Patents

Literature

2297 results about "Consumables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Consumables (also known as consumable goods, non-durable goods, or soft goods) are goods that are intended to be consumed. People have, for example, always consumed food and water. Consumables are in contrast to durable goods. Disposable products are a particular, extreme case of consumables, because their end-of-life is reached after a single use.

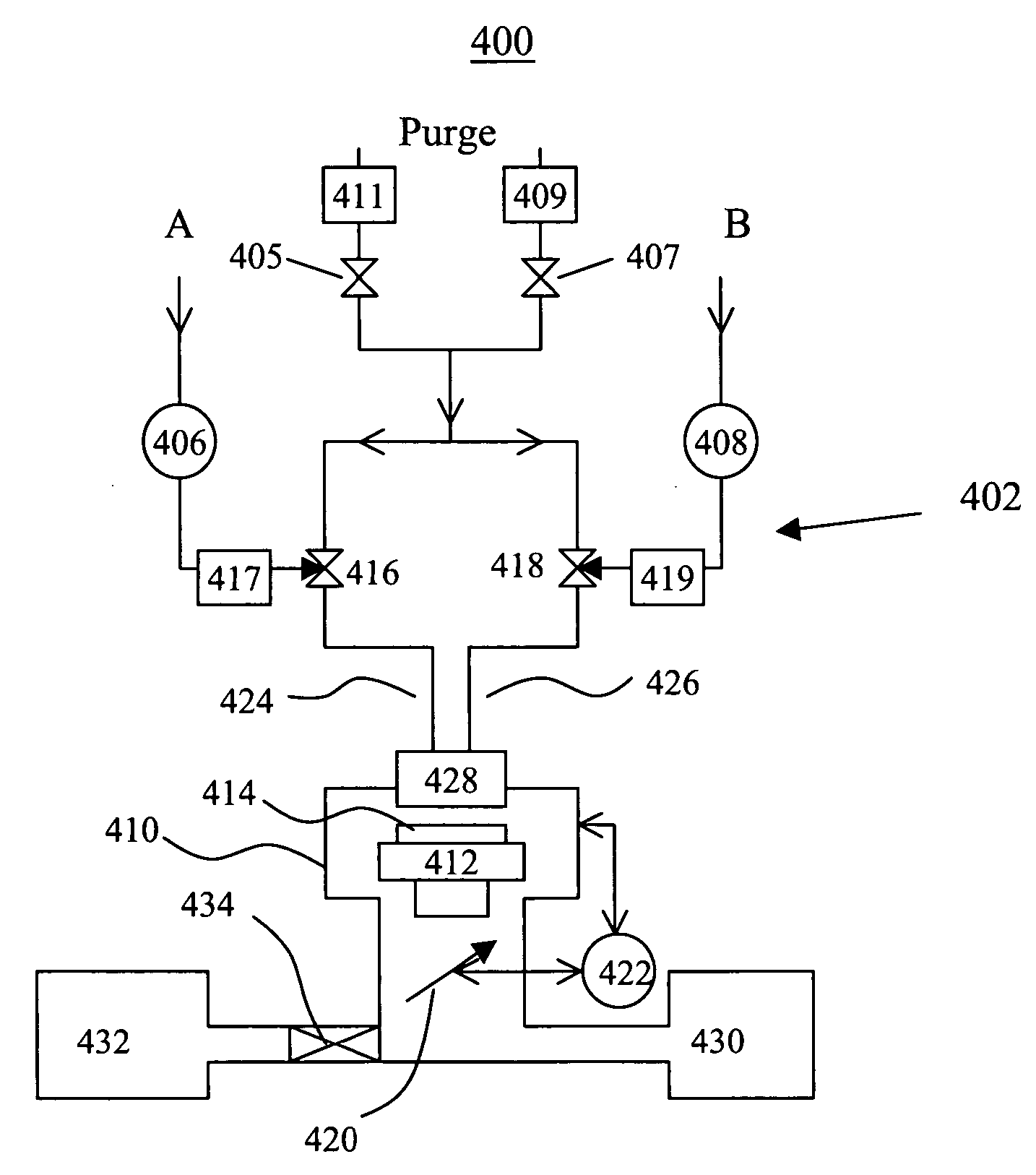

Methods and apparatus for cycle time improvements for atomic layer deposition

InactiveUS20050016956A1Decorative surface effectsFrom chemically reactive gasesProcess engineeringCycle time

Different periods of an ALD cycle are performed using different purge flows and, in some cases, different pumping capacities, while maintaining the reactor chamber at a nominally constant pressure. The purge flows may, in some cases, utilize different gasses and / or may be provided through different flow paths. These operations provide for ALD cycle time improvements and economical operation with respect to consumables usage. In some embodiments the use of an annular throttle valve provides a means for controlling downstream flow limiting conductances in a gas flow path from the reactor chamber.

Owner:AIXTRON INC

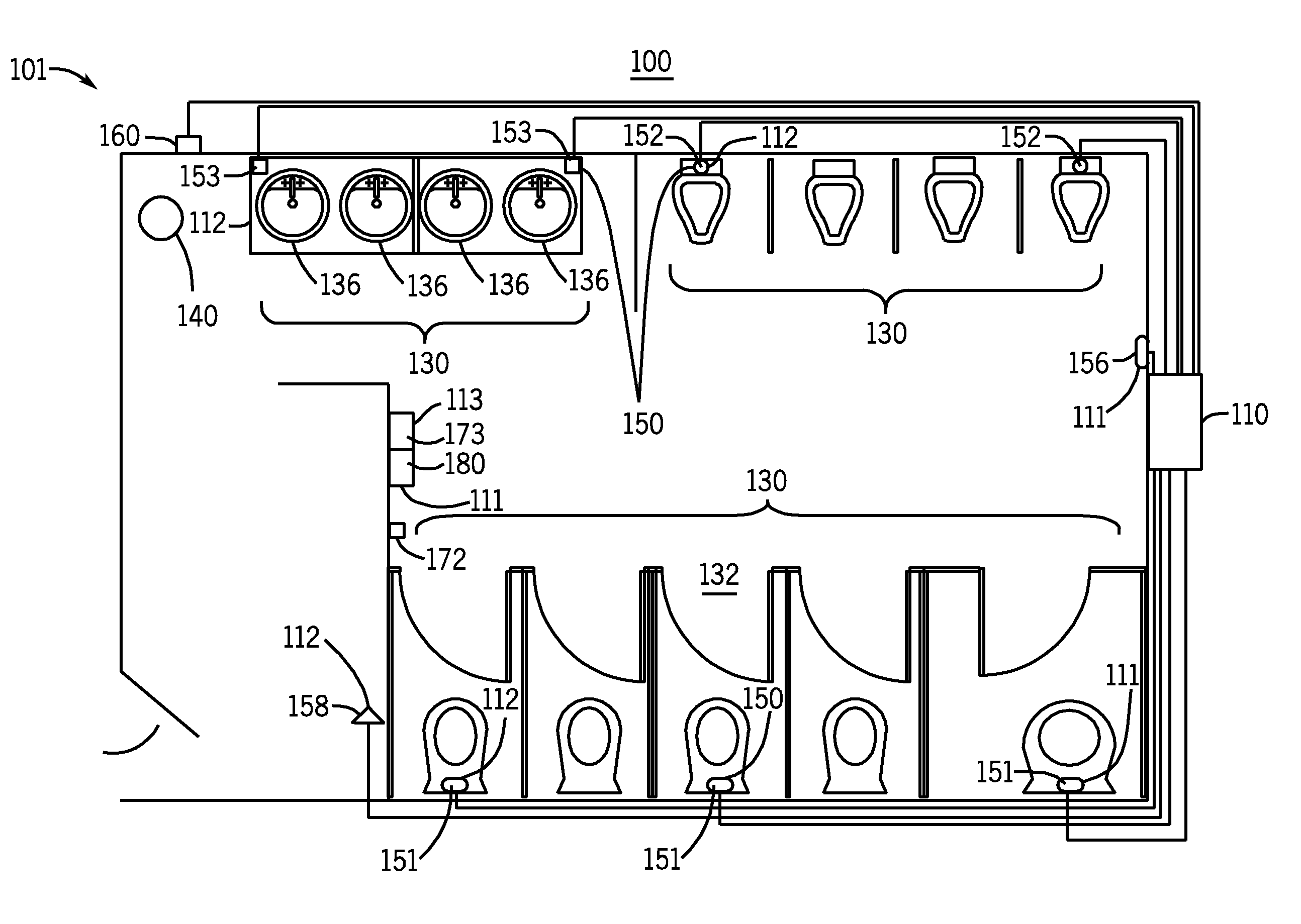

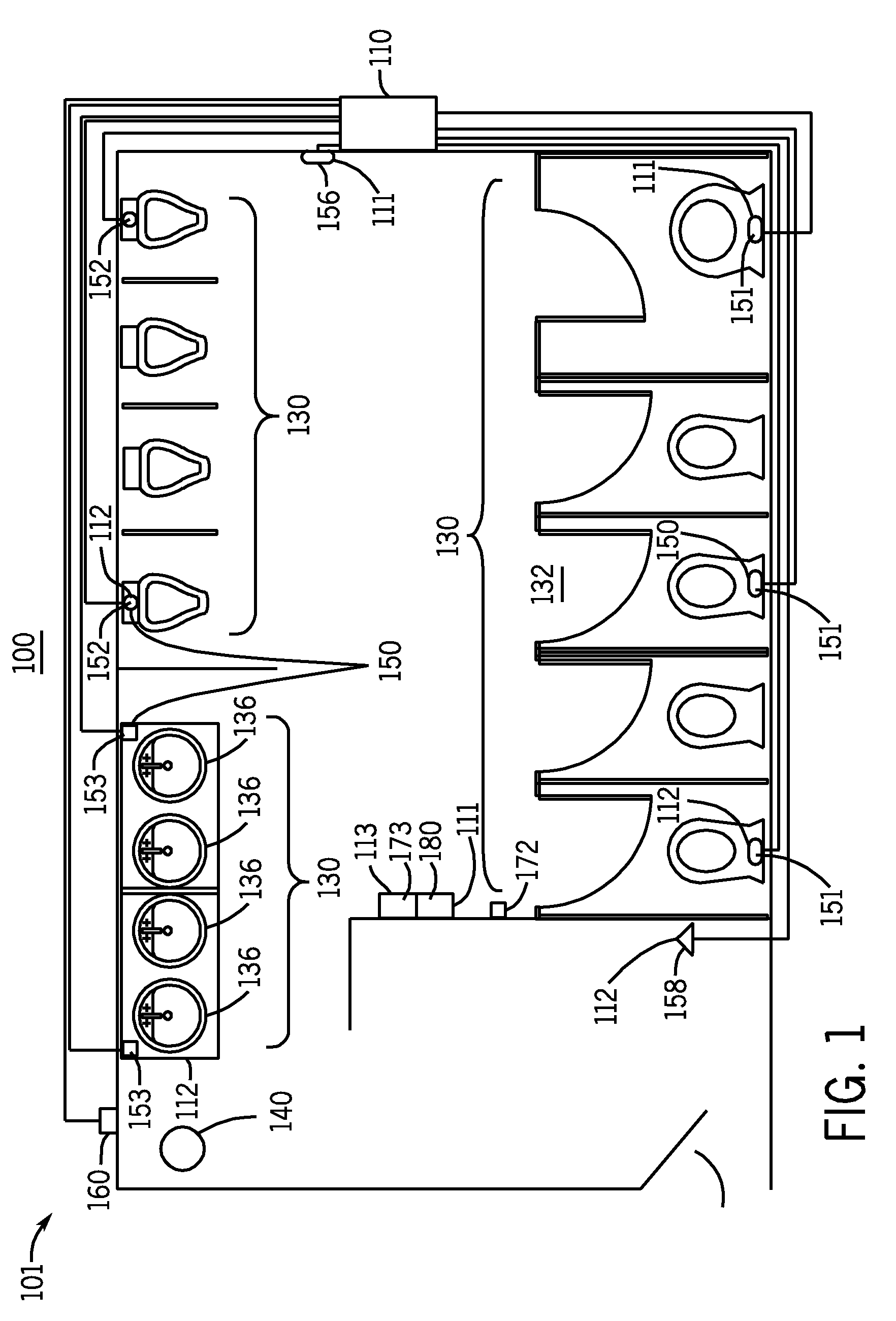

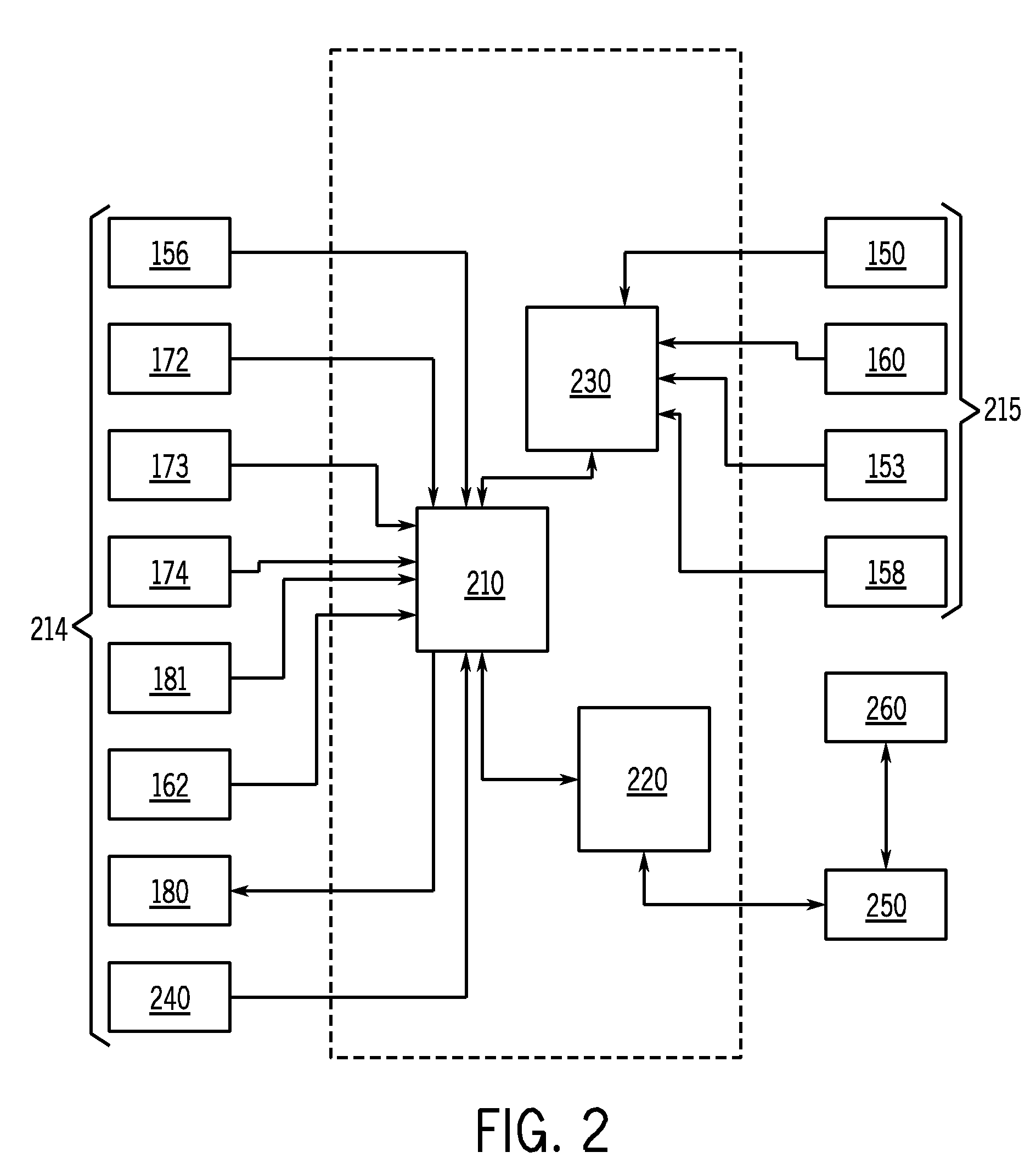

Restroom convenience center

ActiveUS20090119142A1Easy to useHigh trafficVolume/mass flow measurementHolders and dispensersState dependentMonitoring system

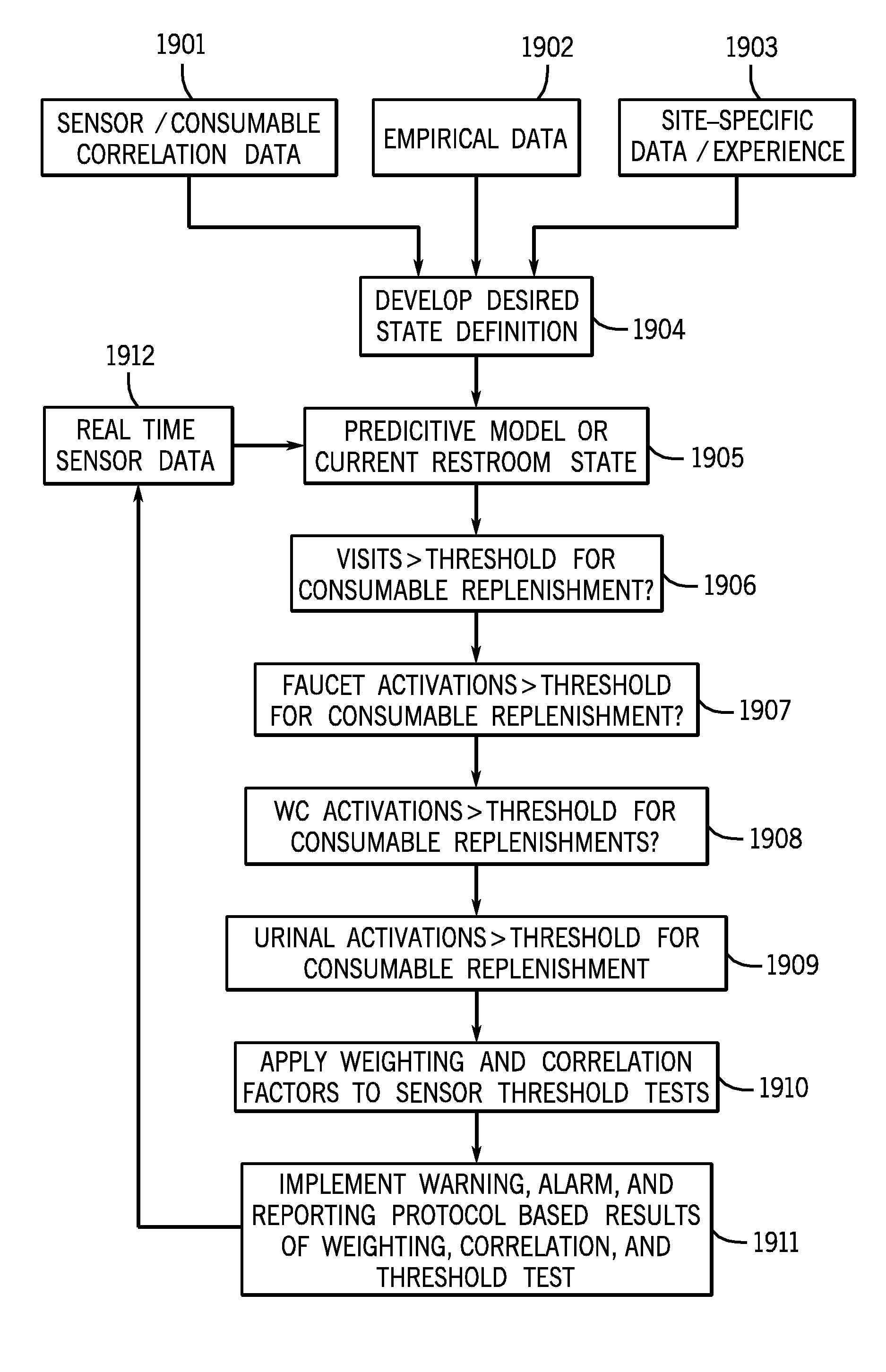

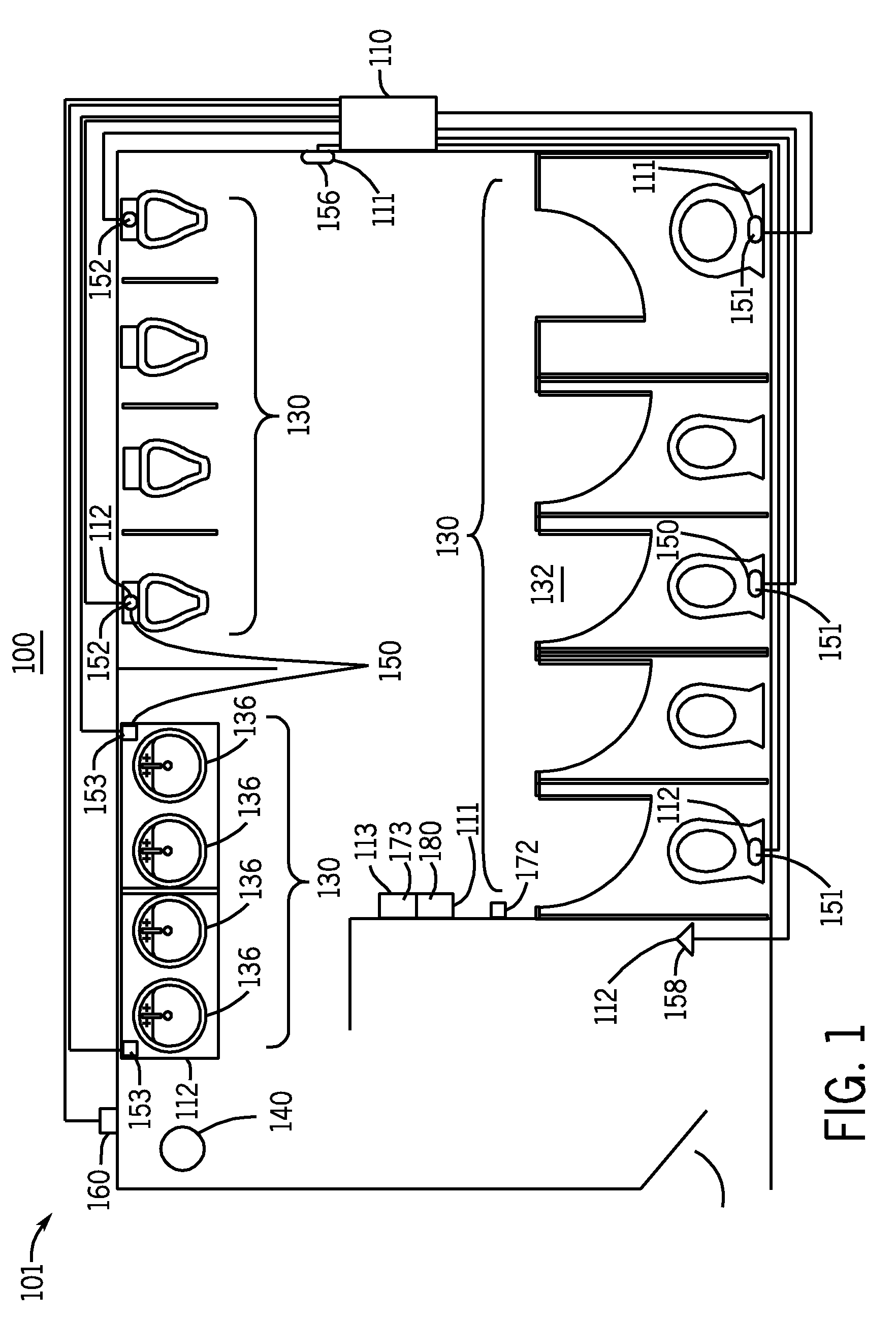

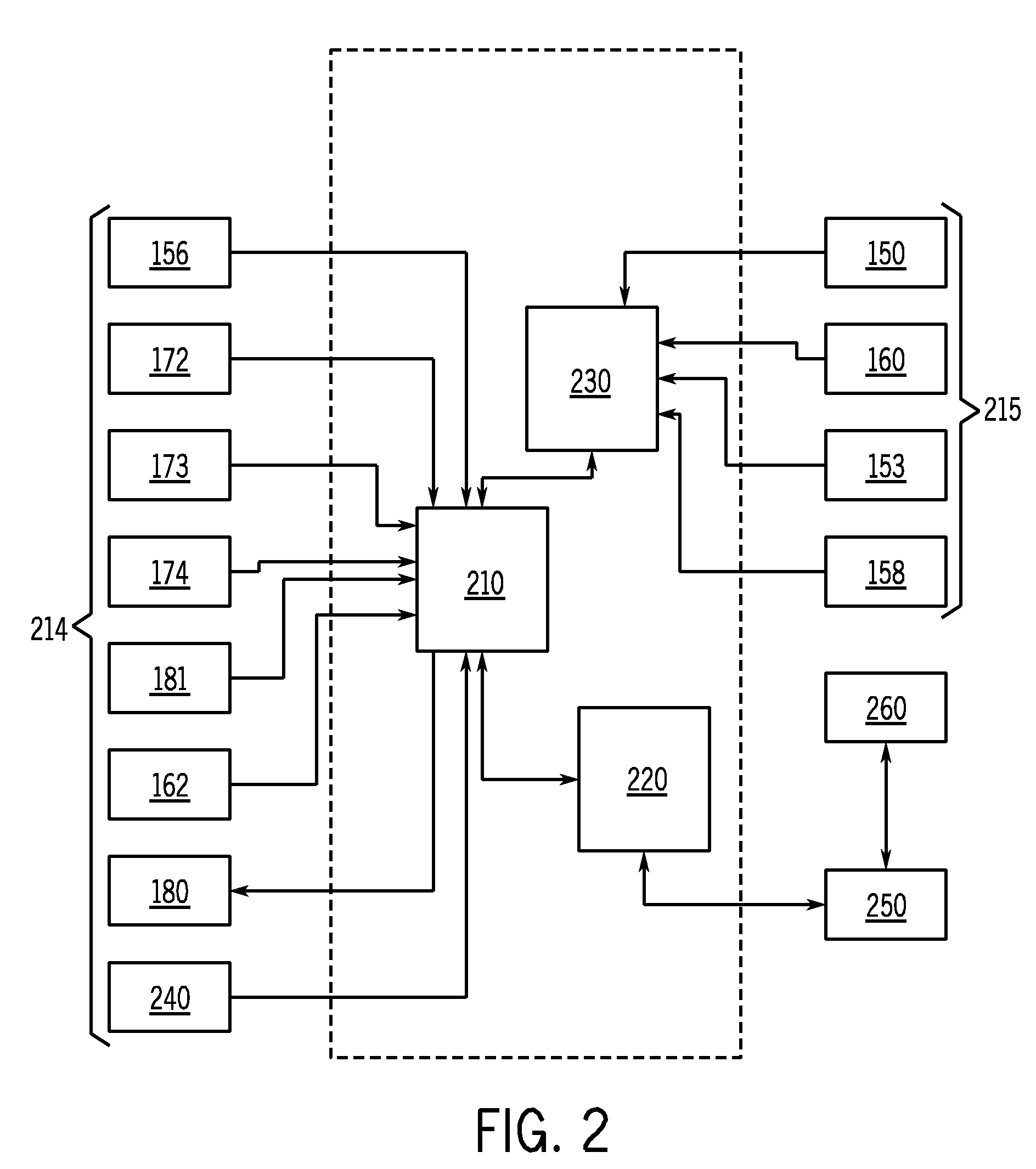

A restroom monitoring system for monitoring attributes of fixtures within a restroom using sensors. Additional attributes are determined from the monitored attributes. Consumable usage levels are estimated based on predetermined consumption levels associated with usage states of the fixtures. The restroom monitoring system provides an indication of the need for replenishment of consumables based on the monitored attributes of the fixtures. In addition, restroom monitoring system may provide additional information regarding the restroom attributes to a service provider, a manager or a user.

Owner:SLOAN VALVE COMPANY

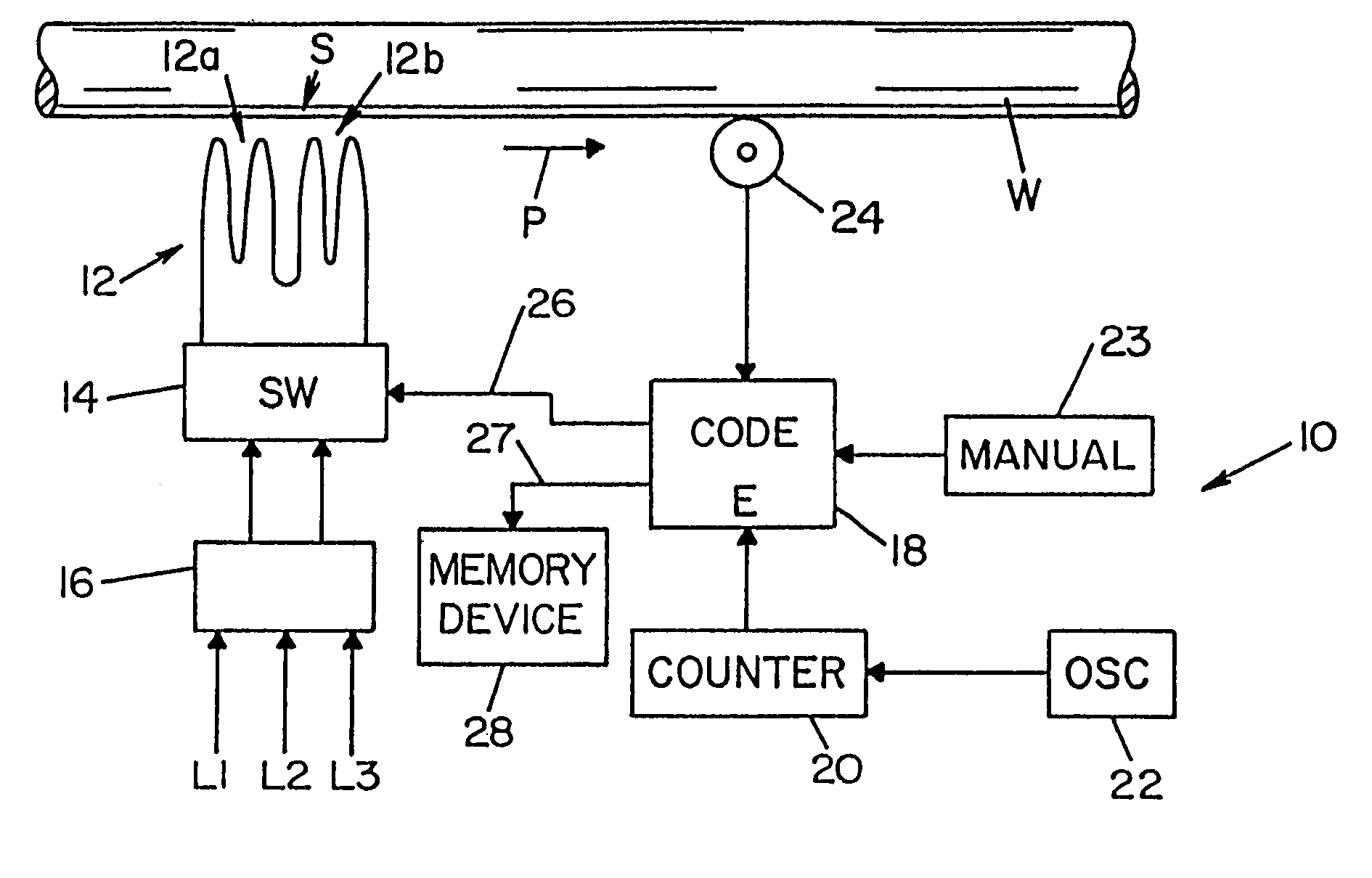

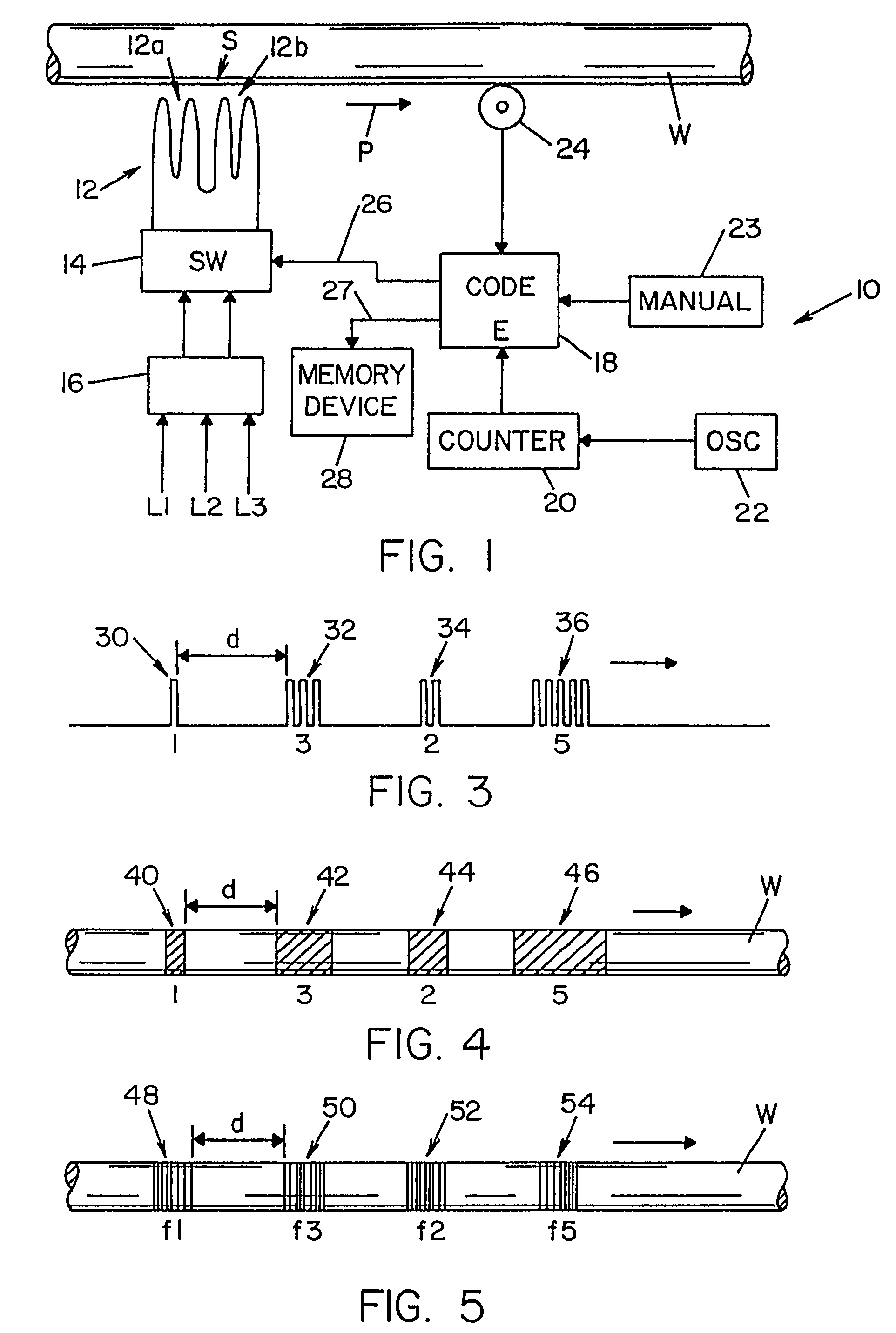

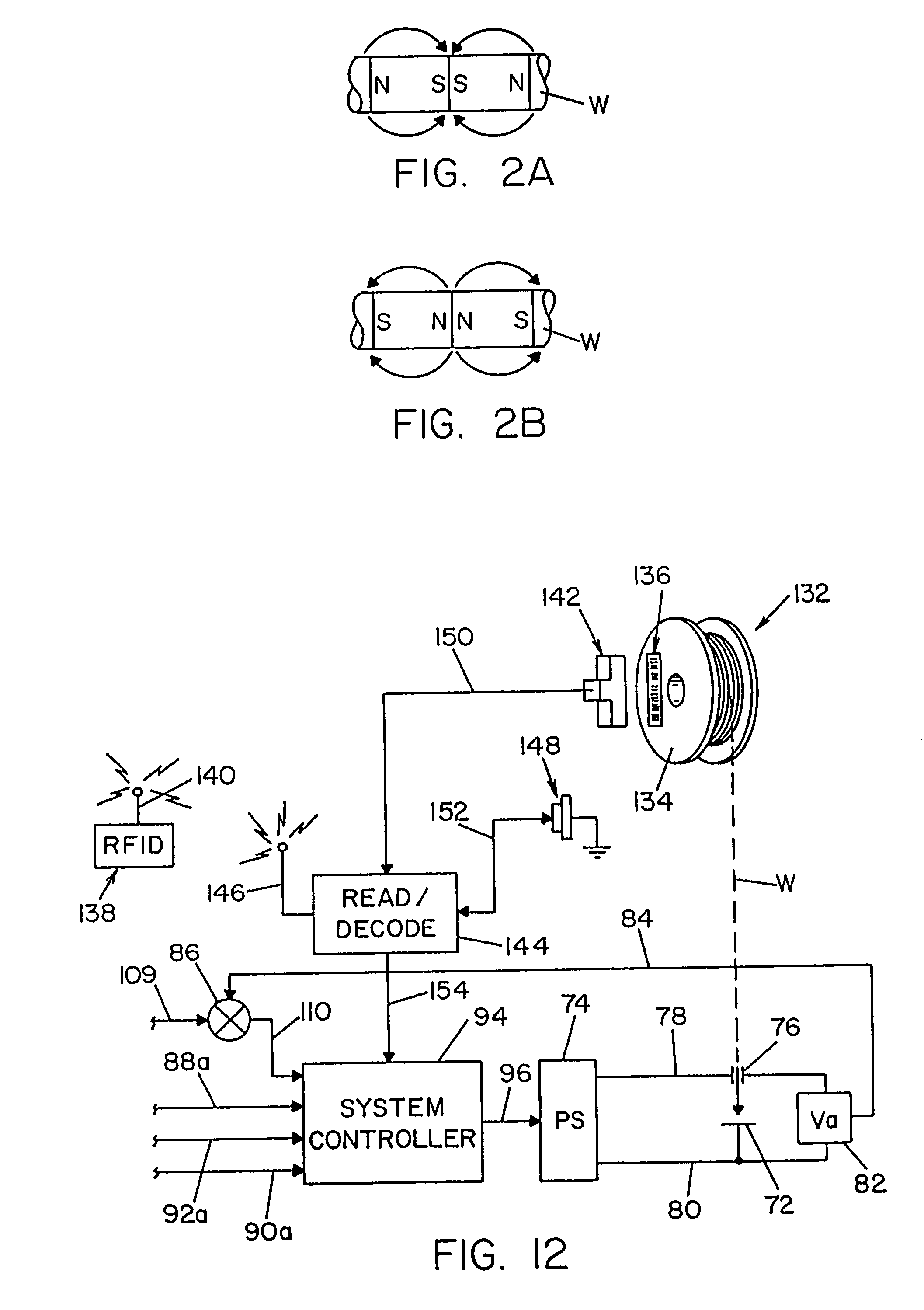

Coded welding consumable

InactiveUS7032814B2Quality improvementImprove welding efficiencyArc welding apparatusCo-operative working arrangementsCarbon Dioxide / HeliumShielding gas

Information pertaining to characteristics of consumables such as metal welding electrode wire and shielding gas and which characteristics are useful in connection with adjusting welding parameters in an arc welding process and / or selecting between operating modes in a welding system are encoded on welding wire and / or on other memory components such as bar code labels and tags, RFID cards and tags, IC cards, and Touch Memory buttons, and the memory device is scanned prior to and / or at the point of use of the welding wire or shielding gas for enabling tracking of product distribution, manual and / or automatic selection of an operating mode for the welding system, manual and / or automatic adjustment of welding parameters in a given operating mode, consumables inventory, and the like.

