Patents

Literature

387 results about "Keatite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Keatite is a silicate mineral with the chemical formula SiO₂ (silicon dioxide) that was discovered in nature in 2013. It is a tetragonal polymorph of silica first known as a synthetic phase. It was reported as minute inclusions within clinopyroxene (diopside) crystals in an ultra high pressure garnet pyroxenite body. The host rock is part of the Kokchetav Massif in Kazakhstan.

Flat float glass

InactiveUS6846760B2High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideTransmittance

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

Method for preparing porous silicon/carbon composite material by using diatomite as raw material and application

The invention provides a method for preparing a porous silicon / carbon composite material by using diatomite as the raw material, which is characterized by comprising the following steps of: with the diatomite as the raw material, performing simple refinement and purification processing to obtain silicon with a porous structure by means of metallothermic reduction; performing mechanical ball-milling with the carbon materials and / or precursors of carbon, hydro-thermal carbonization, pyrolytic carbonization or chemical vapor deposition to prepare the porous silicon / carbon composite material. Thecomposite material can be directly used as the cathode of the lithium ion battery, or can be mixed with other cathode materials to be used as the cathode materials of the lithium ion battery. Compared with a pure silicon material as the cathode material of the lithium ion battery, the porous silicon / carbon composite material has the advantages that the first reversible capacity and the circulation stability of the material are greatly improved. In the method, the inexpensive and accessible natural minerals are used as the raw materials, thus the cost is low and the preparation method is simple.

Owner:UNIV OF SCI & TECH BEIJING

Composite ceramic filter core and preparation method thereof

InactiveCN102924067AGood mesoporous materialHas a hydrophobic surfaceFiltration separationCeramicwareActivated carbonComposite ceramic

The invention relates to a composite ceramic filter core and a preparation method thereof, in particular to a low-temperature sintering and high-strength diatomaceous earth composite ceramic filter core containing multi-walled carbon nanotubes and a preparation method thereof. The composite ceramic filter core comprises, by mass, 60-80% of refined diatomaceous earth, 12-20 parts of activated carbon, 4.5-9 parts of dispersing agent, 2-6 parts of sintering additives, 1-3 parts of antibacterial agents and 0.5-2 parts of carbon nanotubes. According to the low-temperature sintering and high-strength diatomaceous earth composite ceramic filter core containing the carbon nanotubes, due to the fact that the multi-walled carbon nanotubes are evenly distributed in the composite ceramic filter core, mechanical performance of the ceramic filter core can be improved, and the multi-walled carbon nanotubes are of mesoporous structures simultaneously and can perform effective adsorption on remove heavy metal ions in water. In addition, the sintering temperature is reduced to be below 950 DEG C by adding micron-sized metal aluminum powder, natural nano micropores of the diatomaceous earth are reserved, the mechanical strength of the ceramic filter core is further improved, and the compression strength is above 0.5GPa.

Owner:珠海启月生物科技有限公司

Chemically and thermally pre-stressable lithium aluminosilicate float glass of high temperature resistance

ActiveCN1693247AGood quality bubblesImprove heat resistanceBase layers for recording layersGlass tempering apparatusArsenic oxideTemperature resistance

The invention provides a lithium aluminosilicate flat float glass with a high thermal stability which can be chemically and thermally tempered and is suitable for economical and environmentally friendly production. The lithium aluminosilicate flat float glass which can be chemically and thermally tempered, is refined without using a standard refining agent such as arsenic oxide and / or antimony oxide and has excellent thermal stability is constituted so as to contain 2.5-6.0 wt.% Li2O, 0<4 wt.% in total of Na2O+K2O, 0-4 wt.% B2O3, 15-30 wt.% Al2O3, 55-75 wt.% SiO2and <2 wt.% in total of TiO2+ZrO2(the undesirable crystallization of [beta]-quartz and / or keatite solid solution is prevented) as main components per the weight of the total compositions.

Owner:SCHOTT AG

Process for synthesizing ZSM-5 molecular sieve

InactiveCN1504410ALow costAvoid the disadvantages of difficult stirring and poor mass and heat transferPentasil aluminosilicate zeoliteSlurrySolid content

The invention provides a process for synthesizing ZSM-5, characterized in that, diatomaceous soil is used as a silicon source, and total or part of aluminum source to be mixed with other aluminum source, NaOH and water, 0-10 wt.% molecular sieve is added in as seed crystal to prepare slurry of reaction mixture, performing water thermal crystallization in normal condition. The process can reduce gelatification, increase solid content and reduce the cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

