Patents

Literature

2919 results about "Residence time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

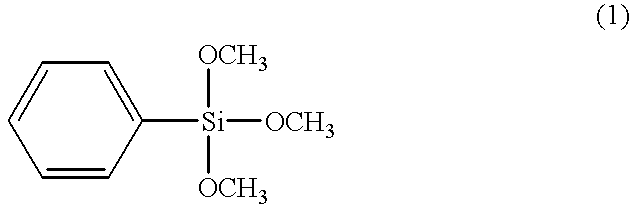

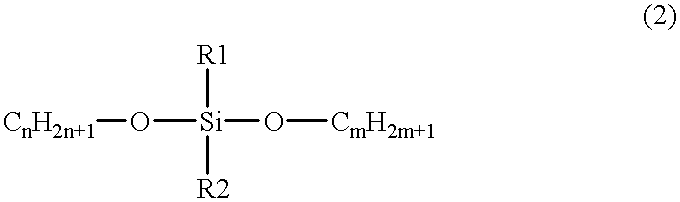

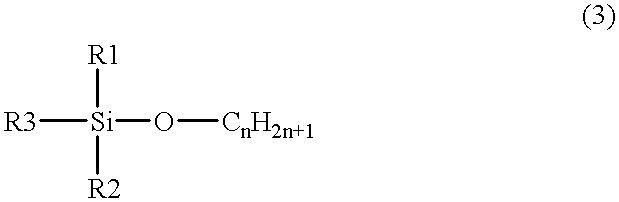

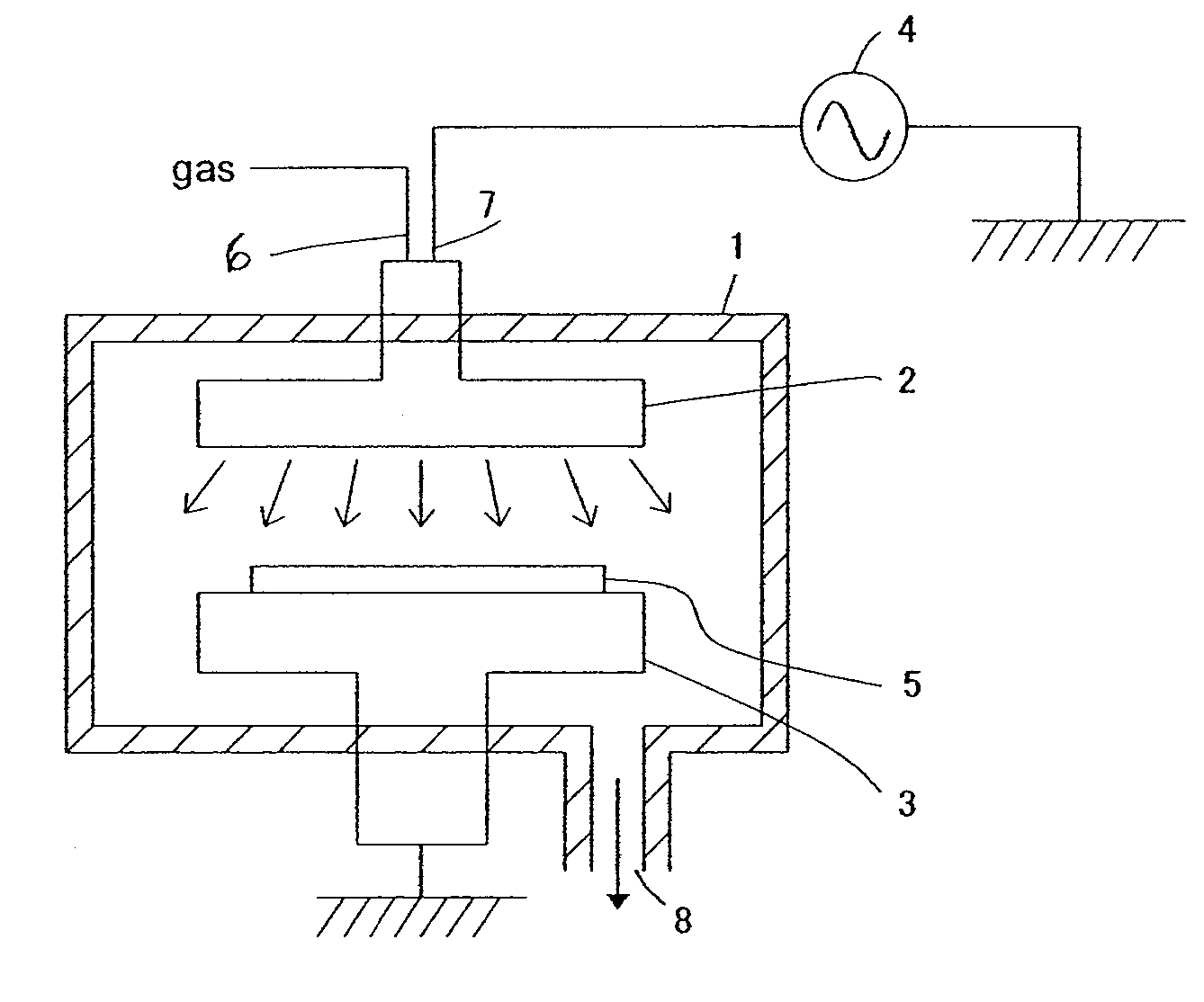

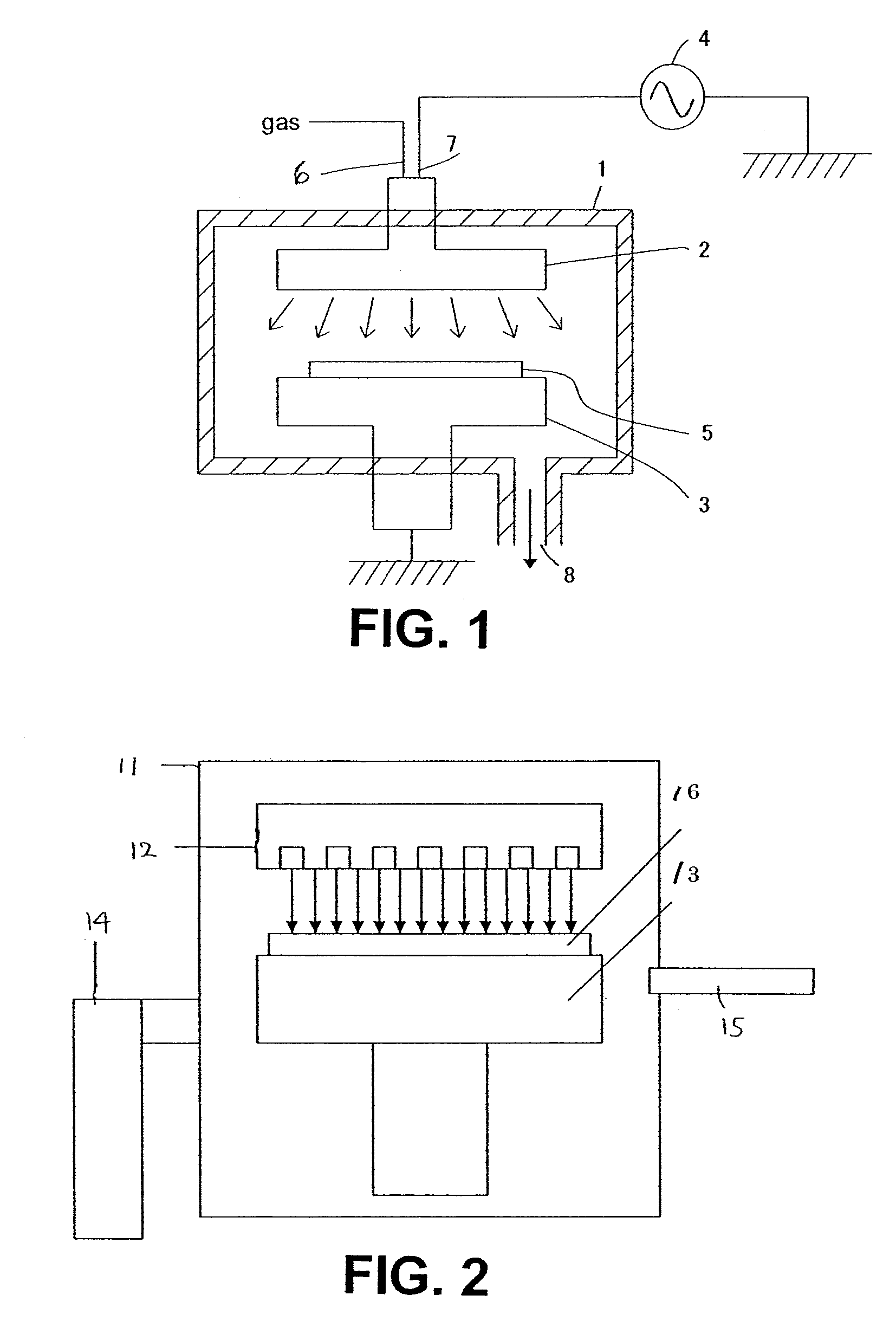

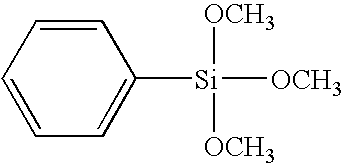

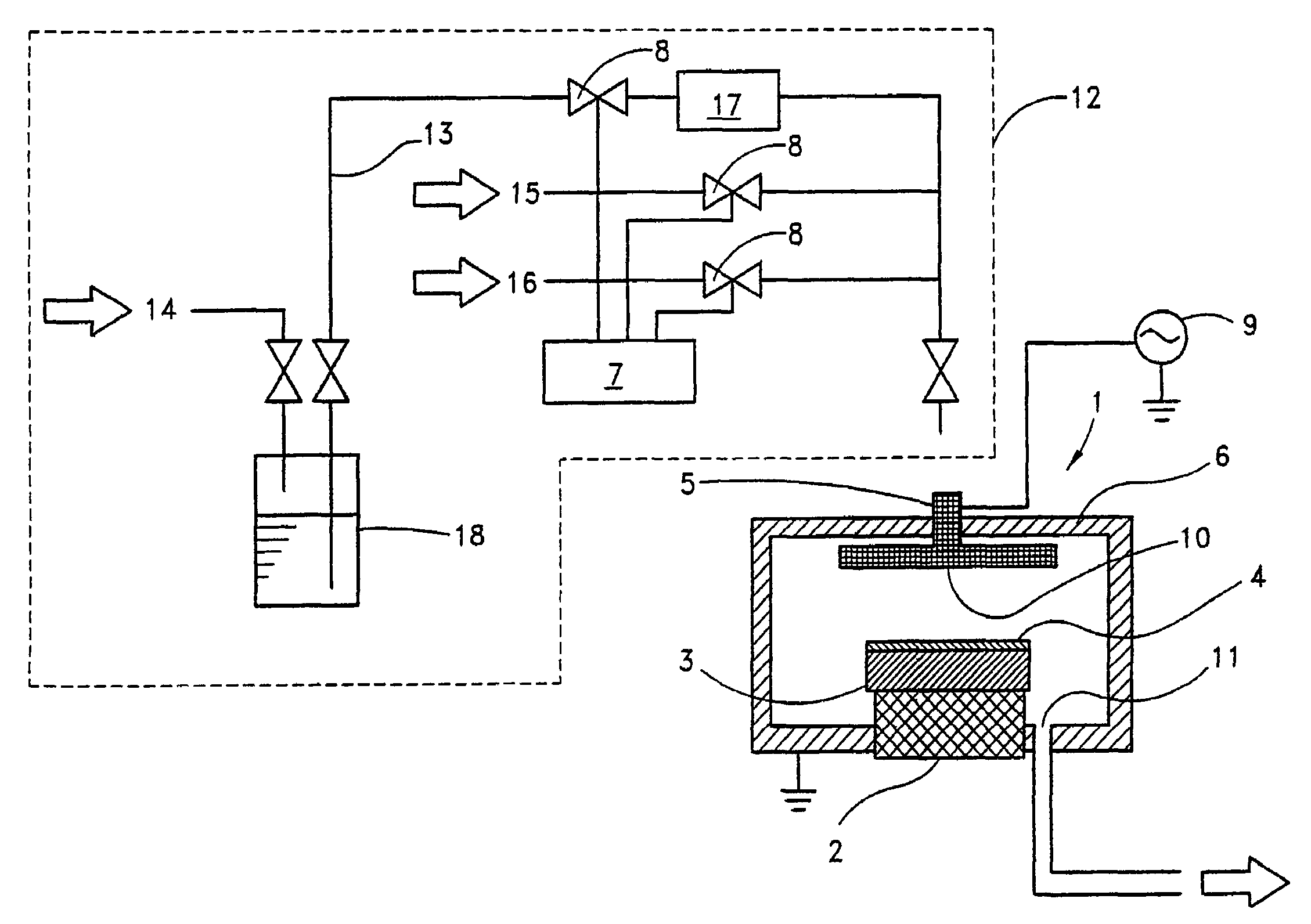

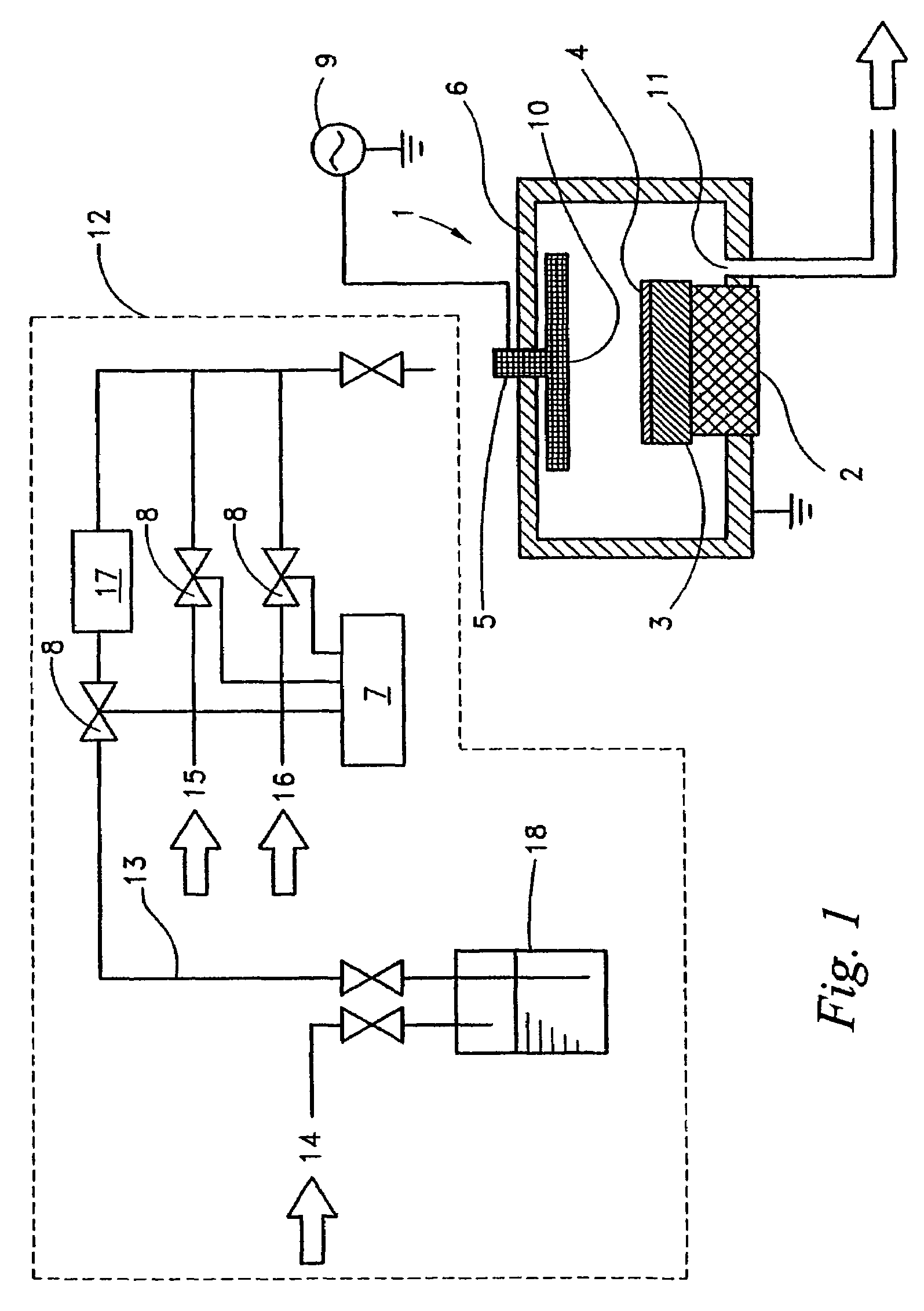

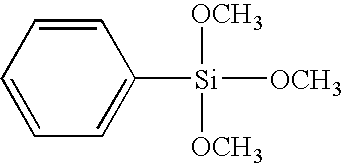

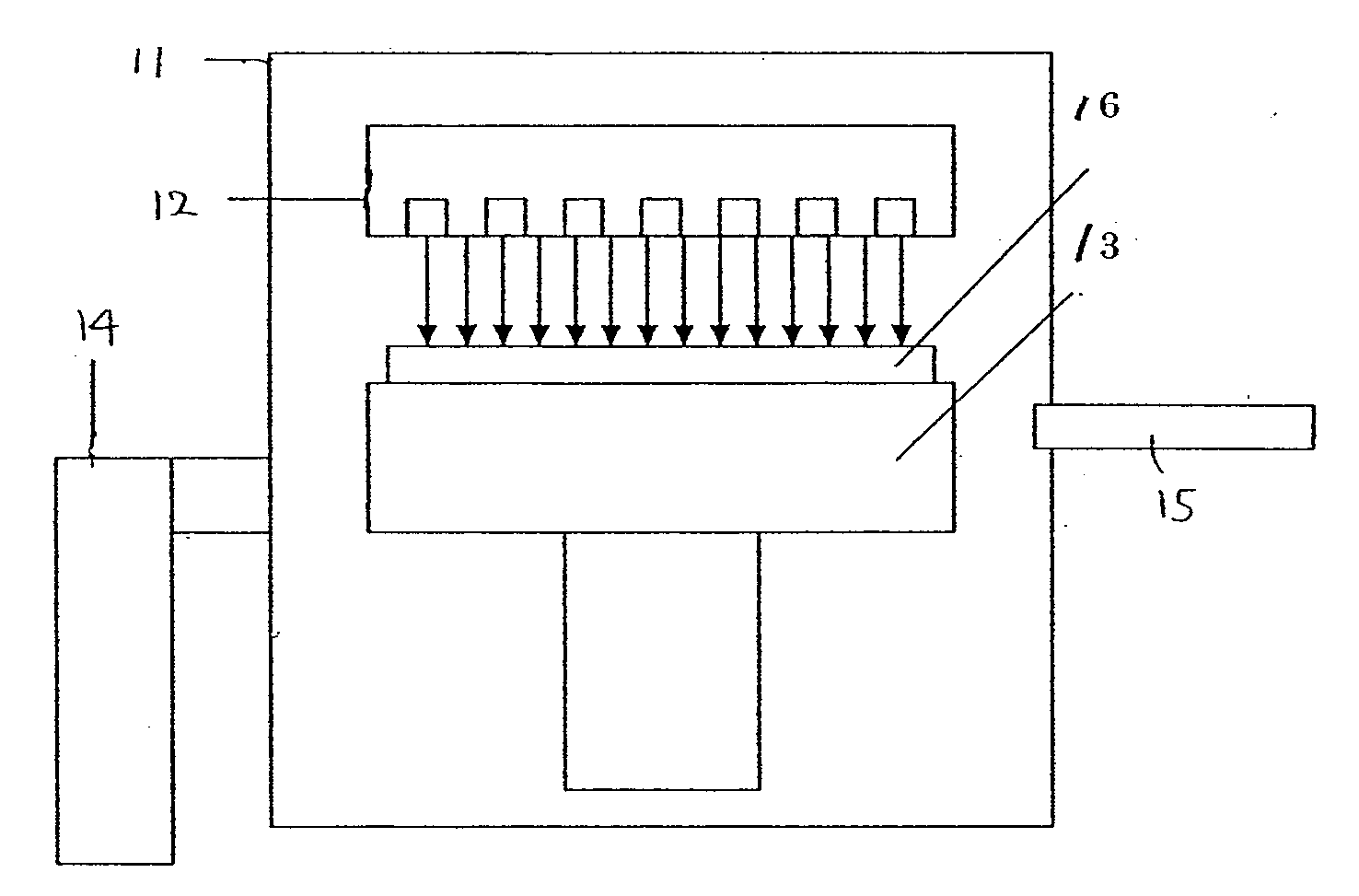

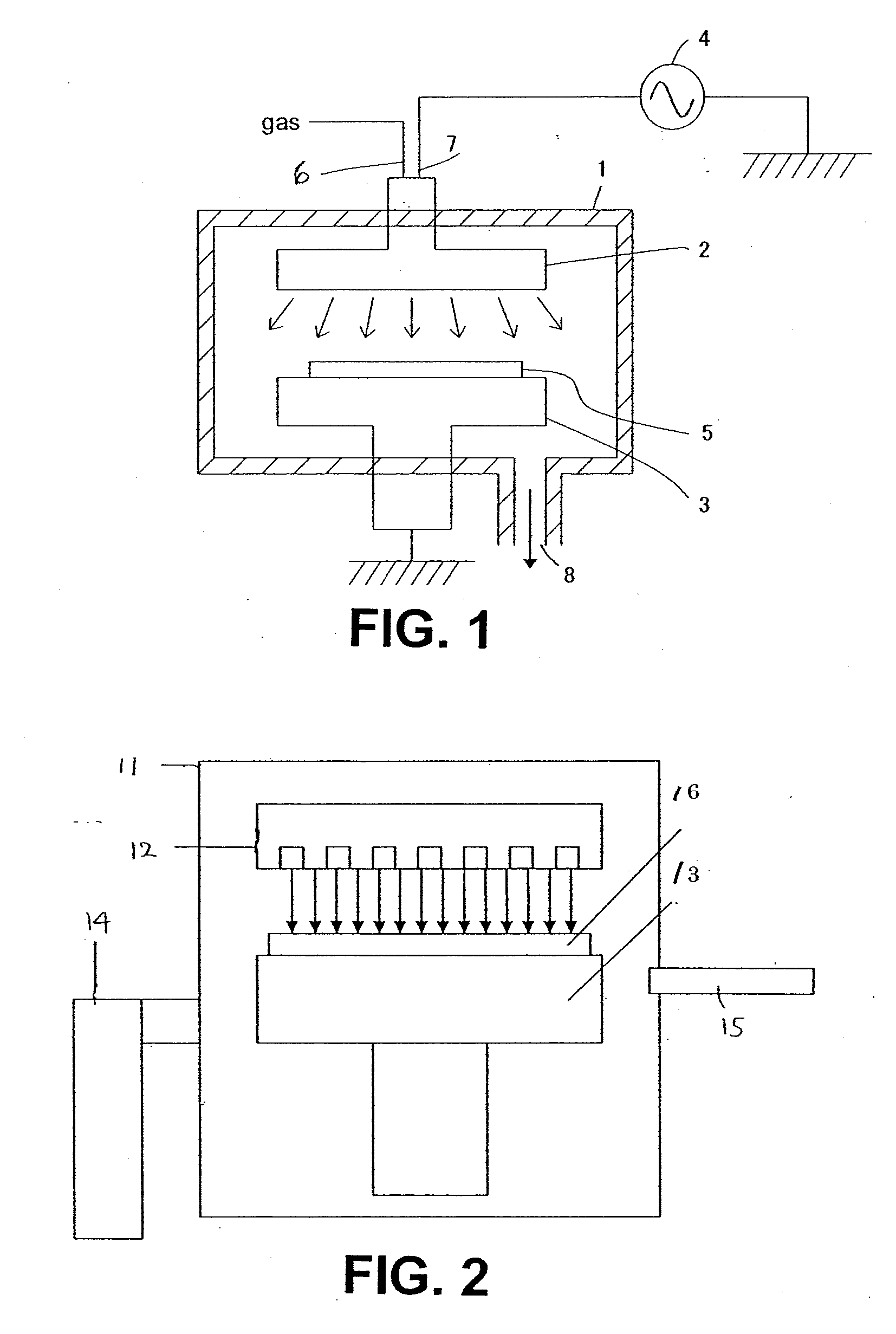

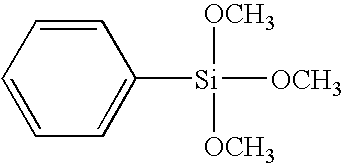

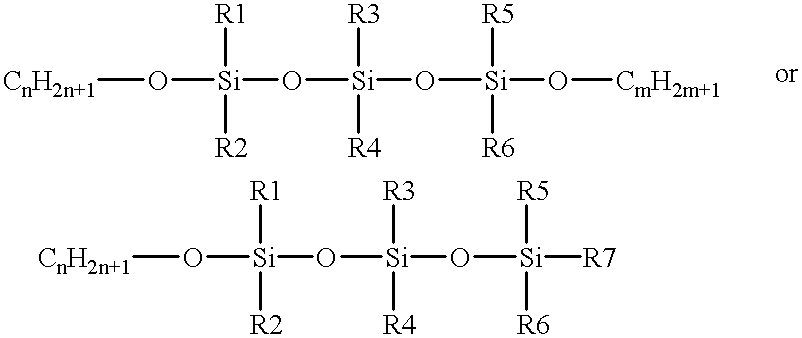

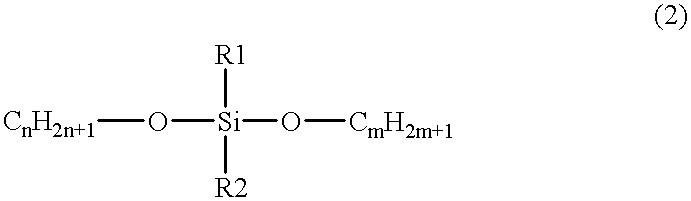

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

Method for forming insulation film

InactiveUS7354873B2Reduce distanceGood film densitySolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Method for forming insulation film

InactiveUS7582575B2Reduce trafficReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Plasma etching method

ActiveUS20140377960A1Electric discharge tubesSemiconductor/solid-state device manufacturingMetallurgyResidence time