Owner:LINCOLN GLOBAL INC

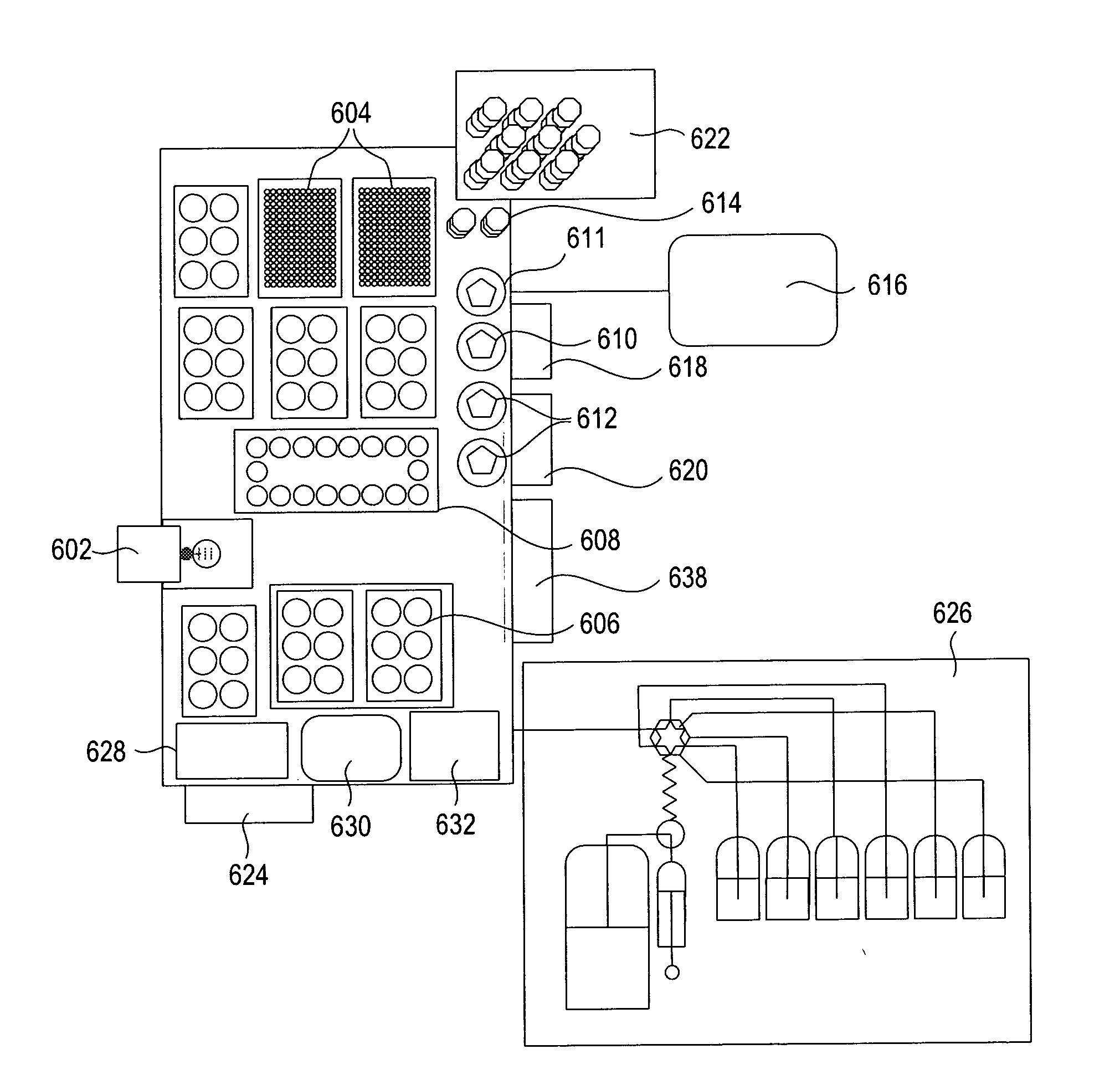

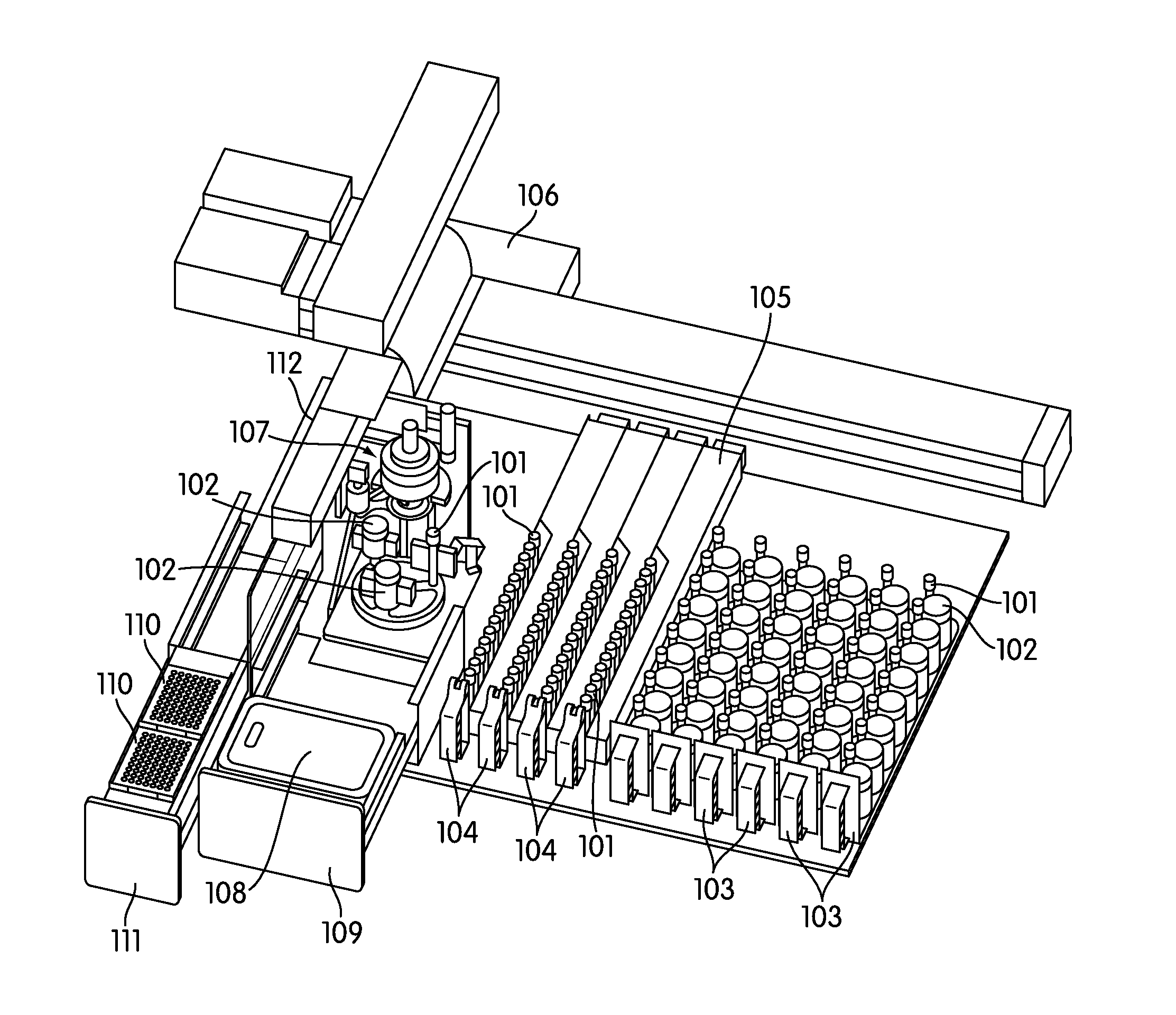

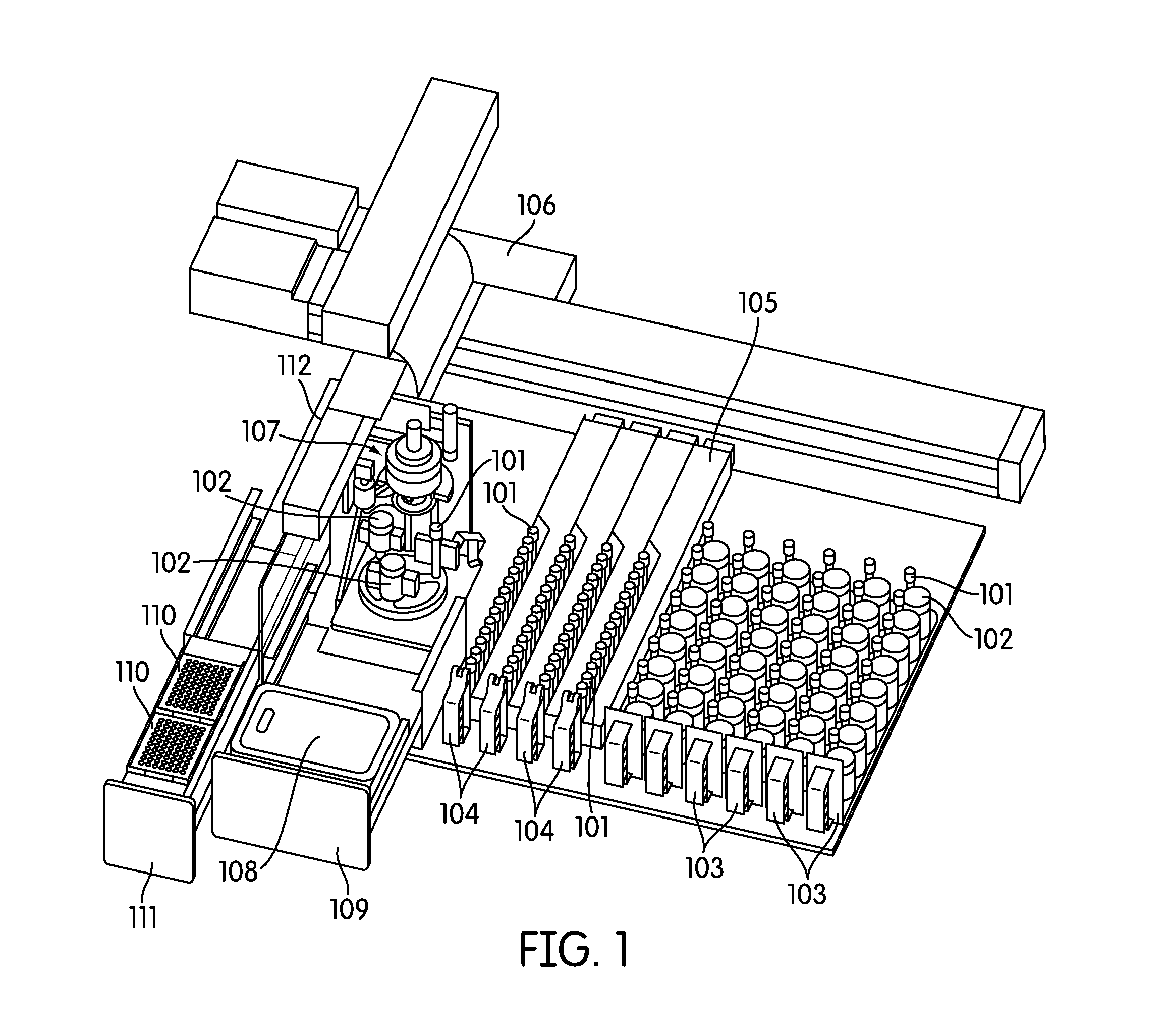

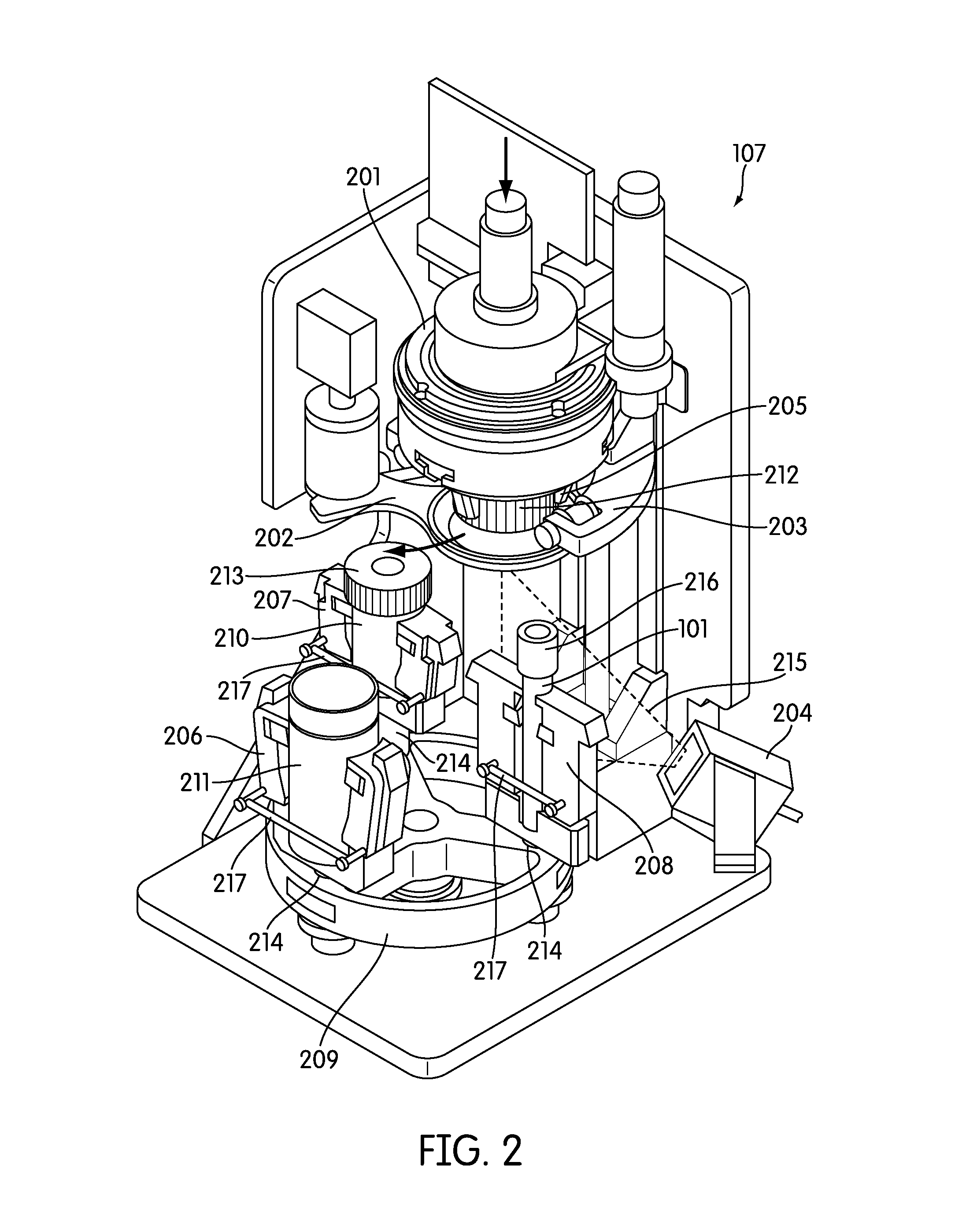

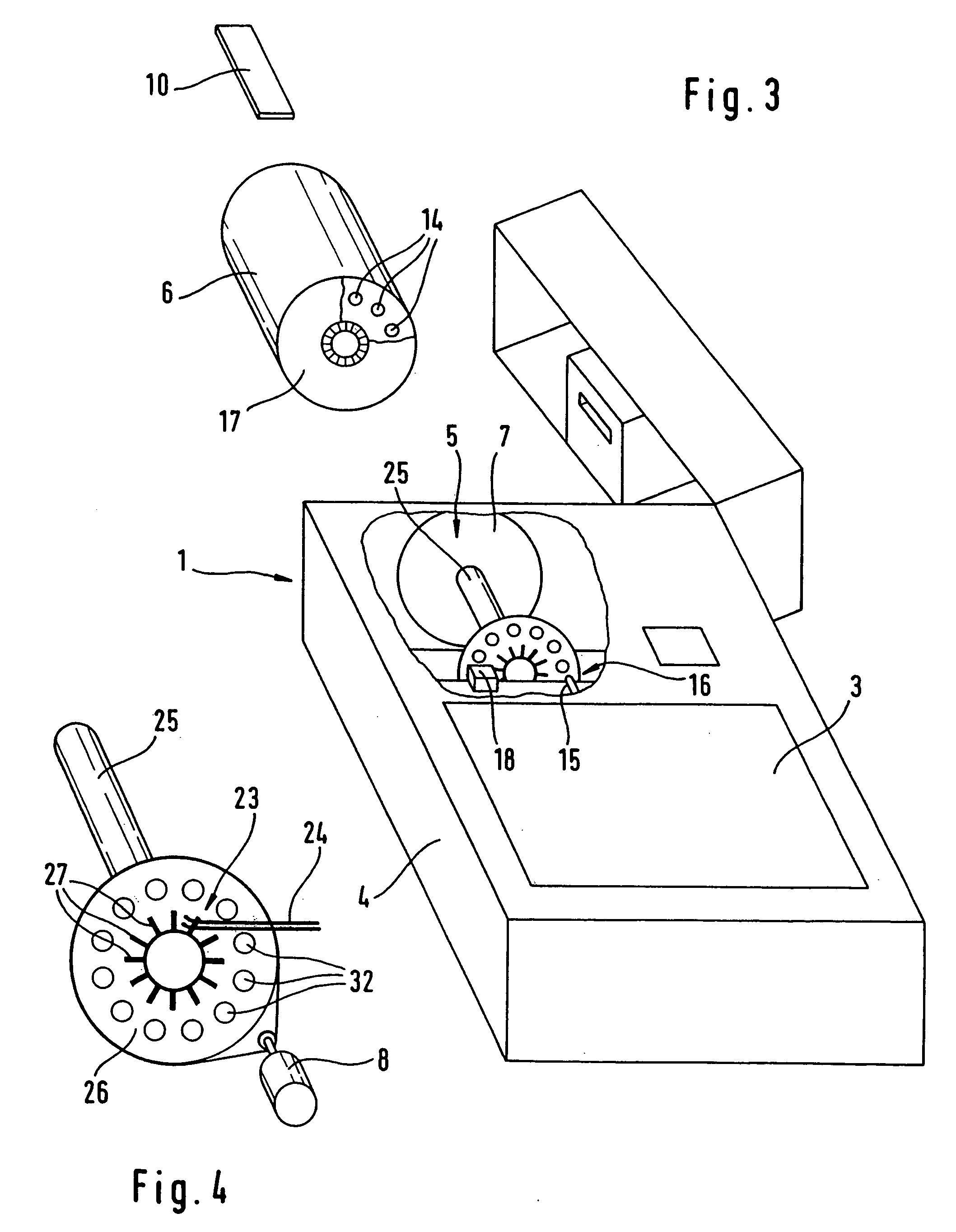

Preparation and characterization of formulations in a high throughput mode

ActiveUS20050058574A1Improve throughputFormula flexibleLibrary tagsFlow propertiesAnalysis dataAdditive ingredient

The invention is an automated robotic system for the production and testing of formulations at a very high throughput. It is an integrated system of hardware and software capable of preparing and evaluating hundreds of emulsions per day. The system can formulate aqueous solutions (SL), oil in water emulsions (EW), suspo-emulsions (SE), micro capsule suspensions (CS), micro-emulsions (ME), and suspension concentrates (SC) at the 1 ml to 25 ml scale. The system can process emulsions rapidly in an automated way and enable very flexible formulation recipes to be introduced. The system allows chemists to generate experimental samples of varying recipe and method to be conducted in parallel with projected throughput of up to 1200 formulations processed and characterized per day. Materials and consumables can be distributed from storage storage systems to the work stations where dispensing of ingredients in various states can be performed, including solids, liquids, gels, pastes, suspensions and waxes. The emulsions formed can be characterized using methods including phase diagnosis, turbidity analysis, viscosity and particle sizing using automated test equipment. An integrated module can also perform Tank Mix Compatibility testing in high throughput mode. The modular system allows future processes and tests to be added, either to a station, or as a new station. The software capability includes tracking of processes from start to finish and the integration of analytical data with the as-designed and as-formulated experimental results.

Owner:SYNGENTA LTD

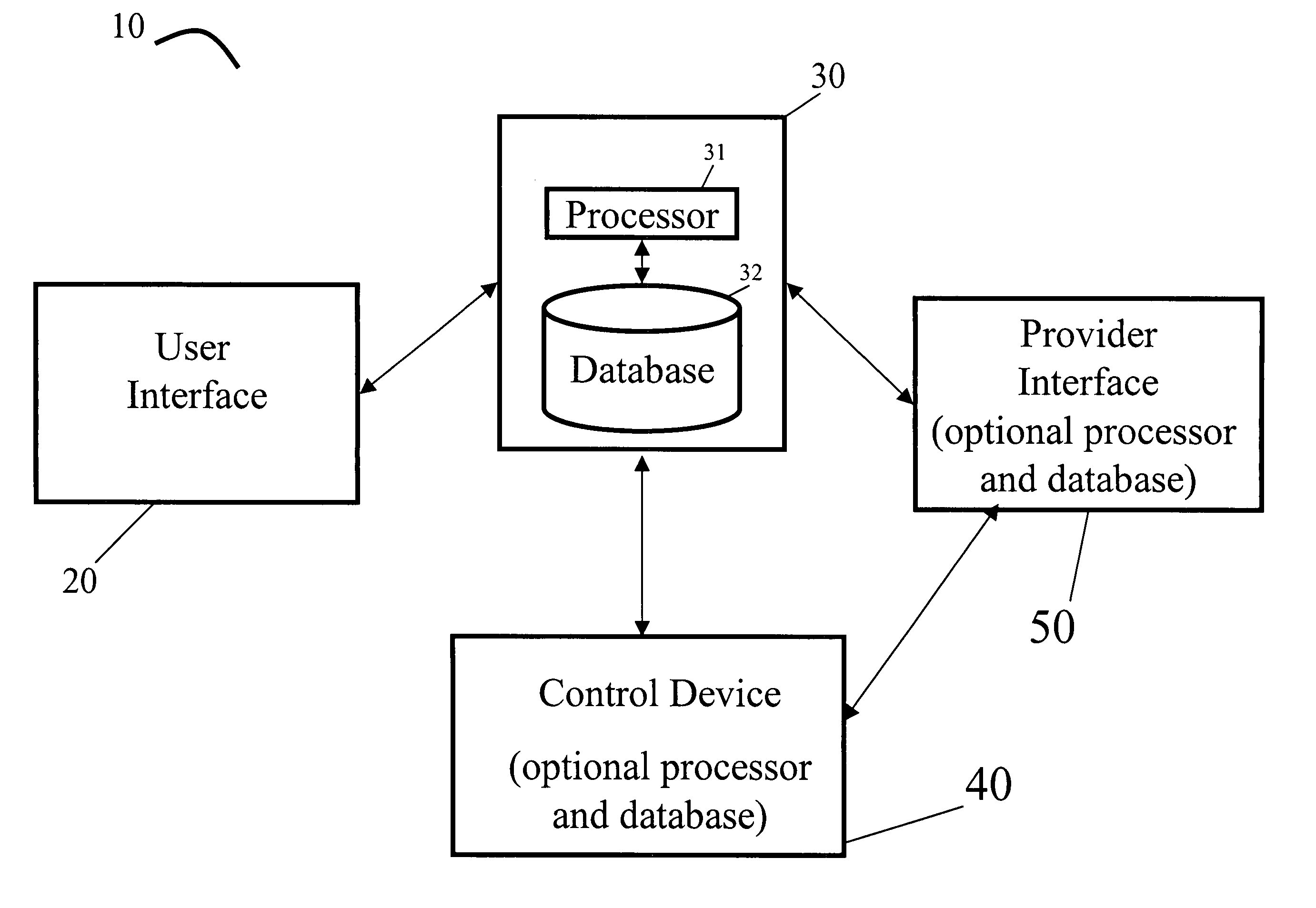

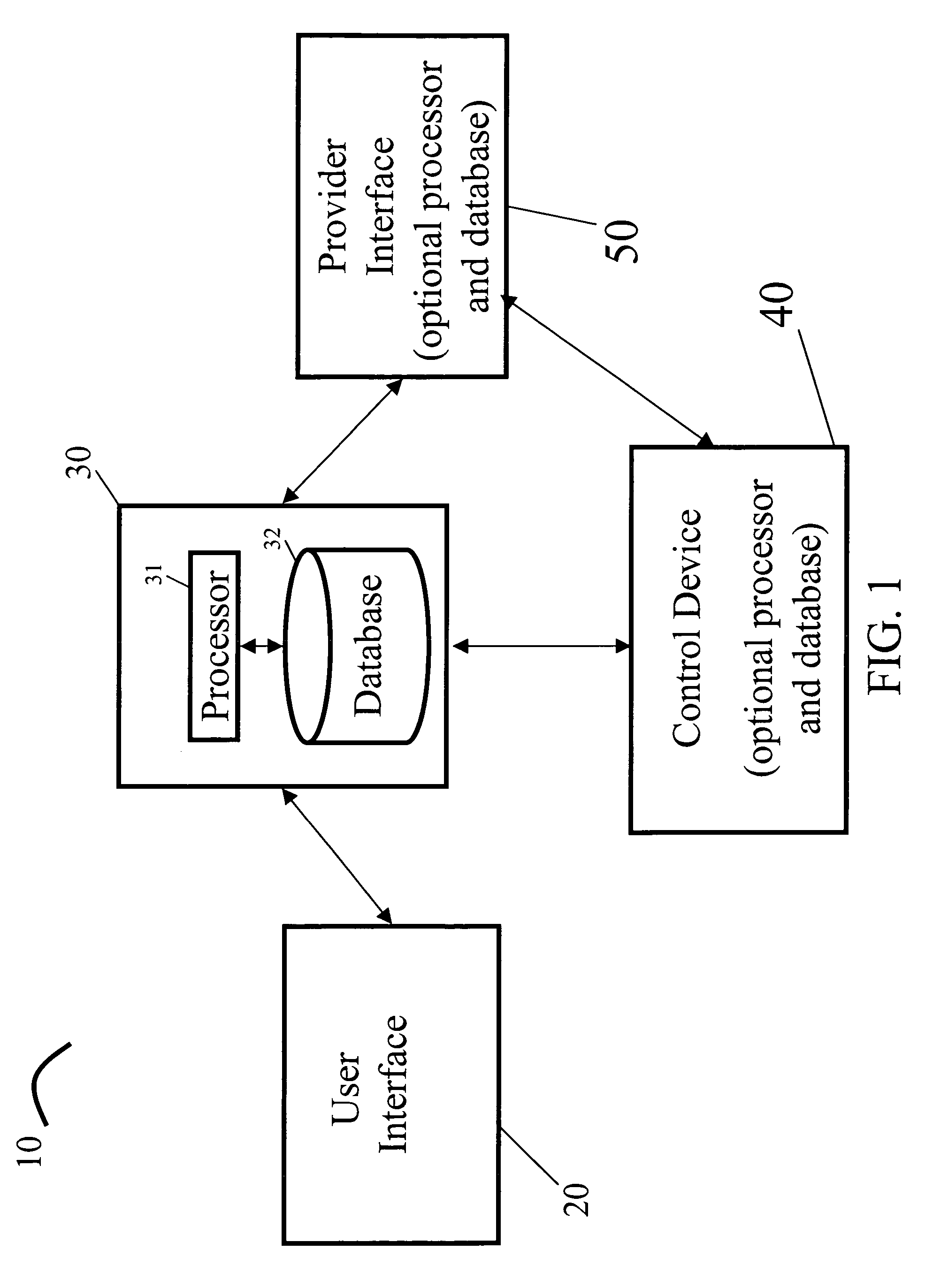

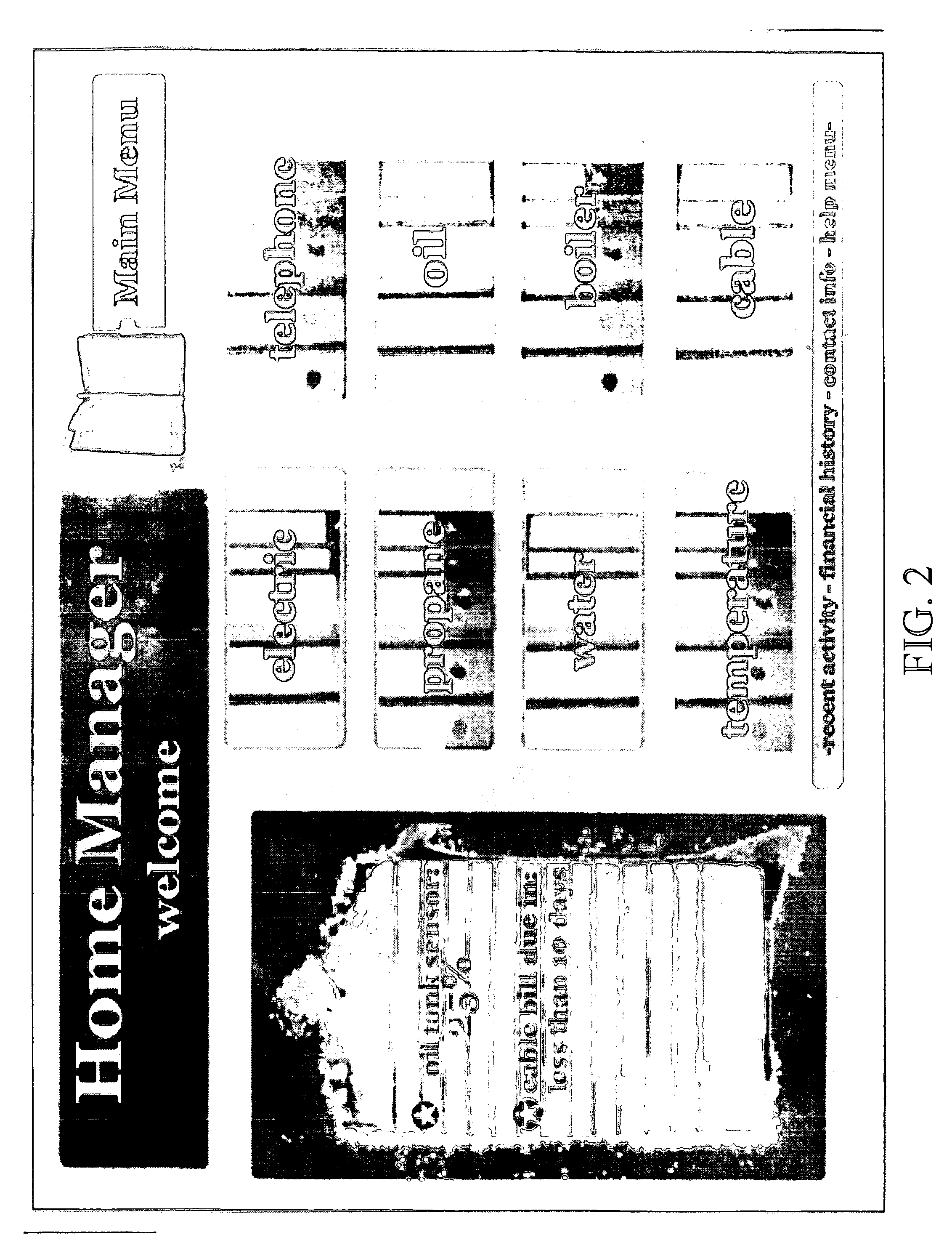

Systems and methods for managing buildings and finances

InactiveUS20070038563A1Avoid shortagePrevent credit card fraudFinancePayment architectureIntegrated softwareComputer science

In various embodiments, building management systems and methods are provided as a stand-alone, or network based system that utilizes integrated software that manages bills, consumables (e.g., oil, propane, water, electric, food, etc.), and appointments. In various embodiments, the building management system provides increased safety, security and convenience to a user.

Owner:RYZERSKI ERIC

Automated sample handling instrumentation, systems, processes, and methods

The present invention provides a processing station for automatically processing a biological sample, a system for automated real-time inventory control of consumables within a biological sample handling or assay instrument, a high throughput random access automated instrument for processing biological samples, an automated instrument for processing or analysis of a sample, and processes for automated mucoid detection and elimination. Methods of using the disclosed instruments, mucoid detection processes, and systems to process and / or analyze samples are also disclosed.

