Patents

Literature

10431 results about "Denitrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

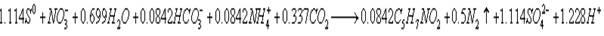

Denitrification is a microbially facilitated process where nitrate (NO₃⁻) is reduced and ultimately produces molecular nitrogen (N₂) through a series of intermediate gaseous nitrogen oxide products. Facultative anaerobic bacteria perform denitrification as a type of respiration that reduces oxidized forms of nitrogen in response to the oxidation of an electron donor such as organic matter. The preferred nitrogen electron acceptors in order of most to least thermodynamically favorable include nitrate (NO₃⁻), nitrite (NO₂⁻), nitric oxide (NO), nitrous oxide (N₂O) finally resulting in the production of dinitrogen (N₂) completing the nitrogen cycle. Denitrifying microbes require a very low oxygen concentration of less than 10%, as well as organic C for energy. Since denitrification can remove NO₃⁻, reducing its leaching to groundwater, it can be strategically used to treat sewage or animal residues of high nitrogen content. Denitrification can leak N₂O, which is an ozone-depleting substance and a greenhouse gas that can have a considerable influence on global warming.

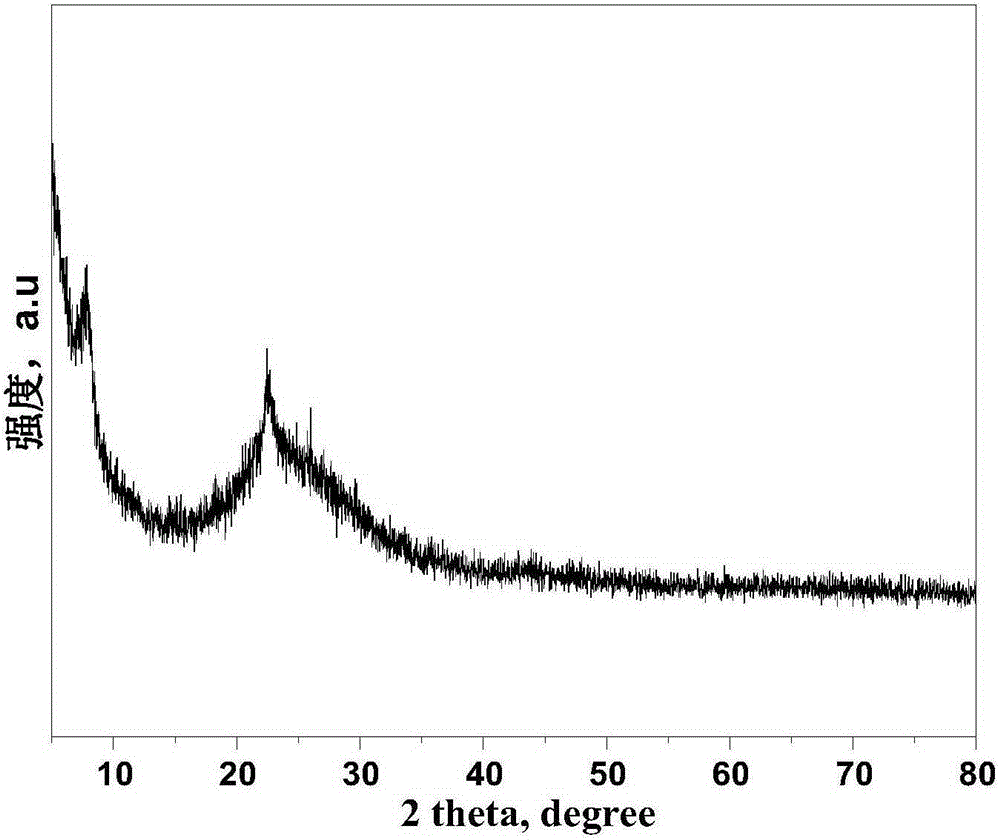

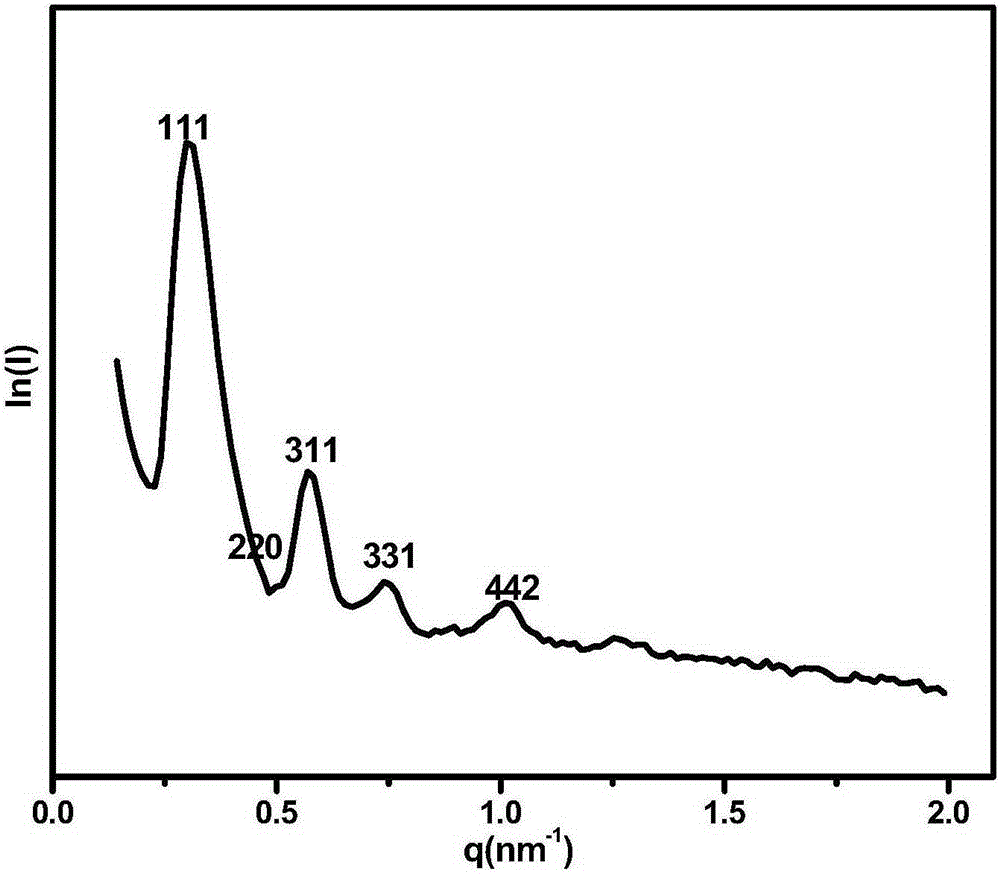

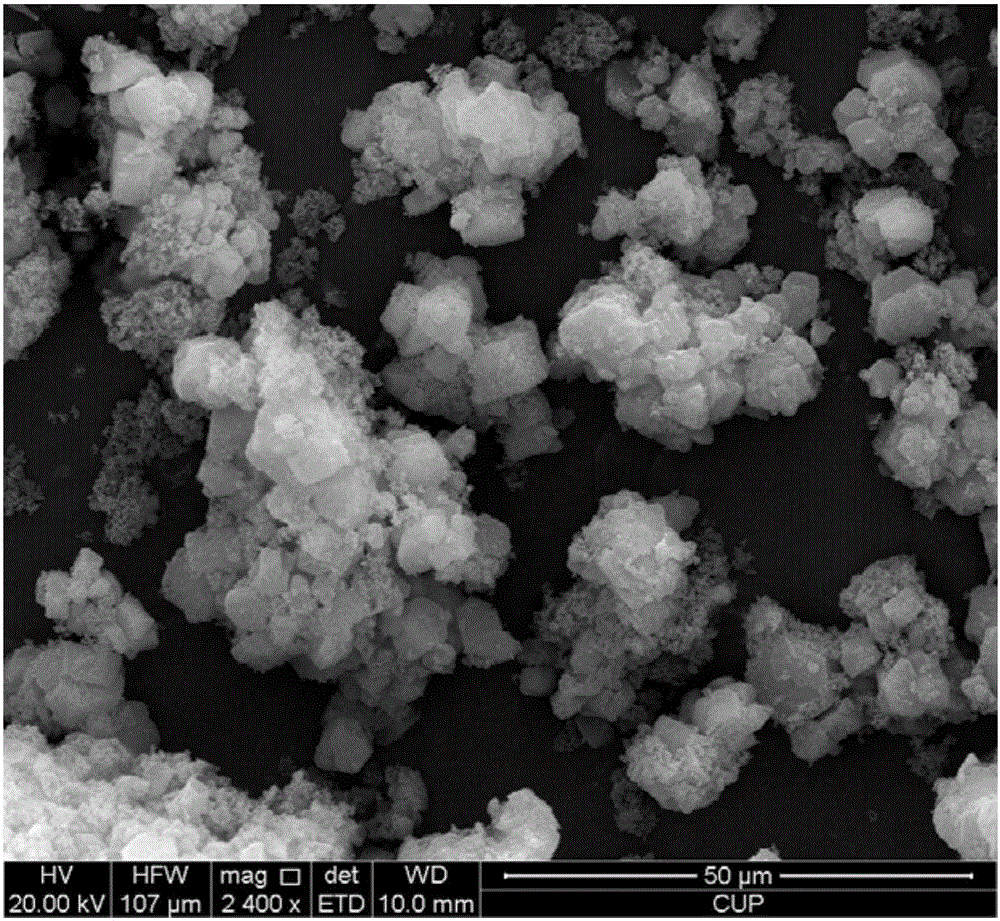

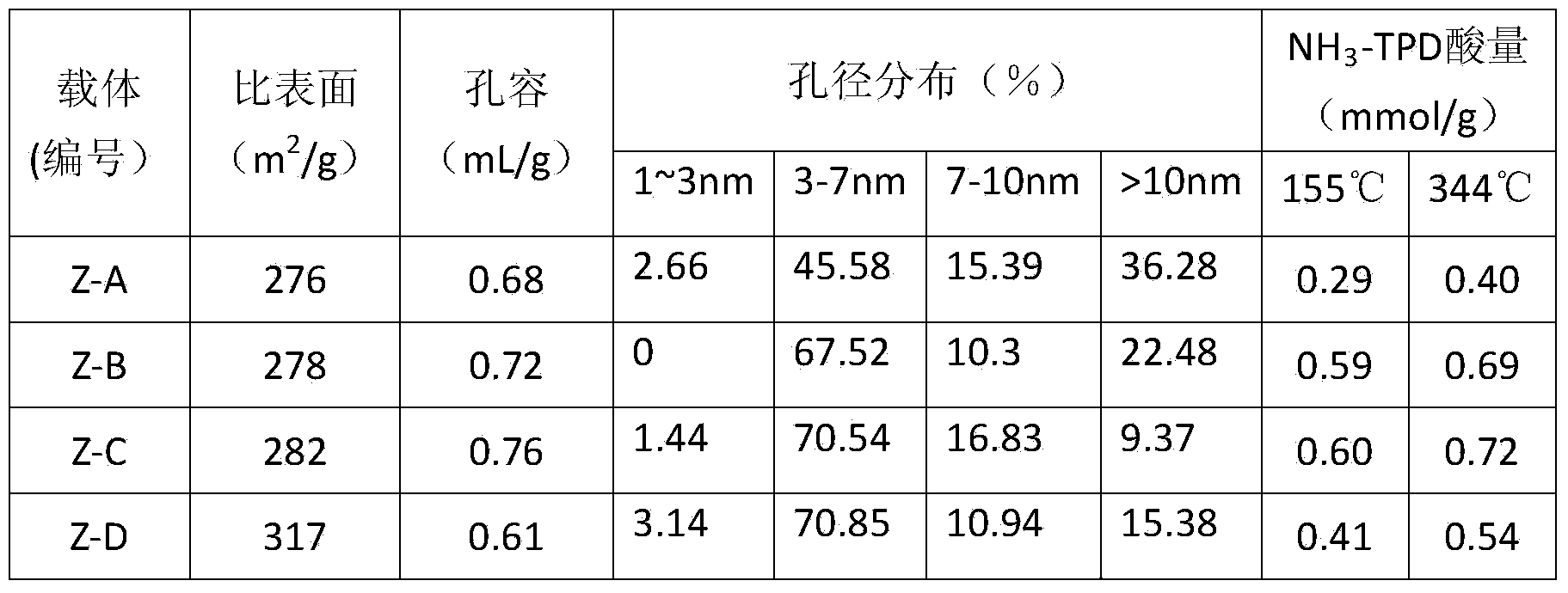

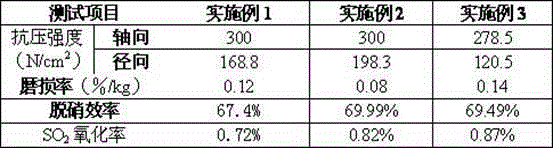

Composite molecular sieve and hydrodesulfurization catalyst prepared with composite molecular sieve as carrier

ActiveCN105251527AGood dispersionModerate dispersionMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention provides a composite molecular sieve and a hydrodesulfurization catalyst prepared with the composite molecular sieve as a carrier. According to the composite molecular sieve and the hydrodesulfurization catalyst, the Beta-FDU-12 composite molecular sieve is of a bimodal porous structure, namely a Beta micropore and an FDU-12 mesoporous, the superficial area of the composite molecular sieve is 800-1000m<2>.g<-1>, the pore diameter is 14-25 nm, and the pore volume is 0.4-0.9 cm<3>.g<-1>.The hydrodesulfurization catalyst prepared with the Beta-FDU-12 composite molecular sieve as the carrier is outstanding in performance, the yield of FCC diesel oil can be higher than 99%, the denitrification percent can be higher than 98%, and the sulphur content is lower than 10 ppm.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

