Patents

Literature

1901 results about "Heat storage material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials capable of storing heat include those such as bricks or concrete that slowly release the stored heat, and others such as water or ethylene glycol that take in heat when they transform from a solid to a liquid.

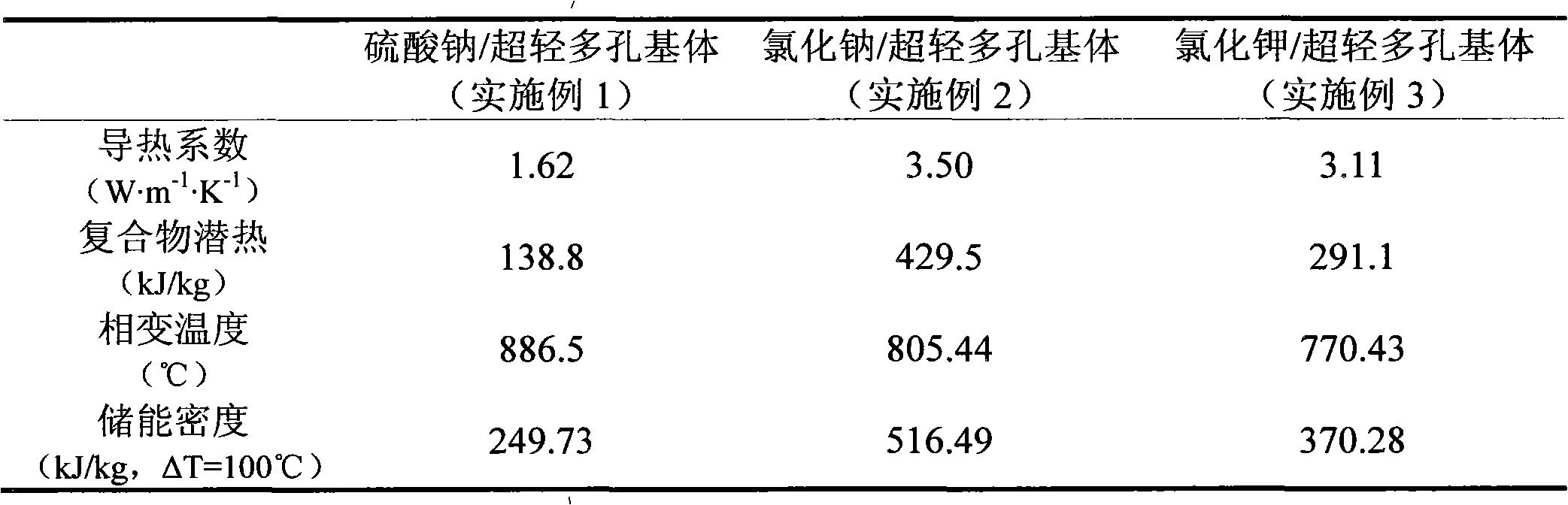

Medium-high temperature composite structural heat storage material, preparation method and application thereof

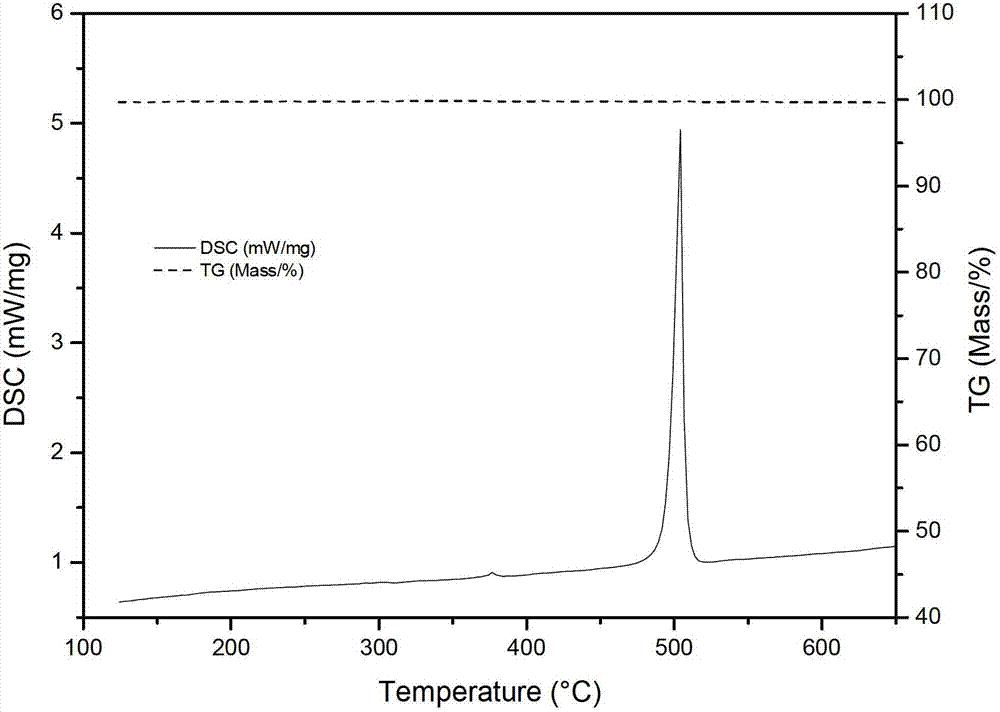

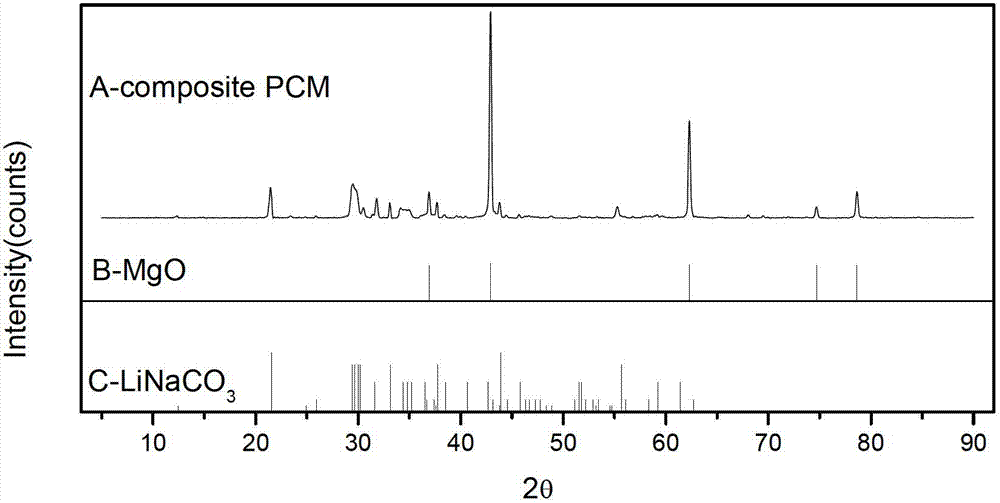

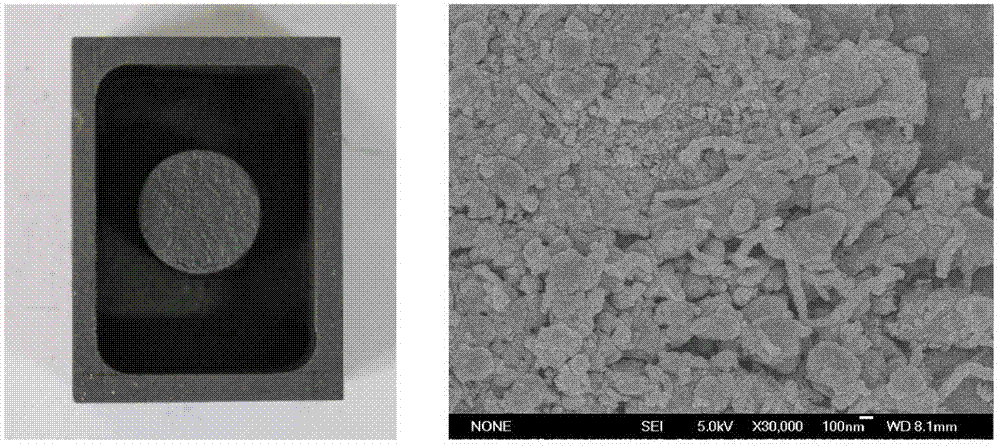

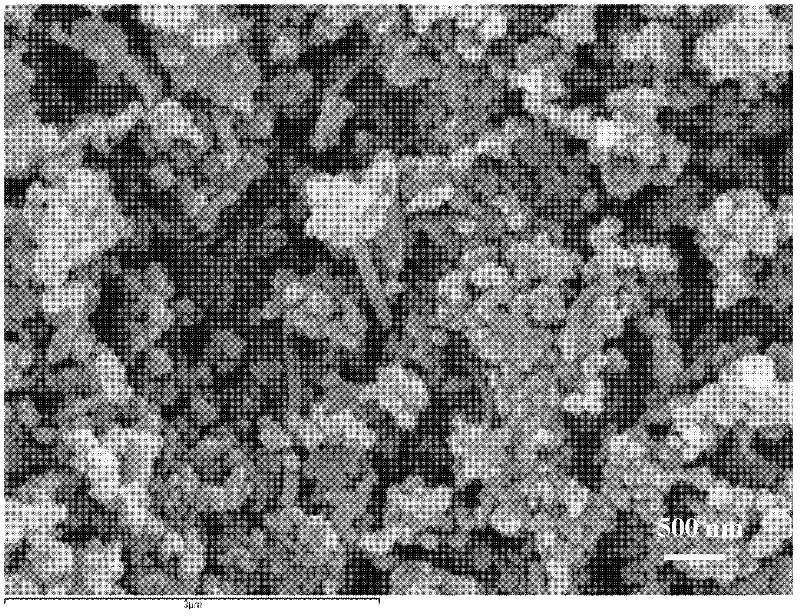

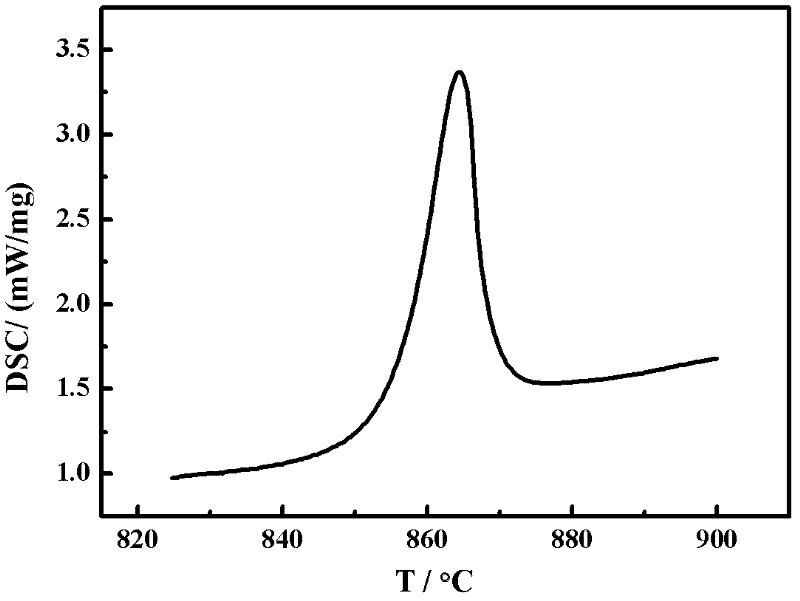

InactiveCN102888209AHigh phase change enthalpyGood chemical compatibilityHeat-exchange elementsMicro nanoMass ratio

The invention relates to a medium-high temperature (120-1000 DEG C or higher) composite structural heat storage material. The medium-high temperature composite structural heat storage material comprises an inorganic salt phase change latent heat material, a sensitive heat storage material and a heat conduction reinforcing material, wherein the mass ratio of the inorganic salt phase change latent heat material to the sensitive heat storage material is of 1: (0.1-10); and the heat conduction reinforcing material is of 0.0001-1kg / (kg heat storage material) based on mass ratio. The preparation method comprises steps as follows: uniformly mixing the inorganic salt phase change latent heat material with the sensitive heat storage material and the heat conduction reinforcing material; pressurizing to form green blank; and then heating and sintering, so as to obtain the medium-high temperature composite structural heat storage material. The medium-high temperature composite structural heat storage material provided by the invention is capable of obviously reducing the corrosion resistance of the sensitive heat storage material; meanwhile, the thermal conductivity of the composite heat storage material is markedly improved by virtue of the micro-nano doping of the heat conduction reinforcing material; and moreover, high heat storage density is achieved, and wide application prospect is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Inorganic hydrated salt expanded graphite composite phase-changing heat storage material and preparation method thereof

The invention relates to an inorganic hydrated salt expanded graphite composite phase-changing heat storage material. In the preparation method thereof, 85-89 mass parts of inorganic hydrated salt sodium acetate trihydrate as a heat storage matrix, 5.5-6.5 mass parts of disodium hydrogenphosphate as a nucleating agent, 2.5-3.5 mass parts of carboxymethyl cellulose as a thickening agent, and 3-4.5 mass parts of expanded graphite is blended in an inorganic hydrated salt mixture as a material with a high thermal conductivity. Due to the use of the expanded graphite, the material not only maintains excellent properties of natural flake graphite such as good thermal conductivity, no toxicity and the like, but also has adsorbability which the natural flake graphite does not have. The invention solves the problems of sub-cooling degree, phase stratification and low thermal conductivity during the heat storage process. The composite phase-changing material has a low sub-cooling degree after the phase changing performance is improved, the solution thereof is uniform without sedimentation and stratification during the solid-liquid phase change, the performance is stable, the repeatability of good, and the phase-changing heat storage can be enhanced through improving the thermal conductivity of the material.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

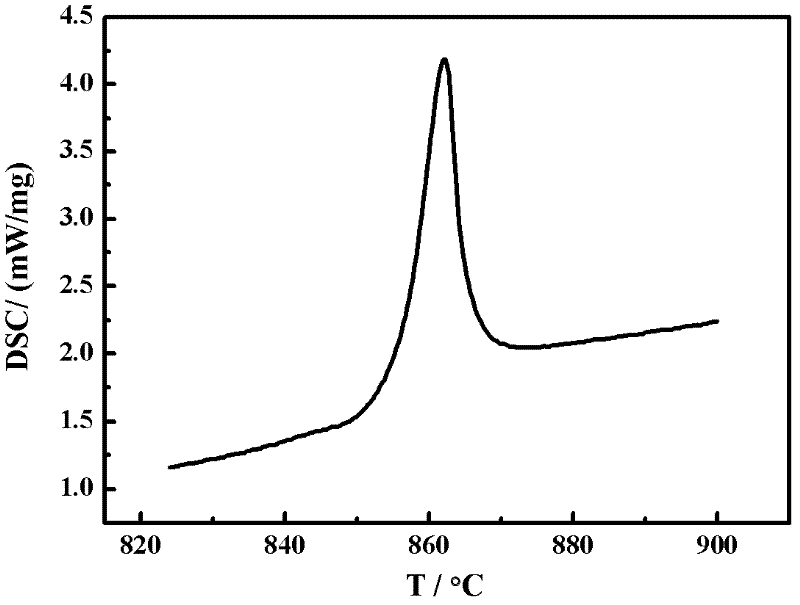

High-temperature composite phase change heat storage material and preparation method thereof

ActiveCN102585775ANo preprocessing requiredSimple manufacturing methodHeat-exchange elementsElectricityHeat conducting

The invention relates to a preparation method of a high-temperature composite phase change heat storage material, and relates to a high-temperature composite phase change heat storage material and a preparation method thereof. The method can be used for preparing high-temperature composite phase change heat storage material with high heat conductivity, so that the heat conductivity of the heat storage material is greatly improved, and the heat storage / release rate is greatly improved; and the preparation method is easy to control and simple to operate. The heat storage material can be directly obtained by sintering, without need of any bonding agent or other protectants, so that the heat-conducting property of the heat storage material is greatly improved, and the utilization ratio of the heat storage material is improved; the preparation method is simple to operate; and the prepared product can also be used for other intermediate-temperature low-temperature composite heat storage materials, as well as light heat utilization, heat-cold-electricity combined use, composite material synthesis and other many fields.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

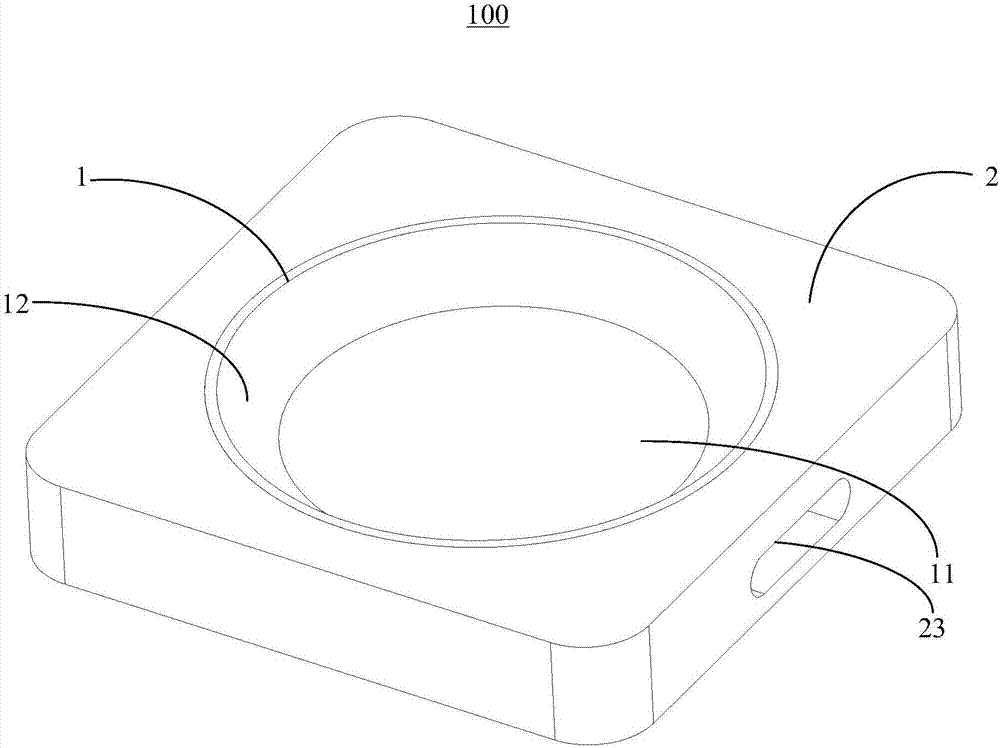

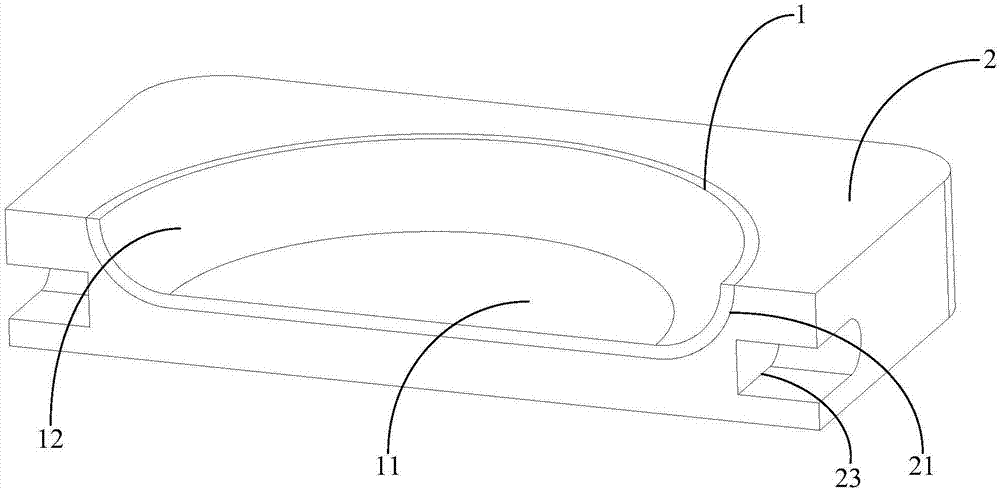

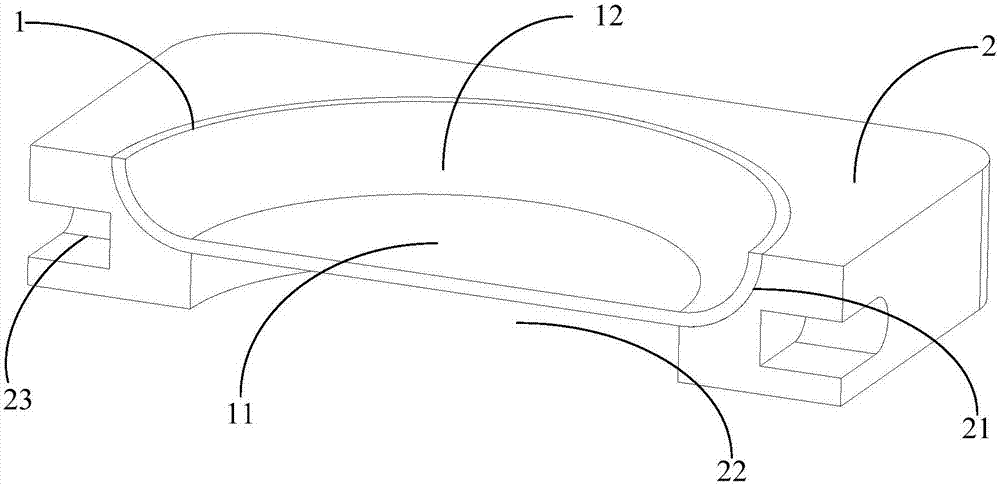

Baking tray and baking oven

ActiveCN107495849AAchieve heatingAchieve rapid heat conductionBaking vesselsRoasters/grillsCooking & bakingFood material

The invention discloses a baking tray and a baking oven, wherein the baking tray comprises a metal article carrying body and a heat storage body; the upper surface of the metal article carrying body is used for carrying food materials to be baked, so that the heat of a heating device of the baking oven can be conducted to the food materials to be baked; and the heat storage body is made of heat storage materials and is in heat conduction connection with the metal article carrying body. According to the technical scheme provided by the invention, the heat is transferred to the food materials through the metal article carrying body; the heating on the food materials is realized, so that the fast heat conduction on the food materials can be realized; the heat storage body can store heat; when the heating device of the baking oven stops heating, the heat stored by the heat storage body is used for continuously conducting heat to the metal article carrying body to realize the heating on the food materials; on one hand, the mouthfeel of the food materials is improved; and on the other hand, the utilization rate of the heat of the baking oven is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Composite amorphous phase-change heat storage material and preparation method thereof

InactiveCN103525373AReduce leakageLeakage is not easy to happenHeat-exchange elementsActive agentHeat conducting

The invention relates to a composite amorphous phase-change heat storage material and a preparation method thereof, and belongs to the technical field of composite materials. The composite material is prepared from a porous material used as a support material and an inorganic hydrous salt used as a phase-change material in manners of absorbing the inorganic hydrous salt into a porous structure of the support material by virtue of the capillary adsorption action of the porous material, and self-assembly of a surfactant. The method comprises the following steps: firstly, emulsifying and dispersing the molten inorganic hydrous salt phase-change material such as calcium chloride hexahydrate by the emulsifying dispersion effect of the surfactant under an ultrasonic condition, so as to form a stable emulsion; adding expanded graphite to the emulsion to evenly disperse; putting the mixture into a vacuum oven, vacuumizing and keeping in a constant state for 30 minutes at room temperature, so as to prepare a novel composite amorphous phase-change heat storage material which is high in phase-change latent heat, good in heat-conducting property, and low in cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

