Patents

Literature

9009 results about "Micro nano" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction generator

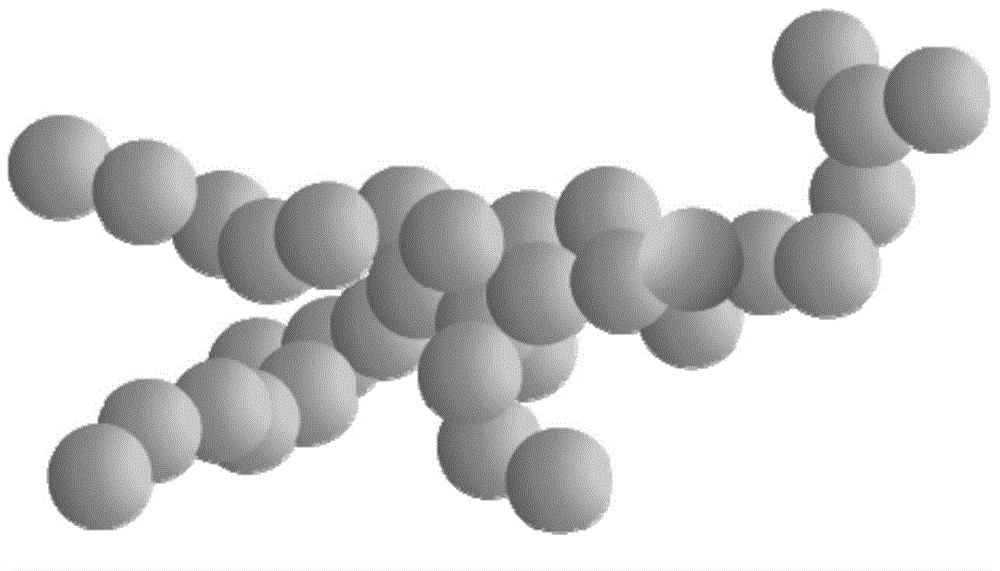

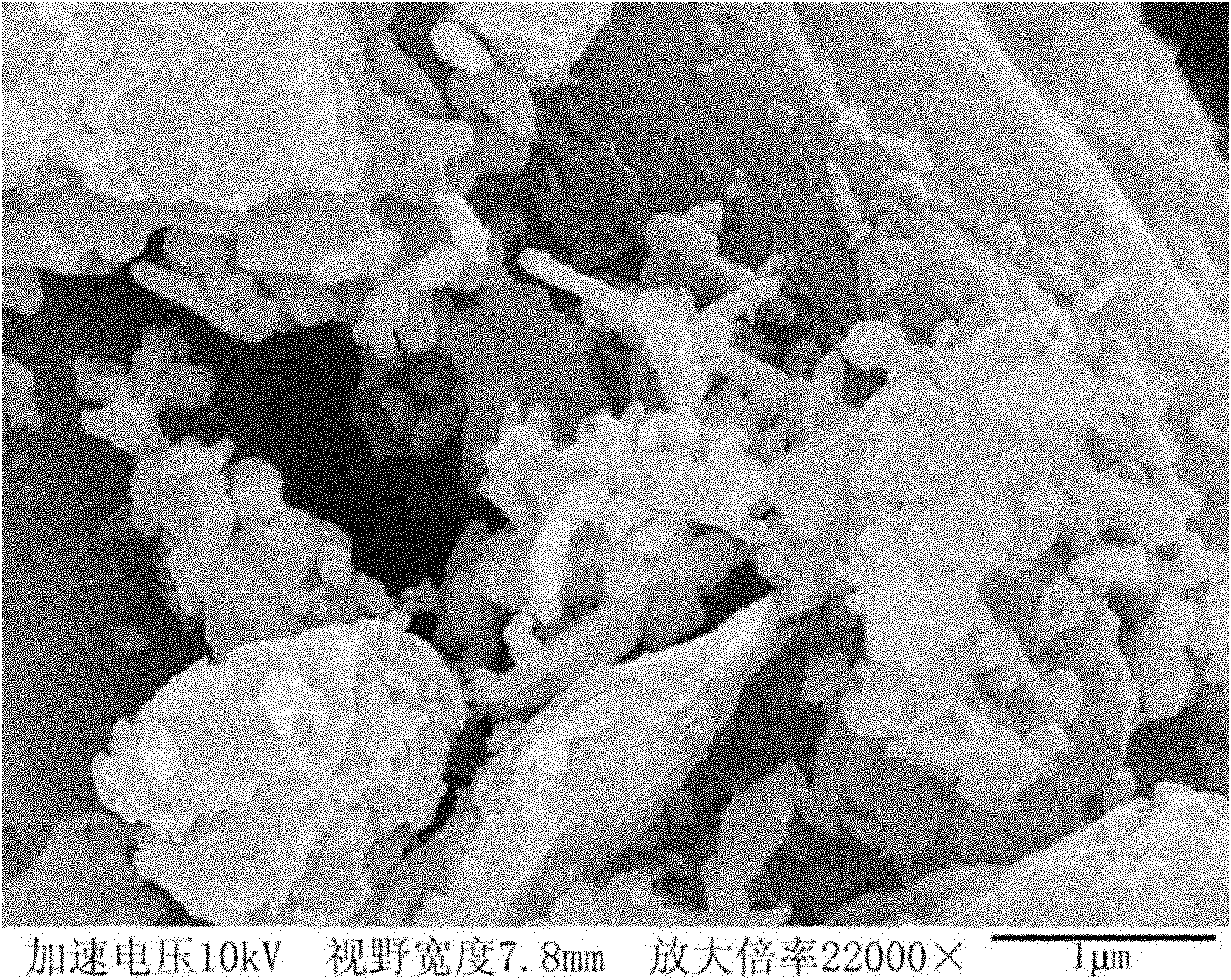

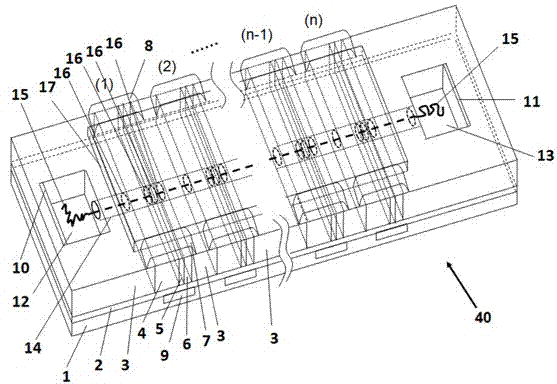

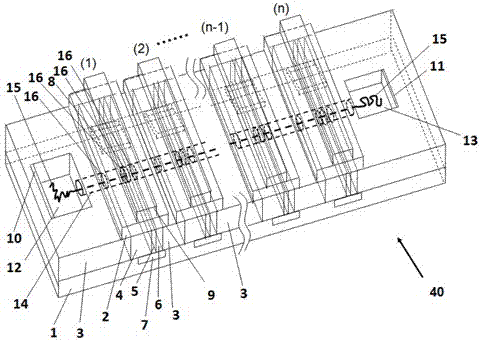

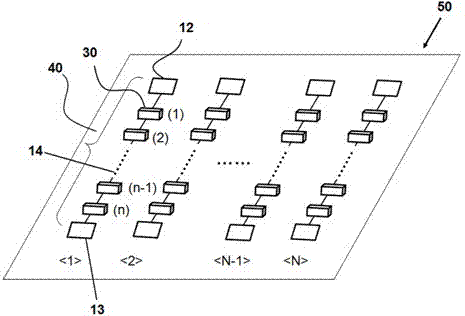

ActiveCN102684546AExtended service lifeLow costFriction generatorsMetal layered productsConvex structureMicro nano

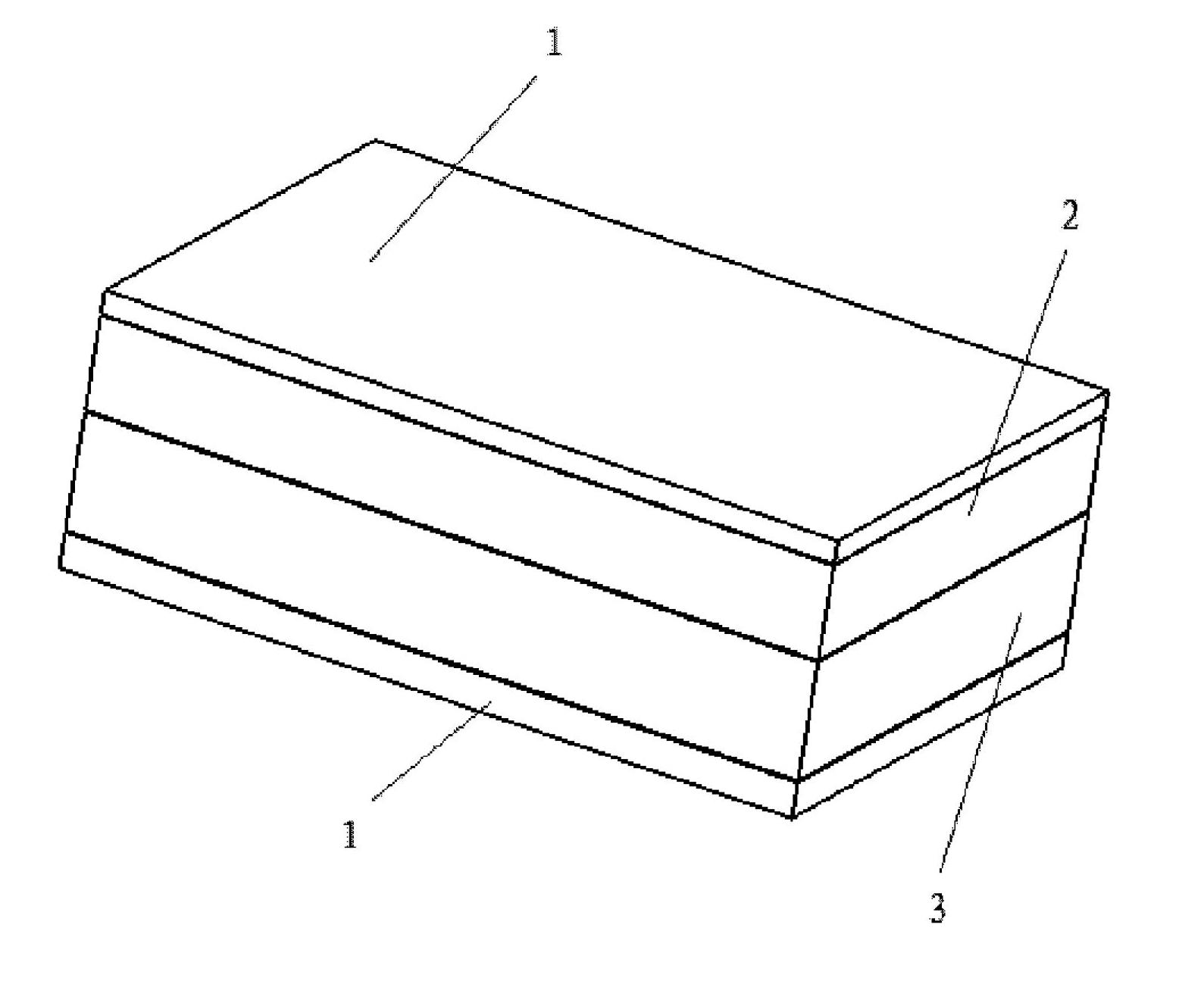

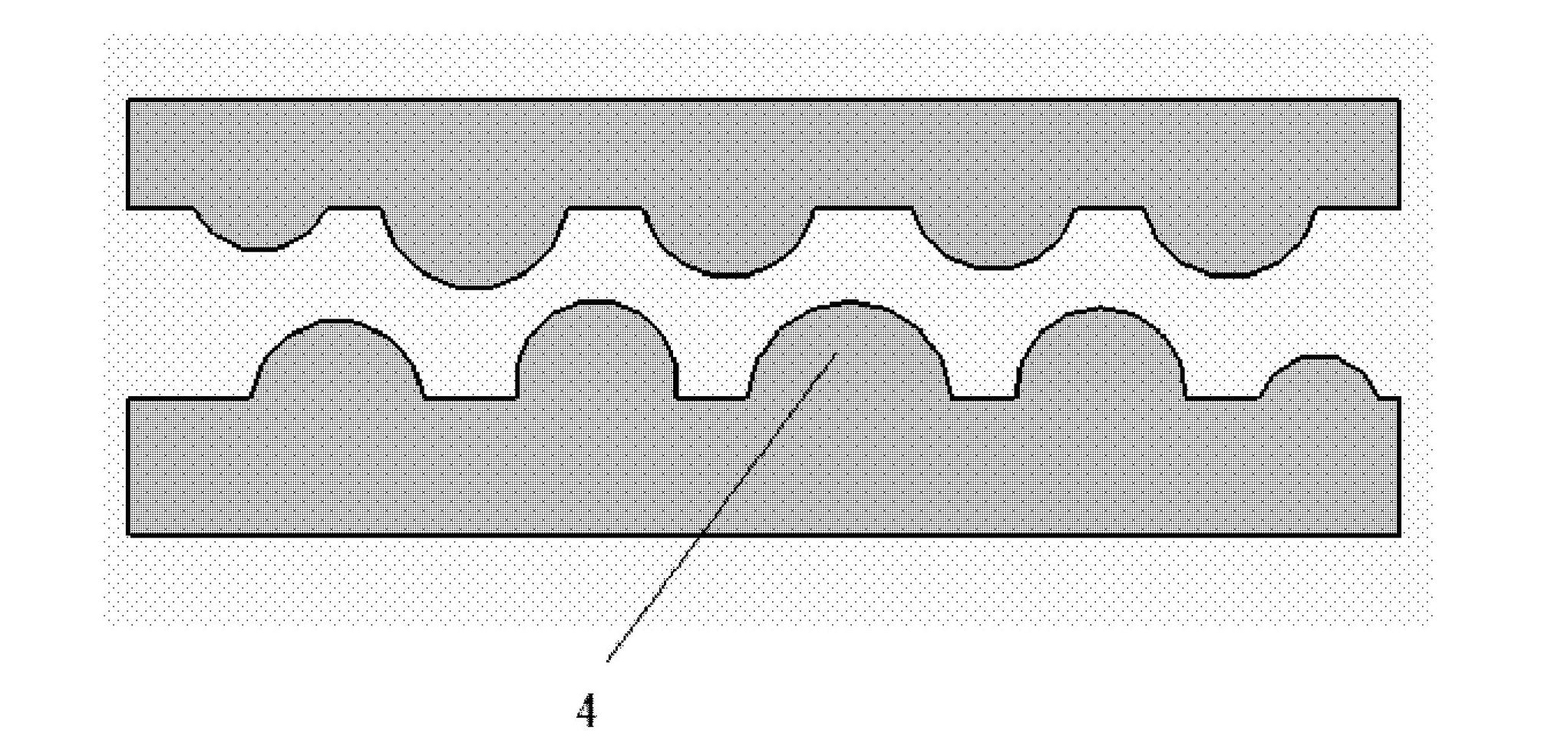

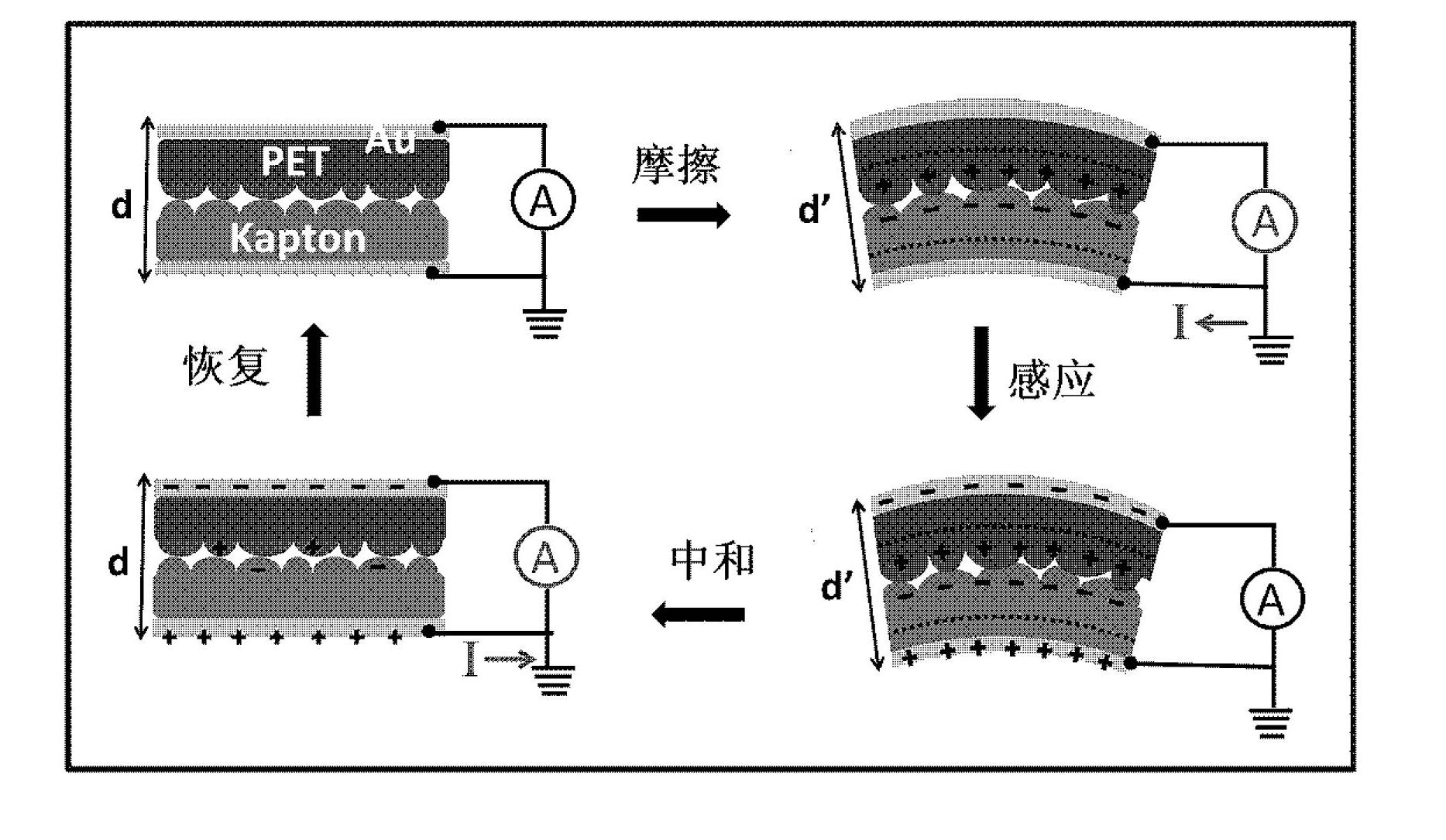

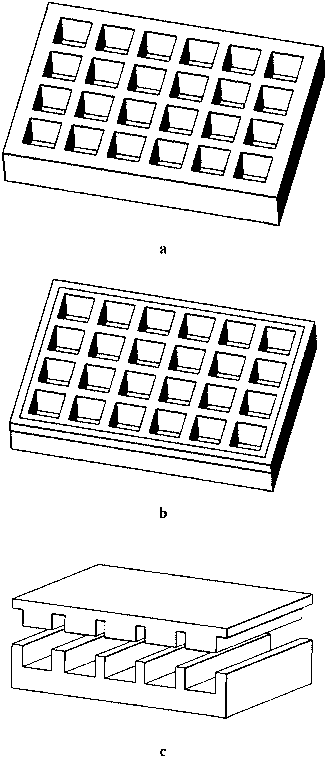

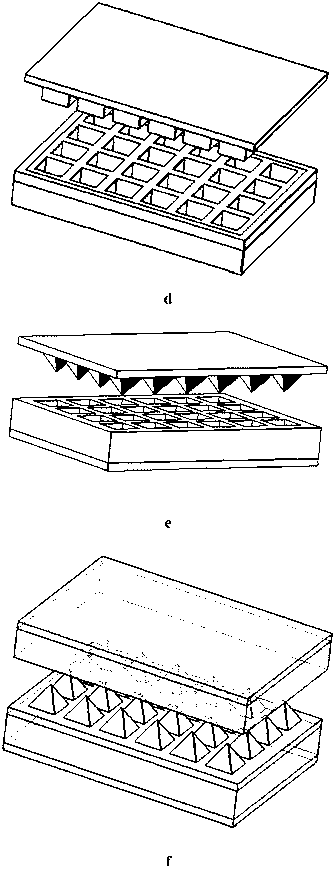

The invention provides a friction generator. The friction generator comprises two electrodes; the electrode comprises a macromolecular polymer insulating layer; a micro-nano concave-convex structure is arranged on one side surface of the macromolecular polymer insulating layer, and a metal film is arranged on the other side surface; the surface of the electrode micro-nano concave-convex structure of one insulating layer is directly attached to the surface of the electrode micro-nano concave-convex structure of the other insulating layer, and the two are fixedly connected through the outer edge; and the metal film is an electrode for outputting voltage and current of the friction generator. The invention provides a novel and effective method for obtaining energy by use of the friction effect. The friction generator generates electric energy by use of the potential change of the internal electrification by friction and the inductive effect of the metal pole plates on the two sides; and the method is simple and efficient and the cost is low.

