Patents

Literature

354 results about "Compatibility testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compatibility testing is a part of non-functional testing conducted on application software to ensure the application's compatibility with different computing environment. The ISO 25010 standard, (System and Software Quality Models) defines compatibility as a characteristic or degree to which a software system can exchange information with other systems whilst sharing the same software and hardware. The degree to which a product can perform its required functions efficiently while sharing a common environment and resources with other products, without detrimental impact on any other product is known as co-existence while interoperability is the degree to which two or more systems, products or components can exchange information and use the information that has been exchanged. In these contexts, compatibility testing would be information gathering about a product or software system to determine the extent of coexistance and interoperability exhibited in the system under test.

Preparation and characterization of formulations in a high throughput mode

ActiveUS20050058574A1Improve throughputFormula flexibleLibrary tagsFlow propertiesAnalysis dataAdditive ingredient

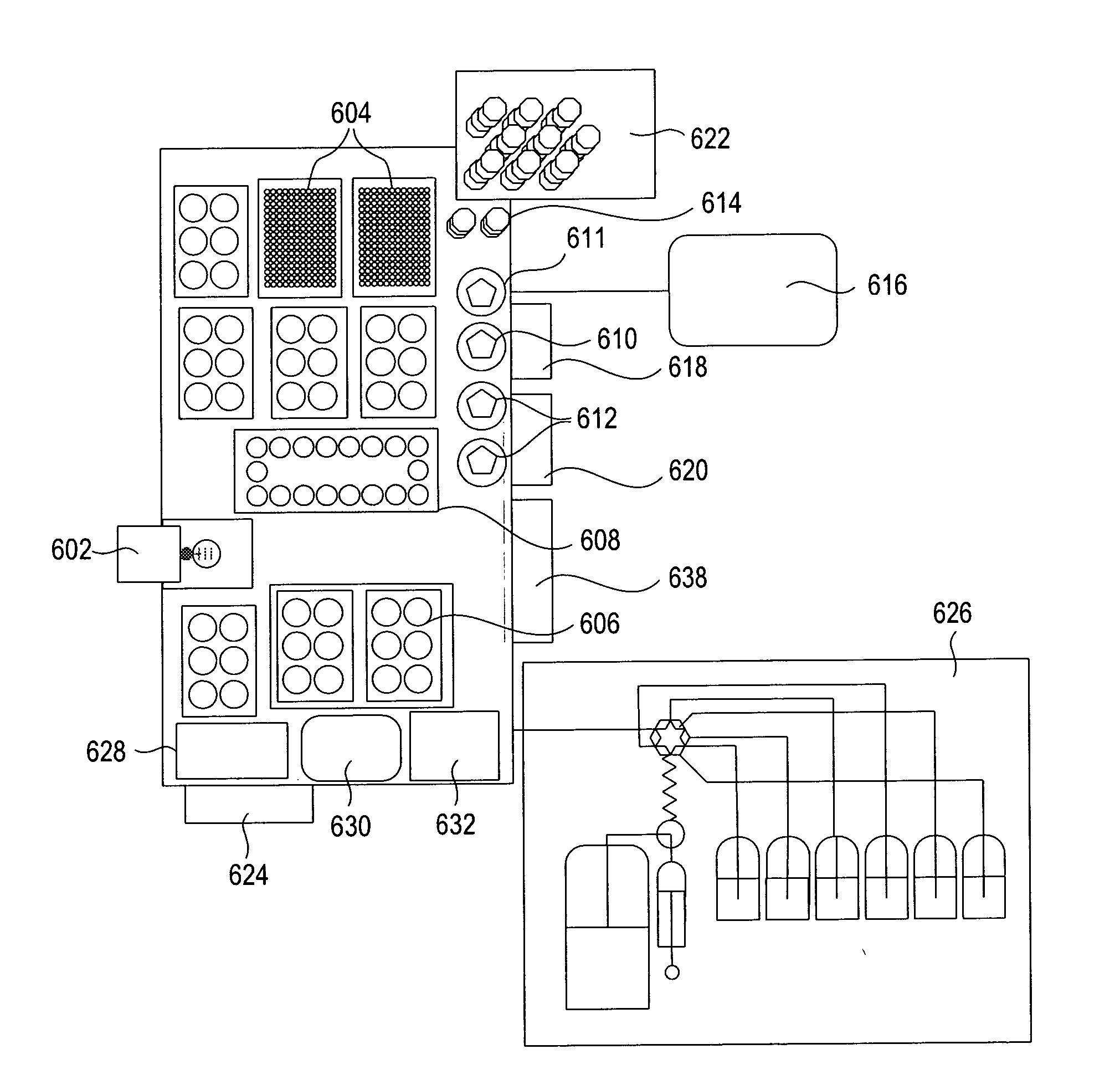

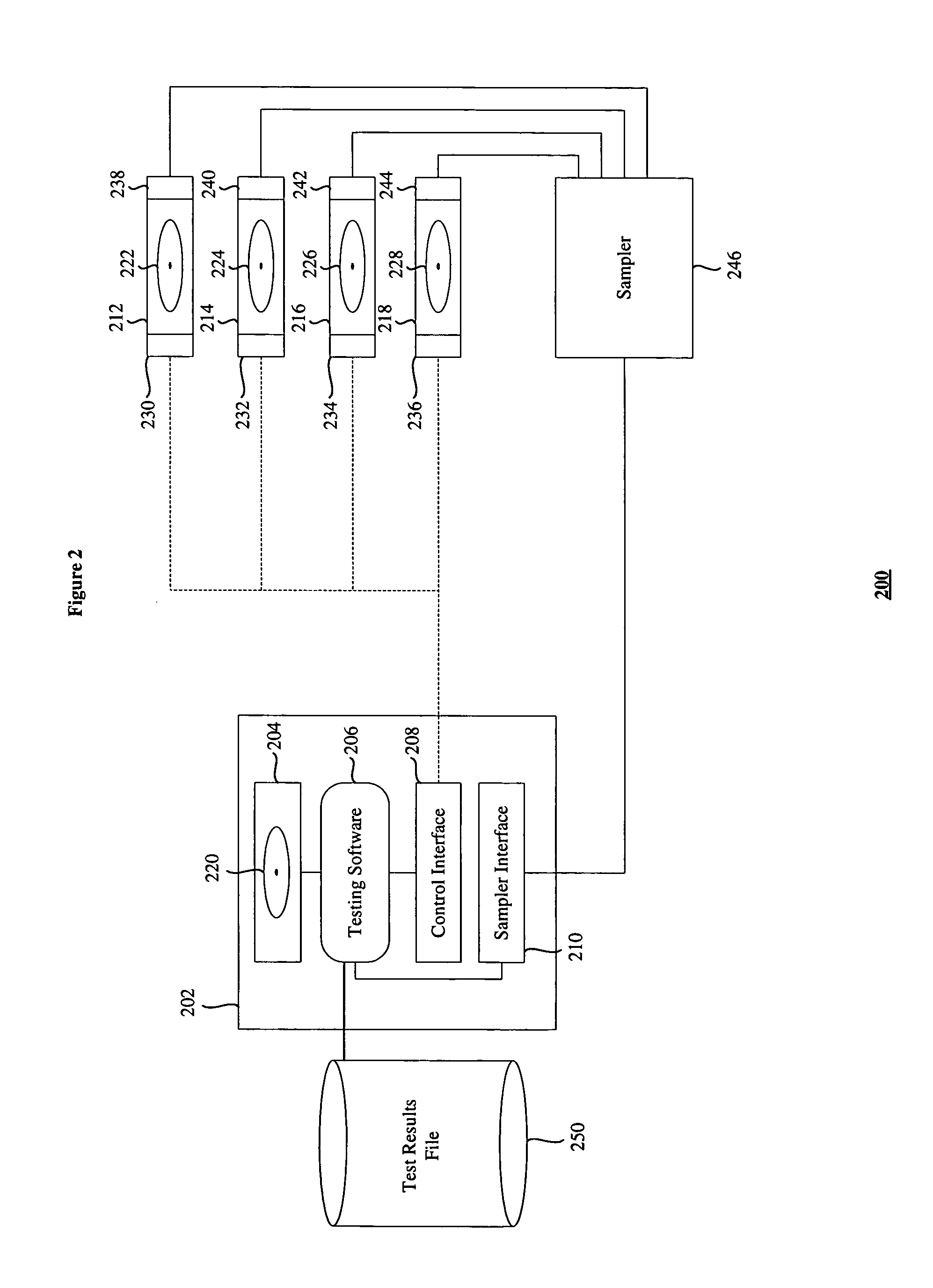

The invention is an automated robotic system for the production and testing of formulations at a very high throughput. It is an integrated system of hardware and software capable of preparing and evaluating hundreds of emulsions per day. The system can formulate aqueous solutions (SL), oil in water emulsions (EW), suspo-emulsions (SE), micro capsule suspensions (CS), micro-emulsions (ME), and suspension concentrates (SC) at the 1 ml to 25 ml scale. The system can process emulsions rapidly in an automated way and enable very flexible formulation recipes to be introduced. The system allows chemists to generate experimental samples of varying recipe and method to be conducted in parallel with projected throughput of up to 1200 formulations processed and characterized per day. Materials and consumables can be distributed from storage storage systems to the work stations where dispensing of ingredients in various states can be performed, including solids, liquids, gels, pastes, suspensions and waxes. The emulsions formed can be characterized using methods including phase diagnosis, turbidity analysis, viscosity and particle sizing using automated test equipment. An integrated module can also perform Tank Mix Compatibility testing in high throughput mode. The modular system allows future processes and tests to be added, either to a station, or as a new station. The software capability includes tracking of processes from start to finish and the integration of analytical data with the as-designed and as-formulated experimental results.

Owner:SYNGENTA LTD

Method of optimizing the design, stimulation and evaluation of matrix treatment in a reservoir

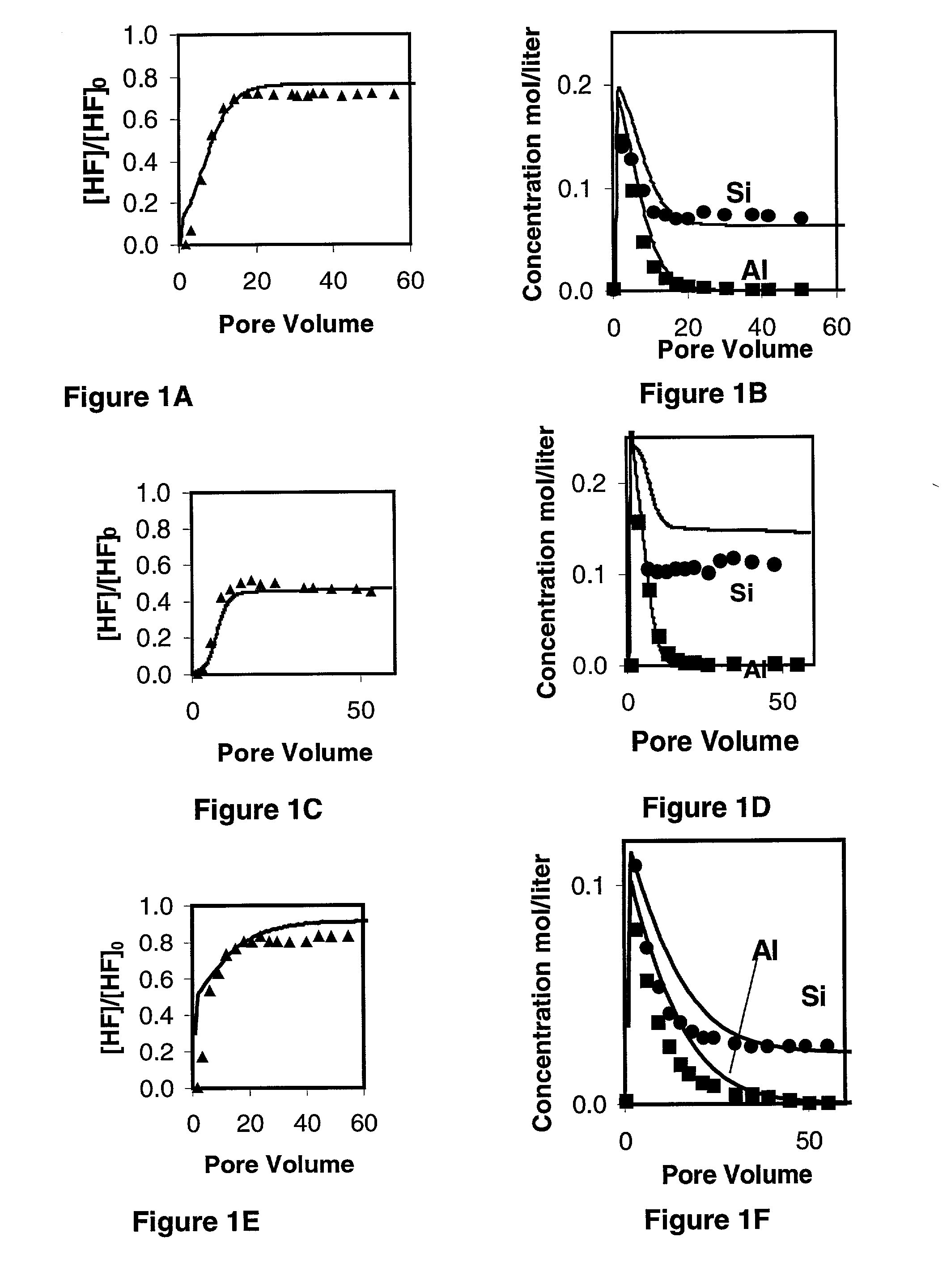

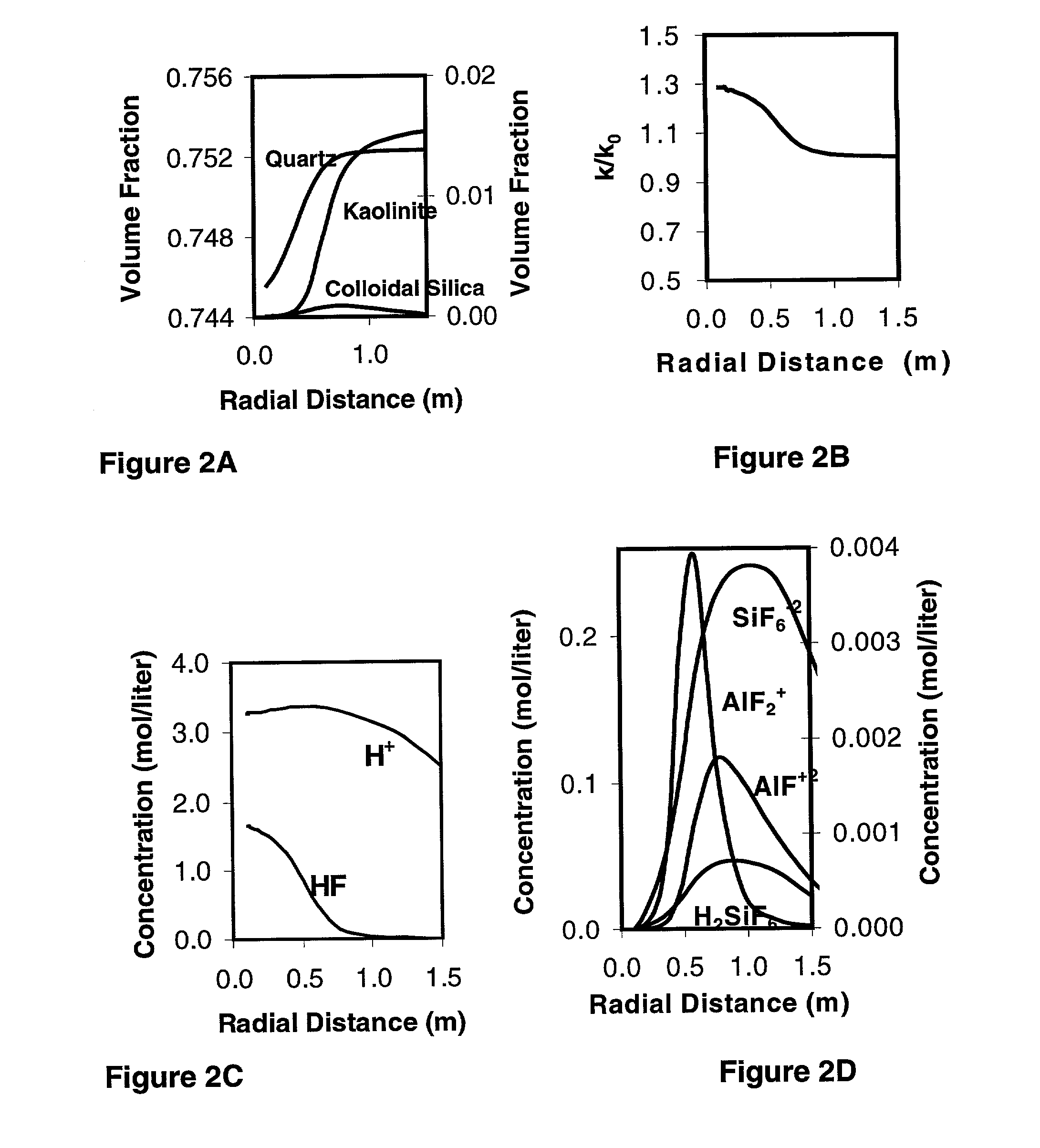

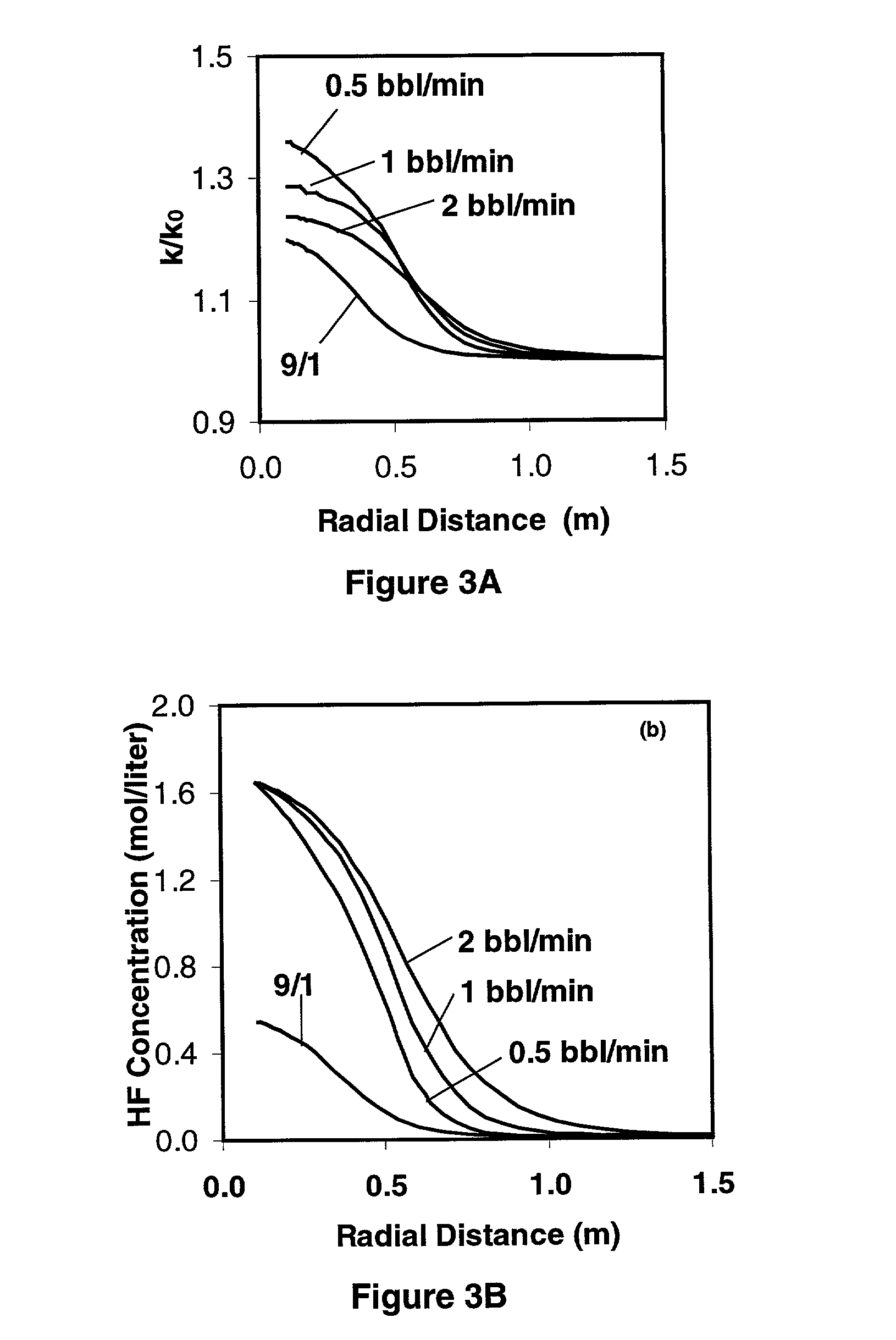

InactiveUS6668922B2Easy to optimizeSimple calculationSurveyPackage sterilisationMathematical modelTreatment strategy

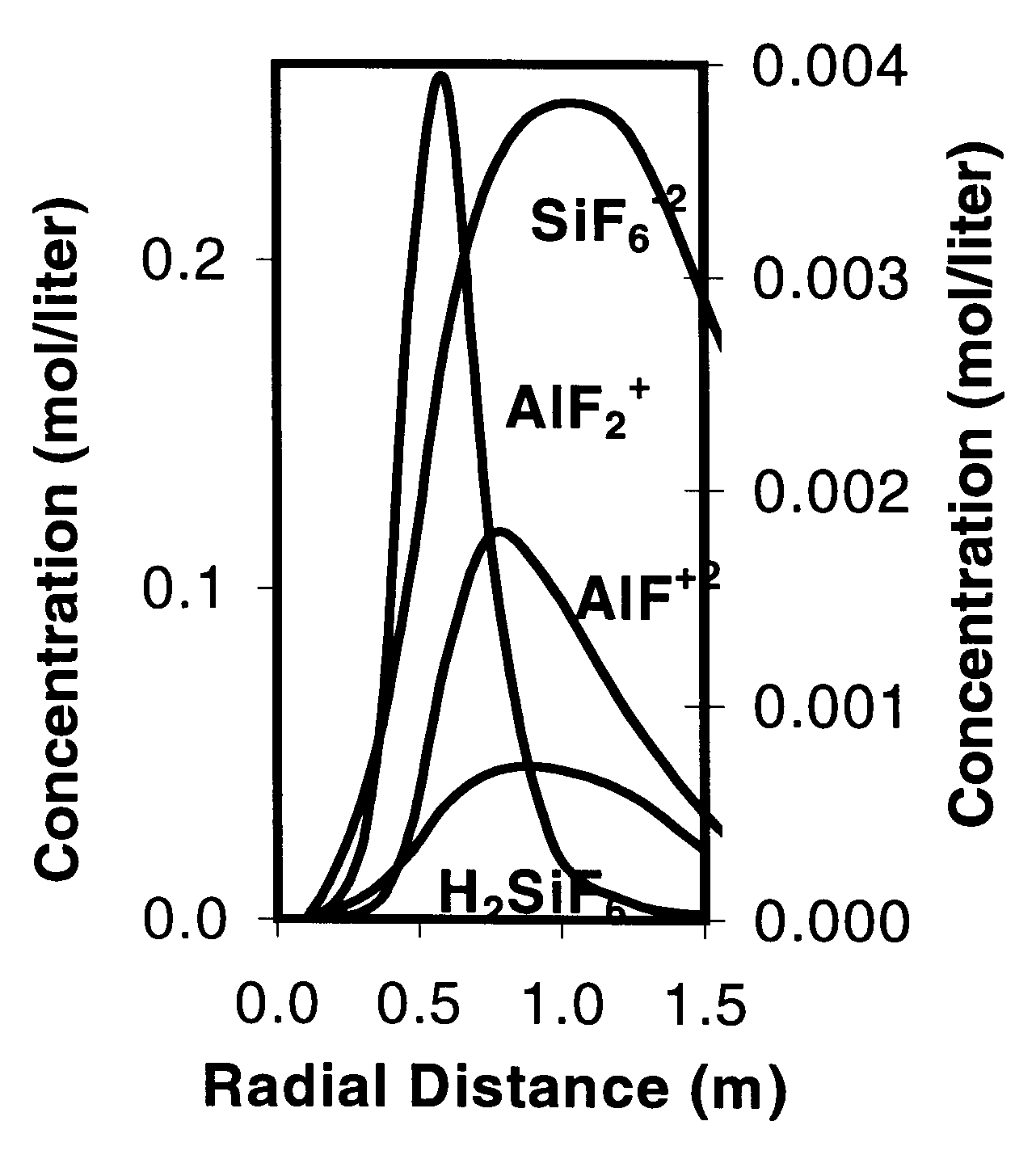

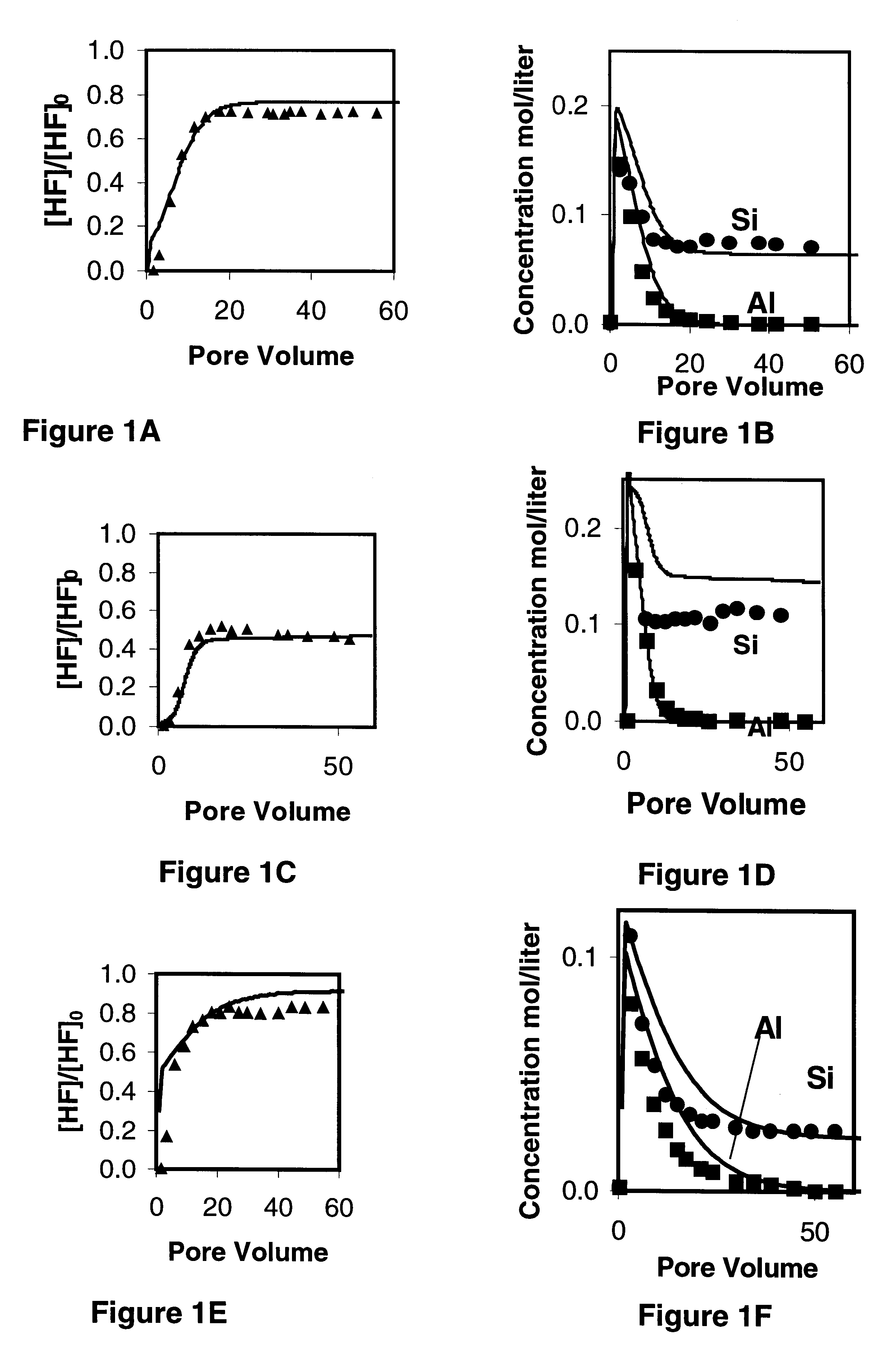

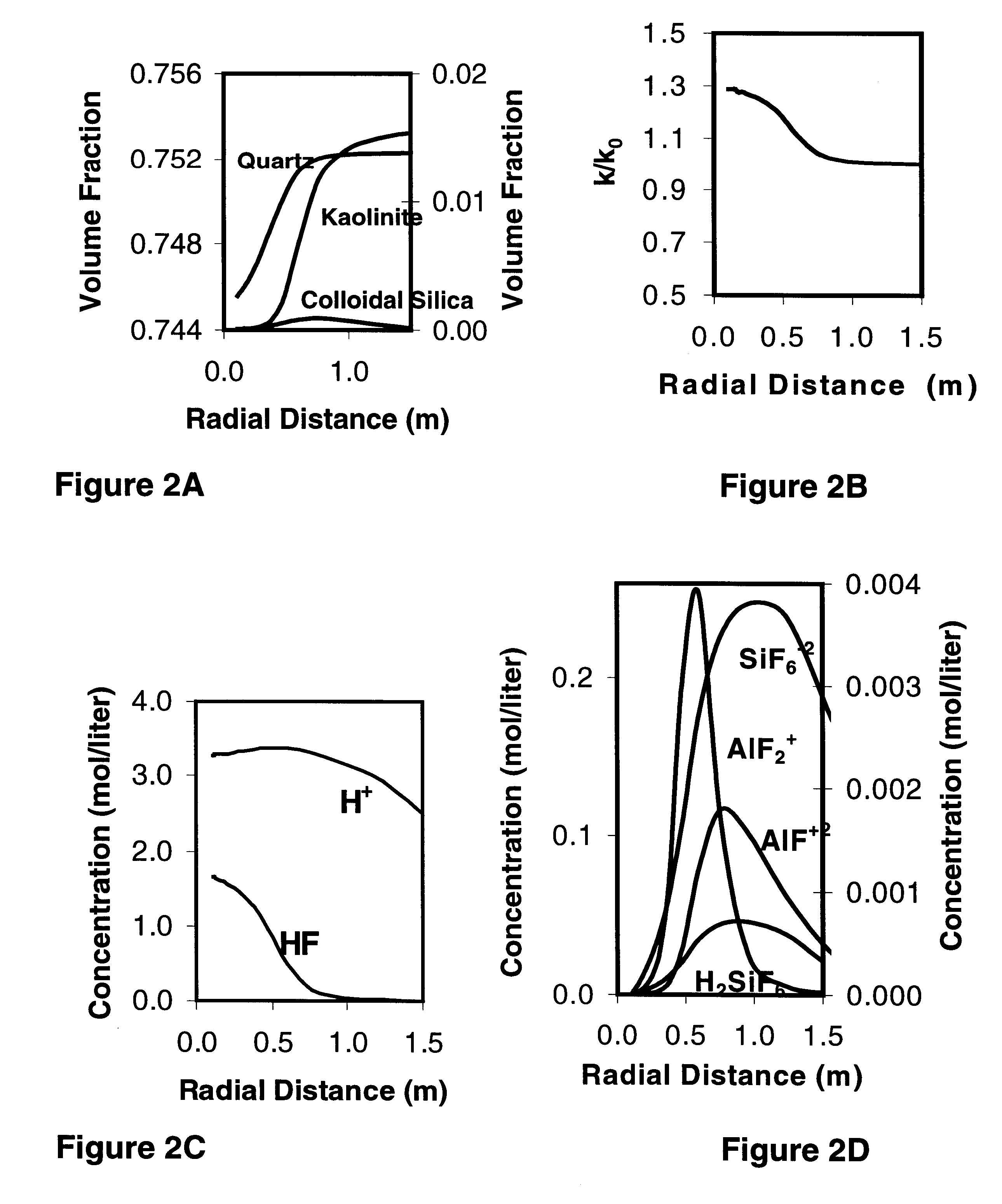

A method for designing acid treatments provides for the selection of optimal treatment for well stimulation wherein reservoir characteristics are obtained to further select the reaction kinetic data on the minerals of interests, the treatment to the reservoir is scaled up using a mathematical model and real time damage are computed based on bottomhole pressure and injection rate and compared to that predicted by the mathematical model to adjust the treatment. The model generated facilitates optimization of matrix treatments by providing a rapid quantitative evaluation of various treatment strategies for a formation. Stimulation with non-traditional fluid recipes containing mixtures of inorganic and organic acids, and chelating agents can be readily computed. The computed values can then be used in an economic model to justify the additional costs associated with the use of the non-traditional fluids. Apart from optimizing matrix treatments, the method can be used as a development tool for new fluid systems, as a tool for prediction and removal of inorganic scale and for fluid compatibility testing such as that required in water flooding projects.

