Patents

Literature

860 results about "Amorphous phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

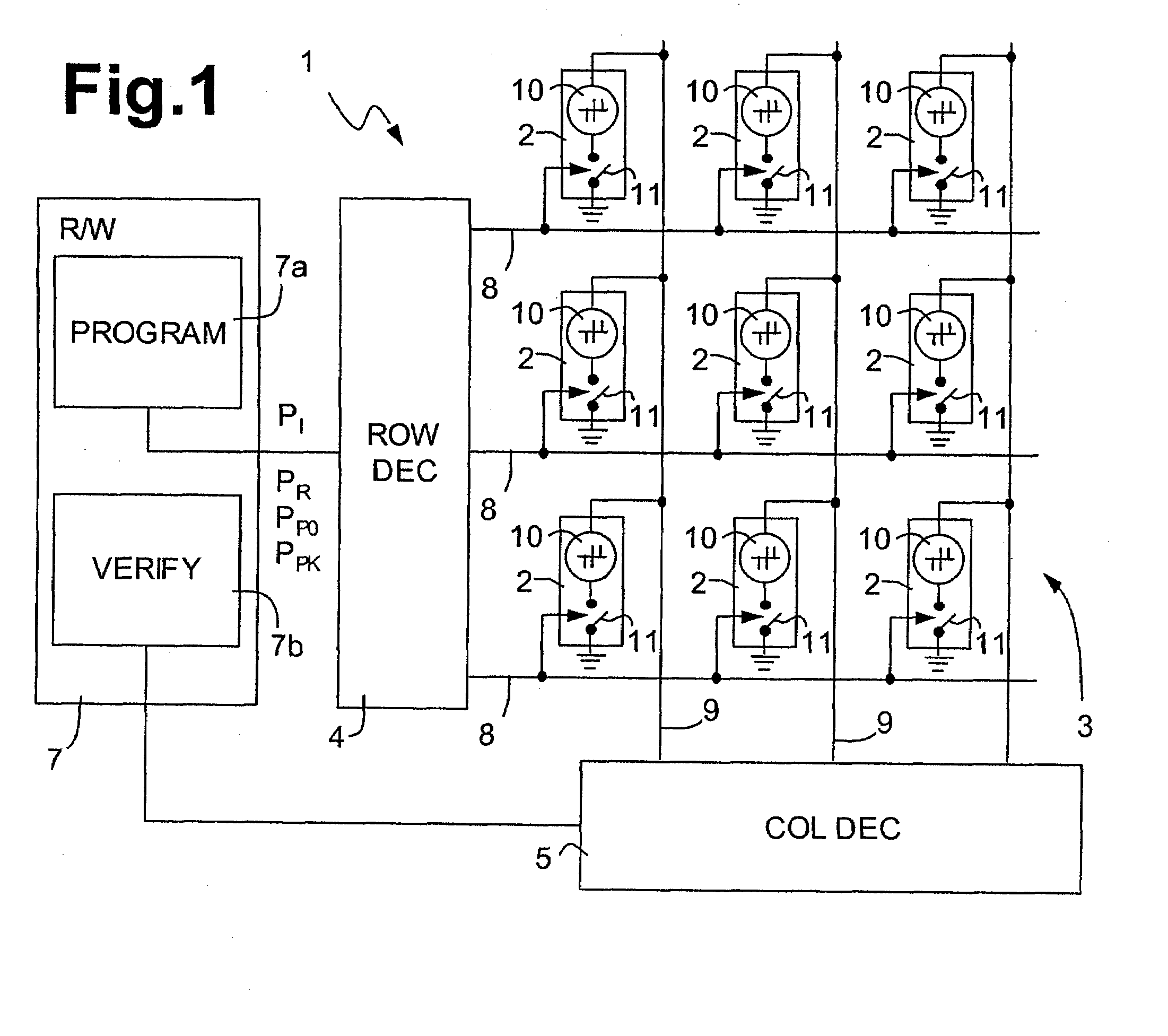