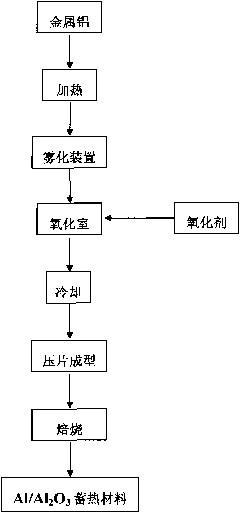

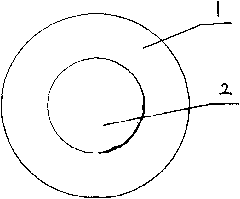

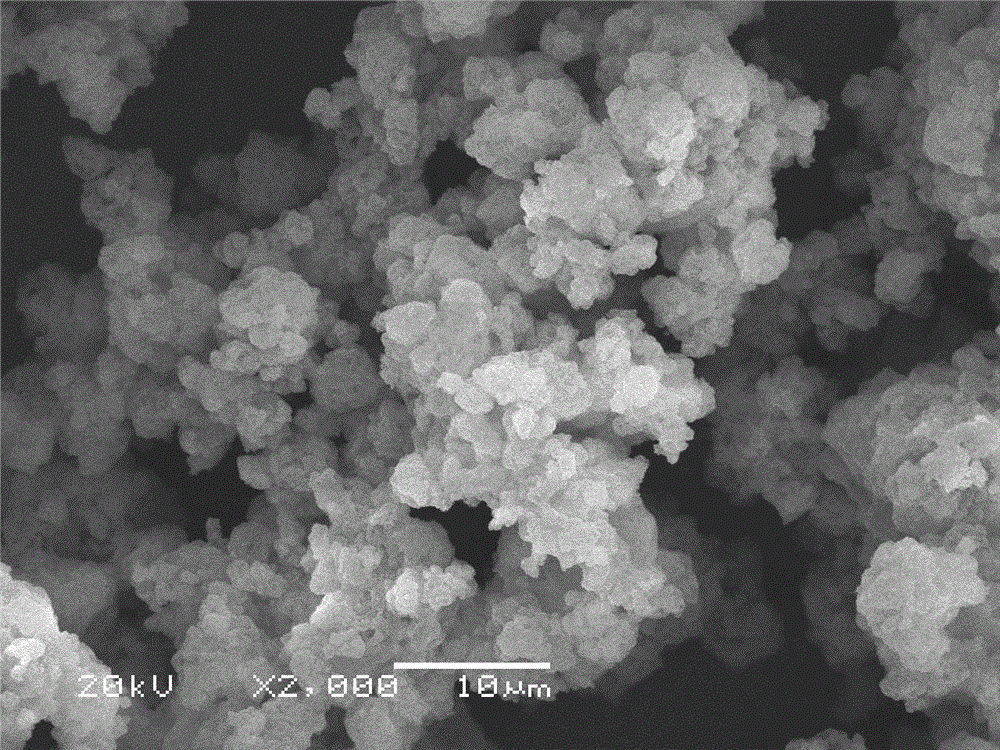

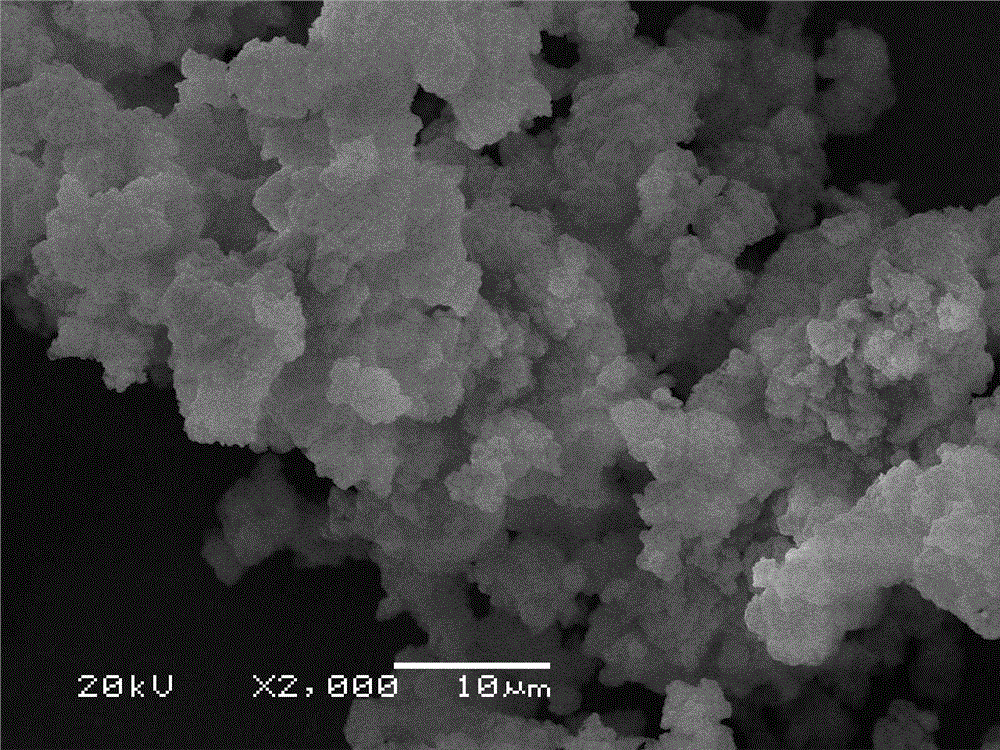

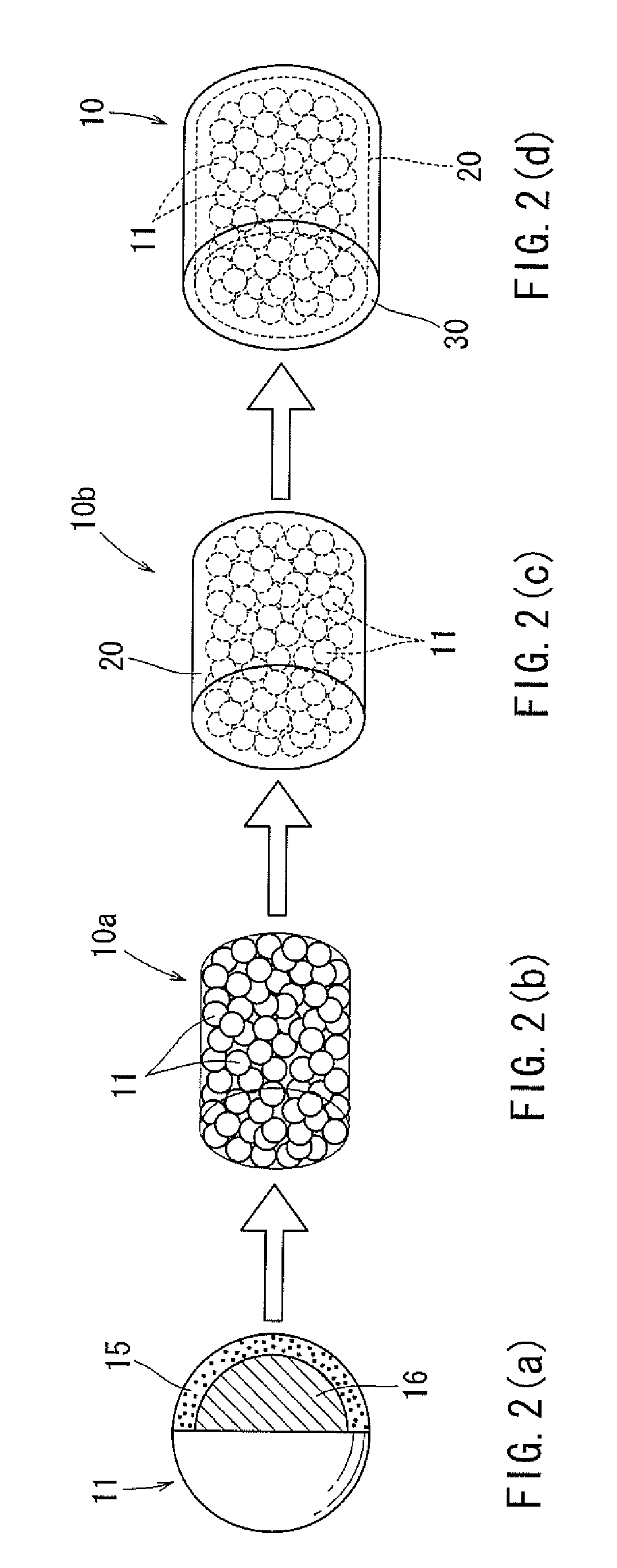

Al/Al2O3 heat storage material and preparation method thereof

The invention discloses an Al / Al2O3 heat storage material and a preparation method thereof. Aluminum oxide serves as a base material; and a spherical metallic aluminum 'core' is enclosed by a layer of aluminum oxide 'enclosure'. In the process of heat storage, metallic aluminum can absorb heat to be changed from a solid state to a liquid state and the temperature of the metallic aluminum rises; at the same time, the external aluminum oxide layer also can absorb the heat, so that the temperature of the external aluminum oxide layer rises; and in the process of heat transfer, the liquid metallic aluminum releases both hidden heat and sensible heat and the aluminum oxide enclosure releases the sensible heat. The preparation process of the Al / Al2O3 heat storage material is obviously different from a conventional method, and comprises the following steps of: atomizing the liquid metallic aluminum (above 660 DEG C) into tiny particles with an atomizing device; and cooling the tiny liquid metallic aluminum particles in an oxidizing atmosphere and oxidizing the external aluminum oxide layer to form the Al / Al2O3 phase-change heat storage material taking the metallic aluminum as the 'core' and taking aluminum oxide as the 'enclosure', wherein the oxidizing atmosphere may adopt oxygen, water vapor, carbon dioxide or air diluted by an inert gas. The preparation method is simple and easy to realize large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

High heat conductive fixed phase change heat storage material suitable for large scale industrial production

InactiveCN1587340ASolve processing technology problemsImprove thermal conductivityHeat-exchange elementsParaffin waxSodium Bentonite

The present invention relates to a high heat conductivity shaped phase change heat storing material suitable for large scale production, and belongs to the field of phase change material for building. The present invention consists of phase change heat storing material paraffin of phase change temperature 15-70 deg.c in 50-80 wt%; high molecular weight support material polyethylene, polypropylene, SBS and / or SEBS in 10-30 wt%; machining modifier alumina, montmorillonite, diatomite, clay, titania powder, calcium carbonate, bentonite and / or silica in 5-20 wt%; and heat conducting additive metal powder or graphite powder 5-15 wt%. The material may be well produced in large scale, has excellent heat conducting performance and is especially suitable for use in building.

Owner:TSINGHUA UNIV

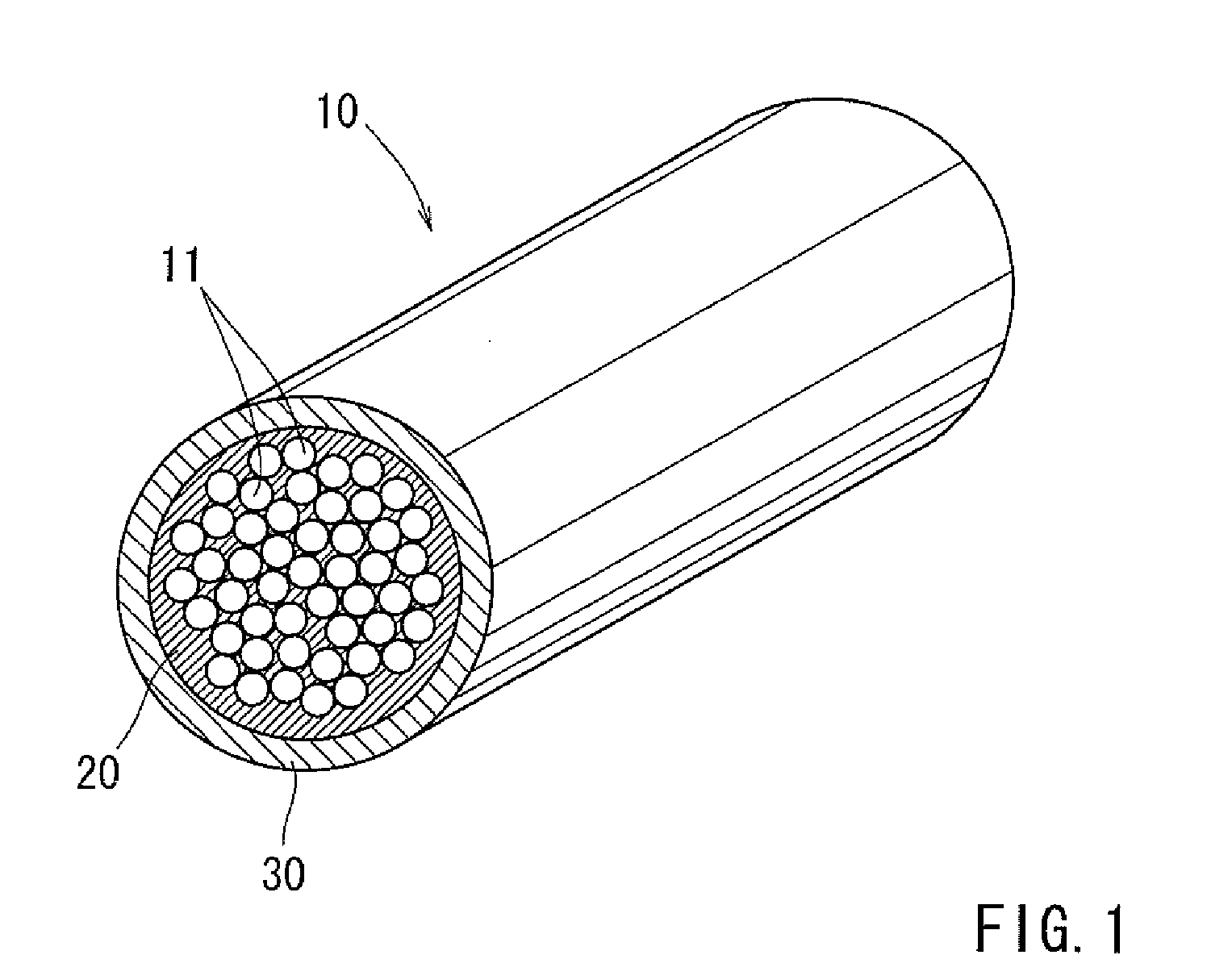

Adsorbent of latent-heat storage type for canister and process for producing the same

ActiveUS20050247202A1High melting pointEvenly distributedCombination devicesNon-fuel substance addition to fuelLatent heat storageDesorption

The present invention provides a latent-heat storage type adsorbent composition for canisters that can effectively prevent changing in temperature due to the heat of absorption / desorption and has a high butane working capacity; a process for producing the adsorbent; and a canister employing the latent-heat storage type adsorbent composition for canisters. The present invention relates to a latent-heat storage type adsorbent composition for canisters which compromises an adsorbent adsorbing a fuel vapor and a heat-storage material comprising microencapsulated phase-changing material which absorbs or releases latent heat in response to temperature change, and a method for producing such an adsorbent.

Owner:OSAKA GAS CO LTD

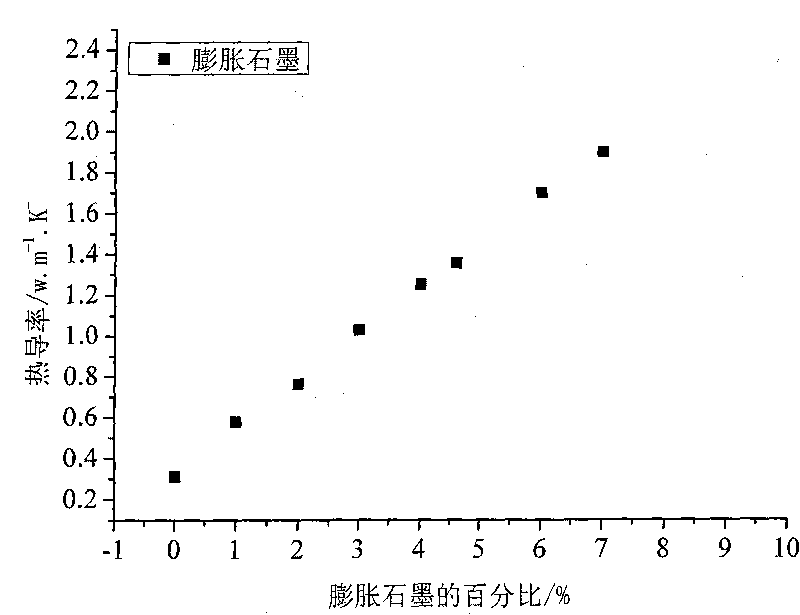

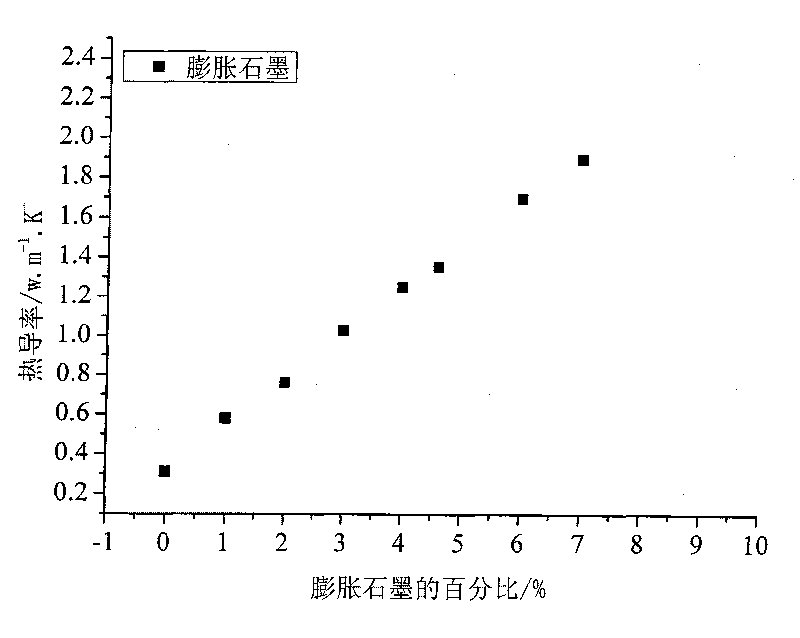

Setting phase change energy storage material with high-thermal conductivity and preparation method thereof

InactiveCN101724381AImprove thermal conductivityImprove heat transfer characteristicsHeat-exchange elementsMolten stateMaterials science

The invention relates to a setting phase change energy storage material with high-thermal conductivity and a preparation method thereof, belonging to the field of phase change heat storage materials. The setting phase change energy storage material with high-thermal conductivity is characterized by containing 65-90 percent by mass of paraffin substances as a phase-change material, 9-34 percent by mass of high-density polyethylene as a support material and 1-7 percent by mass of expanded graphite as a heat conduction intensifier; a method for adding a proper amount of expanded graphite to paraffin / high-density polyethylene in a molten state is adopted to enable the heat conductivity of the setting phase change material to be increased to 1.35W / (m.K) or higher. The method comprises the following steps of: heating to melt the paraffin substances with the mass percent of 65-90 percent, and heating to enable the temperature of the liquid paraffin to reach 120-190 DEG C; adding high-density polyethylene with the mass percent of 9-34 percent and the expanded graphite with the mass percent of 1-7 percent to the liquid paraffin, and then melting and evenly stirring in vacuum; putting the mixture in a hot mould for pressing and molding; taking the mixture from the mould after naturally cooling. The setting phase change material has high thermal conductivity, does not need to be packaged in containers and can directly contact heat-transfer media.

Owner:UNIV OF SCI & TECH OF CHINA

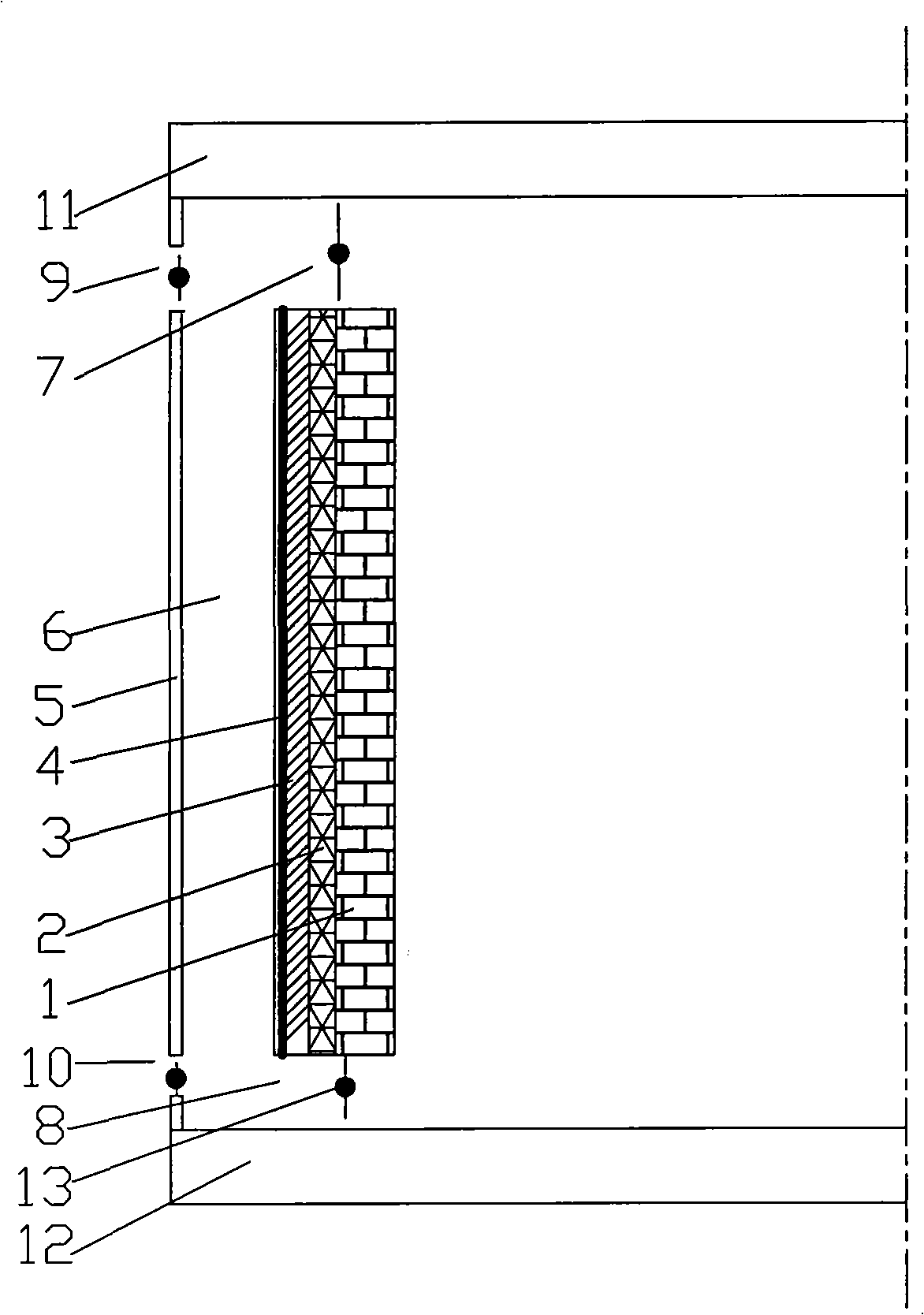

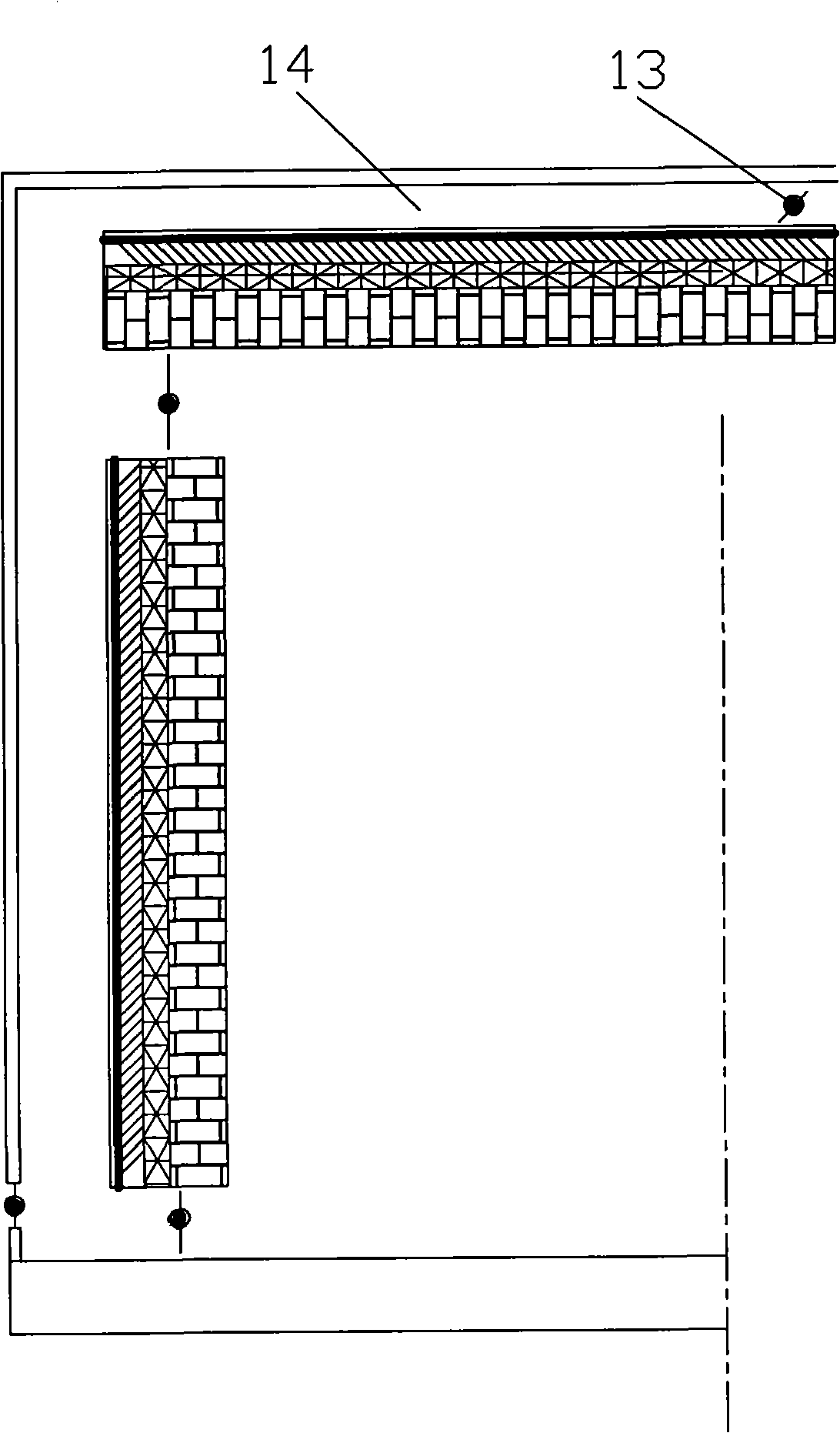

Solar energy storage ventilated heating system

InactiveCN101324352ANo lossNo pollution in the processCentral heating with accumulated heatSolar heat devicesInsulation layerSolar energy storage

The invention discloses a solar energy storage, ventilation and heating system, which comprises a heat storage wall composed of a heat-insulation layer, a heat storage layer and an aluminum plate painted with black paint, a heat storage ventilation channel or a combination thereof, which are sequentially arranged on the outer side of the external wall of a building; a transparent cover plate arranged on the outer side of the heat storage wall or the heat storage ventilation channel; an air sandwich between the transparent cover plate and the heat storage wall; and an upper vent and a lower vent having valves and arranged on the transparent cover plate and the heat storage wall. The solar energy storage, ventilation and heating system can achieve intermittent ventilation and heating without consuming non-renewable energy by using the special heat absorption and release functions of a phase-change heat storage material and by controlling the valves of the vents. The system has the advantages of energy conservation, environmental protection, simple control and handsome structure, and can be widely used for common residential buildings and public buildings.

