Patents

Literature

1029 results about "Total acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

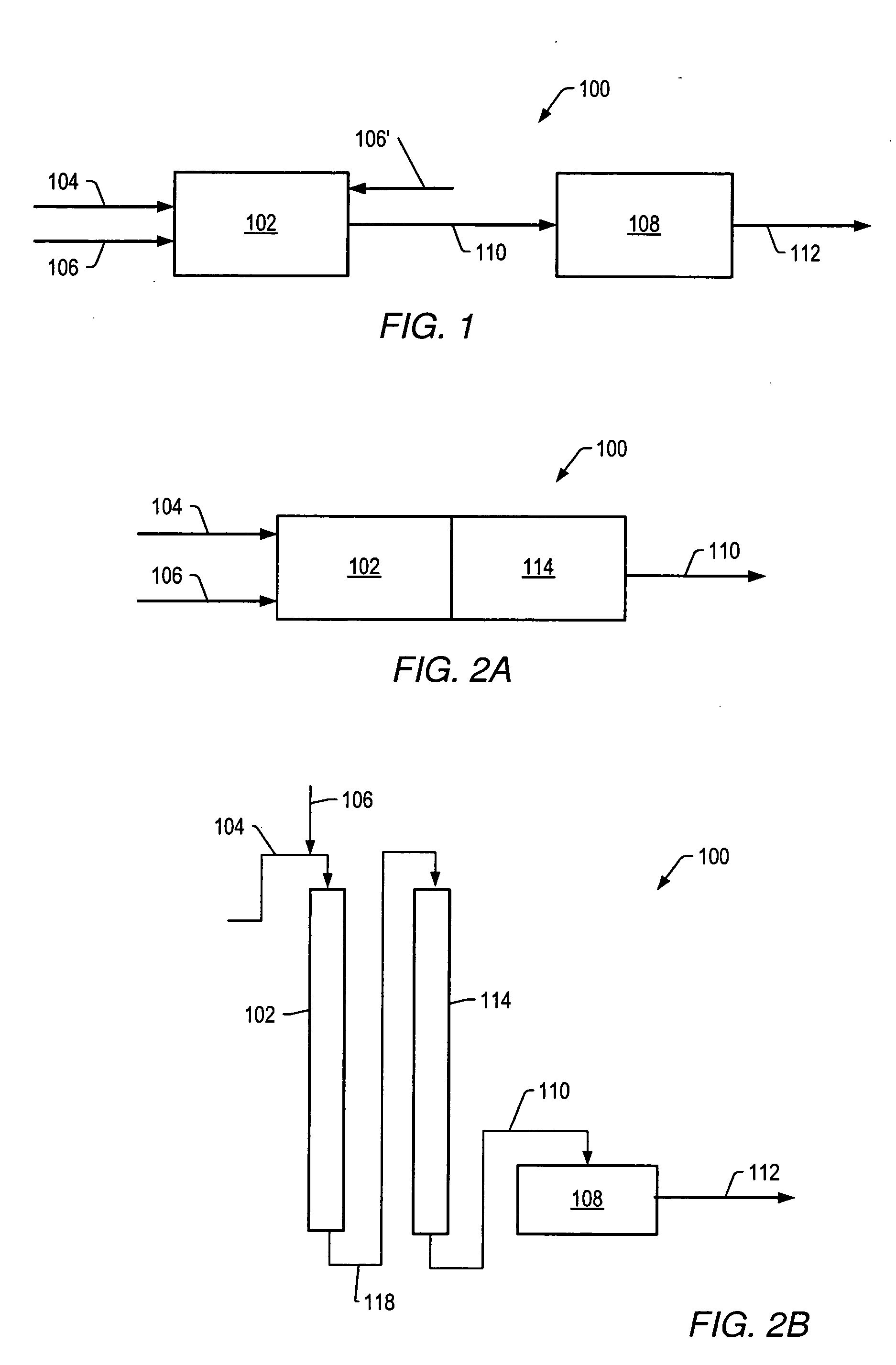

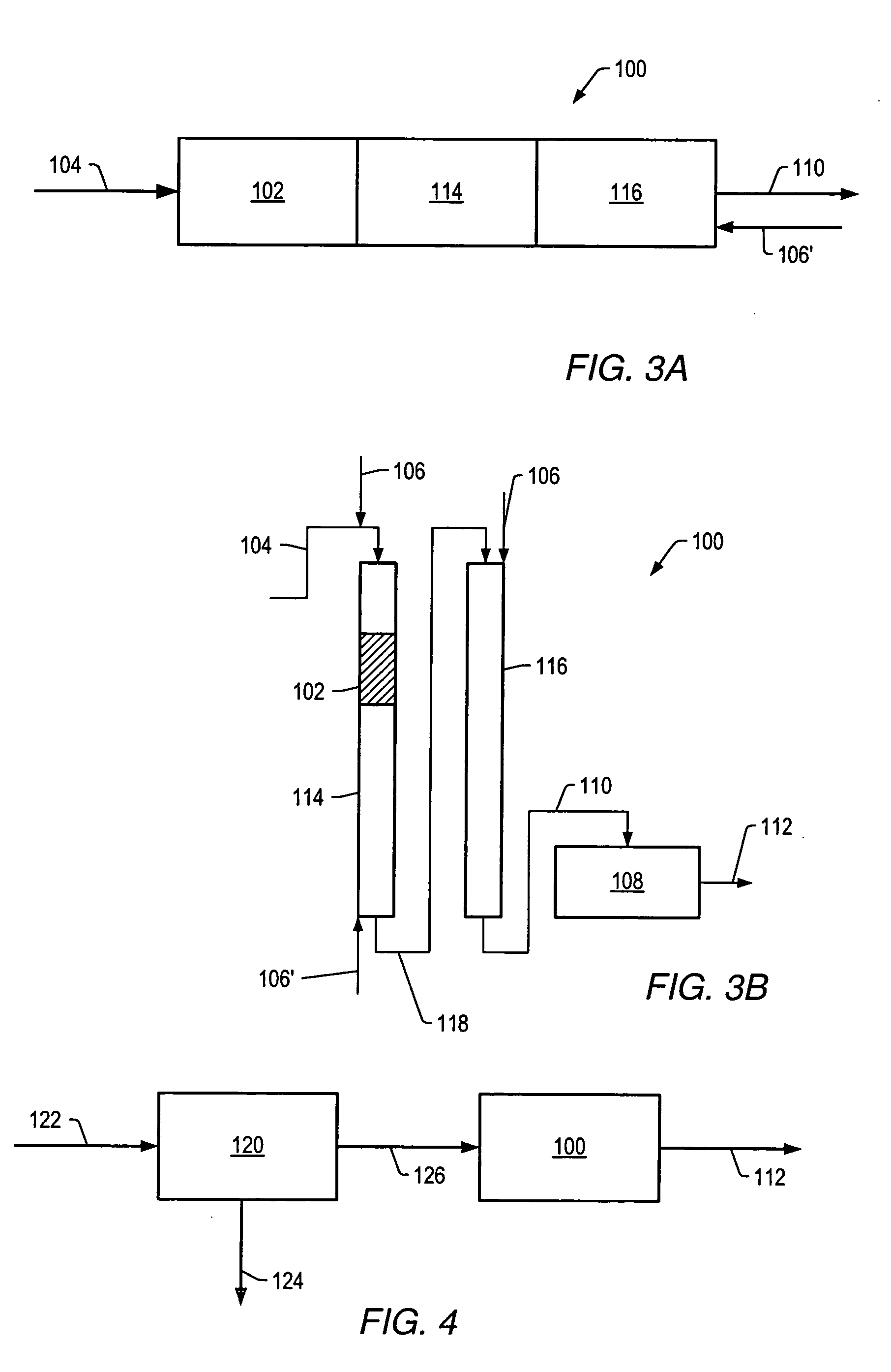

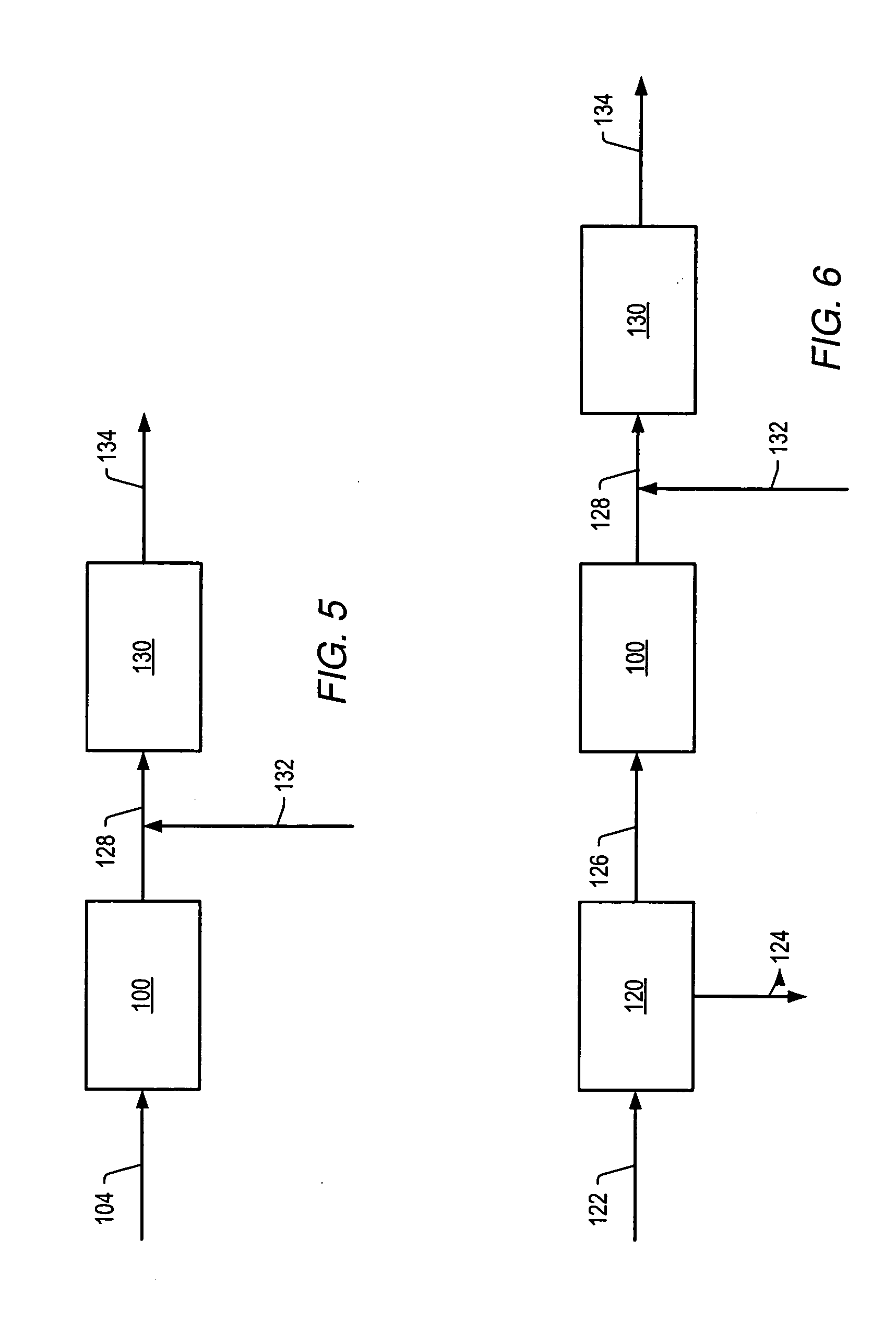

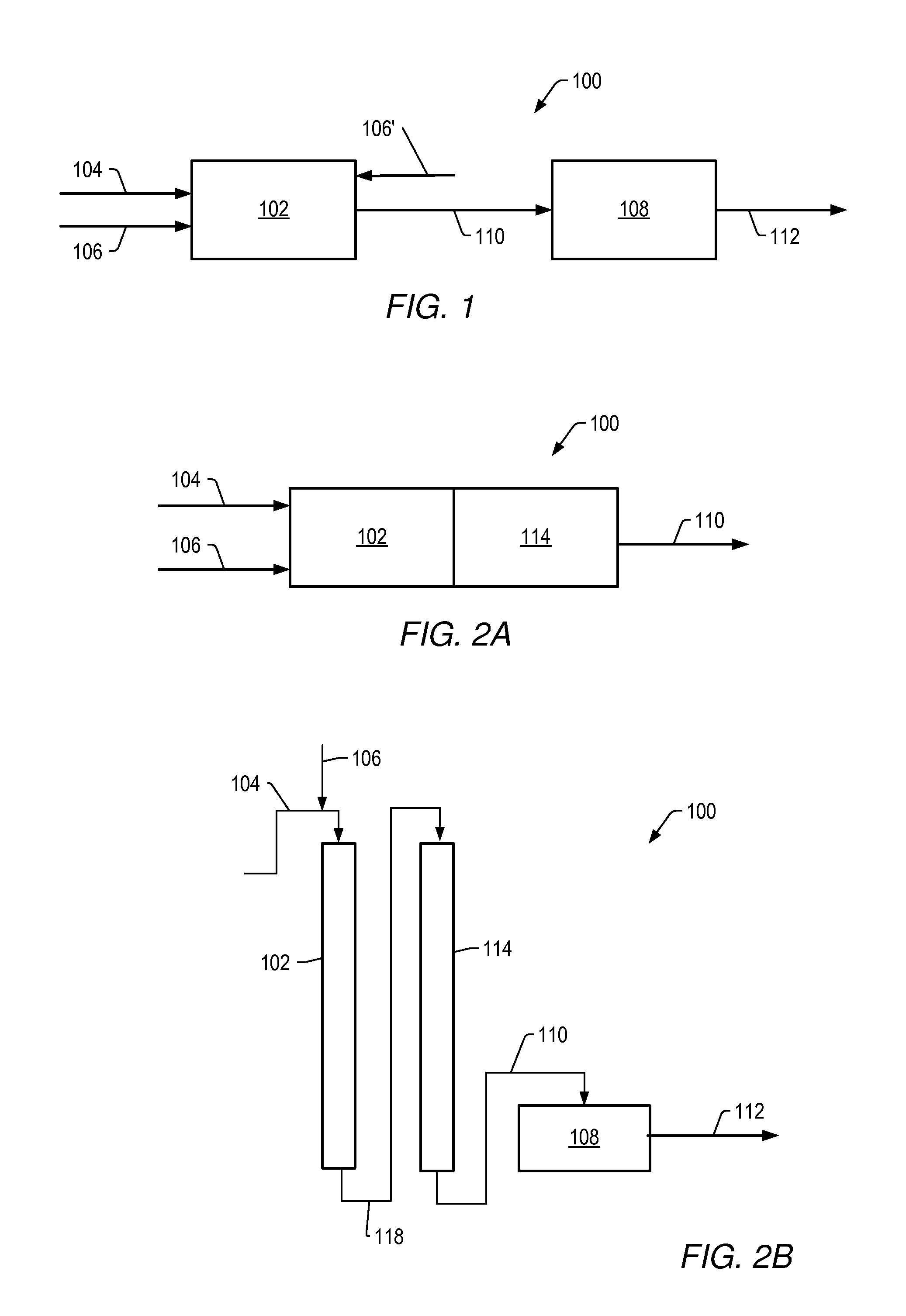

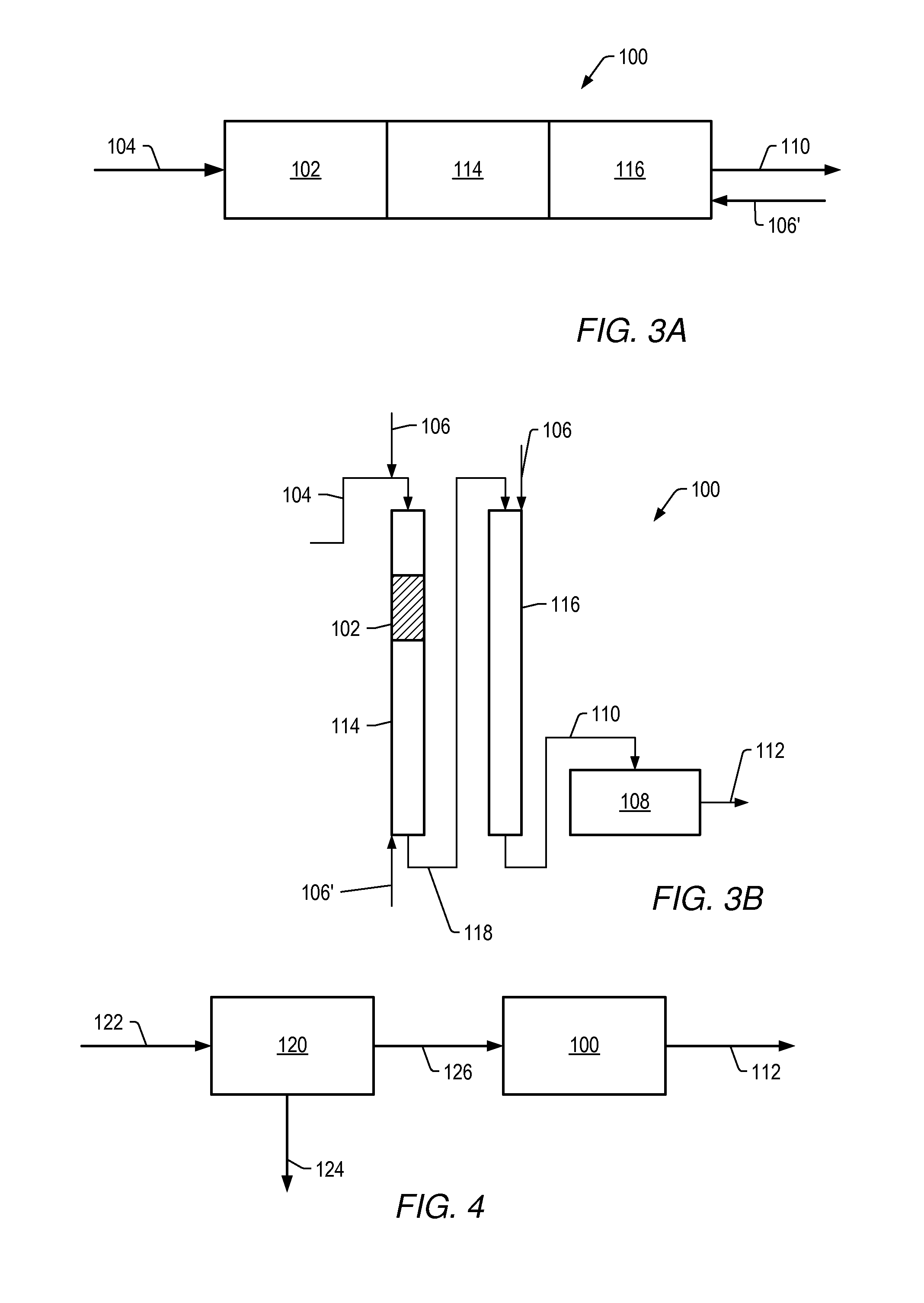

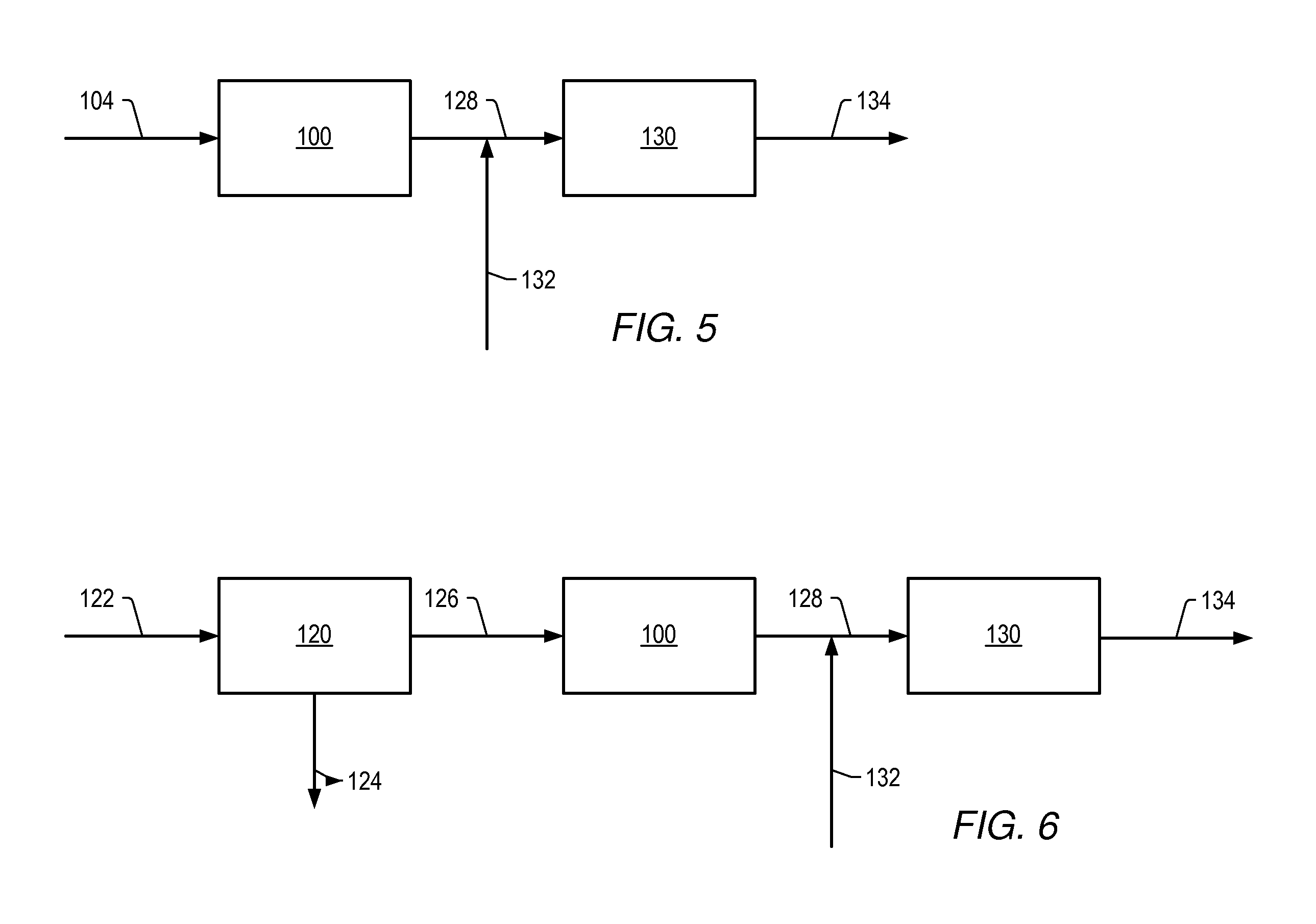

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133417A1Reduce contentCatalytic crackingRefining with metal saltsAcid valueTotal acid

Contact of a crude feed with one or more catalysts produces a total product that include a crude product. The crude feed may a total acid number of at least 0.3. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a total acid number of at most 90% of the total acid number of the crude feed. At least one of the catalysts may include one or more Column 6 metals of the Periodic Table and one or more Column 10 metals of the Periodic Table. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

