Desulfurizing adsorbent Ag2O/NaY based on molecular screen and preparation method thereof

A molecular sieve and adsorbent technology, used in chemical instruments and methods, other chemical processes, gas fuels, etc., can solve the problems of insufficient utilization of active components, agglomeration of active components, and decreased adsorption capacity, and achieve excellent two The effect of sulfide adsorption capacity, reduction of agglomeration, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Ag of the present invention 2 The preparation method of O / NaY renewable desulfurization adsorbent comprises the following steps:

[0028] (A) NaY molecular sieve raw powder was roasted at 550°C for 4h, and slowly cooled to room temperature;

[0029] (B) Granulating the molecular sieve obtained in step (A) to make 40-60 mesh particles;

[0030] (C) Determination of the water absorption of the carrier. Take a certain amount of the granulated carrier obtained in step (B), and dry it at 110°C to constant weight, then weigh a certain amount of the dried carrier, add distilled water dropwise, shake while adding, until the carrier is completely wet, and There is obvious water present on the container wall, which is no longer adsorbed by the carrier. Record the amount of water absorbed by the carrier per unit mass.

[0031] (D) Put a certain amount of the granulated carrier obtained in step (B) and ground urea into a closed container, vacuumize the closed container, and tre...

Embodiment 1

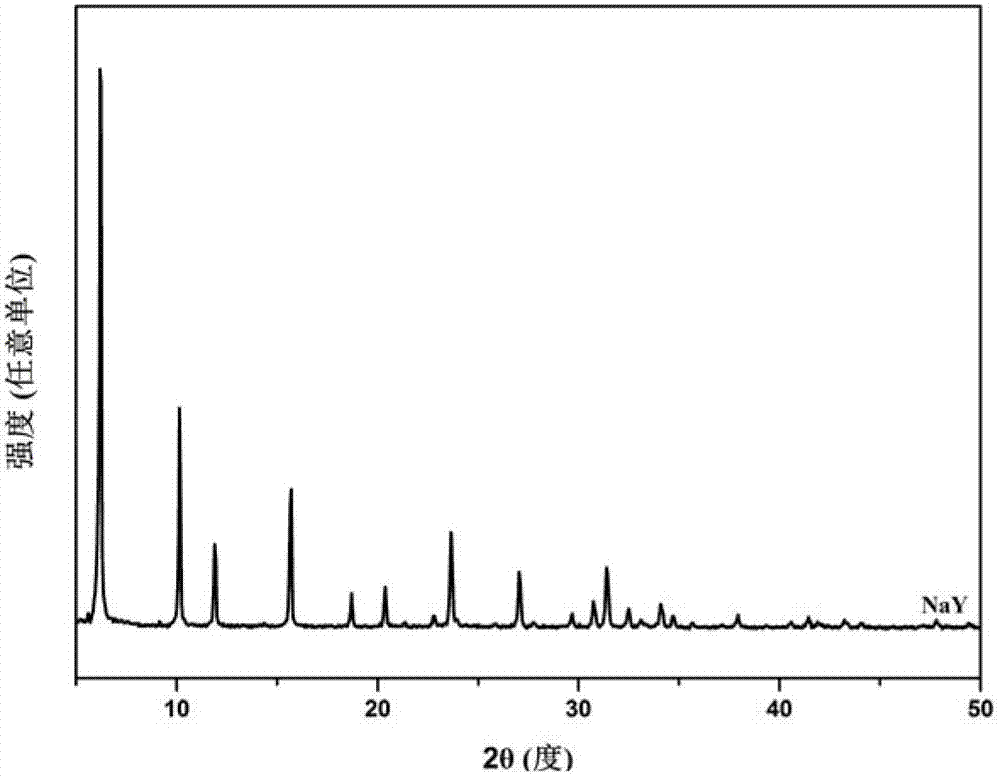

[0045] (A) Weigh 10g of NaY molecular sieve, bake it in a muffle furnace at 550°C for 4 hours, cool slowly to room temperature, and then press it into 40-60 mesh particles; the XRD pattern of NaY molecular sieve is as follows figure 1 As shown, the specific surface area of the NaY molecular sieve carrier measured by the BET method is 541.1m 2 / g.

[0046] (B) Weigh a certain amount of the carrier in (A), dry it in an oven at 110°C to constant weight, weigh 1g of 40-60 mesh NaY molecular sieve carrier particles, and slowly add deionized water dropwise to it, adding lightly while adding Shake lightly until the carrier is completely wet, and there is obvious water on the container wall, which is no longer adsorbed by the carrier. The measured water absorption per unit mass of the carrier is: 1.52 g water / g carrier.

[0047] (C) Weigh 5g of NaY molecular sieve carrier particles of 40-60 mesh, put them together with 1g of urea ground into powder into a closed container for vacu...

