Patents

Literature

515 results about "Fenton reagent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fenton's reagent. Fenton's reagent is a solution of hydrogen peroxide (H 2O 2) with ferrous iron (typically iron(II) sulfate, FeSO 4) as a catalyst that is used to oxidize contaminants or waste waters. Fenton's reagent can be used to destroy organic compounds such as trichloroethylene (TCE) and tetrachloroethylene (perchloroethylene, PCE).

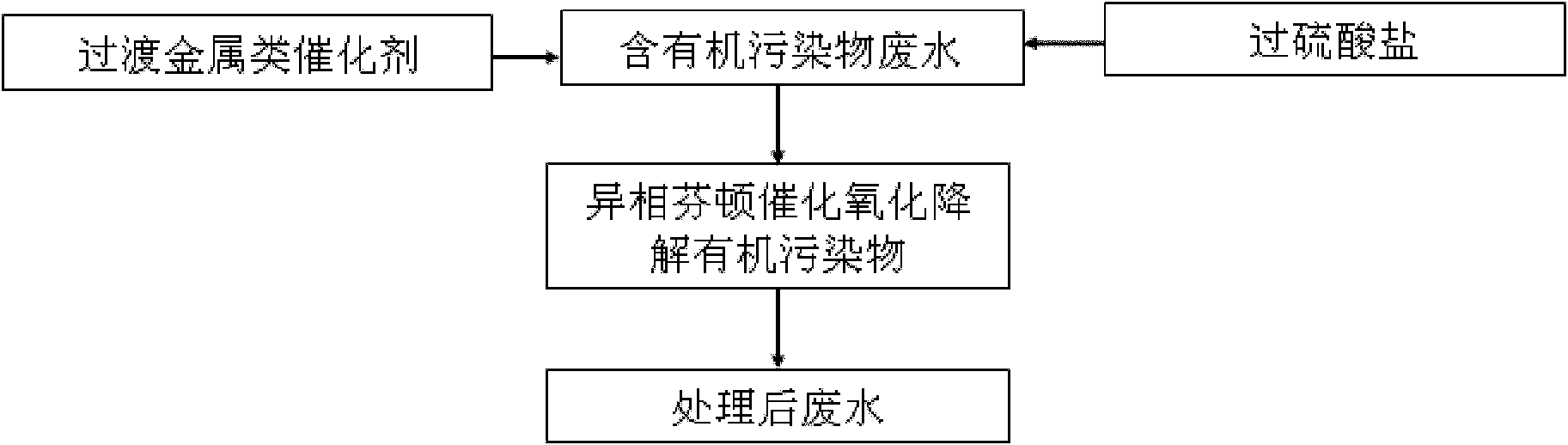

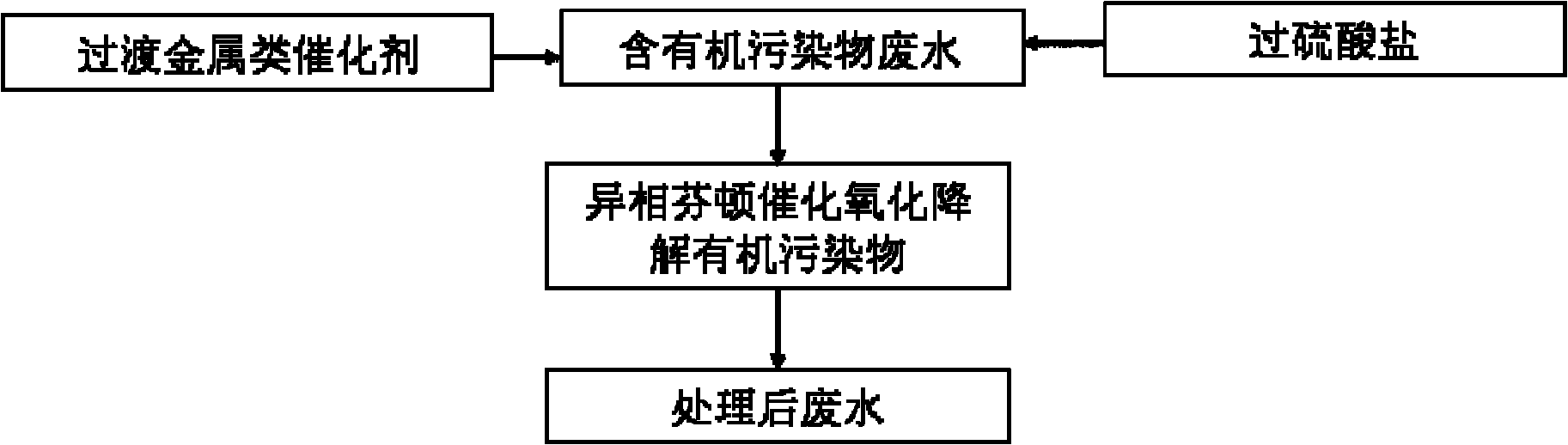

Processing method of heterocatalysis persulfate Fenton oxidation water

InactiveCN102020350ALong-lasting and efficient purificationImprove durabilityWater/sewage treatment by oxidationPersulfateFenton reagent

The invention proposes a processing technology of heterocatalysis persulfate Fenton oxidation water. In the method, transitional metal, transitional metallic oxide and a transitional metal / transitional metallic oxide composite material are used as out-phase Fenton reagents; and persulfate is catalyzed and decomposed to generate hydroxyl radical free radical, thus oxidizing to remove the organic matters in the waste water. Compared with the water treatment technique of homogeneous phase persulfate, the out-phase transitional metal and the transition metal oxide catalyst can slowly release transitional metal icons, thus ensuring that the organic matters in the water are purified lastingly and efficiently by the processing method of the heterocatalysis persulfate Fenton oxidation water. The processing technology of heterocatalysis persulfate Fenton catalyzed oxidation water built by the invention is suitable for processing various organic wastewater, has the advantages of good durability, high efficiency, environmentally friendliness, and no secondary pollution, is easy to operate, conforms to the requirements of actual water treatment units, and has great application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

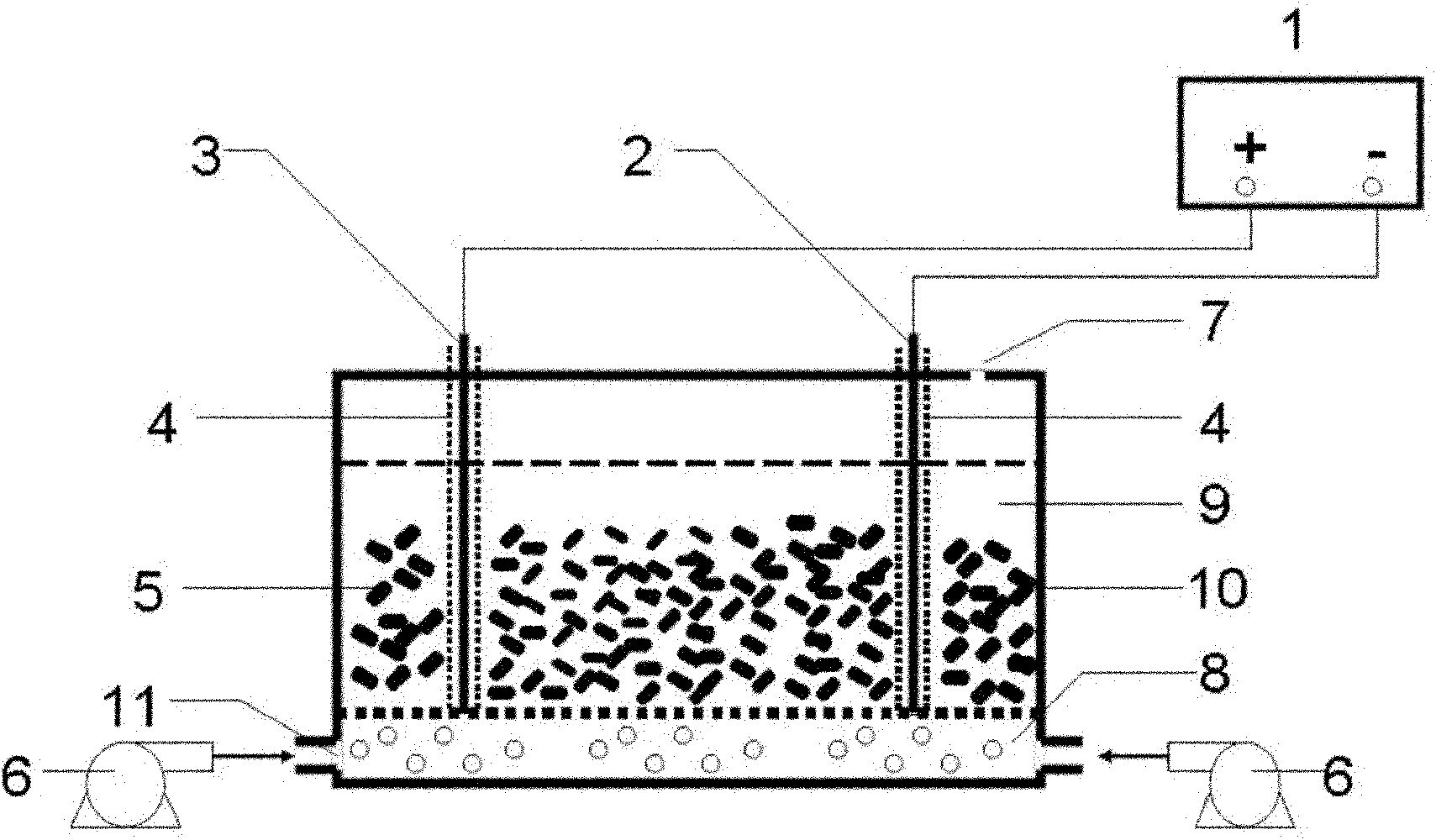

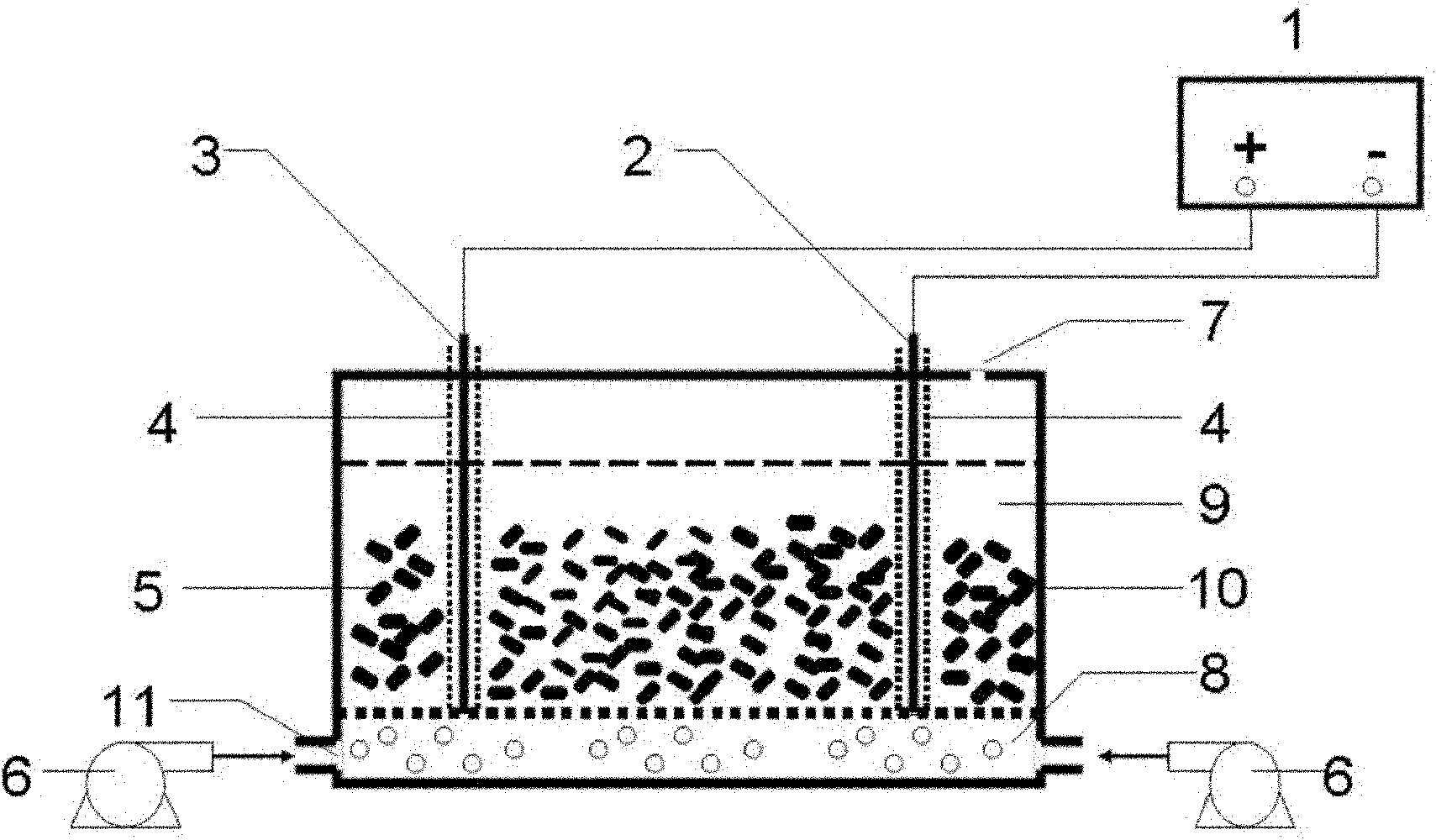

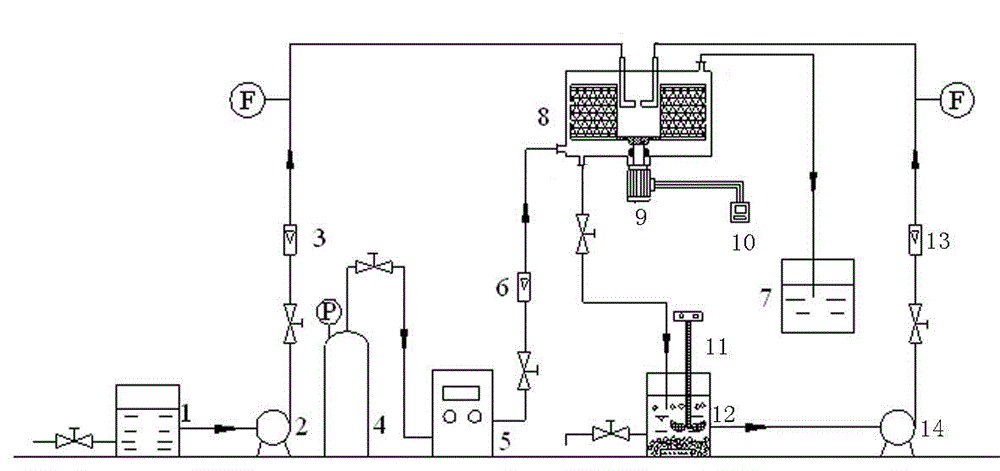

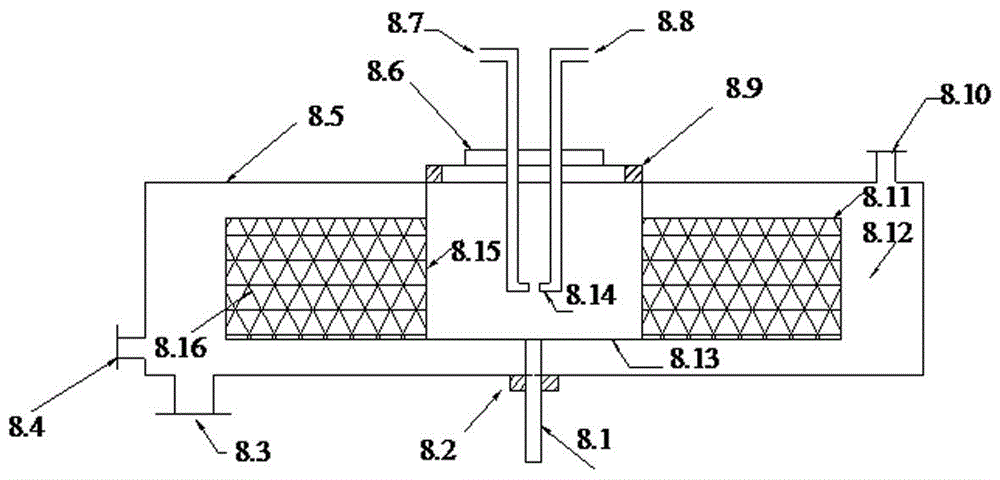

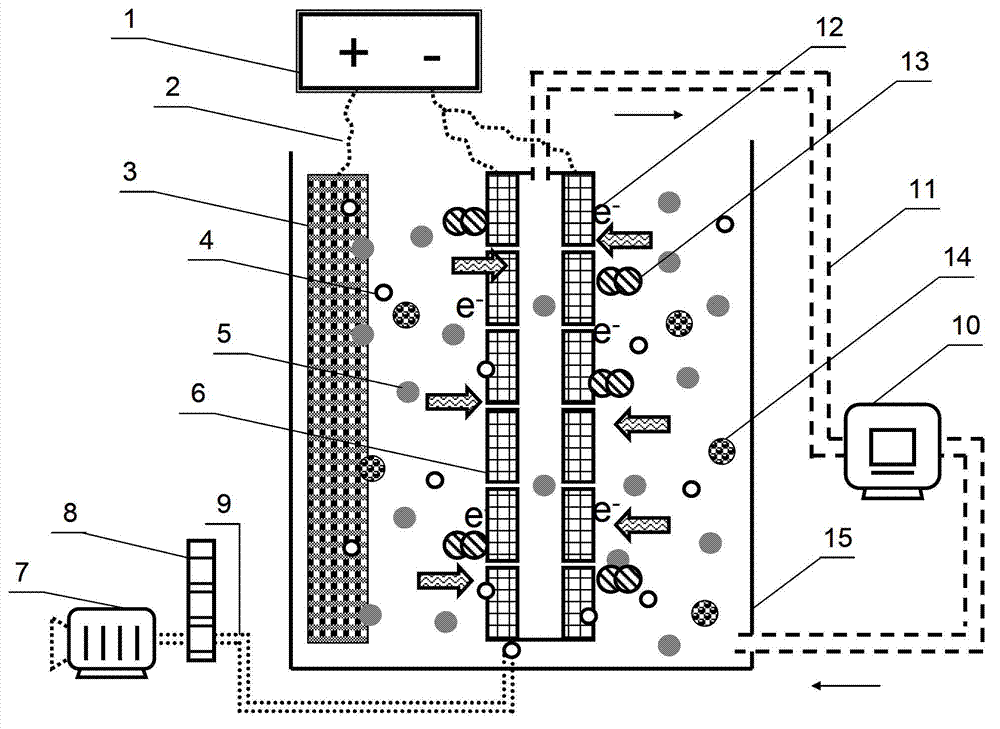

Method for removing organic matters in water by utilizing three-dimensional electrode electro-fenton and device thereof

InactiveCN102070230AIncrease contact areaExtension of timeWater/sewage treatment by oxidationFenton reagentFixed bed