Owner:CHONGQING UNIV

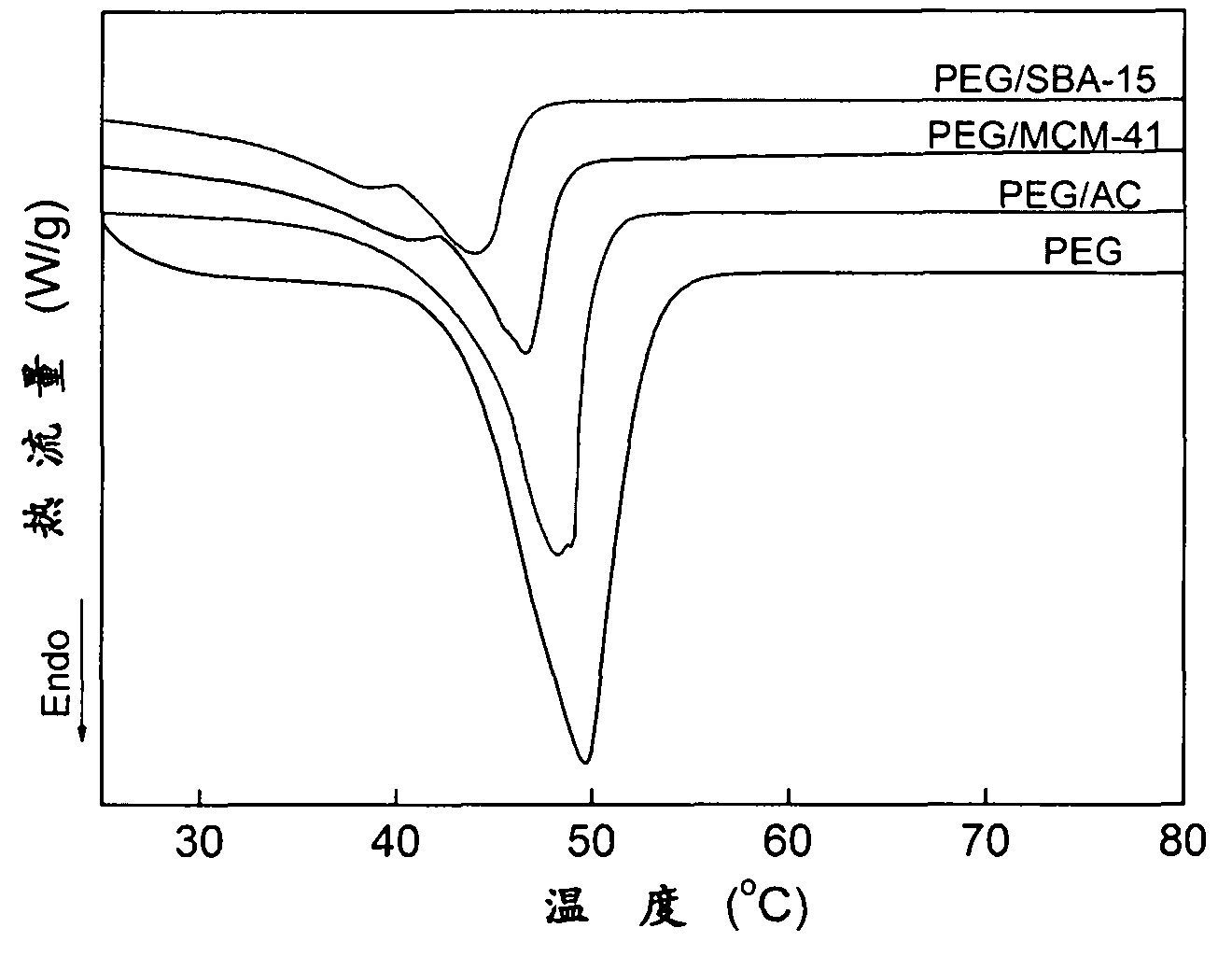

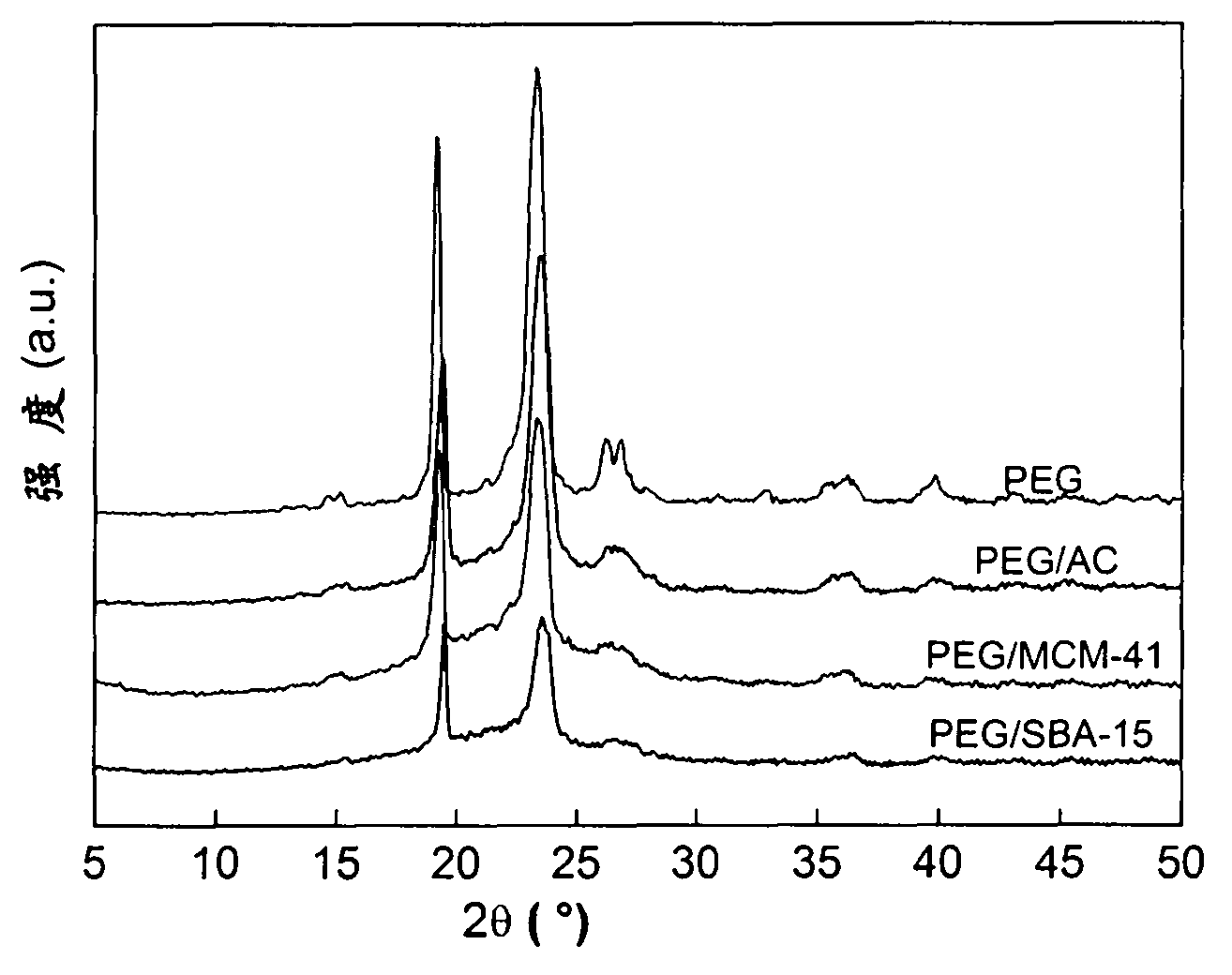

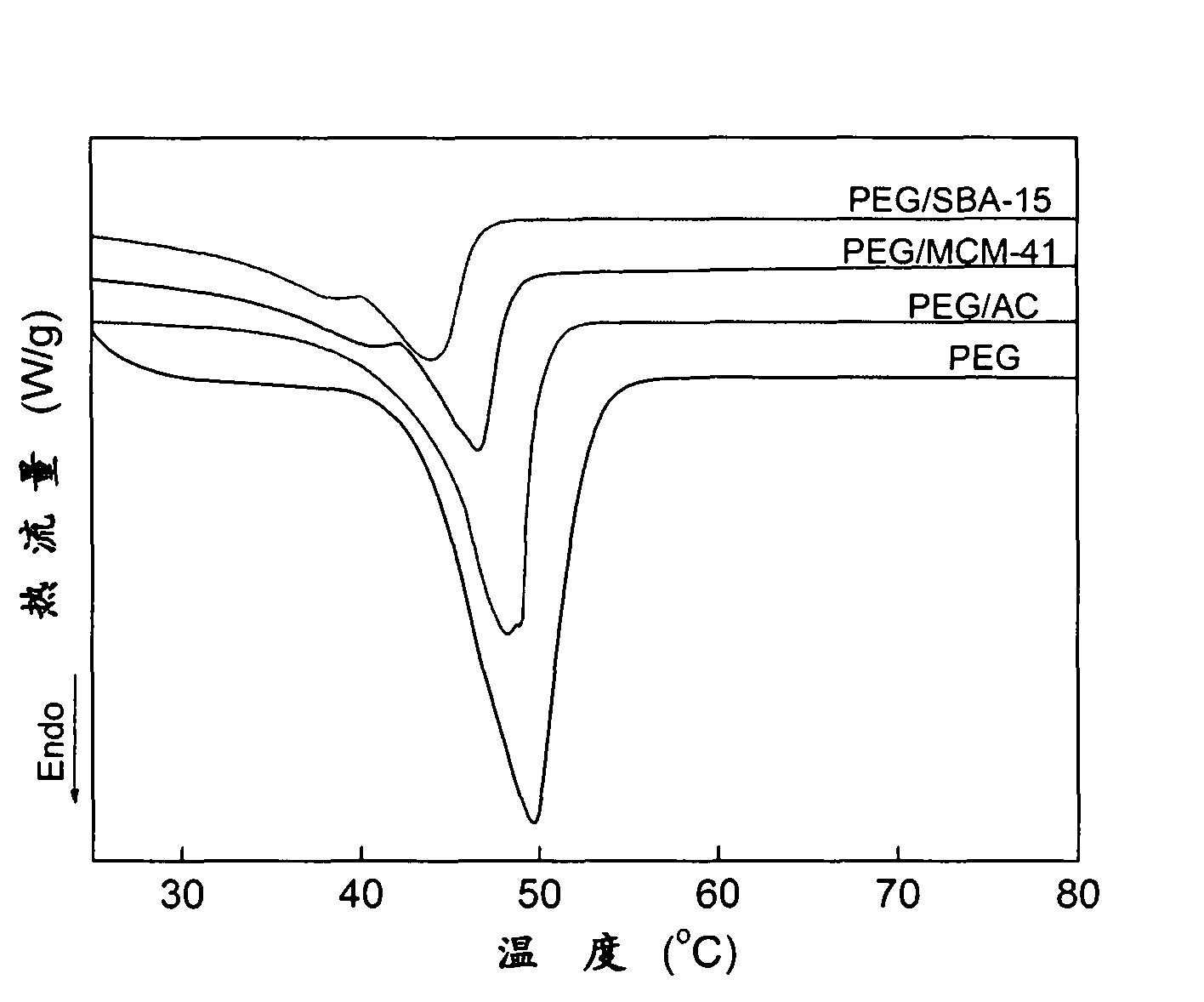

Mesoporous material-based composite phase change heat storage material and preparation method thereof

InactiveCN101812286AReduce contentSolving Phase Change Leakage ProblemsHeat-exchange elementsMesoporous materialHeat storage material

The invention discloses a mesoporous material-based composite phase change heat storage material and a preparation method thereof. The composite phase change heat storage material, which can still keep fixed shape even at the temperature higher than the melting point of phase change substance by 30 DEG C, is prepared by using mesoporous material as carrier matrix and organic substance as phase change substance according to methods of physical blending and impregnation. Compared with other technologies, reported in documents, for the preparation of shape-fixed composite phase change material, the preparation technology has the characteristics of great simplicity and saving time, and the prepared composite phase change heat storage material has high content of the phase change material, high latent heat of phase change and utilization rate of the latent heat, and obviously lowered phase change temperature.

Owner:PEKING UNIV

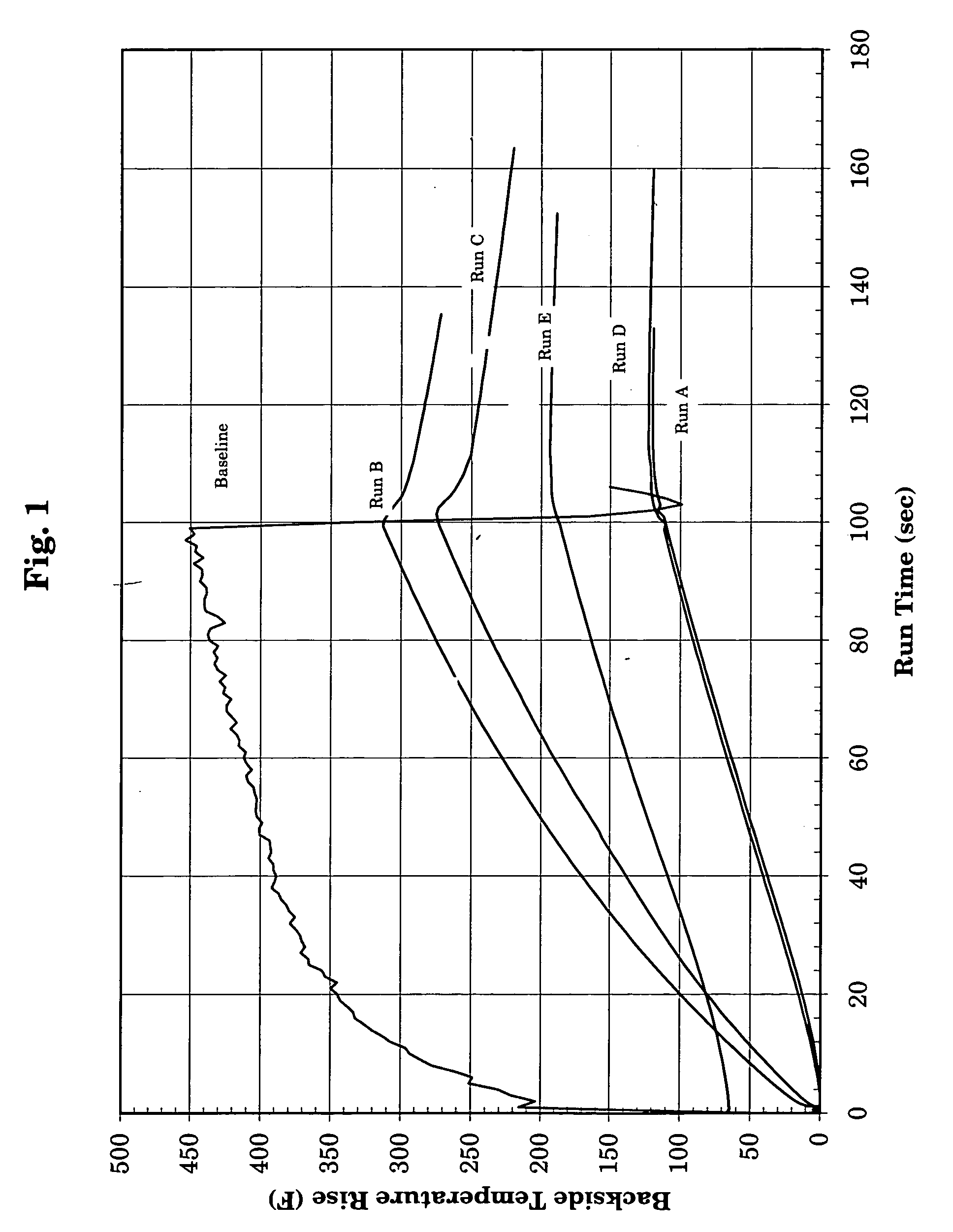

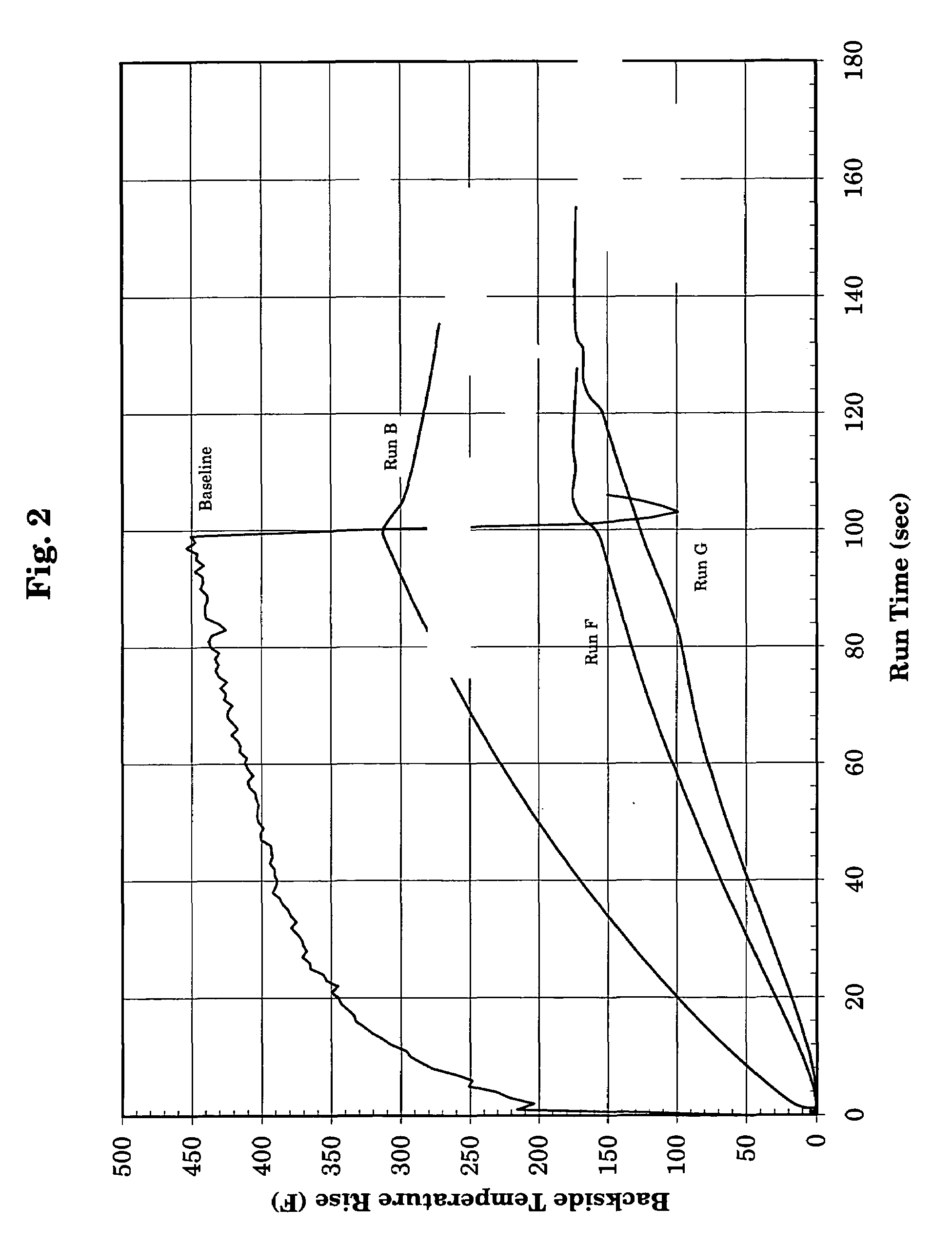

Thermal insulating coating for spacecrafts

InactiveUS6939610B1Minimize temperature gainIncrease energy densityFireproof paintsCosmonautic vehiclesHeat storage materialPhase change

To protect spacecraft and their contents from excessive heat thermal protection systems are essential. For such thermal protection, metal coatings, ceramic materials, ablative materials, and various matrix materials have all been tried, but none have been found entirely satisfactory. The basis for this thermal protection system is the fact that the heat required to melt a substance is 80 to 100 times larger than the heat required to raise its temperature one degree. This led to the use herein of solid-liquid phase change materials. Unlike conventional heat storage materials, when phase change materials reach the temperature at which they change phase they absorb large amounts of heat without getting hotter. By this invention, then, a coating composition is provided for application to substrates subjected to temperatures above 100° F. The coating composition includes a phase change material.

