Patents

Literature

131 results about "Micro plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

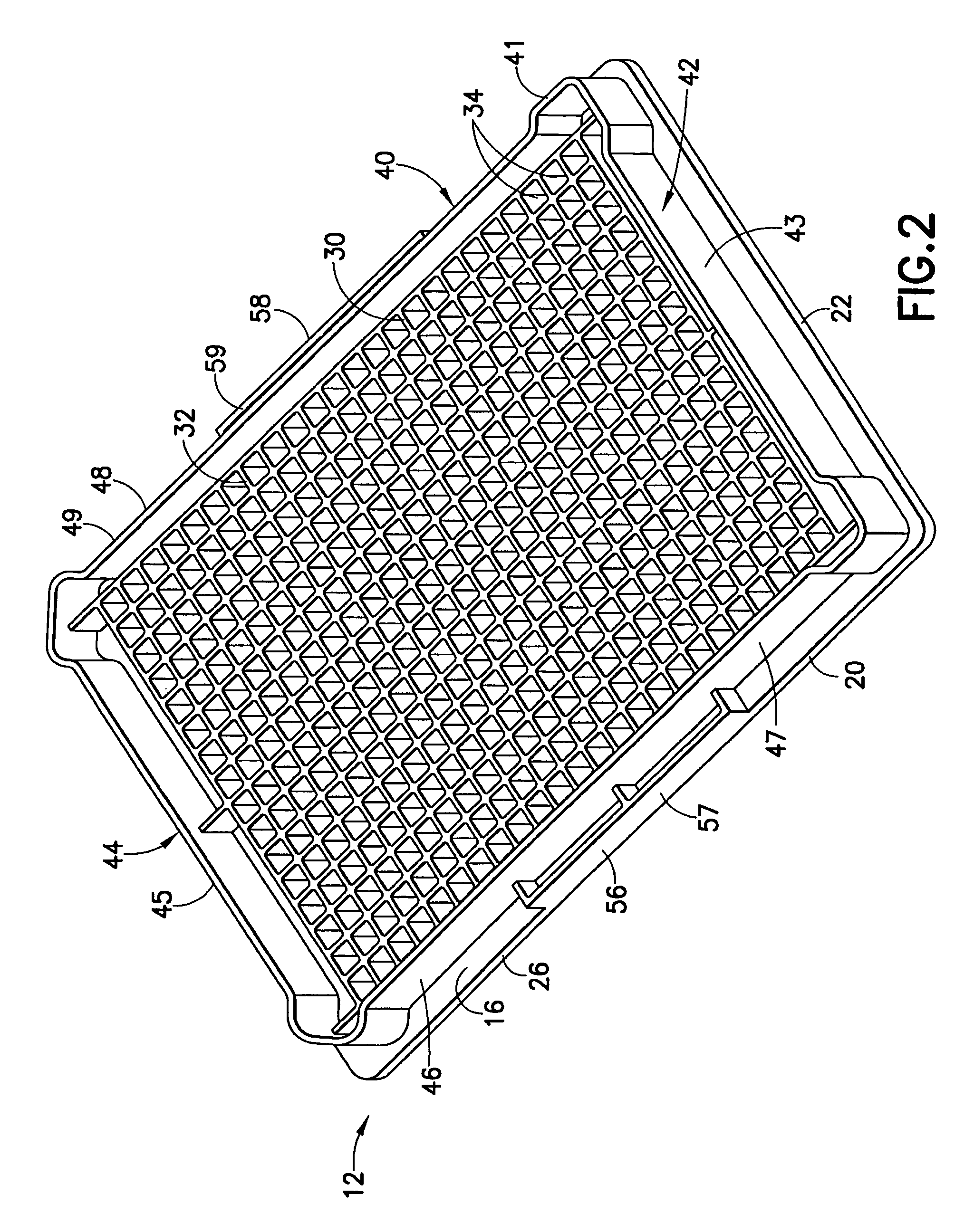

Microplate with fewer peripheral artifacts

InactiveUS20080095673A1Few artifactReduce impactAnalysis using chemical indicatorsLaboratory glasswaresMedicineMicro plate

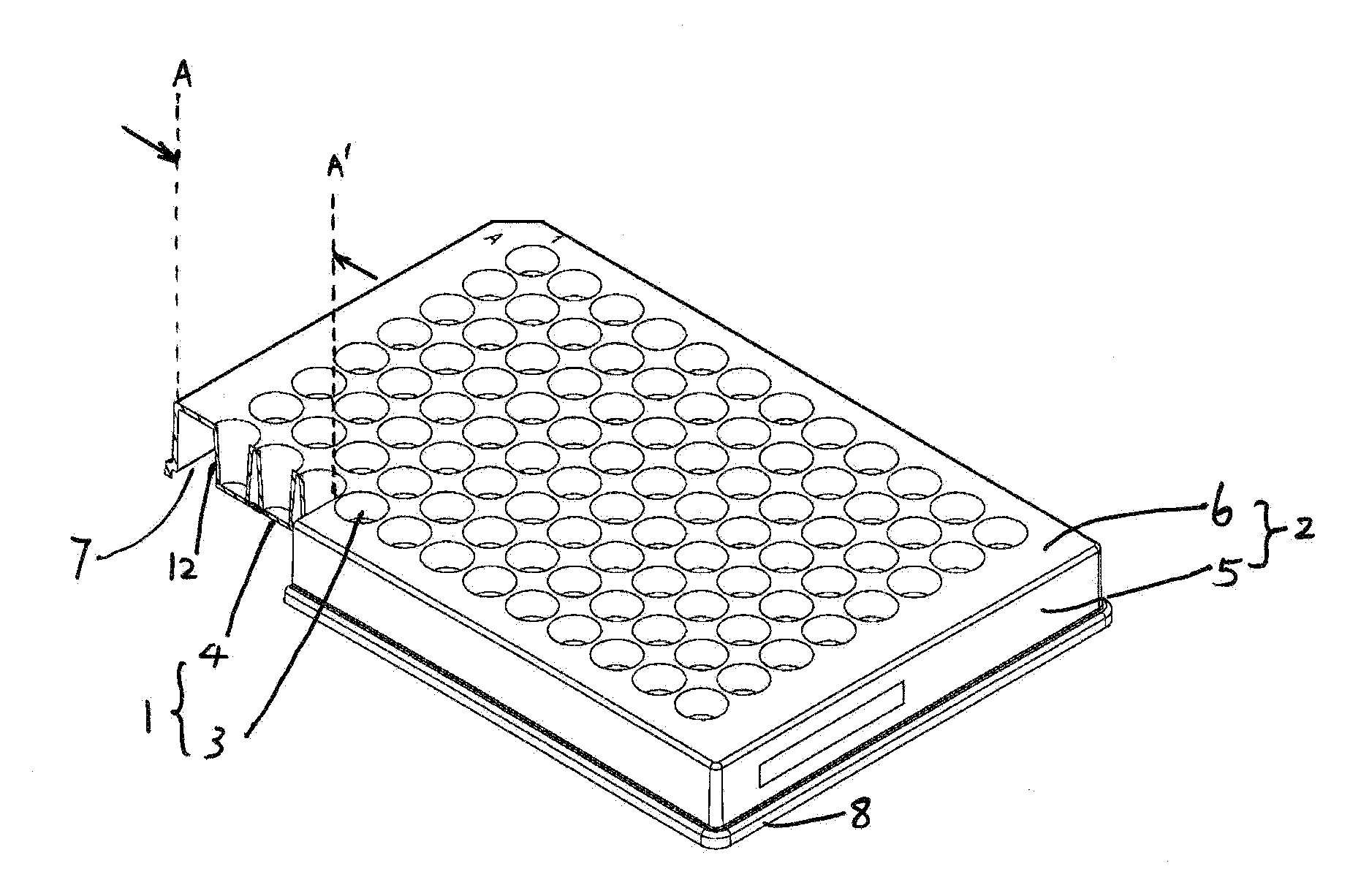

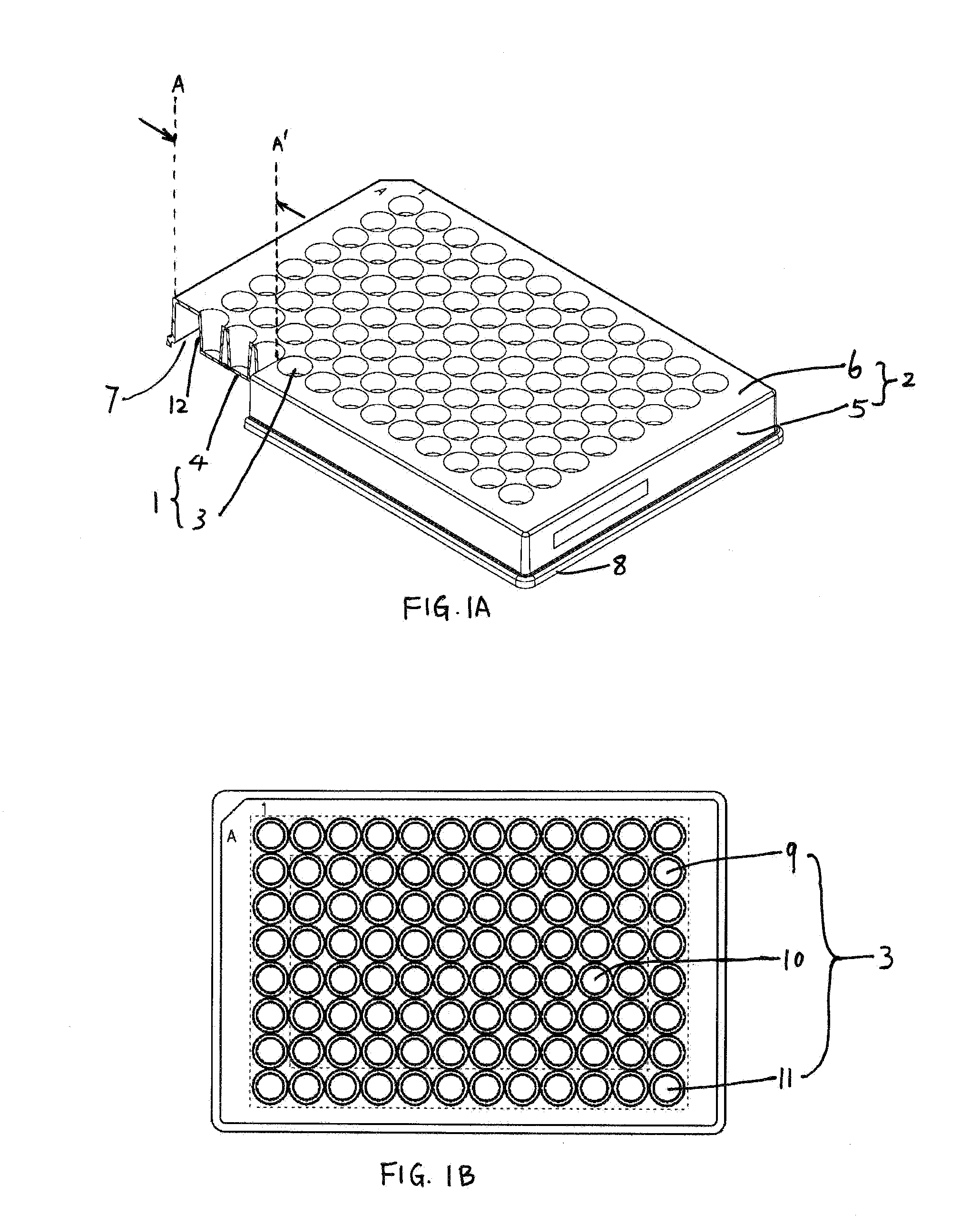

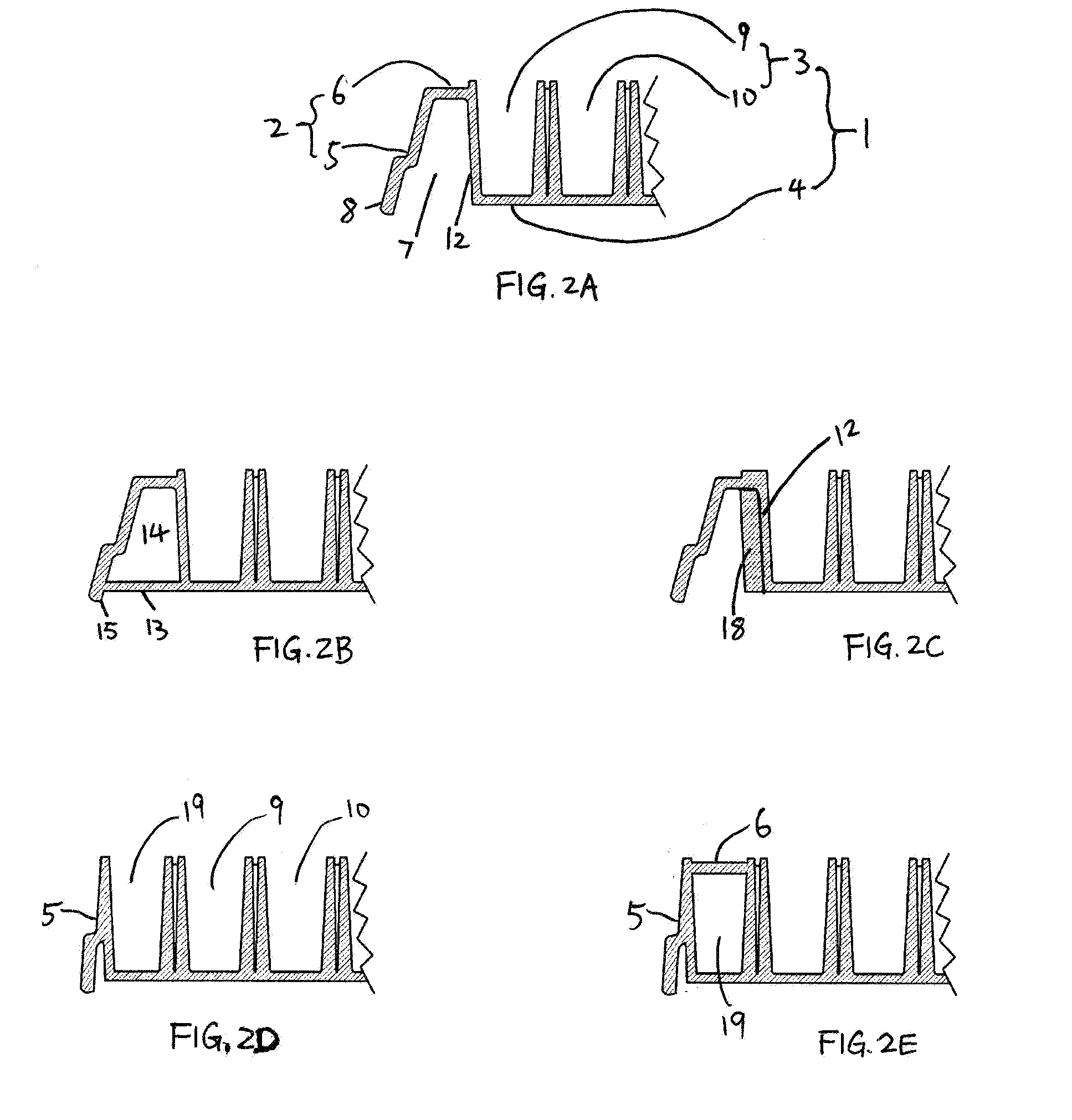

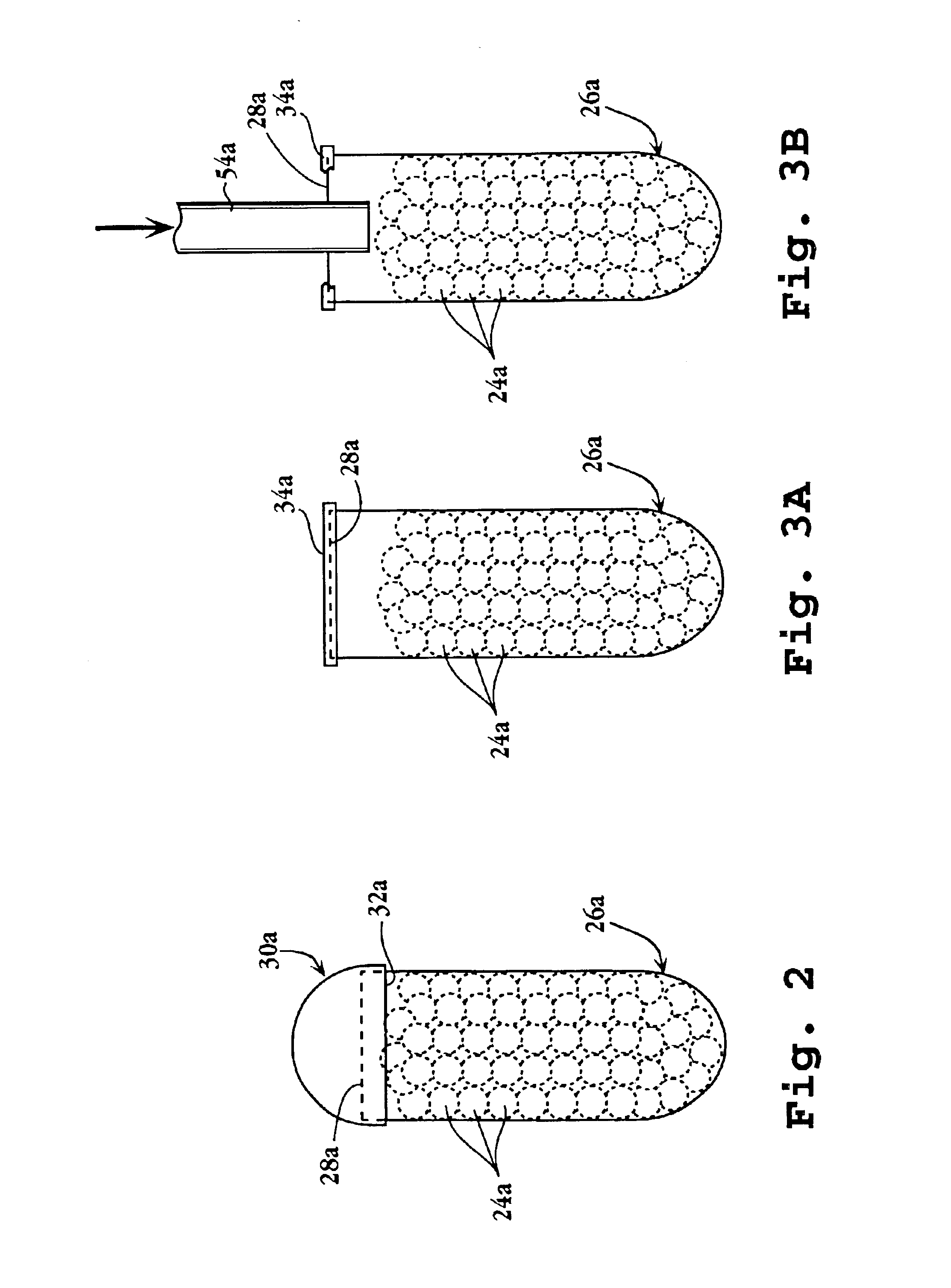

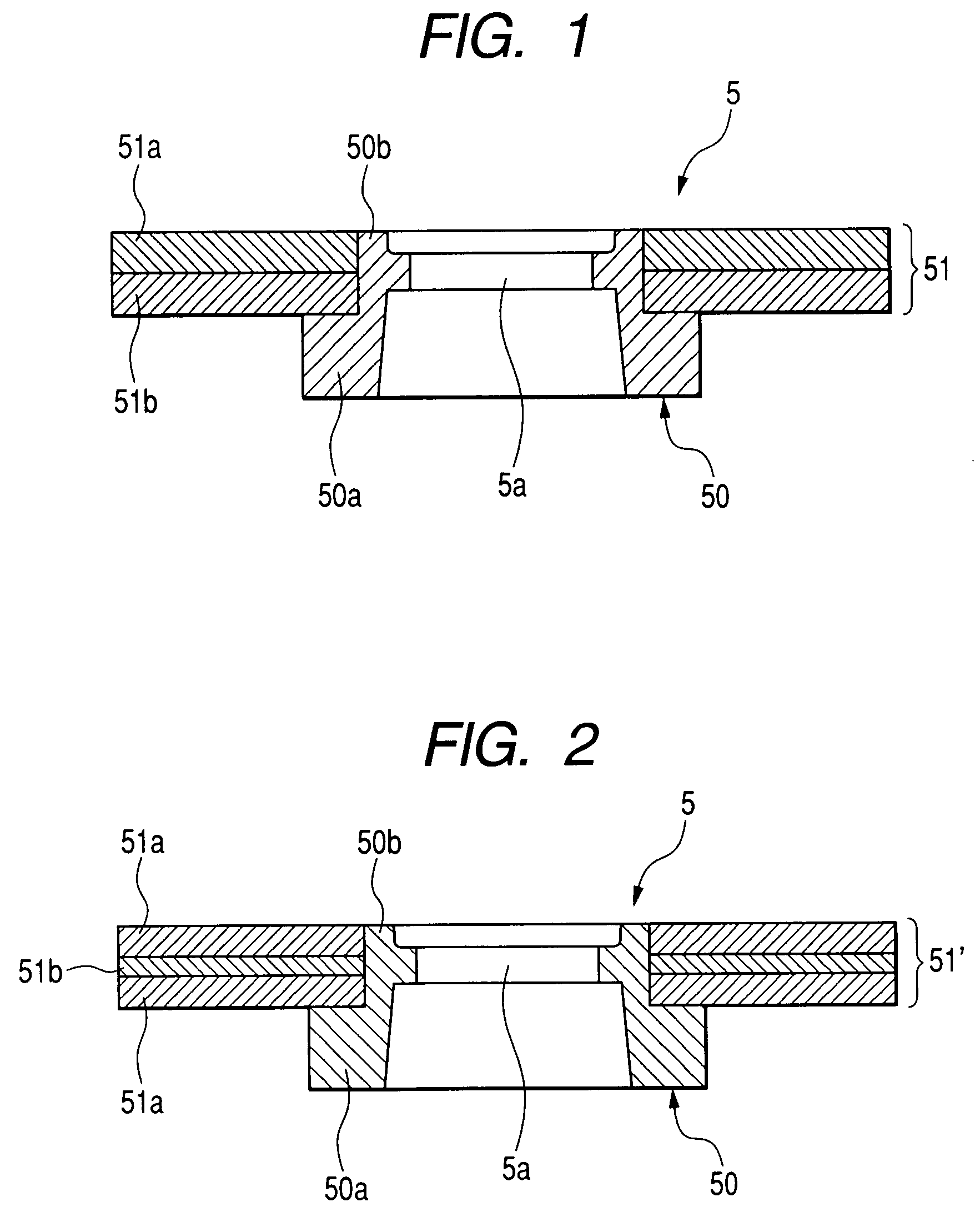

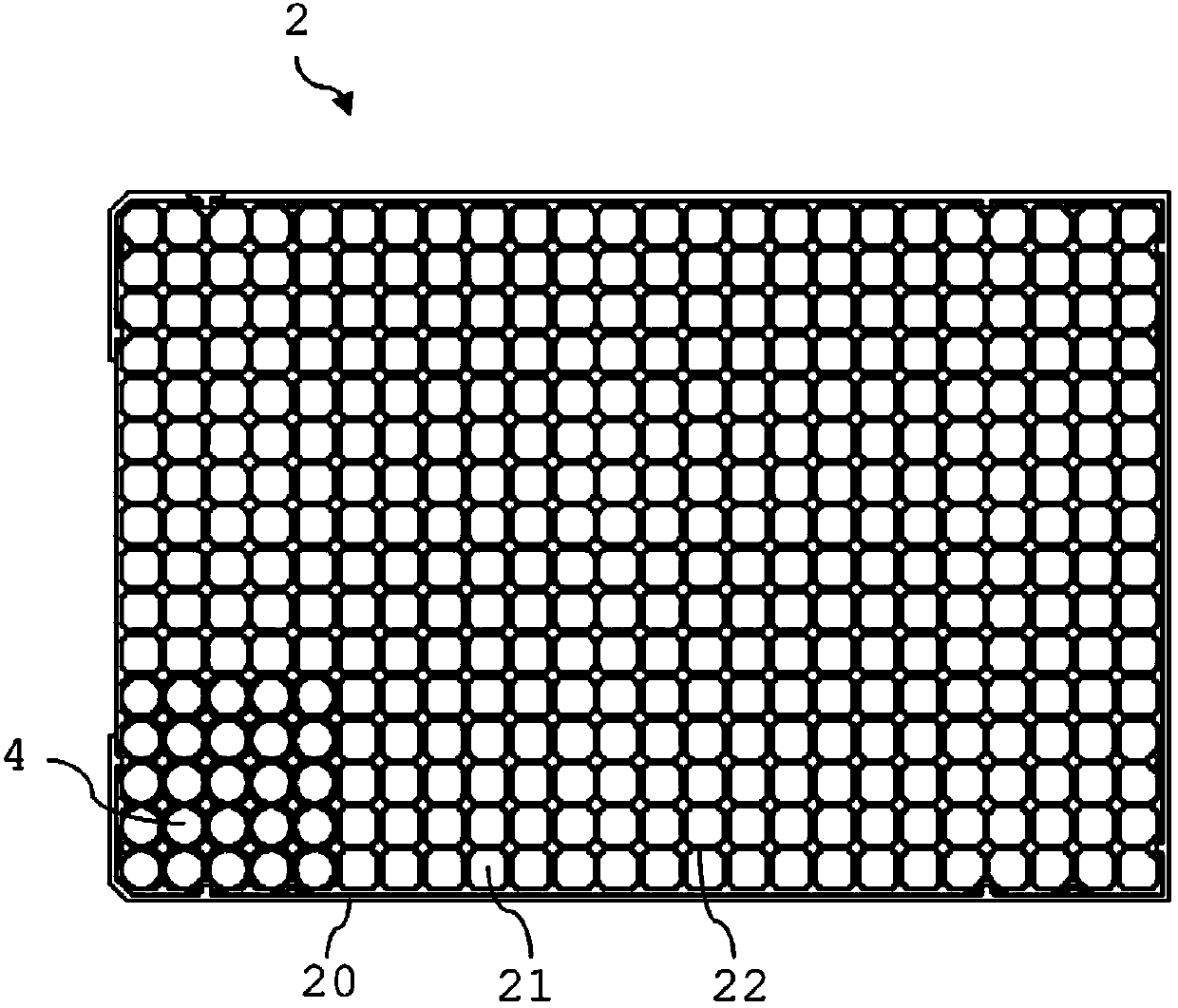

The current invention relates to an improved microplate. The microplate is characterized by modified quadrilateral edges, which bring less artificially induced inaccuracies in peripheral wells, especially in corner wells. Preferably, the microplate possesses a bottom that is elongated to cover the non-experimental slots. The microplate might further comprise sham wells.