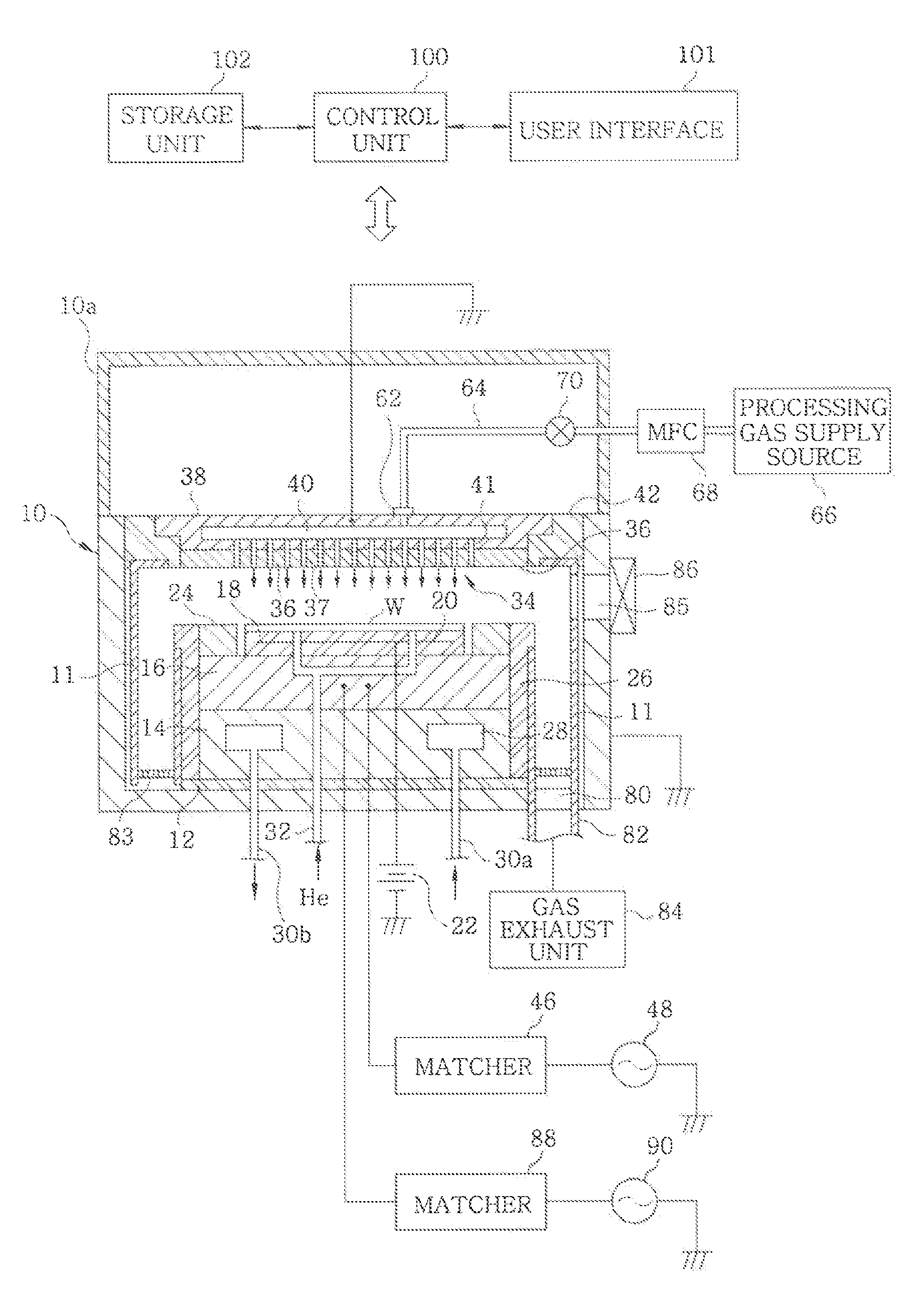

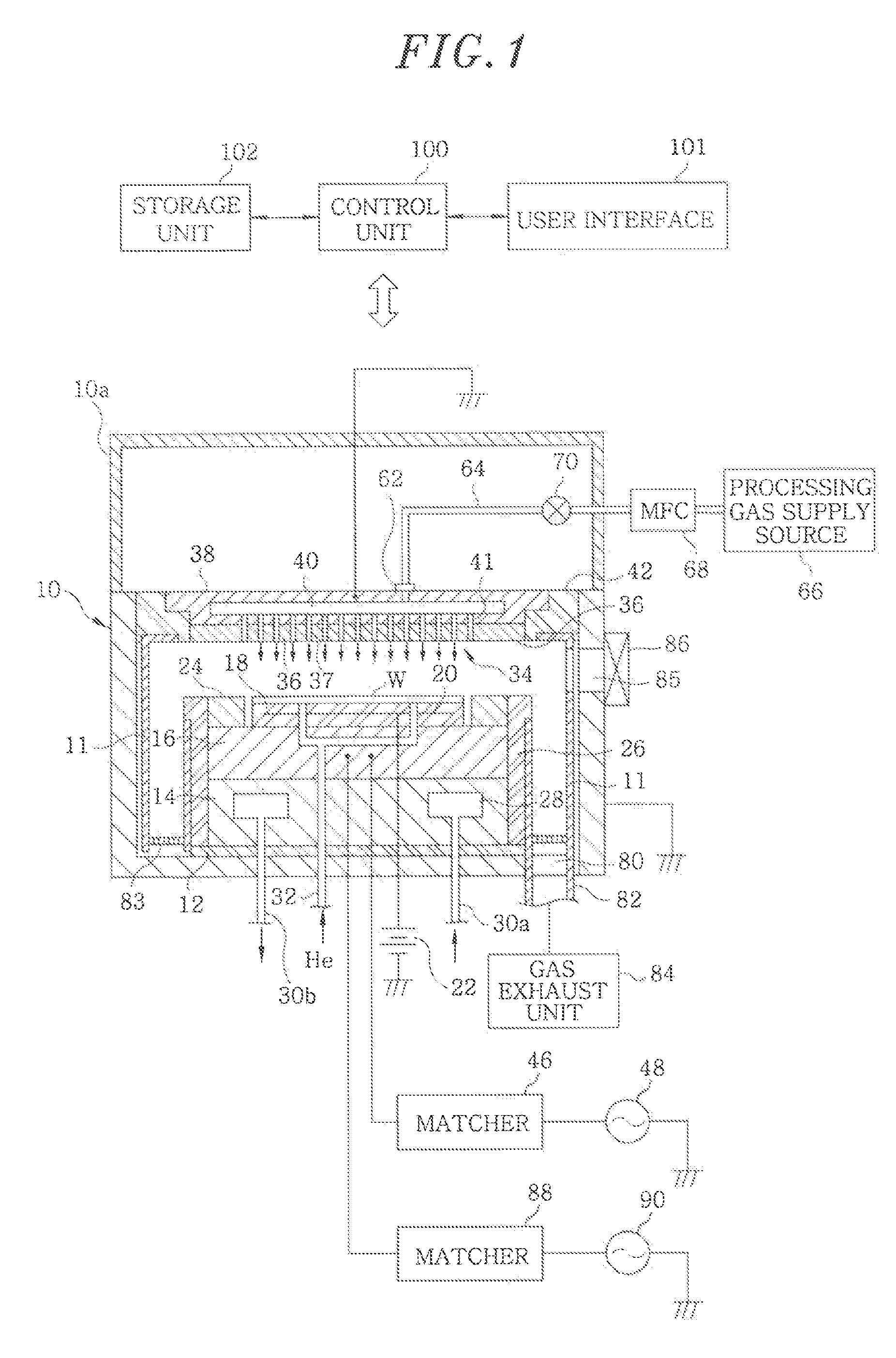

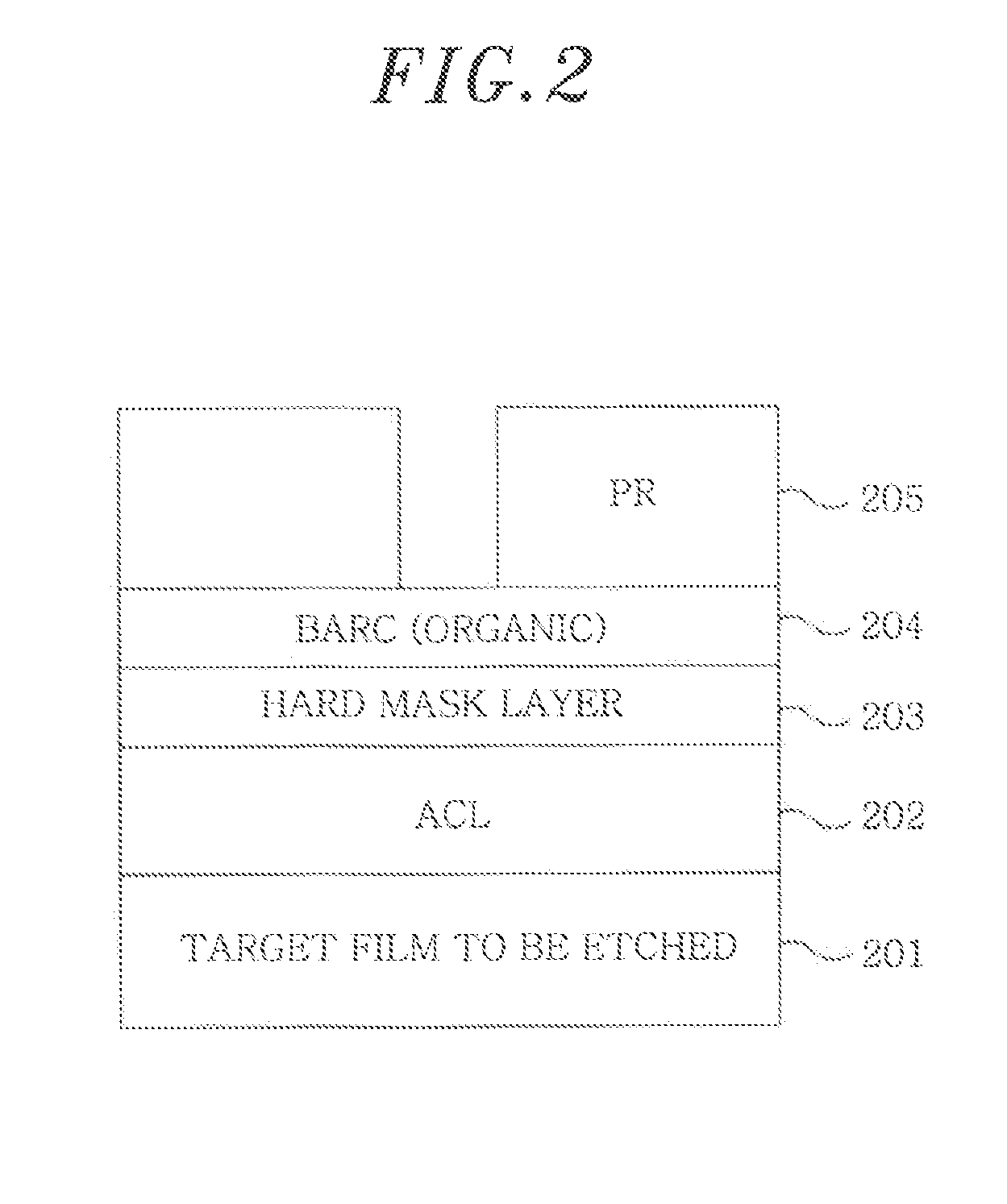

In a plasma etching method of performing a plasma etching on an amorphous carbon layer of a substrate to be processed by using an inorganic film as a mask, the substrate being mounted in a processing chamber, the plasma etching on the amorphous carbon layer is performed by using O2 gas as a processing gas and the O2 gas to flow in the processing chamber such that a residence time of the O2 gas becomes 0.37 msec or less. The amorphous carbon layer is used as an etching mask of an etching target film formed on the substrate. The plasma etching is performed by using the O2 gas only.

Owner:TOKYO ELECTRON LTD

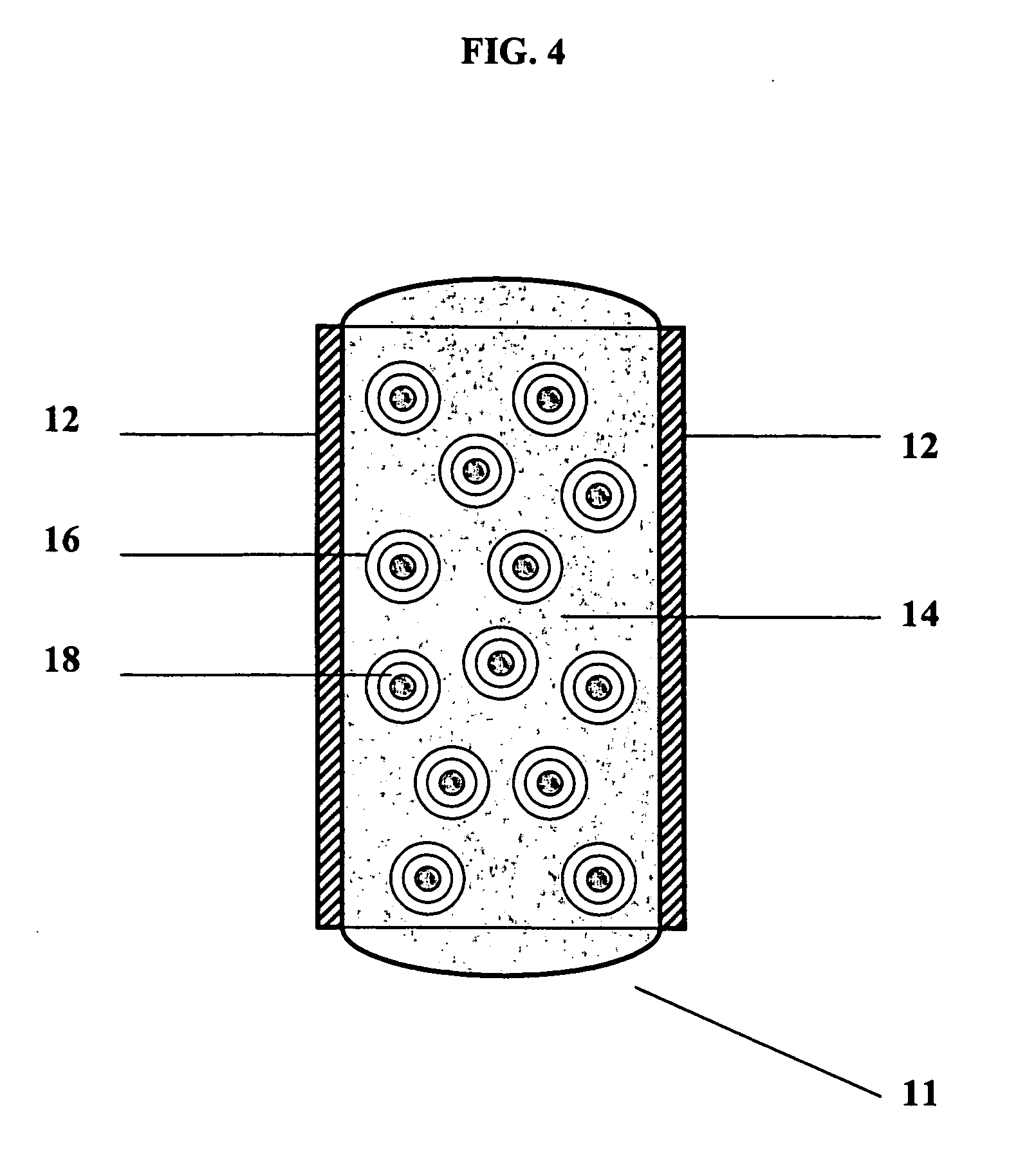

PVC nanocomposite manufacturing technology and applications

InactiveUS20080194736A1Material nanotechnologyPigmenting treatmentPolymer scienceManufacturing technology

The present invention relates to a process and a product of forming polymer (especially PVC) nanocomposites with a variety of nanofillers. The present invention provides a method for forming a polymer nanocomposite, comprising powder mixing a composition comprising polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process. Additionally, the present invention relates to a polymer nanocomposite formed by a process, comprising powder mixing a polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process to achieve homogeneous dispersion of nanofillers in the polymer matrix.

Owner:FORMOSA PLASTICCS CORP

Method for forming insulation film

InactiveUS20070004204A1Reduce trafficDecrease in flow volumeSolid-state devicesSemiconductor/solid-state device manufacturingProduct gasPlasma reaction

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

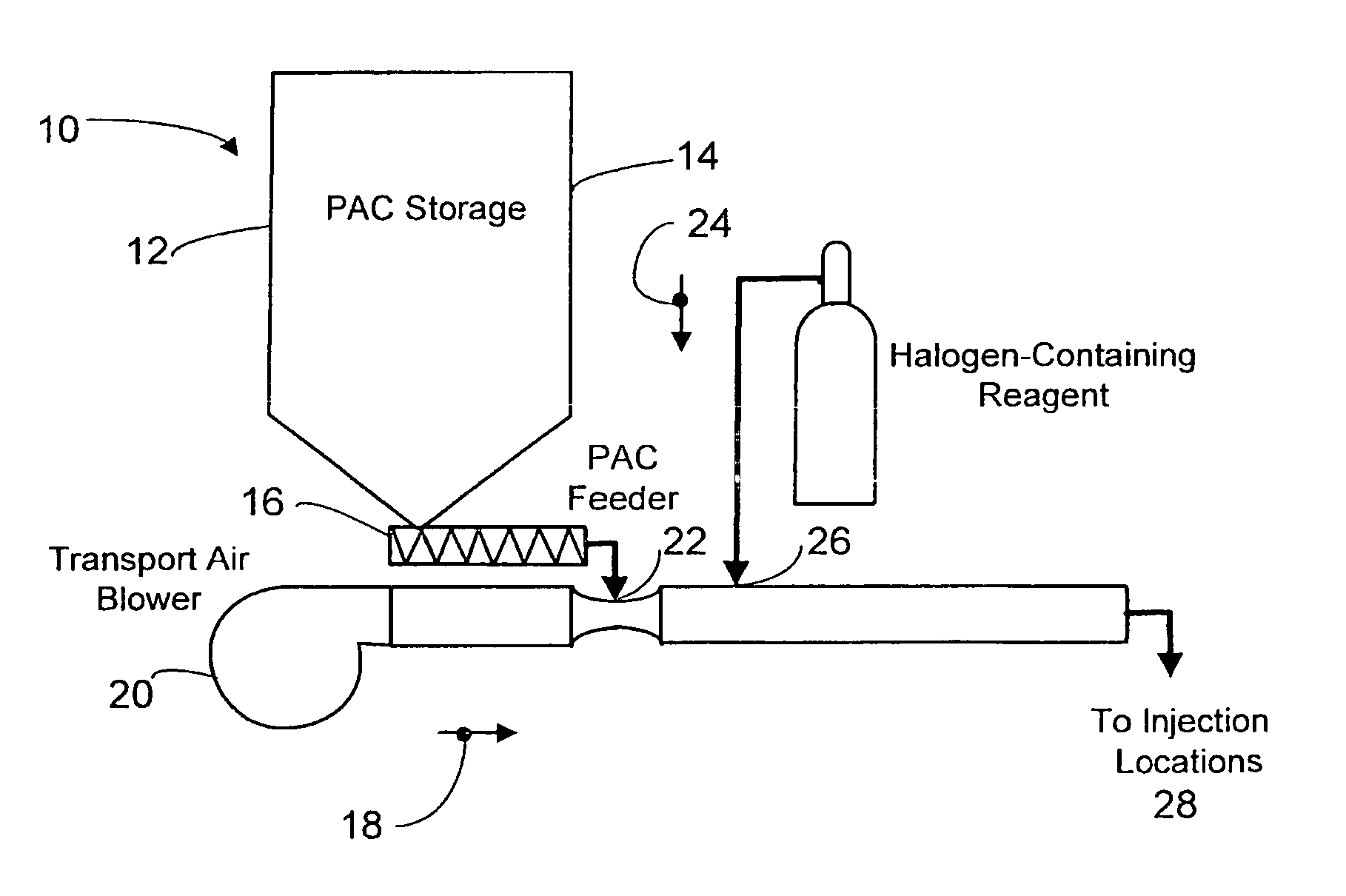

Dynamic halogenation of sorbents for the removal of mercury from flue gases

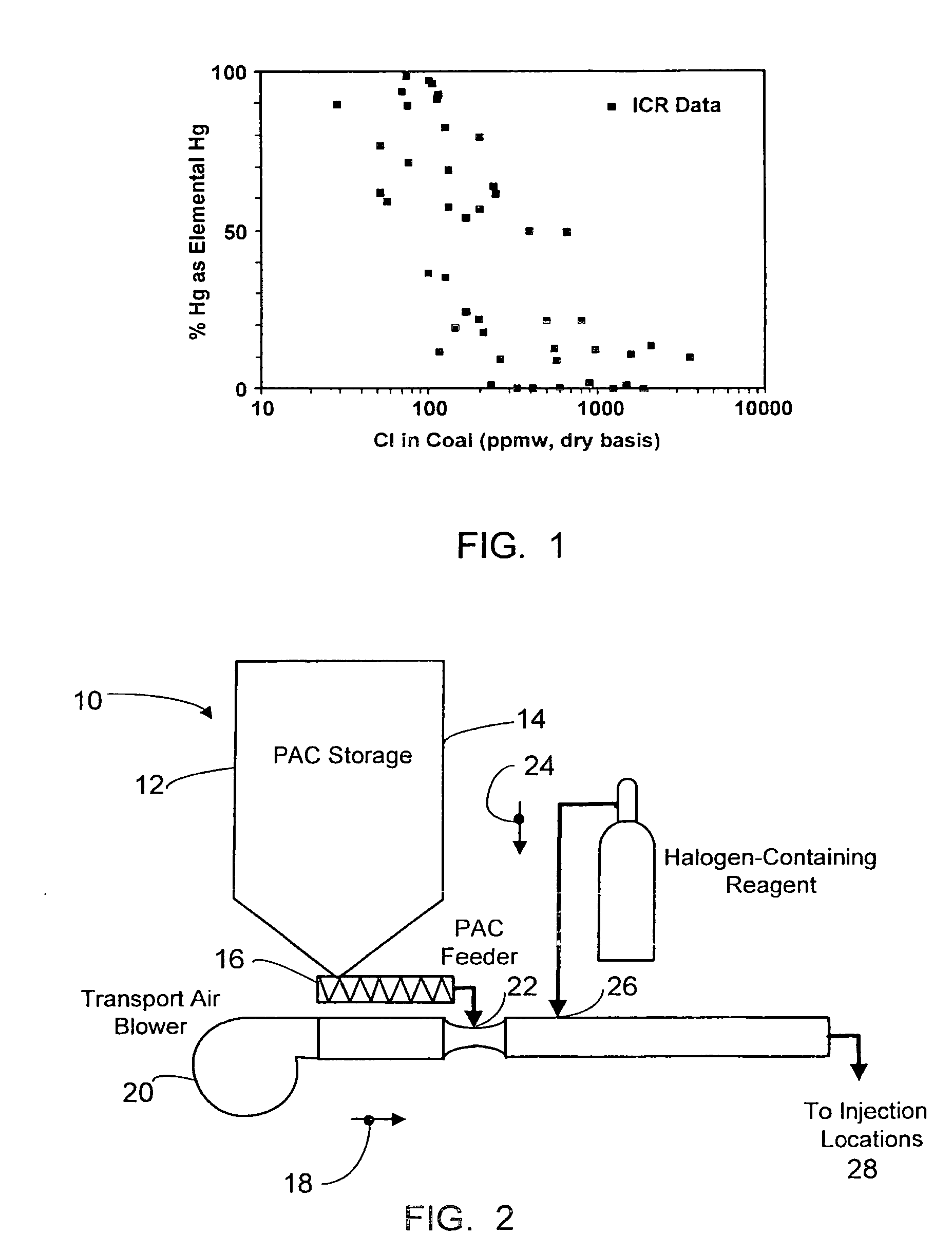

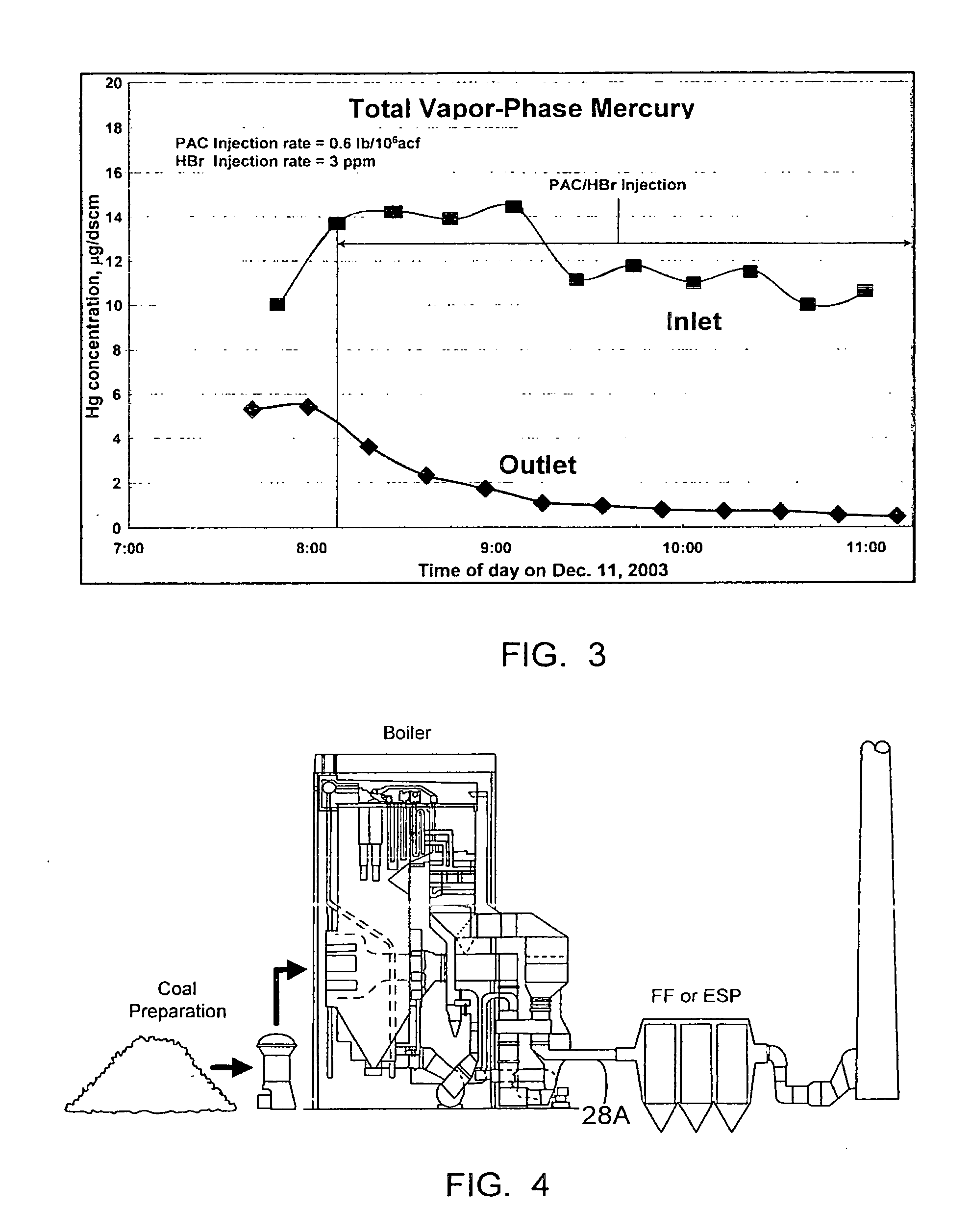

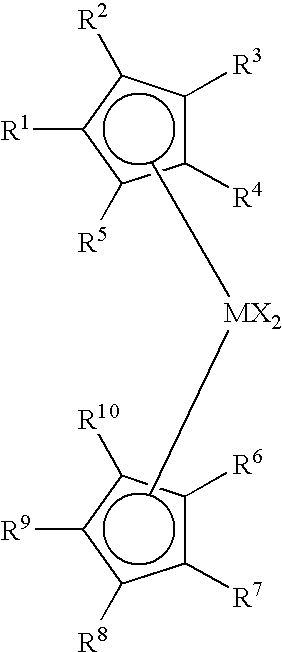

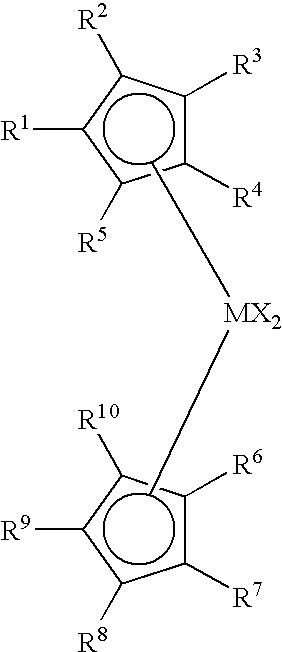

InactiveUS20070180990A1Efficient ConcentrationEasy to captureGas treatmentUsing liquid separation agentHalogenSorbent

A halogen-containing gas is injected into a flowing transport air / sorbent stream at a point close to the point where the sorbent and transport air first mix to maximize the residence time available for the halogen-containing compound to be adsorbed onto the sorbent surface prior to the sorbent being injected into a flue gas containing mercury. This process maximizes the benefit and utilization of the halogen-containing reagent by placing it exactly where it is needed to facilitate elemental mercury removal—on the surface of the sorbent. The sorbent particles with their loading of adsorbed halogen-containing reagent enter the flue gas with a high reactivity for the removal of elemental mercury.

Owner:THE BABCOCK & WILCOX CO

Process to produce low viscosity poly-alpha-olefins

ActiveUS20070043248A1Hydrocarbon by hydrogenationHydrocarbons from unsaturated hydrocarbon additionPolyolefinAlpha-olefin

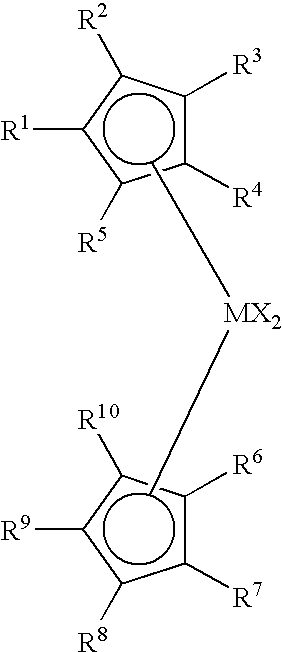

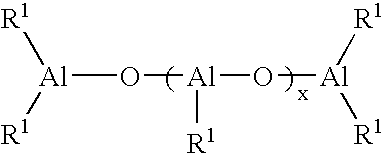

This invention relates to a process to produce a polyalpha-olefin comprising: 1) contacting one or more alpha-olefin monomers having 3 to 24 carbon atoms with an unbridged substituted bis cyclopentadienyl transition metal compound having: 1) at least one non-isoolefin substitution on both cyclopentadientyl rings, or 2) at least two substitutions on at least one cyclopentadienyl ring, a non-coordinating anion activator, and optionally an alkyl-aluminum compound, where the molar ratio of transition metal compound to activator is 10:1 to 0.1:1, and if the alkyl aluminum compound is present then the molar ratio of alkyl aluminum compound to transition metal compound is 1:4 to 4000:1, under polymerization conditions wherein: i) hydrogen is present at a partial pressure of 0.1 to 50 psi, based upon the total pressure of the reactor or the concentration of the hydrogen is from 1 to 10,000 ppm or less by weight; ii) wherein the alpha-olefin monomer(s) having 3 to 24 carbon atoms are present at 10 volume % or more based upon the total volume of the catalyst / activator / alkylaluminum compound solutions, monomers, and any diluents or solvents present in the reaction; iii) the residence time of the reaction is at least 5 minutes; iv) the productivity of the process is at least 43,000 grams of total product per gram of transition metal compound; v) the process is continuous or semi-continuous, and vi) the temperature in the reaction zone does not rise by more than 10° C. during the reaction; and vii) ethylene is not present at more than 30 volume % of the monomers entering the reaction zone; and 2) obtaining a polyalpha-olefin (PAO), optionally hydrogenating the PAO, wherein the PAO comprises at least 50 mole % of a C3 to C24 alpha-olefin monomer, and wherein the PAO has a kinematic viscosity at 100° C. of 20 cSt or less.

