Patents

Literature

66286 results about "Crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystallization or Crystallisation is the (natural or artificial) process by which a solid forms, where the atoms or molecules are highly organized into a structure known as a crystal. Some of the ways by which crystals form are precipitating from a solution, freezing, or more rarely deposition directly from a gas. Attributes of the resulting crystal depend largely on factors such as temperature, air pressure, and in the case of liquid crystals, time of fluid evaporation.

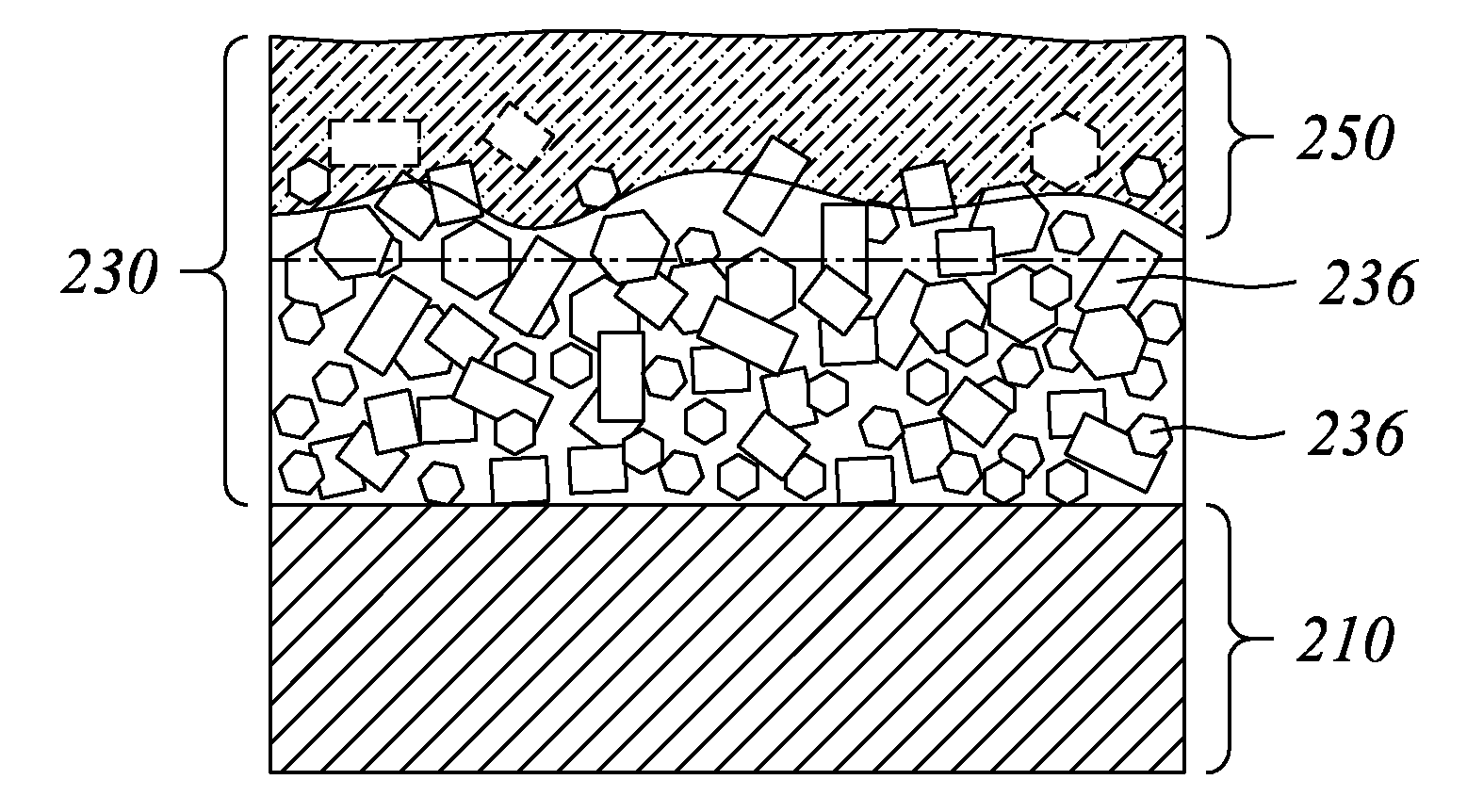

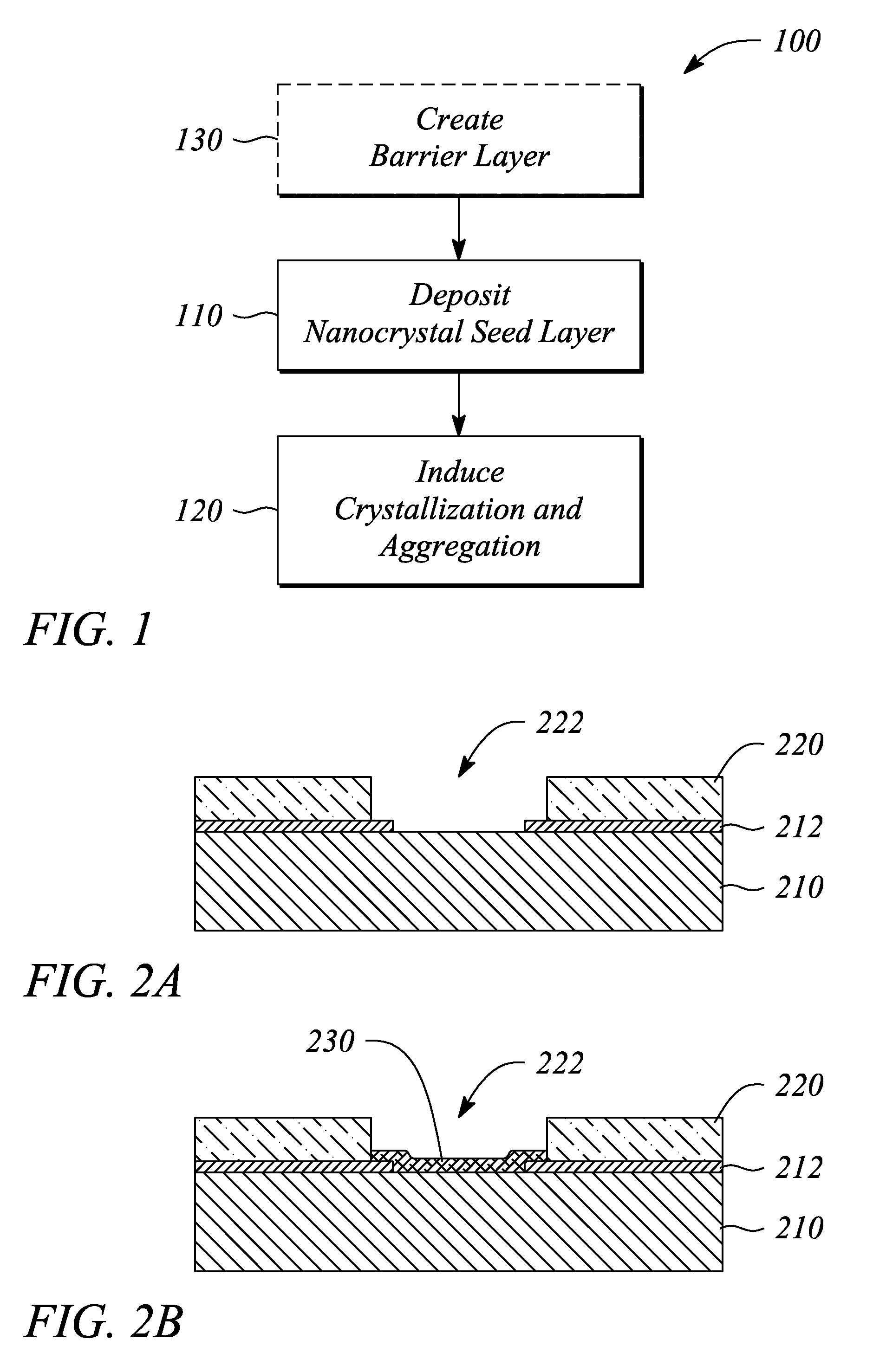

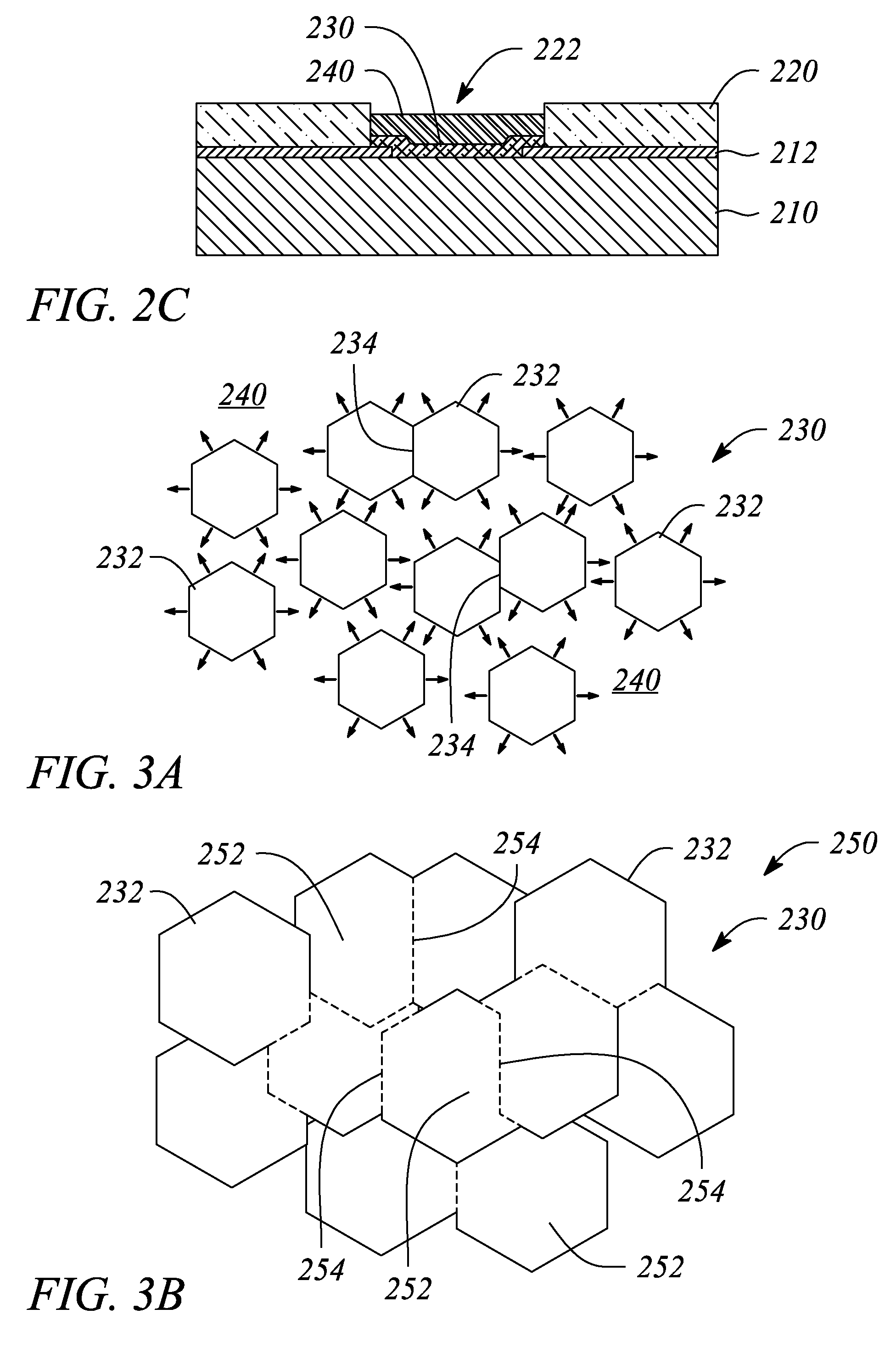

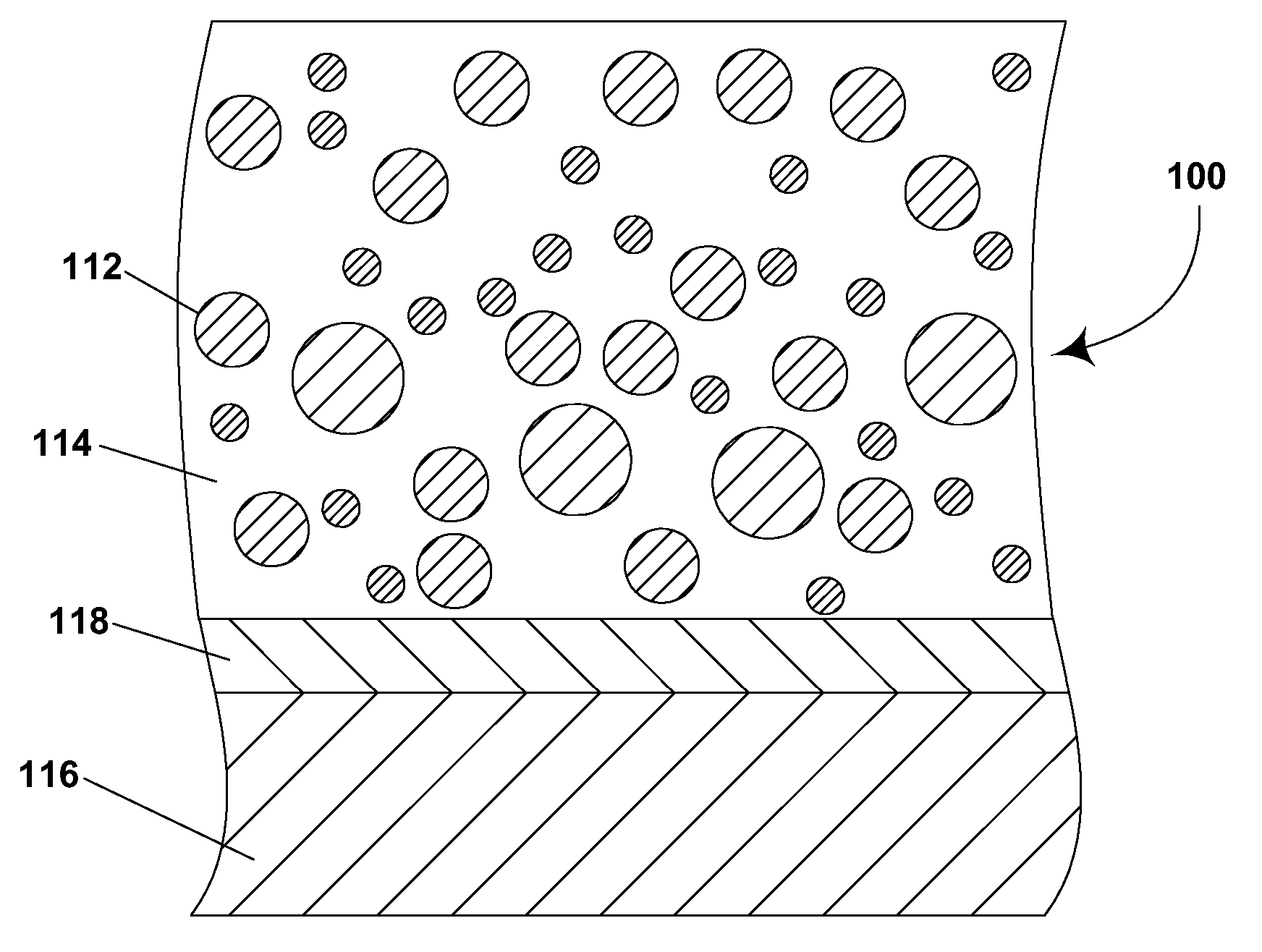

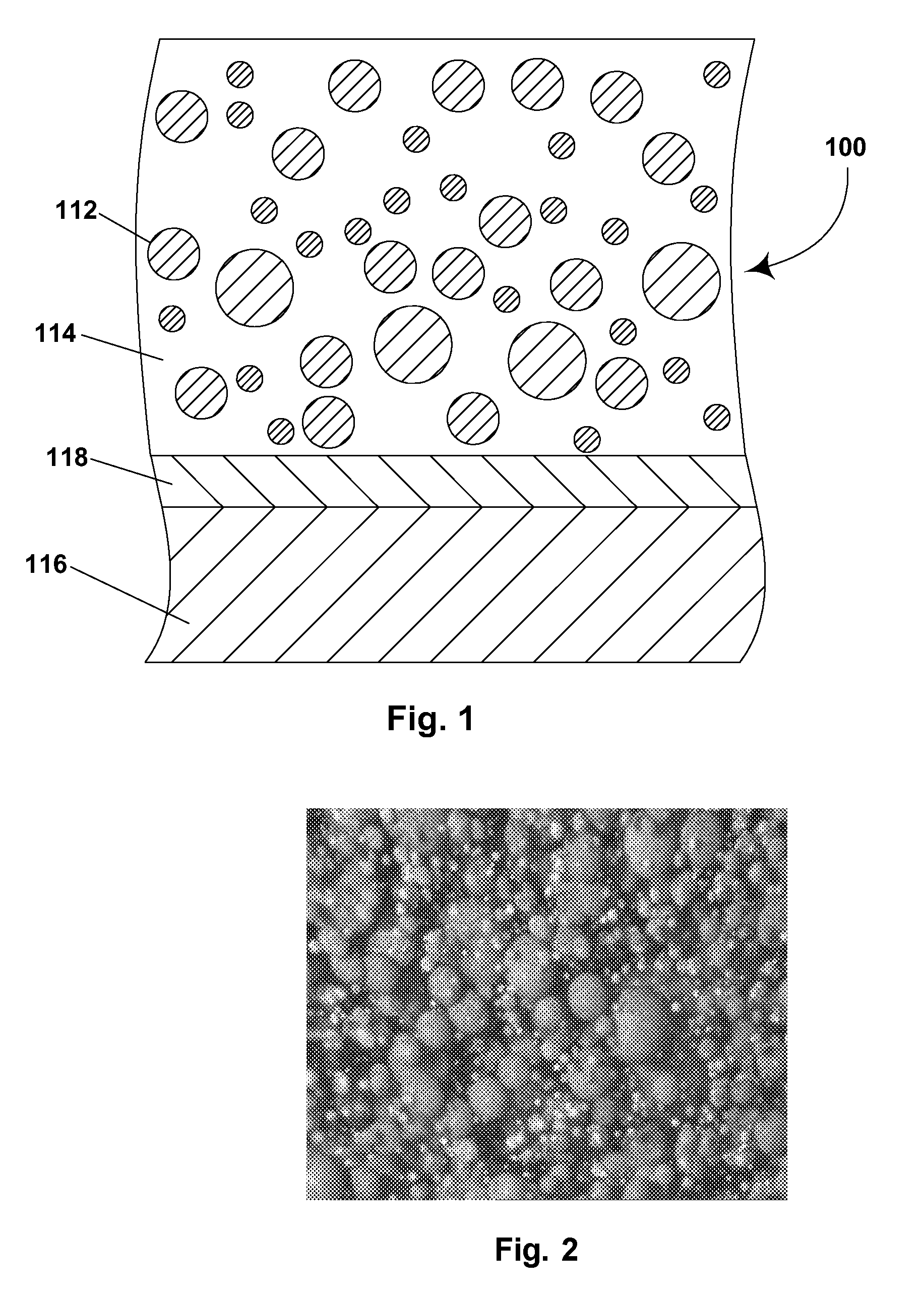

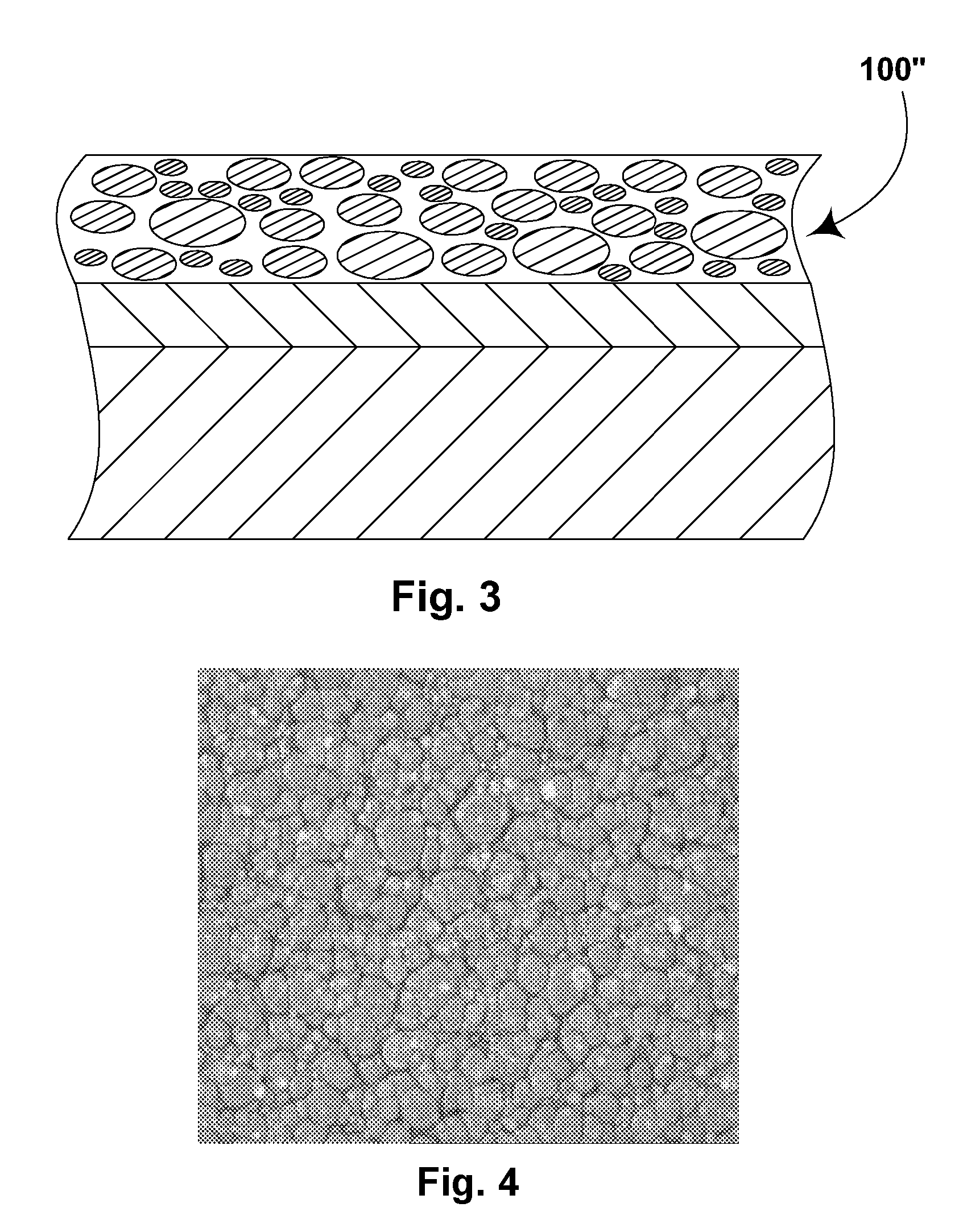

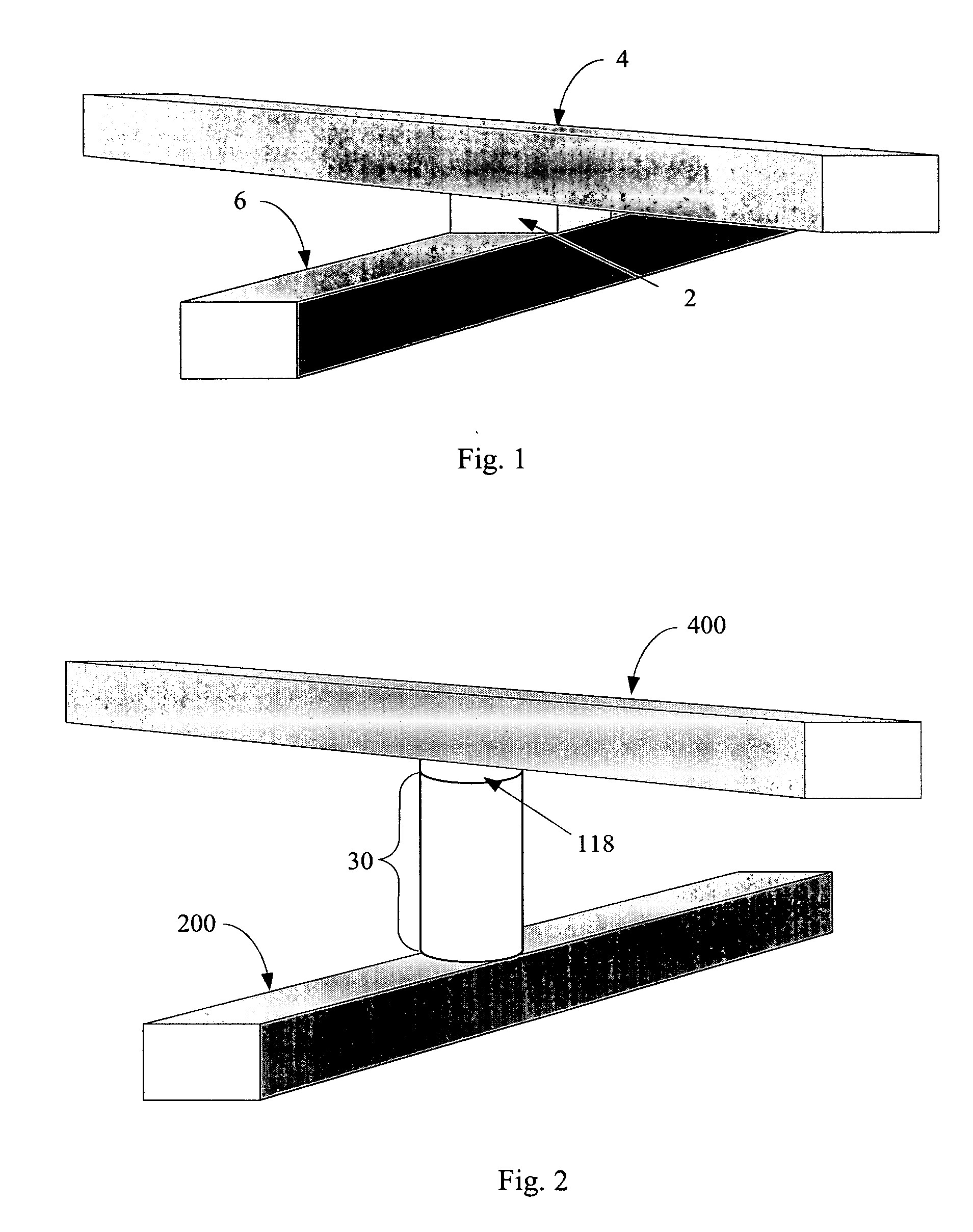

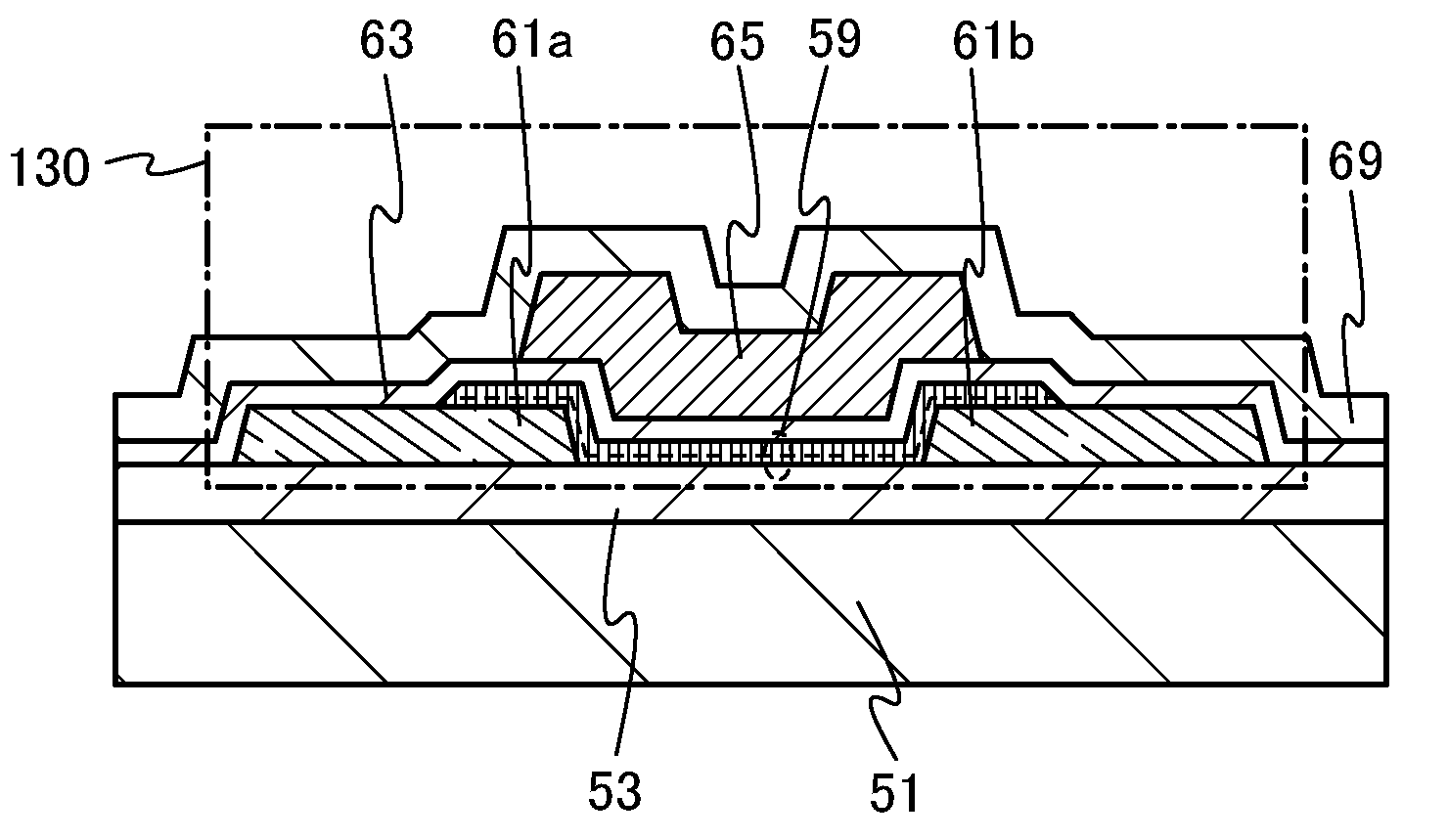

Fused nanocrystal thin film semiconductor and method

A thin film semiconductor and a method of its fabrication use induced crystallization and aggregation of a nanocrystal seed layer to form a merged-domain layer. The nanocrystal seed layer is deposited onto a substrate surface within a defined boundary. A reaction temperature below a boiling point of a reaction solution is employed. A thin film metal-oxide transistor and a method of its production employ the thin film semiconductor as a channel of the transistor. The merged-domain layer exhibits high carrier mobility.