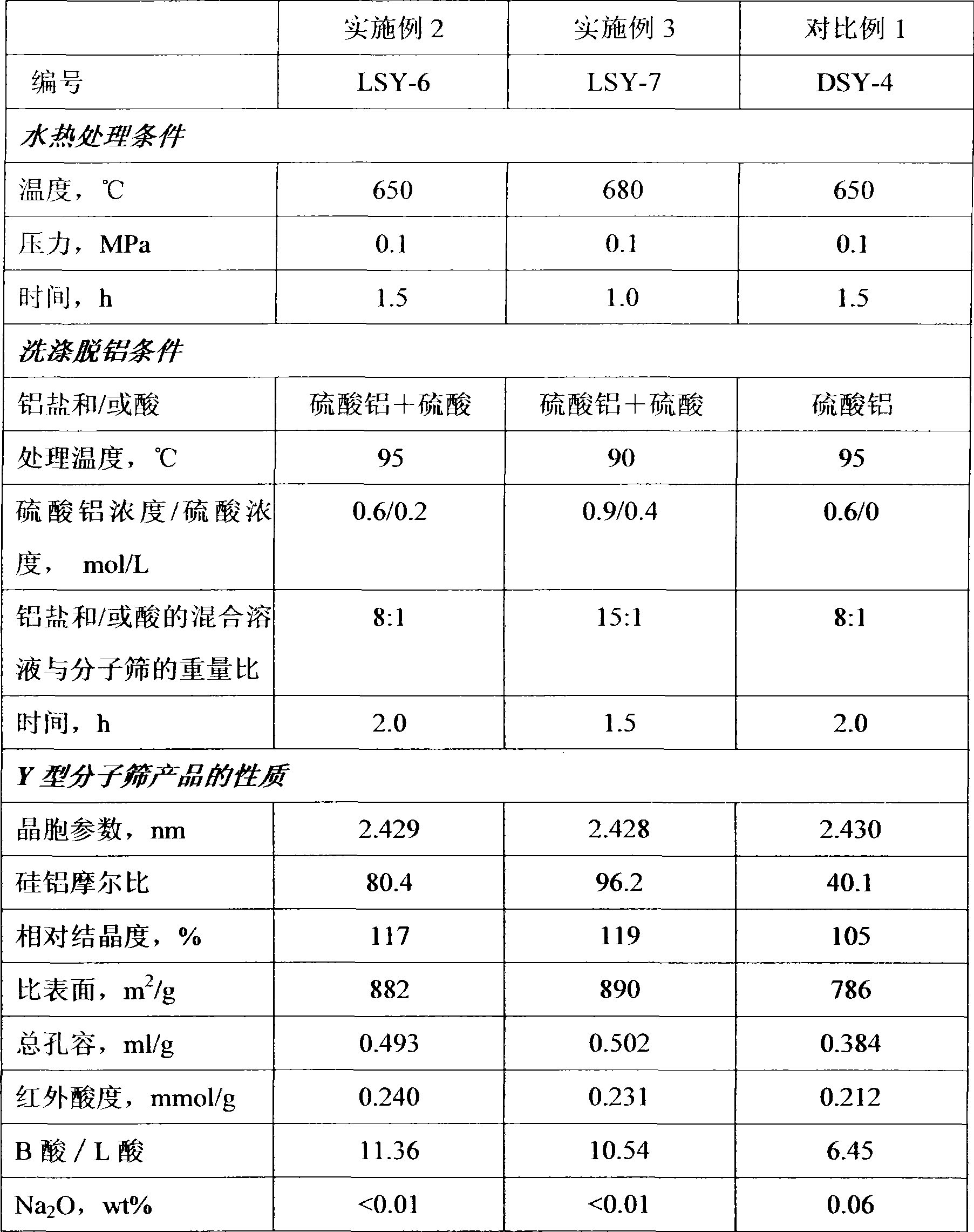

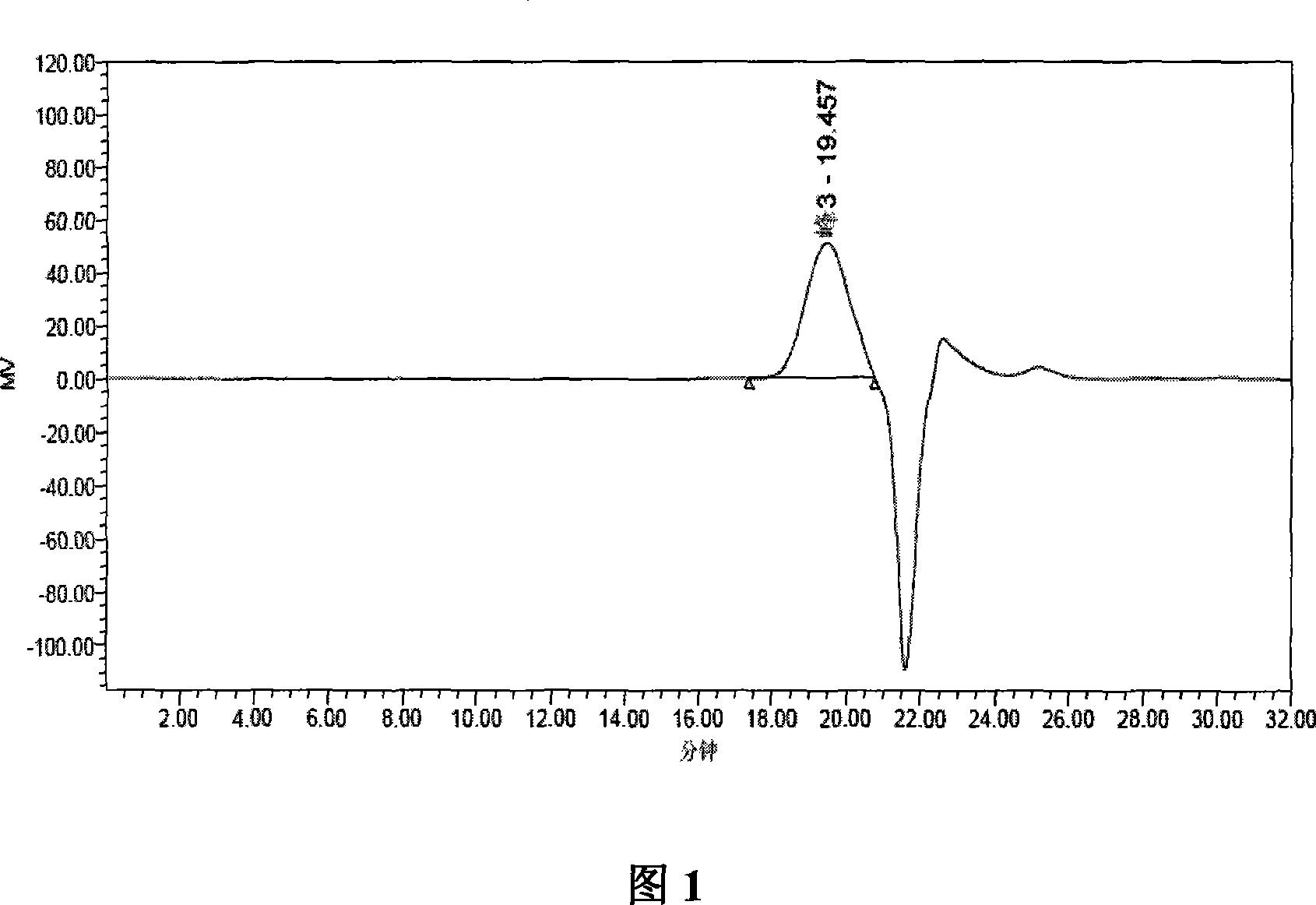

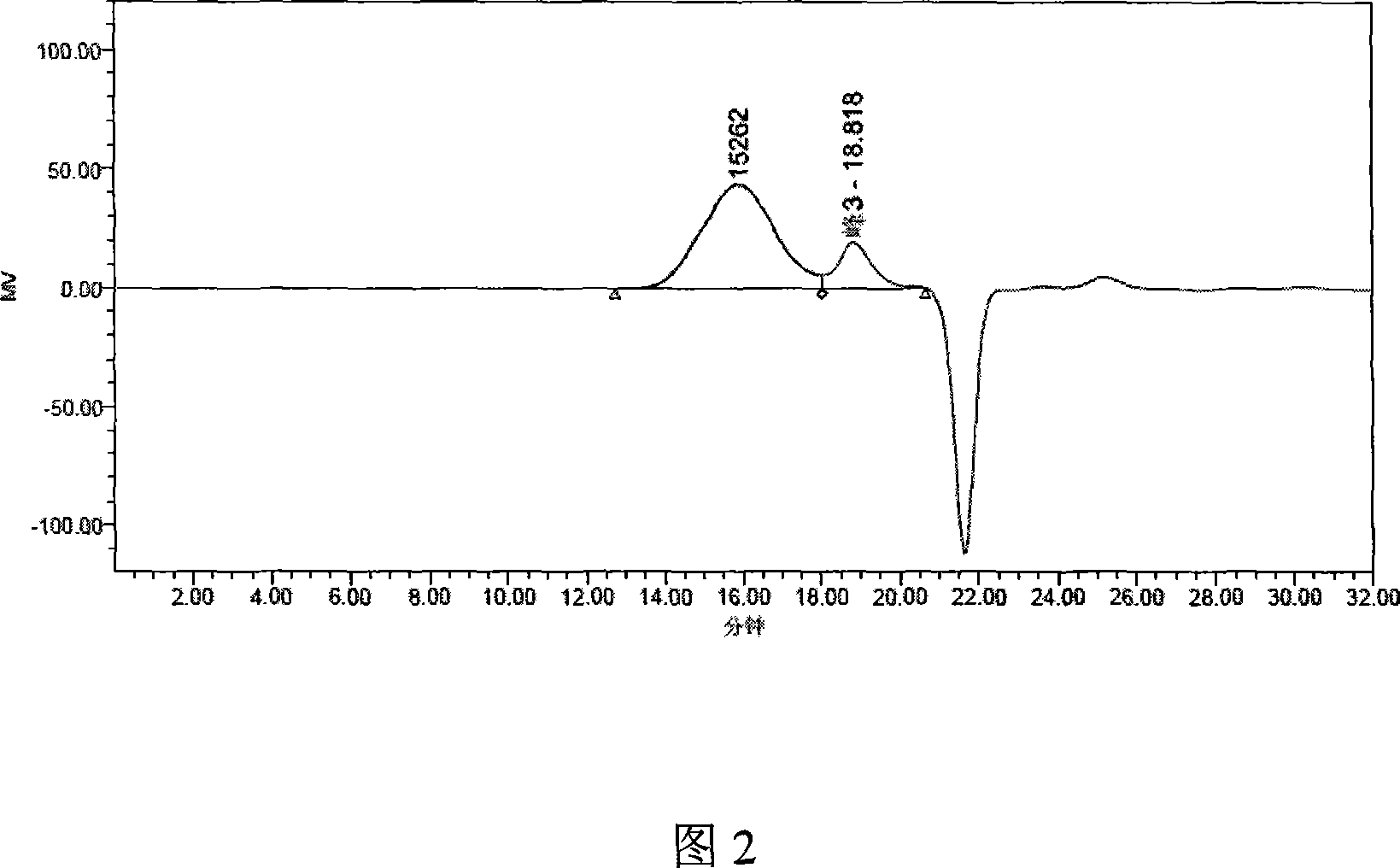

Hydrocracking catalyst for moderate oil and preparation thereof

ActiveCN101450319AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveAmorphous silicon

The invention discloses a high-activity and high and medium oil type hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieves, amorphous silicon aluminum and alumina, wherein the modified Y molecular sieves have high crystallinity, large silicon aluminum ratio and proper total acid amount and acid distribution, and are obtained by treating Y molecular sieves after hydro-thermal treatment by a mixed aqueous solution of aluminum salts and an acid. The hydrocracking catalyst has high activity and good intermediate distillate oil selectivity and product quality, and is particularly suitable for hydrocracking technology for producing intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

