Patents

Literature

345results about "Library tags" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

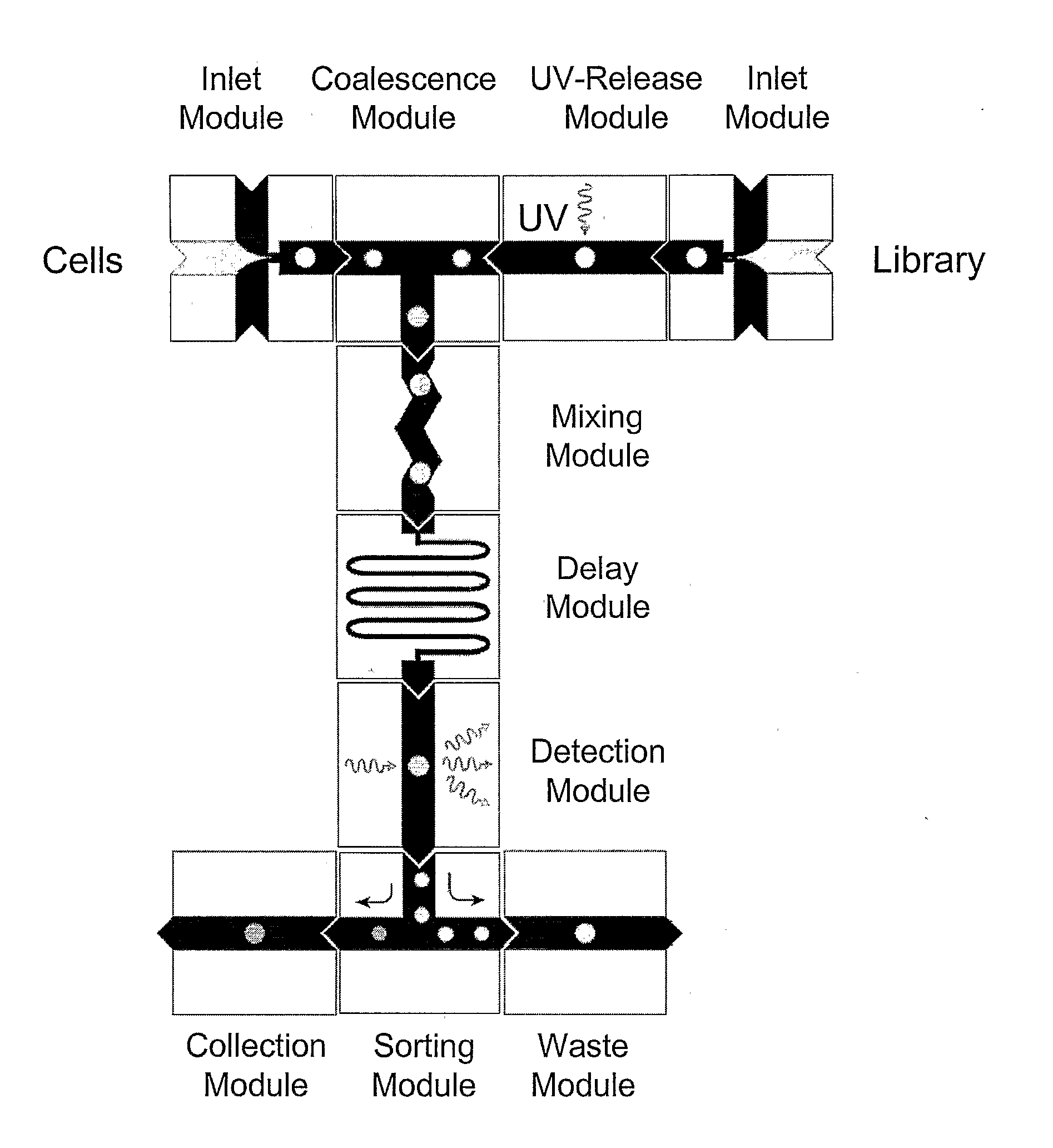

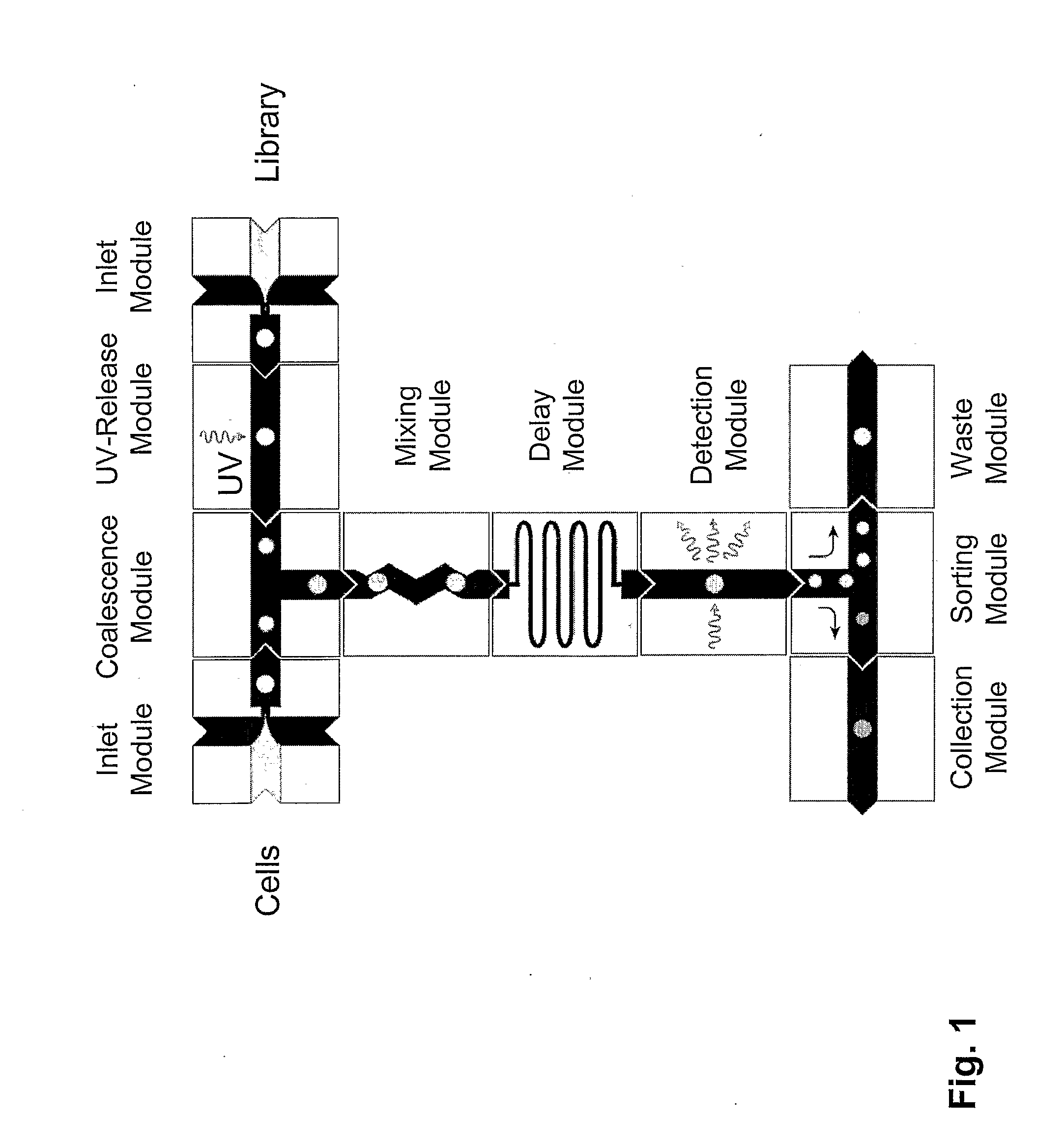

Microfluidic Devices and Methods of Use in The Formation and Control of Nanoreactors

InactiveUS20100137163A1Material nanotechnologyCompound screeningHigh-Throughput Screening AssaysEmulsion

The present invention provides novel microfluidic devices and methods that are useful for performing high-throughput screening assays and combinatorial chemistry. Such methods can include labeling a library of compounds by emulsifying aqueous solutions of the compounds and aqueous solutions of unique liquid labels on a microfluidic device, which includes a plurality of electrically addressable, channel bearing fluidic modules integrally arranged on a microfabricated substrate such that a continuous channel is provided for flow of immiscible fluids, whereby each compound is labeled with a unique liquid label, pooling the labeled emulsions, coalescing the labeled emulsions with emulsions containing a specific cell or enzyme, thereby forming a nanoreactor, screening the nanoreactors for a desirable reaction between the contents of the nanoreactor, and decoding the liquid label, thereby identifying a single compound from a library of compounds.

Owner:BIO RAD LAB INC

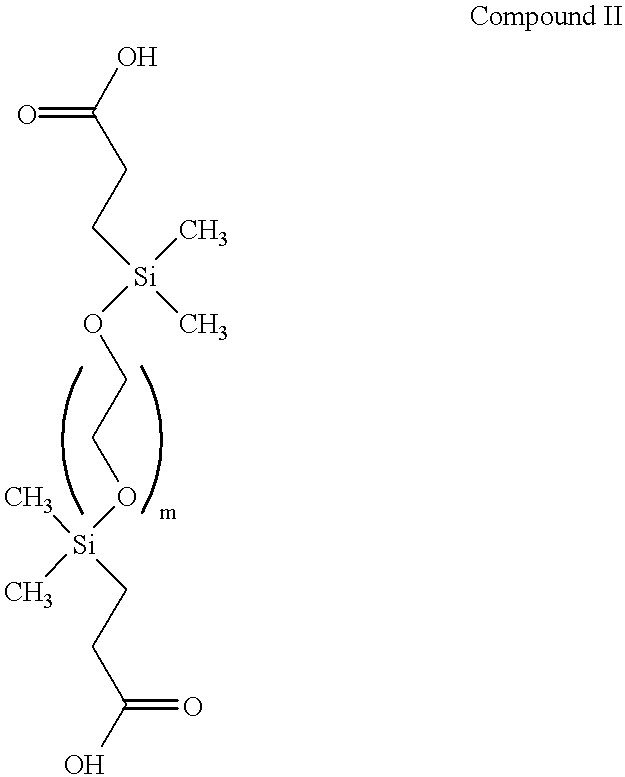

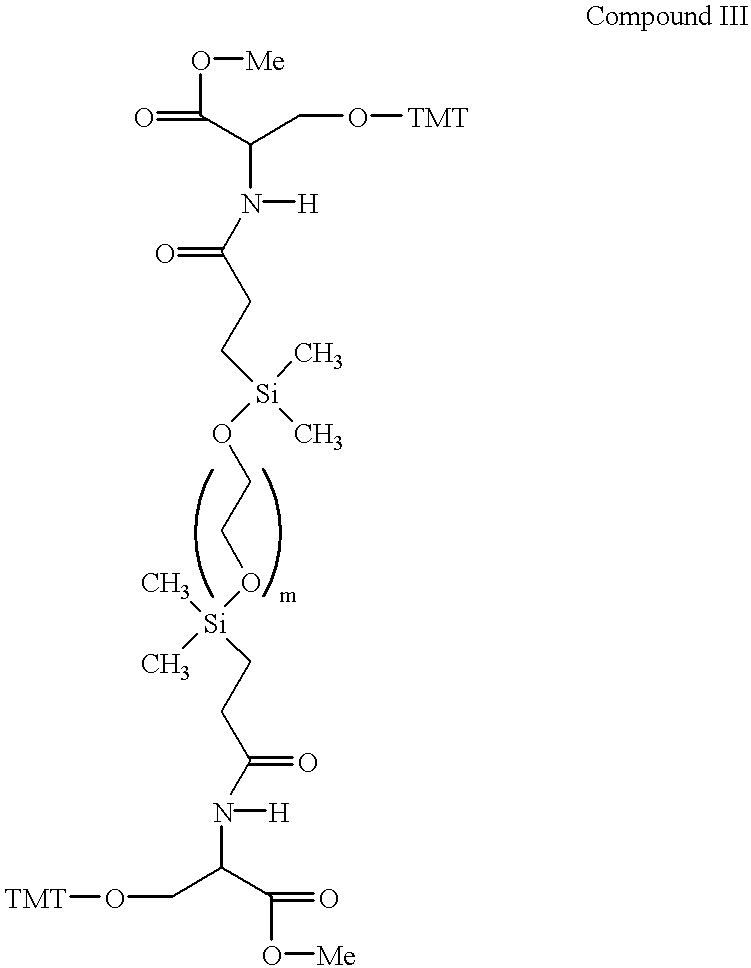

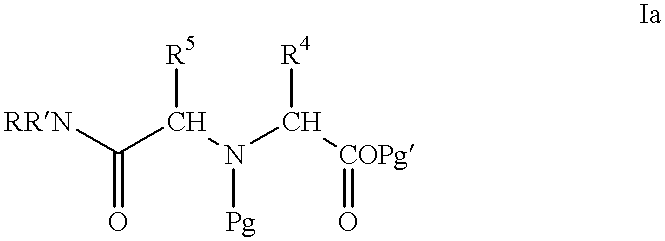

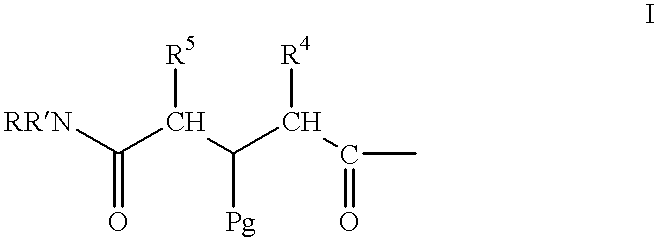

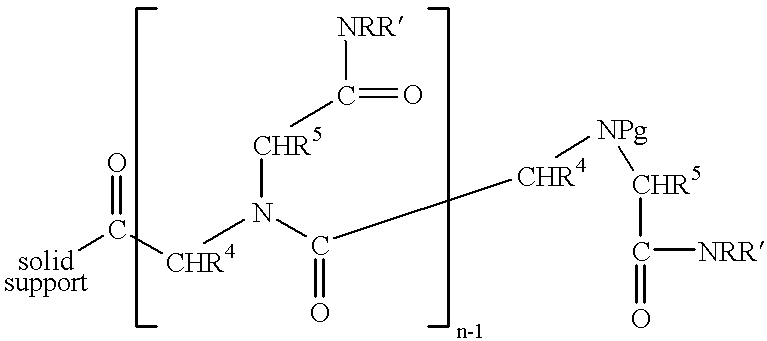

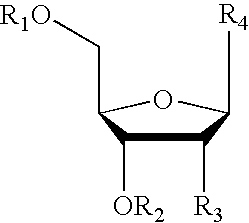

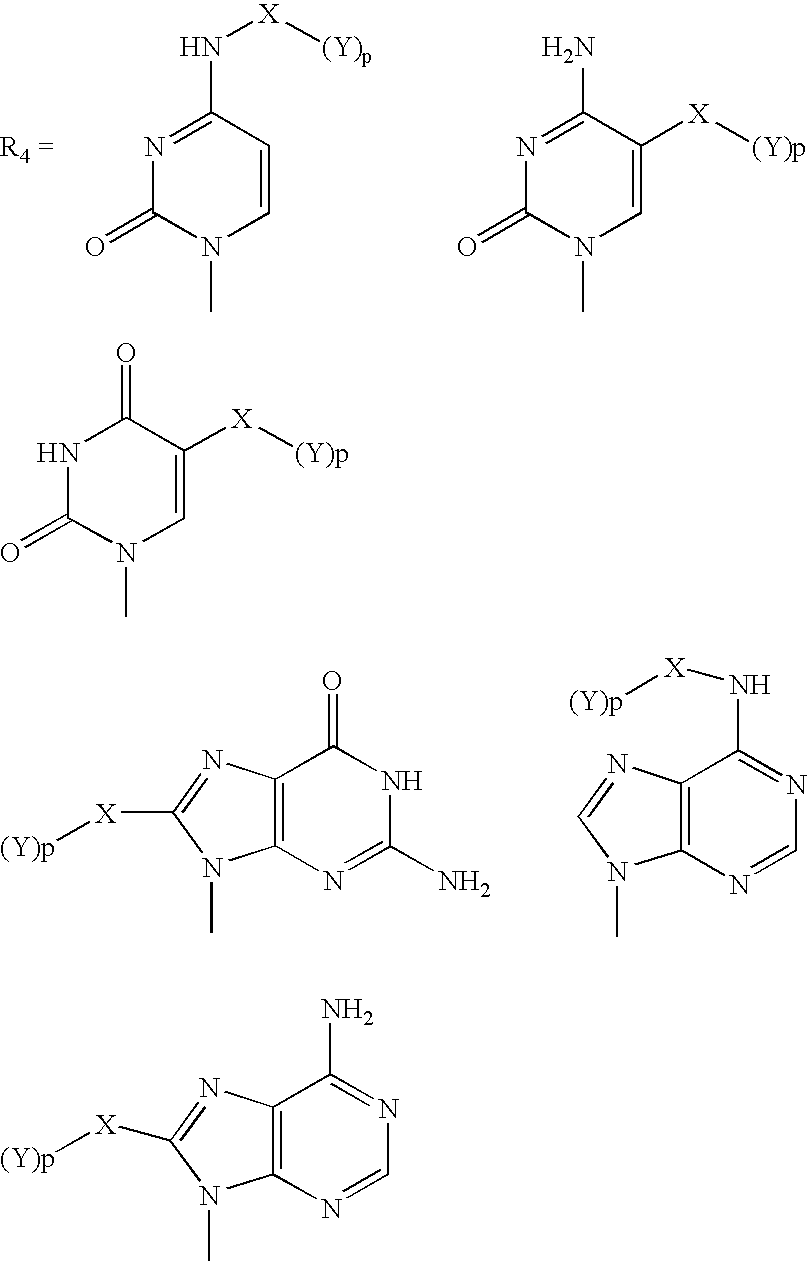

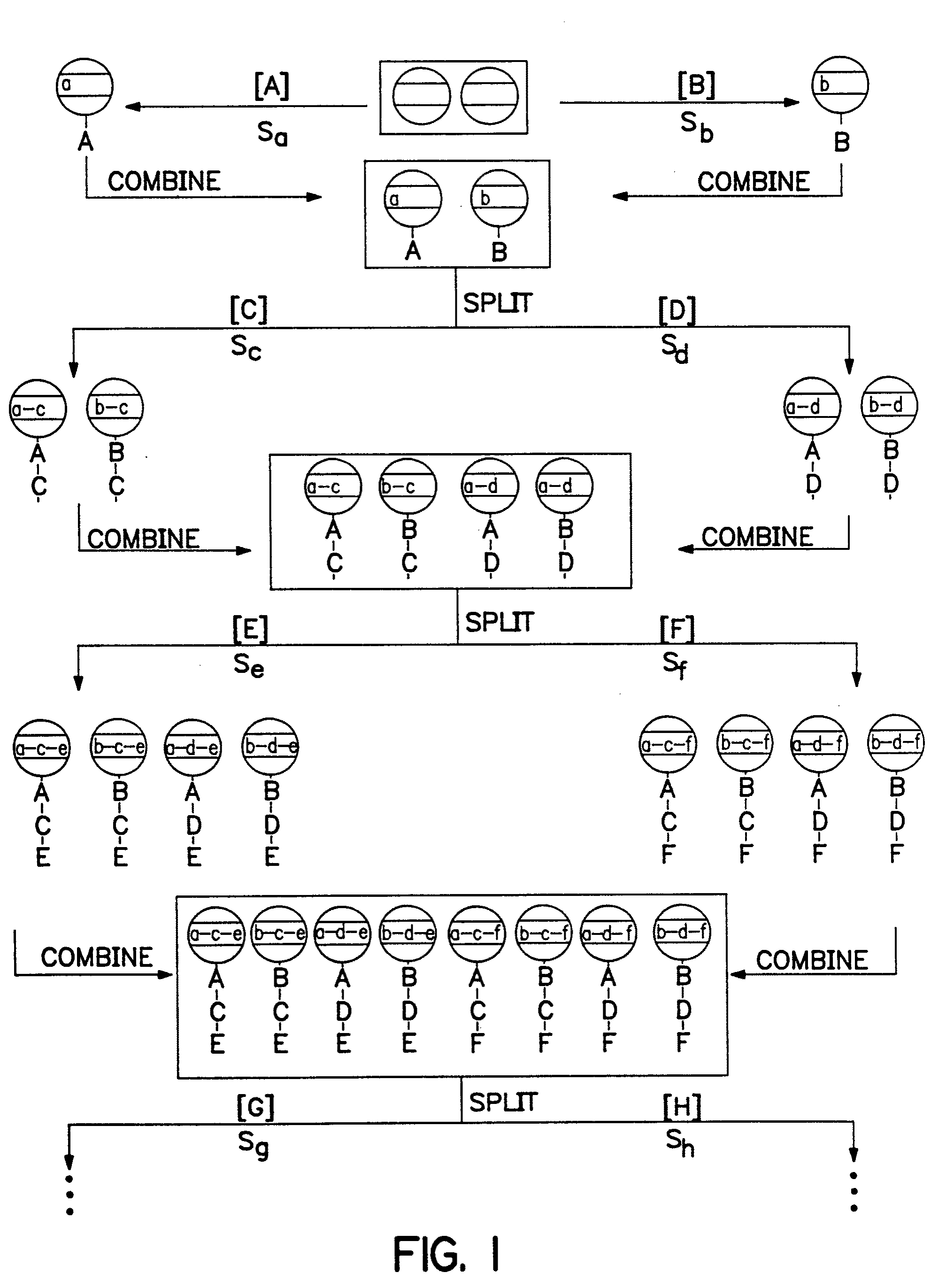

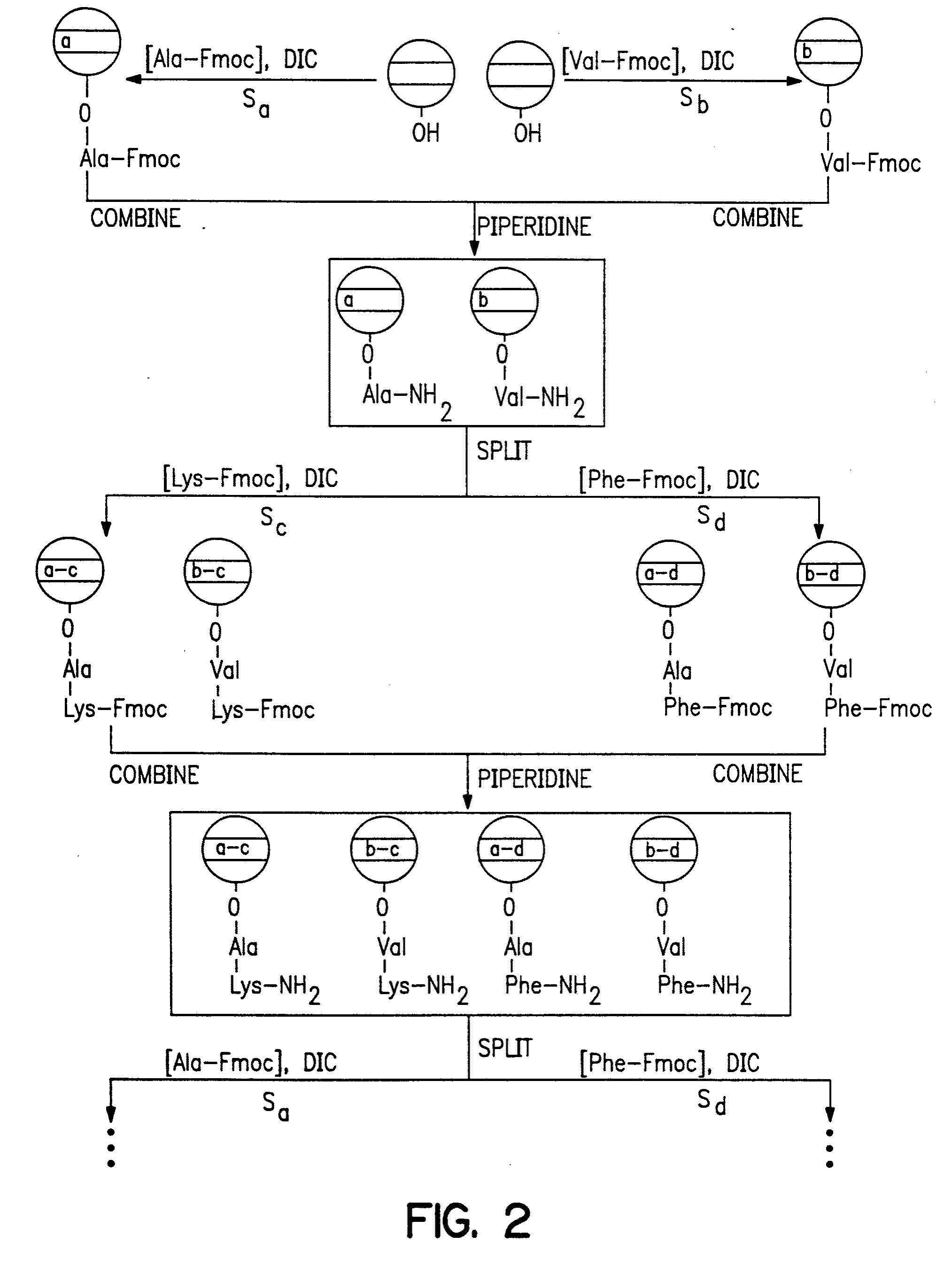

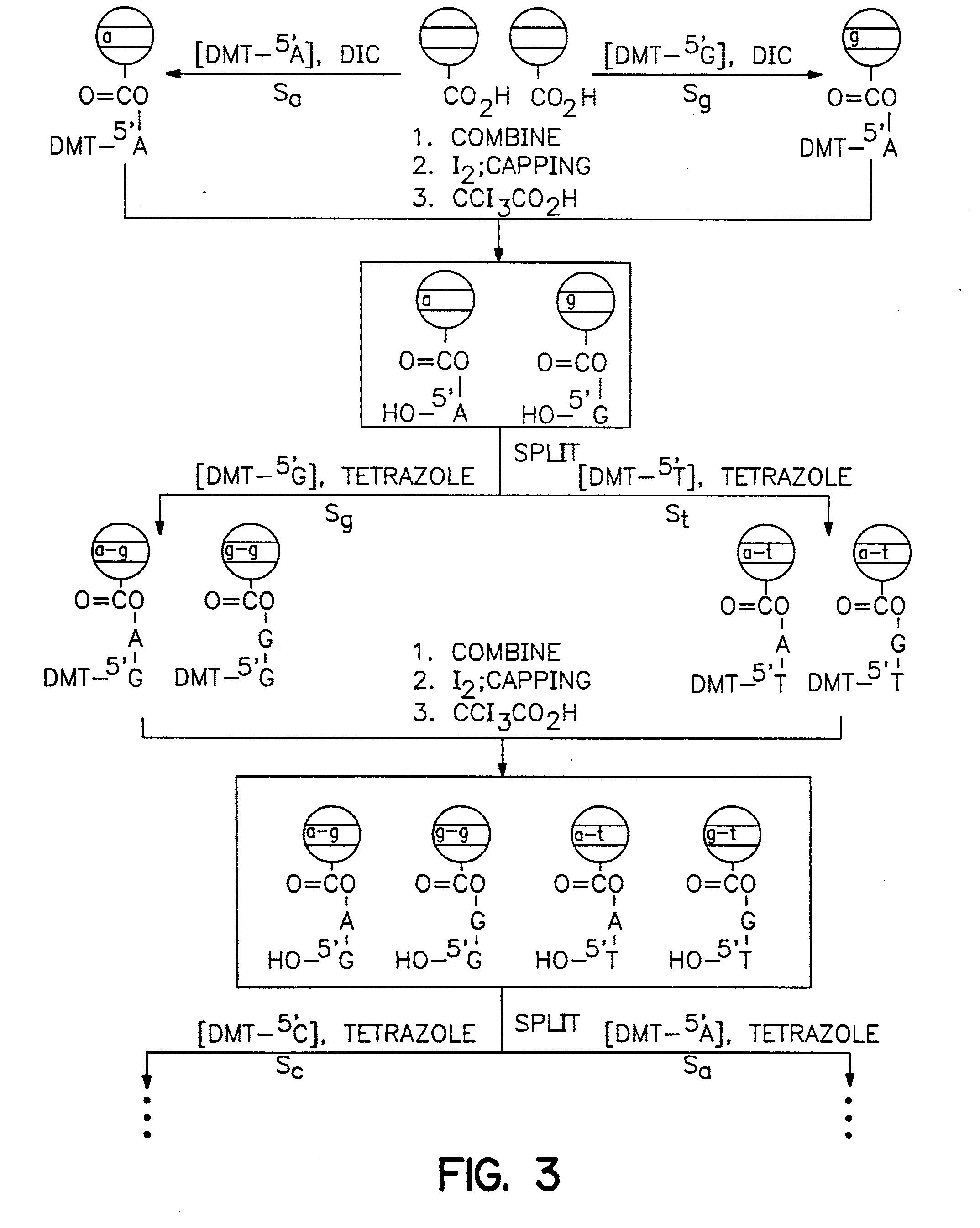

Topologically segregated, encoded solid phase libraries comprising linkers having an enzymatically susceptible bond

The invention relates to libraries of synthetic test compound attached to separate phase synthesis supports. In particular, the invention relates to libraries of synthetic test compound attached to separate phase synthesis supports that also contain coding molecules that encode the structure of the synthetic test compound. The molecules may be polymers or multiple nonpolymeric molecules. Each of the solid phase synthesis support beads contains a single type of synthetic test compound. The synthetic test compound can have backbone structures with linkages such as amide, urea, carbamate (i.e., urethane), ester, amino, sulfide, disulfide, or carbon-carbon, such as alkane and alkene, or any combination thereof. Examples of subunits suited for the different linkage chemistries are provided. The synthetic test compound can also be molecular scaffolds, such as derivatives of monocyclic of bicyclic carbohydrates, steroids, sugars, heterocyclic structures, polyaromatic structures, or other structures capable of acting as a scaffolding. Examples of suitable molecular scaffolds are provided. The invention also relates to methods of synthesizing such libraries and the use of such libraries to identify and characterize molecules of interest from among the library of synthetic test compound.