Owner:NASA

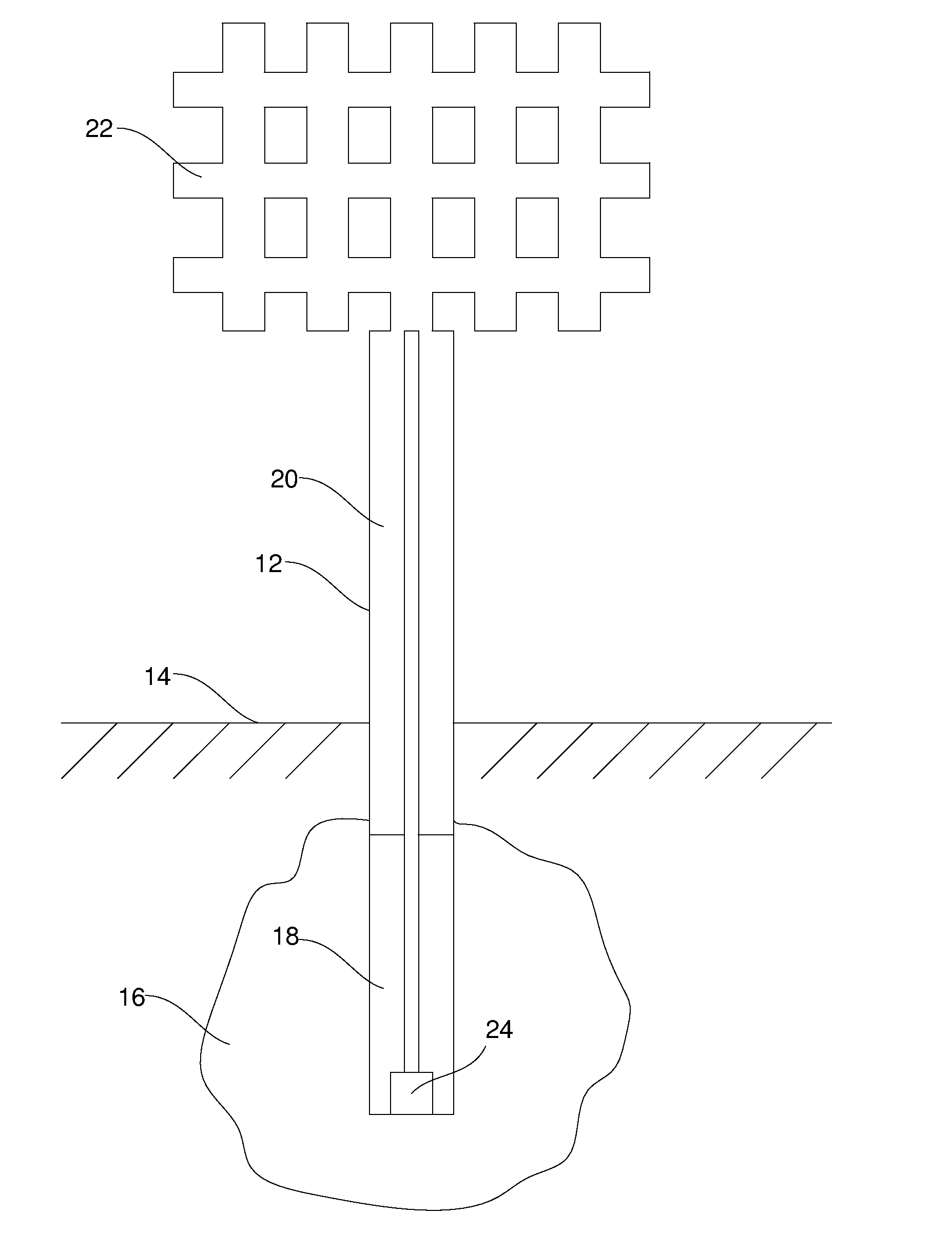

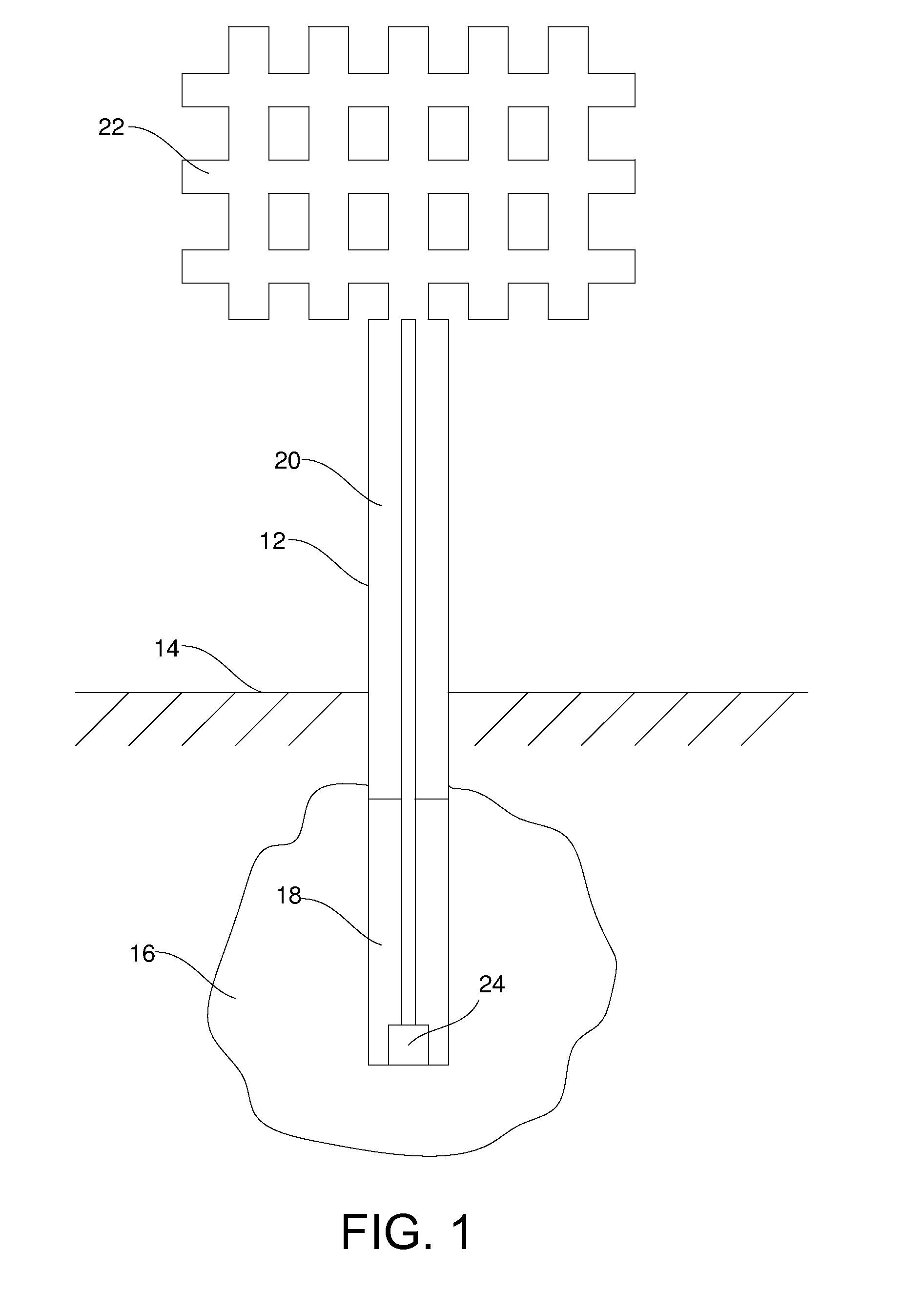

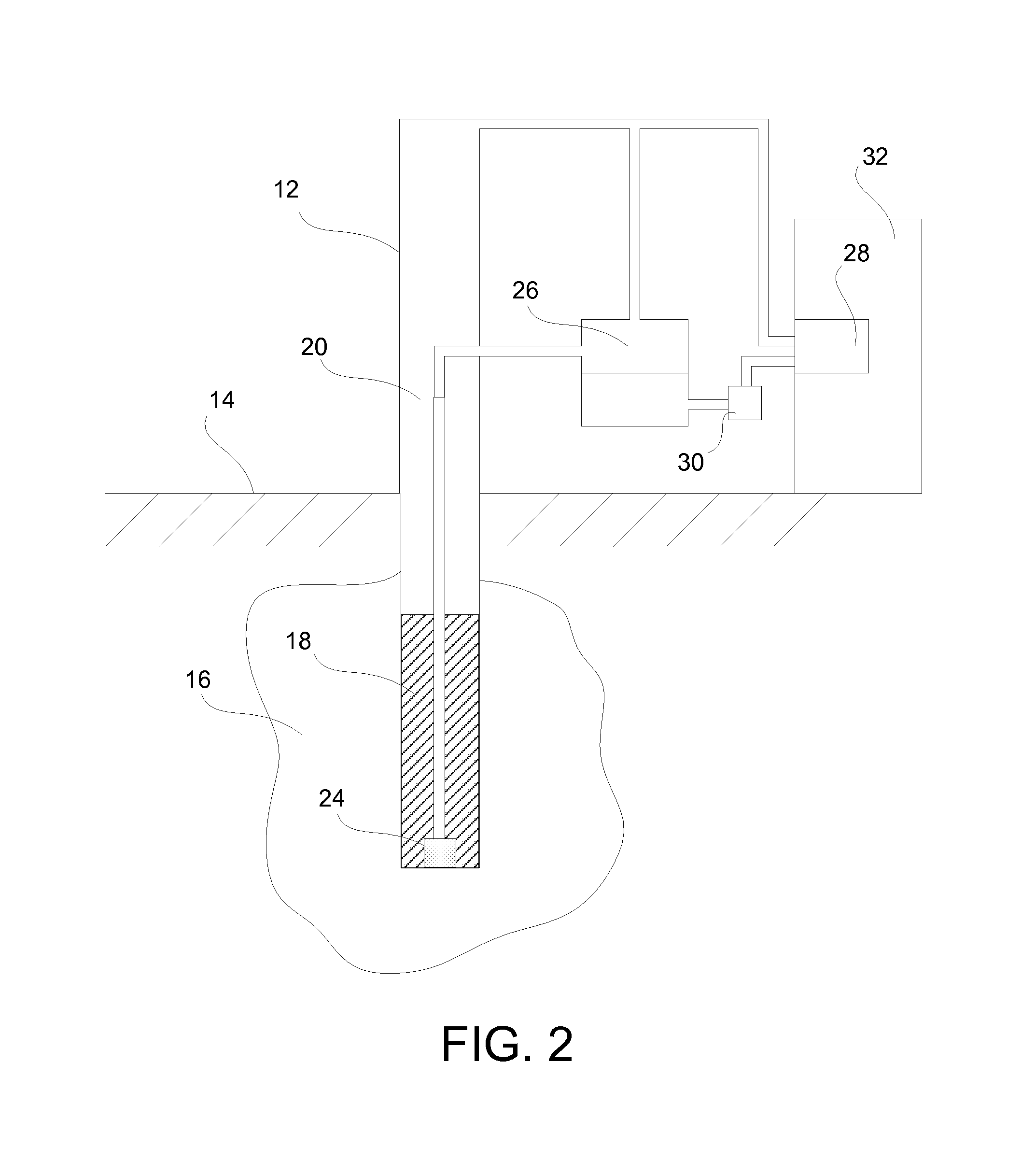

Ground-Coupled Heat Exchange for Heating and Air Conditioning Applications

InactiveUS20100305918A1Minimal energy requirementCost-effectiveHeat pumpsOther heat production devicesThermal energyEngineering

The invention provides systems and methods for cooling and / or heating a structure. Generally, a system for heating or cooling a structure can include at least one thermosiphon in thermal communication with a thermal storage material such as a volume of earth. The thermosiphon can be partially filled with a heat transfer fluid and a heat exchanger operatively connected to the thermosiphon which is in thermal communication with the structure. Thermal energy can be transferred between the thermal storage material and the structure in either a passive or assisted mode, depending on whether the system is charging or in use.

Owner:UNIV OF UTAH RES FOUND

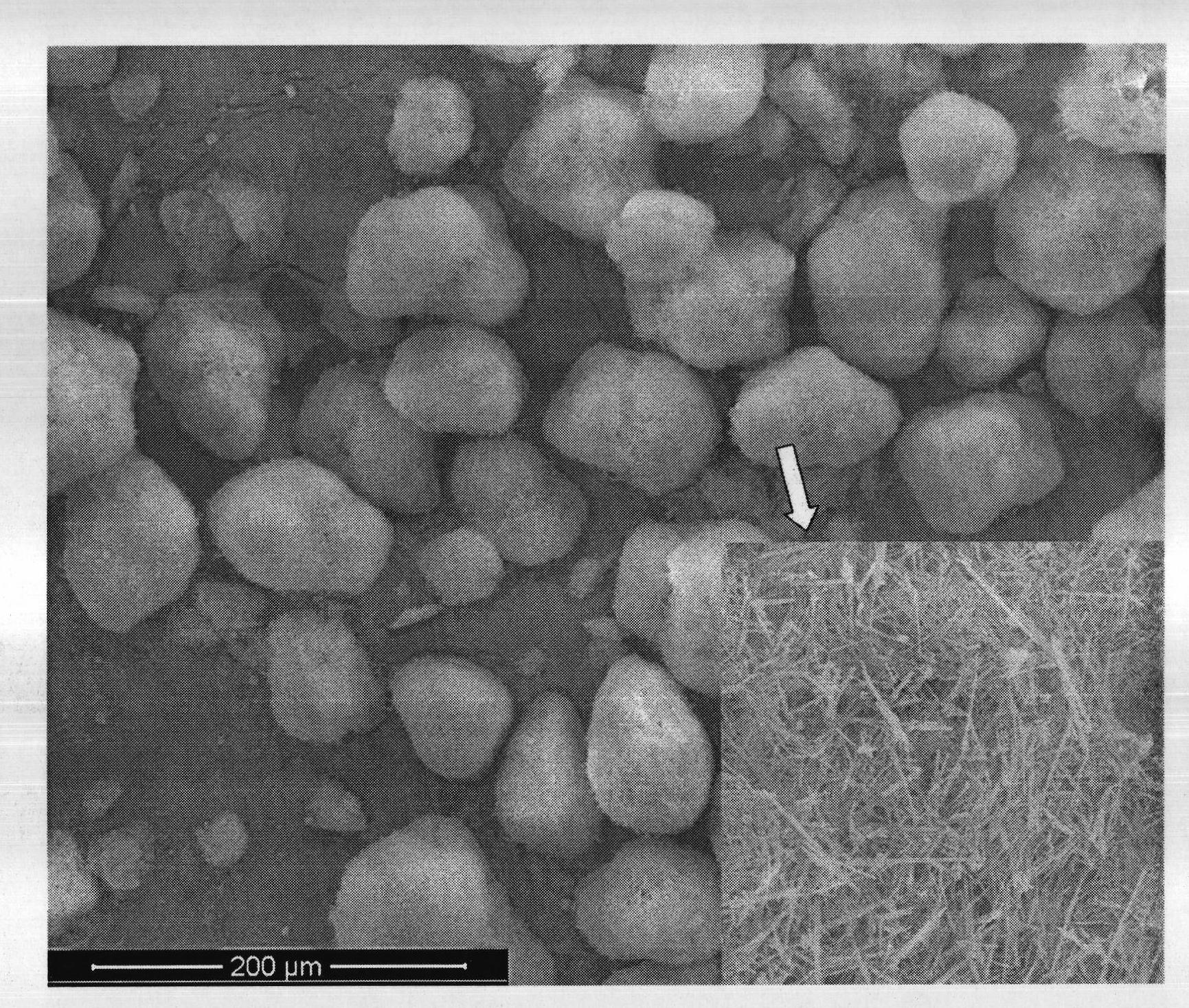

Porous material matrix and composite phase-change heat storage material and preparation methods thereof

InactiveCN102061403AIncrease contentImprove heat storage capacityHeat-exchange elementsCeramicwareWater basedHeat conducting

The invention provides a preparation method of a porous material matrix. The preparation method comprises the following steps: mixing a weighed calcium-containing raw material and a silicon-containing raw material at the mole ratio of Ca to Si of 1:(0.4-1), adding 20-40-times water based on the total weight of the raw materials, stirring and keeping the temperature of 180-320 DEG C for 4-12 hours, and obtaining porous material slurry; and adding 0%-5% of nano-metal powder after the slurry is cooled, drying and molding to obtain the porous material matrix. The preparation method of a composite phase-change heat storage material comprises the following steps: dipping the obtained porous material matrix into a fully fused inorganic salt phase-change material so that the phase-change material is completely infiltrated into a pore path of the porous material matrix; and blowing out for cooling, and then desalting the discharged sample to finally obtain the composite phase-change heat storage material. The obtained matrix material has the advantages of good infiltration property and excellent high-temperature chemical stability relative to inorganic salt; and the obtained composite phase-change heat storage material has the advantages of high heat storage density, good heat-conducting property and cheap raw material.

Owner:SOUTH CHINA UNIV OF TECH

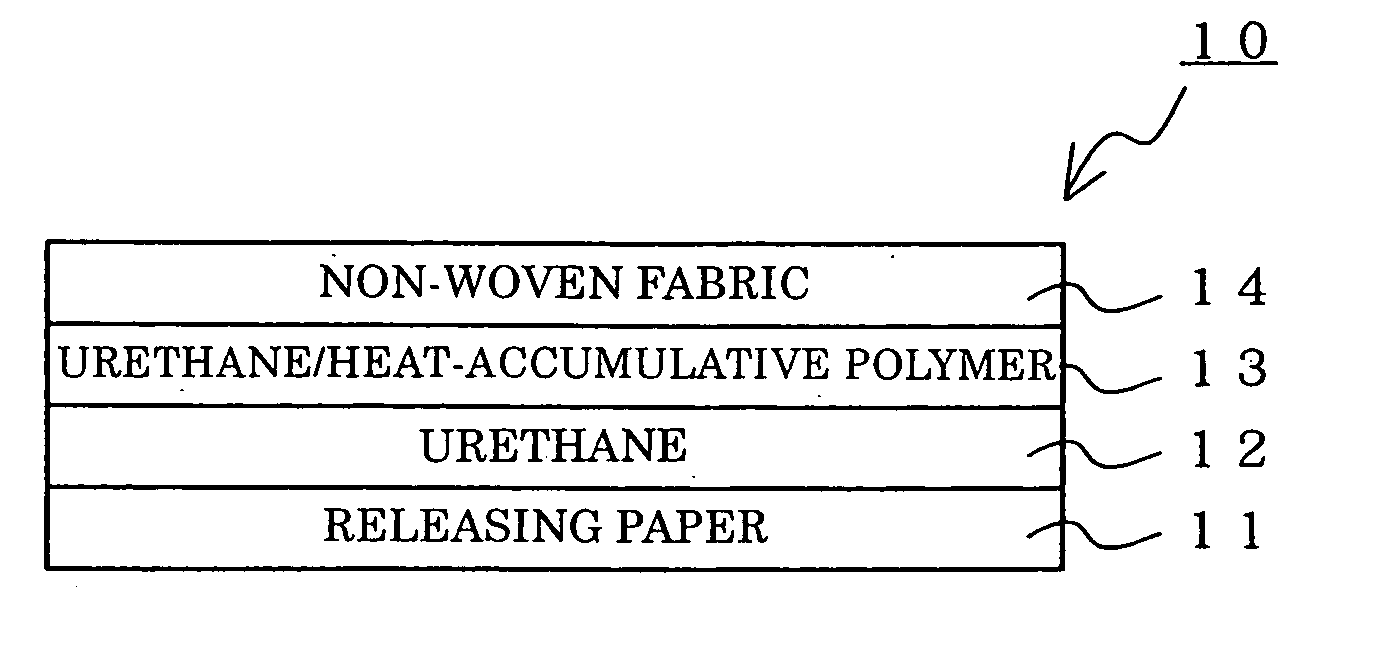

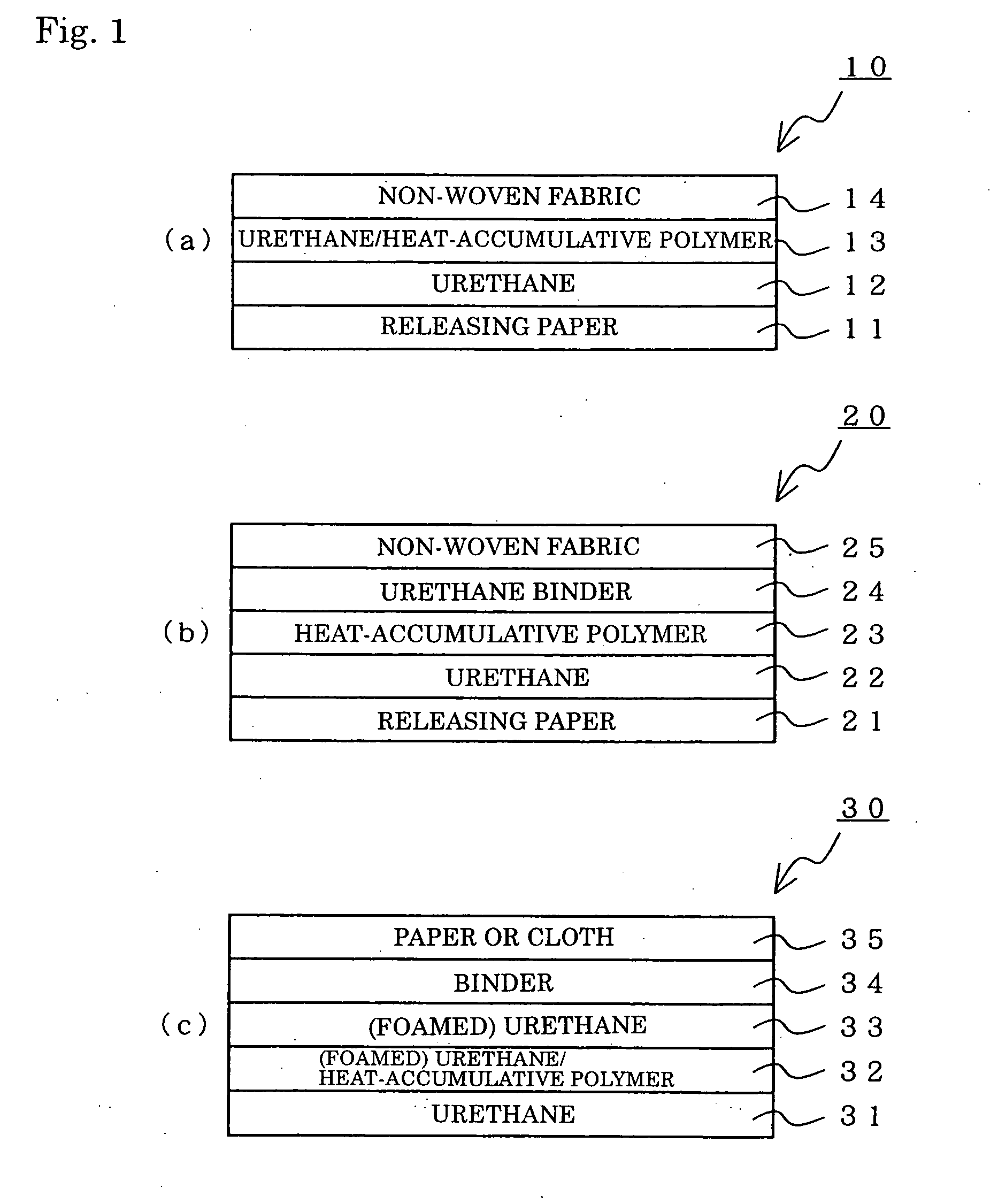

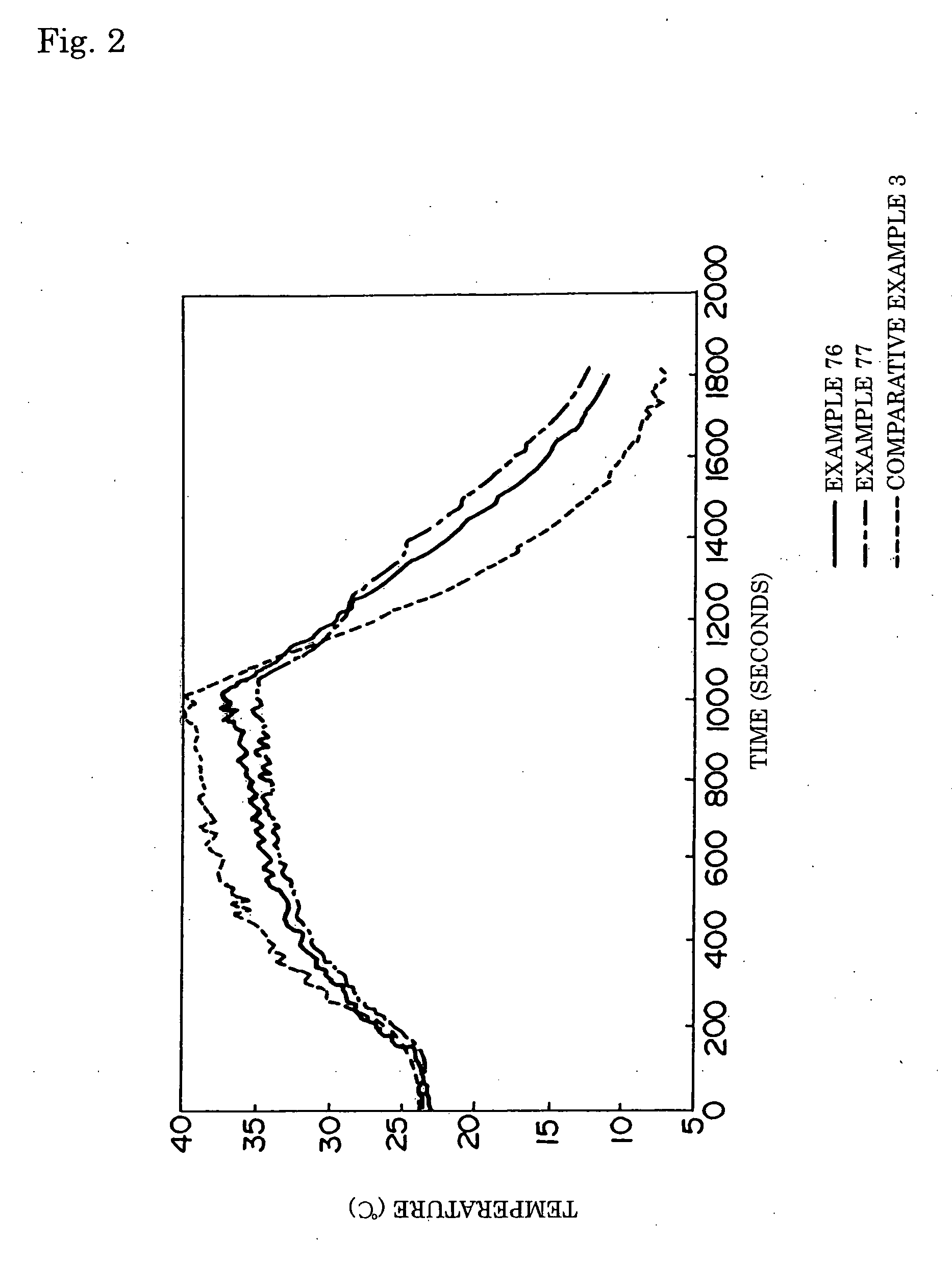

Heat storing material, composition thereof and their use

InactiveUS20050106392A1Preventing excessive heating and coolingSynthetic resin layered productsHeat-exchange elementsFiberOligomer

A heat-accumulative material composed of a polymer or oligomer having a melting point of −10 to 100° C. and latent heat of 30 J / g or more for use around a body, and heat-accumulative composition comprising the same heat-accumulative material. The heat-accumulative material tends to be kept at a constant temperature more effectively by absorbing heat as ambient temperature increases to melt, and releasing heat as ambient temperature decreases to solidify, to moderate the effect of changed ambient temperature, and thereby to exhibit the function as a heat-accumulative material. They have a sufficiently high viscosity, preventing the heat-accumulative material from flowing out even when it is molten. Each of the heat-accumulative material and composition can be made into a heat-accumulative film or sheet, laminate, molded article, composite fiber and cloth which can be suitably used around a body.

