Patents

Literature

205 results about "Bisulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bisulfide (systematically named sulfanide and hydrogen(sulfide)(1−)) is an inorganic anion with the chemical formula HS⁻ (also written as SH⁻). It contributes no color to bisulfide salts, and its salts may have a distinctive putrid smell. It is classified as a strong base, bisulfide solutions are corrosive and attack the skin.

Chemical composition for treatment of nitrate and odors from water streams and process wastewater treatment

InactiveUS20020011447A1Efficient processSolid sorbent liquid separationWater softeningSodium BentoniteBisulfide

Owner:MAXICHEM

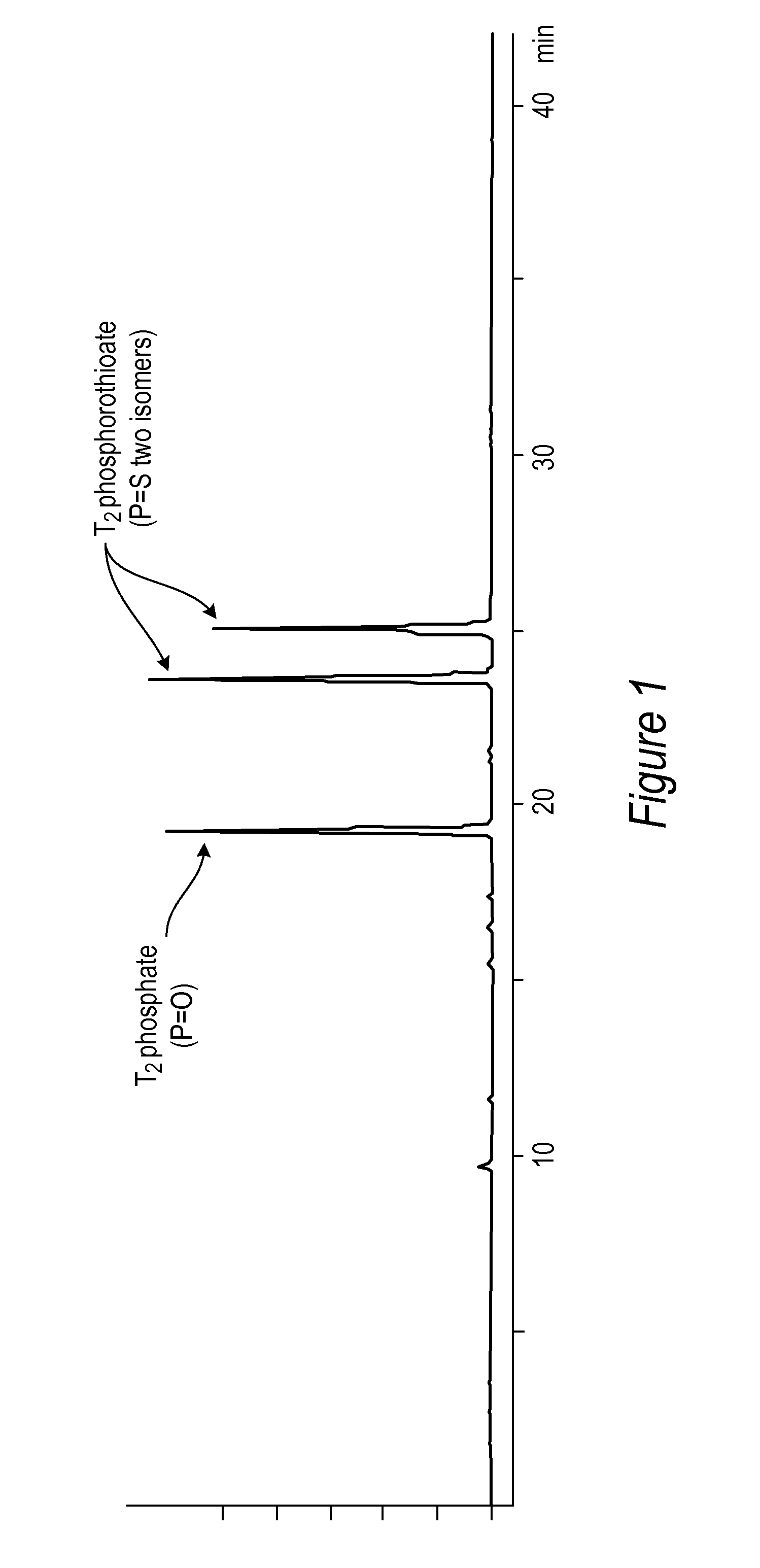

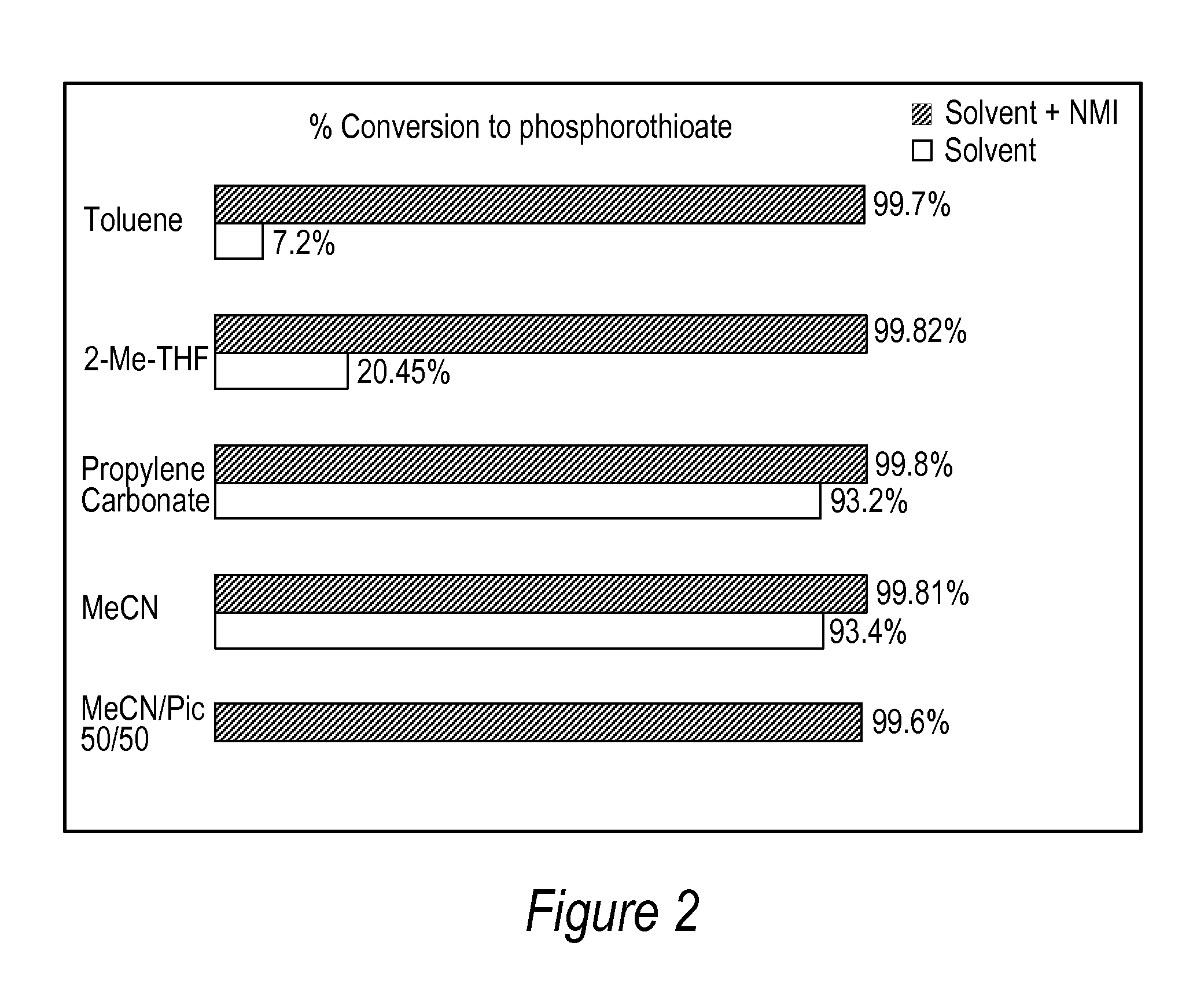

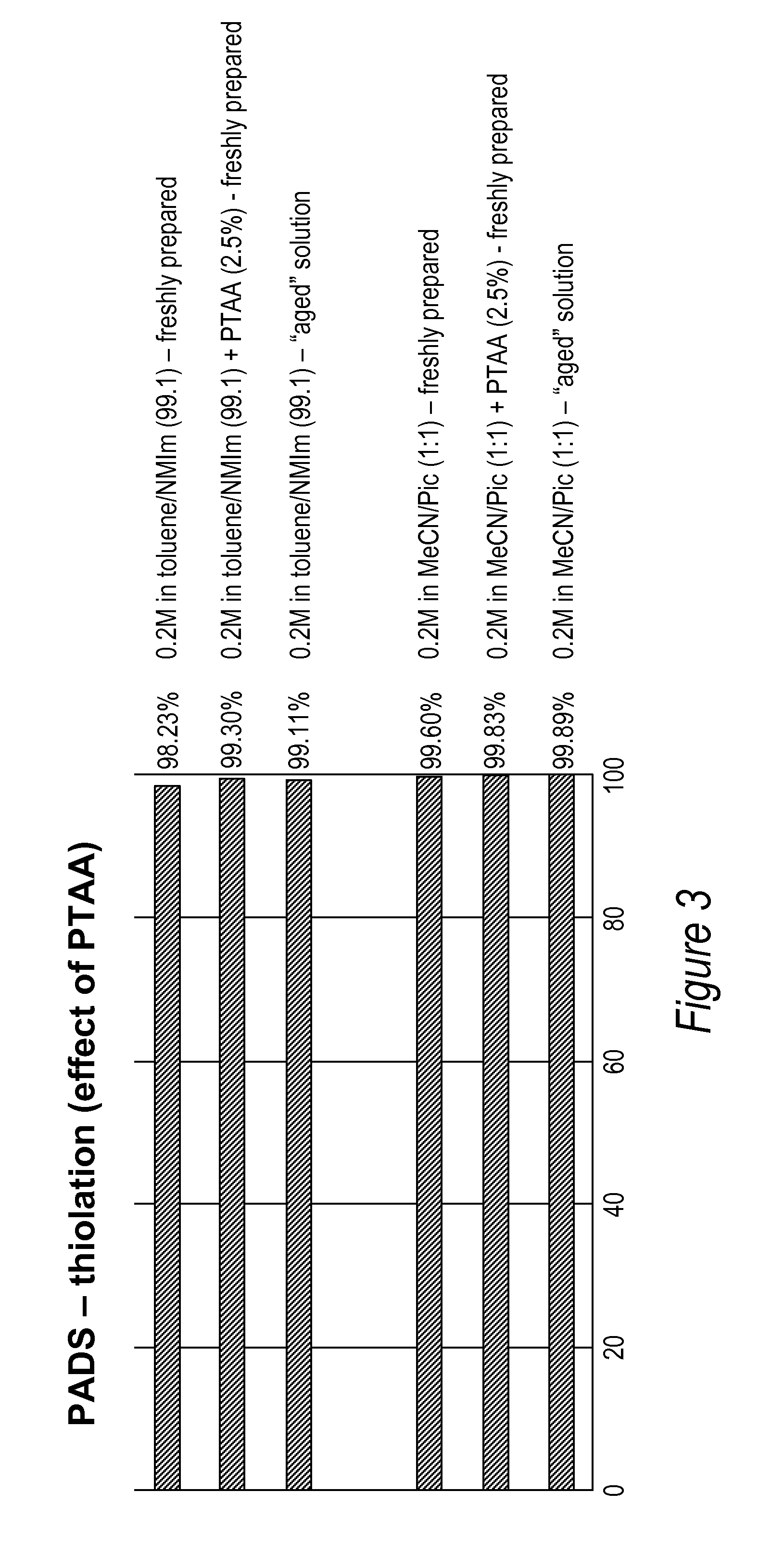

Use of thioacetic acid derivatives in the sulfurization of oligonucleotides with phenylacetyl disulfide

A method and compositions for sulfurizing at least one phosphite or thiophosphite linkage in an oligonucleotide. The methods employ a phenylacetyl disulfide reagent (known as PADS), phenylthioacetic acid (PTAA) in the presence or absence or N-alkyl imidazole in industrially preferred solvents or solvents that are derived from renewable resources. The use of PTAA eliminates the need to “age” the PADS solution prior to its use in sulfurization reactions.

Owner:AGILENT TECH INC

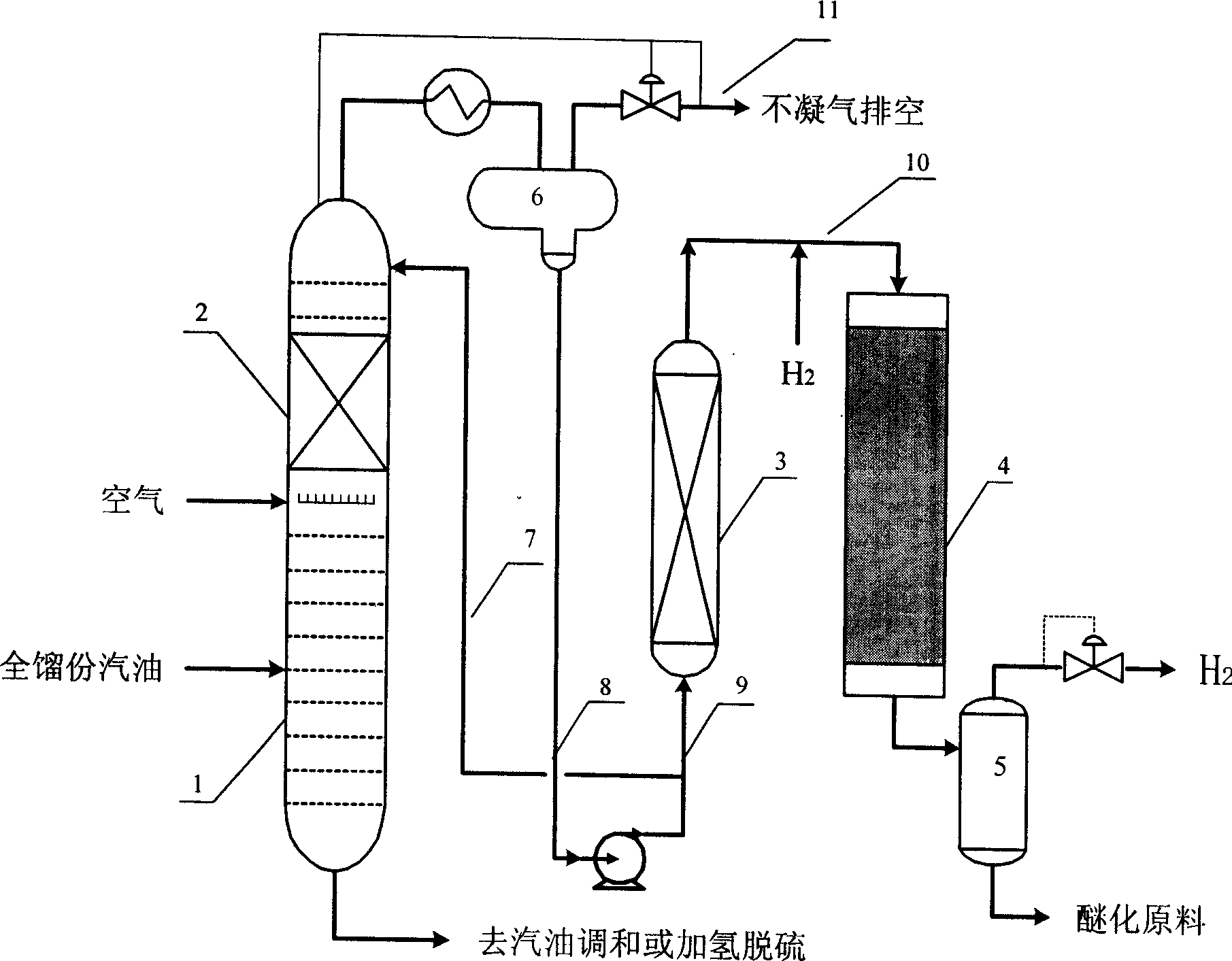

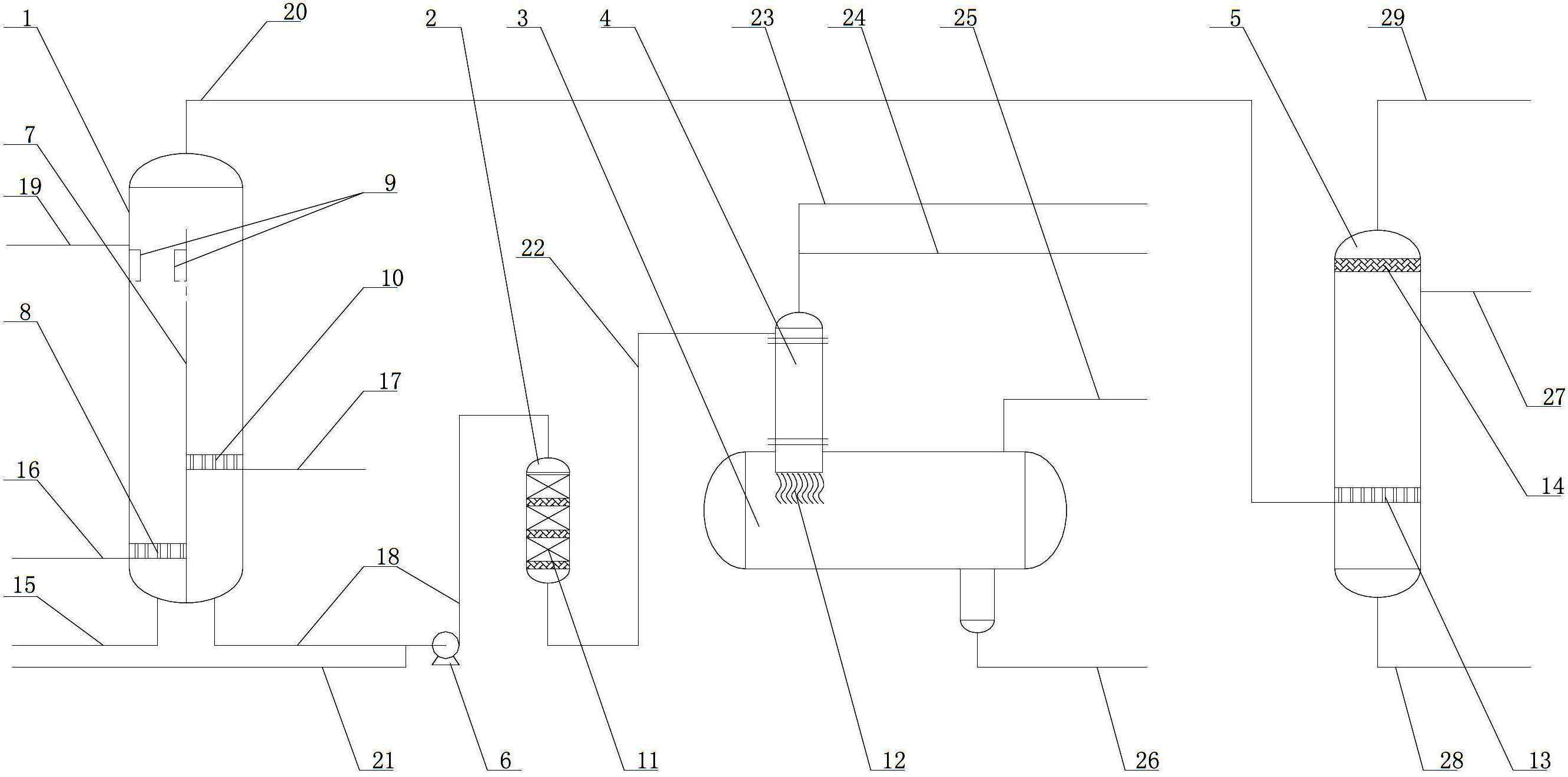

Mercaptan removal and lye regeneration device and method for gasoline light fractions

Owner:NINGBO ZHONGYI PETROCHEM TECH

Silver polyamide composite

InactiveUS20100093851A1DegreeDegree of reductionBiocideAntifouling/underwater paintsPolyvinyl polymerBisulfide

A polymer composite comprising a thermoplastic polyamide polymer compounded with an organo-disulfide additive and a silver-based antimicrobial agent is disclosed. The organo-disulfide additive inhibits undesirable discoloration of the thermoplastic polyamide polymer including one or more silver-based antimicrobial agent. Processes for preparing the composite are also disclosed, including compounding the organo-disulfide additive in a polymeric carrier with the silver-based antimicrobial agent, then with the thermoplastic polyamide polymer, or compounding the organo-disulfide additive with the thermoplastic polyamide polymer before adding the silver-based antimicrobial agent.