Owner:EXXONMOBIL CHEM PAT INC

Continuous process for the production of conjugated diene polymers having narrow molecular weight distribution and products therefrom

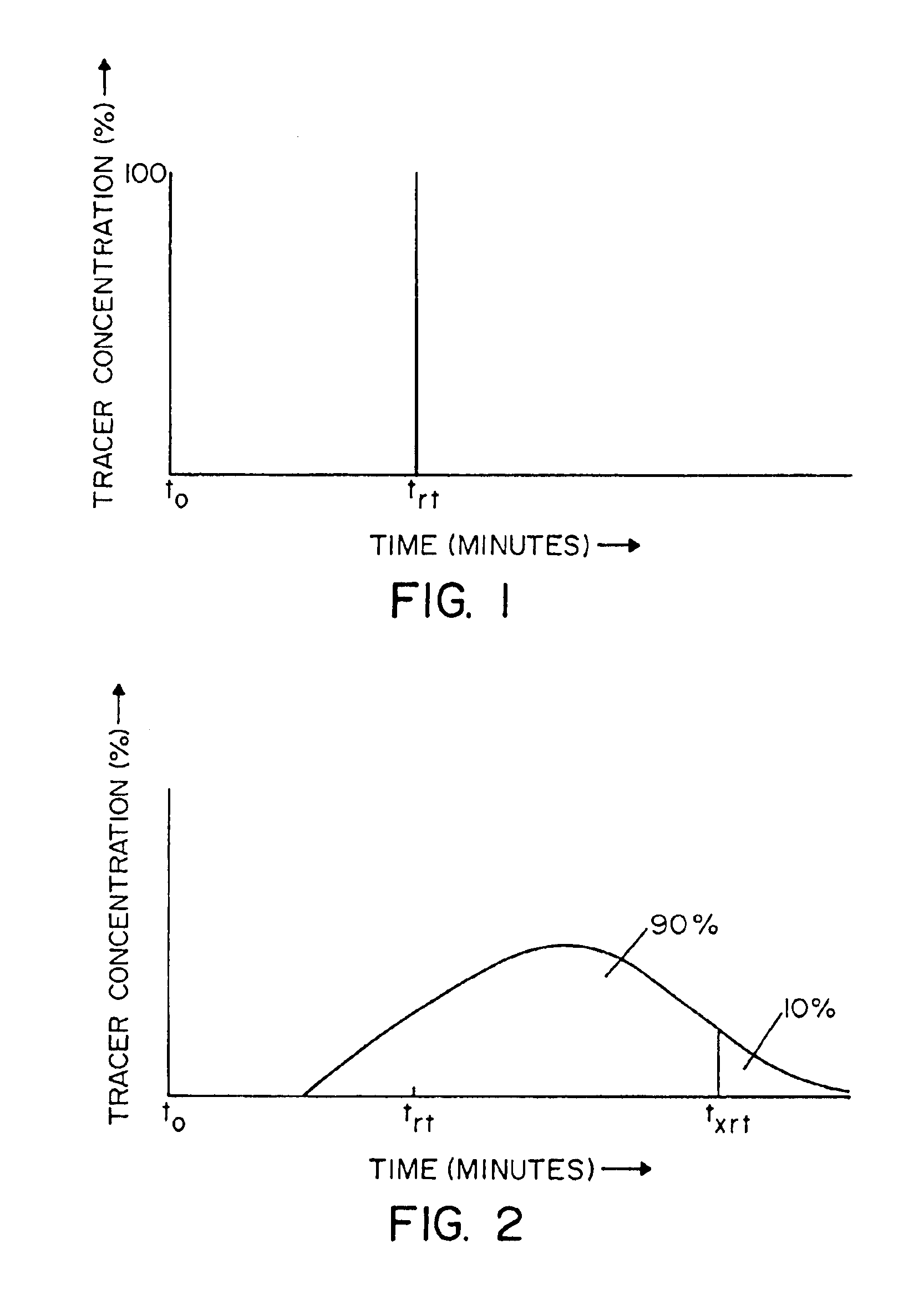

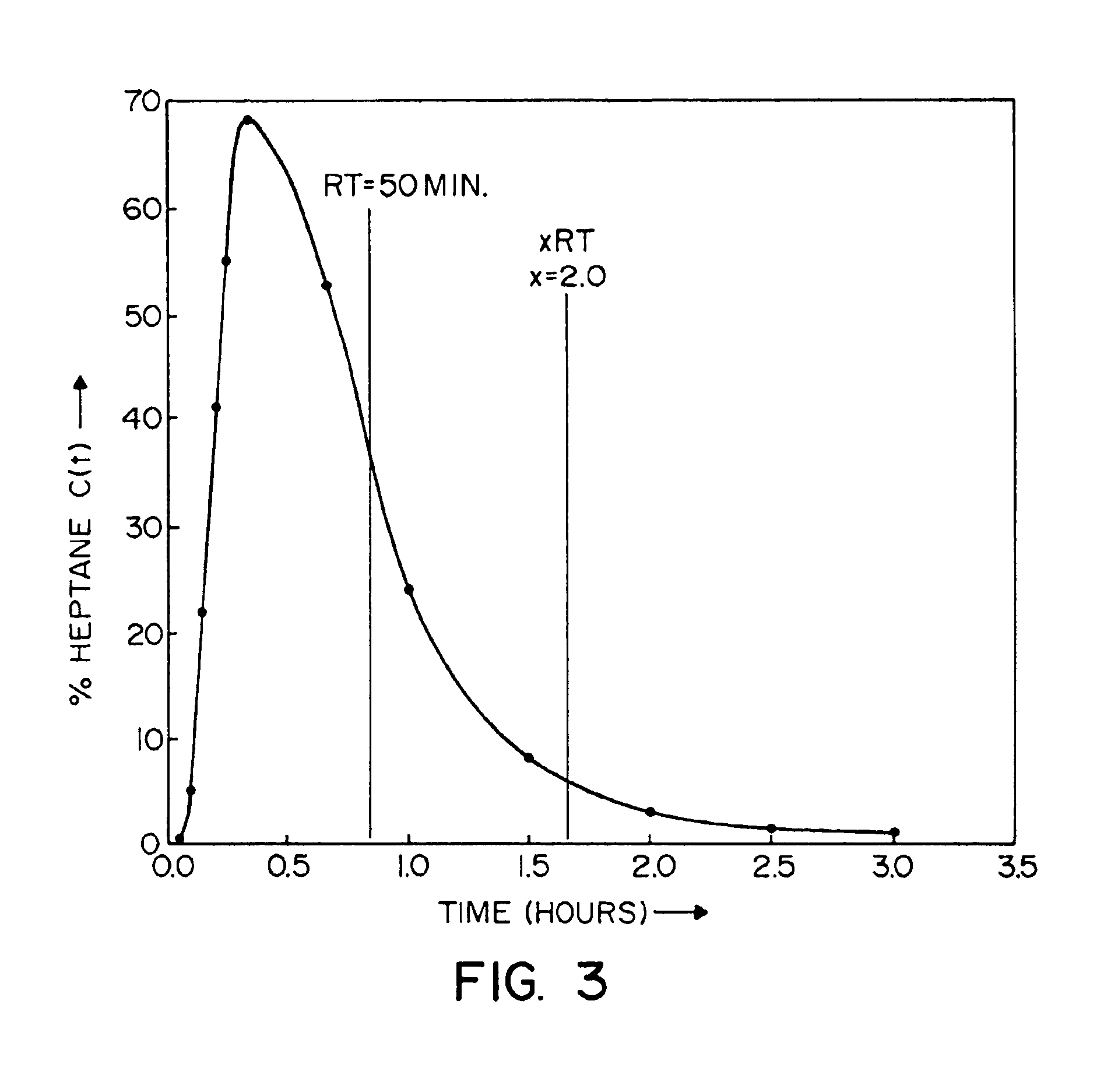

InactiveUS6897270B2Narrow molecular weight distributionImprove responseHydrocarbon solventsContinuous reactor

A continuous process for producing conjugated diene polymers comprising the steps of contacting, within an hydrocarbon solvent and within a continuous reactor, conjugated diene monomer and a catalyst composition prepared by combining: (a) a lanthanide compound, (b) an alkylating agent, and (c) a halogen-containing compound, and maintaining a non-ideal flow pattern within the continuous reactor so that 10% of the reagents entering the reactor at a reference time t0 are still present within the continuous reactor at a time t0+xtrt, where trt is the residence time corresponding to ideal flow within the continuous reactor and x is a numeral greater than 1.5.

Owner:BRIDGESTONE CORP

Multi component controlled release system for oral care, food products, nutraceutical, and beverages

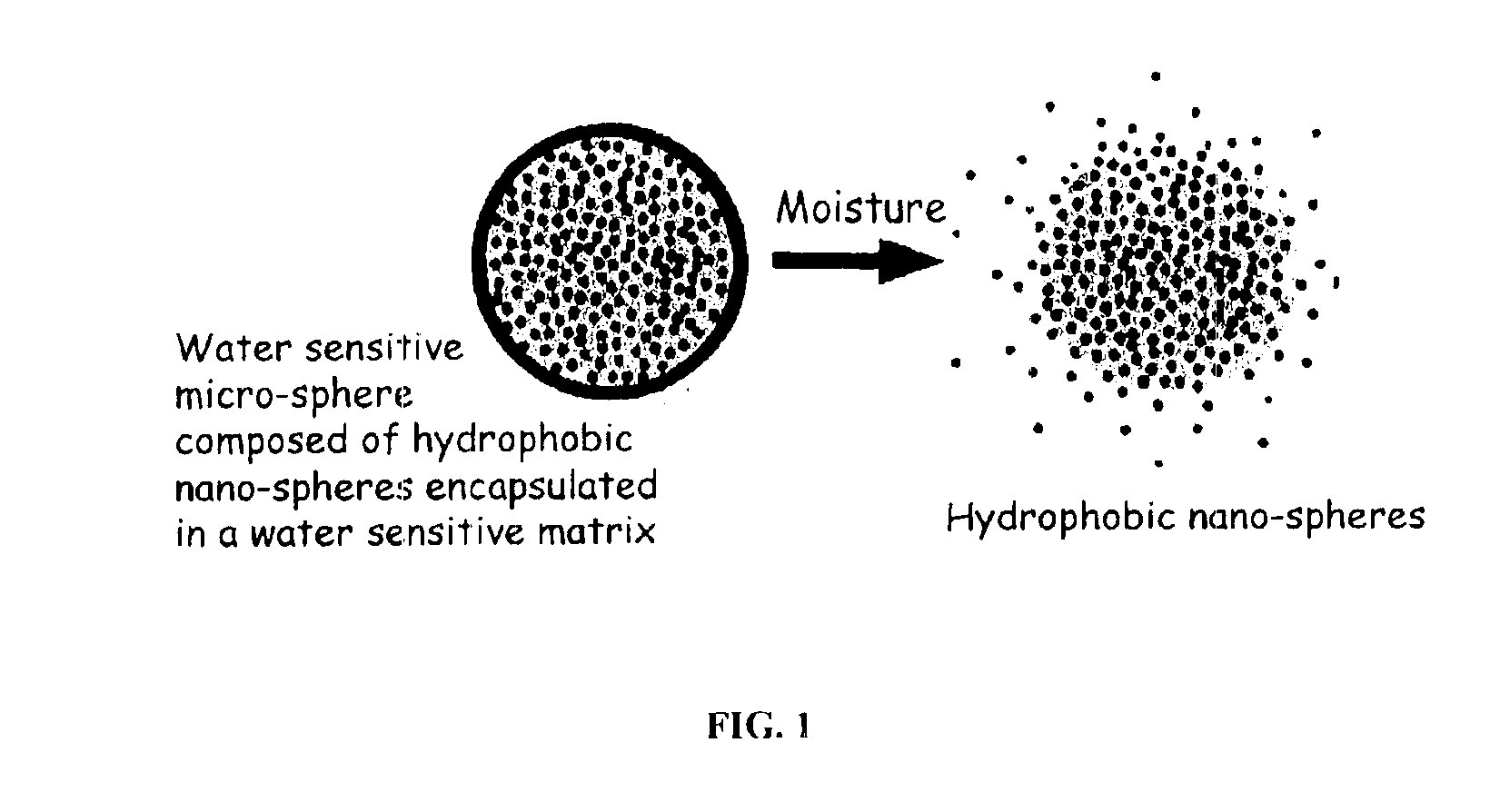

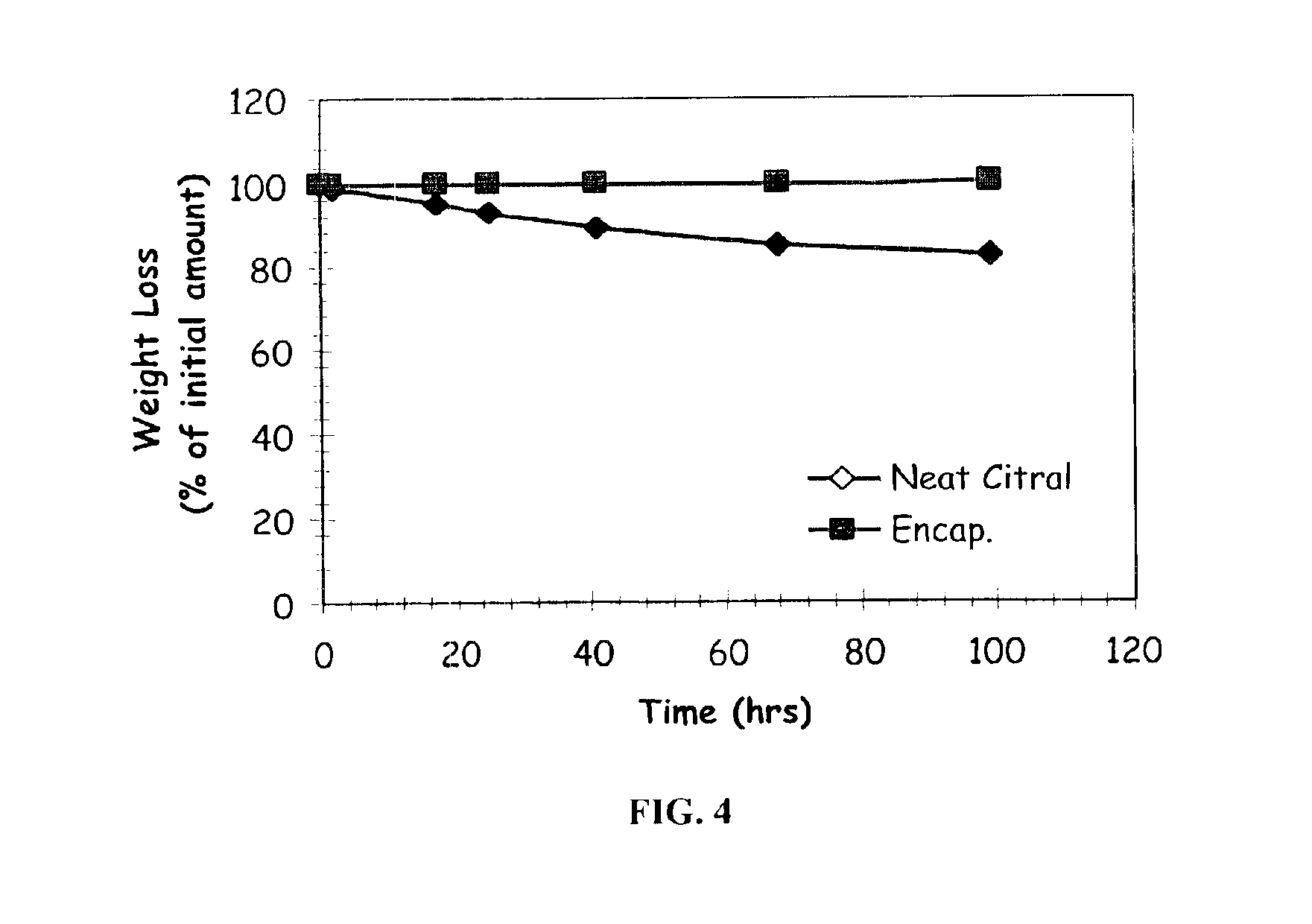

InactiveUS6887493B2Improve bioavailabilityImprove stabilityCosmetic preparationsPowder deliveryActive agentMicrosphere

The present invention relates to an improved controlled release system that can encapsulate different flavors, sensory markers, and active ingredients, or combinations of flavors, sensory markers and various active ingredients and release multiple active ingredients in a consecutive manner, one after the other. The controlled delivery system of the present invention is substantially free-flowing powder formed of solid hydrophobic nanospheres that are encapsulated in a moisture sensitive microspheres. The flavors, and active ingredients encapsulated in the hydrophobic nanospheres, in the water sensitive microsphere, or in both the nano and the microsphere. The flavors and active ingredients encapsulated in the nanospheres can be the same or different from those encapsulated in the microspheres. The encapsulation of different flavors or active agents in the various components of the system, such as nanospheres and microspheres, provides flavor transition (change in flavor character) during the use of the products. The controlled release system of the present invention enhances the stability and bioavailability of wide range of flavors, sensory markers, and other active ingredients, prolong their residence time in the oral cavity, control their release characteristics, and prolong the sensation of flavors and other sensory markers in the mouth to provide long lasting organoleptic perception or long lasting mouthfeel. The invention further relates oral care, food products, and beverages comprising the controlled release system of the present invention.

Owner:SHEFER ADI +1

Rapid solar-thermal conversion of biomass to syngas

ActiveUS20080086946A1Improve reaction kineticsWide rangeElectrical coke oven heatingSolar heating energySyngasReactor design

Methods for carrying out high temperature reactions such as biomass pyrolysis or gasification using solar energy. The biomass particles are rapidly heated in a solar thermal entrainment reactor. The residence time of the particles in the reactor can be 5 seconds or less. The biomass particles may be directly or indirectly heated depending on the reactor design. Metal oxide particles can be fed into the reactor concurrently with the biomass particles, allowing carbothermic reduction of the metal oxide particles by biomass pyrolysis products. The reduced metal oxide particles can be reacted with steam to produce hydrogen in a subsequent process step.

Owner:UNIV OF COLORADO THE REGENTS OF

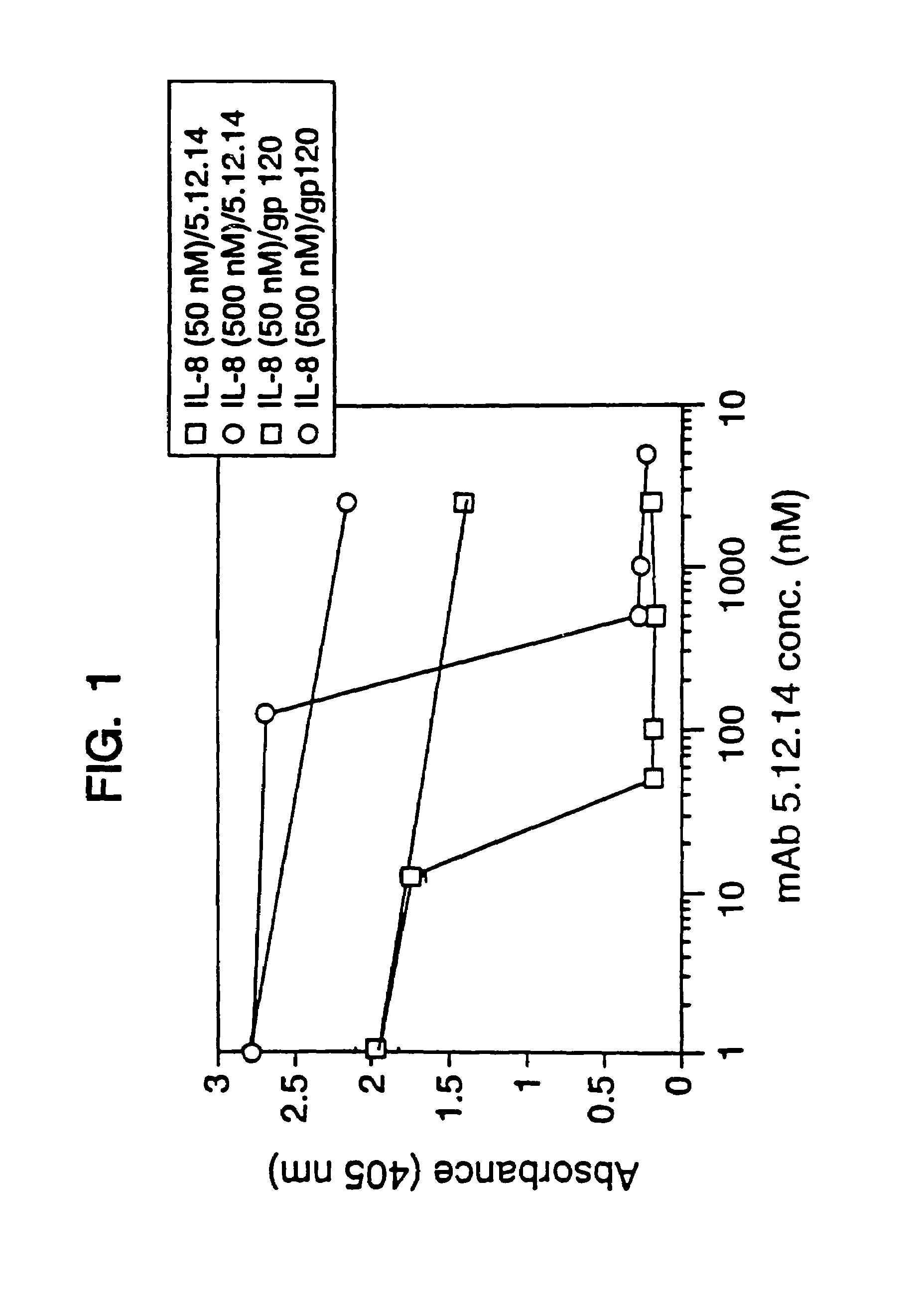

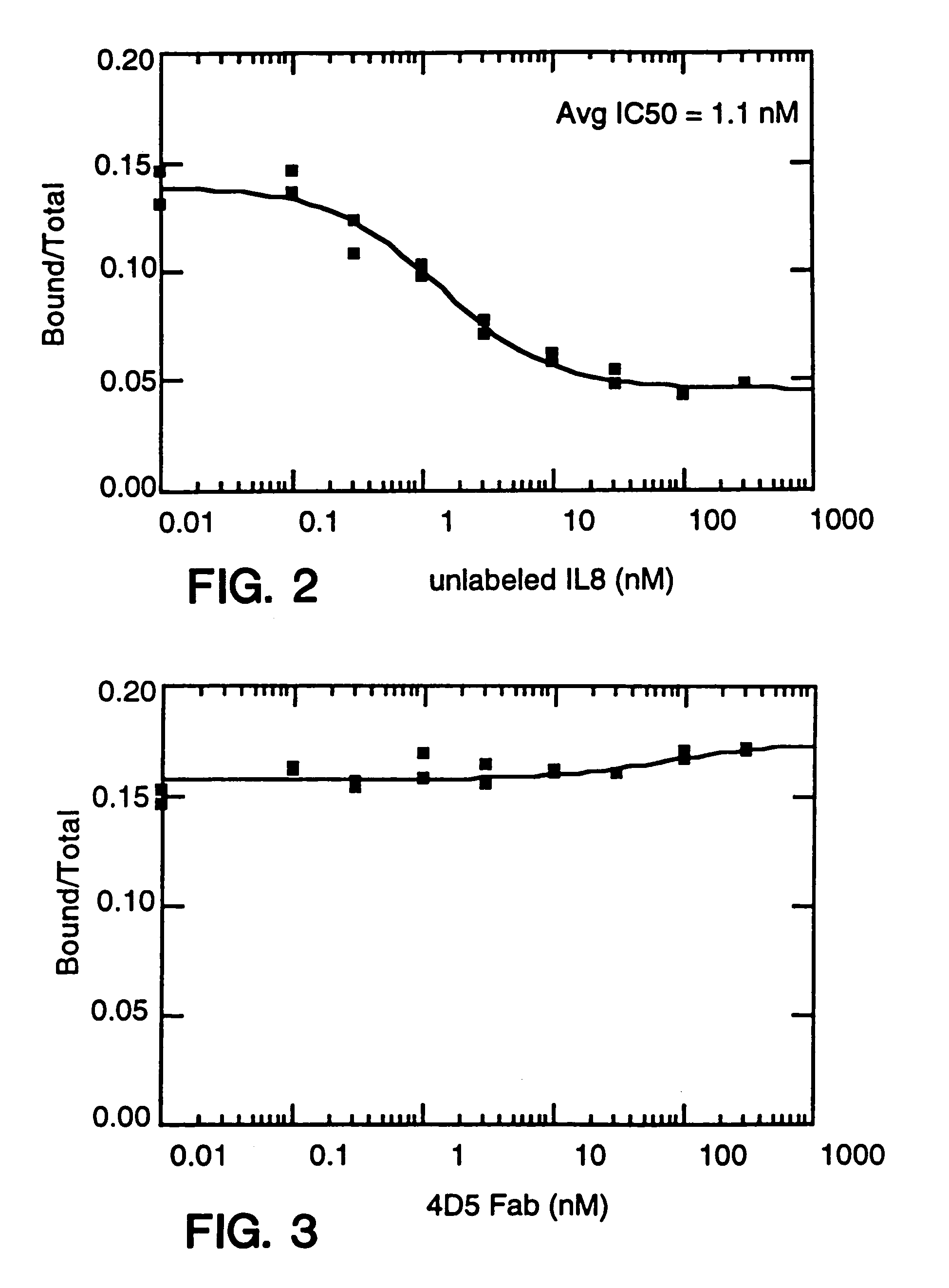

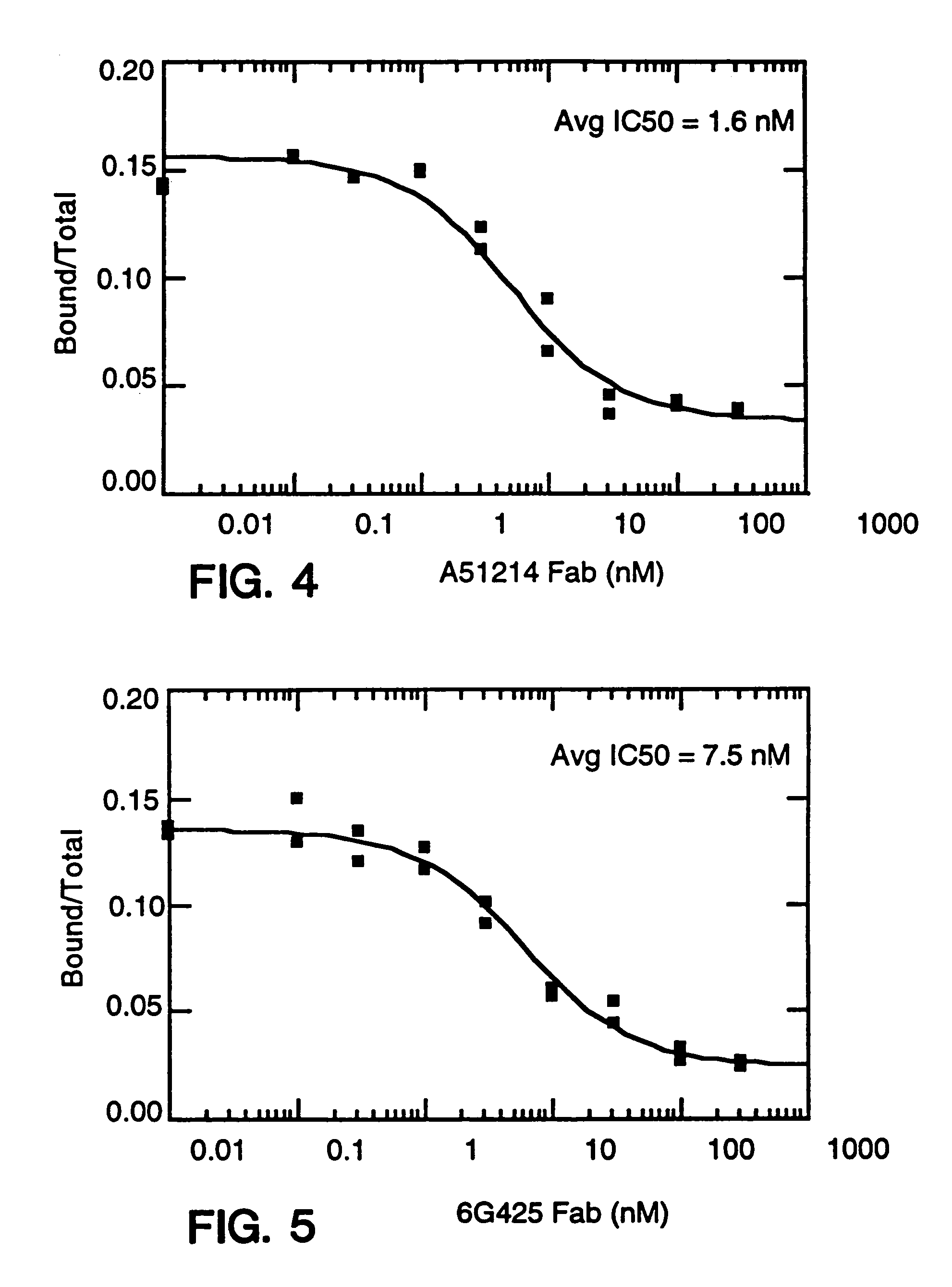

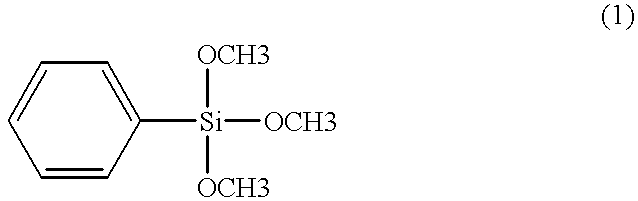

Antibody fragment-polymer conjugates and uses of same

Described are conjugates formed by an antibody fragment covalently attached to a non-proteinaceous polymer, wherein the apparent size of the conjugate is at least about 500 kD. The conjugates exhibit substantially improved half-life, mean residence time, and / or clearance rate in circulation as compared to the underivatized parental antibody fragment. Also described are conjugates directed against human vascular endothelial growth factor (VEGF), human p185 receptor-like tyrosine kinase (HER2), human CD20, human CD18, human CD11a, human IgE, human apoptosis receptor-2 (Apo-2), human tumor necrosis factor-α (TNF-α), human tissue factor (TF), human α4β7 integrin, human GPIIb-IIIa integrin, human epidermal growth factor receptor (EGFR), human CD3, and human interleukin-2 receptor α-chain (TAC) for diagnostic and therapeutic applications.