Owner:IDEMITSU KOSAN CO LTD +1

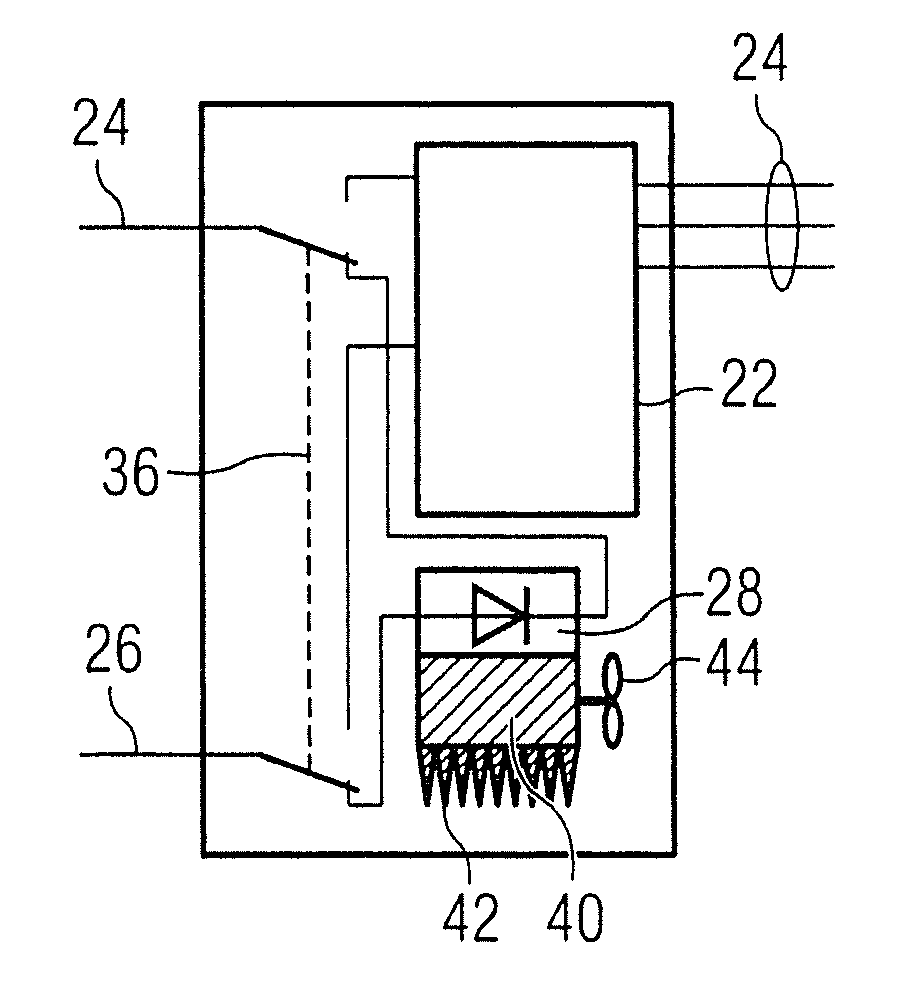

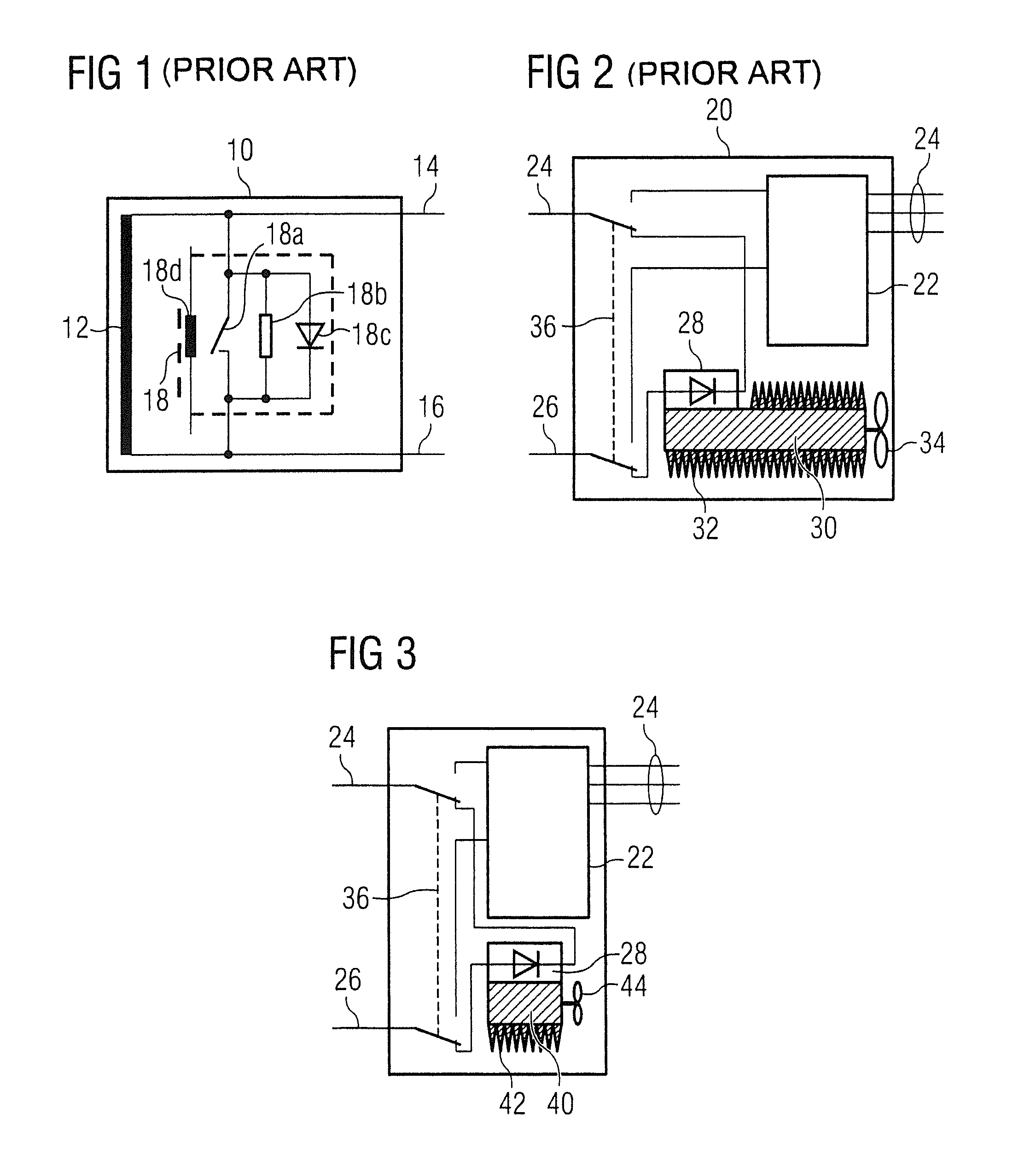

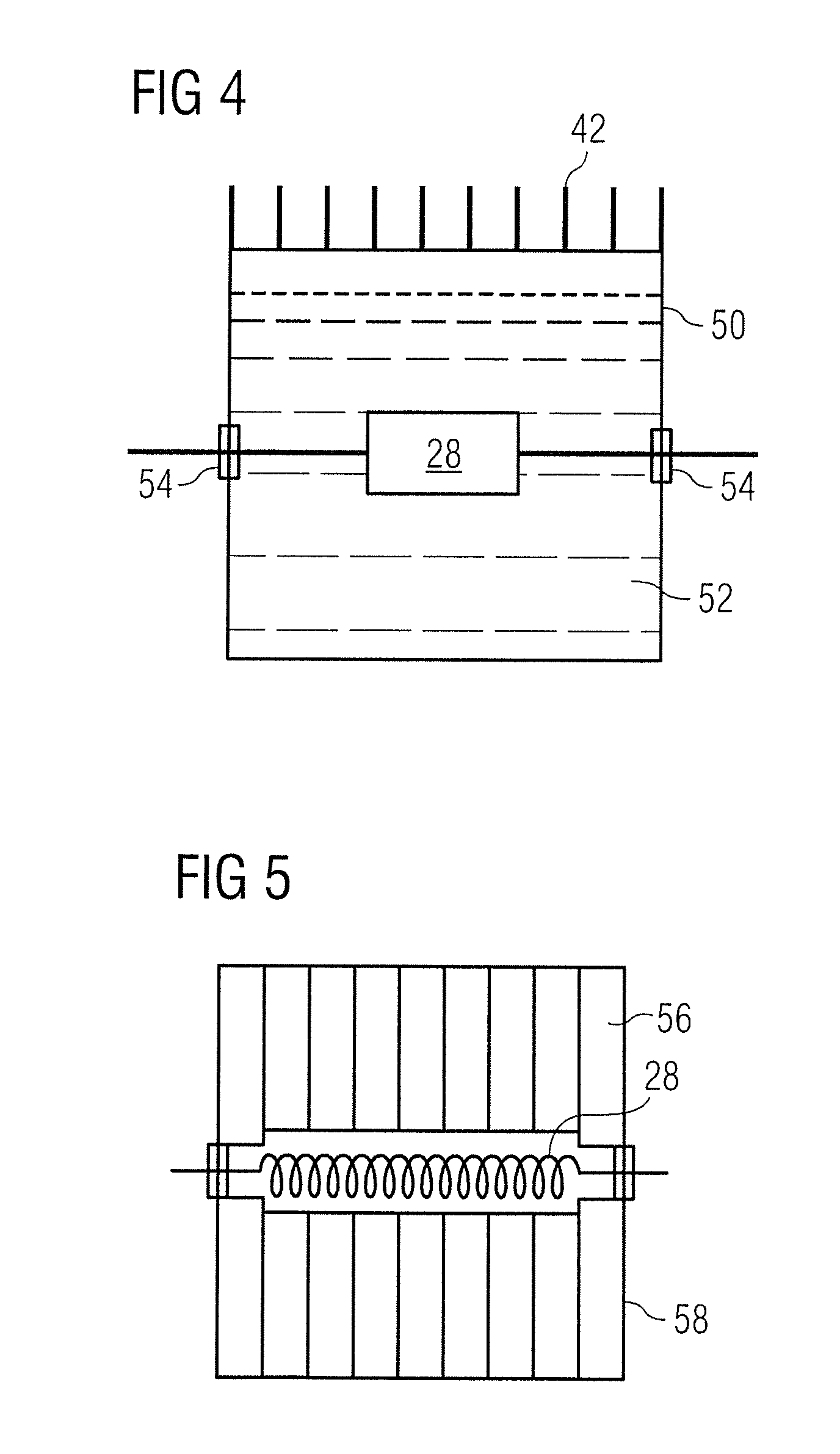

Portable magnet power supply for a superconducting magnet and a method for removing energy from a superconducting magnet using a portable magnet power supply

ActiveUS8699199B2Superconducting magnets/coilsEmergency protective arrangements for limiting excess voltage/currentElectricitySuperconducting Coils

Owner:SIEMENS HEALTHCARE LTD

Packaging shape-stabilizing method of inorganic hydrated salt phase-change heat storage material

InactiveCN104371658AImprove thermal conductivitySimple structureHeat-exchange elementsMolten stateHydration reaction

The invention provides a packaging shape-stabilizing method of an inorganic hydrated salt phase-change heat storage material, which comprises the following steps: (1) adding a nucleator and deionized water into the inorganic hydrated salt phase-change material, and heating until the inorganic hydrated salt phase-change material achieves the molten state; (2) adding a porous propping material into the molten-state inorganic hydrated salt phase-change material, and stirring sufficiently and uniformly; (3) putting the molten-state mixture obtained in the step (2) in a vacuum environment to enhance the adsorptivity of the porous propping material for the inorganic hydrated salt phase-change material; and (4) moving the molten-state mixture out of the vacuum environment, and immediately putting the molten-state mixture into a low-temperature environment suitable for crystallization to perform recrystallization. The composite shape-stabilized phase-change material obtained by the method has the advantages of stable structure, high latent heat, no toxicity, simple preparation process, short time consumption and low cost.