Owner:XU LIN

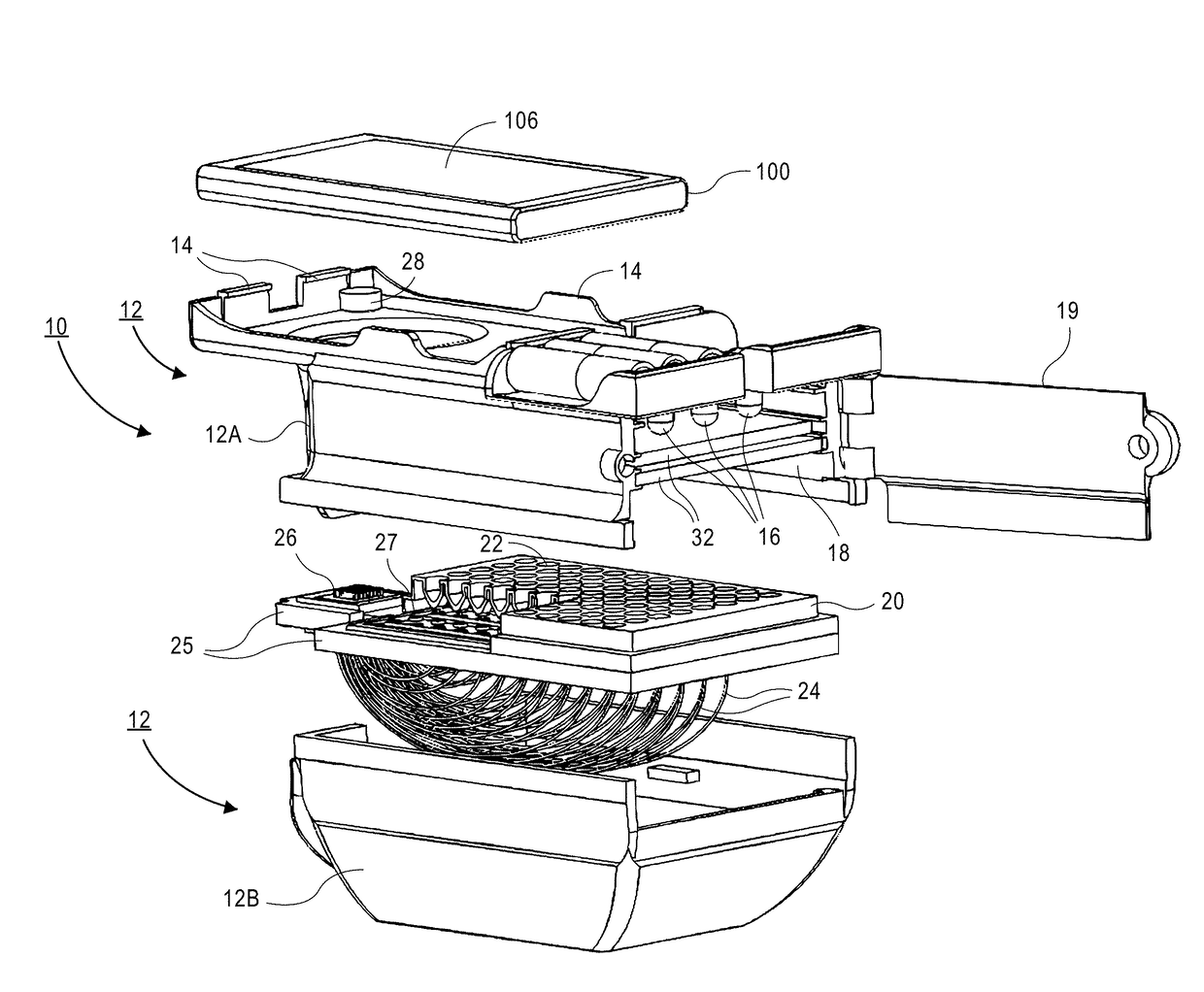

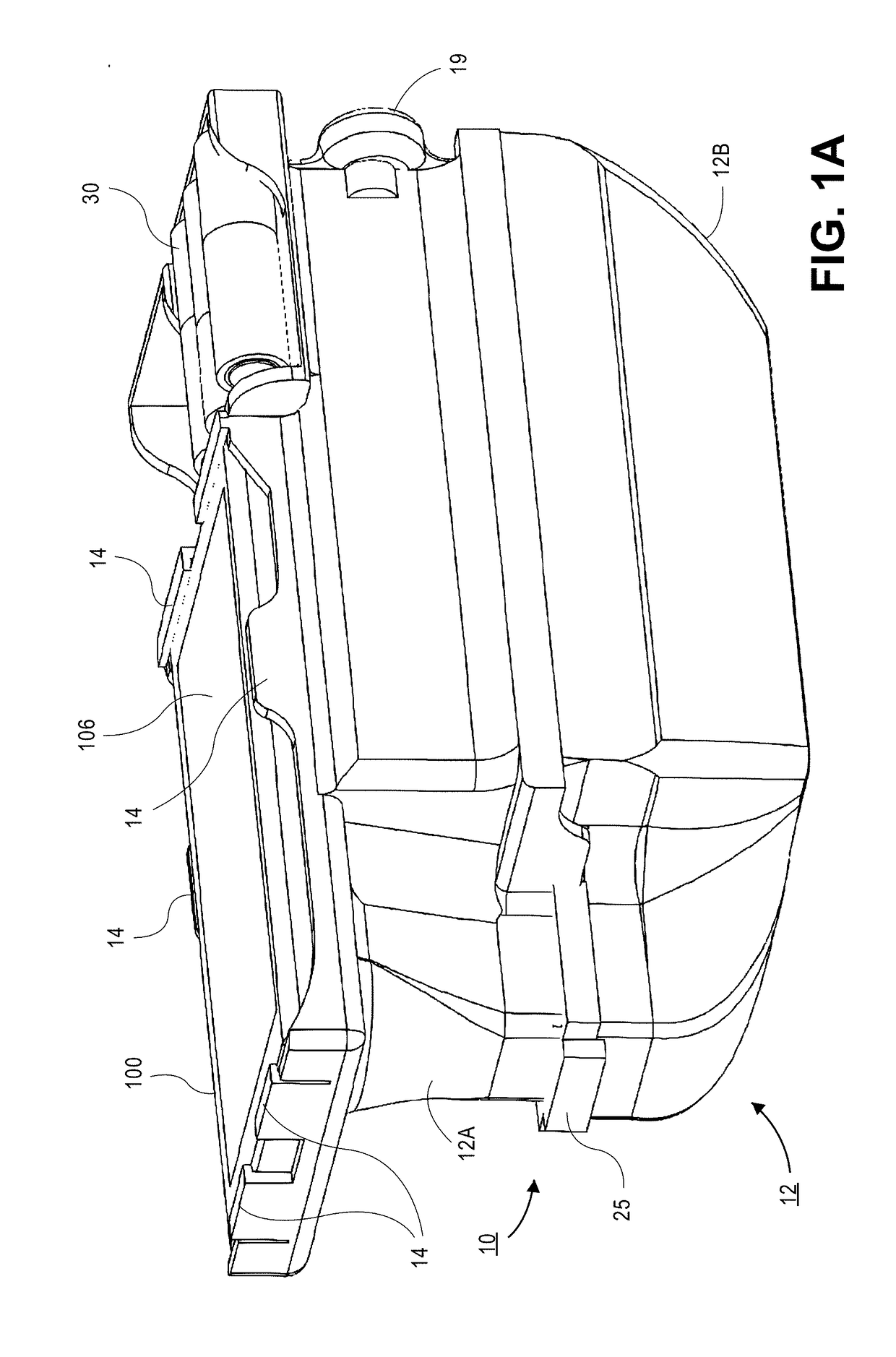

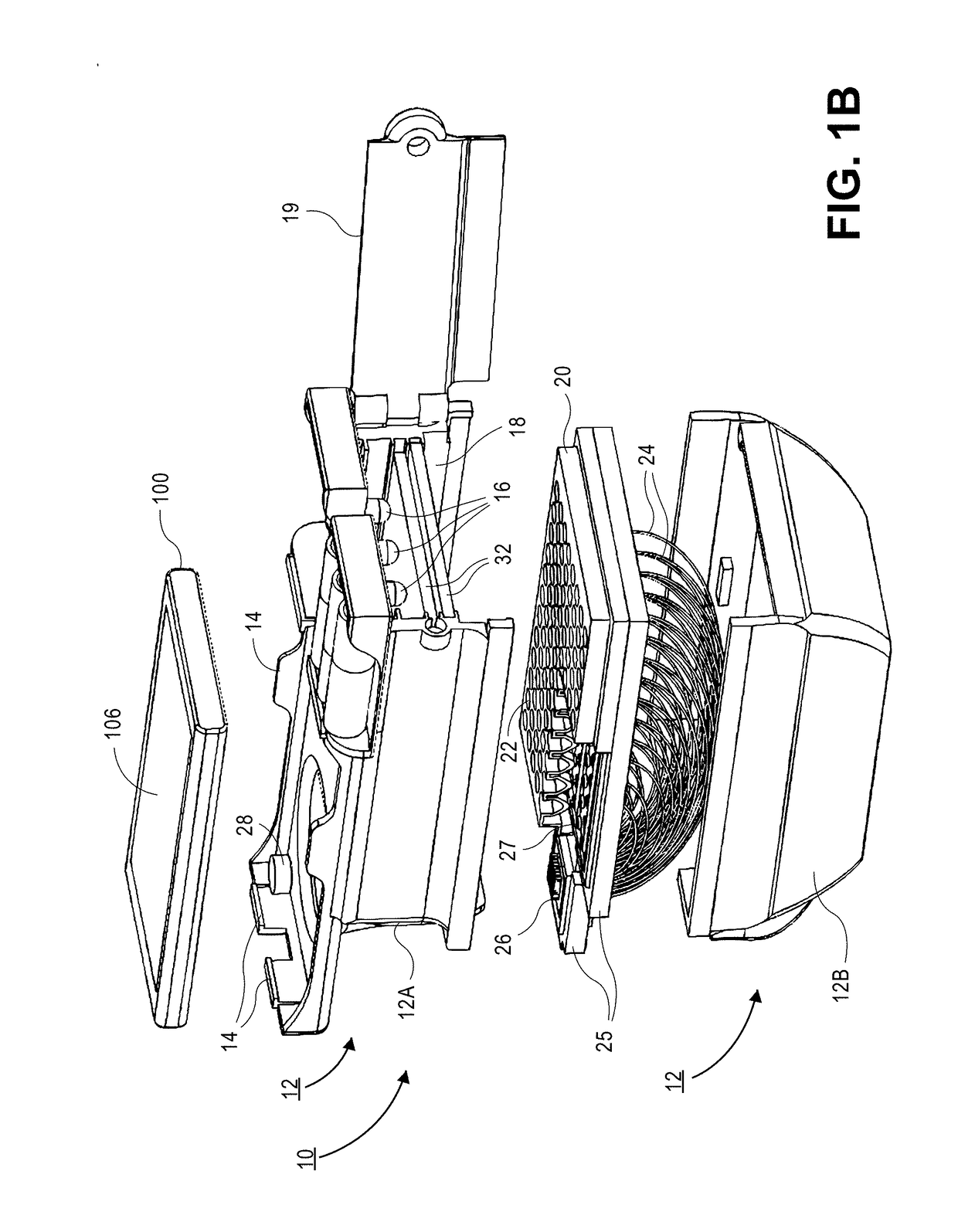

Bead dispensing system

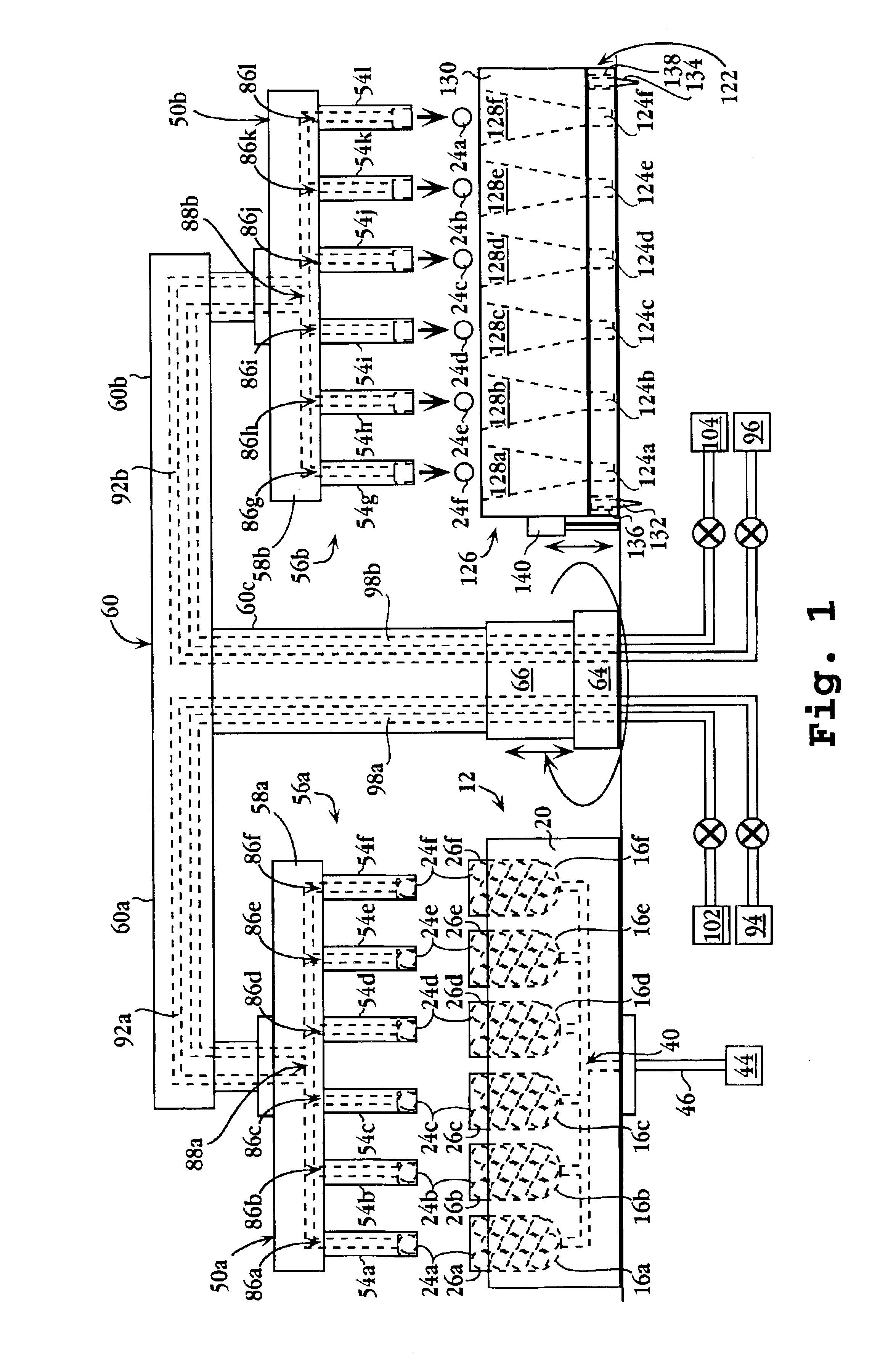

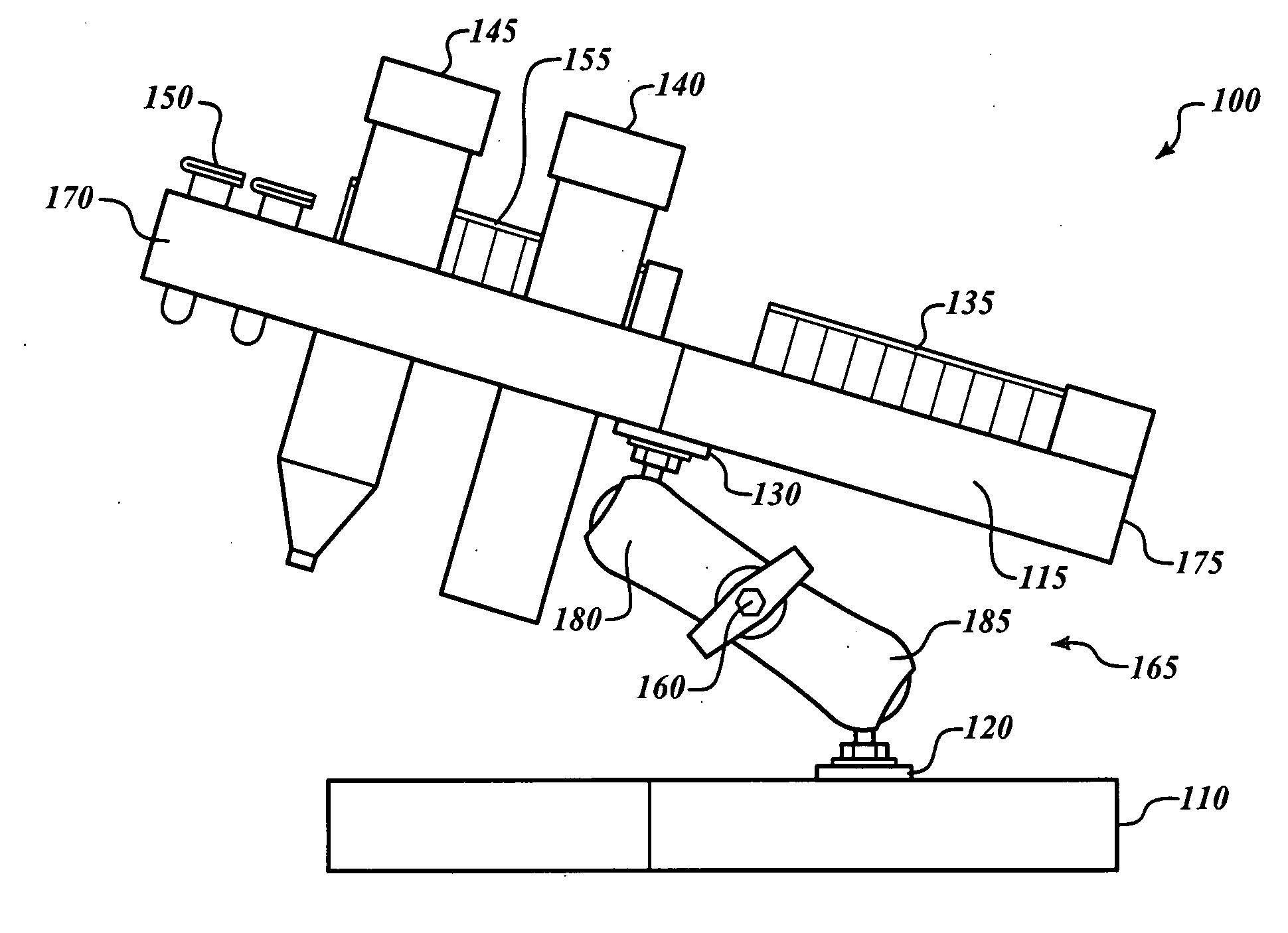

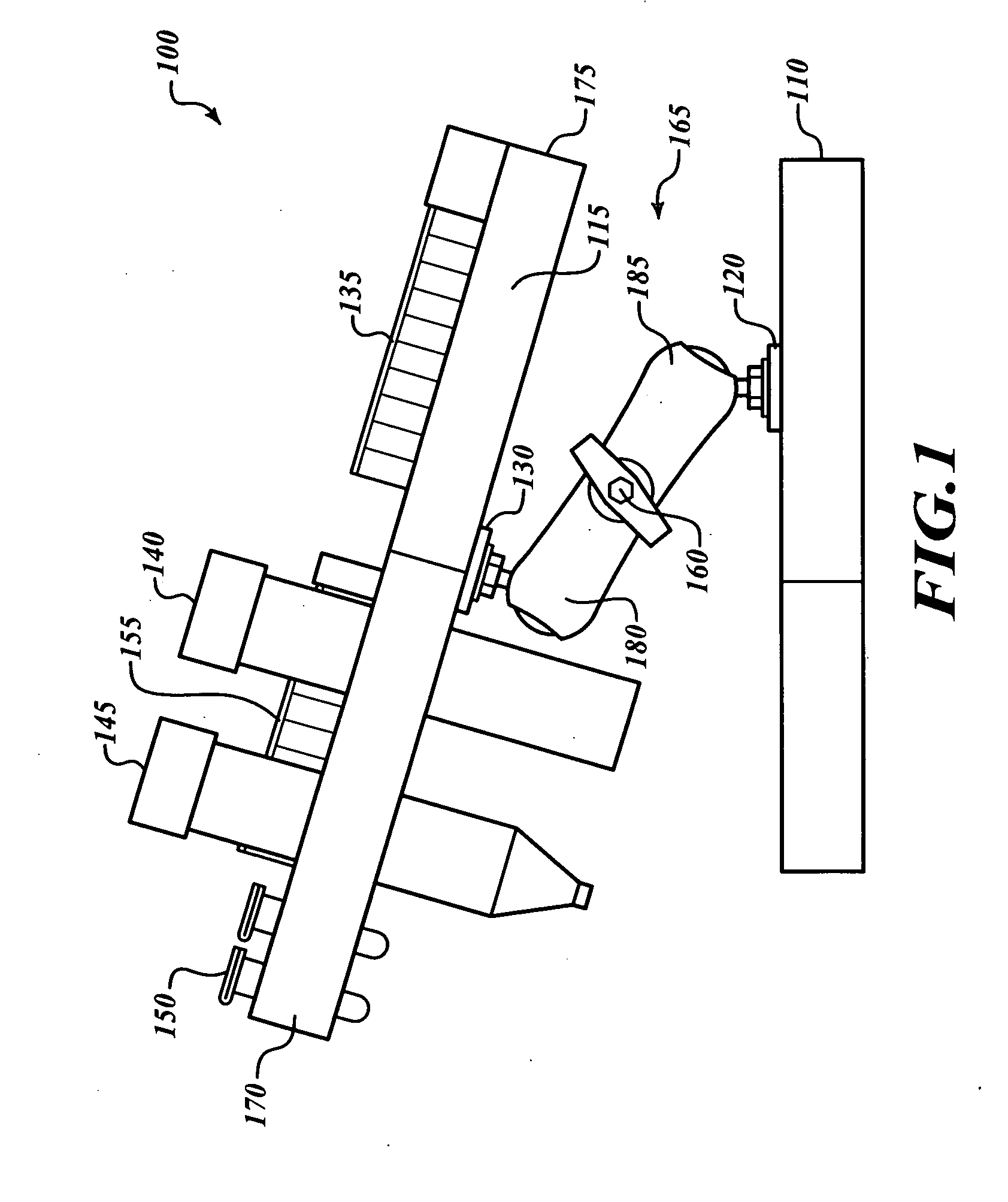

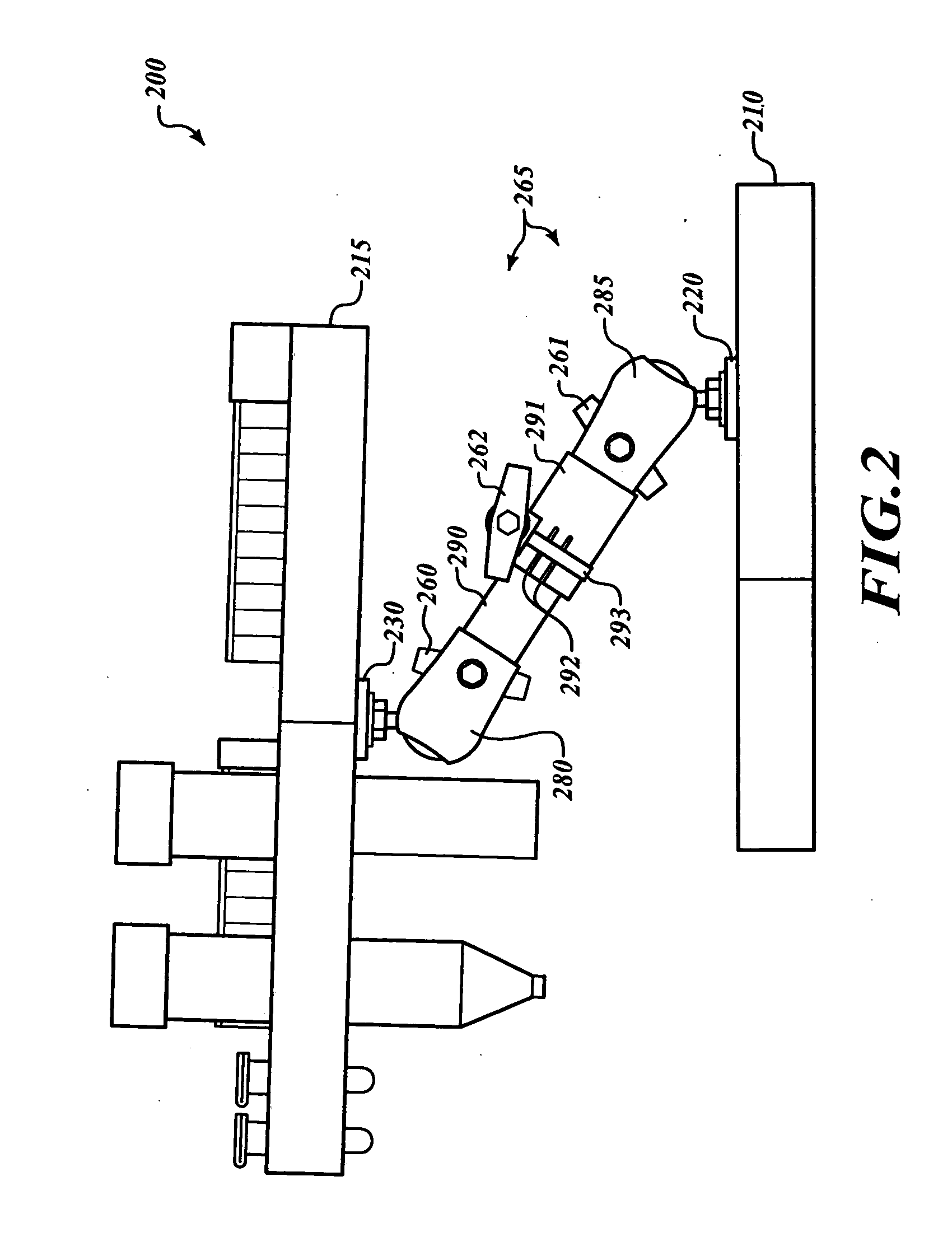

A bead dispensing system is provided for delivering small amounts of substances onto substrates. The system can include, for example, a movable support structure having an array of spaced-apart projections depending from its lower side. An attraction source, such as a vacuum, magnetic, and / or electrostatic force, is operable at each projection end region to attract and retain one bead. The projection array can be aligned with an array of bead-receiving regions of a substrate, e.g., an array of spaced-apart wells of a micro-plate or card. In one embodiment, a plurality of reagent-carrying beads are picked up, retained at respective projection end regions, and moved to a location over a multi-well plate. The beads are then released in a fashion permitting each bead to land in a respective well. The system of the invention is particularly useful for fabricating arrays of reagents.

Owner:APPL BIOSYSTEMS INC

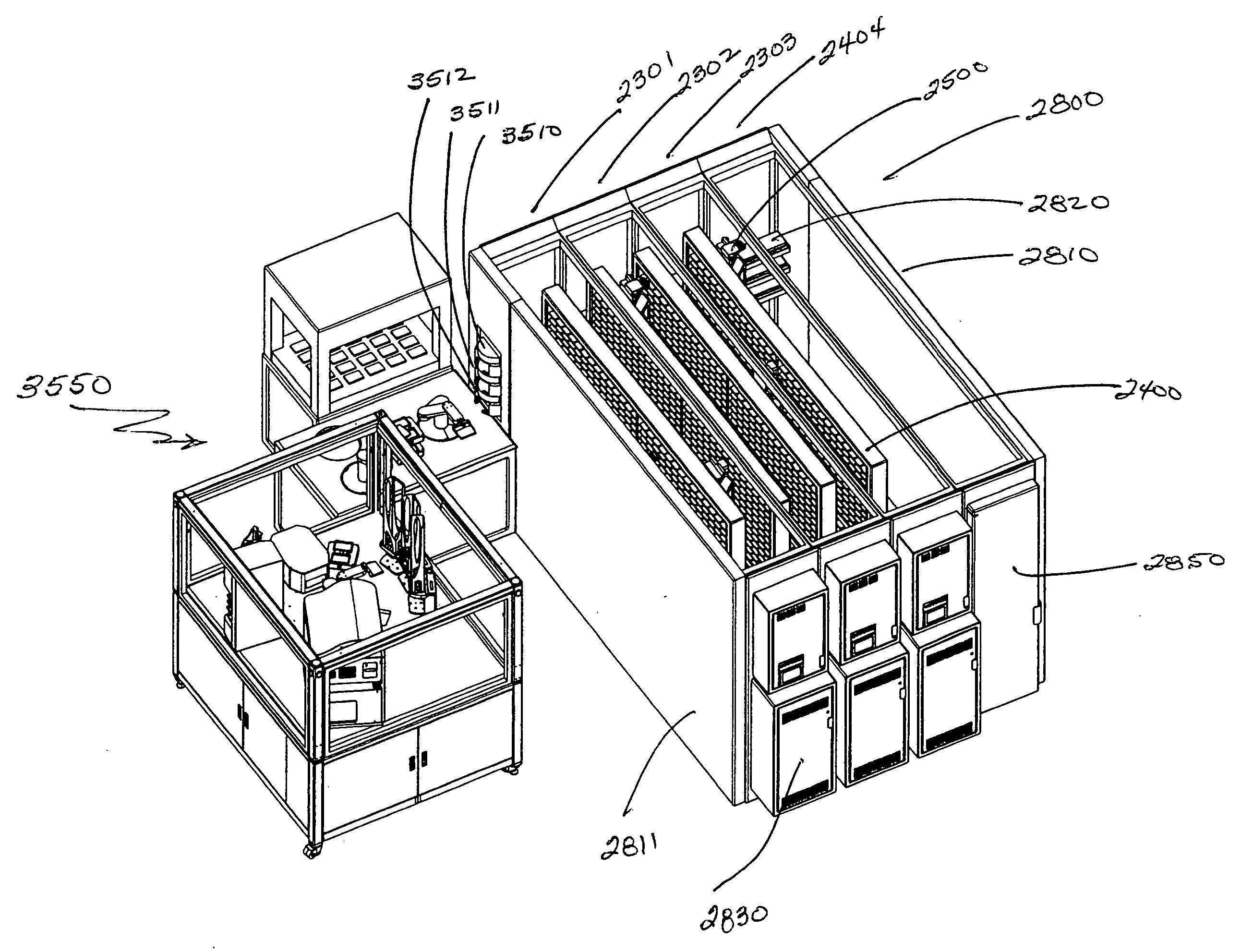

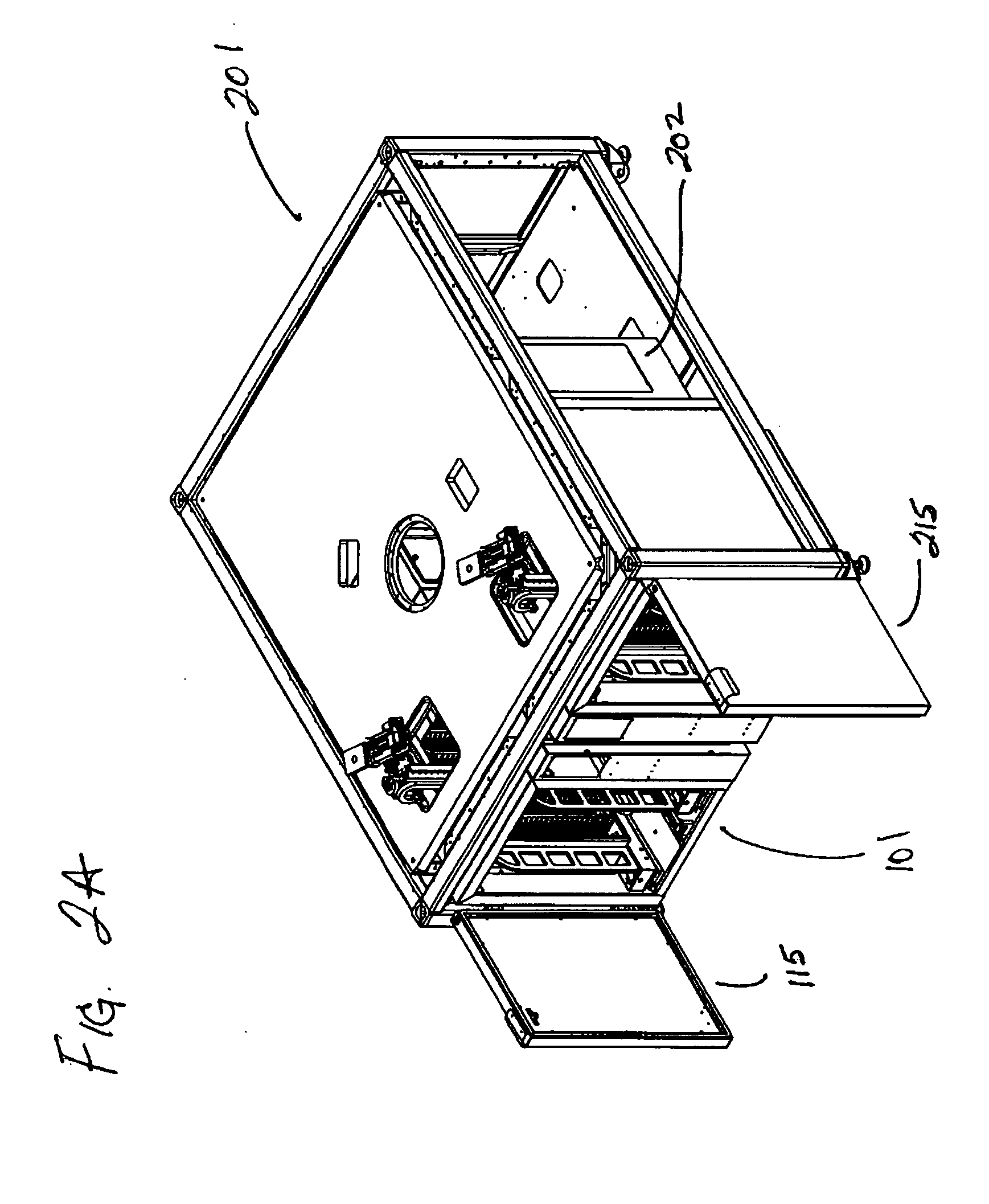

Environmental control incubator with removable drawer and robot

InactiveUS20060177922A1Ultimate compactnessStable and reliable controlBioreactor/fermenter combinationsHeating or cooling apparatusRobot positionMicro plate

An incubator for storing micro-plates or micro-tubes comprises a handling robot positioned between shelves or drawers containing micro-titer plates or other containers useful for biological based reactions. The advantages of this configuration are the ultimate compactness of the system and increased speed or reliability achieved with more than one robot being able to access the same plate or tube. Alternative embodiments standardize the spacing and configuration of a robot track and a shelf track such that a shelf and a robot are interchangeable in a track.

Owner:AGILENT TECH INC

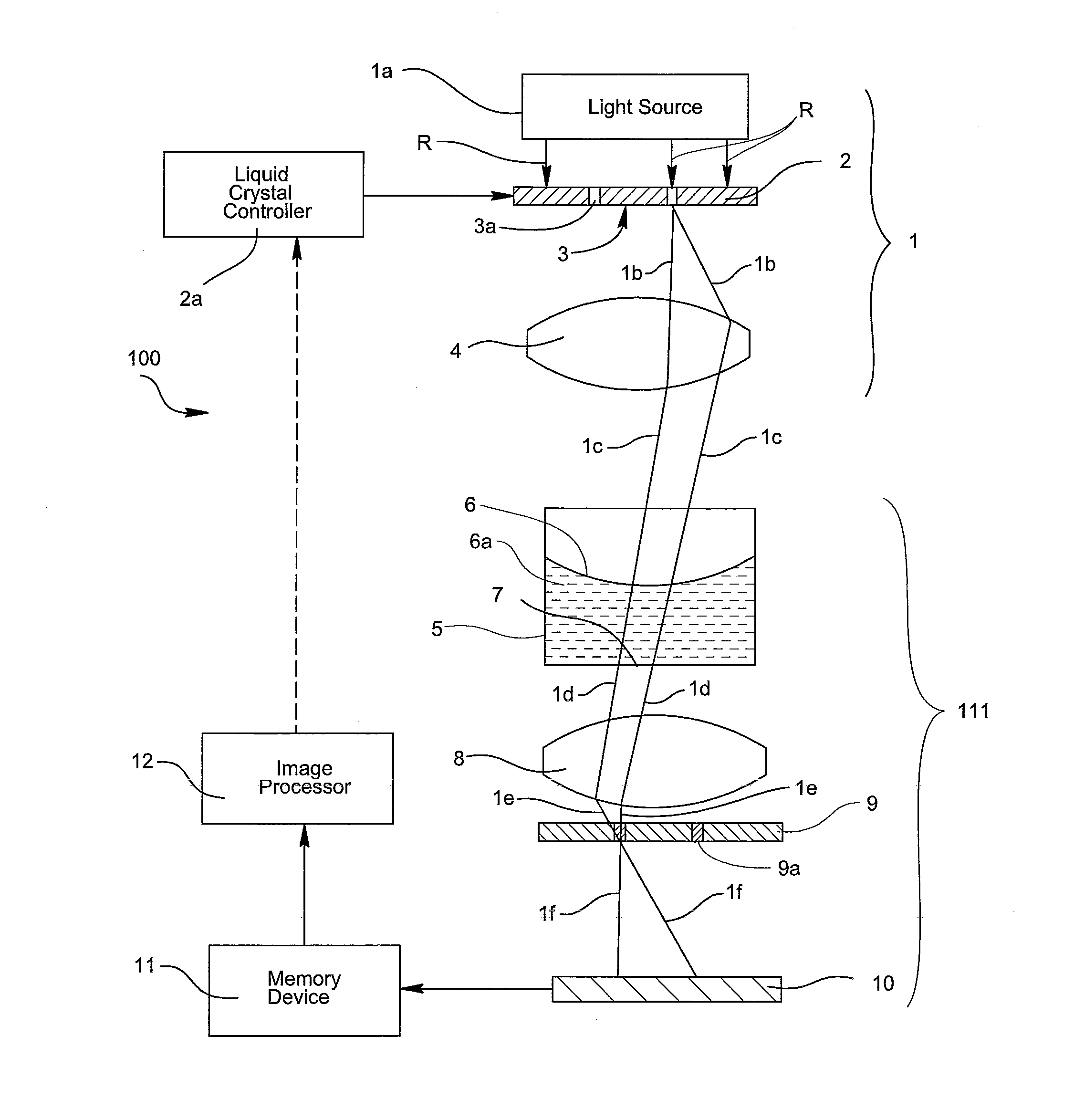

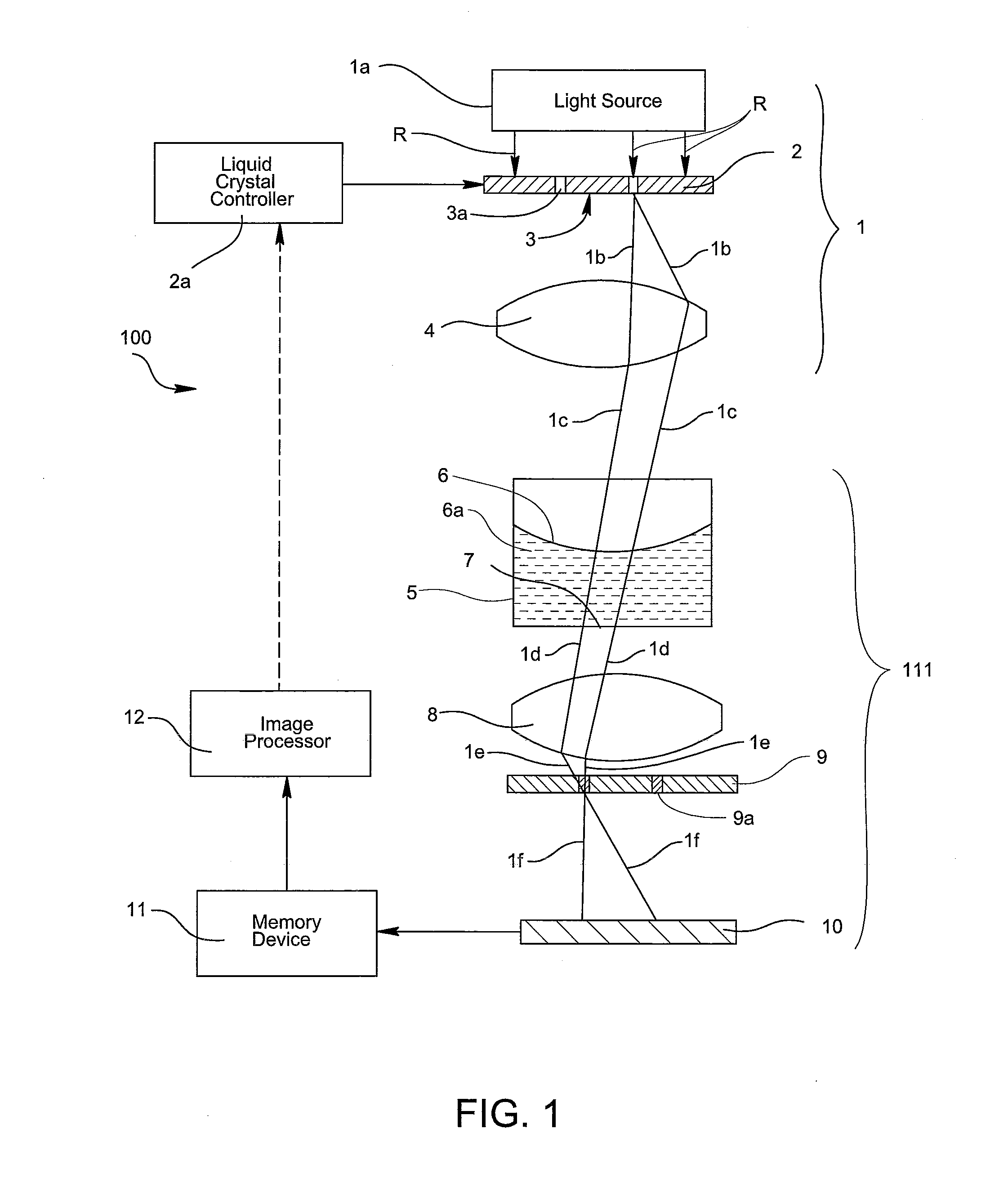

Adaptive phase contrast microscope

InactiveUS20120257040A1Region can be greatEnhance the imageColor television detailsClosed circuit television systemsMicro platePhase image

An optical microscope is provided with an adjustable optical phase ring. The adjustable ring provides a way to compensate for distortion in the visible phase ring before the light reaches the sample. In an inverted microscope, when observing transparent cells under a liquid, the visible light phase ring is distorted. By the use of a Liquid Crystal Display (LCD) in place of a fixed ring, the projected ring is adjusted to realign the light and produce phase. In a typical micro plate, the meniscus formed produces a lens effect that is realigned by providing changes in the position and pattern, to allow phase imaging over a wider portion of the well. The realignment of the ring can be manual or automated and can be dynamically adjusted based upon an observed image of the sample.

