Patents

Literature

30059 results about "Quartz" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quartz is a hard, crystalline mineral composed of silicon and oxygen atoms. The atoms are linked in a continuous framework of SiO₄ silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical formula of SiO₂. Quartz is the second most abundant mineral in Earth's continental crust, behind feldspar.

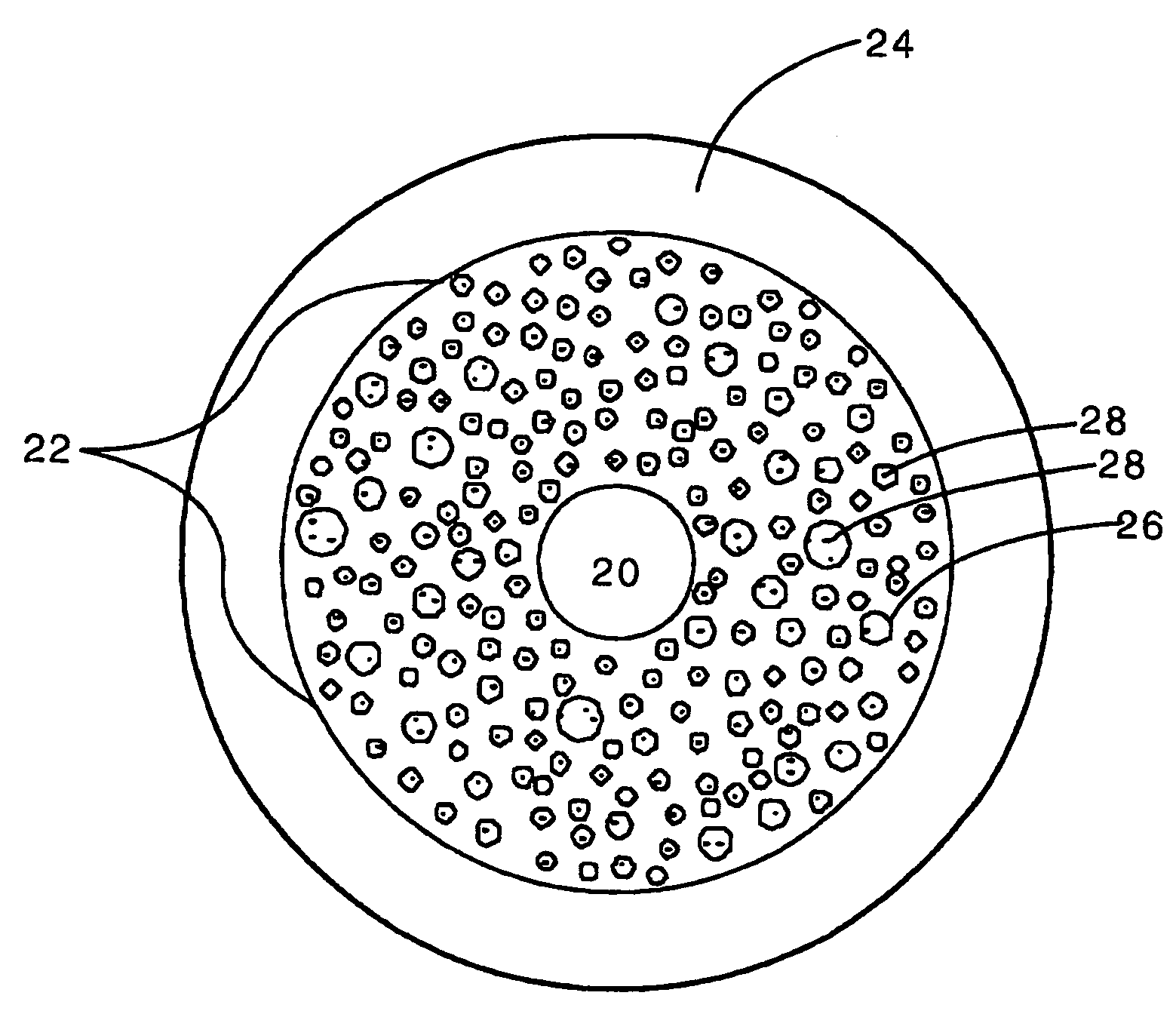

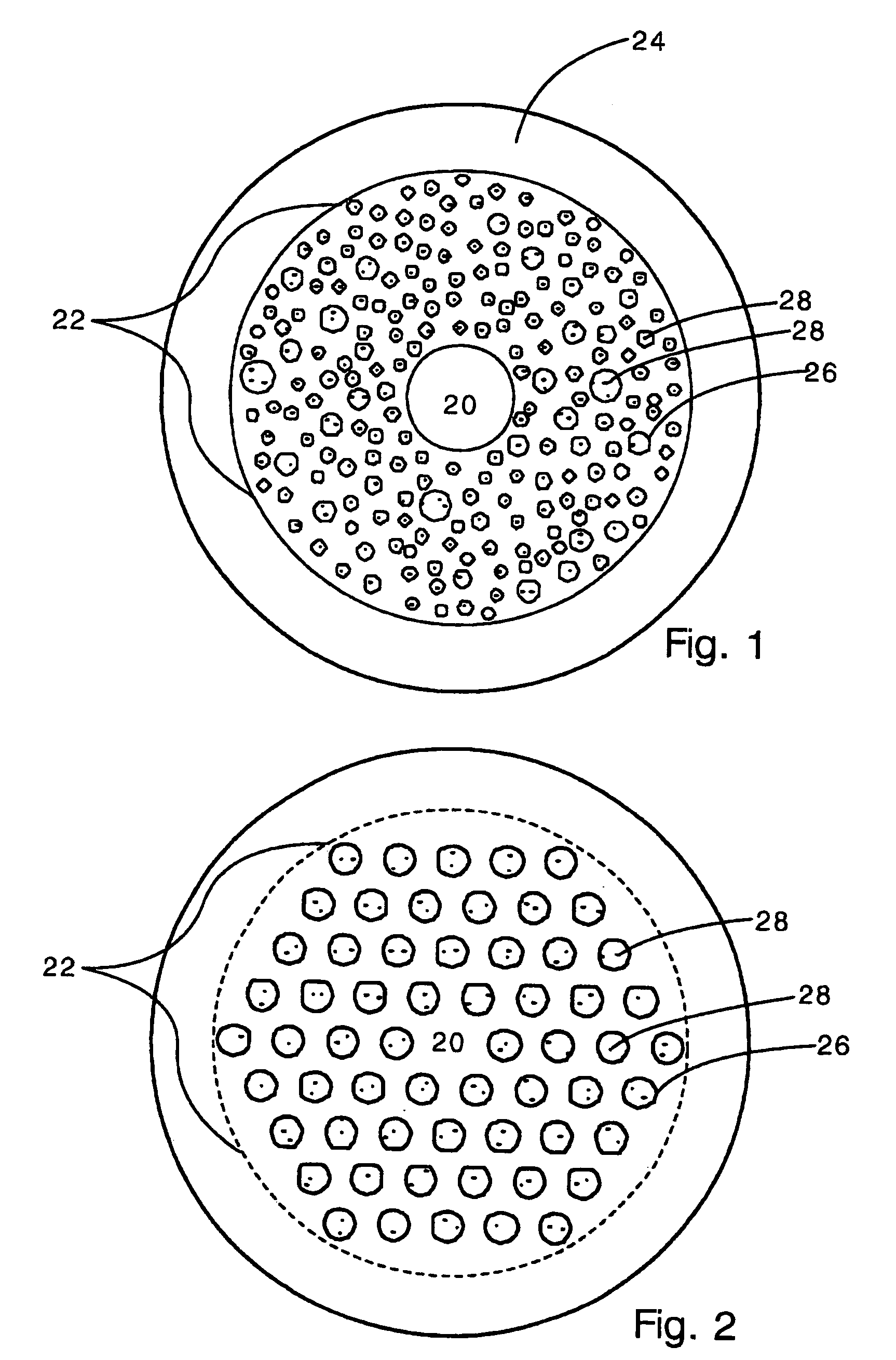

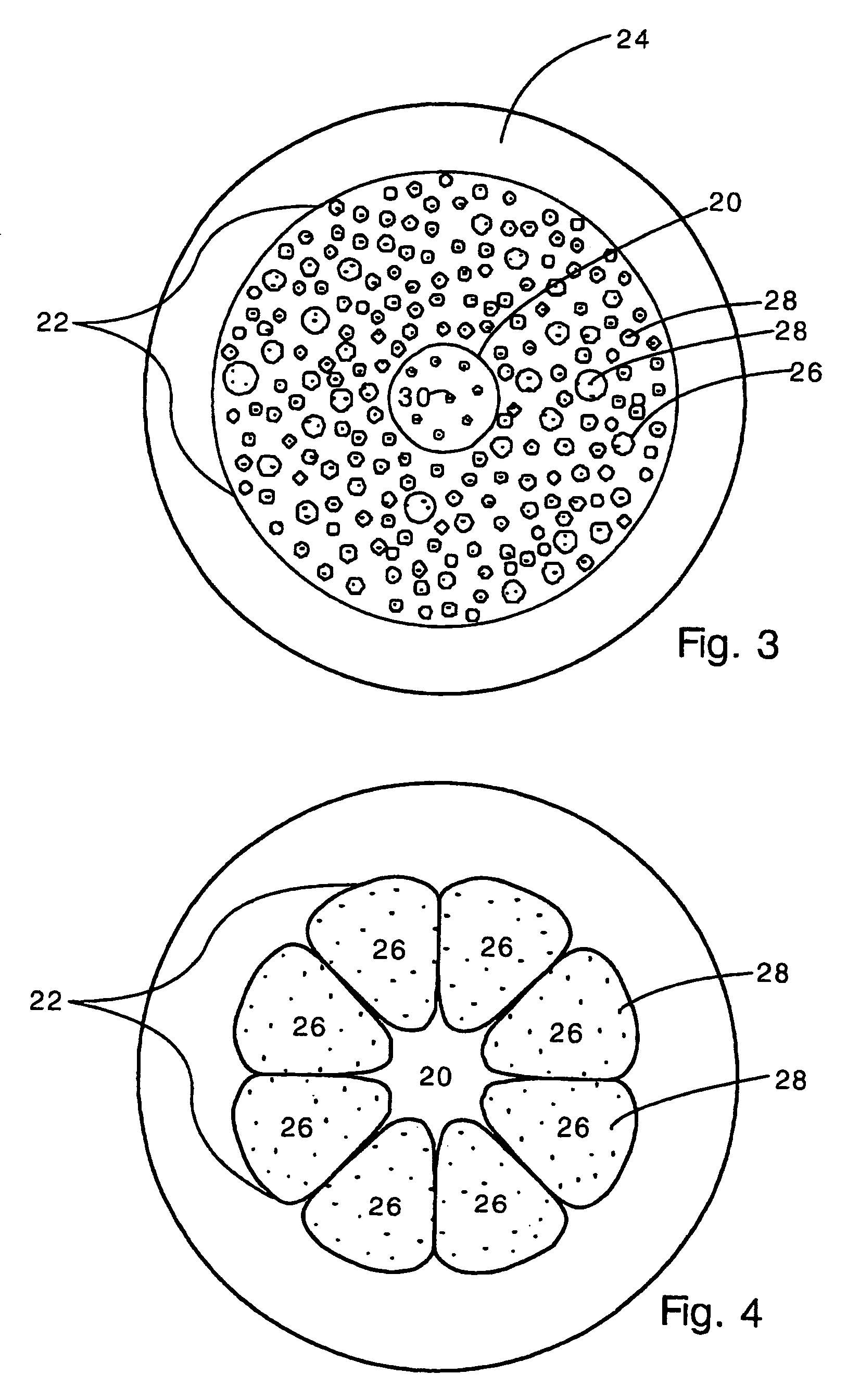

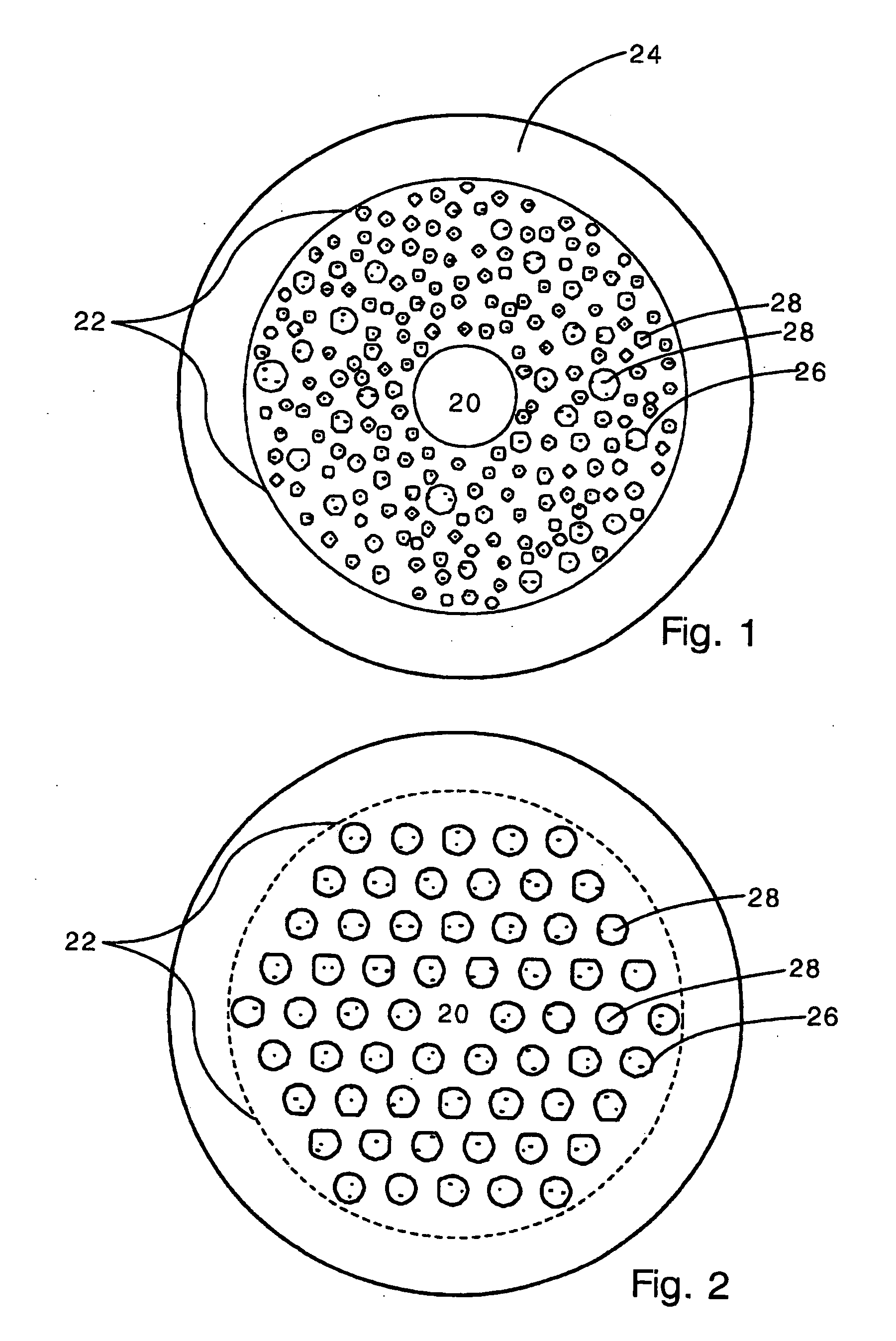

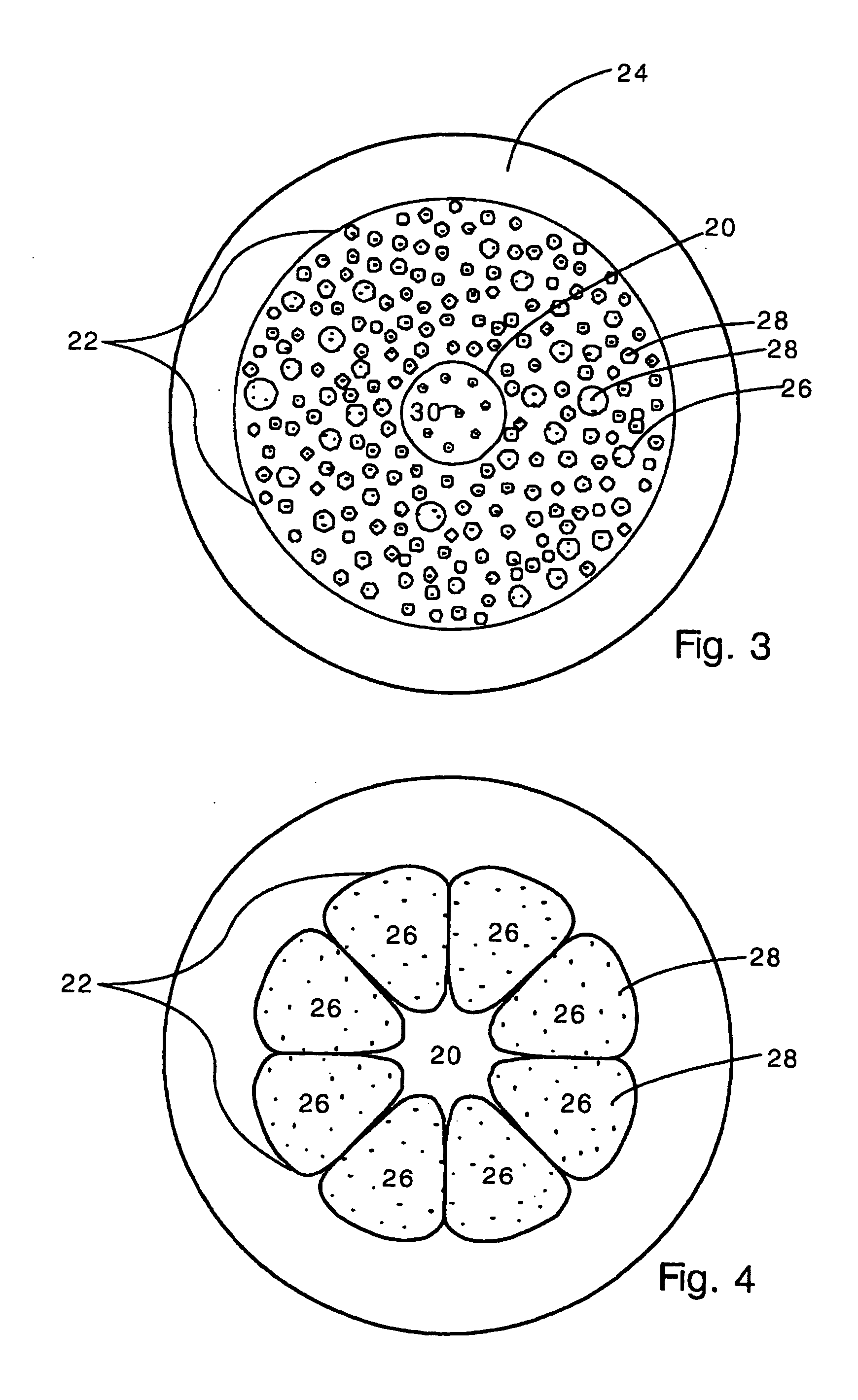

Optical fiber with quantum dots

Holey optical fibers (e.g. photonic fibers, random-hole fibers) are fabricated with quantum dots disposed in the holes. The quantum dots can provide light amplification and sensing functions, for example. When used for sensing, the dots will experience altered optical properties (e.g. altered fluorescence or absorption wavelength) in response to certain chemicals, biological elements, radiation, high energy particles, electrical or magnetic fields, or thermal / mechanical deformations. Since the dots are disposed in the holes, the dots interact with the evanescent field of core-confined light. Quantum dots can be damaged by high heat, and so typically cannot be embedded within conventional silica optical fibers. In the present invention, dots can be carried into the holes by a solvent at room temperature. The present invention also includes solid glass fibers made of low melting point materials (e.g. phosphate glass, lead oxide glass) with embedded quantum dots.

Owner:LAMBDA LABORATORY INSTRUMENTS +1

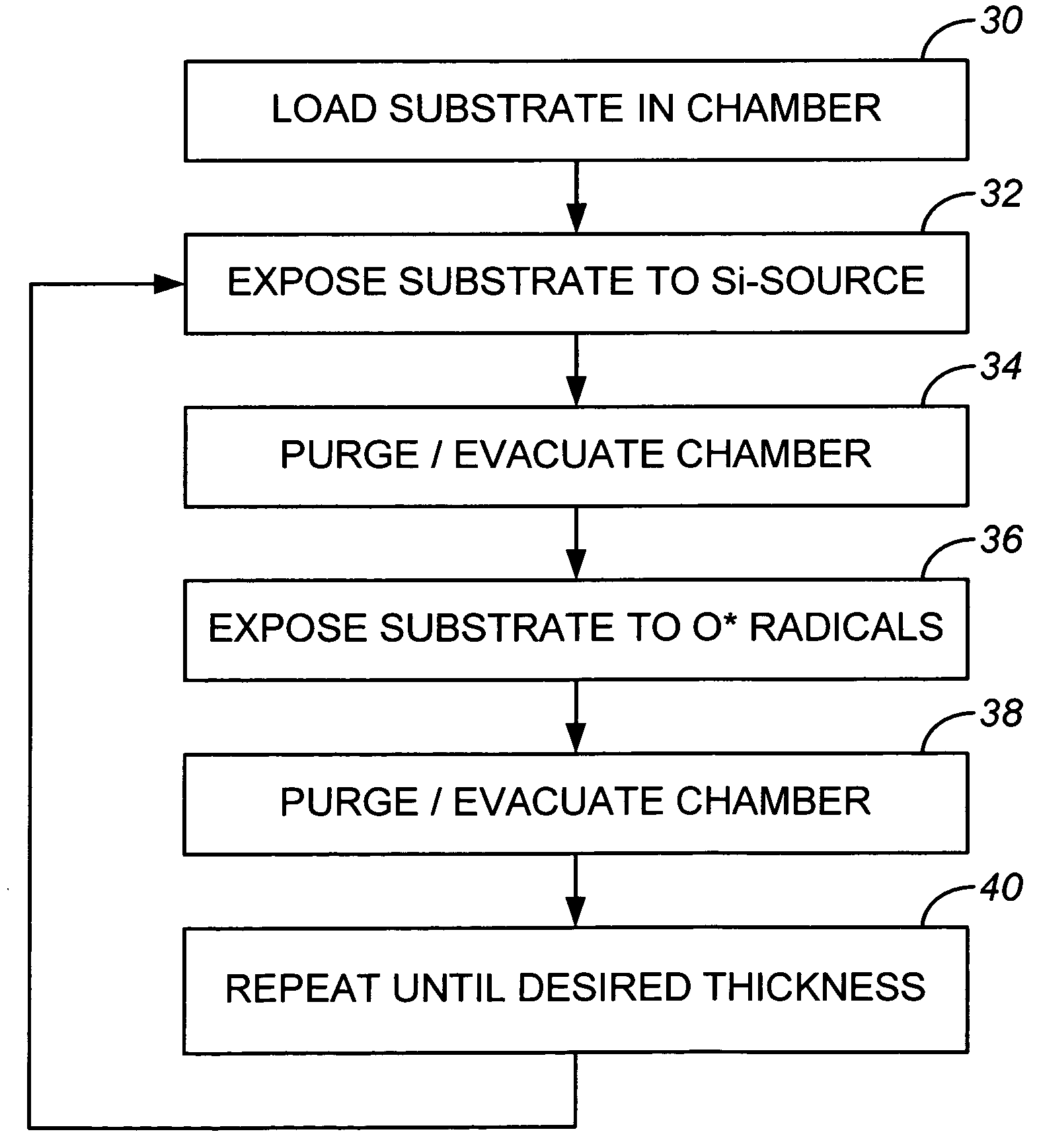

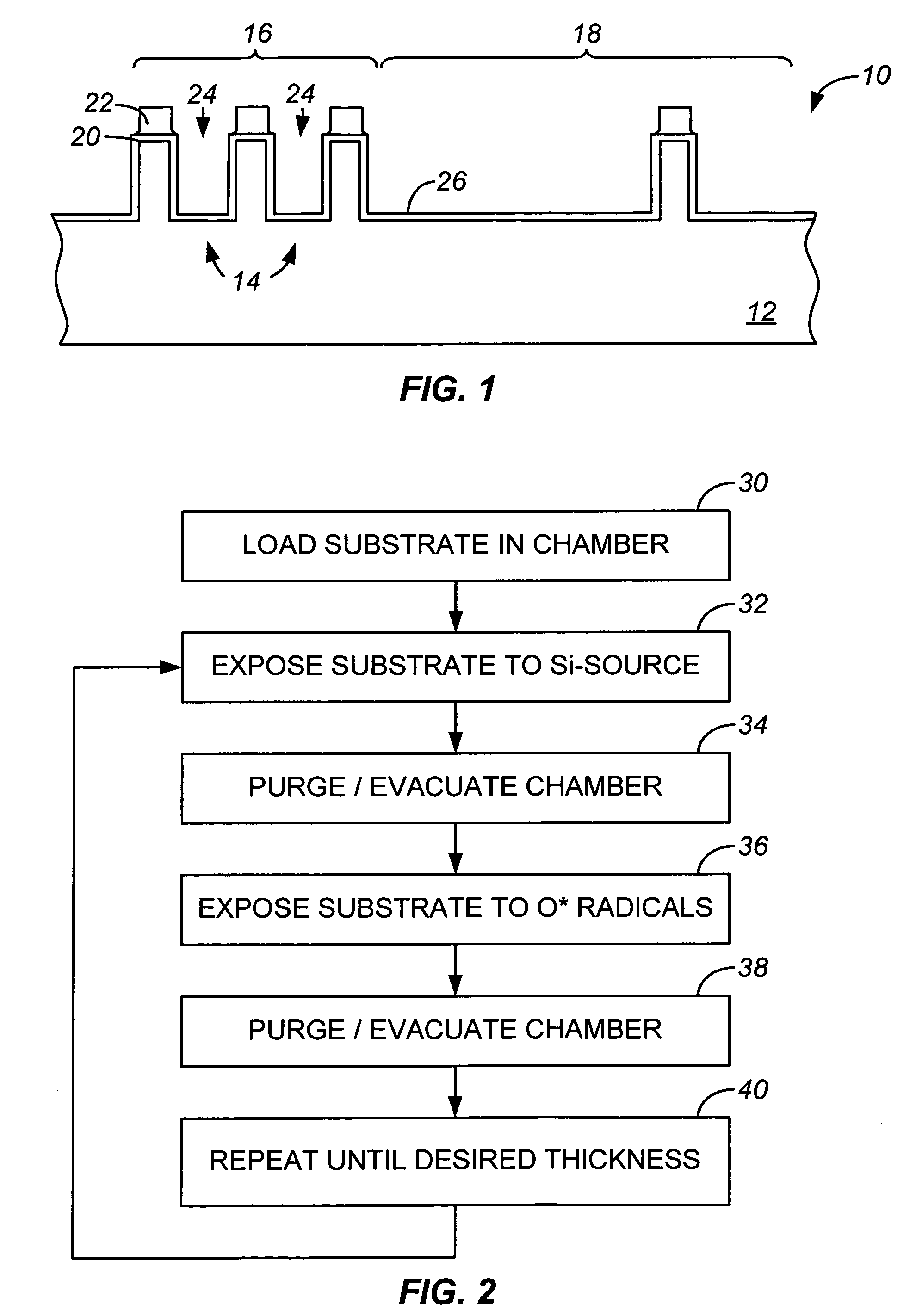

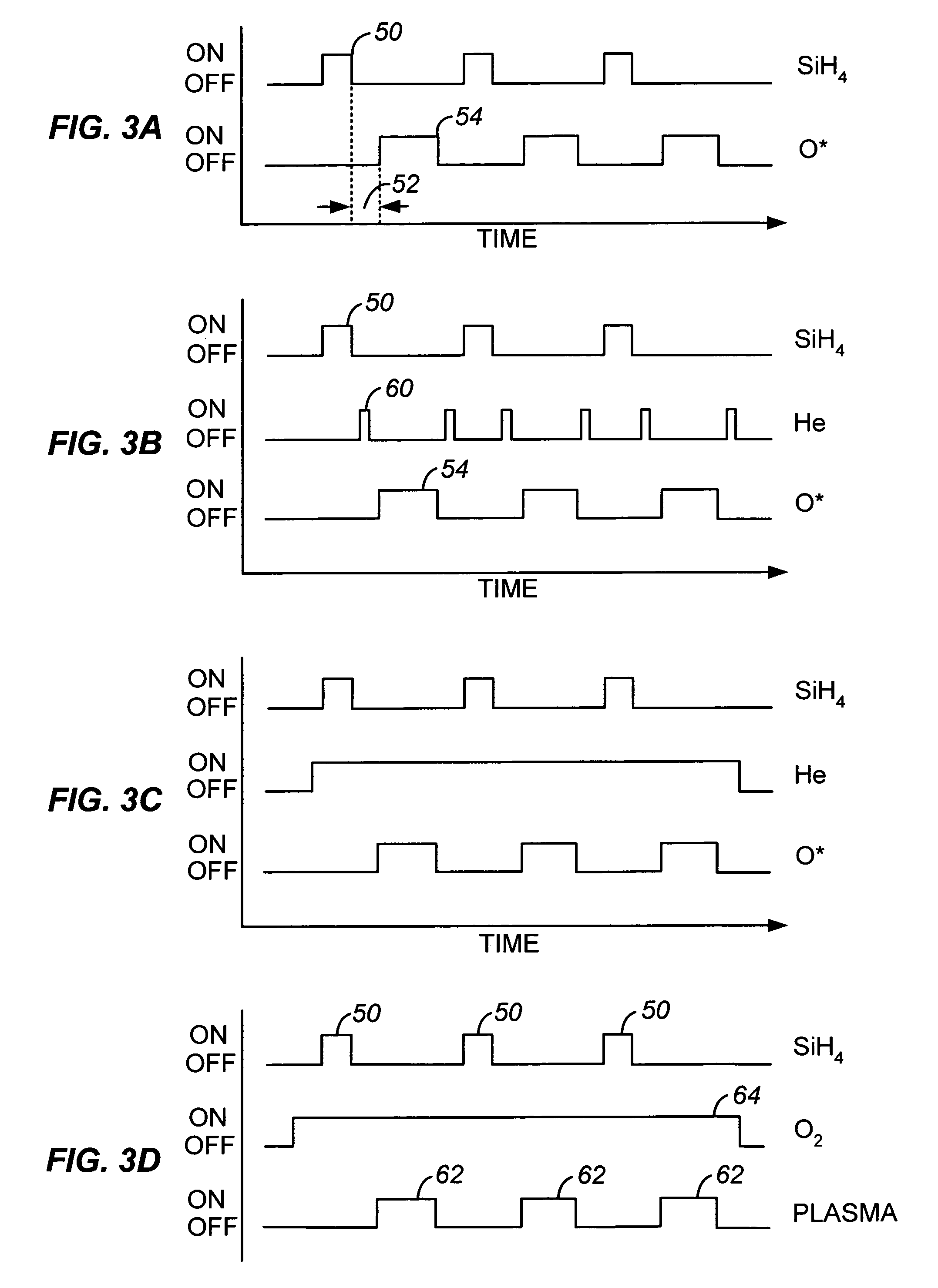

Sequential gas flow oxide deposition technique

A method of depositing a silica glass insulating film over a substrate. In one embodiment the method comprises exposing the substrate to a silicon-containing reactant introduced into a chamber in which the substrate is disposed such that one or more layers of the silicon-containing reactant are adsorbed onto the substrate; purging or evacuating the chamber of the silicon-containing reactant; converting the silicon-containing reactant into a silica glass insulating compound by exposing the substrate to oxygen radicals formed from a second reactant while biasing the substrate to promote a sputtering effect, wherein an average atomic mass of all atomic constituents in the second reactant is less than or equal to an average atomic mass of oxygen; and repeating the exposing, purging / evacuating and exposing sequence a plurality of times until a desired film thickness is reached.

Owner:APPLIED MATERIALS INC

Method for providing a grinding surface on glass implements used in personal care

ActiveUS8790749B2Increase variabilityEasy to manufacturePretreated surfacesManicure/pedicurePersonal careFlat glass

Manufacturing method of grinding surface on glass cosmetics, in particular the nail and skin file, from flat glass of FLOAT type, is carried out by marking at least one abrasive surface on one or two sides of a glass pane or intermediate product. This surface is then coated with fusing glue, powdered with clean quartz sand with grain size between 1 and 500 μm using a sieve, and the surplus sand is knocked-down. The intermediate product with fixed sand is inserted into the fusing furnace where it is baked at the temperature of up to 900° C. The abrasive surface may be roughened by sand blasting before the fusing glue application; the intermediate product coated with fusing glue can be decorated with glass fritte.