Owner:HEWLETT PACKARD DEV CO LP

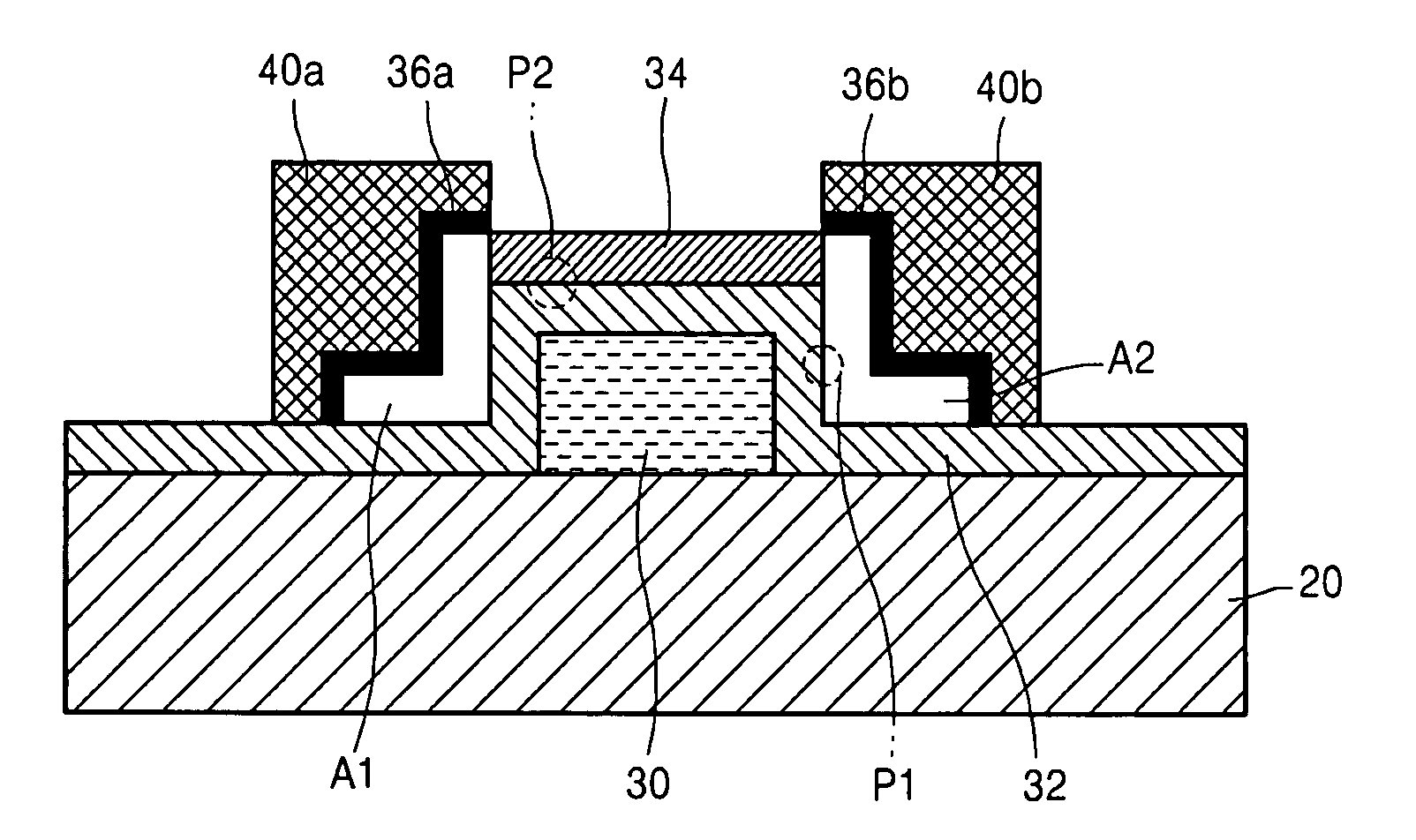

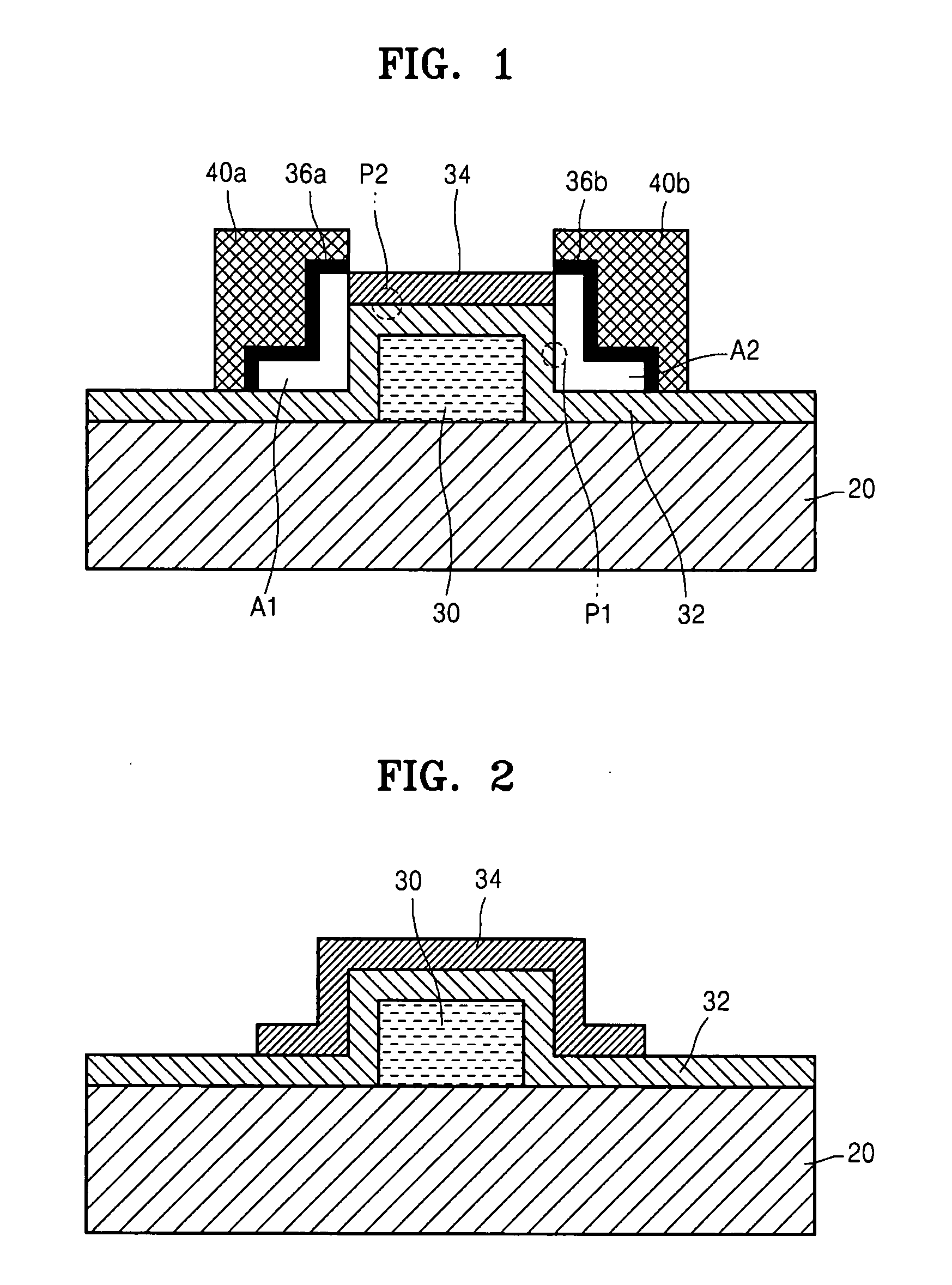

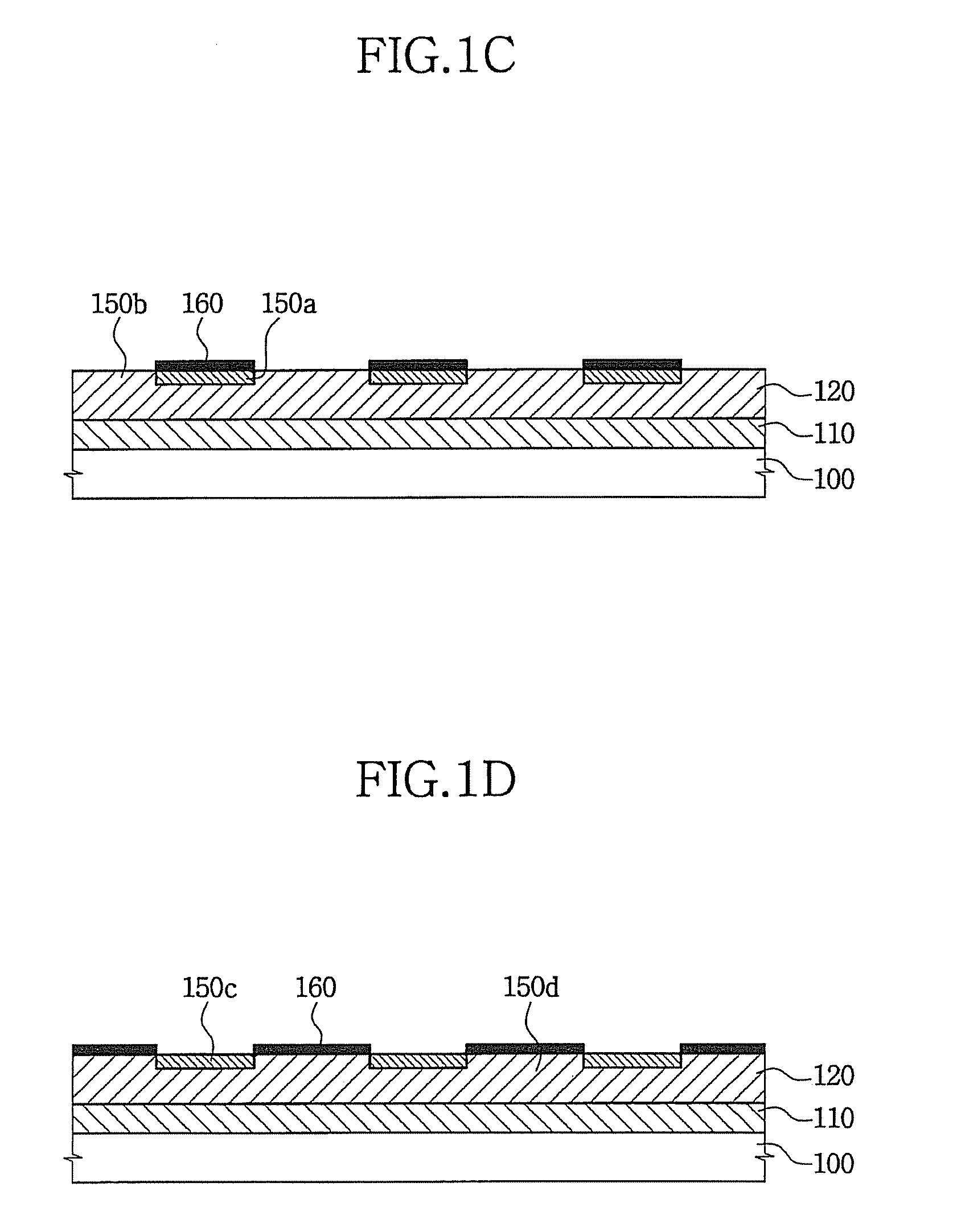

Thin film transistor including selectively crystallized channel layer and method of manufacturing the thin film transistor

ActiveUS20080258140A1Stable contact characteristicHigh carrier mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringIon implantation

Provided are a thin film transistor (TFT) including a selectively crystallized channel layer, and a method of manufacturing the TFT. The TFT includes a gate, the channel layer, a source, and a drain. The channel layer is formed of an oxide semiconductor, and at least a portion of the channel layer contacting the source and the drain is crystallized. In the method of manufacturing the TFT, the channel layer is formed of an oxide semiconductor, and a metal component is injected into the channel layer so as to crystallize at least a portion of the channel layer contacting the source and the drain. The metal component can be injected into the channel layer by depositing and heat-treating a metal layer or by ion-implantation.

Owner:SAMSUNG ELECTRONICS CO LTD

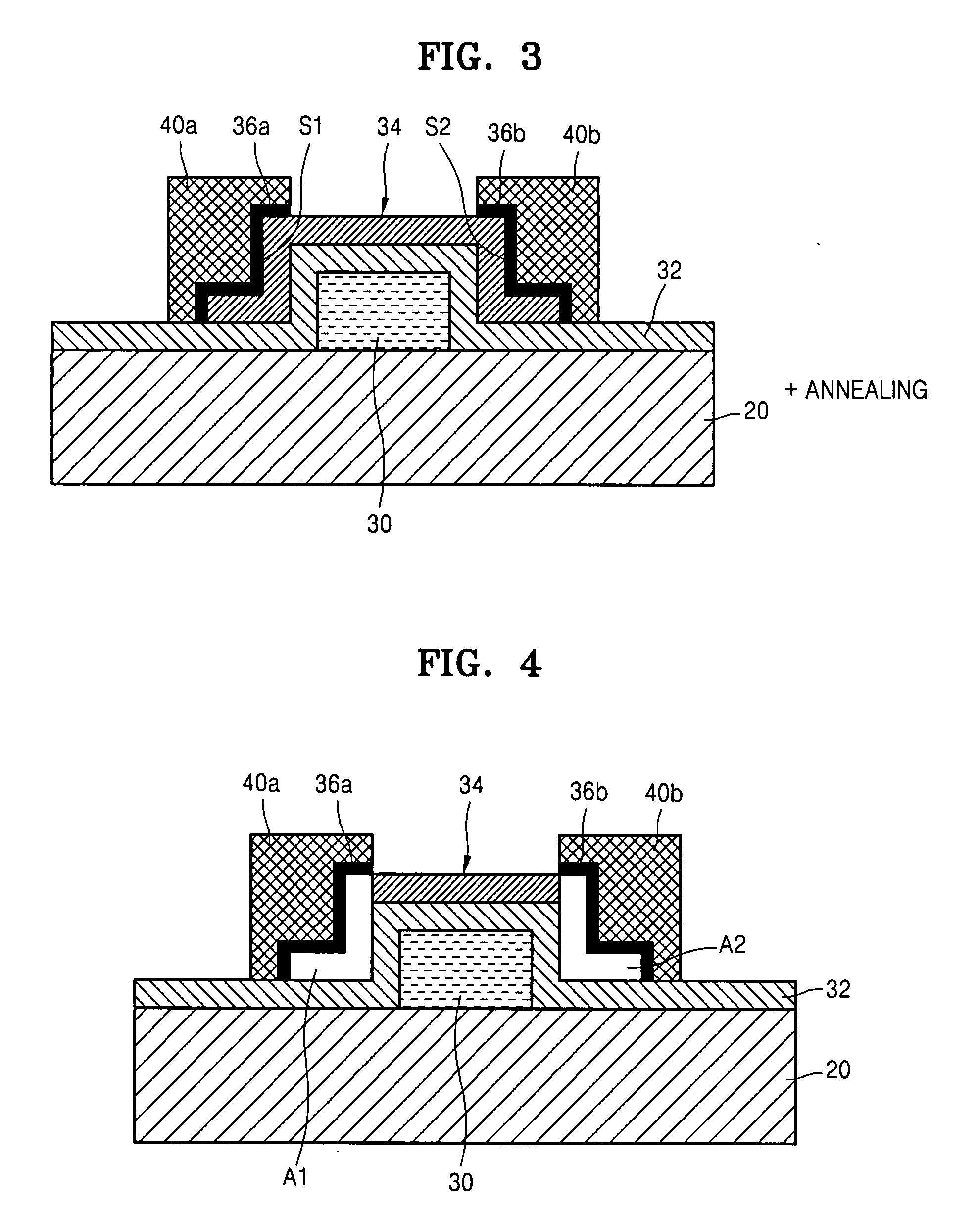

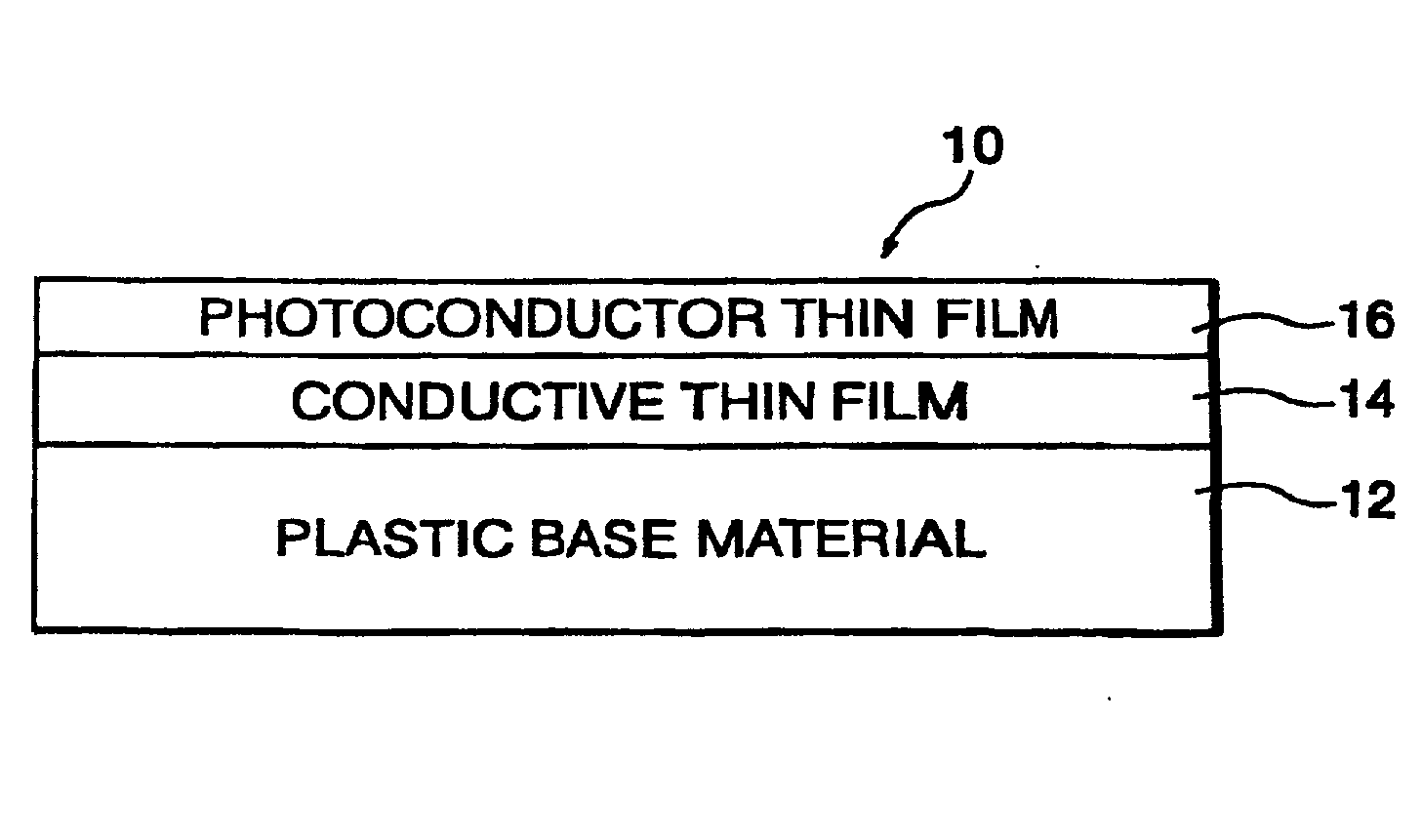

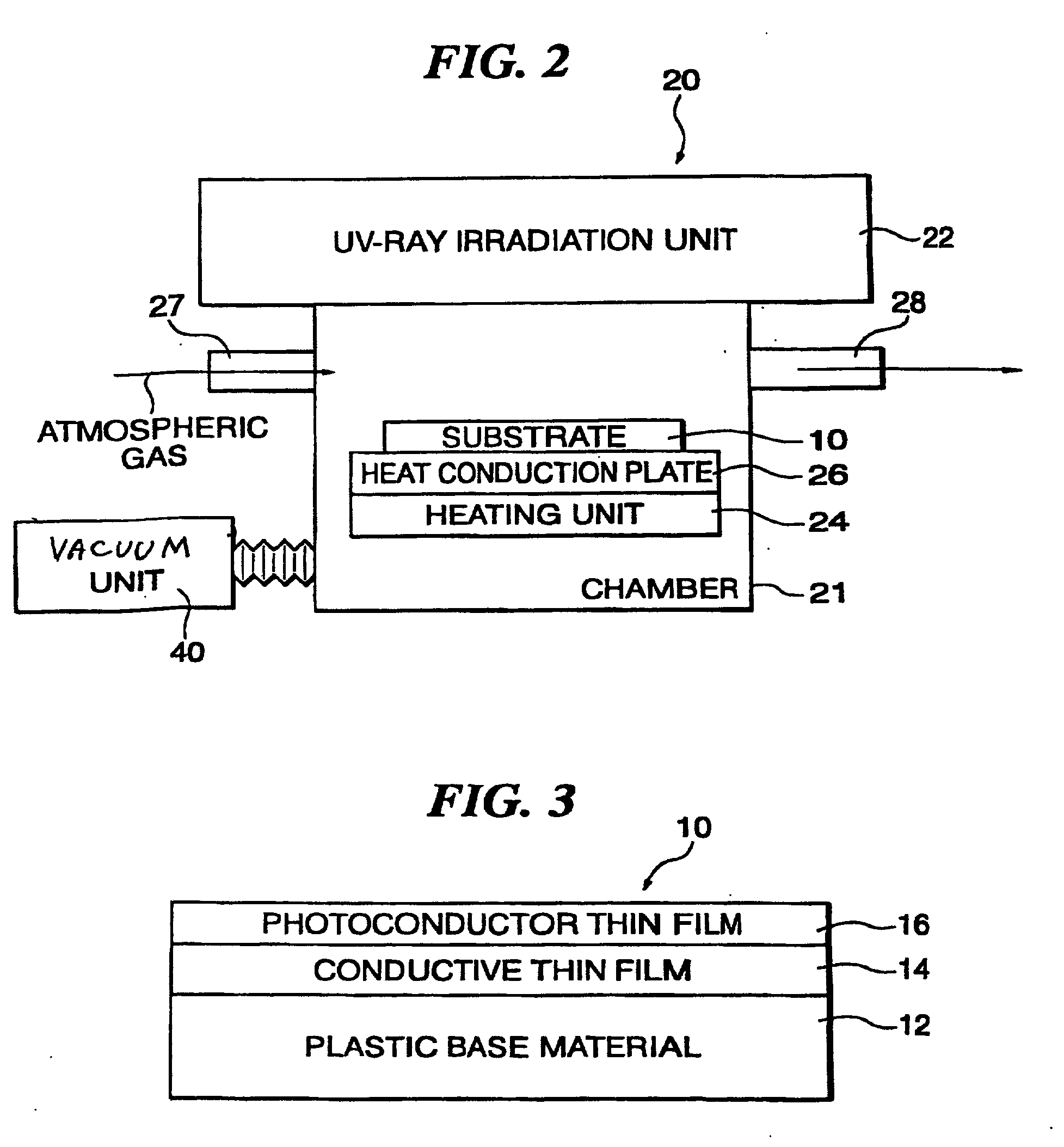

Method of forming crystalline semiconductor thin film on base substrate, lamination formed with crystalline semiconductor thin film and color filter

A method of forming a crystalline semiconductor thin film on a base material which can be prepared at a low temperature by simple step and device, the method including a processing step of applying UV-rays to an amorphous semiconductor thin film provided on a base material while keeping a temperature at not less than 25° C. and not more than 300° C. in a vacuum or a reducing gas atmosphere, as well as a substrate having the semiconductor thin film provided on the base material, a substrate for forming a color filter and a color filter using the substrate.

