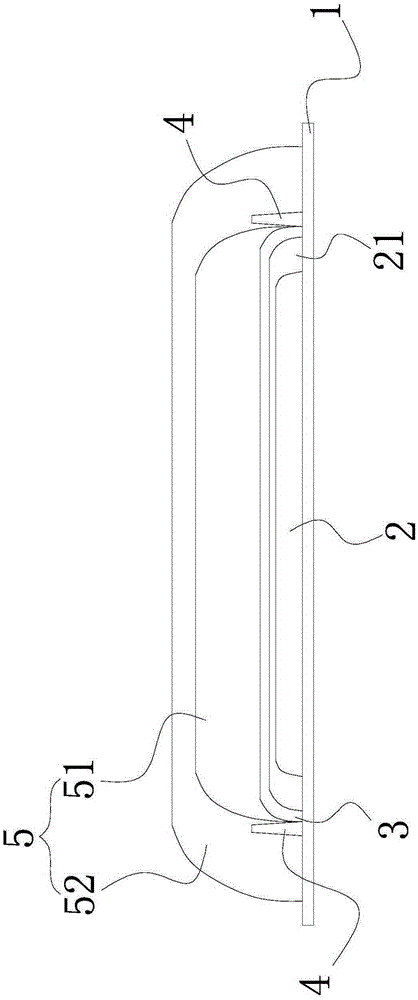

Flexible OLED display panel

ActiveCN105261712AAvoid scratchesPrevent crushingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWater block

The invention discloses a flexible OLED display panel, which comprises a flexible substrate, an OELD device, a first encapsulation layer, a barrier layer and a second encapsulation layer, wherein the OLED device is arranged on the flexible substrate; the first encapsulation layer is arranged on the flexile substrate and covers the OLED device; the barrier layer is arranged on the flexible substrate, surrounds the periphery of the first encapsulation layer, and comprises a plurality of discontinuous barrier units; the plurality of barrier units are arranged in a chain form; and the second encapsulation layer is arranged on the flexible substrate and covers the first encapsulation material and the barrier layer. The flexible OLED display panel is capable of effectively blocking the diffusion effect of atomic deposition coating and enhancing the water blocking capacity of a thin-film encapsulation on the periphery of the flexible OLED display panel; meanwhile, the reelability of the barrier layer is increased; the development requirement of the flexible OLED display panel is relatively well met; and an important idea is also provided for development of the flexible OLED display panel.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Dosage form with impeded abuse

InactiveUS8722086B2Prevent crushingPrevent the subsequent abuseOrganic active ingredientsPill deliveryWaxBreaking strength

A multiparticulate dosage form formulated to make misuse more difficult containing least one active substance with potential for misuse (A), at least one synthetic or natural polymer (C), optionally at least one natural, semi-synthetic or synthetic wax (D), at least one disintegrant (E) and optionally one or more additional physiologically compatible excipients (B), wherein the individual particles of the dosage form display a breaking strength of at least 500 N and a release of active substance of at least 75% after 45 minutes measured according to Ph.Eur. in the paddle mixer with sinker in 600 ml of aqueous buffer solution with a pH value of 1.2 at 37° C. and 75 rpm.

Owner:GRUNENTHAL GMBH

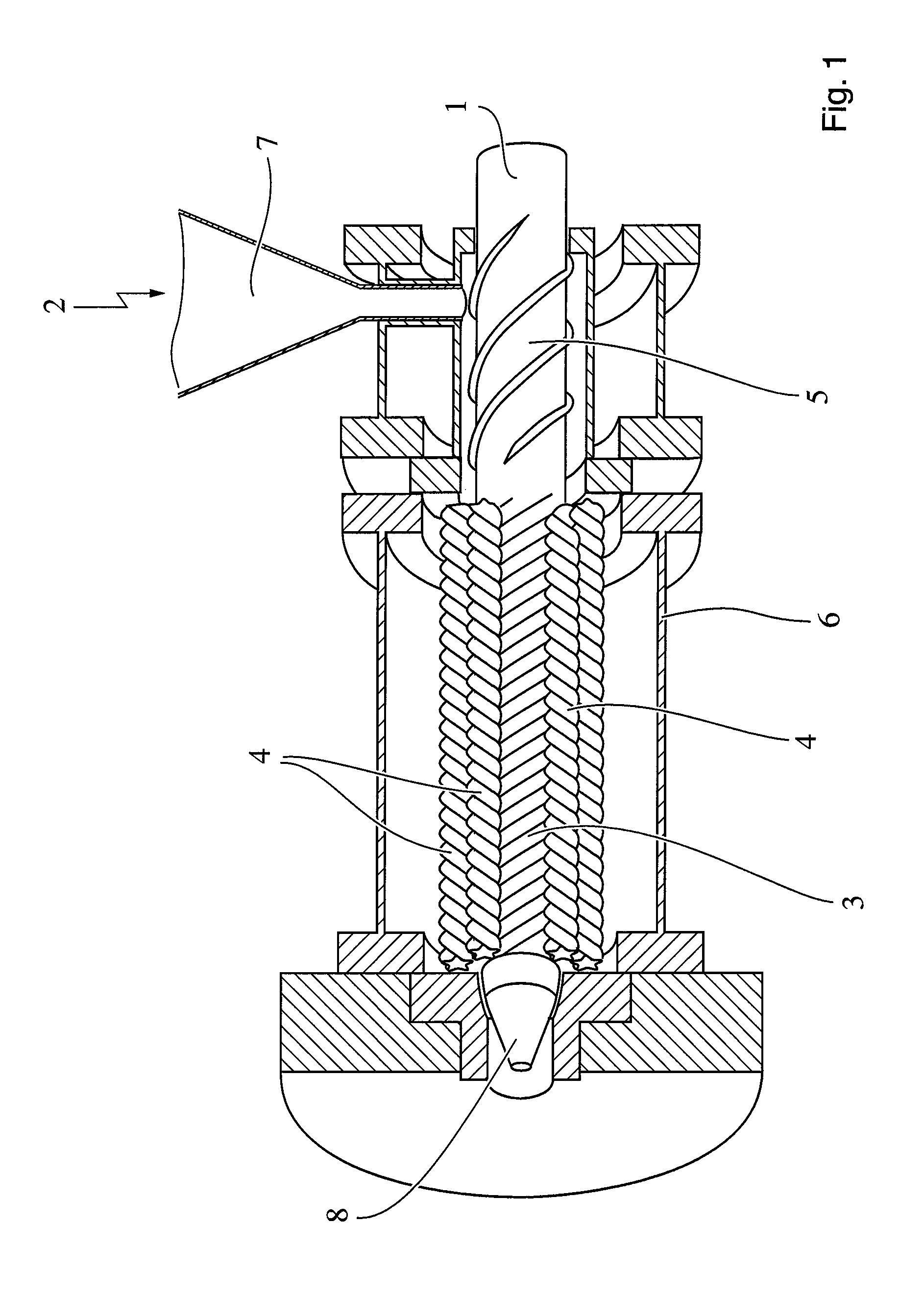

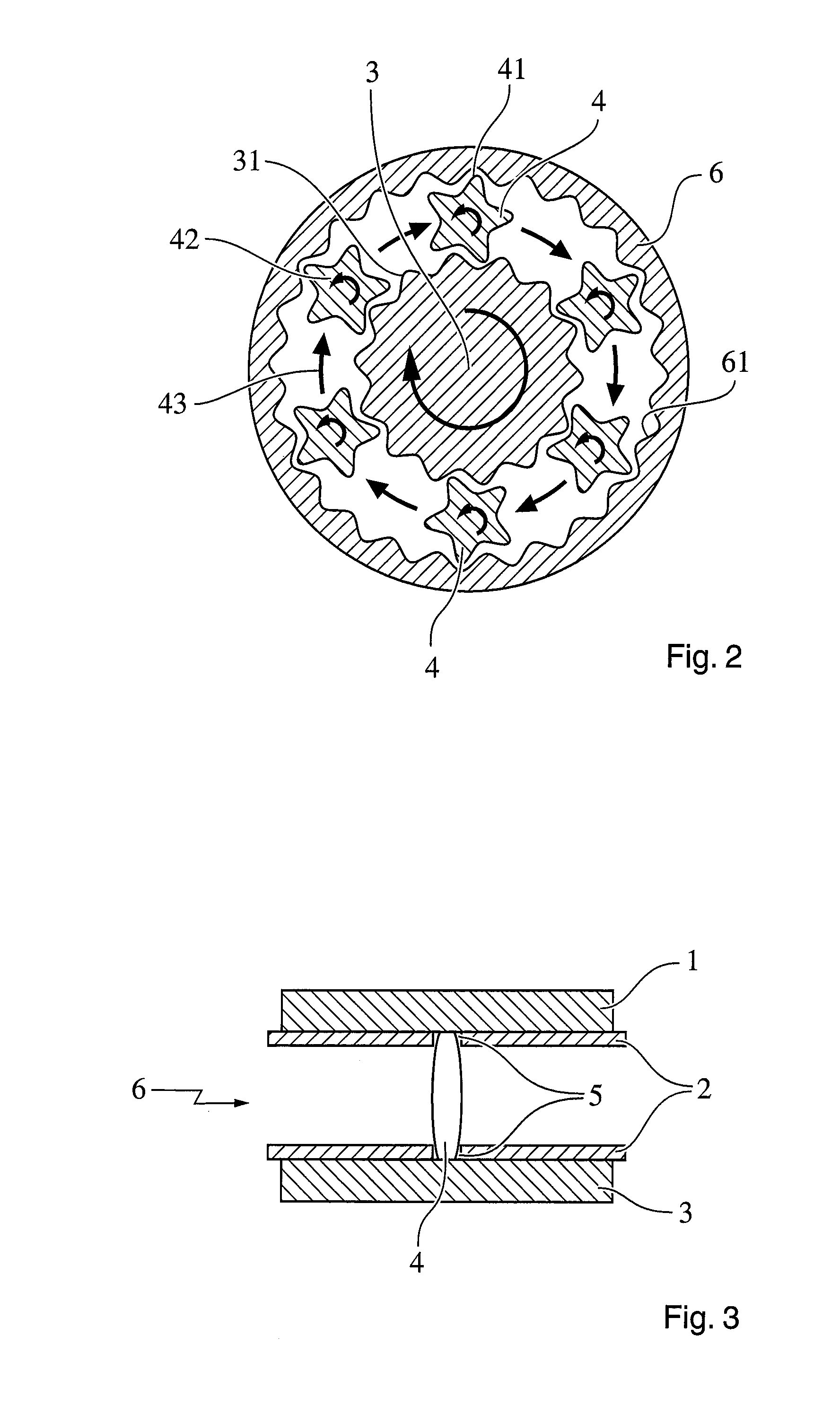

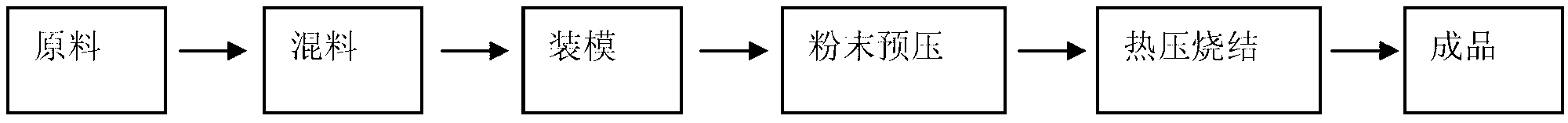

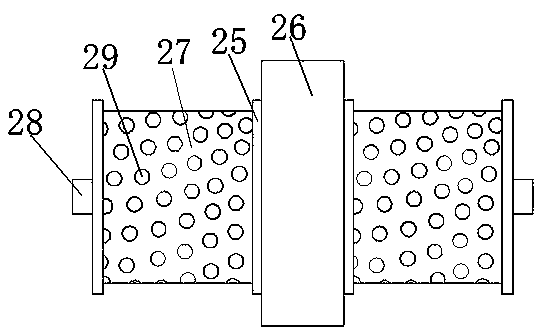

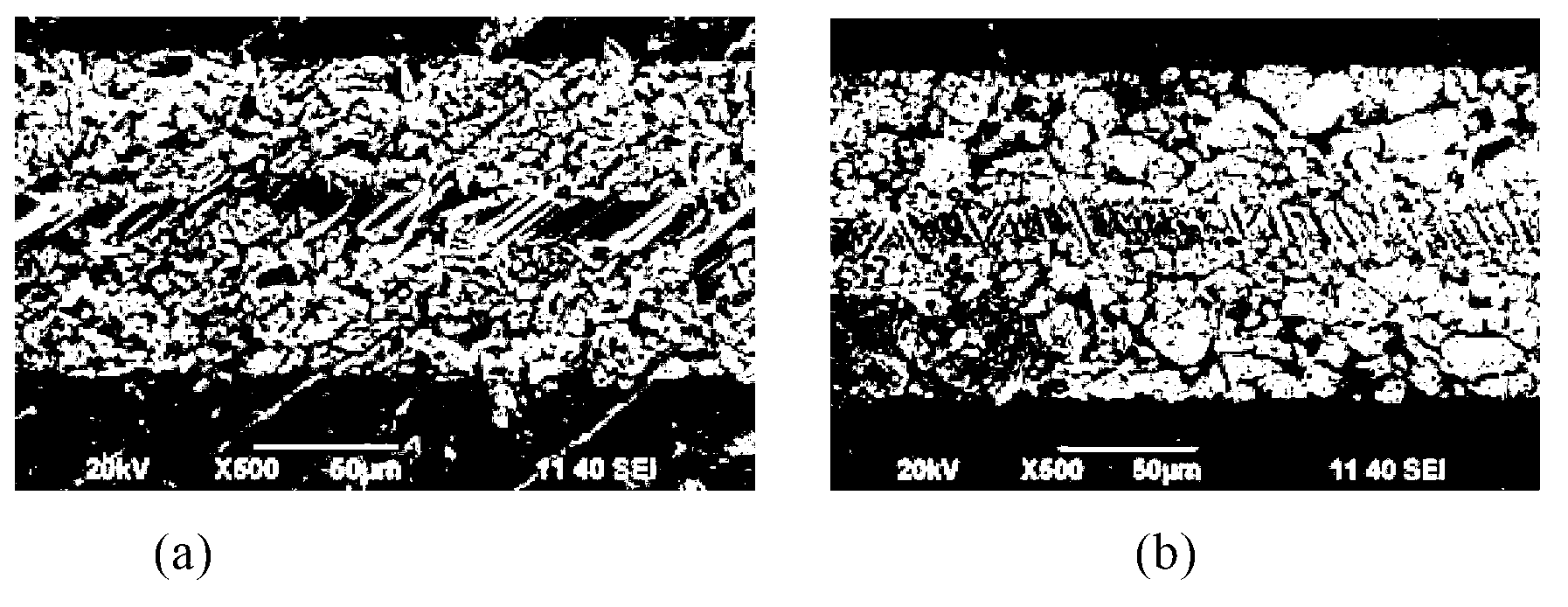

Online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and preparation method thereof

InactiveCN103009270ALow shrinkageHigh strengthAbrasion apparatusGrinding devicesPolyvinyl alcoholDecomposition

The invention provides an online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and a preparation method thereof and belongs to the technical field of precision grinding pellets. Raw materials of the precision grinding pellet comprise a super-hard abrasive and a metallic bond, wherein the super-hard abrasive is diamond micro-powder; the diamond concentration falls within a range of 75-100 %; and the metallic bond uses a multicomponent alloy bond whose main components are copper powder, tin powder, aluminum powder, copper-clad ball shaped graphite powder, silicon dioxide and ferroferric oxide powder. The preparation method comprises the following steps: uniformly mixing and stirring the diamond micro-powder as well as the copper powder, the tin powder and the aluminum powder; adding polyvinyl alcohol to a mixture and mixing the polyvinyl alcohol and the mixture; adding the silicon dioxide, the copper-clad ball shaped graphite powder and the ferroferric oxide powder to an obtained mixture and mixing these materials and the obtained mixture; filling the mixture into a graphite mold; maintaining the pressure of the graphite mold for 5-10 minutes after pressurizing the graphite mold to 100-250 MPa; and carrying out hot pressing sintering on the graphite mold in a sintering furnace, wherein the sintering atmosphere is ammonia decomposition gas. Through the adoption of the online self-sharpening metallic bond and super-hard abrasive precision grinding pellet provided by the invention, online automatic sharpening can be achieved without blockage and offline repairing.

Owner:BEIJING UNIV OF TECH

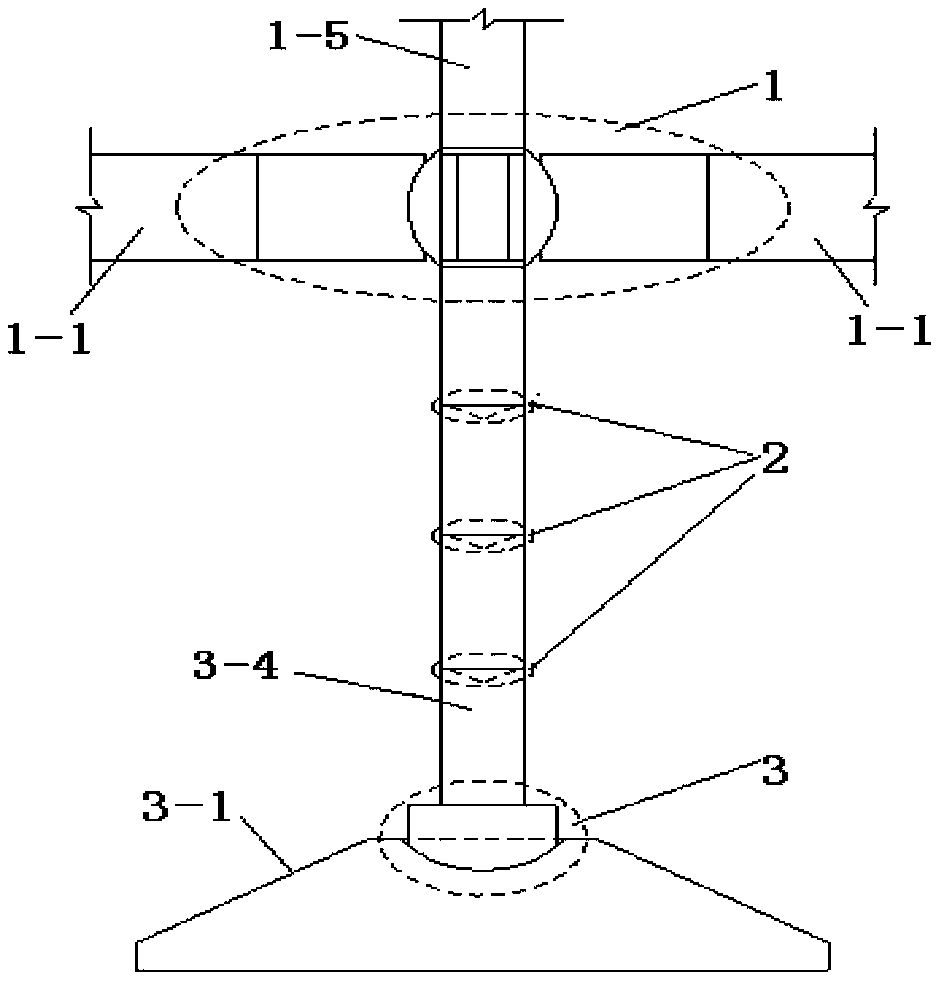

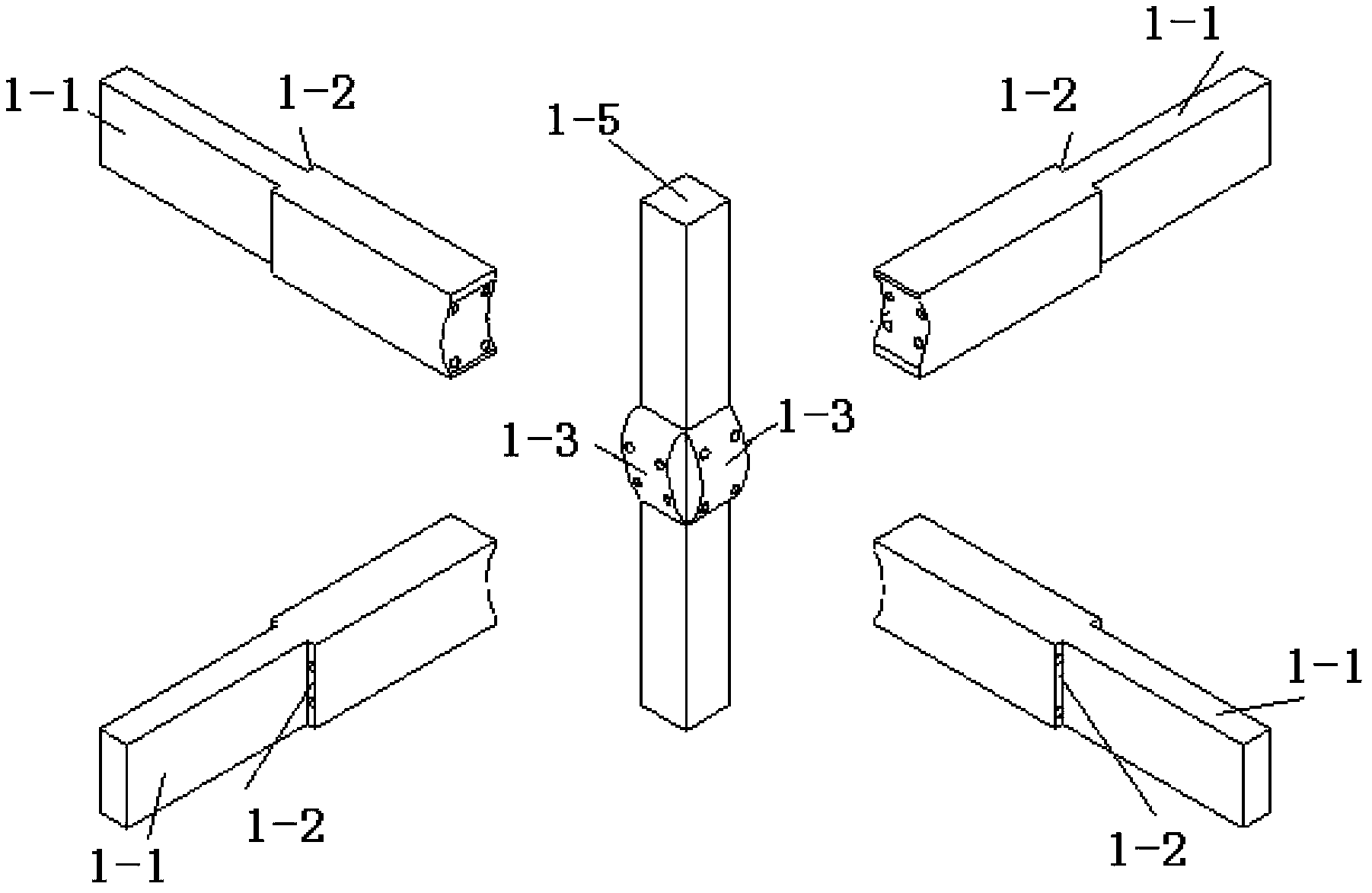

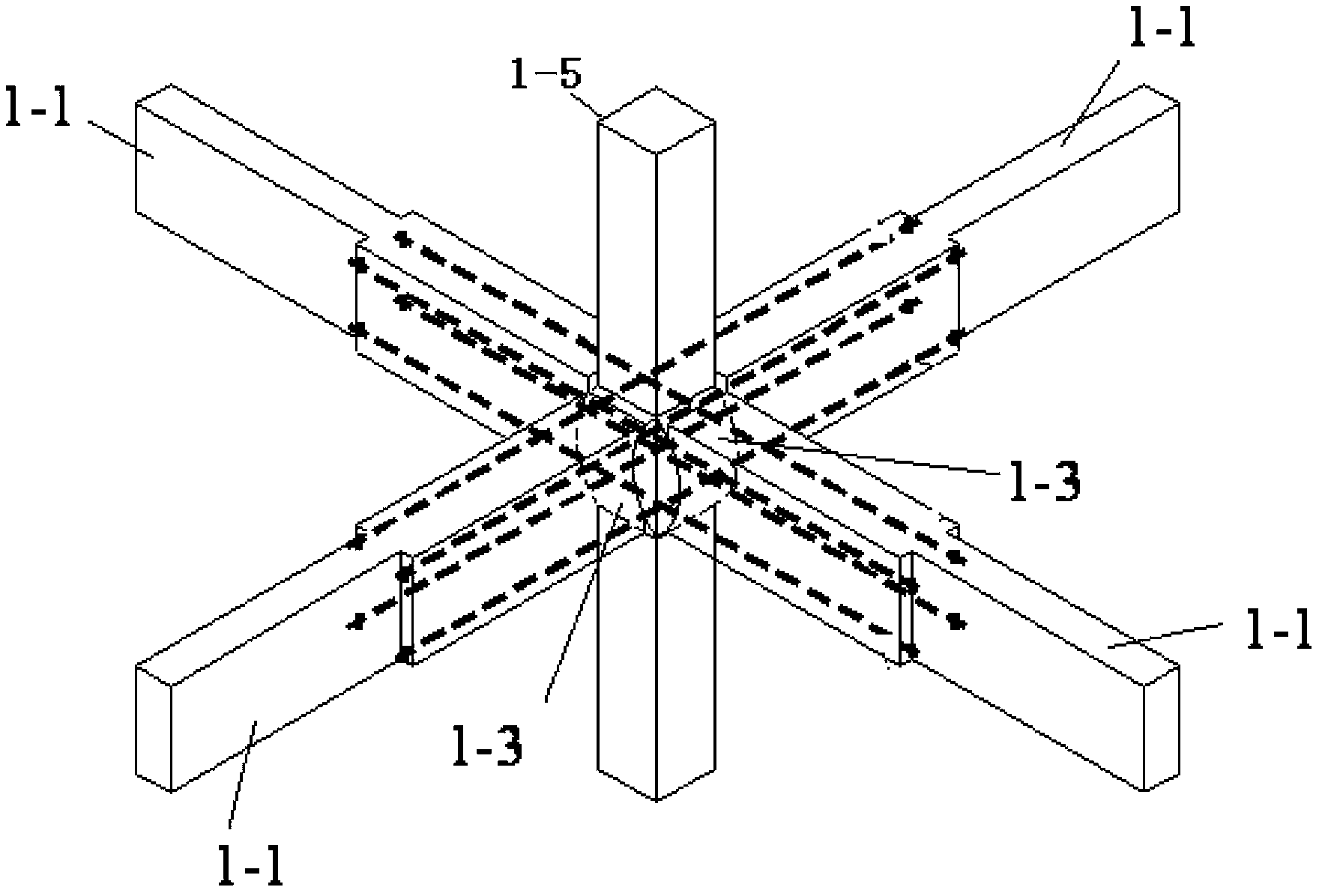

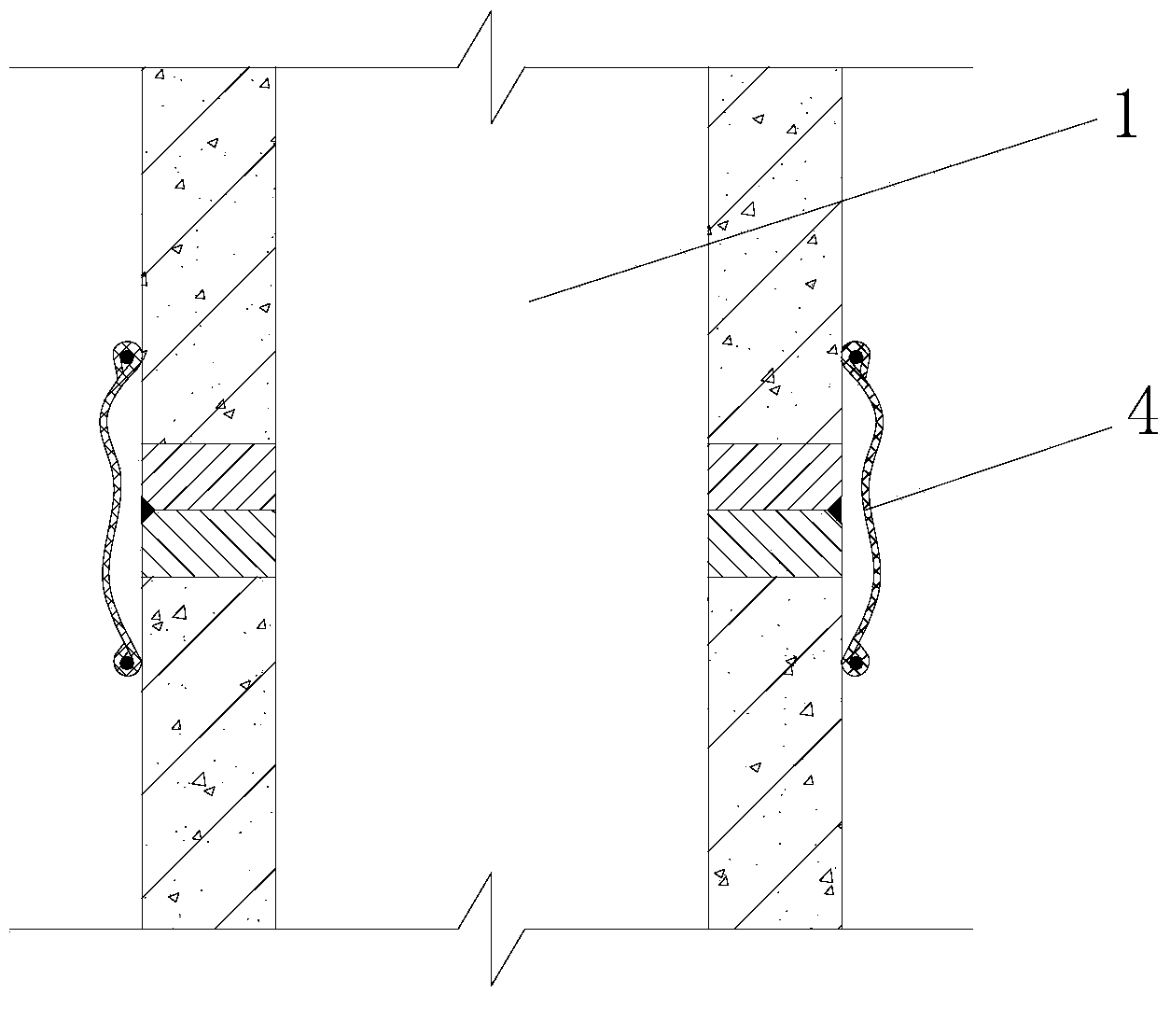

Prestress assembly frame structure

InactiveCN103362210ARealize low carbonizationDoes not affect layoutBuilding constructionsDistribution methodPre stress

The invention discloses a prestress assembly frame structure which comprises floor beams, a floor post and a foundation, wherein the floor post is formed by connecting a plurality of floor post units in sequence from top to bottom, one floor post unit connected with the floor beams is a top post, one floor post unit connected with the foundation is a bottom post, a connecting point between the top post and the floor beams is a beam-post node, a connecting point between two adjacent floor post units is a post-post node, and the connecting point between the bottom post and the foundation is a post-foundation node. Through the improvement on the beam-post node, the post-post node and the post-foundation node, the problems that in a conventional prestress assembly frame structure, the beam-post node and the post-foundation node cannot consume energy effectively under major earthquake, and cannot provide pressed protection for concrete on a pressed area of an interface, and the tendon distribution method is unreasonable are solved, and meanwhile, the problems that the post-post node is inconvenient to accomplish, and an anti-shearing weak part is formed on a connection interface are solved.