Owner:KAIROS INSTR

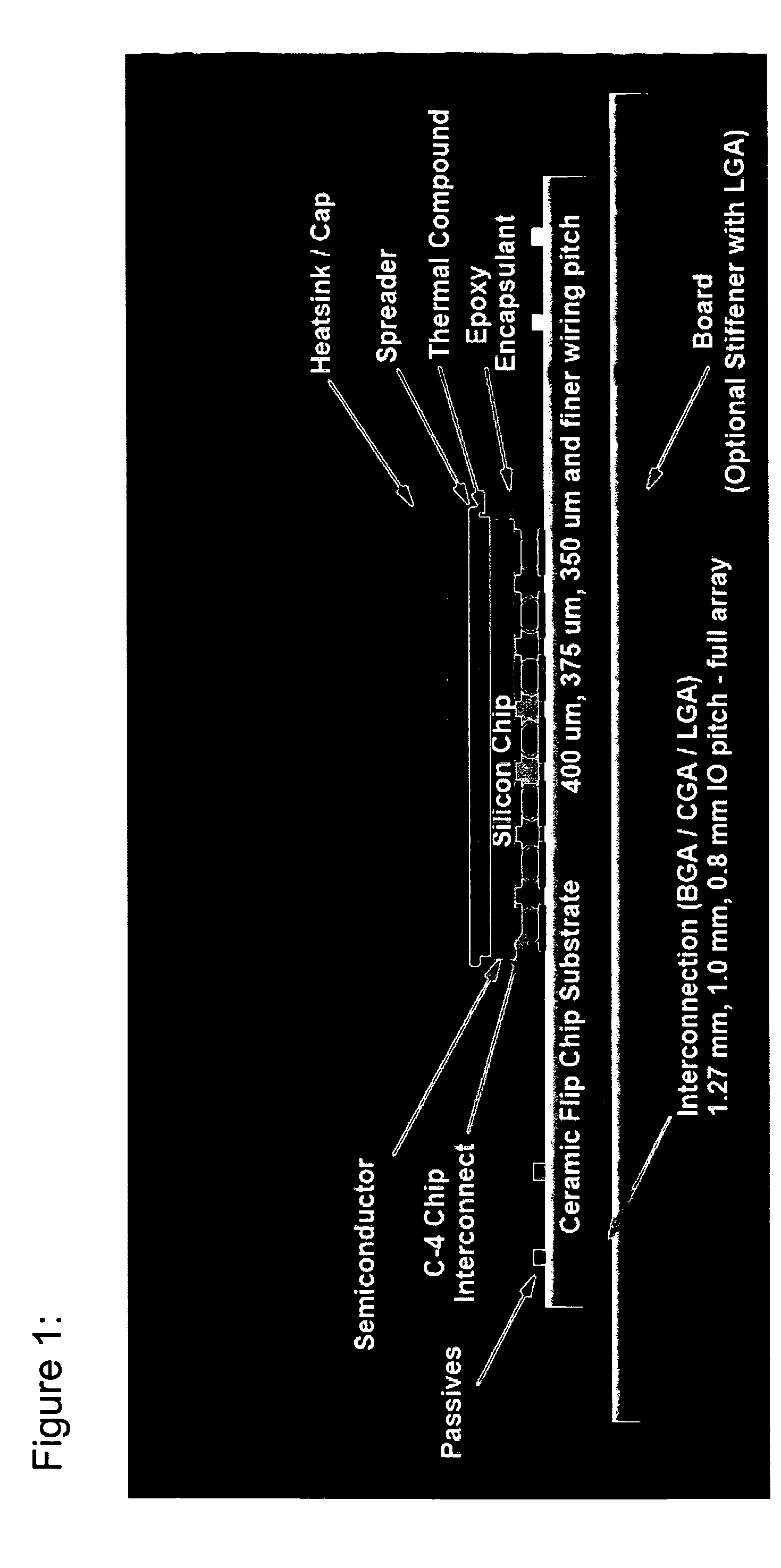

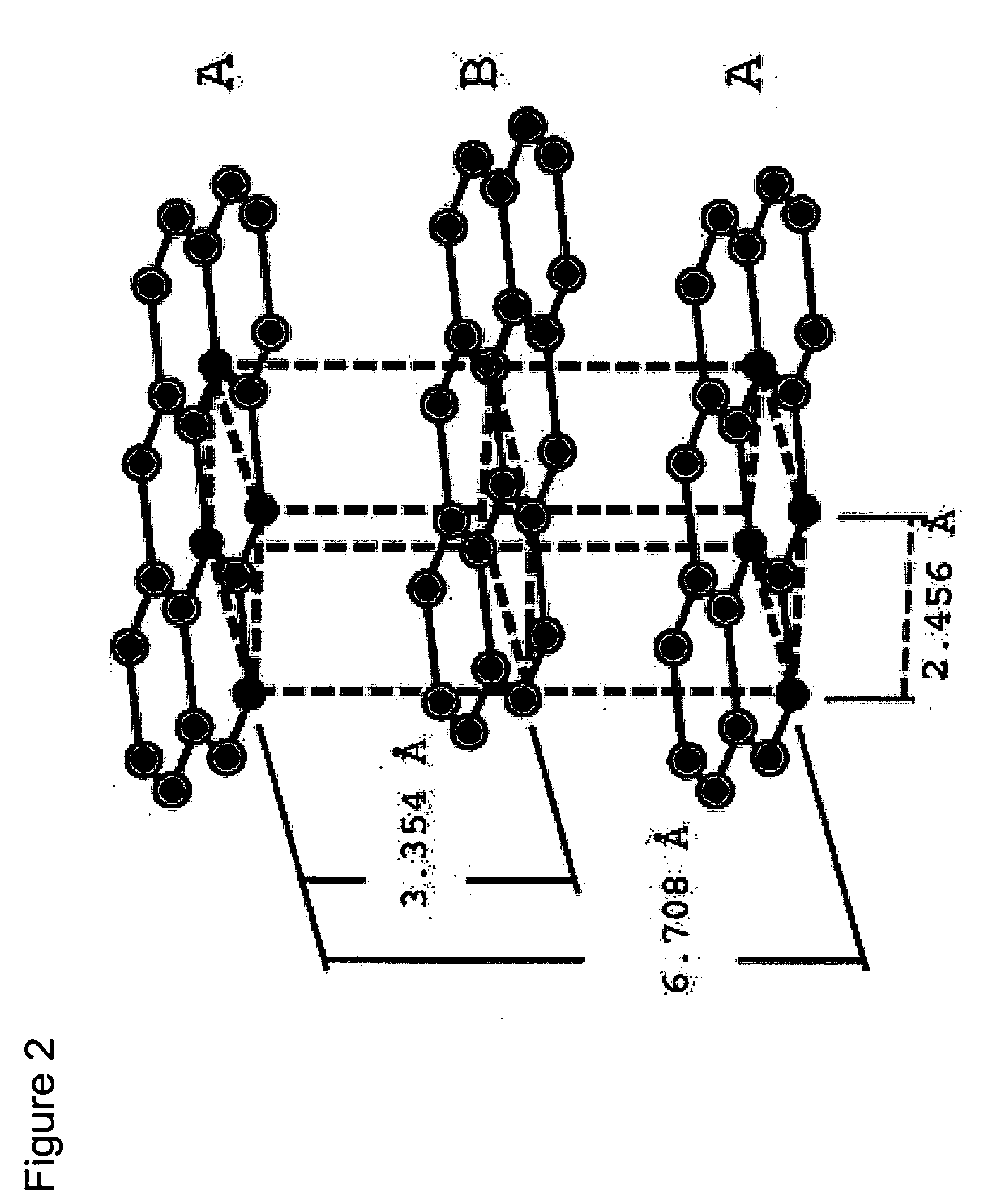

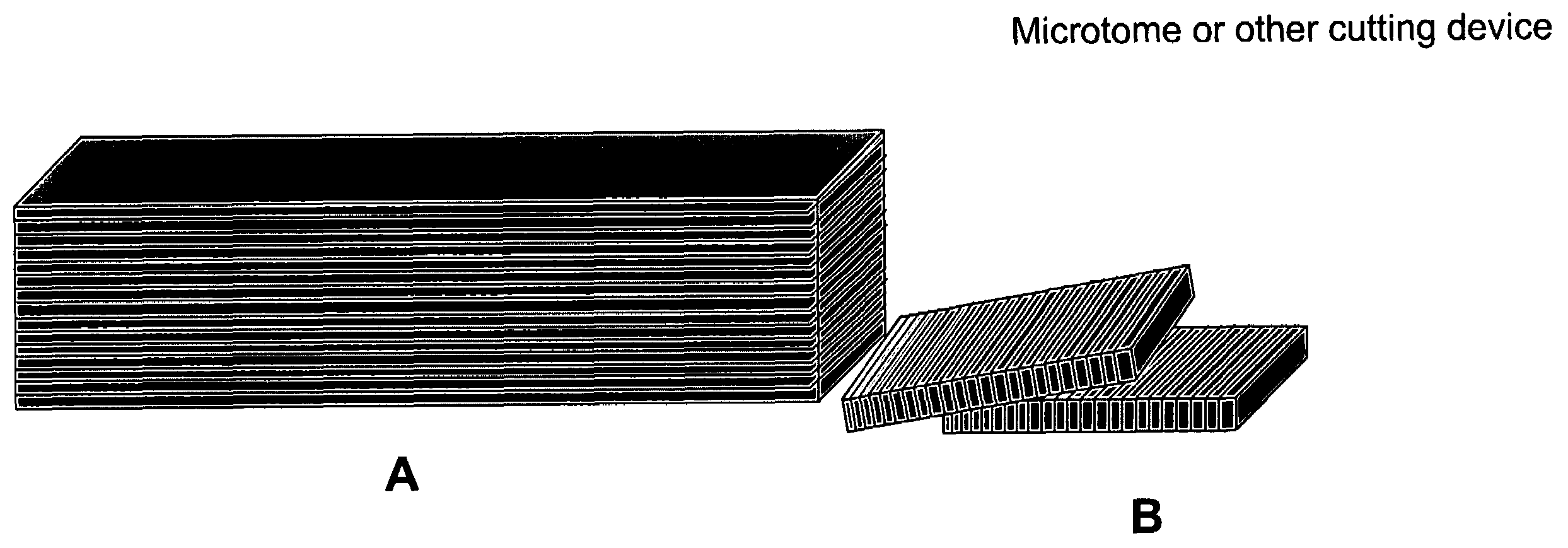

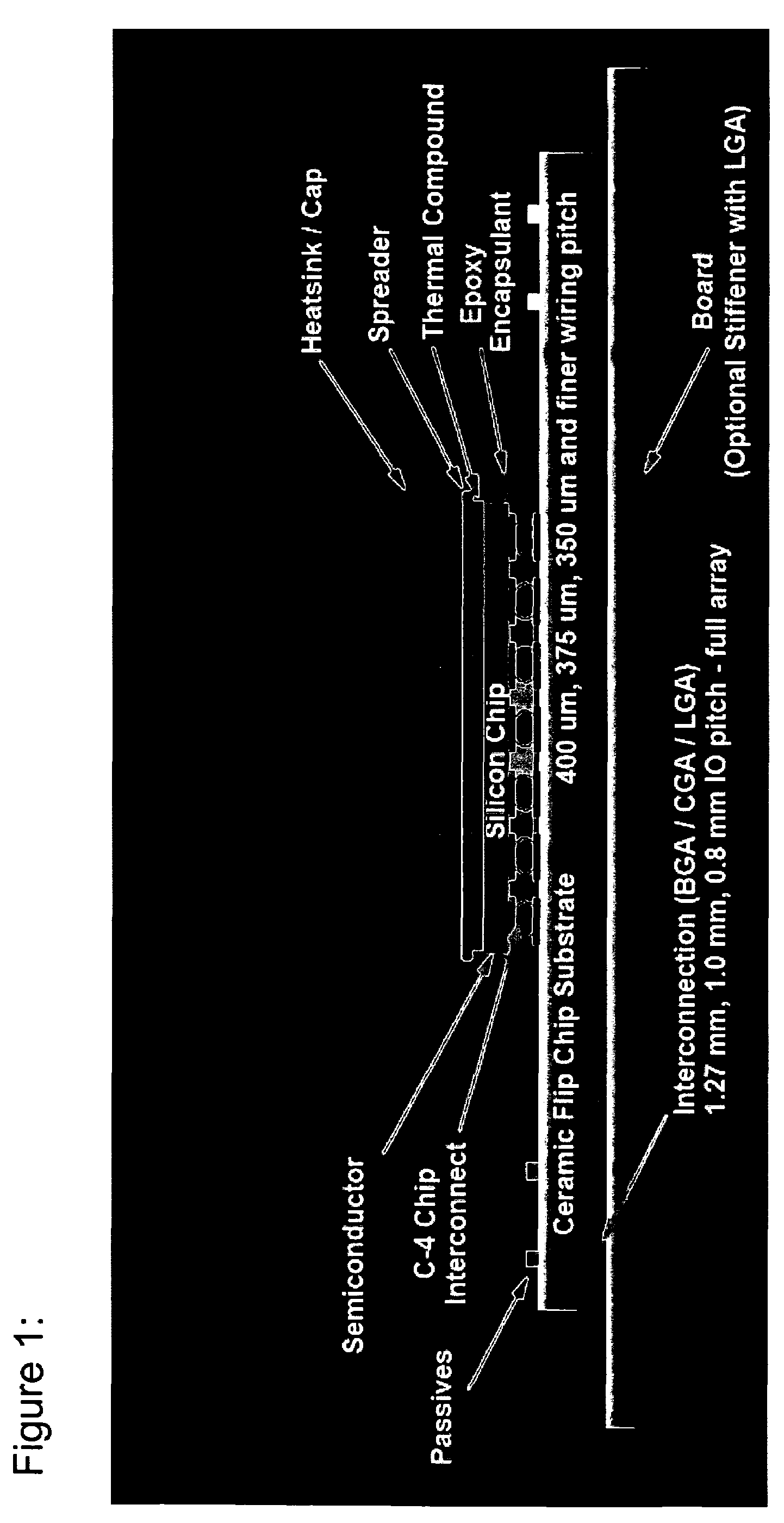

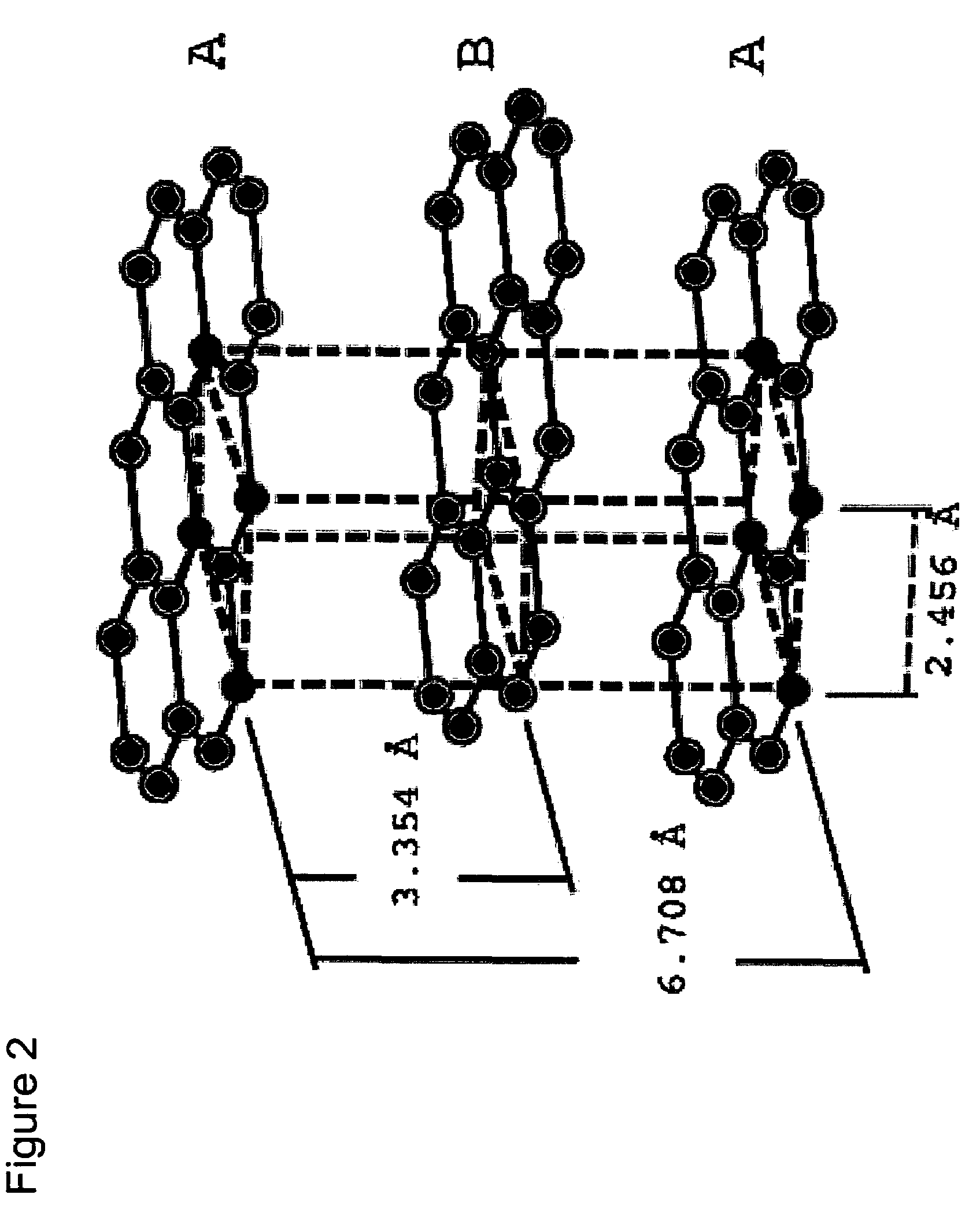

Self orienting micro plates of thermally conducting material as component in thermal paste or adhesive

ActiveUS20060112857A1Readily apparentPigmenting treatmentMaterial nanotechnologyConductive pasteAdhesive

The present invention relates generally to thermally-conductive pastes for use with integrated circuits, and particularly, but not by way of limitation, to self-orienting microplates of graphite.

Owner:GLOBALFOUNDRIES US INC

Electromagnetic switch

InactiveUS20070194867A1Reduce its spring constantIncrease its damping (or its attenuation) coefficientWindingsMagnetic circuitDamping factorEngineering

In an electromagnet switch, a stationary iron core is composed mainly of a base part and a disk part. The base part is faced to a plunger and the disk part is forcedly inserted and fixed to a boss part formed in the base part. The disk part is composed of a metal plate of ferromagnetic substance (iron plate) and another substance plate (made of resin or rubber and the like, for example,) of a smaller spring constant or a larger damping coefficient than that of the metal plate. The metal plate and another substance plate are laminated. Another substance plate absorbs or reduces the impact force when the plunger is electromagnetically attracted toward and collides with the base part. The propagation of a large impact noise or crashing sound is thereby suppressed, and as a result the impact noise can be reduced.

Owner:DENSO CORP

Bead dispensing system

InactiveUS20050130318A1Material nanotechnologySequential/parallel process reactionsMicro plateMechanical engineering

A bead dispensing system is provided for delivering small amounts of substances onto substrates. The system can include, for example, a movable support structure having an array of spaced-apart projections depending from its lower side. An attraction source, such as a vacuum, magnetic, and / or electrostatic force, is operable at each projection end region to attract and retain one bead. The projection array can be aligned with an array of bead-receiving regions of a substrate, e.g., an array of spaced-apart wells of a micro-plate or card. In one embodiment, a plurality of reagent-carrying beads are picked up, retained at respective projection end regions, and moved to a location over a multi-well plate. The beads are then released in a fashion permitting each bead to land in a respective well. The system of the invention is particularly useful for fabricating arrays of reagents.

Owner:APPL BIOSYSTEMS INC

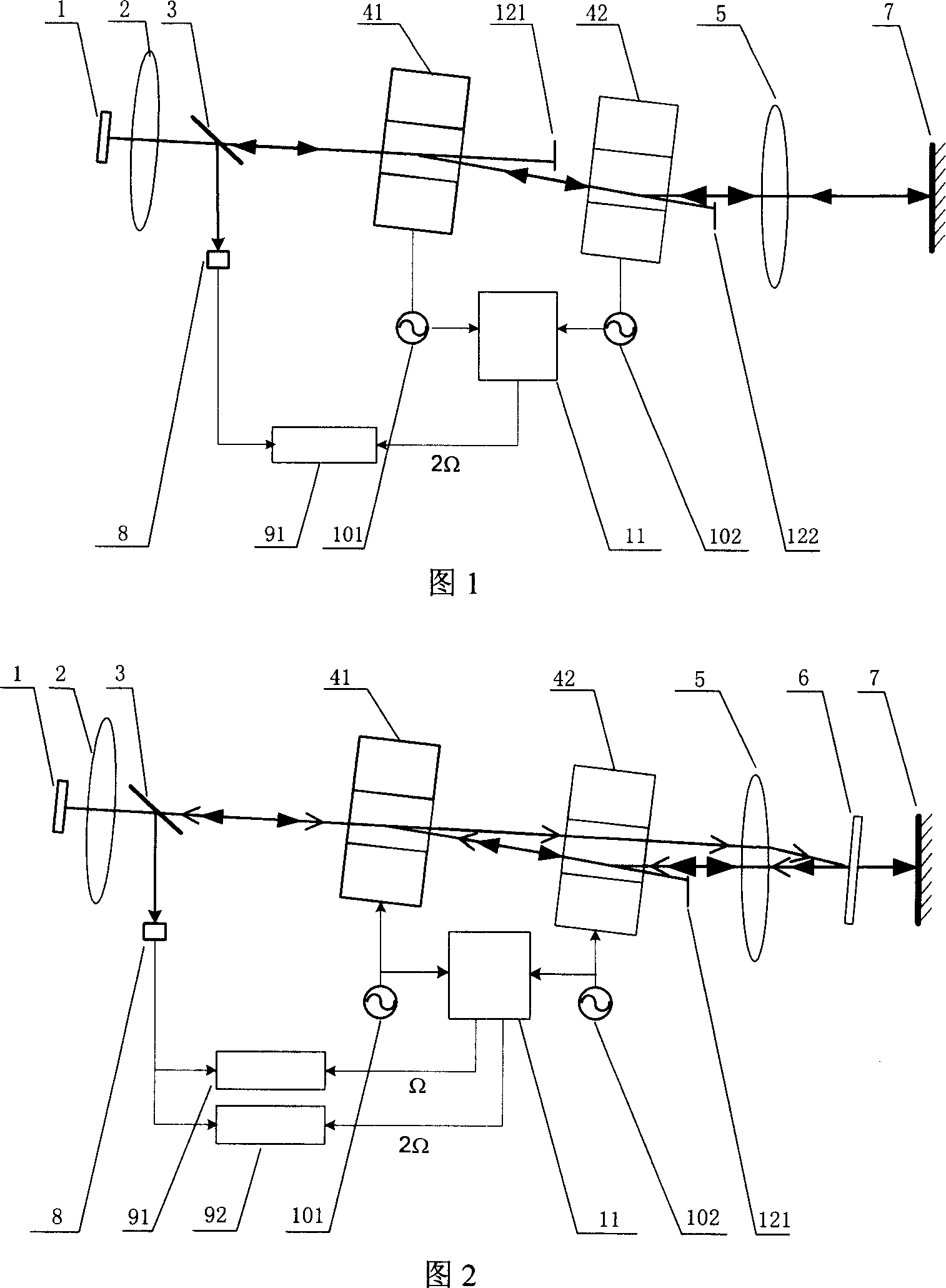

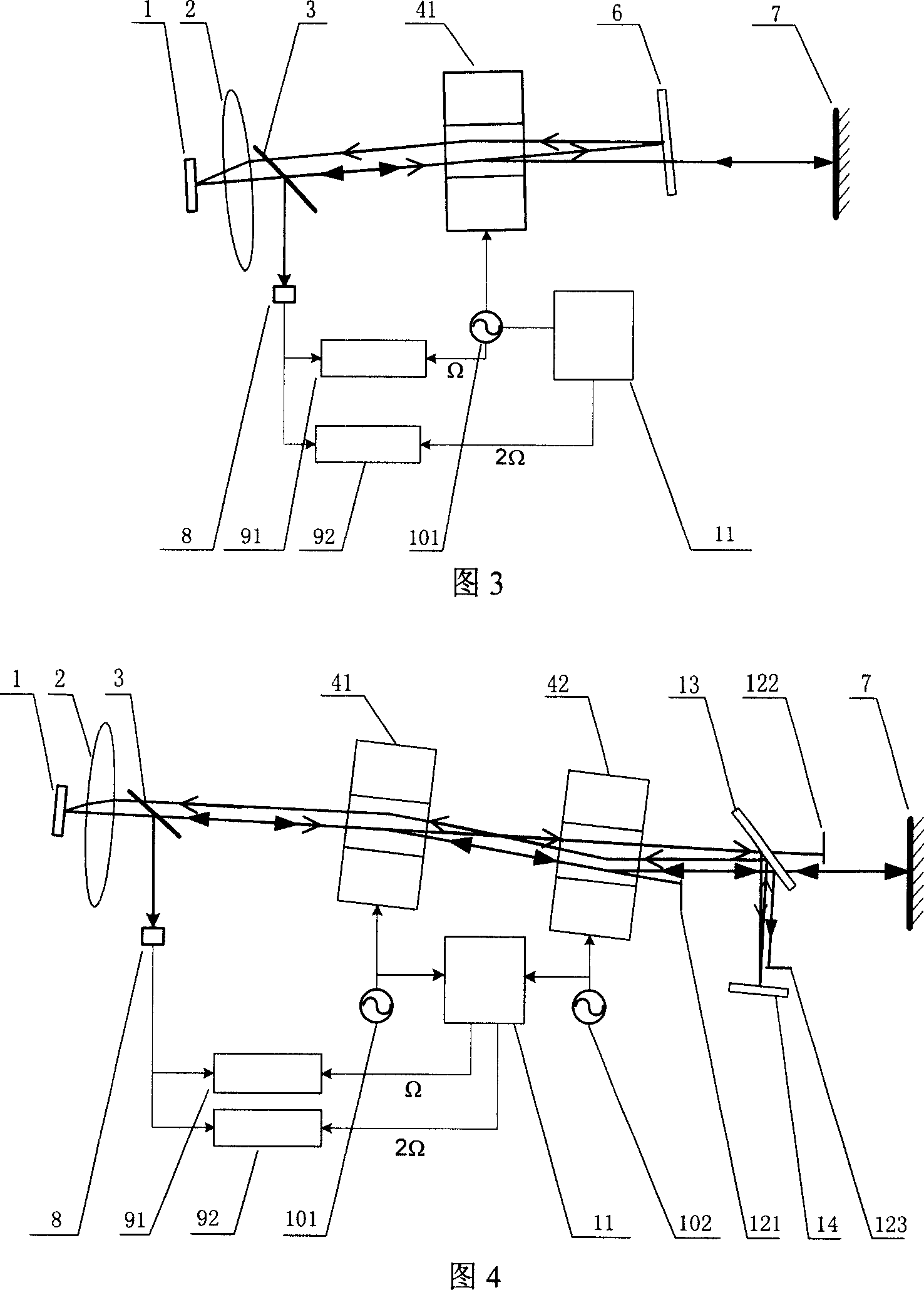

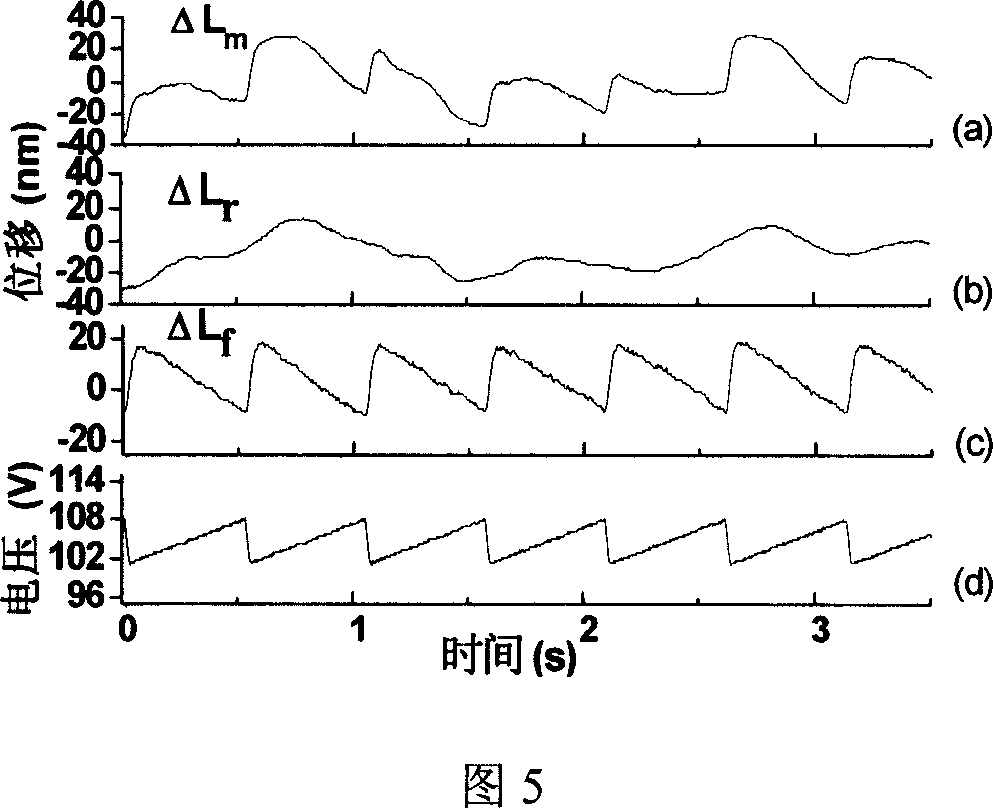

Quasi-common path type feedback interferometer of laser in microchip

InactiveCN101004346AGood effectImprove the ability to resist environmental interferenceLaser detailsUsing optical meansBeam splitterPhase sensitive

A feedback interferometer of quasi-copath micro-plate laser consists of micro-plate laser; lens and beam splitter set on axle of emission end in sequence; two acousto-optic frequency shifters, light block plate, focusing lens and reference reflector set in sequence on transmission light path of beam splitter; photoelectric detector and two sine signal generators set on reflection light path of beam splitter; reference electric signal generating circuit and two orthogonal phase sensitive detectors.