Owner:FUJIFILM BUSINESS INNOVATION CORP

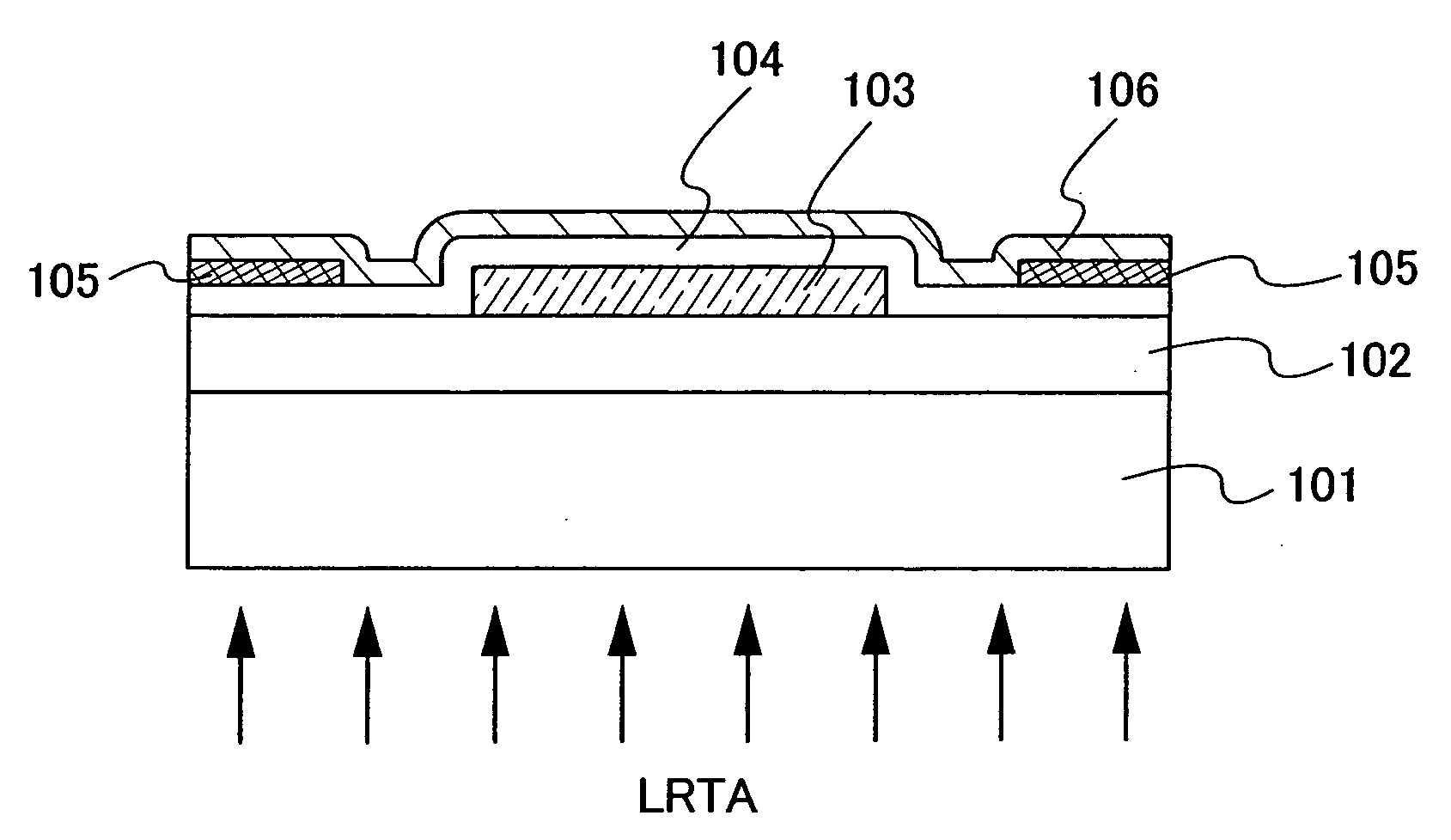

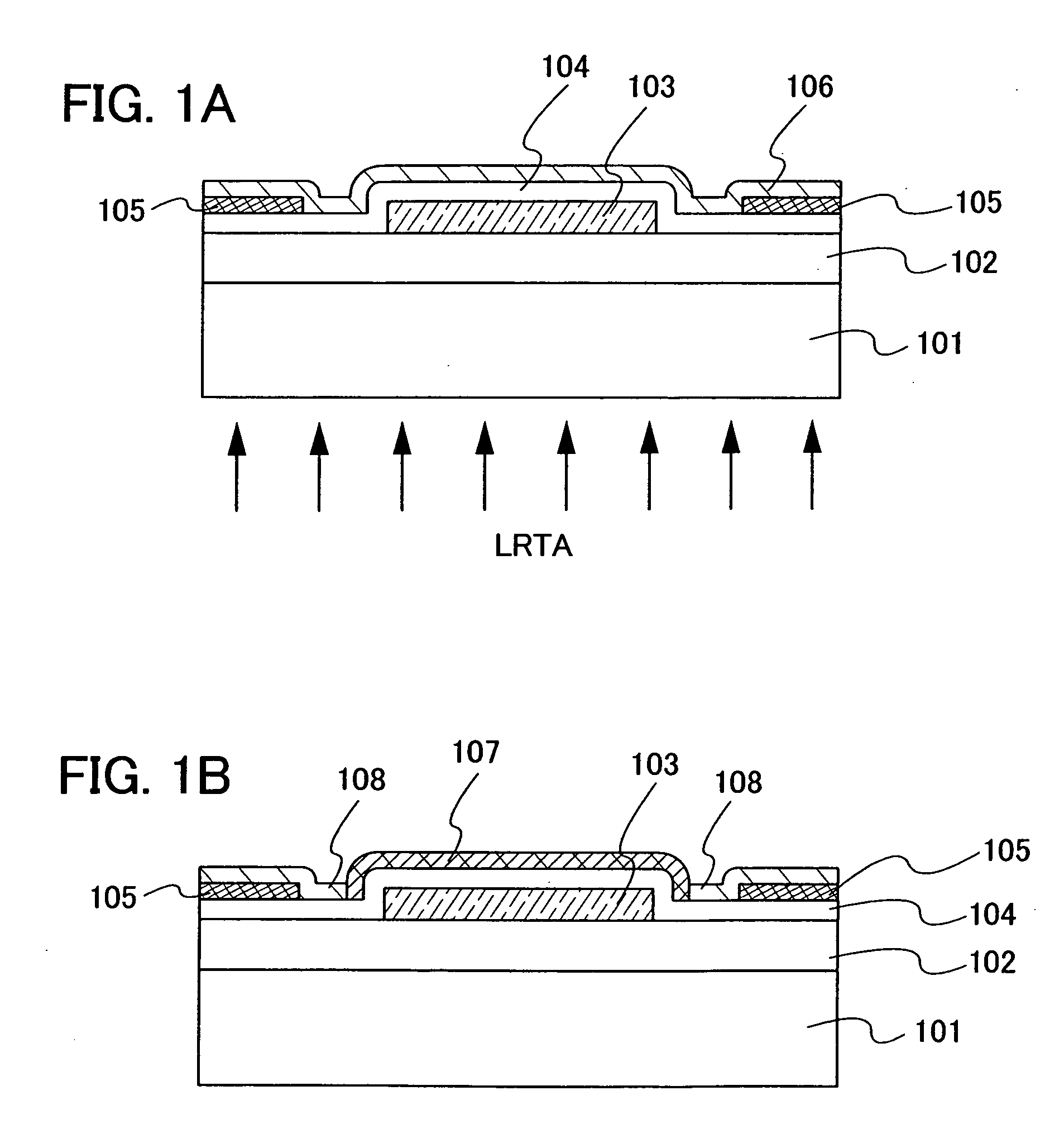

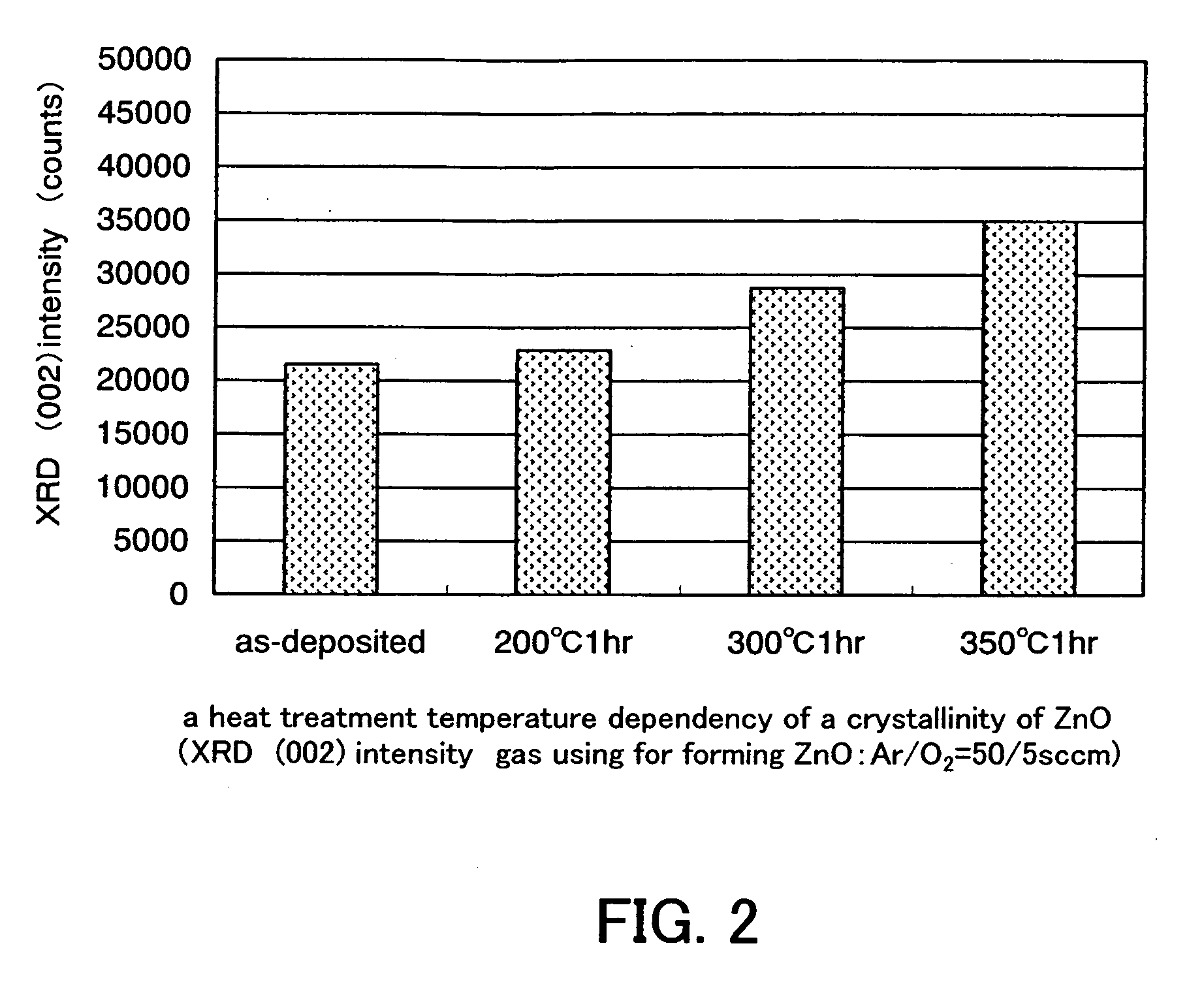

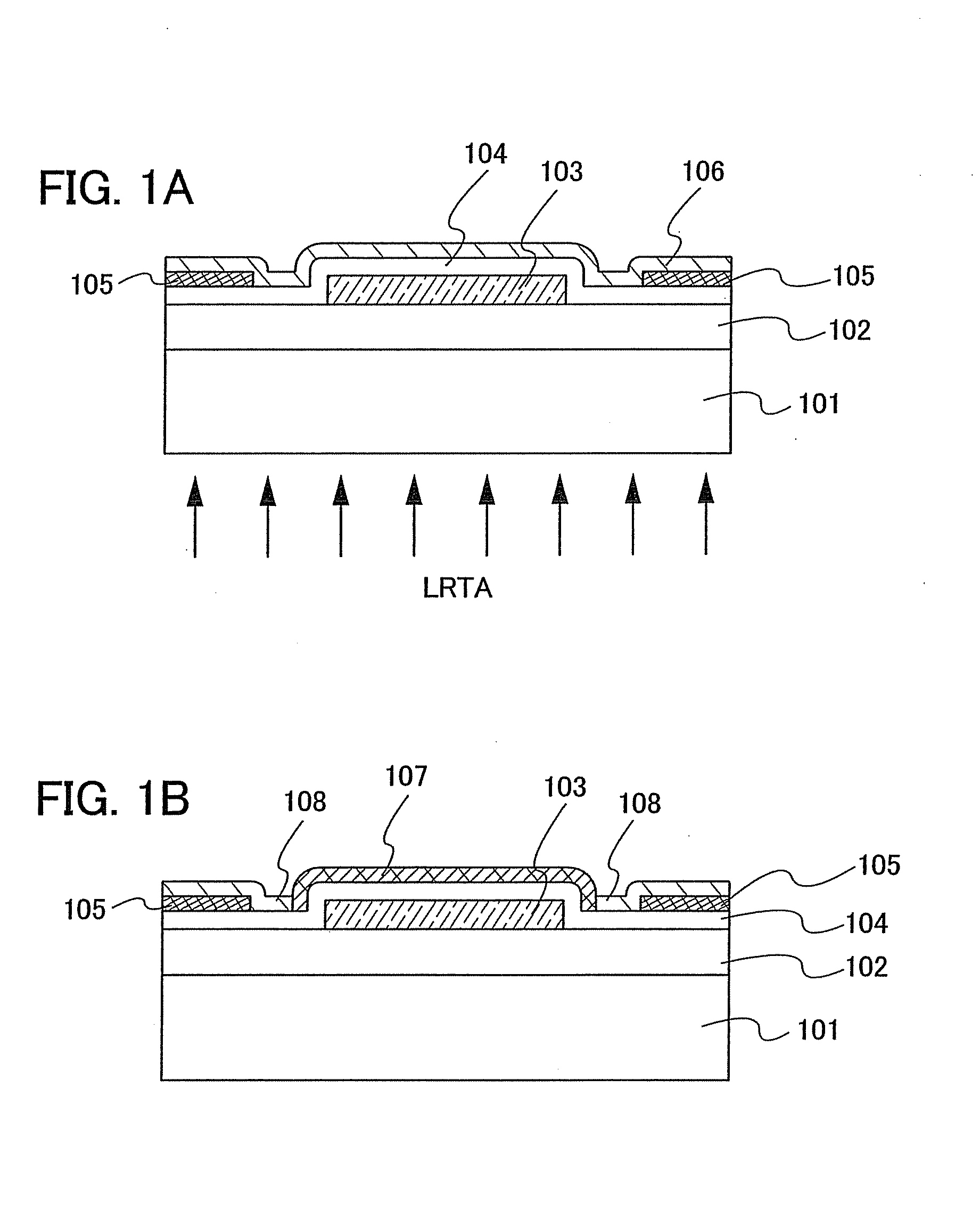

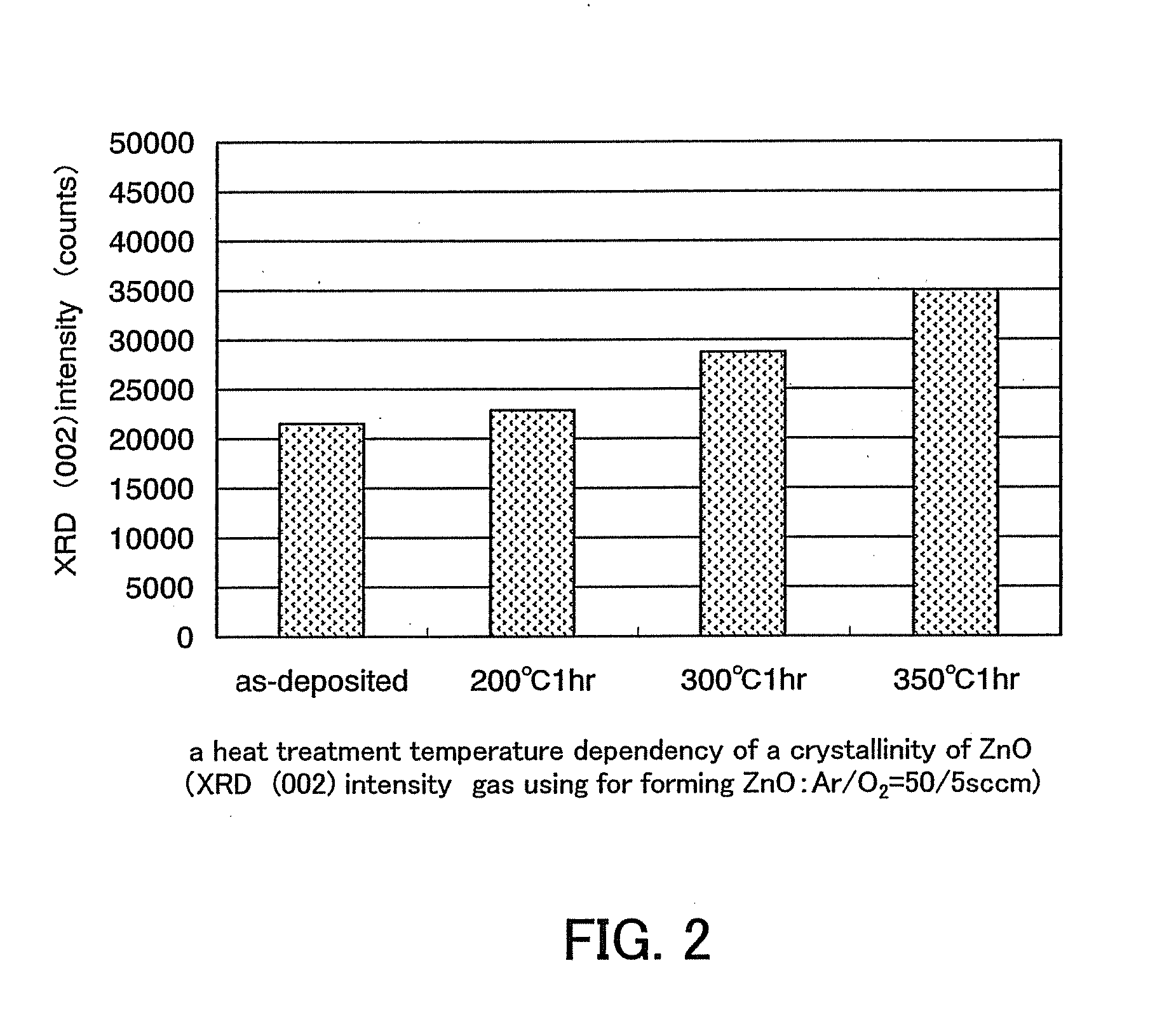

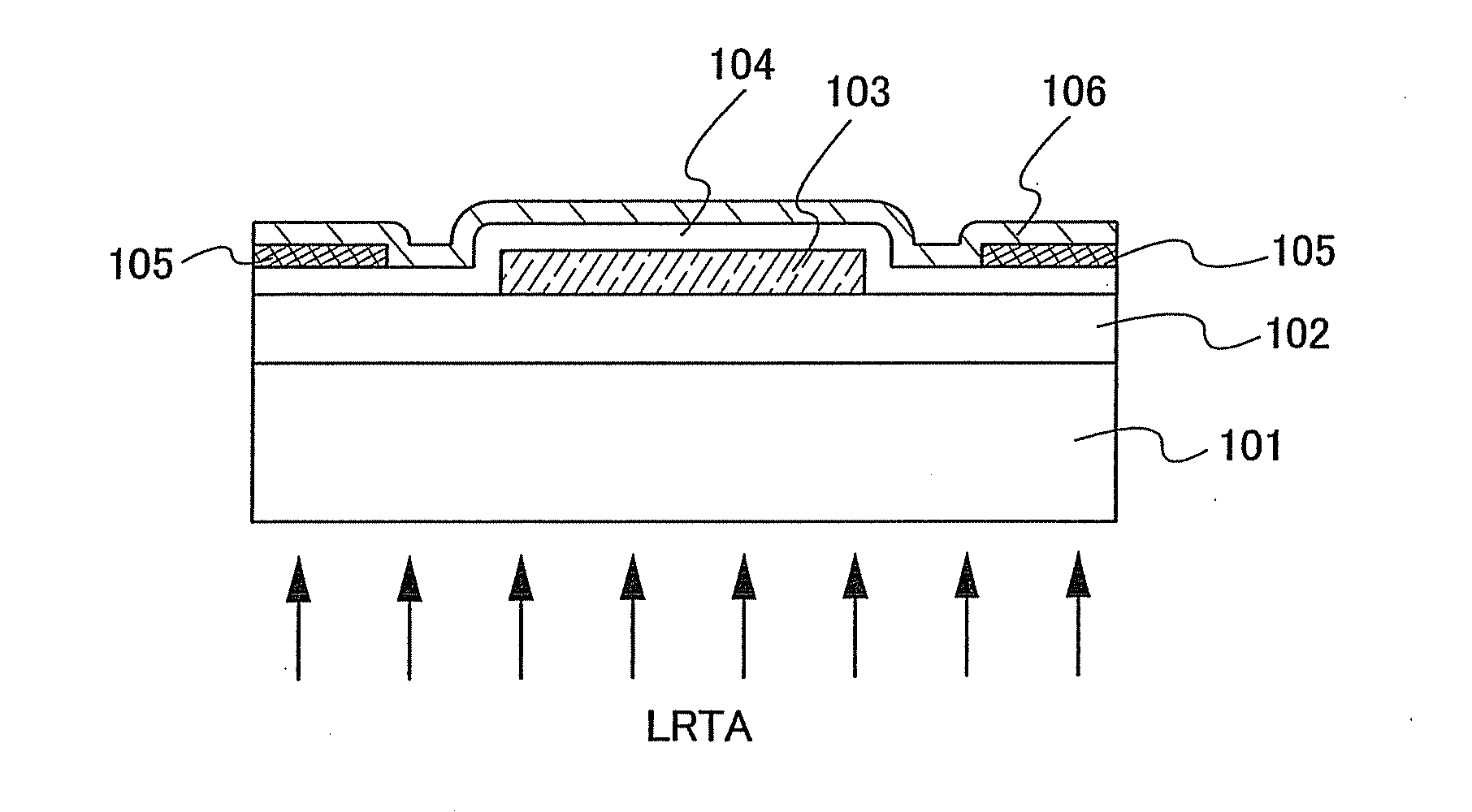

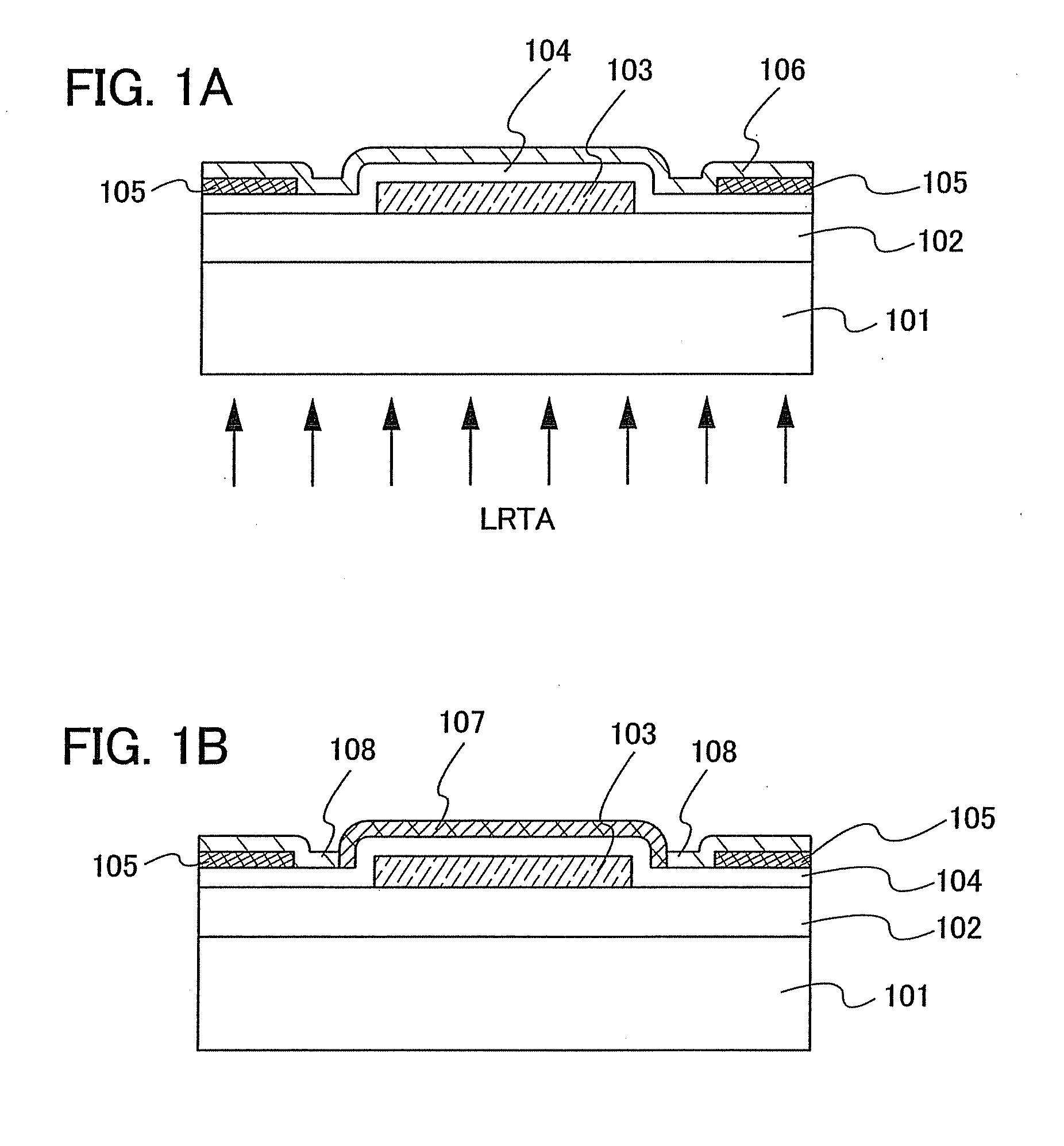

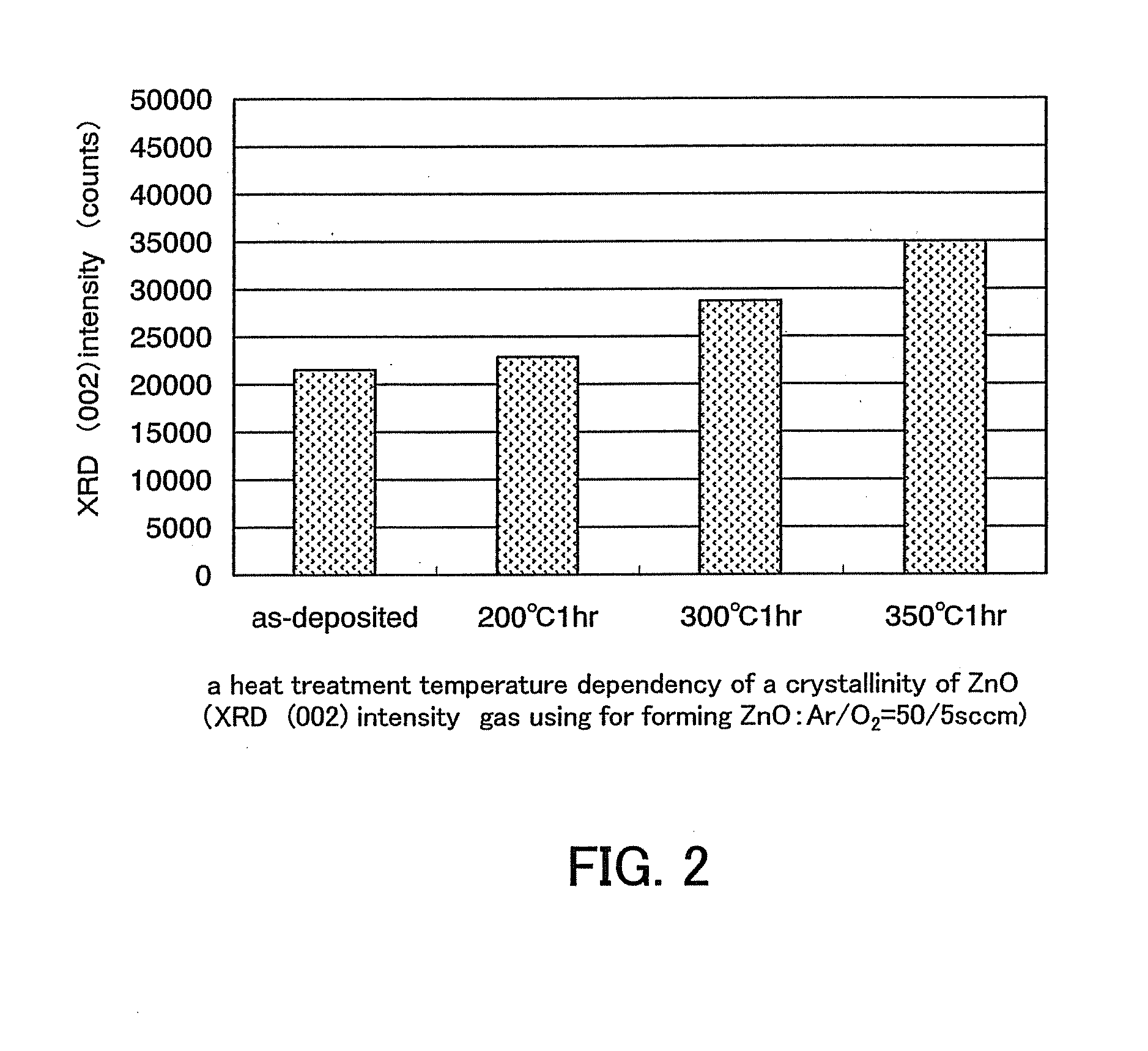

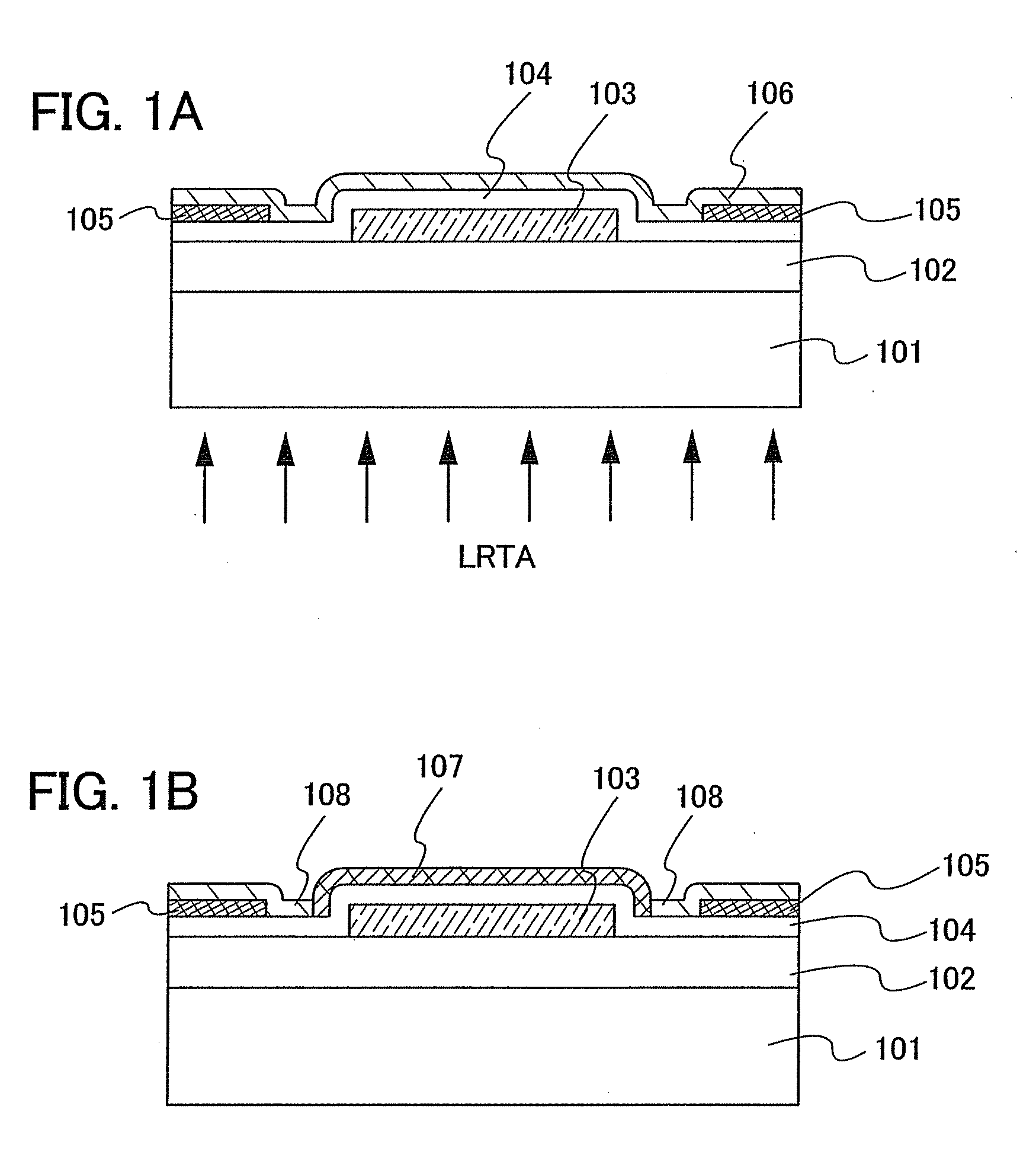

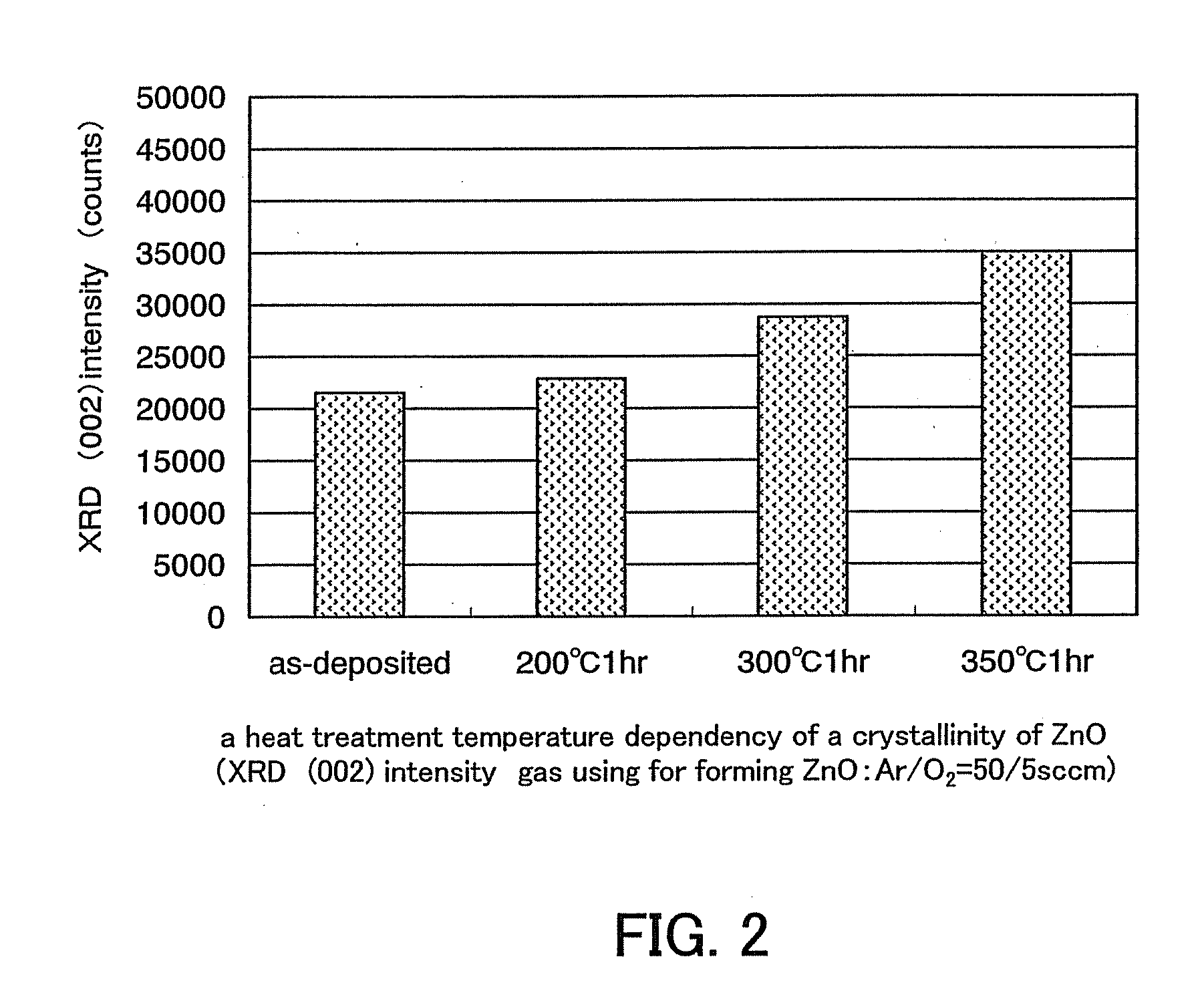

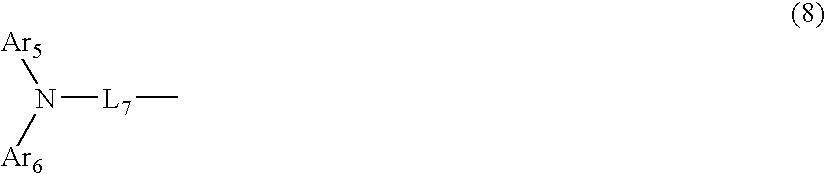

Semiconductor device and manufacturing method thereof

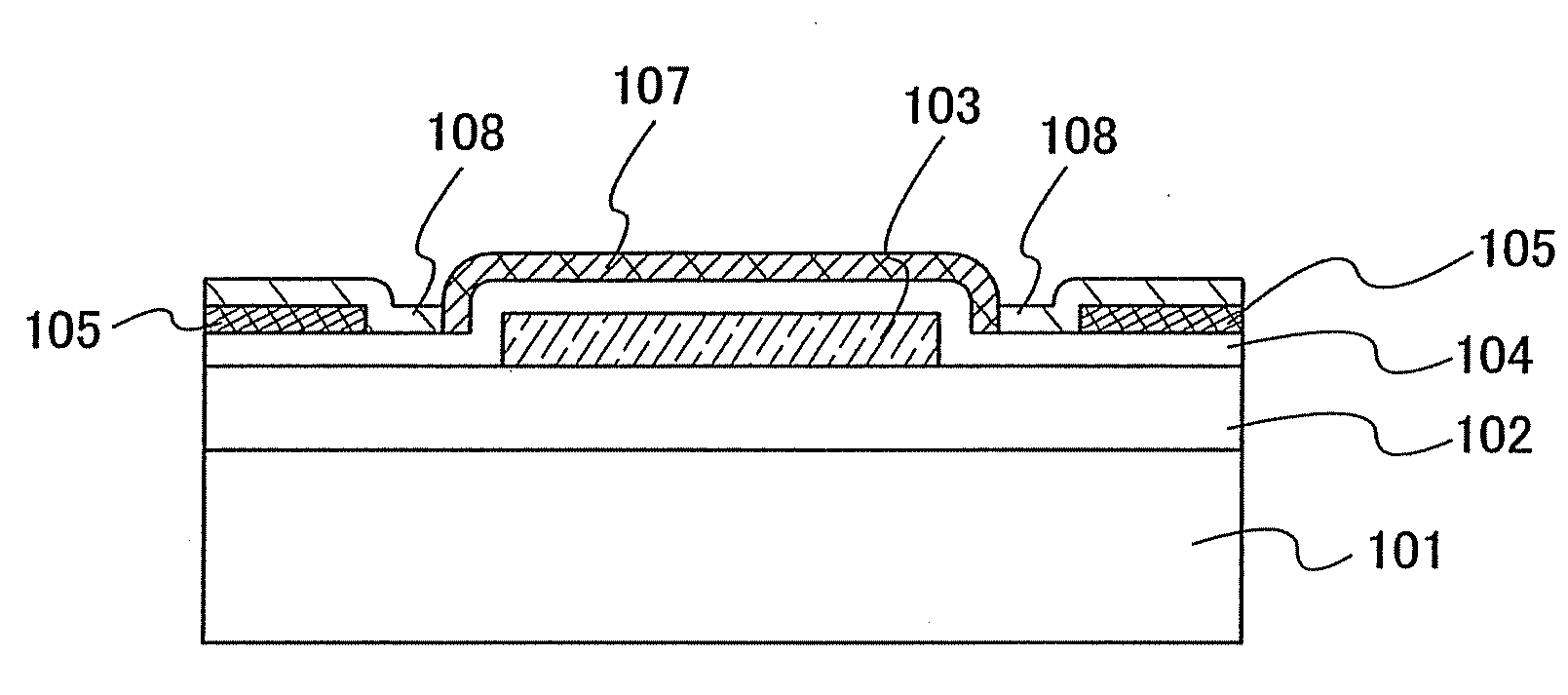

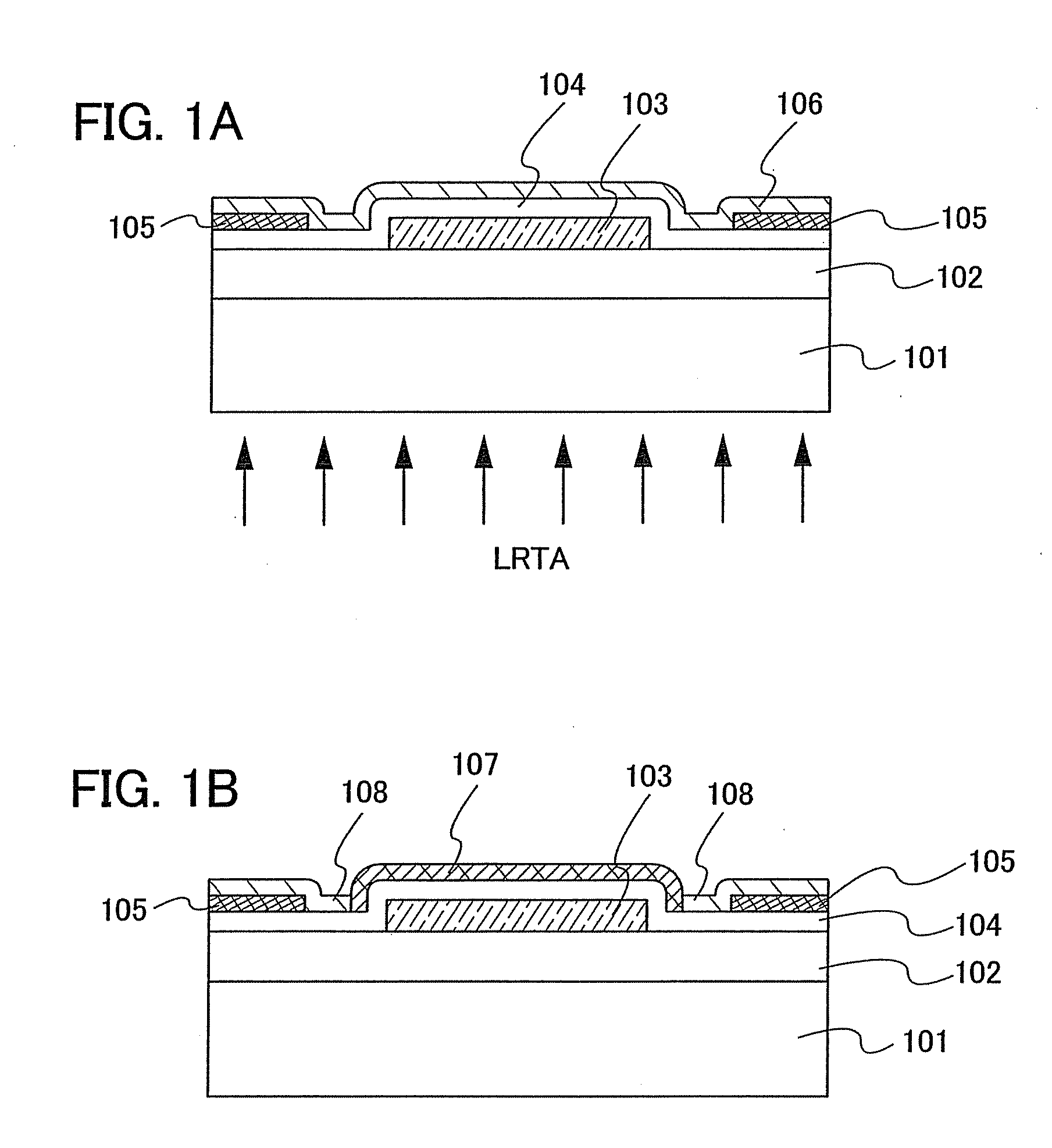

An object is to provide a semiconductor device of which a manufacturing process is not complicated and by which cost can be suppressed, by forming a thin film transistor using an oxide semiconductor film typified by zinc oxide, and a manufacturing method thereof. For the semiconductor device, a gate electrode is formed over a substrate; a gate insulating film is formed covering the gate electrode; an oxide semiconductor film is formed over the gate insulating film; and a first conductive film and a second conductive film are formed over the oxide semiconductor film. The oxide semiconductor film has at least a crystallized region in a channel region.