Owner:CHINA UNIV OF MINING & TECH

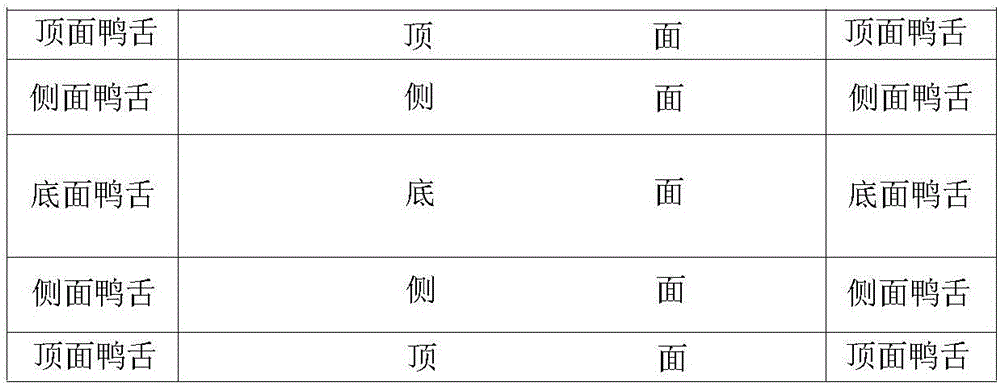

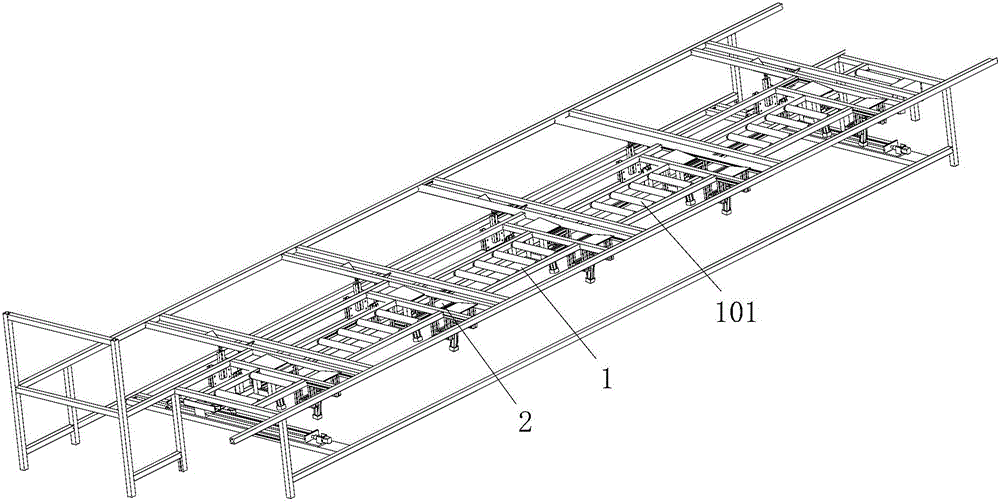

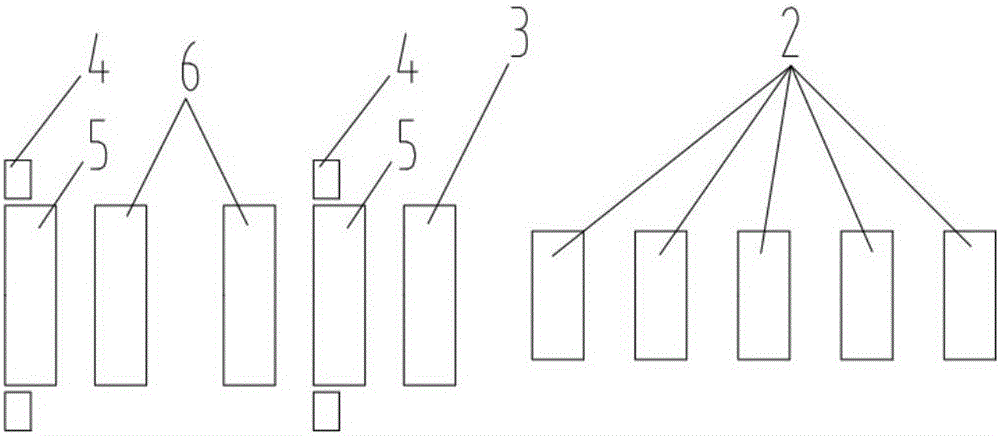

Automatic package machine for corrugated cartons with different lengths

InactiveCN105730772AHigh conveying precisionModerate delivery speedWrapper twisting/gatheringCartonEngineering

The invention discloses an automatic package machine for corrugated cartons with different lengths. The automatic package machine comprises a rack. An initial material position containing area, a wrapping forming area and a carton sealing area are sequentially arranged on the rack in the carton conveying direction. A material conveying device is arranged below the initial material position containing area. A carton containing area is arranged in the wrapping forming area. A top face folding mechanism, a front end folding system and a tail end folding system are arranged in the carton containing area. A side face folding mechanism is arranged below the carton containing area. Each of the front end folding mechanism and the tail end folding mechanism comprises a side face duck tongue folding mechanism, a top face duck tongue folding mechanism and a bottom face duck tongue folding mechanism. A plurality of powerless transmission rollers are arranged in the carton sealing area in the length direction of the carton sealing area. A two-end carton sealing mechanism, a length direction carton sealing system and a width direction carton sealing system are arranged in the carton sealing area in the carton conveying direction. By means of the automatic package machine, packaging of carton type products of different specifications and different sizes can be achieved, and the application range is wide.

Owner:SHANDONG UNIV OF SCI & TECH

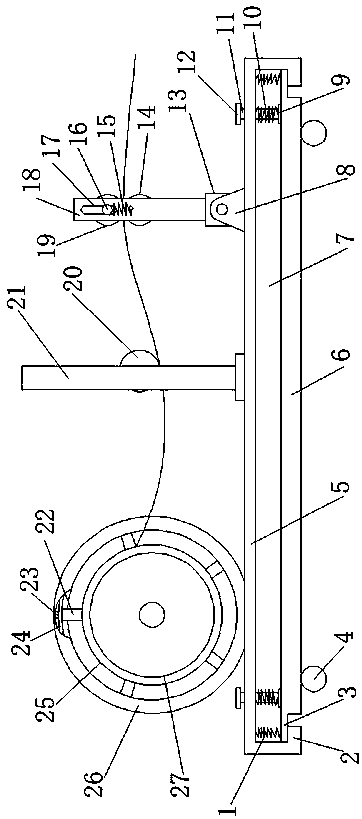

Automatic coiling and uncoiling device for distribution circuit power cable

The invention discloses an automatic coiling and uncoiling device for a distribution circuit power cable. The automatic coiling and uncoiling device comprises a base, wherein a chamber I is arranged at the bottom of the base; a sliding plate is arranged in the chamber I; universal idler wheels are arranged at four corners at the lower end of the sliding plate; an extension spring is arranged between the sliding plate and the top wall of the chamber I; a jacking device is arranged on the base; a coiling device, a tensioning device and a cable uncoiling device are arranged on the base in turn; the coiling device comprises an outer support ring and an inner support ring; a rolling structure is arranged between the outer support ring and the inner support ring; a rotating ring is fixedly connected with the middle part of the inner support ring; coiling plates are respectively arranged at the two ends of the rotating ring; the tensioning device comprises a tensioning bracket and a tensioning roller; the two ends of the tensioning roller are arranged on the tensioning bracket; and the cable uncoiling device comprises an uncoiling mechanism capable of reciprocating and an uncoiling driving motor connected with the uncoiling mechanism. According to the invention, the coiling device, the tensioning device and the cable uncoiling device are successively arranged, so that the automatic coiling and uncoiling of the cable can be realized and the winding intensity, tightness and uniformity of the cable can be guaranteed.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

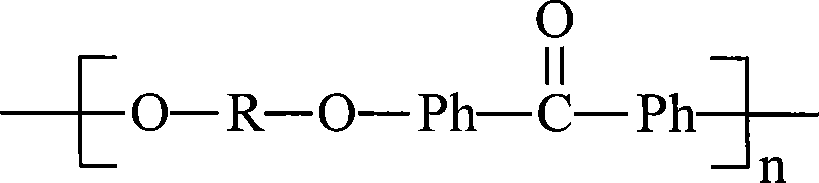

Preparation method for polyetheretherketone

The invention relates to a process for preparing polyetheretherketone products, which is characterized in that the process comprises adopting Na2CO3 to be condensating agent, leading 4, 4'- difluorobenzophenone, hydroquinone and diresorcinol to have polymerization reaction, improving the reaction temperature after producing the relative prepolymer, and secondly adding hydroquinone to be chain extender to react for a period of time to prepare polyetheretherketone products with high viscosity.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

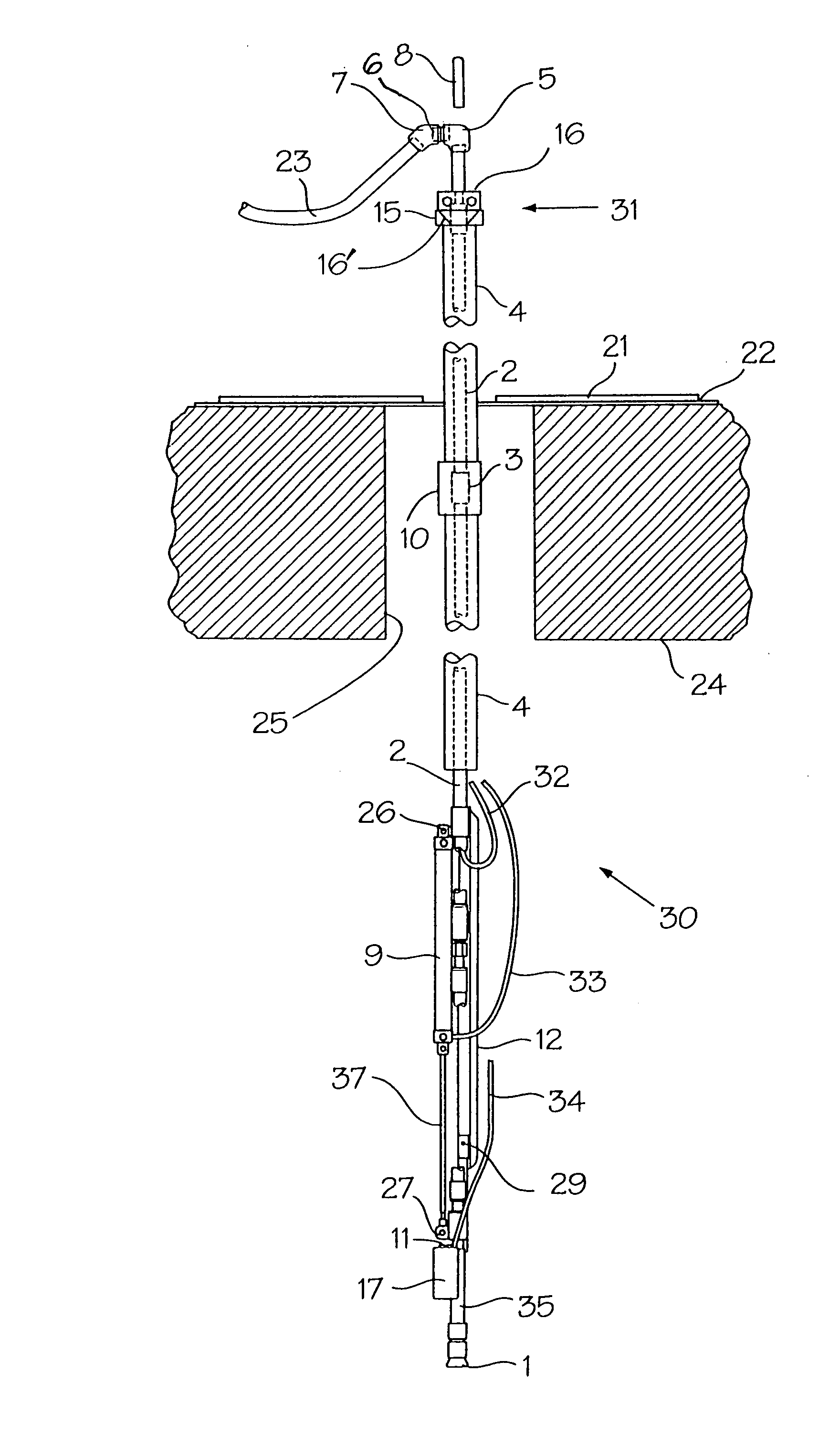

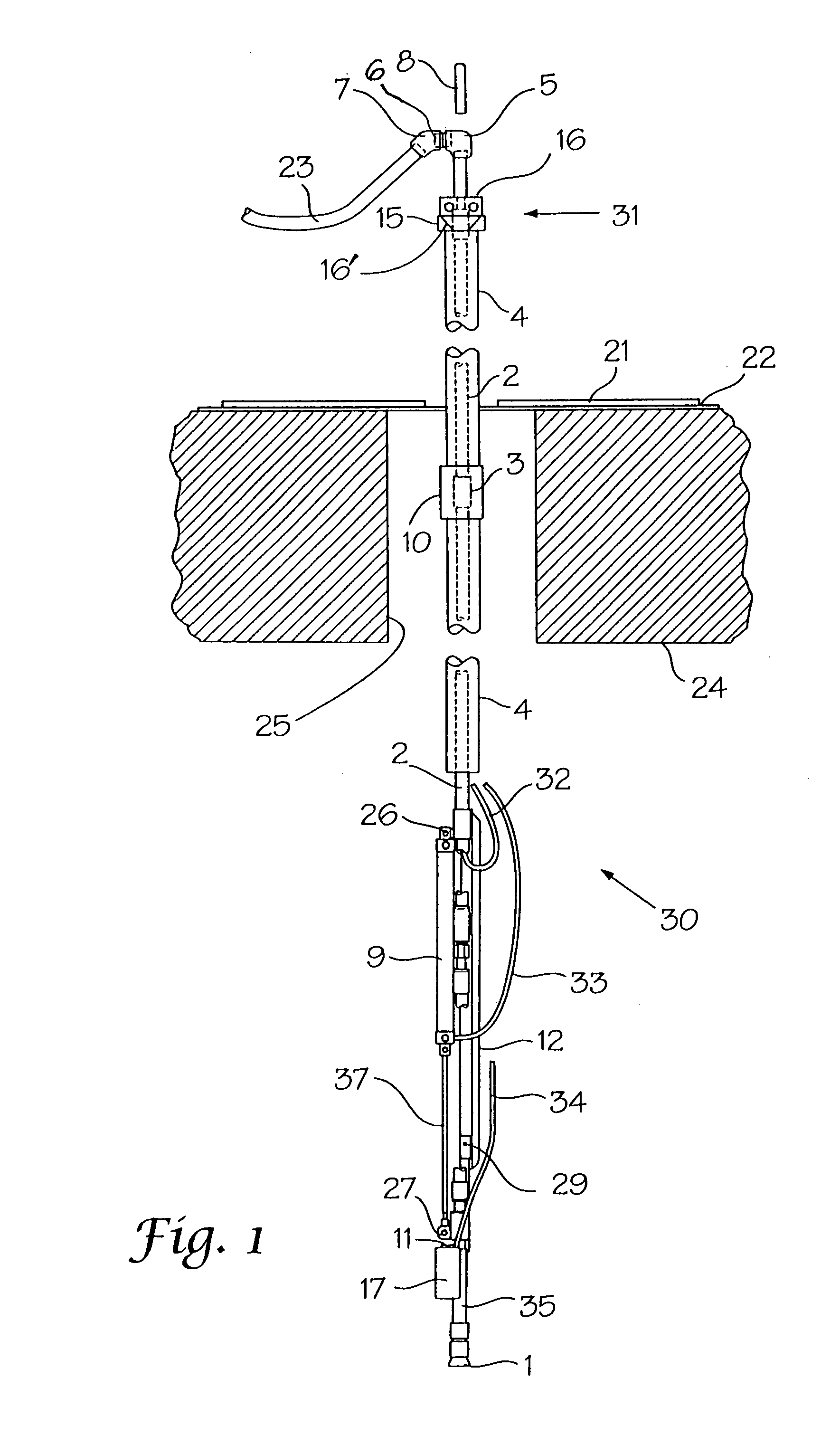

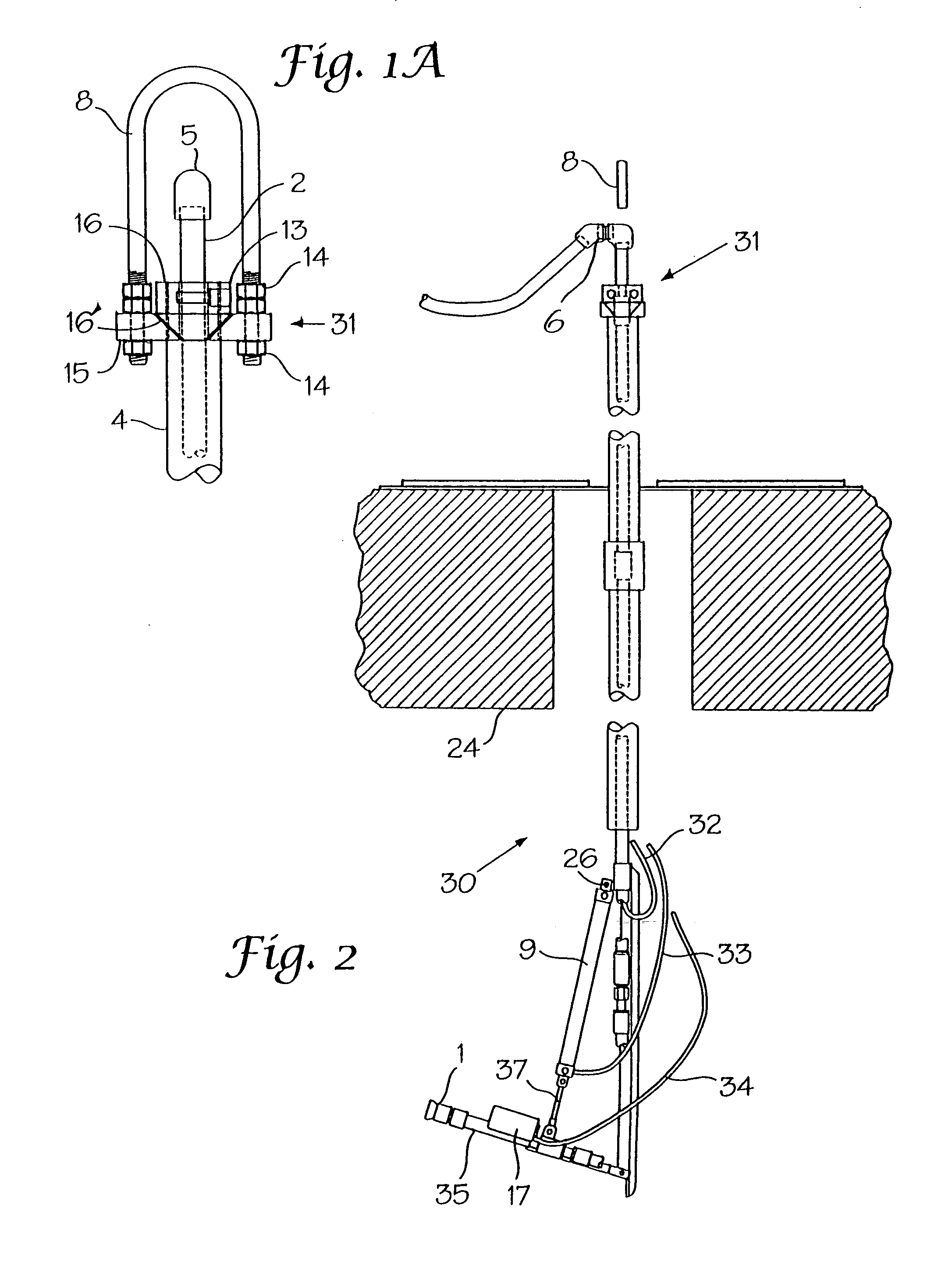

Directed spray mast

InactiveUS6889920B2Prevent crushingAvoid crimpingHollow article cleaningLiquid spraying apparatusSprayerWastewater

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

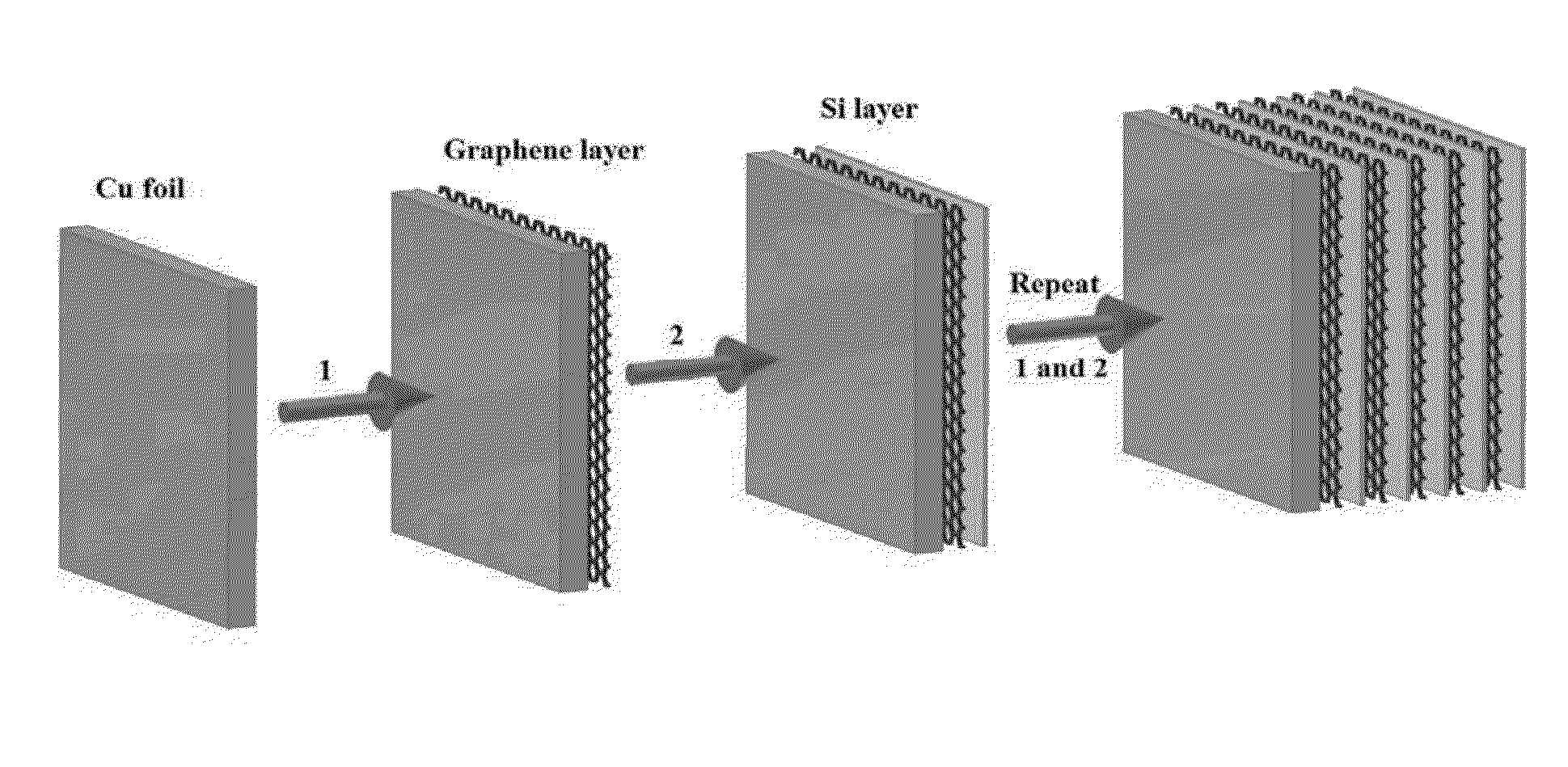

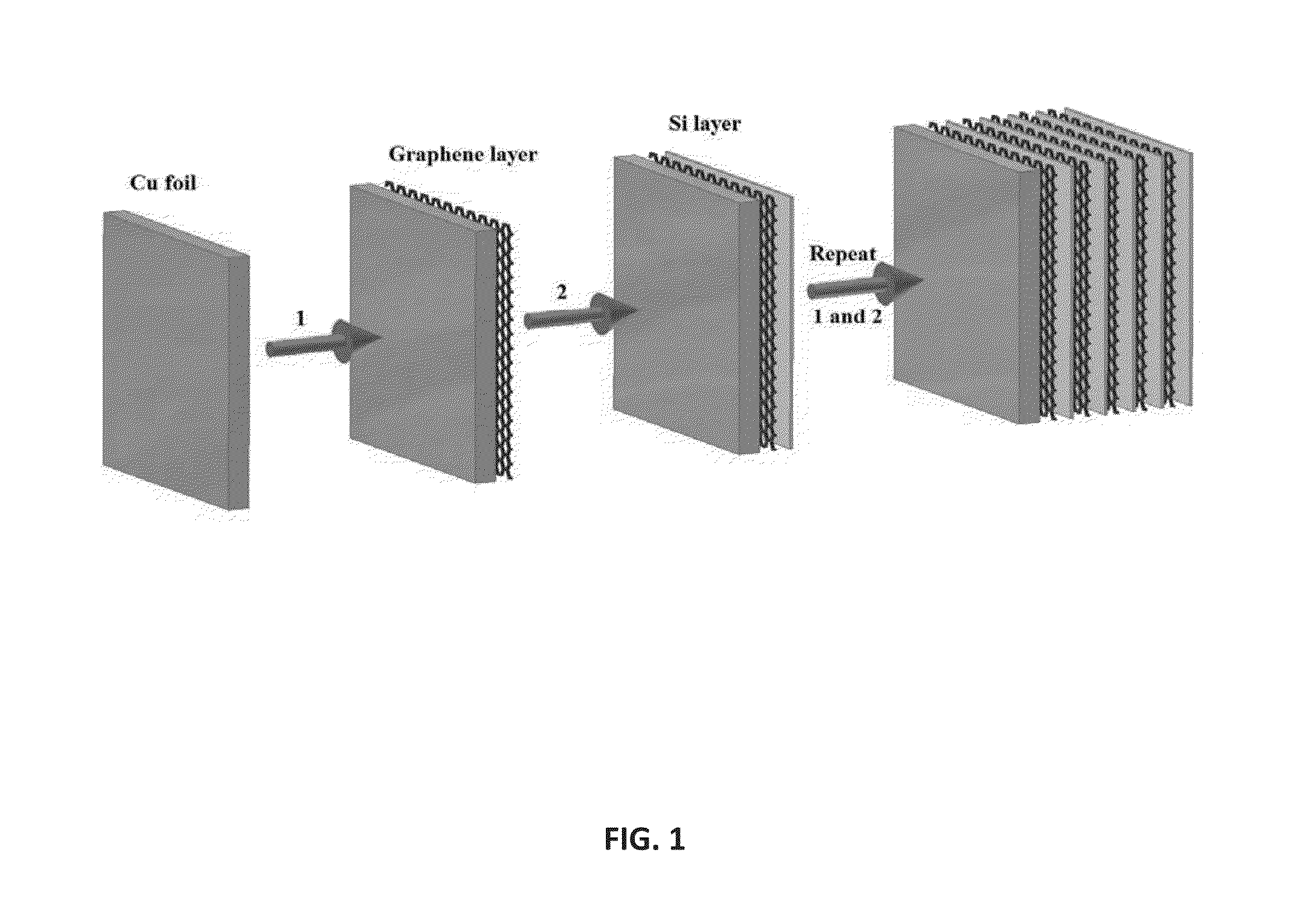

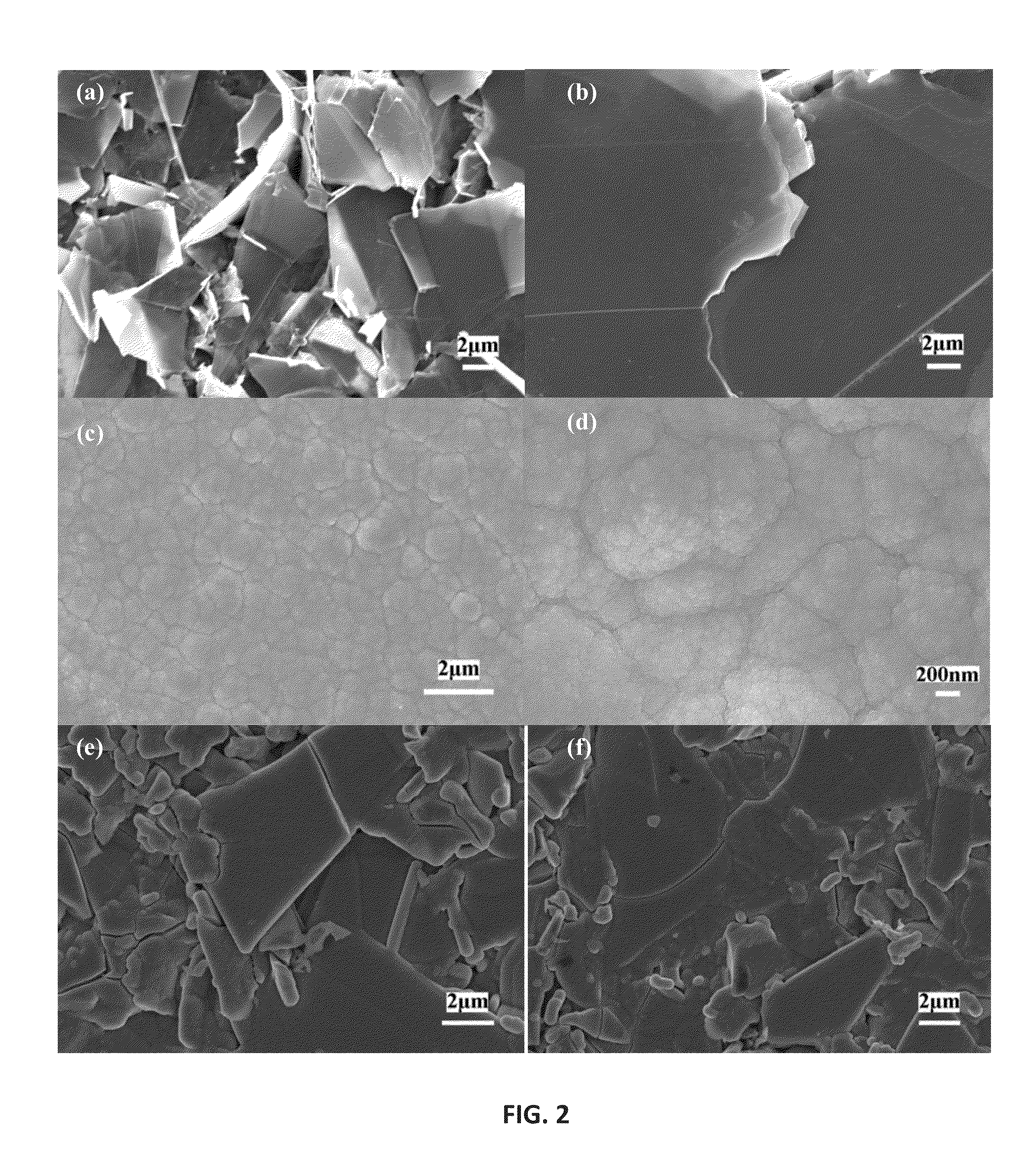

Method for the preparation of graphene/silicon multilayer structured anodes for lithium ion batteries

InactiveUS20140170483A1Effectively improves adhesionPrevent crushingActive material electrodesNon-aqueous electrolyte accumulator electrodesAluminium-ion batteryComposite film

Multilayer structures with alternating graphene and Si thin films were constructed by a repeated process of filtering liquid-phase exfoliated grapheme film and subsequent coating of amorphous Si film using plasma-enhanced chemical vapor deposition (PECVD) method. The multilayer-structure composite films, fabricated on copper current collectors, can be directly used as anodes for rechargeable lithium-ion batteries (LIBs) without the addition of polymer binders or conductive additives. Fabricated coin-type half cells based on the new anode materials easily achieved a capacity almost four times higher than the theoretical value of graphite even after 30 cycles. These cells also demonstrated improved capacity retention and enhanced rate capability during charge / discharge processes compared to those of pure Si film-based anodes.