Owner:HACEK OVER SKUTCHANOVA ZUZANA

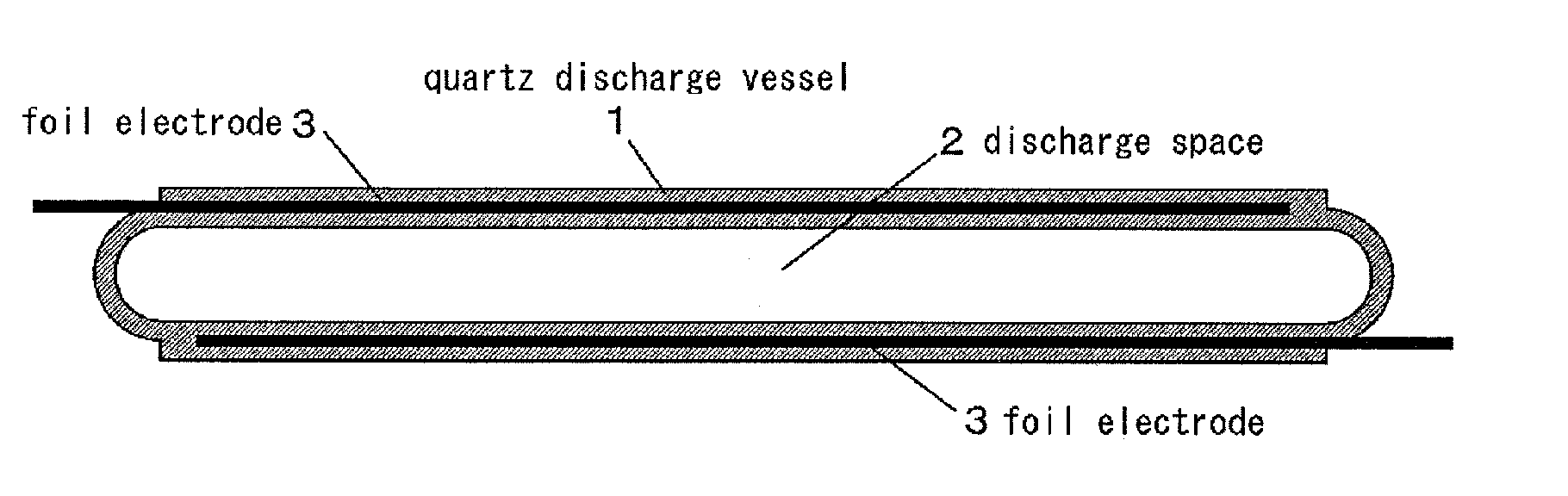

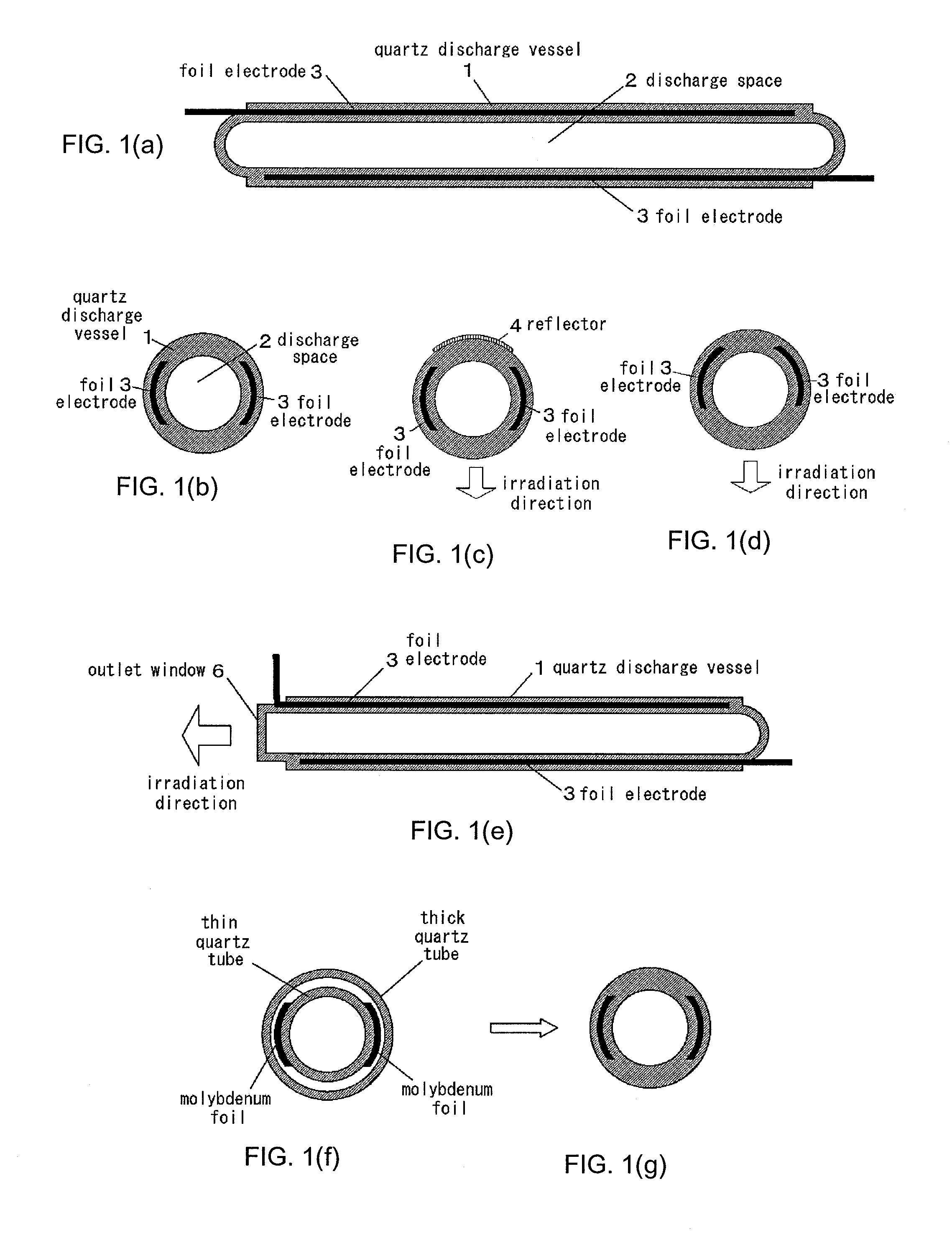

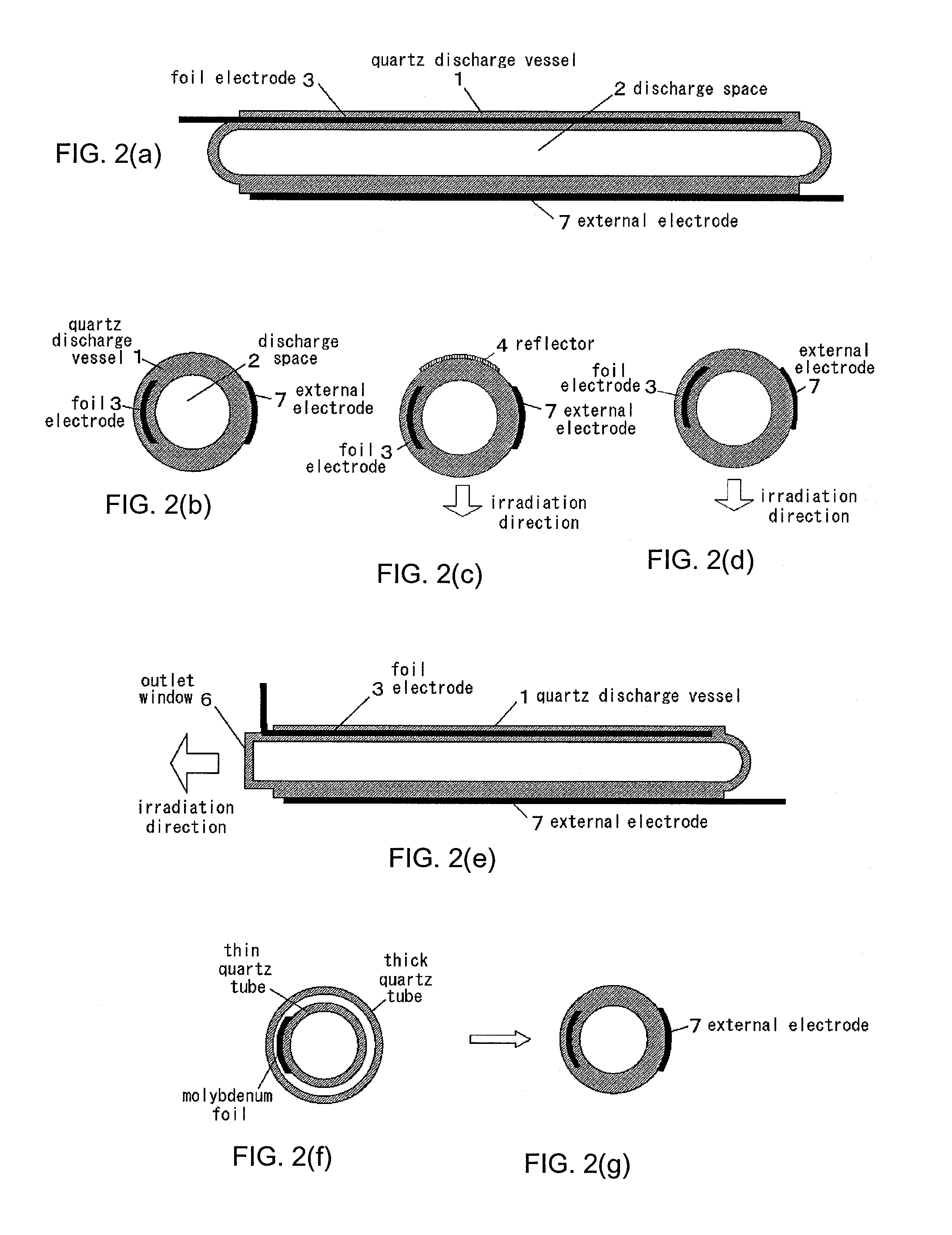

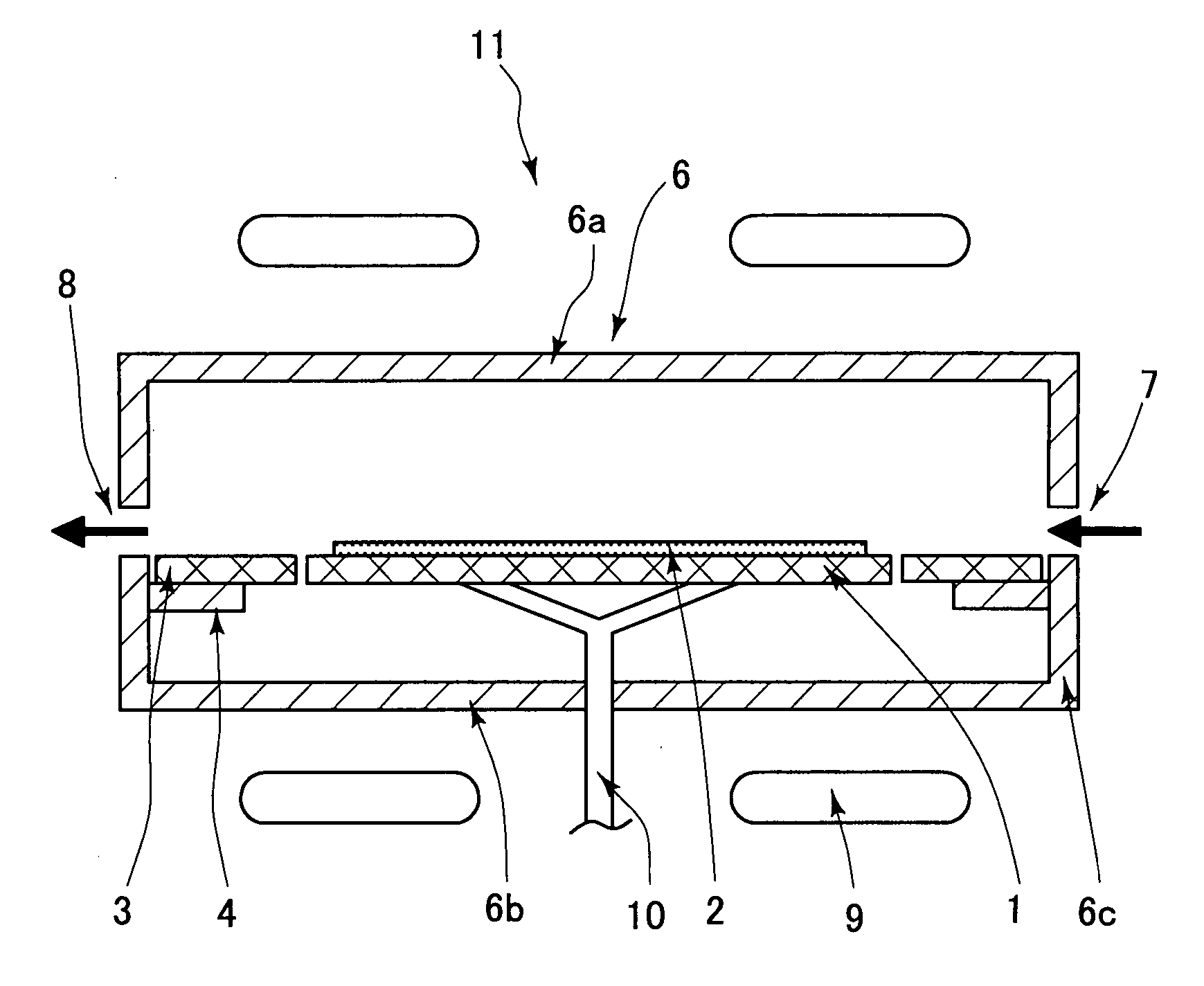

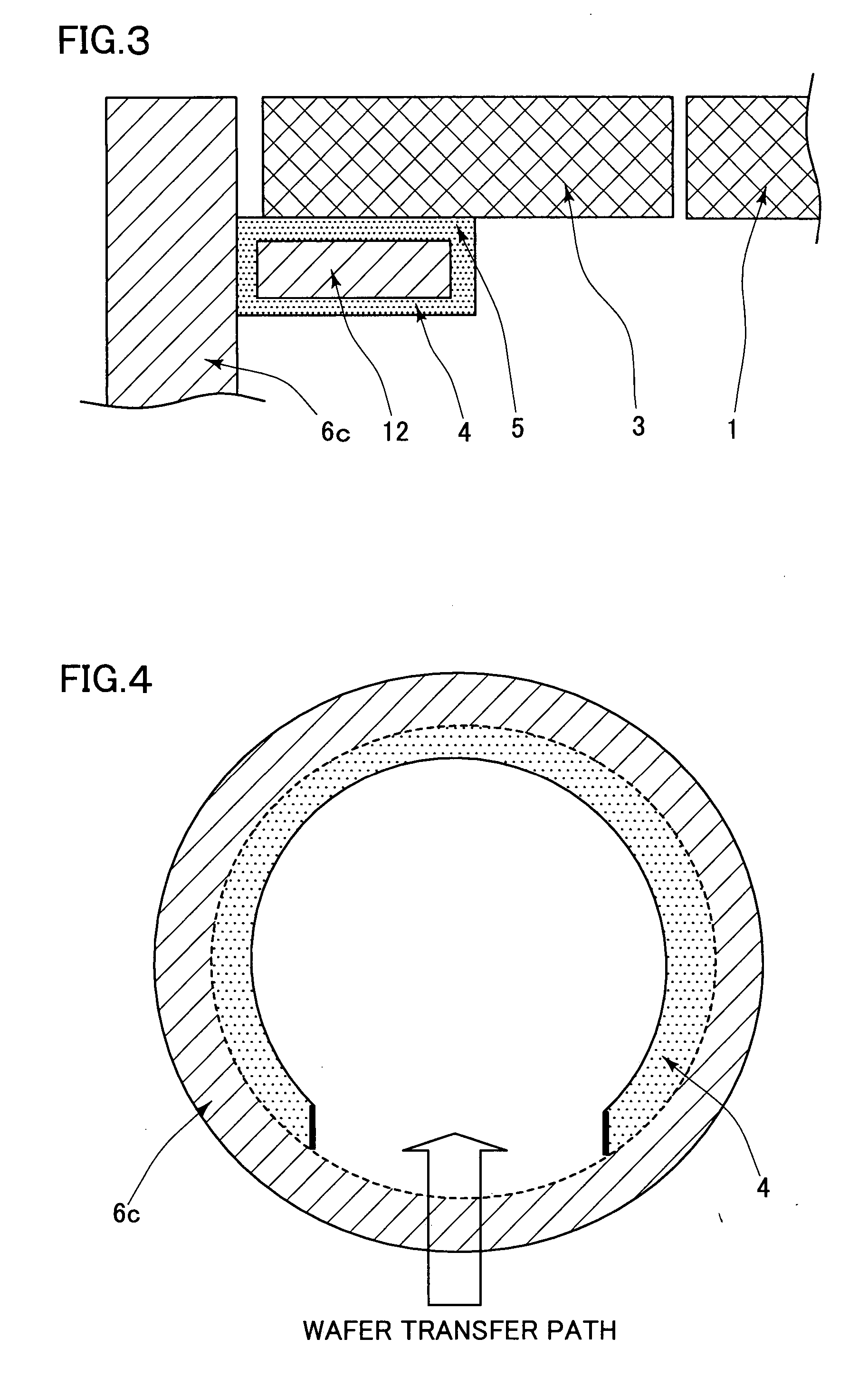

Discharge lamp

InactiveUS20100259152A1Irradiation of becomes intensiveImprove reliabilityIncadescent screens/filtersSolid cathode detailsCapacitanceGas-discharge lamp

The object of this invention is to prevent surface discharge even when a high voltage is applied in a dielectric-barrier discharge lamp or a capacitively coupled high frequency discharge lamp with no electrodes in a discharge space. Ribbon foil electrodes 3 are embedded in the wall of a quartz discharge vessel 1. The discharge vessel 1 is disposed such that the foil electrodes 3 face each other on both sides of the axis of the quartz discharge vessel 1. It may be disposed such that the foil electrodes 3 have a truncated V-shaped cross-section. The single tube quartz discharge vessel 1 is filled with discharge gas to form excimer molecules by dielectric barrier discharge or capacitively coupled high-frequency discharge.

Owner:ORC MFG

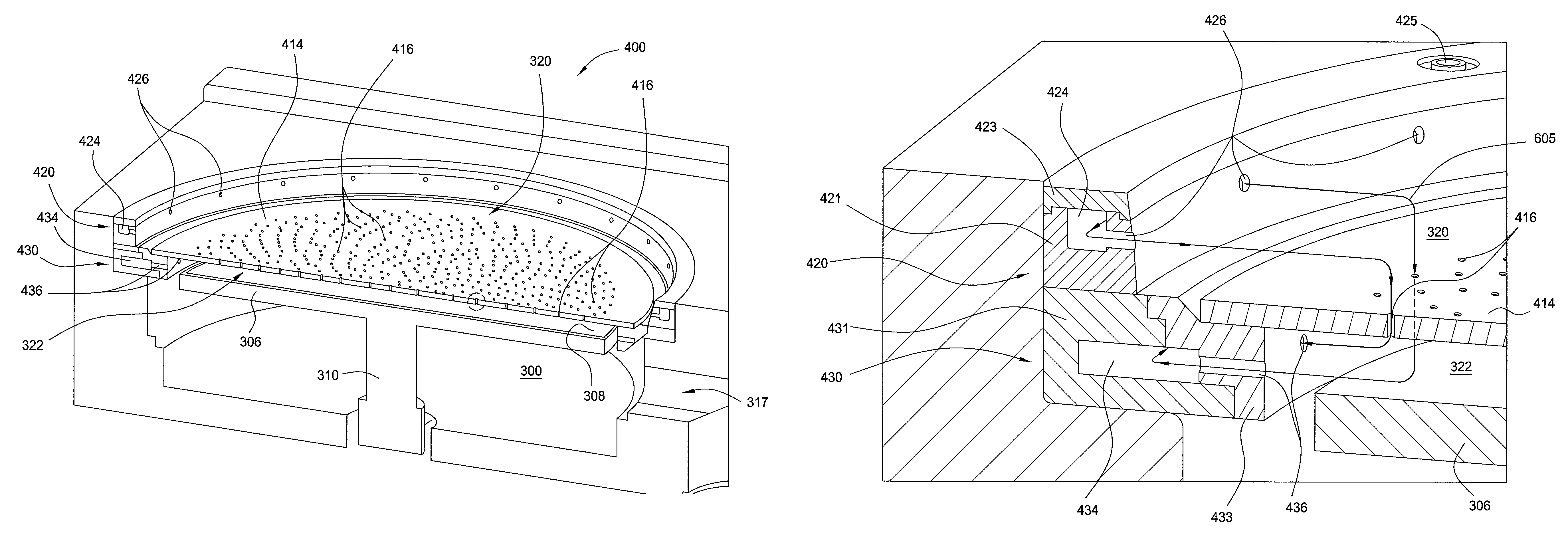

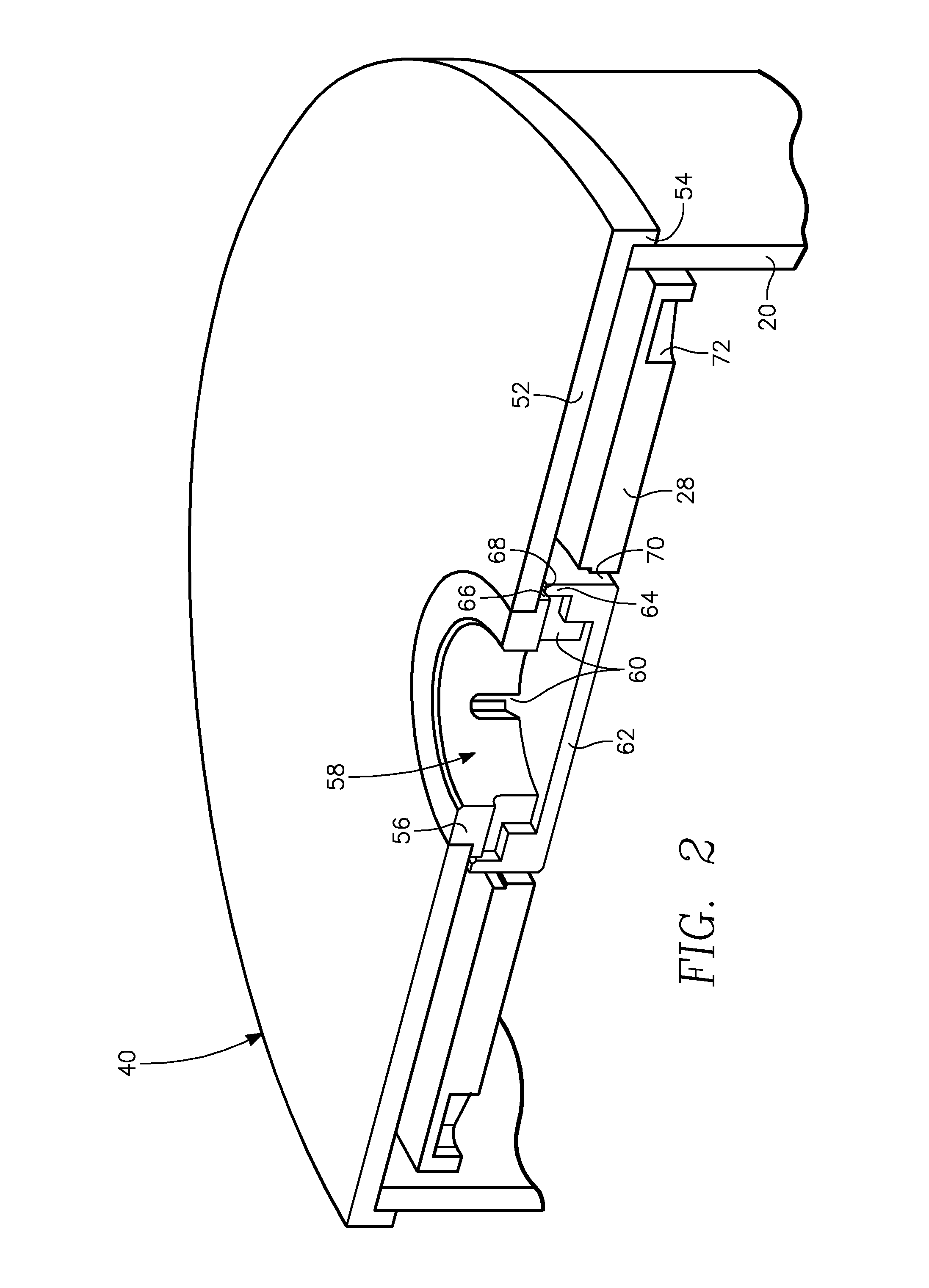

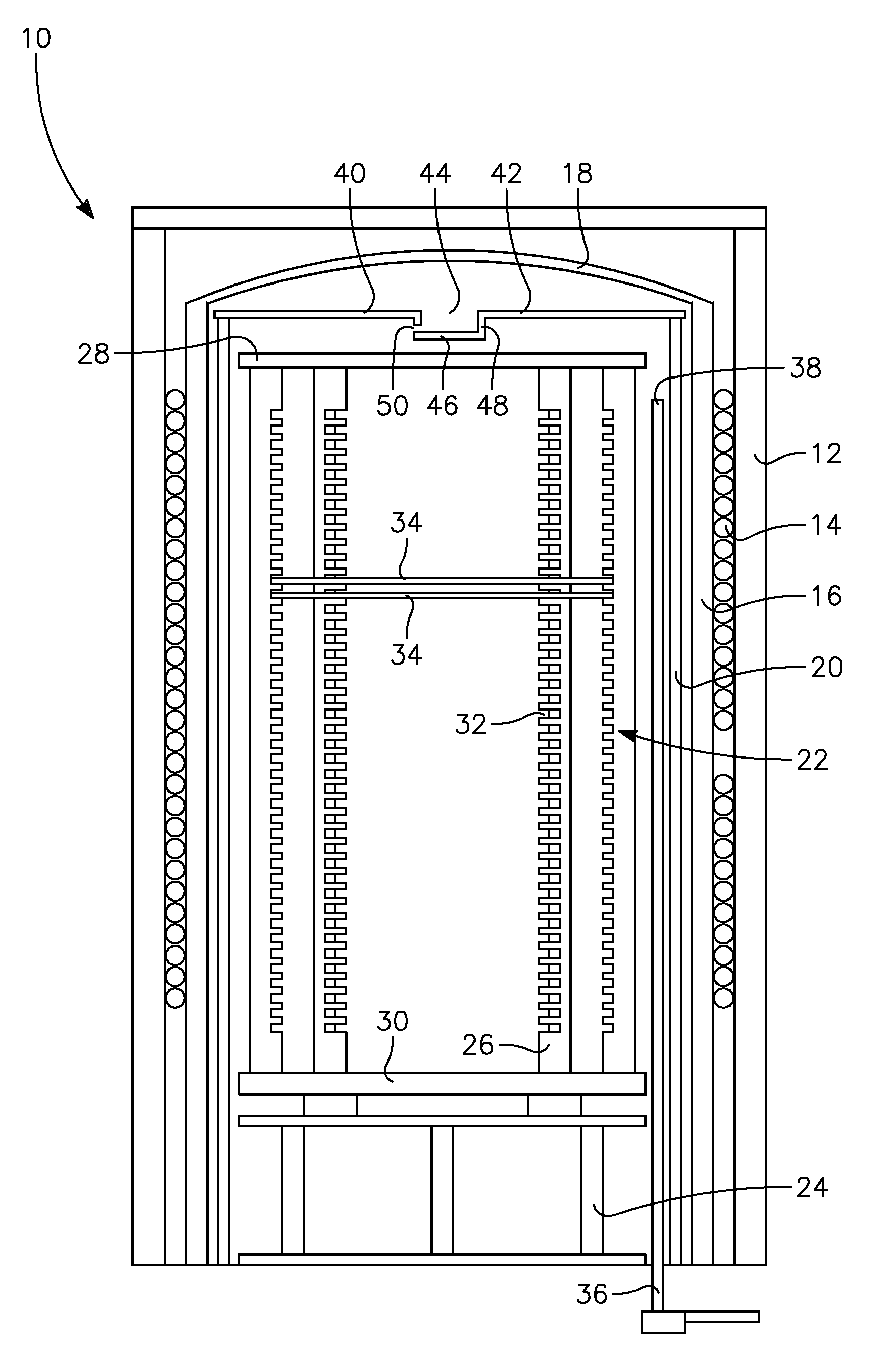

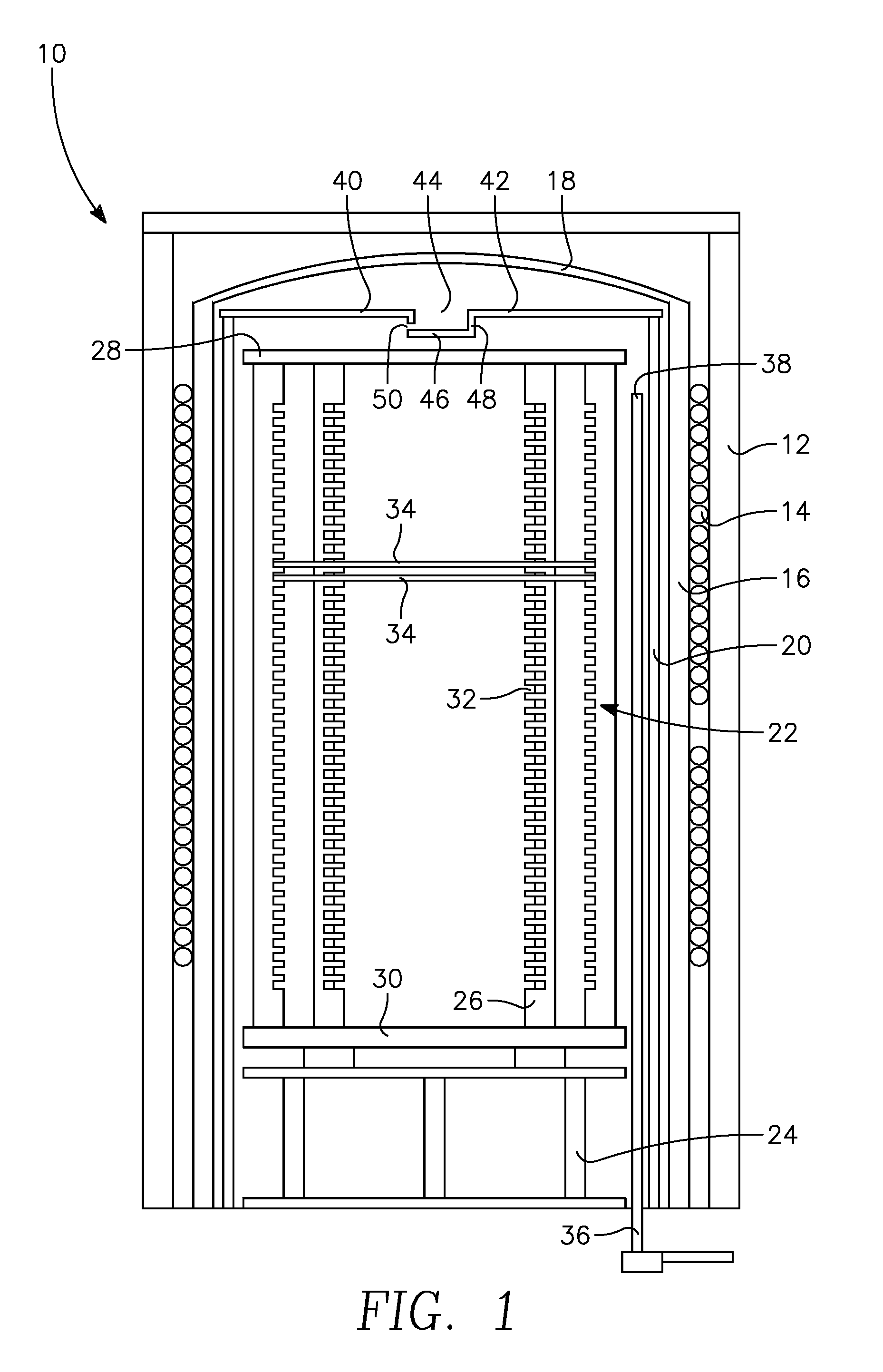

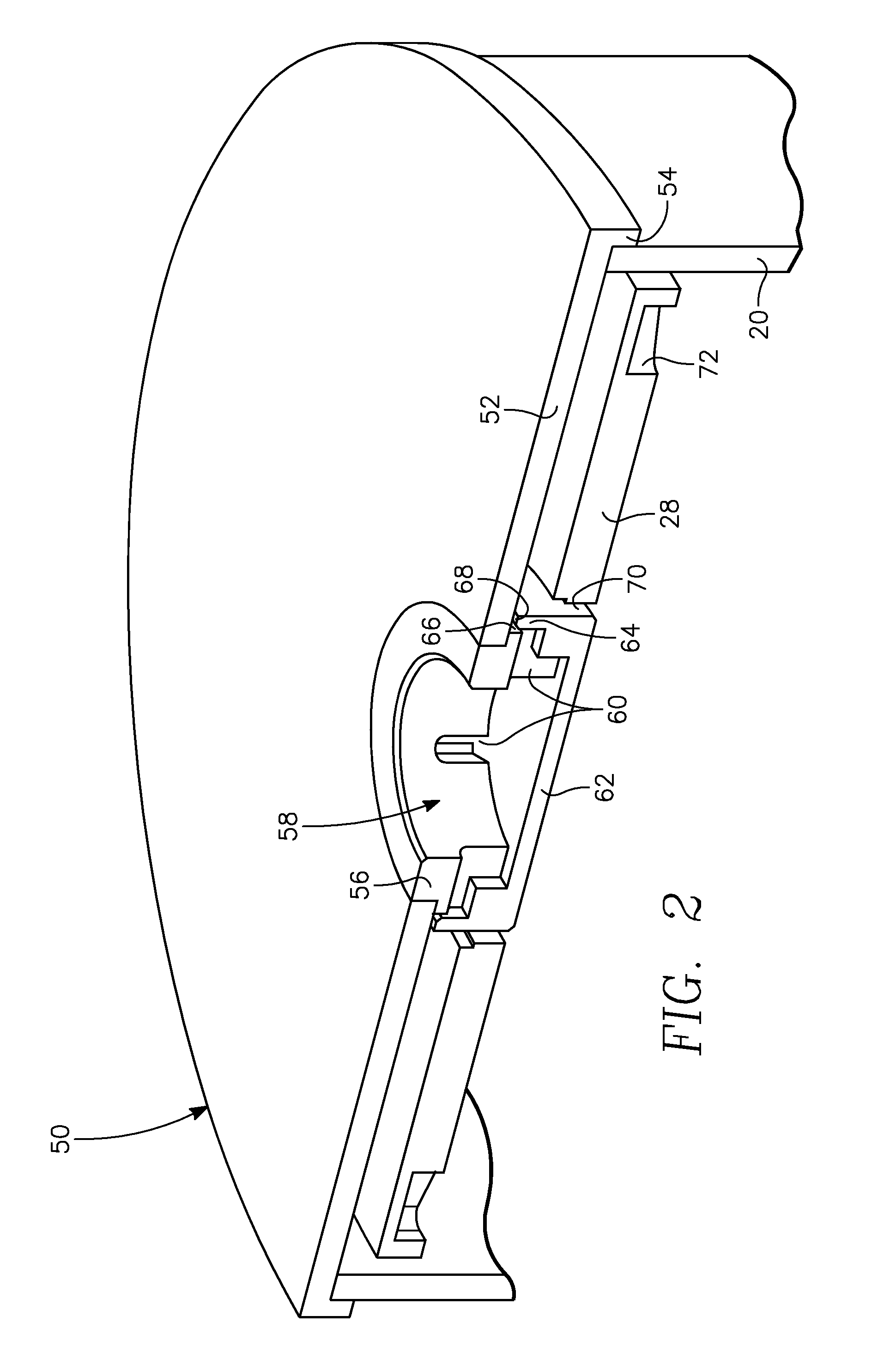

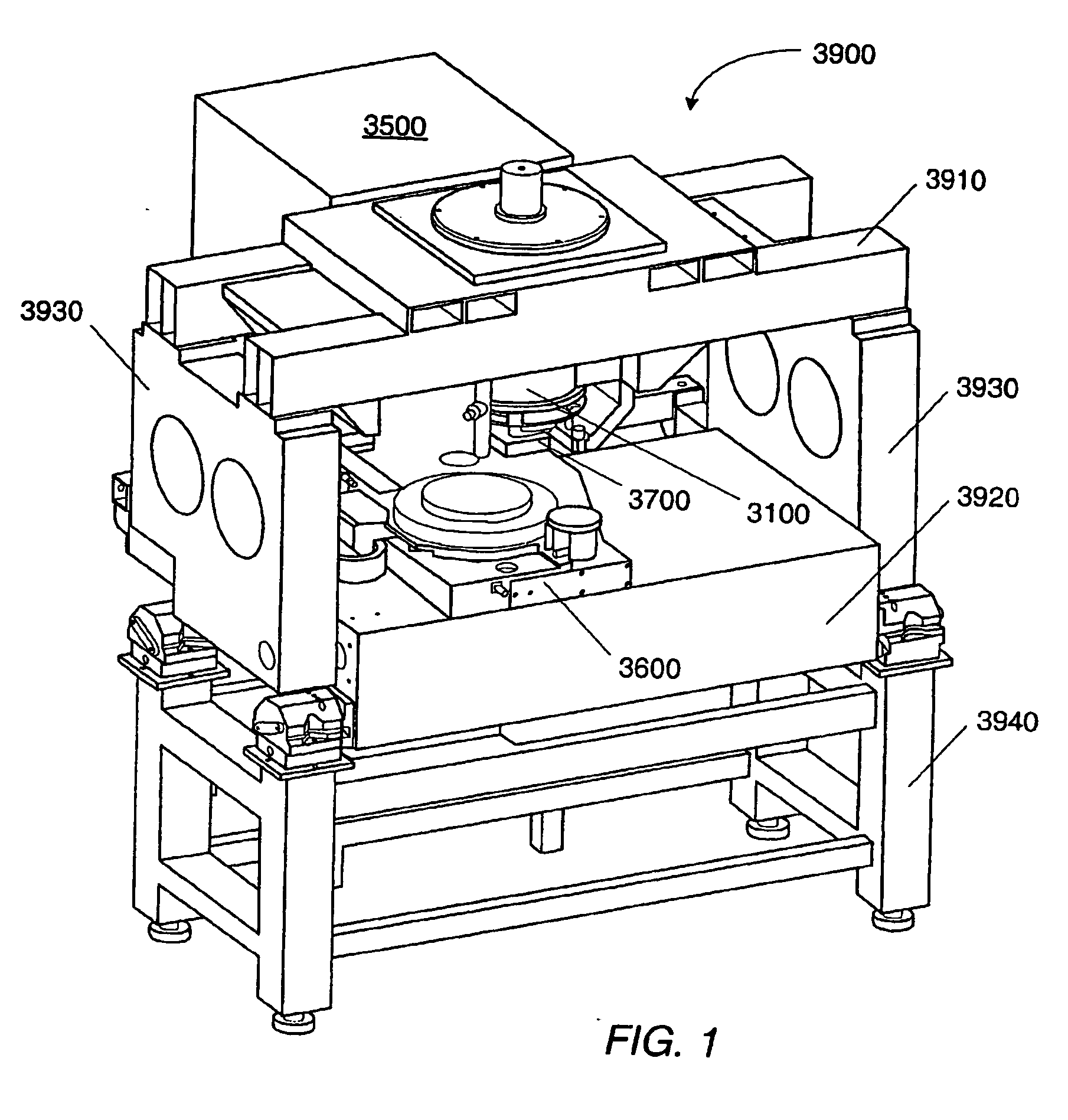

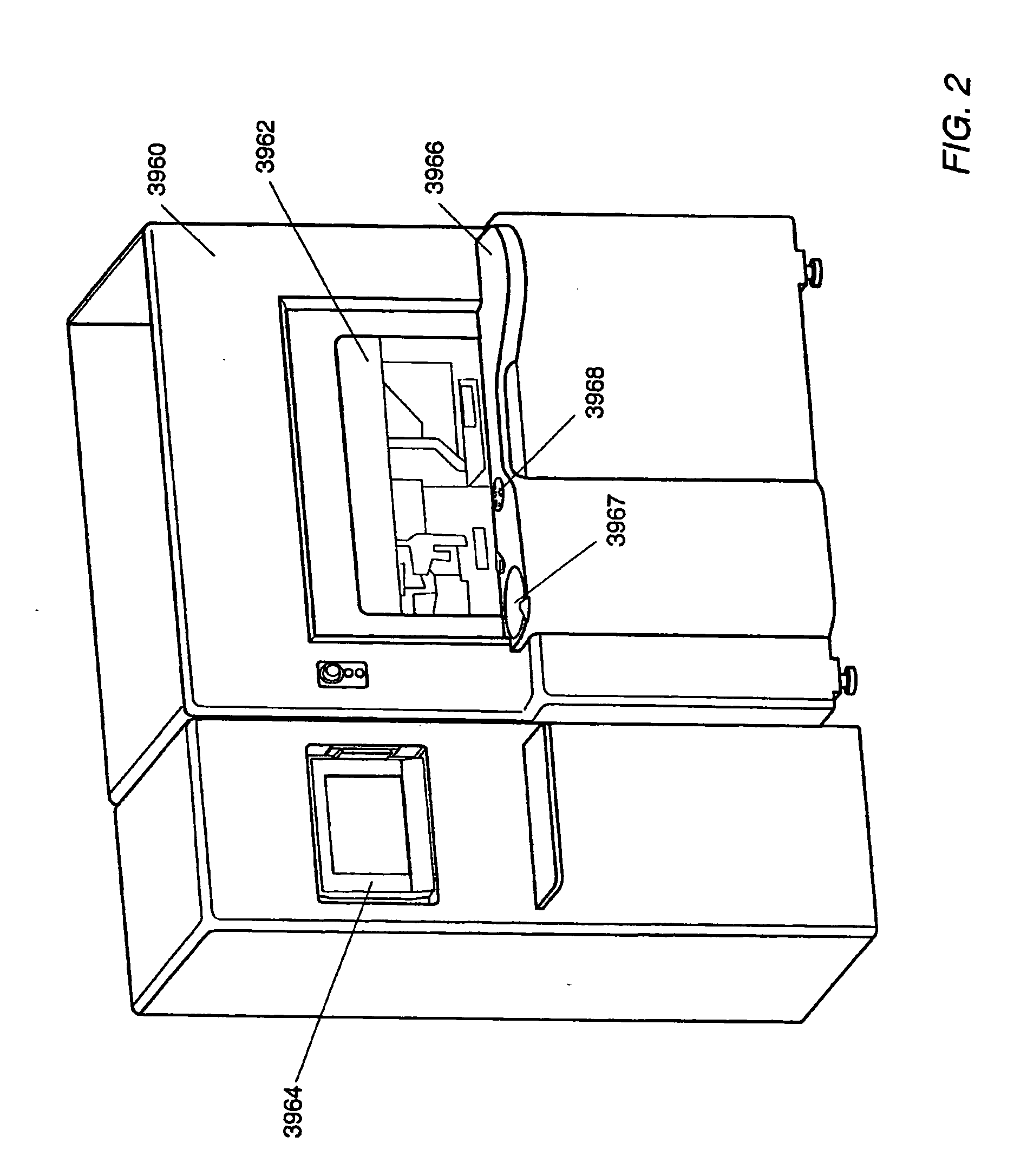

Quartz showerhead for nanocure UV chamber

Embodiments of the invention generally provide apparatuses and methods for controlling the gas flow profile within a processing chamber. In one embodiment, a processing tool includes an ultraviolet processing chamber defining a processing region, a substrate support, a window disposed between a UV radiation source and the substrate support, and a transparent showerhead disposed within the processing region between the window and the substrate support and having one or more transparent showerhead passages between upper and lower processing regions. The processing tool also includes a gas distribution ring having one or more gas distribution ring passages between a gas distribution ring inner channel and the upper processing region and a gas outlet ring positioned below the gas distribution ring, the gas outlet ring having one or more gas outlet passages between a gas outlet ring inner channel within the gas outlet ring and the lower processing region.