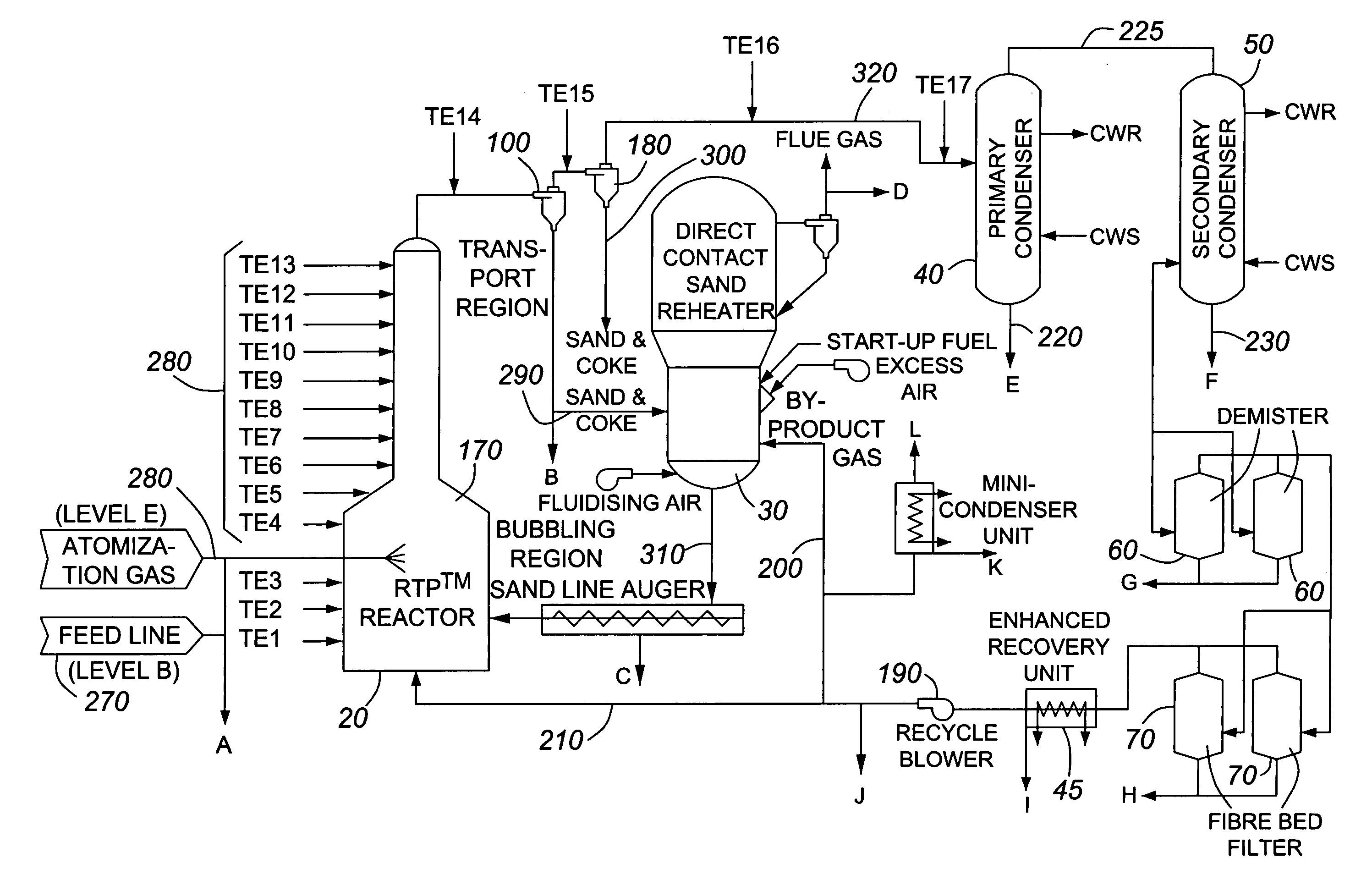

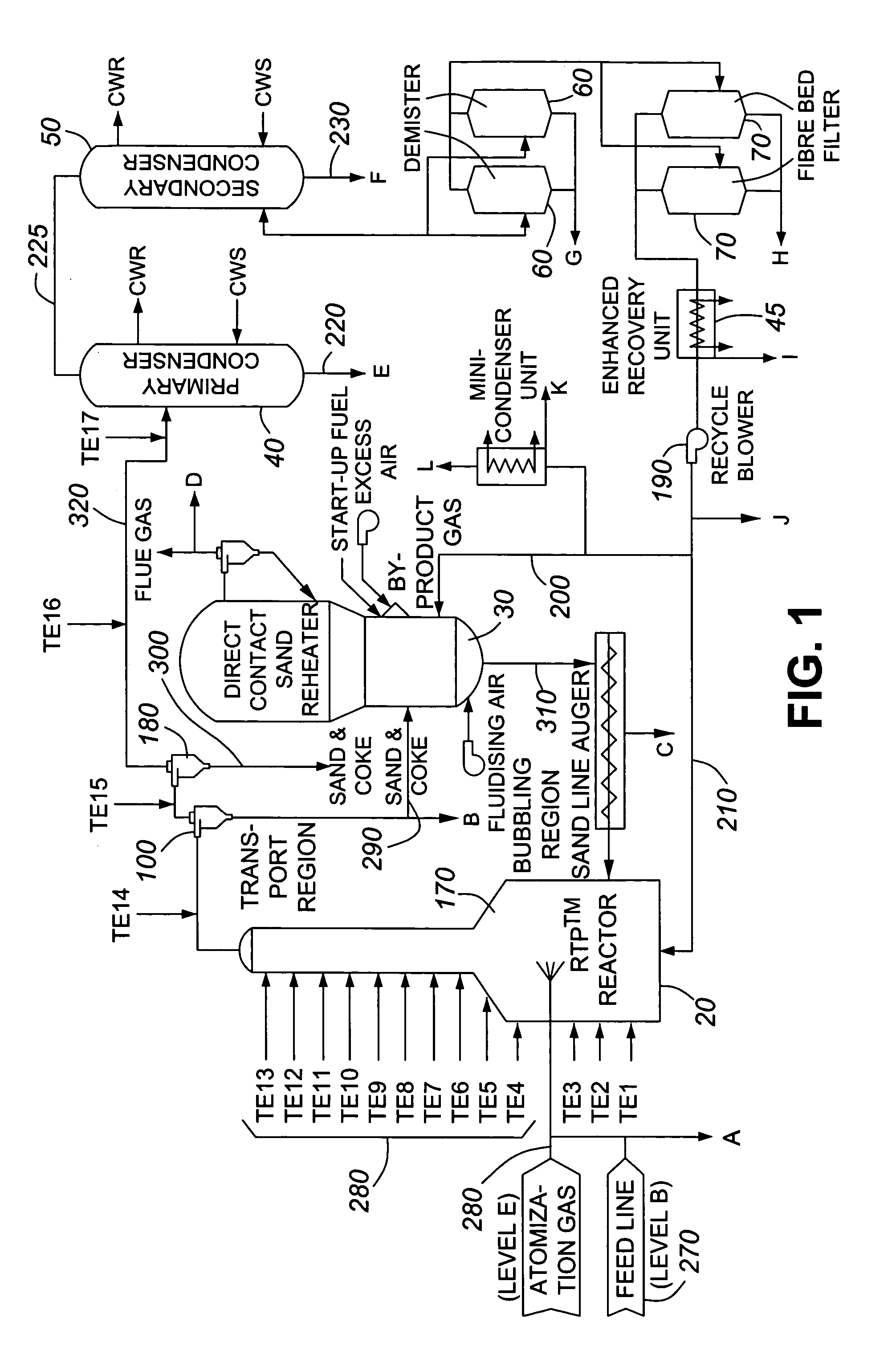

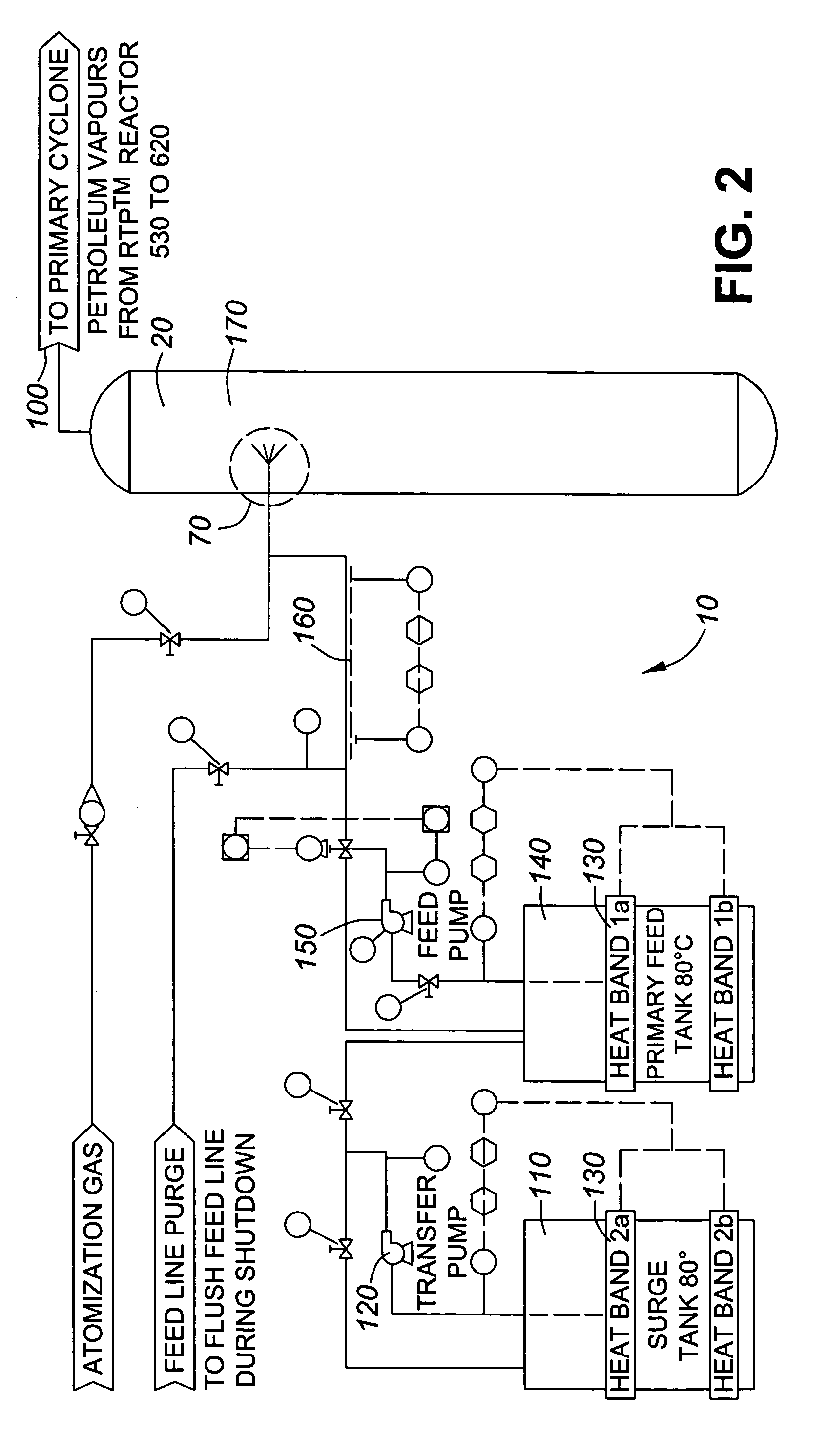

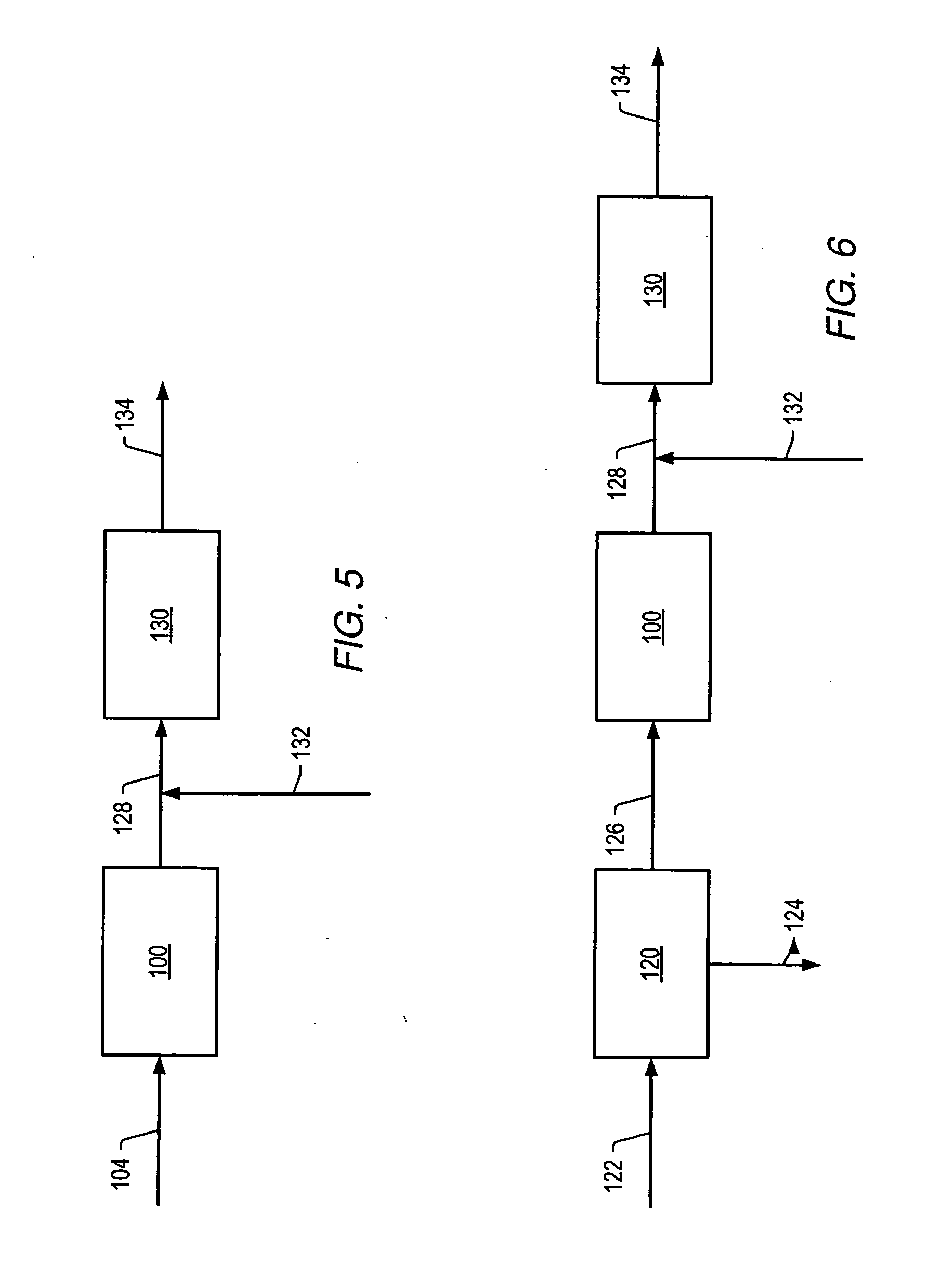

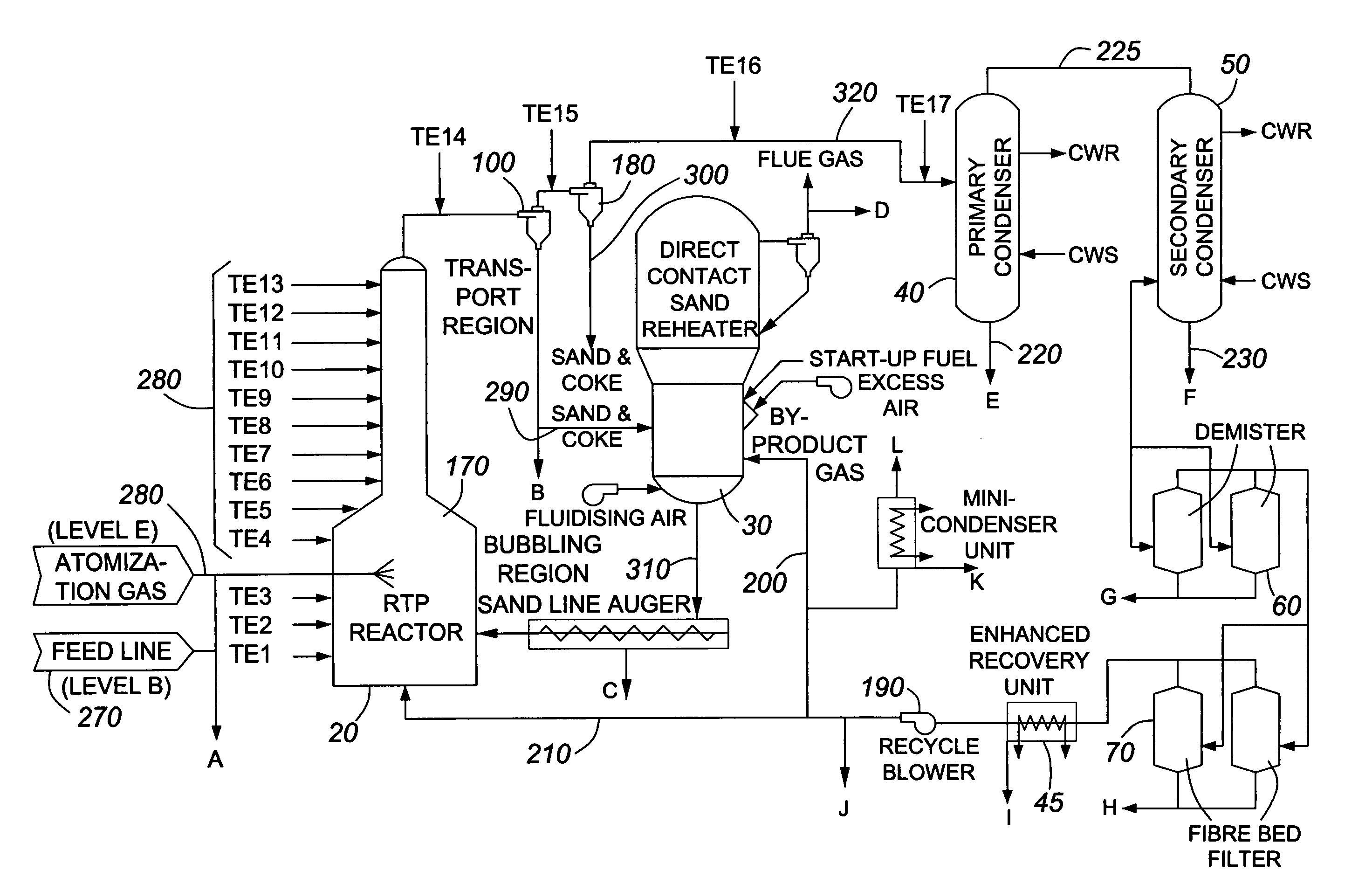

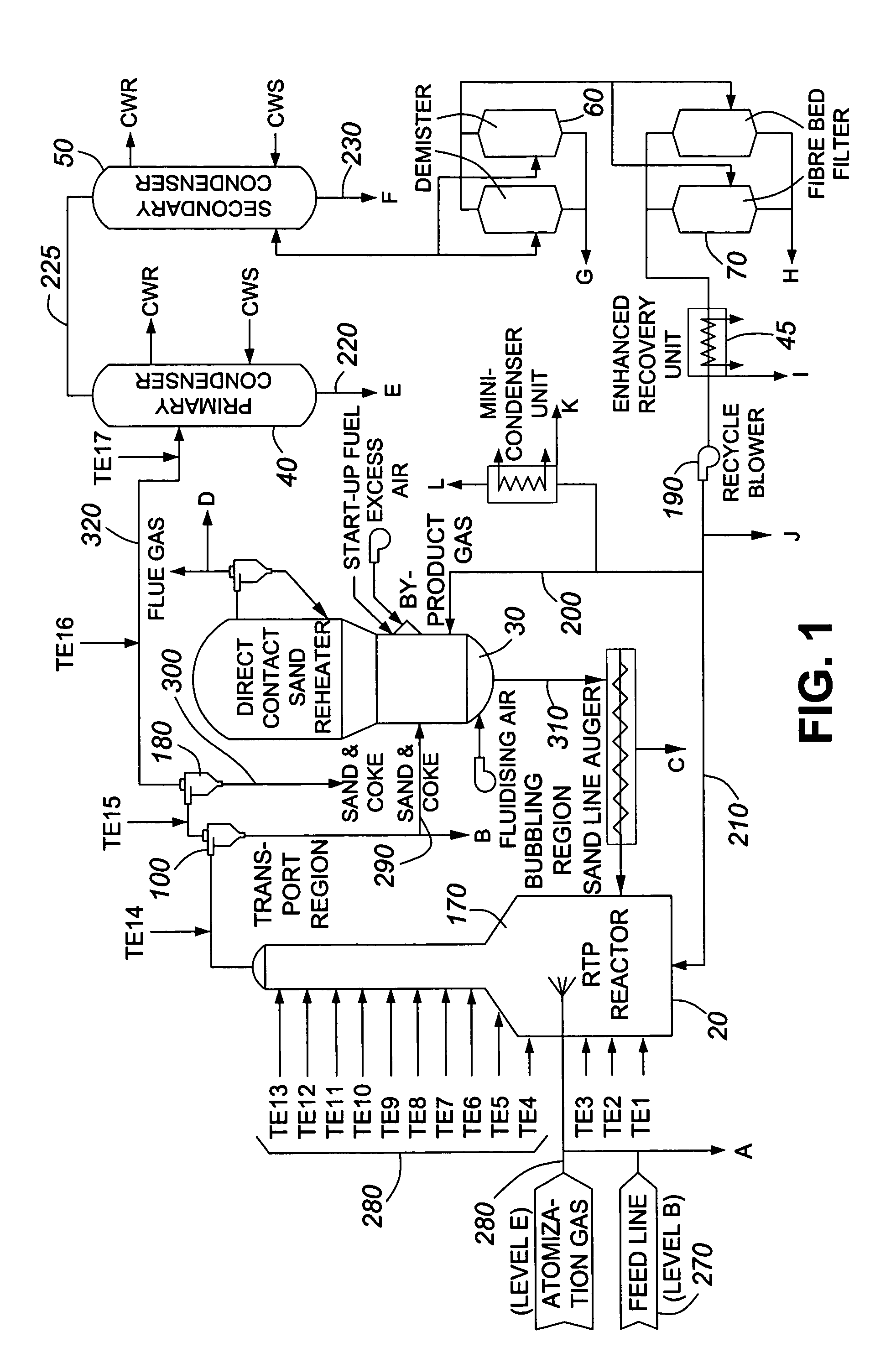

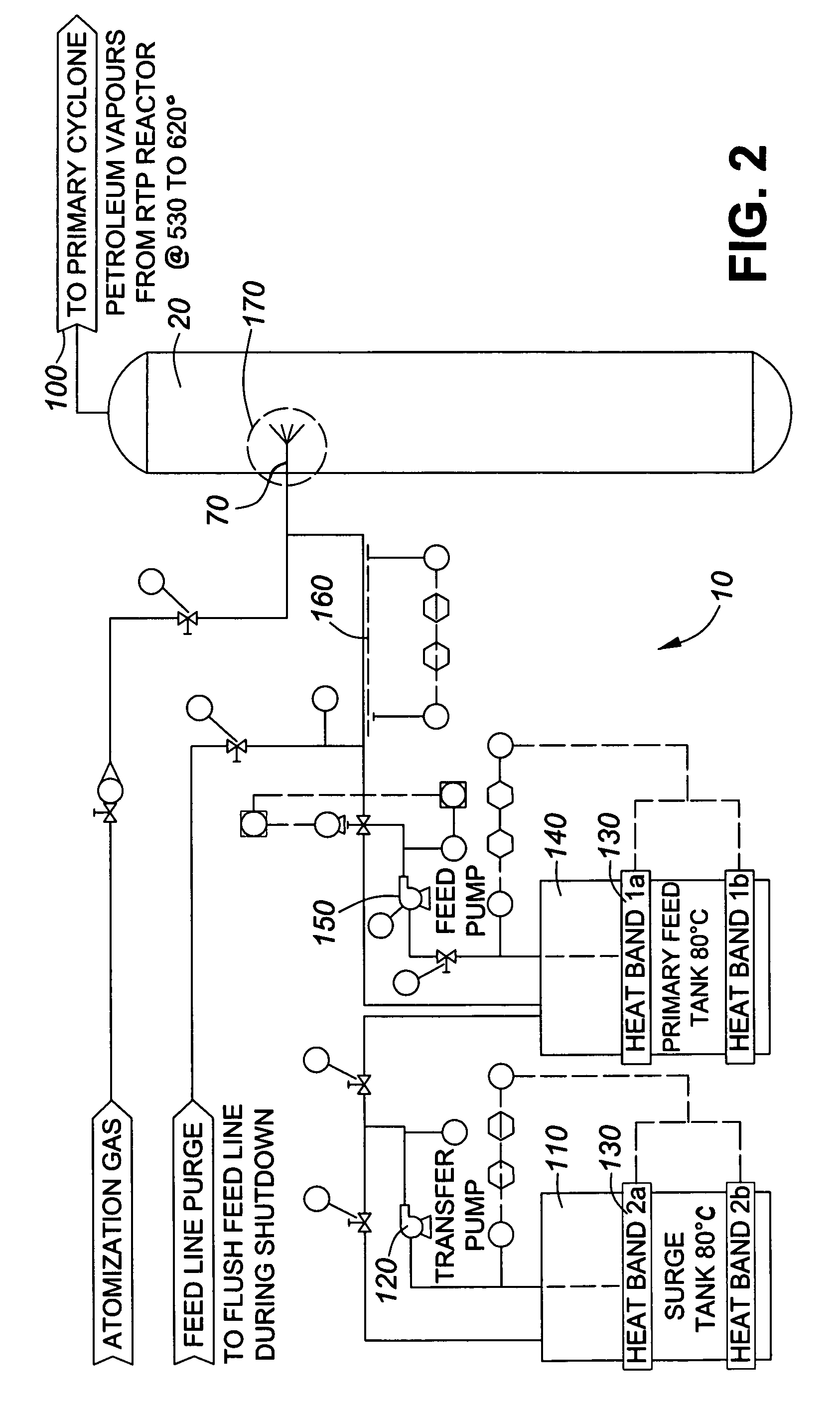

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

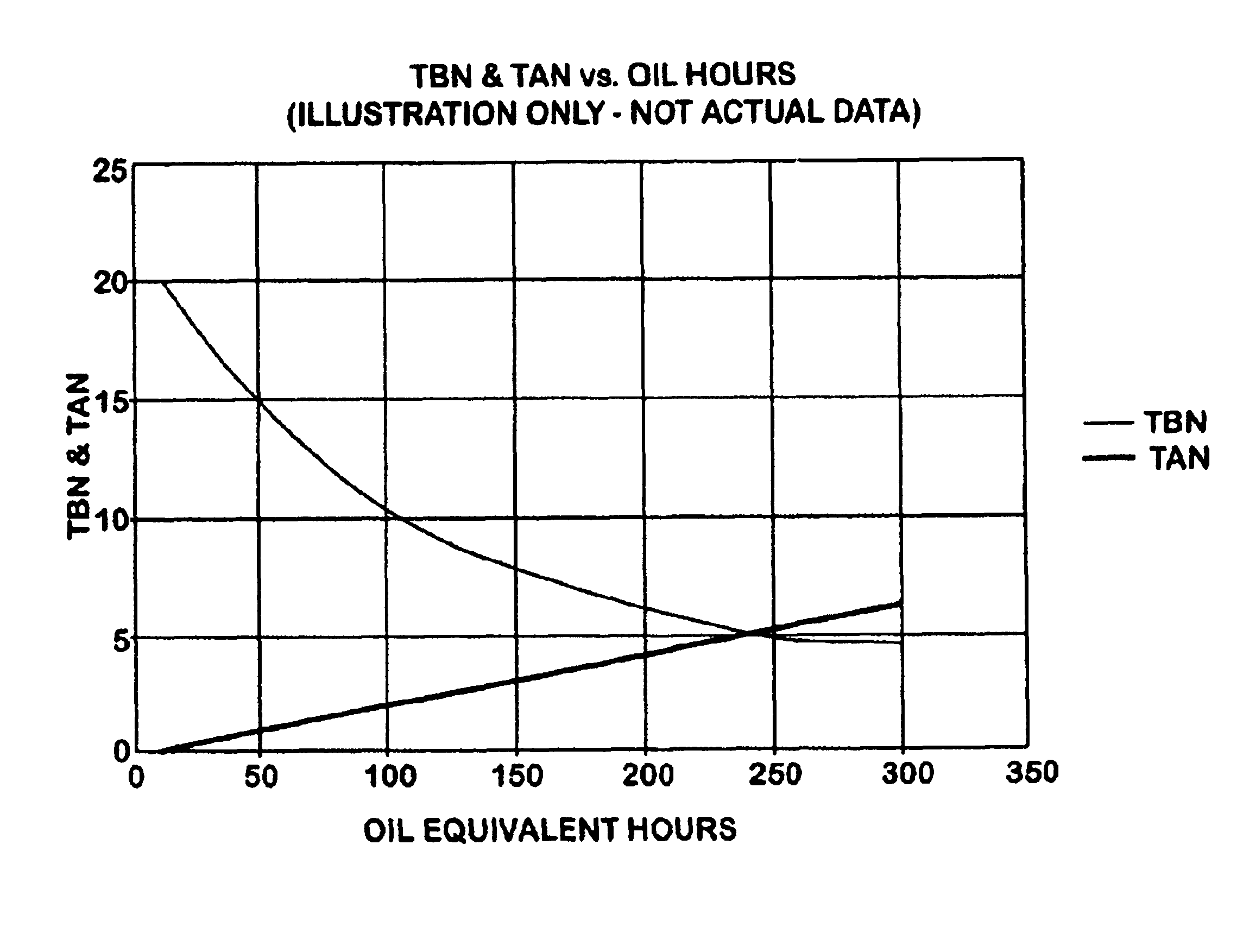

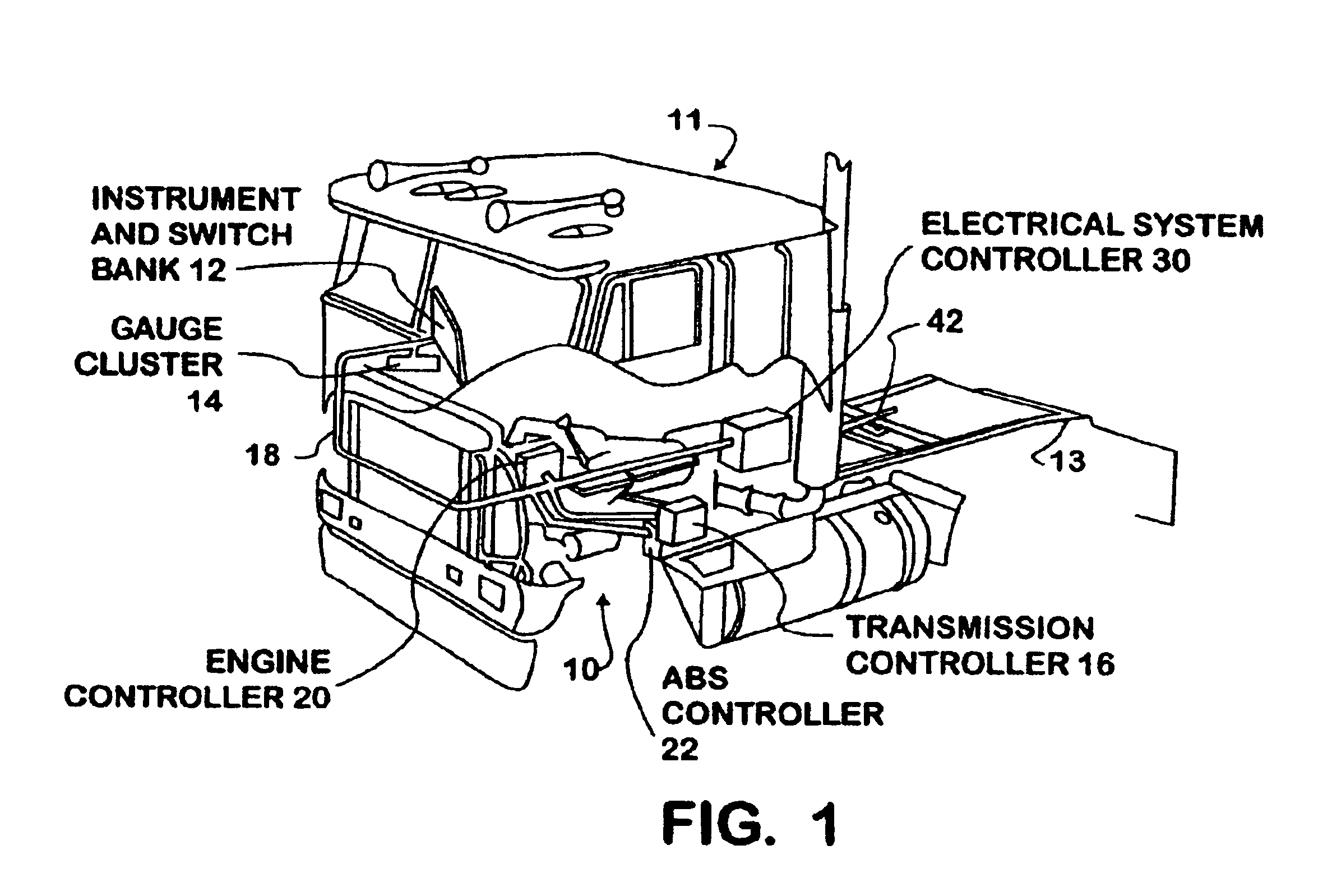

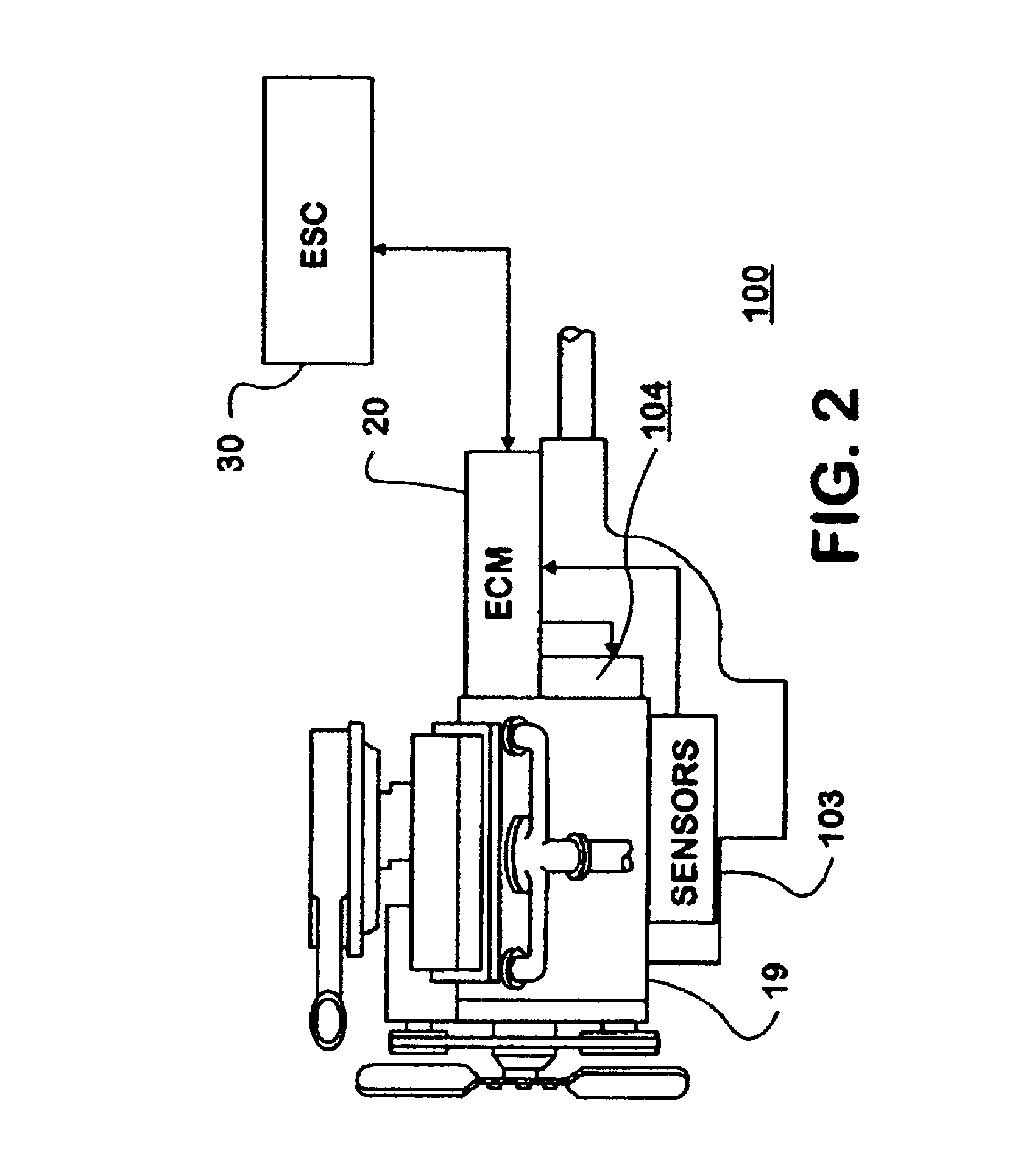

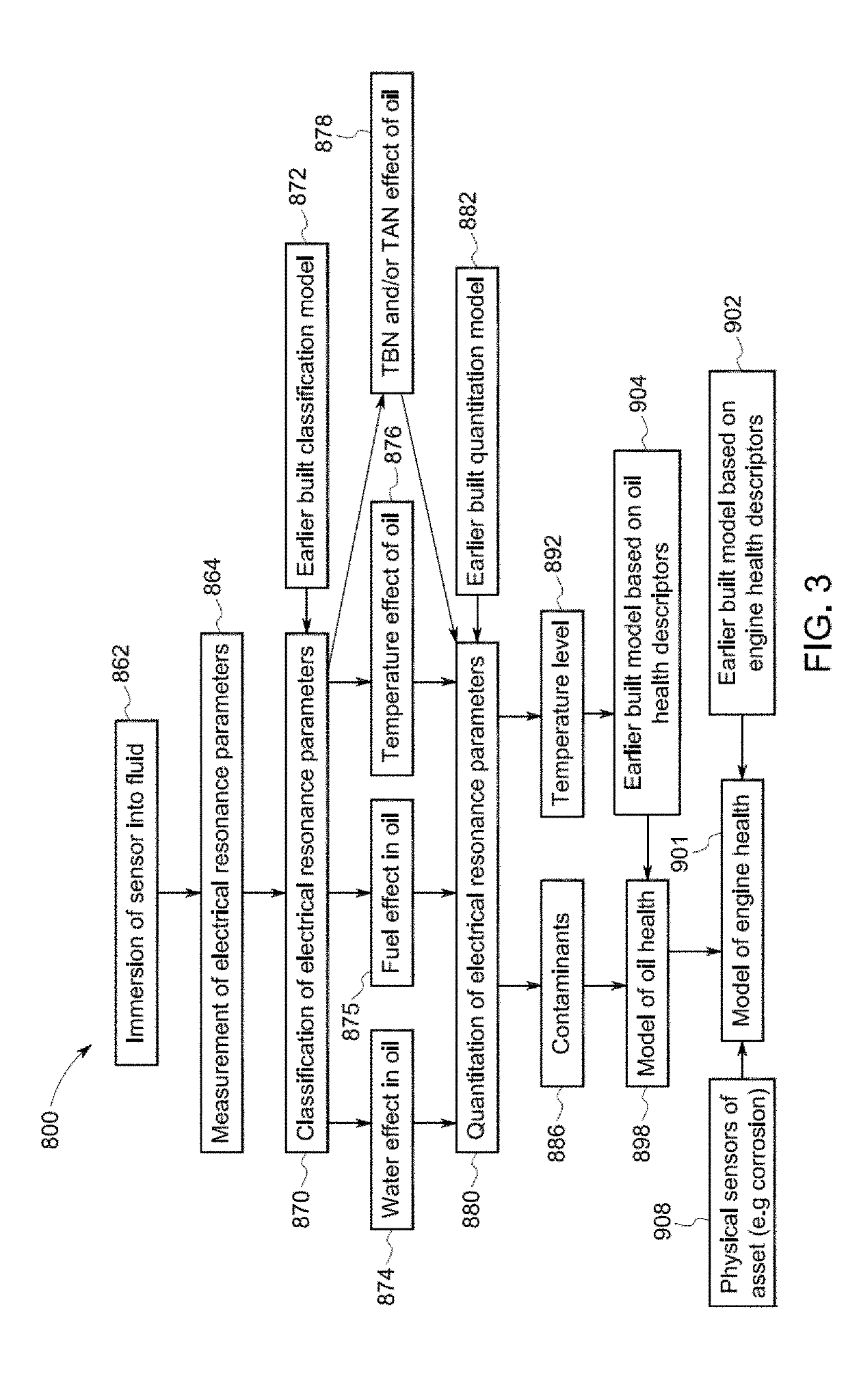

Method of estimating engine lubricant condition

A motor vehicle having an internal combustion engine and a lubricating oil circulation system provides estimates of the distance remaining before an oil change becomes imperative. An indirect estimate of the depletion of various additives and the deterioration of oil operating characteristics is based on engine operating variables including oil temperature, ignition timing and engine load. The limit of depletion of total base number is dynamic, since it is set against total acid number and the two figures are independently calculated.