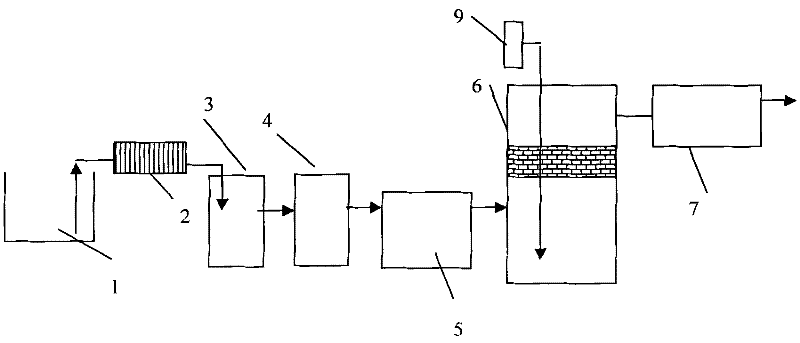

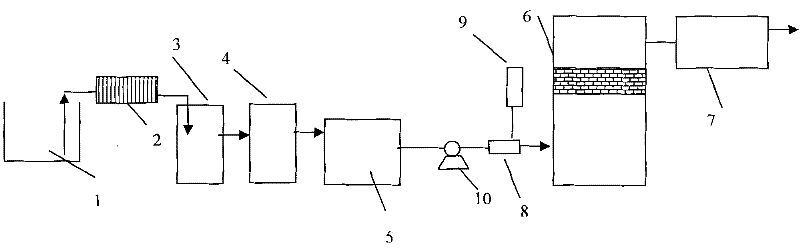

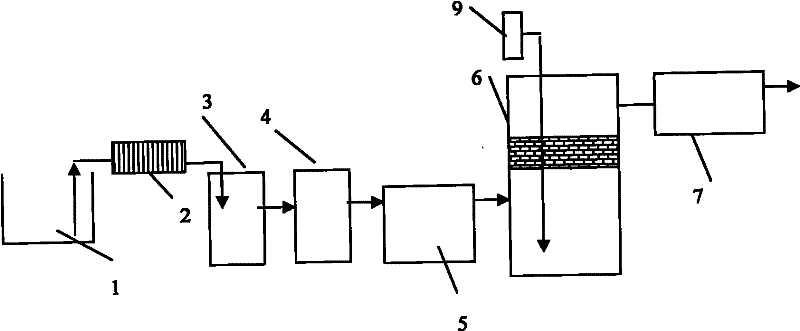

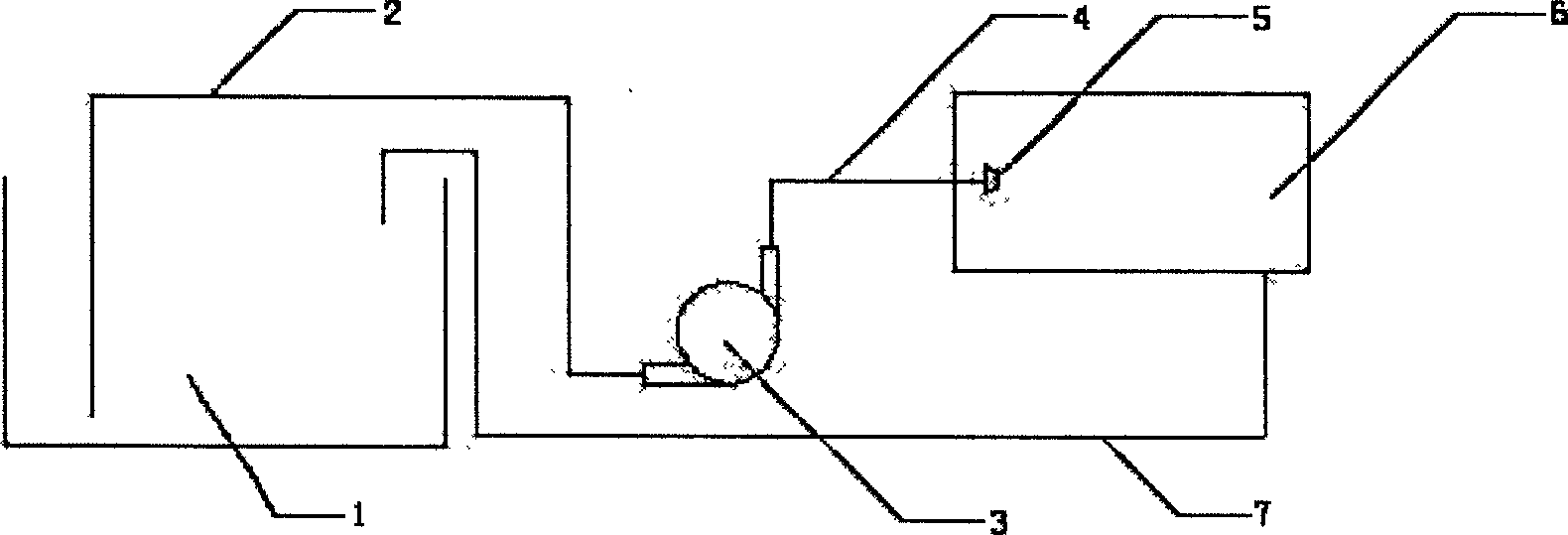

The invention relates to a method for carrying out oxidation treatment on organic waste water by utilizing a three-dimensional electrode electro-fenton and a device thereof. The device comprises a reactor shell, a carbon material cathode, an iron plate anode, a three-dimensional particle electrode of a fixed bed, a direct-current voltage-stabilizing power supply, a microporous aeration plate and an air pump, wherein a reactor consists of a reaction chamber and a gas chamber; the carbon material cathode, the iron plate anode and the particle electrode are positioned in the reaction chamber at the upper part of the reactor; and the gas chamber is formed between the bottom of the reactor and the microporous aeration plate. After direct current is introduced, the iron anode is oxidized to generate iron ions, oxygen in the gas chamber is reduced on the surface of the cathode to generate hydrogen peroxide, and the iron ions and the hydrogen peroxide form a fenton reagent to oxidize and remove organic matters in waste water; and simultaneously, due to the particle electrode, the contact area and the contact time of the waste water and the fenton reagent are increased, and the mass transfer effect of the waste water in the reactor is reduced. The invention is applicable to treatment of various types of organic waste water, the equipment is compact, the operation is easy, the whole reactor is easy to control, and the requirements of an actual water treatment unit are met.

Owner:HUAZHONG NORMAL UNIV

Process method for treating hardly-biodegradable organic wastewater

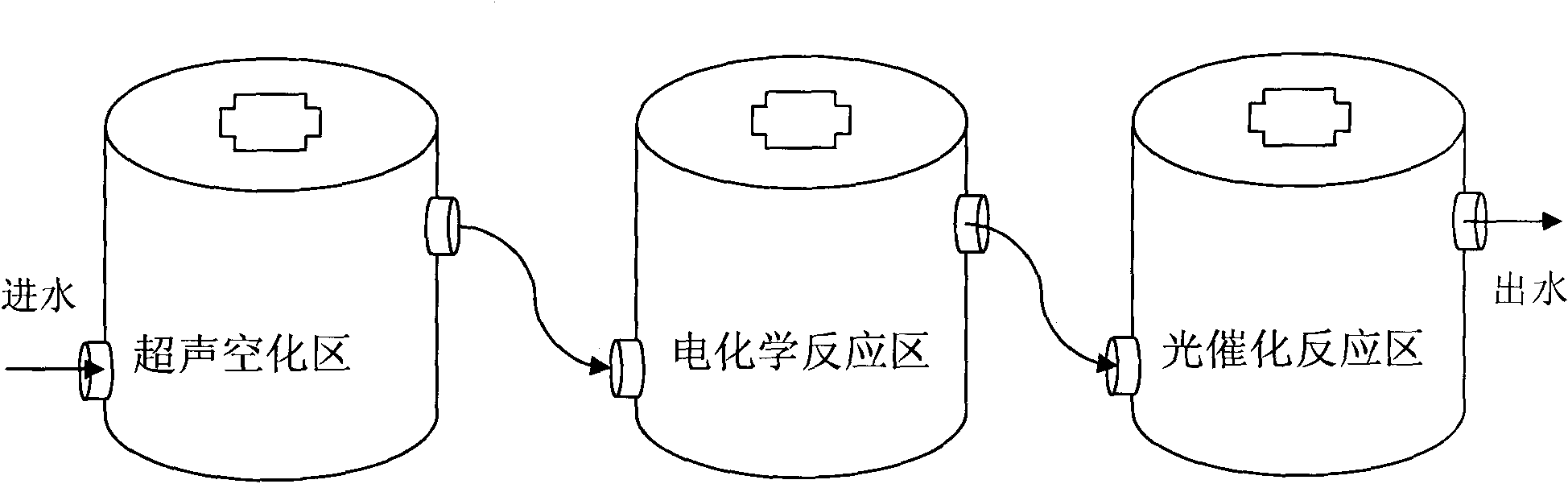

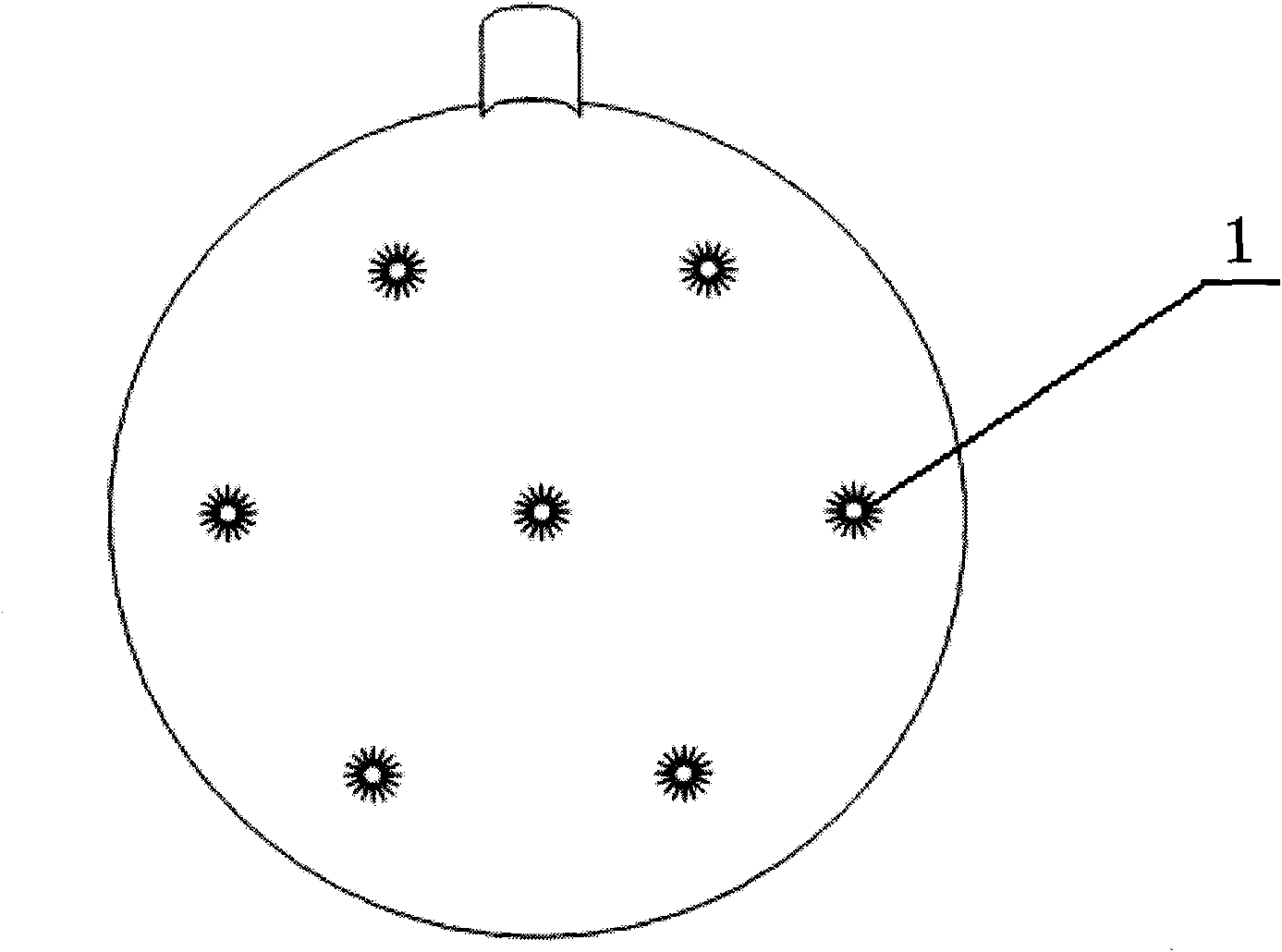

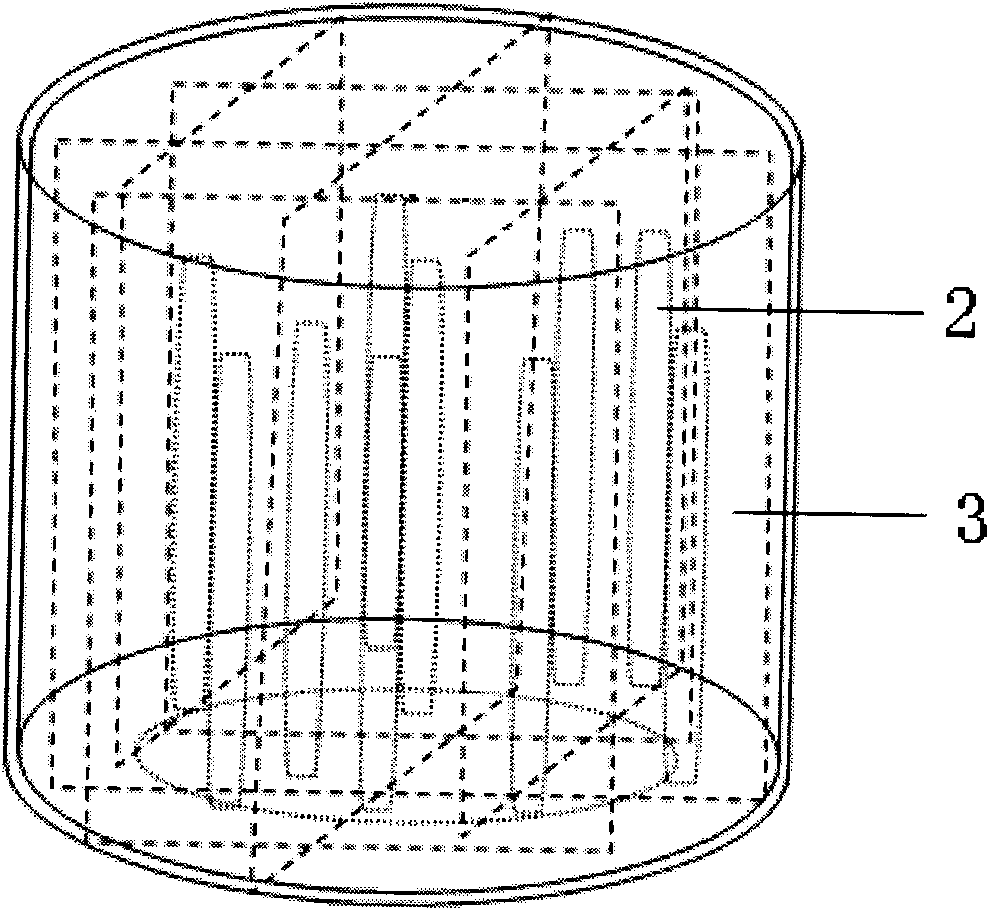

ActiveCN101786756AReduce dosageReduce generationWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsElectrochemical responseUltrasonic cavitation

The invention relates to a process method for treating hardly-biodegradable organic wastewater, and the method comprises the following steps: mainly utilizing the combination of ultraviolet light, electrochemistry, ultrasonic waves and oxidation-reduction chemical reaction for treating the hardly-biodegradable organic wastewater, and treating the wastewater by three reaction units of an ultrasonic cavitation zone, an electrochemical reaction zone and an ultraviolet light catalytic reaction zone, thereby realizing the high-efficient multi-stage deep wastewater oxidation reaction which combines the ultrasonic wastewater treatment method, the ultrasonic light and the collaborative Fenton reagent oxidation wastewater treatment, as well as the electrochemistry and the collaborative Fenton reagent oxidation wastewater treatment, effectively treating a variety of types of hardly-biodegradable organic wastewater and leading the COD removal rate of the wastewater after the treatment to be more than 90%.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

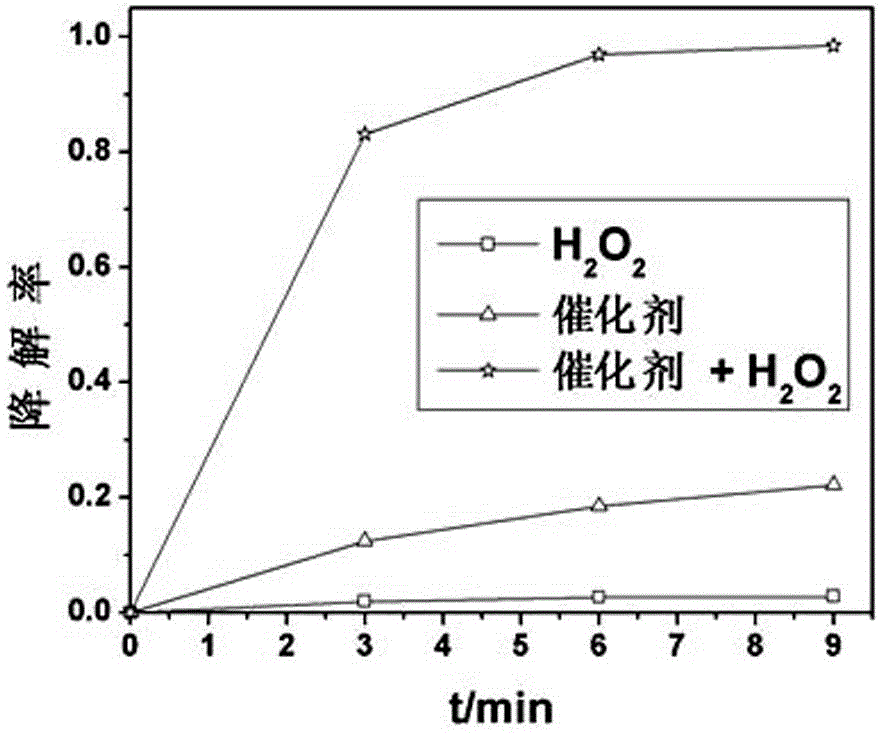

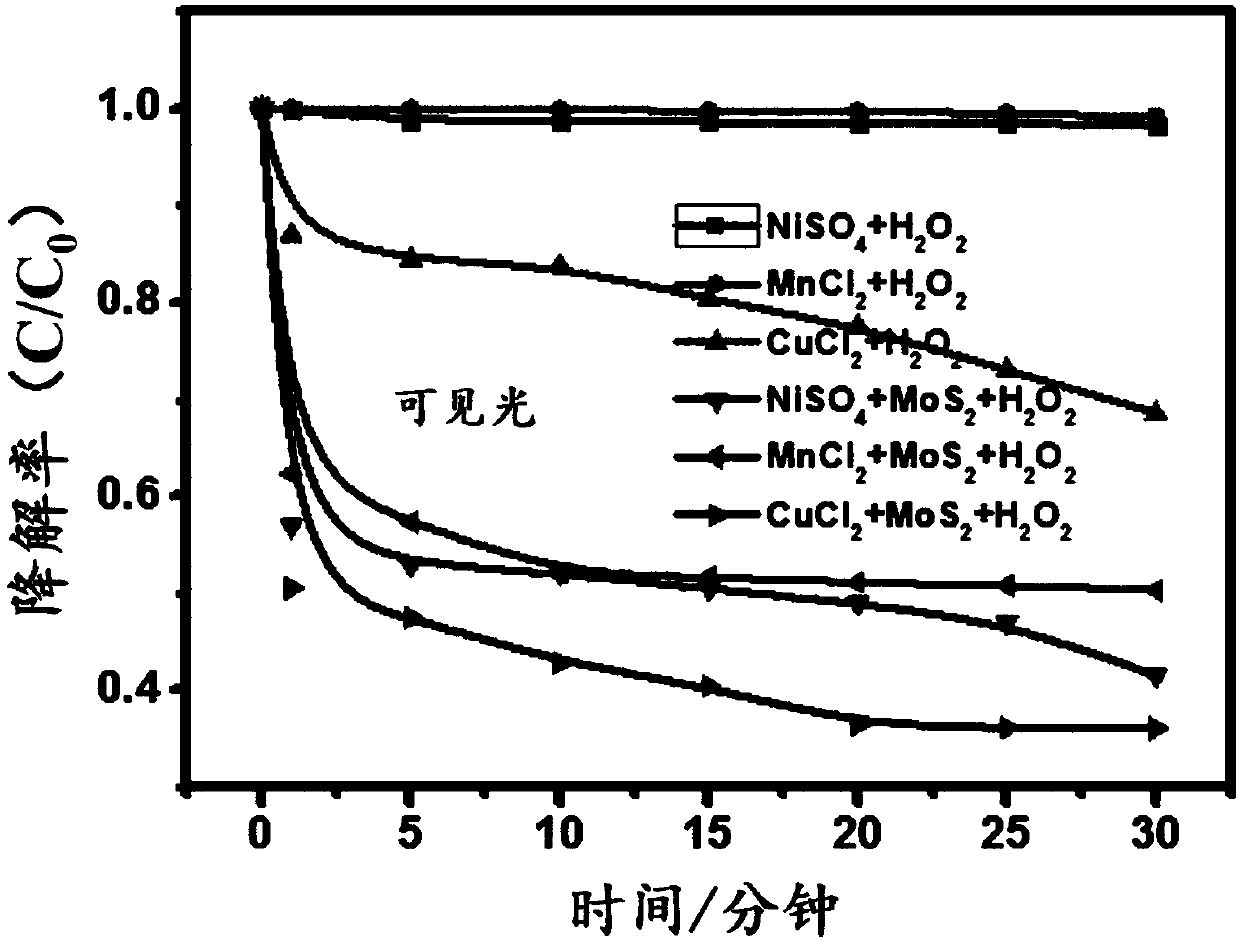

Preparation method and application of heterogeneous Fenton-like catalyst

InactiveCN102909073ALow costEfficient degradationOrganic-compounds/hydrides/coordination-complexes catalystsWaste water treatment from textile industryFiberCarbon fibers

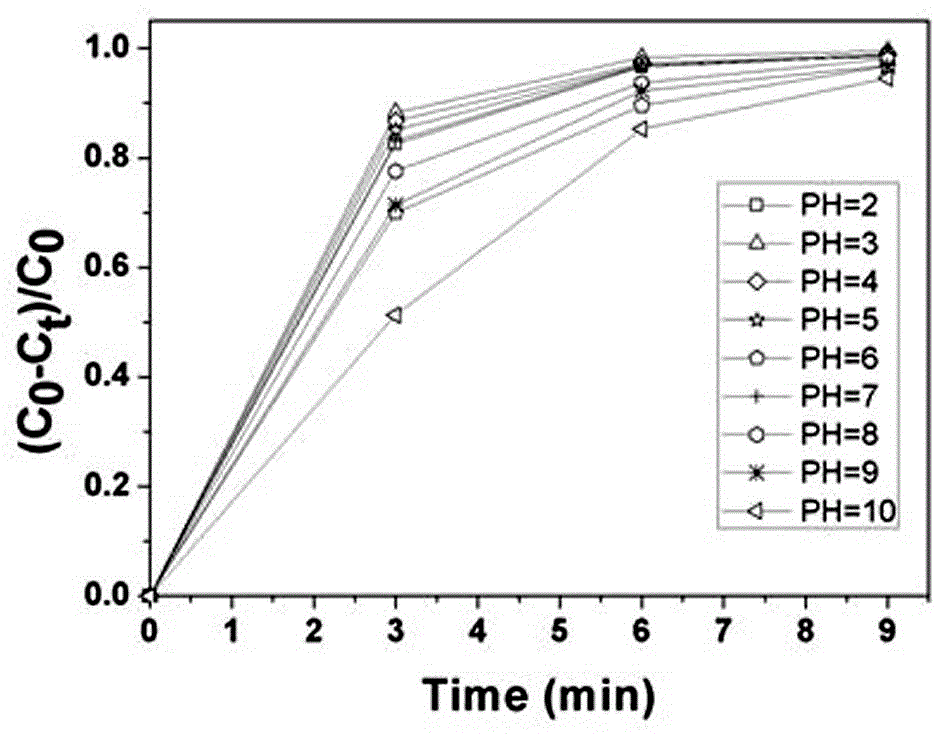

Disclosed are a preparation method and application of heterogeneous Fenton-like catalyst. The preparation method includes the steps of firstly, dissolving complexing agent and metal salt in distilled water to respectively prepare complexing agent and metal salt solutions; secondly dropwise adding the metal salt solution into the complexing agent solution under the action of a magnetic mixer, and mixing for 20-60 after dropwise addition to obtain metal complex solution; and thirdly, impregnating activated carbon fiber in the metal complex solution for 1-24h, and subjecting taken-out activated carbon fiber to distilled water washing and drying to obtain the heterogeneous Fenton-like catalyst. The preparation method is simple, and conditions are mild. Environment-friendly hydrogen peroxide is used as oxidant, no extra ultraviolet light or even visible light is needed, and the heterogeneous Fenton-like catalyst is capable of efficiently degrading organic pollutants such as dye within a wide pH range of 2-10. The heterogeneous Fenton-like catalyst is well repeatable, and secondary pollution of the homogeneous Fenton reagent caused by iron ions is avoided.