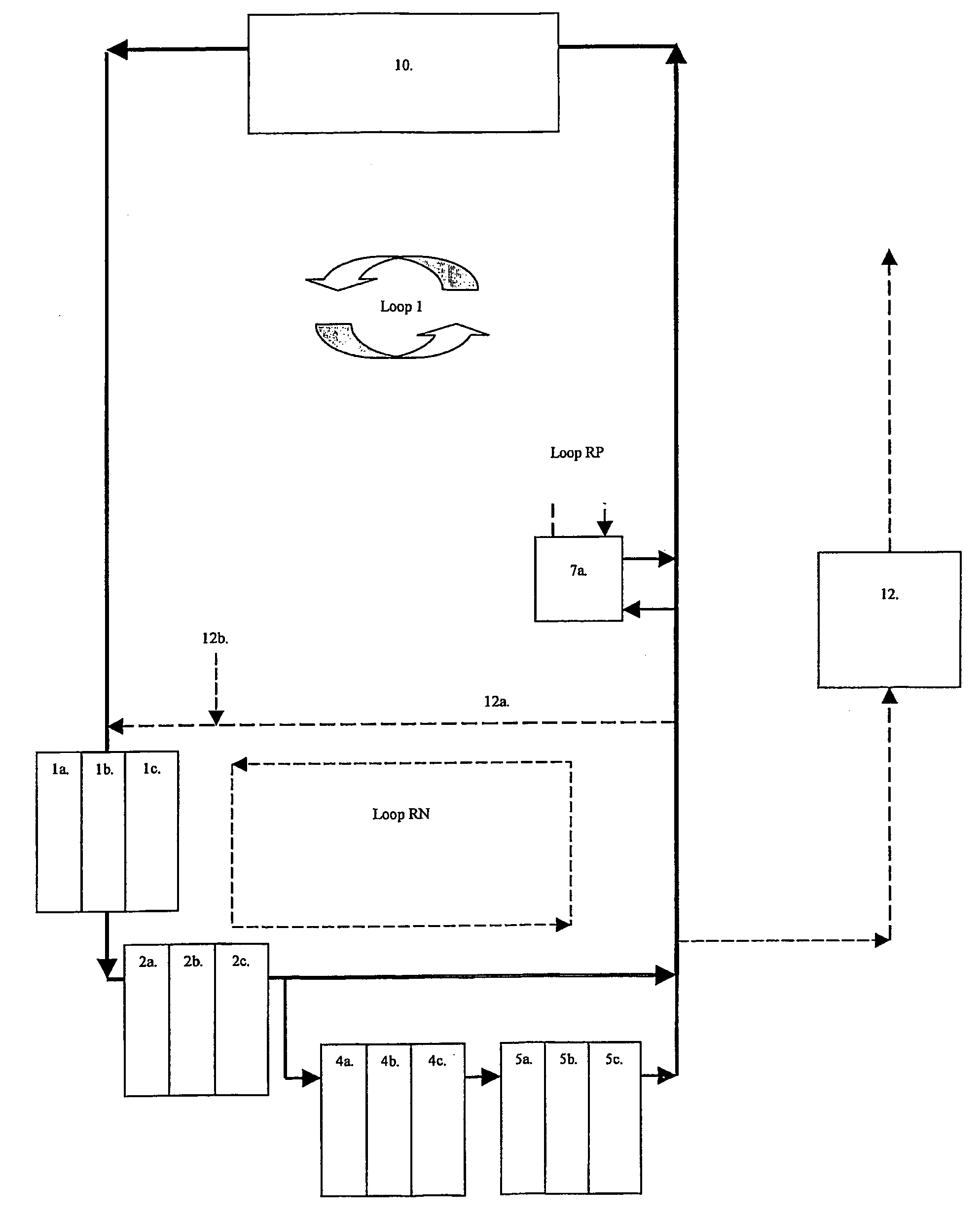

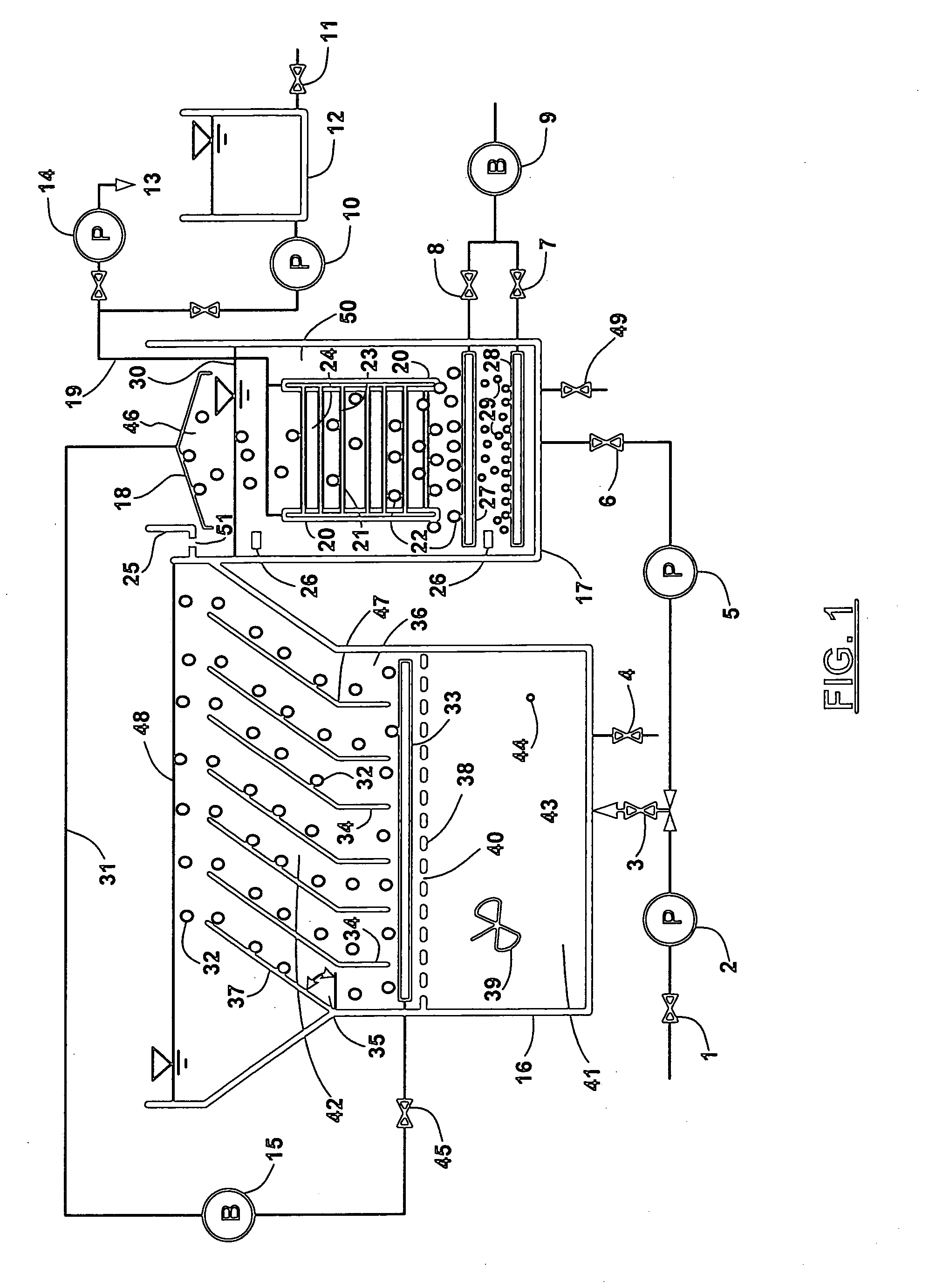

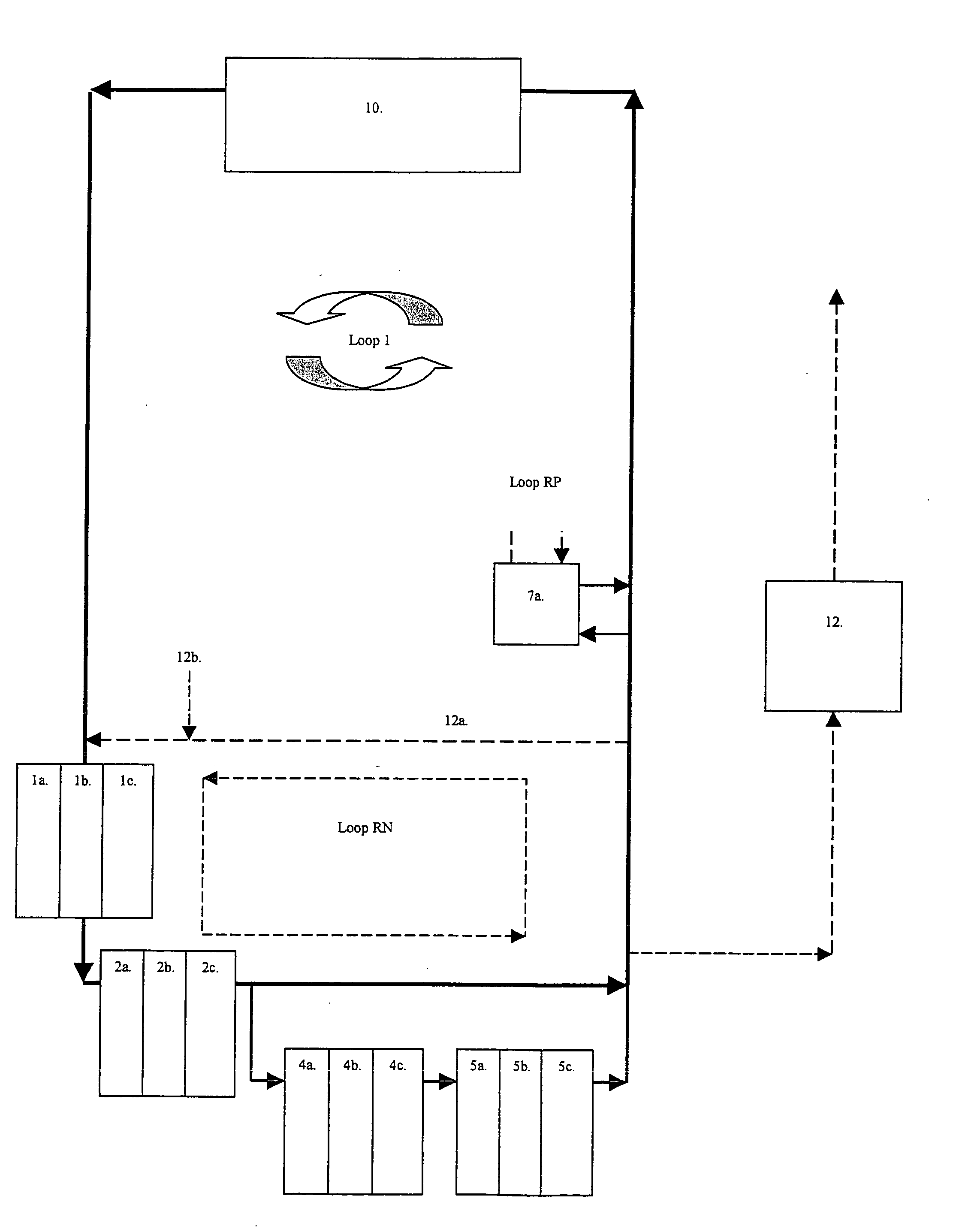

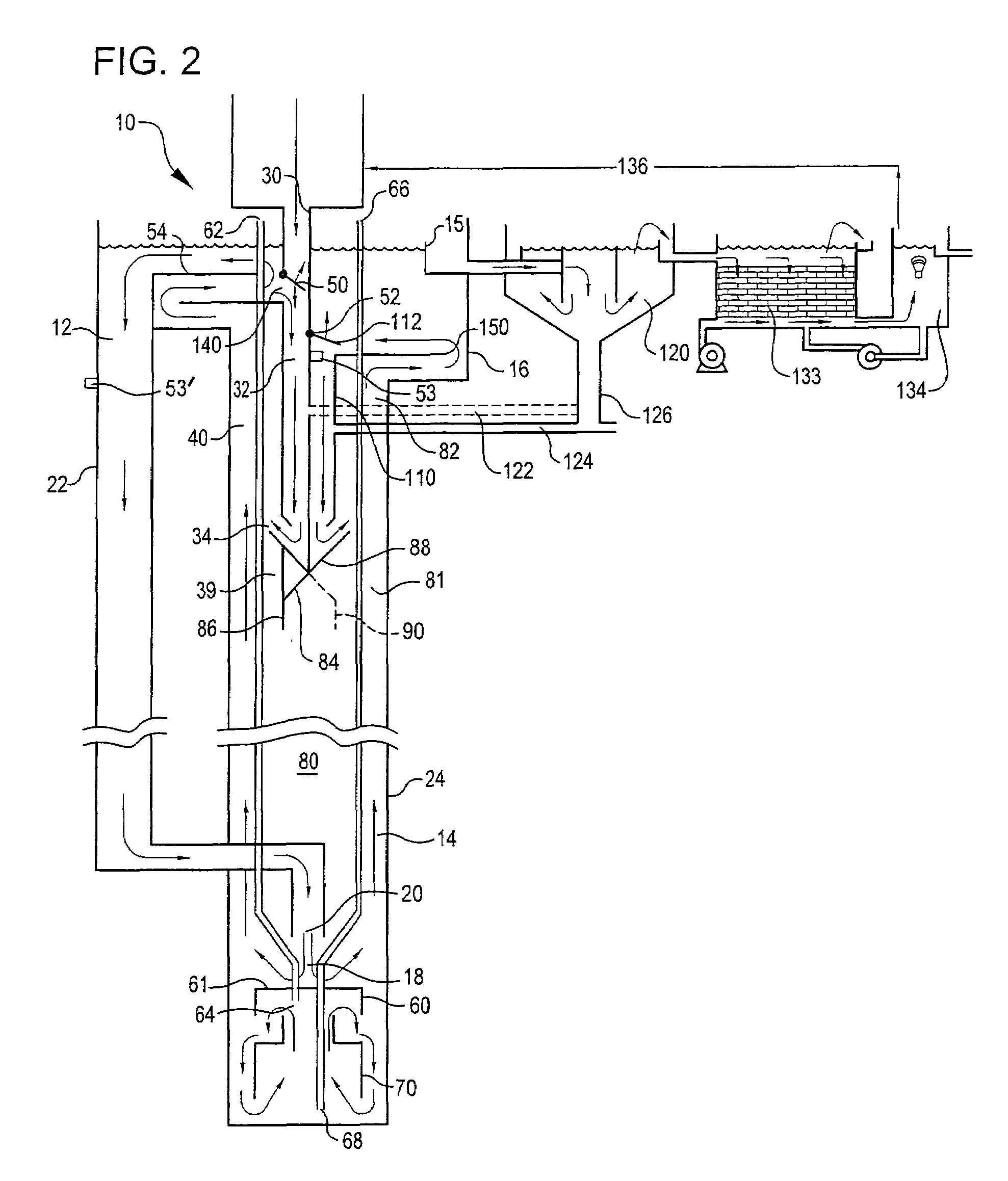

Integrated closed loop system for industrial water purification

InactiveUS7001519B2Improve purification efficiencyTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

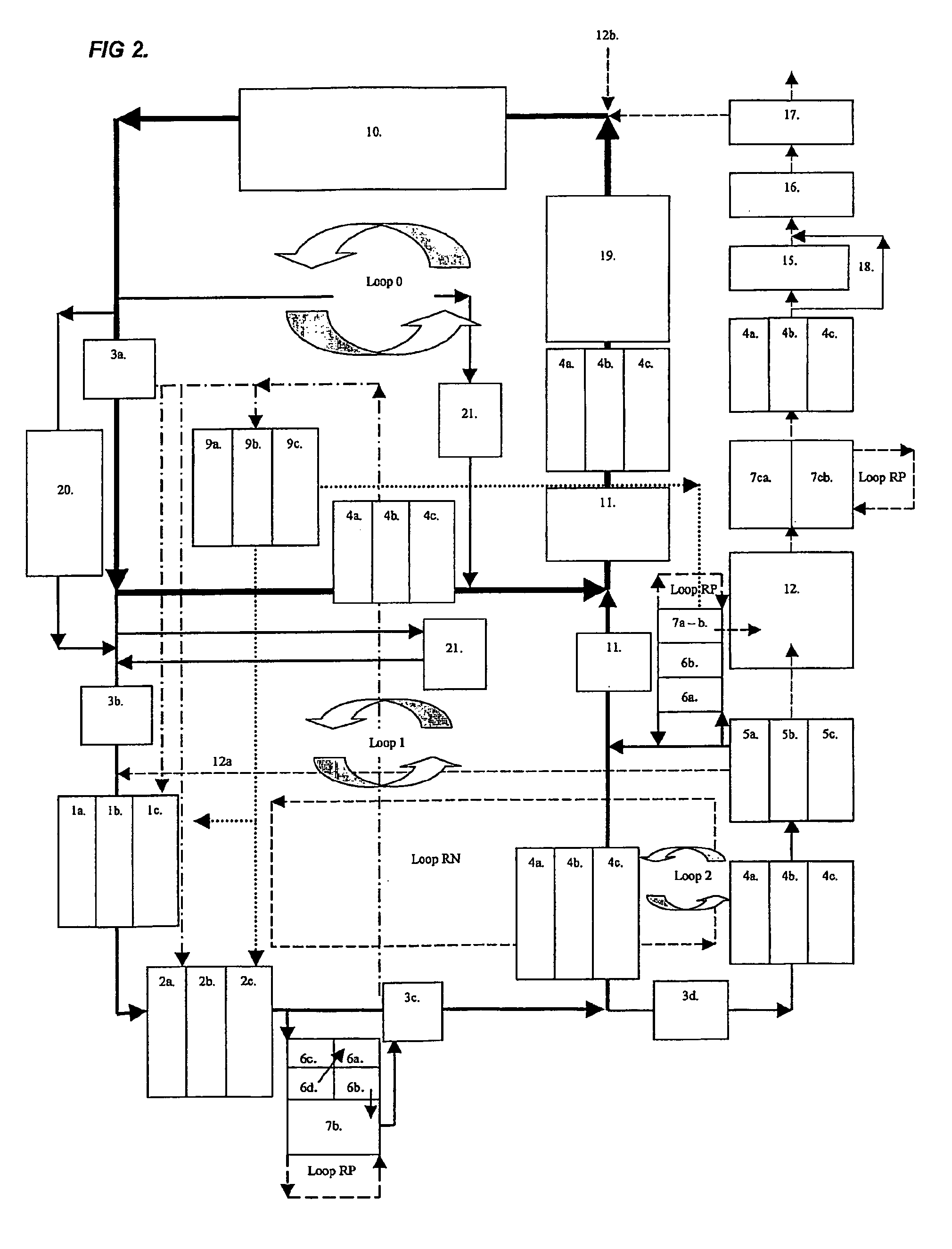

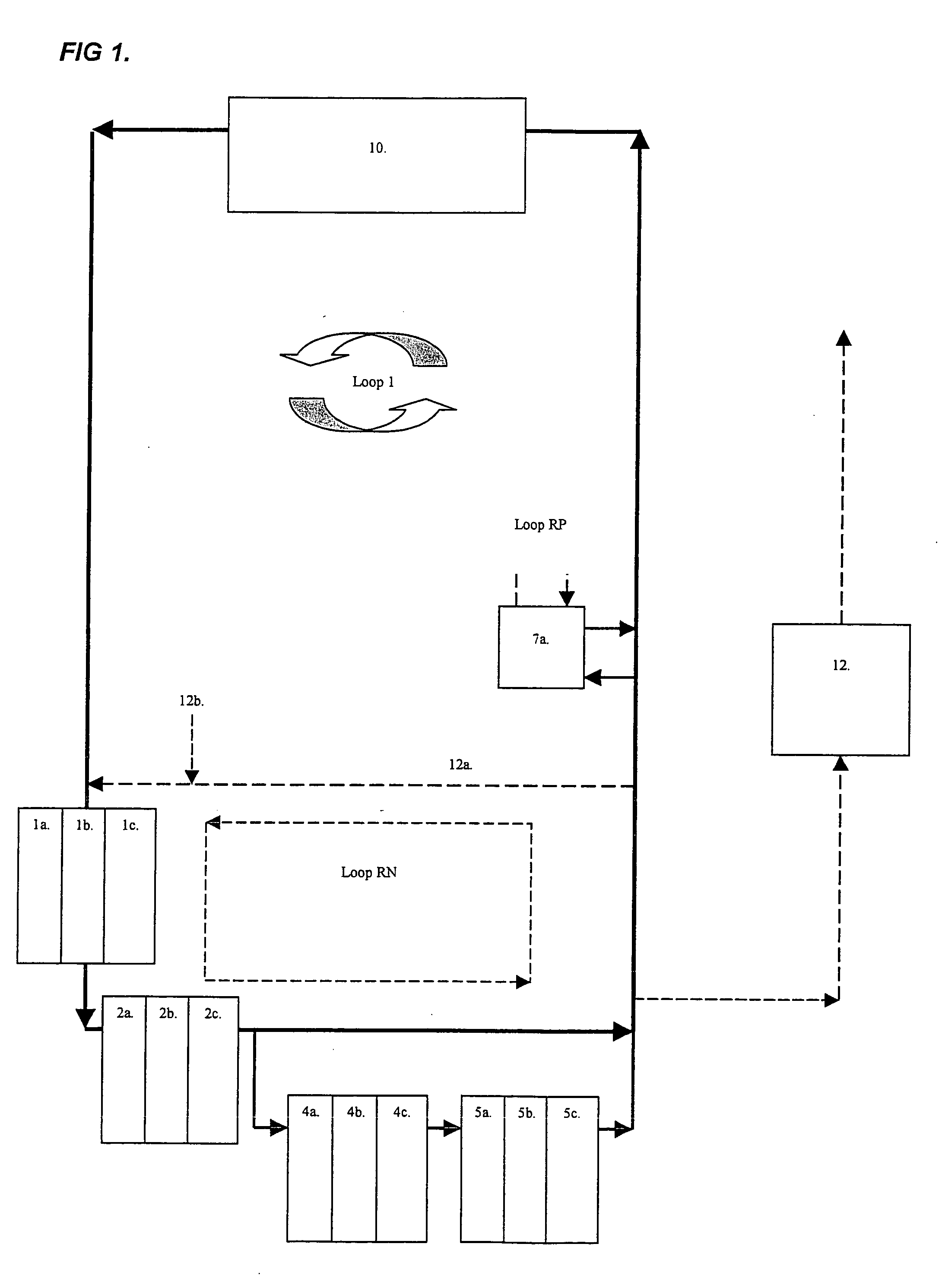

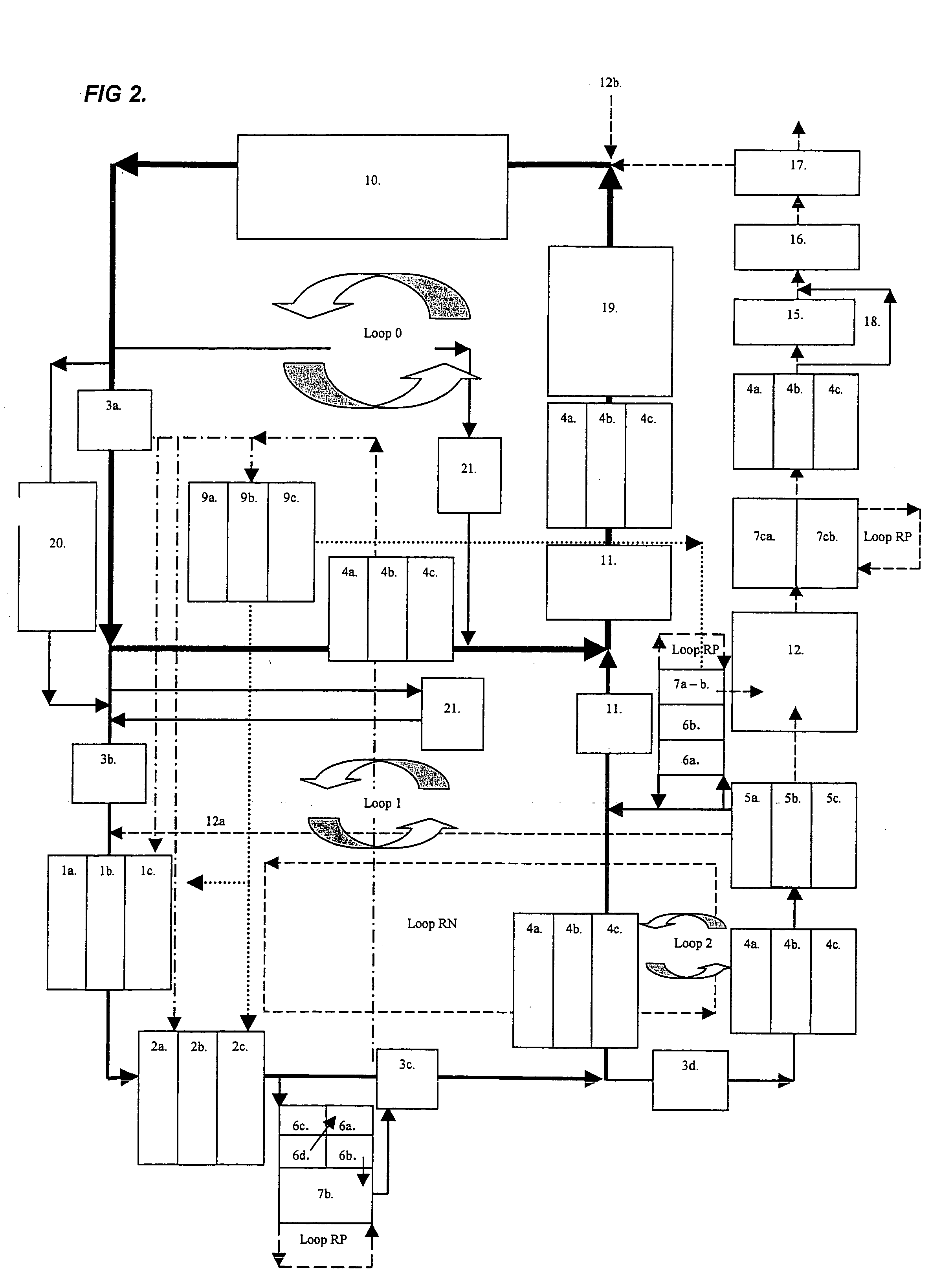

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

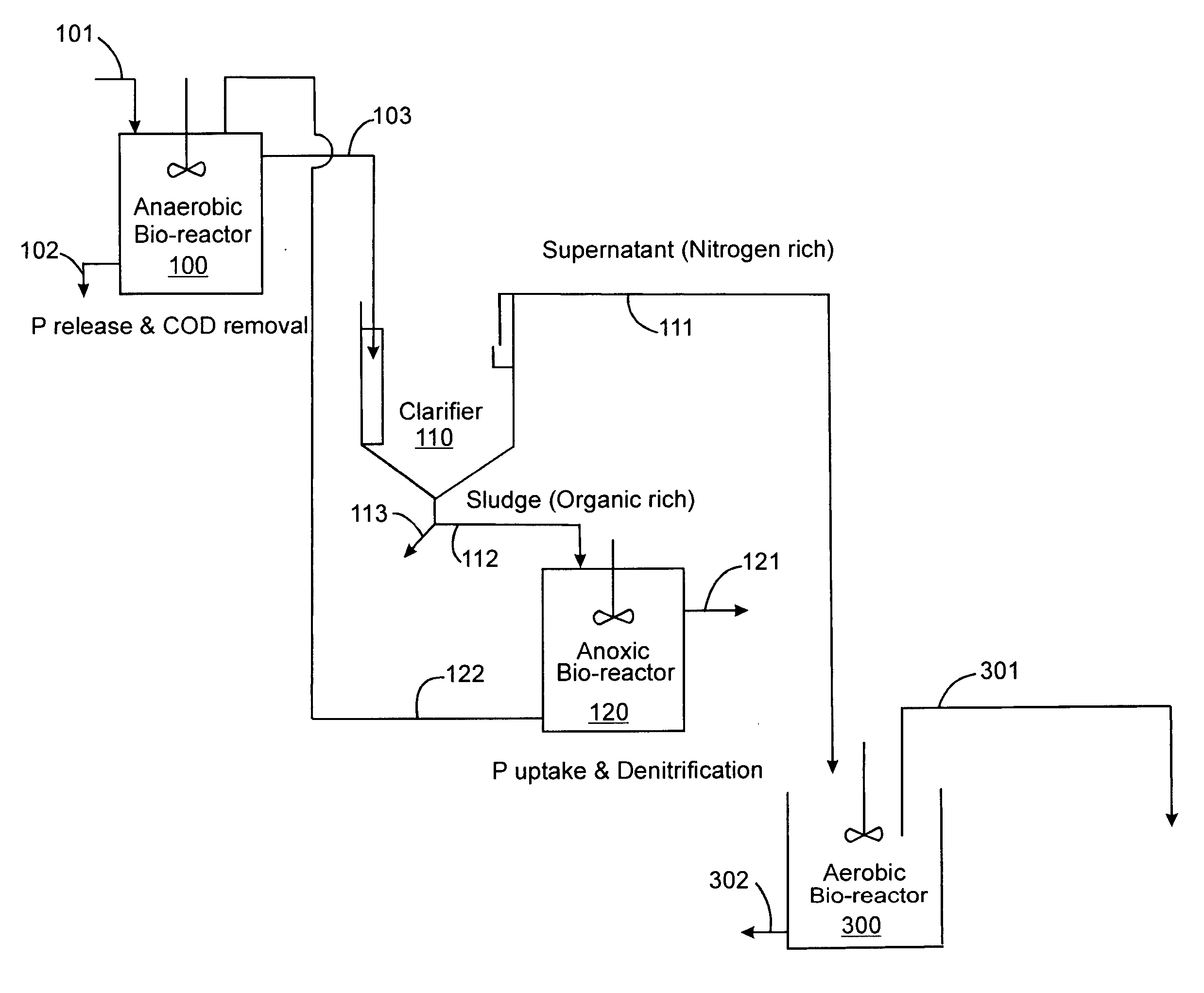

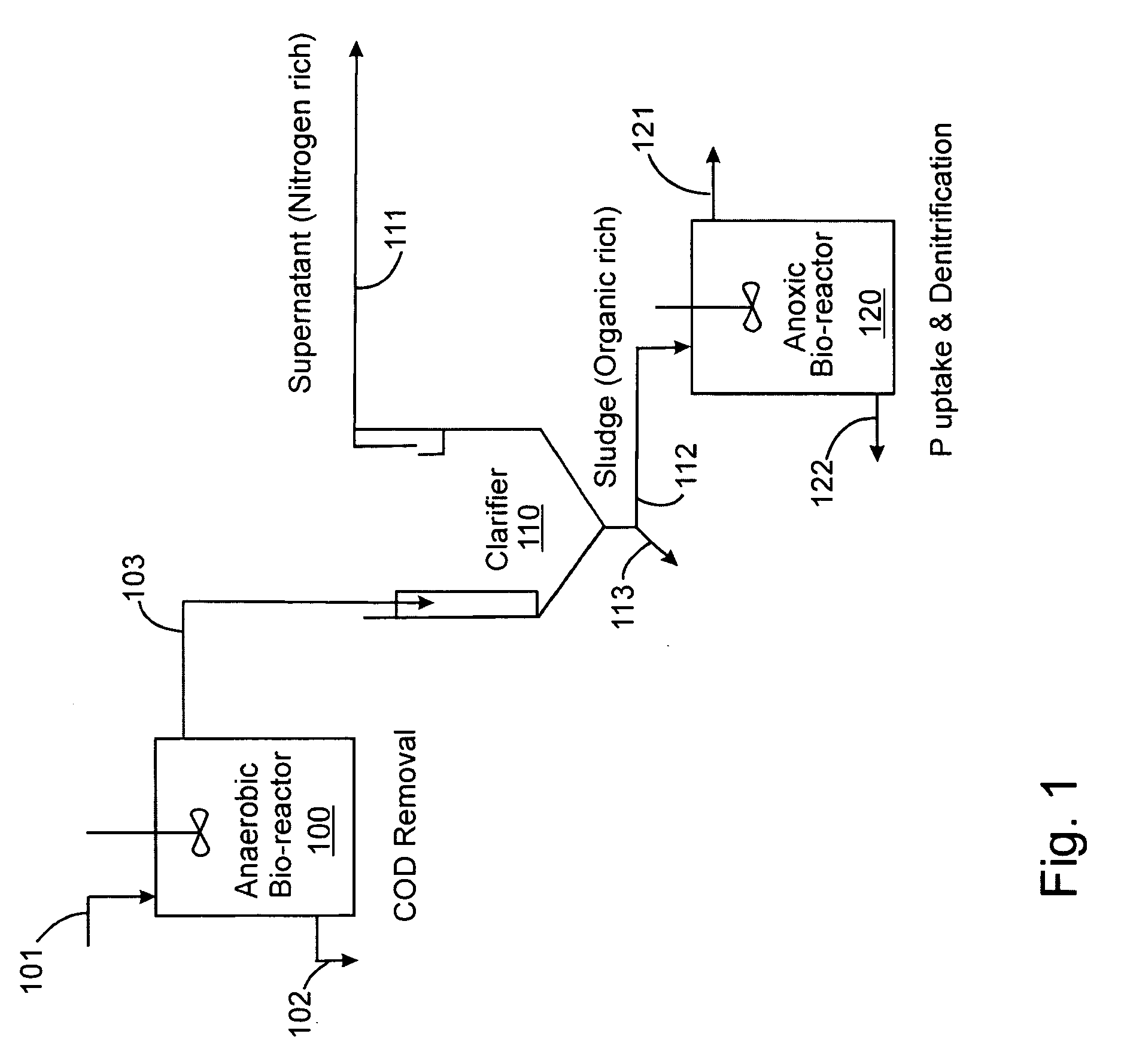

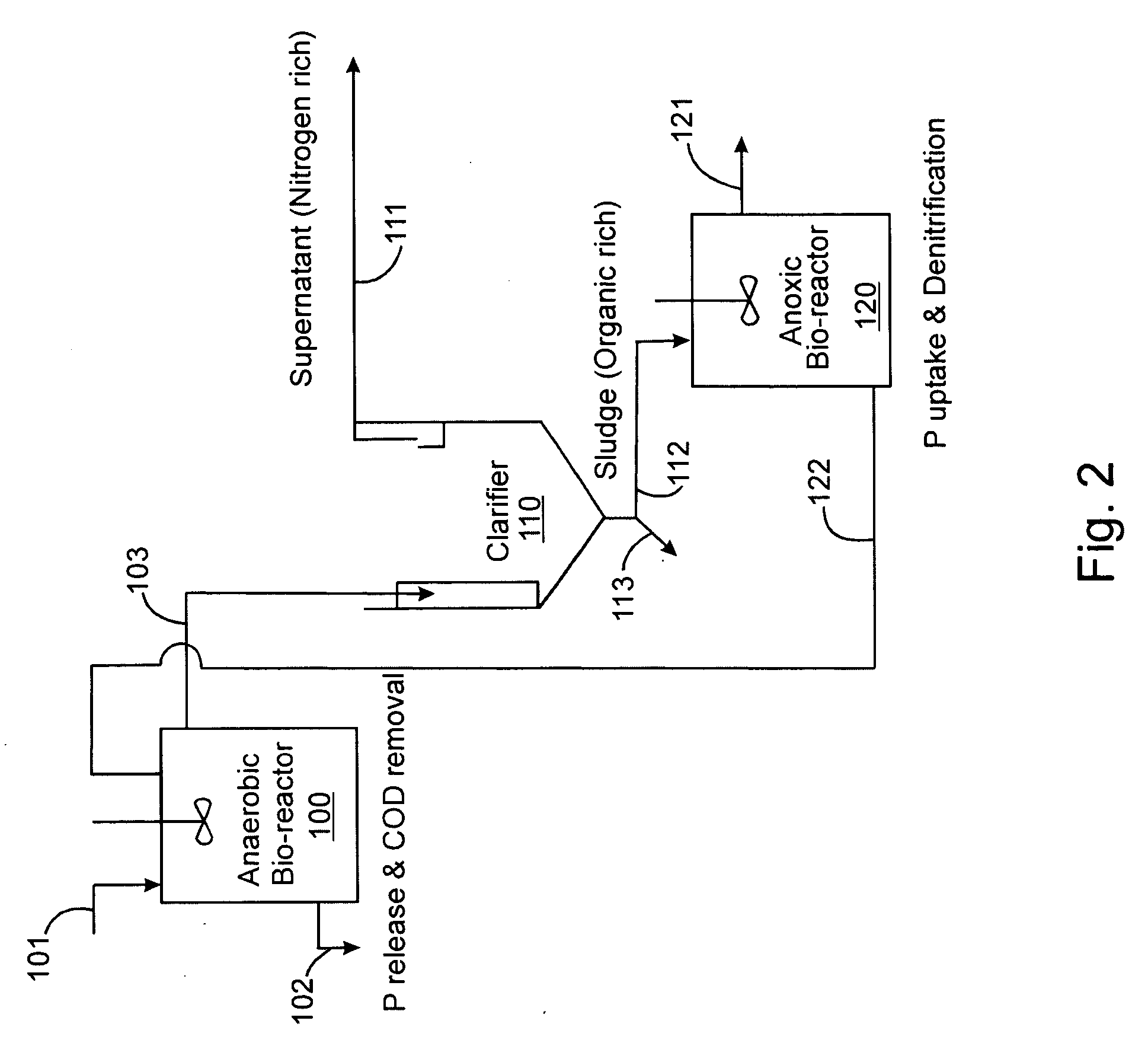

Treatment of wastewater containing phosphorous and nitrogen

InactiveUS20060249449A1Great extent of P releaseHigh P uptakeTreatment using aerobic processesSeparation devicesOxygenClarifier

A method and process for the treatment of wastewater containing phosphorous and nitrogen. The wastewater is first anaerobically treated to produce an anaerobic effluent from which insoluble organic carbon is separated to form a sludge rich in organic carbon that is used as a substrate during anoxic treatment of the wastewater by de-nitrifying phosphorous accumulating organisms (DPAO's) and ordinary de-nitrifying organisms. The separation of insoluble organic carbon is normally conducted using a clarifier located intermediate the anaerobic and anoxic bio-reactors. In one embodiment, the ammonia rich clarifier supernatant is directed to an aerobic reactor for nitrification and the nitrate produced is recycled to the anoxic bio-reactor. The final effluent may be membrane filtered to retain nitrifying biomass within the aerobic bio-reactor. The invention reduces overall hydraulic residence time and sludge volume, which results in a smaller, less expensive wastewater treatment system.