Owner:AVENTIS PHARMA INC

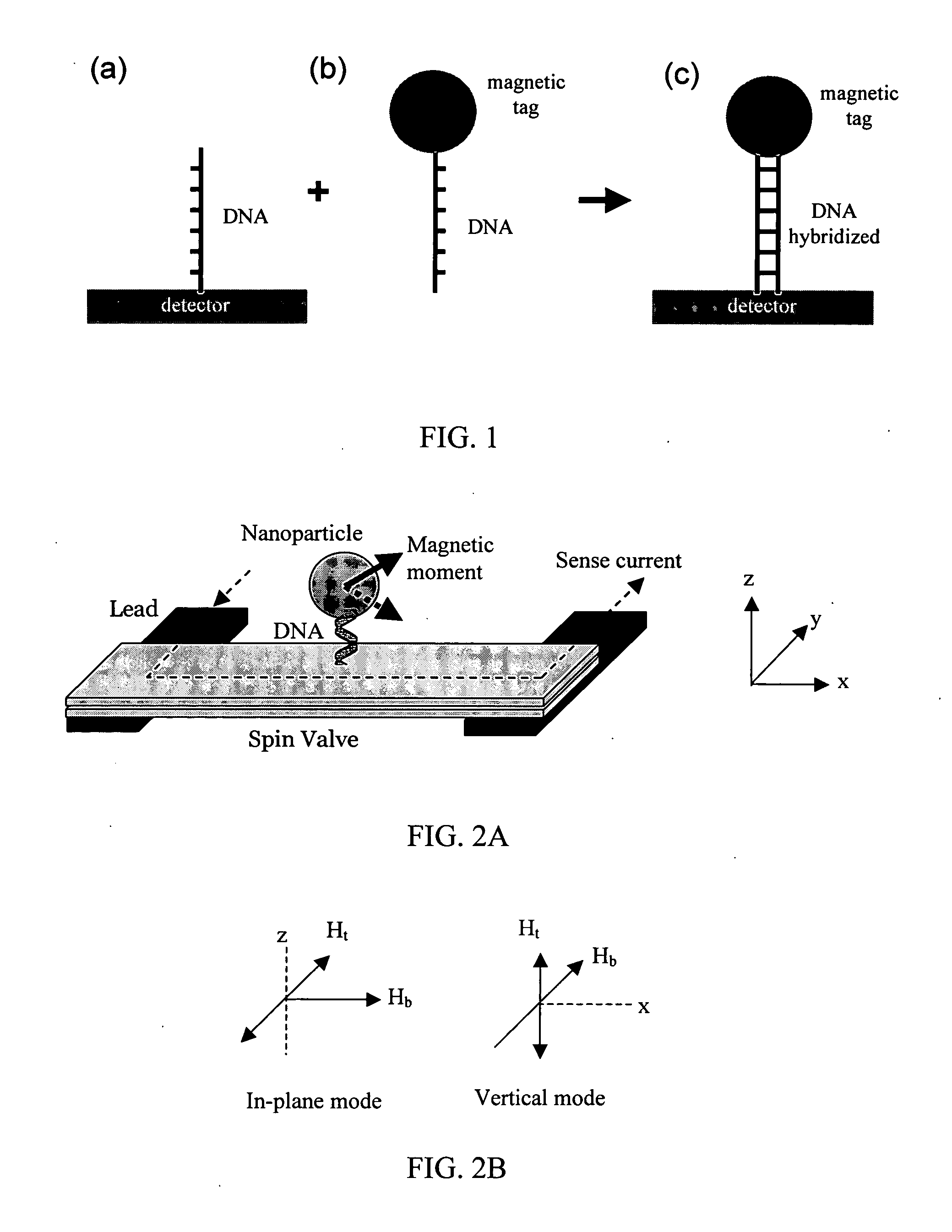

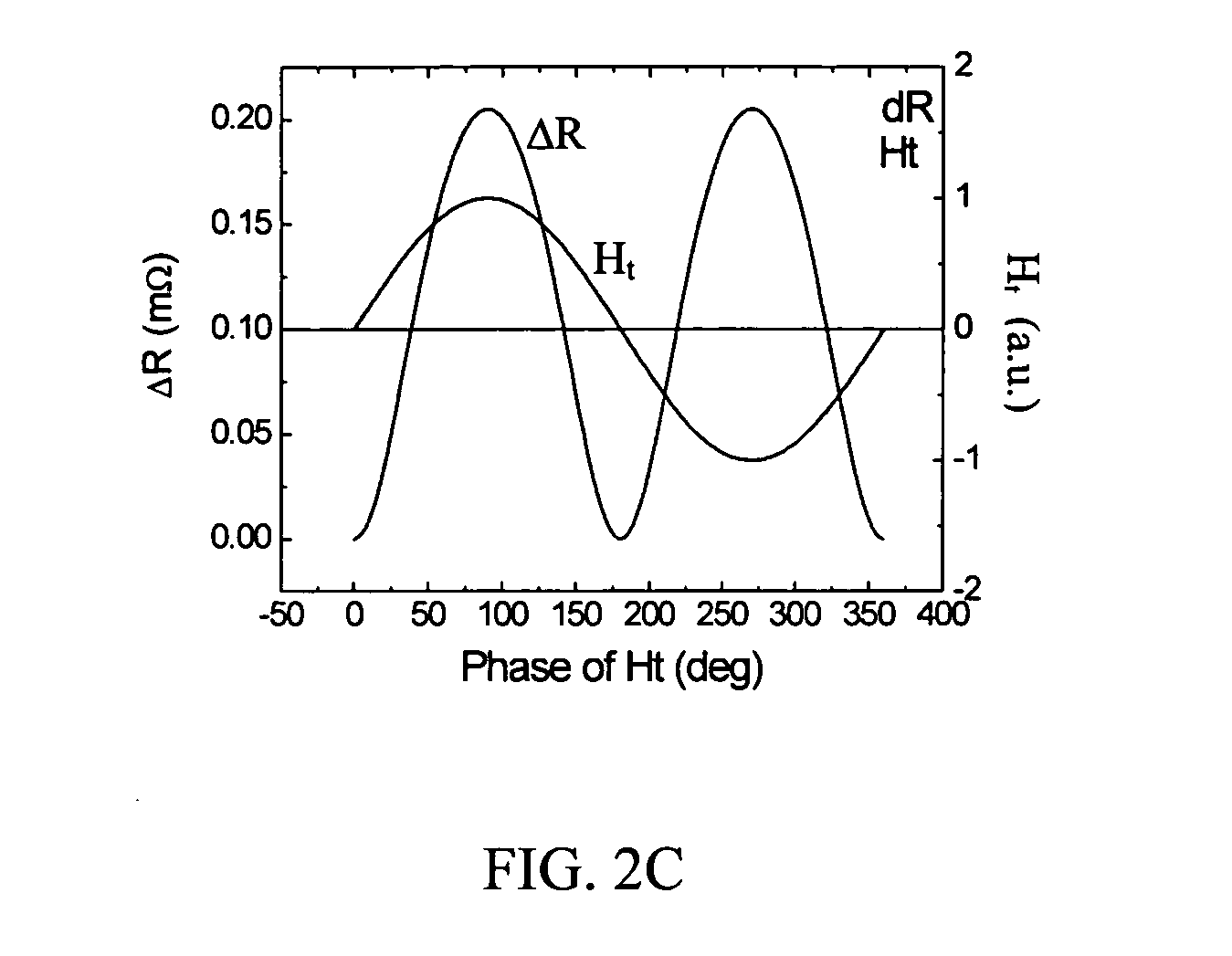

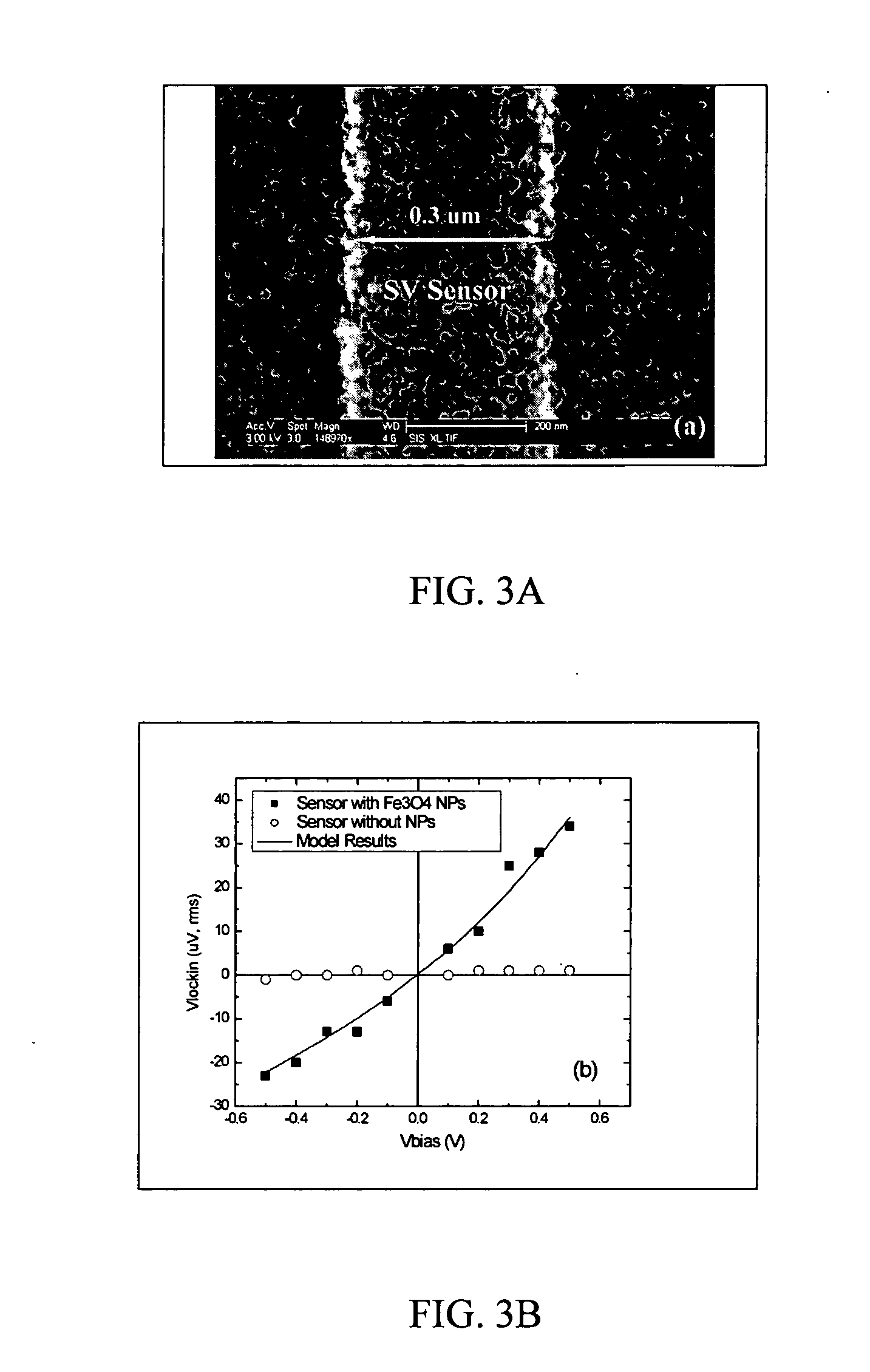

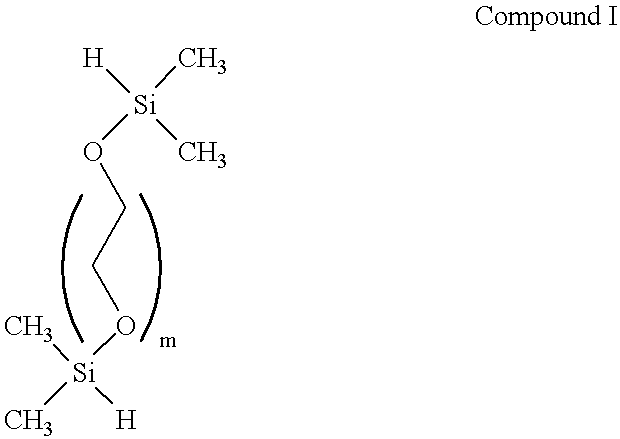

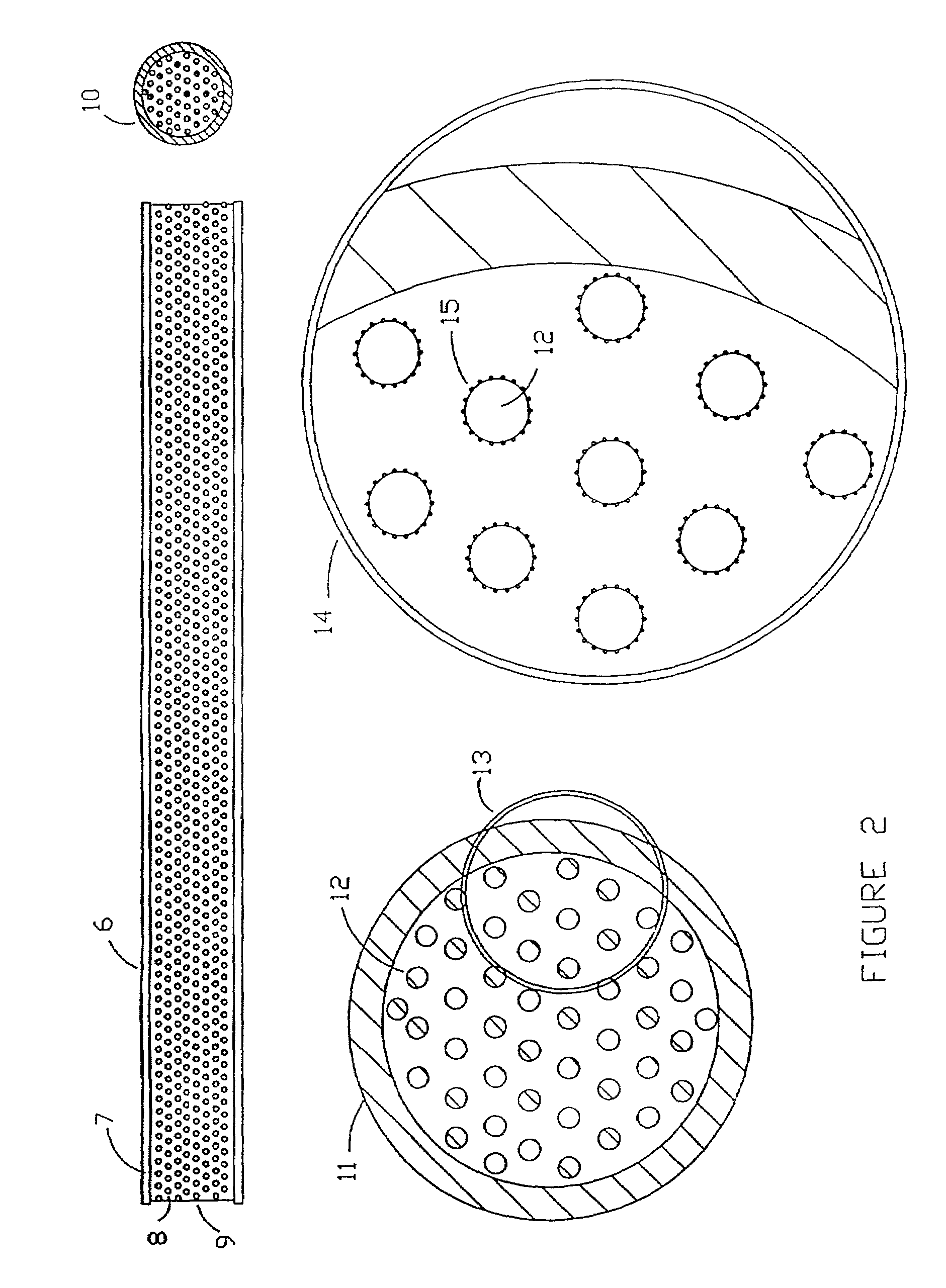

Magnetic nanoparticles, magnetic detector arrays, and methods for their use in detecting biological molecules

Magnetic nanoparticles and methods for their use in detecting biological molecules are disclosed. The magnetic nanoparticles can be attached to nucleic acid molecules, which are then captured by a complementary sequence attached to a detector, such as a spin valve detector or a magnetic tunnel junction detector. The detection of the bound magnetic nanoparticle can be achieved with high specificity and sensitivity.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Optical disk-based assay devices and methods

InactiveUS6342349B1Strong specificityReduce nonspecific bindingSequential/parallel process reactionsSugar derivativesAnalyteLaser light

Optical disk-based assay devices and methods are described, in which analyte-specific signal elements are disposed on an optical disk substrate. In preferred embodiments, the analyte-specific signal elements are disposed readably with the disk's tracking features. Also described are cleavable signal elements particularly suitable for use in the assay device and methods. Binding of the chosen analyte simultaneously to a first and a second analyte-specific side member of the cleavable signal element tethers the signal-responsive moiety to the signal element's substrate-attaching end, despite subsequent cleavage at the cleavage site that lies intermediate the first and second side members. The signal responsive moiety reflects, absorbs, or refracts incident laser light. Described are nucleic acid hybridization assays, nucleic acid sequencing, immunoassays, cell counting assays, and chemical detection. Adaptation of the assay device substrate to function as an optical waveguide permits assay geometries suitable for continuous monitoring applications.

Owner:VINDUR TECH

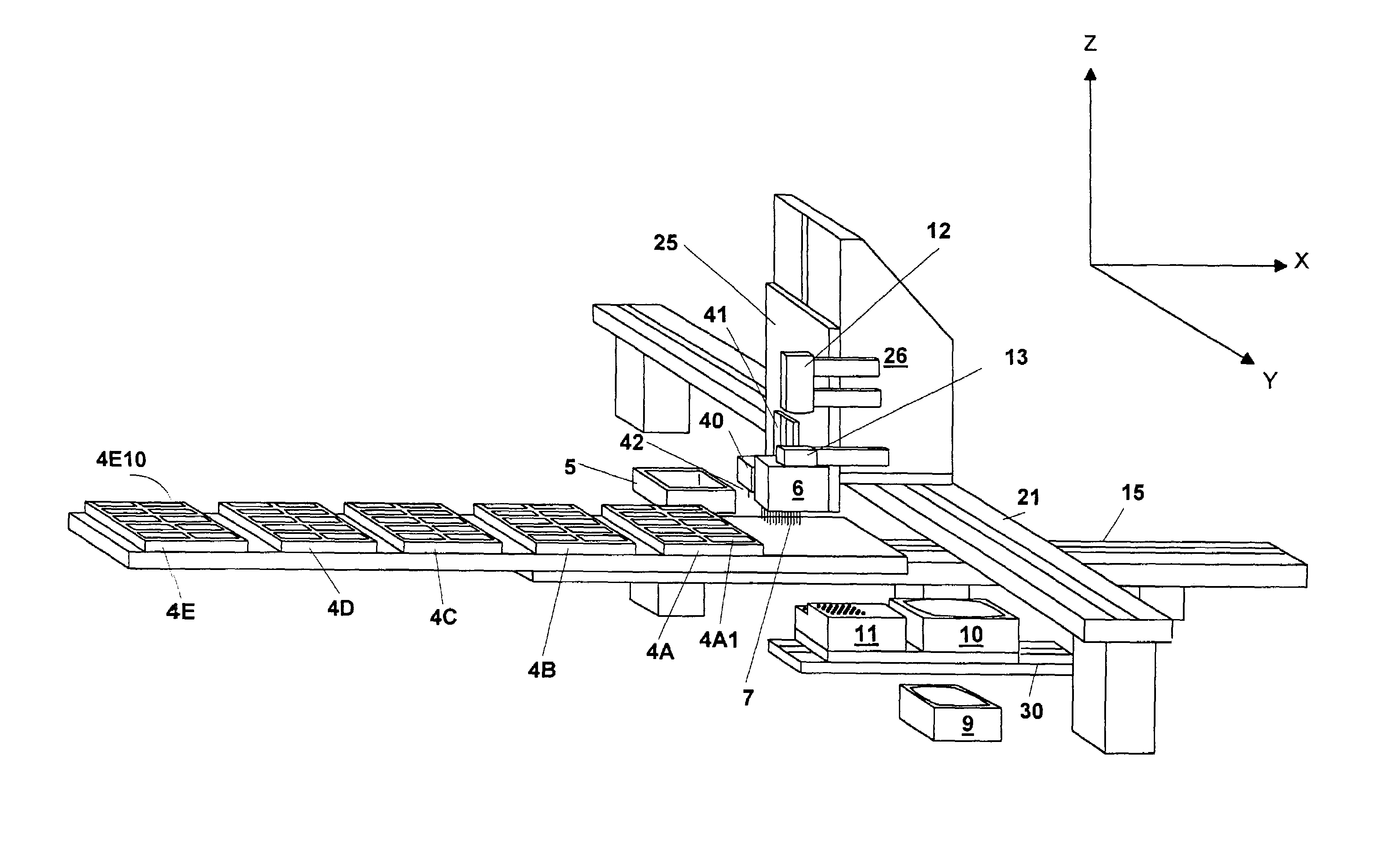

Preparation and characterization of formulations in a high throughput mode

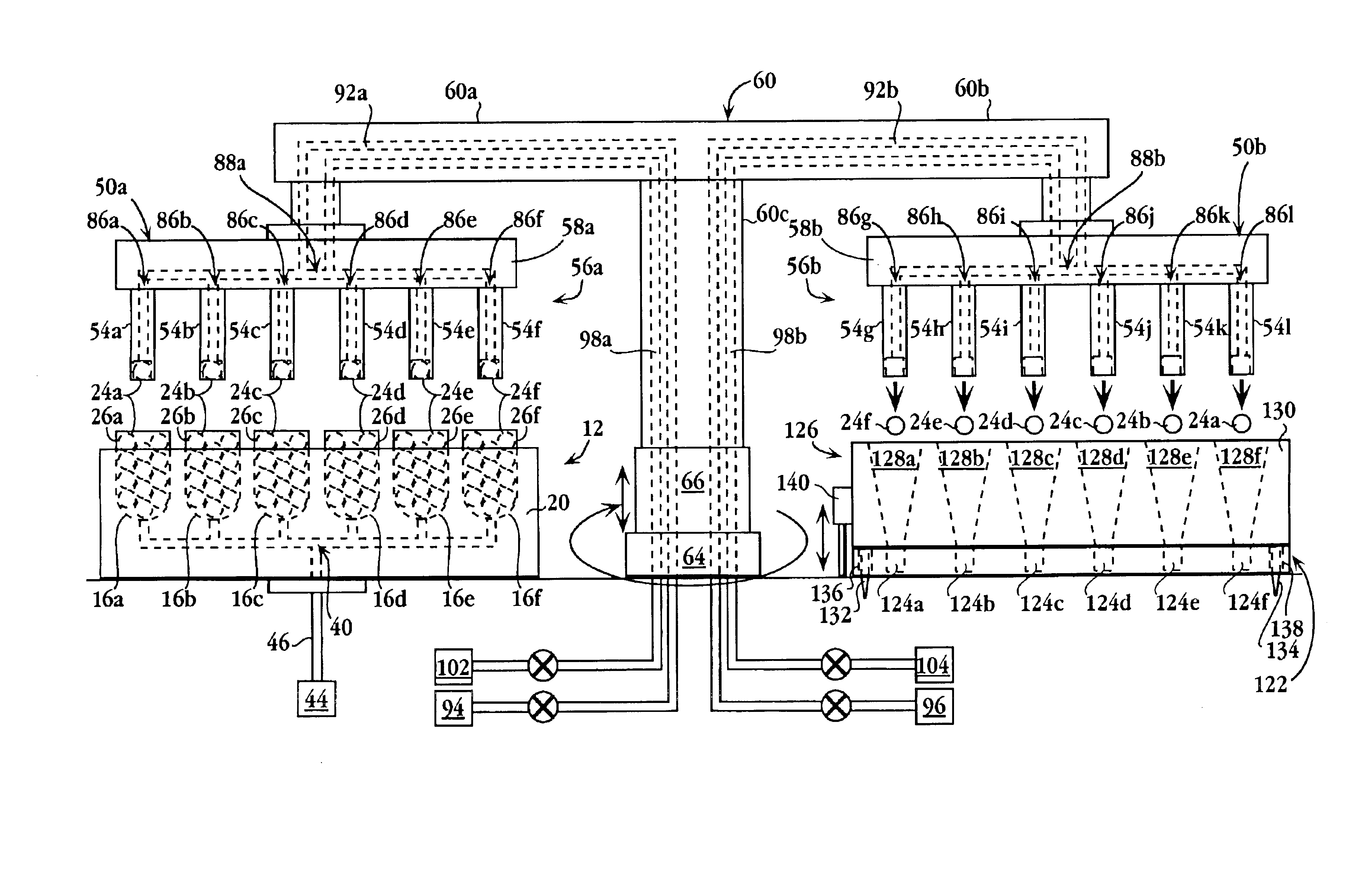

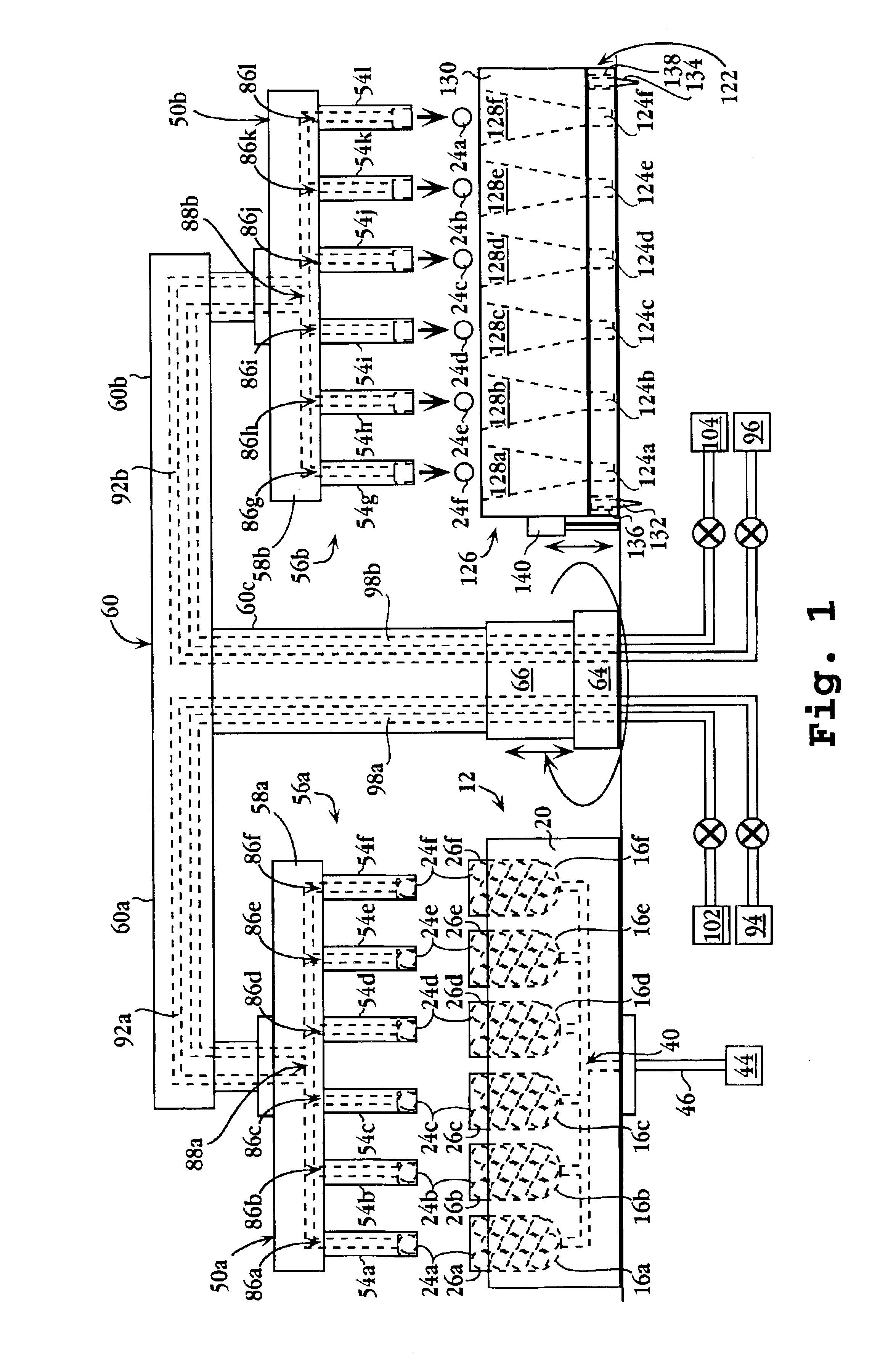

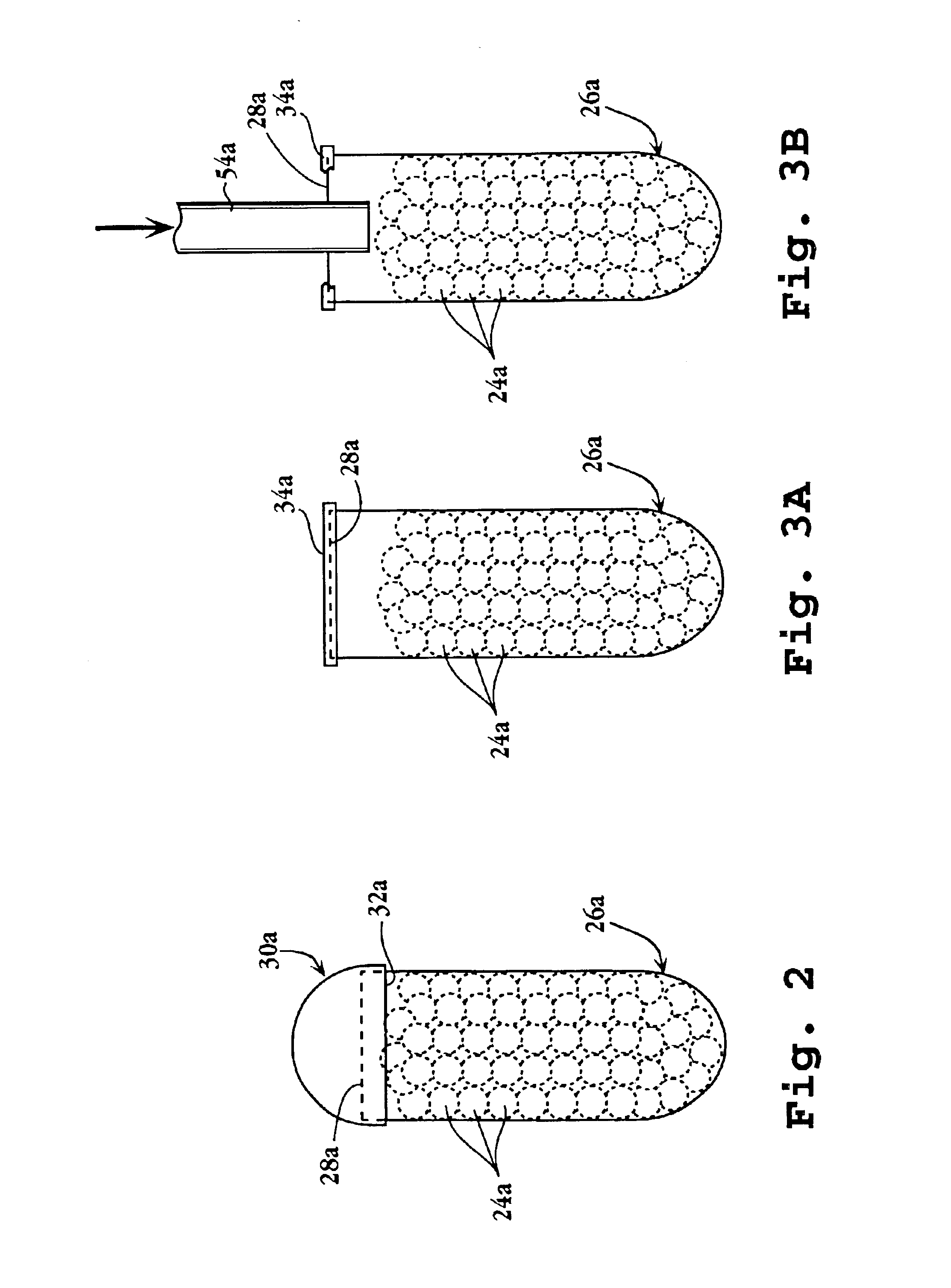

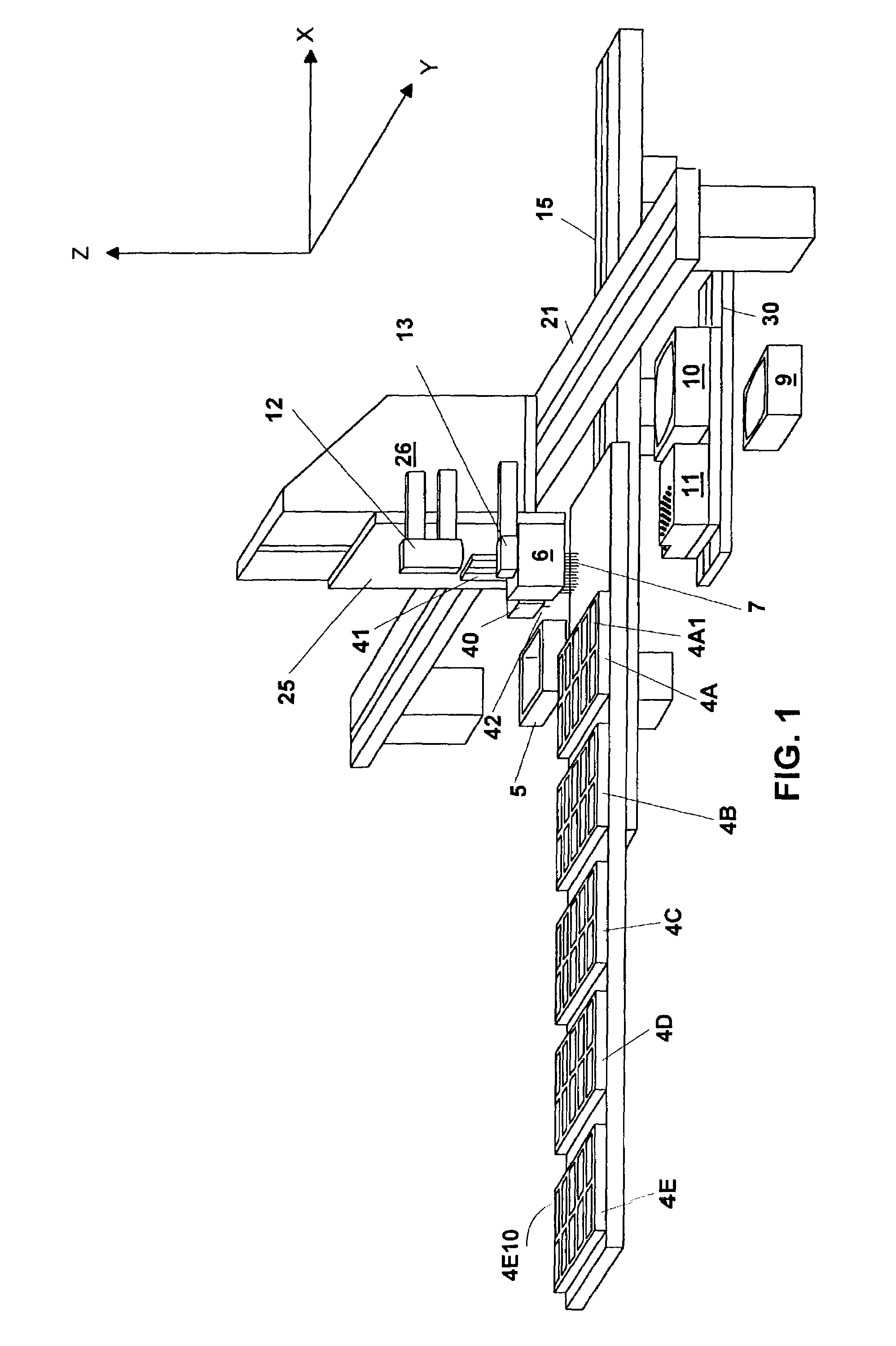

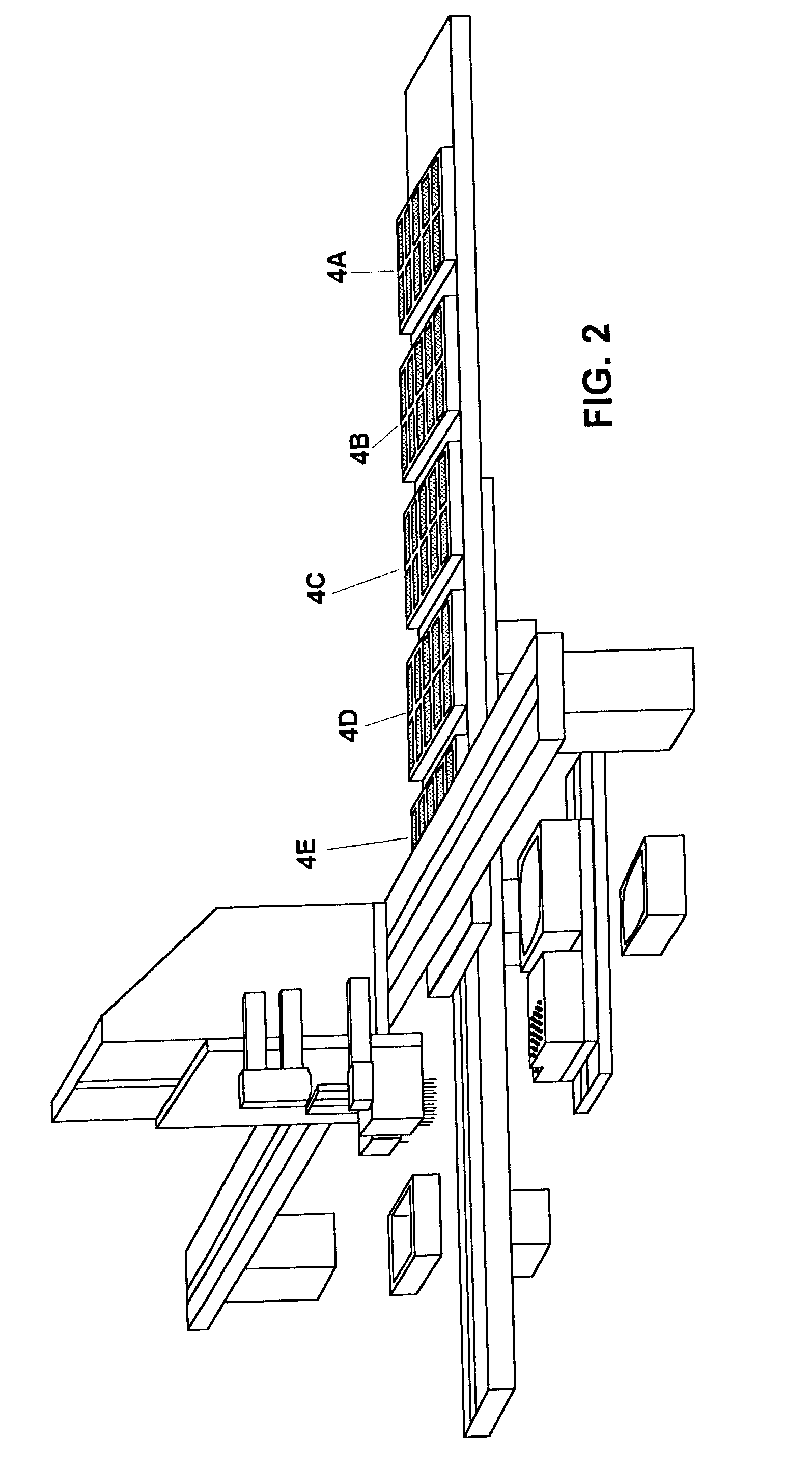

ActiveUS20050058574A1Improve throughputFormula flexibleLibrary tagsFlow propertiesAnalysis dataAdditive ingredient

The invention is an automated robotic system for the production and testing of formulations at a very high throughput. It is an integrated system of hardware and software capable of preparing and evaluating hundreds of emulsions per day. The system can formulate aqueous solutions (SL), oil in water emulsions (EW), suspo-emulsions (SE), micro capsule suspensions (CS), micro-emulsions (ME), and suspension concentrates (SC) at the 1 ml to 25 ml scale. The system can process emulsions rapidly in an automated way and enable very flexible formulation recipes to be introduced. The system allows chemists to generate experimental samples of varying recipe and method to be conducted in parallel with projected throughput of up to 1200 formulations processed and characterized per day. Materials and consumables can be distributed from storage storage systems to the work stations where dispensing of ingredients in various states can be performed, including solids, liquids, gels, pastes, suspensions and waxes. The emulsions formed can be characterized using methods including phase diagnosis, turbidity analysis, viscosity and particle sizing using automated test equipment. An integrated module can also perform Tank Mix Compatibility testing in high throughput mode. The modular system allows future processes and tests to be added, either to a station, or as a new station. The software capability includes tracking of processes from start to finish and the integration of analytical data with the as-designed and as-formulated experimental results.