Owner:NAZHIYUAN TECH TANGSHAN LLC

Friction generator

ActiveCN102710166AExtended service lifeLow costFriction generatorsMetal layered productsMicro nanoConvex structure

The invention provides a friction generator, which comprises a first electrode, a second electrode and an intermediate film, wherein the first electrode comprises a first macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the second electrode comprises a second macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the intermediate film is fixed on the other side surface of the second macromoleclar polymer insulation layer; the non-fixed surface of the intermediate film is provided with a micro-nano concave-convex structure; the surface of the micro-nano concave-convex structure of the intermediate film on the second electrode and the surface without the conductive film of the first electrode are oppositely fit and are mutually fixedly connected; and the conductive film of the first macromoleclar polymer insulation layer and the conductive film of the second macromoleclar polymer insulation layer are both the voltage and current output electrodes of the friction generator. The invention provides an innovated and effective method by the friction action, and electricity energy is generated by the variation of internal friction electrification electric potential and the induction effect of metal pole plates on two sides. The method is simple and efficient and has low cost.

Owner:NEWNAGY TANGSHAN

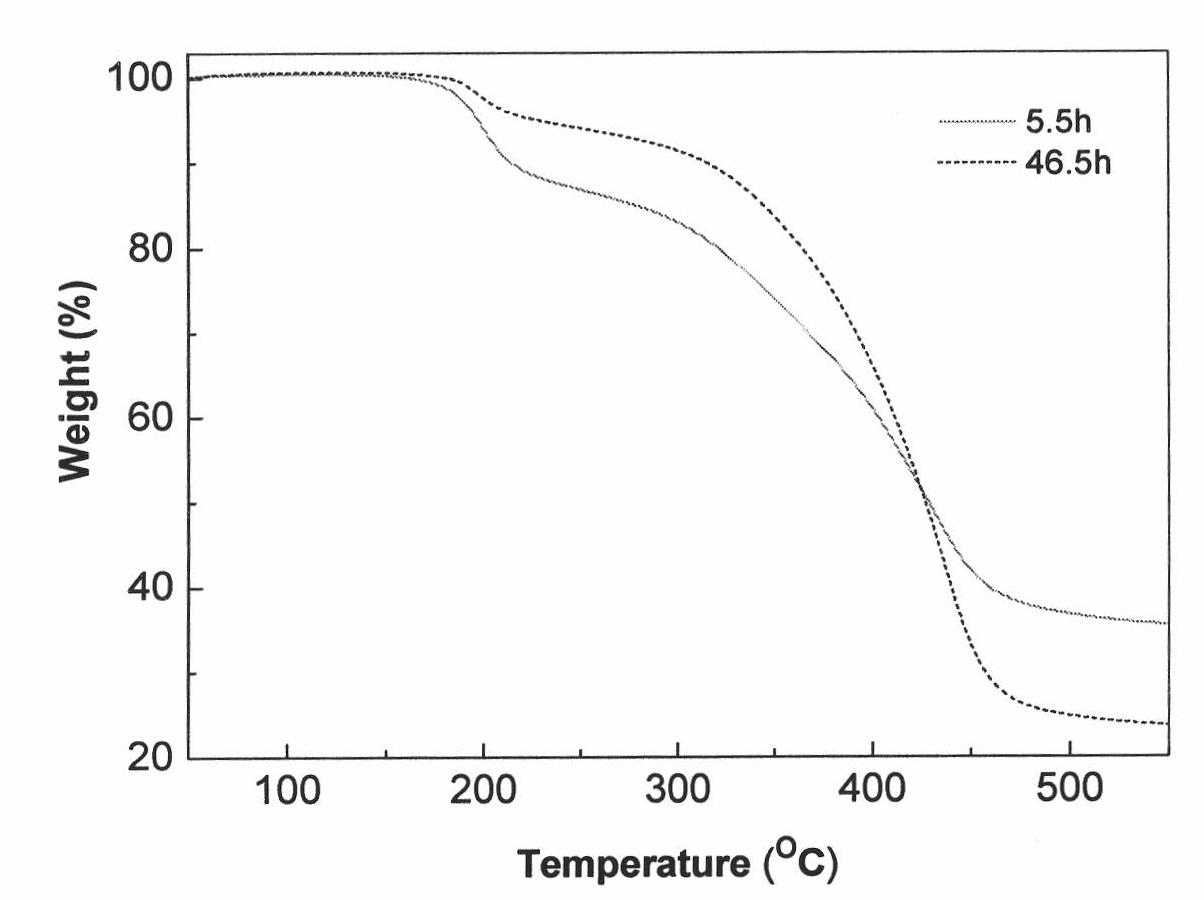

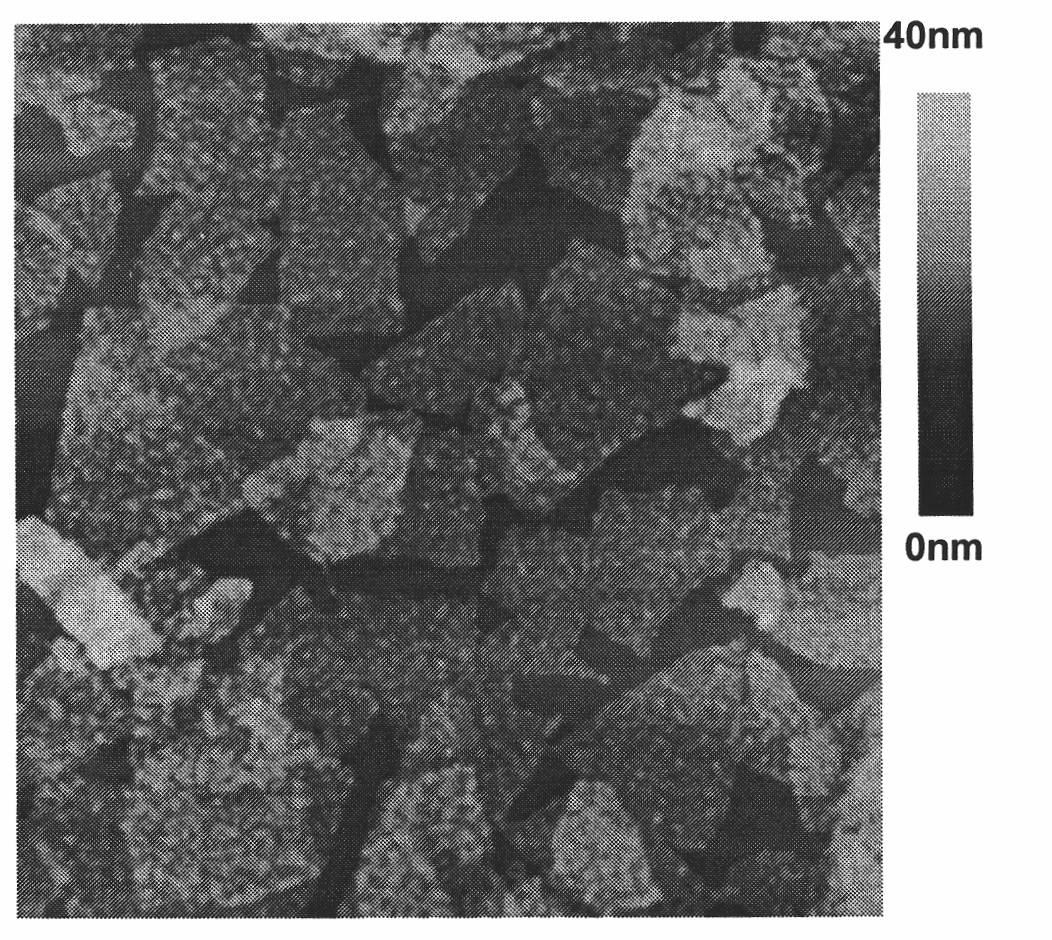

Preparation method of polymer-grafted graphene

The invention discloses a method for grafting a polymer ona surface of graphene. The method comprises the following steps: adding 1 part by weight of graphene or graphene oxide, 10-1000 parts by weight of solvent and 10-1000 parts by weight of vinyl monomer, and adding 0.01-10 parts by weight of initiator under introduction of nitrogen; heating to 55-90 DEG C, and carrying out reaction for 1.5-60hours; and precipitating, centrifugating, washing, and drying, thus obtaining a product of polymer-grafted graphene. The method is convenient and simple in process, can be used for the large-scale production, is the universal method and ensures that a variety of polymers can be grated onto the graphene. The obtained functionalized graphene has good solubility and good solution processability, is conducive and has extensive application value in micro-nano electronics, machinery, chemical industry, high-performance materials and other fields.

Owner:杭州德烯科技集团有限公司

Micron nano material composite modified water-based adhesive

InactiveCN101210157ALow shrinkageImprove performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesMicro nanoExtensibility

The invention relates to an aqueous binder which is compounded and modified by micro nano material. The modified aqueous binder of the invention adopts emulsion adhesive as matrix and micro-size and nano-size inorganic powder as modifier to prepare the compound and modified aqueous binder. The method of the invention can not only enhance the interface binding force of the aqueous binder, but also greatly improve the properties of water resistance, toughness and extensibility, leading comprehensive performance of the aqueous binder to be improved.

Owner:郑旷宇

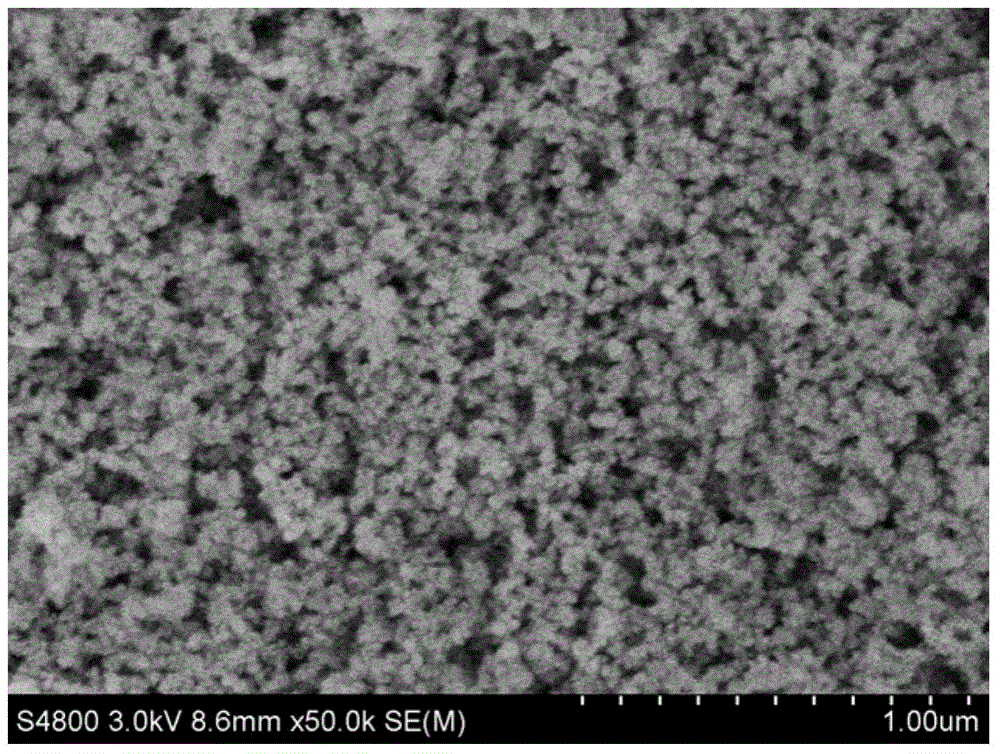

Wear-resisting super-hydrophobic coating composition as well as preparation method and application thereof

InactiveCN107987675AImprove protectionLong-term effective superhydrophobic propertiesLiquid surface applicatorsPolyurea/polyurethane coatingsMicro nanoNanoparticle

The invention relates to a wear-resisting super-hydrophobic coating composition as well as a preparation method and application thereof. The composition is prepared from a nano-material dispersion solution and a binding material dispersion solution. The nano-material dispersion solution is prepared by mixing a nanoparticle material, a hydrophobic silane coupling agent and a volatile solvent, wherein nanoparticles form a rough structure with a micro-nano dual scale through a mutual effect of the nanoparticles and the structure is dispersed in the solution of the hydrophobic silane coupling agent; the hydrophobic silane coupling agent has one or more groups and covalent bond connection is formed by the hydrophobic silane coupling agent and the micro-nano dual rough structure; meanwhile, thewear-resisting super-hydrophobic coating composition at least contains one hydrophobic group. A super-hydrophobic coating layer formed by the super-hydrophobic coating composition keeps a long-term effective super-hydrophobic property; the coating composition adopts a binding material so that the binding force between a super-hydrophobic structure and a matrix is enhanced and the protection effectof the coating layer is enhanced; a processing technology of the super-hydrophobic coating layer is simple and convenient and large-area construction is facilitated.

Owner:杭州纳微生物化学有限公司

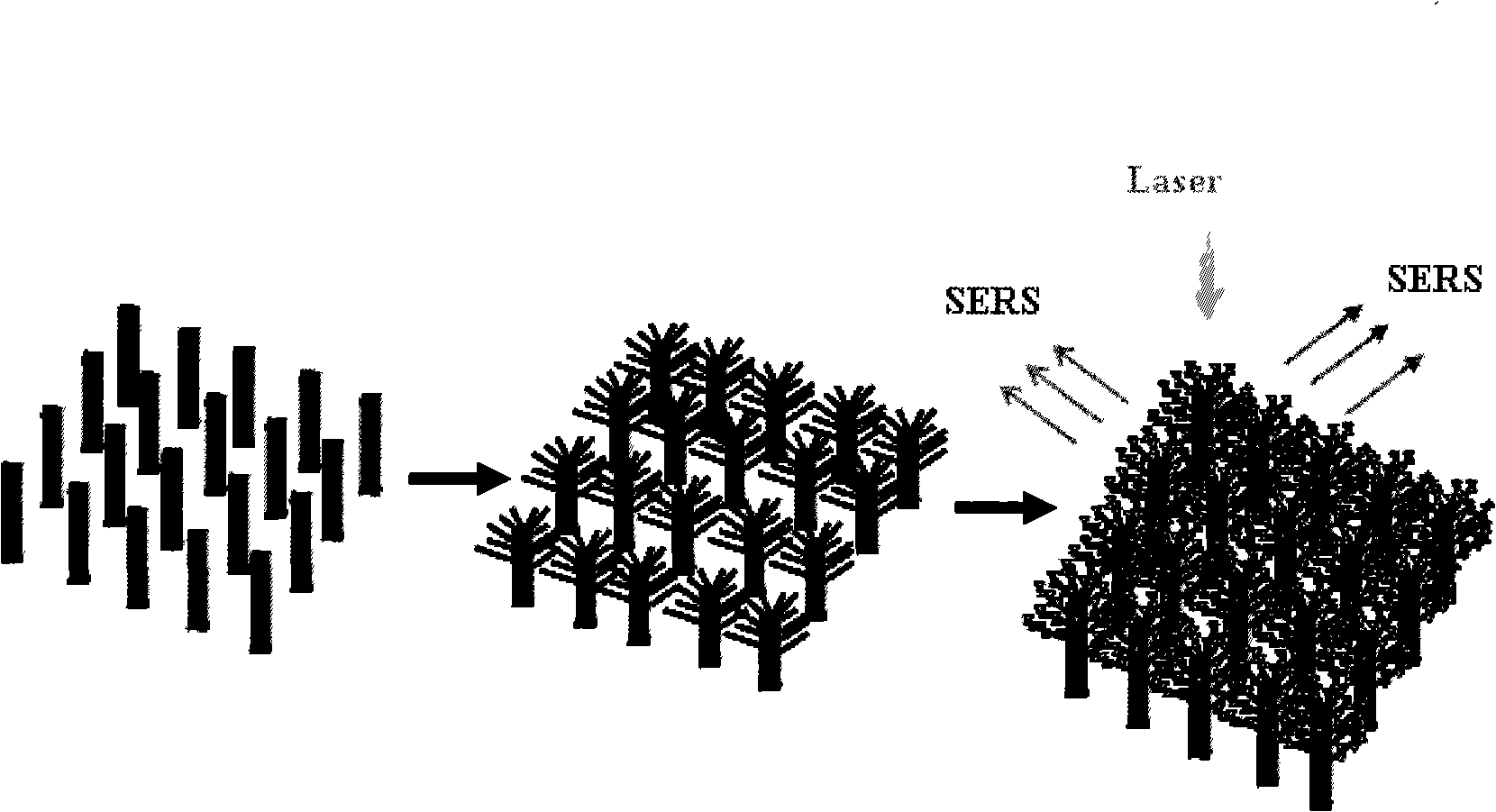

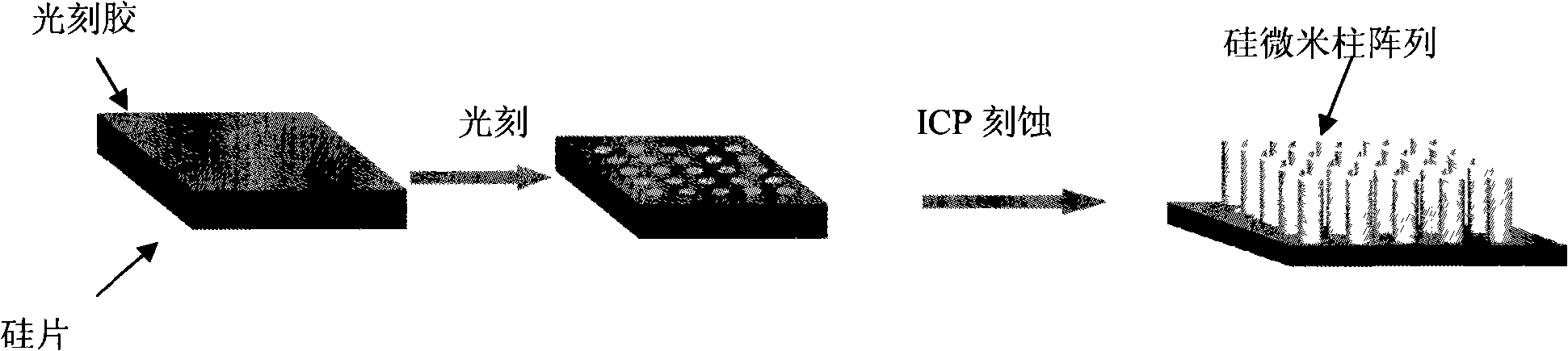

Preparation of surface reinforced Raman active substrate of large area micro-nano dendritical structure array

InactiveCN101281133AHighly sensitive SERS activitySuitable for testingDecorative surface effectsRaman scatteringMicro nanoBasement

The invention discloses a preparation method for increasing raman activity of a basement in a surface of a large area of a micro-nano tree structure array, which firstly prepares a large area of a silicon micron cylinder array; a nanometer assembling technology is used for producing a nanometer stick in the silicon micron cylinder array. then a three-dimensional ordered periodic micro-nano structure array is obtained; and various appearance of metal nano-particles are embedded into the three-dimensional ordered periodic micro-nano structure array by using a way of a hydro-thermal synthesis method. A SERS activity basement of the invention can achieve homogenization from a centimeter grade to a large area. The invention designs SERS activity hot-particles on the three-dimensional ordered micro-nano structure, and assembles increasing effect of antenna, the increasing effect of metal / semiconductor intersection and the increasing effect of a gap into one body, then high sensitivity of the SERS activity is obtained, and the SERS activity hot-particles is firmly embedded into the tree micro-nano structure, then the invention is not only applicable for a SERS test of trace liquid-phase analyte, but also for the SERS test of trace gaseous-phase analyte.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