Owner:ZHEJIANG SCI-TECH UNIV

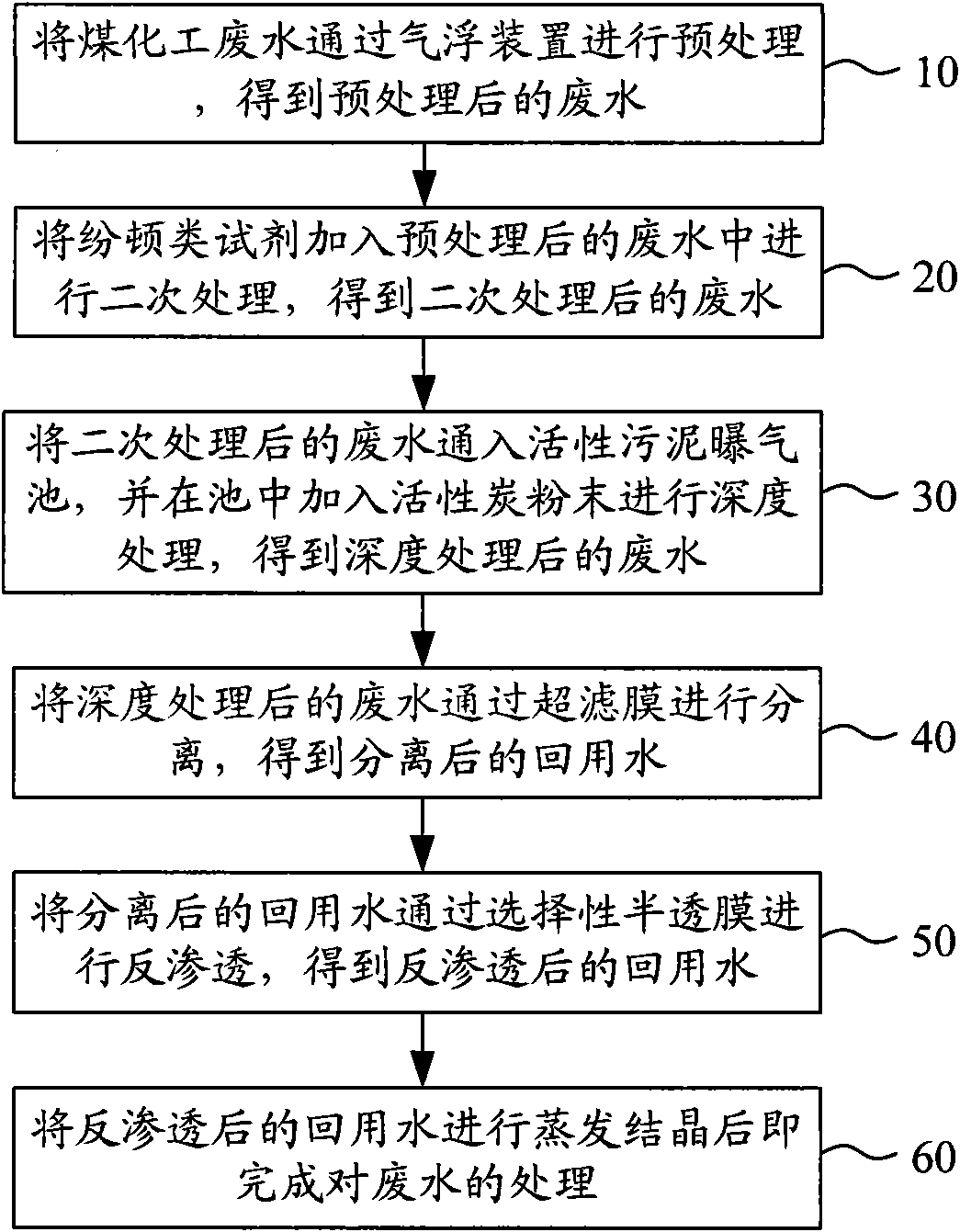

Coal chemical wastewater treating technique

InactiveCN101560045AMeet environmental protection requirementsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentActivated sludgeActivated carbon

The invention relates to a coal chemical wastewater treating technique, which comprises the following steps of: pretreating the coal chemical wastewater by an air-floatation device and obtaining pretreated wastewater; adding a fenton reagent into the pretreated wastewater to carry out secondarily treatment and obtaining secondarily treated wastewater; putting the secondarily treated wastewater into an activated sludge aeration pool and adding active carbon powder into the pool for deep treatment to obtain deeply treated wastewater; separating the deeply treated wastewater with a hyperfiltration membrane and obtaining separated recycled water; reversely penetrating the separated recycled water with a selective semi-permeable membrane and obtaining reversely penetrated recycled water; evaporating and crystallizing the reversely penetrated recycled water and finishing the wastewater treatment. The wastewater, after treated by the coal chemical wastewater treating technique, can realize the 'zero discharge' standard, meet the national environmental requirements, and obtain good economic and social benefits.

Owner:POTEN ENVIRONMENT GRP

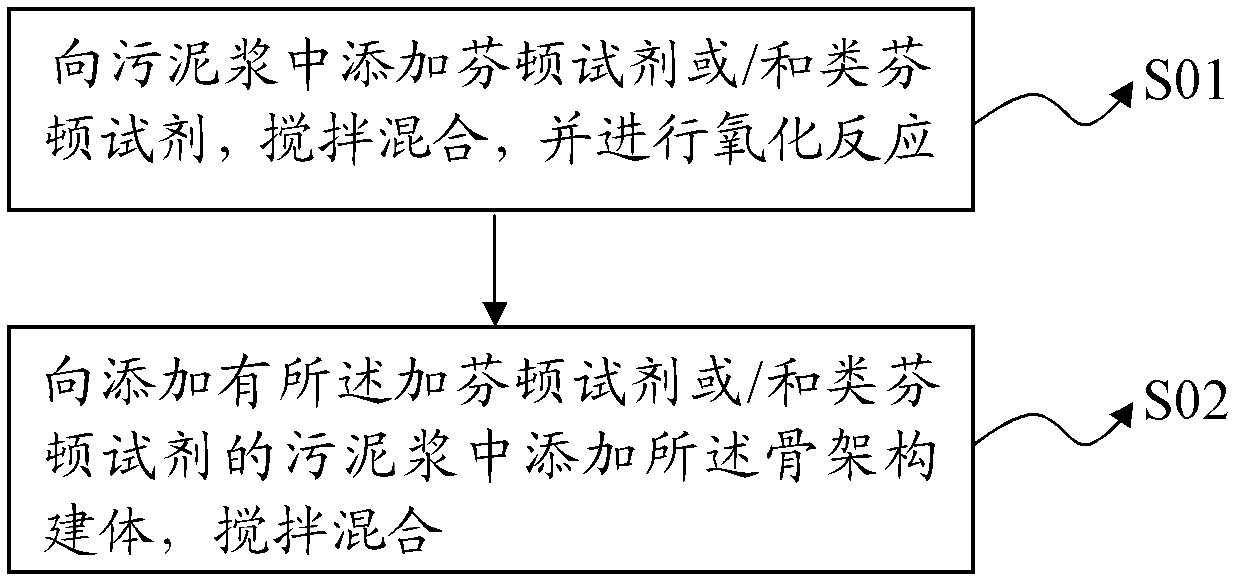

Sludge-dewatering compound conditioning agent and application method thereof

ActiveCN102381828AAchieve deep dehydrationShorten spin timeSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPOLYMER SUBSTANCEFenton reagent

The invention provides a sludge-dewatering compound conditioning agent and an application method thereof. The sludge-dewatering compound conditioning agent comprises a Fenton reagent or / and similar Fenton reagent and a skeleton construct, and the weight ratio of the Fenton reagent or / and similar Fenton reagent and the skeleton construct is 1: (0.05-300); and the skeleton construct adopts a powder body. The application method comprises the following steps: adding the Fenton reagent or / and similar Fenton reagent into sludge slurry, and mixing for oxidation; and adding the skeleton construct into the sludge slurry with the Fenton reagent or / and similar Fenton reagent, and mixing. Due to synergy of the Fenton reagent or / and similar Fenton reagent and the powder type skeleton construct, extracellular polymeric substances in sludge can be destructed effectively, the compressibility of organic substances can be reduced, and the sludge dewatering performance of the sludge-dewatering compound conditioning agent can be improved greatly. The procedures of the application method are simple, the conditions can be controlled easily, the sludge dewatering time can be shortened, and the large-scale treatment of the sludge can be realized.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

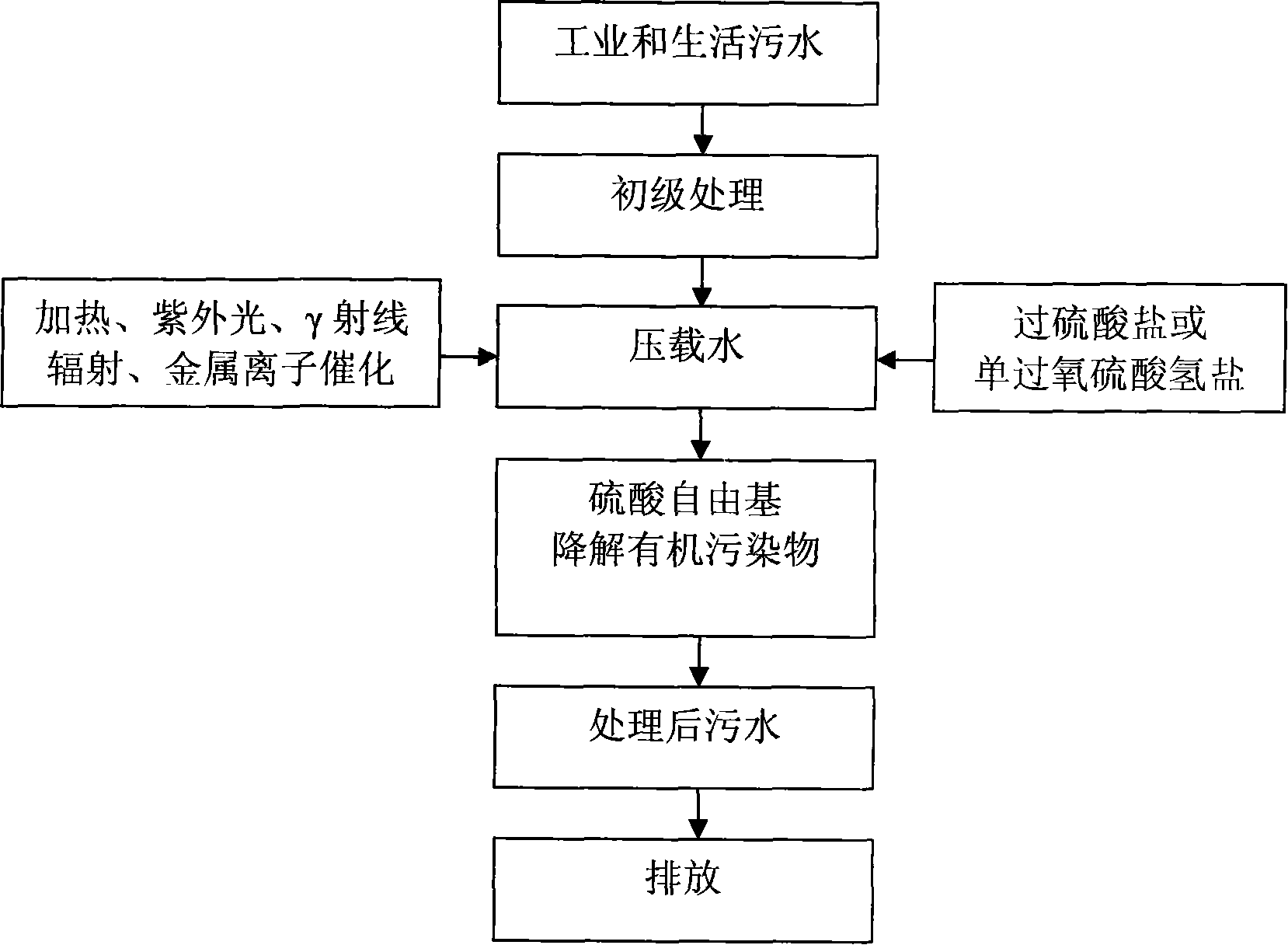

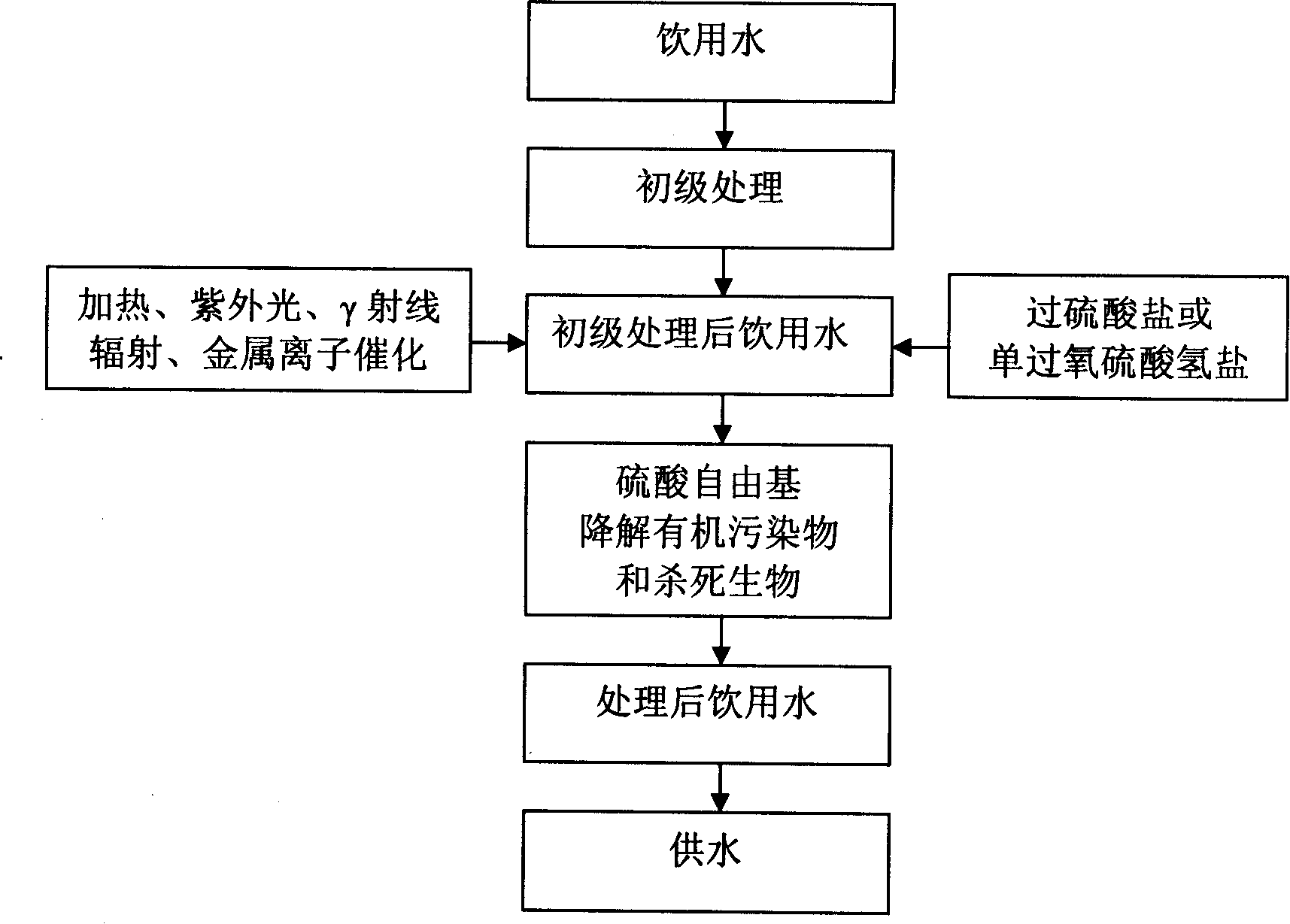

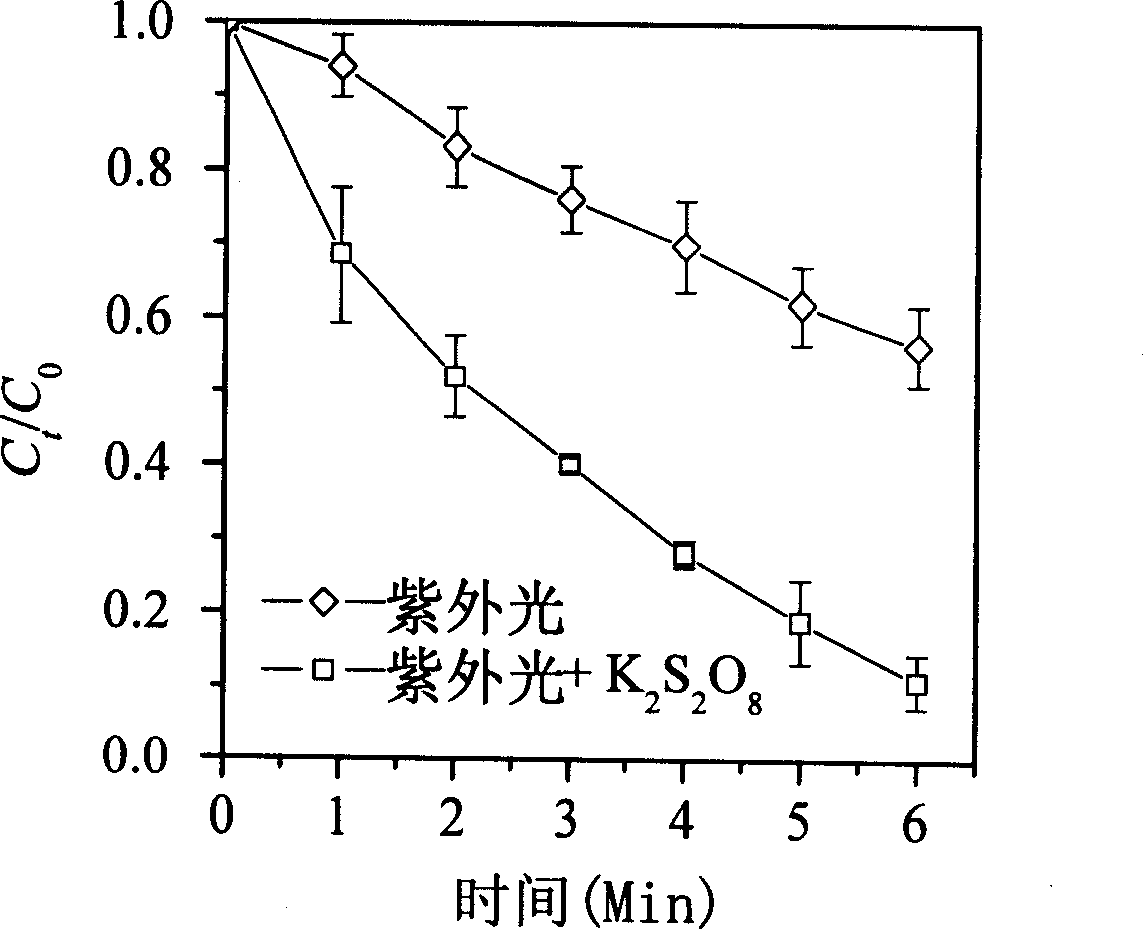

Method for processing sulphuric acid free radical oxidized water

InactiveCN101172691ANo secondary pollutionImprove processing efficiencyWater/sewage treatment by irradiationWater/sewage treatment by oxidationDecompositionFenton reagent

Owner:DALIAN MARITIME UNIVERSITY

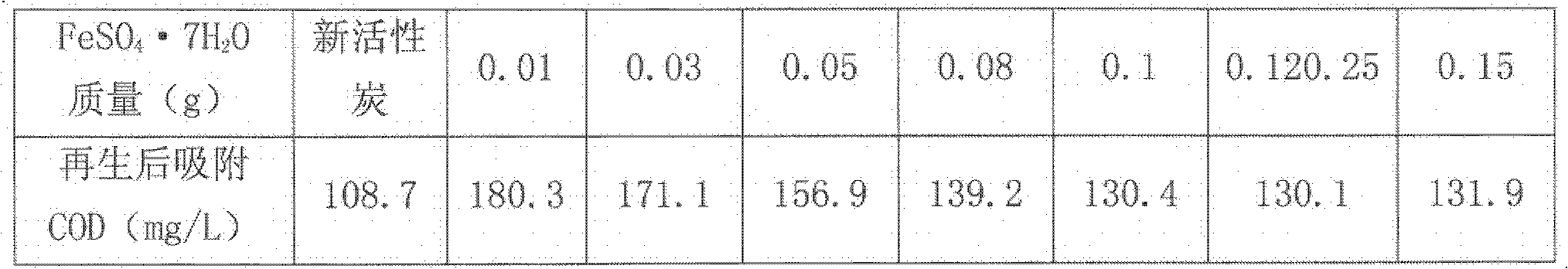

Method for preparing catalyst for treating high-concentration organic wastewater through catalytic oxidation

InactiveCN101601998AChange adsorptionIncrease the number ofWater contaminantsCatalyst activation/preparationHigh concentrationActivated carbon

The invention discloses a method for preparing a catalyst for treating high-concentration organic wastewater through catalytic oxidation, which comprises the following steps: 1) drying a cocoanut active charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, taking out and adding the cocoanut active charcoal into 2 to 10 percent sulfuric acid solution to perform soakage for 12 to 36 hours, adding the cocoanut active charcoal into a 1 to 10 percent oxydol solution to perform soakage for 12 to 36 hours, taking the cocoanut active charcoal out, and draying the cocoanut active charcoal in shade to obtain an activated charcoal for standby; and 2) soaking constant volume of the activated charcoal into transition metal salt solution for 12 to 36 hours, drying the activated charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, and calcining the activated charcoal at a temperature of between 300 and 650 DEG C for 3 to 8 hours to obtain the catalyst for treating the high-concentration organic wastewater through the catalytic oxidation. The service life of an active charcoal catalyst bed prepared by the method can reach over 0.5 to 1 year. After the treatment of the wastewater, compared with a Fenton reagent, the treatment efficiency of the catalyst is improved obviously, and the treatment cost is reduced by about 20 percent.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Advanced treatment method for fracturing flow-back fluid

ActiveCN102161536AHigh removal rateSimple processMultistage water/sewage treatmentWater/sewage treatment by oxidationLiquid wasteTreatment effect

The invention discloses an advanced treatment method for fracturing flow-back fluid, belongs to the field of water treatment of the development of oil and gas fields, and particularly relates to an advanced treatment method for the fracturing flow-back fluid generated during the operation of the oil and gas fields. The treatment method for the fracturing flow-back fluid, which has high effect and continuous treatment process, is provided to solve the problems that the treatment effect is lower, the continuous treatment cannot be performed, and the cost is higher existing in the prior art. The method comprises the following steps of: pre-oxidizing waste liquor with the pH value of between 8 and 12, adding a coagulant and performing gel breaking treatment and adding a Fenton reagent and treating, and performing secondary coagulation and oxidization treatment. In the method, through homogeneous and heterogeneous catalysis reactions, the treatment cost is reduced, and the removal rate of organic substances is also high; and chemical oxygen demand (COD) of effluent can meet the national sewage discharge standard.