Owner:INT TRUCK INTPROP LLC

Production method for tea vinegar drink

The invention discloses a production method for a tea vinegar drink, and relates to the technical field of processing of drinks. The tea vinegar drink is mainly prepared from tea, momordica grosvenori, white sugar, mountain spring water and acetic acid bacterium. The production method comprises the following steps: after the momordica grosvenori is smashed, the tea, the momordica grosvenori, the white sugar, the mountain spring water and the acetic acid bacterium are respectively weighed, and the weighed raw materials are placed in a pot and boiled to obtain an extract liquid; an acetic acid bacterium strain accounting for 2-3 percent of the total weight of the raw materials is -inoculated, covered and fermented, the product temperature is controlled to be 16-28 DEG C, and the fermentation lasts 10-25 days; acid adjustment is performed on a fermented and obtained feed liquid, the total acid content of the feed liquid is controlled within a range of 0.3-1 g / 100ml, and the soluble solid is controlled within a range of 3-5 percent; the tea vinegar drink is obtained via vacuum and sterile filling after the liquid is sterilized. The invention discloses the tea vinegar drink integrating multiple functions of nutrition and health care, vegetal syrup is used as an acetic acid bacteria culture medium for fermentation, the produced tea vinegar drink contains various spicy substances and nutrient ingredients of the tea, the momordica grosvenori and acetate acid, and is good in flavor and high in quality.

Owner:广西三江县康百氏实业有限公司

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133418A1Reduce contentCatalytic crackingRefining with metal saltsOrganic chemistryTotal acid

Methods and systems for contacting a crude feed that has a total acid number (TAN) of at least 0.3 with one or more catalysts produces a total product that includes a crude product are described. The one or more catalysts may include a first catalyst and a second catalyst. The crude product is a liquid mixture at 25° C. and 0.101 MPa and the crude product has a TAN of at most 90% of the TAN of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572365B2Quick upgradeReduce sulfur emissionsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas) and to reducing the total acid number (TAN) of the liquid product. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

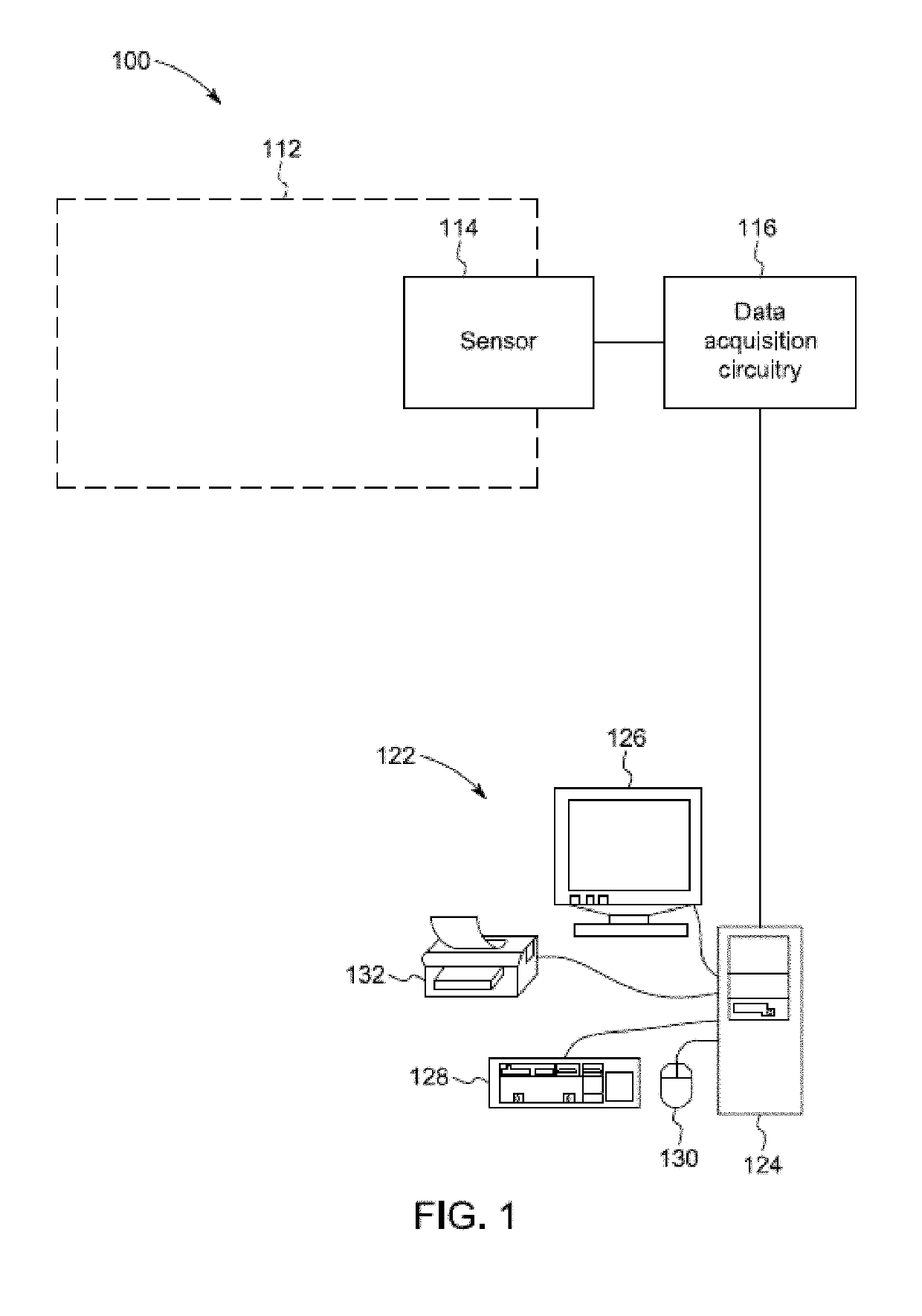

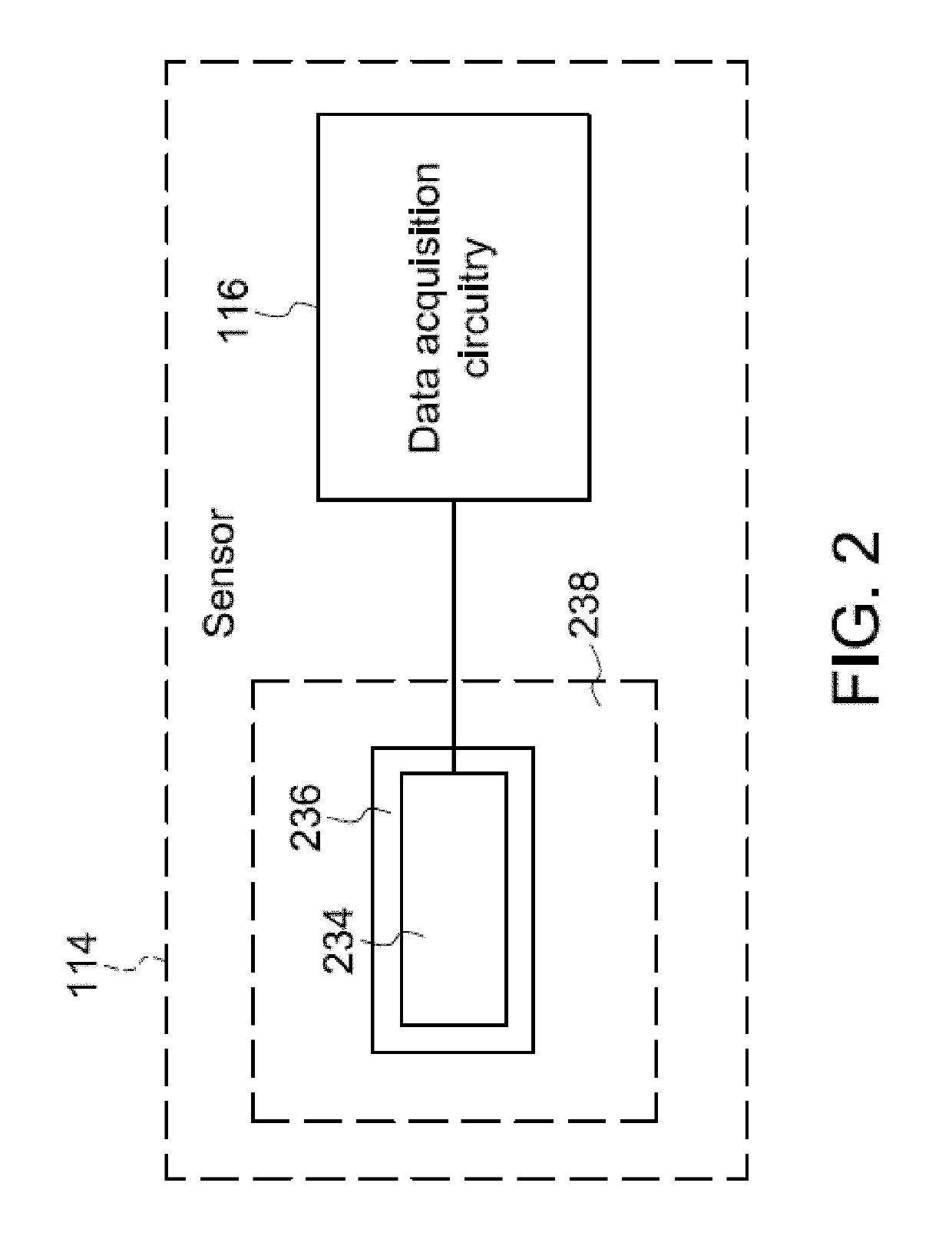

Locomotive sensor system for monitoring engine and lubricant health

PendingUS20190156600A1Registering/indicating working of vehiclesRailway transportTotal Base NumberEngineering

A locomotive sensor system includes a sensor configured to be in contact with lubricant within an engine of a locomotive. The sensor includes a sensing region circuit that is configured to generate stimuli at different times during an operational life of the engine. The system also includes one or more processors configured to receive signals from the sensor. The signals are representative of responses of the lubricant to the stimuli. The one or more processors are configured to analyze the responses and determine a characteristic of the lubricant that represents one or more of a total base number (TBN) or a total acid number (TAN) of the lubricant. The are configured to determine an unhealthy state of one or more of the engine or the lubricant based on the characteristic of the lubricant that is determined.

Owner:GE GLOBAL SOURCING LLC

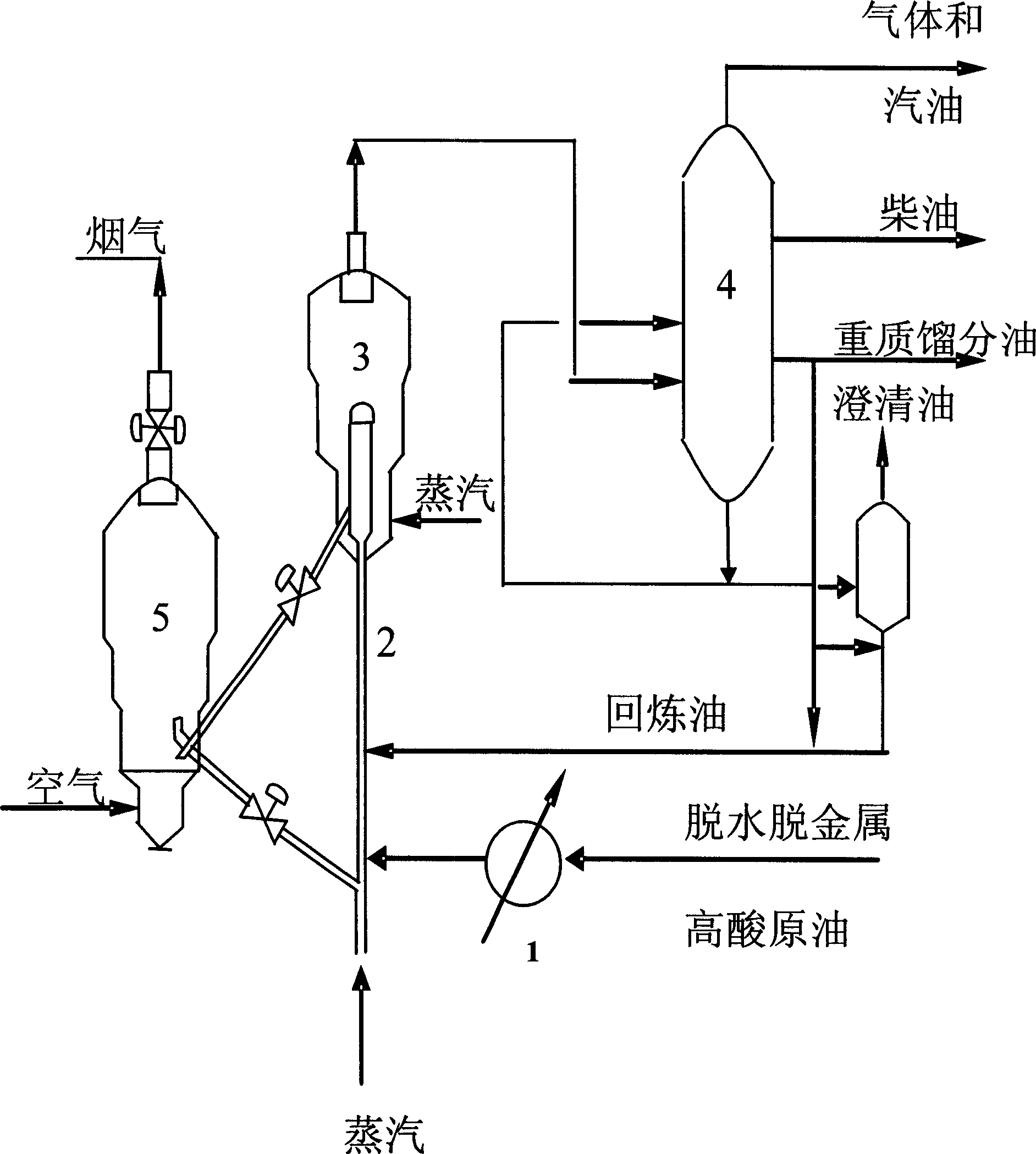

Method for processing crude oil with high acid value

ActiveCN1827744AEvenly distributedInhibition of harmful effectsCatalytic crackingPotassium hydroxideAcid value

A method for producing highly acid value crude oil consists of preheating the crude oil which is total acid number of more than 0.5mg potassium hydroxide per gram after the pretreatment and injecting them into the fluidized catalytic cracker to contact the catalyst, and reacting in catalytically cracked reaction condition, separating the oil gas and the catalyst, in which the oil gas is put into the subsequent separation system, while the catalyst can be circularly used after stripping and regenerating. The method is characterized in that it is of strong industrial practicability, low running cost and fine deacidification effect and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