Owner:EASTMAN KODAK CO

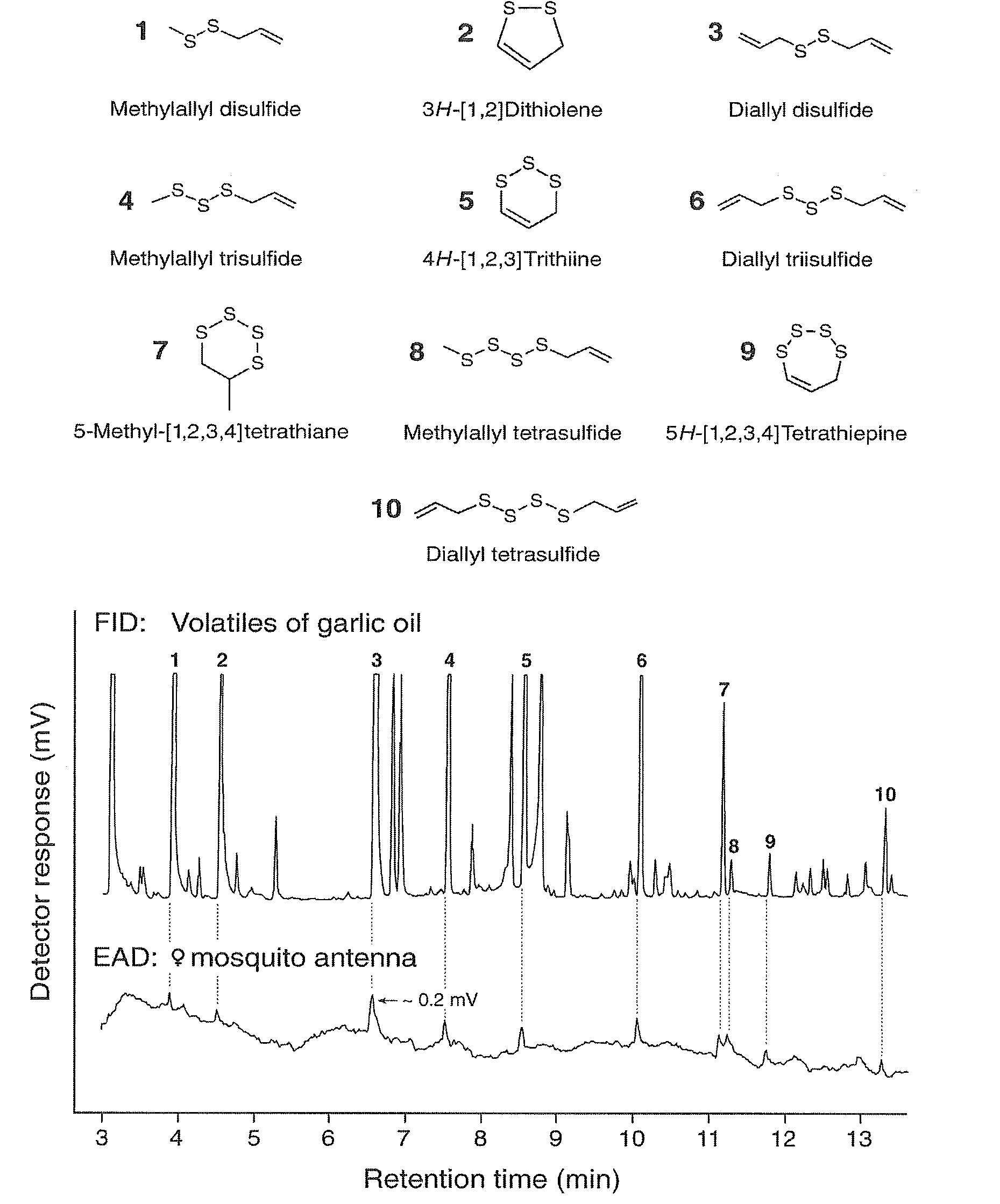

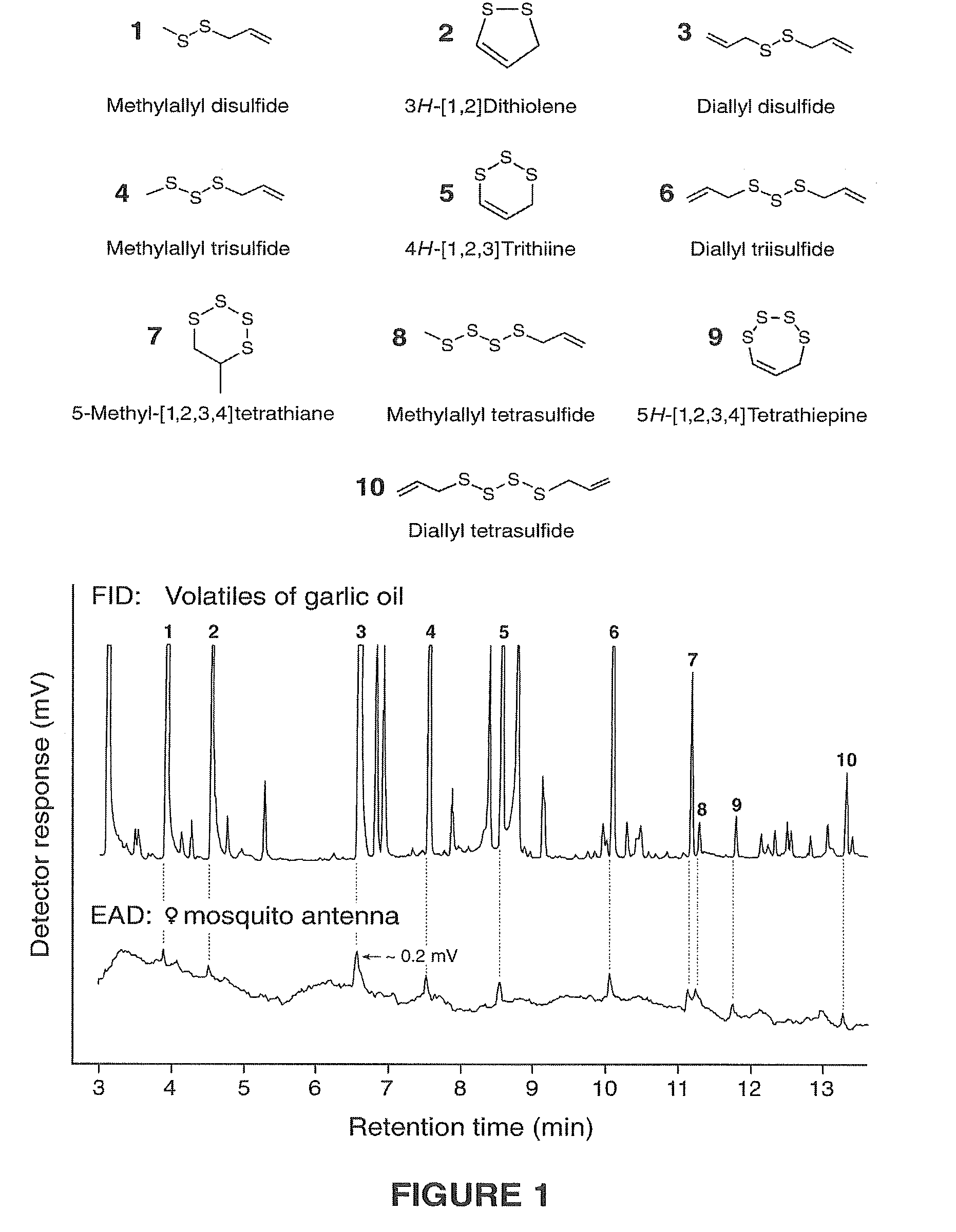

Compounds, compositions and methods for repelling blood-feeding arthropods and deterring their landing and feeding

ActiveUS20090069407A1Enhancing absoluteIncrease abundanceBiocideCosmetic preparationsBisulfideIndividual animal

This invention relates to compositions of one or more compounds that incorporate one or more allyl sulfide, allyl disulfide or allyl polysulfide moieties, or one or more allyl sulfide, allyl disulfide or allyl polysulfide moieties and one or more hydroxyl groups, used in effective amount in formulations, including emulsions, to repel blood-feeding ectoparasitic arthropods, including mosquitoes, and to deter them from landing and feeding when applied to the skin, clothing or environment of animals, including humans. Said compounds can include, but are not limited to, 8-allyl-sulfanyloctan-1-ol. This invention also relates to compositions comprising one or more of said compounds in further combination with other arthropod repellent and deterrent compounds, including vanillin. These compounds may be formulated with inert ingredients to form a liquid, gel, paste, soap, spray, aerosol or powder.

Owner:SCOTTS CANADA

Lubricating composition

A lubricating composition comprising a base oil, (A) one or more kinds of compounds selected from phenolic antioxidants and aminic antioxidants, and (B) an ester compound having a disulfide structure is provided. The lubricating composition of the present invention has excellent stability against oxidation, prevents increase of acid value and sludge formation, and has low corrosivity to non-ferrous metals.

Owner:IDEMITSU KOSAN CO LTD

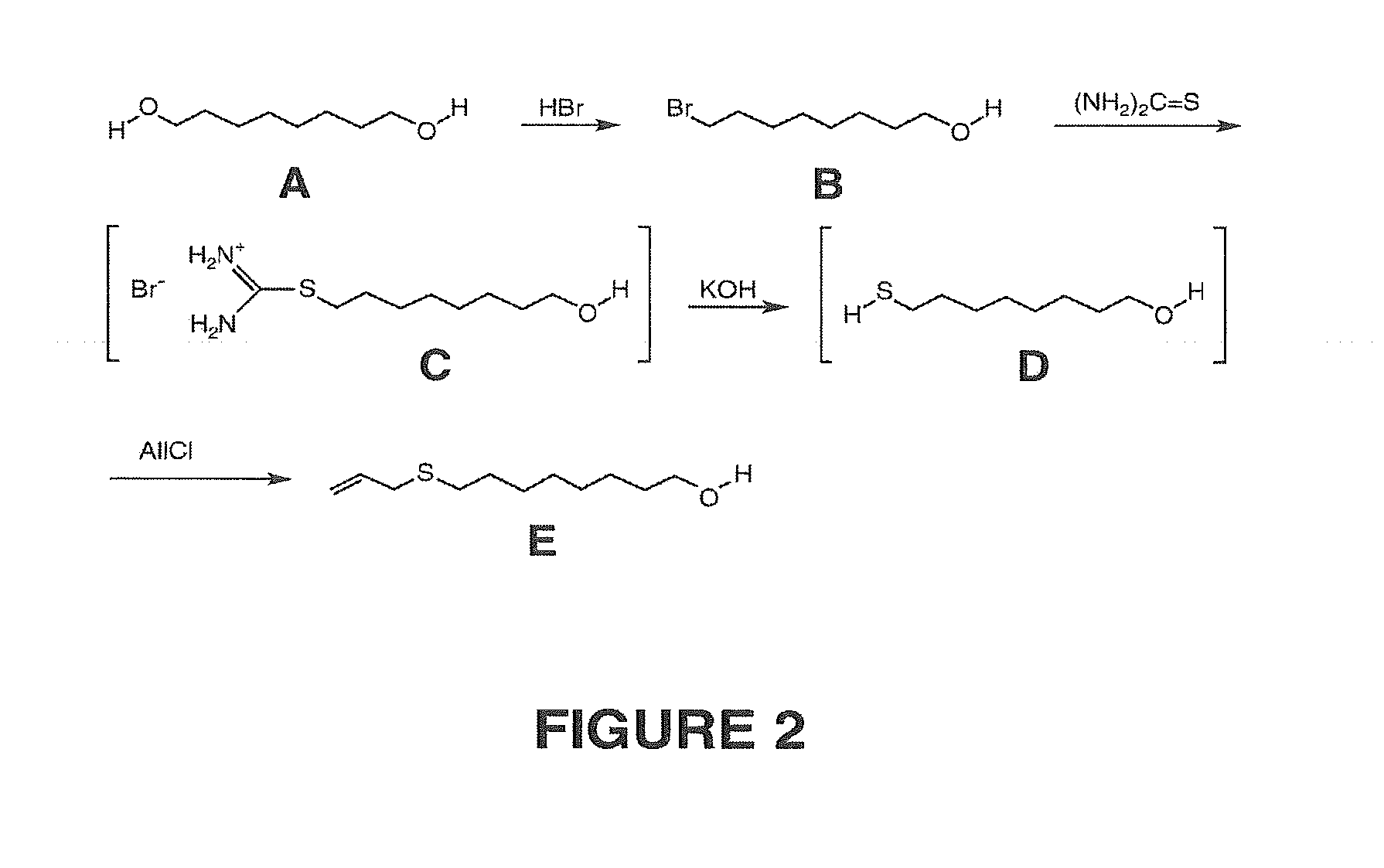

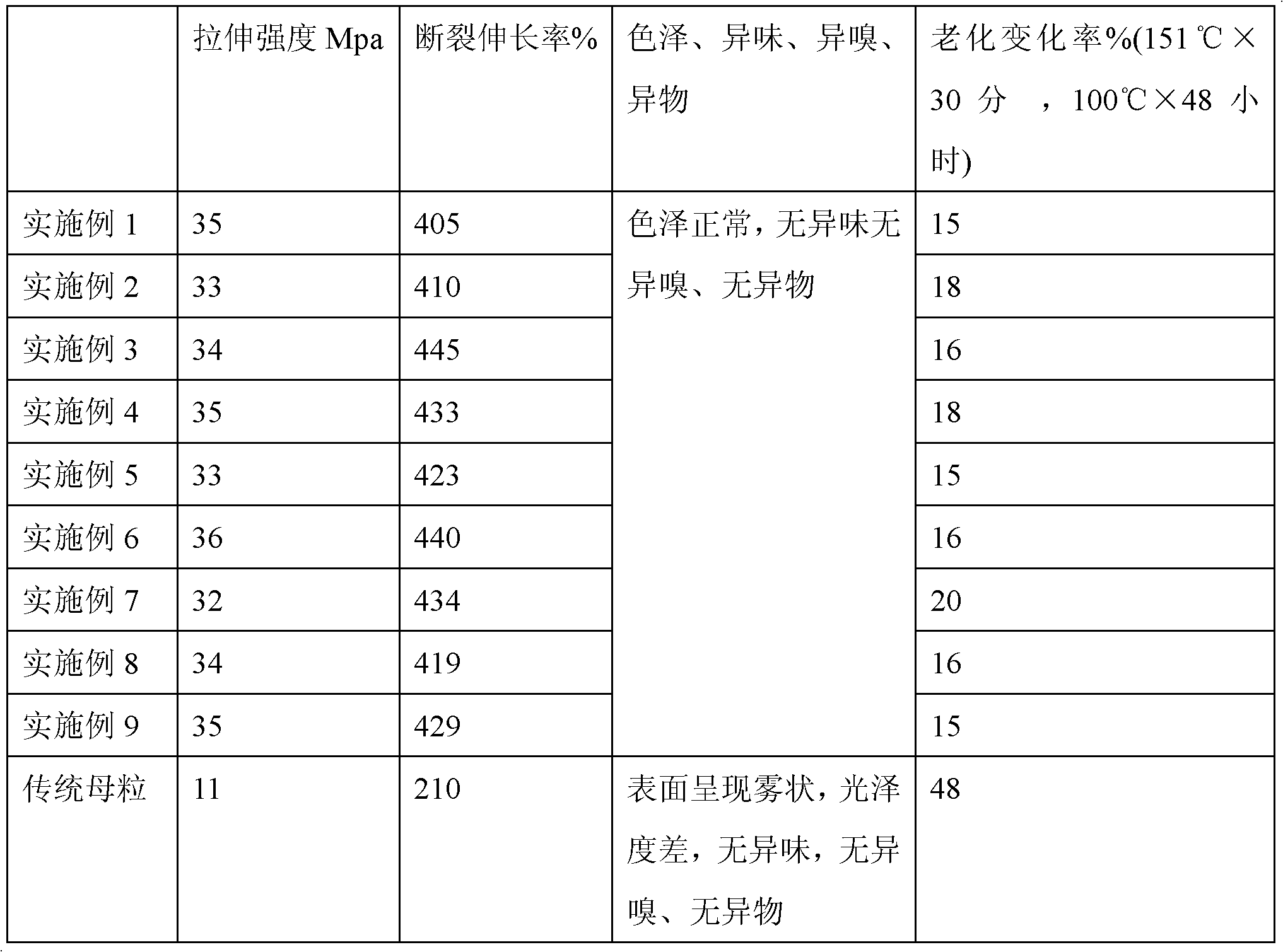

Plastic filling master batch and preparation method thereof

The invention relates to a plastic filling master batch, which contains carrier resin, terephthalic acid metal salt, silane coupling agent and lubricating agent. The carrier resin is selected from new plastic or reprocessed plastic; the terephthalic acid metal salt is selected from one or more of sodium terephthalate, magnesium terephthalate, zinc terephthalate, potassium terephthalate, sodium terephthalate, barium terephthalate, lead terephthalate, aluminum terephthalate and ferric terephthalate; the silane coupling agent is selected from one or more of bis(gamma-triethoxysilylpropyl) tetrasulfide, bis-(triethoxysilylpropyl) disulfide and gamma-chloropropyl triethoxysilane; and the lubricating agent is selected from one or more of paraffin, white oil and stearic acid. The invention also relates to a preparation method for the filling master batch. Through the filling master batch provided by the invention, a plastic product has good surface glossiness and is not easily aged, and the tensile strength and the impact strength of the product are improved.

Owner:江苏爱特恩高分子材料有限公司

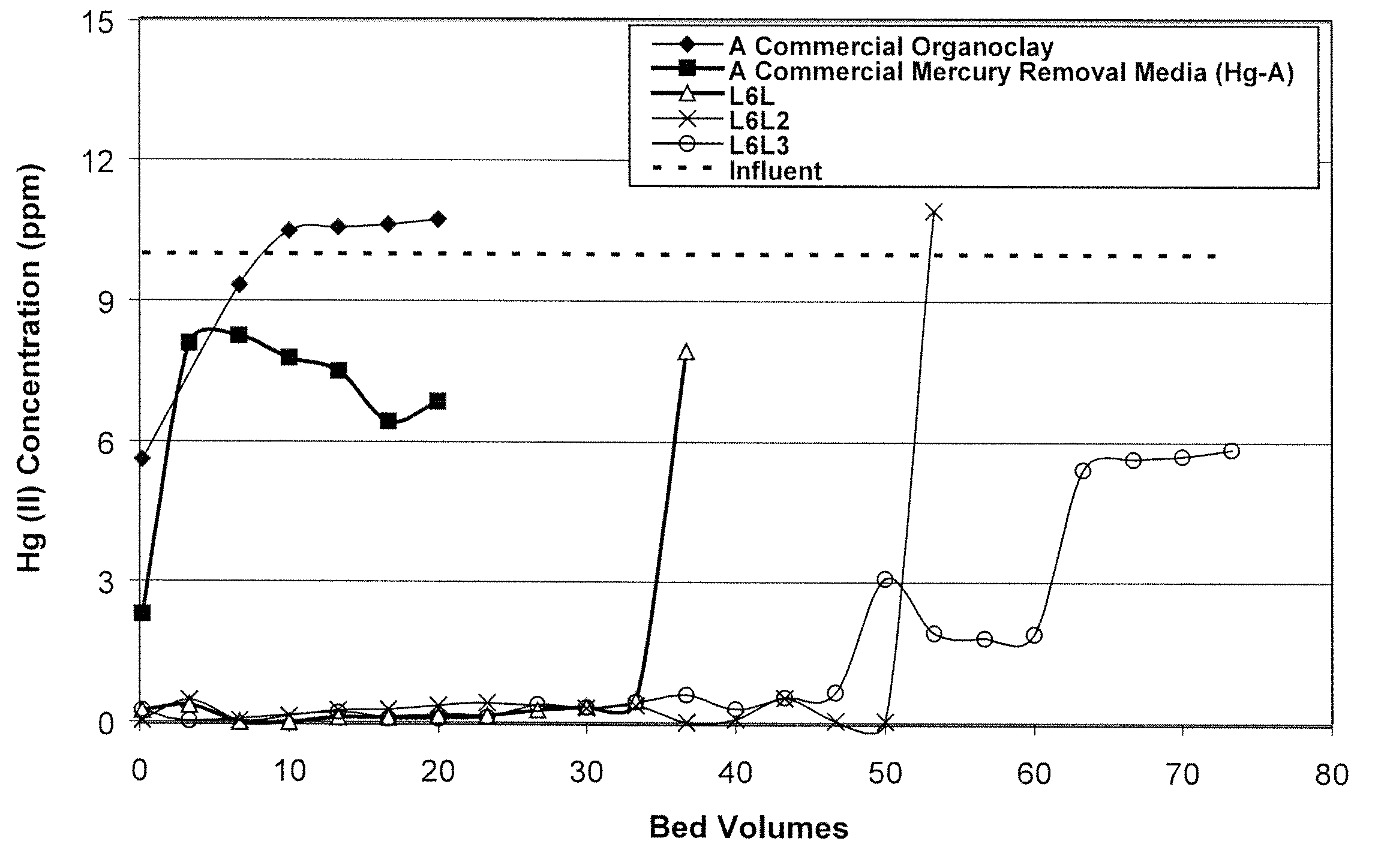

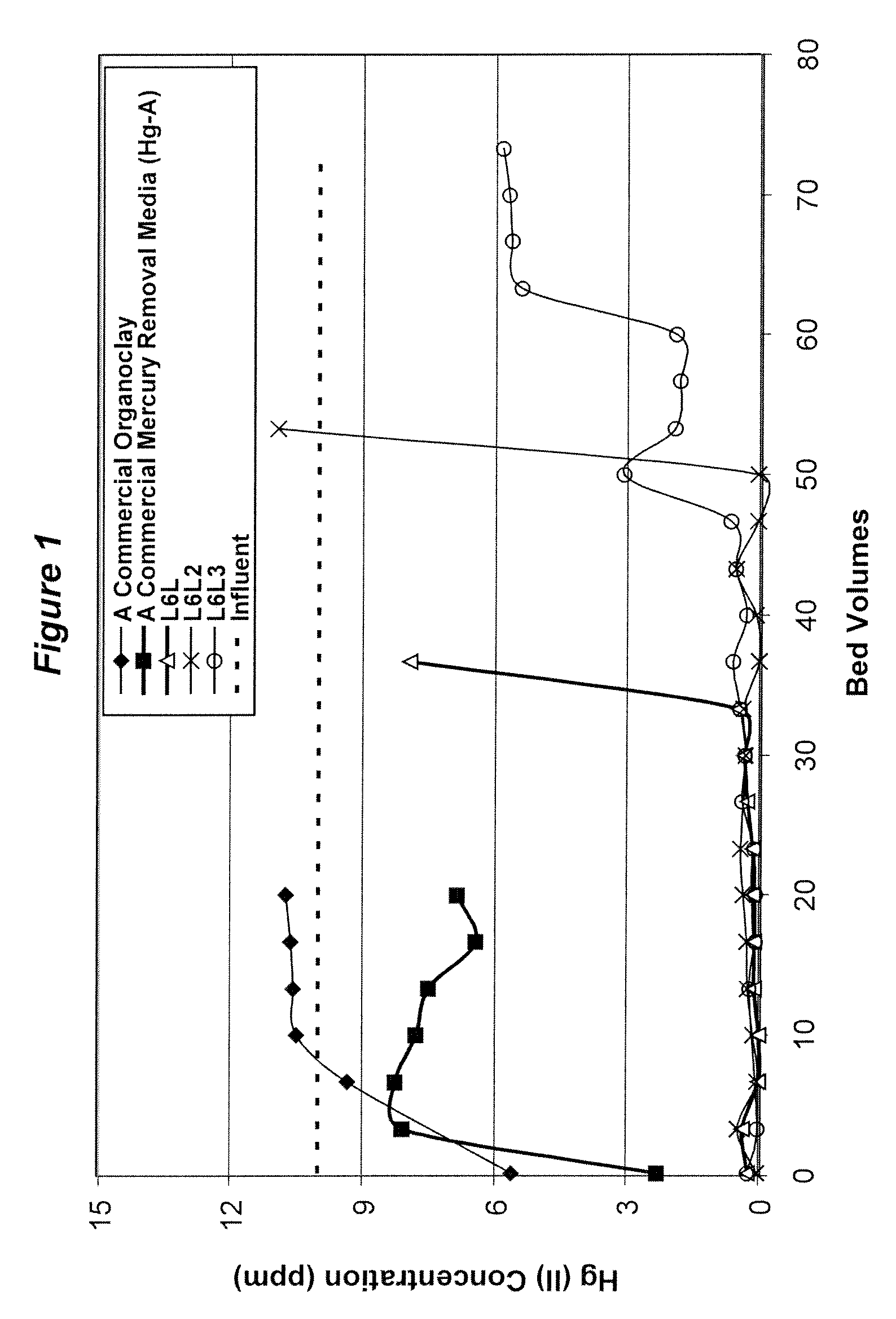

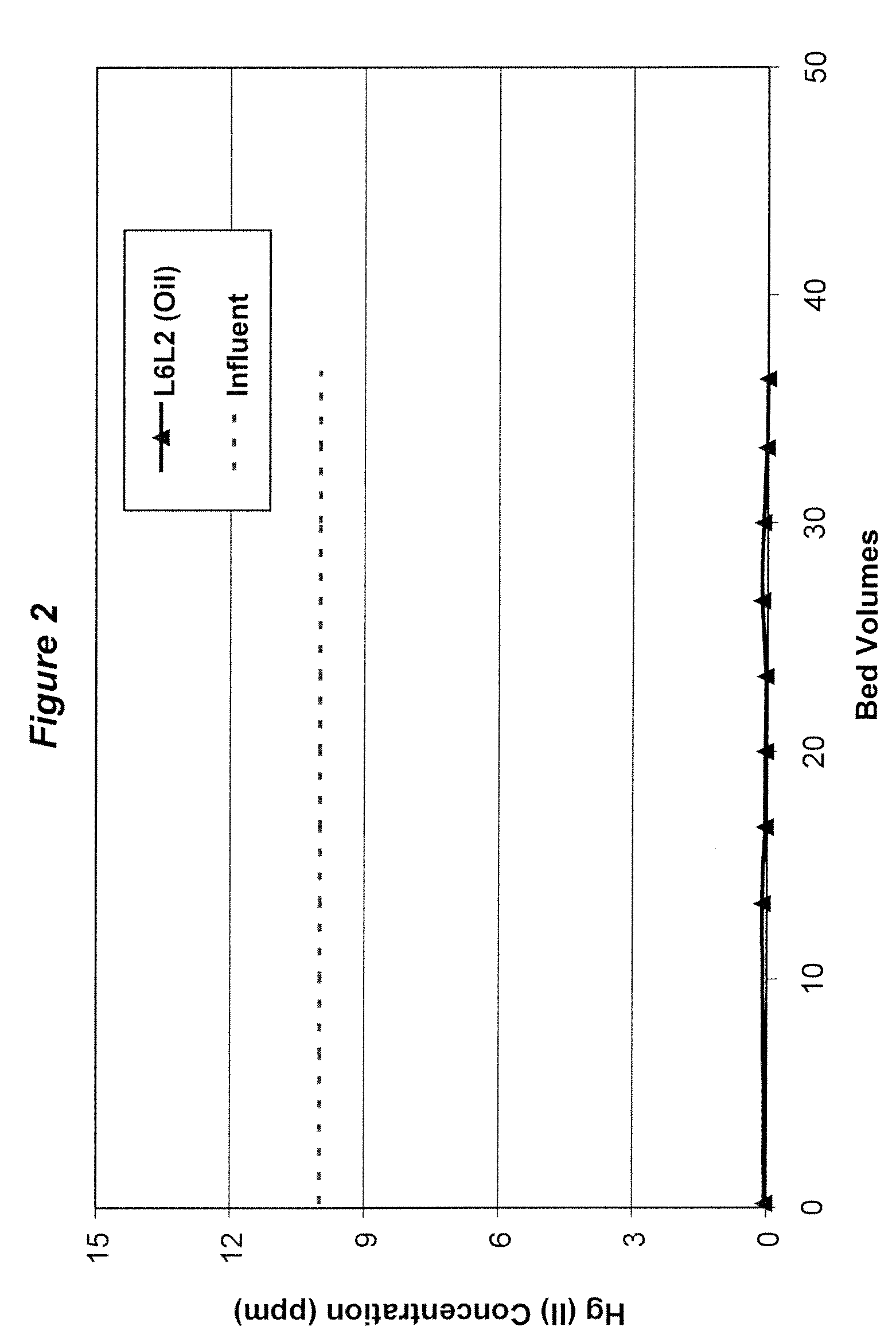

Coupling agent-reacted mercury removal media

InactiveUS20080302733A1Improve abilitiesHigh reactivityWaste water treatment from quariesGas treatmentBisulfideEnd-group