Owner:四川绿源环保技术开发有限公司

Sulfide-containing industrial wastewater treatment reagent and reaction method thereof

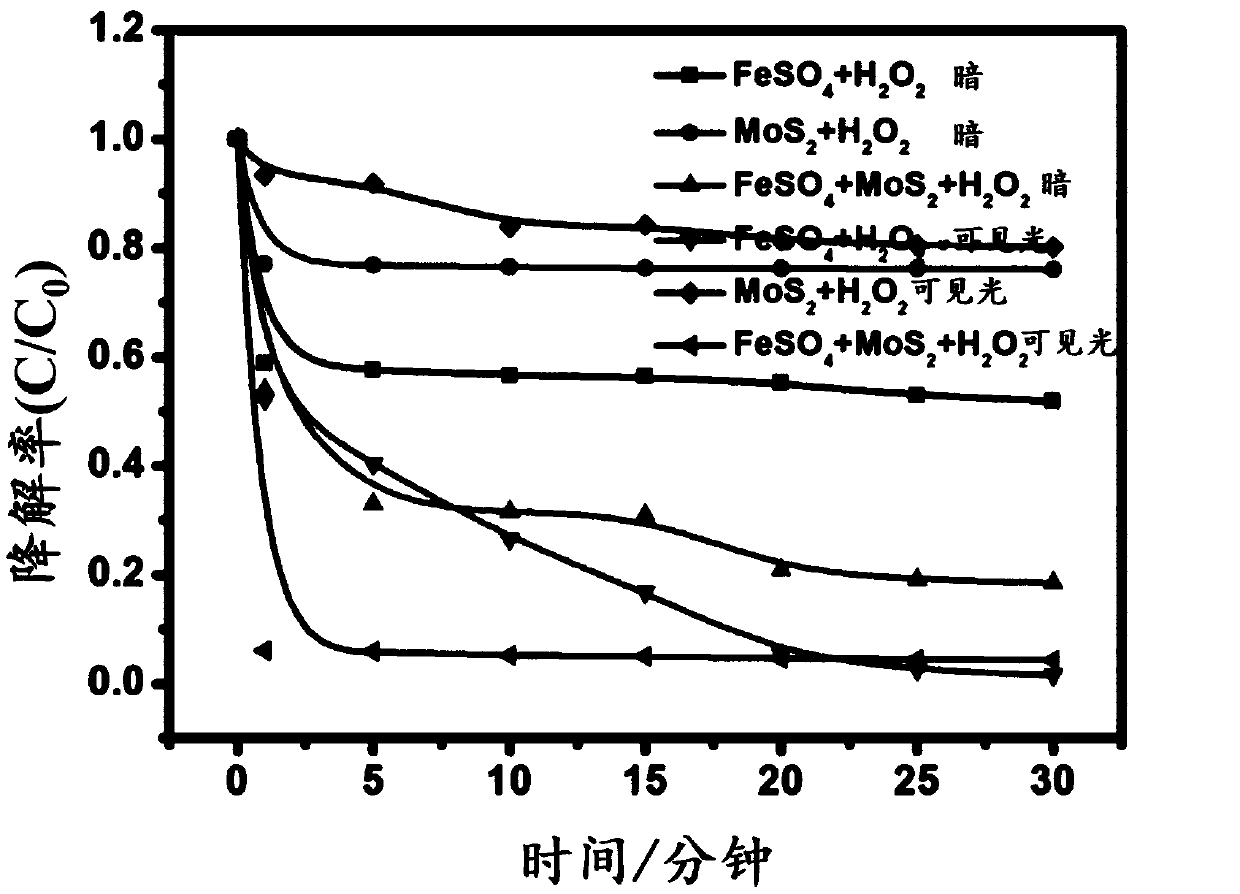

InactiveCN107720930AImprove utilization efficiencyImprove degradation efficiencyWater contaminantsWater/sewage treatment by oxidationHydrogen peroxide breakdownFenton reaction

The invention relates to the field of chemistry, in particular to the treatment of contaminants. A sulfide-containing industrial wastewater treatment reagent comprises a Fenton reagent containing an iron source and hydrogen peroxide, and also comprises sulfide, wherein the sulfide is mixed in the Fenton reagent to be used as a cocatalyst of the Fenton reagent. Compared with the traditional homogeneous Fenton reaction system, the cheap and readily available sulfide is used as the cocatalyst, so that the catalytic reaction is firstly carried out on the surface of the sulfide to improve the efficiency of decomposition of hydrogen peroxide to generate hydroxyl radicals during the Fenton reaction process and improve the degradation efficiency and the utilization efficiency of the hydrogen peroxide, and the sulfide per se can be recycled, and the problem of producing a large amount of iron sludge by homogeneous Fenton can be avoided, thereby reducing the treatment cost.

Owner:EAST CHINA UNIV OF SCI & TECH

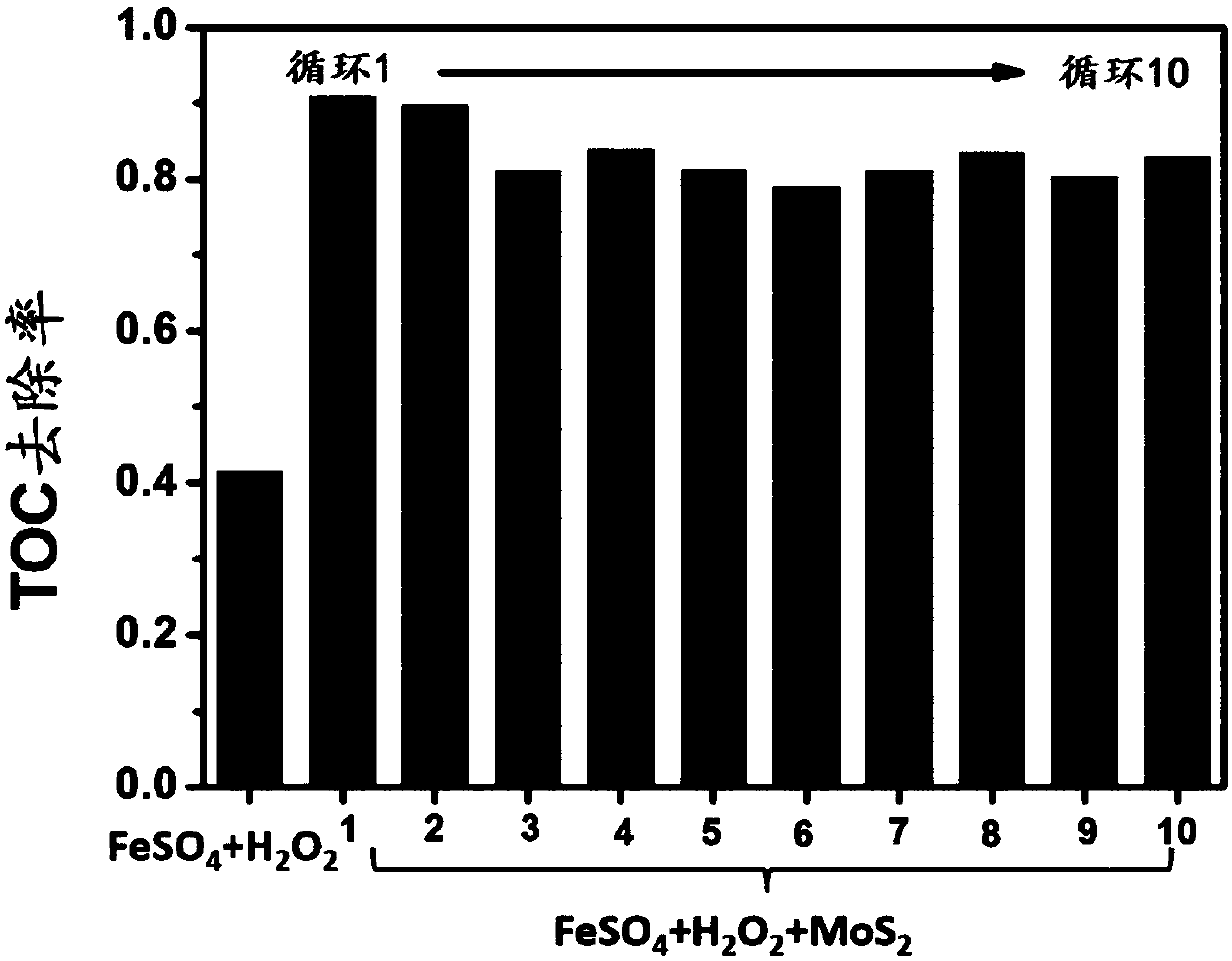

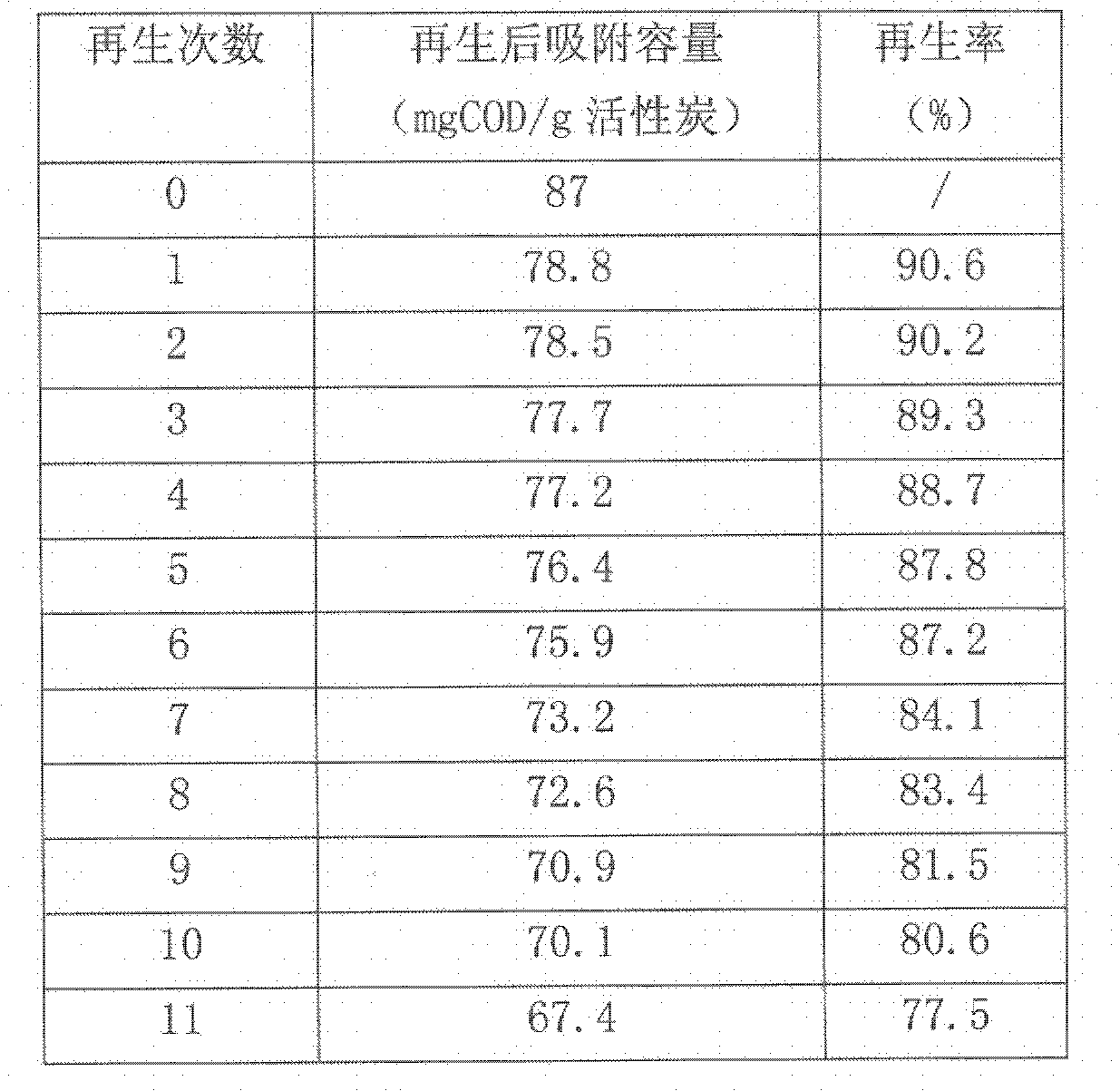

Regeneration method for activated carbon adsorbed and saturated by refractory organics

InactiveCN102658101ARestore adsorption activityEasy to operateCarbon compoundsCombustible gas purificationDisperse dyeActivated carbon

Owner:DONGHUA UNIV

Electrolyte polymer for polymer electrolyte fuel cells, process for its production and membrane-electrode assembly

ActiveUS20060063903A1Increased durabilityReduce in quantityCell electrodesFinal product manufactureFuel cellsFenton reagent

To provide an electrolyte polymer for polymer electrolyte fuel cells, made of a perfluorinated polymer having sulfonic groups, characterized in that in a test of immersing 0.1 g of the polymer in 50 g of a fenton reagent solution containing 3% of an aqueous hydrogen peroxide solution and 200 ppm of bivalent iron ions at 40° C. for 16 hours, the amount of eluted fluorine ions detected in the solution is not more than 0.002% of the total amount of fluorine in the polymer immersed. The electrolyte polymer of the present invention has very few unstable terminal groups and has an excellent durability, and therefore, is suitable as a polymer constituting an electrolyte membrane for polymer electrolyte fuel cells and a polymer contained in a catalyst layer.