Owner:APPLIED MATERIALS INC

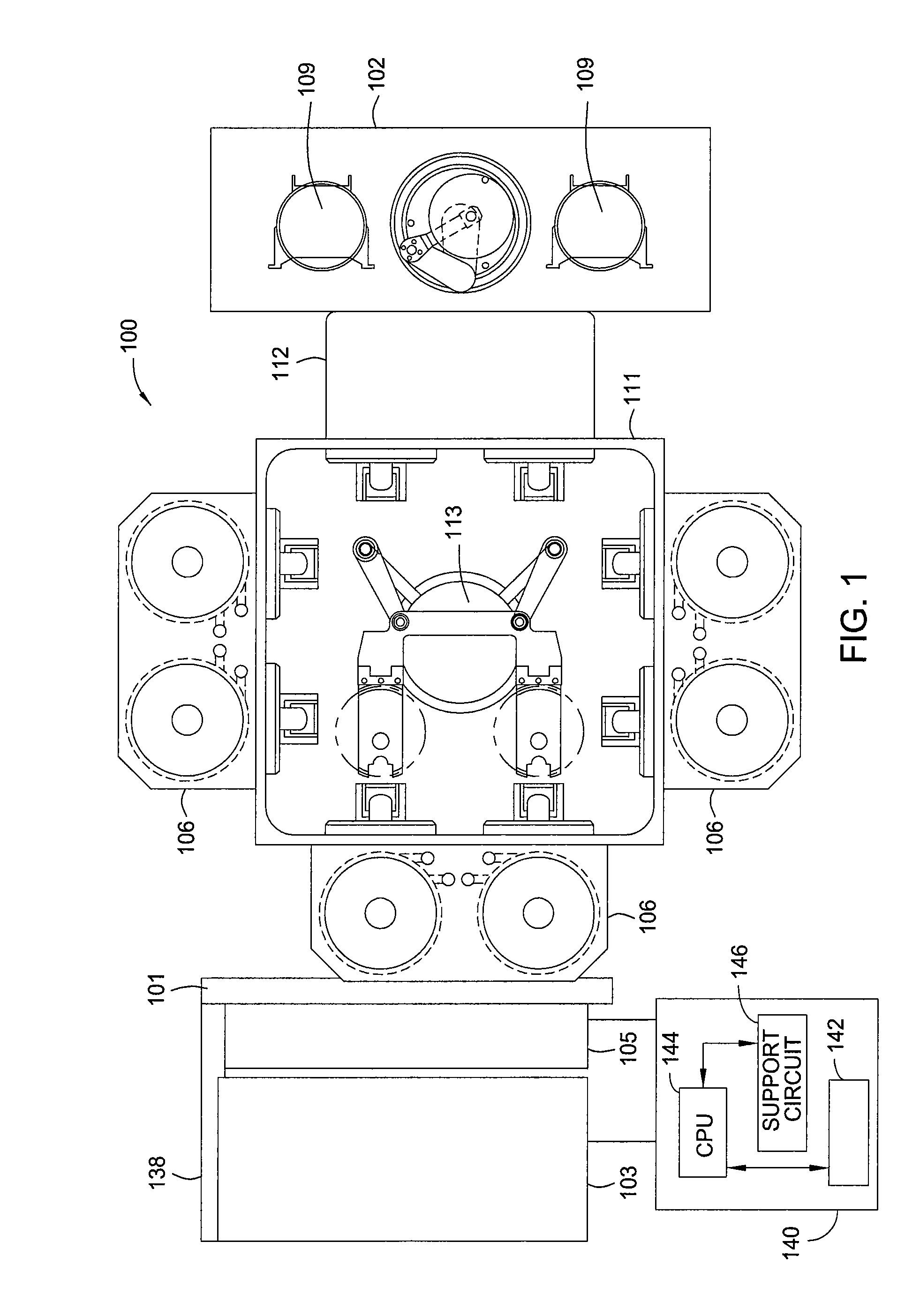

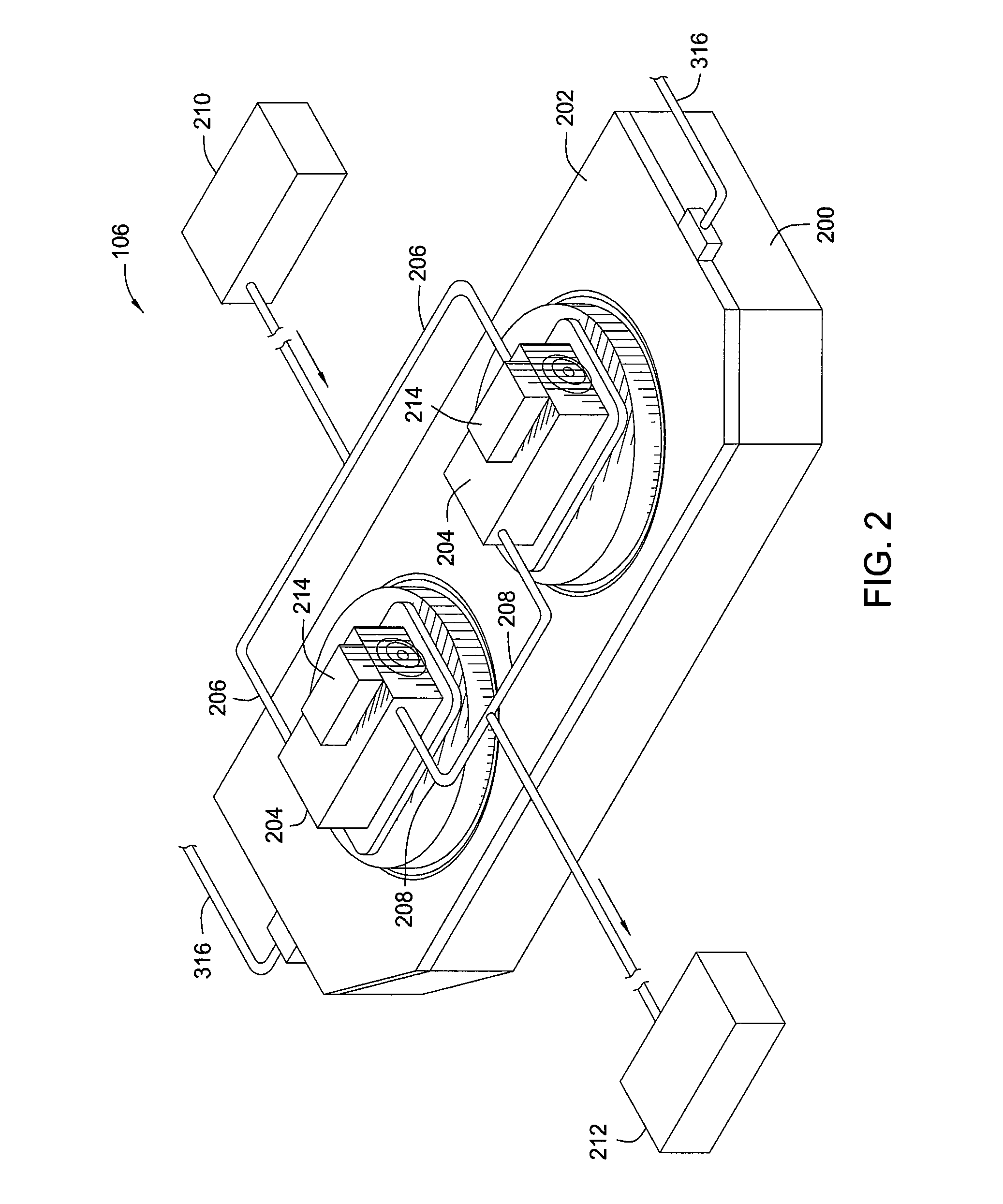

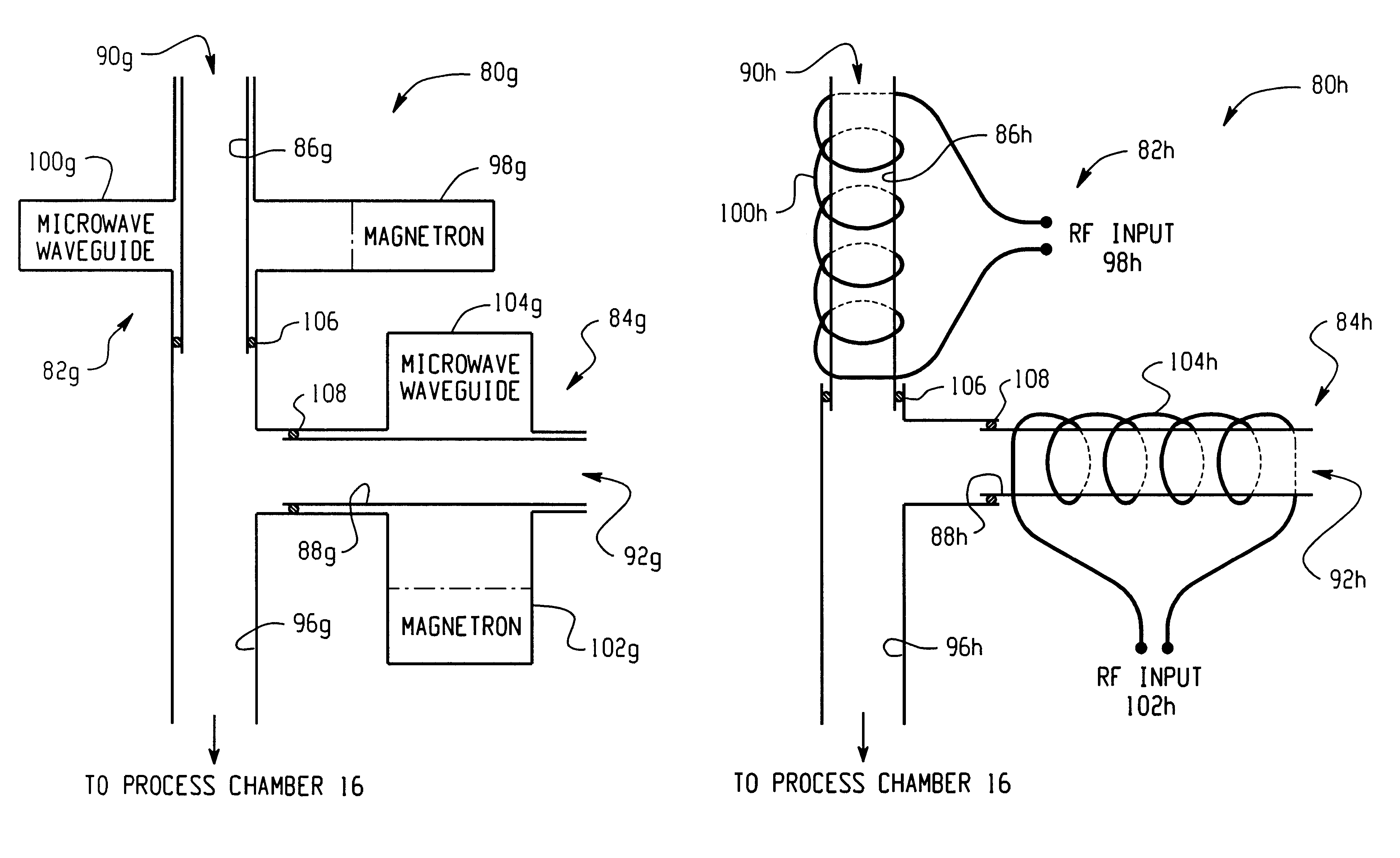

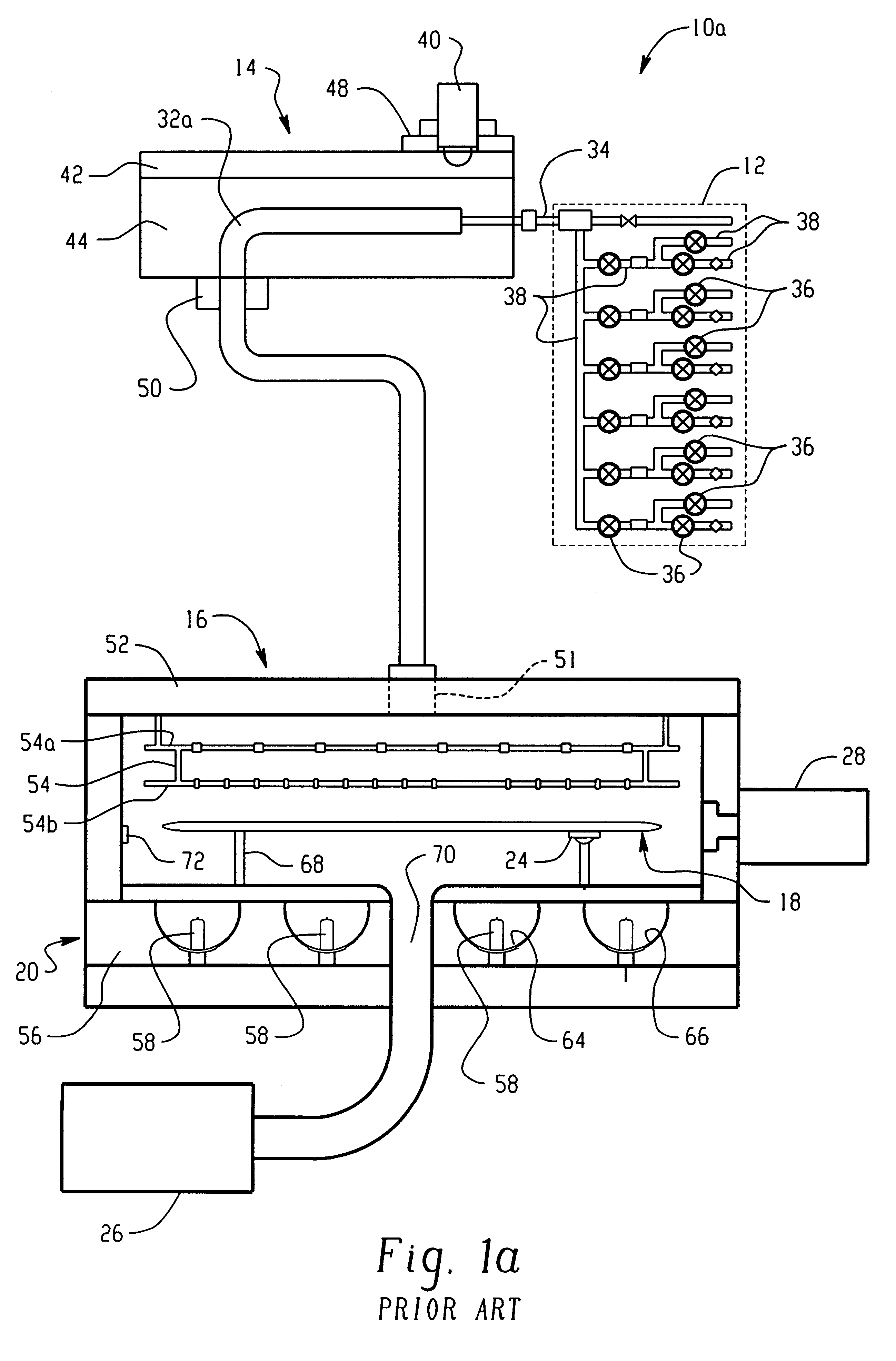

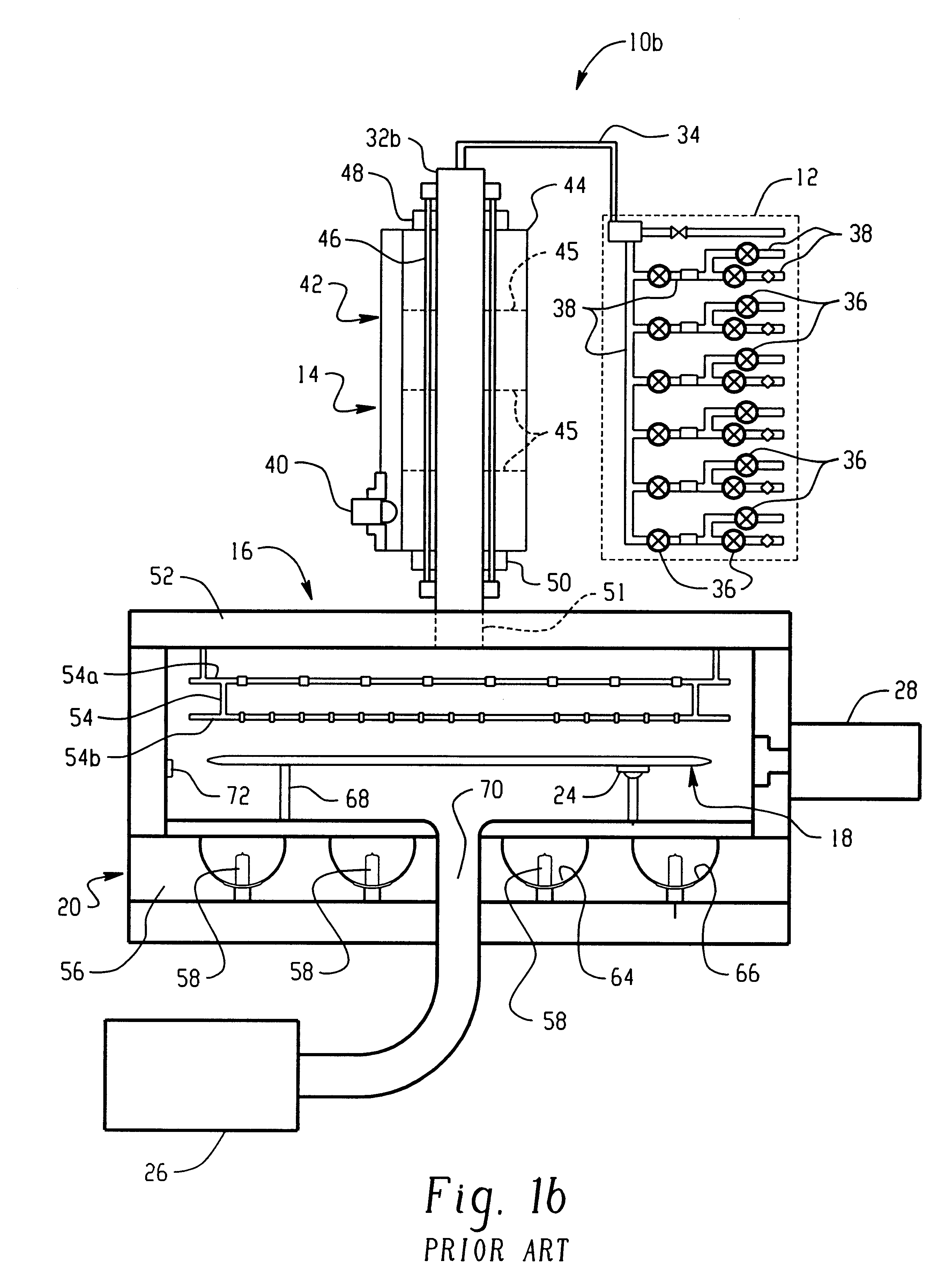

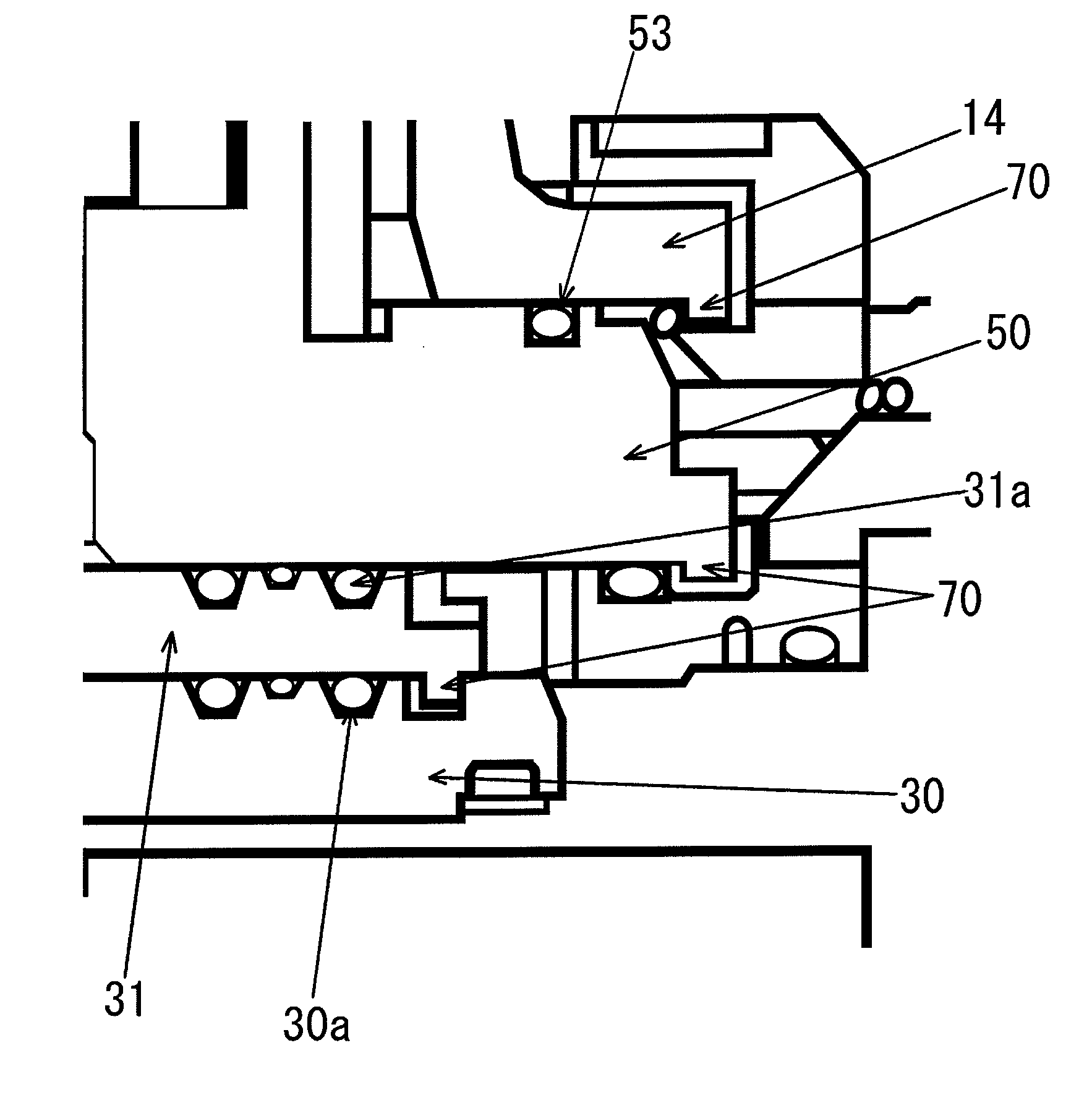

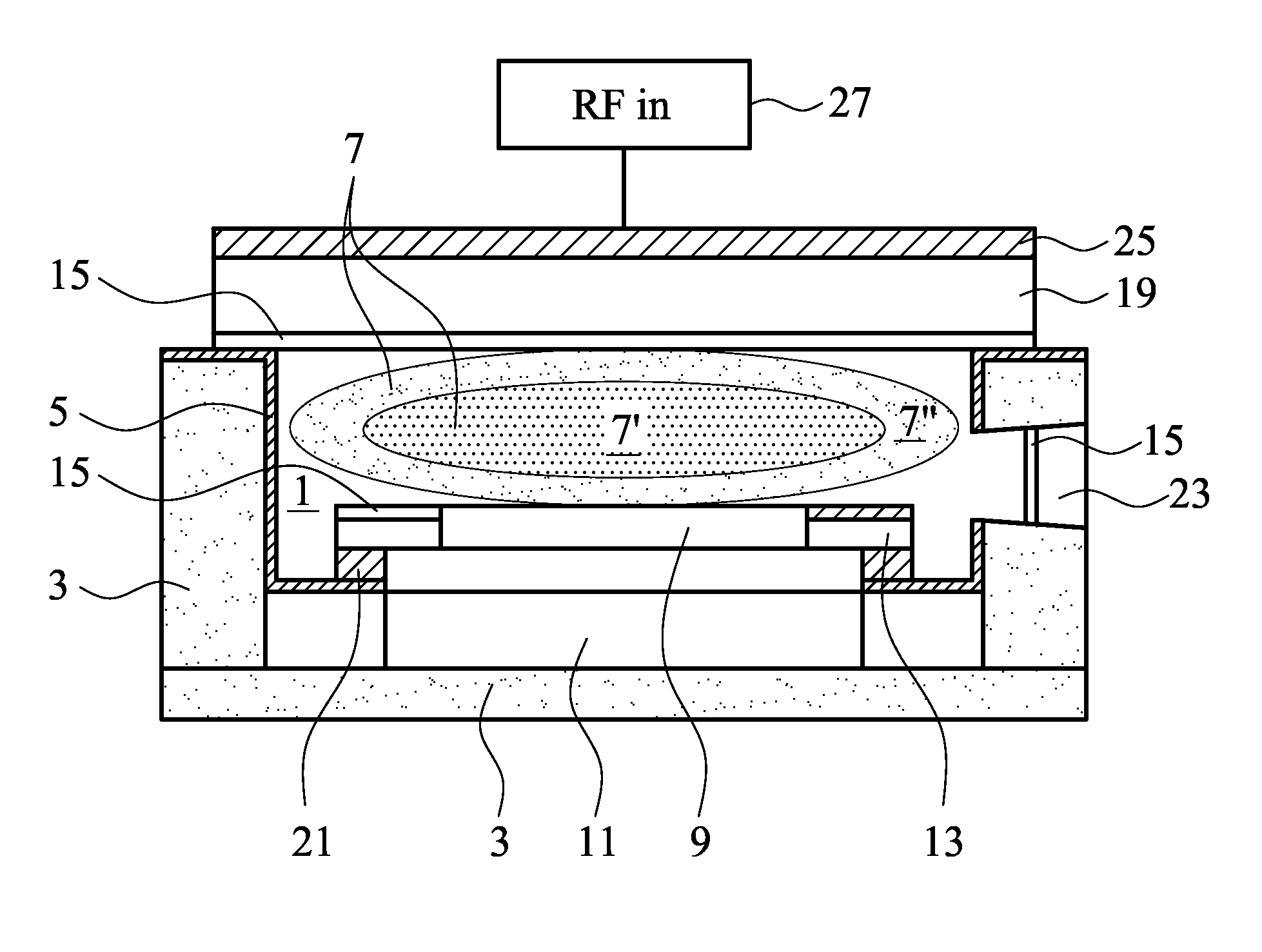

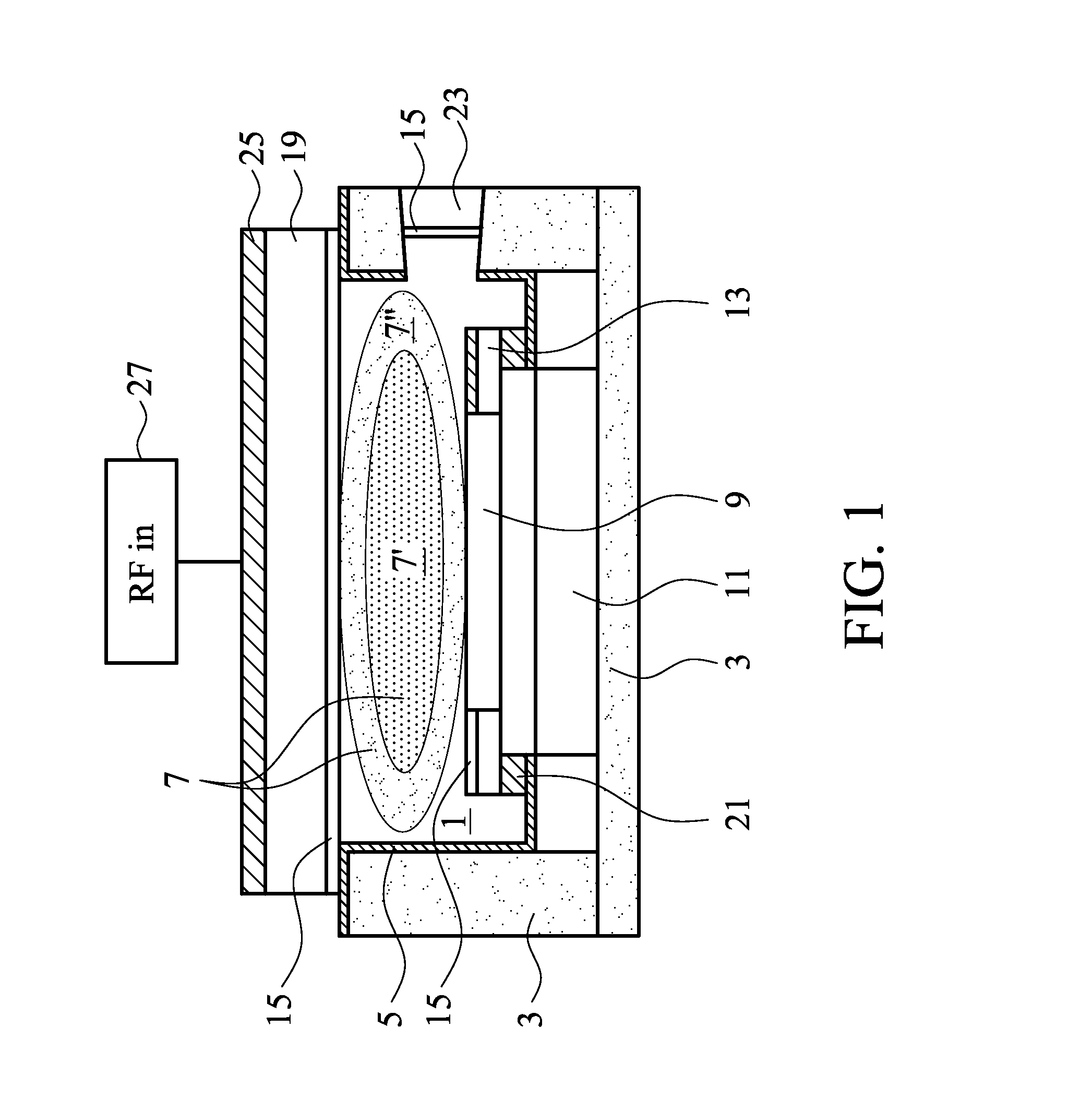

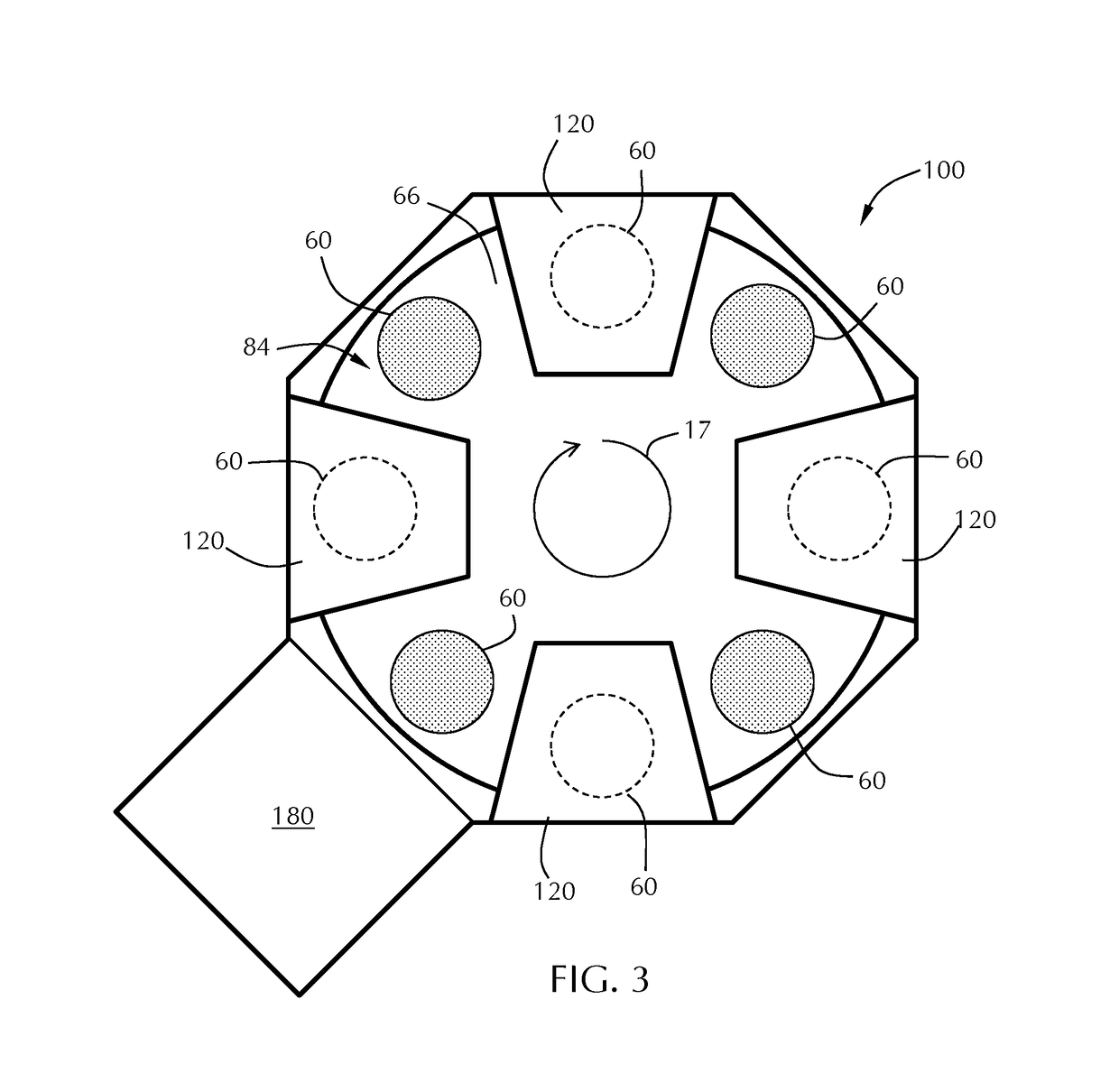

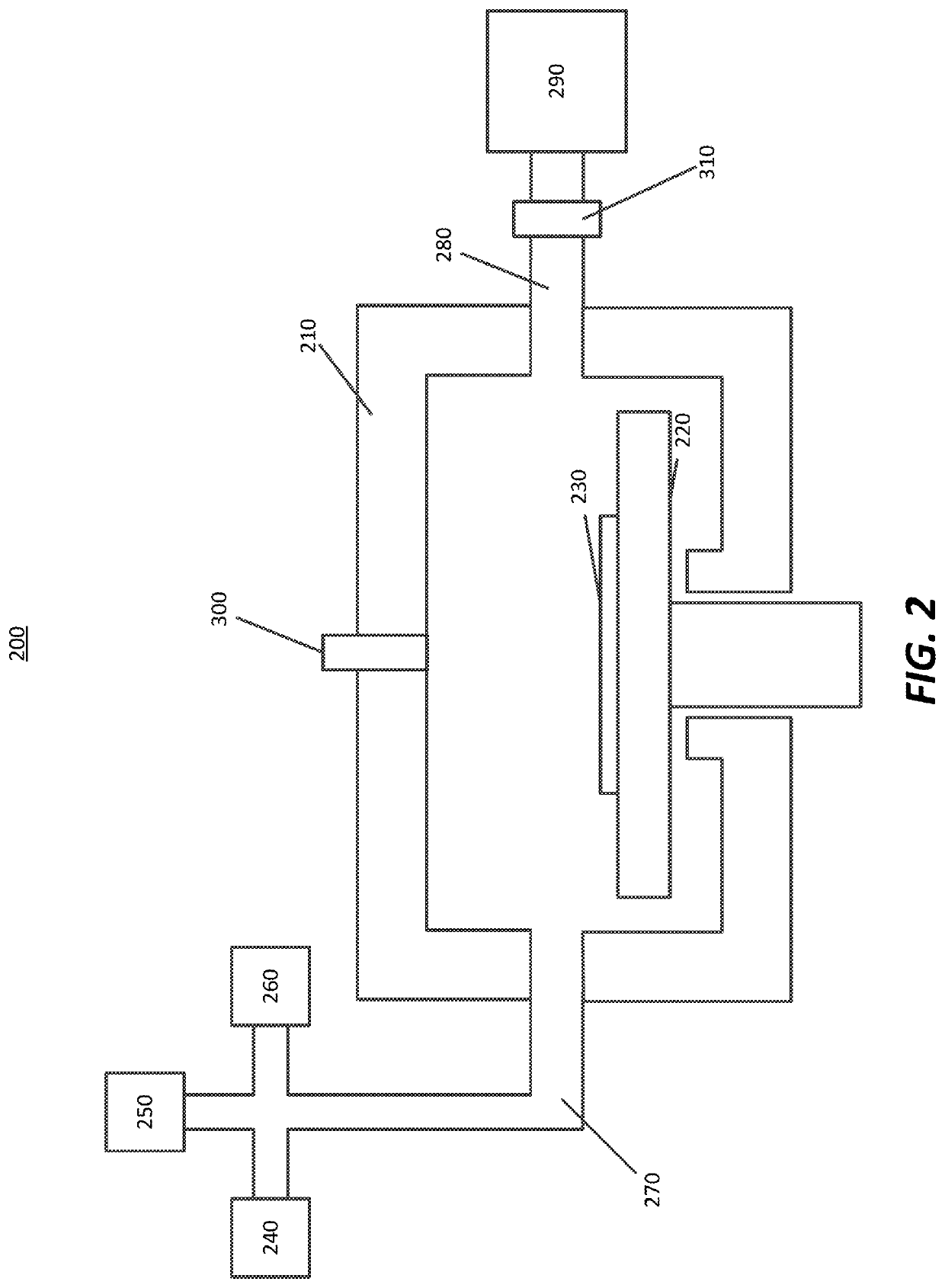

Dual plasma source for plasma process chamber

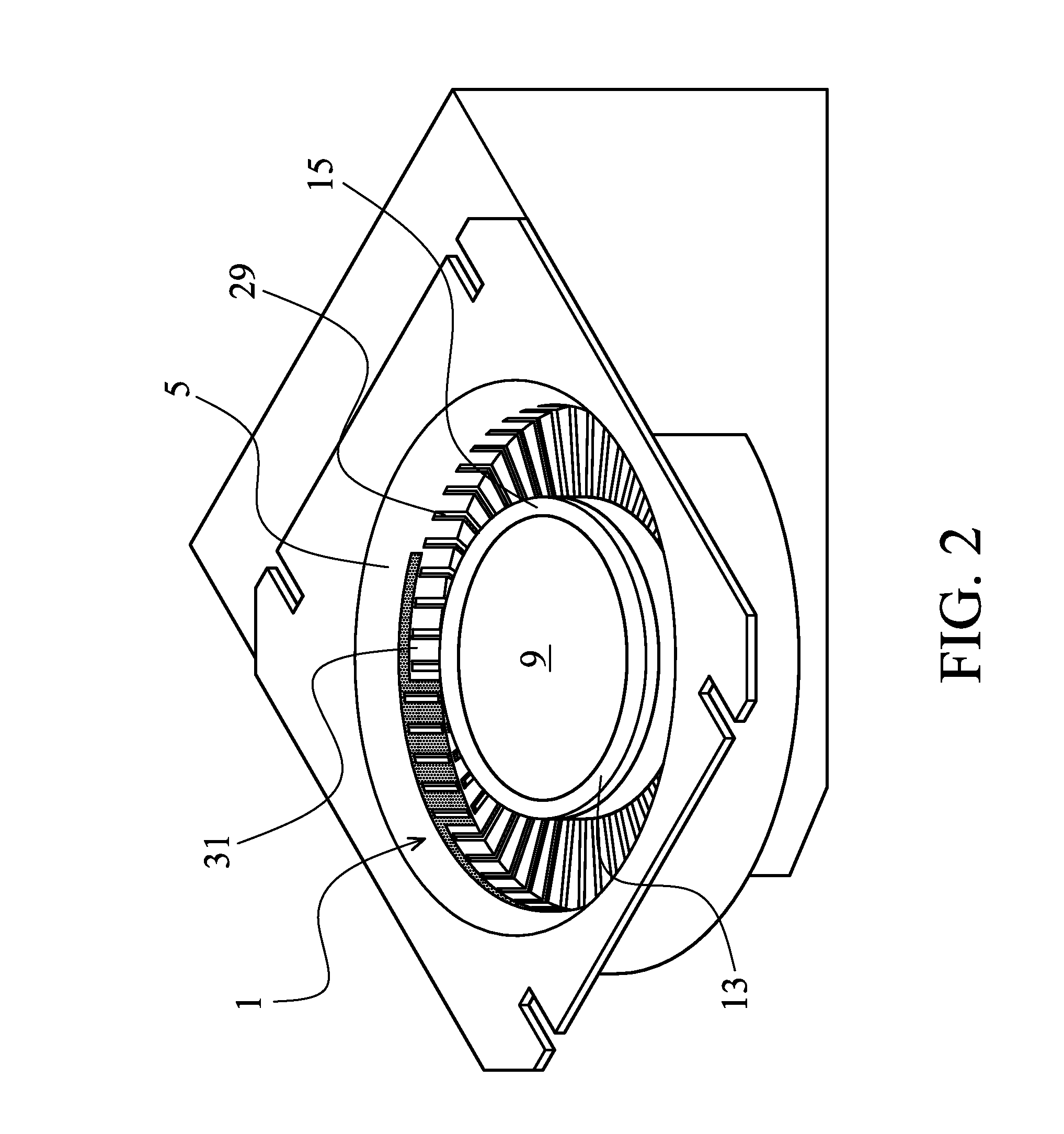

InactiveUS6225745B1Delayed recombinationSemiconductor/solid-state device manufacturingElectric arc lampsSingle crystalSapphire

A dual plasma source (80) is provided for a plasma processing system (10), comprising a first plasma source (82) and a second plasma source (84). The first plasma source (82) has a first plasma passageway (86) for transporting a first plasma therethrough toward a processing chamber (16), the first plasma passageway providing a first inlet (90) for accepting a first gas mixture to be energized by the first plasma source. The second plasma source (84) is connected to the first plasma source (82) and has a second plasma passageway (88) for transporting a second plasma therethrough toward the processing chamber (16), the second plasma passageway providing a second inlet (92) for accepting a second gas mixture to be energized by the second plasma source. The first plasma passageway (86) is constructed from a material that resists atomic oxygen recombination with the first plasma, and the second plasma passageway (88) is constructed from a material that resists etching by the second plasma. In a more limited embodiment, the first plasma passageway (86) is constructed from quartz (SiO.sub.2) and the second plasma passageway is (88) constructed from alumina (Al.sub.2 O.sub.3) or single crystal alumina (sapphire).

Owner:LAM RES CORP

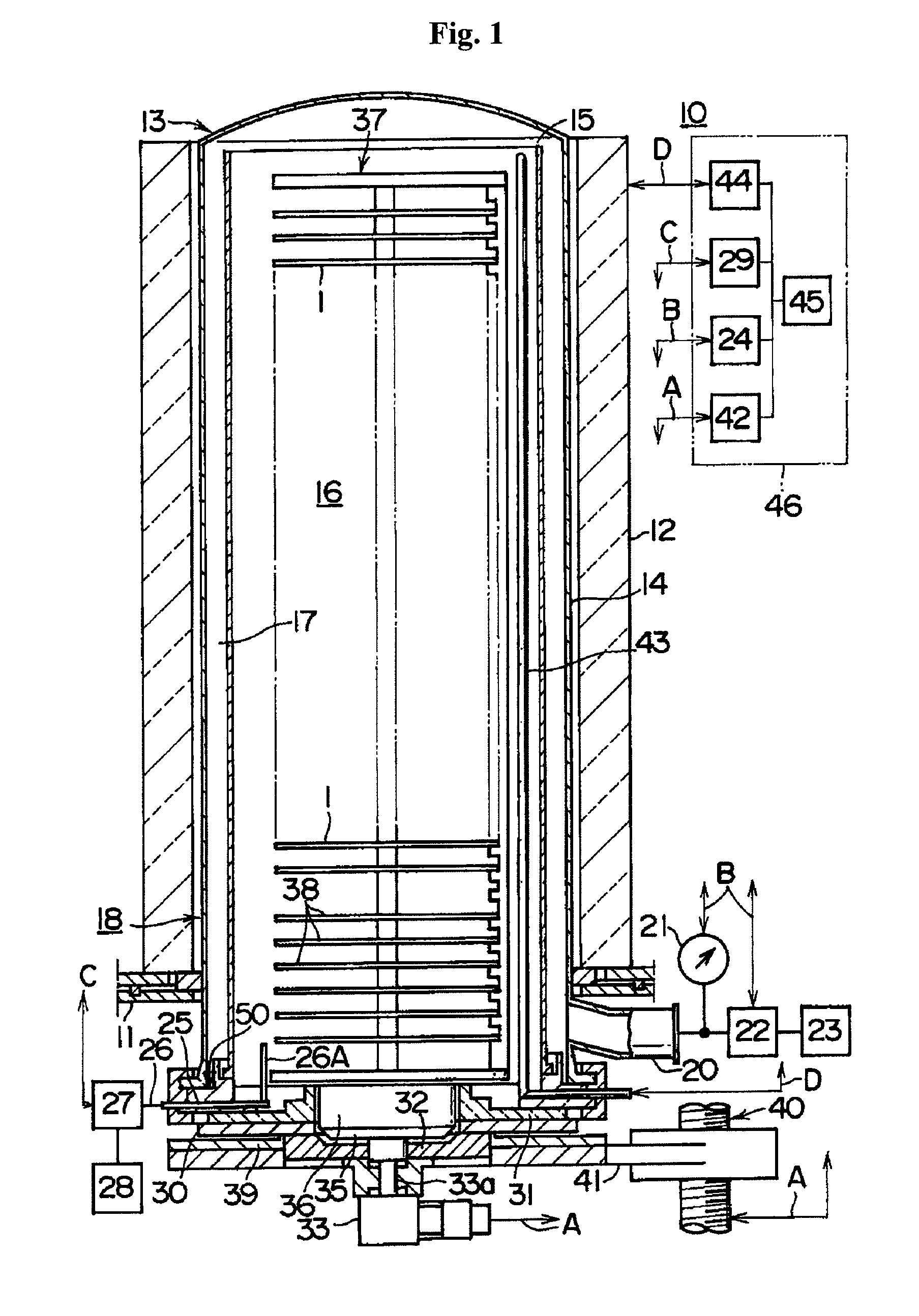

