Patents

Literature

25448results about "Molecular sieve catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroalkylation of aromatic hydrocarbons

InactiveUS6037513AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07.

Owner:MOBIL OIL CORP

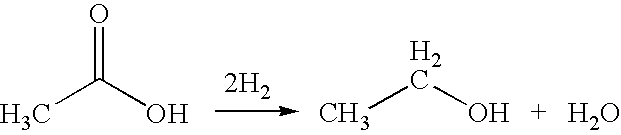

Ethylene production from acetic acid utilizing dual reaction zone process

A process for selective formation of ethylene from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with a first catalytic composition including a suitable hydrogenating catalyst in a first reaction zone to form an intermediate mixture including ethanol and ethyl acetate; and subsequently reacting the intermediate mixture over a suitable dehydrating and / or cracking catalyst in a second reaction zone to form ethylene. Selectivities of ethylene of over 80% are achieved.

Owner:CELANESE INT CORP

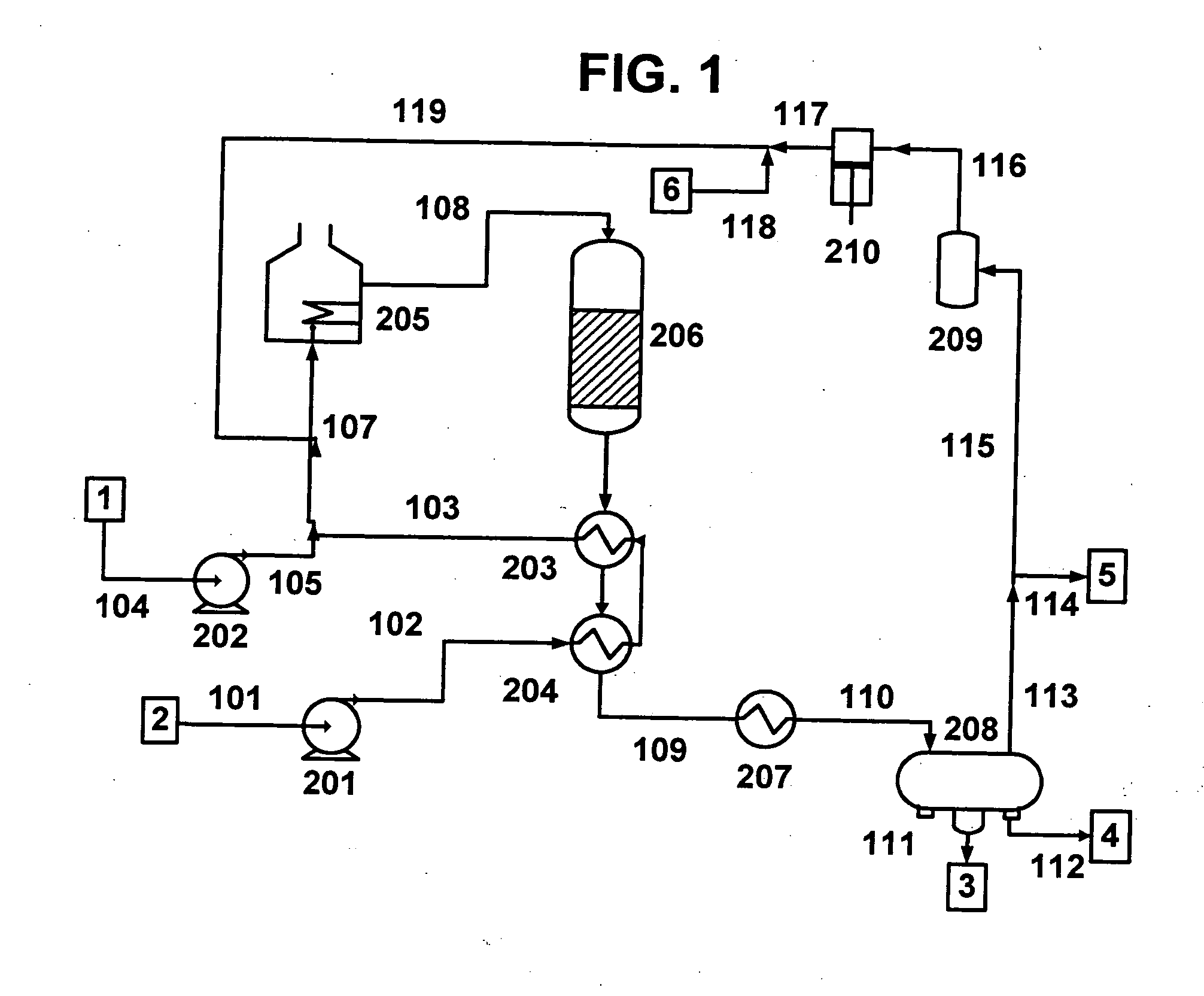

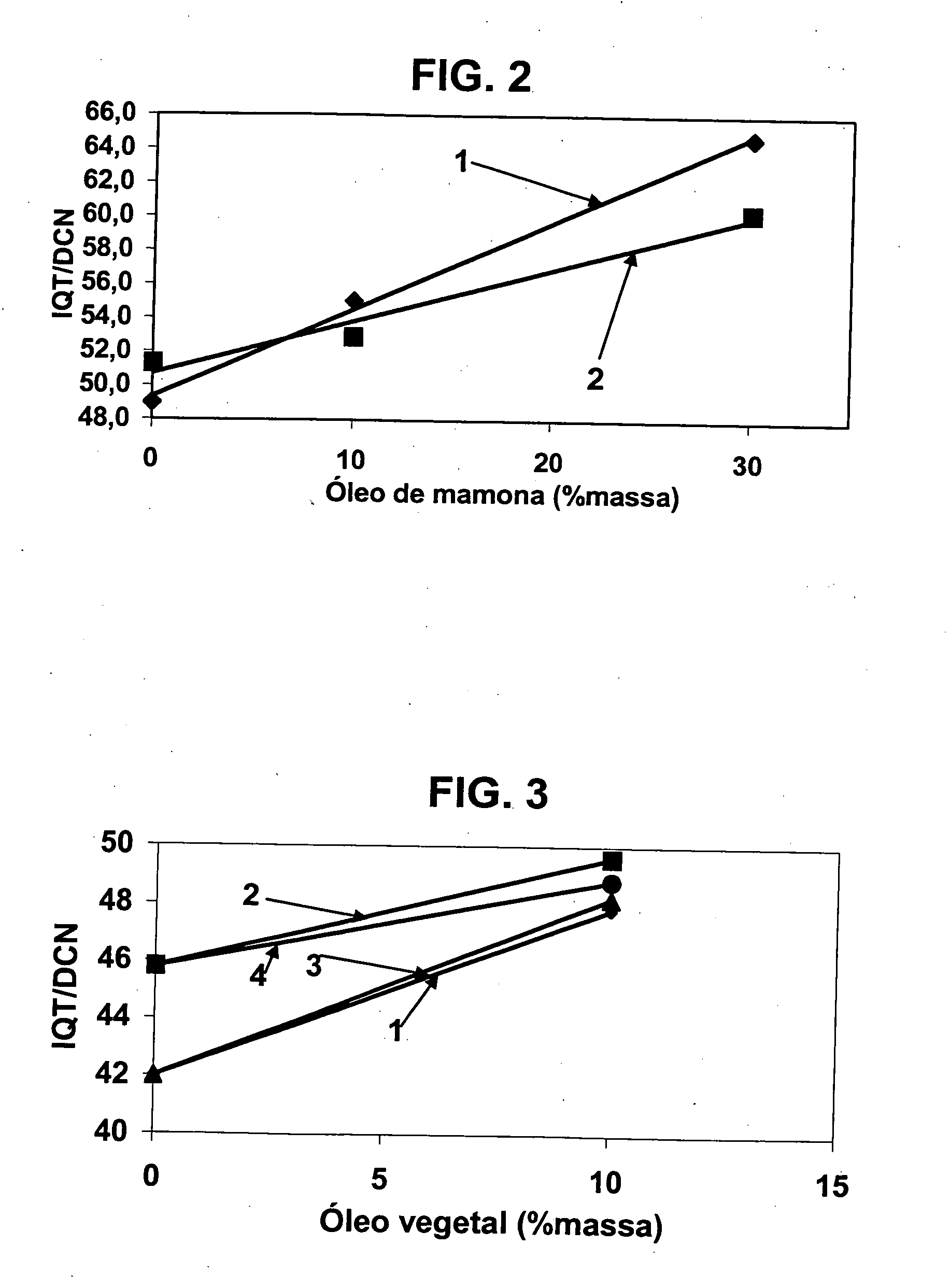

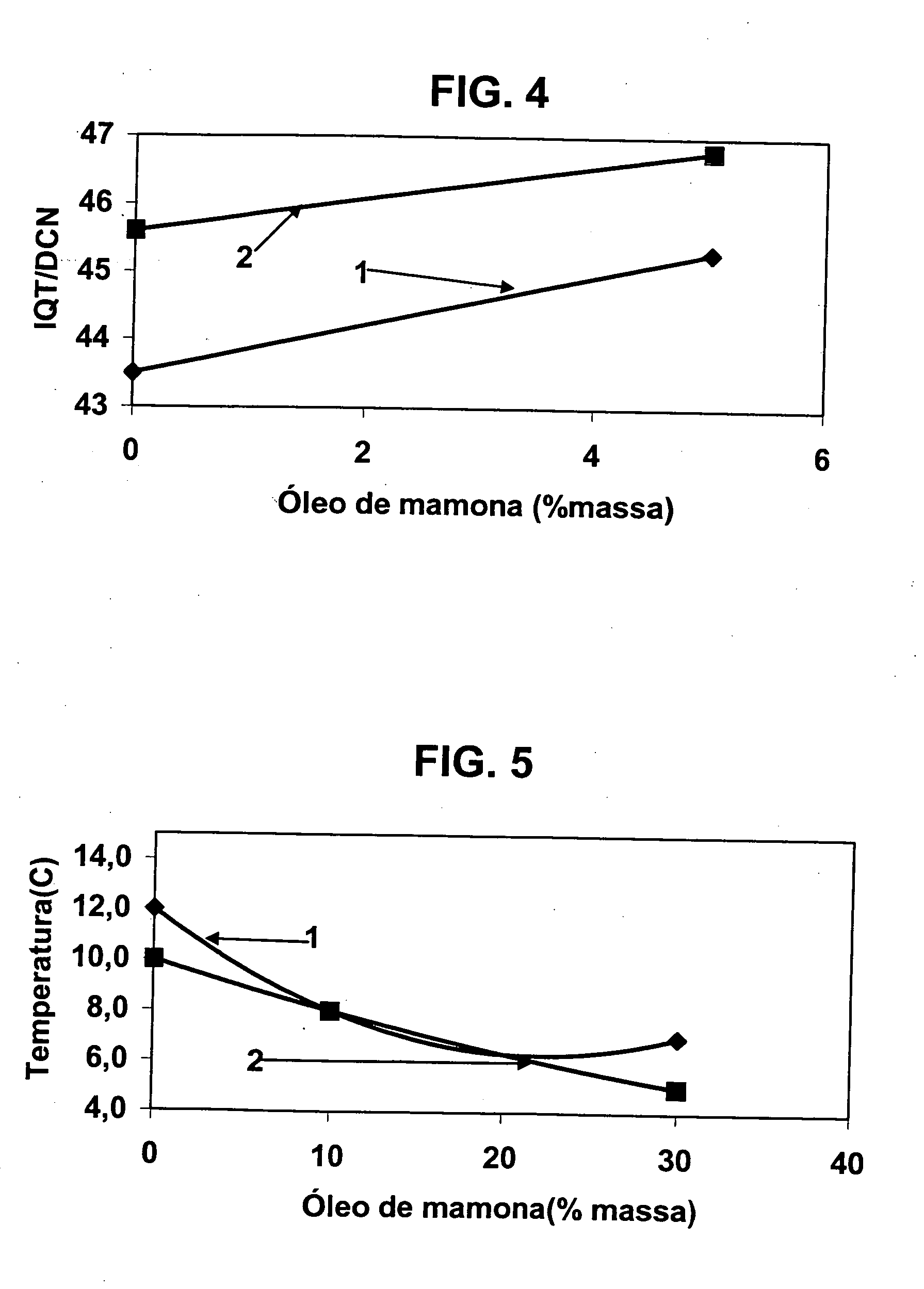

Vegetable oil hydroconversion process

InactiveUS20060186020A1Improved cetane indexAvoid excessive densityMolecular sieve catalystsBiofuelsVegetable oilHydrogen

A vegetable oil hydroconversion process is described for hydroconverting a mixture between 1 to 75% in mass of oil or natural fat (1) and the rest mineral oil (2), hydroconverted in a reactor (205) under conditions of pressure, temperature, hydrogen (flow 119) and sulfide catalyst of Groups VIII and VIB, obtaining, after sour water separation (flow 111) and rectification (flow 112), a specified diesel product (4). The product (4) has an ITQ / DCN (cetane number) higher than a product obtained from a pure mineral based oil would have, lower density than from a base oil and a plugging point depending on the mineral oil flow, as well as greater oxidation stability than the base oil.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

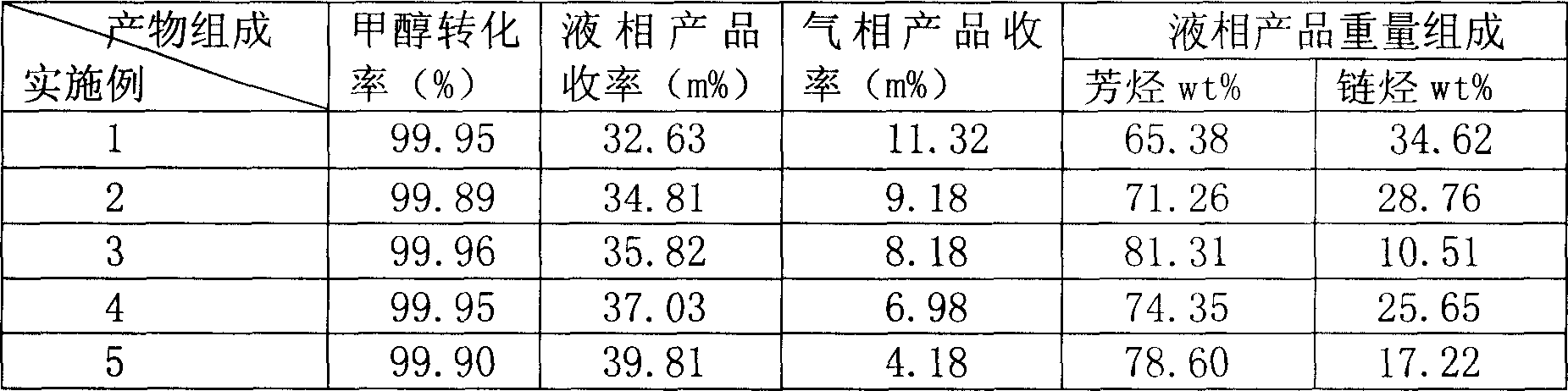

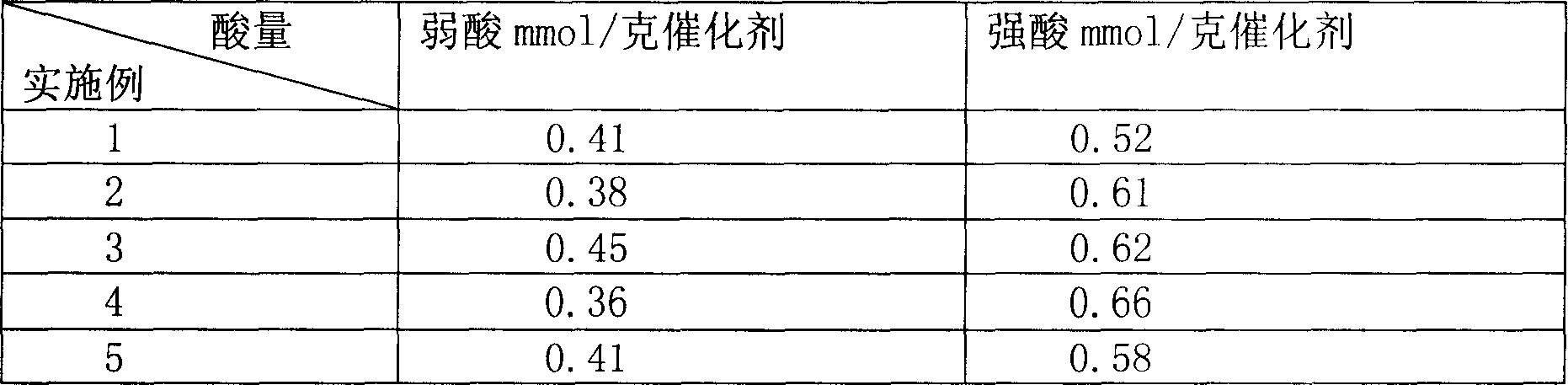

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

Catalytic dewaxing with trivalent rare earth metal ion exchanged ferrierite

InactiveUS6013171AMolecular sieve catalystsRefining to change hydrocarbon structural skeletonCation-exchange capacityIon exchange

A process for dewaxing waxy hydrocarbonaceous materials, such as hydrocarbon fuel and lubricating oil fractions to reduce their cloud and pour points comprises reacting the material with hydrogen in the presence of a dewaxing catalyst comprising at least one metal catalytic component and ferrierite in which at least a portion of its cation exchange positions are occupied by one or more trivalent rare earth metal cations. The rare earth ion exchanged ferrierite catalyst has good selectivity for lubricating oil production, particularly when dewaxing a Fischer-Tropsch wax hydroisomerate. Preferably at least 10% and more preferably at least 15% of the ferreirite cation exchange capacity is occupied by one or more trivalent rare earth metal cations.

Owner:EXXON RES & ENG CO

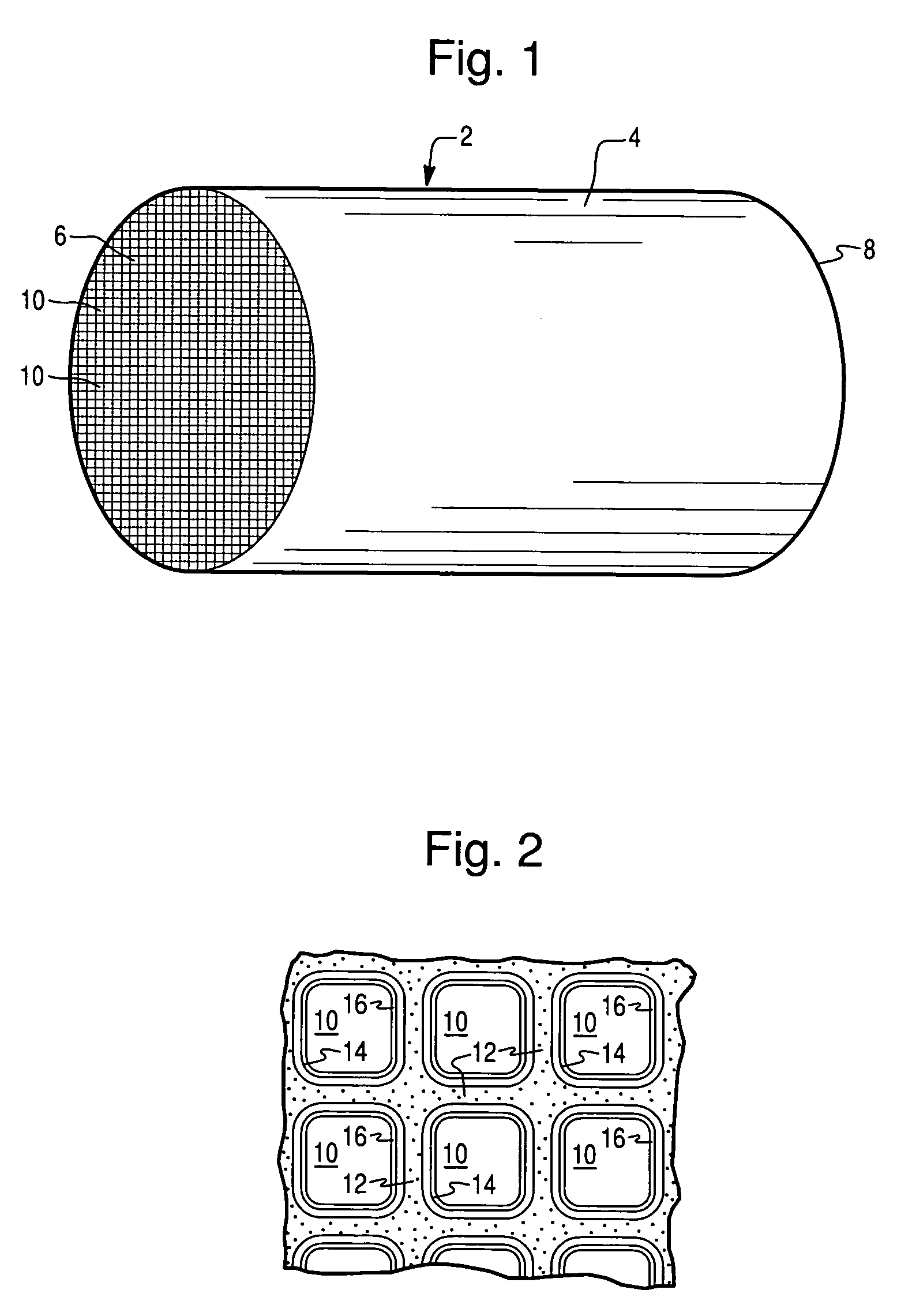

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS20080045405A1Nitrous oxide captureMolecular sieve catalystsExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