Owner:ASAHI GLASS CO LTD

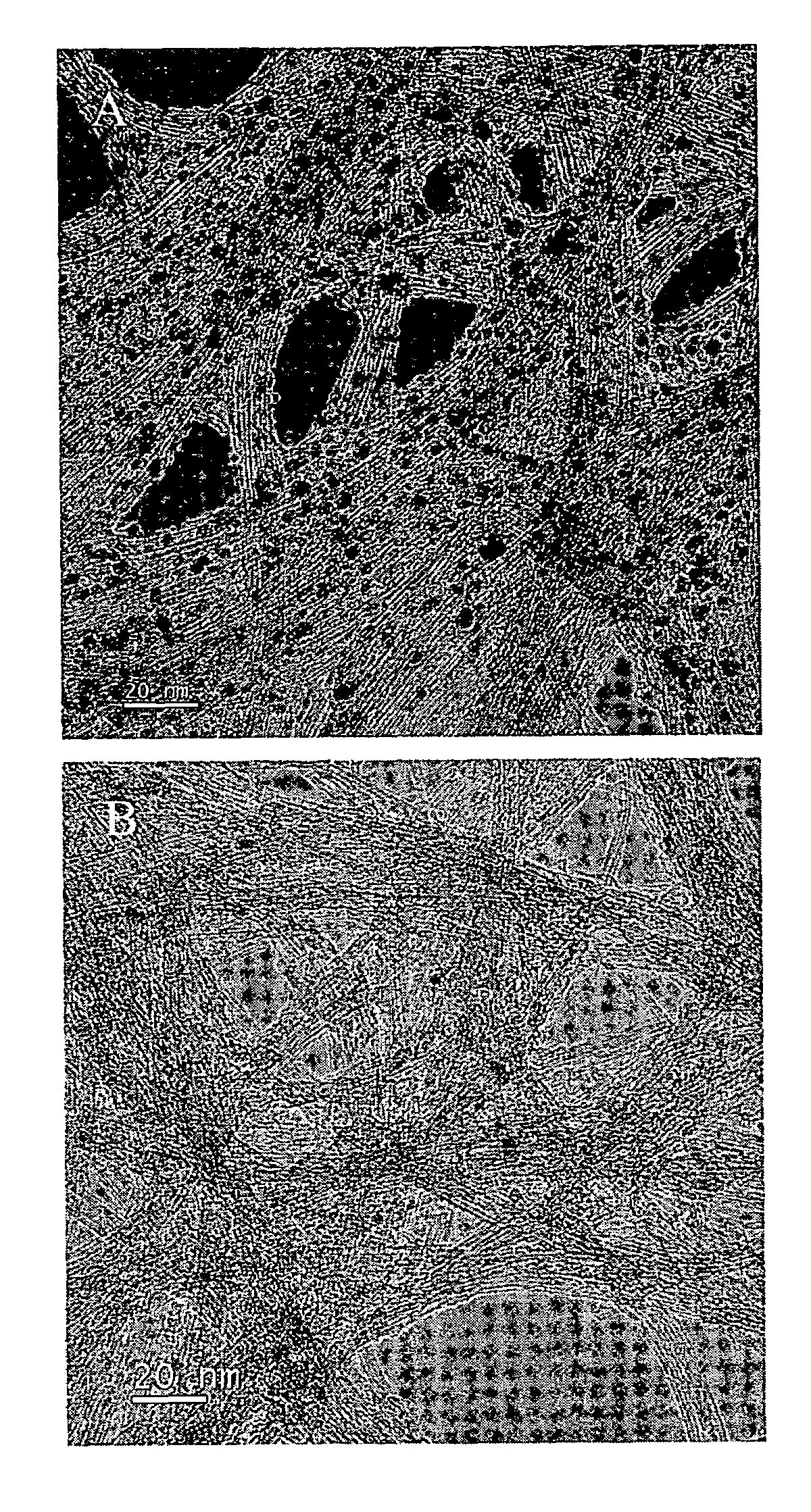

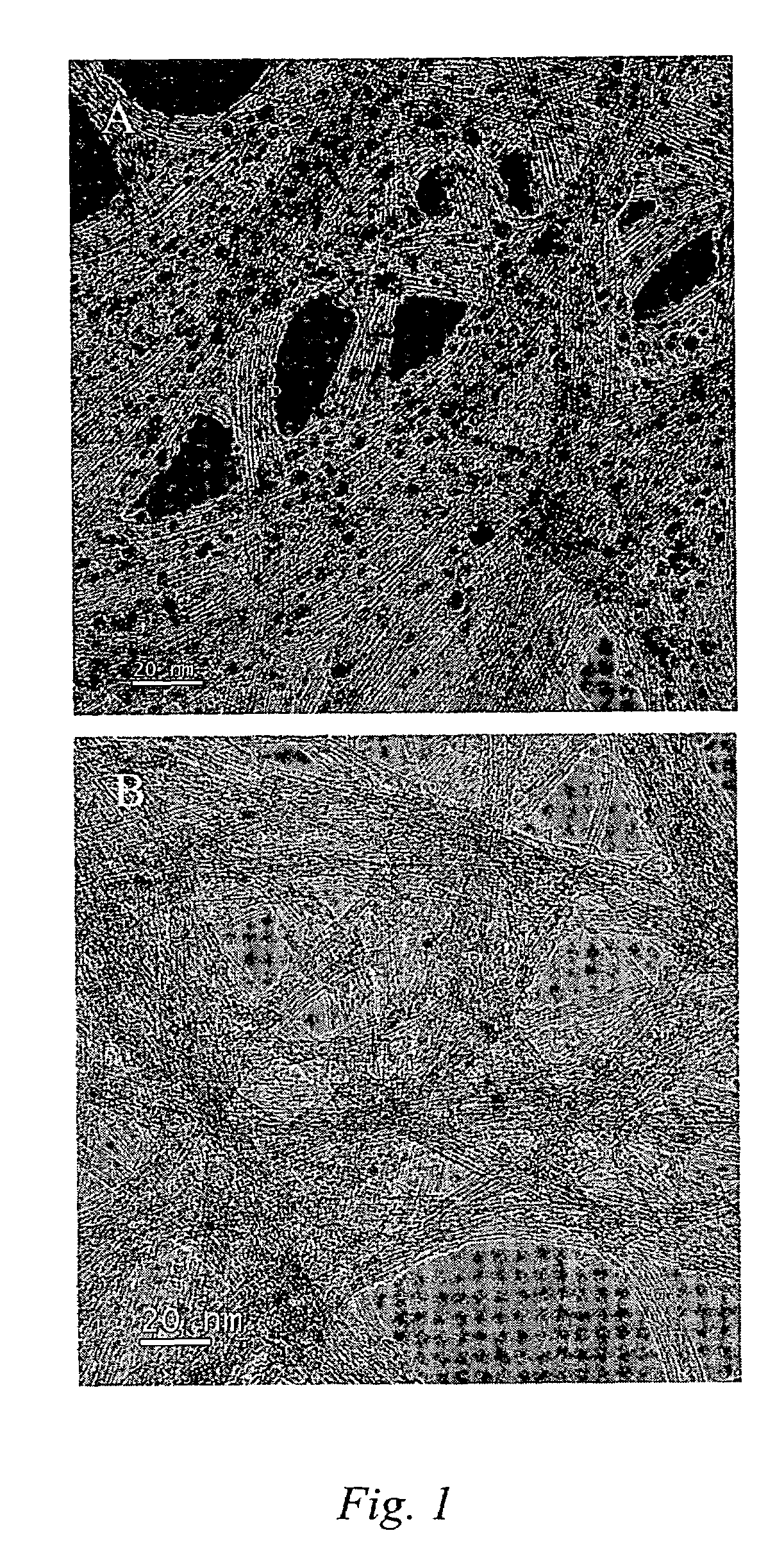

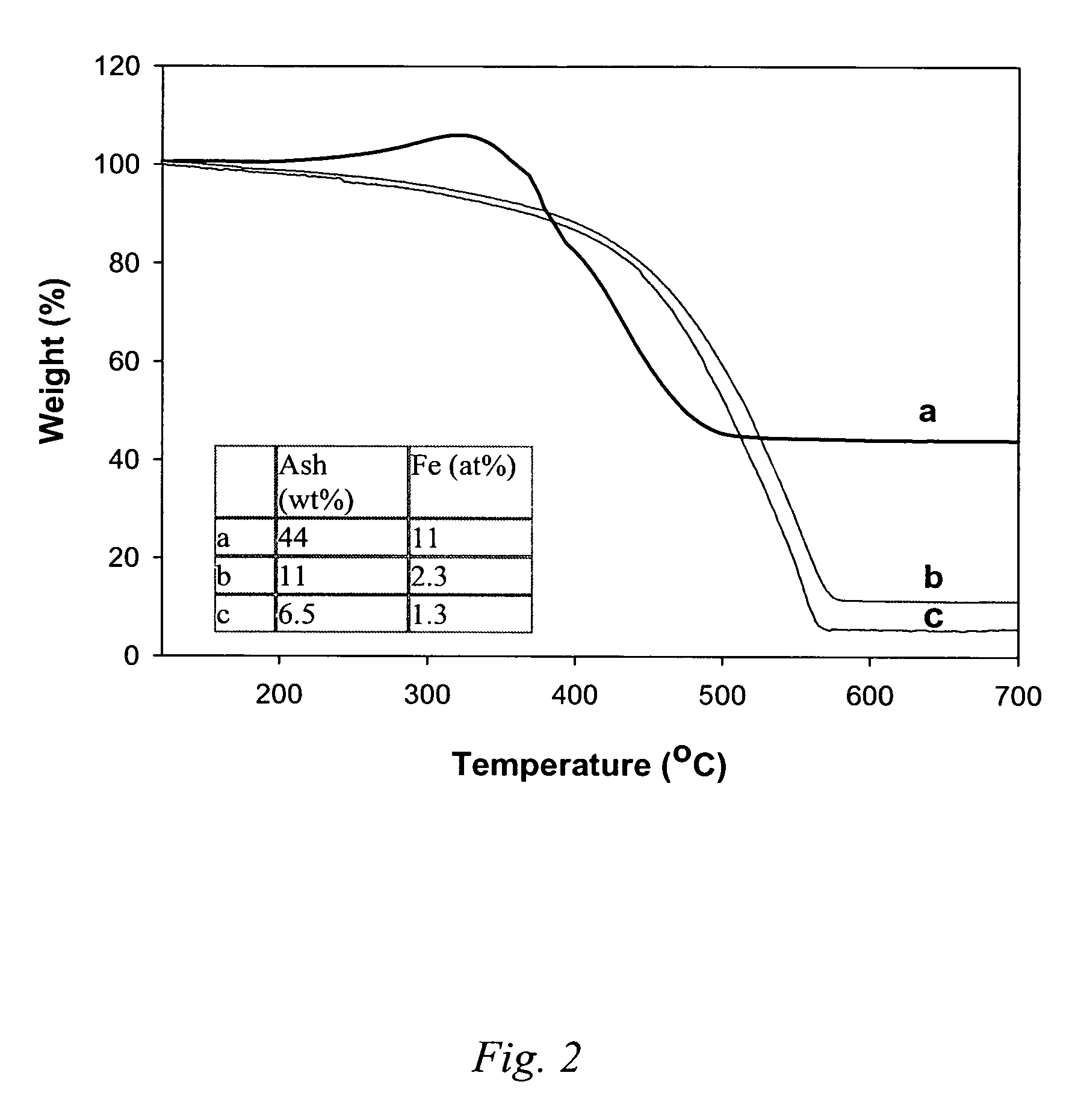

Purification of carbon nanotubes based on the chemistry of fenton's reagent

The present invention is directed to methods of purifying carbon nanotubes (CNTs). In general, such methods comprise the following steps: (a) preparing an aqueous slurry of impure CNT material; (b) establishing a source of Fe2+ ions in the slurry to provide a catalytic slurry; (c) adding hydrogen peroxide to the catalytic slurry to provide an oxidative slurry, wherein the Fe2+ ions catalyze the production of hydroxyl radicals; and (d) utilizing the hydroxyl radicals in the oxidative slurry to purify the CNT material and provide purified CNTs.

Owner:RICE UNIV

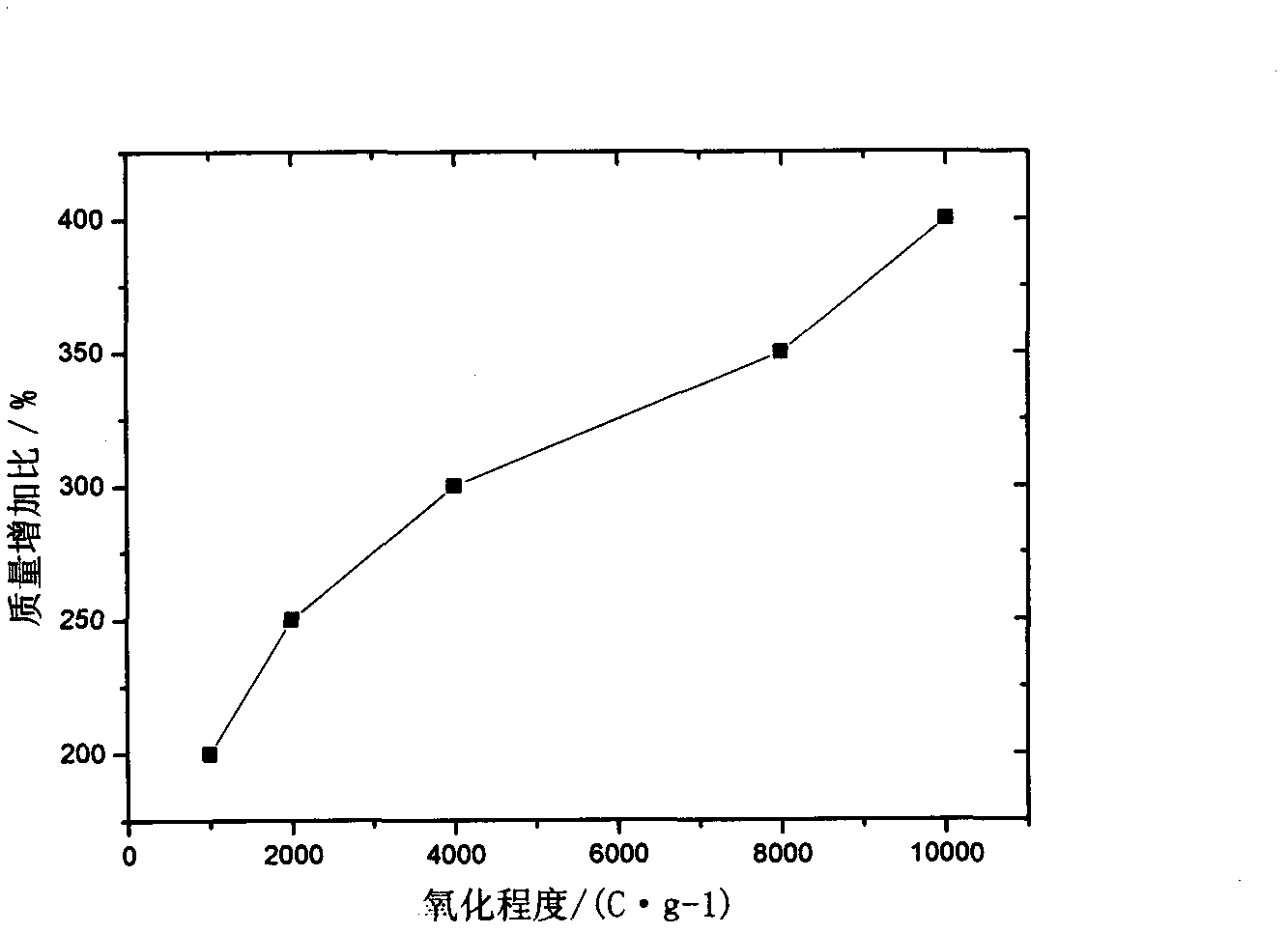

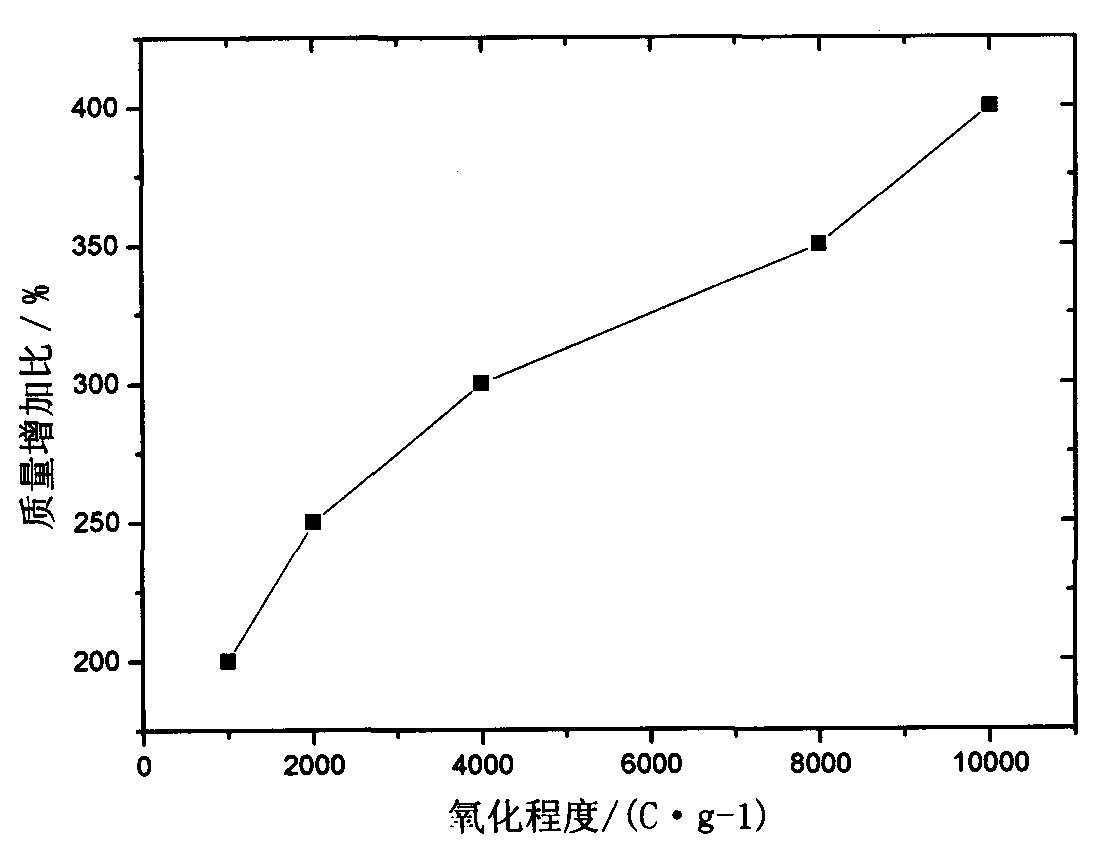

Modified method of graphite felt used for full-vanadium fluid flow battery electrode

ActiveCN102136579AControl the rate of oxidation reactionIncrease the reaction areaCell electrodesFenton reagentDistilled water

The invention relates to a modified method of a graphite felt used for a full-vanadium fluid flow battery electrode. Firstly a graphite felt is processed by an air oxidation method, and then the graphite felt processed by the air oxidation method is modified by utilizing hydrogen peroxide or an Fenton reagent. The modified method comprises the following steps: a. air oxidation processing: placingthe washed graphite felt into a heating device for heating; oxidizing in the hot air environment; naturally cooling to room temperature in the heating device after oxidation; and washing the cooled graphite felt; b. hydrogen peroxide or Fenton reagent modified processing: placing the washed graphite felt into the hydrogen peroxide or the Fenton reagent to be modified to obtain the modified graphite felt; and c. processing residues on the surface of the graphite felt: washing the graphite felt after being processed by a hydrogen peroxide solution or the Fenton reagent by utilizing distilled water; and removing the hydrogen peroxide or the Fenton reagent residual on the surface of the graphite felt. The modified method provided by the invention has the advantages of being simple and feasible in operation and low in cost and environment-friendly.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

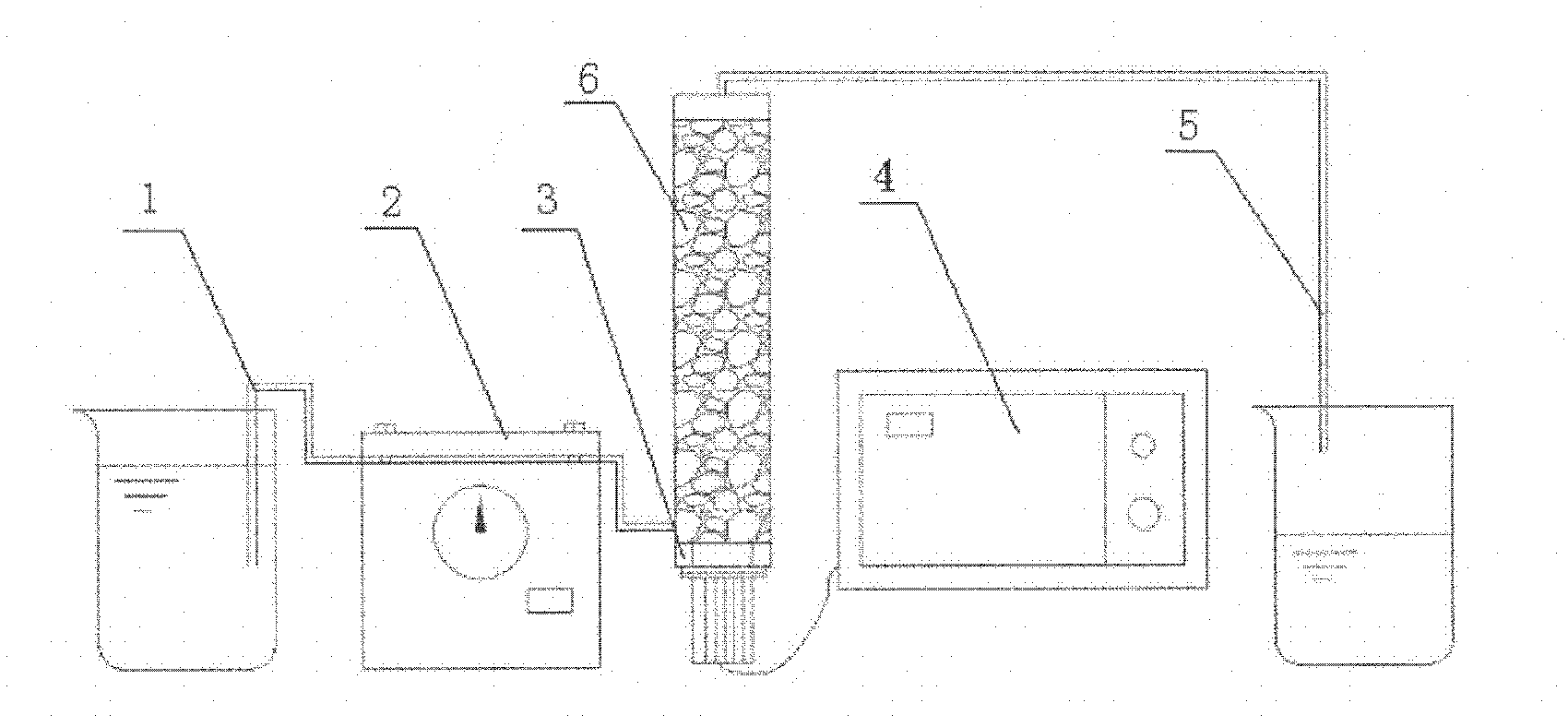

Method and device for treating wastewater by advanced oxidation process

ActiveCN103145274ATo achieve the purpose of biochemicalTo achieve the purpose of treating waste with wasteWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentElectrolysisFenton reagent

The invention belongs to the technical field of treatment for industrial production wastewater, and particularly relates to a method and a device for treating wastewater by an advanced oxidation process, which solve the shortages in the existing methods for treating industrial wastewater. The method comprises the following steps of: performing micro-electrolysis reduction reaction on wastewater; impinging the wastewater with hydrogen peroxide in liquid-liquid reaction equipment; forming Fenton reagent by Fe<2+> and hydrogen peroxide in the wastewater; and performing contact reaction on the wastewater and ozone in the liquid-liquid reaction equipment. The device comprises an impinging stream-rotating packed bed device, wherein nozzles are formed at the outlets of two liquid inlet tubes respectively, the two nozzles are coaxial and the outlets are oppositely arranged, the two liquid inlet tubes are connected with a hydrogen peroxide storage tank and a micro-electrolysis tank respectively, and liquid outlets are connected with the micro-electrolysis tank; and an intake port is connected with an ozone generator, and an exhaust port is connected with a KI adsorption liquid storage tank. The method and the device disclosed by the invention have the beneficial effects that the technical process is simple, the operation is convenient, and wastes are used for treating wastes, thus furthest reducing the treatment cost.

Owner:ZHONGBEI UNIV

Sewage treatment method coupled with organic membrane and electro-Fenton catalytic technology

InactiveCN103193297AReduce pollutionReduce workloadWater/sewage treatment by electrochemical methodsWater/sewage treatment bu osmosis/dialysisConductive polymerFiltration

A sewage treatment method coupled with an organic membrane and electro-Fenton catalytic technology belongs to the technical field of sewage treatment in environmental engineering. The sewage treatment method is characterized in that a conductive polymer modified organic fabric membrane is used as a cathode membrane, while a stainless steel mesh is used as an anode, a Fenton reagent is formed in the vicinity of the membrane under the conditions of appropriate electric field, dissolved oxygen, pH value and ferrous ion concentration, and the reaction liquid is circulated through membrane filtration so that the Fenton reagent is dispersed in the system. For the characteristics of sewage, the type and the size of the cathode membrane, the voltage and the like can be optimized. Power generation microorganisms in sewage-treatment microbial fuel cells generate electric power by utilizing sewage, oxygen is reduced by using electrons transmitted from the anode while the organical membrane serves as the cathode; and hydrogen peroxide is formed to arouse Fenton reaction so as to degrade pollutants. The sewage treatment method provided by the invention has the following advantages that organic membrane separation is combined with the electro-Fenton catalytic technology, the pollution and the load of the membrane assembly are reduced, effective contact and reaction of the pollutants and the membrane electrode are enhanced by membrane filtration; and furthermore, through membrane filtration, large-particle pollutants difficult to degrade can be removed.