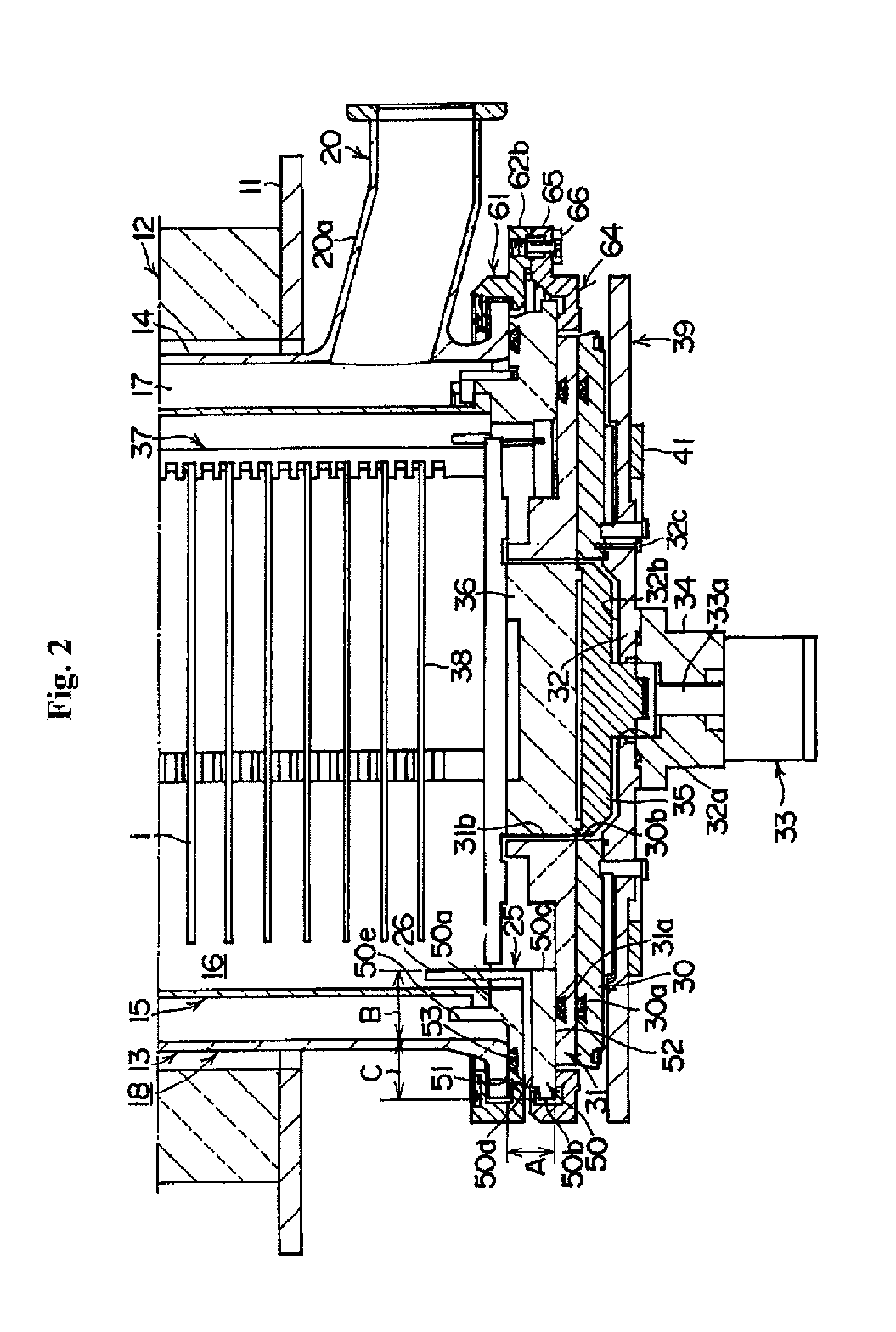

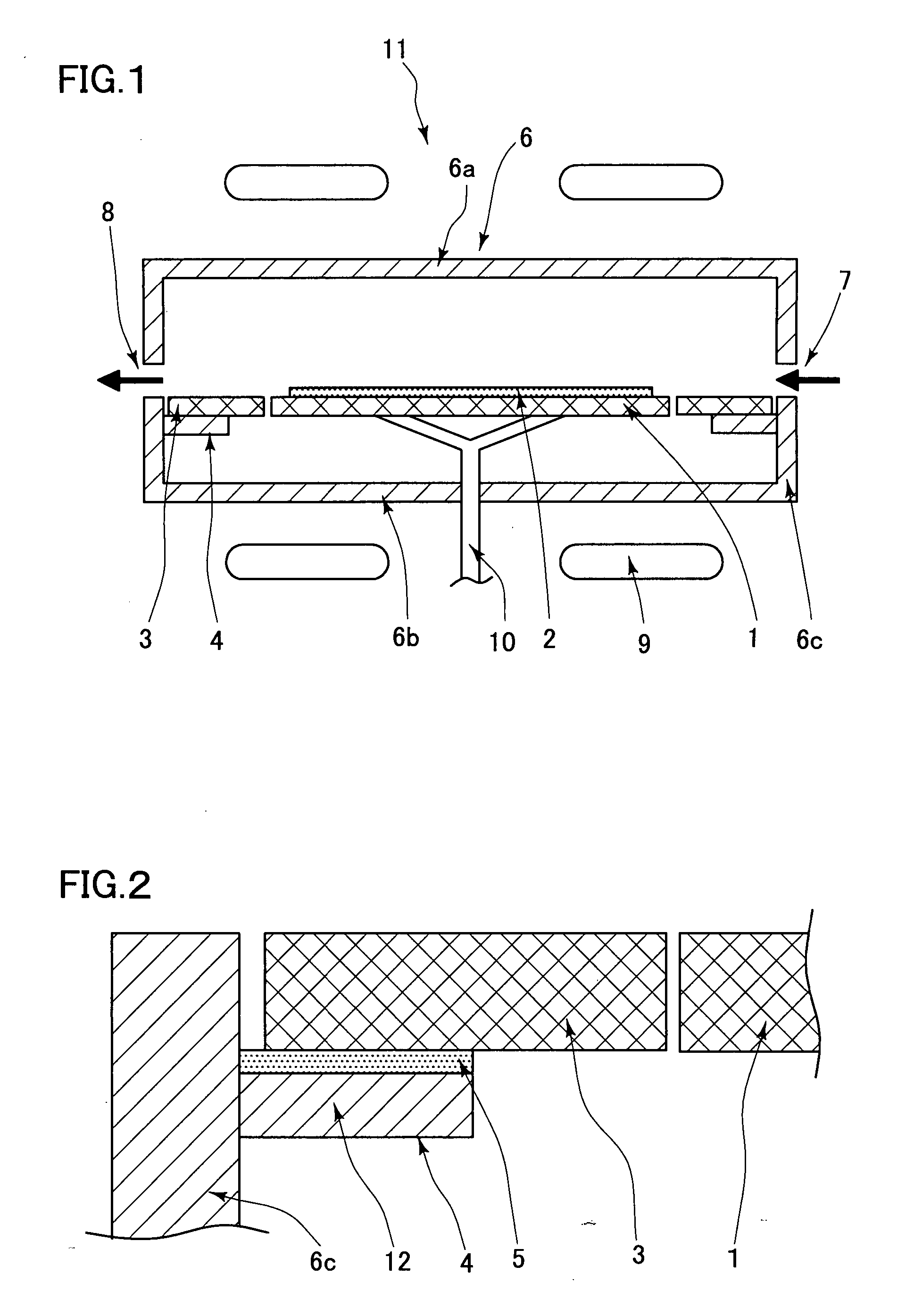

Substrate processing apparatus

ActiveUS8529701B2Damages of breakageDamages of partSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A substrate processing apparatus includes a reaction tube, the reaction tub including an inner tube made of quartz and an outer tube made of quartz; a manifold made of quartz disposed under the outer tube, a top surface of the manifold being in air-tight contact with a bottom surface of the outer tube via a sealing member; a seal cap cover made of quartz disposed under the manifold, a top surface of the seal cap cover being in air-tight contact with a bottom surface of the manifold via a sealing member; a seal cap covered by the seal cap cover, a top surface of the seal cap being in air-tight contact with a bottom surface of the seal cap cover via a sealing member; and at least one protrusion disposed at the bottom surface of one of the outer tube, the manifold, the seal cap cover, and combinations thereof.

Owner:KOKUSA ELECTRIC CO LTD

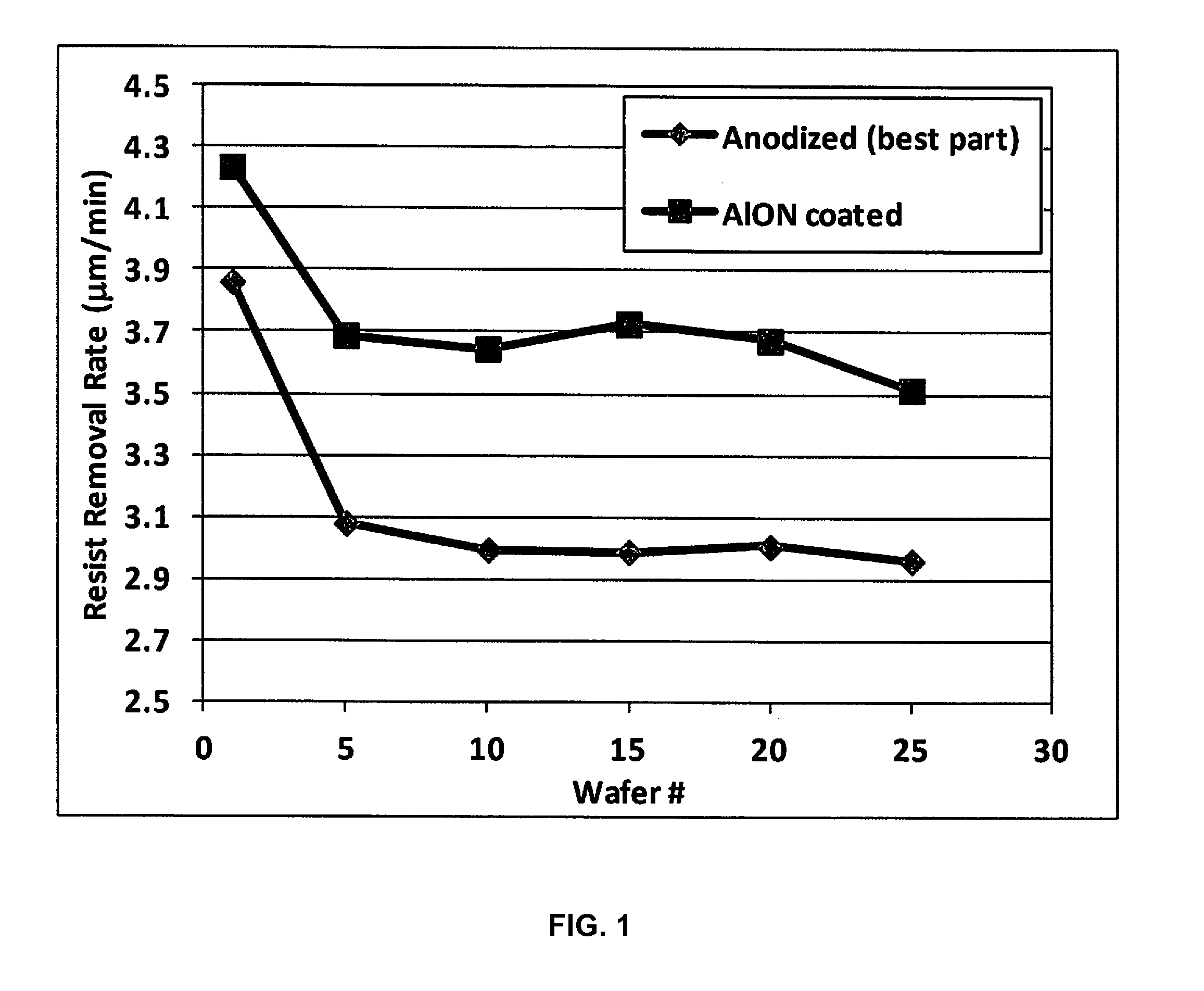

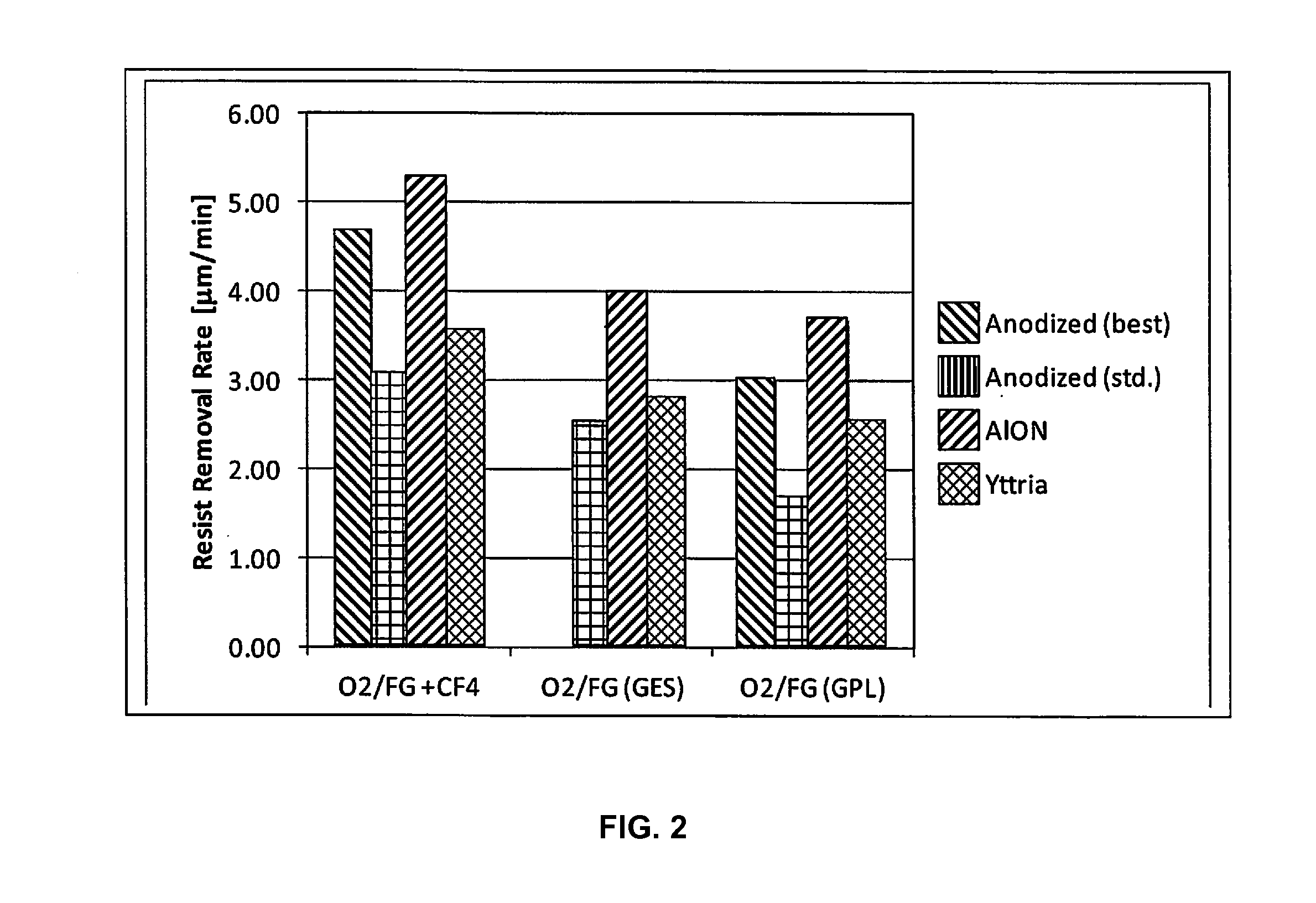

Thin film coated process kits for semiconductor manufacturing tools

InactiveUS20110207332A1Convenient coatingElectric discharge tubesElectrostatic cleaningQuartzSilicon

A plasma processing apparatus used in semiconductor device manufacturing includes a process kit formed of insulating materials such as quartz and coated with a Y2O3 coating. The Y2O3 coating is a thin film formed using suitable CVD or PVD operations. The Y2O3 coating is resistant to degradation in fluorine etching chemistries commonly used to etch silicon in semiconductor manufacturing. The plasma processing apparatus may be used in etching, stripping and cleaning operations. Also provided in another embodiment is a plasma processing apparatus having a quartz process kit coated with a sapphire-like film.