Owner:SEMICON ENERGY LAB CO LTD

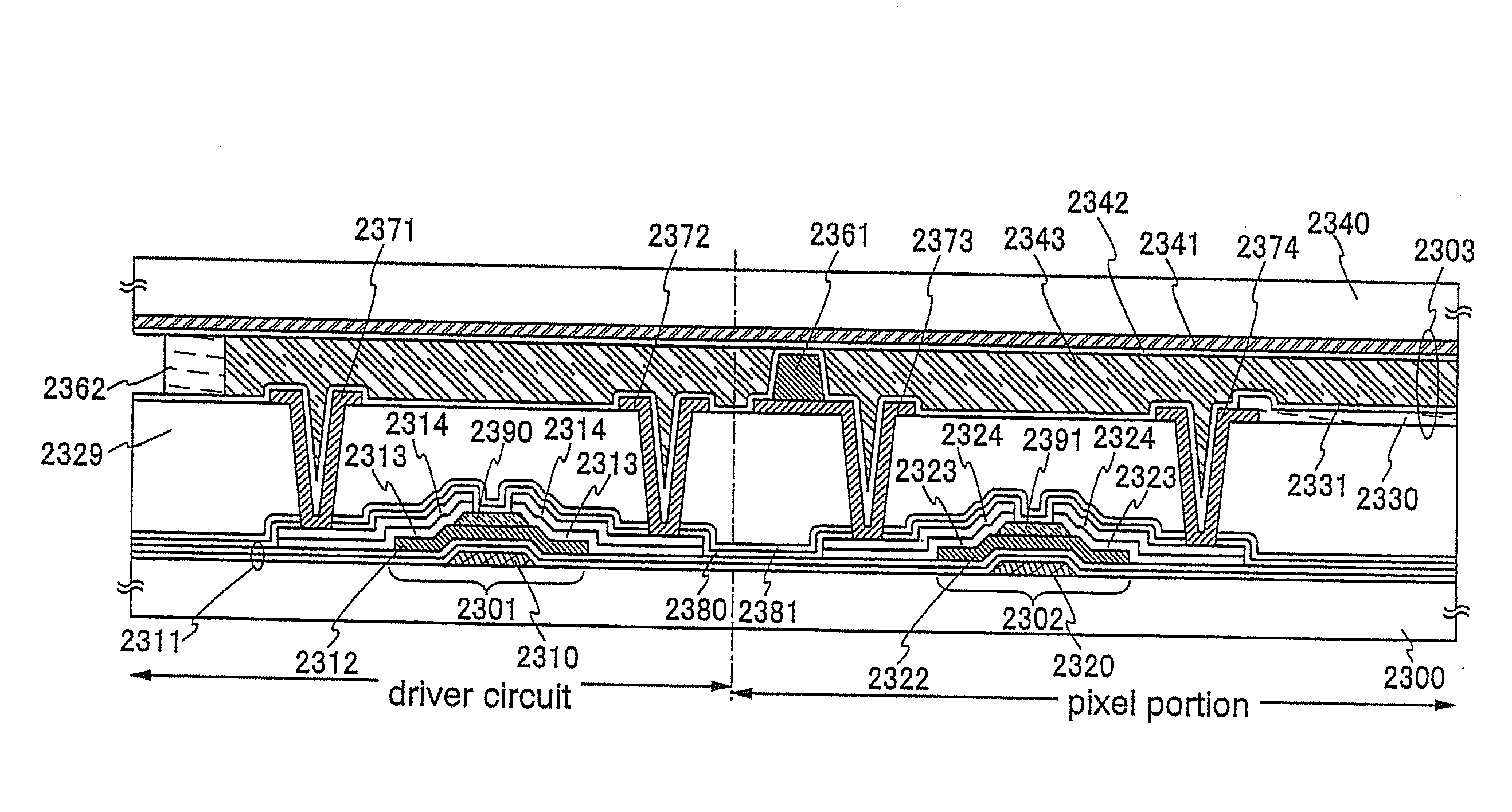

Semiconductor Device and Manufacturing Method Thereof

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor Device and Manufacturing Method Thereof

An object is to provide a semiconductor device of which a manufacturing process is not complicated and by which cost can be suppressed, by forming a thin film transistor using an oxide semiconductor film typified by zinc oxide, and a manufacturing method thereof. For the semiconductor device, a gate electrode is formed over a substrate; a gate insulating film is formed covering the gate electrode; an oxide semiconductor film is formed over the gate insulating film; and a first conductive film and a second conductive film are formed over the oxide semiconductor film. The oxide semiconductor film has at least a crystallized region in a channel region.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor Device and Manufacturing Method Thereof

An object is to provide a semiconductor device of which a manufacturing process is not complicated and by which cost can be suppressed, by forming a thin film transistor using an oxide semiconductor film typified by zinc oxide, and a manufacturing method thereof. For the semiconductor device, a gate electrode is formed over a substrate; a gate insulating film is formed covering the gate electrode; an oxide semiconductor film is formed over the gate insulating film; and a first conductive film and a second conductive film are formed over the oxide semiconductor film. The oxide semiconductor film has at least a crystallized region in a channel region.

Owner:SEMICON ENERGY LAB CO LTD

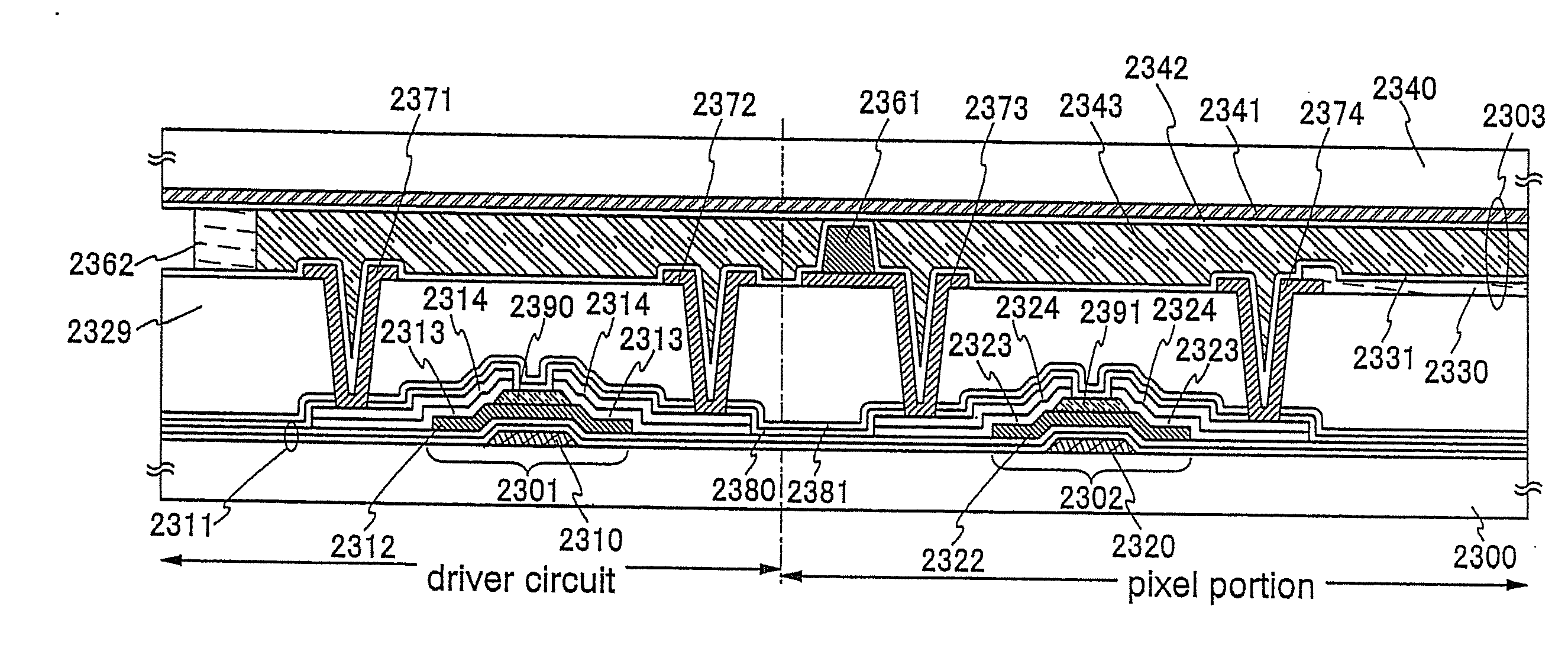

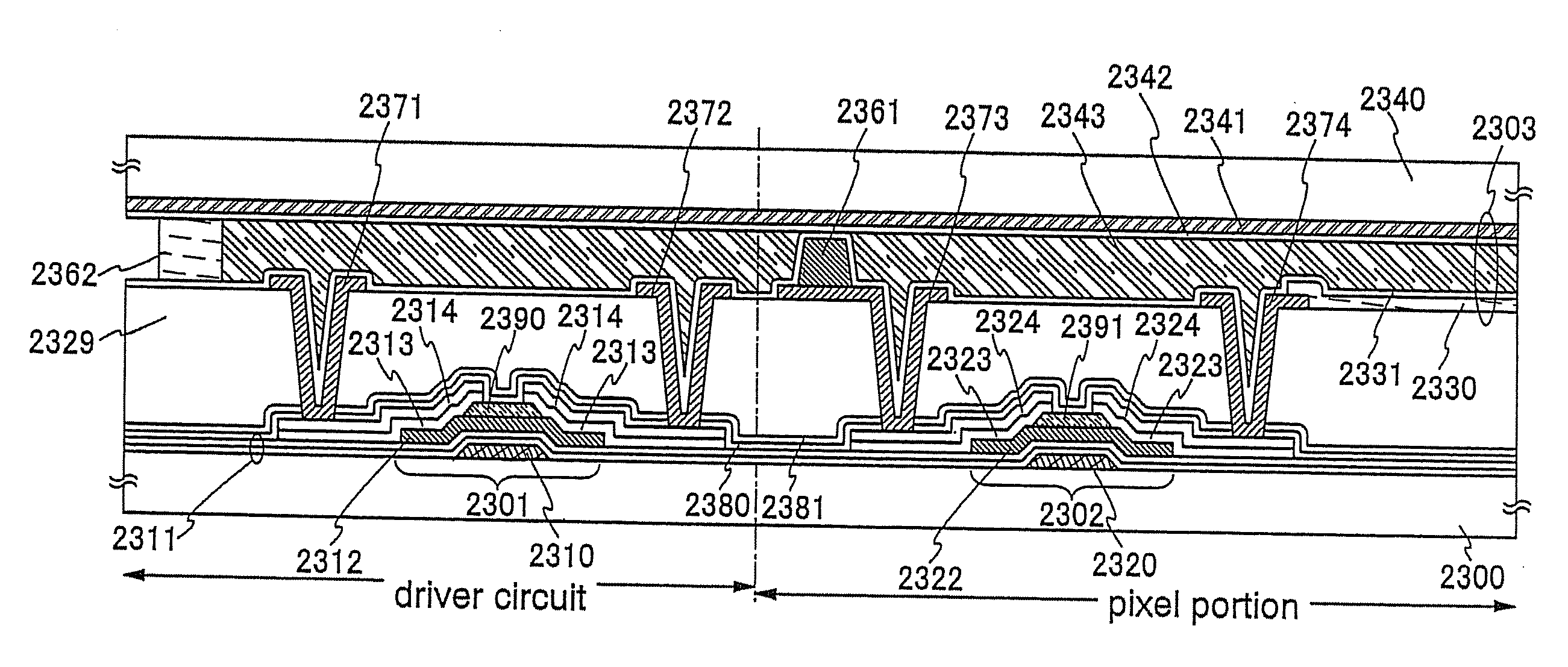

Semiconductor Device and Manufacturing Method Thereof

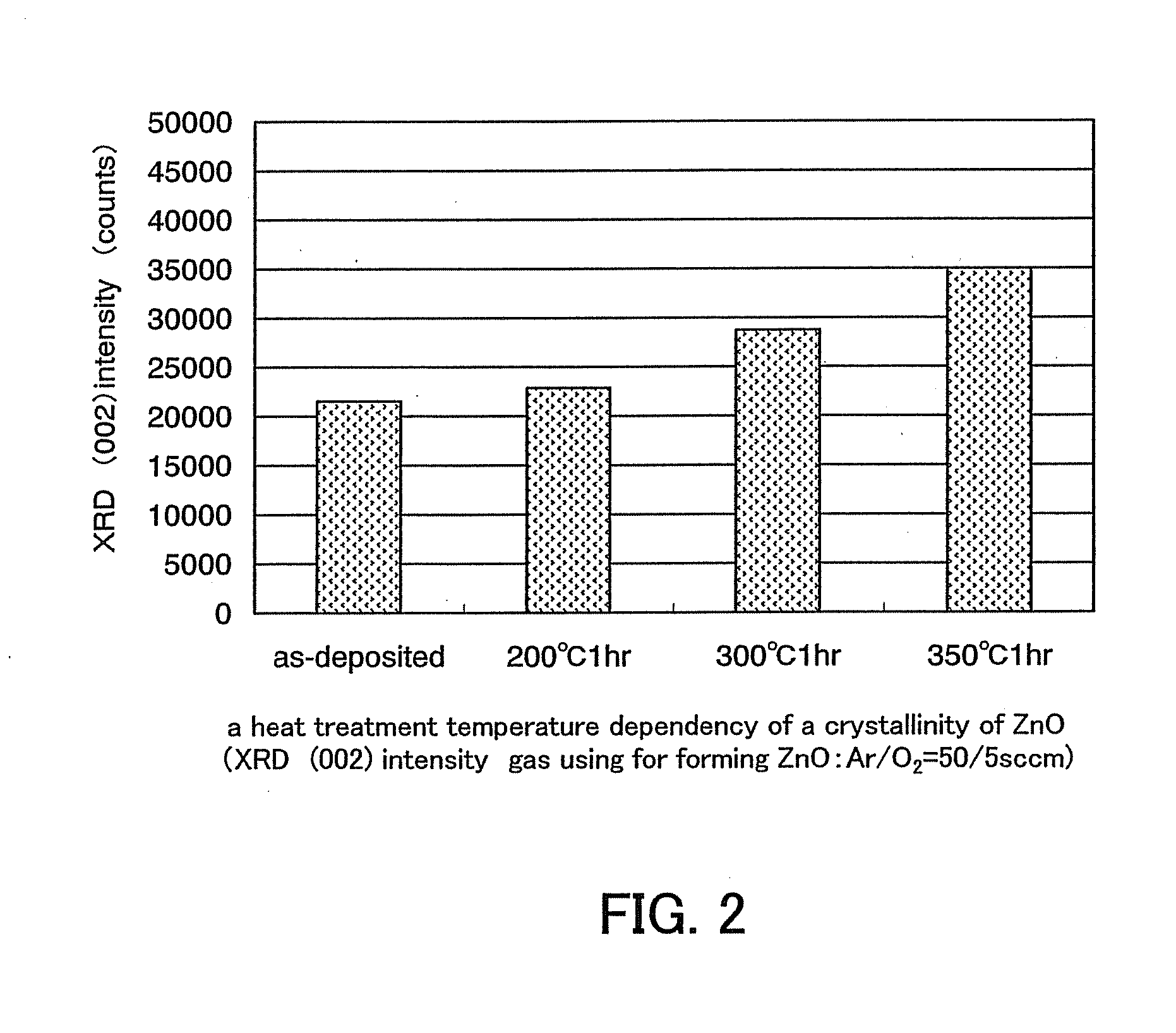

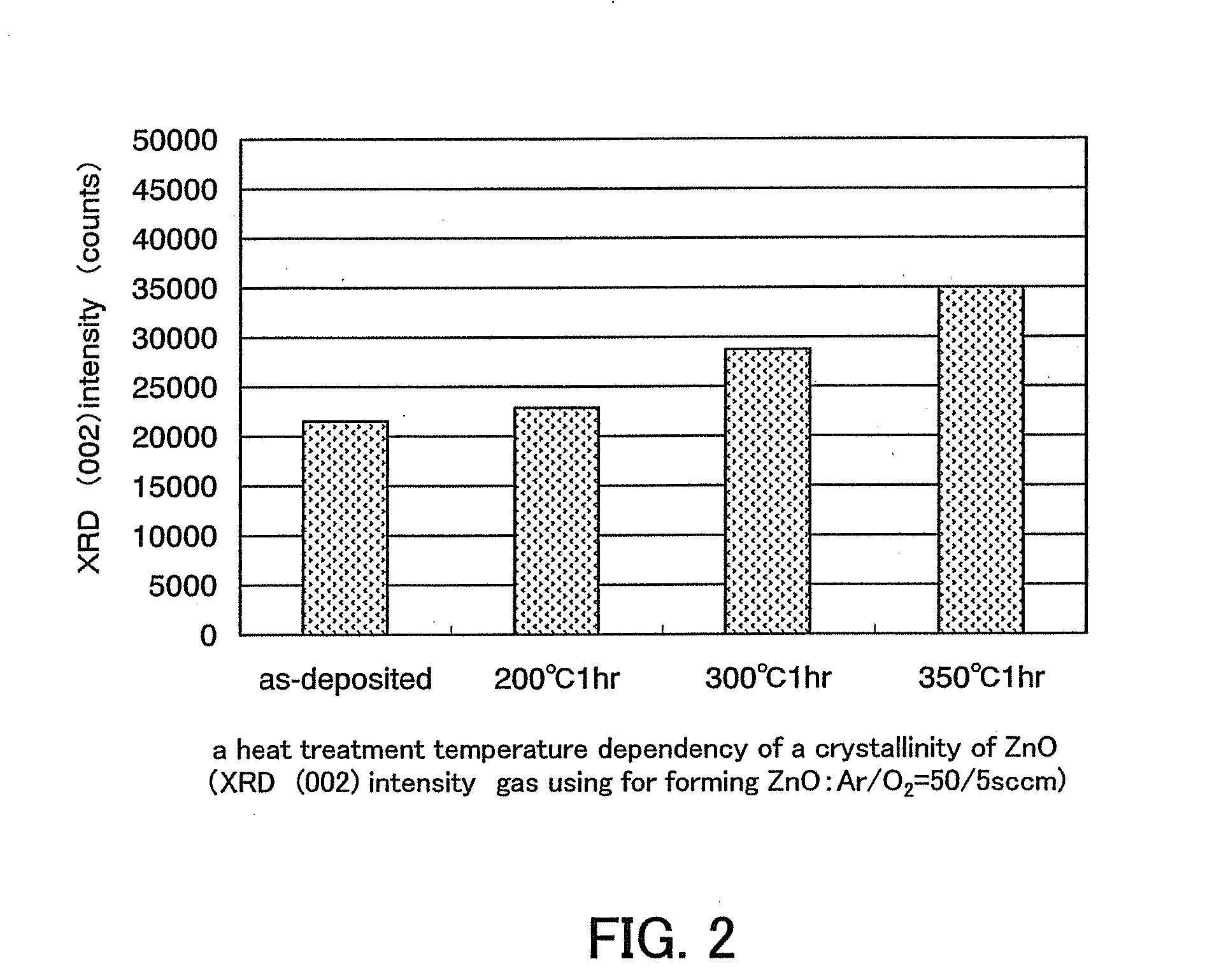

ActiveUS20080308797A1High yieldReduce the ratioTransistorDischarge tube luminescnet screensEngineeringZinc

An object is to provide a semiconductor device of which a manufacturing process is not complicated and by which cost can be suppressed, by forming a thin film transistor using an oxide semiconductor film typified by zinc oxide, and a manufacturing method thereof. For the semiconductor device, a gate electrode is formed over a substrate; a gate insulating film is formed covering the gate electrode; an oxide semiconductor film is formed over the gate insulating film; and a first conductive film and a second conductive film are formed over the oxide semiconductor film. The oxide semiconductor film has at least a crystallized region in a channel region.

Owner:SEMICON ENERGY LAB CO LTD

Electrophoretic medium and process for the production thereof

InactiveUS7411719B2Static indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisElectric field

A two-phase electrophoretic medium comprises a continuous phase and a discontinuous phase. The discontinuous phase comprises a plurality of droplets, each of which comprises a suspending fluid and at least one particle disposed within the suspending fluid and capable of moving through the fluid upon application of an electric field to the electrophoretic medium. The continuous phase surrounds and encapsulates the discontinuous phase. To reduce the humidity sensitivity of the medium, a non-ionizable or crystalline polymer may be used as the continuous phase.

Owner:E INK CORPORATION

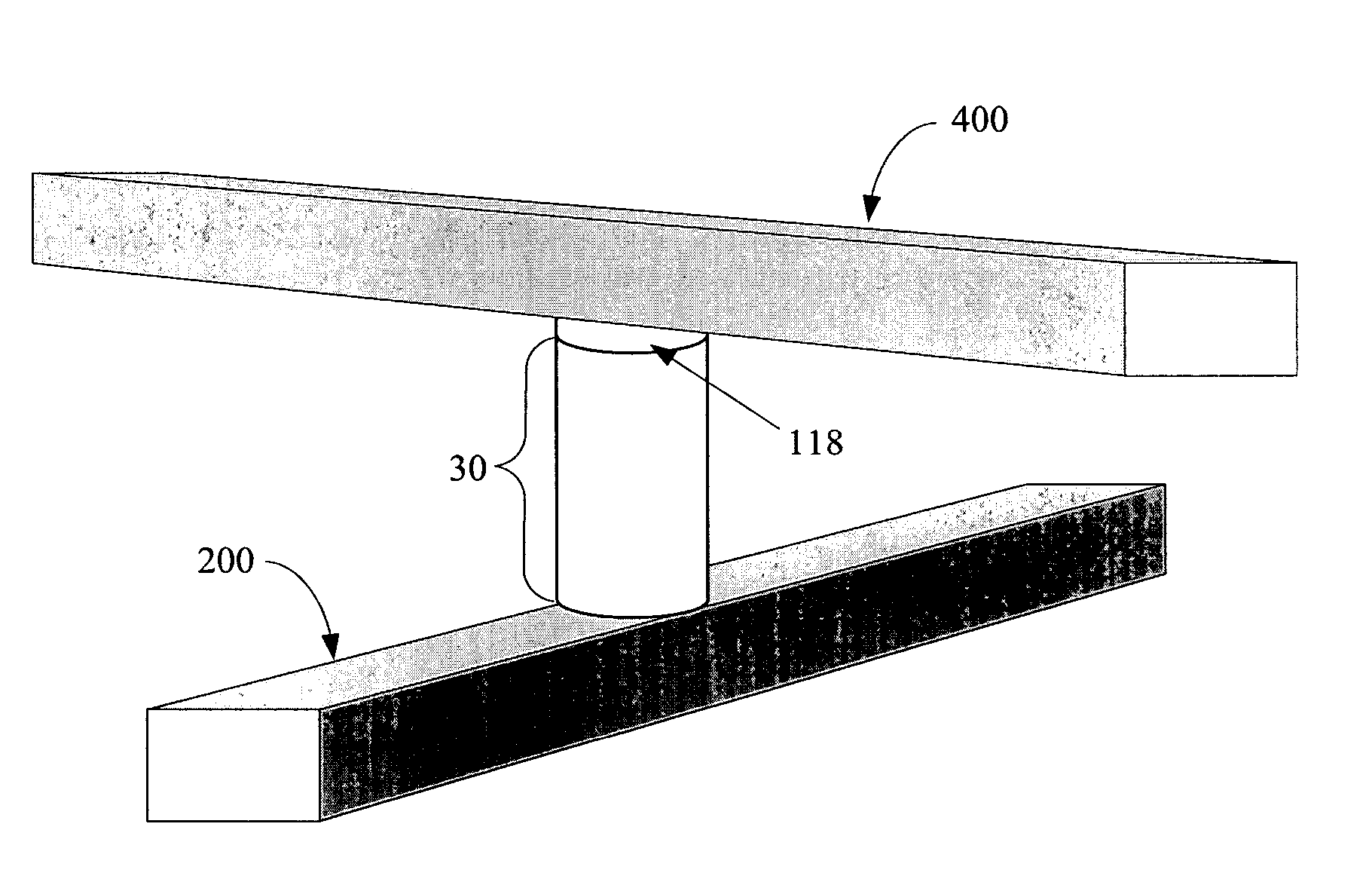

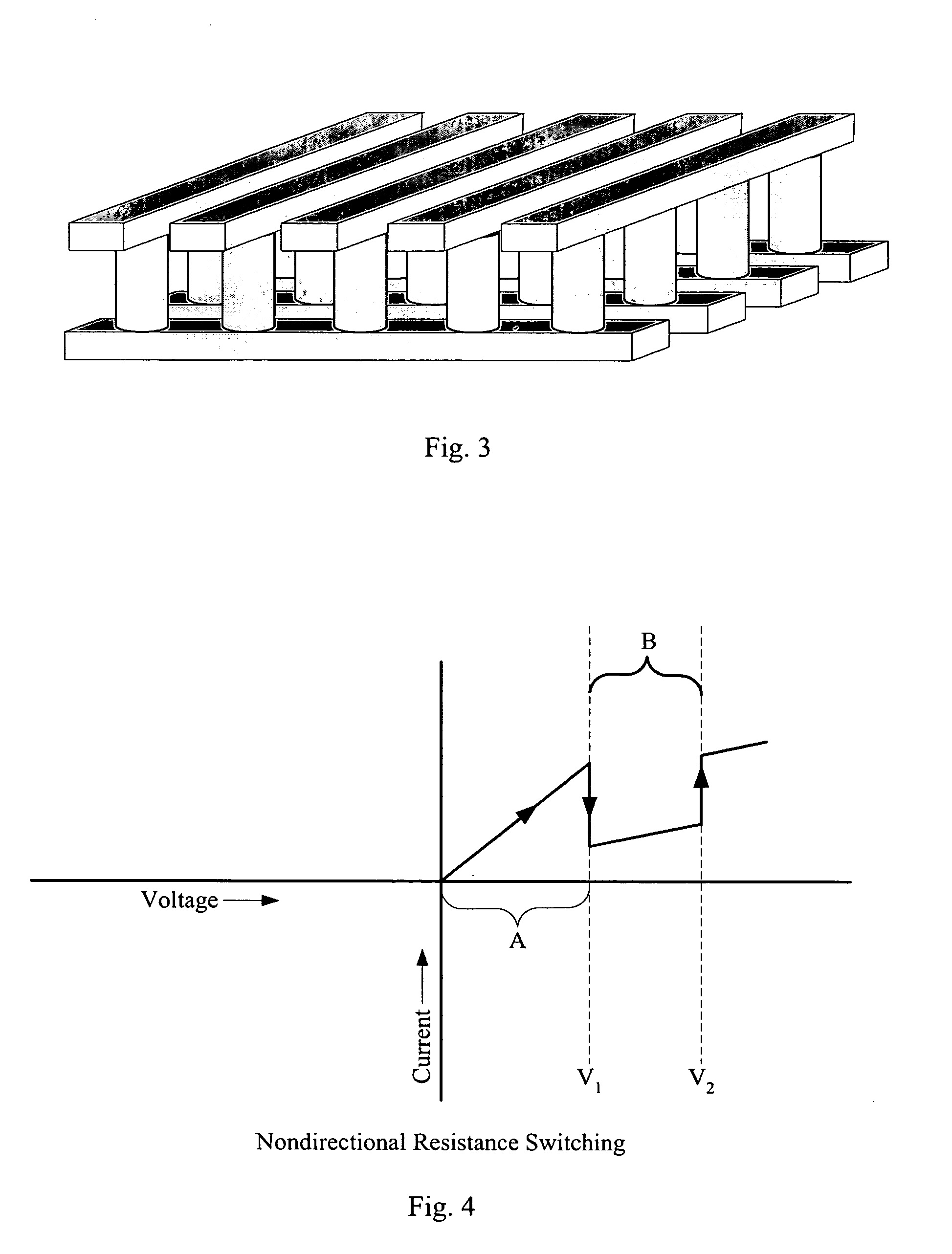

Rewriteable memory cell comprising a diode and a resistance-switching material

In a novel rewriteable nonvolatile memory cell formed above a substrate, a diode is paired with a reversible resistance-switching material, preferably a metal oxide or nitride such as, for example, NiO, Nb2O5, TiO2, HfO2, Al2O3, MgOx, CrO2, VO, BN, and AlN. In preferred embodiments, the diode is formed as a vertical pillar disposed between conductors. Multiple memory levels can be stacked to form a monolithic three dimensional memory array. In some embodiments, the diode comprises germanium or a germanium alloy, which can be deposited and crystallized at relatively low temperatures, allowing use of aluminum or copper in the conductors.

Owner:SANDISK TECH LLC

Semiconductor Device and Manufacturing Method Thereof

An object is to provide a semiconductor device of which a manufacturing process is not complicated and by which cost can be suppressed, by forming a thin film transistor using an oxide semiconductor film typified by zinc oxide, and a manufacturing method thereof. For the semiconductor device, a gate electrode is formed over a substrate; a gate insulating film is formed covering the gate electrode; an oxide semiconductor film is formed over the gate insulating film; and a first conductive film and a second conductive film are formed over the oxide semiconductor film. The oxide semiconductor film has at least a crystallized region in a channel region.

Owner:MOLECULAR DEVICES

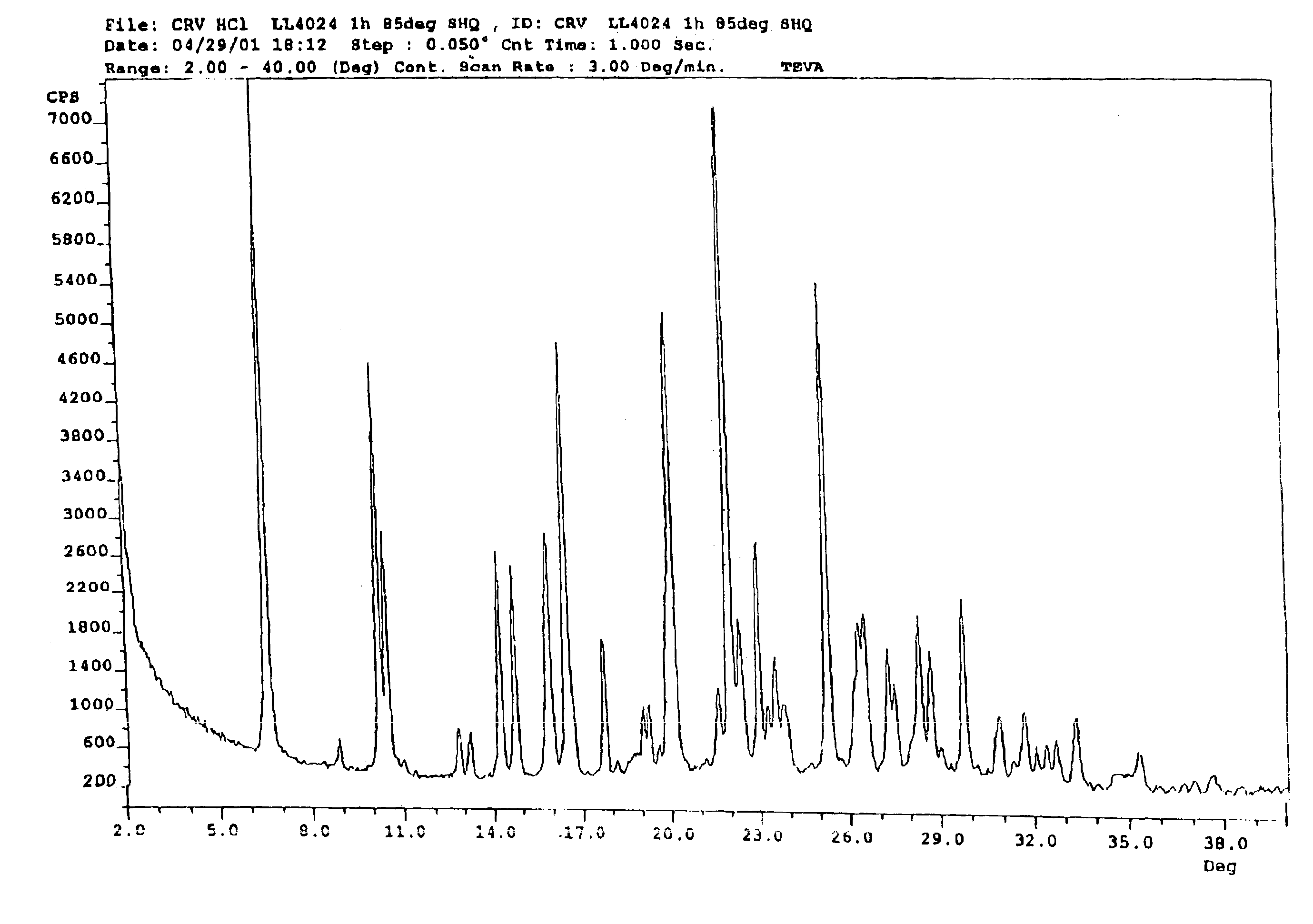

Hydroalkylation of aromatic hydrocarbons

InactiveUS6037513AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07.