Owner:GEN PROBE INC

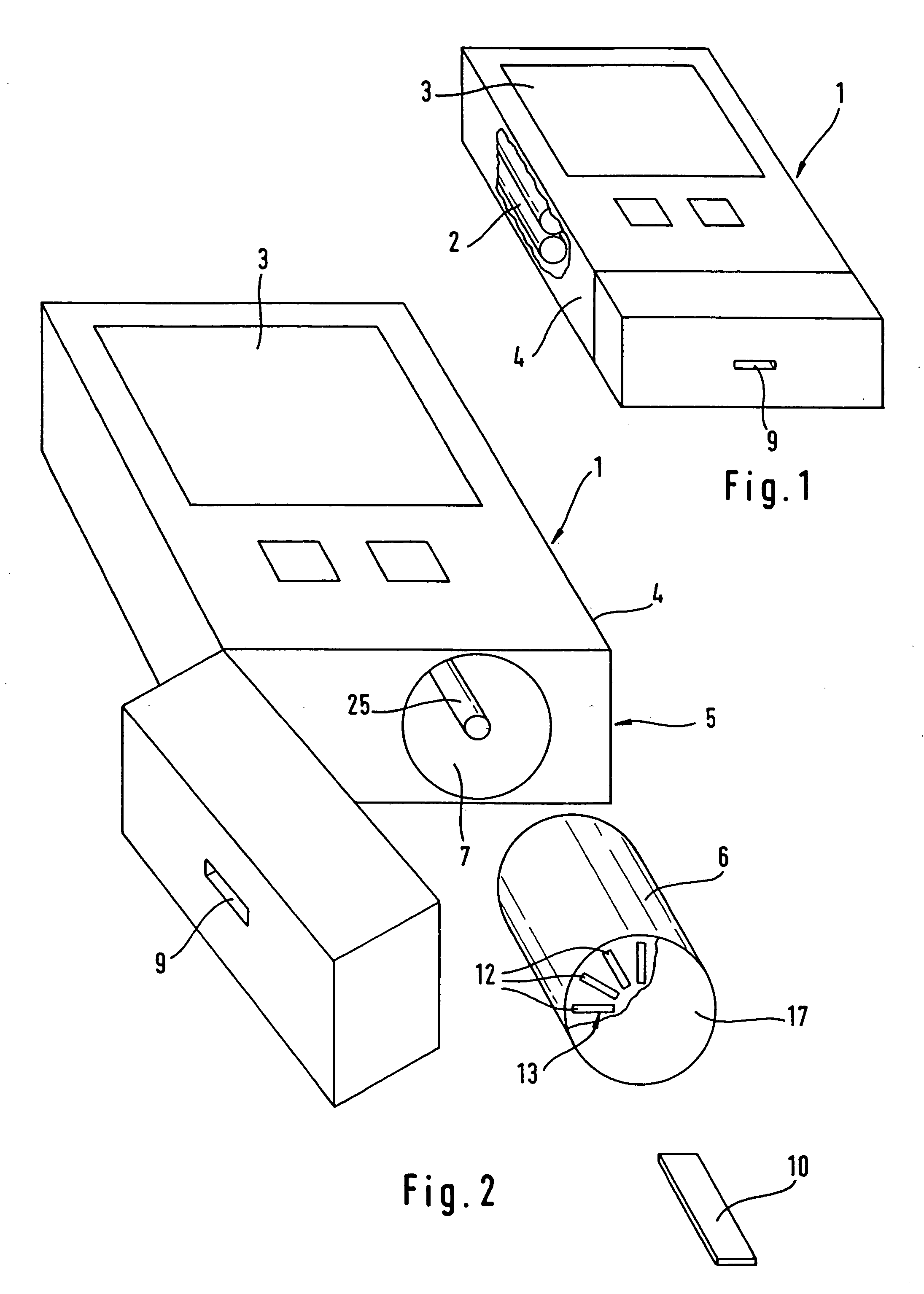

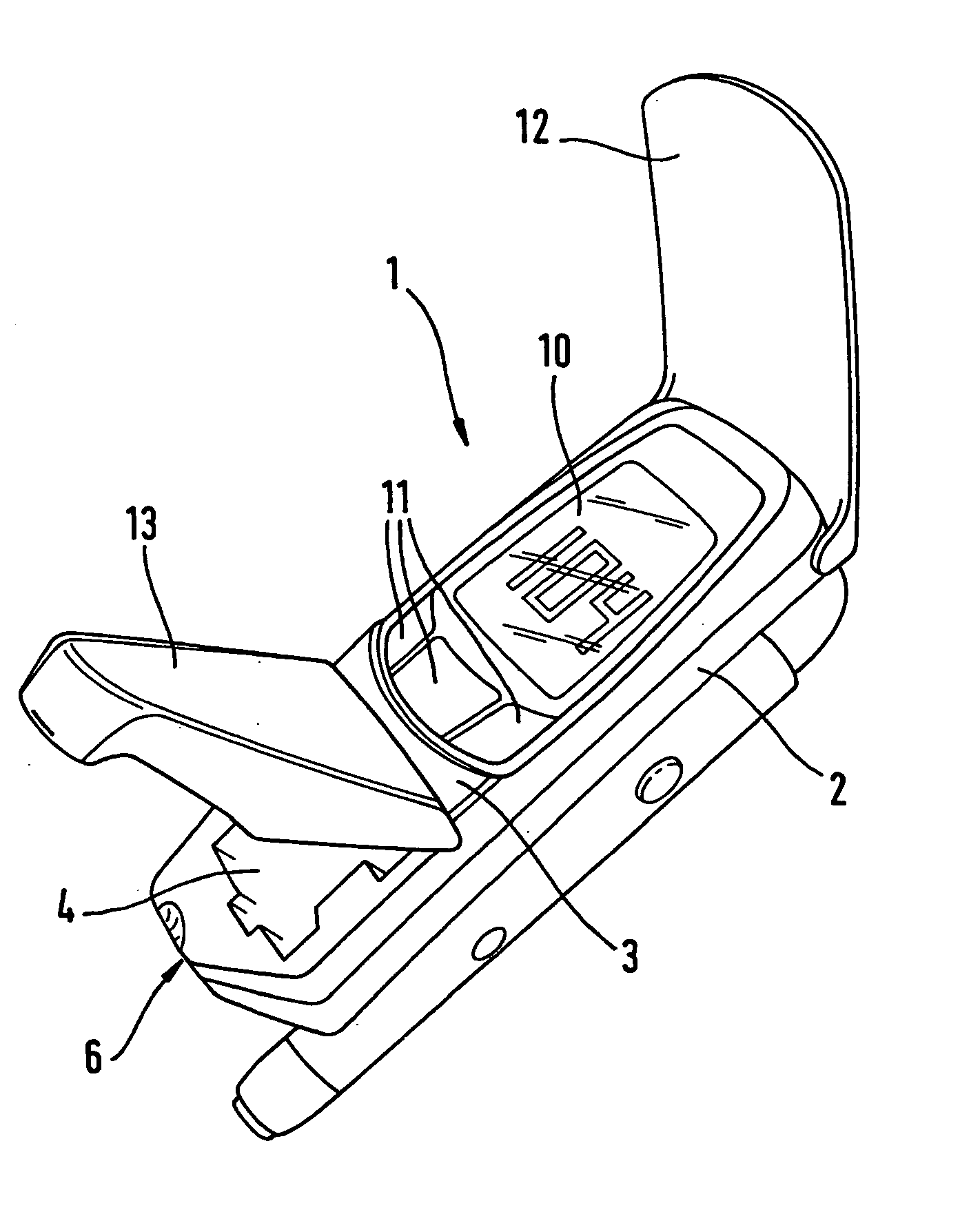

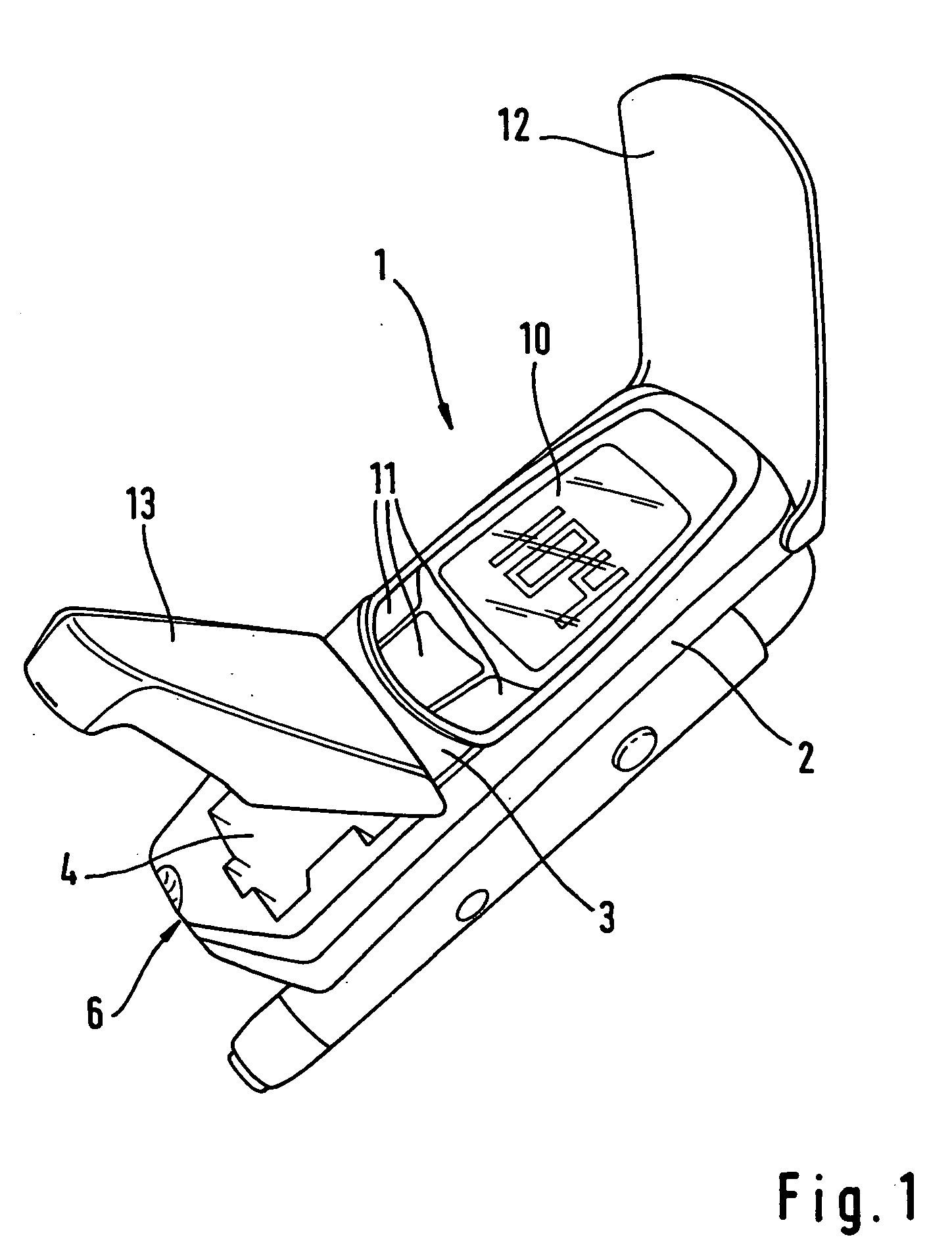

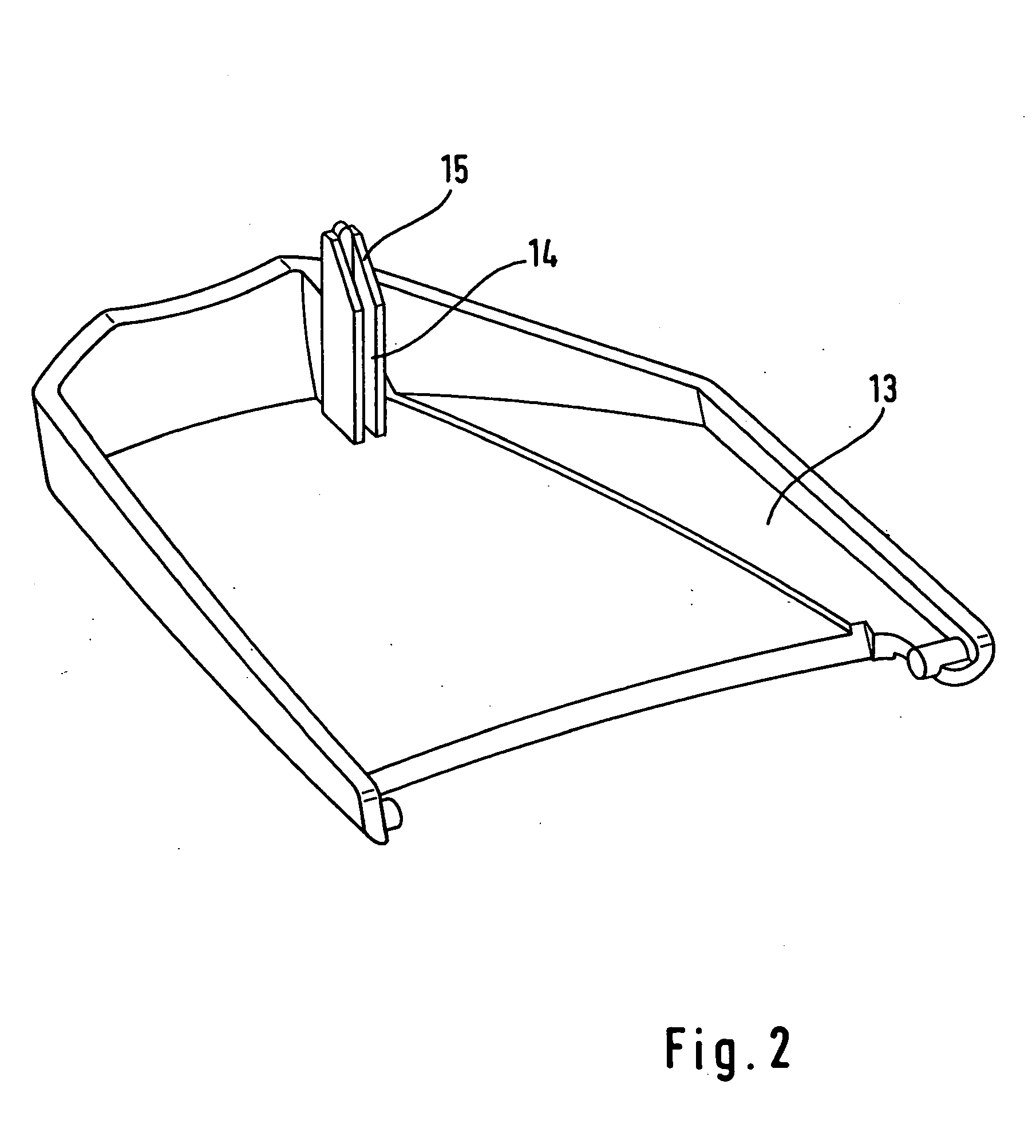

Hand-held analysis device

ActiveUS20070009381A1Reduce power consumptionAverage power consumptionAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionHand heldEngineering

The invention relates to a hand-held analytical device for analyzing a sample, in particular a biological fluid, for a medically significant component, comprising a housing comprising a loading opening for receiving a replaceable cartridge having multiple chambers that may contain analytical consumables, in particular test strips, and each chamber comprising an opening on at least one face of the cartridge and each opening may be sealed by a sealing foil, a removal facility for removing one of the analytical consumables from the cartridge. The removal facility can be used to remove one of the consumables from one of the chambers of the cartridge, in the process of which the opening sealed by the sealing foil is opened. A drive allows the cartridge to be moved in order to position one chamber in a removal position in which a consumable can be removed from the chamber by the removal facility. The invention provides for the hand-held analytical device to comprise a testing facility that can generate a signal containing information regarding whether the opening of one of the chambers is sealed by sealing foil.

Owner:ROCHE DIABETES CARE INC

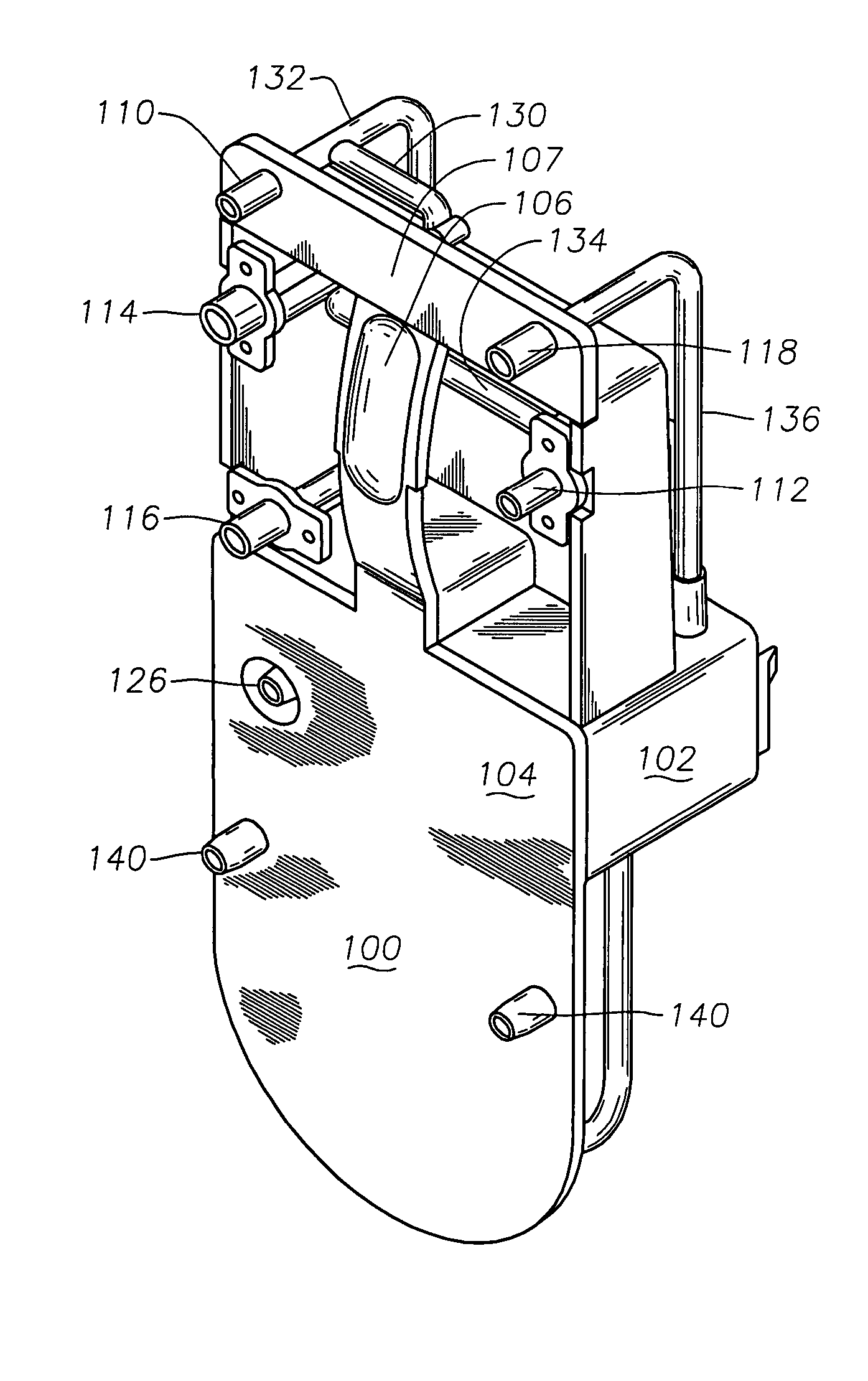

Surgical cassette and consumables for combined opthalmic surgical procedure

An ophthalmic surgical cassette for removably receiving in a cassette receiving mechanism of an ophthalmic surgical system. The system includes first and second plunger valves. The cassette includes a body having a rear surface, an irrigation inlet for receiving irrigation fluid from a source, a first irrigation outlet for providing irrigation fluid to a first ophthalmic microsurgical instrument for use in an anterior segment ophthalmic surgical procedure, a first manifold fluidly coupling the irrigation inlet with the first irrigation outlet, a second irrigation outlet for providing irrigation fluid to a second ophthalmic microsurgical instrument for use in a posterior segment ophthalmic surgical procedure, and a second manifold fluidly coupling the irrigation inlet with the second irrigation outlet. The surgical cassette greatly simplifies a combined anterior segment and posterior segment ophthalmic surgical procedure by eliminating the need for separate anterior segment and posterior segment cassettes for the combined procedure.

Owner:ALCON INC

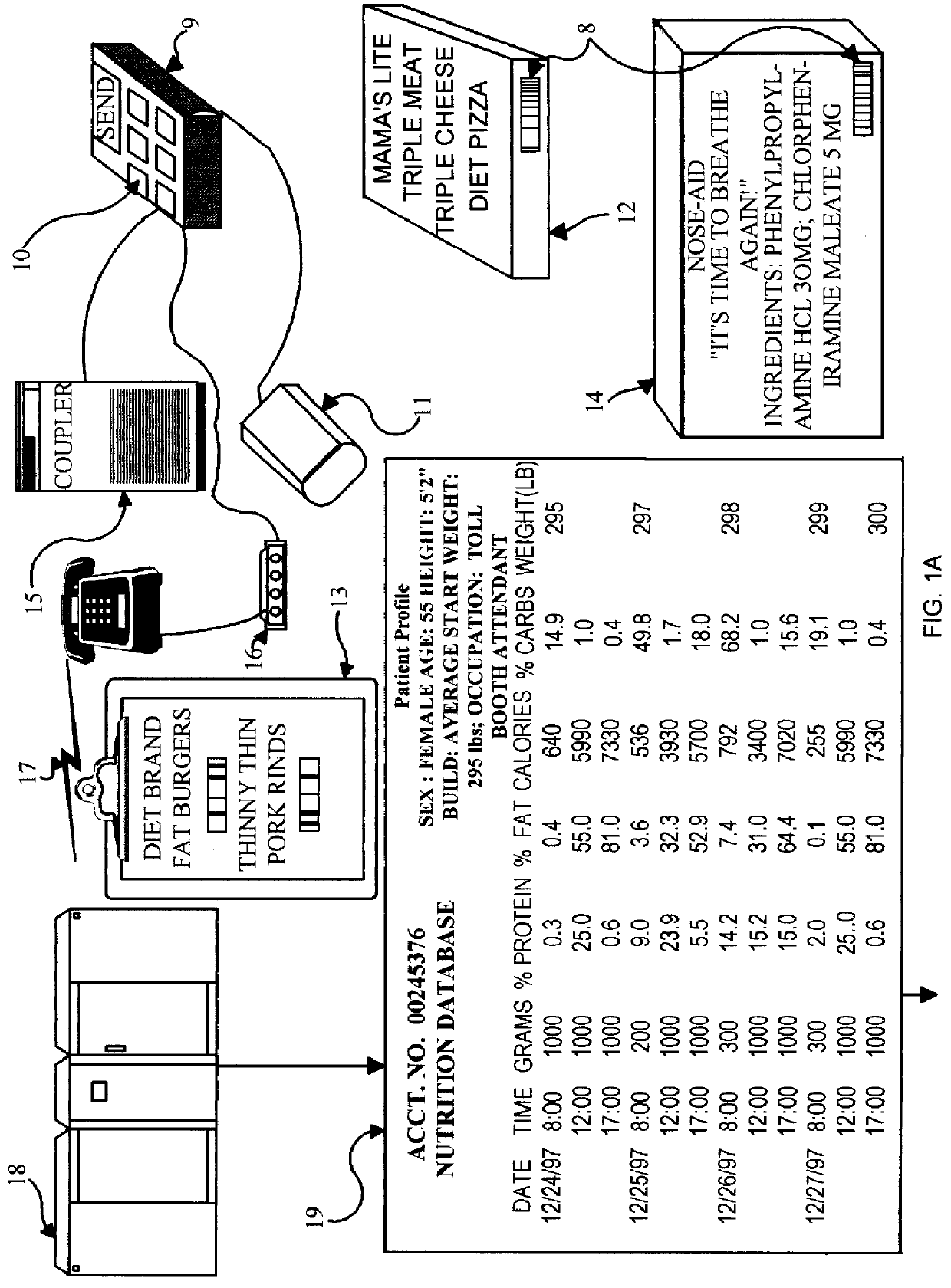

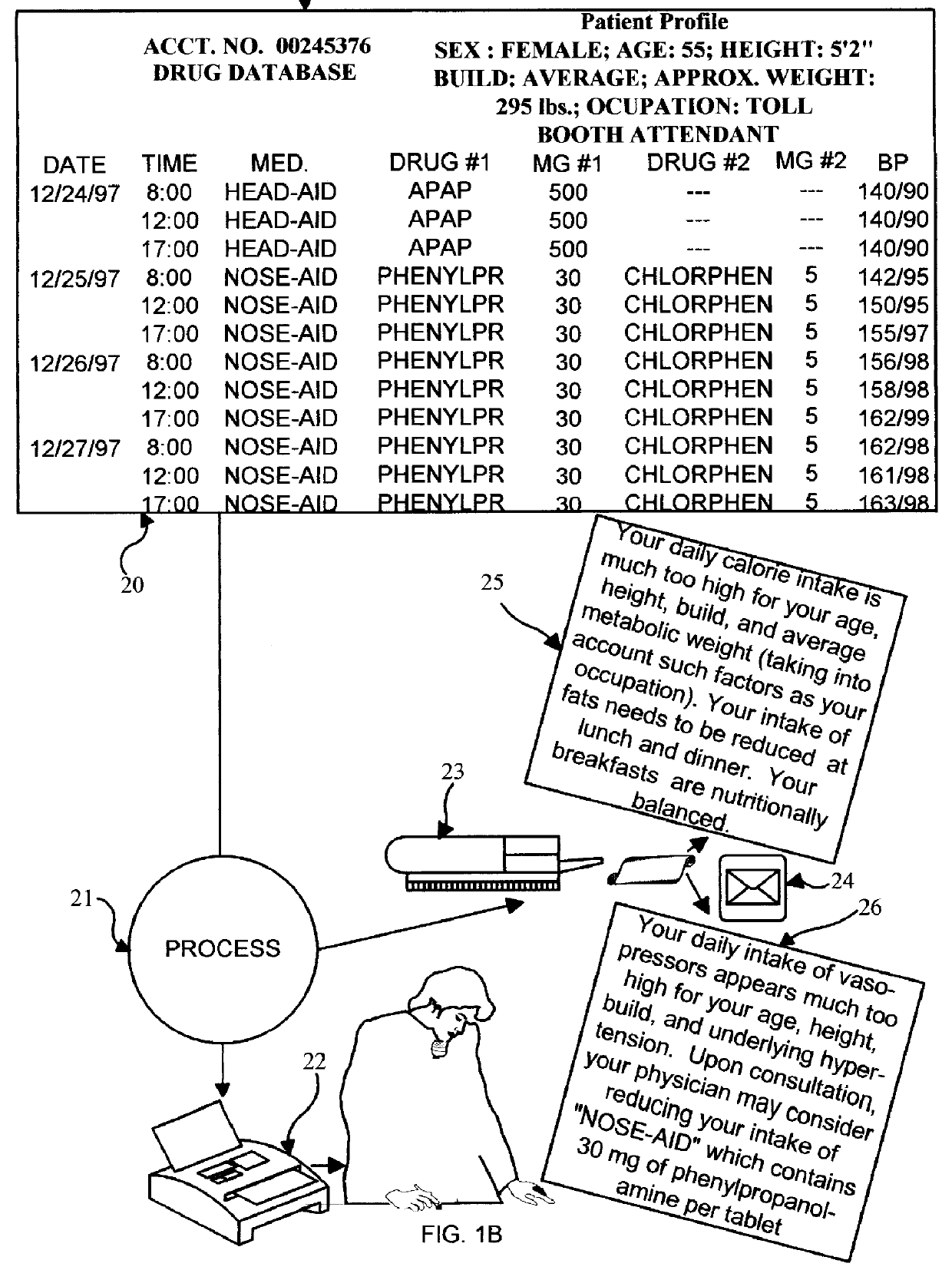

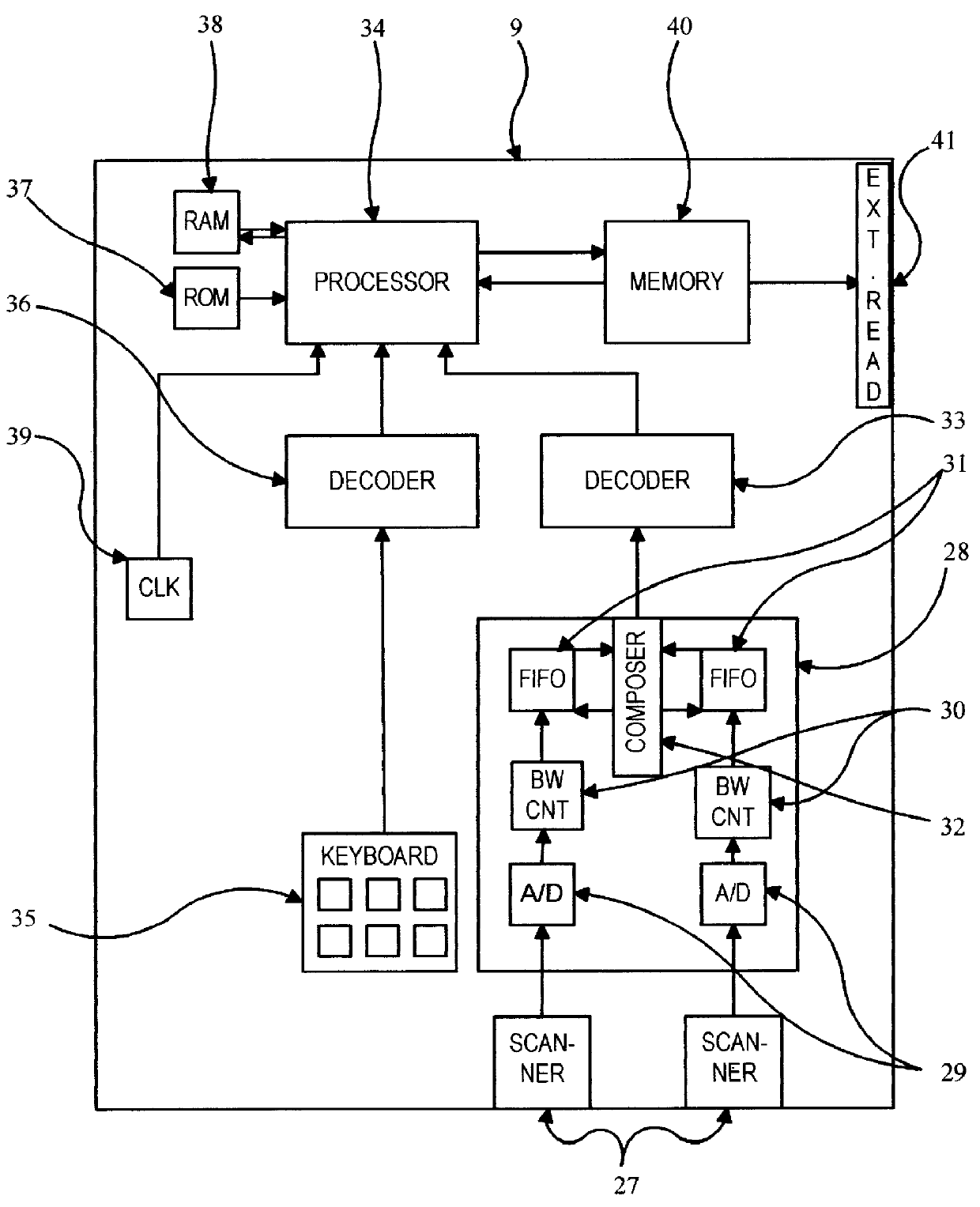

Method for correlating consumable intakes with physiological parameters

A computer-assisted system and method for adjudging the effect of consumable intakes on physiological parameters is disclosed wherein a consumer records in a database a plurality of consumable identifiers identifiying consumables consumed, the amounts of each consumable consumed, times of consumption of each consumable, a plurality of physiological measurements and time of physiological measurements, and such information is computationally related to consumption information, such as nutritional information, linked to the consumable identifier in another database.