Owner:RGT UNIV OF CALIFORNIA

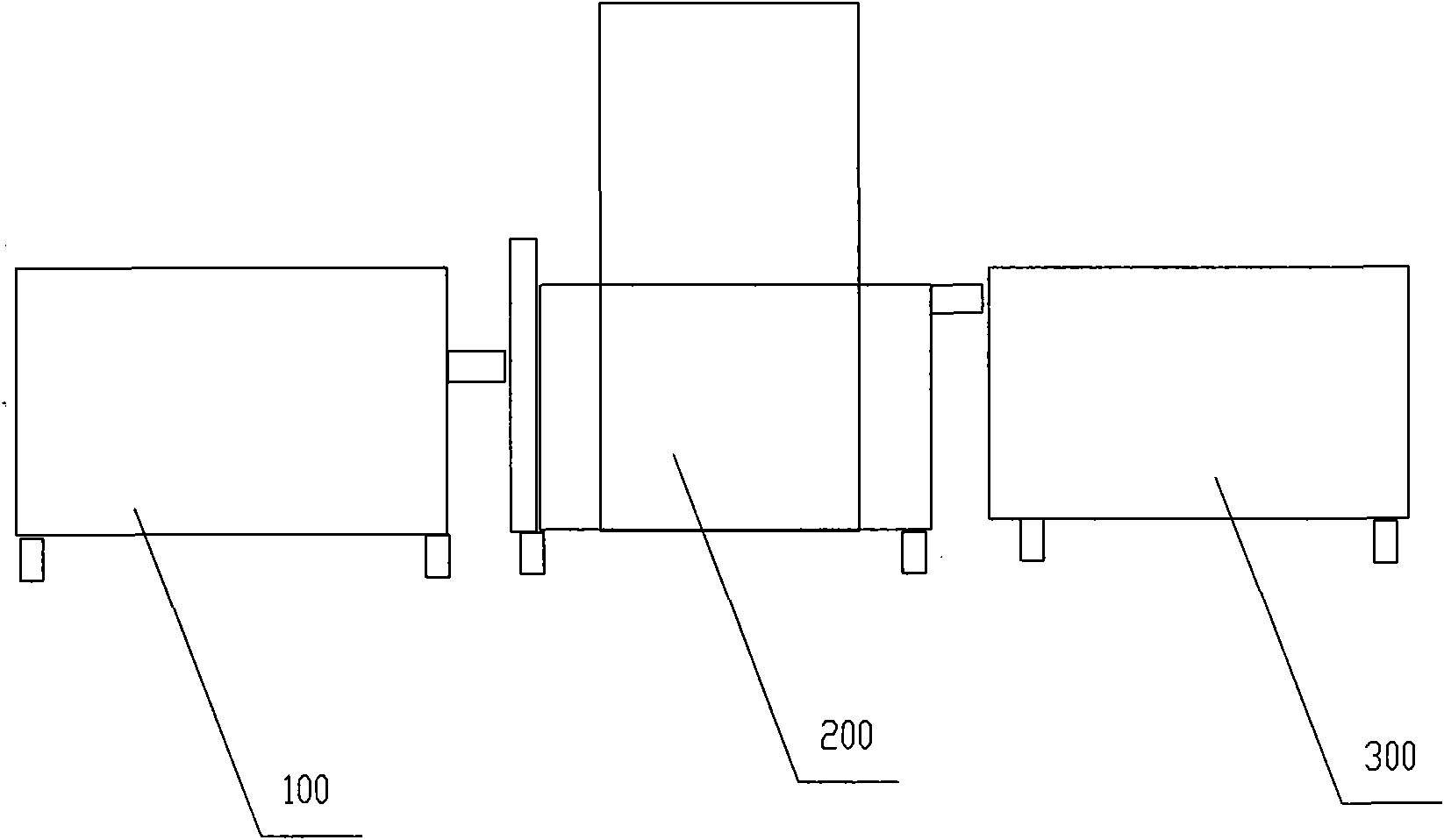

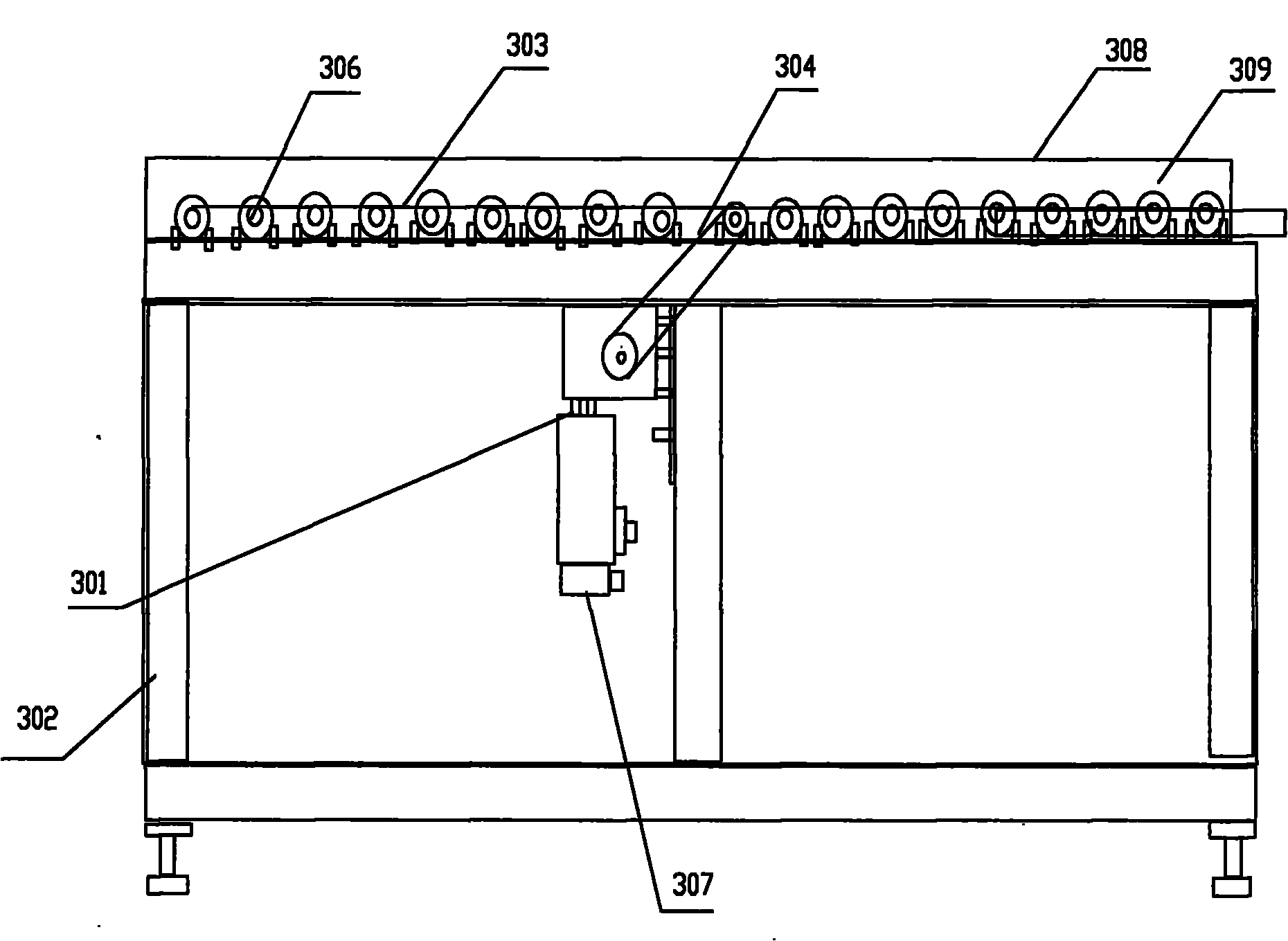

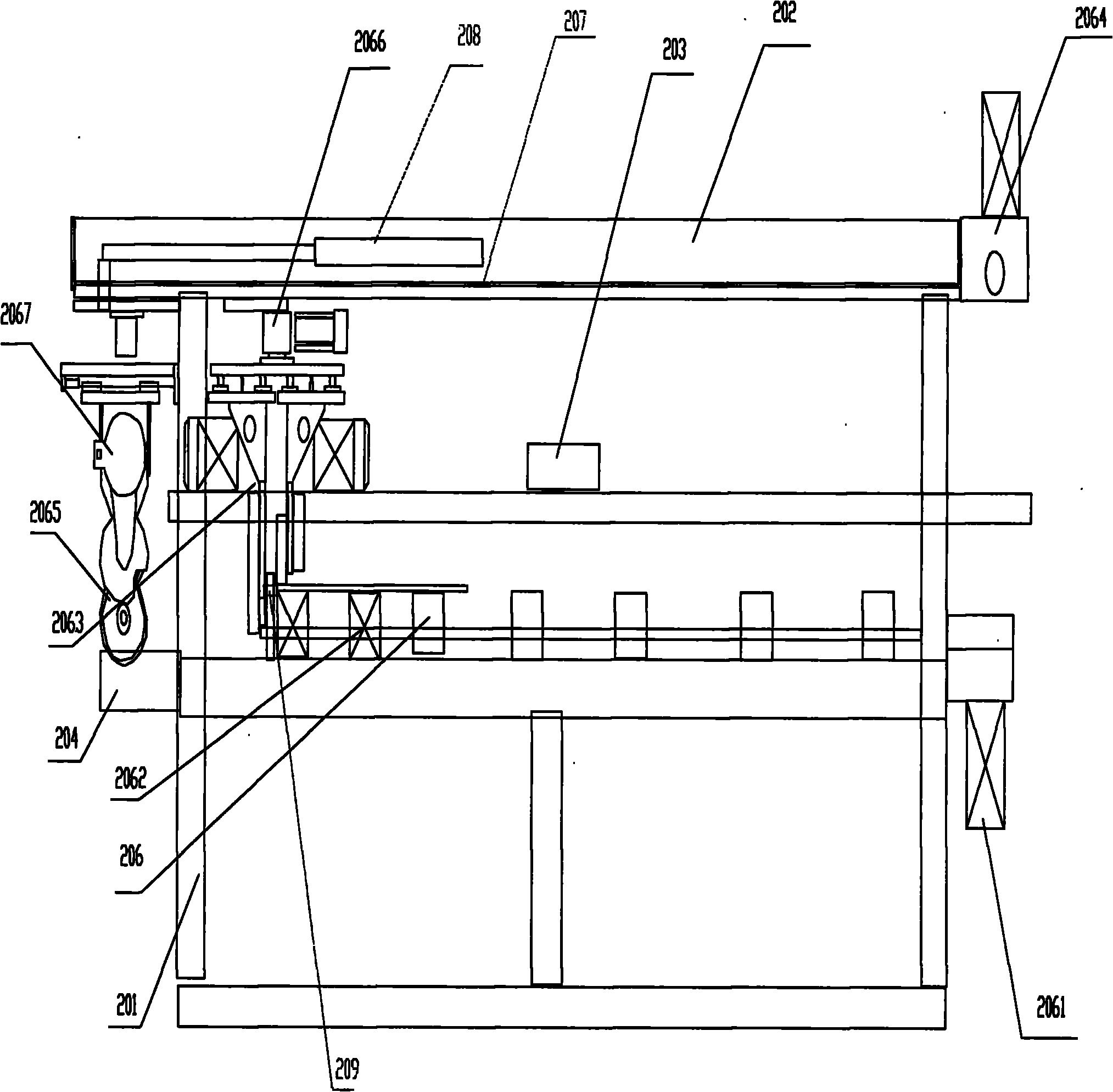

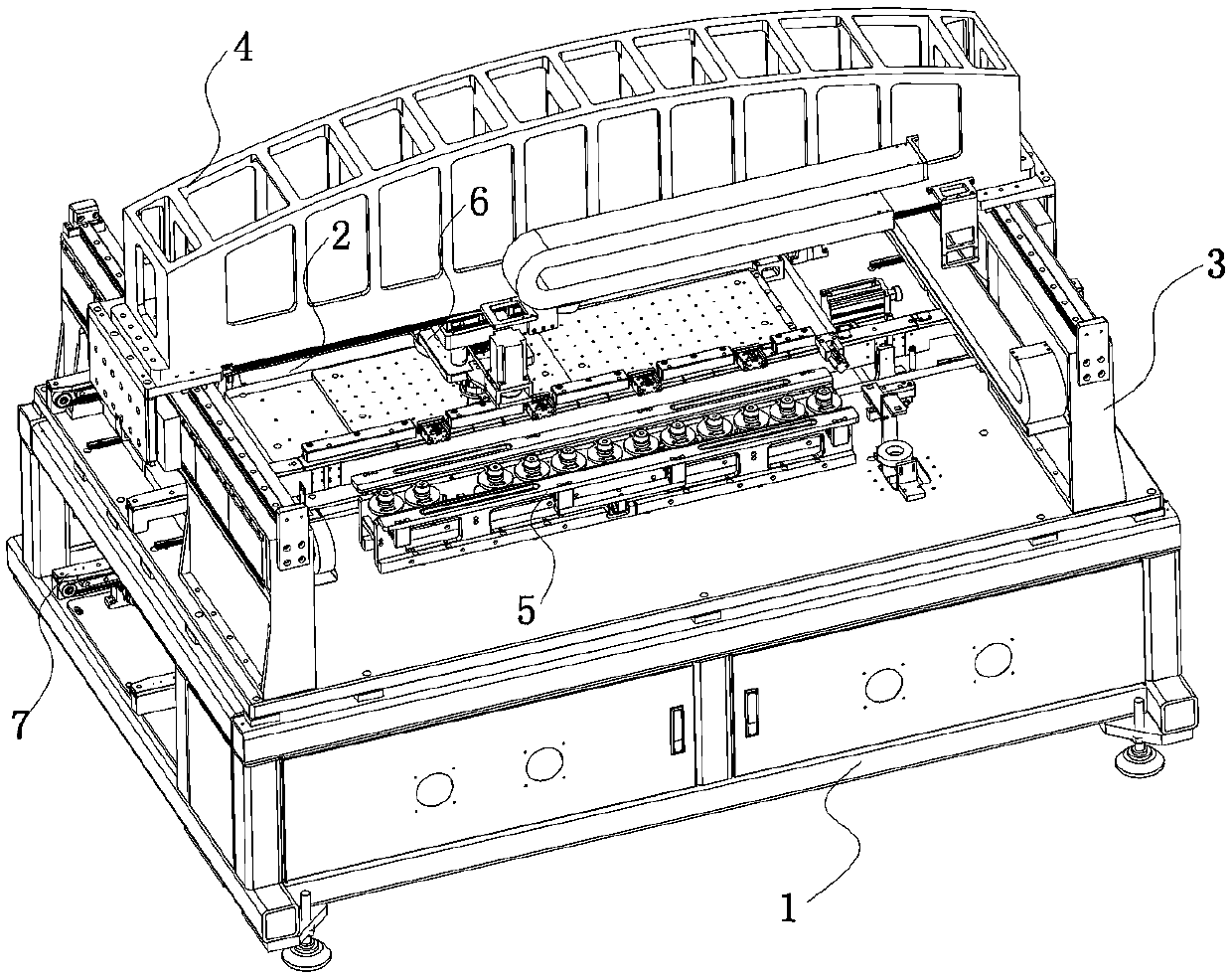

Horizontal glass straight-line four-side grinding wheel type edge grinding machine

ActiveCN101844323AImprove work efficiencyWith corner trimming functionEdge grinding machinesEngineeringGrinding wheel

The invention aims at providing a horizontal glass straight-line four-side grinding wheel type edge grinding machine. The edge grinding machine reduces the waste of grinding wheels and extends the service life of the grinding wheels by the structural design of changing the grinding points of the grinding wheels on glass, and prevents the glass from being crushed and scratched and improves the transmission precision in the grinding process by the structural design of utilizing a sucker for transmission. When the sizes of the glass are different, the glass edge-grinding task can be completed by shaping eight edges in one step without adjustment.

Owner:北京特能设备有限公司 +1

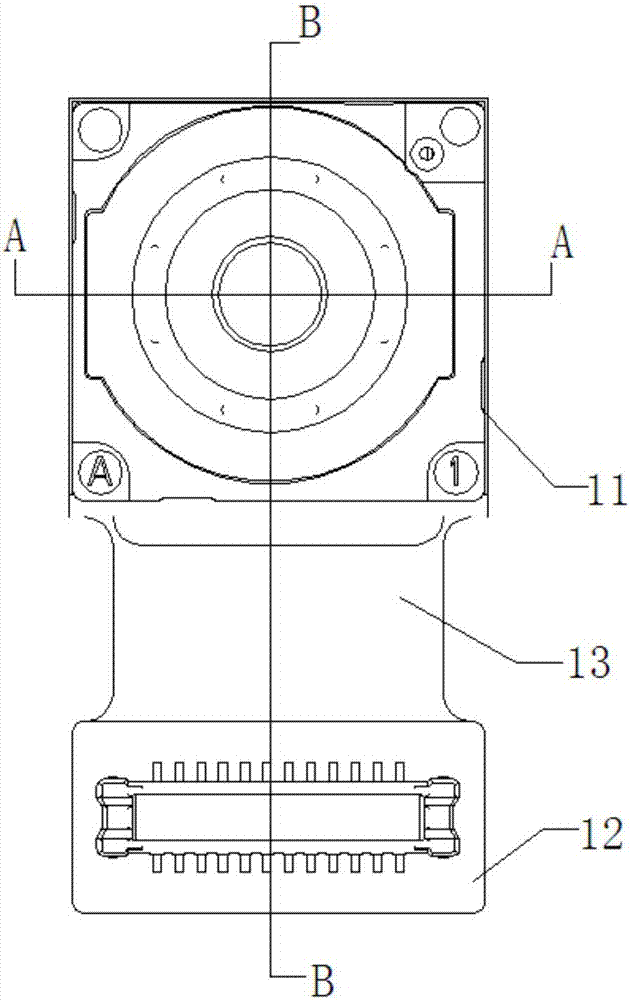

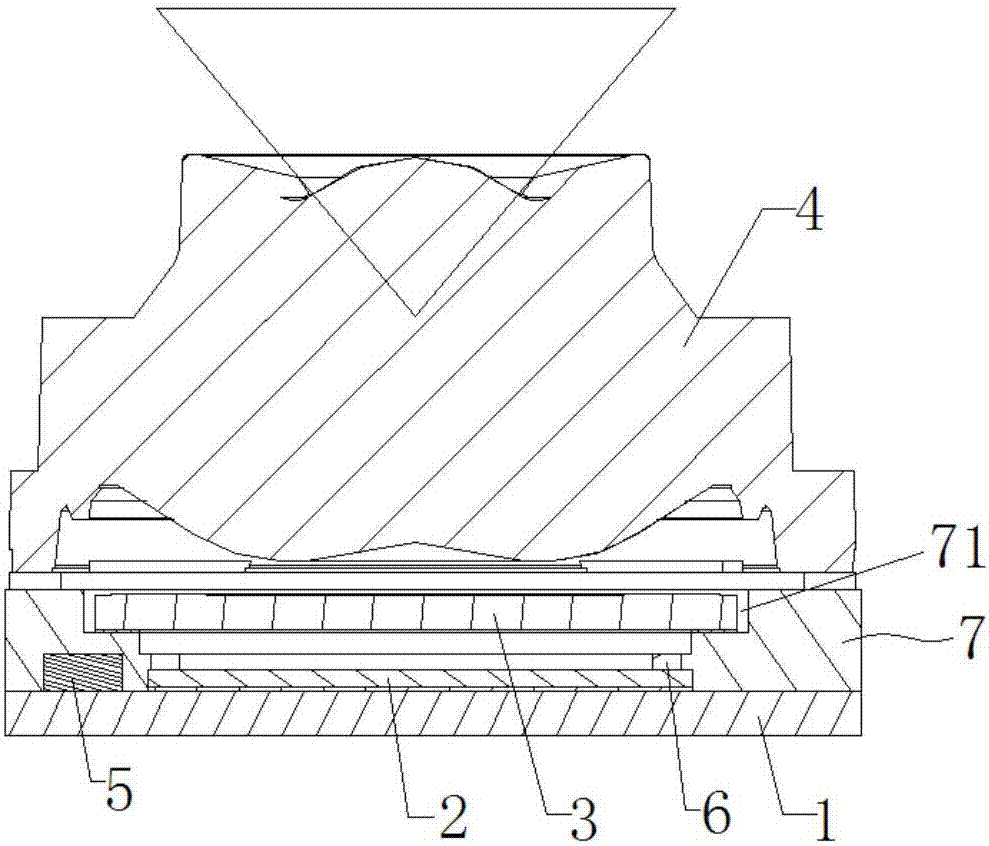

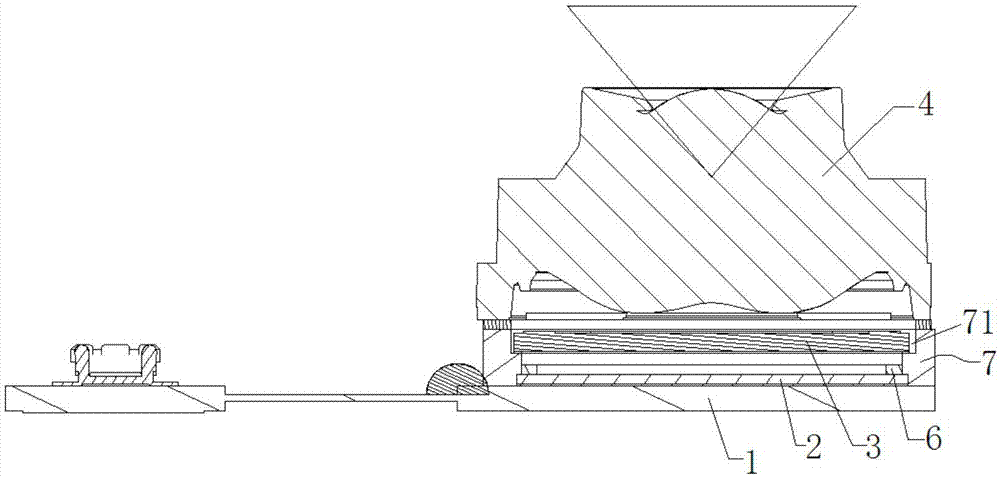

Miniature camera device with directly adhered optical filter and manufacturing method thereof

InactiveCN107071252ASmall footprintPrevent crushingTelevision system detailsColor television detailsMiniaturizationEngineering

The invention discloses a miniature camera device comprising a circuit board, a photosensitive chip, an optical filter and a lens component, wherein the photosensitive chip is adhered on the middle of the circuit board, a passive element and a gold thread are arranged on the circuit board on the surrounding of the photosensitive chip, a circle of annular blocking edge surrounding the photosensitive chip is formed on a non photosensitive area of the photosensitive chip, a plastic package body for wrapping the passive element and the gold thread is formed on the photosensitive chip beyond the annular blocking edge and the circuit board through a plastic package material, a sinking groove is formed in the middle of the upper side of the plastic package body, the periphery of the optical filter is adhered in the sinking groove, therefore a light through hole is aligned to the photosensitive area of the photosensitive chip; and the lens component is installed on the upper side of the plastic package body. According to the miniature camera device disclosed by the invention, the plastic package body replaces the traditional bracket, the sinking groove is reserved in the plastic package body, and the optical filter is directly adhered in the sinking groove, thereby reducing the size of the camera module, and as the passive element and the gold thread on the periphery of the photosensitive chip are entirely cast in the plastic package body, the reliability of the product is enhanced.