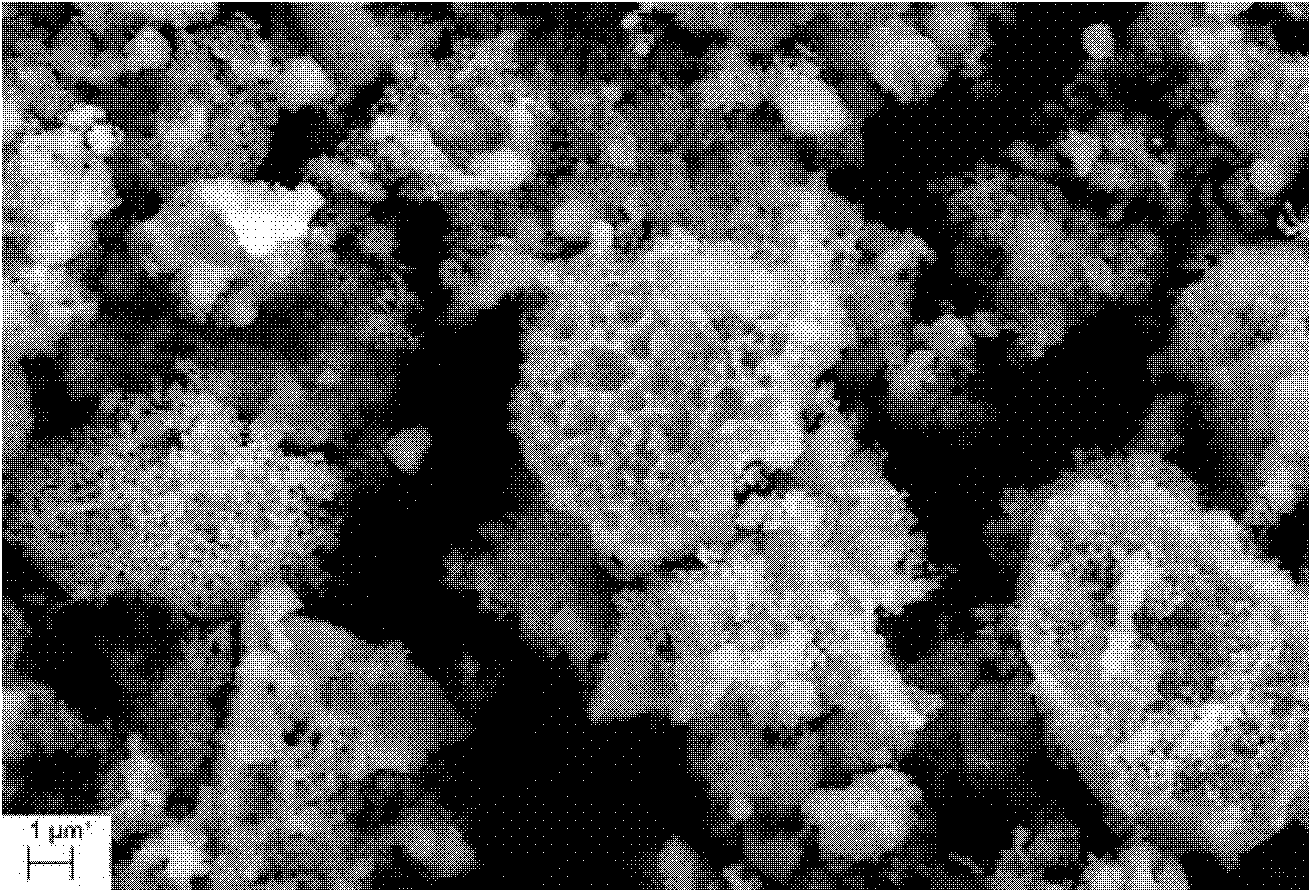

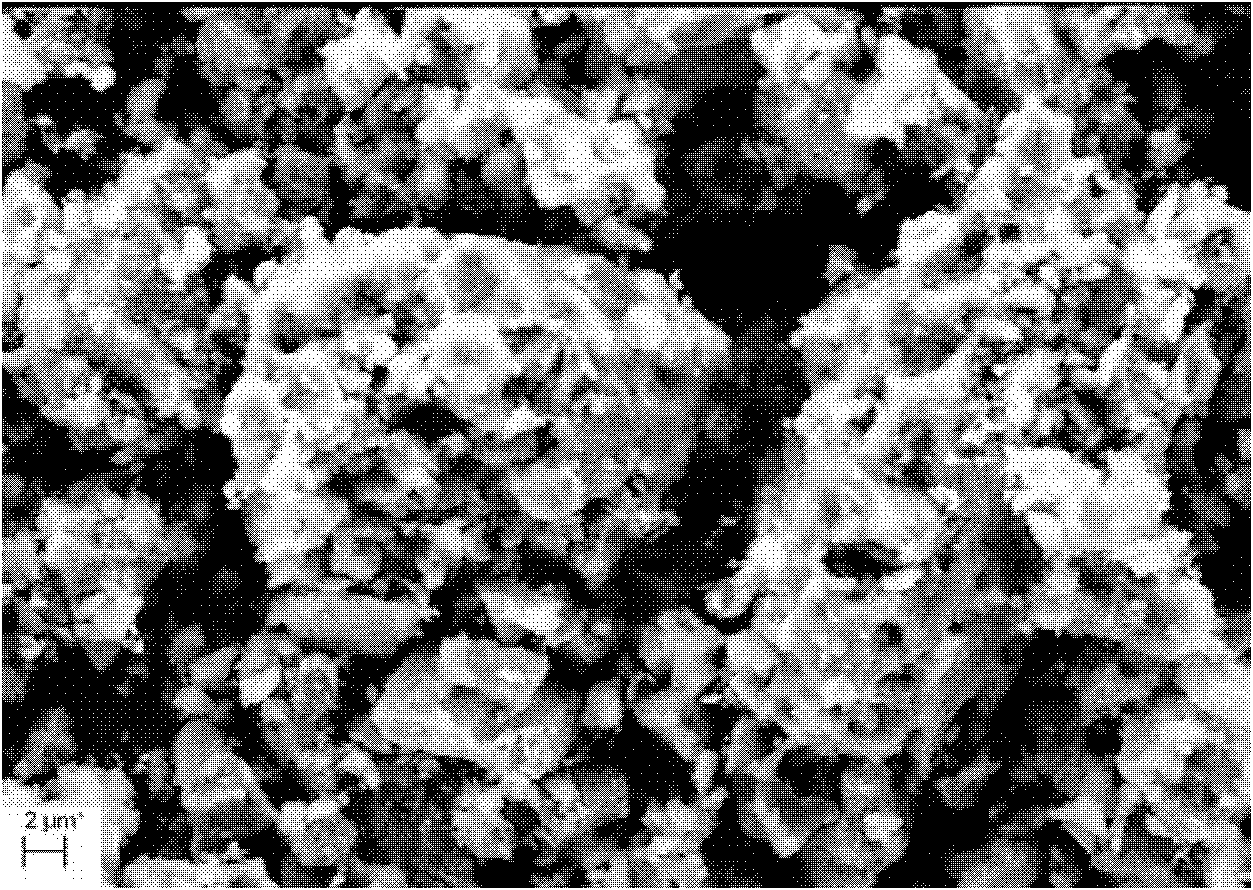

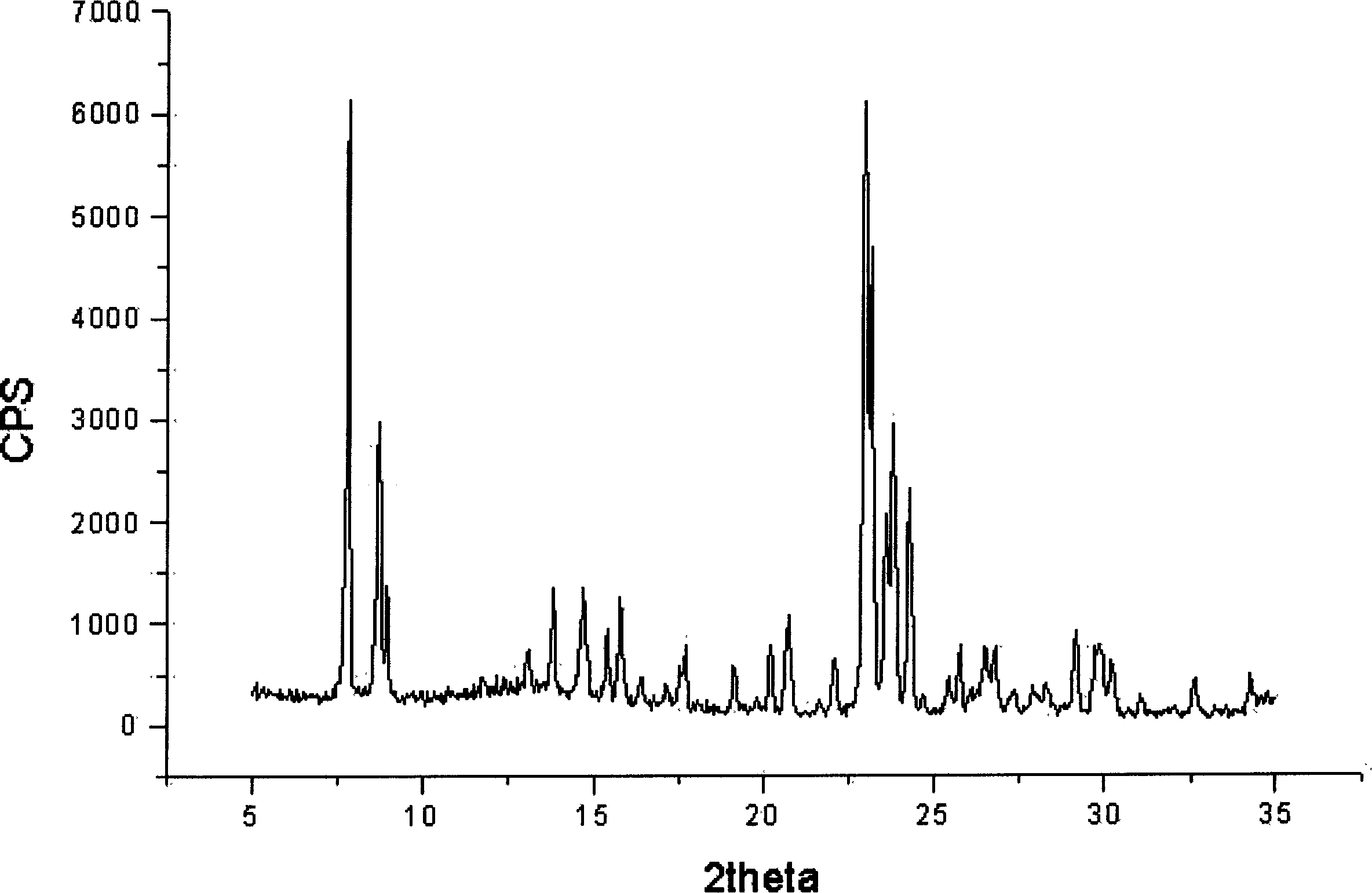

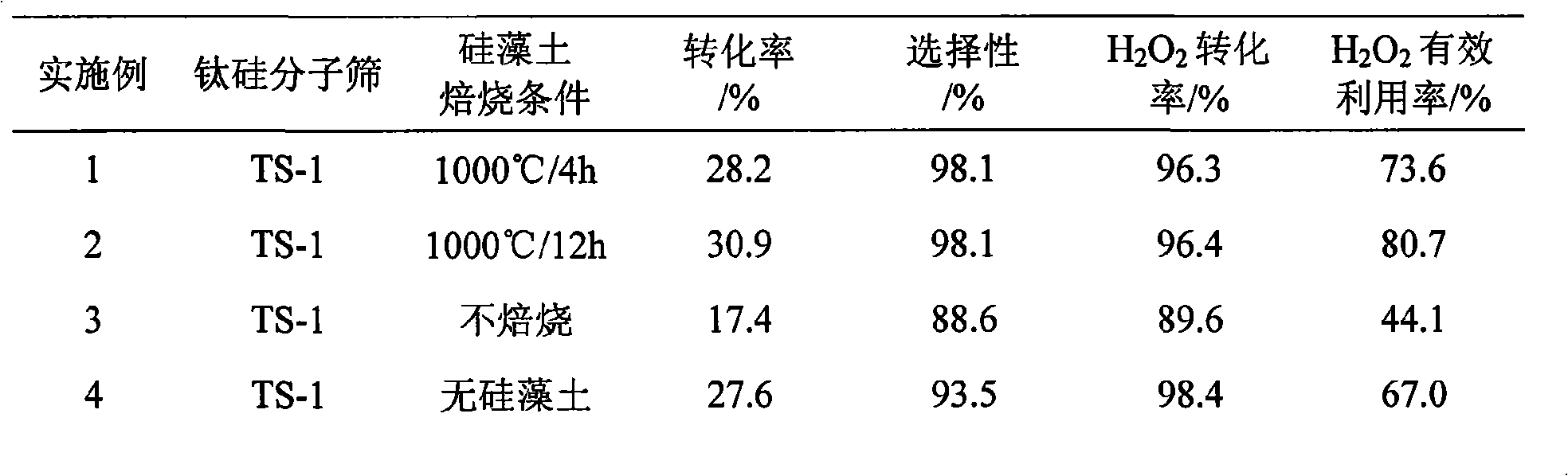

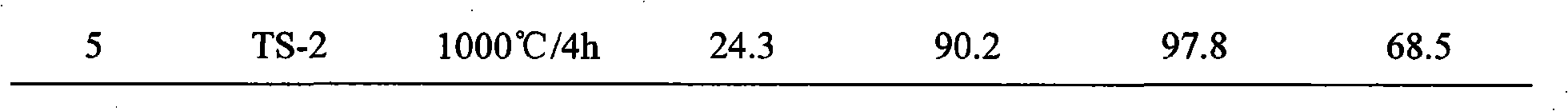

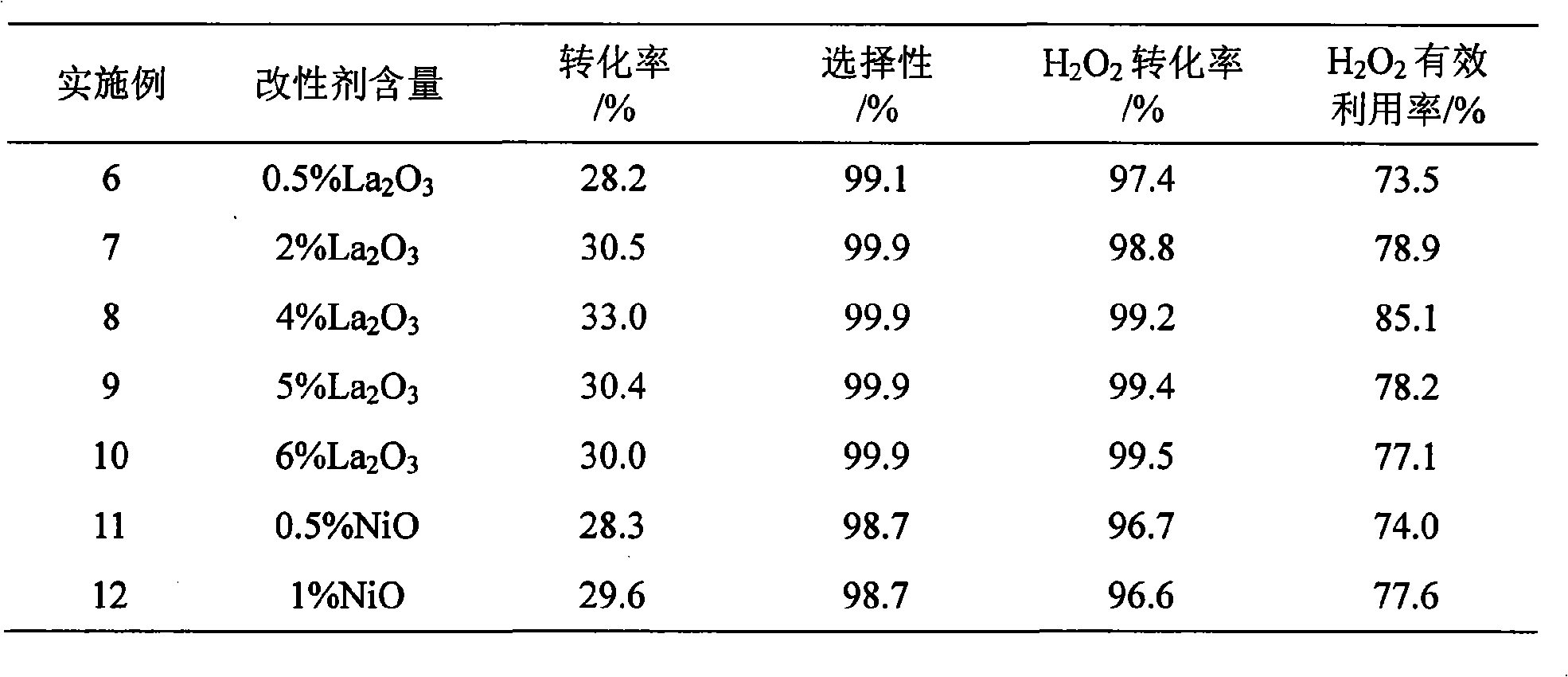

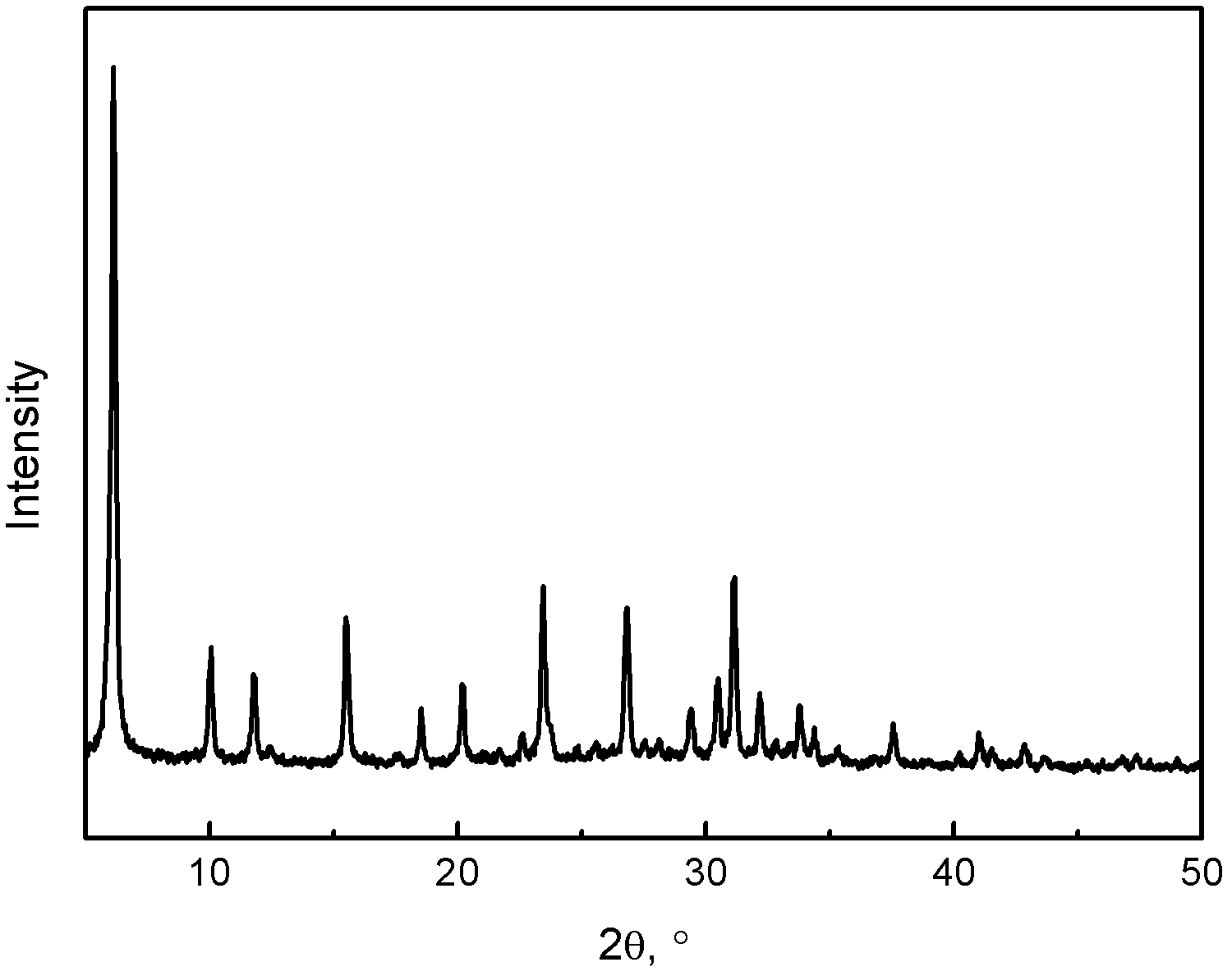

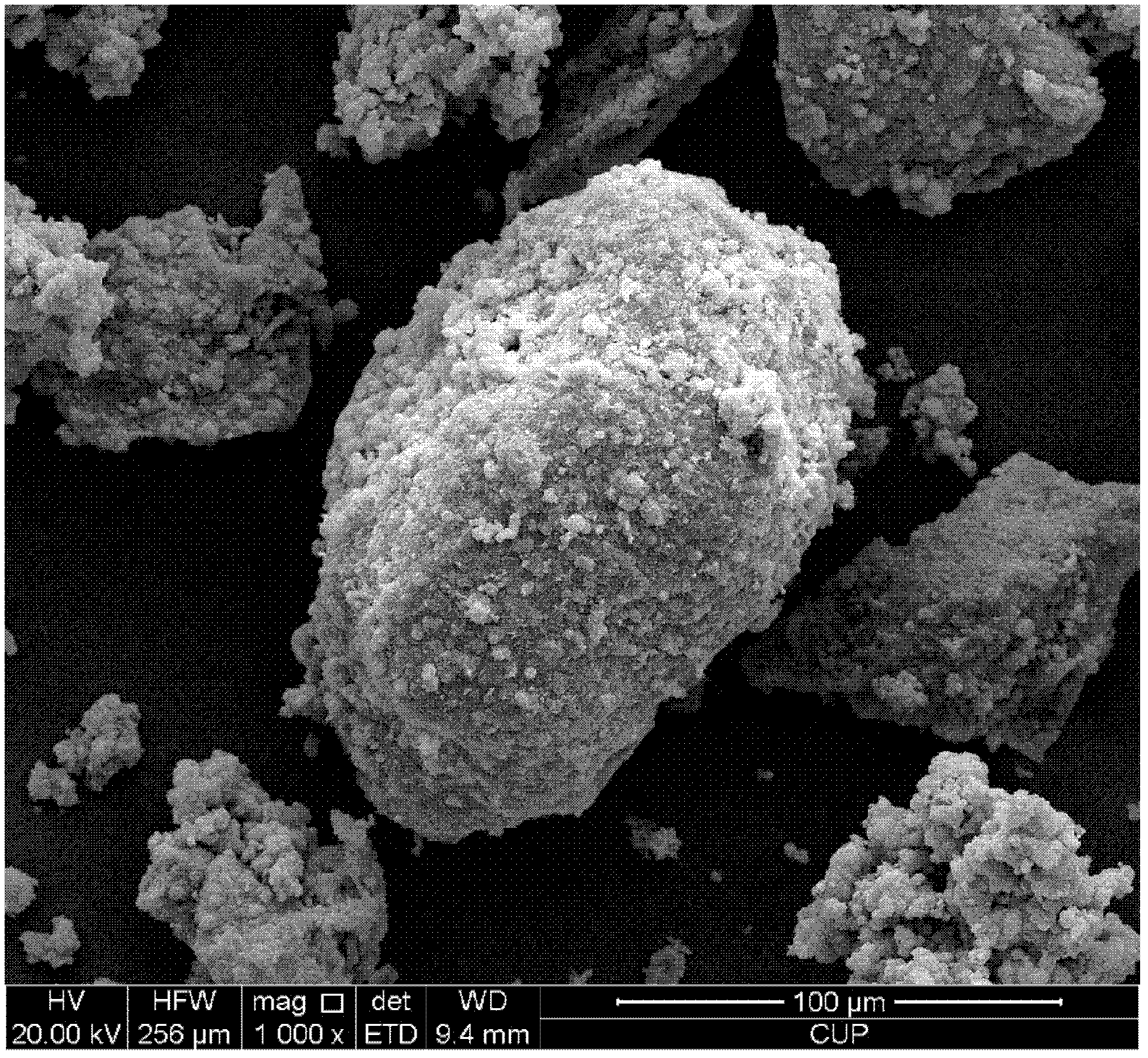

Titanium-silicon molecular sieve/tripolite composite catalyst and preparation

InactiveCN101264453AImprove catalytic performanceHigh selectivityOrganic oxidationMolecular sieve catalystsFixed bedLanthanum

The invention discloses a Ti-Si molecular sieve / diatomite composite catalyst and a preparation method thereof, which is characterized in that: the catalyst is formed by compounding Ti-Si molecular sieve (such as TS-1 and TS-2) and diatomite with particular chemical property which is treated in a particular way, and is modified chemically by transition metal oxide after molding; the preparation method comprises the following steps: (1) after being treated with acid solution and alkaline solution, the diatomite needs heat treatment in high temperature to obtain particular chemical property; (2) the molding Ti-Si molecular sieve / diatomite composite catalyst is modified chemically by transition metal oxide (such as lanthanum and nickel). The composite catalyst can be used as the catalyst of selective oxidation reaction of the organic compound (such as the catalytic hydroxylation reaction of phenol) on fixed bed liquidoid, which uses hydrogen peroxide as the oxidant. The Ti-Si molecular sieve / diatomite composite catalyst has the advantages of high catalytic activity, high stability, long service life and easy separation, recovery and regeneration of the catalyst. When using the catalyst in the hydroxylation reaction of phenol of fixed bed liquidoid, under the reaction conditions of 84 DEG C, atmospheric pressure and 8.46h<-1> space velocity, the conversion rate of phenol is greater than 33%, the selectivity of diphenol reaches 99.9%, and the effective use rate of hydrogen peroxide is greater than 85%.

Owner:EAST CHINA UNIV OF SCI & TECH

Magnesium-alloy metal-type casting coating and preparation method thereof

ActiveCN101658899ASimple componentsEasy to prepareFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention relates to a magnesium-alloy metal-type casting coating and a preparation method thereof. Magnesia and forsterite are used as refractory aggregates; titania, asbestos powder or talcum powder or diatomite, and the like are added as heat-insulation aggregates; a mixed caking agent with favorable high-temperature caking property and a compound suspending agent are selected; and boric acid is added as a flame retardant. The preparation method comprises the following steps: mixing the magnesia, the forsterite, the titania, and the asbestos powder or talcum powder or diatomite, and preparing A after ball milling; mixing the caking agent and bentonite, and adding water to activate so as to obtain B; mixing the boric acid, sodium carboxymethyl cellulose and