The use of a coupling agent containing a mercapto, disulfide, tretrasulfide and / or polysulfide end group provides a mercury removal media having increased reactivity, stability, and mercury removal ability. The mercury removal media described herein is prepared by reacting an organophilic clay containing onium ions with a mercapto, disulfide, tetrasulfide, and / or polysulfide end moiety. Alternatively, the clay can be made organophilic by onium ion reaction prior to or simultaneously with the coupling reaction of the mercapto- or sulfide-end group-containing coupling agent.

Owner:AMCOL INTERNATIONAL CORPORATION

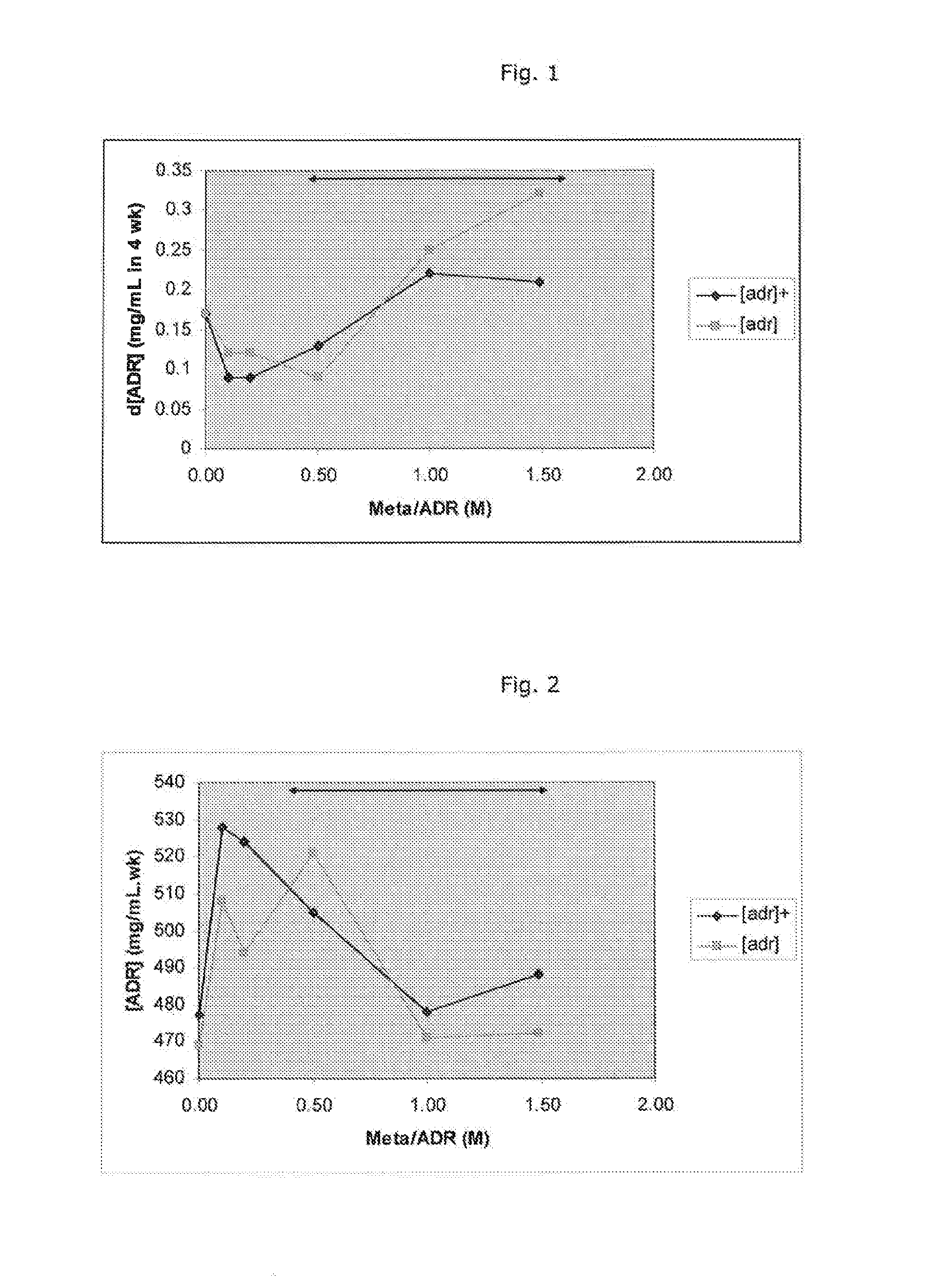

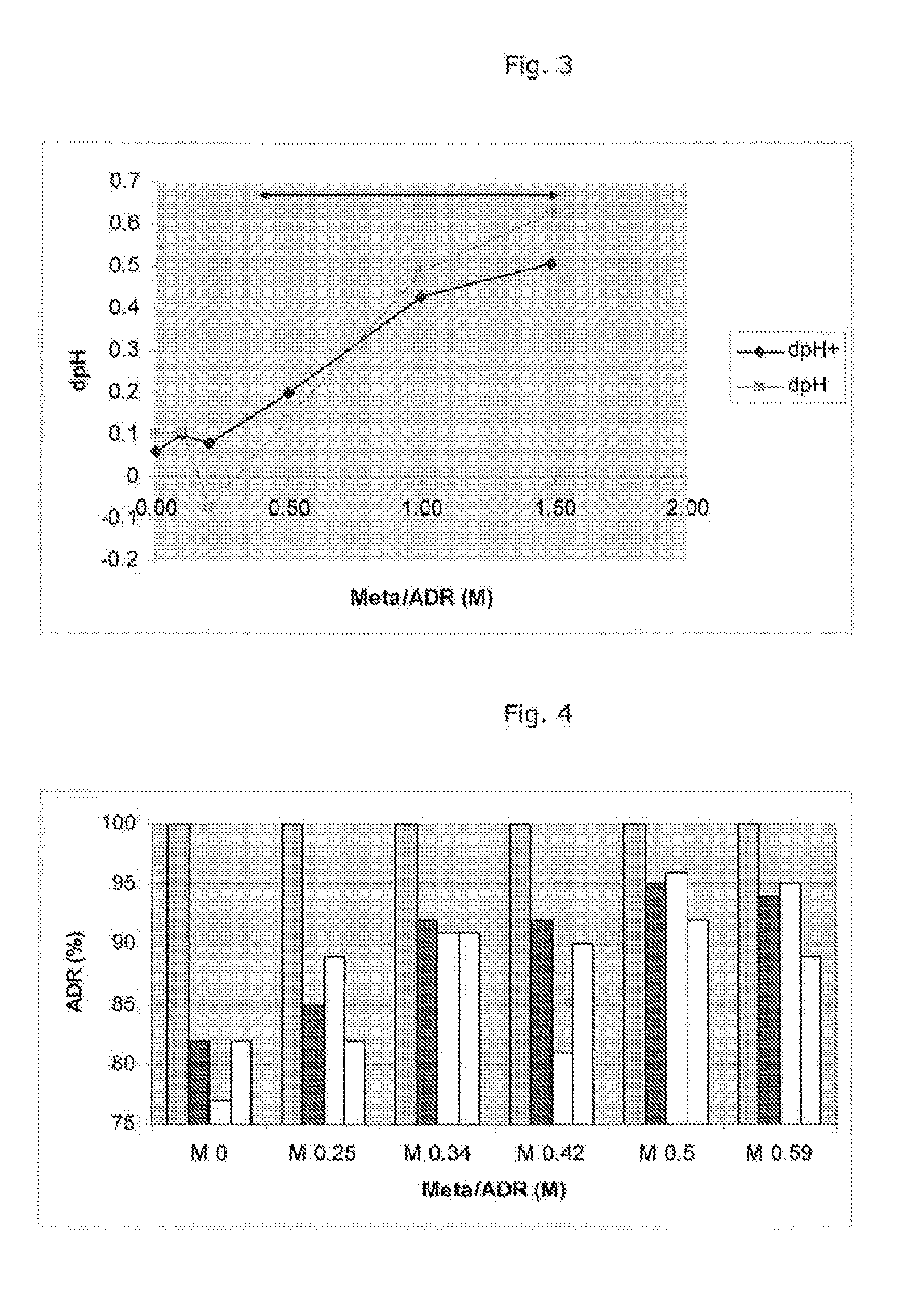

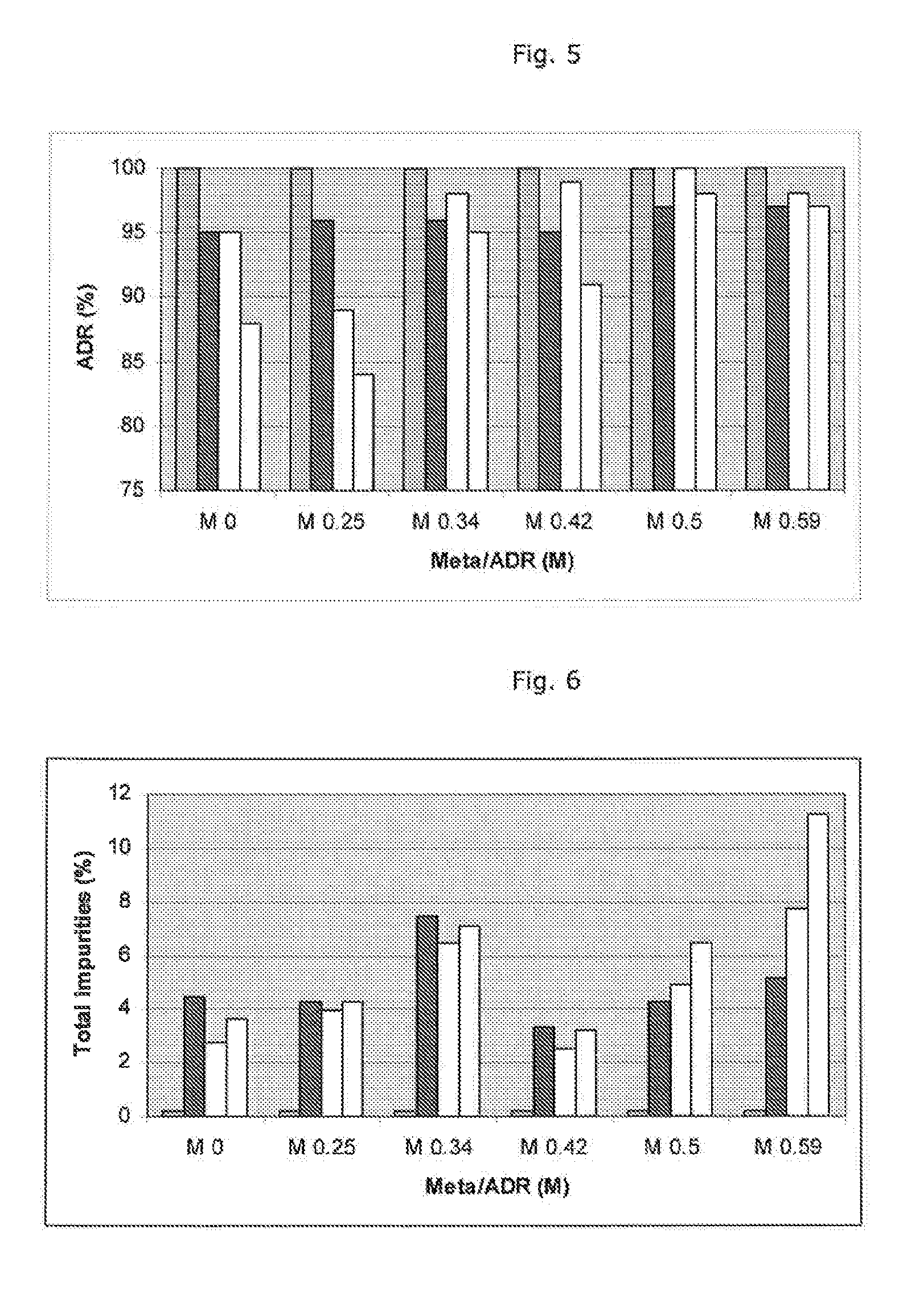

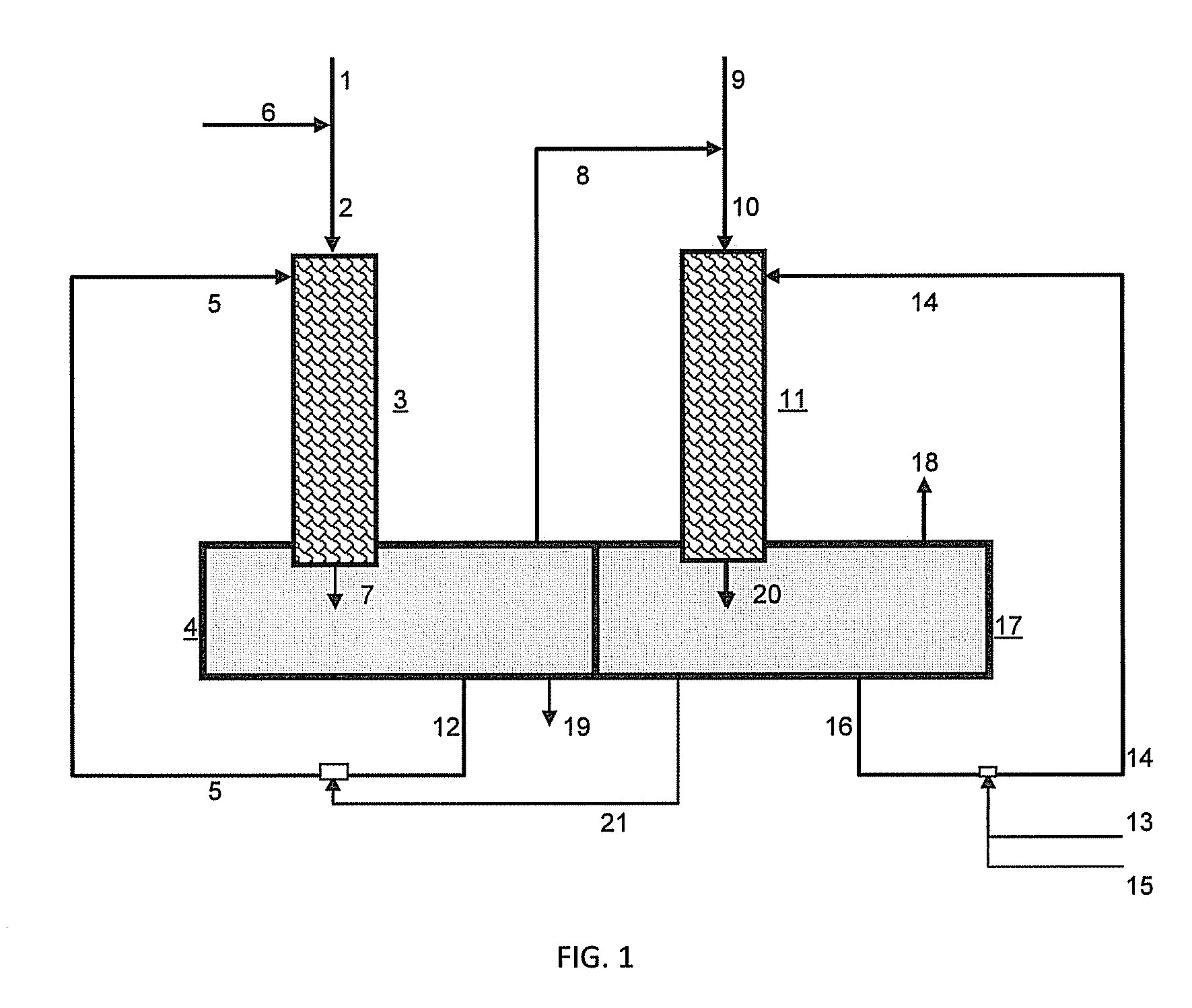

Stabilized composition comprising at least one adrenergic compound

ActiveUS20120129944A1Improve stabilityExtended shelf lifeBiocideOrganic active ingredientsCompound aBisulfide

A stabilised composition comprising at least one adrenergic compound and at least one antioxidant selected from the group consisting of a bisulfite, a metabisulfite and a sulfite compound.

Owner:ALK ABELLO SA

Composition with capability of providing thermal stability for polymer and application of composition

The invention relates to a composition with the capability of providing the thermal stability for polymer and application of the composition. The composition is prepared from the following raw materials: (1) hindered phenol, (2) phosphate or thioester, (3) an acid-removing agent and (4) sulfite, bisulfate or sulfide, wherein the mass ratio of hindered phenol, phosphate or thioester, the acid-removing agent and sulfite, bisulfate or sulfide is 1:(1-4):(0.5-2):(0.5-3). The invention also provides the application of the composition serving as an antioxidant in polymer resin. The composition is capable of lowering the melt index of polyolefin, eliminating a quinones compound serving as an intermediate and lowering the yellow index of polyolefin.

Owner:INST OF CHEM CHINESE ACAD OF SCI

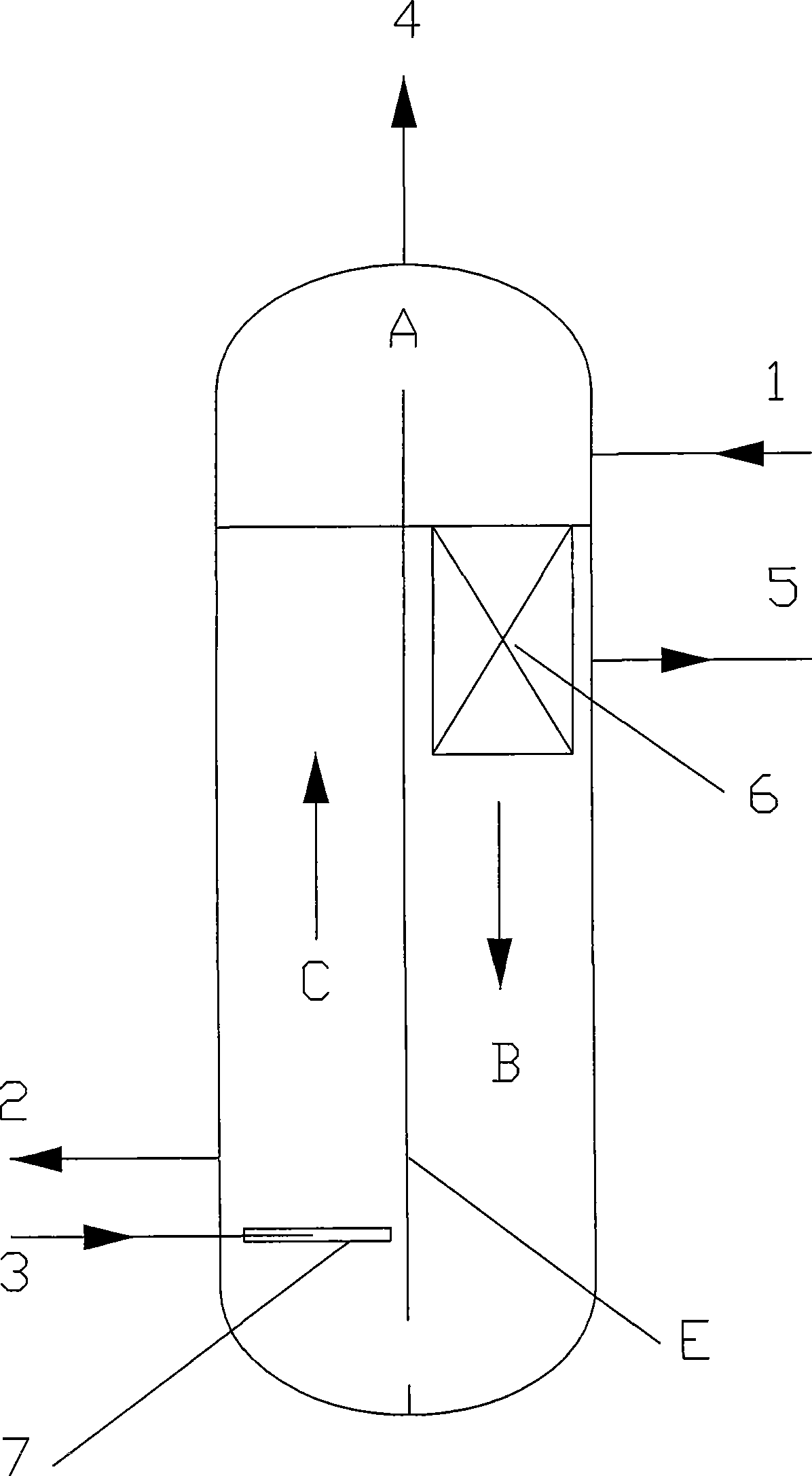

Hydrocarbon Treatment Process

InactiveUS20110127194A1Rapid liquid-liquid mass transferReduce entrainmentOther chemical processesRefining with oxygen compoundsBisulfideThiol

In a catalytic treatment process, mercaptans in sour hydrocarbon are oxidized to disulfide oils using an aqueous treatment solution containing a chelated polyvalent metal catalyst, alkali metal hydroxide, and the alkali metal salt of at least one alcohol in a non-dispersive mixing apparatus wherein an upgraded hydrocarbon containing the disulfide oils is produced.