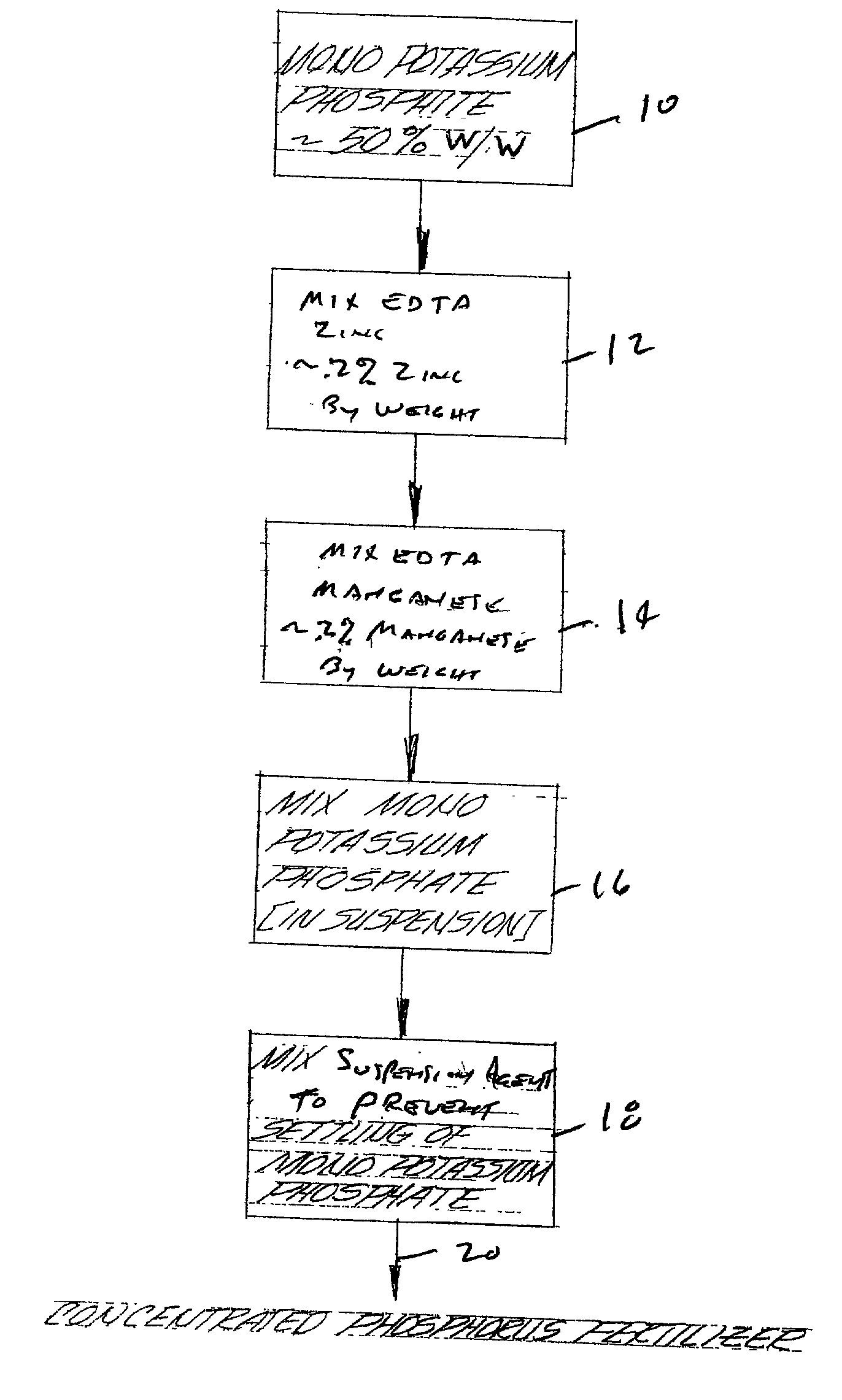

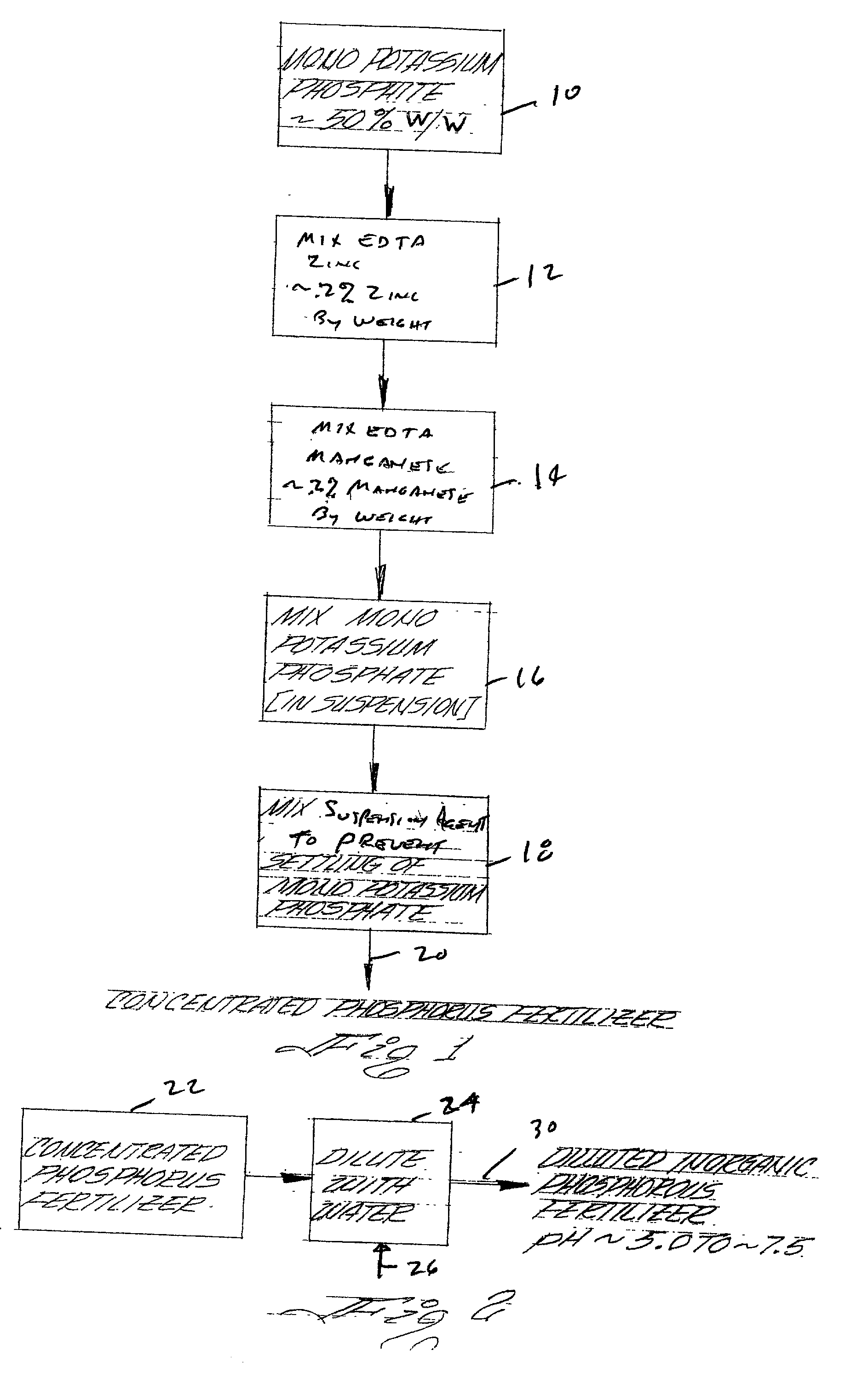

Concentrated phosphorus fertilizer

InactiveUS20020129632A1Easy to diluteImproving phosphorus uptakeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorous acidSalt content

A concentrated fluid phosphorus fertilizer is shown. In the preferred embodiment, the concentrated fluid phosphorus fertilizer is an aqueous suspension fertilizer composition. The composition comprises one or more phosphorus-containing acids or salts thereof selected from the group consisting of phosphoric acid, polyphosphoric acid, phosphorous acid, polyphosphorous acid, hypophosphorous acid and polyhypophosphorous acid, and salts thereof. A suspension agent maintains undissolved solids in substantially homogeneous suspension wherein the suspension has a total acid and salt content of about 50% w / w to about 80% w / w. The concentrated fluid phosphorus fertilizer is a stable suspension and when diluted with water a substantially fully soluble fertilizer having acceptable pH for phosphorus uptake is formed. Methods for improving the phosphorus uptake and improving the growth rate of plants is also shown.

Owner:INTERFARM

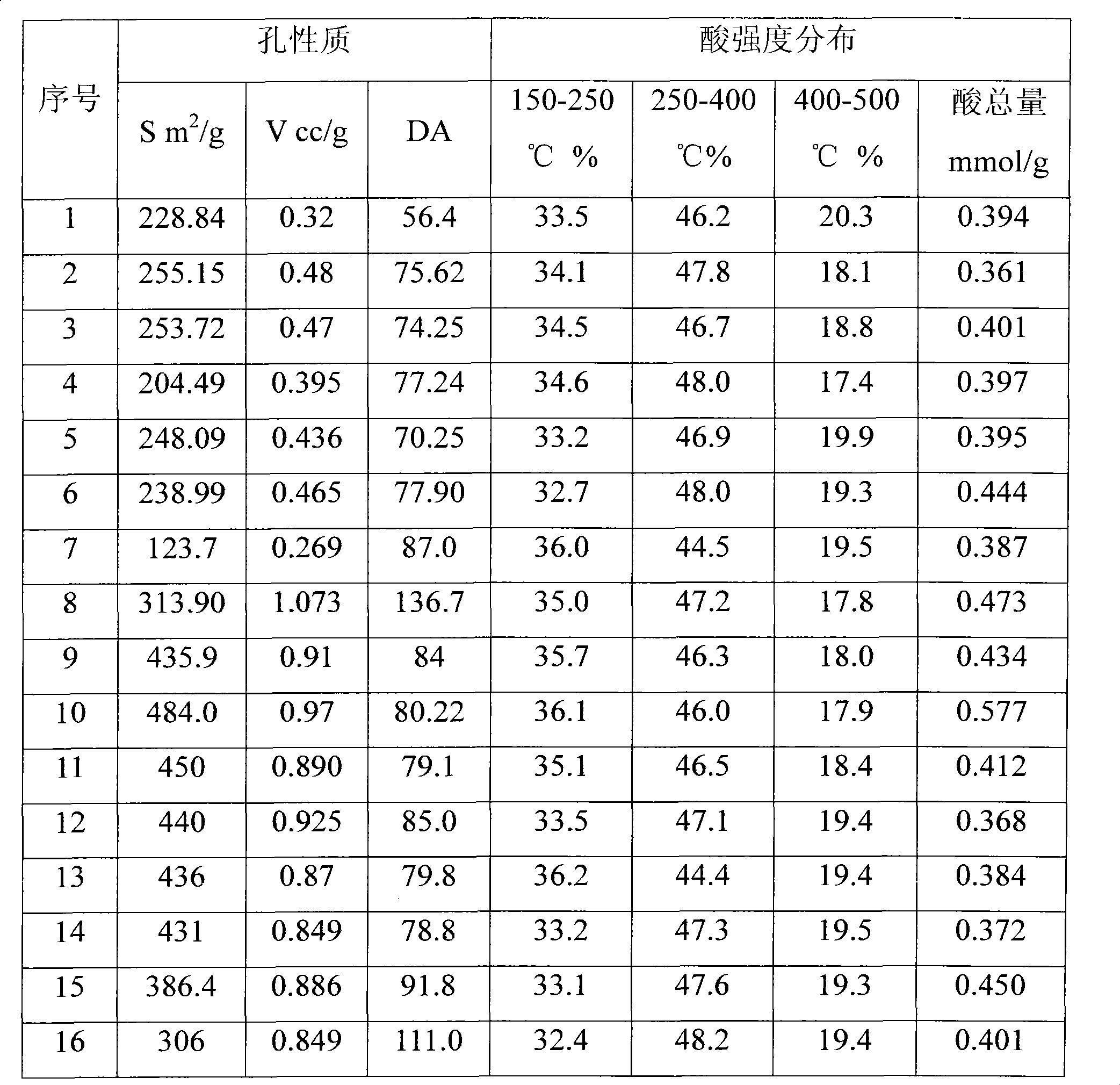

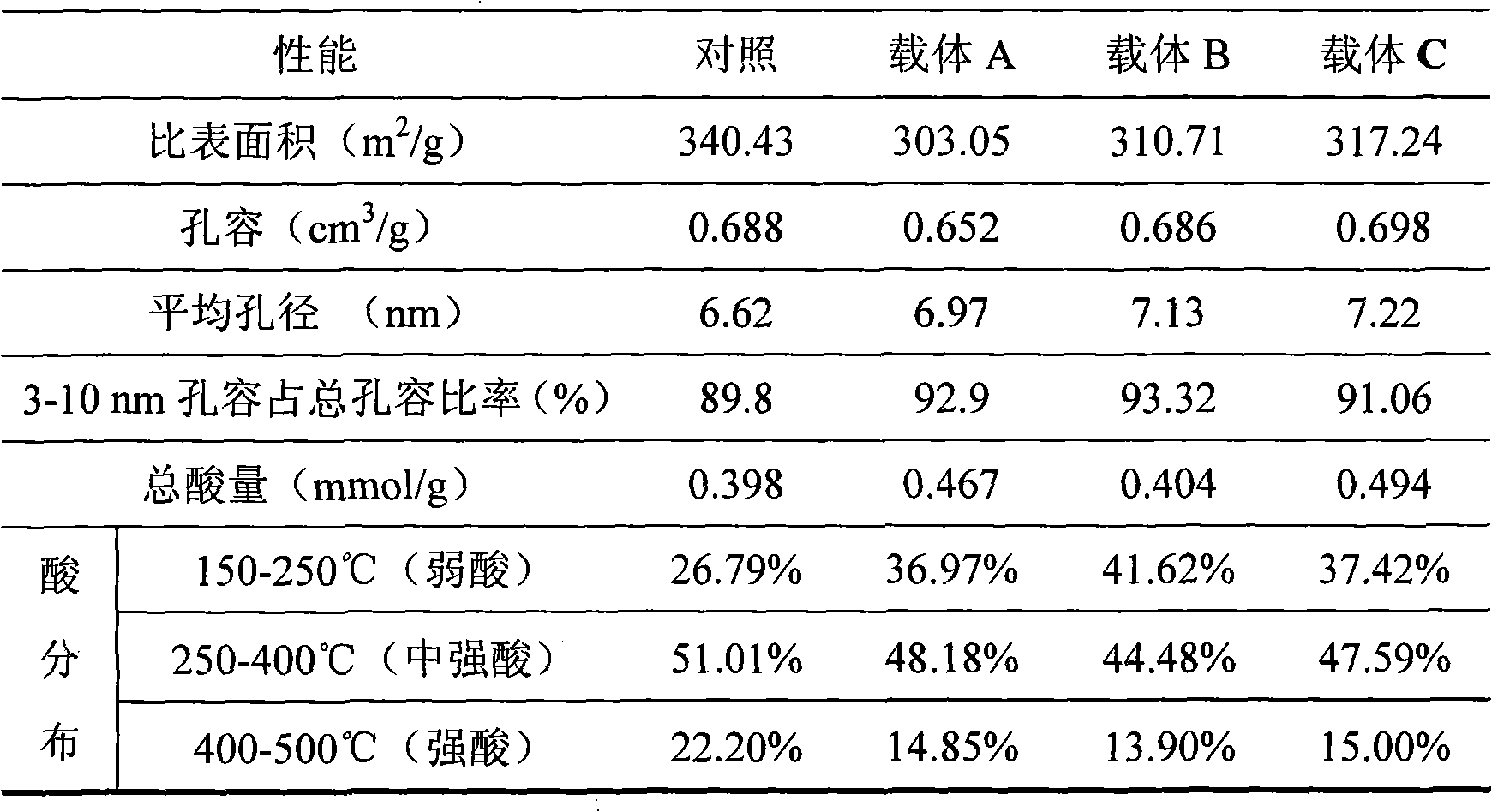

Composite oxide carrier and preparation method thereof

ActiveCN101433863ALarge hole volumeLarge specific surface areaCatalyst carriersZirconium hydrideSilicon dioxide

The invention relates to a compound oxide carrier and a preparation method, and belongs to the filed of catalyst preparation, wherein the compound oxide carrier is prepared by compounding gamma-aluminum oxide, silicon dioxide and zirconium dioxide. The method comprises the following steps: co-precipitating precursors of the aluminum oxide, the silicon dioxide and the zirconium dioxide with alkali solution, adding surfactant into the mixture to improve the pore structure and acidity and alkaline, then washing, filtering and roasting the obtained sediment at high temperature to obtain compound oxide powder, and finally extruding and molding the compound oxide powder to obtain the carrier. The pore structure and the acidity and the alkaline of the obtained carrier have wide adjustable ranges, the specific surface of the carrier is 200 to 500 m<2> per gram, the pore volume thereof is 0.4 to 1.2 milliliters per gram, and the total acid amount of NH3-TPD is 0.2 to 0.8mmol / g. The carrier prepared by the method is suitable for preparing hydrogenation catalysts of petroleum fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified carbon-coated alumina supporter with nucleocapsid structure and preparation method thereof

InactiveCN101327454ALarge specific surface areaLarge hole volumeCatalyst carriersCatalyst activation/preparationOil processingModified carbon

The present invention discloses a modified carbon-covered alumina support with a core-shell structure and a preparation method thereof. The modified carbon-covered alumina support of the present invention is a granule with the core-shell structure. A shell of the core-shell structure is alumina deposited with carbon, and an inner core of the core-shell structure is an industrial alumina support. The modified carbon-covered alumina support of the present invention has the advantages of high specific surface area, large pore volume, high mechanical strength, and the like; the aperture distribution is more concentrated; total acid quantity is increased obviously, and strong acid quantity is reduced; the modified carbon-covered alumina support can be directly used as a catalyst during certain processes and is more applicable to be used as a catalyst support, in particular as a hydrogenation treatment catalyst support during petroleum processing course.

Owner:EAST CHINA UNIV OF SCI & TECH

Composition and method for preparing food and beverage products with improved taste impression containing protein and fruit juices nutritionally supplemented with calcium and trace minerals

InactiveUS20070196539A1Food ingredient as buffering agentVitamin food ingredientsFruit juiceCITRATE ESTER

The present invention provides a food product comprising: calcium citrate malate in an amount providing a level of solubilized calcium of at least about 0.18% by weight of the product, and a level of total acids of at least about 0.7% by weight of the product; vitamin D in an amount of at least about 10% of the RDA; one or more trace minerals in an amount of at least about 10% of the RDA of each trace mineral provided; and a stabilized buffering protein component in an amount of at least about 0.1% by weight of the product. A method for forming such a calcium and trace mineral fortified product is also provided which uses a stabilized acidified buffering protein component.

Owner:NUTRIJOY INC

Method for promoting white spirit aging

ActiveCN102703297AAccelerated agingLow costAlcoholic beverage preparationAge methodHazardous substance

The invention discloses a method for promoting white spirit aging. The method promotes the association of molecules in the wine as well as the collision of molecular energy through the heating temperature control and ventilation treatment, and can quickly promote the white spirit aging. Through the aging method, the aging time of the white spirit can be obviously shortened, and the content of total acid and total ester reaches the national standard; and moreover, the content of harmful substances in the white spirit is effectively reduced in short time, and the need for large-scale industrialization is met. The method disclosed by the invention has a very broad market prospect.

Owner:广东省九江酒厂有限公司

Instant preserved flowering cabbage and production method thereof

InactiveCN101933591ALong aftertasteInhibit and reduce productionClimate change adaptationFood preparationBiotechnologyLactarius

The invention relates to the field of agricultural product processing, in particular to an instant preserved flowering cabbage and a production method thereof. The method comprises the following steps of: firstly, preprocessing cruciferous brassica mustard leaf serving as a main raw material; then performing pickling, tank transferring, airing, embrittlement, pure lactic acid bacteria fermentation, nitrite removal, packaging and sterilization; and finally obtaining the instant preserved flowering cabbage, wherein dehydration and / or blending can be performed before packaging. The method has the advantages of low cost and simple process. The instant preserved flowering cabbage produced by the method has the advantages of unique mouthfeel, crisp texture, brownish yellow color and aromatic flavor, wherein the water content is 22 to 45 percent; the salt content is 2 to 6 percent, the total acid content (accounting by lactic acid) is less than or equal to 1 percent; the peroxide value (accounting by fat) is less than or equal to 20 meq / kg; and the ammoniacal nitrogen content is 0.15 to 0.16 percent.

Owner:GUANGDONG ZHENZHOU GRP

Pressure-Sensitive Adhesive and Method for Producing Same, and Pressure-Sensitive Adhesive Sheet

InactiveUS20080248299A1Good optical performanceImprove adhesionLayered productsEster polymer adhesivesVitrificationPolymer science

A pressure-sensitive adhesive, comprising a polymer (A), which is formed by polymerization of a radical polymerizable monomer, contains carboxyl groups, and has a glass transition temperature within a range from −80 to 0° C. and a weight average molecular weight within a range from 500,000 to 1,500,000, a tricyclic diterpene carboxylic acid (B), and a curing agent (C) capable of reacting with a carboxyl group, wherein the total acid value of the combination of the polymer (A) and the tricyclic diterpene carboxylic acid (B) is within a range from 5 to 50 (mgKOH / g).