Owner:TAIWAN SEMICON MFG CO LTD

Baffled liner cover

ActiveUS7736437B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringTower

Owner:HANGZHOU DUNYUANJUXIN SEMICON TECH CO LTD

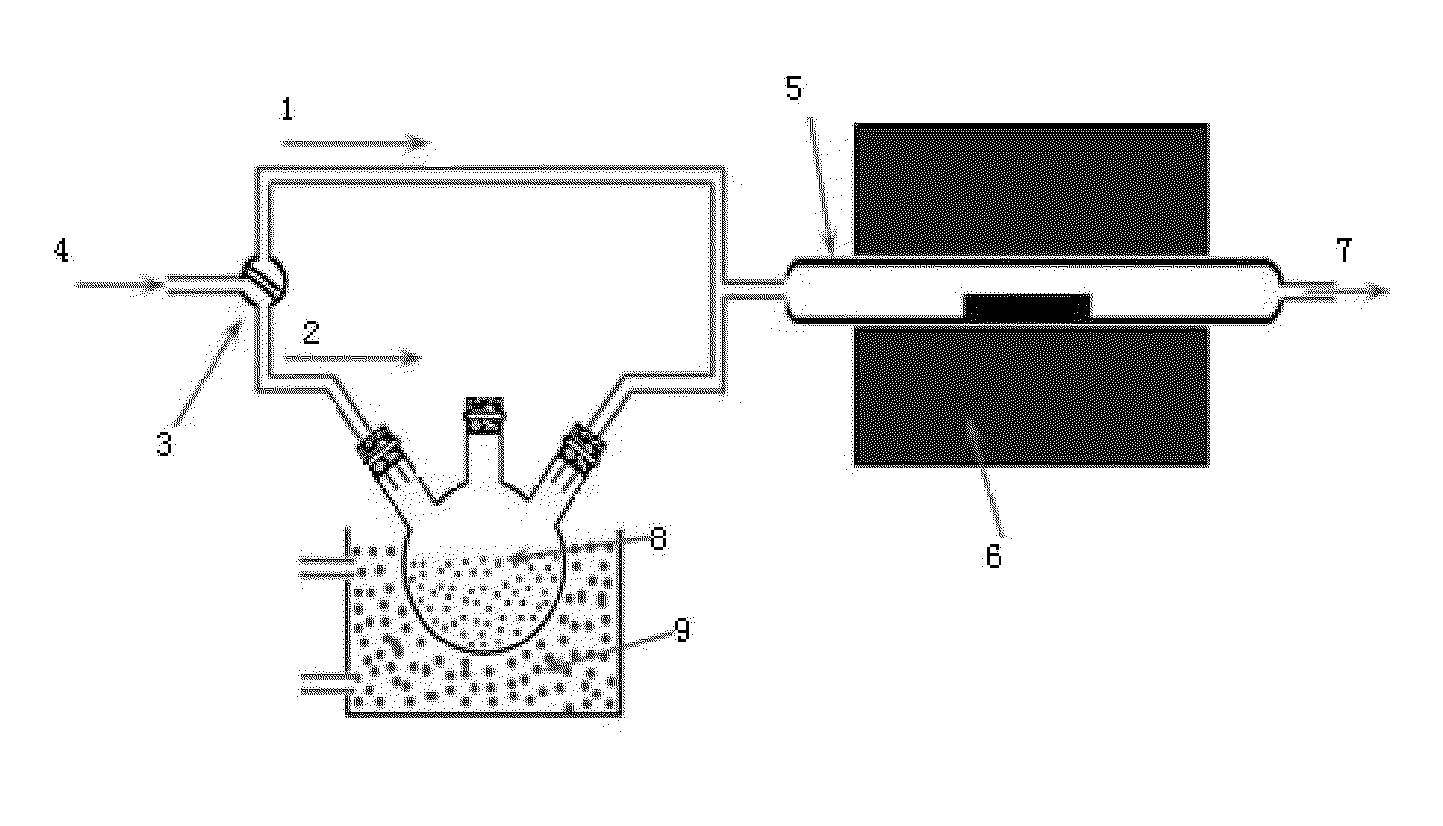

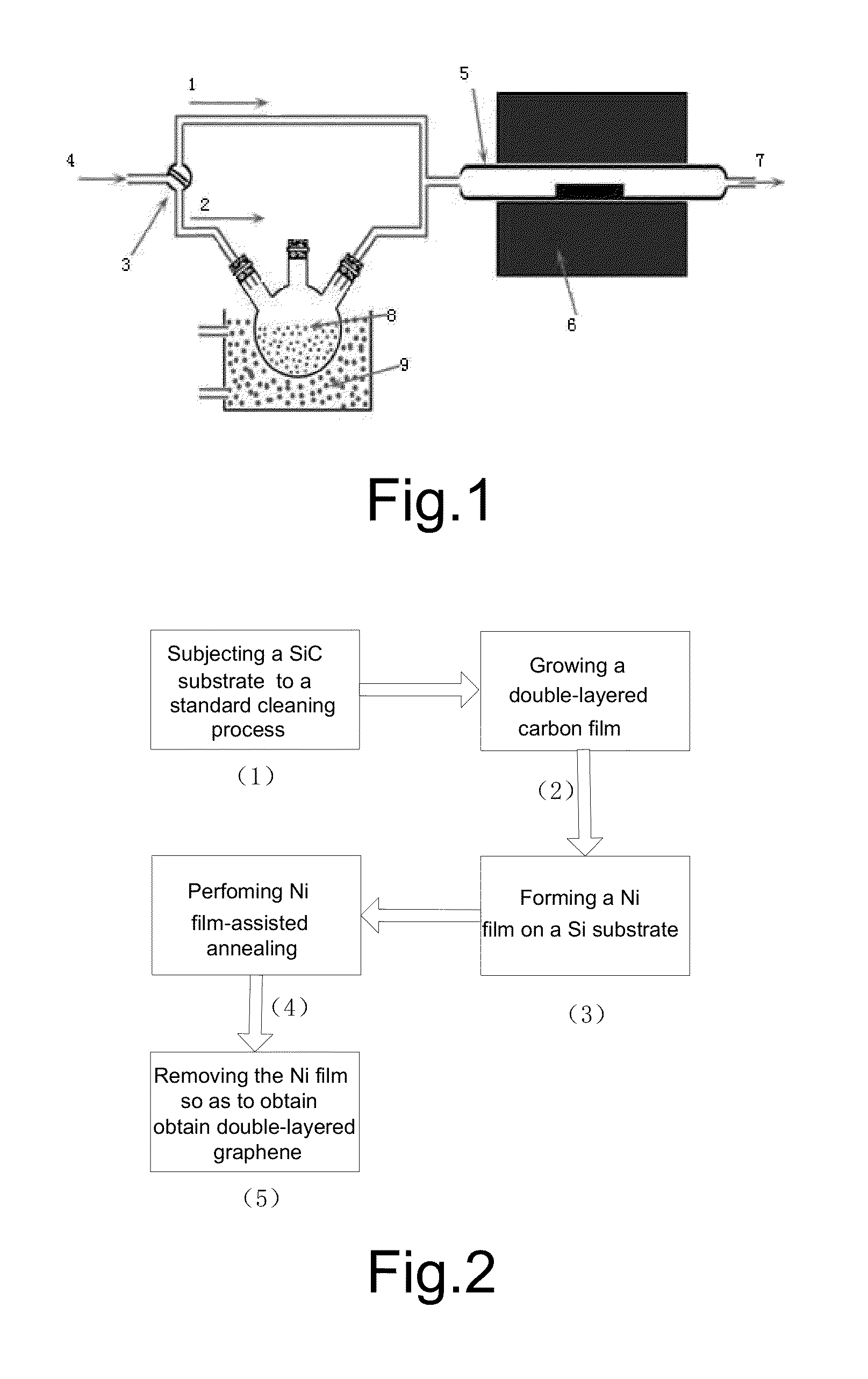

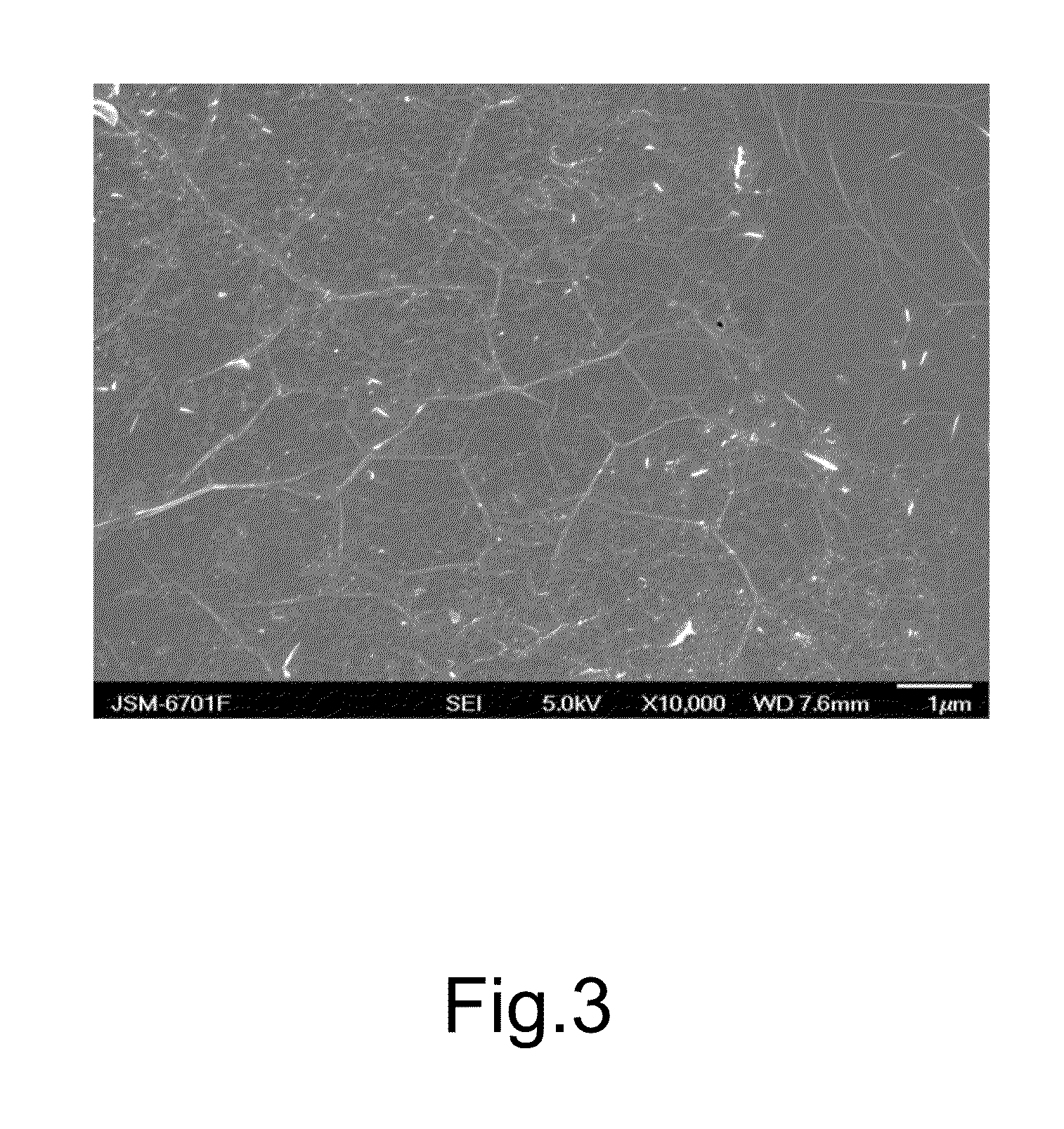

Process for Preparing Graphene on a SiC Substrate Based on Metal Film-Assisted Annealing

ActiveUS20140367642A1Simply and energy-efficientFlat surfaceMaterial nanotechnologyVacuum evaporation coatingCarbon filmElectron beam deposition

Provided is a process for preparing graphene on a SiC substrate, based on metal film-assisted annealing, comprising the following steps: subjecting a SiC substrate to a standard cleaning process; placing the cleaned SiC substrate into a quartz tube and heating the quartz tube up to a temperature of 750 to 1150° C.; introducing CCl4vapor into the quartz tube to react with SiC for a period of 20 to 100 minutes so as to generate a double-layered carbon film, wherein the CCl4 vapor is carried by Ar gas; forming a metal film with a thickness of 350 to 600 nm on a Si substrate by electron beam deposition; placing the obtained double-layered carbon film sample onto the metal film; subsequently annealing them in an Ar atmosphere at a temperature of 900 to 1100° C. for 10-30 minutes so as to reconstitute the double-layered carbon film into double-layered graphene; and removing the metal film from the double-layered graphene, thereby obtaining double-layered graphene. Also provided is double-layered graphene prepared by said process.

Owner:XIDIAN UNIV

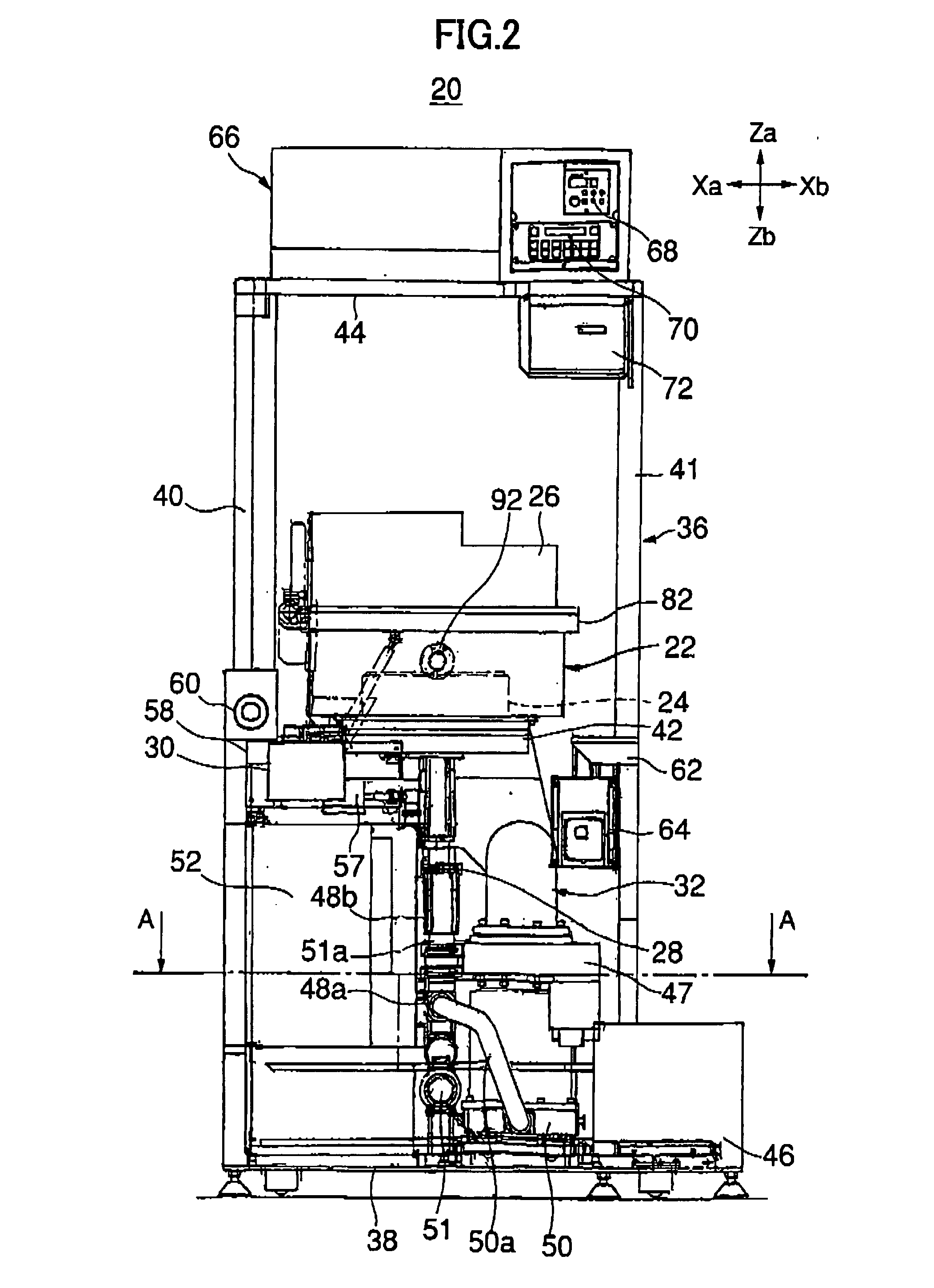

Substrate processing apparatus

ActiveUS20060048710A1Avoid pollutionUniform temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

The substrate processing apparatus according to the present invention is aimed to stably and efficiently perform a deposition process on a substrate W. The substrate processing apparatus supports the substrate W in a position facing a heater portion and thus rotates a holding member holding the substrate W. Furthermore, the heating portion houses a SiC heater and a heat reflecting member in an internal portion of a quartz bell jar made of transparent quartz, and depressurizes an internal space of a processing vessel and an internal space of the quartz bell jar at the same time; thereby allowing the thickness of the quartz bell jar to be thinner, and thus improving thermal conductivity of heat from the SiC heater and preventing contamination by the SiC heater.

Owner:TOKYO ELECTRON LTD

Substrate processing apparatus

InactiveUS20060057799A1Reliable formingAvoid pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltraviolet lightsEngineering

A substrate processing apparatus stably and efficiently conducts a film forming process on a substrate to be processed. In the substrate processing apparatus, the substrate to be processed is supported at a position facing a heater portion, and a holding member for holding the substrate is rotated, whereby the temperature distribution of the substrate is kept uniform and a warp of the substrate is suppressed. The inner wall of the processing vessel is covered with a quartz liner which is made of opaque quartz, and thus protected from ultraviolet rays emitted from an ultraviolet light source. The temperature rise of the inner wall caused by heat from the heater portion is suppressed due to the heat insulating effect of the quartz liner. Consequently, the life cycle of the processing vessel can be prolonged.

Owner:TOKYO ELECTRON LTD

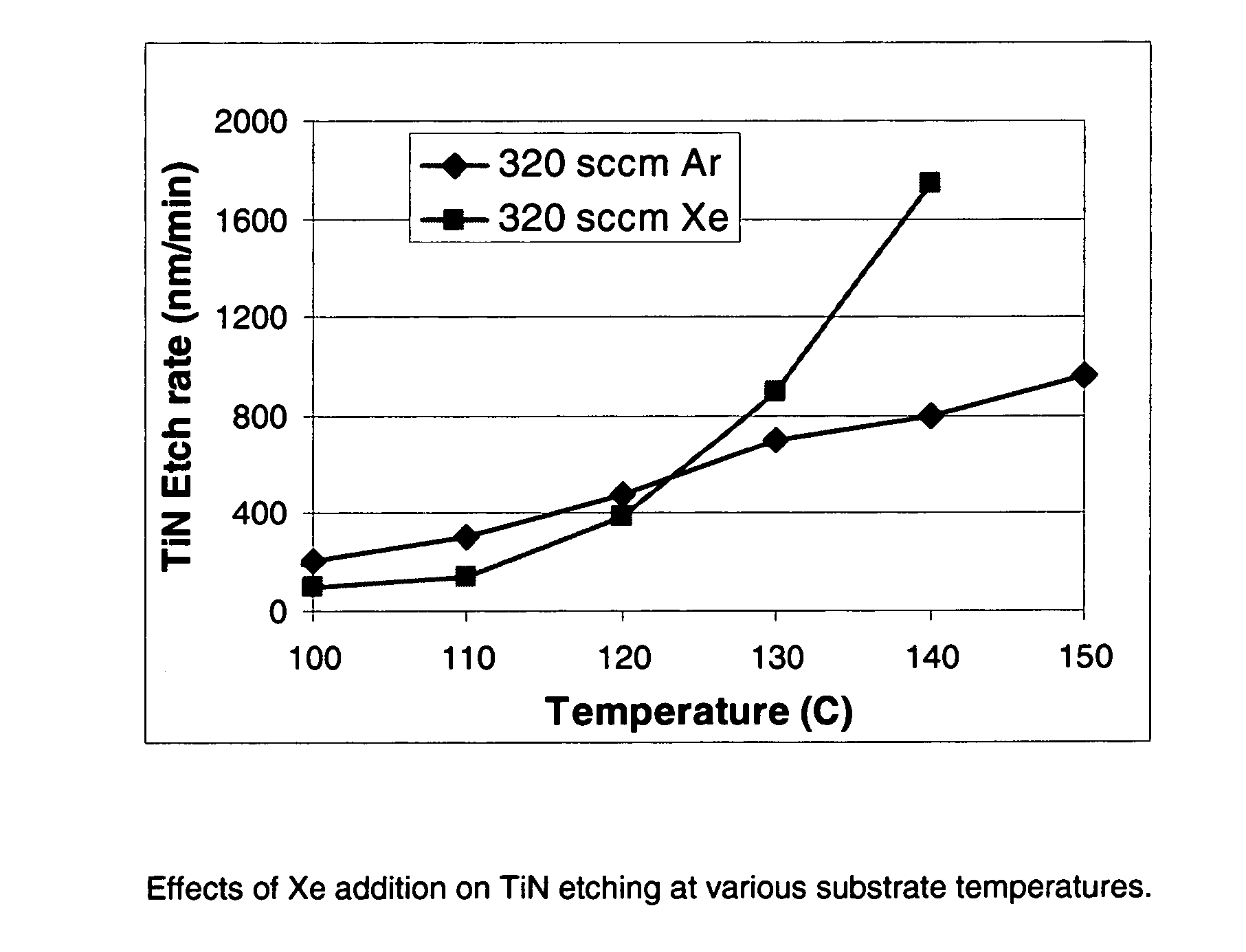

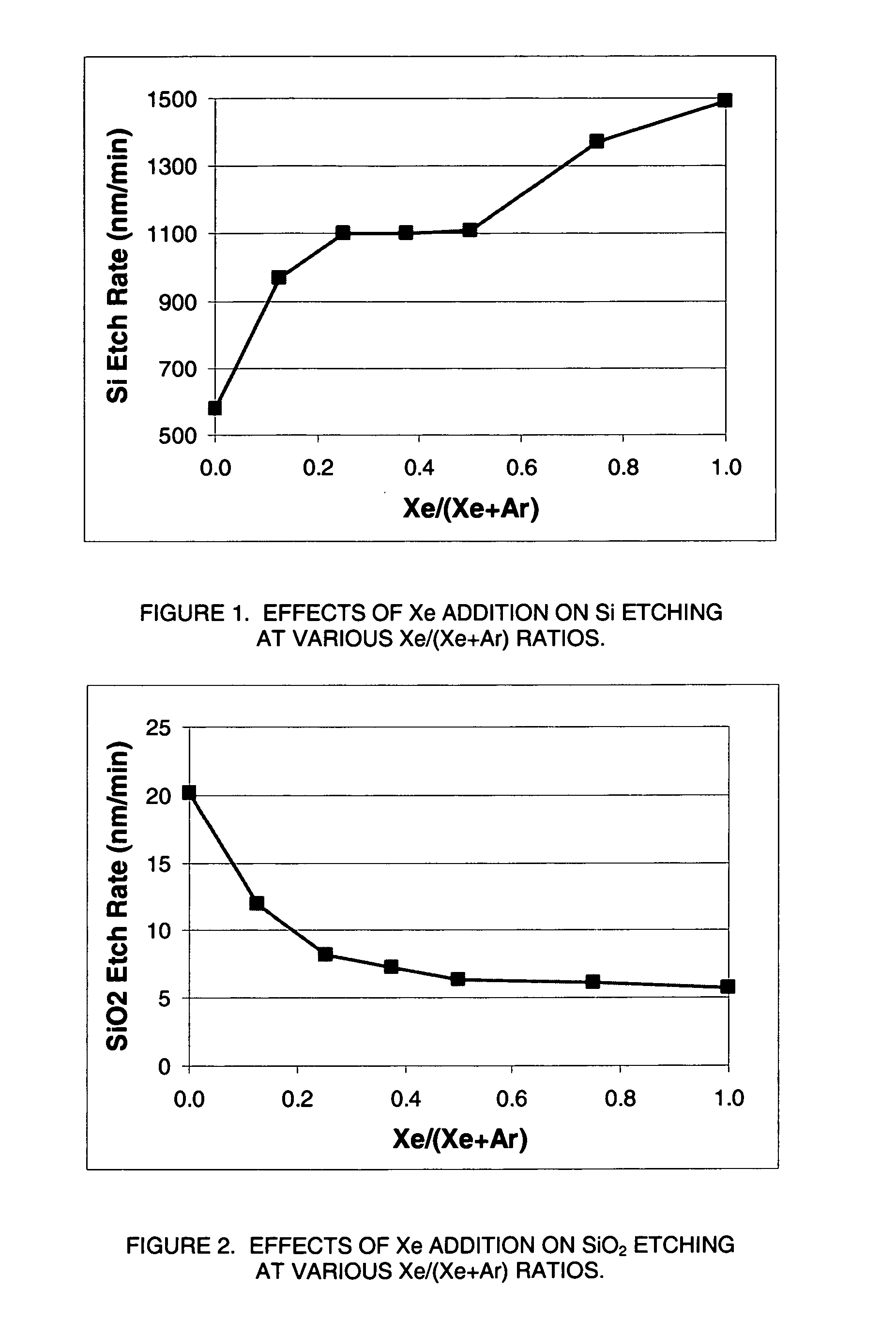

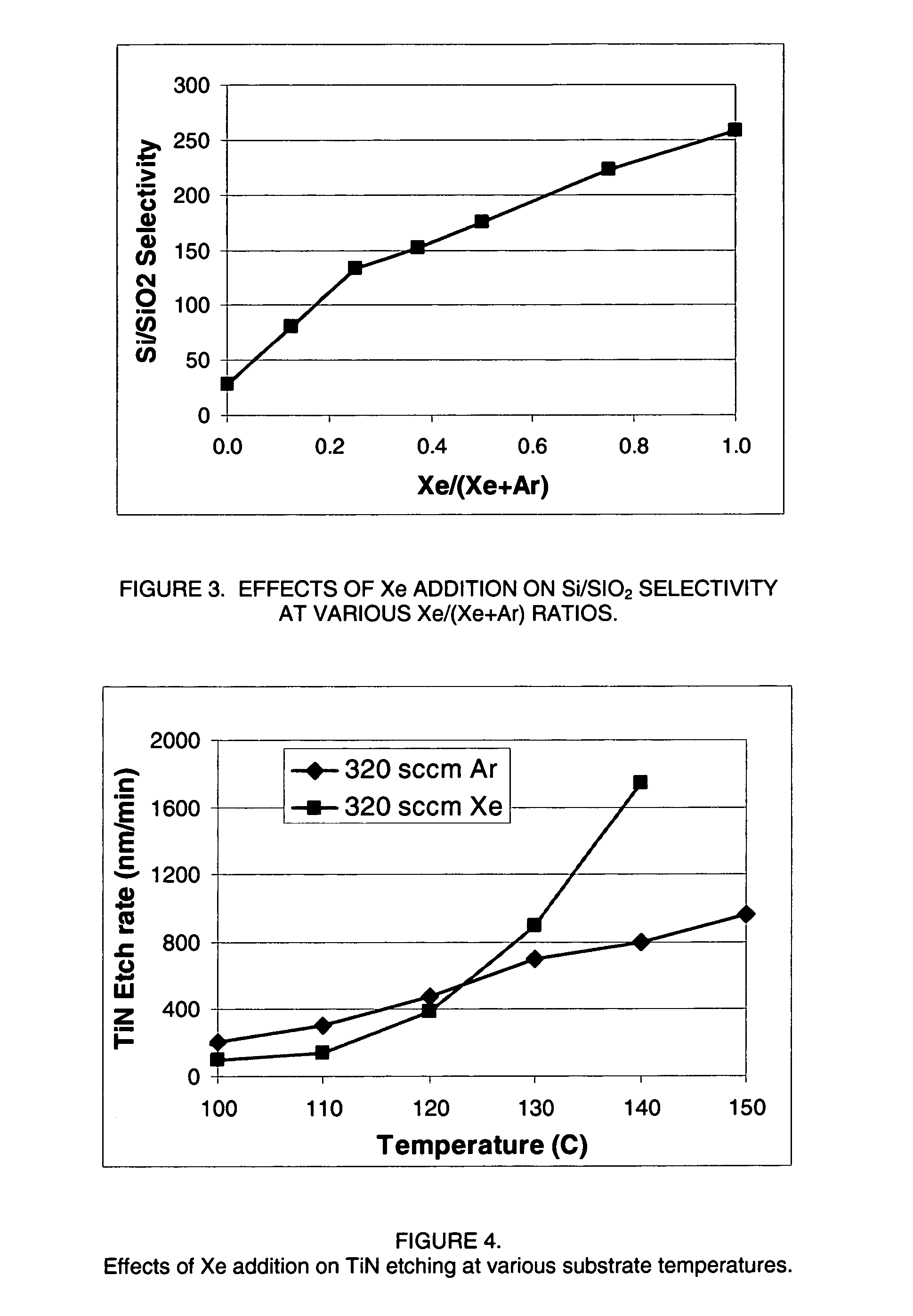

Selective etching of titanium nitride with xenon difluoride

InactiveUS20070117396A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEtchingTitanium nitride

This invention relates to an improved process for the selective etching of TiN from silicon dioxide (quartz) and SiN surfaces commonly found in semiconductor deposition chambers equipment and tools. In the process, an SiO2 or SiN surface having TiN thereon is contacted with XeF2 in a contact zone to selectively convert the TiN to a volatile species and then the volatile species is removed from the contact zone. XeF2 can be preformed or formed in situ by reaction between Xe and a fluorine compound.