Owner:MOORE STEVEN JEROME

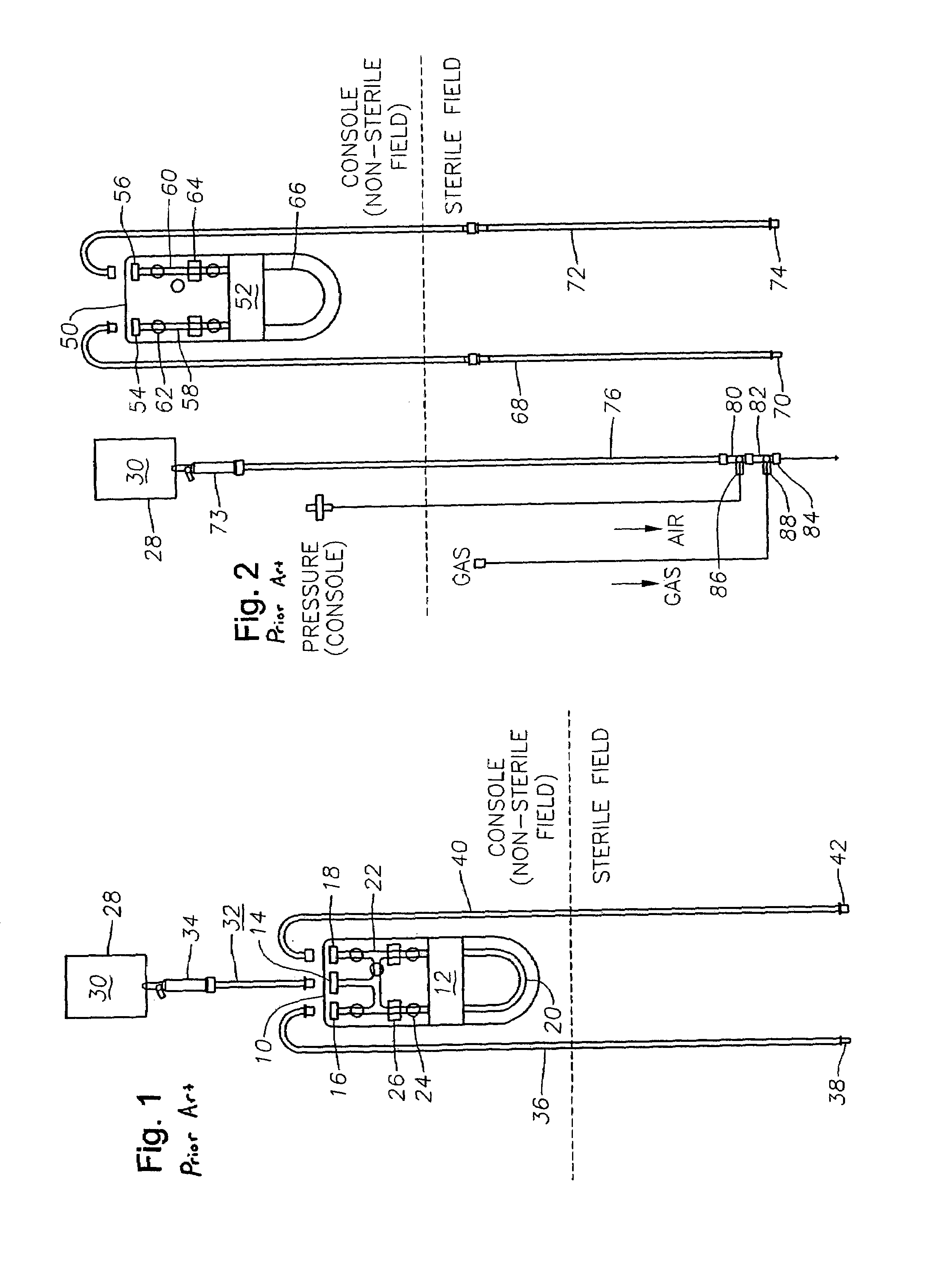

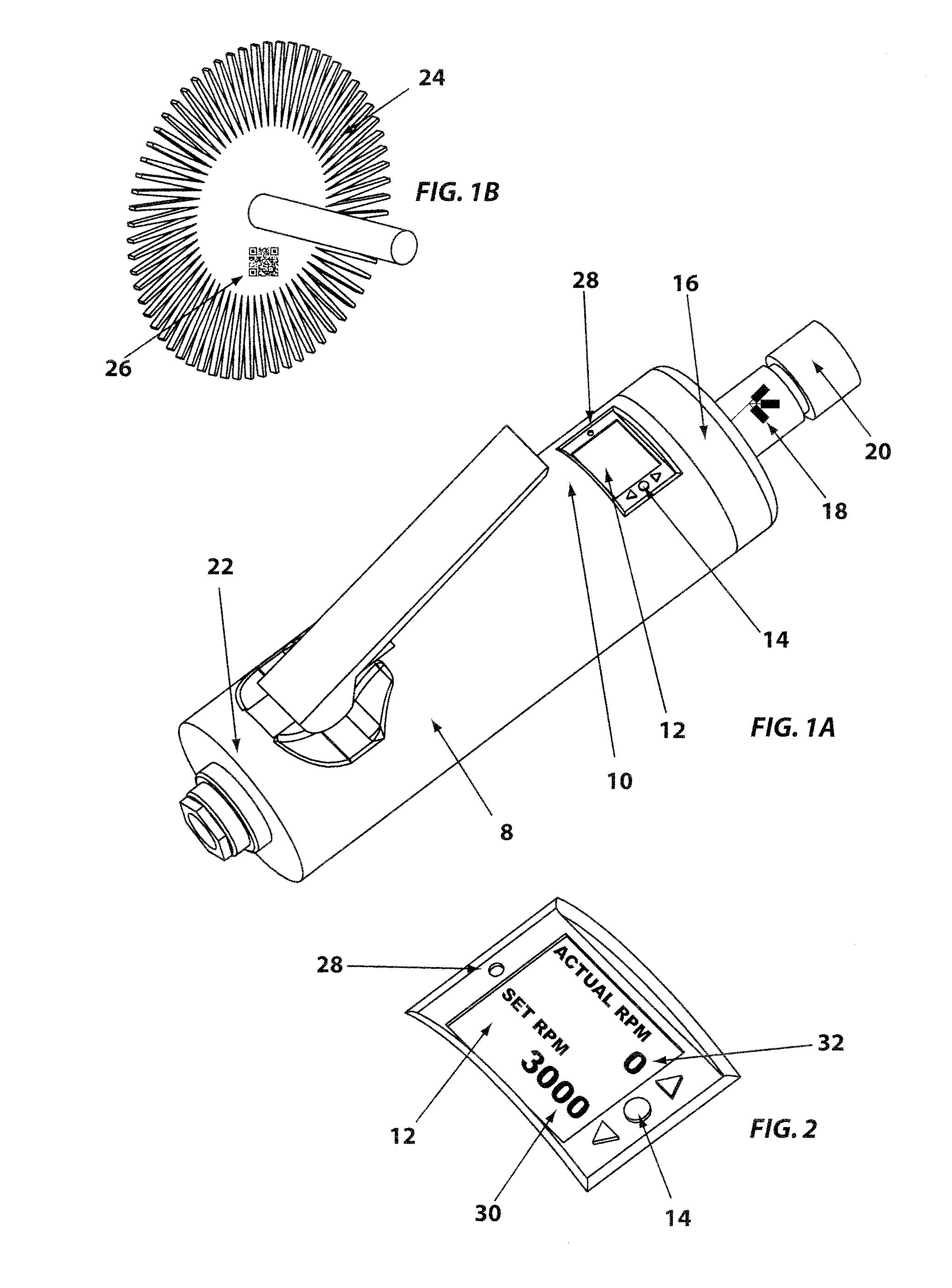

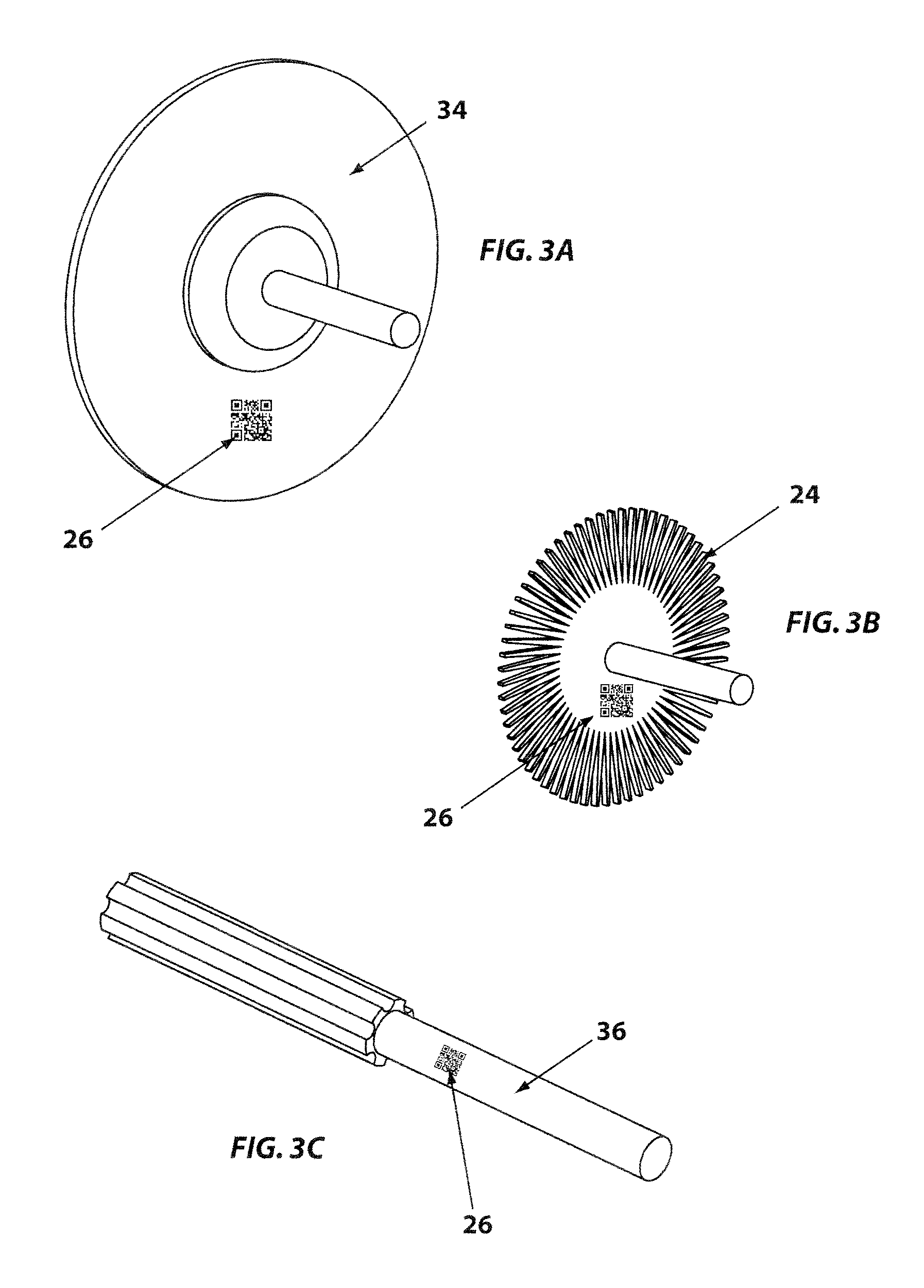

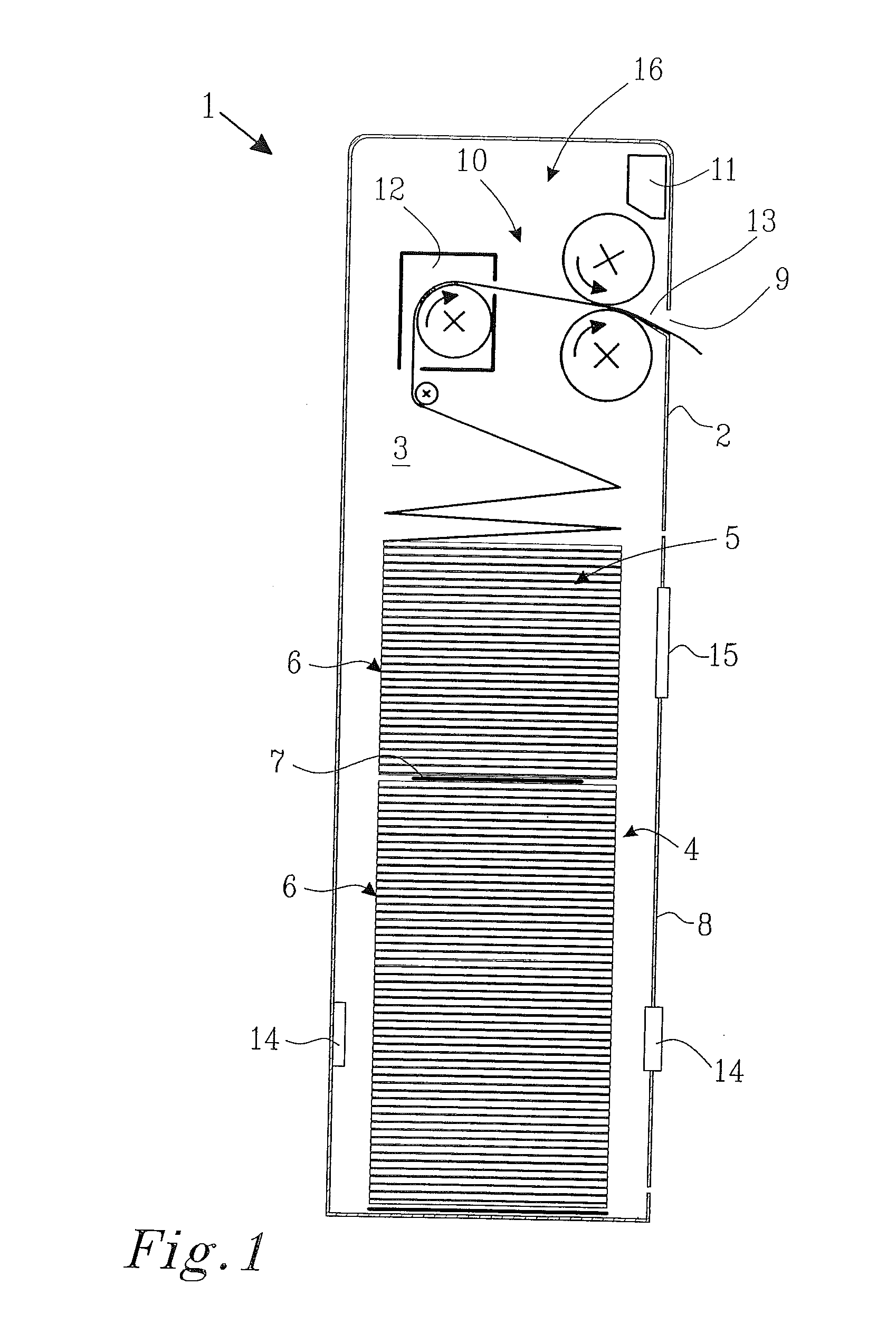

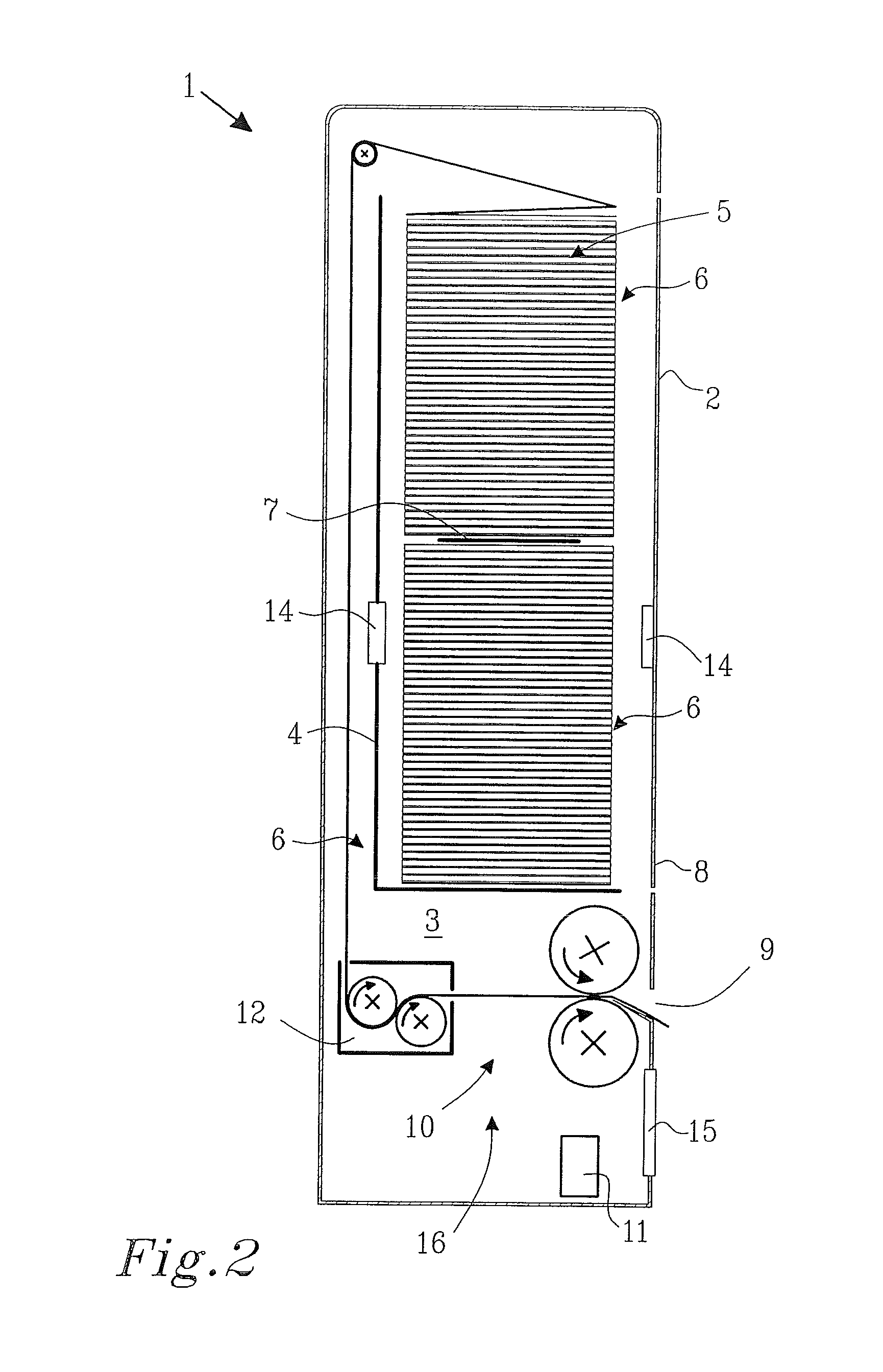

Controlled electro-pneumatic power tools and interactive consumable

ActiveUS20120007748A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsMicrocontrollerElectrical battery

A controlled electro-pneumatic power tool includes an electro-mechanical adjustable valve, a pneumatic motor and a rotational speed sensor connected to a microcontroller for the selection, monitoring and adjustement of the rotational speed in real time. The electro-pneumatic power tool may include input buttons, data ports to save data and a communication port to read / write data from an interactive consumable. The electo-pneumatic power tool may also include a battery and a generator as well as a variable speed transmission with flexible shaft and lightweight handpiece. Using the communication port, important data for the consumable, such as optimum rotation speed, optimum applied pressure and average usage time, can be transmitted to the controlled electro-pneumatic power tool. The controlled electro-pneumatic power tool can read and utilise the transmitted data to select, adjust and maintain the optimum process parameters for the consumable without any input from the operator person. Furthermore, the communicated data can be used to warn the operator person that the tool used is inadequate for the selected consumable, to caution the operator person if he is using the consumable inadequately and to advise him when the consumable should be replaced for safe operation. This will increase the safety of the operator person, improve the quality of the work performed with pneumatic power tools and limit potential damages to the parts being treated.

Owner:FORGUES SYLVAIN +1

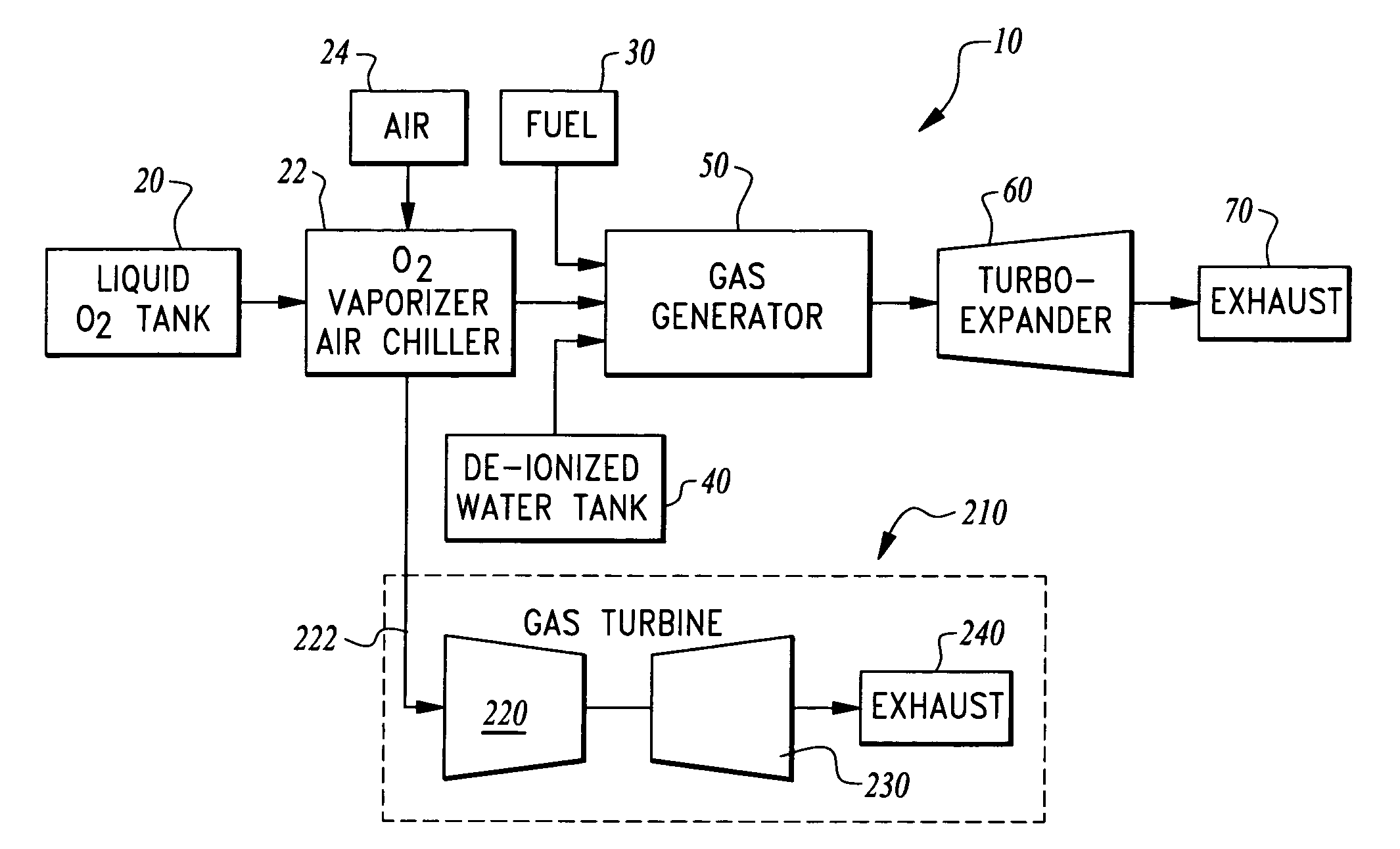

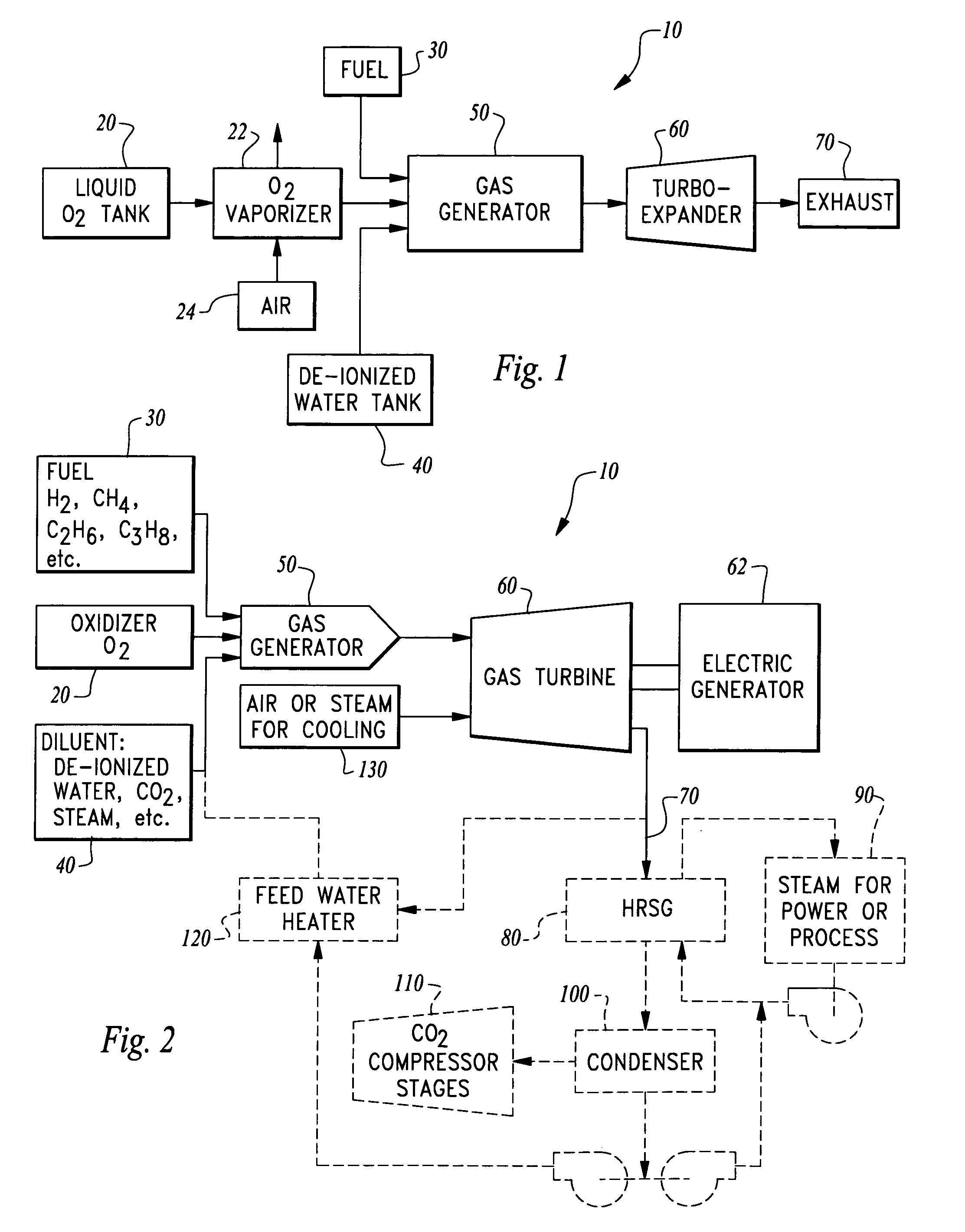

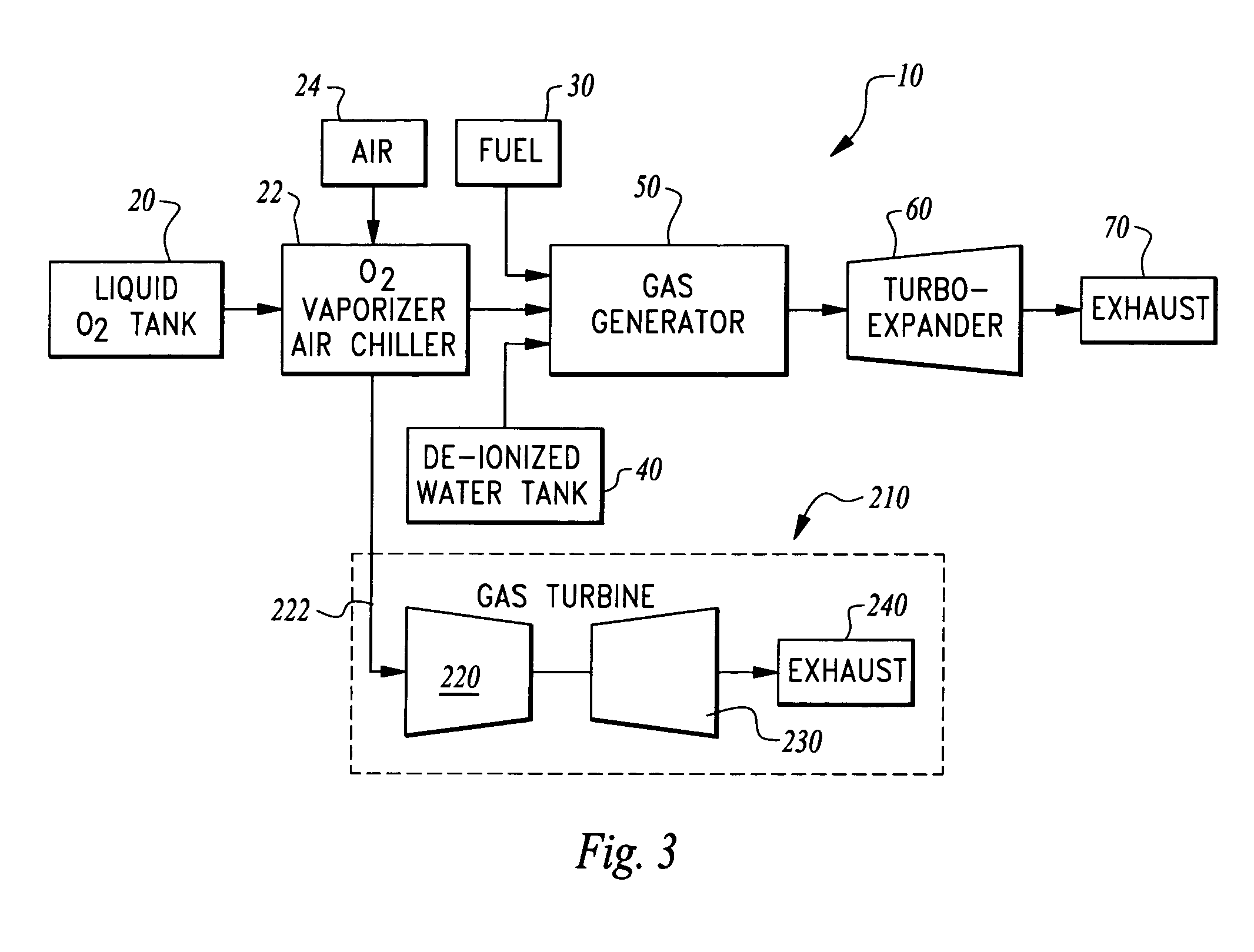

Ultra low emissions fast starting power plant

InactiveUS7827794B1Fast starting low emissionMinimal capital expenseTurbine/propulsion engine coolingGas turbine plantsNuclear engineeringLiquid fuel

The power plant combusts a hydrocarbon fuel with oxygen to produce high temperature high pressure products of combustion. These products of combustion are routed through an expander to generate power. The products of combustion are substantially free of oxides of nitrogen because the oxidizer is oxygen rather than air. To achieve fast starting, oxygen, fuel and water diluent are preferably stored in quantities sufficient to allow the power plant to operate from these stored consumables. The fuel can be a gaseous or liquid fuel. The oxygen is preferably stored as liquid and routed through a vaporizer before combustion in a gas generator along with the hydrocarbon fuel. In one embodiment, the vaporizer gasifies the oxygen by absorption of heat from air before the air is routed into a separate heat engine, such as a gas turbine. The gas turbine thus operates on cooled air and has its power output increased.

Owner:CLEAN ENERGY SYST

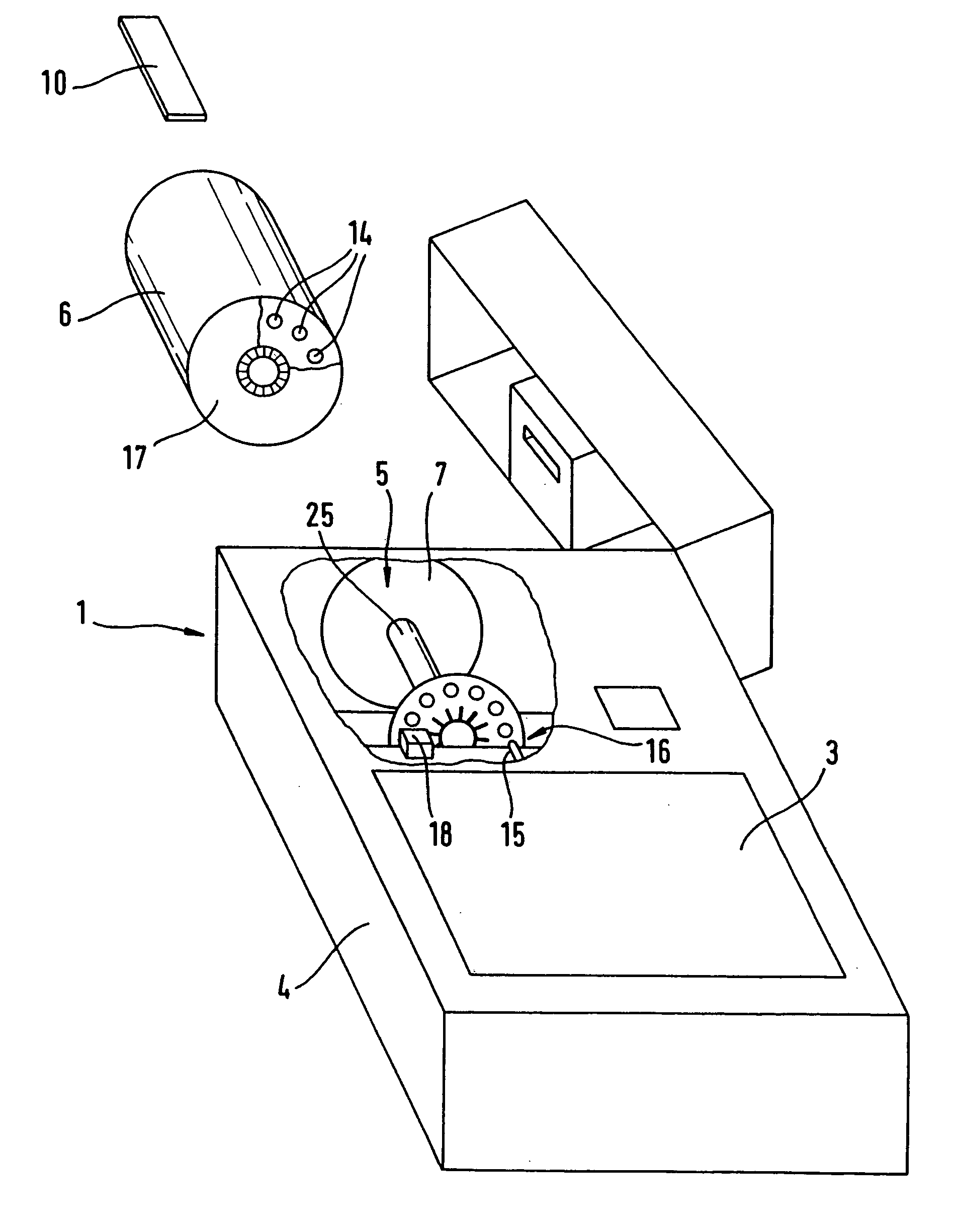

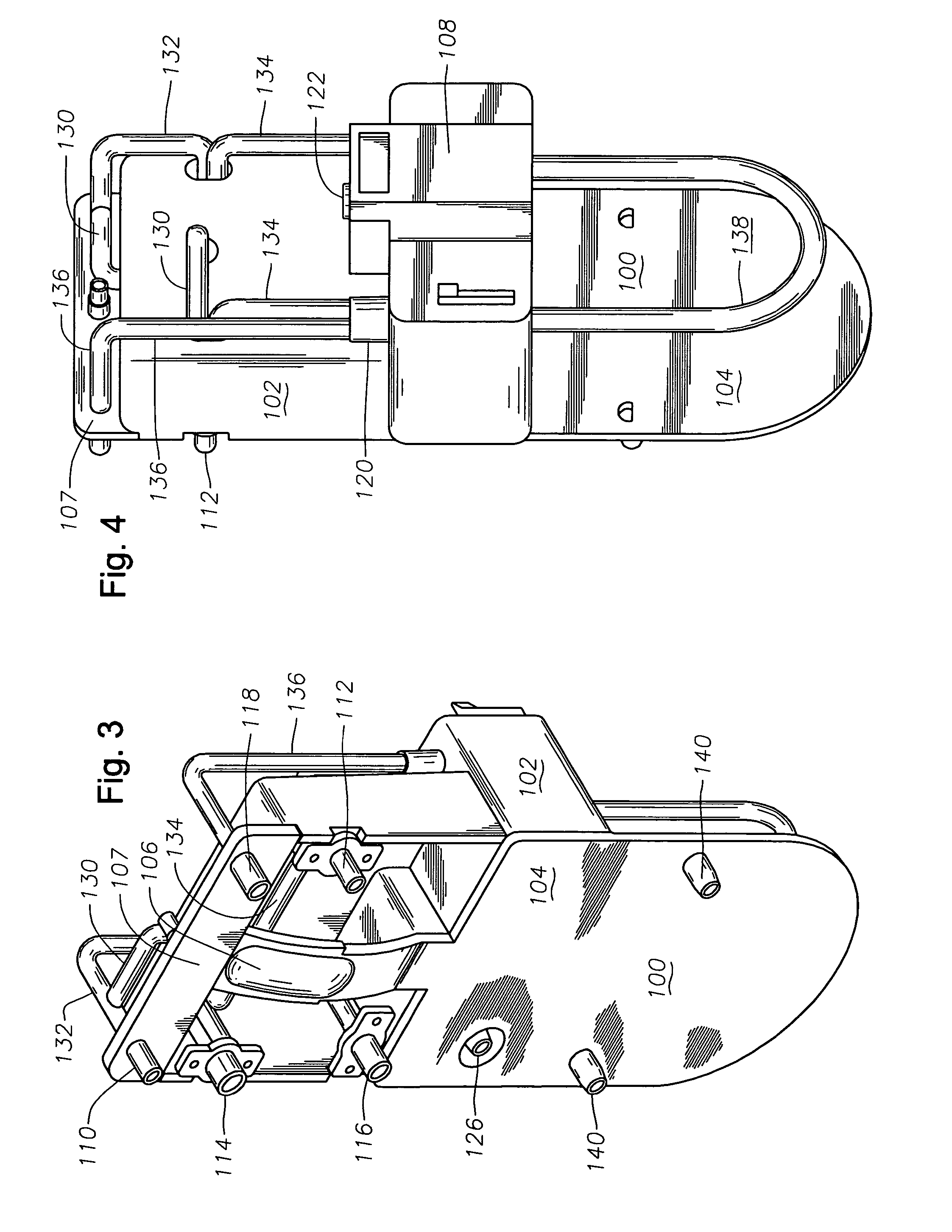

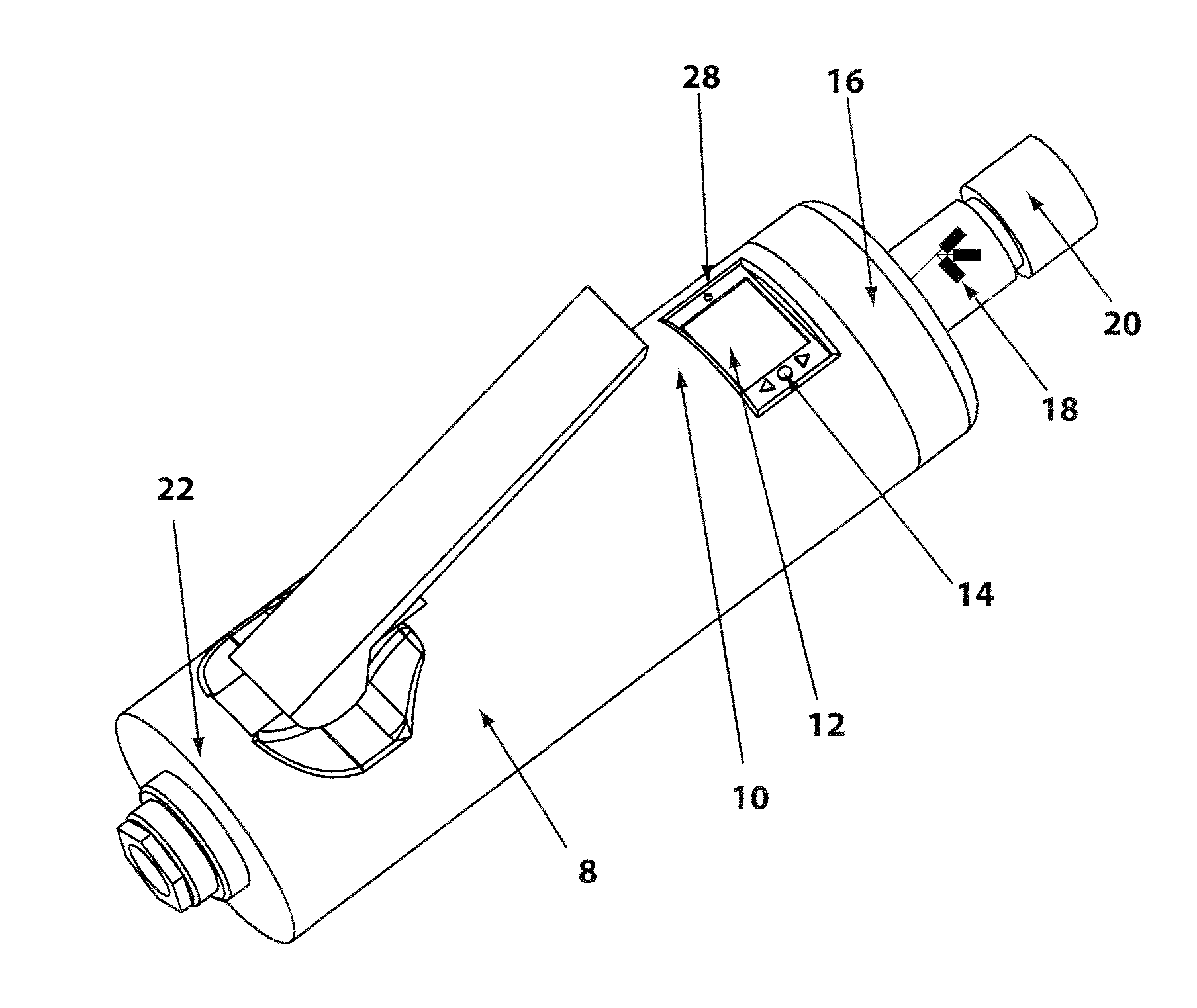

Hand-held analytical device

InactiveUS20050187444A1Easy to operatePrecise positioningAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionLinear motionHand held

The invention relates to a portable hand-held analytical device for analysis of a medically significant component of a sample, the device including a housing having a loading opening for receiving a replaceable drum cartridge containing analytical consumables, whereby the housing comprises on an outer side a dispensing opening through which the consumables can be pushed by means of a removal facility. The device includes a loading opening which is closeable by means of a lid, which upon closing effects a linear motion of a pushing part which moves the drum cartridge to a working position, in which it can be rotated about its geometric longitudinal axis.