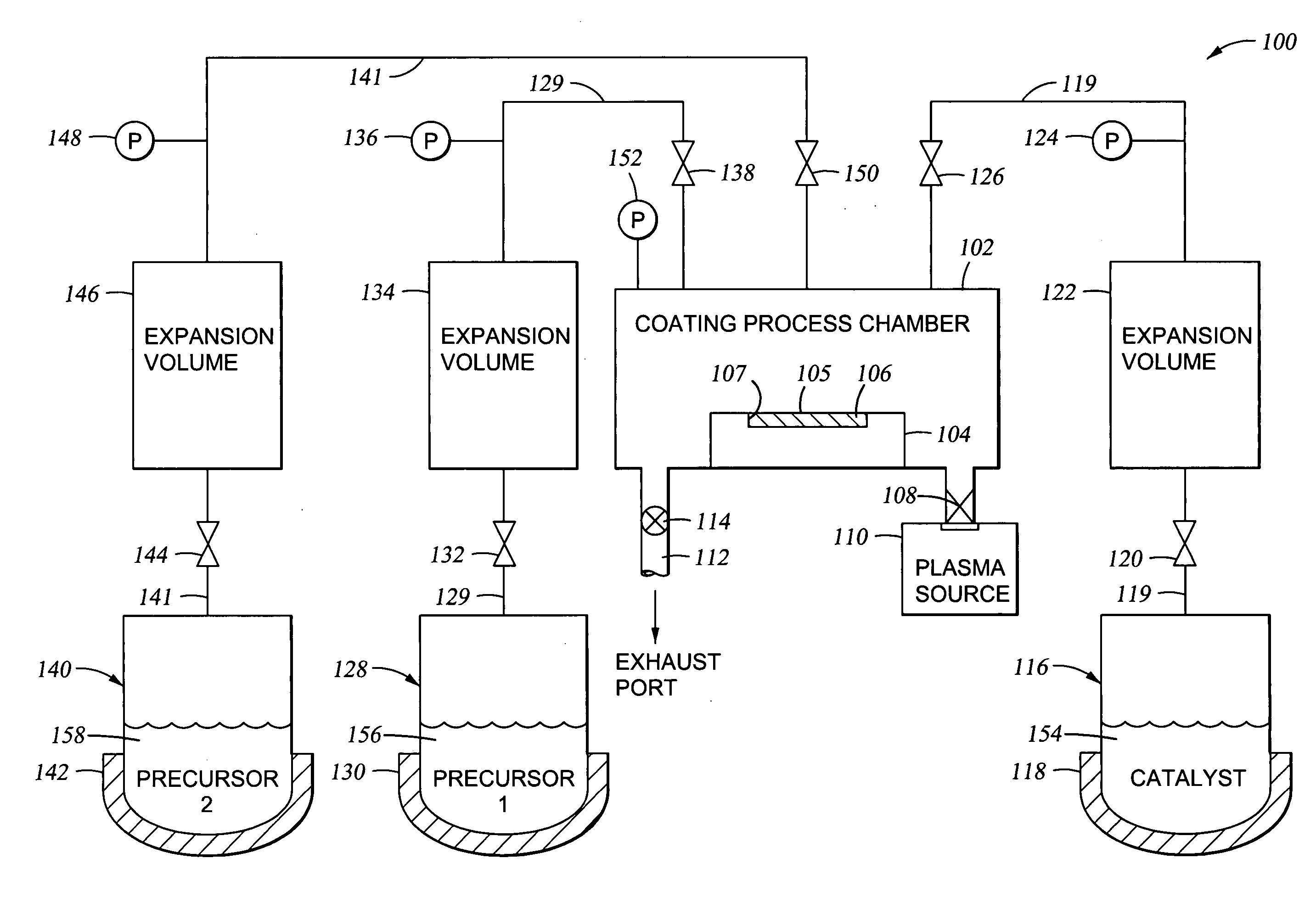

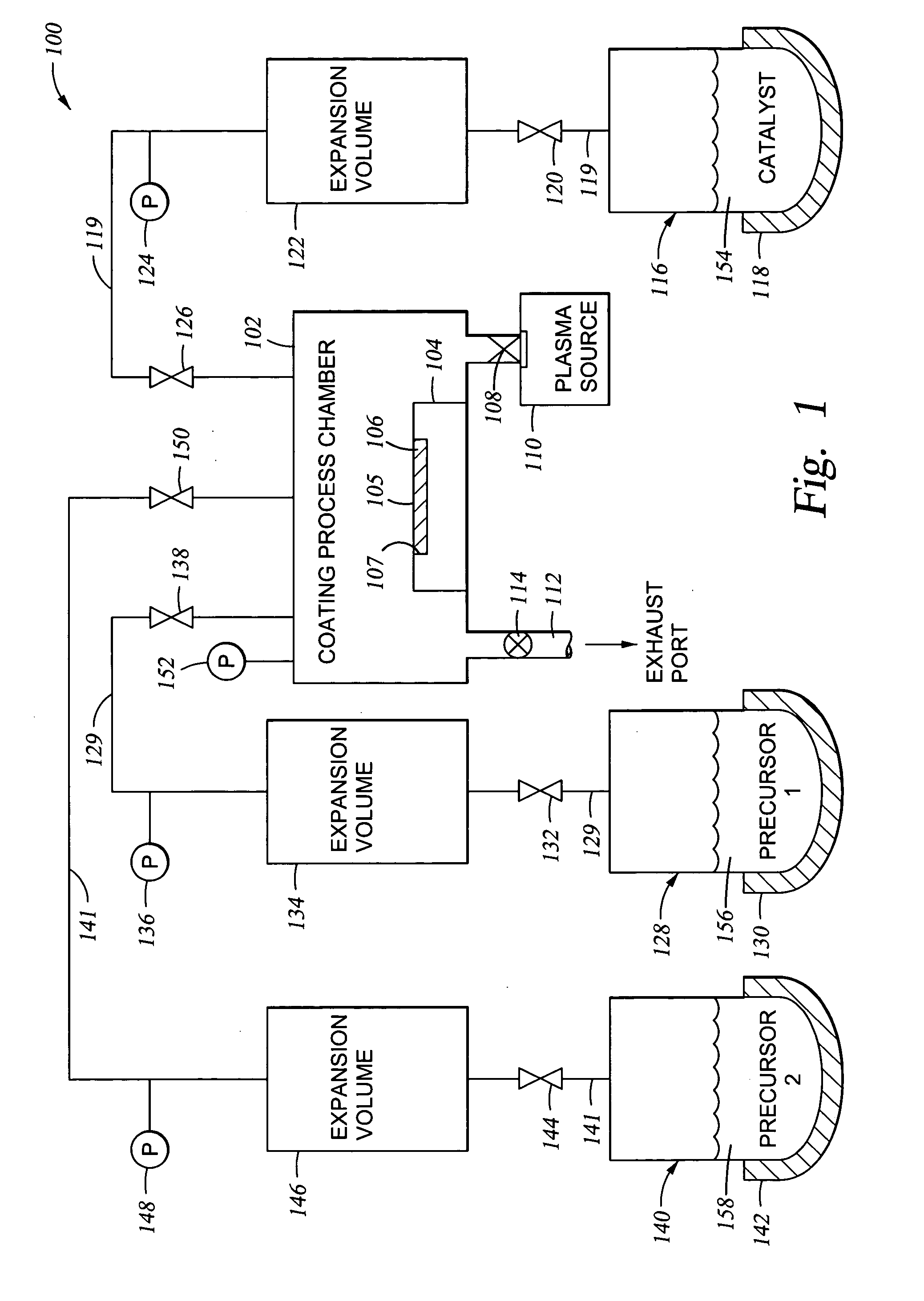

Apparatus and method for controlled application of reactive vapors to produce thin films and coatings

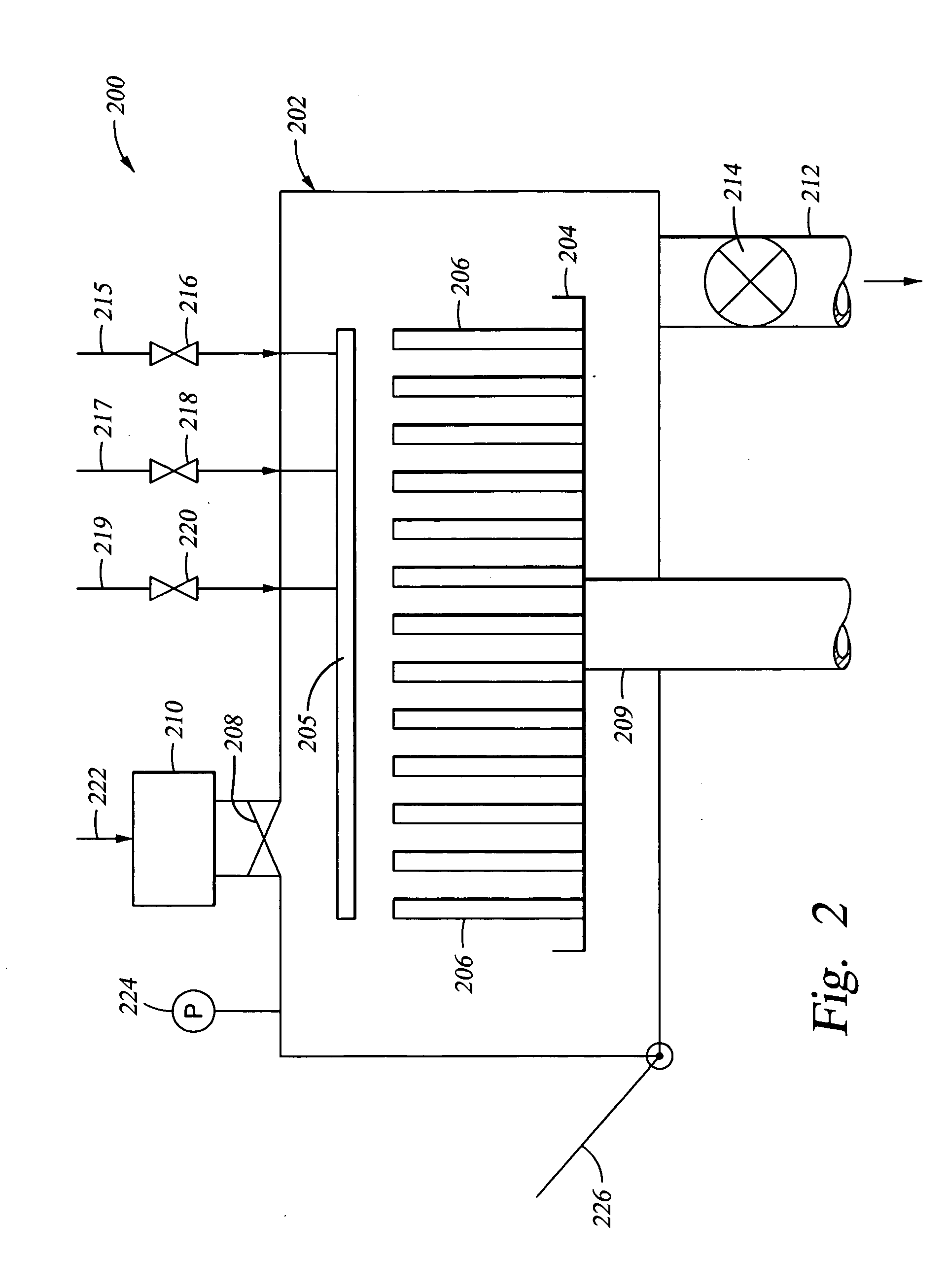

InactiveUS20040261703A1Prevent stictionReduce workMaterial nanotechnologyElectrical apparatusVapor phaseThin layer

A vapor phase deposition method and apparatus for the application of thin layers and coatings on substrates. The method and apparatus are useful in the fabrication of electronic devices, micro-electromechanical systems (MEMS), Bio-MEMS devices, micro and nano imprinting lithography, and microfluidic devices. The apparatus used to carry out the method provides for the addition of a precise amount of each of the reactants to be consumed in a single reaction step of the coating formation process. The apparatus provides for precise addition of quantities of different combinations of reactants during a single step or when there are a number of different individual steps in the coating formation process. The precise addition of each of the reactants in vapor form is metered into a predetermined set volume at a specified temperature to a specified pressure, to provide a highly accurate amount of reactant.

Owner:APPLIED MICROSTRUCTURES

Graphene transistor based on metamaterial structure, optical sensor based on metamaterial structure, and application of graphene transistor

ActiveCN103117316APromote absorptionAdjustableRadiation pyrometrySpectrum investigationMicro nanoUltra-wideband

Disclosed are a graphene transistor based on a metamaterial structure, an optical sensor based on a metamaterial structure, and application of the graphene transistor. The graphene transistor sequentially comprises a liner, a grid metal layer, a grid medium layer, a grapheme layer and a source and drain metal layer from bottom to top. At least local area of the source and drain metal layer is provided with a periodicity micro-nano structure. The periodicity micro-nano structure, the grid metal layer and the grid medium layer match to form the metamaterial structure with the feature of complete absorption. By changing refractive index, thickness and the like of the periodicity micro-nano structure and the grid medium layer material, optical absorption frequency range of the metamaterial structure can be adjusted. Due to the feature of perfect wavelength selectivity absorption, higher flexibility and narrow-band response of the metamaterial structure, the graphene transistor can work under visible light to infrared even longer wave bands by selecting different metamaterial structures. By integrating optical sensor working in different wave bands, image sensors, spectrum detecting analyzing device and the like which can work in ultra-wide bands can be formed.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

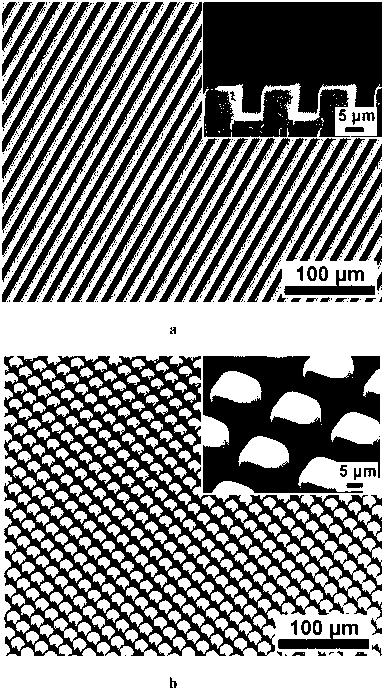

Light processing method for preparing conducting micro-nano structure by utilizing graphene oxide

ActiveCN101723310AAchieve regulationEasy to manufactureNanostructure manufactureMicrostructural devicesMicro nanoLaser processing

The invention belongs to the technical field of micro-nano manufacture, and particularly relates to a method for obtaining a graphene micro-nano structure by using graphene oxide as a raw material and utilizing a laser processing technology, which comprises the following steps of: firstly preparing a graphene oxide film on a substrate, and then building a laser micro-nano processing system for carrying out laser micro-nano processing for the graphene oxide to obtain the grapheme micro-nano structure on the substrate. The method has the following advantages: the method can prepare the micro-nano structure with various patterns easily; a three-dimensional structure can be realized by utilizing point-by-point processing; the conducting capability of the micro-nano manufacture can be regulated and controlled through controlling the reduction degree of a graphene material, and the reduction degree can be changed by changing laser processing power; and the adjustment of the graphene structure can be realized through the change of a processing atmosphere.

Owner:中科精仪科技(广东)有限公司

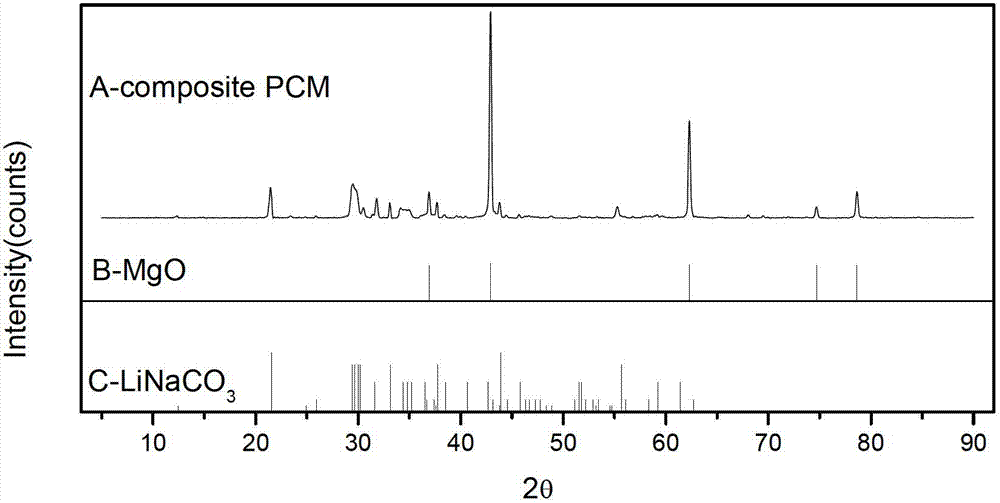

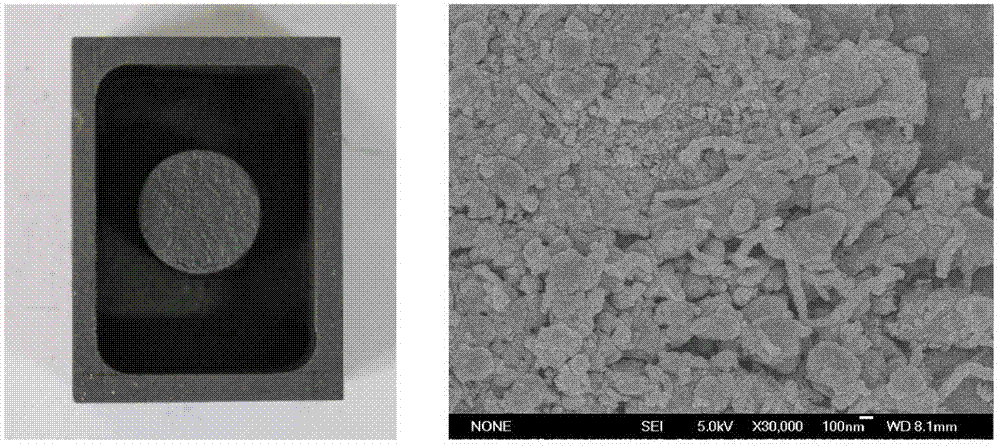

Medium-high temperature composite structural heat storage material, preparation method and application thereof

InactiveCN102888209AHigh phase change enthalpyGood chemical compatibilityHeat-exchange elementsMicro nanoMass ratio

The invention relates to a medium-high temperature (120-1000 DEG C or higher) composite structural heat storage material. The medium-high temperature composite structural heat storage material comprises an inorganic salt phase change latent heat material, a sensitive heat storage material and a heat conduction reinforcing material, wherein the mass ratio of the inorganic salt phase change latent heat material to the sensitive heat storage material is of 1: (0.1-10); and the heat conduction reinforcing material is of 0.0001-1kg / (kg heat storage material) based on mass ratio. The preparation method comprises steps as follows: uniformly mixing the inorganic salt phase change latent heat material with the sensitive heat storage material and the heat conduction reinforcing material; pressurizing to form green blank; and then heating and sintering, so as to obtain the medium-high temperature composite structural heat storage material. The medium-high temperature composite structural heat storage material provided by the invention is capable of obviously reducing the corrosion resistance of the sensitive heat storage material; meanwhile, the thermal conductivity of the composite heat storage material is markedly improved by virtue of the micro-nano doping of the heat conduction reinforcing material; and moreover, high heat storage density is achieved, and wide application prospect is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