Embodiment 2

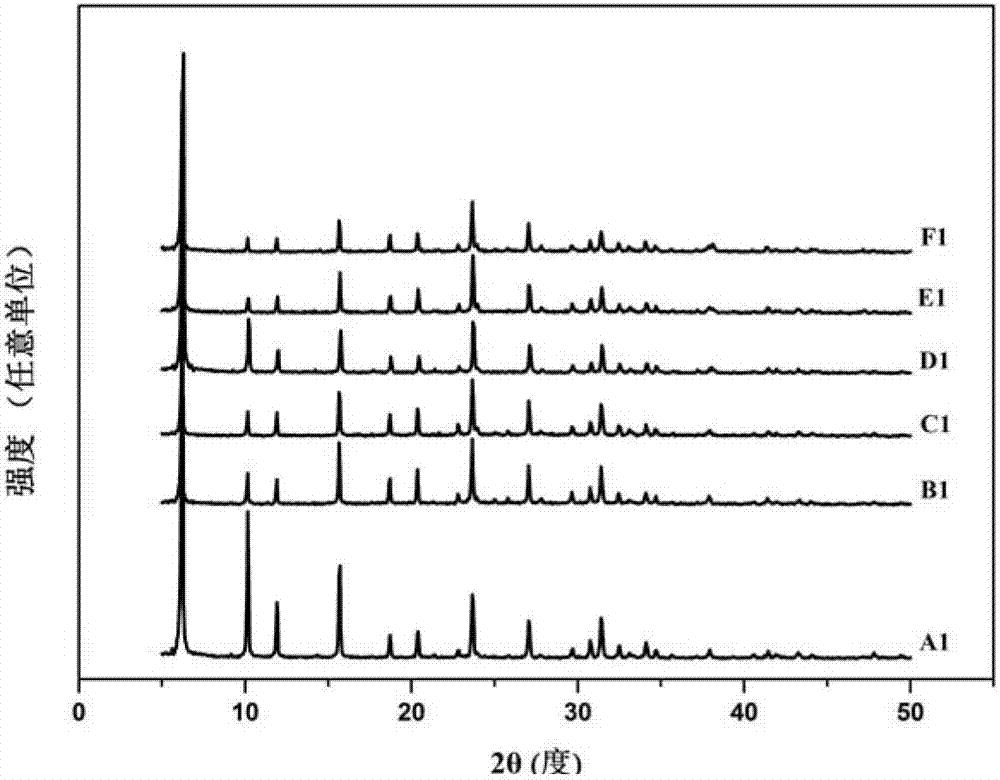

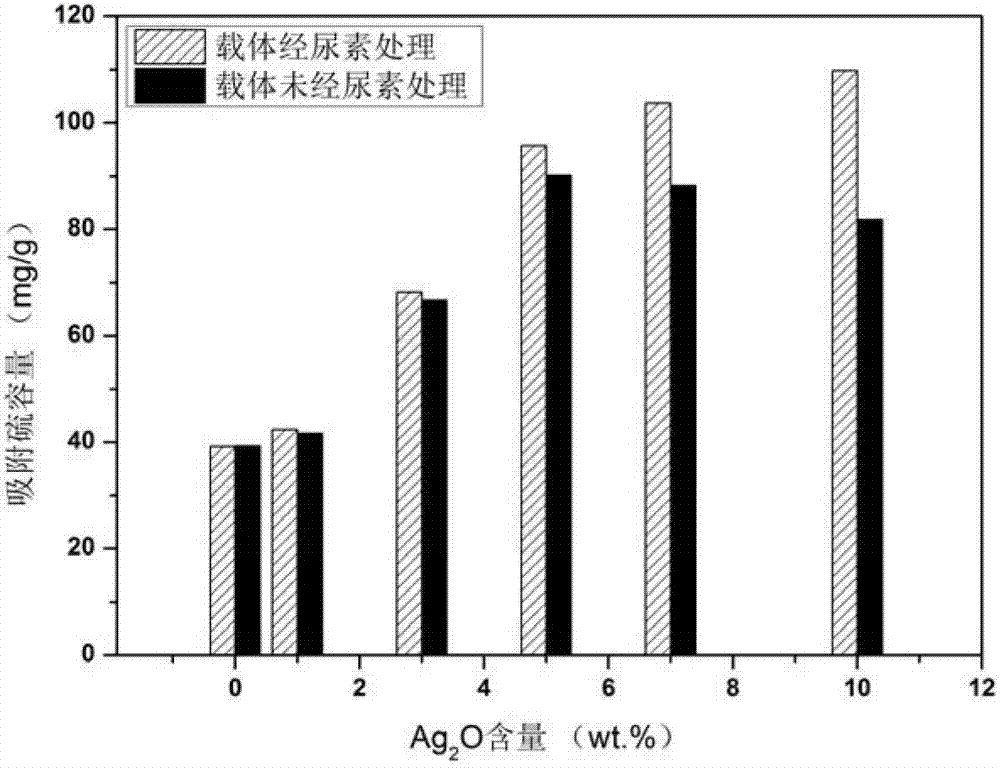

[0057] Adopt the method of embodiment 1, weigh starting material AgNO respectively 3 0.00g, 0.073g, 0.220g, 0.367g, 0.513g, 0.733g were dissolved in 7.60g deionized water respectively to obtain a desulfurization agent preparation solution, and then the NaY molecular sieve carriers pretreated with urea were impregnated with equal volume and dried , roasted, and cooled to room temperature to obtain Ag 2 Desulfurization adsorbents A1, B1, C1, D1, E1, F1 with O content of 0wt.%, 1wt.%, 3wt.%, 5wt.%, 7wt.%, 10wt.%, respectively.

[0058] The X-ray diffraction pattern of the prepared adsorbent is as follows figure 2 shown. The XRD spectrum of the prepared adsorbent is basically the same as that of the unmodified NaY molecular sieve, indicating that the structure of the molecular sieve is still well preserved during the process of impregnation and roasting, and the modified adsorbent still retains the unique properties of NaY molecular sieve. The pore structure, and no new crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakthrough sulfur capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com