Owner:SYNGENTA LTD

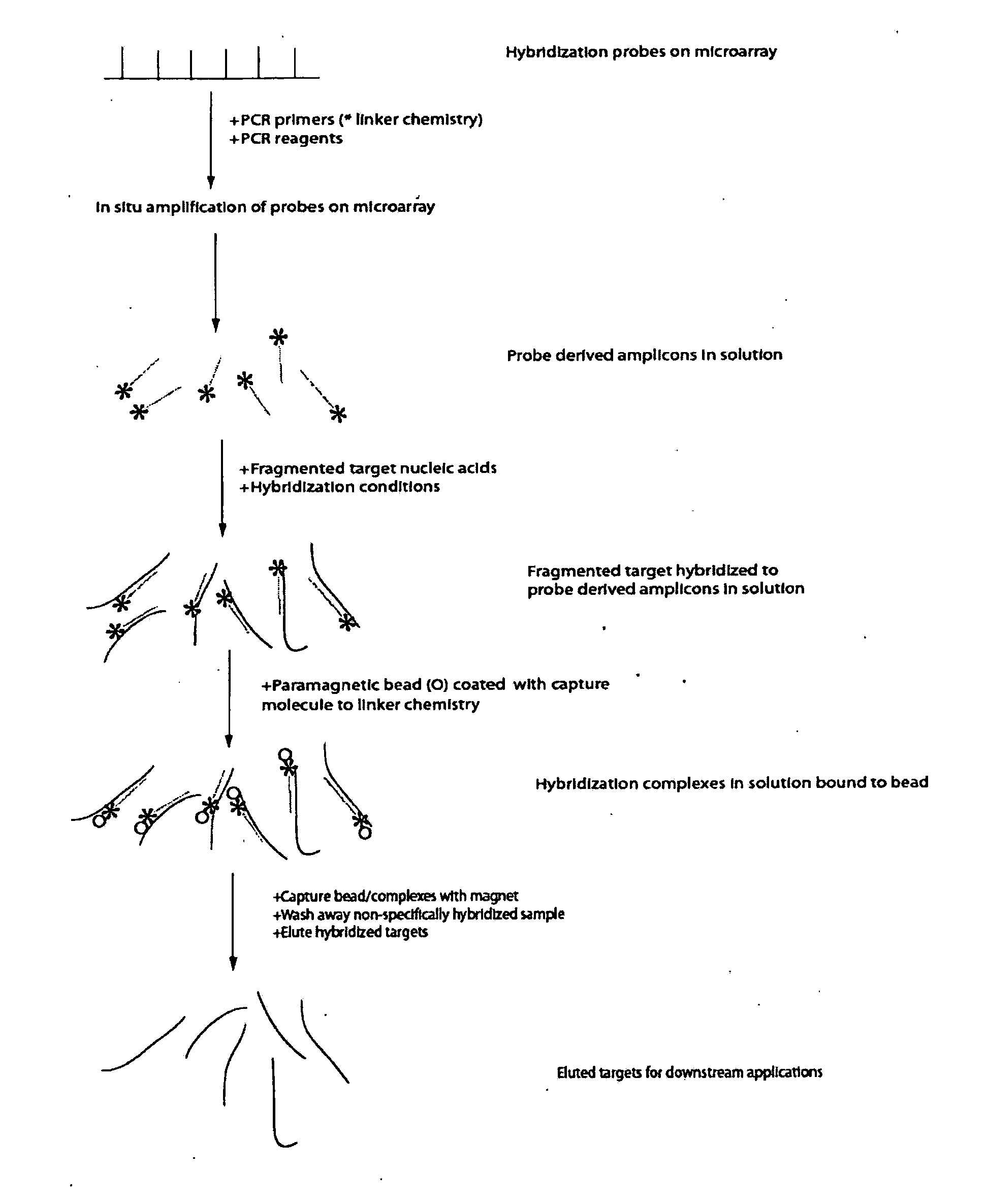

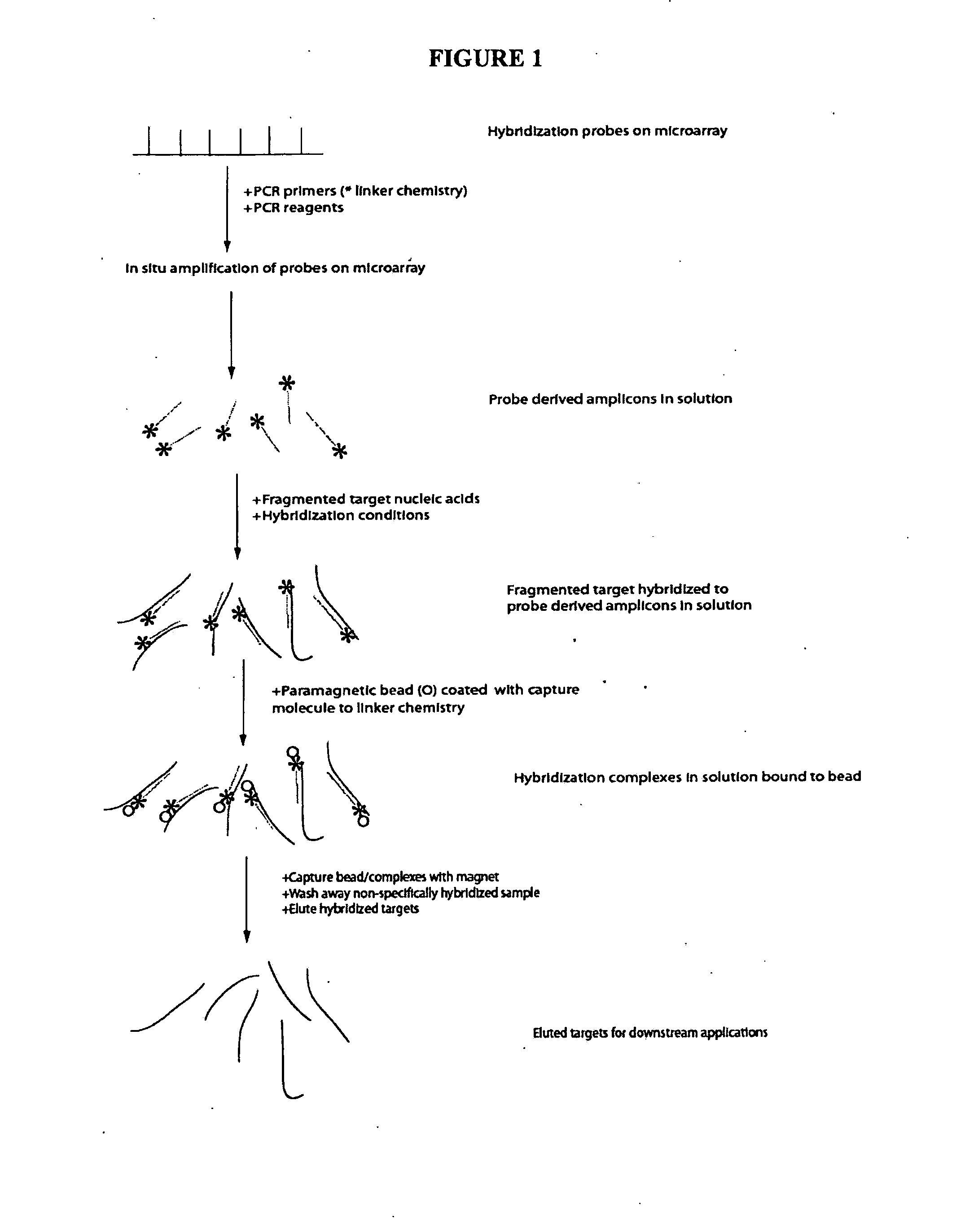

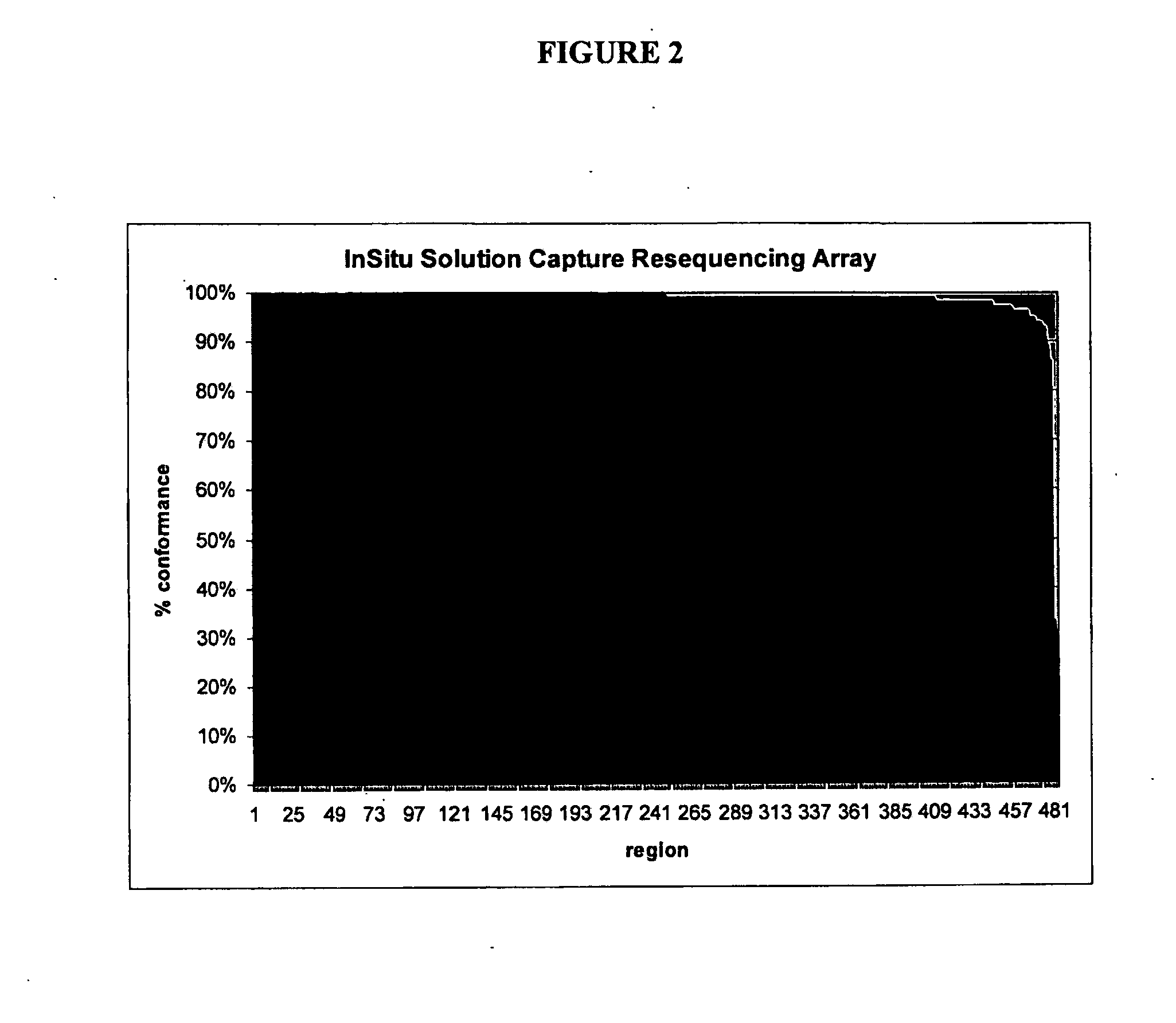

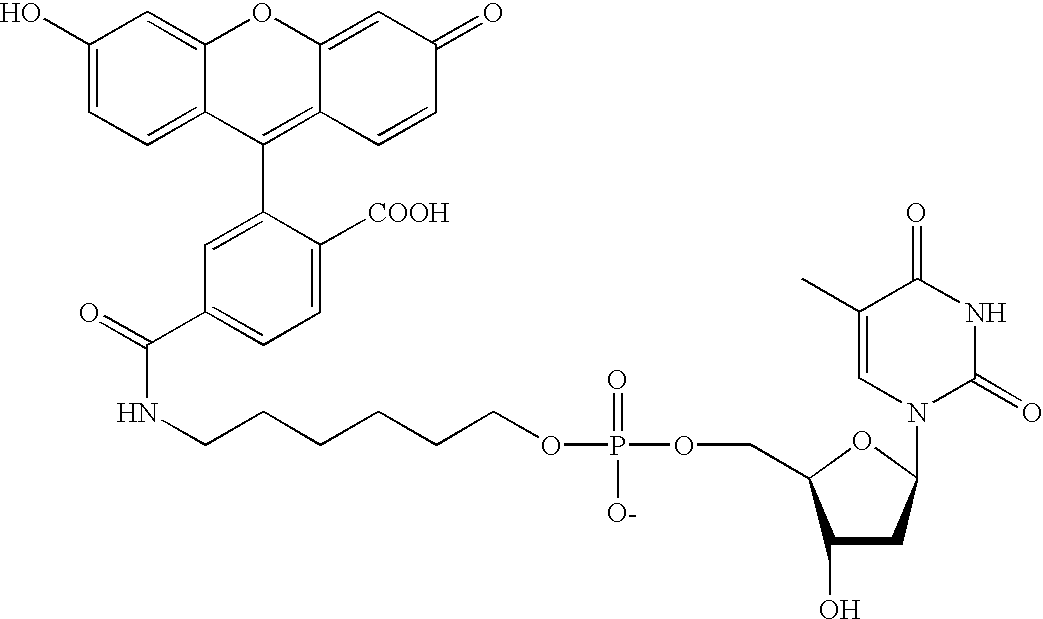

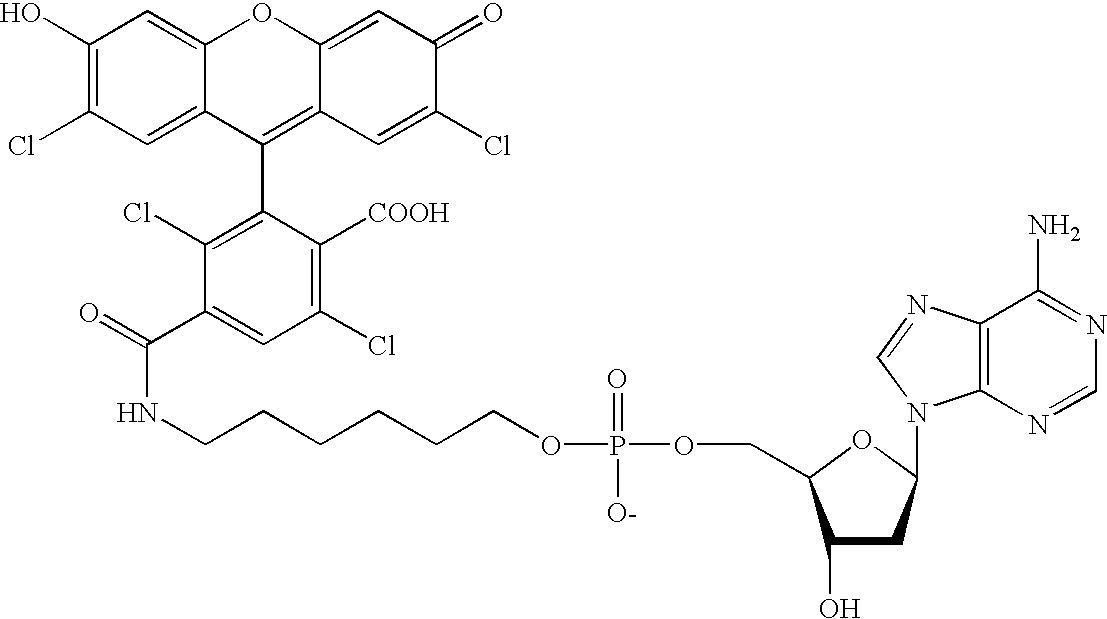

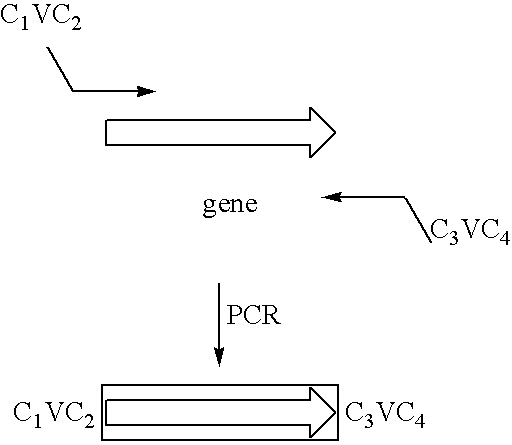

Methods and systems for solution based sequence enrichment

ActiveUS20120046175A1Significant complexityEasy to analyzeSugar derivativesLibrary tagsBase sequenceBioinformatics