Owner:GENENTECH INC

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6432846B1Low dielectric constantImprove thermal stabilitySolid-state devicesPretreated surfacesPolymer scienceHigh humidity

A method for forming a silicone polymer insulation film having low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is vaporizing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha=3, beta=3 or 4, x, and y are integers) and then introducing the vaporized compound to the reaction chamber of the plasma CVD apparatus. The next step is introducing additive gas into the reaction chamber. The residence time of the material gas is lengthened by reducing the total flow of the reaction gas, in such a way as to formed a silicone polymer film having a micropore porous structure with low relative dielectric constant.

Owner:ASM JAPAN

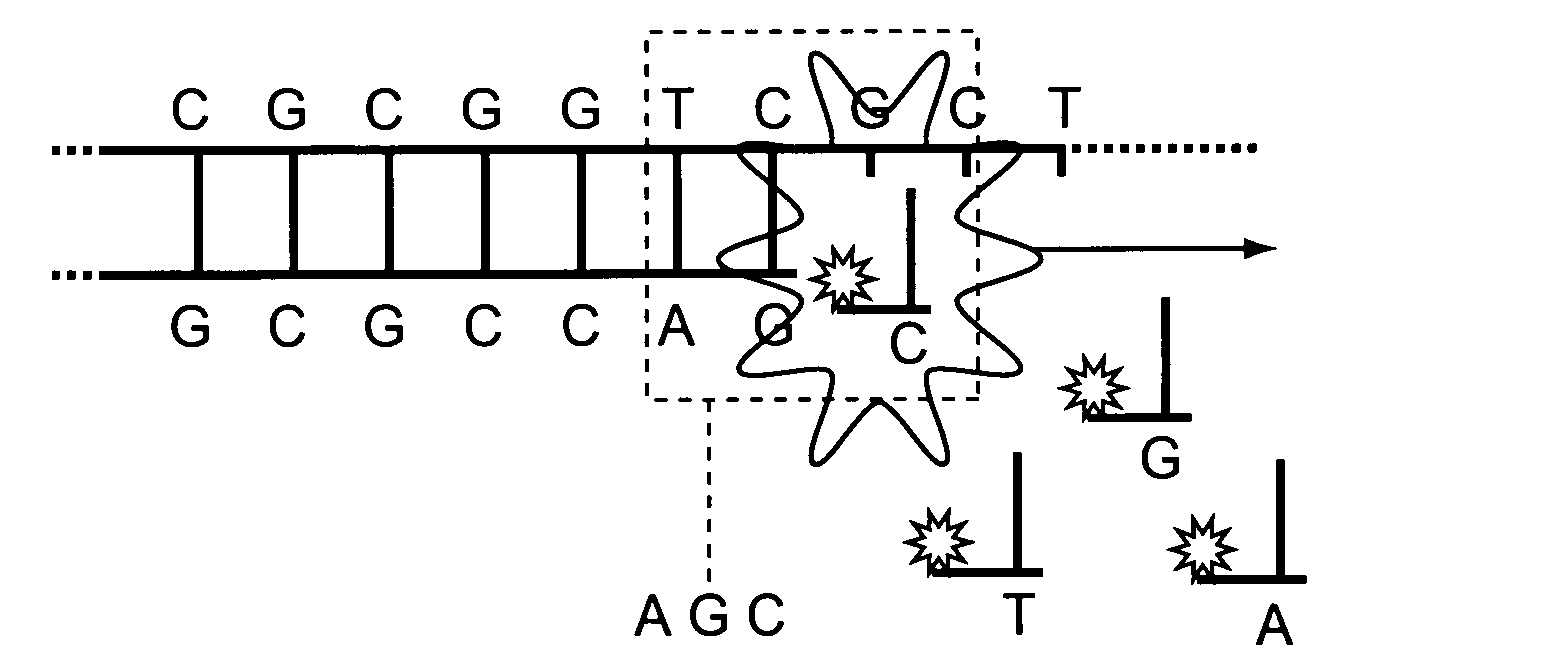

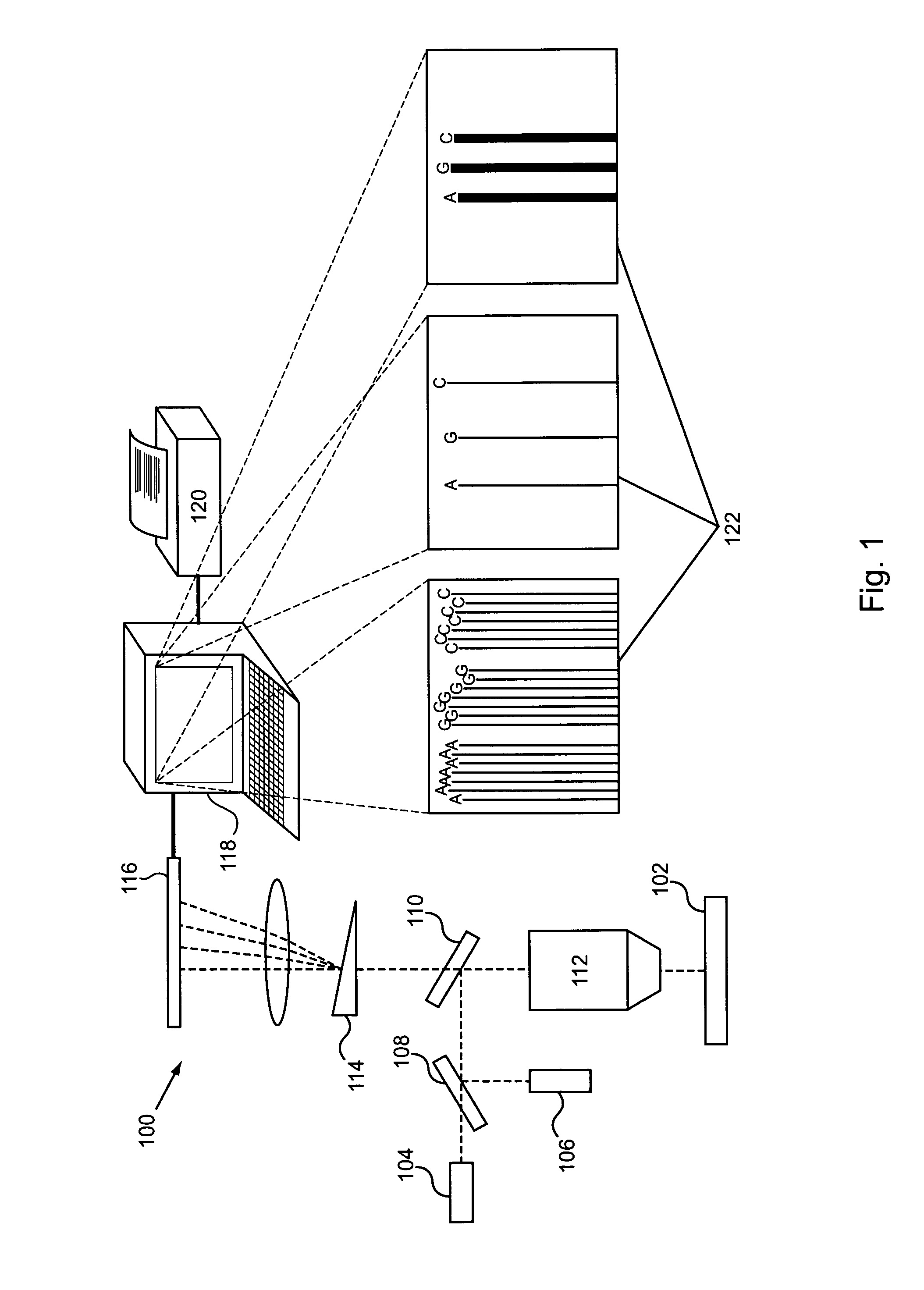

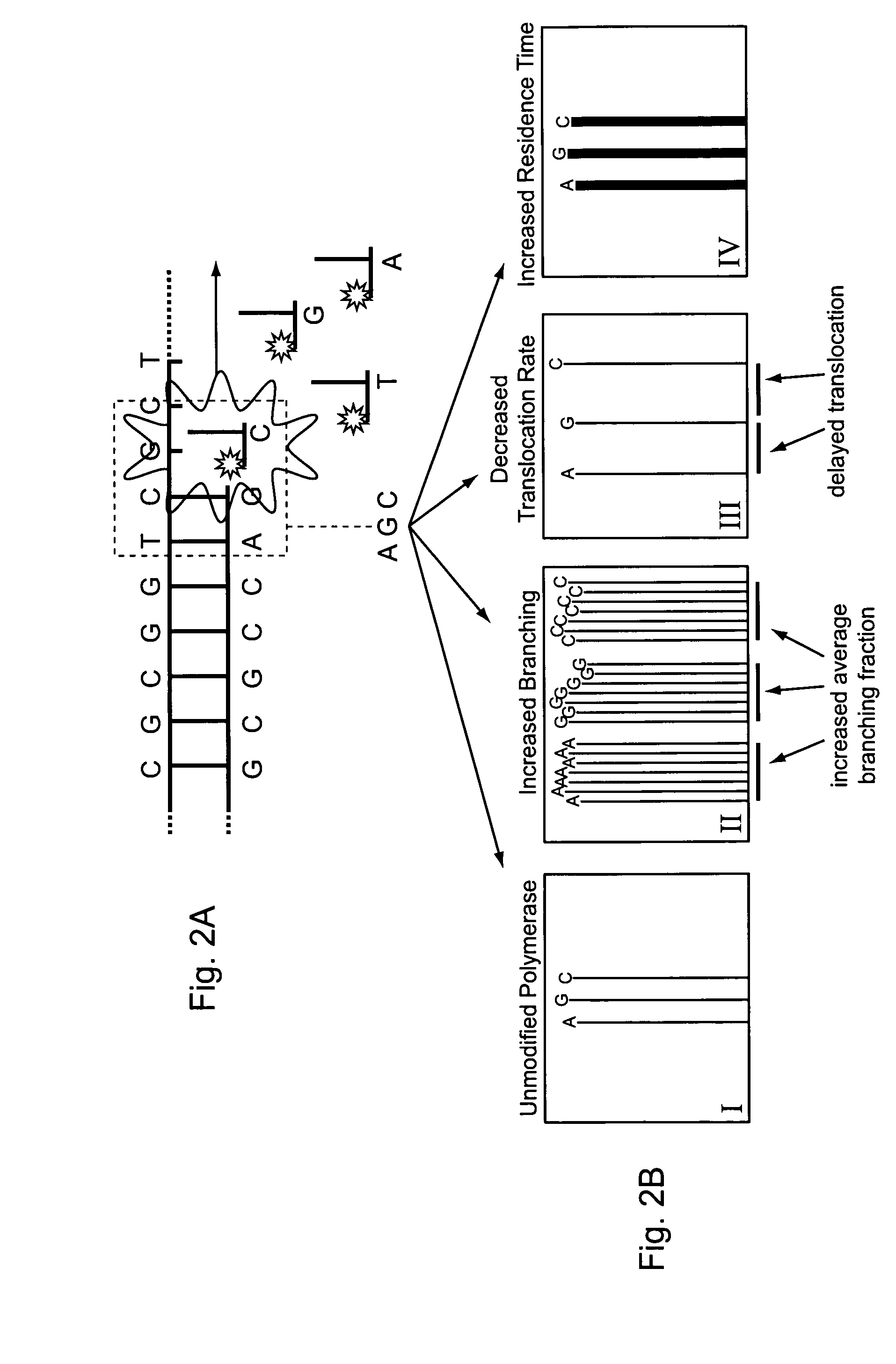

Engineering polymerases and reaction conditions for modified incorporation properties

ActiveUS20100075332A1Easy to identifyDelayed translocationBioreactor/fermenter combinationsBiological substance pretreatmentsPolymerase LA-DNA

Owner:PACIFIC BIOSCIENCES

Process for drawing gel-spun polyethylene yarns

InactiveUS20050093200A1Domestic articlesMonocomponent polyolefin artificial filamentProduction rateForced convection

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

Continuous-Batch Hybrid Process for Production of Oil and Other Useful Products from Photosynthetic Microbes

InactiveUS20080118964A1Lower potentialIncreased complexityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismCarrying capacity

A process for cultivating photosynthetic microbes comprising Closed Systems for continuous cultivation and Open Systems for batch cultivation, in which (a) the Closed System Area occupies no more than 20% of the Total Land Area of the cultivation facility; (b) batch cultures in the Open Systems are initiated with an inoculum from the Closed Systems containing a cell biomass of no less than 5% of the carrying capacity of said Open System; (c) the doubling rate of said photosynthetic microbe is no less than once every 16 hours; and (d) the residence time of the batch culture in said Open System is no more than a period of 5 days.

Owner:CELLANA

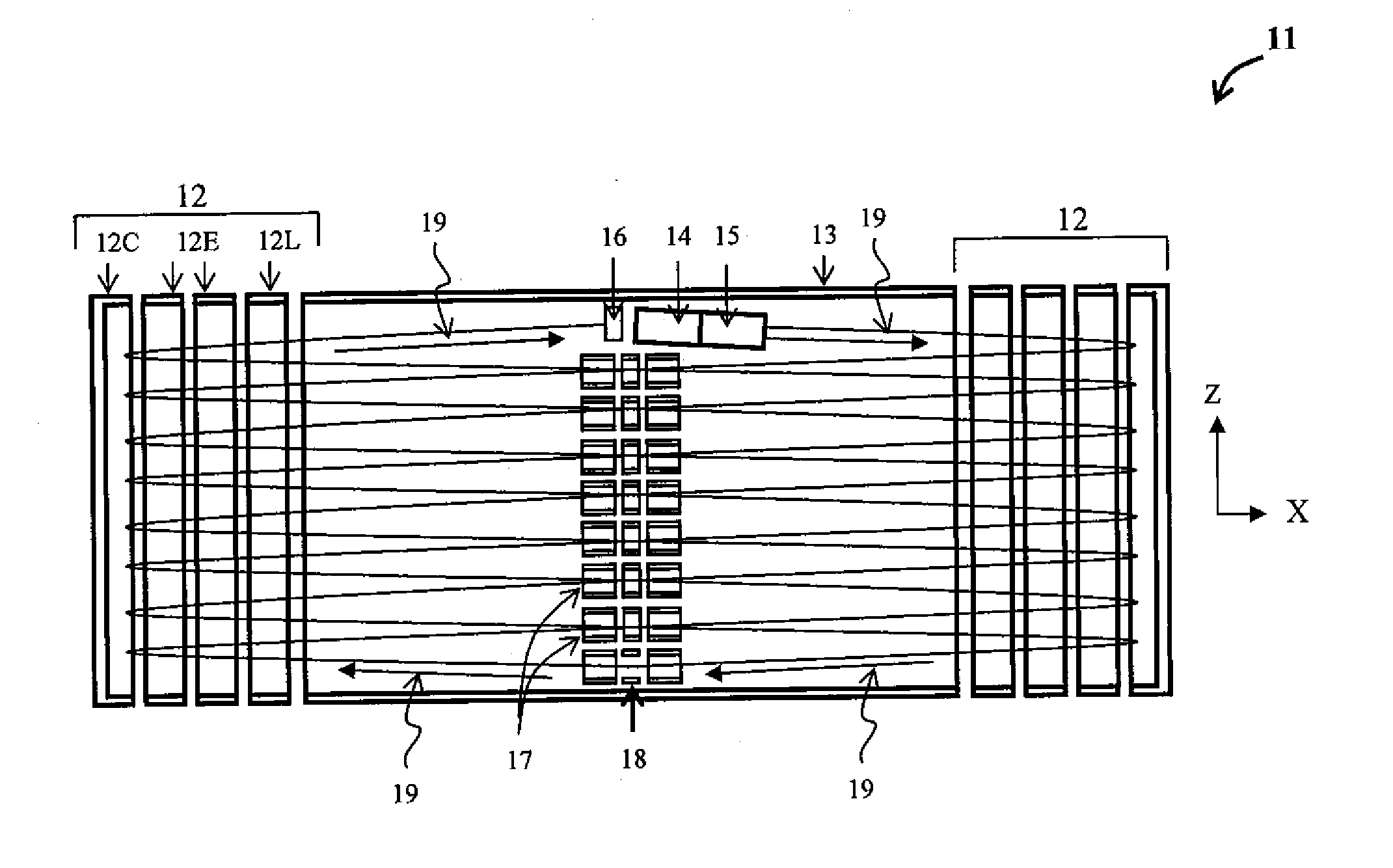

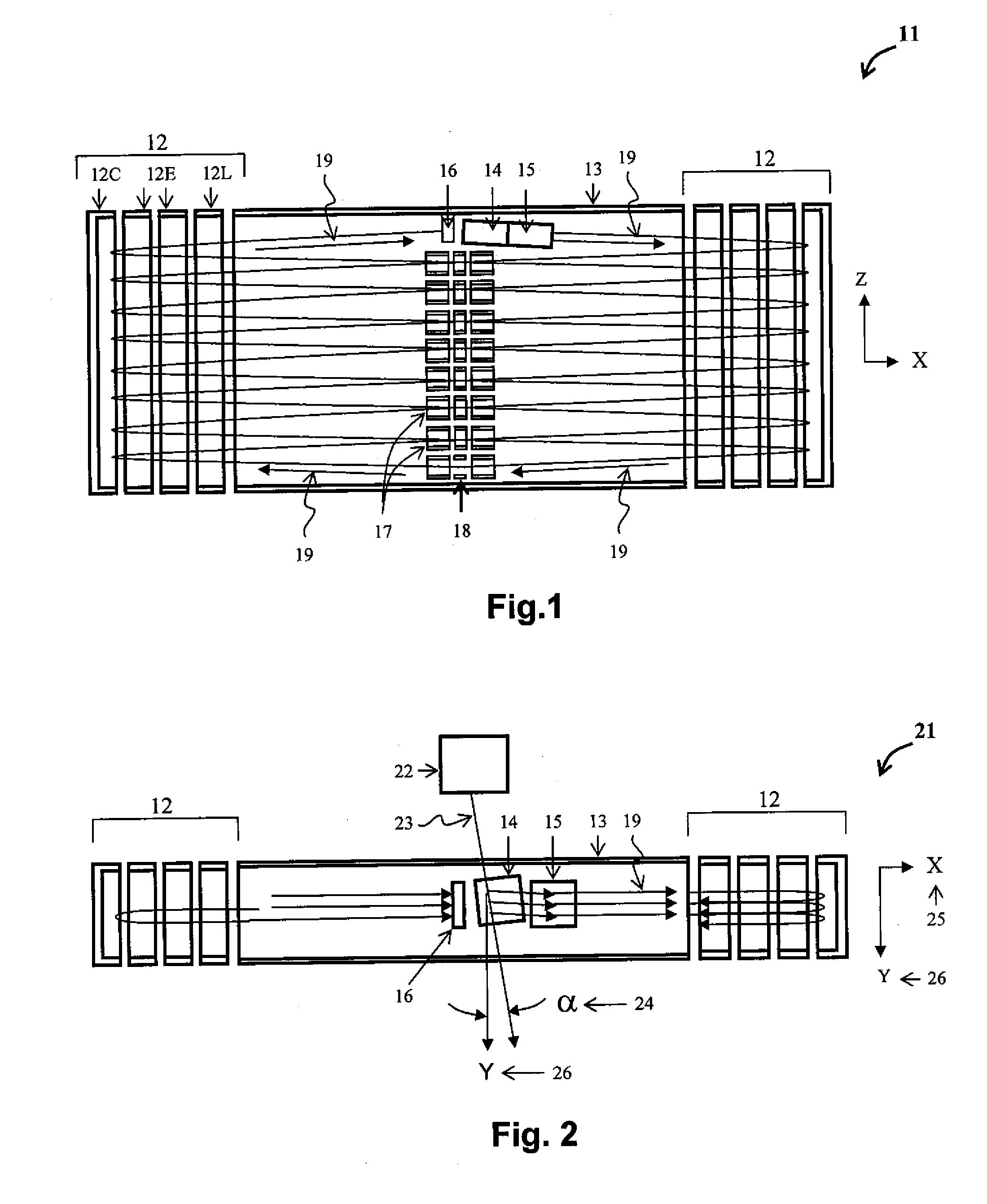

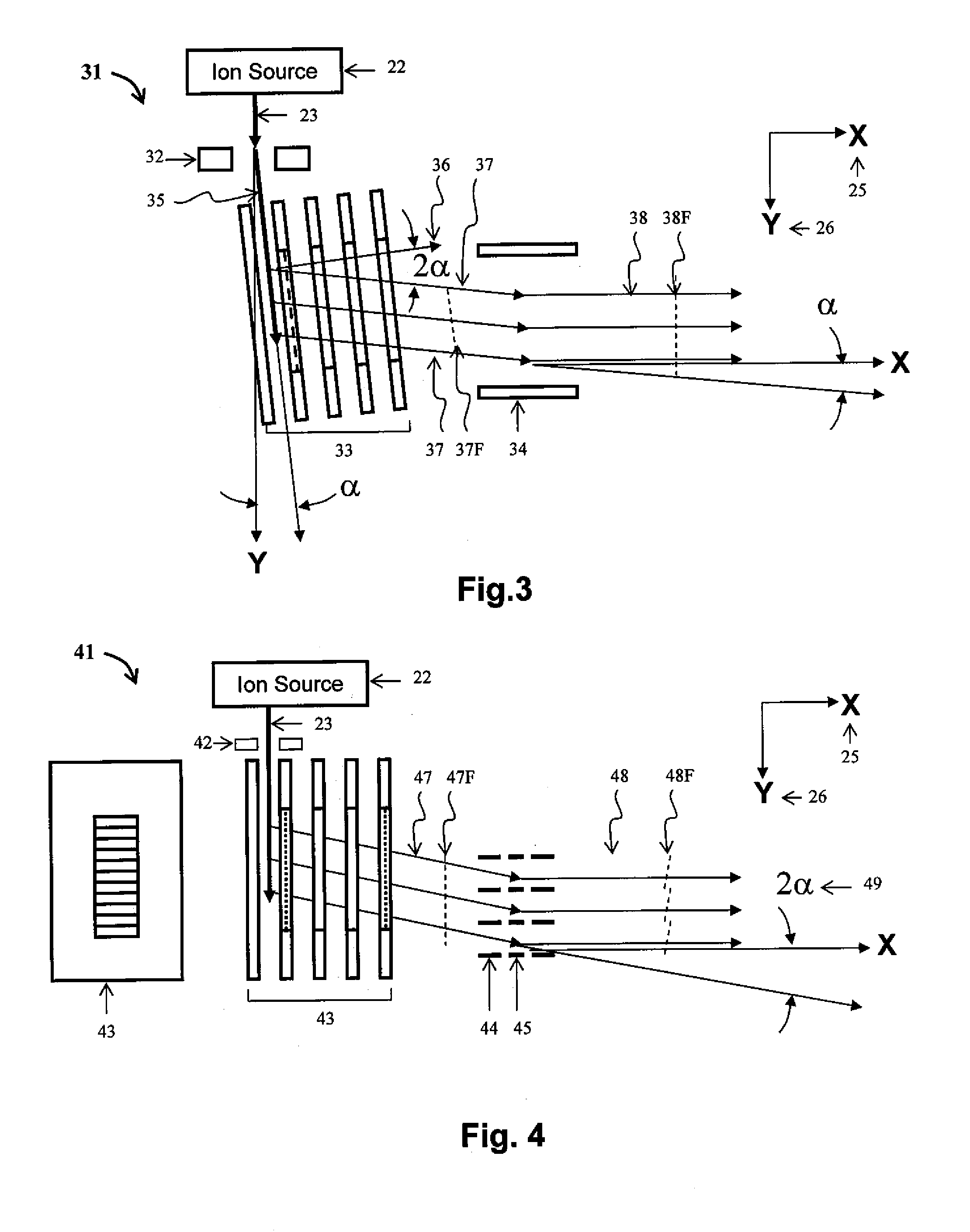

Multi-reflecting Time-of-flight Mass Spectrometer With Orthogonal Acceleration

The disclosed apparatus includes a multi-reflecting time-of-flight mass spectrometer (MR-TOF MS) and an orthogonal accelerator. To improve the duty cycle of the ion injection at a low repetition rate dictated by a long flight in the MR-TOF MS, multiple measures may be taken. The incoming ion beam and the accelerator may be oriented substantially transverse to the ion path in the MR-TOF, while the initial velocity of the ion beam is compensated by tilting the accelerator and steering the beam for the same angle. To further improve the duty cycle of any multi-reflecting or multi-turn mass spectrometer, the beam may be time-compressed by modulating the axial ion velocity with an ion guide. The residence time of the ions in the accelerator may be improved by trapping the beam within an electrostatic trap. Apparatuses with a prolonged residence time in the accelerator provide improvements in both sensitivity and resolution.