Owner:SCHLUMBERGER TECH CORP

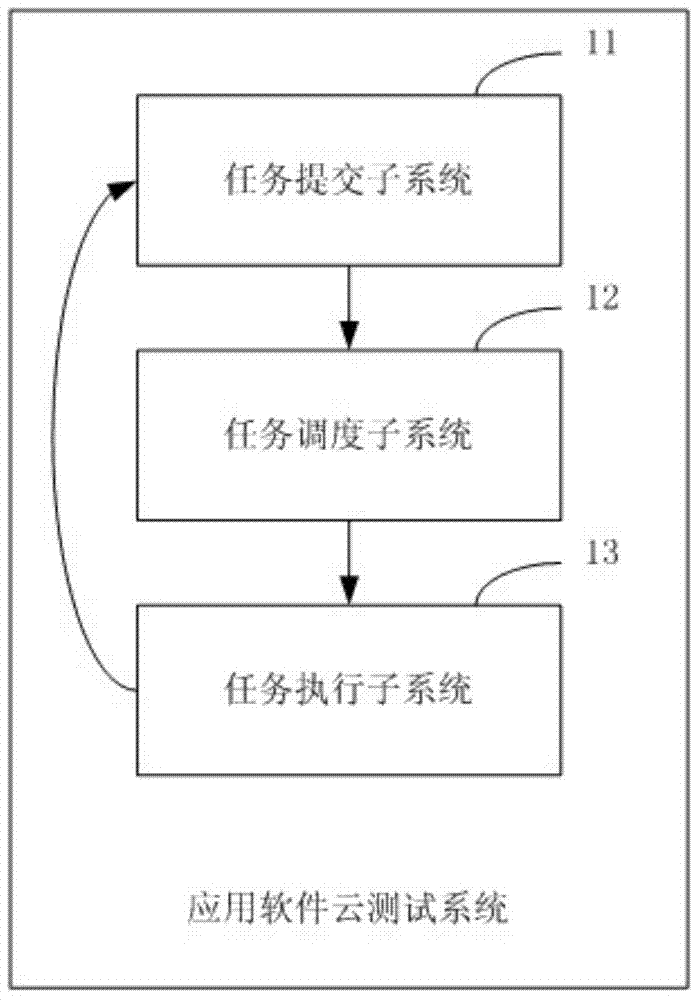

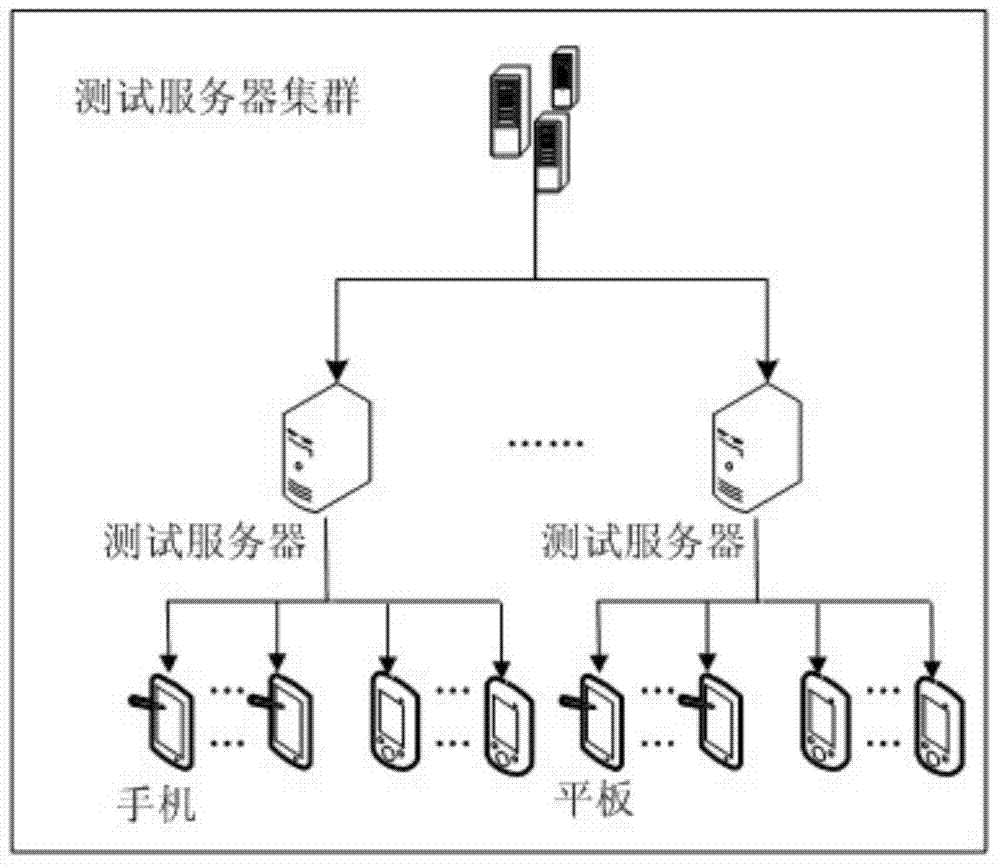

Application software cloud testing system

InactiveCN103678132AEnsure comprehensivenessSoftware testing/debuggingFunctional testingCloud testing

The invention belongs to the technical field of information, and provides an application software cloud testing system. The application software cloud testing system comprises a task submission subsystem, a task scheduling subsystem and a task execution subsystem. The task submission subsystem is used for testing test tasks submitted by testing personnel, the test tasks indicate the types of the test tasks, and the types of the testing tasks comprise compatibility testing, performance testing, and function testing or quality testing of application software. The task scheduling subsystem is used for conducting task scheduling according to the test tasks submitted by the task submission subsystem. The task execution subsystem is used for executing the test tasks according to the task scheduling condition of the task scheduling subsystem and collecting and generating corresponding testing reports according to the types of the testing tasks. According to the application software cloud testing system, based on the characteristics of the application software of a mobile terminal, testing content of four different types can be supported simultaneously, and therefore the comprehensiveness of the cloud testing result of the application software is guaranteed.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

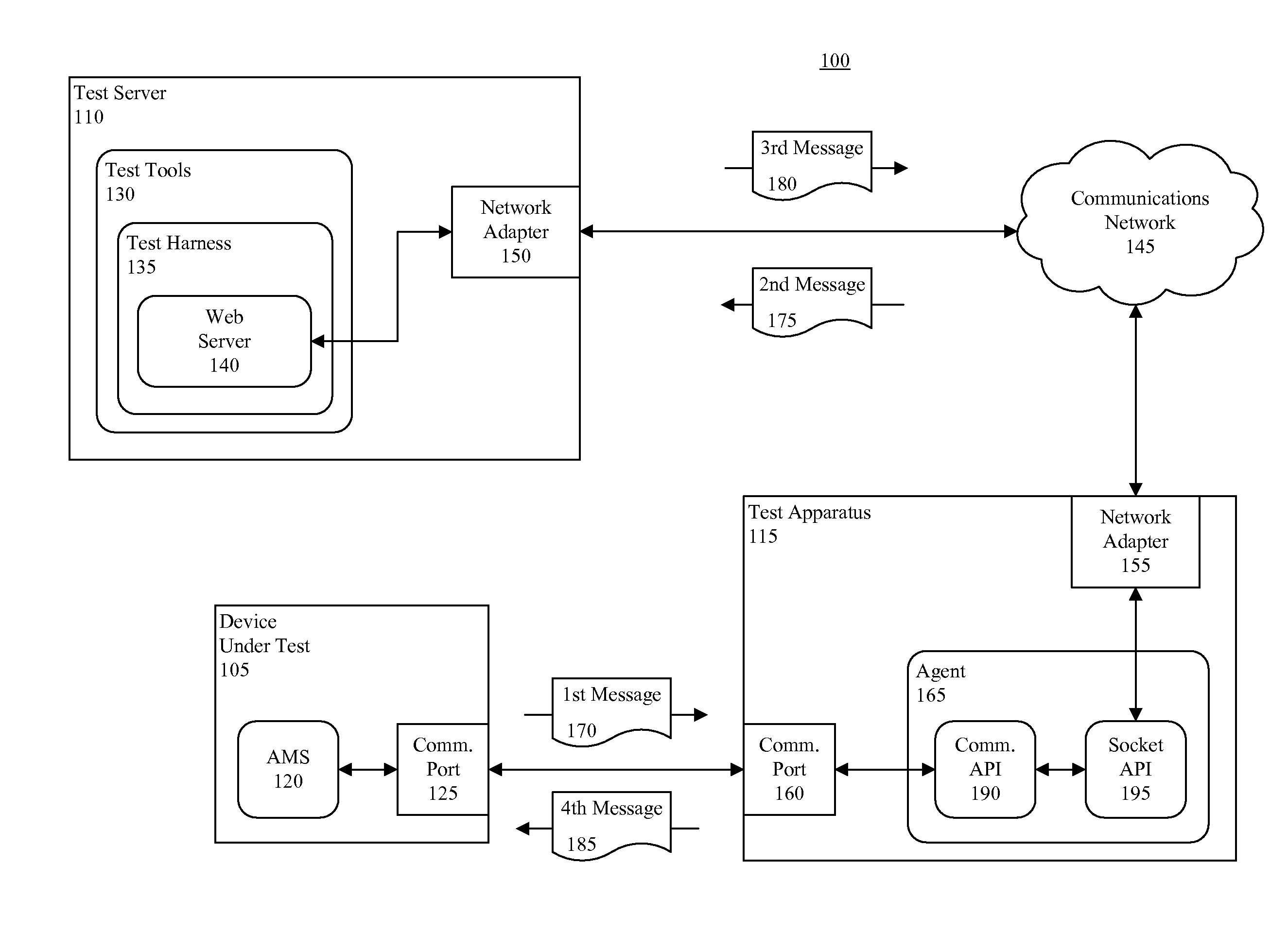

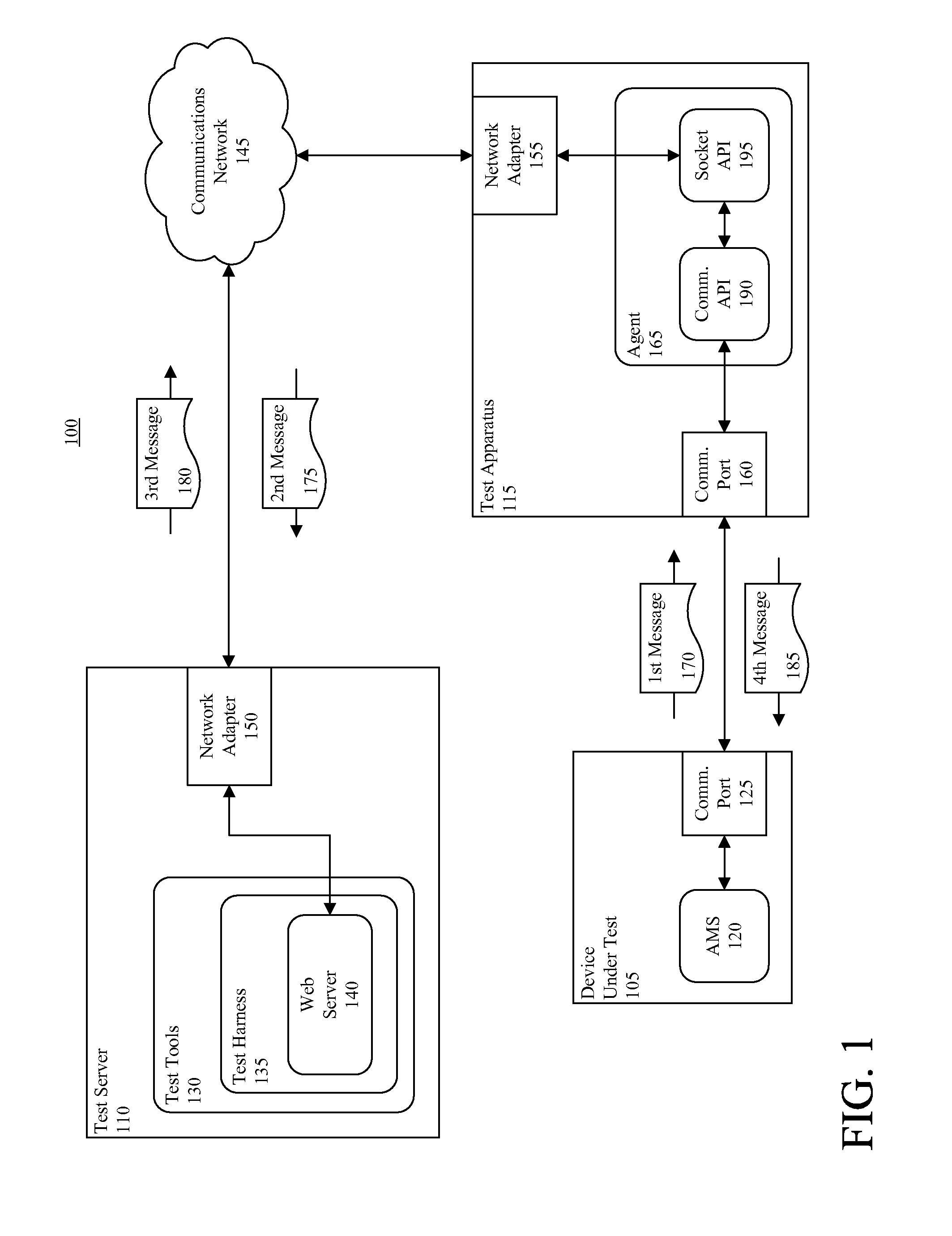

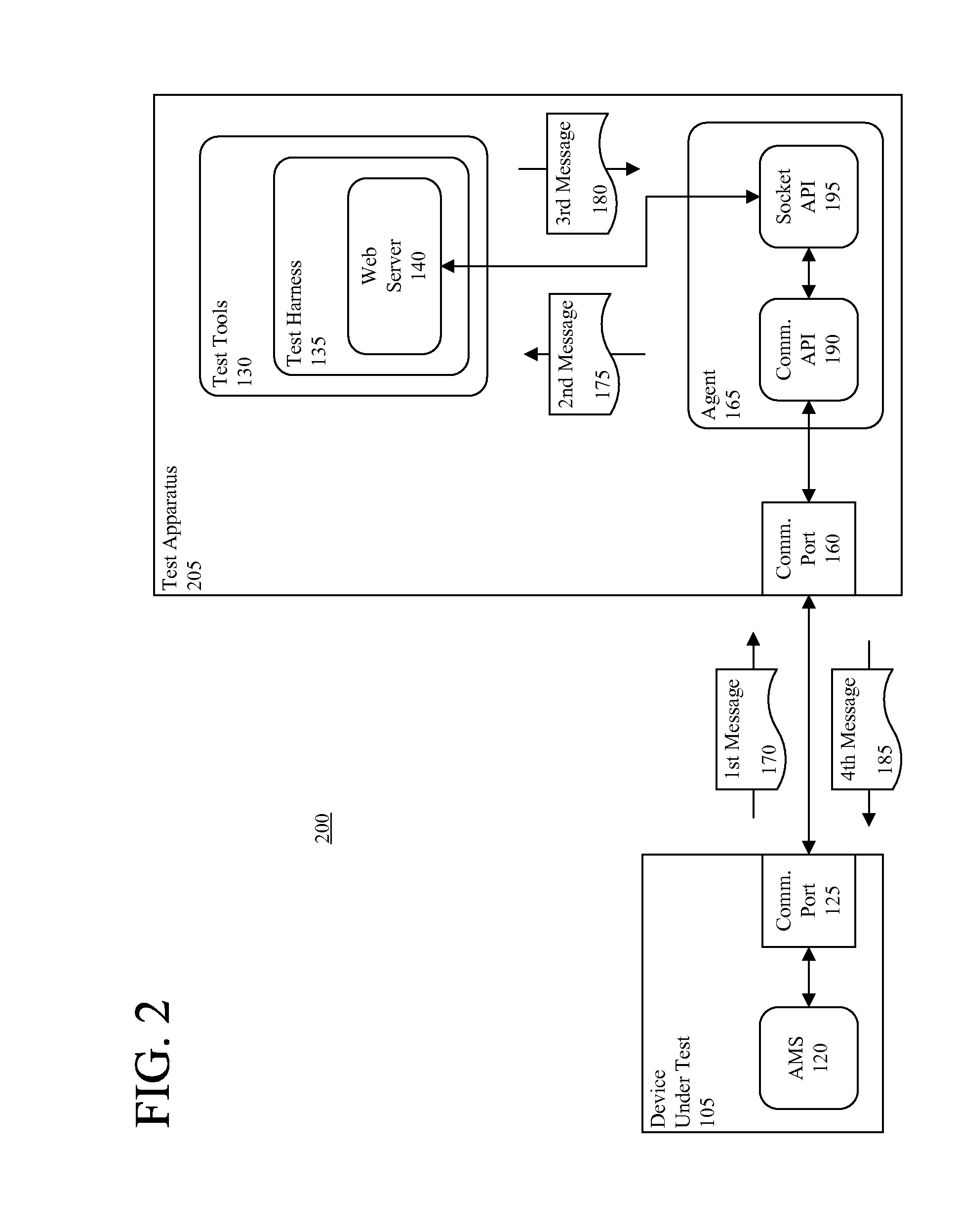

Agent for implementing automated compatibility test

InactiveUS20080104575A1Software testing/debuggingSpecific program execution arrangementsComputer hardwareNetwork Communication Protocols

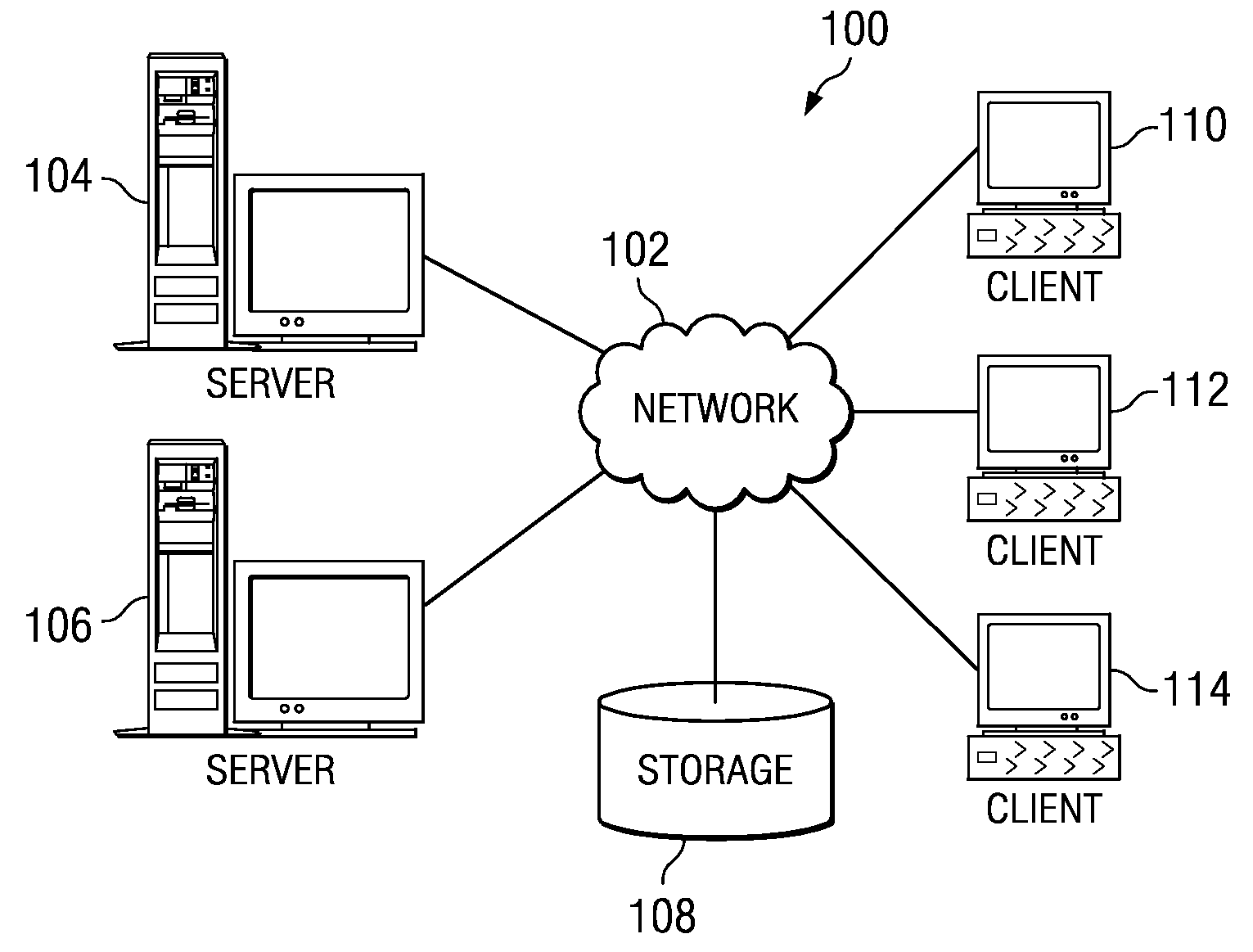

A method (400) of testing a device (105). The method can include receiving from the device a test request identifying at least one test to be performed on the device. The test request can be received in accordance with a first communications protocol. The test request can be communicated to a test tool (130) in accordance with a second communications protocol. Further, a response to the test request can be received from the test tool. The response can be received in accordance with the second communications protocol. The response then can be communicated to the device in accordance with the first communications protocol.

Owner:MOTOROLA INC

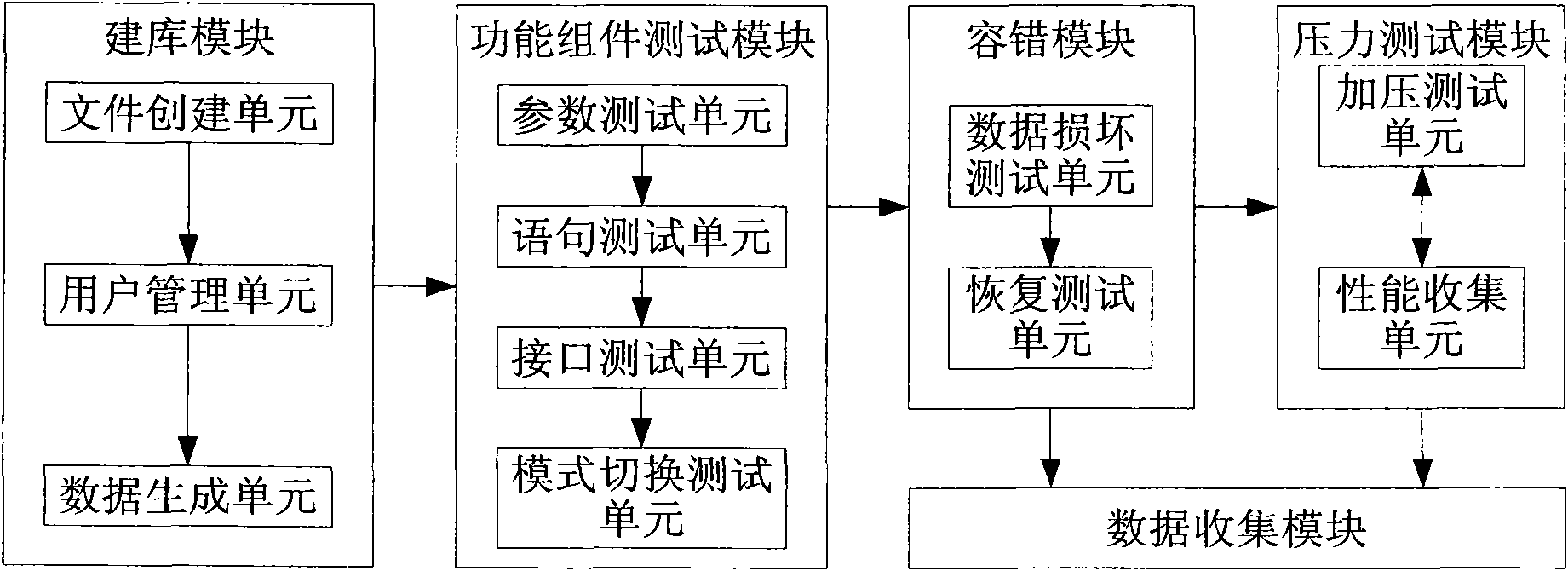

Database compatibility test device and method for server

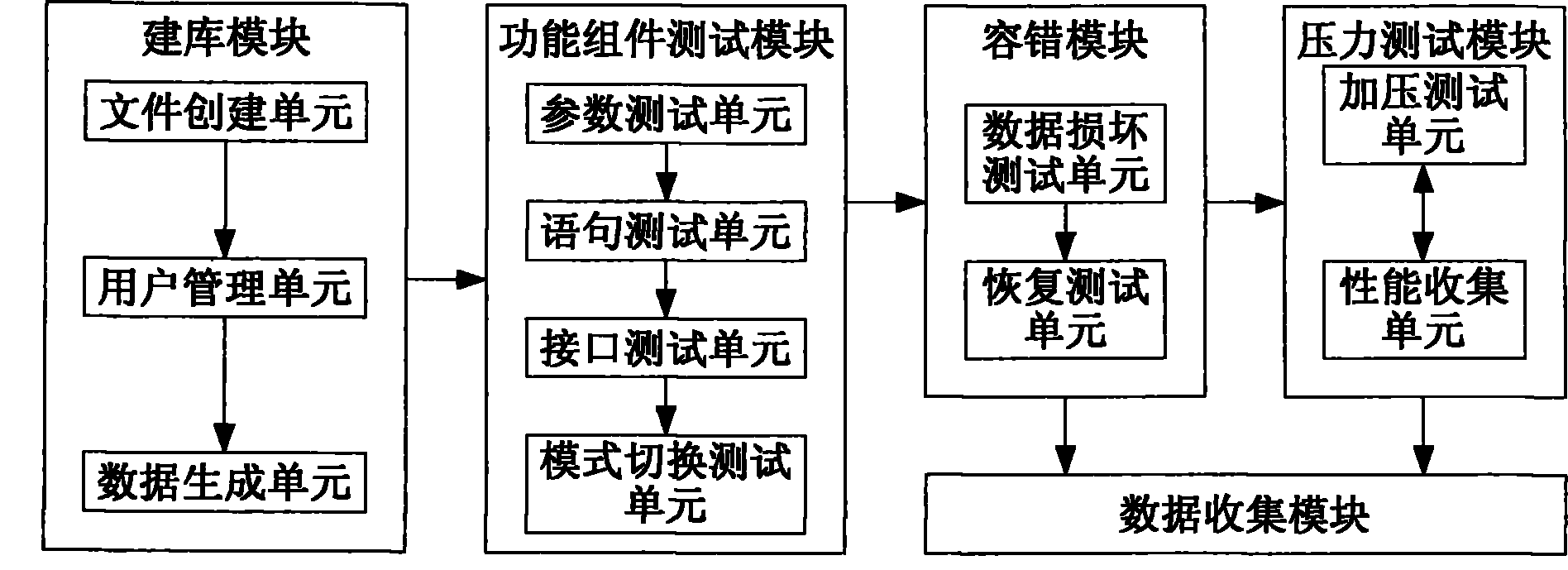

ActiveCN101789002ARelease performanceWide range of testsSpecial data processing applicationsRedundant hardware error correctionComputer compatibilityClient-side

The invention relates to a database compatibility test device and a method for a server. The method comprises the following steps: building a database on the server and carrying out data sufficiency on the database by generated data or actual data; simulating operation of a database administrator to regulate and test functional units provided by the database; deleting data in the database, testing whether the deleted database can be accessed and restored; simulating database access by a plurality of clients to test limitation performance of the server and maximum concurrent number and transaction ability of a hardware platform; and judging whether the built database is compatible with the server based on test results of the functional unit test module, fault-tolerant module and pressure test module. The invention has strong promptness, accuracy and flexibility, can be unmanned, and conducts test based on true database protocol.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Method for pre-testing software compatibility and system thereof