Owner:ROCHE DIABETES CARE INC

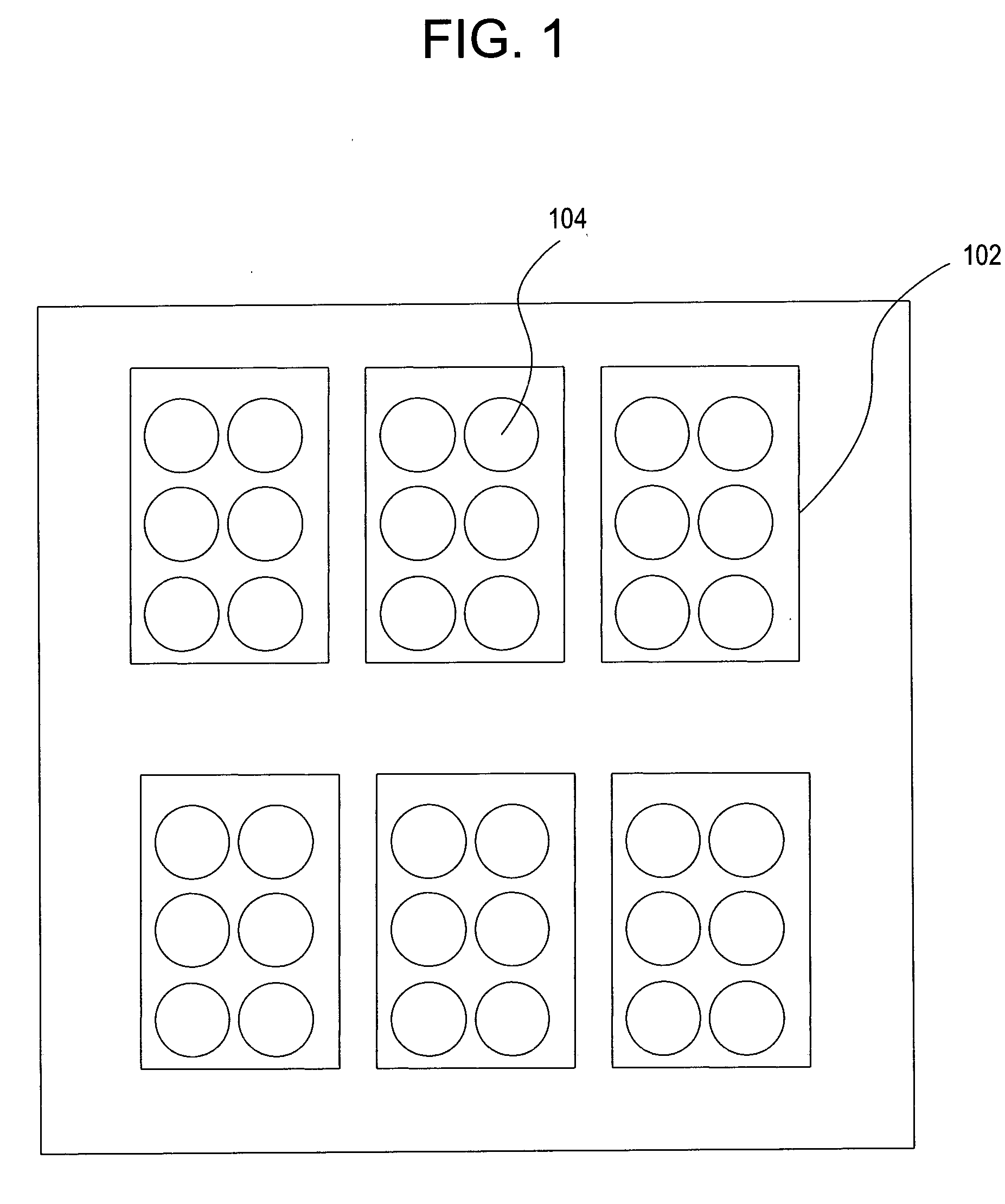

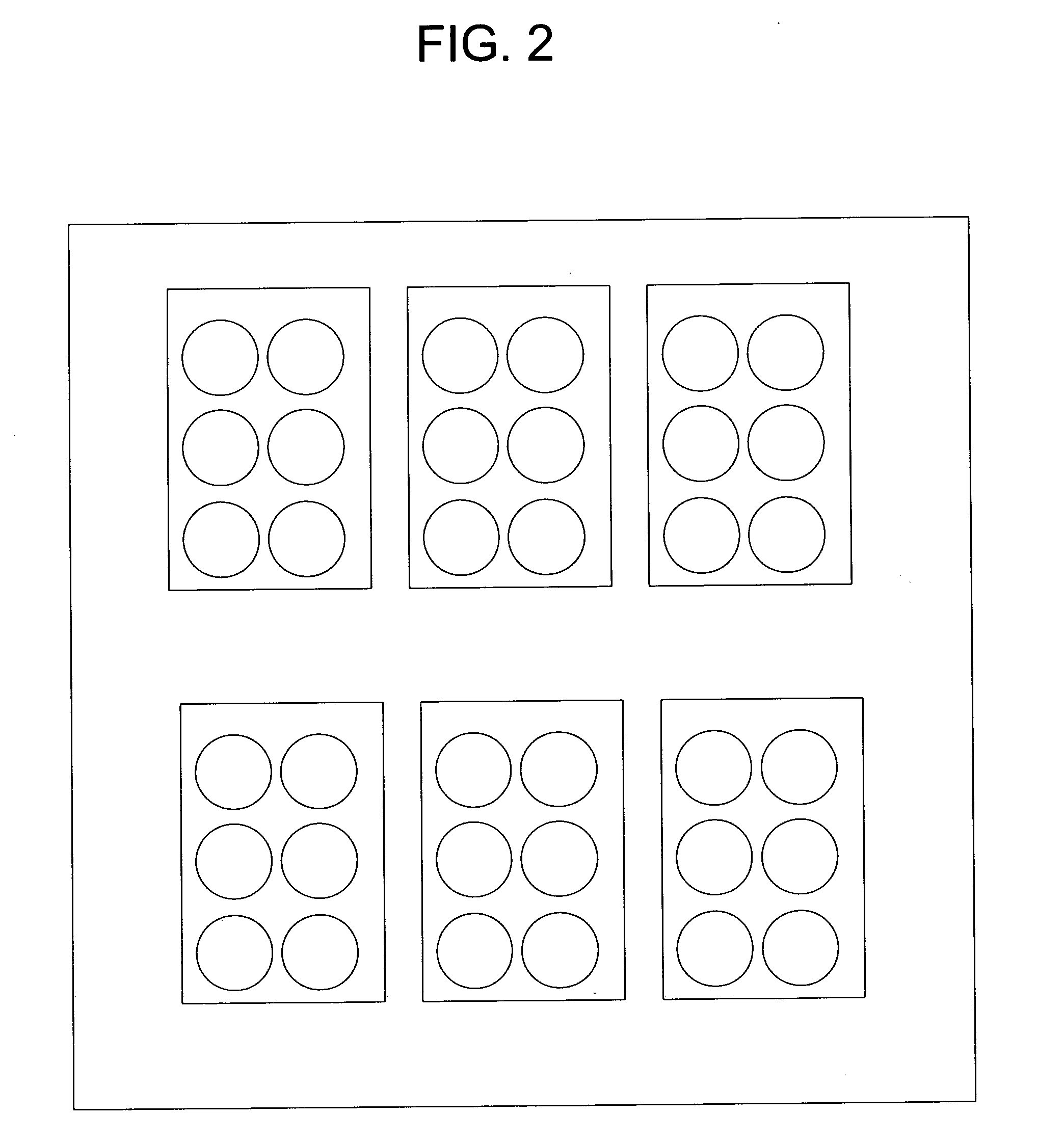

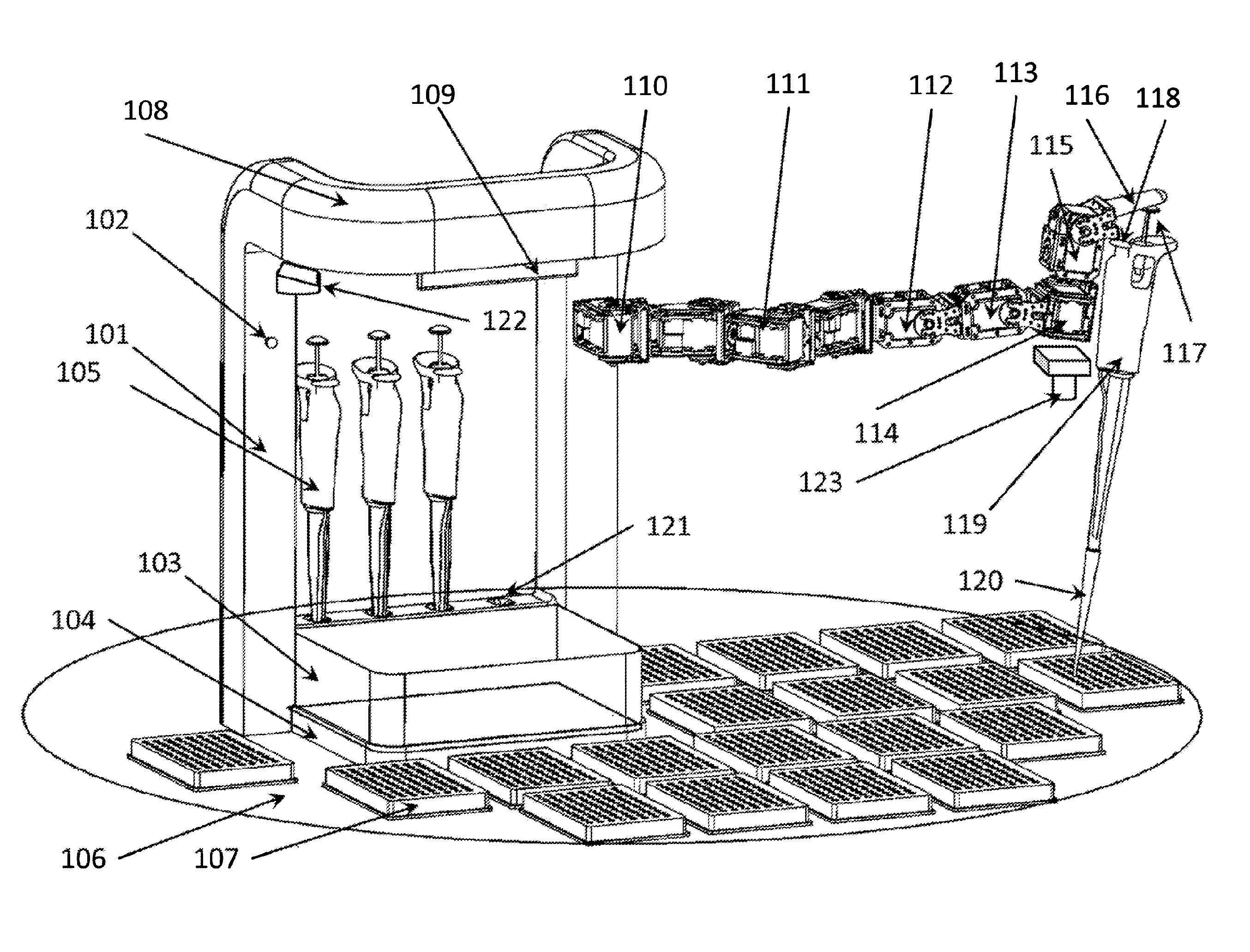

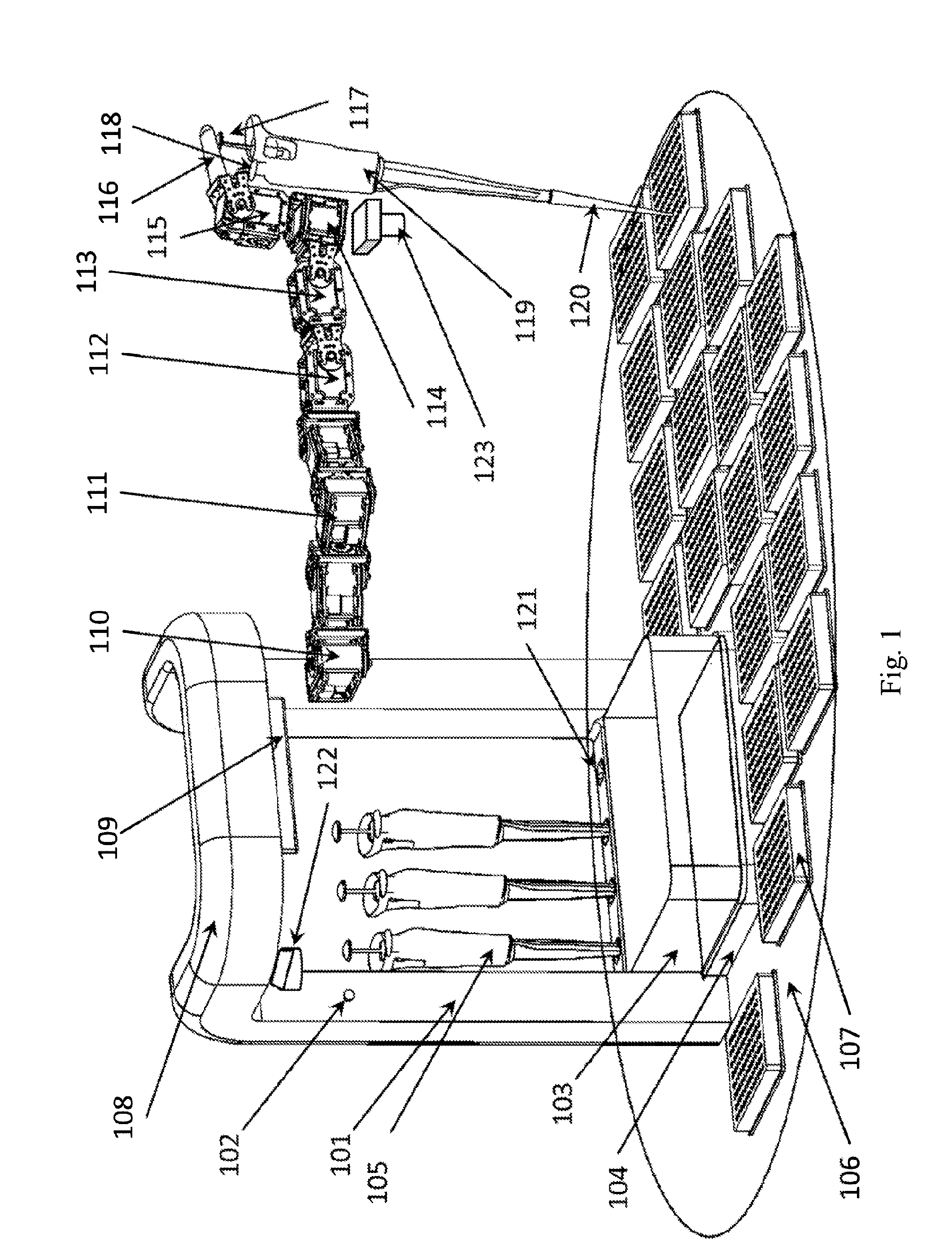

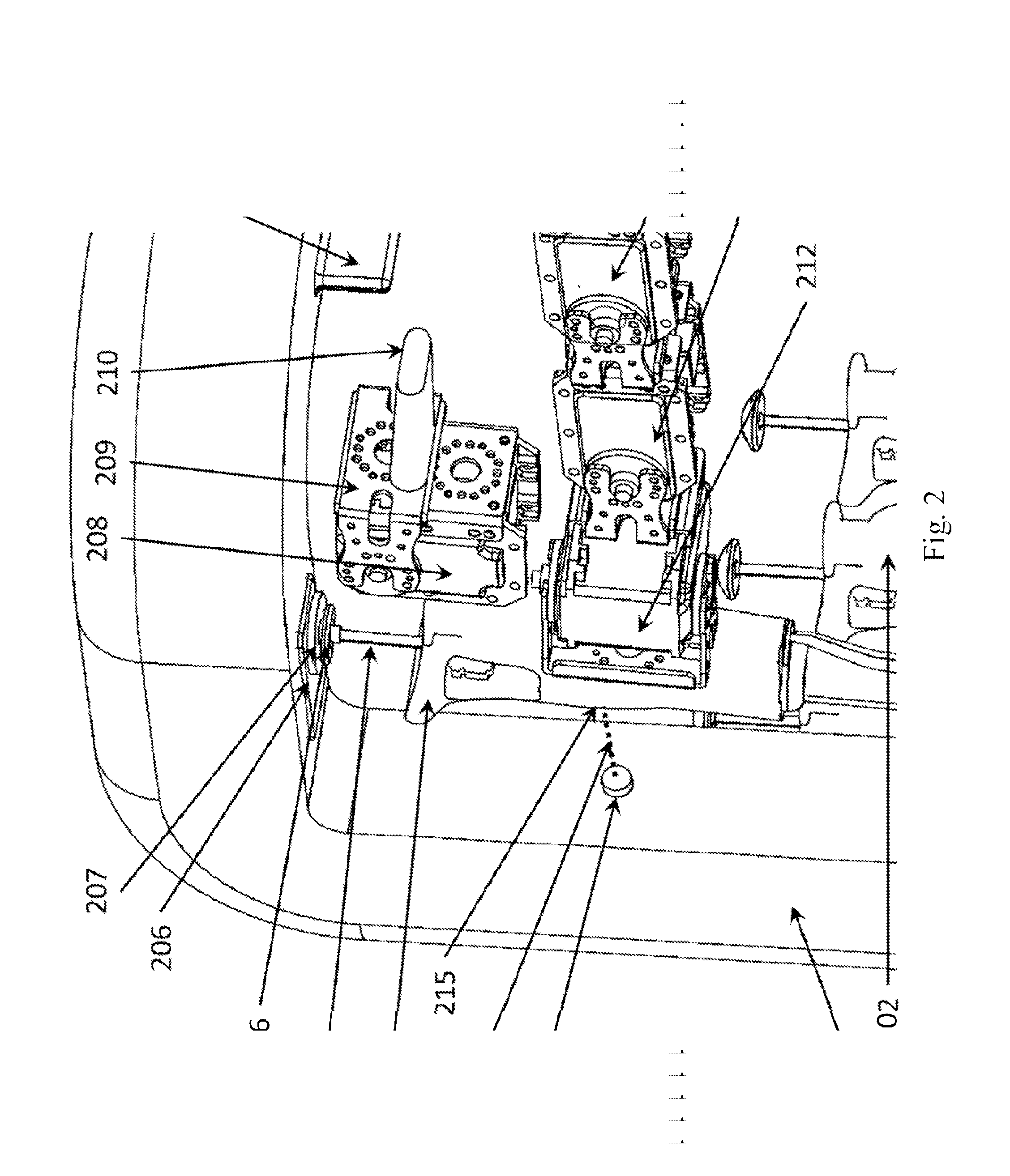

Devices and methods for programmable manipulation of pipettes

ActiveUS20130280143A1Final costSmall footprintProgramme controlProgramme-controlled manipulatorVirtualizationPipette

The present invention is directed generally to devices and methods for manipulating laboratory pipettes in a programmable manner. The present invention is directed to an apparatus and methods for allowing a user to instruct the device to perform a specific process; identifying the type, location and identity of the consumables to be used; manipulating a plurality of pipettes for performing the liquid handling; monitoring the process during and after its execution; generating a detailed report for the plurality of actions. Other aspects of this invention include optimization of the liquid dispensing performances of a pipette; monitoring and controlling individual actions by means of vision; virtualization of the protocol definition by means of a reality augmented software interface; integration of the system in a conventional laboratory environment workflow.

Owner:ANDREW ALLIANCE

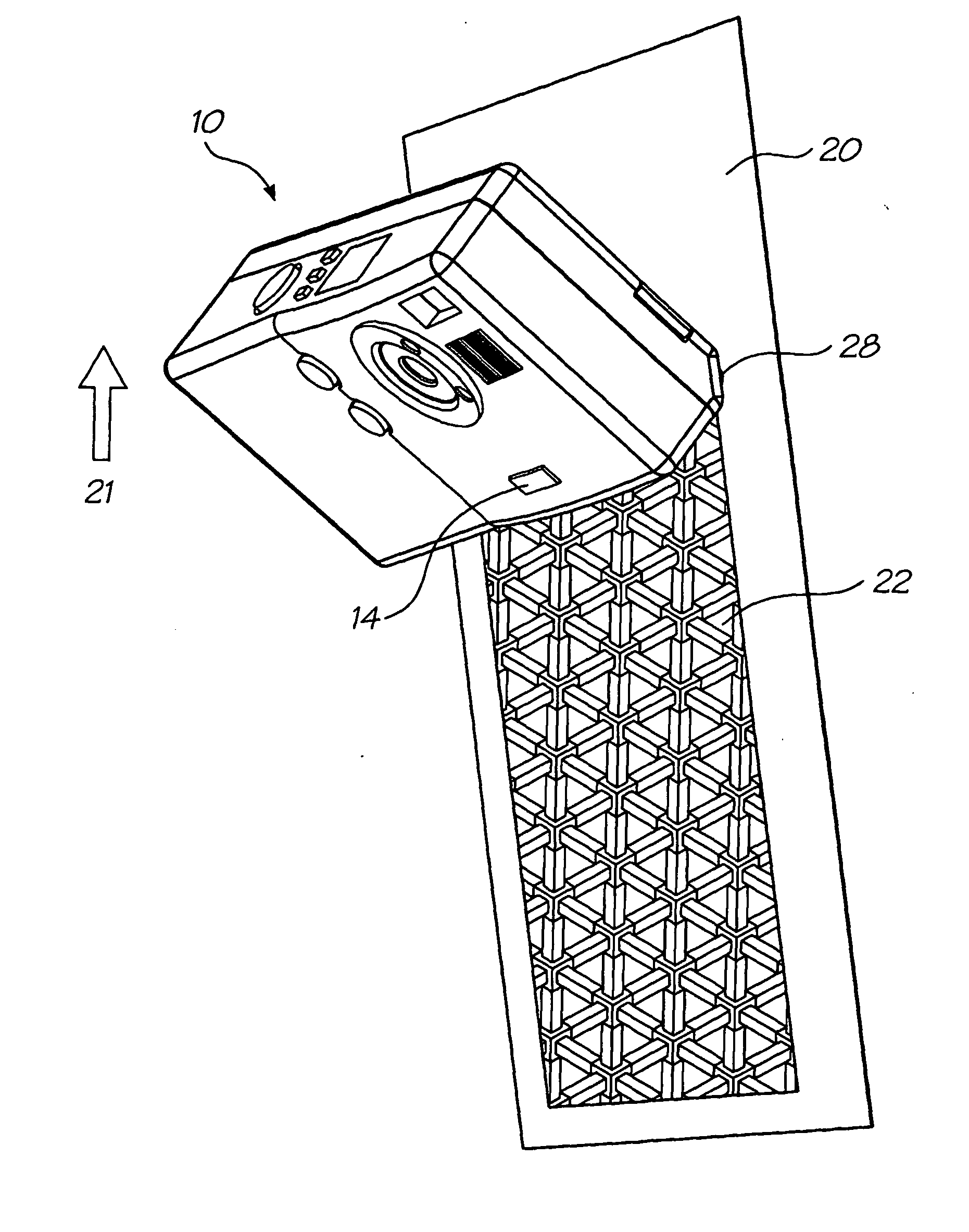

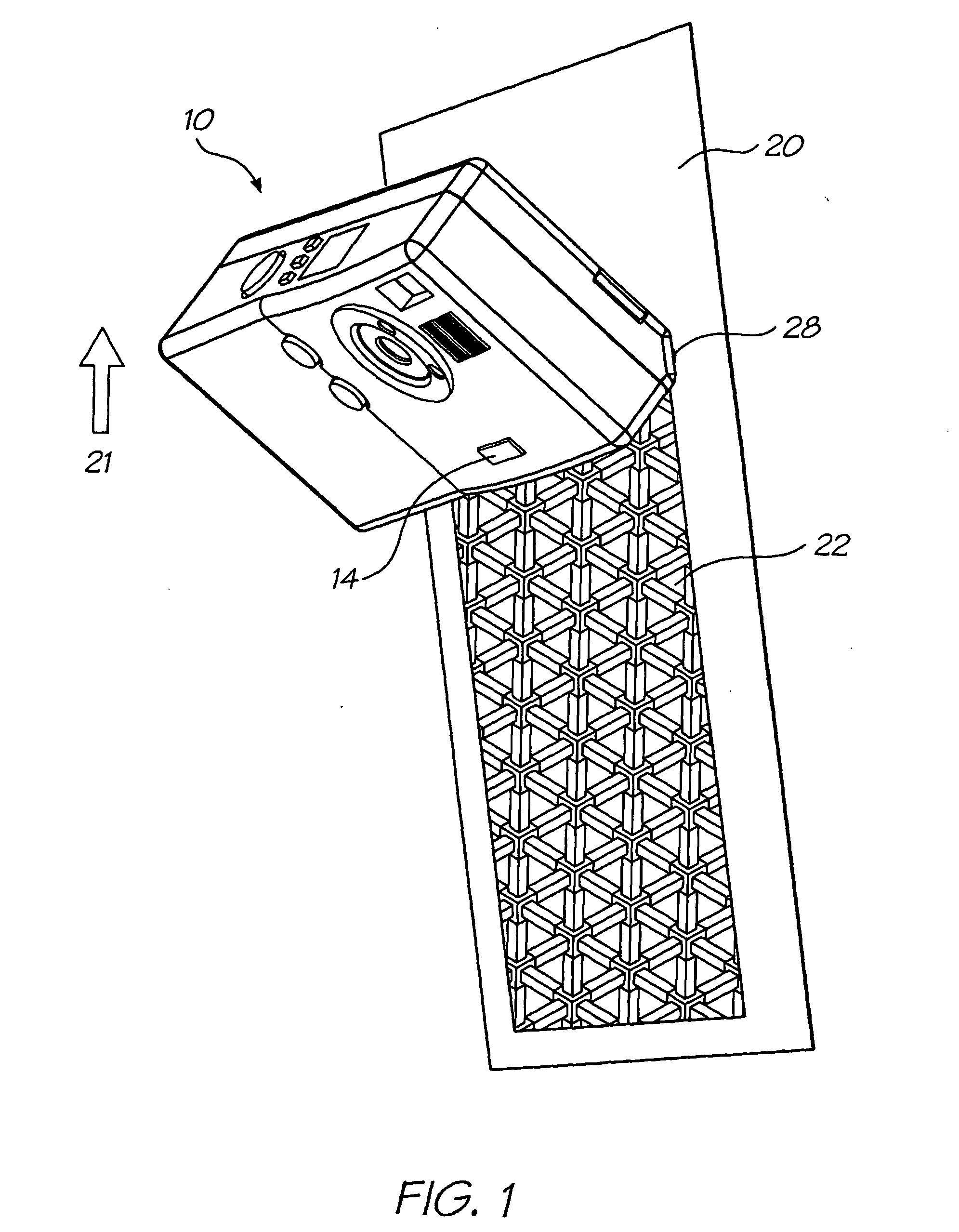

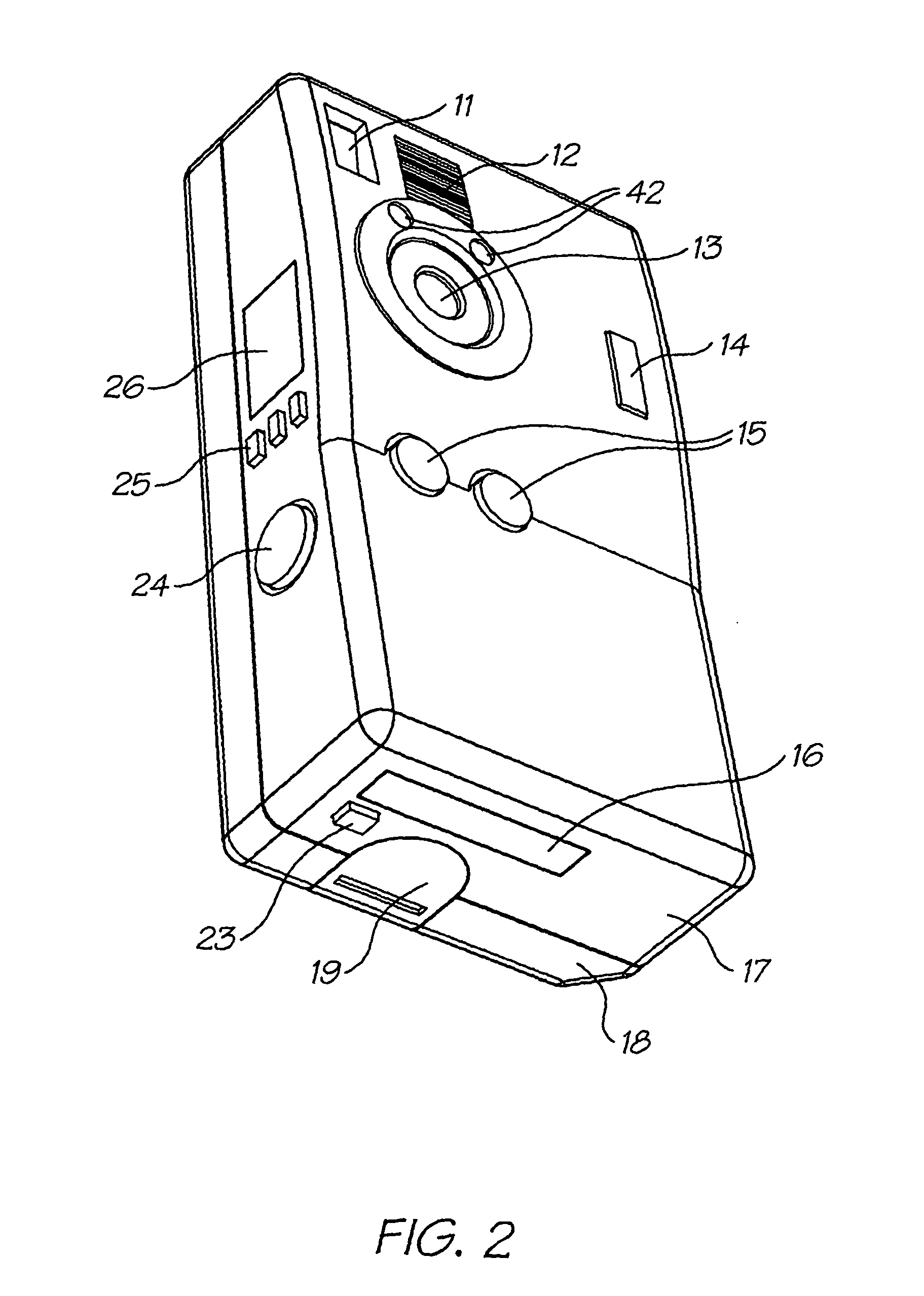

Camera with swipe printer

ActiveUS20050088527A1Television system detailsTypewritersComputer graphics (images)Computer printing

A digital camera has a built-in printer to enable the printing of a stored image upon a page external to the camera as the camera traverse the page. The camera can be maintained compact and lightweight as no paper storage or papered mechanism need be provided A replaceable ink cartridge that detachable connects to the printhead reduces the cost of ongoing consumables.

Owner:GOOGLE LLC

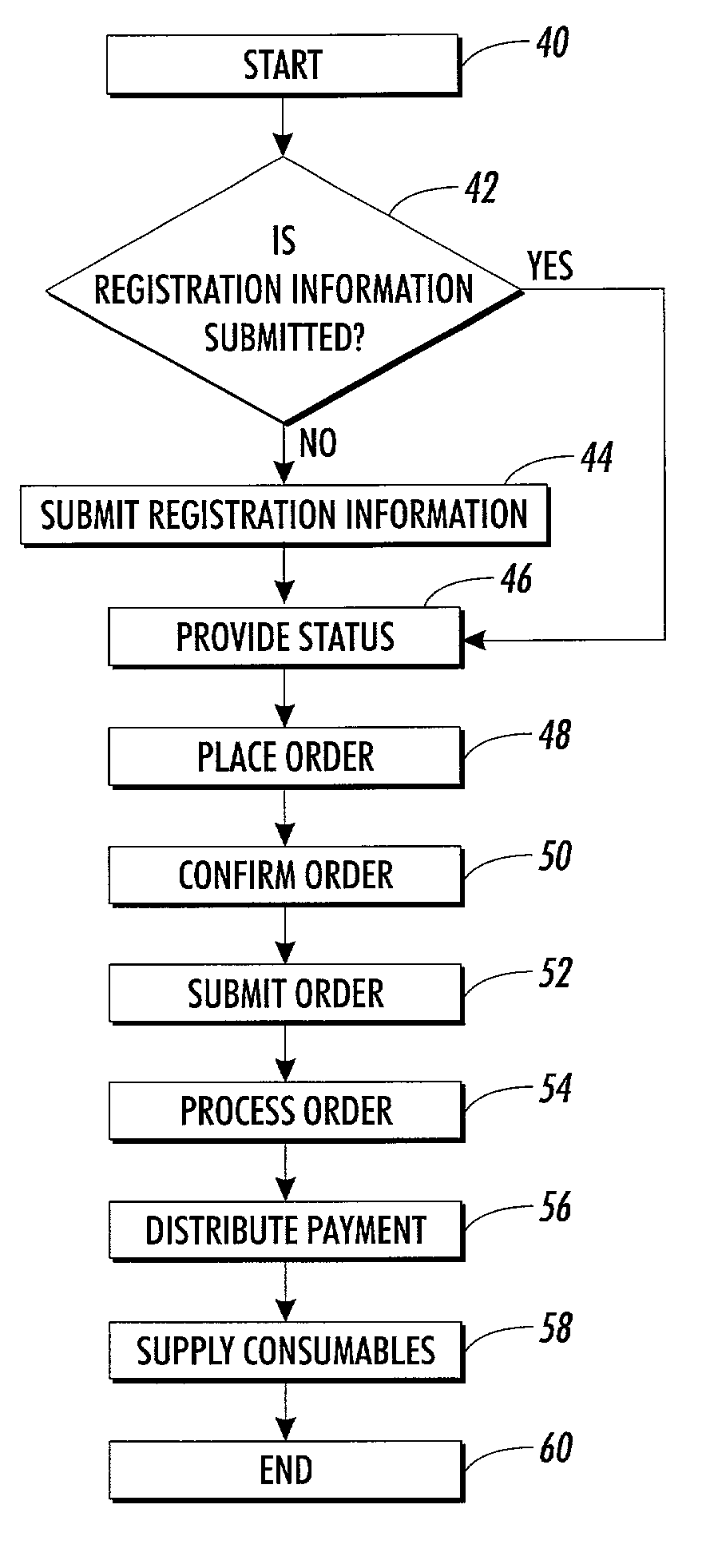

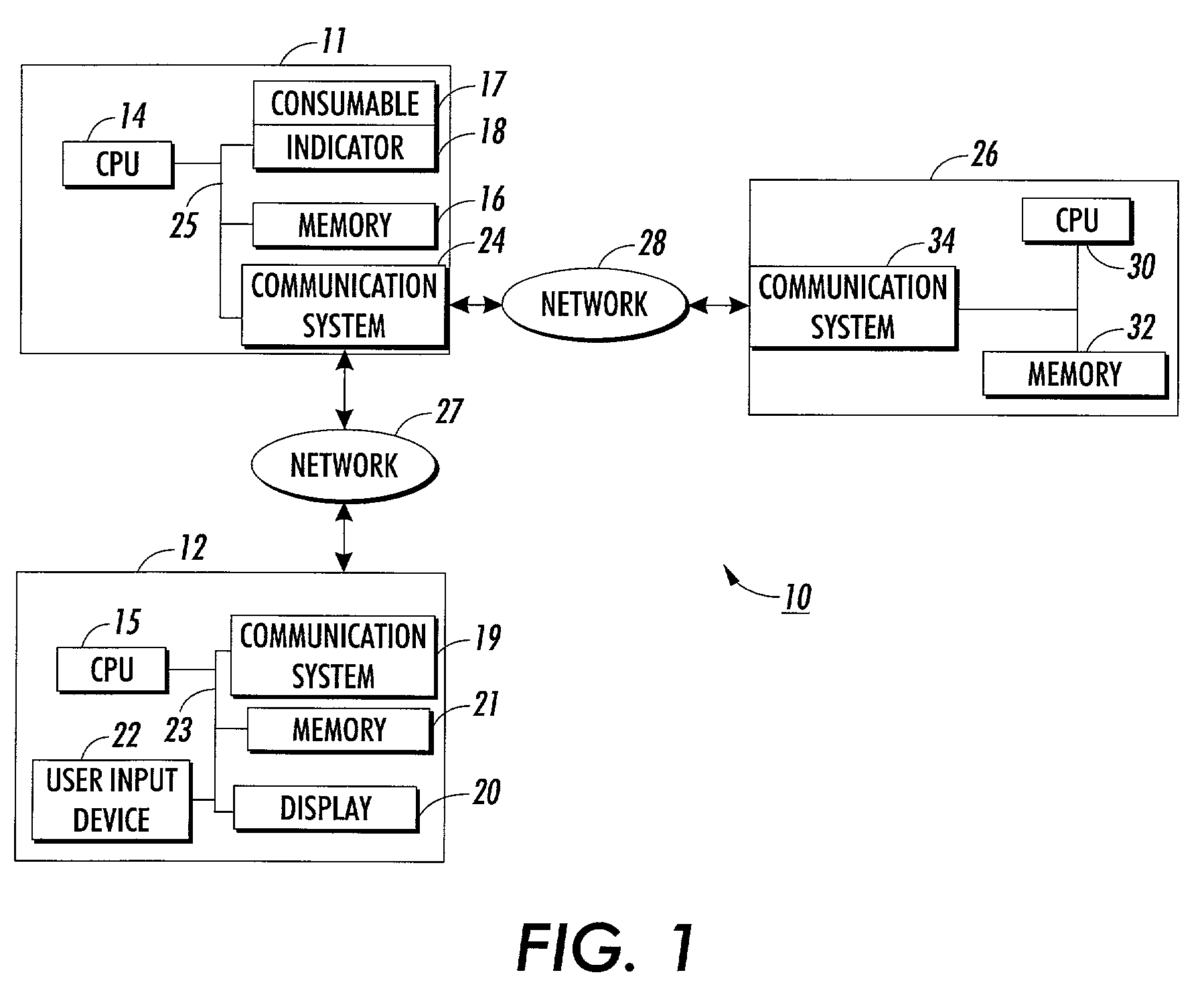

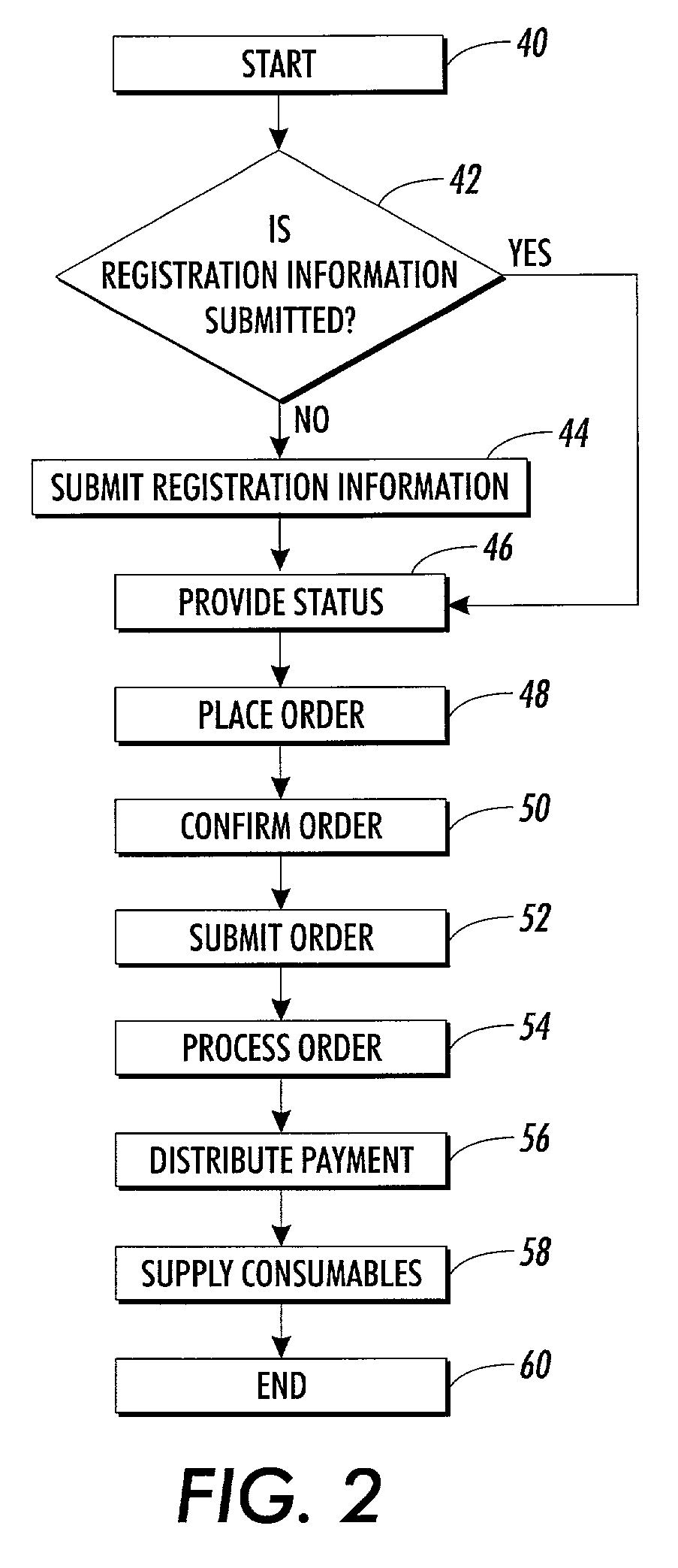

Method and system for ordering a consumable for a device

InactiveUS7124097B2Shorten the timeIncreases customer 's productivityElectrographic process apparatusBuying/selling/leasing transactionsCommunications systemOrder system

A method for ordering one or more consumables for a device includes selecting one or more of the consumables used in the device to order using the device and submitting the order for the selected consumables using the device to one or more suppliers. A device for ordering one or more consumables for the device includes an ordering system in the device and a communication system in the device. The ordering system providing a menu of one or more of the consumables to select to place an order. The communication system submits the order for the selected consumables when completed.