Owner:UNIV OF WESTERN ONTARIO

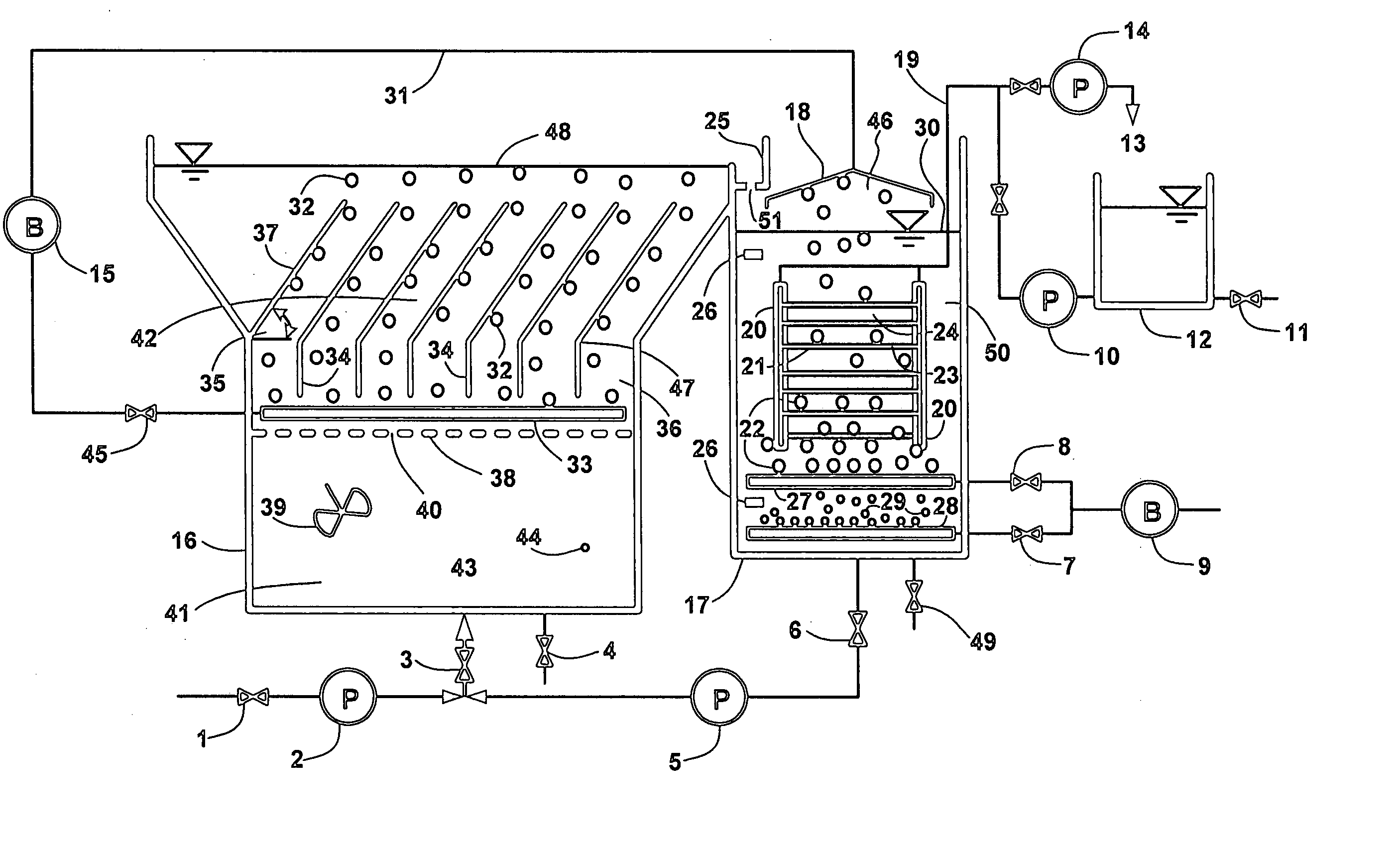

Zero excess sludge membrane bioreactor

InactiveUS20050194310A1High yieldAcceptable levelTreatment using aerobic processesDialysis systemsChemical oxygen demandTotal nitrogen

An inclined plate coupled membrane bioreactor for treating feed water having excessive level of nutrients in particular chemical oxygen demand and total nitrogen and suspended solids has an aerobic bioreactor for nitrification and aerobic biodegradation in which membranes are submerged for permeate extraction, and an anoxic bioreactor for denitrification within which the inclined plates are outfitted to confine as much anoxic sludge as possible. An air oxygenating and an air scouring are continuously provided to the aerobic bioreactor to maintain a desired aerobic environment and to mitigate membrane fouling while an intermittent air blowing is provided to the anoxic bioreactor to blow out gaseous content generated through denitrification and to rectify the uniformed flow along the inclined plates. The aerobic sludge is recycled to the lower compartment of anoxic bioreactor and the supernatant of anoxic bioreactor is collected as weir effluent and delivered to the downstream aerobic bioreactor. Permeate is intermittently extracted from the membranes by a suction pump. There is no excess sludge withdrawn from the inclined plate coupled membrane bioreactor throughout the experiment.

Owner:YAMAMOTO KAZUO +1

Integrated closed loop system for industrial water purification

InactiveUS20050061737A1Small surface areaIncreasing biofilm thicknessTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

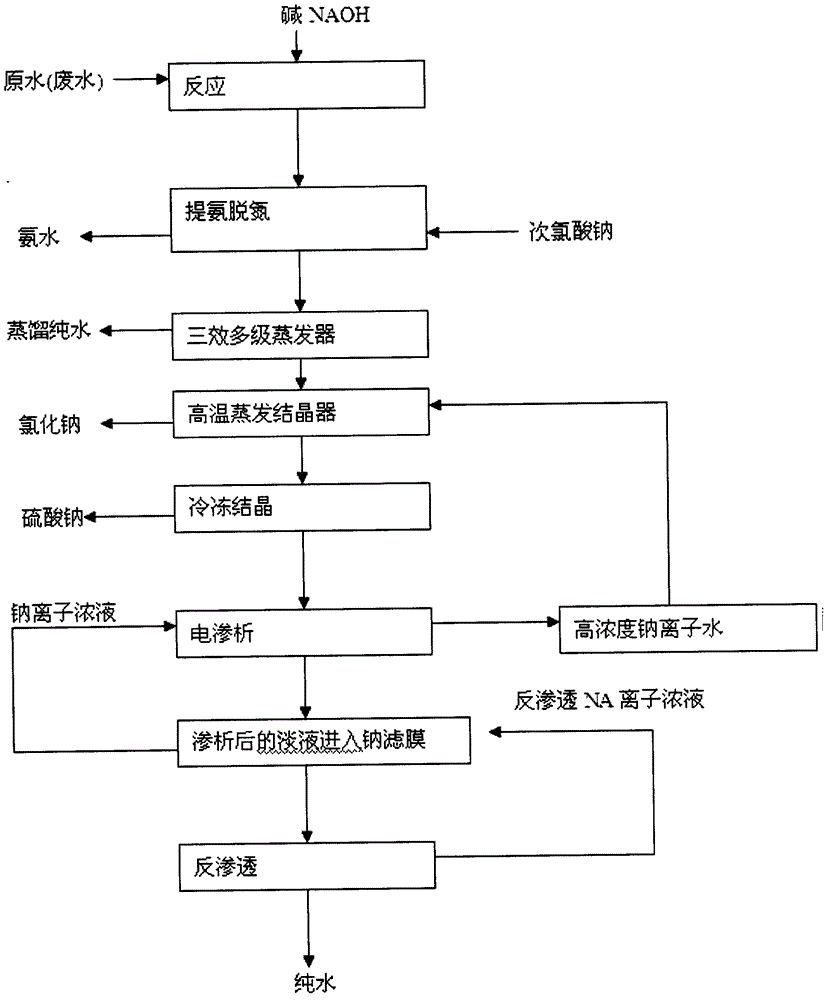

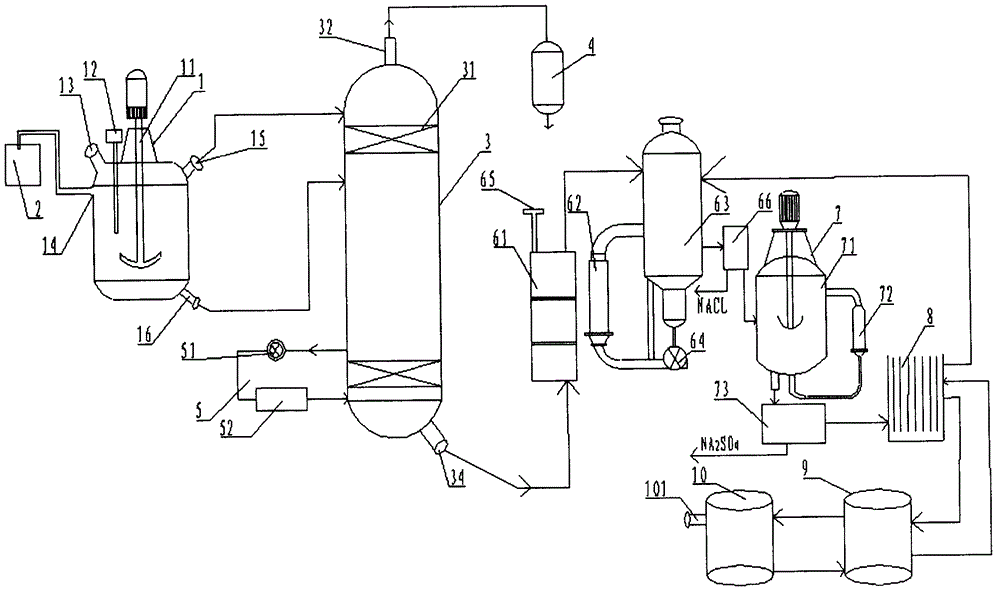

Method and device for utilizing sewage containing ammonia and sodium

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

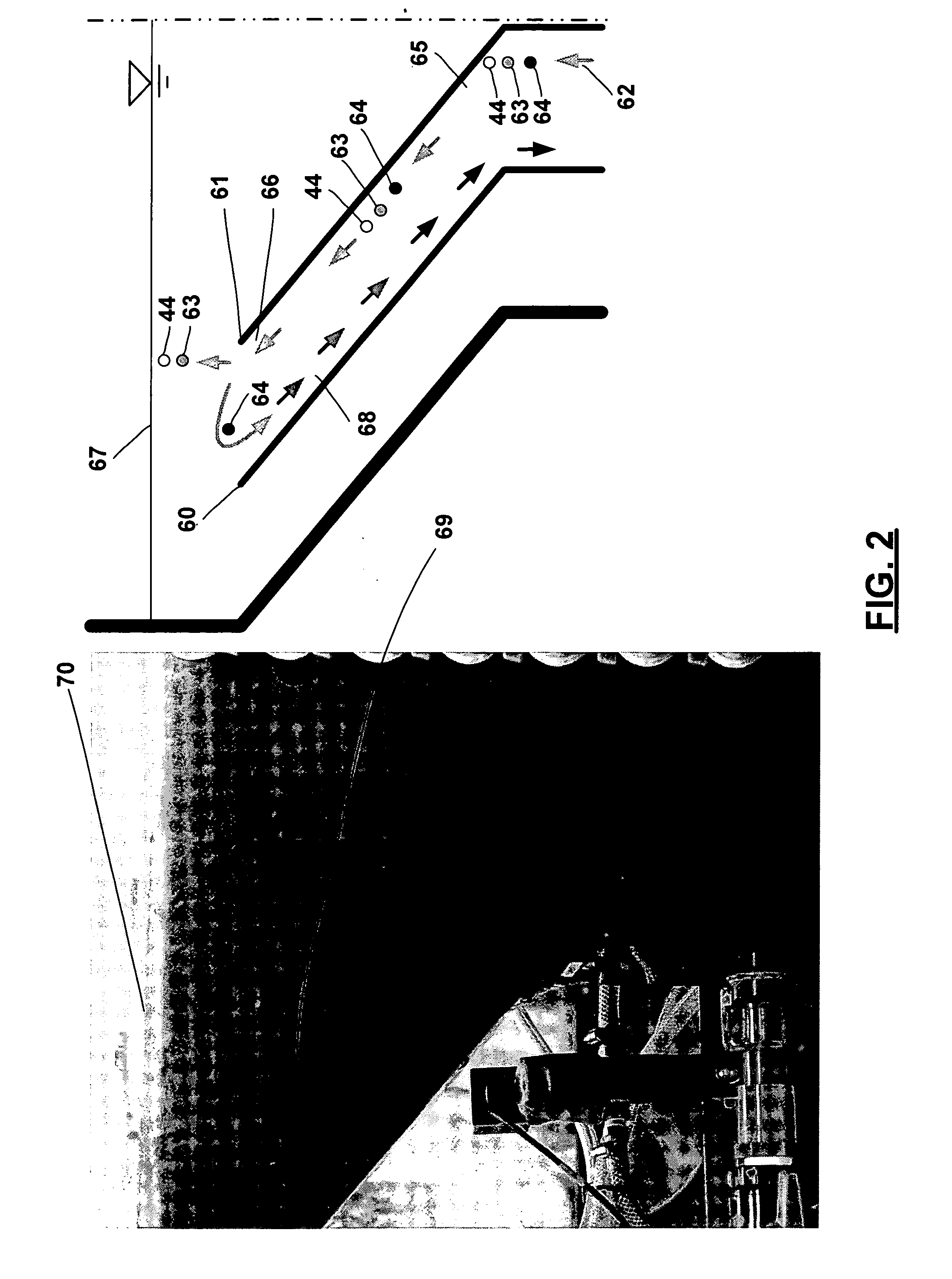

Apparatus and method for purification of agricultural animal waste

InactiveUS6039874AEffective treatment of wastewaterReducing fertilizer nutrientTreatment using aerobic processesOther chemical processesAbove groundFiltration