Owner:DALIAN UNIV OF TECH

Adsorption oxidation method for treating high-concentration acrylonitrile wastewater

InactiveCN102190387AReduce COD valueLarge specific surface areaMultistage water/sewage treatmentWater/sewage treatment by sorptionHigh concentrationSuspended particles

The invention relates to an adsorption oxidation method for treating high-concentration acrylonitrile wastewater, which comprises the following steps of: adding aqueous solution of a flocculating agent into the acrylonitrile wastewater, stirring, and standing until flocs are settled at the bottom of a container for later use; making the wastewater pass through a microfiltration membrane or an ultrafiltration membrane to remove suspended particles, the flocs and acrylonitrile oligomer from the wastewater, regulating the pH value of the wastewater, adding activated carbon and a Fenton reagent, and stirring for adsorption oxidation; filtering the wastewater by using activated carbon filter cloth, adding the activated carbon and hydrogen peroxide into the wastewater, and stirring for secondary adsorption oxidation; and filtering the wastewater by using the activated carbon filter cloth, and neutralizing filtrate by using sodium hydroxide until the filtrate is neutral. The method improves treatment efficiency, is not limited by the chemical oxygen demand (COD) of the wastewater, avoids secondary pollution, is low in energy consumption, easy and convenient to operate and small in occupied area, and has the characteristics that the method is high-efficiency, economic and environment-friendly.

Owner:TSINGHUA UNIV

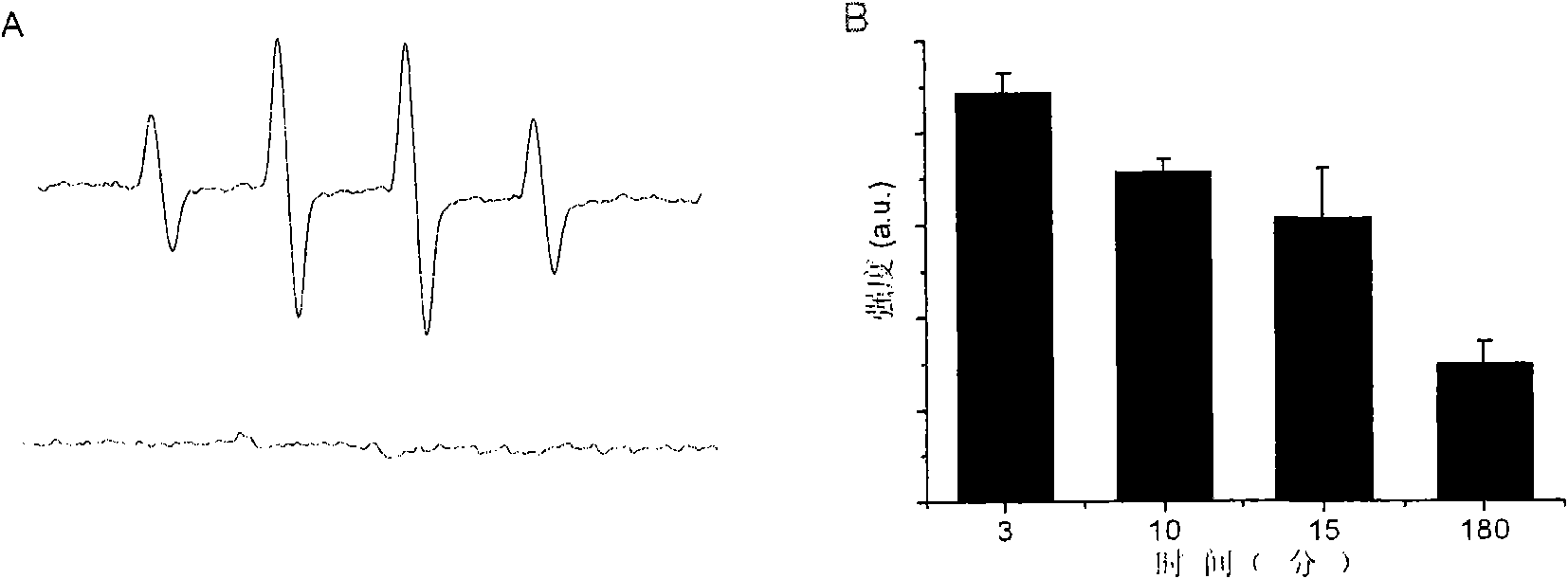

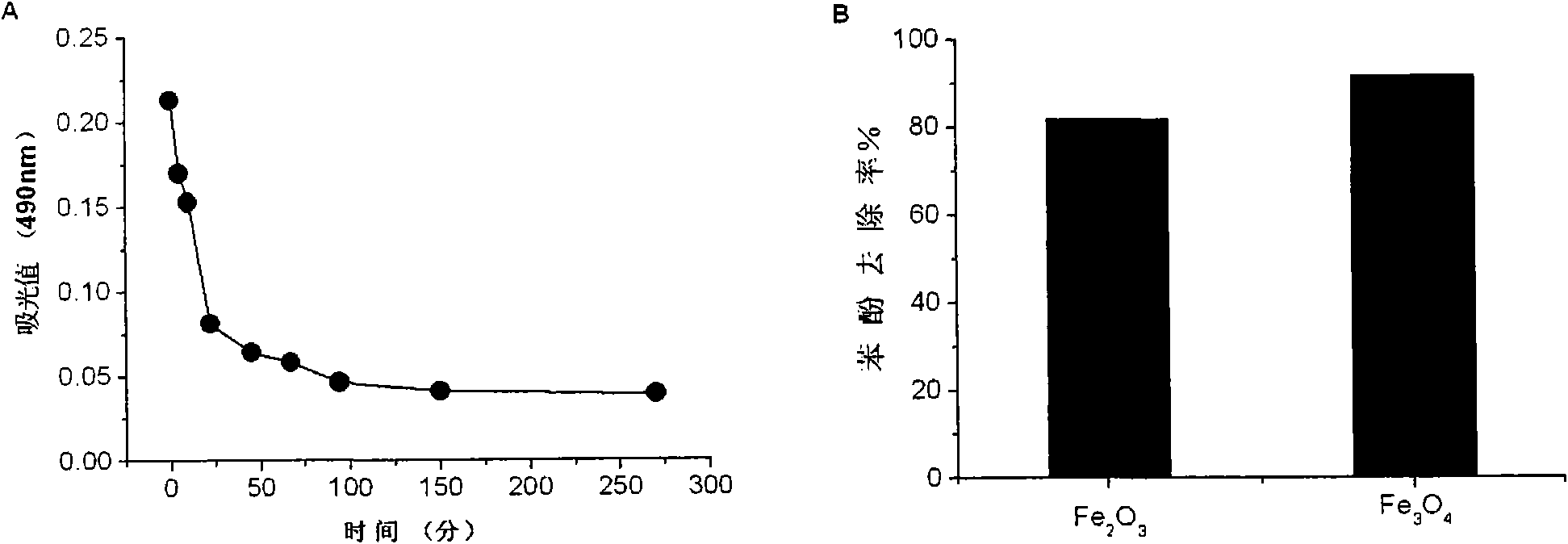

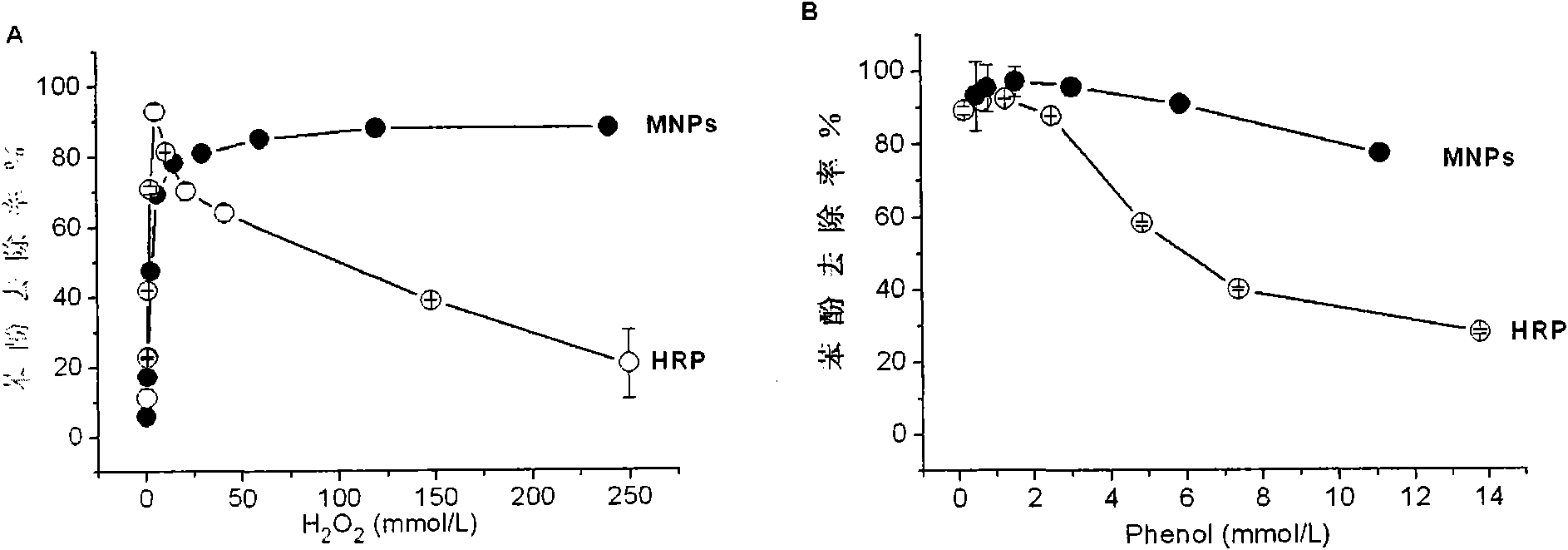

Magnetic nanometer material for processing organic pollutants

InactiveCN101549294AHigh catalytic efficiencyLow costMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by reductionClearance rateFenton reagent

The invention relates to a magnetic nanometer material for processing organic pollutants. It is found that the magnetic nanometer material has the capability of catalyzing H2O2 to generate a large numbers of hydroxyl radicals and can be widely applied to process various poisonous and harmful substances in the environment. For example, the magnetic nanometer material can be utilized to oxidize phenol in sewages, and the final clearance rate can reach more than 95 percent. The invention provides a novel reagent and a novel method for degrading the organic pollutants. Compared with a convention Fenton reagent and a peroxydase catalyzing method, the magnetic nanometer material has the advantages of low cost, easy preparation, high stability, no secondary pollution and recovery for repeated use. The novel functions of the magnetic nanometer material have great values in the aspects such as sewage disposal, and the like.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES

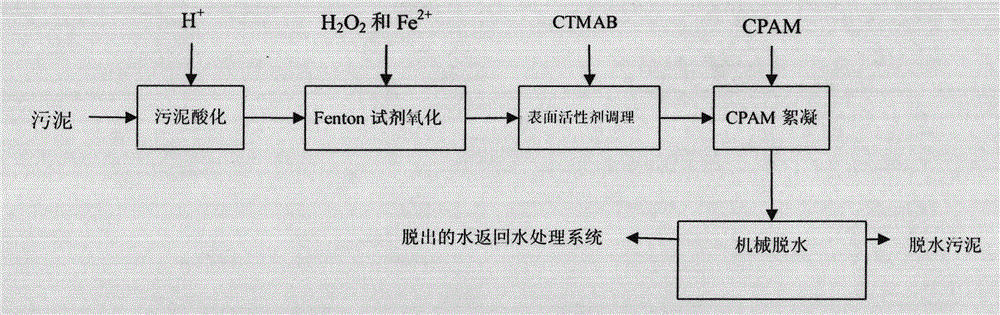

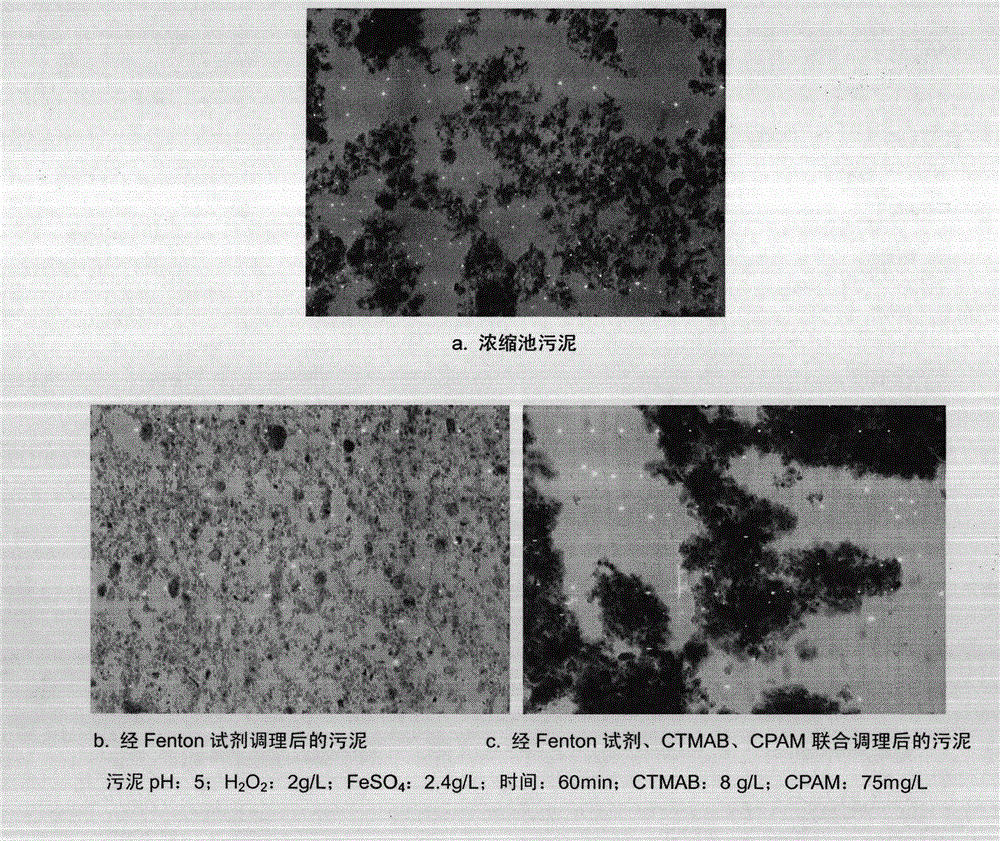

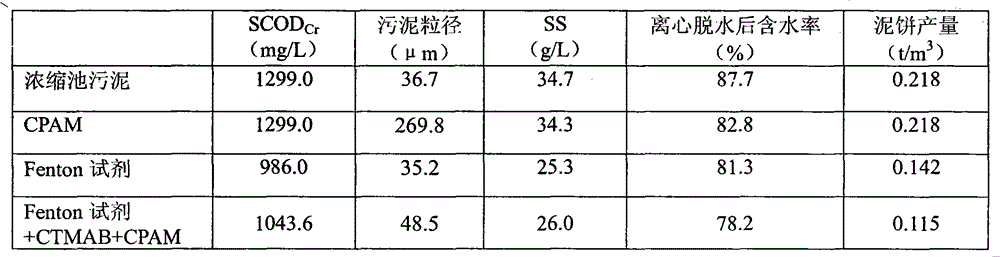

Joint-conditioning dehydration method for sludge

InactiveCN102910793AImprove dehydration effectIncrease solid contentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationParticulatesFenton reagent

The invention is named as 'a joint-conditioning dehydration method for sludge', belonging to the technical field of environmental engineering and sludge treatment. The joint-conditioning dehydration method comprises the following steps of: adding H202 and FeSO4 into the sludge (with pH being equal to 5) acidified by mineral acid, degrading organic matter by virtue of strong oxidation of a Fenton reagent, and dissolving and cracking microbial cells and extracellular polymeric substances in the sludge; adding a surfactant CTMAB (Cetyl Trimethyl Ammonium Bromide) into the sludge to reduce the surface tension of the sludge and change the surface characteristics of the sludge, and transforming a part of interstitial water into free water; and flocculating sludge particulates with disperse structure, small particle diameter and large specific surface area by virtue of flocculation action of polyacrylamide (CPAM) to the sludge particulates. After the sludge is subjected to joint conditioning of the Fenton reagent, the surfactant and the CPAM, the moisture content of the sludge after being centrifugally dewatered is reduced to 78.2% from 87.7%, and the output of mud cakes is reduced to 0.115t / m<3> from 0.218t / m<3>, therefore, the dehydration property of the sludge can be improved remarkably, the investment and operation costs are reduced effectively, and an ideal sludge reduction goal is reached.

Owner:BEIJING NORMAL UNIVERSITY

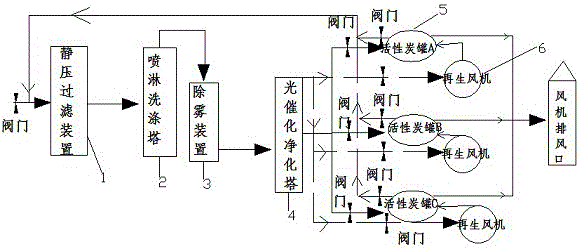

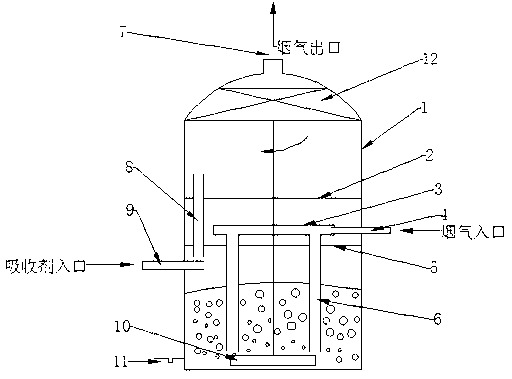

Purifying device and method for spraying industry VOCs exhaust gas

InactiveCN106693573AEasy to handleEfficient and thorough processingCombination devicesGas treatmentPhotocatalytic reactionFiltration

The invention discloses a purifying device and method for spraying industry VOCs exhaust gas; the purifying device comprises the following processing systems: a static pressure filtration device, a spray scrubber, a demister, a photocatalytic purification tower, multiple groups of activated carbon adsorption tanks, a regeneration fan and a draught fan chimney which are connected successively; the static pressure filtration device is internally provided with a coarse-effect filter; the spray scrubber is internally provided with a water tank, and a Fenton reagent solution can be added in the water tank; the demister is used for removal of water mist brought out when exhaust gas passes through the spray scrubber; a photocatalytic reaction cavity of the photocatalytic purification tower is internally provided with a nano composite anatase titanium dioxide photocatalyst and an UV light; the multiple groups of activated carbon adsorption tanks are internally provided with coconut shell activated carbon. The purifying device and method have better processing effect on organic exhaust gas generated in spraying industries.

Owner:易能环境技术有限公司

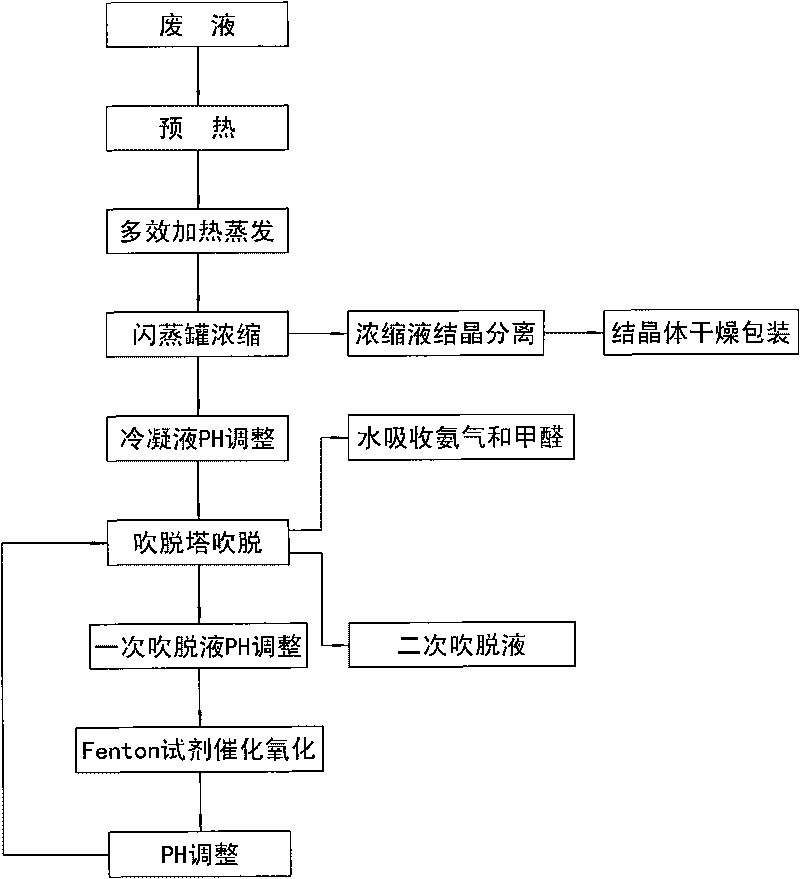

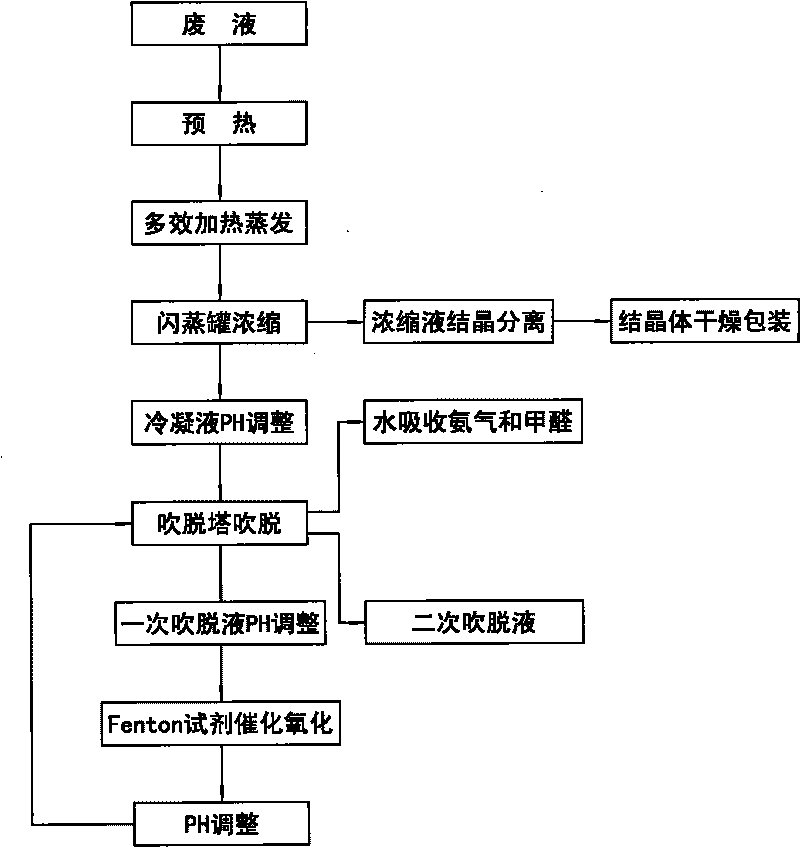

Method for treating wastewater from preparation of glycine by chloroacetic acid ammonolysis process

InactiveCN101717165AReduce energy consumptionReduce corrosionWater contaminantsMultistage water/sewage treatmentLiquid wasteFenton reagent

The invention discloses a method for treating wastewater from the preparation of glycine by the chloroacetic acid ammonolysis process, comprising the following steps: throwing waste liquid into a multi-effect falling film vacuum evaporation system, preheating the waste liquid in the multi-effect falling film vacuum evaporation system, heating and evaporating the waste liquid with a multi-effect falling film evaporator, putting the waste liquid in a flashing pot, concentrating the waste liquid until achieving the ammonium chloride concentration of 35-45%, crystallizing the concentrated solution with a crystallizer at normal temperature, drying and packaging the crystalline solid, adjusting the pH value of condensate which is generated by the multi-effect falling film vacuum evaporation system to 10-11 with NaOH, stripping the condensate in a stripping tower, absorbing methanol and ammonia which are generated from stripping with water, adjusting the pH value of primary stripping solution to 2-4 with dilute sulfuric acid, catalyzing and oxidizing the primary stripping solution with Fenton reagent at 30-40 DEG C, adjusting the pH value of the catalyzed and oxidized primary stripping solution to 10-11 with dilute sulfuric acid, throwing the primary stripping solution into the stripping tower, stripping the primary stripping solution for the second time in the stripping tower, absorbing methanol and ammonia which are generated from the primary stripping solution stripping with water, and discharging secondary stripping solution.