Owner:TOYO INK SC HOLD CO LTD

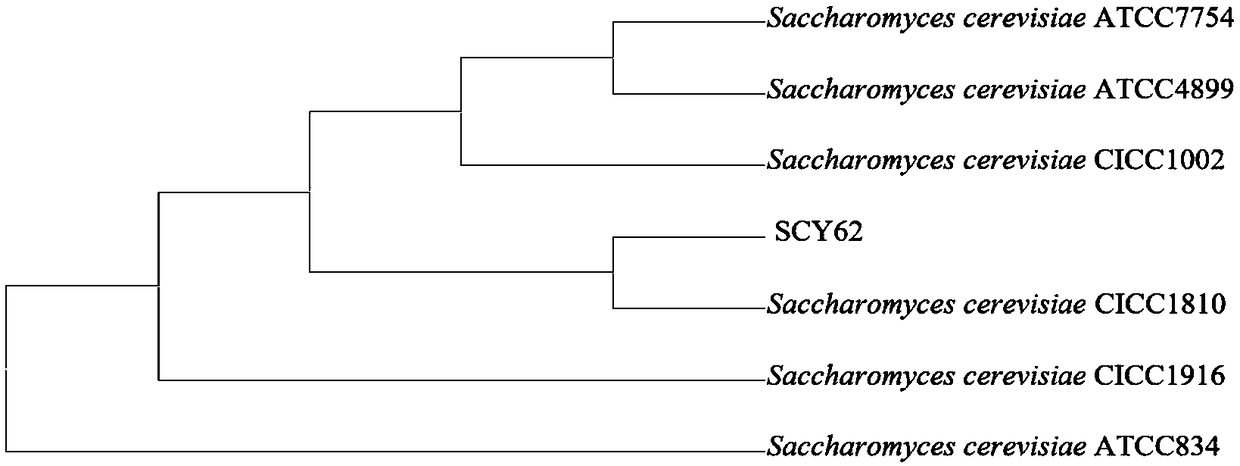

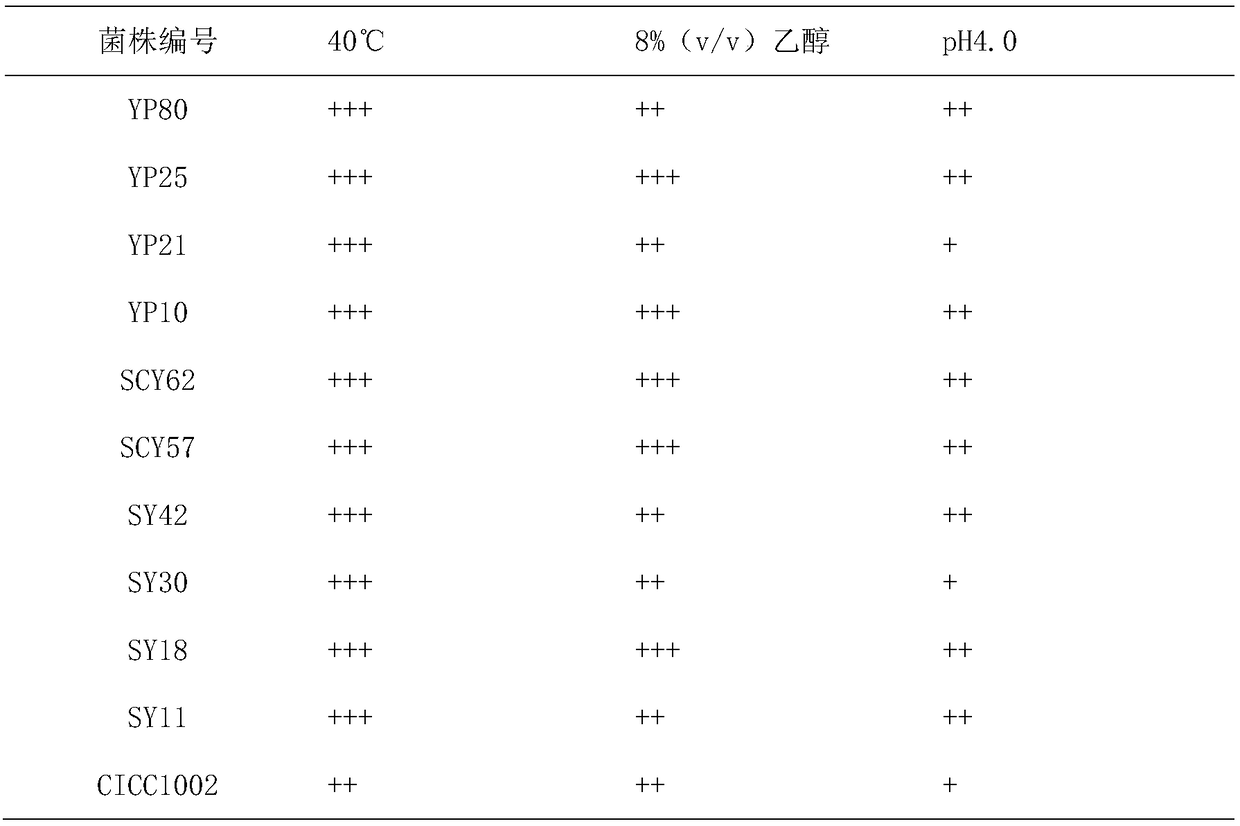

Saccharomyces cerevisiae with high acid yield and low yield fusel oil as well as composition and application of saccharomyces cerevisiae

InactiveCN109439557AStrong high temperature resistance growth abilityPromote growthFungiBacteriaMicroorganismTemperature resistance

The invention discloses novel saccharomyces cerevisiae, a brewing microorganism inoculant containing the saccharomyces cerevisiae and application of the saccharomyces cerevisiae in baijiu brewing. Thesaccharomyces cerevisiae disclosed by the invention has the advantages of high acid-producing capacity and ester-producing capacity, low content of higher alcohol, high temperature resistance, acid resistance and higher ethanol-producing ability; fermented baijiu has the advantages of high contents of total acid and total ester, low content of fusel oil and the like; a brewing microorganism inoculant composition and brewing reinforced distiller's yeast can be applied to baijiu solid state fermentation, so that the quality and the yield of the baijiu can be improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Copolyester with low melting point and synthesis method thereof

InactiveCN101735437AAddress reactivityFix stability issuesFlexible coversWrappersPolymer scienceSynthesis methods

The invention discloses polyester with an extensive amorphous region. The components of terephthalic acid, m-phthalic acid and dihydric alcohol and a dihydroxy compound with an ether bond are used as basic raw materials, an acid component contains 10-30 percent by mol of m-phthalic acid and 70-90 percent by mol of terephthalic acid, total acid and total alcohol are prepared into uniform slurry inthe mol ratio of 1.05:2.0, and the polyester which does not have an obvious melting peak under a DSC (differential scanning calorimetry) and has the extensive amorphous region and low melting point is generated by the reactions of esterification and polycondensation. The method can utilize a traditional semicontinuous and continuous polyester production line to realize industrialized production. The polyester produced by utilizing the method provided by the invention is used for preparing a packaging film, a sheet, a hot melt adhesive and the like. The invention is especially suitable for being prepared into a thermal contraction film used for a packaging purpose or a tag purpose so as to replace a polyvinyl chloride (PVC) thermal contraction film used in the market at present.

Owner:ZHONGFU GUANGHAN CHEM IND

Systems, methods, and catalysts for producing a crude product

InactiveUS20100098602A1Reduce contentRefining with metal saltsTreatment with hydrotreatment processesOrganic chemistryTotal acid

Methods and systems for contacting a crude feed that has a total acid number (TAN) of at least 0.3 with one or more catalysts produces a total product that includes a crude product are described. The one or more catalysts may include a first catalyst and a second catalyst. The crude product is a liquid mixture at 25° C. and 0.101 MPa and the crude product has a TAN of at most 90% of the TAN of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:BHAN OPINDER KISHAN +1

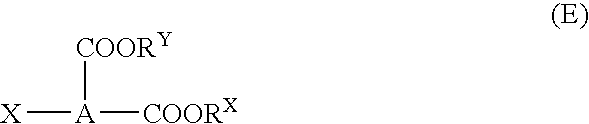

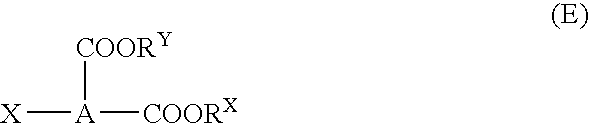

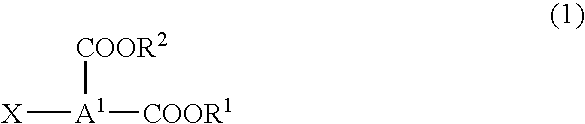

Dicarboxylic diester, process for producing the same, and refrigerating machine lubricating oil comprising the ester

A diester represented by the formula wherein A represents a cyclohexane ring, cyclohexene ring or benzene ring, X is H or methyl group, RX and RY are the same or different and each is C3-C18 branched-chain alkyl group, C1-C18 straight-chain alkyl group, C2-C18 straight-chain alkenyl or C3-C18 cycloalkyl, provided that when A is a benzene ring, RX and RY are different from each other and —COORX and —COORY are attached to two adjacent carbon atoms of the benzene ring, and having the following properties: 1) a total acid number of 0.05 mgKOH / g or less, 2) a sulfated ash content of 10 ppm or less, 3) a sulfur content of 20 ppm or less, 4) a phosphorus content of 20 ppm or less, 5) a peroxide value of 1.0 meq / kg or less, 6) a carbonyl value of 10 or less; 7) a volume resistivity of 1×1011 Ω·cm or more, 8) a hydroxyl value of 3 mgKOH / g or less, and 9) a water content of 100 ppm or less, a process for preparing the same and a refrigerator lubricating oil comprising the diester.

Owner:NEW JAPAN CHEM CO

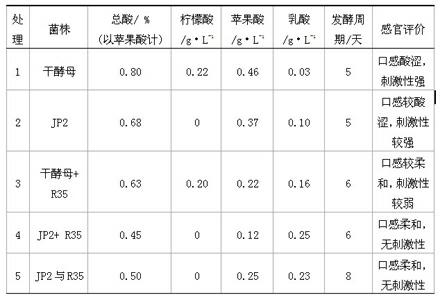

Double-effect fermentation and biological acid reduction brewing method for fruit wine

ActiveCN102161958AIncrease softnessModified flavorAlcoholic beverage preparationMicroorganism based processesBiotechnologyFruit wine

The invention relates to a double-effect fermentation and biological acid reduction brewing method for fruit wine, which is characterized in that: fruits, which contain both malic acid and citric acid and contain over 0.6 volume percent of total acid based on malic acid, are used as a fermentation raw material, and in the early period of fermentation, saccharomycetes with acid degrading capability are used for alcoholic fermentation of the fermentation raw material and acid degradation; and in the late middle period of alcoholic fermentation, lactic acid bacteria with malic acid and lactic acid fermenting capability are inoculated into swort for further fermentation. The method can conveniently and quickly lower the acidity of the swort to a great extend, improve the softness of wine body, enhance the flavor of the wine body and brew high-quality fruit wine with a mellow mouthfeel and harmonious fragrance.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

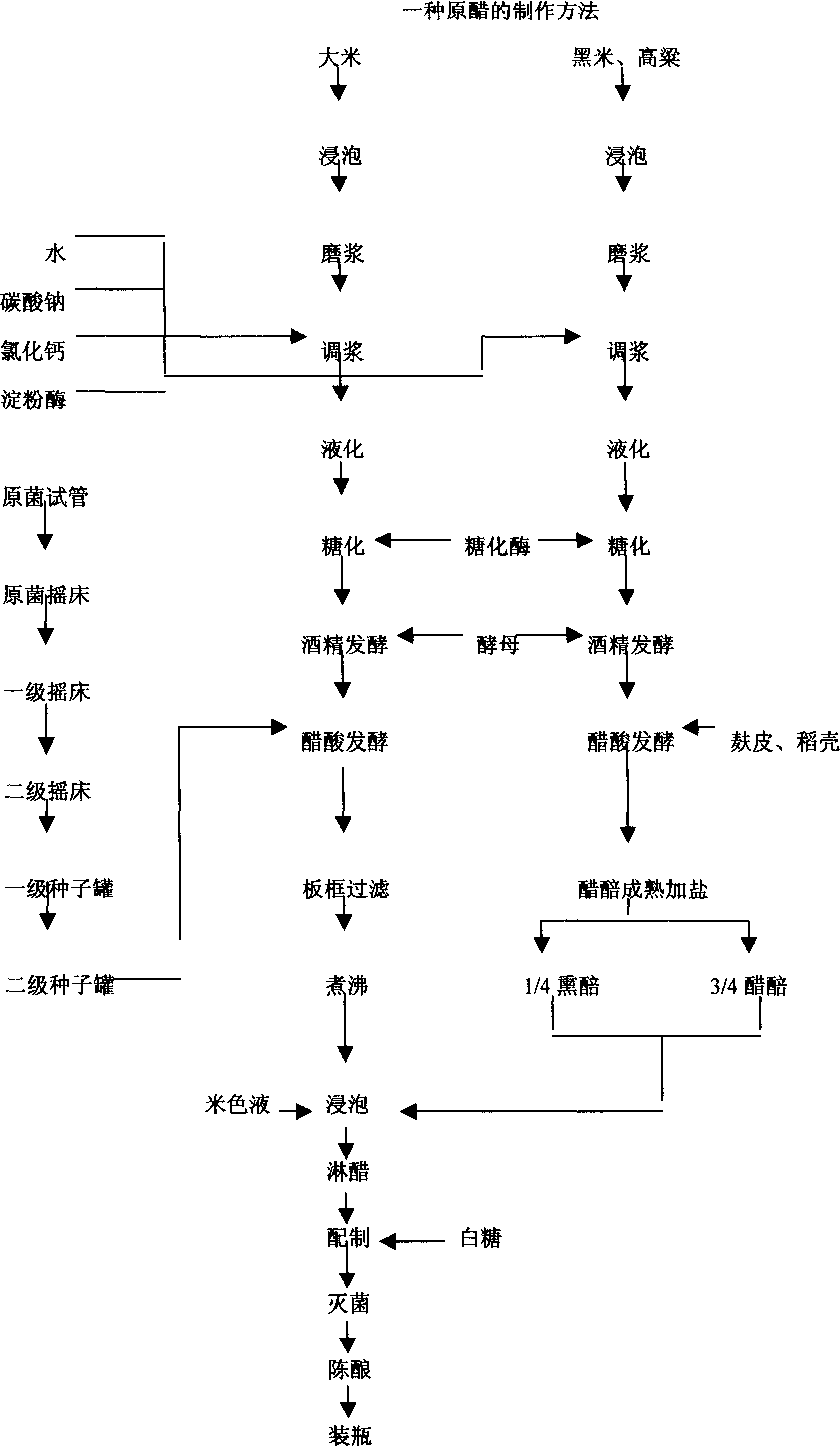

Vinegar making process

The present invention discloses vinegar making process, in which rice, sodium carbonate, salt, calcium chloride, alpha-amylase, sugar, saccharifying enzyme, yeast, water and rice hull or wheat bran in certain weight proportion are used as material. The made vinegar is brown, bight, fragrant, mildly sour and slightly sweet, and has total acid amount account with acetic acid not less than 4.0 g each 100 ml.

Owner:陈松

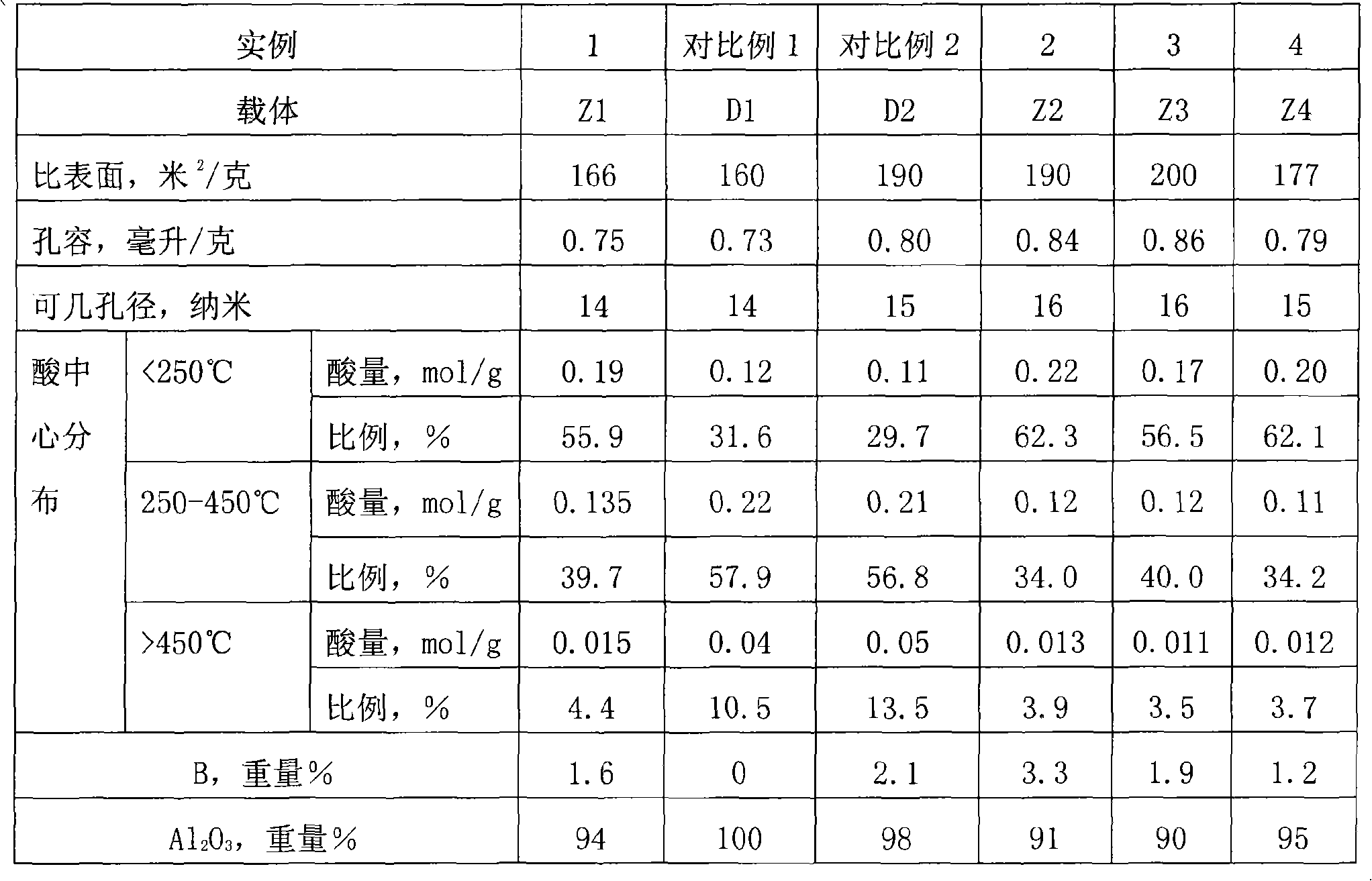

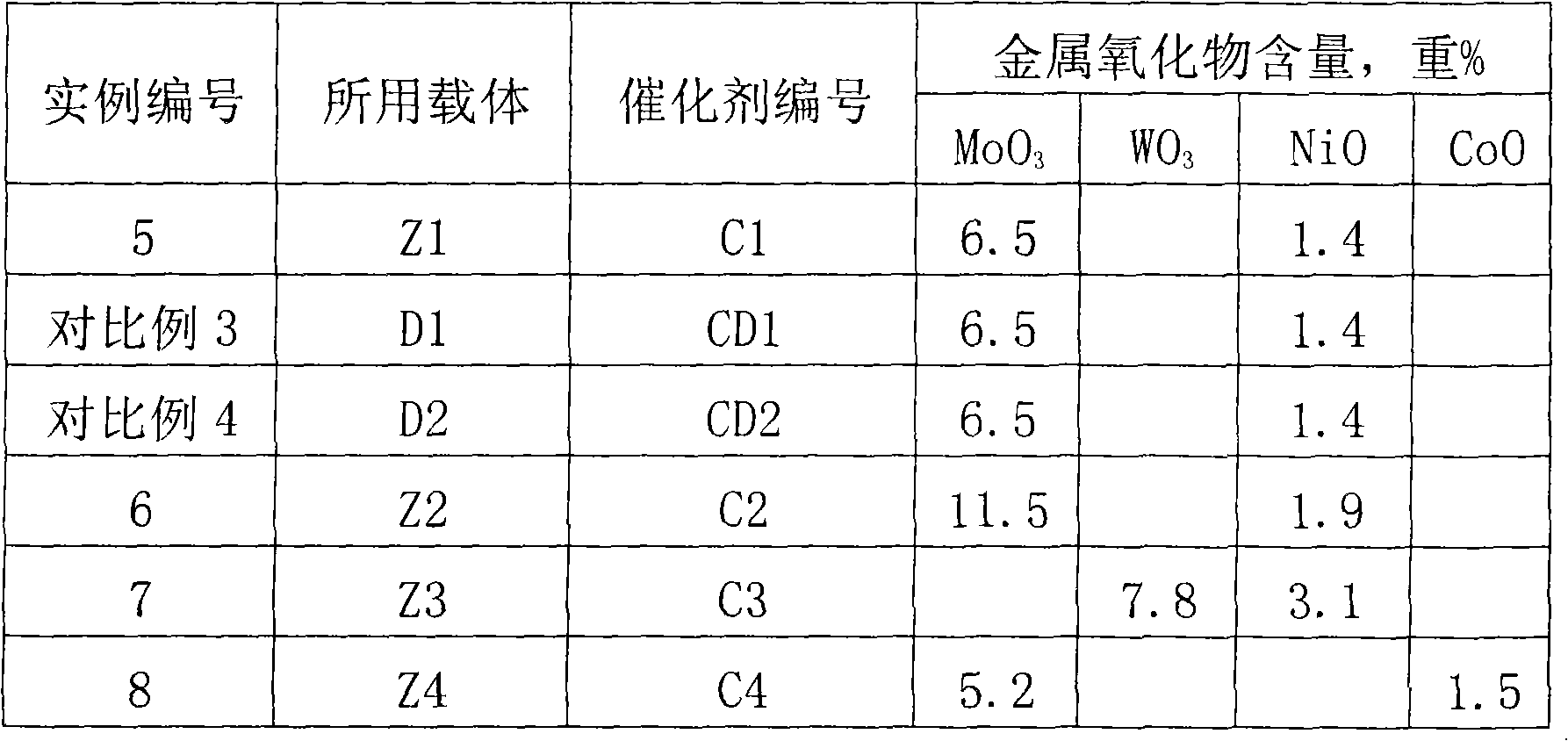

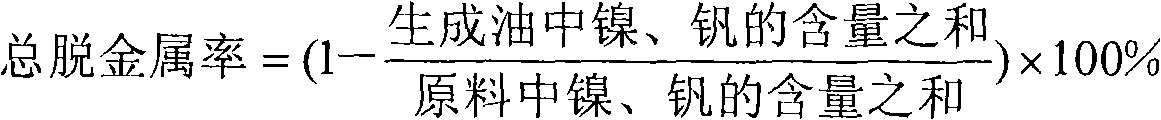

Heavy oil hydrogenating treatment catalyst and preparation method thereof

ActiveCN101332430AImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentStrong acidsFuel oil