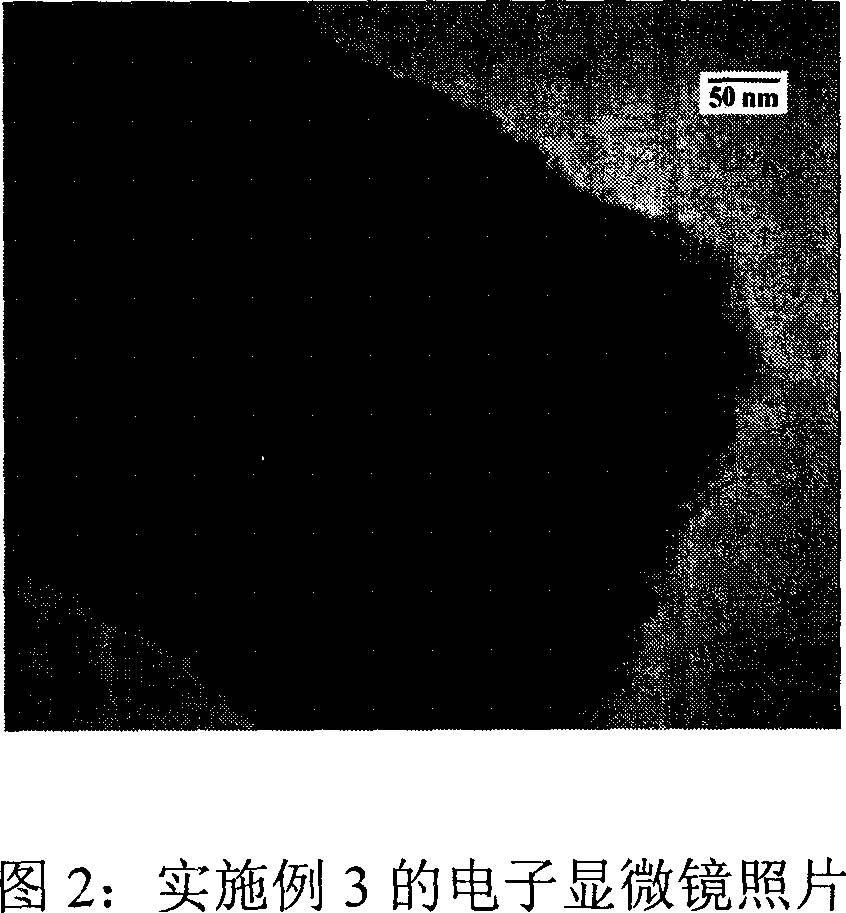

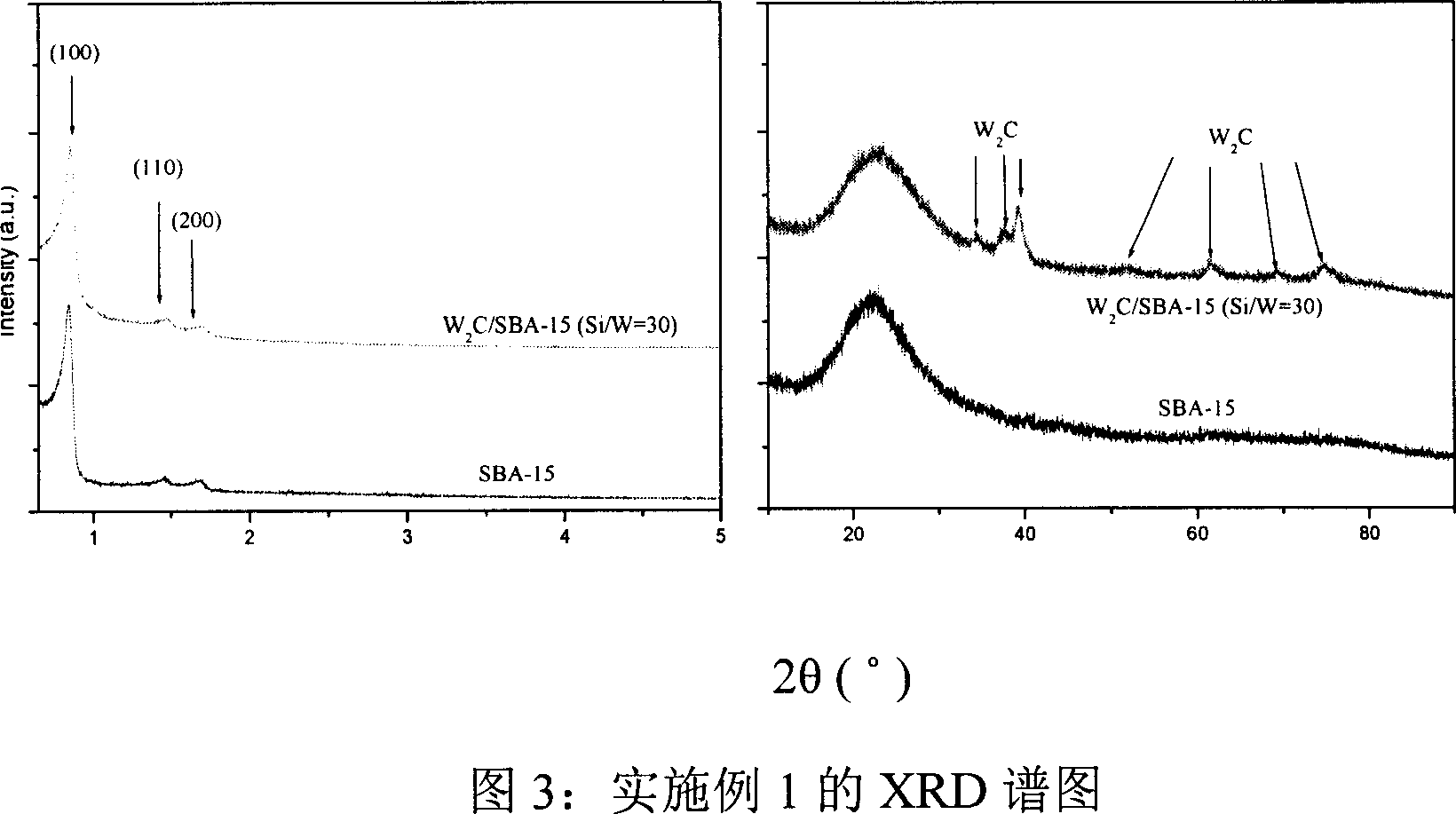

Porous molecular-sieve catalyst for assembling carbide and its preparation

InactiveCN1895777AImprove performanceImprove stabilityMolecular sieve catalystsMolecular sieveActive component

A meso-porous molecular sieve catalyst with carbide features that the carbide particles are assembled in the pores of meso-porous molecular sieve, resulting in high isolation and dispersion of active component particles and in turn high stability and activity.