Owner:KUNSHAN Q TECH CO LTD

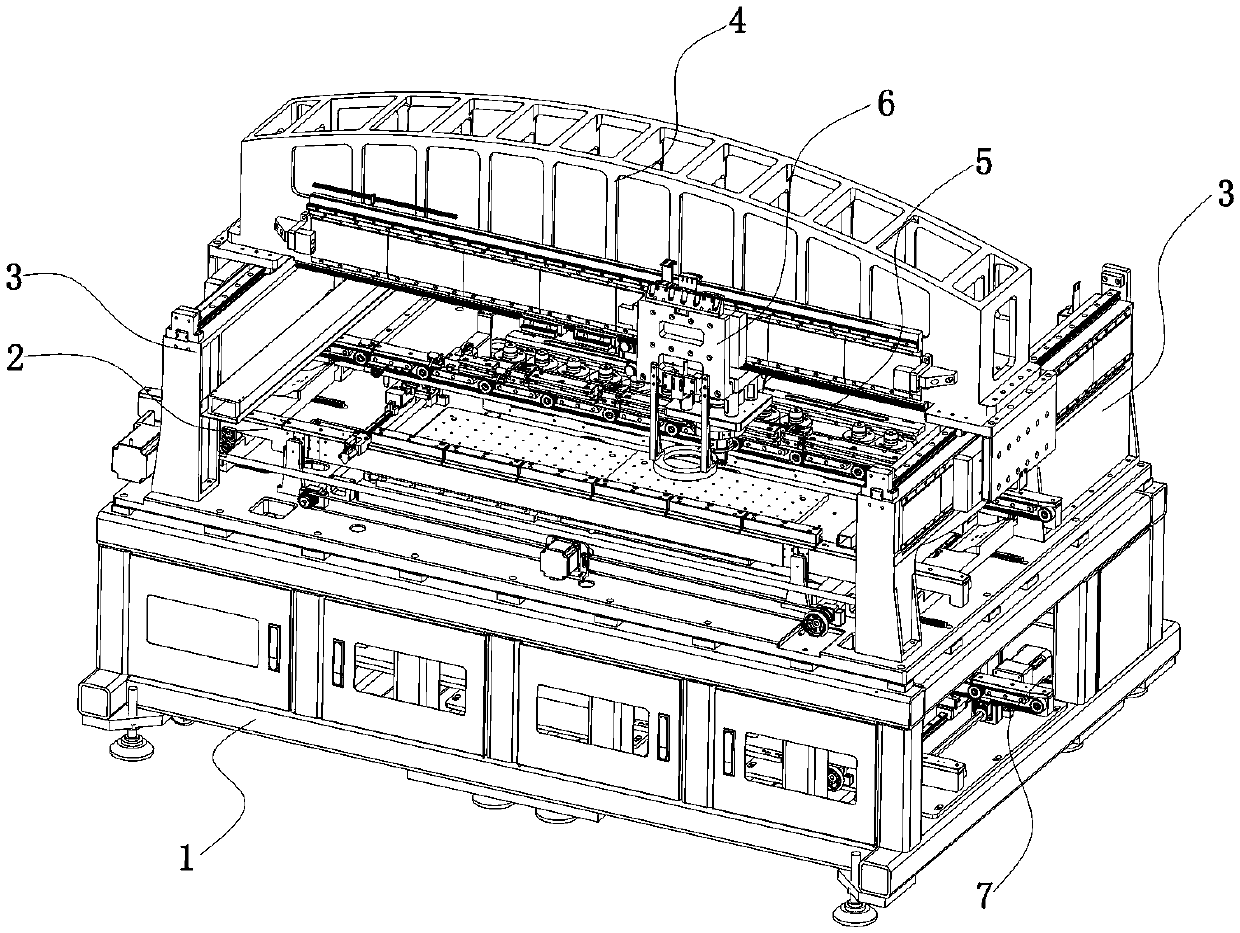

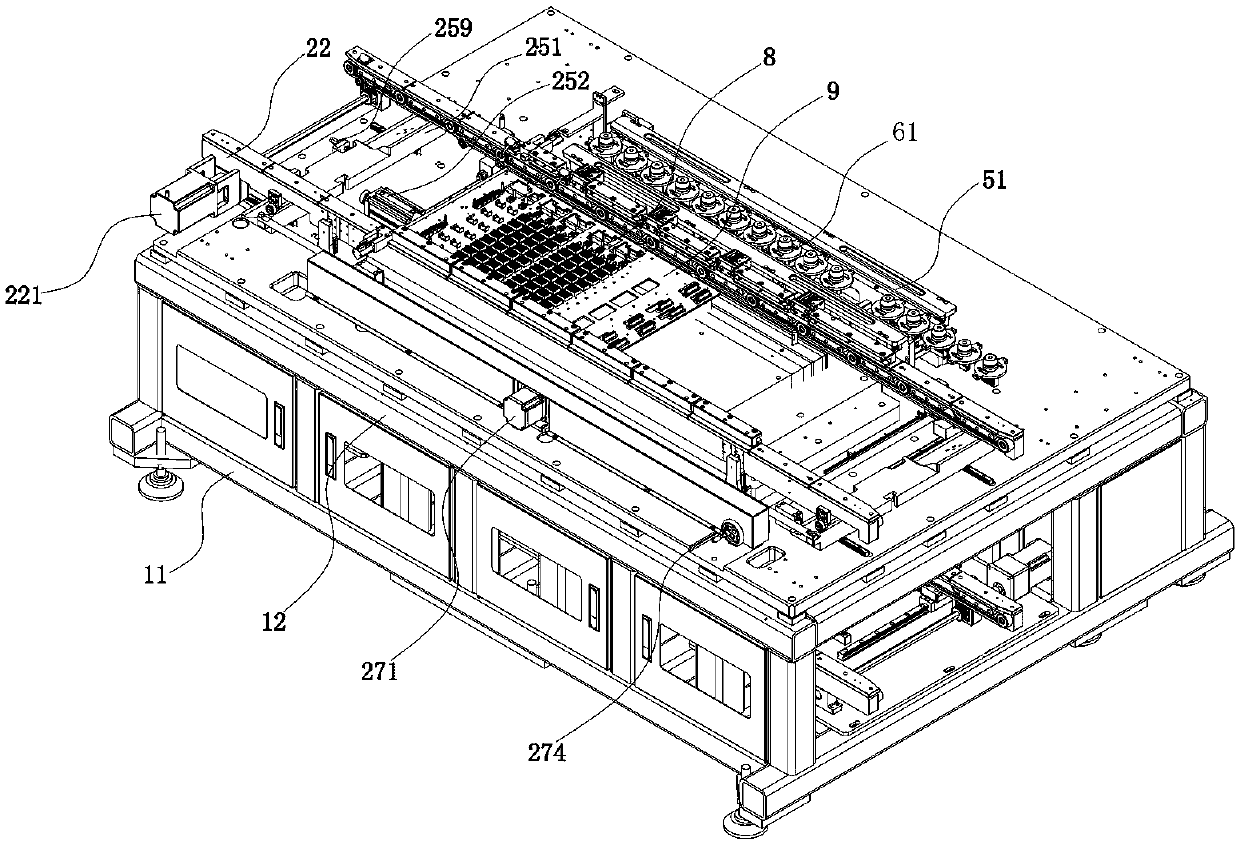

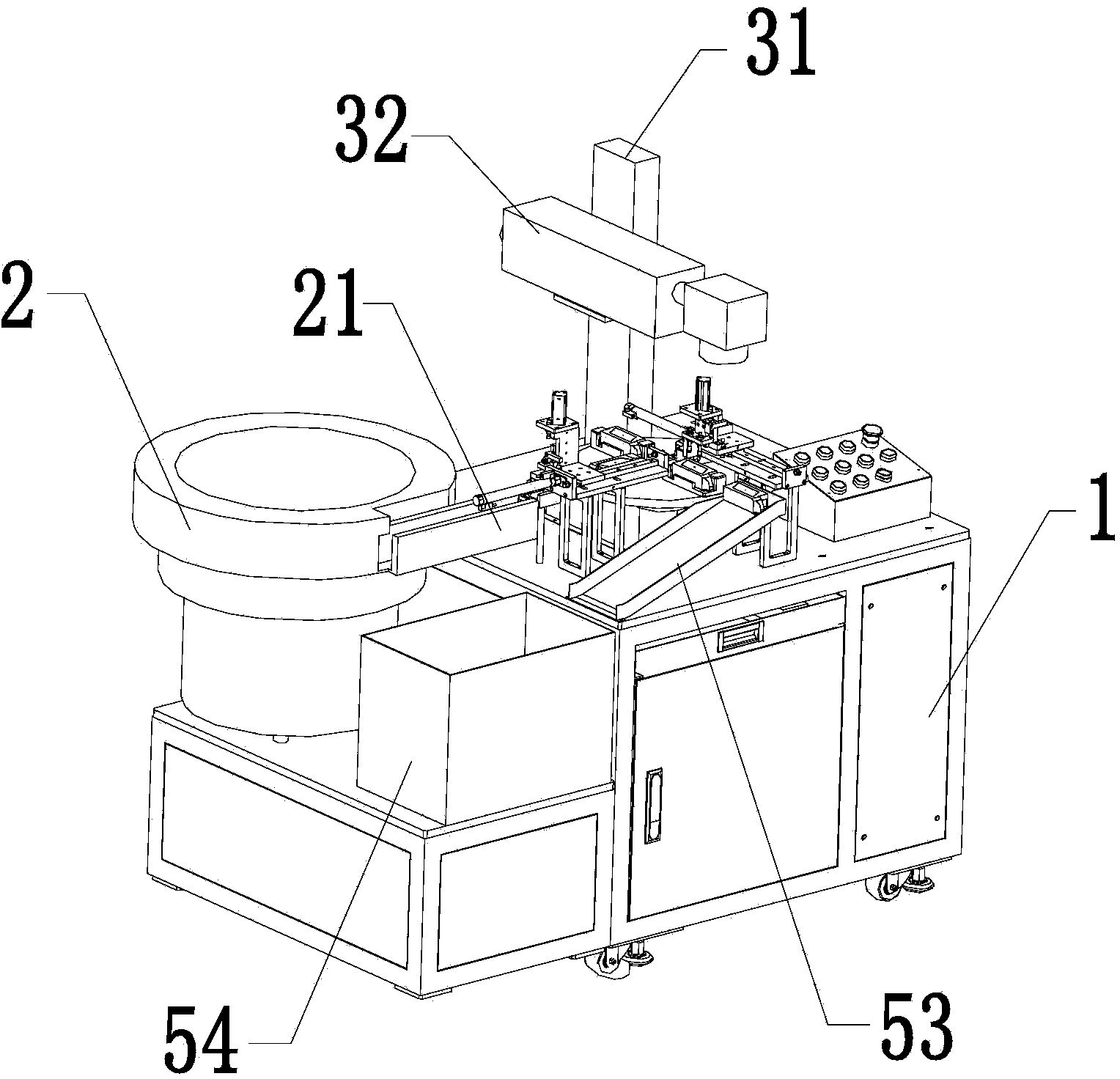

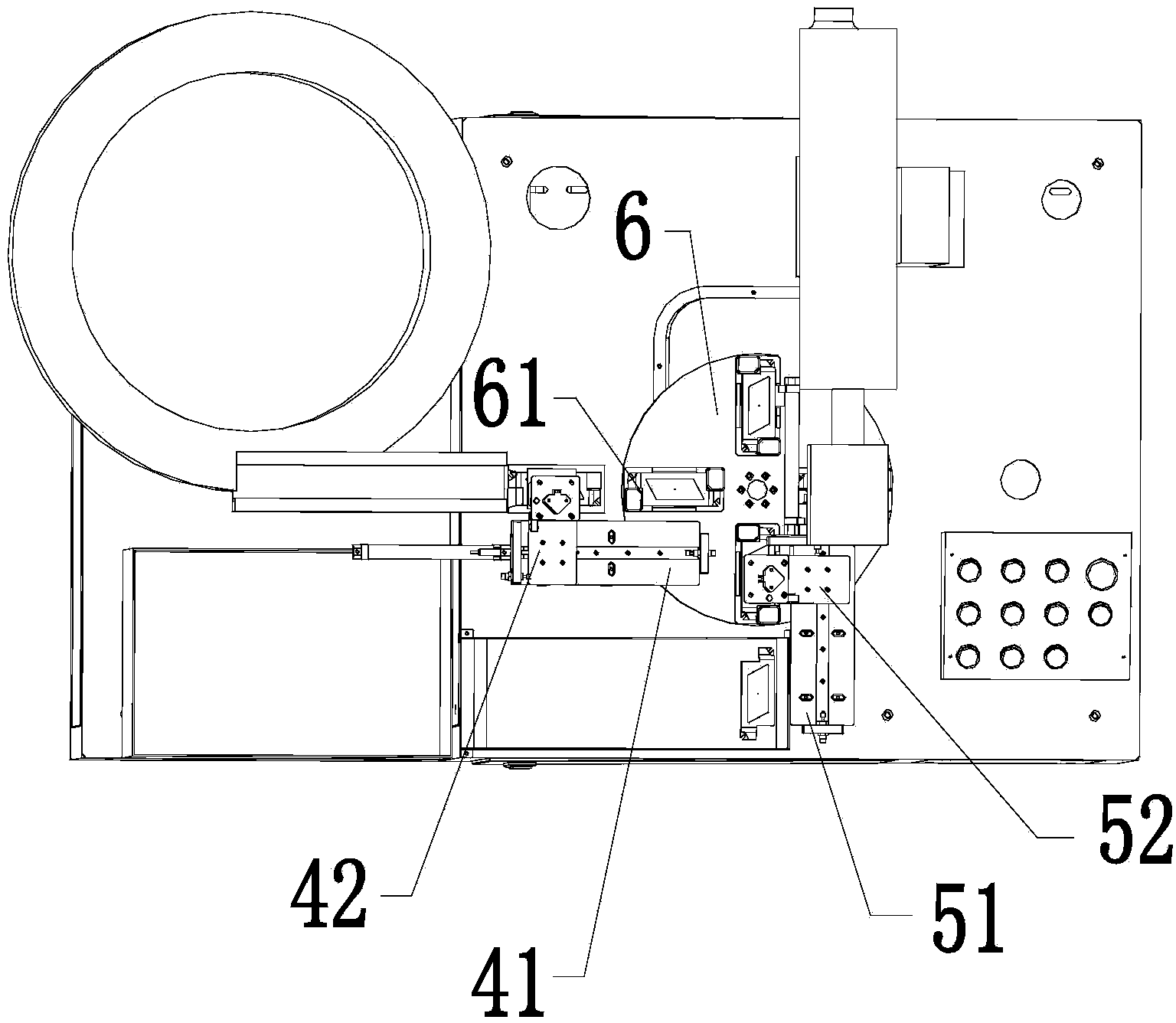

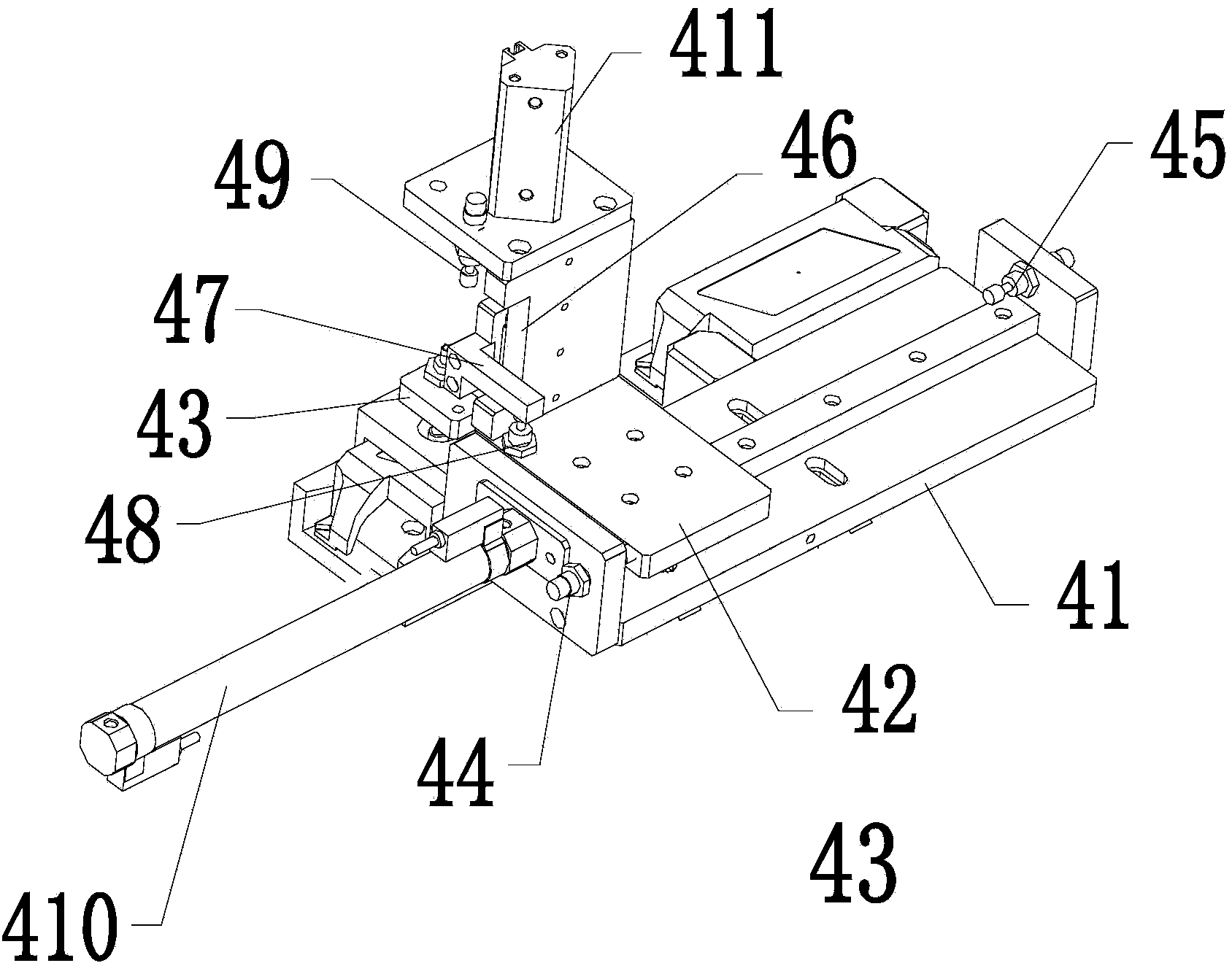

Automatic press-connection machine of connector and press-connection system and press-connection process thereof

ActiveCN105514754ACompact designAccurate crimp positioningLine/current collector detailsFixed connectionsComputer moduleData acquisition

The invention discloses an automatic press-connection machine of a connector and a press-connection system and press-connection process thereof. The automatic press-connection machine comprises a machine body, a portal frame supporting and guiding assembly, a material guiding assembly, a press-connection head replacing assembly and a press-connection assembly; the press-connection system comprises an IPC control chip, a height sensor connected with the IPC control chip, a CCD module, a movement control card, a linear motor and a data acquisition card; the press-connection process comprises a PARS press-connection module, a pressure press-connection module and a distance press-connection module. The automatic press-connection machine of the connector and the press-connection system and press-connection process thereof are applicable to a modern assembly line, fully-automatic material guiding control is adopted, a plurality of press-connection head components are arranged therein, multiple types of press-connection modes are correspondingly matched with the press-connection head components, in the press-connection process, pres-connection heads are replaced automatically, and product press-connection diversity is achieved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

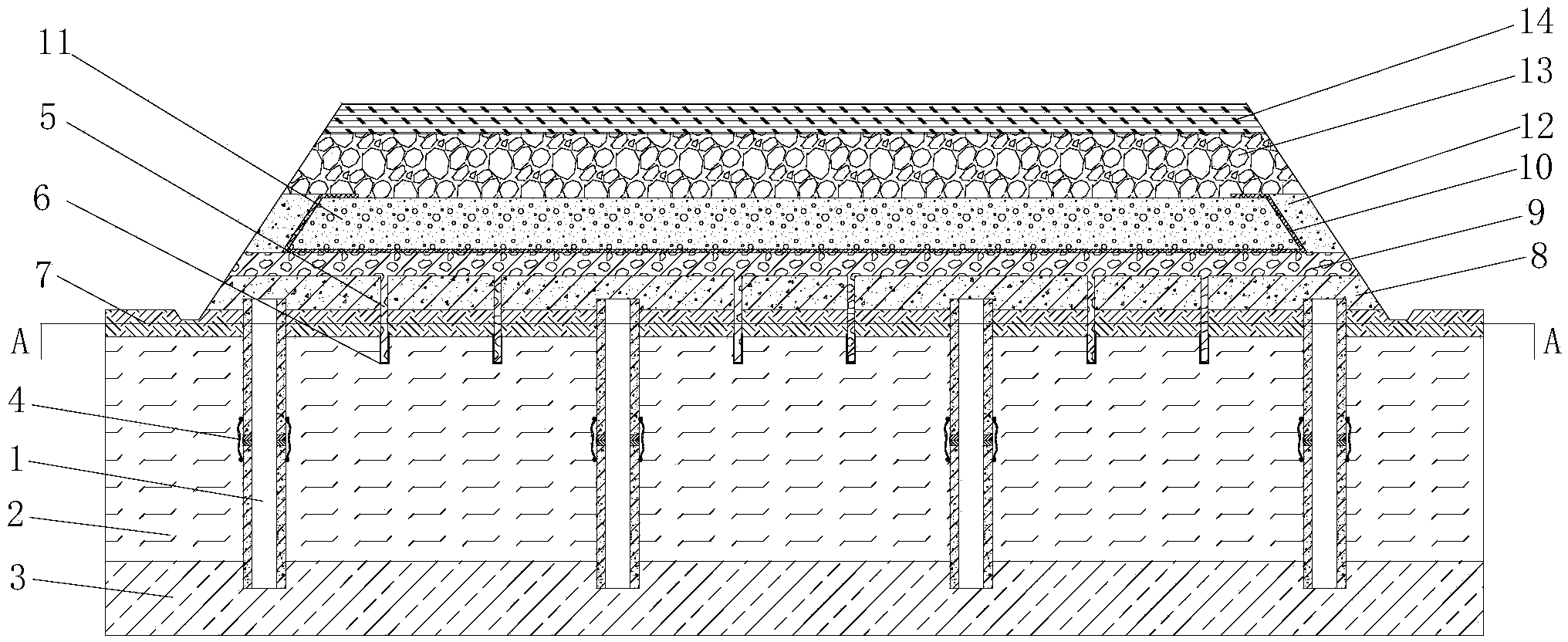

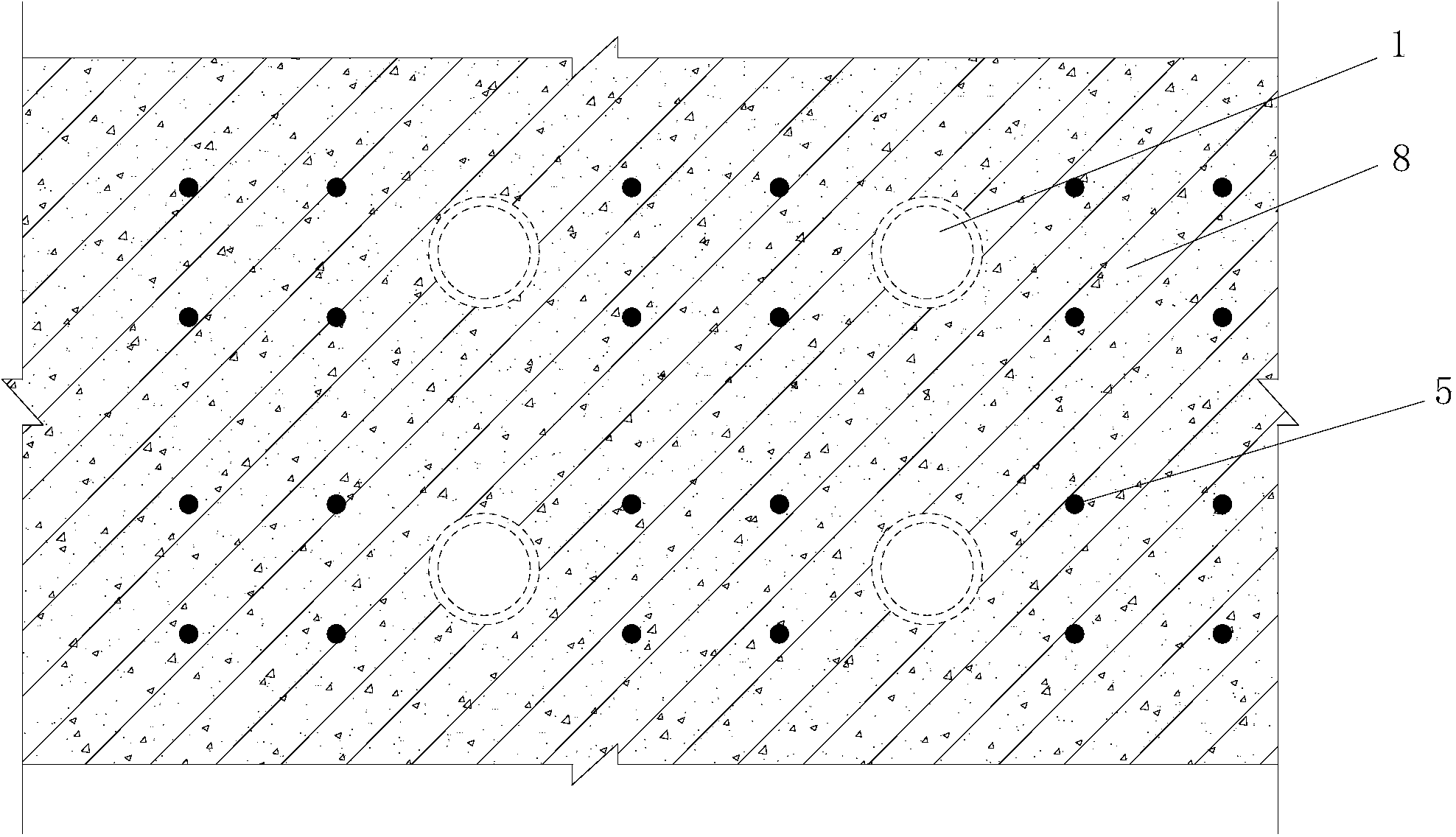

Prefabricated tube pile embankment structure and construction method thereof

InactiveCN103774514AReduce settlementEnsure stabilityRoadwaysProtective foundationReinforced concreteSlag

The invention relates to a prefabricated tube pile embankment structure, which mainly comprises a prefabricated tube pile, a vertical drain tube, a shallow curing plate, a thin reinforcement concrete continuous plate, a rubble layer, a bubble concrete rolling-resistant layer, a concrete protection layer, a slag layer and a pavement structure, wherein the prefabricated tube pile penetrates through a soft soil layer and extends a relative bearing stratum; a weld seam protection device is arranged outside a prefabricated tube pile welding end plate; the shallow curing plate is arranged at the periphery of the top of the prefabricated tube pile; the thin reinforcement concrete continuous plate is arranged on the shallow curing plate; the top of the prefabricated tube pile is embedded in the thin reinforcement concrete continuous plate; the vertical drain tubes are pre-buried in the thin reinforcement concrete continuous plate and the shallow curing plate, the lower ends of the vertical drain tubes are externally coated with a reverse filter geotextile which is communicated with the rubber layer on the thin reinforcement concrete continuous plate; the bubble concrete rolling-resistant layer, the slag layer and the pavement structure are sequentially arranged on the rubble layer. The prefabricated tube pile embankment structure is high in bearing capacity, less in differential settlement, high in overall structure stability, and convenient to construct.

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

Laser marking device capable of feeding and discharging materials automatically

ActiveCN103832085ARealize fully automatic markingSolve the problem that marking products cannot be transportedPrintingLaser etchingEngineering

The invention discloses a laser marking device capable of feeding and discharging materials automatically and belongs to the field of laser marking. The laser marking device capable of feeding and discharging the materials automatically comprises a vibrating disk, a machine base, a laser etching mechanism and a central processing unit which controls the laser marking device capable of feeding and discharging the materials automatically to operate. The vibrating disk is provided with a conveying track. The machine base is provided with a material taking mechanism, a discharging mechanism and a rotating disk which can rotate around the center. The material taking mechanism is arranged at the discharging position of the conveying track. The rotating disk is arranged at the discharging position of the material taking mechanism. The rotating disk is provided with multiple carrying frames. The laser etching mechanism is arranged above the marking position of the rotating disk. The discharging mechanism is arranged at the discharging position of the rotating disk. According to the laser marking device capable of feeding and discharging the materials automatically, the vibrating disk is used for solving the problem that an existing laser marking device cannot adjust marked products to be conveyed in a correct state; as a result, full-automatic marking through the laser marking device is realized, marking efficiency is greatly improved, and labor cost is reduced.

Owner:深圳市艾雷激光科技有限公司

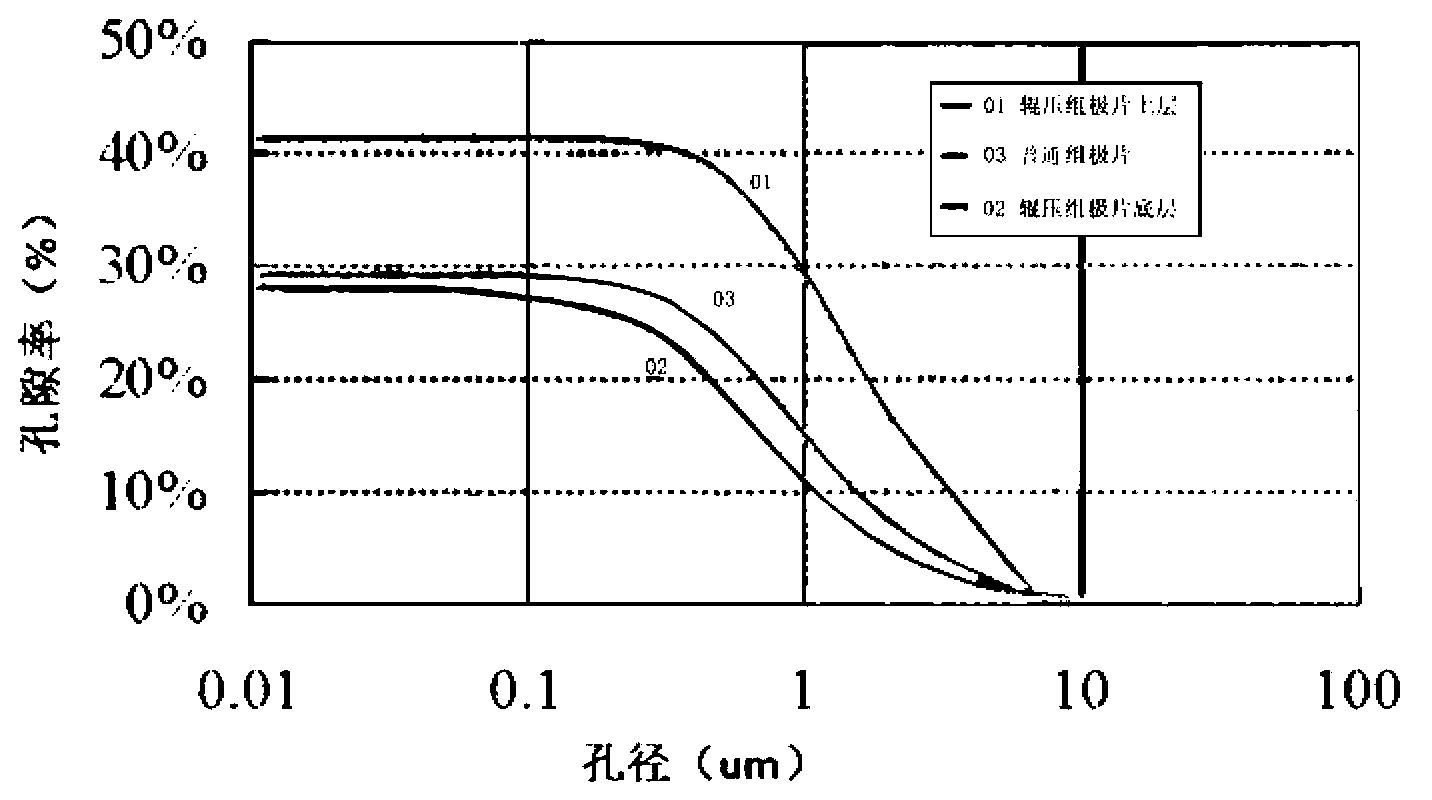

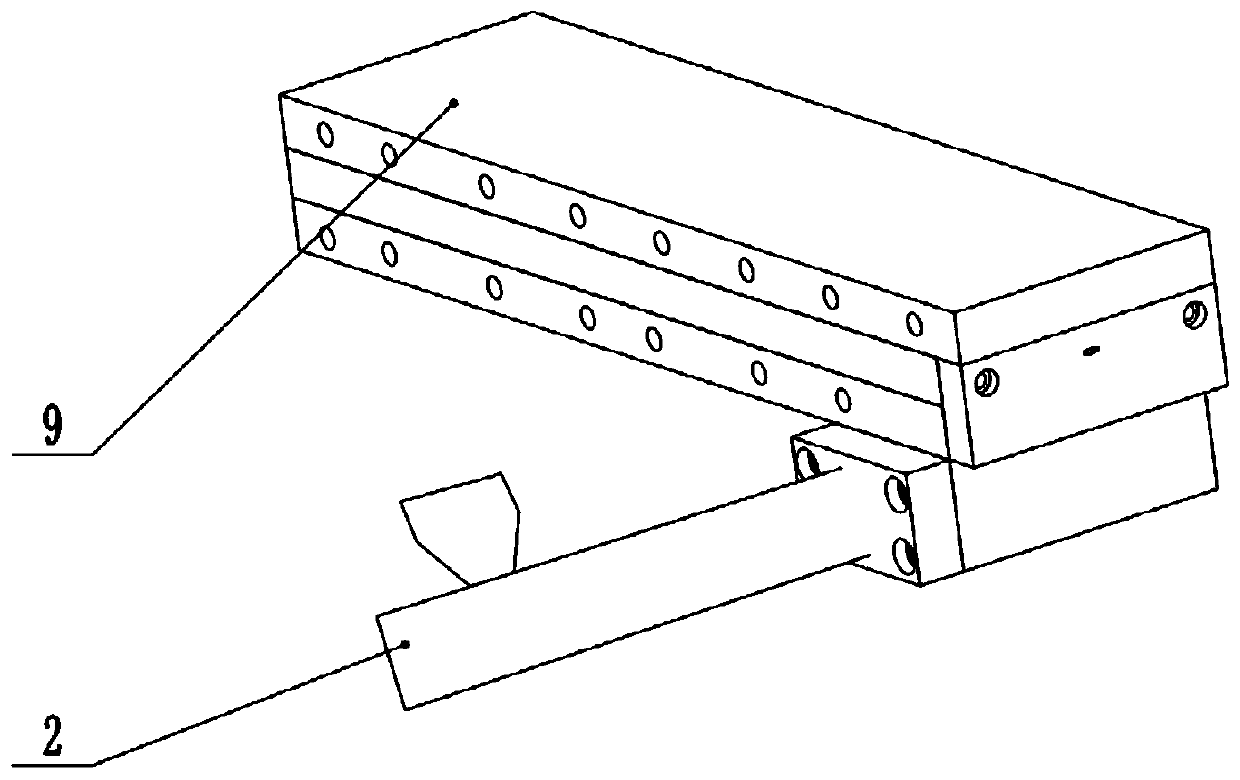

Pole piece roll-forming method and device

The invention provides a pole piece roll-forming method and a pole piece roll-forming device. The method comprises the steps that: slurry is coated on the surface of a current collector, such that a pole piece is prepared; the pole piece is bake-dried in a baking oven of a coating machine; the dried pole piece is delivered into a rolling mechanism, and rolling is carried out, wherein the bake-drying treatment and the rolling of the rolling mechanism are carried out in the baking oven of the coating machine. The pole piece roll-forming device is used for implementing the pole piece roll-forming method. The device comprises a coating machine baking oven used for carrying out the bake drying treatment upon the pole piece formed by the current collector coated with the slurry, and the rolling mechanism used for rolling the dried pole piece. The rolling mechanism is arranged in the coating machine baking oven. With the pole piece roll-forming method and device, battery core electrochemical properties can be improved, and pole piece thickness rebound can be reduced. In industrial production, the method and the device have the advantages of simple operation and easy realization.

Owner:DONGGUAN AMPEREX TECH +1

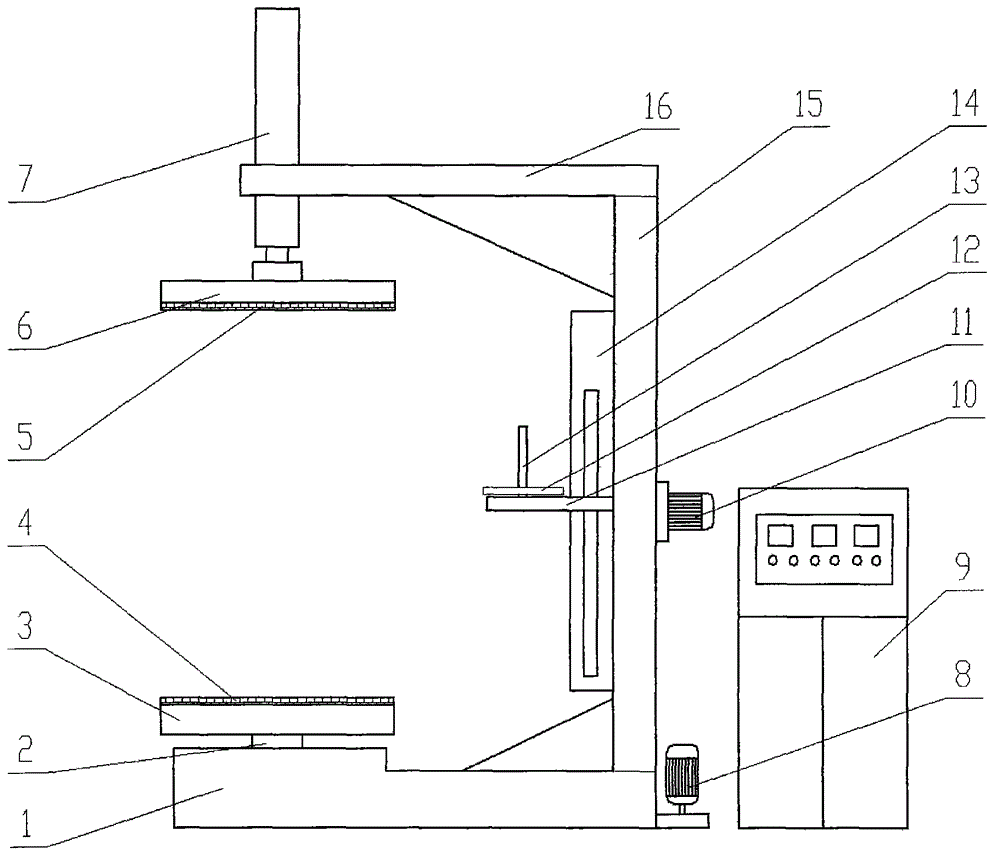

Packaging machine

InactiveCN104477432ASimple structureEasy to packPackaging automatic controlWrapping with article rotationSteel barEngineering

The invention discloses a winding packaging machine which comprises a base, a vertical column, a beam, a lifting mechanism and a control cabinet. One end of the base is fixedly connected with the vertical column through a diagonal draw steel bar, the beam is fixedly connected at the upper end of the vertical column through a diagonal draw steel bar, the lifting mechanism is mounted on the vertical column, a turntable motor is arranged at the rear end of the base, a spindle and a driving turntable are connected on the turntable motor, a lower turntable rubber mat is mounted on the turntable, the lifting mechanism and a lifting motor are mounted on the vertical column, a lifting table is mounted on the lifting mechanism, a tray and a rotating shaft are connected on the lifting table, a cylinder is mounted at one end of the beam, a servo pressure plate is connected on the cylinder, and an upper turntable rubber mat is mounted on the pressure plate. The packaging machine is simple in structure, wide in packaging product range and fine in packaging effect, and products can be effectively prevented from being scratched in packaging.