Owner:XEROX CORP

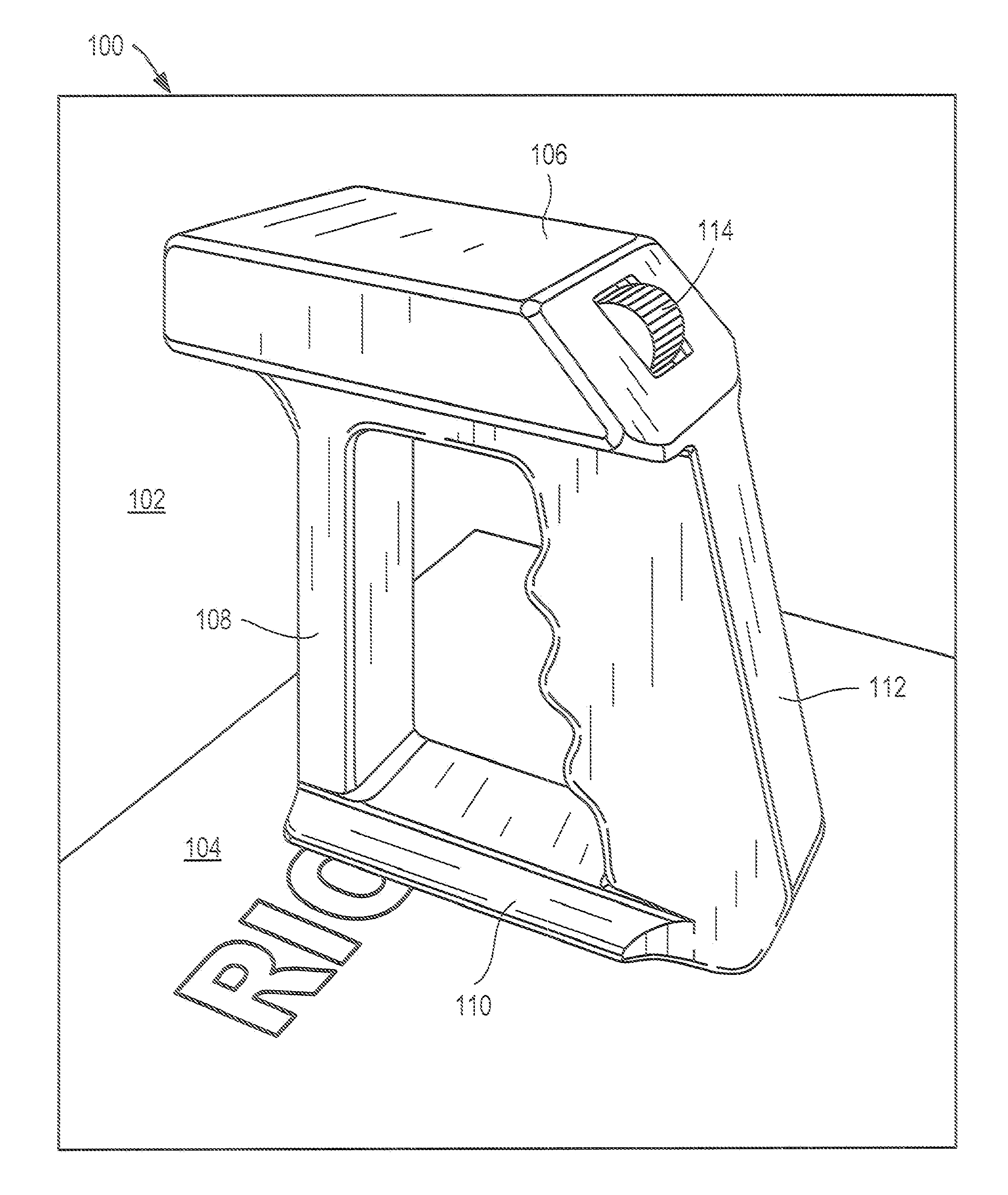

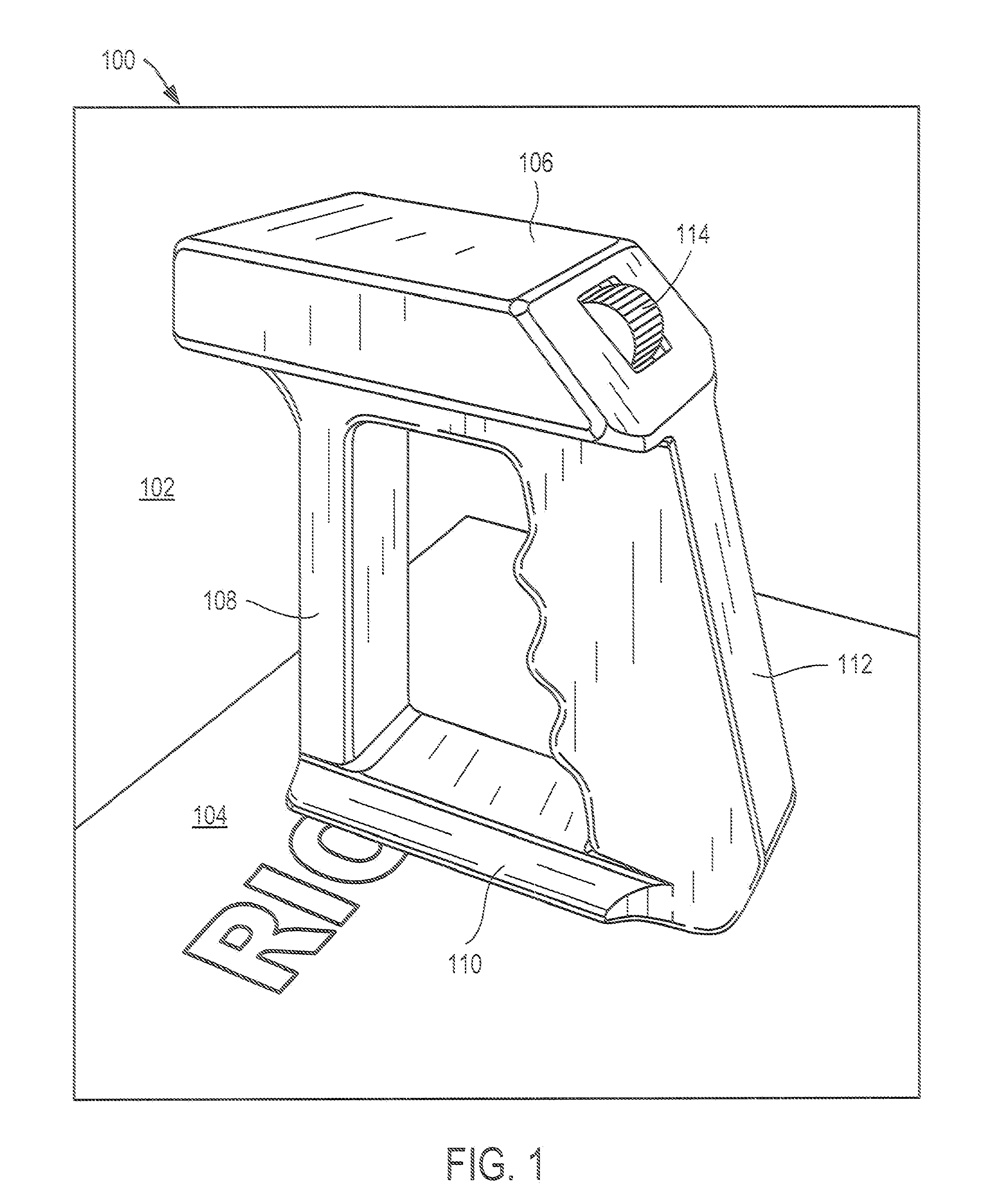

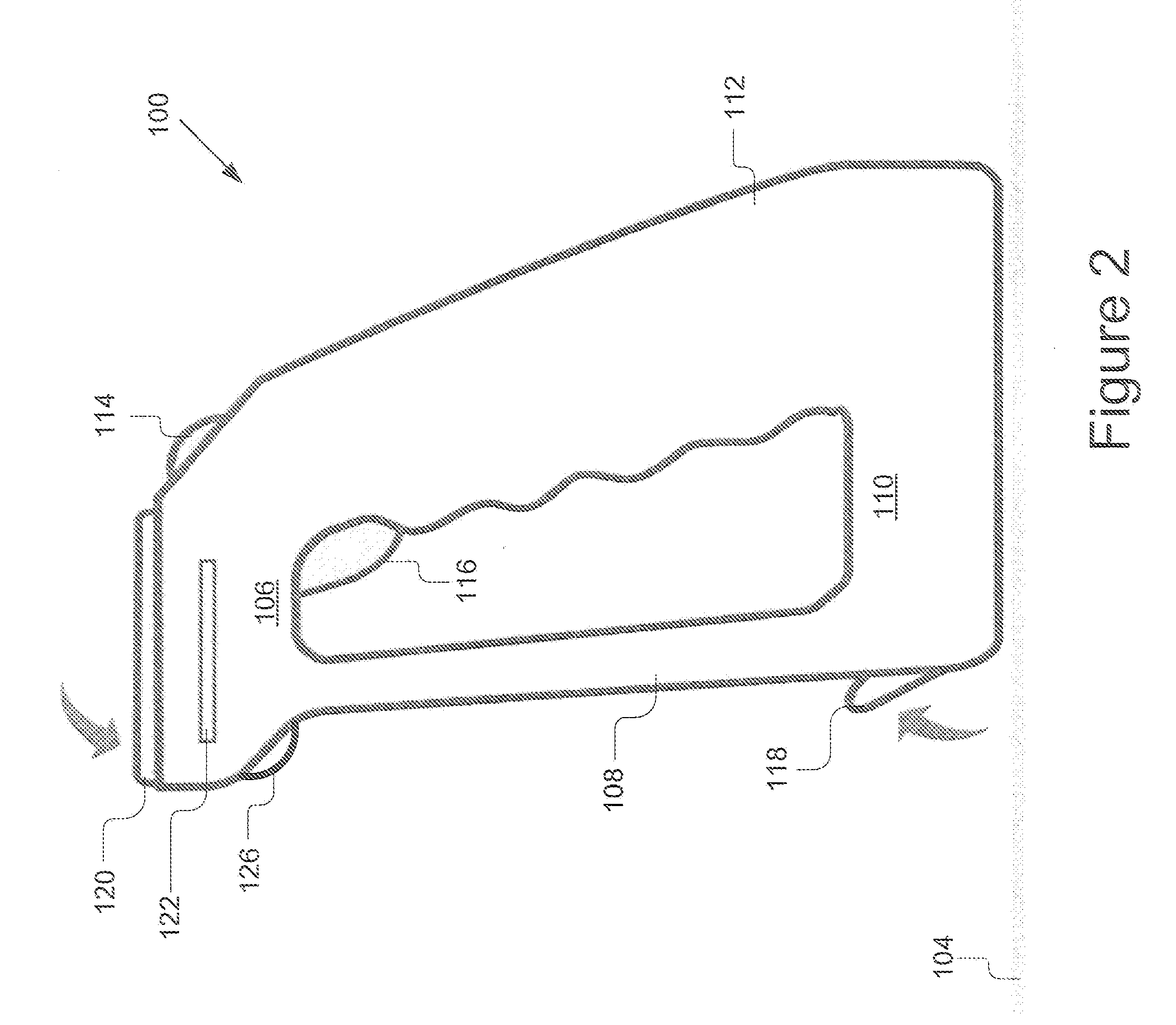

Handheld printer and method of operation

ActiveUS20080144053A1Rigid and strong structureImprove abilitiesDigitally marking record carriersDigital computer detailsHand heldDisplay device

A handheld portable printer includes a top member, a front member, a bottom member and a handle that are joined together to form a generally O-shaped device. The top member defines a hole through which a scroll dial protrudes and is adapted to support a retractable display on its top surface. The front member provides an area for storing consumables, a battery, and houses a projector to project an image on the print surface of the image to be printed. The bottom member houses optical sensors to detect and measure movement of the handheld printer; and a print head for outputting ink on the print surface. The handle provides additional buttons for inputting command to lock an image or begin printing, and in one embodiment housing electronics for control and projection of the image to be printed, providing user feedback, and communicating with other devices. The present invention also includes a number of novel methods including: a method for printing an image with a handheld printer, a method for projecting an image to be printed, and a method for registering a location of a printer and portions of a printed image.

Owner:RICOH KK

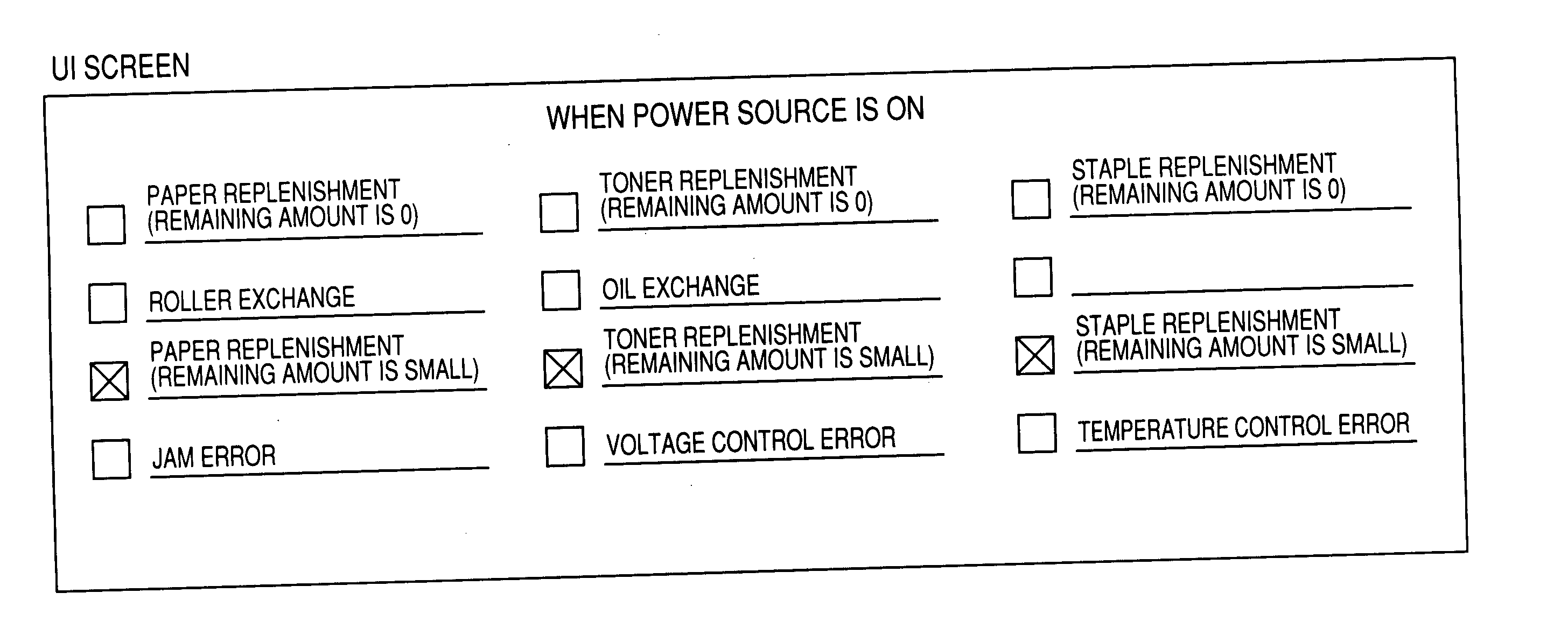

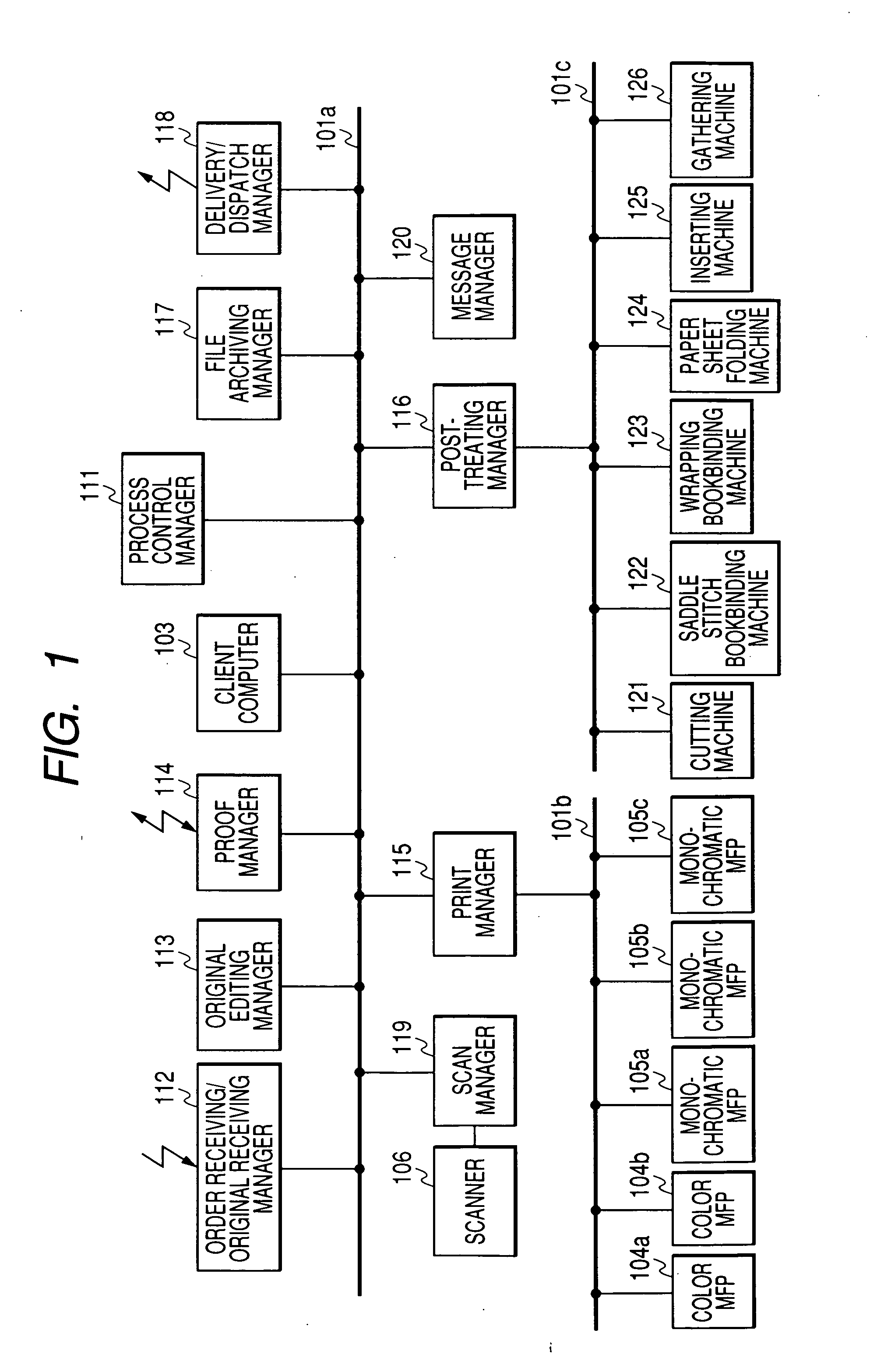

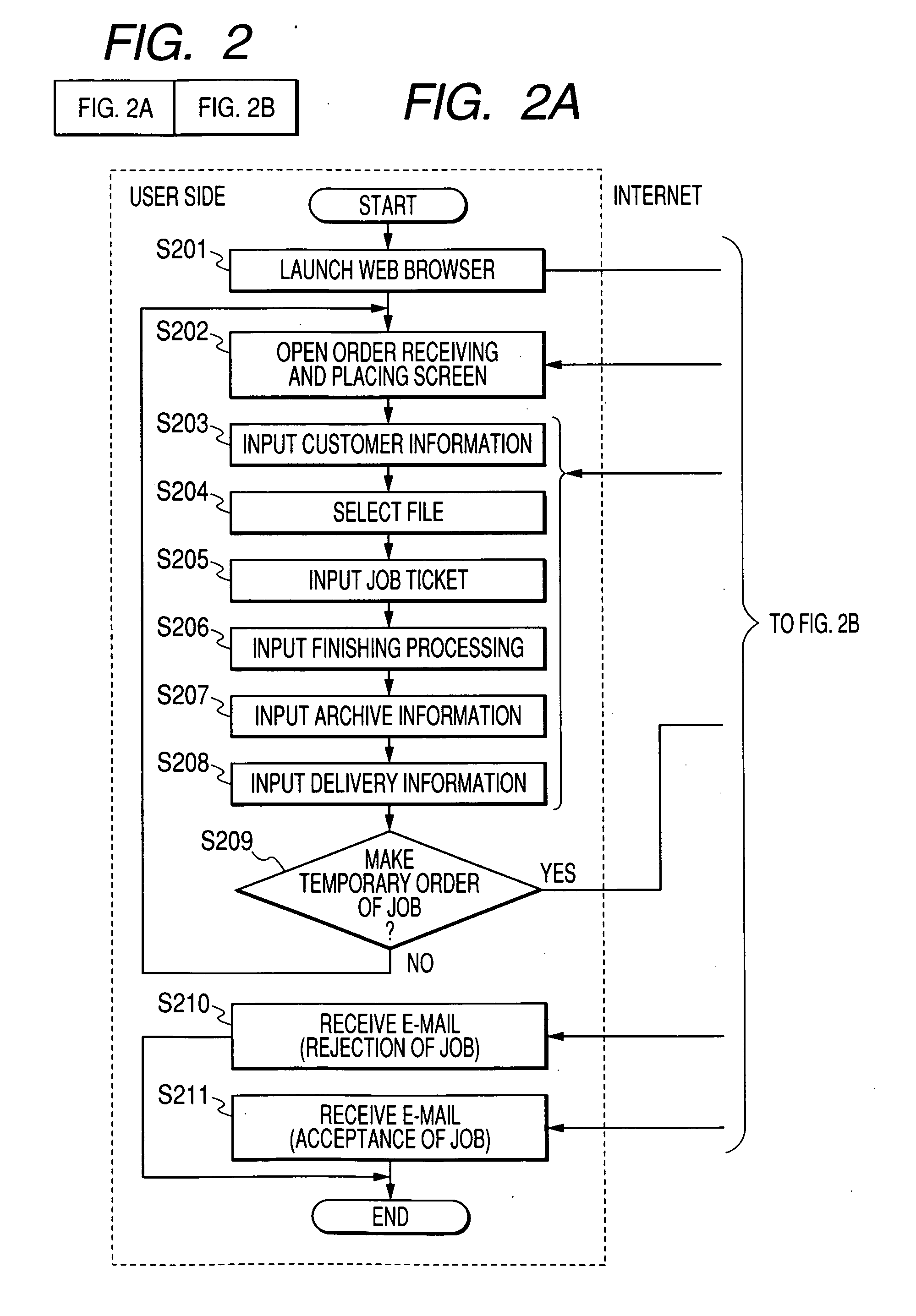

Image forming system and image forming apparatus

InactiveUS20060039707A1Reliably reporting informationReliable informationElectrographic process apparatusOther printing apparatusOrder formImage formation

Provided is an image forming system and an image forming apparatus capable of reliably reporting information relating to a remaining amount of consumables to an operator without increasing the number of operations of the operator of the image forming system. The image forming system connects a variety of kinds of managers such as a process control manager, an order receiving / original receiving manager, and a message manager, and post-treatment devices such as MFPs, a cutting machine, and a saddle stitch bookbinding device, via a network. The message manager reads the remaining amount of paper sheets of an applicable printer device from a consumption degree table which is stored in an HDD; computes an expected amount of consumption of the paper sheet of the applicable printer device to be consumed due to execution of a job; and when the remaining amount of the paper sheet is below 0 as a result of subtraction of the expected consumption amount of the paper sheet from the remaining amount of the paper sheet, displays on a UI a warning message indicating that an operator maintenance is necessary.

Owner:CANON KK

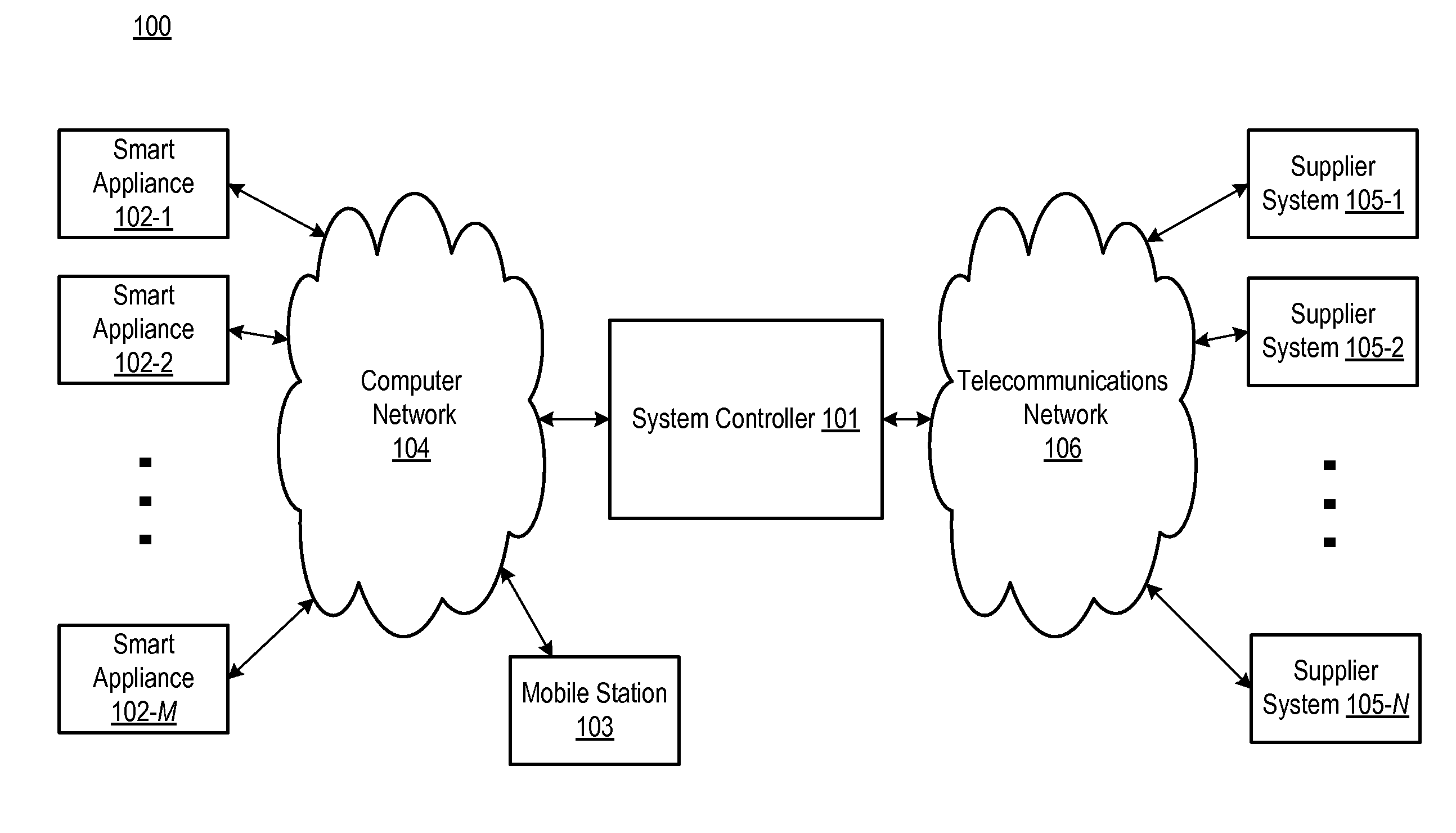

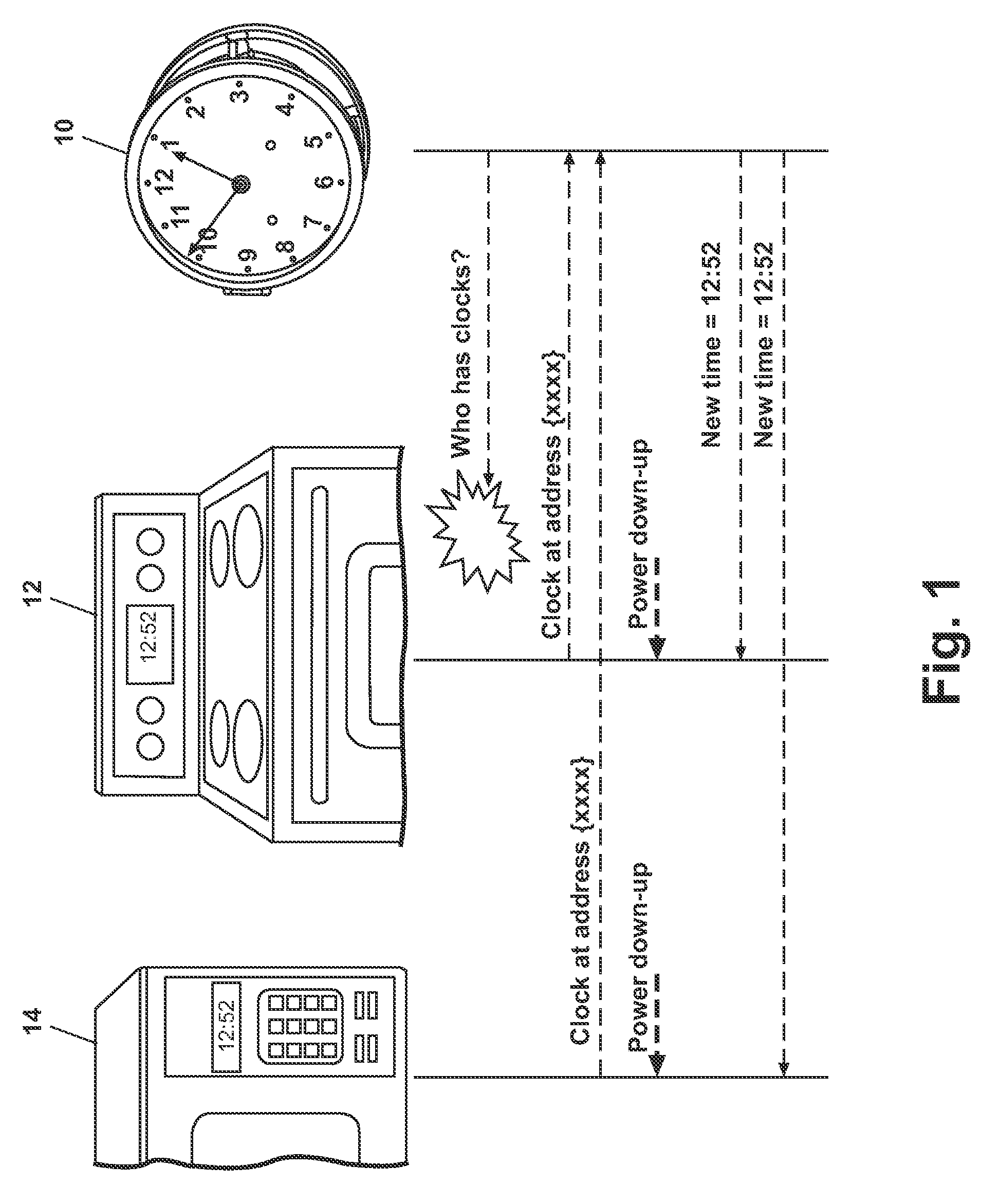

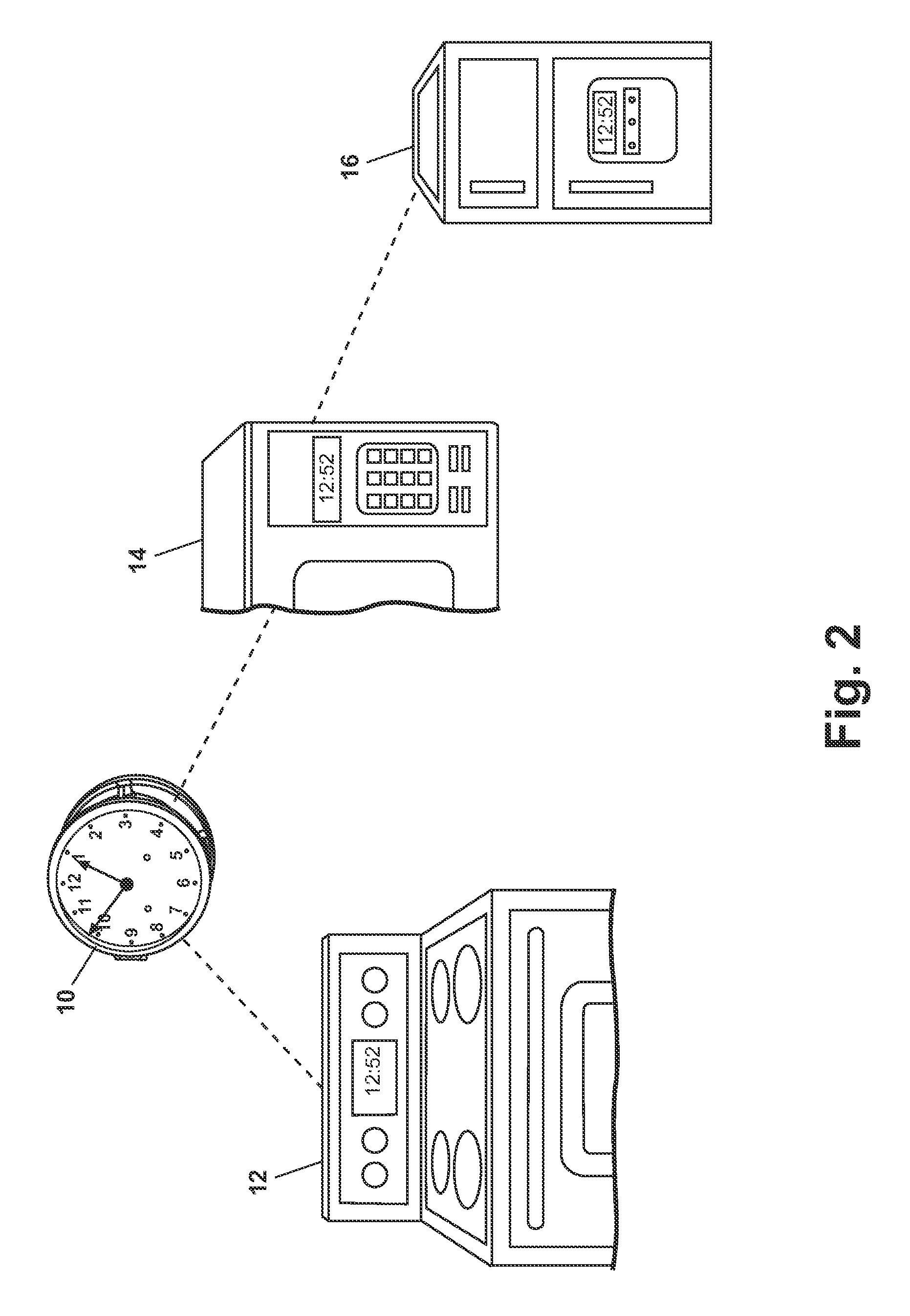

System and Apparatus for Reordering Consumable Goods Associated with Appliances, and Method Thereof

ActiveUS20150105880A1Low costImprove user experienceProgramme controlComputer controlContext awarenessSystem controller

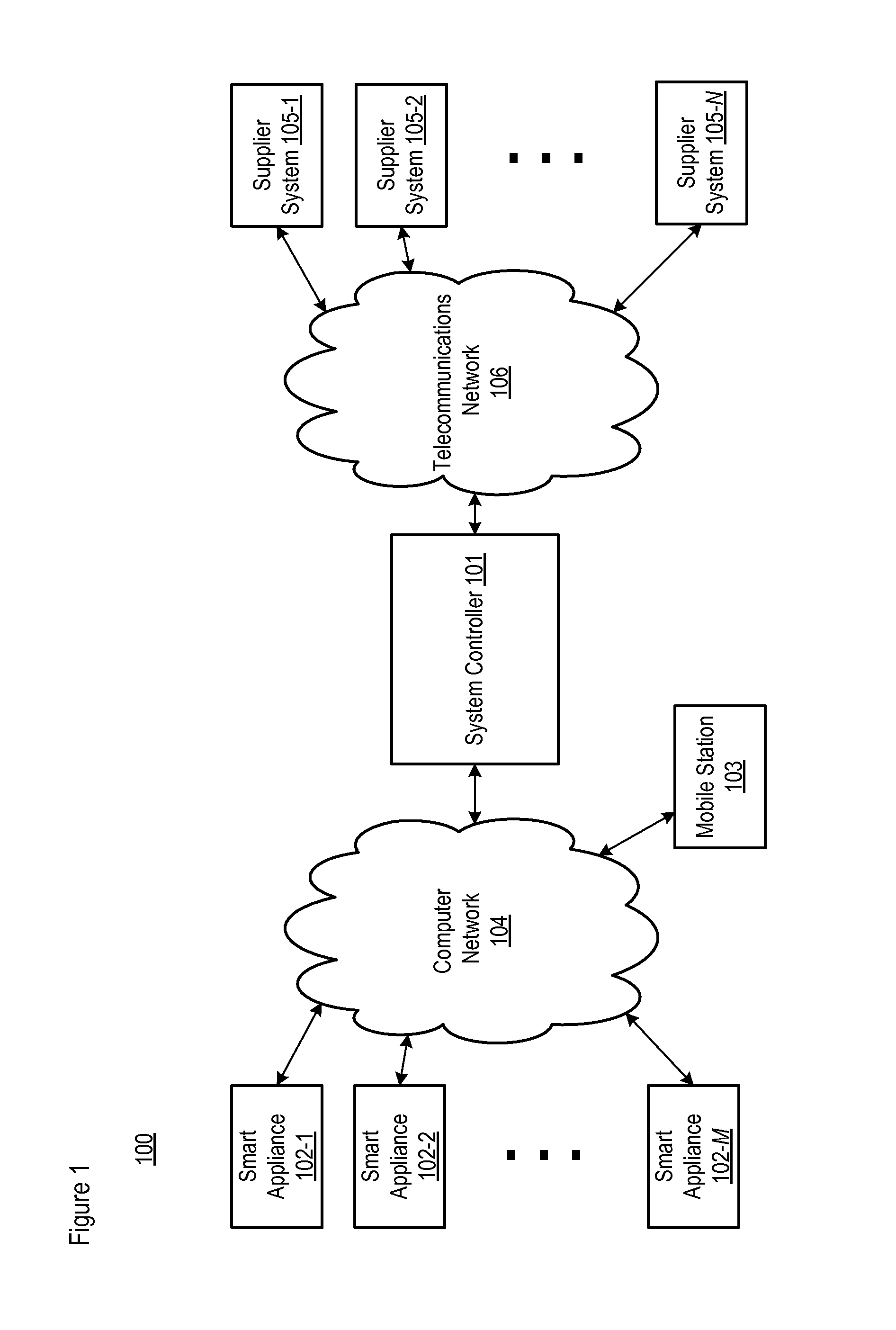

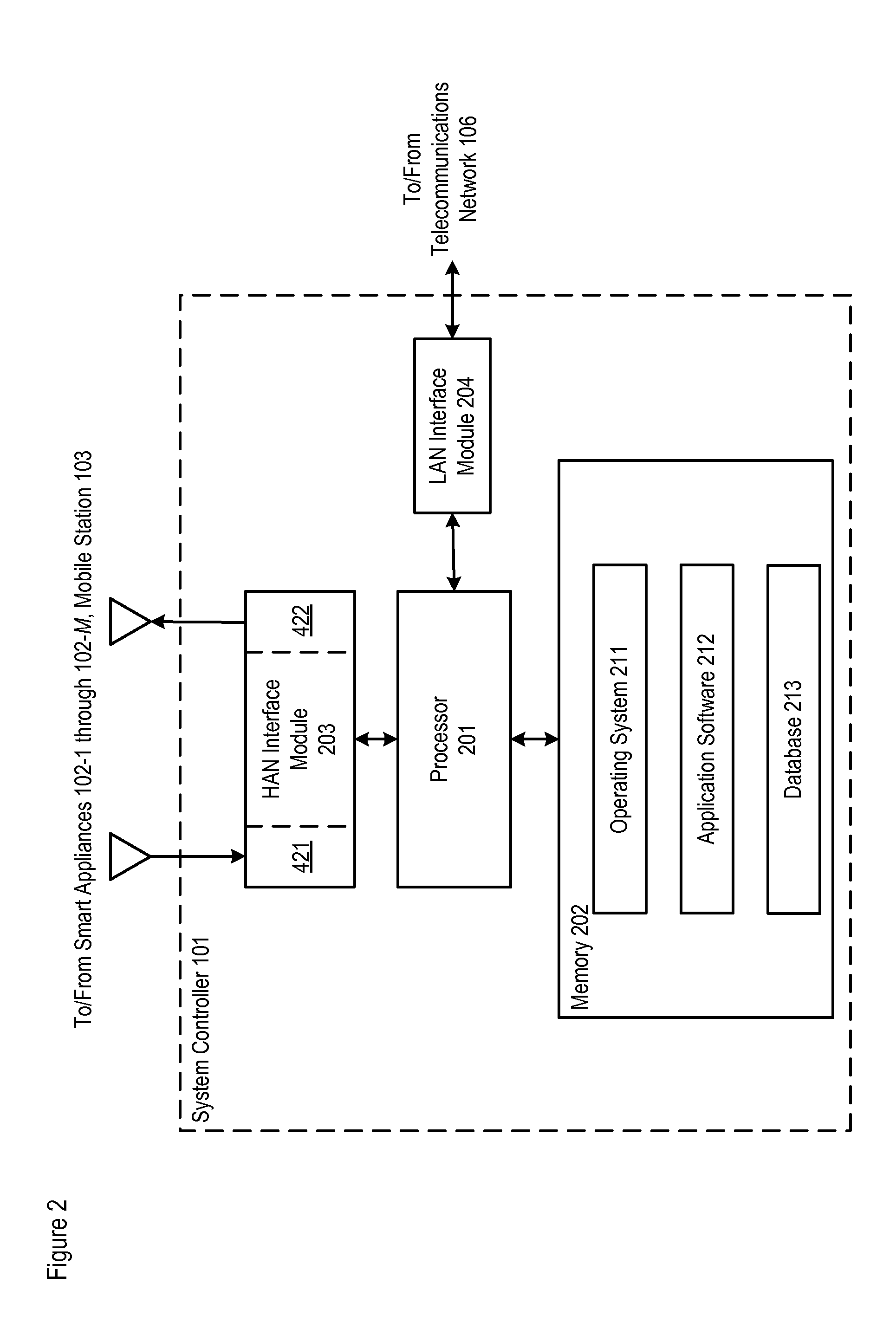

A consumable-goods reordering system in which a system controller has access to the signals transmitted by each smart appliance relevant to the environment being monitored, such as a home. Each appliance monitors a particular physical condition that is related to the appliance's usage of a consumable good, senses changes in the condition being monitored, and reports states of the condition. Meanwhile, the system controller memorizes and maintains the states of various processing events, such as when an appliance reported a particular state of the monitored condition. By considering the information reported by the multiple smart appliances, as well as by accounting for the states corresponding to the various events, the system controller is able to continually update a representation of the state of the monitored environment. Having such context awareness enables the system controller to generate intelligently various reorder messages for transmission to the various suppliers of the consumables.