Owner:LECO CORPORATION

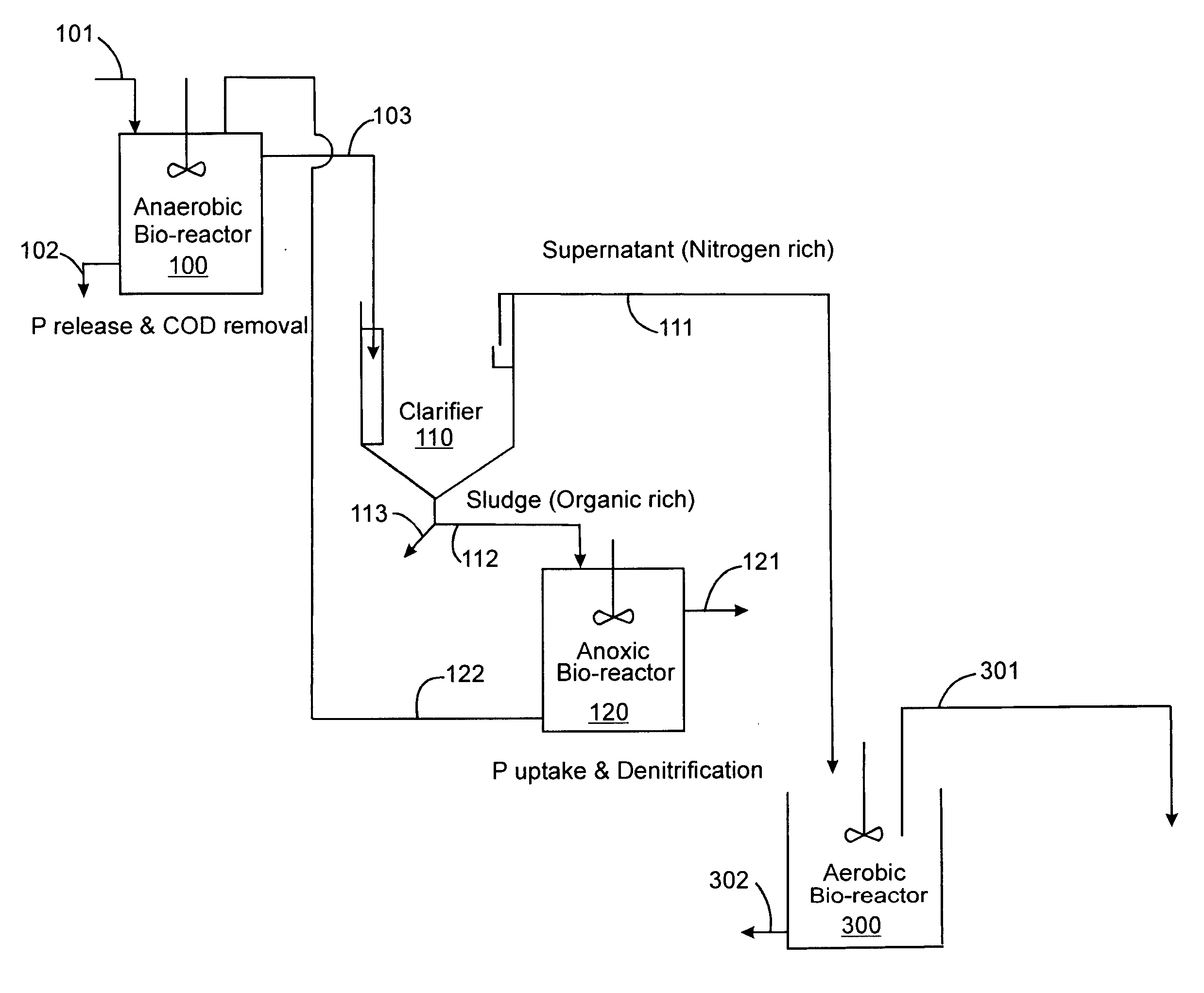

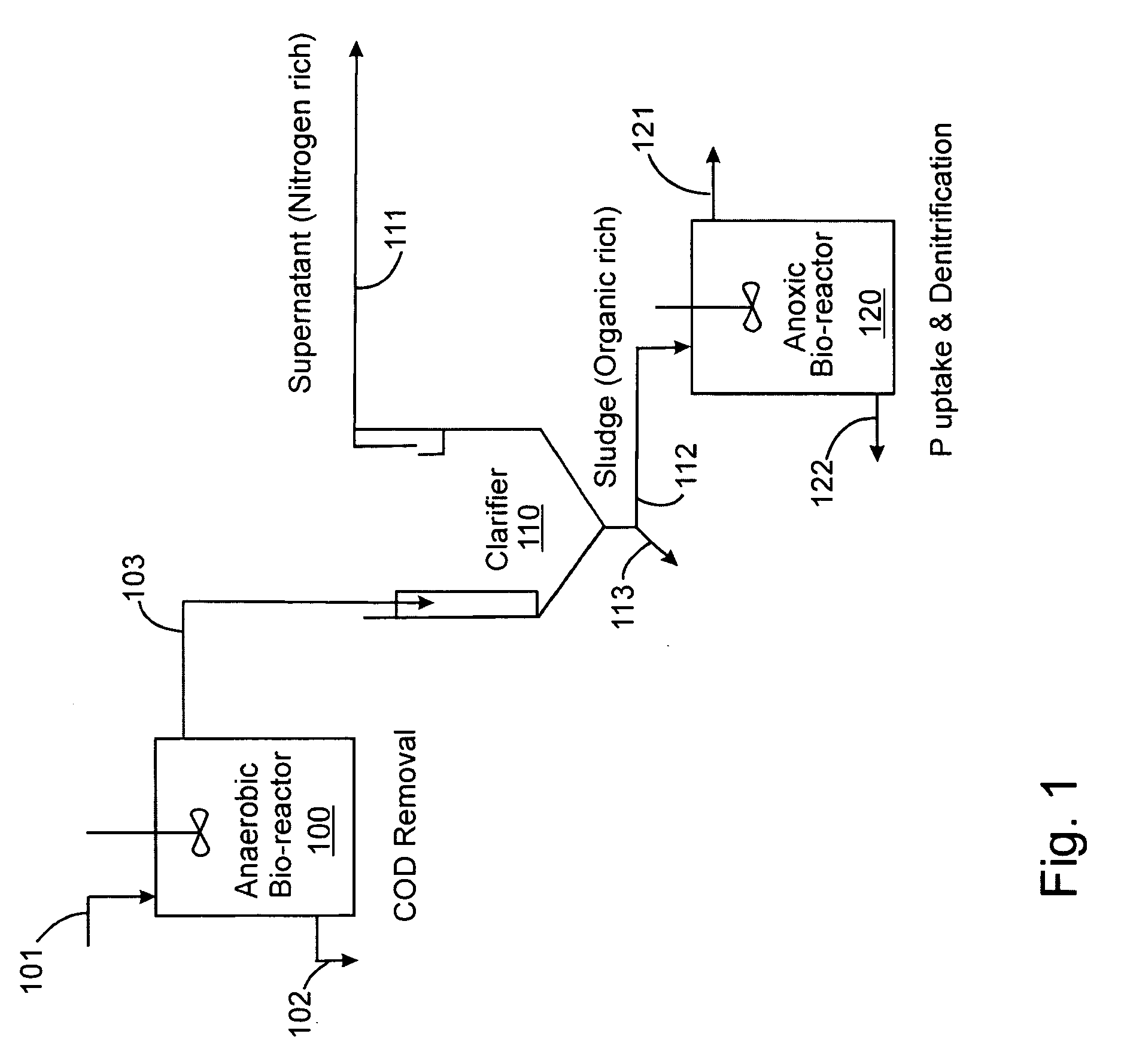

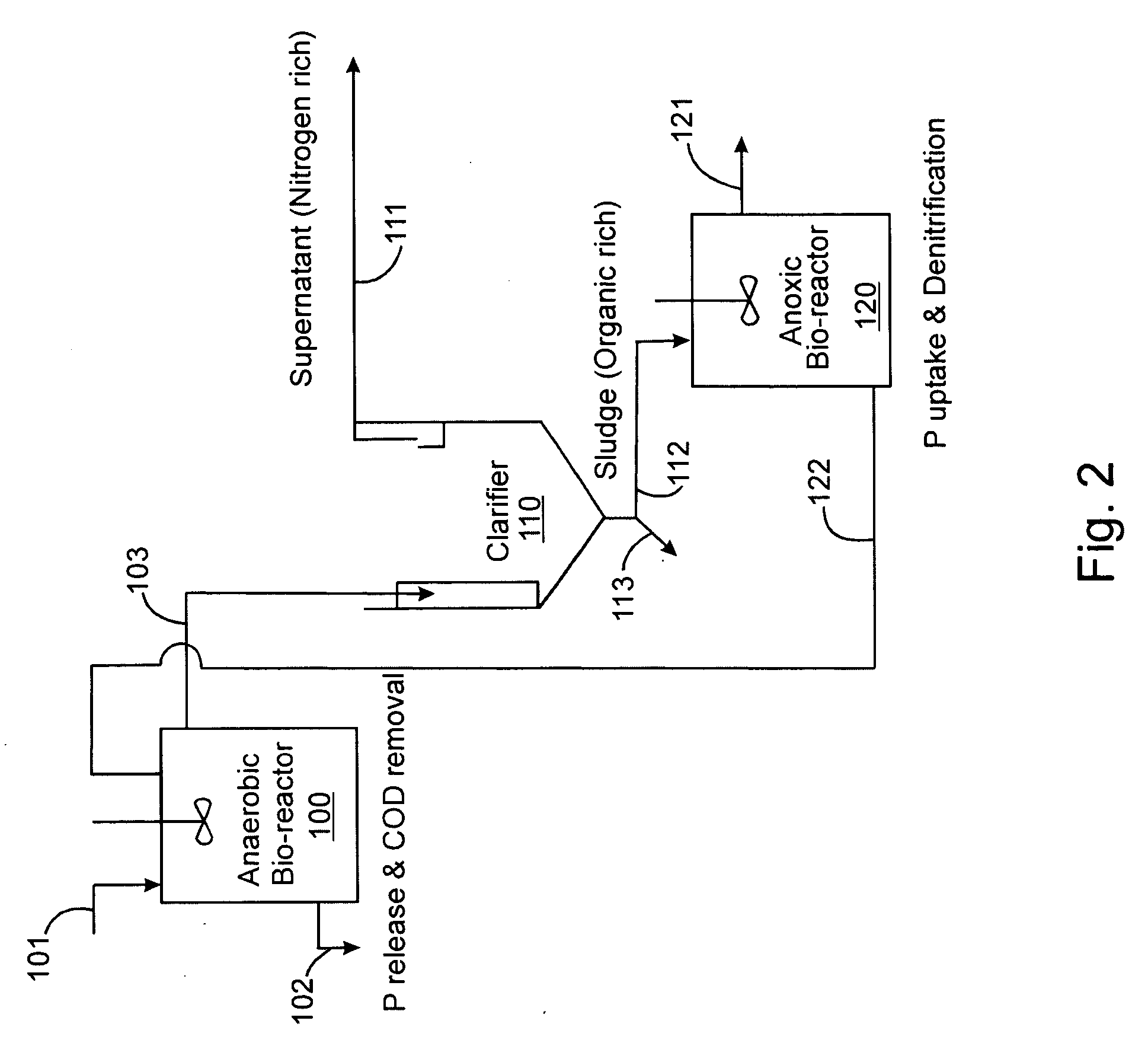

Treatment of wastewater containing phosphorous and nitrogen

InactiveUS20060249449A1Great extent of P releaseHigh P uptakeTreatment using aerobic processesSeparation devicesOxygenClarifier

A method and process for the treatment of wastewater containing phosphorous and nitrogen. The wastewater is first anaerobically treated to produce an anaerobic effluent from which insoluble organic carbon is separated to form a sludge rich in organic carbon that is used as a substrate during anoxic treatment of the wastewater by de-nitrifying phosphorous accumulating organisms (DPAO's) and ordinary de-nitrifying organisms. The separation of insoluble organic carbon is normally conducted using a clarifier located intermediate the anaerobic and anoxic bio-reactors. In one embodiment, the ammonia rich clarifier supernatant is directed to an aerobic reactor for nitrification and the nitrate produced is recycled to the anoxic bio-reactor. The final effluent may be membrane filtered to retain nitrifying biomass within the aerobic bio-reactor. The invention reduces overall hydraulic residence time and sludge volume, which results in a smaller, less expensive wastewater treatment system.

Owner:UNIV OF WESTERN ONTARIO

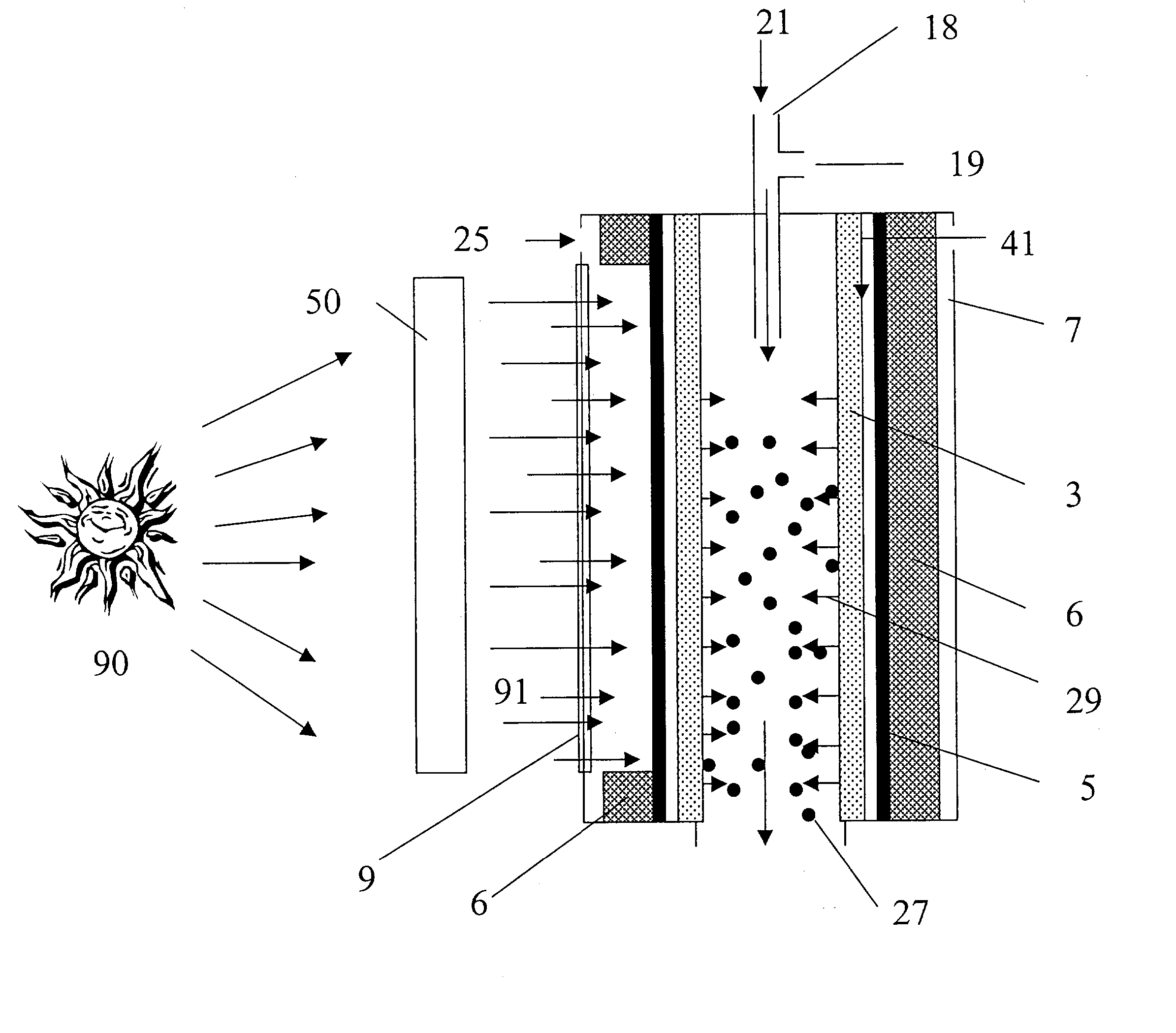

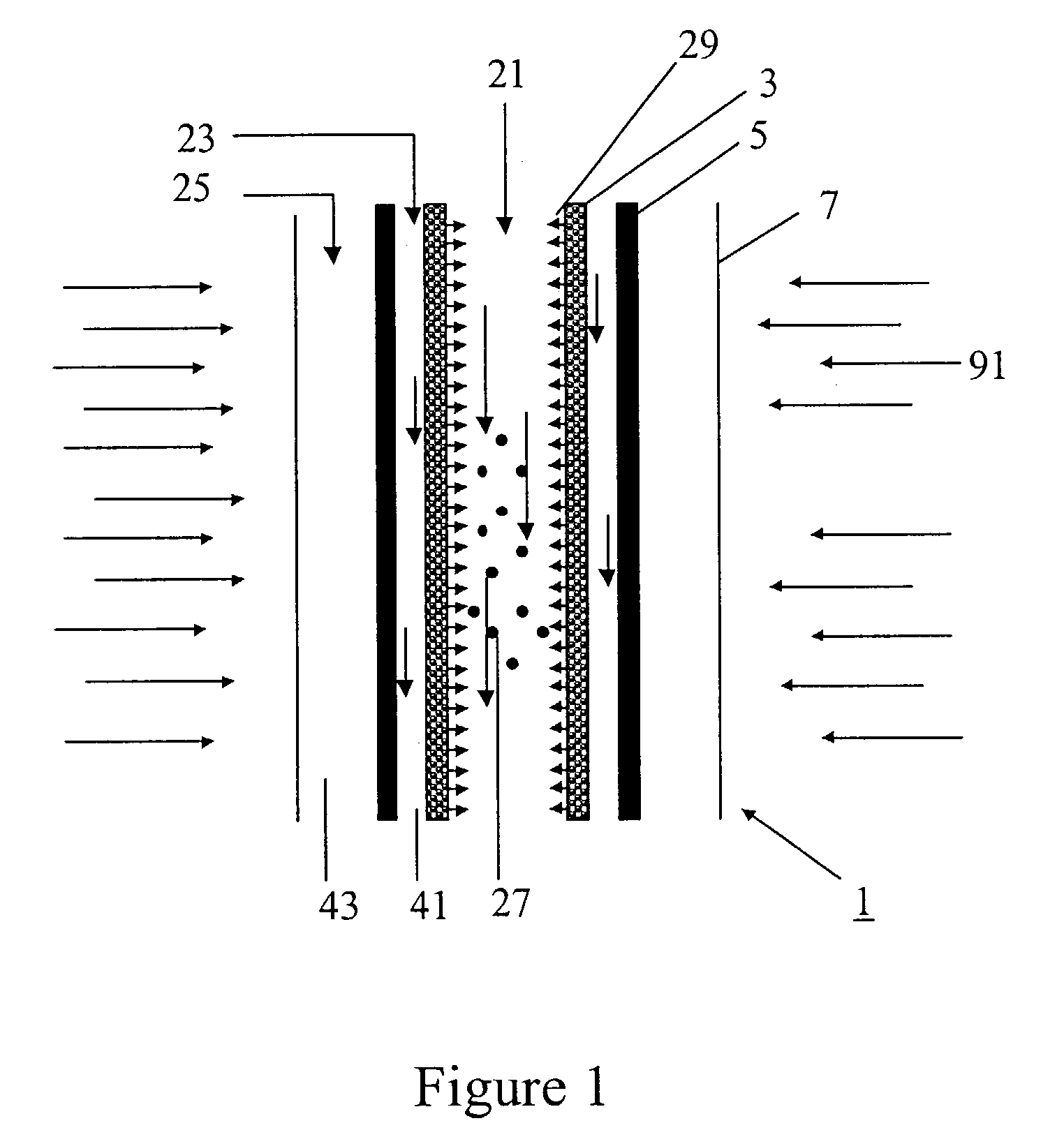

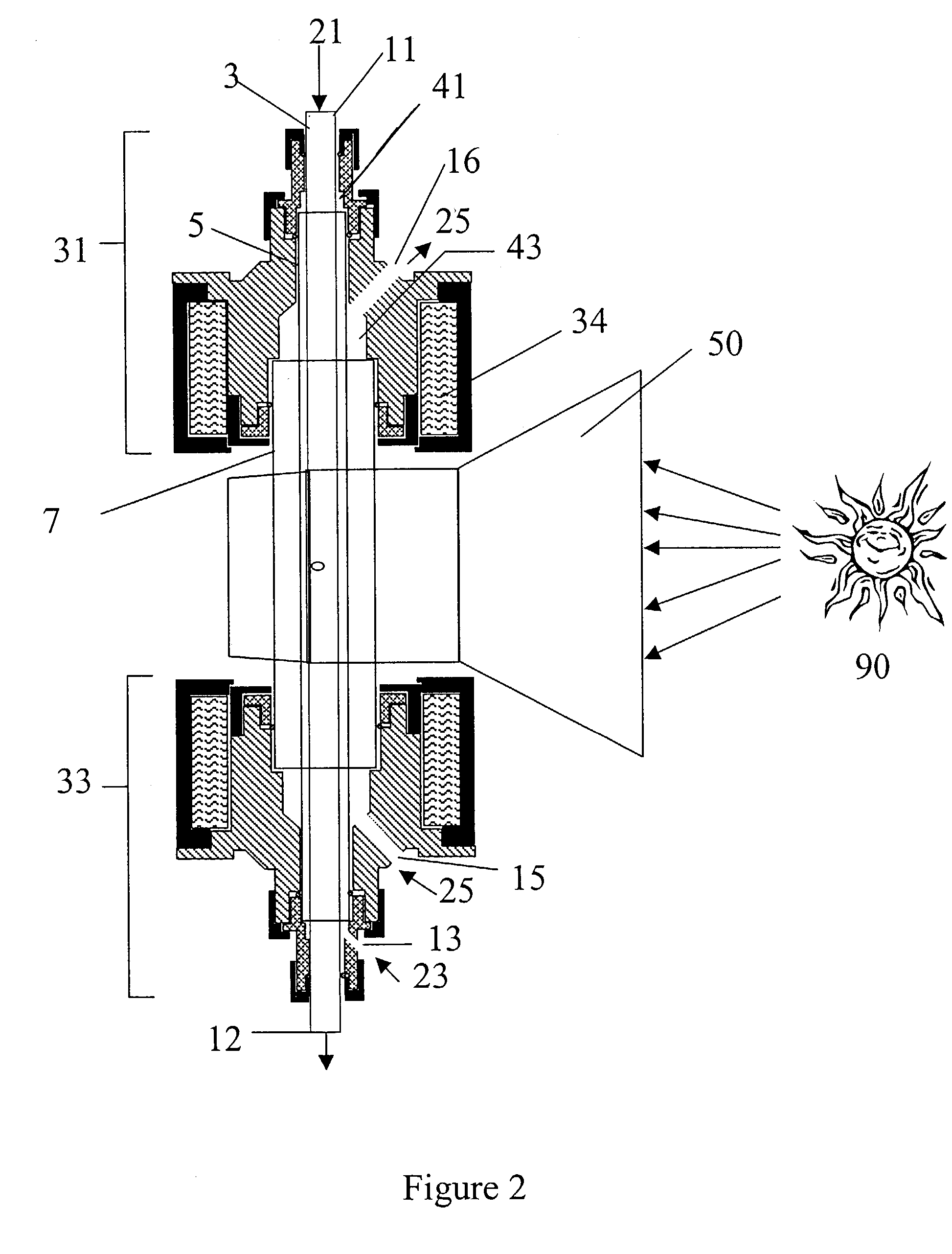

Solar-thermal fluid-wall reaction processing

InactiveUS7033570B2Reduce and preventShort stayThermal non-catalytic crackingSolar heating energyHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Manufacture of polyolefin fishing line

InactiveUS6148597AReduce resistanceReduce wearAgriculture tools and machinesFilament/thread formingYarnPolyolefin

Yarns and fishing lines are made by a process that includes the step of exposing an opaque yarn made from ultrahigh molecular weight, gel spun polyolefin filaments to a temperature within the melting point range of the filaments for a time sufficient to at least partially fuse the contact surfaces of adjacent filaments. For ultrahigh molecular weight, gel spun polyethylene, this temperature is preferably within the range from about 150 DEG -157 DEG C. The surface fusion between and among filaments imparts desirable handling characteristics to the ultrahigh molecular weight, gel spun polyolefin yarns and fishing lines that are similar to those of a conventional monofilaments. Preferably, the temperature, residence time, and stretching ratio at the selected temperature are chosen to provide a fishing line exhibiting a tensile modulus within the range from about 230 g / d to about 780 g / d with a tenacity of at least 15 g / d.