Owner:MOBIL OIL CORP

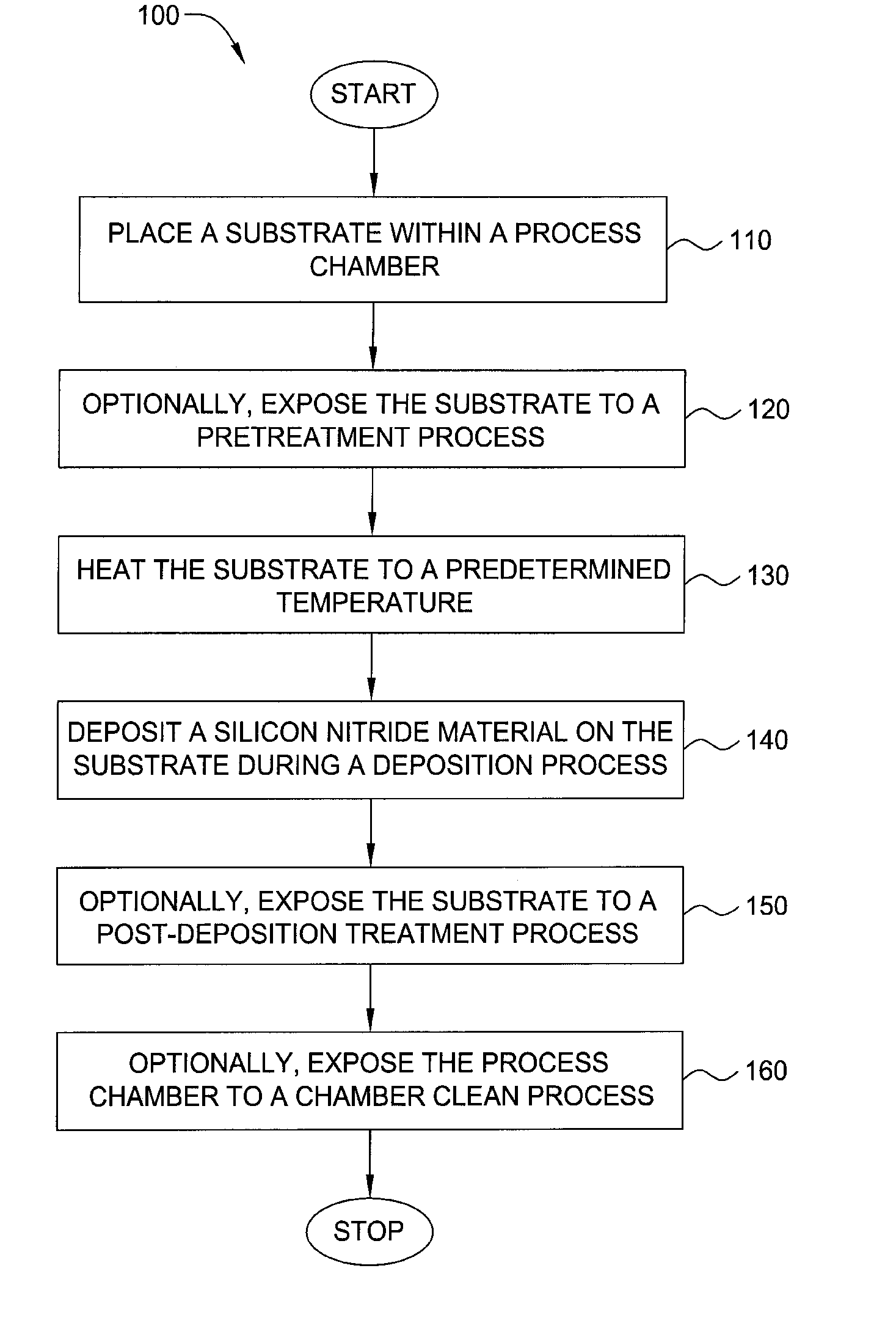

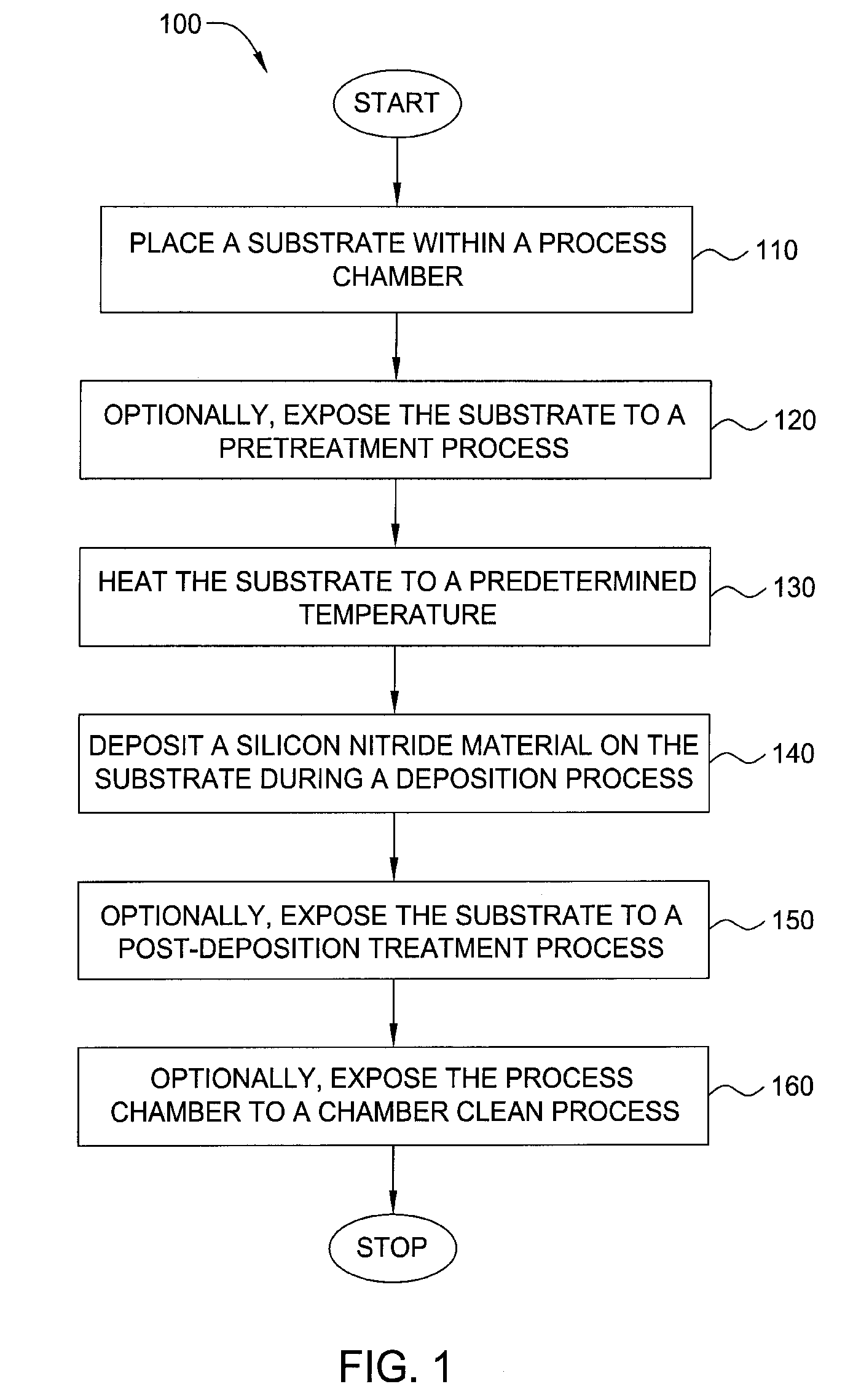

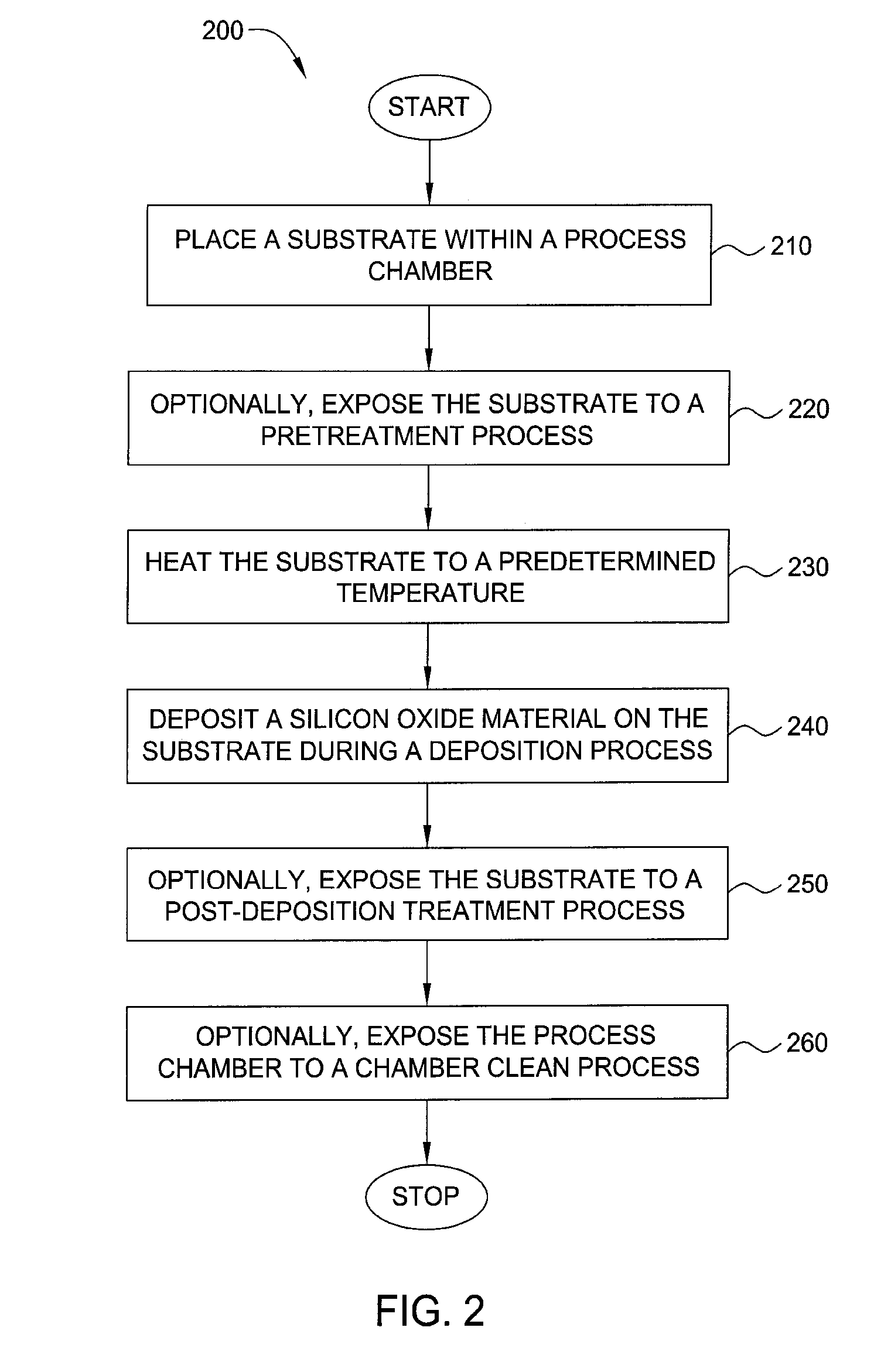

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS20060286774A1Enhance chamber cleaning processHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingVolatilesSilicon oxide

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

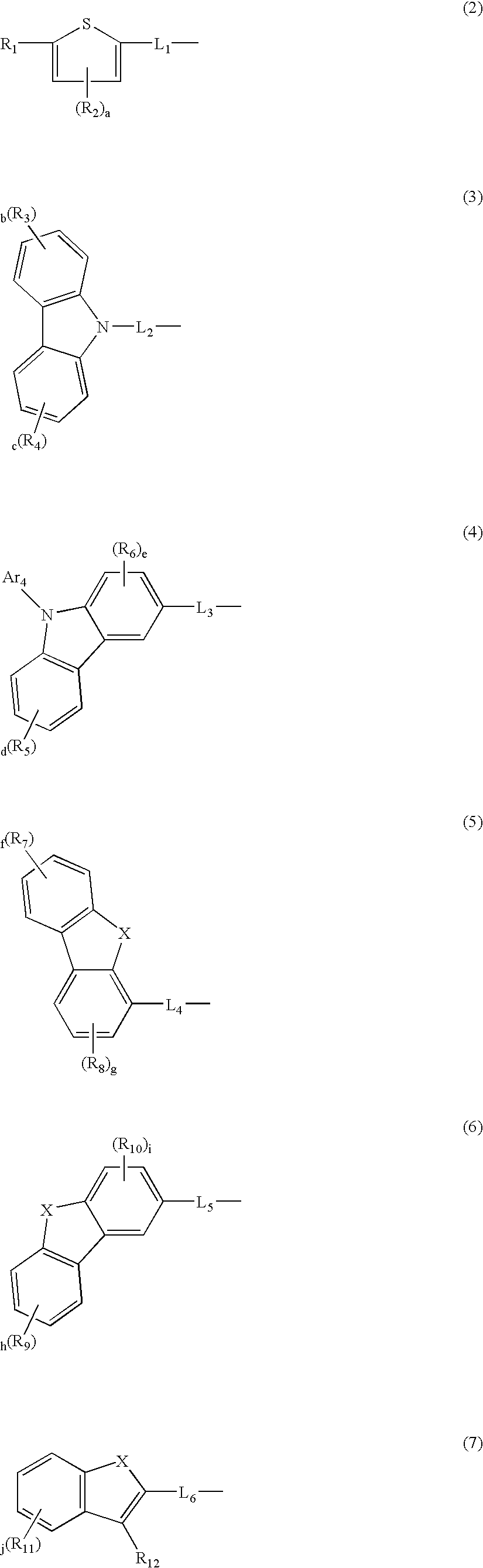

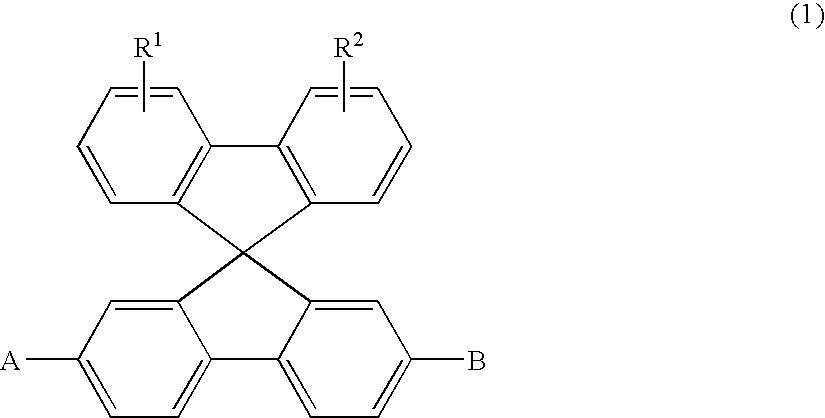

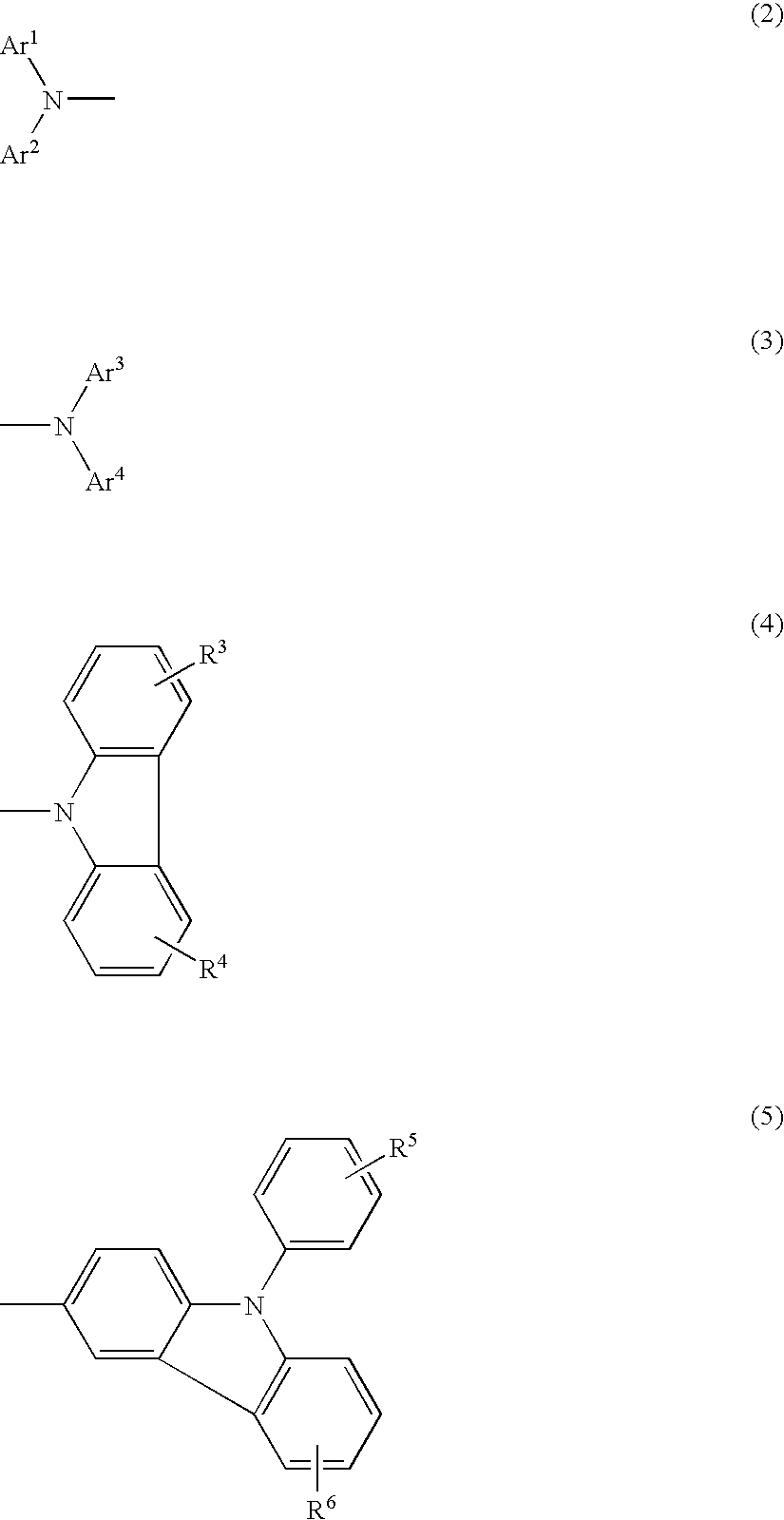

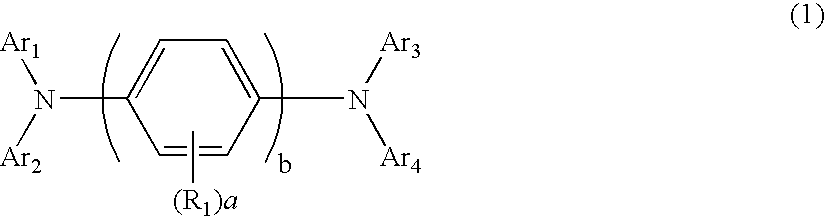

Aromatic amine derivative and organic electroluminescence device using the same

ActiveUS20090066235A1Long lastingIncrease productionOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceLight-emitting diode

Provided are an organic electroluminescent device including an aromatic amine derivative formed of a specific structure having a thiophene structure and an organic thin film layer interposed between a cathode and an anode and formed of one layer or a plurality of layers including at least a light emitting layer, in which at least one layer of the organic thin film contains the aromatic amine derivative alone or as a component of a mixture, the organic electroluminescent device in which molecules hardly crystallize, and which decreases a driving voltage, can be produced with improved yields upon the production of the organic electroluminescent device, and has a long lifetime, and an aromatic amine derivative realizing the organic electroluminescent device.

Owner:IDEMITSU KOSAN CO LTD

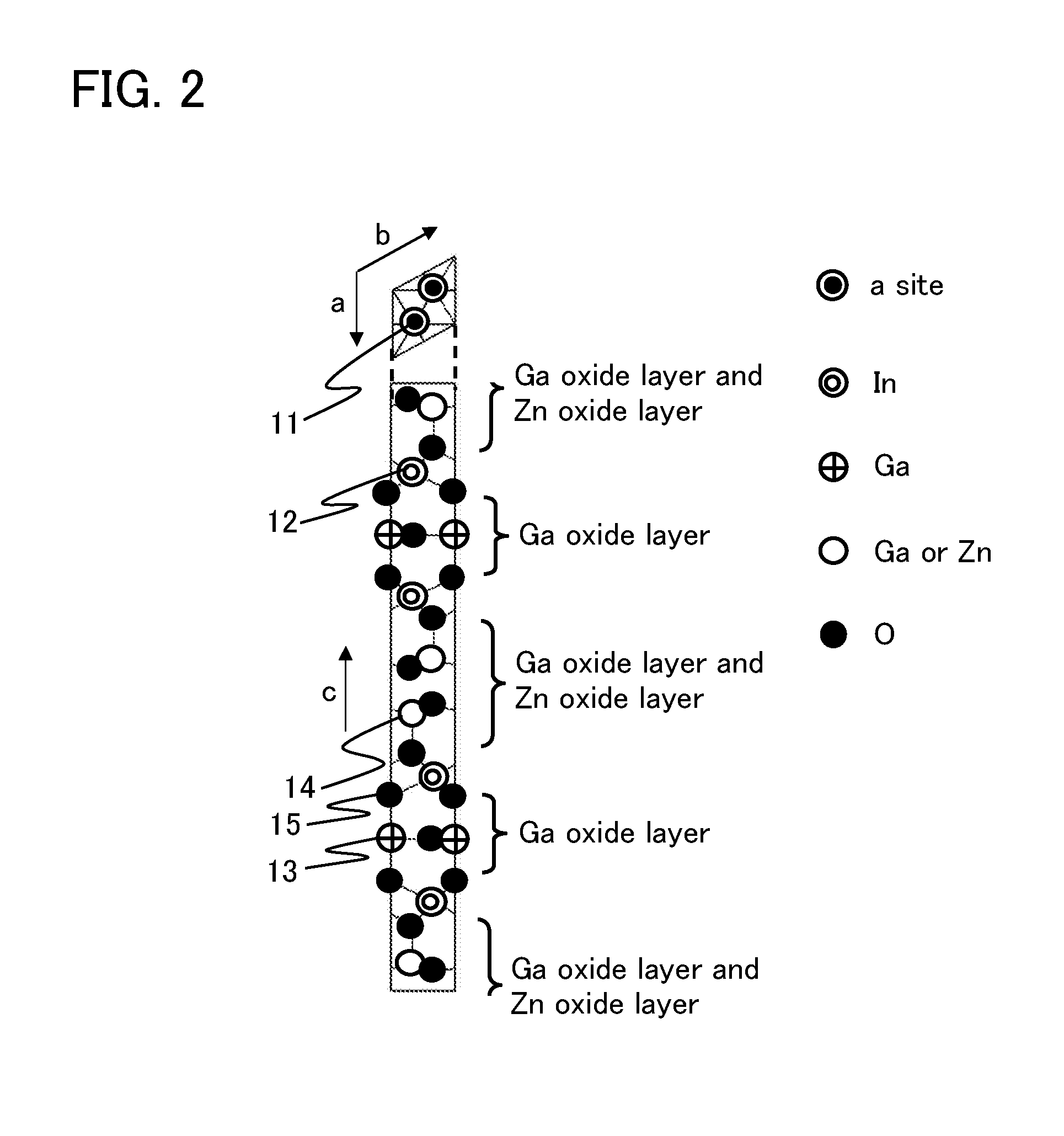

Oxide semiconductor film and semiconductor device

ActiveUS20120138922A1Improve conductivityMore electrically stableElectroluminescent light sourcesSemiconductor devicesUltraviolet lightsIrradiation

An oxide semiconductor film which has more stable electric conductivity is provided. Further, a semiconductor device which has stable electric characteristics and high reliability is provided by using the oxide semiconductor film. An oxide semiconductor film includes a crystalline region, and the crystalline region includes a crystal in which an a-b plane is substantially parallel with a surface of the film and a c-axis is substantially perpendicular to the surface of the film; the oxide semiconductor film has stable electric conductivity and is more electrically stable with respect to irradiation with visible light, ultraviolet light, and the like. By using such an oxide semiconductor film for a transistor, a highly reliable semiconductor device having stable electric characteristics can be provided.

Owner:SEMICON ENERGY LAB CO LTD

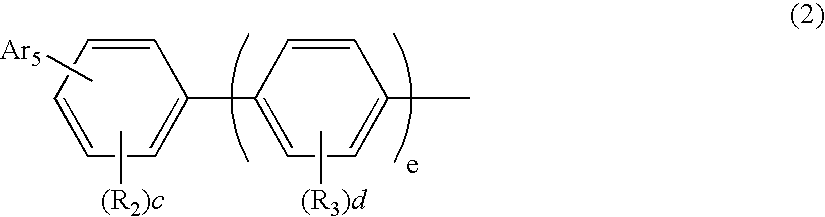

Aromatic amine derivatives and organic electroluminescence device using the same

InactiveUS20090167161A1Increase productionLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceHole transport layer

Provided are an organic electroluminescence device and an aromatic amine derivative for realizing the device. The aromatic amine derivative improves the luminous efficiency of an organic electroluminescence device using the derivative, and its molecules hardly crystallize. The organic electroluminescence device has an organic thin film layer composed of one or a plurality of layers including at least a light emitting layer, the organic thin film layer being interposed between a cathode and an anode, and at least one layer of the organic thin film layer, especially a hole transporting layer contains the aromatic amine derivative alone or as a component of a mixture, so the organic electroluminescence device can be produced in improved yield, and has a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

Aromatic amine derivatives and organic electroluminescence device using the same

InactiveUS20070145888A1Increase productionLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceAmine derivatives

Provided are: a novel aromatic amine derivative having an asymmetric structure; and an organic electroluminescence device having one or multiple organic thin film layers including at least a light emitting layer, the one or multiple organic thin film layers being interposed between a cathode and an anode. The aromatic amine derivative realizes the organic EL device capable of suppressing the crystallization of a molecule, improving yields upon production of the organic EL device, and having a long lifetime when at least one layer of the one or more multiple organic thin film layers contains the aromatic amine derivative alone or as a component of a mixture.