Owner:TONGXIANG GUANGYU PLASTIC PROD

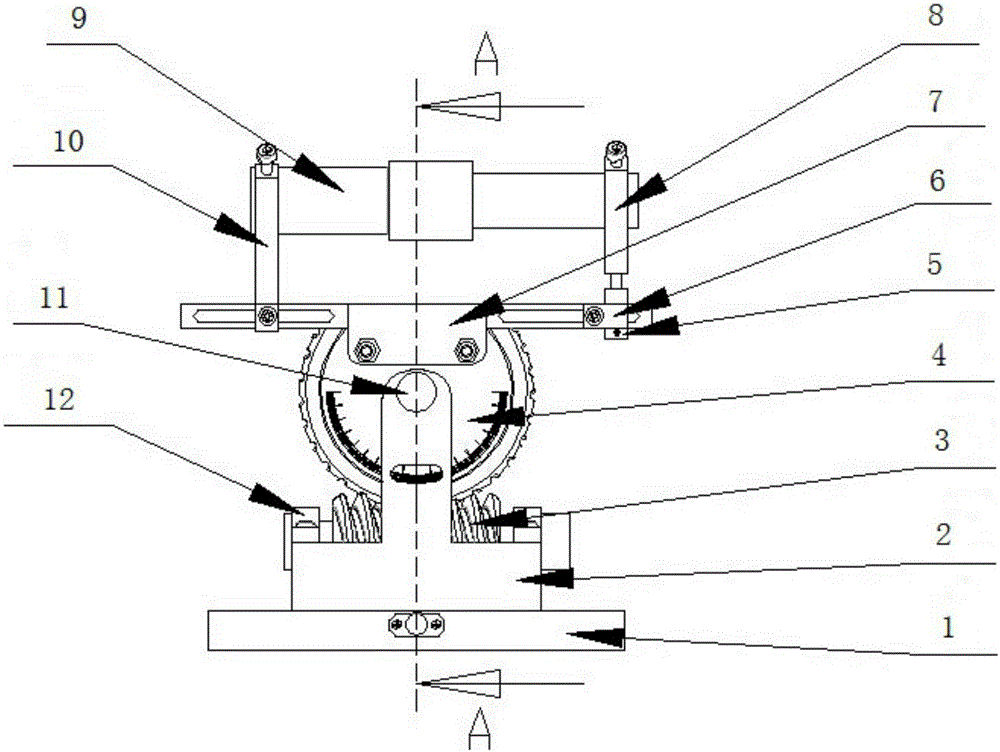

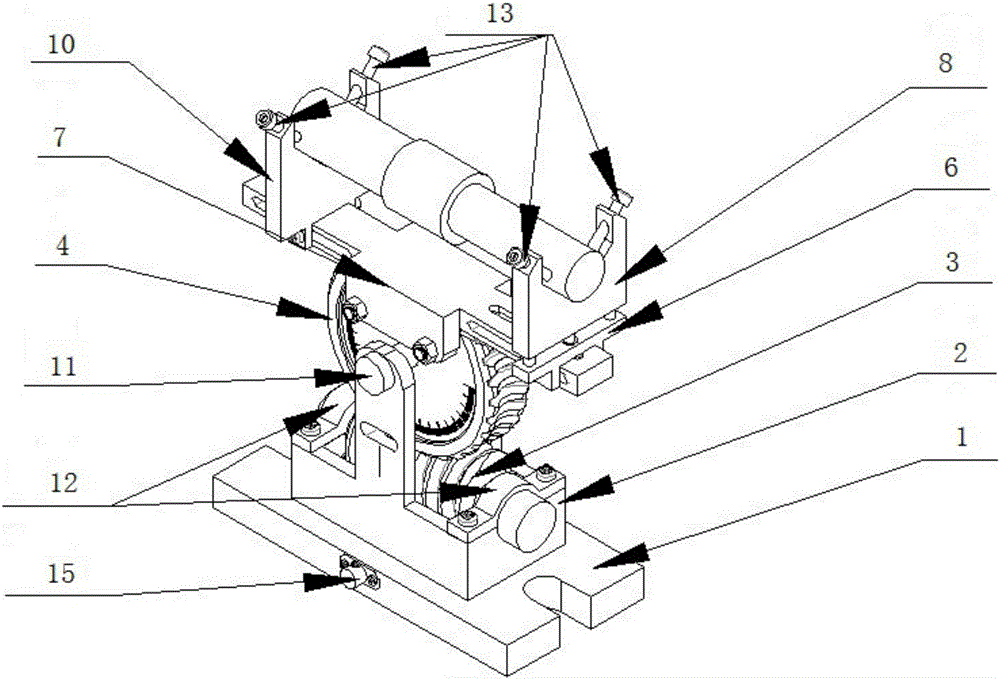

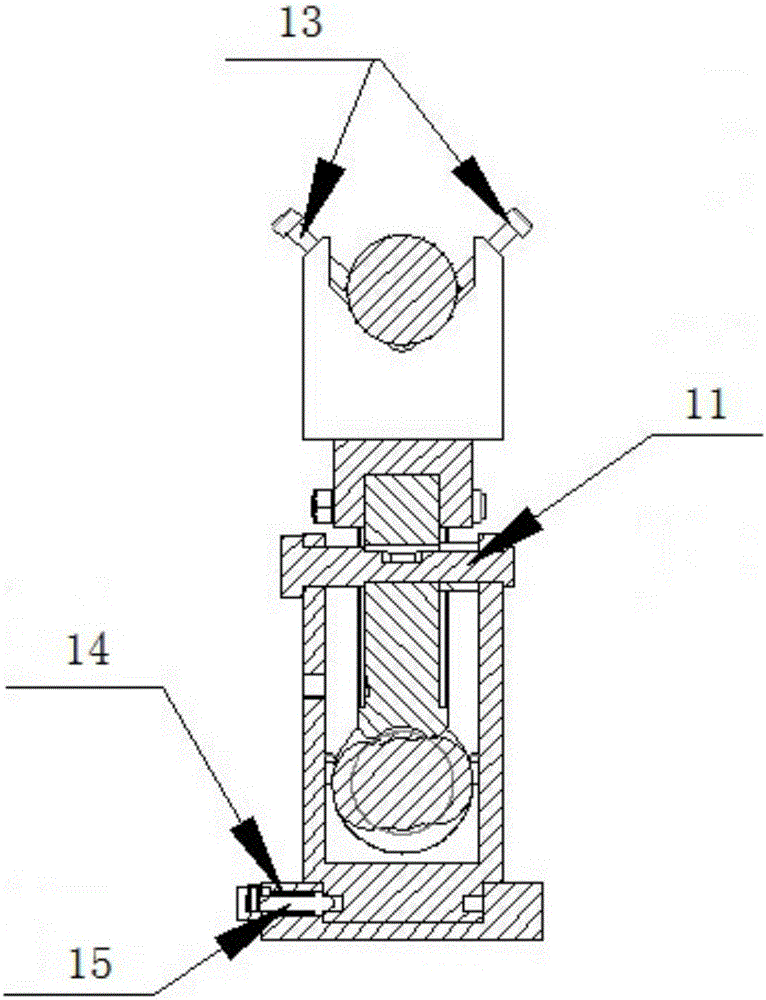

General frock clamp for shaft parts

InactiveCN105855934AConvenient and efficient processingEfficient and convenient detectionPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a universal tooling fixture for shaft parts, which comprises a base fixed on a workbench, a clamping mechanism, an adjusting mechanism and an angle adjusting mechanism. Using the general tooling and fixture for shaft parts described in the present invention, an angle adjustment mechanism is set to realize the placement of shaft parts at any angle and all-round rotation, and the adjustment mechanism is set to adjust different shaft diameters and different lengths. As well as adjusting the clamping position of shaft parts with various shaft diameters on the same shaft, a clamping mechanism with adjustment parts is set up to clamp shaft parts. This device makes shaft parts more accurate during processing, testing and assembly. Efficient and convenient, especially for fast switching when clamping different positions of different shaft parts, which brings great convenience, and can effectively solve the problem of single specification of clamping parts, inflexible placement and troublesome operation of existing shaft parts tooling fixtures, etc. Problem, the device is simple in structure, easy to use, low in cost, and easy to popularize.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

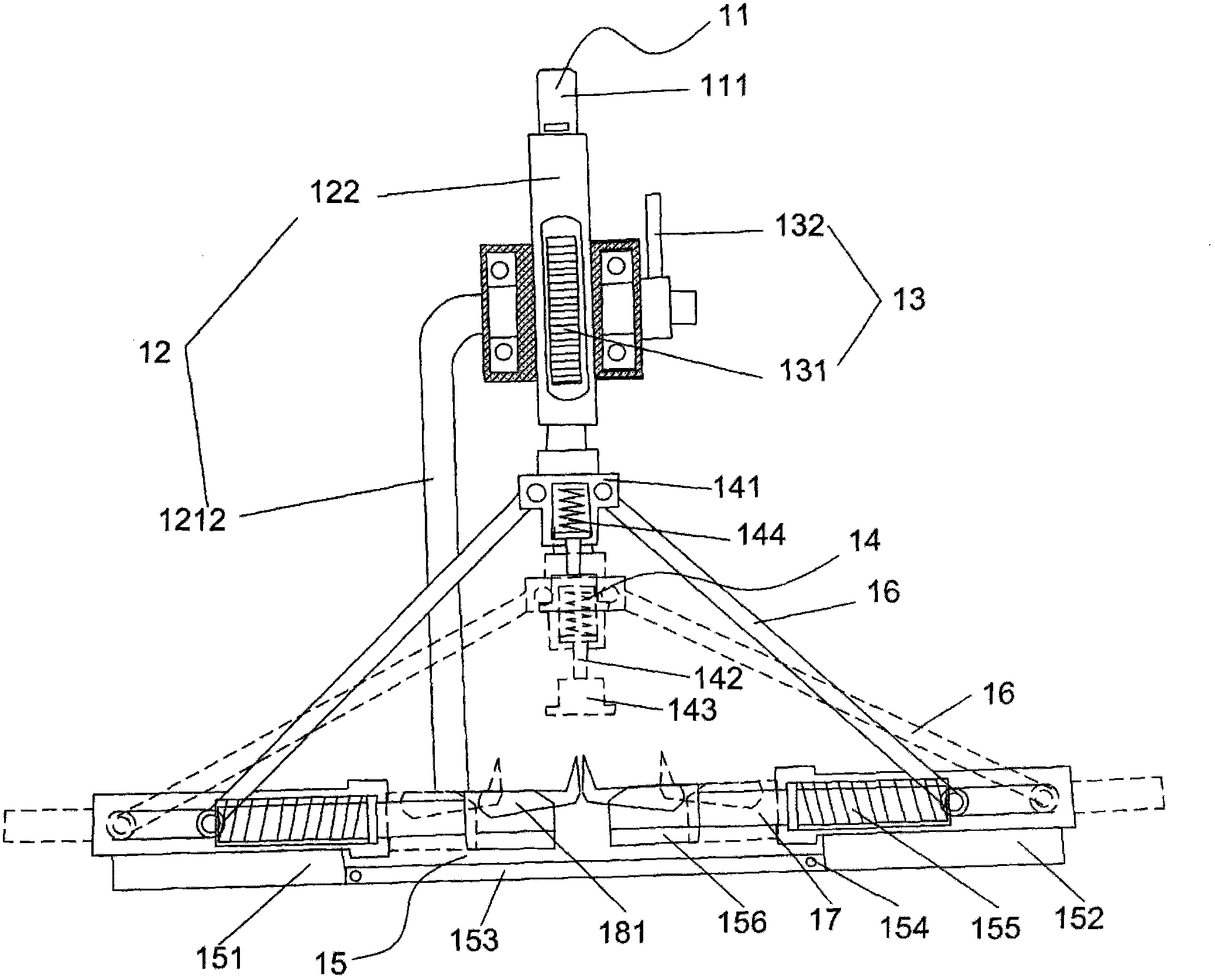

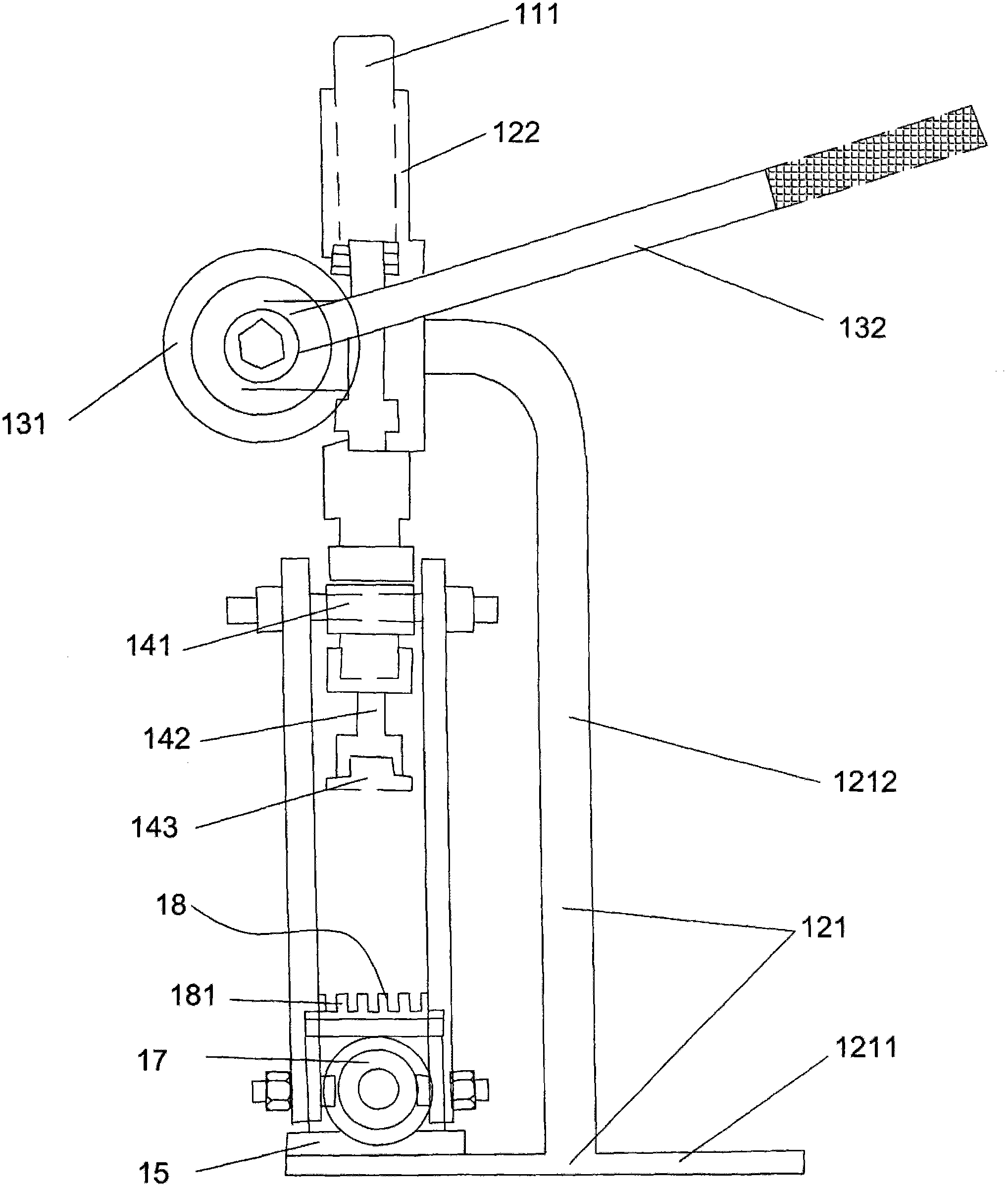

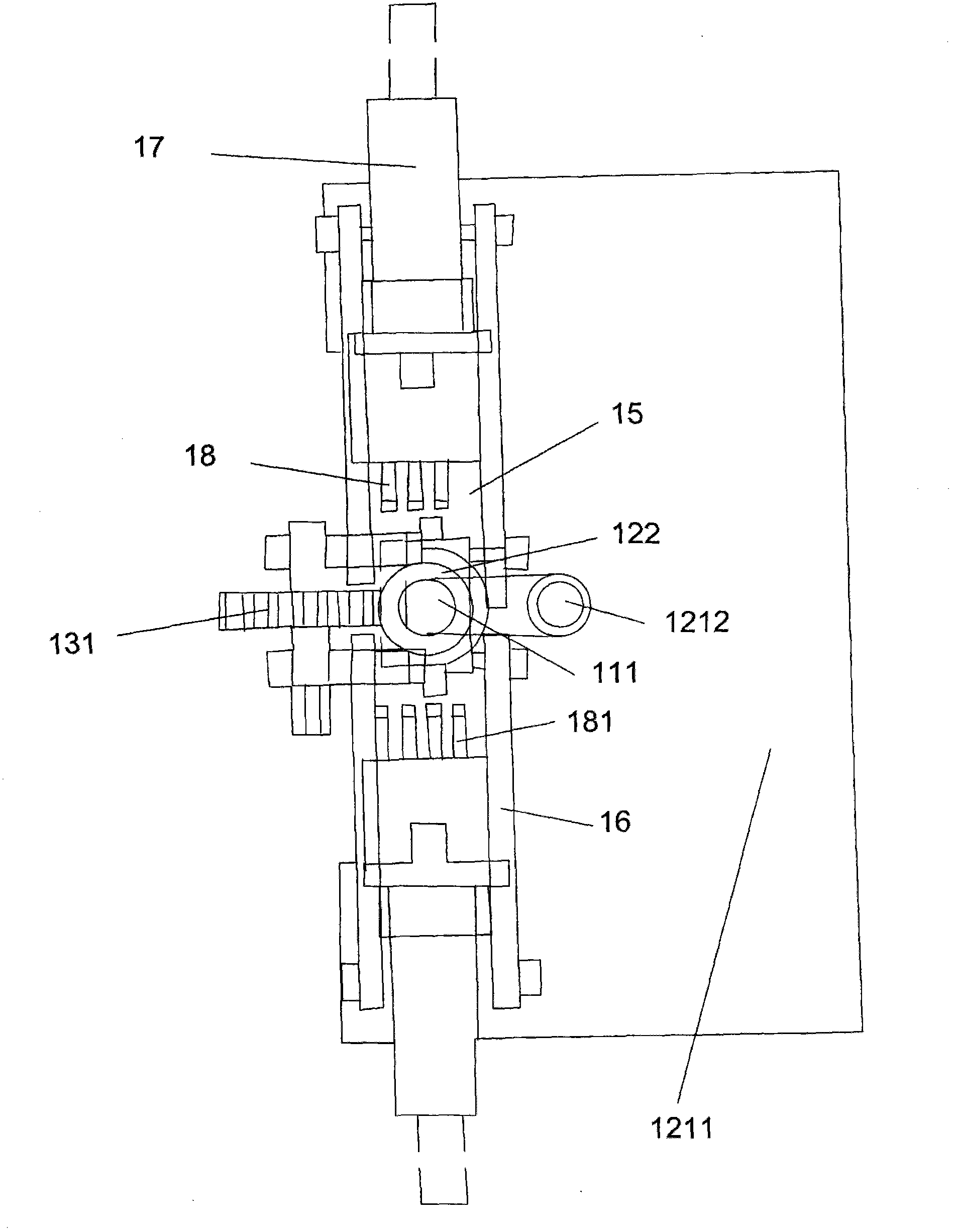

Hand-operated Chinese chestnut shucking machine

ActiveCN103230082AGood removal effectSimple structureHuskingHullingEngineeringMechanical engineering

The invention relates to a hand-operated Chinese chestnut shucking machine which comprises a compression bar assembly, a support assembly, a transmission assembly, a sliding chute, two slide bars and an inclined connecting bar, wherein the compression bar assembly reciprocates vertically; the support assembly is used for supporting the compression bar assembly to reciprocate vertically; the transmission assembly drives the compression bar assembly to reciprocate vertically; the sliding chute is horizontally placed and fixed with the support assembly; the two slide bars slide relatively and horizontally in the sliding chute; the inclined connecting bar drives the slide bars to move horizontally by the aid of the vertical reciprocation of the compression bar assembly; at least one hooked blade is connected to the opposite end parts of the two slide bares respectively; the shucking machine further comprises a material pressing assembly which is elastically pressed against Chinese chestnuts under the drive of the compression bar assembly; hook tips of the hooked blades are upward; and the hook tips of the hooked blades which are arranged at the end parts of the two slide bars encounter right below the material pressing assembly. The hand-operated Chinese chestnut shucking machine is simple in structure, low in cost and simple to operate and can very conveniently remove both Chinese chestnut hair bulbs and hulls.

Owner:启东市天汾电动工具技术创新中心

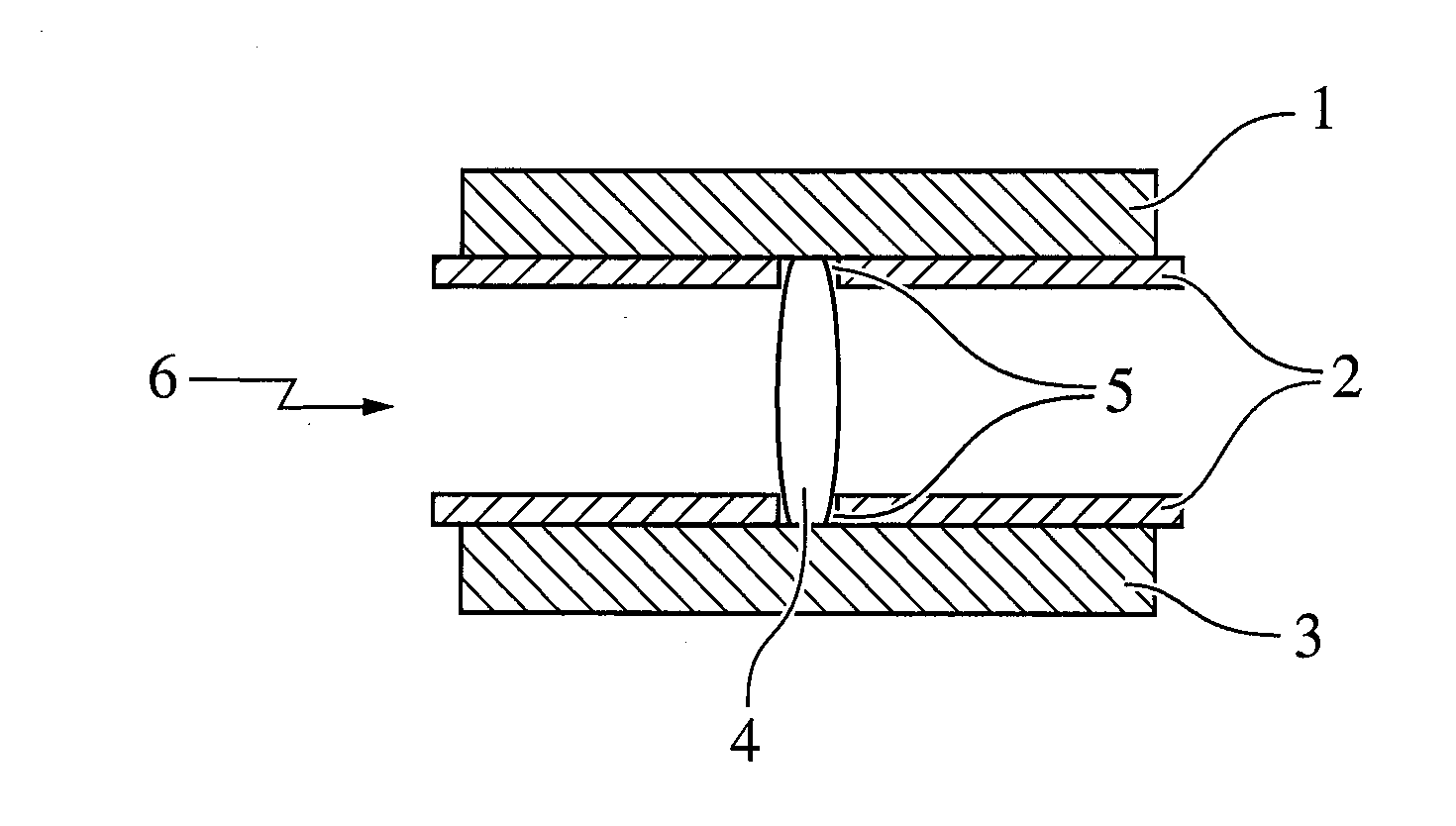

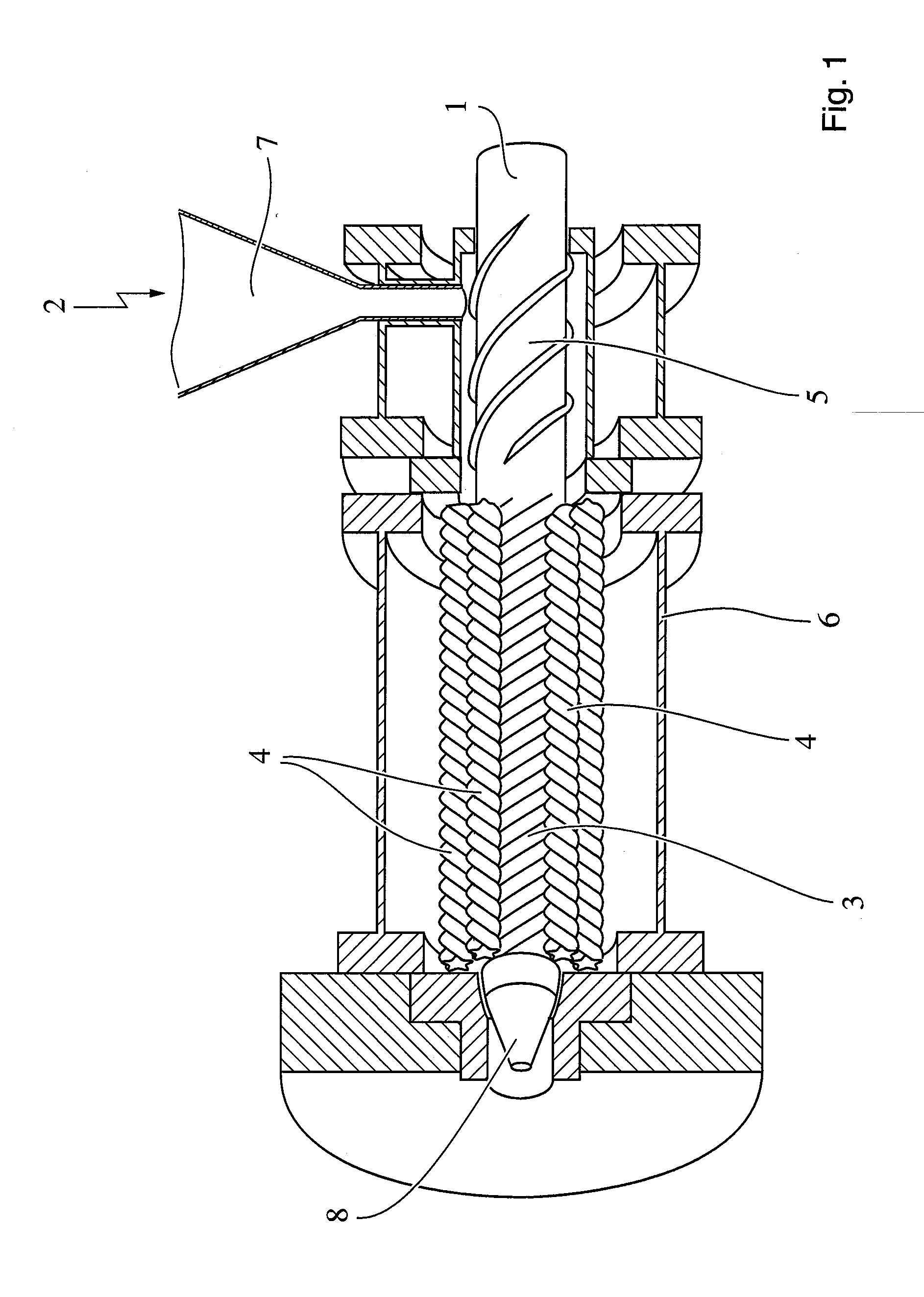

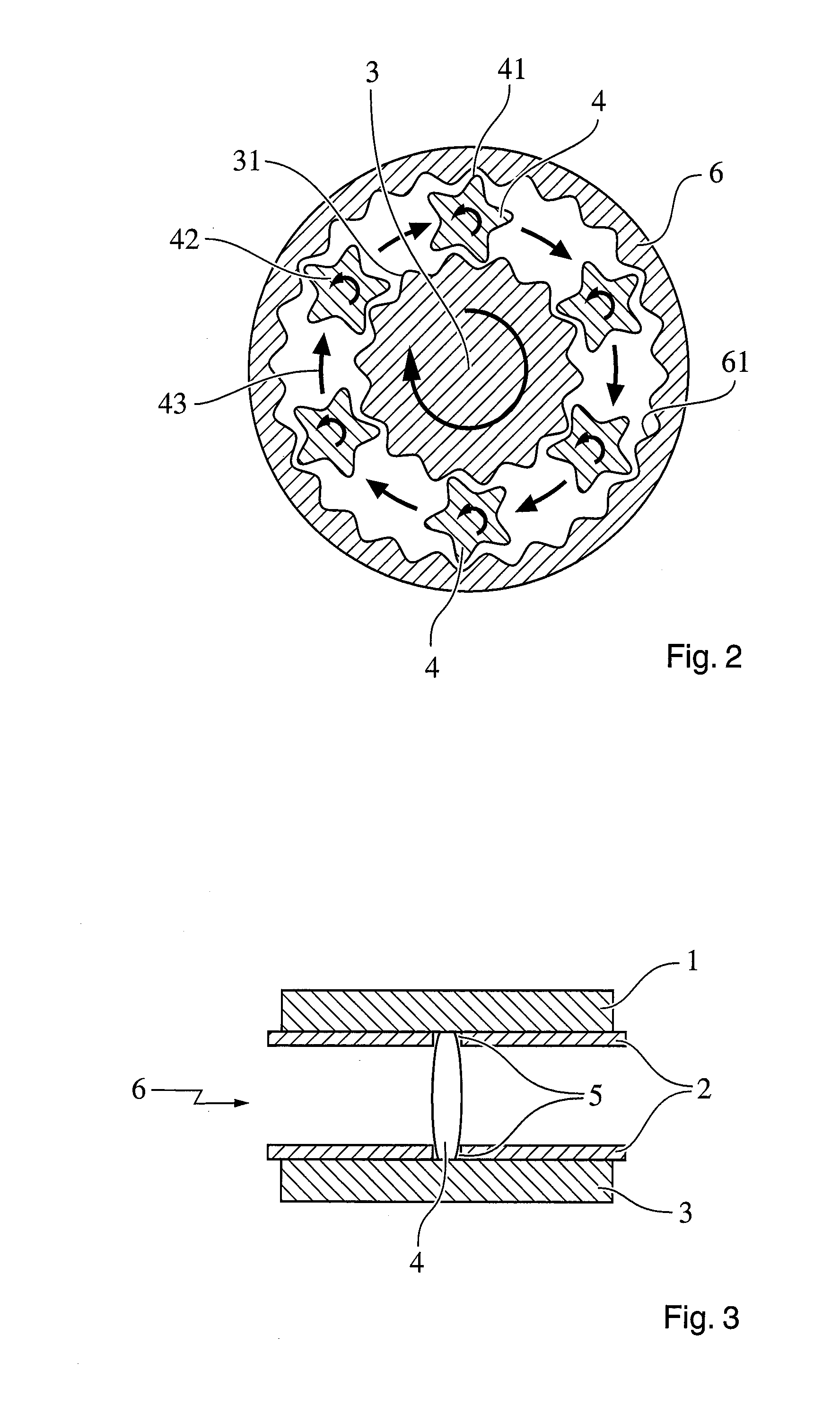

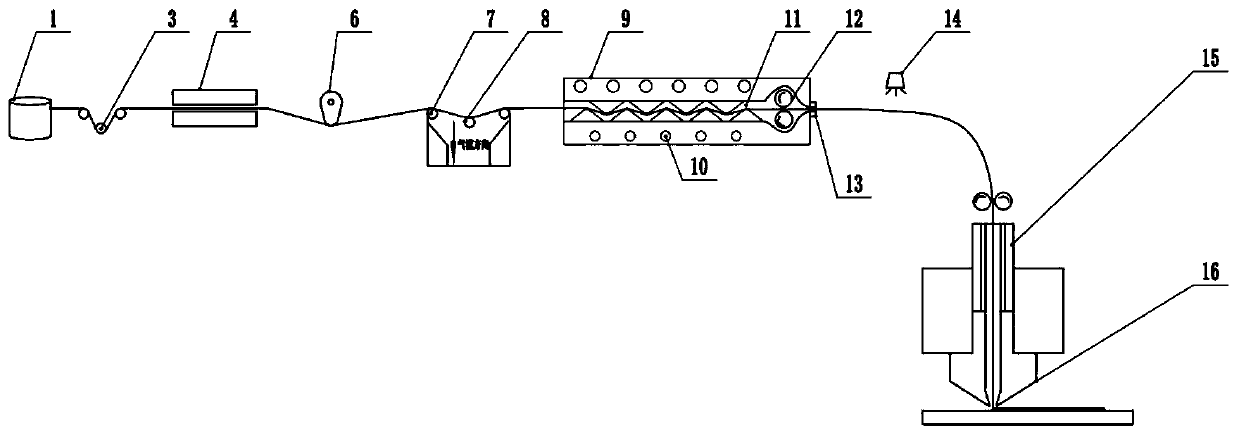

Continuous fiber melt impregnation 3D printing device and process

ActiveCN111186138AHigh molding pressureEnough molding pressure3D object support structuresApplying layer means3d printPolymer science