Owner:PURE FISHING

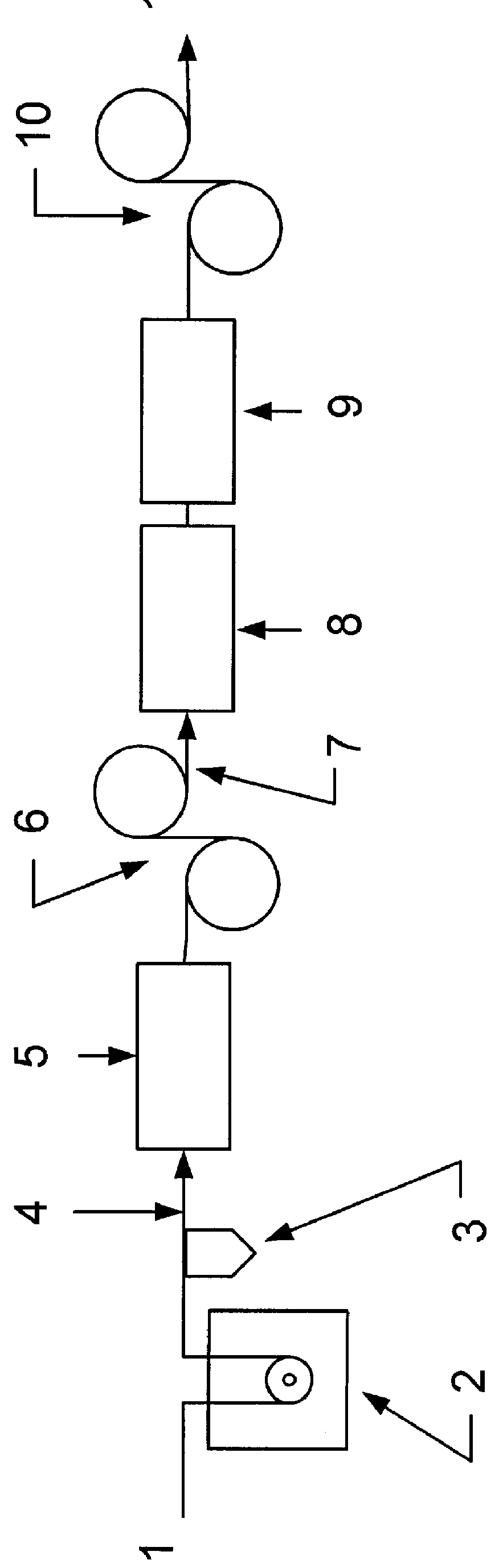

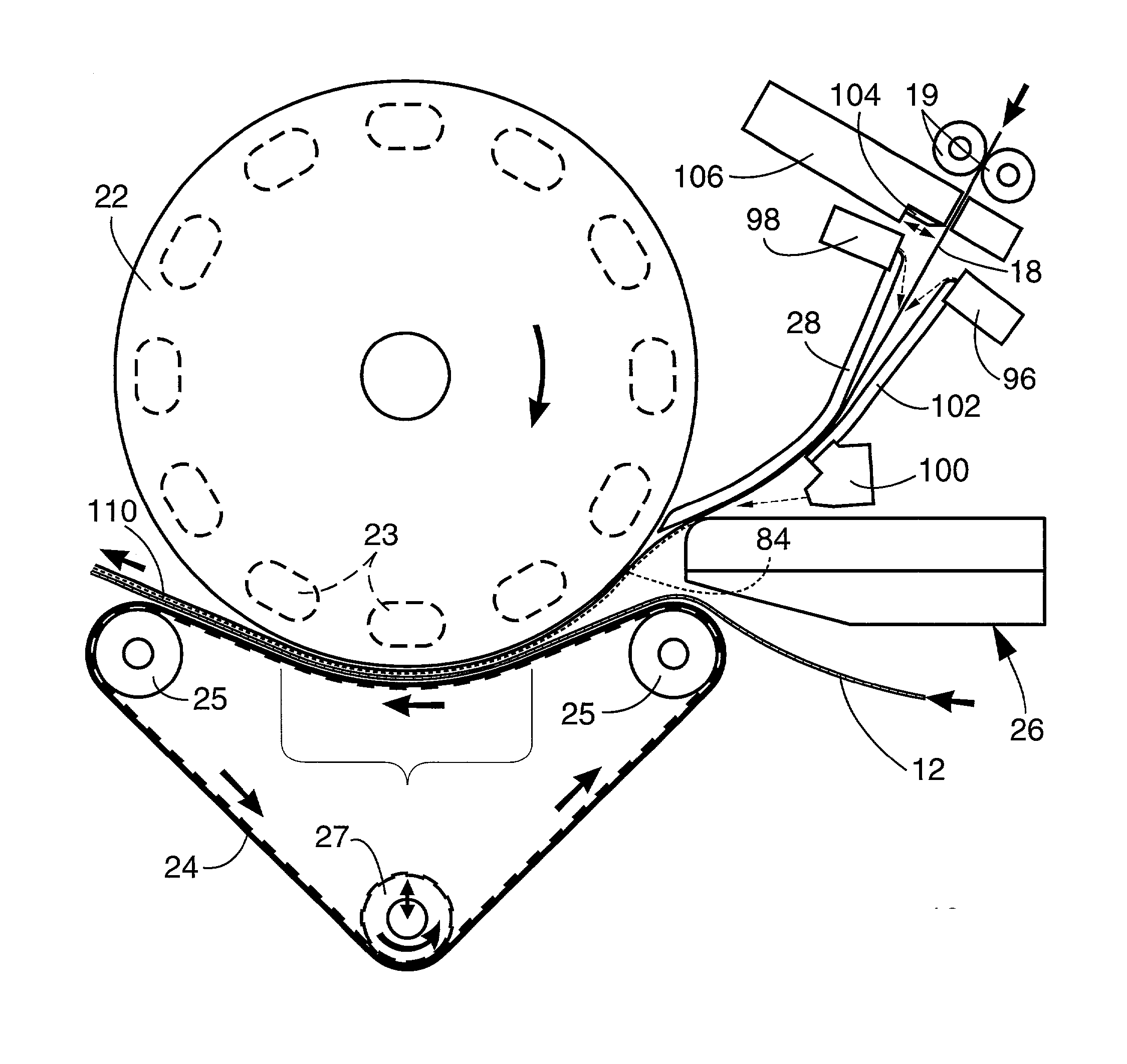

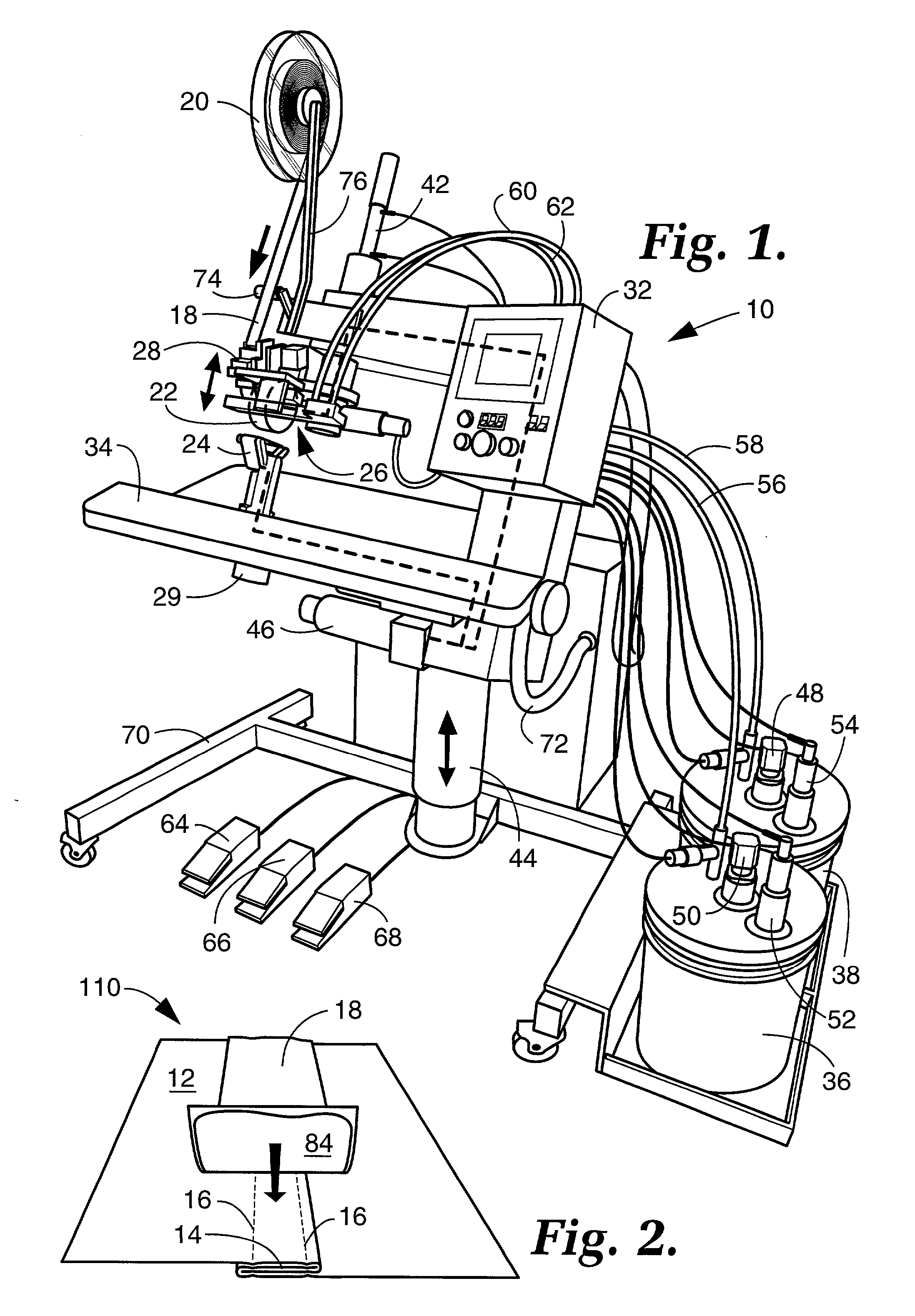

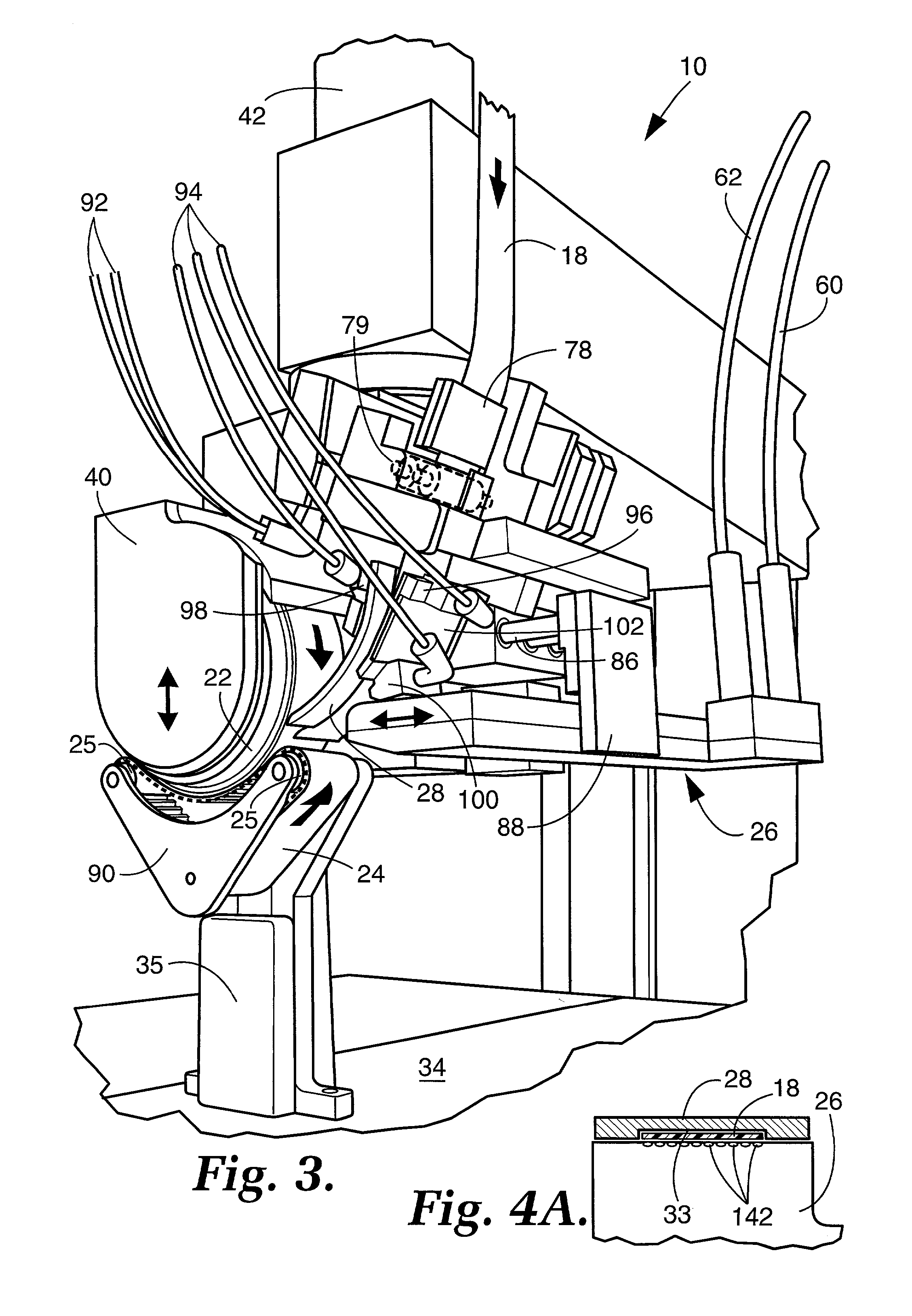

Seam sealing apparatus and process therefor

InactiveUS20030010439A1Easy to cleanWell mixedAdhesive processesManual label dispensersAdhesiveSurgical Gowns

Apparatus and a method for sealing of protective barrier fabric seams in otherwise impermeable articles such as garments, footwear, surgical gowns and the like, are provided, the sealed seams maintaining the imperviousness of the article, including seamed joints, to water, body fluids, pathogens and chemicals. In one pass through the apparatus, a sealed seam in a protective barrier fabric joint, using a curable adhesive sealant, is provided along a predetermined and specified length of the joint. The preferred adhesive is a silicone, most preferably a two-part, thermosetting silicone elastomeric adhesive. Also provided are mixing dies for use, inter alia, in the process which are especially suited for applying the two-part adhesive sealant. In addition, variable-residence-time curing apparatus, which effects variable, controlled, desired cures of the adhesive, all in a one-pass operation, is provided, together with precise metering pumps, especially suited for supplying the seam sealing adhesives in the process of the invention.

Owner:WL GORE & ASSOC INC

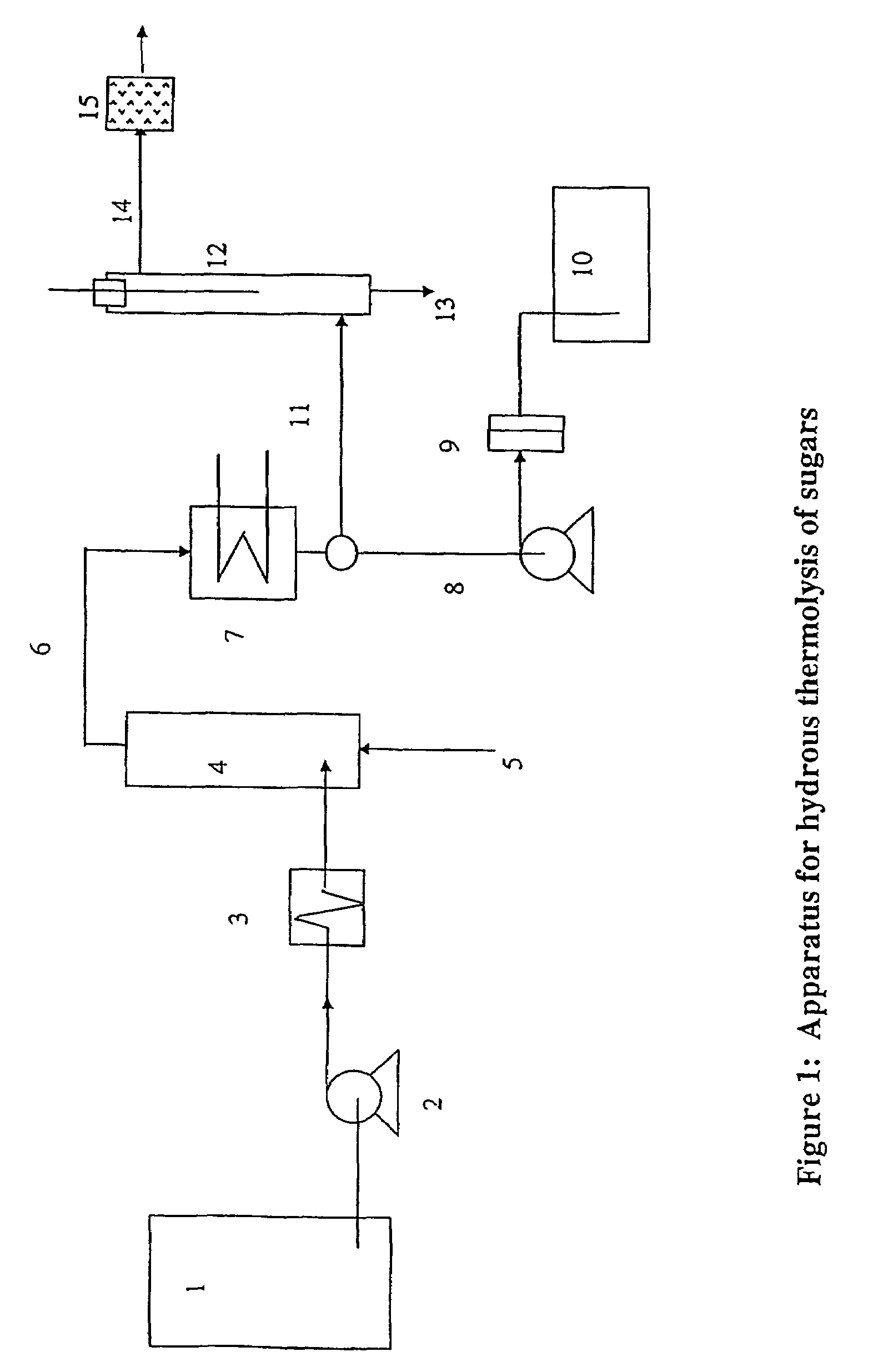

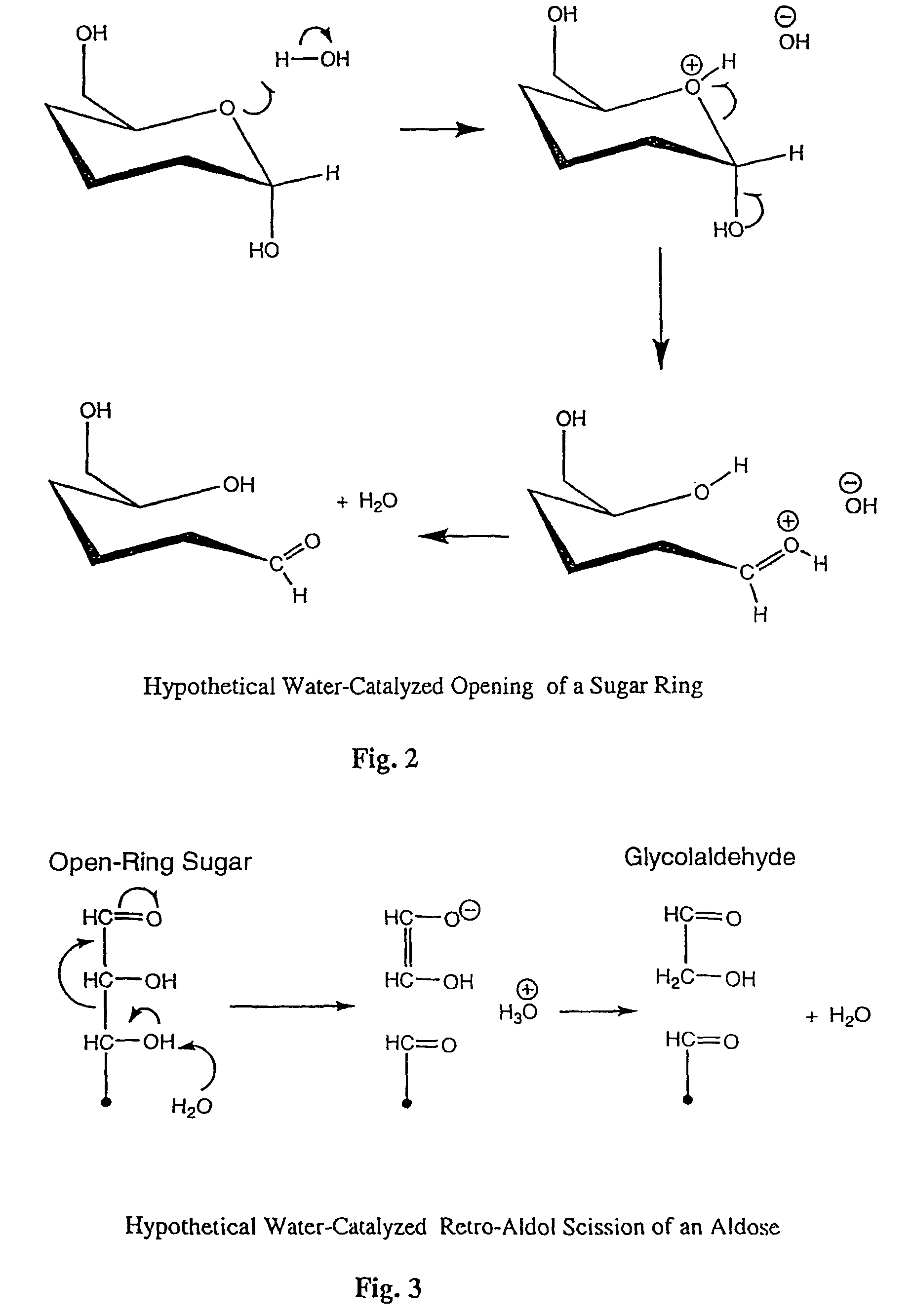

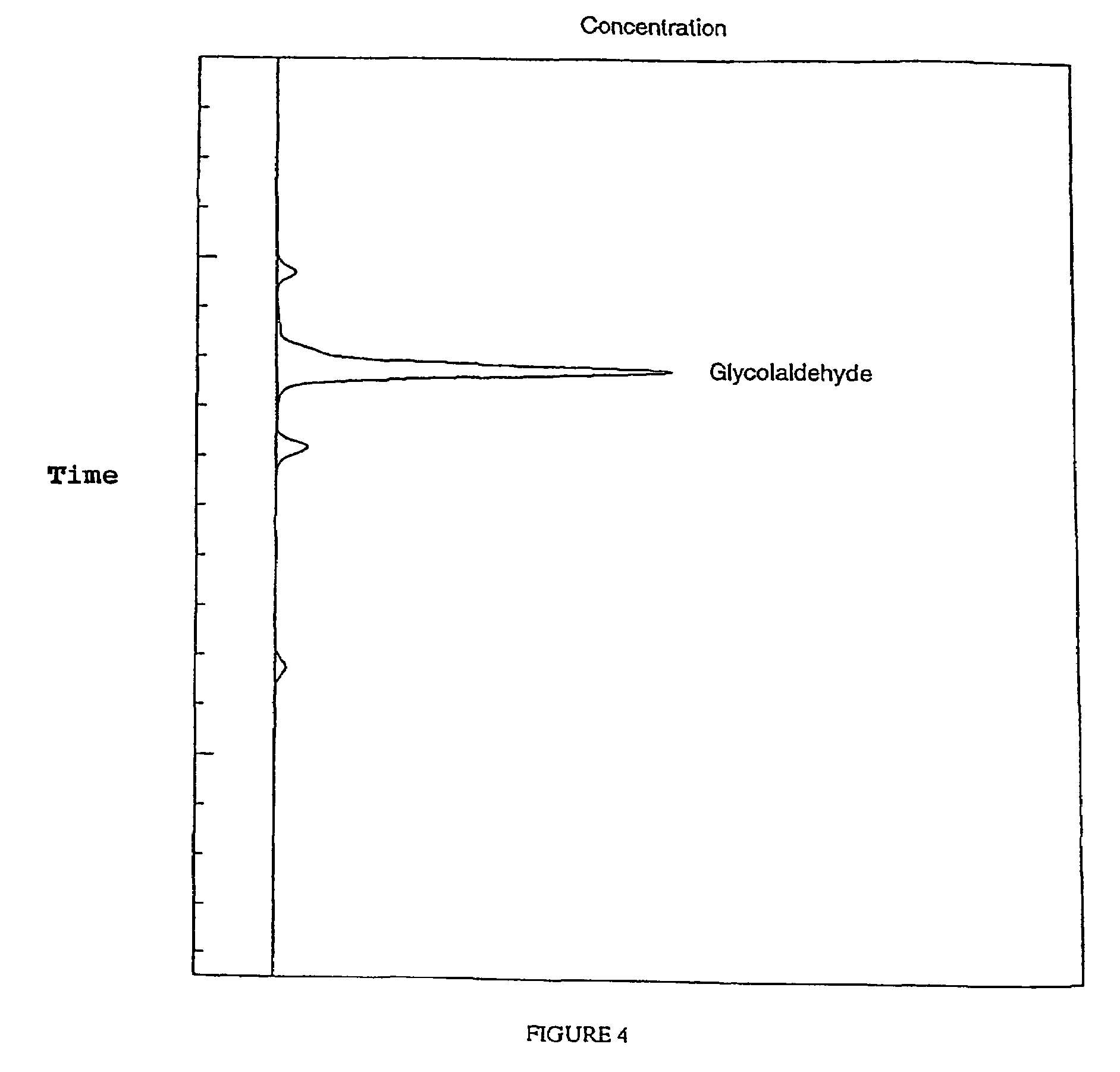

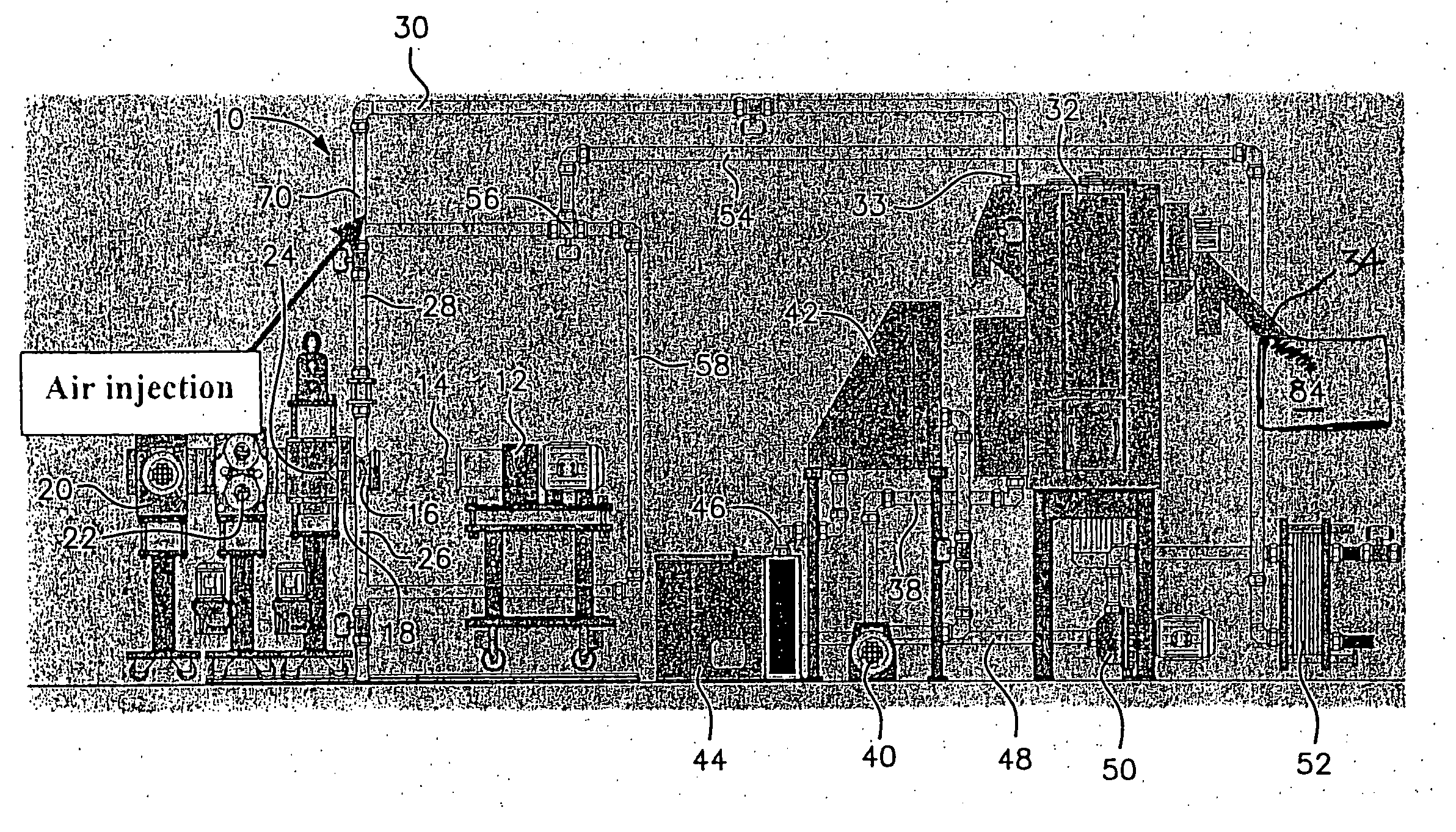

Production of glycolaldehyde by hydrous thermolysis of sugars

ActiveUS7094932B2Increase productionMinimize formationOrganic compound preparationConfectioneryGlucose polymersD-Glucose

The present invention provides a method for the production of glycolaldehyde with high specificity. The hydrous thermolysis consists of the spraying of aqueous sugar solutions containing from 25 to 80% of water but preferably 30 to 60% water, as a fine mist into a reactor held at the between 500 and 600° C., but preferably between 520 and 560° C. and the condensation of the resulting vaporous product in a surface condenser with optional heat recovery. The residence time of the vaporous product in the reactor should be in the range 0.1–5 seconds, but preferably in the range 0.5 to 2 seconds. Aldose monomeric sugars, preferably glucose (also known as dextrose), are preferred for use in the aqueous solution. The yield of glycolaldehyde in the condensed liquid is minimum 50% by weight of the sugar fed for glucose solutions.

Owner:KERRY GRP SERVICES INT

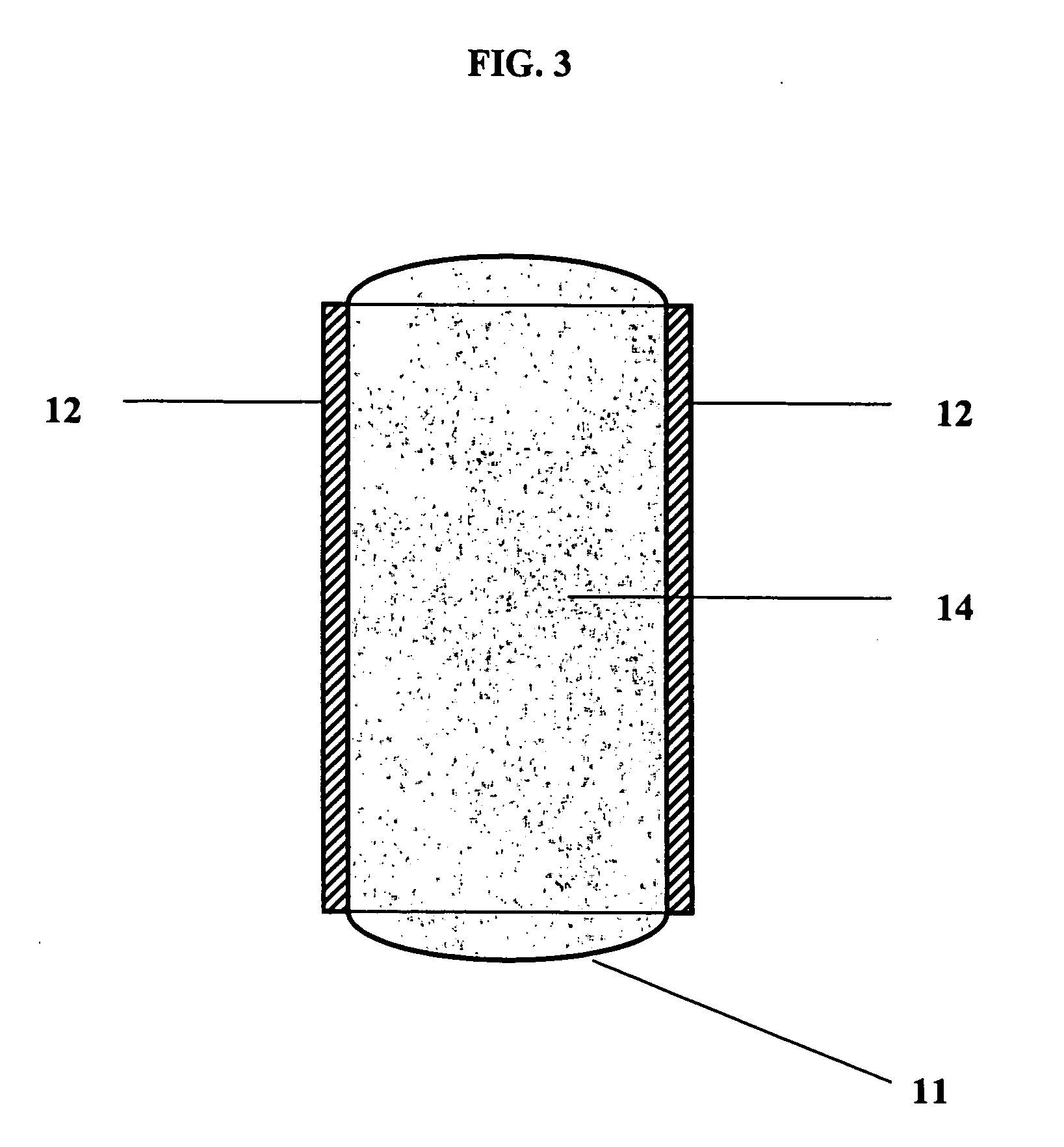

Method and apparatus for making crystalline PET pellets

InactiveUS20050110182A1Reduce dwell timeIncrease speedMouldsDrying solid materials without heatSlurryCrystallinity

A method and apparatus for underwater pelletizing and subsequent drying of polyethylene terephthalate (PET) polymers and other high temperature crystallizing polymeric materials to crystallize the polymer pellets without subsequent heating. High velocity air or other inert gas is injected into the water and pellet slurry line to the dryer near the pelletizer exit. Air is injected into the slurry line at a velocity of from about 100 to about 175 m3 / hour, or more. Such high-speed air movement forms a vapor mist with the water and significantly increases the speed of the pellets into and out of the dryer such that the PET polymer pellets leave the dryer at a temperature sufficient to self-initiate crystallization within the pellets. A valve mechanism in the slurry line after the gas injection further regulates the pellet residence time and a vibrating conveyor after the dryer helps the pellets to achieve the desired level of crystallinity and to avoid agglomeration.