Owner:VERSUM MATERIALS US LLC

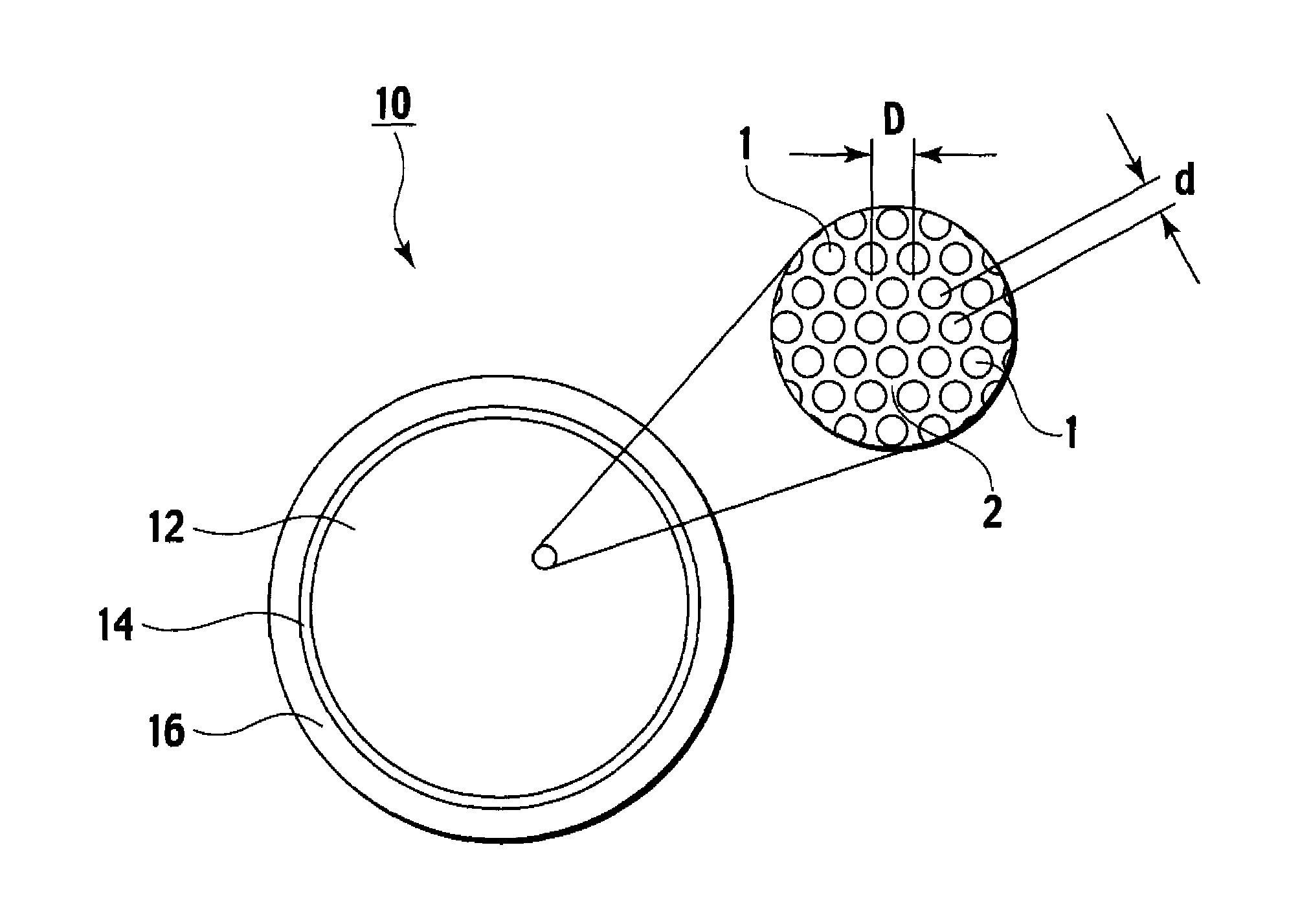

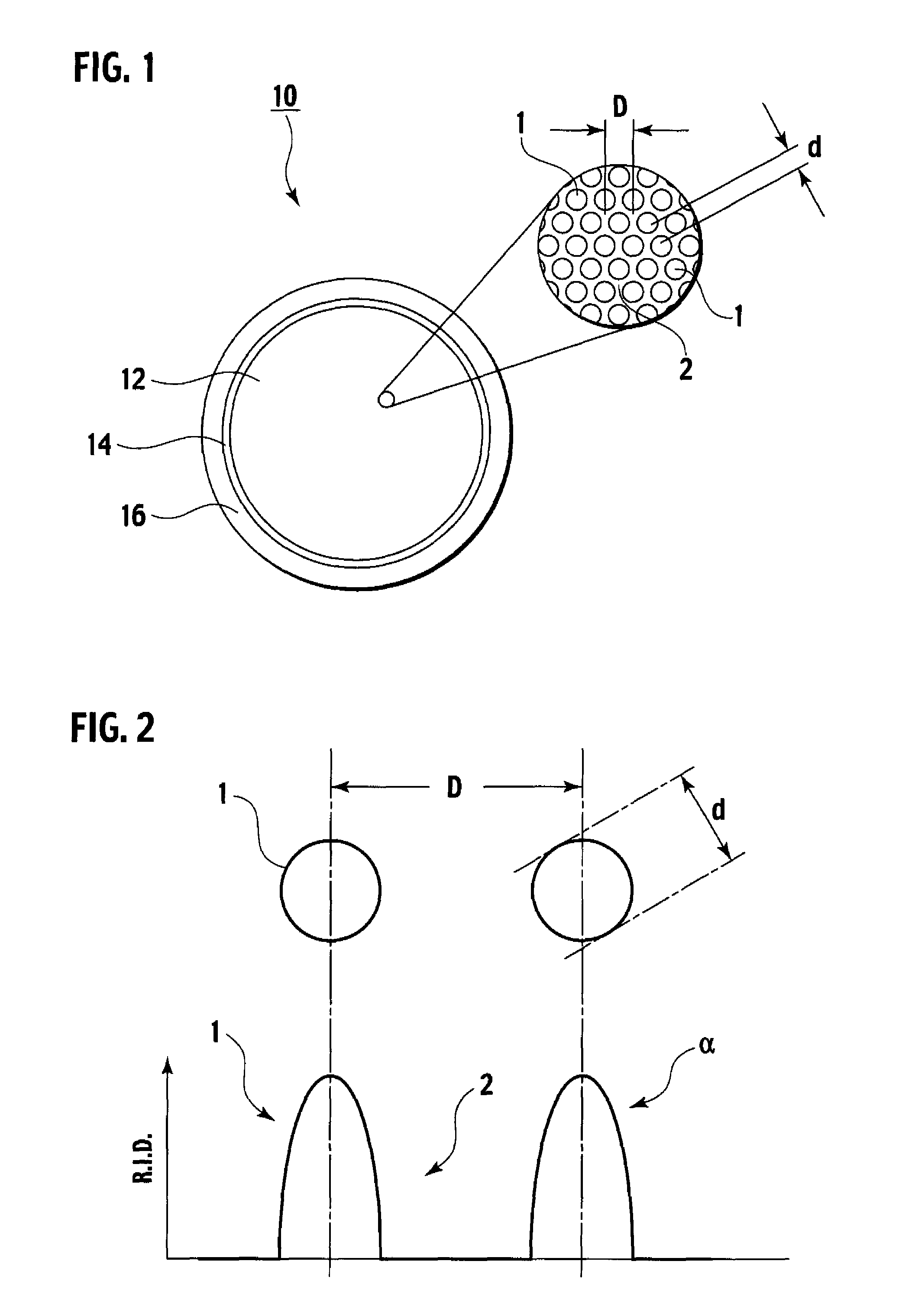

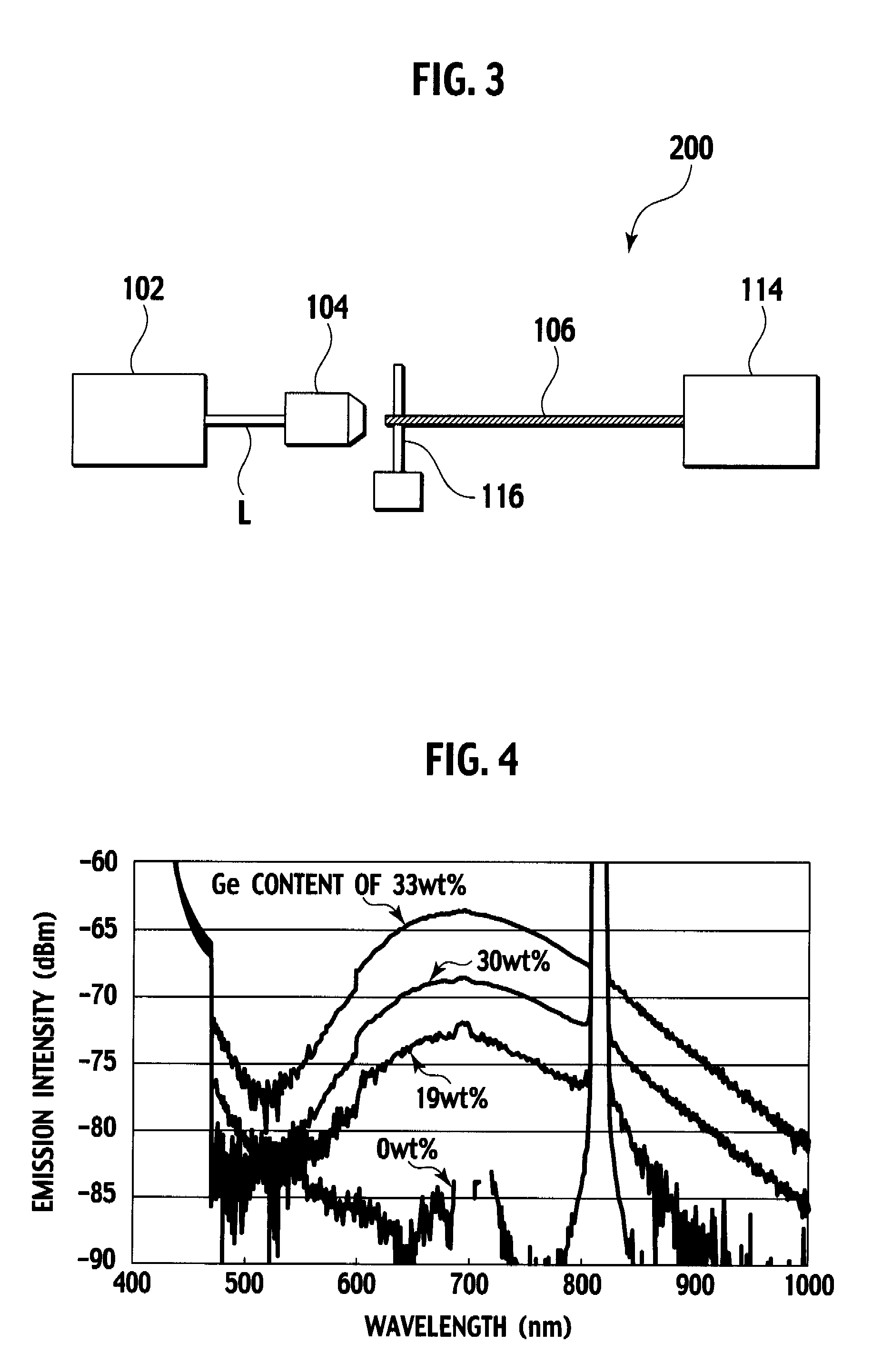

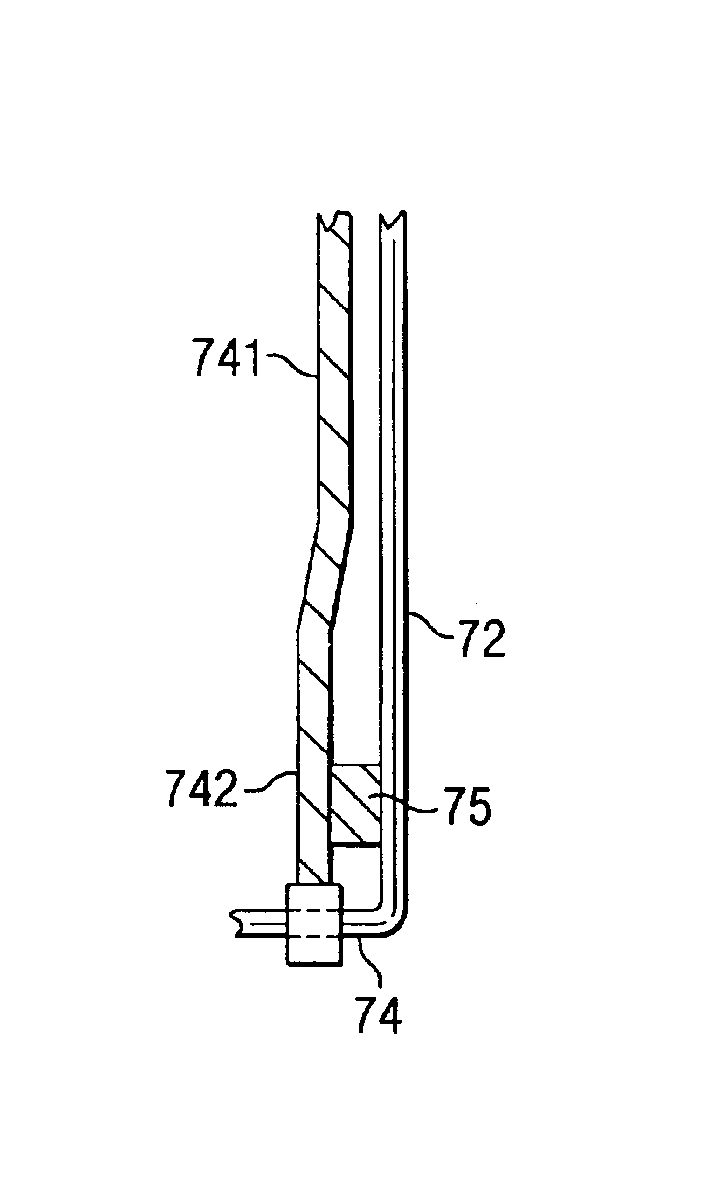

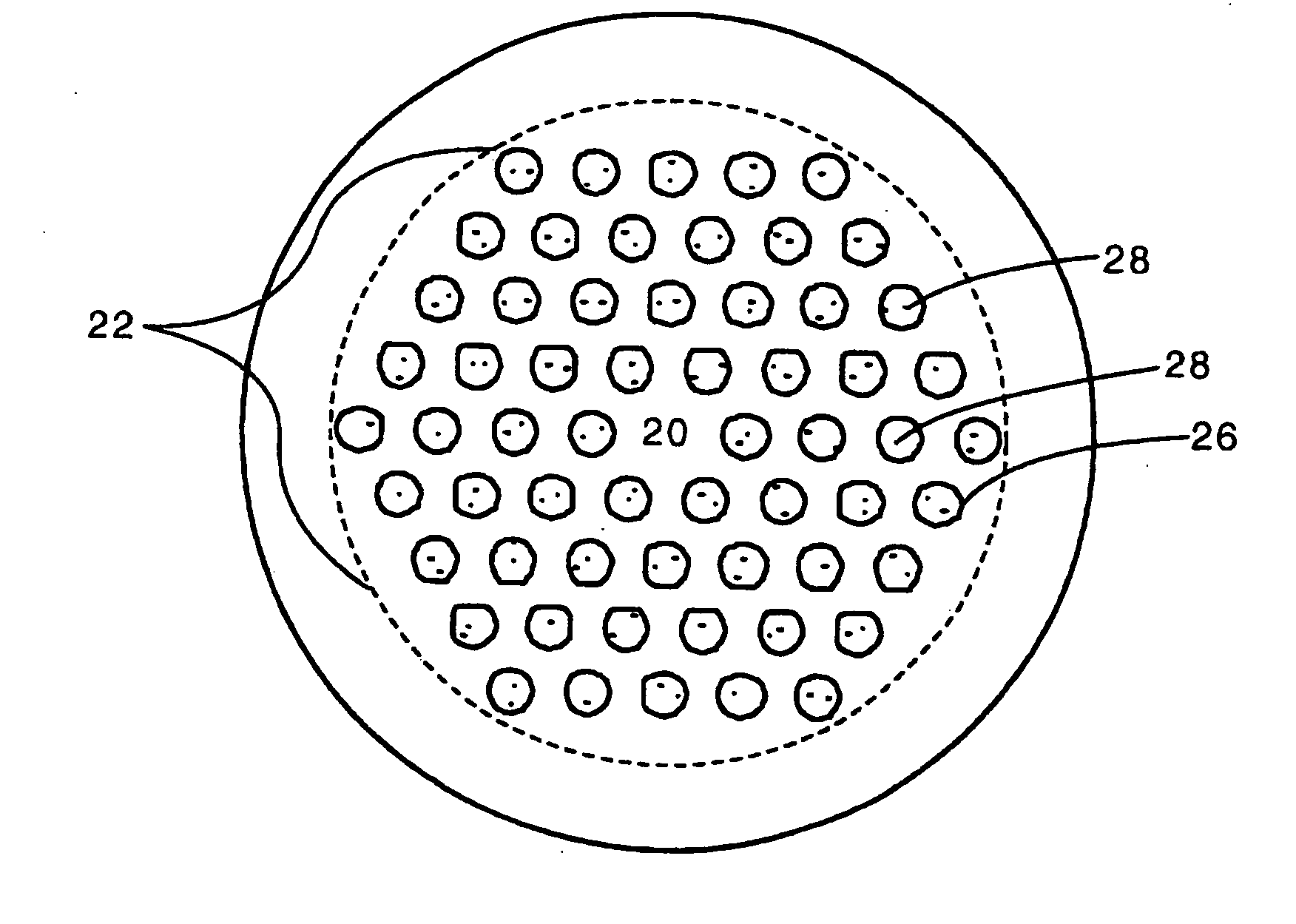

Multi-core fiber

ActiveUS7418178B2Optical fibre with multilayer core/claddingBundled fibre light guideQuartzNumerical aperture

A multi-core optical fiber apparatus is disclosed. The multi-core optical fiber apparatus includes a cladding comprising quartz and a plurality of cores embedded in the cladding. Each of the cores has a diameter (D) ranging from 1.3 μm to 2.0 μm, a numerical aperture (NA) from 0.35 to 0.45 and a refractive index profile factor (α) from 2.0 to 4.0. A center of each of the cores has a germanium content of 20 wt % to 30 wt %. An interval between adjacent cores is 3.0 μm or more.

Owner:THE FUJIKURA CABLE WORKS LTD

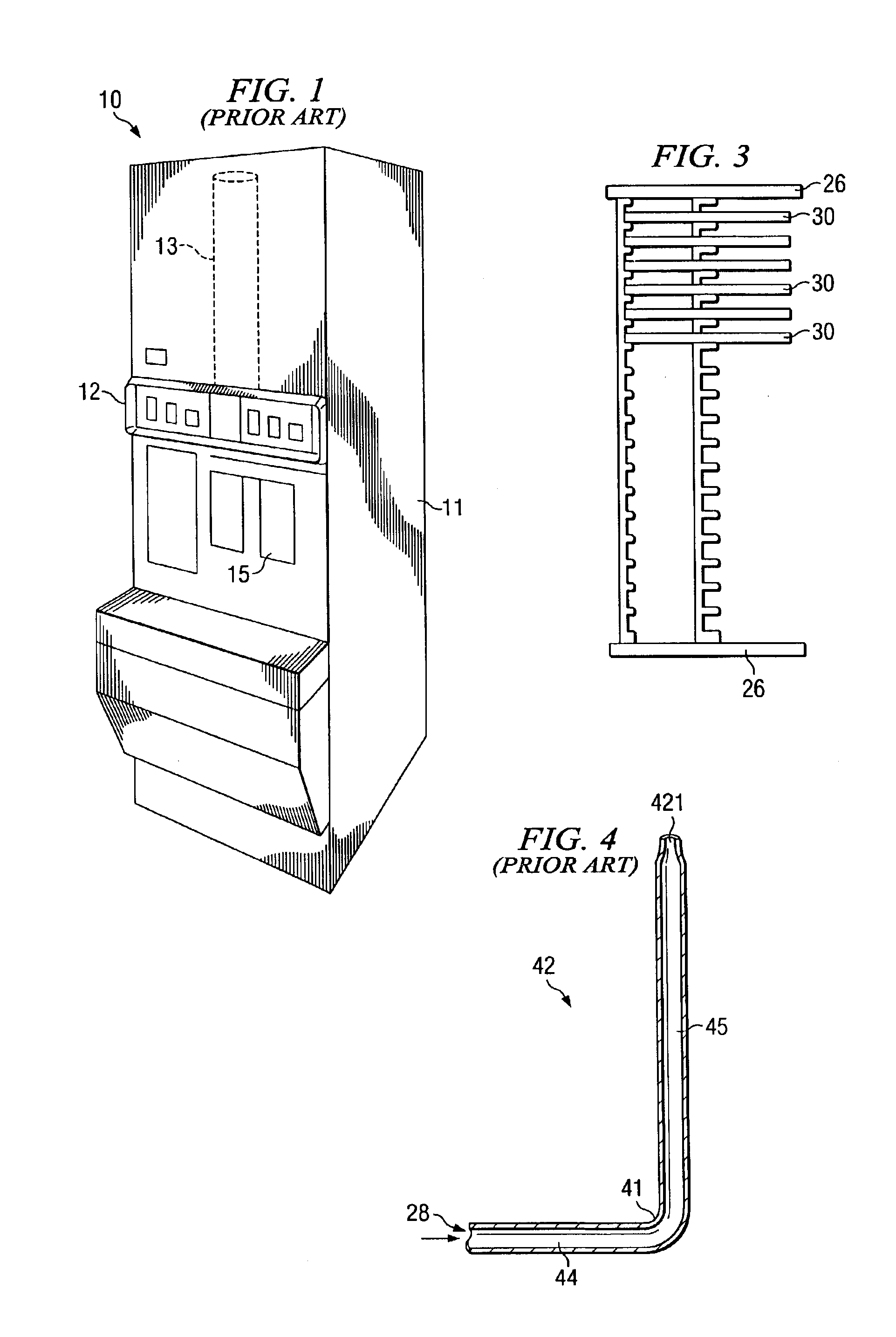

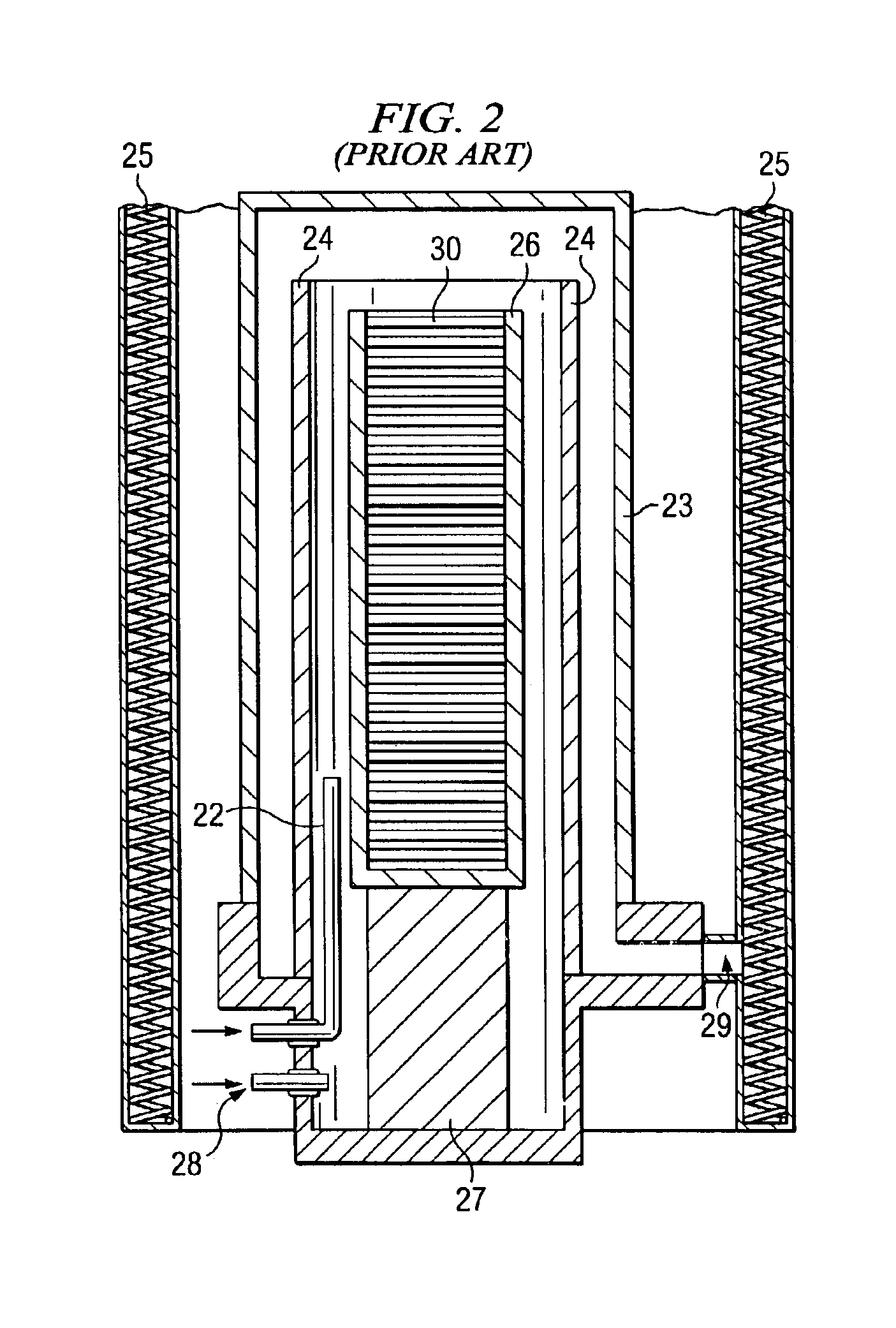

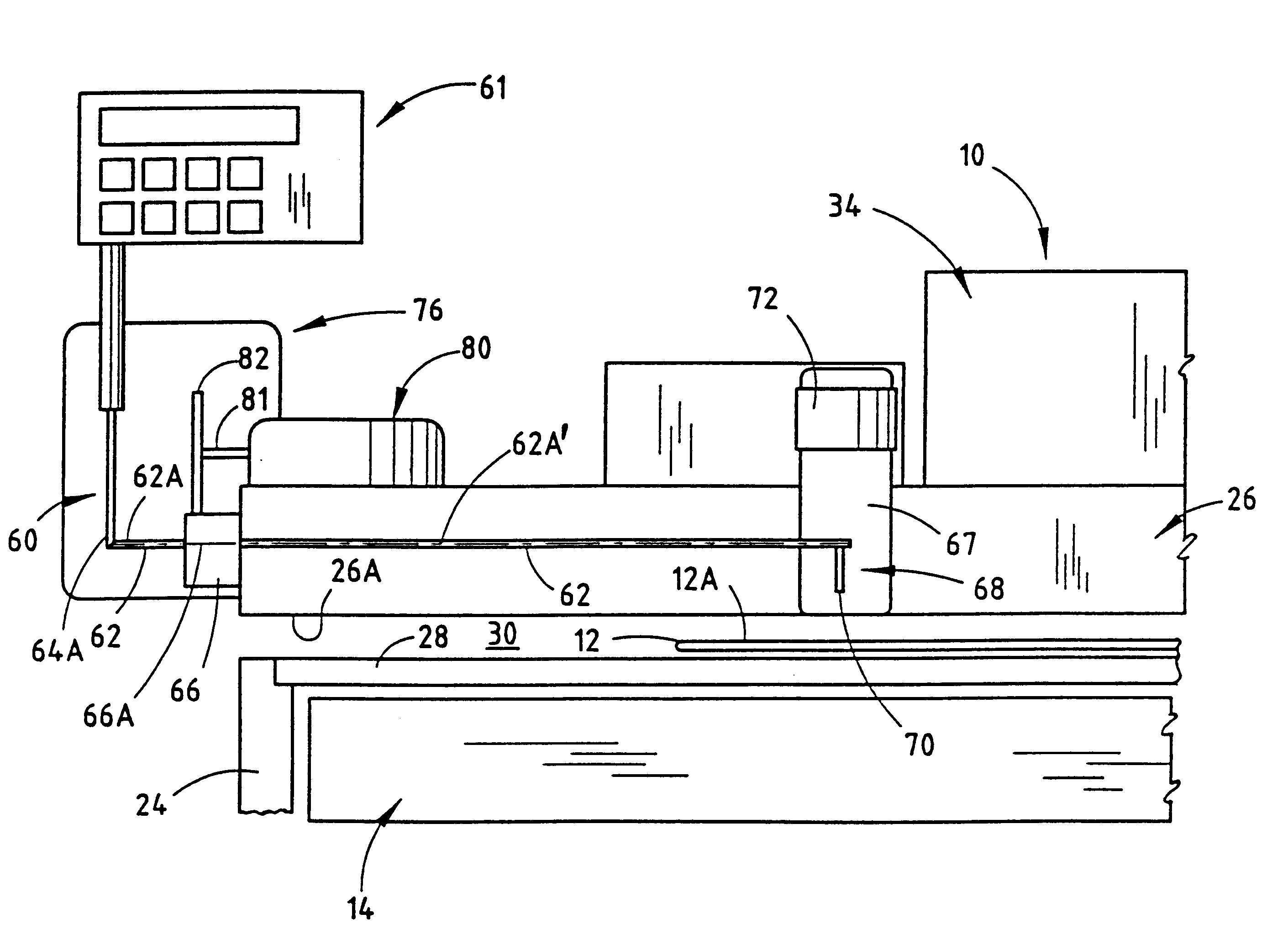

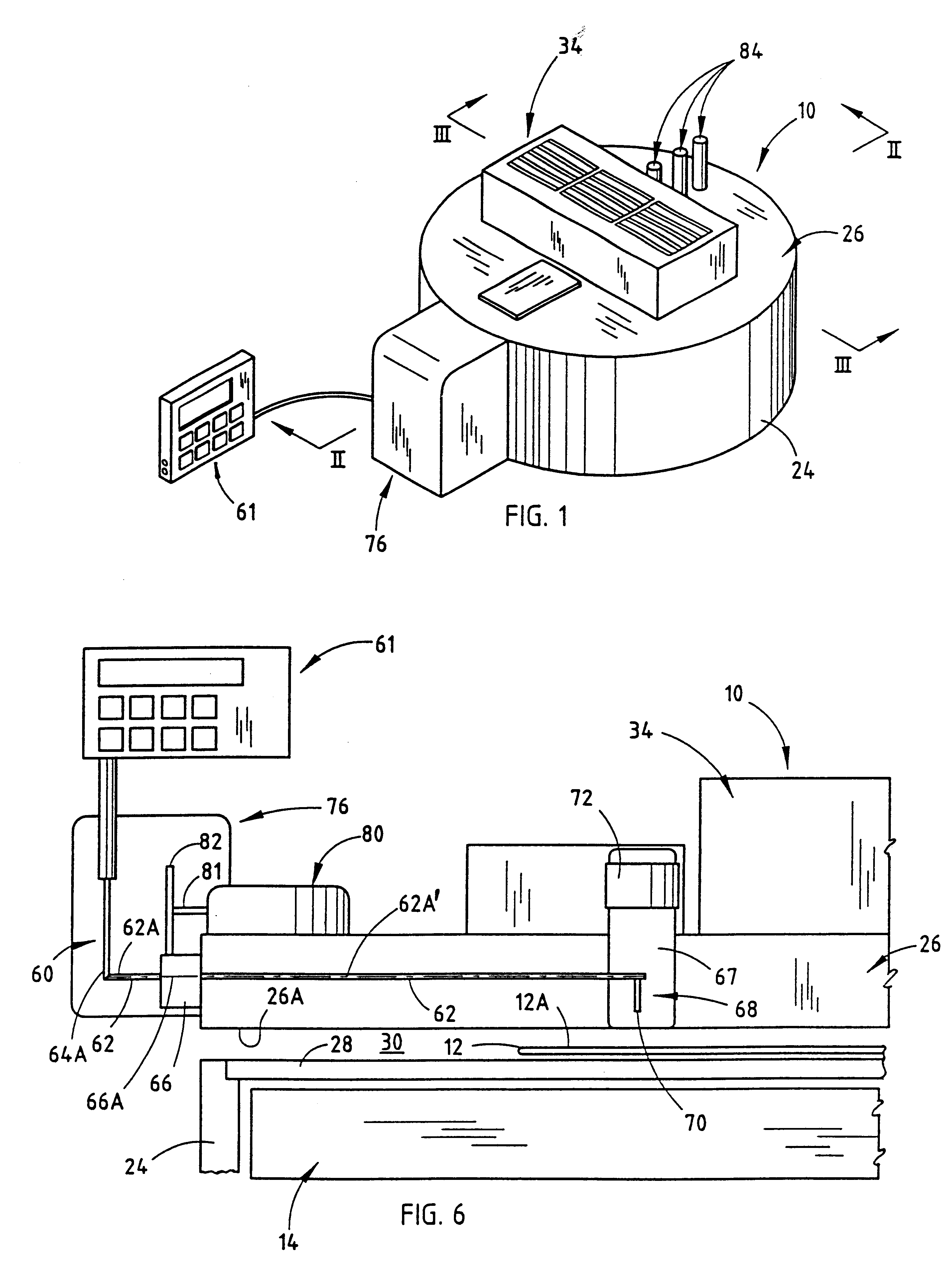

Gas injectors for a vertical furnace used in semiconductor processing

InactiveUS6929699B2Simple designStable positionChemical vapor deposition coatingEngineeringProduct gas

Improved long gas injectors for a vertical furnace used in semiconductor wafer processing are useful to minimize particulate contamination in the wafer processing area of the furnace, and minimize distortion of the long injectors during thermal excursions. The improved injectors are fabricated with a stabilizing quartz standoff positioned near the onset of the vertical portion of the injector tube which adds support to the long tube. Thickness of the standoff is calculated to define and enforce a specified separation distance between liner and injector, as well as to provide dual alignment points at the base of the liner and at the tip of the injector.

Owner:TEXAS INSTR INC

Surface coating for chamber components used in plasma systems

ActiveUS20170032942A1Low plasma surface recombination rateHigh trafficElectric discharge tubesVacuum evaporation coatingBlood plasmaPlasma chamber

Disclosed herein are surface coatings for plasma components that have the benefit of being robust against chemical and plasma physical attack in aggressive (e.g., fluorine-based) plasma environments. The coatings also provide low plasma surface recombination rates for active oxygen, nitrogen, fluorine, and hydrogen species when compared with other known surface treatments. The coatings can be applied to any plasma system component not requiring etching or plasma cleaning including but not limited to materials like quartz, aluminum, or anodized aluminum. Additionally, the efficiency of the system is increased by applying a non-reactive coating to system components thereby increasing the flow of excited plasma species to the plasma chamber of the system.

Owner:ENTEGRIS INC

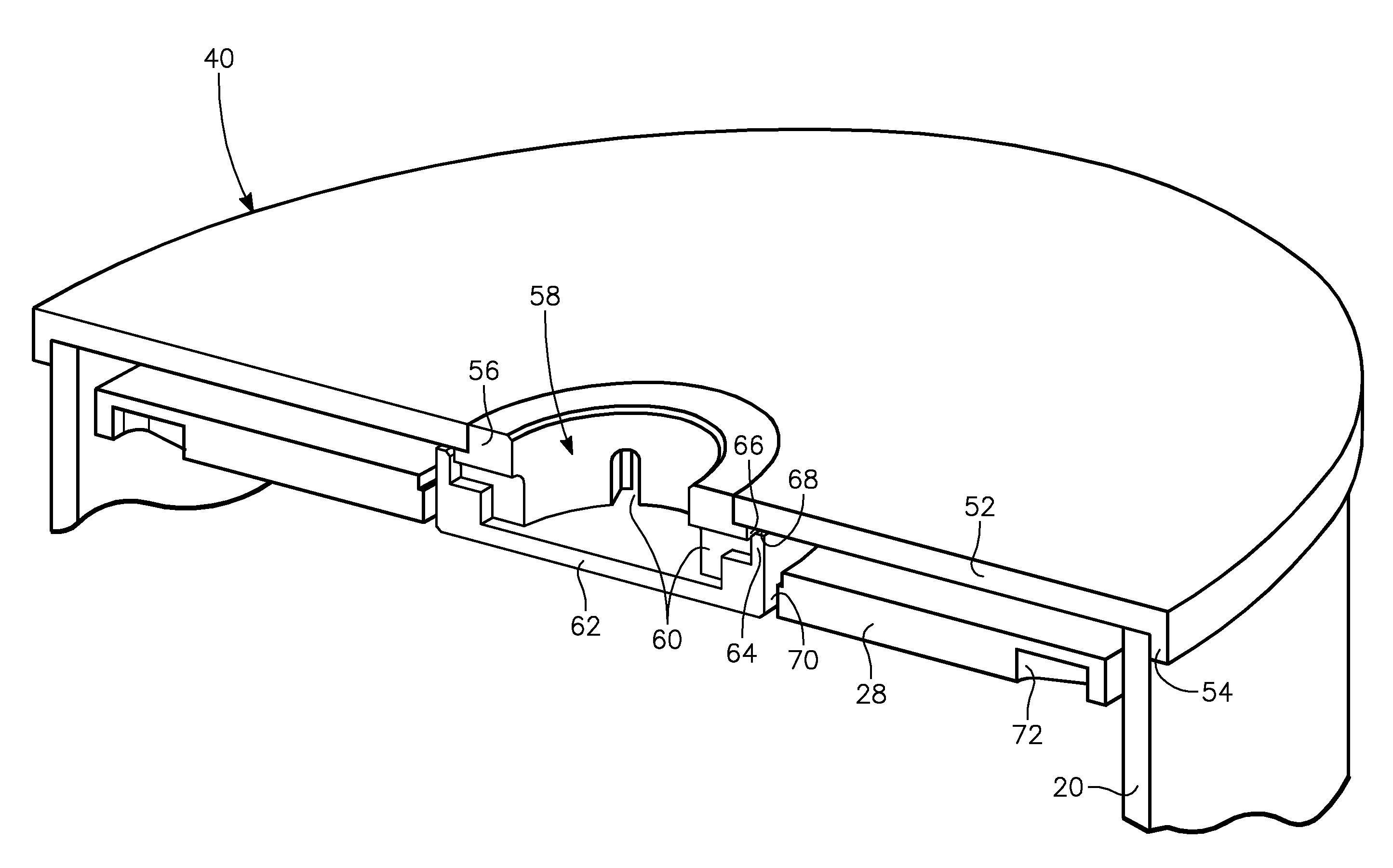

Baffled liner cover

ActiveUS20070181066A1High trafficPrevent fallingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringTower

A baffled liner cover supported at the top of a liner surrounding a wafer support tower for semiconductor thermal processing. The cover may present a continuous horizontal surface for preventing particles from falling within the liner but present horizontal extending gas passageways in a baffle assembly to allow the flow of processing gas through the cover. In one embodiment, the baffle assembly includes a cup-shaped member disposed in a central aperture of a top plate having an open top, a continuous bottom, horizontal holes through the sides, and a flange around sides defining a convolute annular passage. Alternatively, the planar top plate may included slanted holes therethrough or vertical holes occupying a small fraction of the surface area. The liner and cover may be composed of quartz, silicon carbide, or preferably silicon.

Owner:HANGZHOU DUNYUANJUXIN SEMICON TECH CO LTD

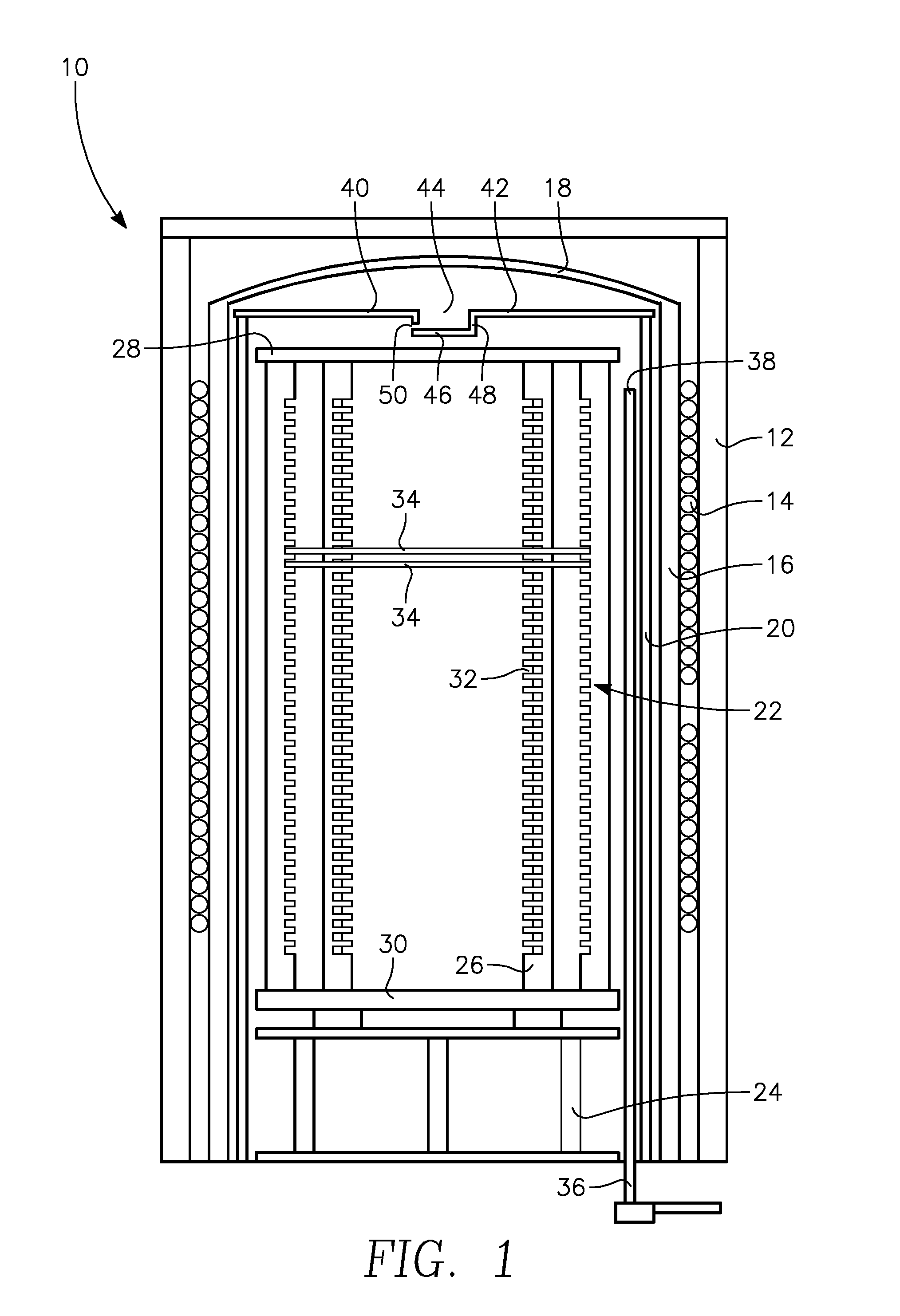

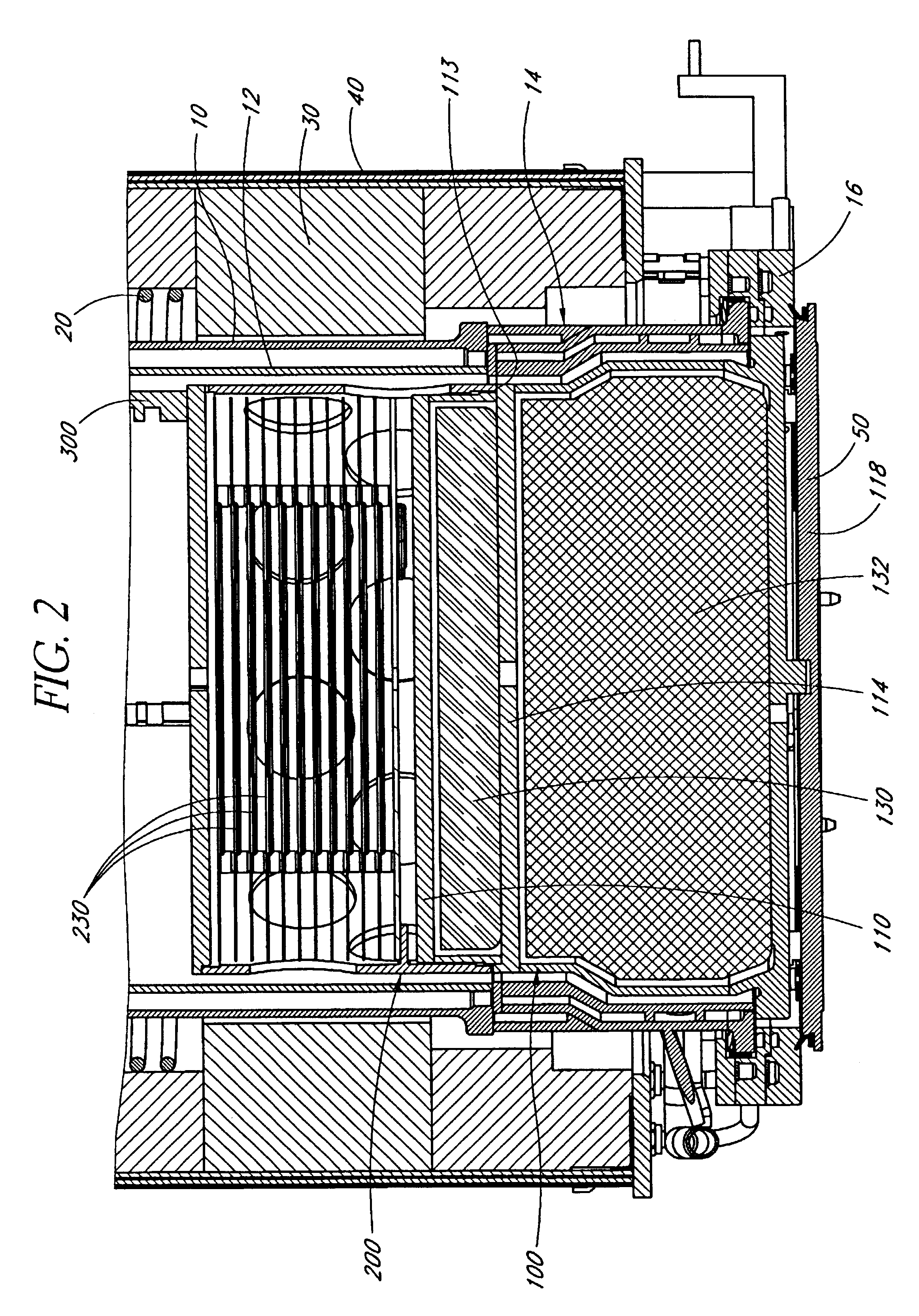

Reactor and method of processing a semiconductor substrate

InactiveUSRE37546E1Accurately determineEliminate needThermometer detailsRadiation pyrometryGas syringeEngineering