Owner:ROCHE SEQUENCING SOLUTIONS INC

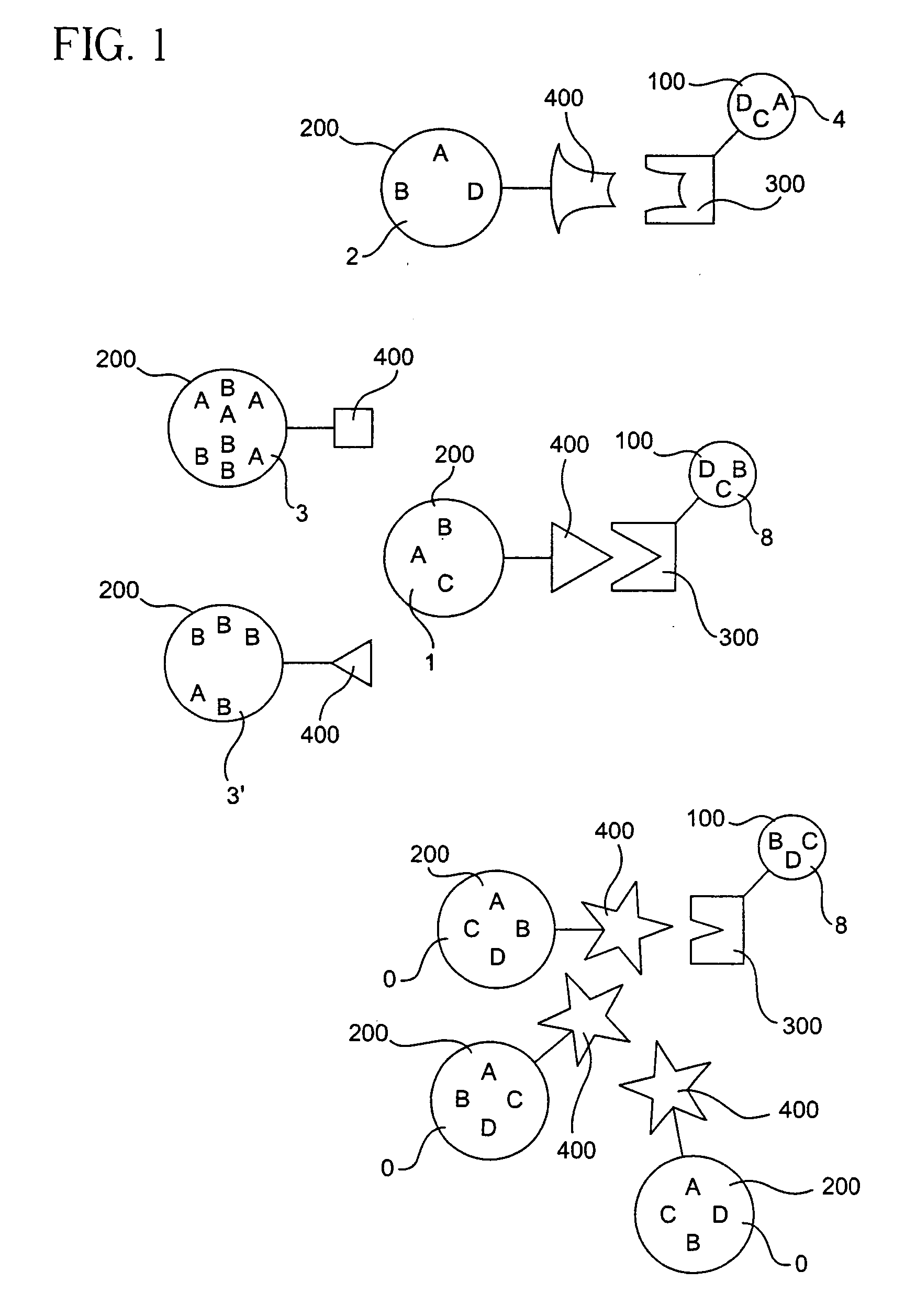

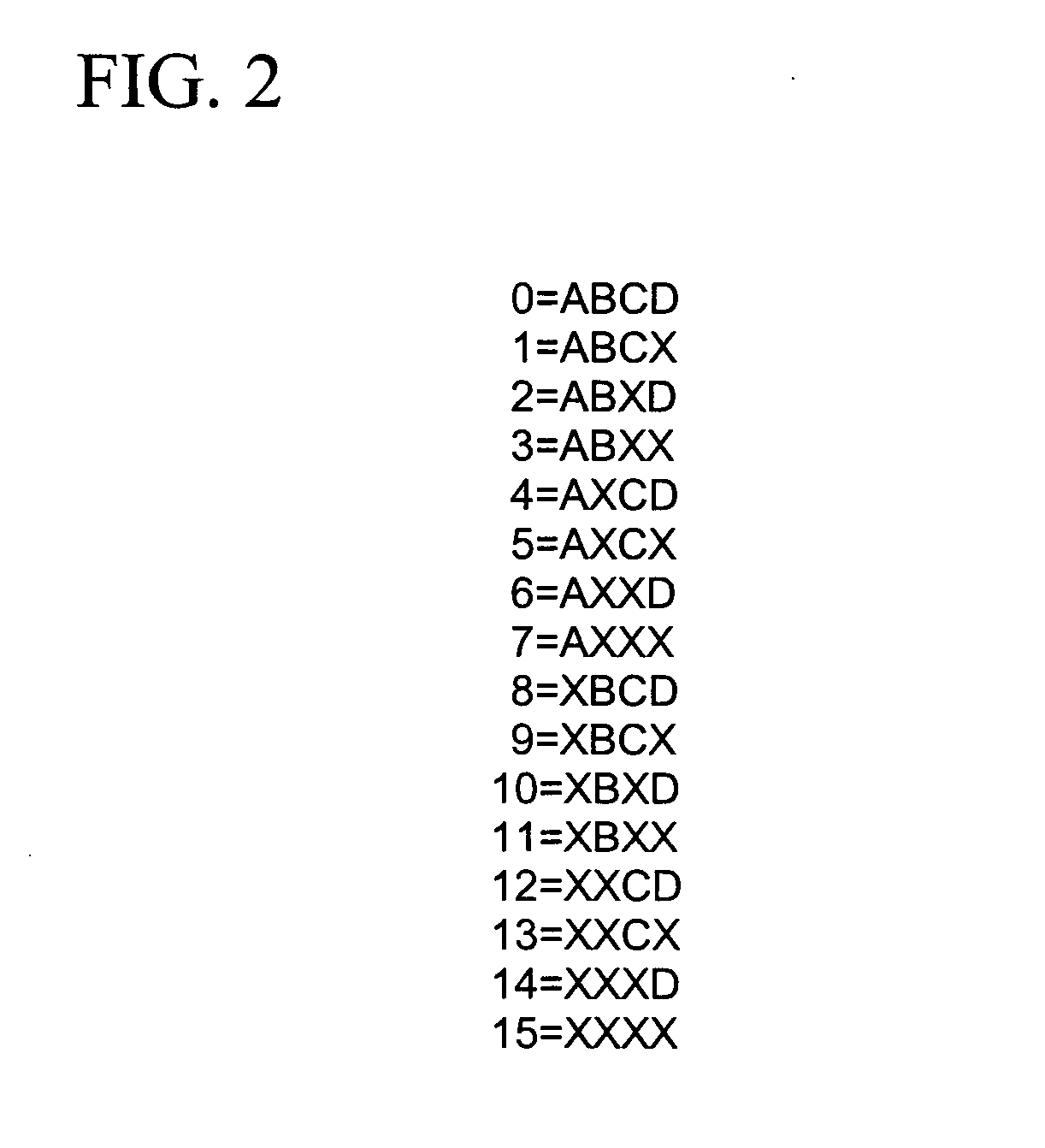

Multiplexed measurement of membrane protein populations

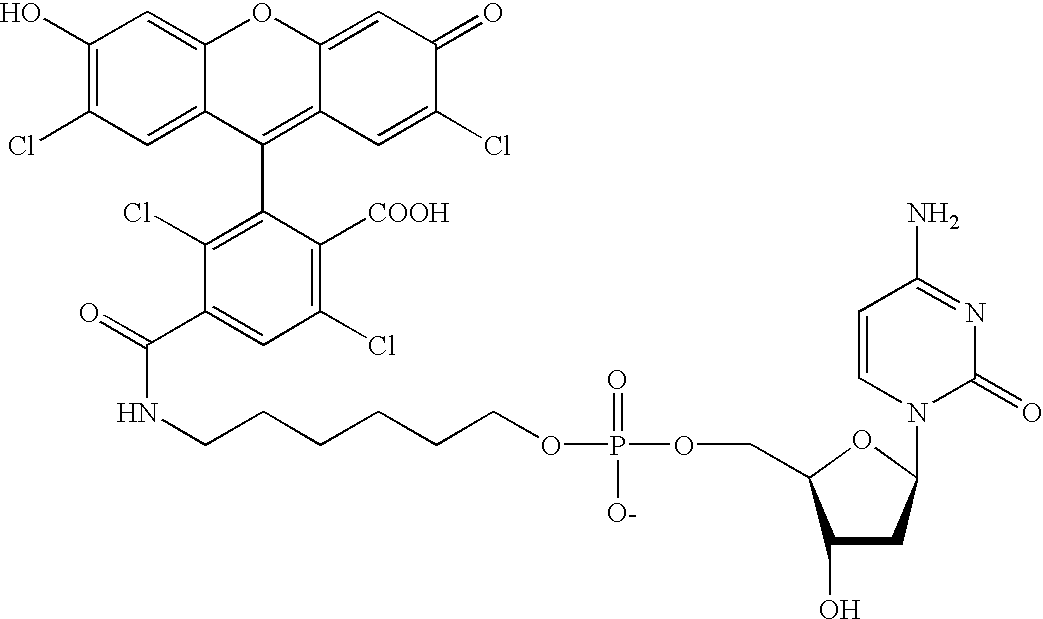

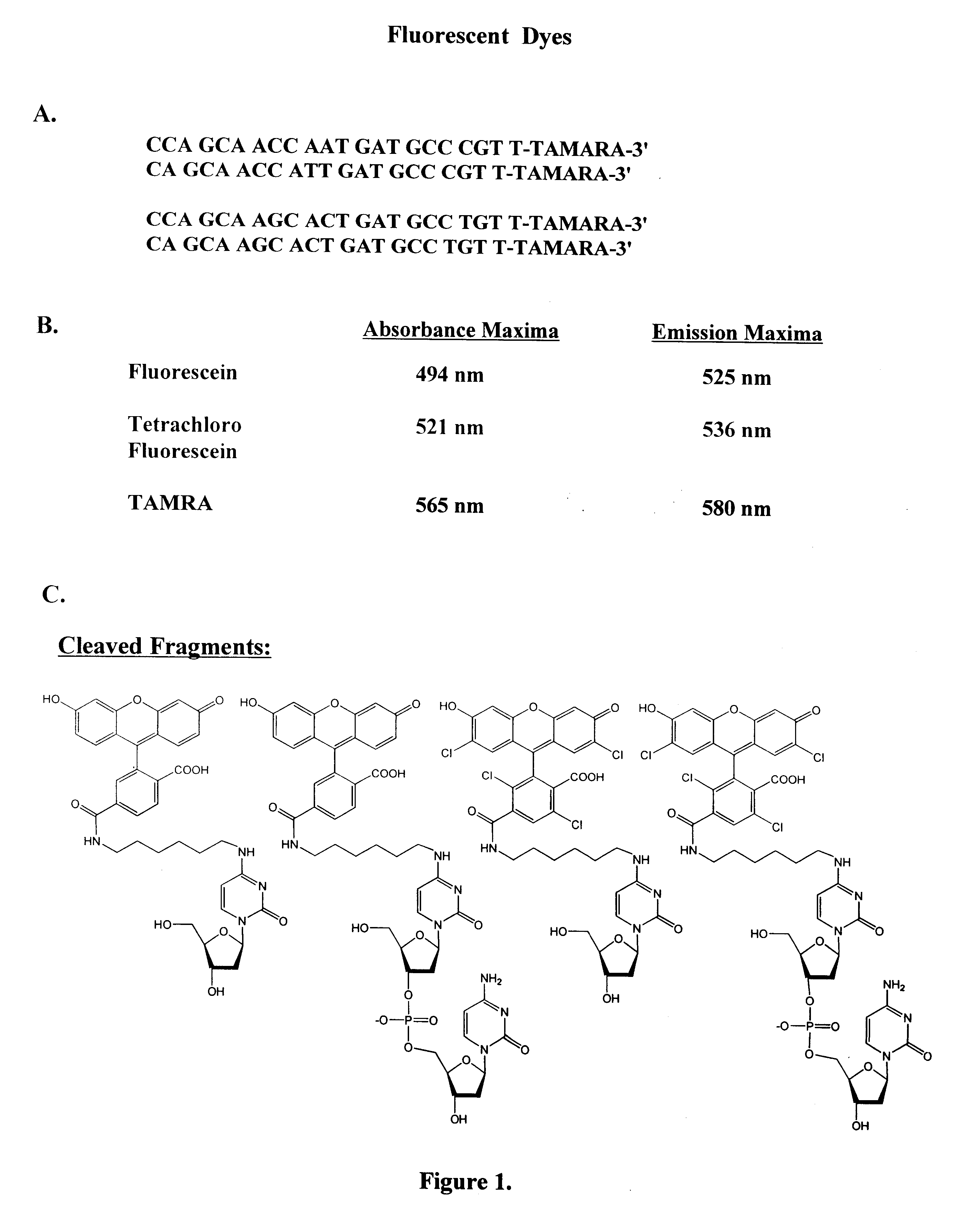

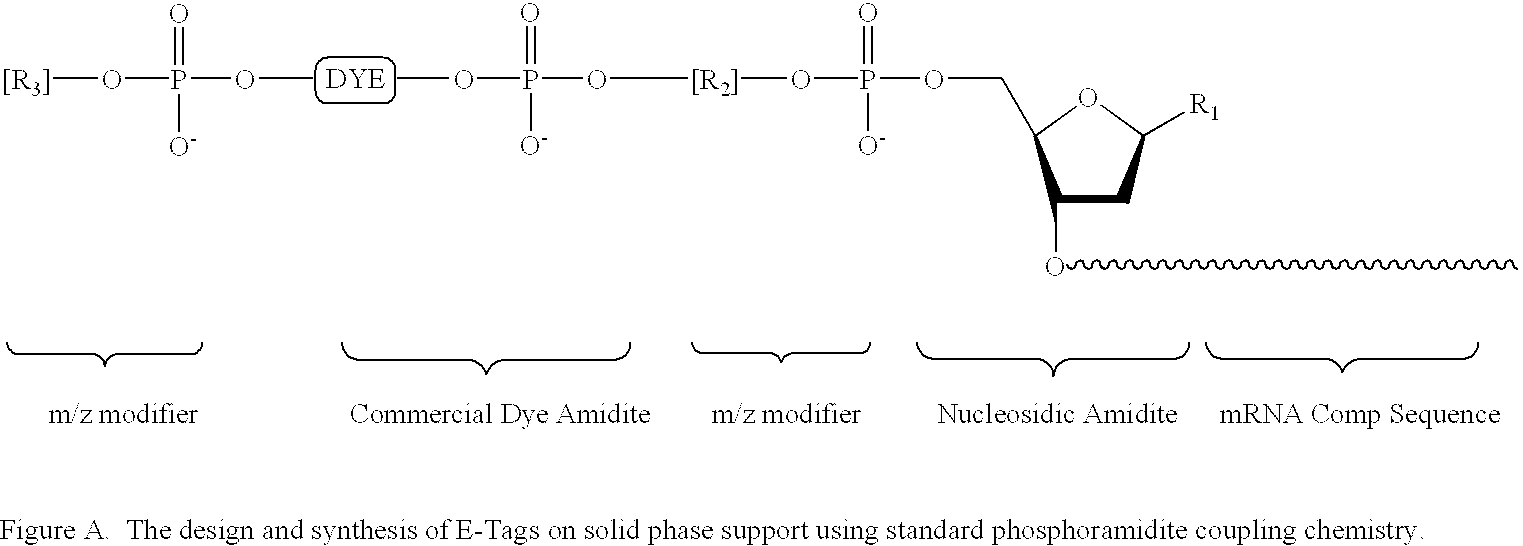

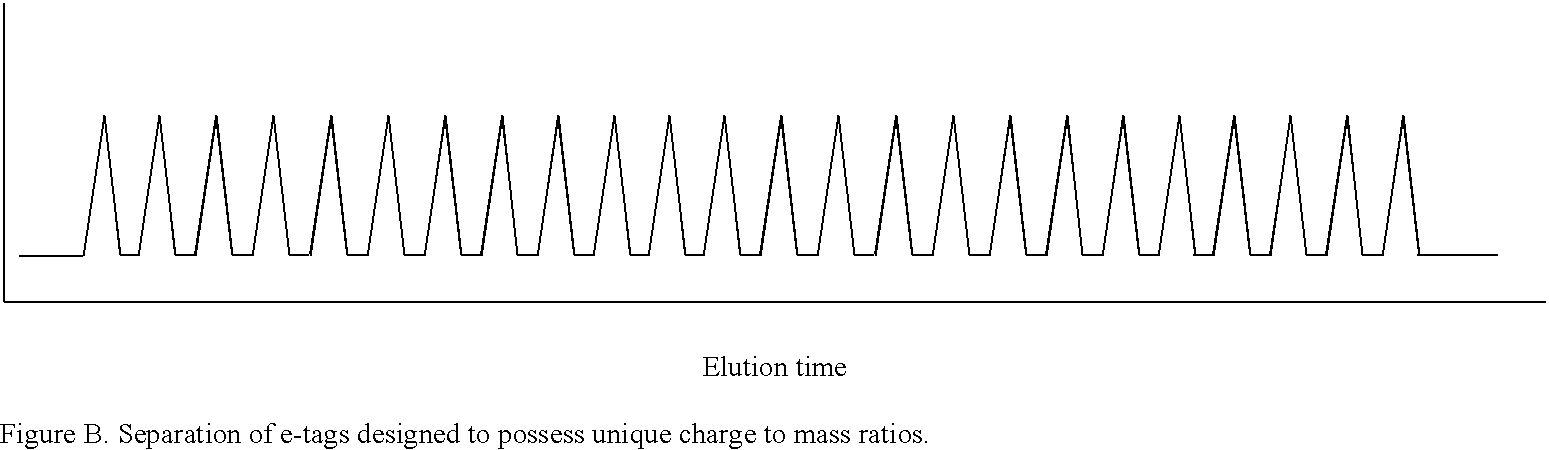

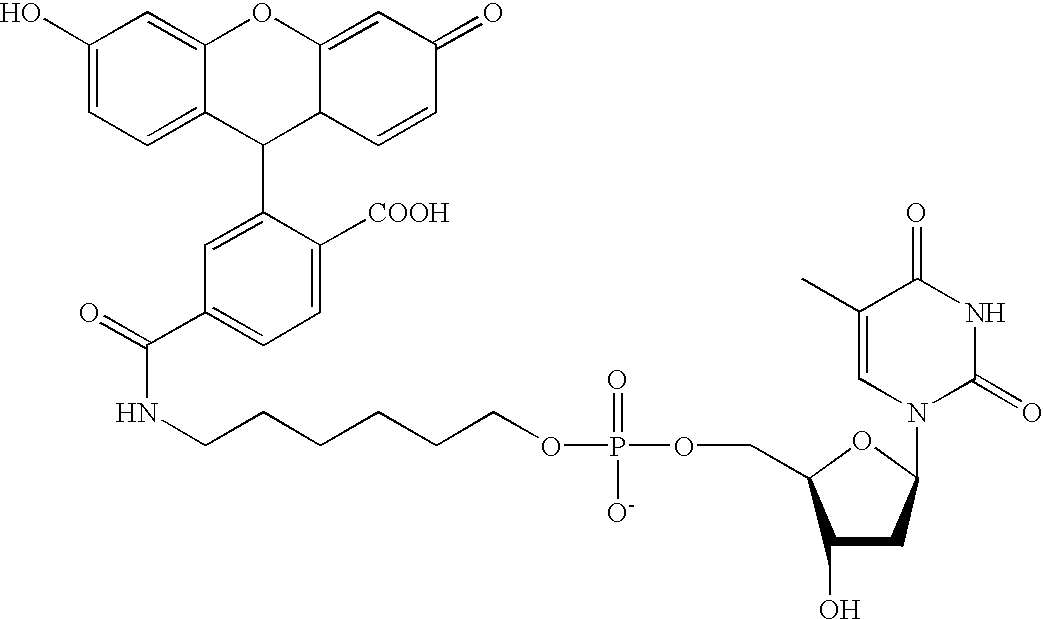

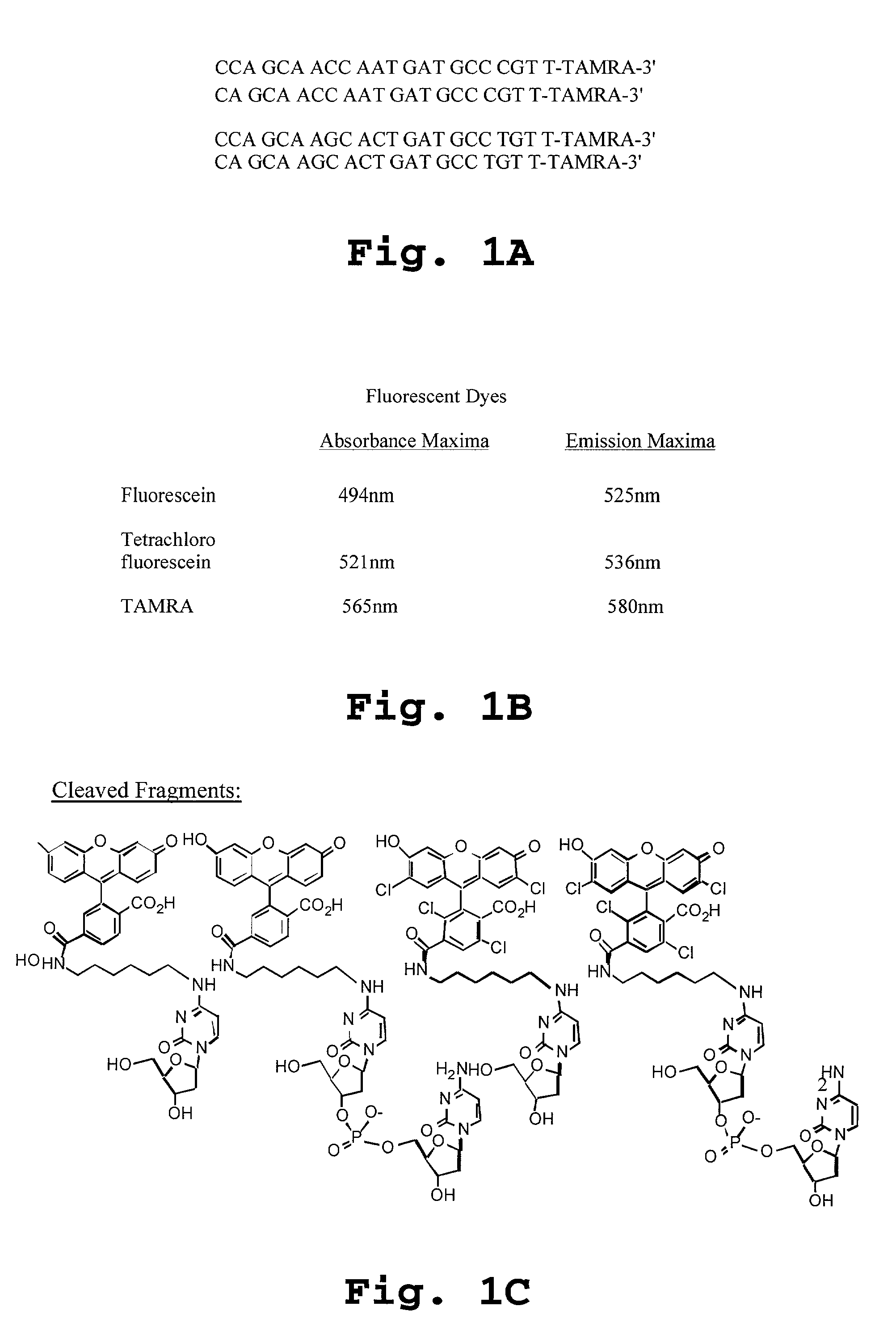

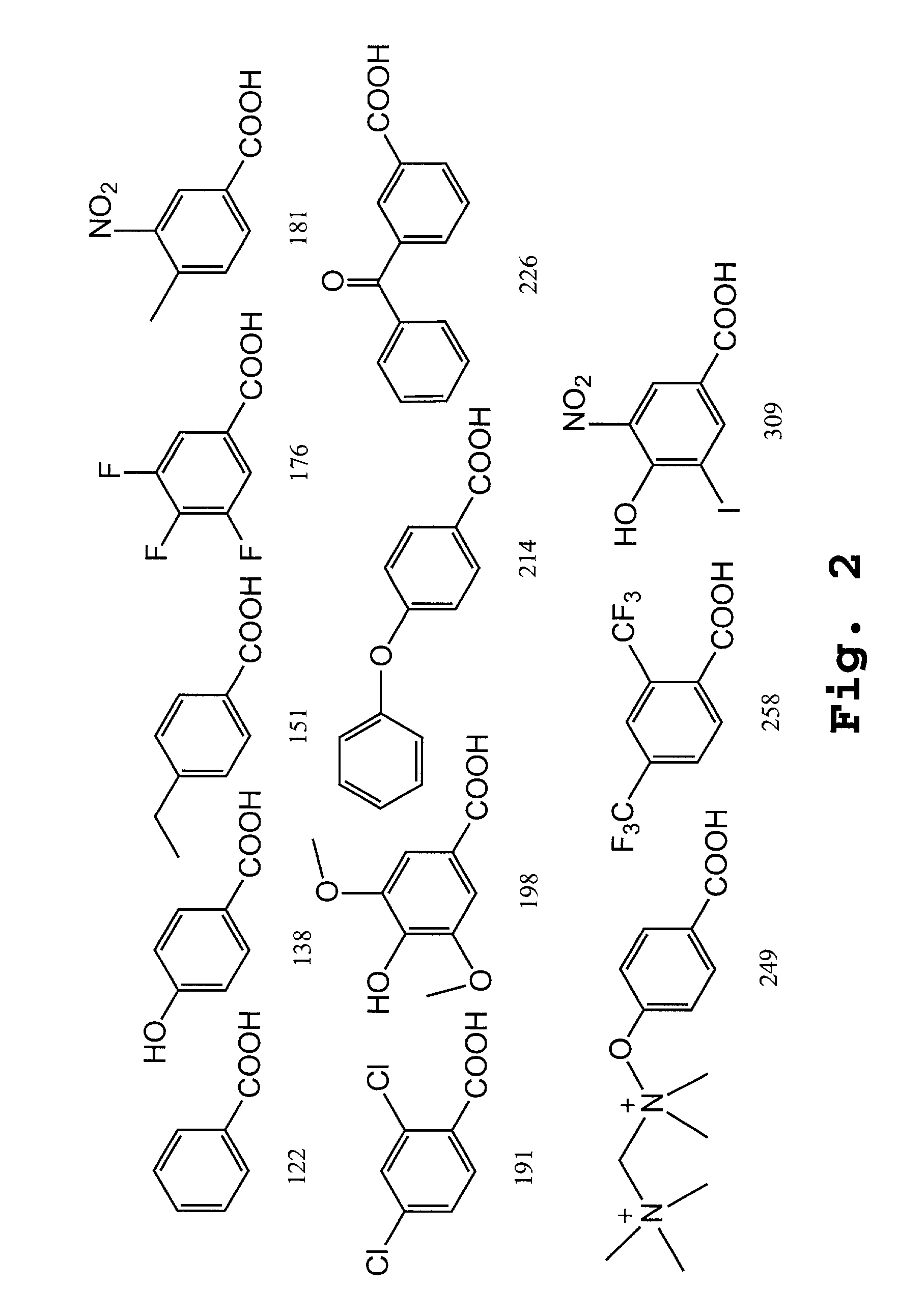

Families of compositions are provided as labels, referred to as eTag reporters for attaching to polymeric compounds and assaying based on release of the eTag reporters from the polymeric compound and separation and detection. For oligonucleotides, the eTag reporters are synthesized at the end of the oligonucleotide by using phosphite or phosphate chemistry, whereby mass-modifying regions, charge-modifying regions and detectable regions are added sequentially to produce the eTag labeled reporters. By using small building blocks and varying their combination large numbers of different eTag reporters can be readily produced attached to a binding compound specific for the target compound of interest for identification. Protocols are used that release the eTag reporter when the target compound is present in the sample.

Owner:MONOGRAM BIOSCIENCES

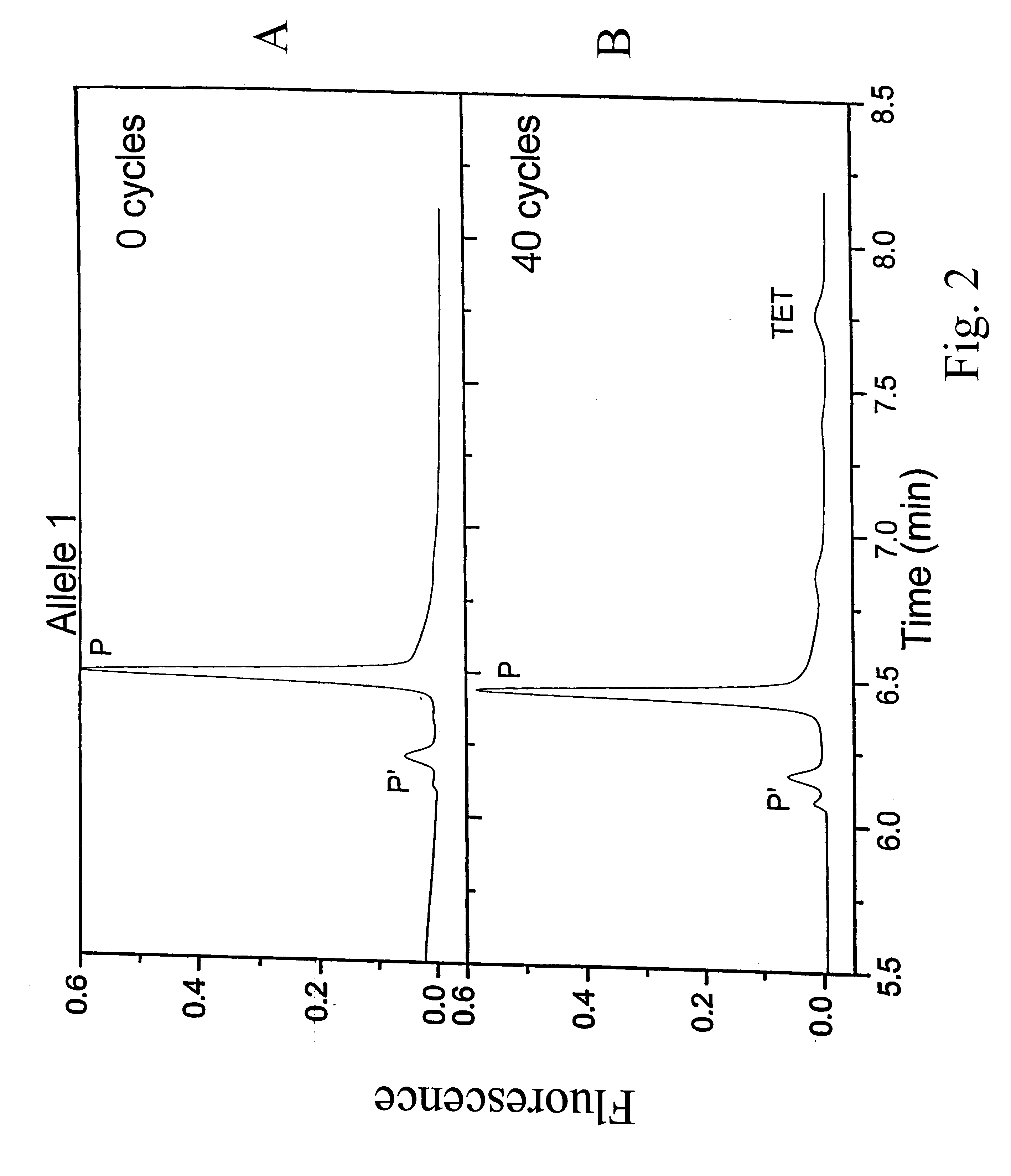

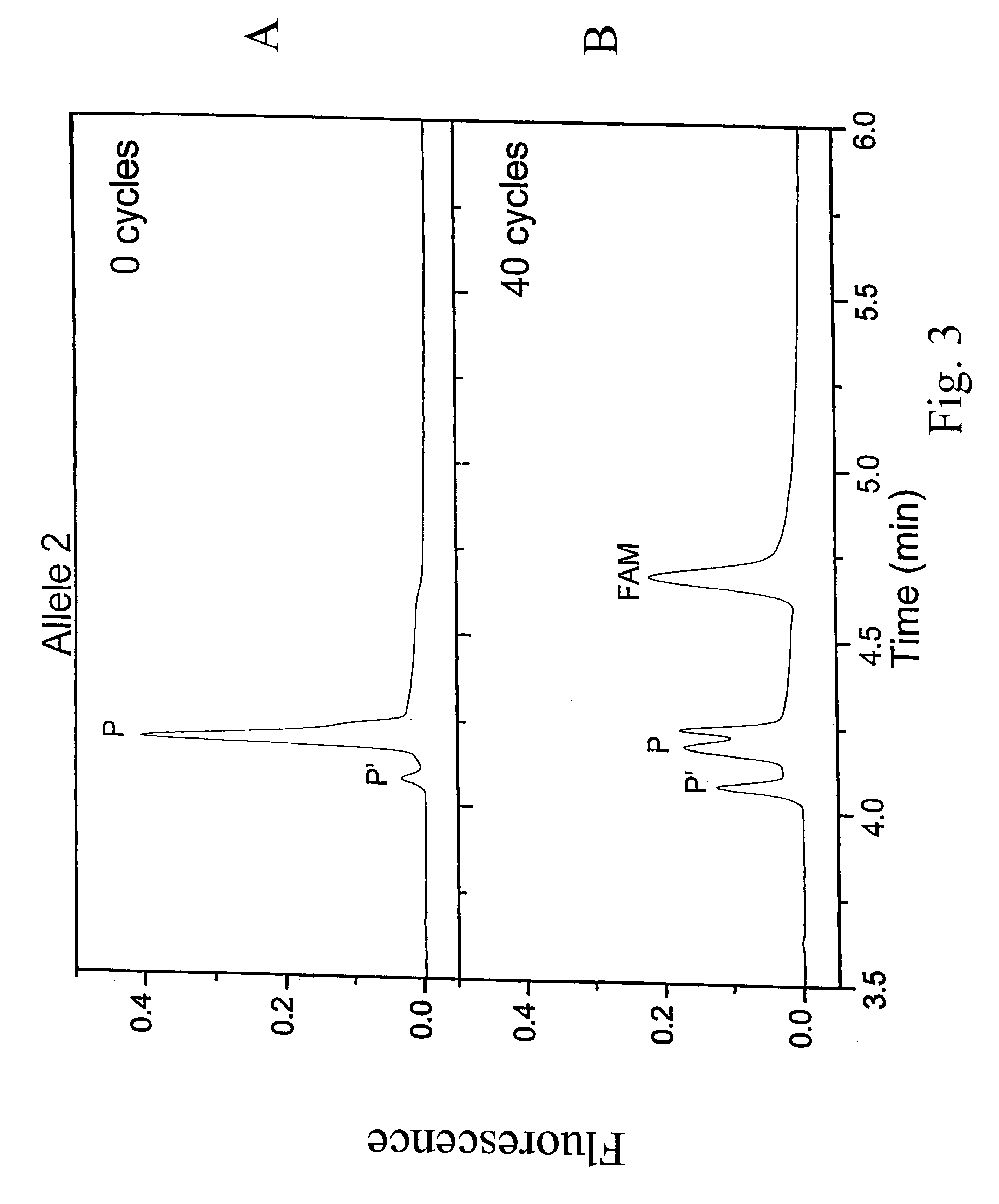

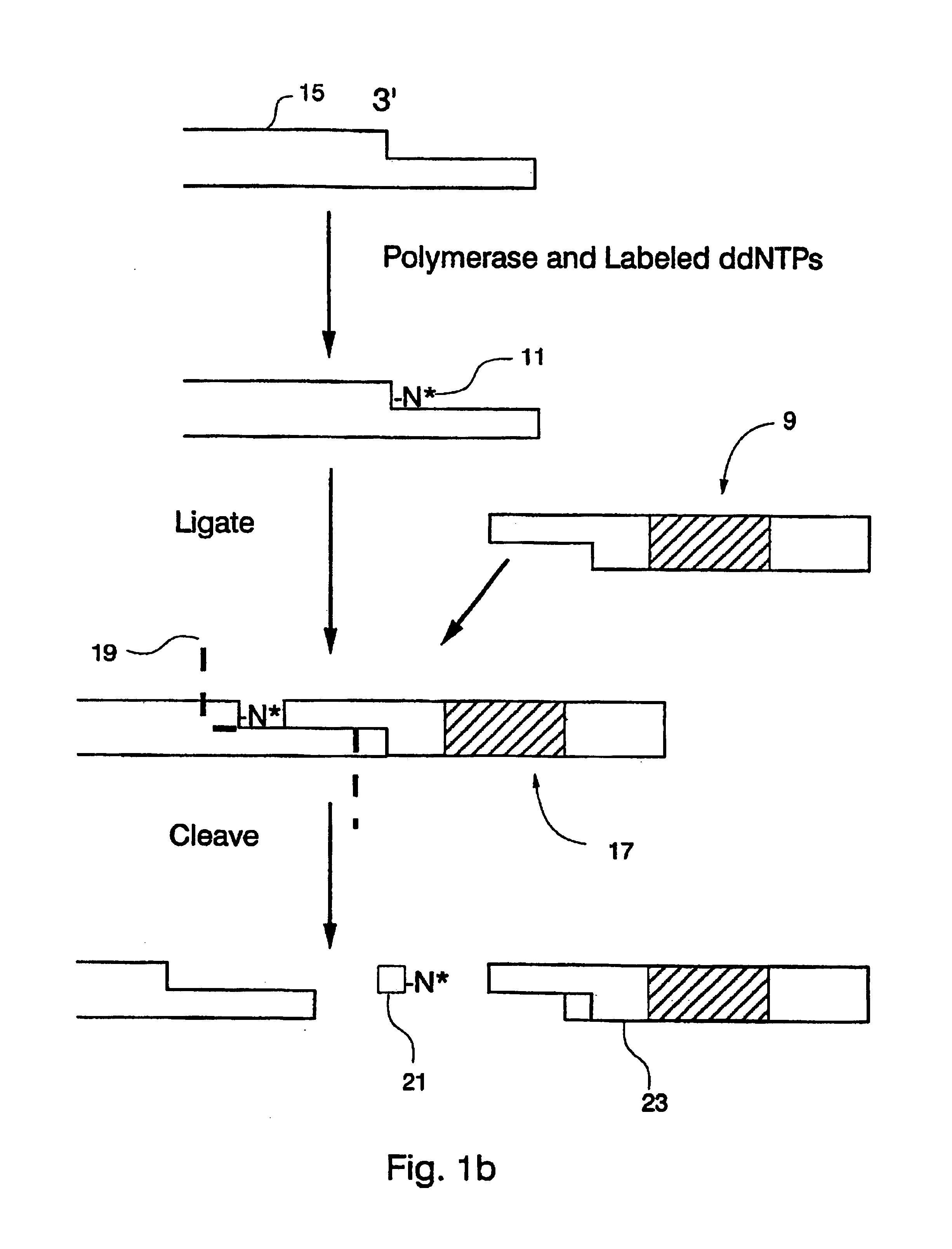

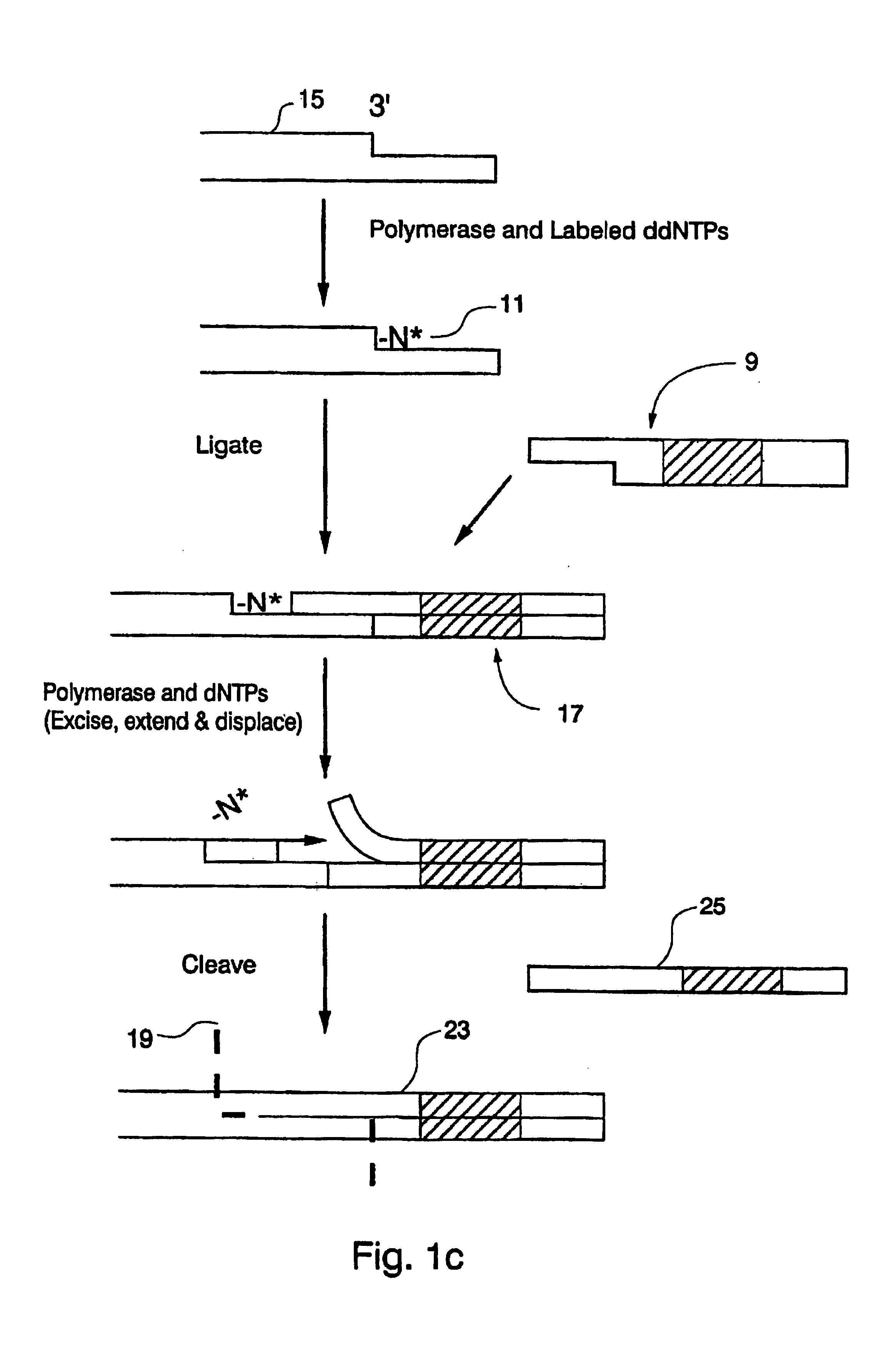

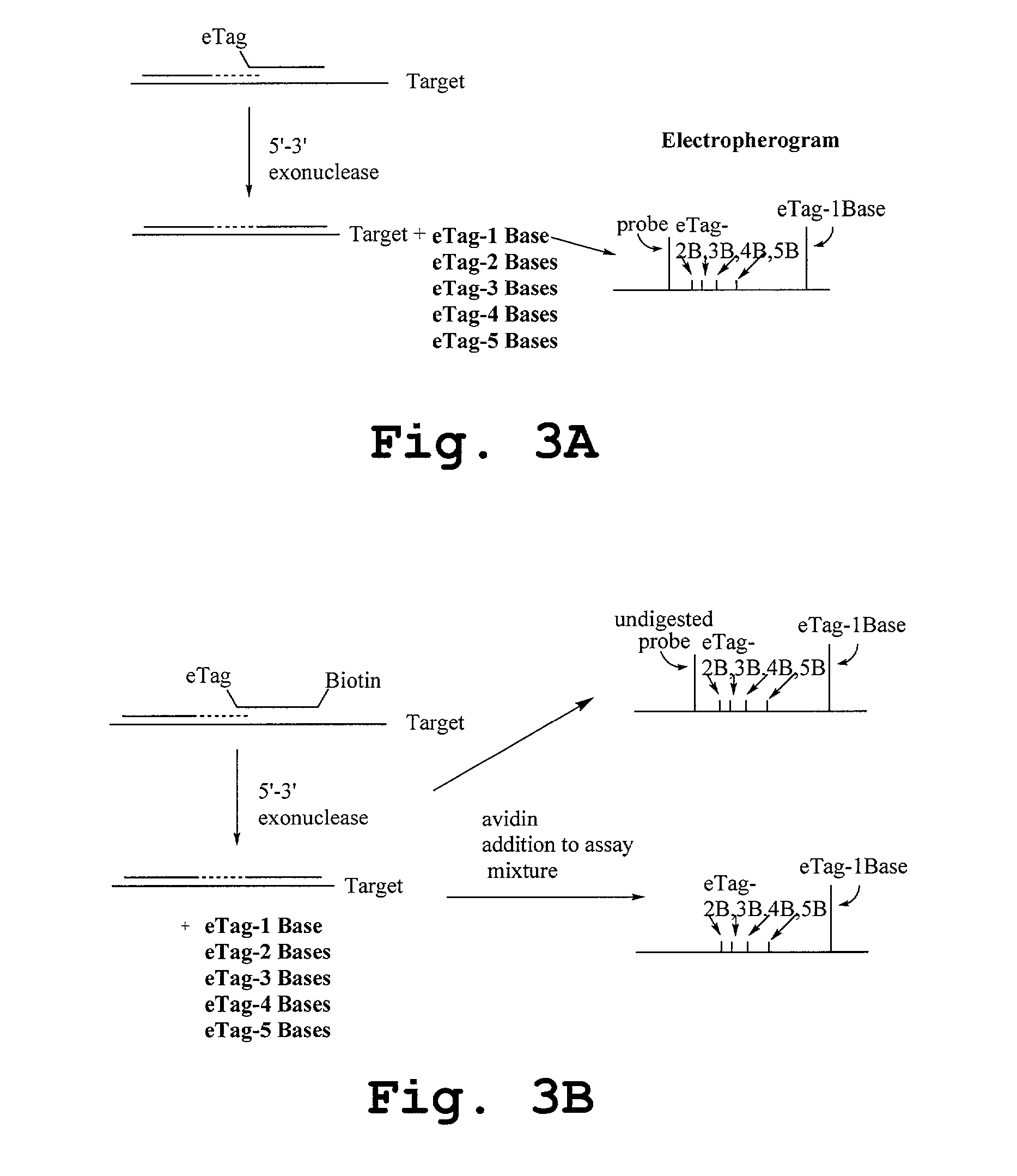

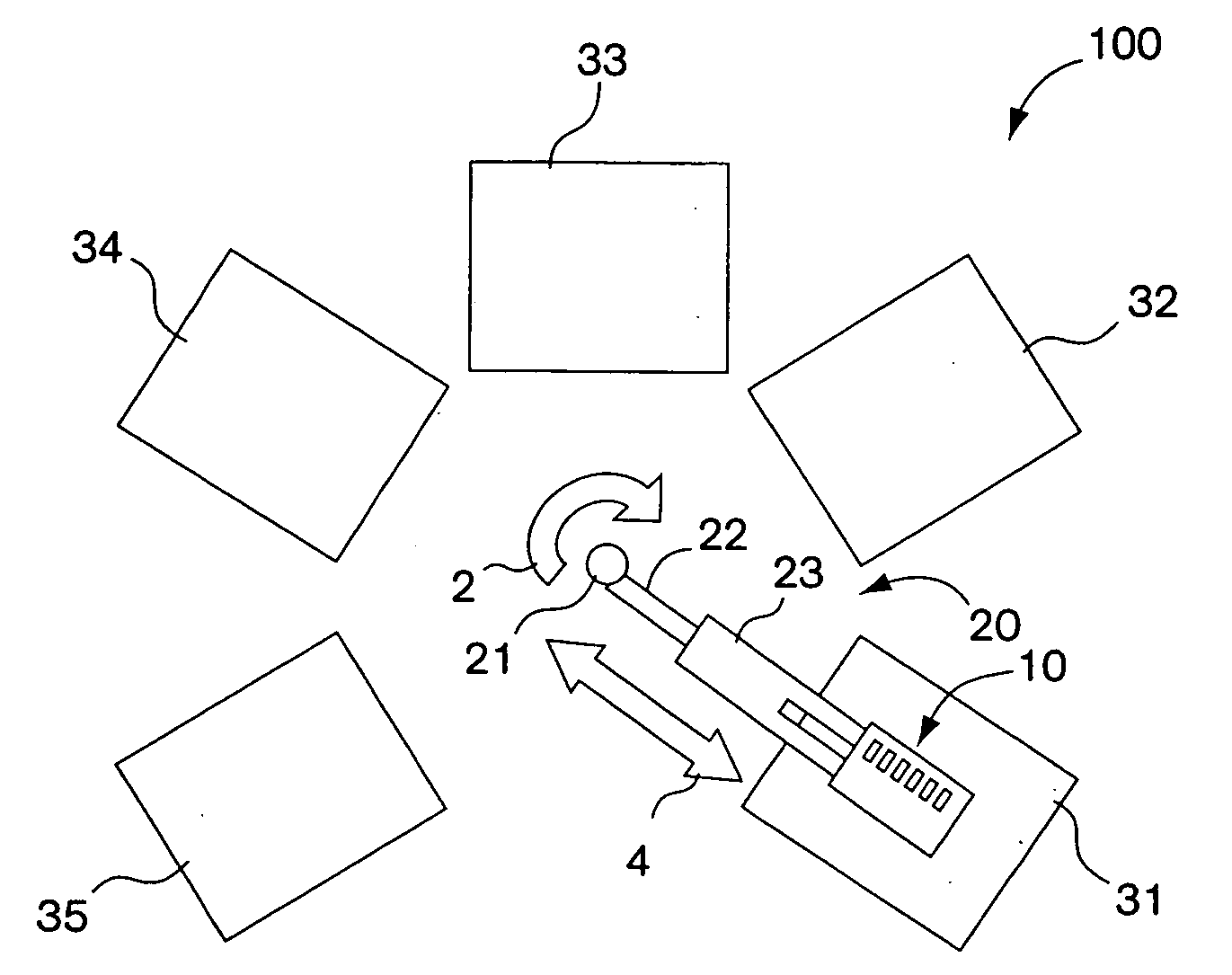

Single nucleotide detection using degradation of a fluorescent sequence

Methods and compositions are provided for detecting single nucleotide polymorphisms using a pair of oligonucleotides, a primer and a snp detection sequence, where the snp detection sequence hybridizes to the target DNA downstream from the primer and in the direction of primer extension. The snp detection sequence is characterized by having a nucleotide complementary to the snp and adjacent nucleotide complementary to adjacent nucleotides in the target and an electophoretic tag bonded to the 5'-nucleotide. The pair of oligonucleotides is combined with the target DNA under primer extension conditions, where the polymerase has 5'-3' exonuclease activity. When the snp is present, the electophoretic tag is released from the snp detection sequence, and can be detected by electrophoresis as indicative of the presence of the snp in the target DNA.

Owner:MONOGRAM BIOSCIENCES

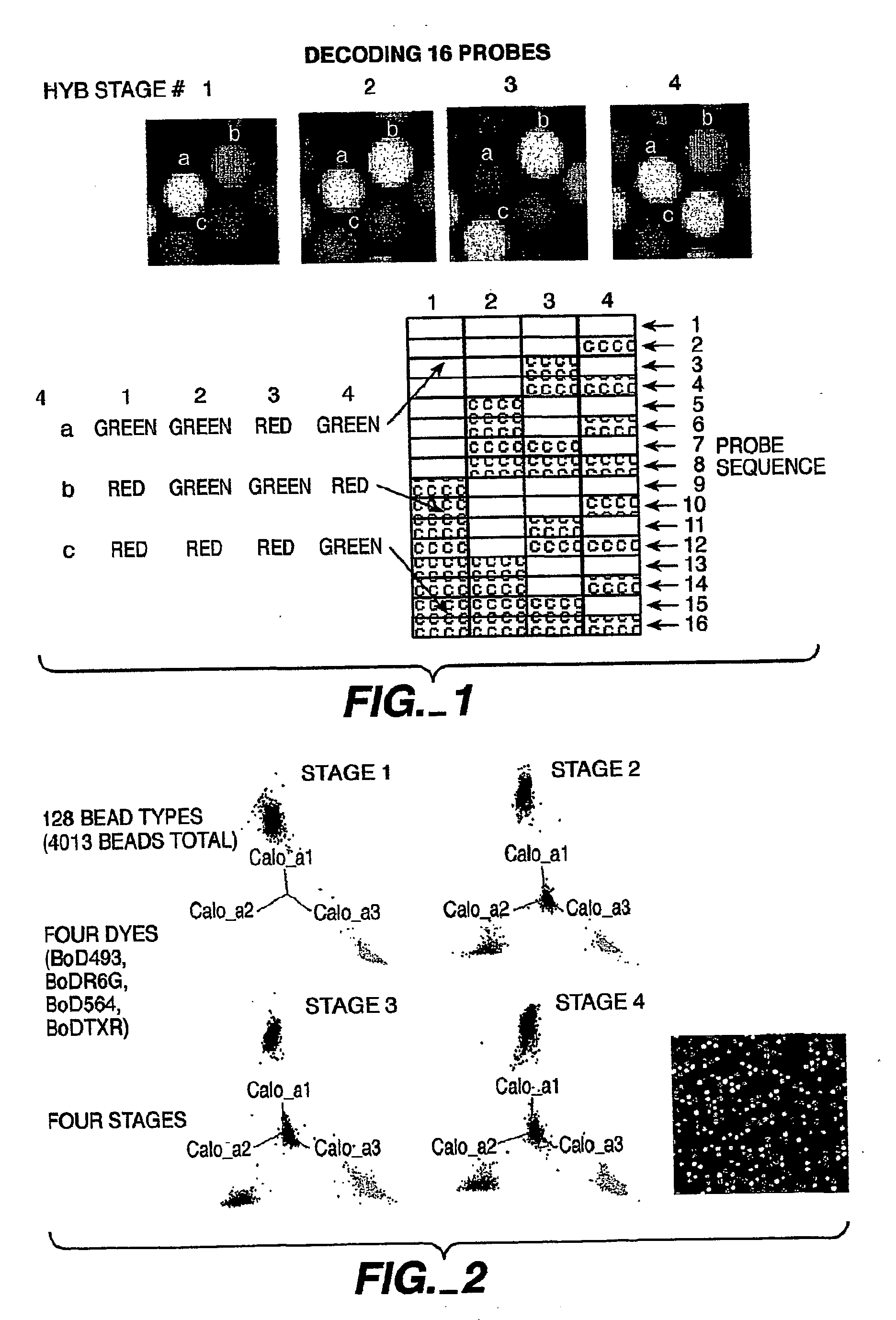

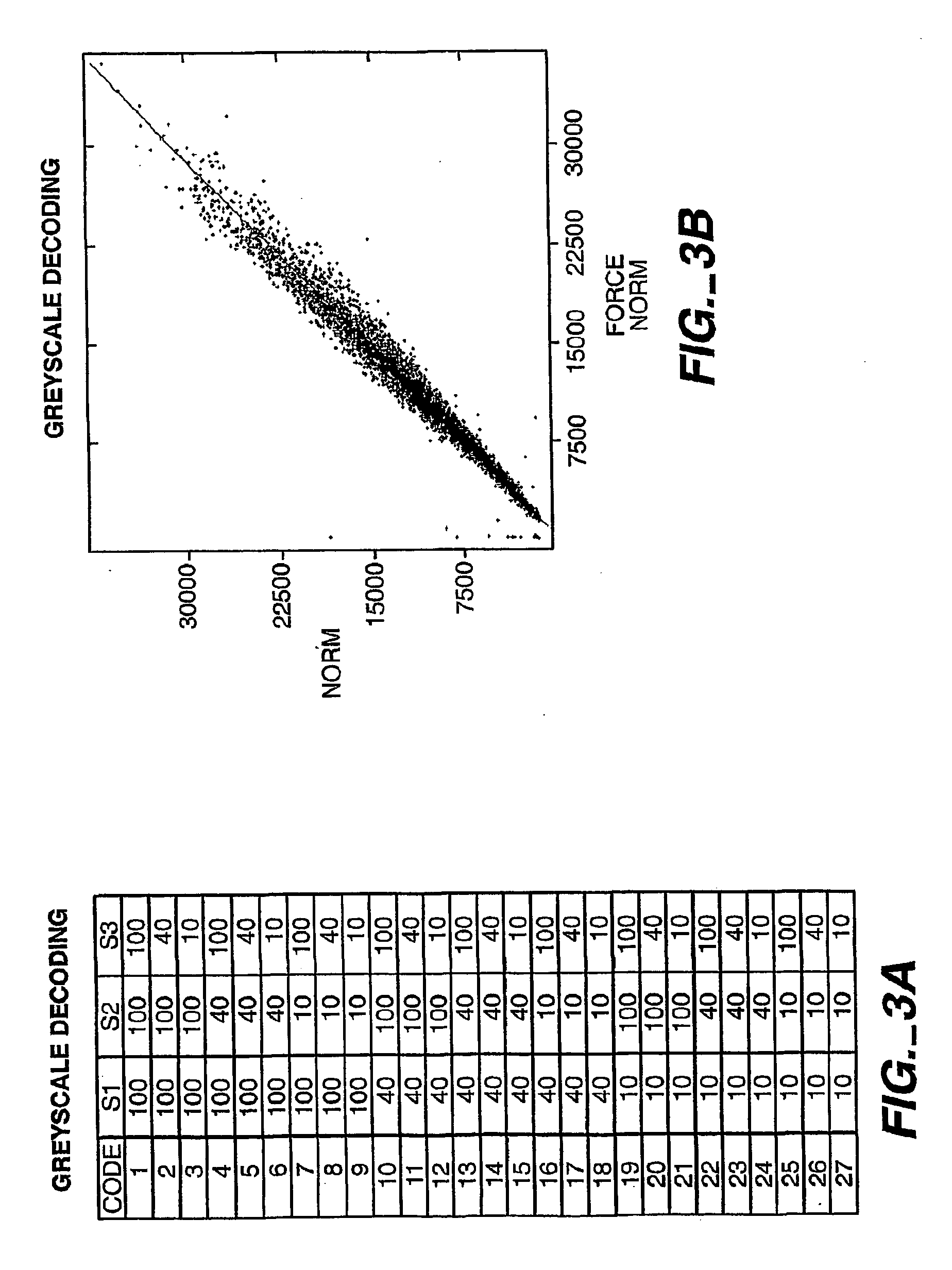

Multiplex decoding of array sensors with microspheres

InactiveUS20060073513A1ConfidenceMaterial nanotechnologySequential/parallel process reactionsMicrosphereBiology

The invention relates to compositions and methods for multiplex decoding of microsphere array sensors.