Owner:GUILIN UNIV OF ELECTRONIC TECH

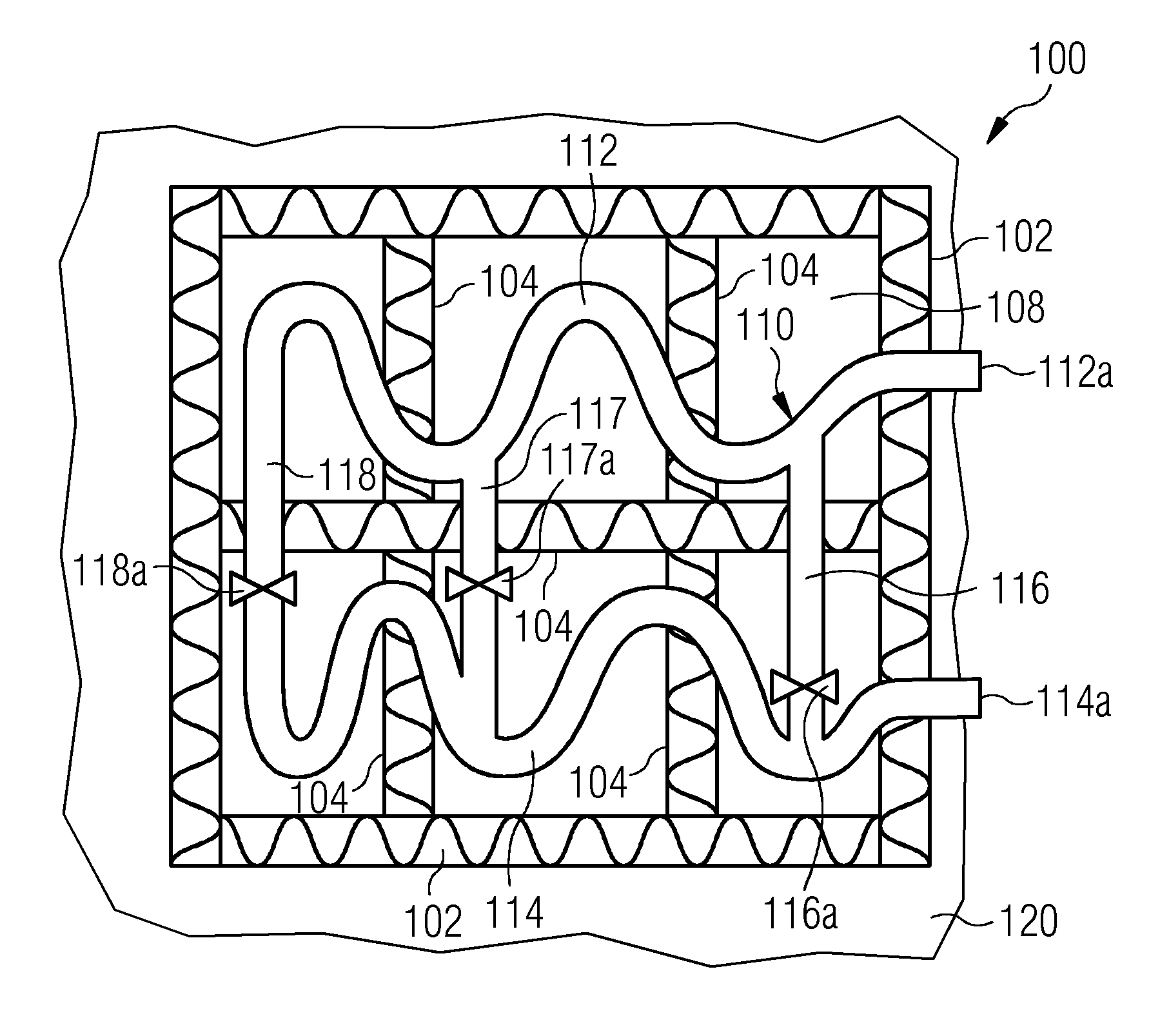

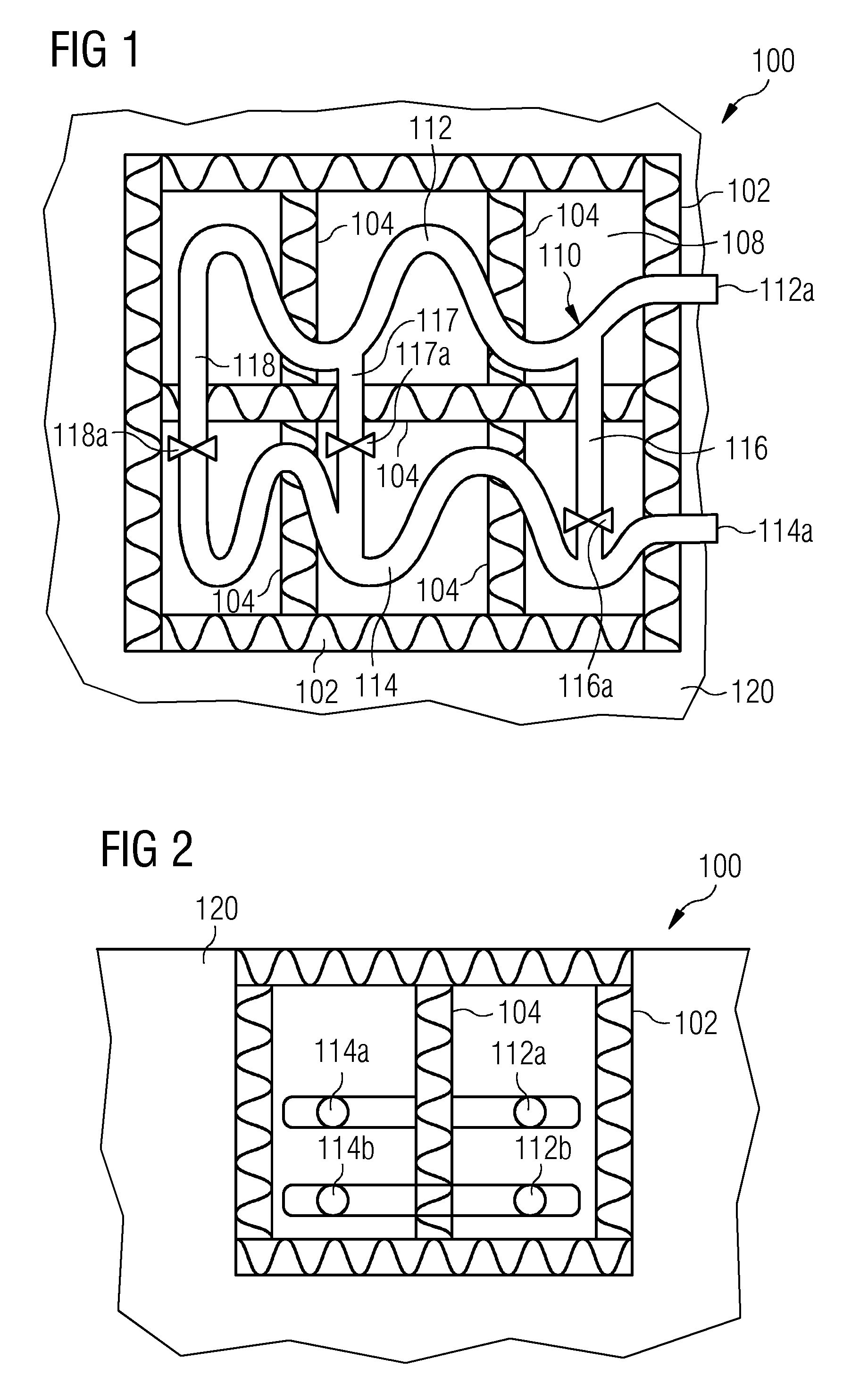

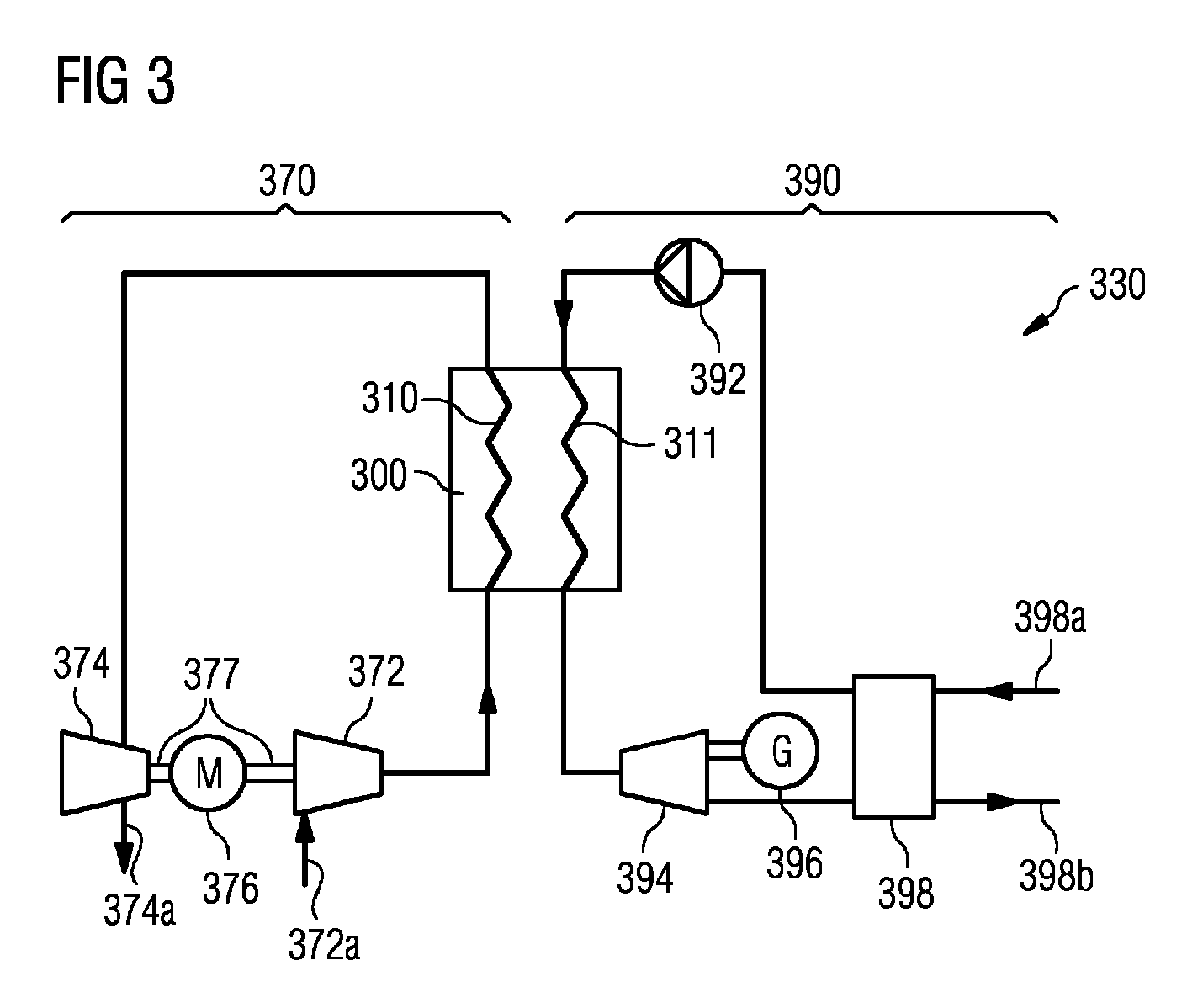

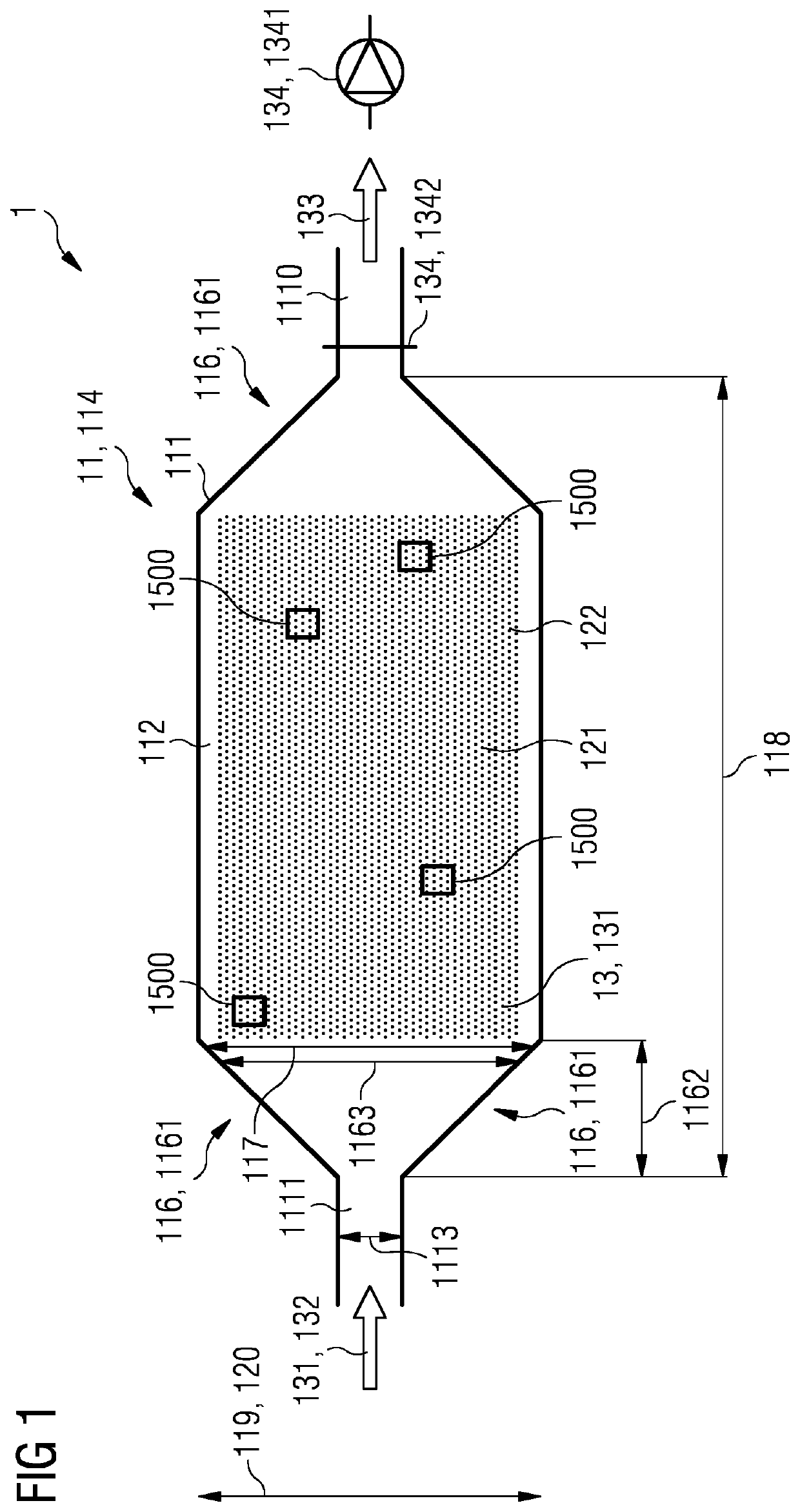

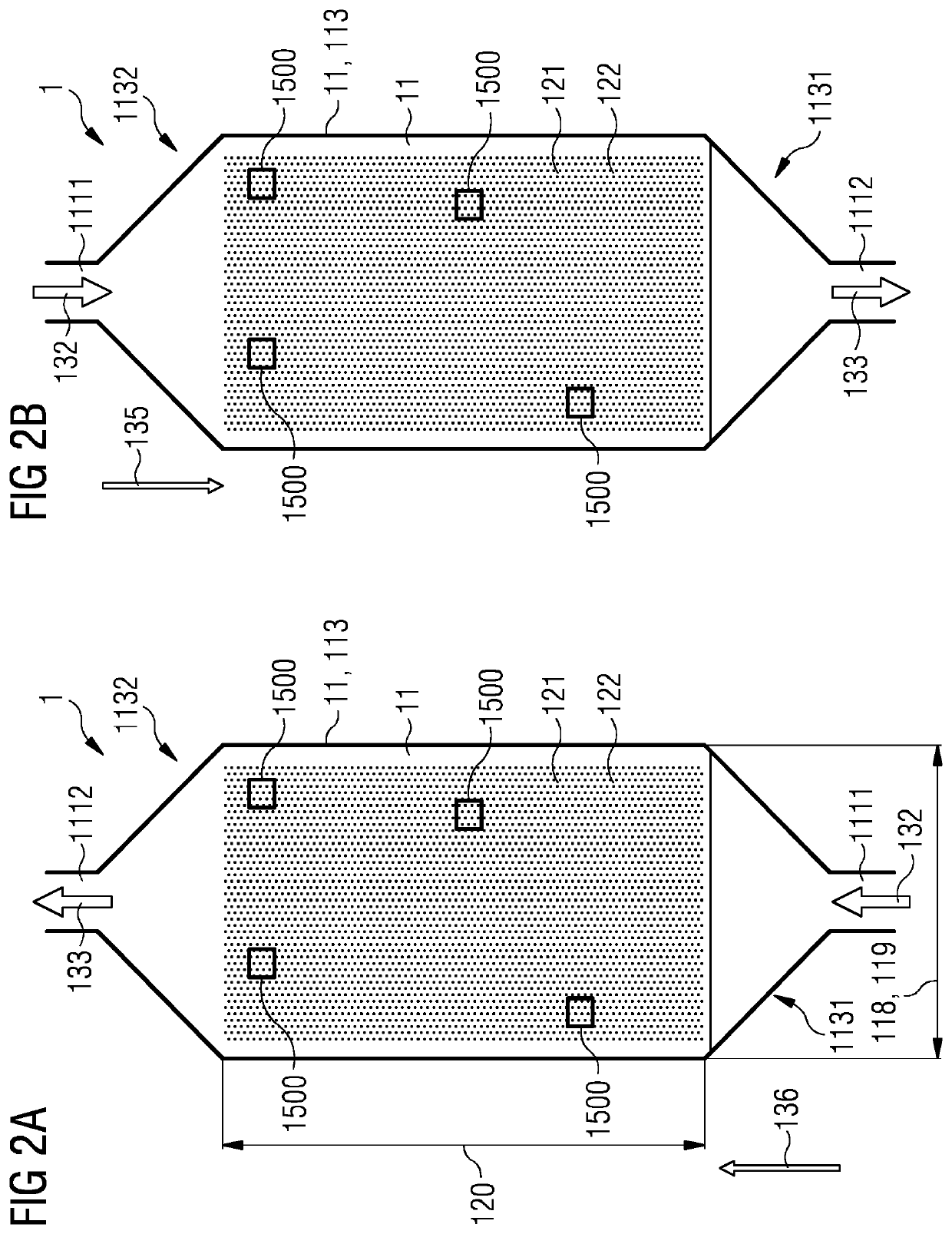

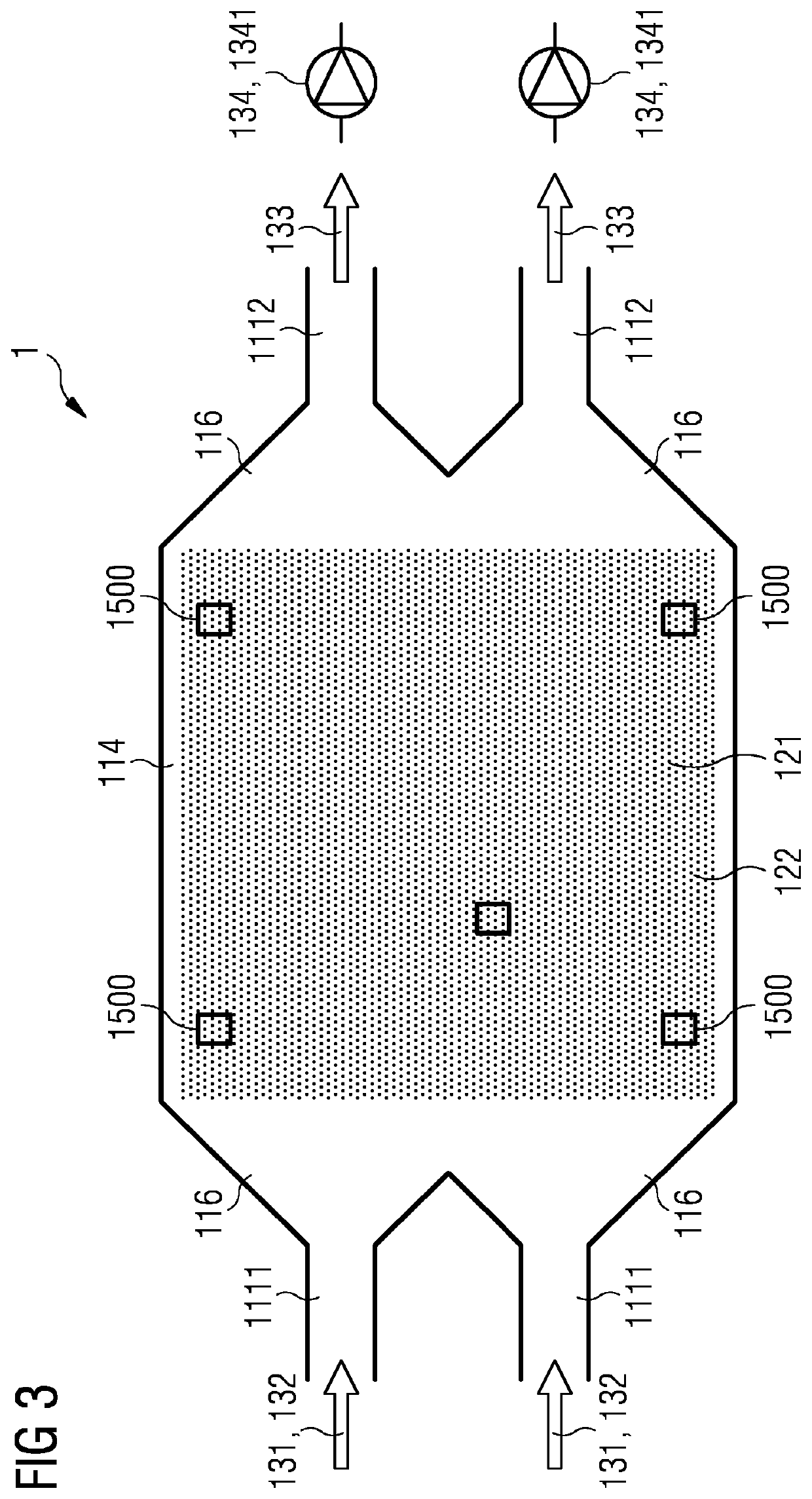

Thermal energy storage and recovery device and system having a heat exchanger arrangement using a compressed gas

ActiveUS8991183B2Improve efficiencyEasy feedingHeat storage plantsSteam accumulatorsThermal energyEngineering

A thermal energy storage and recovery device is disclosed which includes a heat exchanger arrangement configured for guiding a flow of a heat transfer medium between a first end and a second end, and a heat storage material surrounding the heat exchanger arrangement so that a thermal interaction region is formed for thermally coupling the heat transfer medium with the heat storage material. The heat exchanger arrangement is sealed against the heat storage material so that, when in a first operational mode, in which the heat storage material is supposed to receive thermal energy from the heat transfer medium, a compressed gas is usable as the heat transfer medium for transferring thermal energy from the heat transfer medium to the heat storage material.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Solar heat collector system with heat storage function

InactiveCN104075464ATake advantage ofAvoid lostSolar heat devicesSolar thermal energy generationCollector deviceHeat storage material

The invention provides a solar heat collector system which comprises a heat collector, a heat storage device, a water outlet pipe and a water return pipe. The heat collector and the heat storage device are connected through a pipeline, the heat storage device comprises a shell, a heat storage material is arranged in the shell, a water pipe of the solar heat collector system is arranged in a heat storage material, the water pipe is of a coiler structure, heat exchange is carried out between water in the water pipe and the heat storage material, and absorbed solar energy is transmitted to the heat storage material and then is returned to the heat collector for heating. The solar heat collector system has an automatic heat storage function, can effectively make use of excess solar energy, and achieves the effects of energy conservation and environment protection.

Owner:湖北丰缘科技股份有限公司

Charging system with a high temperature thermal energy exchange system and method for charging heat storage material of the high temperature thermal energy exchange system with thermal energy

ActiveUS10724805B2Reduce lossesEfficient heat transferHeat storage plantsSteam engine plantsThermodynamicsEngineering

A charging system with a least one high temperature thermal energy exchange system is provided. The high temperature thermal energy exchange system includes at least one heat exchange chamber with chamber boundaries which surround at least one chamber interior of the heat exchange chamber, wherein the chamber boundaries include at least one inlet opening for guiding in an inflow of at least one heat transfer fluid into the chamber interior and at least one outlet opening for guiding out an outflow of the heat transfer fluid out of the chamber interior. At least one heat storage material is arranged in the heat exchange chamber interior such that a heat exchange flow of the heat transfer fluid through the heat exchange chamber interior causes a heat exchange between the heat storage material and the heat transfer fluid.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

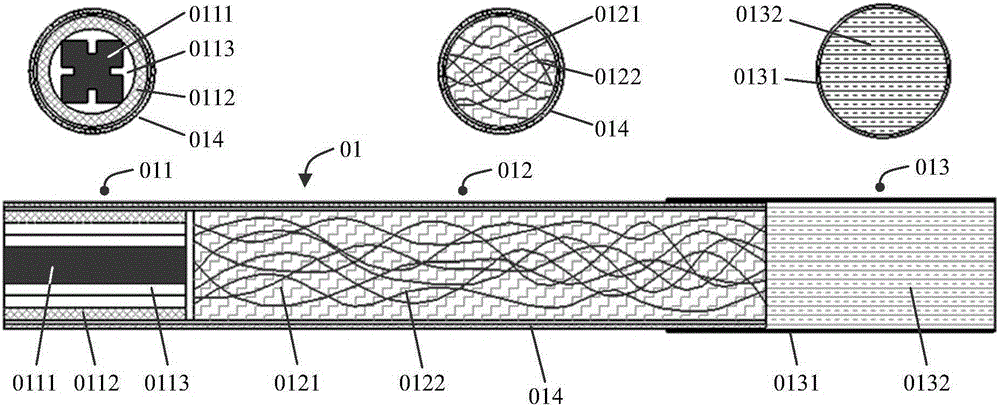

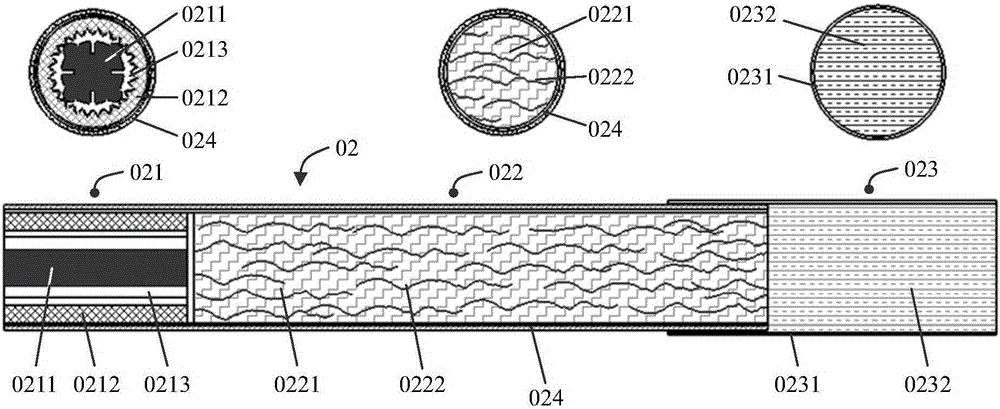

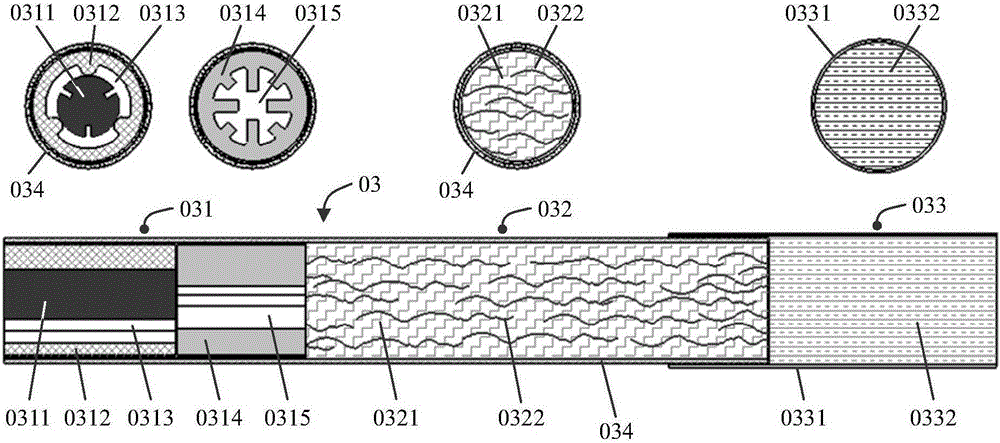

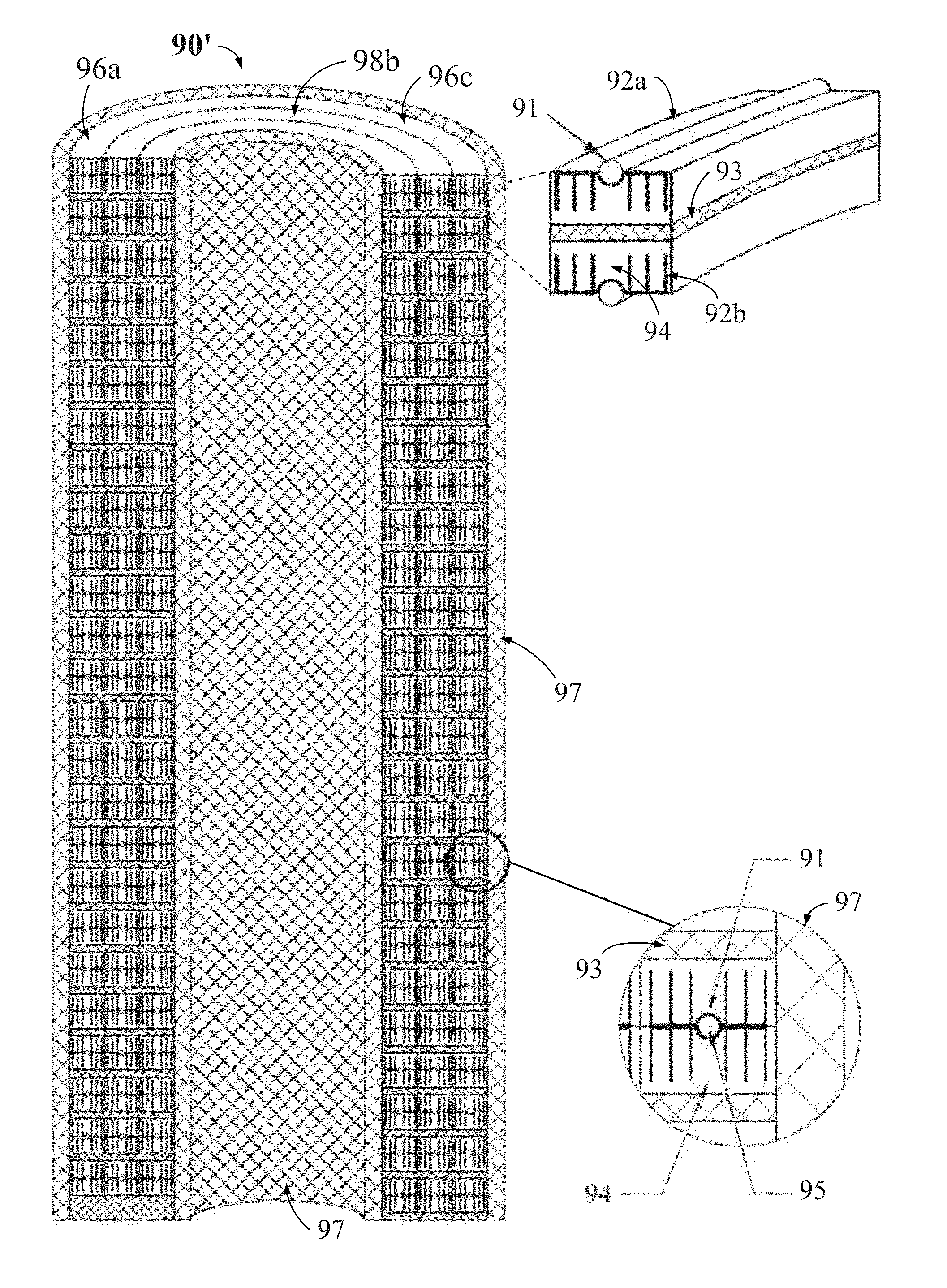

Non-combustion type low temperature cigarette product based on phase change temperature-controlled fuel assembly and preparation method of aerosol generating section

InactiveCN105167182AAvoid conduction heatingLow conduction heatingCigar manufactureFiberProduct base

The invention relates to a non-combustion type low temperature cigarette product based on a phase change temperature-controlled fuel assembly. The cigarette product comprises a phase change temperature-controlled fuel assembly section, an aerosol generating section and a filter section which are sequentially connected. Energy released in a combustion process is transmitted to the aerosol generating section through mainstream smoke, and under the action of a phase change heat storage material, adsorbing purification and oxidation catalysis on CO are achieved, so that unexpected pyrolysis on a smoke matrix due to excessive temperature is avoided. The aerosol generating section is prepared by uniformly blending and mixing the smoke matrix and high-thermal-conductivity MPCF carbon fiber long filaments or short filaments, so that the temperature of an aerosol generating system is reduced in a gradient mode in the axial direction of the cigarette and the entire aerosol generating section is uniformly heated; therefore, a smoking experience is prevented from being rapidly decreased with increase in smoking times. The phase change temperature-controlled fuel assembly section and the aerosol generating section are integrally covered and rolled by virtue of heat-insulating cigarette paper, so that consumption of heat energy is reduced, and effective thermal excitation of the smoke matrix is achieved under relatively low heat distribution.

Owner:叶菁 +2

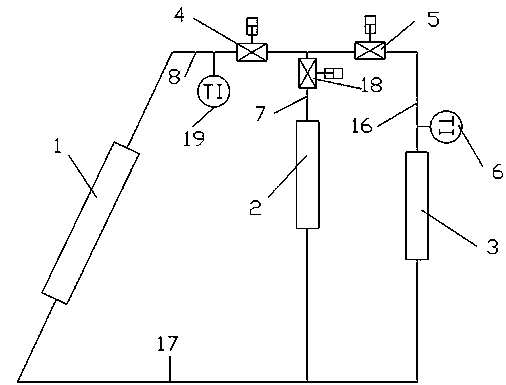

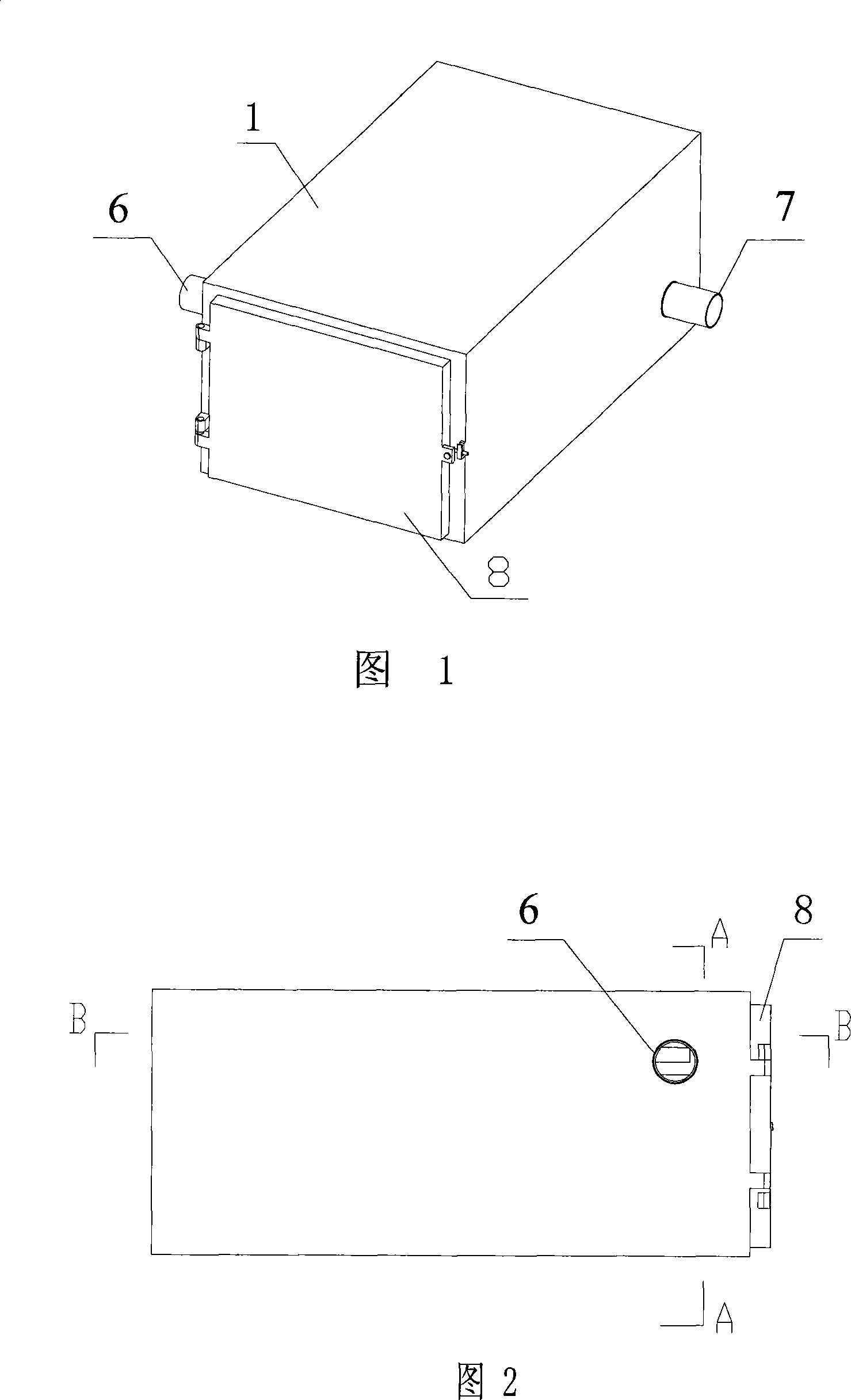

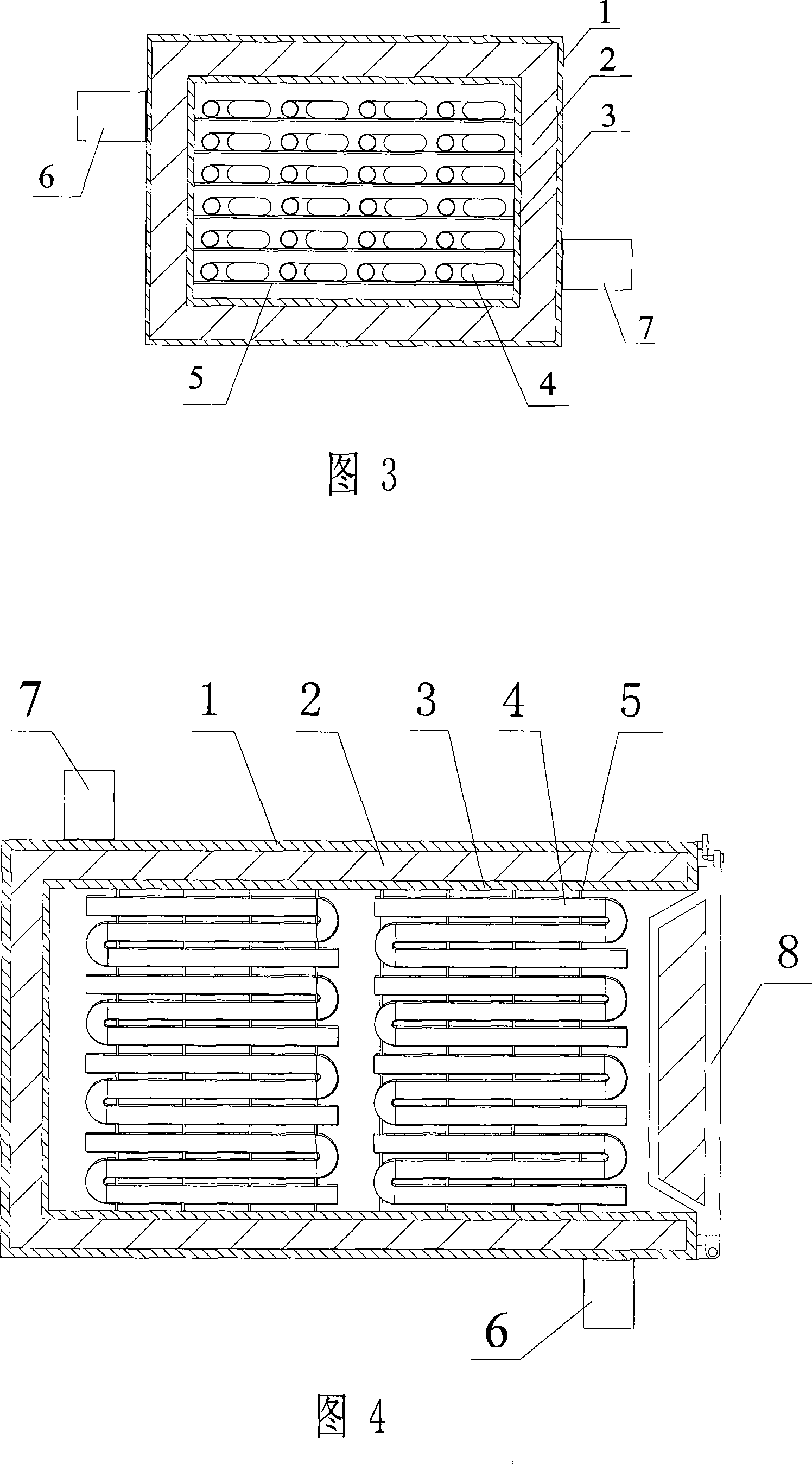

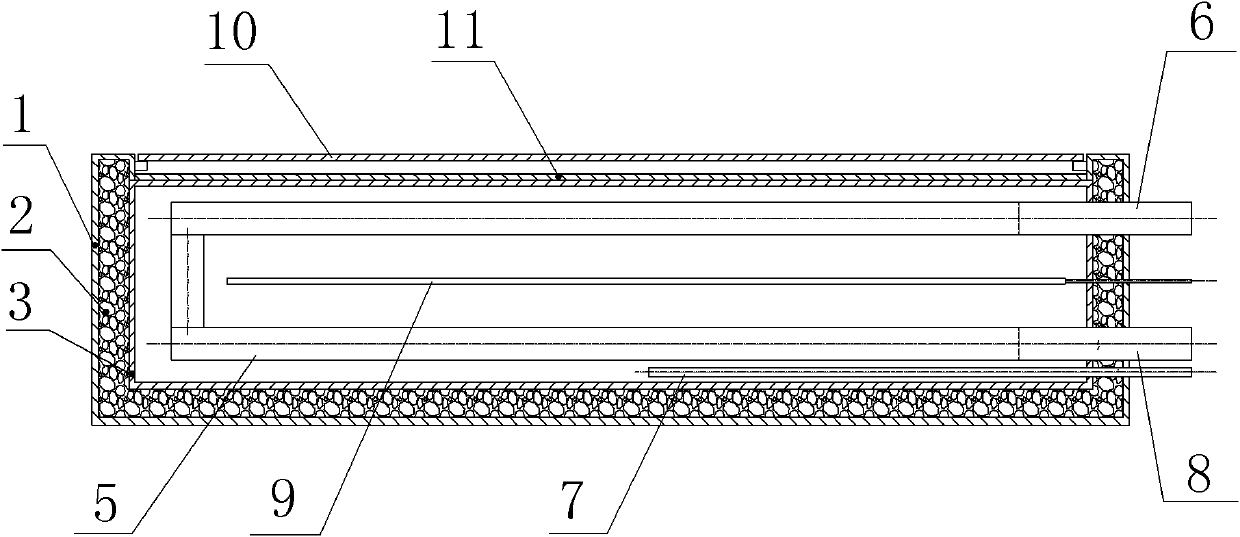

Solar heat-storing device using gas as heat transfer medium

InactiveCN101226035AFull heat exchangeThe heat exchange process is reversibleSolar heating energySolar heat devicesThermal insulationEngineering

The invention relates to a solar energy heat storage device, in particular to a solar energy heat storage device using gas as heat transfer medium, comprising a housing of a heat storage chamber, thermal insulation material (2), a metal pipeline (4), a holding frame (5), an inlet pipe (6), an outlet pipe (7) and a door of the heat storage chamber (8). The solar energy heat storage device is characterized in that the housing of the heat storage chamber is composed of an outer wall of the heat storage chamber (1) and an inner wall of the heat storage chamber (3); the door (8) and the inner wall (3) of the heat storage chamber form a sealed heat storage space; the inlet pipeline (6) and the outlet pipeline (7), communicated with the heat storage space respectively, are positioned asymmetrically on the housing of the heat storage chamber; at least one layer of the holding frame (5) is positioned in the heat storage space; the holding frame (5) is fixedly connected with the inner wall of the heat storage chamber (3); the metal pipeline (4) is positioned on the holding frame (5); the heat storage material is encapsulated in the metal pipeline (5); the heat transfer medium in the heat storage space is gas. The olar energy heat storage device has the advantages of simple structure, and high efficiency, suitability for using gas as the transfer medium.