The invention relates to a continuous fiber reinforced thermoplastic resin melt impregnation 3D printing device and a method, wherein thermoplastic resin is used as a matrix, and continuous glass fiber or carbon fiber is used as a reinforcement. The 3D printing device comprises an extruder, an unwinding roller, a pre-tensioning roller, an infrared radiation device, a gas-assisted swinging device,a wire wetting mold, a cooling device and a 3D printer. A continuous fiber bundle is firstly pre-dispersed by the pre-tensioning roller, the upper surface and the lower surface of the continuous fiberare pre-heated by the infrared radiation device, the pre-heated continuous fiber is unfolded to a certain width under the action of the gas-assisted swinging device, then the pre-heated continuous fiber enters the wire wetting mold, the wetting process of the resin matrix on the fiber bundle is completed under the action of a wave-shaped runner, the fiber bundle is conveyed forwards by the traction of an inner traction roller and passes through a circular shaping die to form continuous fiber prepreg filaments which can be used for 3D printing, and cooling, feeding and printing are carried outto finally obtain the 3D printed product of the continuous fiber reinforced thermoplastic composite material. According to the device and the method, uniform dispersion and full impregnation of the continuous fiber in the resin matrix can be realized, the 3D printing continuous fiber reinforced thermoplastic composite material product with good interface bonding and excellent performance can be prepared, and meanwhile real-time integrated forming of continuous fiber consumables and the 3D printing composite material product can be realized.

Owner:BEIJING UNIV OF CHEM TECH

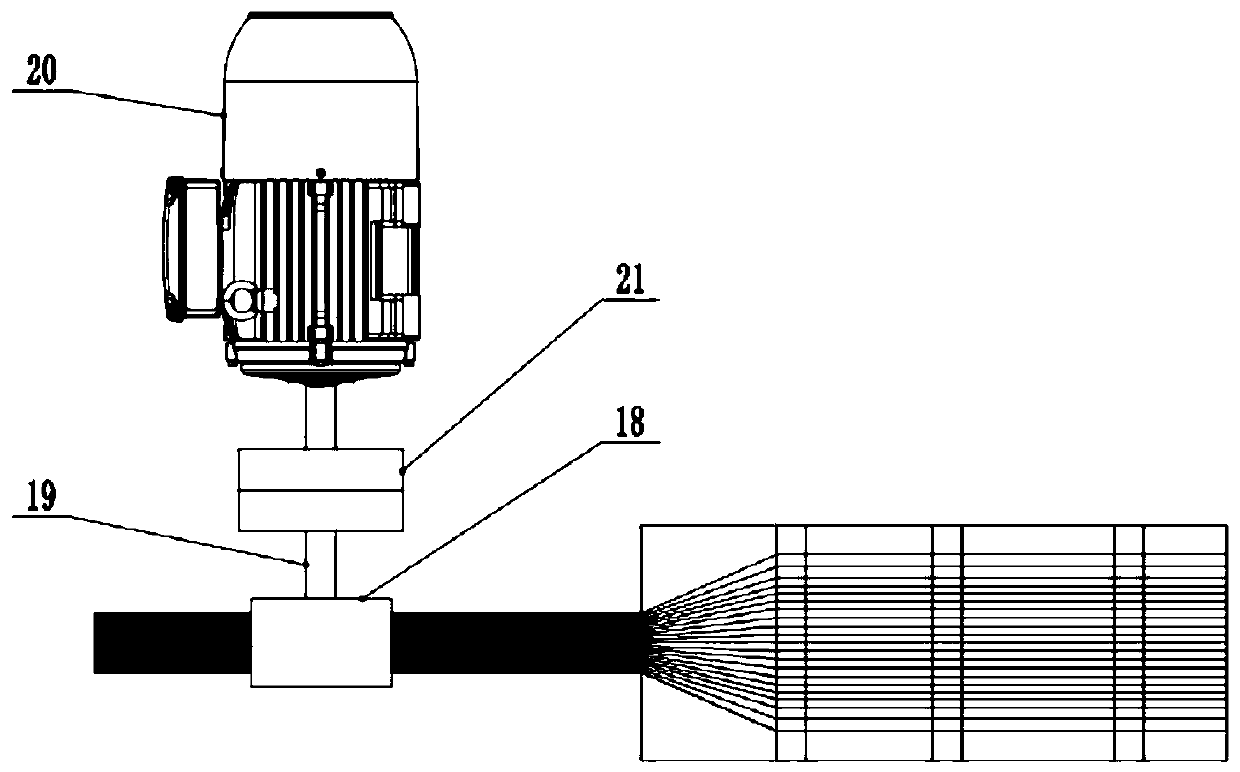

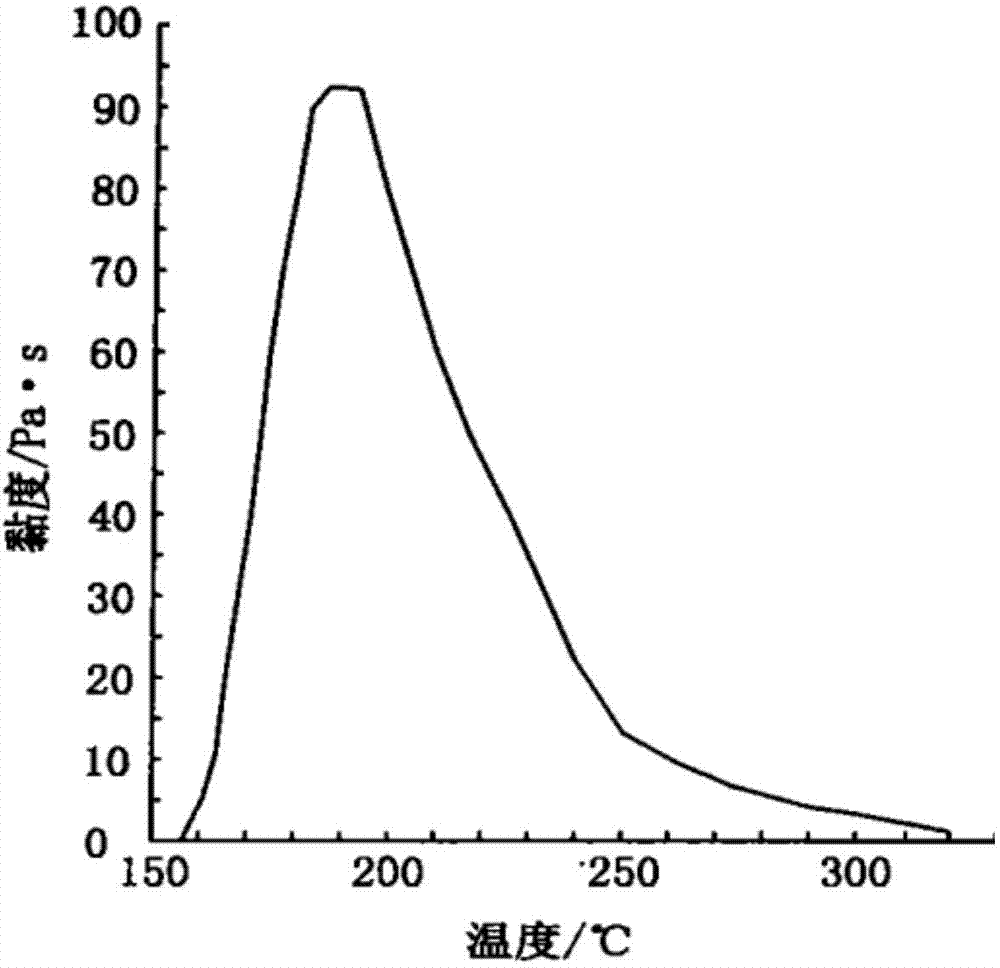

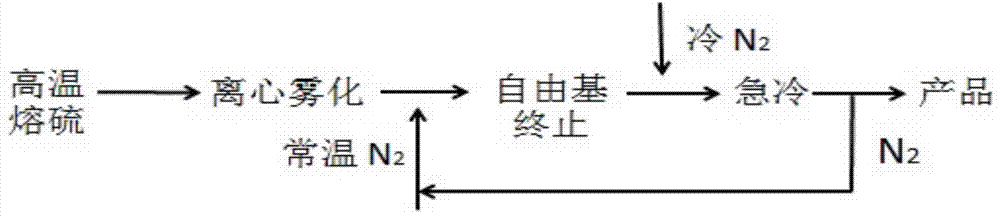

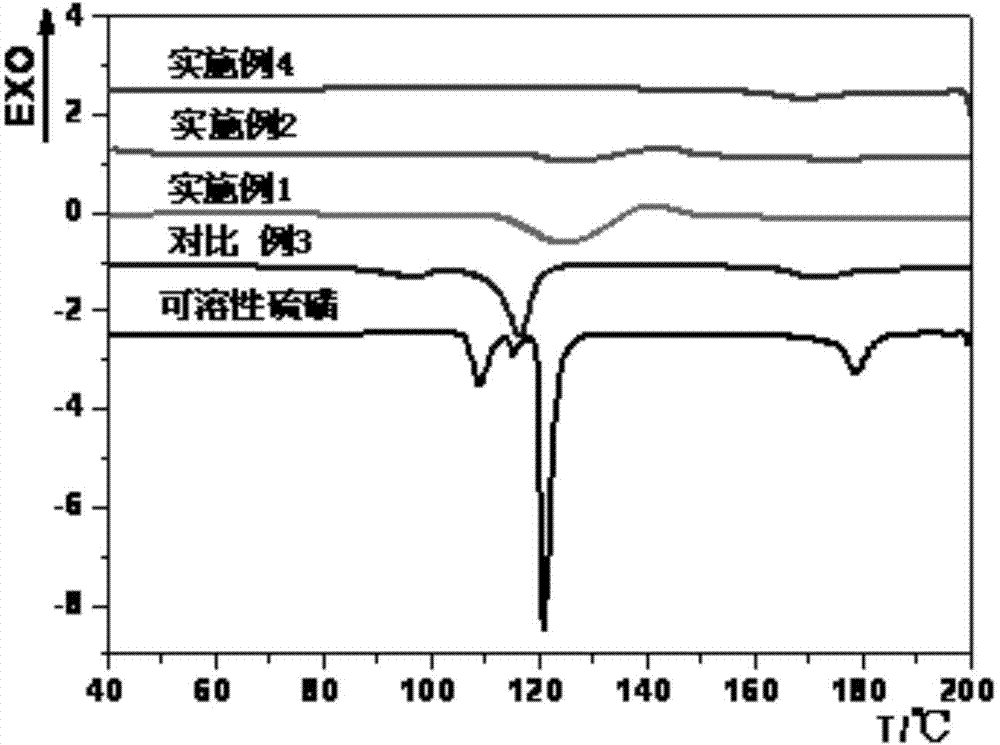

Method for preparation of insoluble sulfur

ActiveCN103539078AIncrease contentSmall particle sizeSulfur preparation/purificationSulfur productDirect effects

The invention relates to a method for preparation of insoluble sulfur. In a production process of insoluble sulfur, rapid cooling is one of very key process steps, realizes an effect of instantly stopping a reversible reaction and further directly affects the content of insoluble sulfur in a product. The method provided by the invention comprises the following steps of directly heating raw material sulfur to 280-400 DEG C, forming a large number of sulfur liquid droplets by centrifugal atomization through an atomizer, and increasing the specific surface area of sulfur; then cooling to 180-240 DEG C by circulating nitrogen at room temperature and keeping for 2-25 seconds; further cooling by circulating cold nitrogen to below 60 DEG C within 2-20 seconds; performing cyclone separation, collecting and packaging to obtain the insoluble sulfur product, wherein the average particle size of the product is 10 mu m-50 mu m; recycling the separated nitrogen. The method provided by the invention has the advantages of high safety in operation, low toxicity, high production efficiency, easiness in industrialization and high stability of prepared insoluble sulfur.

Owner:BEIJING UNIV OF CHEM TECH

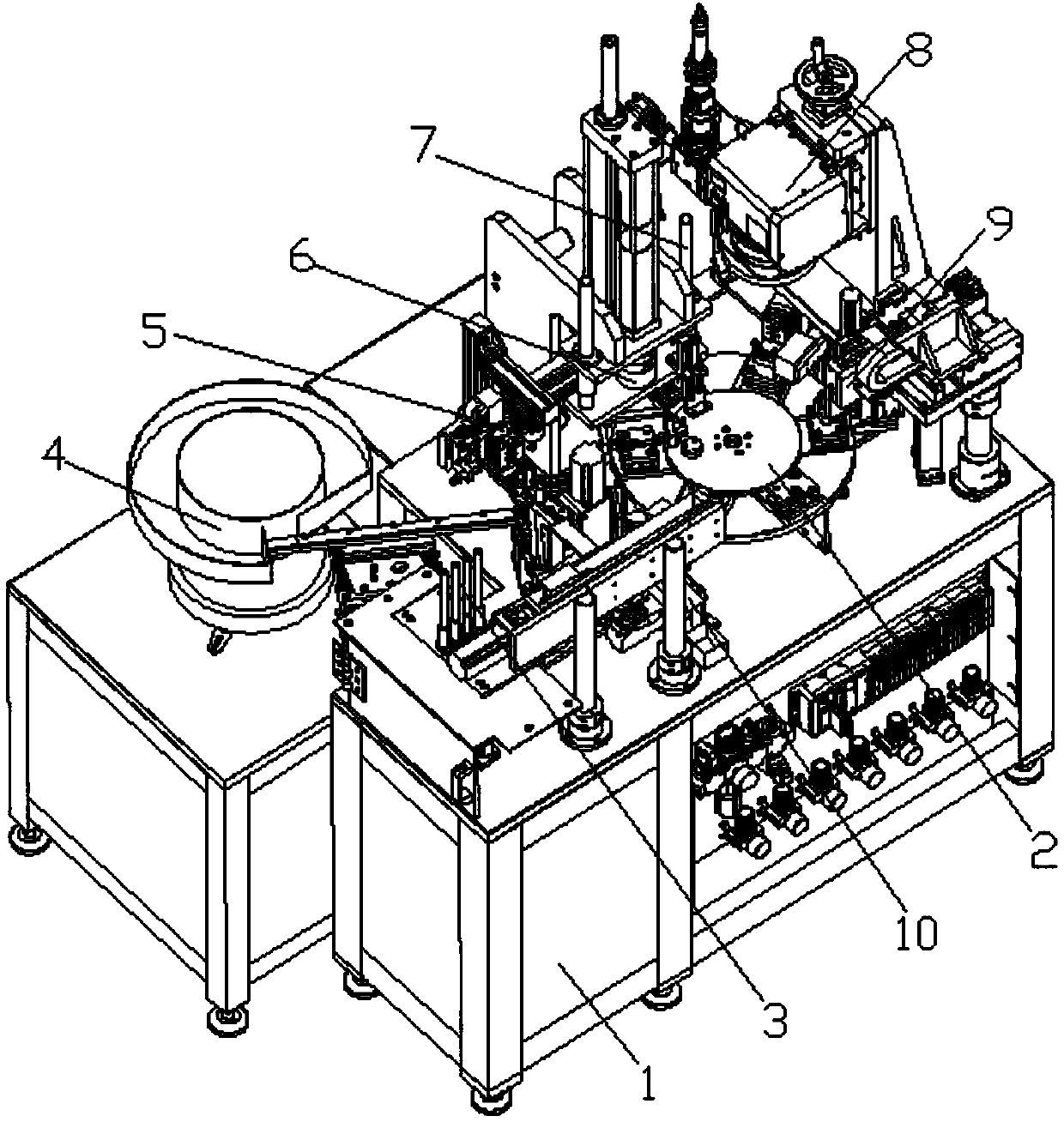

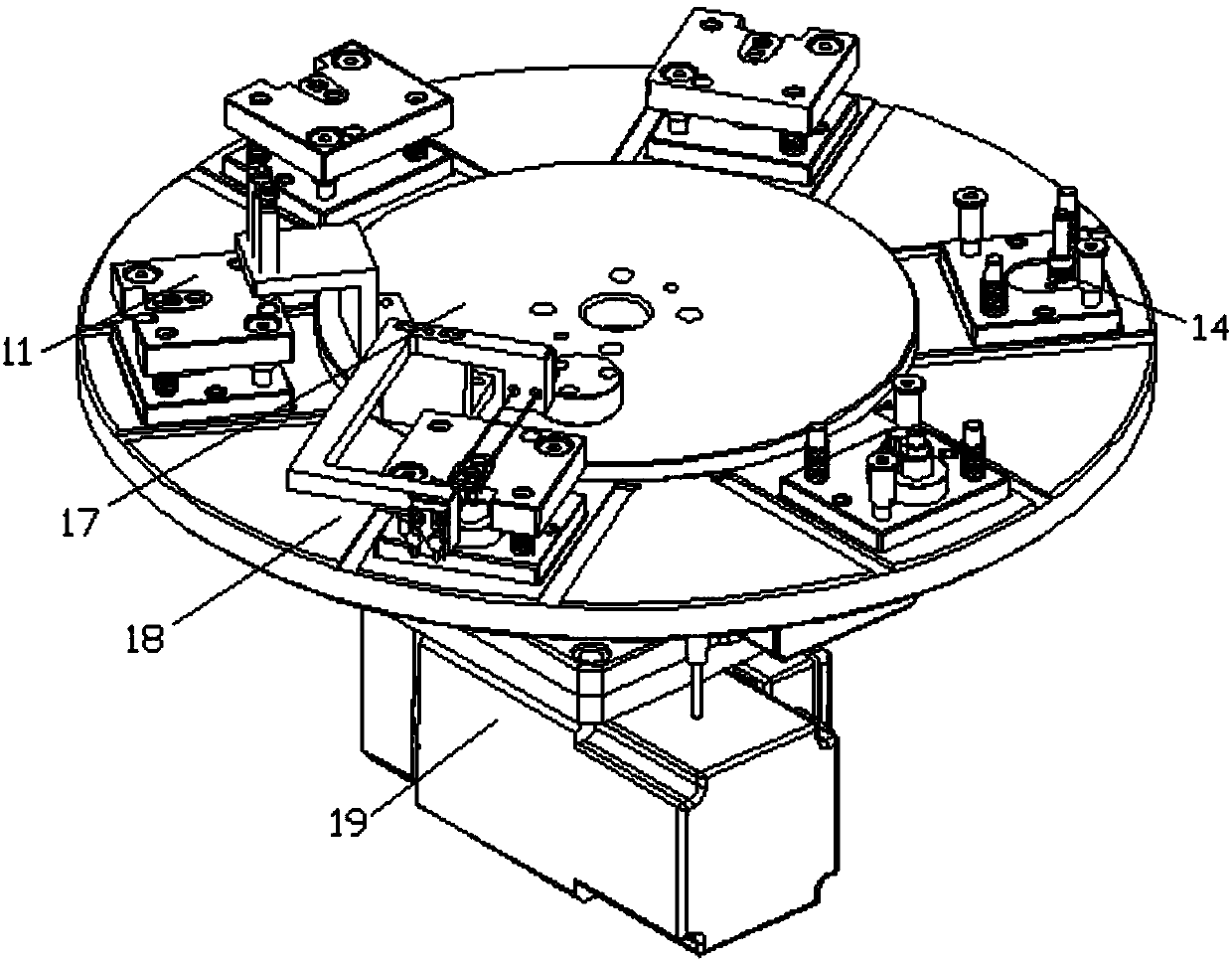

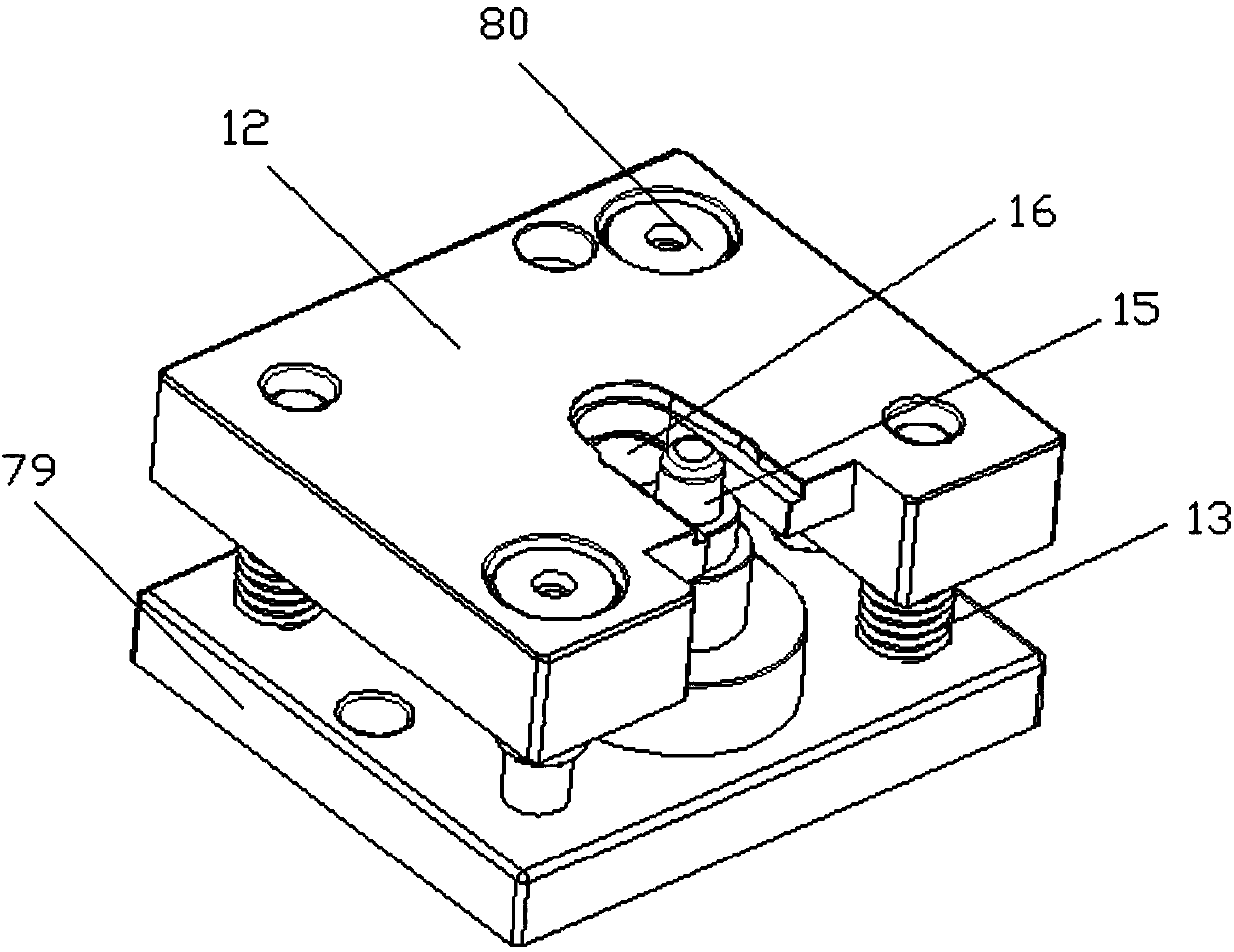

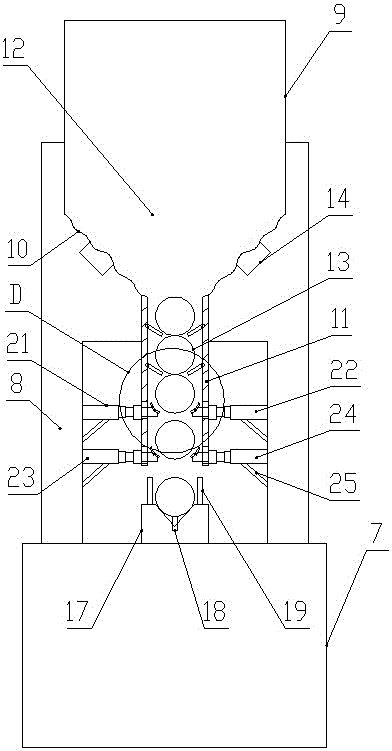

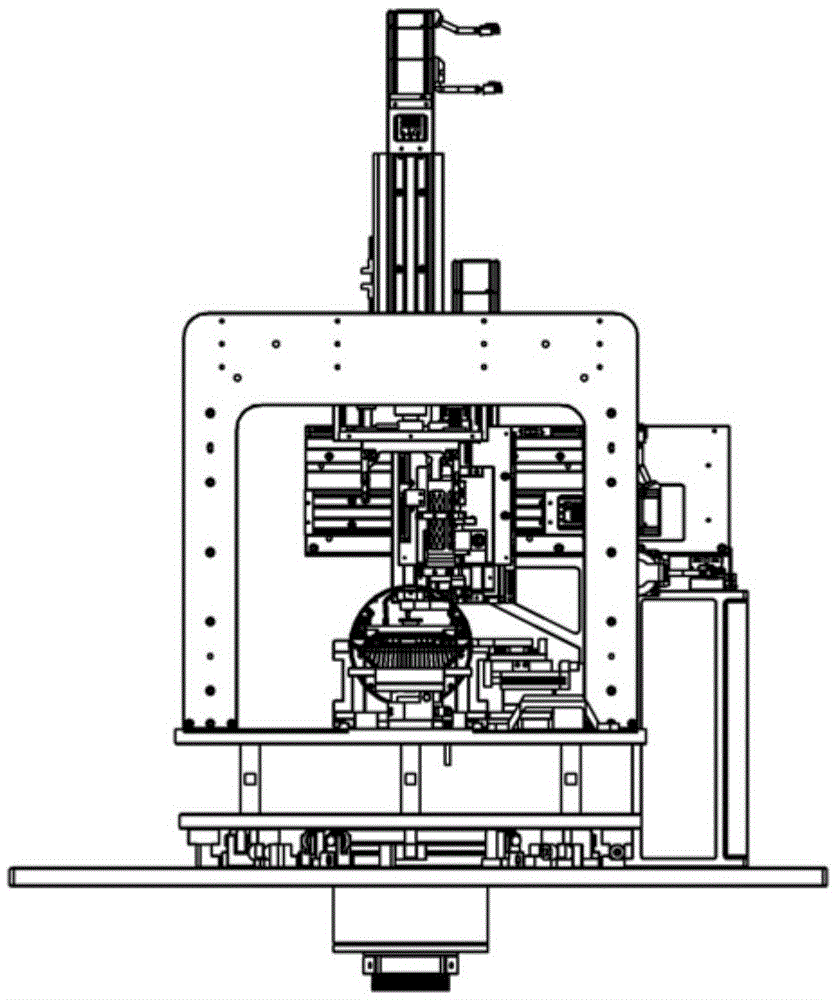

Full-automatic camshaft assembling machine

InactiveCN107717435ATimely detectionHigh positioning accuracyAssembly machinesLaser beam welding apparatusDistribution controlButt joint

The invention relates to a full-automatic camshaft assembling machine. The full-automatic camshaft assembling machine comprises a rack and a power distribution control cabinet arranged in the rack; arotating disk device is arranged on the middle portion above the rack; and a shaft feeding device, a cam vibrating feeding disk, a cam feeding device, a press-fitting device, a floating shaft pressingdevice, a laser welding device, a flaw detecting device and a discharging device in butt joint with carrier assemblies are sequentially arranged above the rack in the rotating direction of a rotatingdisk. According to the full-automatic camshaft assembling machine, by means of the shaft feeding device, a shaft is placed in the carrier assembly on the rotating disk device, and the carrier assembly rotates clockwise along the rotating disk and sequentially rotates onto the cam feeding device to perform cam feeding, onto the press-fitting device so as to press a cam into a matching groove of the shaft, onto the floating shaft pressing device to push down the shaft to be clamped with the matching groove, onto the laser welding device to perform laser welding on the matched portion of the shaft and the cam, onto the flaw detecting device to detect bruised damage and scratches, and onto the discharging device to perform discharging; and the assembling process of the cam and the shaft is completed, the positioning precision is high, and defective products are detected in time.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