Owner:MERICHEM CO

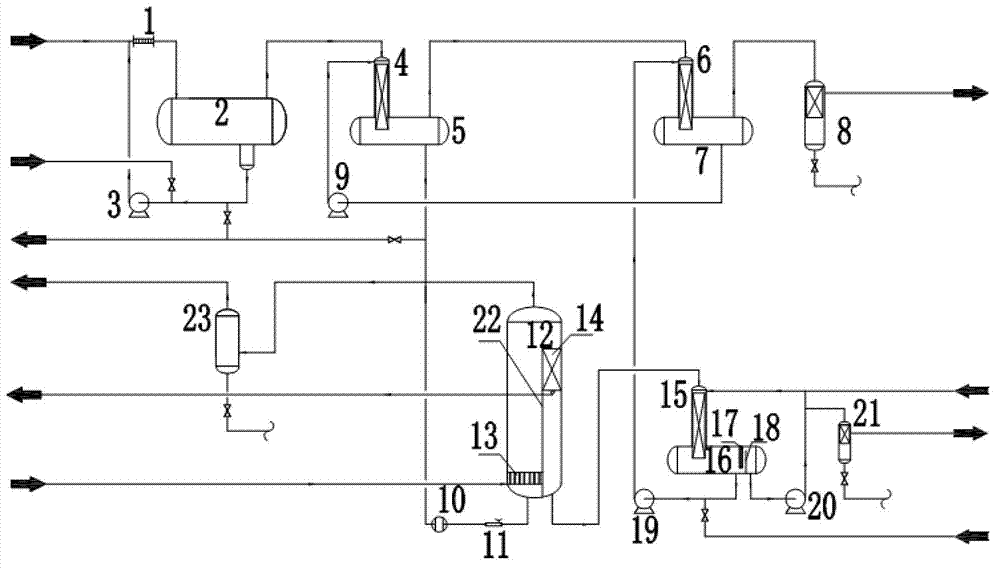

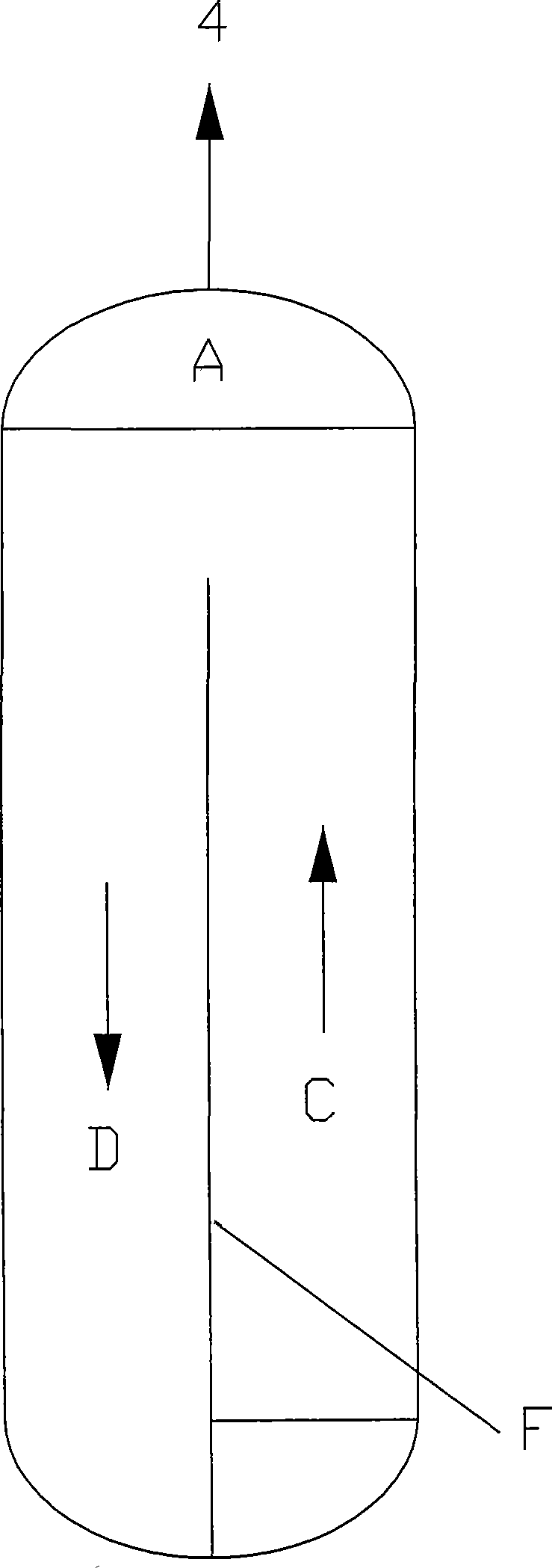

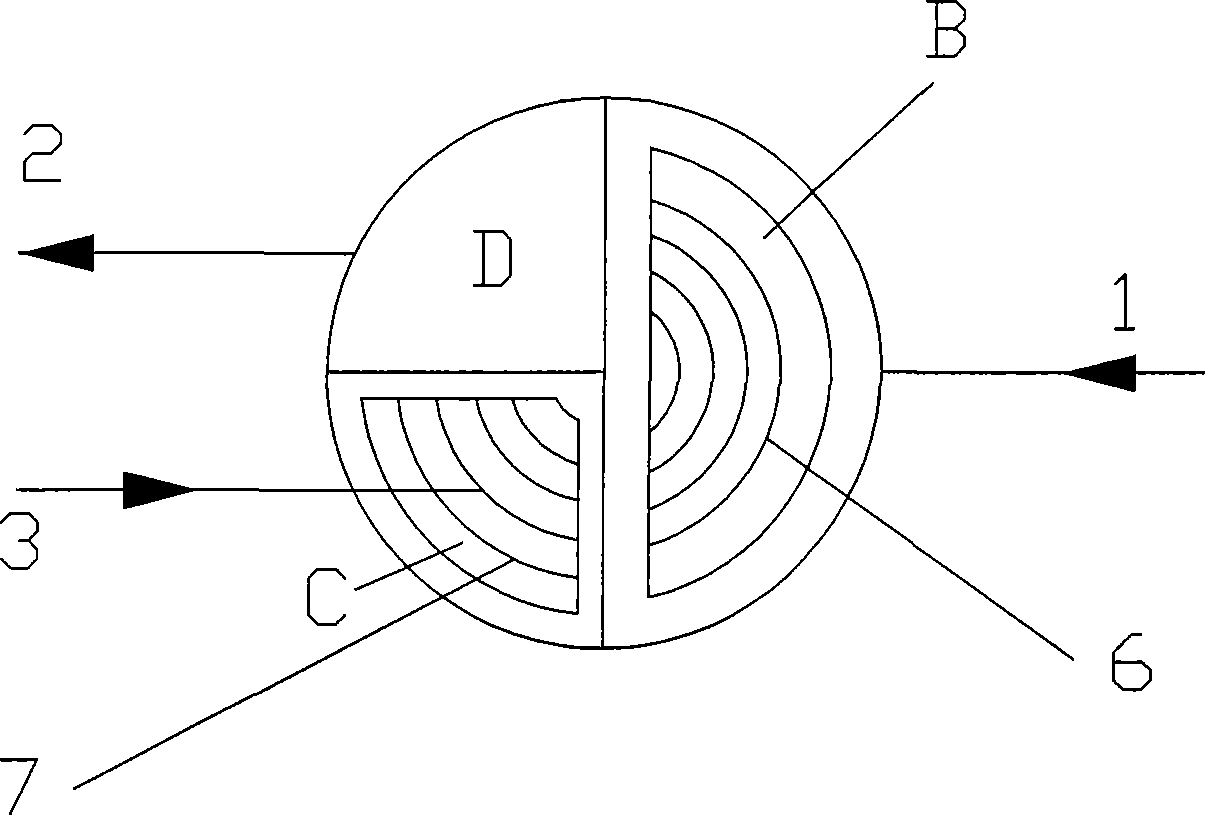

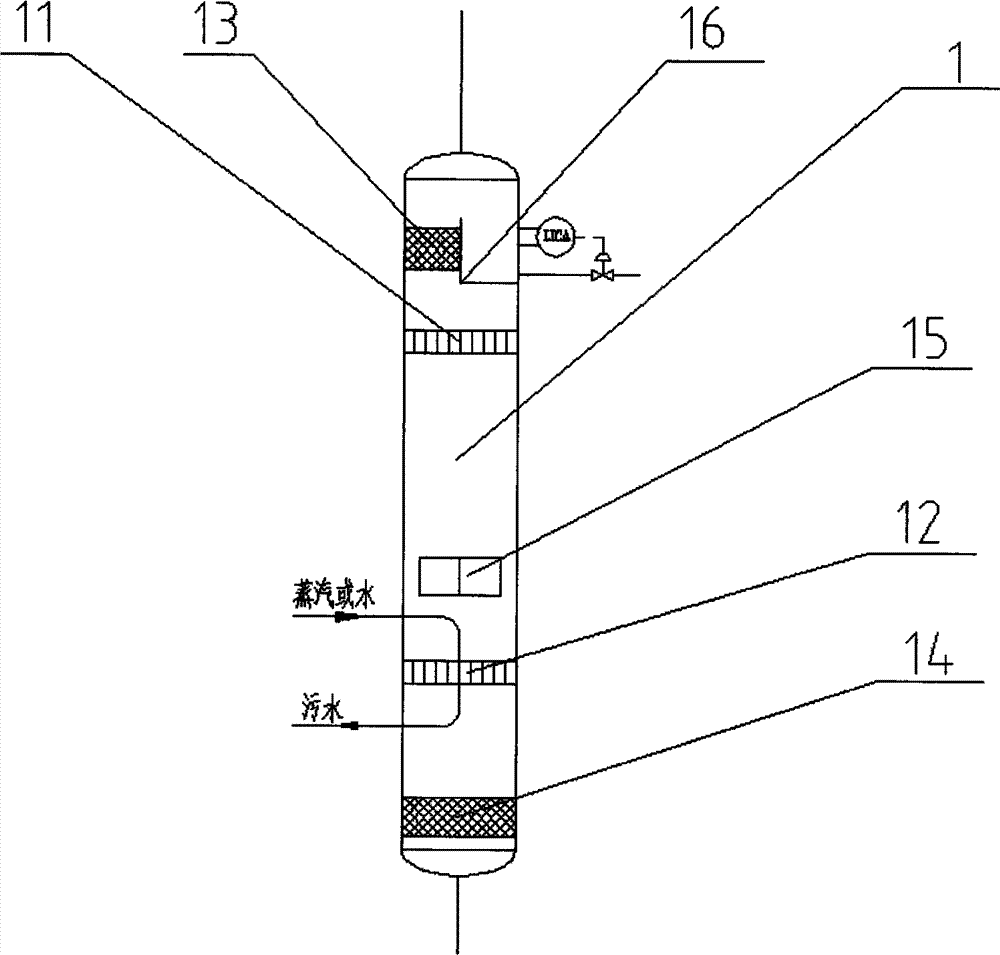

Oil-containing alkali liquor separation apparatus and method

ActiveCN101469276AImprove cleanlinessReduce contentLiquid separationRefining with aqueous alkaline solutionsBisulfidePhase separation process

The invention relates to an oil-contained lye separating device, which at least comprises a device shell and is characterized in that the upper space of the device shell is a tail gas separation zone provided with a tail gas outlet, and the circumferential surface of the middle-lower space of the device shell is at least distributed with an oil-alkali separation zone provided with an oxidized lyeinlet and a gas stripping separation zone, wherein an oil phase aggregation separating device and an oil phase outlet are arranged in the oil-alkali separation zone which is communicated with the bottom of the gas stripping separation zone; a gas distributor and a gas stripping gas inlet connected therewith are arranged in the gas stripping separation zone; and the device shell is provided with aregenerated lye outlet. A method comprises the following steps: adopting the oil phase aggregation separating device to perform oil-alkali separation on the oxidized lye in the oil-alkali separation zone, and then using the gas distributor to perform gas stripping in the gas stripping zone so as to obtain the regenerated lye through a lye stabilization zone, wherein the tail gas zone is communicated with other zones so as to exhaust the tail gas after the treatment. The oil-contained lye separating device integrates the separation processes of the three phases including the tail gas generatedin the lye regeneration process, the lye and disulphide into a whole; the cleanliness of the lye obtained through separation is improved, the content of the disulphide is low, and the separation effect is good; besides, the oil-contained lye separating device has the advantages of more compact structure, small volume, and reasonable and practical process.

Owner:NINGBO ZHONGYI PETROCHEM TECH

Method for separating and refining etherification material from catalytic cracking gasoline

A process for separating the raw esterifying material from catalytically cracked gasoline and refining it includes such steps as introducing said gasoline to catalytic distilling tower, contacting with thiol-removing catalyst while fractionating to convert thiol to bisulfide, discharging the bisulfide and heavy component from tower bottom and the light gasoline rich in C5-C6 isomerized olefine from tower top, removing N-contained compound from said light gasoline by denitrifying absorption bed, and selective hydrogenating for removing biolefine.

Owner:CHINA PETROLEUM & CHEM CORP +1

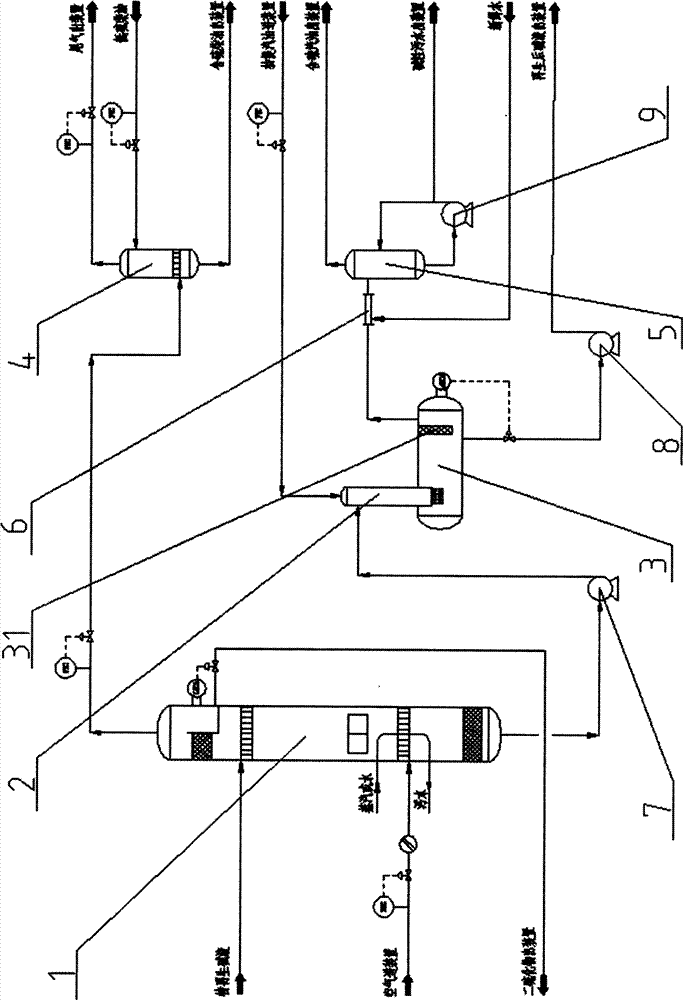

Method and device for deep oxidation of sweetening alkali liquor and separation of disulfide

InactiveCN104263403AFully contactedQuality improvementHydrocarbon oils refiningHydrocarbon oils treatmentFiberBisulfide

The invention relates to a method and a device for deep oxidation of sweetening alkali liquor and separation of disulfide. The method comprises the following steps: a, alkali liquor oxidation; b, primary separation; c, deep extraction; d, oil-gas separation; and e, oil-alkali separation. By using a liquor distributor and an air distributor, the alkali liquor is in full contact with the oxygen and the oxidation conversion speed; the disulfide is deeply extracted through a fibrous membrane extraction contactor, so that the contact area is enlarged, the extraction depth is increased, the content of the disulfide in the alkali liquor is reduced to be below 200ppm, the quality of the regenerated alkali liquor is improved; the tail gas after the reaction is absorbed by a diesel absorption tank, so that the pollution of the disulfide to the atmosphere is decreased; and the gasoline after the extraction is washed, so that the influence of the residual alkali liquor to the gasoline hydrogenation is prevented. The method and the device are simple in process, energy-saving, environmentally friendly, good in device controllability, stable in operation, in accordance with the market requirement and suitable for large-scale popularization.