polyacrylamide, and addingwater to activate so as to obtain C; and finally, mixing A, B and C, and carrying out ball milling or colloid milling for more than 30 minutes to obtain the magnesium-alloy metal-type casting coating. The coating has the advantages of favorable heat insulation, caking property, coating property, flame retardance, stability and durability, is beneficial to continuous production and convenient forobtaining magnesium-alloy metal-type castings with favorable surface quality and superior performance, and prolongs the service life of moulds.

Owner:SHANGHAI JIAO TONG UNIV

NaY molecular sieve/natural mineral composite material having multistage pore structure and preparation method thereof

ActiveCN103043680ALower synthesis costReduce manufacturing costFaujasite aluminosilicate zeoliteIn situ crystallizationMolecular sieve

The invention belongs to the technical field of petrochemical industry, and relates to a NaY molecular sieve / natural mineral composite material having a multistage pore structure and a preparation method thereof. The composite material is a crystal product formed through in-situ crystallization by taking a natural kaolin mineral and a natural kieselguhr mineral as entire silicon sources and aluminum sources for molecular sieve synthesis and using the minerals as substrates for molecular sieve growth. In the composite material, the mass percent of the NaY molecular sieve is 25-50%, and the silicon-aluminum ratio of the NaY molecular sieve is 3-5.5. The invention widens the raw material sources in the preparation of the molecular sieve / natural mineral composite material through an in-situ synthesis method, and can simultaneously greatly lower the production cost of the molecular sieve / natural mineral composite material.

Owner:PETROCHINA CO LTD +1

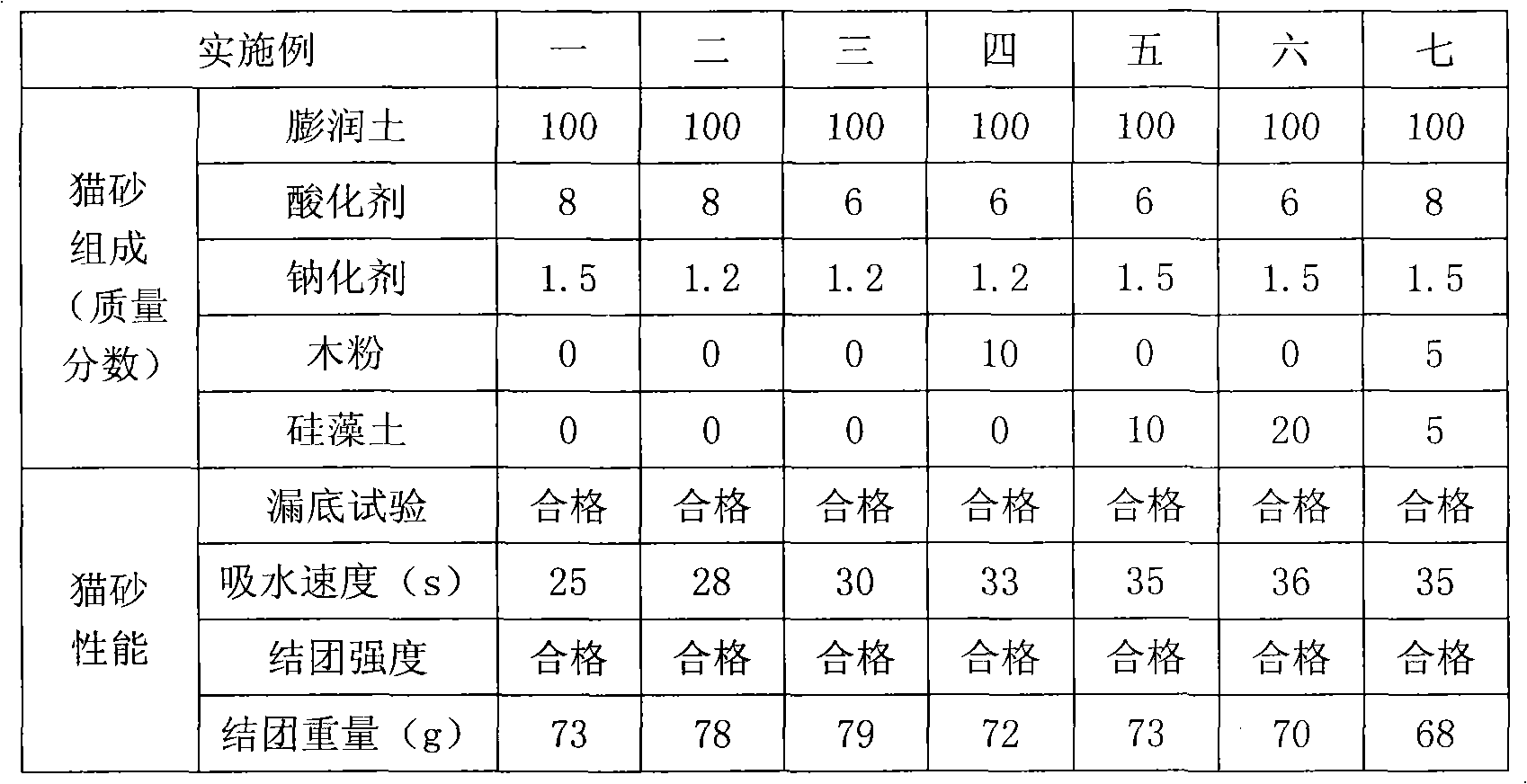

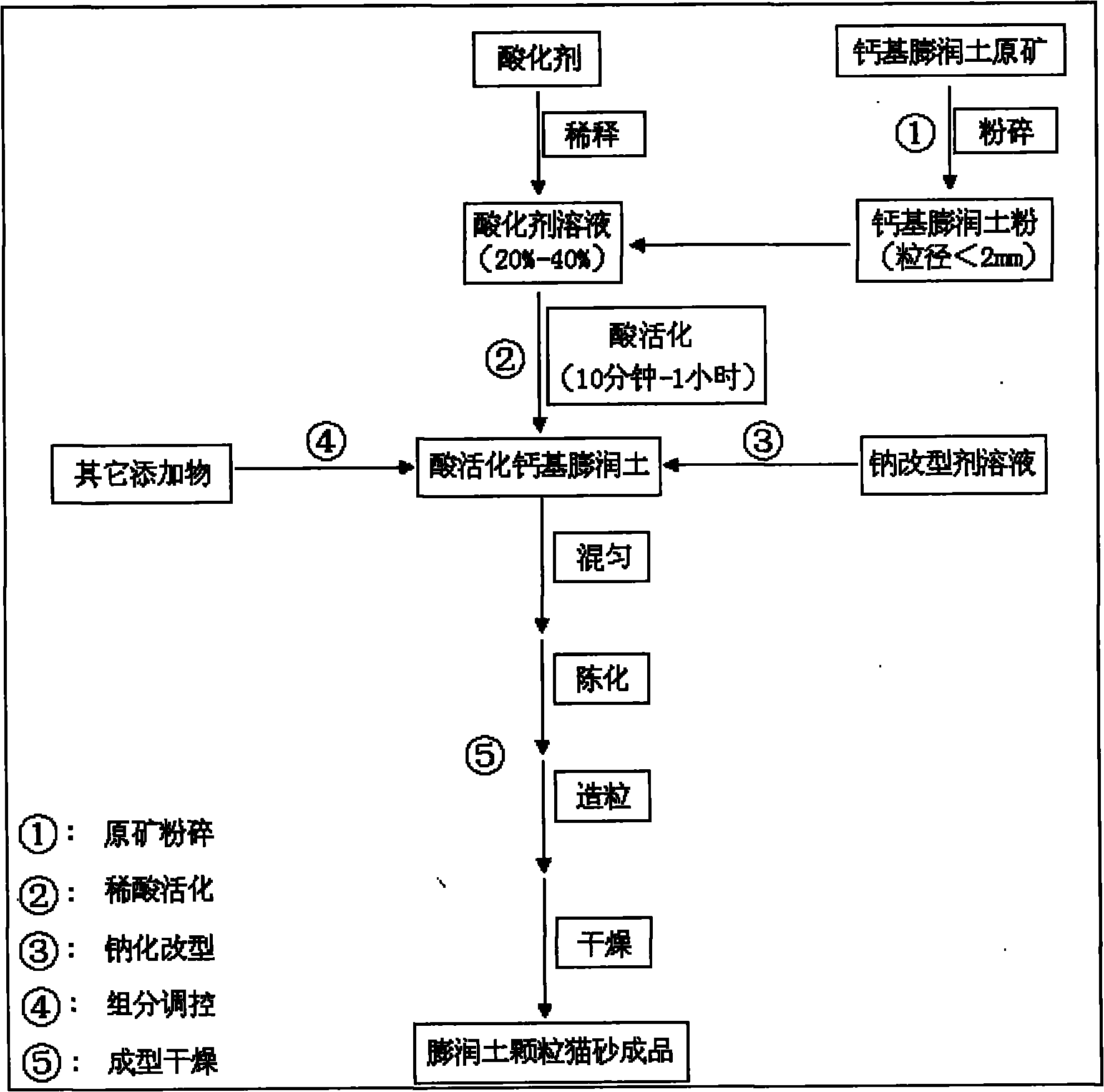

Method for producing bentonite cat litter

The invention discloses a method for producing bentonite cat litter by calcium-based bentonite. The method comprises the following steps of: grinding, acidification, sodium-modification, forming, drying and the like. In method, the calcium-based bentonite crude ores are used as a starting point, the bentonite slices are acidified and corroded by an acidifier so as to greatly increase a specific surface area of the bentonite, a sodium-modification agent is used for sodium-modification of the acidified calcium-based bentonite so as to improve a water absorption rate and bonding property of the bentonite, other additives such as wood flour and diatomite are added so as to adjust indexes, such as density and whiteness, of the cat litter, and finally the bentonite undergoes granulation, drying, screening and the like to form the bentonite cat litter having the advantages of quick water absorption, large amount of water absorption, high whiteness and high strength. The method has the advantages of good quality of the bentonite cat litter prepared by the method, simple process and low cost.