Owner:GALA INDUSTRIES INC

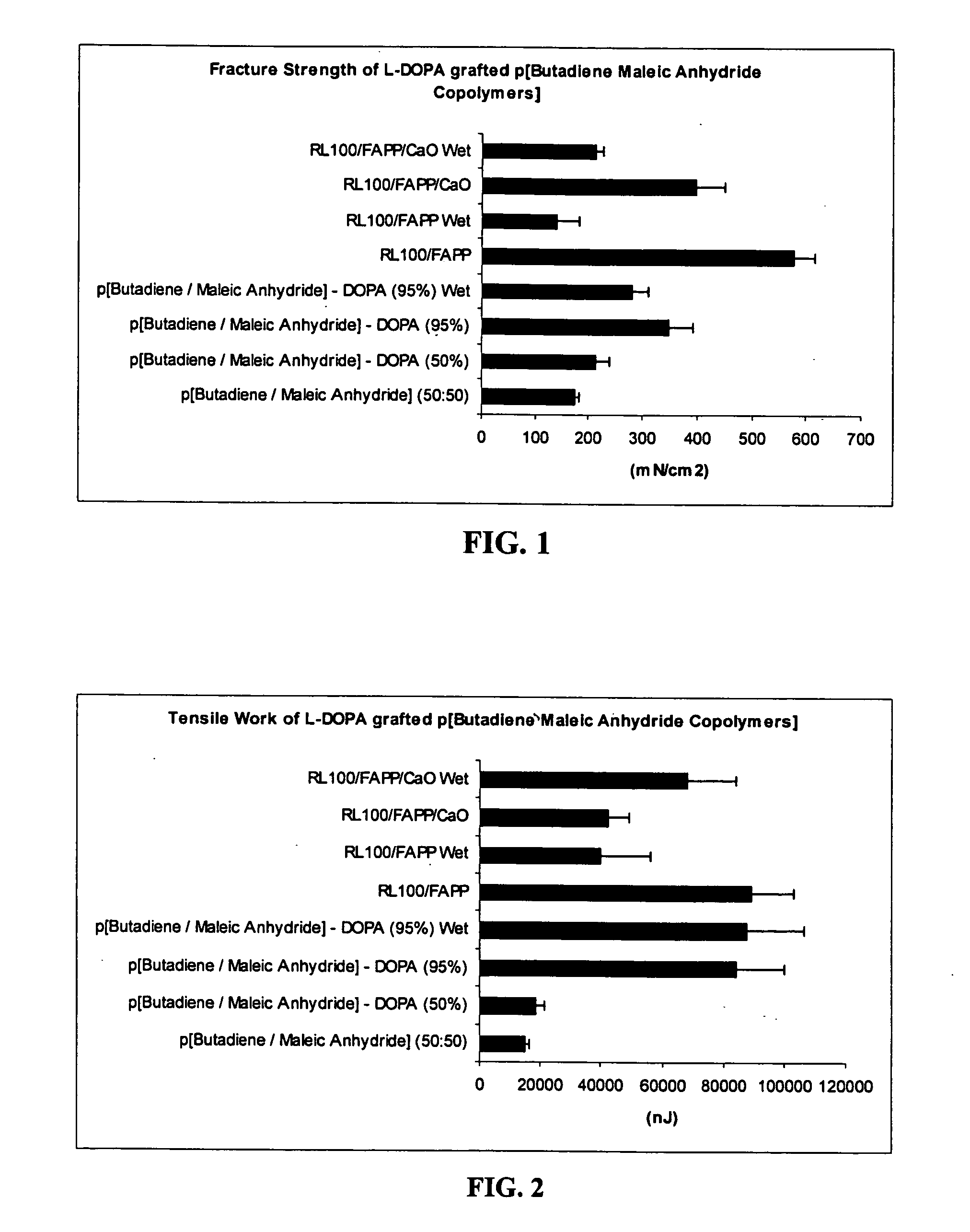

Bioadhesive polymers with catechol functionality

InactiveUS20050201974A1Good bioadhesionExtended stayNervous disorderPill deliveryArameHydrophobic polymer

Polymers with improved bioadhesive properties and methods for improving bioadhesion of polymers have been developed. A compound containing an aromatic group which contains one or more hydroxyl groups is grafted onto a polymer or coupled to individual monomers. In one embodiment, the polymer is a biodegradable polymer. In another embodiment, the monomers may be polymerized to form any type of polymer, including biodegradable and non-biodegradable polymers. In some embodiments, the polymer is a hydrophobic polymer. In the preferred embodiment, the aromatic compound is catechol or a derivative thereof and the polymer contains reactive functional groups. In the most preferred embodiment, the polymer is a polyanhydride and the aromatic compound is the catechol derivative, DOPA. These materials display bioadhesive properties superior to conventional bioadhesives used in therapeutic and diagnostic applications. These bioadhesive materials can be used to fabricate new drug delivery or diagnostic systems with increased residence time at tissue surfaces, and consequently increase the bioavailability of a drug or a diagnostic agent. In a preferred embodiment, the bioadhesive material is a coating on a controlled release oral dosage formulation and / or forms a matrix in an oral dosage formulation.

Owner:SPHERICS

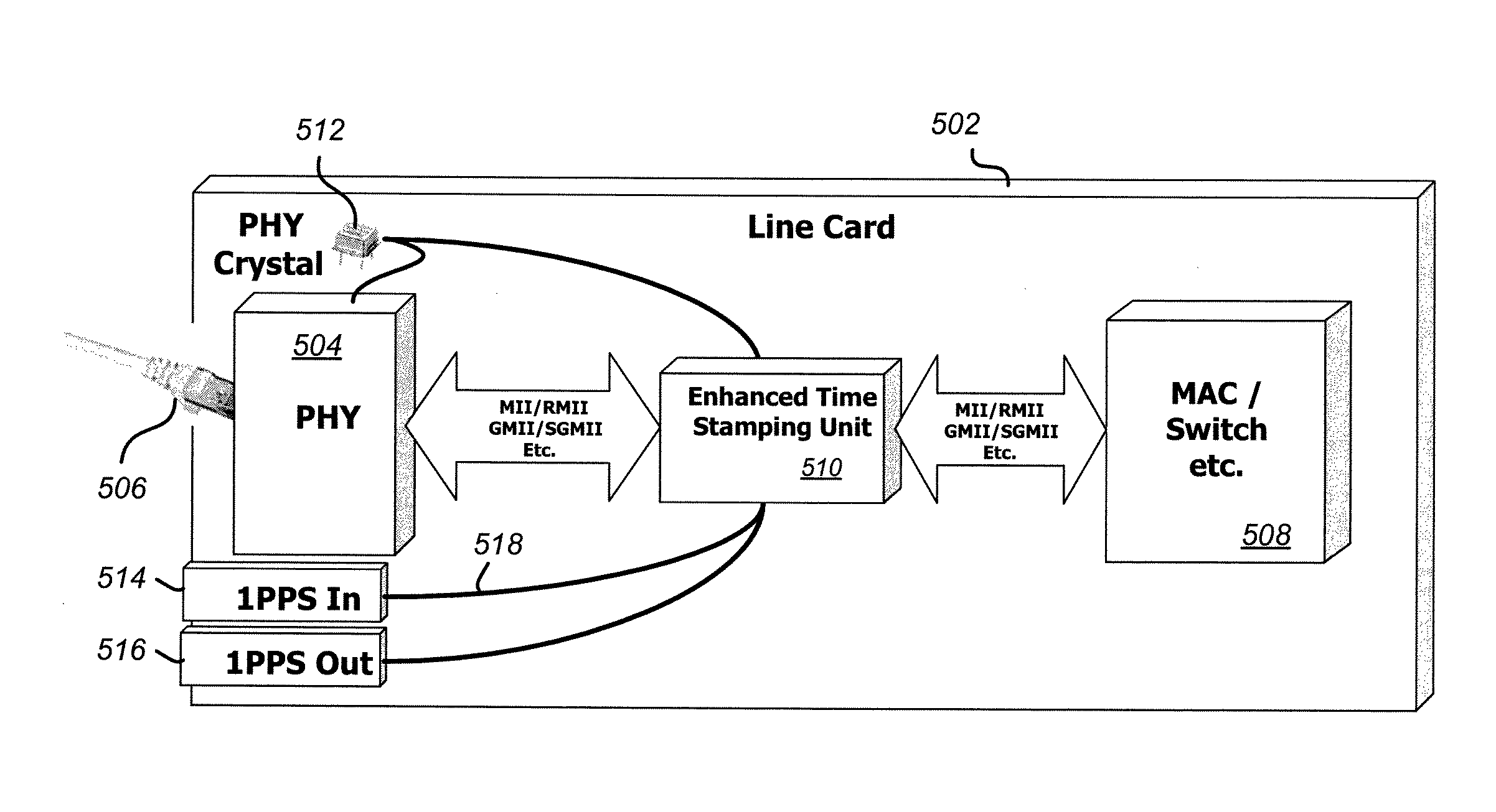

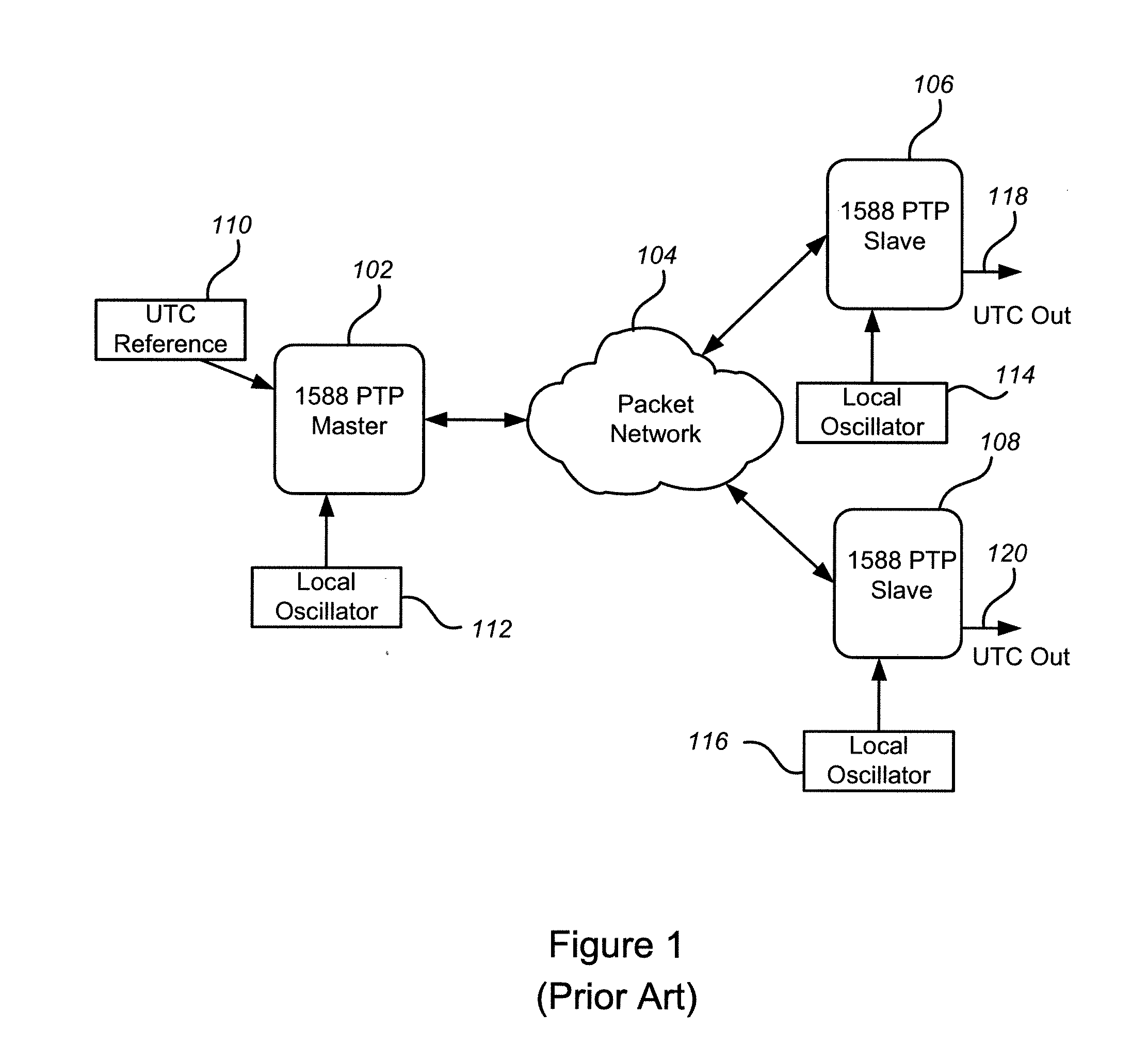

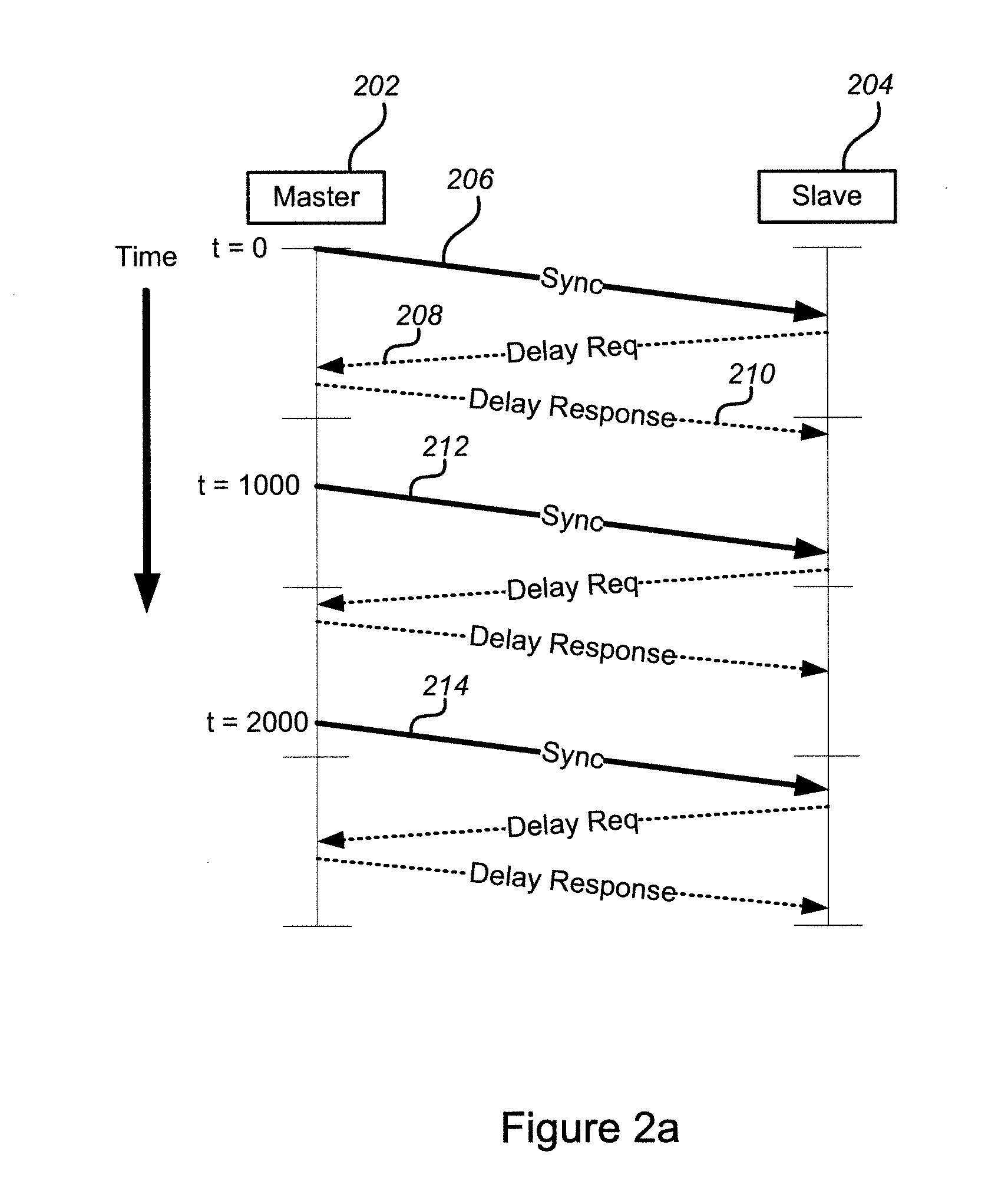

Measurement and adjustment of real-time values according to residence time in networking equipment without access to real time

InactiveUS20110051754A1Easy to applyCompensation delayTime-division multiplexNetwork elementResidence time

A system and method of synchronizing clocks in a distributed network is disclosed. A simple 1-pulse-per-second timing pulse is routed to time-stamping units in each network device and utilized to measure traffic-dependent synchronization packet residence delays within network elements. Synchronization messages are updated to reflect the measured residence times, thus creating transparent clocks that can readily be synchronized across the network. The simple timing pulse architecture allows the method to be applied readily both to new designs and to retrofit existing hardware.

Owner:SEMTECH CORP

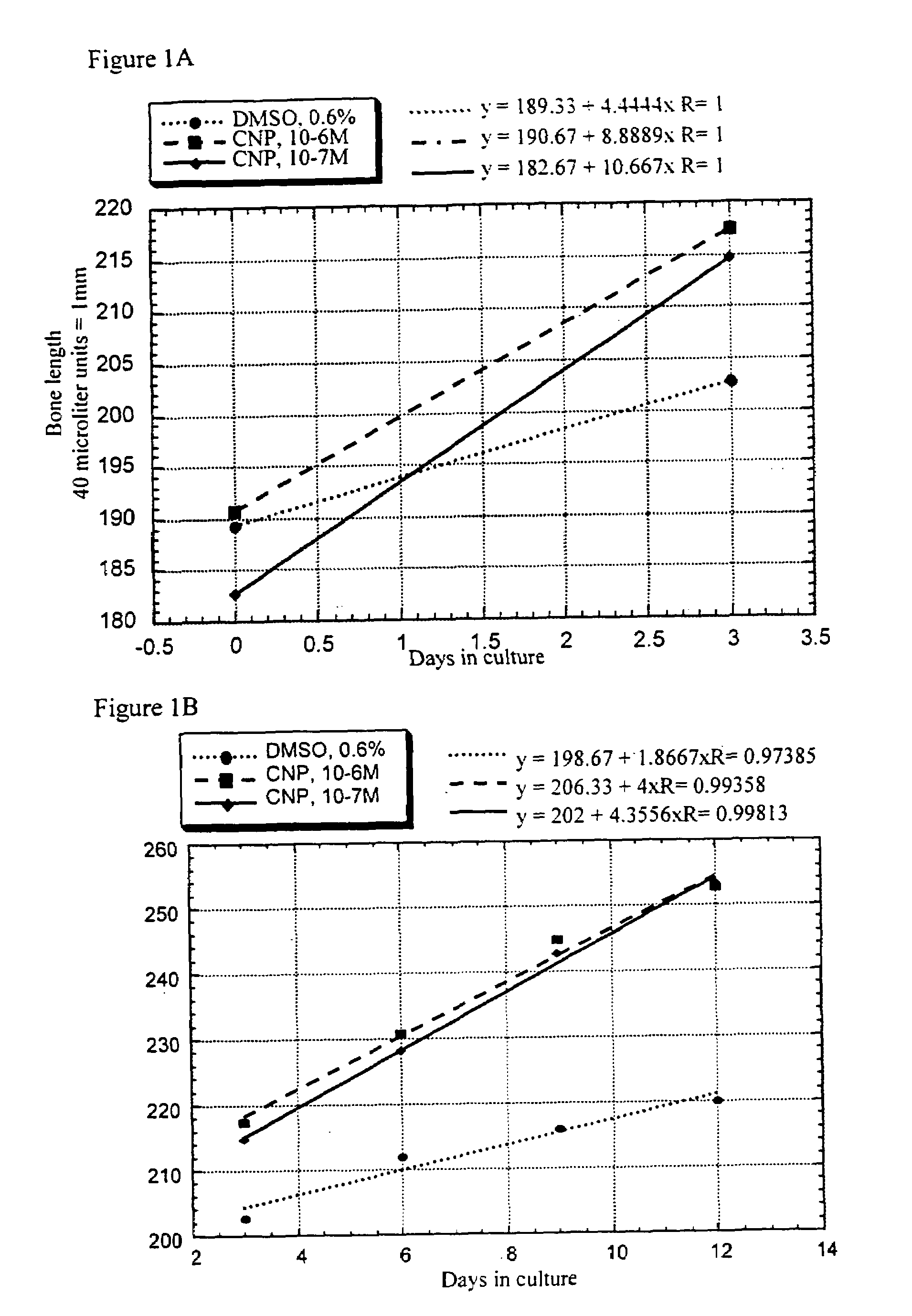

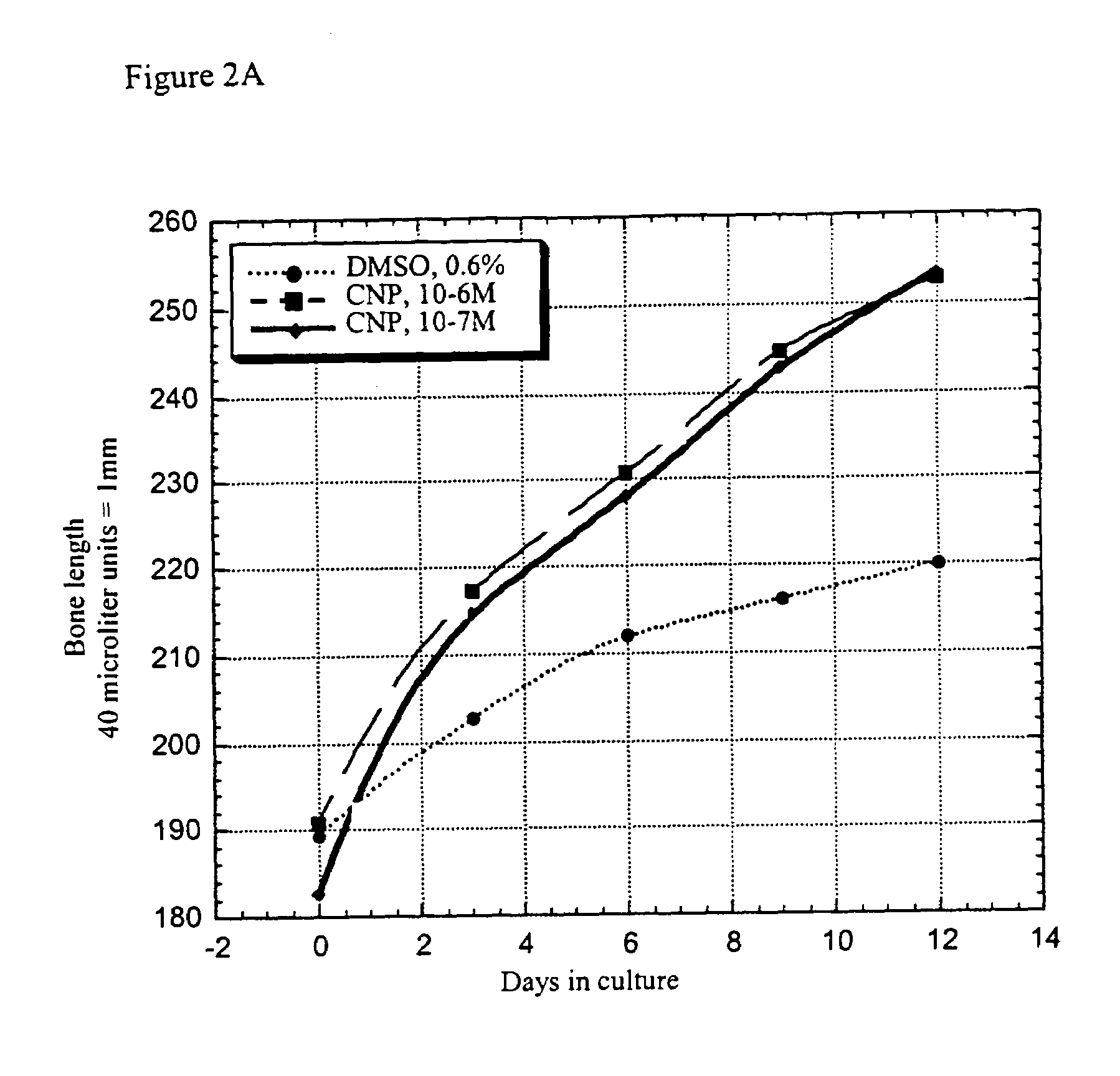

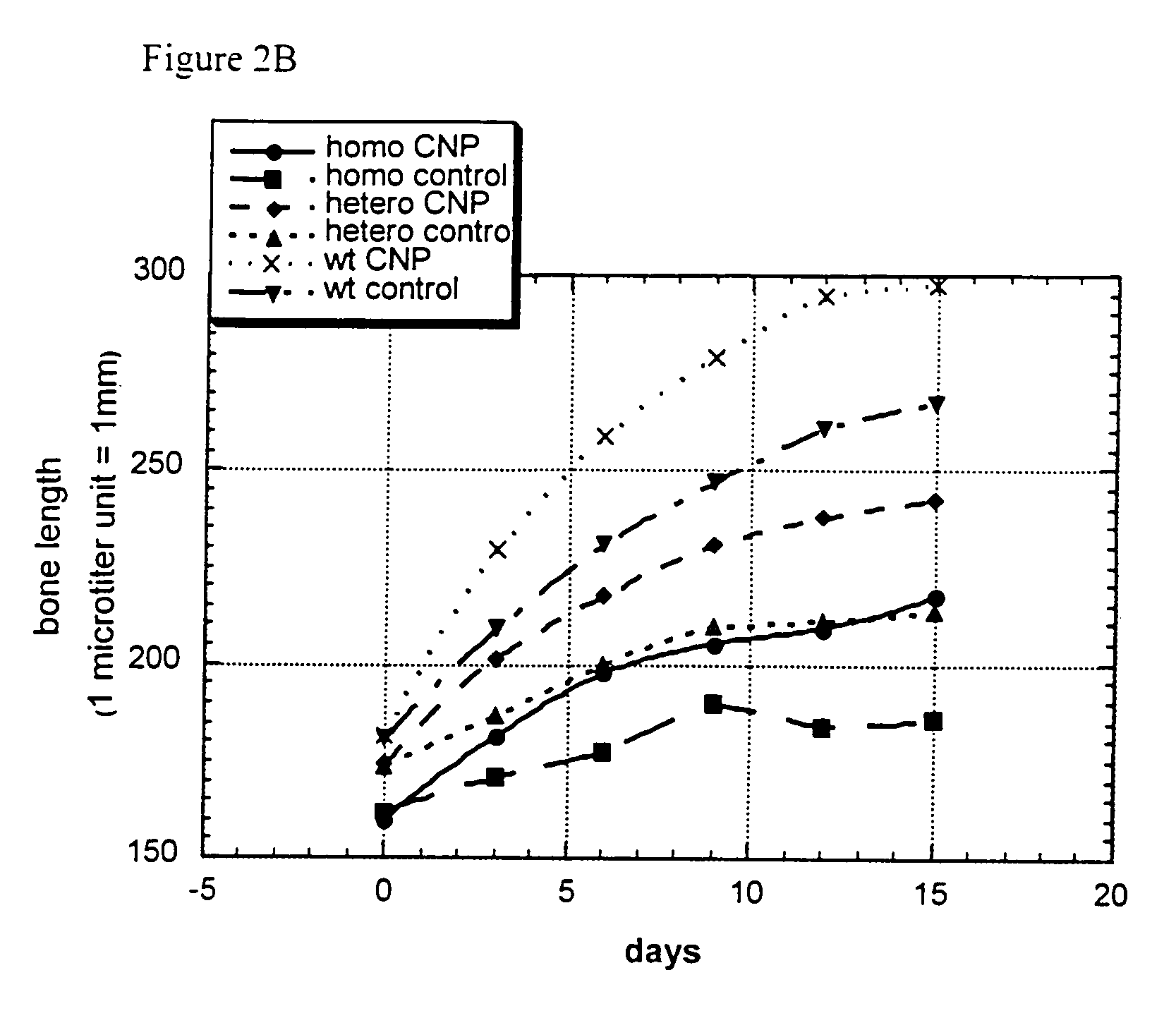

Method and composition for treatment of skeletal dysplasias

InactiveUS7276481B2Improve stabilityEnhance NP stabilizationPeptide/protein ingredientsGenetic material ingredientsBone growthBULK ACTIVE INGREDIENT

The present invention discloses pharmaceutical compositions for the treatment of skeletal dysplasias, comprising as an active ingredient at least one natriuretic peptide. Unexpectedly, it has been shown that the natriuretic factors may be effective for bone elongation in situations of abnormal bone growth especially for achondroplasia. The effects of the natriuretic peptide may be further enhanced by prolonging its residence time or action at the target site.

