Resource ozone oxidation dry method capable of removing sulfur dioxide and nitrogen oxides in flue gas

A technology of sulfur dioxide and nitrogen oxides, applied in the fields of plasma chemistry and environmental engineering, to achieve the effects of reducing equipment, reducing equipment investment and operating costs, and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

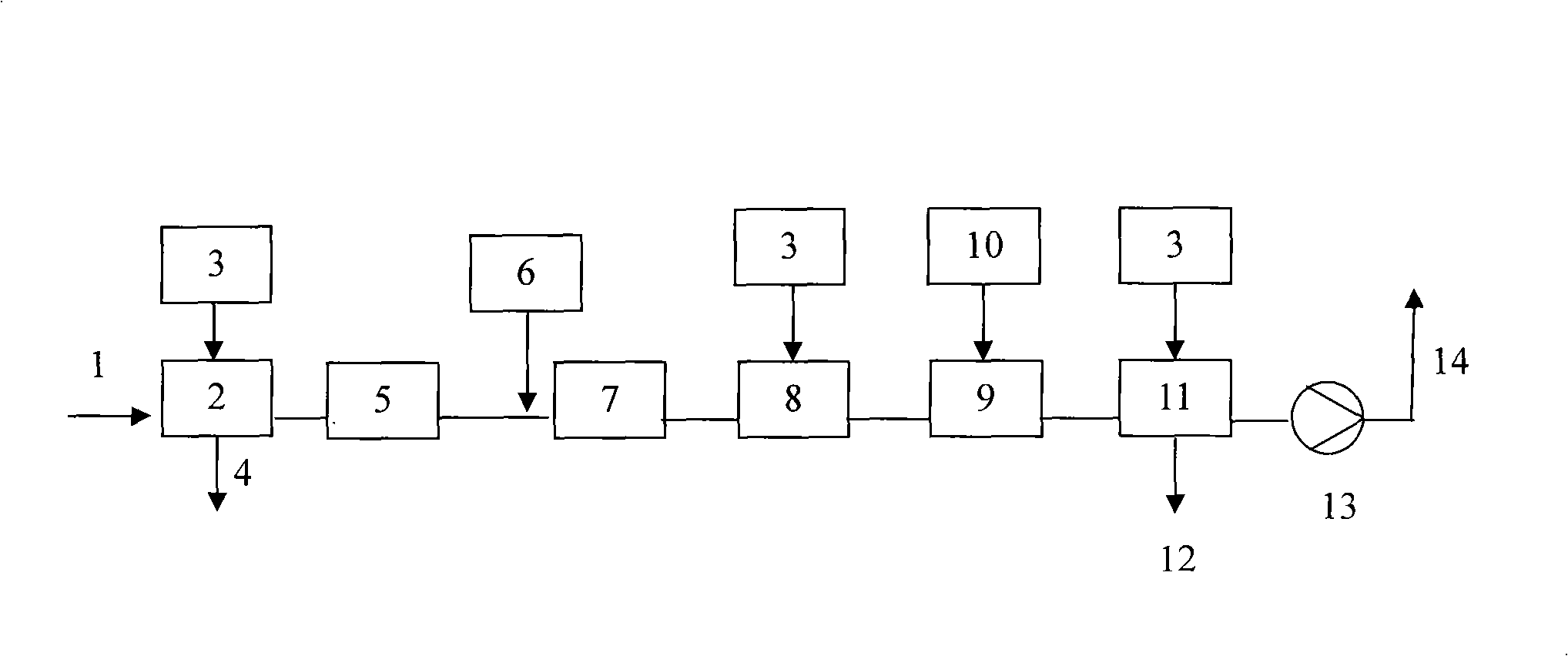

[0024] The technological process of the ozone oxidation dry process for simultaneous removal of sulfur dioxide and nitrogen oxides in flue gas is shown in the attached figure. The high-temperature flue gas 1 containing sulfur dioxide, nitrogen oxides and soot is transported into the electrostatic precipitator 2 . The flue gas 1 dust removal system is composed of an electrostatic precipitator 2 and a DC negative high-voltage power supply 3. The DC high-voltage power supply 3 outputs a negative high voltage (40-160kV) and is applied to the corona electrode of the electrostatic precipitator 2 to form an electric field with a strength of 10-100kV. The electrostatic electric field of 40kV / cm traps the saturated charged smoke and dust on the dust collecting plate of the electrostatic precipitator, and collects the smoke and dust after vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com