Owner:BEIJING UNIV OF CHEM TECH

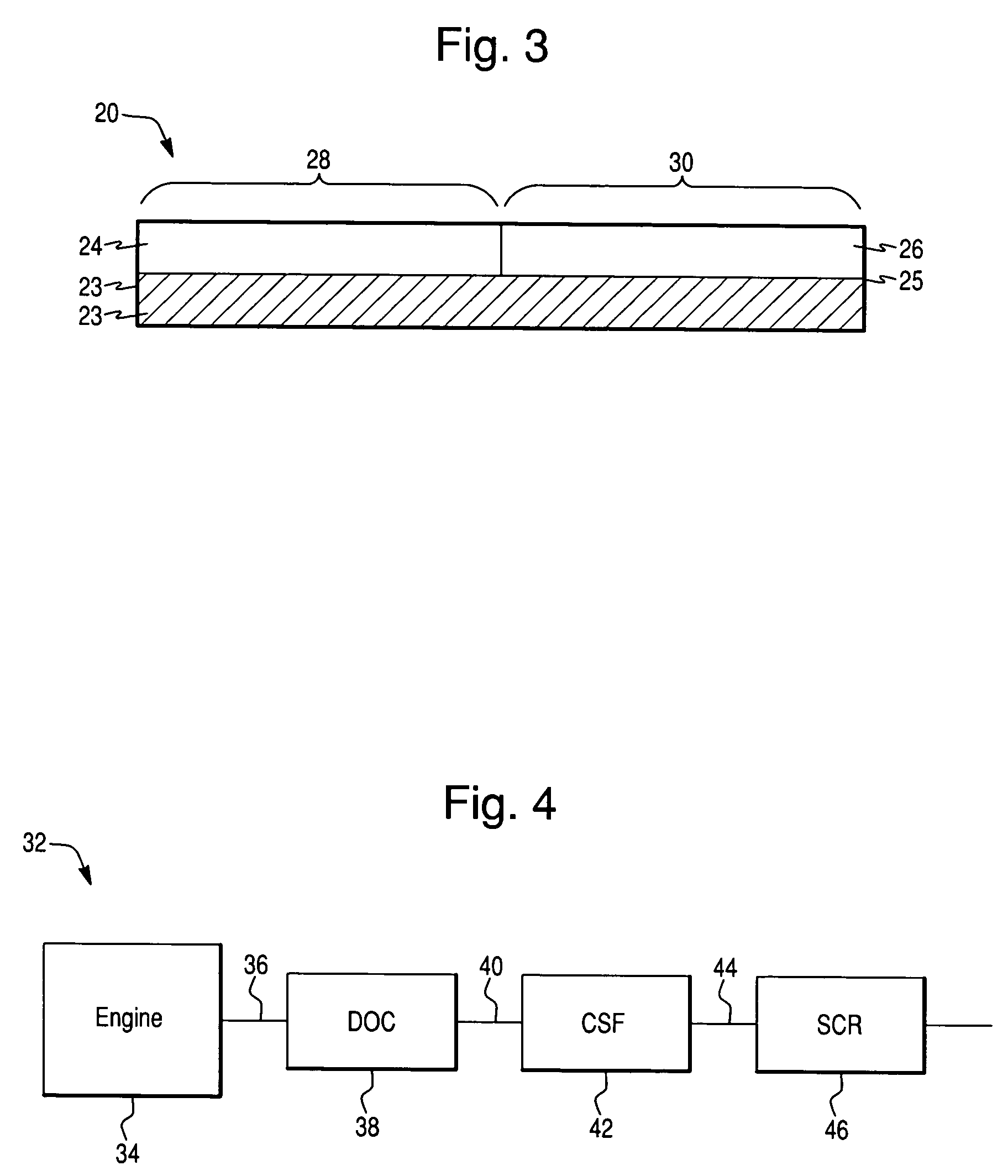

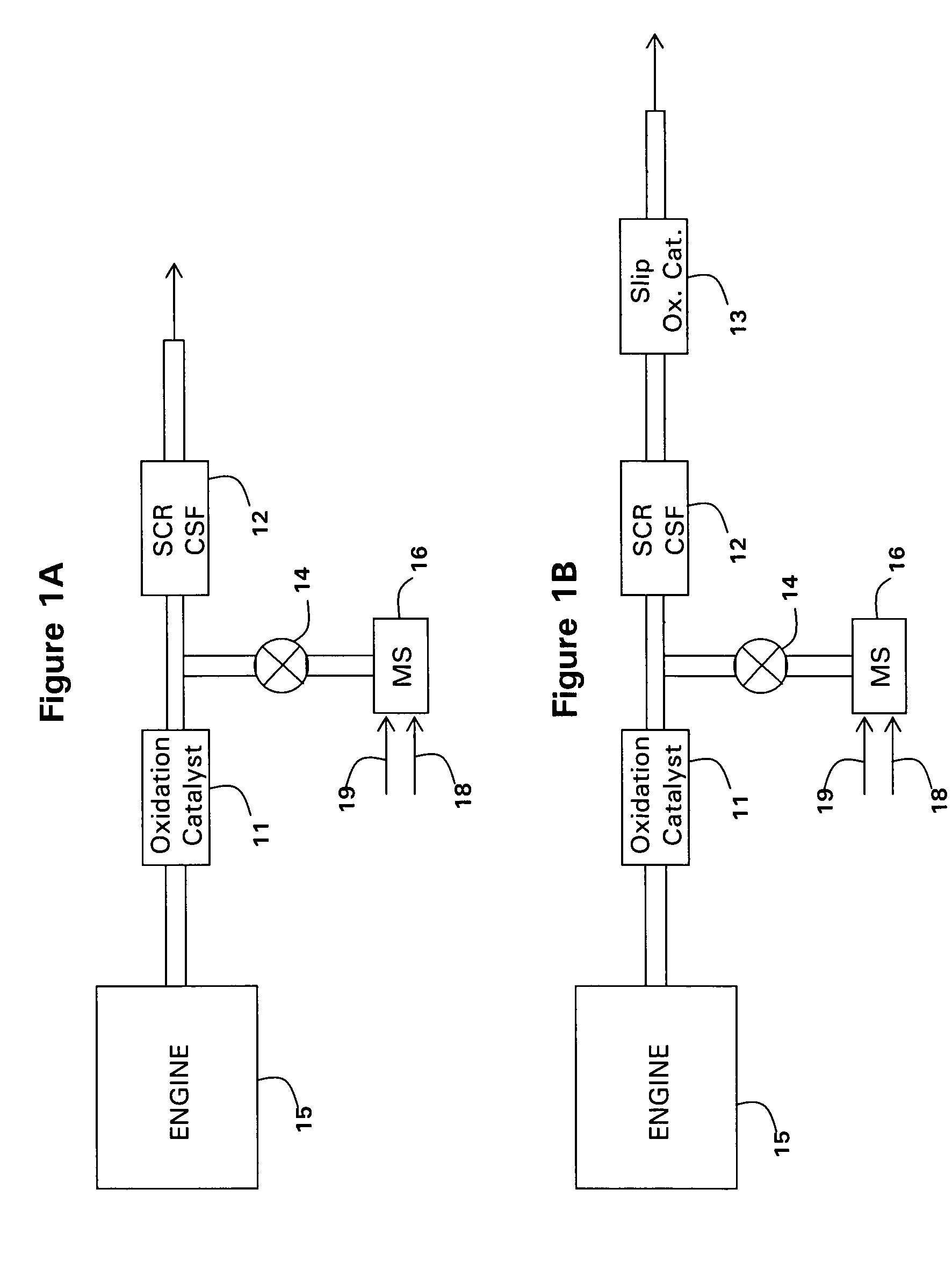

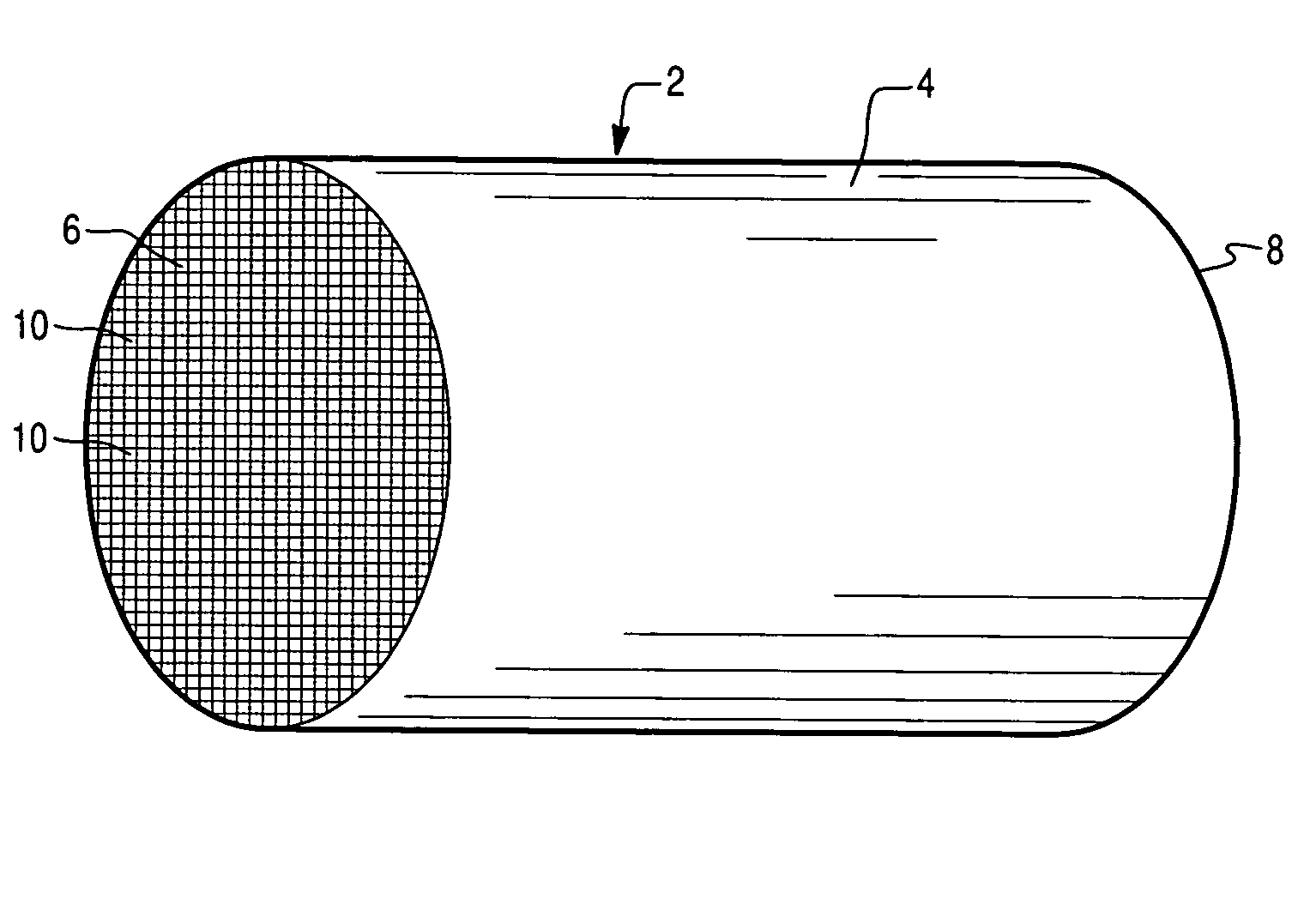

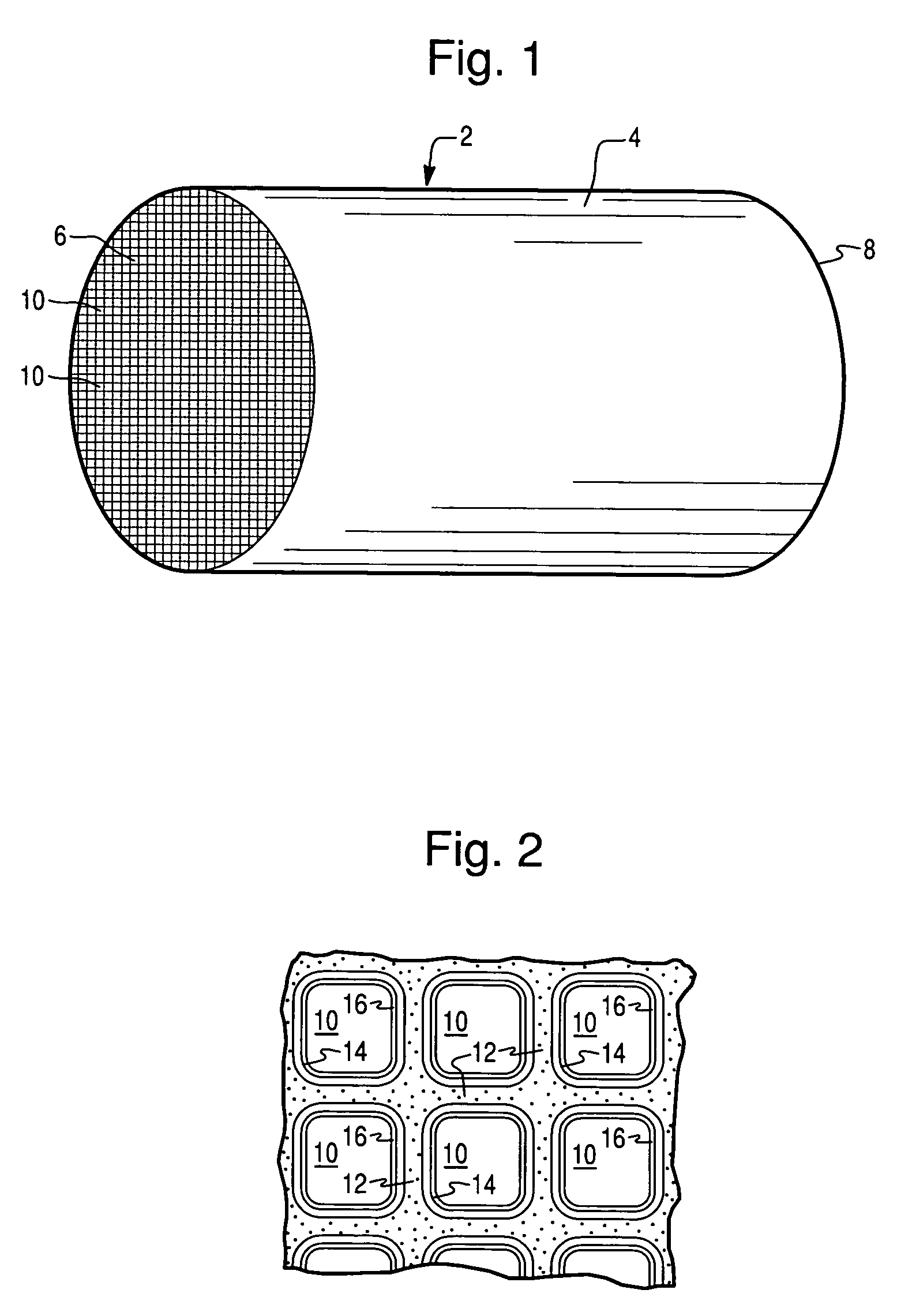

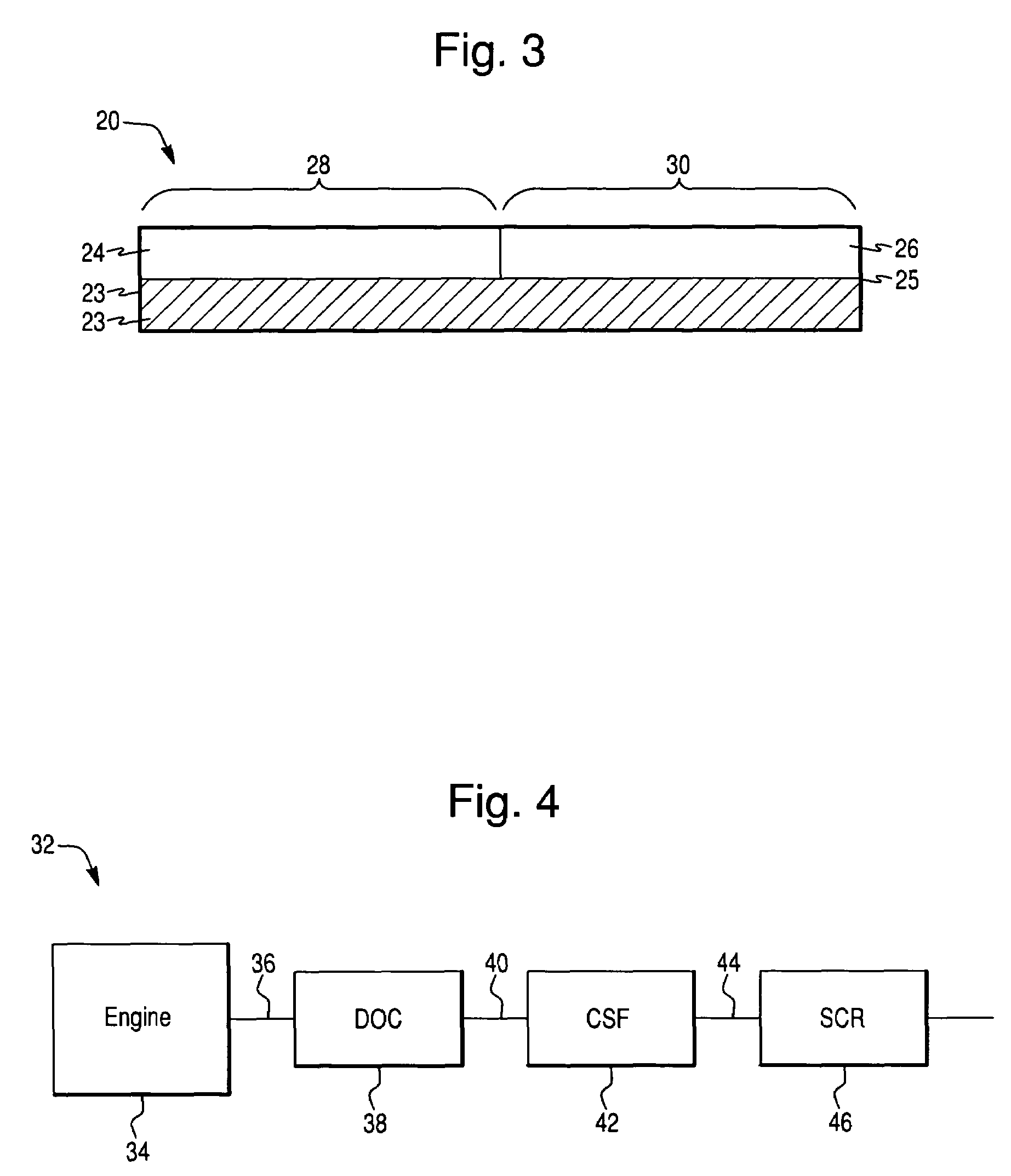

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

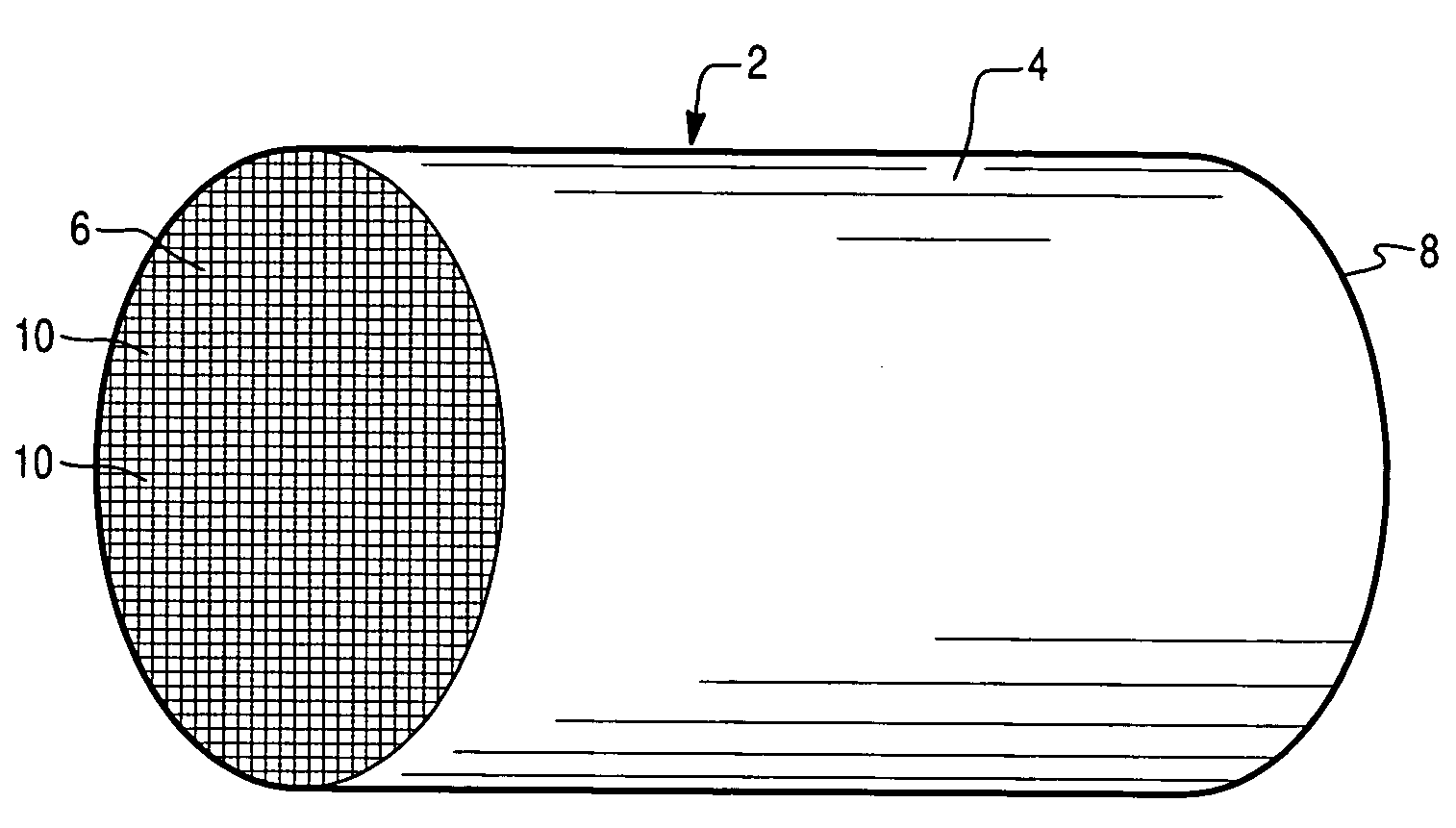

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

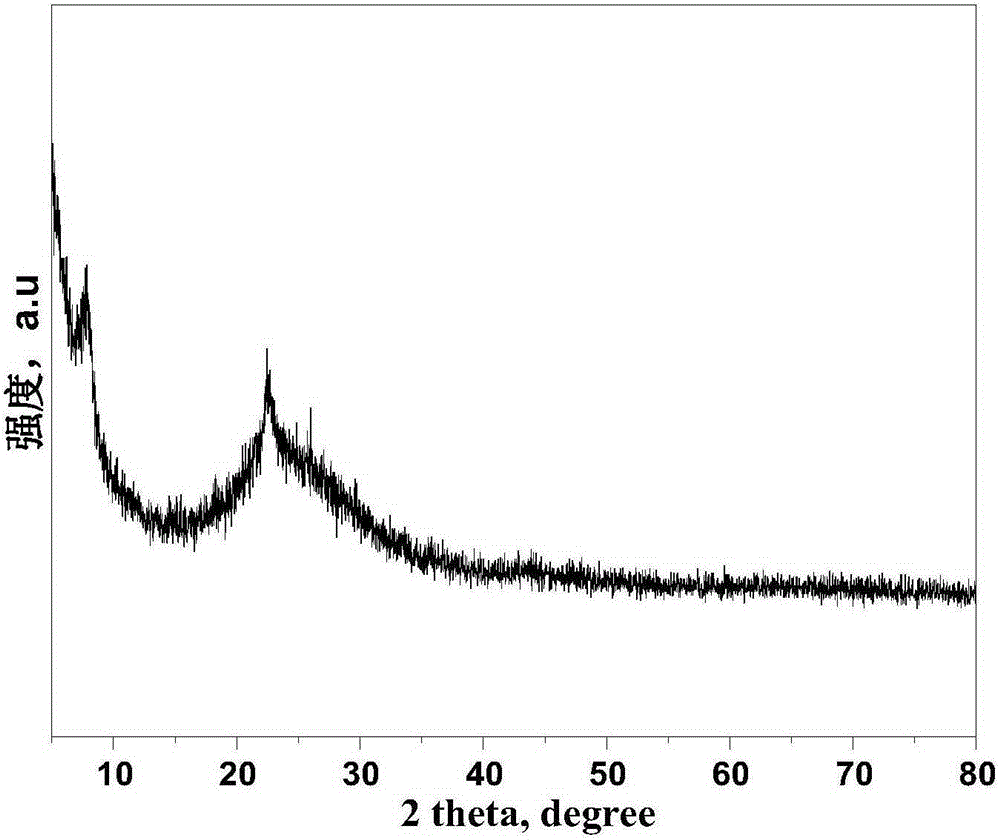

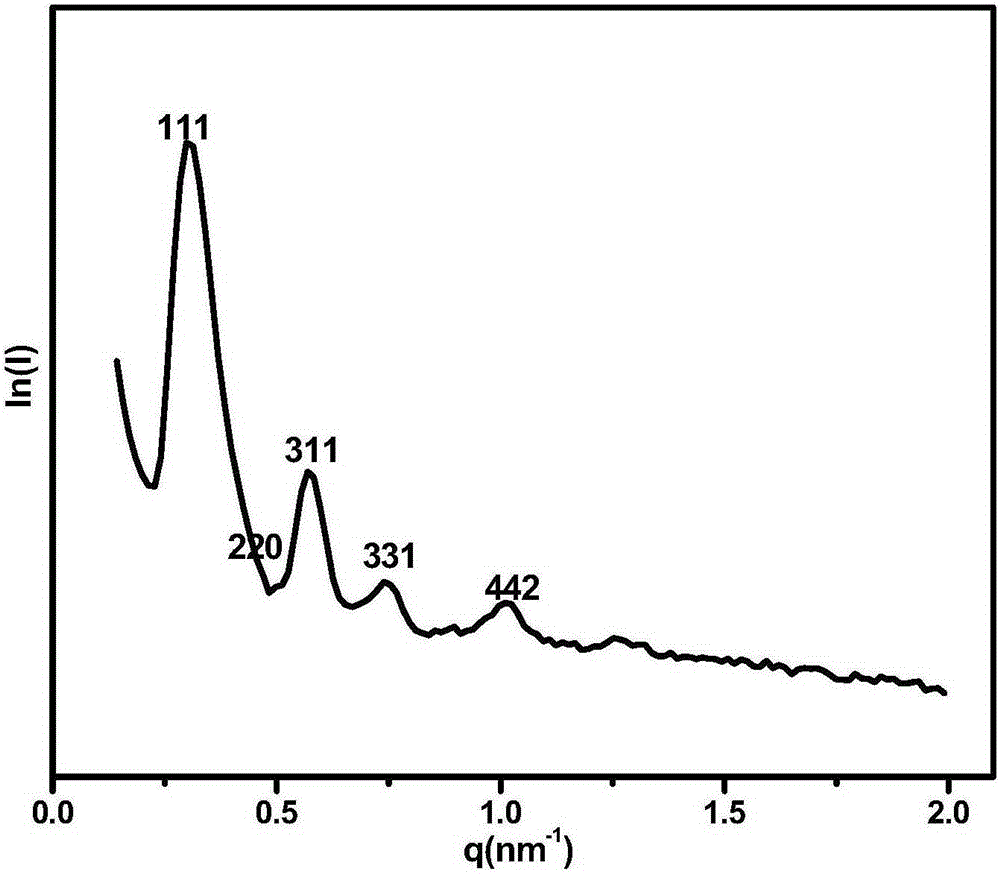

Composite molecular sieve and hydrodesulfurization catalyst prepared with composite molecular sieve as carrier

ActiveCN105251527AGood dispersionModerate dispersionMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention provides a composite molecular sieve and a hydrodesulfurization catalyst prepared with the composite molecular sieve as a carrier. According to the composite molecular sieve and the hydrodesulfurization catalyst, the Beta-FDU-12 composite molecular sieve is of a bimodal porous structure, namely a Beta micropore and an FDU-12 mesoporous, the superficial area of the composite molecular sieve is 800-1000m<2>.g<-1>, the pore diameter is 14-25 nm, and the pore volume is 0.4-0.9 cm<3>.g<-1>.The hydrodesulfurization catalyst prepared with the Beta-FDU-12 composite molecular sieve as the carrier is outstanding in performance, the yield of FCC diesel oil can be higher than 99%, the denitrification percent can be higher than 98%, and the sulphur content is lower than 10 ppm.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Copper CHA zeolite catalysts