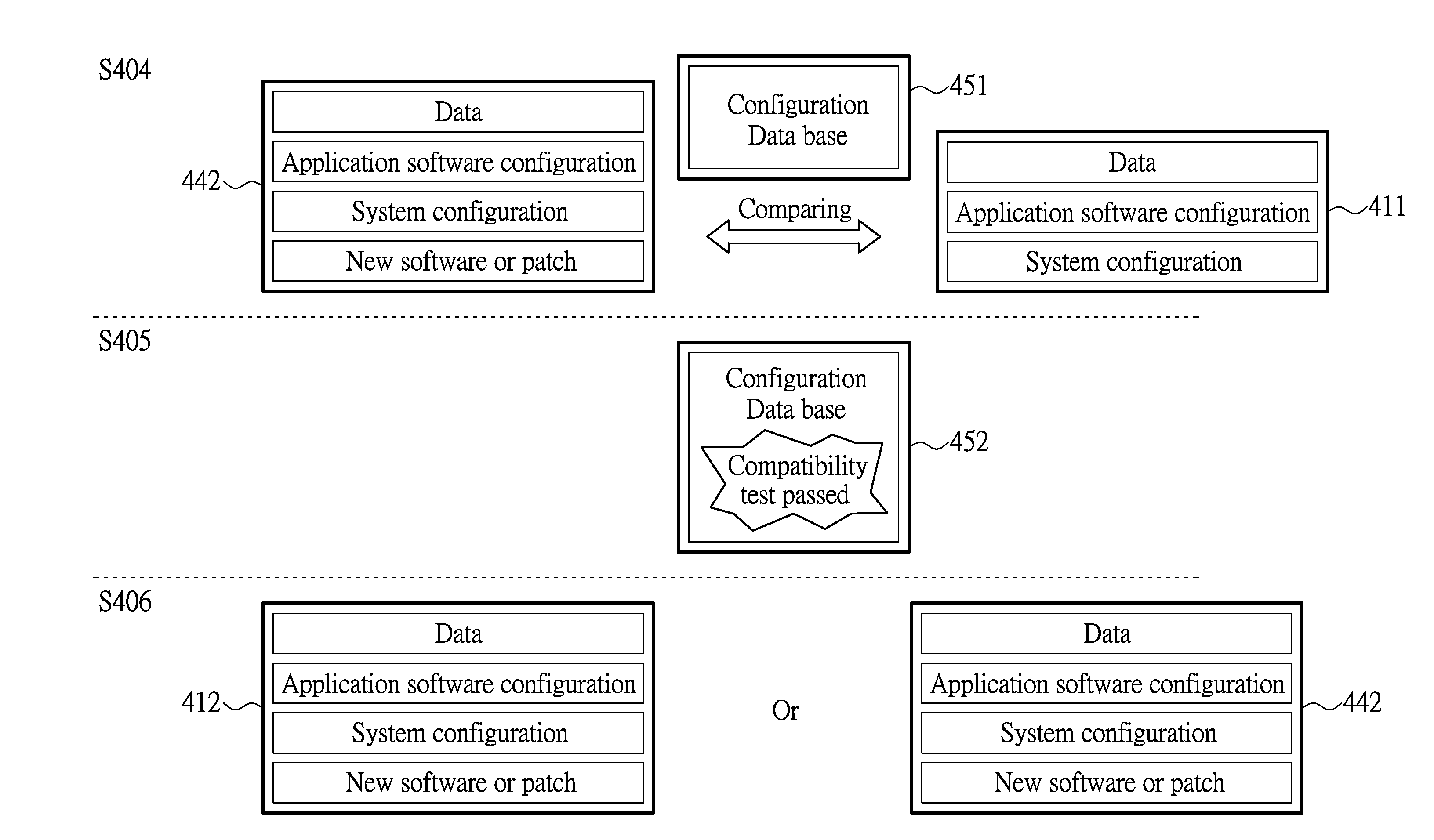

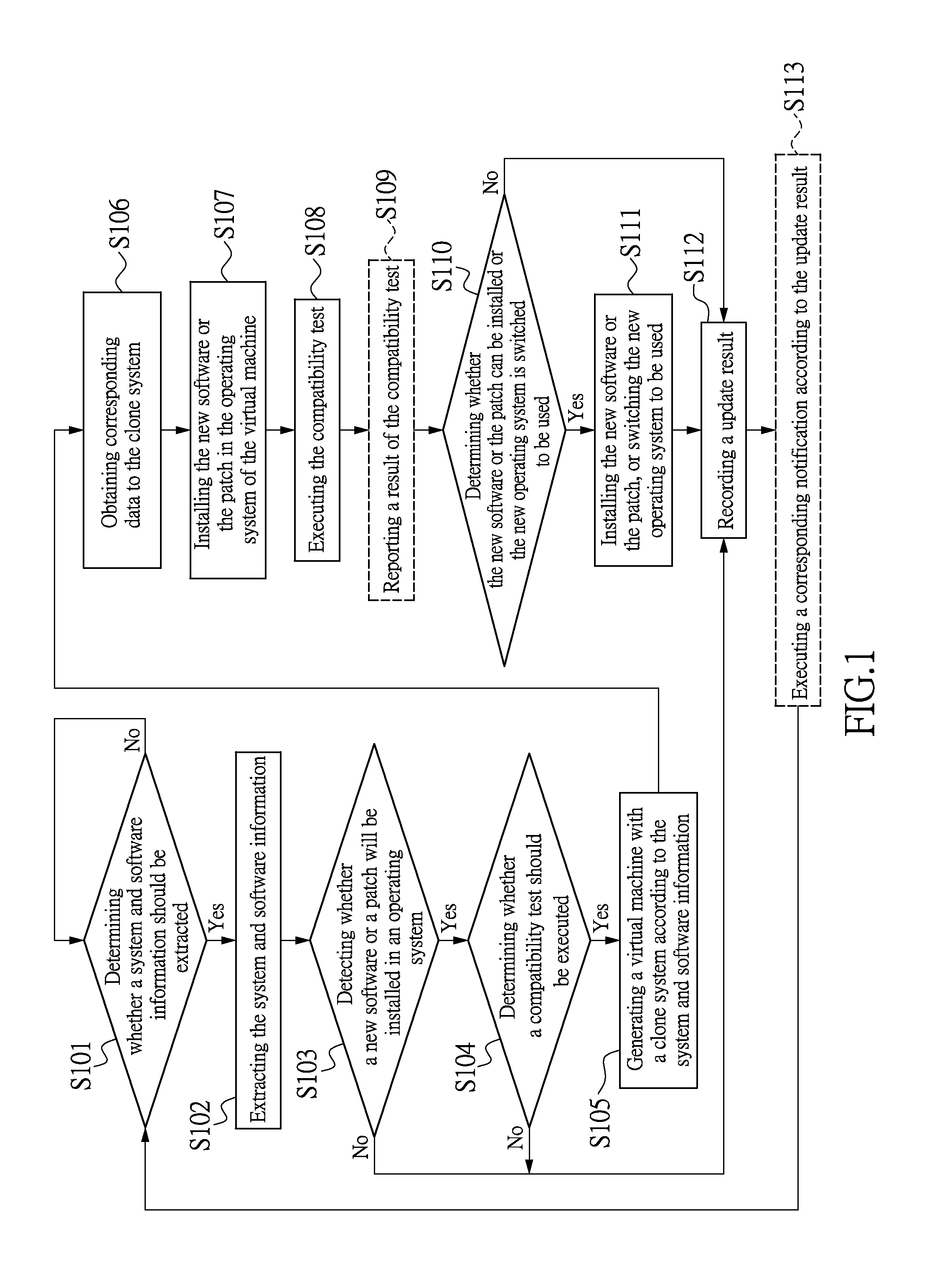

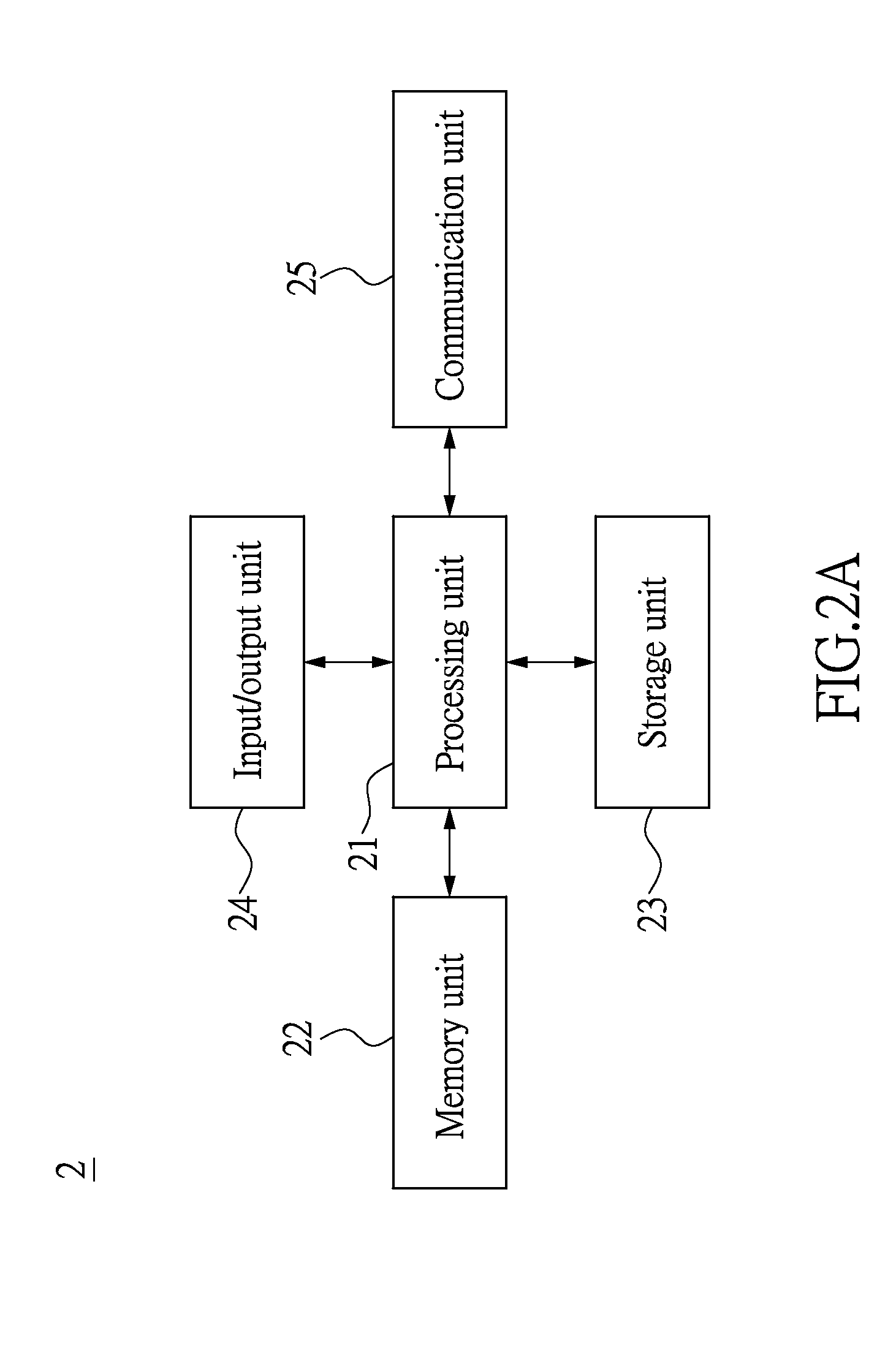

ActiveUS20150089479A1Software testing/debuggingSpecific program execution arrangementsOperational systemComputer compatibility

A method for pre-testing software compatibility is illustrated. A system and software information of an operating system is extracted. While that a patch or new software will be installed in the operating system is detected, whether a compatibility test should be executed is determined. While that the compatibility test should be executed is detected, a virtual machine with a first clone system is generated, wherein the first clone system is generated according to the system and software information. The patch or the new software is installed in the first clone system to generate a second clone system. The compatibility test for the second clone system is executed. According to a result of the compatibility test, whether the patch or new software can be installed in the operating system or the second clone system can be switched to be used is determined.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

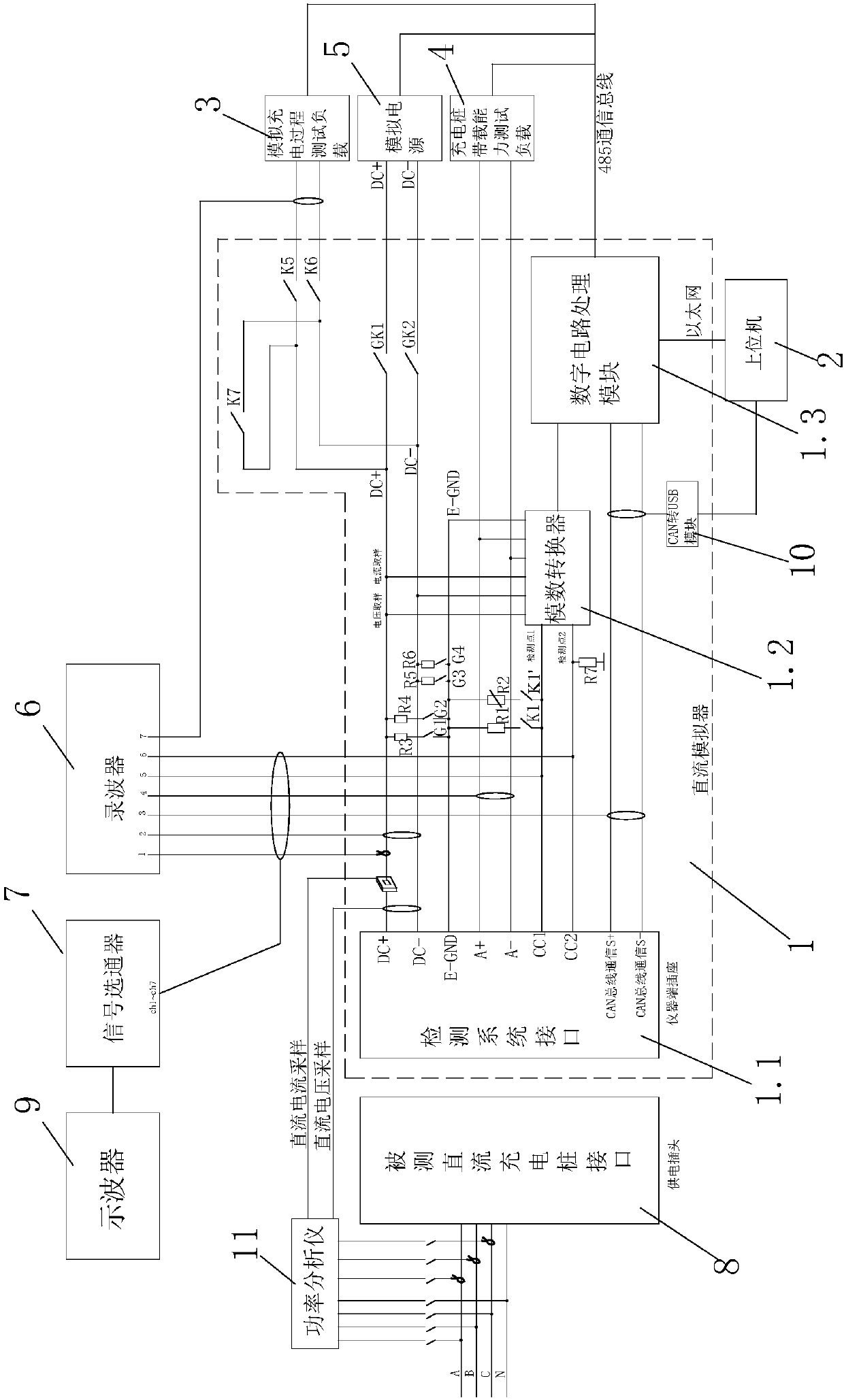

Direct-current charging pile detection system and detection method

ActiveCN107807290AGuaranteed uptimeSimple structureEnvironmental/reliability testsComputer compatibilityComputer module

The invention relates to a direct-current charging pile detection system comprising a direct-current simulator, a simulation charging process testing load, a charging pile on-load capacity testing load, a simulated power source, an oscillograph and a signal gating device. The direct-current simulator consists of an analog-digital converter, a digital circuit processing module and a detection system interface matching a tested direct-current charging pile interface. According to the invention, the input and output current and voltage signals can be detected and analyzed; and the charge controlcompatibility detection of the charging pile body and charging communication compatibility detection can be realized. The control compatibility tests include a pile body control guidance parameter test, a normal charging process test, and a simulated storage battery fault test; and the communication compatibility test includes communication testing of a direct-current charging pile handshake stage, a configuration stage, a charging stage, and an ending stage. The direct-current charging pile performance indexes can be detected comprehensively and thus the direct-current charging pile can workreliably.

Owner:国网浙江省电力公司电动汽车服务分公司 +3

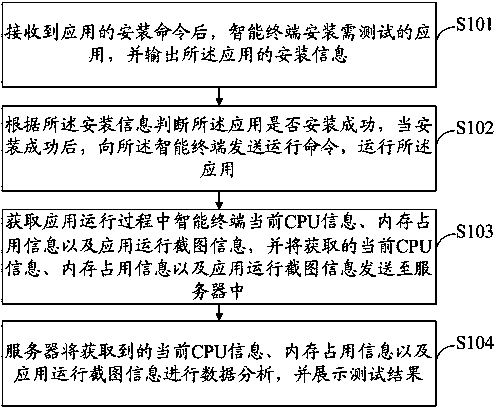

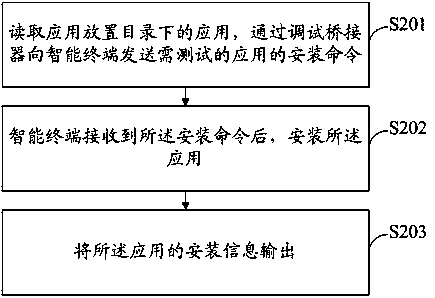

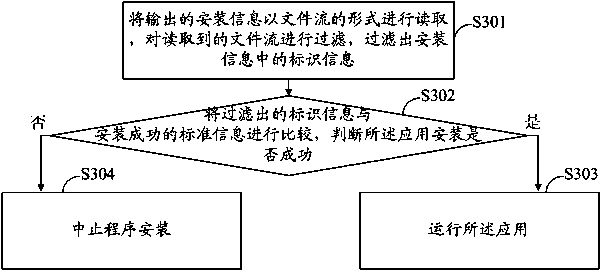

Method and system for testing application compatibility of intelligent terminal

InactiveCN103516559AImprove compatibilityReduce workloadData switching networksComputer hardwareTest efficiency

The invention discloses a method and system for testing application compatibility of an intelligent terminal. The method comprises the steps of (1), installing an application needing testing on the intelligent terminal after an installation instruction of the application is received, and outputting installation information, (2), judging whether the application is installed successfully or not according to the installation information, and after the application is installed successfully, sending an operation instruction to the intelligent terminal and enabling the application to operate, (3), obtaining current CPU information, memory usage information and application operation screenshot information of the intelligent terminal in the operation process of the application, and sending the obtained current CPU information, the memory usage information and the application operation screenshot information to a server, and (4), carrying out data analysis on the obtained current CPU information, the memory usage information and the application operation screenshot information through the server, and displaying a test result. The method and system for testing the application compatibility of the intelligent terminal greatly relieve workloads of testing personnel, improve testing efficiency, lower testing cost and improve testing quality.

Owner:TCL CORPORATION

Method of optimizing the design, stimulation and evaluation of matrix treatment in a reservoir

InactiveUS20020153137A1Easy to optimizeSimple calculationSurveyPackage sterilisationMathematical modelTreatment strategy

A method for designing acid treatments provides for the selection of optimal treatment for well stimulation wherein reservoir characteristics are obtained to further select the reaction kinetic data on the minerals of interests, the treatment to the reservoir is scaled up using a mathematical model and real time damage are computed based on bottomhole pressure and injection rate and compared to that predicted by the mathematical model to adjust the treatment. The model generated facilitates optimization of matrix treatments by providing a rapid quantitative evaluation of various treatment strategies for a formation. Stimulation with non-traditional fluid recipes containing mixtures of inorganic and organic acids, and chelating agents can be readily computed. The computed values can then be used in an economic model to justify the additional costs associated with the use of the non-traditional fluids. Apart from optimizing matrix treatments, the method can be used as a development tool for new fluid systems, as a tool for prediction and removal of inorganic scale and for fluid compatibility testing such as that required in water flooding projects.

Owner:SCHLUMBERGER TECH CORP

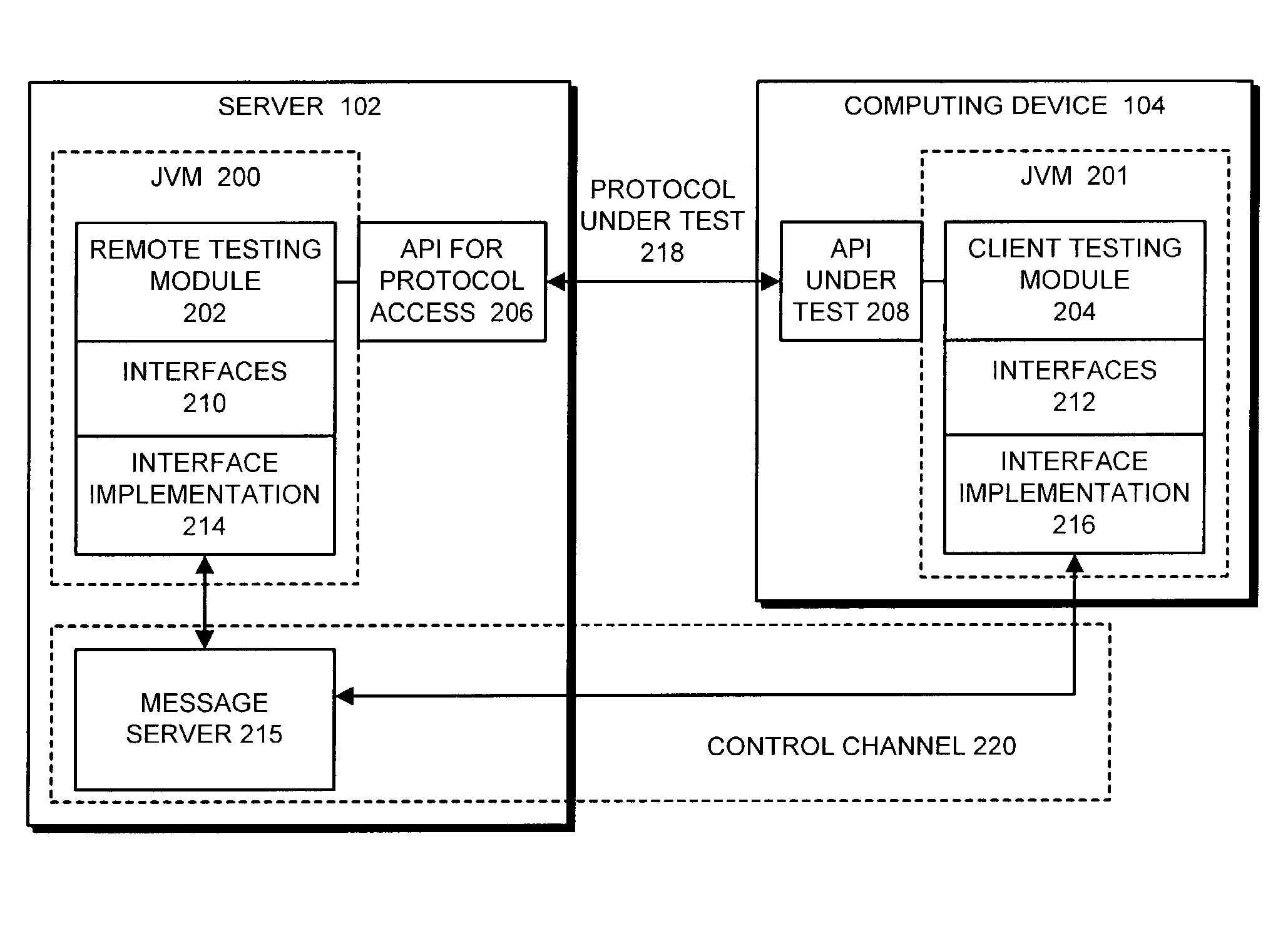

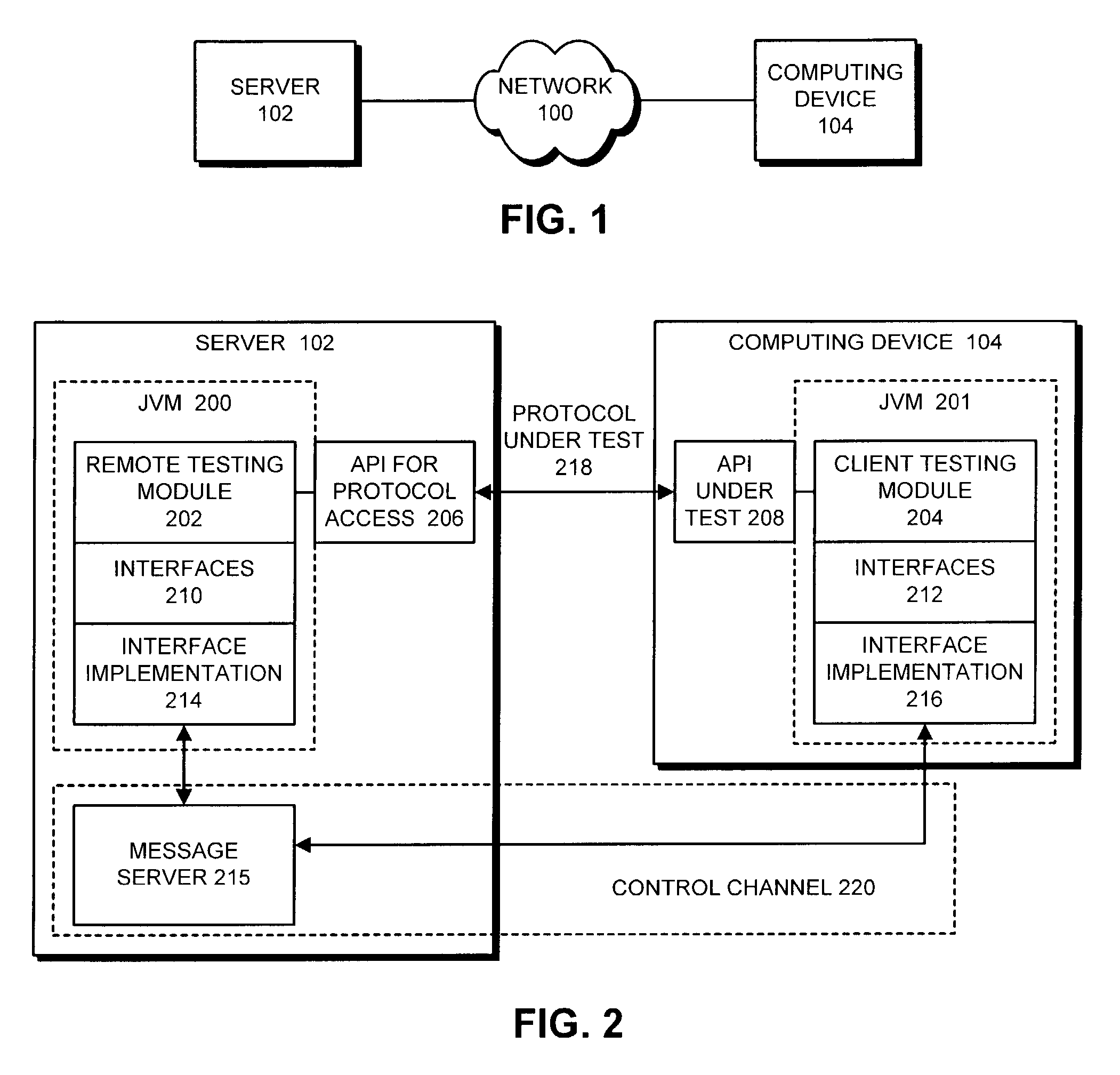

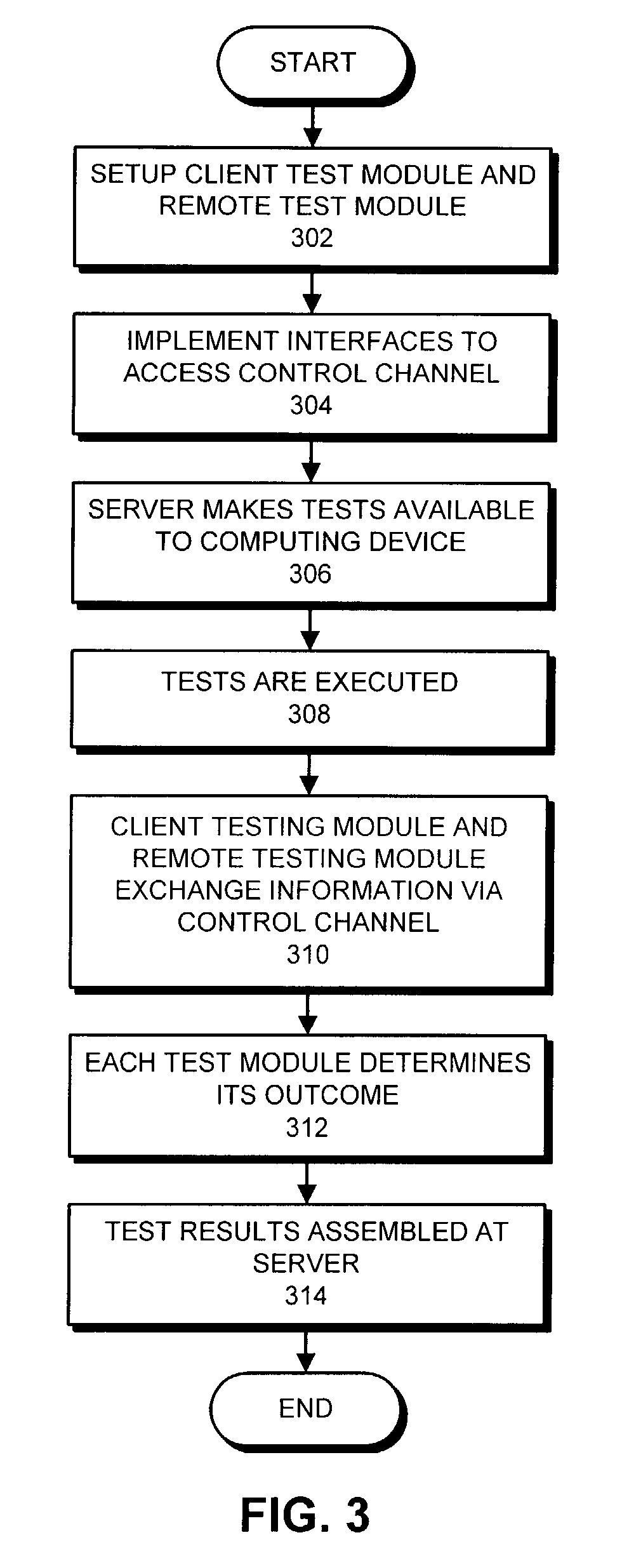

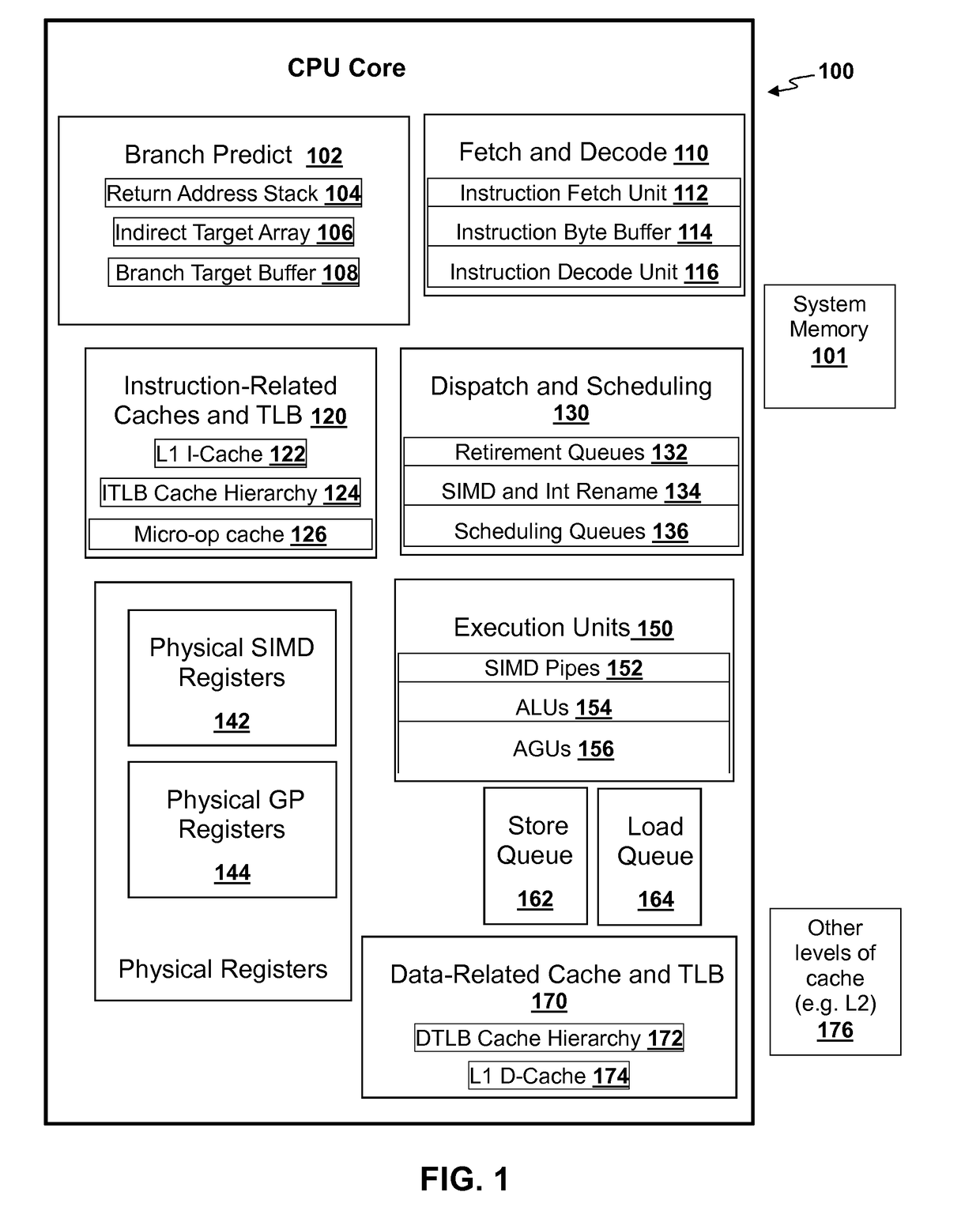

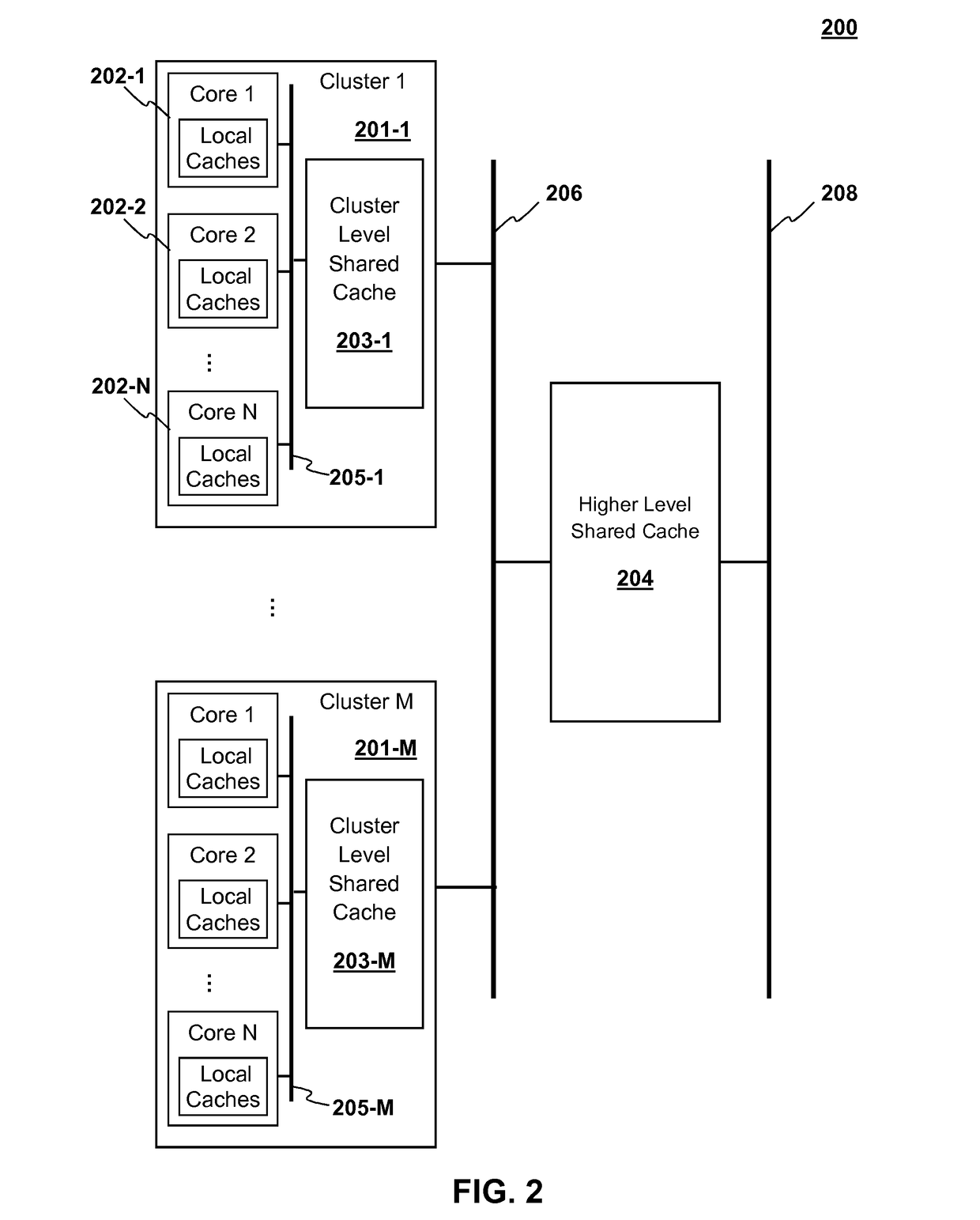

Compliance testing communication protocols implemented on resource-constrained computing devices

ActiveUS7155639B2Error preventionError detection/correctionComputer hardwareApplication programming interface

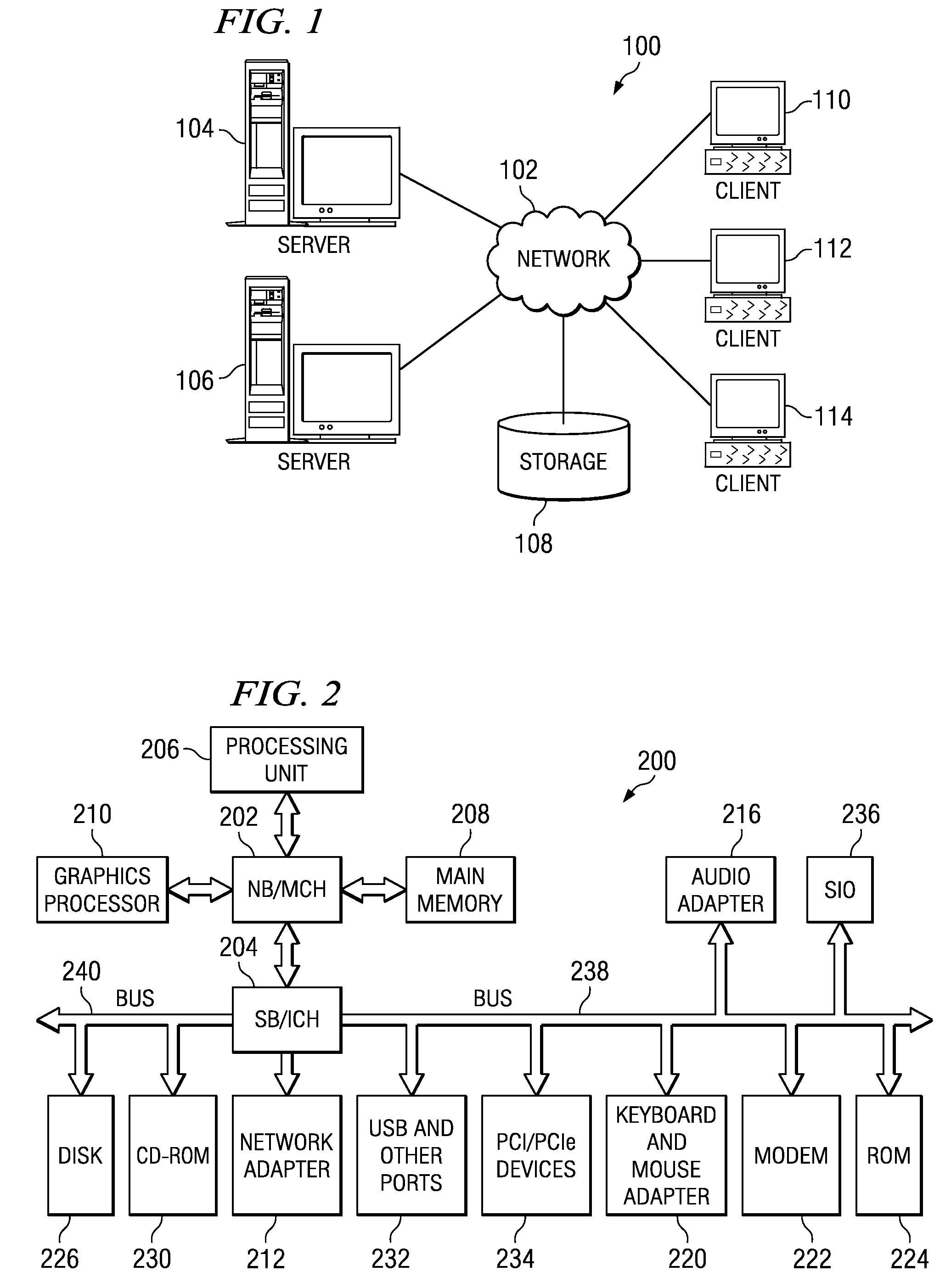

One embodiment of the present invention provides a system that supports compatibility testing of functionality provided through an Application Programming Interface (API) on a computing device. During operation, the system loads a client testing module on the computing device. The system also loads a remote testing module on a server. Once the client testing module and the remote testing module have been loaded, the system identifies a communication protocol that is available between the computing device and the server, and configures a communication-protocol-specific portion of the client testing module to communicate with the remote testing module through the available communication protocol. The system then compatibility tests the functionality provided through the API on the computing device. During this compatibility testing, certain portions of the test execute within the client testing module while other portions of the test execute within the remote testing module. Hence, the client testing module and the remote testing module work together in a distributed manner to compatibility test the computing device.