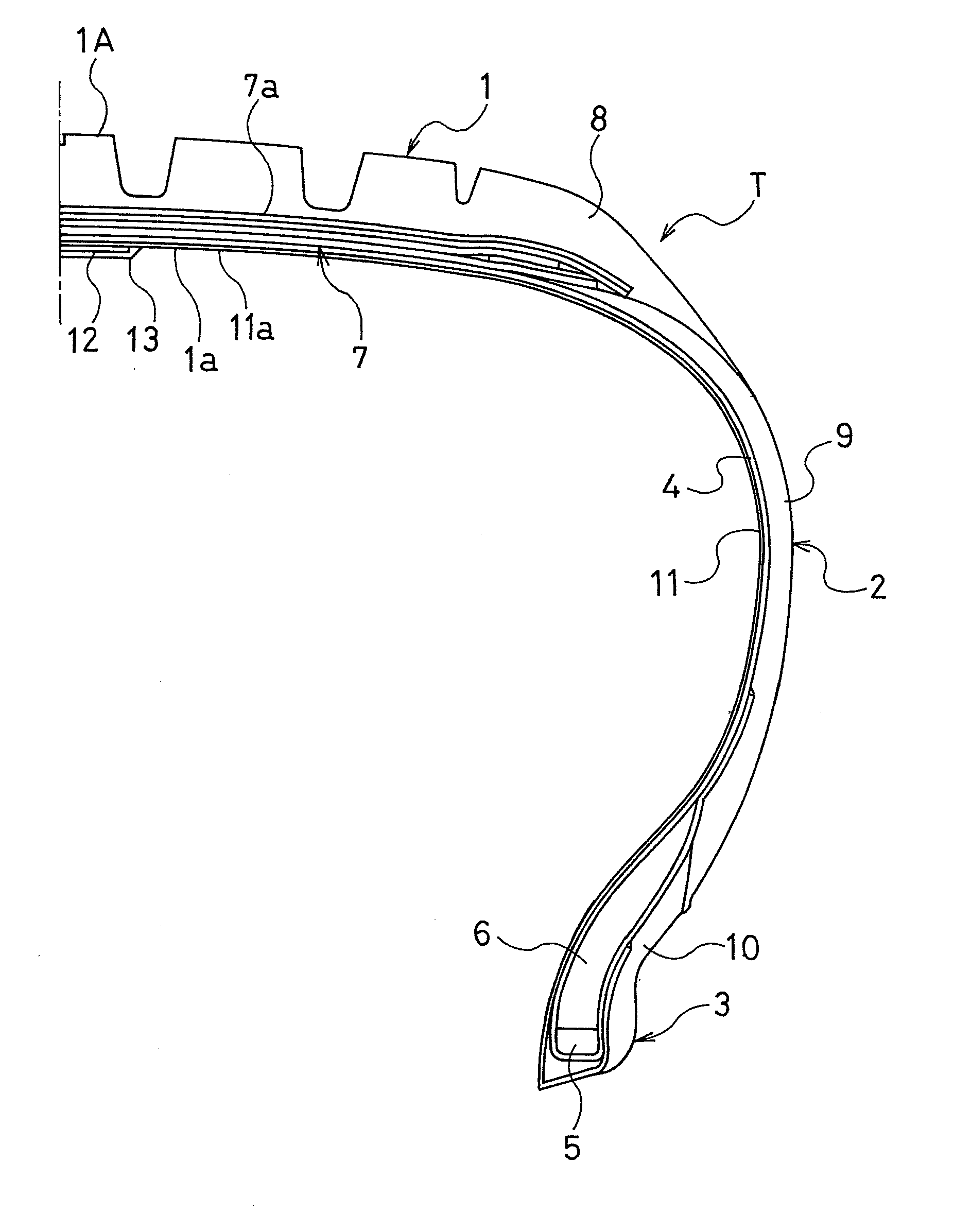

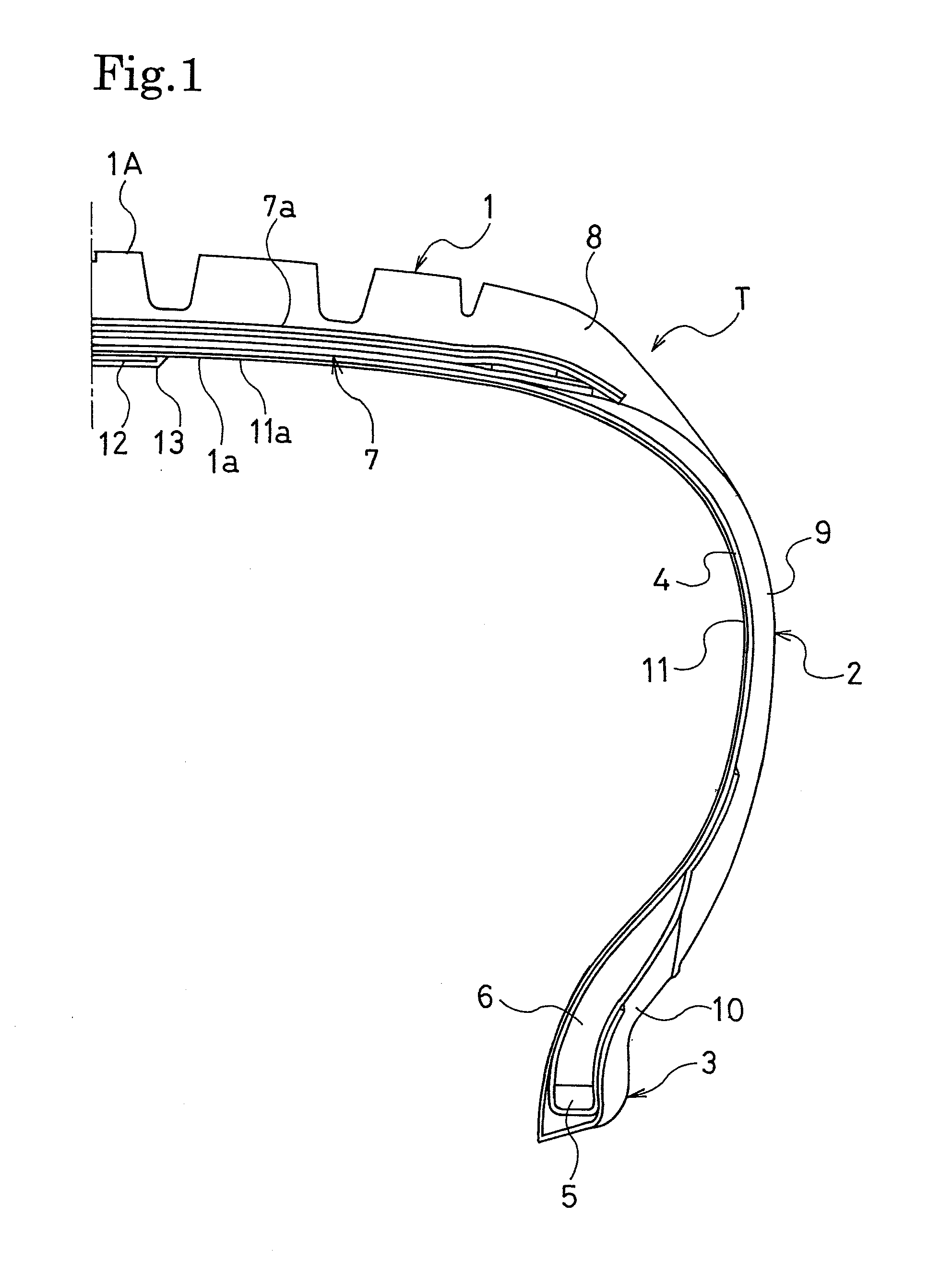

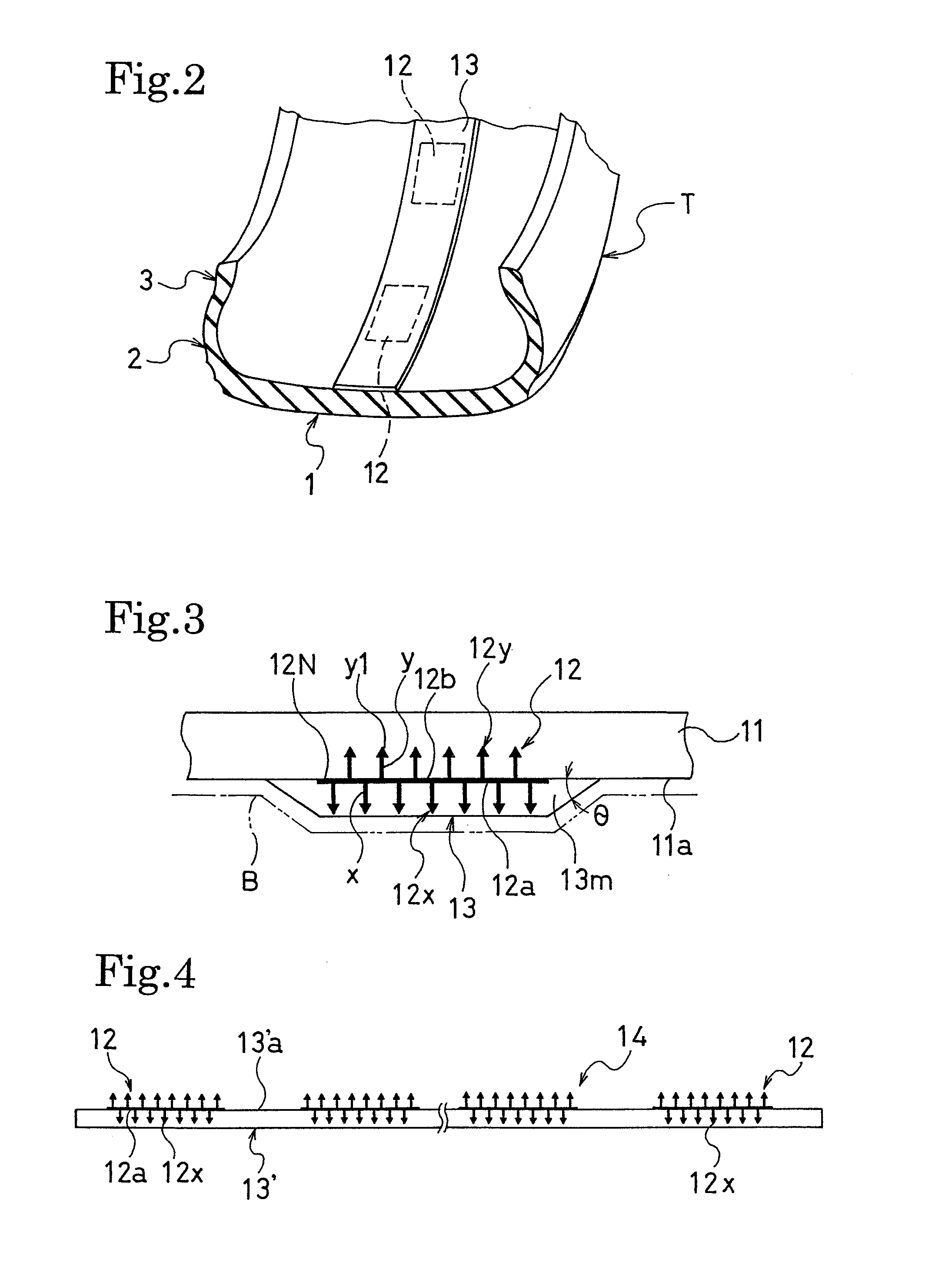

Pneumatic tire manufacturing method and pneumatic tire

ActiveUS20090159172A1Improve productivityGood adhesionTyresPneumatic tyre reinforcementsEngineeringFastener

Provided is a pneumatic tire manufacturing method capable of improving the productivity of pneumatic tires each having surface fasteners in its tire inner surface, and of avoiding manufacturing a pneumatic tire having a deteriorated uniformity, as well as of preventing engagement elements of each surface fastener from being crushed. Also, provided is a pneumatic tire manufactured by the pneumatic tire manufacturing method. The pneumatic tire manufacturing method according to the present invention includes the steps of, in making a green tire having two-side fasteners in its tire inner surface in its tire circumferential direction, each two-side fastener including an engagement element group on both sides: covering the engagement element groups on first sides of the two-side fasteners with a protective rubber layer made of an uncured rubber; making a cylindrical first formed body on a making drum, with the two-side fasteners covered with the protective rubber layer being intermittently attached to an inner circumferential surface of the first forming body in a circumferential direction thereof with the engagement element groups on second sides of the two-side fasteners being interposed in between; bonding the first formed body to an inner circumference of an annular second formed body by compression through expanding the first formed body into a toroidal shape, and thereby making the green tire; and curing the green tire inside a mold of a curing machine while pressing the green tire from its inside by a bladder.

Owner:YOKOHAMA RUBBER CO LTD

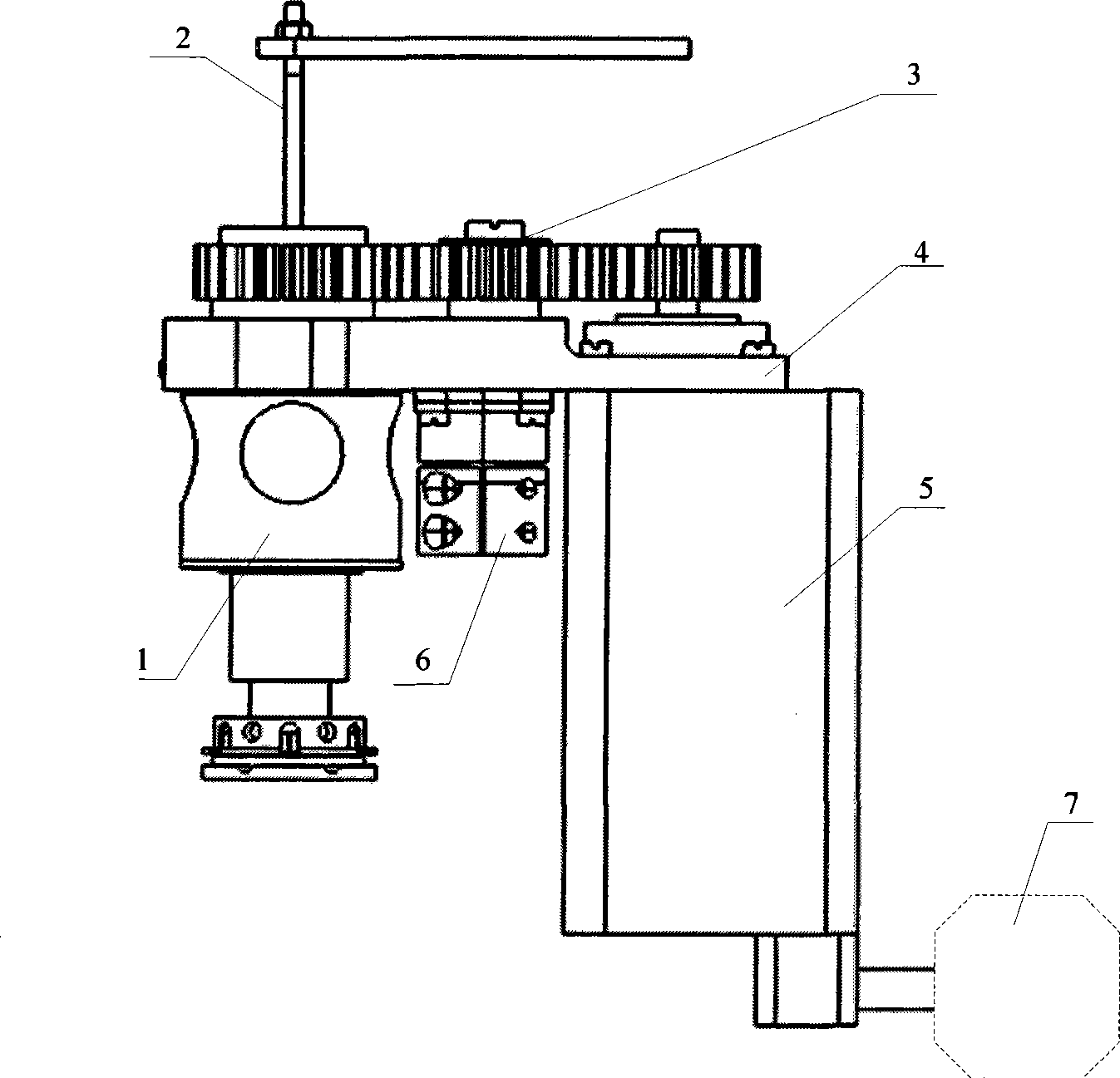

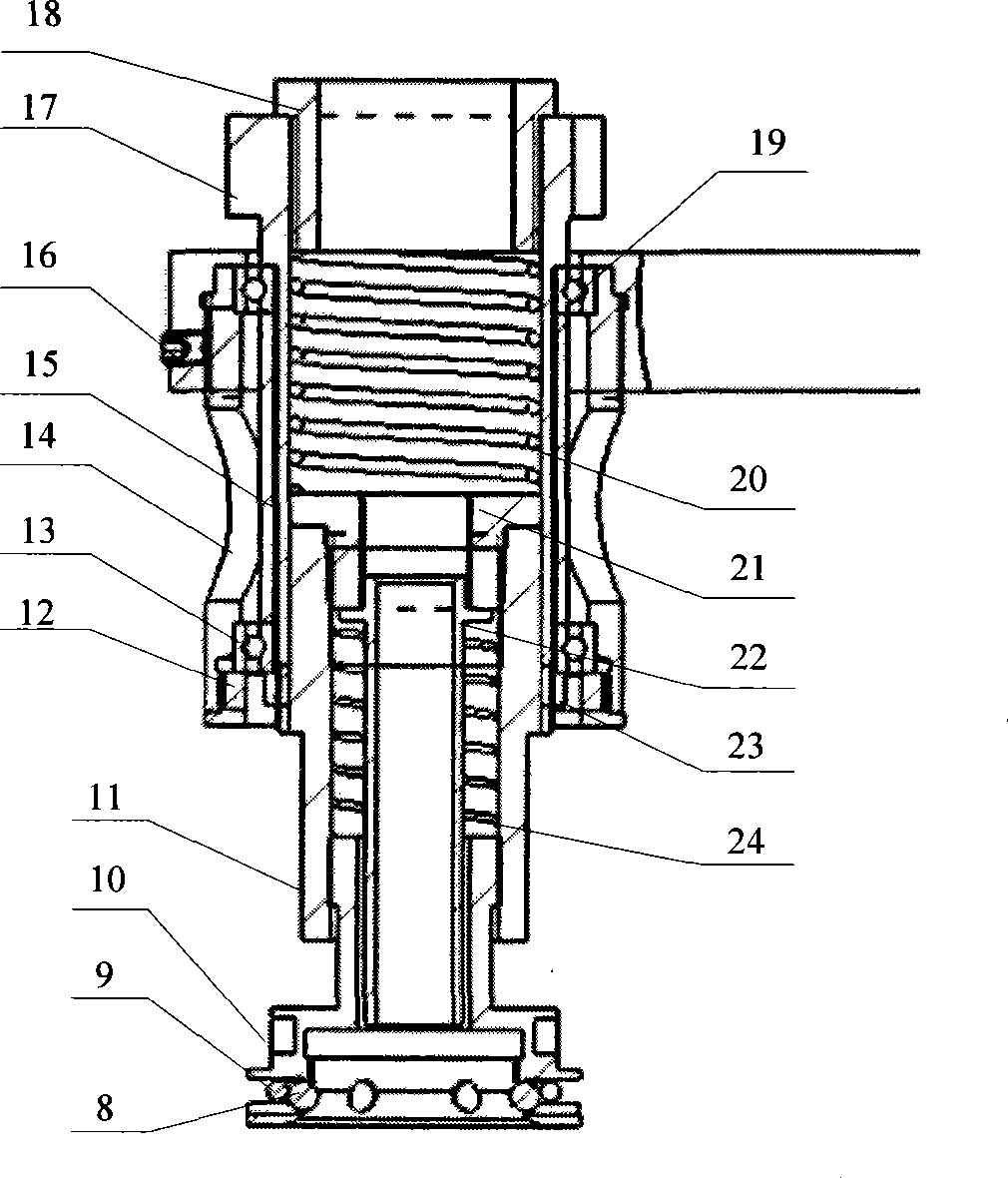

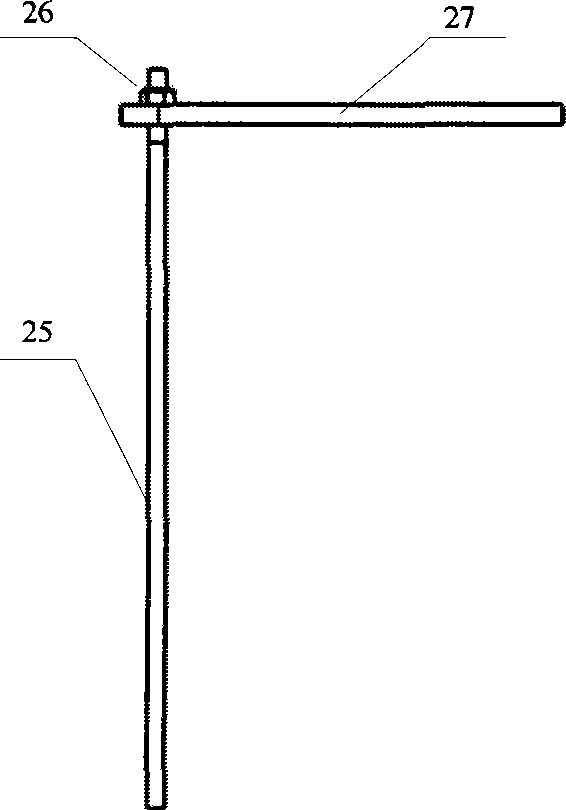

Servo bottle cap screwing mechanism

InactiveCN101386399APrevent crushingEffective screwingThreaded caps applicationPulp and paper industryServomotor

The invention relates to a servo bottle cap screwing mechanism in the technical field of packaging machinery, which comprises a cap screwing head, a waste cap withdrawing mechanism, an idler wheel mechanism, base blocks, a servomotor, a connecting support and a motor control system, wherein, the cap screwing head, the idler wheel mechanism, the servomotor and the connecting support are arranged on the base blocks, the motor control system controls the servomotor to rotate at certain rotating speed and torque, and the generated dynamic power is transferred to the cap screwing head by the idler wheel mechanism, so as to cause the cap screwing head to rotate along with the servomotor; the connecting support is connected with a lifting guide rod to drive the base blocks to raise and fall periodically, and the height of the waste cap withdrawing mechanism is unchanged, and the waste cap withdrawing mechanism is arranged at a cap screwing machine. Under the germfree condition, the entire bottle cap screwing mechanism is lubrication free, has no leakage, is convenient for frequent rinsing and disinfection; the cap screwing torque is controlled by computer, the cap screwing mechanism is driven by servomotor and has large adjustable range; and besides, the working torque, the cap screwing speed, and the like, of the single cap screwing mechanism can be displayed, and the cap screwing mechanism can automatically discharge waste or abnormal caps.

Owner:SHANGHAI JIAO TONG UNIV

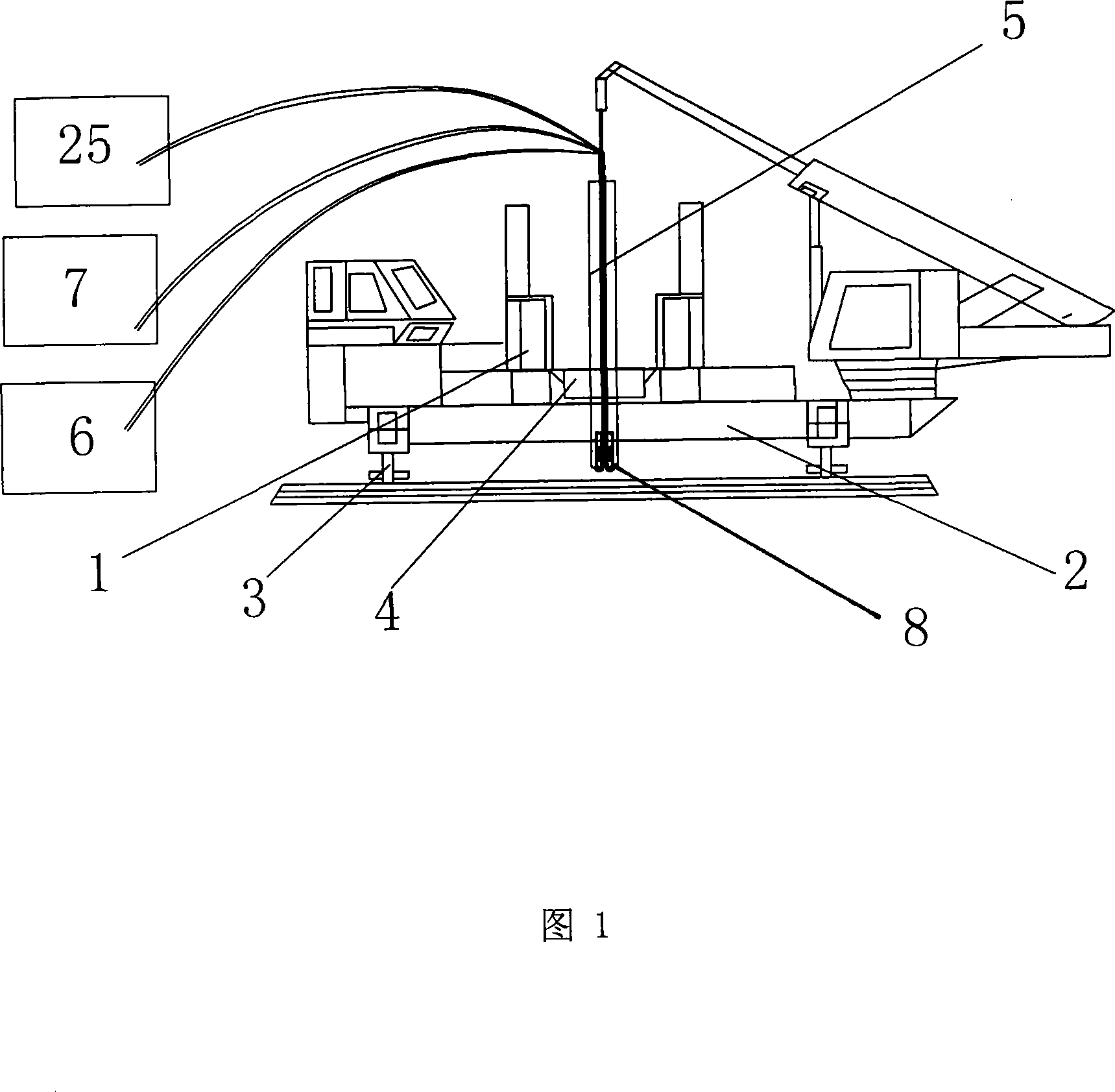

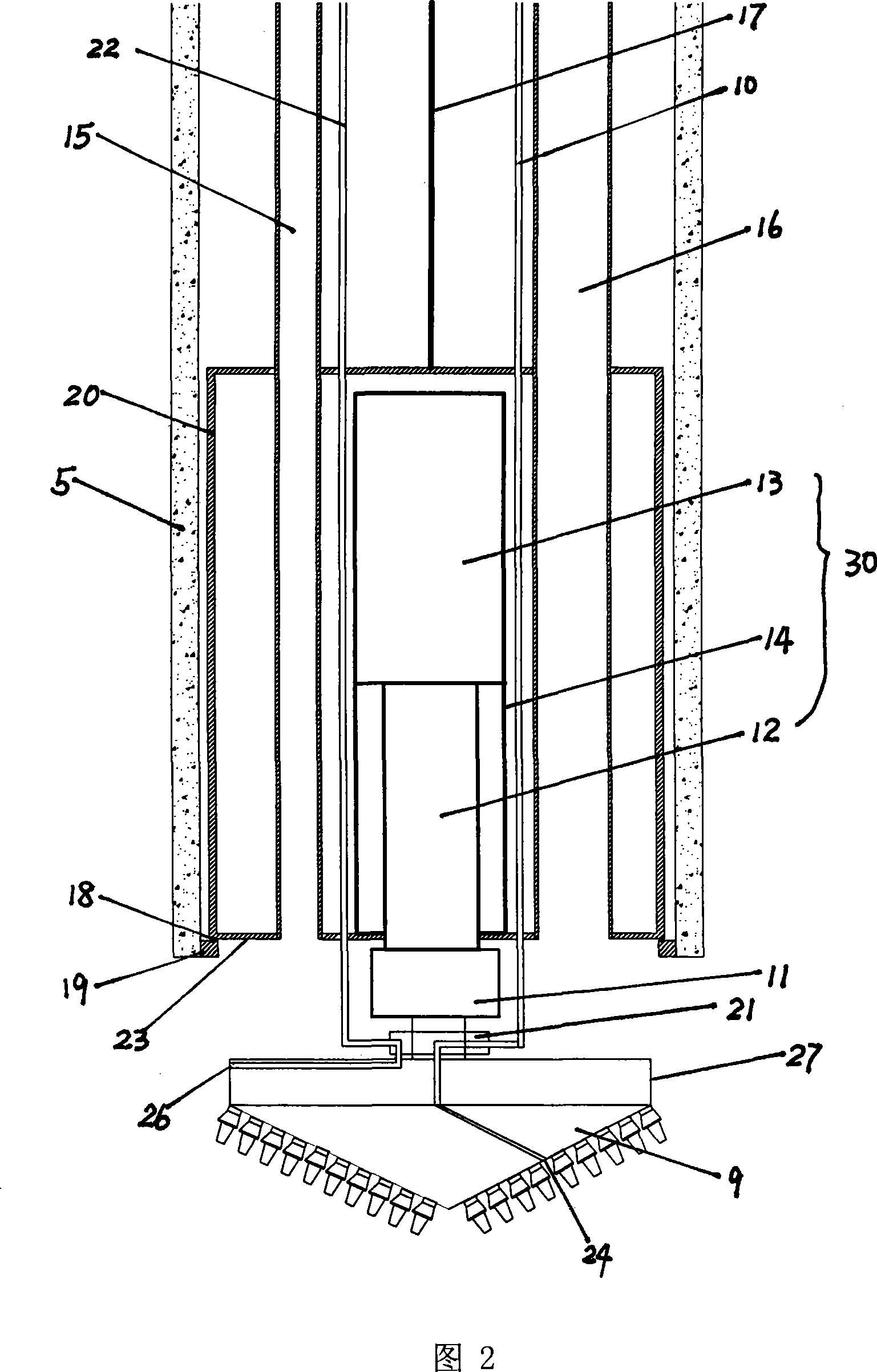

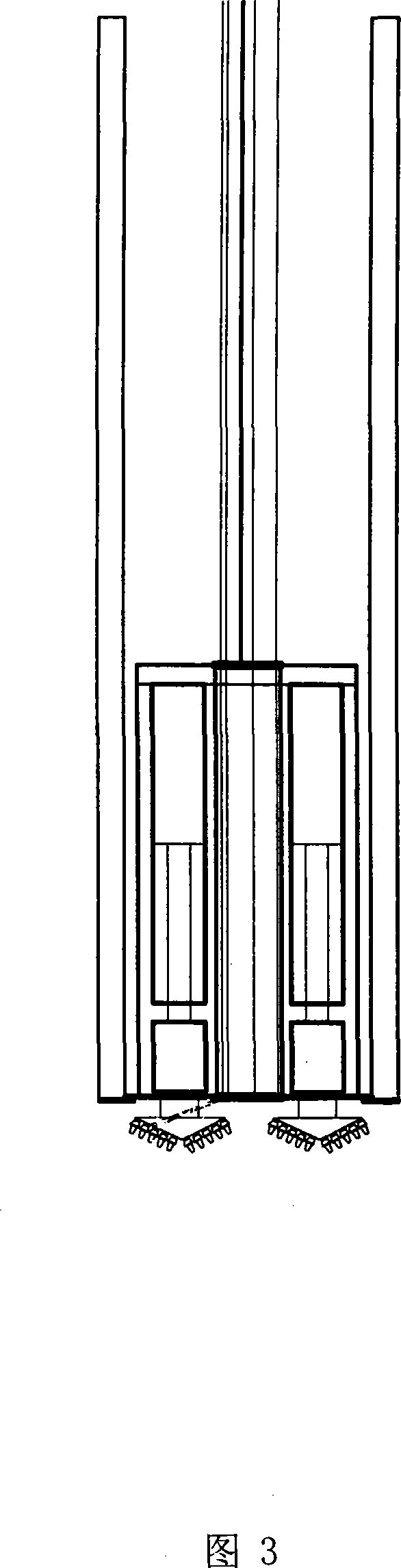

Construction machinery used for large diameter hollow pile and its construction method and use

InactiveCN101215836AReduce side frictionIncreased vertical bearing capacity of single pileBulkheads/pilesDrilling machines and methodsHigh pressureHigh load

The invention discloses a construction machine for hollow piles with large diameter and the construction method and usage, which comprises a drilling system, a pile pounding system, a drainage system which are integrated into one part. The pile forming method comprises: a high-spray drilling bit is arranged on a steel tube (a protection cylinder) or on the bottom of an inner hole of a pre-made tube pile for hole drilling and mud making; the mud is drained from a water joint or a drainage pipe; the protection cylinder or tube pile is pressed asynchronously or synchronously along with the drilling bit; during pile-sinking process, water mud is sprayed to the outer soil of the hole to solidify the surrounding soil of the pile and fill the gaps between the pile and surrounding soil of the pile; after the drilling bit reaches certain depth, the water mud is again sprayed to solidify surrounding soil of the pile; lifting the drilling bit; putting down reinforcement cage; casting concrete for piling. The invention is a construction method for foundation piles and drilling with large diameter, super long and high load, which especially provides convenient, labor-saving, rapid and economical equipment and method for marine pile driving.