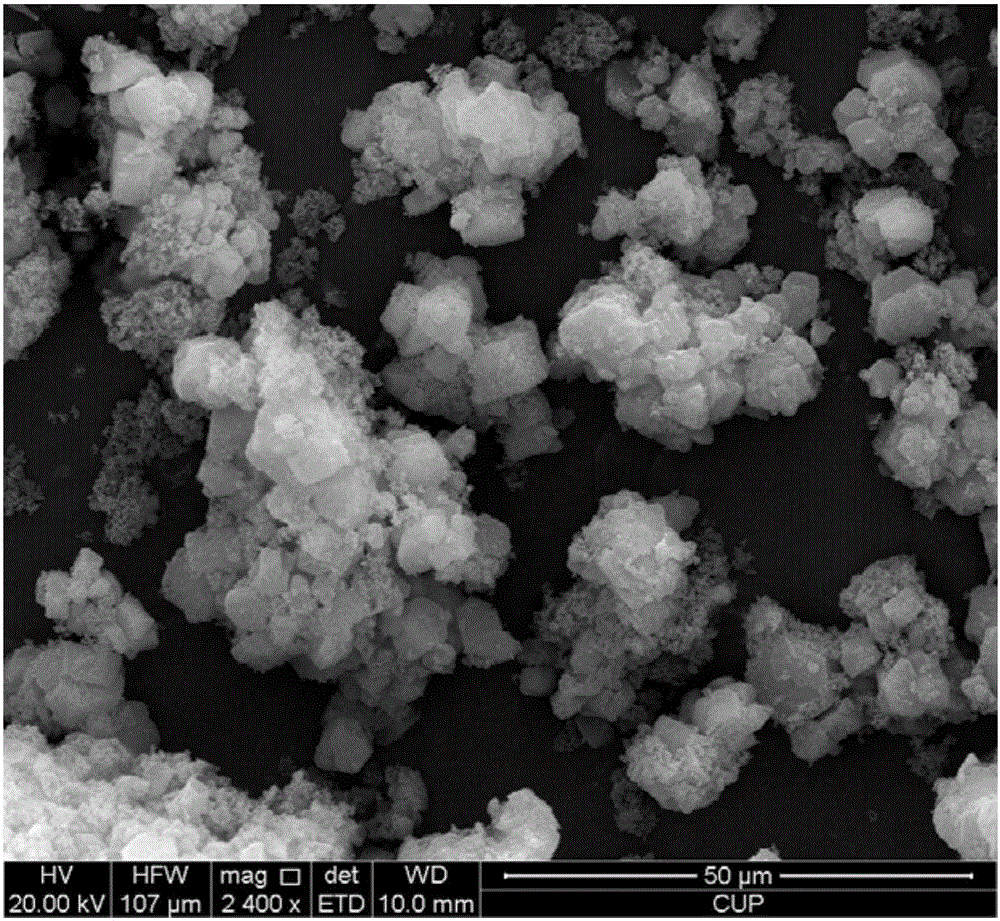

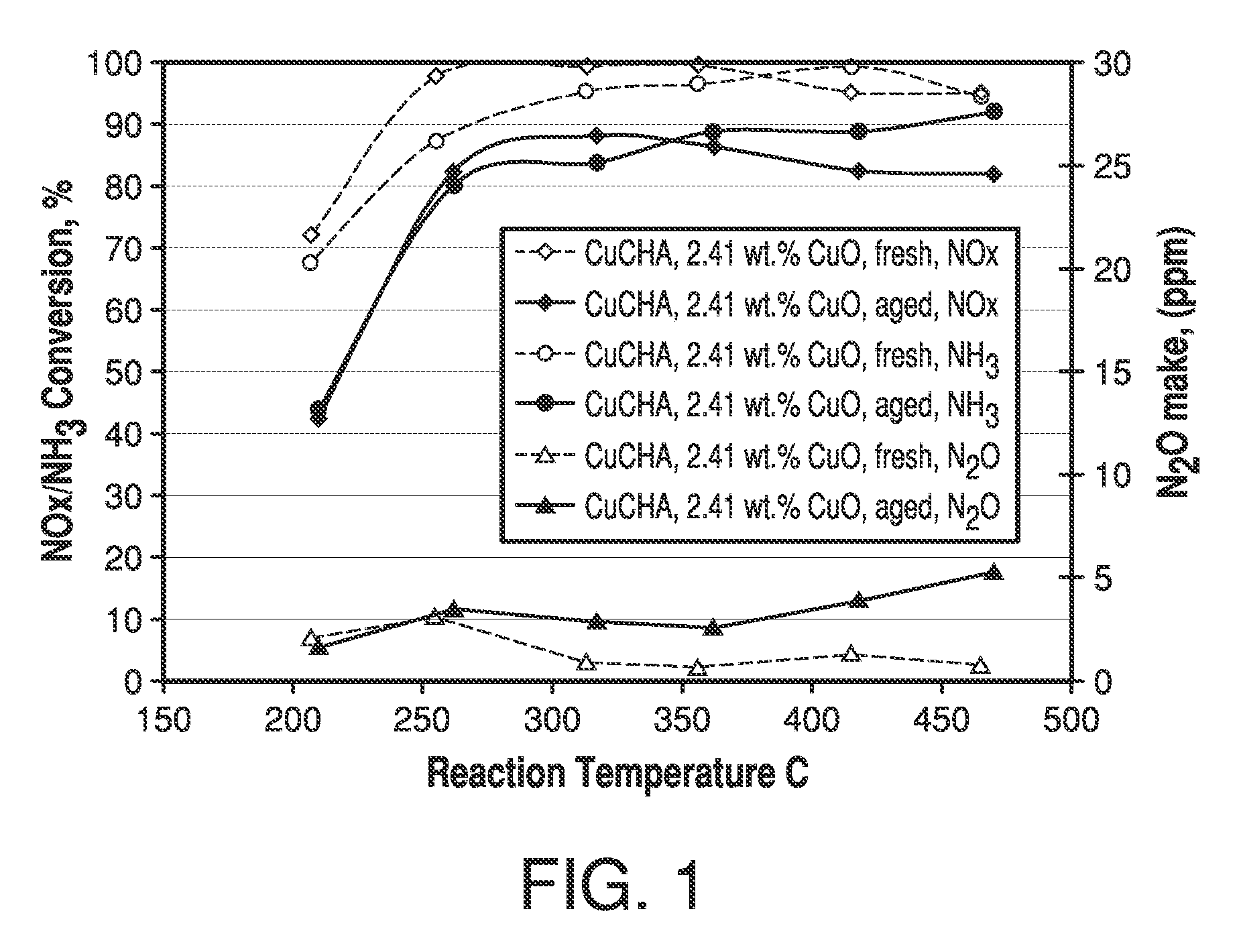

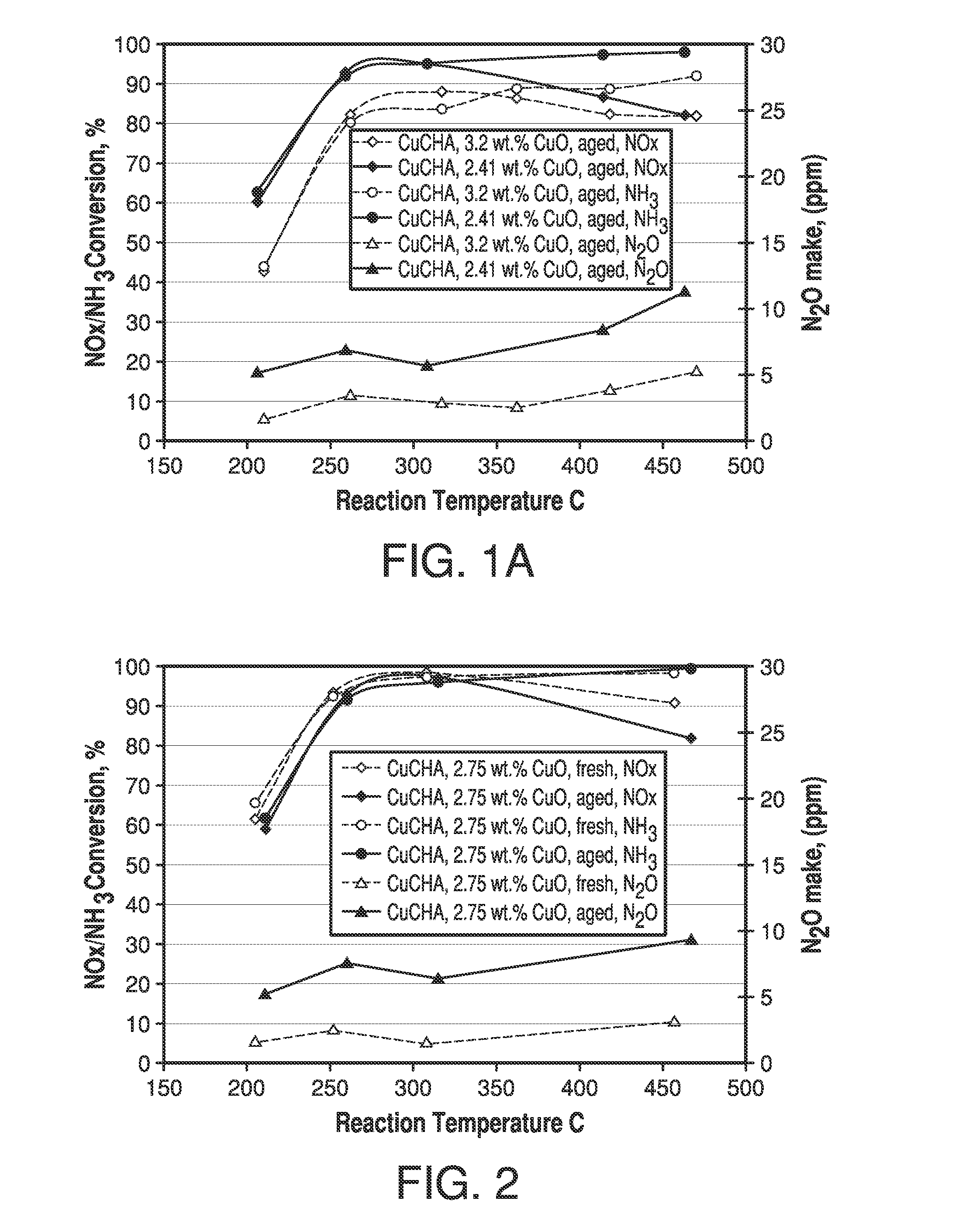

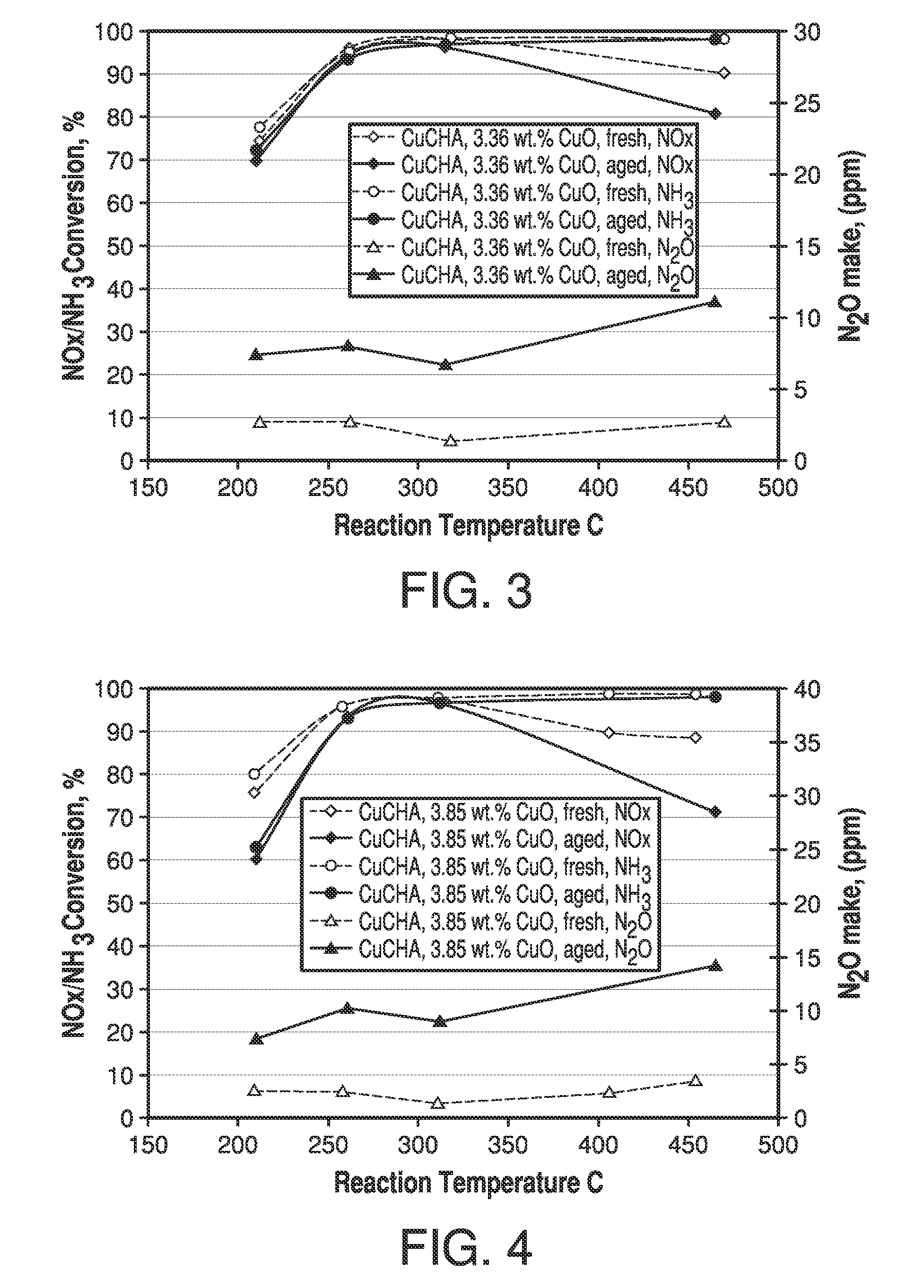

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

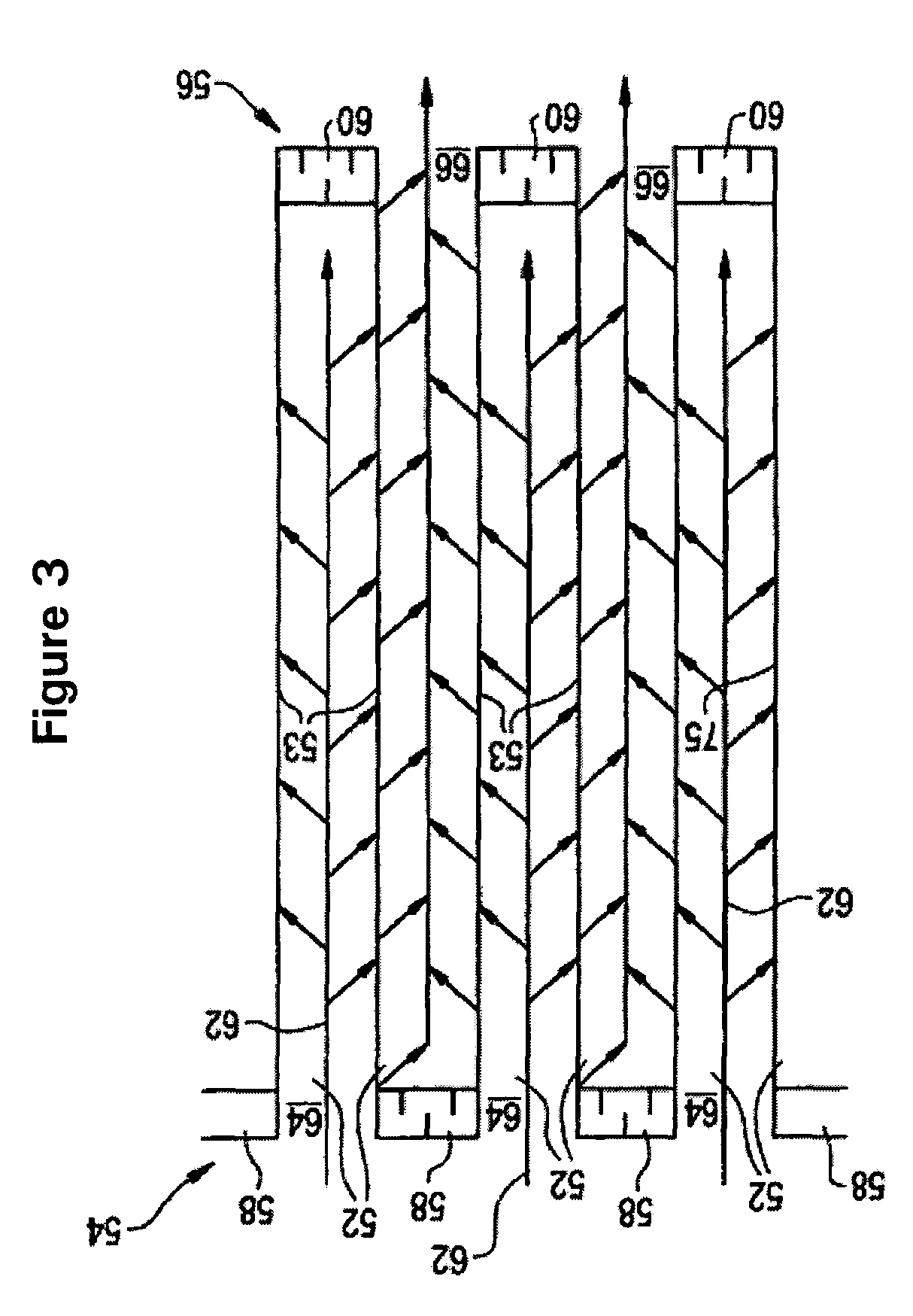

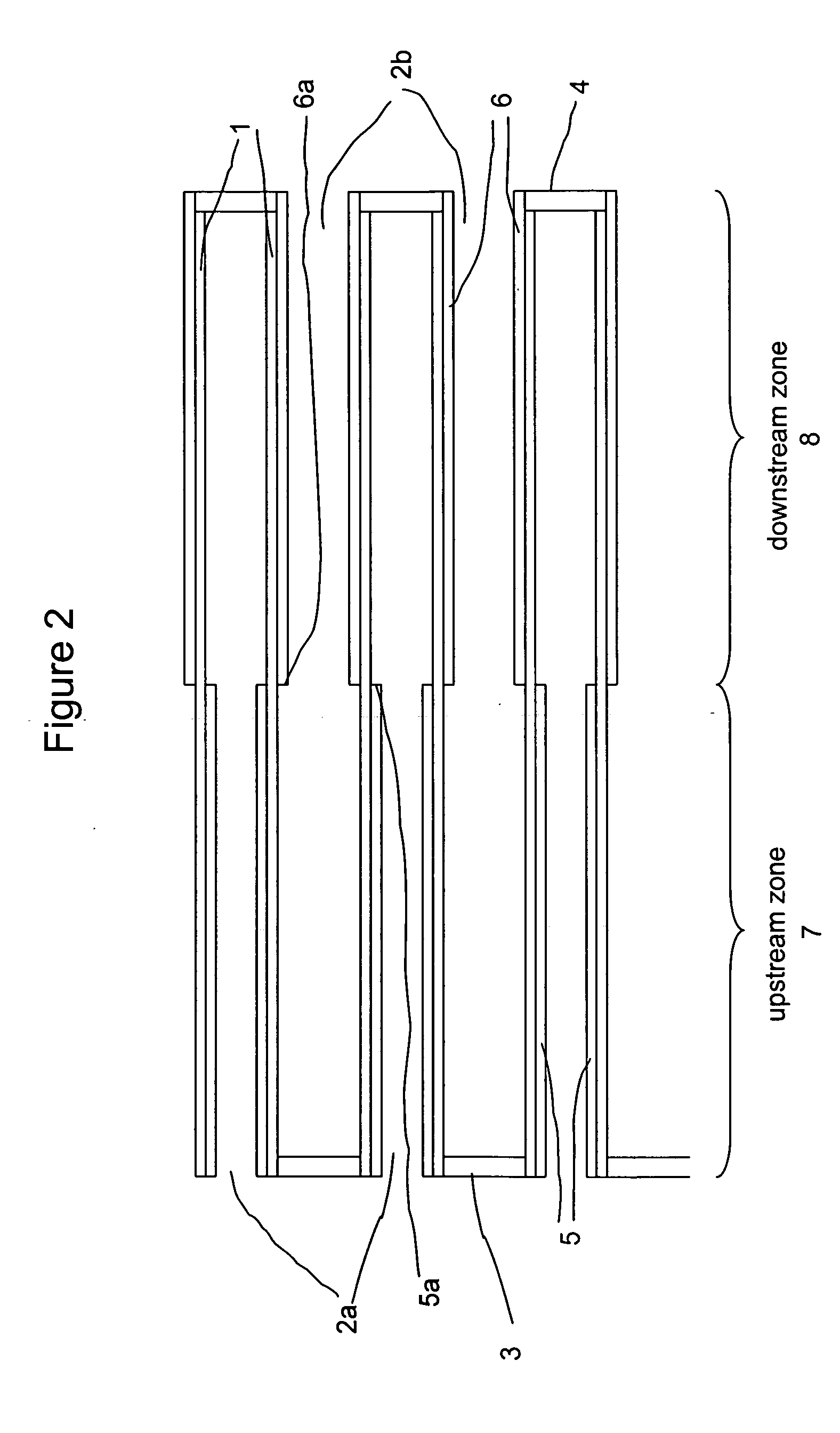

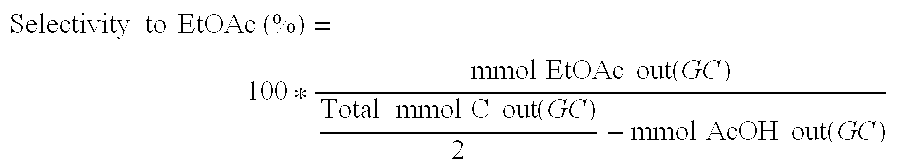

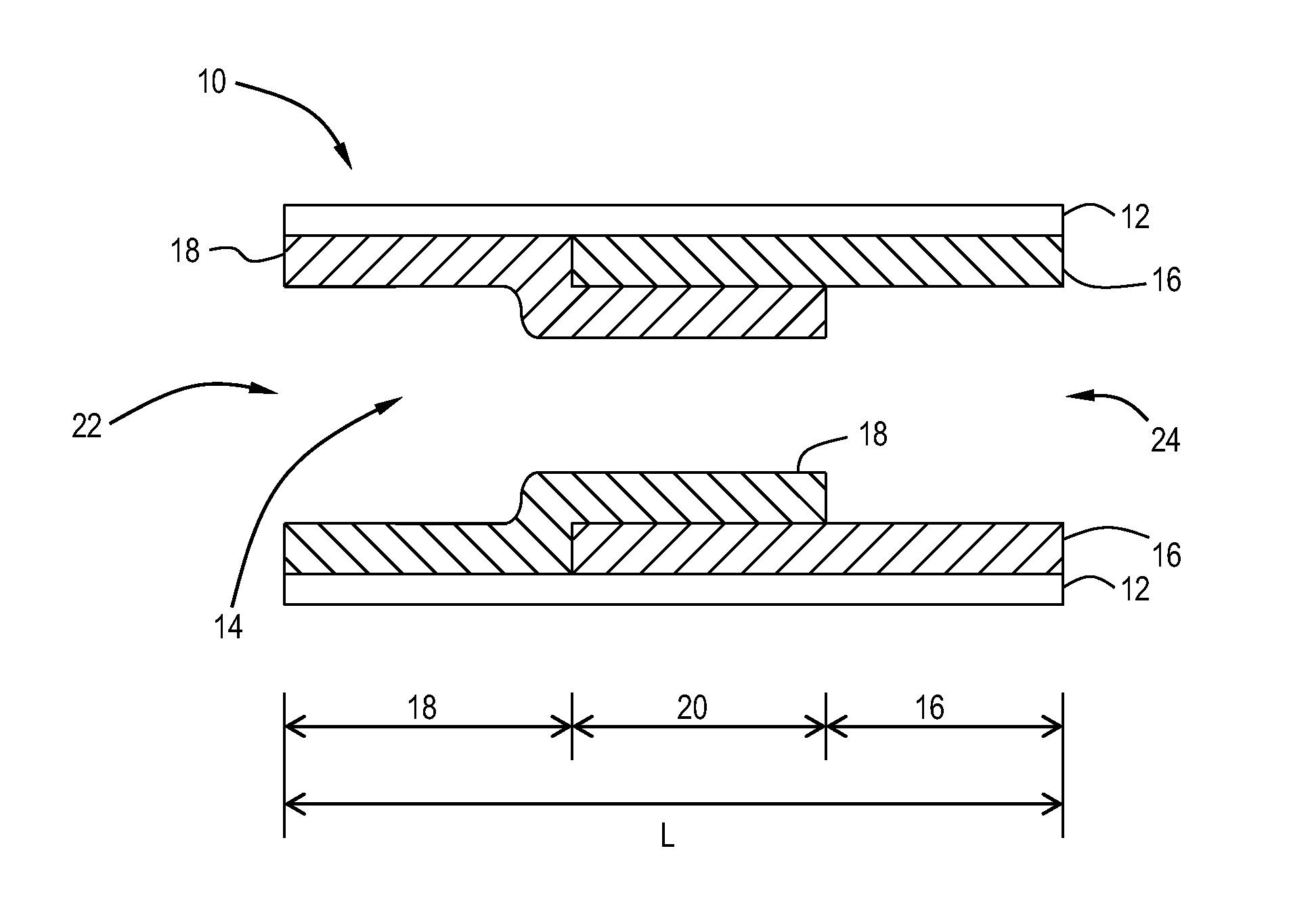

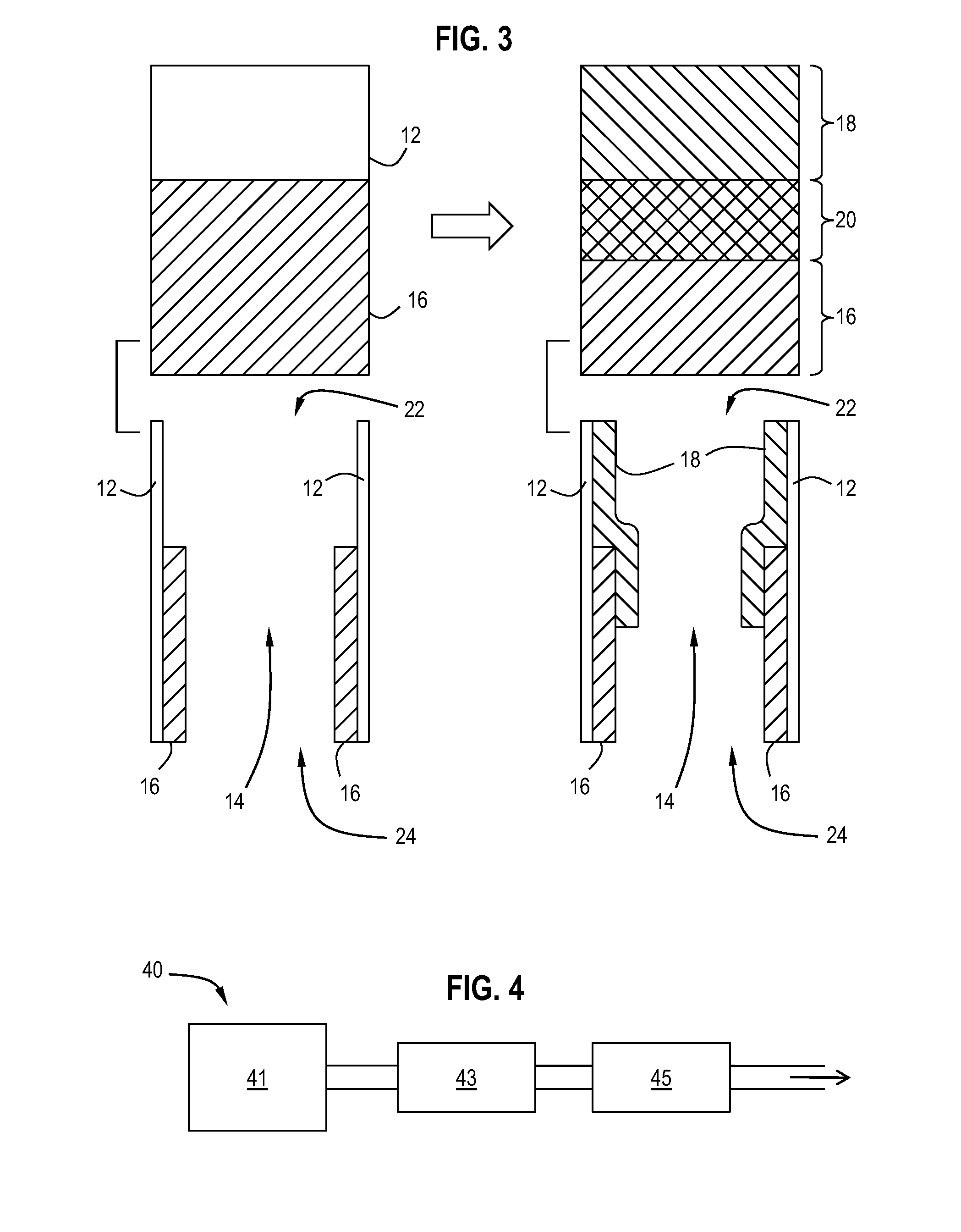

Pressure-balanced, catalyzed soot filter

ActiveUS20060057046A1Minimal overall platinum group metal component material costSpeed up the conversion processCombination devicesMolecular sieve catalystsParticulatesCatalytic function