Owner:SILVAIR SP ZOO

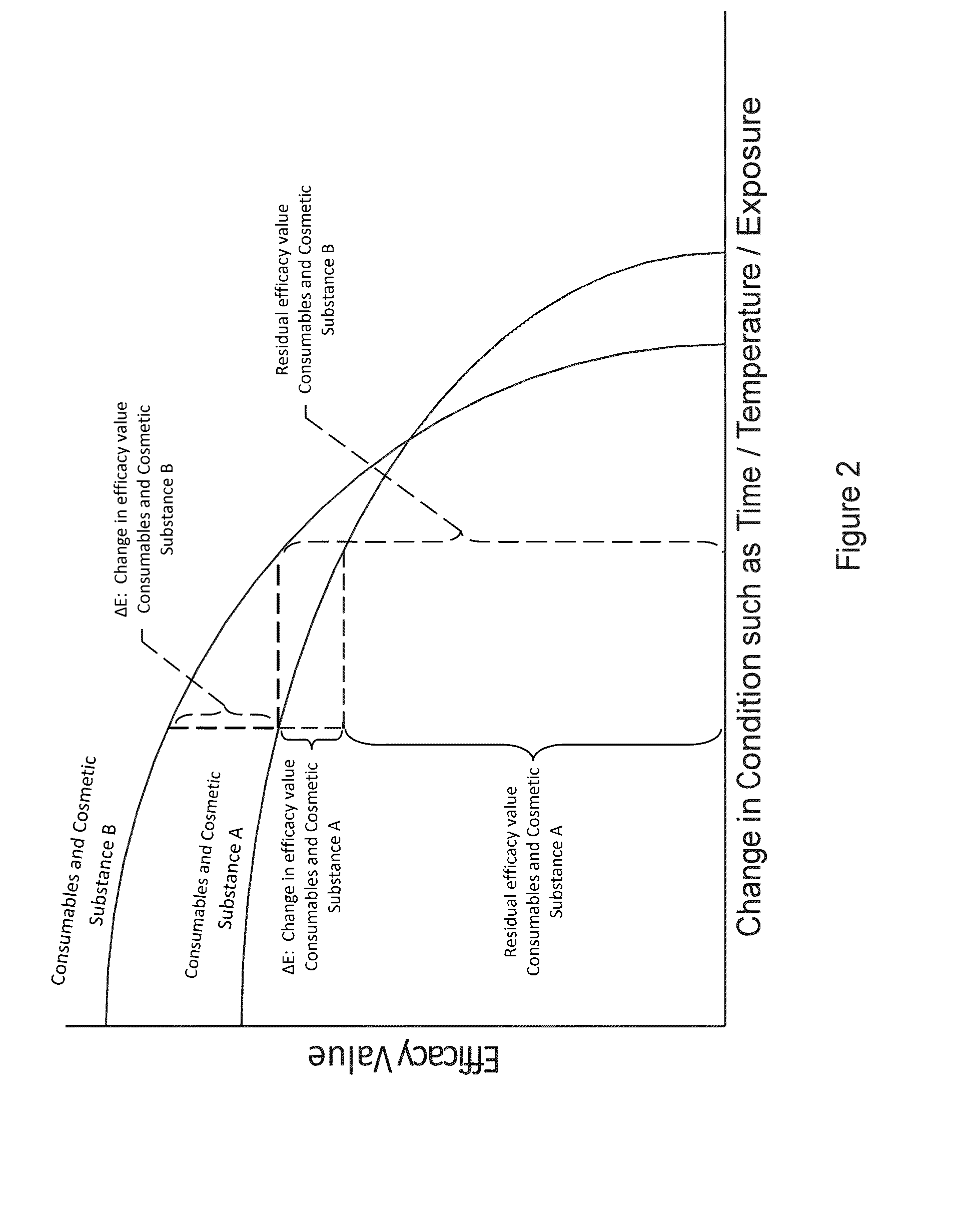

Consumer Information and Sensing System for Consumables and Cosmetic Substances

InactiveUS20130309637A1Degradation of of minimizedMaps/plans/chartsNavigation instrumentsEngineeringNavigation system

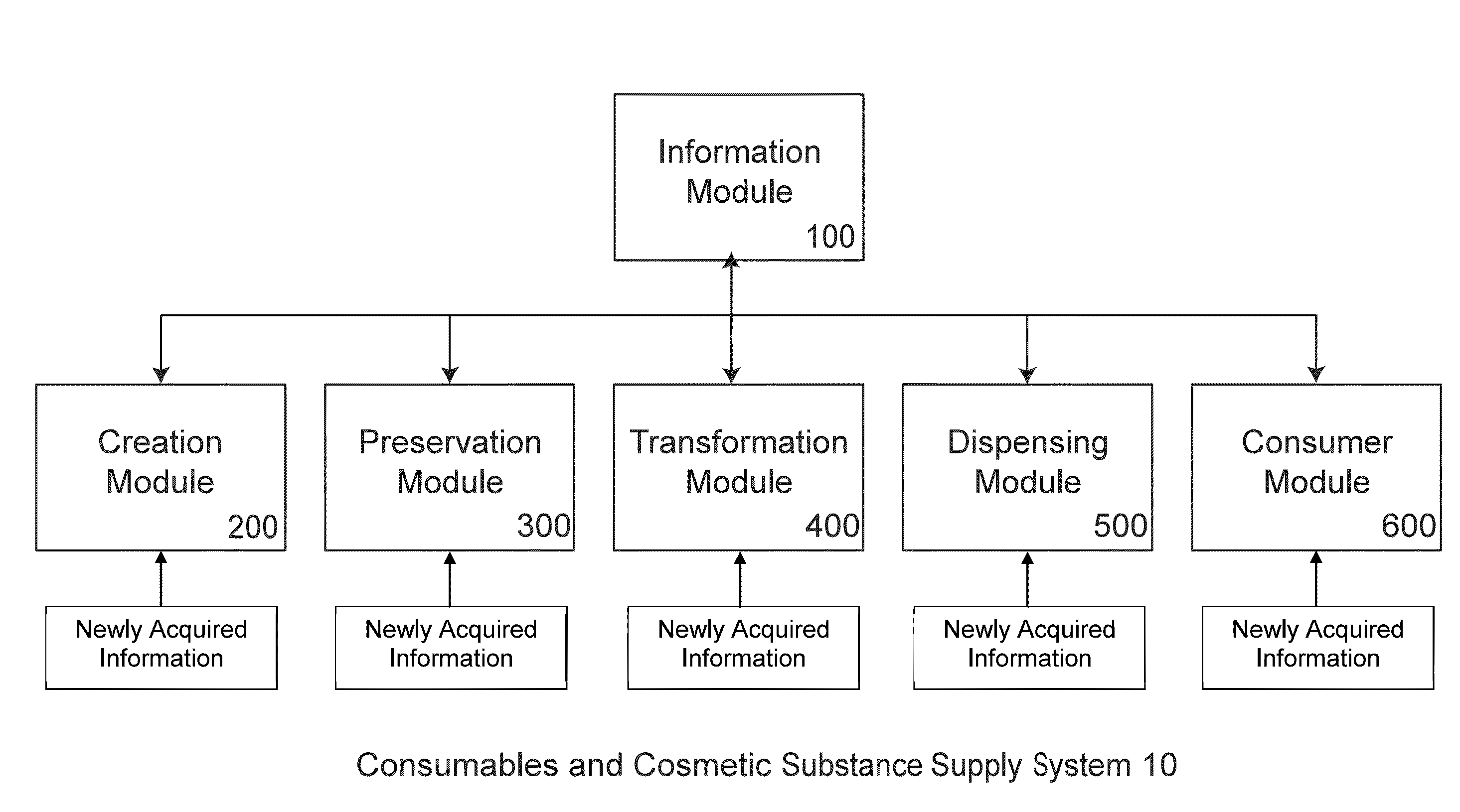

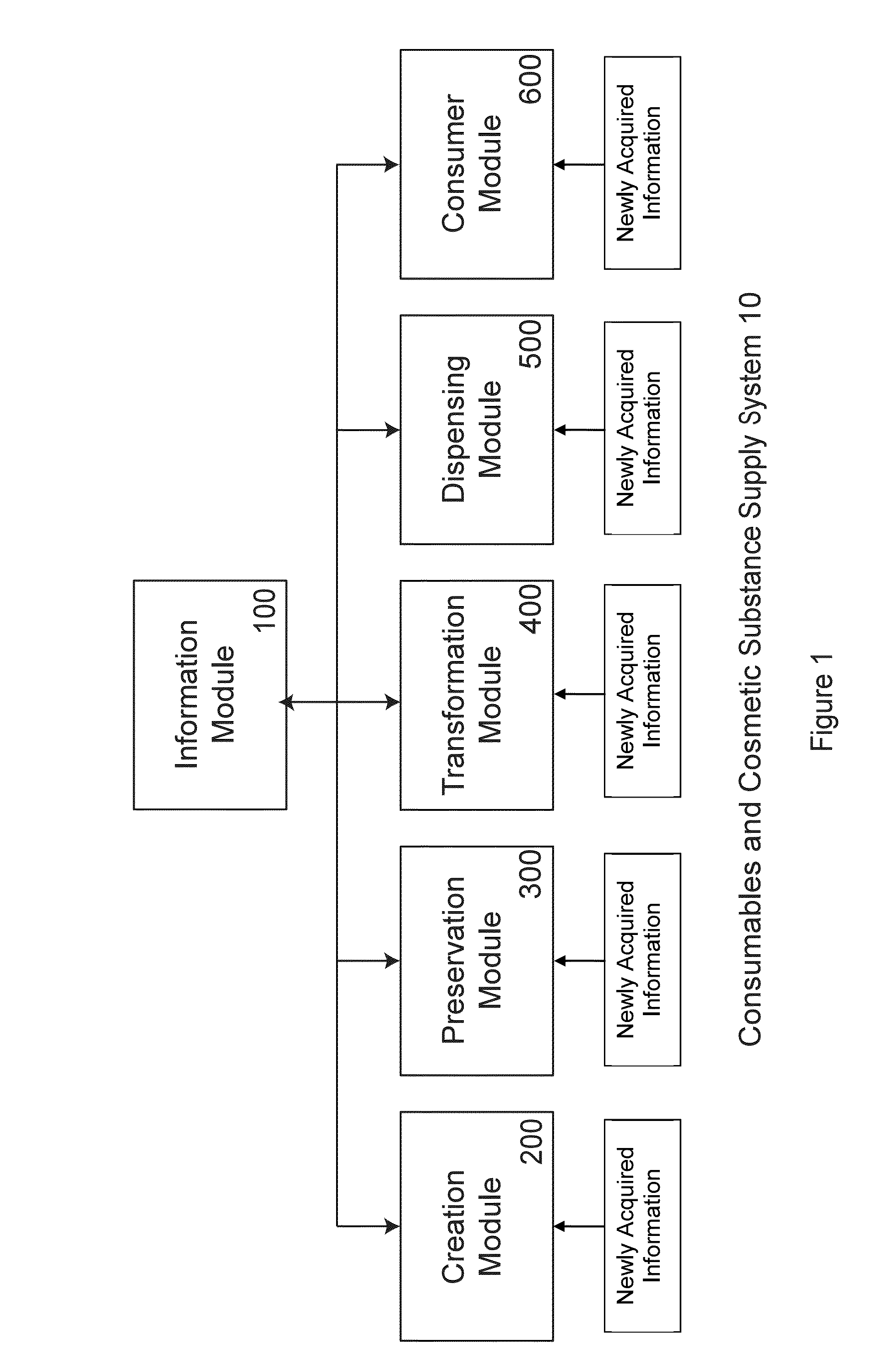

A consumer information and sensing system for consumables and cosmetic substances. The consumer information and sensing system tracks an determines information regarding the efficacy state of consumables and cosmetic substances, obtains input from consumers regarding a desired efficacy state at consumption, and provides an indoor navigation system to locate such consumables and cosmetic substances.

Owner:MINVIELLE EUGENIO

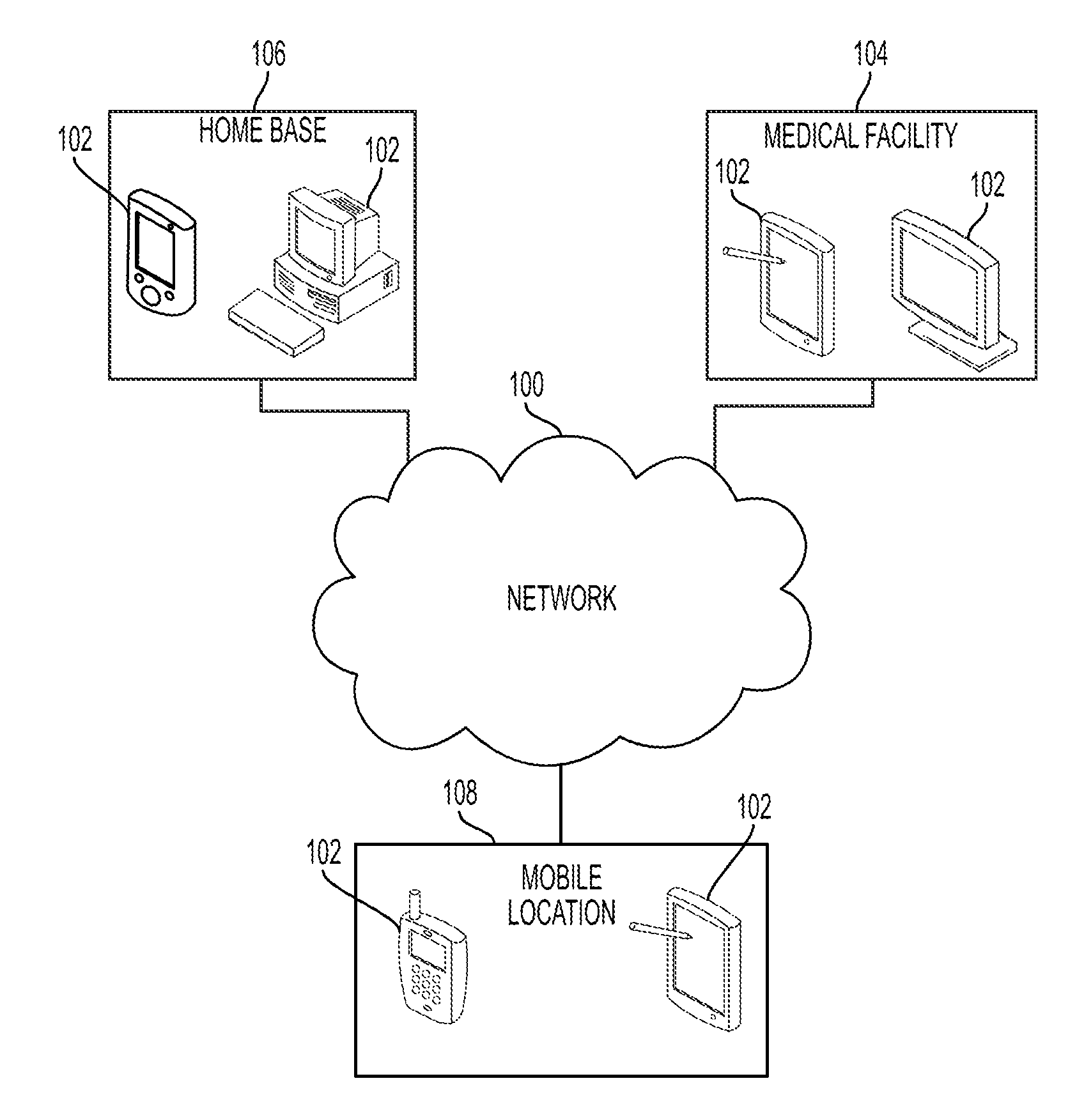

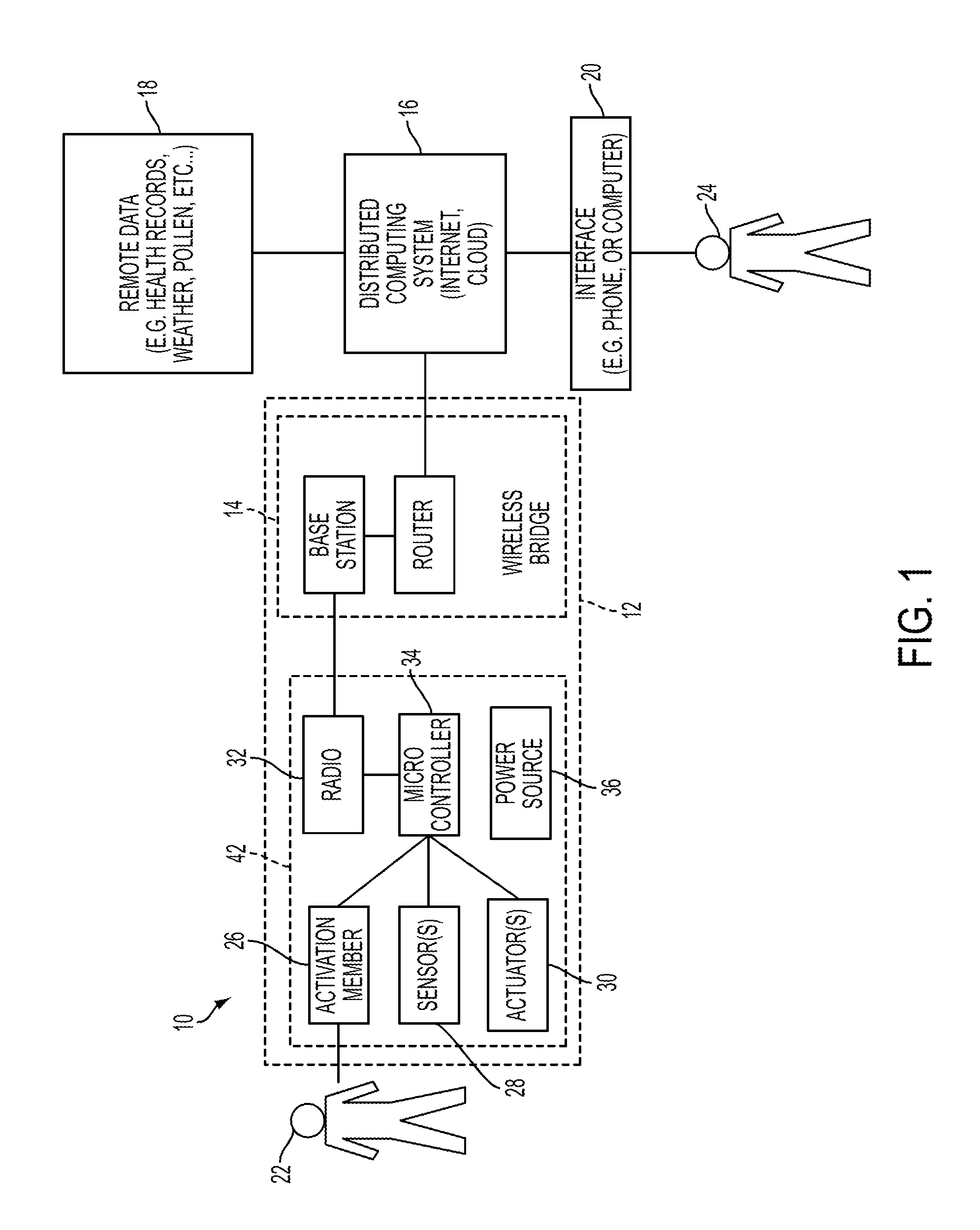

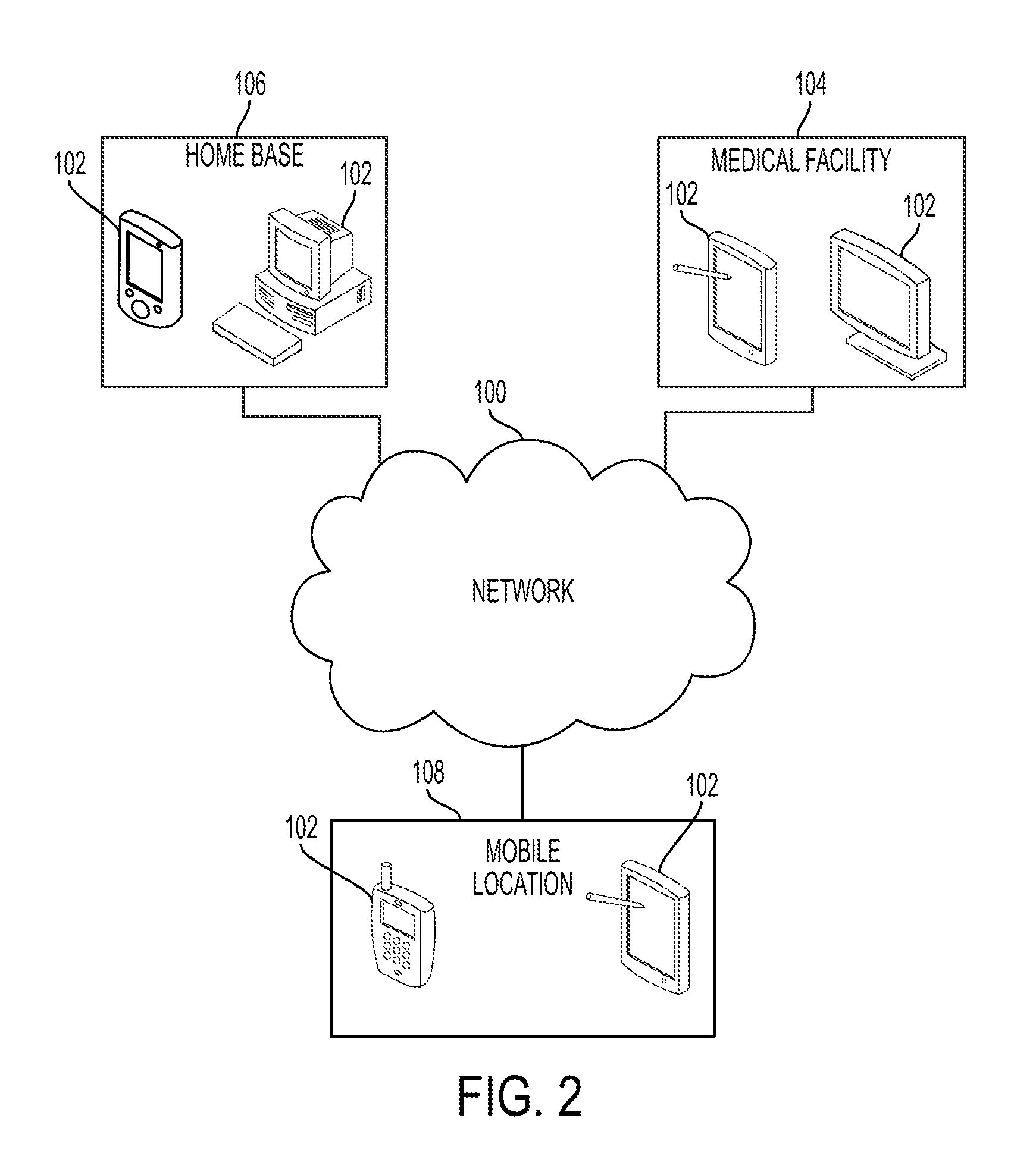

Devices, systems, and methods for adherence monitoring and devices, systems, and methods for monitoring use of consumable dispensers

ActiveUS20150061867A1Effective distributionData processing applicationsDrug and medicationsComputerized systemEngineering

Devices, systems, and methods are provided for adherence monitoring, and devices, systems, and methods are provided for monitoring use of consumable dispensers. In general, the devices, systems, and methods can facilitate an individual's adherence to a schedule for consuming consumables and can facilitate monitoring and tracking of the individual's adherence to the schedule. The devices, systems, and methods can allow data regarding the individual's historical adherence to the schedule to be accessible via a computer system. In one embodiment, an accessory is provided that can be configured to attach to consumable dispensers. The accessory can be configured to be removably and replaceably coupled to the dispenser. The accessory can be configured to provide a notification to a user indicating that a certain event occurred and / or that a certain action needs to be taken. The accessory can be configured to sense attachment thereof to and removal thereof from the dispenser.

Owner:GECKO HEALTH INNOVATIONS

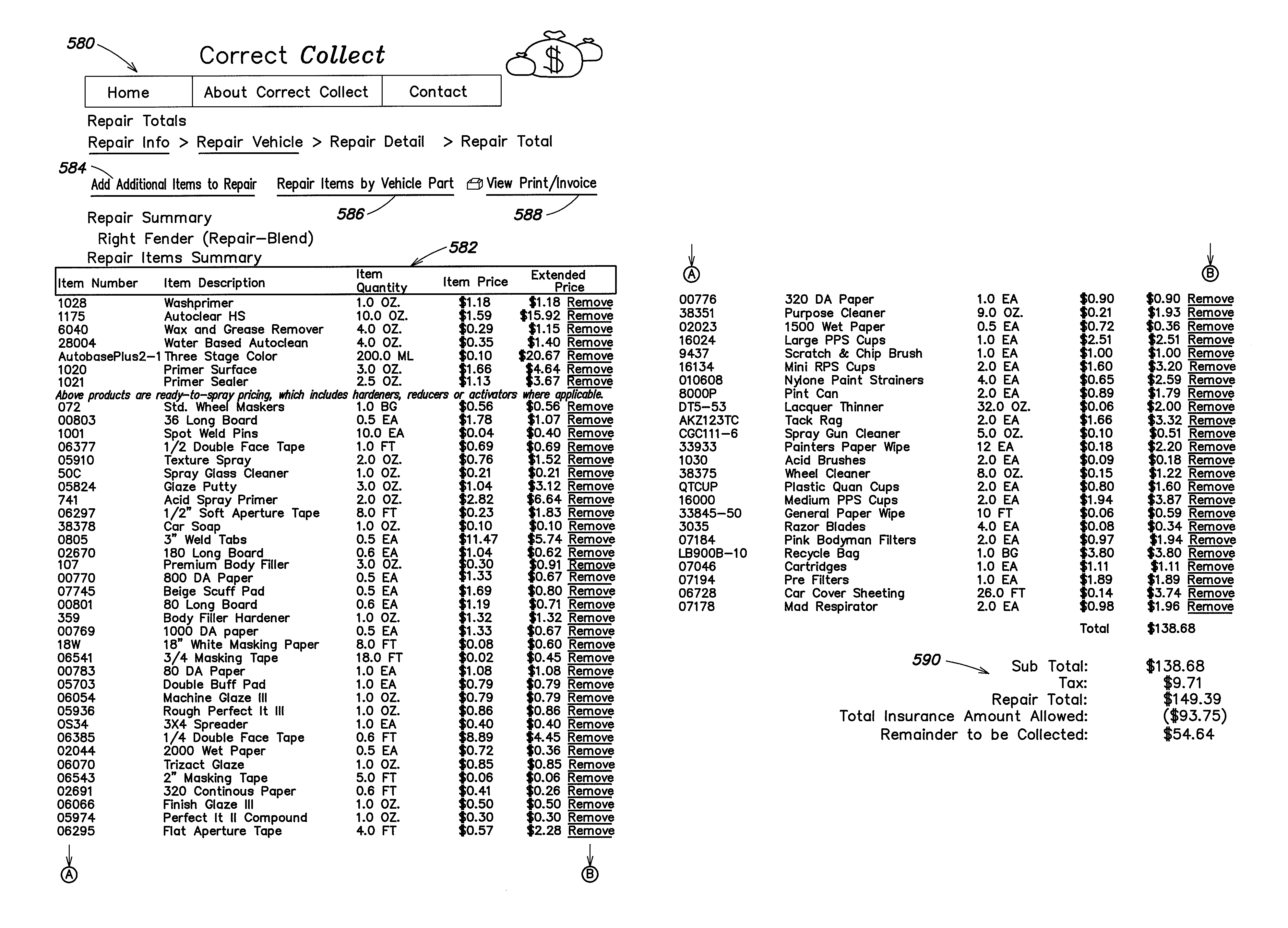

System and method for standardizing accounting of consumables

InactiveUS8364563B2Good flexibilitySignificant overheadComplete banking machinesHand manipulated computer devicesService provisionProviding material

According to one aspect, the system for standardizing accounting of consumables provides material lists of consumables used in particular repairs. The development of the material lists takes place through tracking of consumables used during the repair of various parts of different types of automotive vehicles. The size, shape, time, and material for repair may vary by make and model of vehicle, as well as the characteristics associated with each make and model. Once a materials list for a reasonable repair is assembled, the process is repeated for each vehicle make, model, and part to be repaired. The end result is a material list template for each part that a body shop repairs. In one embodiment, a wholesaler maintains and provides access to a system for standardizing accounting to body shops. The interface is customized for each body shop, so that specific materials will be provided on the material list for a repair. In another embodiment, user selectable options provide brand selection for the materials used in a particular repair. Providing brand selections and / or restricting selection of brand may provide an incentive for material purchases into specific brands. According to another aspect, maintaining material lists for each any every part of each model and make of vehicle represents significant overhead for any service provider. Creating standardized automobile objects for use in conjunction with a system for standardizing accounting of consumables provides for easier maintenance and greater flexibility to updates.

Owner:CAR PARTS COLOR SYST

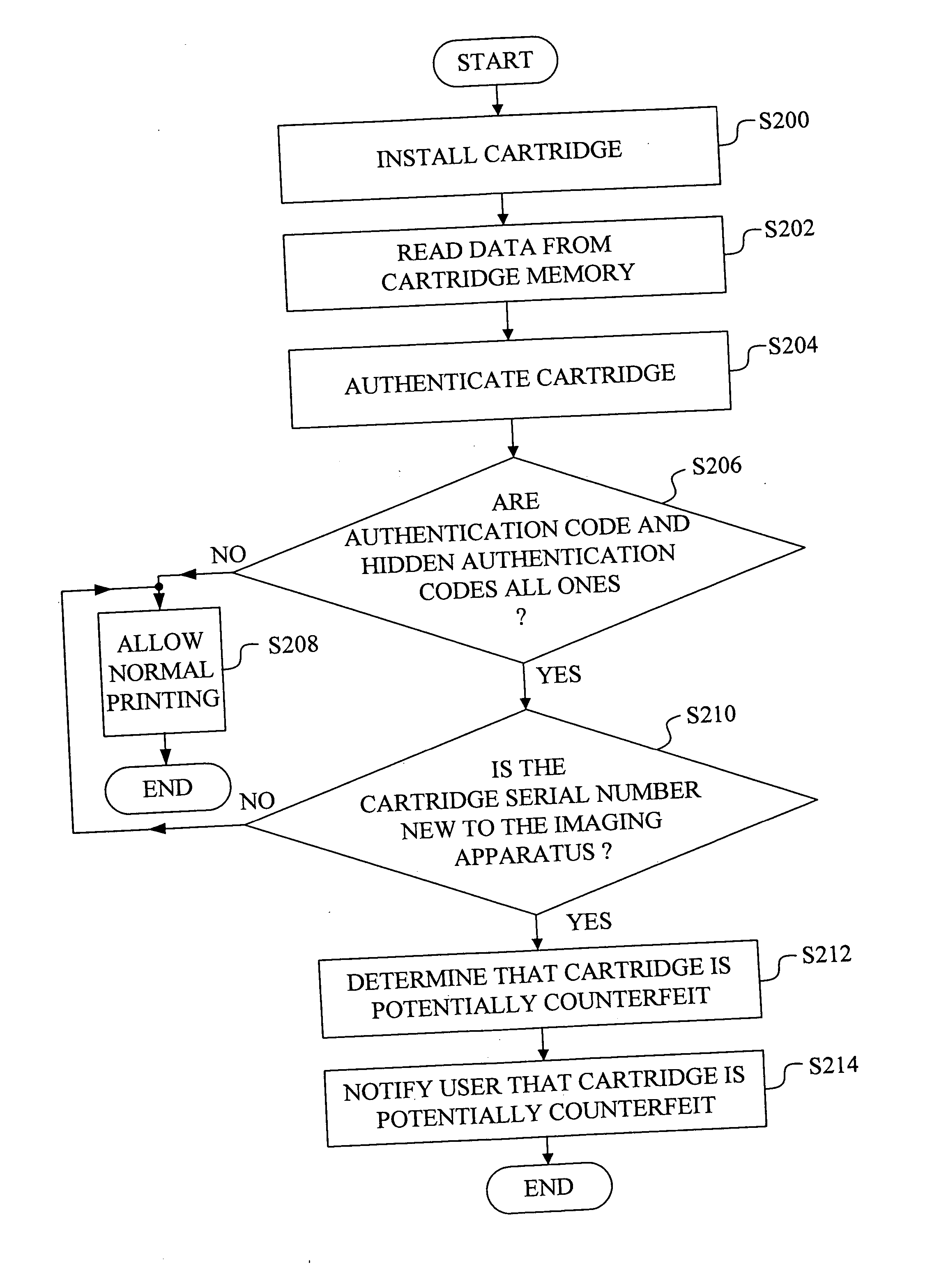

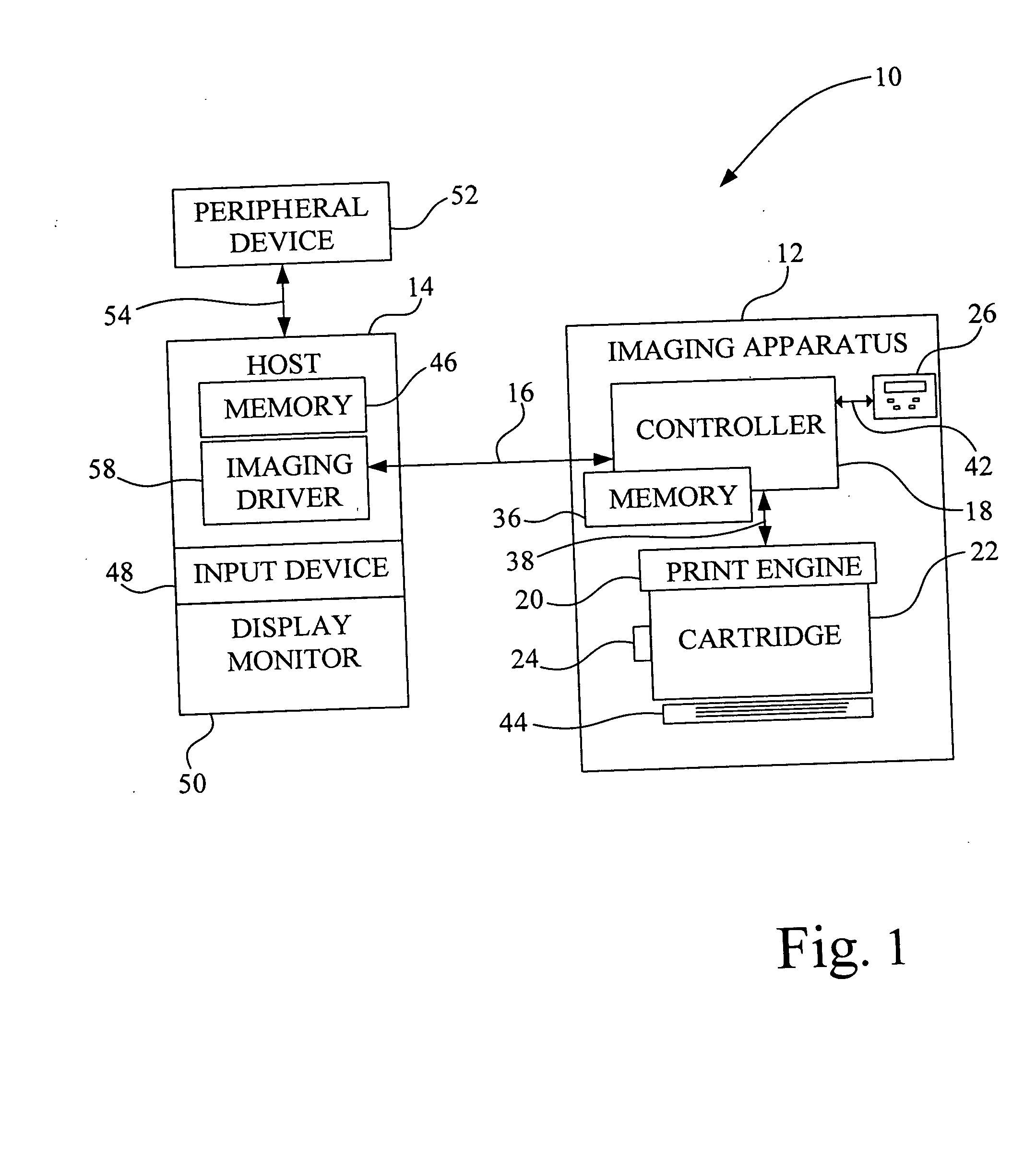

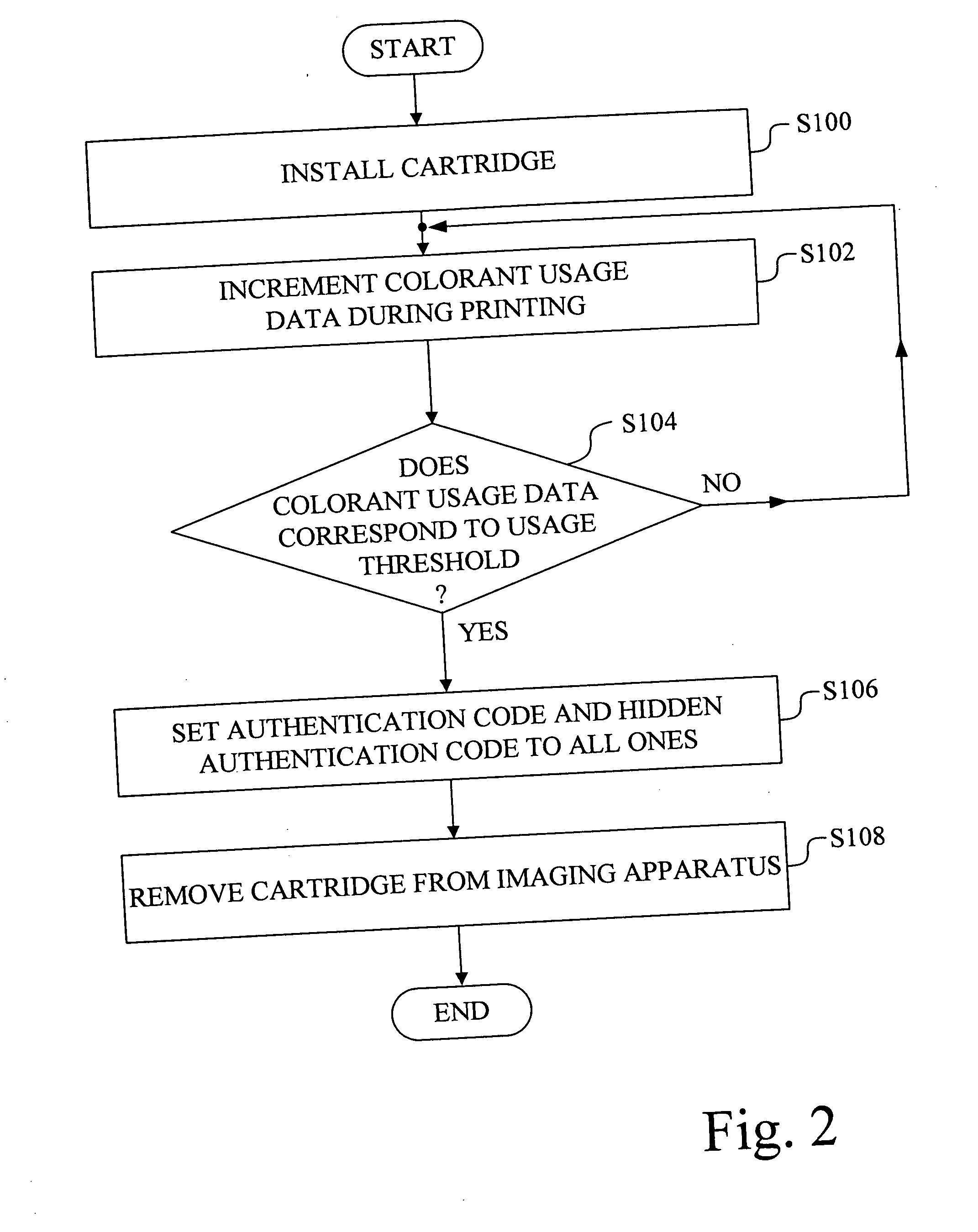

Apparatuses and methods for identifying a consumable for use with an imaging apparatus

Apparatuses and methods for identifying consumables intended for use in an imaging apparatus, such as consumables having a memory storing at least first data and second data. One such method involves incrementing the first data during printing operations using the imaging apparatus; the imaging apparatus determining when the first data corresponds to a first predetermined value; and setting the second data to a second predetermined value based on a correspondence of the first data to the first predetermined value.