Owner:ORACLE INT CORP

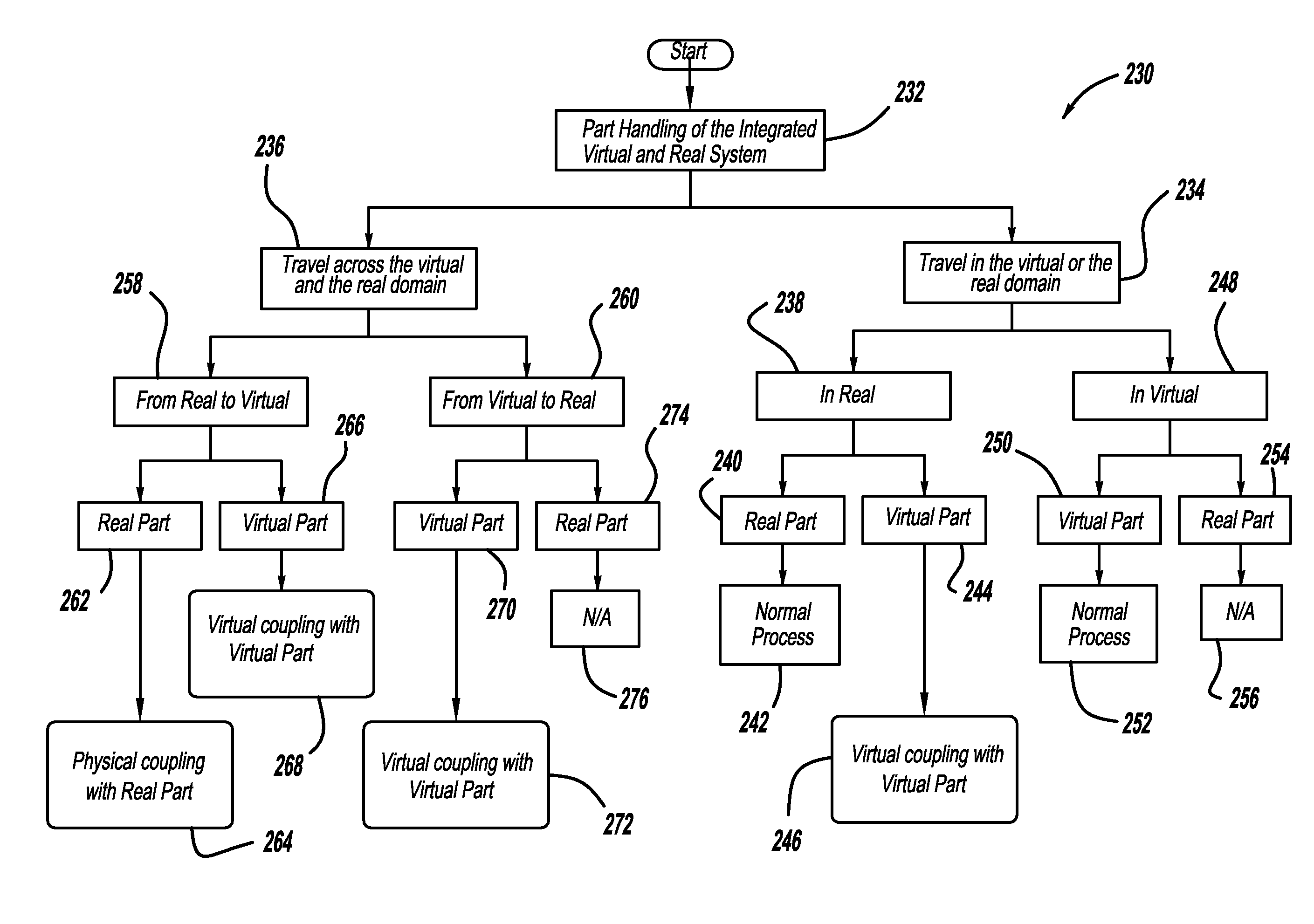

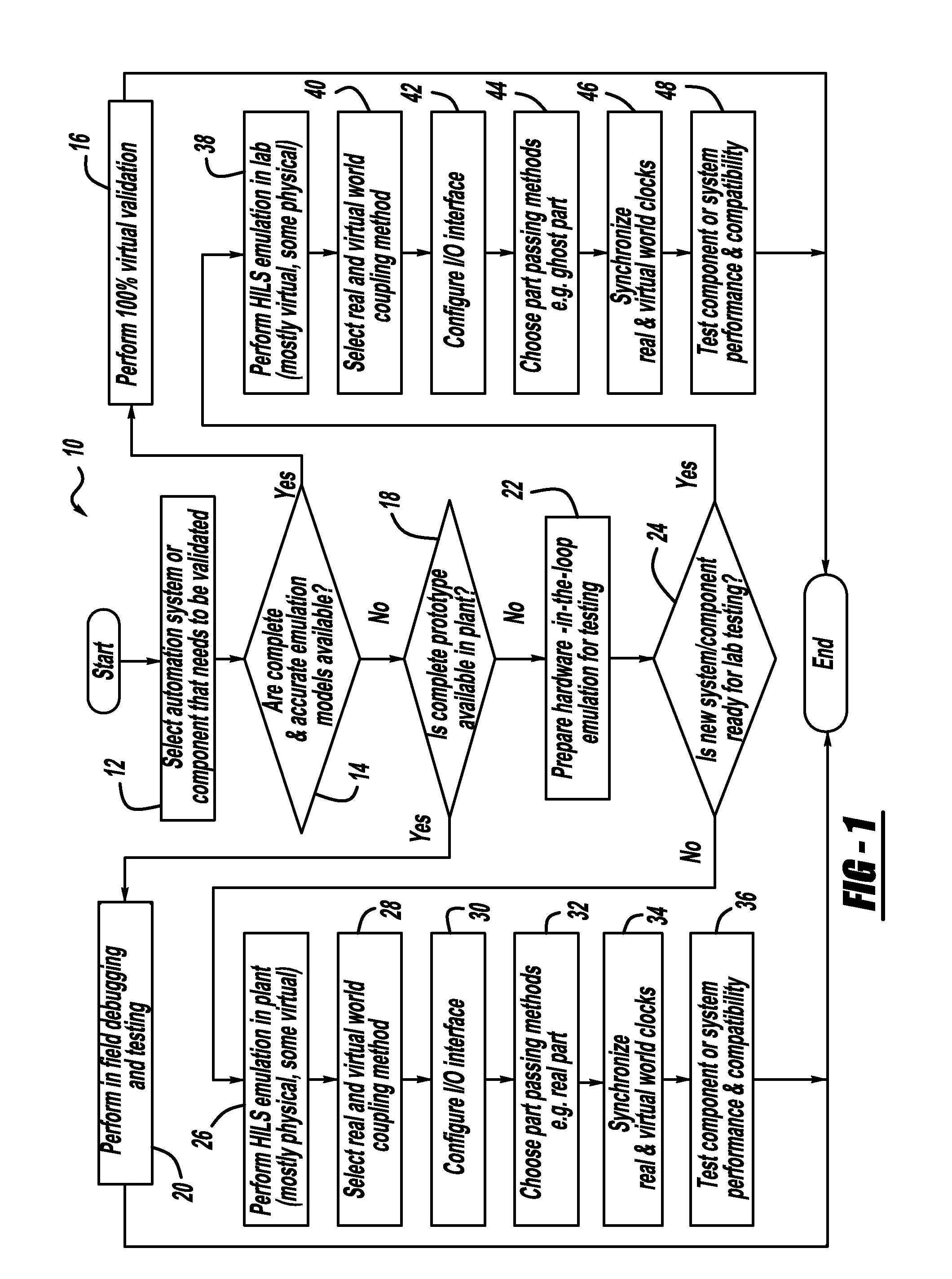

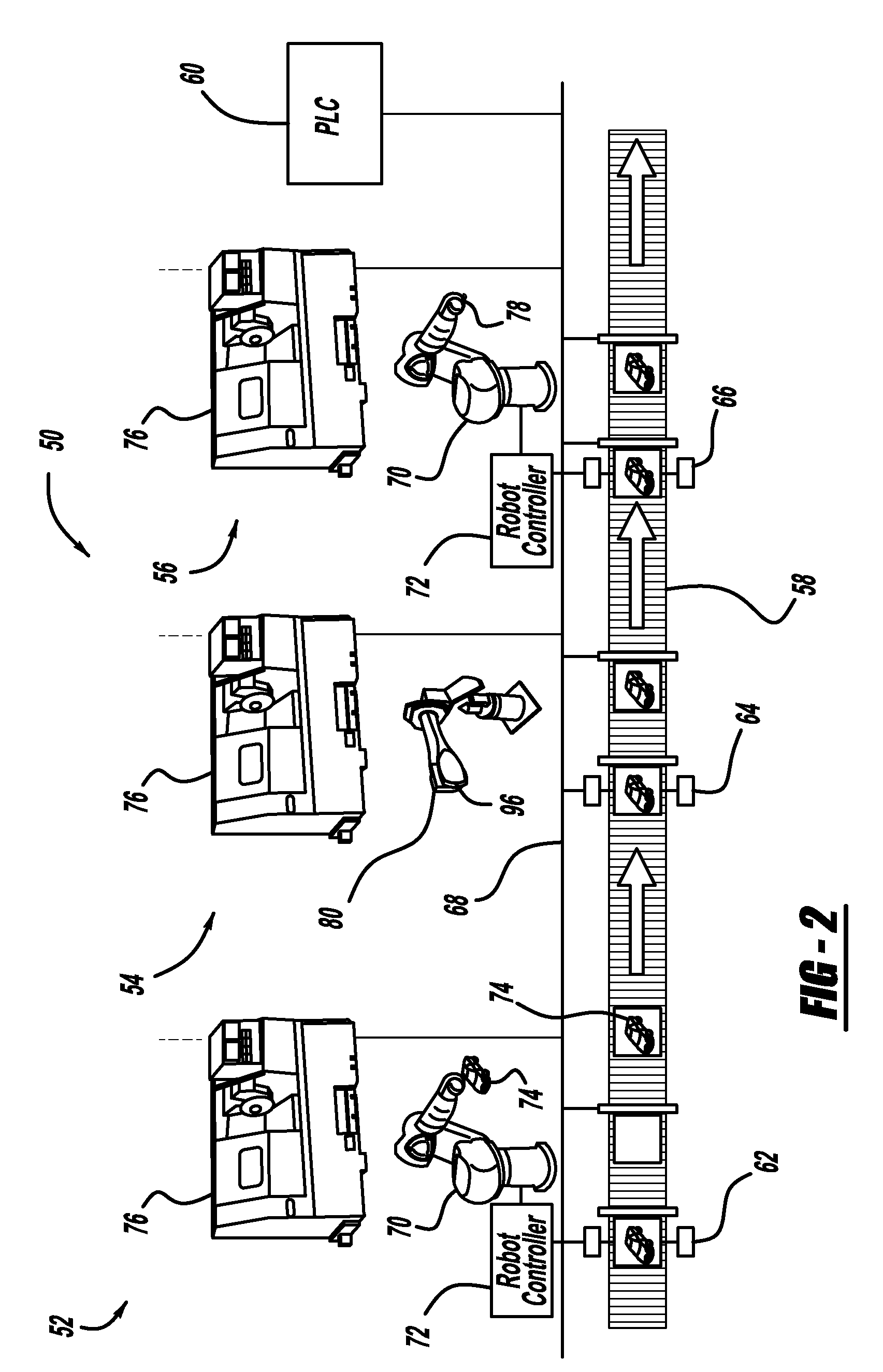

Manufacturing automation system components compatibility and performance testing with integrated virtual and real environment

InactiveUS20090088884A1Programme controlTotal factory controlReal systemsProgrammable logic controller

A system and method for providing an integrated virtual and real emulation environment for a manufacturing process to provide component compatibility testing and system performance prediction. In one embodiment, a real manufacturing system includes one or more real components that are controlled by a programmable logic controller. The real component can be replaced with a virtual component to determine whether it is compatible in the process, where the programmable controller sends signals to and receive signals from the virtual component as if it were the real component. For system performance prediction, a virtual manufacturing process is provided that includes virtual components where the virtual process is controlled by a programmable logic control as if it were a real process to determine the performance of a real system using the virtual process.

Owner:GM GLOBAL TECH OPERATIONS LLC

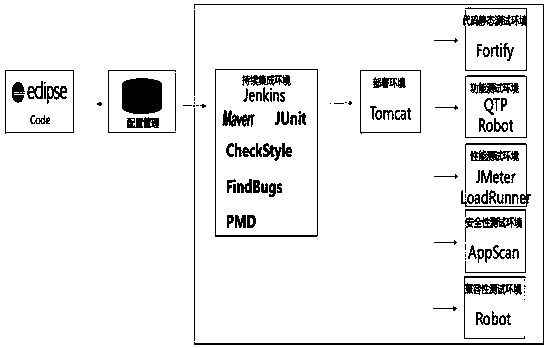

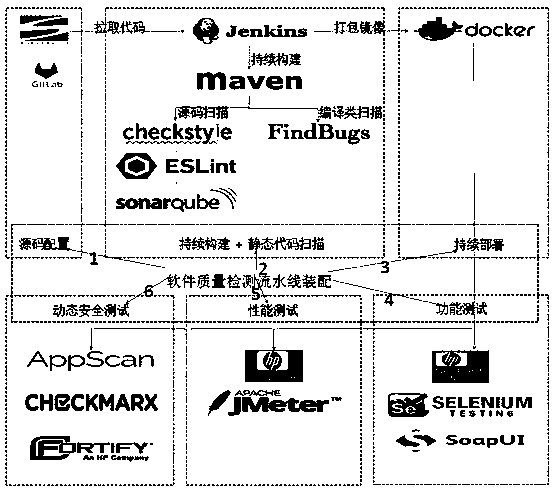

Software continuous delivery acceptance method based on continuous integration and automated testing

InactiveCN108334437AComprehensive test resultsImprove test efficiencyHardware monitoringSoftware testing/debuggingTest scriptContinuous integration

The invention discloses a software continuous delivery acceptance method based on continuous integration and automated testing. From source code submission, a code is downloaded from a source code configuration tool to carry out automated construction, and FindBugs code vulnerability scanning is integrated through a construction tool; after construction is finished, Docker is used for creating deployment environment or integrating with existing environment; then, function test script management, performance test script management, compatibility test script management and code vulnerability scanning configuration management are realized; the integrated environment of integrated function testing, performance testing, compatibility testing and source code auditing is provided; and various tests are executed, and results are uniformly managed. Through the method, test personnel do not need to build the complex continuous integration and testing environment, the test of each dimension of one item can be quickly realized, the comprehensive test result of the whole item is provided, and test efficiency is greatly improved.

Owner:JIANGSU ELECTRIC POWER INFORMATION TECH +1

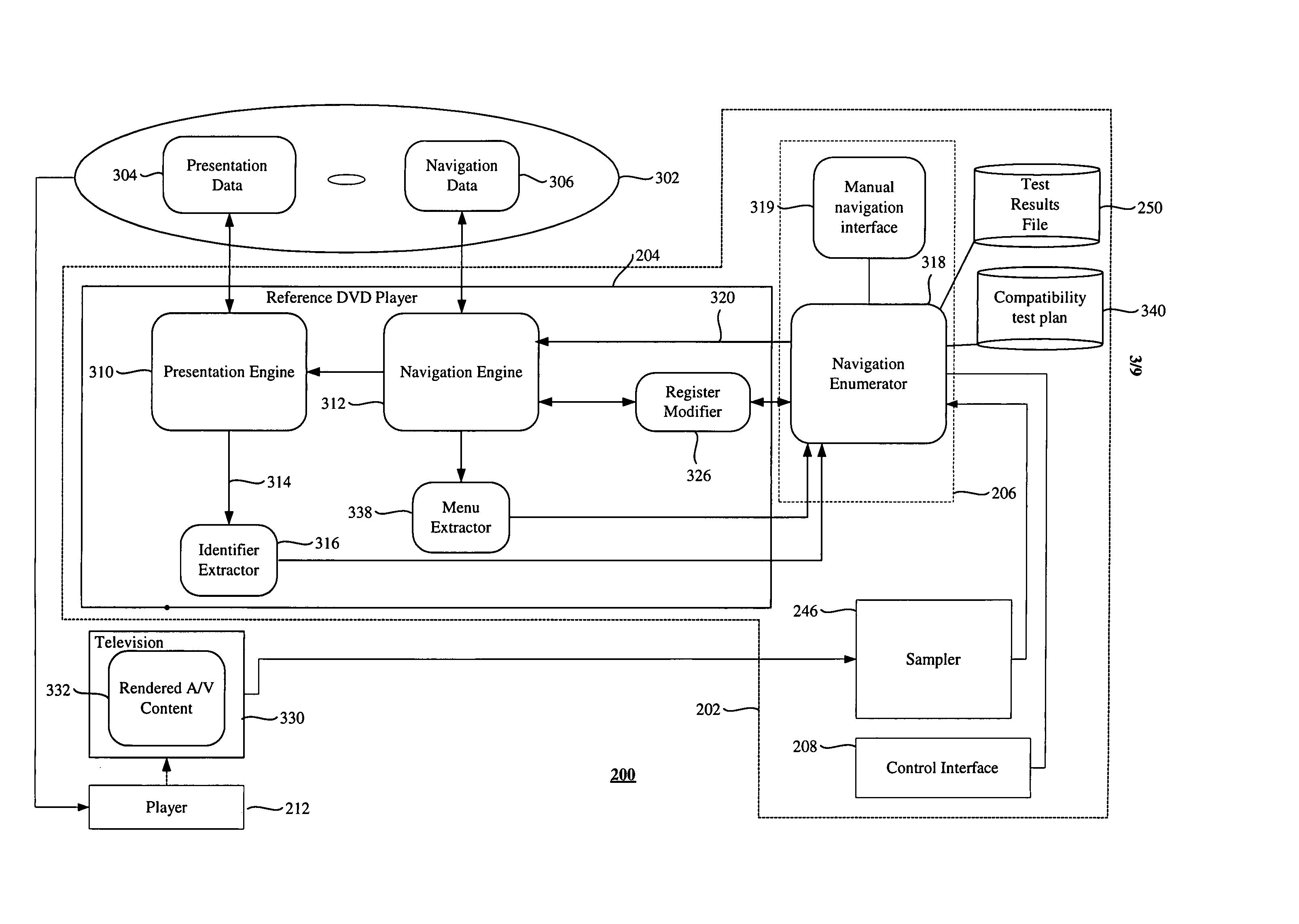

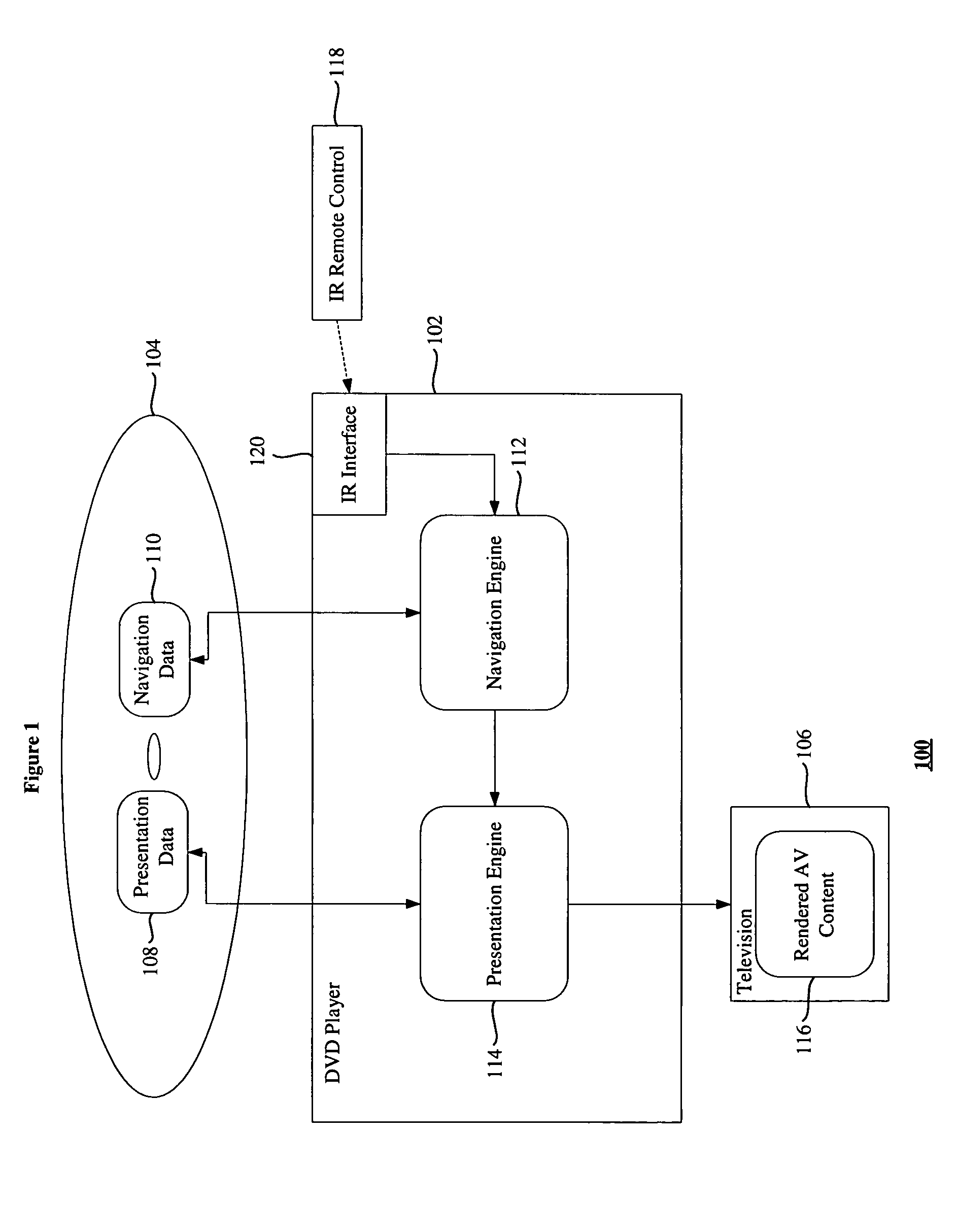

Compatibility Testing

ActiveUS20050232577A1Automatic testingTelevision system detailsColor television signals processingData processing systemComputer graphics (images)

Embodiments of the present invention relate to a data processing system and method for automatically testing a digital content player to ensure compliance with a video image data specification.

Owner:ZOO DIGITAL

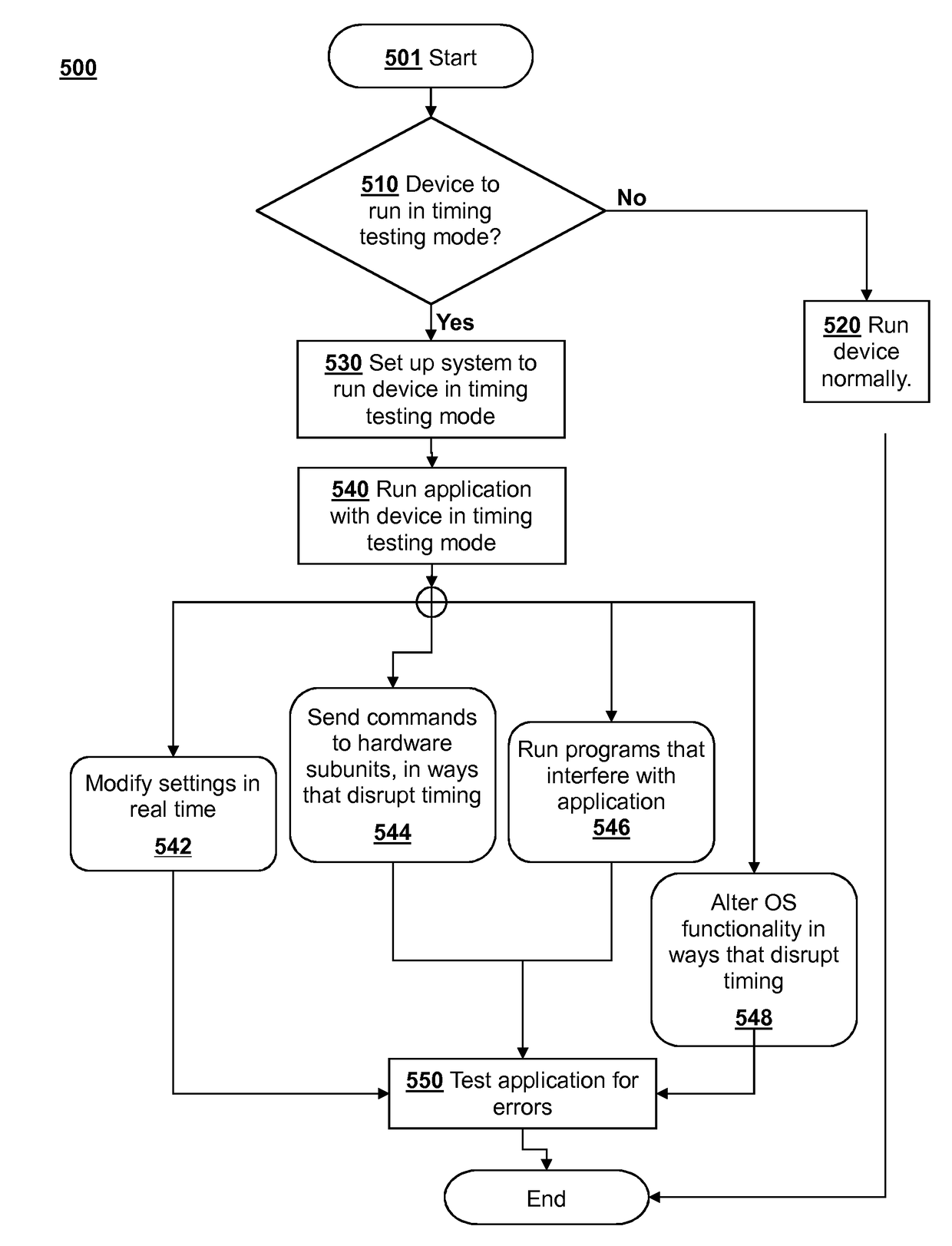

Backward compatibility testing of software in a mode that disrupts timing

ActiveUS20170123961A1Memory architecture accessing/allocationMemory adressing/allocation/relocationCompatibility testingSoftware

A device may be run in a timing testing mode in which the device is configured to disrupt timing of processing that takes place on the one or more processors while running an application with the one or more processors. The application may be tested for errors while the device is running in the timing testing mode