Owner:NINGBO ZHANGFU ENERGY TECH CO LTD

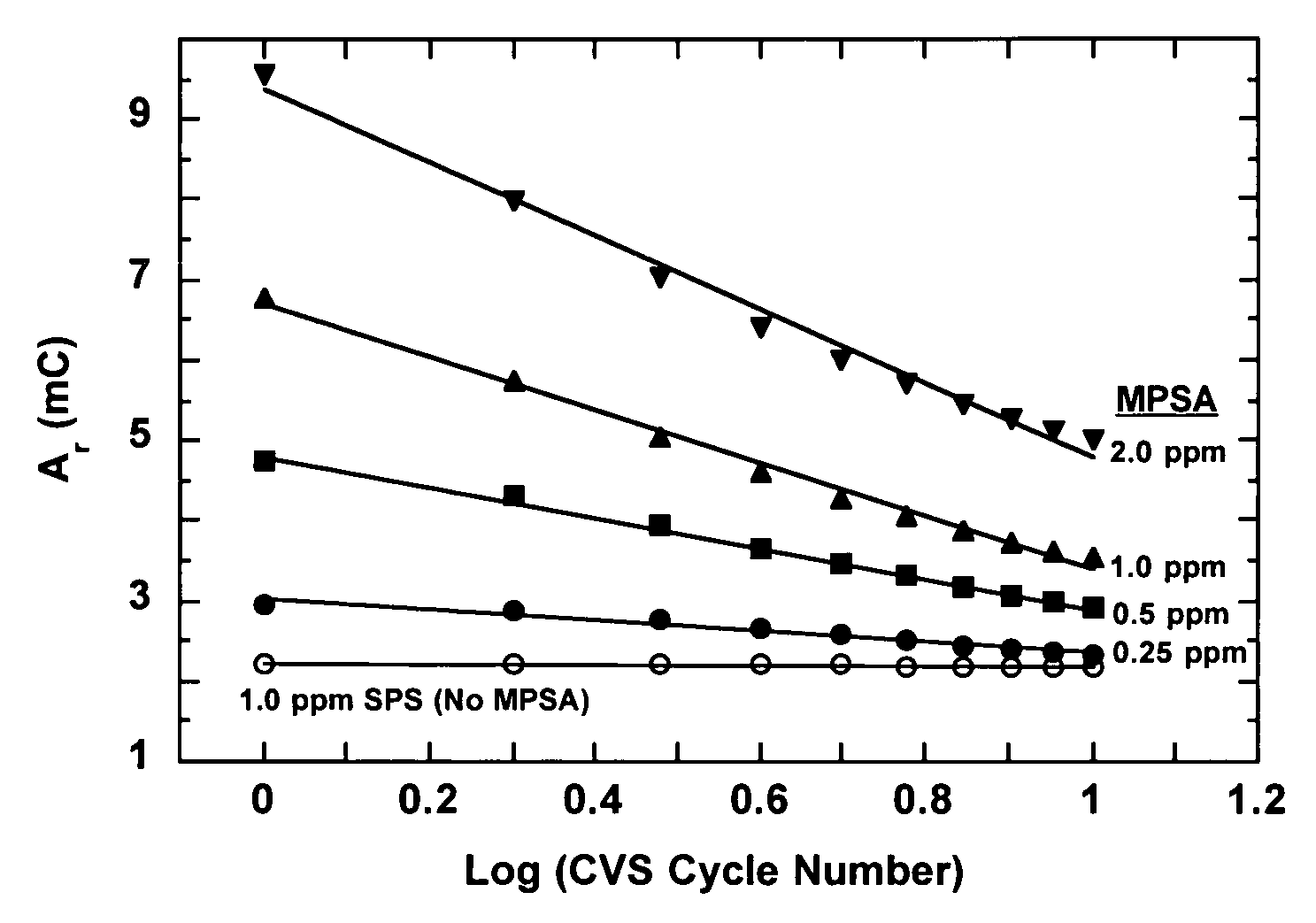

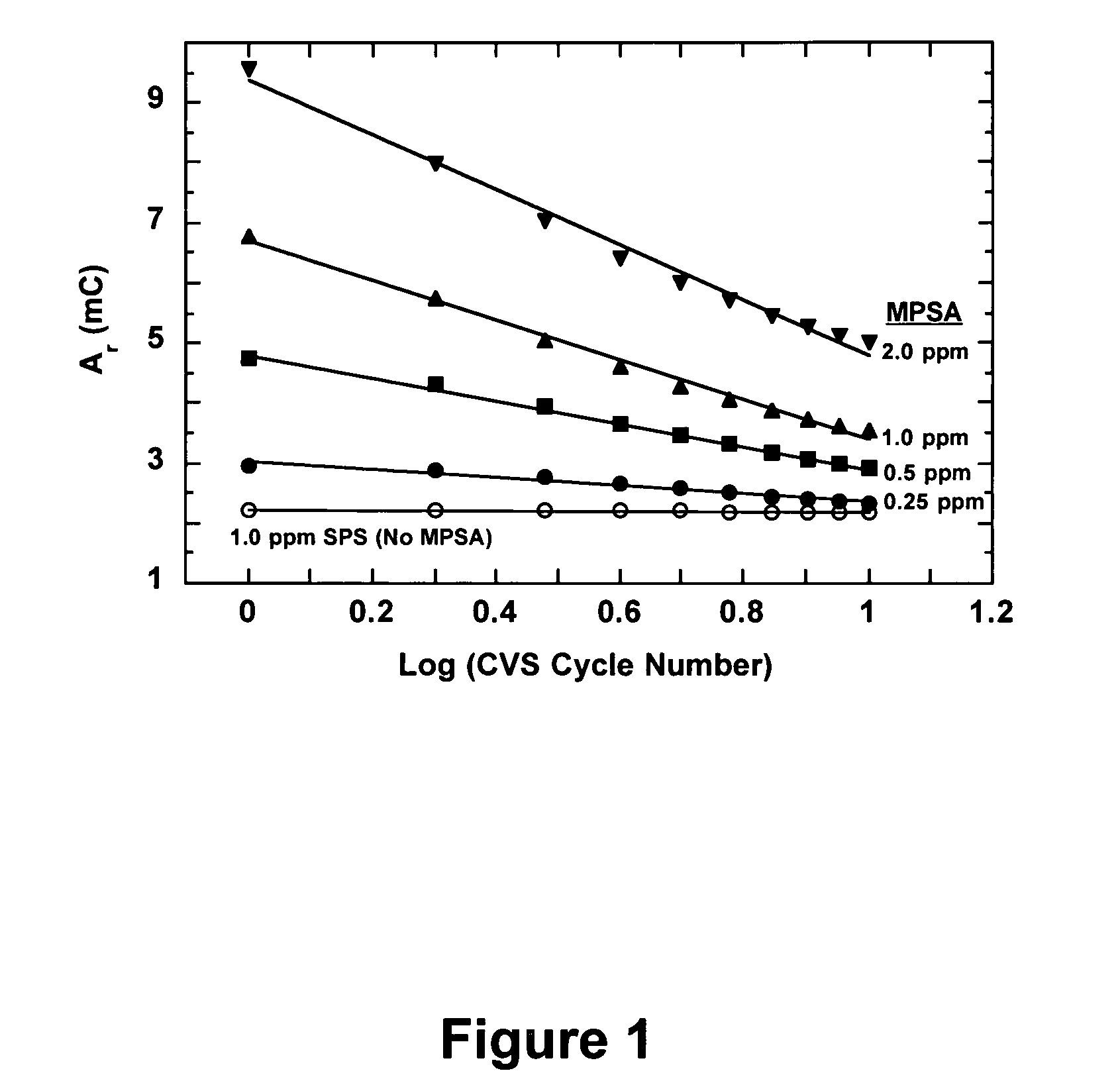

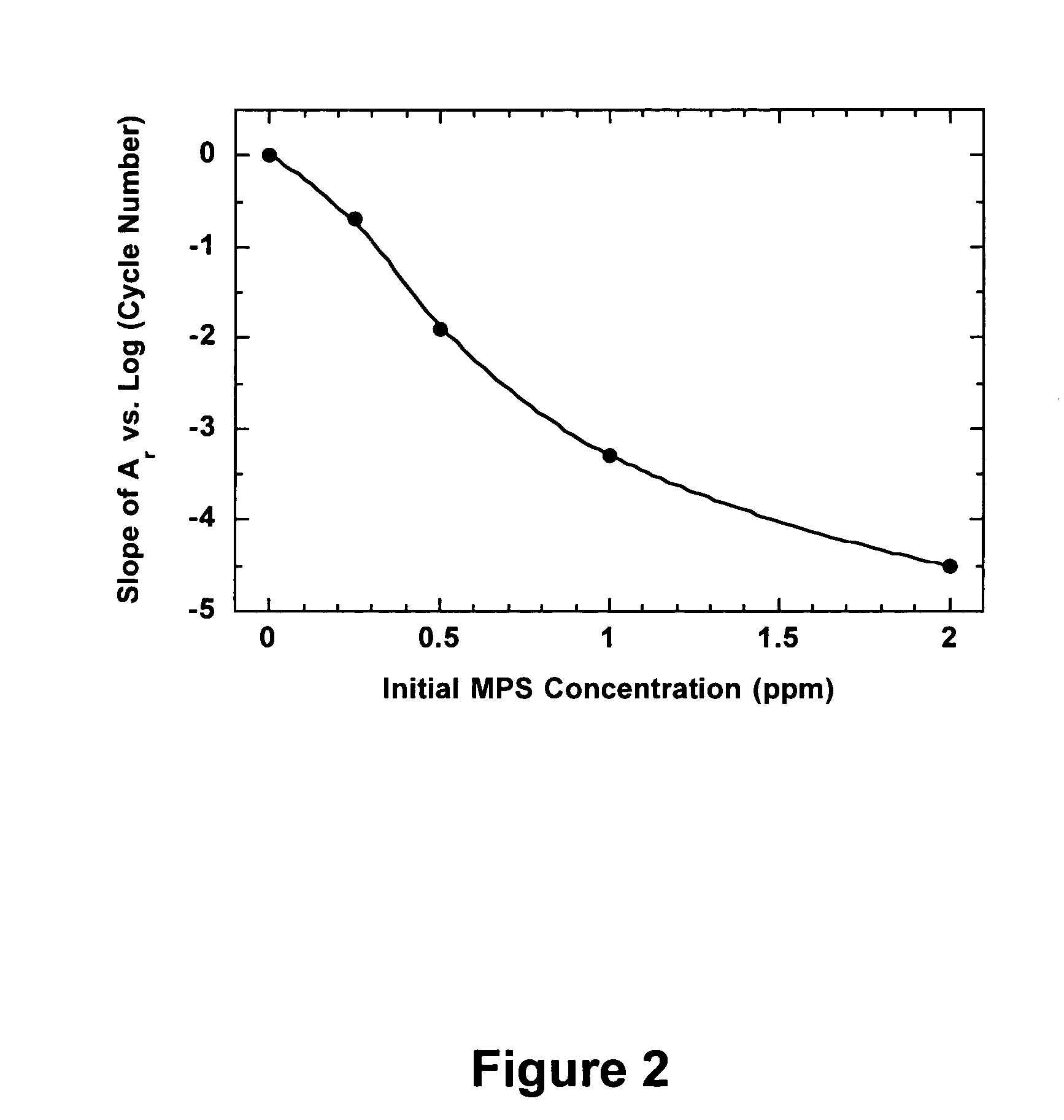

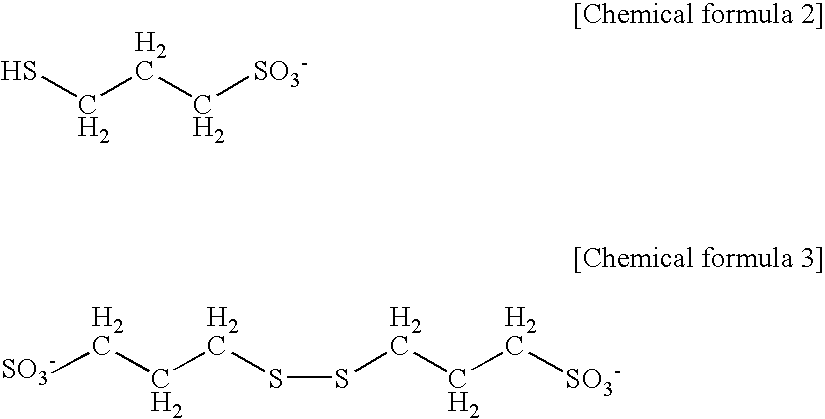

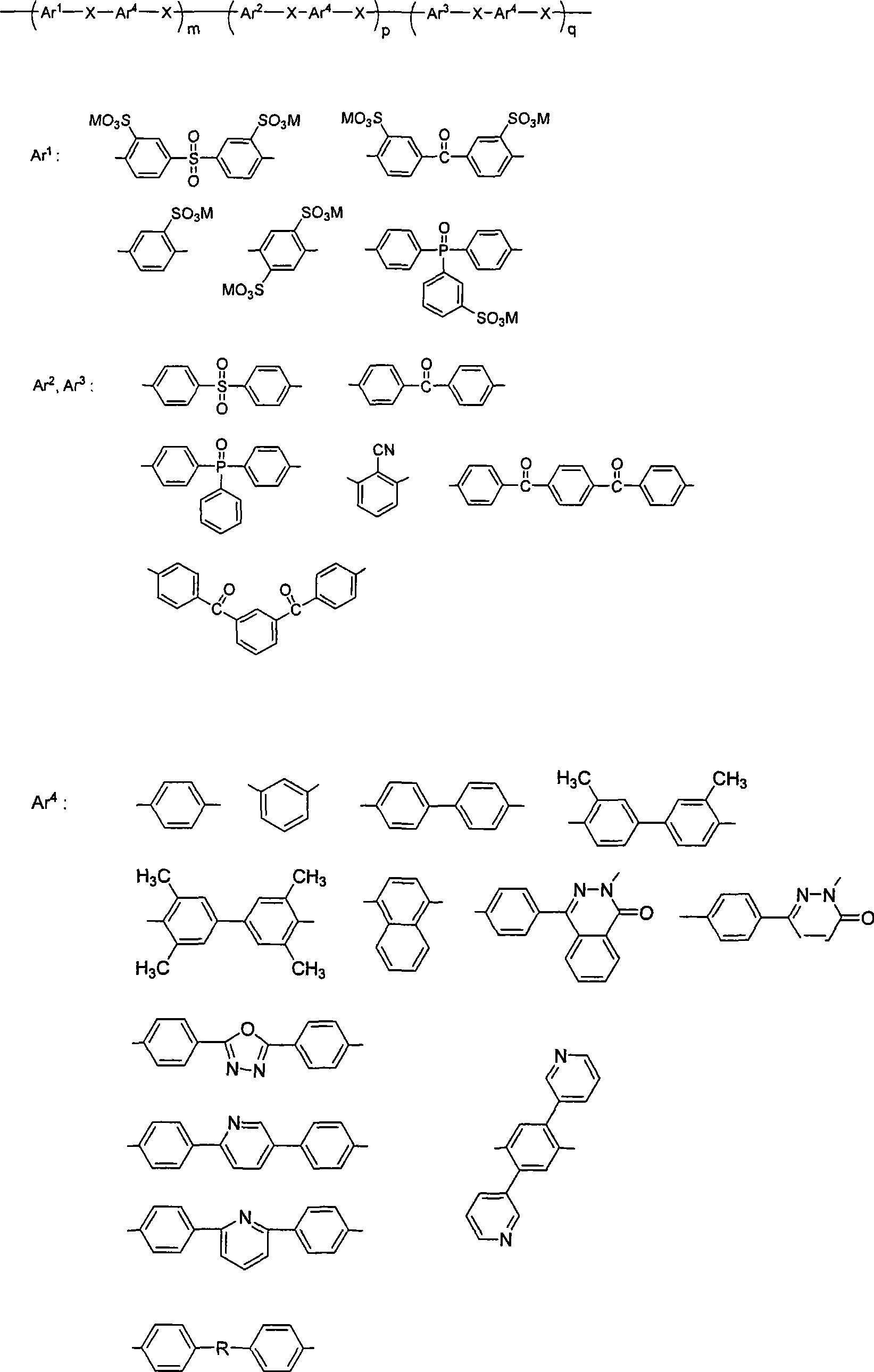

Detection of an unstable additive breakdown product in a plating bath

InactiveUS7291253B2Reduce consumptionPrevent buildupCellsWeather/light/corrosion resistanceElectricityBisulfide

The 3-mercaptopropylsulfonic acid (MPSA) breakdown product of the bis(sodiumsulfopropyl)disulfide (SPS) additive used in acid copper plating baths accelerates copper electrodeposition and can be detected by cyclic voltammetric stripping (CVS) analysis. In the presence of oxygen, MPSA decomposes rapidly in acid copper sulfate baths so that the CVS stripping peak area (Ar) decreases on successive cycles. The slope of a plot of Ar vs. CVS cycle number (or time) or logarithm of the CVS cycle number (or time) provides a measure of the initial MPSA concentration.

Owner:ECI TECH INC

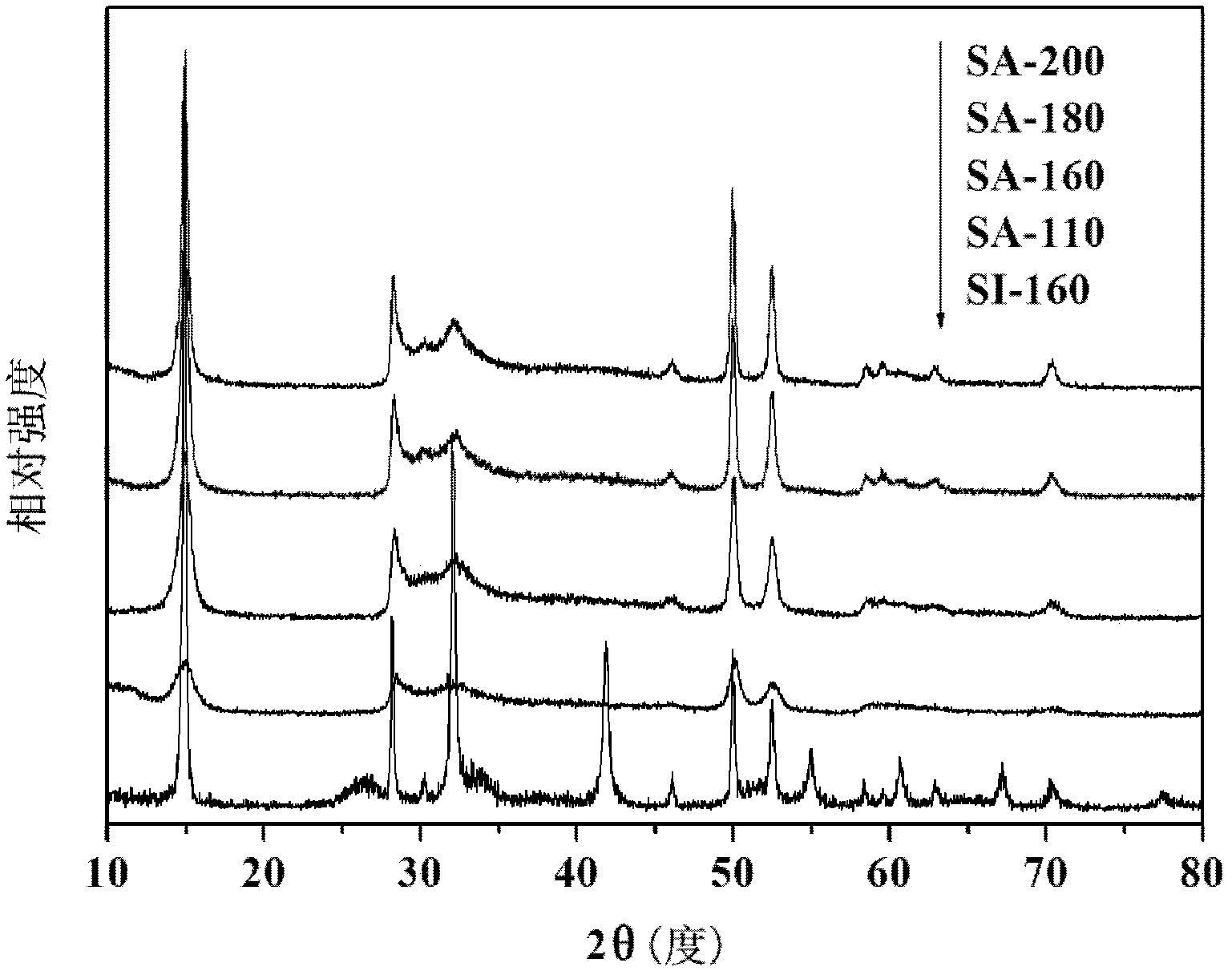

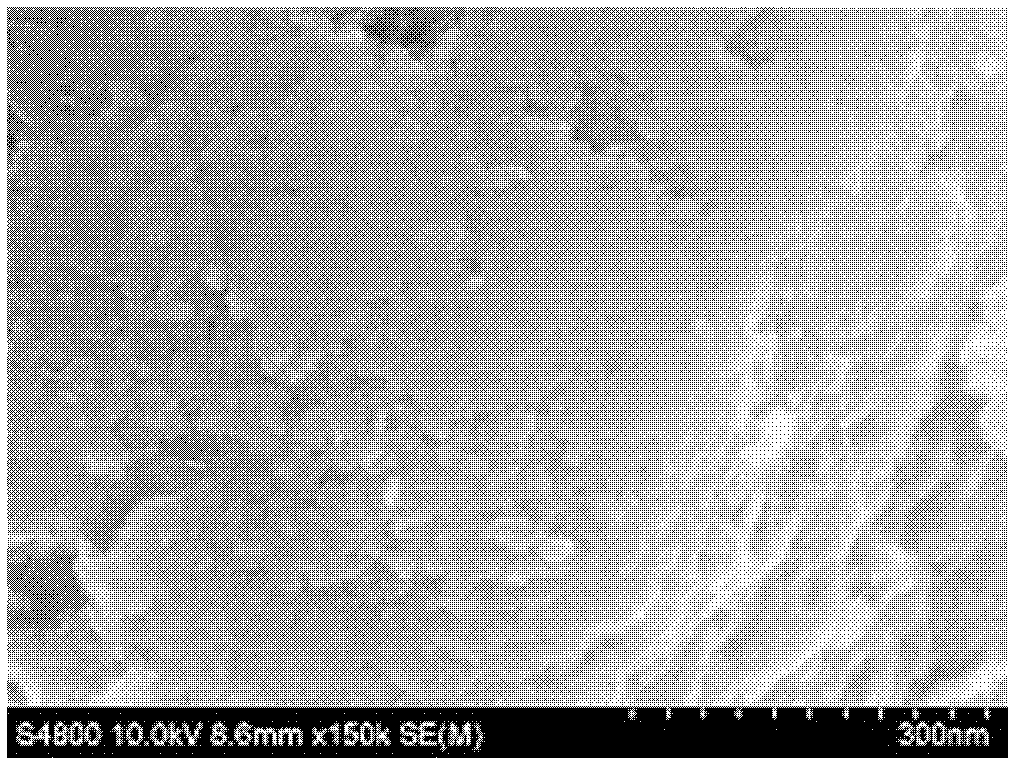

Preparation method of non-water-soluble transition metal disulphide nanosheets

InactiveCN105140517AQuality improvementUniform sizeMaterial nanotechnologyCell electrodesBisulfideThiourea

The invention relates to a preparation method of non-water-soluble transition metal disulphide nanosheets. The preparation method comprises the following steps that water-soluble salts containing transition metal elements are used as transition metal sources; thiourea is used as a sulphur source; the transition metal sources, the sulphur source and NaCl are added into deionized water to be dissolved according to the mol ratio of transition metal elements in the transition metal sources to the sulphur element in the sulphur source being 1: (1.8 to 2.5) and according to the mol ratio of the transition elements in the transition metal source to the NaCl being 1:(150 to 600); then, freezing and vacuum drying are performed to obtain a mixture; the prepared mixture is ground into powder; the powder is put into a tubular furnace constant-temperature region for calcination and chemical vapor deposition to obtain products; water washing and vacuum drying are carried out; the disulphide nanosheets are obtained. The disulphide nanosheets with the characteristics of high quality, uniform dimension, relatively controllable layer number, higher yield, lower relative preparing cost and the like can be obtained.