Owner:IDEMITSU KOSAN CO LTD

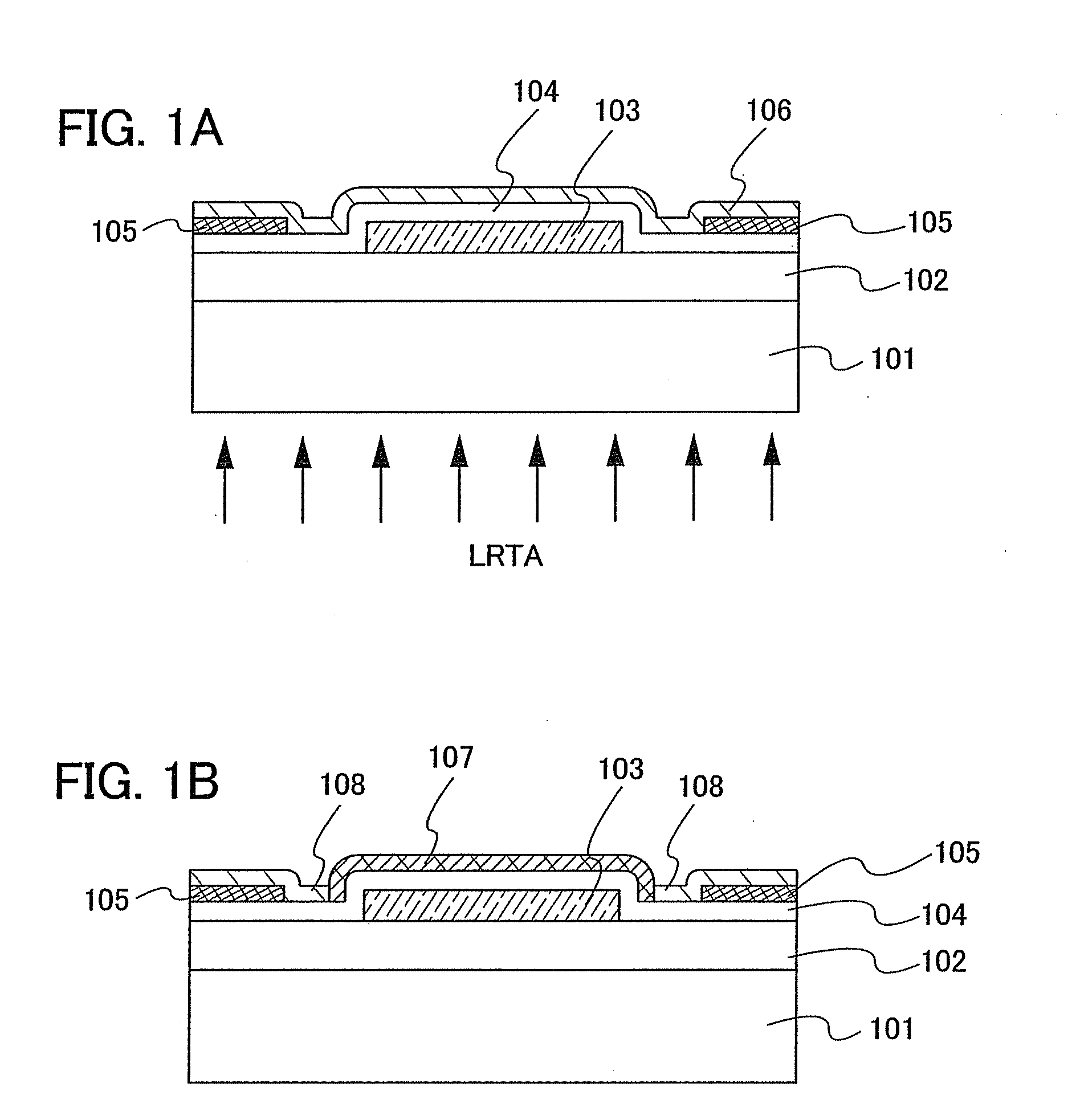

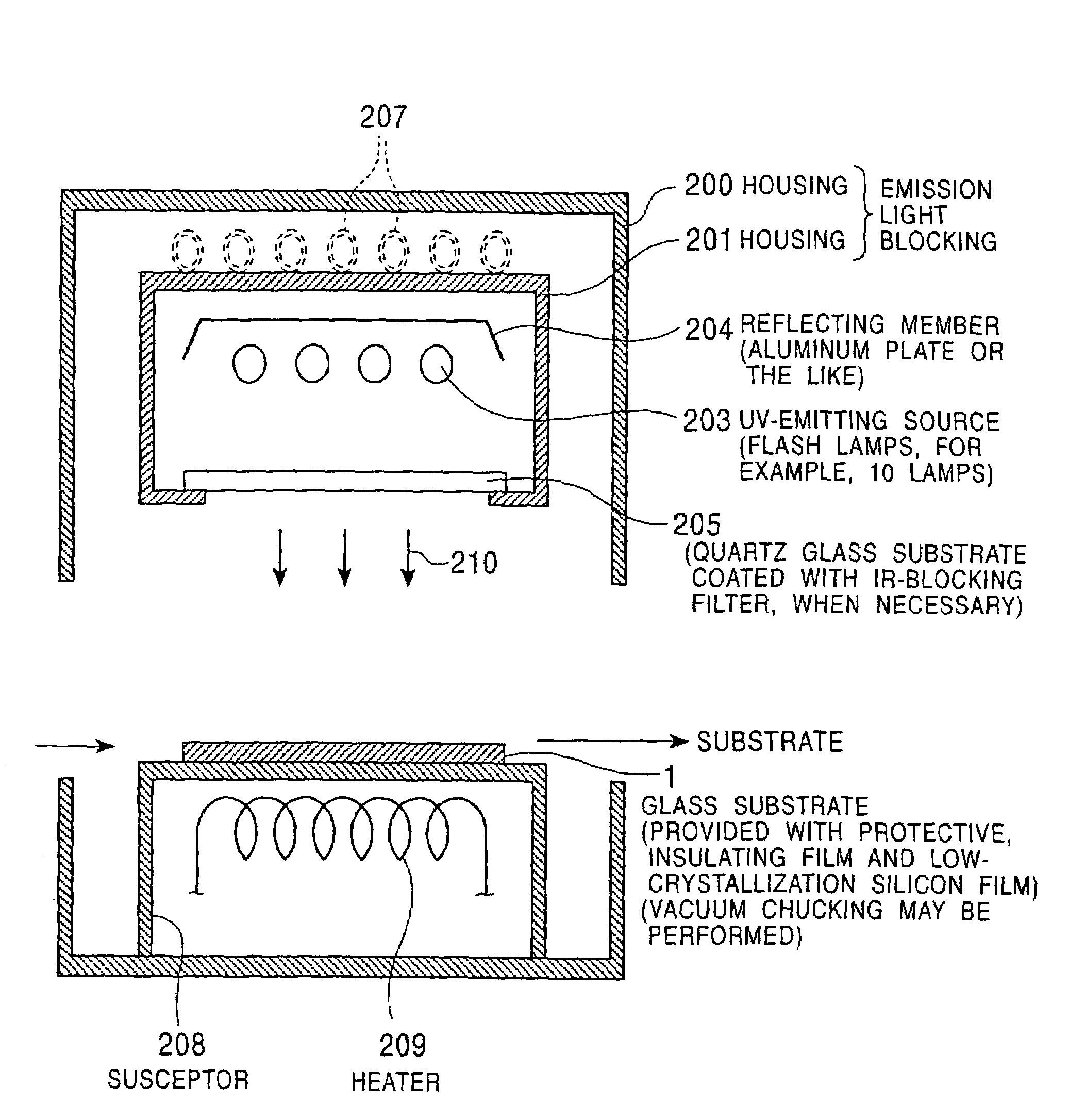

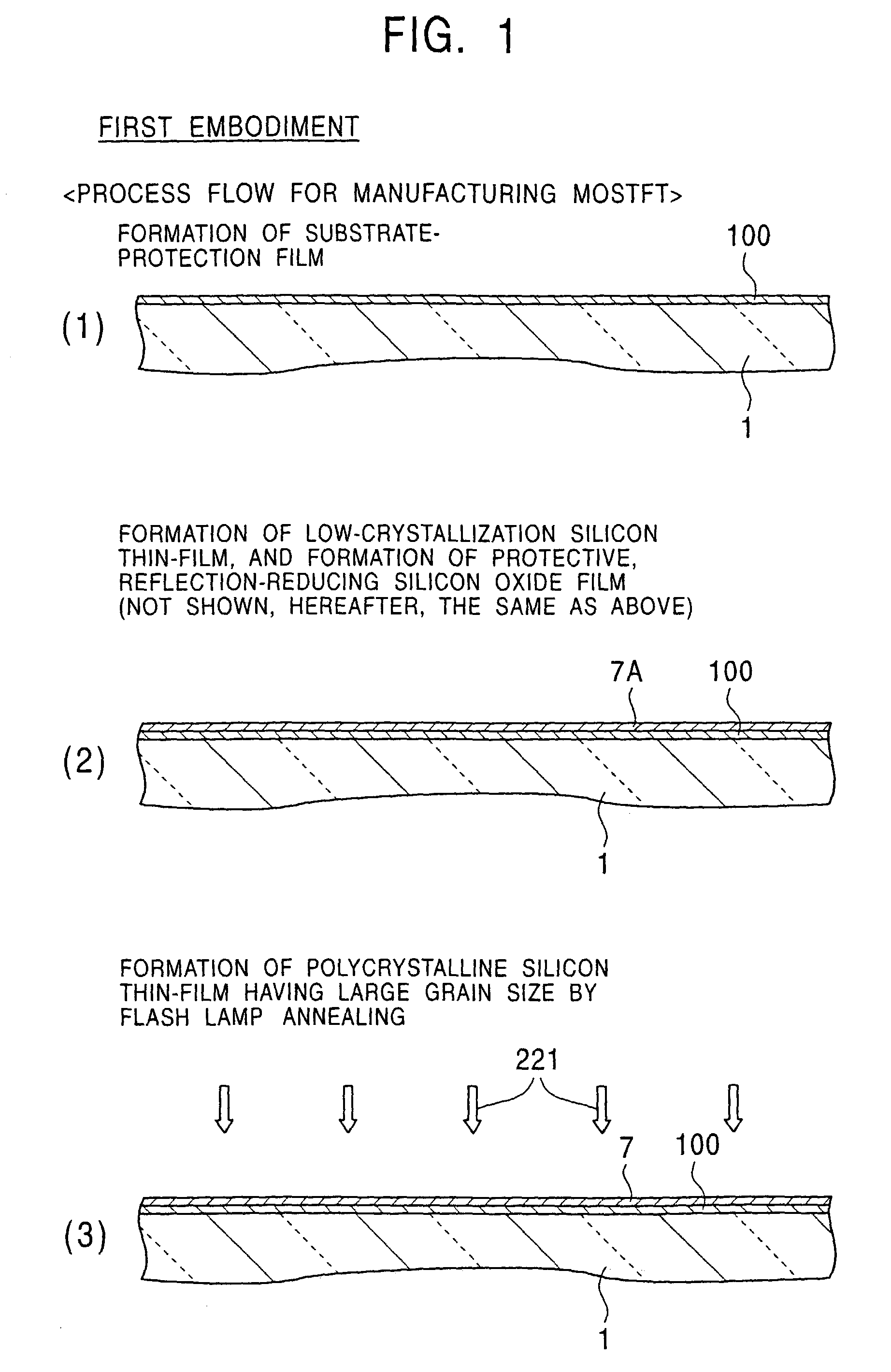

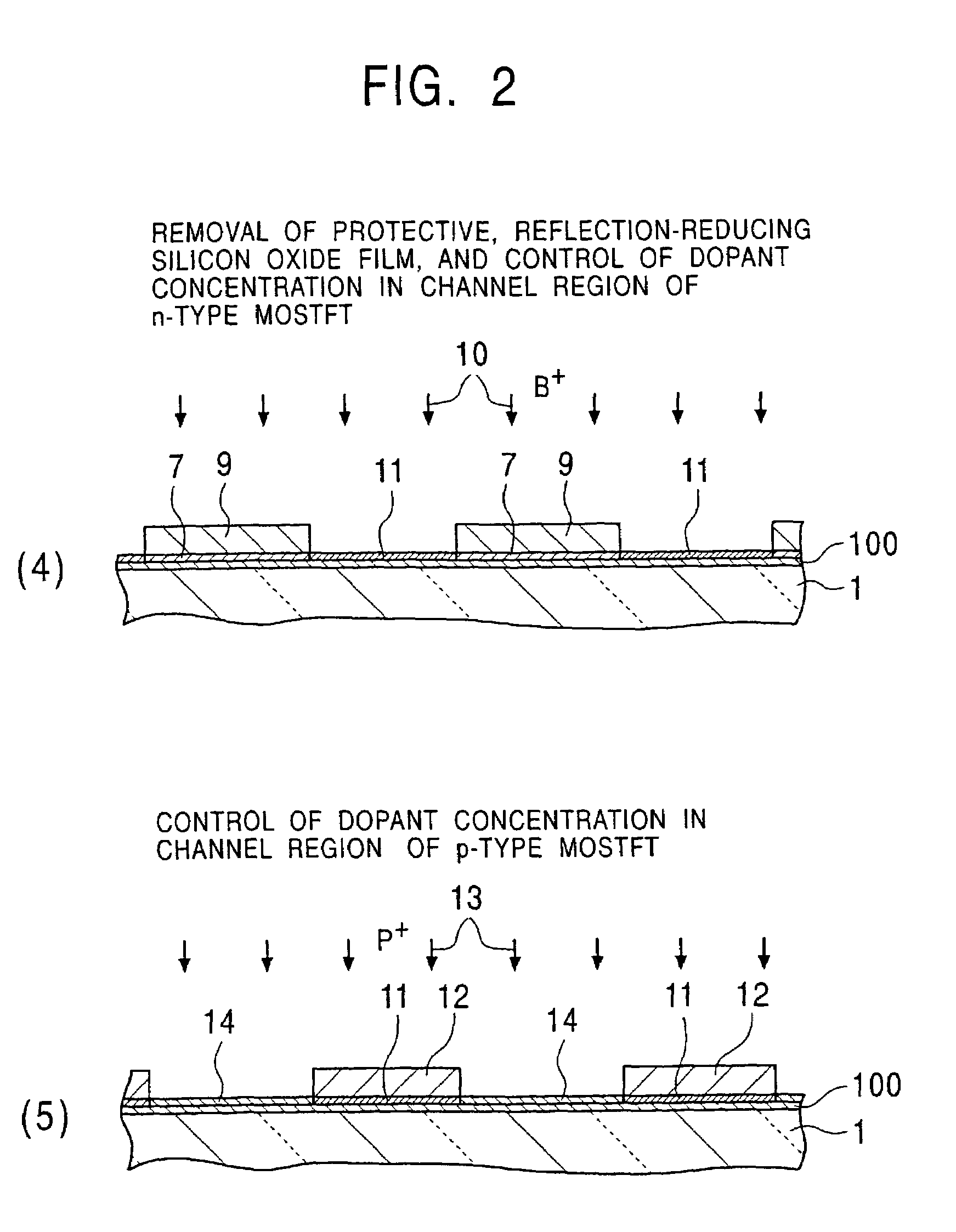

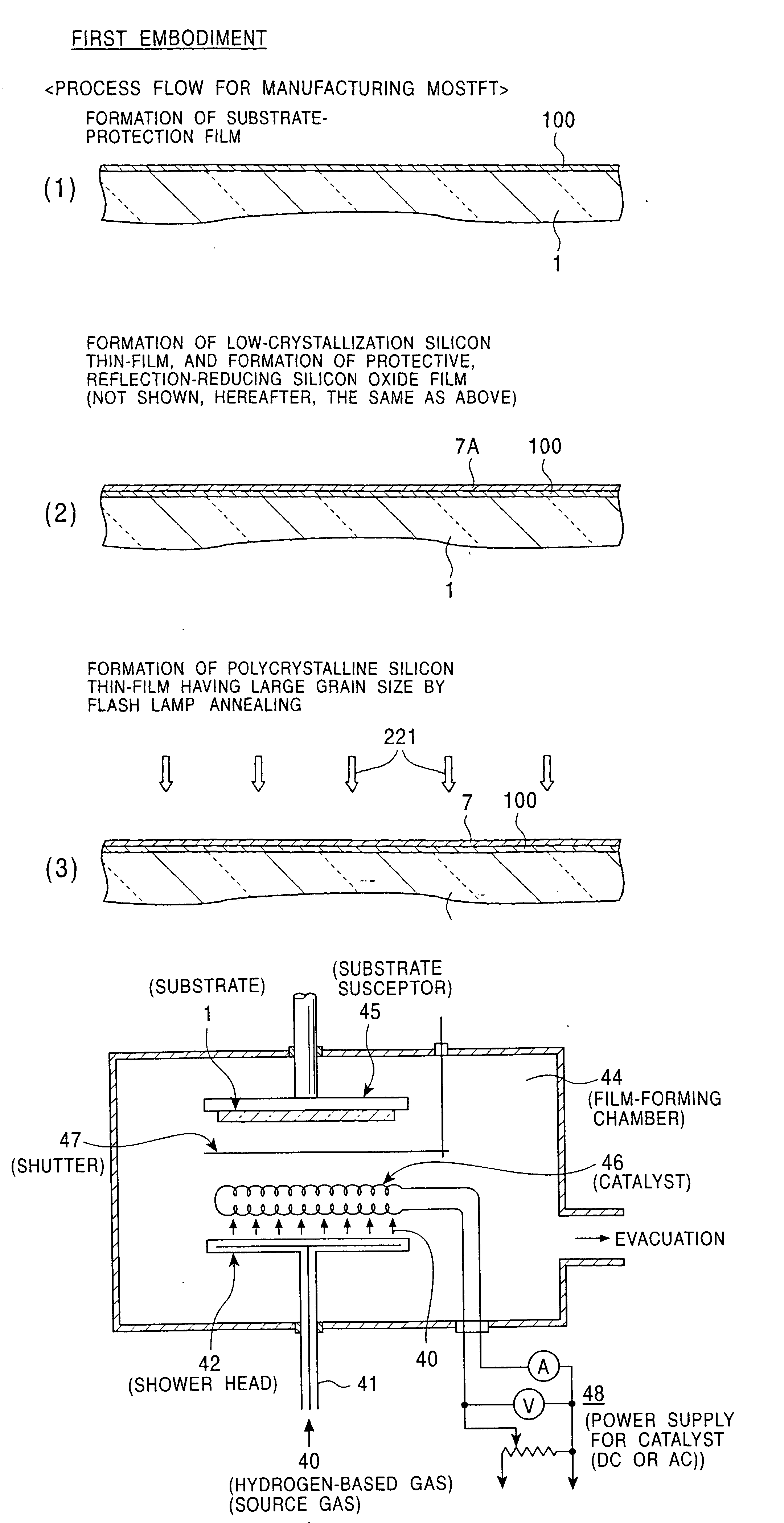

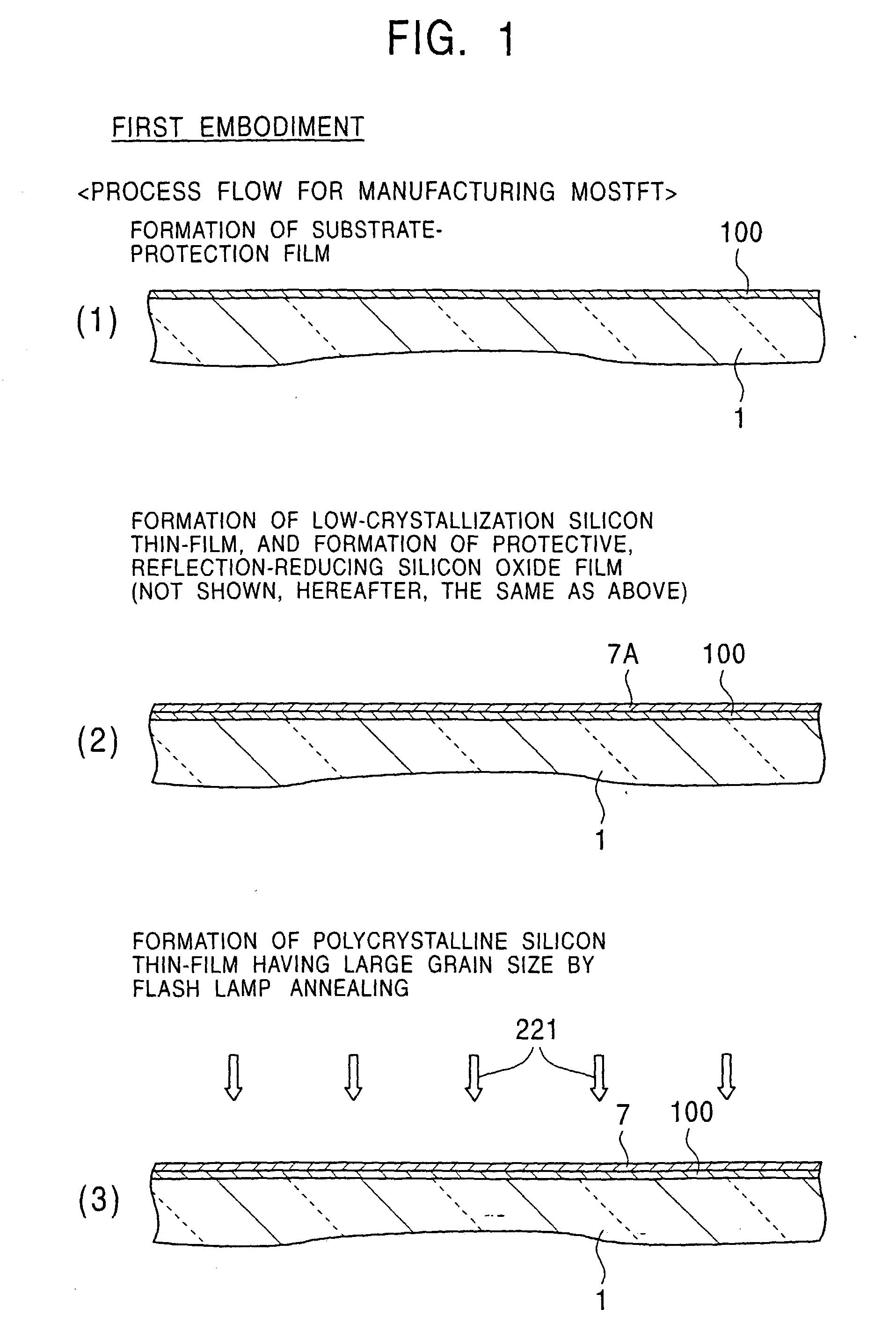

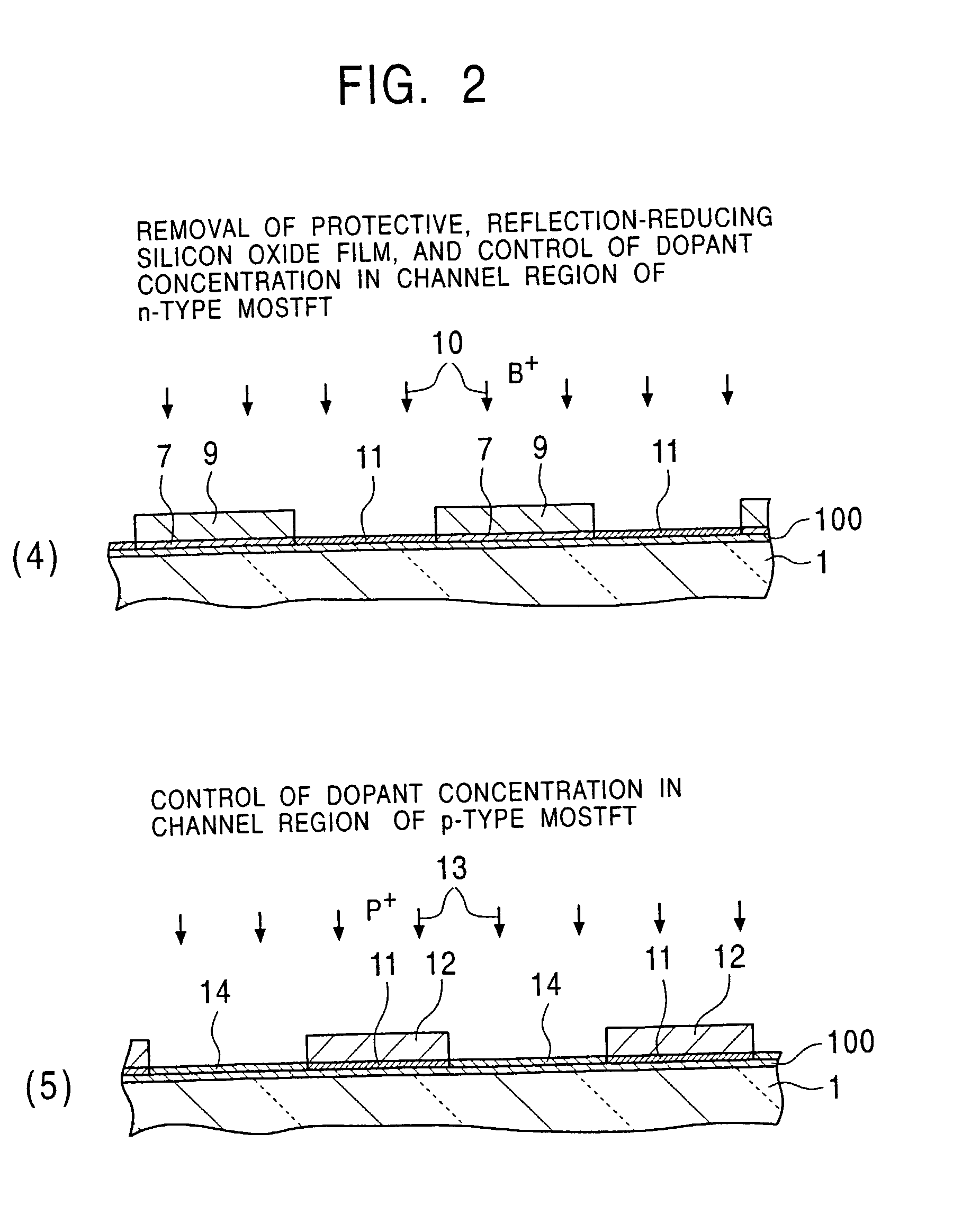

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

Aromatic amine derivative and organic electroluminescence device using the same

InactiveUS20080091025A1Increase productionLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceHole transport layer

The present invention provides an organic electroluminescence device which can be driven at a reduced voltage, hardly causes the crystallization of a molecule, can be produced in improved yield, and has a long lifetime because of difficulty of molecular crystallization, and aromatic amine derivatives for realizing the device. The aromatic amine derivatives are novel aromatic amine derivatives having a specific structure. The organic electroluminescence device includes an organic thin film layer formed of one or more layers including at least a light emitting layer, the organic thin film layer being interposed between a cathode and an anode. In the organic electroluminescence device, at least one layer of the organic thin film layer, especially a hole transporting layer, contains the aromatic amine derivative alone or as a component of a mixture.

Owner:IDEMITSU KOSAN CO LTD

Method of preparing catalyst for manufacturing carbon nanotubes

InactiveUS20070020167A1Improve uniformityMinimize agglomerationMaterial nanotechnologyNanostructure manufactureFreeze-dryingCarbon nanotube

A novel method of forming catalyst particles, on which carbon nanotubes grow based, on a substrate with increased uniformity, and a method of synthesizing carbon nanotubes having improved uniformity are provided. A catalytic metal precursor solution is applied to a substrate. The applied catalytic metal precursor solution is freeze-dried, and then reduced to catalytic metal. The method of forming catalyst particles can minimize agglomeration and / or recrystallization of catalyst particles when forming the catalyst particles by freeze-drying the catalyst metal precursor solution. The catalyst particles formed by the method has a very uniform particle size and are very uniformly distributed on the substrate.