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

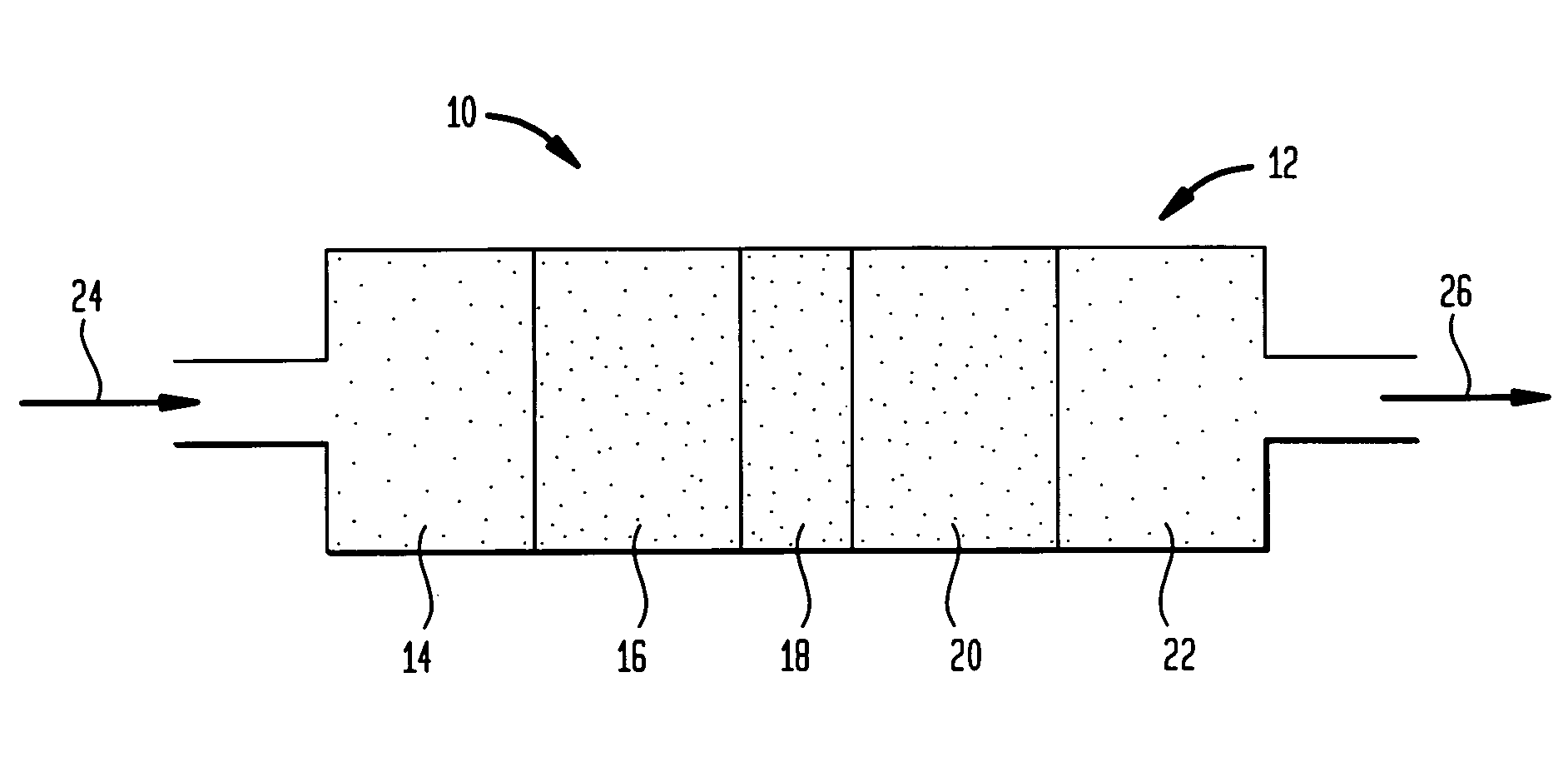

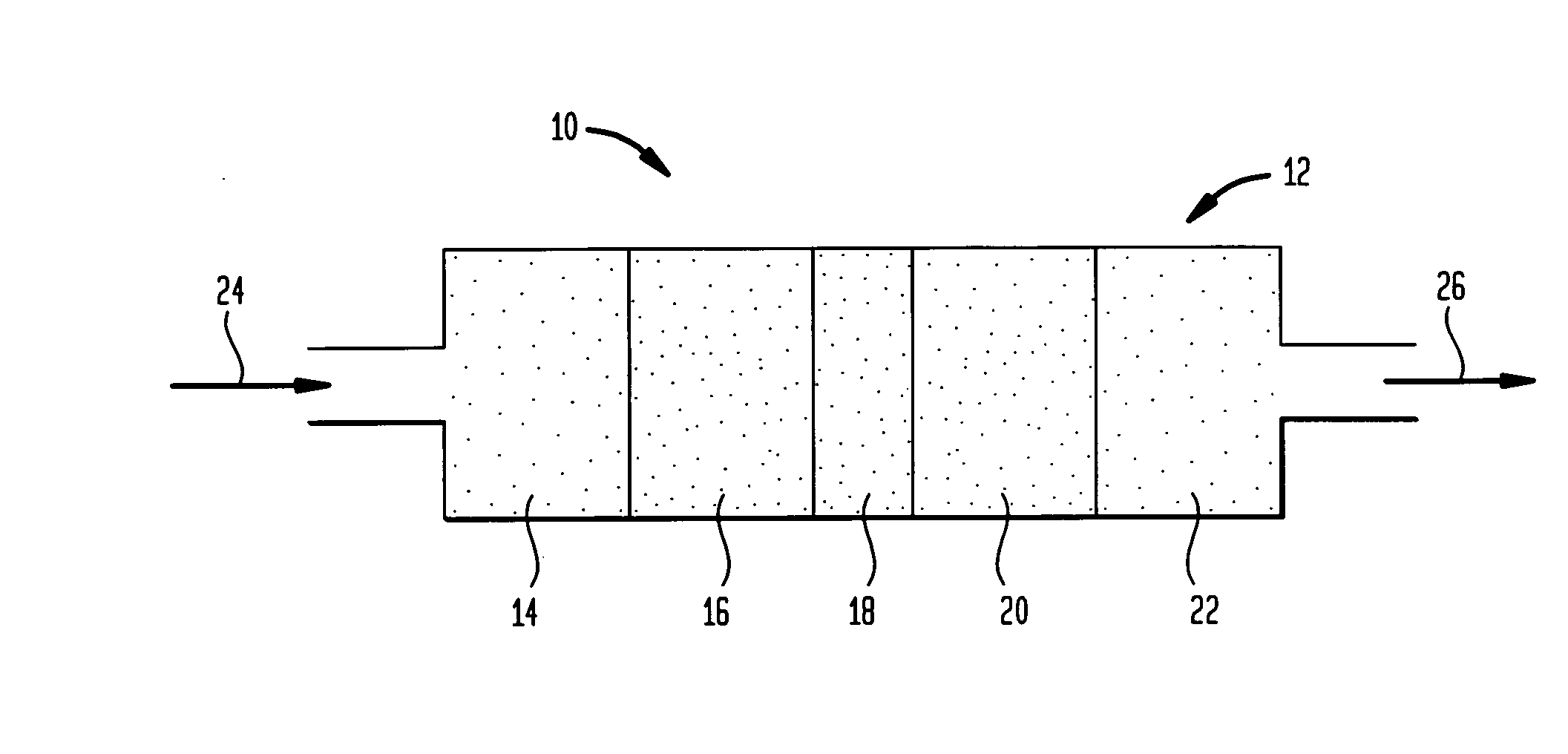

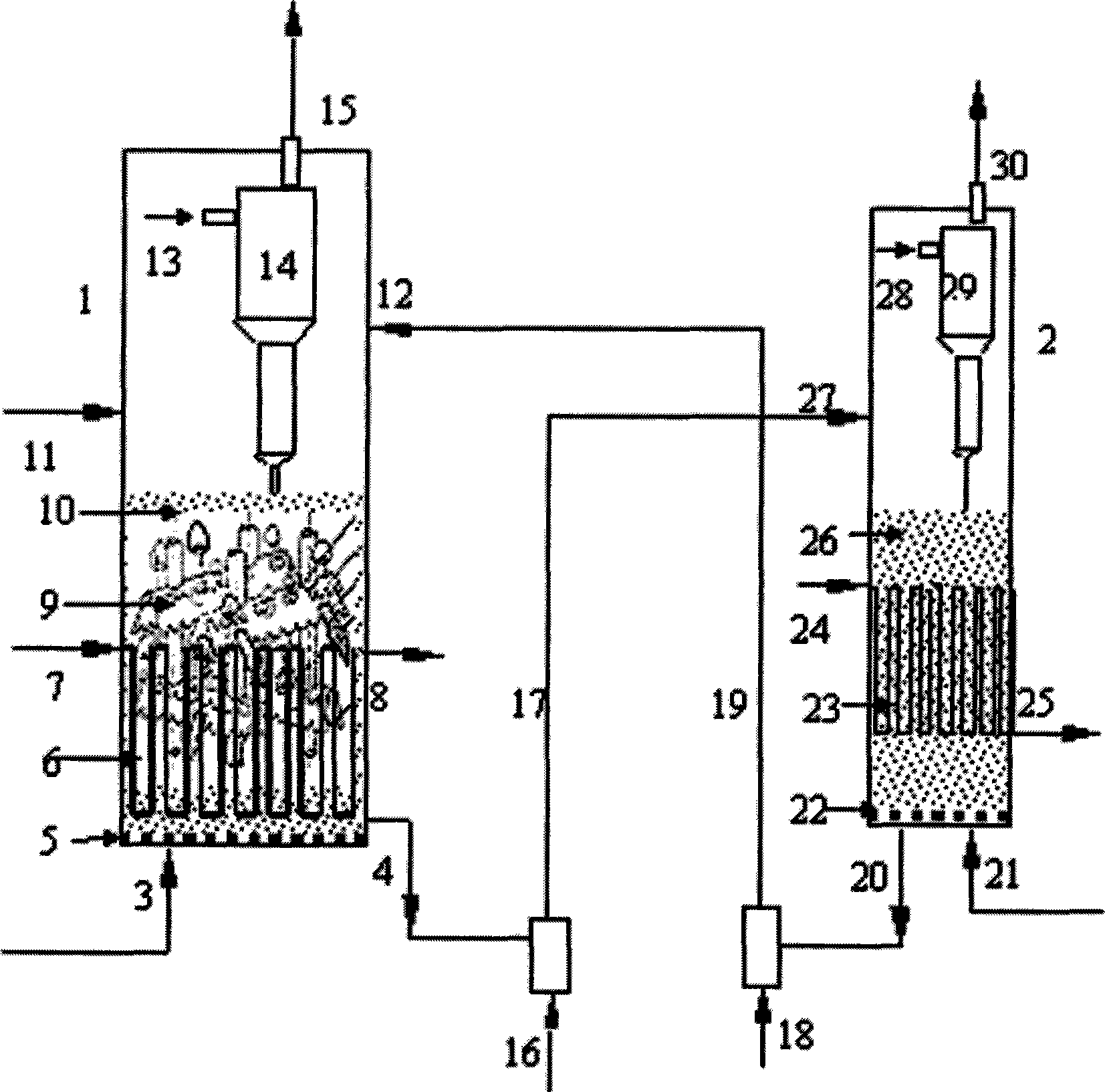

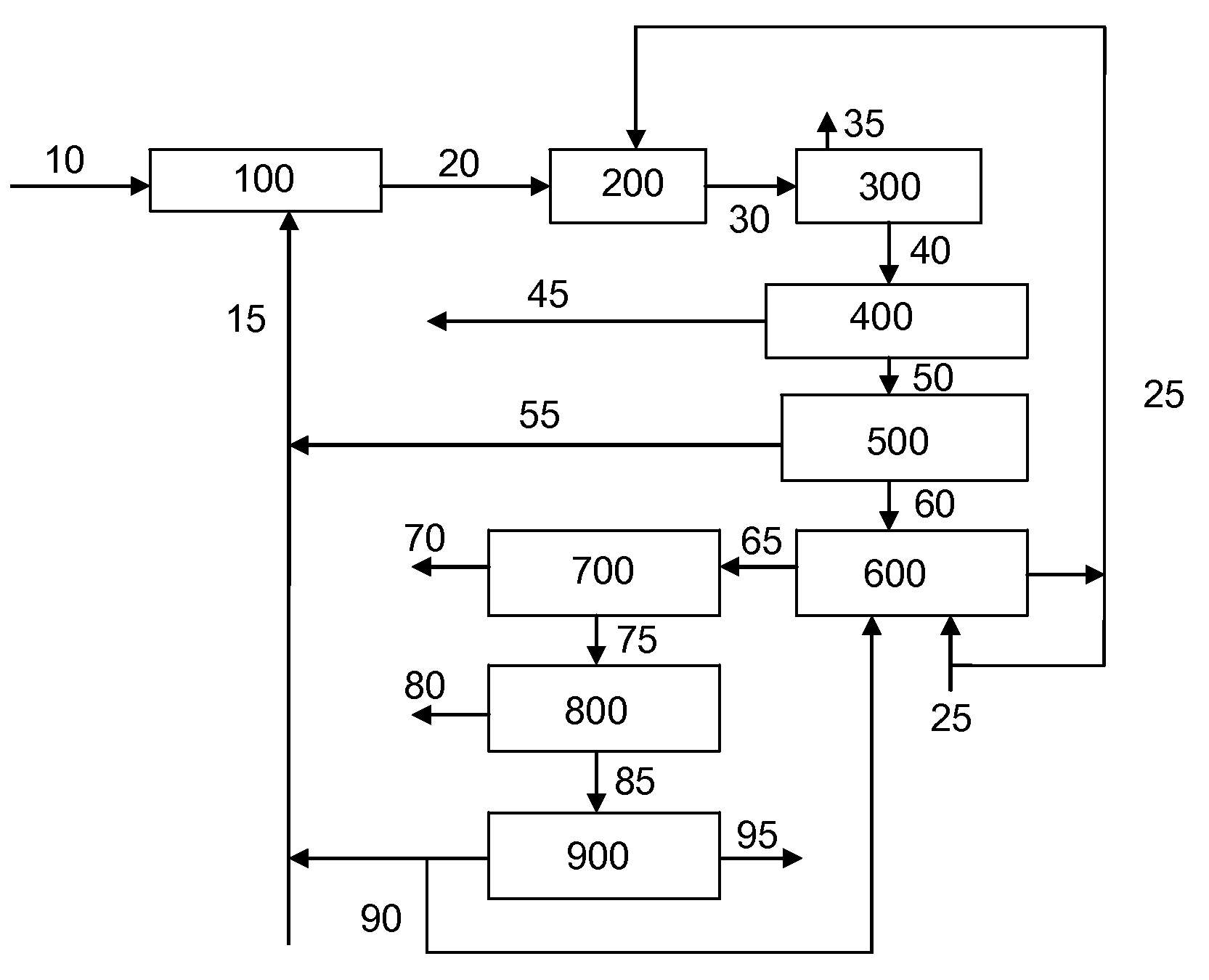

Continuous aromatization and catalyst regeneration device and method thereof

ActiveCN101244969ANo temperature fluctuationsDoes not affect aromatization reactionMolecular sieve catalystsCatalyst regeneration/reactivationFluidized bedAromatization

The invention discloses and belongs to the chemical equipment field, which more particularly relates to a C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device (comprising an aromatization fluidized bed, a catalyst continuous regeneration fluidized bed, a pipeline used for catalyst transportation and a solid transportation device which are arranged between the two fluidized beds), and an aromatization catalyst which is suitable for the fluidized bed operations and the operation methods of aromatization reaction, catalyst regeneration and the device. The device, the catalyst and the method are used for regulating the coking status of the catalyst in an aromatization reactor at any time, thus achieving the aim of transforming the C1-C2 hydrocarbon or the methanol continuously and efficiently and generating aromatics with high selectivity. The C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device of the invention with adjustable catalyst activity and selectivity can improve the purity and yield of the aromatics, can lead the aromatization reactor operates continuously without stopping at the same time, can improve the strength of aromatics production, and lower the operation cost of the catalyst regeneration when stopping and restarting the whole system.

Owner:TSINGHUA UNIV

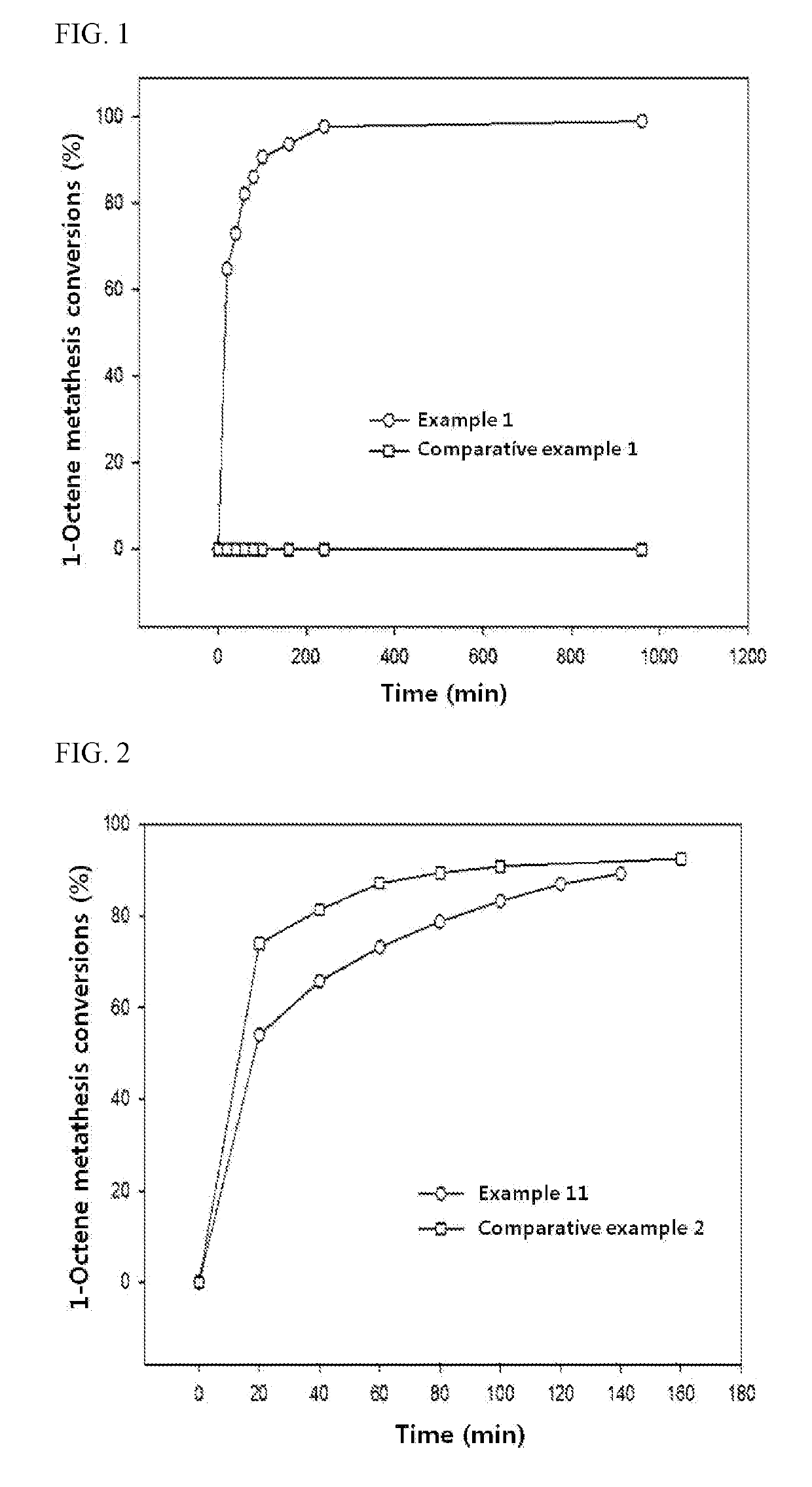

Olefin metathesis reaction catalyst and preparation method therefor

ActiveUS20190217277A1Separated/recovered readilyEasy to useMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumUnsaturated hydrocarbon

The present invention relates to an olefin metathesis reaction catalyst where rhenium (Re) oxide or molybdenum (Mo) oxide is supported, as a catalyst main component, on a surface-modified mesoporous silica or mesoporous alumina support, and a preparation method therefor. The olefin metathesis reaction catalyst of the present invention allows highly efficient metathesis of long-chain unsaturated hydrocarbons having at least eight carbons at a low temperature of 150° C. or lower. The catalyst can be separated readily from reaction solution, regenerated at a low temperature of 400° C. or lower by removing toxins accumulated on it during the metathesis reaction, and used repeatedly in metathesis reaction many times, thereby being made good use in commercial olefin metathesis processes.