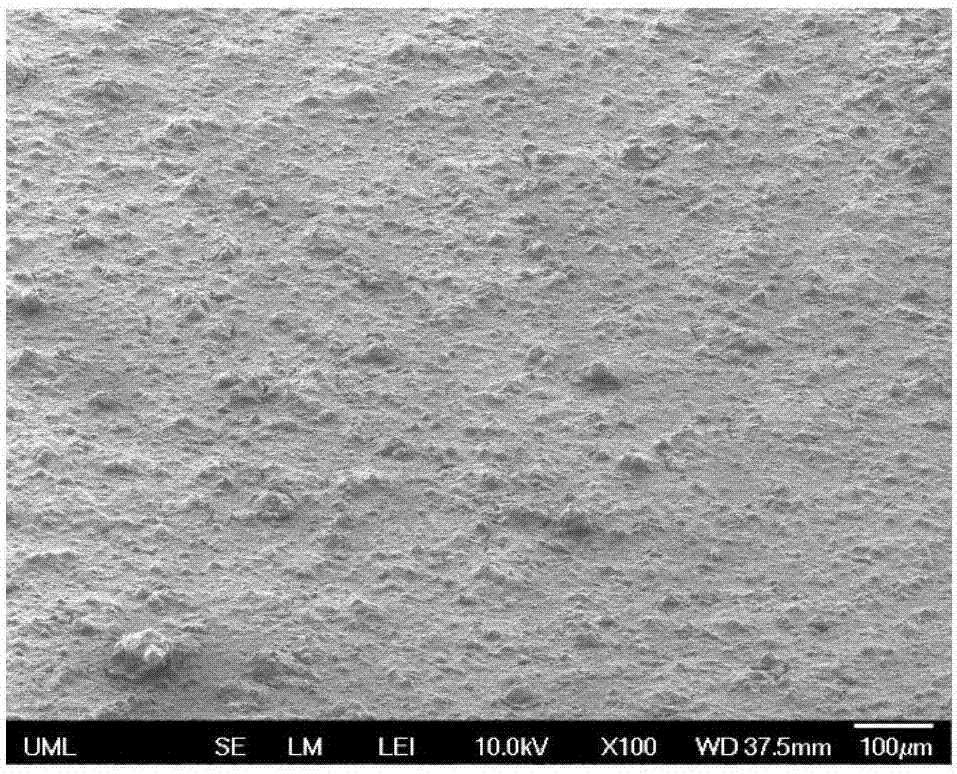

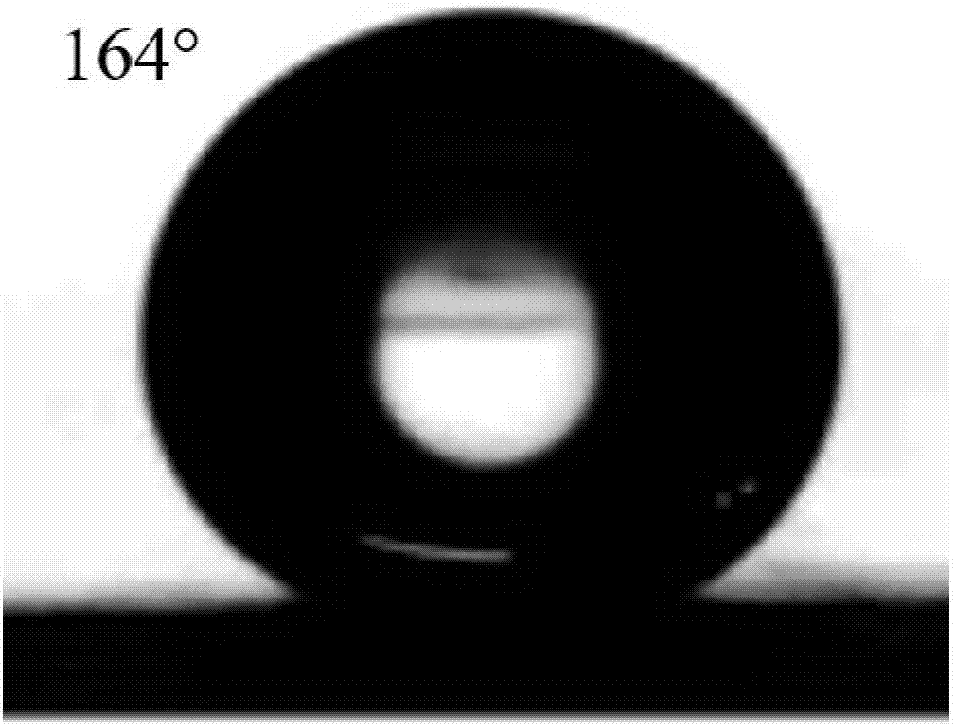

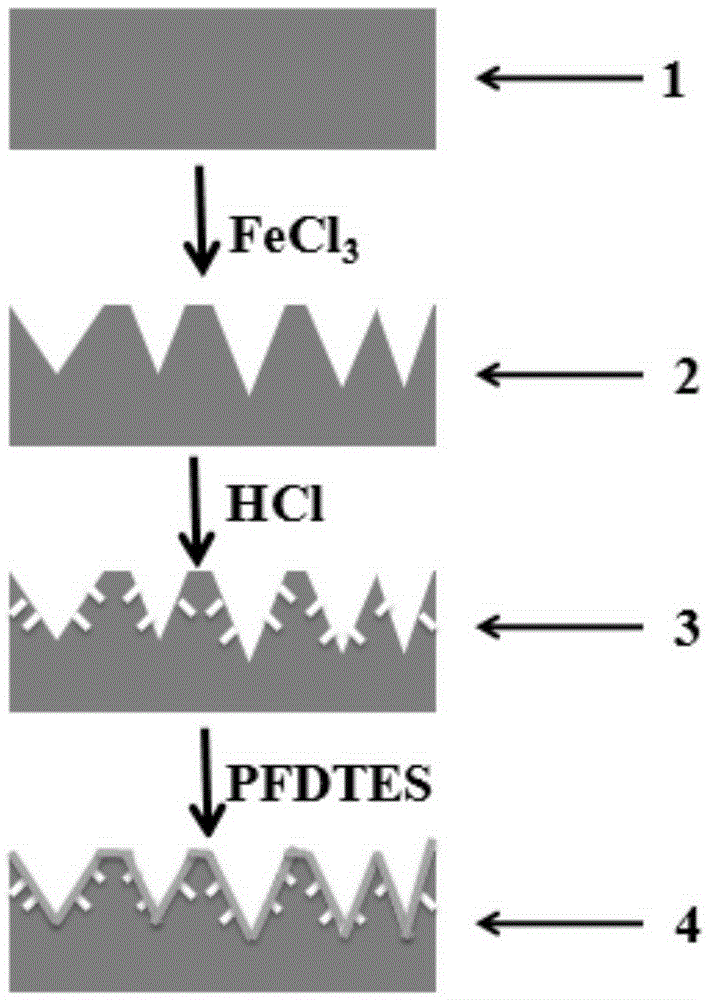

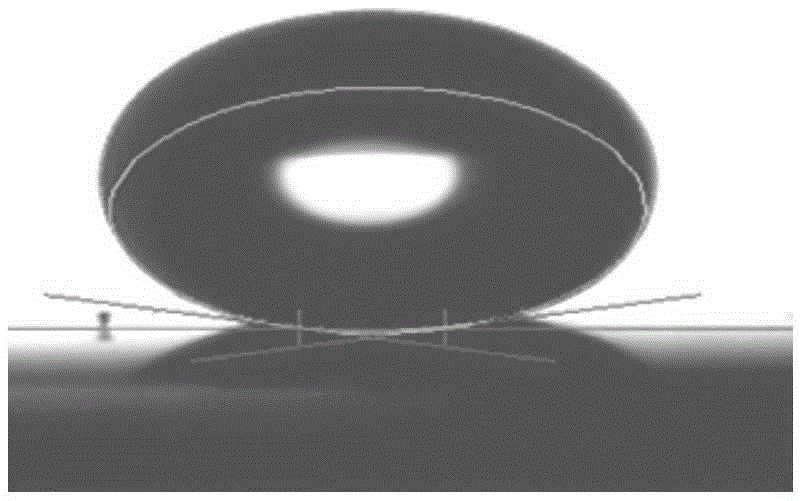

Preparation method for super-hydrophobic surface with bionic micro-nano composite structure

InactiveCN105413994AExcellent surface superhydrophobicityLow costPretreated surfacesSpecial surfacesMicro nanoElectrochemical response

The invention belongs to the technical field of preparation of super-hydrophobic surfaces, and relates to a preparation method for a super-hydrophobic surface with a bionic micro-nano composite structure. From the angle of the super-hydrophobic surface, the super-hydrophobic surface is prepared by virtue of a mesoscale two-step etching method; etching treatment is carried out on a substrate surface twice; a micro-nano composite structure similar to a lotus leaf surface is constructed by utilizing a chemical or an electrochemical reaction etching substrate, and surface modification is carried out by virtue of a surface modifier to reduce surface free energy. The size of the micro-nano structure can be controlled by virtue of reaction time, a reaction temperature and concentration. A contact angle, on the surface of the micro-nano composite structure, of water drops is as high as 170 degrees while a rolling angle of the water drops is smaller than 5 degrees. According to electrochemical test results, corrosion resistance of a super-hydrophobic stainless steel sheet is 22 times that of common stainless steel. The method provided by the invention does not need special equipment, is low in cost, good in stability, excellent in super-hydrophobic property, good in corrosion resistance and can be applied to metal corrosion-resistant protection.

Owner:DALIAN UNIV OF TECH

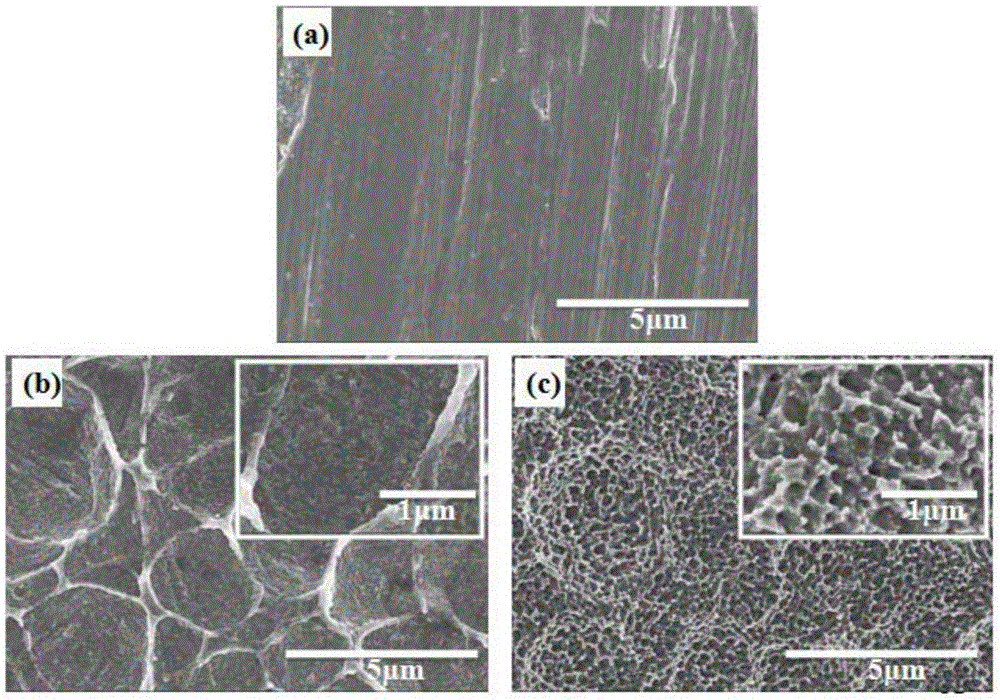

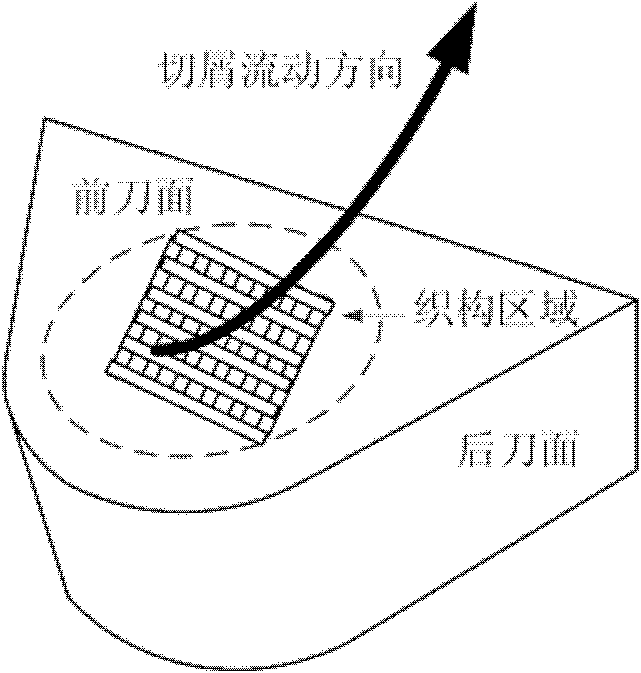

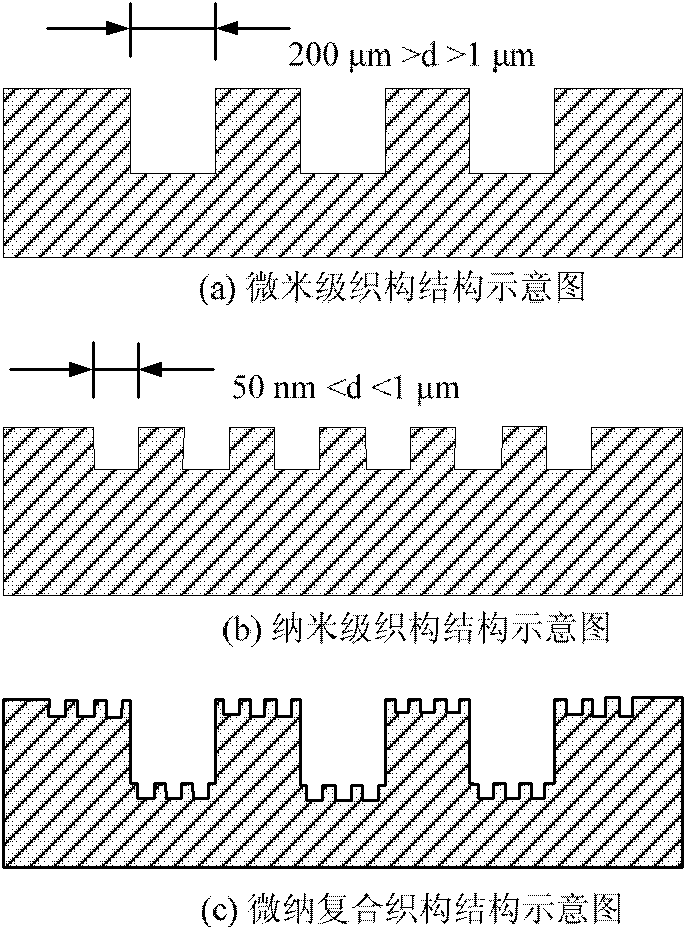

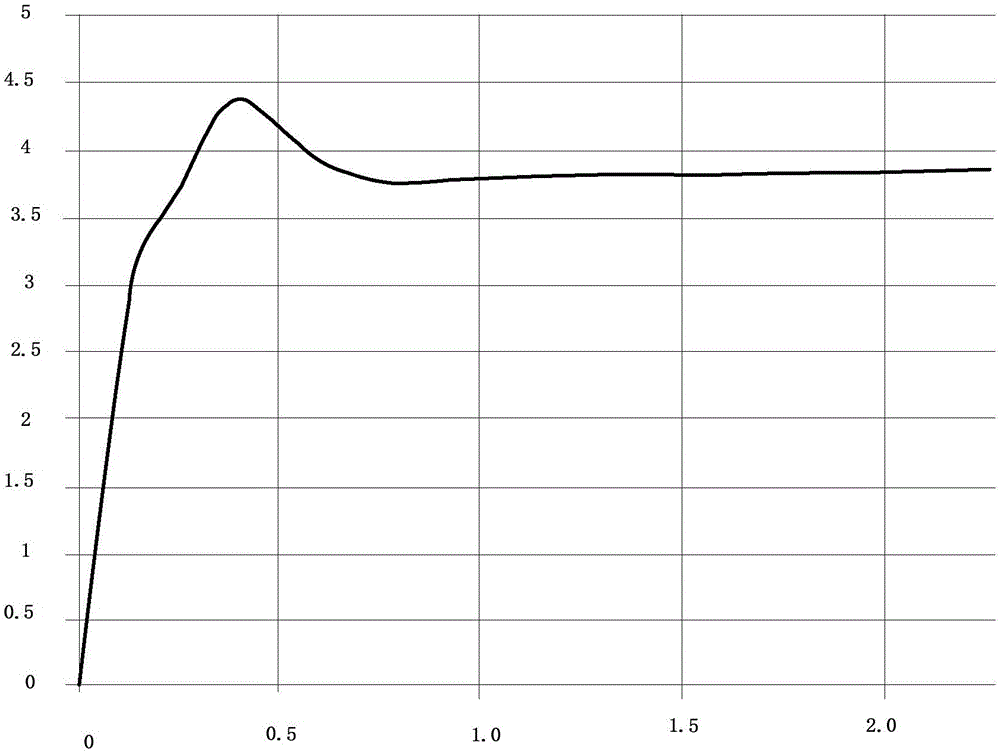

Method for preparing micro-nano composite texturing cutting tool by using femtosecond laser

The invention relates to the technical field of micro-structural surface preparation and laser micro-processing, and in particular provides a method for preparing a micro-nano composite texturing cutting tool by using femtosecond laser. In the method, micro-nano texturing and micro / nano composite texturing preparation is performed on the cutting tool surface by utilizing the unique interaction property between femtosecond laser and materials, the operation is simple, and the accuracy can be controlled. The preparation of micro / nano composite texture can be performed on a coated cutting tool by adopting a coated surface direct texturing method or a two-step composite texturing method. The method overcomes the defect of singleness of texturing only in micron scale in the conventional cutting tool texturing technology, and can further improve the abrasion resistance of the cutting tool, and prolong the service life of the cutting tool.

Owner:XI AN JIAOTONG UNIV

Preparation method of super-hydrophobic cellulose material with micro-nano structure

The invention relates to a preparation method of a super-hydrophobic cellulose material with a micro-nano structure. The method comprises the following steps: (1) adding ethyl orthosilicate and functionalized siloxane into an ethanol system containing deionized water to obtain a dispersion liquid of functionalized silica particles A in the presence of ammonium hydroxide serving as a catalyst; with the dispersion liquid of functionalized silica particles A as seeds, sequentially adding the ethyl orthosilicate, the functionalized siloxane, the deionized water, the ammonium hydroxide and the ethanol so as to obtain a dispersion liquid of functionalized silica particles B; (2) performing ultrasonic dispersion on the two types of functionalized silica particles in dimethylformamide, then adding a hydrophobic polymer and a low surface energy additive into the system and evenly stirring so as to form white dispersion liquid; and (3) coating the white dispersion liquid obtained in the step (2) on a natural cellulose material in a direct spraying manner or a spin coating manner so as to obtain the super-hydrophobic cellulose material with the micro-nano structure. The coating material has strong scouring resistance and acid-alkali resistance besides the excellent hydrophobic property.