Owner:DALIAN FISHERIES UNIVERSITY

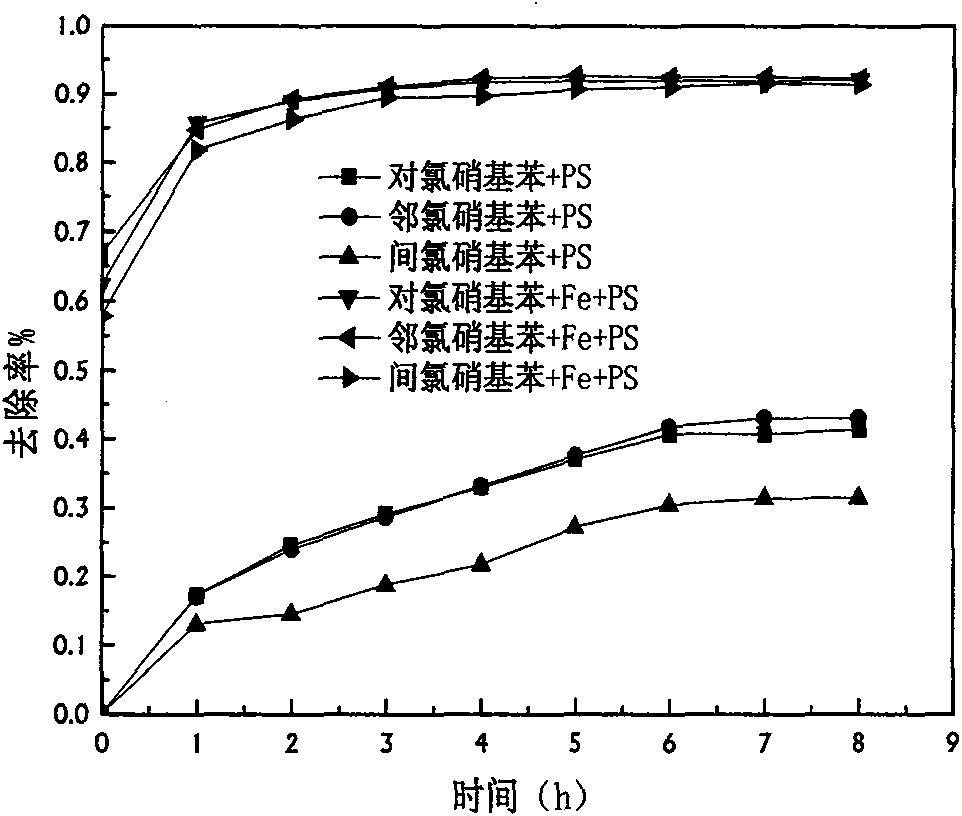

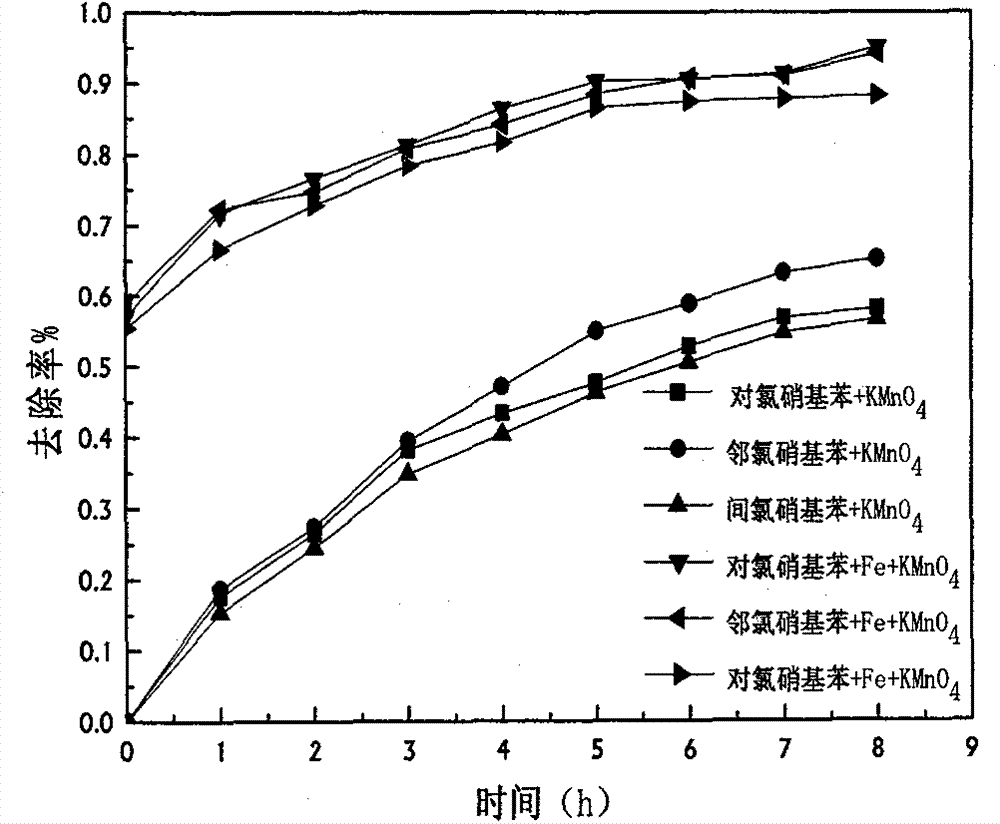

Method for increasing speed of oxidative degradation of organic pollutant in soil

ActiveCN104511476AShort repair timeImprove conversion rateContaminated soil reclamationPotassium persulfateFenton reagent

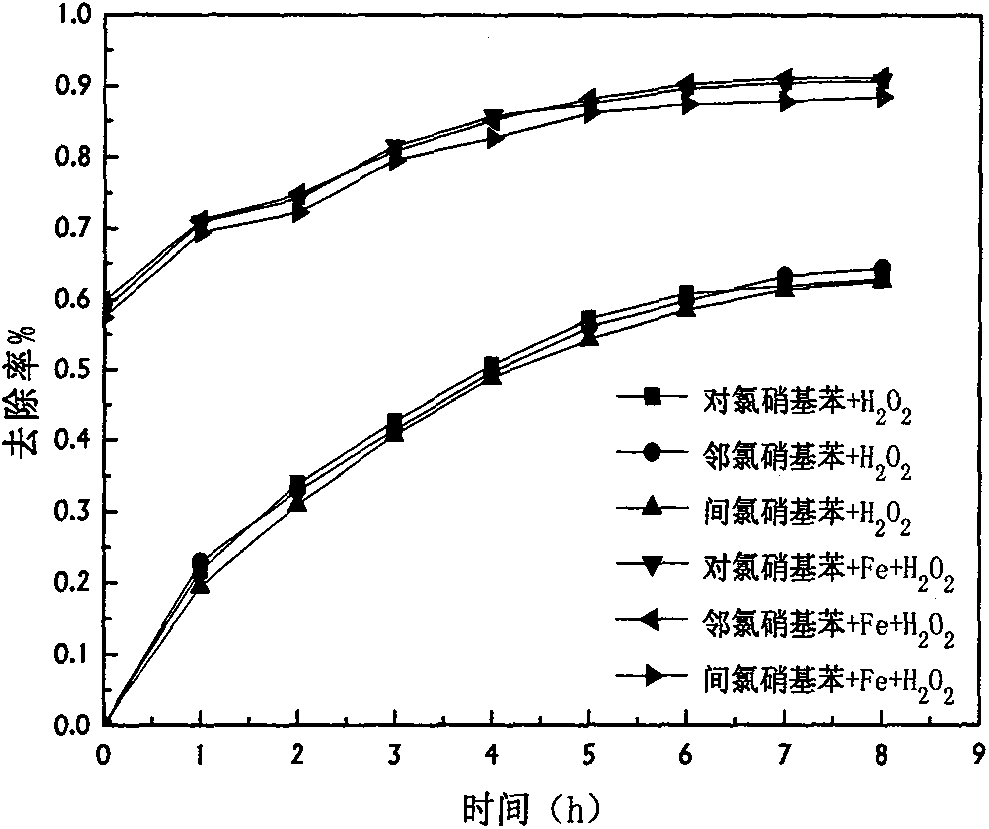

The invention relates to the technical field of pollution repairing and treatment of organic pollutants in soil, and especially discloses a chemically repairing method used in soil polluted by nitrobenzene, nitrochlorobenzene and the like. By means of the method in which the nitrobenzene, the nitrochlorobenzene and the like are firstly reduced into phenylamine which is easy to oxidatively degrade with zero-valent iron and finally the degraded product is oxidized to generate carbon dioxide and water, the soil, which is polluted by the organic pollutants including the nitrobenzene and the like, is completely repaired and removal efficiency of the organic pollutants is increased. The method can achieve a removal rate of the nitrochlorobenzene being 88.3-95.8%, wherein the nitrochlorobenzene is a difficultly-degraded organic substance. The method can overcome problems of low removal efficiency, high medicine cost and troublesome follow-up treatment during removal of the nitrobenzene-series organic pollutants in the soil with Fenton reagents, potassium persulfate, sodium permanganate and the like which are common in the prior art. By means of an indirectly oxidative degradation in which reduction is carried out firstly and oxidization is carried out after that, usage amount of an oxidizing agent can be reduced and the removal rate of the nitrobenzene-series organic pollutants can be increased. Meanwhile, the method is simple in operation and can avoid secondary pollution to environment by the oxidizing agent. The method can effectively achieve in-situ repairing of polluted soil and is especially suitable for complete repair of the soil severely polluted by the organic pollutants in local factory removal.

Owner:江苏迈克环境工程有限公司

Heterogeneous Fenton reagent and preparation method and application thereof

InactiveCN103007753AMild reaction conditionsEasy to controlNitrous oxide captureDispersed particle separationPtru catalystFenton reagent

The invention discloses a heterogeneous Fenton reagent and a preparation method of the heterogeneous Fenton reagent and a method for removing NO out of smoke by wet oxidization by using the heterogeneous Fenton reagent. The heterogeneous Fenton reagent is a mixed solution which comprises an H2O2 water solution and an Al2O3 loaded Fe catalyst and has a pH of 5-6, wherein the concentration of the H2O2 waters solution in the mixed solution is 0.5-1.5mol / L, and the concentration of the Al2O3 loaded Fe catalyst is 2g / L. According to the method, NO is removed out of smoke by wet oxidization by using the heterogeneous Fenton reagent; particularly, the heterogeneous Fenton reagent is added in a conventional bubble tower, NO in the smoke is oxidized into HNO3, and thus the purpose of removing NO is reached. The method for removing NO out of the smoke by wet oxidization by using the heterogeneous Fenton reagent is low in denitration cost and does not cause secondary pollution.

Owner:上海电气电站环保工程有限公司 +1

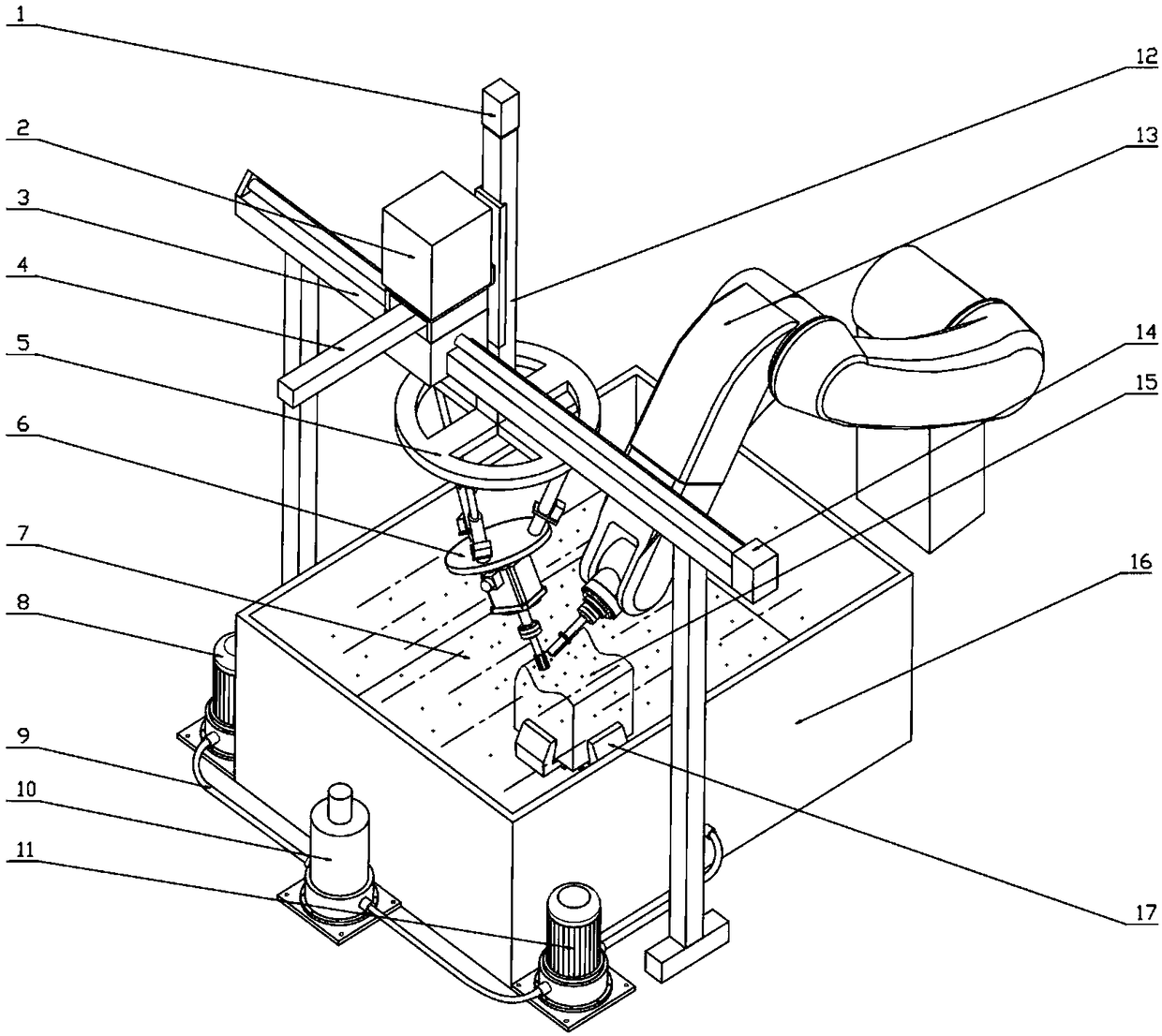

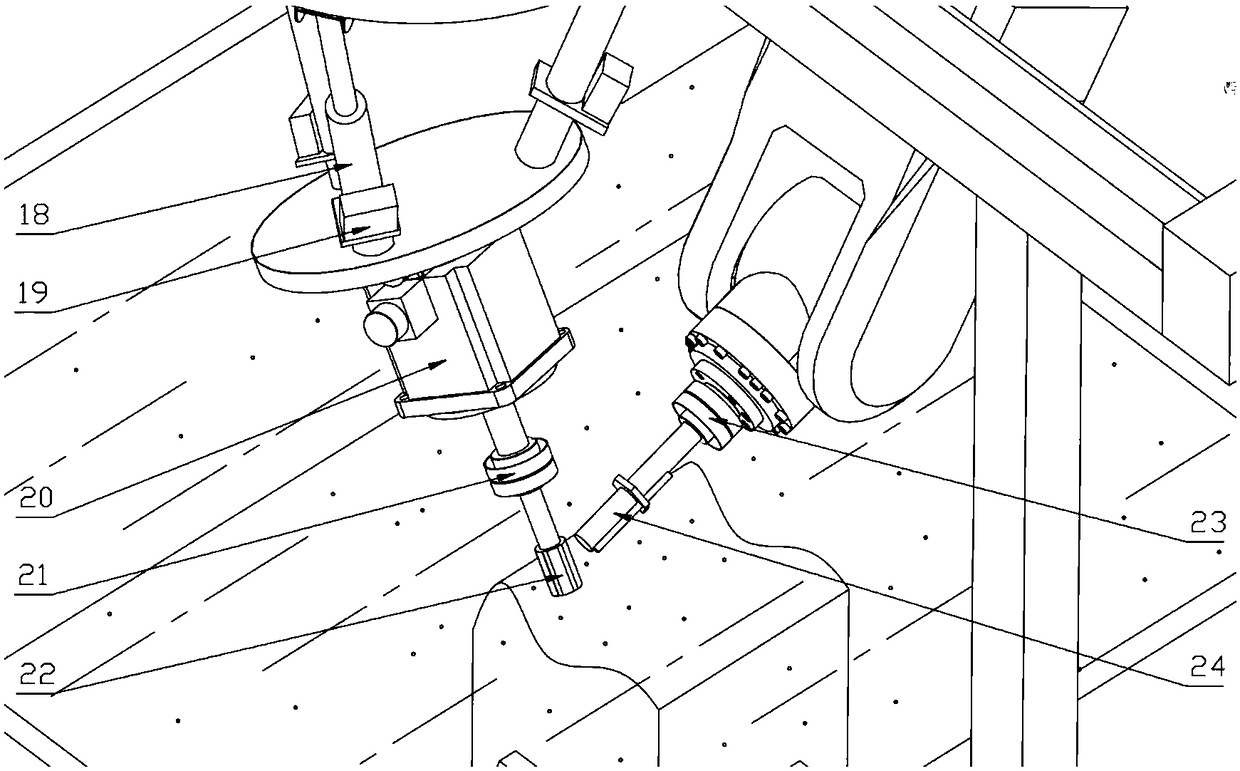

Fenton-assisted three-phase flowing pressure cavitation polishing SiC optimal curved surface method and device

ActiveCN108581817AHardness: SoftReduce the binding forceEdge grinding machinesPolishing machinesCavitationMotor drive

The invention discloses a Fenton-assisted three-phase flowing pressure cavitation polishing SiC optimal curved surface method. Firstly, the parts, have no need to be machined, of SiC workpieces are wrapped by insulation materials; then, the SiC workpieces are dipped in a reaction pool with a Fenton reagent; after a period of time for reaction, the workpieces are taken out and fixed in a polishingliquid container by a fixture; a series and parallel connection polishing platform controls poses of a cylindrical polishing tool relative to the workpieces, so that a tiny machining gap is always kept between the polishing tool and the surfaces of the workpieces; the tool and the workpieces are totally dipped in the polishing liquid; a servo motor drives the cylindrical polishing tool to rotate at high speed; an ultrasonic bubble generation mechanism continuously adjusts poses of an amplitude change rod relative to a dynamic pressure area; and along with polishing, an abrasive particle current circulating system circularly conveys abrasive particles in a polishing container. The invention further provides a Fenton-assisted three-phase flowing pressure cavitation polishing SiC optimal curved surface. The method improves the polishing efficiency under the precondition of not generating the surface and subsurface damage.