Owner:TSINGHUA UNIV

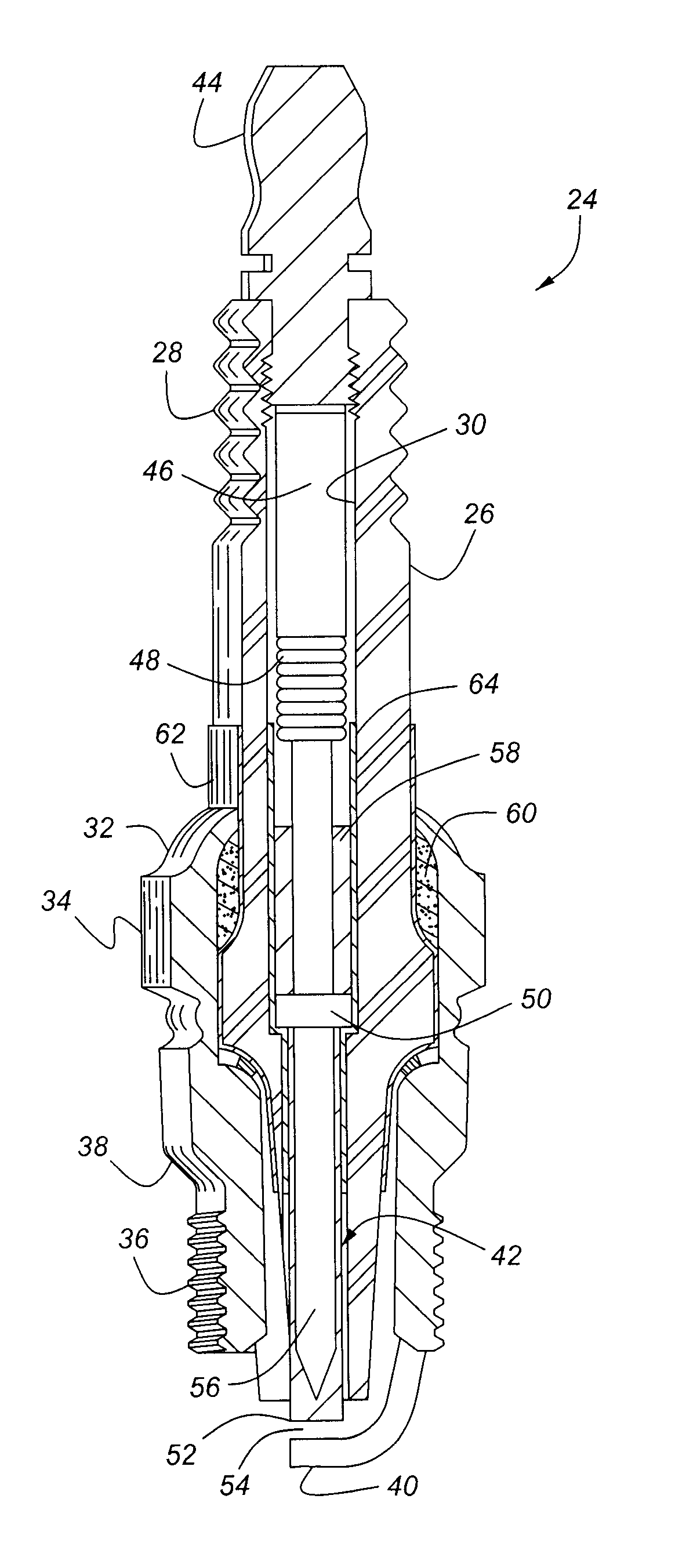

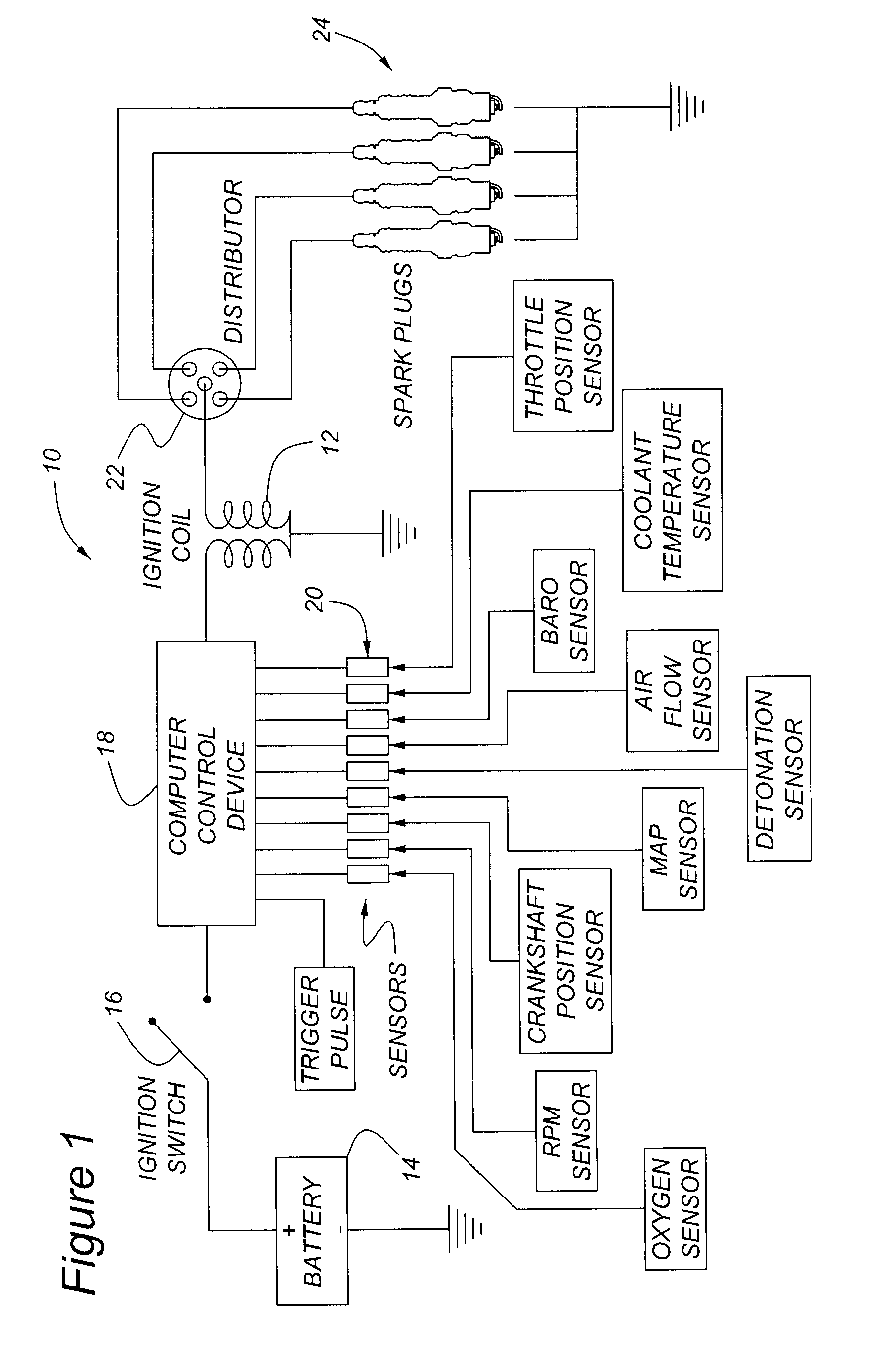

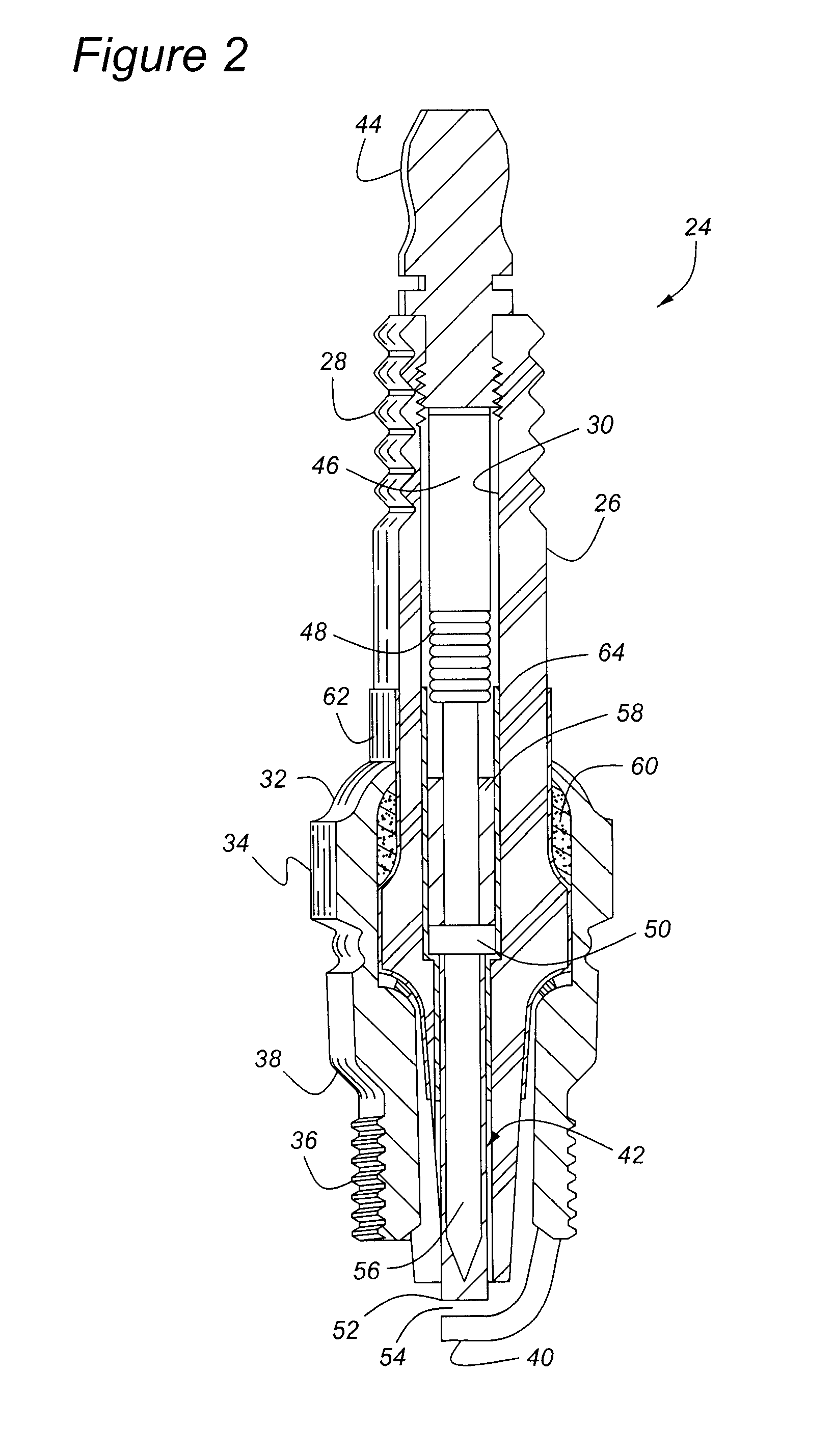

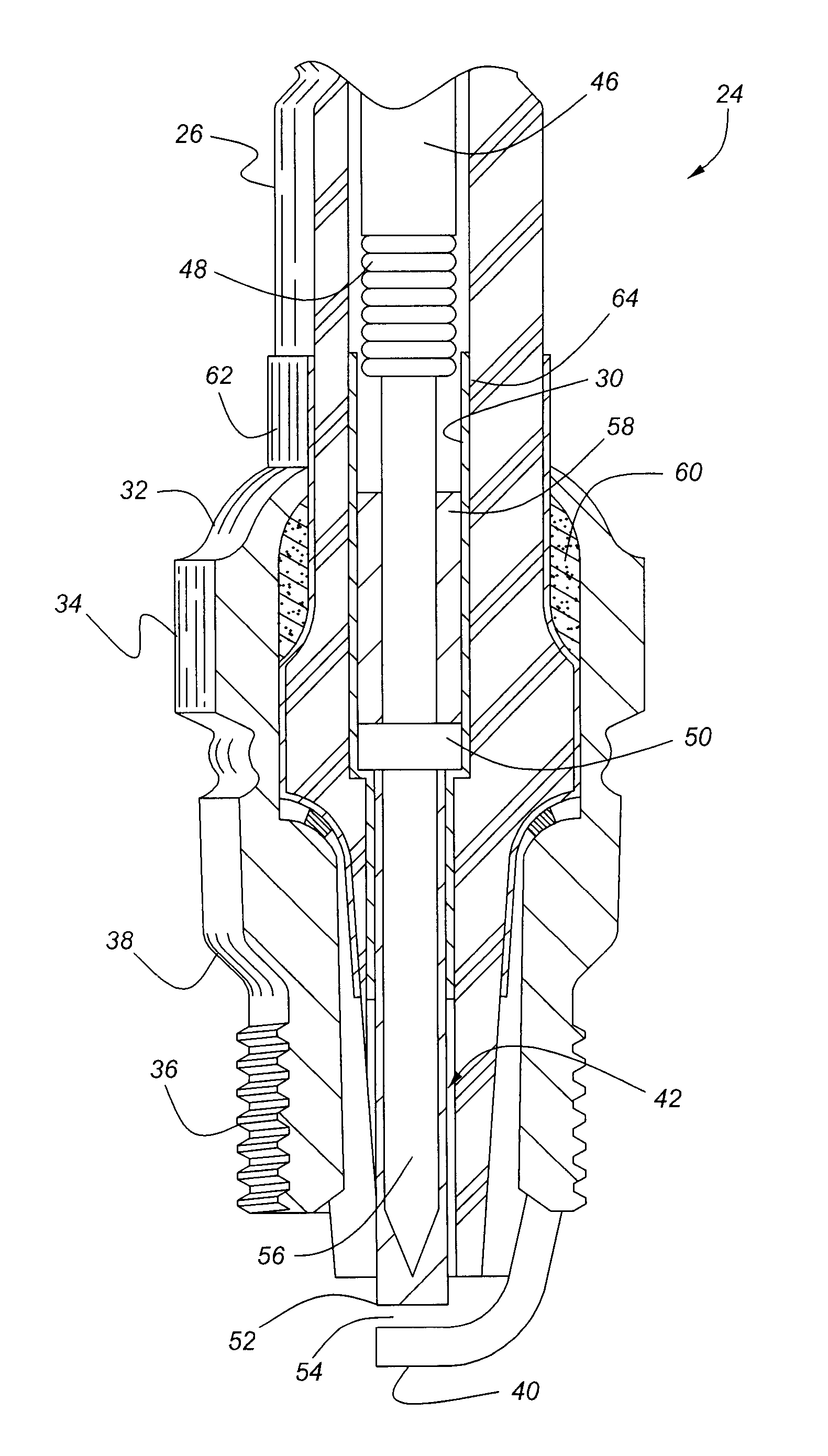

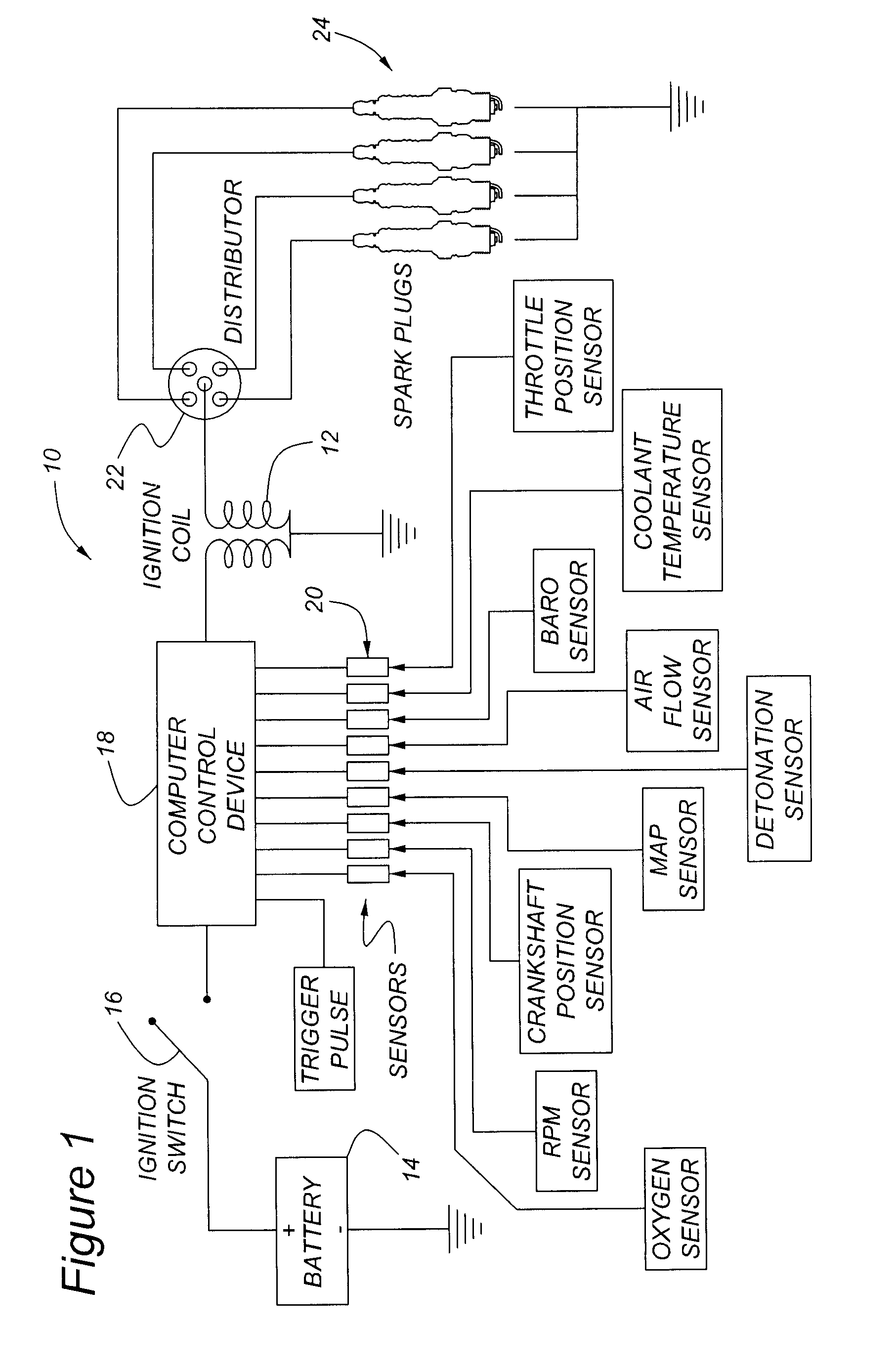

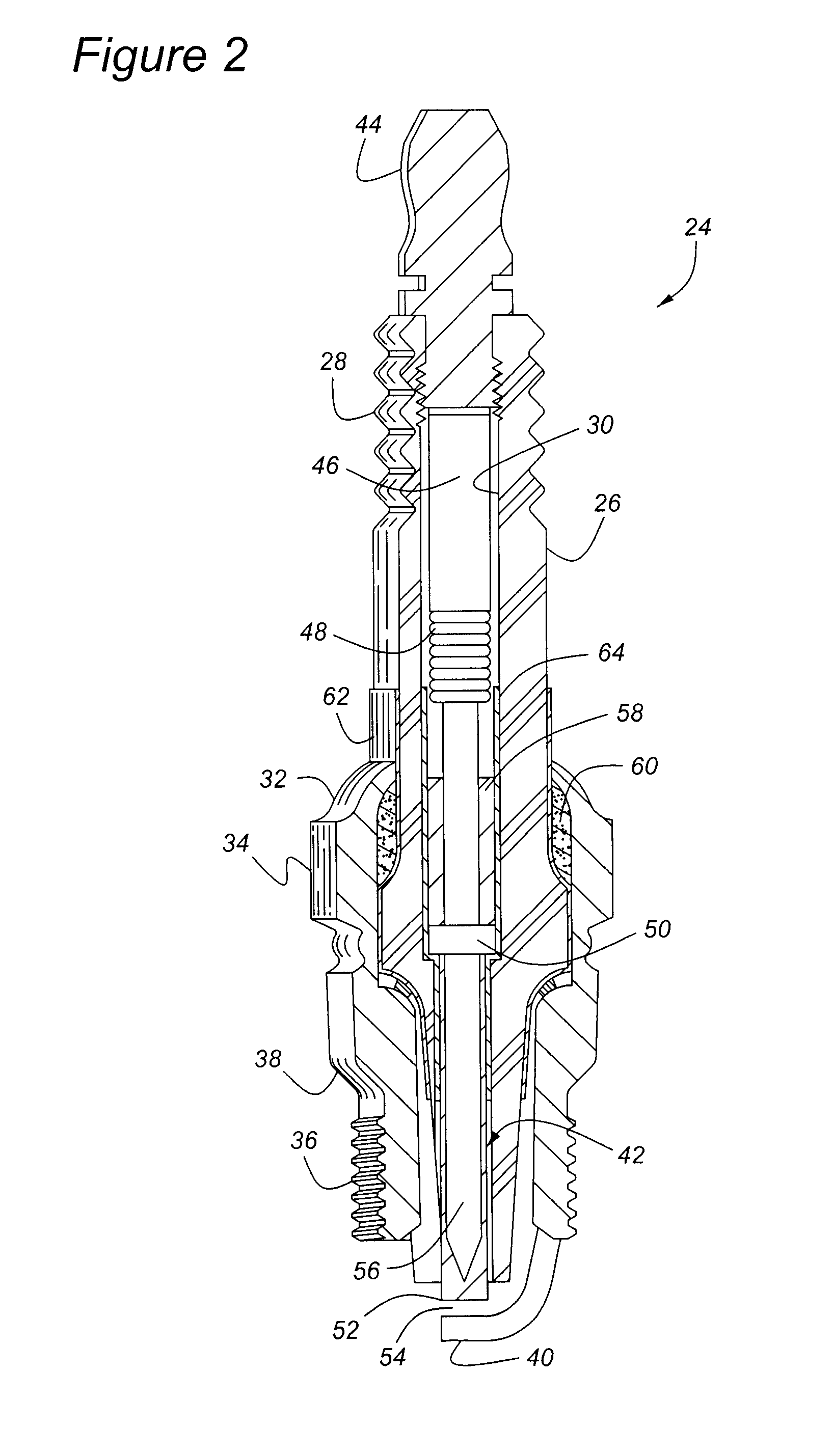

Metallic insulator coating for high capacity spark plug

A spark plug (24) is used in an ignition system (10) of the type for creating a precisely timed spark to ignite an air / fuel mixture in an internal combustion engine. The spark plug (24) is provided with an integrated capacitor feature to increase the intensity of its spark. The capacitor feature is formed by applying metallic film (62, 64) to the inner (30) and outer surfaces of a tubular insulator (26). The insulator (26), made from an alumina ceramic material, forms a dielectric and sustains an electrical charge when an electrical differential is established between the inner (64) and outer (62) metallic films. The stored electrical charge is discharged with the firing of a spark in the spark gap (54). The inner (64) and outer (62) metallic films can be applied as a paint or ink directly to the surfaces of the insulator (26), or can be mixed with a glazing compound to form conductive coatings simultaneous with the glazing operation. Ganged (62′) or serpentine (62″) micro-plates can be formed within either or both of the inner and outer metallic films to increase the charge-carrying surface area. The metallic film (62, 64) is specially selected from materials that will not migrate into the porous matrix of the ceramic insulator (26). The metallic film (62, 64) is preferably gold, platinum, copper, or a platinum group metal.

Owner:PASSAIC RIVER CO INC

Self orienting micro plates of thermally conducting material as component in thermal paste or adhesive

ActiveUS7351360B2Readily apparentPigmenting treatmentMaterial nanotechnologyConductive pasteAdhesive

The present invention relates generally to thermally-conductive pastes for use with integrated circuits, and particularly, but not by way of limitation, to self-orienting microplates of graphite.

Owner:GLOBALFOUNDRIES U S INC

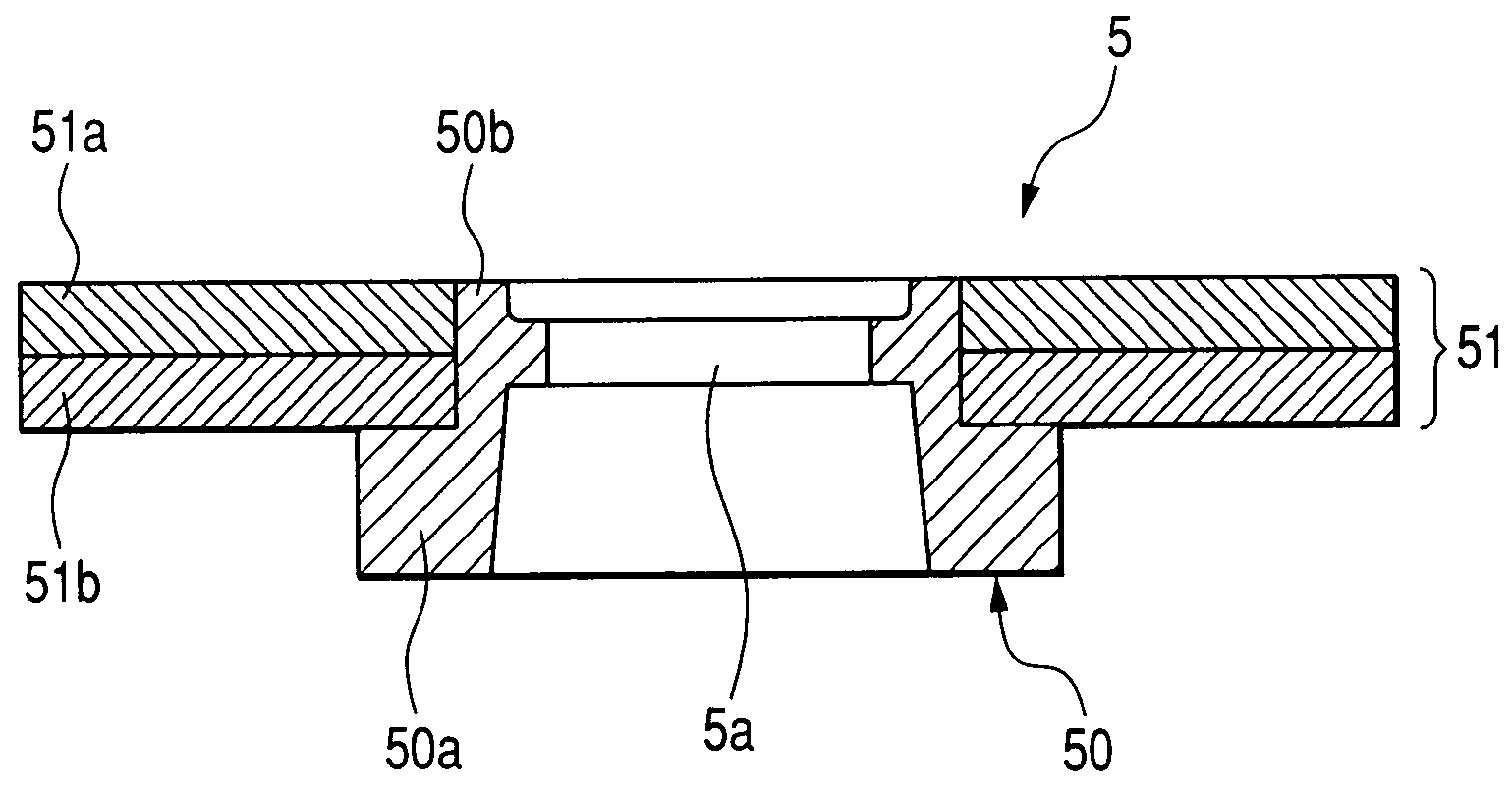

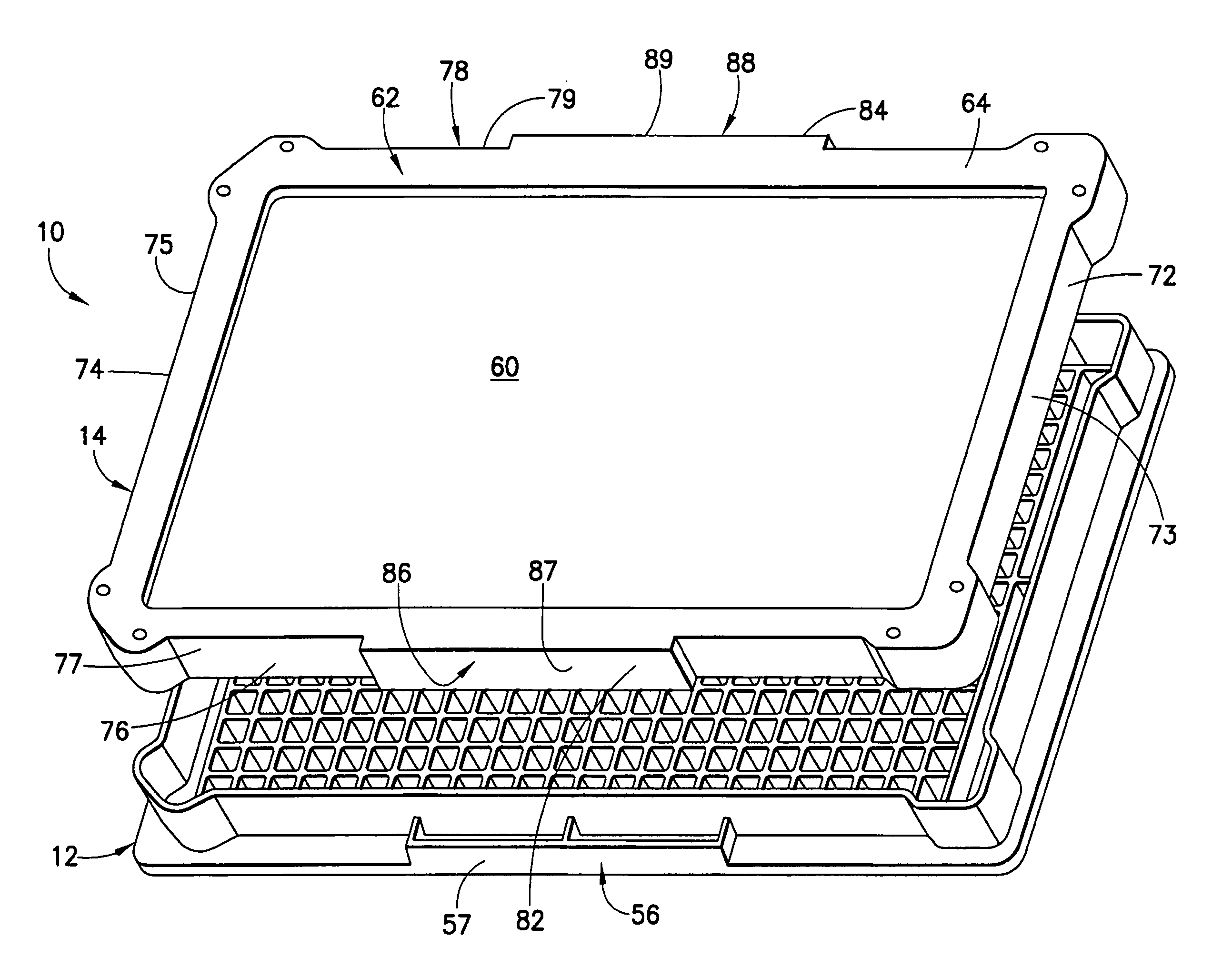

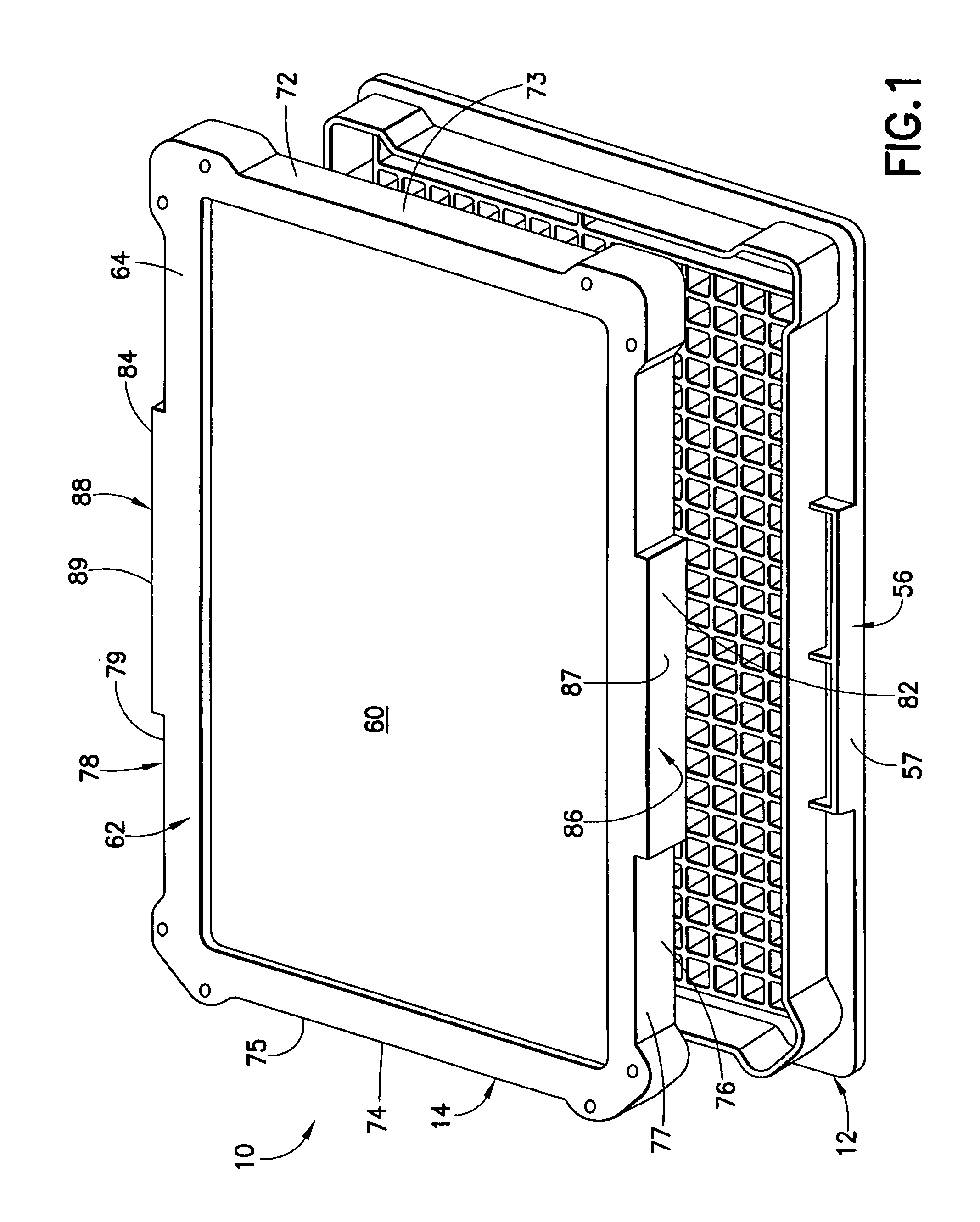

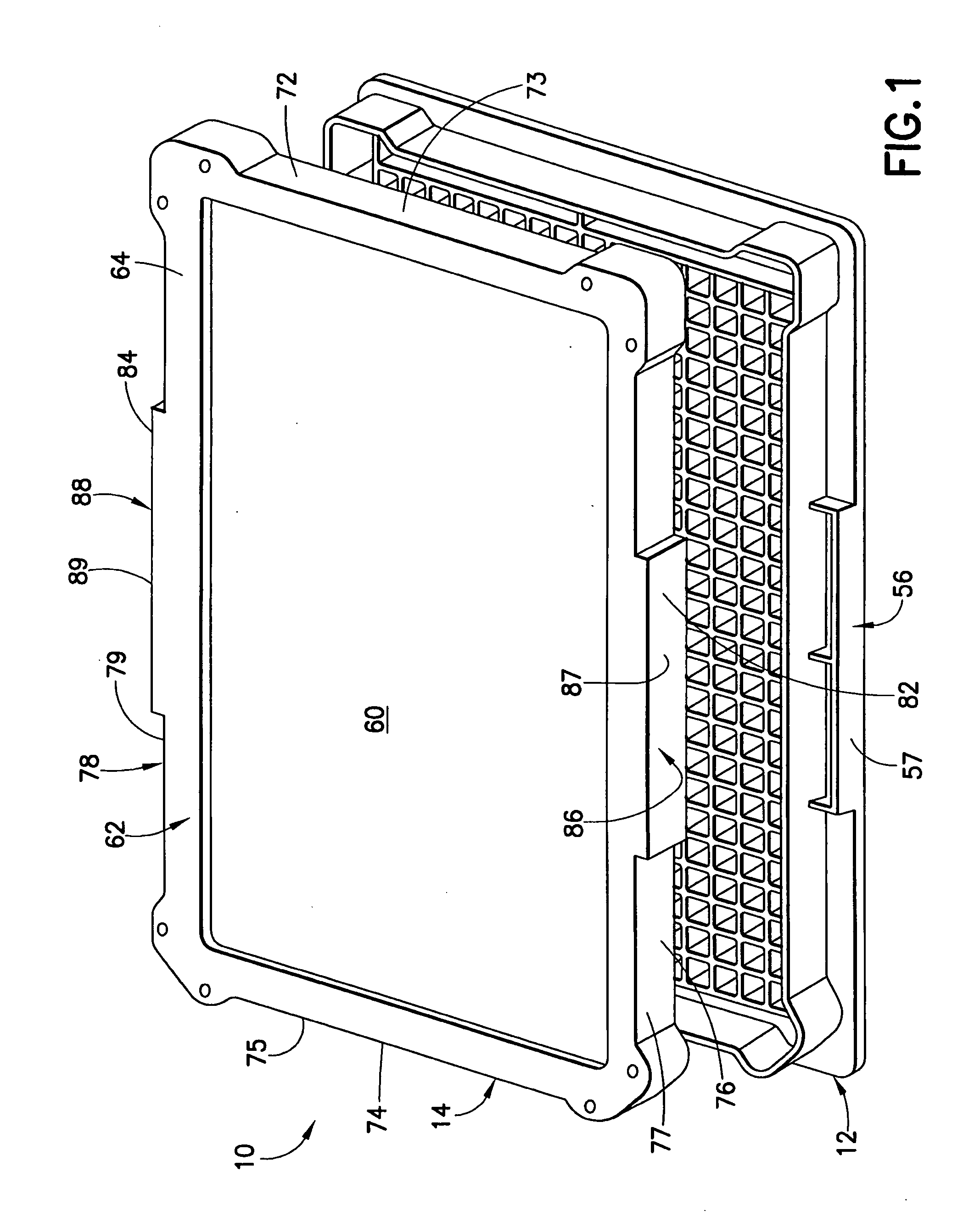

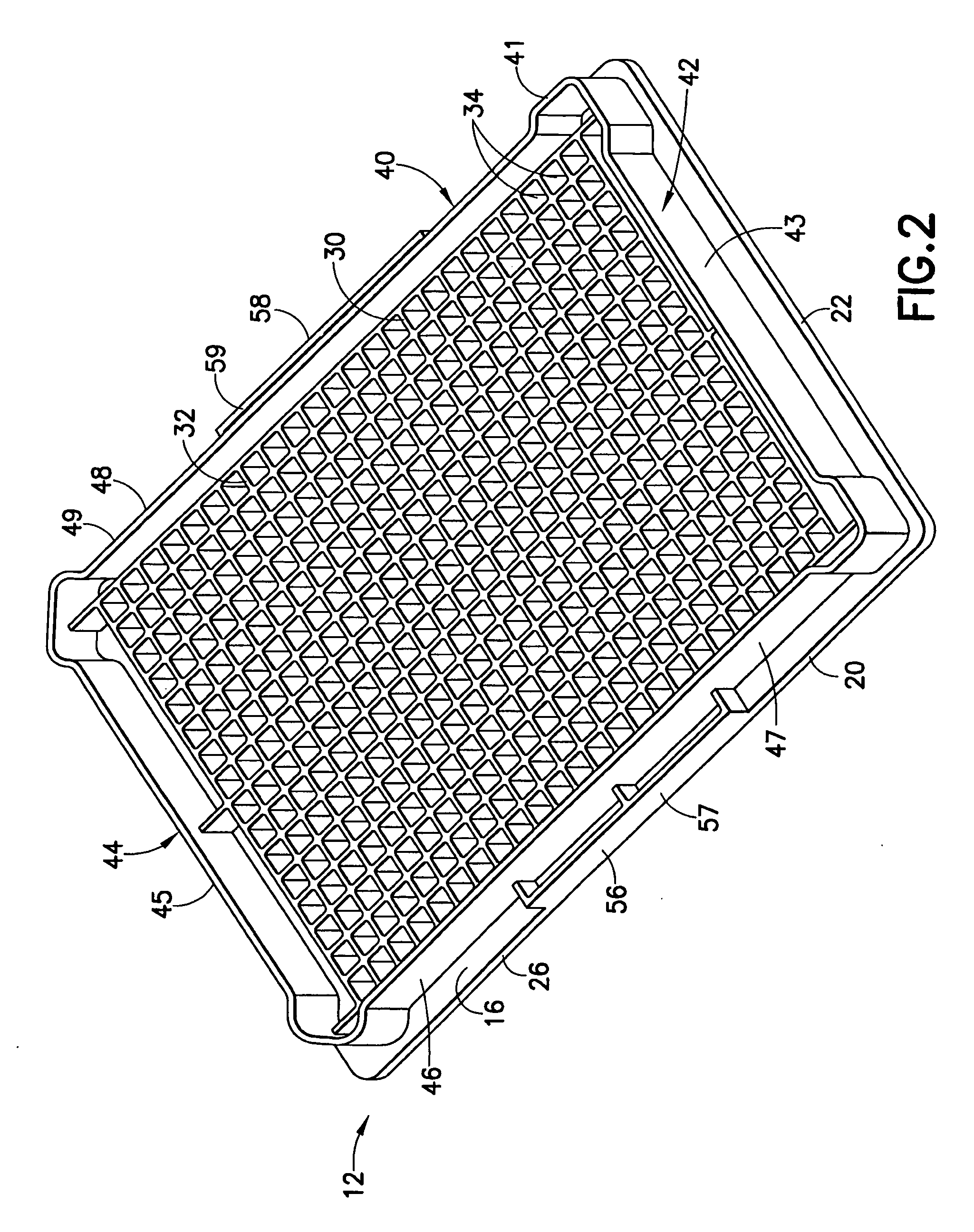

Micro-plate and lid for robotic handling

InactiveUS7666362B2Bioreactor/fermenter combinationsAnalysis using chemical indicatorsEngineeringMicro plate

Owner:CORNING INC

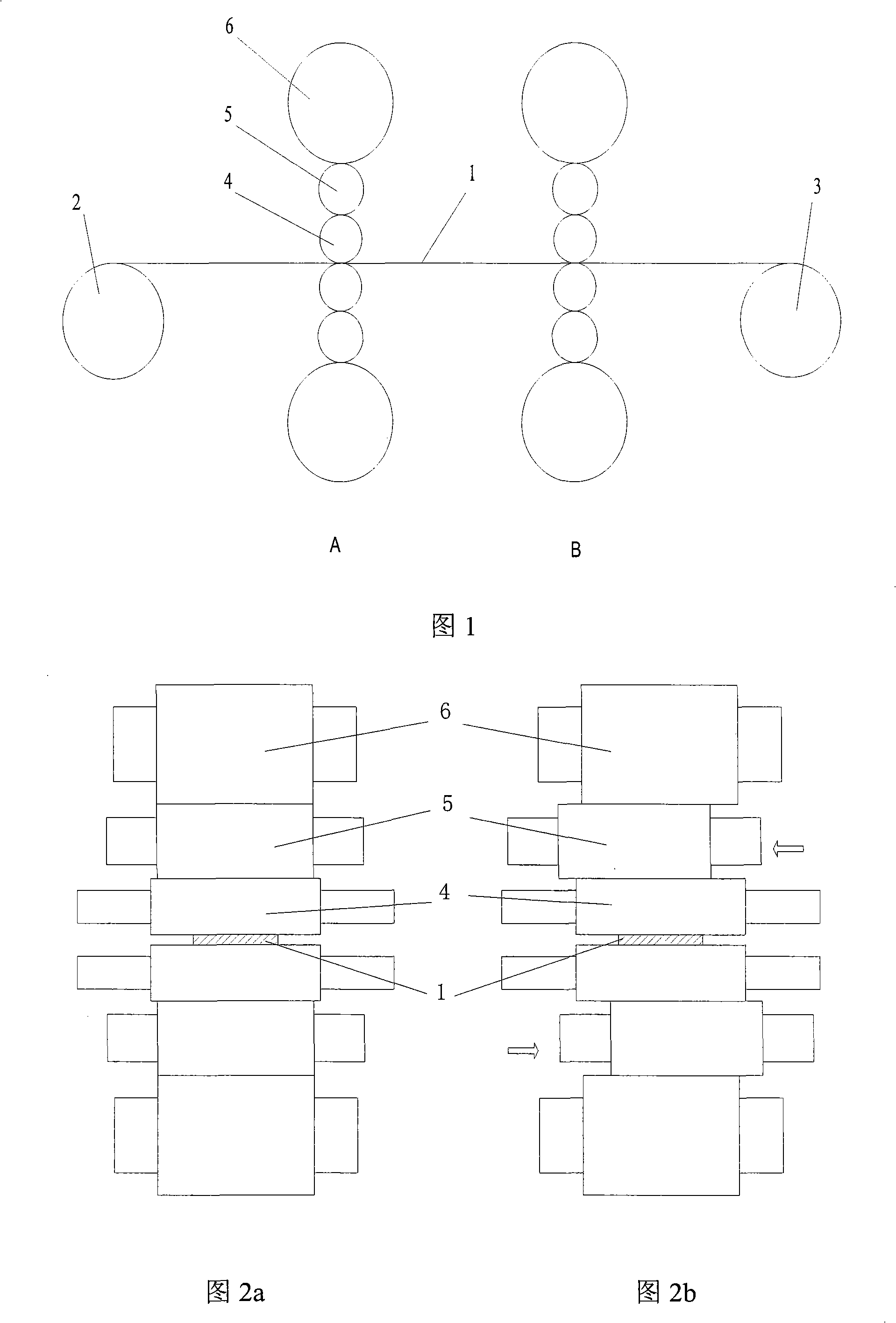

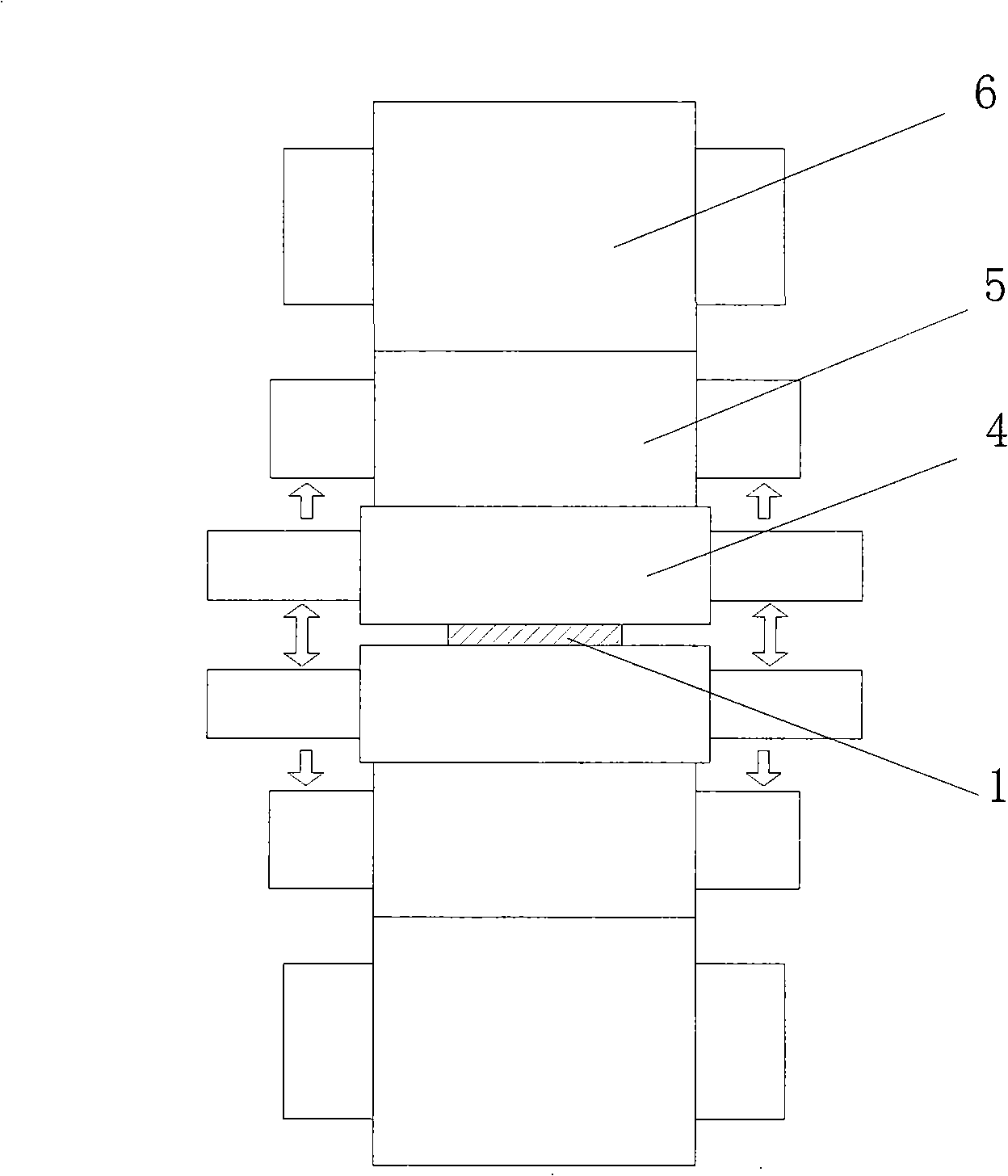

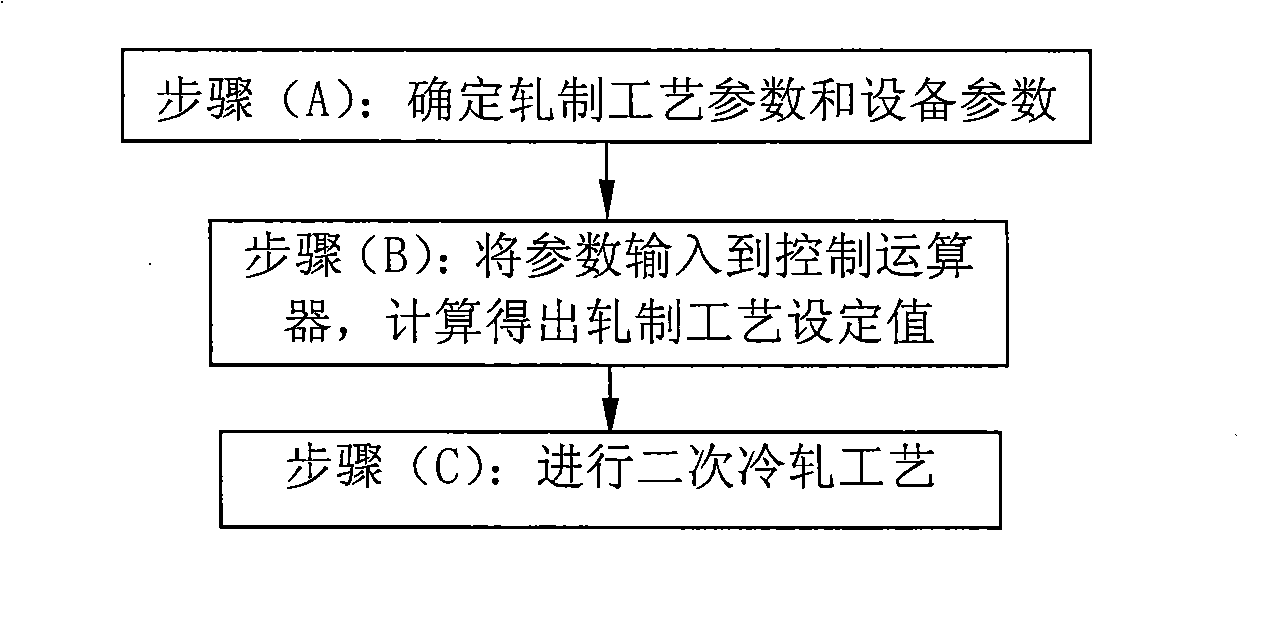

Method for leveling strip produced by secondary cold rolling unit

ActiveCN101513647AEasy to shapeQuality improvementTension/compression control deviceProfile control deviceHorizontal distributionWork roll

