Method for treating or ganic waste water with nigh concentration

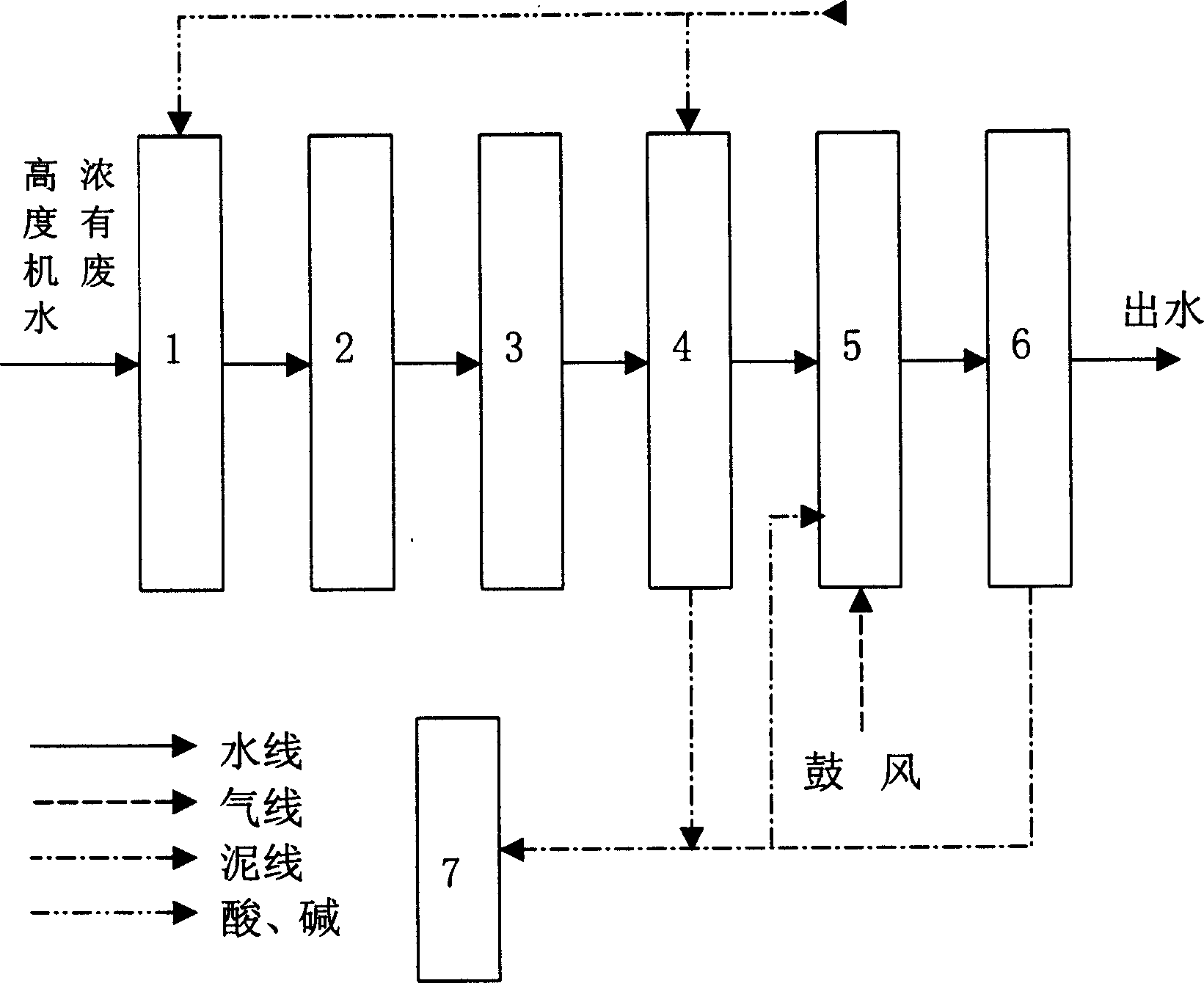

A technology for organic wastewater and wastewater treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems that do not involve the treatment effect of high-concentration organic wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Take ketone-containing wastewater (COD 11680mg / L) from a chemical plant for testing. After the pH of the wastewater is adjusted to 8.0, it enters the anaerobic biofilter with a residence time of 3 days, and then the wastewater enters the Fenton reagent oxidation reactor. 2 o 2 / COD(W / W)=3.5, Fe 2+ / H 2 o 2 Add H at a ratio of (W / W)=0.08 2 o 2 and Fe 2+ , After reacting for 180 minutes, it enters the neutralization sedimentation tank, and the pH of the effluent of the neutralization sedimentation tank is 8.0, followed by contact oxidation treatment, the residence time is 12 hours, and the water is discharged through the secondary sedimentation tank.

[0046] After the ketone-containing wastewater is treated above, the COD of the effluent is reduced to 55mg / L, which meets the national wastewater discharge standard.

Embodiment 2

[0048] The phenolic wastewater (COD 28960mg / L) from a chemical plant was used for testing. After the pH of the wastewater is adjusted to 8.0, it enters the anaerobic biofilter with a residence time of 10 days, and then the wastewater enters the Fenton reagent oxidation reactor. 2 o 2 / COD(W / W)=8.5, Fe 2+ / H 2 o 2 Add H at a ratio of (W / W)=0.08 2 o 2 and Fe 2+ , After reacting for 280 minutes, it enters the neutralization sedimentation tank, and the pH of the effluent of the neutralization sedimentation tank is 8.0, followed by contact oxidation treatment, the residence time is 16h, and the water is discharged through the secondary sedimentation tank.

[0049] After the phenolic wastewater is treated above, the COD of the effluent is reduced to 68mg / L, which meets the national wastewater discharge standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com