Owner:HEPACORE LTD

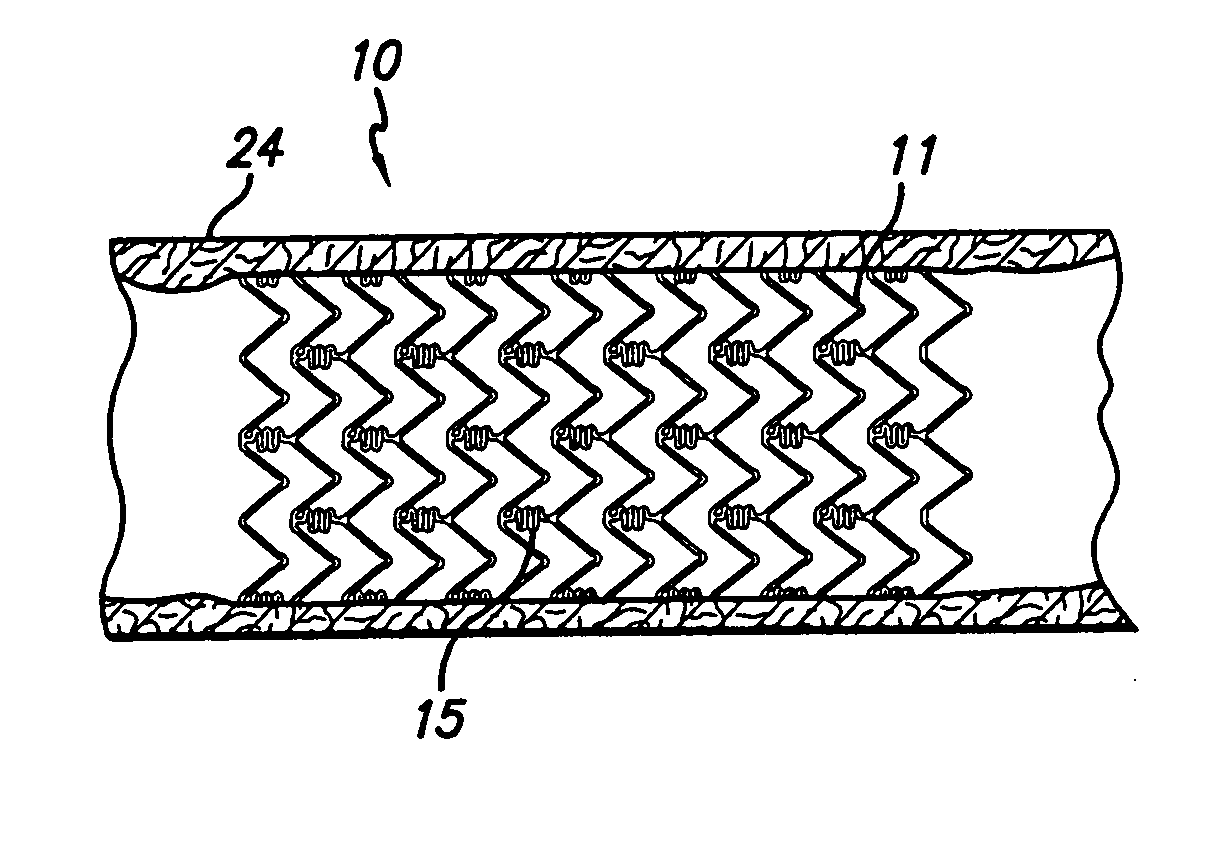

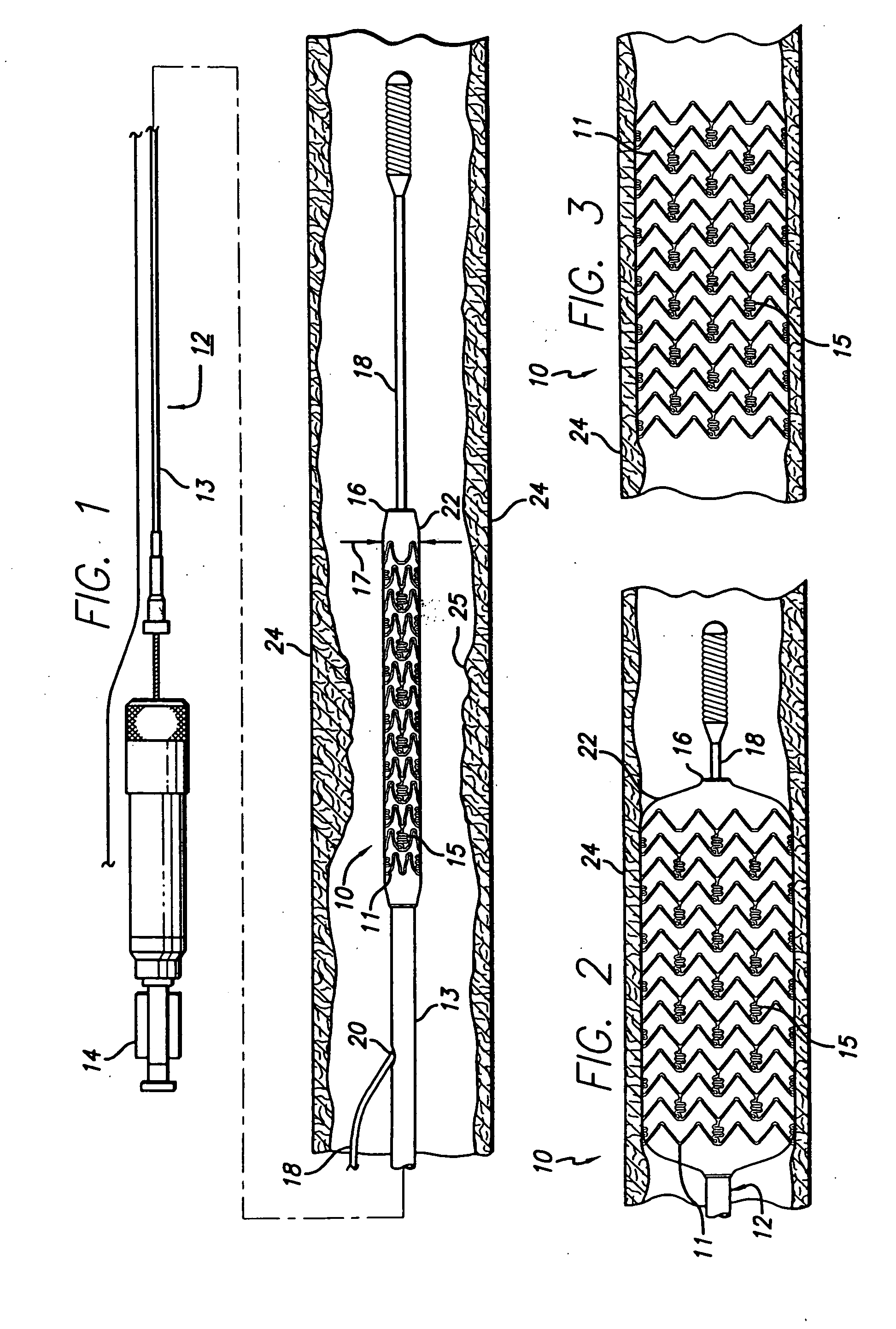

Degradable medical device

An implantable medical device is provided that degrades upon contact with body fluids so as to limit its residence time within the body. The device is formed of a porous corrodible metal to simultaneously provide high strength and an accelerated corrosion rate. The corrosion rate of a device formed of metal subject to self-dissolution or of a combination of metals subject to galvanic corrosion is accelerated by its porous structure. Coating the corrodible metallic device with a degradable polymer serves to delay the onset of corrosion of the underlying metallic structure.

Owner:KLEINE KLAUS +1

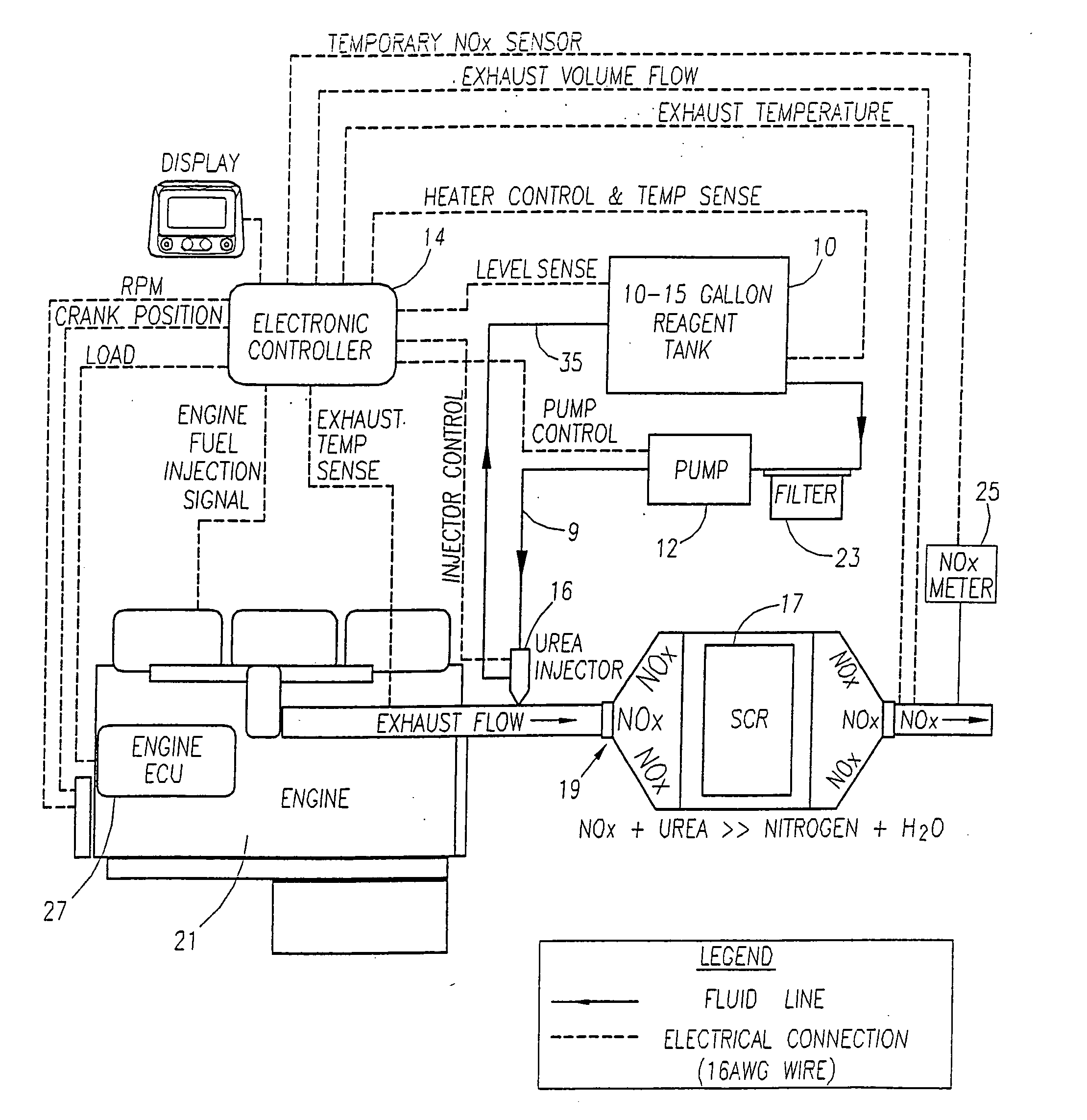

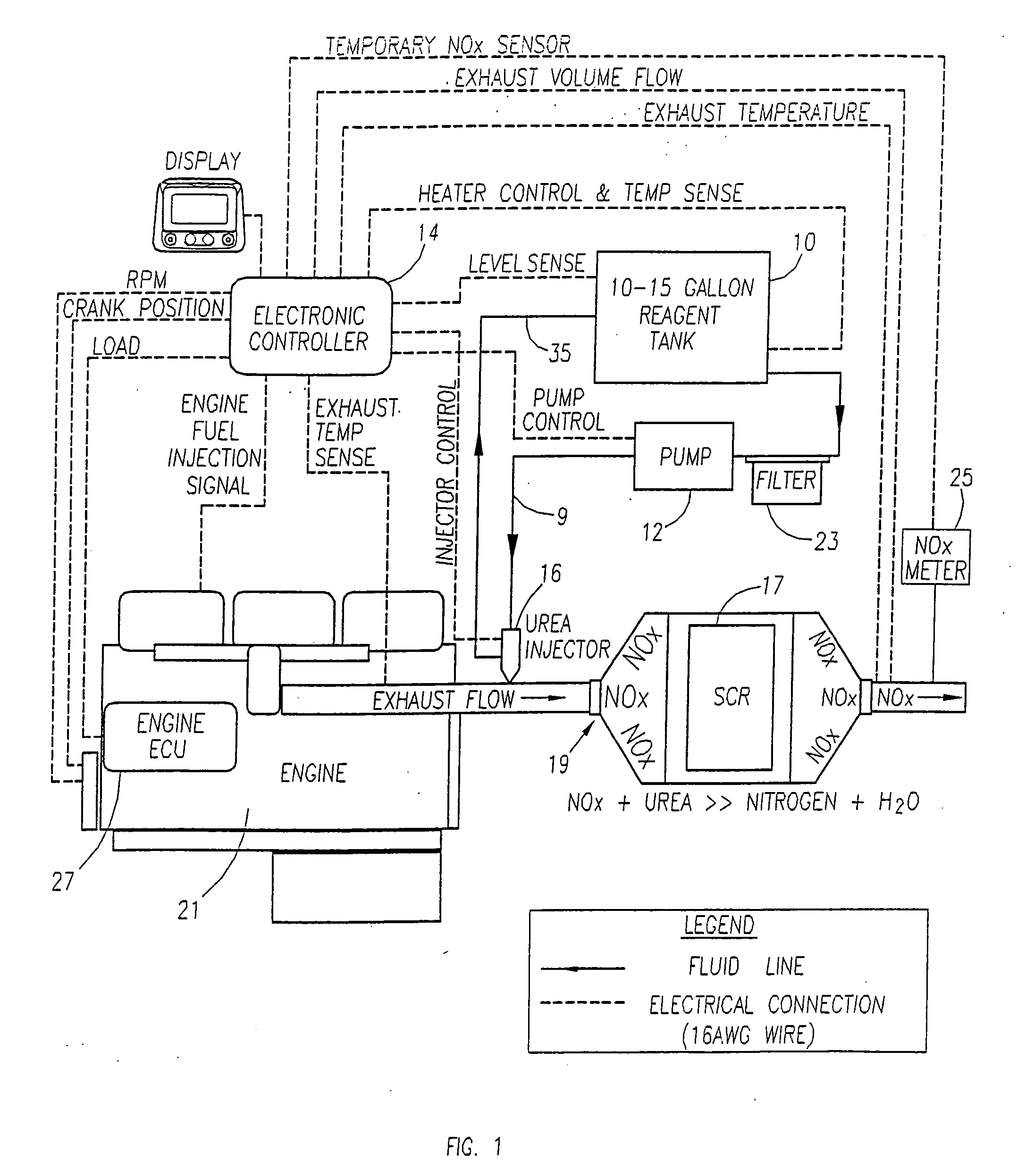

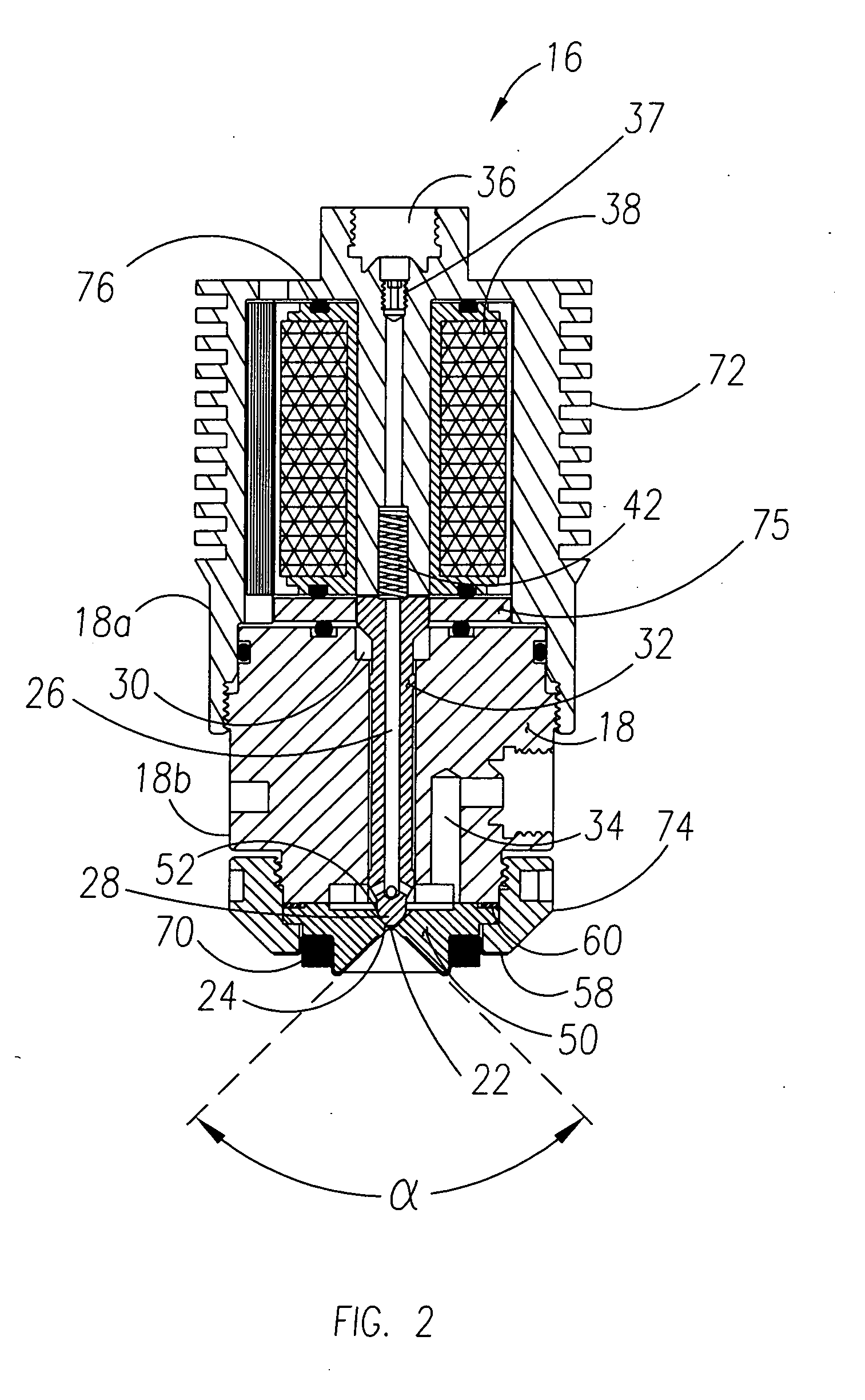

Methods and apparatus for injecting atomized fluid

ActiveUS20050235632A1Reduce oxide of nitrogen (NOx) emissionImprove performanceInternal combustion piston enginesExhaust apparatusDiesel engineNOx

The present invention provides methods and apparatus for injecting fluid, such as an aqueous urea solution, into an exhaust stream in order to reduce oxides of nitrogen (NOx) emissions from diesel engine exhaust The present invention uses mechanical spill return atomization techniques to produce droplets approximately 50 μm SMD (Sauter mean diameter) or smaller. This size range is appropriate to allow urea to react into ammonia within the residence time associated with an on-road diesel engine. This effect is achieved through the use of a whirl plate having a plurality of whirl slots surrounding an exit orifice of the injector, which produce a high velocity rotating flow in the whirl chamber. When the rotating flow of fluid is passed through the exit orifice into an exhaust stream, atomization occurs from a combination of centrifugal force and shearing of the fluid by air as it jets into the exhaust stream.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Process for drawing gel-spun polyethylene yarns

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

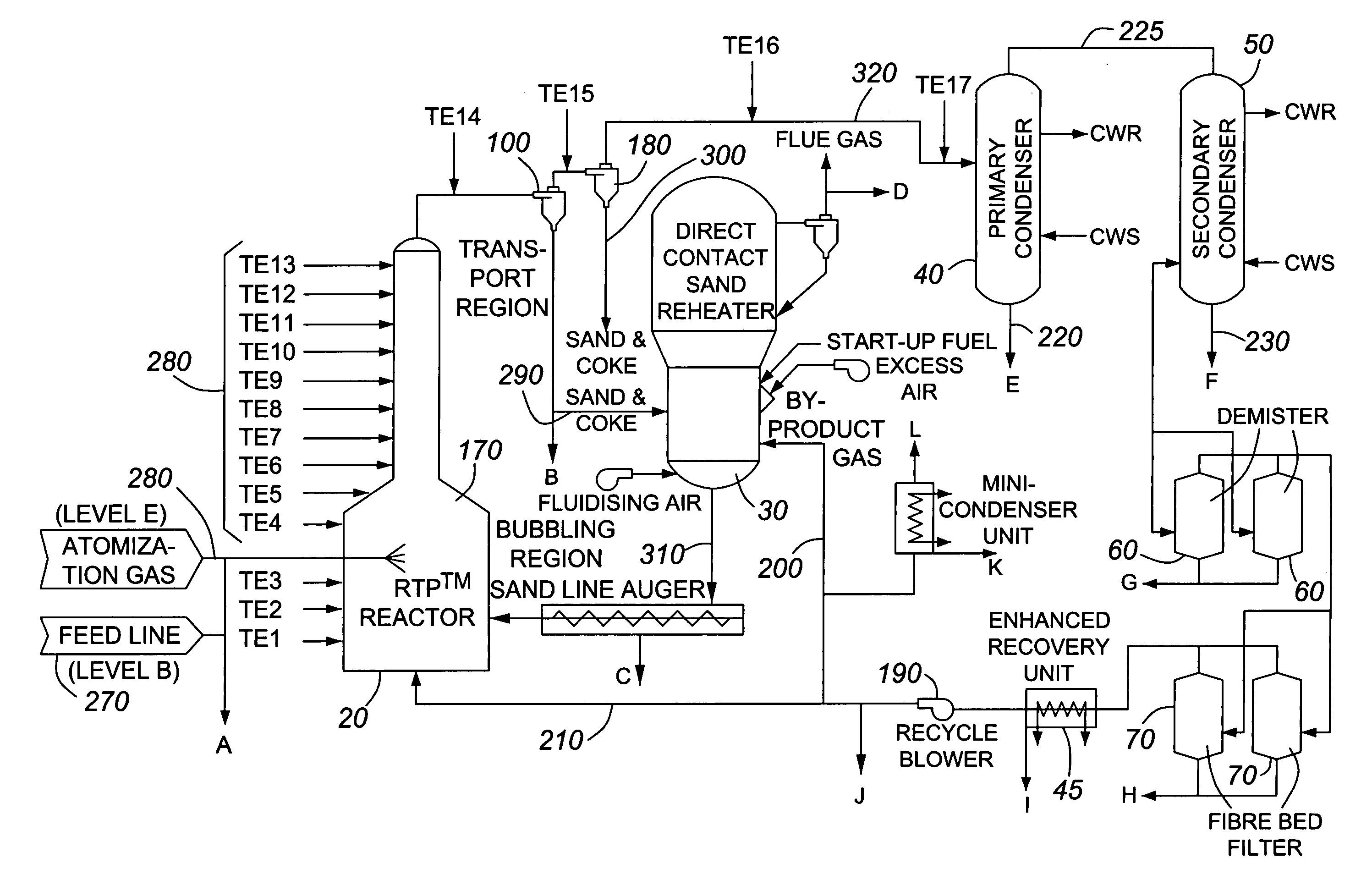

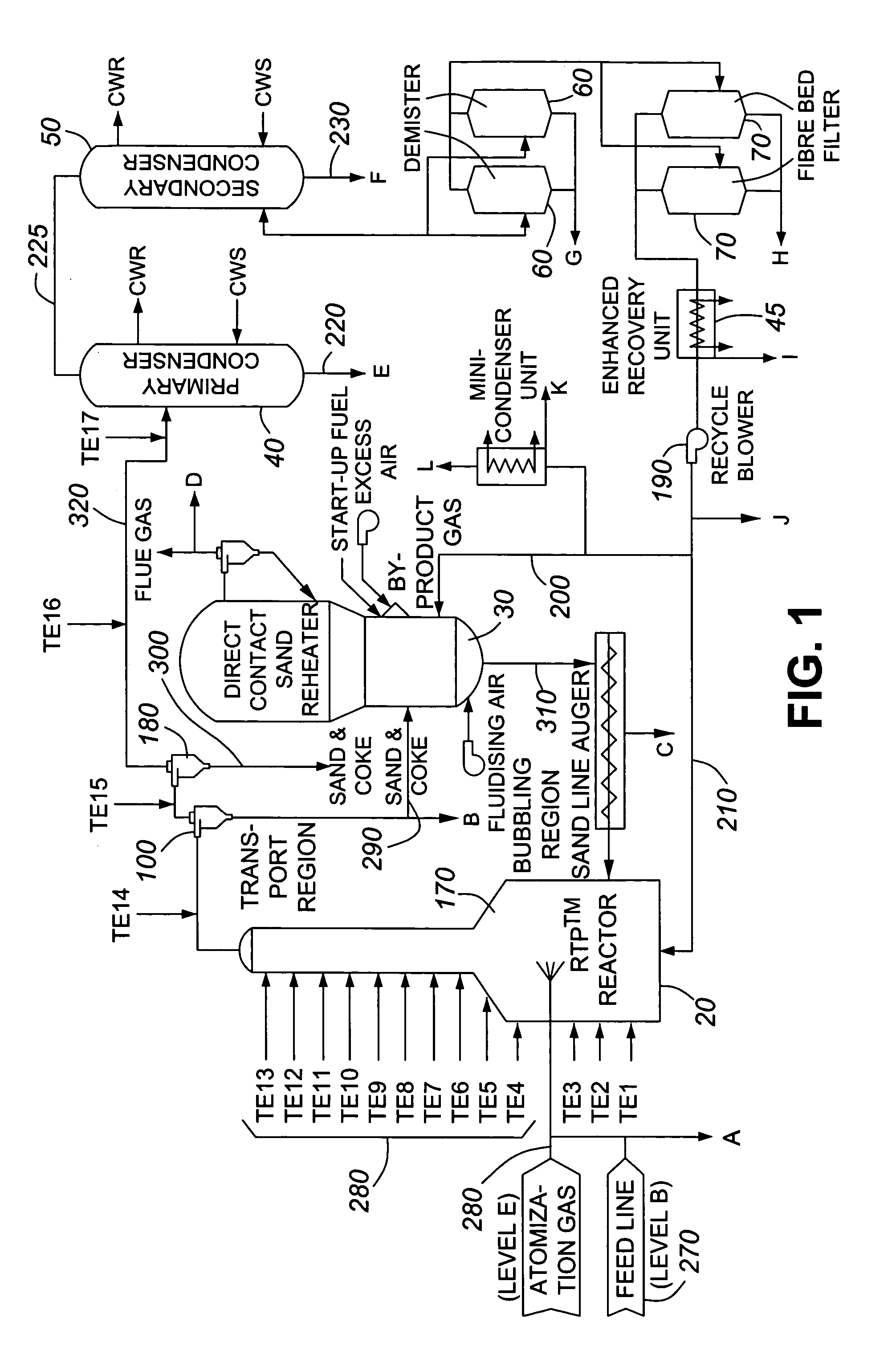

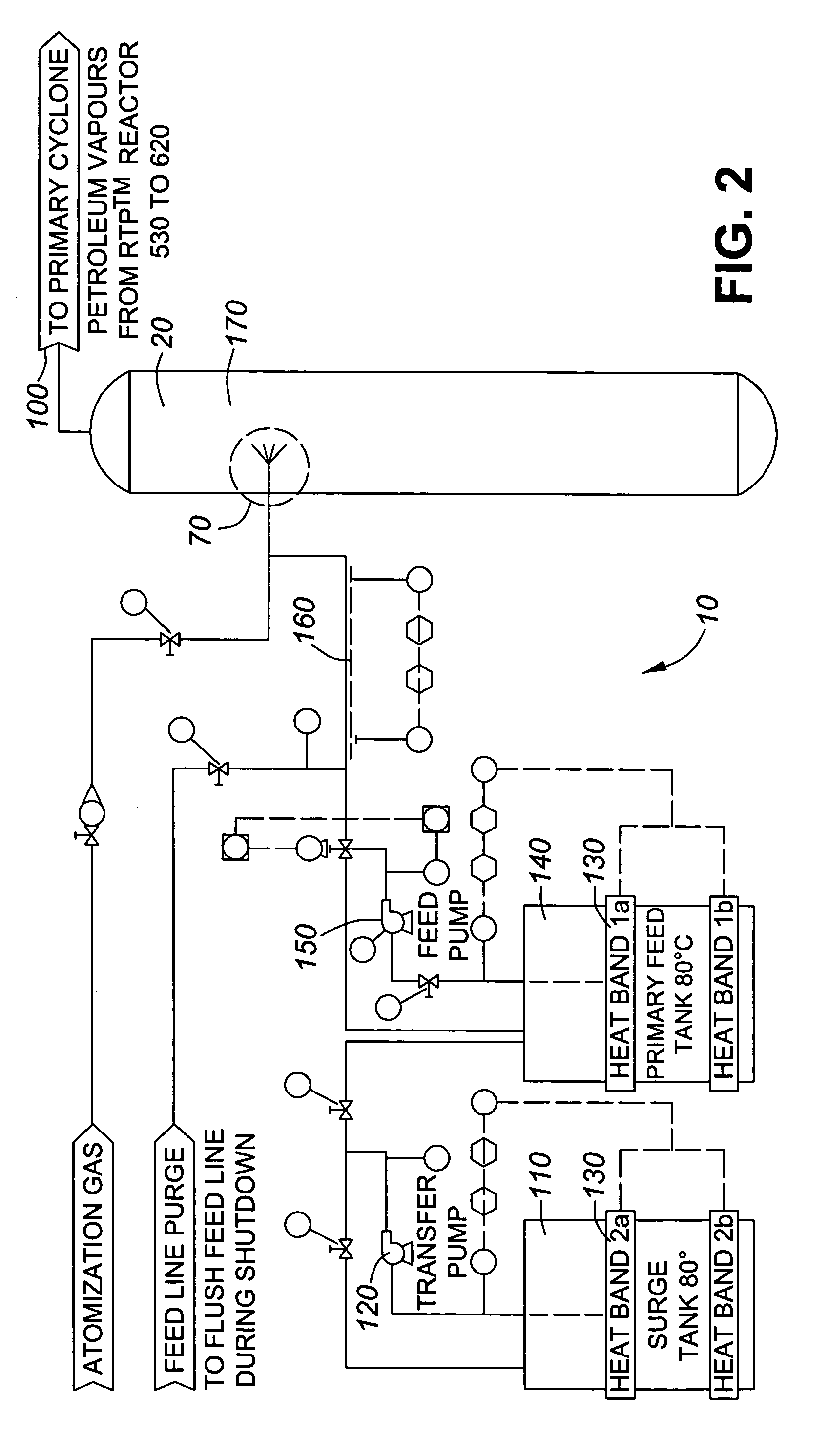

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com