Owner:雷玉华

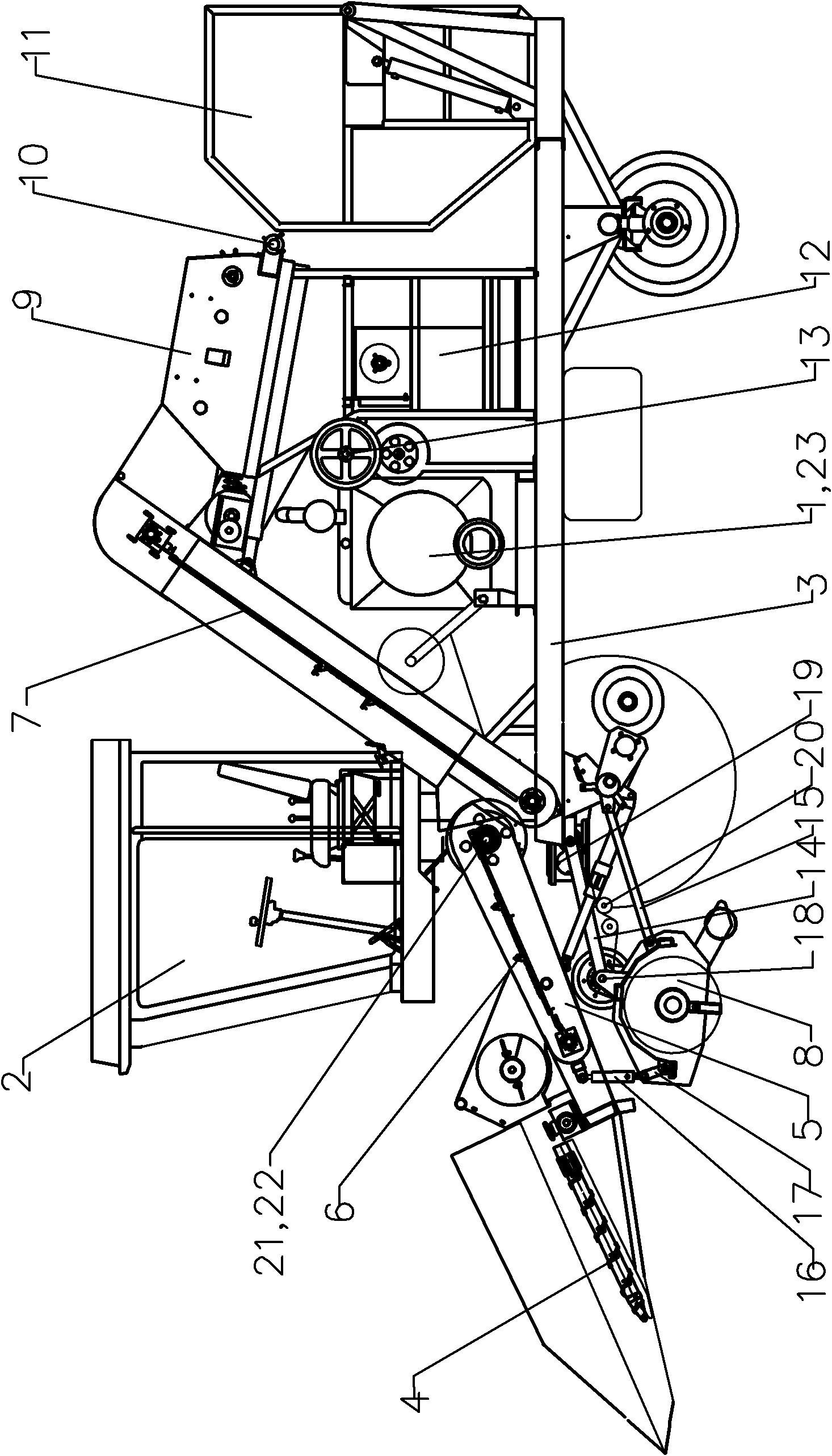

Self-propelled corn combine harvester

ActiveCN101889497AAvoid crushingImprove the quality of field returnMowersAgricultural engineeringDrivetrain

The invention discloses a self-propelled corn combine harvester and belongs to the field of agricultural machinery. The self-propelled corn combine harvester comprises a working chassis assembly and a harvesting assembly. The working chassis assembly consists of a power system, a driving control system, a walking chassis system. The harvesting assembly is arranged on the working chassis and comprises a corn ear picking table, an ear picking table mounting rack, a primary ear elevator, a secondary ear elevator, an ear stripper, an ear throwing roller, an ear box, a stripper seed recovery device and a power transmission system which are mutually connected. The self-propelled corn combine harvester is characterized in that a straw chopper is arranged in front of a driving wheel of the walking chassis system, and is mounted under the ear picking table mounting rack in front of the driving wheel through a chopper suspension device. Due to the structure optimized design, the straw chopper is arranged in the front and is mounted in front of the driving wheel and under the ear picking table mounting rack, and the ear-picked straw directly enters the chopper to be cut. Therefore, the straw is prevented from being rolled by wheels, and the straw chopping quality is improved.

Owner:SHANDONG JUMING MASCH CO LTD

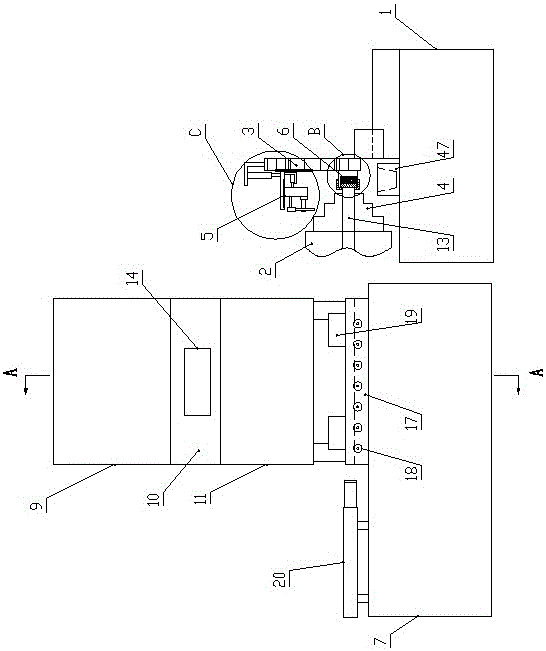

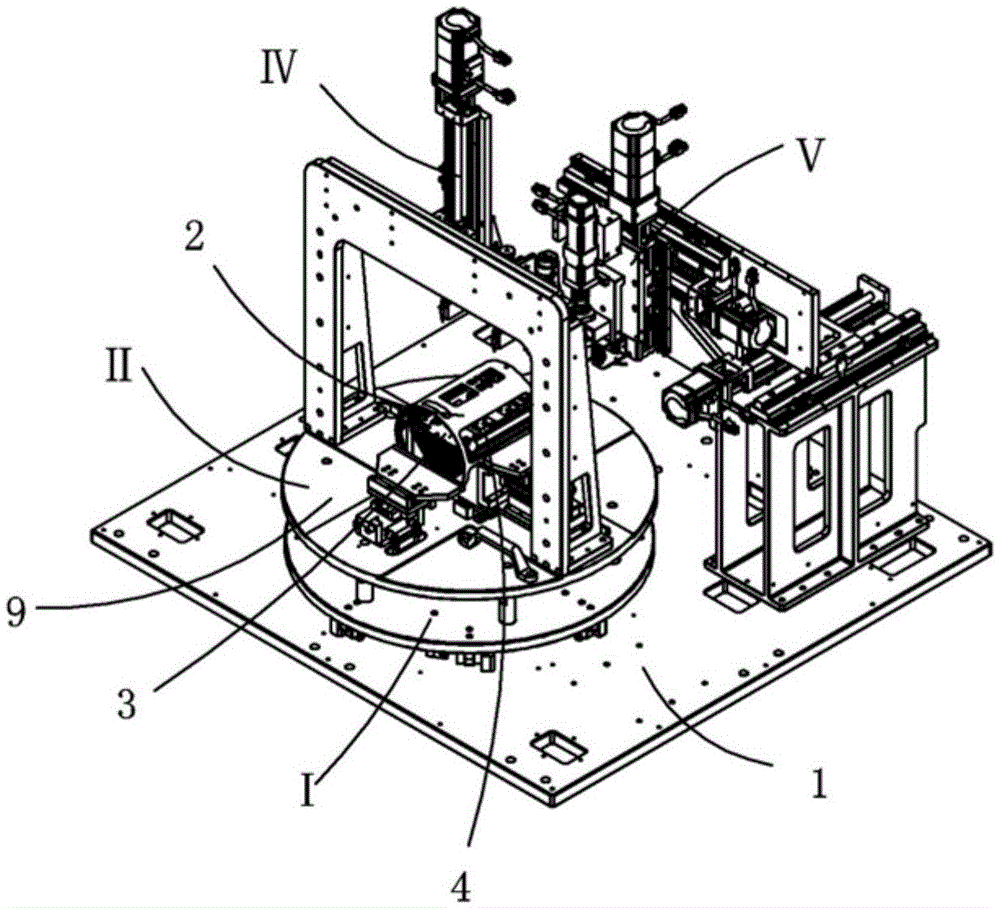

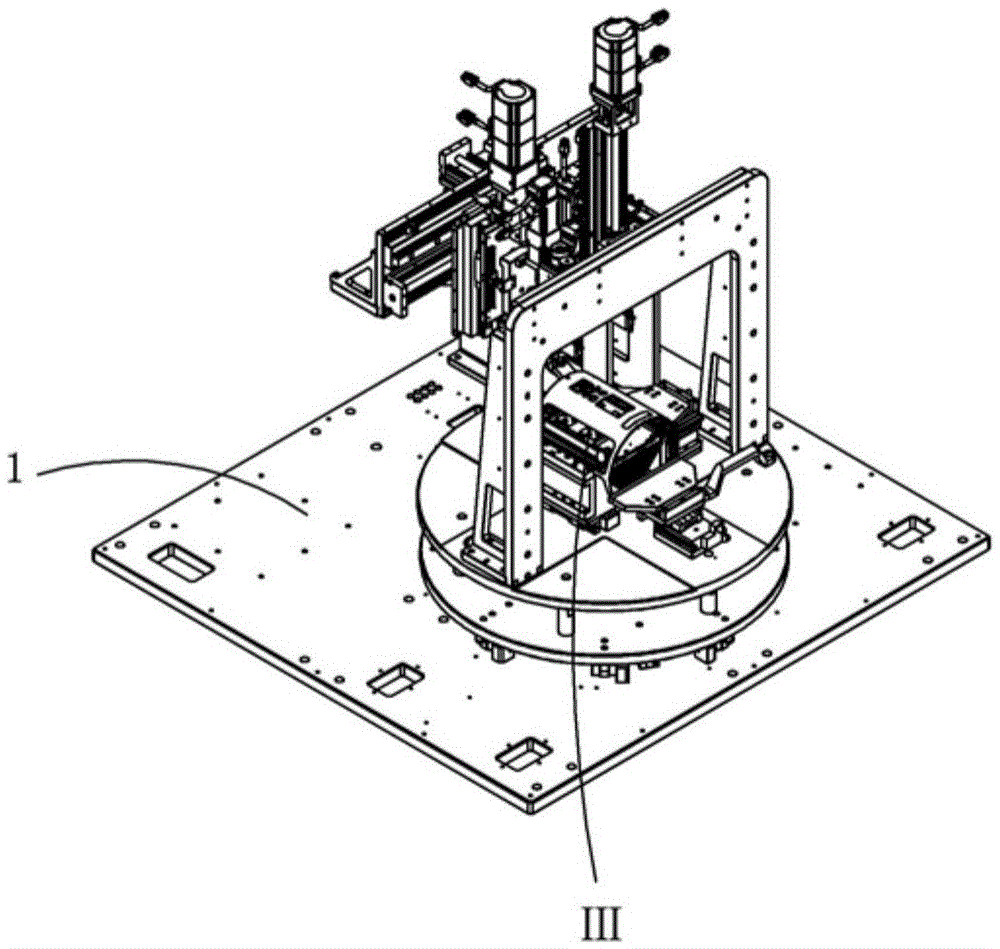

Automatic CPU alignment assembling machine

The invention relates to an automatic CPU alignment assembling machine. The automatic CPU alignment assembling machine comprises a bottom plate. The bottom plate is provided with a rotating mechanism used for facilitating manual feeding and discharging. A rotary disc of the rotating mechanism is provided with a carrier mechanism used for positioning a product. The product is positioned on the carrier mechanism. A CPU is placed in the product. A pressing plate is placed on the CPU. A plurality of sets of screw positioning modules are arranged on the pressing plate and correspond to to-be-locked positions of the product. The bottom plate is provided with a downward pressing mechanism used for downwards pressing the pressing plate. A locking mechanism used for locking the CPU to the product through screws is arranged on the bottom plate. The CPU is locked on a cylinder computer case through the screws, automatic alignment and centering of the left side and the right side of the CPU can be achieved, and accurate screw locking is achieved.

Owner:BOZHON PRECISION IND TECH CO LTD

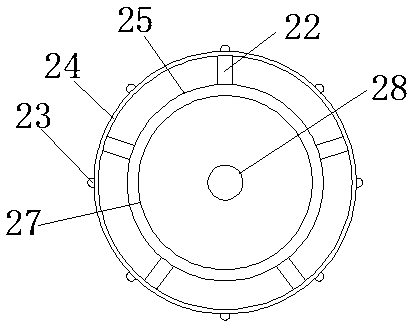

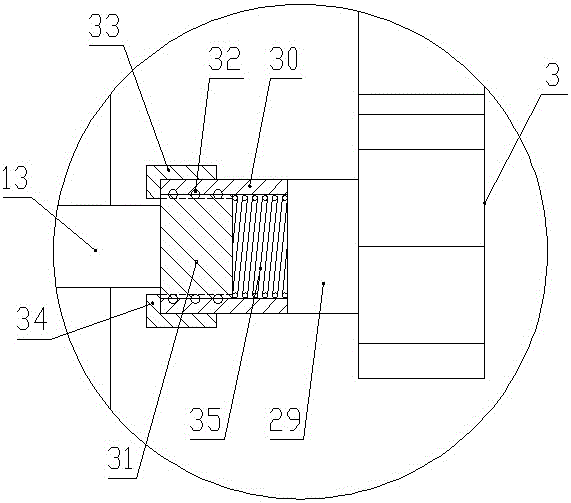

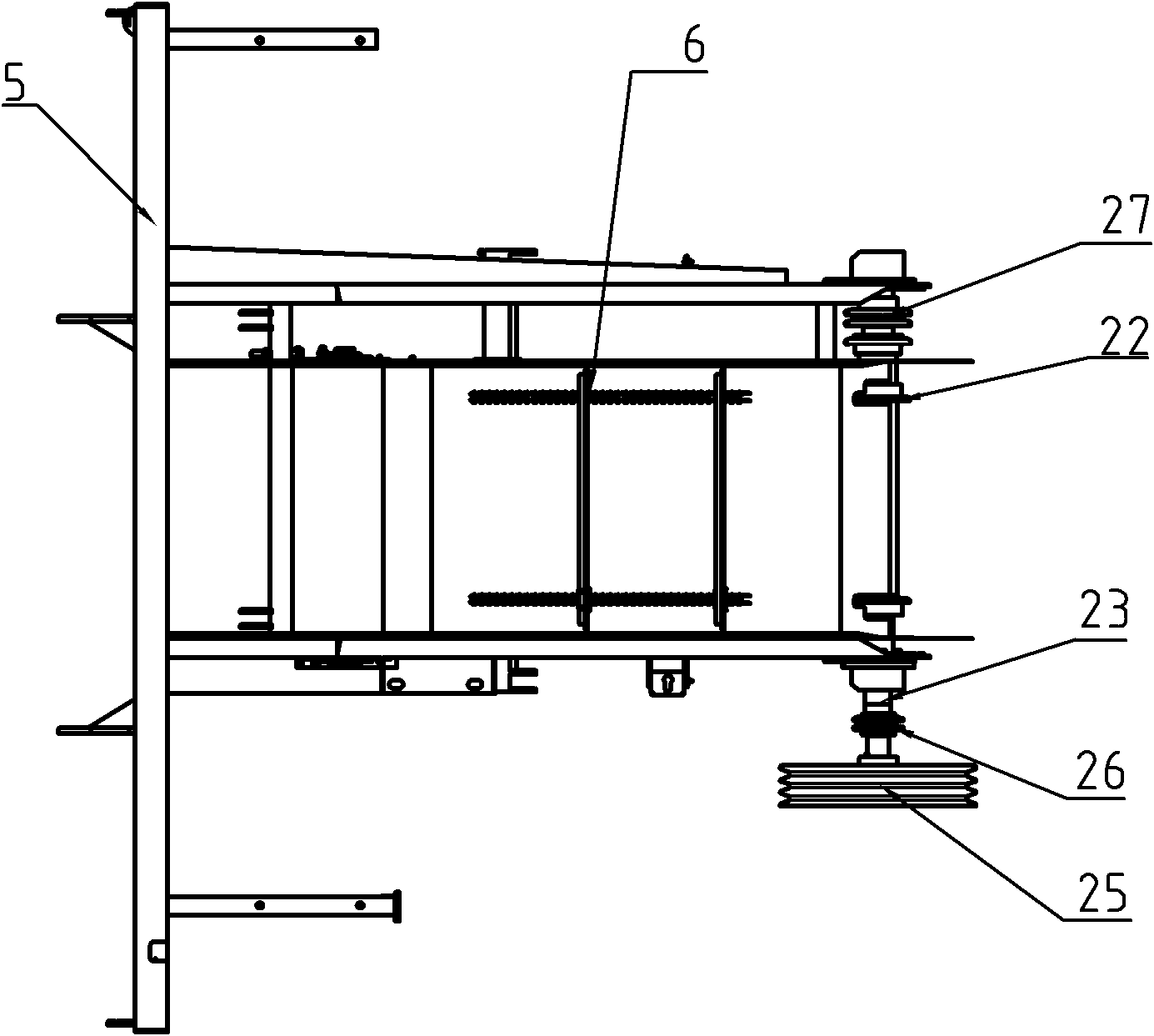

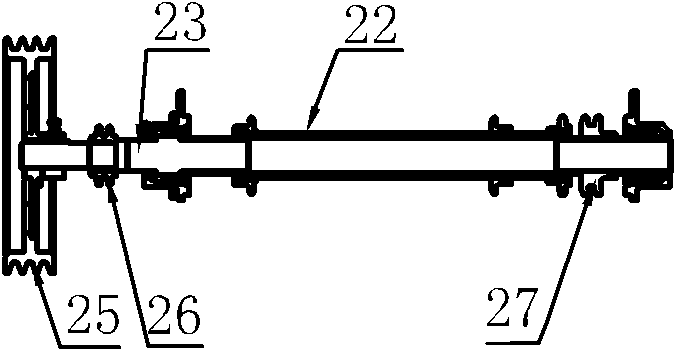

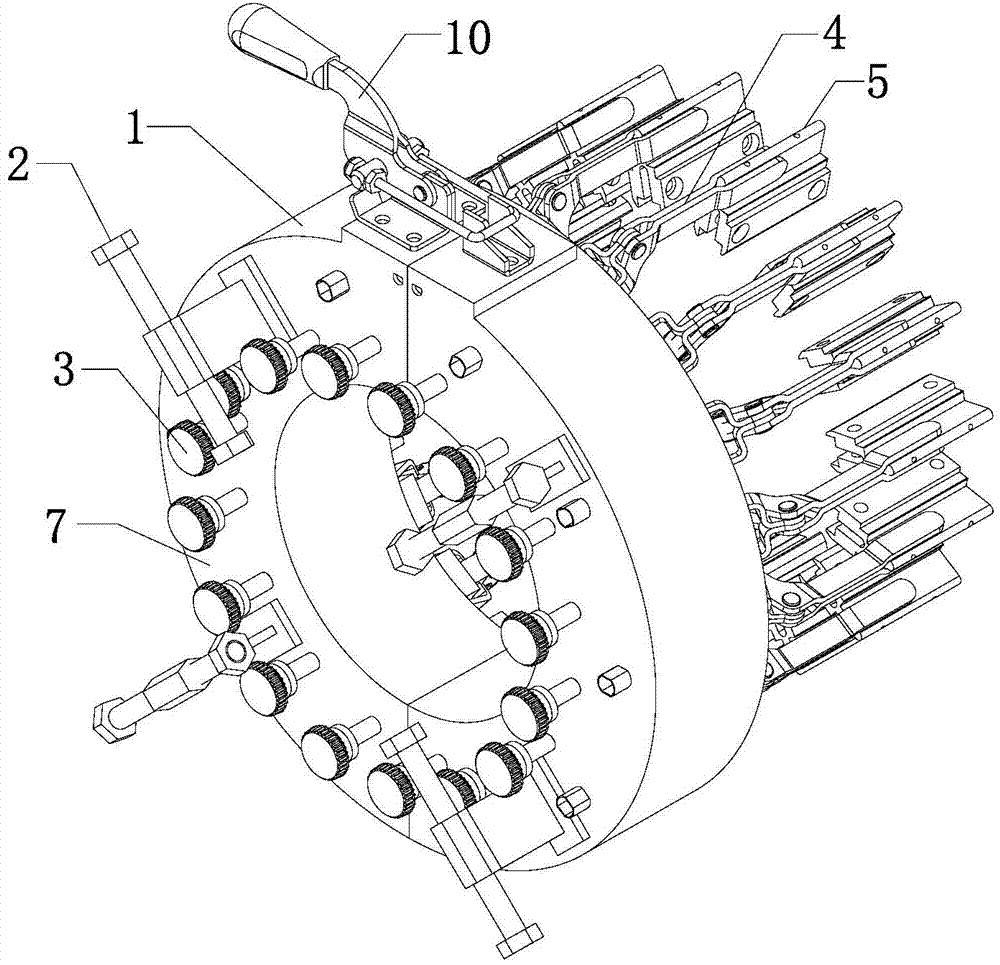

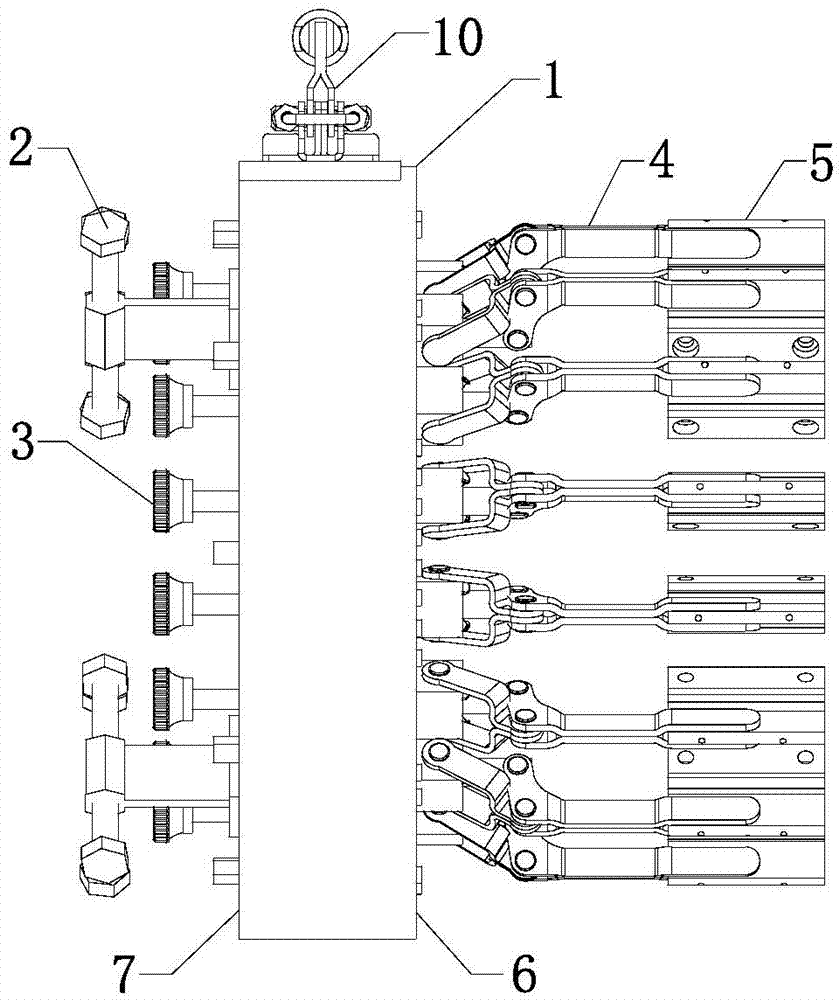

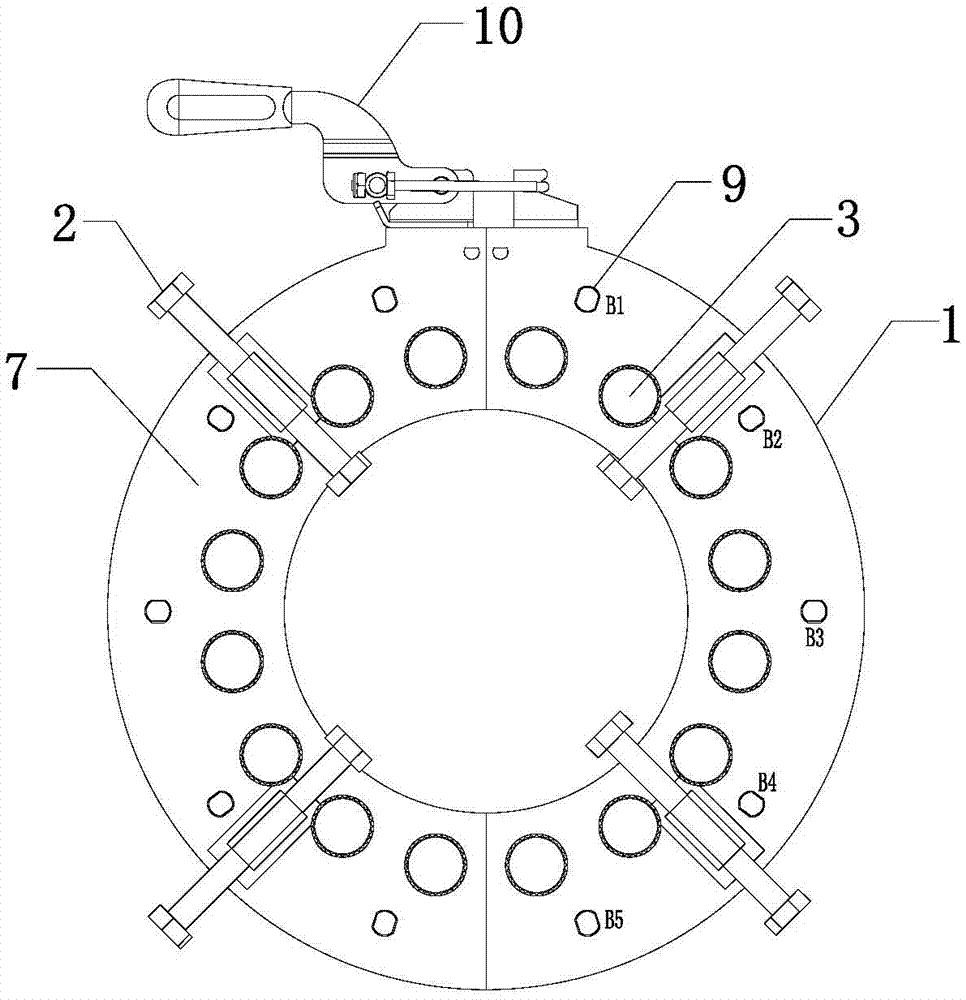

Ultrasonic guided-wave probe array fixing device used for tube fitting detection

ActiveCN104749258AImprove versatilityOvercome the defect that only a single outer diameter pipe can be detectedMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic guided waveBiomedical engineering

The invention discloses an ultrasonic guided-wave probe array fixing device used for tube fitting detection. The ultrasonic guided-wave probe array fixing device comprises a mechanical part and a signal circuit part, wherein the mechanical part comprises a circular-ring-shaped base, a plurality of positioning bolts, a plurality of spiral telescopic components, a plurality of swing rods and a plurality of probe bases; the inner diameter of the circular-ring-shaped bases is larger than the outer diameter of a detected tube fitting; two side panels of the circular-ring-shaped bases are respectively a panel A and a panel B; the positioning bolts are mounted on the panel B; each spiral telescopic component penetrates through the panel B and the panel A in sequence and then is correspondingly connected with one end of each swinging rod to regulate the opening and the closing of the swinging rod, the other end of each swinging rod is correspondingly connected with each probe base; a structure consisting of the spiral telescopic component, the swinging rods and the probe bases is uniformly distributed on the circular-ring-shaped base. The ultrasonic guided-wave probe array fixing device used for tube fitting detection, disclosed by the invention, is simple in structure, quick and convenient to operate, and capable of adapting to detection needs of tube fittings with different outer diameters within a design range.

Owner:JINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com