Owner:KOREA RES INST OF CHEM TECH

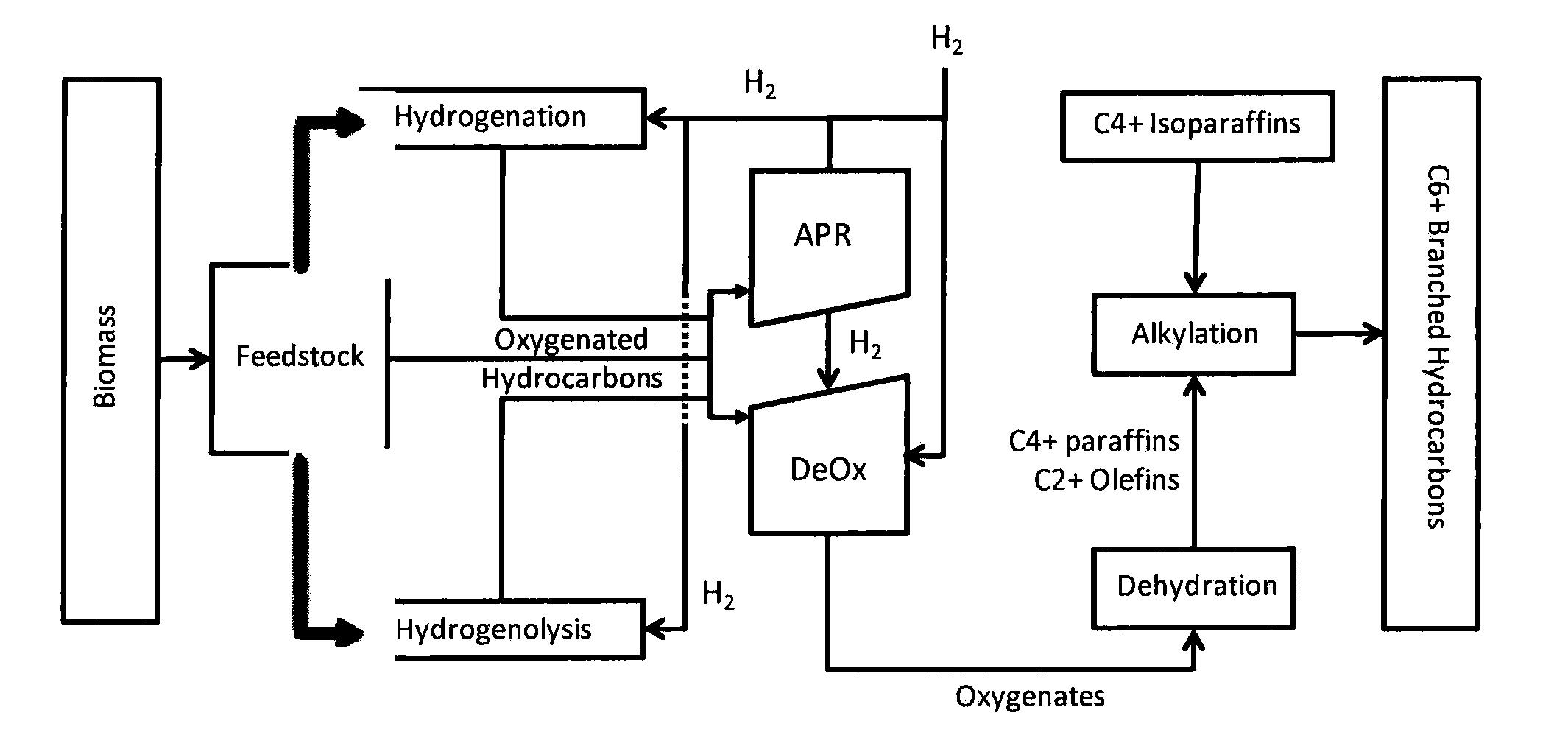

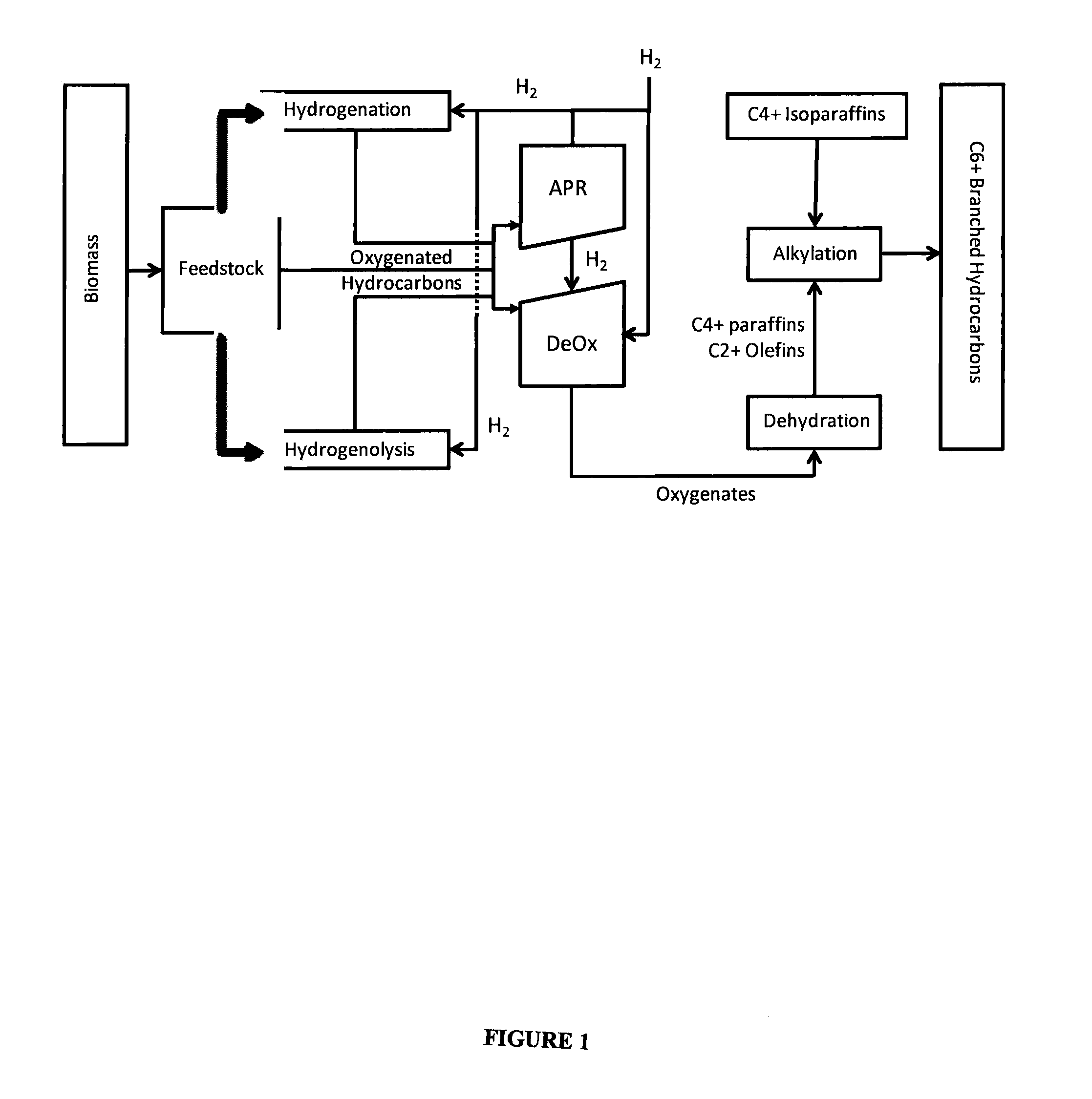

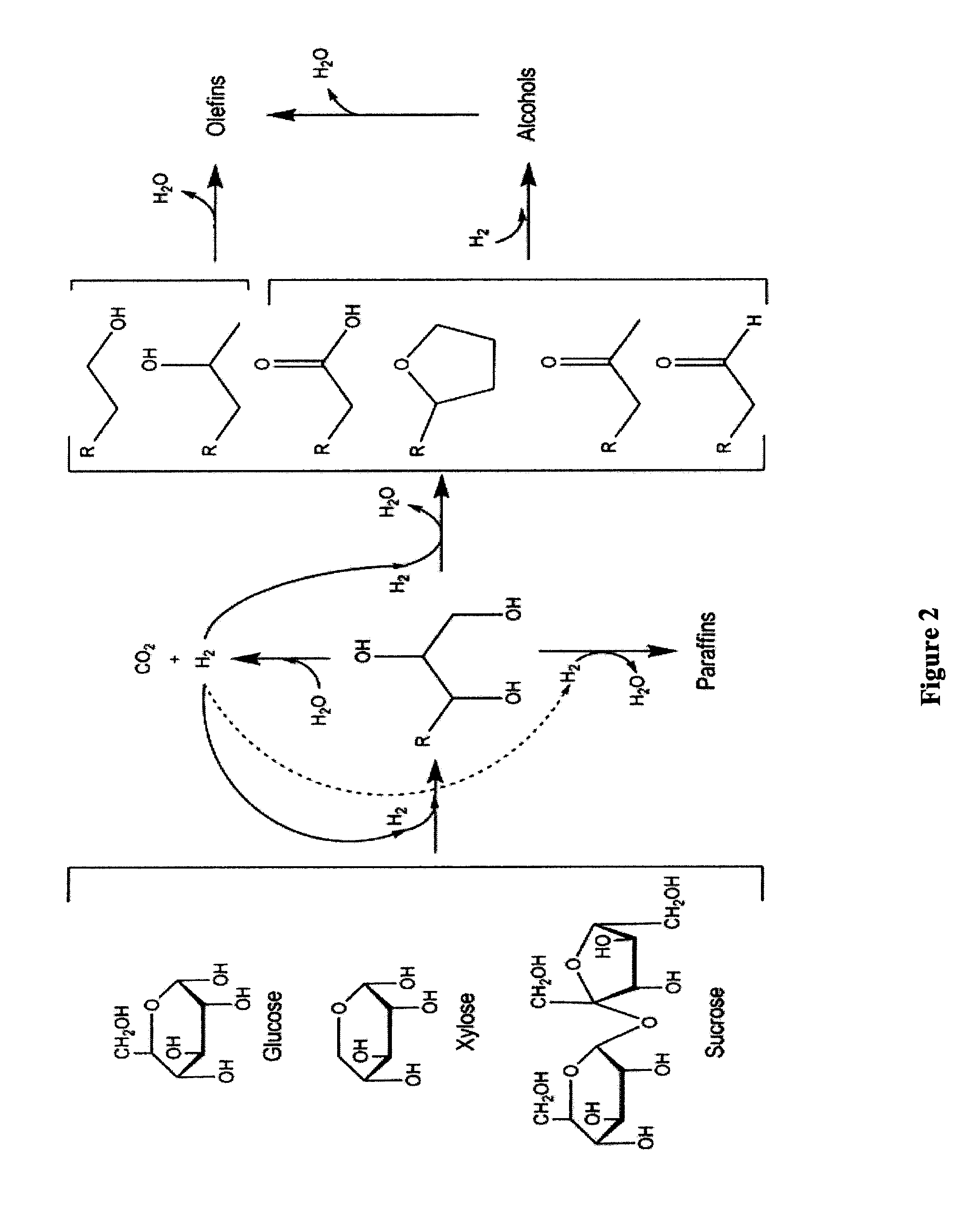

Synthesis of liquid fuels from biomass

ActiveUS20100076233A1Hydrocarbon by metathesis reactionLiquid hydrocarbon mixture productionFuranAlkane

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to paraffins useful as liquid fuels. The process involves the conversion of water soluble oxygenated hydrocarbons to oxygenates, such as alcohols, furans, ketones, aldehydes, carboxylic acids, diols, triols, and / or other polyols, followed by the subsequent conversion of the oxygenates to paraffins by dehydration and alkylation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

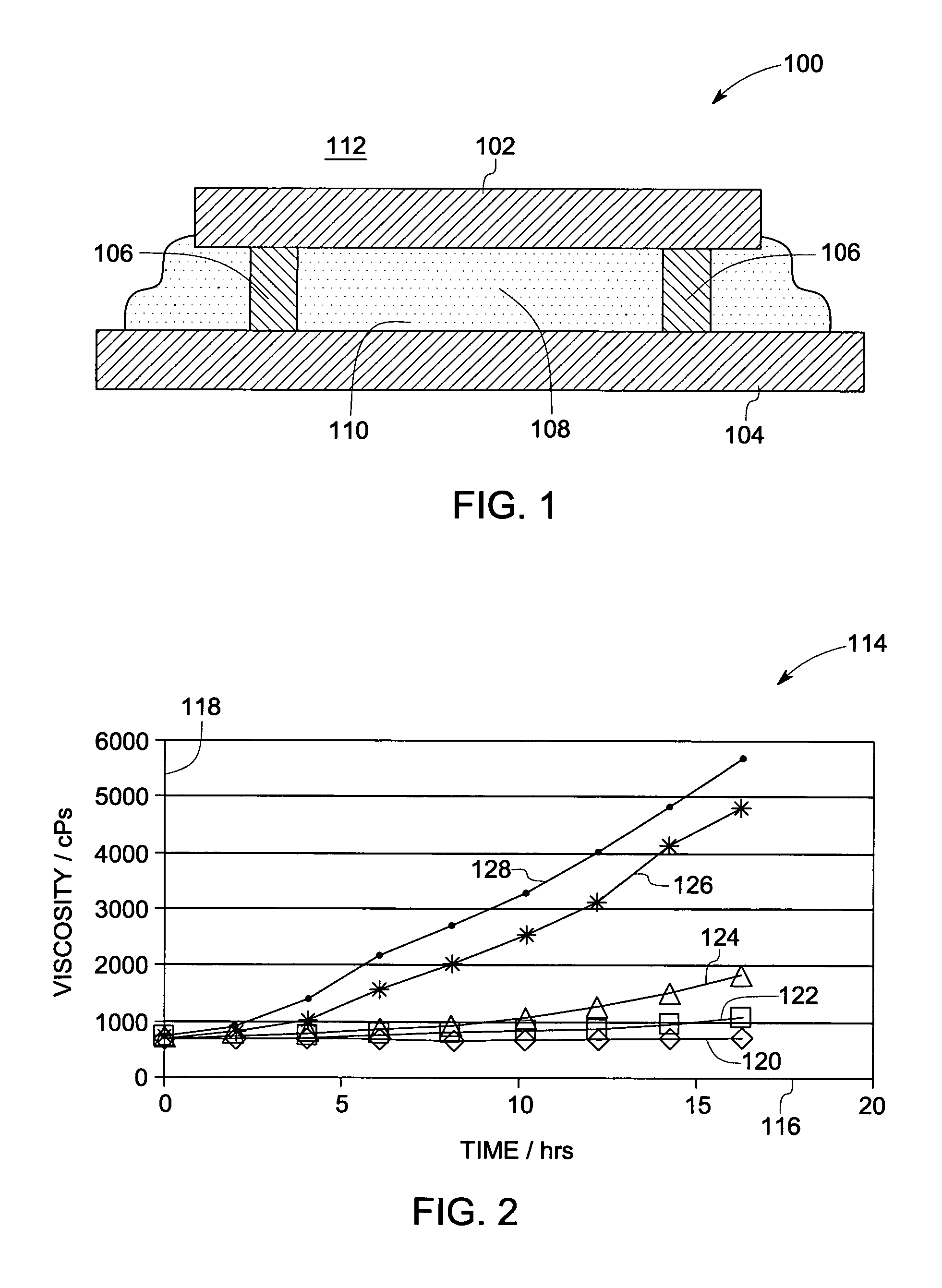

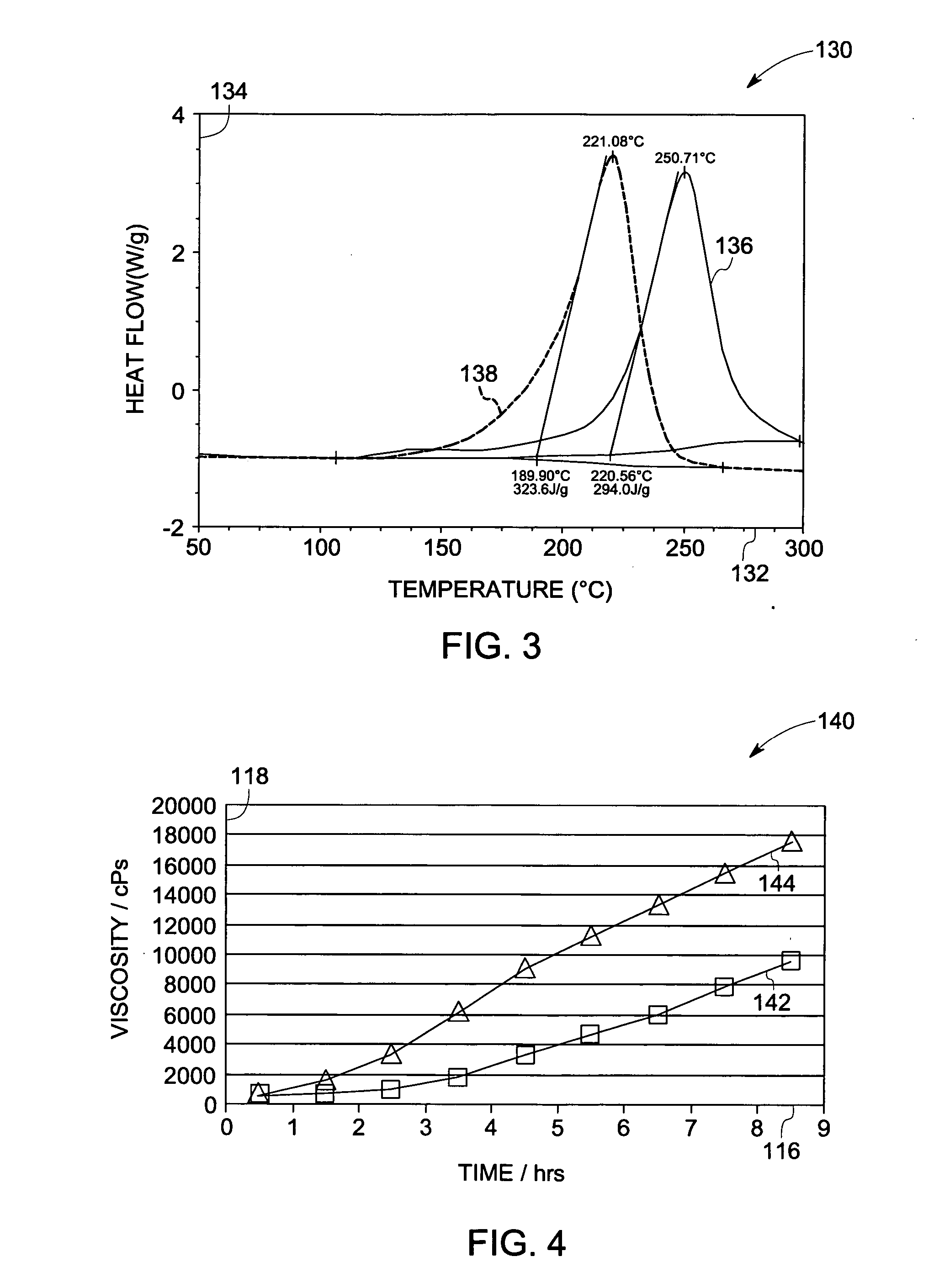

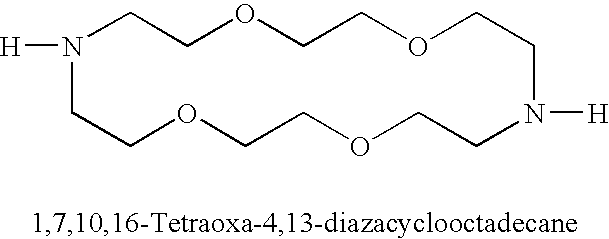

Cure catalyst, composition, electronic device and associated method

InactiveUS20060293172A1Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsSimple Organic CompoundsNitrogen

A cure catalyst is provided. The cure catalyst may include a Lewis acid and one or both of a nitrogen-containing molecule or a non-tertiary phosphine. The nitrogen-containing molecule may include a mono amine or a heterocyclic aromatic organic compound. A curable composition may include the cure catalyst. An electronic device may include the curable composition. Methods associated with the foregoing are provided also.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

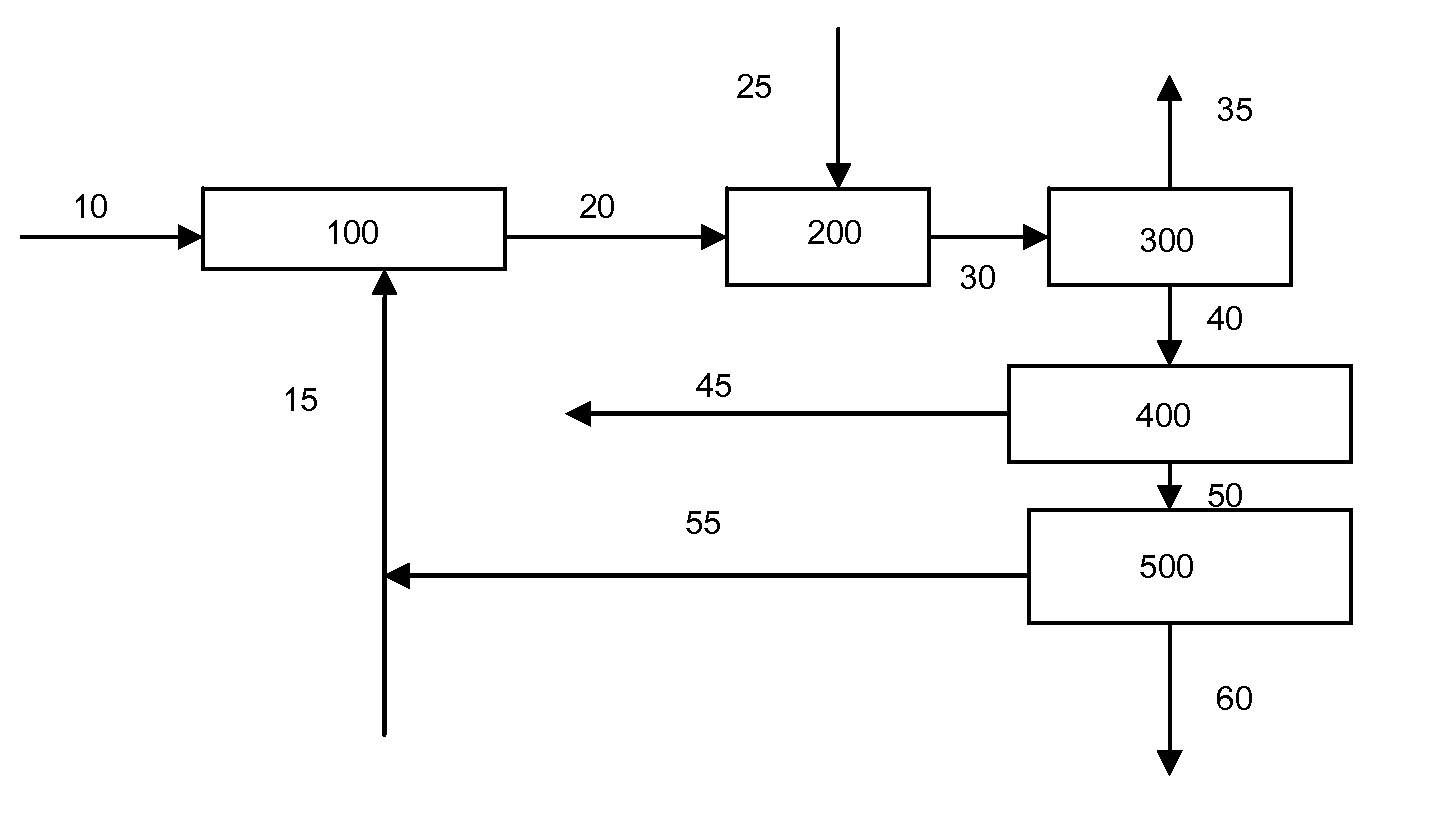

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169448A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesPhysical chemistryAlkali metal

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

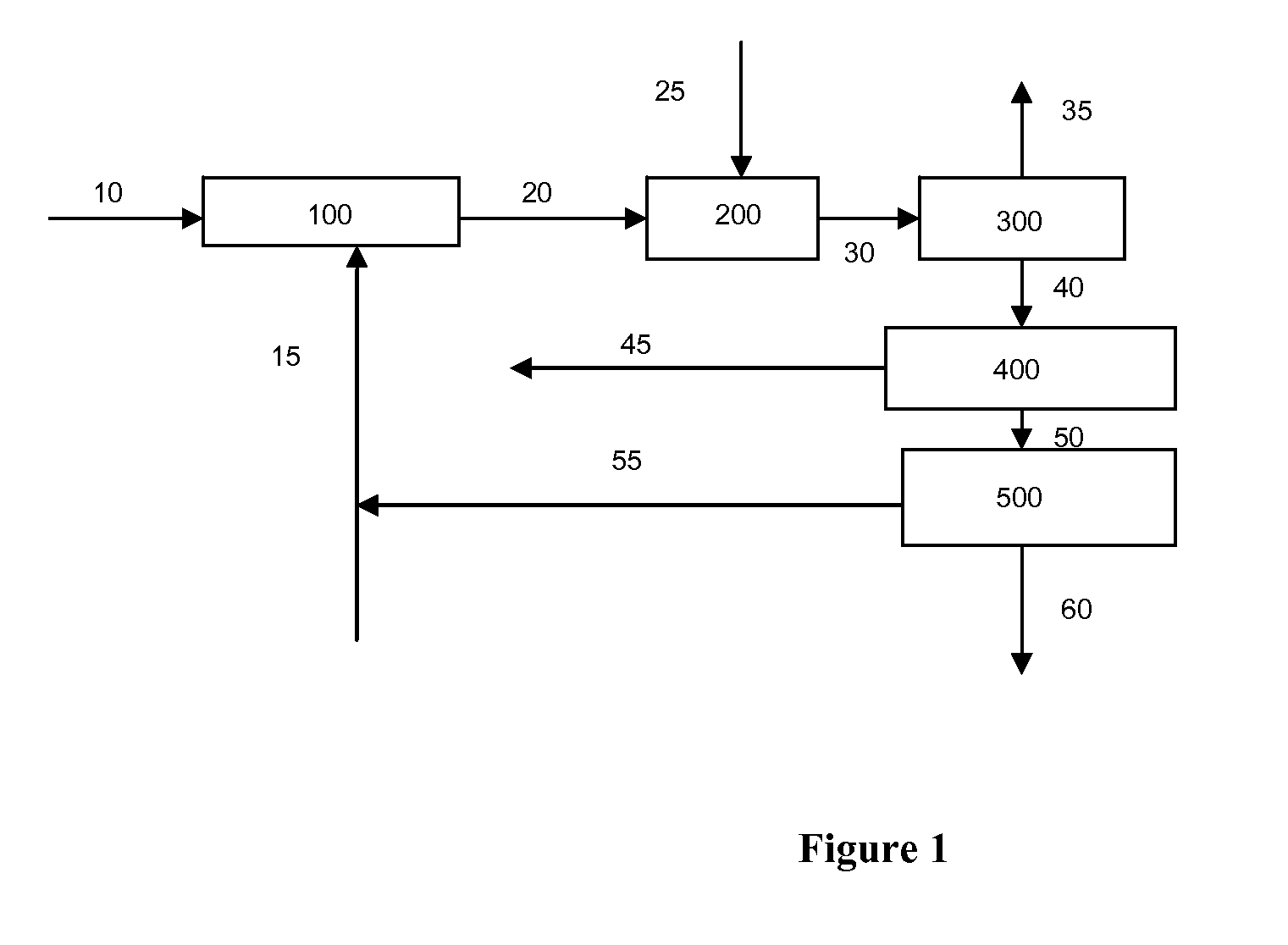

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Hydroalkylation of aromatic hydrocarbons

InactiveUS6730625B1High activityHigh selectivityMolecular sieve catalystsMolecular sieve catalystBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07.

Owner:EXXONMOBIL CORP (US)

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly cumene, comprising the step of contacting a polyalkylated aromatic compound with an alkylatable aromatic compound under at least partial liquid phase conditions and in the presence of a transalkylation catalyst to produce the monoalkylated aromatic compound, wherein the transalkylation catalyst comprises a mixture of at least two different crystalline molecular sieves, wherein each of said molecular sieves is selected from zeolite beta, zeolite Y, mordenite and a material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom.