Owner:ILLUMINA INC

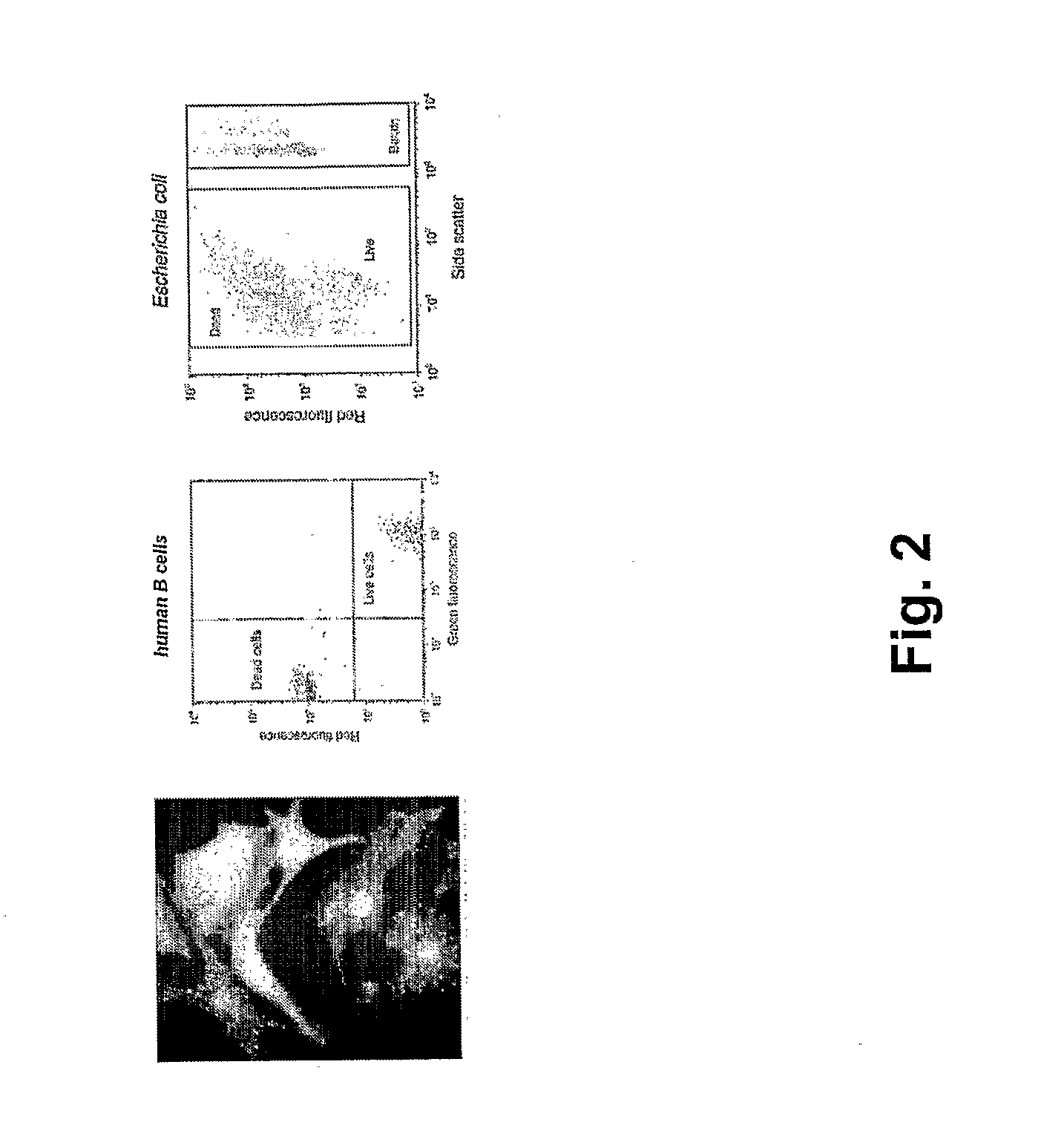

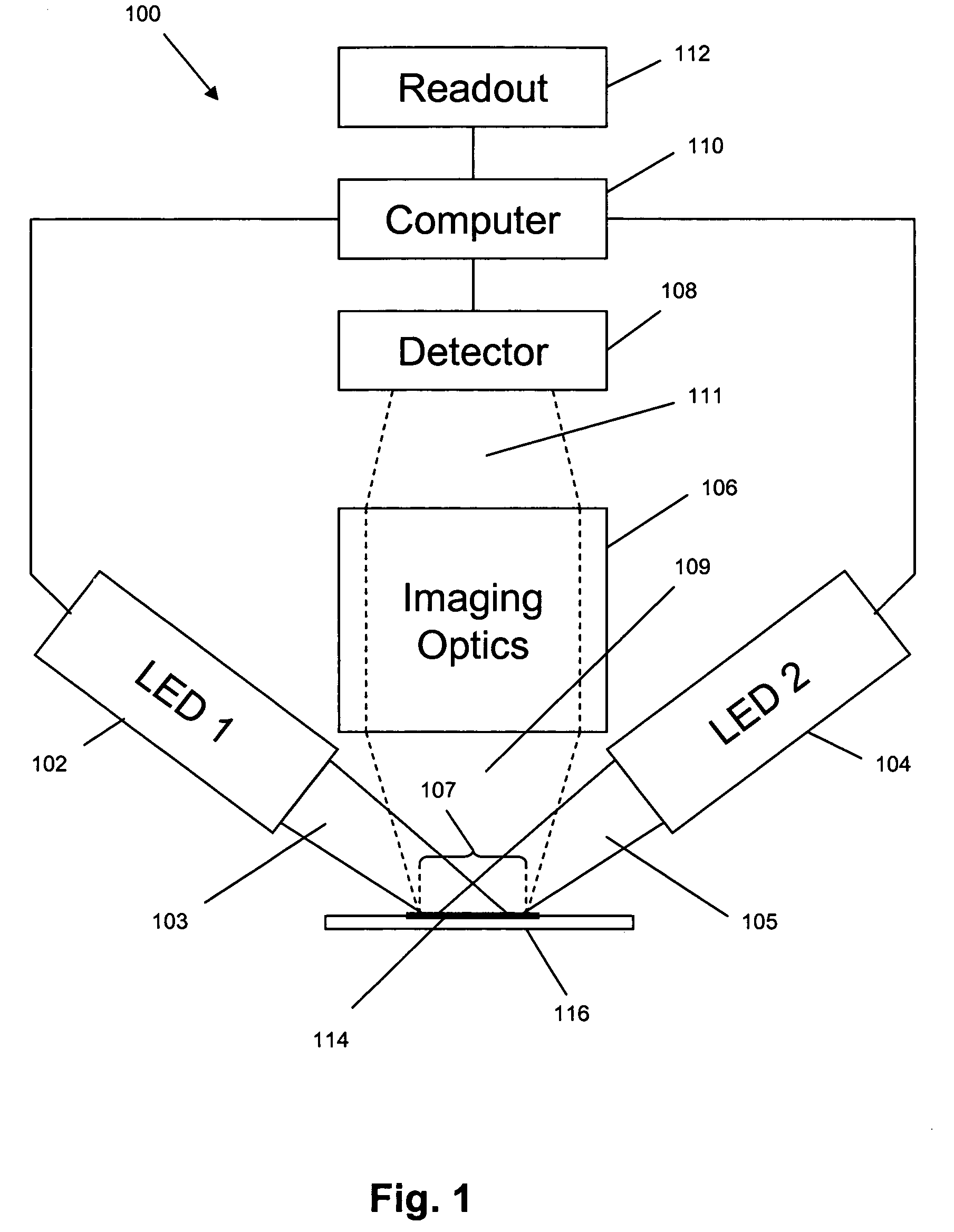

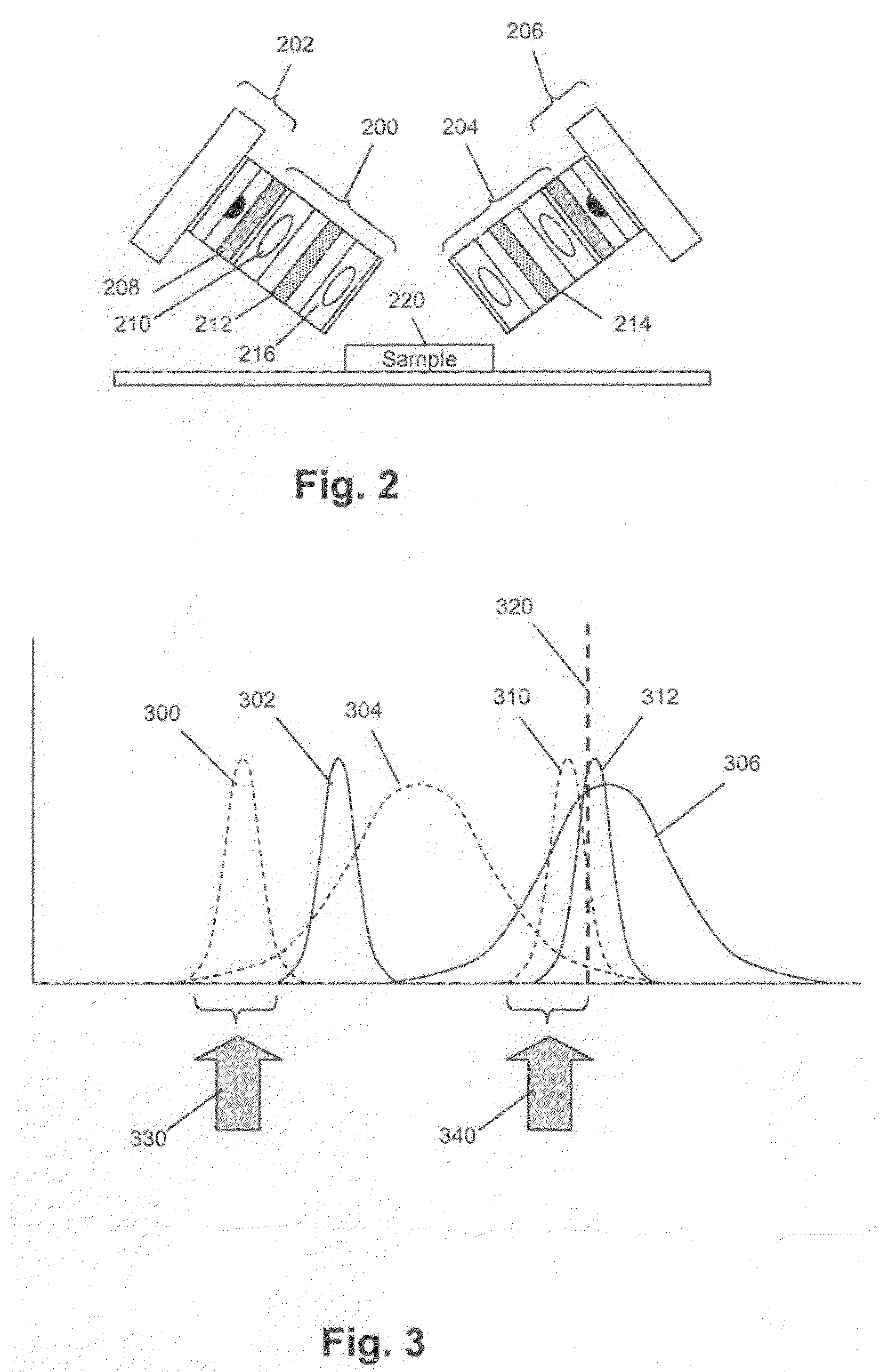

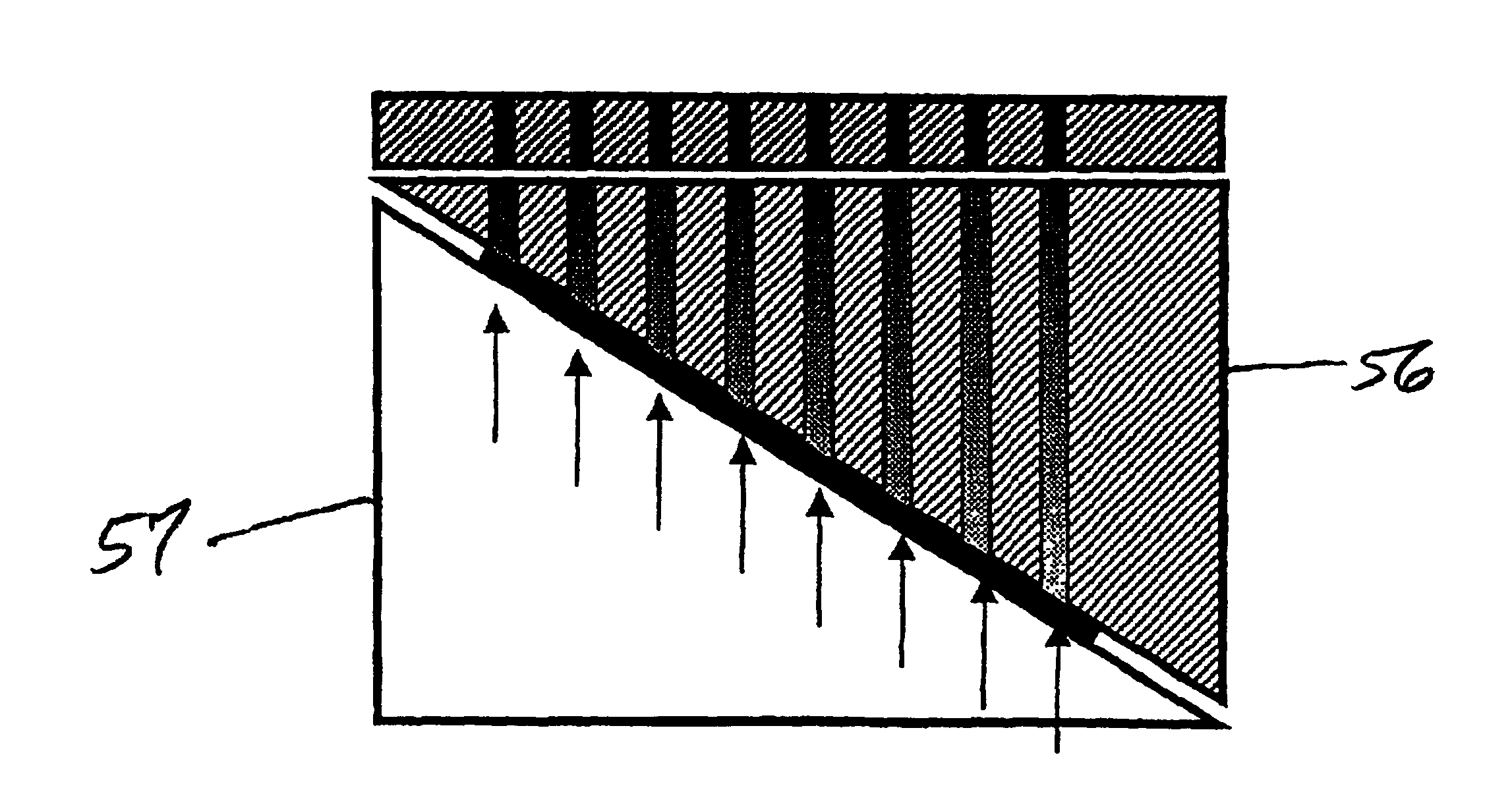

Method, system, and compositions for cell counting and analysis

ActiveUS7738094B2Low costEfficient detection and countingLibrary tagsWithdrawing sample devicesData setRed blood cell

The present invention provides a low cost imaged-based system for detecting, measuring and / or counting labeled features of biological samples, particularly blood specimens. In one aspect, the invention includes a system for imaging multiple features of a specimen that includes one or more light sources capable of successively generating illumination beams each having a distinct wavelength band and a plurality of differentially excitable labels capable of labeling a specimen comprising multiple features, such that each different feature is labeled with a different differentially excitable label. System of the invention may further include a controller operationally associated with the one or more light sources for successively directing illumination beams onto the specimen so that each of the different differentially excitable labels is successively caused to emit an optical signal within the same wavelength band, an optical system capable of collecting such emitted optical signals and forming successive images corresponding to the labeled features of the specimen on a light-responsive surface to form successive sets of image data thereof, and a disposable cuvette for collection and optical analysis of non-red blood cells.