Owner:SAMSUNG SDI CO LTD

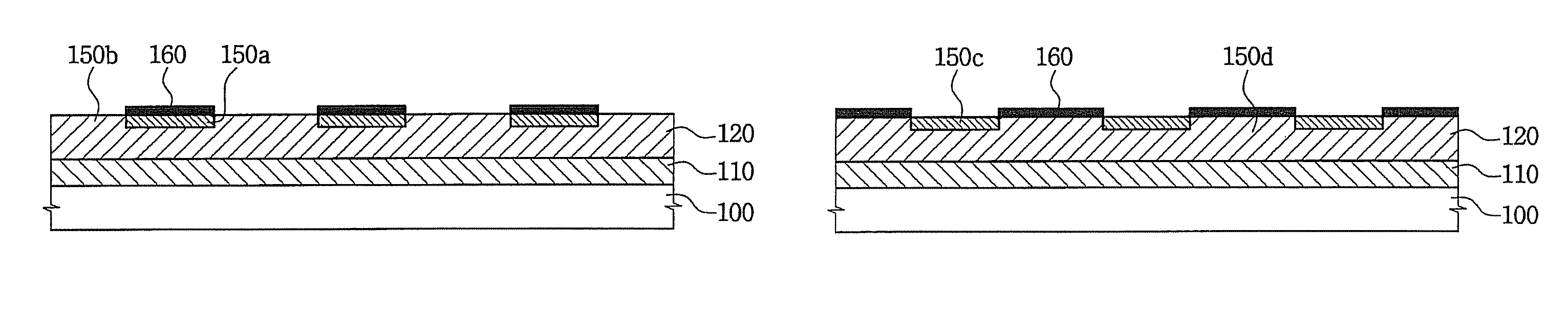

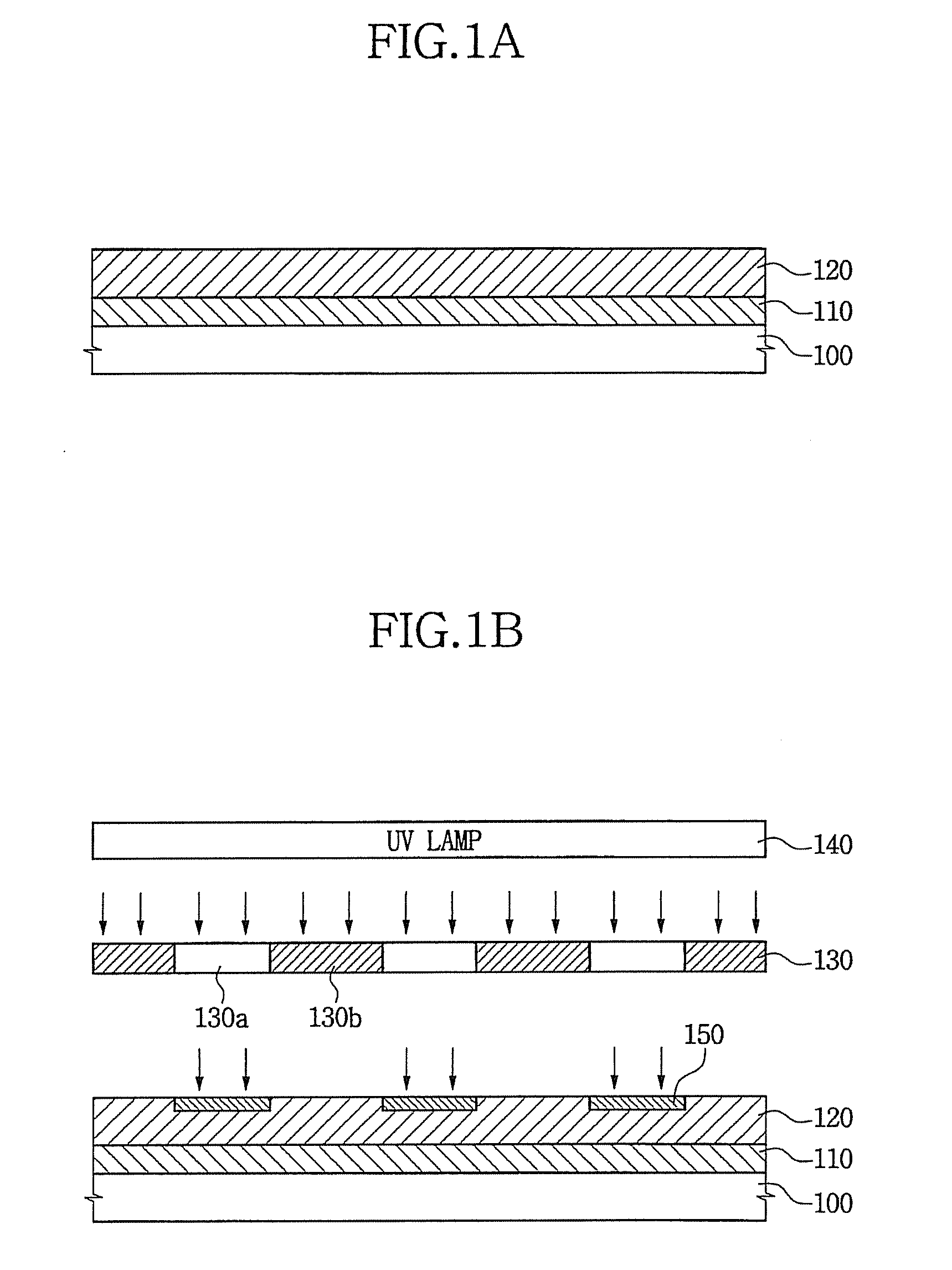

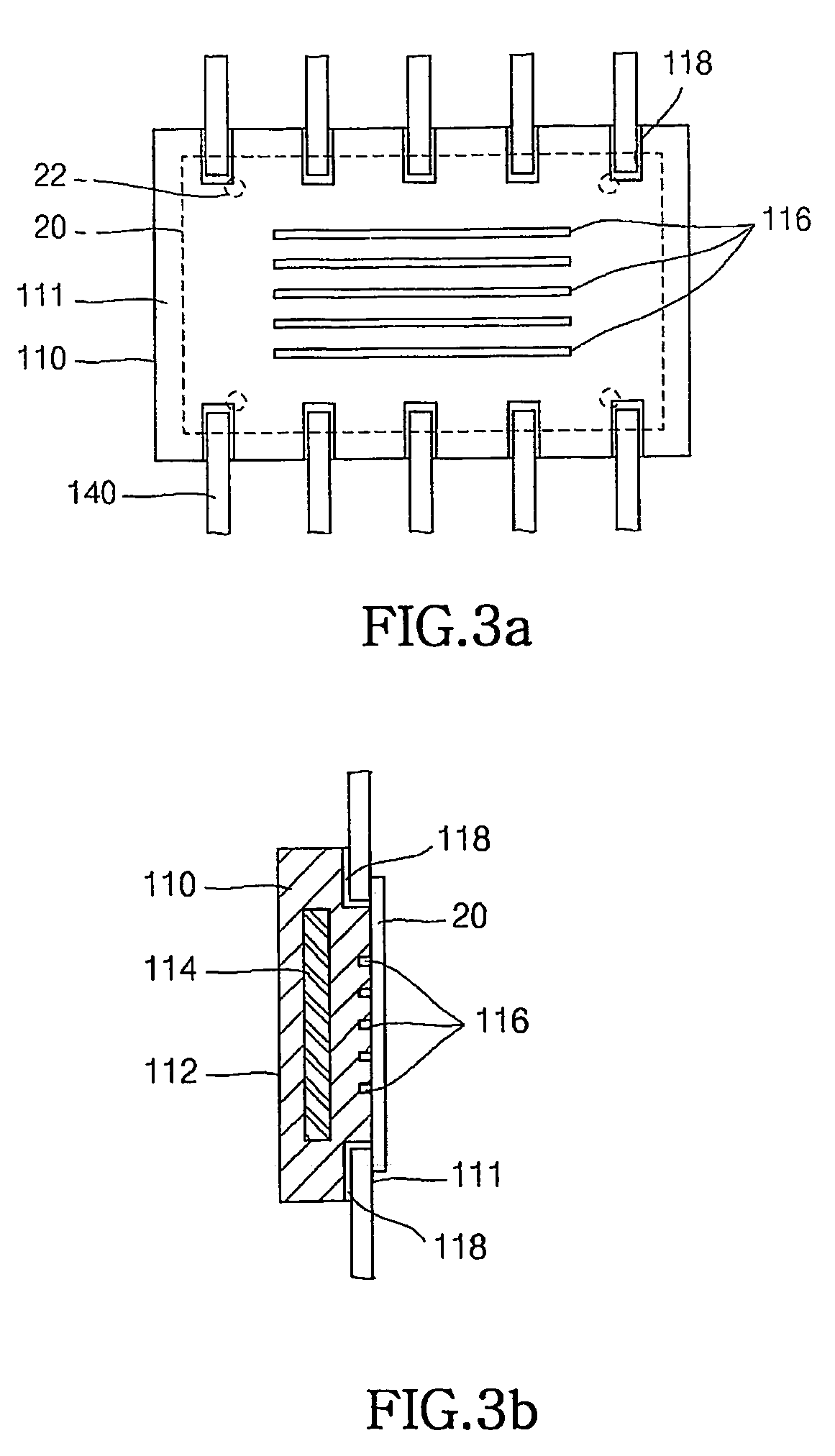

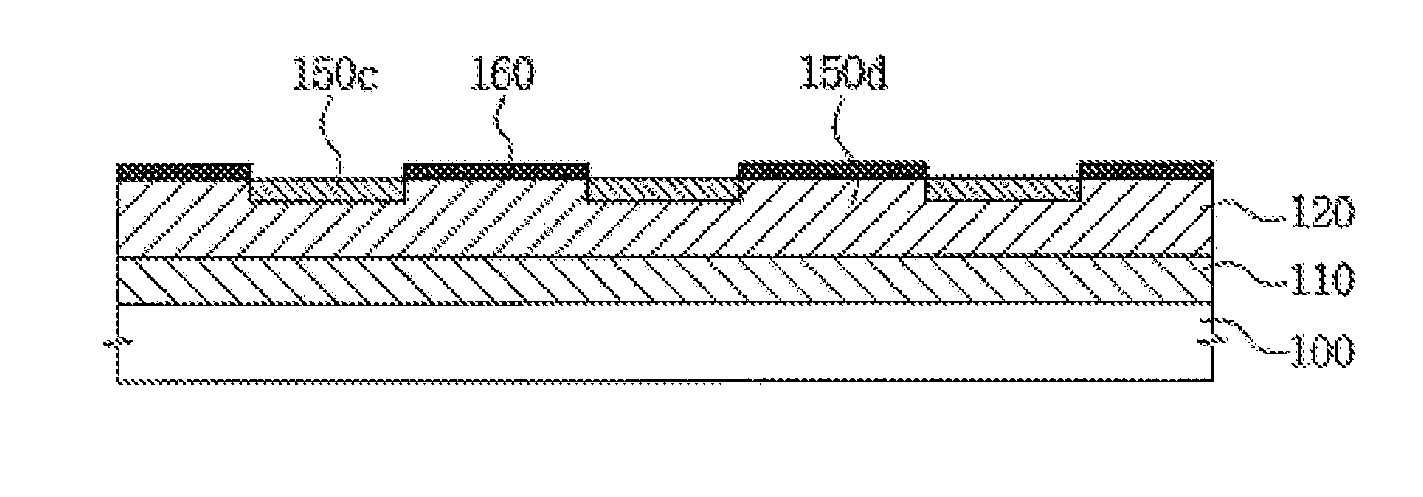

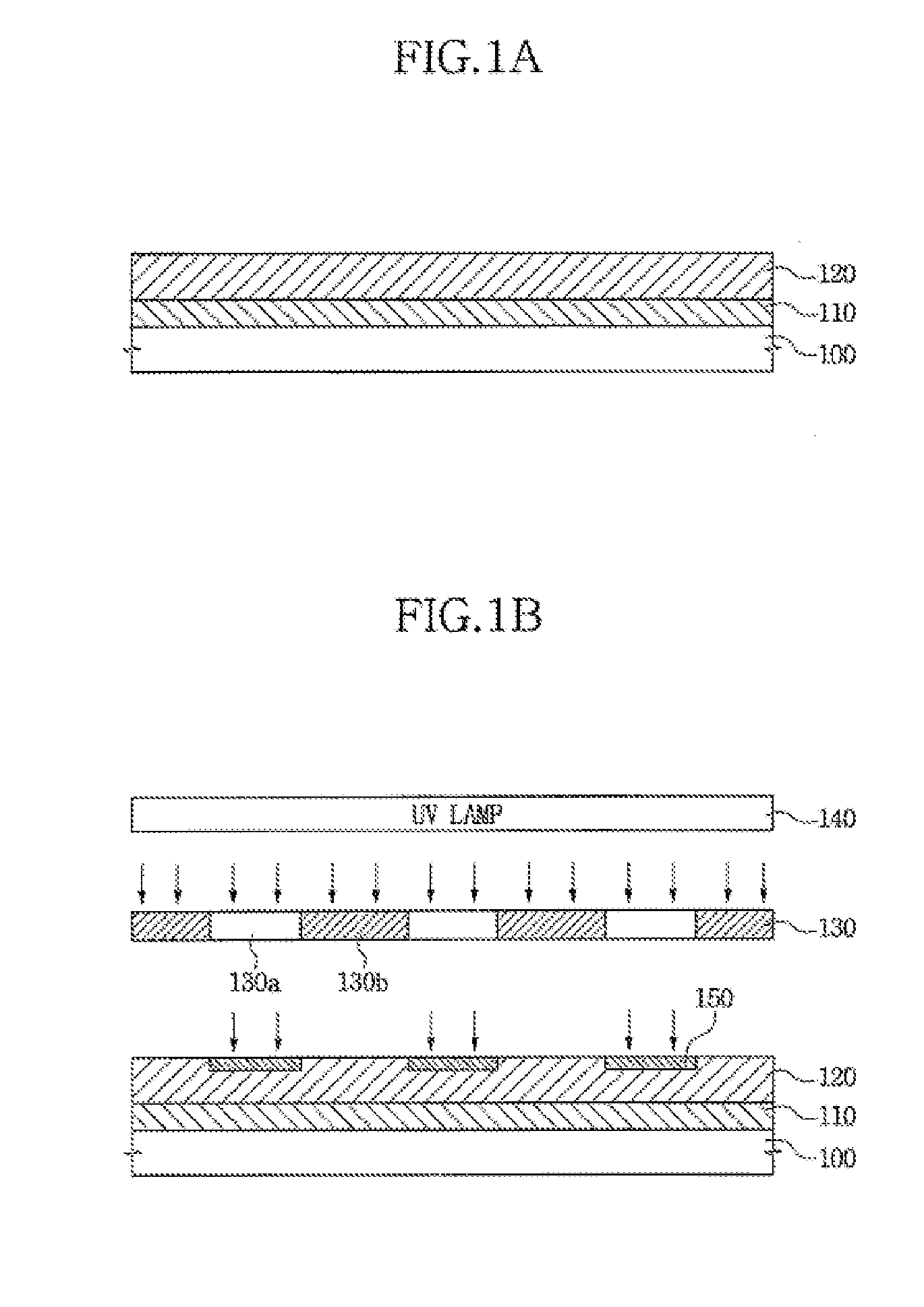

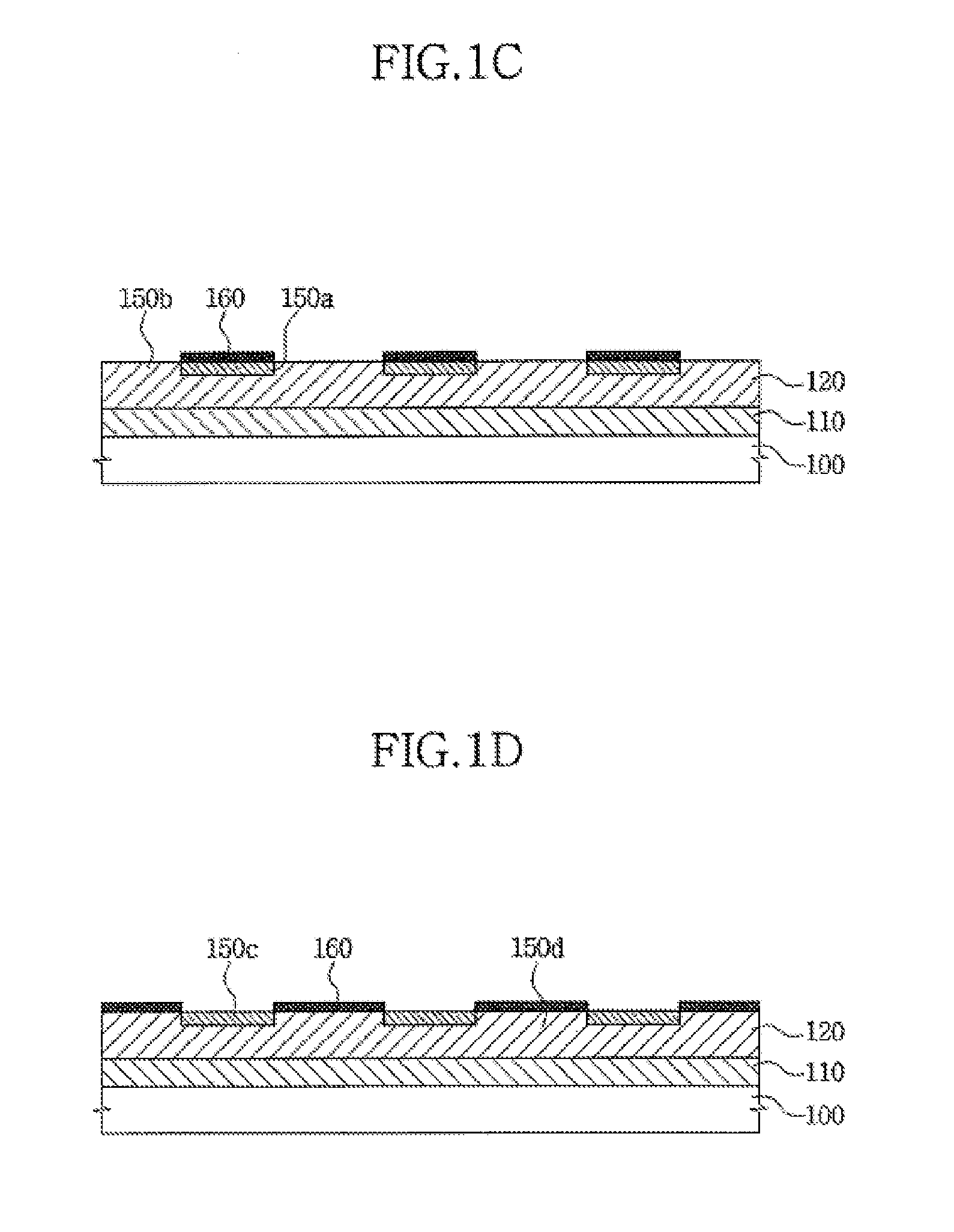

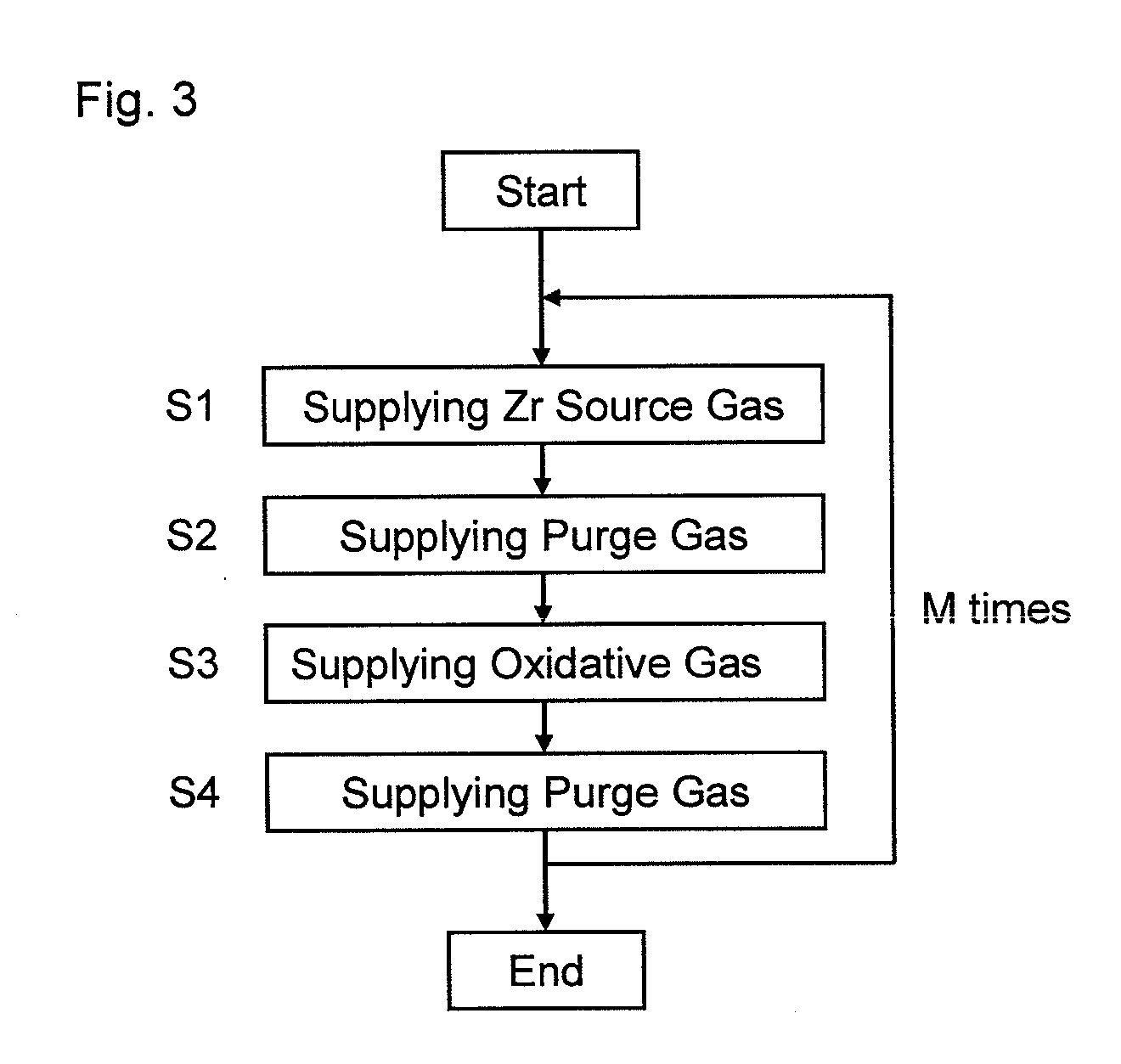

Method of forming polycrystalline silicon layer and atomic layer deposition apparatus used for the same

A method of forming a polycrystalline silicon layer and an atomic layer deposition apparatus used for the same. The method includes forming an amorphous silicon layer on a substrate, exposing the substrate having the amorphous silicon layer to a hydrophilic or hydrophobic gas atmosphere, placing a mask having at least one open and at least one closed portion over the amorphous silicon layer, irradiating UV light toward the amorphous silicon layer and the mask using a UV lamp, depositing a crystallization-inducing metal on the amorphous silicon layer, and annealing the substrate to crystallize the amorphous silicon layer into a polycrystalline silicon layer. This method and apparatus provide for controlling the seed position and grain size in the formation of a polycrystalline silicon layer.

Owner:SAMSUNG DISPLAY CO LTD

Degradable Compositions, Apparatus Comprising Same, and Method of Use

InactiveUS20070181224A1Improve responseSafe handlingDrilling compositionSealing/packingElemental compositionSubject matter

Compositions, apparatus incorporating a composition, and methods of use are described, one composition embodiment consisting essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Compositions of the invention may exist in a variety of morphologies, including a reactive metal or degradable alloy processed into an alloy of crystalline, amorphous or mixed structure that may constitute the matrix of other composition, for instance a composite. Methods of using apparatus comprising a composition, particularly in oilfield operations are also described (e.g. flow and displacement control, sensors, actuators). This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS20030013280A1Promote crystallizationTransistorPolycrystalline material growthSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

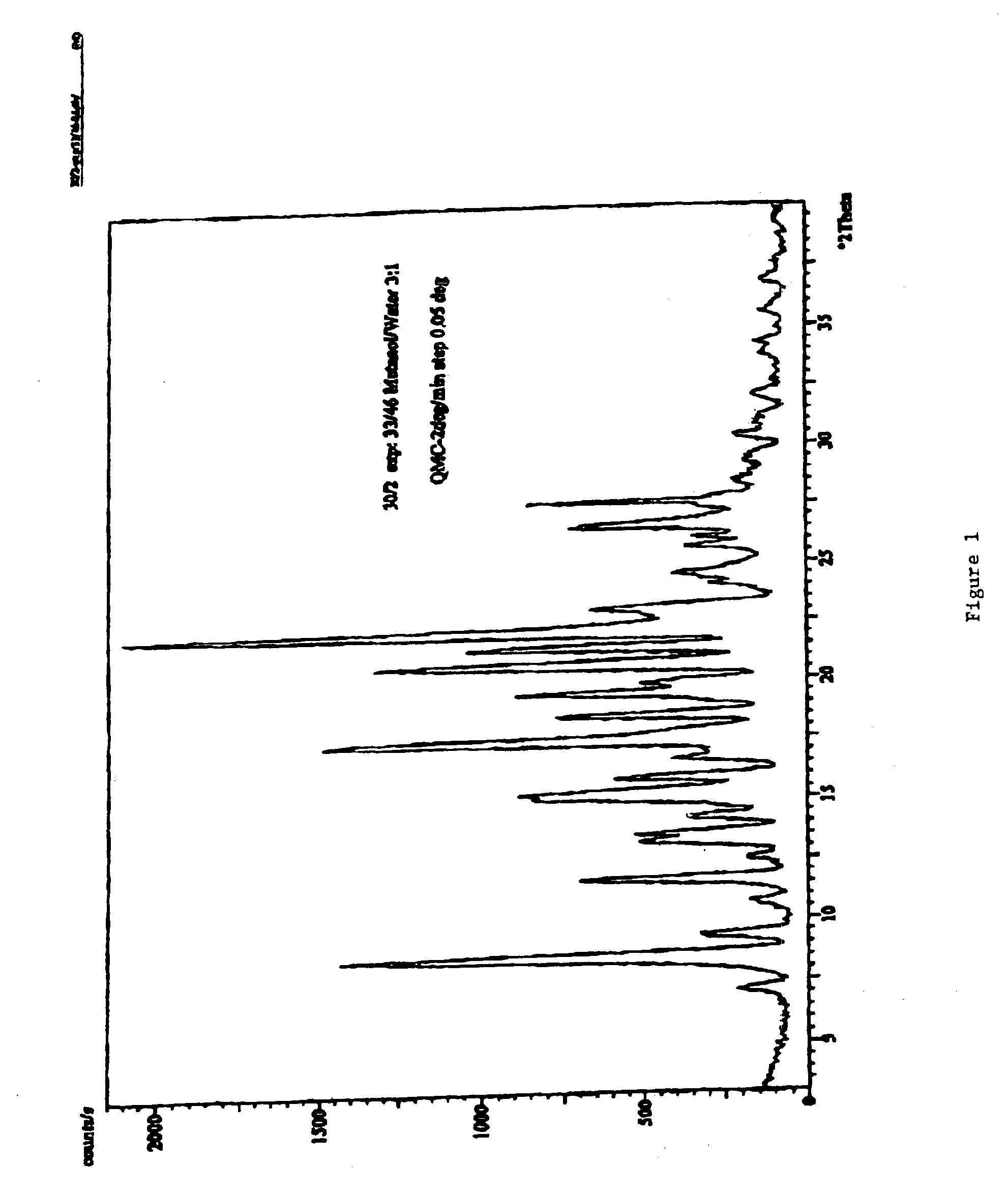

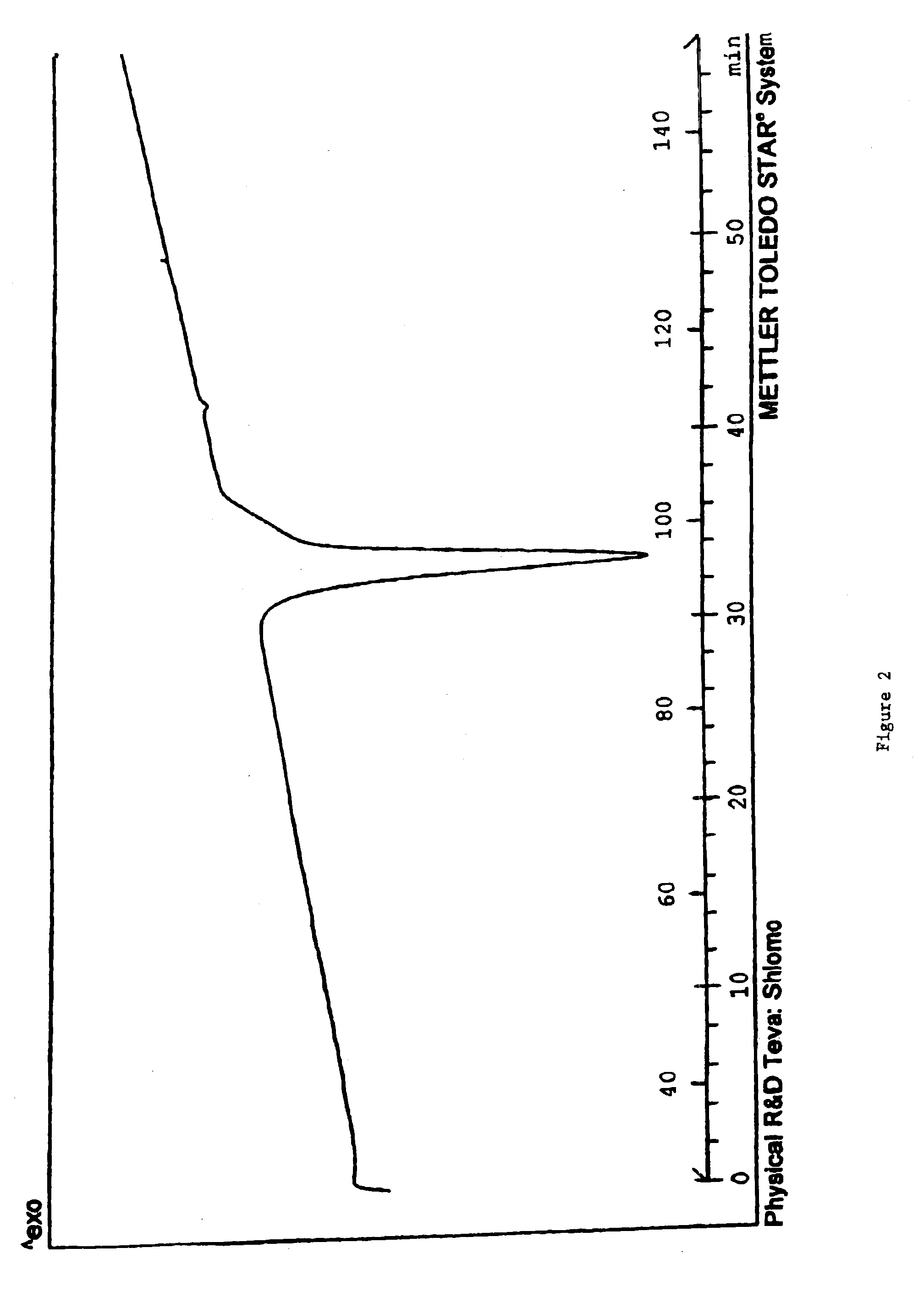

Carvedilol

InactiveUS7056942B2Lower the temperature of the solutionBiocideOrganic chemistryCarvedilolMedicinal chemistry

This invention relates to an improved process of preparing carvedilol, as well as a new crystalline hydrate and solvate and forms of carvedilol, processes for the manufacture thereof, and pharmaceutical compositions thereof.

Owner:TEVA PHARMA IND LTD

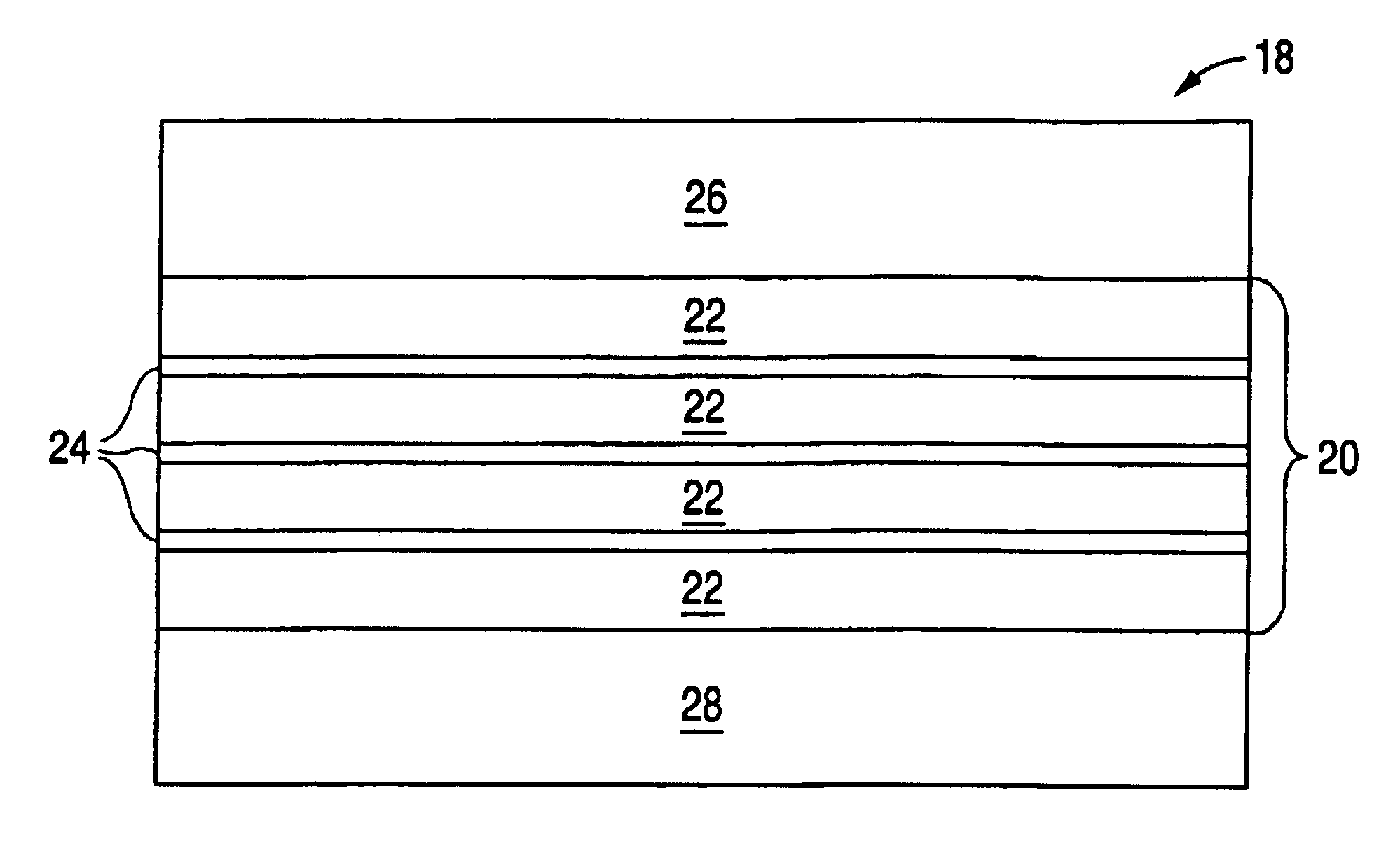

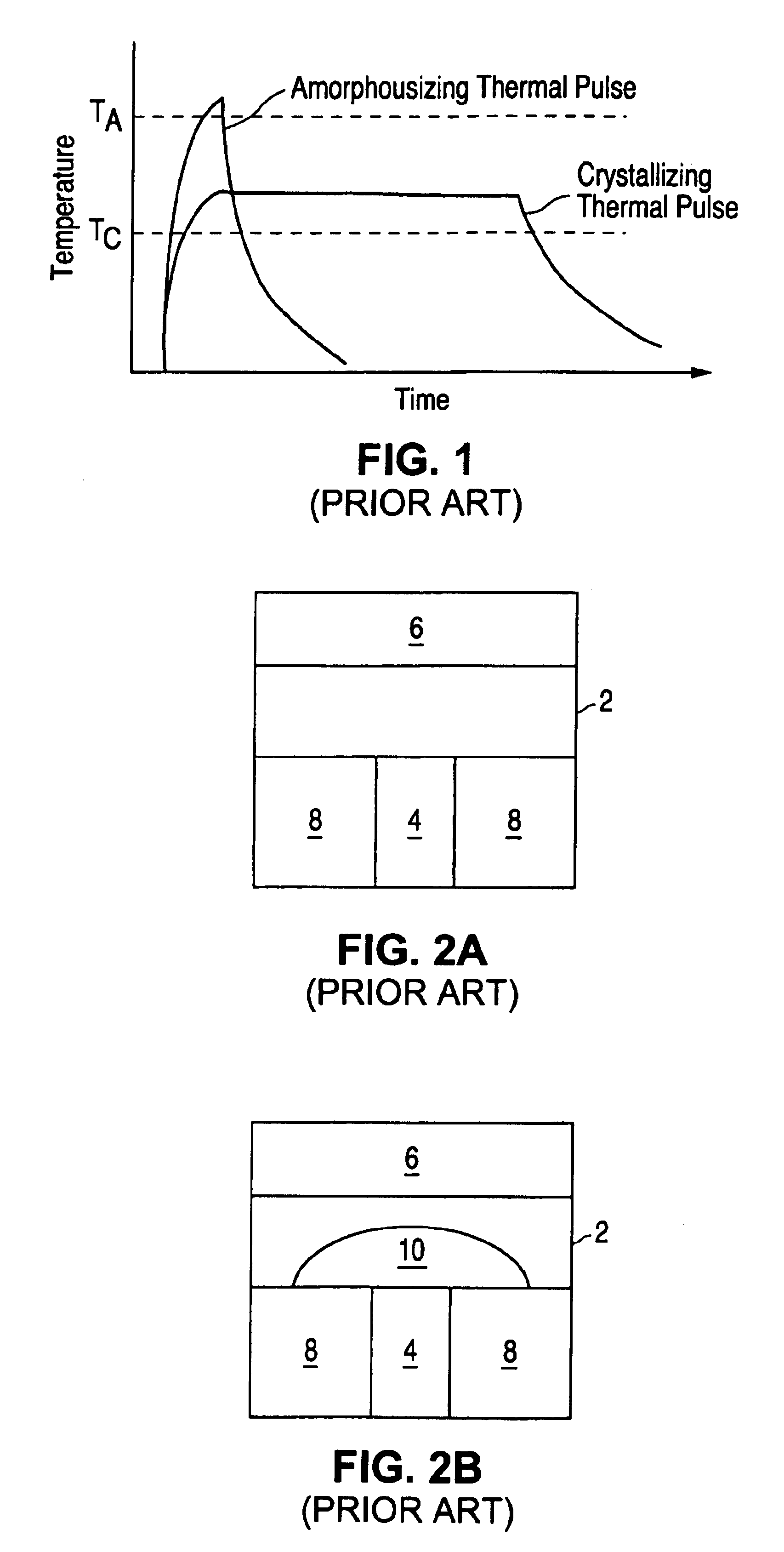

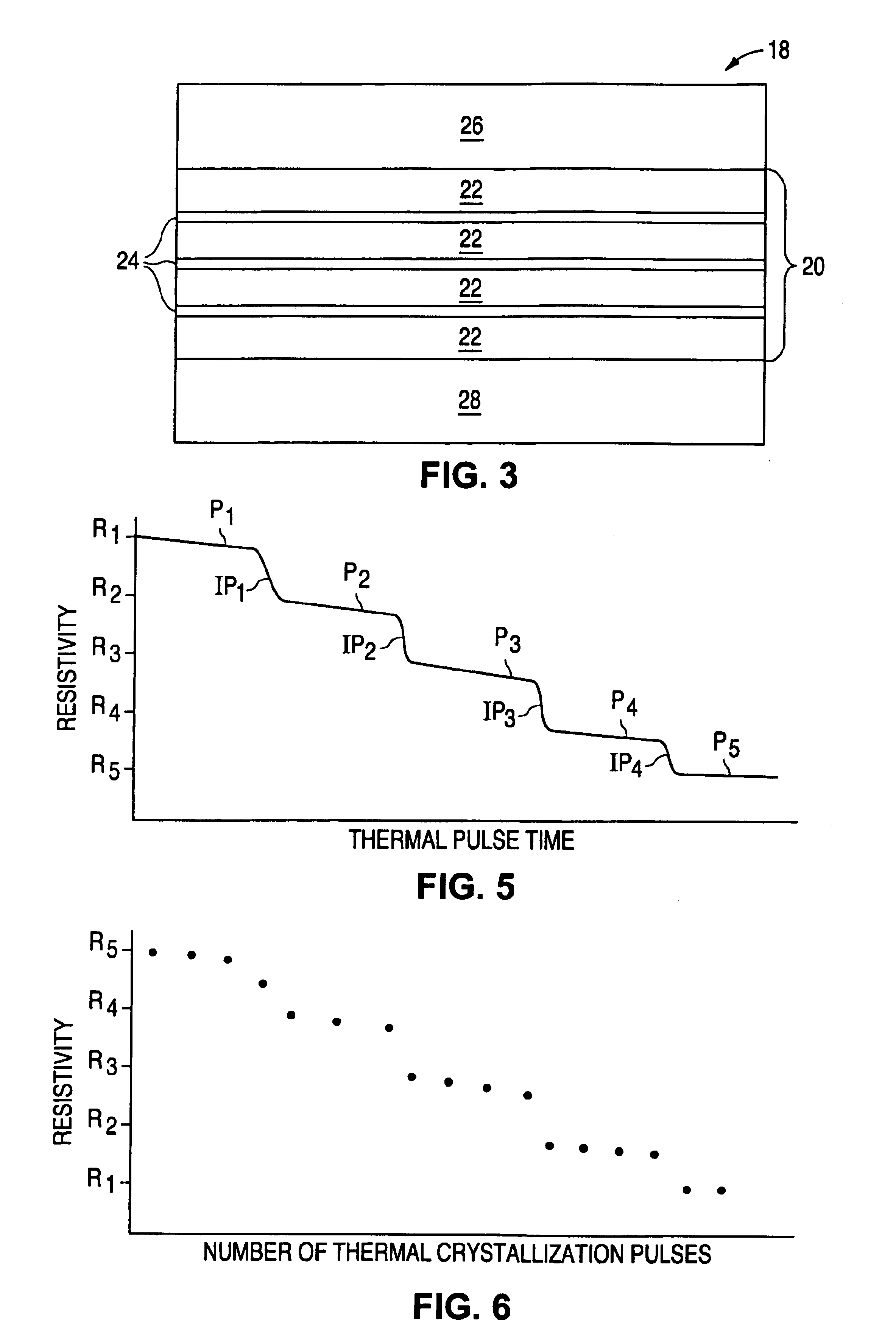

Memory device with discrete layers of phase change memory material

InactiveUS6927410B2Reliably and more repeatedly programmableSemiconductor/solid-state device detailsSolid-state devicesPhase-change memoryInterface layer

A phase changing memory device, and method of making the same, that includes programmable memory material disposed between a pair of electrodes. The programmable memory material includes discrete layers of phase change material, separated by conductive interface layers, that exhibits relatively stable resistivity values over discrete ranges of crystallizing and amorphousizing thermal pulses applied thereto, for multi-bit storage. The memory material and one of the electrodes can be disposed along spacer material surfaces to form an electrical current path that narrows in width as the current path approaches the other electrode, such that electrical current passing through the current path generates heat for heating the memory material disposed between the electrodes.