Owner:EXXONMOBIL CHEM PAT INC

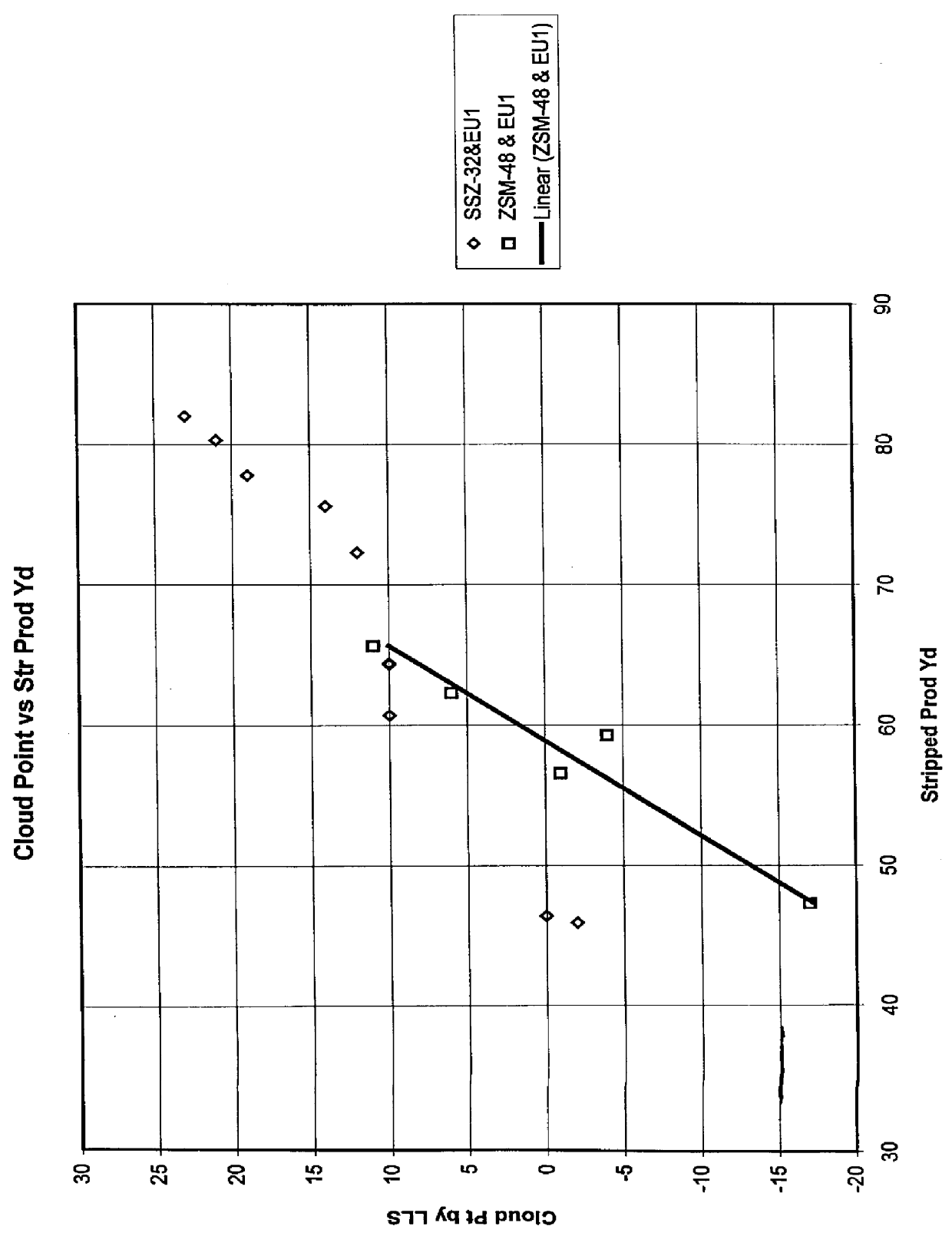

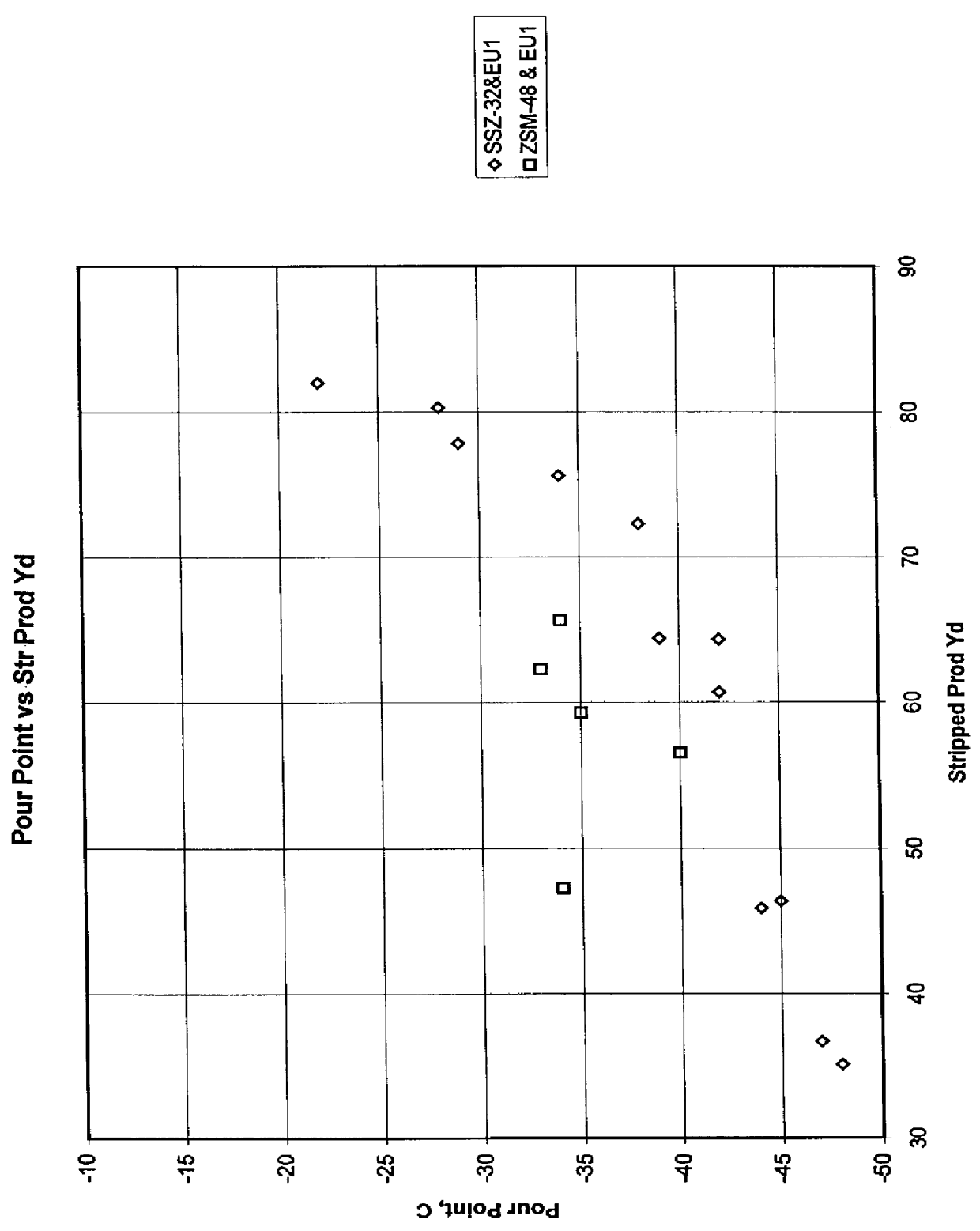

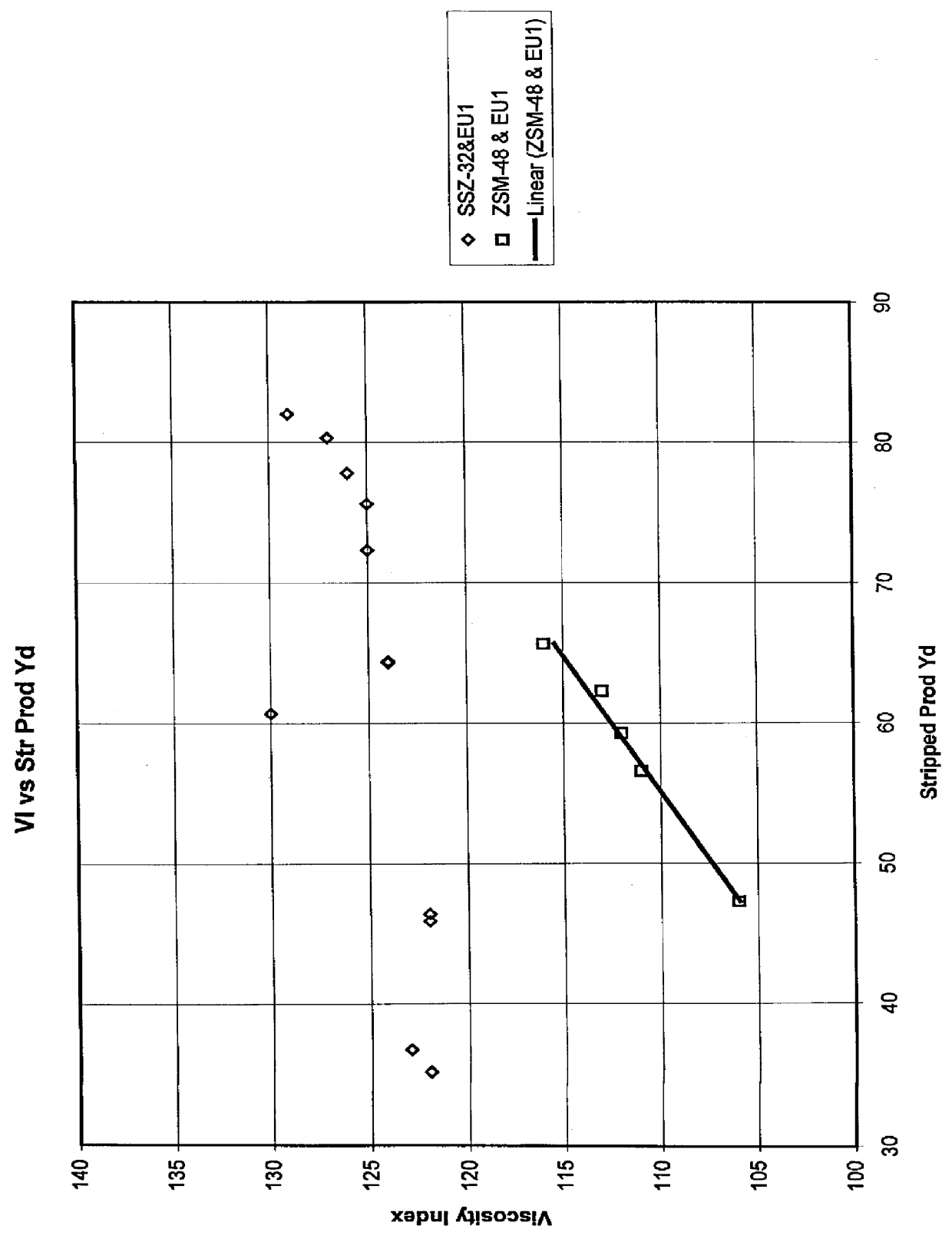

Process for reducing haze point in bright stock

InactiveUS6051129ASuperior lube oil yieldHigh yieldMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenHaze

Owner:CHEVROU USA INC

Ultrastable Y-type RE molecular sieve active component and its prepn process

InactiveCN1506161AReasonable matching activityIncreased hydrogen transfer activityMolecular sieve catalystsMolecular sieveActive component

The active component of ultrastable Y-type RE molecular sieve is composite modified Y-zeolite containing RE oxide 8-25 wt%, P 0.1-3.0 wt% and sodium oxide 0.3-2.5 wt%, and with degree of crystallization 30-55 % and unit cell parameter 2.455-2.477 nm. It is prepared with Y-zeolite as material and through the steps of exchange with RE and the first roasting to obtain RE-Na Y-zeolite; reaction with RE, reaction with P-containing compound, and the second roasting. The ultrastable Y-type RE molecular sieve is used as the active component of cracking catalyst and has the obvious effect of lowering olefin content in gasoline and the features of resulting in moderate coke yield and high diesel oil yield. The preparation process is simple and high in the utilization of the modifying elements.

Owner:PETROCHINA CO LTD

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS7576031B2Nitrous oxide captureInternal combustion piston enginesExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

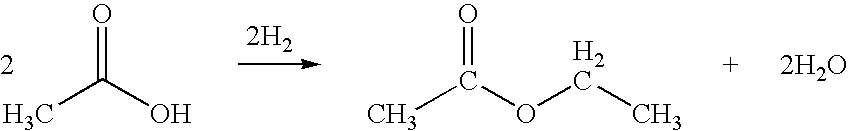

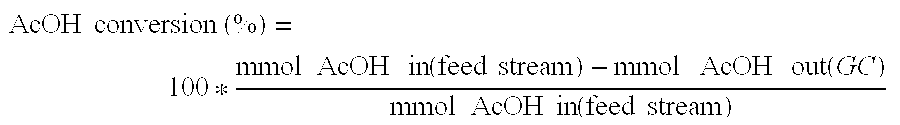

Direct and selective production of ethyl acetate from acetic acid utilizing a bimetal supported catalyst

InactiveUS20100029980A1High selectivityHigh yieldMolecular sieve catalystsOrganic compound preparationChemistryEthyl ester

A process for the selective production of ethyl acetate by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethyl acetate is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and copper supported on silica selectively produces ethyl acetate in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

Reclamation of a Titanosilicate, and Reconstitution of an Active Oxidation Catalyst

InactiveUS20080064591A1Acceptable product selectivityAcceptable selectivityMolecular sieve catalystsOther chemical processesCatalytic metalTitanium

A method of reclaiming a titanosilicate from a deactivated or spent oxidation catalyst containing a titanosilicate having deposited thereon one or more catalytic metals, such as gold, and optionally, one or more promoter metals, the method involving treating the deactivated catalyst with an oxidant; contacting the oxidant-treated catalyst with acid, preferably aqua regia; washing the titanosilicate to remove residual acid; and optionally drying and / or calcining. A method of reconstituting an active oxidation catalyst from a spent or deactivated oxidation catalyst, the method involving reclaiming the titanosilicate as noted above, and then depositing one or more catalytic metals and, optionally, one or more promoter metals onto the reclaimed titanosilicate.

Owner:DOW GLOBAL TECH LLC

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

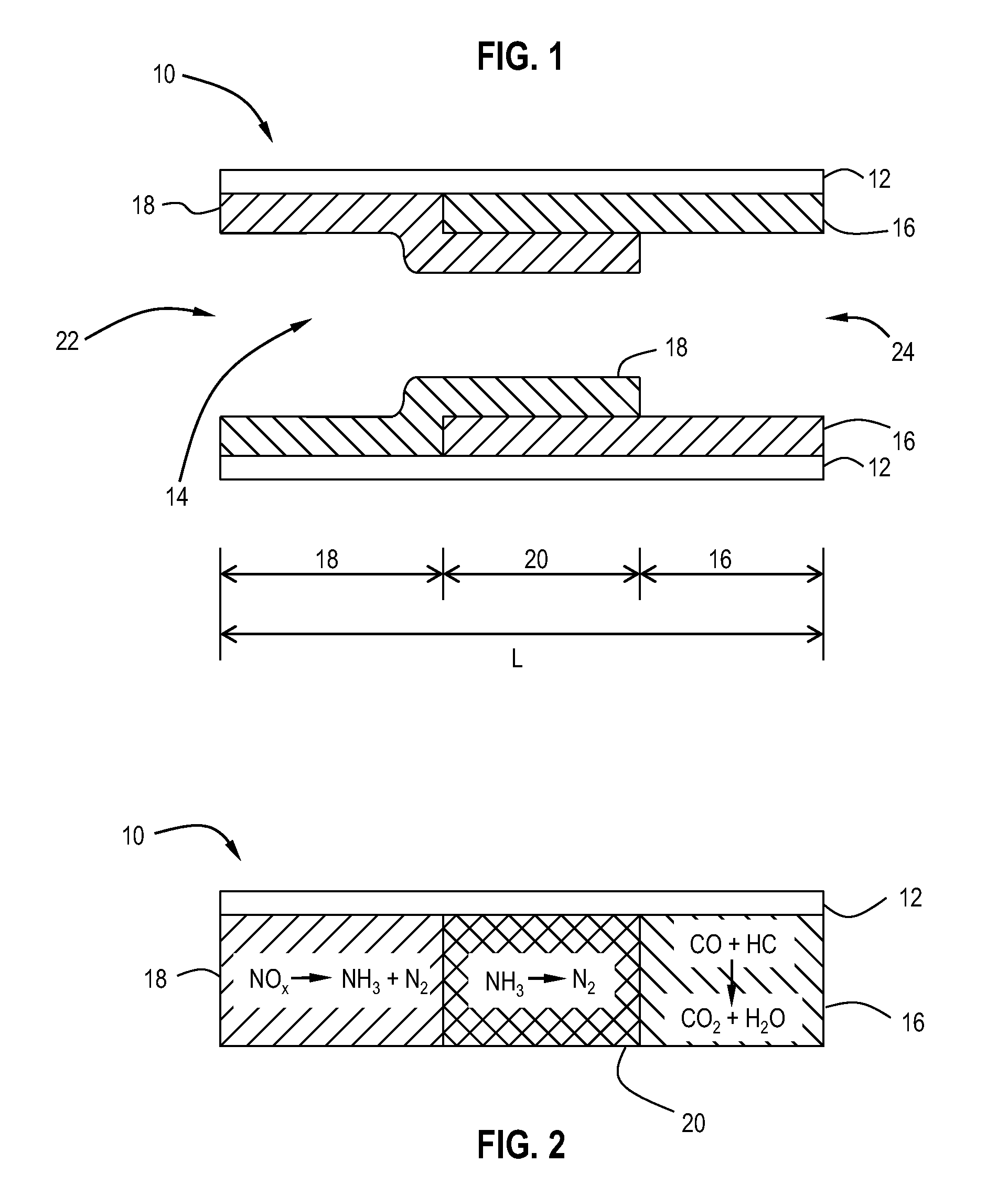

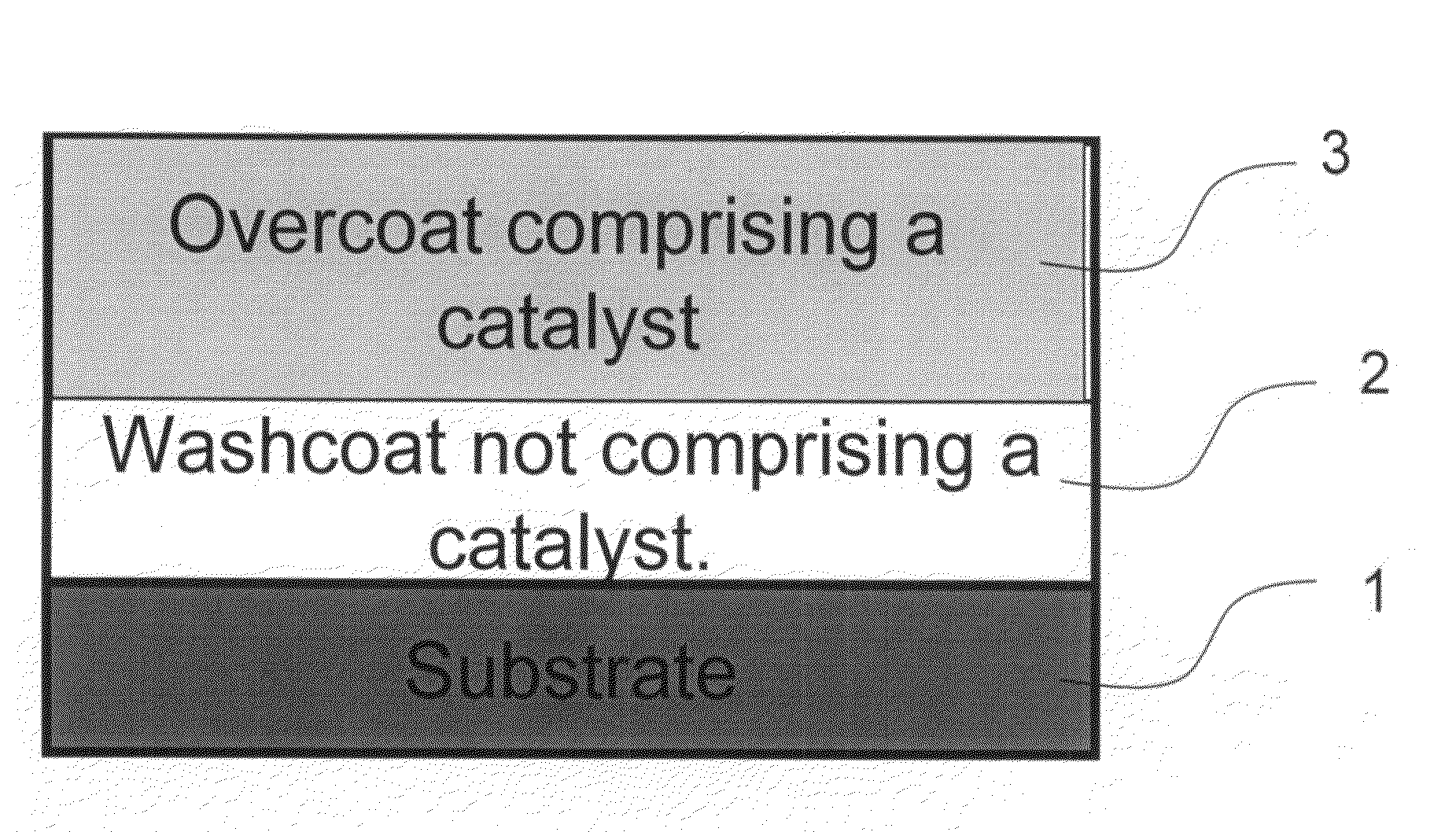

Integrated SCR and AMOX Catalyst Systems

Catalysts and catalytic articles for treating exhaust gas streams are described. In one or more embodiments, a catalyst system includes a first zone to abate nitrogen oxides by selective catalytic reduction, a second zone to oxidize ammonia and a third zone to oxidize carbon monoxide and hydrocarbons. Methods for treating the exhaust gas stream are also provided. Methods of making and using such catalysts and catalytic articles are also described.