Owner:LEXMARK INT INC

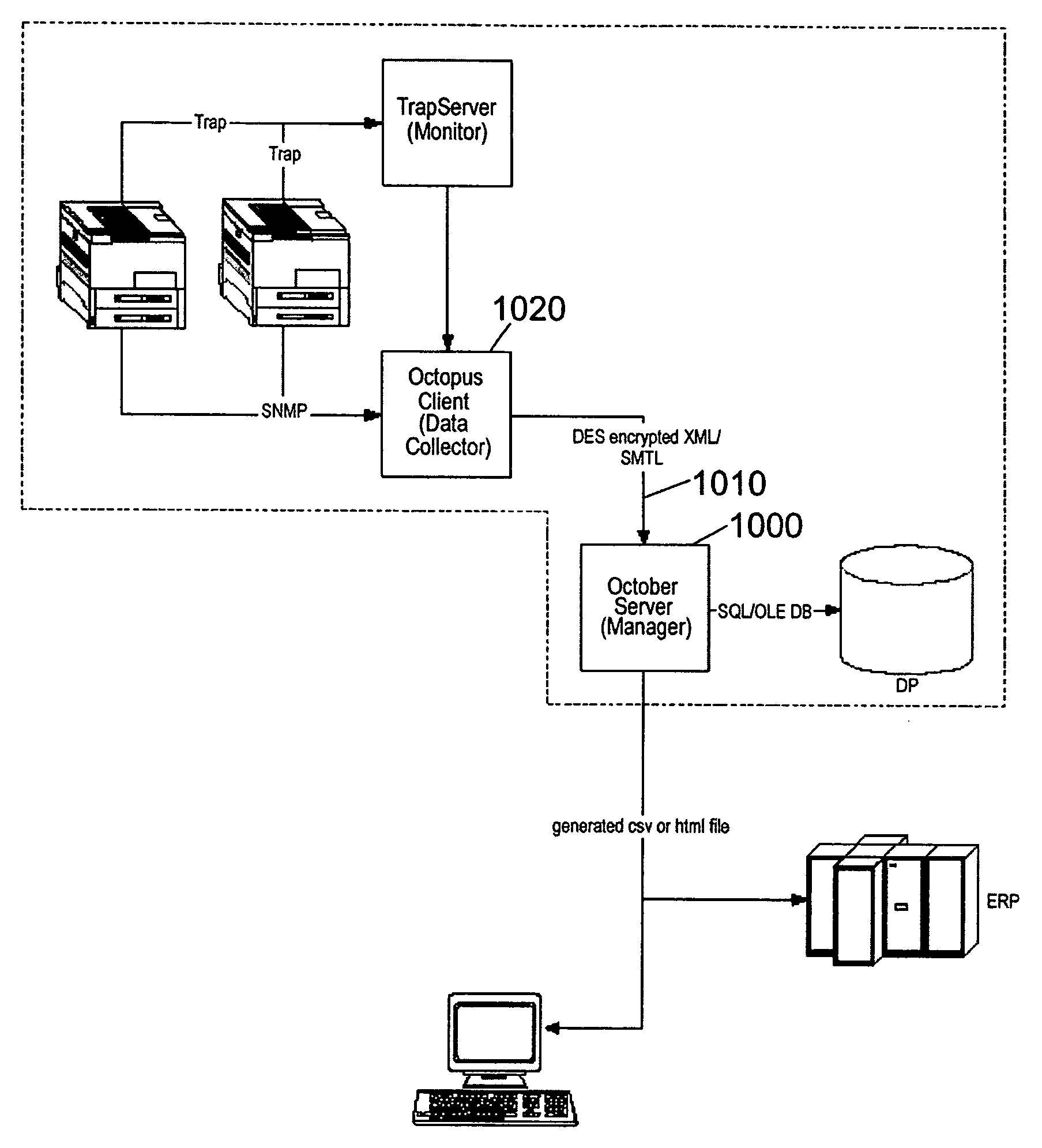

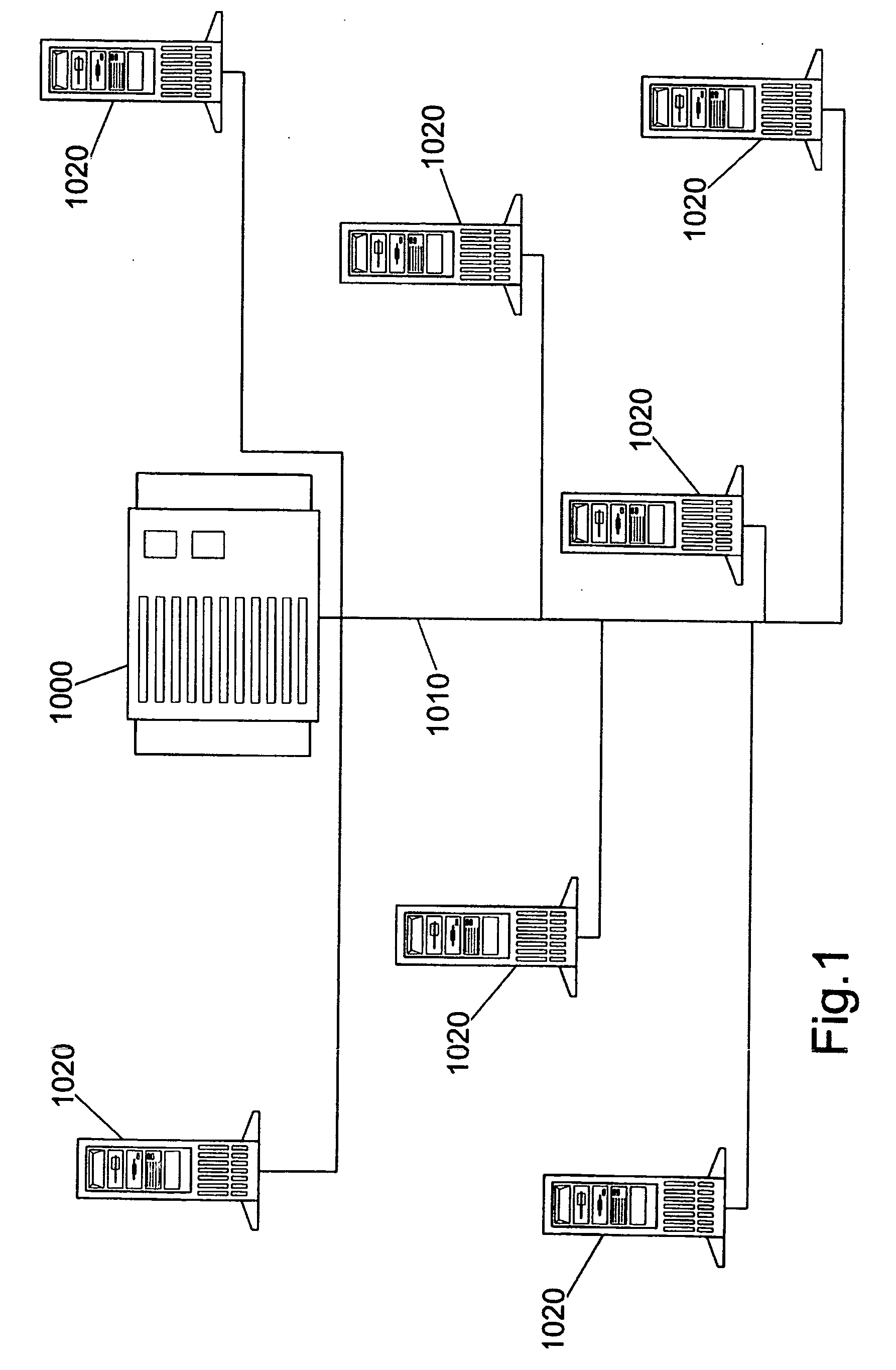

Method and apparatus for managing printing devices

A process of management of printing devices at distributed sites, comprising providing a database portal accessible continuously, the portal giving a visual display of performance of the printing devices compared with predetermined targets for key performance indicators. A process of preparing for and implementing management of printing devices located at distributed sites carried out by a contractor for a client, comprising: the step of the contractor negotiating with the client key performance indicators applicable for the duration of a management service contract and including targets for the key performance indicators, and rewards and penalties for performance of the printing devices against those targets, and the step of the contractor periodically monitoring the key performance indicators to provide the client with an indication of performance against the targets. A process of management of printing devices at geographically distributed sites within a client organisation, carried out exclusively by a contractor under a management contract, comprising allocating a contract manager in the contractor organisation and dedicating that contract manager to the task of managing all the client's printing devices over a plurality of the distributed sites, whereby the contract manager regularly monitors the status and usage of the printing devices and associated software and services and consumables supplies, regularly seeks to optimise their overall performance against predetermined key performance indicators including cost, implements changes over the period of the management contract to optimise performance, and regularly provides reports to the client organisation.

Owner:RICOH KK

Information on consumables

Owner:ETSUSERUTO DAIMO NV

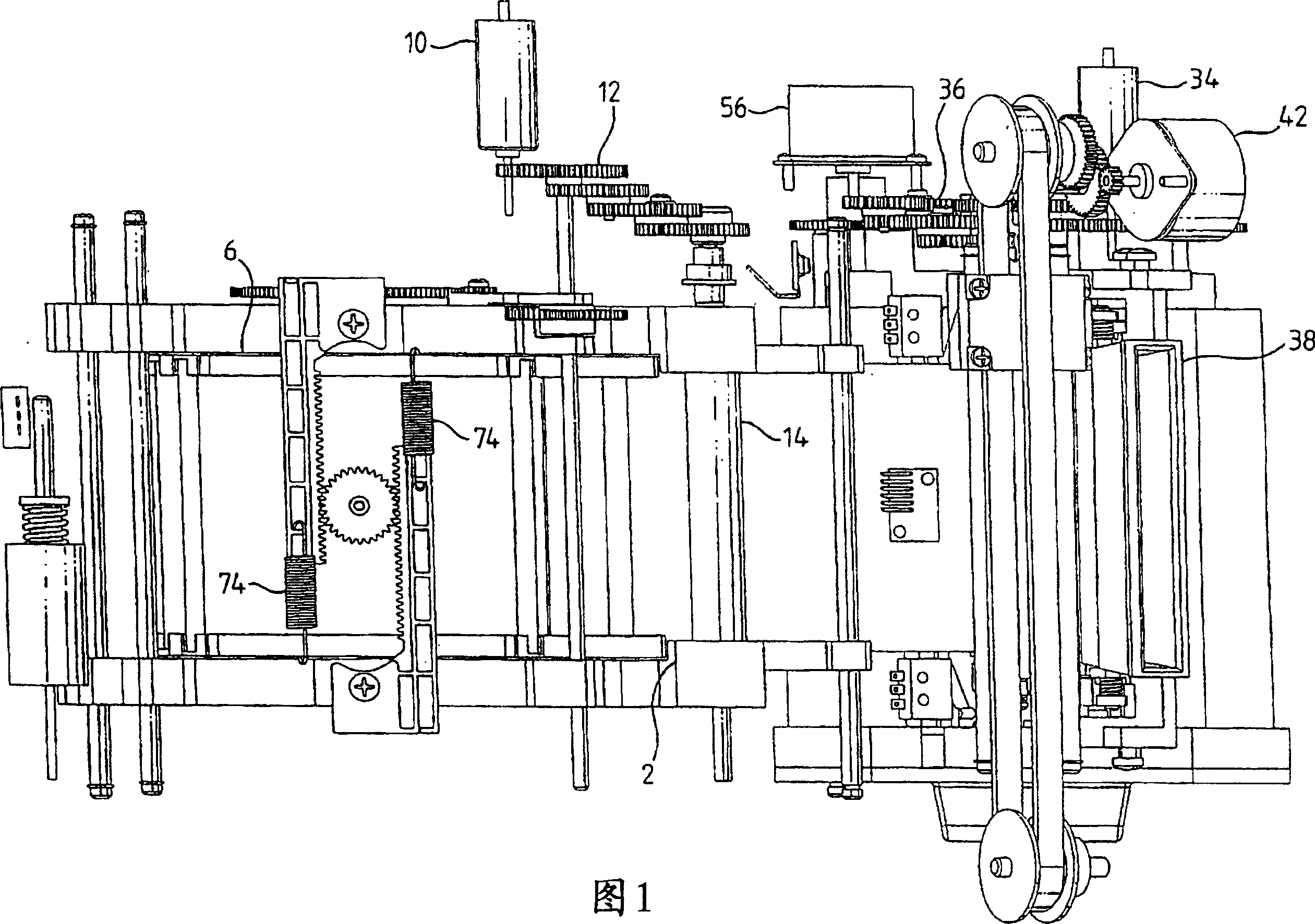

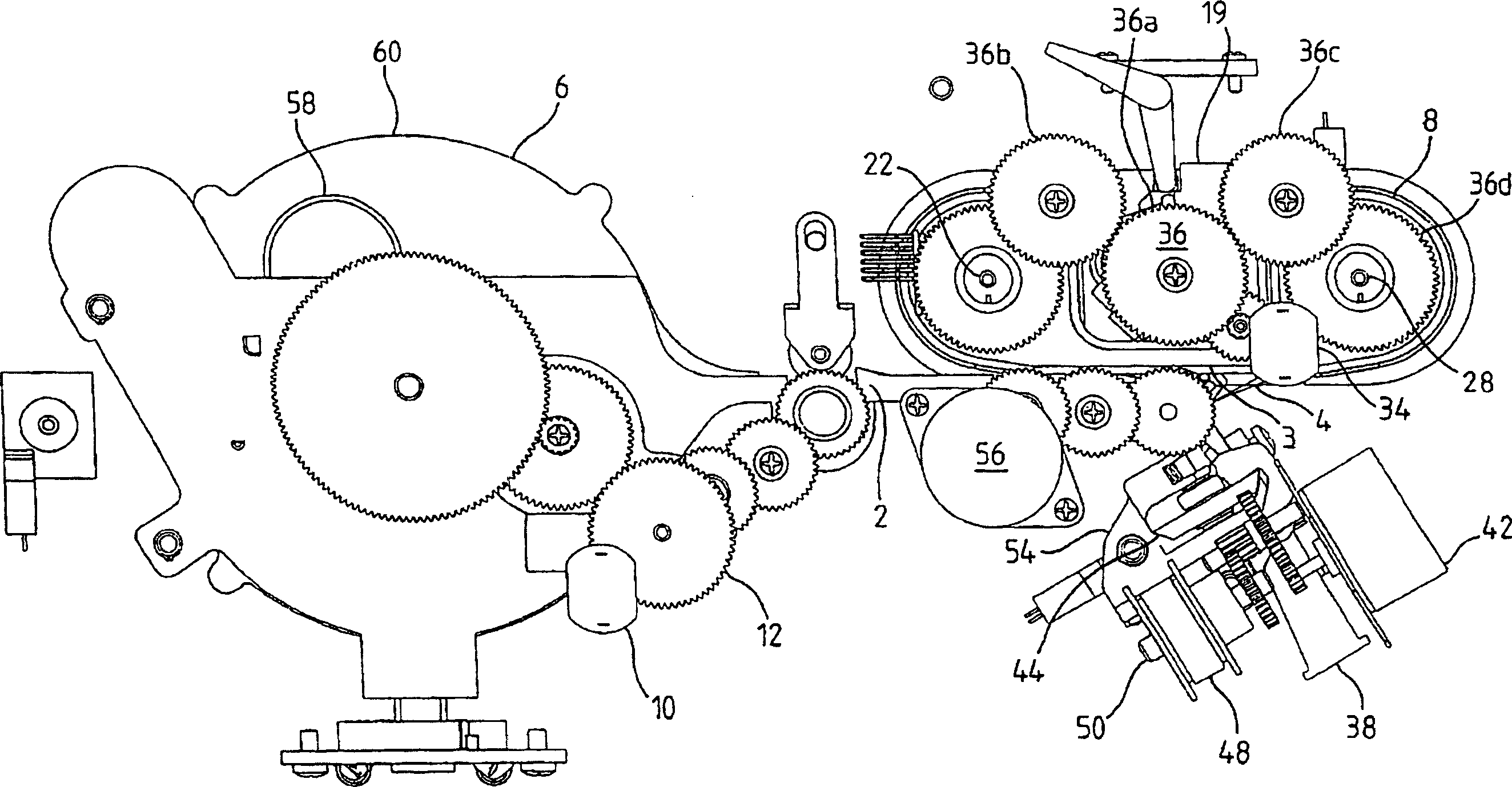

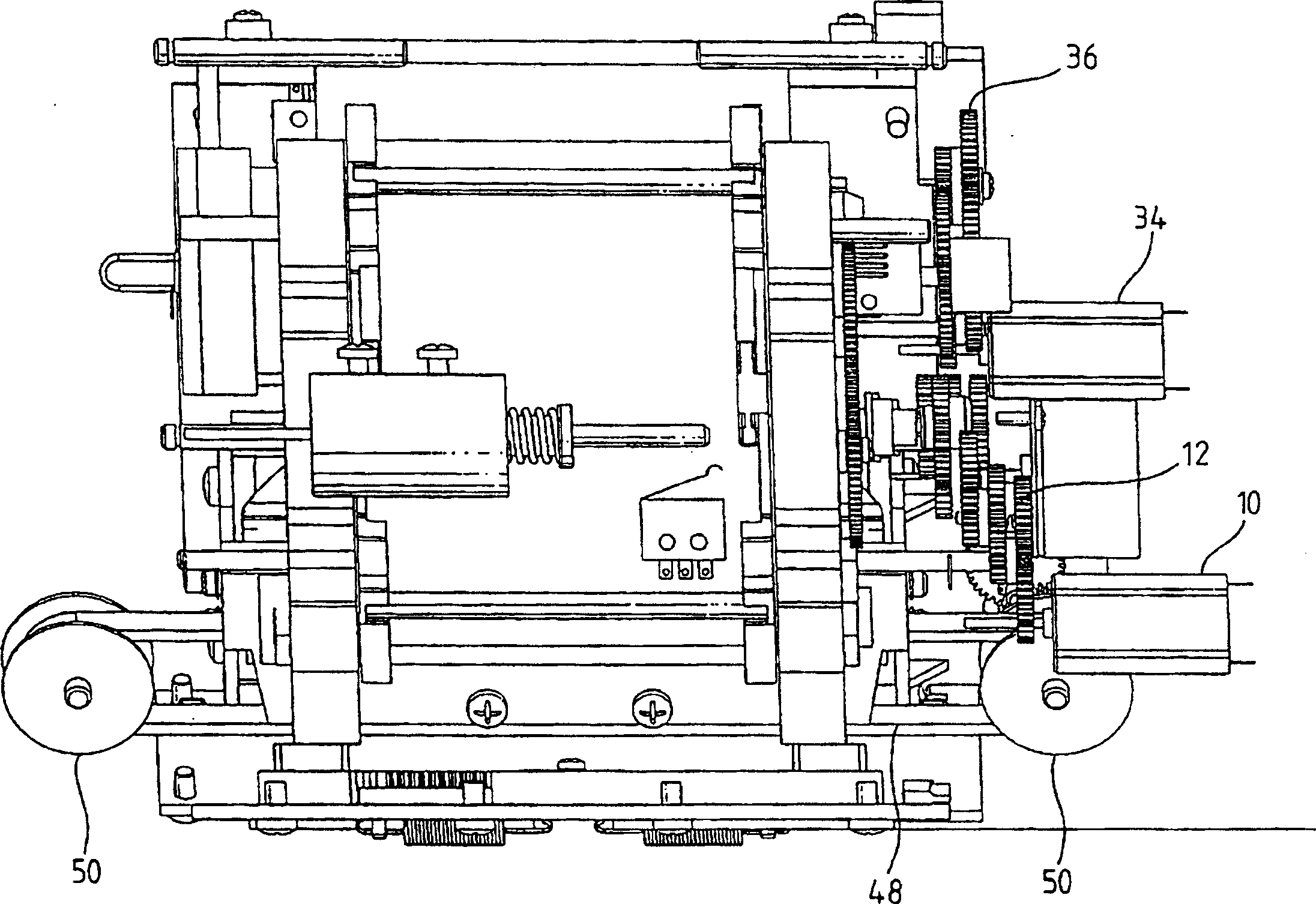

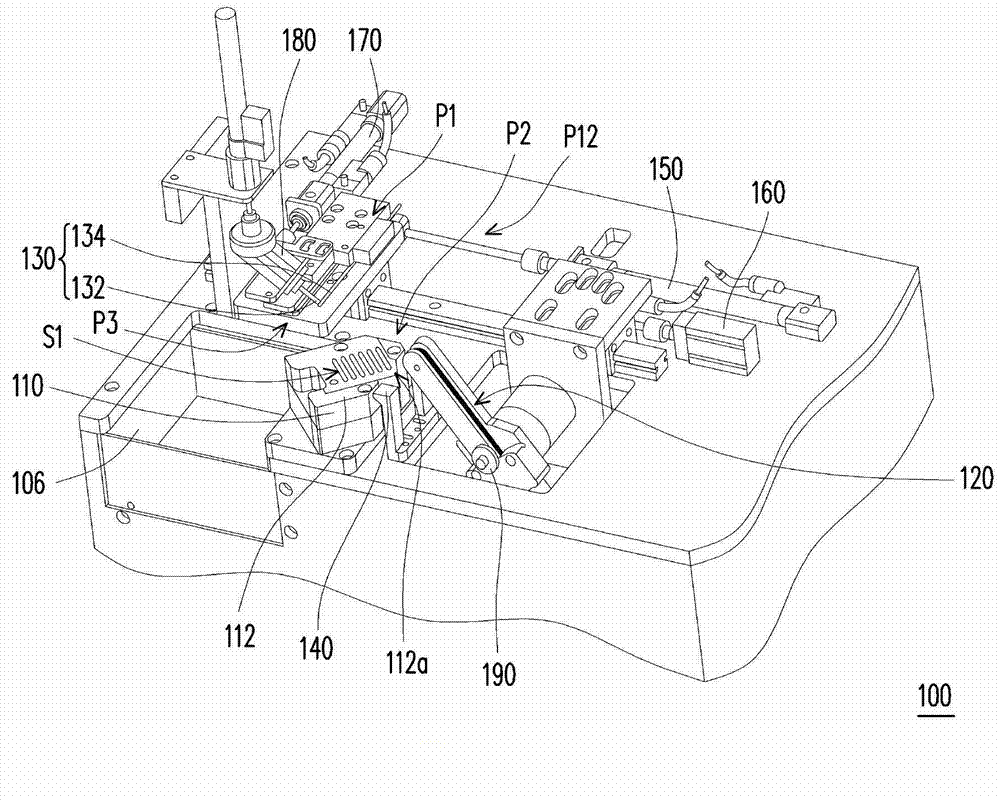

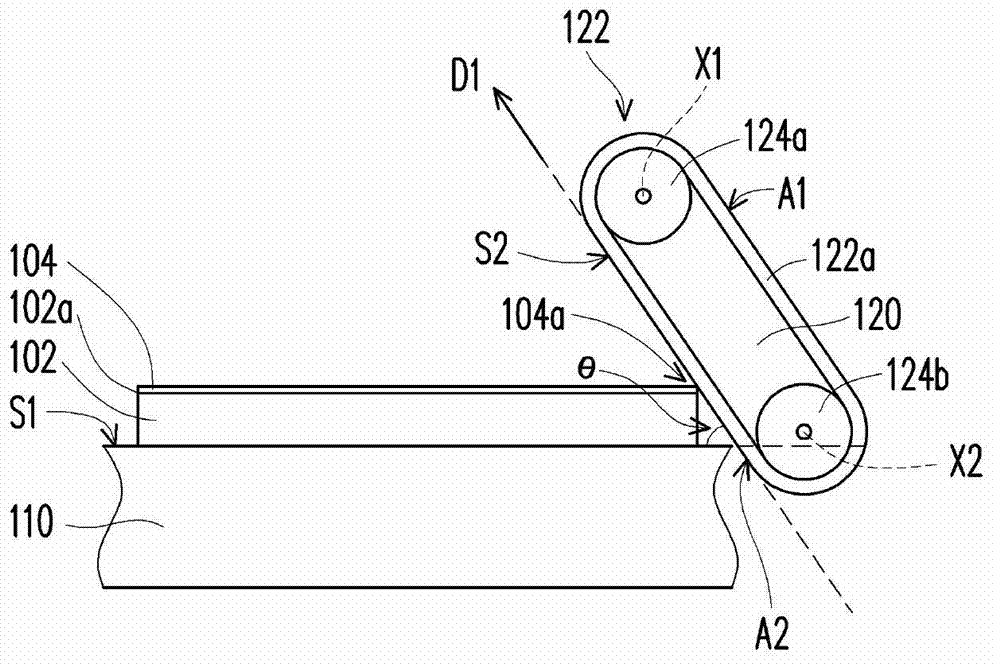

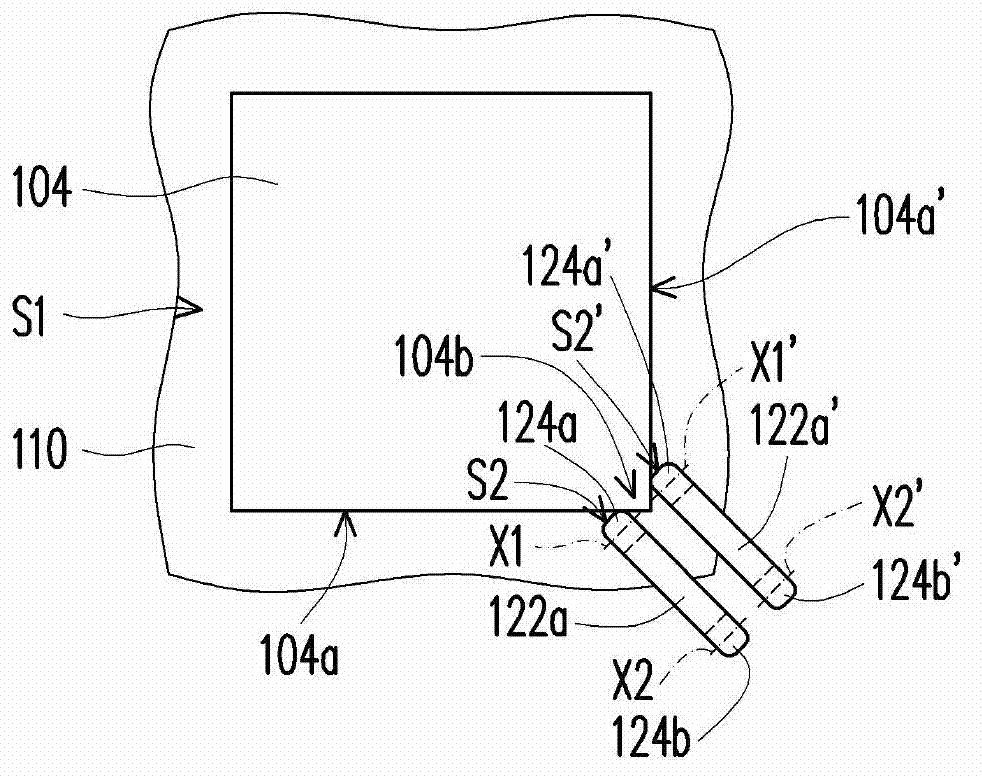

Film tearing machine and film tearing method

InactiveCN102896876AReduce the cost of tearing filmFully automatedLamination ancillary operationsLaminationEngineeringBearing surface

A film tearing machine is suitable for removing a film on surface of a substrate, and comprises a carrier, a tearing-start device and a clamp, wherein the carrier has a carrier surface for carrying the substrate; the tearing-start device is located at one side of the carrier and has a movable tearing-start element which has a contact surface used for contacting edges of the film; and the clamp is provided with a movable mechanism so that the clamp can move to the upper side of the carrier surface or the clamp moves far away from a bearing surface. The invention further discloses a film tearing method, and according to the method, the film tearing machine is utilized to remove the film on the substrate. The film tearing machine uses actions of the element, instead of using consumables, to remove the film on the substrate, thereby reducing film tearing cost, and automatically tearing the films.

Owner:AU OPTRONICS CORP

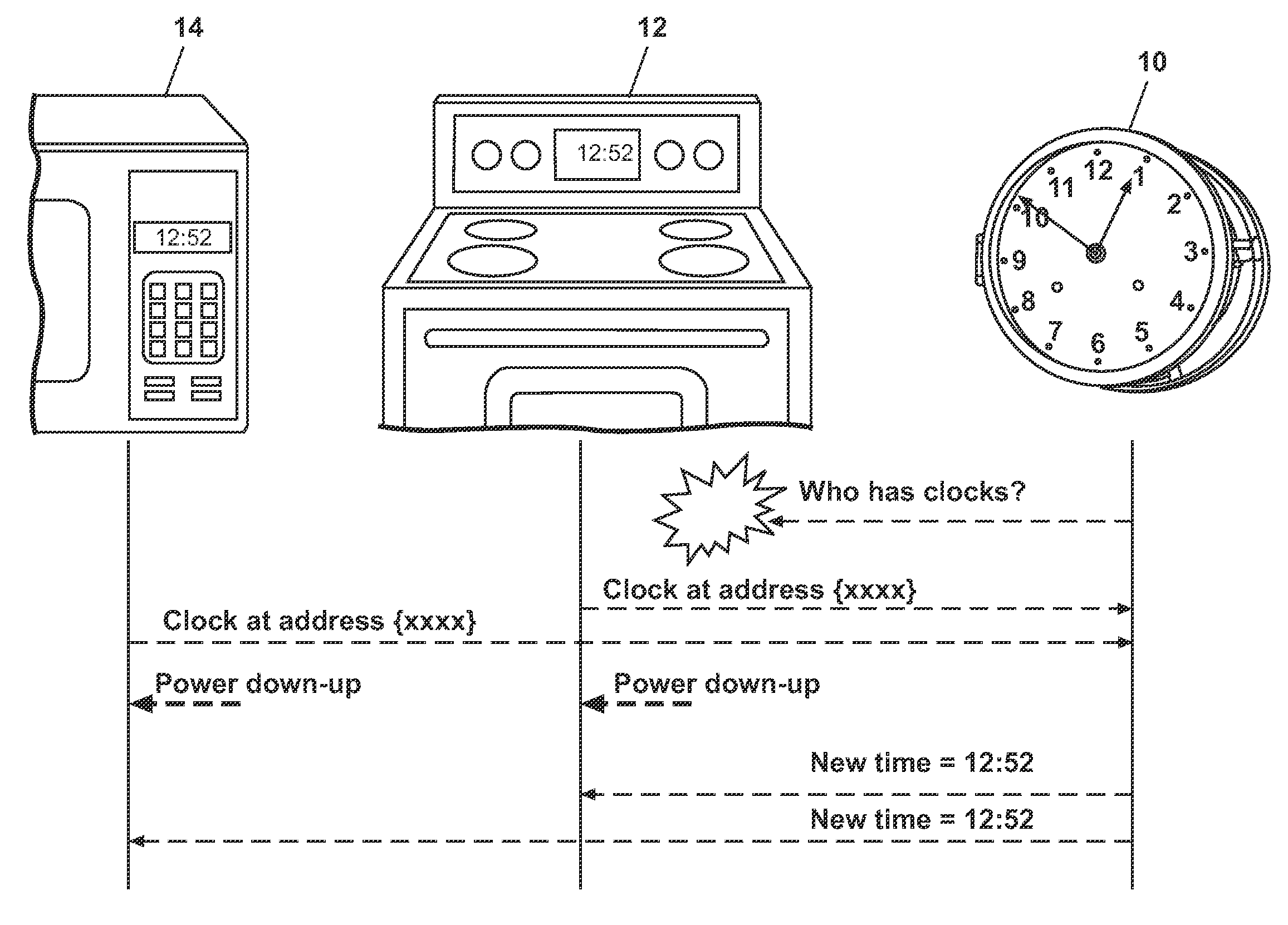

Network for communicating information related to a consumable to an appliance

ActiveUS20080130520A1Error detection/correctionInterprogram communicationComputer networkConsumables

Owner:WHIRLPOOL CORP

Methods and compositions for consumables

ActiveUS9011949B2Increase aromaAdd flavorMilk preparationAnimal feeding stuffBiotechnologyConsumables

Owner:IMPOSSIBLE FOODS

Hands-free paper towel dispenser and dispensing system

InactiveUS20110210137A1Easy to separateFlat designCoin-freed apparatus detailsMetal-working apparatusPaper towelStructural engineering

A dispensing unit includes an outer front wall, two outer side walls, a housing for holding a pile of a continuous length of accordion-like folded web of towels of tissue paper or nonwoven including bundles, the outer front wall having an access opening to the pile, a dispensing opening for the web of towels and a feeding mechanism including a member for controlling the dispensing of the web of towels, a drive unit and a braking arrangement for the web of towels. A unit of consumable articles includes the pile of bundles with connecting elements therebetween, which are inserted through the access opening into the housing in the dispensing unit and added to the bottom of the pile. The web of towels is dispensed from the upper part of the pile by a feeding mechanism, which positions the web of towels in a starting mode in the dispensing opening.

Owner:SCA HYGIENE PROD AB

Restroom convenience center

ActiveUS8364546B2Easy to useHigh trafficVolume/mass flow measurementHolders and dispensersState dependentMonitoring system

A restroom monitoring system for monitoring attributes of fixtures within a restroom using sensors. Additional attributes are determined from the monitored attributes. Consumable usage levels are estimated based on predetermined consumption levels associated with usage states of the fixtures. The restroom monitoring system provides an indication of the need for replenishment of consumables based on the monitored attributes of the fixtures. In addition, restroom monitoring system may provide additional information regarding the restroom attributes to a service provider, a manager or a user.

Owner:SLOAN VALVE COMPANY

Methods and compositions for consumables

ActiveUS20150305361A1Increased creamy, milky, buttery, fruityReduced nutty, planty, beanyMilk preparationCheese manufactureBiotechnologyConsumables

Provided herein are methods and compositions for the production of cheese replicas. Generally the cheese replicas are produced by inducing the enzymatic curdling of non-dairy milks.

Owner:IMPOSSIBLE FOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com