Owner:INNER MONGOLIA UNIVERSITY

Porous material and its synthesis method

ActiveCN1751994AHas a compound pore structureMolecular sieve catalystsCrystalline aluminosilicate zeolitesSynthesis methodsAluminium hydroxide

A process material with compound artery is prepared from the Si source chosen from amorphous SiO2, si sol, silicon oxide solid, silicon gel, diatomite and water glass, the Al source chosen from sodium aluminate, sodium metaaluminate, aluminium sulfate, aluminium nitrate, etc, at least one of lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide and cesium hydroxide, and template agent through proportional mixing, reaction, ageing and crystallizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Centrifugal casting radiant tube paint and preparation method thereof

ActiveCN101502868AWide variety of sourcesLow costFoundry mouldsFoundry coresCrack resistanceSodium Bentonite

The invention is a centrifugal casting radiant tube coating and a preparation method thereof, the coating comprises the ingredients (mass percent) of: 25-30% of diatomite of, 5-10% of zircon powder, 1.0-1.2% of titanium powder, 1.5-1.8% of iron powder, 4.5-5.0% of sodium bentonite, 2.0-2.5% of polyvinyl alcohol, 0.8-1.0% of sodium alginate, 3.5-4.0% of silica sol, 0.8-1.0% of sodium dodecylbenzene sulfonate, 0.05-0.08% of silane and 46.82-49.95% of water, wherein, the mass percent of the diatomite and the zircon powder is not less than 35% and not more than 37%, the mass percent of the titanium powder and the iron powder is not less than 2.7% and not more than 2.9%, and the mass percent of the sodium bentonite plus the polyvinyl alcohol plus the sodium alginate is not less than 8.0% and not more than 8.2%. The inventive coating is used for the centrifugal casting radiant tube after dry-blending, mixed grinding and sieving, uniformly distributed bulges (namely pitting surface) can be formed on the outer surface of the radiant tube to improve heat efficiency of the radiant tube. The inventive coating also has excellent adhesive force, high temperature strength and crack resistance, thus reducing defects on the surface of the radiant tube and improving quality of complex tube. Using the inventive coating to cast the radiant tube can result in remarkable economical benefit.

Owner:靖江市黎明铸造材料厂

Decorative brick with diatomite as main component

The invention discloses a decorative brick with diatomite as a main component. The decorative brick with the diatomite as the main component comprises the following components: 20-40 percent of refined diatomite, 50-70 percent of gypsum powder, 1-3 percent of plant fiber, 3-8 percent of titanium white powder, 0.5-2 percent of nano titanium dioxide and 1-3 percent of negative ion material. The decorative brick with the diatomite as the main component is made by adding a proper amount of plant pigment and water, uniformly stirring the mixture into paste, pouring the paste into a mould, solidifying and demoulding, putting into a drying box, and drying for 11-13 hours at the temperature of 70-90 DEG C. The diatomite brick has the characteristics that: the diatomite material with an air purifying function does not contain any harmful substance, has the functions of adsorbing and decomposing harmful gas, has a strong air humidity regulating function, and can be made into decorative bricks and mosaic tiles with different shapes; the transportation and the construction are simple; and the decorative bricks can be bonded onto a wall surface on site by using a special bonding agent.

Owner:JILIN PROVINCE LANSHE DIATOM NEW MATERIALS

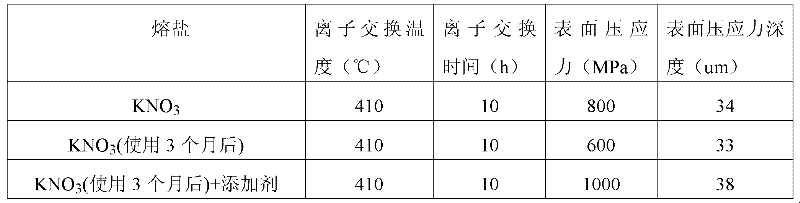

Additive and chemical tempering process for glass

InactiveCN102503101AReduce replacement frequencyExtended service lifeGlass tempering apparatusPotassium hydroxideIon exchange

The invention provides an additive which can accelerate ion exchange, purify a molten salt and prolong the service life of the molten salt aiming at the KNO3 molten salt in low-temperature ion exchange. The additive comprises the following components in percentage by weight: 2 to 10 percent of potassium hydroxide, 4 to 12 percent of potassium carbonate and 78 to 94 percent of kieselguhr. The chemical tempering process for glass comprises the following steps of: (1) adding the additive into the KNO3 molten salt in a weight ratio of the additive to the KNO3 molten salt of (1:15)-(1:25), heating to the temperature of between 400 and 440 DEG C, and keeping constant temperature for 24 to 72 hours; (2) heating the glass to the temperature of between 300 and 380 DEG C, and keeping the temperature for 30 to 90 minutes; and (3) putting the glass into the molten salt, and processing for 4 to 24 hours to obtain chemical tempered glass. According to the chemical tempering process, the additive is added into the KNO3 molten salt, so impurities in the molten salt can be adsorbed, the molten salt is purified, the quality of the ion exchange is stabilized, the replacement frequency of the molten salt is reduced, the service life of the molten salt is prolonged, and the production cost is reduced.

Owner:CDGM OPTICAL GLASS

Lead and cadmium-free glass composite for coating porcelain glaze and enamel on and decorating glass or glass ceramics

The invention relates to lead and cadmium-free glass composite for coating porcelain glaze and enamel on and decorating glass or glass ceramics. Particularly, the invention relates to lead and cadmium-free glass for coating porcelain glaze and enamel on and decorating glass or glass ceramics, which takes high-quartz mixed crystal and / or keatite mixed crystal as a main crystal phase after crystallization, has low-heat expansion which is less than 2X10-6 at the temperature of between 20 and 700 DEG C, and comprises the following components in percentage by weight: 0 to 5 percent of LiO2, 0 to 5 percent of Na2O, 0 to 2 percent of K2O, 1 to 1 percent of sigma Li2O+Na2O+K2O, 0 to 3 percent of MgO, 0 to 4 percent of CaO, 0 to 4 percent of SrO, 0 to 4 percent of BaO, 0 to 4 percent of ZnO, 15 to 27 percent of B2O3, 10 to 20 percent of Al2O3, 43 to 58 percent of SiO2, 0 to 3 percent of TiO2, 0 to 4 percent of ZrO2, 0 to 2 percent of Sb2O3, 0 to 3 percent of F which is used for replacing oxygen, and at most 30 percent of dye which is stabilized at the sintering temperature.

Owner:SCHOTT AG

Multifunctional filter material for circulating water treatment and preparation method thereof

InactiveCN101857311AReduce scaleEfficient removalScale removal and water softeningBiological water/sewage treatmentSodium bicarbonateSludge

The invention discloses a multifunctional filter material for circulating water treatment, which is prepared from 1 to 10 weight percent of nano tourmaline powder, 55 to 80 weight percent of coarse tourmaline powder, 1 to 15 weight percent of kieselguhr, 1 to 15 weight percent of sepiolite powder, 1 to 15 weight percent of scallop powder, 1 to 10 weight percent of sodium bicarbonate and 0.5 to 1 weight percent of silver-carried zeolite powder. A preparation method comprises the following steps of: stirring and mixing raw materials uniformly, injecting the uniformly mixed powder into a turntable machine, and rotating the powder for 15 to 30 minutes with controlled humidity of 15 to 50 percent and rotational speed of 20 to 200 revolutions per minute by using attapulgite of 0.1 to 1 millimeter as a core; and finally sintering the powder for 4 to 8 hours at the temperature of between 400 and 600 DEG C in a muffle furnace to form a ceramic filter material with the diameter of 1 to 10 millimeters. The filter material can effectively remove Ca2+ and Mg2+ from the water and achieve the effects of inhibiting scales, preventing corrosion and removing biological sludge.

Owner:厦门柏斯顿智能科技有限公司

Crystalline silica-free diatomaceous earth filter aids and methods of manufacturing the same