The invention provides a method for leveling a strip produced by a secondary cold rolling unit, which controls the surface roughness of the strip by reasonably setting the partition coefficients of the roughness and elongation of the working rolls of first and second machine frames and controls the shapes of finished strips other possible surface defects by reasonably setting a bending-roller force, a roll shifting rate and the tension of the front, middle and rear sections of the machine frames to achieve uniform front tension of finished strips and uniform horizontal distribution of a rolling force, thereby establishing effectively improved technology for leveling high-brightness micro plates produced by a secondary cold rolling unit. The principle of the method is clear, a secondary cold rolling process is carried out smoothly according to obtained rolling process set values, the quality of the shape and surface of leveled strips is high, the calculation is quick, and the method issuitable for online use.

Owner:BAOSHAN IRON & STEEL CO LTD

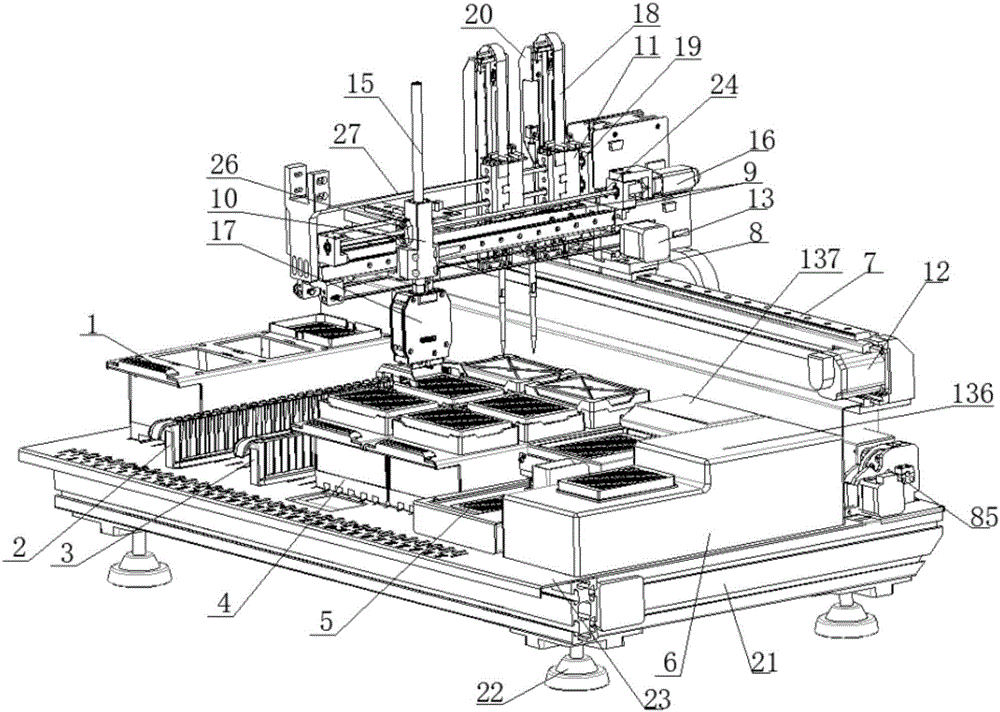

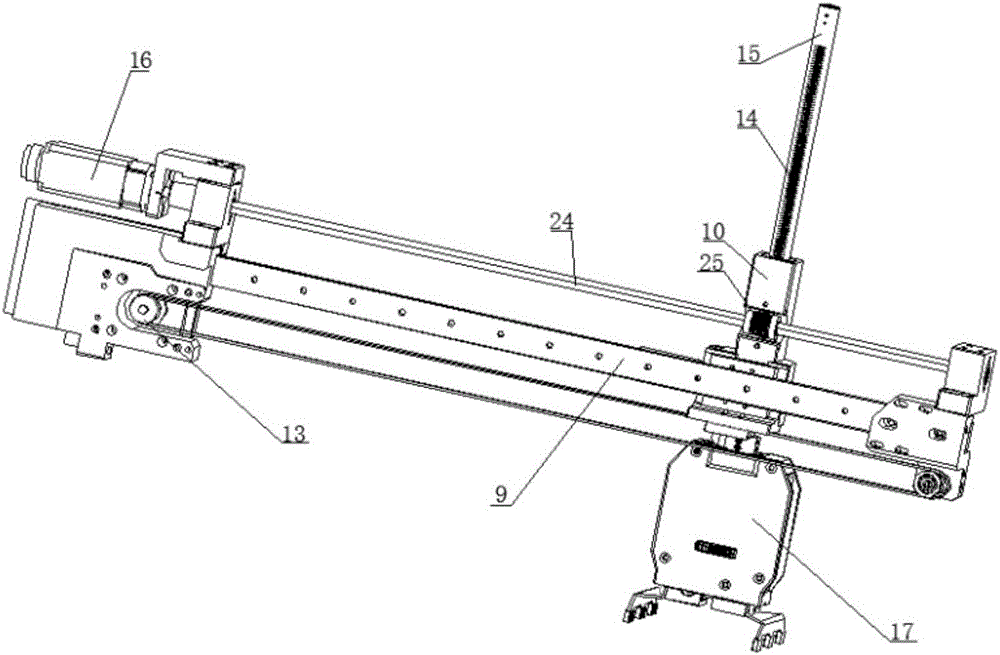

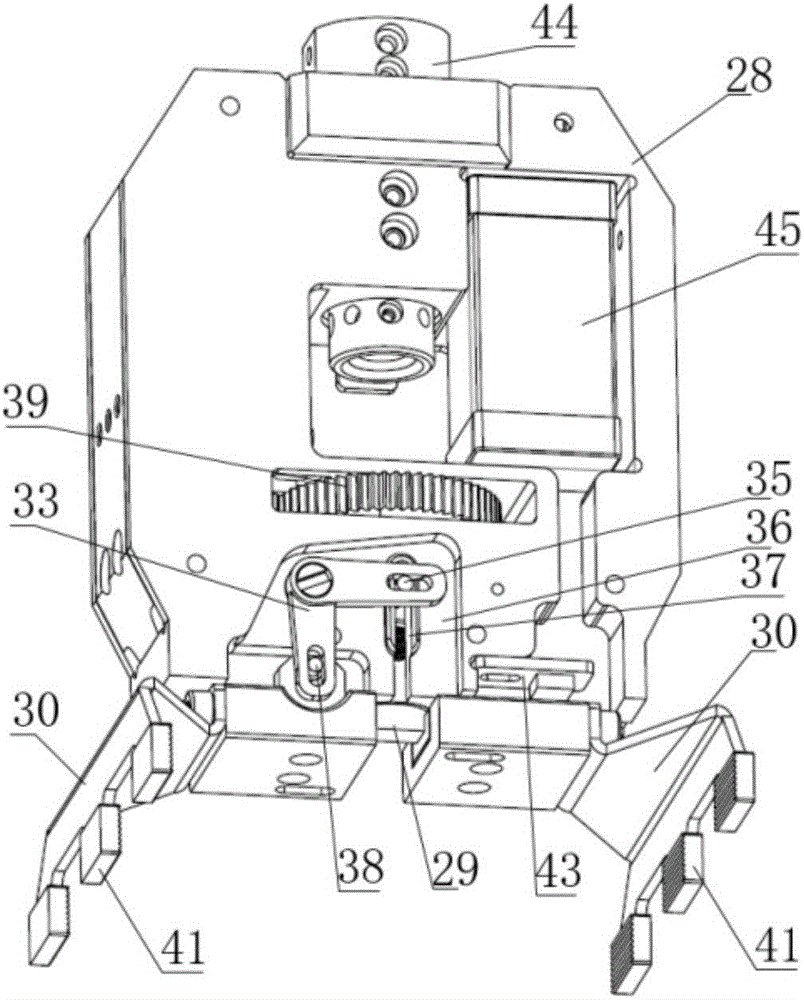

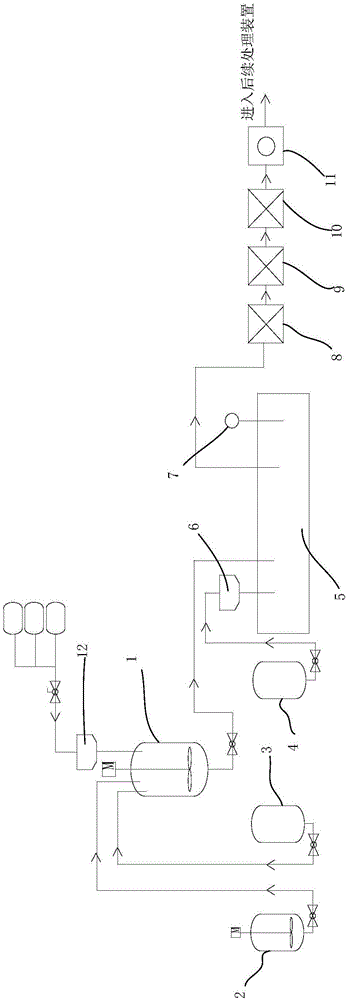

Full-automatic enzyme-linked immunoluminescence analyzer

The invention discloses a full-automatic enzyme-linked immunoluminescence analyzer which comprises a working table, wherein a suction head carrier frame, a sample carrier frame, a reagent carrier frame, a sample injection, vibration and incubation unit, a plate washing unit and a reading unit are arranged on the upper surface of the working table, wherein a transverse guide rail is further arranged on one side of the working table; a support is mounted on the transverse guide rail in a sliding manner; two longitudinal guide rails are arranged on the support; a micro plate catching mechanical arm and a sample injection arm are mounted on the longitudinal guide rails in a sliding manner; the micro plate catching mechanical arm is provided with a first perpendicular arm capable of ascending and descending along the perpendicular direction and a fourth driving device for driving the first perpendicular arm to rise up and drop down; a micro plate catching device is fixedly mounted at the bottom of the first perpendicular arm; the sample injection arm is provided with a second perpendicular arm capable of ascending and descending along the perpendicular direction and a fifth driving device for driving the second perpendicular arm to ascend and descend; and a sample collection and injection device is mounted on the sample injection arm. The full-automatic enzyme-linked immunoluminescence analyzer has the beneficial effects that operation of sample injection, plate washing, vibration, incubation, reading and judgment of a developing reaction result and the like during enzyme-linked immunosorbent assay can be automatically completed, the working efficiency is improved, labors are saved, and a test result is guaranteed.

Owner:山东新域生物技术有限公司

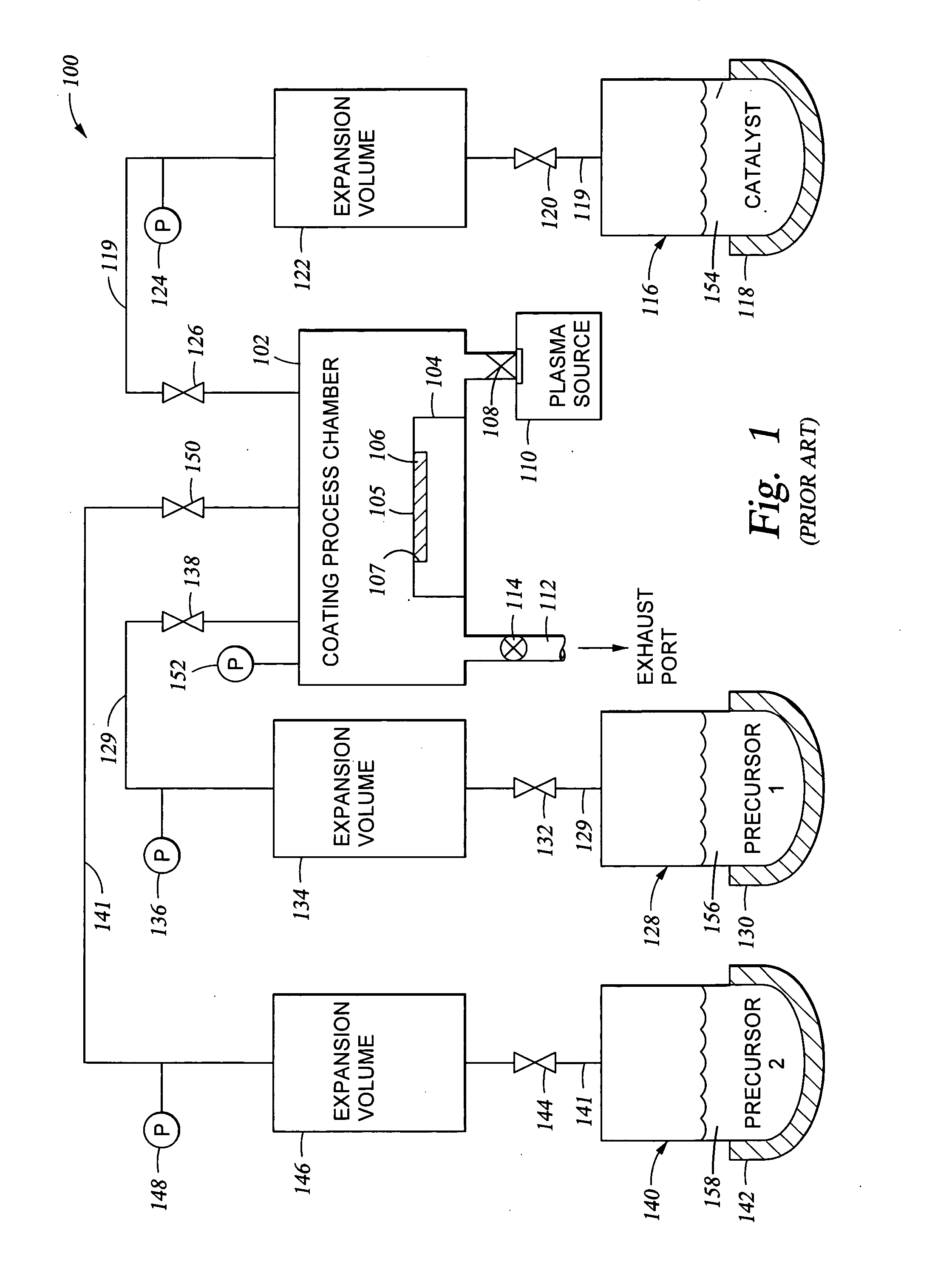

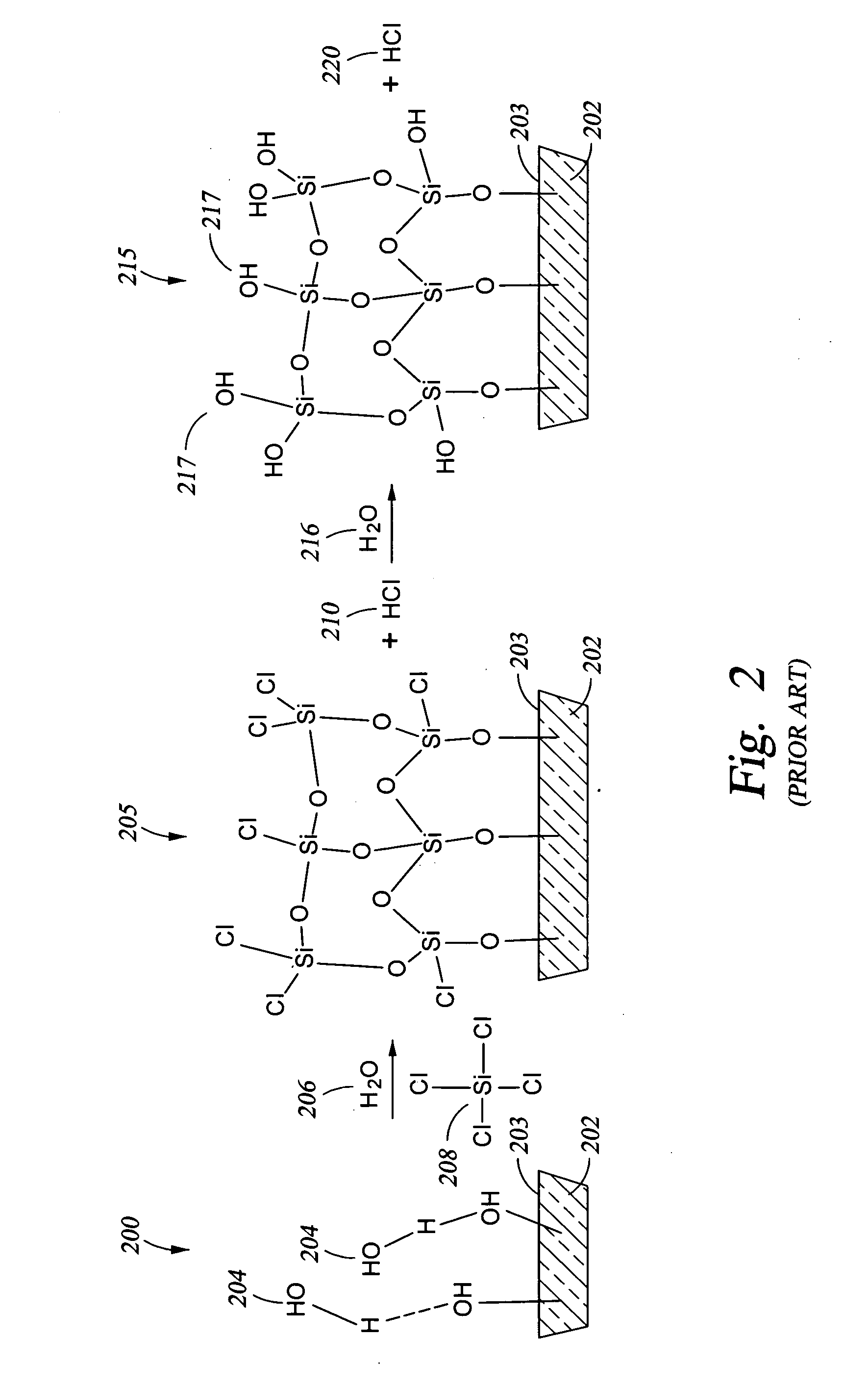

High aspect ratio performance coatings for biological microfluidics

ActiveUS20050271810A1Simple methodPrevent wrong additionMaterial nanotechnologySynthetic resin layered productsBiotechnologyWater based

We have developed an improved vapor-phase deposition method and apparatus for the application of layers and coatings on various substrates. The method and apparatus are useful in the fabrication of biotechnologically functional devices, Bio-MEMS devices, and in the fabrication of microfluidic devices for biological applications. In one important embodiment, oxide coatings providing hydrophilicity or oxide / polyethylene glycol coatings providing hydrophilicity can be deposited by the present method, over the interior surfaces of small wells in a plastic micro-plate in order to increase the hydrophilicity of these wells. Filling these channels with a precise amount of liquid consistently can be very difficult. This prevents a water-based sample from beading up and creating bubbles, so that well can fill accurately and completely, and alleviates spillage into other wells which causes contamination.

Owner:SPTS TECH LTD

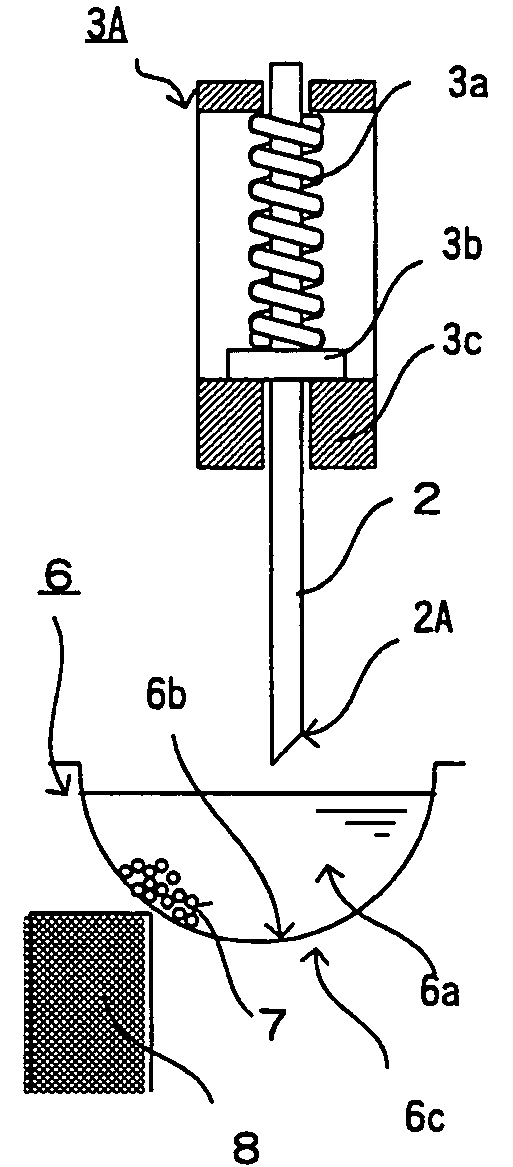

Drainage system

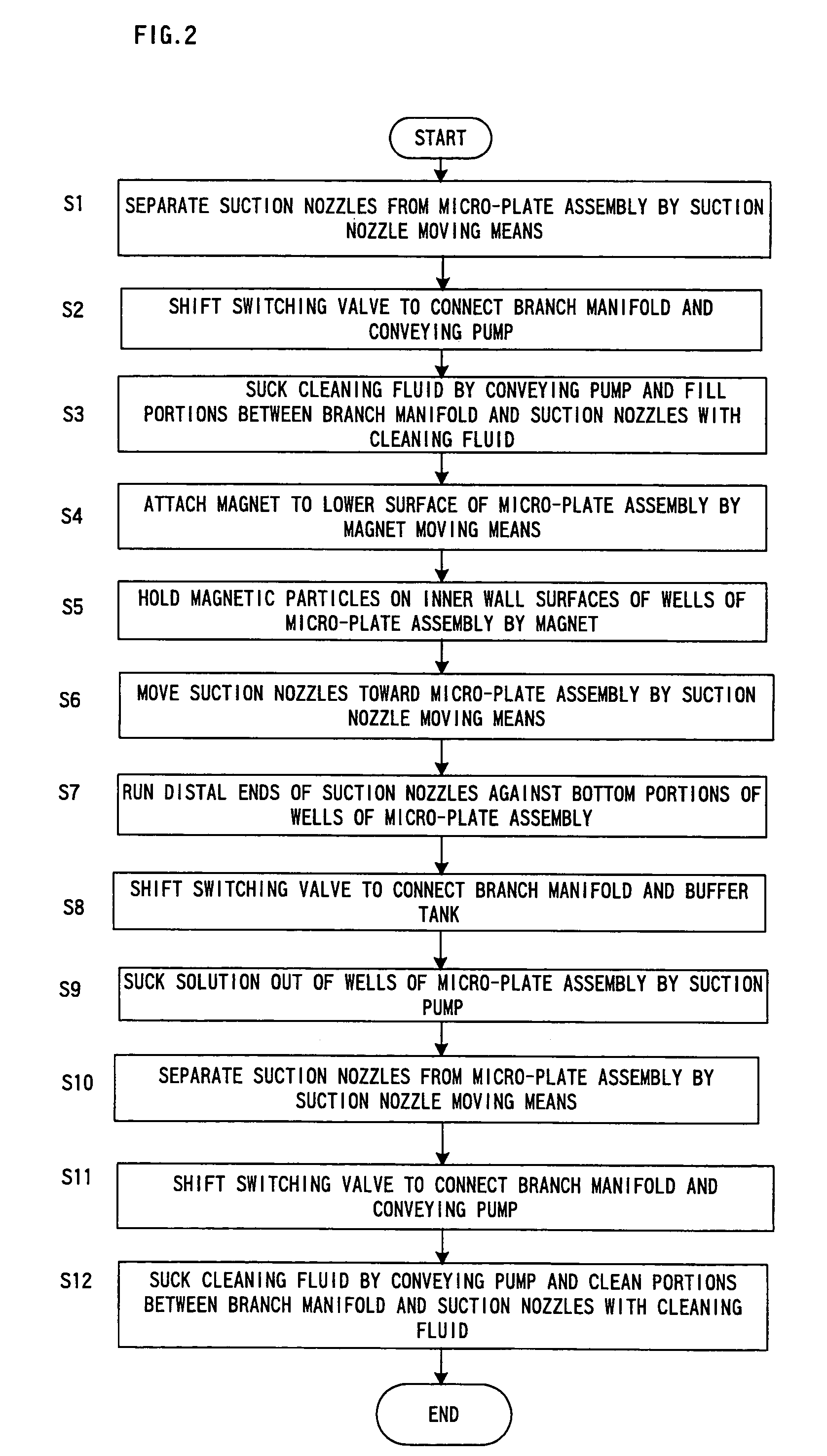

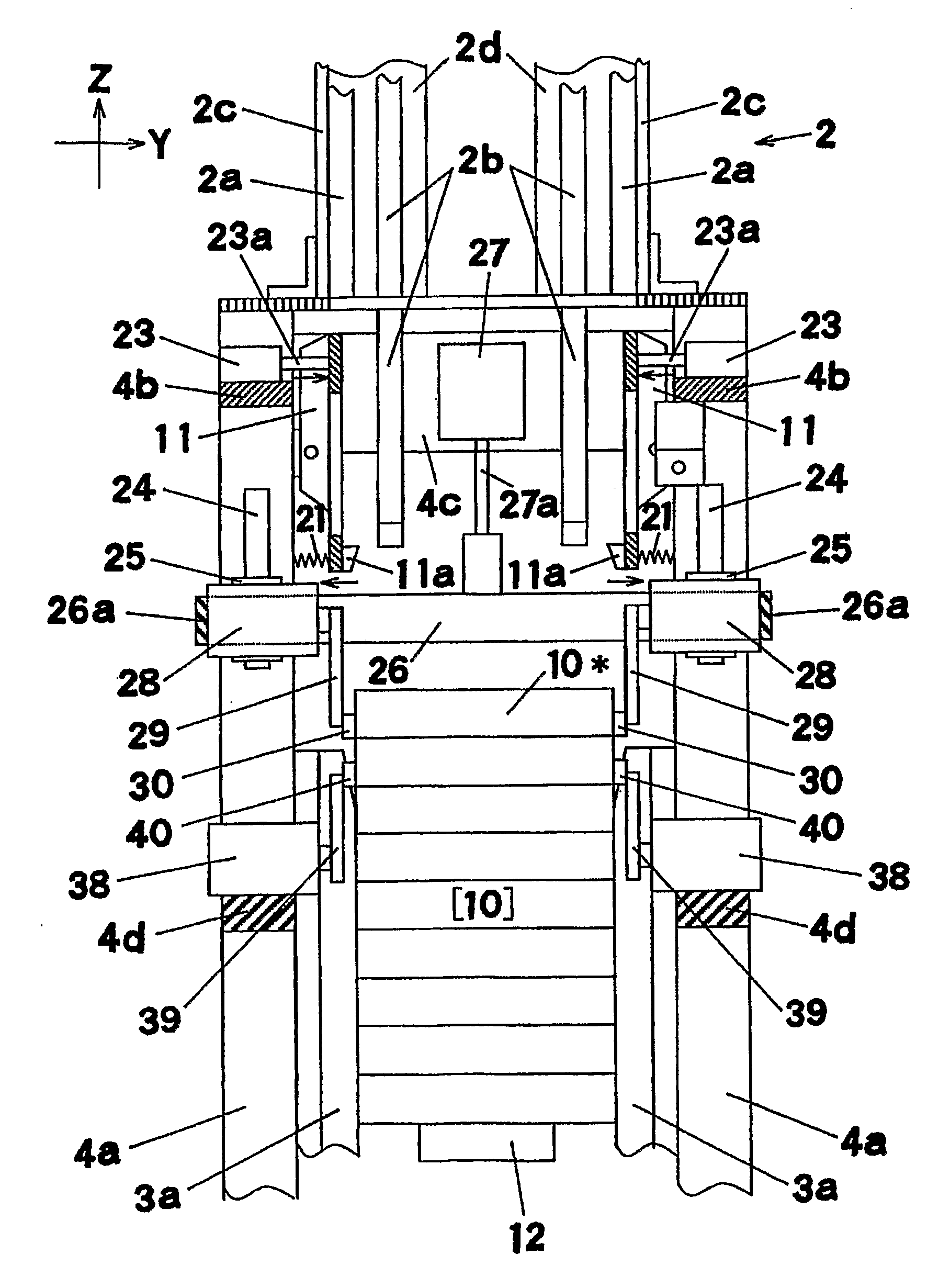

InactiveUS7267800B2Optimization mechanismReduce in quantityWithdrawing sample devicesBurettes/pipettesEngineeringMicro plate

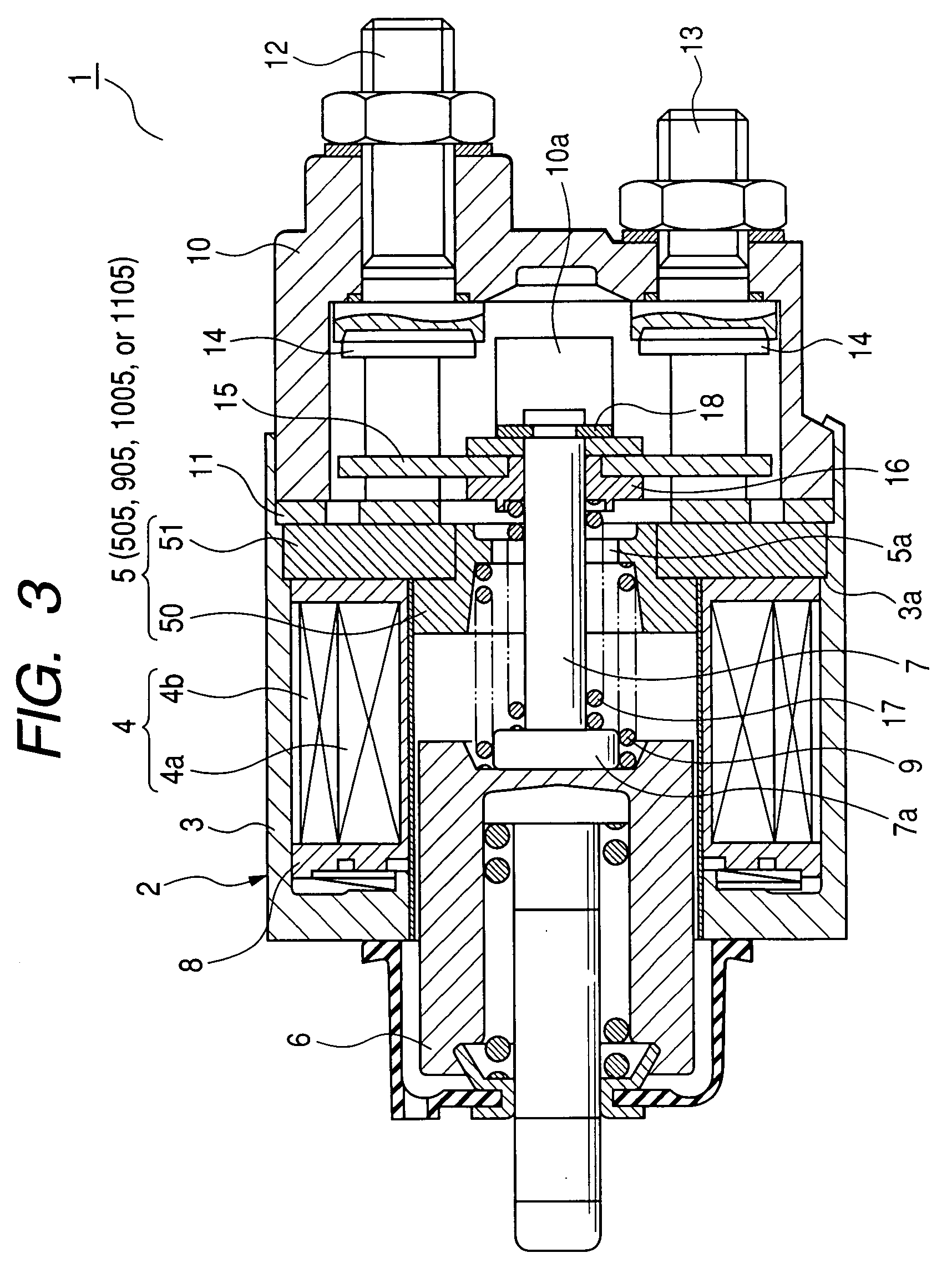

In a system for sucking and discharging a solution from a vessel (micro-plate assembly 6) by suction nozzles 2, processes for suction, discharge, separation, etc. can be carried out with use of a simple mechanism, including suction nozzle moving means 3 for positioning the respective distal ends of the suction nozzles on the inner wall surface of the vessel, magnetic particle holding means 4 for magnetic particles 7 in a given position in the vessel, and solution discharge means 5 for sucking out and discharging the solution simultaneously from the vessel through the suction nozzles. Each or a combination of these means constitutes a drainage system.

