Method for preparing porous silicon/carbon composite material by using diatomite as raw material and application

A carbon composite material, porous silicon technology, applied in electrical components, battery electrodes, circuits, etc., to achieve the effects of abundant raw materials, simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

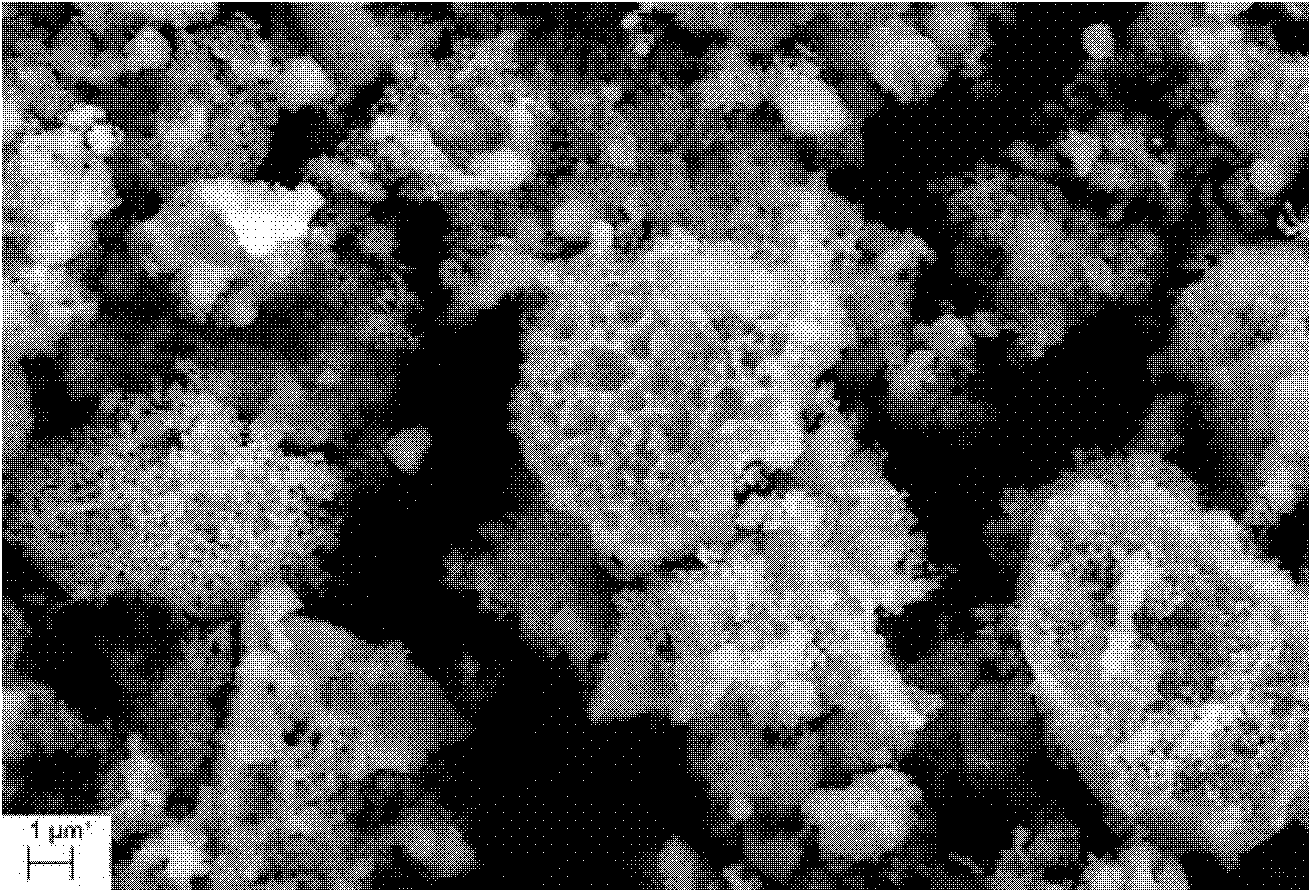

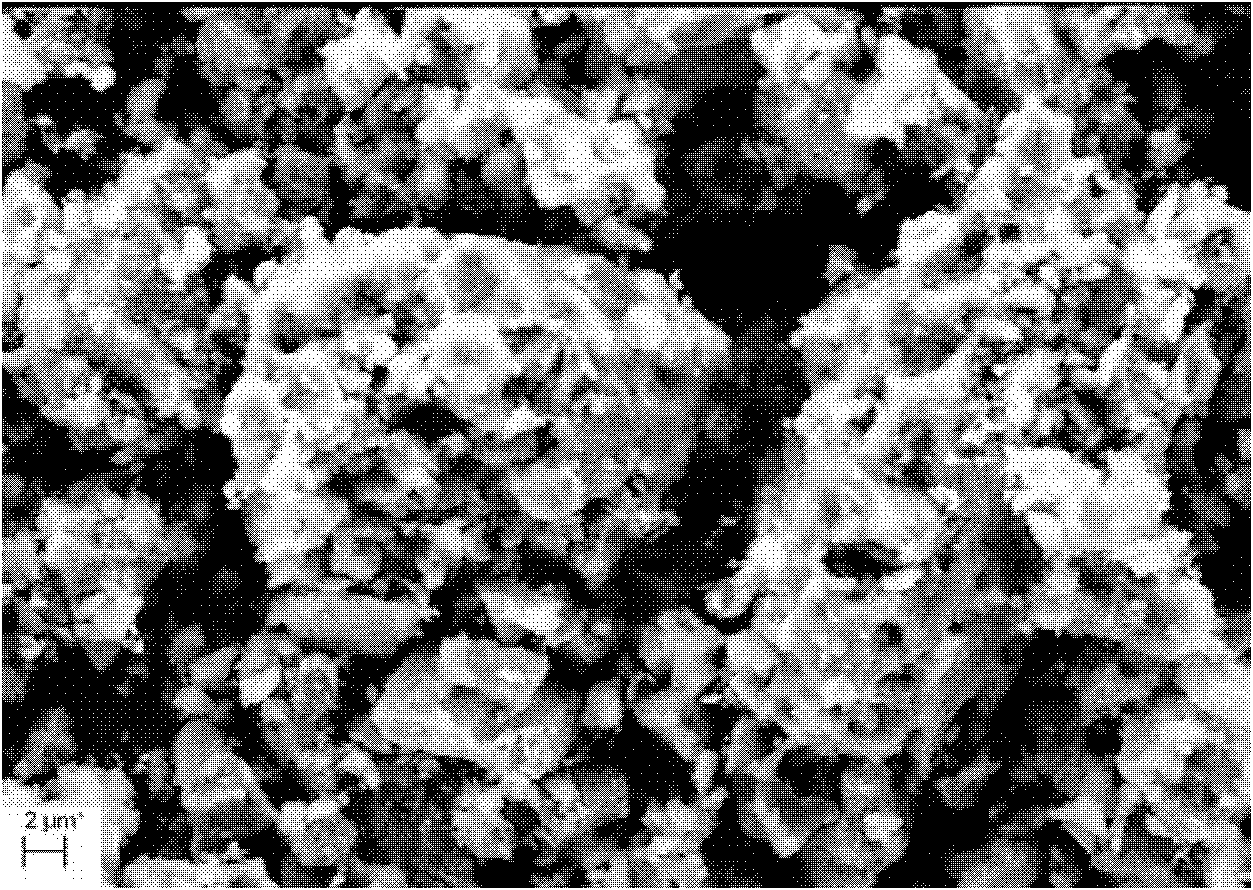

[0031] Grind diatomaceous earth and mix it with water at a mass ratio of 1:10 and impregnate it until it fully absorbs water, then add 10 ml of NaOH with a concentration of 0.01 mol / L as a dispersant, stir well and let it stand for 2 hours, suck out the upper layer of suspended mud . The mud is filtered and dried. Take 2.5 g of the dried solid and heat it up to 600 °C at 5 °C / min for 10 hours in an air atmosphere. Sulfuric acid with a mass fraction of 30% was prepared, diatomite with organic matter removed was added to the solution, stirred at 95 °C for 8 hours, cooled to room temperature, the solution was diluted and washed, and diatomite with high purity was obtained. Mix diatomaceous earth and magnesium powder in a mass ratio of 1:1, in N 2Under protective atmosphere, keep warm at 700 ℃ for 10 hours, after natural cooling, soak the solid mixture in 0.1 mol / L hydrochloric acid solution for 12 hours, dilute the solution, wash, filter and dry to obtain silicon with porous st...

Embodiment 2

[0034] Grind diatomaceous earth and mix it with water at a mass ratio of 1:15. After it fully absorbs water, add 15 ml of NaOH with a concentration of 0.01 mol / L as a dispersant, stir well and let it stand for 2 hours, suck out the upper layer of suspended mud. The mud is filtered and dried. Take 2.5 g of