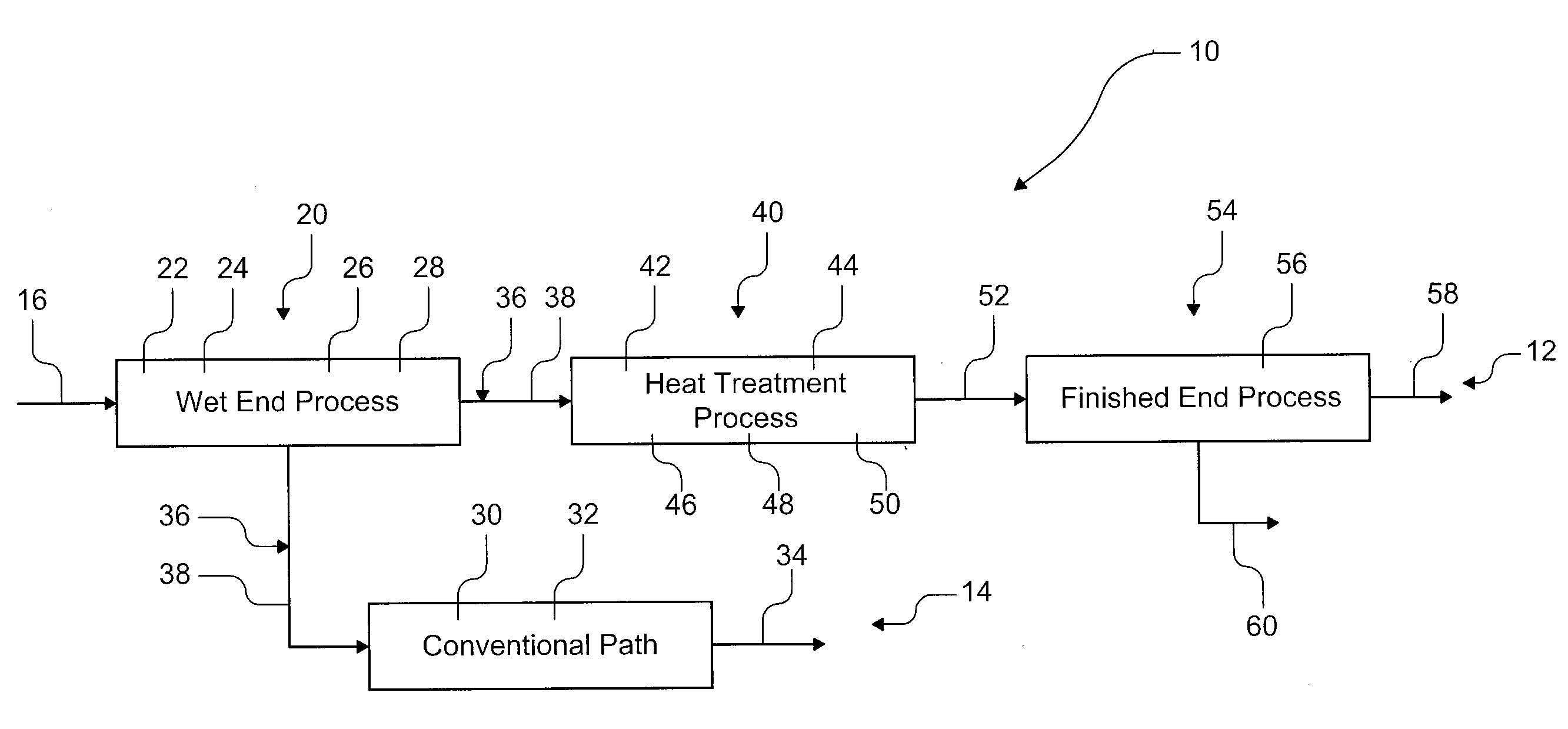

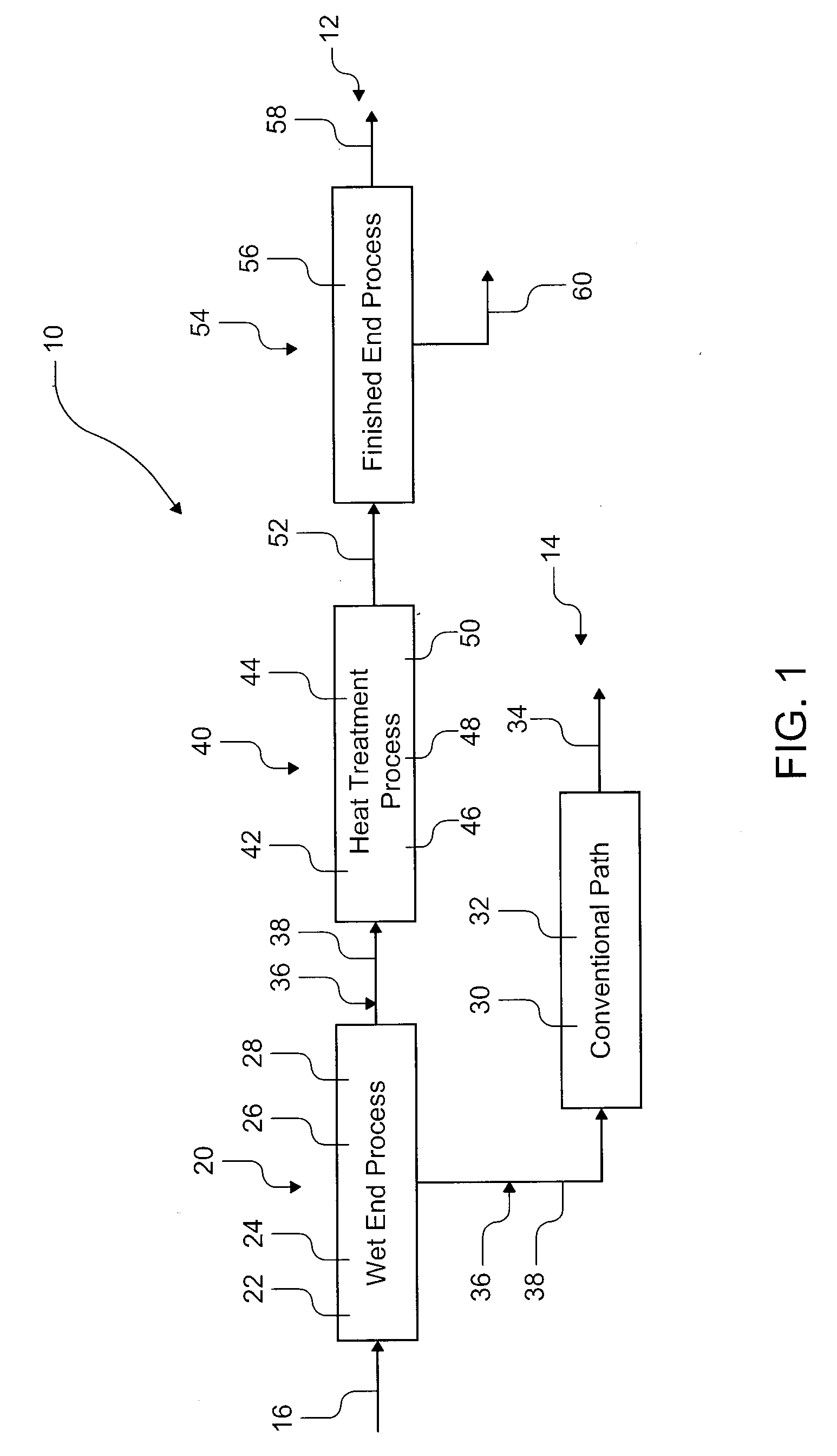

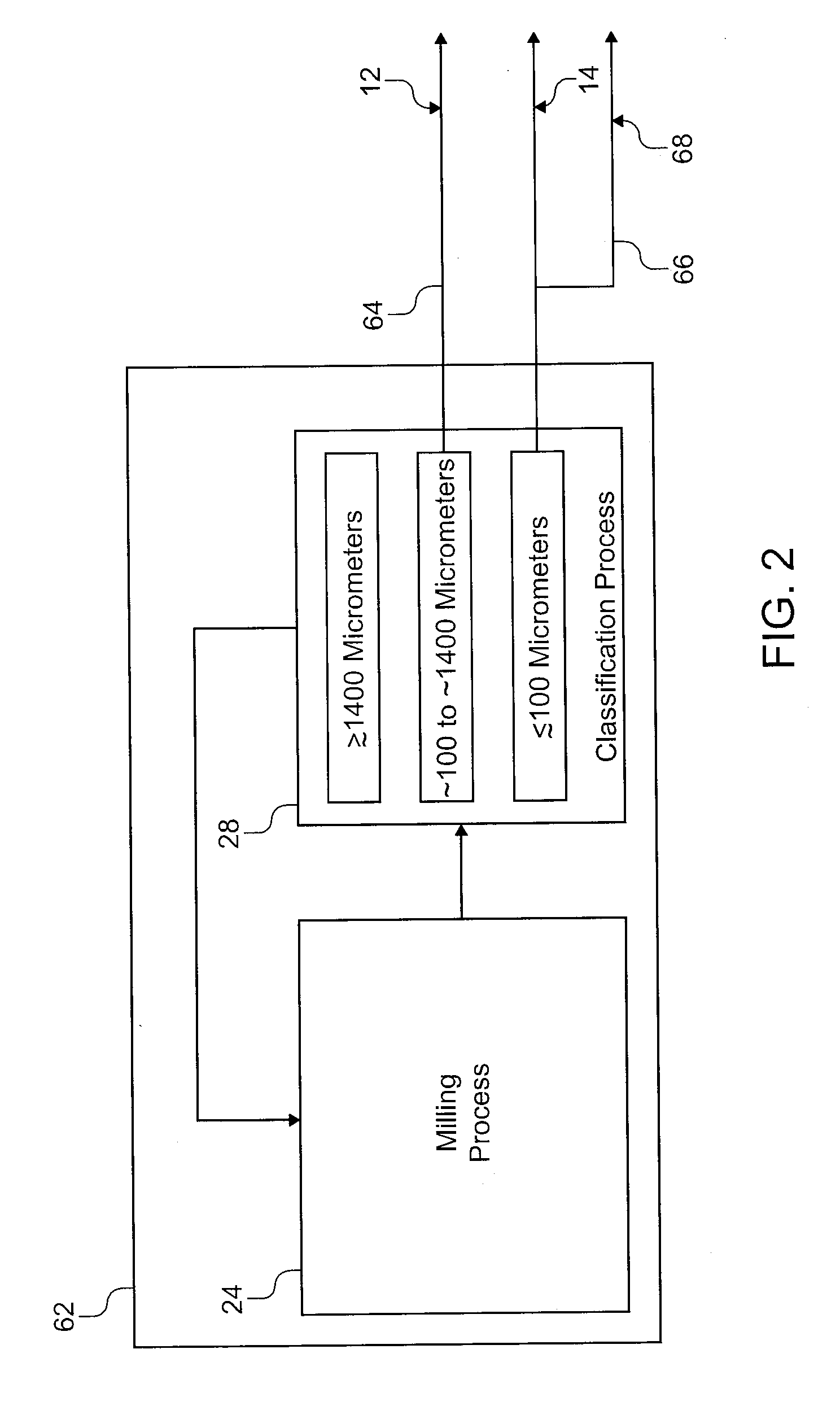

A method of producing a range of diatomaceous earth filter aids having selectable permeabilities and less than about 1 percent by weight total crystalline silica. The method includes milling diatomaceous earth ore to a size range of between about 100 micrometers and about 1400 micrometers; calcining the milled diatomaceous earth in a calciner; and milling the calcined diatomaceous earth in an adjustable milling and classification system to produce diatomaceous earth filter aids. Systems to implement such methods and compositions produced by such methods are also described.

Owner:EP MINERALS LLC

Method for preparing mesoporous silica material

The invention provides a method for preparing a mesoporous silica material, which comprises: grinding raw materials, which comprises one or more of rice hull ash from biomass power plants, silicon dioxide(SiO2)-containing smoke dust from metallurgical enterprises, micro silicon powder from metallurgical silicon plants and natural kieselguhr minerals, into fine powder, stirring and mixing the fine powder with 0.5 to 4 mol / L solution of hydrochloric acid, processing for 2 to 4 hours at 40 to 60 DEG C and separating out an intermediate raw material; mixing the intermediate raw material, NaOH, structure director and H2O in a molar ratio of 1:0.2-0.5:0.05-0.2:150-200 and stirring for 8 to 24 hours; performing hydrothermal synthesis or microwave synthesis and regulating the pH value of the synthesis solution to 10 to 12; and drying the synthesis solution, roasting for 2 to 5 hours at 400 to 800 DEG C, and cooling to obtain the mesoporous silica material. In the invention, the provided process flow is short; the operation is simple; the application range is wide; the product performance is high; the environmental load is small; the energy consumption is low; the cost is low; the added value of the product is high; and the problem of the shortage of a mesoporous silica raw material is solved.

Owner:KUNMING UNIV OF SCI & TECH

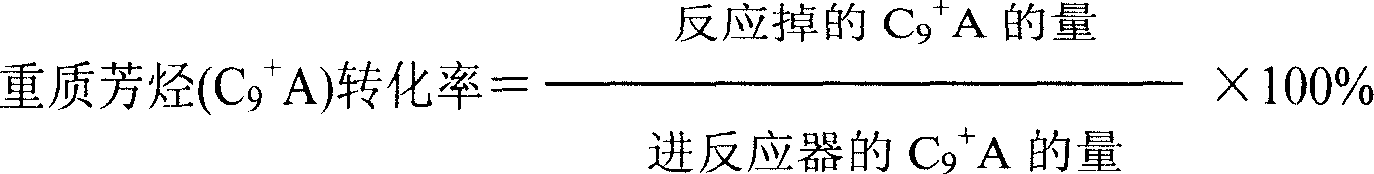

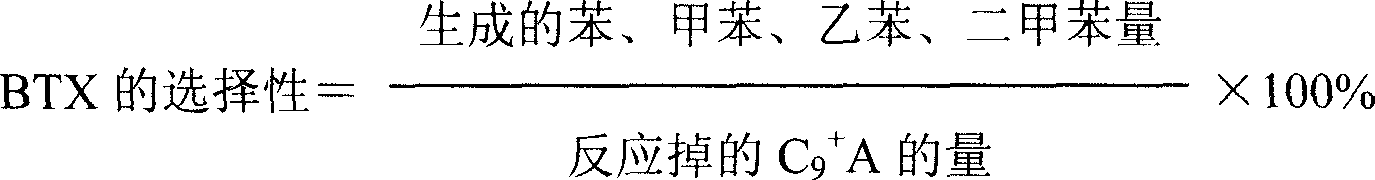

Catalyst used for heavy arene lightenation and alkyl transfer and its preparation method

InactiveCN100998950AHigh acid strengthIncrease acidityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAlkyl transfer

A catalyst for lightening heavy arylhydrocarbon and transferring alkyl with high transform rate and low cost is prepared from the beta-zeolite and mordenite symbiotic molecular sieve (10-80 Wt%) and at least one inorganic adhesive chosen from gamma- Al2O3, alpha-AlO(OH), SiO3, silicon aluminum oxide, bentone, kaolinite, diatomite and montmorillonite through ammonium salt exchange to said symbiotic molecular sieve, calcining to become hydrogen-type symbiotic molecular sieve, mixing it with said adhesive, shaping, drying, and calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