Owner:TIANJIN UNIV

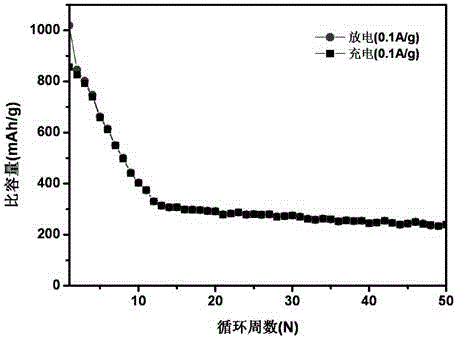

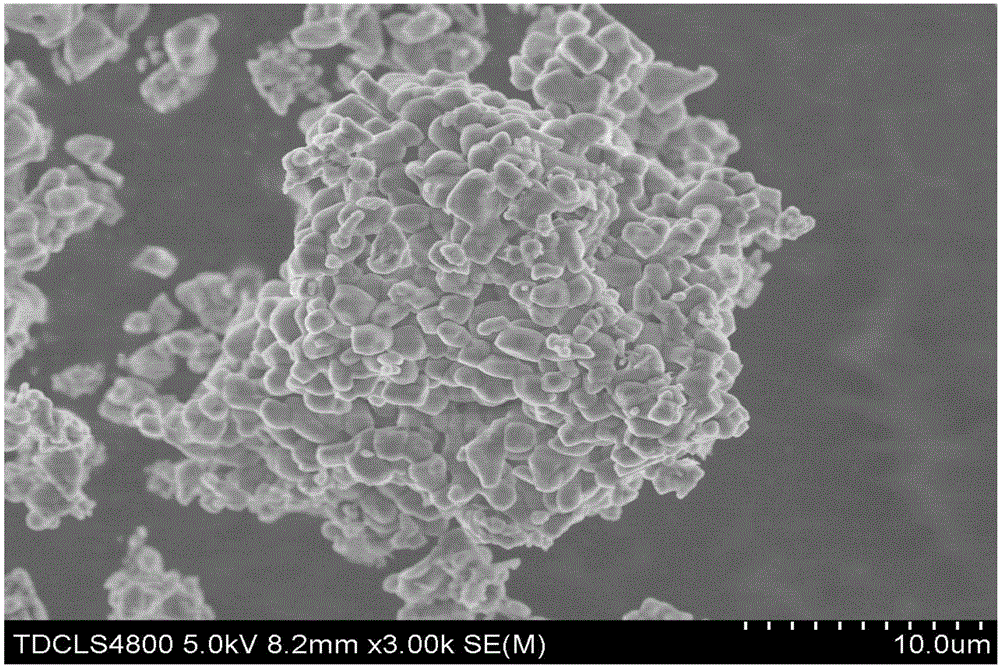

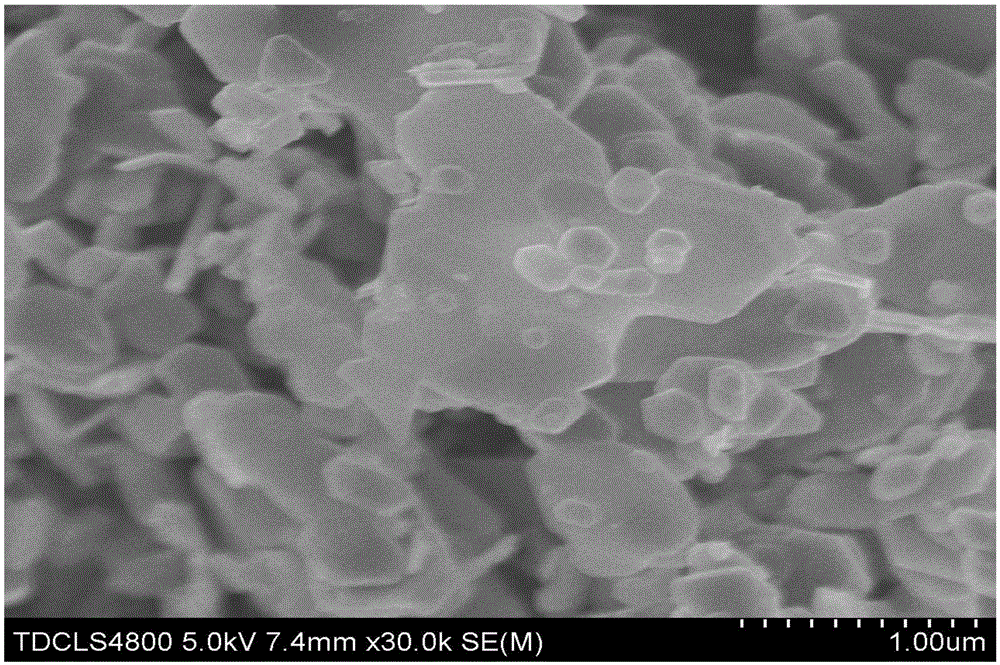

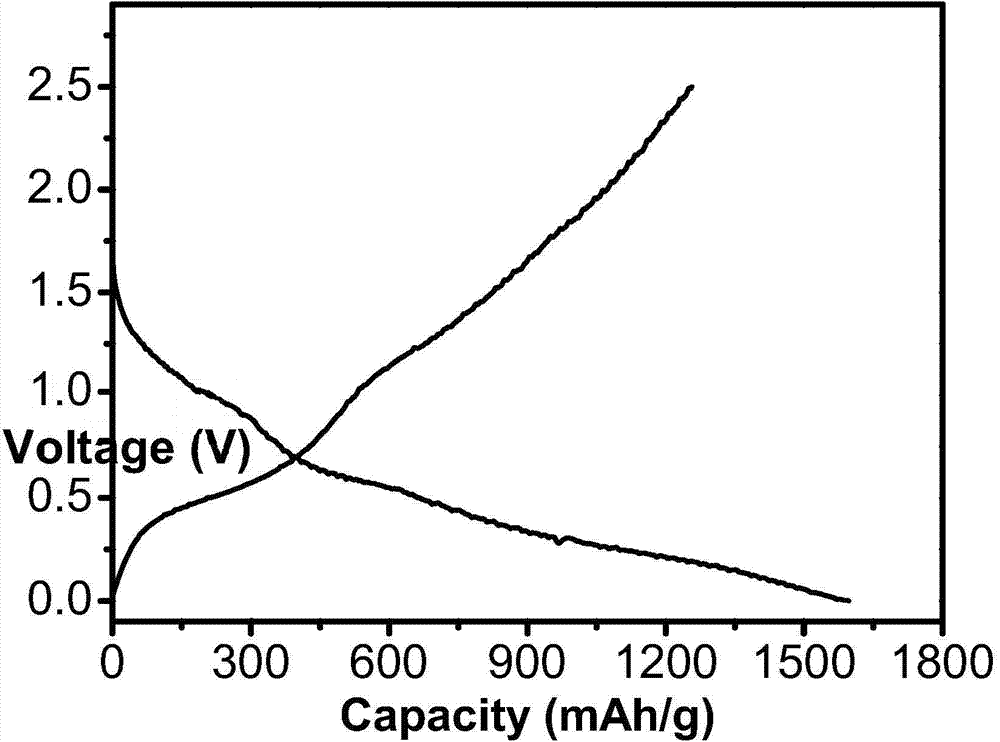

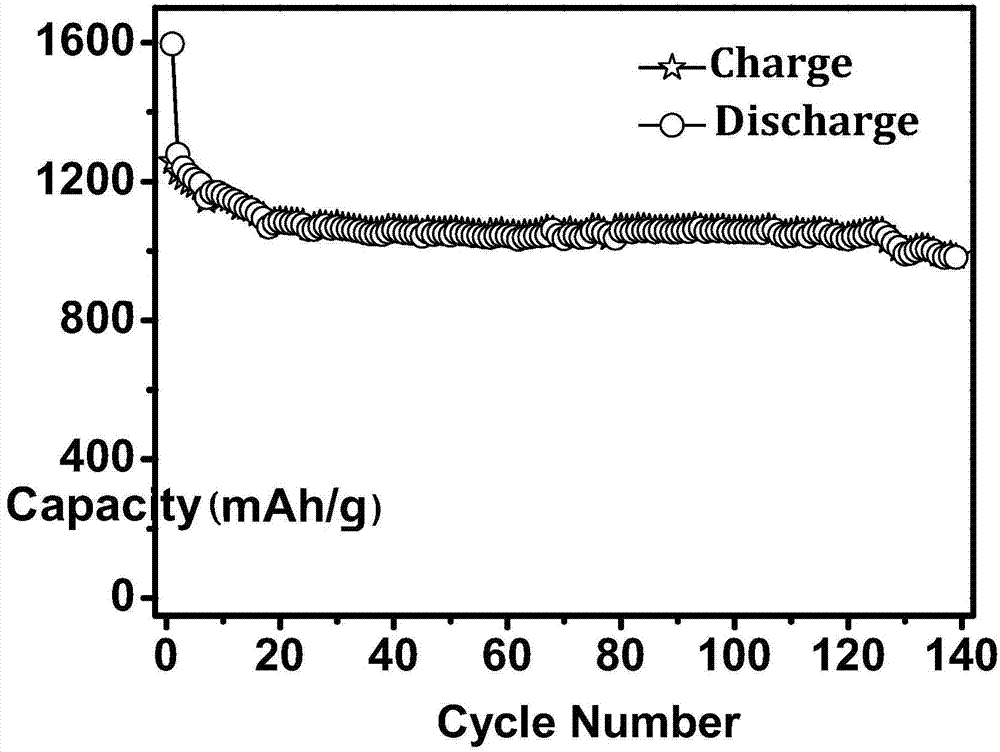

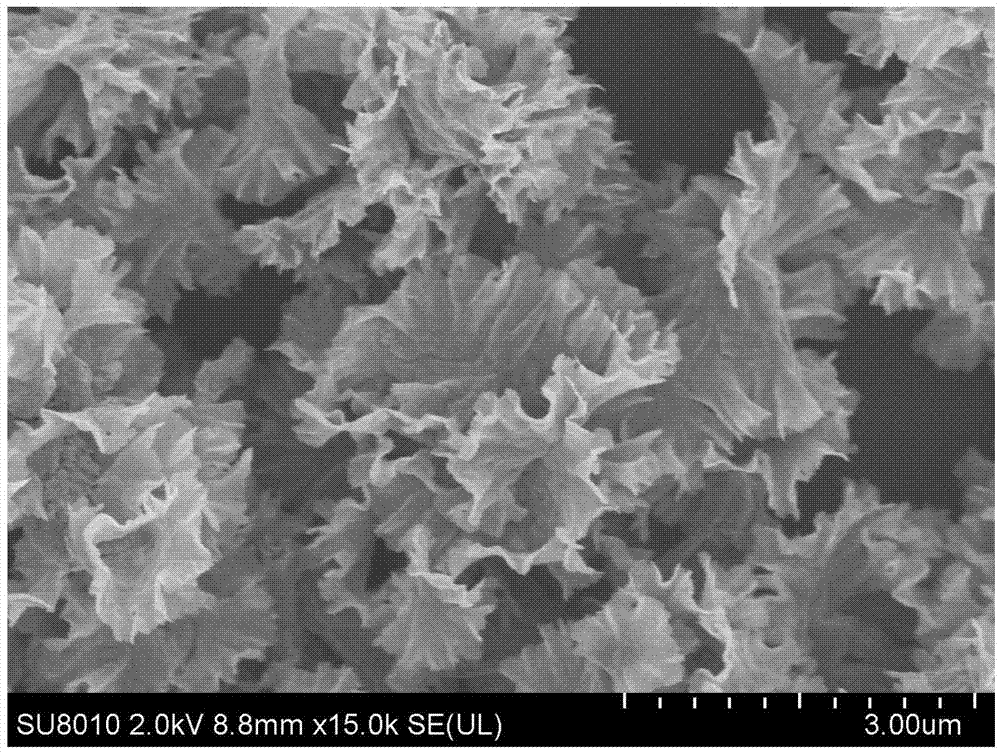

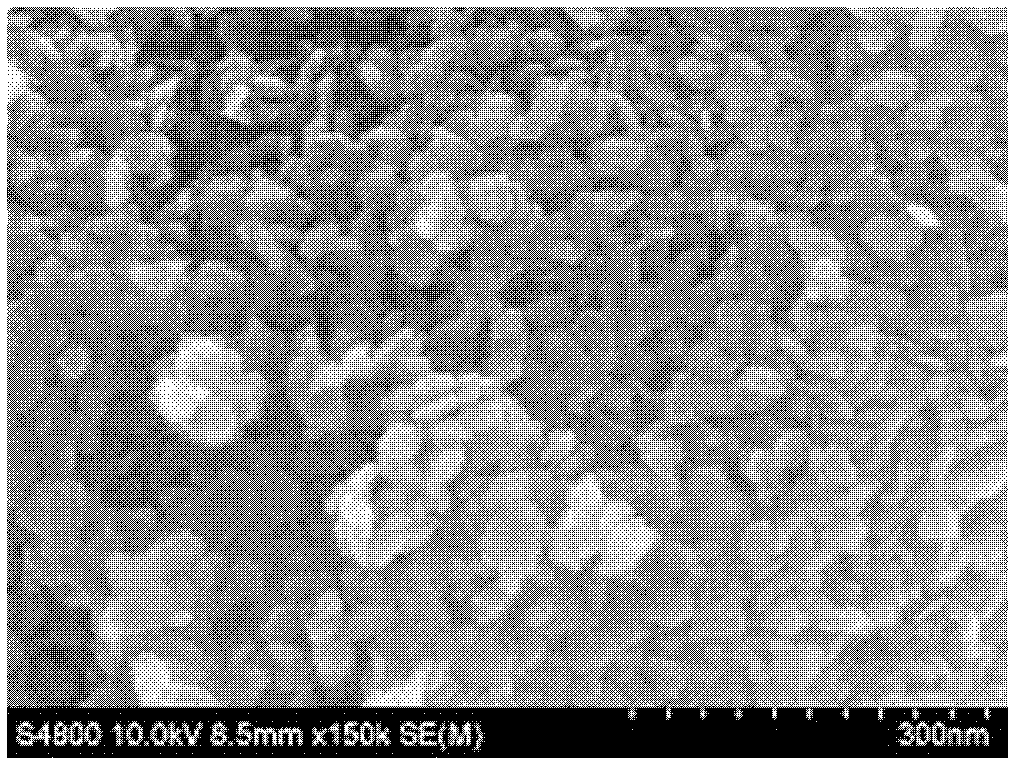

Tin bisulfide nanosheet composite material, as well as preparation method and application thereof

ActiveCN104716311AIncrease surface areaImprove cycle stabilityMaterial nanotechnologyCell electrodesBisulfideCysteine thiolate

The invention discloses a tin bisulfide nanosheet composite material, as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) uniformly mixing a tin source and an L-cysteine solution, performing heating reaction for 5 to 30 hours, naturally cooling the reaction product, and alternately washing the reaction product with water and ethanol to obtain a flower-like tin bisulfide nanosheet; (2) mixing tin bisulfide and oleic acid according to the weight ratio of (1 to 20) to (1 to 60), performing soaking for 24 to 48 hours, centrifugally removing redundant oleic acid, and performing heating for 1 to 8 hours in the inert gas atmosphere of 400 to 1,000 DEG C to obtain an amorphous carbon-coated tin bisulfide nanosheet composite material. According to the method, amorphous carbon is formed by oleic acid adsorption material surface annealing, and the surface of the flower-like tin bisulfide nanosheet prepared by a hydrothermal method is coated with an amorphous carbon layer, so that the method is simple and easy to operate; the prepared amorphous carbon-coated tin bisulfide nanosheet composite material is large in surface area and thin, and has the characteristics of high cycling stability, high rate capacity and the like when being used as a battery cathode.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

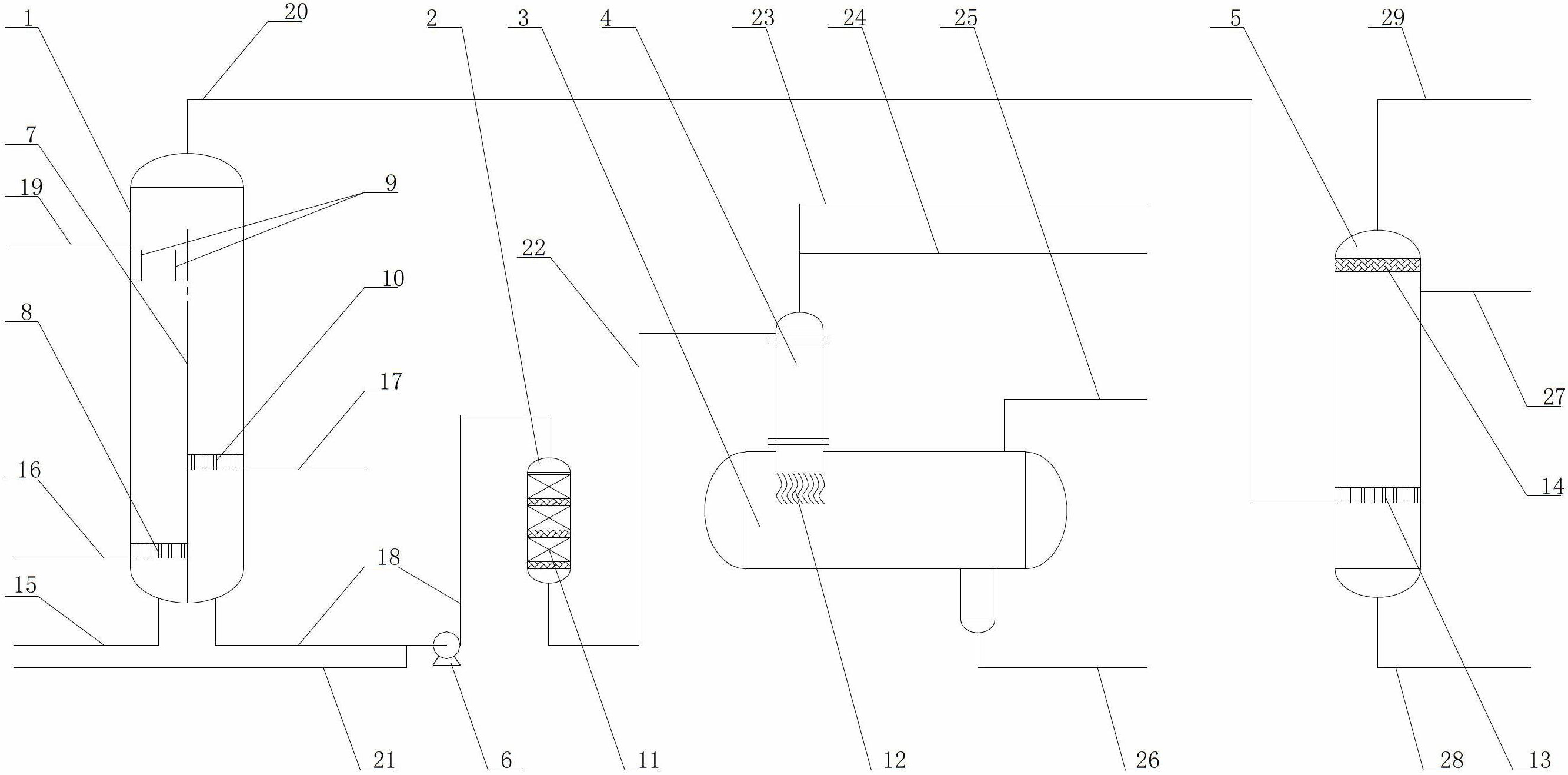

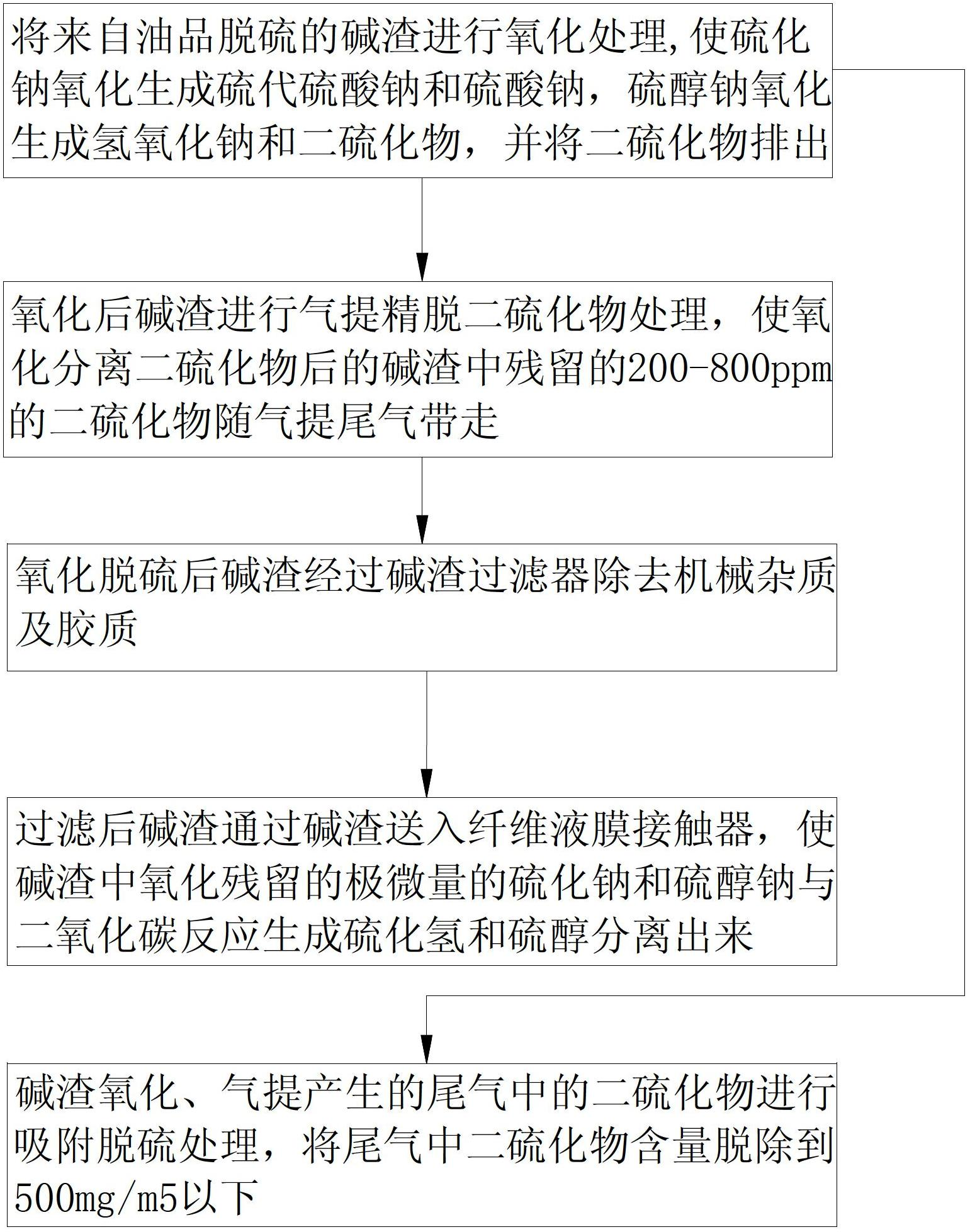

Combination method and device of caustic sludge desulfuration and dephenolization neutralization and tail gas desulphurization processing

The invention relates to a combination method and a device of caustic sludge desulfuration and dephenolization neutralization and tail gas desulphurization processing. The device comprises a caustic sludge oxidation desulfurization tower, a caustic sludge filter, a carbonization precipitation tank, a fiber liquid membrane contactor and a tail gas adsorption desulfurization tank, the top of the caustic sludge oxidation desulfurization tower is connected with a tail gas adsorption desulfurization tank through a tail gas discharging pipe one, the bottom of the caustic sludge oxidation desulfurization tower is connected with the caustic sludge filter through a caustic sludge discharging pipe, the caustic sludge filter is connected with the fiber liquid membrane contactor through a caustic sludge feeding pipe two, and the bottom of the fiber liquid membrane contactor is fixed on the carbonization precipitation tank through a flange; and the method includes subjecting the caustic sludge to oxidation treatment, air stripping fine taking off disulphide treatment and removing mechanical impurities ad colloids, separating hydrogen sulfide and mercaptan and adsorption desulfurization treatment successively. The combination method and the device of caustic sludge desulfuration and dephenolization neutralization and tail gas desulphurization processing have the advantages that disulphide of sodium sulphide and mercaptan sodium can be separated and recycled, and the tail gas after desulfuration can meet the relevant state standard requirements of direct discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tin bisulfide single-crystal nanosheets selectively absorbing organic dyes, and preparation method thereof

InactiveCN102527318AImprove adsorption capacityMaterial nanotechnologyPolycrystalline material growthHigh concentrationBisulfide

Owner:SHANGHAI NORMAL UNIVERSITY

Water-phase synthesis method for di-[(triethoxylsilicon)propyl]-bisulfide

ActiveCN101260118AReduce manufacturing costSimple reaction conditionsGroup 4/14 element organic compoundsBisulfideSilanes

The invention provides a method for the aqueous synthesis of bis-[(tirethoxy silicon)propyl]-bisulfides, relating to a method of synthesizing bis-[(tirethoxy silicon)propyl]-bisulfides. The invention resolves the problems that because the production of sodium disulphide needed for the preparation of Si-75 is conducted in a nitrogen protection and ethanol system, the operating requirement is high and manufacturing costs are increased. The steps of the method are as follows: the elemental sulfur and alkali metal hydrosulfides or alkali metal sulphides are dissolved in the aqueous phase, and the Ph value is adjusted, and after the phase transfer catalyst and the hydrolysis inhibitor are added to solution, the chloropropyl triethoxy silane is dropwise added to the solution, and the upper layer organic phase is isolated after the backflow, cooling and filtering, and the active carbons are used for the adsorption after processes of washing, separation and deposition, combination and drying of the organic phase. In the invention, the preparation of Si-75 is completed in the aqueous phase, and the ethanol used as a solvent is unnecessary and the nitrogen protection is also unnecessary, thereby the method of the invention has the advantages of simple reaction condition, easy collection of materials, low manufacturing costs and suitable mass production.

Owner:HARBIN INST OF TECH

Organic sulfur desulfurizer and preparation method thereof

The invention relates to a desulfurizer of organic sulfur (such as carbonyl sulfide, thiol, disulphide and the like) for removing hydrocarbon, in particular for removing hydrocarbon with less than six carbon atoms; the desulfurizer comprises gamma-Al2O3 used as a carrier and alkali metal oxide used as an active constituent. The desulfurizer has the advantages of high precision for removing organic sulfur, simple preparation process and low cost, and the organic sulfur can be transferred to carbonyl sulfide with above 95% of conversion rate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

C4 hydrocarbon deep desulfurization method and thiol and disulfide removal agent used therein

ActiveCN101591213AImprove pore structureImprove adsorption capacityOther chemical processesAdsorption purification/separationMolecular sieveBisulfide

The invention relates to a thiol and disulfide removal agent which is an X molecular sieve exchanged from positive ions Cs<+>, Mg<2+>, La<3+>, Ce<3+>, Cu<2+>, Zn<2+>, Mn<2+> or a Y molecular sieve exchanged from positive ions Cs<+>, Mg<2+>, La<3+>, Ce<3+>, Zn<2+>, Mn<2+>.The invention further discloses a C4 hydrocarbon deep desulfurization method which adopts the thiol and disulfide removal agent, in the invention, removal is carried out continuously and systematically on H2S, COS, thiol and disulfide in the C4 hydrocarbon; the method is easy to operate; C4 hydrocarbon can be refined to ensure that total sulfer therein is less than 0.5ppm and the carbonyl sulfide is less than 0.05ppm.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Production method of electro-deposited copper foil, electro-deposited copper foil obtained by the production method, surface-treated copper foil obtained by using the electro-deposited copper foil and copper-clad laminate obtained by using the electro-deposited copper foil or the surface-treated copper foil

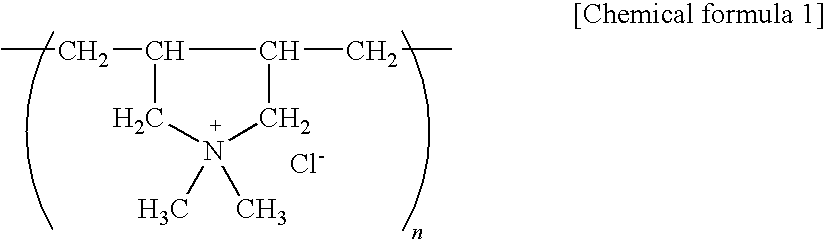

InactiveUS20090166213A1Fast operationHigh speedDuplicating/marking methodsActive material electrodesQuaternary ammonium cationElectrolysis

An object of the present invention is to provide a production method which enables efficient production of an electro-deposited copper foil with further lower profile when compared to the low-profile electro-deposited copper foils which have been supplied to the market and is excellent in mechanical strength. For the purpose of achieving the object, a production method adopted obtains the electro-deposited copper foil by electrolyzing a sulfuric acid based copper electrolytic solution which contains a quaternary ammonium salt polymer having cyclic structure and chlorine, wherein for the quaternary ammonium salt polymer contained in the sulfuric acid based copper electrolytic solution, a DDAC dimer or higher polymer is used. For the quaternary ammonium salt polymer, a diallyl dimethyl ammonium chloride polymer having a number average molecular weight of 300 to 10000 is preferably used. The sulfuric acid based copper electrolytic solution preferably contains bis(3-sulfopropyl) disulfide or 3-mercapto-1-propanesulfonic acid that is a compound having a mercapto group.