Owner:BECTON DICKINSON & CO

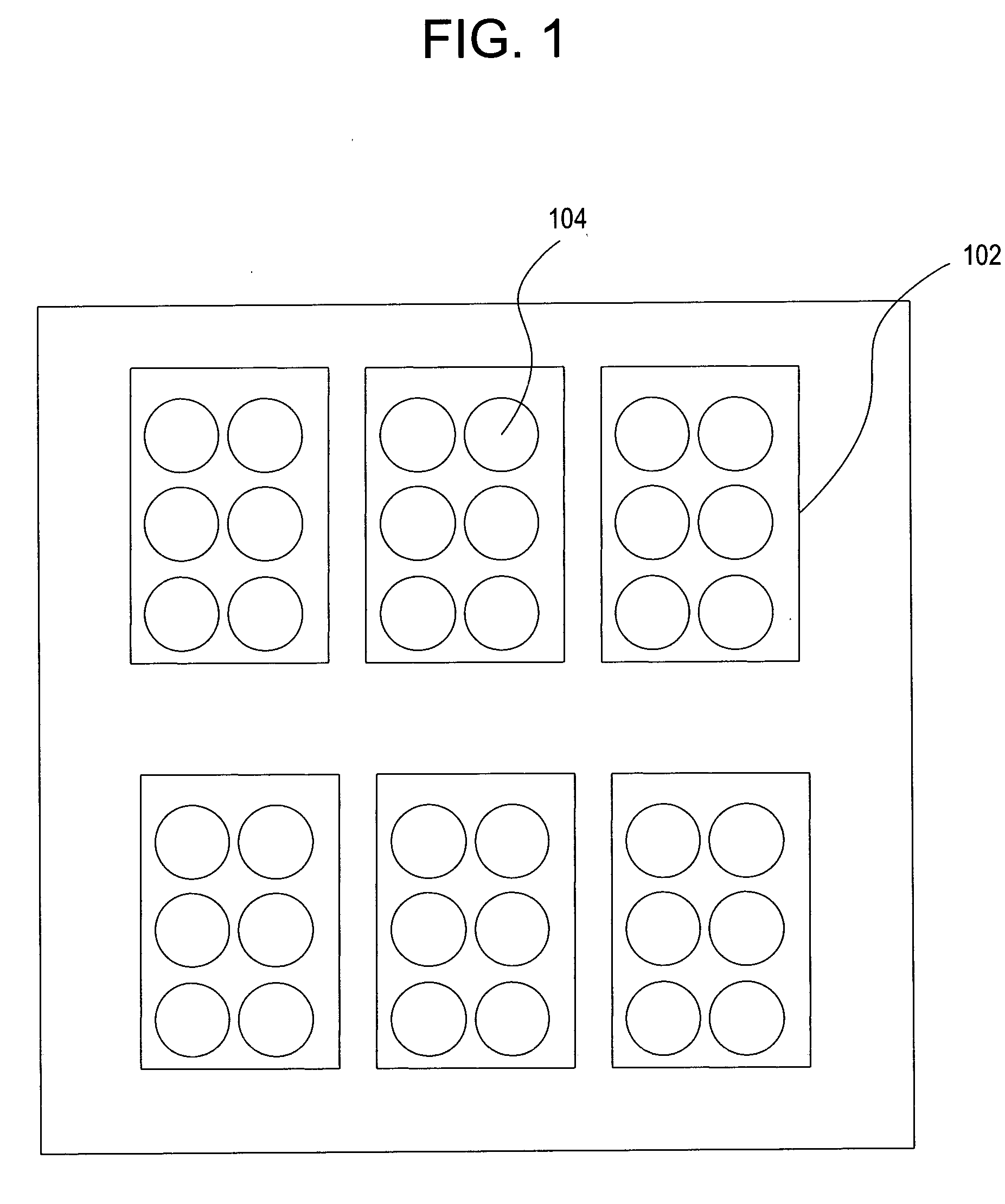

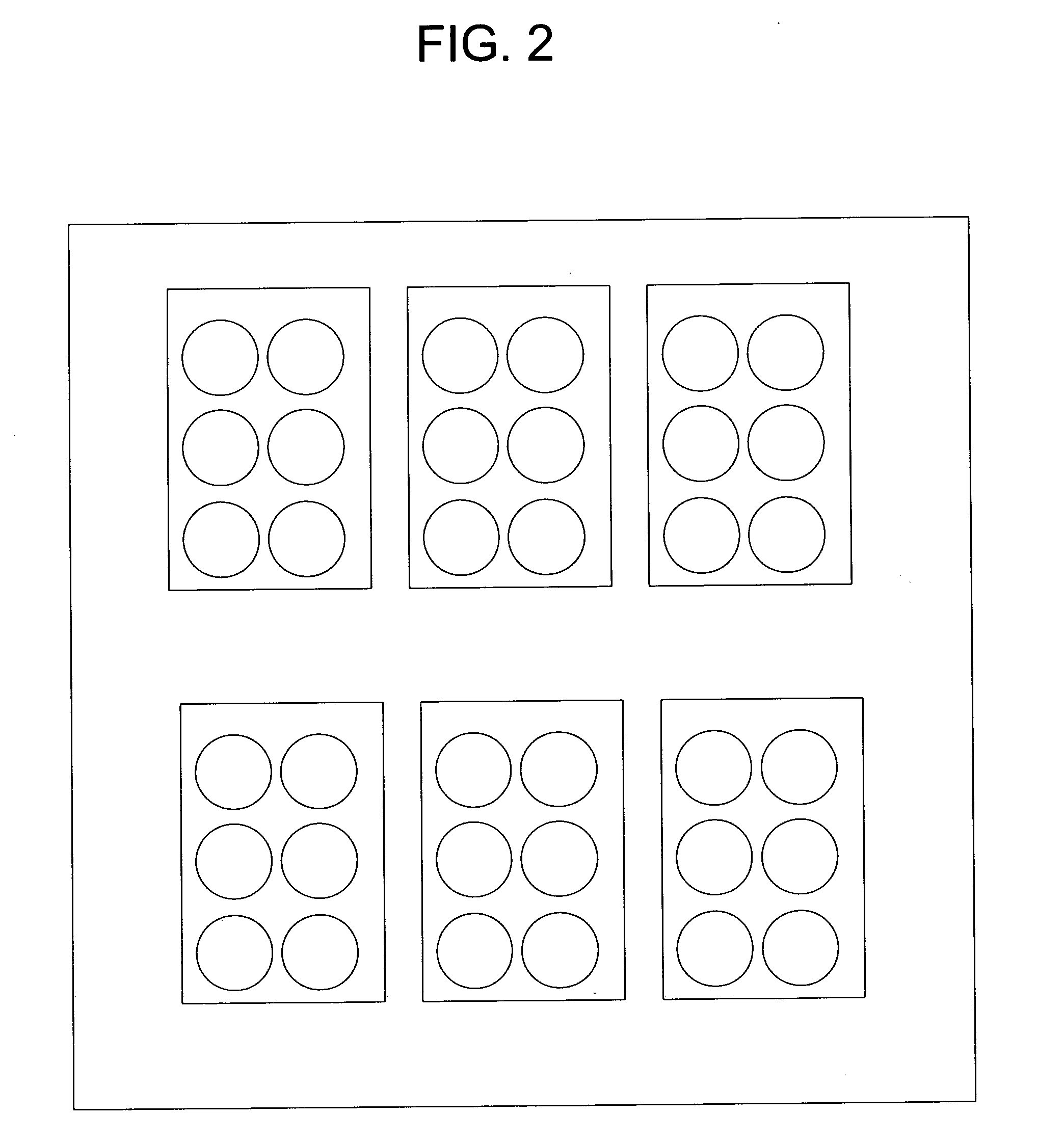

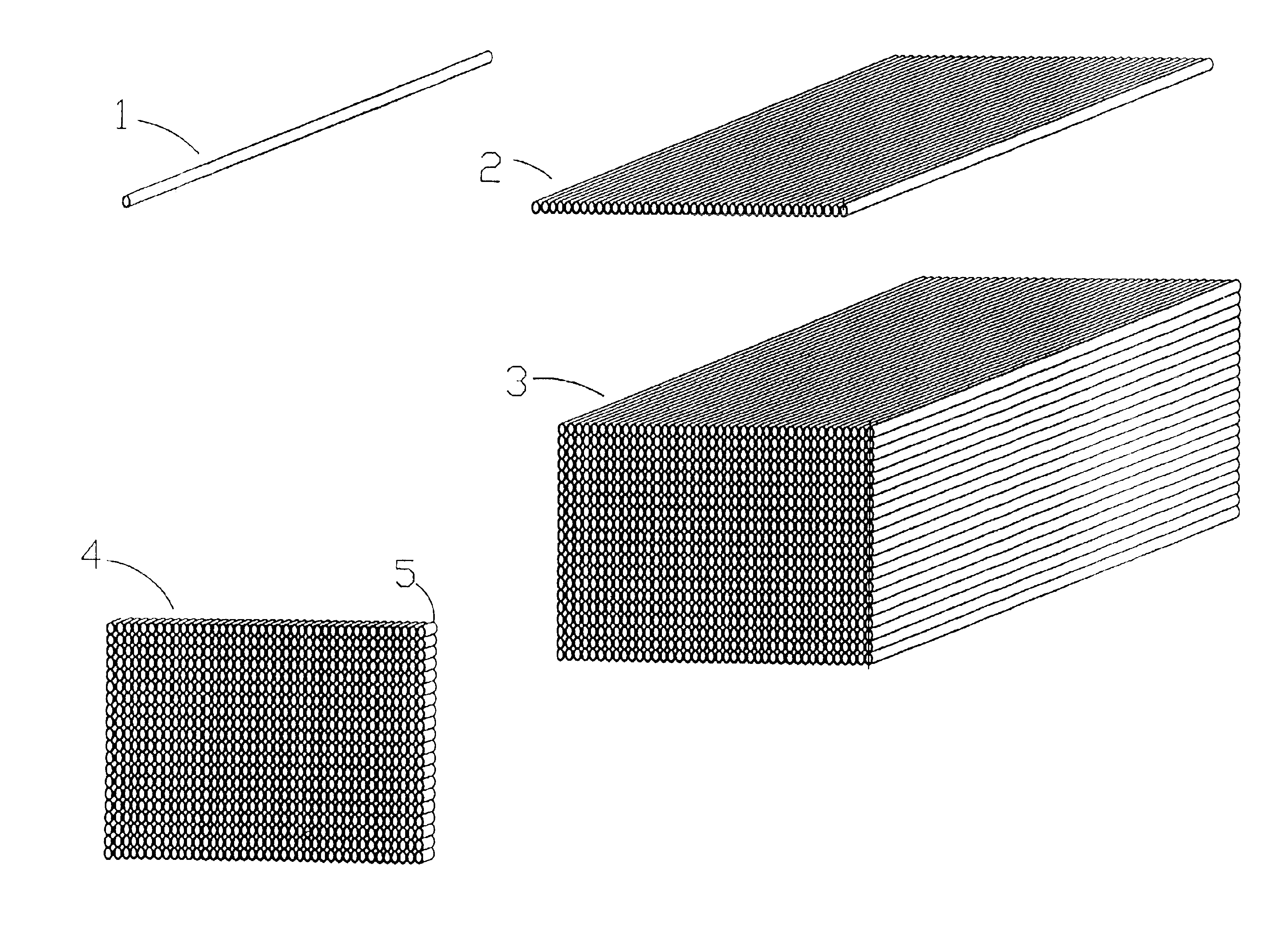

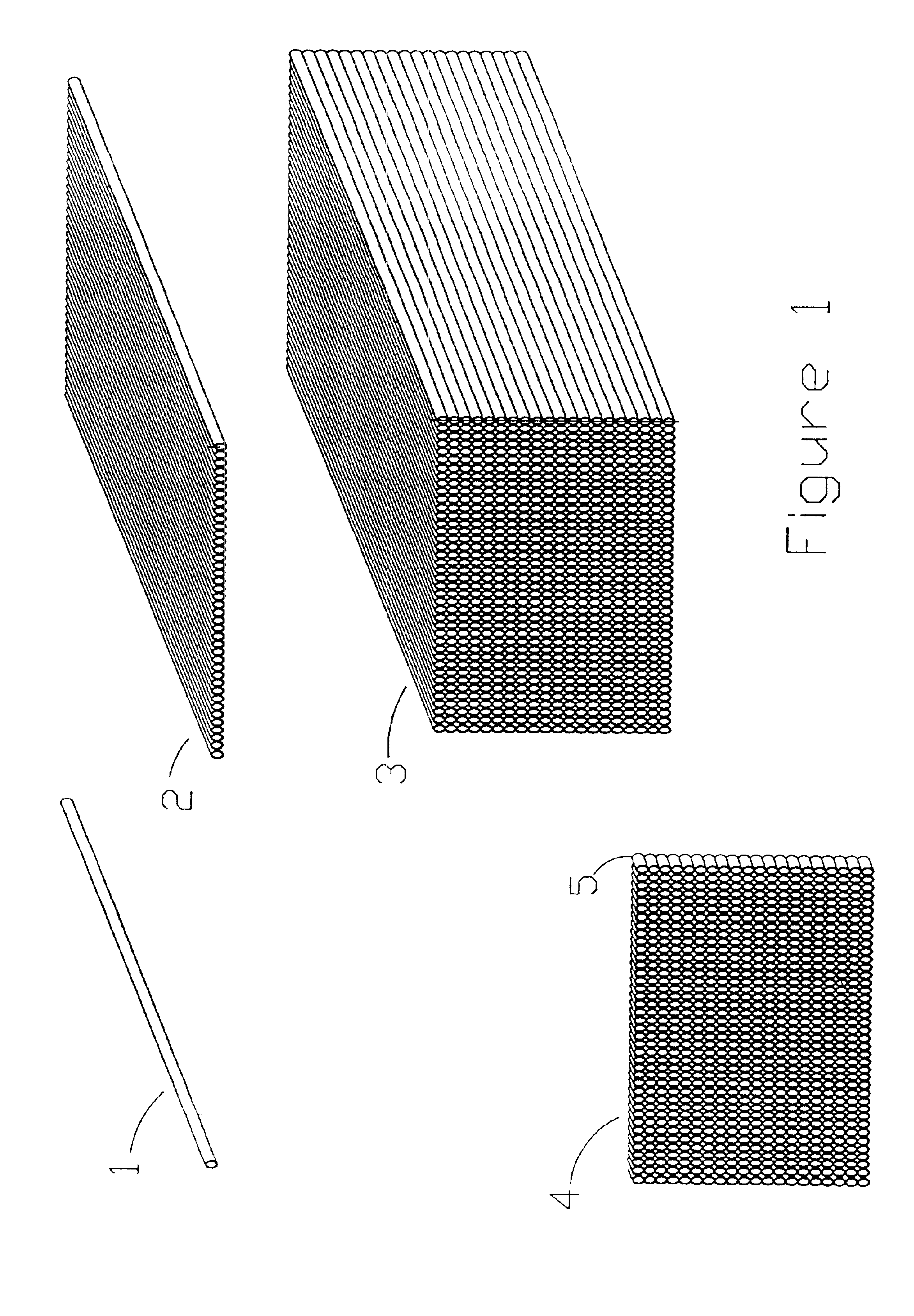

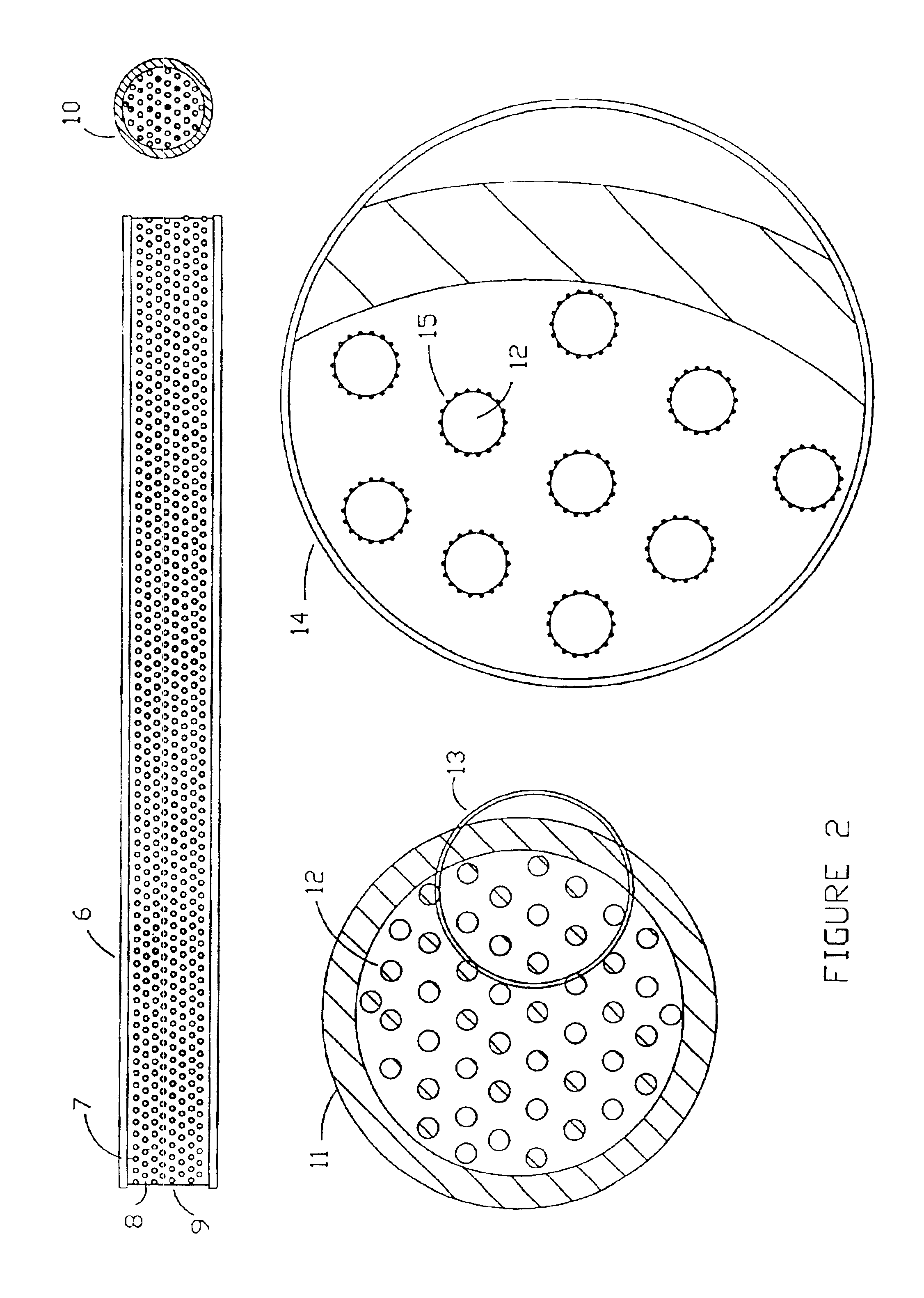

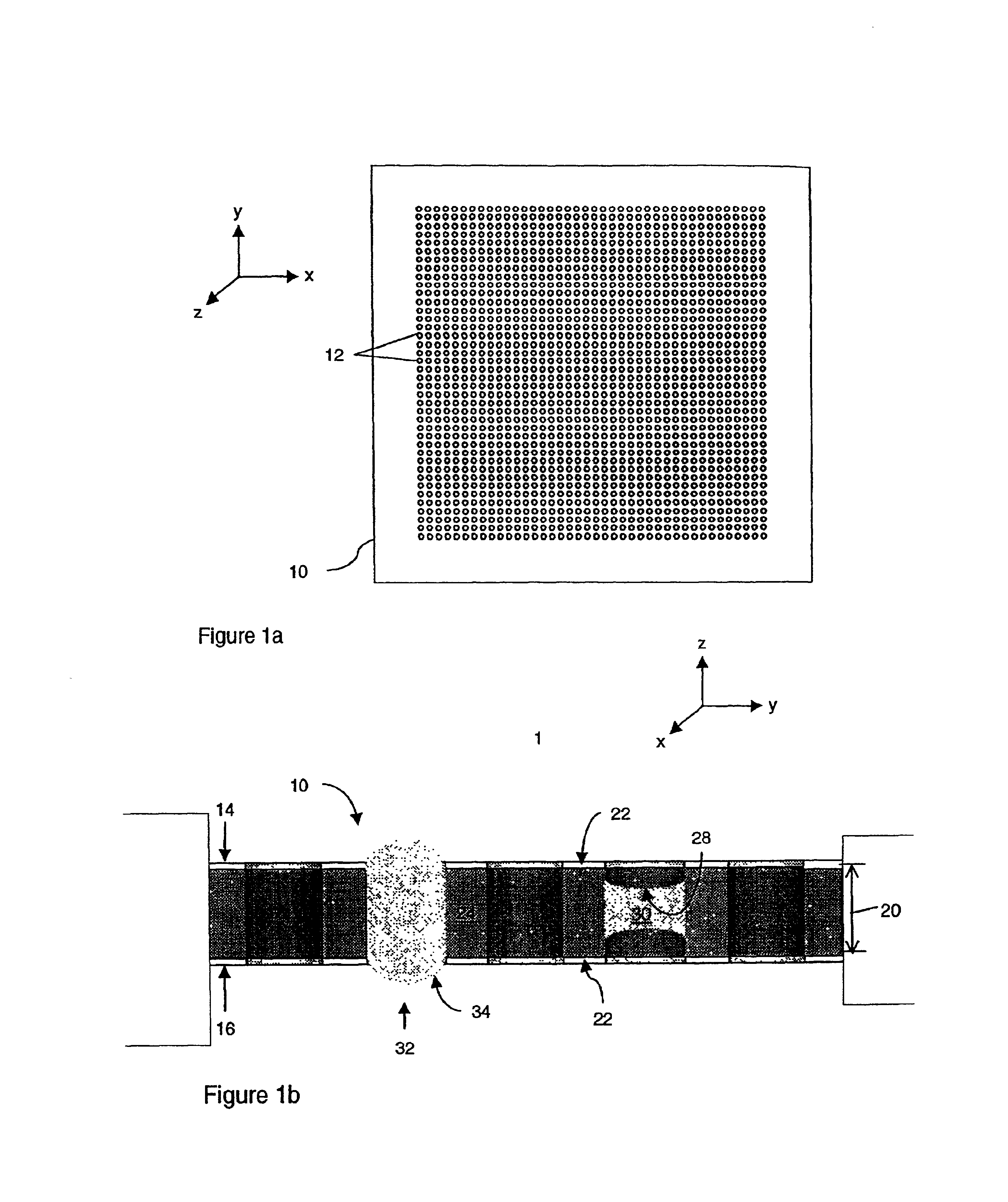

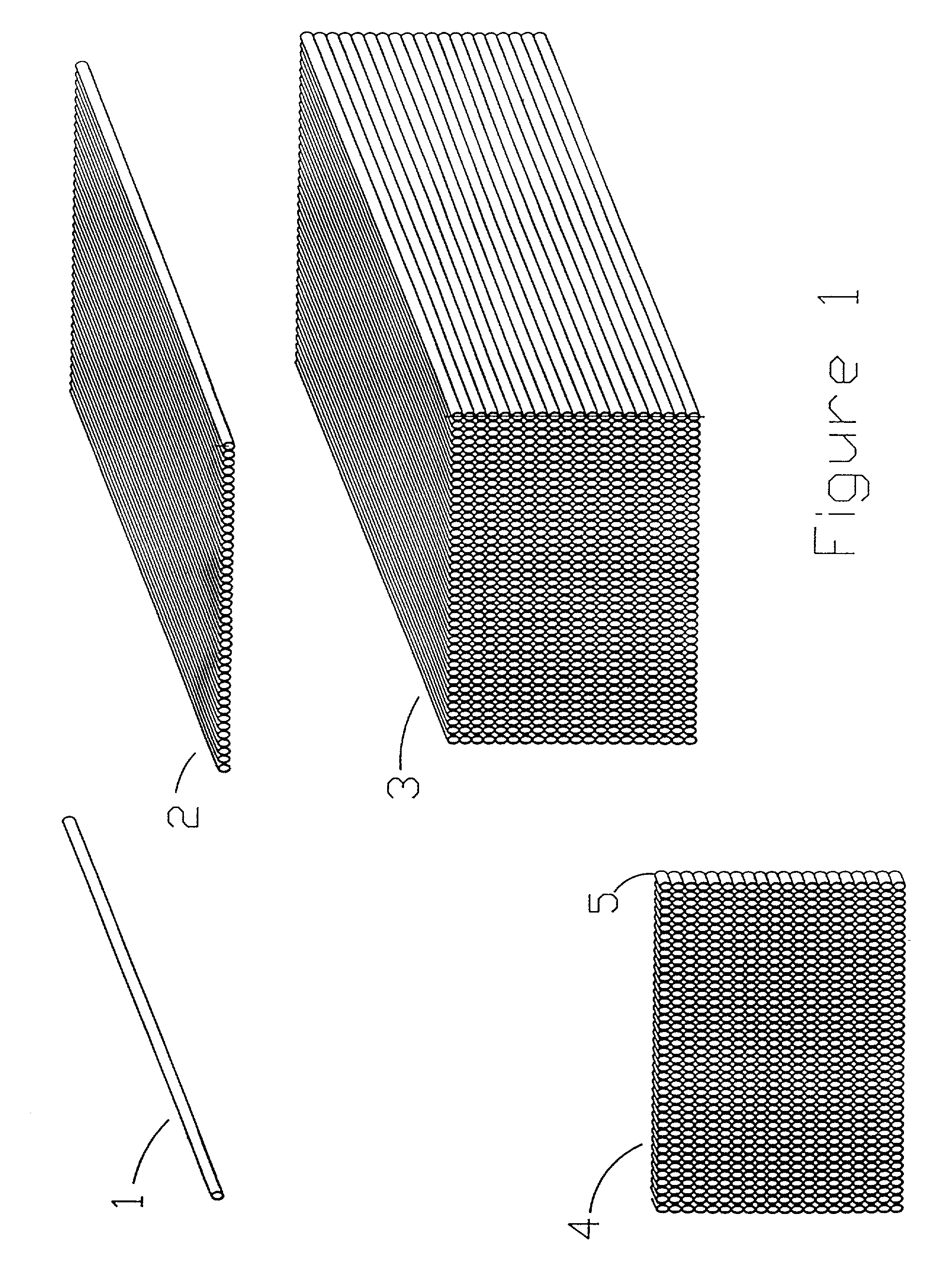

Microarrays and their manufacture

InactiveUS6887701B2Reduces cost and delay and inconvenienceInexpensive to fabricateBioreactor/fermenter combinationsSequential/parallel process reactionsFiberMaterials science

The microarrays of the present invention are prepared by using a separate fiber for each compound being used in the microarray. The fibers are bundled and sectioned to form a thin microarray that is glued to a backing.

Owner:LARGE SCALE PROTEOMICS

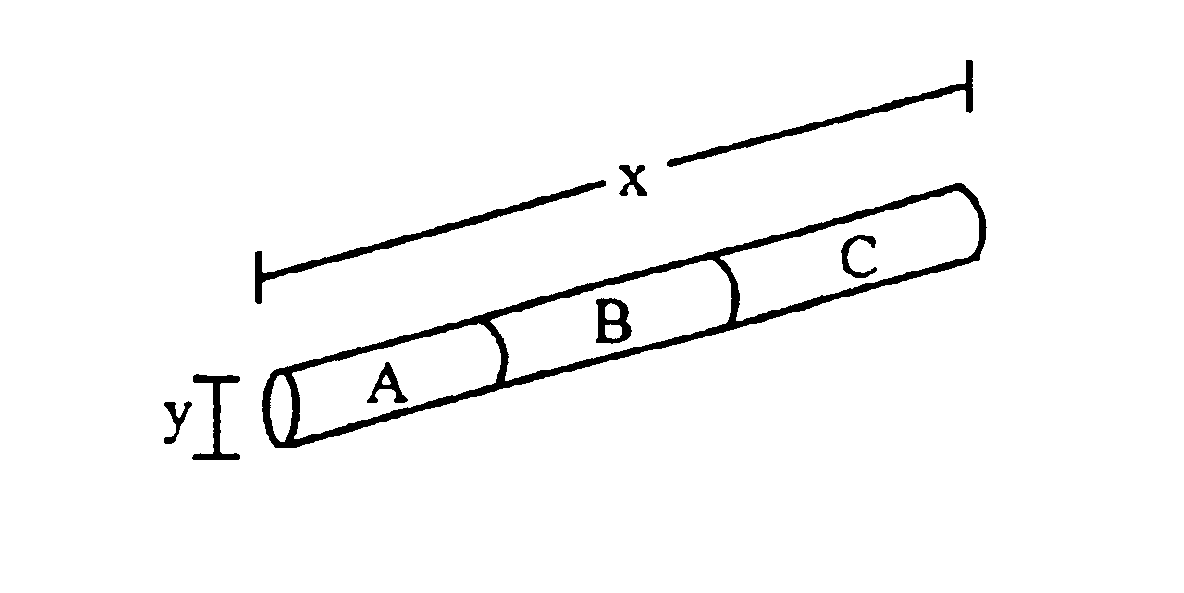

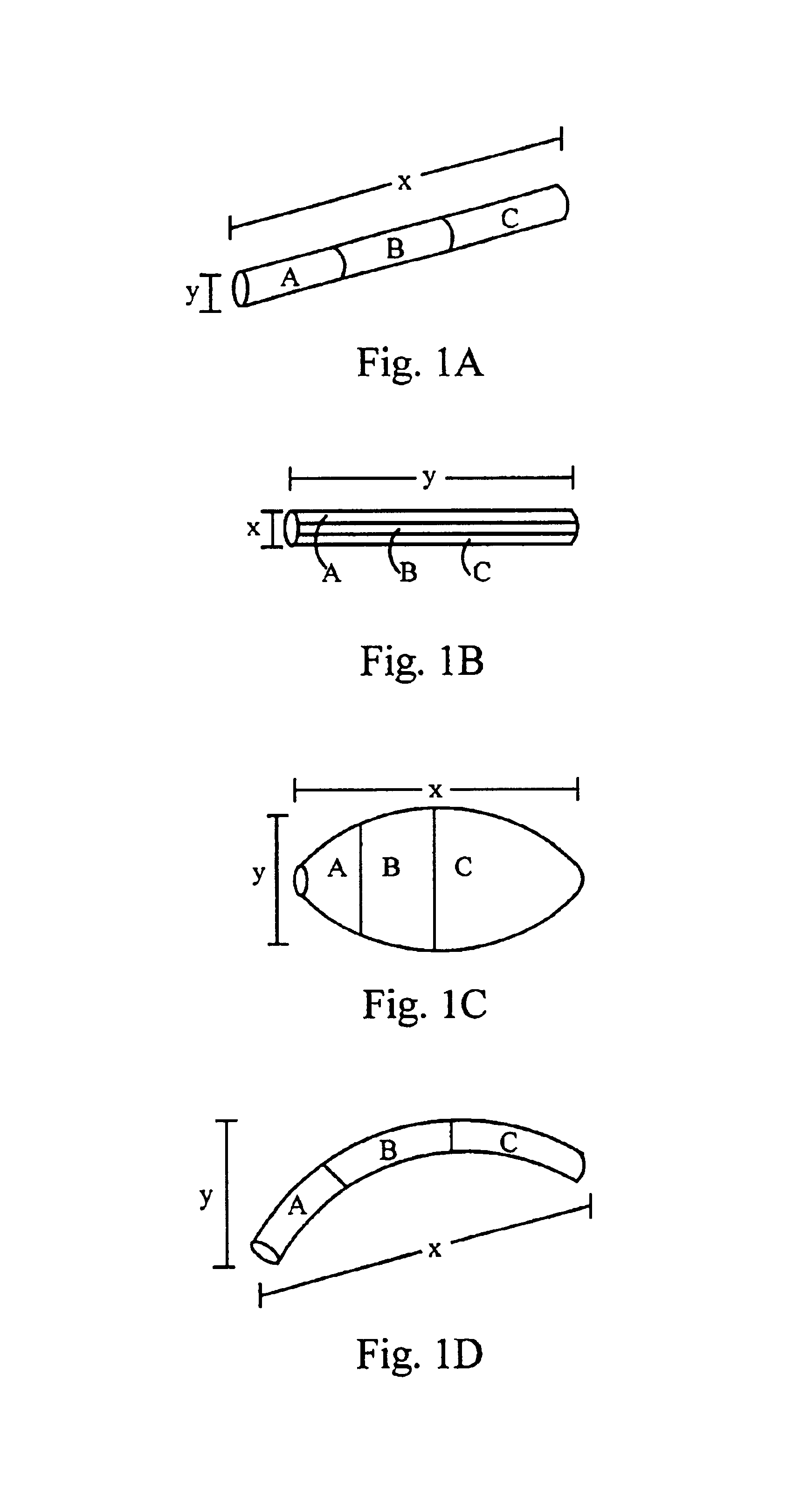

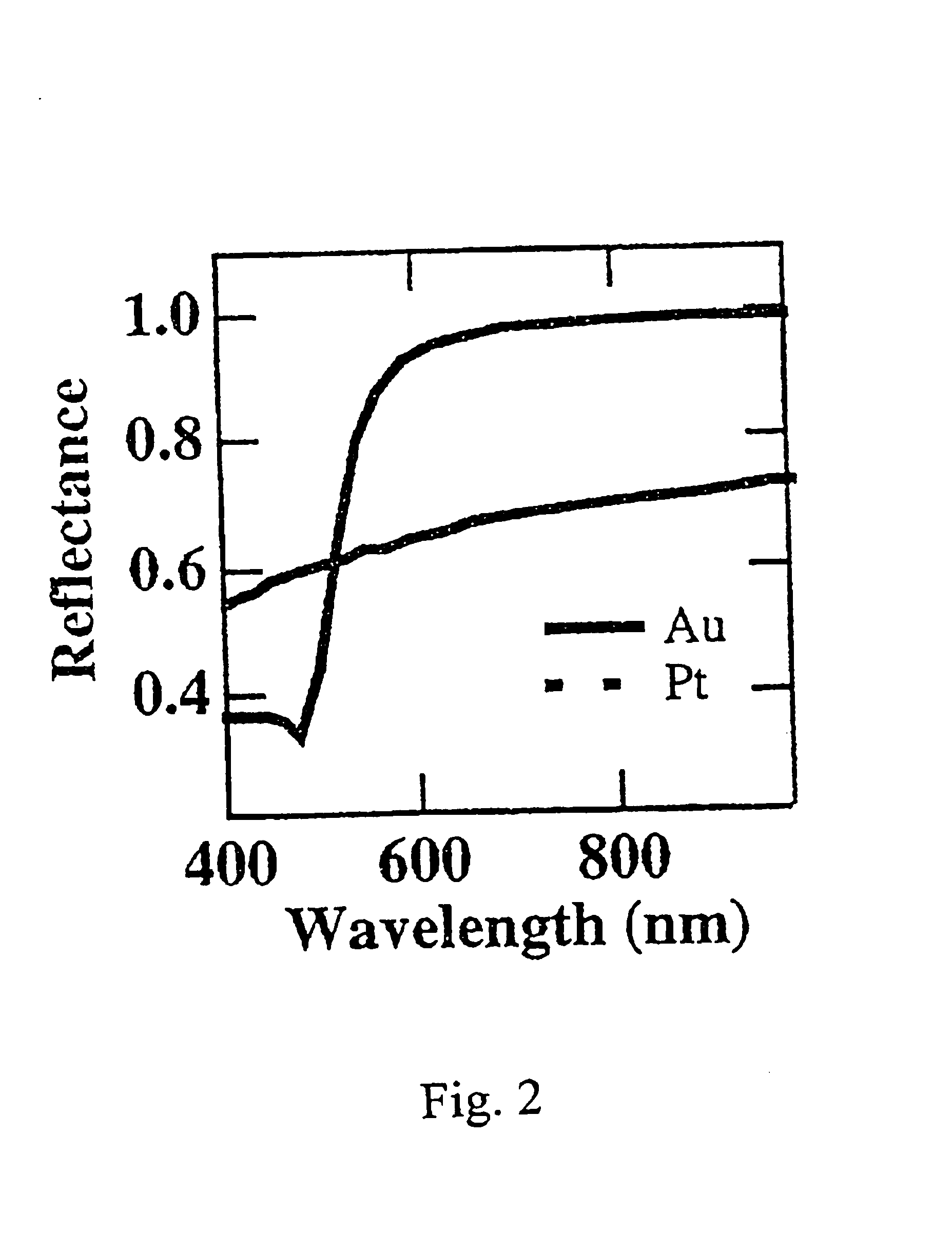

Colloidal rod particles as nanobar codes

Owner:SURROMED +1

Methods for hard-tagging an encoded synthetic library

Disclosed are chemical encryption methods for determining the structure of compounds formed in situ on solid supports by the use of specific amines tags which, after compound synthesis, can be deencrypted to provide the structure of the compound found on the support.

Owner:AFFYMAX

Method of manufacture of colloidal rod particles as nanobarcodes

Owner:SURROMED +1

Compositions for sorting polynucleotides

InactiveUSRE39793E1Reduced stabilityAvoid precision problemsSequential/parallel process reactionsSugar derivativesPolynucleotideBiology

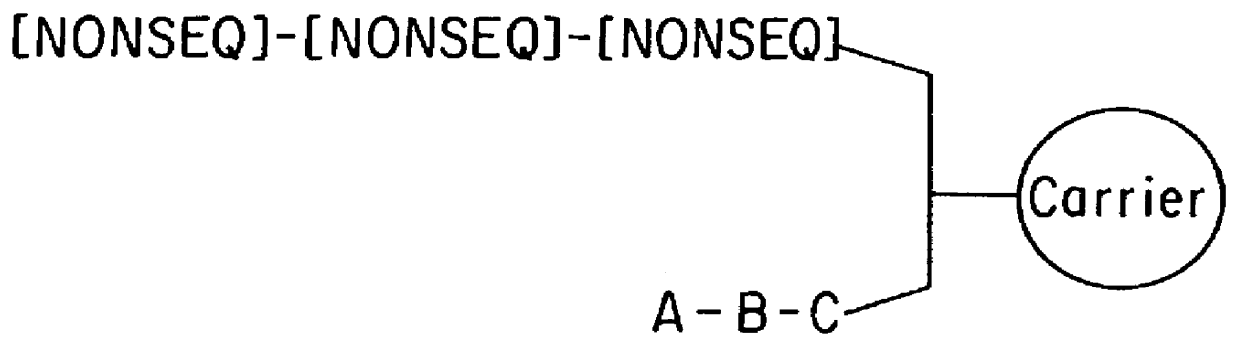

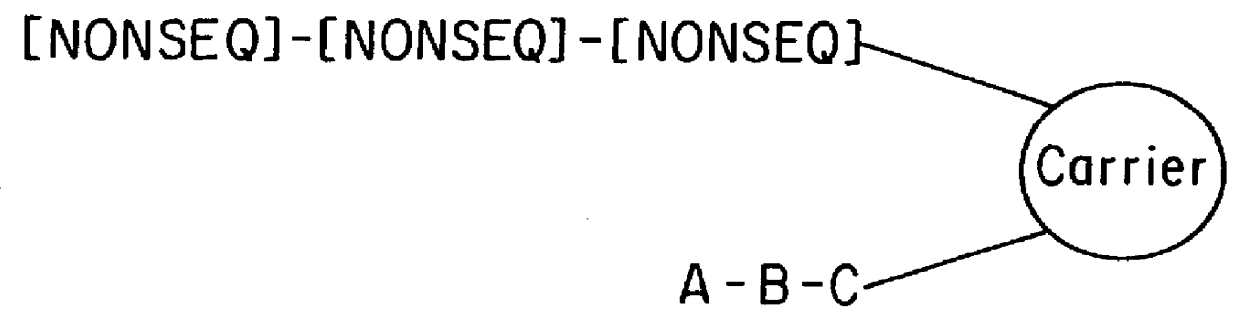

The invention provides a method of tracking, identifying, and / or sorting classes or subpopulations of molecules by the use of oligonucleotide tags. Oligonucleotide tags of the invention each consist of a plurality of subunits 3 to 6 nucleotides in length selected from a minimally cross-hybridizing set. A subunit of a minimally cross-hybridizing set forms a duplex or triplex having two or more mismatches with the complement of any other subunit of the same set. The number of oligonucleotide tags available in a particular embodiment depends on the number of subunits per tag and on the length of the subunit. An important aspect of the invention is the use of the oligonucleotide tags for sorting polynucleotides by specifically hybridizing tags attached to the polynucleotides to their complements on solid phase supports. This embodiment provides a readily automated system for manipulating and sorting polynucleotides, particularly useful in large-scale parallel operations, such as large-scale DNA sequencing, mRNA fingerprinting, and the like, wherein many target polynucleotides or many segments of a single target polynucleotide are sequenced simultaneously.

Owner:SOLEXA

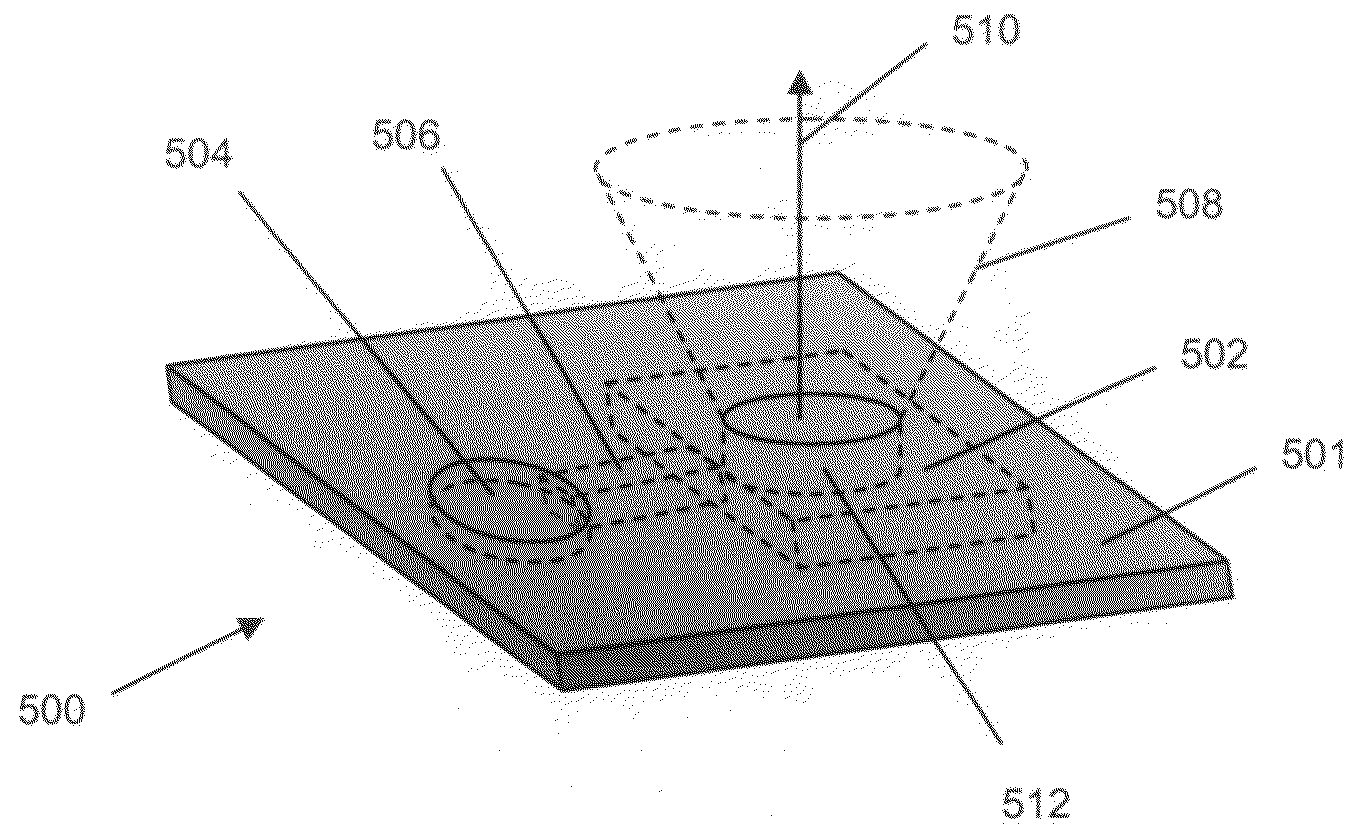

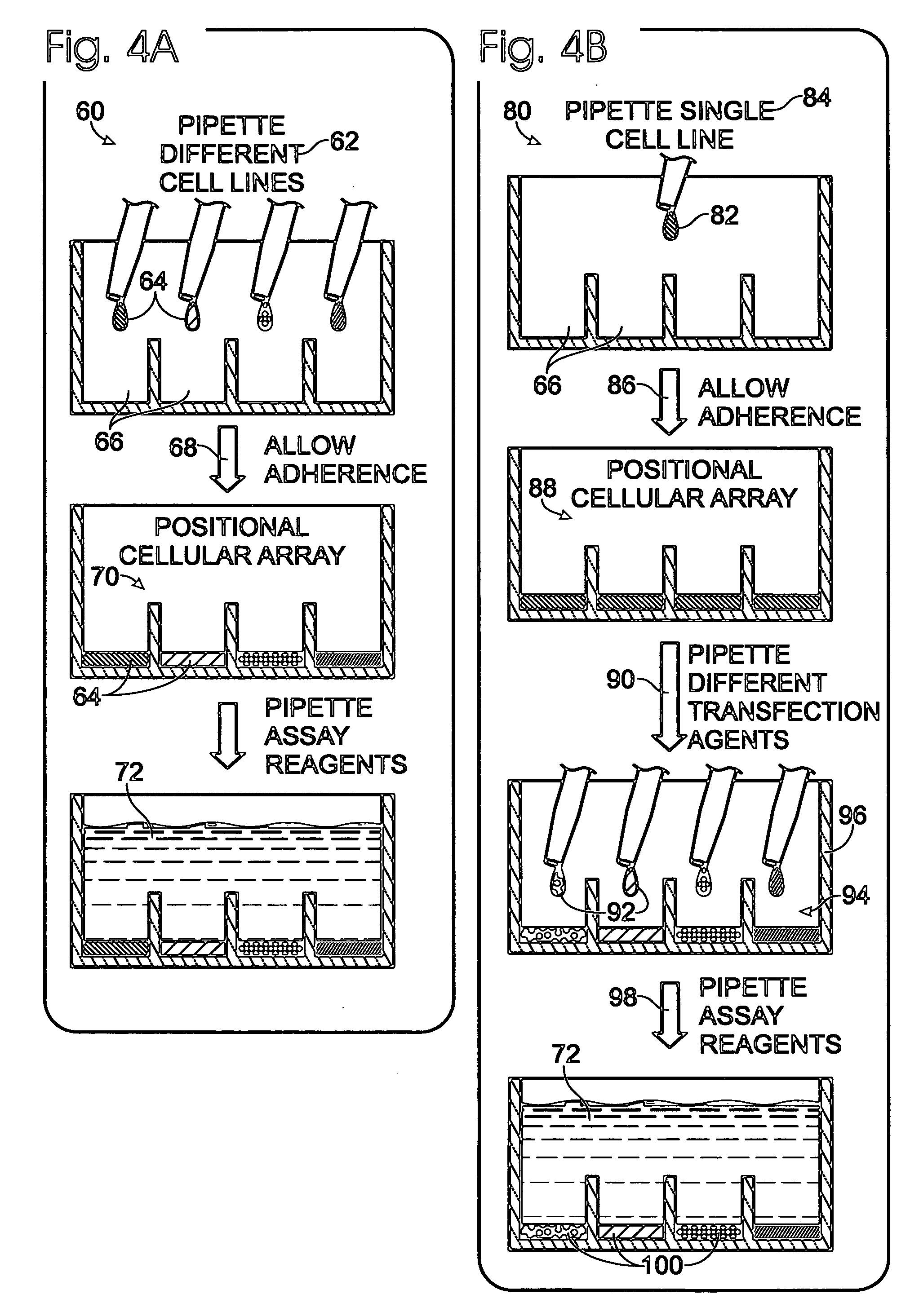

Methods for screening substances in a microwell array

InactiveUS6893877B2Sequential/parallel process reactionsVolume/mass flow measurementEngineeringLiquid suspension

Methods for manufacturing and using an apparatus for manipulating and analyzing a large number of microscopic samples of a liquid or materials, including cells, in liquid suspension. Parallel through-holes are formed in a platen and loaded with a liquid. Loading may be performed in such a way as to create a gradient, with respect to the position of the through-holes, of the concentration of a particular substance or of another quantity. Mixing of the contents of through-holes may be obtained by bringing filled microwell arrays into contact with each other with registration of individual through-holes.