Owner:SHIMADZU CORP

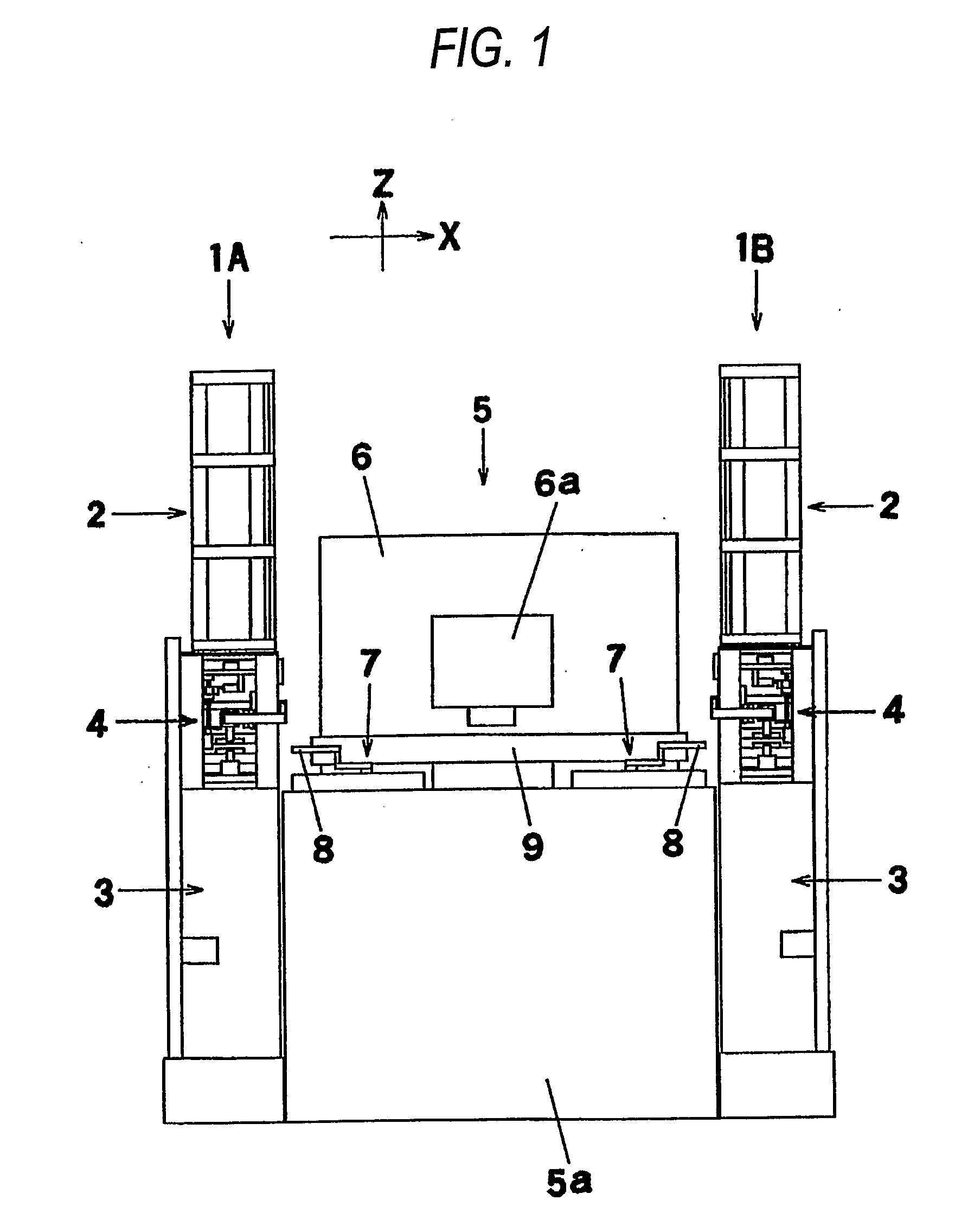

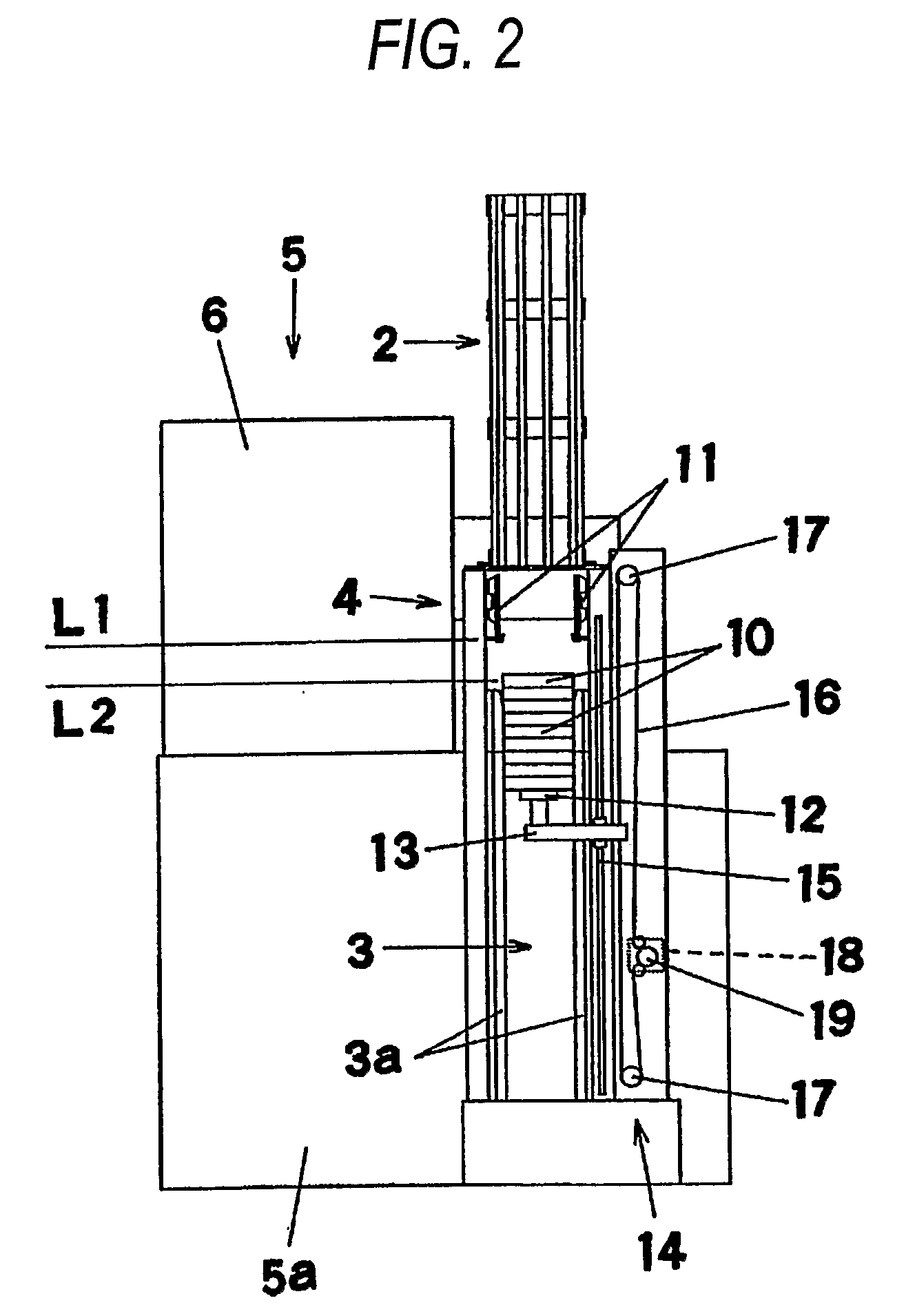

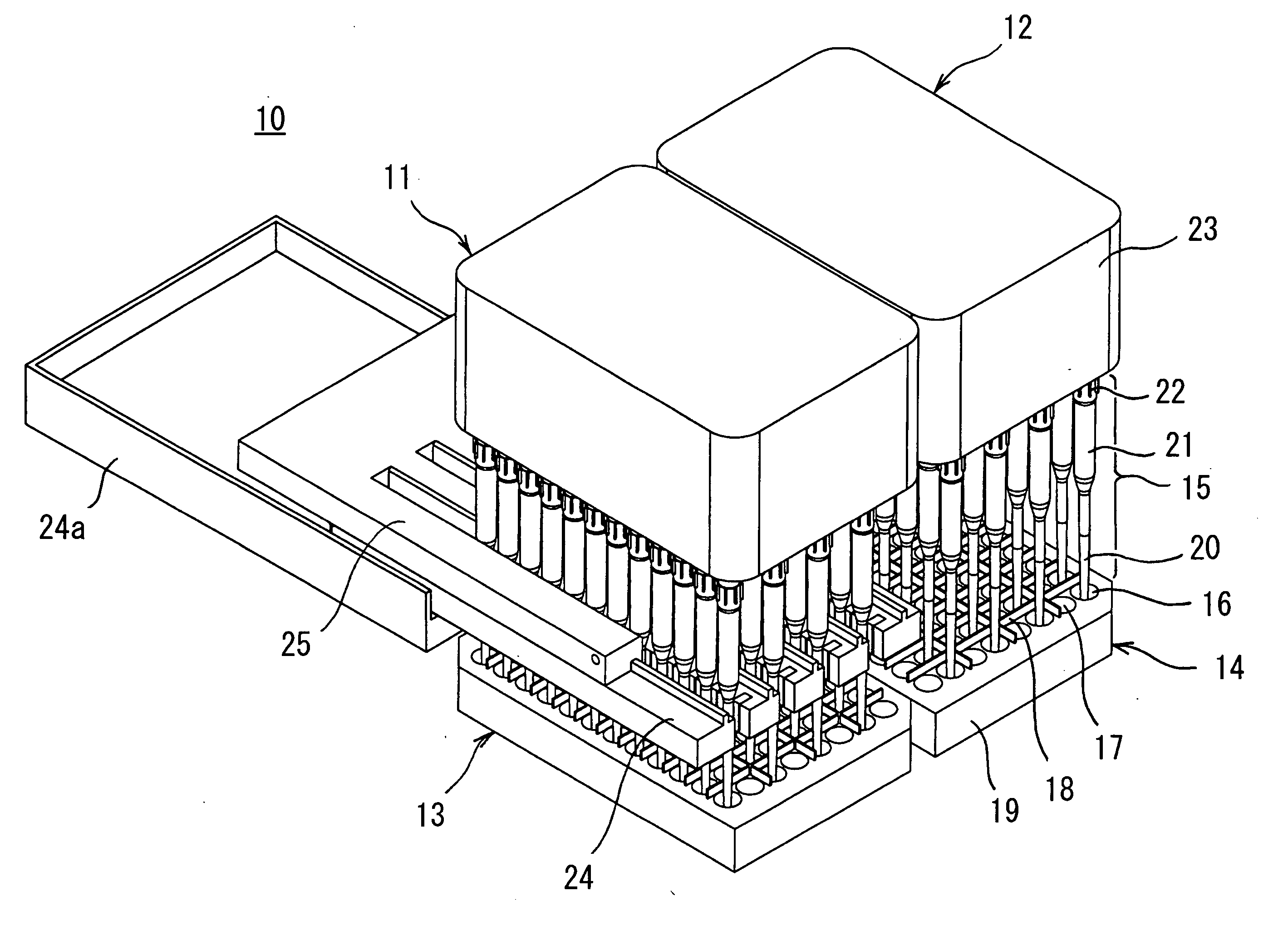

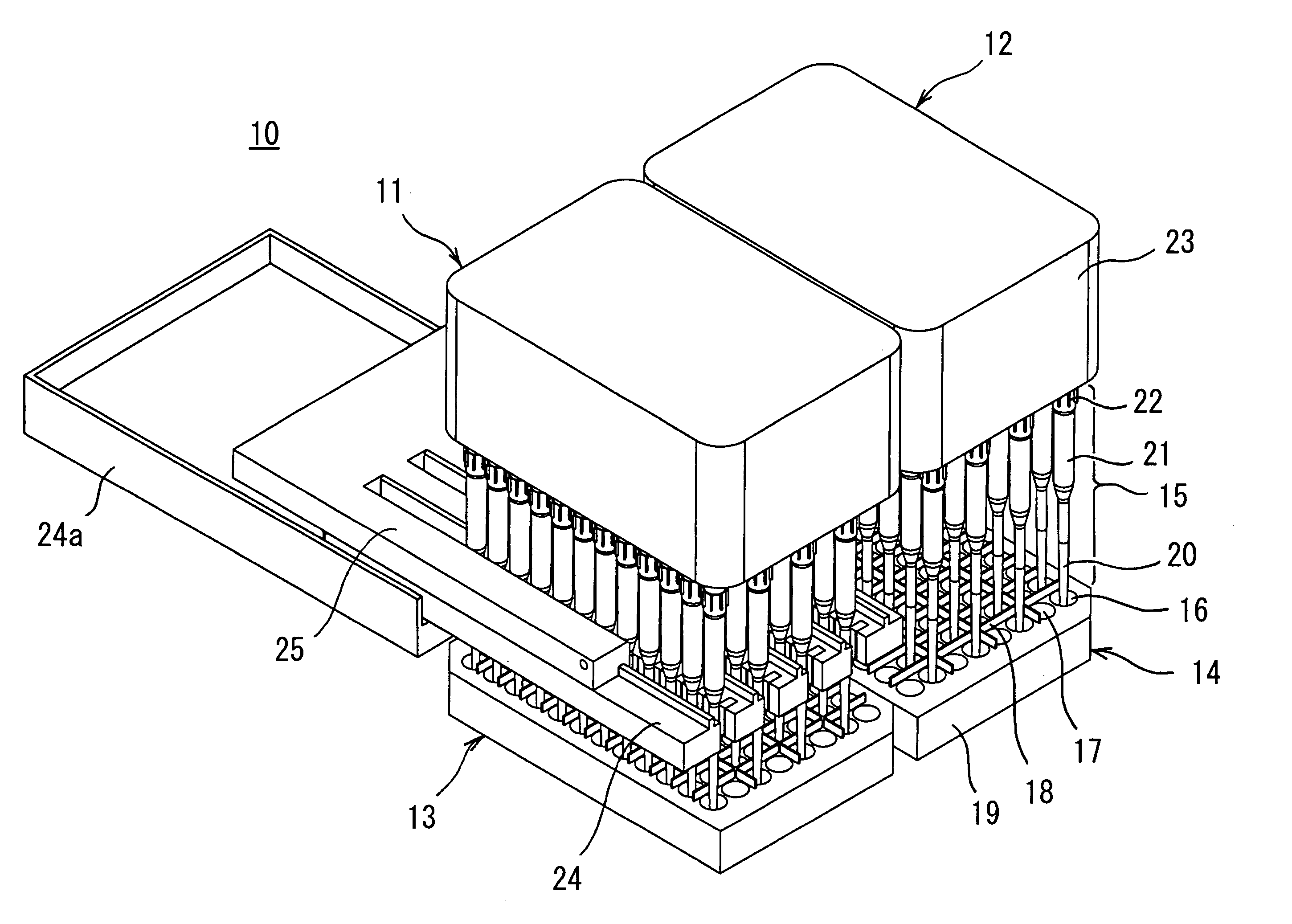

Apparatus of supplying and containing micro-plate, method of supplying and method of containing micro-plate and apparatus of processing micro-plate

It is an object of the invention to provide an apparatus of supplying a micro-plate excellent in operating performance and operability.In a micro-plate supplying apparatus for separating micro-plates 10 mounted in a stacked state sheet by sheet to supply, a first stock portion 2, a second stock portion 3 for containing the micro-plates in the stacked state are arranged in series in an up and down direction by interposing a micro-plate take out and take in mechanism 4, the micro-plates 10 are moved from the first stock portion 2 to the second stock portion 3 while staying in the stacked state, the micro-plate at a uppermost stage of the plurality of micro-plates 10 is disposed at a micro-plate carry out level L2, and the micro-plate is taken out by a micro-plate carrying out mechanism to supply to a working apparatus 5. Thereby, the micro-plate is set in an excellent operation attitude and the micro-plate can stably be taken out.

Owner:PANASONIC CORP

Micro-plate reader for elisa testing

ActiveUS20180196193A1More compactMore denseTelevision system detailsDigital computer detailsFiberReduced size

A micro-plate reader for use with a portable electronic device having a camera includes an opto-mechanical attachment configured to attach / detach to the portable electronic device and includes an array of illumination sources. A slot in the opto-mechanical attachment is dimensioned to receive an optically transparent plate containing an array of wells. Optical fibers are located in the opto-mechanical attachment and transmit light from each well to a reduced size header having, wherein the fiber array in the header has a cross-sectional area that is ≤10× the cross-sectional area of the wells in the plate. A lens located in the opto-mechanical attachment transmits light from the header fibers to the camera. Software executed on the portable electronic device or other computer is used to process the images to generate qualitative clinical determinations and / or quantitative index values for the separate wells.

Owner:RGT UNIV OF CALIFORNIA

Metallic insulator coating for high capacity spark plug

A spark plug (24) is used in an ignition system (10) of the type for creating a precisely timed spark to ignite an air / fuel mixture in an internal combustion engine. The spark plug (24) is provided with an integrated capacitor feature to increase the intensity of its spark. The capacitor feature is formed by applying metallic film (62, 64) to the inner (30) and outer surfaces of a tubular insulator (26). The insulator (26), made from an alumina ceramic material, forms a dielectric and sustains an electrical charge when an electrical differential is established between the inner (64) and outer (62) metallic films. The stored electrical charge is discharged with the firing of a spark in the spark gap (54). The inner (64) and outer (62) metallic films can be applied as a paint or ink directly to the surfaces of the insulator (26), or can be mixed with a glazing compound to form conductive coatings simultaneous with the glazing operation. Ganged (62′) or serpentine (62″) micro-plates can be formed within either or both of the inner and outer metallic films to increase the charge-carrying surface area. The metallic film (62, 64) is specially selected from materials that will not migrate into the porous matrix of the ceramic insulator (26). The metallic film (62, 64) is preferably gold, platinum, copper, or a platinum group metal.

Owner:PASSAIC RIVER CO INC

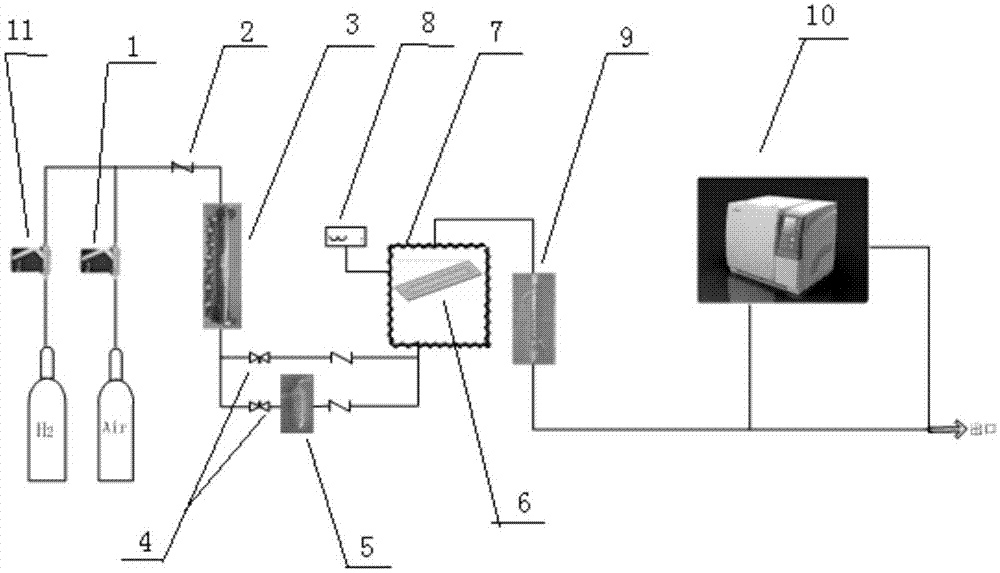

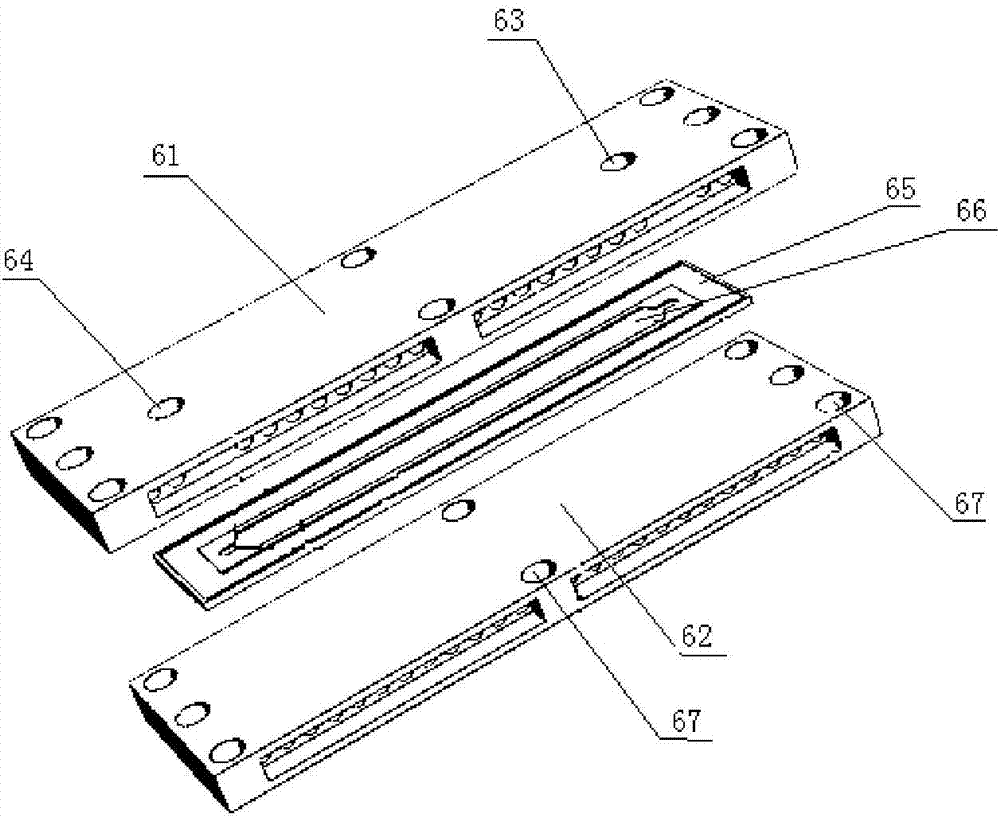

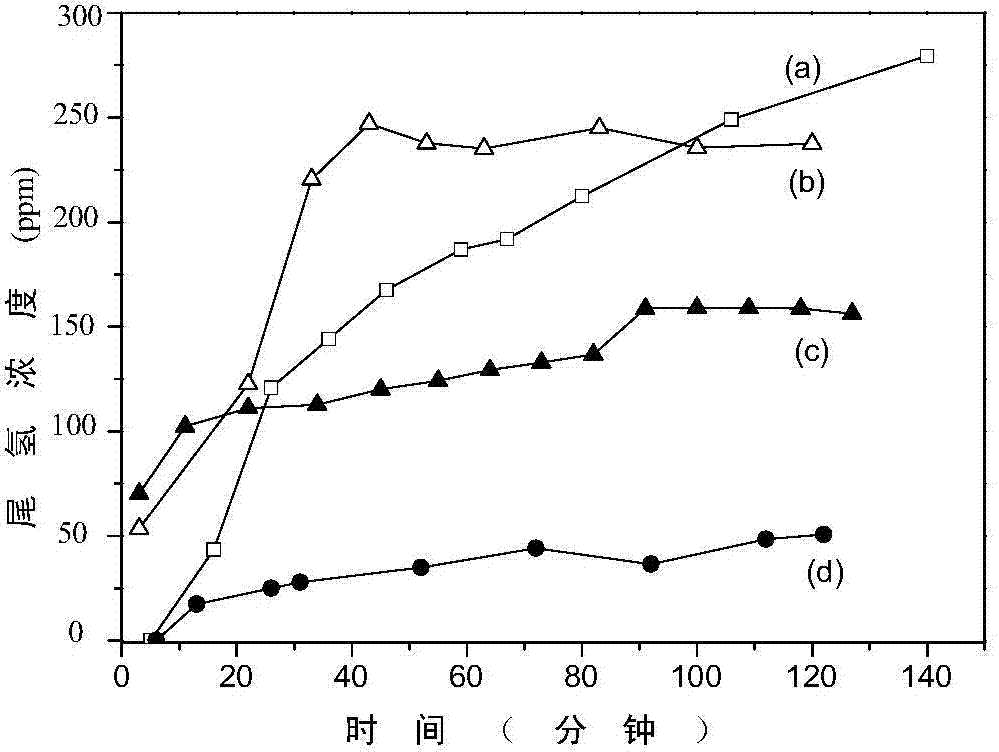

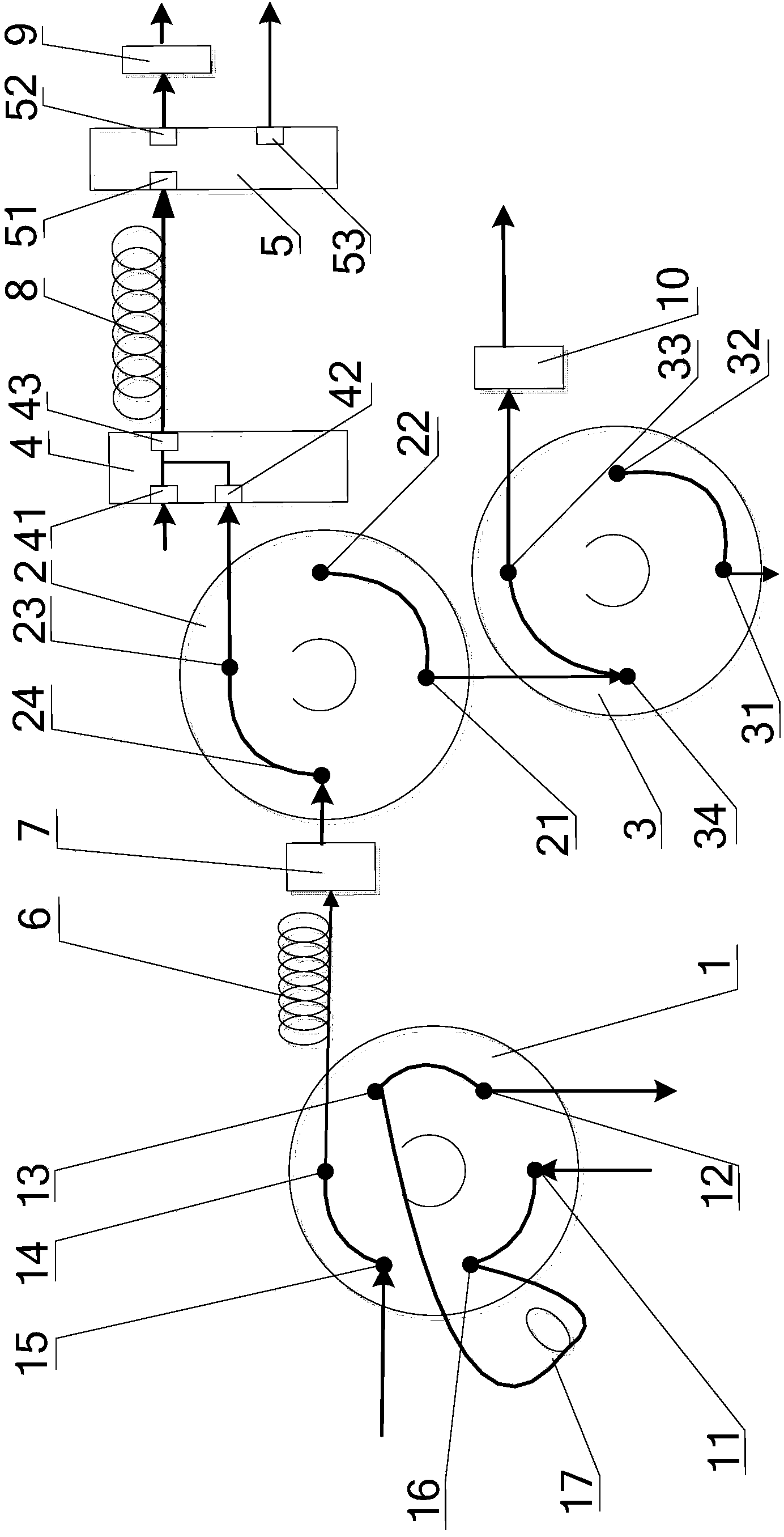

Catalytic treatment device and catalytic treatment method for tail gas of fuel cell

ActiveCN104733758AAccurate temperature controlAvoid spreadingFuel cell auxillariesHydrogen fuel cellMicro plate

The invention belongs to the field of the tail gas treatment of a fuel cell, and relates to a catalytic treatment device and a catalytic treatment method for tail gas of a hydrogen-oxygen fuel cell. The catalytic treatment device for the tail gas of the fuel cell comprises a gas mixer, wherein an inlet of the gas mixer is respectively connected with a hydrogen outlet pipeline of a fuel cell anode end and an air outlet pipeline of a fuel cell cathode end, an outlet of the gas mixer is connected with a micro plate-type reactor, a passage plate which is provided with a hydrophobic modification Pt-Al2O3 catalyst coating is arranged inside the micro plate-type reactor, and the periphery of the micro plate-type reactor is provided with a heating system and a thermocouple for precisely controlling the temperature of the reactor. The iron-chromium-aluminum plate which is coated with the hydrophobic Pt-Al2O3 coating is adopted to catalytically treat the tail gas of the hydrogen fuel cell, and the tail gas of the hydrogen fuel cell is efficiently and simply treated under a damp atmosphere mainly by utilizing the narrow-slit flame-blocking effect of the micro plate-type reactor and the hydrophobic characteristic of the hydrophobic catalyst.