Owner:SONY INTERACTIVE ENTRTAINMENT LLC

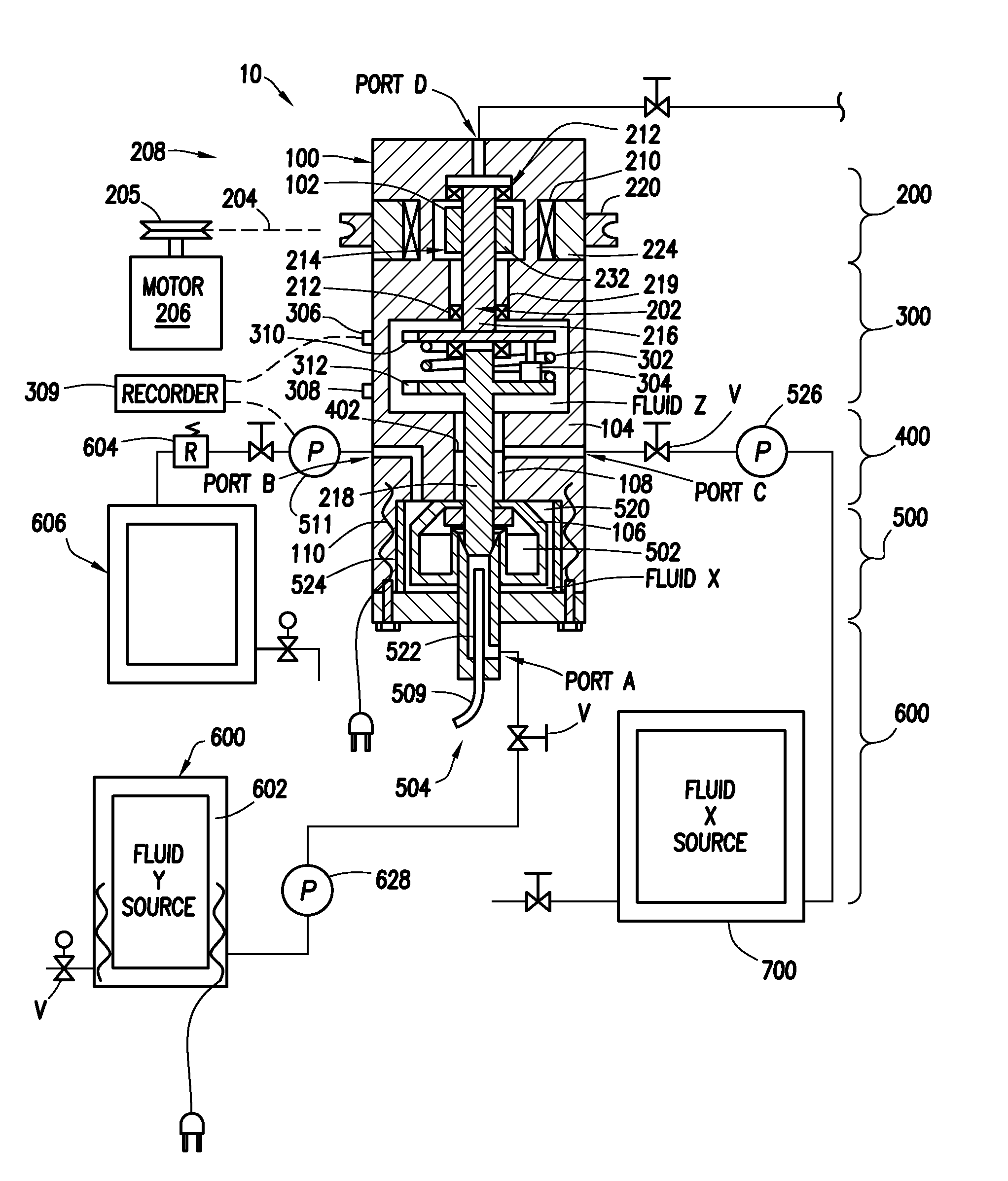

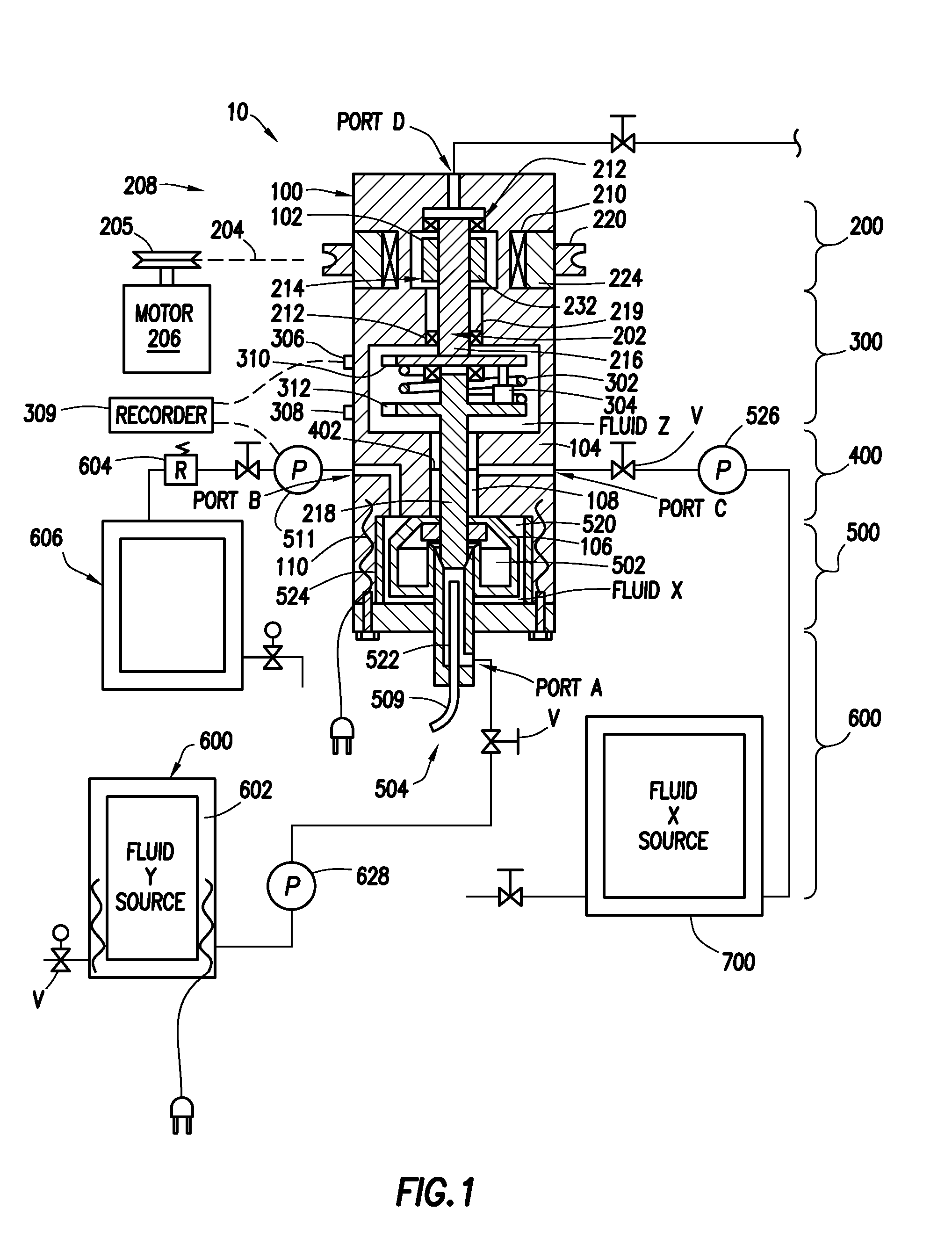

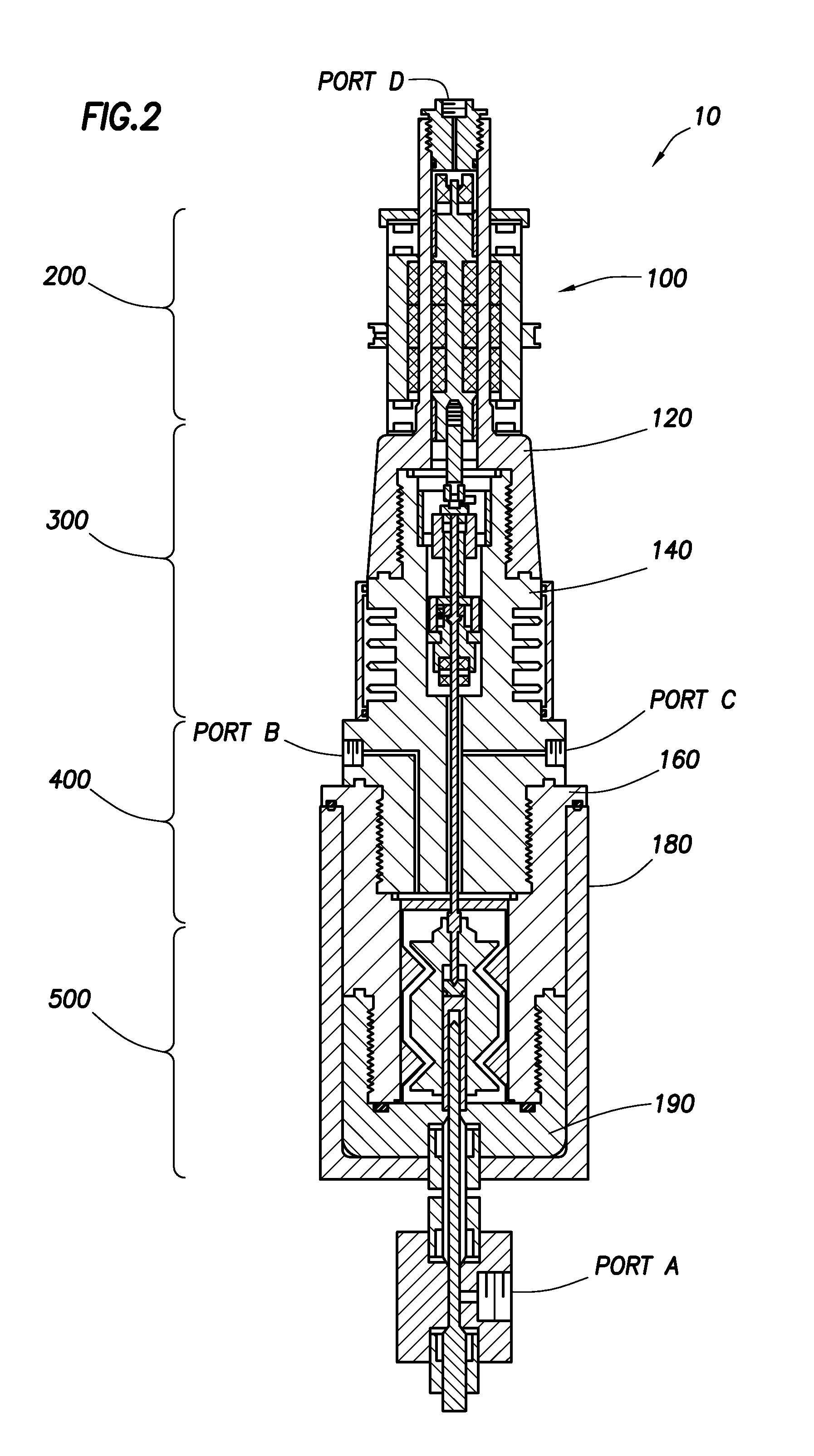

Apparatus and methods for continuous compatibility testing of subterranean fluids and their compositions under wellbore conditions

Disclosed is a fluid testing device which utilizes a small, cross-section fluid interface to separate a test fluid chamber from a drive and measuring chamber. The test fluid chamber contains the test fluid and a paddle-type fluid test assembly. The drive and measuring chamber contains a second fluid and assemblies for moving the paddle and for determining the resistance movement. The two chambers are connected together by a narrow cross-section passageway allowing for continuous testing while test fluids are flowed through the test chamber and for successive testing of different samples without breaking down the device between tests. A pair of coaxial shafts extends between the test fluid chamber and the drive and measuring chamber. The shafts are connected together by a spring located in the drive chamber whereby the resistance to movement is determined by measuring the deflection in the spring. The shafts are magnetically coupled to a motor to rotate the shafts.

Owner:HALLIBURTON ENERGY SERVICES INC

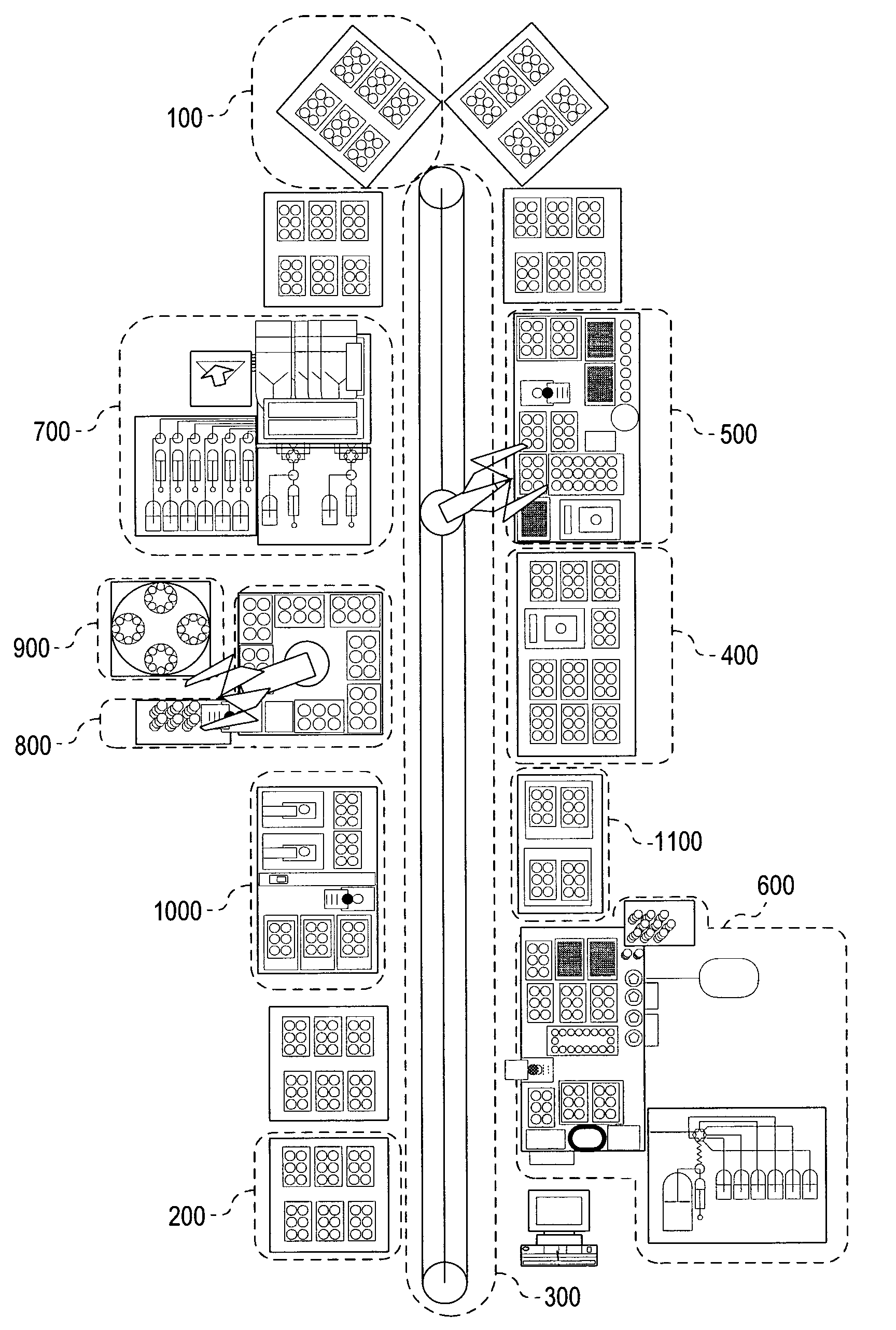

Preparation and characterization of formulations in a high throughput mode

ActiveUS7501094B2Improve throughputFormula flexibleLibrary tagsFlow propertiesSoftware systemAdditive ingredient

The invention is an automated robotic system for the production and testing of formulations at a very high throughput. It is an integrated system of hardware and software capable of preparing and evaluating hundreds of emulsions per day. The system can formulate aqueous solutions (SL), oil in water emulsions (EW), suspo-emulsions (SE), micro capsule suspensions (CS), micro-emulsions (ME), and suspension concentrates (SC) at the 1 ml to 25 ml scale. The system can process emulsions rapidly in an automated way and enable very flexible formulation recipes to be introduced.The system allows chemists to generate experimental samples of varying recipe and method to be conducted in parallel with projected throughput of up to 1200 formulations processed and characterized per day. Materials and consumables can be distributed from storage storage systems to the work stations where dispensing of ingredients in various states can be performed, including solids, liquids, gels, pastes, suspensions and waxes. The emulsions formed can be characterized using methods including phase diagnosis, turbidity analysis, viscosity and particle sizing using automated test equipment. An integrated module can also perform Tank Mix Compatibility testing in high throughput mode. The modular system allows future processes and tests to be added, either to a station, or as a new station. The software capability includes tracking of processes from start to finish and the integration of analytical data with the as-designed and as-formulated experimental results.

Owner:SYNGENTA LTD

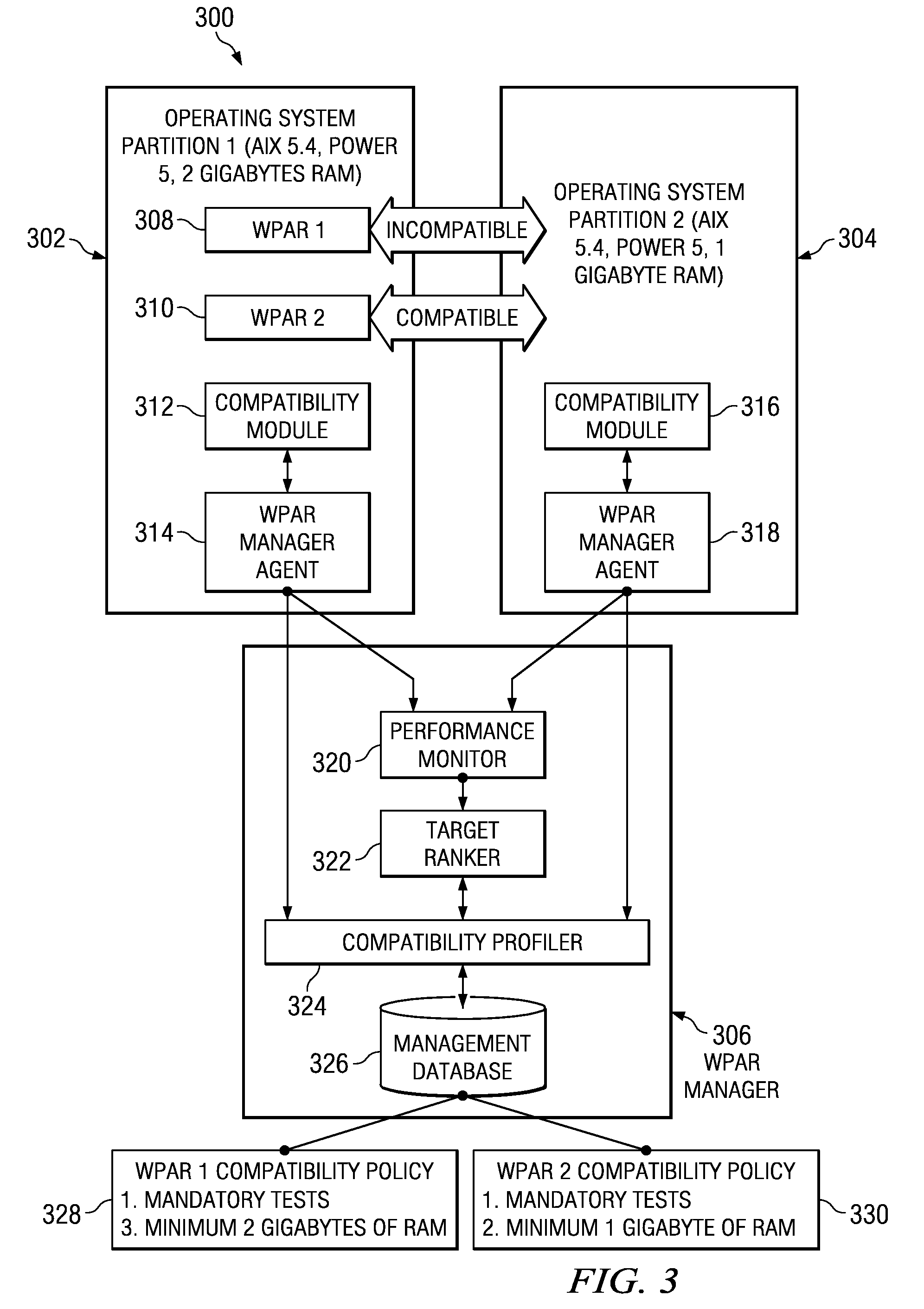

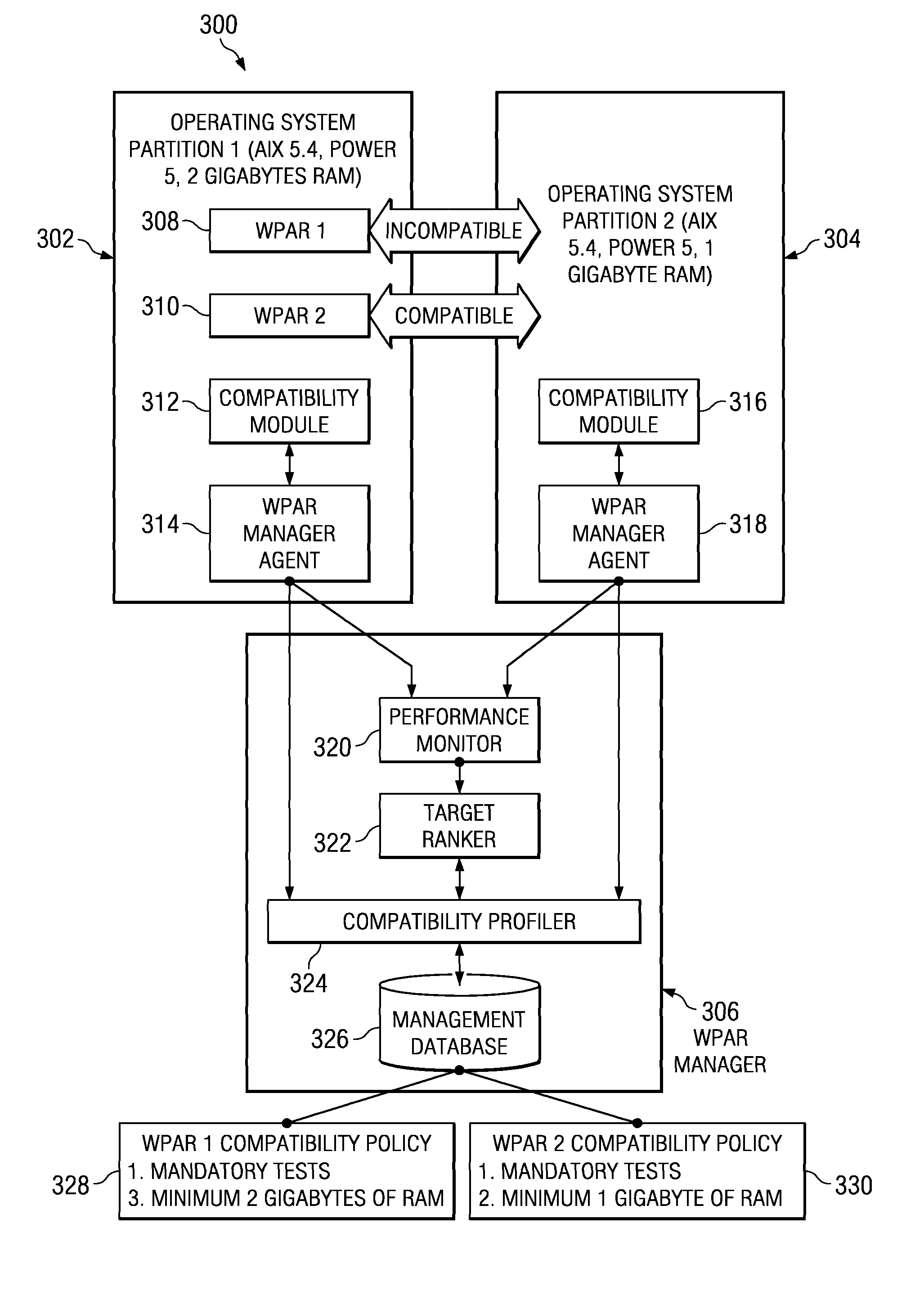

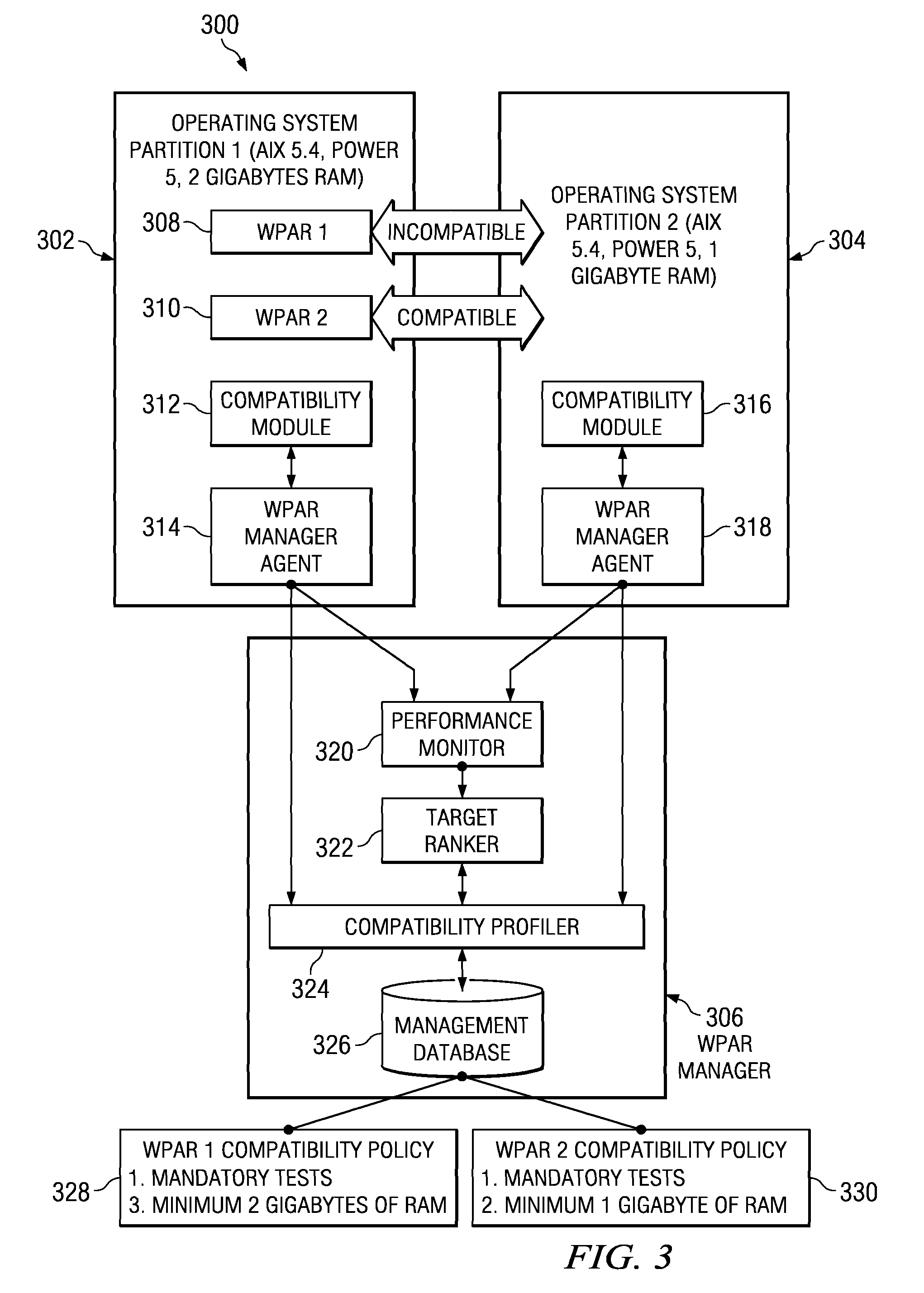

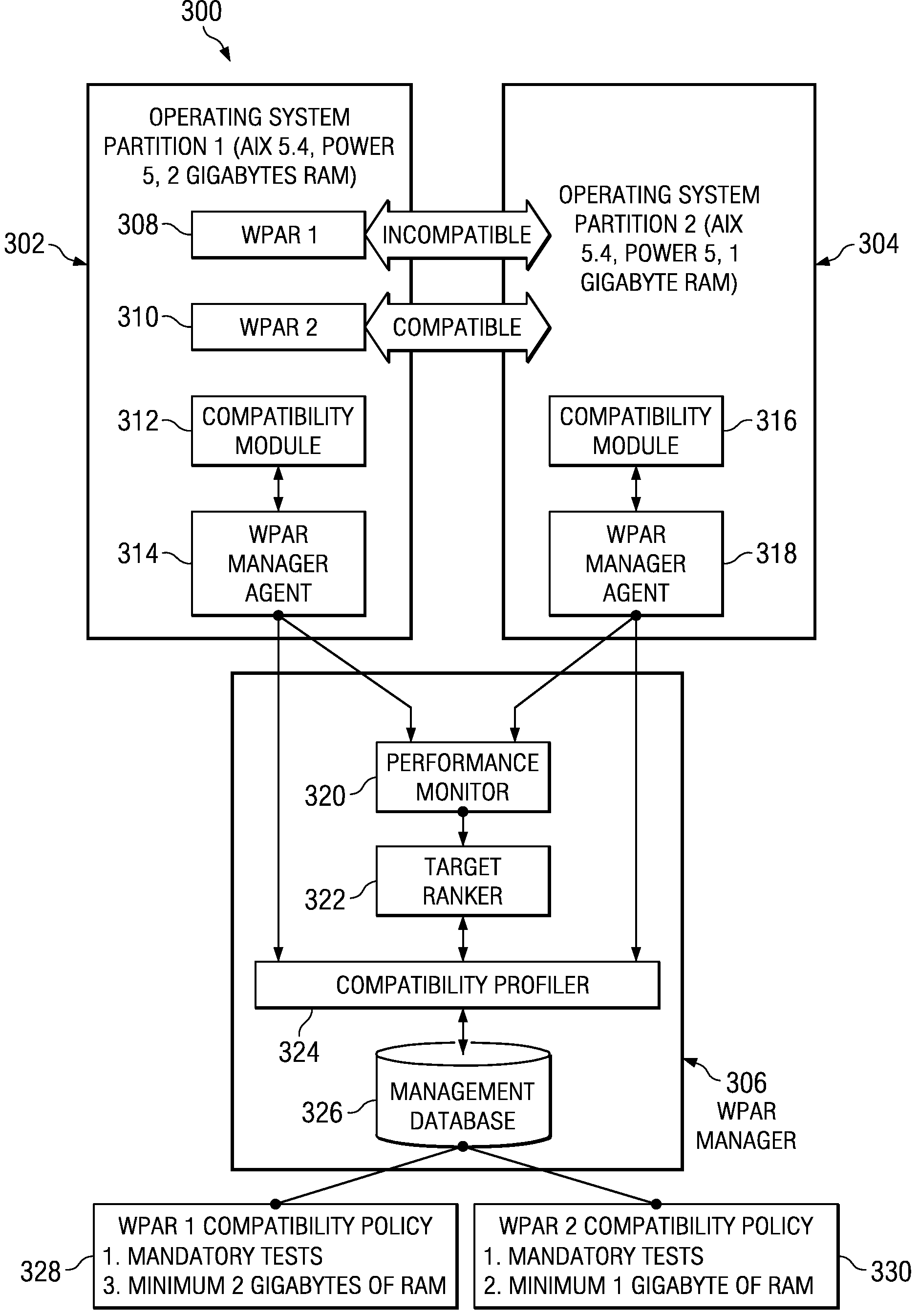

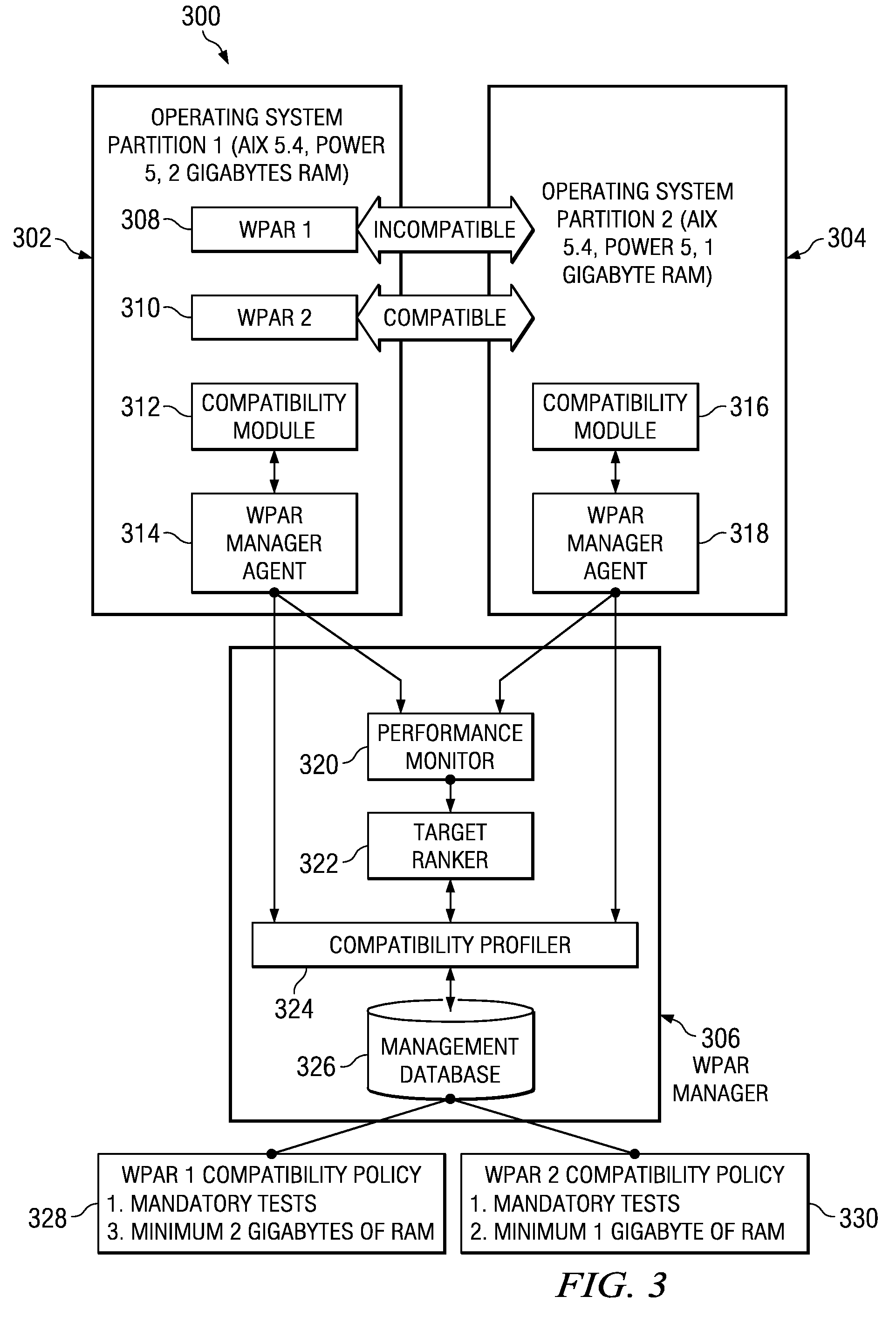

Method and apparatus to determine hardware and software compatibility related to mobility of virtual servers

ActiveUS20080235388A1Multiple digital computer combinationsProgram controlComputer hardwareComputer compatibility

A method and system for determining hardware and software compatibility related to mobility of virtual servers. Upon receiving an inventory of properties of a managed server which are relevant for compatibility testing, mandatory and optional properties available for use in a compatibility policy for a WPAR instance running on the managed server are defined. Mandatory compatibility tests are selected based on the mandatory properties in the compatibility policy for the WPAR instance. Optional compatibility tests are selected based on the optional properties in the compatibility policy for the WPAR instance. The selected mandatory and optional compatibility tests are associated with the compatibility policy, wherein the selected tests are executed to compare a profile of a potential target system with the WPAR instance and to determine compatibility of the potential target system with the WPAR instance prior to performing a mobility operation of the WPAR instance.