Owner:WUHAN UNIV OF TECH

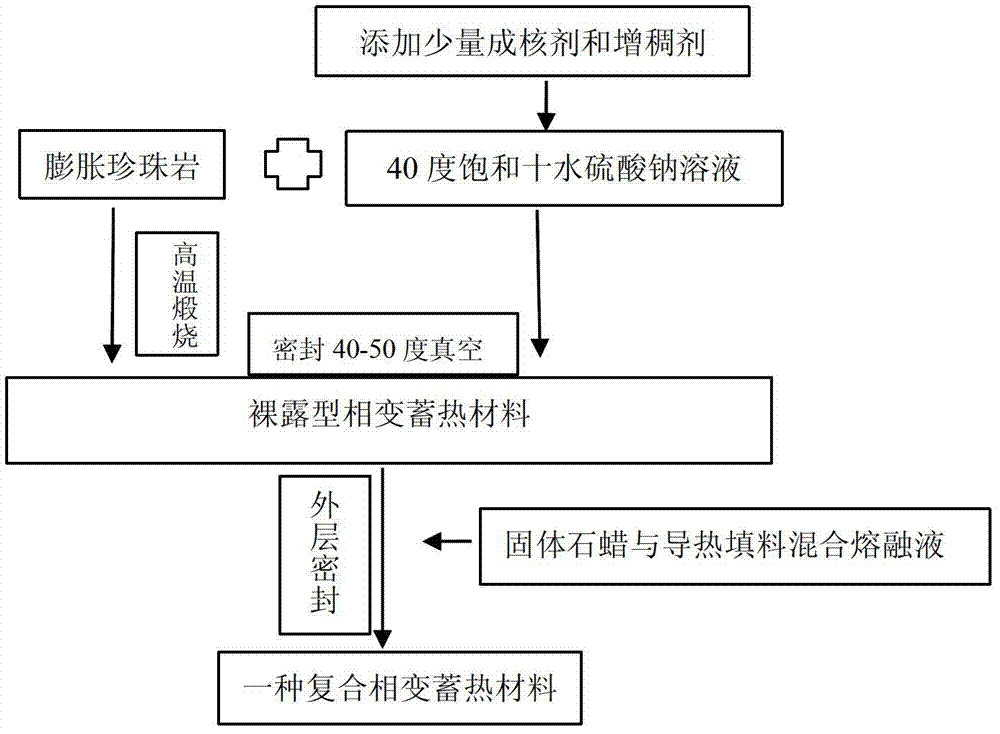

Composite phase change heat storage material and preparation method thereof

InactiveCN103194179AImprove overcoolingEasy to separateHeat-exchange elementsParaffin waxFluid phase

The invention discloses a composite phase change heat storage material and a preparation method thereof. The composite phase change heat storage material is characterized by comprising the following materials in parts by weight: 39.4-40.3 parts of saturated sodium sulfate decahydrate solution, 0.8-1.2 part of nucleating agent, 1.2-2 parts of thickening agent, 23.6-24.0 parts of solid paraffin, 1.2-2.4 parts of heat-conducting filler, 17.8-18.6 parts of expanded perlite and 13.6-13.9 parts of distilled water, wherein a 40 DEG C saturated sodium sulfate decahydrate solution containing the nucleating agent and the thickening agent is adsorbed into the expanded perlite by employing a vacuum absorption method and then is sealed by employing industrial solid paraffin after adsorption is finished, and the heat-conducting filler is added in the sealing process. The composite phase change heat storage material has the advantages that after being modified and micro-packaged, the composite phase change heat storage material has low supercooling degree, the solution is uniform and not layered during solid-liquid phase change, the performance is stable, the repeatability is high, the service life is prolonged, and the composite phase change heat storage material can be widely applied to actual building energy conservation engineering.

Owner:HENAN POLYTECHNIC UNIV

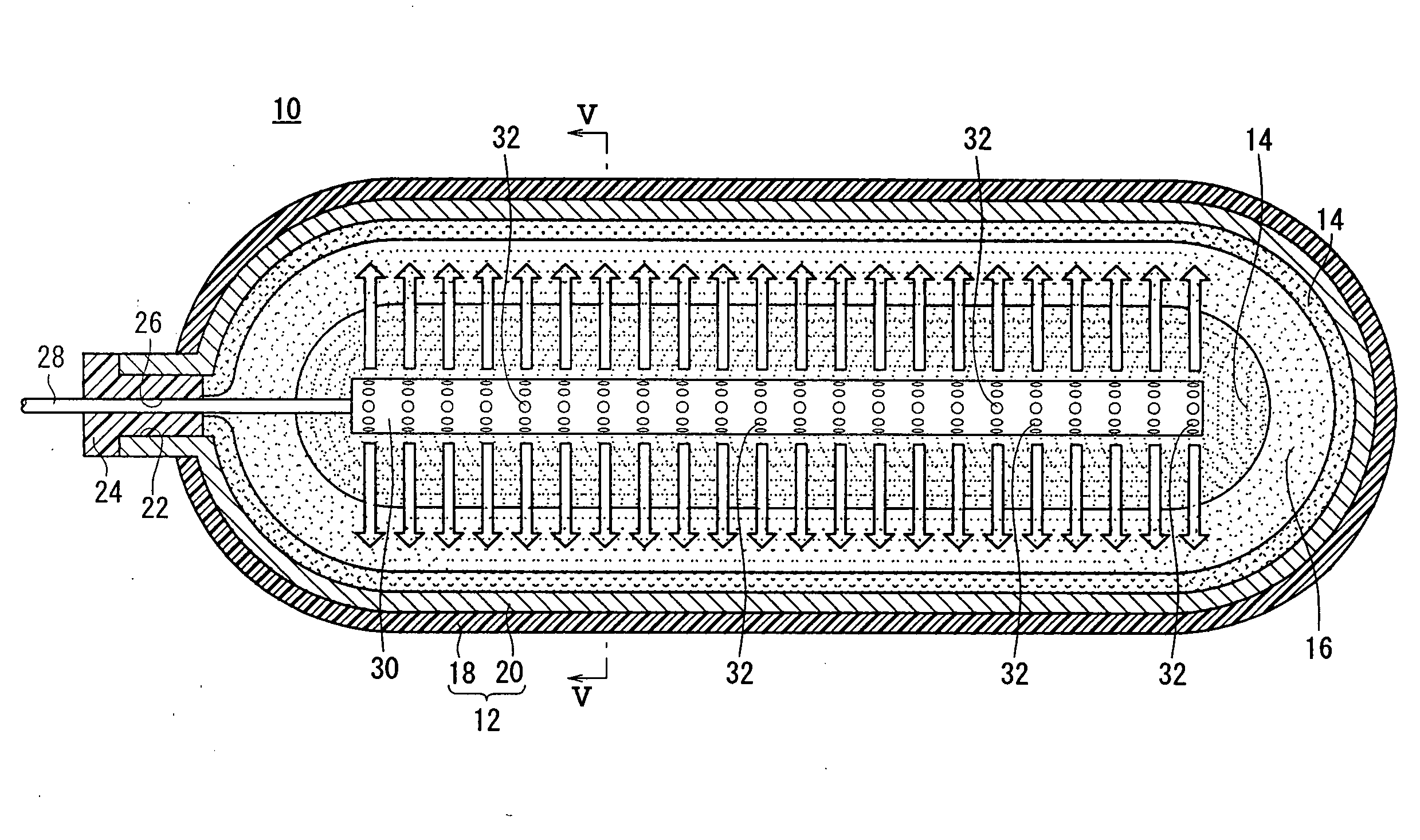

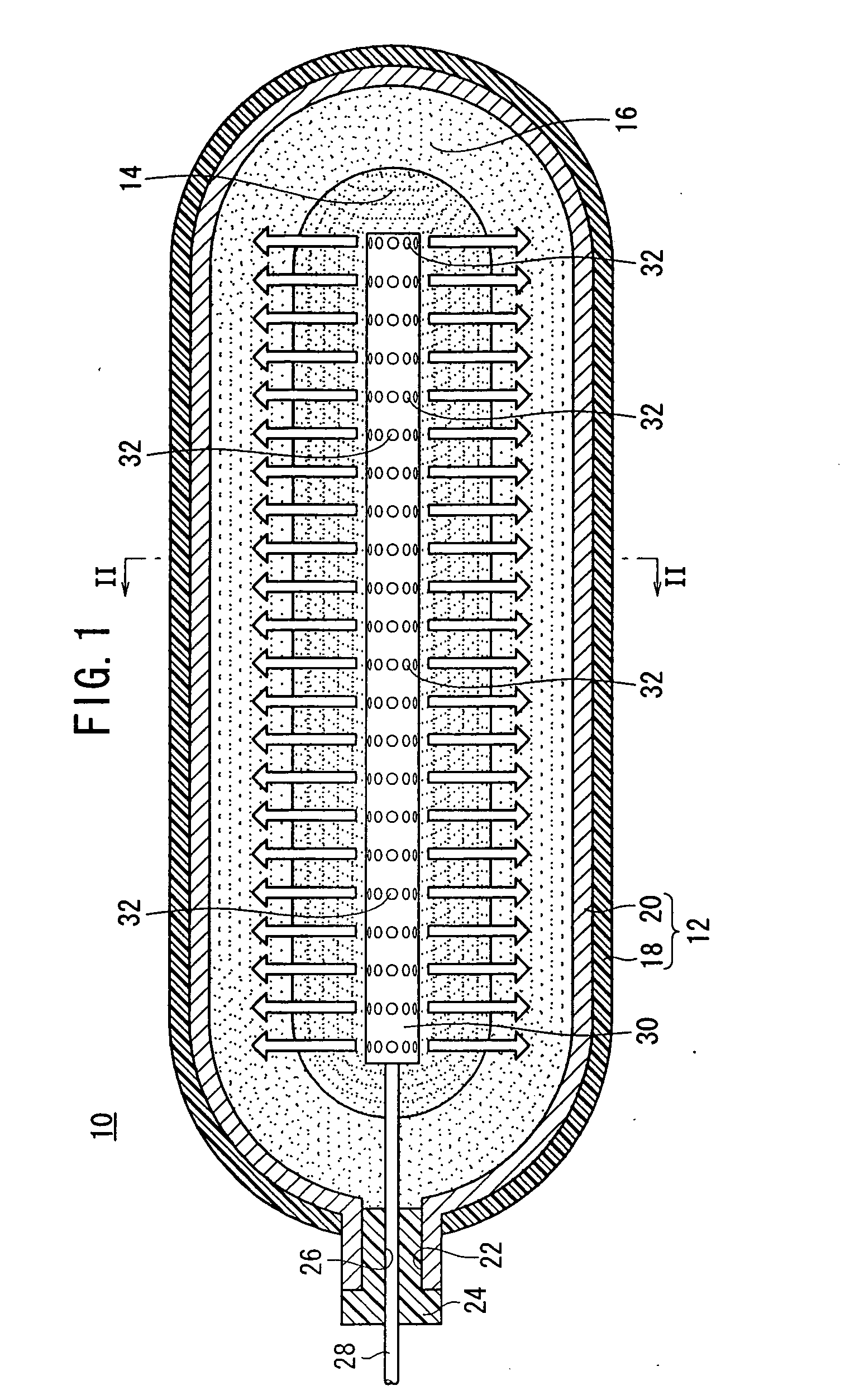

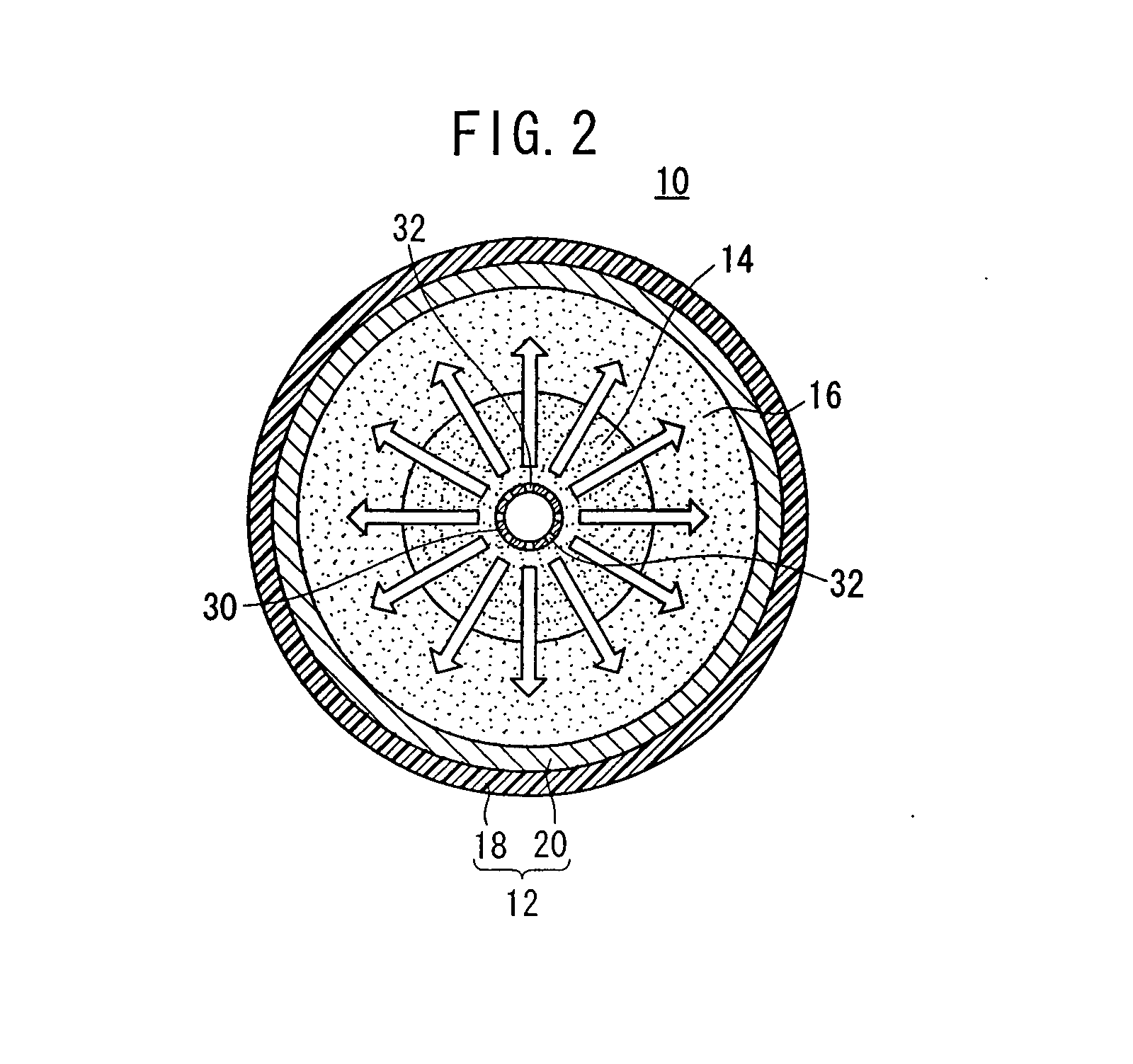

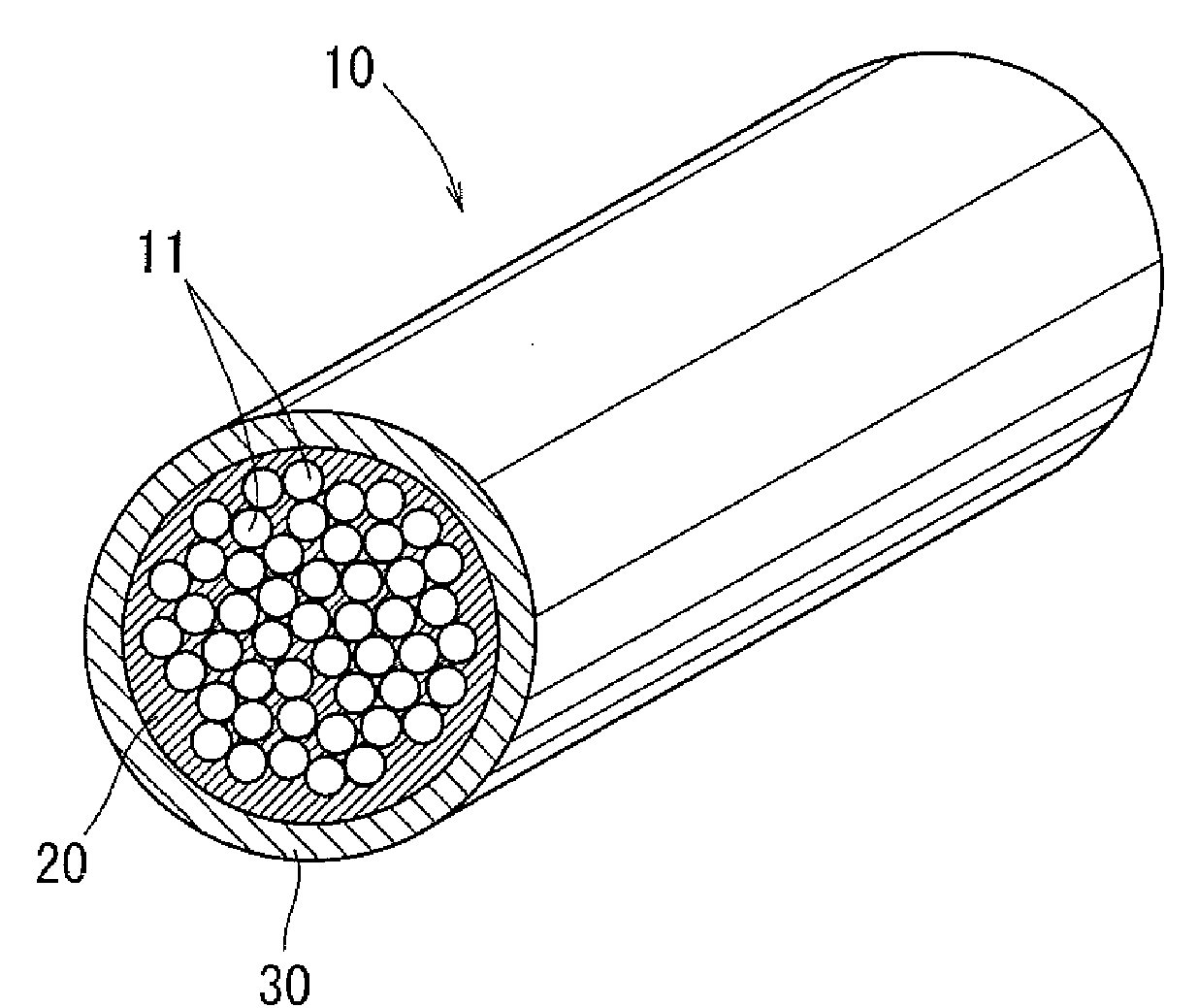

Gas storage container

InactiveUS20080142377A1Inhibit temperature riseSmall sizeReactant parameters controlDomestic cooling apparatusProduct gasHeat storage material

An elongate gas distributing tube, which extends in a longitudinal direction of a container, is accommodated within the container that constitutes a gas storage container. Discharge ports, through which the gas is discharged, are provided only on a side circumferential wall of the gas distributing tube. Therefore, the discharged gas advances while being directed toward the inner side wall of the container. The gas distributing tube is surrounded by a gas absorbing / adsorbing material. On the other hand, the gas absorbing / adsorbing material is surrounded by a mixture, which is prepared by mixing the gas absorbing / adsorbing material with a heat storage material, such that heat is absorbed by the heat storage material contained therein.