Owner:KOKUSAI SEMICON EQUIP CORP

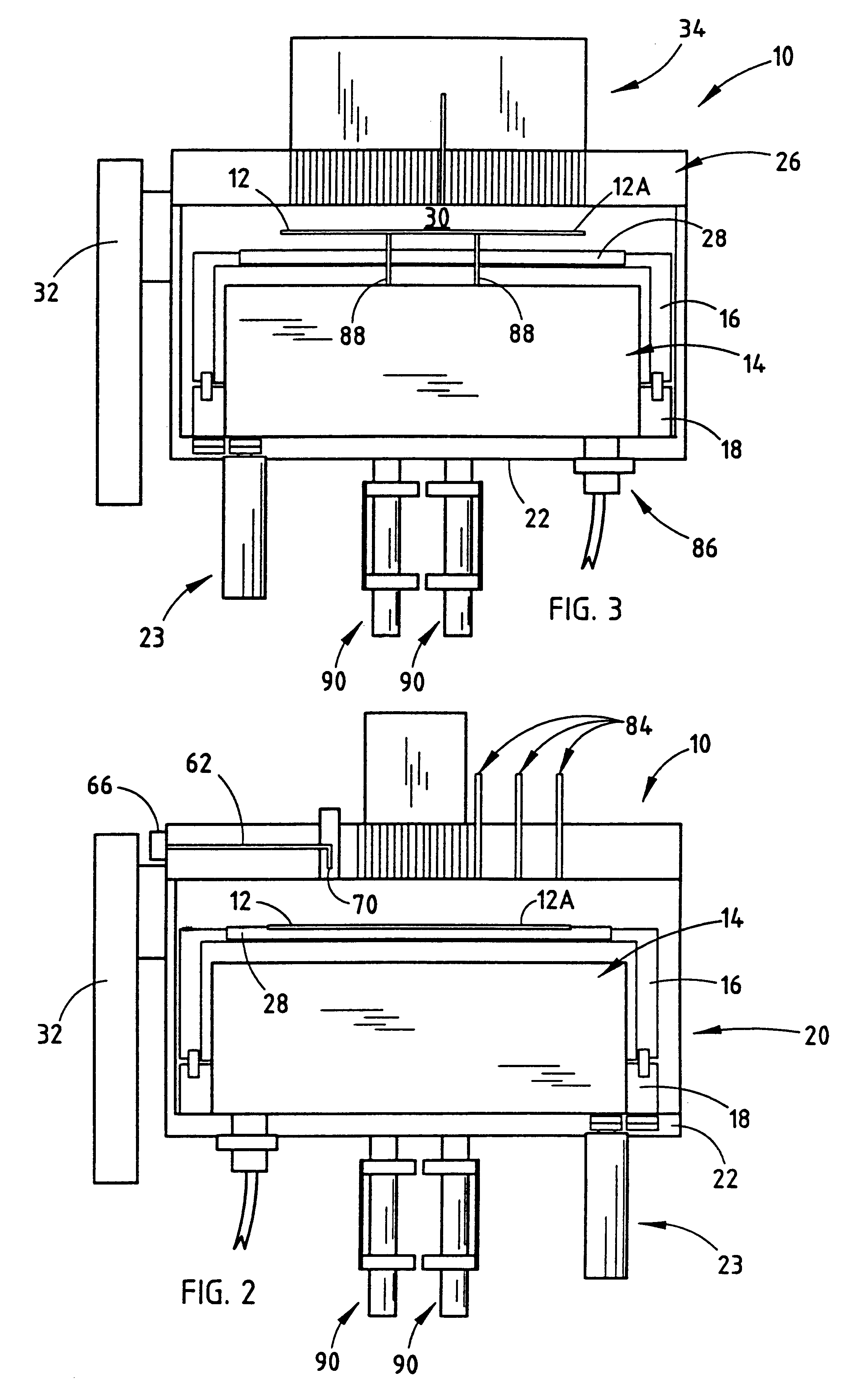

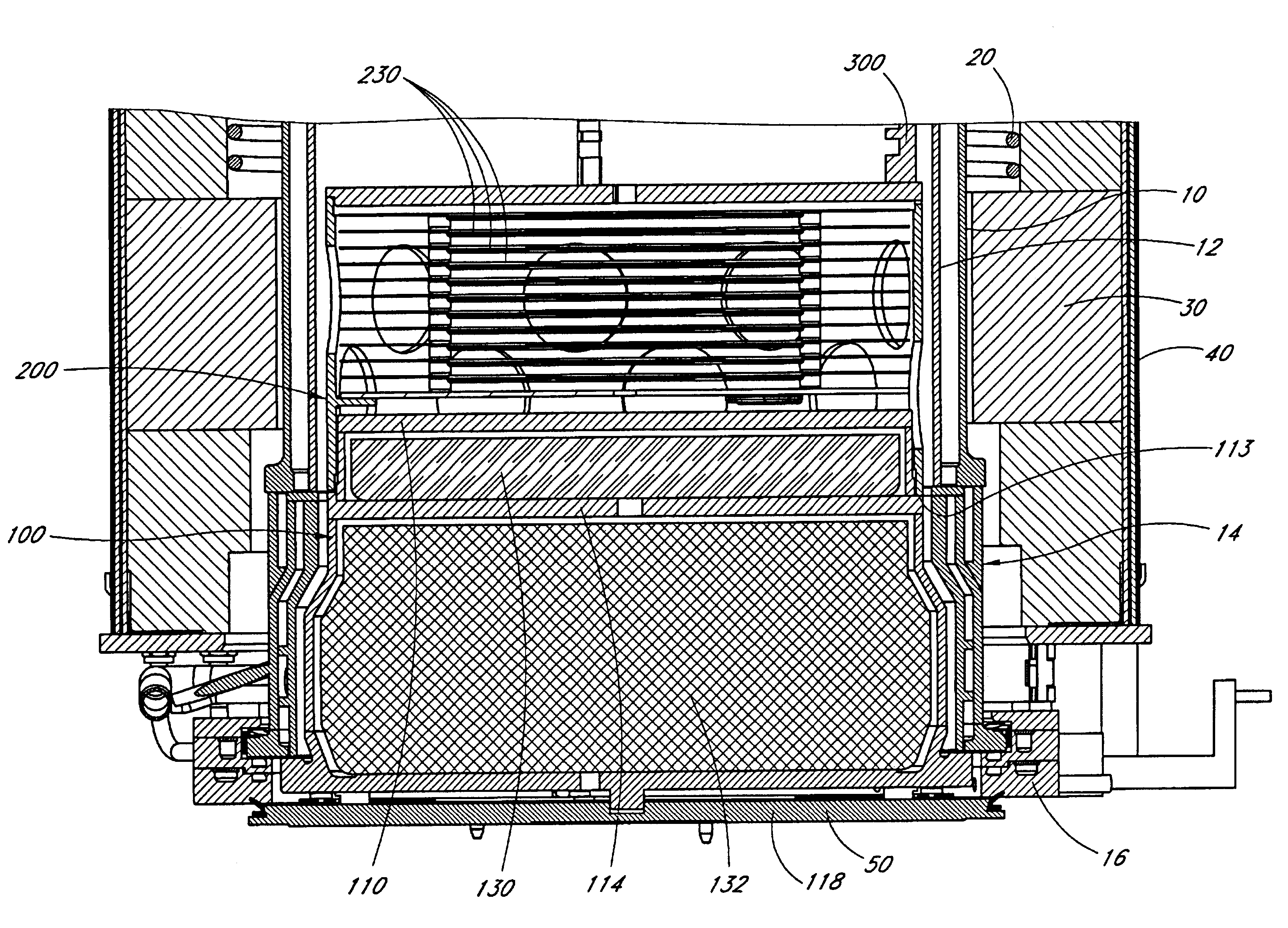

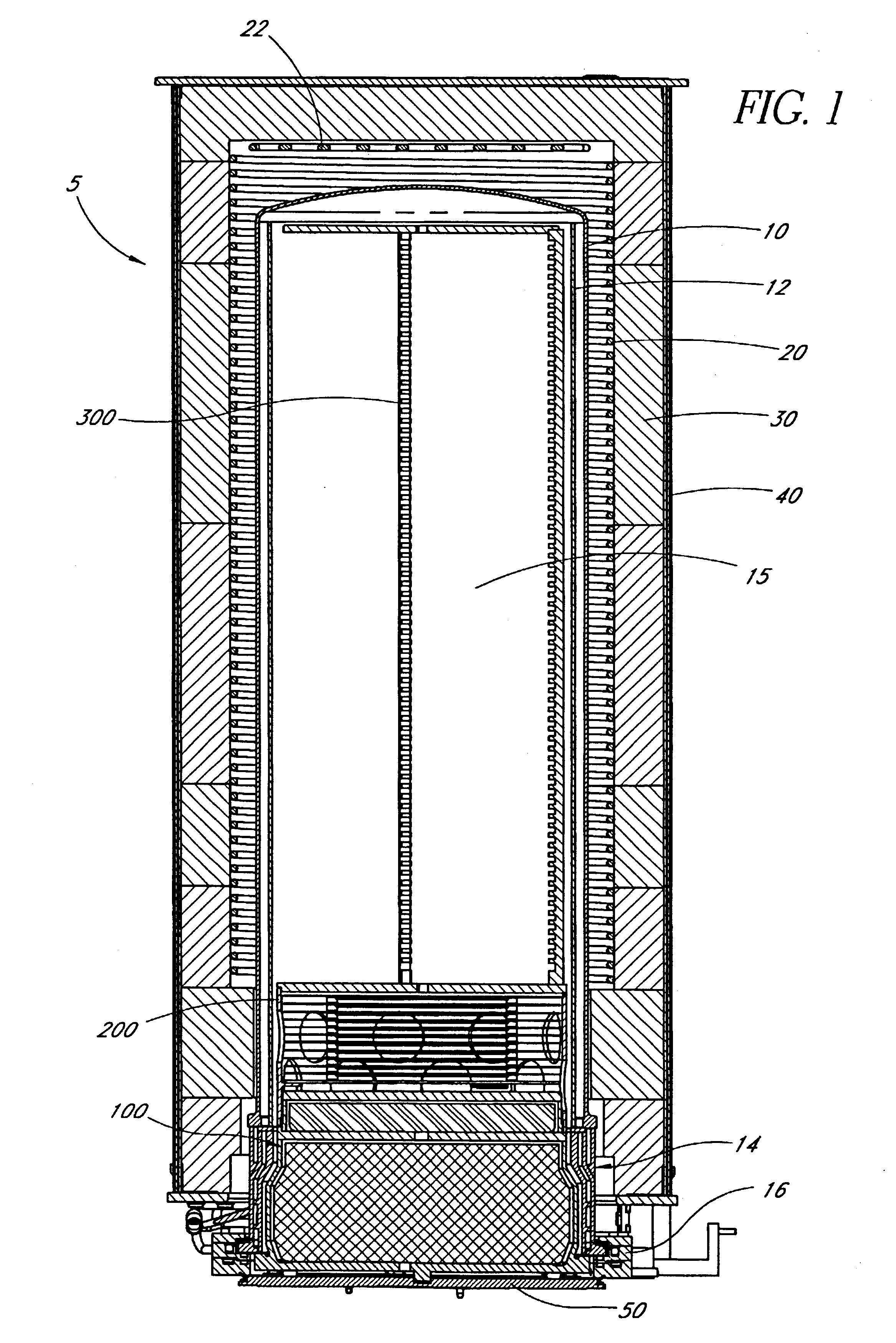

Multilevel pedestal for furnace

A pedestal for use in a high temperature vertical furnace for the processing of semiconductor wafers provides a closure and heat insulation for the lower end of the furnace and is a wafer boat support. The pedestal, comprising quartz-enveloped insulation material, supports a wafer boat at a boat support level and is provided with an upper section disposed above the boat support level. The upper section comprises enveloped insulating material. The envelope of the upper section is also formed of quartz and the insulating material in the upper section has a lower thermal conductance than the insulating material in a lower quartz enveloped section.

Owner:ASM INTERNATIONAL

Flat float glass

InactiveUS6846760B2High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideTransmittance

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

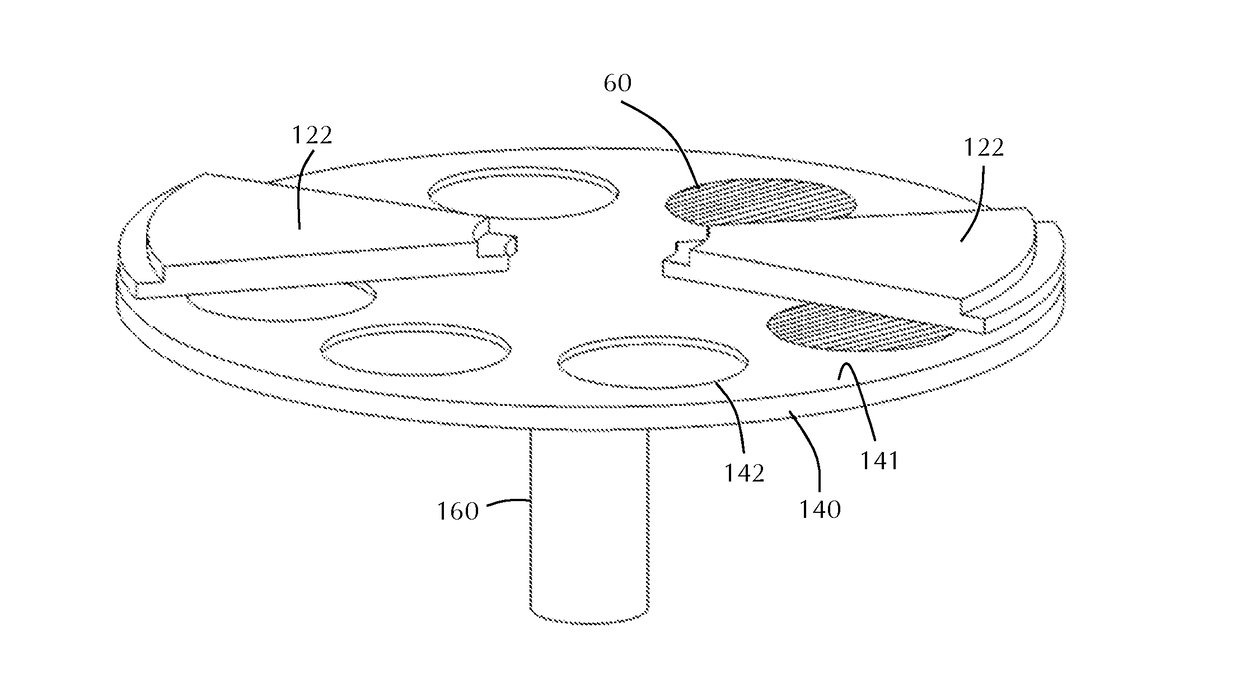

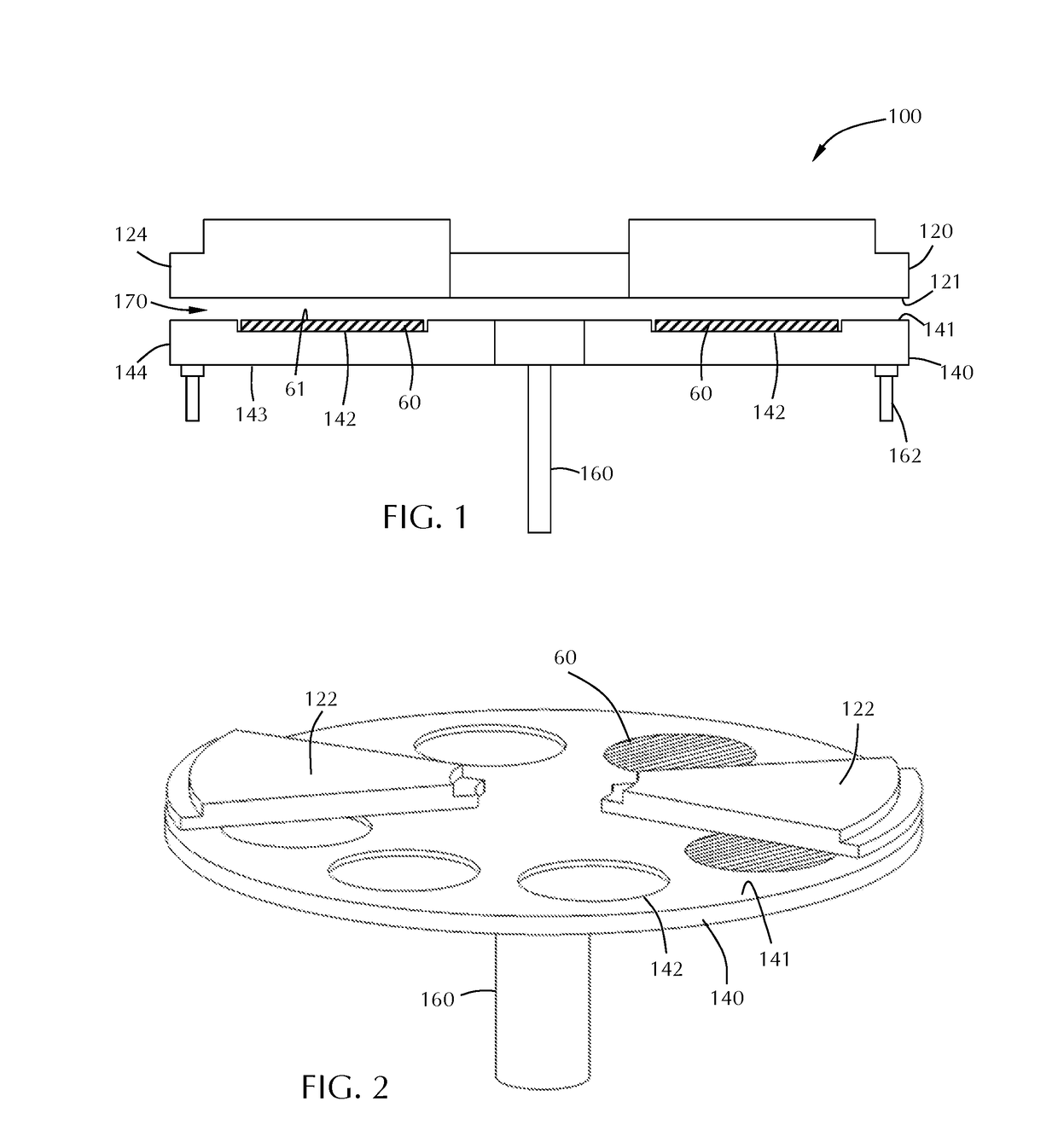

Non-Metallic Thermal CVD/ALD Gas Injector And Purge System

ActiveUS20170191159A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCircular discReactive gas

Gas distribution assemblies and processing chambers using same are described. The gas distribution assemblies comprise a cooling plate with a quartz puck, a plurality of reactive gas sectors and a plurality of purge gas sectors suspended therefrom. The reactive gas sectors and purge gas sectors having a coaxial gas inlet with inner tubes and outer tubes, the inner tubes and outer tubes in fluid communication with different gas or vacuum ports in the front faces of the sectors. The sectors may be suspended from the cooling plate by a plurality of suspension rods comprising a metal rod body with an enlarged lower end positioned within a quartz frame with a silicon washer around the enlarged lower end.

Owner:APPLIED MATERIALS INC

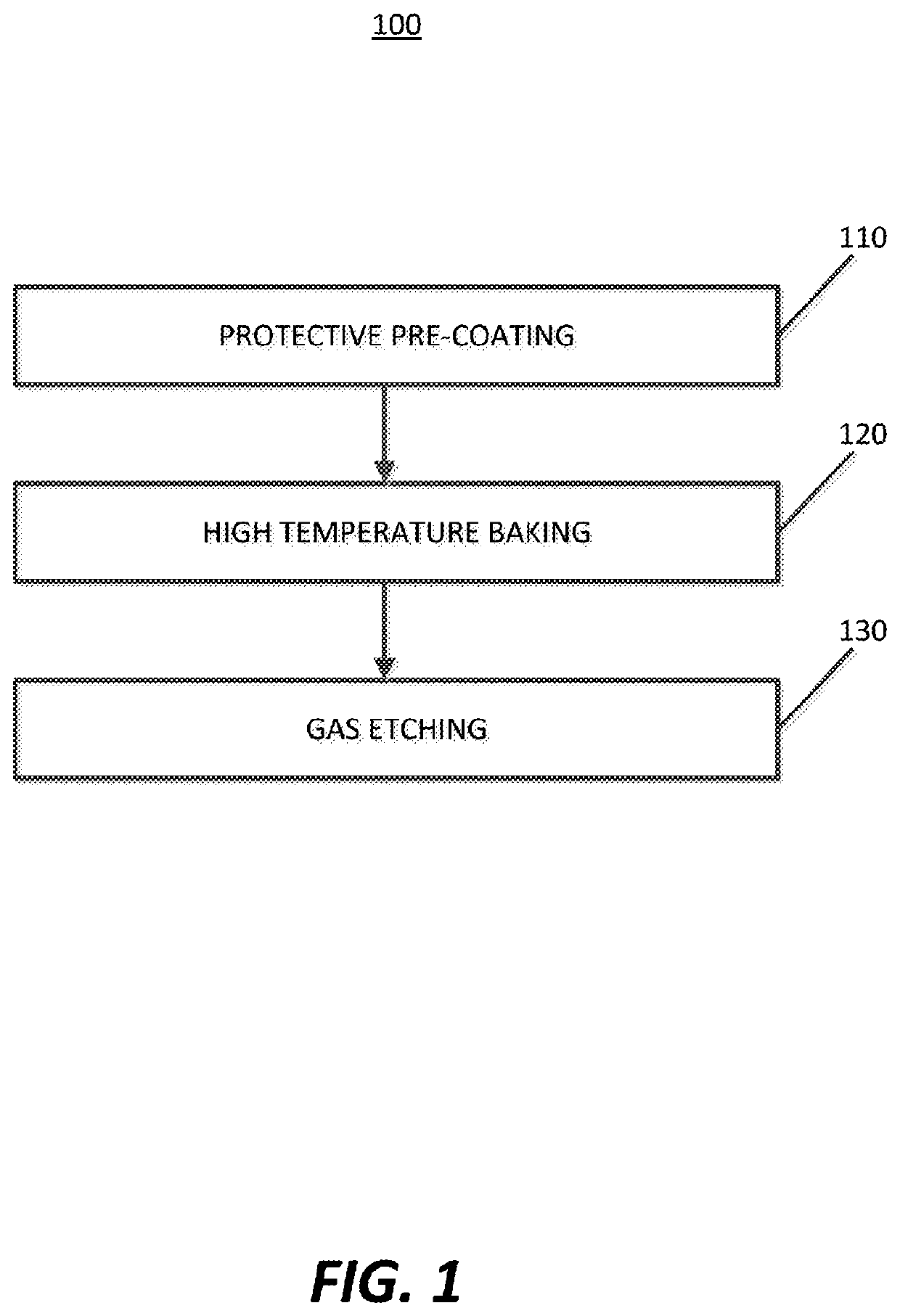

Method for cleaning quartz epitaxial chambers

PendingUS20200385861A1Electric discharge tubesDetergent mixture composition preparationPhysical chemistryQuartz

A method of cleaning an epitaxial reaction chamber in-situ is disclosed. The method may include a pre-coating step, a high temperature baking step, and a gas etching step. The method is able to remove residue buildup within the reaction chamber, which may be made of quartz.

Owner:ASM IP HLDG BV

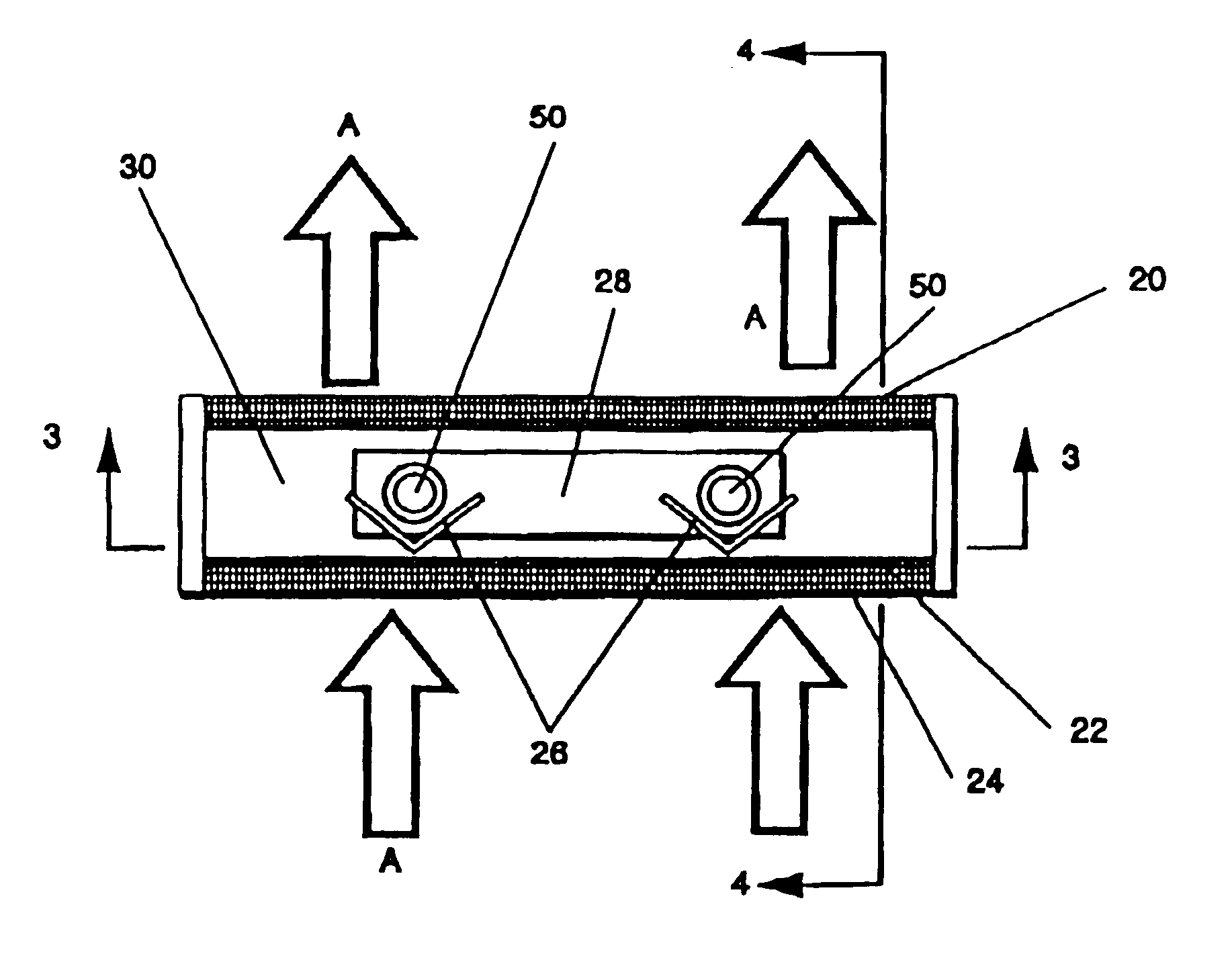

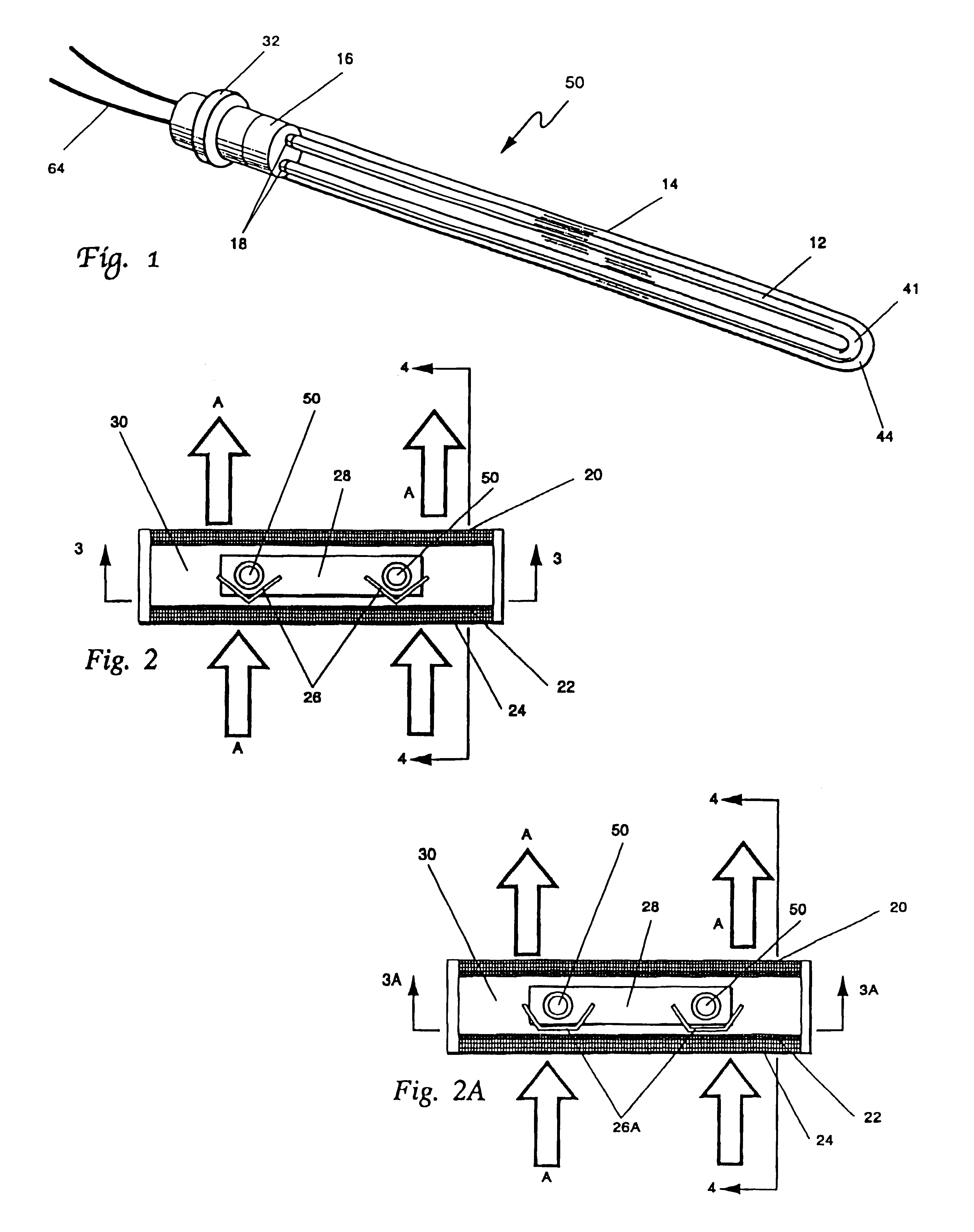

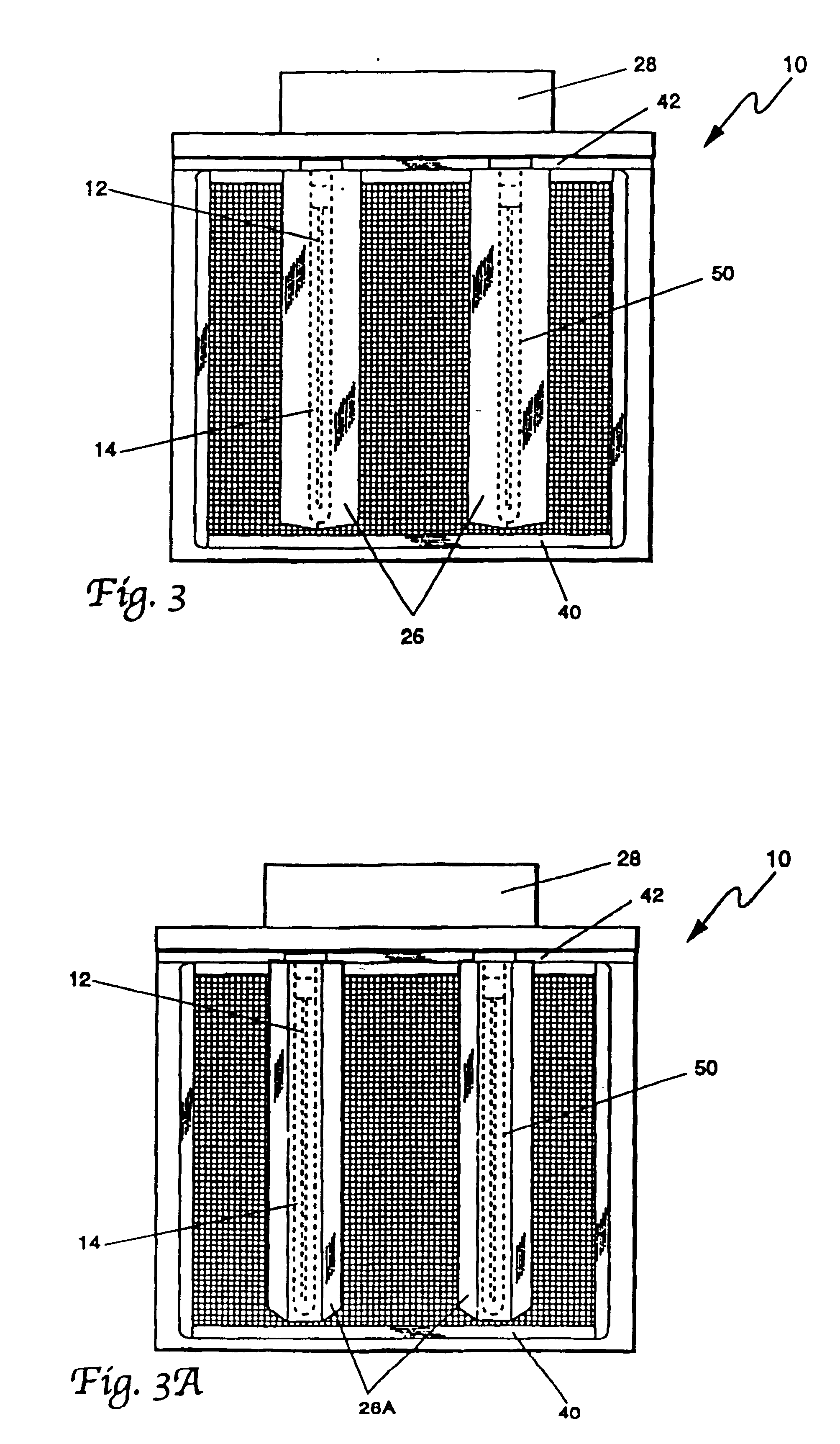

Air actinism chamber apparatus and method

An apparatus and method for ultraviolet irradiation of air for the purpose of removing contaminants from that air is disclosed. A U-shaped ultraviolet bulb enshrouded within a quartz tube provides enhanced contaminant destruction characteristics. By combining a plurality of those bulbs in a chamber that is of polished aluminum, and further combining aluminum filters therewith, added irradiation enhancement is achieved. Further provided are baffles or baffling proximate the ultraviolet bulbs that cause the air to go turbulent thus drawing the air closer to the ultraviolet bulb and further enhancing the contaminant destruction characteristics. Moreover disclosed is treatment of substrates with a chemical agent that facilitates the arrest of contaminants from the air onto the substrate for further irradiation of the contaminants from the bulbs. This further irradiation breaks down the arrested contaminants thus providing the substrate with a self-cleansing effect.