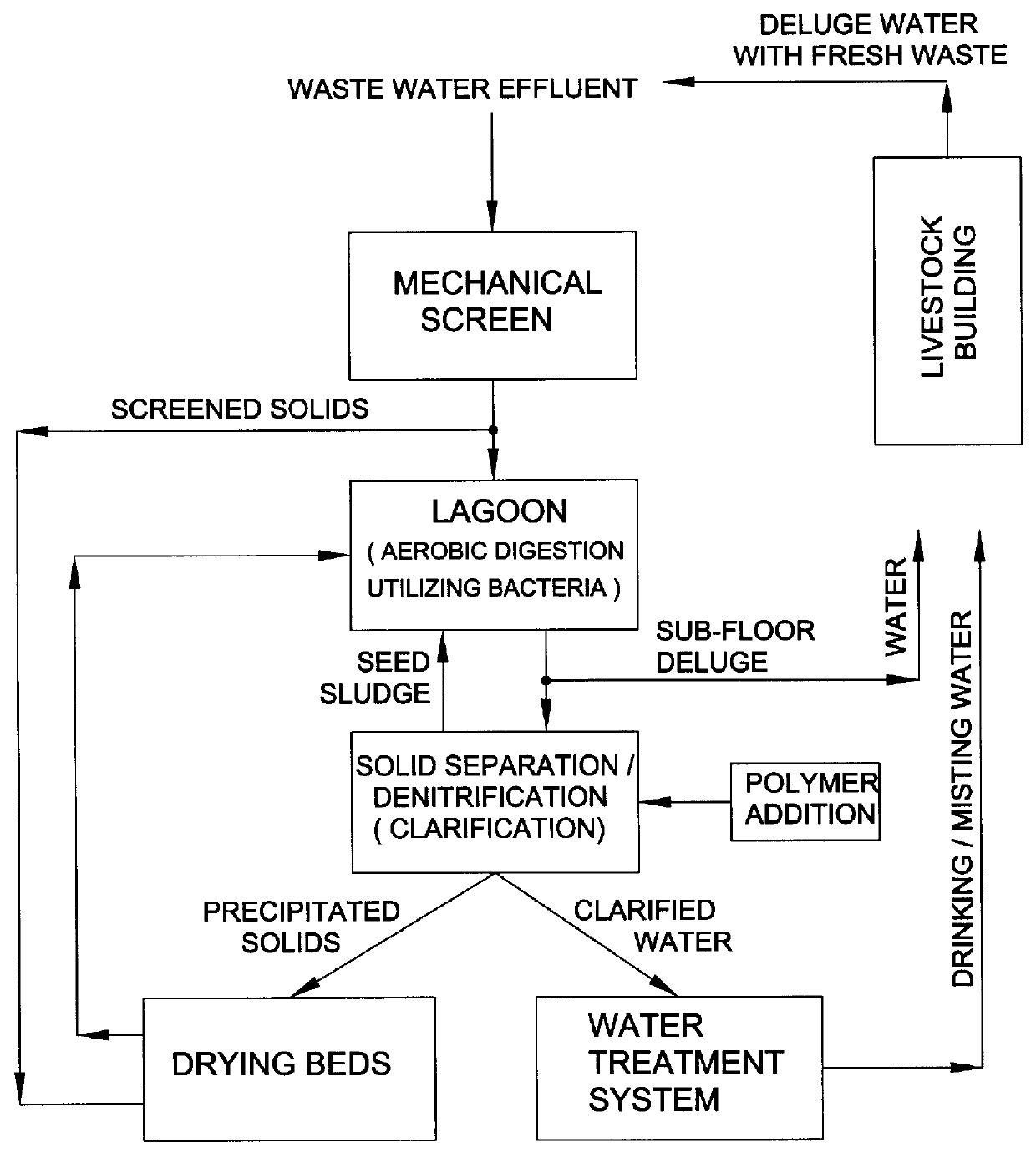

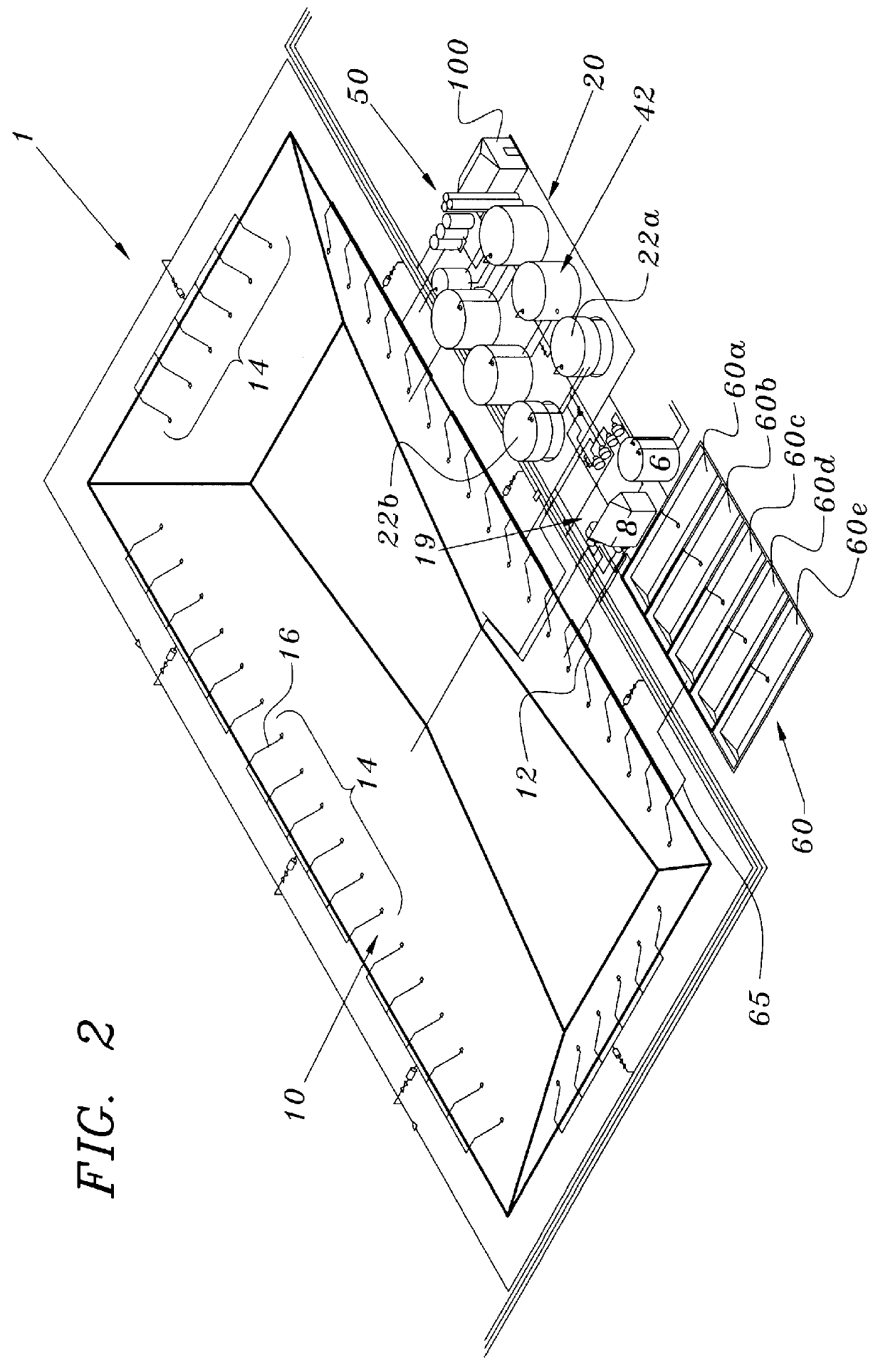

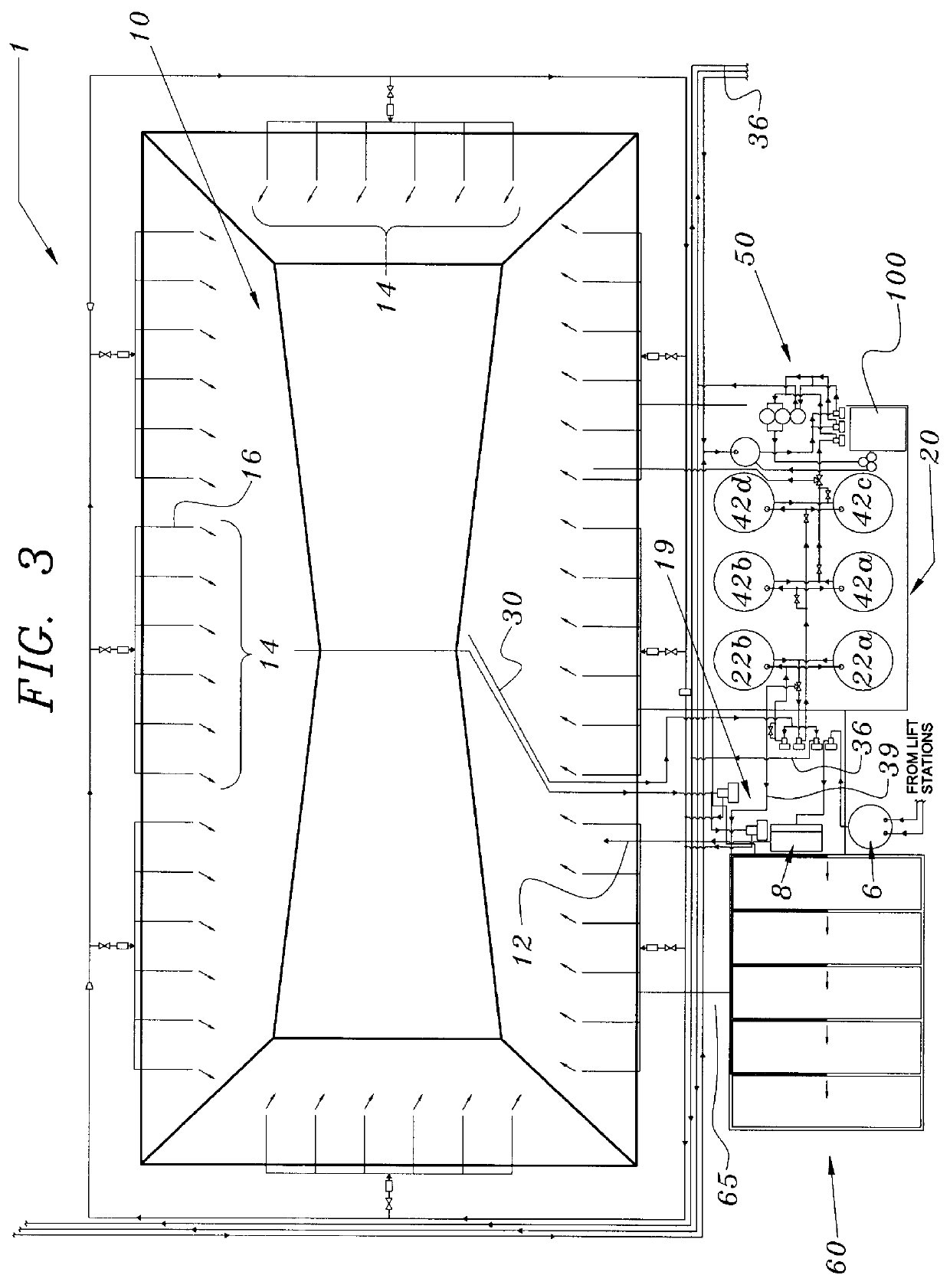

An apparatus and method for treating and reusing the wastewater discharged from agricultural animal farms. The apparatus and method of the present invention is designed to be a zero discharge system in which no wastewater will be discharged or spray irrigated. The wastewater effluent is first passed through a mechanical screen were bulk solids are separated and partially de-watered. The screened effluent is then directed to a primary plastic-lined earthen lagoon where it undergoes aerobic digestion utilizing specially selected bacteria. After treatment in the primary lagoon, the wastewater effluent is used to wash the floors of the hog houses or undergoes a purification phase including solids separation / denitrification, filtration and sterilization. The solids separation / denitrification phase (clarification) preferably takes place in an anoxic environment in preferably above-ground tanks where suspended solids removal will occur as well as denitrification for nitrate reduction. The clarification process may be facilitated through use of polymer addition. The majority of solids will be sent to a plurality of drying beds for de-watering and subsequent removal.

Owner:AGRIMOND USA CORP

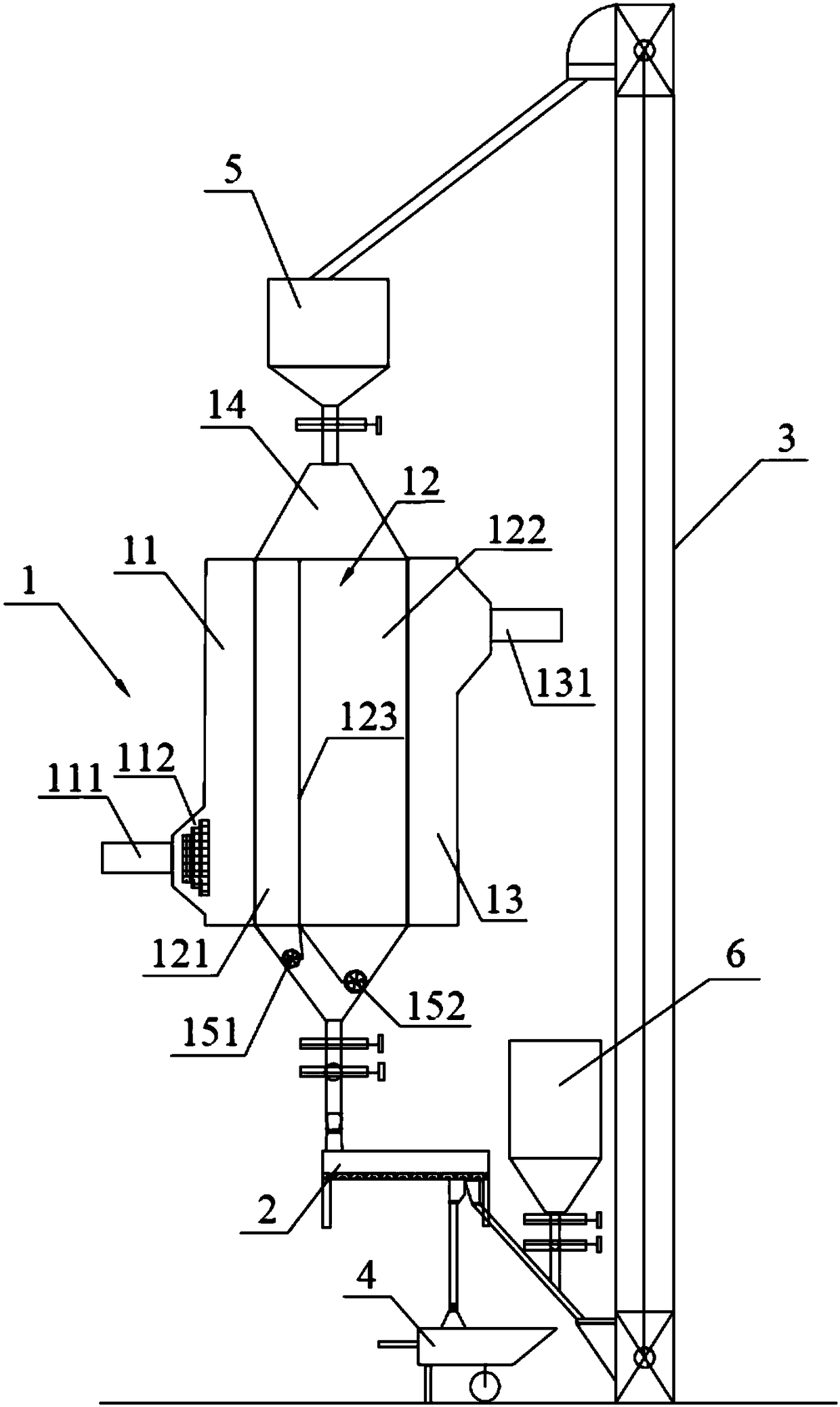

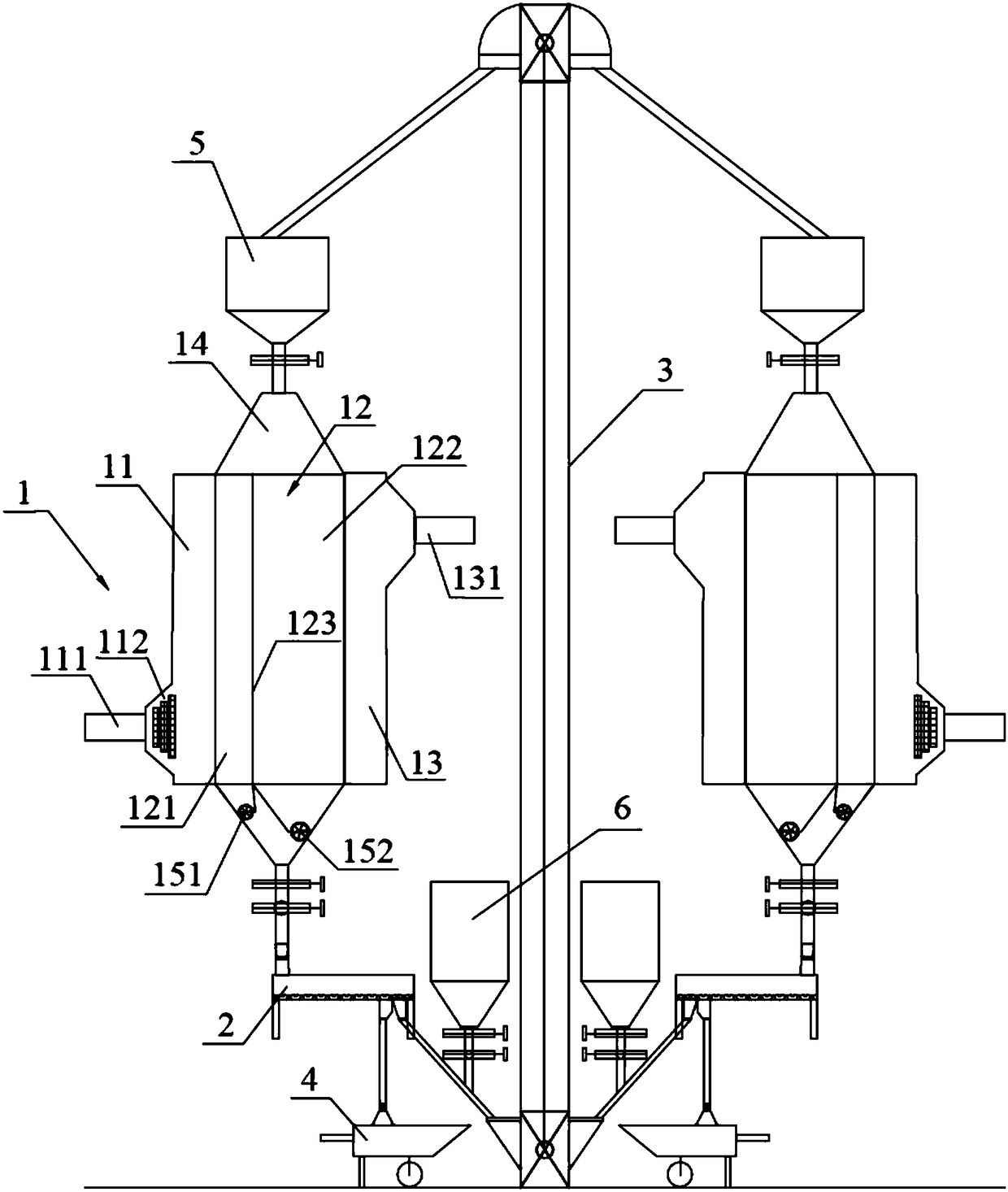

Low-sulfur flue gas desulfurization and denitrification apparatus

ActiveCN108525466AImprove controllabilitySimple processGas treatmentDispersed particle separationActivated carbonFlue gas

The invention belongs to the technical field of flue gas purification equipment and discloses a low-sulfur flue gas desulfurization and denitrification apparatus, comprising an adsorbing column and avibrating screen; the adsorbing column is provided with a first region, a second region and a third region sequentially along a flow gas circulation direction; the first region is provided with a fluegas incoming port and an ammonia spray grille arranged at the flue gas inlet; the third region is provided with a flue gas outlet; the second region is provided with a mobile activated carbon layer inside; the activated carbon layer flows in from a top inlet of the adsorbing column and flows out of a bottom outlet; the vibrating screen is connected with the bottom outlet of the adsorbing column and is connected with the top inlet of the adsorbing column through a delivery mechanism. The low-sulfur flue gas desulfurization and denitrification apparatus has the main advantages that an activatedcarbon resolution device is provided, the adsorbing column structure is selectively designed according to the characteristics of flue gas, activated carbon suitable for direct reuse is screened and separated in conjunction with the vibrating screen, efficient deep denitrification is provided for the flue gas with relatively low content of sulfur, no dependence on resolution procedures occurs, theprocess is simple, the controllability is high, and great convenience and high efficiency are achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