Owner:山东天洋新材料有限公司

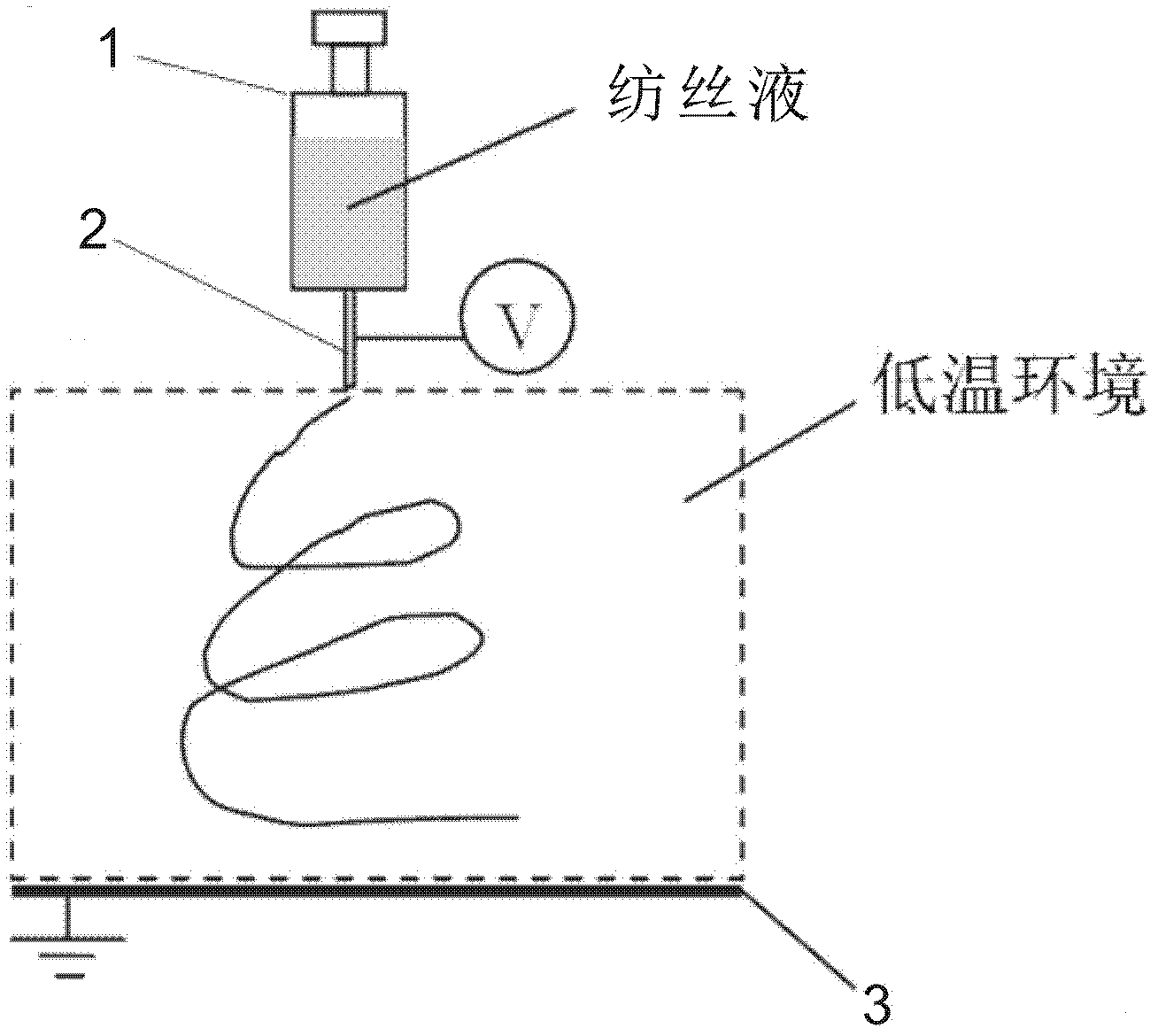

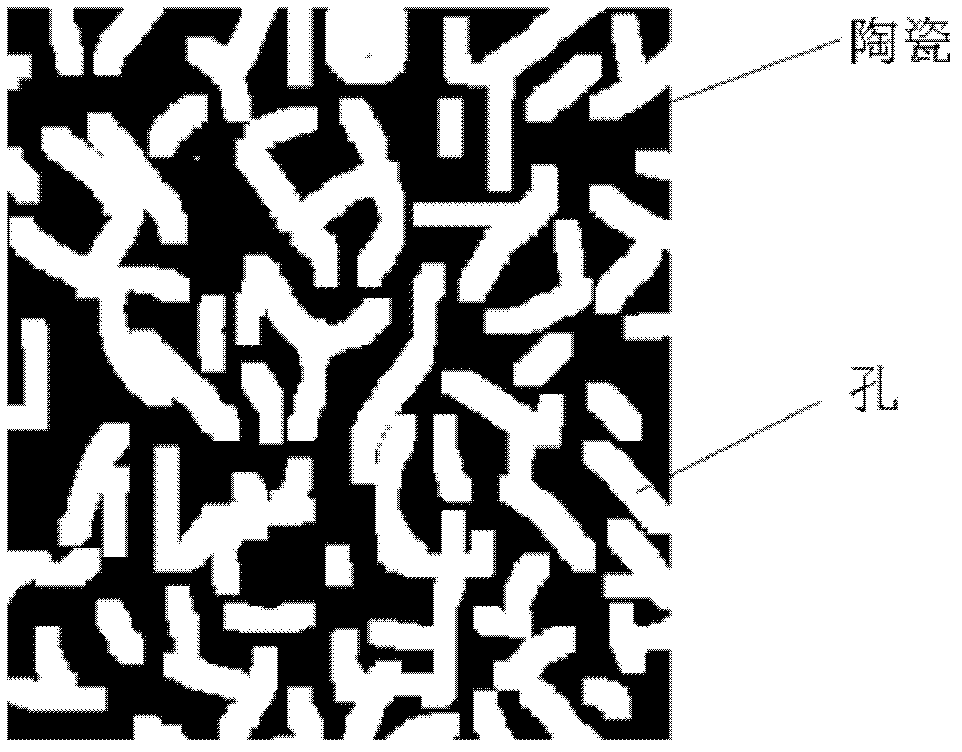

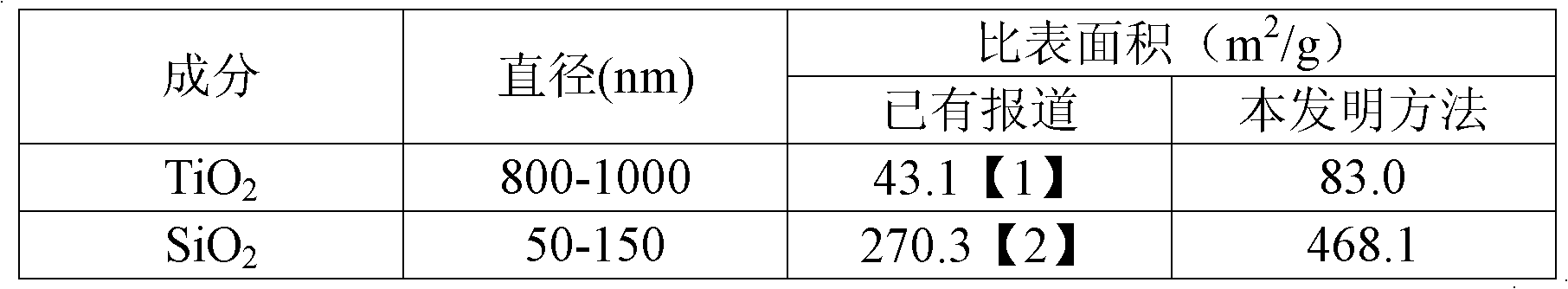

Method for preparing micro/nano porous ceramic fibers by low-temperature electrostatic spinning

The invention relates to a method for preparing micro / nano porous ceramic fibers by low-temperature electrostatic spinning. With combining electrostatic spinning technology and freeze-drying technology, the micro / nano porous ceramic fibers are prepared by freeze-drying and sintering after electrostatic spinning at a low temperature; and the method comprises four steps of preparing a spinning solution, electrostatic spinning at a low temperature, freeze-drying and sintering. The method for preparing micro / nano porous ceramic fibers by low-temperature electrostatic spinning can obtain an extremely high specific surface area, and is beneficial to improving performances of contacting, catalyzing, separating and sensing of ceramic fibers, and has wide application prospects in fields of biomedicine, filter materials, catalyst carriers, fuel cells, electronic element appliances and the like.

Owner:XIAN UNIV OF TECH

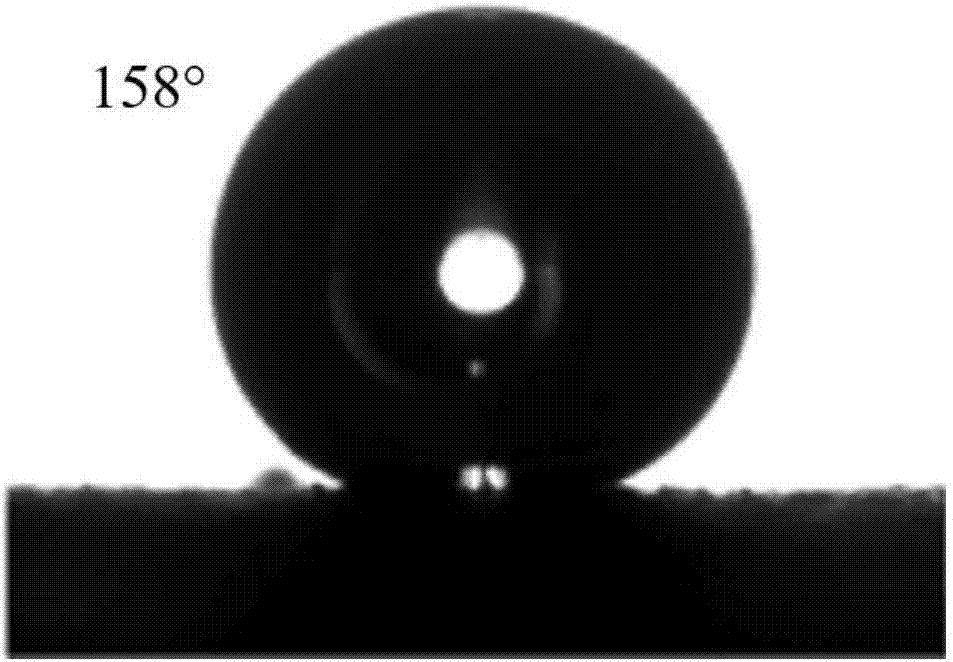

Production method of aluminum alloy bionic superhydrophobic surface

ActiveCN103204457AImprove hydrophobicityImprove adhesionDecorative surface effectsChemical vapor deposition coatingMicro nanoAlcohol

The invention relates to the technology of metal material surface modification, in particular to a production method of bionic superhydrophobic surface of an aluminum alloy base, and aims to improve hydrophobicity of the aluminum alloy surface. The production method includes: pre-processing, namely washing aluminum alloy with absolute ethyl alcohol; subjecting the surface of the aluminum alloy to laser processing to obtain a plurality of micro-scale crater structures on the surface of a sample; immersing the sample in chemical etching solution to change morphology features of the surface of the sample, keep the surface to contain chemical elements different from the base, and form micro-nano double-layer hierarchical structure on the surface of the aluminum alloy; and after reaction, placing the chemically etched aluminum alloy sample in DTS-bearing (dodecyltrichlorosilane-bearing) toluene solution for modification so that a low surface energy film gradually forms on the surface. Therefore, the surface of the aluminum alloy in the micro-nano double-layer hierarchical structure has typical biological super-hydrophobicity and has typical petal-effect adhesion.

Owner:JILIN UNIV

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Transparent super-hydrophobic coating material and method for preparing transparent super-hydrophobic coating by transparent super-hydrophobic coating material

ActiveCN104449357AEasy to prepareDoes not damage surface propertiesPolyurea/polyurethane coatingsSpecial surfacesMicro nanoGas phase

The invention discloses a transparent super-hydrophobic coating material. The raw materials of the transparent super-hydrophobic coating material comprise gas-phase silica nano-particle dispersion liquid which consists of gas-phase silica nano-particles and a solvent, and a hydrophobic treating agent. The invention further discloses a preparation method of a transparent super-hydrophobic coating; a coating of a micro-nano structure is prepared by rubbing and coating a substrate with the gas-phase silica nano-particle dispersion liquid, and then the coating is subjected to surface hydrophobization treatment by the hydrophobic treating agent to obtain the transparent super-hydrophobic coating. According to the super-hydrophobic coating material provided by the invention, hydrophobization treatment manners can be changed flexibly according to the difference of coated substrates; the method for preparing the super-hydrophobic coating has low requirement on equipment; the using cost is extremely low; the method is simple; the coating application is convenient; a large-area high-efficiency super-hydrophobic coating can be prepared; the prepared super-hydrophobic has excellent super-hydrophobicity, high transparency, droplet impact resistance, temperature and pH stability, durability, and repeated rubbing and coating capacity, and can be applied to almost all currently known solid surfaces.

Owner:ZHEJIANG UNIV

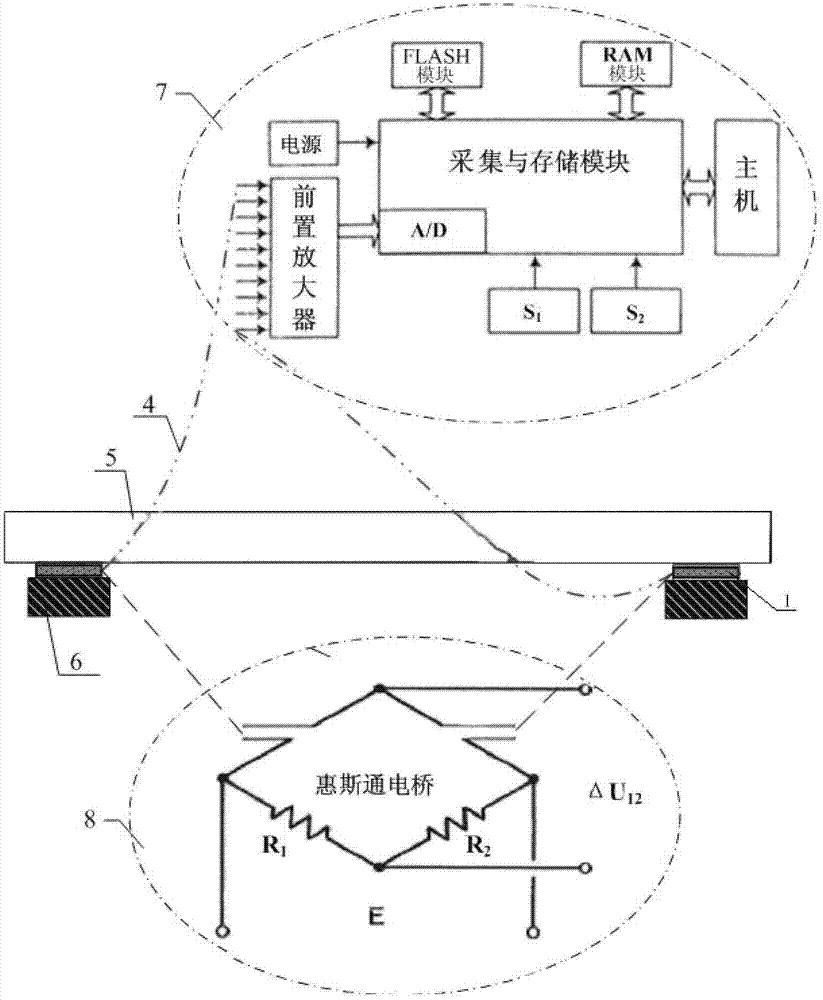

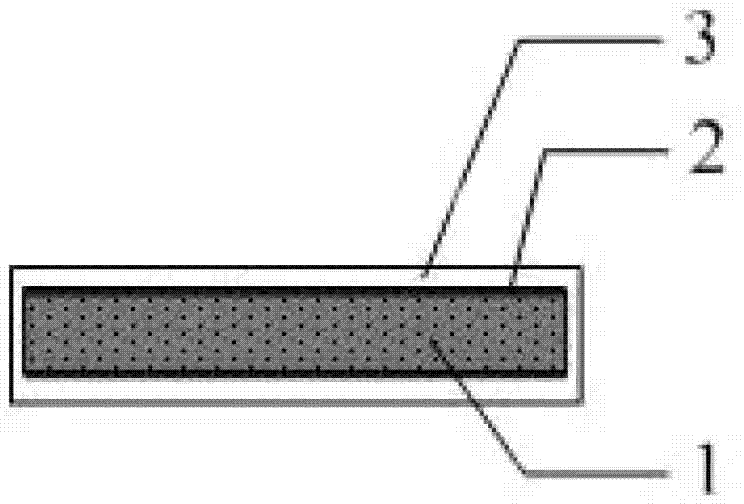

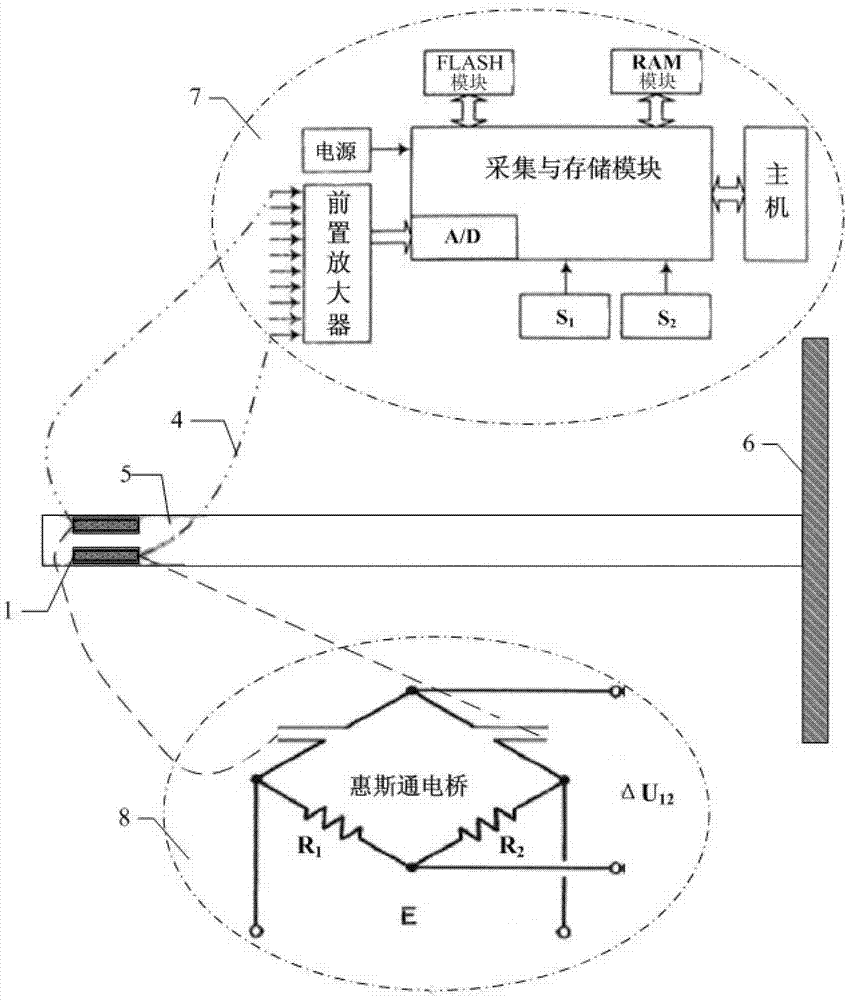

Piezoresistance/piezoelectric composite material, manufacturing method of material, sensor utilizing material and manufacturing method of sensor

InactiveCN102924020AImprove structural toughnessGood compatibilityConverting sensor output electrically/magneticallyFiberBridge deck

The invention relates to a piezoresistance / piezoelectric material system and production and application methods of the piezoresistance / piezoelectric material system. The piezoresistance / piezoelectric composite material comprises the following components in parts by weight: 100 parts of cement, 105-500 parts of micro / nano grade piezoelectric ceramic powder body, 10-30 parts of fly ash, 15-50 parts of water, 0.01-2 parts of super plasticizer, 0.1-10 parts of toughness fiber and 0.01-15 parts of conductive fillers. A sensor utilizing the piezoresistance / piezoelectric composite material comprises a piezoresistance / piezoelectric composite material layer, wherein the upper surface and the lower surface of the piezoresistance / piezoelectric composite material layer are respectively provided with one electrode, the piezoresistance / piezoelectric composite material layer and the electrodes are coated in a package shell, the upper electrode and the lower electrode are connected by an electromagnetic shielding wire passing through the package shell, and the sensor is arranged between a bracket and a support bridge deck unit or is embedded in the support bridge deck unit. The sensor utilizing the material, disclosed by the invention, has intrinsic structure toughness and synchronous monitoring capability of covering a whole-frequency-domain static / dynamic traffic and structure parameters.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

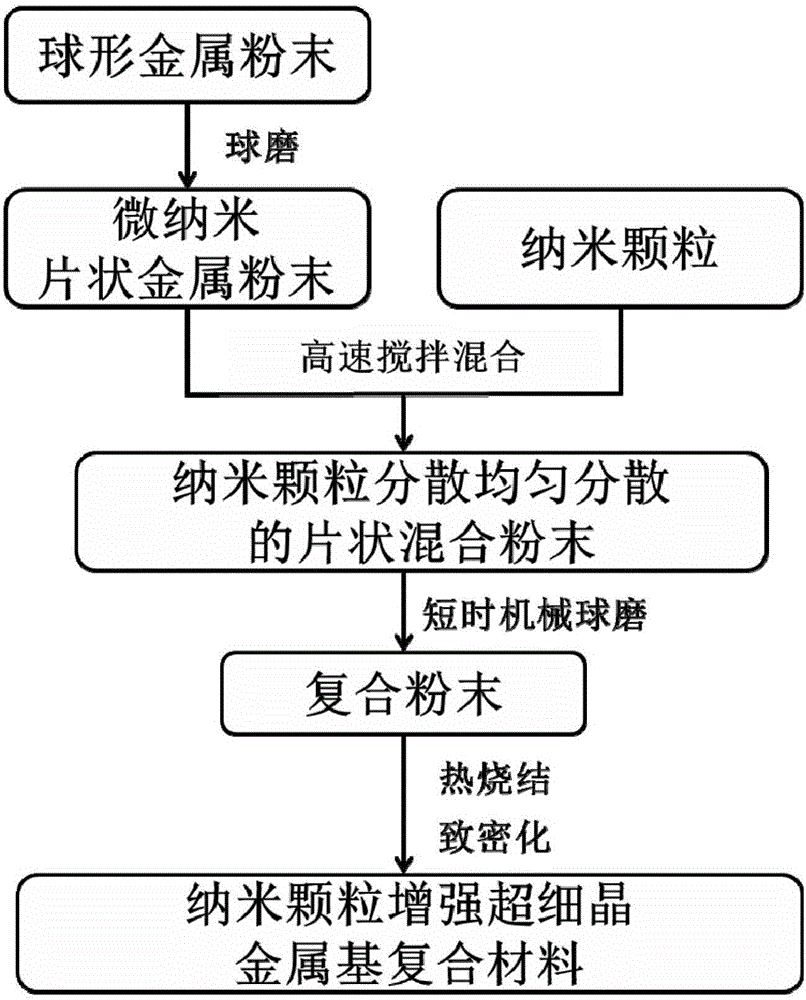

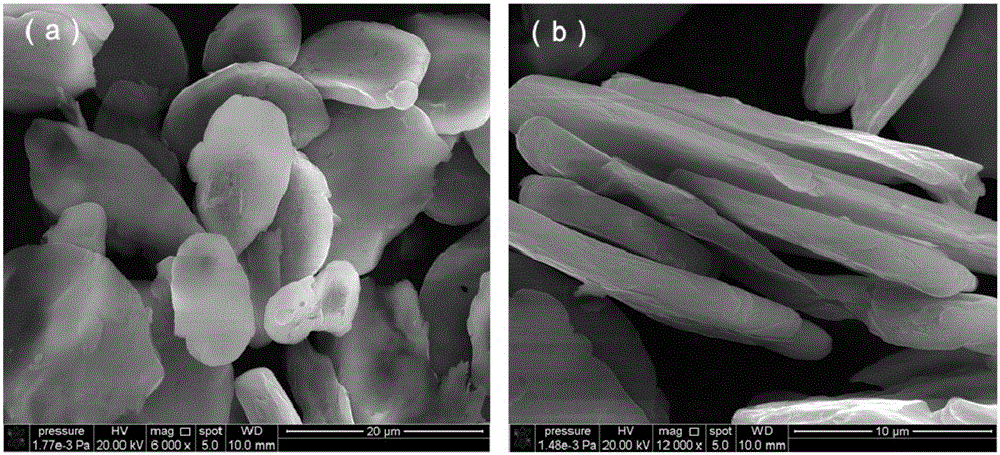

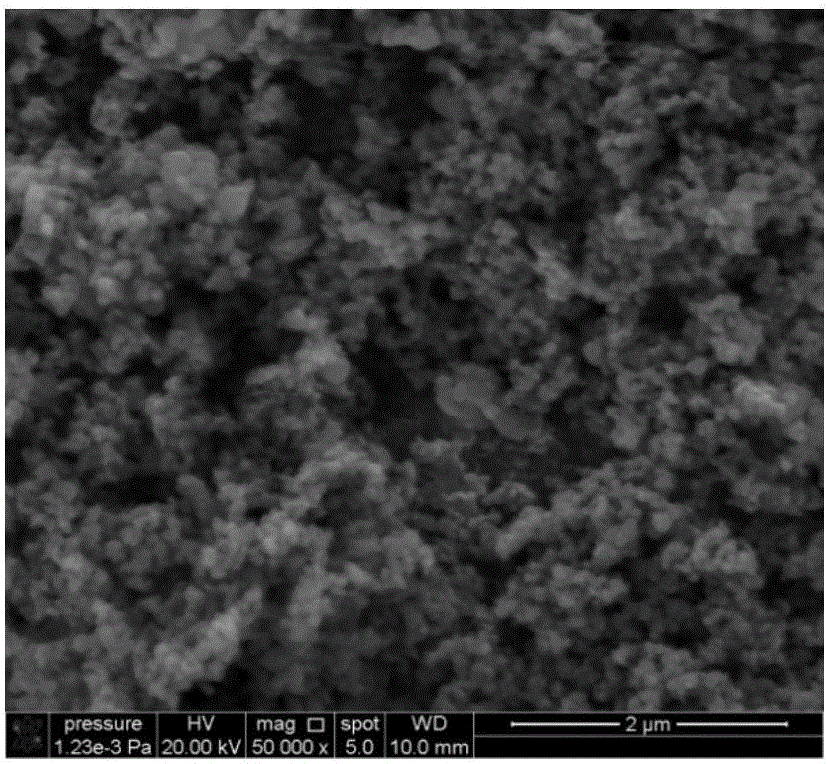

Powder metallurgy preparation method for nano-particle reinforced ultra-fine grain metal-matrix composite

The invention provides a powder metallurgy preparation method for a nano-particle reinforced ultra-fine grain metal-matrix composite. According to the method, a metal-matrix grain refining process and a nano-particle dispersing process are carried out in steps. The method comprises the steps that firstly, micro-nano flaky metal-matrix powder is prepared in advance; nano-particles and the flaky metal-matrix powder are stirred and mixed in a stirrer at the high speed under protective atmosphere, and by means of high shear force and pressure generated between stirring blades and a tank body, the nano-particles are uniformly dispersed to the surface of the micro-nano flaky metal-matrix powder; through short-time mechanical ball-milling treatment, the nano metal particles are embedded into the micro-nano flaky metal-matrix powder, so that composite powder of nano-particle reinforced metal is obtained; and compression moulding, sintering and compacting treatment are conducted, so that the ultra-fine grain metal-matrix composite with the nano-particles uniformly dispersed is obtained. By means of the powder metallurgy preparation method, time and energy are saved; cost is low; the application range is wide; and the prepared material is high in comprehensive mechanical performance and has large-scale application potential.