Owner:IBM CORP

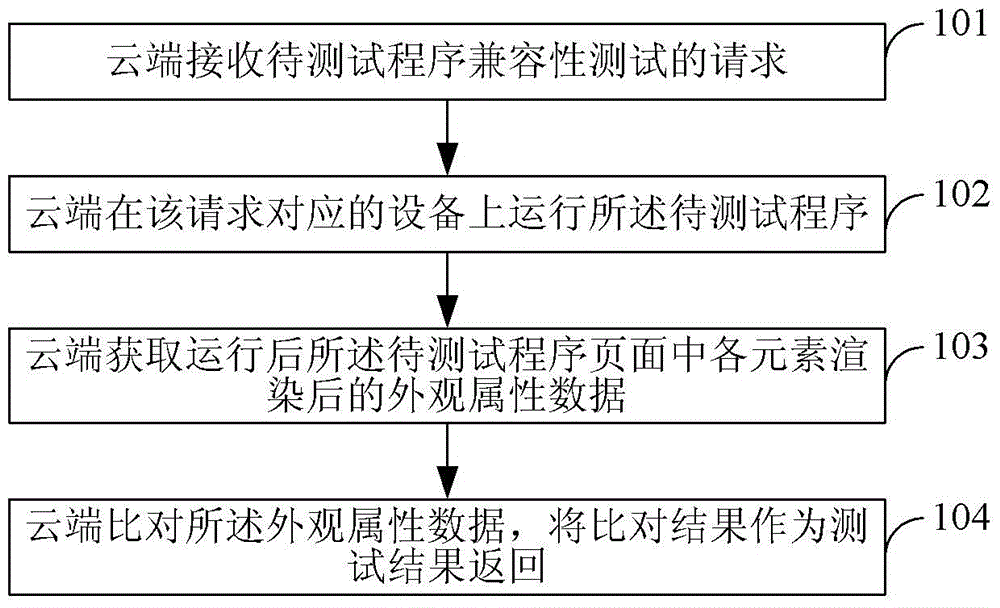

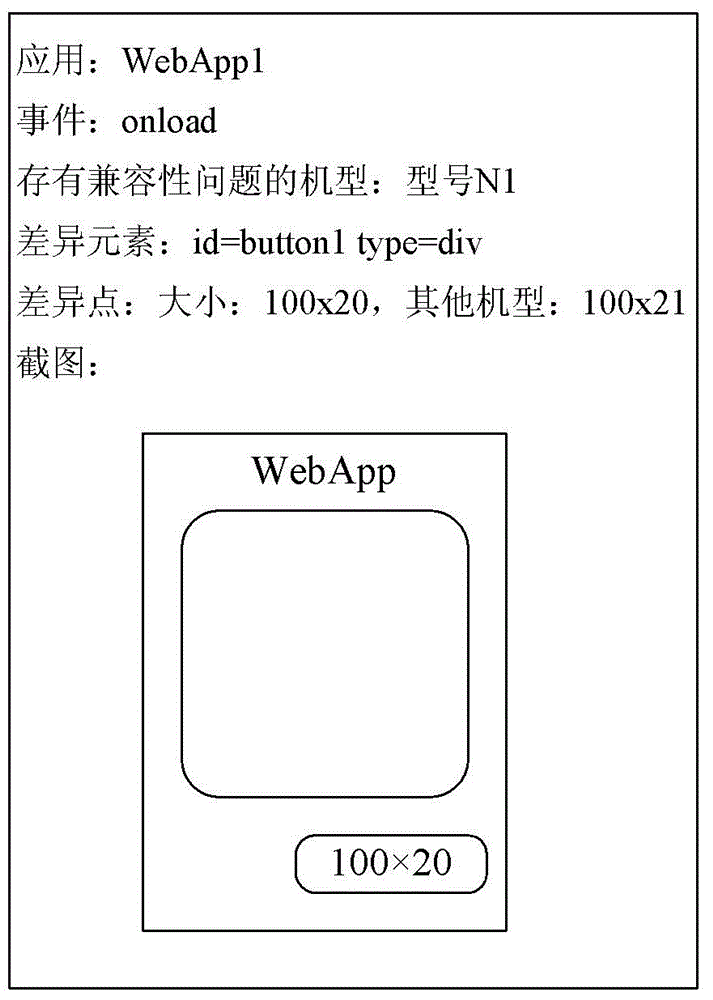

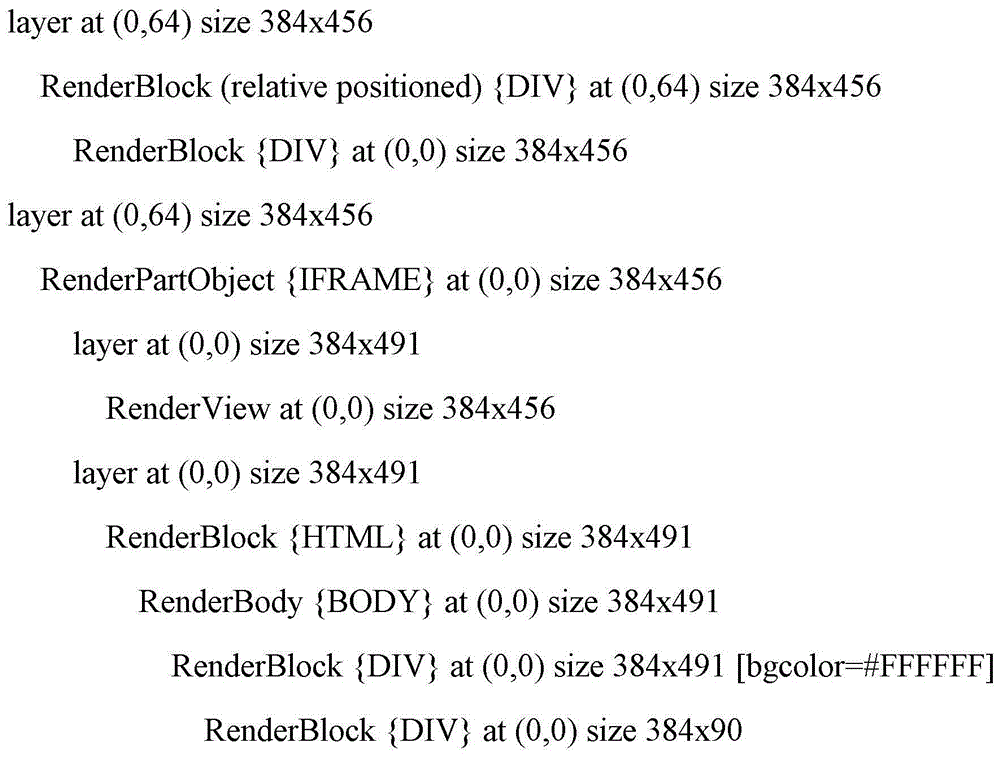

Compatibility testing method and system

InactiveCN104424093AImprove efficiencyHigh frequencySoftware testing/debuggingComputer hardwareComputer compatibility

The invention discloses a compatibility testing method and device. The compatibility testing method includes that a cloud end receives a compatibility test request from a program to be tested; the cloud end runs the program to be tested in equipment corresponding to the request; the cloud end acquires the rendered appearance attribute data of each element in the page of the program to be tested after running the program to be tested; the cloud end compares the appearance attribute data and returns the comparison result, wherein the comparison result is the test result. The compatibility testing method and device are capable of effectively and precisely testing the compatibility.

Owner:ALIBABA GRP HLDG LTD

Method and apparatus to determine hardware and software compatibility related to mobility of virtual servers

A method and system for determining hardware and software compatibility related to mobility of virtual servers. Upon receiving an inventory of properties of a managed server which are relevant for compatibility testing, mandatory and optional properties available for use in a compatibility policy for a WPAR instance running on the managed server are defined. Mandatory compatibility tests are selected based on the mandatory properties in the compatibility policy for the WPAR instance. Optional compatibility tests are selected based on the optional properties in the compatibility policy for the WPAR instance. The selected mandatory and optional compatibility tests are associated with the compatibility policy, wherein the selected tests are executed to compare a profile of a potential target system with the WPAR instance and to determine compatibility of the potential target system with the WPAR instance prior to performing a mobility operation of the WPAR instance.

Owner:INT BUSINESS MASCH CORP

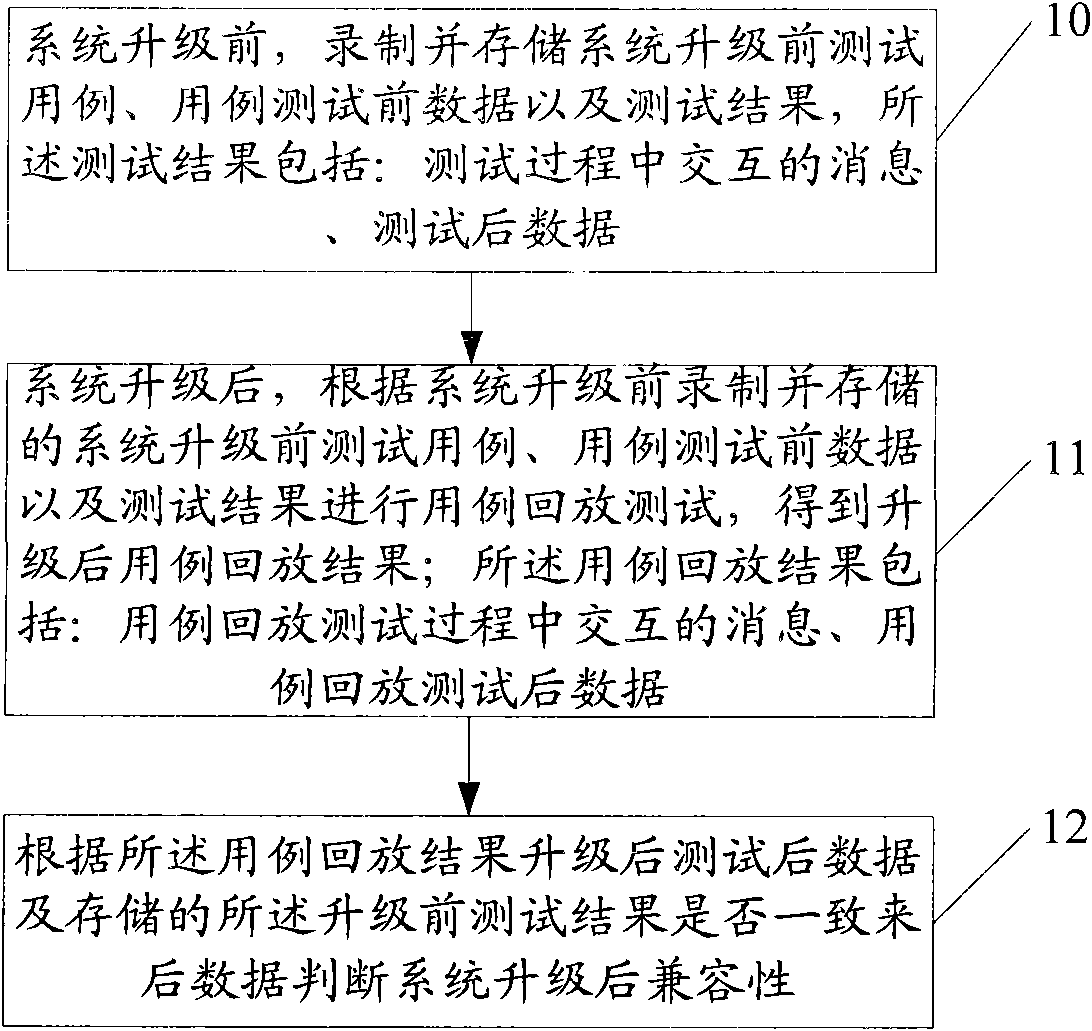

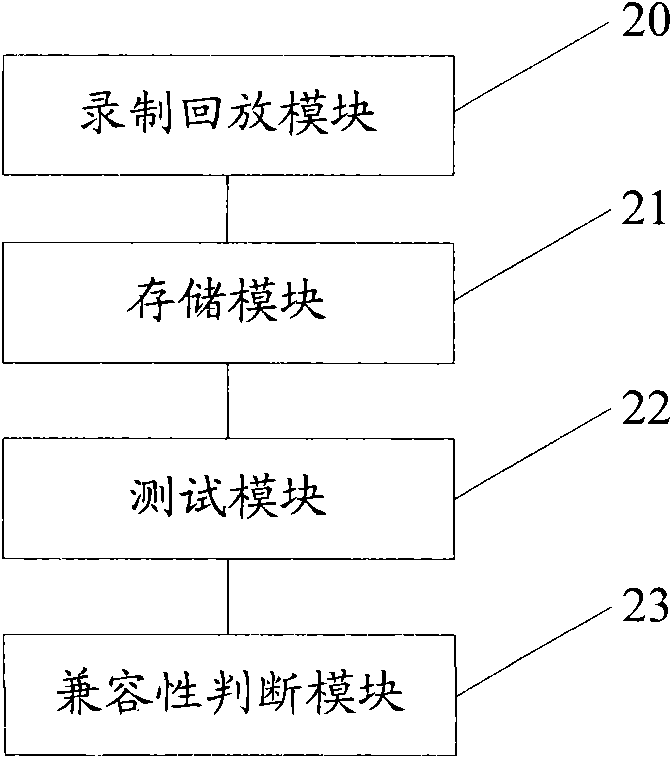

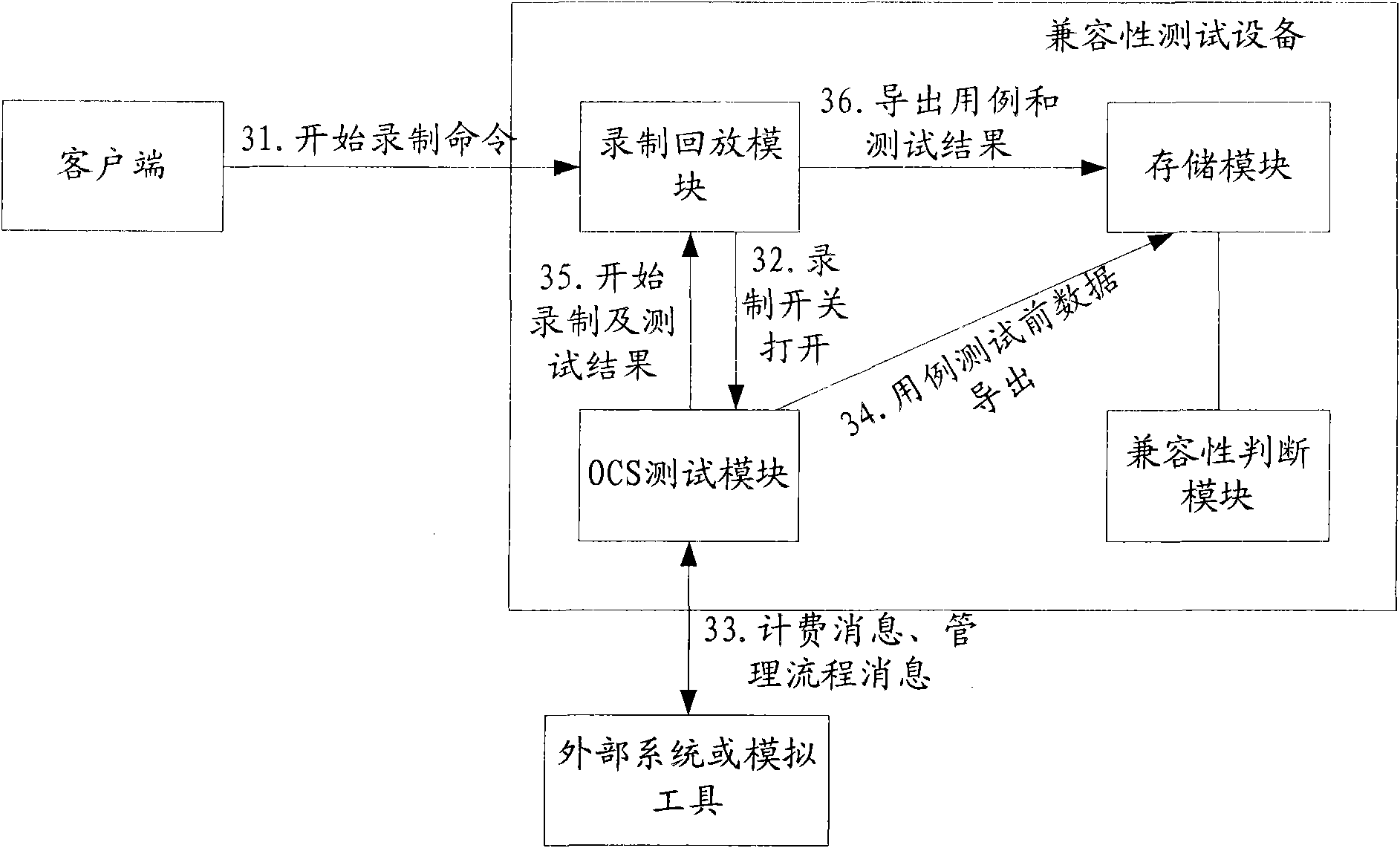

Method and equipment for testing compatibility after upgrading of system

ActiveCN102045191AGuaranteed randomnessGuaranteed complexityData switching networksTest efficiencyComputer compatibility

The embodiment of the invention relates to a method and equipment for testing compatibility after upgrading of a system. The method comprises the following steps of: before the system is upgraded, recording and storing a test case before upgrading of the system, date before testing of a use case, and a test result; after the system is upgraded, performing use case playback testing according to the test case before upgrading of the system, the date before testing of the use case, and the test result which are recorded and stored before the system is upgraded to obtain a use case playback result after upgrading; and judging the compatibility after upgrading of the system according to the consistency between the use case playback result and the recorded and stored test result. In the invention, various test scenes before upgrading of the system are recoded and are played back after upgrading, data is not needed to be constructed in advance, randomness and complexity of the use case can be guaranteed, the automation degree of a test is improved, and the test efficiency is effectively improved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

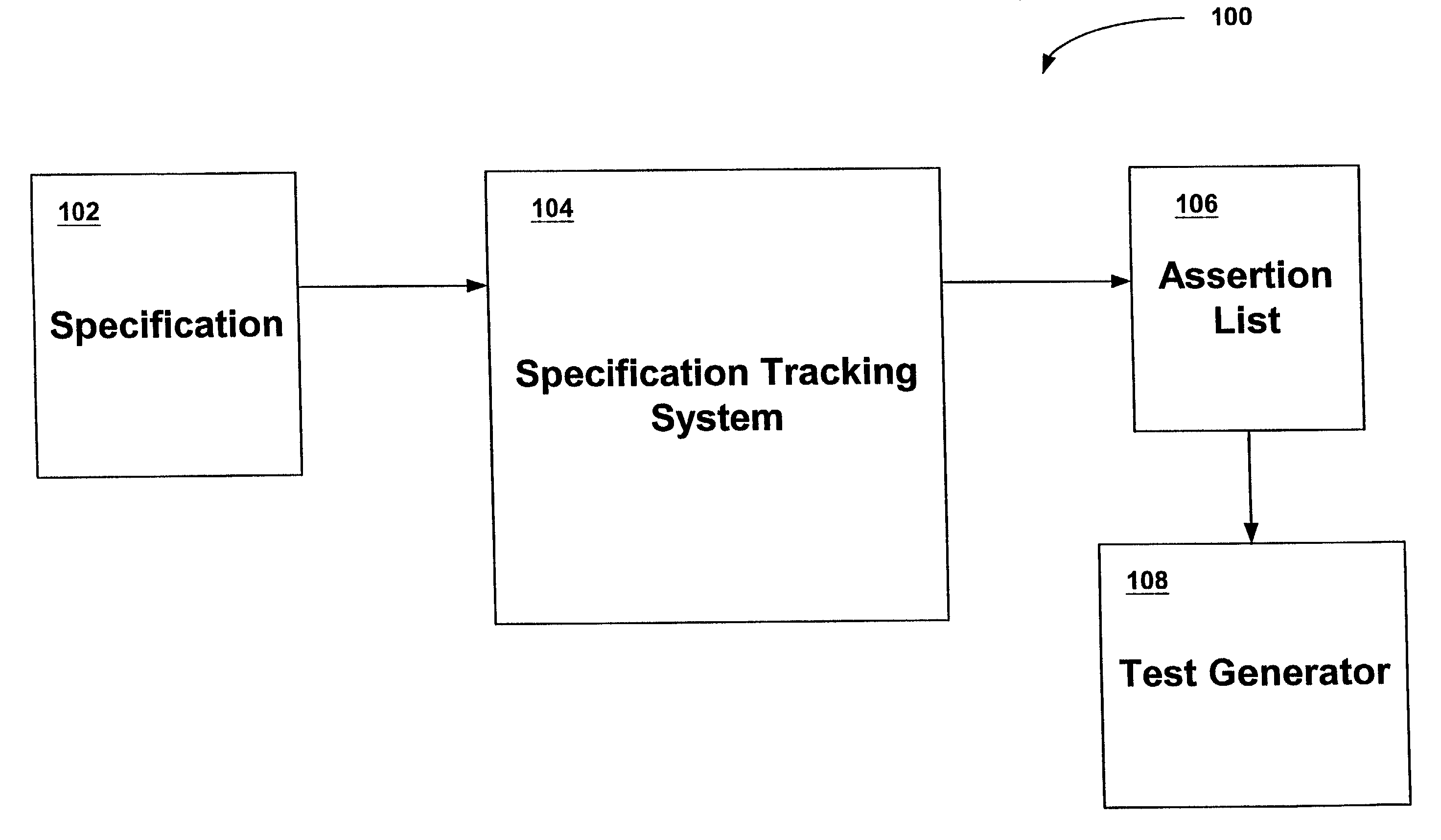

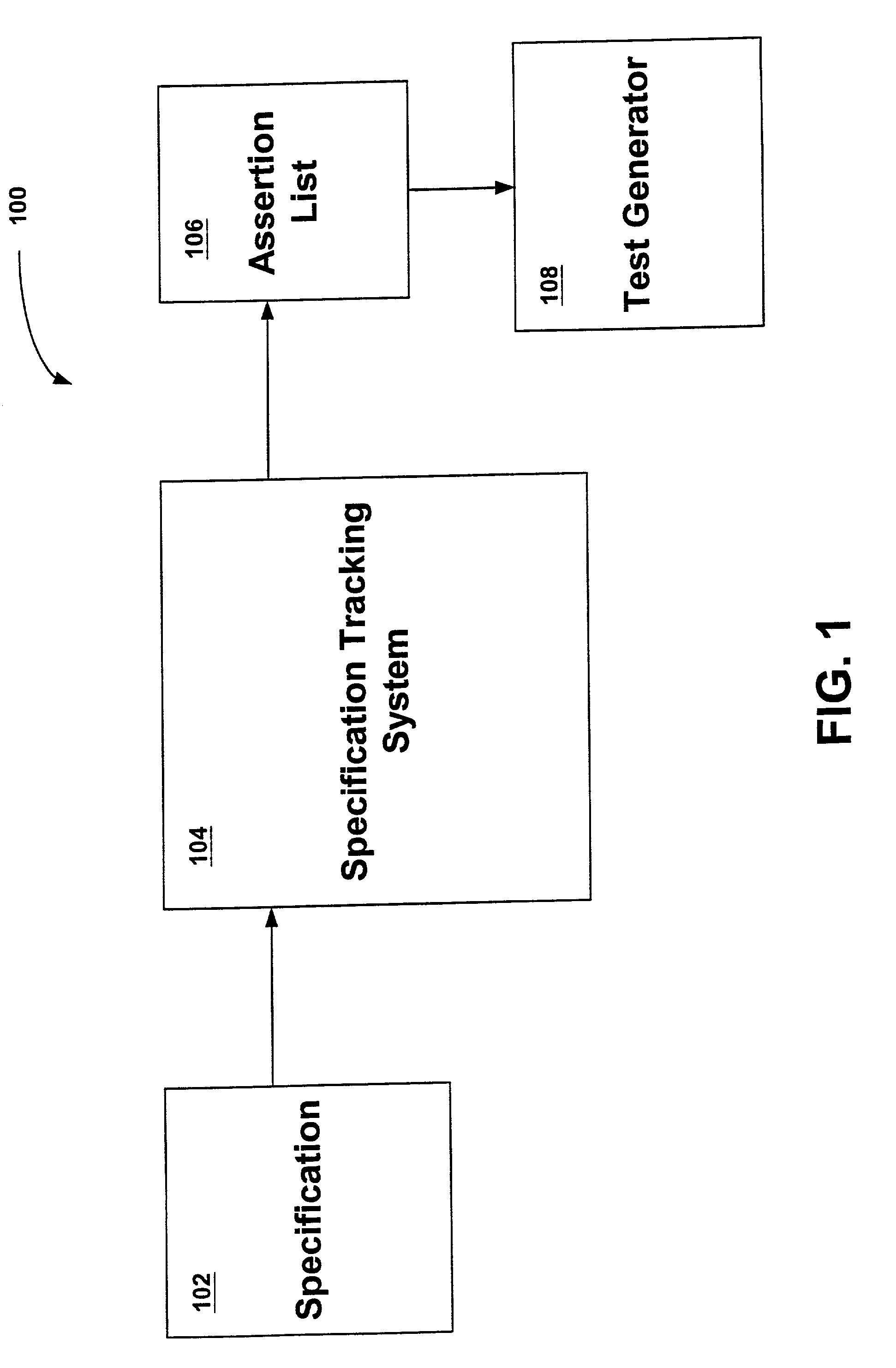

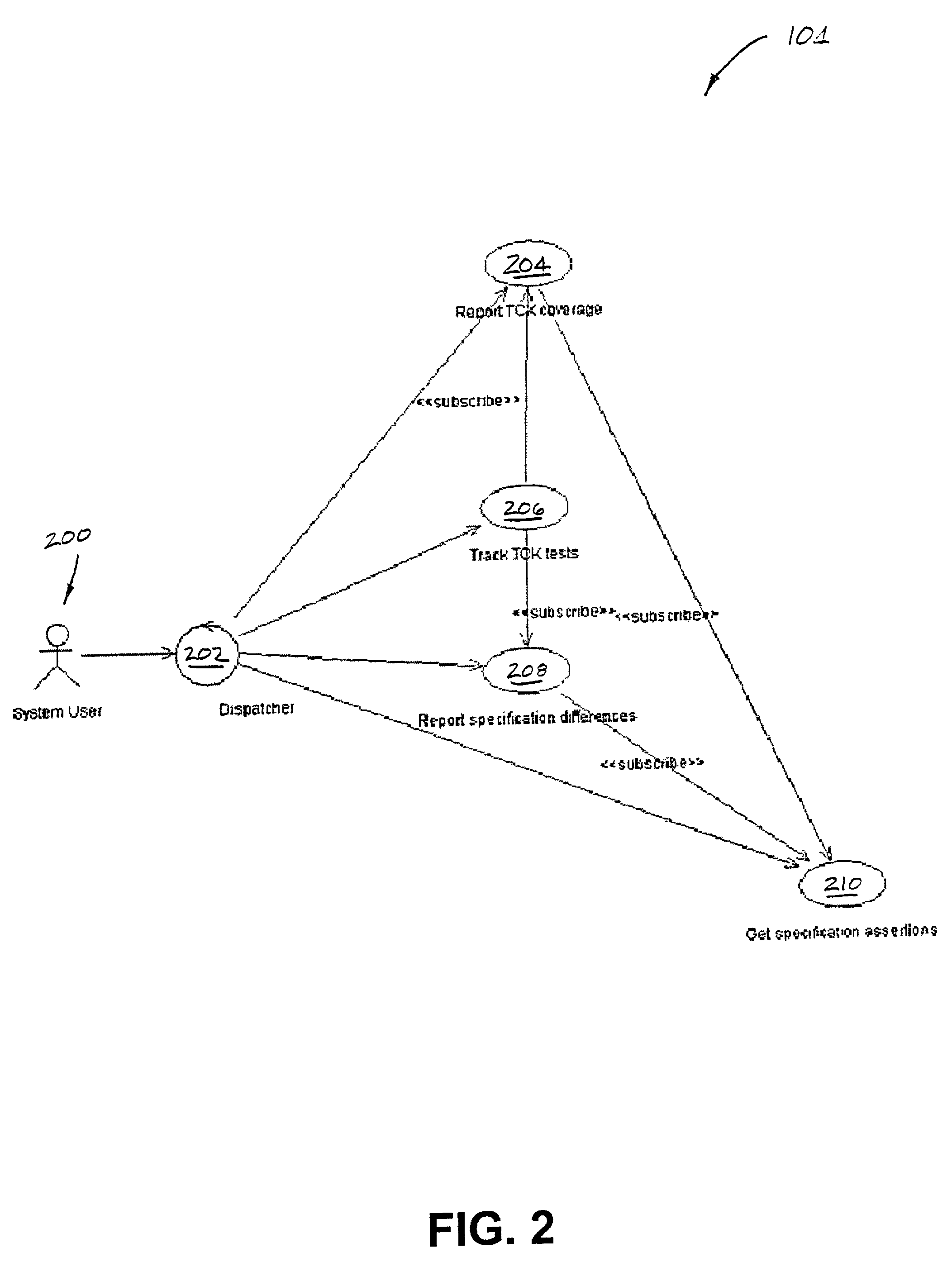

System and method for specification tracking in a Java compatibility testing environment

InactiveUS7243090B2Improve performanceReduce human errorData processing applicationsDigital data processing detailsComputer compatibilityProgram specification

An invention is disclosed for collecting information on a specification of a computer program. A plurality of classes is provided, where each class is capable of performing a particular task related to obtaining information from a specification. Then a command is received from a user. The command requests a particular task to be performed. A class is then selected from the plurality of classes based on the task requested by the received command, and the selected class is run. In this manner, information on the specification is obtained. The plurality of classes can include a get assertion class that obtains assertions from the specification, and a reporting class that provides information on test coverage of the specification.

Owner:ORACLE INT CORP

Continuous Delivery and Automated Testing Integration Software Quality Assurance Approach

InactiveCN109344080AConvenience Test PlanReduce complexitySoftware testing/debuggingPlatform integrity maintainanceTest efficiencyContinuous integration

The invention discloses a software quality assurance method integrating continuous delivery and automated test, The method provides users with the function of individually customizing the software quality detection pipeline, which is composed of source code configuration, static code scanning, continuous construction, continuous deployment, functional testing, performance testing, compatibility testing and dynamic security testing. By using the software quality assurance system, Testers do not need to build a complex continuous integration and testing environment, and can quickly implement automated testing of each dimension of a project, or predefine a software quality inspection pipeline for automated testing, and provide the overall test results of the entire project, which greatly improves the test efficiency and reduces the complexity of test configuration.