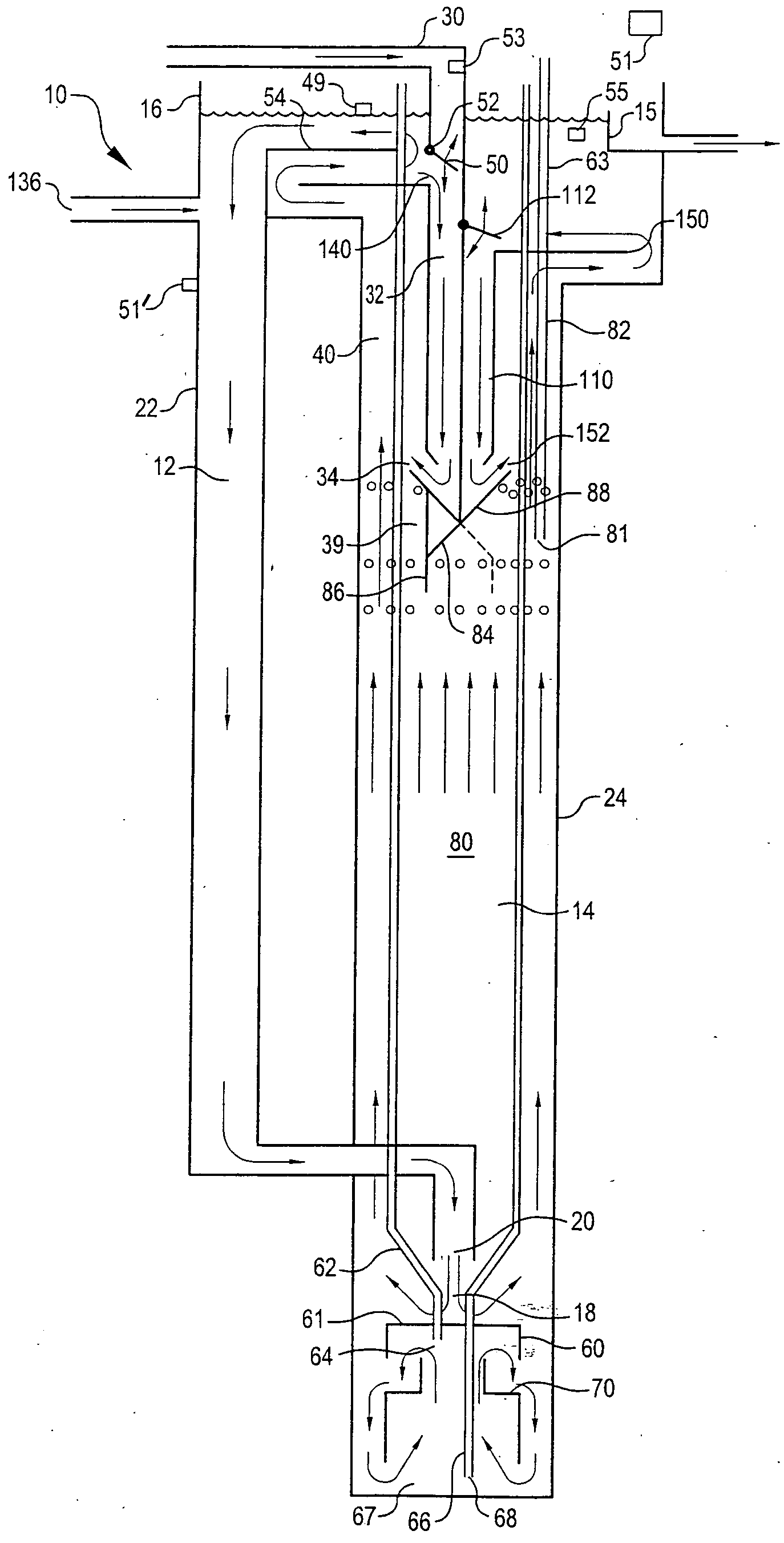

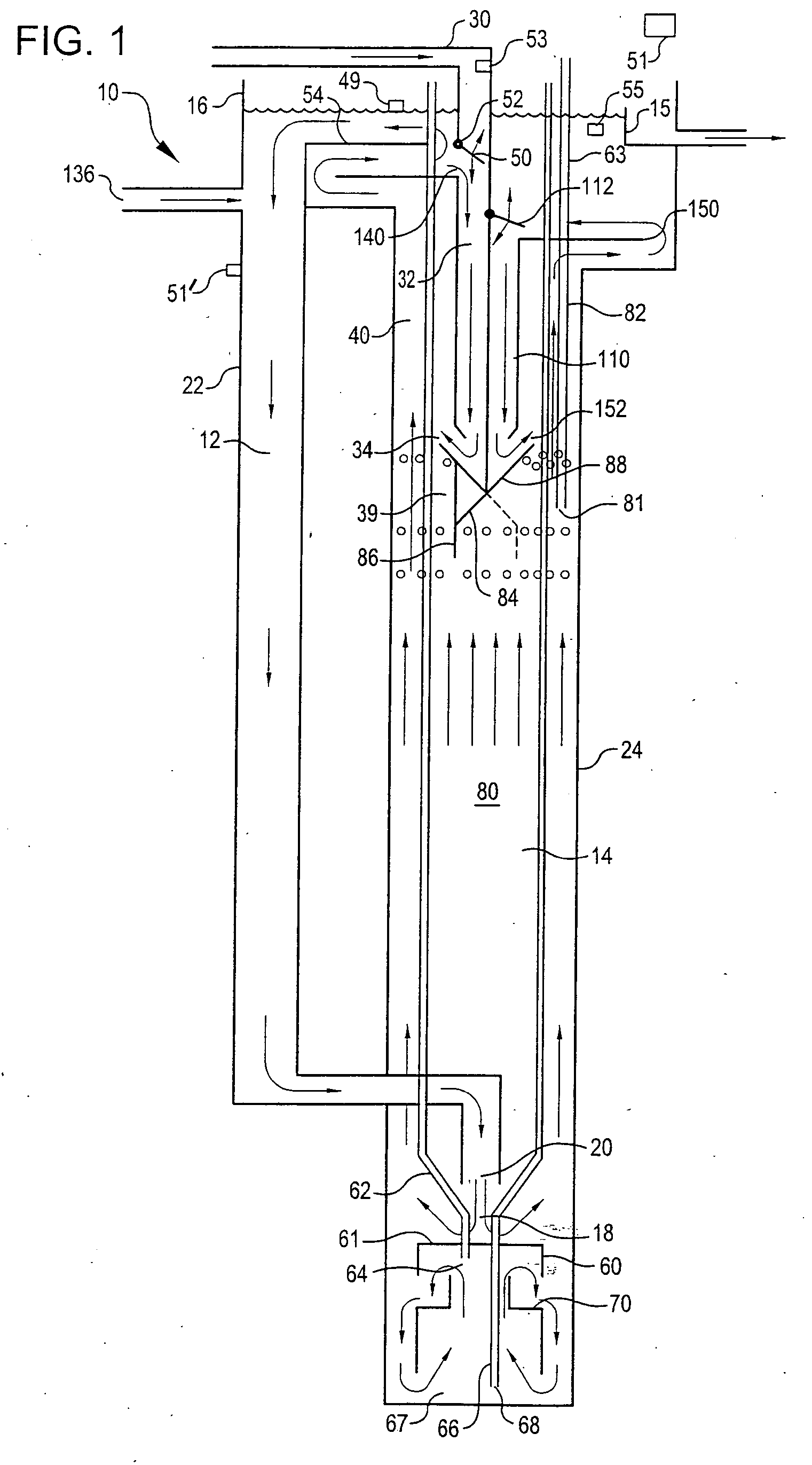

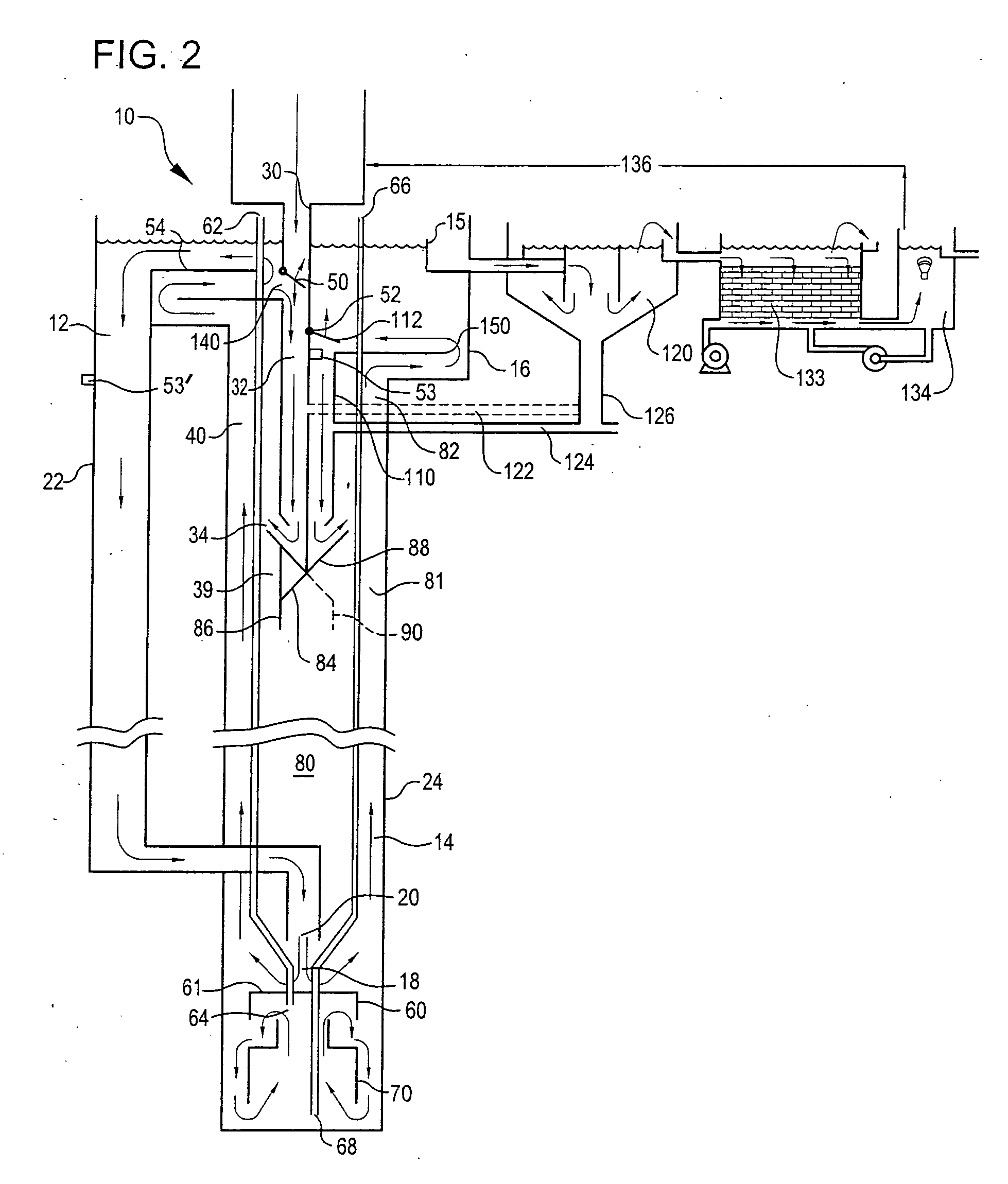

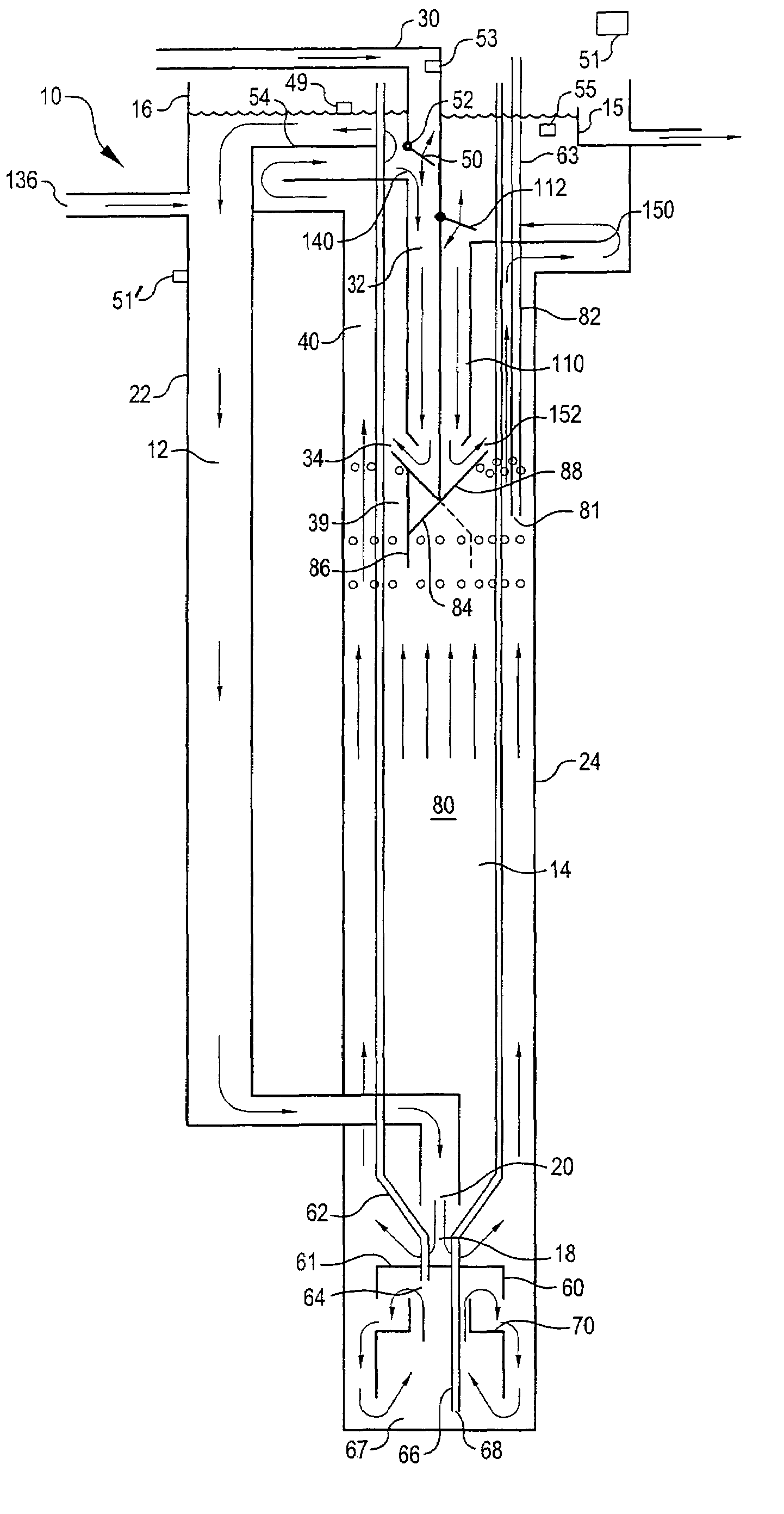

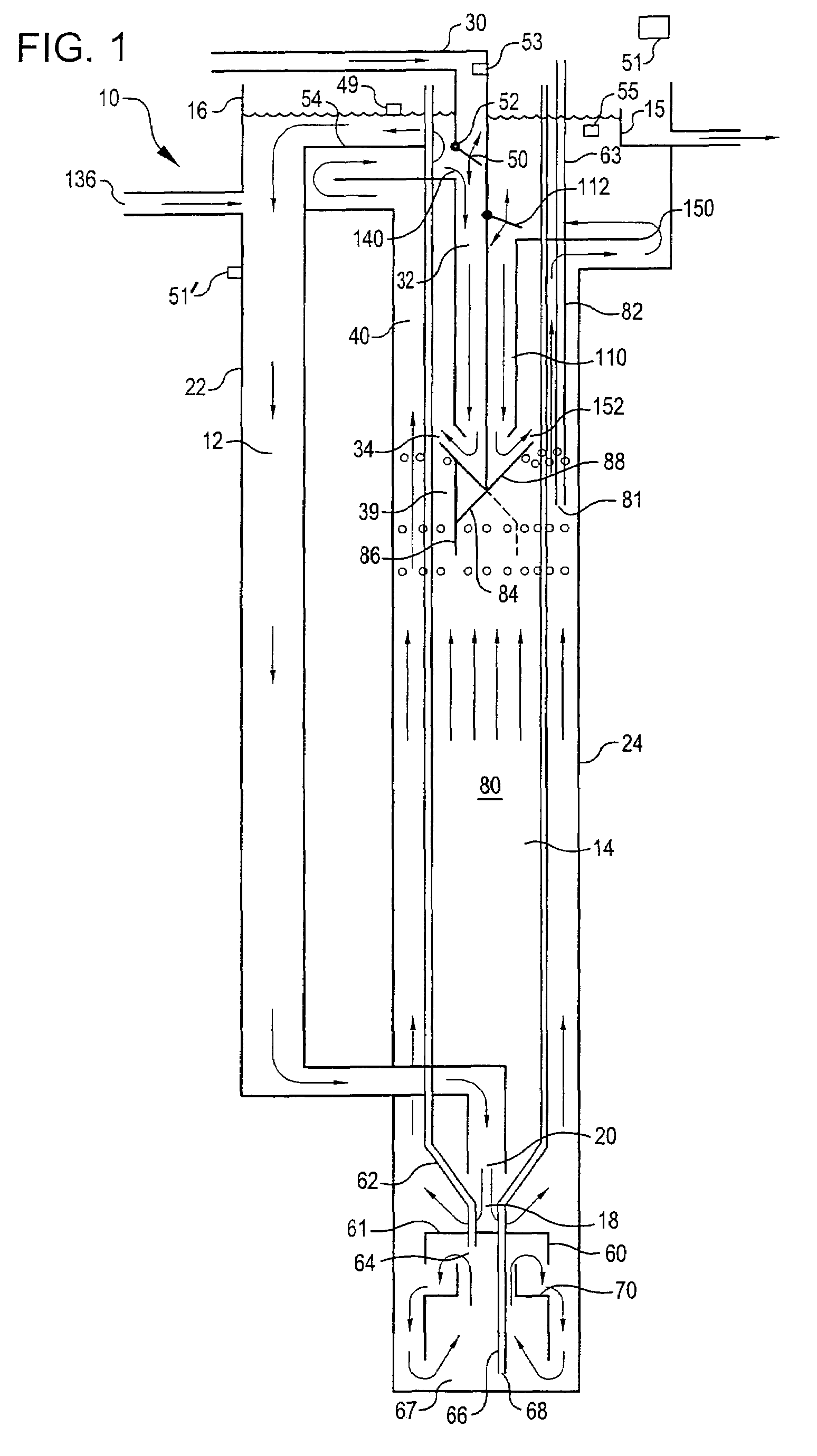

Methods and apparatus for biological treatment of waste waters

InactiveUS20050115880A1Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

Salt-tolerant microbial agent and preparation method thereof

ActiveCN103374524ASimple compositionImprove the effect of biochemical treatmentBacteriaMicroorganism based processesStaphylococcus cohniiMicrobial agent

The invention discloses a salt-tolerant microbial agent and a preparation method thereof. The microbial agent contains staphylococcus cohnii FSND-C, arthrobacter creatinolyticus FDN-1, flavobacterium mizutaii FDN-2, paracoccus denitrificans DN-3 and methylobacterium phyllosphaerae SDN-3. The microbial agent can achieve removal of ammonia nitrogen, total nitrogen and CODcr in the same reactor, has a good wastewater treatment effect, and can achieve short-cut nitrification and denitrification or simultaneous nitrification and denitrification while removing COD. Staphylococcus cohnii FSND-C can utilize various carbon sources, has certain salt tolerance, can be applied to the high-salinity wastewater treatment process, simultaneously can secrete a substance under environmental stimulus to enhance the flocculability of sludge, and further widens the application range of the microbial agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

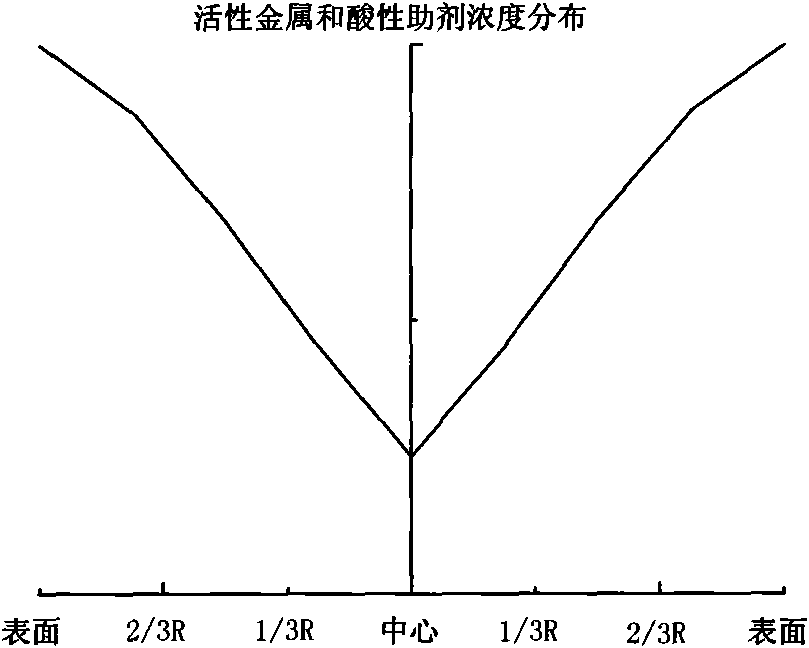

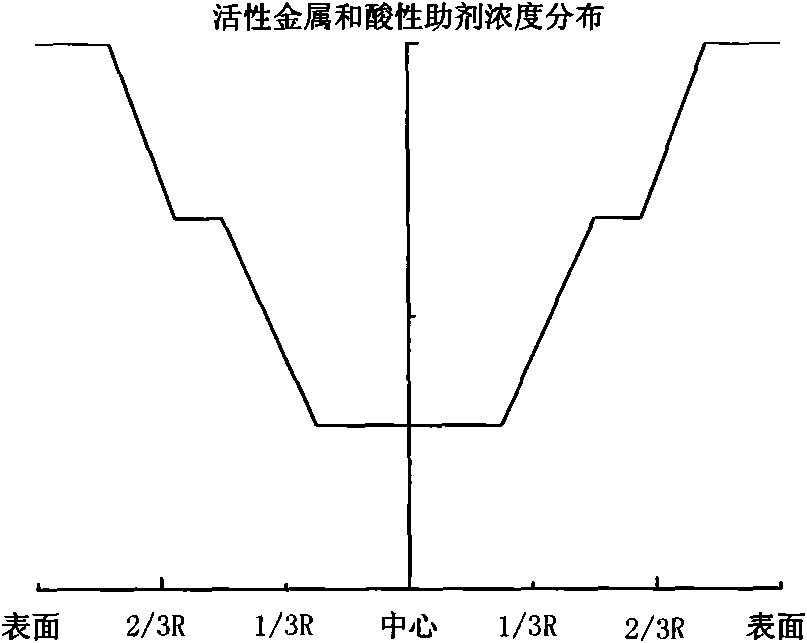

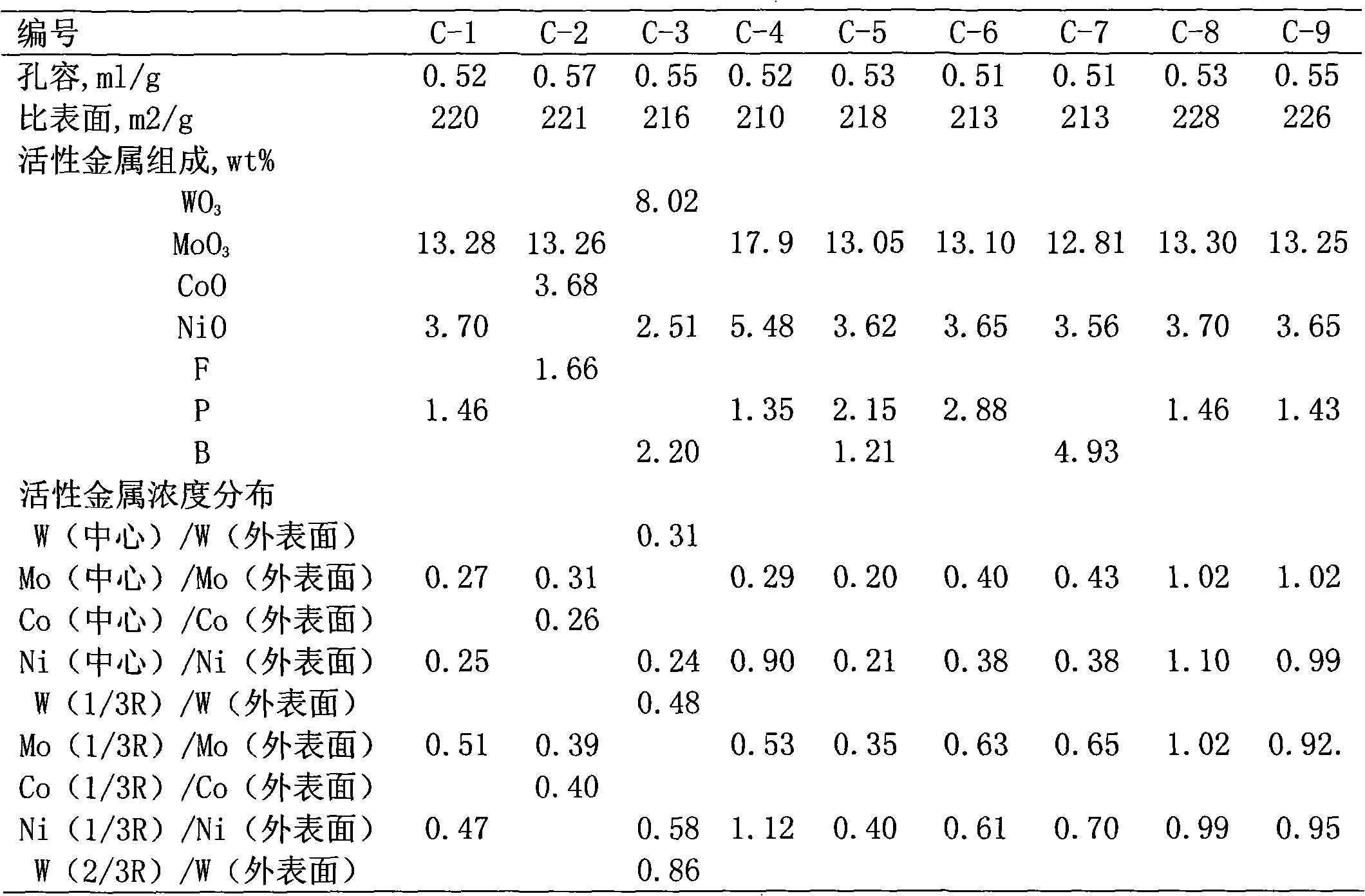

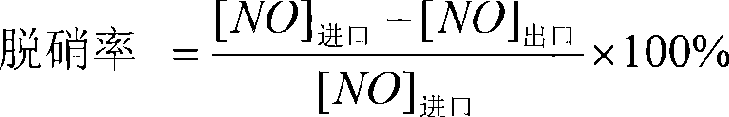

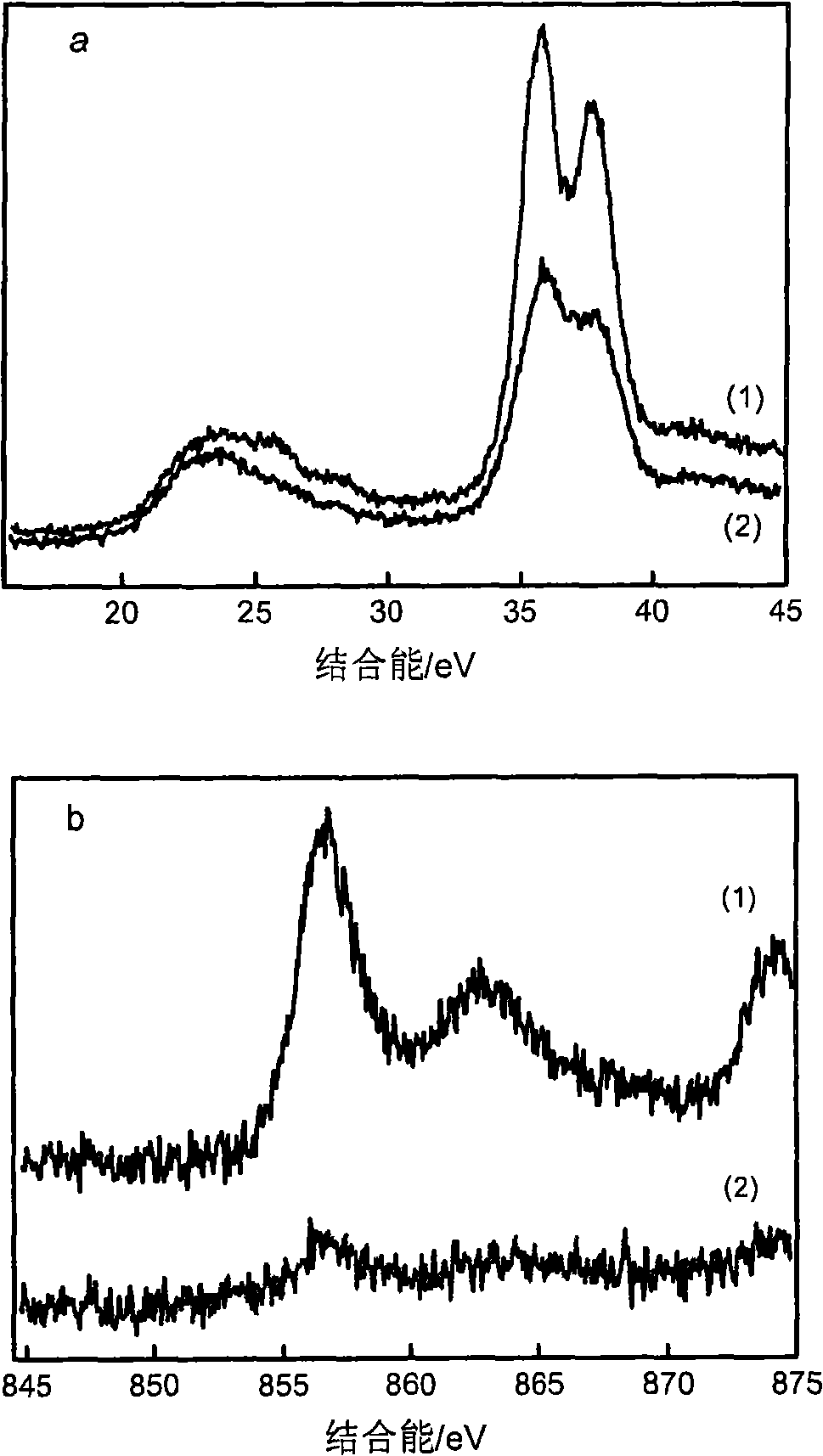

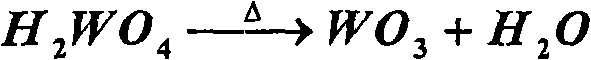

Hydrogenation catalyst showing gradient increase and distribution of concentration of active metal and acid additive and preparation method thereof

ActiveCN101927176AImprove desulfurizationPromote denitrificationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationResidual carbon

The invention relates to a preparation method of a hydrogenation catalyst showing gradient increase and distribution of concentration of an active metal and an acid additive. The method comprises the following steps: firstly preparing a relatively dilute active metallic solution and an acid additive solution and deionized water, and then gradually adding a relatively concentrated active metallic solution and an acid additive solution to dip a carrier under a saturate condition during the dipping process; or preparing an active metallic solution and an acid additive solution with different concentrations, and then dipping the active metallic impregnation liquid and the acid additive solution on the carrier in a low-to-high order based on the concentrations; or dipping the carrier with the low-concentration acid additive solution and the deionized water, and gradually adding the high-concentration acid additive solution to the impregnation liquid during the dipping process; drying and roasting; dipping the carrier with the low-concentration active metallic solution and the deionized water, and gradually adding the high-concentration active metallic solution to the impregnation liquid during the dipping process; or dipping the carrier with the active metallic solution followed by the acid additive solution. The method of the invention has higher desulfuration activity, higher denitrification activity and higher residual carbon removal activity, higher stability and simple preparation process.

Owner:PETROCHINA CO LTD

Titanium-base multi-component catalyst for power plant flue-gas SCR denitration and preparation method thereof

InactiveCN101396655AHigh activityActivity has no effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateManganese

The invention belongs to the chemical material field, in particular to a titanium-base multicomponent catalyst used for the denitrification of power plant flue gas SCR and a preparation method thereof. The catalyst comprises a catalyst carrier TiO2 accounting for 80-99wt percent of the total content, and the active components of 1-5wt percent of V2O5, 5-15wt percent of WO3 and 1-5wt percent of oxide of molybdenum or cerium or manganese according to the total content. The catalyst also comprises the other components of 0-5wt percent of MoO3, 0-5wt percent of CeO2 and 0-5wt percent of MnO3. The preparation process is: ammonium metananadate, ammonium paratungstate and titanium dioxide are mixed in water solution and are dried, calcined and sieved to obtain the catalyst. The catalyst has the advantages of active temperature region of 240-480 DEG C, high denitration efficiency, and good SO3 poisoning resistance. Added SO2 has almost no influence on the activity of the catalyst.

Owner:TSINGHUA UNIV +1

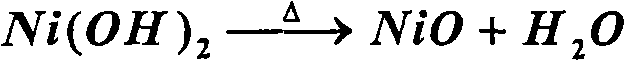

Hydrogenation catalyst of containing fluorin with alumina being as carrier, and preparation

ActiveCN1872959AHigh activityImprove denitrification activityRefining to eliminate hetero atomsDenitrificationAluminium oxide

This invention provides a method for preparing hydrogenation catalyst containing fluorine supported by aluminum oxide. The catalyst is composed of nickel oxide 1-10 wt.%, molybdena oxide and tungsten oxide 10-50 wt.%, fluorine 1-10 wt.%, and aluminum oxide. The method comprises introducing nickel oxide, molybdena oxide, tungsten oxide and fluorine into aluminum oxide carrier. The catalyst has such advantage as high hydrogenation and denitrification activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Apparatus for biological treatment of waste waters

InactiveUS7018530B2Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

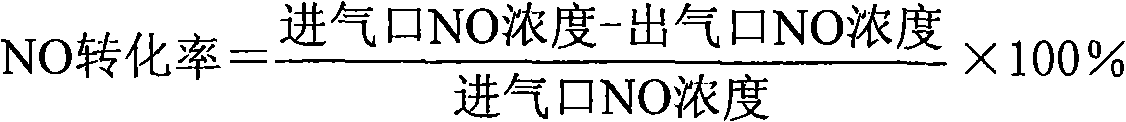

Composite catalyst flue gas denitrating under low-temperature condition and method of preparing the same

InactiveCN101254464ALarge specific surface areaImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention relates to a composite catalyst used for denitrification of flue gases under low-temperature conditions. The catalyst contains a Ti / Zr composite oxide as carrier, an oxide of manganese as catalytically-active component, and at least one oxide of vanadium, chromium, iron, copper, nickel and cerium as auxiliary agent. The Ti / Zr composite oxide is prepared by coprecipitation method and loads the catalytically-active component and the auxiliary agent by immersion method, wherein the mole ratio of Ti / Zr in the composite oxide is controlled in a range from 0.25 to 4, the oxide of manganese accounts for 1-15% of the weight of the Ti / Zr composite oxide, and the auxiliary agent accounts for 1-5% of the weight of the Ti / Zr composite oxide. The catalyst has good catalytic activity at low temperature and high NO conversion rate up to 100% at 100-300 DEG C, and has good prospect in industrial application.