Owner:SHANGHAI JIAO TONG UNIV

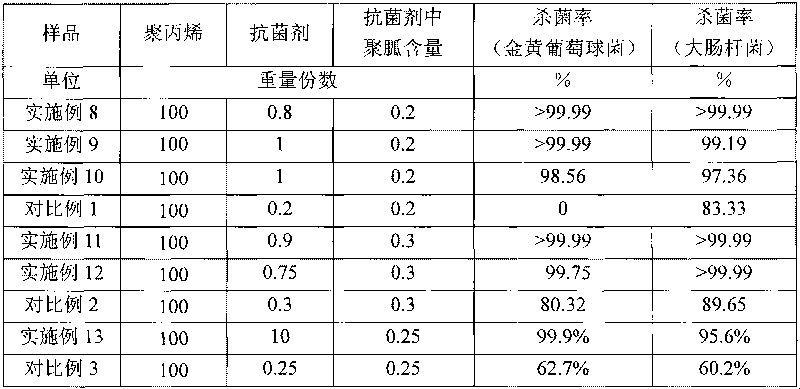

Compound antimicrobial and preparation method thereof

The invention provides a compound antimicrobial and a preparation method thereof. The compound antimicrobial comprises micro-nano particles and guanidine polymers by the weight ratio of 1:1 to 1:50, wherein the micro-nano particles at least have the one-dimensional average dimension of 1nm to 1000 mu m; the guanidine polymers are coated on the surfaces of the micro-nano particles and / or embedded in holes or among layers of the micro-nano particles; inorganic or organic particles comprising micro-nano particles are added to a solution of the guanidine polymers; organic alkali is added or not added; the particles and the solution are uniformly mixed and dried for obtaining the compound antimicrobial. When applied to plastics, fibers and rubber, the antimicrobial has high sterilization efficiency, also largely reduces the processing cost of antibacterial materials, and has simple and convenient preparation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

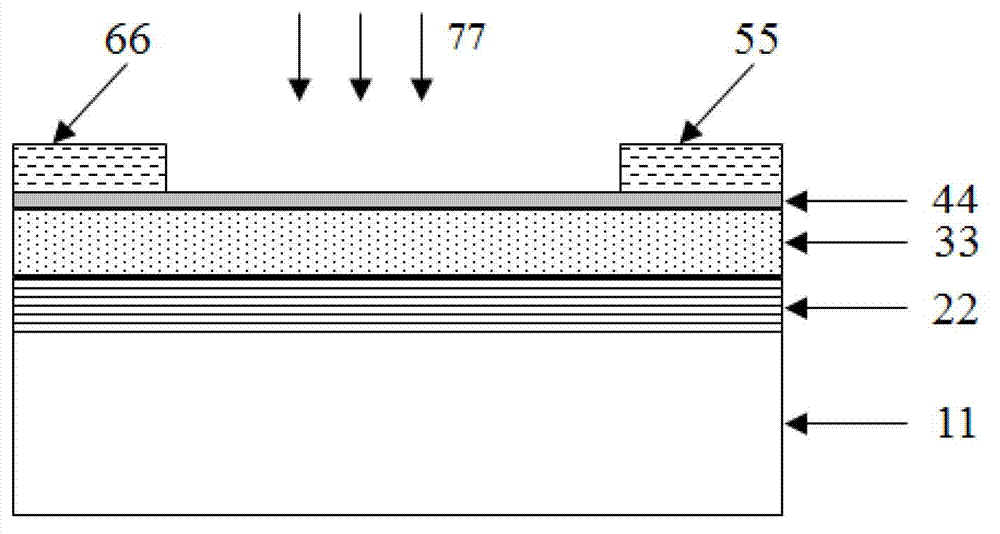

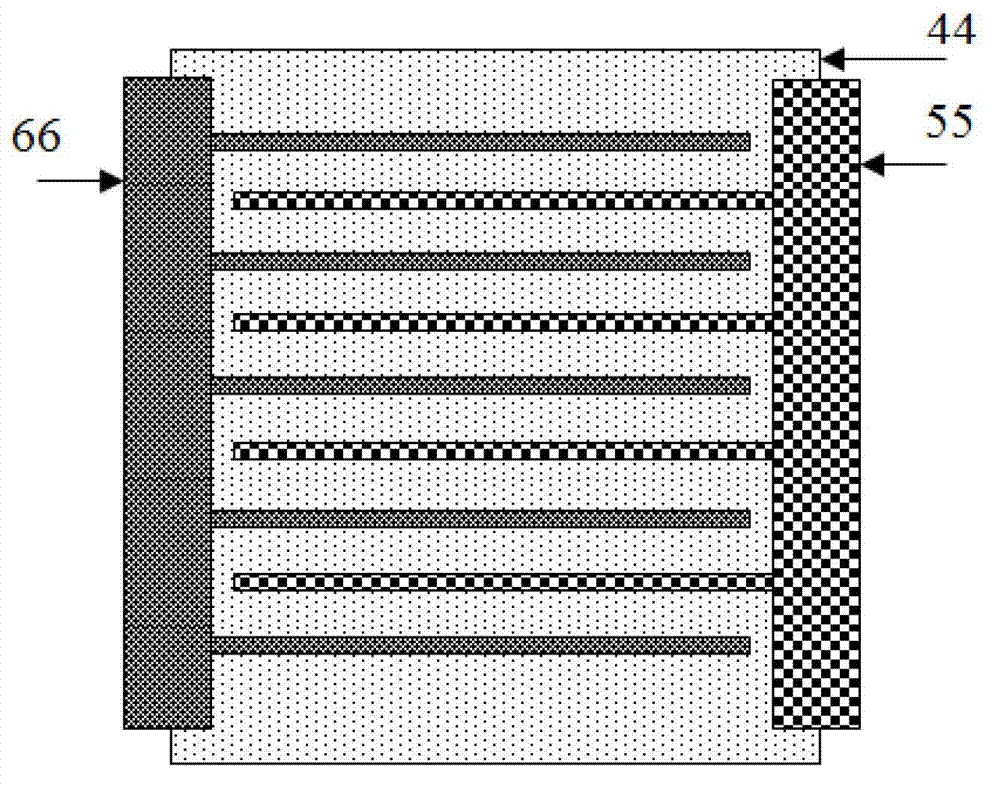

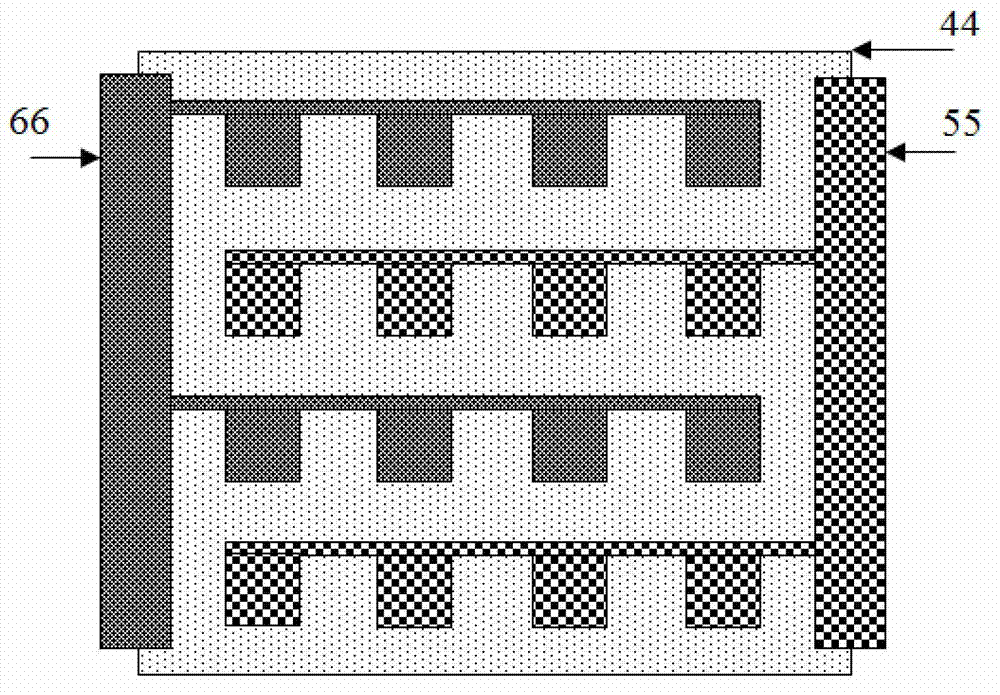

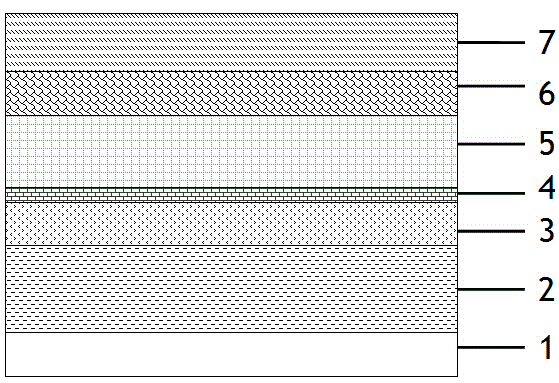

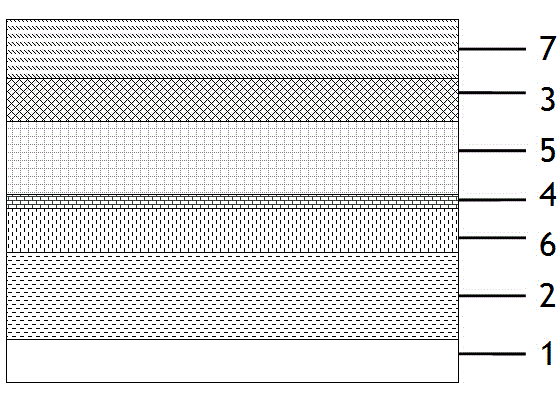

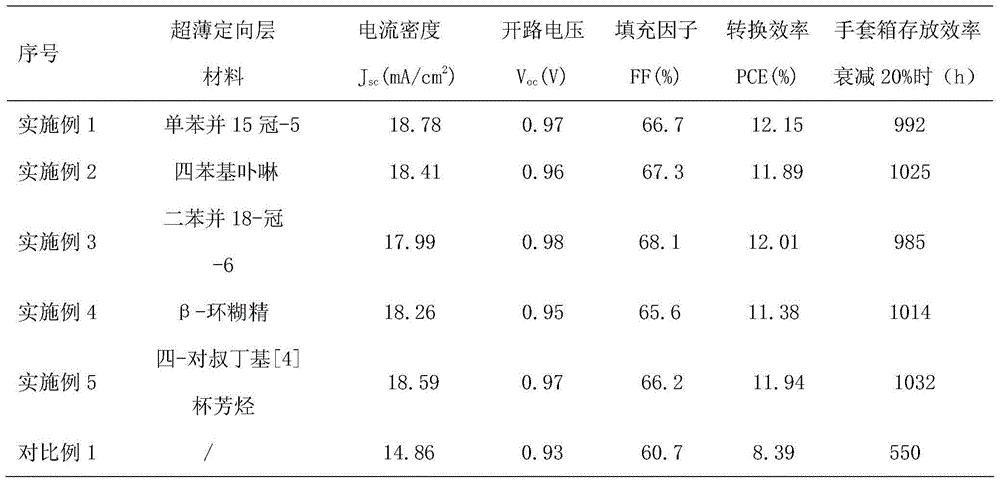

Organic and inorganic hybrid perovskite-based solar cell and method for manufacturing same

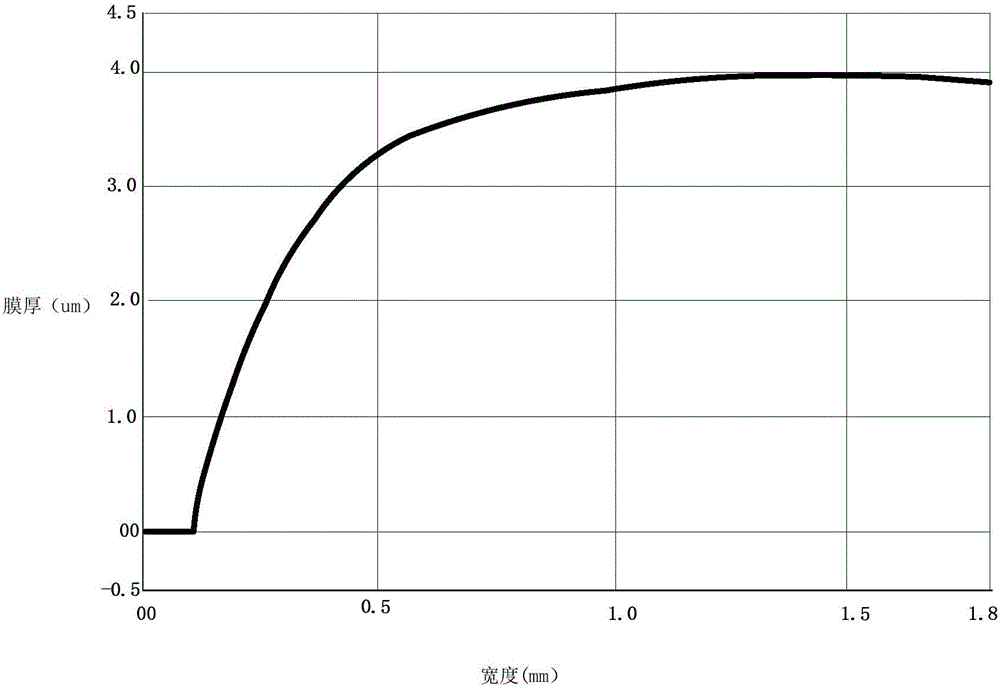

ActiveCN104795499AReduce internal defectsIncrease the diffusion lengthSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoElectron hole

The invention relates to an organic and inorganic hybrid perovskite-based solar cell and a method for manufacturing the same. The organic and inorganic hybrid perovskite-based solar cell comprises a substrate, a transparent electrode, an electron transport layer, an ultrathin orientation layer, a perovskite light absorption layer, a hole transport layer and a counter electrode. The transparent electrode, the electron transport layer, the ultrathin orientation layer, the perovskite light absorption layer, the hole transport layer and the counter electrode are sequentially stacked on the substrate. The method includes modifying micro-nano structures on the surfaces of the electron transport layer or the hole transport layer to form the ultrathin orientation layer before the perovskite light absorption layer is manufactured by the aid of a liquid phase process. The organic and inorganic hybrid perovskite-based solar cell and the method have the advantages that orientated growth of crystals of perovskite is controlled under large-ring structural effects of molecules in the ultrathin orientation layer, accordingly, the crystallization regularity can be improved, and internal defects can be reduced; the diffusion lengths of current carriers inside the perovskite light absorption layer can be effectively increased, accordingly, recombination of electron-hole pairs on the inside and interfaces of the perovskite light absorption layer can be prevented, and the photoelectric conversion efficiency and the stability of the cell can be obviously improved; the crystallization quality of the perovskite light absorption layer cannot be easily affected by film forming conditions under the orientation mold plate effects of the ultrathin orientation layer, accordingly, the device manufacturing repeatability can be improved, and the low-temperature solution method is applicable to industrially producing large-area perovskite solar cells.