Owner:MITSUI MINING & SMELTING CO LTD

Organic sulfur desulfurizer and preparation method thereof

ActiveCN101591555AHigh pore volumeIncrease the areaGaseous fuelsRefining with metal oxidesBisulfideThiol

The invention relates to a desulfurizer of organic sulfur (such as carbonyl sulfide, thiol, disulphide and the like) for removing hydrocarbon, in particular for removing hydrocarbon with less than six carbon atoms; the desulfurizer comprises gamma-Al2O3 modified by silicon dioxide, which is used as a carrier and alkali metal oxide used as an active constituent. The desulfurizer has the advantages of high precision for removing organic sulfur, simple preparation process and low cost, and the organic sulfur can be transferred to carbonyl sulfide with above 95% of conversion rate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

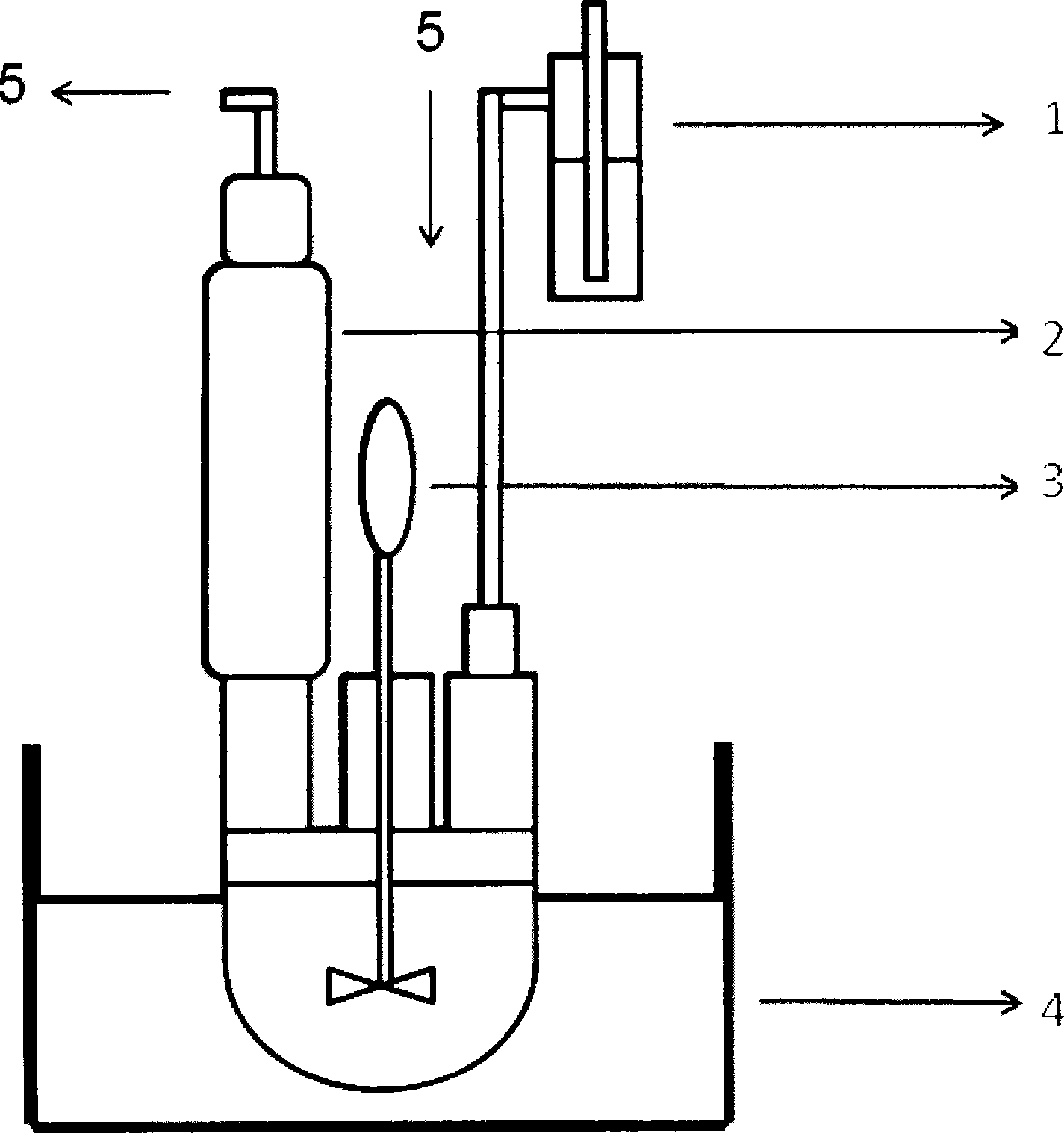

Method for preparing irregular sulfonated poly aromatic (sulfur) ether with high efficiency

The invention discloses a method for preparing irregular sulfonated poly aromatic (sulfur) ether with high efficiency. The method comprises the following steps that: a sulfonated monomer, a non-sulfonated monomer and a bisphenol (bisulfide) monomer are used as initial raw materials; carbonate which is 2 to 2.25 times of the total mole number of the bisphenol (bisulfide) is used as alkali and is added into the raw materials; the mixed materials react for 10 to 24 hours in a non-protonic solvent with high boiling point; then reaction solution is slowly poured into deionized water to obtain a white fibriform polymer; subsequently, the white fibriform polymer is soaked for 5 to 10 hours under the condition that the temperature is between 60 and 80 DEG C and the process is repeated for 3 to 5 times; and the white fibriform polymer is subjected to filtering, drying and vacuum drying to obtain the irregular sulfonated poly aromatic (sulfur) ether. The preparation method does not need the addition of toluene, removes the step of water separation, simplifies the process, avoids the use of mass organic, flammable, volatile and toxic solvents and the subsequent complex process of reclaiming and processing waste liquid, reduces the volume of the reaction liquid, shortens the reaction time and reduces energy consumption so as to reduce the cost of the production process and improve the working efficiency.

Owner:安徽摩纳珀里科技有限公司

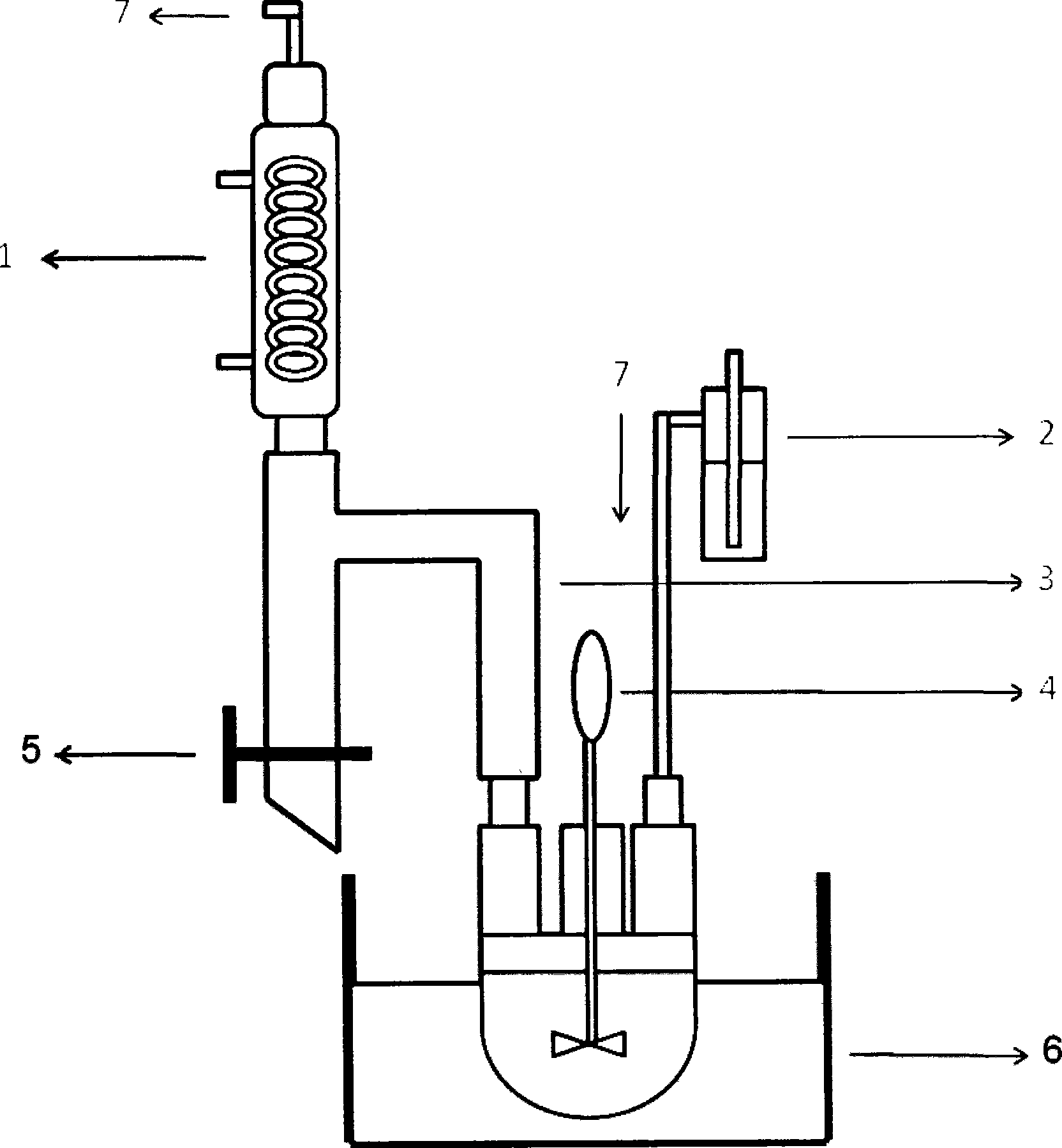

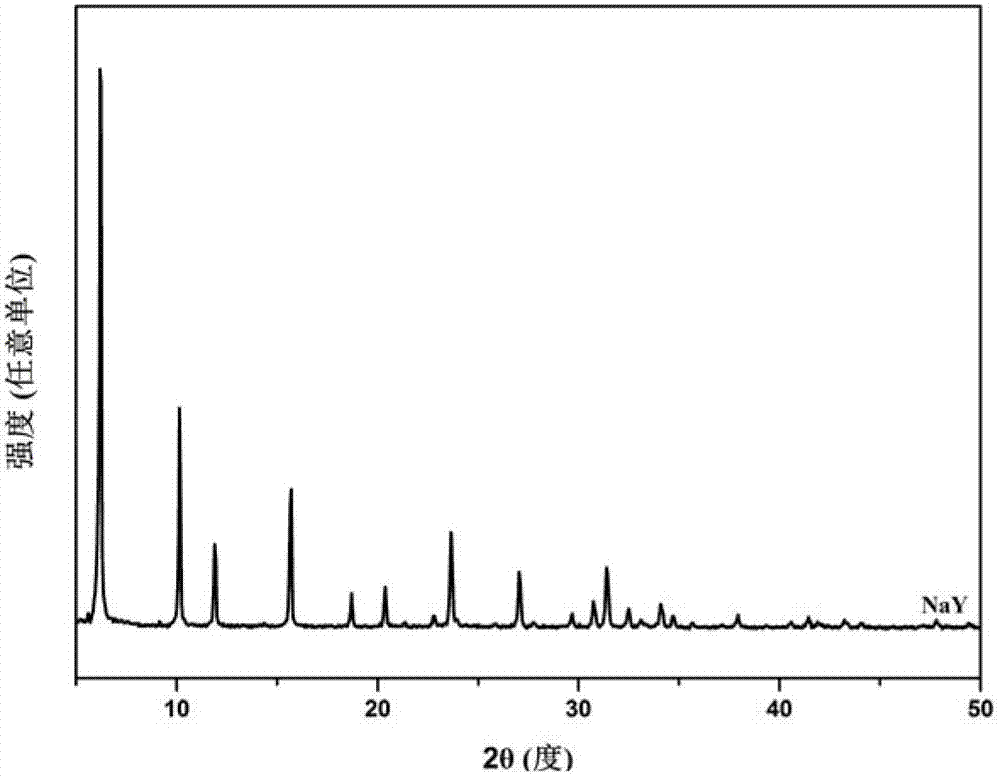

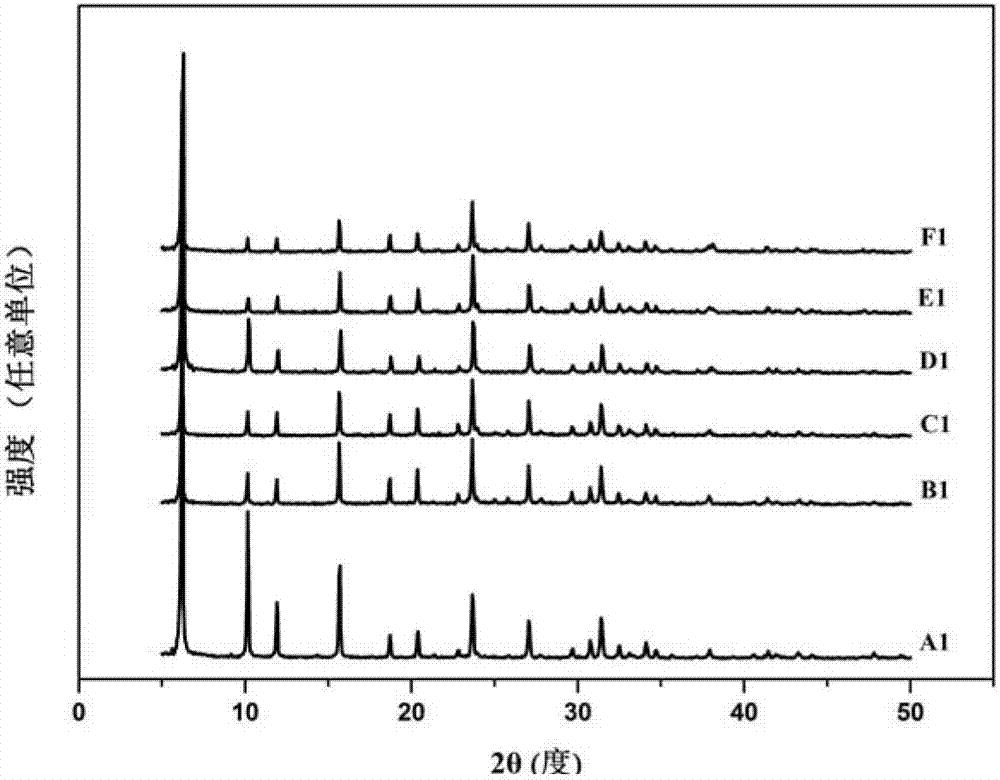

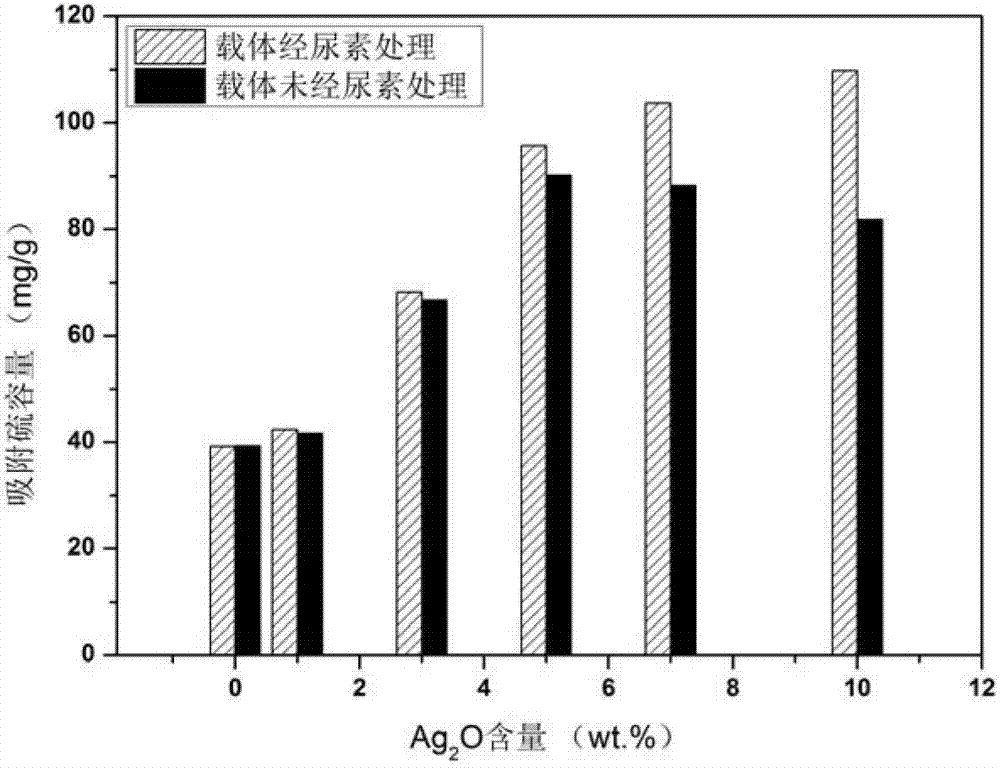

Desulfurizing adsorbent Ag2O/NaY based on molecular screen and preparation method thereof

InactiveCN103191697AImprove adsorption capacityGood dispersionOther chemical processesGaseous fuelsMolecular sieveBisulfide

The invention relates to a desulfurizing adsorbent Ag2O / NaY based on a molecular screen and a preparation method thereof, belonging to the technical filed of desulfurizing adsorbents. The preparation method mainly comprises the steps of carrier pretreatment based on a urea sublimation and desublimation method; incipient impregnation of a NaY type molecular screen by using a silver salt solution and calcining of the Y type molecular screen. The desulfurizing adsorbent Ag2O / NaY based on a molecular screen has an excellent performance of dispersing the active components of carriers and therefore has an excellent adsorbent desulfurizing performance although the content of Ag2O is little; so that an excellent desulfurizing effect with lower cost can be achieved by using the desulfurizing adsorbent based on a molecular screen to remove disulfides in hydrocarbon fuel.

Owner:BEIJING UNIV OF CHEM TECH

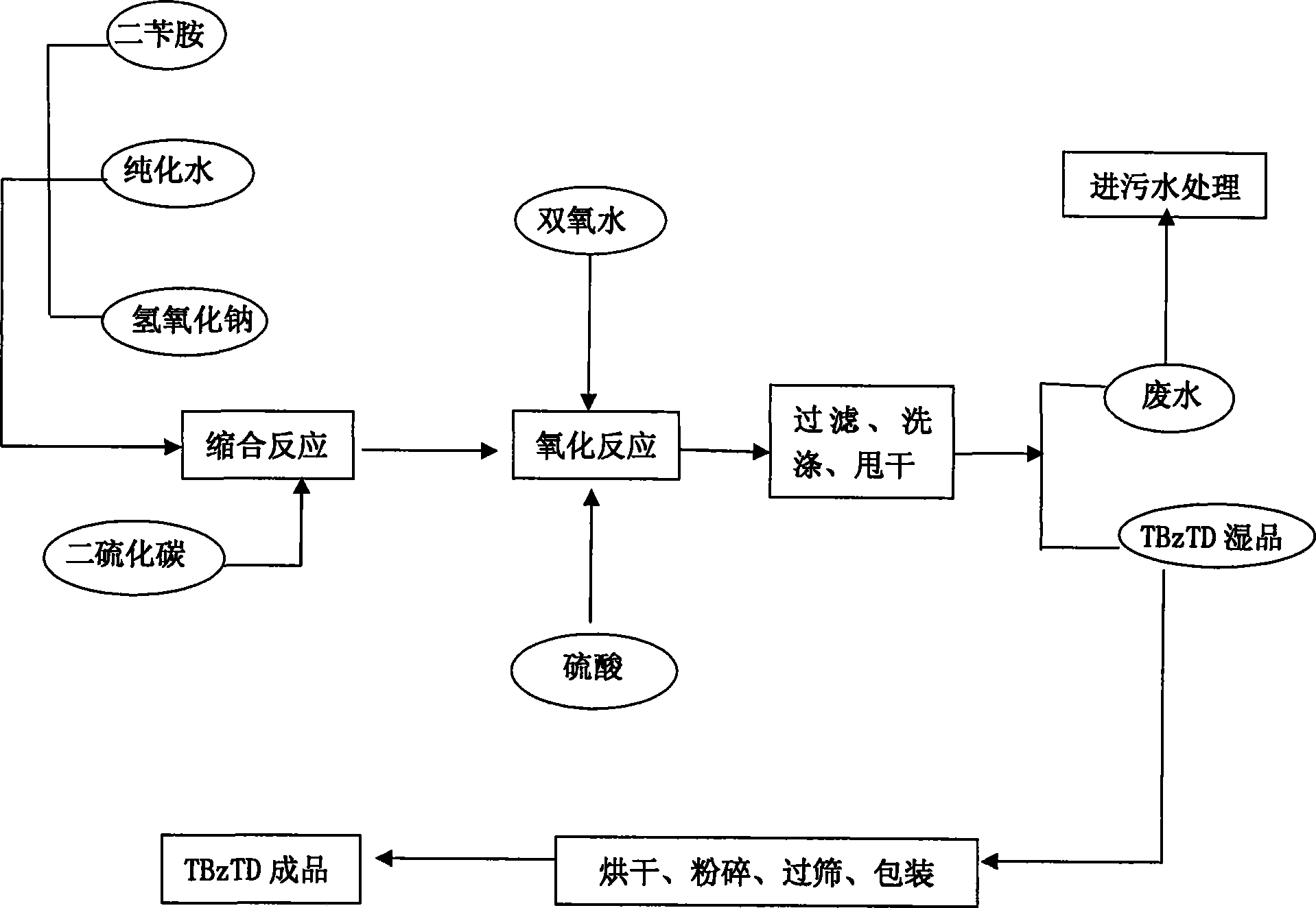

Preparation of rubber vulcanization accelerator tetrabenzylthiuram disulfide

The invention relates to a method for preparing a thiofide of tetraethylthiuram disulfide. The method uses raw materials with the mol ratio as follows: the mol ratio of dibenzyl amine, carbon bisulfide, sodium hydroxide, hydrogen peroxide and sulphuric acid is 1:1-1.30:1.0-1.2:0.5-0.6:0.28-0.35mol. The method comprises the technical process as follows: under normal pressure, the dibenzyl amine and the sodium hydroxide are sequentially added into a reaction kettle which contains purified water under the state of being stirred; subsequently, the temperature is reduced to 20 DEG C to 30 DEG C, liquid carbon bisulfide is dropwise added for 2 to 3 hours; after dropwise adding, reactant continues to be stirred for 0.5 hour; then, at the temperature of 58 DEG C to 63 DEG C, the hydrogen peroxide is dropwise added into the reactant for oxidation reaction which lasts 3 to 4 hours; when the oxidation reaction is going to finish, the sulphuric acid is added to adjust the pH value of reaction solution to be within the range of 6.5-7.5, and the reaction is finished; then the reaction is taken for 1 hour again by heat preservation for solid-liquid separation, and the solid is dried, crushed, filtered and packed to obtain a product. The method can improve the quality, the yield and the performance of the product effectively, reduce the potential safety hazard during the production process greatly, save energy, reduce consumption, reduce the waste water and exhaust emission during the production process and meet the national relative policy of environmental protection.