Owner:NANJING UNIV OF TECH

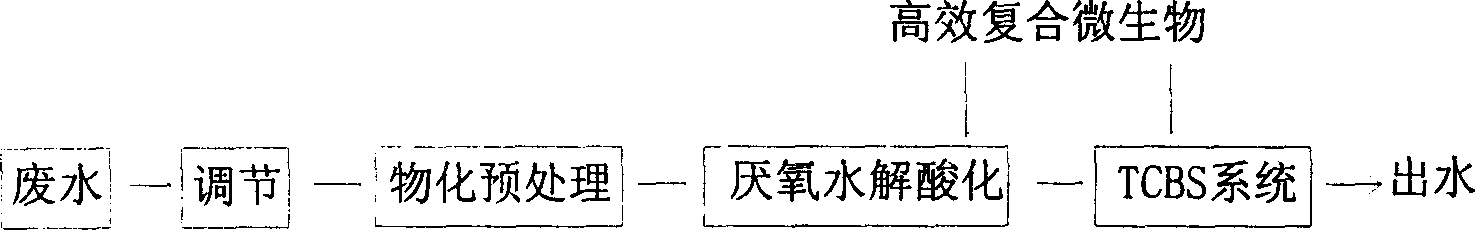

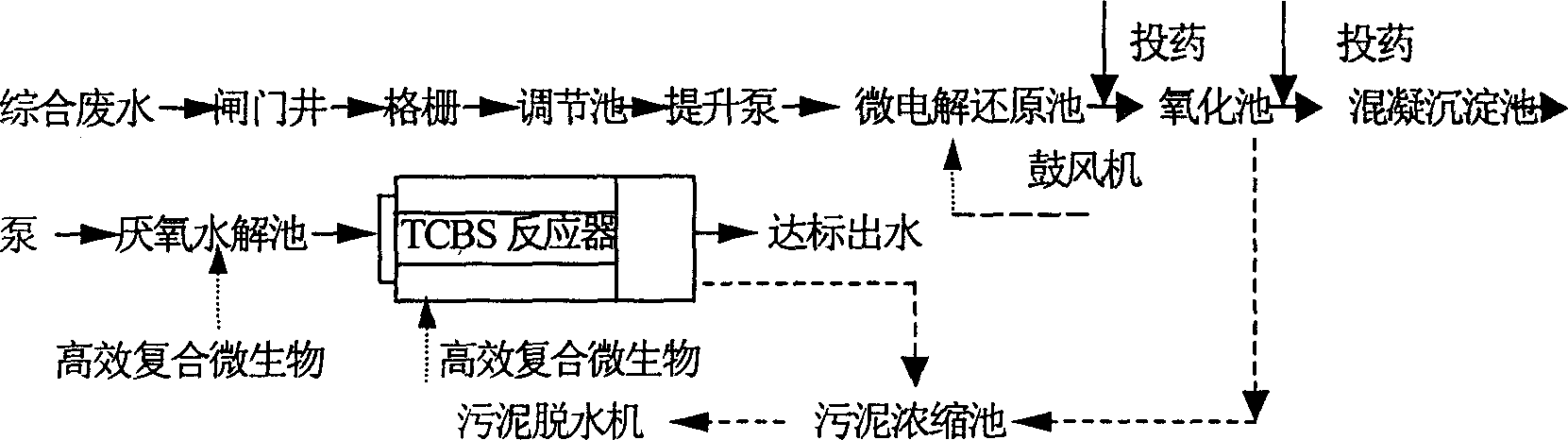

Organic waste water treatment process

InactiveCN1631818AAvoid toxicityHigh removal rateMultistage water/sewage treatmentHigh densityElectrolysis

Disclosed is a technique for processing organic waste water, including the following steps: (a) preprocession: pour the waste water into the micro electrolytic reducing pool where the iron-carbon micro electrolytic reaction occurs under the agtatering effect, add hydrogen peroxide into it to have. Fento oxidation, then the water enters into coagulation pool into which add NaOH and PAM; (b) anaerobe hydrolysis oxidation procession: power the organic waste water preprocessed into high effective anaerobe hydrolysis oxidation pool in which add into the TCBS reactor in which add into high effective compound microbe, making the water mix with the flowing-back mud with high density after denitrification. The invention can increase the biochemical of organic waste water, strengthen its resistance to poison and impact as well as the biological denitrification funcation, and making the waste water reach the national environment protection requirement by reducing the polluting load by steps.

Owner:何义亮 +1

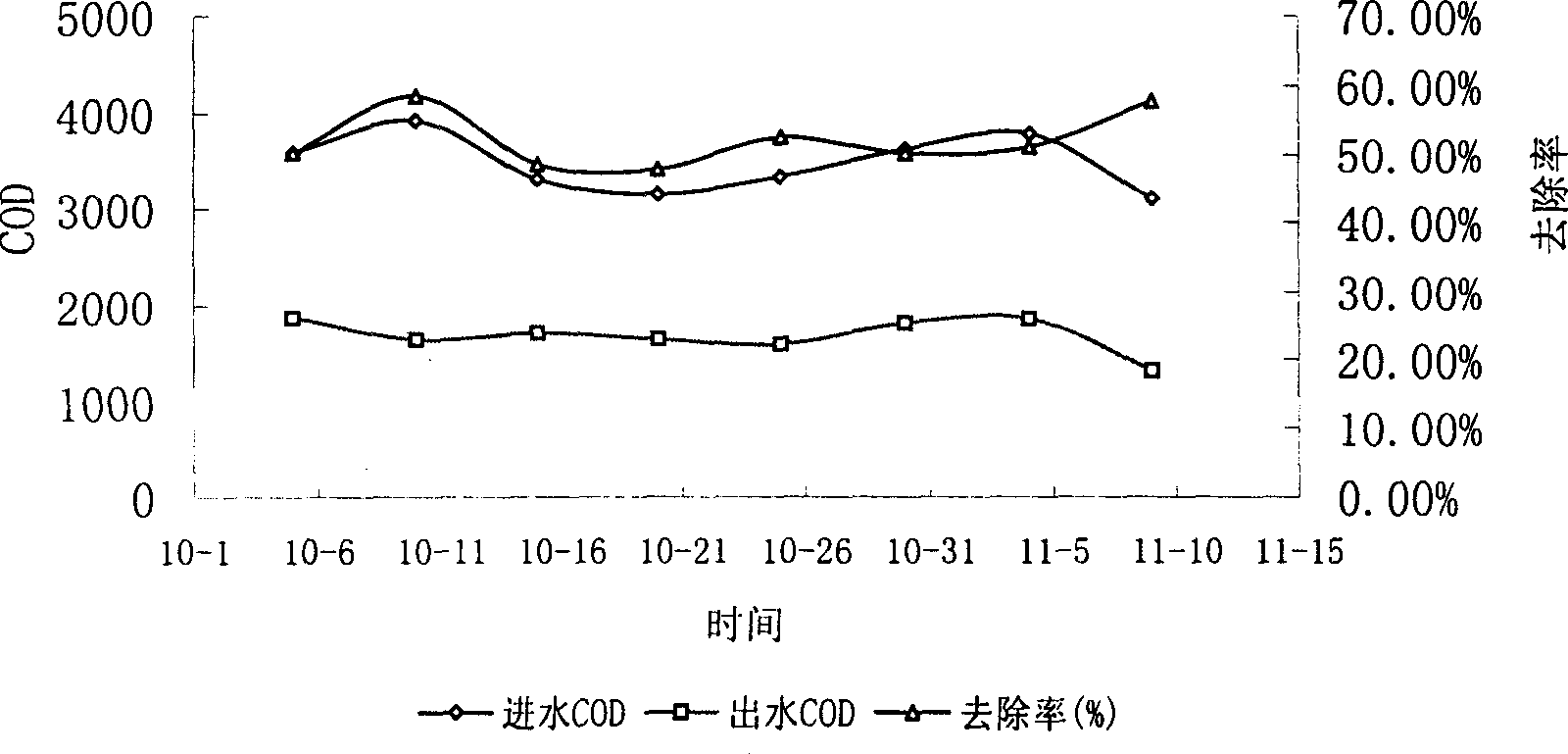

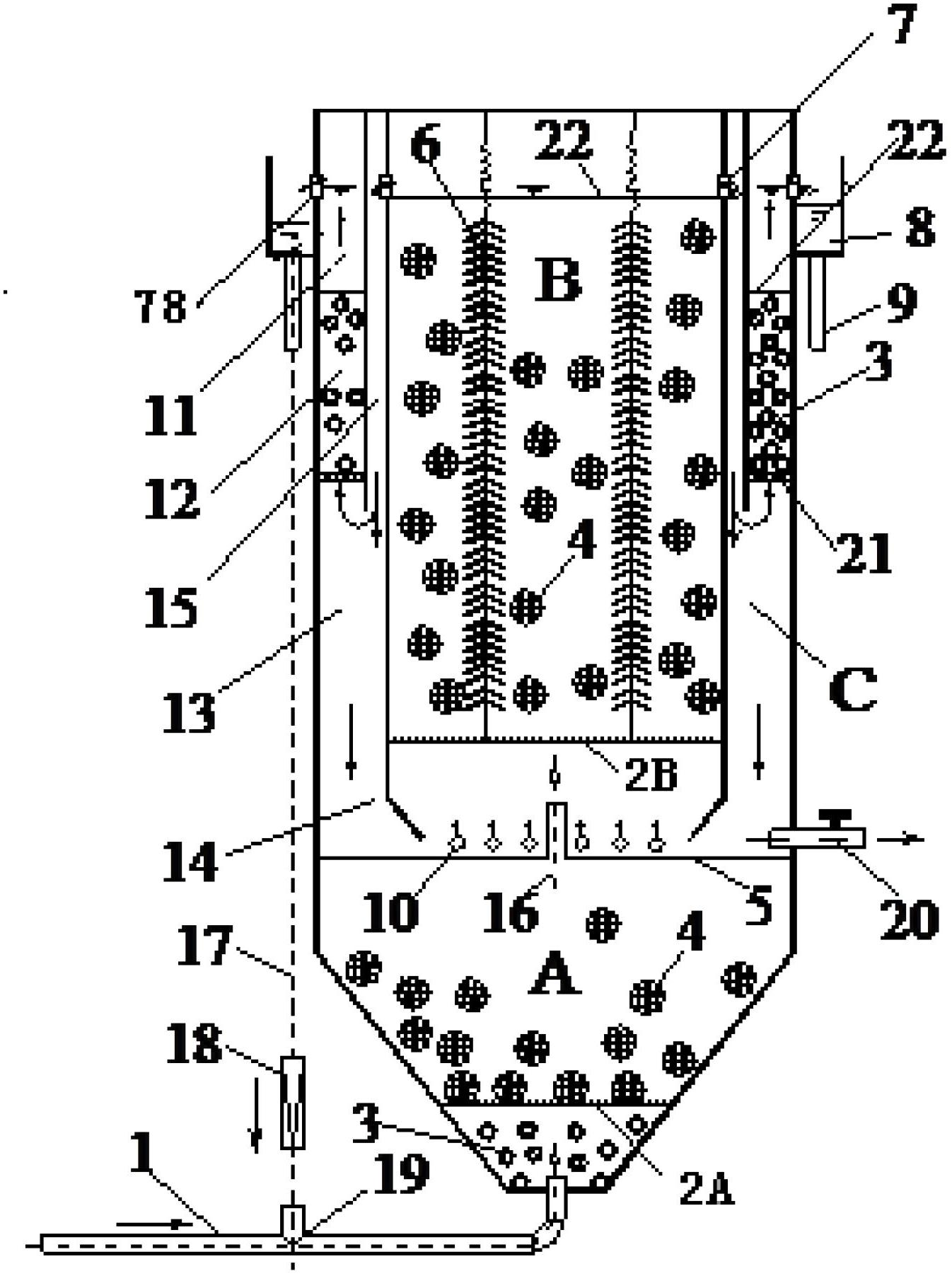

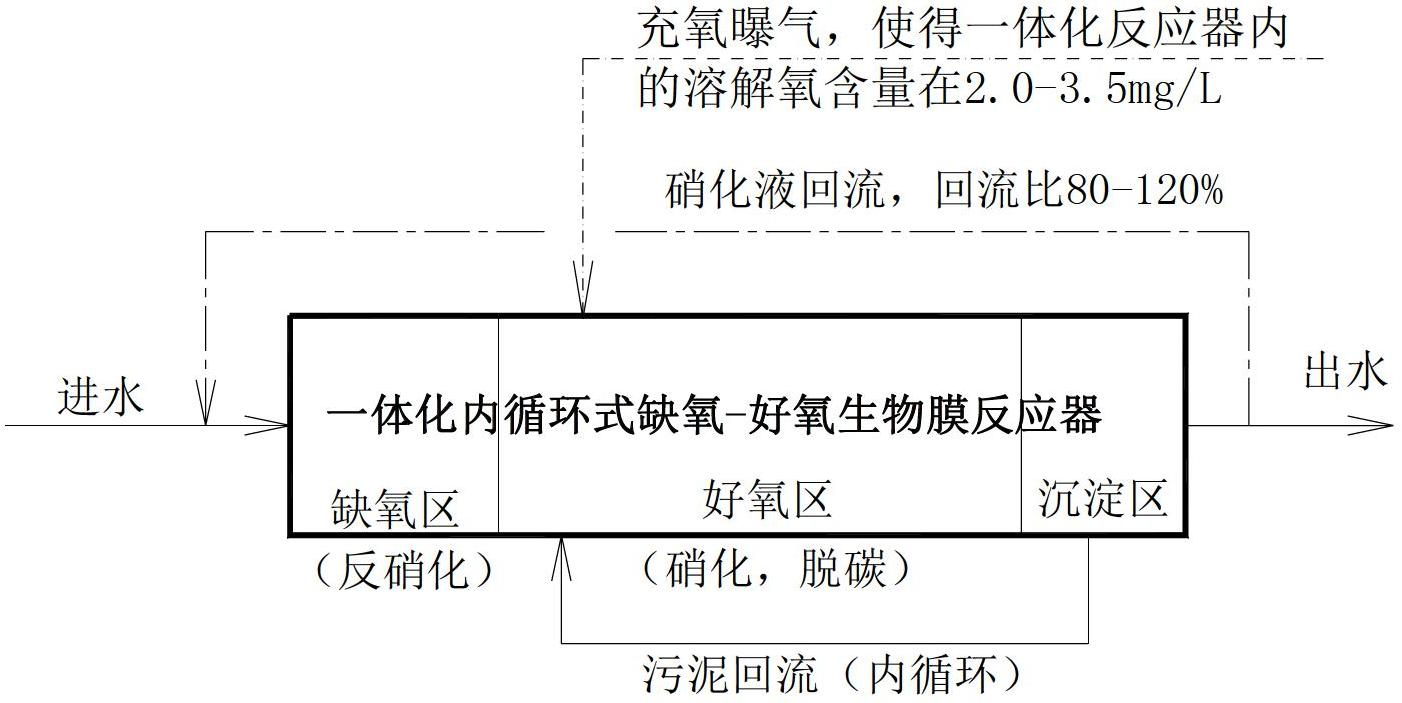

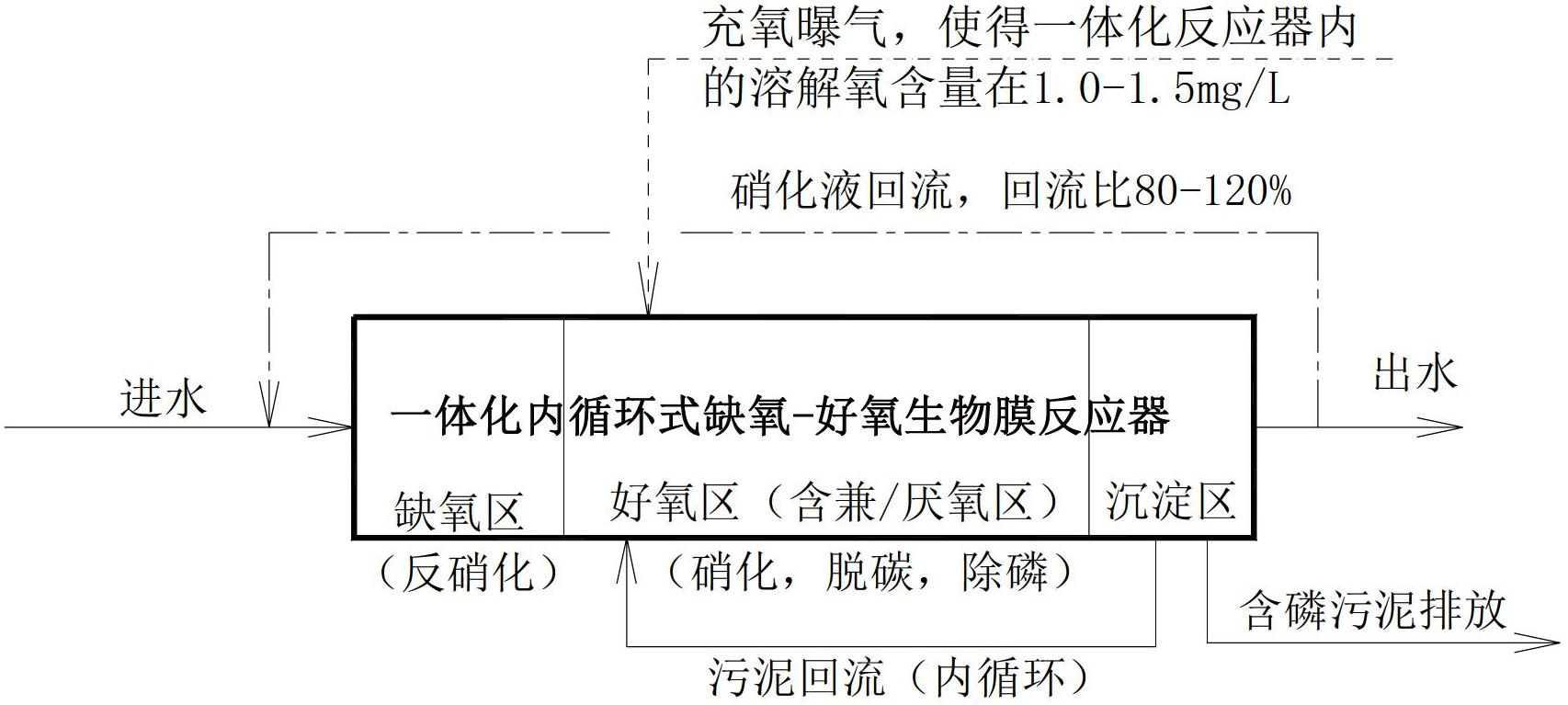

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

Preparation of hydrogenation catalyst

InactiveCN101298047AEvenly dispersedSmall sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHigh activationReaction temperature

The invention provides a method for preparing a hydrogenation catalyst with high activation. A disposition method is adopted to carry out step-by-step loading to the active components of the metals of VIB and VIII families; the VIB metal comprises tungsten or molybdenum, while the VIII metal comprises nickel or cobalt; a carrier is alumina. The loading of VIB metal takes a corresponding soluble salt as raw material, an acid solution as a precipitator and a cationic surface active agent as a dispersant. In a hydrothermal condition, the corresponding soluble salt, the acid solution and the cationic surface active agent produce metallic oxide particles by a liquid deposition reaction; the loading of VIII metal also takes a corresponding soluble salt as raw material and carbamide as a precipitator; the adding of the precipitator and the generation of precipitation are separated by controlling reaction temperature in sections and even precipitation is realized to disperse the particles of the active components on the carrier evenly. The hydrogenation catalyst prepared shows good effects in the respects of desulfurization and denitrification activation and can greatly reduce the usage of the active components.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

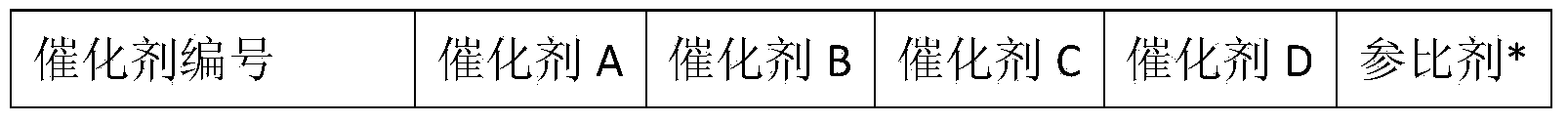

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

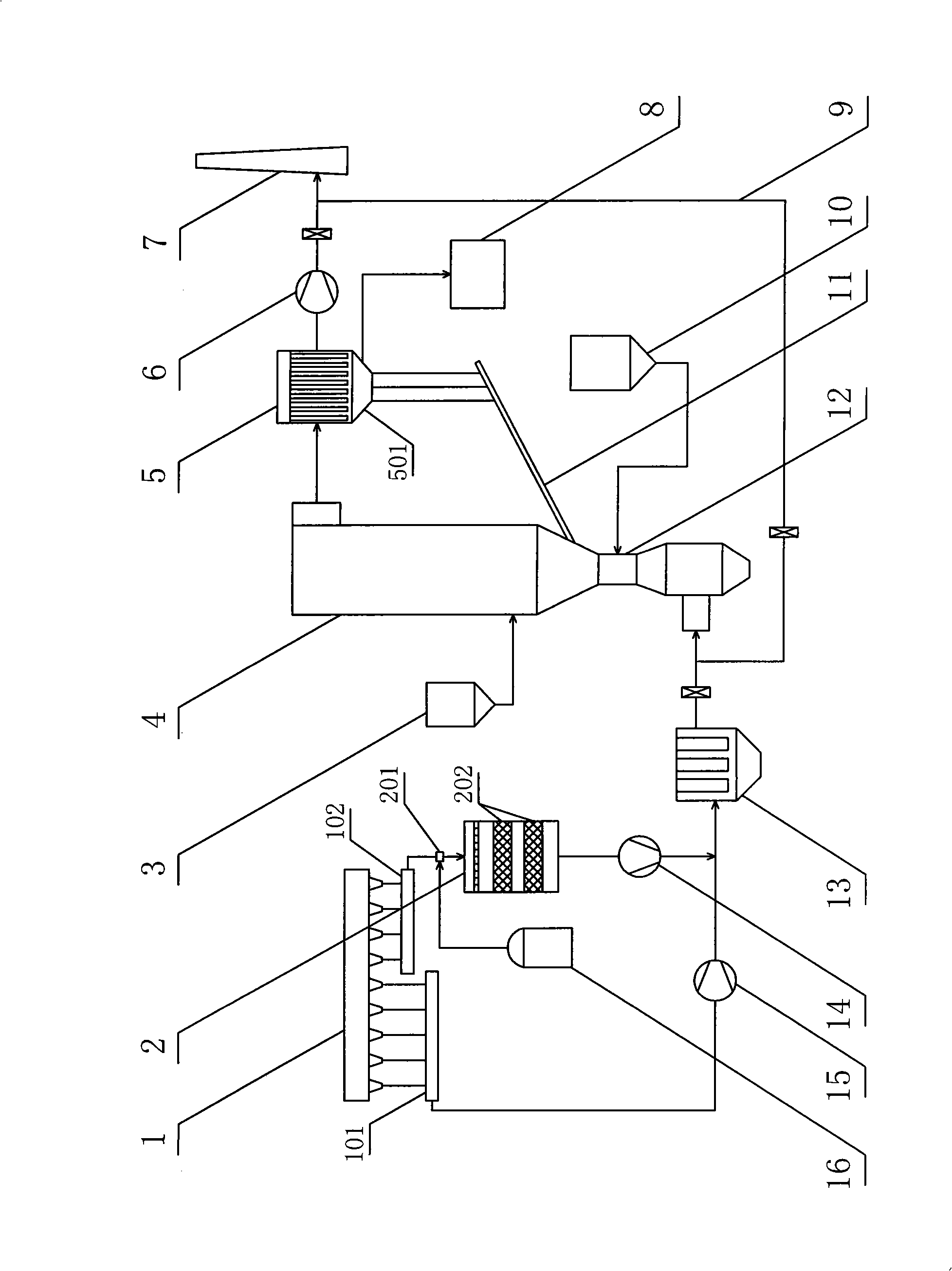

Sintering device flue gas multiple pollutant removing process and system thereof

ActiveCN101254394ALow flow resistanceReduce investmentDispersed particle filtrationElectrostatic separationFluidized bedMulti pollutant

The invention provides a process used for removing multiple contaminants in the off-gas of a sintering machine, as well as the system thereof. The process has the following steps: firstly, the machine tail off-gas undergoes SCR denitrification treatment; then, primary dedusting treatment is carried out to the denitrated machine tail off-gas and un-denitrated machine head off-gas at the same time, so as to remove the dust and ash particles in the off-gas; and then, circulating fluidized bed desulfurization treatment is carried out to the off-gas; finally, secondary dedusting treatment is carried out to the off-gas, so as to remove the resultant particles in the off-gas, the resultant particles are used for recycling, and the purified gas is separated out. The system thereof is mainly composed of a machine head off-gas header and a machine tail off-gas header which are used for collecting the machine head off-gas and the machine tail off-gas of the sintering machine, a SCR denitrification reactor which is used for removing the multiple contaminants in the off-gas, a primary dust remover, a circulating fluidized bed desulfurization reactor and a secondary dust remover. The process can carry out the classification integrated processing as well as the high efficient and synchronous removing to the sulfur dioxide, the nitrogen oxides and the dust in the sintering off-gas. The system has the characteristics of simple and compact whole design, low investment and running cost, and stable and reliable working.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