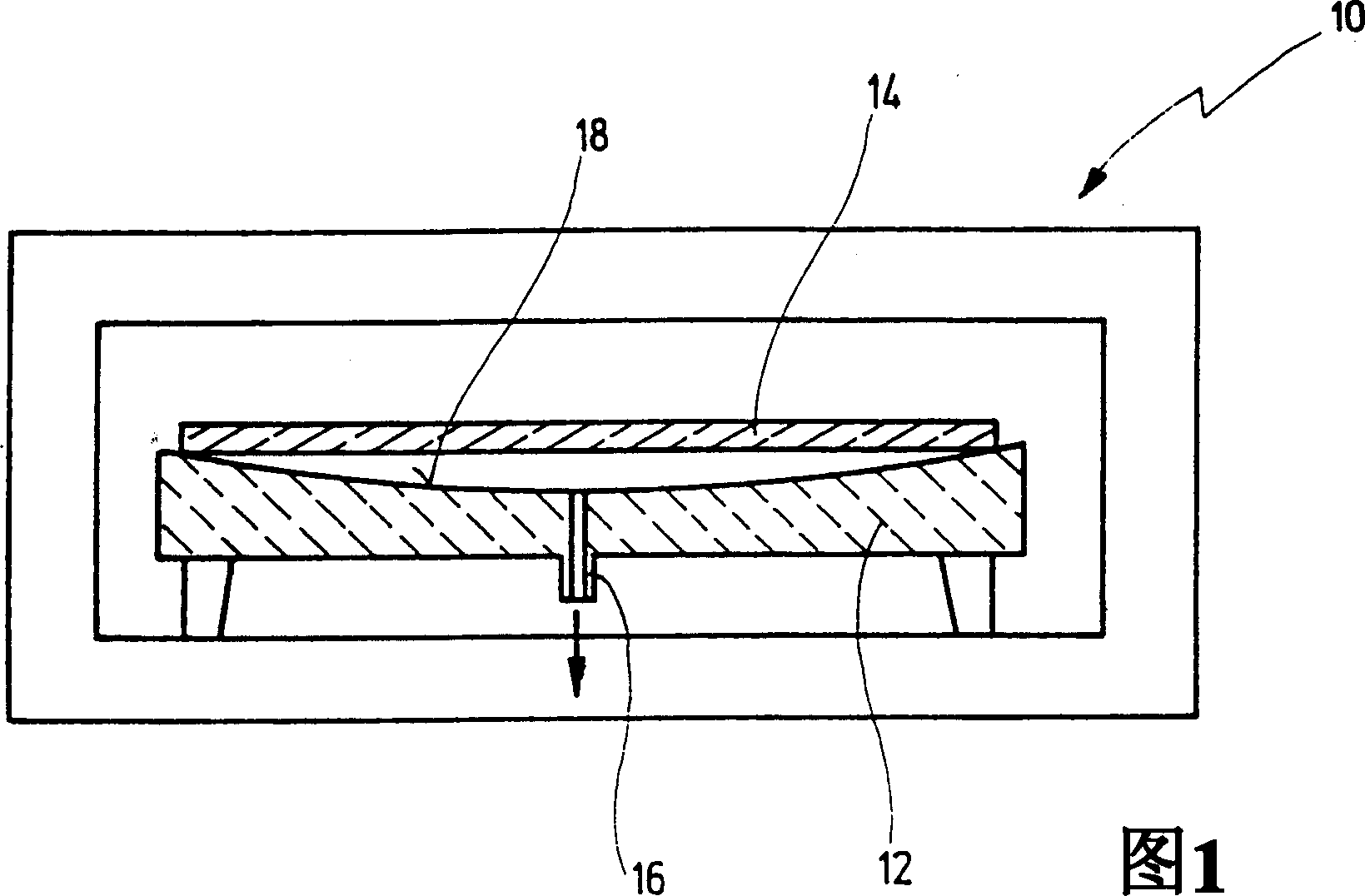

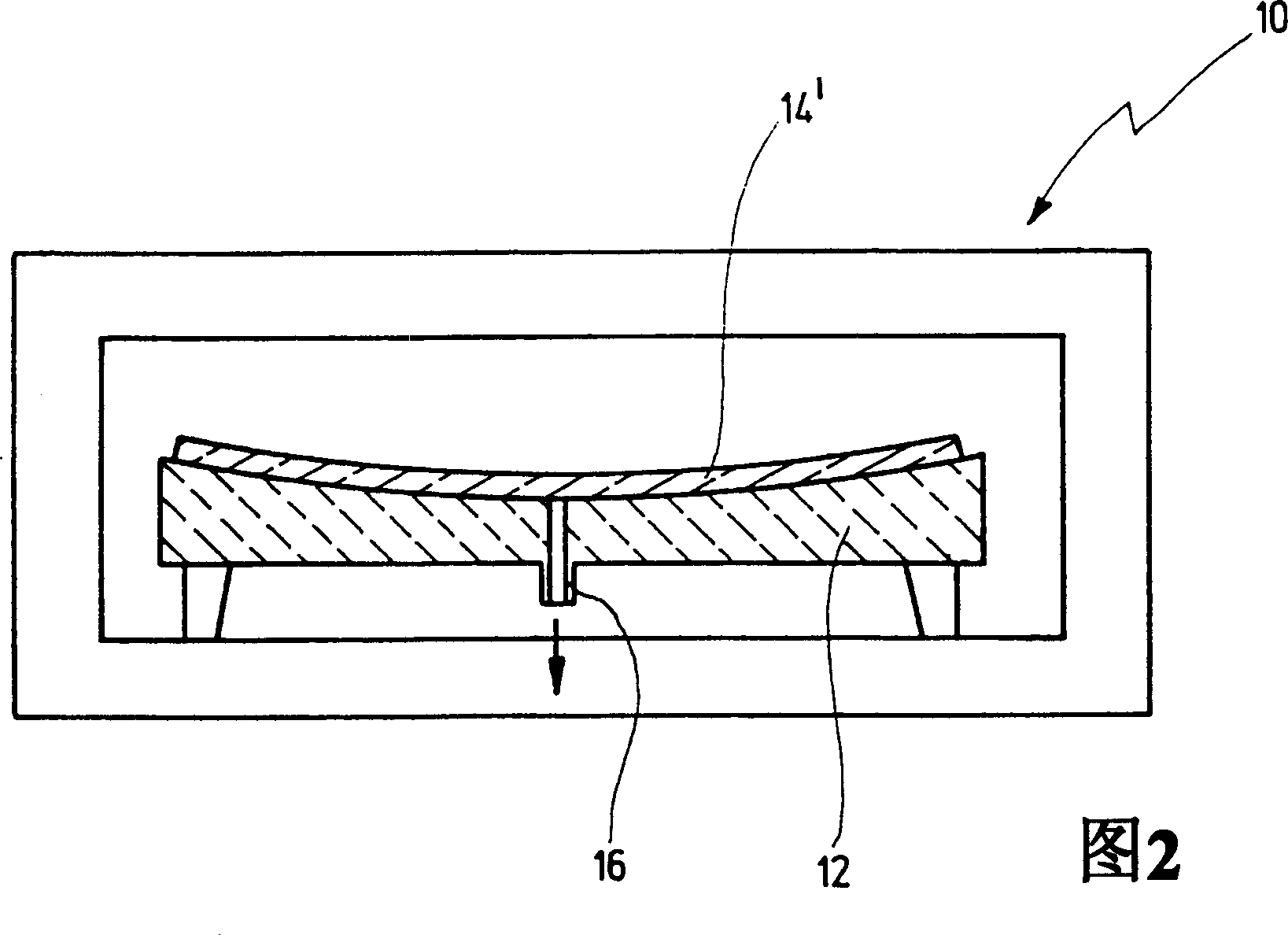

Forming method for glass and glass-ceramic

InactiveCN1495134AHandling using diffraction/refraction/reflectionGlass pressing apparatusGlass-ceramicTransition temperature

Production of a mold for hot deformation of glass or glass ceramics comprises producing the mold as a glass ceramic mold from a starting glass by casting and converting into a keatite glass ceramic with a predominant keatite mixed crystal phase by heat treatment. Independent claims are also included for the following: (1) process for molding glass or glass ceramic; (2) mold produced by the above method; and (3) molded body made from a glass or glass ceramic.

Owner:SCHOTT AG

High activity deoxidant, and its preparing method

ActiveCN101003014ALarge capacityExtend the life cycleNitrogen purification/separationOther chemical processesOxygenHigh activity

A high-activity deoxidant for the deep deoxidization of N2, H2, CO, CH4, C2H4, C3H6, etc is composed of active component (the low-valence oxide of Mn and Fe) and the carrier chosen from cement, gypsum, kaolinite, alumina, diatomite, etc. Its preparing process is also disclosed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

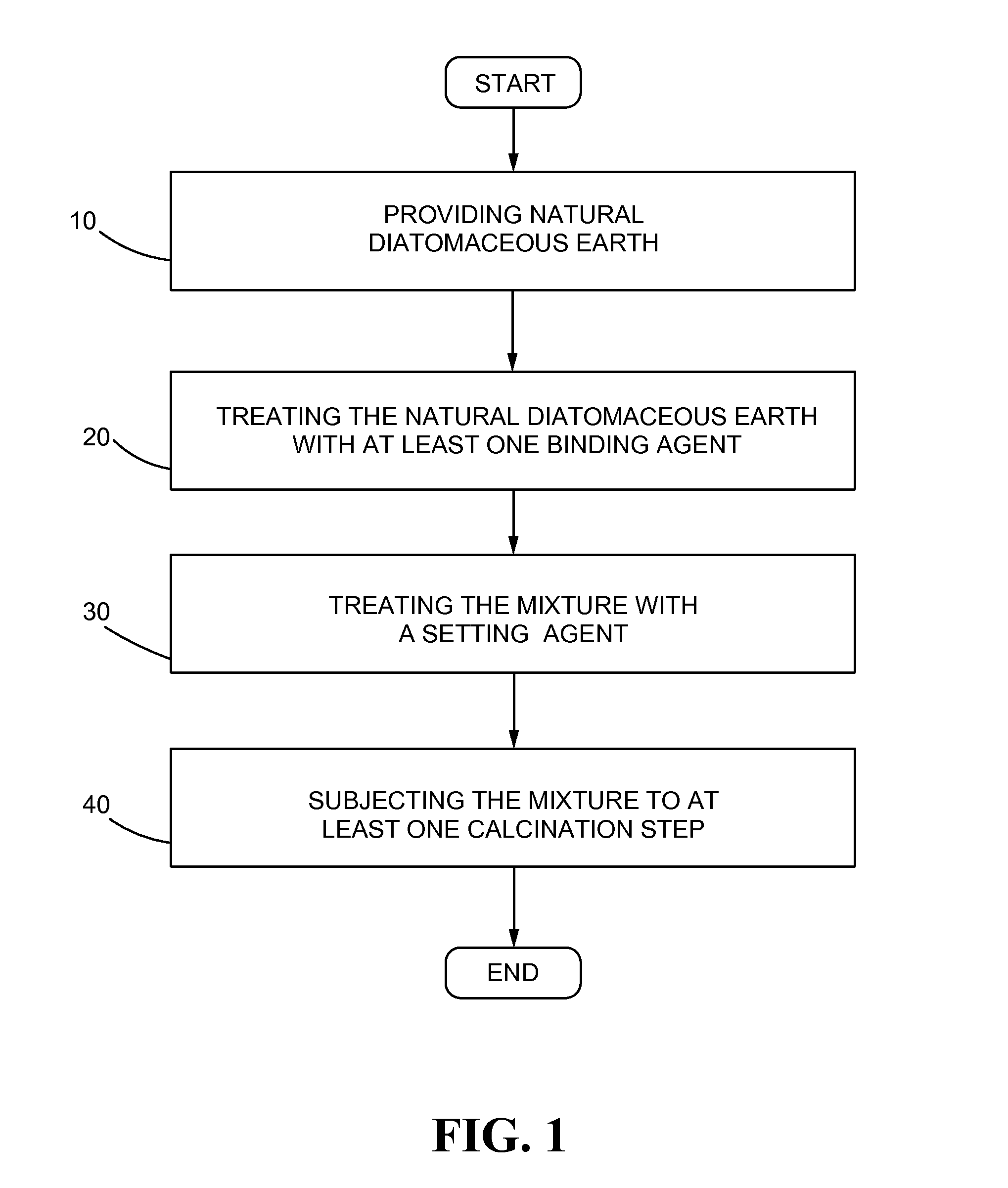

Diatomaceous Earth Filter Aid Containing a Low Crystalline Silica Content

ActiveUS20140171305A1Other chemical processesAlcoholic beverage preparationCrystallographyPotassium silicate

A diatomaceous earth product with low crystalline silica content after at least one calcination step of between about 927° C. (1700° F.) and about 1149° C. (2100° F.) is disclosed. The product comprises natural diatomaceous earth and at least one binding agent comprising potassium silicate. Further the product comprises no more than about 4.0 wt % of crystalline silica and has a permeability in the range of about 0.3 darcy to greater than about 20 darcy. A process for making such diatomaceous earth product with a low crystalline silica content is disclosed. Moreover, a diatomaceous earth filter aid comprising such a diatomaceous earth product is disclosed.

Owner:EP MINERALS LLC

Spherical diatomite mesoporous composite and supported catalyst, preparation method thereof and application thereof, and ethyl acetate preparation method

ActiveCN104248980AHigh catalytic activityLess side effectsCatalyst carriersMolecular sieve catalystsMolecular sieveAcetic acid

The invention relates to a spherical diatomite mesoporous composite, a preparation method of the spherical diatomite mesoporous composite, the spherical diatomite mesoporous composite prepared by the method, a supported catalyst containing the spherical diatomite mesoporous composite, a preparation method of the supported catalyst, the supported catalyst prepared by the method, an application of the supported catalyst in an esterification reaction, and a method for preparing ethyl acetate by using the supported catalyst. The spherical diatomite mesoporous composite contains diatomite and a mesoporous molecular sieve material having a three dimensional cube tunnel structure. The spherical diatomite mesoporous composite can be used as a carrier to prepare the supported catalyst for obviously increasing the conversion rate of the raw materials in the esterification reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

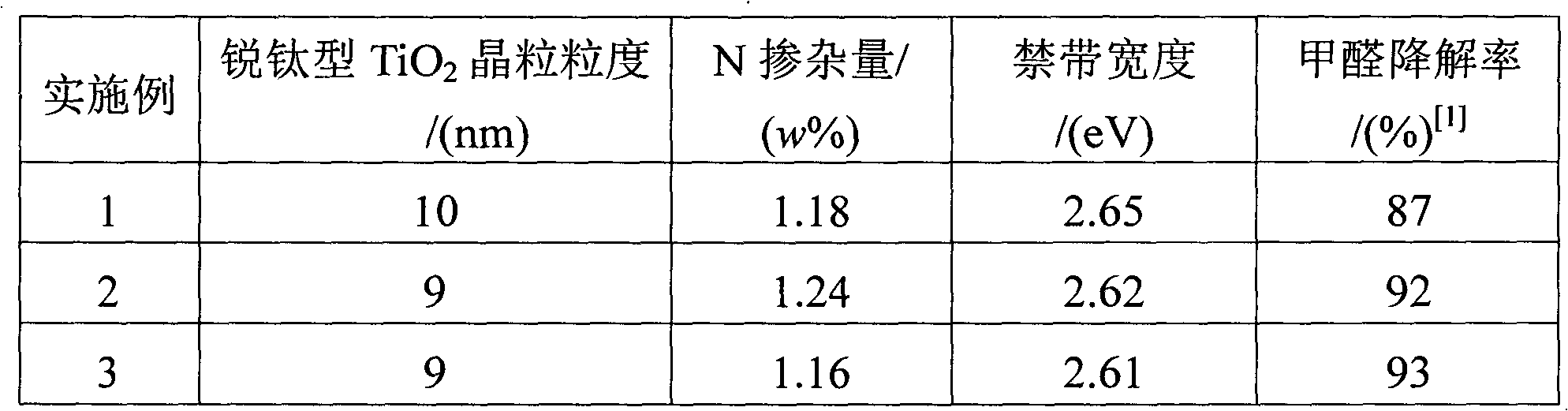

Preparation method of diatomite-loaded nitrogen-doped nanometer TiO2 photocatalysis material