Owner:BASF CORP

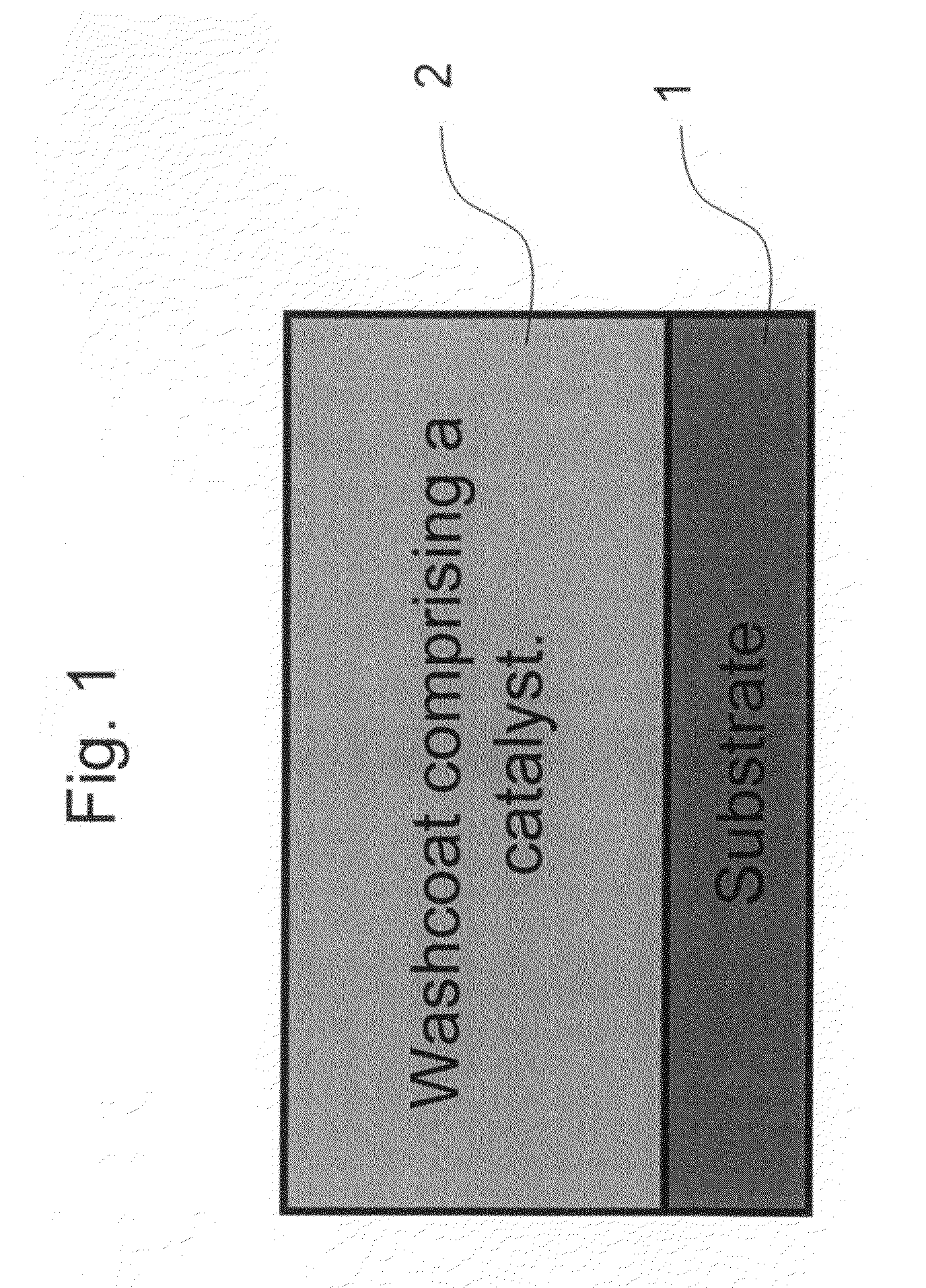

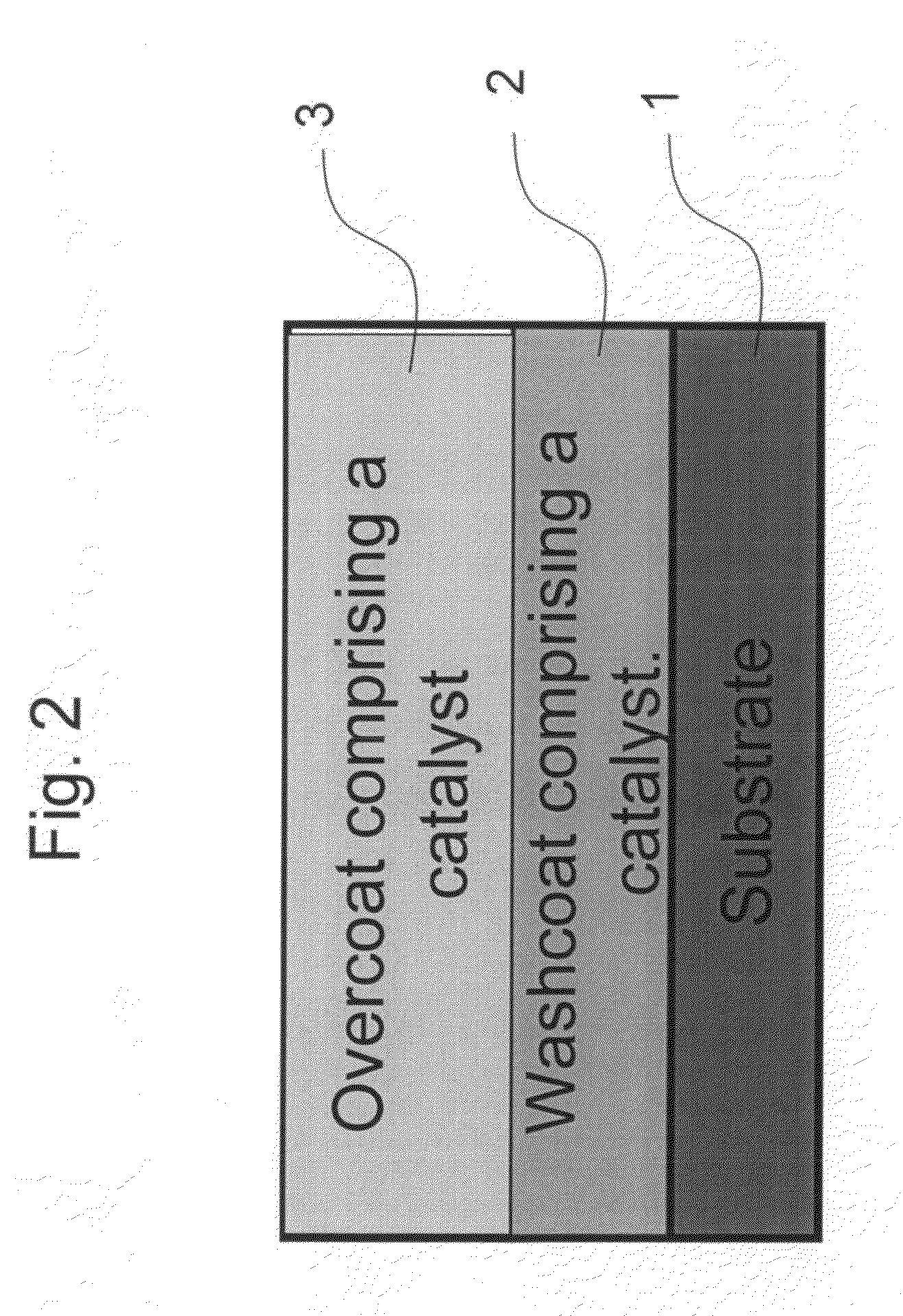

Zero platinum group metal catalysts

The present invention pertains to catalyst systems for nitrogen oxide, carbon monoxide, hydrocarbon, and sulfur reactions that are free or substantially free of platinum group metals. The catalyst system of the present invention comprise a substrate and a washcoat, wherein the washcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst system may optionally have an overcoat, wherein the overcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst comprises one or more selected from the group consisting of a ZPGM transition metal catalyst, a mixed metal oxide catalyst, a zeolite catalysts, or mixtures thereof.

Owner:CATALYTIC SOLUTIONS INC

Porous composite materials having micro and meso/macroporosity

InactiveUS20070087934A1Molecular sieve catalystsOrganic compound preparationMaterials scienceInorganic oxide

A composite material comprises: (a) a porous crystalline inorganic oxide material comprising a first framework structure defining a first set of uniformly distributed pores having an average cross-sectional dimension of from 0.3 to less than 2 nanometers and comprising a second framework structure defining a second set of uniformly distributed pores having an average cross-sectional dimension of from 2 to 200 nanometers and (b) a co-catalyst within the second set of pores of the porous crystalline inorganic oxide material (a).

Owner:EXXONMOBIL CHEM PAT INC

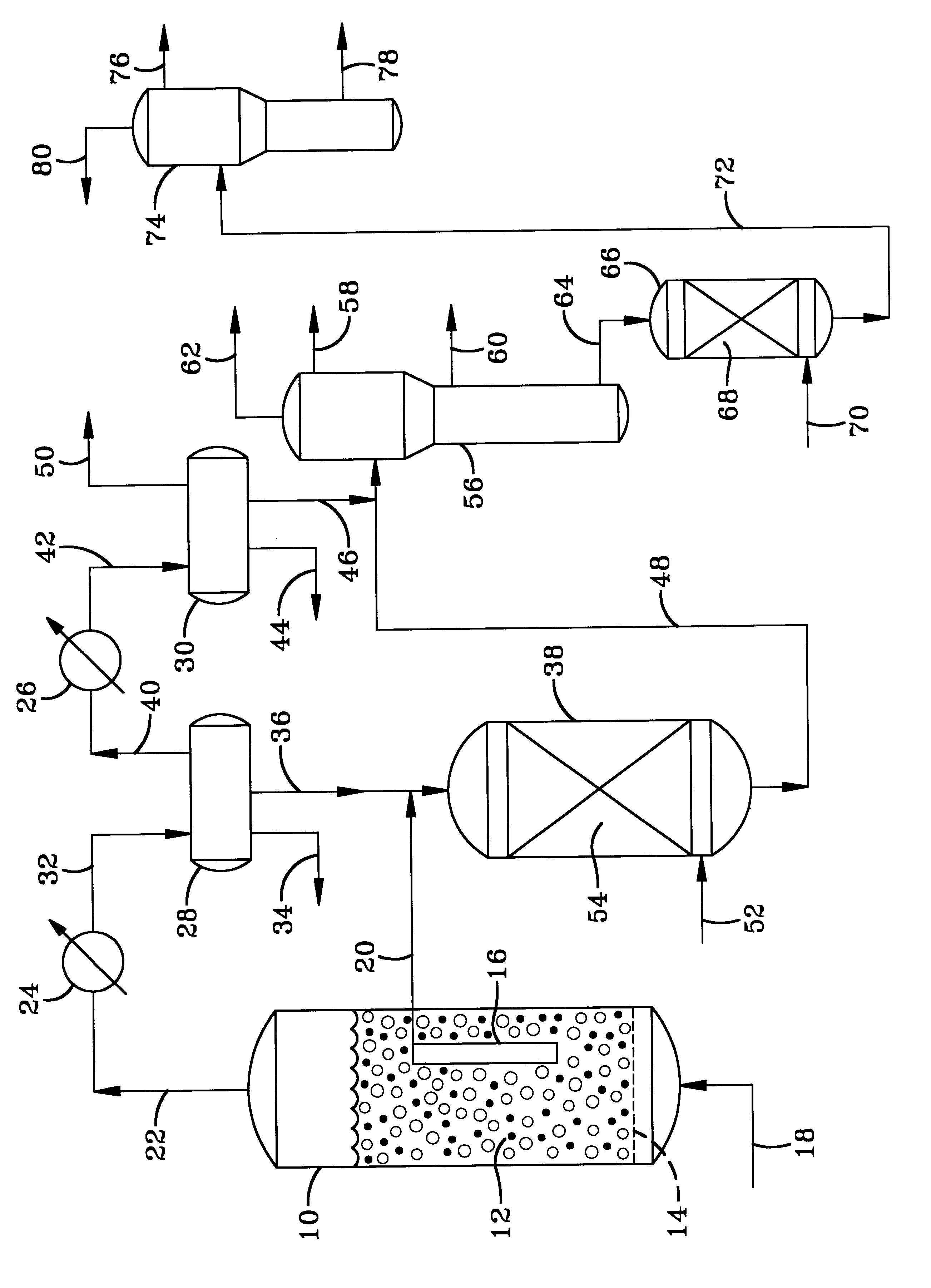

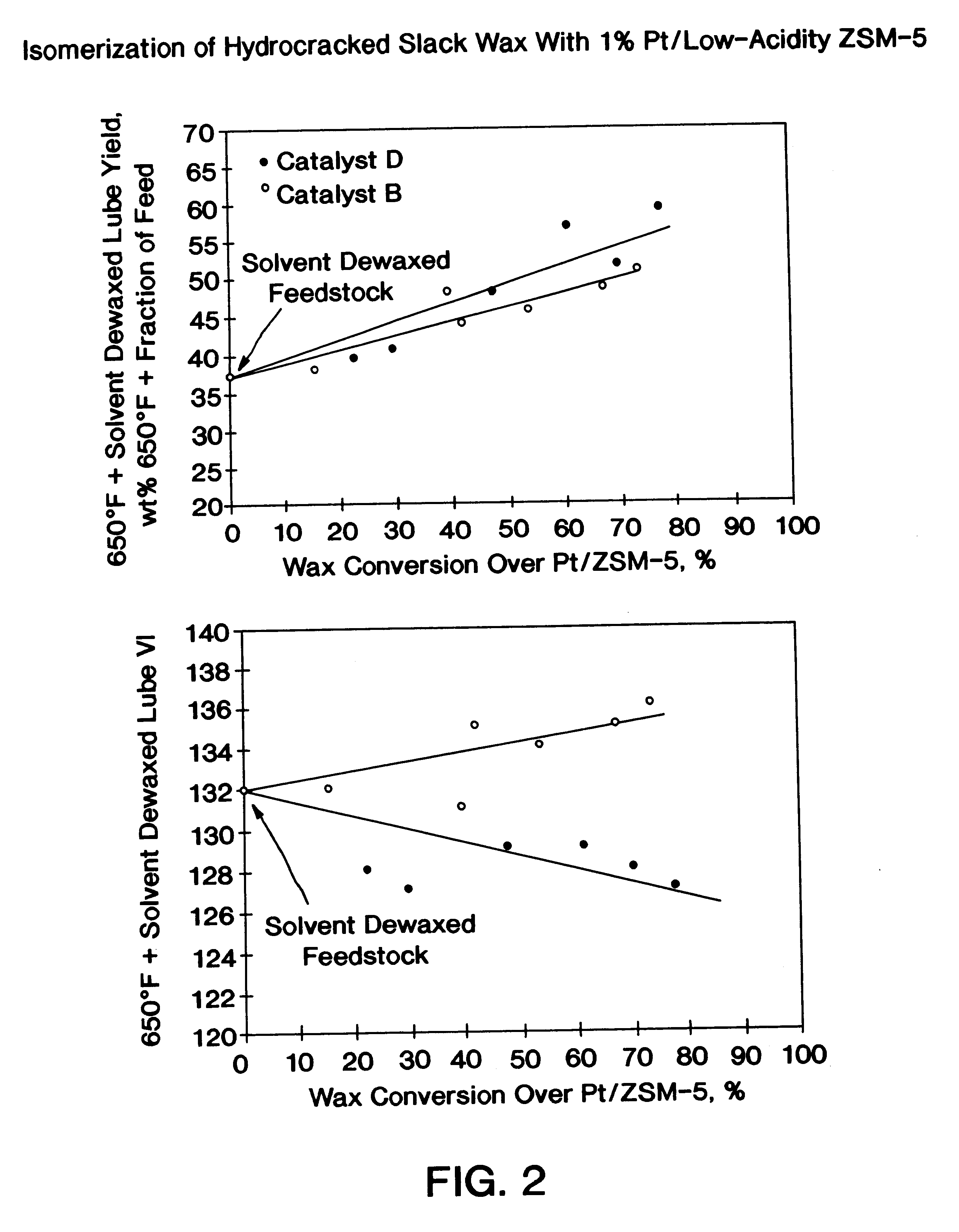

Isoparaffinic base stocks by dewaxing fischer-tropsch wax hydroisomerate over Pt/H-mordenite

A high VI and low pour point lubricant base stock is made by hydroisomerizing a high purity, waxy, paraffinic Fischer-Tropsch synthesized hydrocarbon fraction having an initial boiling point in the range of 650-750° F., followed by catalytically dewaxing the hydroisomerate using a dewaxing catalyst comprising a catalytic platinum component and an H-mordenite component. The hydrocarbon fraction is preferably synthesized by a slurry Fischer-Tropsch using a catalyst containing a catalytic cobalt component. This combination of the process, high purity, waxy paraffinic feed and the Pt / H-mordenite dewaxing catalyst, produce a relatively high yield of premium lubricant base stock.

Owner:EXXON RES & ENG CO

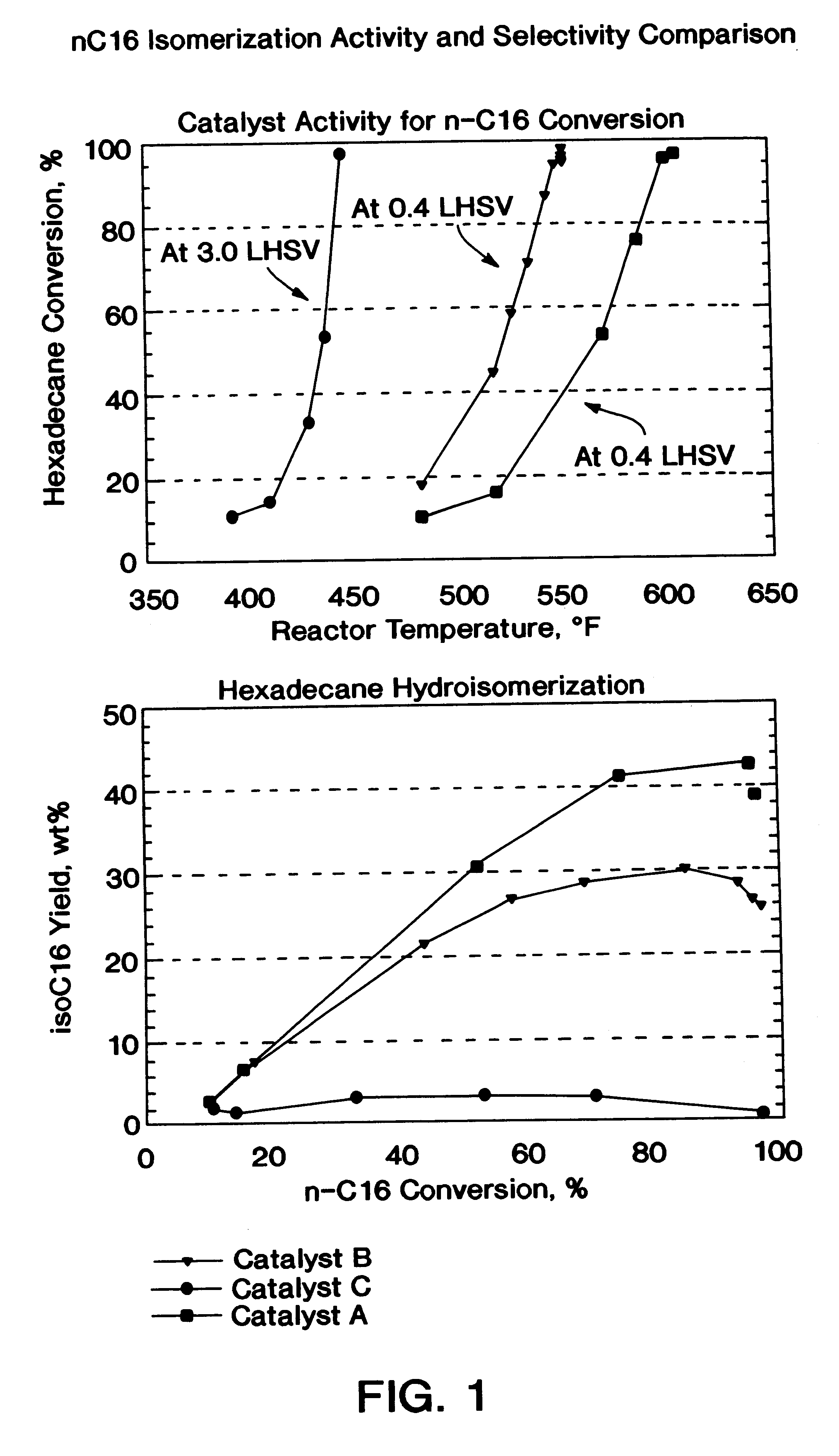

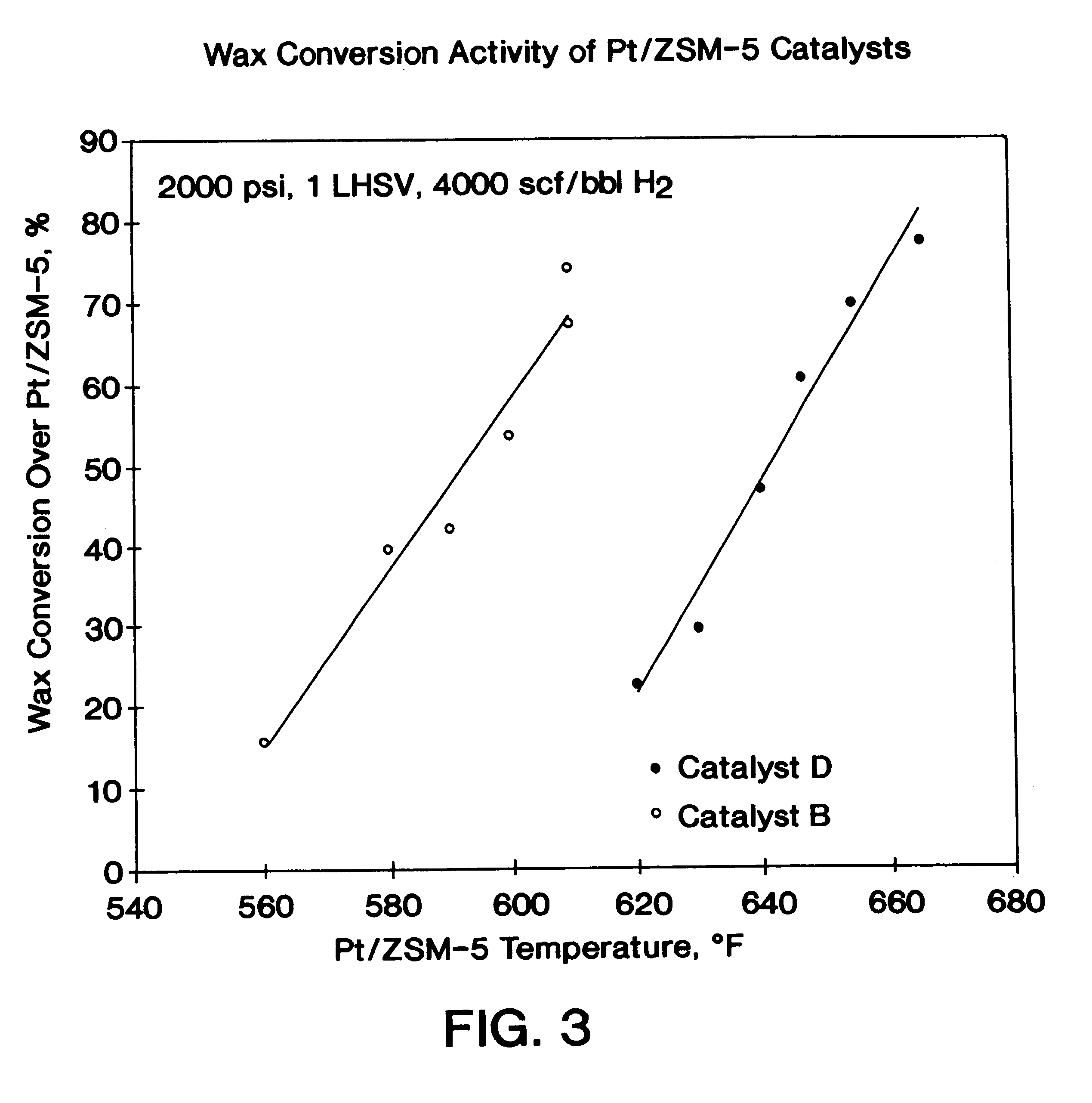

Production of high viscosity lubricating oil stock with improved ZSM-5 catalyst

InactiveUS6294077B1Low pour pointHigh viscosity indexMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenParaffin oils

The present invention is a process for producing a high viscosity index and low pour point lubricating oil base stock which comprises catalytically converting a hydrotreated hydrocarbon lube oil feedstock containing waxy paraffins in the presence of hydrogen and in the presence of a low acidity ZSM-5 catalyst having a highly dispersed noble metal component. The ZSM-5 catalyst is subjected to controlled acidity reduction to an alpha value below 15 prior to incorporation of the noble metal component.

Owner:MOBIL OIL CORP

Popular searches

Hydrocarbon from oxygen organic compounds Hydrocarbon by hydrocarbon and non-hydrocarbon condensation Hydrocarbon by addition and hydrogenation Hydrocarbon preparation catalysts Metal/metal-oxides/metal-hydroxide catalysts Bulk chemical production Bio-feedstock Refining by aromatic hydrocarbon hydrogenation Hydrocarbon oils treatment products Hydrocarbon preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com