Owner:JIANGSU ELECTRIC POWER INFORMATION TECH +1

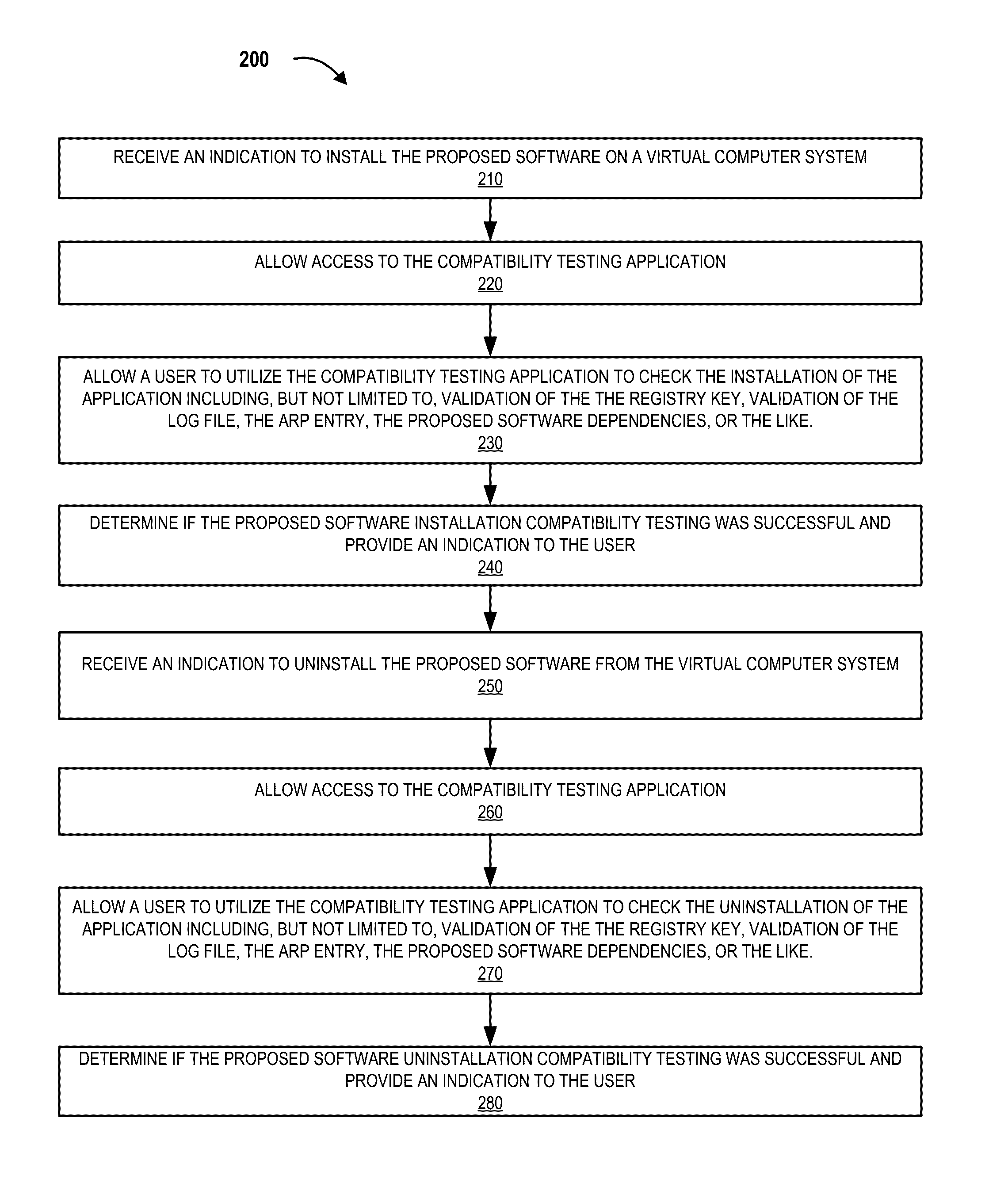

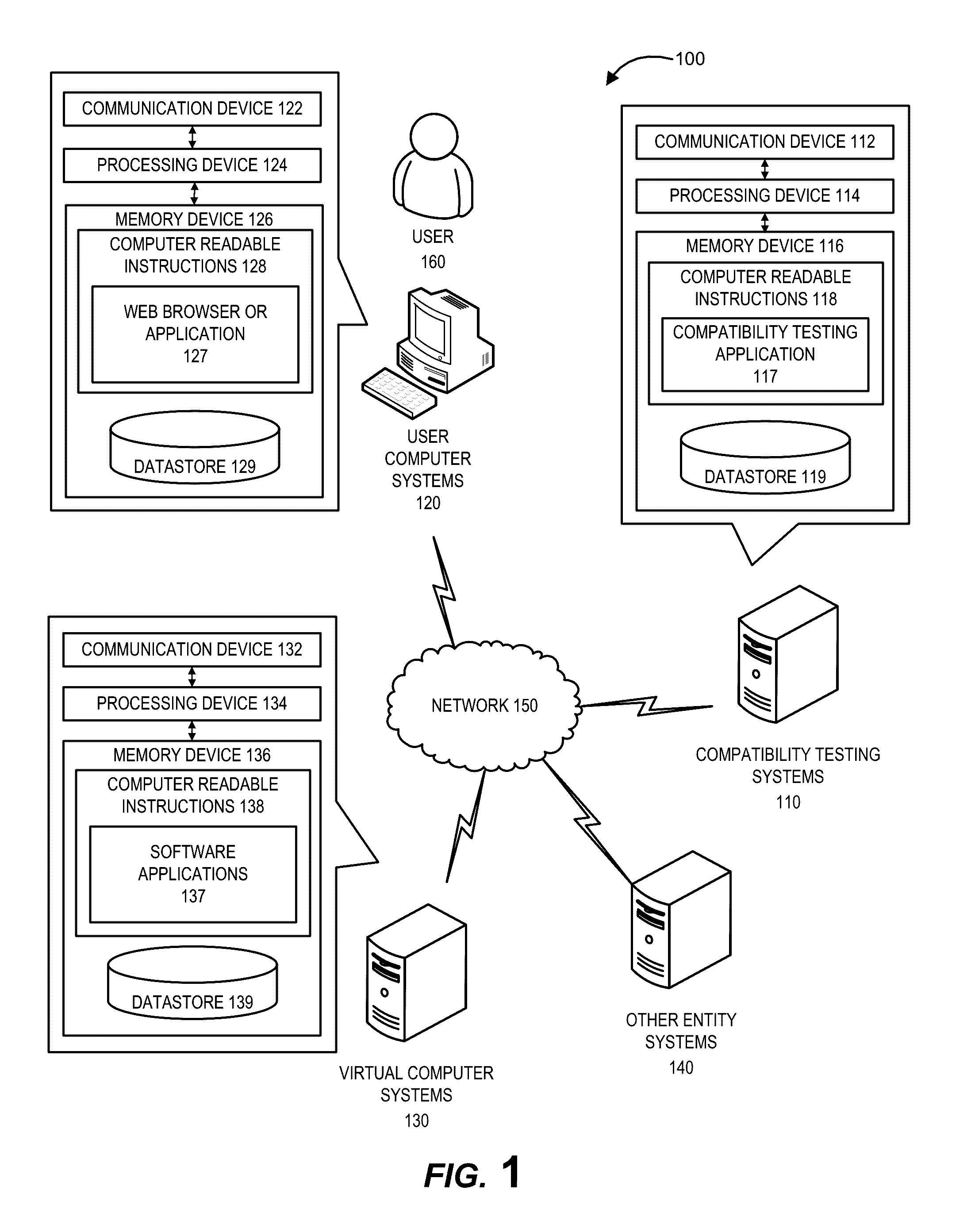

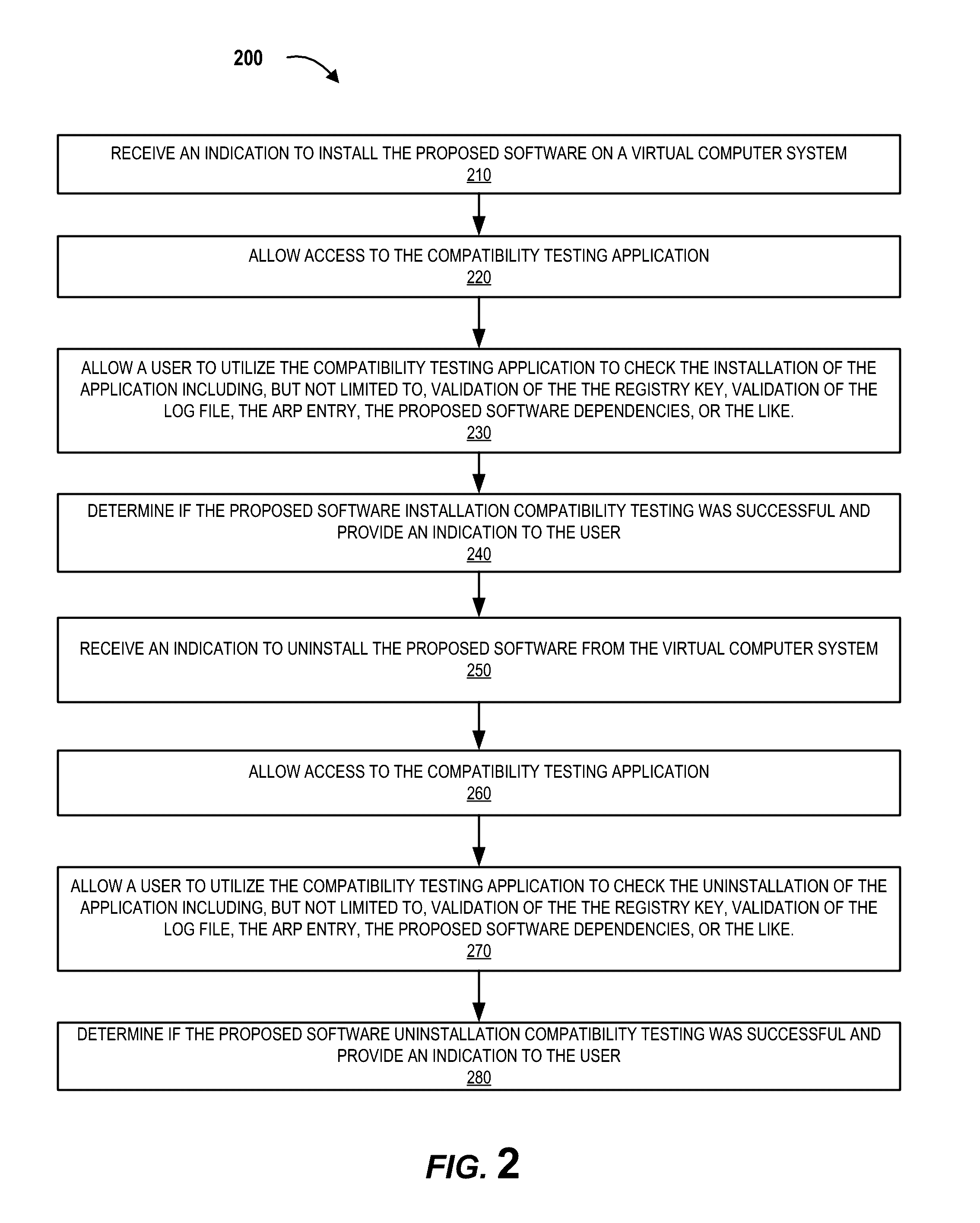

Software and associated hardware regression and compatiblity testing system

The present disclosure describes testing regression and compatibility of software and associated hardware. Embodiments herein disclosed receive an indication from a user to test the regression and the compatibility of proposed software; access software files related to installation of the proposed software; present a verification interface to the user, wherein the verification interface includes various validation functions for validating entries created or updated along with the proposed software being installed or uninstalled, such as a registry entry, a log file entry, an Add or Remove Programs entry, and the like, wherein when each of the validation functions is selected, the system automatically determines if the corresponding entry for installation or uninstallation of the proposed software is successful. Embodiments herein disclosed further receive an indication from the user for selection of the validation functions and present to the user an indication of success of the validation of the entries.

Owner:BANK OF AMERICA CORP

Method and device for testing peripheral compatibility of electronic device

ActiveCN103530226AShorten the timeSave on mistakesSoftware testing/debuggingSpecific testTest efficiency

The invention provides a method and a device for testing the peripheral compatibility of an electronic device. Newest or specific test program is automatically inquired from the server side through the electronic device side and automatically installed, test reports are automatically submitted after an electronic device finishes testing, then the server side classifies, memorizes backs up received reports according to types, and meanwhile all of types of intuitive test reports are generated. Furthermore, the time for manual installation of the test program is saved, the error occurrence probability is reduced, and meanwhile the testing efficiency is improved. In addition, intuitive reports are generated by analyzing test results, and analysis of developers is facilitated.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

Policy algorithm for selection of compatible systems for virtual server mobility

A method and system for selecting compatible systems for virtual server mobility. Responsive to determining a current location of a workload partition instance running on a managed server, mandatory compatibility tests specified in a compatibility policy associated with the workload partition instance are executed to compare properties of the managed server with properties of potential target systems. A list of potential target systems is generated that have passed the mandatory compatibility tests specified in a compatibility policy. Optional compatibility tests specified in a compatibility policy associated with the workload partition instance are executed. The potential target systems that have failed any of the optional compatibility tests are removed from the list to form a filtered list, wherein the filtered list comprises a list of potential target systems compatible to support relocation of process collections within the workload partition instance.

Owner:IBM CORP

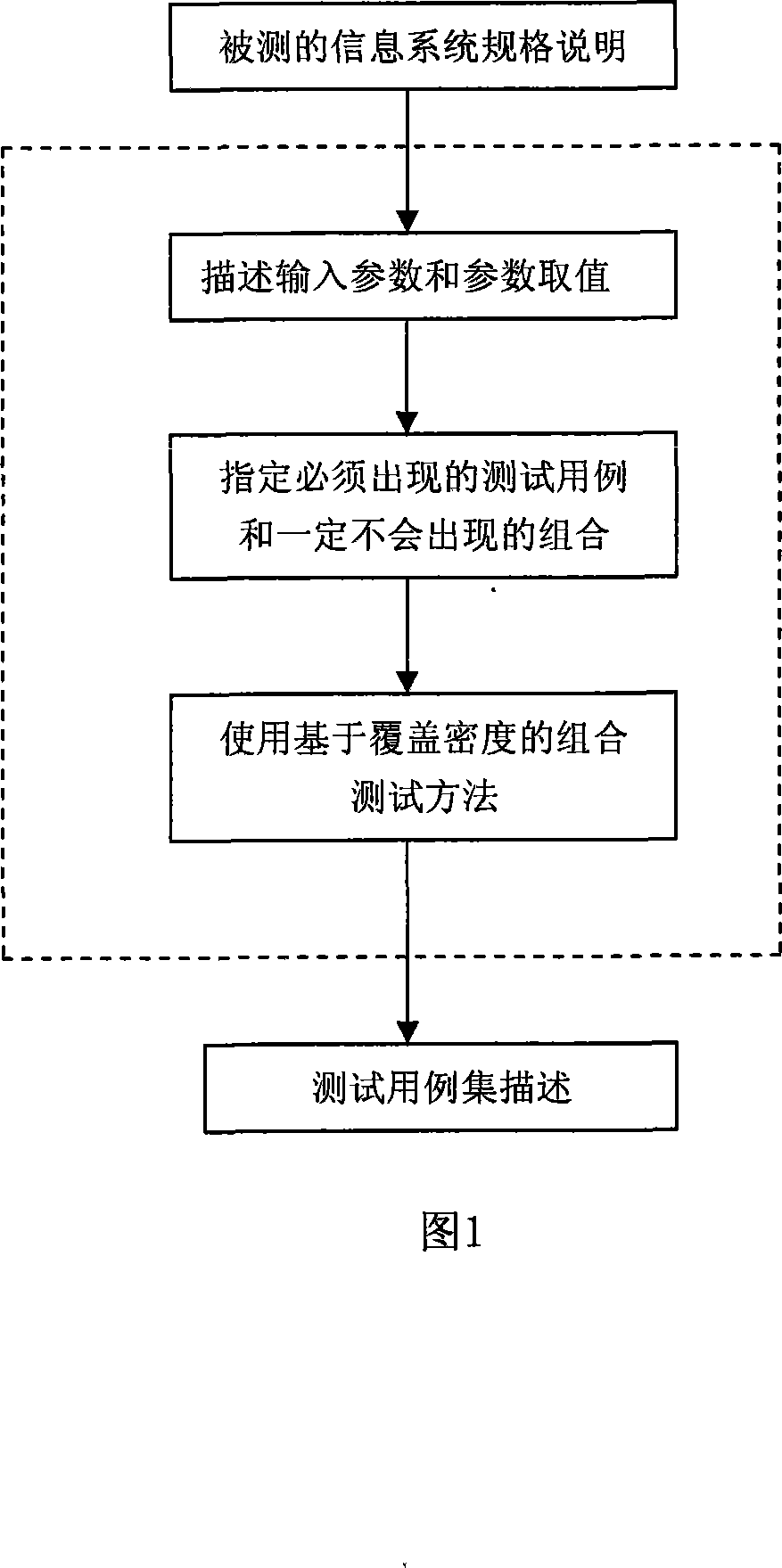

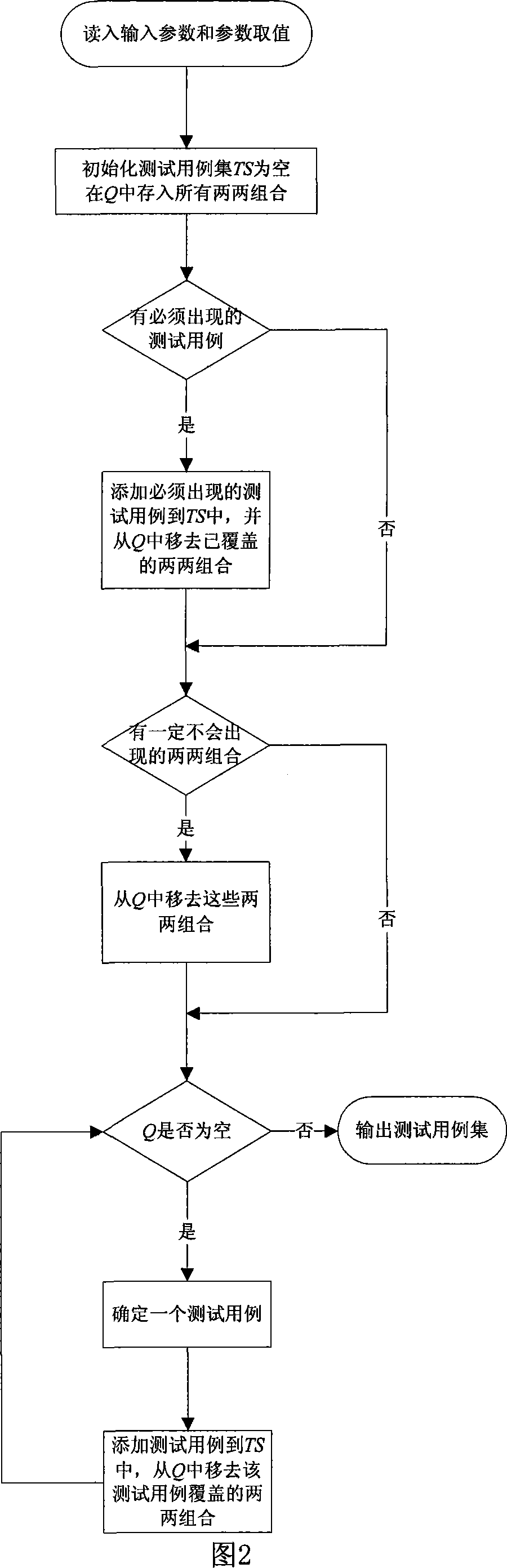

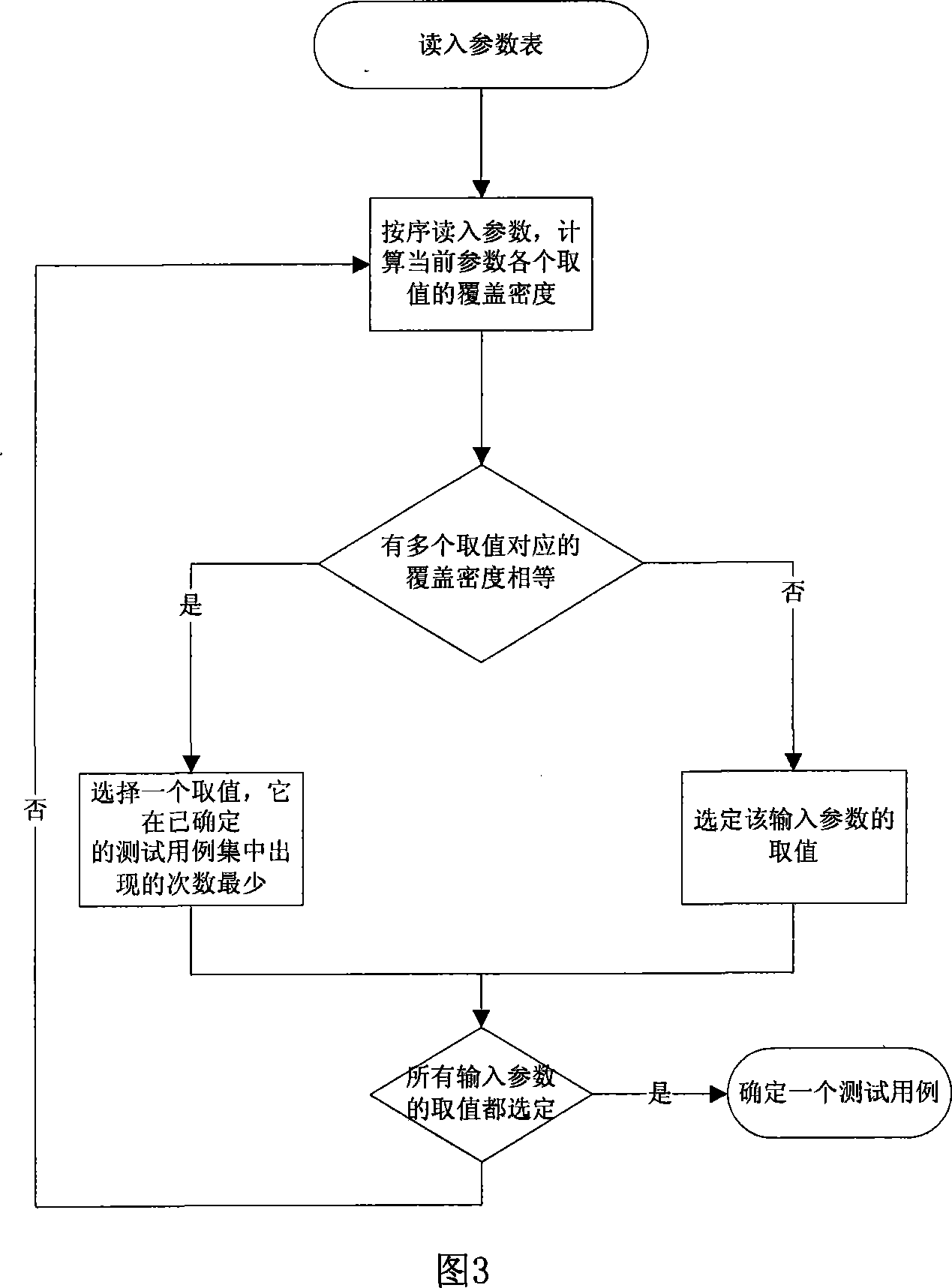

Information systems test combination generation method based on coverage density

InactiveCN101236494AImprove efficiencyCalculation method is simpleSoftware testing/debuggingSpecific program execution arrangementsSystem testingProtocol testing

The present invention discloses a composite generation method based on information system testing for coverage density, which adopts a framework (as shown) that: (1) input parameters and parameter values of information system to be tested are described through XML files according to the specification of the tested system; (2) the testing use cases needed to appear and the testing use cases which cannot appear through combination in pairs are assigned; (3) the values of all the input parameters are combined one by one on the basis of coverage density so as to generate a testing use case; (4) the testing use case finally generated is expressed and output in the format of the XML files. The composite generation method can be widely applied to embedded system testing, distributed system testing, web page testing, graphical interface testing, protocol testing, configuration and compatibility testing, etc., is easy to append constraints among the parameters and consider the parameter combinations needed to be covered, is easy to consider the priority among the parameters, is simple and effective in the calculation method of coverage density, and has good expansibility.

Owner:NANJING UNIV

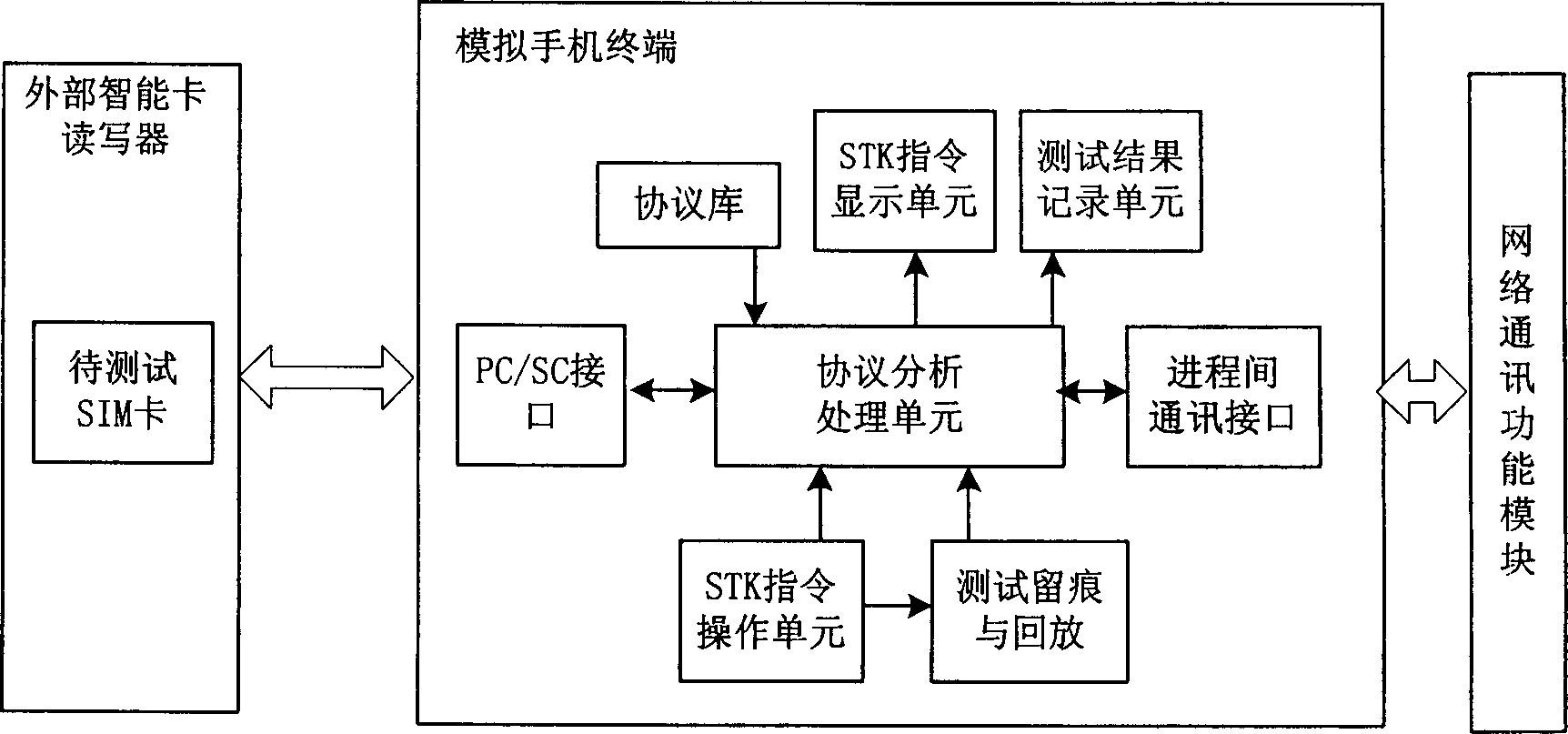

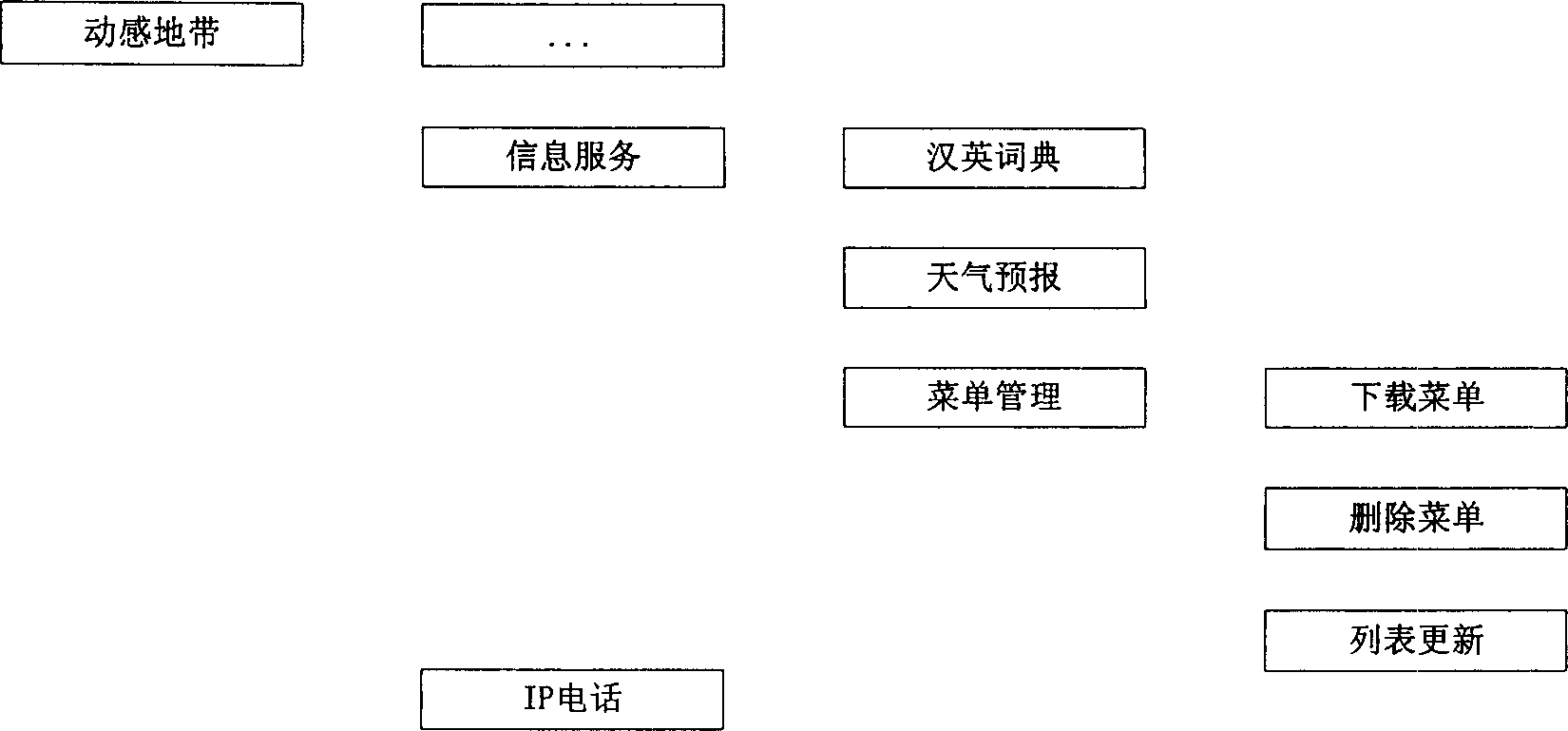

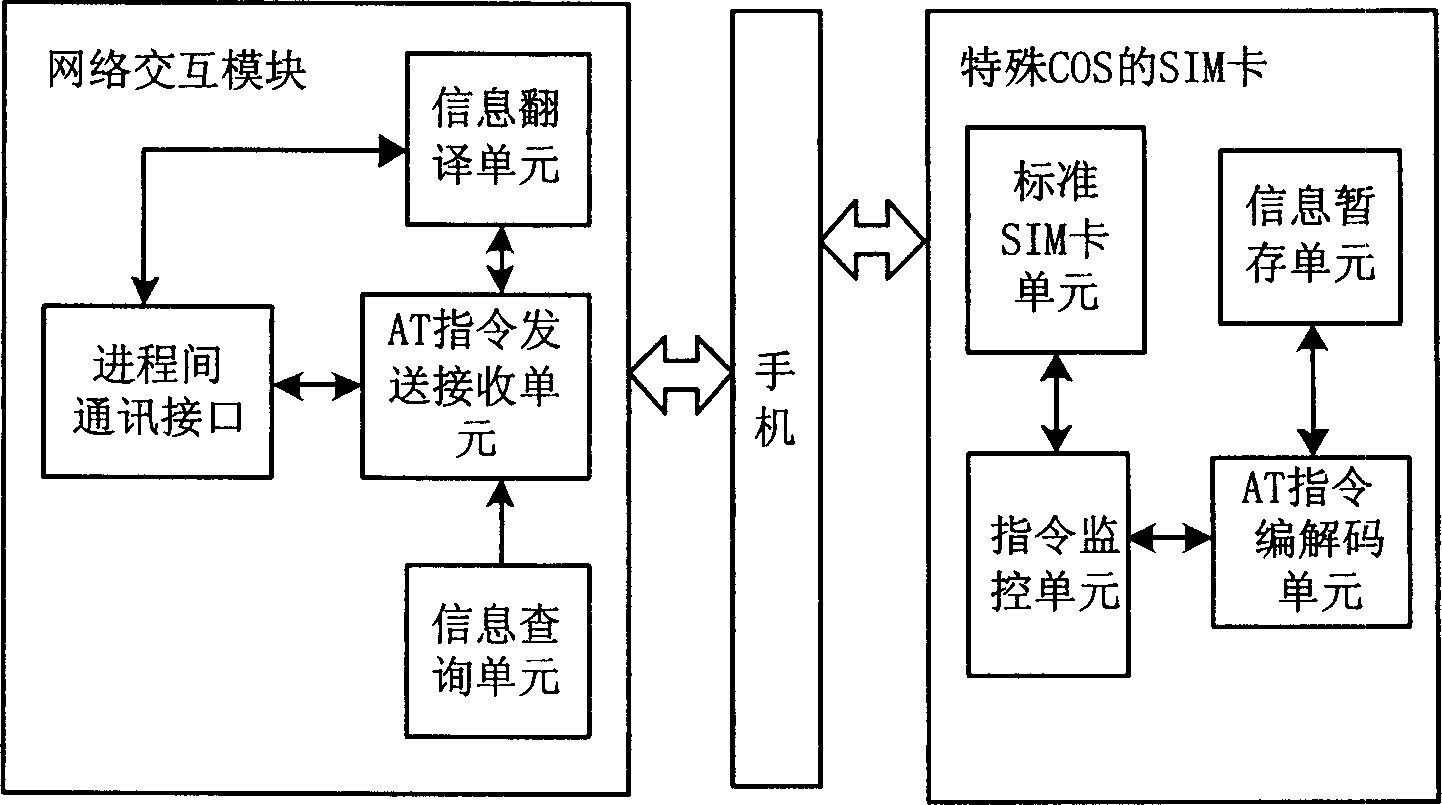

A method and system for compatibility test of subscriber identification module tool kit card

ActiveCN1633198AReduce dependencyEfficient and faster testingRadio/inductive link selection arrangementsWireless communicationComputer compatibilityNetwork communication

This invention discloses a compatibility test method for the tool external member card of user identifying module, which sets up a system containing an intelligent card read-write device, SIM / UIM cards to be tested, analog cell terminals with a standard protocol library and several-character protocol libraries against different cell phone terminals and a network communication function module. The test person operates on the menu, the system records the operation and sends the operation order to the being tested SIM card and analyzes its returned data to judge if it involves the network operation, if not, it records the content and waits for the next operation, otherwise, it sends the order to the network communication module, records the returned content and sends it to SIM card. The test person selects a new character protocol library, automatically replays the operation recordings and makes record till finishing test the compatibility to all cell phone terminals.