Owner:CHINA LUCKY FILM CORP

Water-based drilling fluid of shale gas horizontal well reinforced well wall and application thereof

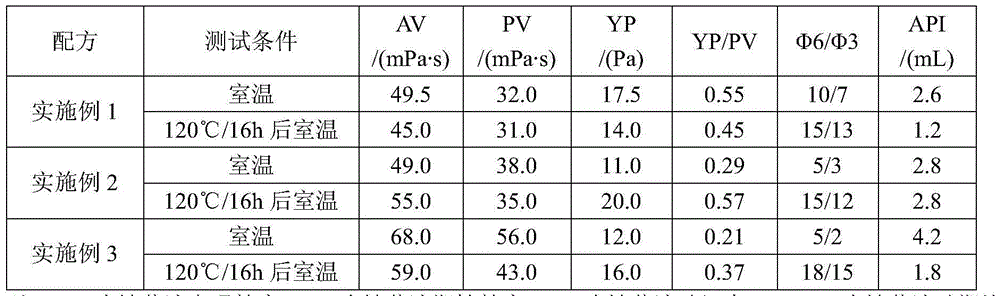

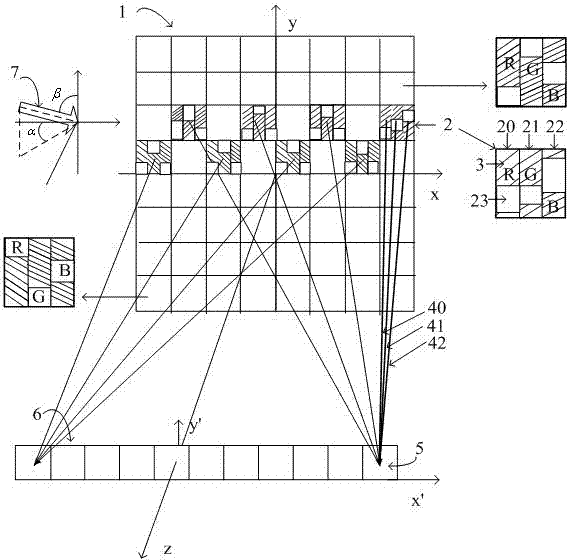

ActiveCN104694092AImprove stabilityGood dispersionDrilling compositionBorehole/well accessoriesMicro nanoWater based

The invention relates to a water-based drilling fluid of a shale gas horizontal well reinforced well wall and an application thereof. The water-based drilling fluid comprises, by weight, 100 parts of water, 0-5 parts of clay, 0.5-3 parts of micro-nano particle blocking agents, 0.5-3 parts of chemical blocking agents, 0.1-2 parts of tackifier, 1-5 parts offiltrate reducer, 0.05-2 parts of encapsulating inhibiting agents, 0.1-3 parts of polyamine inhibiting agents, 1-5 parts of lubricant, 0.1-1 part of alkalinity regulator, 2-25 parts of inorganic salt, and 0-200 parts of weighting agents. The micro-nano particle blocking agents and the chemical blocking agents in the water-based drilling fluid of the shale gas horizontal well reinforced well wall have the effect of reinforcing the well wall in a cooperative mode, can effectively block micropore seams of shale to hinder pressure transmission, can further obviously improve the membrane efficiency of the shale, and facilitates the balance anti-collapse function of chemical activity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

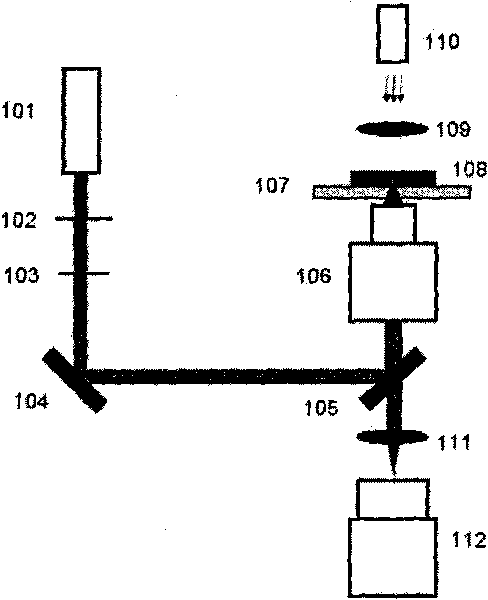

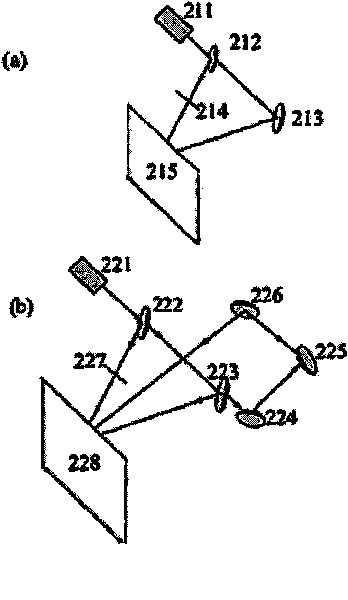

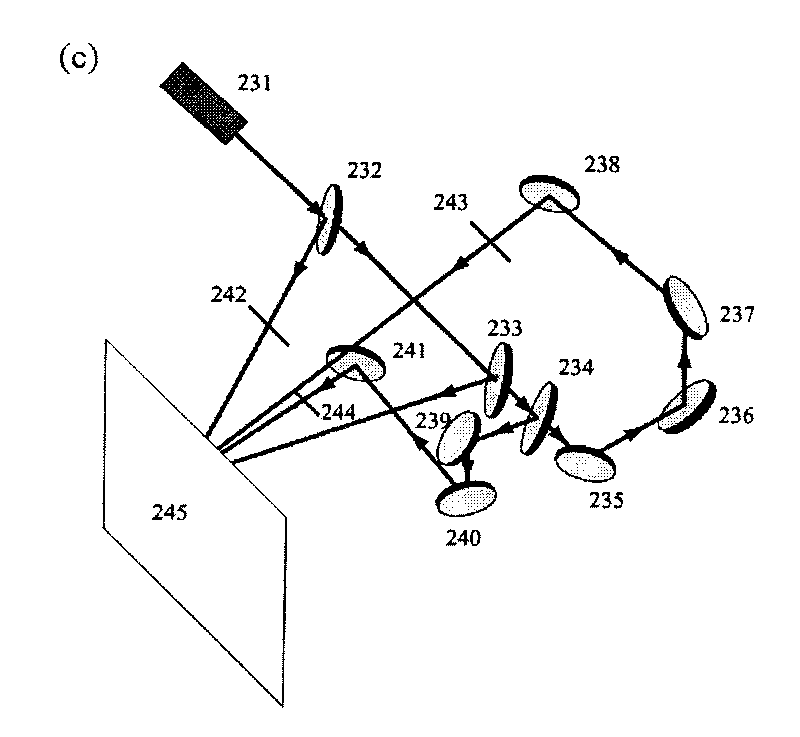

3D laser printing method and system

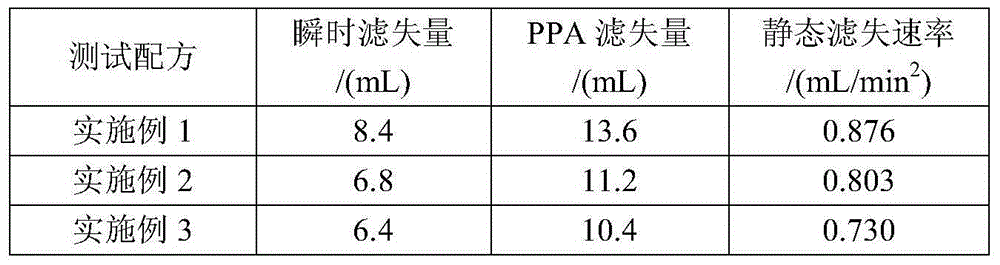

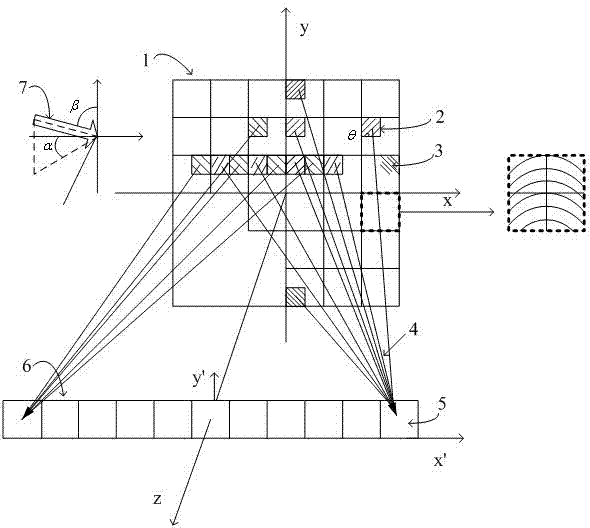

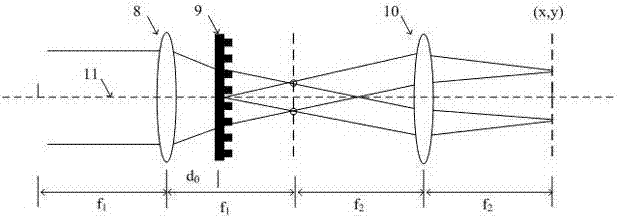

ActiveCN103246195ARealize continuously adjustableStrong three-dimensional senseDiffraction gratingsColor imageMicro nano

The invention discloses a 3D laser printing method and system. A four-parameter continuous modulation laser printout method is adopted to prepare a 3D image consisting of diffraction pixels arranged according to the position coordinates and provided with both a specific grating space frequency and an angle of orientation; the modulation method of parameters of grating stripes in the diffraction pixels is realized on the basis of a 4F imaging system and a diffraction grating; the 4F imaging system comprises a first Fourier transformation lens or lens group and a second Fourier transformation lens or lens group; the diffraction grating is placed between the first Fourier transformation lens or lens group and the second Fourier transformation lens or lens group; the distance between the diffraction grating and the first Fourier transformation lens or lens group is changed to realize continuous modulation of the space frequency of the grating stripes; and the diffraction grating is rotated to realize continuous modulation of the grating orientation angle of the grating stripes. The 3D laser printing method and system realize continuous adjustment of the space frequency and the orientation of the grating, and encodes on the basis of the four-parameter micro-nano structure with continuously changeable space frequency and orientation of the grating to form a 3D color image.

Owner:SVG TECH GRP CO LTD

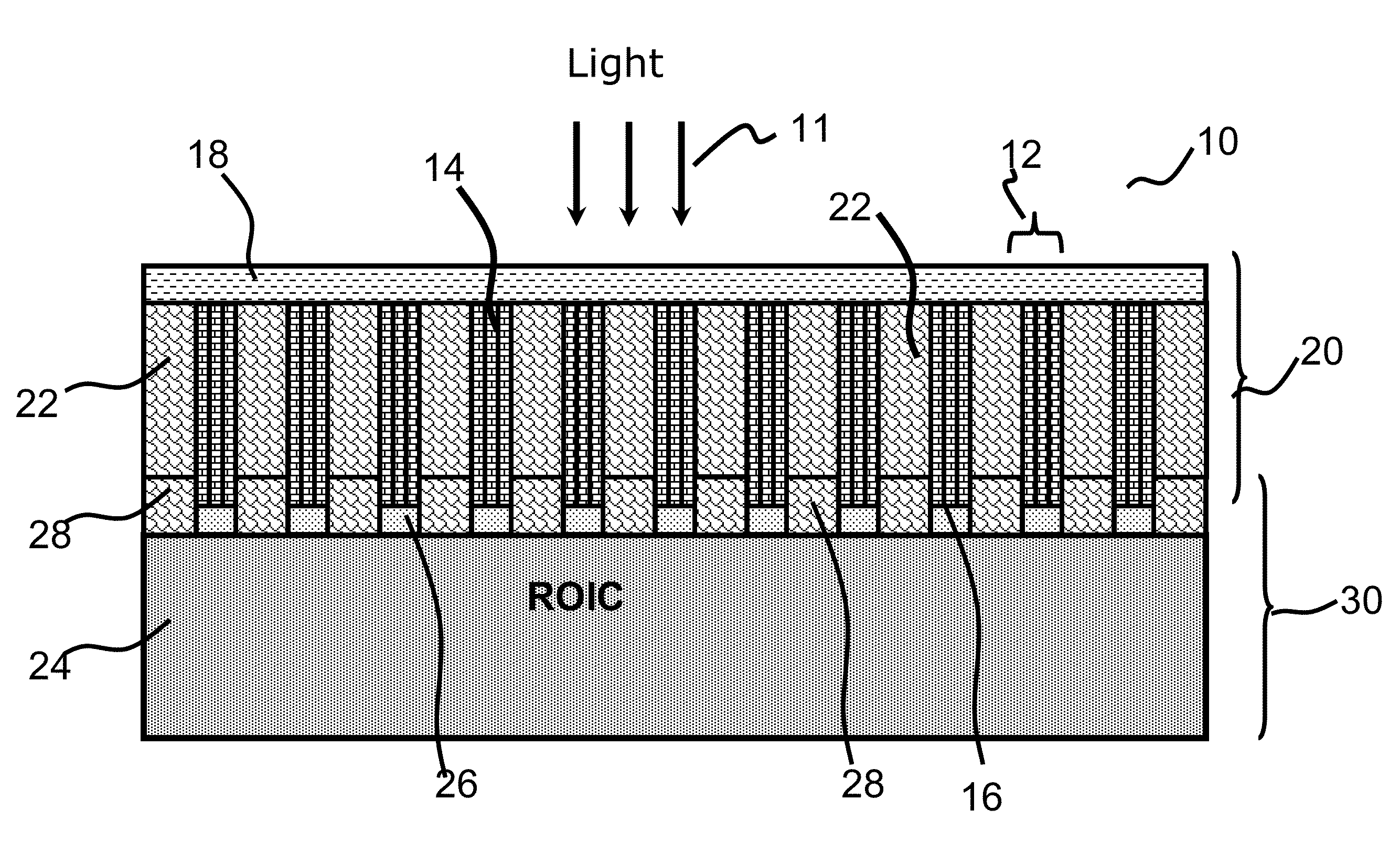

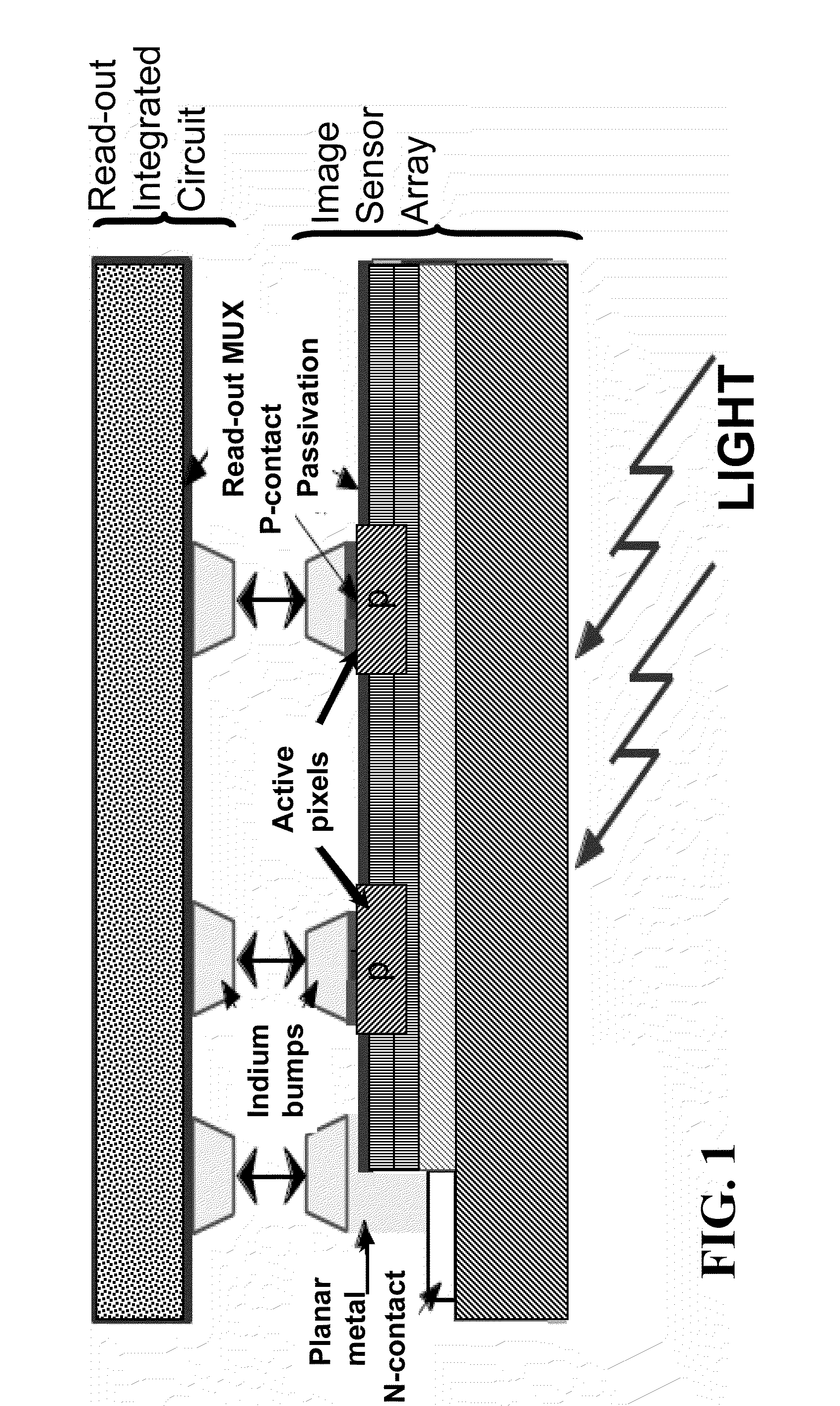

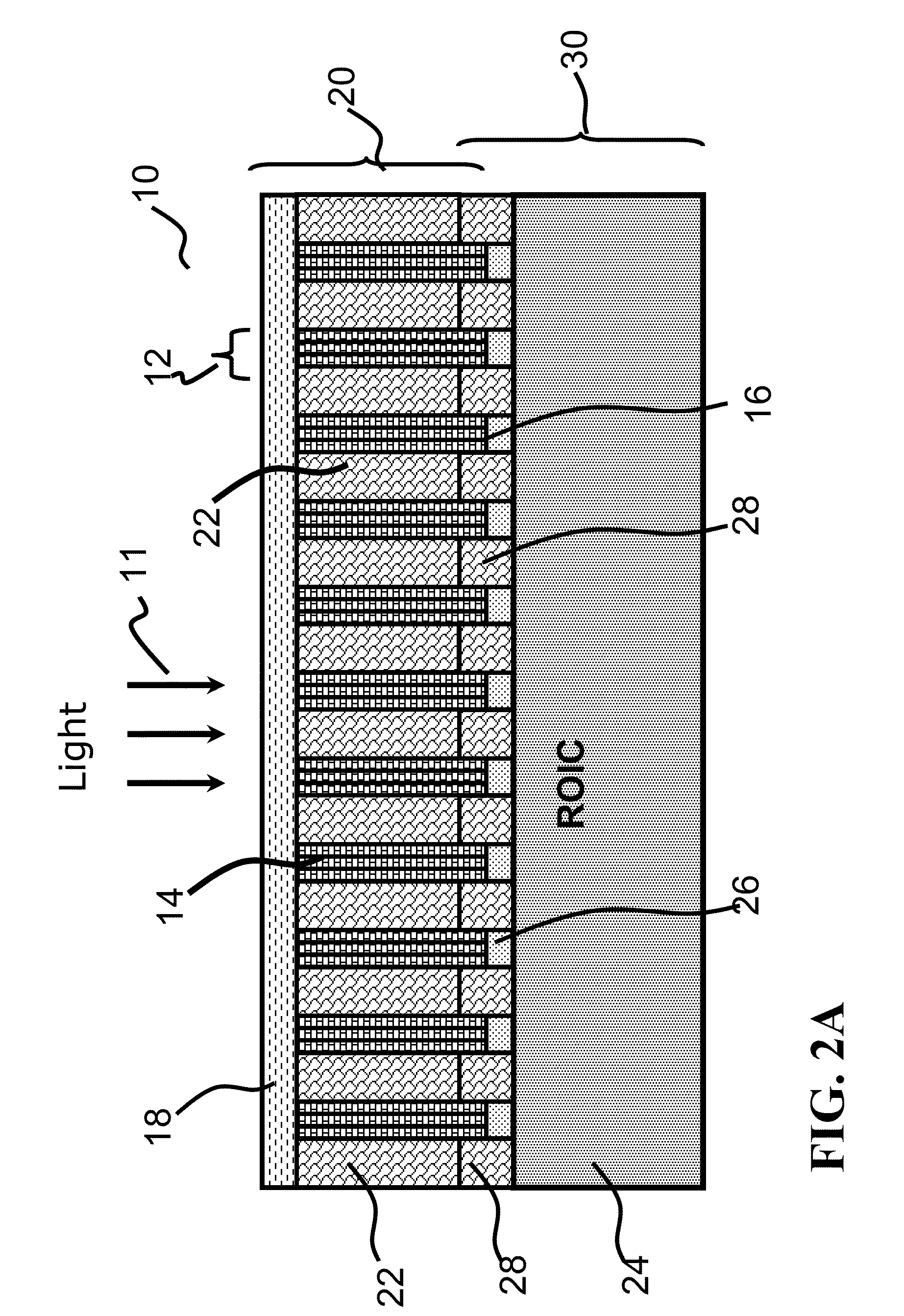

Broadband imaging device

ActiveUS8035184B1Easy to makeImprove quantum efficiencySolid-state devicesNanoopticsMicro nanoManufacturing technology

This invention relates to imaging device and its related transferring technologies to independent substrate able to attain significant broadband capability covering the wavelengths from ultra-violet (UV) to long-Infrared. More particularly, this invention is related to the broadband image sensor (along with its manufacturing technologies), which can detect the light wavelengths ranges from as low as UV to the wavelengths as high as 20 μm covering the most of the wavelengths using of the single monolithic image sensor on the single wafer. This invention is also related to the integrated circuit and the bonding technologies of the image sensor to standard integrated circuit for multicolor imaging, sensing, and advanced communication. Our innovative approach utilizes surface structure having more than micro-nano-scaled 3-dimensional (3-D) blocks which can provide broad spectral response. Utilizing multiple micro-nano scaled blocks help to increase the absorption spectra more than the material used as the absorption layer. In addition, utilizing the multiple nano-scaled 3-D blocks help to increase the absorption over the wavelength due to the multiple reflections and diffractions inside the 3-D structures. The absorption layers will be designed to achieve the required quantum efficiency and also required speed.