Owner:EAST CHINA UNIV OF SCI & TECH

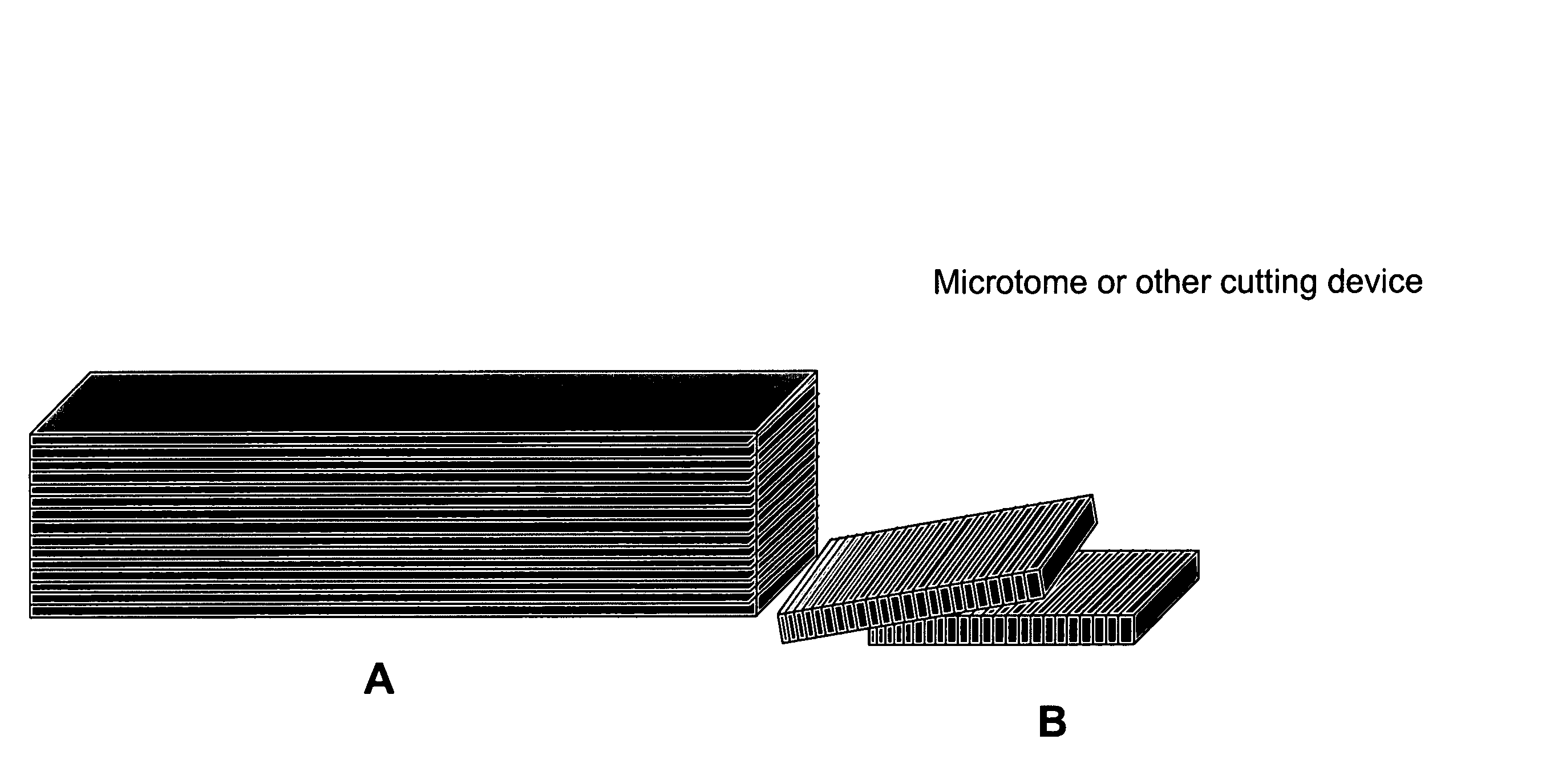

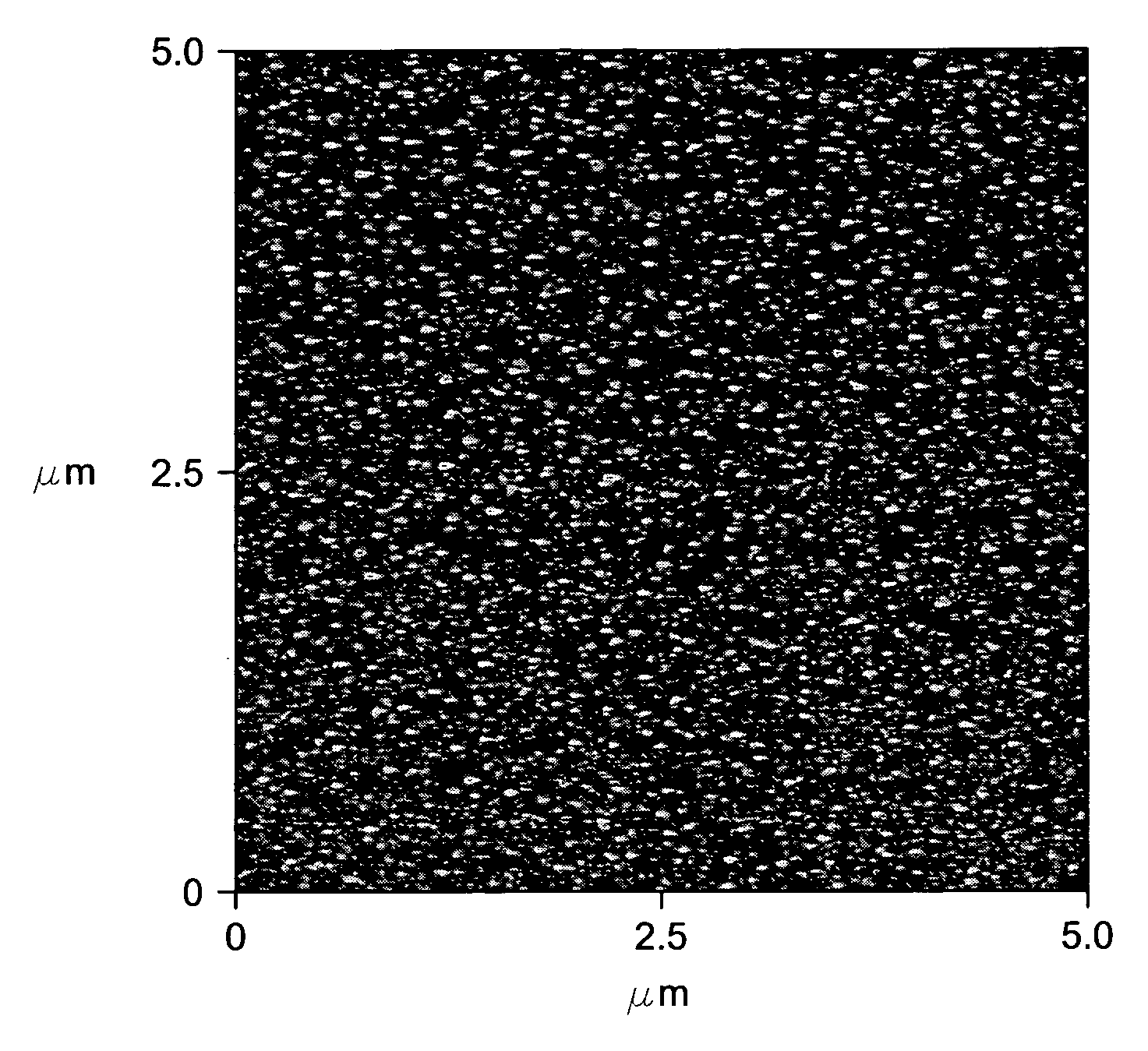

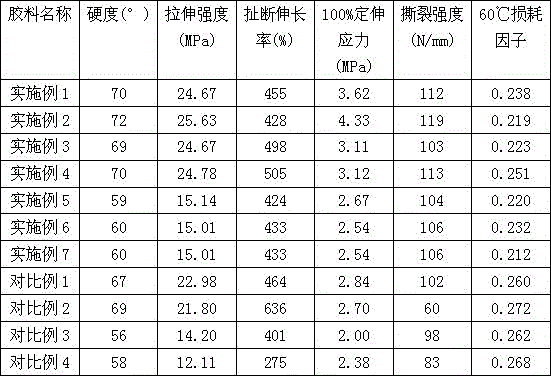

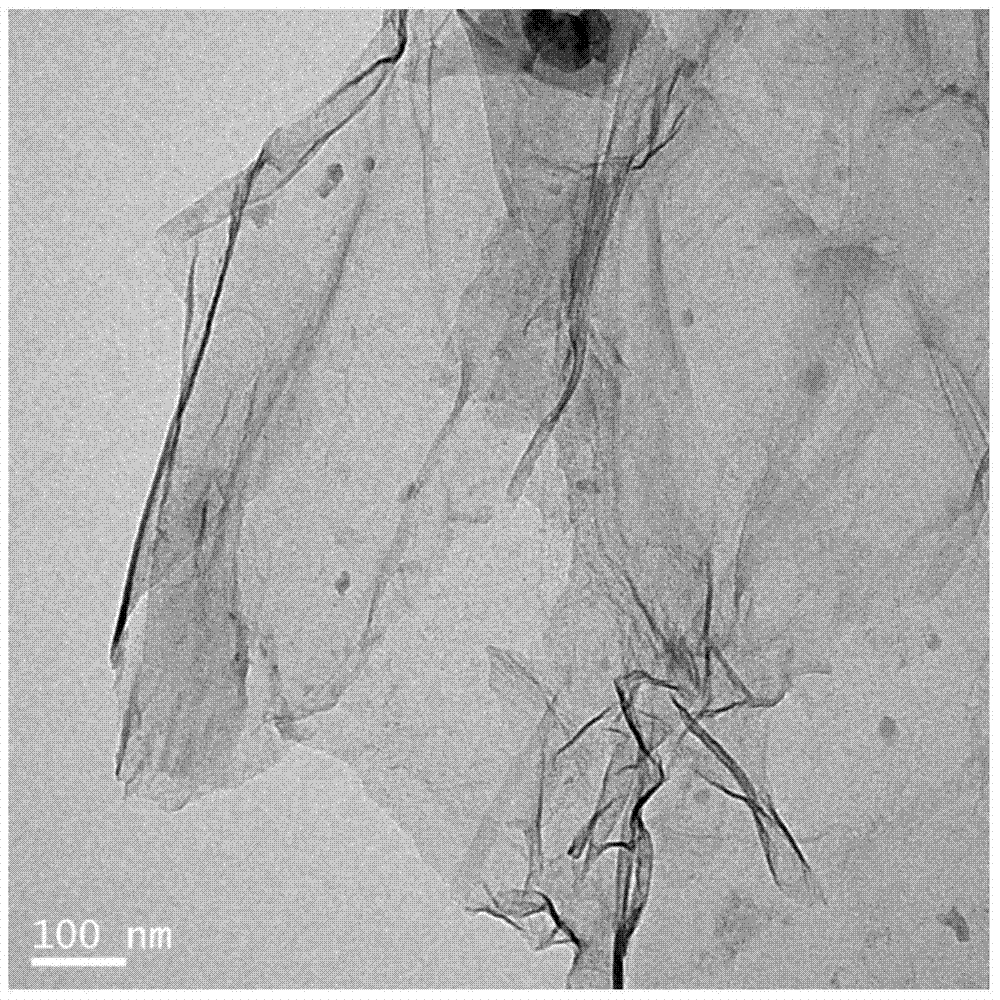

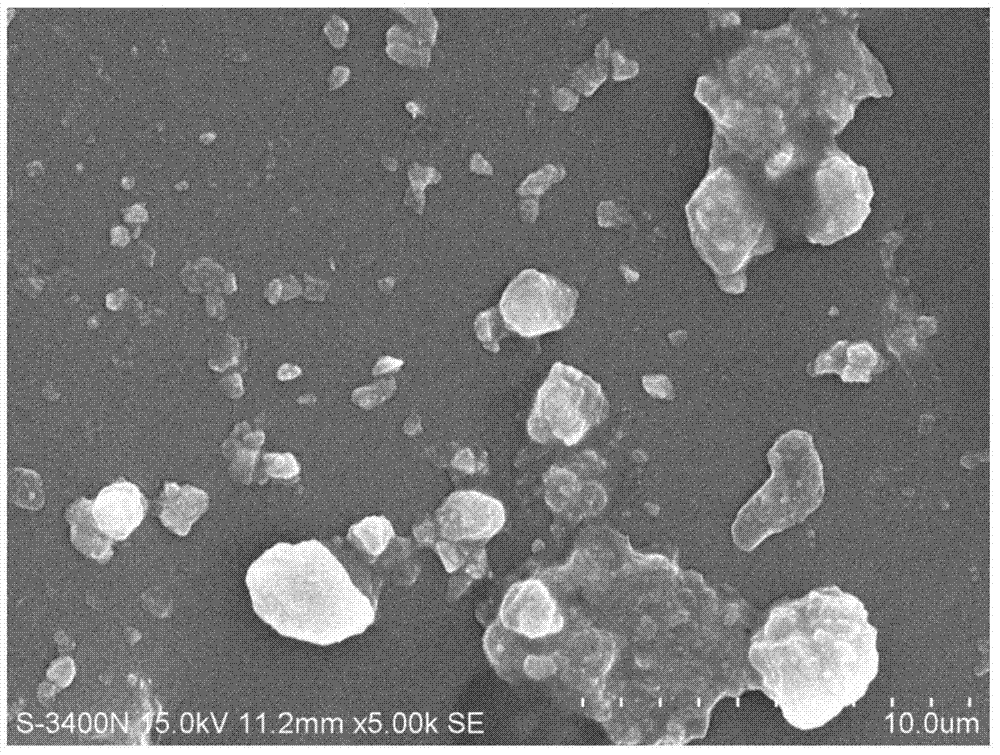

Method and production device for preparing graphene micro-plate pre-dispersion master batch

The invention relates to the technical field of technologies for processing rubber, in particular to a method and a production device for preparing graphene micro-plate pre-dispersion master batch. The method includes stirring and mixing graphene micro-plate dispersion liquid and latex with each other by the aid of a high-speed stirring machine to obtain mixed materials, adding flocculating agents into the mixed materials and coagulating the mixed materials to obtain pulp; dehydrating and drying the pulp to obtain the master batch. The method and the production device have the advantages that technologies are simple, the method and the production device are safe in operation, the graphene micro-plate pre-dispersion master batch can be continuously produced on a large scale, and the production efficiency can be improved as compared with original preparation technologies by the aid of batch processes; graphene micro-plates in the master batch prepared by the aid of the method can be highly dispersed as compared with melt processing methods; quick mixing and condensation can be implemented as compared with previous methods, drying and dehydrating phases are combined with squeezing drying and oven-drying modes, accordingly, the drying time can be shortened, rubber materials can be prevented from being aged, and the graphene micro-plate pre-dispersion master batch with excellent performance can be prepared by the aid of the method and the production device.

Owner:青岛蓝湾烯碳材料科技有限责任公司

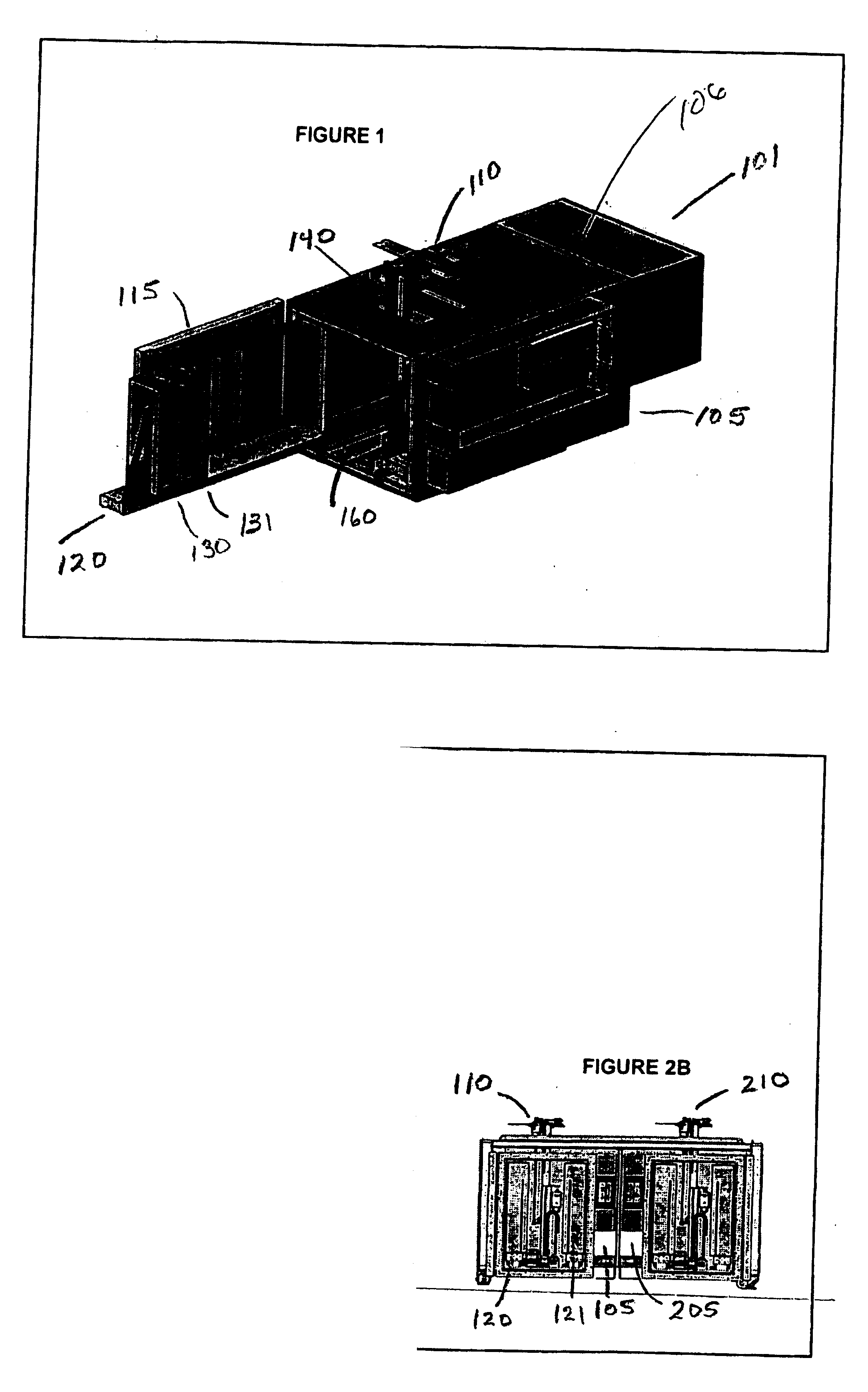

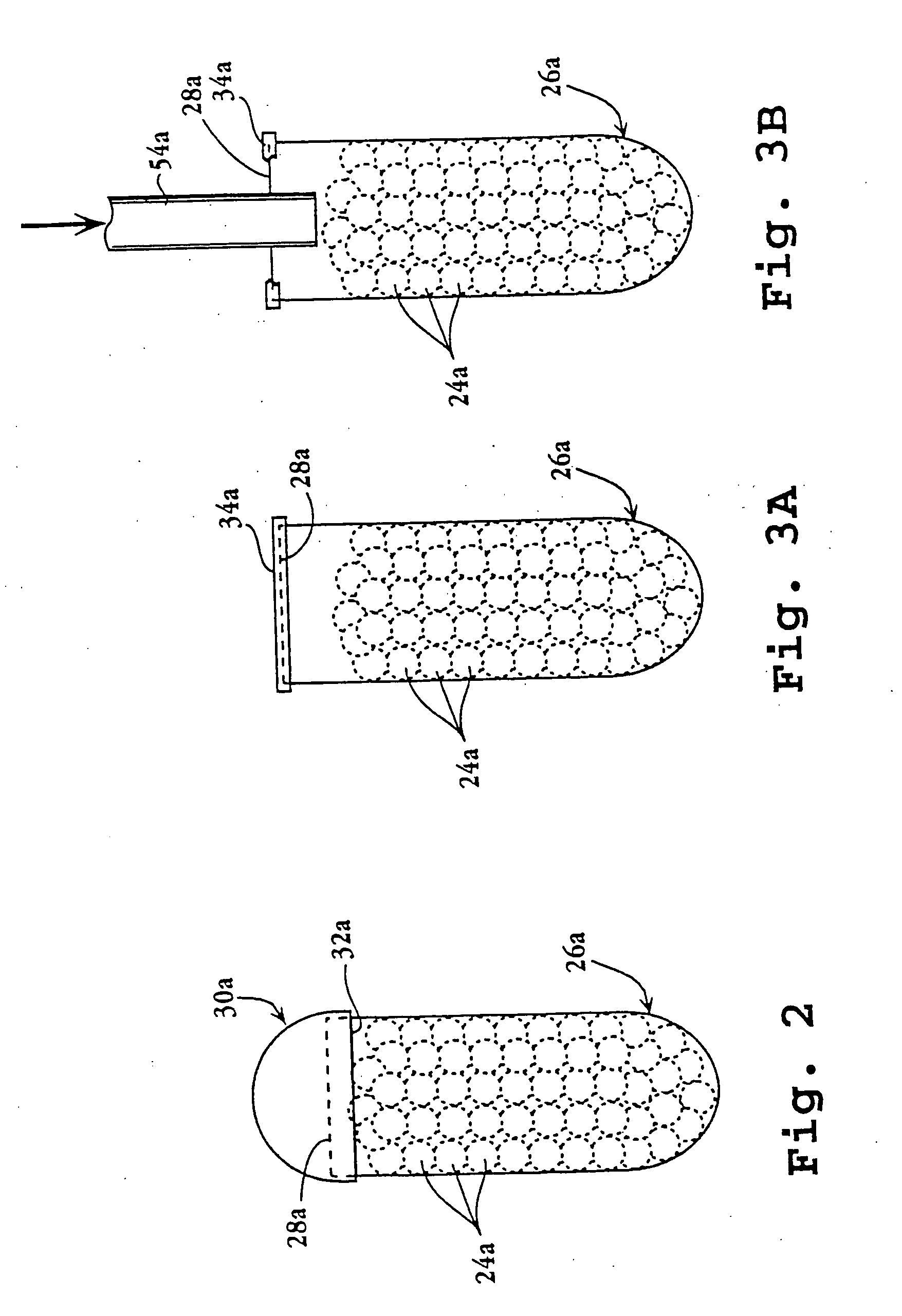

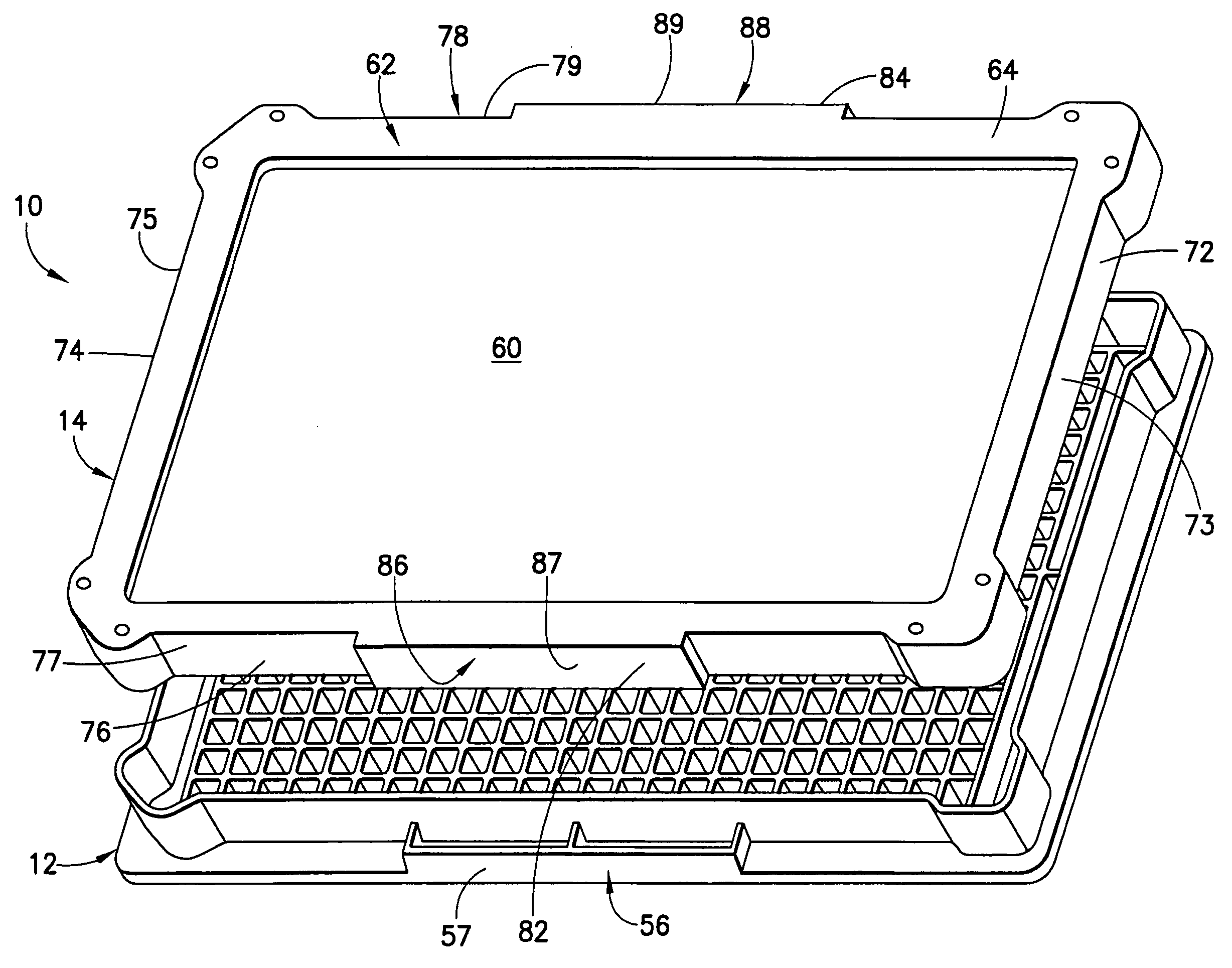

Micro-plate and lid for robotic handling

InactiveUS20050226787A1Bioreactor/fermenter combinationsAnalysis using chemical indicatorsEngineeringMicro plate

A well plate assembly includes a well plate with a base wall, a peripheral wall extending up from the base wall and spaced inwardly from the outer periphery of the base wall. A well array is formed on the base wall at locations inwardly from the peripheral wall. A lid is mounted on the peripheral wall of the well plate. The lid and the peripheral wall have areas that are indented from the outer periphery of the base wall to facilitate manipulation by robotic stacking equipment. The well plate and the lid further include substantially registered robotic gripper plates aligned with the outer periphery of the base wall to facilitate manipulation of the assembled well plate and lid by robotic grippers.

Owner:CORNING INC

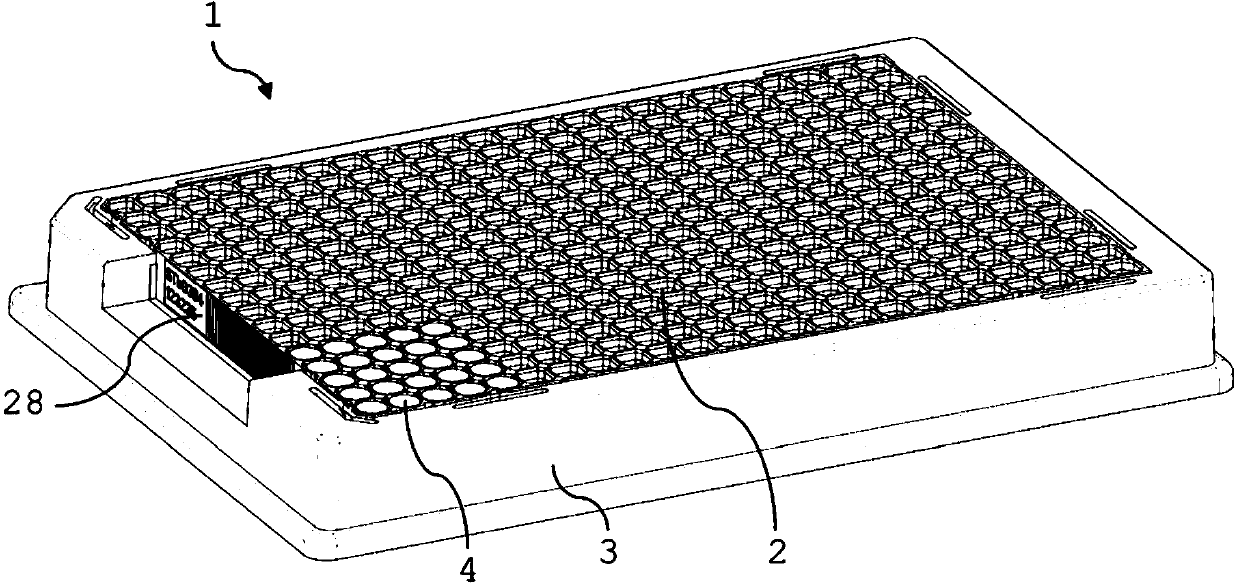

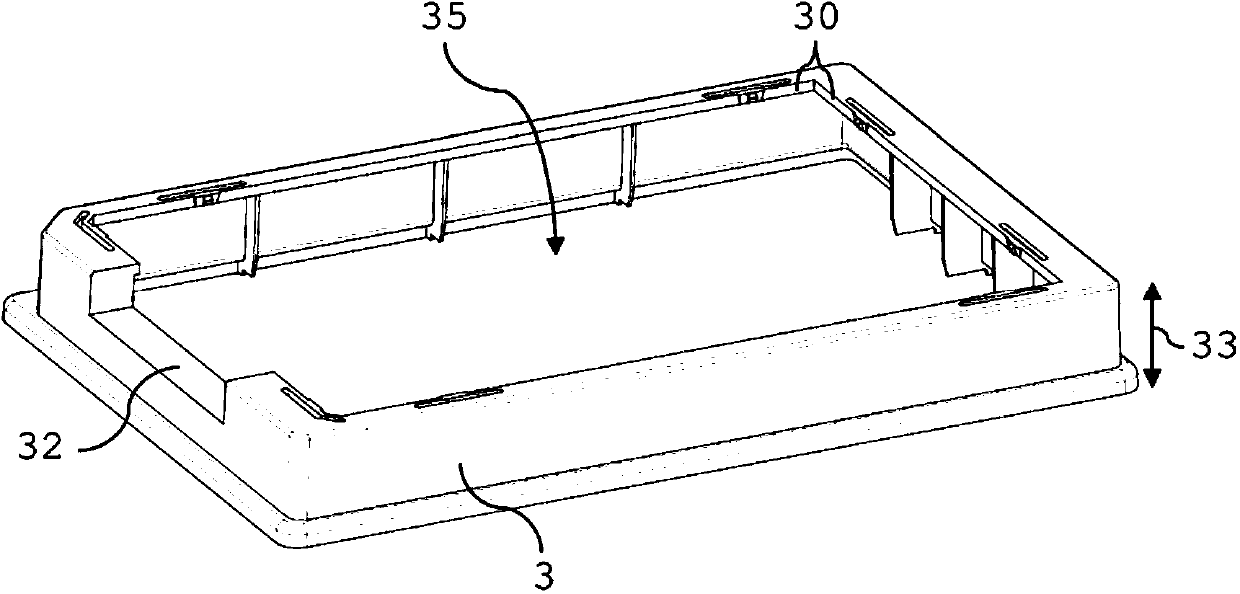

Sample handling system

Sample handling system for handling samples contained in tubes (4), each tube (4) having a hollow body, a closed bottom and an open top for accessing the sample contained in the tube (4). The system comprises a micro-plate (1) comprising at least one grid insert (2) having a plurality of compartments. Each compartment comprises one or more side walls laterally confining a through-hole for receiving a said tube (4). The through-hole has a top opening and a bottom opening and extends between the top opening and the bottom opening. A frame (3) to which the at least one separate grid insert (2) is to be attached to form the micro-plate (1). The frame (3) laterally confines a through-opening which is dimensioned to allow for accessing each compartment (21) of the attached at least one grid insert (2) from above and from below. This allows for moving such tube (4) into and out of each compartment (21) through each of the top opening (202) and the bottom opening (203) of the through-hole (201).

Owner:F HOFFMANN LA ROCHE & CO AG

Ergonomic pipetting workstation

InactiveUS20100310427A1Chemical analysis using titrationMaterial analysis by optical meansEngineeringWorkstation

A workstation for pipetting provides for an ergonomic pipetting environment. Test tubes, centrifuge tubes, micro tubes and micro plates are inserted into a top plate, which is designed to hold such devices in a desired configuration. The top plate is adjustable with respect to height and planar angle, so that extensive pipetting efforts are less likely to result in repetitive stress related injuries.

Owner:HOLMES JEFFREY MICHAEL +2

Gas chromatography device for detecting sulfuryl fluoride in sulfur hexafluoride decomposition product

The invention discloses a gas chromatography device for detecting sulfuryl fluoride in a sulfur hexafluoride decomposition product. The gas chromatography device comprises a sulfur hexafluoride separation device, a capillary column sampling device, a Gaspro chromatographic column, a micro-plate flow path control valve and a second sulfide detector, wherein the capillary column sampling device comprises a first inlet, a second inlet and a first outlet which are communicated with one another; the second inlet is communicated with the sulfur hexafluoride separation device; auxiliary gas is fed through the first inlet; the micro-plate flow path control valve comprises a third inlet, a second outlet and a third outlet; the Gaspro chromatographic column is respectively communicated with the first outlet and the third inlet; the second sulfide detector is communicated with the second outlet. The gas chromatography device for detecting the sulfuryl fluoride in the sulfur hexafluoride decomposition product, provided by the invention, can be used for accurately detecting the sulfuryl fluoride.