Owner:WILLING NEW MATERIALS TECH CO LTD

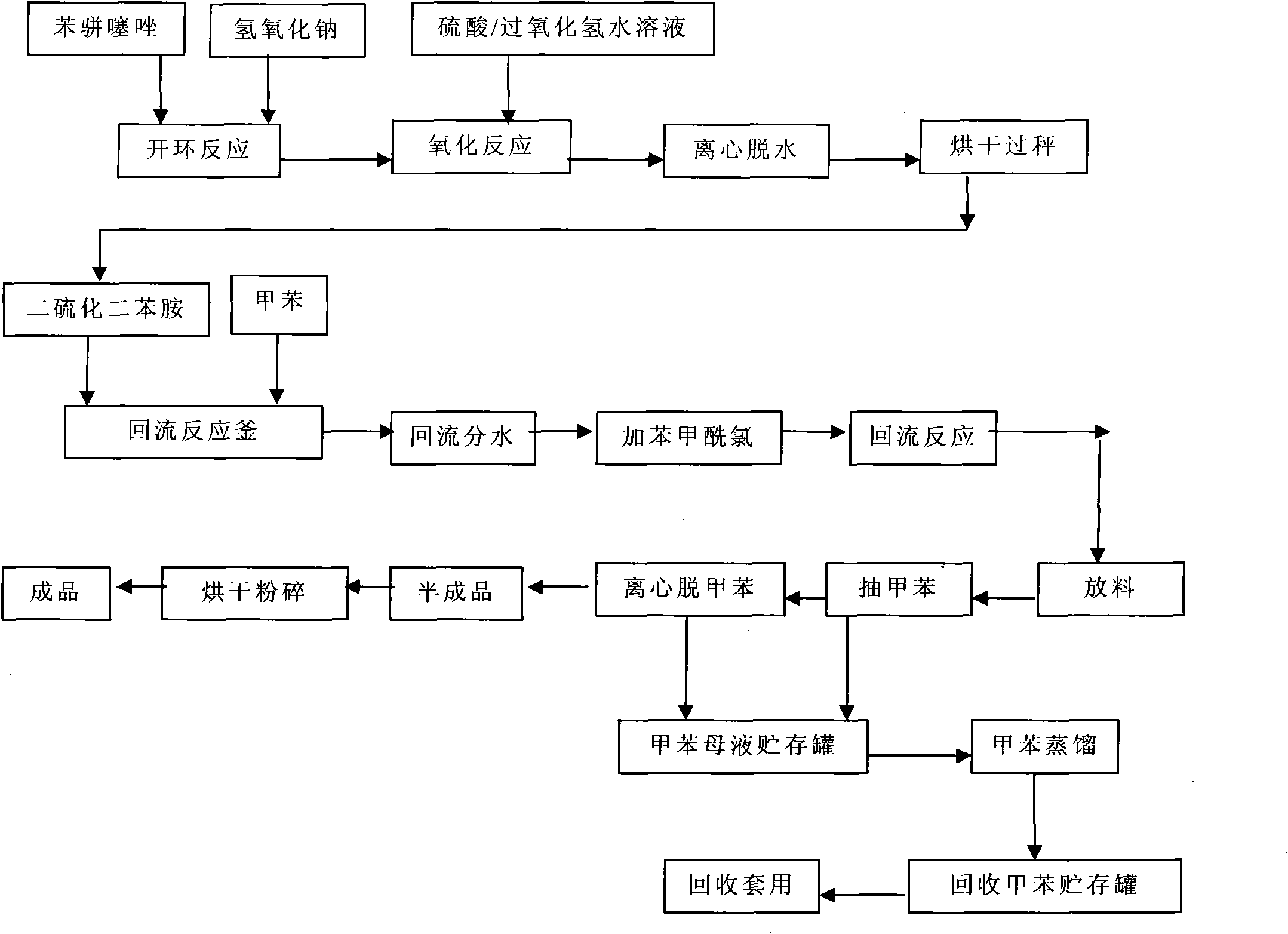

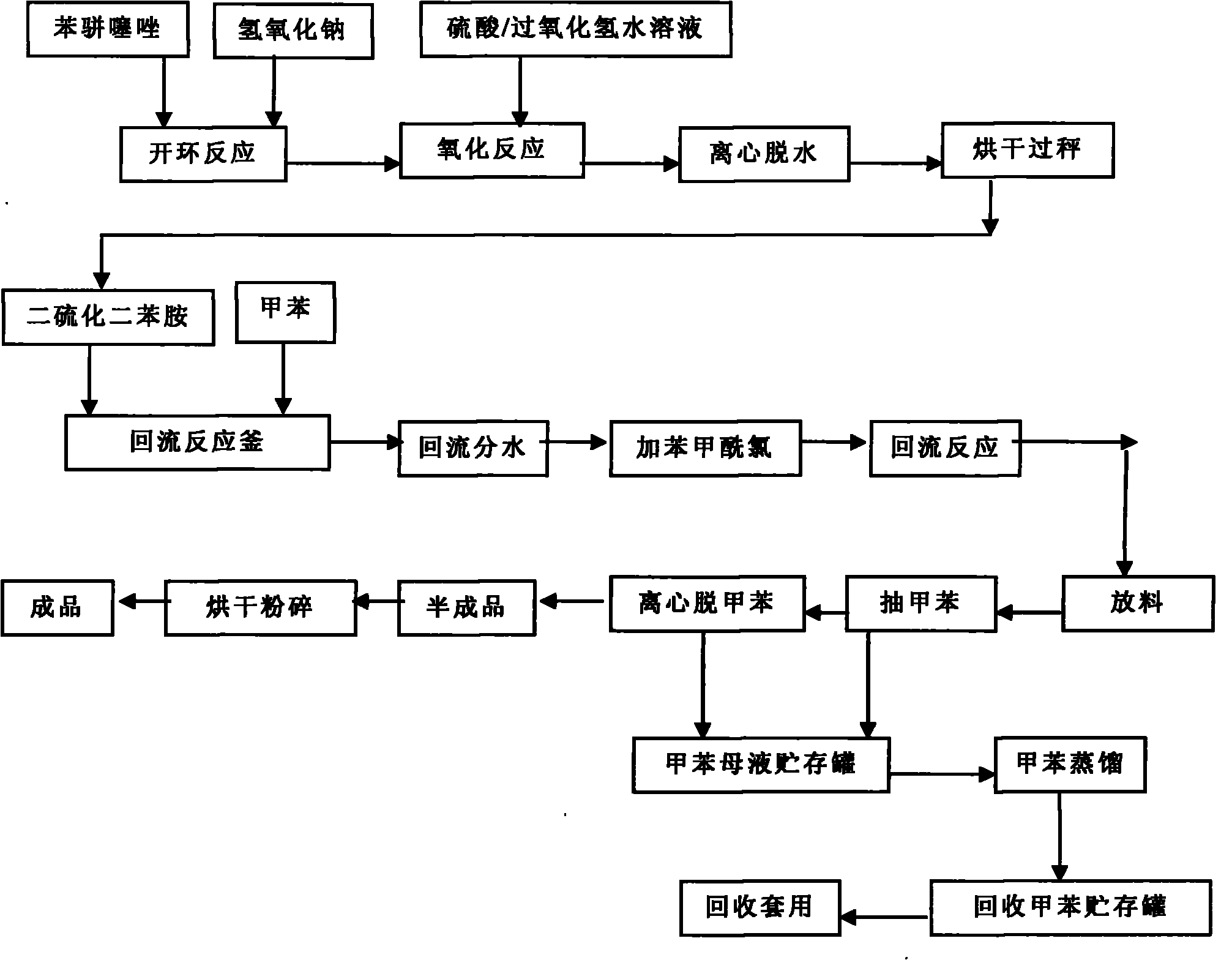

Method for preparing rubber peptizer DBD

ActiveCN102153495ALow costReduce the cost of three wastes treatmentHydropoly/poly sulfide preparationPolymer scienceBisulfide

The invention relates to a method for preparing a rubber auxiliary agent, and particularly discloses a method for preparing rubber peptizer 2,2-dibenzoylamino diphenyl disulphide (DBD). The method for preparing the rubber peptizer DBD is characterized by comprising the following steps of: performing ring opening reaction on benzothiazole to obtain a ring opening product; oxidizing the ring opening product to prepare diphenylamine disulphide; and performing acylation reaction on the diphenylamine disulphide and benzoyl chloride to generate the DBD. According to the method for preparing the rubber peptizer DBD, compared with the conventional process, the product cost is remarkably reduced; the method is favorable for popularization and application of the environmentally-friendly peptizer DBD, and simultaneously breaks through the situation that the product depends on import for a long term; the organic solvent is used as a reaction medium and can be recycled, so little three-waste is discharged; and the production flow is simple and easily controlled, high-temperature and high-pressure reaction does not exist in the method, the equipment investment is low, and the method is easy for production and operation.

Owner:HEZE JIACHENG CHEM CO LTD

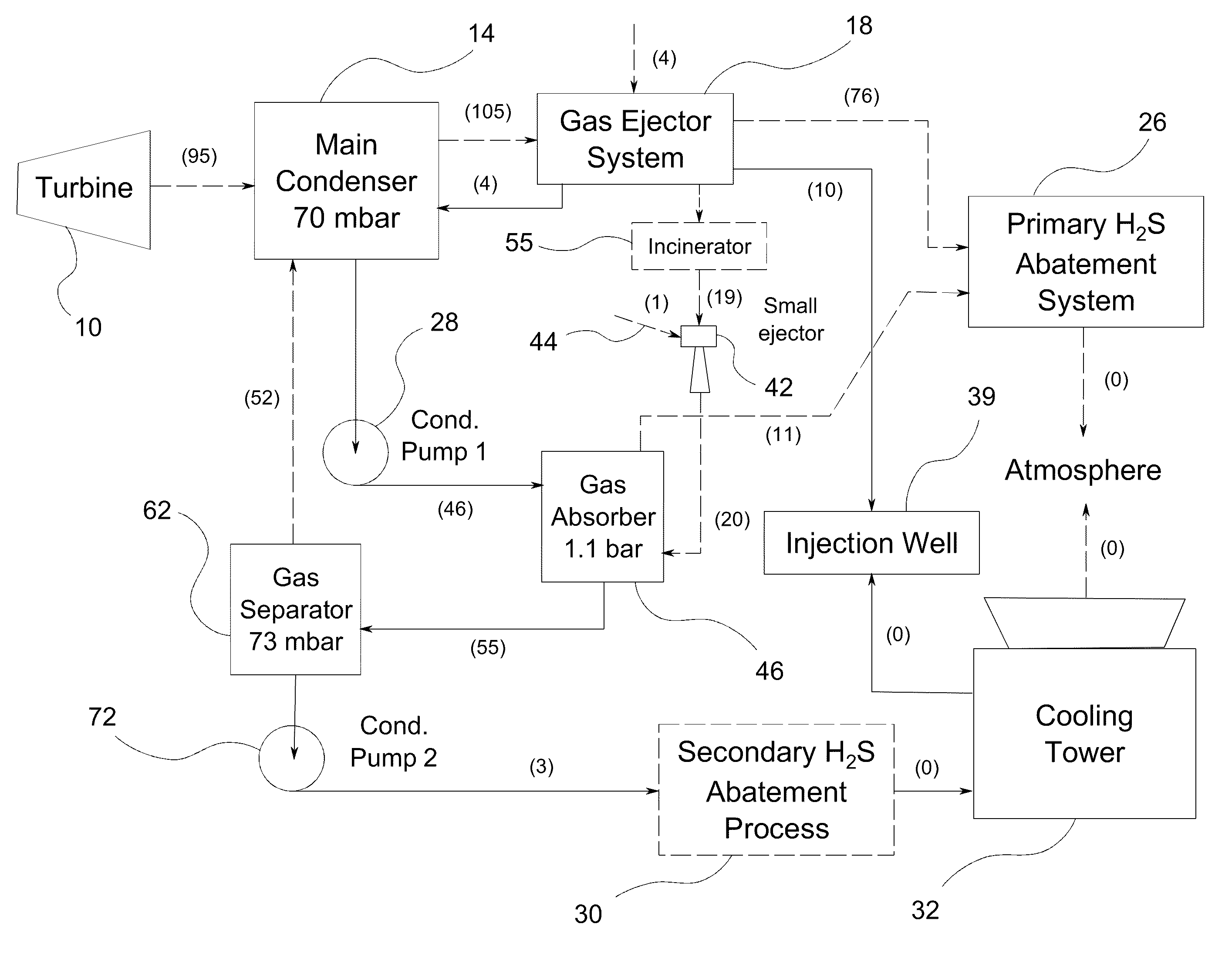

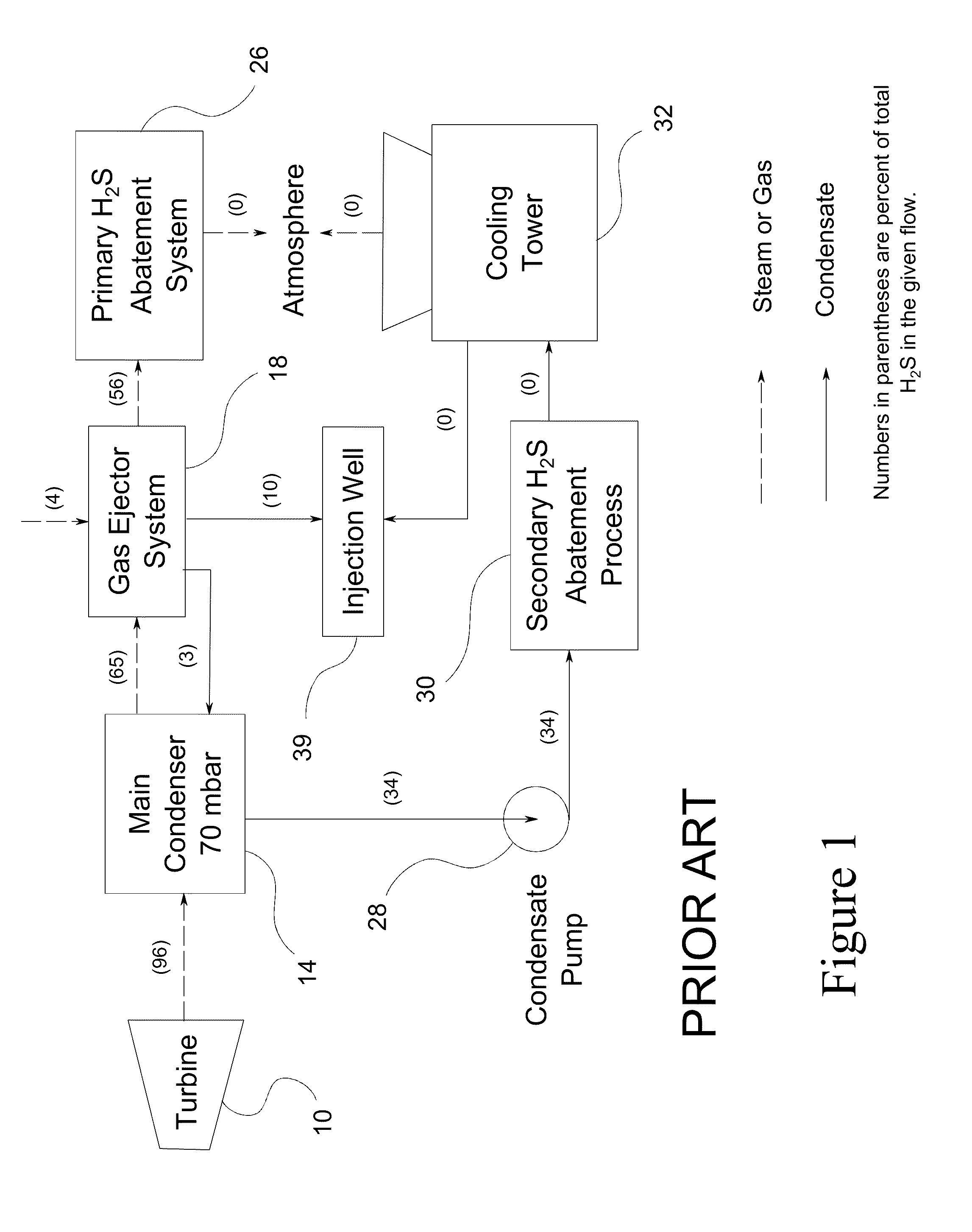

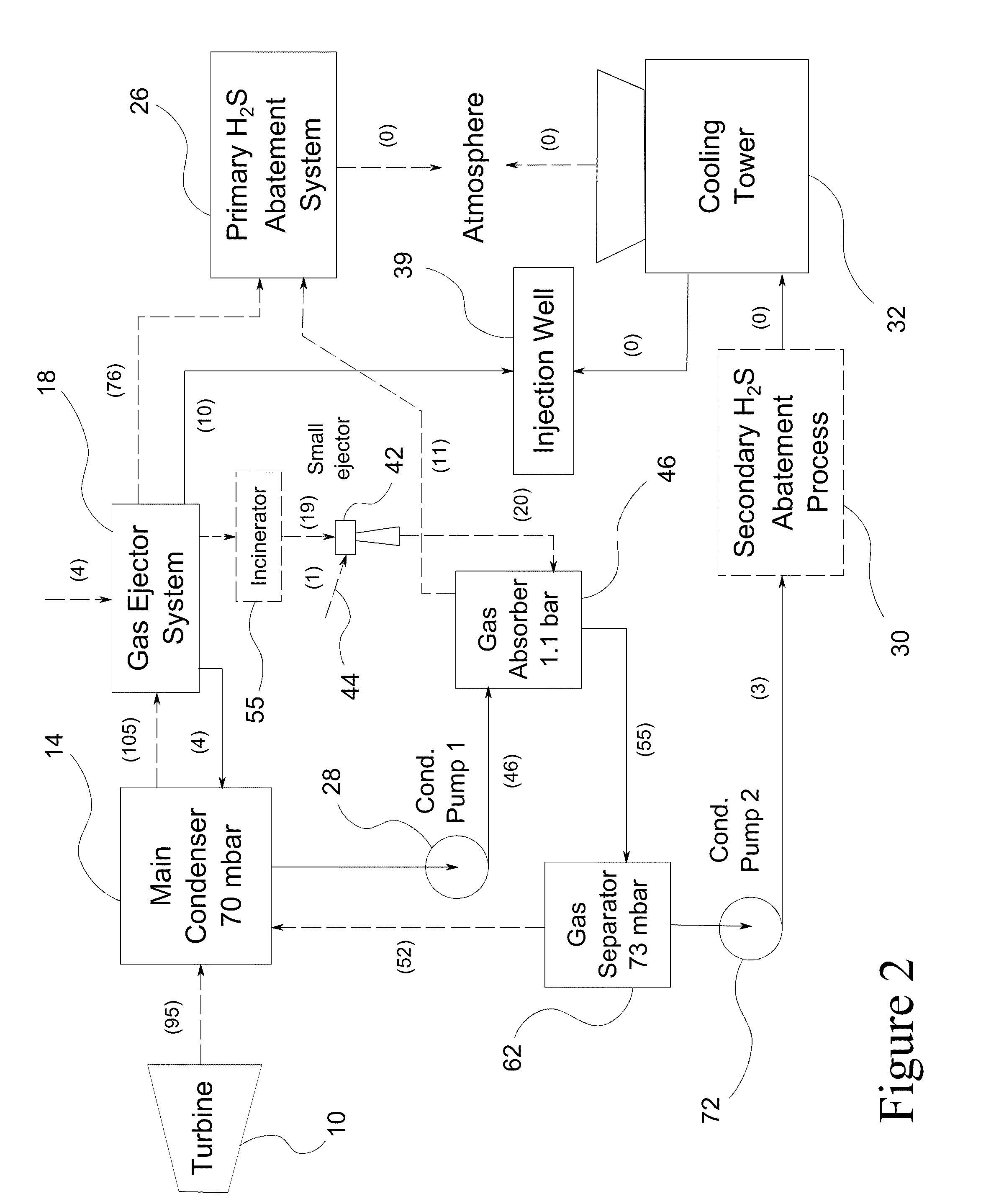

Method and Device to Remove Hydrogen Sulfide from Steam Condensate in a Geothermal Power Generating Unit

InactiveUS20110225971A1Improve condensation effectIncrease the volume ratioUsing liquid separation agentGeothermal energy generationChemical treatmentSolubility

Ammonia sometimes present in geothermal steam increases the solubility of hydrogen sulfide in the steam condensate produced by the surface condenser in a steam cycle geothermal power generating unit by reacting with the hydrogen sulfide to produce nonvolatile ammonium bisulfide. The condenser vent gas also produced contains carbon dioxide. Contacting the steam condensate with the condenser vent gas at a pressure slightly greater than atmospheric causes carbon dioxide to dissolve in the condensate, decreasing pH and converting bisulfide ion back to hydrogen sulfide. Subsequently exposing the acidified condensate to condenser vacuum strips the hydrogen sulfide from the condensate, eliminating the need for further chemical treatment of the condensate to prevent air pollution. Hydrogen sulfide partitioning performance is further improved by converting the hydrogen sulfide in the vent gas to sulfur dioxide before contacting it with the condensate.

Owner:CHEMTREAT

Gas chromatography device for detecting sulfuryl fluoride in sulfur hexafluoride decomposition product

The invention discloses a gas chromatography device for detecting sulfuryl fluoride in a sulfur hexafluoride decomposition product. The gas chromatography device comprises a sulfur hexafluoride separation device, a capillary column sampling device, a Gaspro chromatographic column, a micro-plate flow path control valve and a second sulfide detector, wherein the capillary column sampling device comprises a first inlet, a second inlet and a first outlet which are communicated with one another; the second inlet is communicated with the sulfur hexafluoride separation device; auxiliary gas is fed through the first inlet; the micro-plate flow path control valve comprises a third inlet, a second outlet and a third outlet; the Gaspro chromatographic column is respectively communicated with the first outlet and the third inlet; the second sulfide detector is communicated with the second outlet. The gas chromatography device for detecting the sulfuryl fluoride in the sulfur hexafluoride decomposition product, provided by the invention, can be used for accurately detecting the sulfuryl fluoride.

Owner:STATE GRID CORP OF CHINA +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com