Owner:BANPIL PHOTONICS

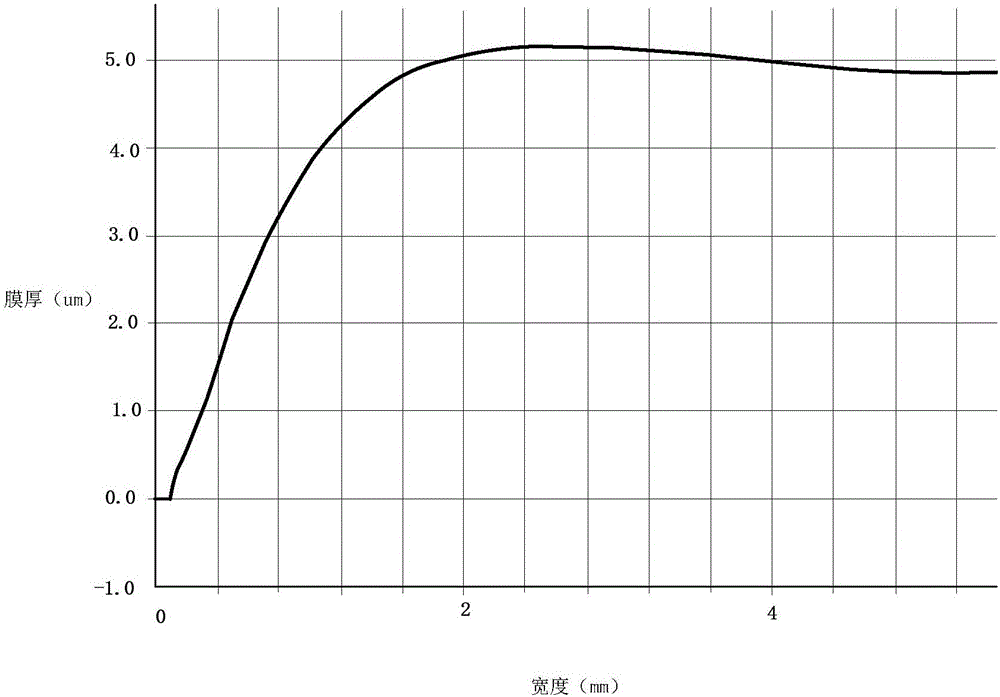

Organic light-emitting diode display substrate, manufacturing method therefore, and display device thereof

InactiveCN105914224ALimit climbing distanceBlock fluiditySolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeMicro nano

The present invention provides an organic light-emitting diode display substrate, a manufacturing method therefore, and a display device thereof. The organic light-emitting diode display substrate comprises a substrate, an organic light-emitting diode device located on the substrate and a film encapsulation layer. The film encapsulation layer is configured to package the organic light-emitting diode device, and includes at least one inorganic thin layer and at least one organic thin layer which are mutually and alternatively arranged and a hydrophobic retaining wall with a micro-nano structure arranged on the substrate and located at the periphery of the film encapsulation layer. The hydrophobic retaining wall is formed prior to formation of the organic thin layer, and is able to block the fluidity of the ink used for ink-jet printing when a printing technology is employed to prepare the organic thin layer so as to restrict the climbing distance of the organic thin layer and provide technology guarantee for the narrow-edge framing of displaying products of a soft organic light-emitting diode.

Owner:BOE TECH GRP CO LTD

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

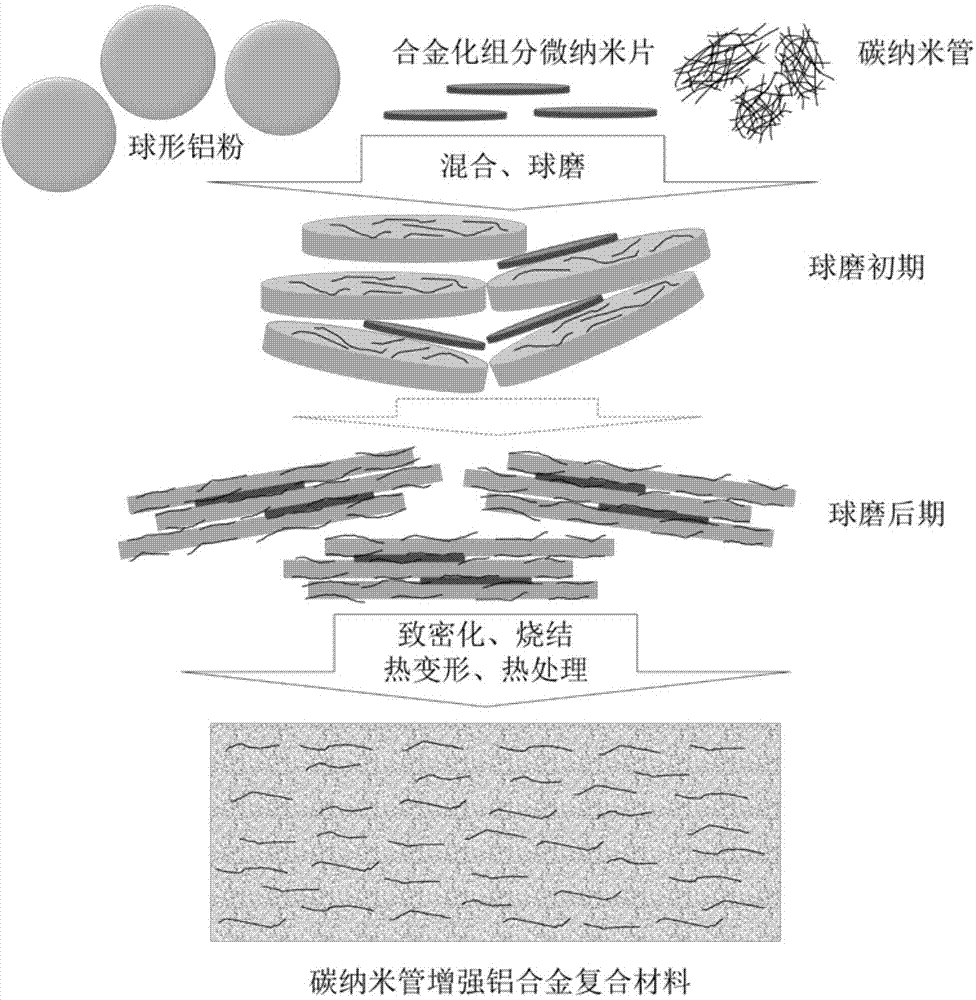

Powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

ActiveCN103789564ARapid precipitation strengtheningReliable and efficient processMicro nanoThermal deformation

The invention provides a powder metallurgy preparation method of a carbon nanotube reinforced aluminum alloy composite material. The method comprises the following steps: pre-preparing micro-nano flake powder of an alloying component, subsequently ball-milling the powder with a carbon nanotube and spherical pure aluminum powder to prepare flake composite powder, and further performing densifying, sintering, thermal deformation processing and thermal treatment to achieve alloying so as to finally obtain the carbon nanotube reinforced aluminum alloy composite material. Uniform compounding of the matrix aluminum powder, the carbon nanotube and the alloying component can be achieved through limited ball-milling, and meanwhile dangerous elements or uneasy grinding elements such as magnesium and silicon which are high in activity and likely to combust and explode are avoided by adopting the stable and easily ground pre-alloying aluminum powder, so that the security and the reliability are improved; in addition, because of large interlayer boundary and small layer thickness distance, the flake structure is beneficial for uniformly dispersing the alloying component and forming refined dispersed separated phase. The method is beneficial for bringing the effects of composite reinforcement of carbon nanotubes and alloy reinforcement into play to the maximum extent, is energy-saving and time-saving, and is safe and feasible.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of straw micro-nano cellulose

ActiveCN101949103AHigh aspect ratioLarge specific surface areaPaper material treatmentMicro nanoHydrolysis

The invention discloses a preparation method of straw micro-nano cellulose, relating to a preparation method of micro-nano cellulose. The invention solves the problems that the prior art for preparing nano cellulose comprises more steps, and rodlike nano cellulose has low draw ratio. The preparation method is as follows: 1, stewing; 2, dipping and washing; 3, screening; 4, bleaching; 5, carrying out hydrolysis and supersonic treatment; and 6, neutralizing, rinsing, breaking, decentralizing and drying to obtain the straw micro-nano cellulose. The micro-nano cellulose prepared by the preparation method of the invention has fibroid appearance, has the diameter of 10-200 nm and the length of 200-10 mu m, and has high draw ratio and large specific surface area. The invention is applied to the field of composite materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

High-resolution biosensor

InactiveCN102242062AHigh resolutionMaterial nanotechnologyBioreactor/fermenter combinationsMicro nanoElectrophoreses

The invention discloses a high-resolution biosensor. Specifically, a basic unit consisting of a first insulating layer, a nanometer functional layer and a second insulating layer is provided with a nano-pore in the center, thus forming a nanometer functional layer unit. A first electrophoresis electrode or micropump, a first store room, a second store room, a second electrophoresis electrode or micropump, and a micro-nanometer separation channel constitute a micro-nanometer fluid device unit. The nanometer functional layer unit, a source electrode, a drain electrode, a dielectric layer and a gate electrode compose a field effect transistor unit. When a biomolecule passes through the nano-pore in the micro-nanometer fluid device and interacts with the nanometer functional layer, the field effect transistor unit measures the field effect characteristic change resulted from the interaction, thus reaching the purpose of biomolecule detection. The invention provides a solution to the technical difficulty of integrating the nano-pore in the nanometer functional layer, and can control the form change when a biomolecule passes through the nano-pore, thus meeting the resolution requirements for detecting the biomolecule characteristic and structure. In addition, the manufacturing method of the sensor is simple.

Owner:ZHEJIANG UNIV

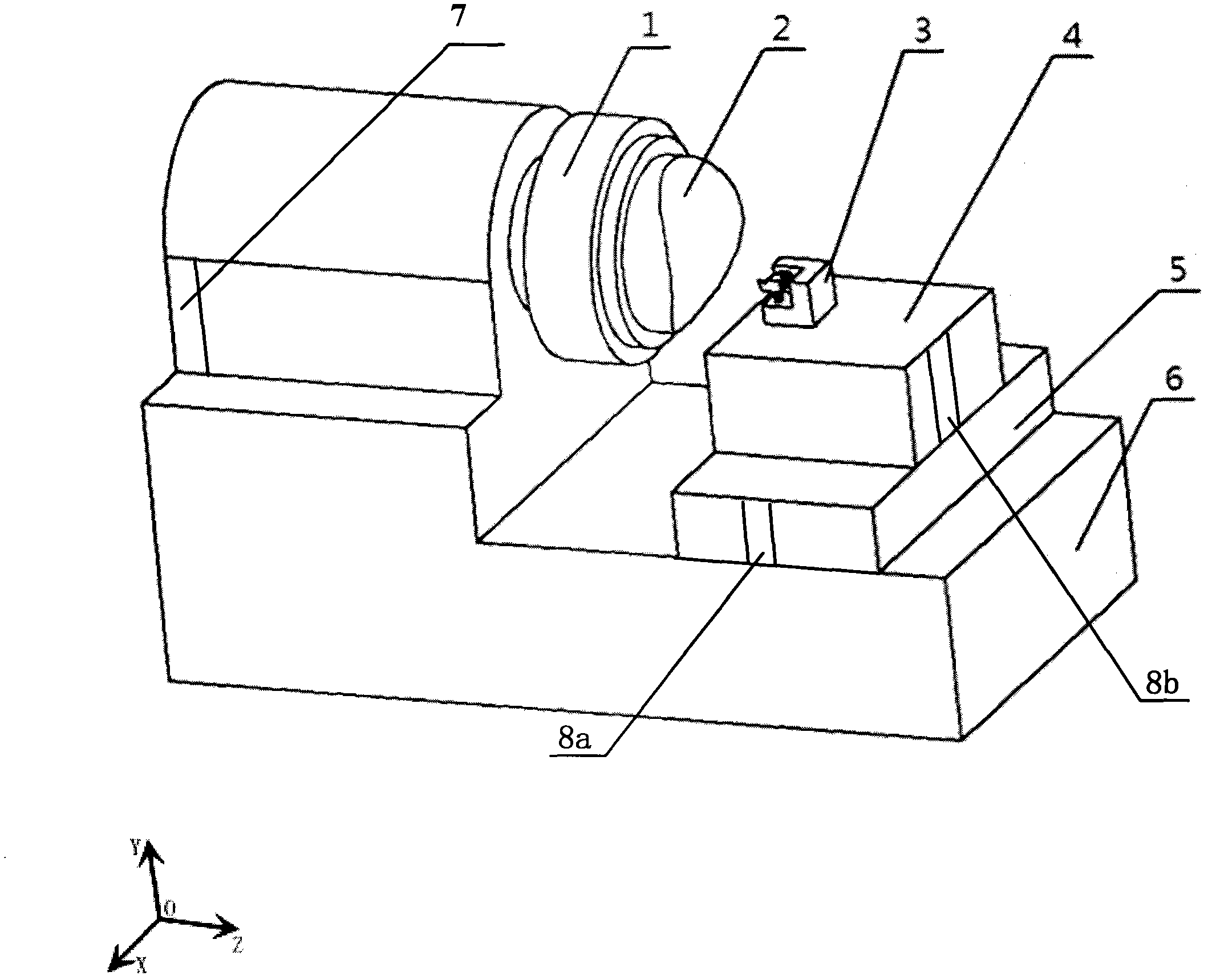

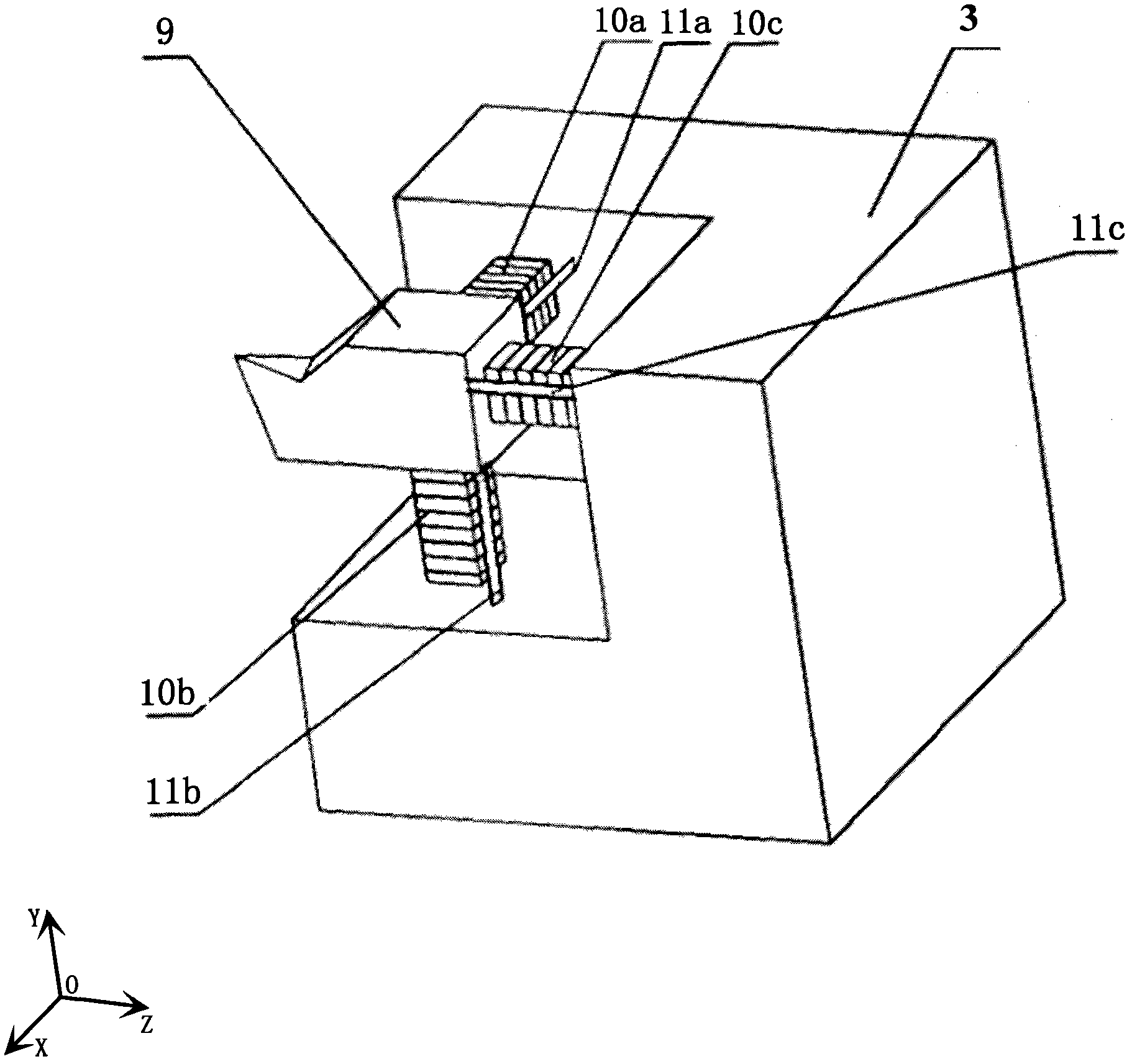

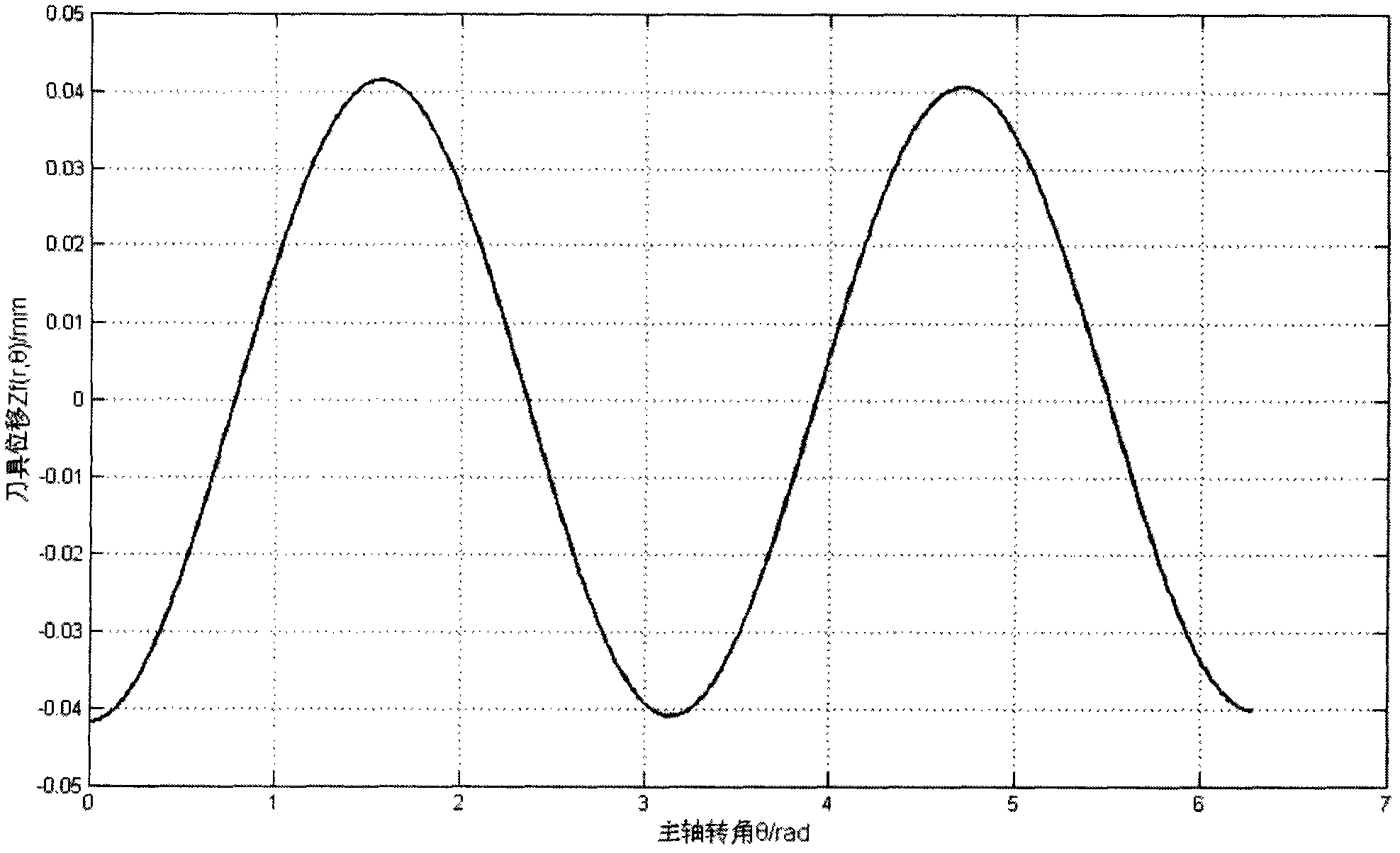

Hybrid frequency-driven three-dimensional ellipse turning method

ActiveCN102078967AParameter Tuning OptimizationMotion path optimizationTurning toolsTurning machinesMicro nanoElectricity

The invention relates to a hybrid frequency-driven three-dimensional ellipse turning method, which belongs to the technical field of micro-nano ultraprecision cutting of free-form surfaces and cutting of materials difficult to machine. The method comprises the following steps of: driving a diamond cutter by using three piezoelectric stacking actuators along an X-axis direction, a Y-axis direction and a Z-axis direction respectively; applying a group of hybrid frequency driving signals onto each piezoelectric stacking actuator, wherein the hybrid frequency driving signal mainly comprises two components of which one is a sine wave signal for producing three-dimensional ellipse cutting and the other is a fast cutter servo signal for turning the generative free-form surfaces; matching amplitudes and phases of the three sine wave signals to make the diamond cutter produce three-dimensional ellipse turning movement at cutter position points; and driving the three piezoelectric stacking actuators to produce required fast cutter servo movement according to the disturbance components of projection components of a diamond cutter position point track on each coordinate axis respectively. The two kinds of turning movement can be independently controlled and optimized, so the method provided by the invention is simple, convenient and easy to implement.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com