Owner:HONDA MOTOR CO LTD

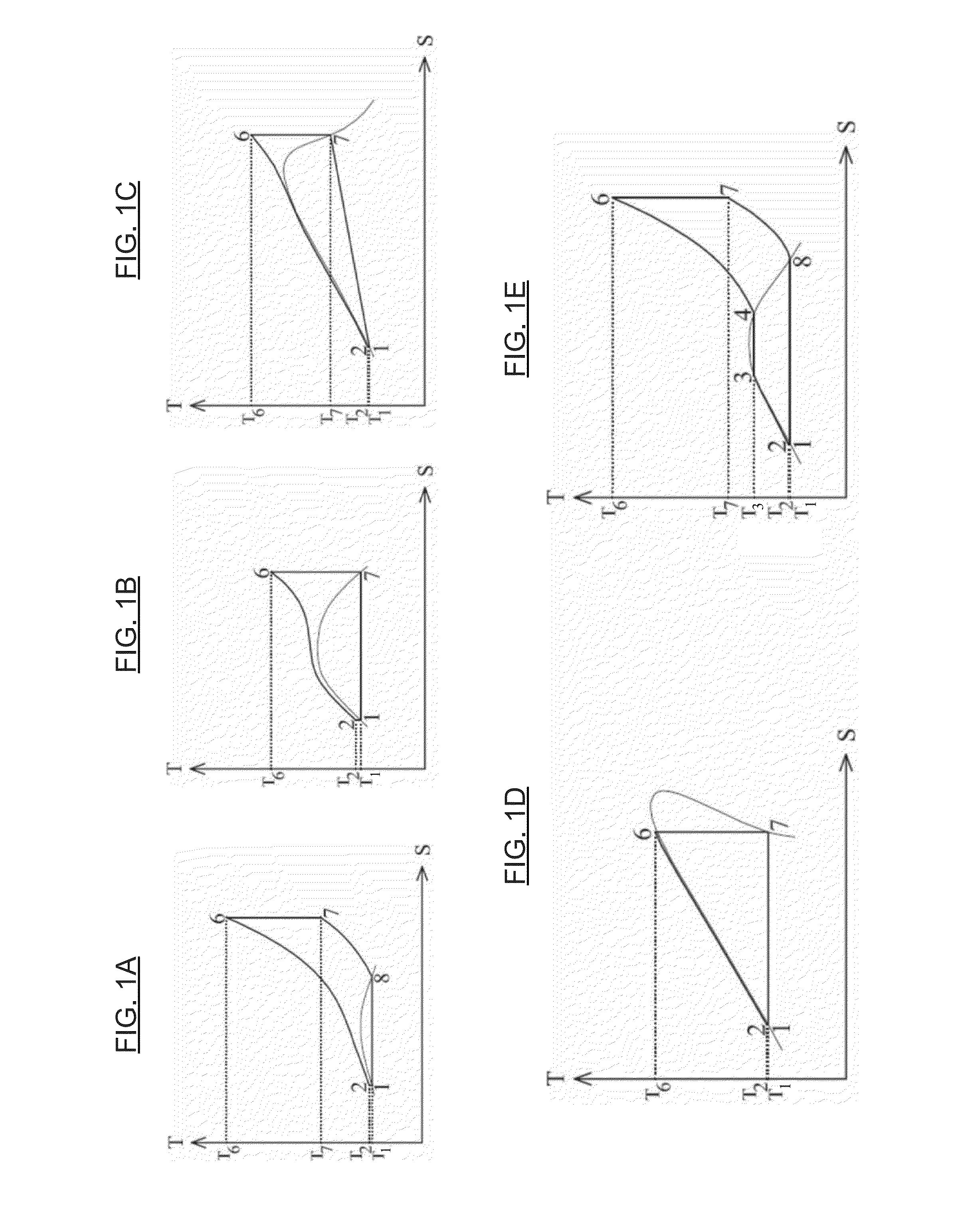

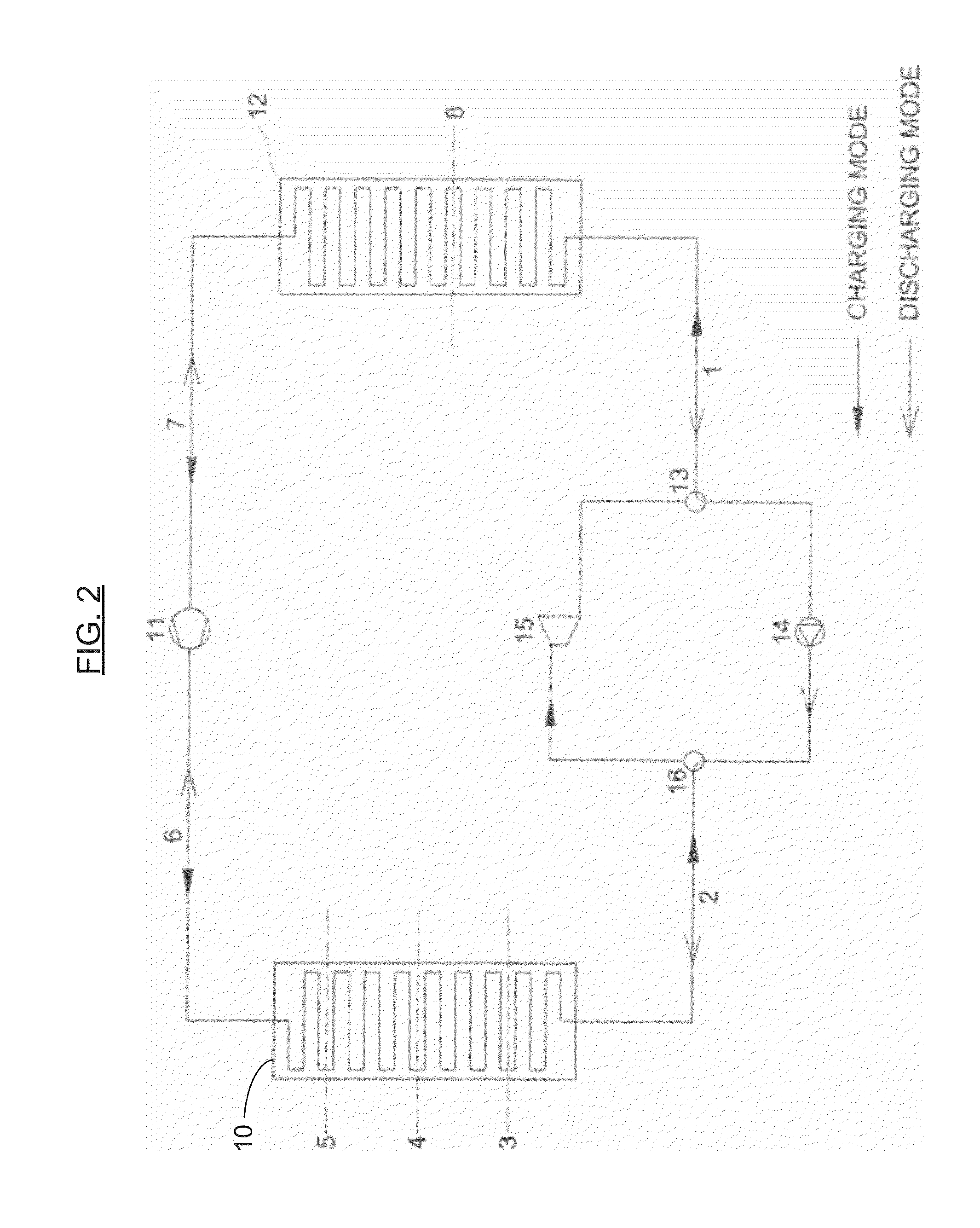

Apparatus, system, and methods for mechanical energy regeneration

ActiveUS9394807B1Small second law lossPresent inventionHeat storage plantsSteam useWorking fluidThermal force

Systems and methods for storing and retrieving thermo-mechanical energy are disclosed. The systems and methods generally include a thermodynamic loop or cycle (e.g., a reversible transcritical, trilateral, or Rankine / vapor compression cycle) that works as a heat pump in a charging mode and as a heat engine in a discharging mode. The thermodynamic loop or cycle includes a gas pressure changing device, a liquid pressure changing device, and a working fluid. The system further includes one or more heat storage devices with solid heat storage material(s). Heat is transferred between the working fluid and the solid heat storage material(s) in the high and low pressure sides of the thermodynamic cycle, respectively.

Owner:KREUGER STEN

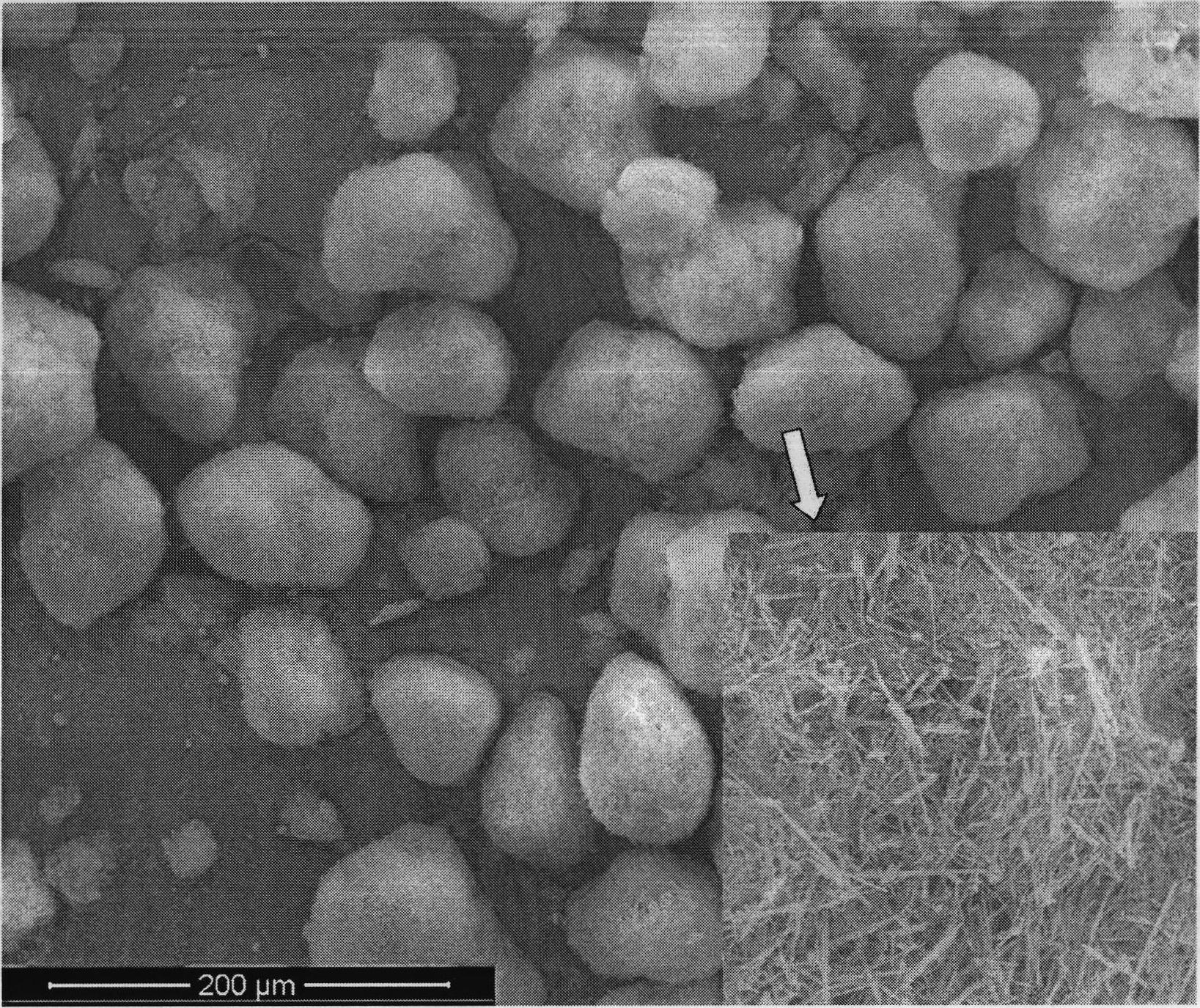

Heat storage materials and methods of manufacturing the heat storage materials

InactiveUS20090294094A1Change temperatureHeat storage plantsMetal-working apparatusAlcoholHeat storage material

The present invention includes a heat storage granule having a plurality of microcapsules mixed with a binder and granulated into the heat storage granule. Each of the microcapsules may have an outer case and a phase change material contained therein. The outer case may be made of synthetic resin. The phase change material can absorb and dissipate latent heat in response change in temperature. The heat storage granule may have a cover layer that has heat conductivity and resistance against alcohol, both of which may be higher than those of a thermosetting resin or a thermoplastic resin.

Owner:AISAN IND CO LTD +1

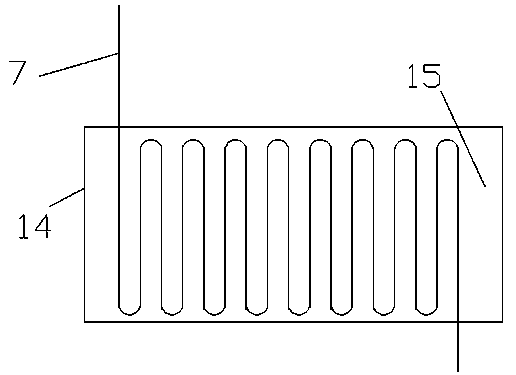

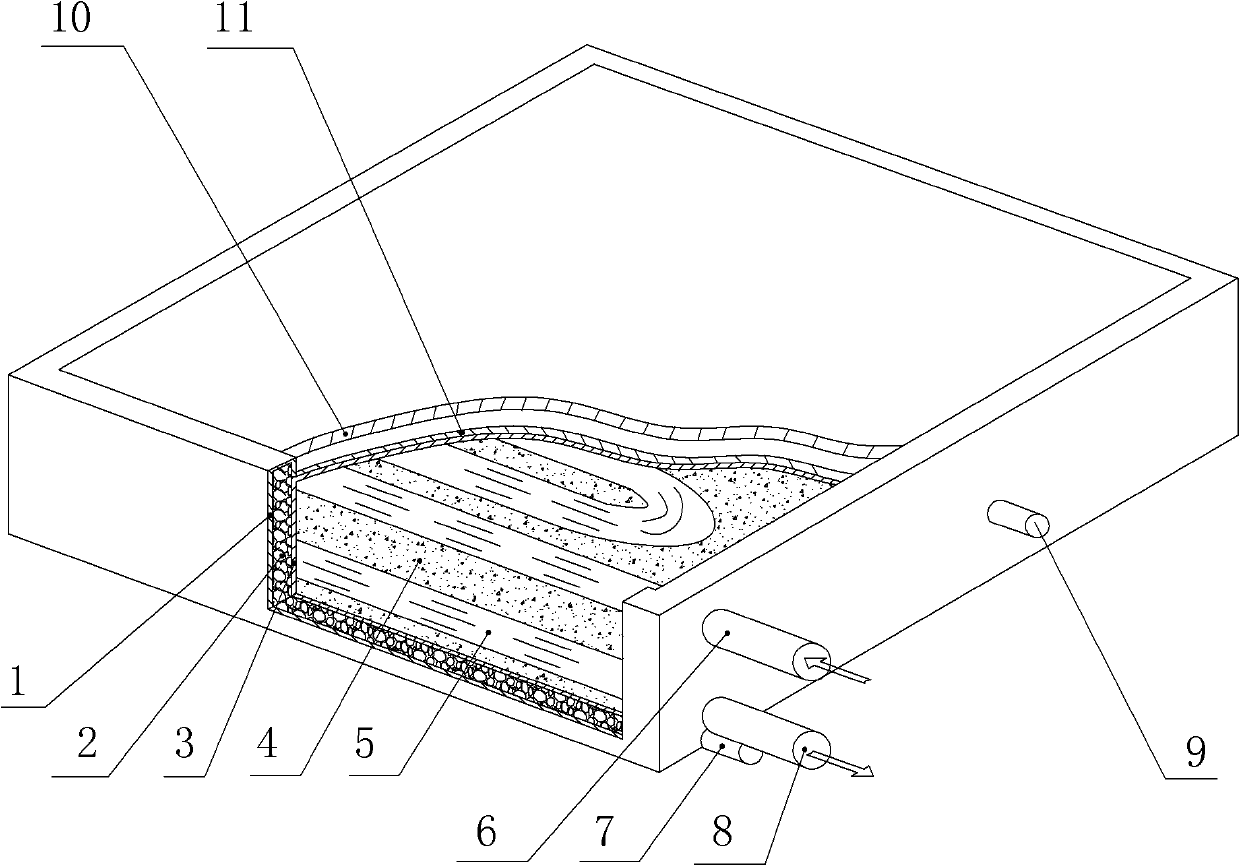

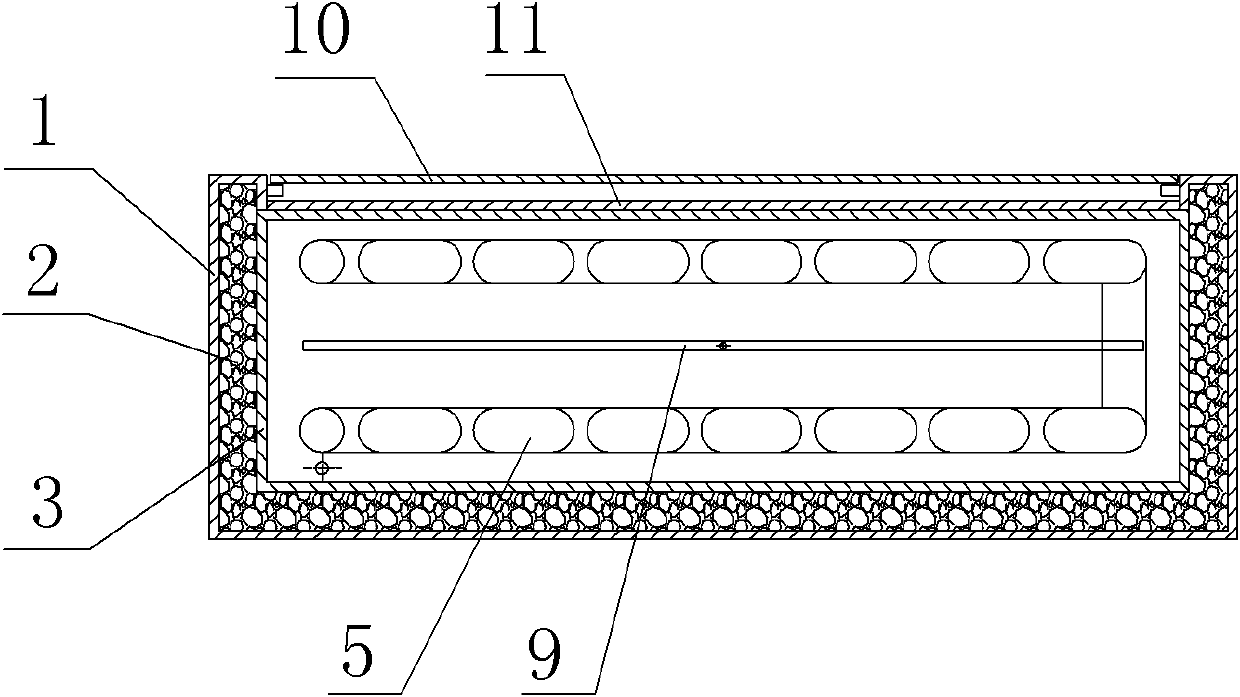

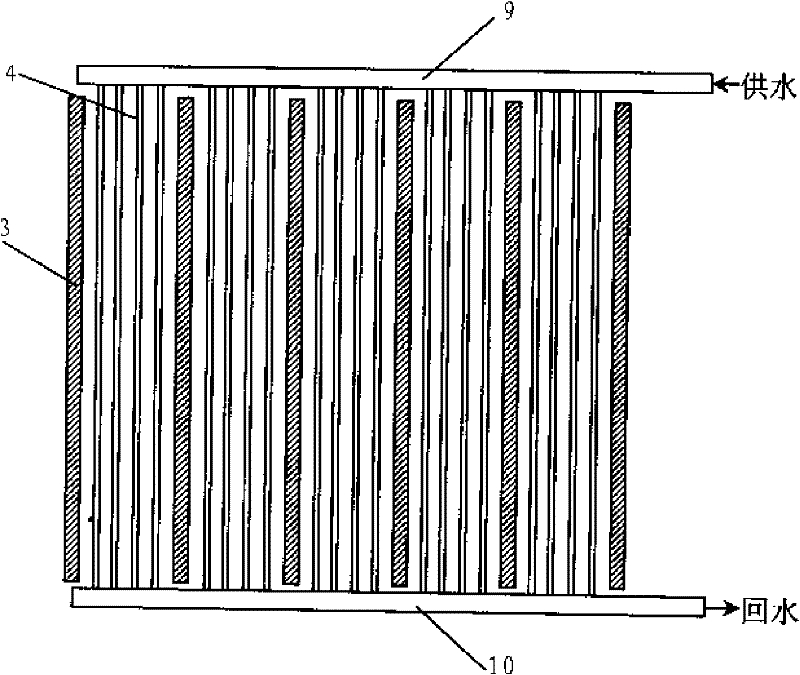

Tank-free flat type phase change heat storage solar heat utilization unit

InactiveCN102168892AReduce volumeLow costSolar heating energySolar heat devicesEngineeringHeat storage material

The utility model relates to a tank-free flat type phase change heat storage solar heat utilization unit, which is applied to the field of medium-low temperature solar heat utilization. The tank-free flat type phase change heat storage solar heat utilization unit is characterized by comprising a metal shell, a metal container, heat exchanging pipelines, a thermoelectric couple, an auxiliary heating plate, and a double-layer transparent vacuum cover plate; the metal container is arranged in the metal shell; a sealed insulating cavity is formed between the metal container and the metal shell; the heat exchanging pipelines are situated in the metal container, and are arranged into 2-10 layers; the thermoelectric couple and the auxiliary heating plate are arranged in the metal container; a phase change heat storage material is sealed in the metal container; the heat exchanging pipelines, the thermoelectric couple, and the auxiliary heating plate are all buried into the phase change heat storage material; a selective absorption coating is sprayed on the upper surface of the metal container; and the double-layer transparent vacuum cover plate is covered on the metal container. The tank-free flat type phase change heat storage solar heat utilization unit has the characteristics of convenient installation and connection, and higher heat storing / exchanging efficiency.

Owner:WUHAN UNIV OF TECH

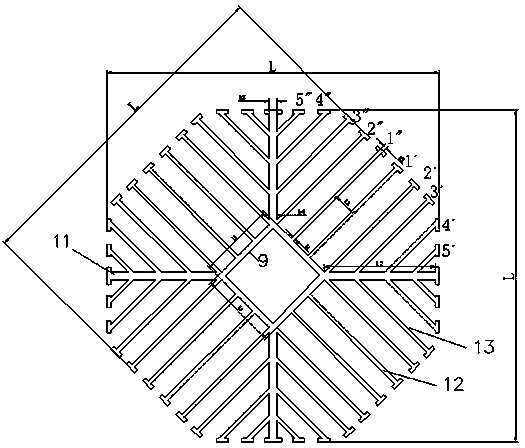

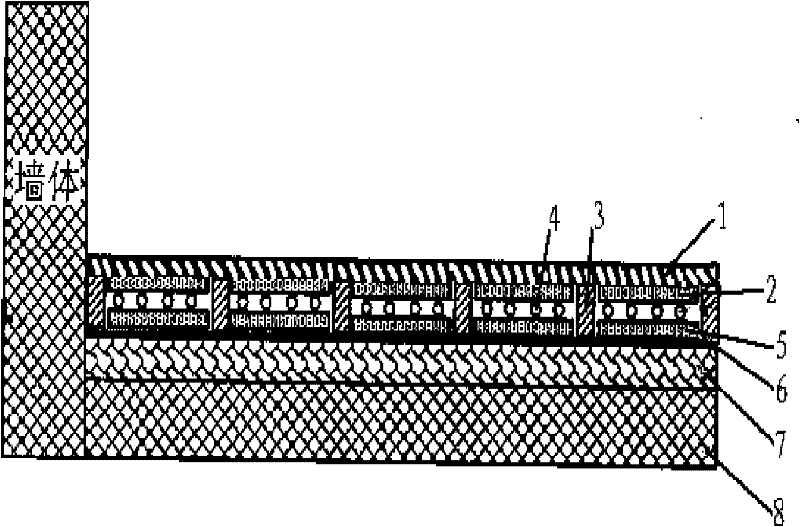

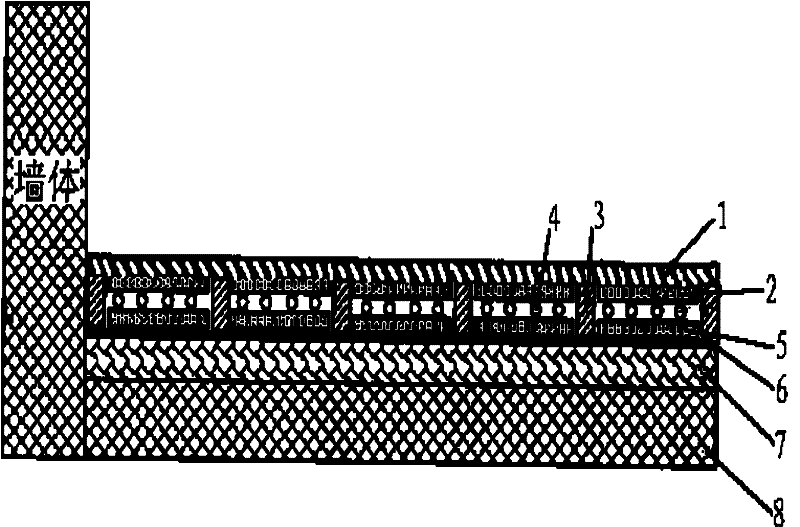

Indoor geothermal heating structure using capillary network and phase change heat storage material

InactiveCN102269443AImprove heat storage capacitySolve the problem of slow heatingLighting and heating apparatusEnergy efficient heating/coolingCapillary networkInsulation layer

The invention discloses an indoor geothermal heating structure utilizing a capillary network and a phase-change thermal storage material, which belongs to the technical field of solar building heating. The structure includes a floor decoration layer, an upper phase change material, a capillary grid, a lower phase change material, a reflection film, an insulation layer and a floor base layer from top to bottom. The floor decoration layer is supported by dragon frames laid on the insulation layer, the dragon frames pass through the tube gaps of capillary grids, and the phase change material layers are arranged between adjacent dragon frames. The hot water from the low-temperature heat source exchanges heat with the upper and lower phase-change materials in the capillary, and supplies heat to the room through the floor decoration layer; at night, the phase-change material solidifies and releases heat to supply heat to the room through the floor decoration layer. The indoor geothermal heating structure of this capillary network and phase change heat storage material has the characteristics of large heat exchange area, uniform temperature, fast start-up, less space occupation, more flexible layout, and convenient installation. The indoor temperature is uniform, and the indoor thermal comfort is good. Wide application prospects and promotion value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Heat-storage material composition

InactiveUS20070079825A1Less bleedingLess stickinessSolar heat devicesHeat-exchange elementsElastomerWax

The present invention relates to a heat storage material composition comprising 20 to 100% by weight of a heat storage material, 80 to 0% by weight of crystalline polyolefin (B) and 50 to 0% by weight of an elastomer (C), and the heat storage material described above contains a side chain-crystalline polymer (A), wherein the heat storage material described above comprises preferably a higher α-olefin polymer (a) containing 50 mole % or more of higher α-olefin having 10 or more carbon atoms and a petroleum wax (b) in which a melting point (Tm) is higher by 10° C. or more than that of the polymer (a). Provided is a heat storage material composition which has less bleeding and stickiness and is excellent in stability at high temperature and which can meet a change in temperature such as a difference in room temperature when applied to a material for floor heating and can avoid a heating state deviated to high temperature or low temperature.

Owner:IDEMITSU KOSAN CO LTD

Solar phase change heat storage heating and hot water supply system

InactiveCN103017239AAvoid wastingEfficient use ofCentral heating with accumulated heatLighting and heating apparatusThermodynamicsCollector device

The invention discloses a solar phase change heat storage heating and hot water supply system. The system mainly comprises a solar thermal collector (1), a supplementary heat source (2), a solar circulating pump (4), a phase change heat storage box (5), a plate-type heat exchanger (6), a heating circulating pump (9) and a heating end (10) which are connected through water pipes and are regulated through arranging a valve, wherein the solar thermal collector is connected with the supplementary heat source in series or in parallel; phase change materials within 0-100 DEG C are adopted by the phase change heat storage box according to requirements; when the system is just started, the solar thermal collector directly exchanges heat with heating return water through the plate-type heat exchanger; when residual heat exists, the residual heat is firstly stored in the phase change heat storage box; and when solar radiation is not enough, the residual heat exchanges heat with the heating return water. With the adoption of the solar phase change heat storage heating and hot water supply system, a manner of combining various pipelines and various valves of the solar thermal collector, and the characteristics of large heat storing amount of the phase change heat storage material and stable heat storage temperature are utilized, so that the defect that the solar radiation is not stable is solved, the supplementary heat source starting time is shortened, the energy is saved, and the environment is protected.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com