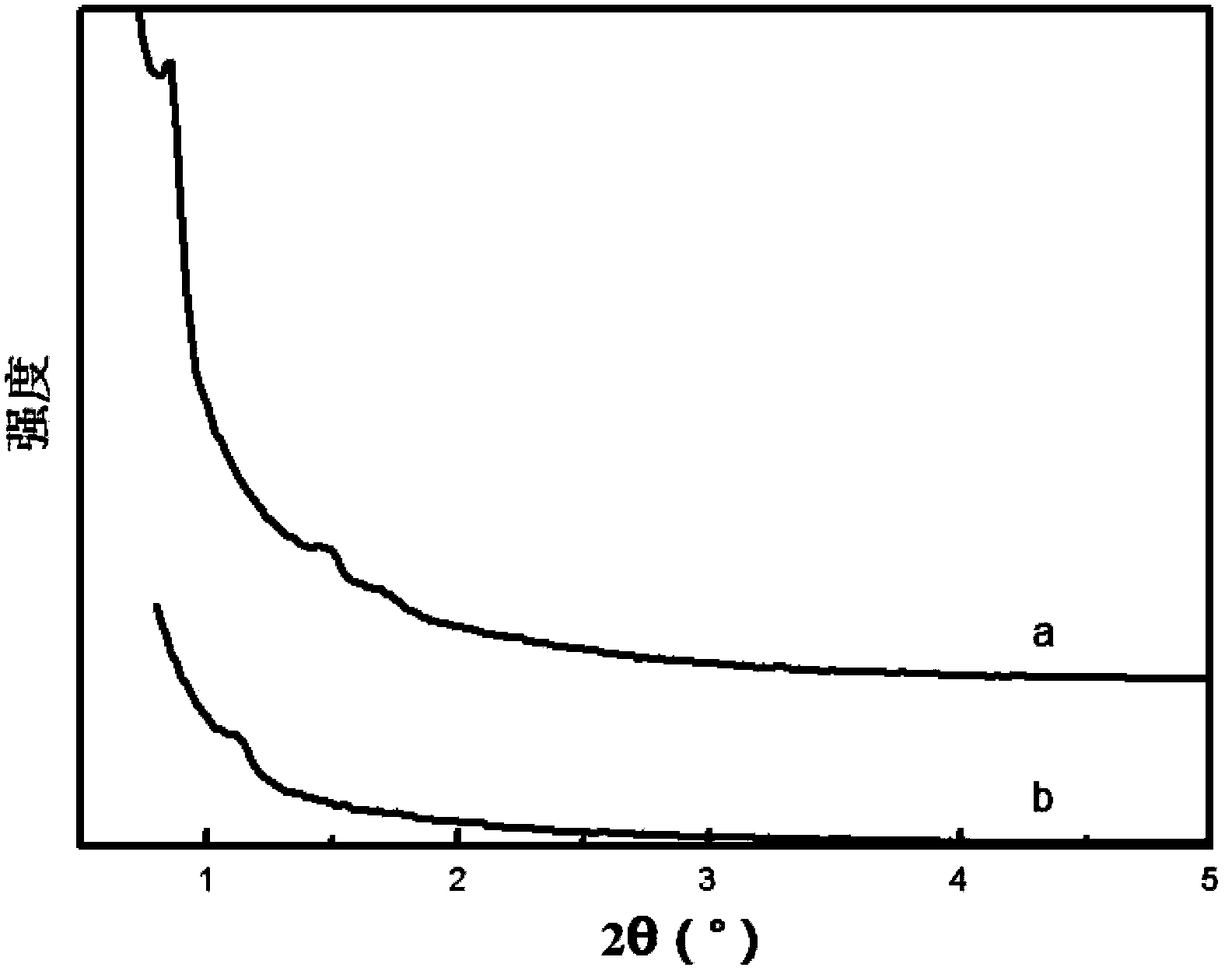

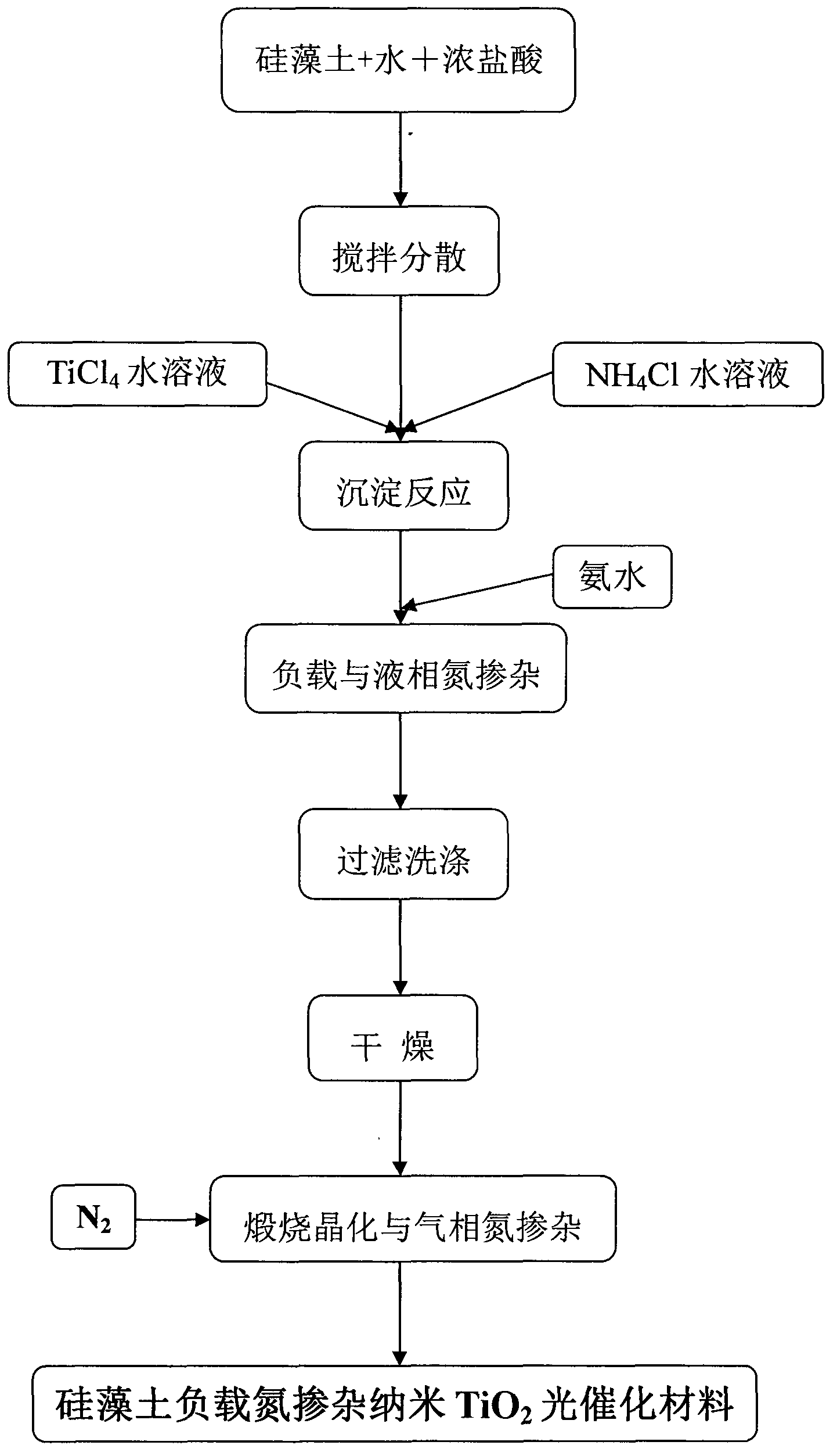

ActiveCN102698785AImprove photocatalytic performanceContinuous degradationPhysical/chemical process catalystsNitrogen gasNitrogen doped

The invention relates to a preparation method of a diatomite-loaded N-doped nanometer TiO2 photocatalysis material, which belongs to the technical fields of mineral materials and photocatalysis. The method comprises the following steps of: adding water and concentrated hydrochloric acid into diatomite mineral powder, stirring, pulping, and adding a TiCl4 aqueous solution and an NH4Cl aqueous solution, adding an ammonia aqueous solution for adjusting the pH value of a reaction liquid, and performing a hydrolytic precipitation loading and liquid phase N doping reaction on NH<4+> serving as a nitrogen source; and filtering a reaction product, washing, drying, and calcining and crystalizing in a nitrogen atmosphere to obtain the diatomite-loaded N-doped nanometer TiO2 photocatalysis material. According to the diatomite-loaded N-doped nanometer TiO2 photocatalysis material prepared with the method disclosed by the invention, the photocatalysis performance of nanometer TiO2 under visible light can be improved remarkably, a continuous degradation function on formaldehyde is realized, and the degradation rate of formaldehyde is over 86 percent within 24 hours under the condition of visible light.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Hollow glass mineral agent

InactiveCN1736554AReduce manufacturing costHigh particle strengthDispersed particle separationSilicon compoundsAbsorption ratioDesiccant

The invention discloses a glazing glass mineral desiccant, the technique highlight of which is that, the glazing glass mineral desiccant comprises warp clay, sodium-hydroxide, calcium oxide, diatom earth, and high-alumina earth, and the product is prepared after milling, granulating, drying, sifting, and packing. It has a good stability, a high wet absorption ratio, and a strong intensity. And it can apply to glazing glass devices and other location needing to keep dry.