Owner:DATANG MICROELECTRONICS TECH CO LTD

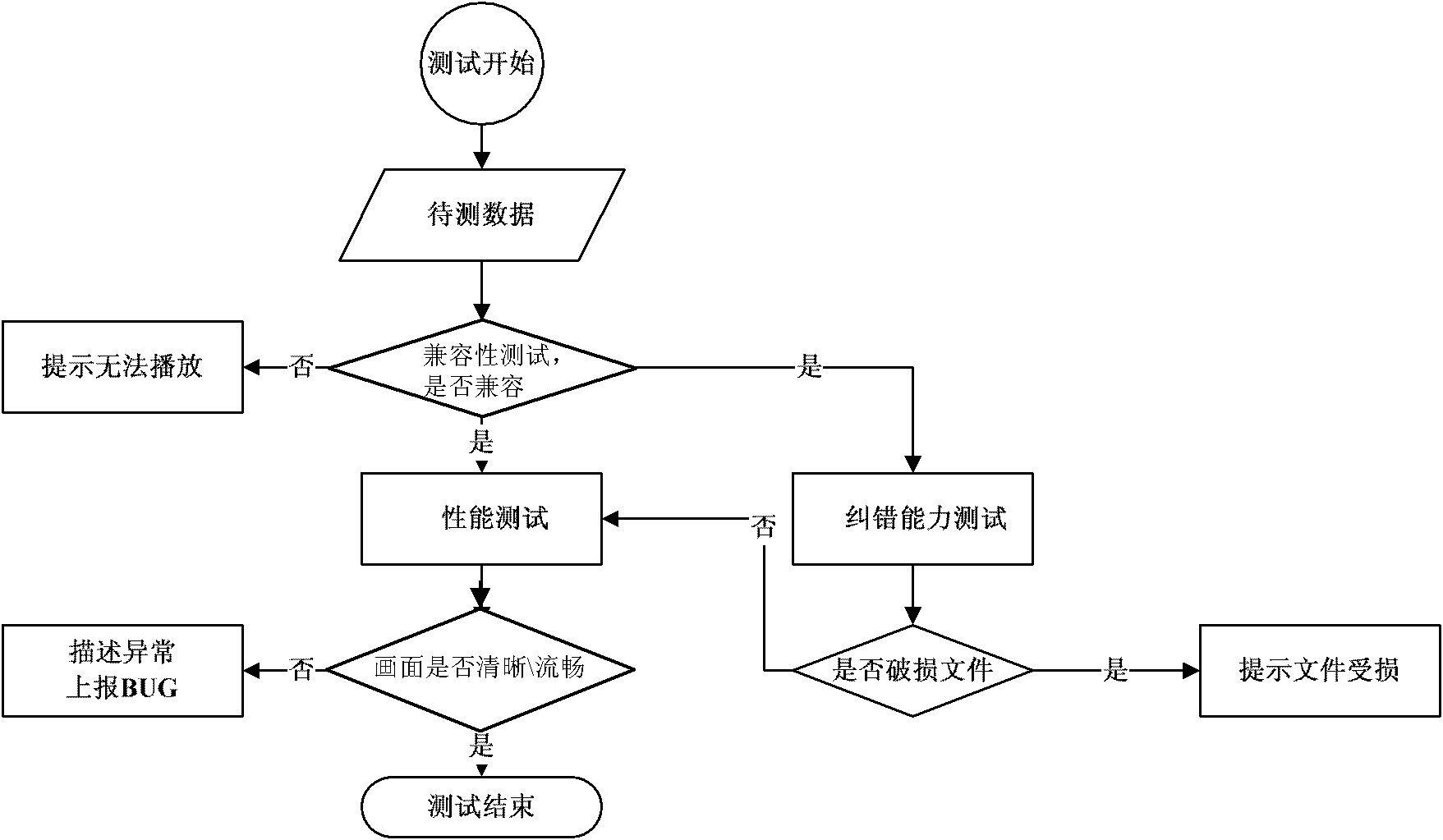

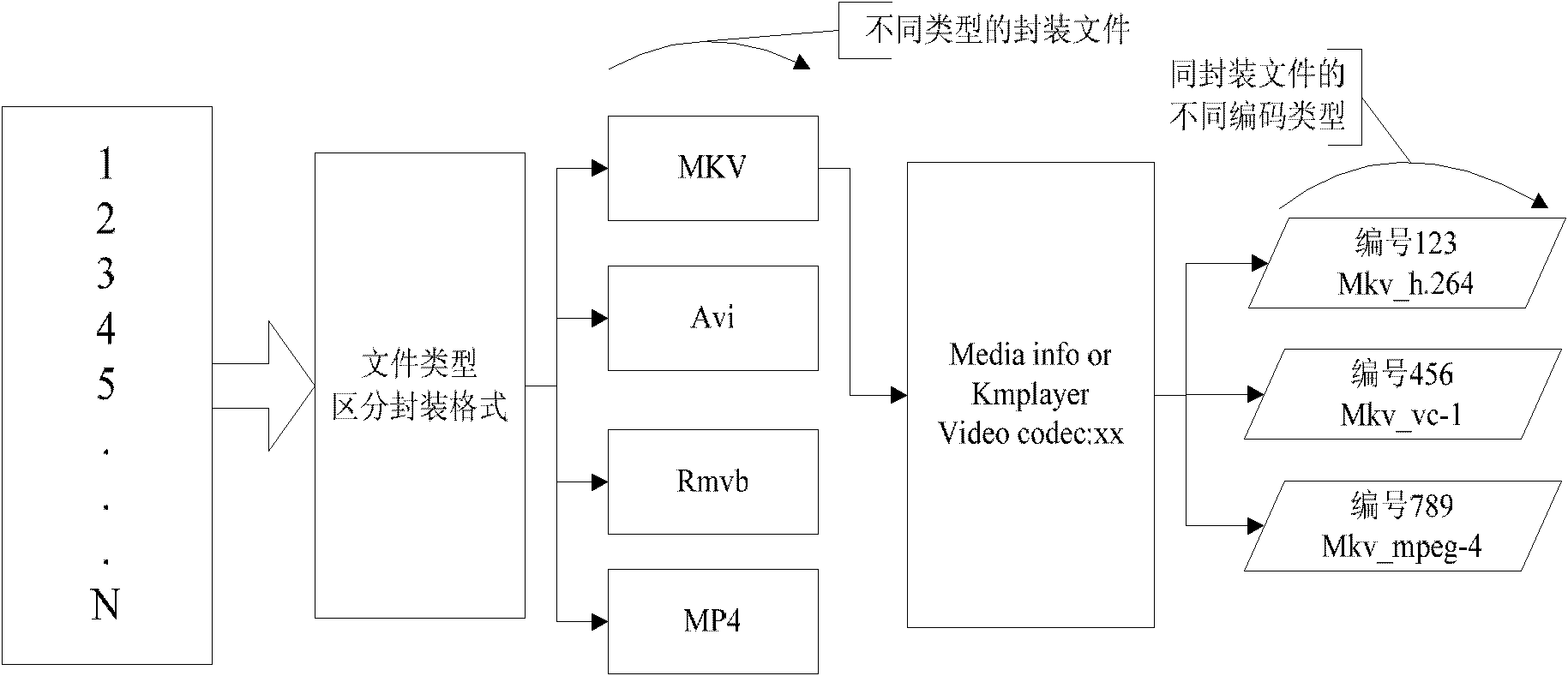

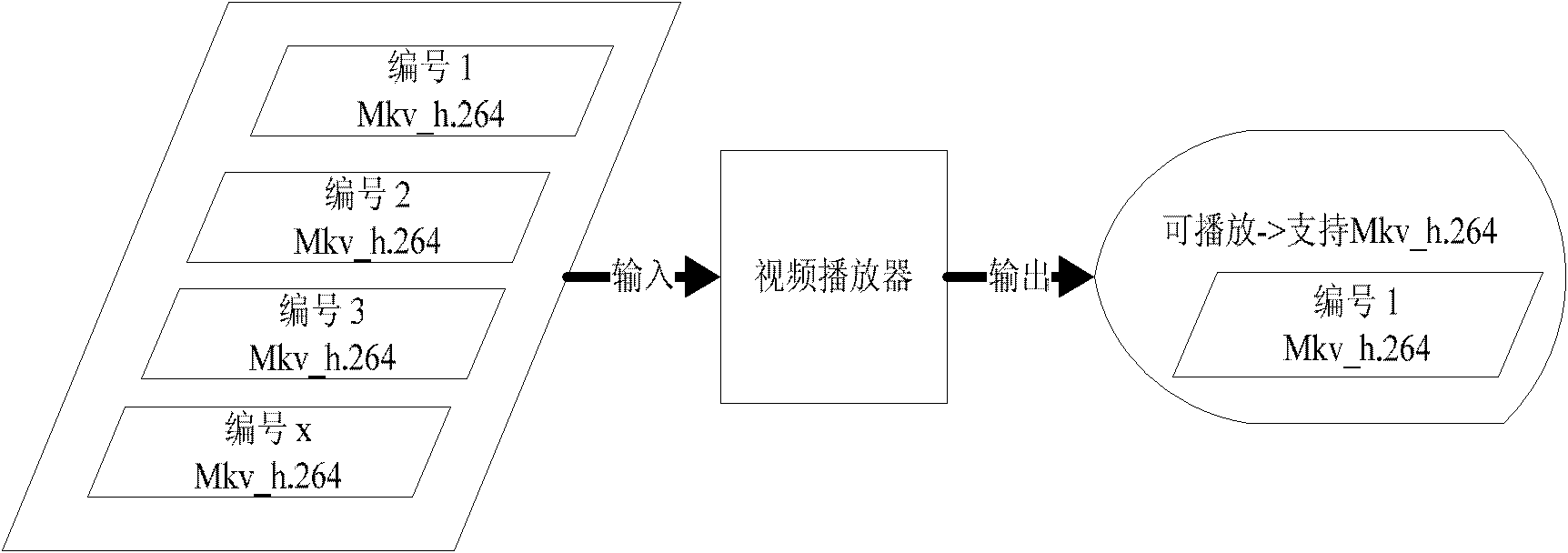

Efficient test method for video decoding

ActiveCN102026017AThe test effect is goodThe test result data is accurateTelevision systemsDigital video signal modificationVideo playerThree stage

The invention provides an efficient test method for video decoding, which is characterized by comprising three stages such as a compatibility test, a performance test and an error correcting capability test, wherein an equivalent divide method is adopted in the compatibility test: video data to be tested is classified, files of the different coding types in the same packaging files are input into a video player for playing and outputting files results corresponding to different coding types, and the results are compared; a boundary test method is adopted in the decoding performance test: the video data to be tested is collected, the collected video data is played through a video player so as to test whether the video data can be played, and is fluent and synchronous, performance assessment is carried out based on the output result; and the equivalent divide method is adopted in the error correcting capability test: the stability and error correcting capability of a player are assessed after ensuring the basic work of the video player. By the test method, the test of the video decoding is more comprehensive and convenient.

Owner:FUZHOU ROCKCHIP SEMICON

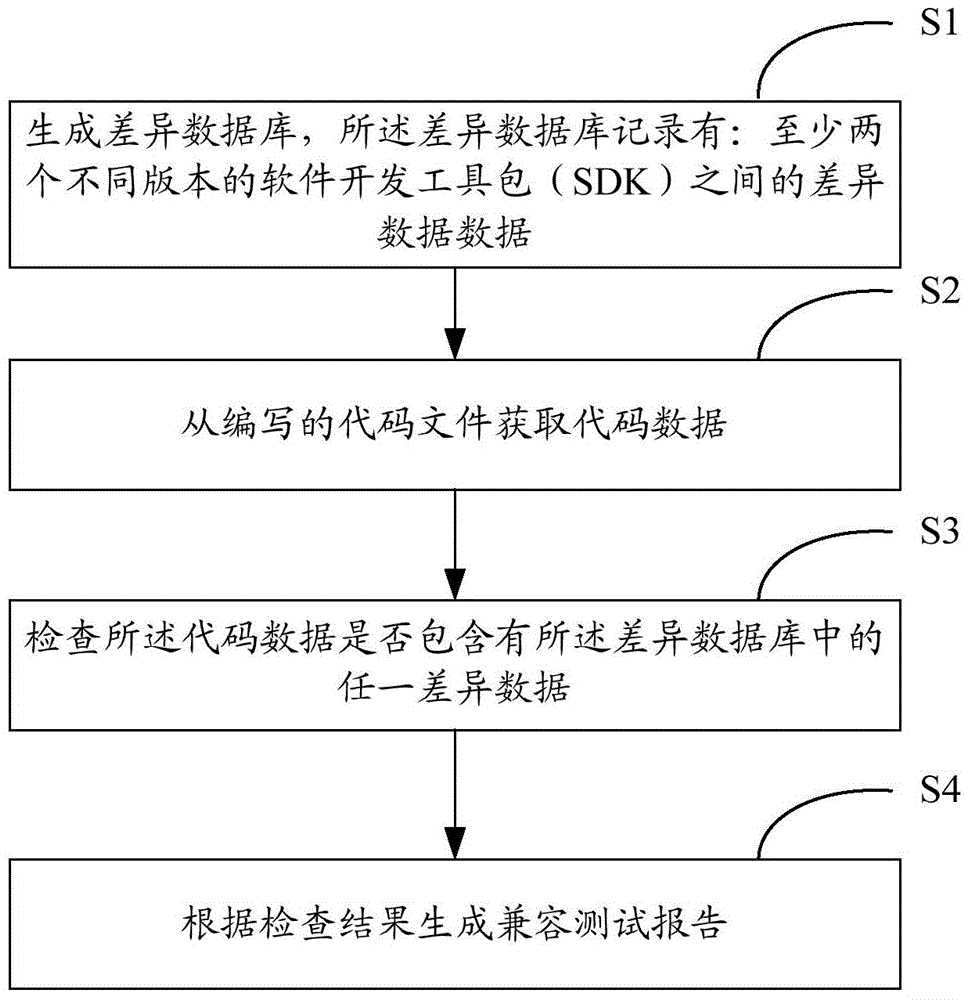

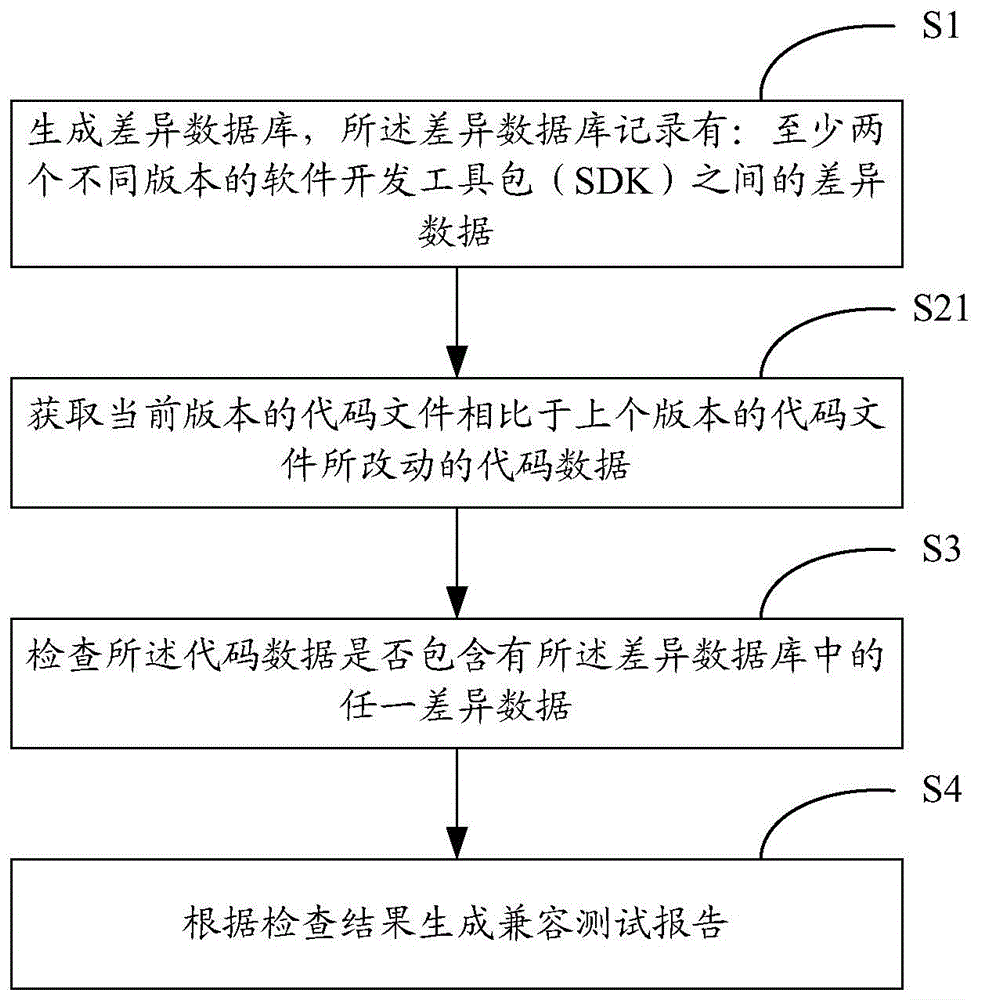

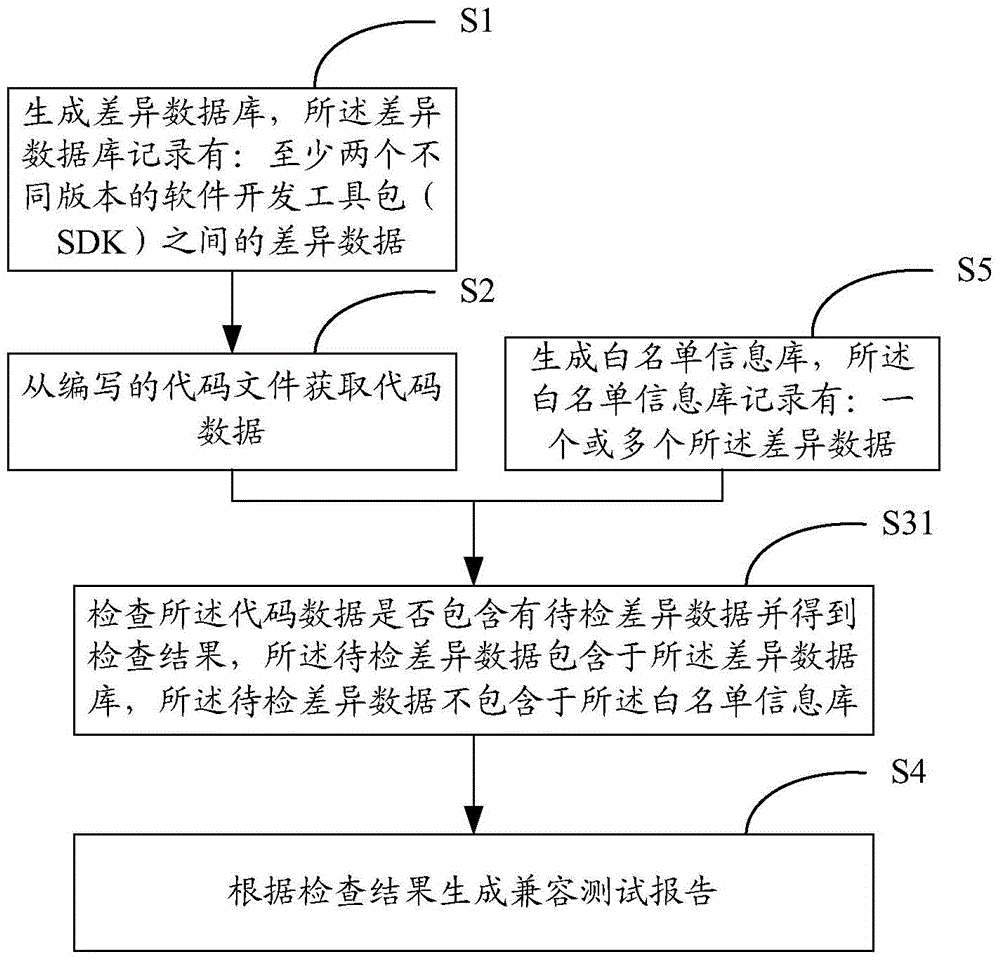

Version compatibility test method and apparatus

ActiveCN104932973AImprove compatibilitySoftware testing/debuggingSoftware engineeringComputer compatibility

The present invention is applicable to the field of code test and provides a version compatibility test method and apparatus. The method comprises: generating a difference database, wherein the difference database records difference data existing between at least two different versions of software development kits (SDK); acquiring code data from a programmed code file; inspecting whether the code data contains any difference data in the difference database or not; and generating a compatibility test report according to the inspecting result. Thus, the difference database is generated by directly obtaining different versions of the SDKs from an official network server, and the difference database is used for performing a compatibility test on the code data, so as to obtain the compatibility test report; therefore, if the compatibility test report indicates that the code data contains the difference data, the part where the code data contains the difference data can be modified until the modified code data can be compatible with different versions of the SDKs.

Owner:TENCENT TECH (SHENZHEN) CO LTD

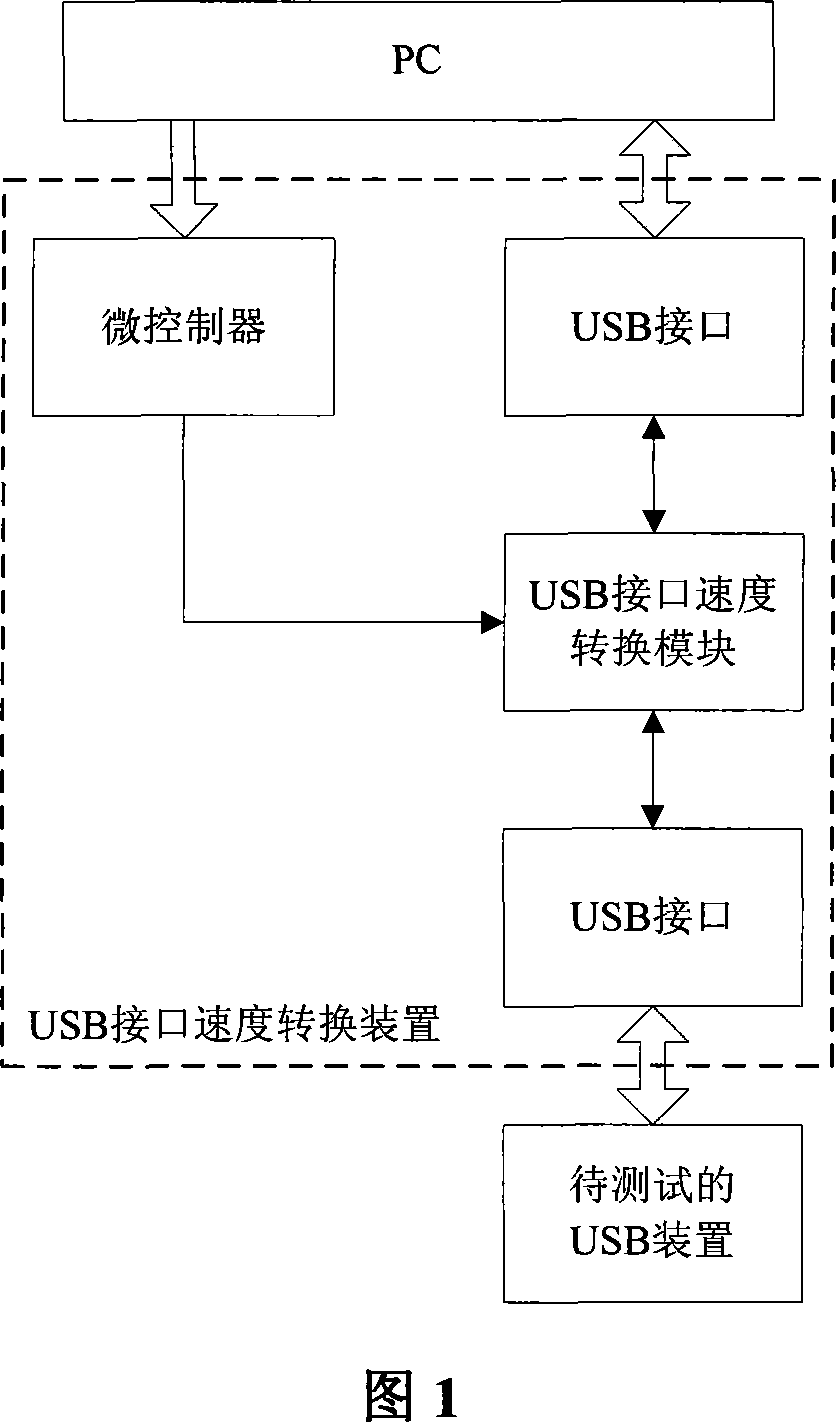

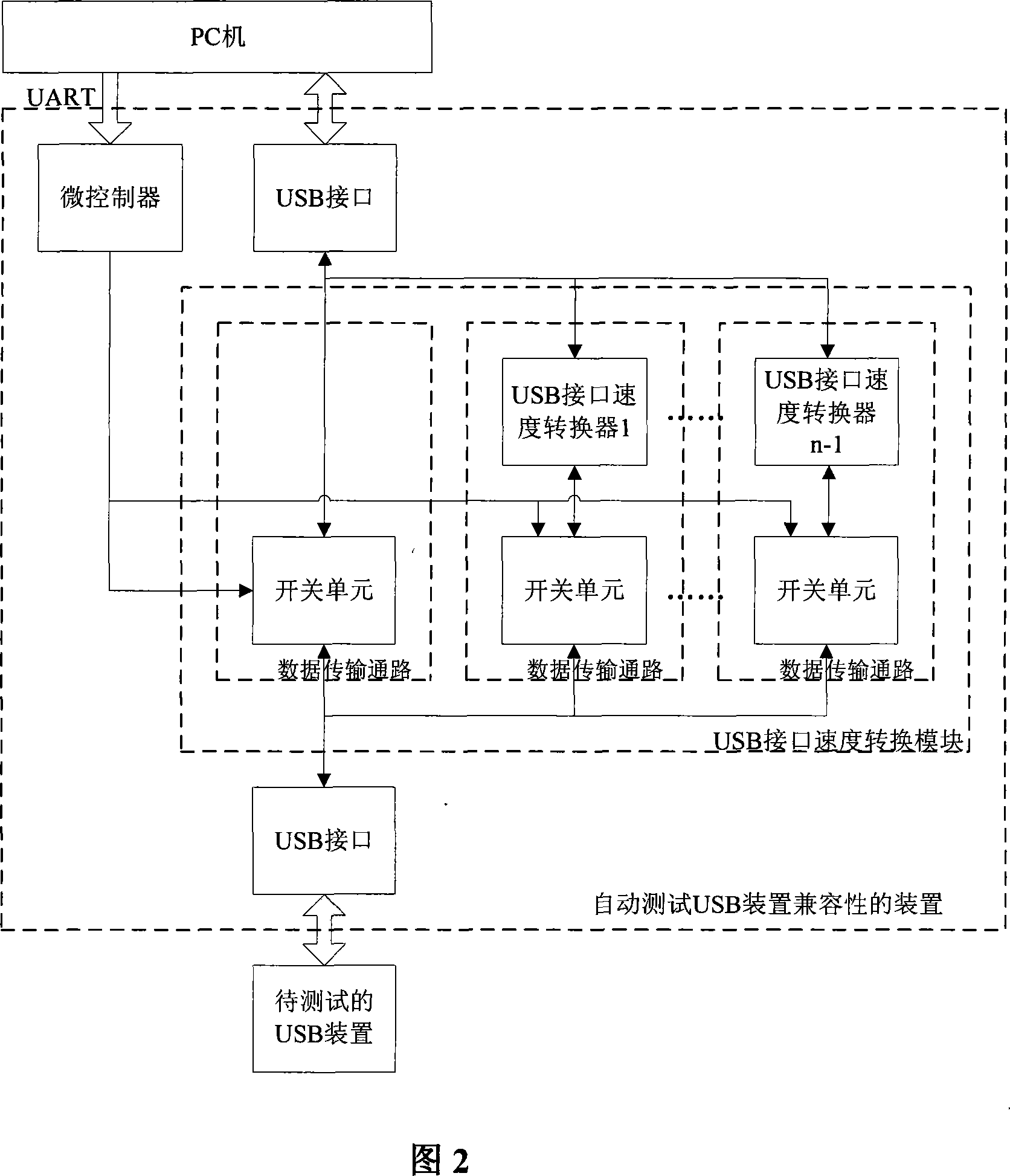

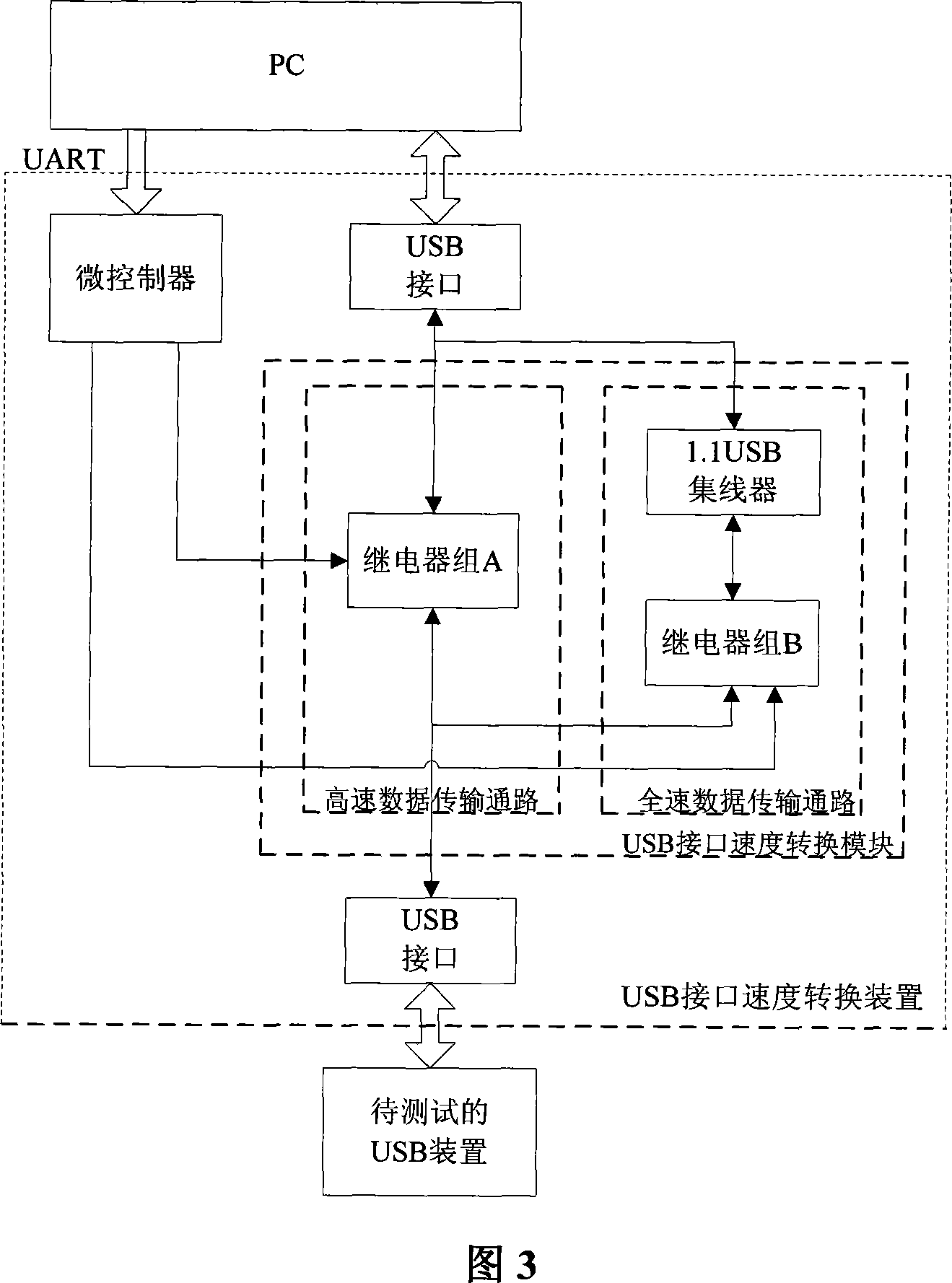

System for automatic testing USB compatibility

InactiveCN101059770ATo achieve the purpose of speed conversionReduce labor costsError detection/correctionSleep stateComputer compatibility

The invention provides a system for automatically testing the compatibility of USB device, which uses a USB interface speed convert module based on the control command of PC to convert the USB interface speed, to test the compatibility of USB device under different USB interface speeds. Compared with artificial USB compatibility test, the invention reduces cost, improves efficiency, simplifies operation, and resolves the problem that the transmitted video flow may be delayed, mistake color, shifts image, and discontinuously display image when the PC is returned to normal state from wait / sleep state or the USB device is plugged several times.

Owner:VIMICRO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com