Owner:PHASYC

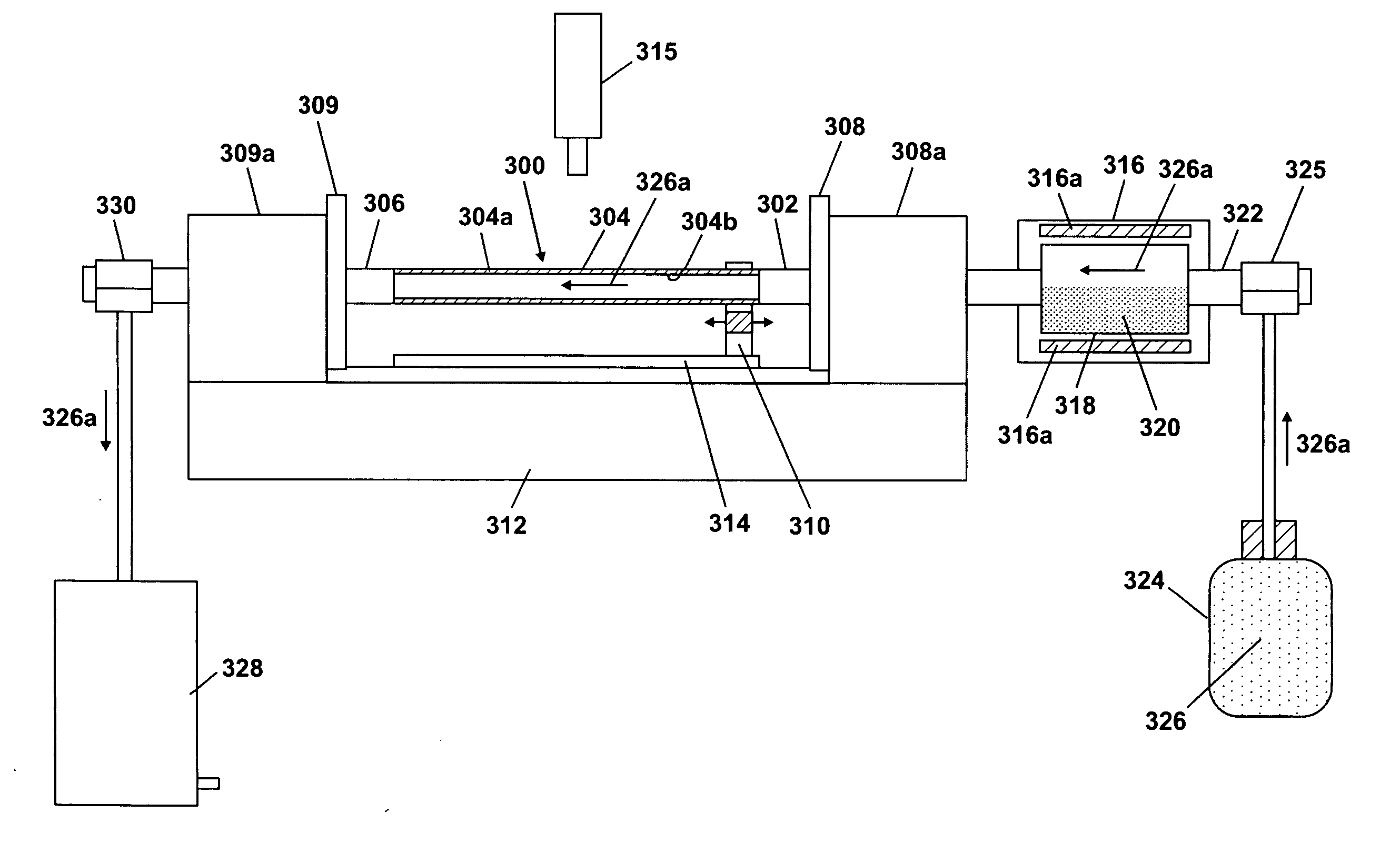

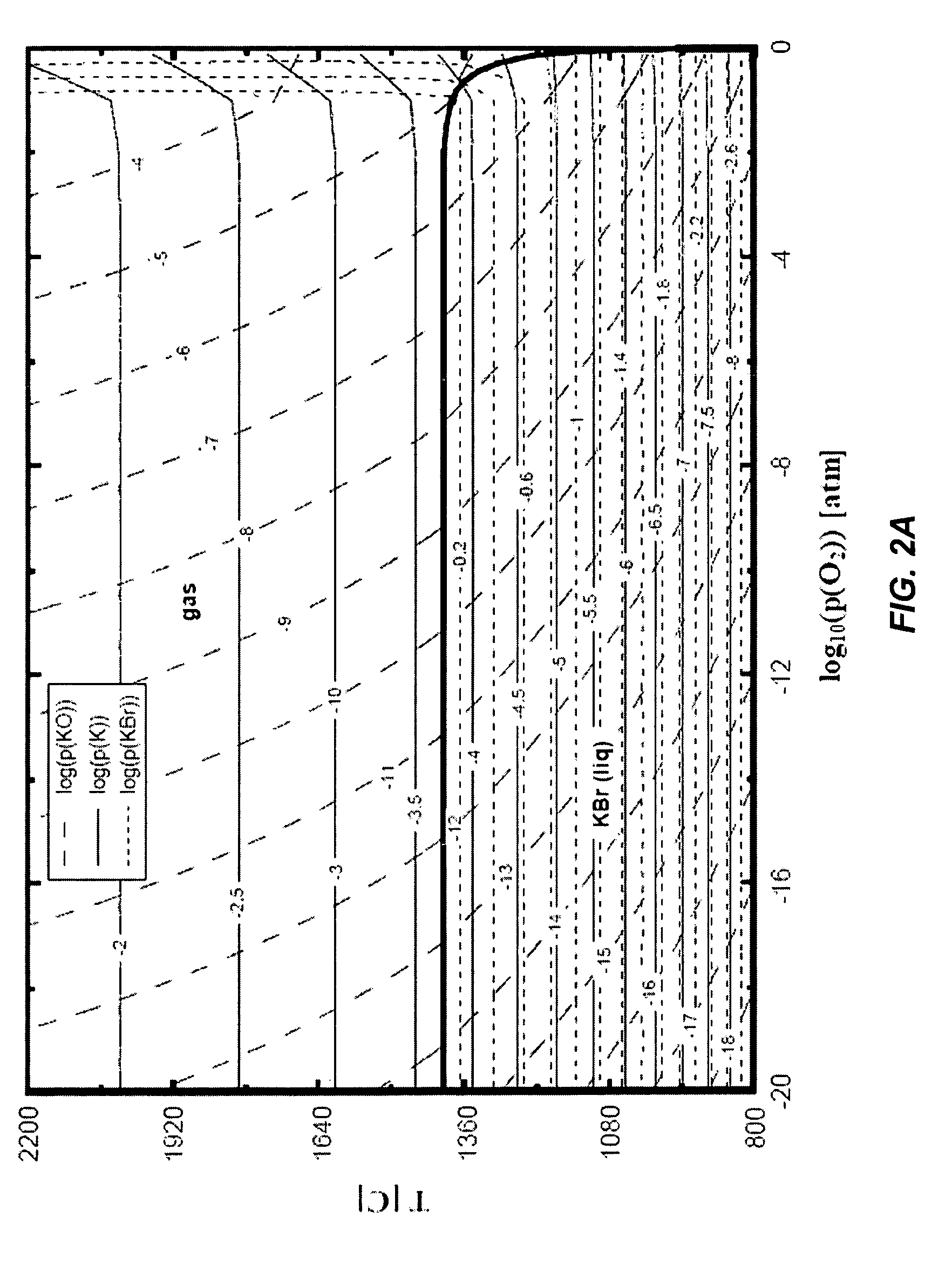

Method of doping silica glass with an alkali metal, and optical fiber precursor formed therefrom

A method of making an optical fiber precursor includes generating vapors from an alkali metal source comprising compound containing oxygen and one or more alkali metals and applying the vapors to a surface of a glass article comprising silica at a temperature that promotes diffusion of the alkali metal into the surface of the glass article. An optical fiber has a core comprising silica and an alkali metal oxide of the form X2O, where X is selected from the group consisting of K, Na, Li, Cs, and Rb, wherein a concentration of the alkali metal oxide along a length of the core is uniform.

Owner:CORNING INC

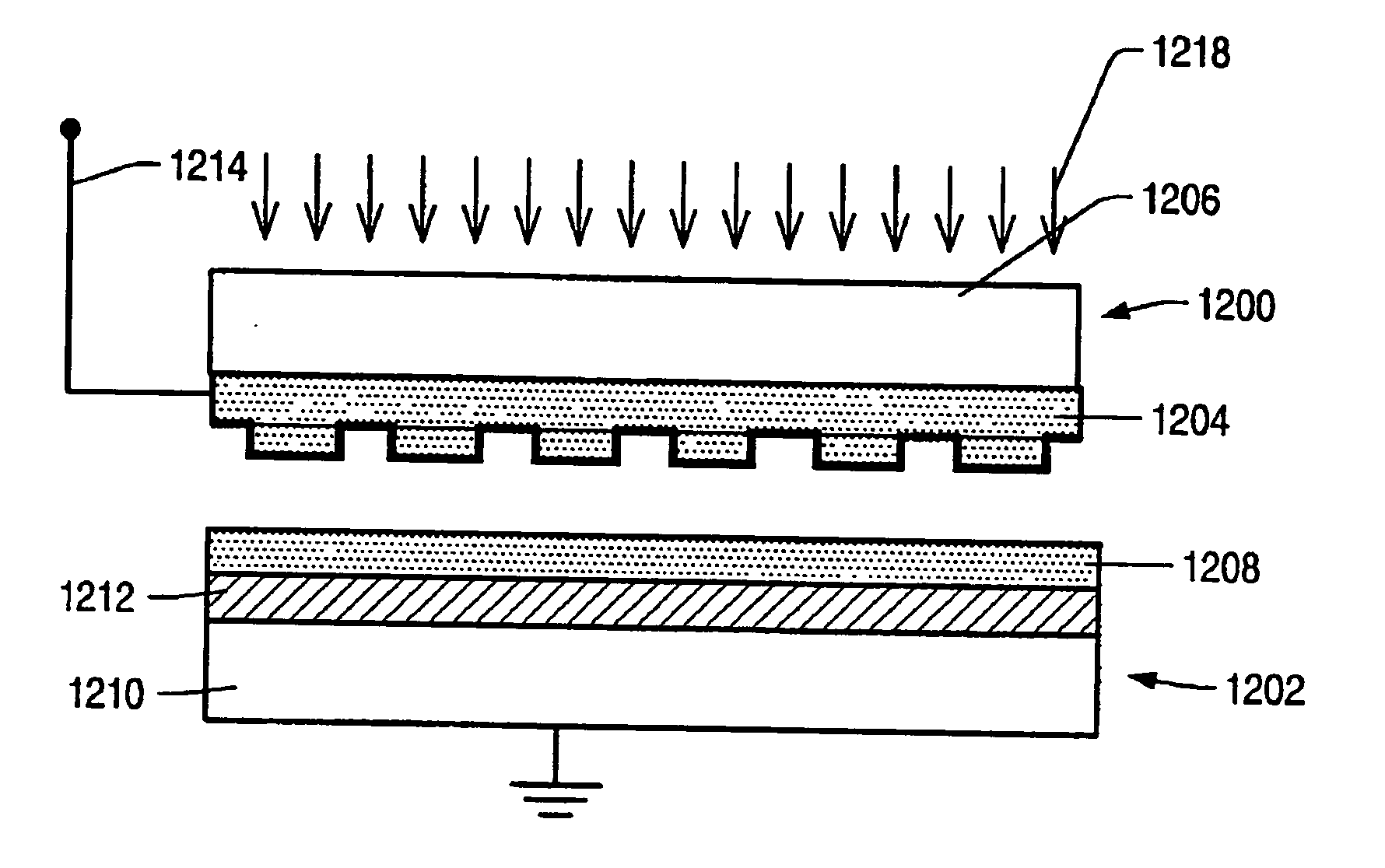

Formation of discontinuous films during an imprint lithography process

The present invention is directed to a template having a body including a surface with first and second regions. The first region has first wetting characteristics for a given material and the second region has second wetting characteristics for the given material. The first wetting characteristics differ from the second wetting characteristics. Specifically, the first region is formed from a surface treatment layer with a first surface energy to provide the first wetting characteristics. The second region is exposed portions of the body, typically quartz of fused silica, having a second surface energy associated therewith. The second surface energy is greater than the first surface energy to provide the second region with the second wetting characteristics.

Owner:CANON KK +1

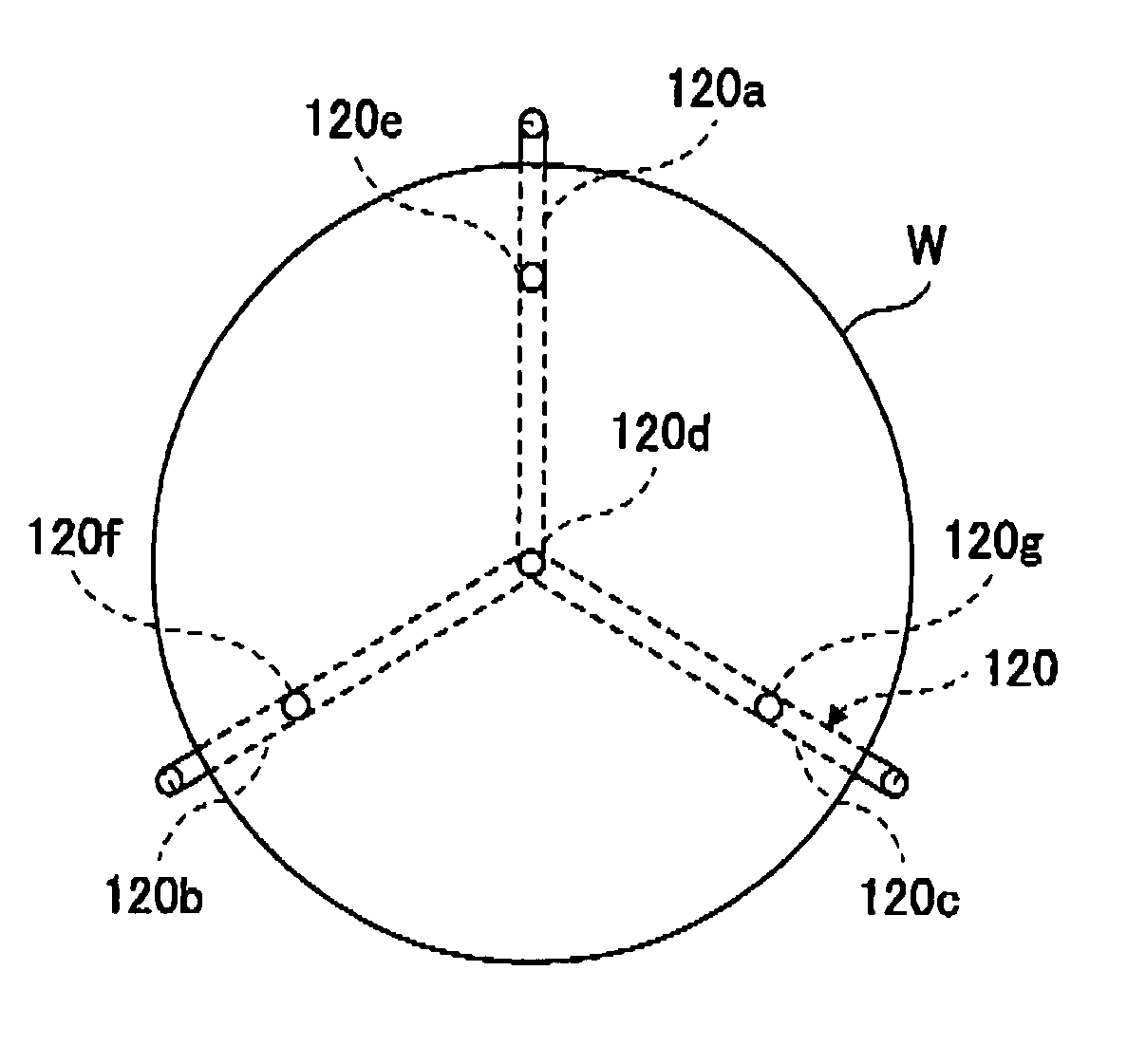

Quartz Jig and Semiconductor Manufacturing Apparatus

InactiveUS20080092821A1Easy to storeAvoid exposureSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorManufactured apparatus

A quartz jig of this invention is such as being provided inside a semiconductor manufacturing apparatus allowing therein growth of an epitaxial layer on a main surface of a semiconductor wafer, capable of supporting a soaking jig which keeps, during epitaxial growth, uniform temperature of a susceptor allowing thereon placement of the semiconductor wafer, and has the top surface thereof aligned almost at the same level of height with the top surface of the susceptor, and is characterized as being composed of transparent quartz at least in a portion thereof brought into contact with the soaking jig. This configuration successfully provides a quartz jig supporting the soaking jig in the semiconductor manufacturing apparatus while suppressing generation of particles, and a semiconductor manufacturing apparatus provided with this sort of quartz jig.

Owner:SHIN-ETSU HANDOTAI CO LTD

Optical fiber with quantum dots

Holey optical fibers (e.g. photonic fibers, random-hole fibers) are fabricated with quantum dots disposed in the holes. The quantum dots can provide light amplification and sensing functions, for example. When used for sensing, the dots will experience altered optical properties (e.g. altered fluorescence or absorption wavelength) in response to certain chemicals, biological elements, radiation, high energy particles, electrical or magnetic fields, or thermal / mechanical deformations. Since the dots are disposed in the holes, the dots interact with the evanescent field of core-confined light. Quantum dots can be damaged by high heat, and so typically cannot be embedded within conventional silica optical fibers. In the present invention, dots can be carried into the holes by a solvent at room temperature. The present invention also includes solid glass fibers made of low melting point materials (e.g. phosphate glass, lead oxide glass) with embedded quantum dots.

Owner:LAMBDA LABORATORY INSTRUMENTS +1

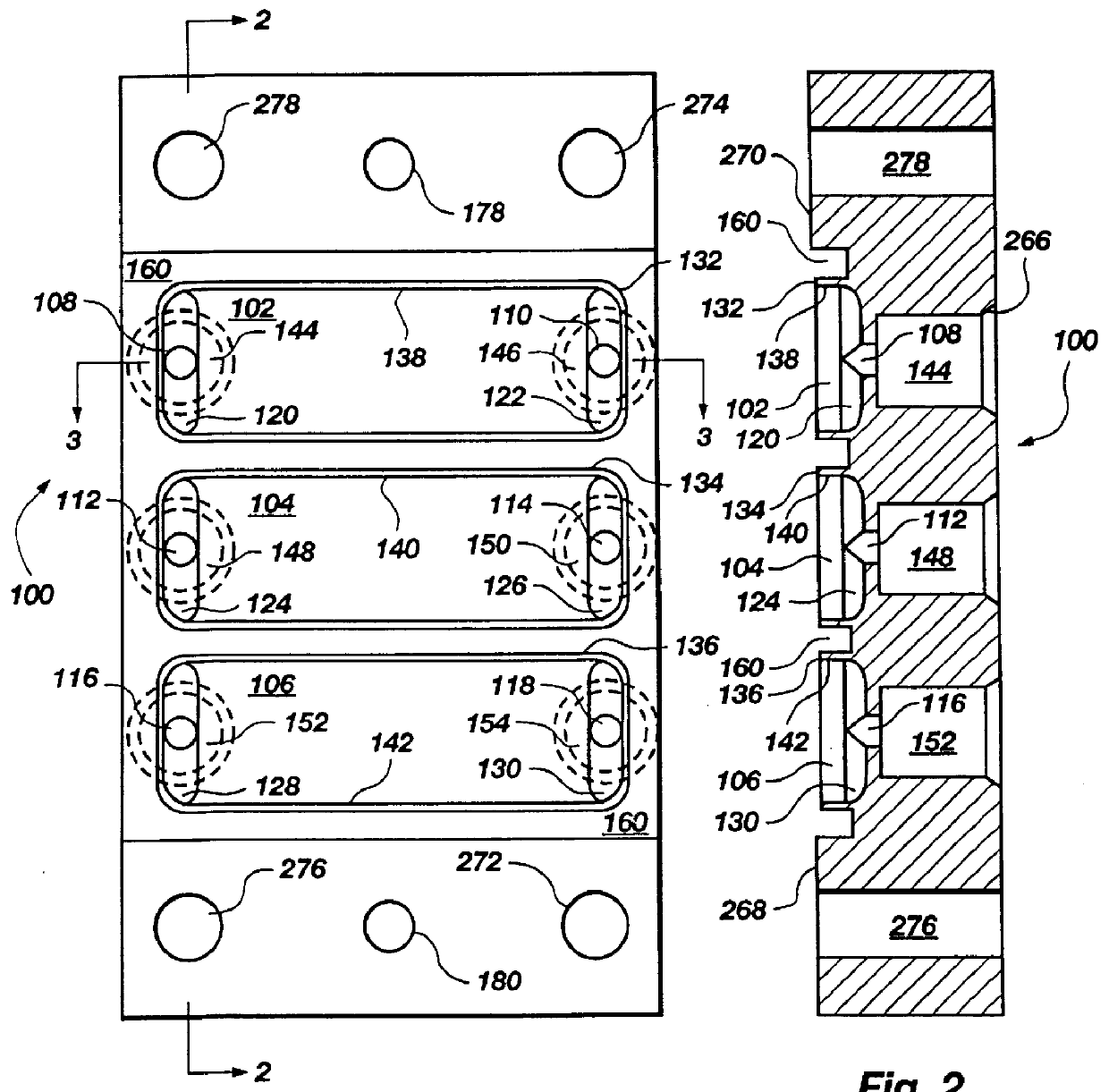

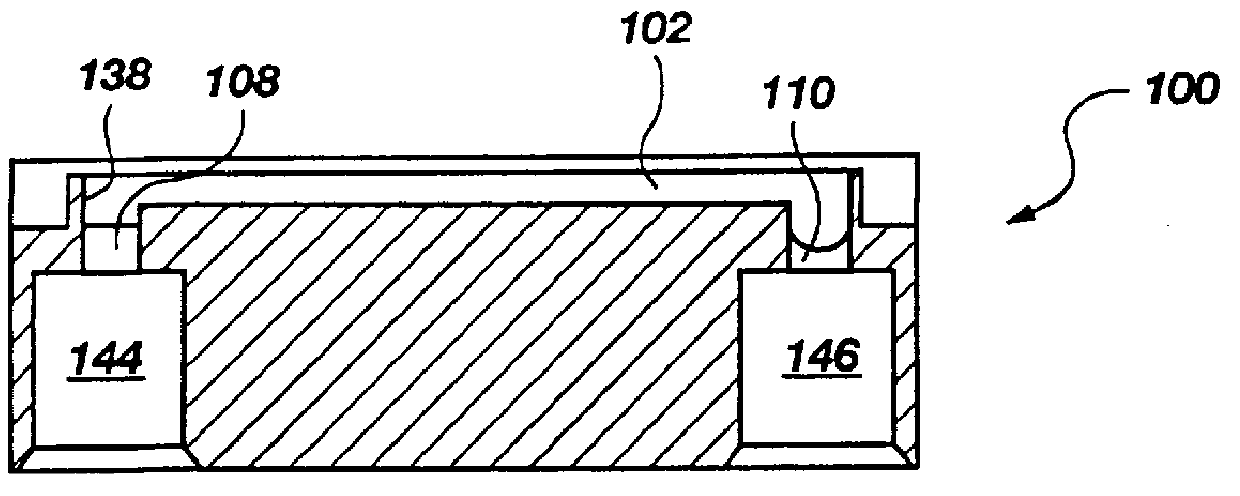

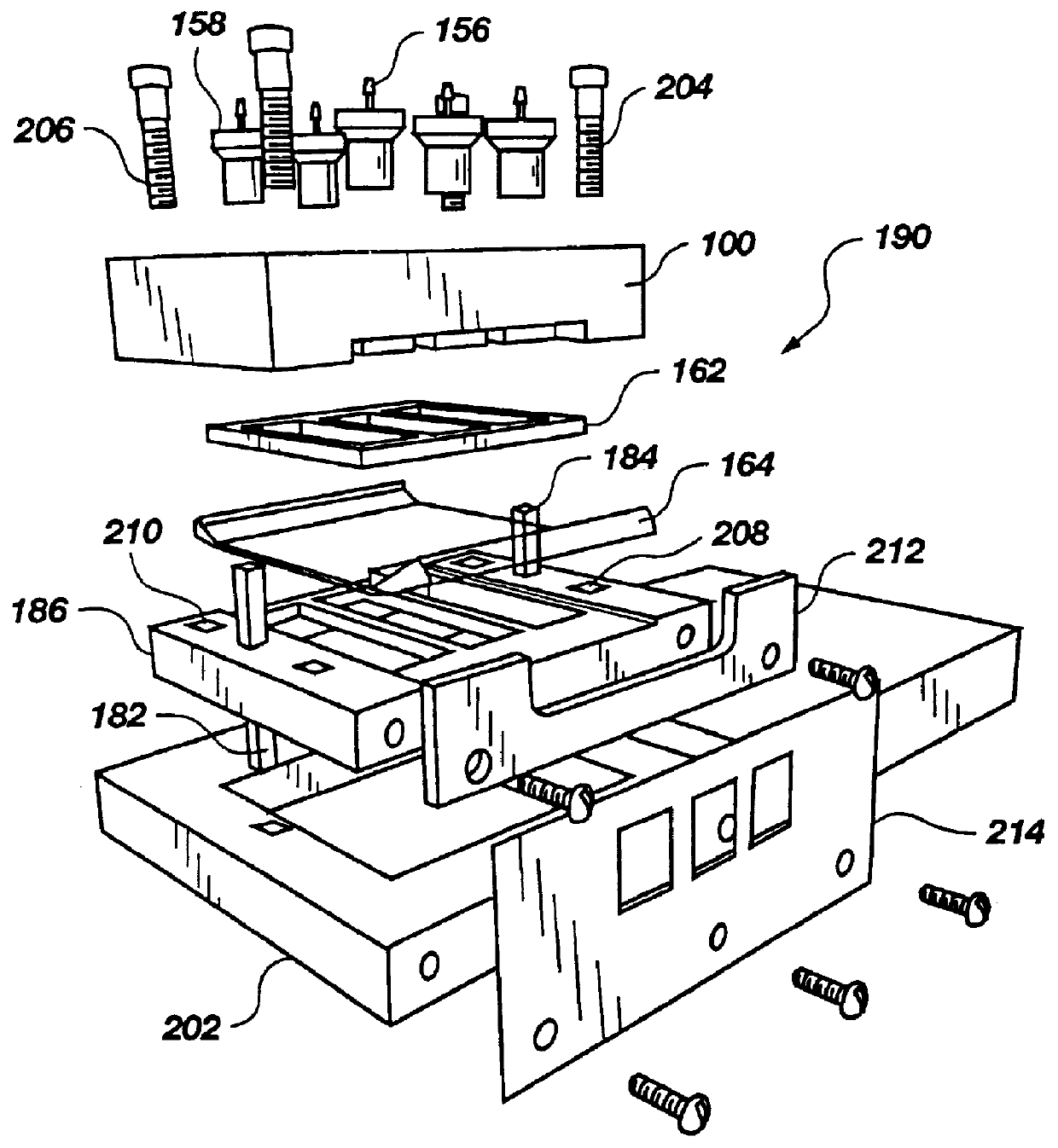

Lens and associatable flow cell

InactiveUS6108463AImprove abilitiesHigh degreeCoupling light guidesBiological testingCamera lensWaveguide

PCT No. PCT / US97 / 04398 Sec. 371 Date Sep. 18, 1998 Sec. 102(e) Date Sep. 18, 1998 PCT Filed Mar. 19, 1997 PCT Pub. No. WO97 / 35176 PCT Pub. Date Sep. 25, 1997Improvements in a biosensor of the type having reservoirs or wells for analyzing a biological liquid are disclosed. A biosensor (190) includes a waveguide (164) placed between a plurality of members such as plates (100, 186), at least one of the members (100) being formed to define the walls (132, 134, 136) of the reservoirs where the liquid is biologically analyzed. The walls of the reservoirs are made of an inert, opaque material such as a metal. Although the biosensor may include a gasket (162), the gasket is associated with the members and waveguide in such a way (e.g. by recessing the gasket into a channel formed into a metal plate) so that the gasket does not form any significant portion of the reservoir wall. Waveguides of varying composition (e.g. plastic, quartz or glass) may be associated with the members to form the biosensor. The metal plate of the biosensor has input and output ports for infusing, draining, or oscillating the liquid to be analyzed in the reaction reservoir. Also disclosed is a sled-shaped waveguide associated with a rear lens to couple light out of the waveguide to serve as a quality control measure thus insuring that the biosensor is properly placed and that the light is working.

Owner:UNIV OF UTAH RES FOUND

Glass-ceramic materials, precursor glass thereof and process-for making the same

The present invention relates to: novel glass-ceramics of β-quartz and / or of β-spodumene; articles made from said novel glass-ceramics; and ithium alumino-silicate glasses, which are precursors of said novel glass-ceramics; methods of preparing said novel glass-ceramics and articles made from said novel glass-ceramics. The present invention relates to the use of SnO2 and of Br, as an agent for fining the glass-ceramic glass precursor.

Owner:EUROKERA SOC & NOM COLLECTIF

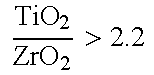

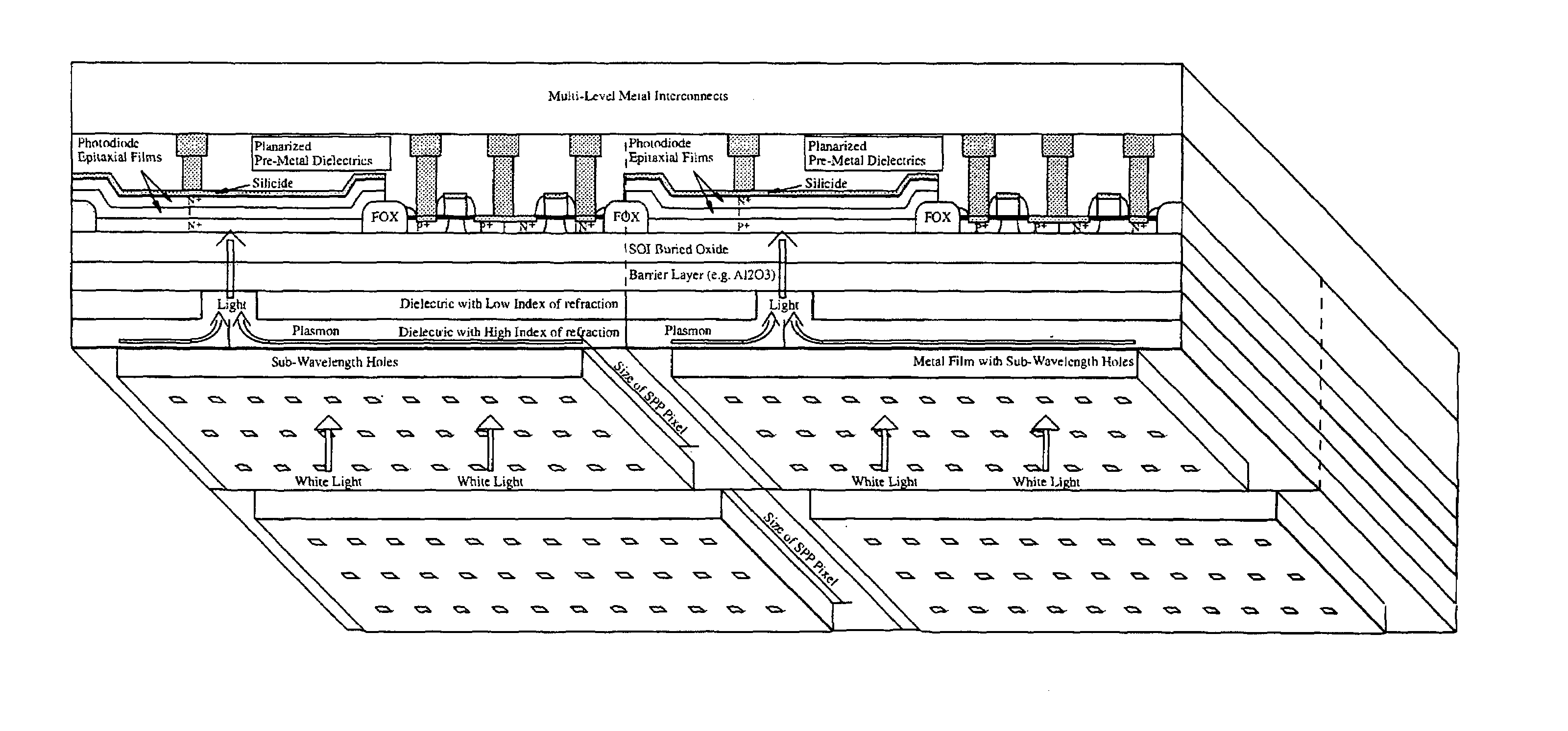

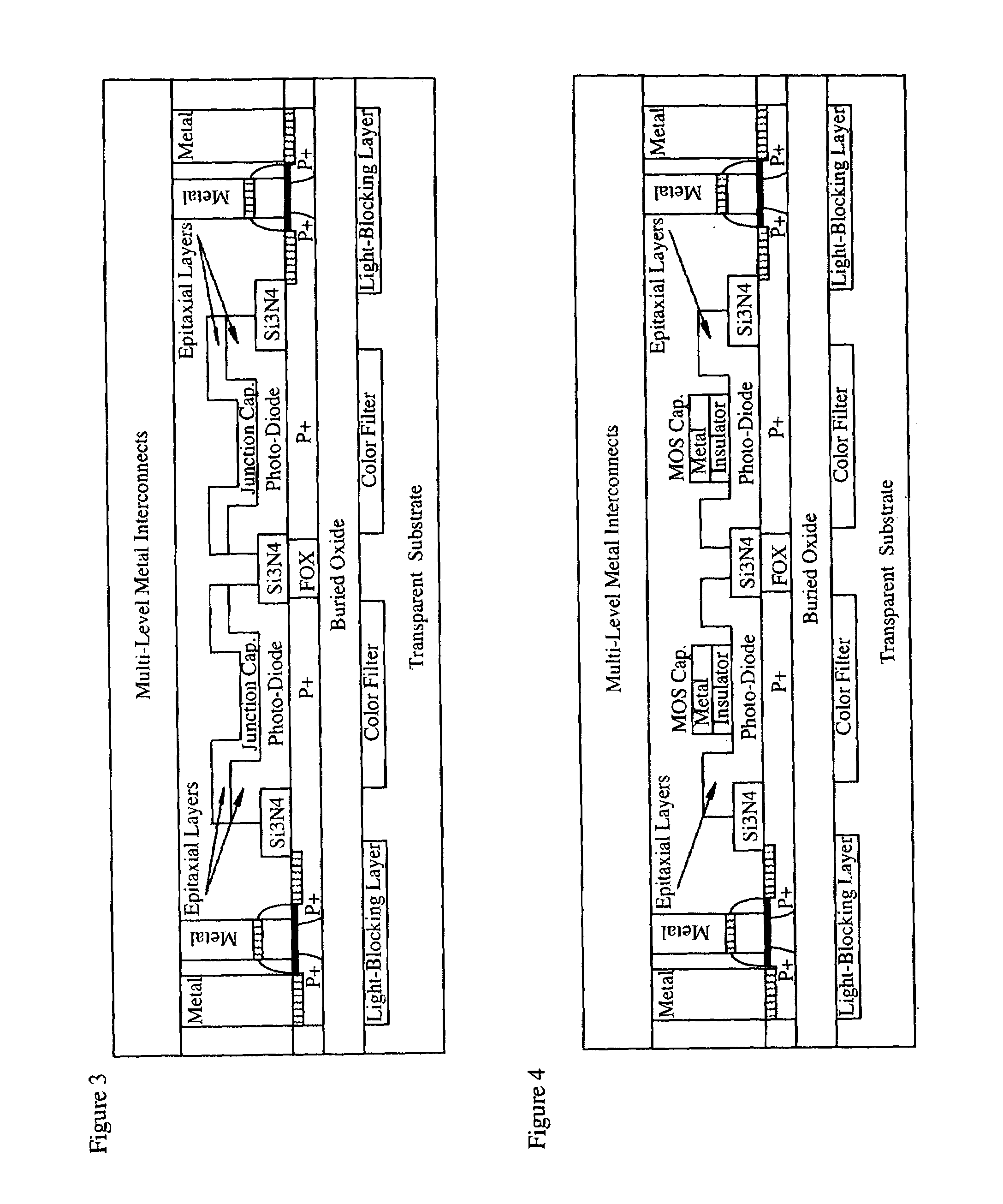

CMOS image sensor

Light sensing devices are monolithically integrates with CMOS devices on Thin-Film Silicon-On-insulator (TF-SOI) or Thin-Film Germanium-On-Insulator (TF-GeOI) substrates. Photo-diode active layers are epitaxially grown on the front-side of the substrate and after full processing of the front-side of the substrate, the substrate material is removed under the buried insulator (buried oxide). Monolithically integrated structures are then fabricated on the back of the buried oxide. The back-side is then bonded to a new substrate that is transparent to the wavelengths of interest. For example, quartz, sapphire, glass, or plastic, are suitable for the visible range. Back-side illumination of the sensor matrix is thereby allowed, with light traveling through the structures fabricated on the back of the substrate, opposite to the side on which CMOS is made.

Owner:QUANTUM SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com