The invention discloses a heavy oil hydrotreating catalyst and a preparation method thereof; the catalyst contains a carrier and a component containing an effective amount of at least a metal component selected from VIII family and at least a metal component selected from VIB family, wherein, the carrier is a compound alumina supporter with boron, the content of boron in the carrier f is 0.3 - 5% by weight and the acid content of the carrier is 0.2 - 0.5 mmol / g based on elements and the total amount of the carrier, wherein, the amount of weak acid which is lower than 250 DEG C accounts for 50 - 100% of that of the total acid, while the amount of strong acid which is higher than 450 DEG C accounts for 0-5% of that of the total acid. Compared with the catalysts provided by the prior art, the catalyst provided by the invention improves the carbon deposit resistance obviously while keeping high hydrotreating activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Image recording element comprising extrudable polyester-containing image-receiving layer

ActiveUS7091157B2Reduce material costsHigh transfer efficiencyDecorative surface effectsSynthetic resin layered productsPolyesterPolyol

The present invention is directed to an image-receiving layer comprising a polyester, or a polyester blend, which exhibits excellent lightfade and high dye transfer efficiency, as well as low materials cost. In particular, the invention relates to an image recording element comprising a support having on one side thereof an image-receiving layer comprising a polyester comprising at least 0.1 mole percent of a multifunctional polyol having more than two hydroxy groups and / or a polyacid having more than two carboxylic acid groups, including derivatives thereof, based on the total acid derived units. The invention is useful, for example, as a dye-receiver element for thermal dye transfer having on one side of the support a dye-image receiving layer. The polyester is especially advantageous for use in dye-receiving layers that are extruded instead of solvent-coated.

Owner:KODAK ALARIS INC

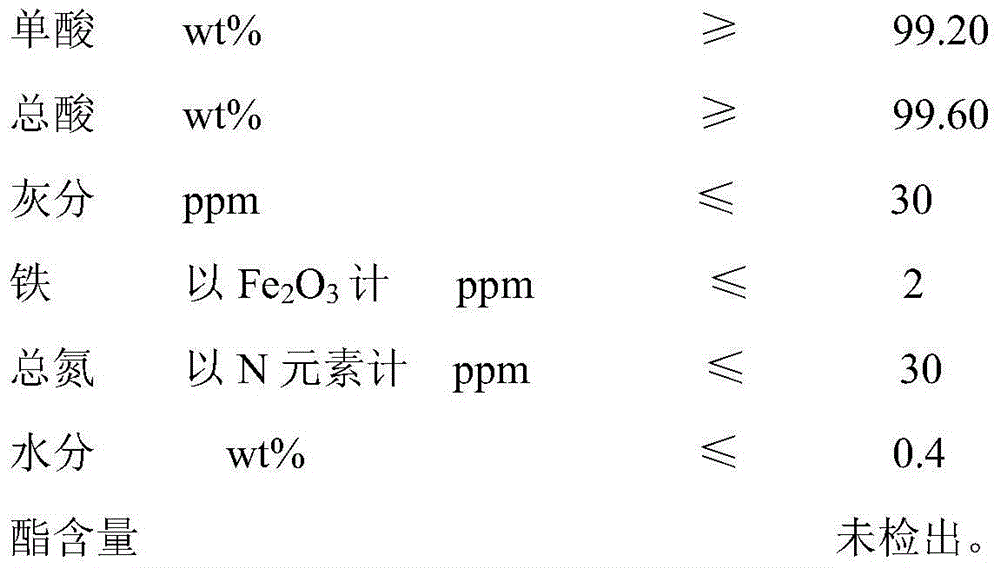

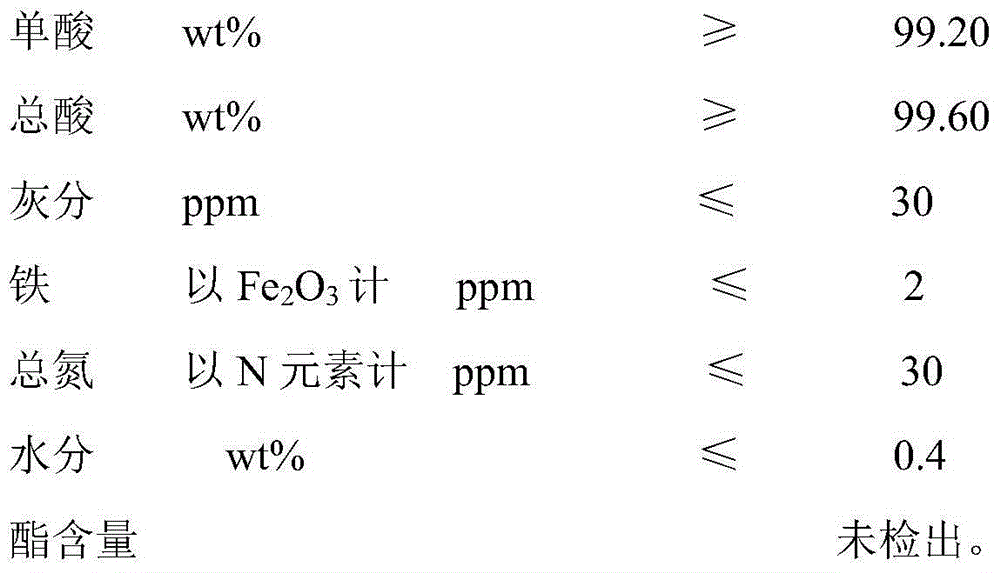

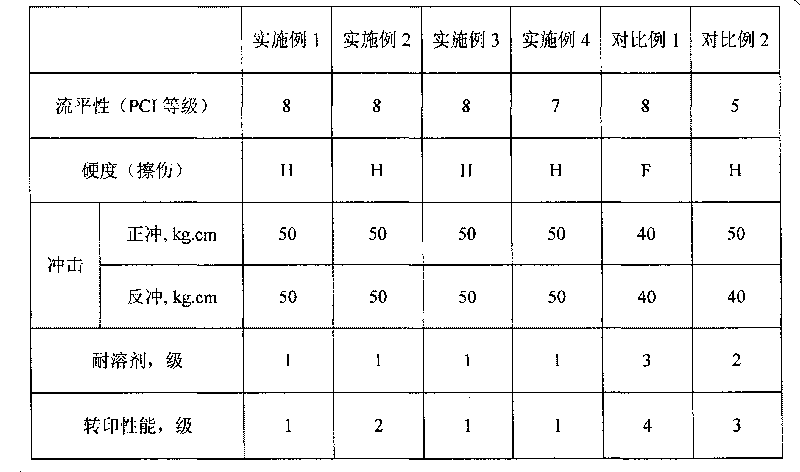

Purification method of long-carbon-chain dicarboxylic acid

ActiveCN104529741AReduce coexistence timeReduce generationCarboxylic compound separation/purificationPurification methodsTotal nitrogen

The invention relates to a purification method of long-carbon-chain dicarboxylic acid, belonging to purification treatment of cycle-free dicarboxylic acid with more than 10 carbon atoms. The invention is characterized in that recrystallizing purification is performed by using a long-carbon-chain dibasic acid crude product produced by a microbial fermentation process as an initial raw material and methanol as a solvent. The method comprises the following steps: (1) dissolving and decolorizing: a. feeding at room temperature, b. dissolving by preheating, c. decolorizing by adsorption, and d. four-stage filtering; (2) gradient cooling and crystallization; (3) eluting and centrifugal filtration; and (4) vacuum drying. The technical indexes of the purified long-carbon-chain dicarboxylic acid are as follows: the single acid content is at least 90.20%, the total acid content is 99.60 wt%, the ash content is at most 30 ppm, the iron content on the basis of Fe2O3 is at most 2 ppm, the total nitrogen on the basis of N is at most 30 ppm, the moisture content is at most 0.4 wt%, and no ester content is detected. The purification yield of C11-C14 is greater than or equal to 98.4%. The long-carbon-chain dicarboxylic acid is suitable to be used as a polycondensation monomer to perform polycondensation reaction with diamine to synthesize the long-carbon-chain nylon, and is also suitable to be used as a raw material of synthetic perfume and drugs. The purification method of long-carbon-chain dicarboxylic acid has the advantages of favorable product color, high product purity, high refinement yield and lower cost.

Owner:山东广通新材料有限公司

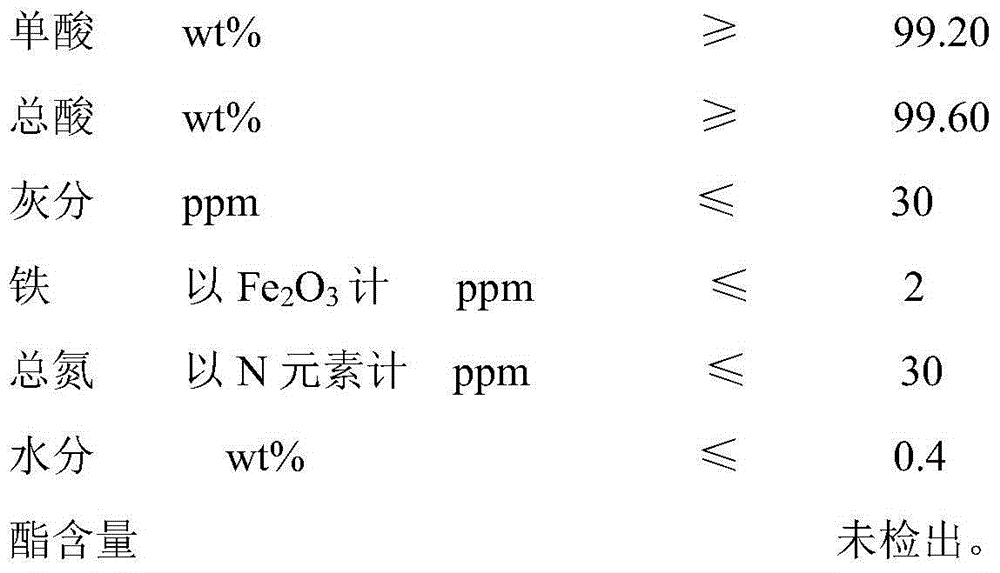

Polyester resin for mixed powder coating and preparation method thereof

ActiveCN101704945AUniform reaction rateGood solvent resistancePowdery paintsPolyester coatingsLow temperature curingAdipic acid

The invention relates to the field of powder coatings, in particular to a polyester resin for a mixed thermal transfer powder coating and a preparation method thereof. The polyester resin for the mixed thermal transfer powder coating comprises the following components and contents: 1 mole percent of acids, 1.05-1.20 mole percent of alcohols, 10-15wt% of trimellitic anhydride and 0.1-1.0wt% of recomposed onium salts, wherein the alcohols accounting for the total alcohol mol percent comprise 10-90 mol% of neopentyl glycol, 0-45 mol% of dimethyl-1,3-propanediol, 0-20 mol% of ethanediol, 10-25 mol% of diethylene glycol; and the acids accounting for the total acid mol percent comprise 80-100 mol% of terephthalic acid, 0-10 mol% of m-phthalic acid and 0-10 mol% of mol% of adipic acid. The functionality of the polyester resin is regulated according to the amount of the branched components of the trimellitic anhydride, thus the obtained cured film has better surface appearance, low temperature (160 DEG C) curing is realized, the curing percent of film coating at low temperature is high, the curing film has fine solvent resistance and the transfer-printed transfer printing film is clear, vivid and easy to tear.

Owner:HUANGSHAN SHENJIAN NEW MATERIAL CO LTD

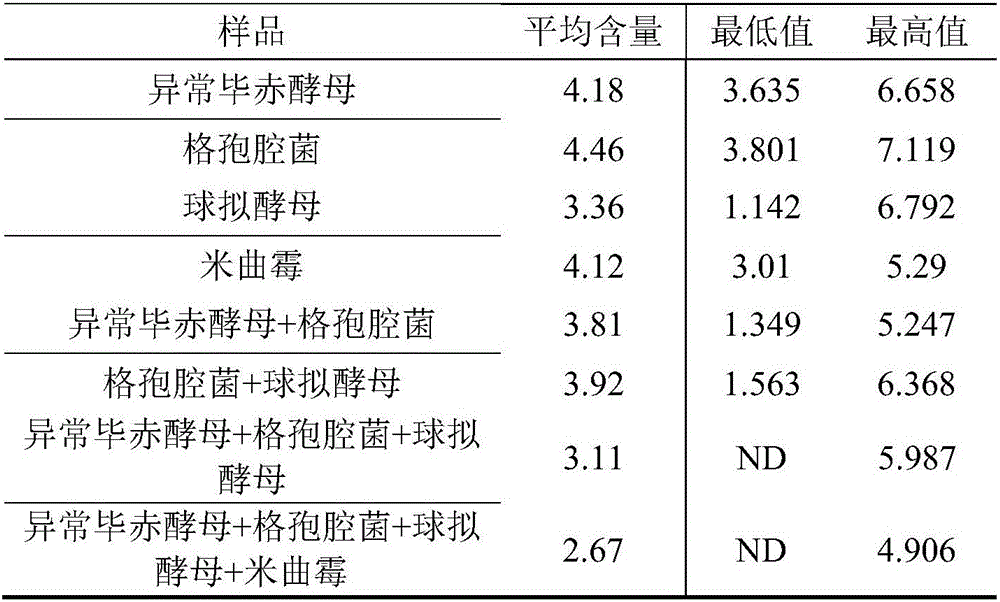

Preparation method and application of microbial agent composition for enhancing secondary fermentation of bean paste

ActiveCN106520583AInhibit metabolismShorten the production cycleFungiMicroorganism based processesMicrobial agentSaccharomycetes

The invention relates to the field of bioengineering, in particular to a preparation method and an application of a microbial agent composition for enhancing secondary fermentation of a bean paste. The microbial agent composition consists of a saccharomycetes agent, an aspergillus oryzae agent and a pleospora agent; and the three microbial agents are prepared, and then the prepared microbial agents are mixed with the secondary-fermented bean paste, so as to promote the secondary fermentation of the bean paste. The whole process of the preparation method of the microbial agent composition provided by the invention is applicable to continuous industrial production; by-products (chili and radix platycodonis), from the production of Pixian bean paste, are comprehensively utilized; a production cycle can be shortened by 6 months, the content of amino nitrogen can be improved by 20% and the content of volatile aroma-producing components can be improved by more than 3 times (the contents of total ester, total acid and total aldehyde); by inoculating aflatoxin B1 with the saccharomycetes agent at a production peak (after being fermented for 30-60 days), an ester producing and aroma generating process can be enhanced, the metabolism of aspergillus flavus and partial aspergillus parasiticus can be competitively inhibited and the content of the aflatoxin B1 can be reduced, and the content of the aflatoxin B1 is lower than 0.5ppm, so that food safety is enhanced.

Owner:XIHUA UNIV

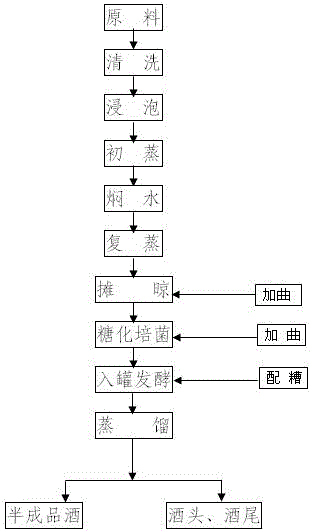

Pure sorghum distilled fen-flavor liquor and manufacturing method thereof

The invention discloses pure sorghum distilled fen-flavor liquor, and belongs to the technical field of brewing of distilled liquor. The pure sorghum distilled fen-flavor liquor is prepared from 97-98% of non glutinous sorghum and 2-3% of glutinous sorghum through the steps of soaking, pre-distilling, water-stewing, repeated distilling, airing, saccharifying bacterium cultivation, fermenting in a tank and distilling. The physicochemical indexes of the strong liquor at 41-69 DEG, manufactured through the method, can achieve the superior standard requirement of the Yunnan distilled fen-flavor liquor (DB53 / T92-2008), the total acid content (counted by acetic acid) is not less than 0.4g / L, the total ester content (counted by acetate) is not less than 0.6g / L, and the solid content is not more than 0.4g / L.

Owner:祥云源海酒业有限公司

Wine of low or free alcohol and its brewing method

The invention disclosed the method of brewing the non-low alcohol grape wine, which is enzyme treatment and penetration vaporzatioin method. The characteristics of the invention is the alcohol ranging from 0.5% to 7%, the sugar content which is the glucose below 12g / L in baked mold and below 120g / L in sweet mold, the total acid ranging from 4.5 to 8.0g / L measured by dihydroxysuccinic acid, the extract above 15g / L, free sulfur dioxide below 50mg / L, and total sulfur dioxide below 250mg / L. The said non-low alcohol grape wine is harmonization, delicate fragrance, suitable for the particular group and occasion,

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com