Owner:ZHEJIANG UNIV OF TECH

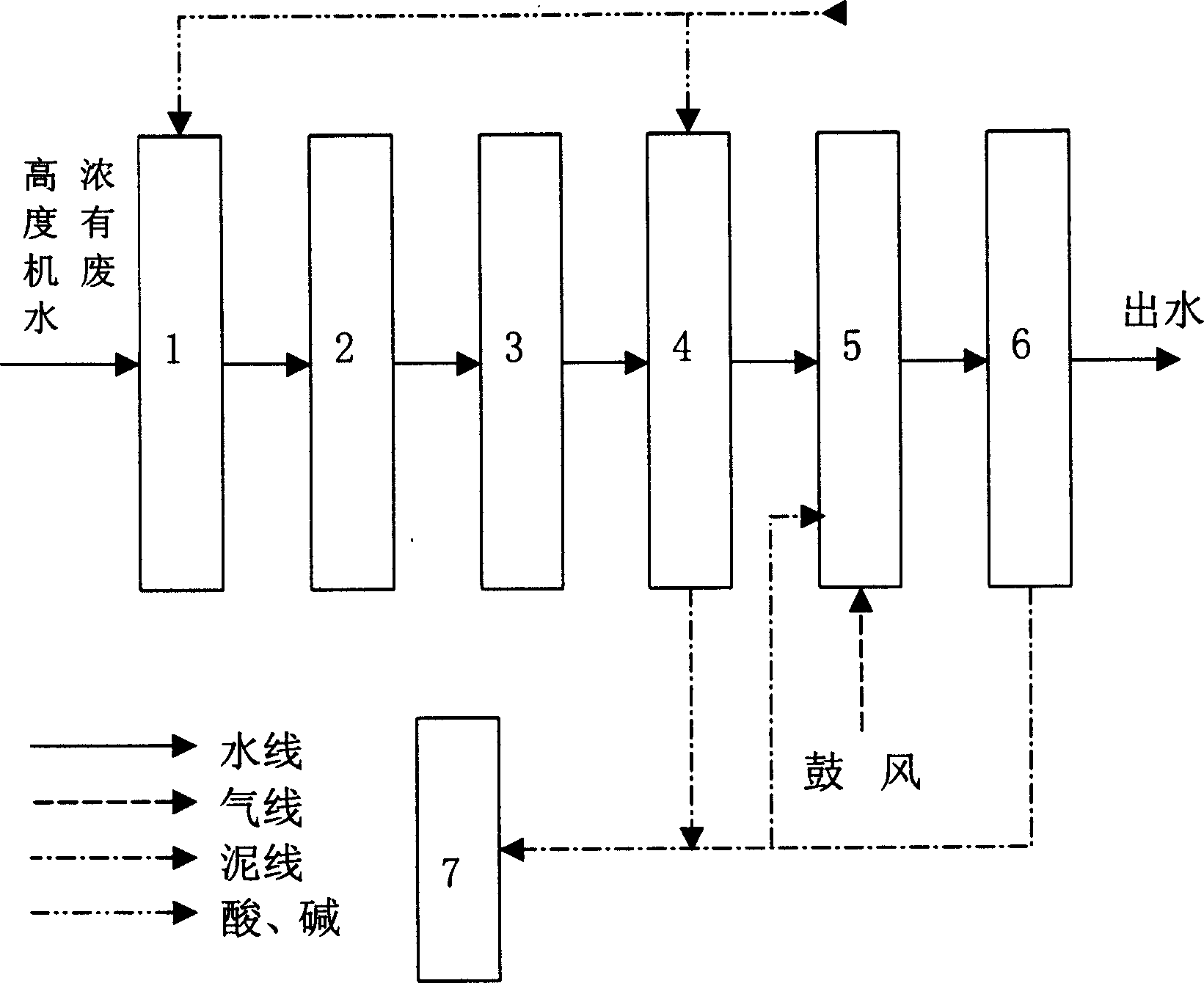

Method for treating or ganic waste water with nigh concentration

ActiveCN1611457AMeet the requirements of emission standardsMultistage water/sewage treatmentHigh concentrationFenton reagent

The invention relates to a kind of treatment method of high concentration organic wastewater. The invention takes anaerobic organism filter tank- Fenton reagent oxidization - contact oxidization method (A-F-O method) as the core. After adjusting PH of high concentration organic wastewater, it runs through bottom of anaerobic organism filter tank (AF), and then overflows into Fenton reagent oxidization reactor from top of AF. After reacting by some time, it runs into neutralization sedimentation tank. When having removed vestigial Fe2+ in the wastewater, it gets into contact oxidization system, then control by regular hour, and last, flux through quadratic sedimentation tank. Treated by this method, COD of high concentration organic wastewater can decline to lower than 80mg / L, so it can achieve national discharge standard. The invention has stable and reliable treating effictiveness, convenient and steerable operation, low running cost, so that it adapts to treat high concentration organic wastewater discharged by petroleum chemical enterprise and other analogous enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

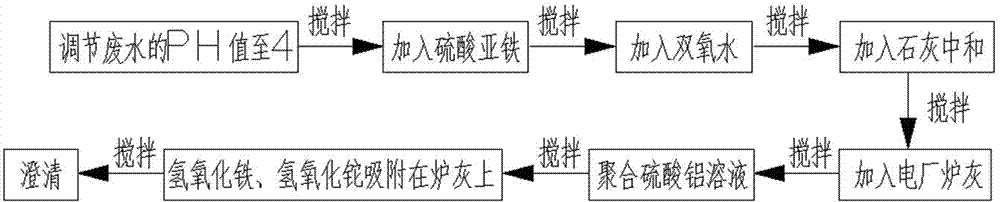

Method for removing trace of thallium in sewage

InactiveCN104773878AStrong oxidizingImprove adsorption capacityWater contaminantsMultistage water/sewage treatmentFenton reagentSulfate

The invention relates to a method for removing a trace of thallium in sewage. The method includes the process steps of regulating the PH value of the thallium-contained sewage to 4, adding a ferrous sulfate solution to the sewage, evenly mixing the sewage with the ferrous sulfate solution, adding hydrogen peroxide to the sewage again, conducting stirring, oxidizing fluorosis univalence thallium (T1+) in the sewage into tervalence thallium (T13+), mixing ferrous iron and hydrogen peroxide into a fenton reagent, adding lime to the sewage and evenly conducting stirring so that the PH value of the sewage can be neutralized to be 7 to 9, hydrolyzing tervalence iron (Fe3+) in the sewage at the same time to form flocculent ferric hydroxide, adding an appropriate amount of power plant stove ash (electric duct collector stove ash) to the sewage, evenly conducting stirring, and adding a polyaluminium sulfate solution so that ferric hydroxide and thallium hydroxide can be adsorbed to the stove ash. Flocculent sediment generated through hydrolysis has the great surface area and quite strong adsorption capacity; the power plant stove ash can adsorb the flocculent sediment and colloid particles in the sewage and sink.

Owner:广东云测环境科技有限公司

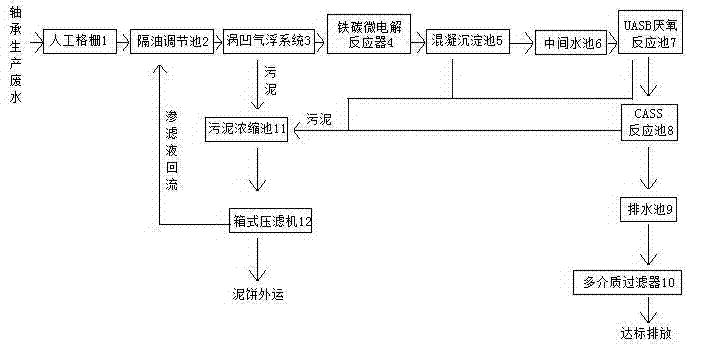

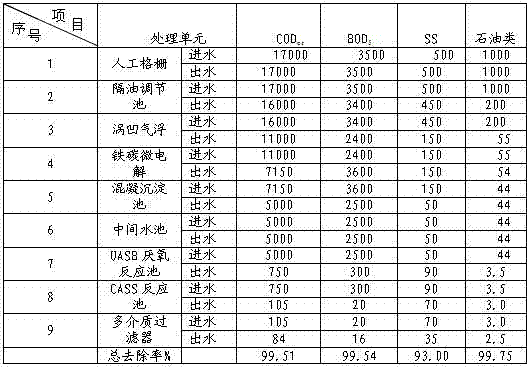

Treatment process for bearing production wastewater

InactiveCN103613247ASolve the bloat problemEasy to adjust working conditionsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentEcological environmentElectrolysis

The invention discloses a treatment process for bearing production wastewater. The treatment process comprises the following steps: firstly, enabling bearing production wastewater to enter an oil-separation adjusting tank; separating floating oil in the wastewater and agitating uniformly; then lifting the wastewater into a cavitation air floatation system to remove suspension matters and petroleum in the wastewater; conveying the wastewater treated by the cavitation air floatation system into an iron-carbon micro-electrolysis reactor and carrying out a Fenton reagent and iron-carbon micro-electrolysis combined oxidation reaction to reduce chemical oxygen demand and improve the ratio value of biochemical oxygen demand / chemical oxygen demand of the wastewater; conveying the wastewater reacted in the iron-carbon micro-electrolysis reactor into a coagulation precipitation tank, adjusting the pH (Potential of Hydrogen) and carrying out a coagulation and flocculation reaction; enabling reacted liquid supernatant to flow into a middle water pond to sequentially enter a UASB (Up-flow Anaerobic Sludge Bed / Blanket) anaerobic reaction tank, a CASS (Cyclic Activated Sludge System) reaction tank and a water discharging tank and filtering by a multi-medium filter; discharging after the water reaches standards. The treatment process is simple in management and good in wastewater treatment effect; a sludge expansion problem which usually and easily occurs in a traditional active sludge method is overcome; the water can be discharged after the water quality reaches the standards and the treatment process is good for protecting the ecological environment.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

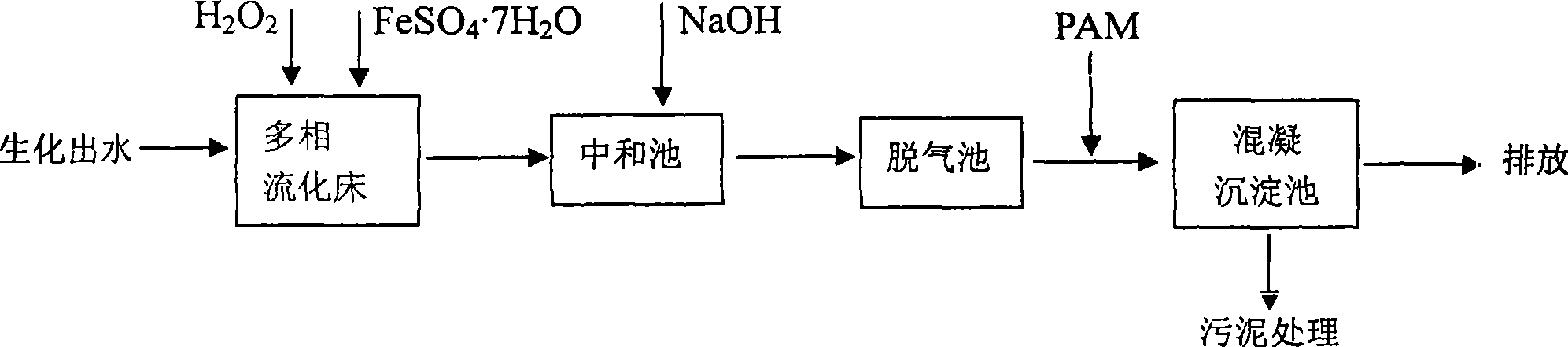

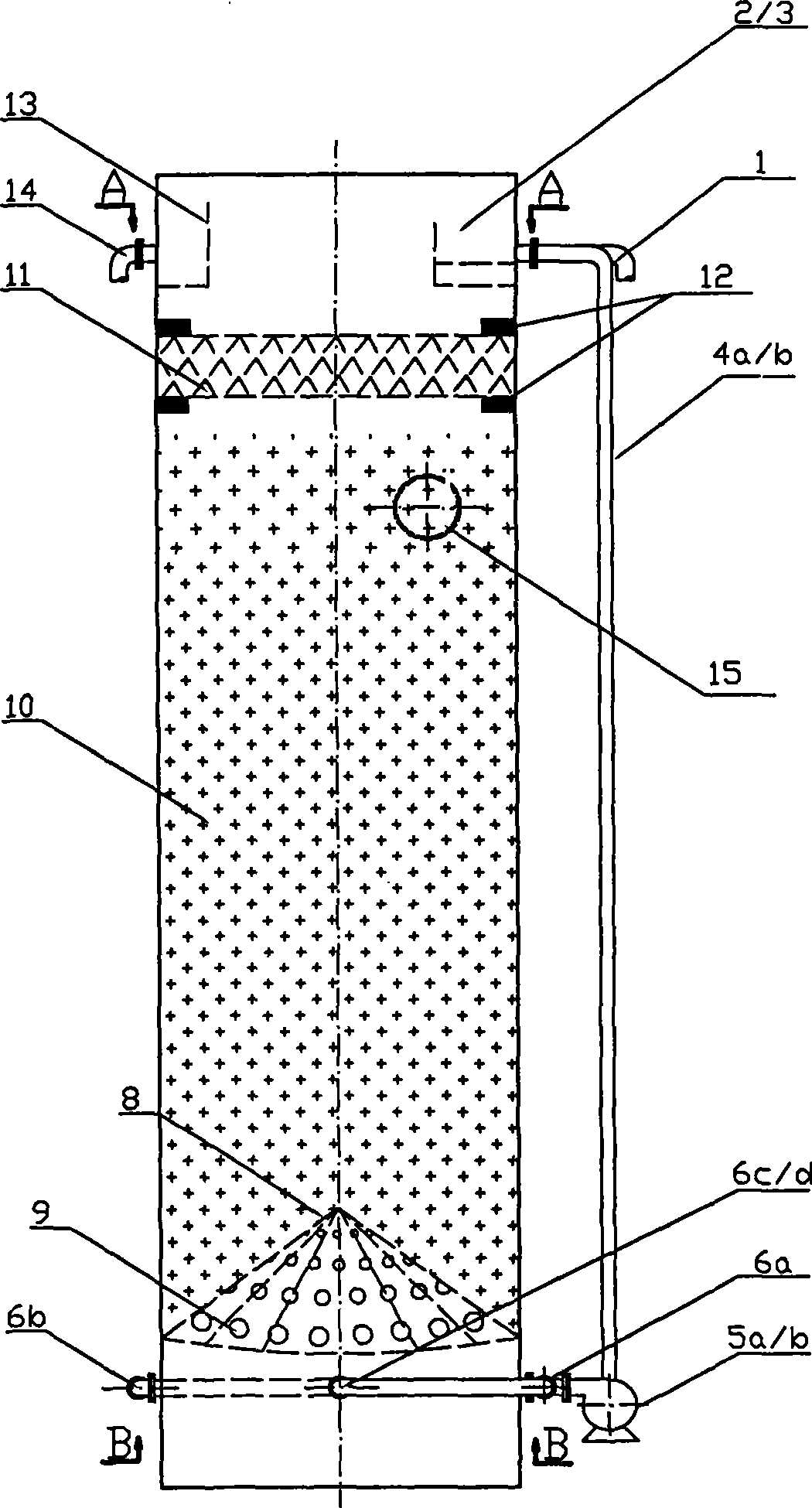

Process for treating bio-refractory waste water by up-flow multi-phase oxidation column

ActiveCN101519251AReduce dosageReduce outputMultistage water/sewage treatmentWater/sewage treatment by neutralisationFenton reagentOxygen

The invention relates to a process for treating bio-refractory waste water by an up-flow multi-phase oxidation column. Fenton reagent and waste water to be treated are pumped into the up-flow multi-phase oxidation column for reacting 0.5-1h by a pump, wherein the molar ratio of H2O2 to Fe<2+> is 5-20:1 in the process of adding Fenton reagent, wherein the mass ratio of the added hydrogen peroxide and the COD in the waste water to be treated is 2-3:1. The waste water processed in the oxidation column enters a neutralization tank, a degassing tank and a coagulating precipitation tank in sequence, the pH value of the waste water is adjusted to be neutral in the neutralization tank, the waste water is blasted and degassed for 10-20 min in the degassing tank to degas small oxygen bubbles generated in the process of reacting, and is coagulated and precipitated by adding polyacrylamide in the coagulating precipitation tank to obtain supernatant fluid which reaches the discharge standard and is discharged. Experiments prove that the removal rates of the COD and the colority are both larger than 70 percent. The process has simple operation, easy obtaining of reactants, cheapness, no complex equipment, short treating time and high contamination removing rate.

Owner:GUANGXI UNIV

Process for treating epoxy resin production wastewater

ActiveCN103613244AEasy to handleHigh degree of automationMultistage water/sewage treatmentNature of treatment waterSuspended particlesEpoxy

The invention discloses a process for treating epoxy resin production wastewater. The process comprises: removing oils, suspended particle organic matters, a part of high polymers and toluene in high-salinity wastewater through a cavitation air flotation system, transforming macromolecular organic matters in the wastewater into micromolecular organic matters through an iron-carbon micro-electrolysis reactor, then, oxidizing non-biodegradable and non-chemical oxidable organic matters in the wastewater through a catalytic oxidation reactor under the action of an Fenton reagent, carrying out anaerobic biochemical treatment to reduce the chemical oxygen demand and the biochemical oxygen demand in the wastewater, carrying out aerobic biochemical treatment to anaerobically degrade a part of aerobic organic matters incapable of being degraded by aerobiont into biochemically degradable organic matters, finally, conveying the wastewater into a clean-water reservoir, filtering the wastewater through a multi-medium filter, and discharging the wastewater after meeting the standard. The process disclosed by the invention has the advantages of small energy consumption, high removal load and capability of recycling biogas as an energy source, and the purified water quality meets the emission standard so as to protect the ecological environment.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

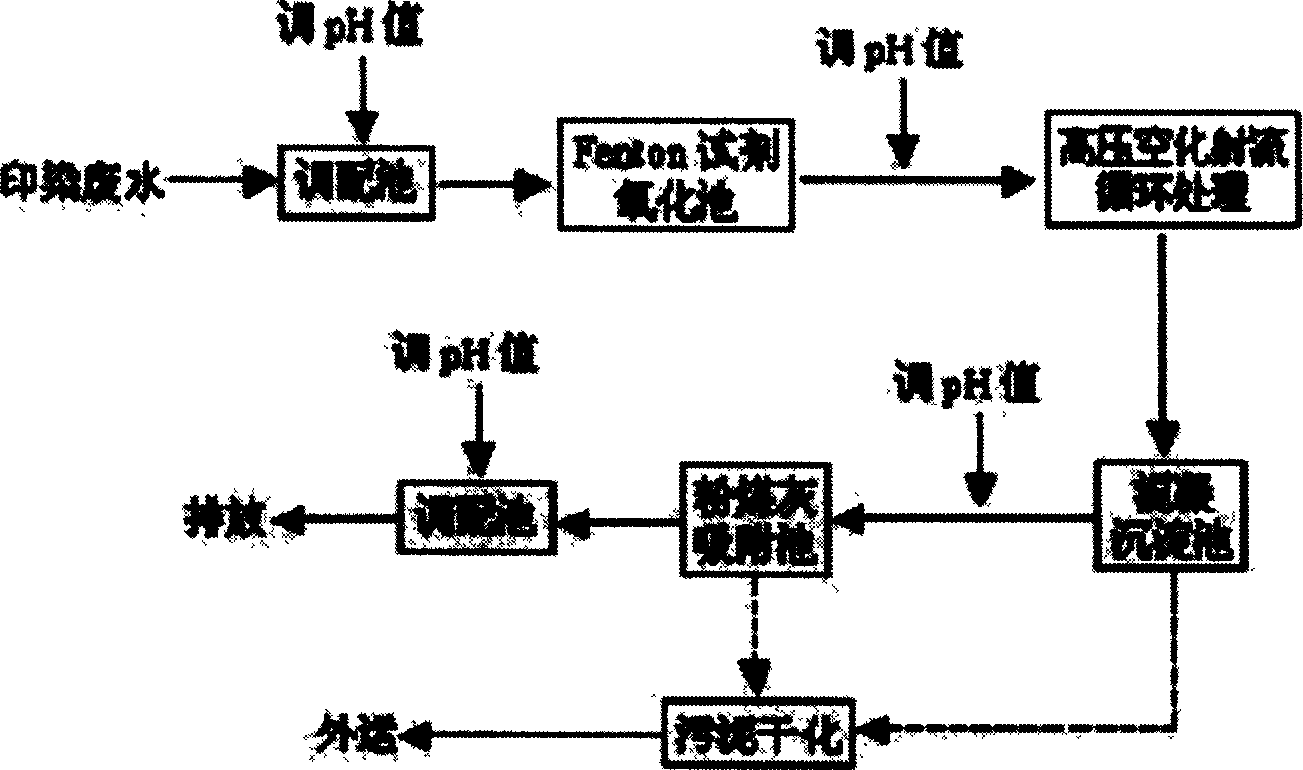

Method for treating printing and dyeing waste water by high pressure cavitation jet combined with fenton reagent

InactiveCN1899986ACompletely degradedEfficient degradationWaste water treatment from animal husbandryMultistage water/sewage treatmentCavitationFenton reagent

The present invention relates to treatment of printing and dyeing waste water. The process of treating printing and dyeing waste water includes the following steps: regulating pH value with acid, oxidizing with the Fenton reagent, cavitation treating with high pressure jet, coagulating sedimentation, adsorbing with fly ash and regulating pH value before exhausting. The present invention features the organic combination of high pressure cavitation jet and the Fenton reagent in treating printing and dyeing waste water. The present invention has obviously raised COD eliminating rate and decolorizing rate, high energy utilizing rate and other advantages.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com