the dried solid and heat it up to 800 °C at 5 °C / min for 10 hours in an air atmosphere. A hydrochloric acid solution with a mass fraction of 50% was prepared, diatomite with organic matter removed was added to the solution, stirred at 95 °C for 8 hours, cooled to room temperature, the solution was diluted and washed, and diatomite with high purity was obtained. Mix diatomaceous earth and sodium powder at a mass ratio of 1:2, and keep warm at 97°C for 6 hours under a He protective atmosphere. After natural cooling, soak the solid mixture in 0.01 mol / L hydrochloric acid solution for 12 hours to dilute the solution. After washing, filtering and drying, silicon with a porous str...

Embodiment 3

[0037] Grind diatomaceous earth and mix it with water at a mass ratio of 1:10. After it fully absorbs water, add 30 ml of NaOH with a concentration of 0.01 mol / L as a dispersant, stir evenly and let it stand for 1 hour, suck out the upper layer of suspended mud. The mud is filtered and dried. Take 2.5 g of the dried solid and heat it up to 850 °C at 5 °C / min in an air atmosphere, and calcinate for 3 hours. Sulfuric acid with a mass fraction of 50% was prepared, diatomite with organic matter removed was added to the solution, stirred at 100 °C for 5 hours, cooled to room temperature, the solution was diluted and washed, and diatomite with high purity was obtained. After mixing diatomaceous earth and aluminum powder in a mass ratio of 1:2, under an Ar protective atmosphere, heat up to 650 °C and keep warm for 6 hours. After natural cooling, soak the solid mixture in 0.1 mol / L hydrochloric acid solution for 6 hours, dilute The solution was washed and filtered and then dried to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com