Owner:许盛英

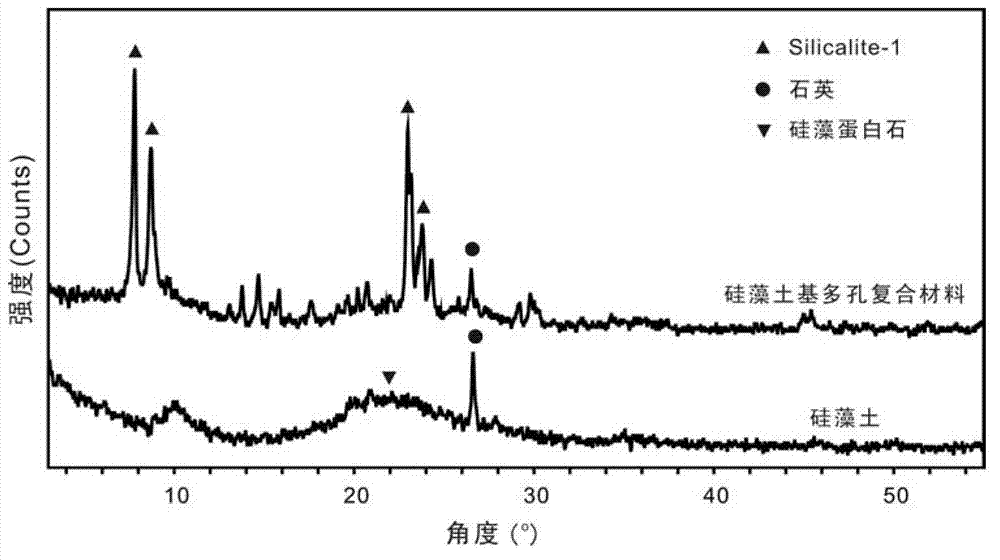

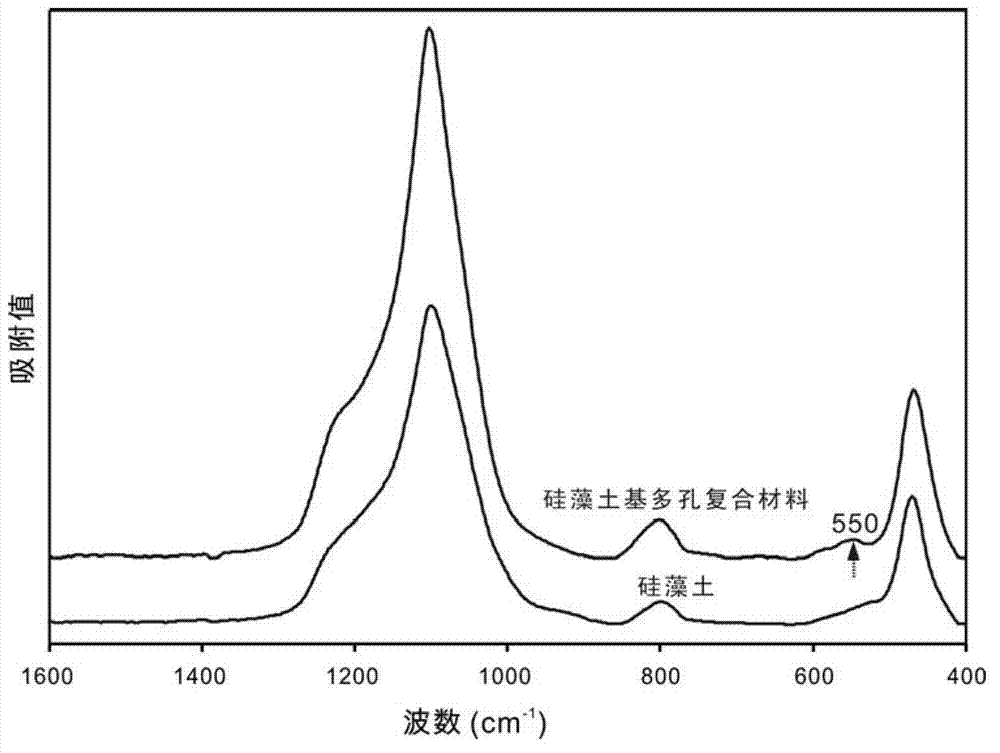

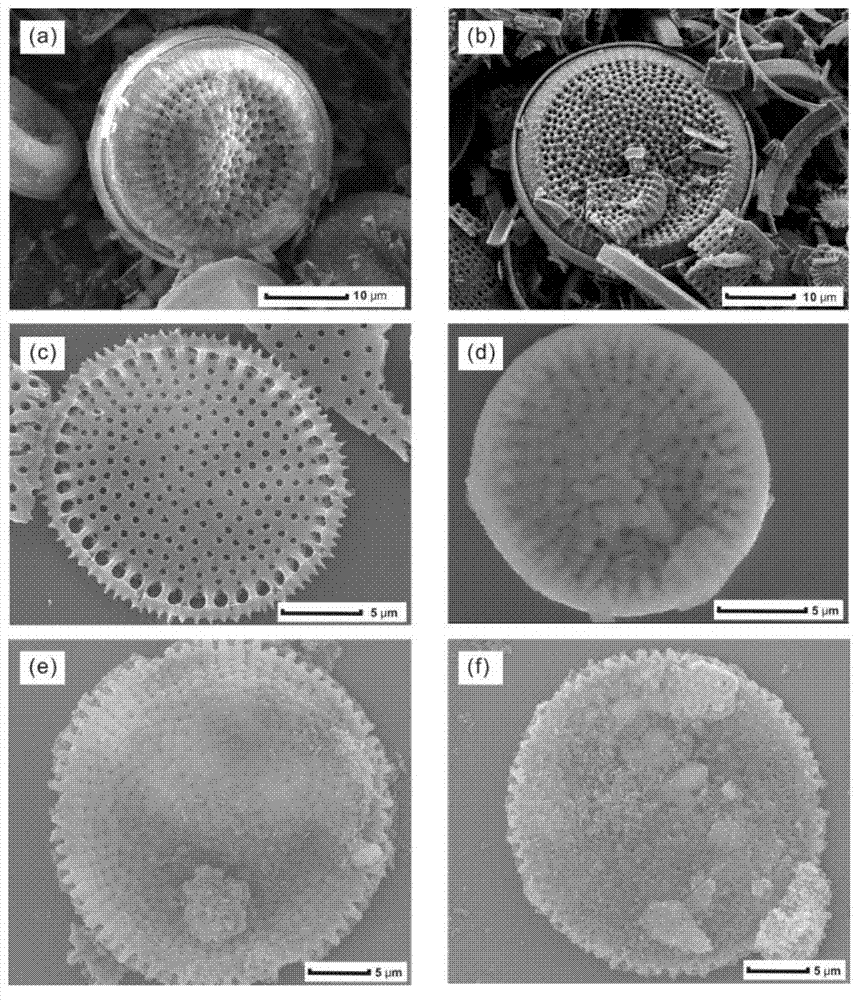

Diatomite-based porous composite material for adsorbing volatile organic pollutants and preparation method thereof

ActiveCN103084144AIncreased macropore/mesopore diameterAvoids the problem of easy clogging of large poresOther chemical processesDispersed particle separationSilicon dioxideSeed crystal

The invention discloses a diatomite-based porous composite material for adsorbing volatile organic pollutants and a preparation method thereof. Diatomaceous silica in diatomite is denuded by using a strong alkali solution, so that the diameter of the large pores / mesopores of silica is increased, and micropores are formed, thereby increasing the porosity; then, a nano zeolite seed crystal is loaded on the surface of silica, and the nano zeolite seed crystal grows to a dense zeolite film through hydro-thermal treatment. Because the growth of zeolite uses an external silicon source, a small amount of aluminum contained in diatomite does not enter a zeolite skeleton, and formed zeolite is high-hydrophobicity pure silicon zeolite. Due to the bearizing function of alkali, the zeolite film does not block large pore structures in the diatomite. The prepared diatomite-based porous composite material still keeps the unique macroporous skeleton of diatomite and contains rich zeolite microcellular structures. The material is large in specific surface area and pore volume and high in hydrophobicity and thermal stability, and has a high adsorption capacity to volatile organic pollutants such as n-hexane, benzene, toluene and o-xylene and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method and application method of hydrated calcium silicate seed crystal

InactiveCN105753000AGood dispersionGood early strengthAlkaline-earth metal silicatesCalcium silicateCarbonization

The invention relates to a preparation method and application method of a hydrated calcium silicate seed crystal. The materials for preparing the hydrated calcium silicate seed crystal comprise a calcium material, a silicon material, deionized water, a dispersant, anhydrous ethanol and sodium hydroxide. The adopted calcium material is calcium oxide, the adopted silicon material is one of sodium silicate and diatomite, and the adopted dispersant is a poly-carboxylic acid high molecular polymer. The controlled factors comprise the ratio of calcium to silicon, the ratio of water to solid, the dosage of the dispersant, the reaction temperature, the reaction pressure and the reaction time. The product prepared by the method provided by the invention is suitable for a construction engineering adopting mixed material cement as a cementitious system, and has an obvious effect of promoting the development of the early strength of a mixed material cement base material, so that the application scope of the mixed material cement is expanded, the dilemma of solid waste emission is relieved, the cement production cost is reduced, the emissions of wastes during cement production are reduced, and the product is beneficial to low-carbonization and greening development of cement, and has good environmental protection benefits and social and economic benefits.

Owner:TONGJI UNIV

Calcium silicate material prepared from waste ceramic powder and preparation method thereof

The invention relates to a calcium silicate material prepared from waste ceramic powder. The material comprises the following raw materials in part by weight: 35 to 70 parts of waste ceramic powder, 0 to 35 parts of other siliceous raw materials, 35 to 55 parts of calcareous raw material, 0 to 15 parts of reinforcing fiber and 0 to 10 parts of Portland cement, wherein the other siliceous raw materials are one or more of quartz powder, diatomite and mica. The calcium silicate material has the following advantages that: the waste ceramic powder is used for gradually replacing the primary siliceous raw material in the raw materials for producing the calcium silicate material; the cost is saved and environmental protection and quality stability are ensured; and the produced calcium silicate material can be used as gas filling blocks, calcium silicate boards or exterior wall bricks or as a porous carrier material.

Owner:NANJING MINGYUHENG MATERIAL TECH

Low-cost green method for synthesizing Fe-ZSM-5 molecular sieve

InactiveCN105731492AReduce manufacturing costToxic reductionGalloaluminosilicates/ferroaluminosilicatesPentasil aluminosilicate zeoliteNatural mineralMaceral

The invention belongs to the technical field of molecular sieves and preparation methods thereof, and particularly relates to a technique for preparing an Fe-ZSM-5 molecular sieve. According to the method, natural mineral diatomite is used as the raw material to provide all of the silicon source, aluminum source and iron source required by synthesis of Fe-ZSM-5, and conventional hydrothermal crystallization is carried out under the condition of not adding any organic template. The natural mineral diatomite is used as the raw material to provide all the silicon and aluminum sources required by the synthesis of the molecular sieve, the Fe2O3 impurity contained in the diatomite raw material is fully utilized as the iron source, and a conventional hydrothermal process is carried out under the condition of not adding any organic template, thereby preparing the framework-iron-containing ZSM-5 molecular sieve (Fe-ZSM-5 molecular sieve). The method has obvious advantages in the aspects of widening the molecular sieve synthesis raw material range, enhancing the added value of the natural mineral product, lowering the molecular sieve production cost, reducing the environmental pollution and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

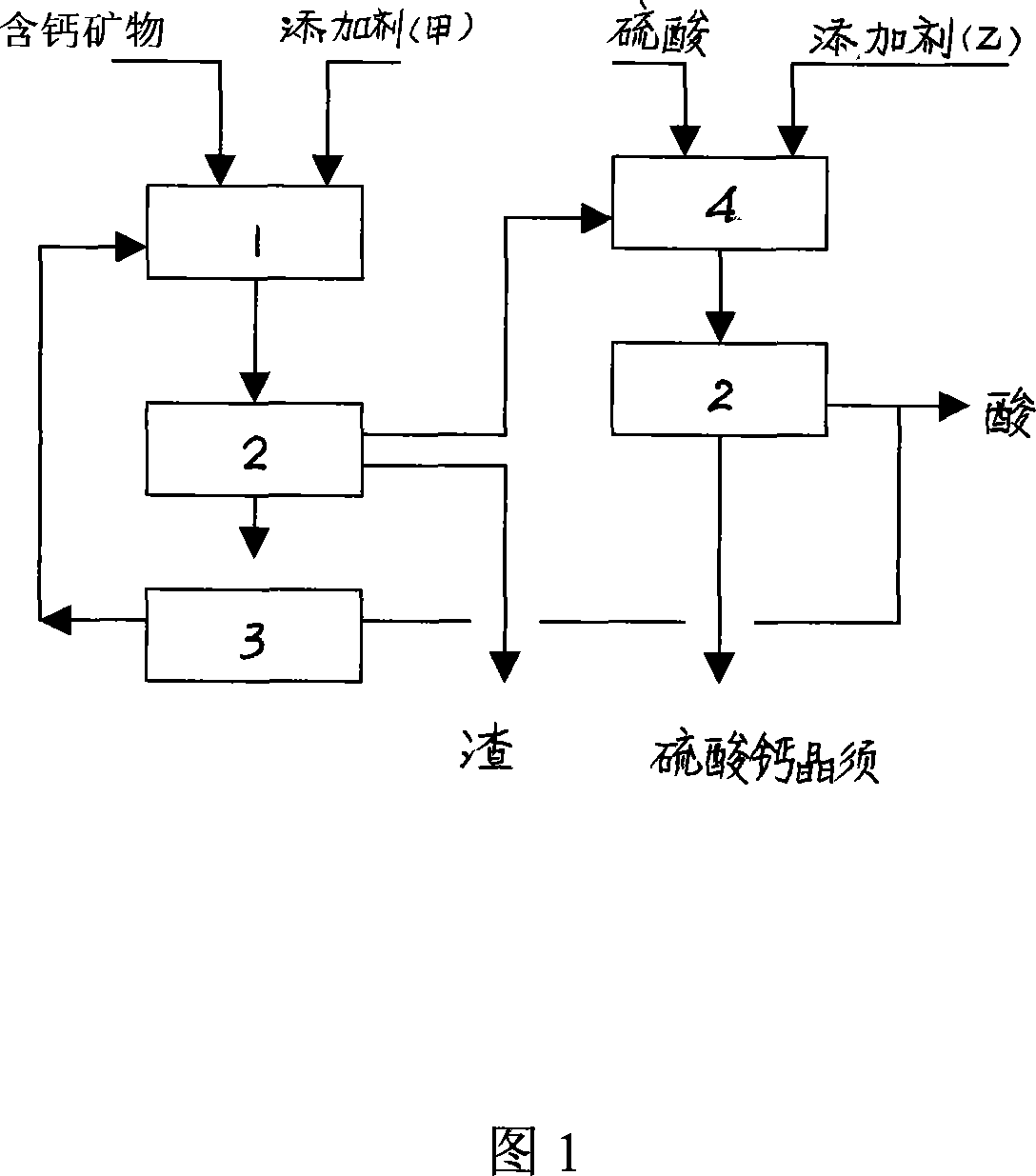

Method for preparing crystal whisker of calcium sulphate, and phosphonic acid

InactiveCN101092734AImprove decomposition rateReduce in quantityPolycrystalline material growthFrom normal temperature solutionsDecompositionFiltration

This invention discloses a method for preparing calcium sulfate whiskers and phosphoric acid. The method comprises: phosphate ore decomposition, slurry filtration and separation, calcium sulfate whisker crystallization, separating, washing and drying. The method adds composite additive A during the during phosphate ore decomposition process, and adds composite additive B during calcium sulfate whisker crystallization process to form calcium sulfate whiskers and phosphoric acid. Composite additive A is composed of humic acid and diatomite at a ratio of 1:(2-10). Composite additive B is composed of sodium dodecyl sulfonate and sulfate or phosphate of magnesium and aluminum at a ratio of (2-5):1. The addition amount of composite additive A is 0.5-5.0% of phosphate ore. The addition amount of composite additive B is 0.1-2.0% of theoretical formation amount of calcium sulfate whiskers. The method has such advantages as adequate utilization of raw materials, low solid waste discharge amount, and low production cost.

Owner:云南常青树化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com