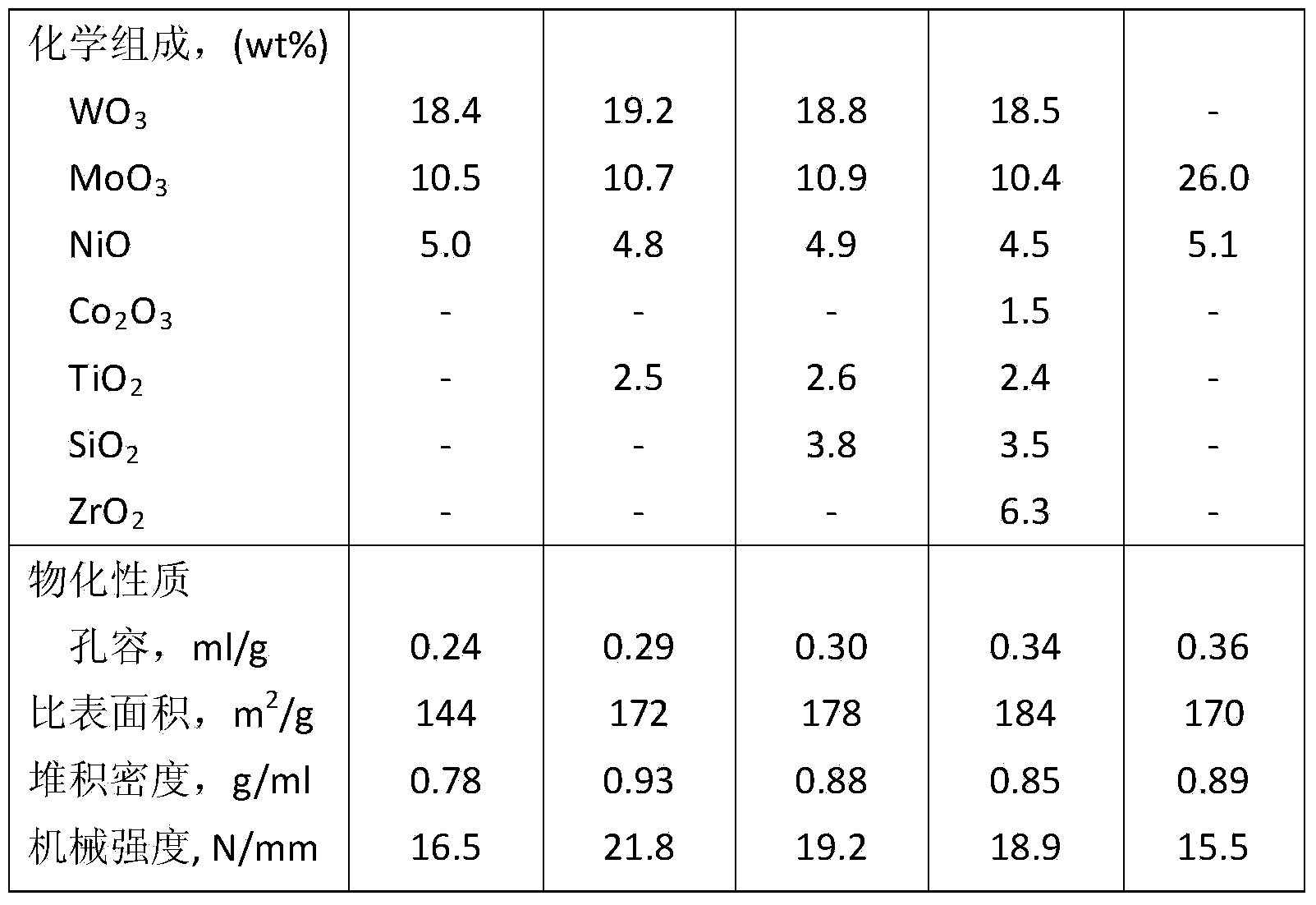

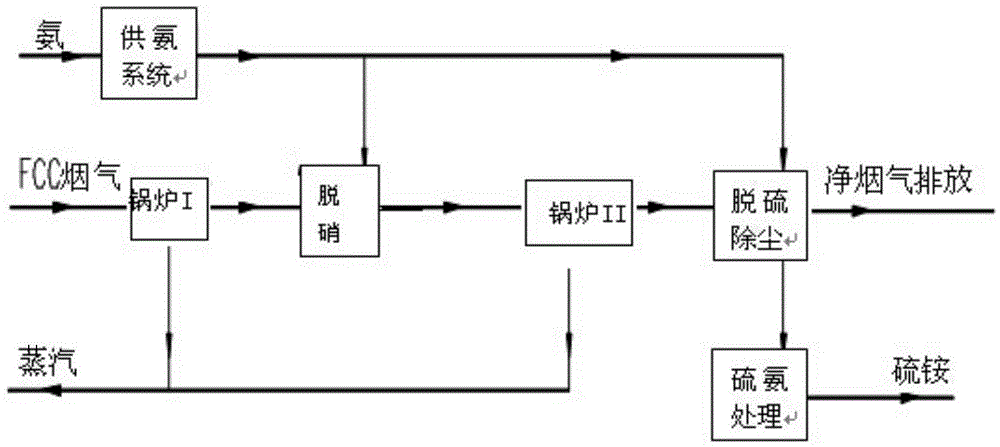

Ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas

ActiveCN104941423ALess investmentLow running costUsing liquid separation agentEnergy inputNitric oxidePetroleum

The invention relates to an ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas, comprising the following steps: enabling high-temperature catalyst regeneration flue gas coming from a catalytic cracking unit and containing catalyst dust to firstly enter a waste heat boiler I, reducing the temperature of the flue gas to 280-430 DEG C, wherein the heat of the flue gas is externally supplied by steam produced by the waste heat boiler I; enabling flue gas at temperature of 280-430 DEG C to enter a denitrification device for denitrification and enter a waste heat boiler II through an outlet flue after sufficiently reacting on the surface of a denitrification catalyst in a denitrification reactor; removing sulfur dioxide, nitric oxide and byproduct ammonium sulfate by taking ammonia as a reactant, and removing catalyst dust in the regeneration flue gas to achieve clean gas up-to-standard release; the three waste free release purifying method can be applied to catalytic cracking catalyst regeneration flue gas treatment in oil refining.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

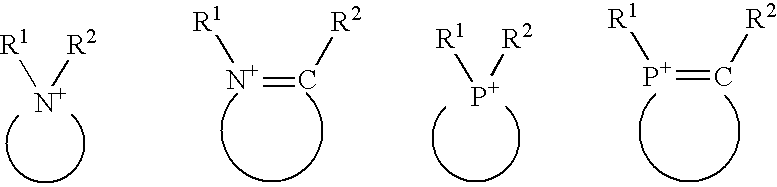

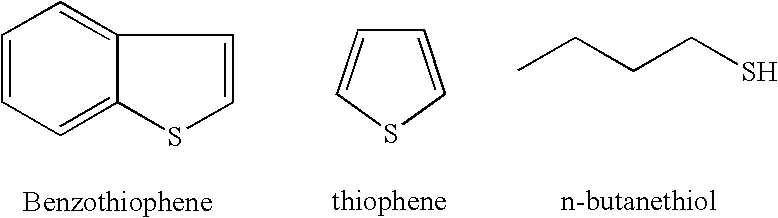

Processing for eliminating sulfur-containing compounds and nitrogen-containing compounds from hydrocarbon

InactiveUS20040045874A1Preferred solubilityPhysical/chemical process catalystsElectrolysis componentsSolubilityHydrocarbon mixtures

A process for desulfurization and, if necessary, for denitrification of hydrocarbon fractions is characterized in that: said hydrocarbon mixture is brought into contact with a non-aqueous ionic liquid of general formula Q<+>A<-> that contains at least one alkylating agent, making it possible to form ionic sulfur-containing derivatives (and, if necessary, nitrogen-containing derivatives) that have a preferred solubility in the ionic liquid; and said ionic liquid is separated from the hydrocarbon mixture that is low in sulfur and nitrogen by decanting.

Owner:INST FR DU PETROLE

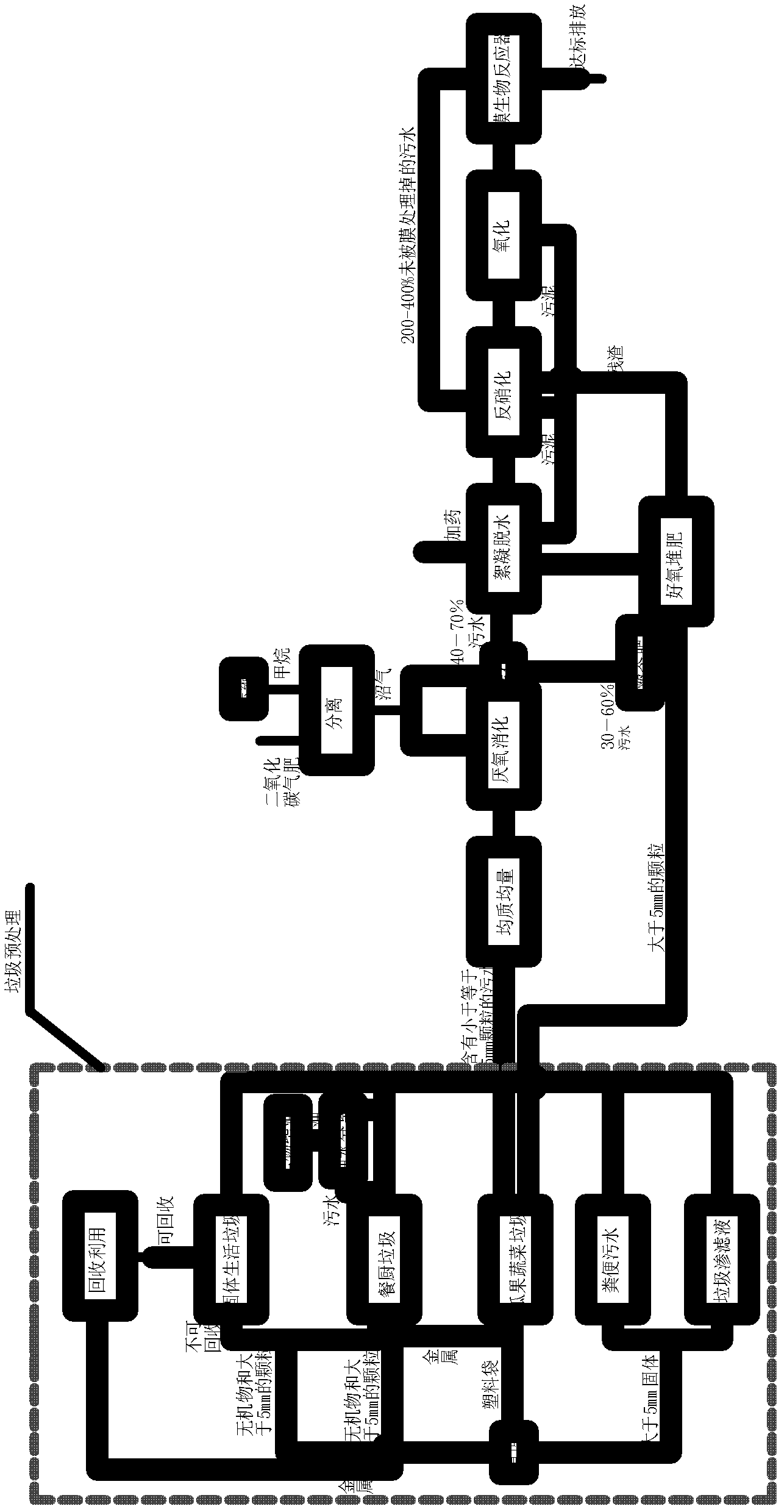

Method for jointly treating different garbage

ActiveCN102531295ASave processing powerProportional balanceBio-organic fraction processingWaste processingFlocculationBiodiesel

The invention discloses a method for jointly treating different garbage. In the implementation process, different garbage is subjected to pretreatment, homogenization, anaerobic digestion, flocculation dewatering, denitrification, oxidation treatment, membrane bioreactor treatment, aerobic composting and biodiesel production, treated sewage can reach the third grade Standard of Water Pollutants Discharge of DB11 / 307-2005, the process flow is greatly shortened, the cost is reduced, and methane generated in the treatment process and the recovered waste oil are subjected to deep processing to beutilized as green energy.

Owner:北京昊业怡生科技有限公司

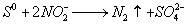

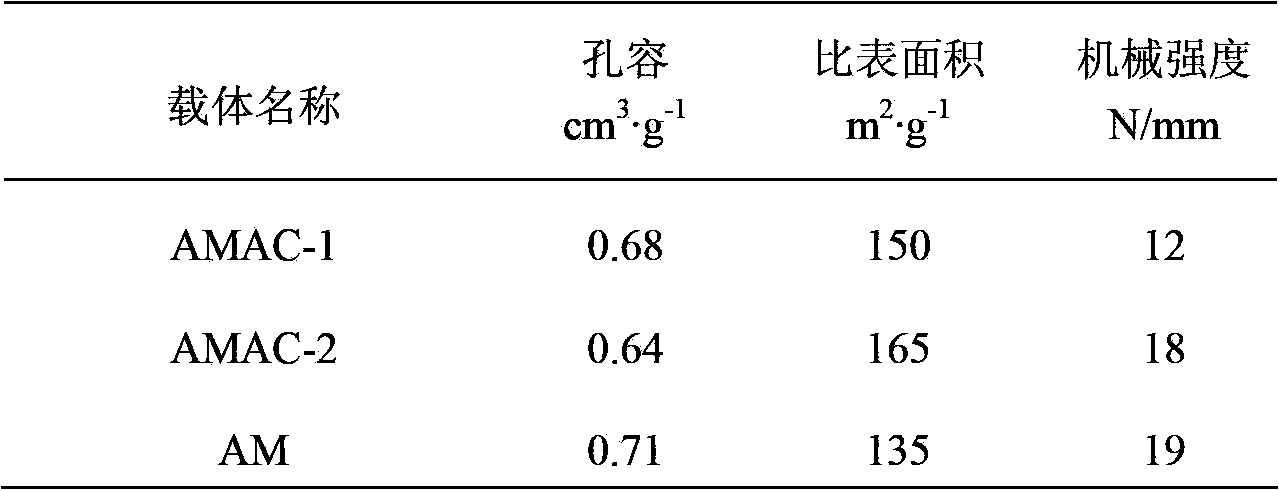

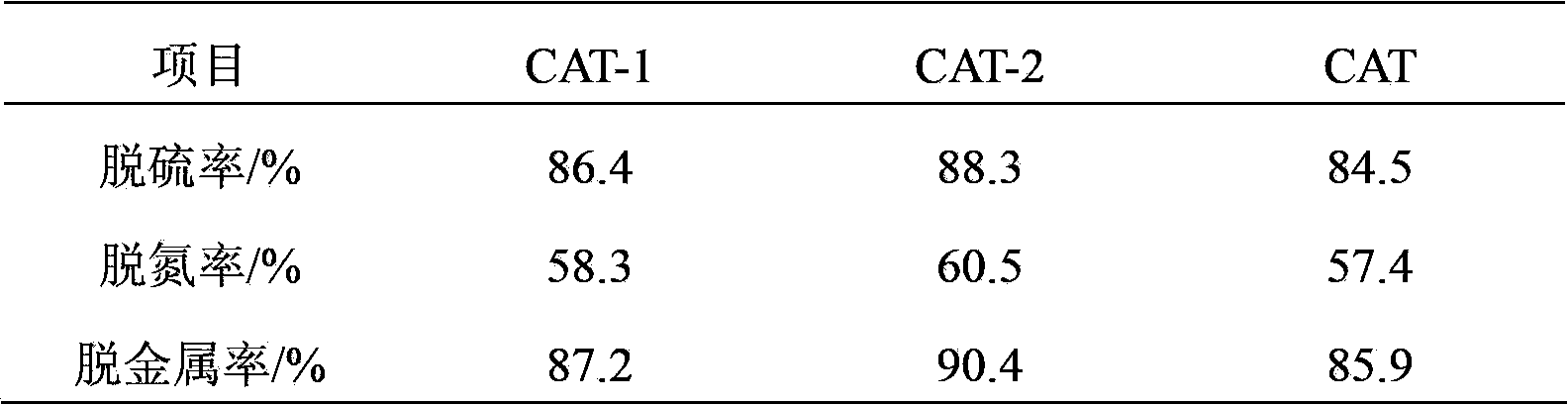

Activated carbon/aluminum oxide composite type catalyst carrier and preparation method and application of activated carbon/aluminum oxide composite type catalyst carrier

InactiveCN103657736ALarge specific surface areaHigh mechanical strengthCatalyst carriersWorking-up pitch/asphalt/bitumen by chemical meansActivated carbonFixed bed

The invention relates to an activated carbon / aluminum oxide composite type catalyst carrier and a preparation method and application of the activated carbon / aluminium oxide composite type catalyst carrier. The preparation method comprises the steps of washing circularly with 20-35% hydrochloric acid in a boiling state, wherein the mass ratio of hydrochloric acid to activated carbon is (5-20):1, performing oxidation with 10-50% nitric acid, wherein the mass ratio of an oxidizing agent to activated carbon is (20-40):1, kneading the activated carbon, aluminium oxide and an assistant into cakes in a kneading machine, extruding the kneaded cakes through an extruding machine, drying the extruded carrier, and roasting in nitrogen protection atmosphere to prepare the activated carbon / aluminum oxide composite type catalyst carrier. The activated carbon / aluminum oxide composite type catalyst carrier is suitably used as a residual oil hydrogenation catalyst carrier of a fixed bed, and is particularly used as the residual oil hydrodemetallization catalyst carrier. The activated carbon / aluminum oxide composite type catalyst carrier has high desulfurization rate up to 86.4-88.3%, high denitrification rate up to 58.3-60.5% and high demetalization rate up to 87.2-90.4%.

Owner:PETROCHINA CO LTD

Resource ozone oxidation dry method capable of removing sulfur dioxide and nitrogen oxides in flue gas

InactiveCN101337152ASolve the problem of high energy consumptionNo governance issuesDispersed particle separationAir quality improvementPlasma chemistrySulfur dioxide

The invention belongs to the application technical field, such as gas ionization discharge, plasma chemistry and environment engineering, and relates to a method for reutilizing fume while removing sulfur dioxide and nitrogen oxides by adopting the ozone oxidation method. The method comprises the following steps: ozone gas with a concentration of 40 to 240 g / Nm<3> is fed into a reactor or a flue together with fume at 65 DEG C to 250 DEG C with a smoke dust concentration lower than 40 mg / Nm<3>; the ozone simultaneously oxidizes sulfur dioxide, nitrogen oxides and water in the fume and generates micro-fog drops which are collected into a mixed acid solution after being electrically coagulated; and the mixed acid solution is separated and purified into the sulfuric acid and the nitric acid by adopting a chemical method. The method has the advantages that during the process for simultaneously removing the sulfur dioxide and the nitrogen oxides in the fume, no catalyst is used, no absorbent is added, no byproduct is generated, and no any adverse effect on the environment is generated, and provides a reutilization method for the desulfurization and the denitrification of the fume from coal burning.