Owner:MASSACHUSETTS INST OF TECH

Color-encoding and in-situ interrogation of matrix-coupled chemical compounds

InactiveUS7083914B2Ensure identificationPeptide librariesSequential/parallel process reactionsAssayChemical compound

Owner:RUTGERS THE STATE UNIV

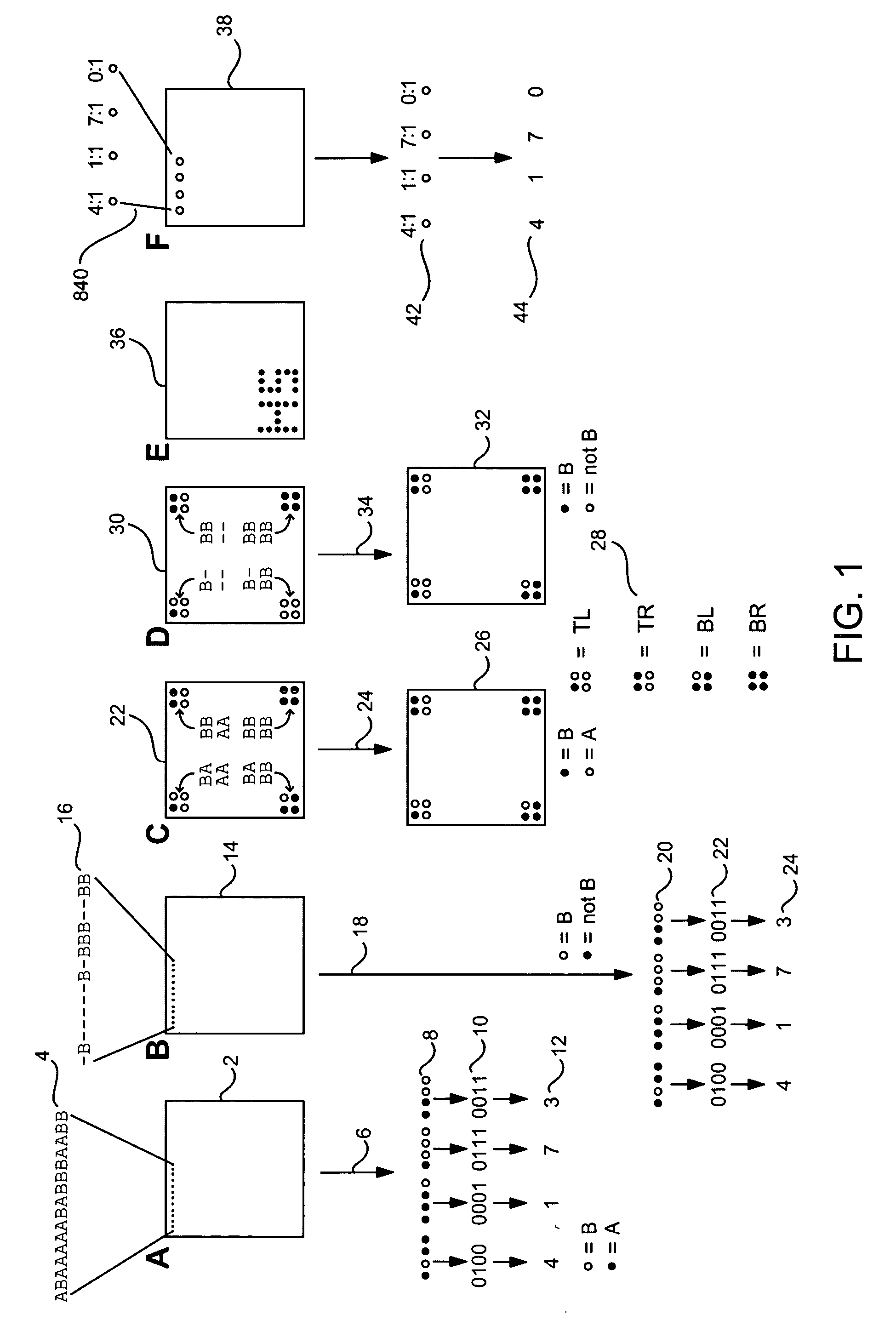

Combinatorial decoding of random nucleic acid arrays

Owner:ILLUMINA INC

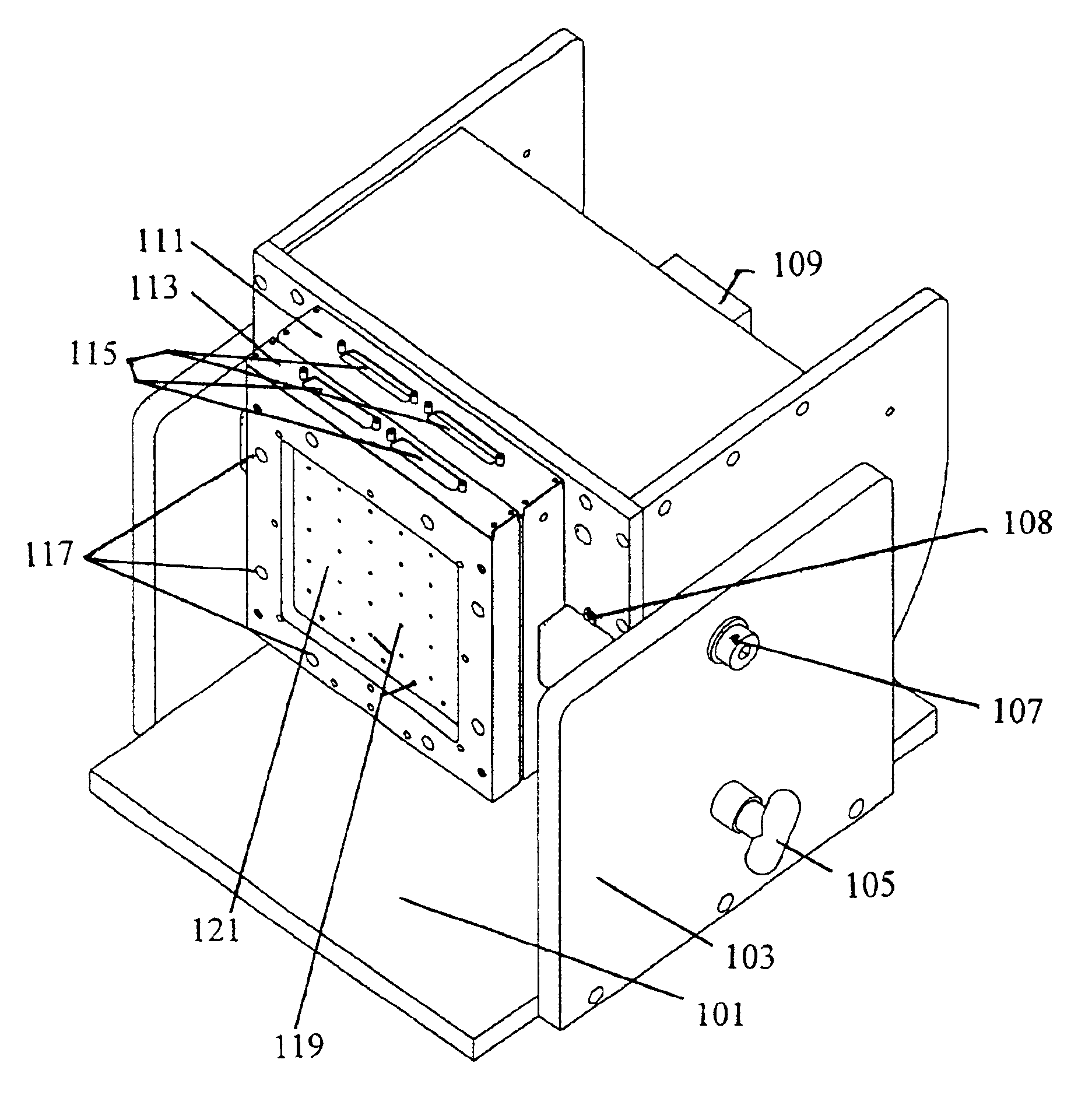

Bead dispensing system

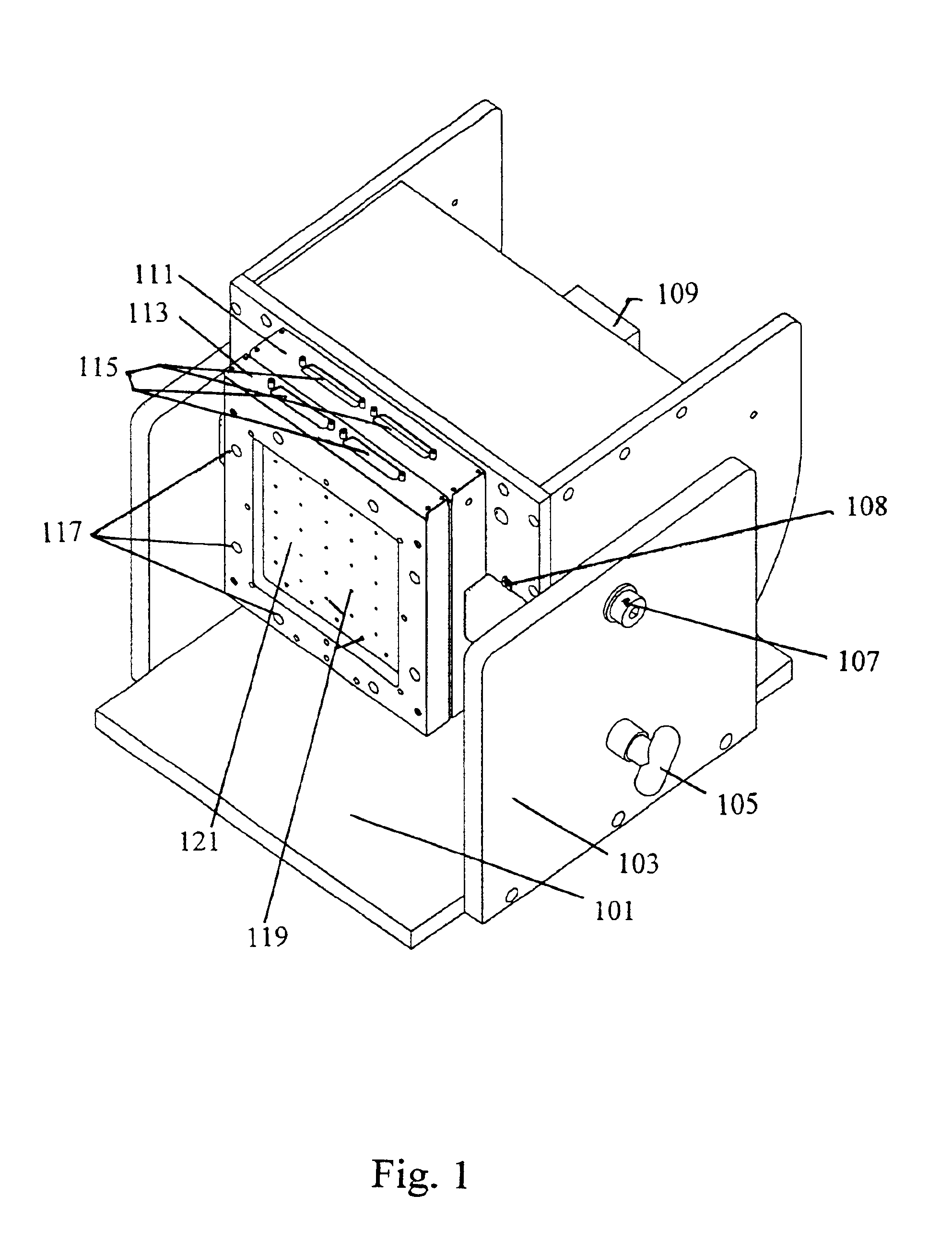

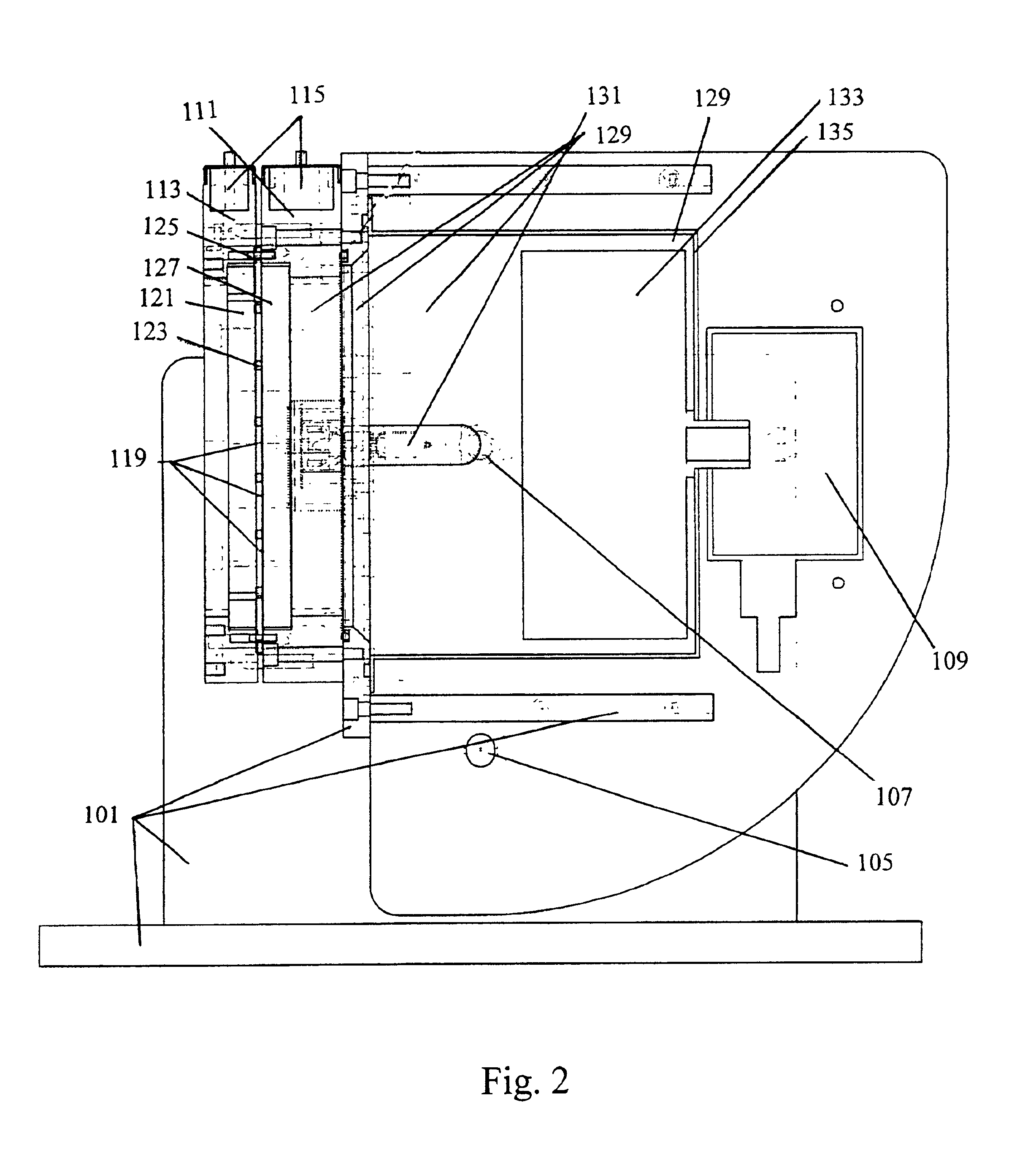

A bead dispensing system is provided for delivering small amounts of substances onto substrates. The system can include, for example, a movable support structure having an array of spaced-apart projections depending from its lower side. An attraction source, such as a vacuum, magnetic, and / or electrostatic force, is operable at each projection end region to attract and retain one bead. The projection array can be aligned with an array of bead-receiving regions of a substrate, e.g., an array of spaced-apart wells of a micro-plate or card. In one embodiment, a plurality of reagent-carrying beads are picked up, retained at respective projection end regions, and moved to a location over a multi-well plate. The beads are then released in a fashion permitting each bead to land in a respective well. The system of the invention is particularly useful for fabricating arrays of reagents.

Owner:APPL BIOSYSTEMS INC

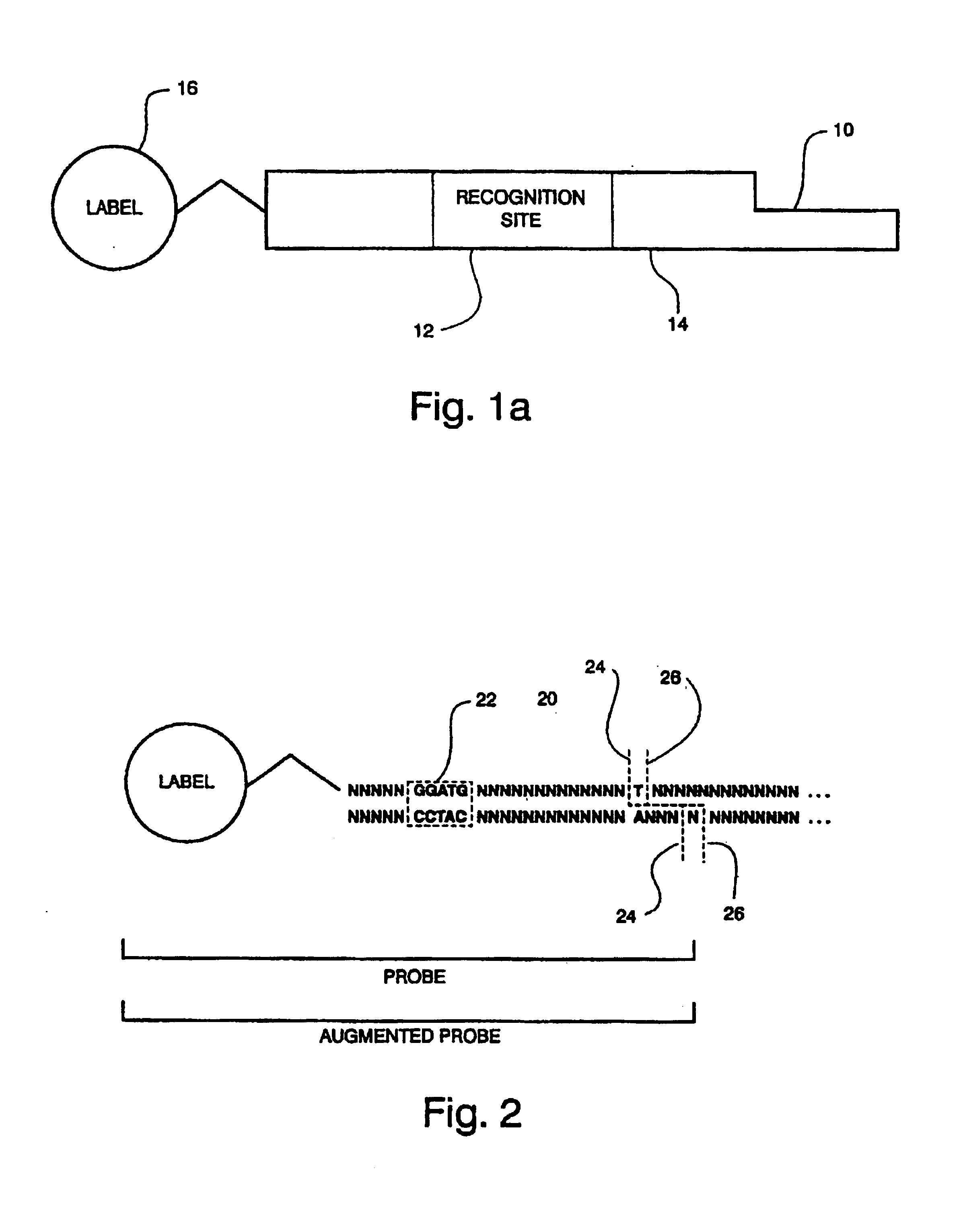

Nucleic acid detection using degradation of a tagged sequence

Methods and compositions are provided for detecting target molecules, e.g. DNA sequences, particularly single nucleotide polymorphisms, using a pair of nucleotide sequences, a primer and a snp detection sequence, where the snp detection sequence binds downstream from the primer to the target DNA in the direction of primer extension, or ligands and receptors. The methods employ e-tags comprising a mobility-identifying region joined to a detectable label and a target-binding region. The result of the binding of the target-binding region to the target is to have a bond cleaved in the starting material with the production of a detectable product with a different mobility from the starting material, where the different e-tags can be separated and detected.

Owner:MONOGRAM BIOSCIENCES

Methods and compositions for enhancing detection in determinations employing cleavable electrophoretic tag reagents

InactiveUS20040096825A1Accurate detectionDifferent massPeptide/protein ingredientsOrganic chemistry methodsElectrophoresisBiology

Probe sets for the multiplexed detection of the binding of, or interaction between, one or more ligands and target antiligands are provided. Detection involves the release of identifying tags as a consequence of target recognition. The probe sets include electrophoretic tag probes or e-tag probes, comprising a detection region and a mobility-defining region called the mobility modifier, both linked to a target-binding moiety. The probes comprise interactive functionalities adjacent the cleaved portion positioned in the probes such that the interactive functionality does not form part of the e-tag reporters. Target antiligands are contacted with a set of e-tag probes and the contacted antiligands are treated with a selected cleaving agent resulting in a mixture of e-tag reporters and uncleaved and / or partially cleaved e-tag probes. The mixture is exposed to a capture agent effective to bind to uncleaved or partially cleaved e-tag probes, followed by electrophoretic separation. In a multiplexed assay, different released e-tag reporters may be separated and detected providing for target identification.

Owner:MONOGRAM BIOSCIENCES

Microarray dispensing with real-time verification and inspection

InactiveUS7025933B2Improve spotImprove accuracySequential/parallel process reactionsElement comparisonAnalysis dataReal time validation

A microarrayer for spotting solution onto a receiving surface in an automated microarray dispensing device. Elements of the present invention include: at least one dispense head for spotting the receiving surface, at least one light source capable of illuminating the receiving surface, at least one camera operating in conjunction with the at least one light source. The at least one camera is capable of acquiring and transmitting surface image data to a computer. The computer is programmed to receive the surface image data and analyze it. The computer will then generate post analysis data based on the analysis of the surface image data. The post analysis data is available for improving the spotting of the solution onto the receiving surface. In a preferred embodiment, the surface image data includes information relating to receiving surface alignment, information relating to spot quality, and receiving surface identification information. In a preferred embodiment, the analysis of the information relating to receiving surface alignment enables the computer to make automatic adjustments to the relative positions of the at least one dispense head and the receiving surface to increase the accuracy of the spotting. In a preferred embodiment, the analysis of the information relating to spot quality identifies a spot as pass or fail. An operator is then able to rework the spot. In a preferred embodiment, the analysis of the receiving surface identification information enables the computer to track each receiving surface. In a preferred embodiment the receiving surface is a plurality of slides.

Owner:AGENA BIOSCI

Methods employing generalized target-binding e-tag probes

Methods for the multiplexed detection of the binding of, or interaction between, one or more ligands and target antiligands are provided. Detection involves the release of identifying tags as a consequence of target recognition. The methods include the use of electrophoretic tag probes or e-tag probes, comprising a detection region and a mobility-defining region called the mobility modifier, both linked to a target-binding moiety. In practicing the methods, target antiligands are contacted with a set of e-tag probes and the contacted antiligands are treated with a selected cleaving agent resulting in a mixture of e-tag reporters and uncleaved and / or partially cleaved e-tag probes. The mixture is exposed to a capture agent effective to bind to uncleaved or partially cleaved e-tag probes, followed by electrophoretic separation. In a multiplexed assay, different released e-tag reporters may be separated and detected providing for target identification.