Owner:SILICON STORAGE TECHNOLOGY

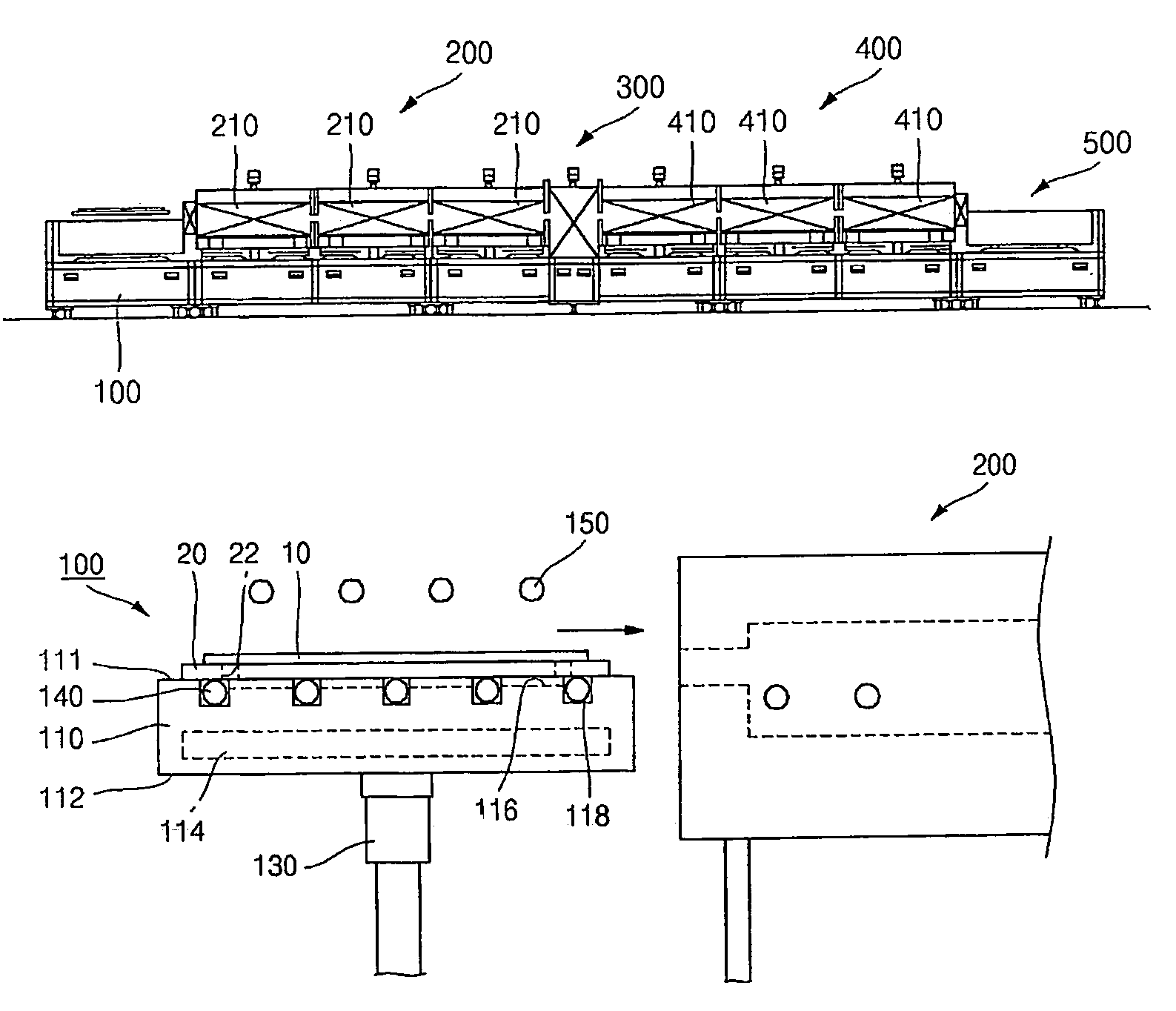

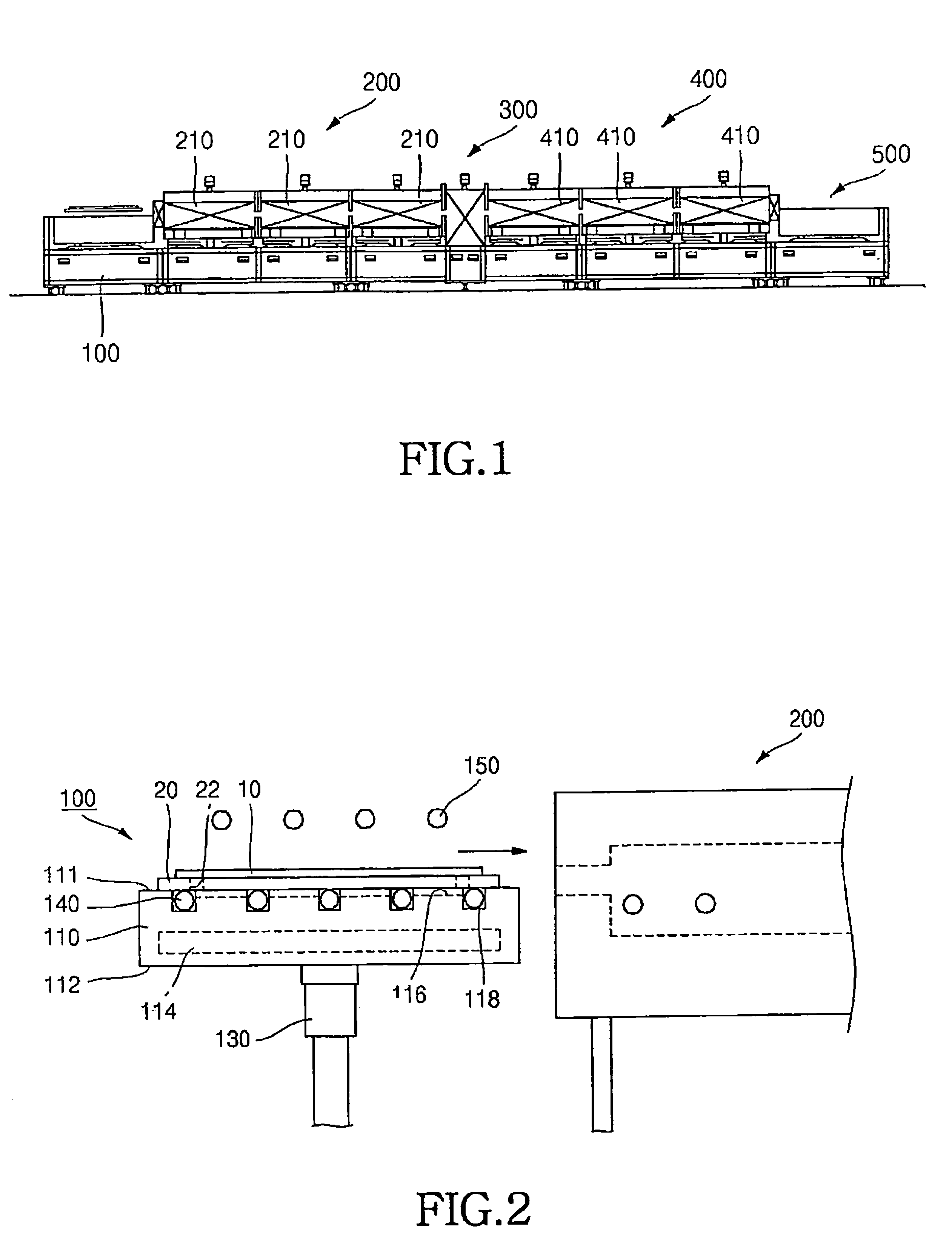

System for heat treatment of semiconductor device

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

Method of forming polycrystalline silicon layer and atomic layer deposition apparatus used for the same

ActiveUS20110263107A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingAmorphous siliconOptoelectronics

A method of forming a polycrystalline silicon layer and an atomic layer deposition apparatus used for the same. The method includes forming an amorphous silicon layer on a substrate, exposing the substrate having the amorphous silicon layer to a hydrophilic or hydrophobic gas atmosphere, placing a mask having at least one open and at least one closed portion over the amorphous silicon layer, irradiating UV light toward the amorphous silicon layer and the mask using a UV lamp, depositing a crystallization-inducing metal on the amorphous silicon layer, and annealing the substrate to crystallize the amorphous silicon layer into a polycrystalline silicon layer. This method and apparatus provide for controlling the seed position and grain size in the formation of a polycrystalline silicon layer.

Owner:SAMSUNG DISPLAY CO LTD

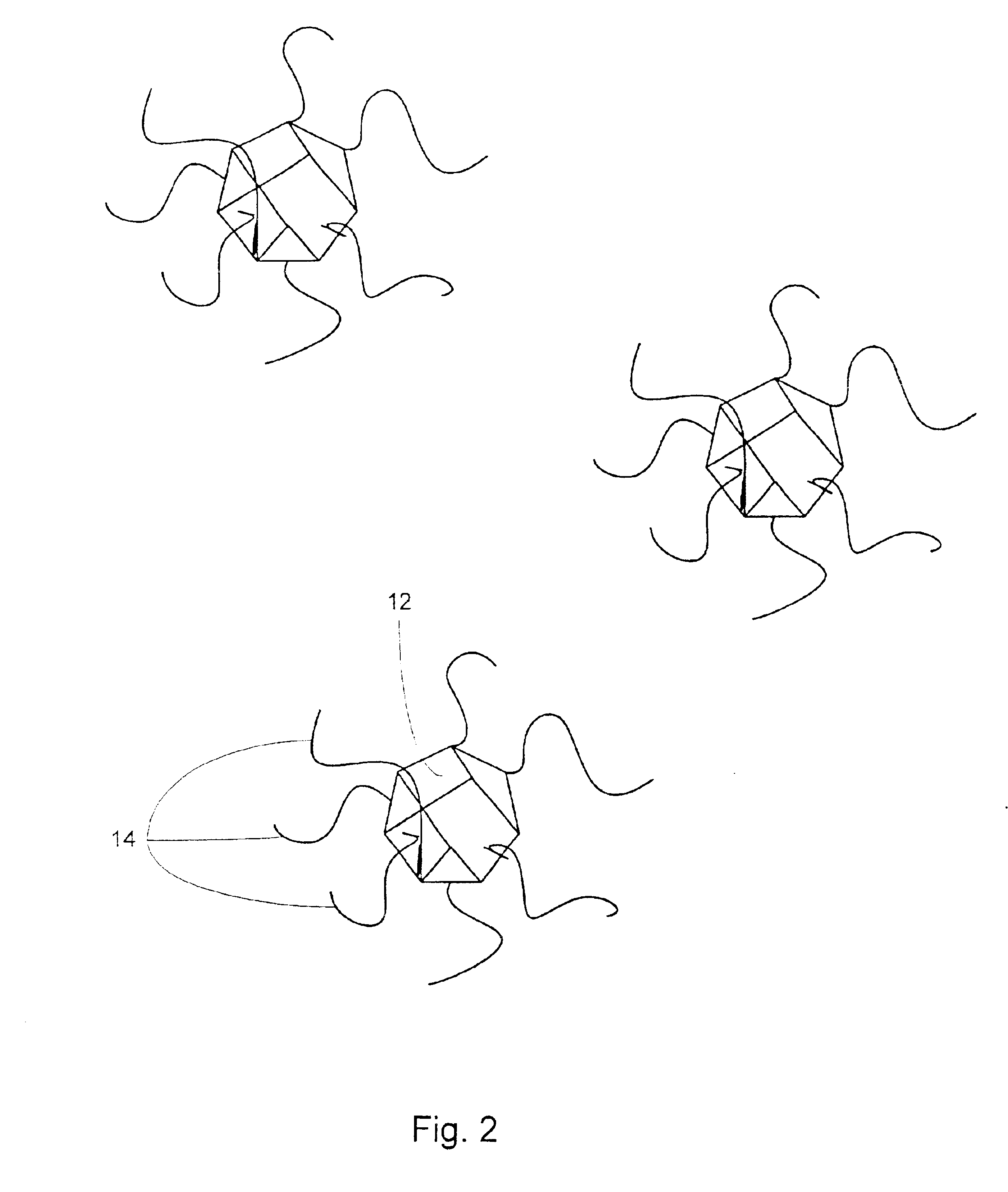

Light-emitting nanoparticles and method of making same

InactiveUS6846565B2Reduce aggregationResist formationMaterial nanotechnologyLiquid surface applicatorsParticle compositionHigh pressure

A method for the production of a robust, chemically stable, crystalline, passivated nanoparticle and composition containing the same, that emit light with high efficiencies and size-tunable and excitation energy tunable color. The methods include the thermal degradation of a precursor molecule in the presence of a capping agent at high temperature and elevated pressure. A particular composition prepared by the methods is a passivated silicon nanoparticle composition displaying discrete optical transitions.

Owner:MERCK PATENT GMBH +1

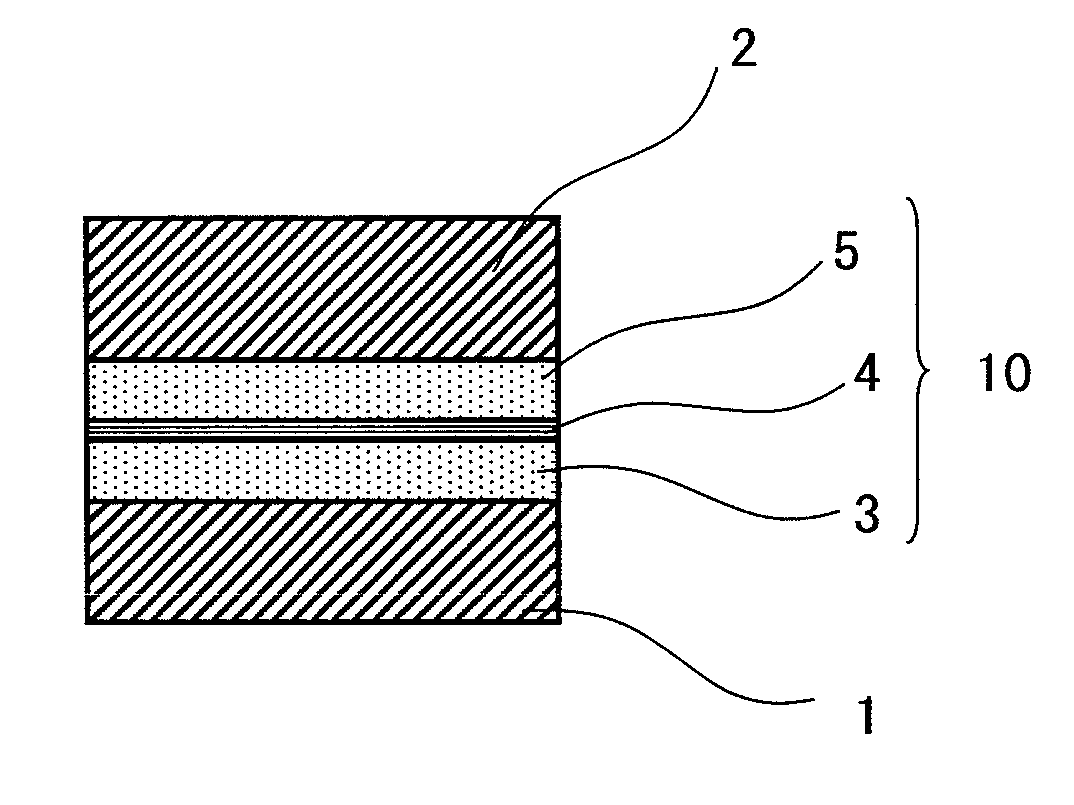

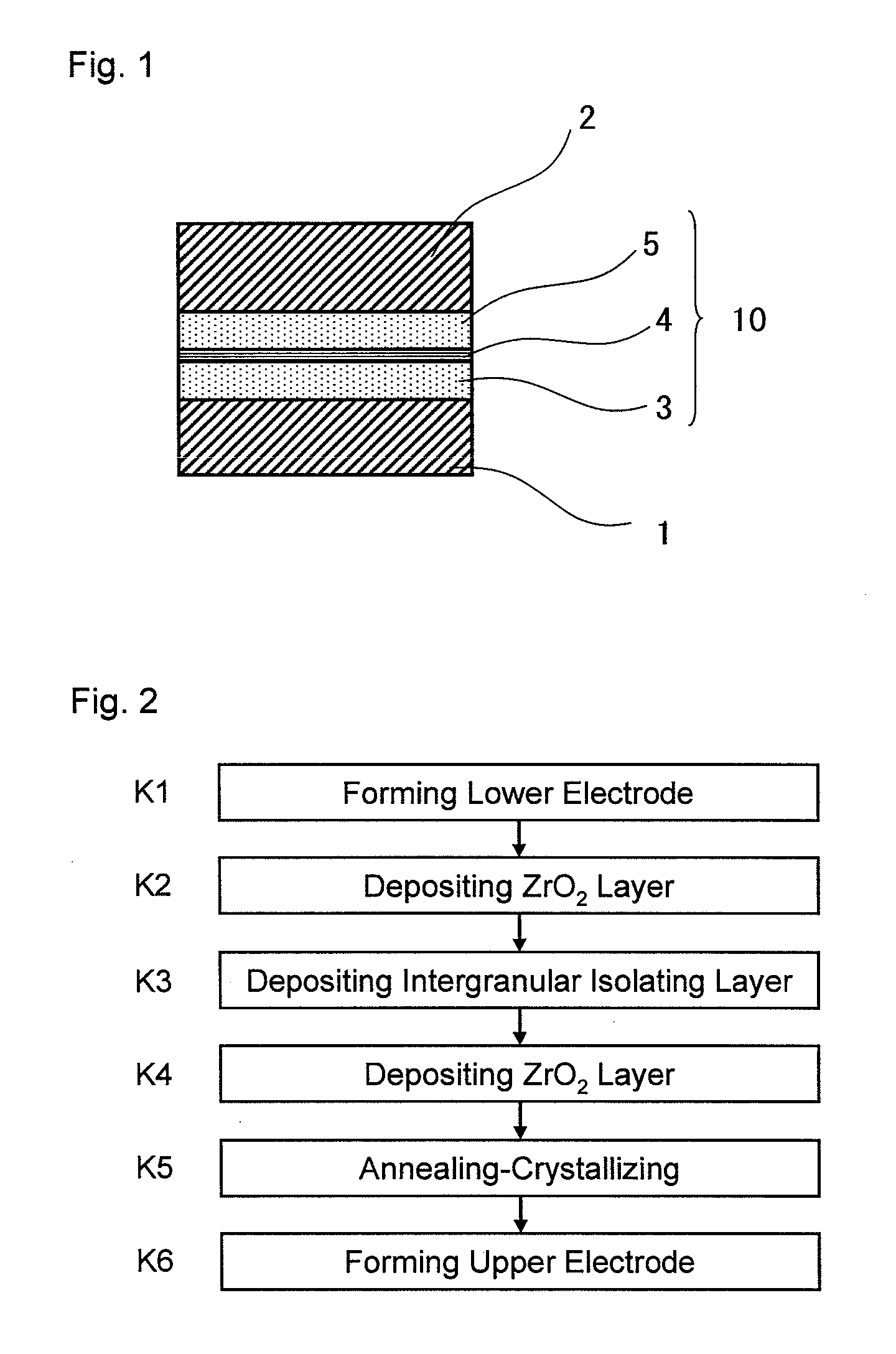

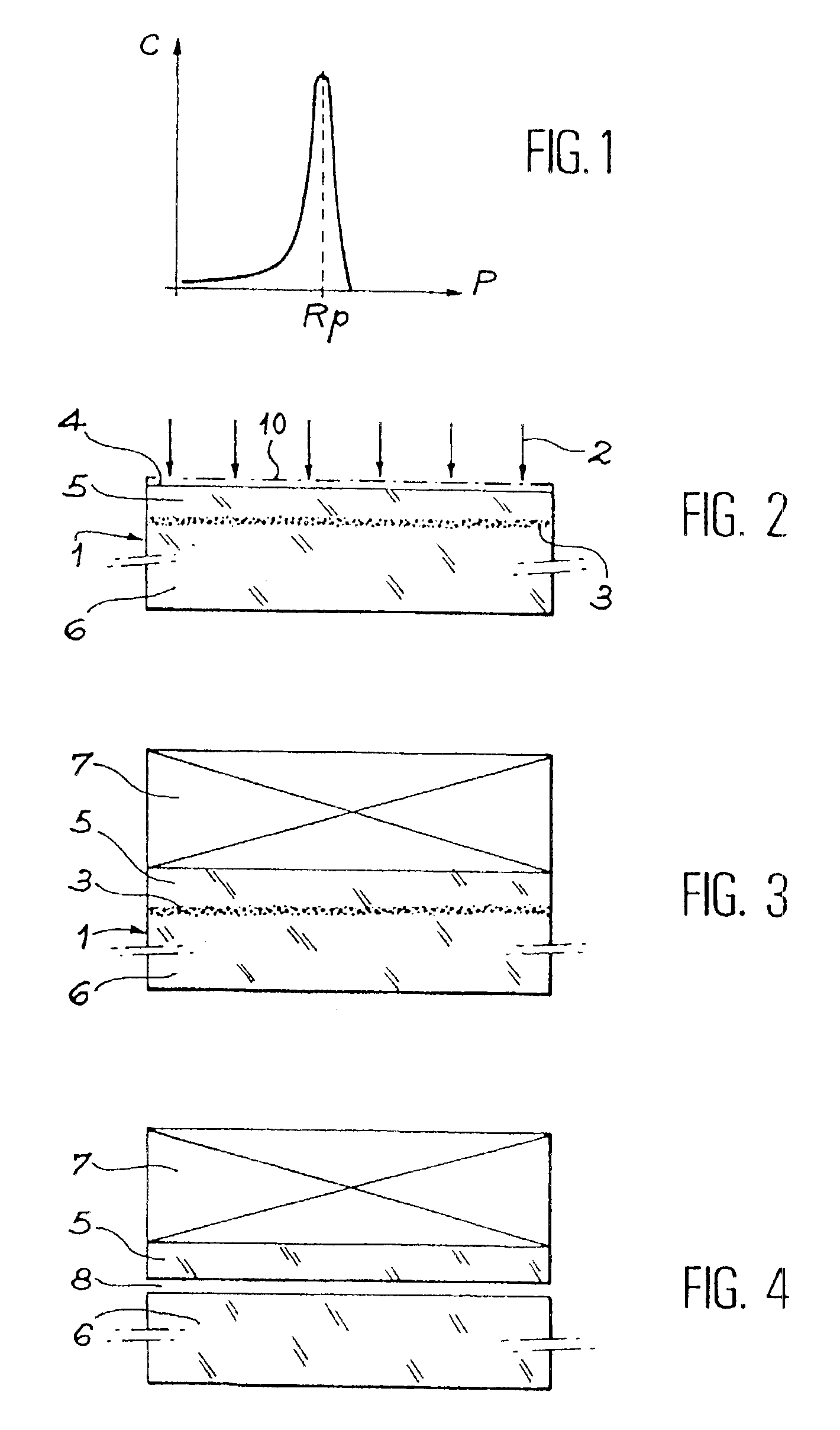

Insulating film, method of manufacturing the same, and semiconductor device

InactiveUS20110048769A1High dielectric constantSmall currentThin/thick film capacitorCeramicsCapacitanceSemiconductor

An exemplary aspect of the invention provides an insulating film which has a high dielectric constant and has small leakage current even when it is sandwiched between electrodes. The insulating film comprises two zirconium oxide layers in crystallized state; and an intergranular isolating layer composed of an amorphous material having a dielectric constant higher than that of zirconium oxide in crystallized state; wherein the intergranular isolating layer is sandwiched between the two zirconium oxide layers. The insulating film is properly used as a capacitive insulating film in a semiconductor device comprising a memory cell including a capacitor element having the capacitive insulating film between an upper electrode and a lower electrode, or as an intergate insulating film in a semiconductor device comprising a nonvolatile memory device having the intergate insulating film between a control gate electrode and a floating gate electrode.

Owner:ELPIDA MEMORY INC

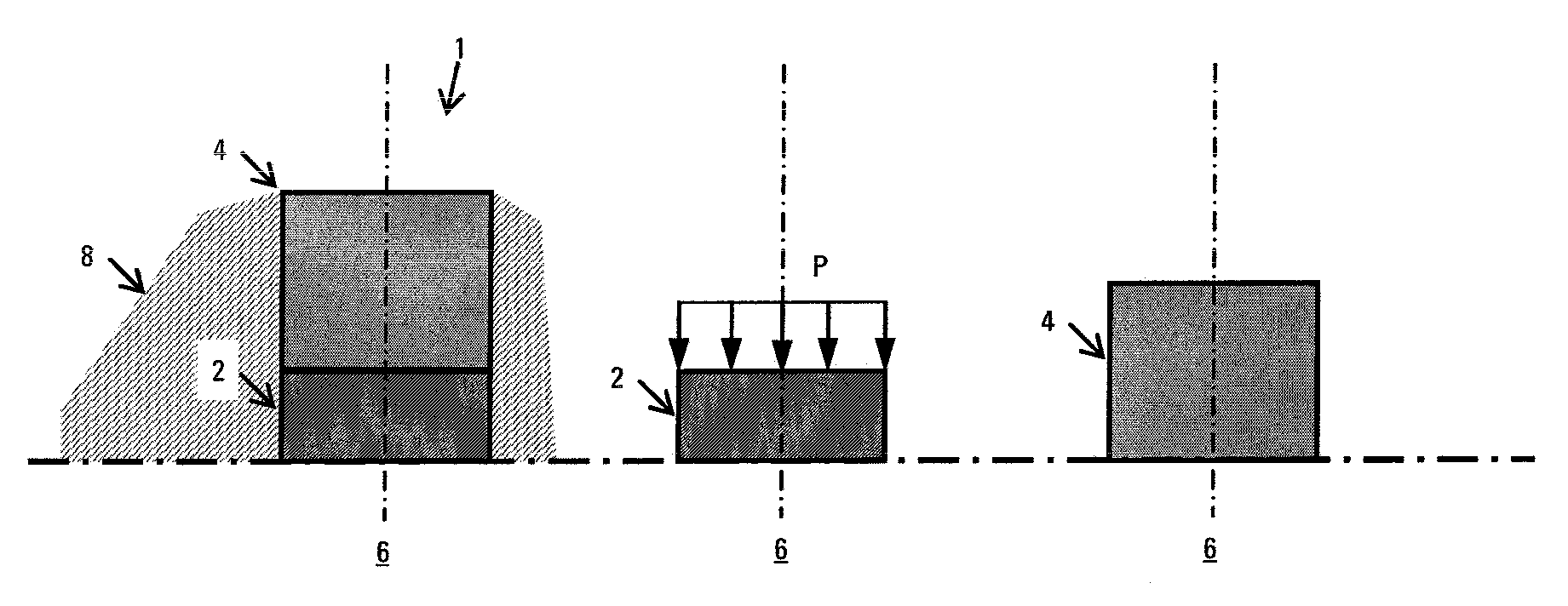

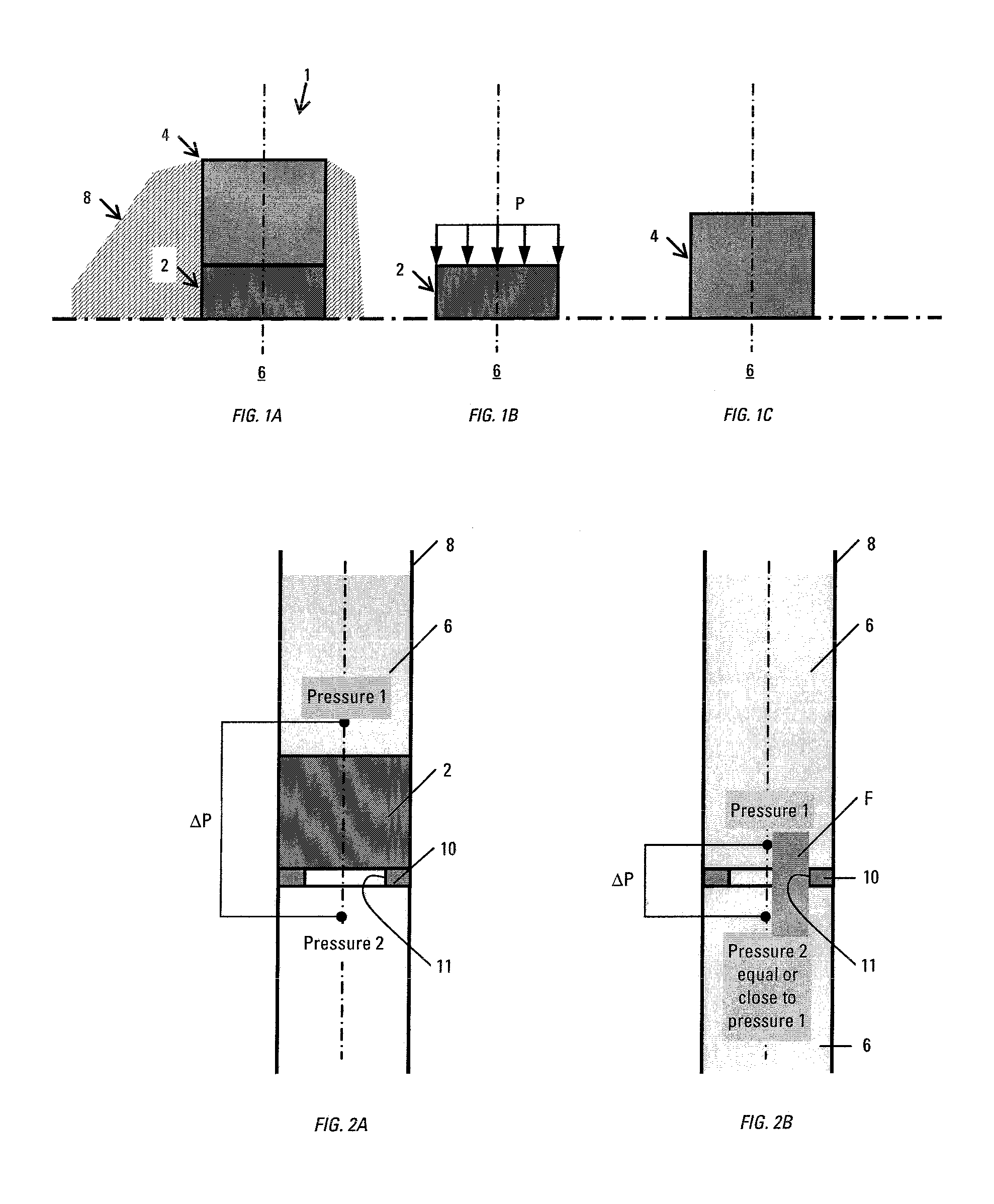

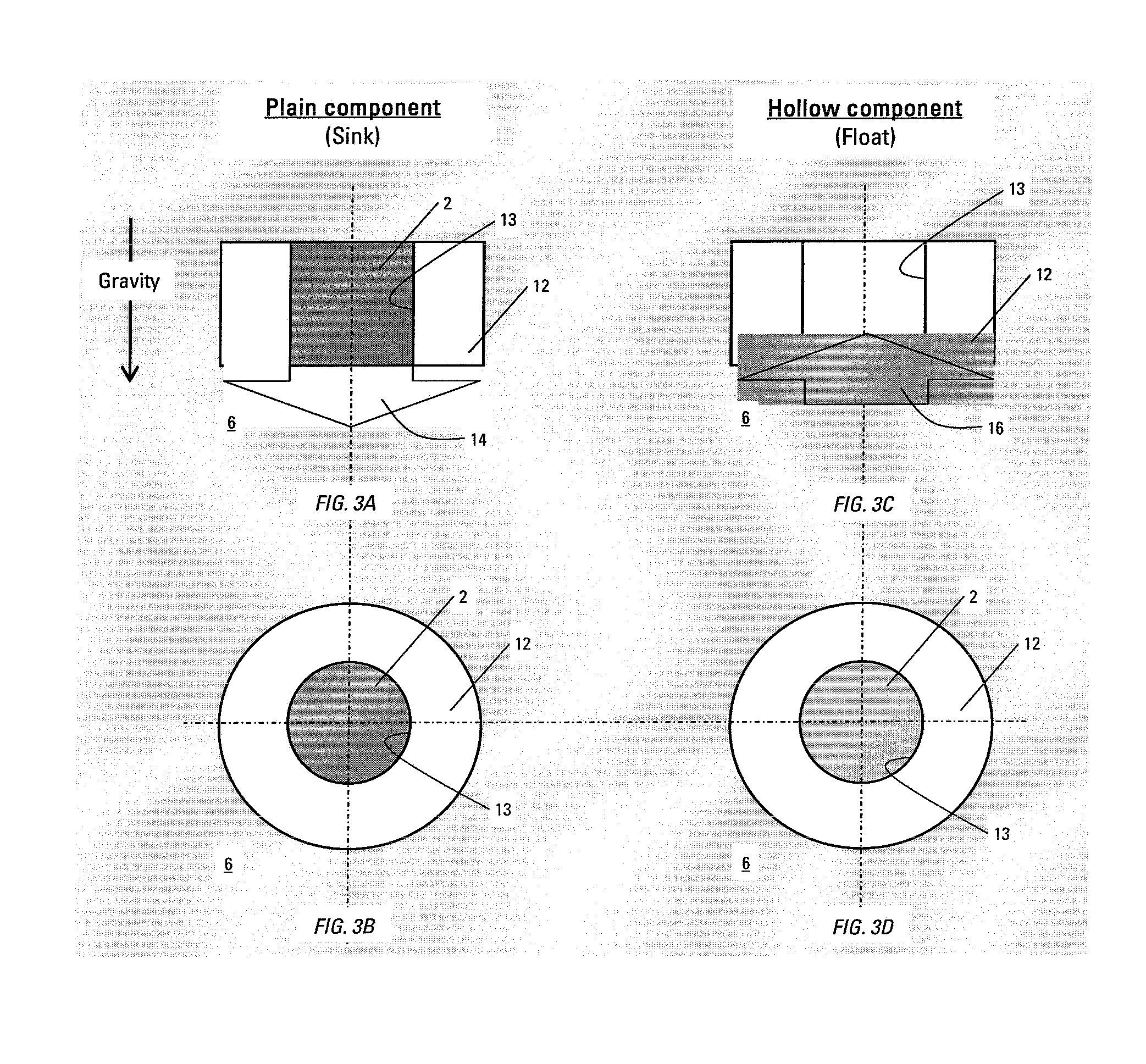

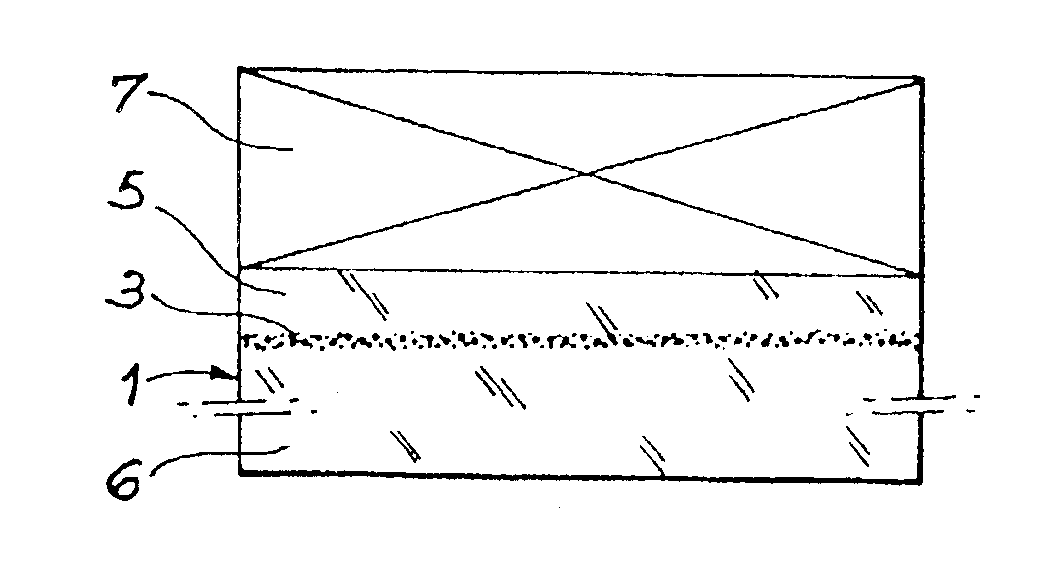

Process for the production of thin semiconductor material films

InactiveUSRE39484E1Uniform and controlled thicknessHigh implantationFluid pressure measurement by electric/magnetic elementsSolid-state devicesIon bombardmentMicrobubbles

Process for the preparation of thin monocrystalline or polycrystalline semiconductor material films, characterized in that it comprises subjecting a semiconductor material wafer having a planar face to the three following stages: a first stage of implantation by bombardment (2) of the face (4) of the said wafer (1) by means of ions creating in the volume of said wafer a layer (3) of gaseous microbubbles defining in the volume of said wafer a lower region (6) constituting the mass of the substrate and an upper region (5) constituting the thin film, a second stage of intimately contacting the planar face (4) of said wafer with a stiffener (7) constituted by at least one rigid material layer, a third stage of heat treating the assembly of said wafer (1) and said stiffener (7) at a temperature above that at which the ion bombardment (2) was carried out and sufficient to create by a crystalline rearrangement effect in said wafer (1) and a pressure effect in the said microbubbles, a separation between the thin film (5) and the mass of the substrate (6).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com