Owner:STATE GRID CORP OF CHINA +1

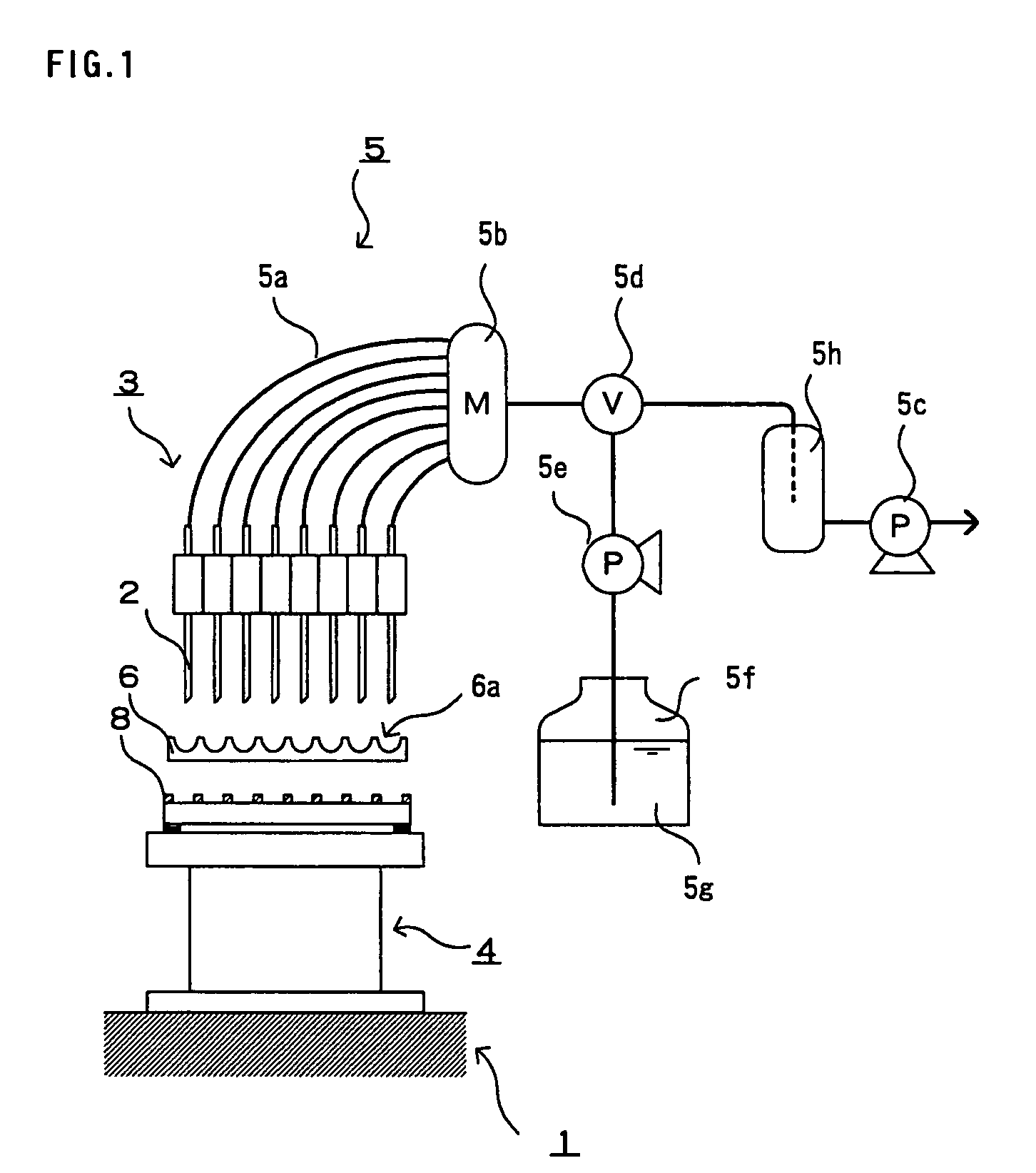

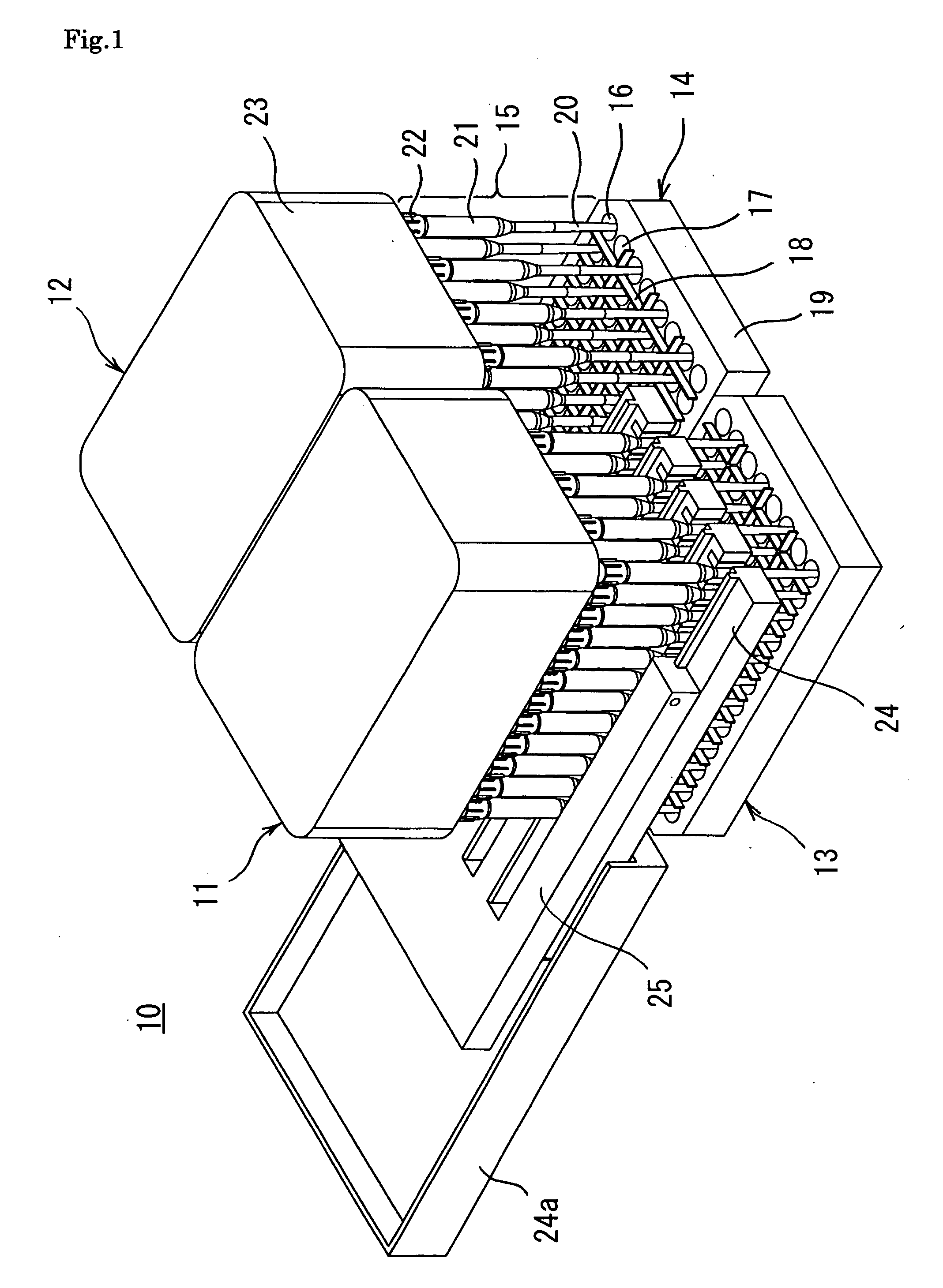

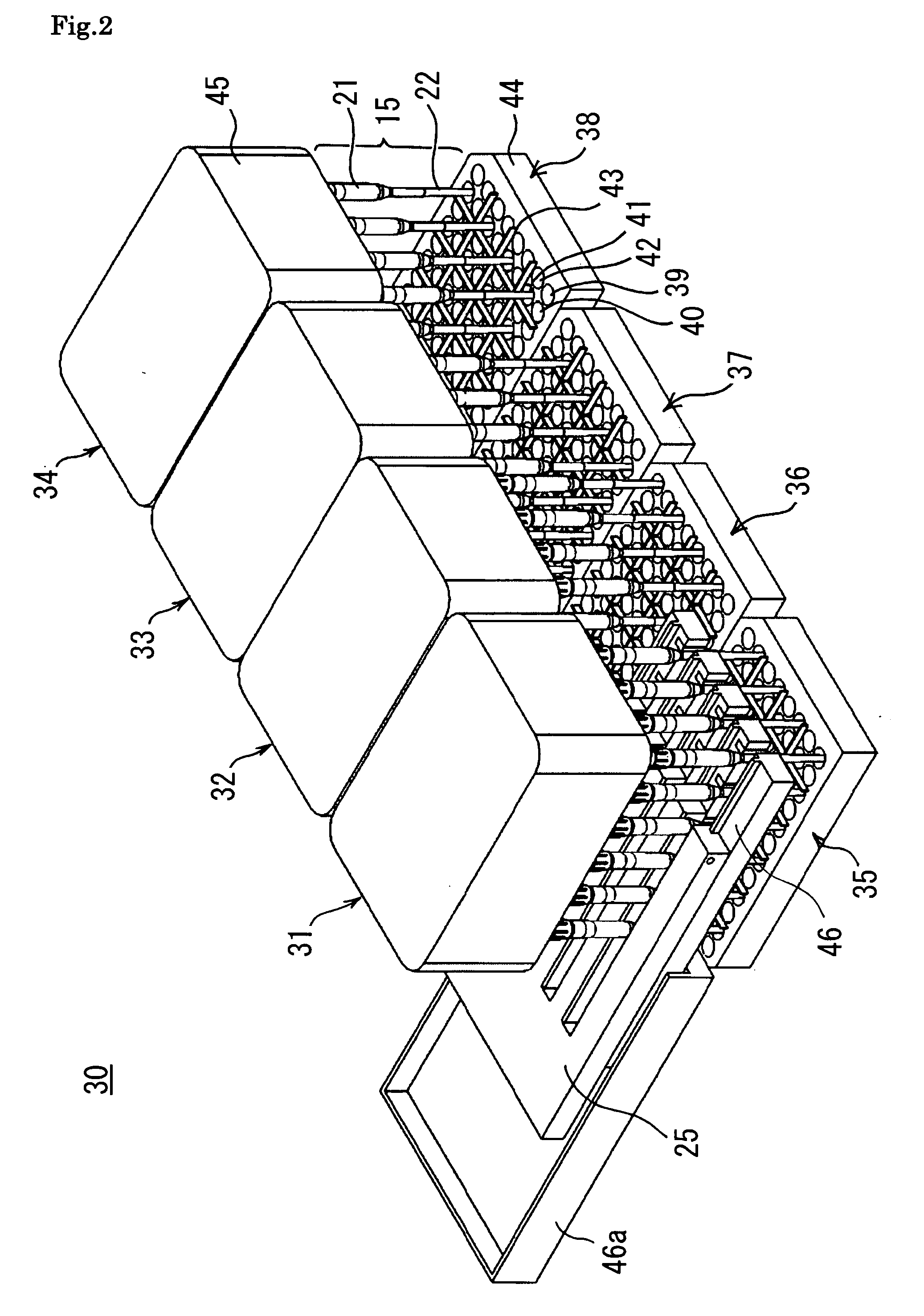

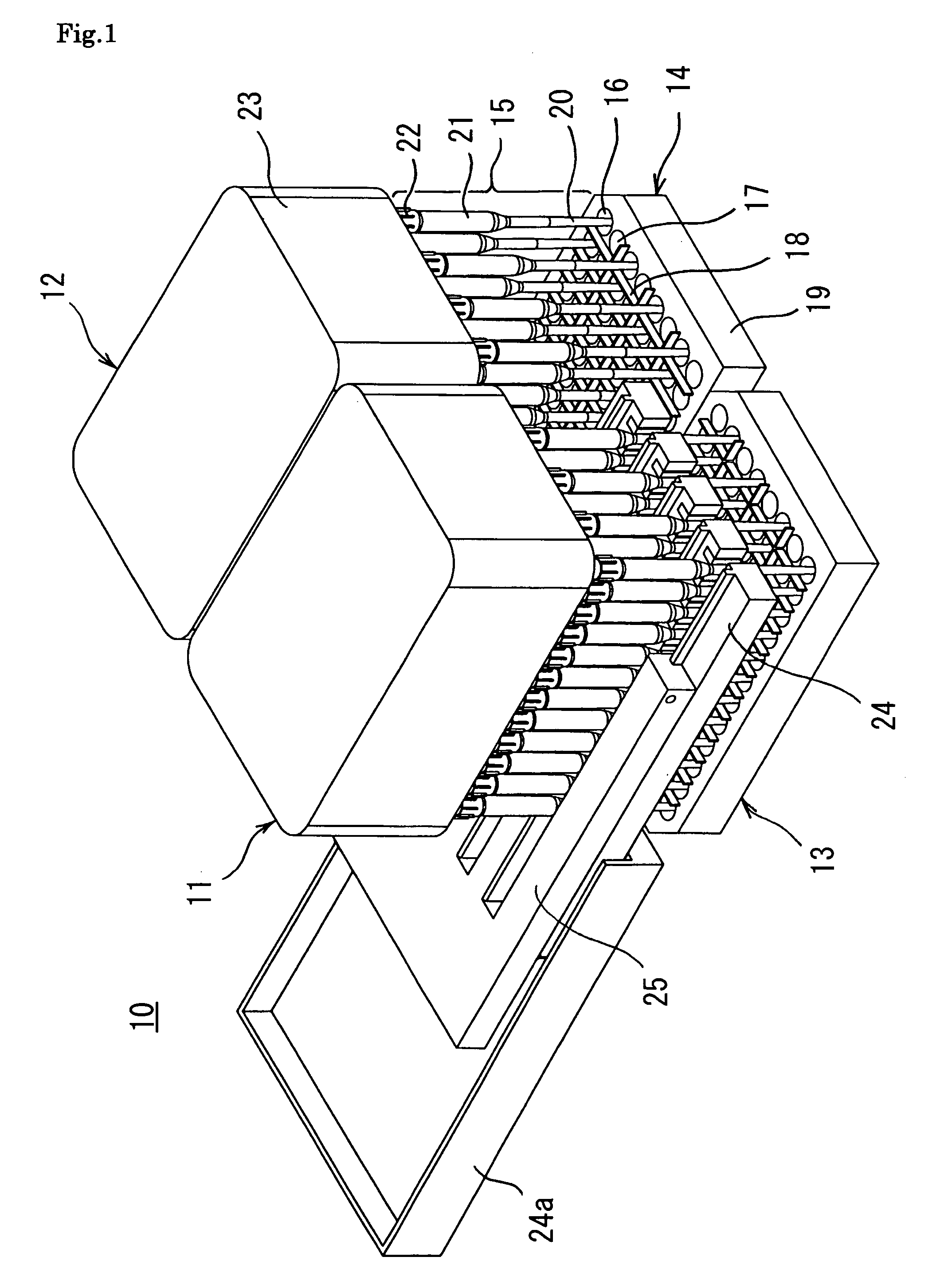

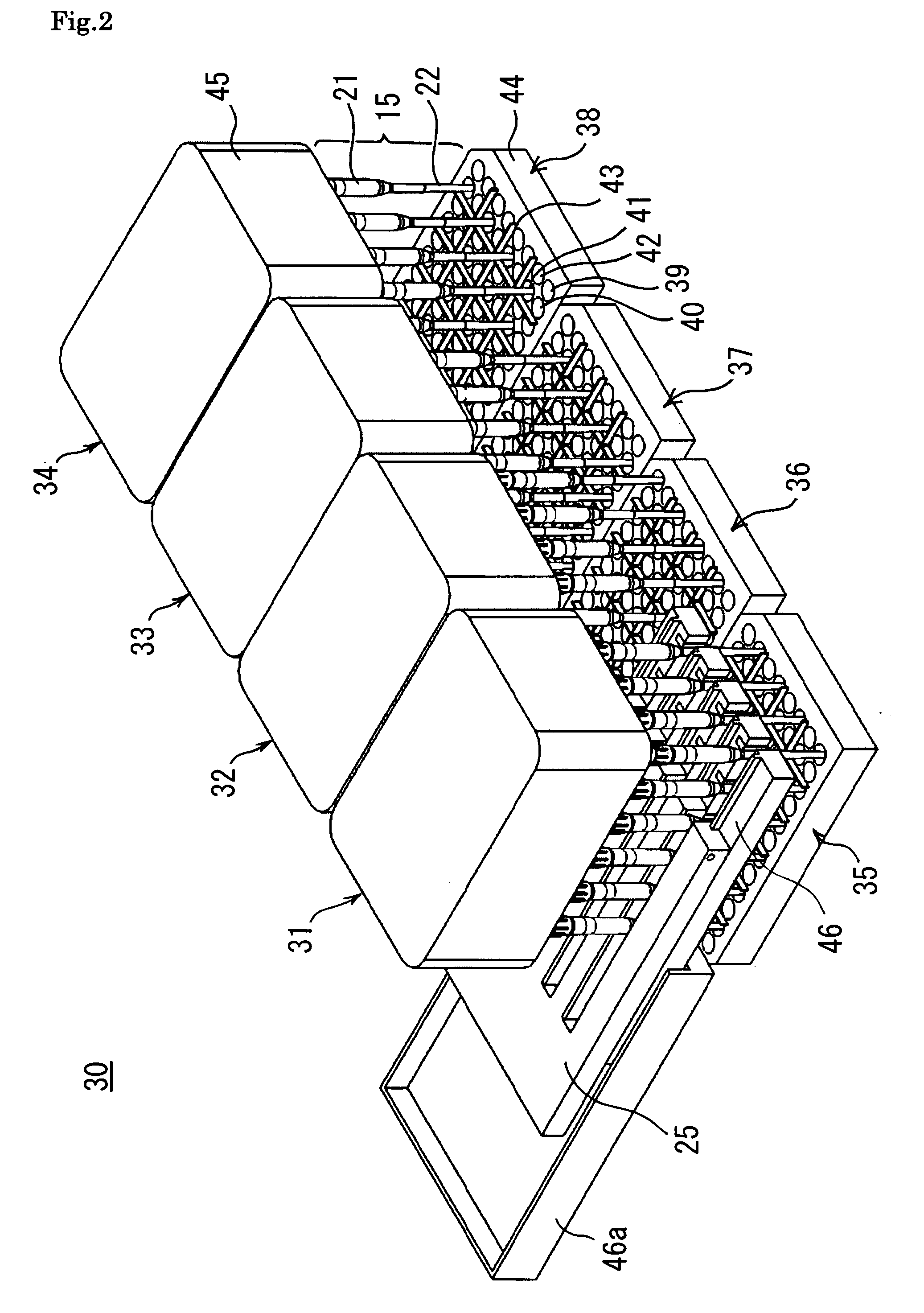

Micro Plate Treating Device and Micro Plate Treating Method

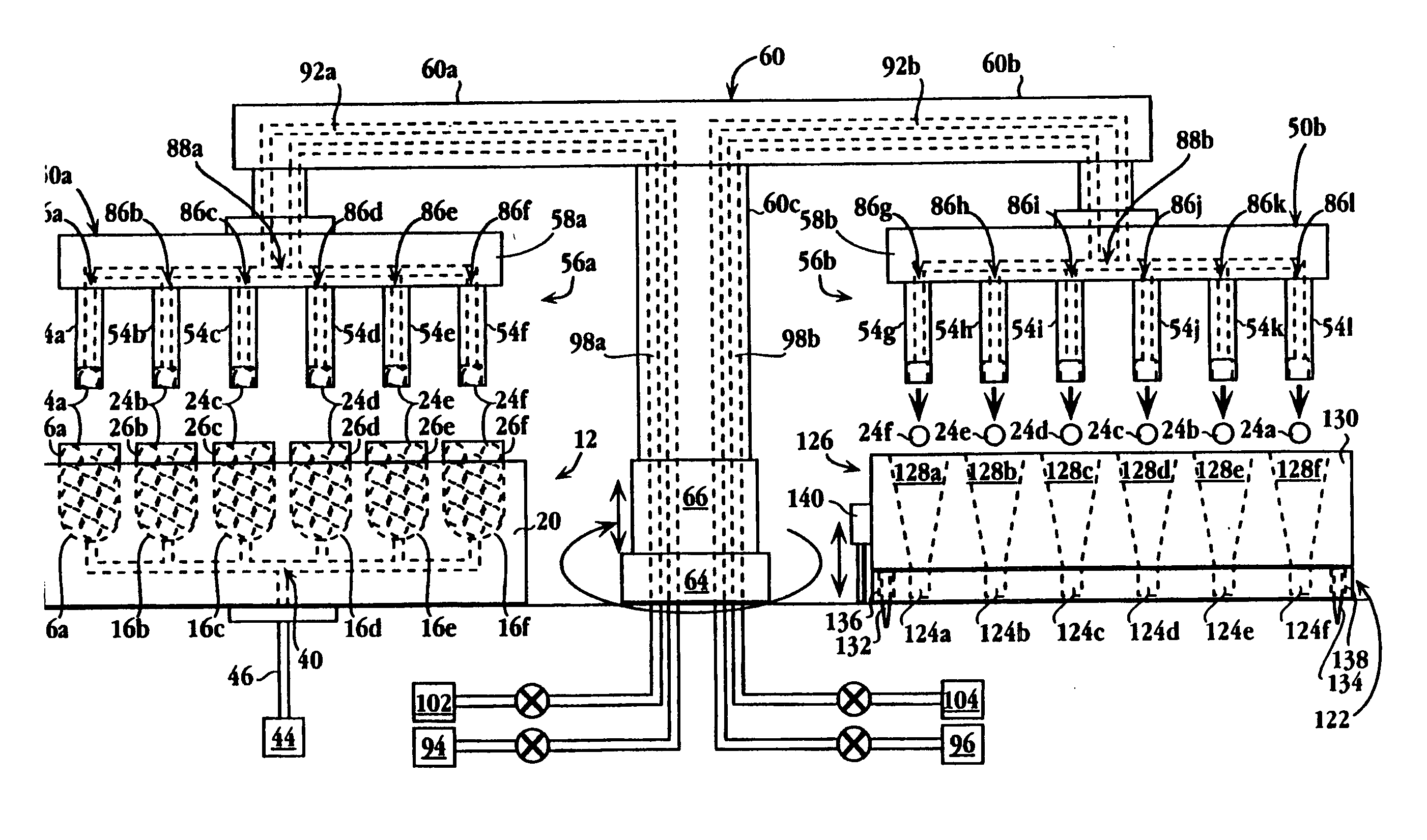

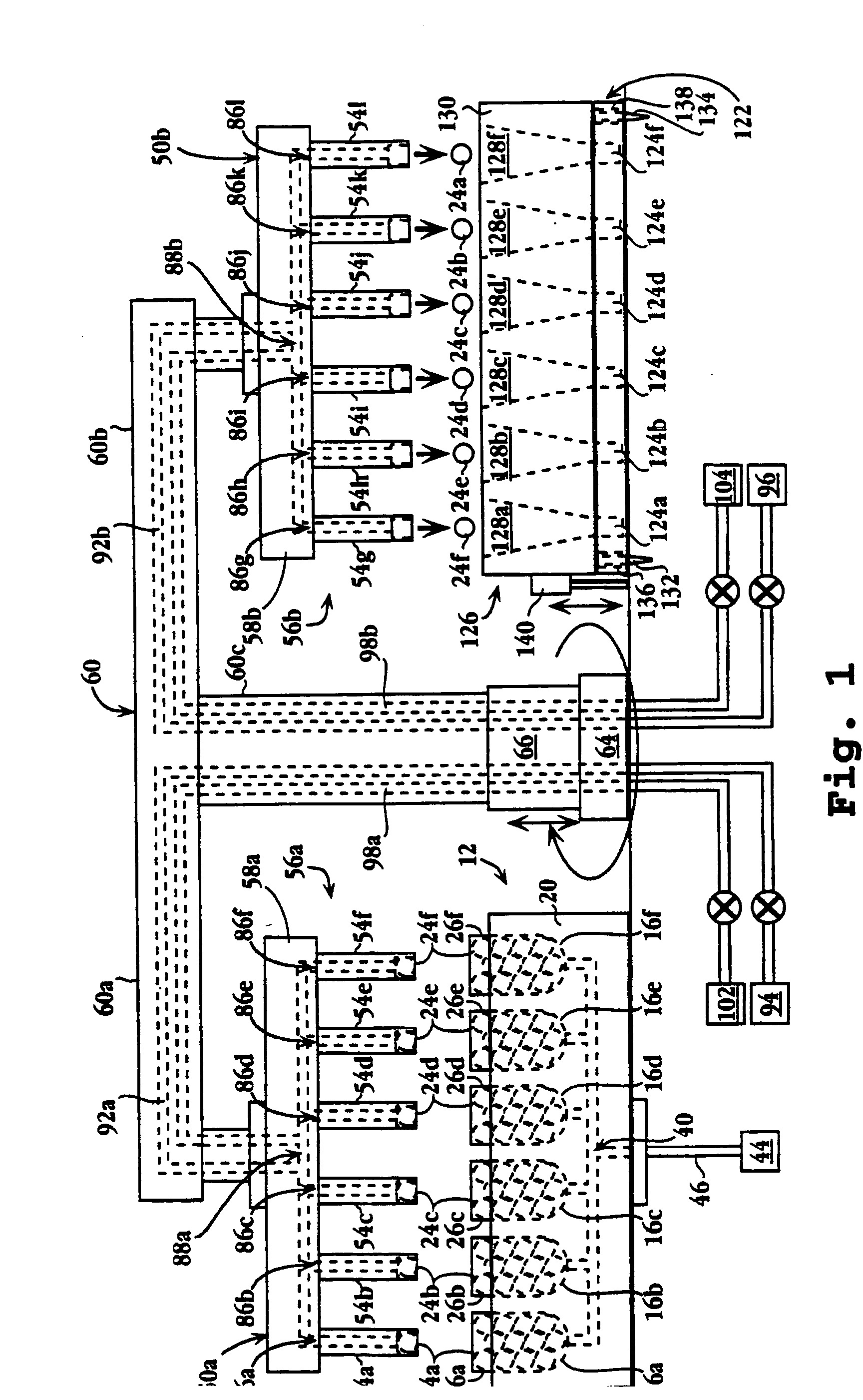

ActiveUS20100047132A1Without increasing area for workIncrease the number ofAnalysis using chemical indicatorsChemical analysis using titrationEngineeringMicro plate

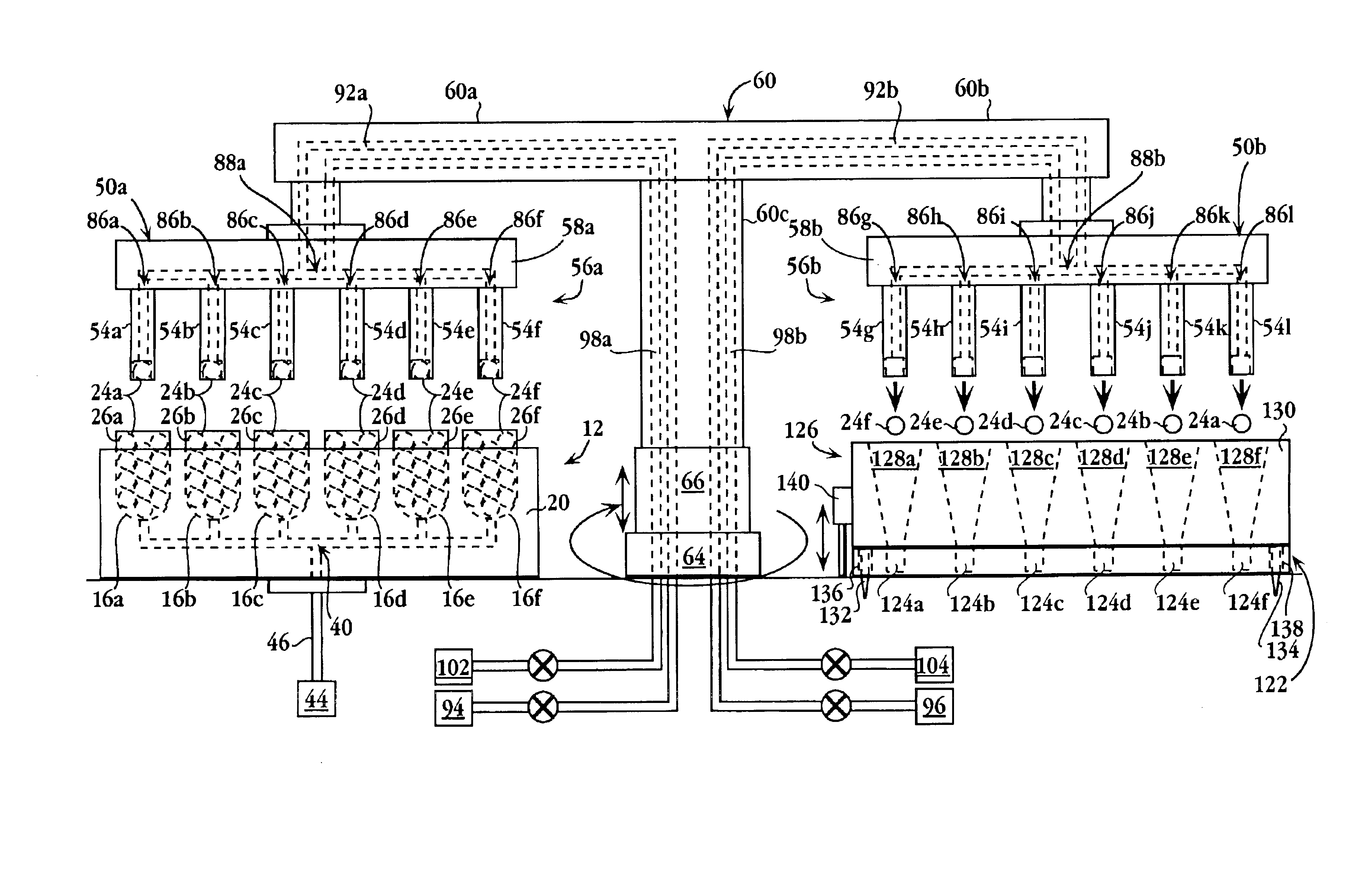

An object is to provide a micro plate treating device and micro plate treating method capable of handling a larger number of kinds of solution or suspensions or a larger volume of solutions or suspensions per work area by use of a normalized micro plate without enlarging the scale of the device.The micro plate treating device comprises a micro plate having wells arranged in a matrix form, one or two or more nozzle heads each having nozzles capable of sucking and discharging a fluid and arranged in a matrix form, and moving means capable of moving relatively an interval between the micro plate and the nozzle heads, wherein tips of all the nozzles are configured to be permitted to be simultaneously inserted into some of the wells in the micro plate, at least one of the row interval or the column interval of the nozzles is set to a natural number multiple of the row interval or the column interval of the corresponding wells, the natural number being two or more, and at least one of the row number or the column number of all the corresponding nozzles is one to the natural number of the row number or the column number of the wells.

Owner:UNIVERSAL BIO RESEARCH CO LTD

Method and kit for fast detection of human chlamydia pneumoniae antigen based on magnetic resolution and quantum dot labelling

ActiveCN105203768AIt has the effect of synergistic amplification of multiple signalsFast separationBiological testingFluorescenceMagnetic bead

The invention provides a method for detection of human chlamydia pneumoniae antigen based on magnetic resolution and quantum dot labelling. The method comprises the following steps: (1) preparing anti-human chlamydia pneumoniae immune nano magnetic beads; (2) preparing quantum dot labelled anti-human chlamydia pneumoniae nanoprobes; (3) dissolving a sample to be detected with a PBST buffer solution, adding the anti-human chlamydia pneumoniae immune nano magnetic beads into the dissolved solution, carrying out magnetic separation after sufficient mixing and reaction, washing with the PBST buffer solution, adding the quantum dot labelled anti-human chlamydia pneumoniae nanoprobes into the obtained precipitate, carrying out magnetic separation after a reaction, washing with the PBST buffer solution, and detecting the fluorescence value with a fluorescence micro-plate reader. The method is accurate, fast, and high in sensitivity, and has very high practical value in the aspects of clinical diagnosis, etiological differentiation, epidemiological surveys and the like of human chlamydia pneumoniae.

Owner:湖北诺美华抗体药物技术有限公司

Method and kit for fast detection of moraxella catarrhalis based on magnetic resolution and quantum dot labelling

ActiveCN105203754AFast separationIt has the effect of synergistic amplification of multiple signalsFluorescence/phosphorescenceAntigenMagnetic bead

The invention provides a method for detection of moraxella catarrhalis based on magnetic resolution and quantum dot labelling. The method comprises the following steps: (1) preparing anti-moraxella catarrhalis nano immunomagnetic beads; (2) preparing quantum dot labelled anti-moraxella catarrhalis nanoprobes; (3) dissolving a sample to be detected with a PBST buffer solution, adding the anti-moraxella catarrhalis immune nano magnetic beads into the dissolved solution, carrying out magnetic separation after sufficient mixing and reaction, washing with the PBST buffer solution, adding the quantum dot labelled anti-moraxella catarrhalis nanoprobes into the obtained precipitate, carrying out magnetic separation after a reaction, washing with the PBST buffer solution, and detecting the fluorescence value with a fluorescence micro-plate reader. The method is accurate, fast, and high in sensitivity, and has very high practical value in the aspects of clinical diagnosis, etiological identification, epidemiological surveys and the like of moraxella catarrhalis.

Owner:湖北诺美华抗体药物技术有限公司

Micro plate treating device and micro plate treating method

ActiveUS8562920B2Without increasing area for workIncrease the number ofAnalysis using chemical indicatorsChemical analysis using titrationEngineeringMicro plate

An object is to provide a micro plate treating device and micro plate treating method capable of handling a larger number of kinds of solution or suspensions or a larger volume of solutions or suspensions per work area by use of a normalized micro plate without enlarging the scale of the device.The micro plate treating device comprises a micro plate having wells arranged in a matrix form, one or two or more nozzle heads each having nozzles capable of sucking and discharging a fluid and arranged in a matrix form, and moving means capable of moving relatively an interval between the micro plate and the nozzle heads, wherein tips of all the nozzles are configured to be permitted to be simultaneously inserted into some of the wells in the micro plate, at least one of the row interval or the column interval of the nozzles is set to a natural number multiple of the row interval or the column interval of the corresponding wells, the natural number being two or more, and at least one of the row number or the column number of all the corresponding nozzles is one to the natural number of the row number or the column number of the wells.

Owner:UNIVERSAL BIO RESEARCH CO LTD

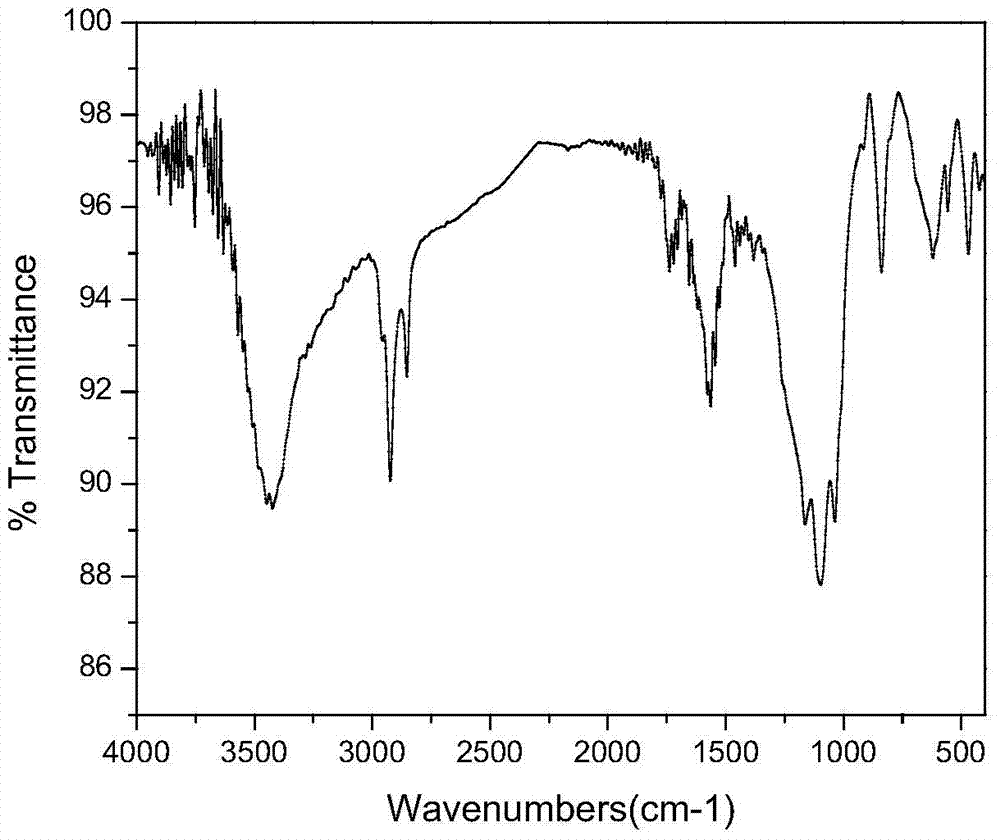

Preparation method of ionic liquid modified graphite micro plate/silicon rubber conductive composite material

InactiveCN103897405AOptimize the conductive network structureLower volume resistivitySilanesLiquid state

The invention discloses a preparation method of an ionic liquid modified graphite micro plate / silicon rubber composite material. The preparation method comprises the steps of preparing graphite flakes into graphite oxide by virtue of an improved Hummers method, and then obtaining expanded graphite by adopting an instant high-temperature heating method; adding the expanded graphite into ionic liquid, thereby obtaining released graphite micro plates after ball-milling treatment, wherein ionic liquid is adsorbed on the surfaces of the graphite micro plates, and dispersion of the graphite micro plates in the composite material is greatly improved due to the adding of the ionic liquid; taking normal hexane as a solvent, adding dimethyl vinyl and trimethyl silane dioxide, further adding ionic liquid-modified graphite micro plates as a filler, heating and stirring to remove the solvent after uniformly dispersing; and adding a curing agent in a weight ratio of liquid-state raw silicone rubber to the curing agent of 10:1, controlling the temperature to 60 DEG C-150 DEG C, and heating and curing in vacuum to obtain the ionic liquid-modified graphite micro plate / silicon rubber composite material.

Owner:EAST CHINA UNIV OF SCI & TECH

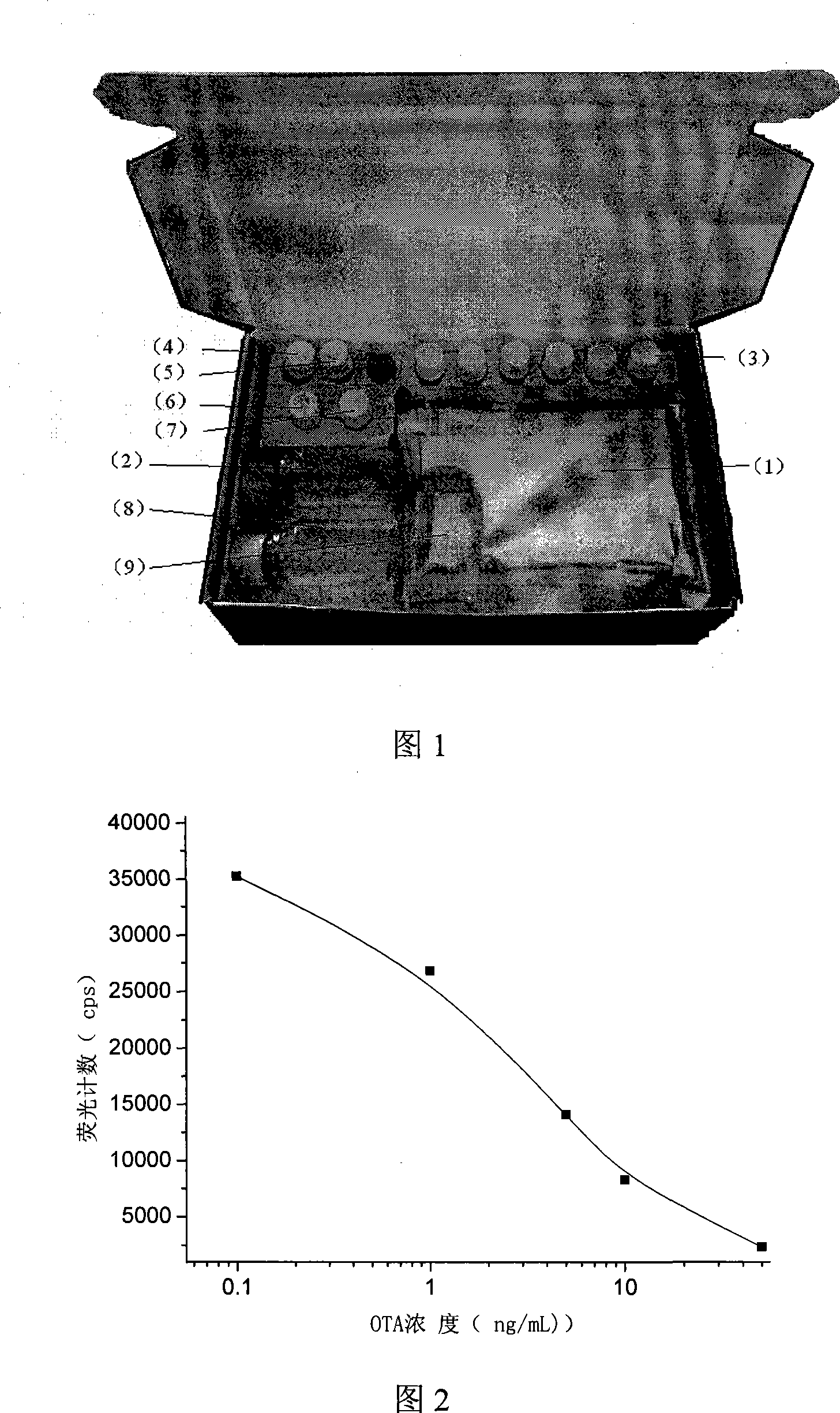

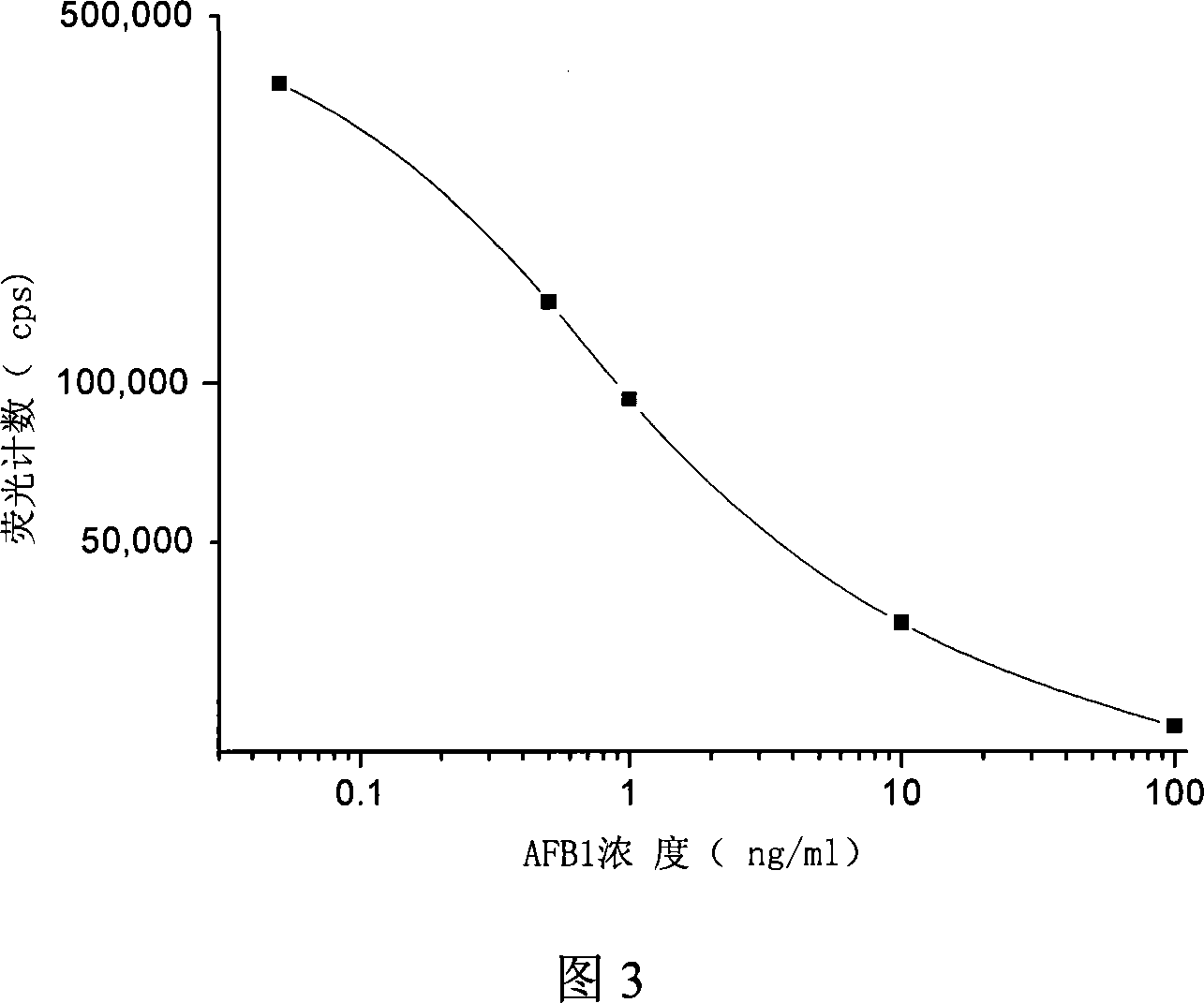

Reagent kit for simultaneously detecting ochratoxin A and aspergillus flavus toxin B1 and its detection method

InactiveCN101241131ASimple structureEasy to useMaterial analysisTime resolved fluorescence immunoassayMonoclonal antibody

A reagent kit for detecting ochratoxin A and aflatoxin B1 at the same time and method thereof are provided, which belongs to fields of time-resolved fluoroimmunoassay. Micro plate is coated with OTA-BSA, AFB1-BSA, adding OTA, AFB1 standard or sample, and then adding OTA monoclonal antibody, AFB1 polyclonal antibody. Dissociated OTA, AFB1 and OTA-BSA, AFB1-BSA on micro plates competing corresponding antibody, and antibody which haven't be connected is eliminated after washing, adding Sm3+-goat anti rat and Eu3+- goat anti rabbit, labeled antibody haven't be connected after immune reaction are eliminated after washing. After adding enhancement solution, detecting Eu and scythe fluorescence intensity cps respectively which are inversely proportional to intensity of OTA and AFB1 in sample respectively by time resolved luminoscope, comparing standard curve and the content of OAT and AFB1 in sample is determined. The reagent kits of present invention has merits of simple structure, convenient operation and low cost, two examining results of OAT and AFB1are obtained by one operation, the present invention is used for detecting of grain, feed and food.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com