Owner:MONOGRAM BIOSCIENCES

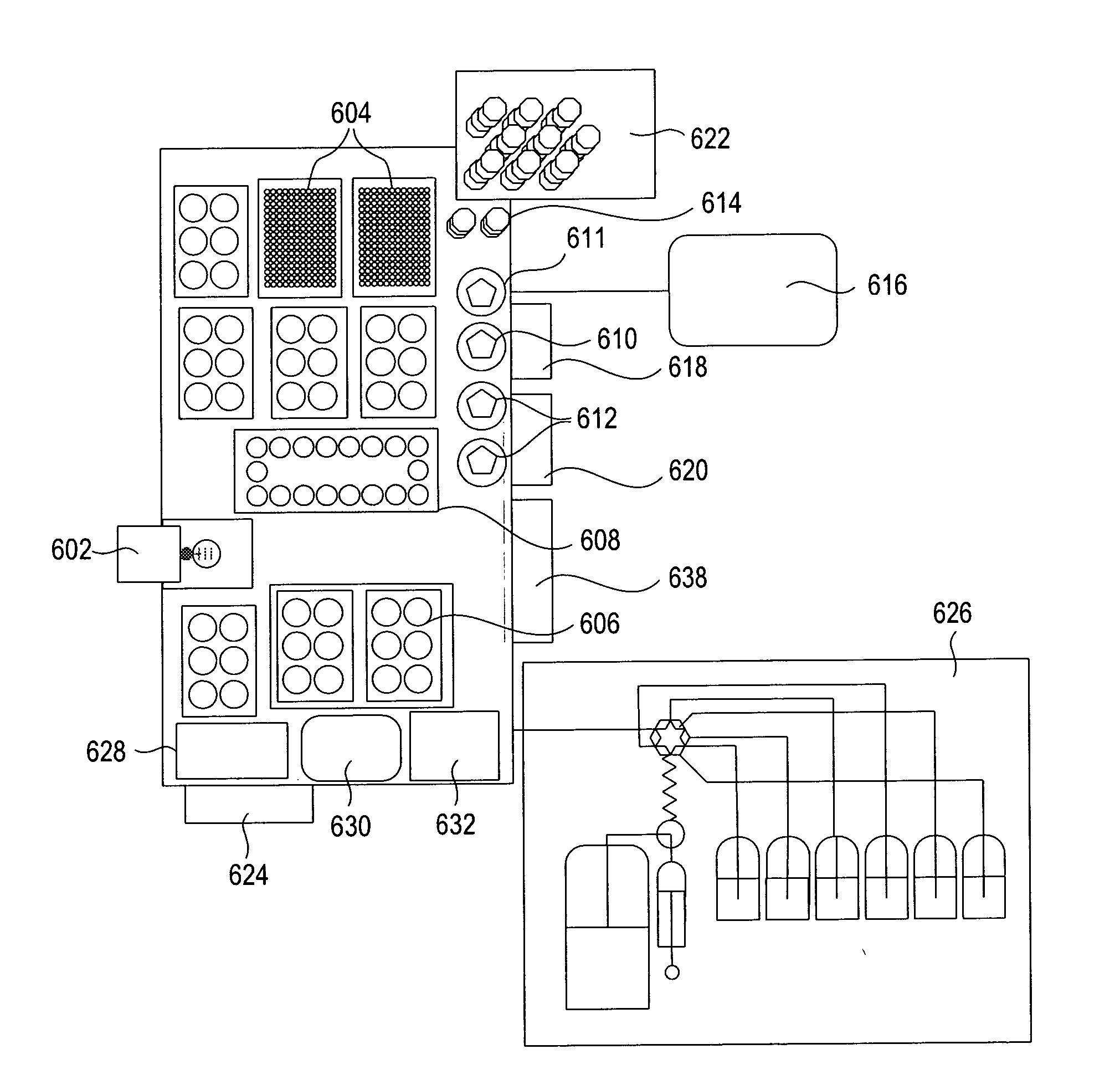

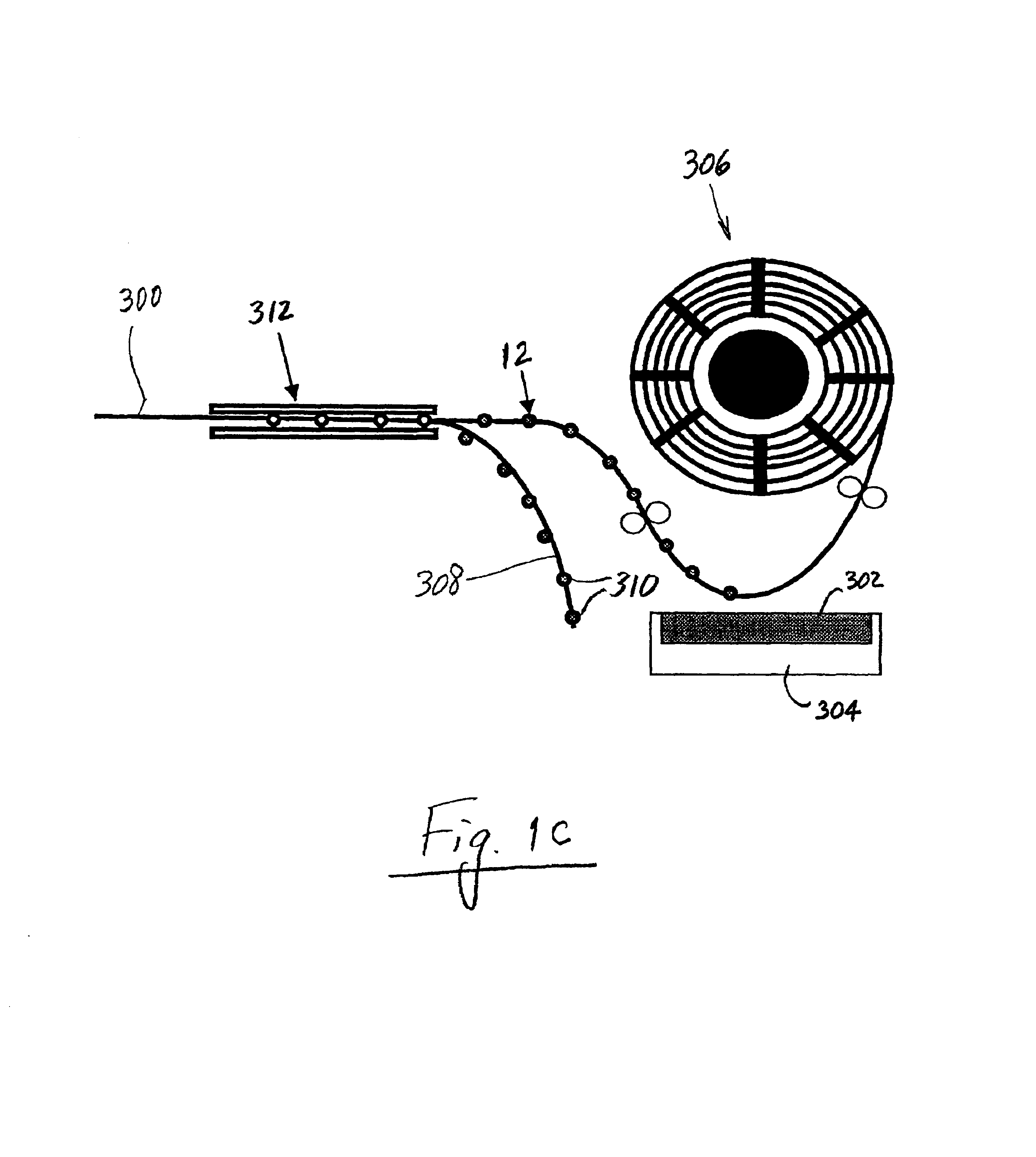

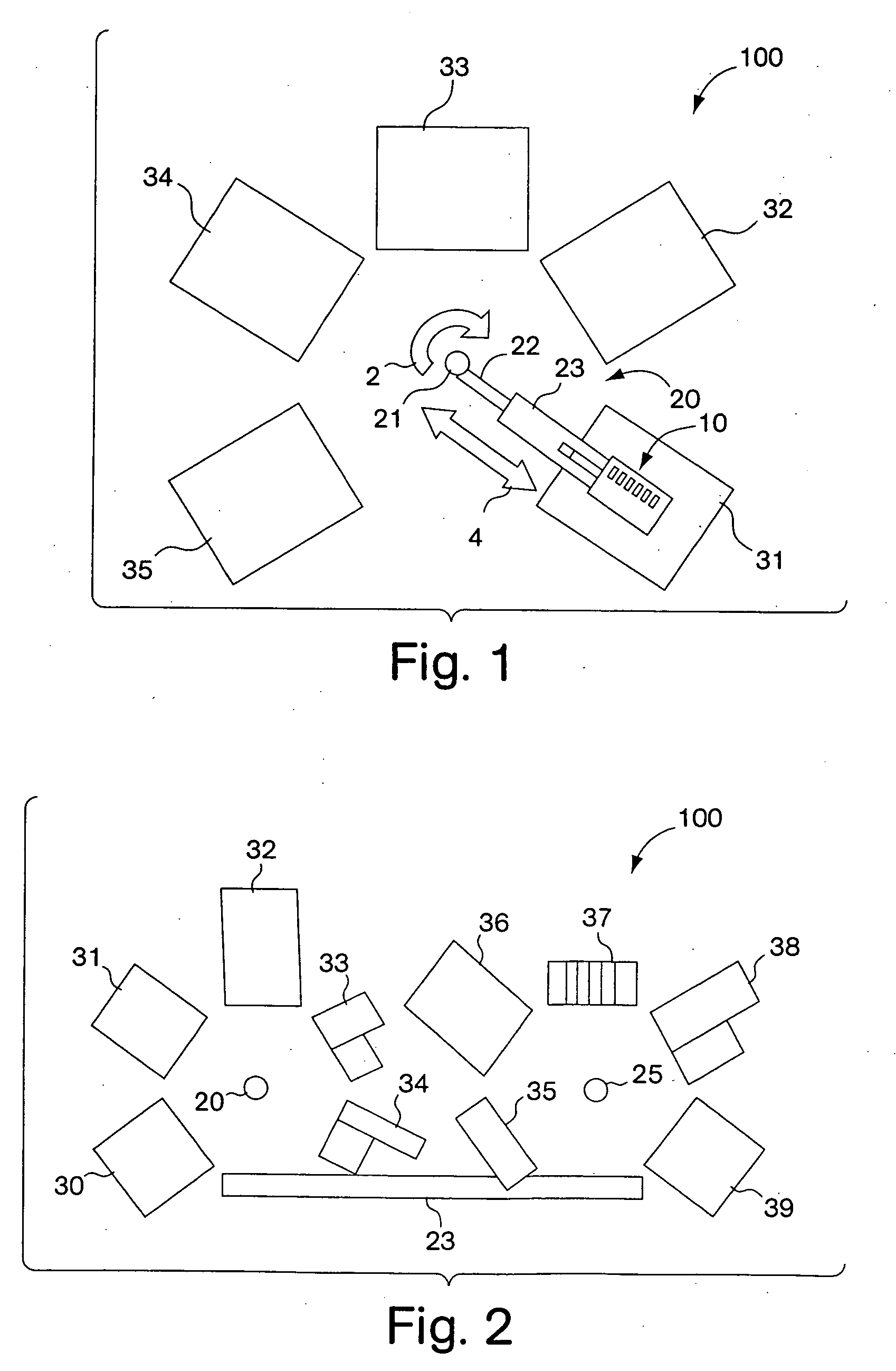

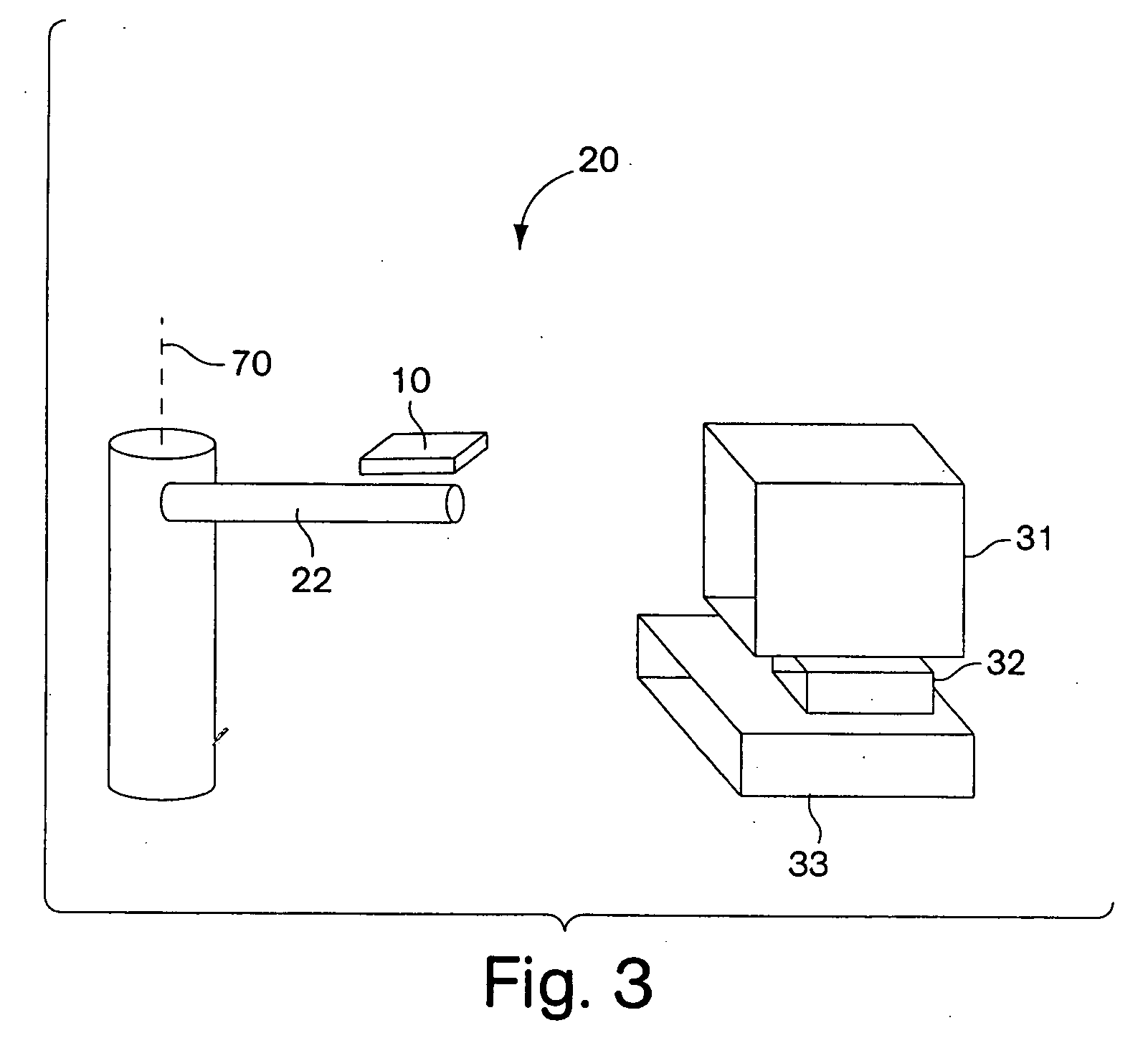

System and method for process automation

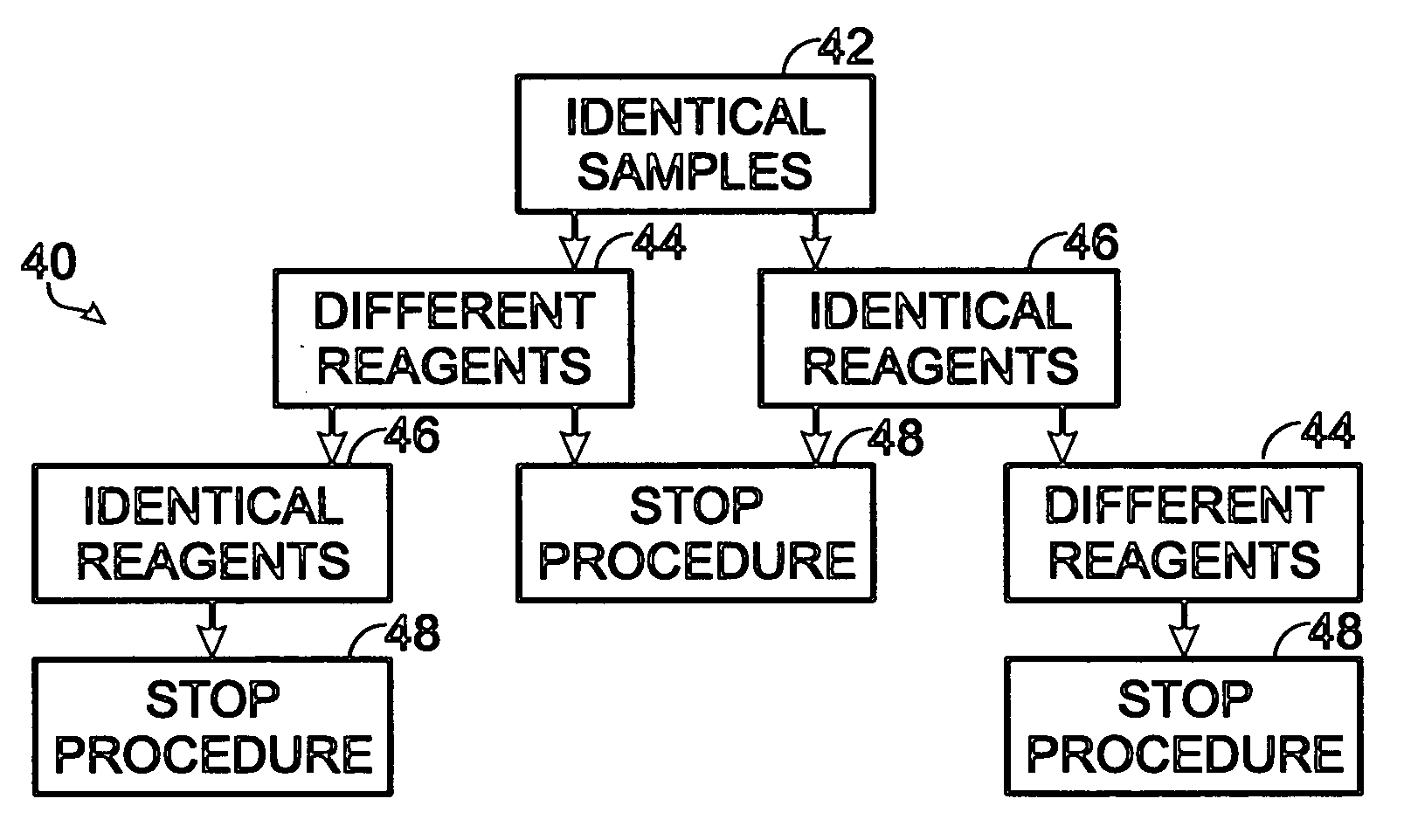

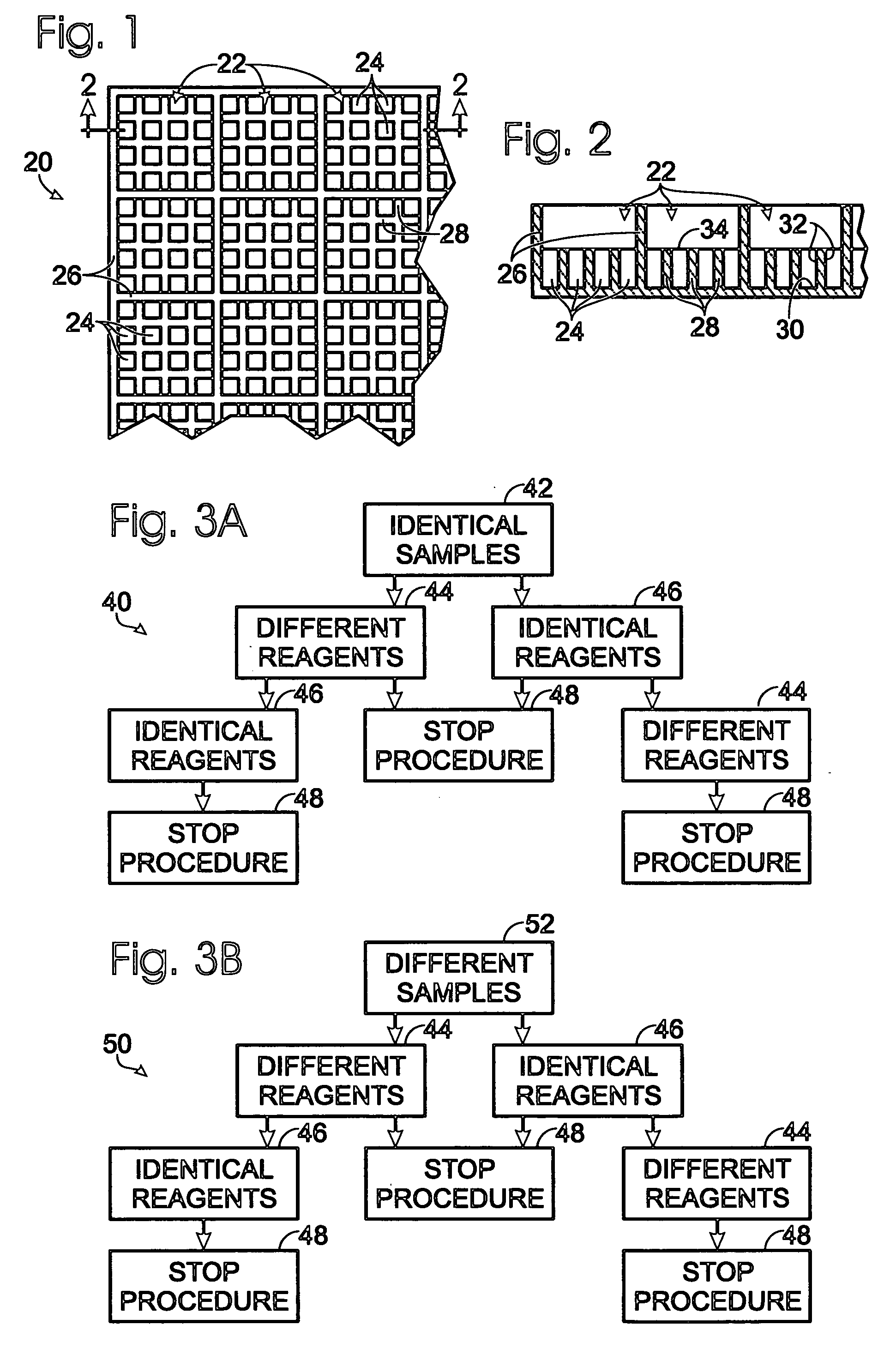

InactiveUS20070207450A1Bioreactor/fermenter combinationsPeptide librariesChemical synthesisAutomatic control

Disclosed are systems and methods for manipulating chemical, biological, and / or biochemical samples, optionally supported on substrates and / or within chambers, for example biological samples contained on chips, within biological chambers, etc. In certain embodiments, an apparatus configured to be able to position a chamber or other substrate in one or more modules surrounding the apparatus is disclosed. The apparatus may be configured to be able to move the chamber or substrate in any set of directions, such as radially, vertically, and / or rotationally, with respect to the apparatus. The apparatus may be manually operated and / or automatically controlled. Examples of modules include, but are not limited to, stacking or holding modules, barcode readers, filling modules, sampling modules, incubation modules, sensor modules (e.g., for determining cell density, cell viability, pH, oxygen concentration, nutrient concentration, fluorescence measurements, etc.), assay modules (e.g., for ELISA or other biological assays), data analysis and management modules, control modules, etc. Sensors, control systems, and the like may also be positioned to facilitate operation of the device. Certain embodiments of the invention may be used, for example, to promote or optimize chemical synthesis or cell or biological growth, for instance, for the production of compounds such as drugs or other therapeutics.

Owner:BIOPROCESSORS CORP

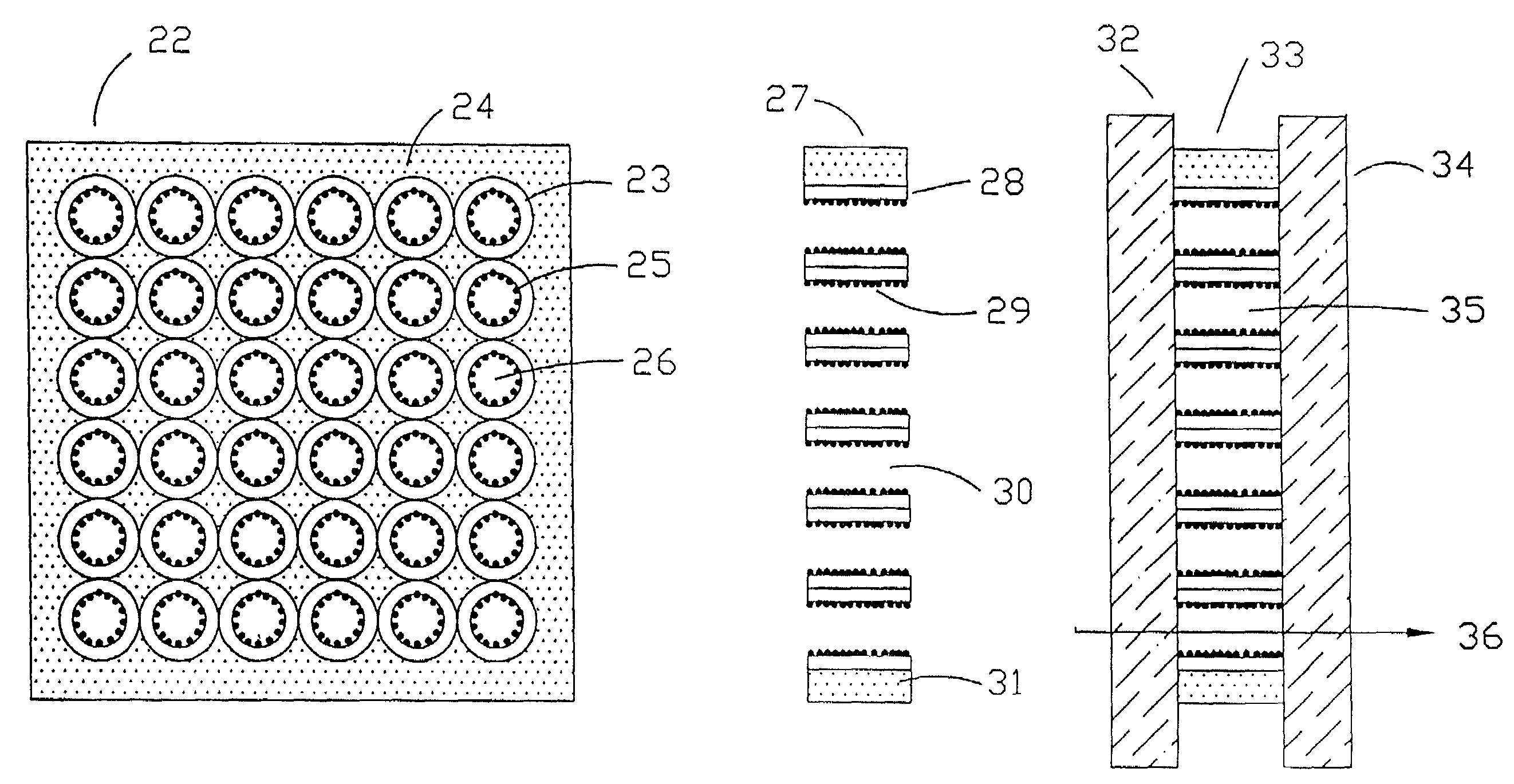

Encoded solid supports for biological processing and assays using same

InactiveUS20090226891A2Sequential/parallel process reactionsNon-electrical signal transmission systemsAntifuseSolid phases

Owner:IRORI TECH

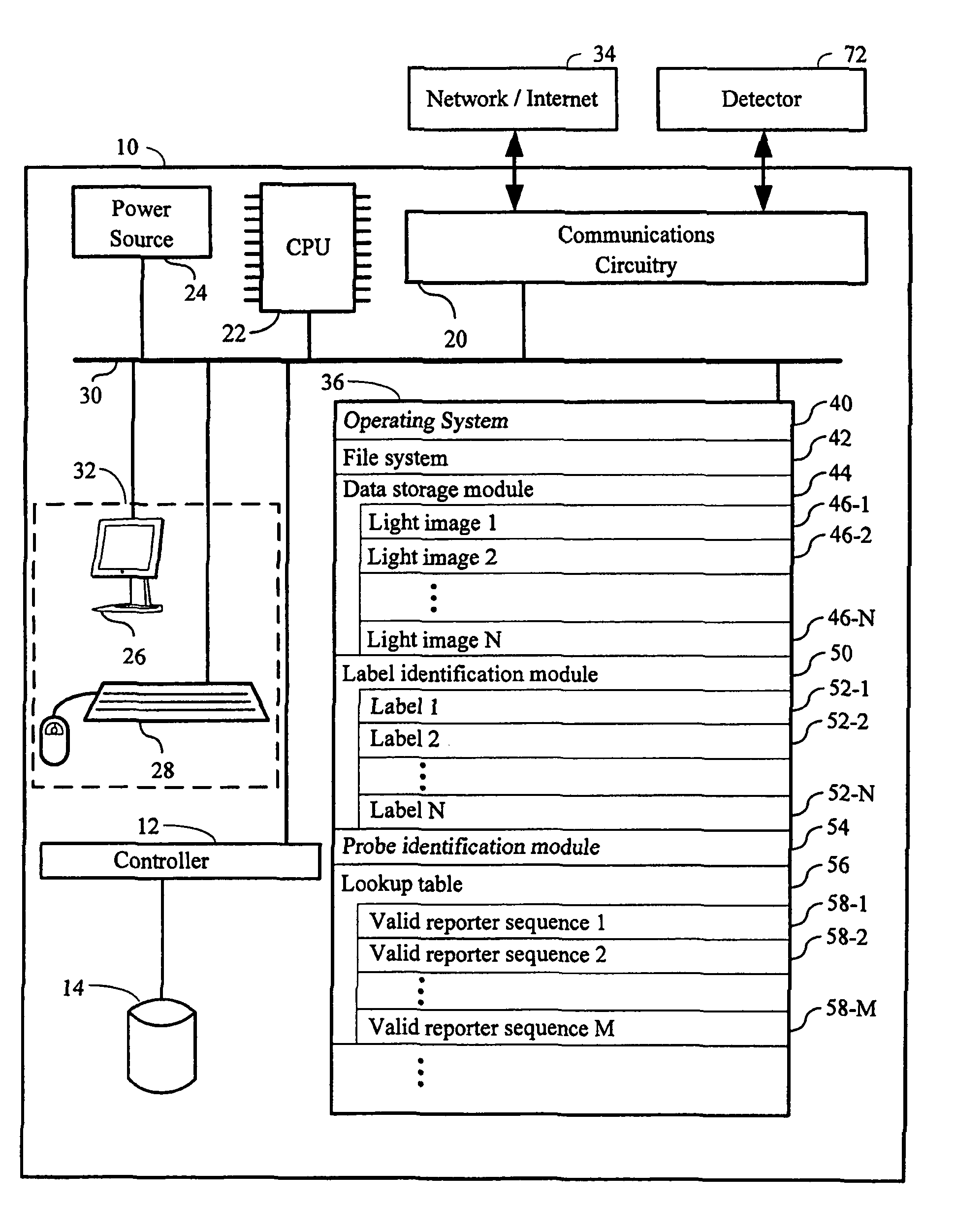

Systems and methods for analyzing nanoreporters

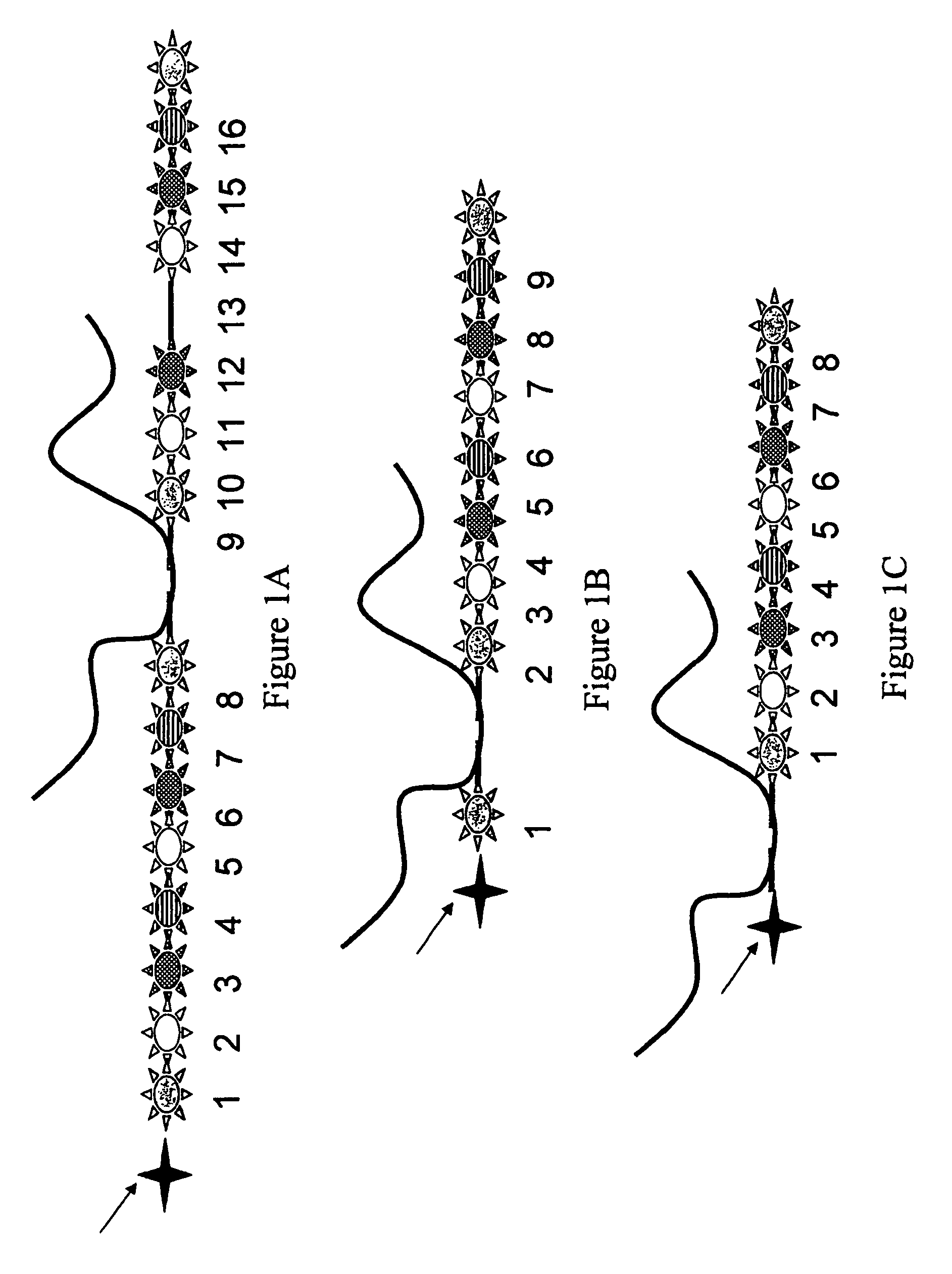

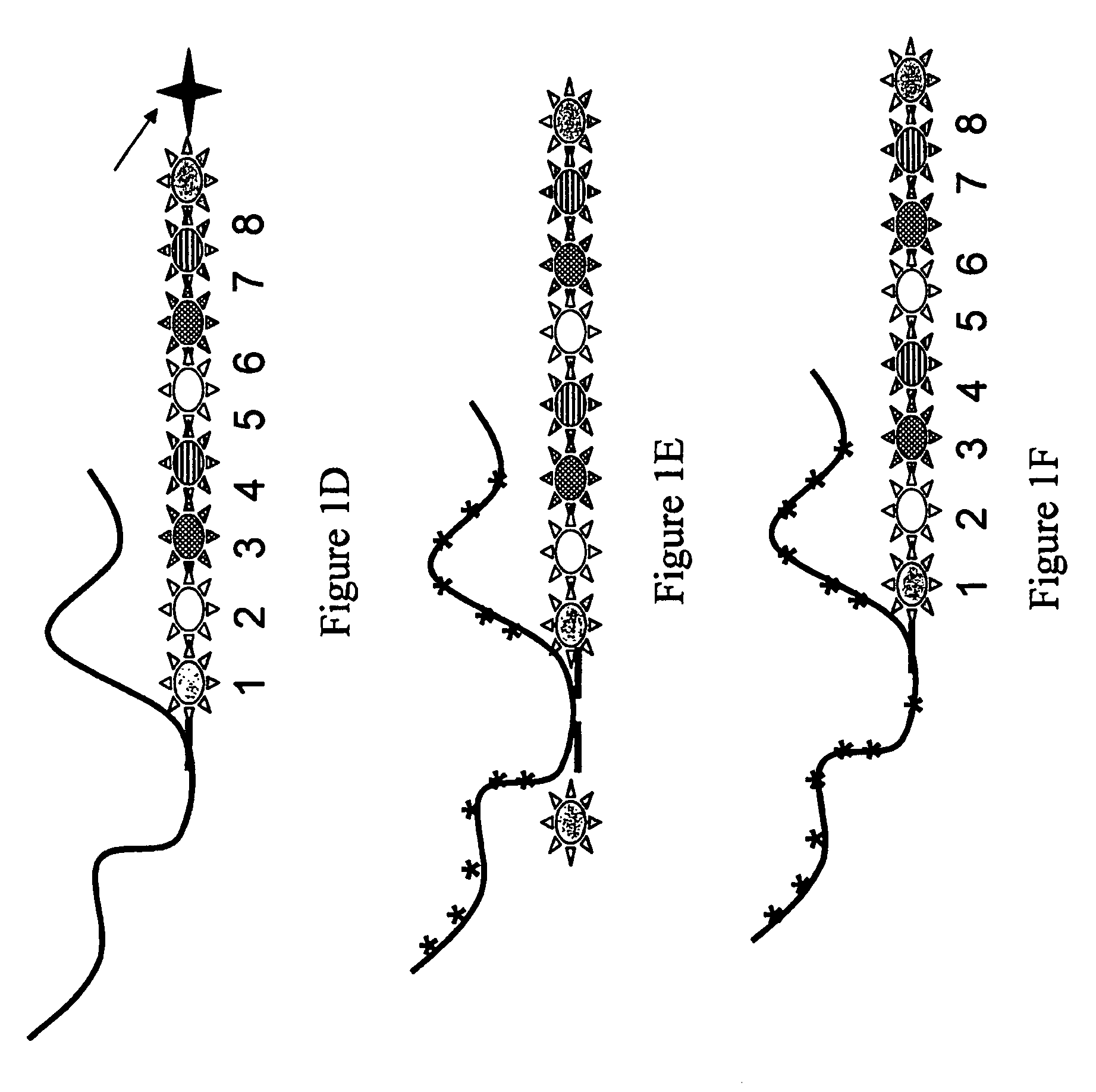

Methods, computers, and computer program products for detecting the presence of a probe within a sample overlayed on a substrate are provided. The probe comprises a plurality of spatially arranged labels. A data storage module stores a plurality of light images, where each light image has light from the sample at a corresponding wavelength range in a plurality of different wavelength ranges. A label identification module identifies a plurality of labels in the plurality of light images that are proximate to each other on the substrate. A spatial order of the plurality of labels determines a string sequence of the plurality of labels. A probe identification module determines whether the string sequence of the plurality of labels comprises a valid reporter sequence.

Owner:NANOSTRING TECH INC

Detectable micro to nano sized structures, methods of manufacture and use

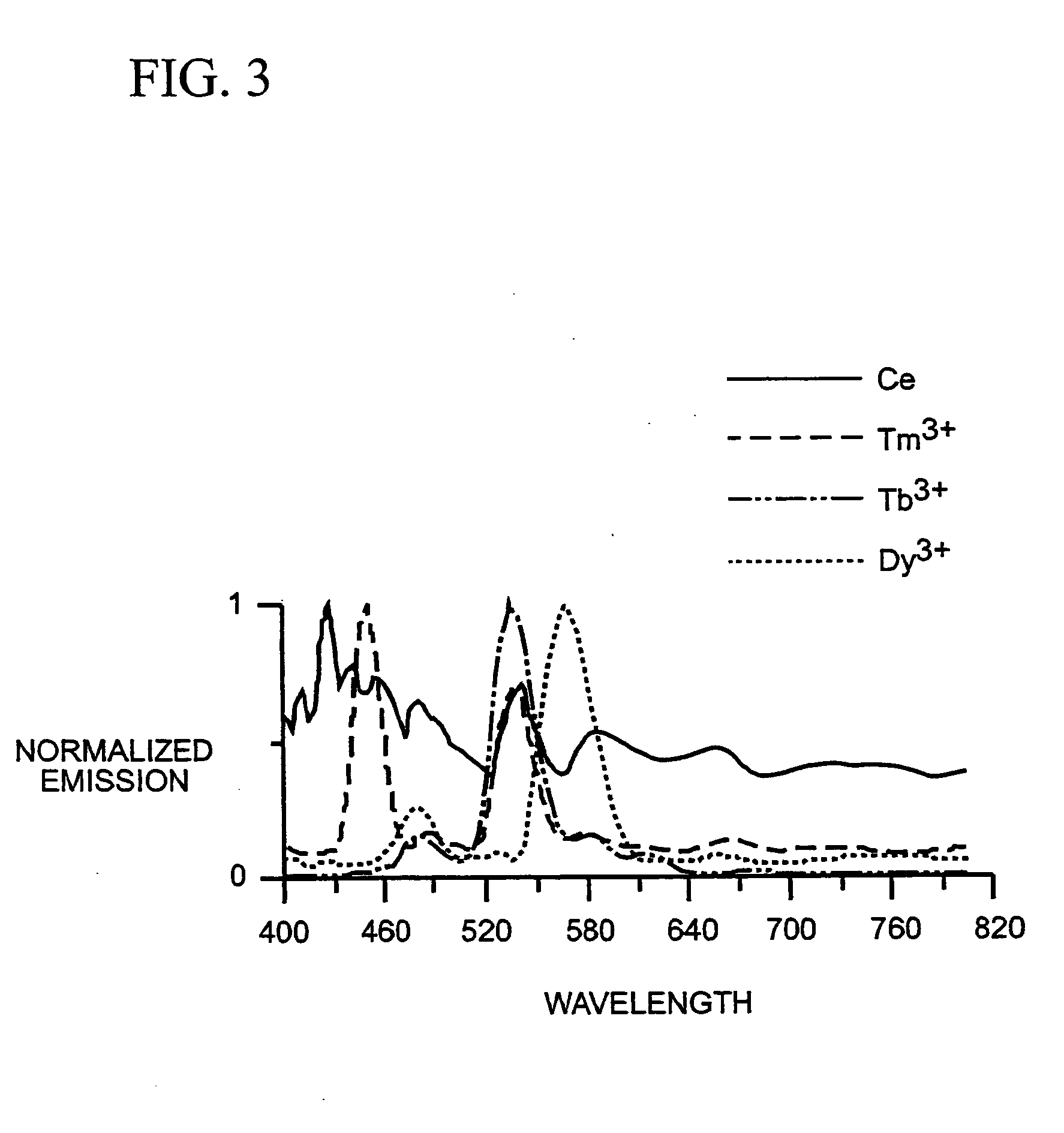

InactiveUS20040171076A1InexpensivelyEasy to mass producePeptide librariesNucleotide librariesAnalyteRare earth

Homogeneously mixed rare-earth doped particles and methods of using such particles include nano to microsized particles having a concentration of at least about 0.0005 mole percent of a Rare-Earth Oxide (Re2O3). The particles can be used for detecting the presence of an analyte in a sample and for detecting interactions of biomolecules.

Owner:CORNING INC

Assay systems with adjustable fluid communication

InactiveUS20060013031A1Material nanotechnologyBioreactor/fermenter combinationsCommunications systemComputer science

Owner:VITRA BIOSCIENCES ASSIGNMENT FOR THE BENEFIT OF CREDITORS LLC +1

Microarrays and their manufacture by slicing

InactiveUS7179638B2Inexpensive and sufficiently standardizedQuality assuranceBioreactor/fermenter combinationsCompound screeningFiberMaterials science

Microarrays are prepared by using a separate fiber for each compound being used in the microarray. The fibers are bundled and sectioned to form a thin microarray that may be glued to a backing.

Owner:LARGE SCALE PROTEOMICS

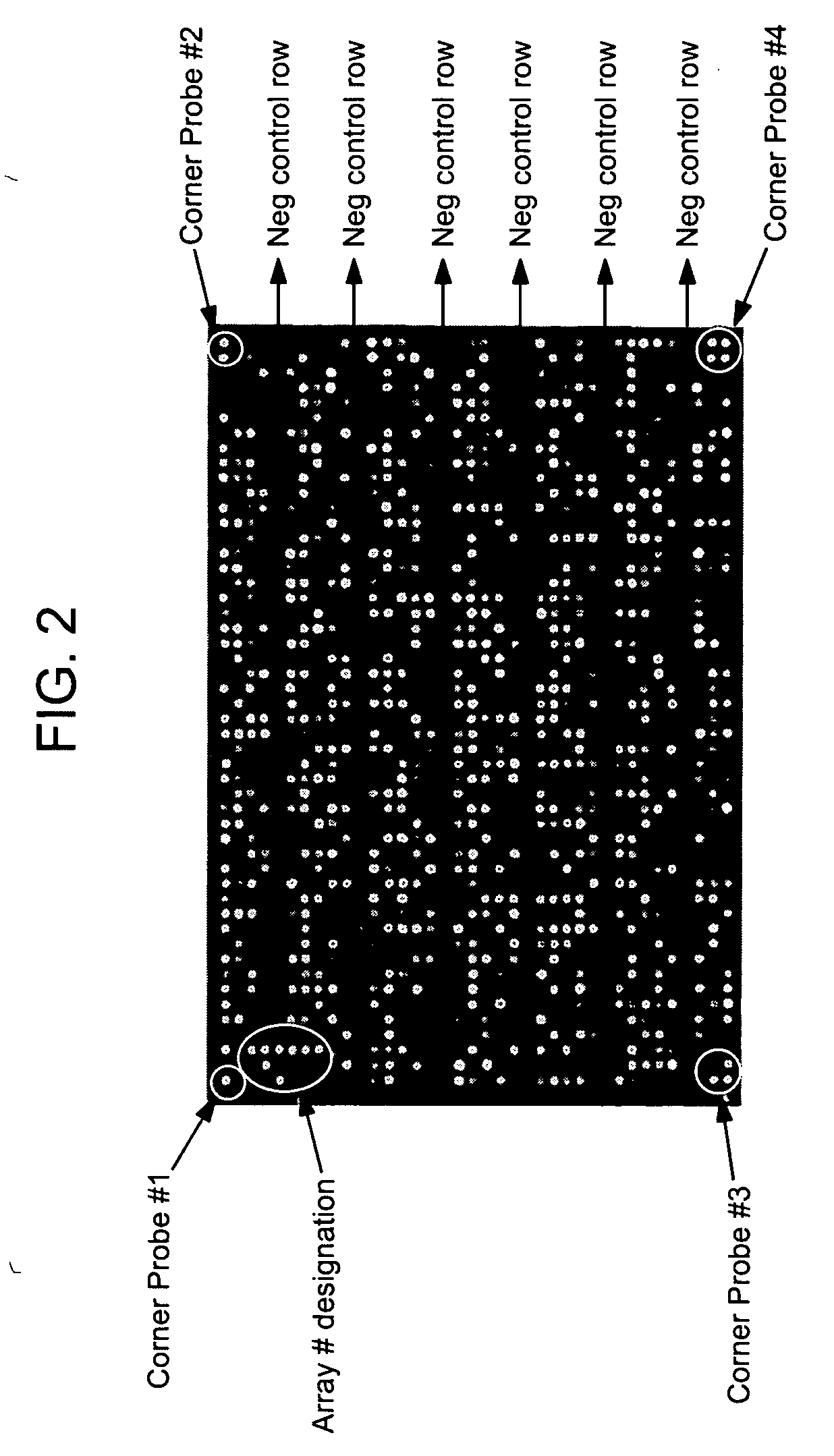

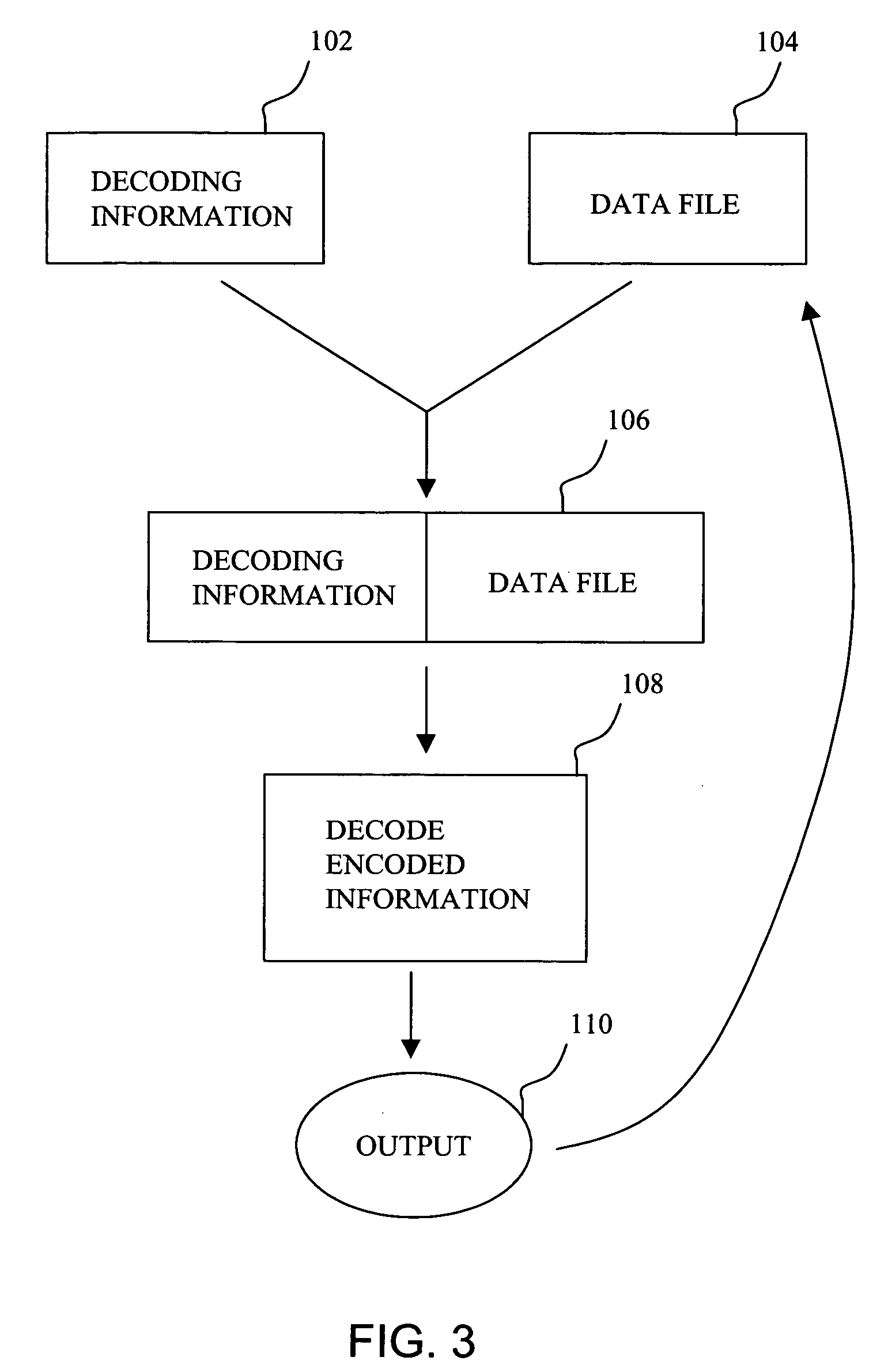

Methods for encoding non-biological information on microarrays

InactiveUS20050049796A1Bioreactor/fermenter combinationsSequential/parallel process reactionsComputer scienceMicroarray method

Methods and compositions for encoding and decoding array information on an array are provided. The methods involve contacting an array containing one or more array information features with a sample containing target that binds to at least one of the one or more array information features to produce at least one signal that provides information about the array.

Owner:AGILENT TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com