Owner:DALIAN MARITIME UNIVERSITY

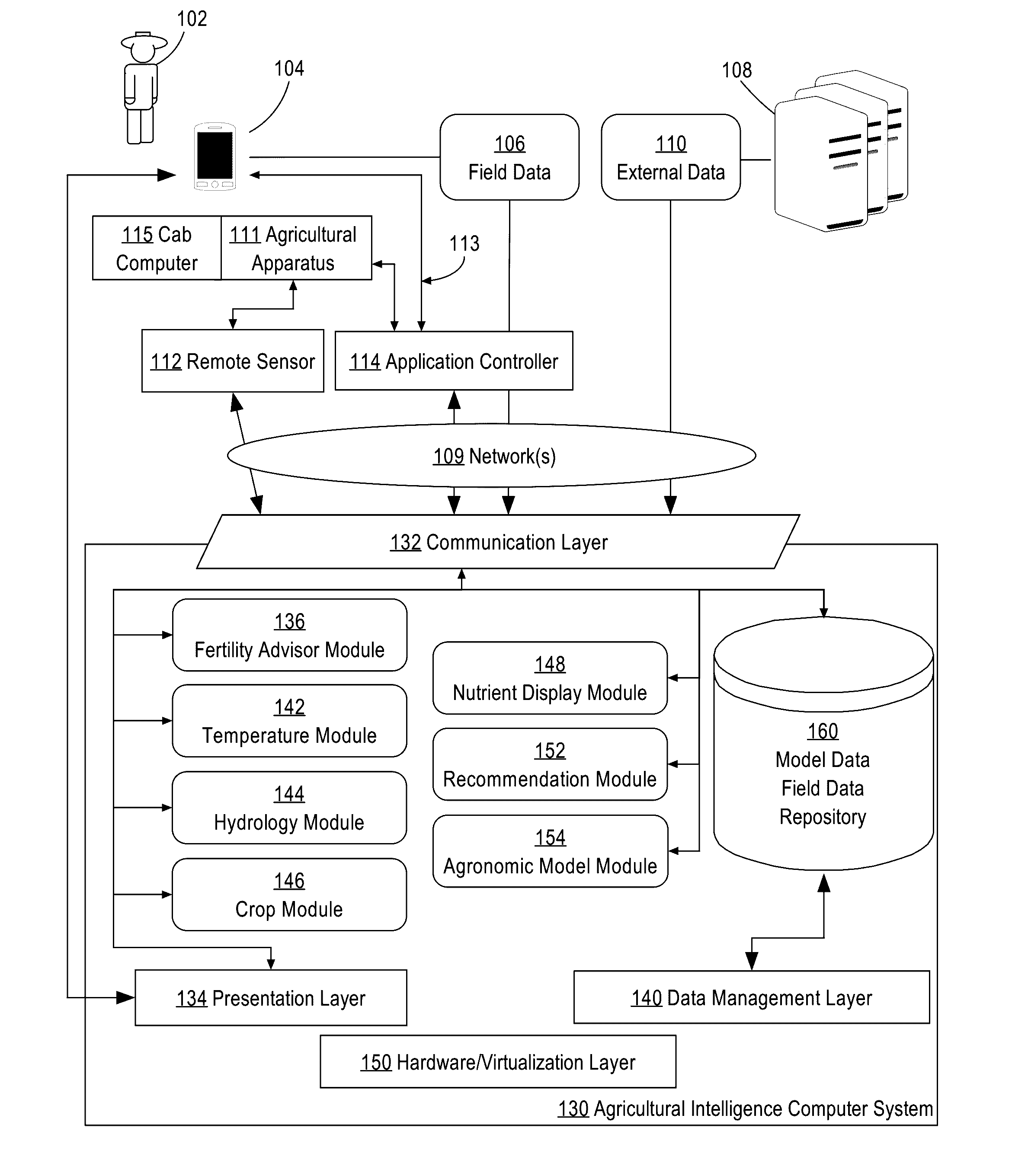

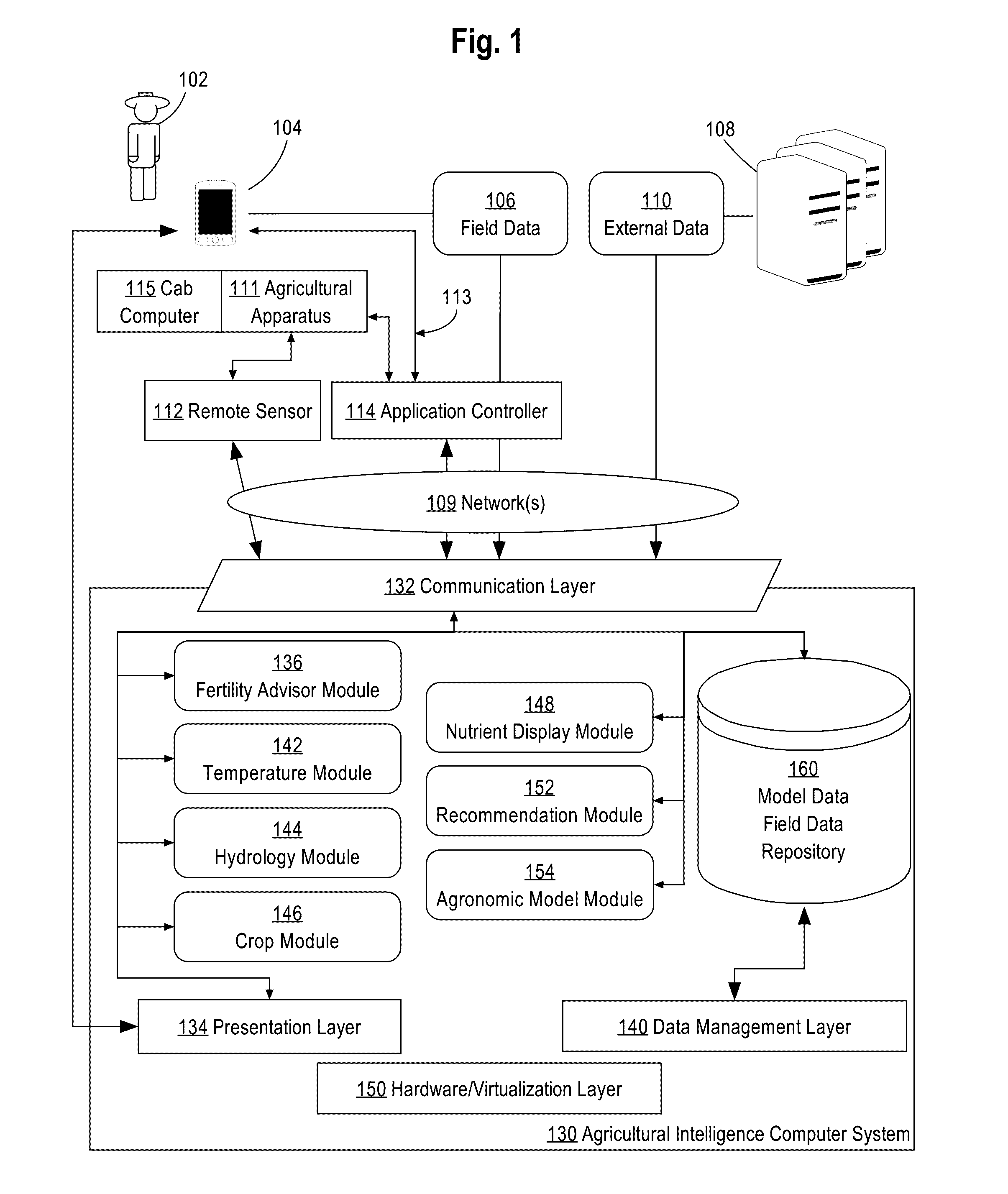

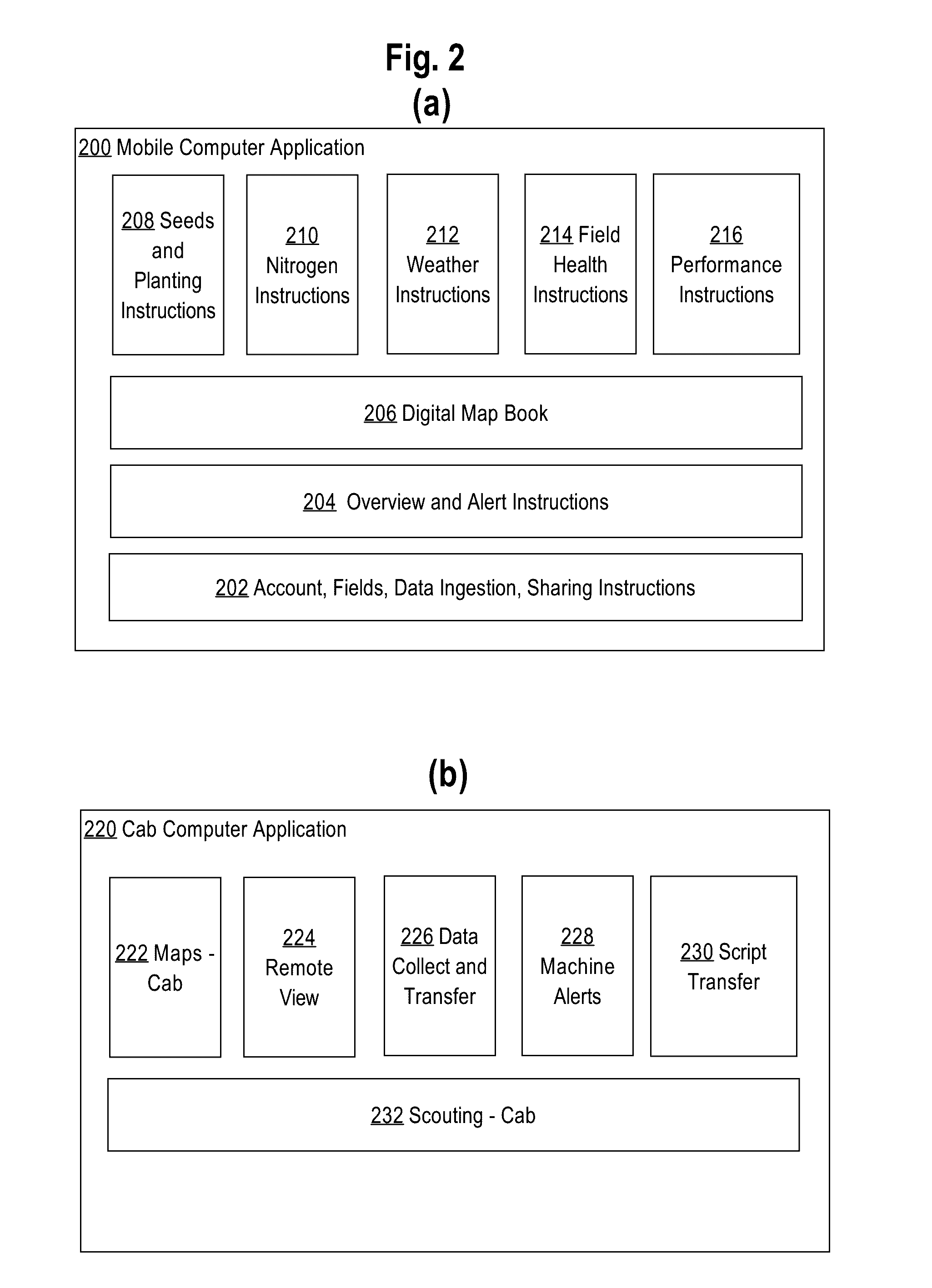

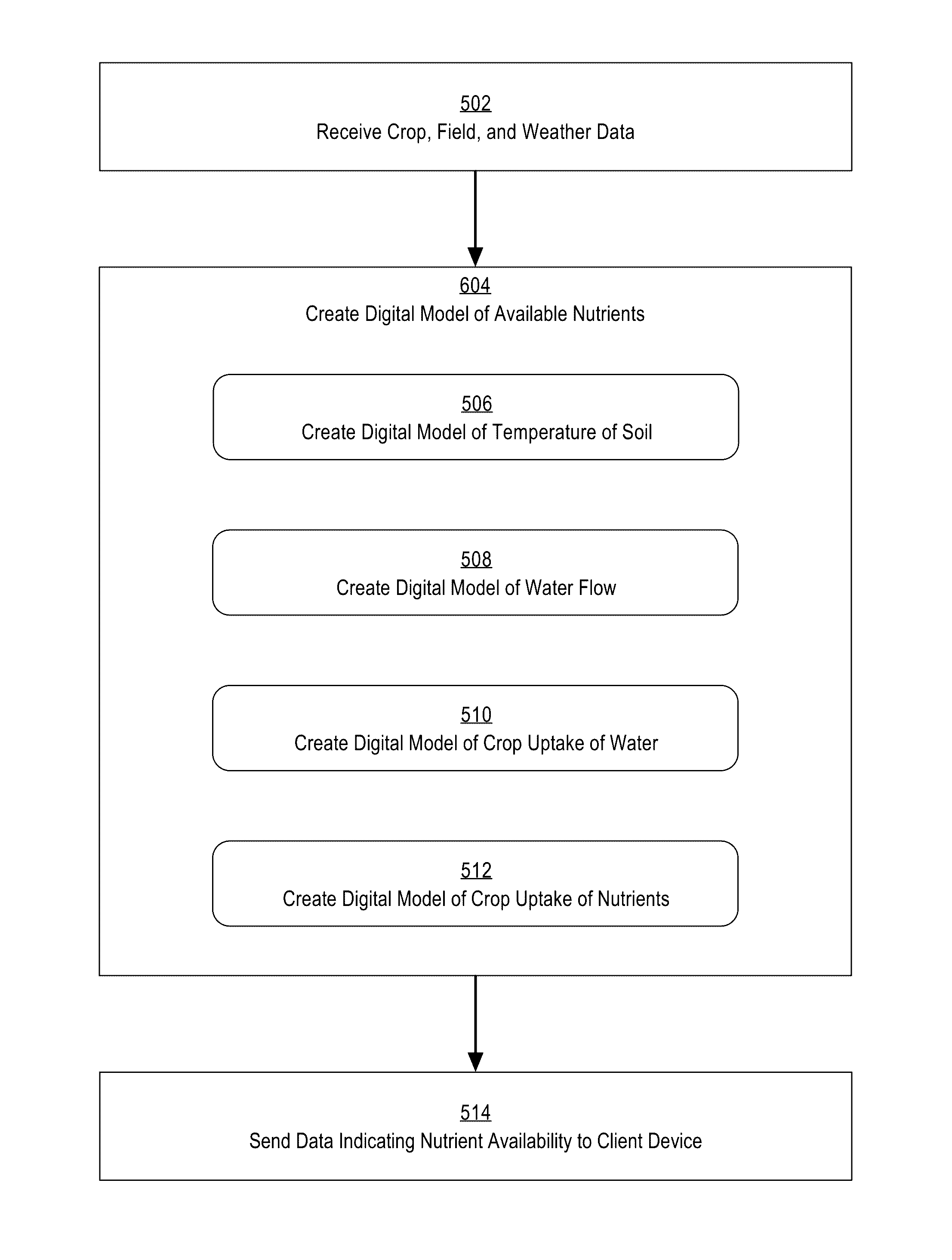

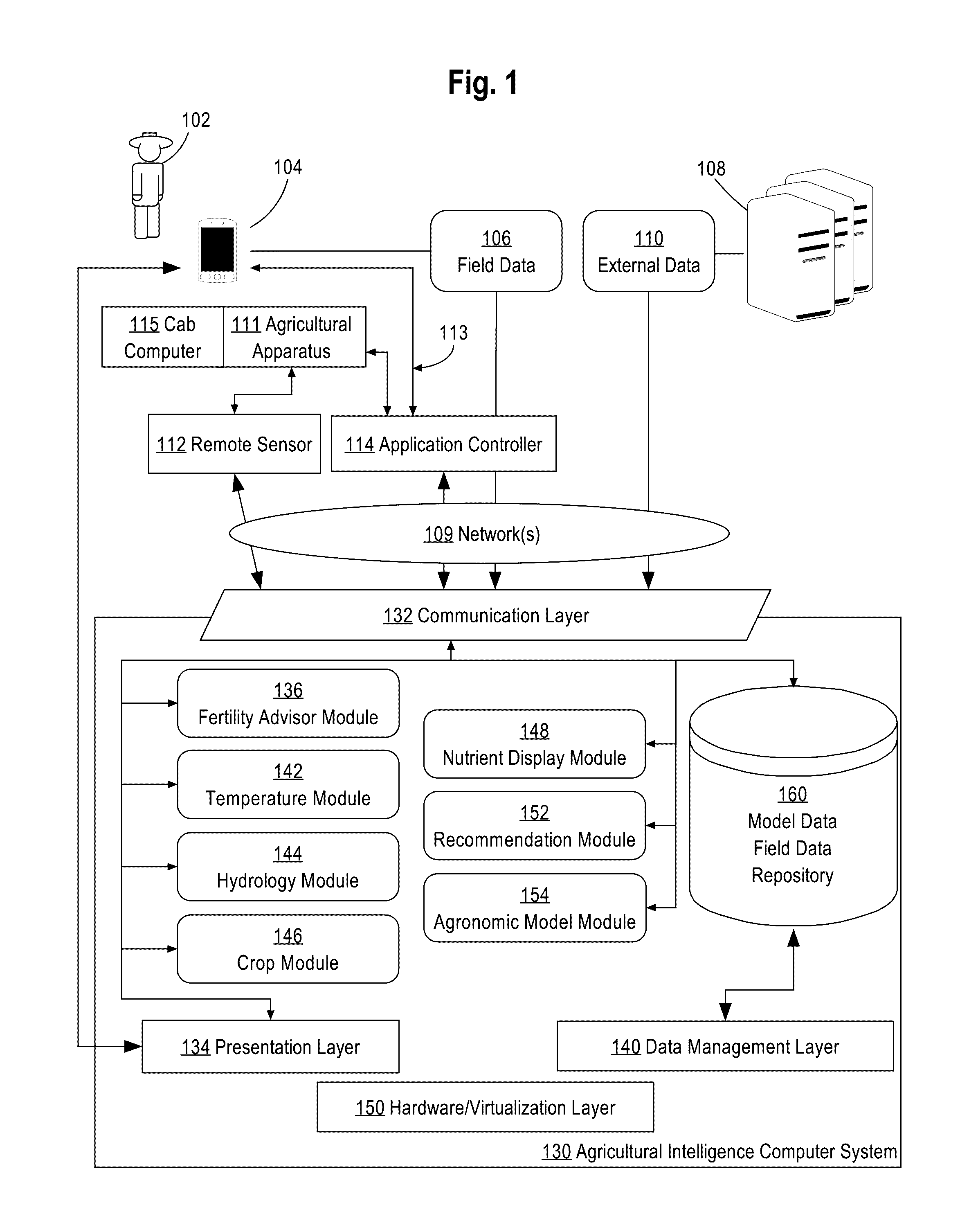

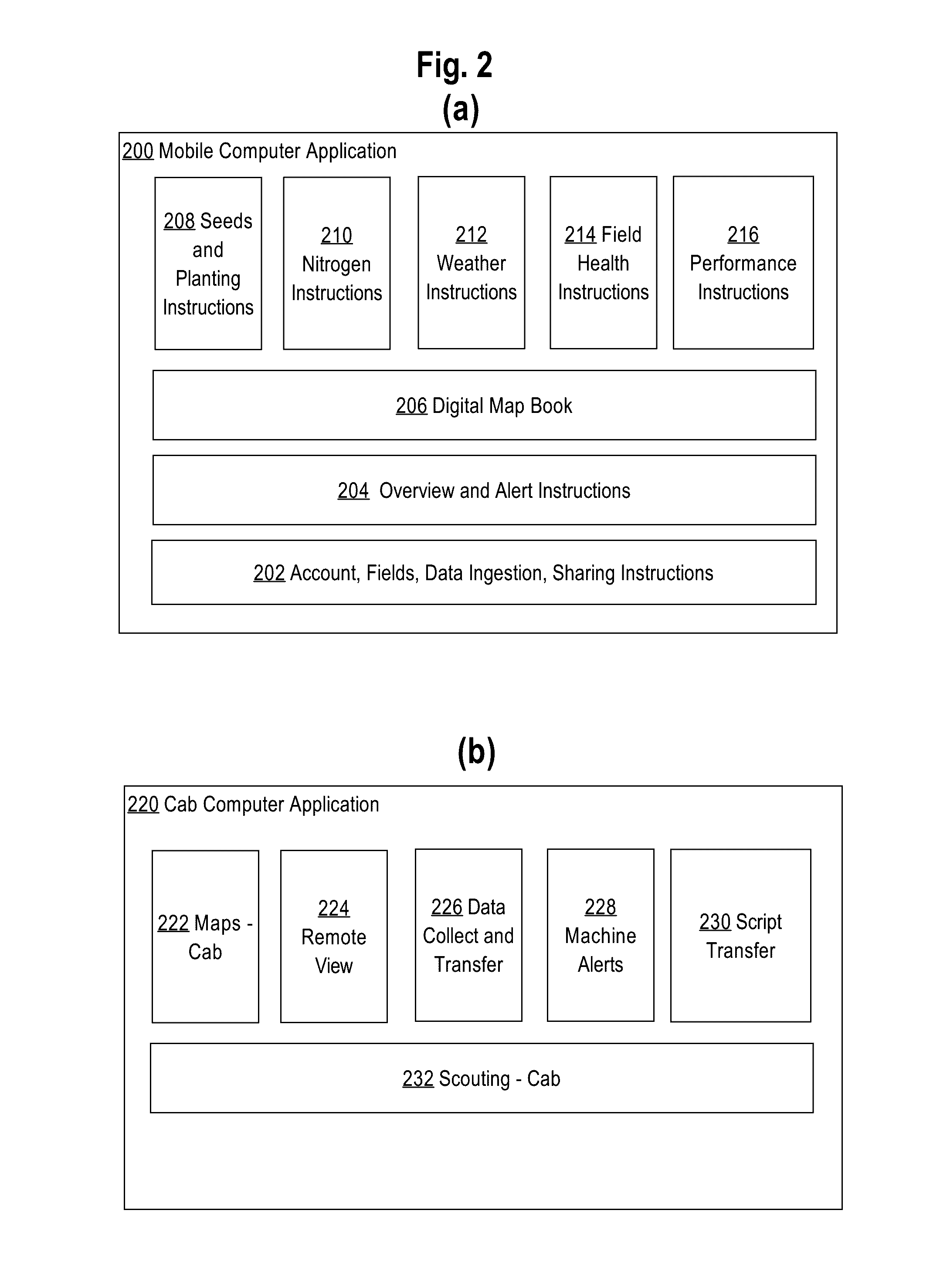

Generating Digital Models Of Nutrients Available To A Crop Over The Course Of The Crop's Development Based On Weather And Soil Data

A system for generating digital models of nitrogen availability based on field data, weather forecast data, and models of water flow, temperature, and crop uptake of nitrogen and water is provided. In an embodiment, field data and forecast data are received by an agricultural intelligence computing system. Based on the received data, the agricultural intelligence computing system models changes in temperature of different soil layers, moisture content of different soil layers, and loss of nitrogen and water to the soil through crop uptake, leaching, denitrification, volatilization, and evapotranspiration. The agricultural intelligence computing system creates a digital model of nitrogen availability based on the temperature, moisture content, and loss models. The agricultural intelligence computing system may then send nitrogen availability data to a field manager computing device and / or use the nitrogen availability data to create notifications, recommendations, agronomic models, and / or control parameters for an application controller.

Owner:THE CLIMATE CORP

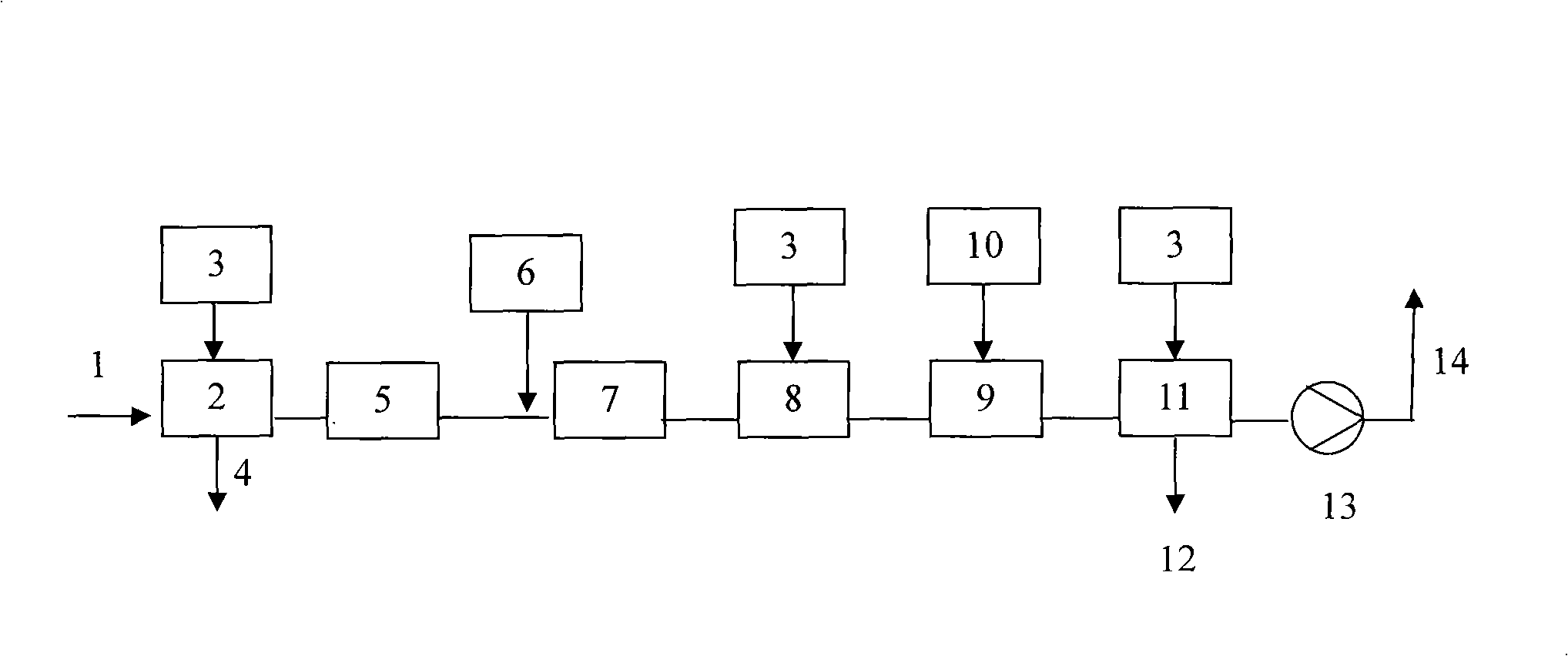

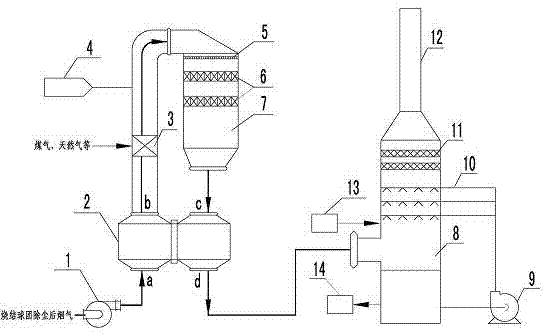

Sintering and pelletizing flue gas desulfurization and denitrification coordinating management system and process

InactiveCN103785290AGuaranteed uptimeLess investmentDispersed particle separationMetallurgical industryOperating cost

The invention relates to a coordinating management system and process for sulfur dioxide, oxynitride, heavy metal, dioxin and other pollutants in flue gas emitted in the sintering and pelletizing processes in the metallurgical industry. The system comprises a booster fan 1, a flue gas heat exchanger 2, a combustor 3, a denitrification reactor 7 and a desulfurization tower 8. The flue gas heat exchanger 2 is a rotary type or tubular heat exchanger. Sintering and pelletizing flue gas after dust removal enters the booster fan 1. The booster fan 1 is connected with an inlet a of the flue gas heat exchanger 2 through a flue. An outlet b of the flue gas heat exchanger 2 is connected with the combustor 3. An outlet of the combustor 3 is connected with the denitrification reactor 7 through a flue. A denitrification reductive agent injector 4 is arranged on the flue through which the combustor 3 is connected with the denitrification reactor 7. An outlet of the denitrification reactor 7 is connected with an inlet c of the flue gas heat exchanger 2. An outlet d of the flue gas heat exchanger 2 is connected with the desulfurization tower 8. The sintering and pelletizing flue gas desulfurization and denitrification coordinating management system and process have the advantages that operation is stable and reliable, investment is lowered, operating cost is low, and by-products can be comprehensively utilized, thereby being a sintering and pelletizing flue gas desulfurization and denitrification coordinating management technology suitable for national conditions of China.

Owner:中钢集团天澄环保科技股份有限公司

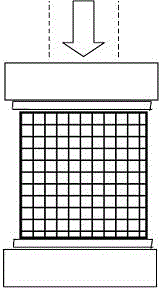

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

Generating digital models of nutrients available to a crop over the course of the crop's development based on weather and soil data

A system for generating digital models of nitrogen availability based on field data, weather forecast data, and models of water flow, temperature, and crop uptake of nitrogen and water is provided. In an embodiment, field data and forecast data are received by an agricultural intelligence computing system. Based on the received data, the agricultural intelligence computing system models changes in temperature of different soil layers, moisture content of different soil layers, and loss of nitrogen and water to the soil through crop uptake, leaching, denitrification, volatilization, and evapotranspiration. The agricultural intelligence computing system creates a digital model of nitrogen availability based on the temperature, moisture content, and loss models. The agricultural intelligence computing system may then send nitrogen availability data to a field manager computing device and / or use the nitrogen availability data to create notifications, recommendations, agronomic models, and / or control parameters for an application controller.

Owner:THE CLIMATE CORP

Heterotrophic nitrification microbial preparation, cultivation method and use thereof

ActiveCN101302485AWide range of substratesEasy to trainImmobilised enzymesBacteriaHigh concentrationMicroorganism

The invention belongs to the environmental microorganism field, and in particular relates to a heterotrophic nitrification microorganism agent, a method for cultivating the same, and a use of the same in culture wastewater treatment. The microorganism agent contains Stenotrophomonas maltophilias strain DN1.1 and Pseudomonas putida strain DN1.2 which have the preservation registration numbers respectively as CCTCC M 207074 and CCTCC M 207075. The microorganism agent can effectively remove ammonia nitrogen and total nitrogen in a water body, accumulates no nitrite or nitrate during denitrification, and can simultaneously remove CODCr in organic wastewater, which is applicable to the treatment of high-concentration culture wastewater. The use of the microorganism agent in treating culture wastewater is simple in process and stable in effect.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com