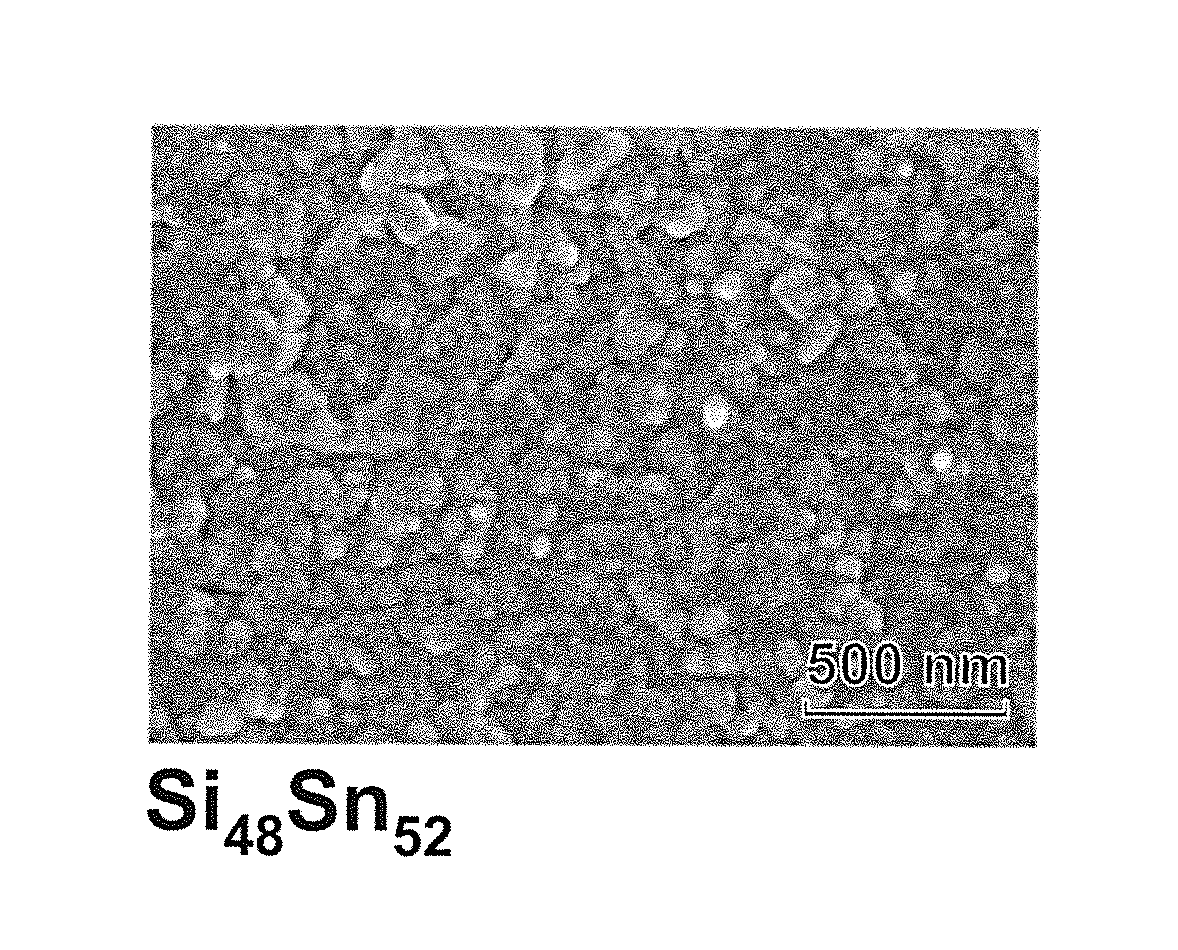

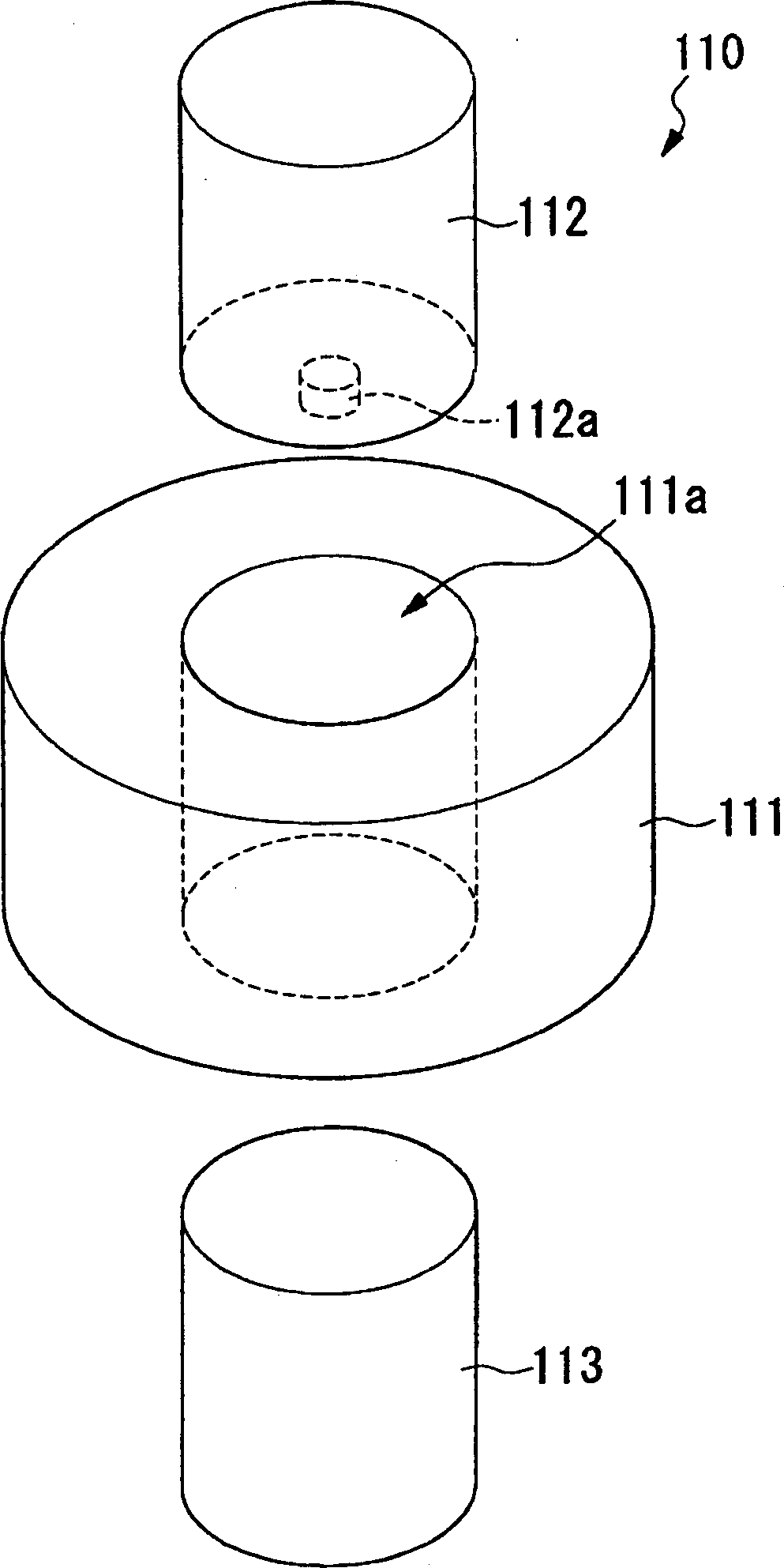

Phase Change Memory, Phase Change Memory Assembly, Phase Change Memory Cell, 2D Phase Change Memory Cell Array, 3D Phase Change Memory Cell Array and Electronic Component

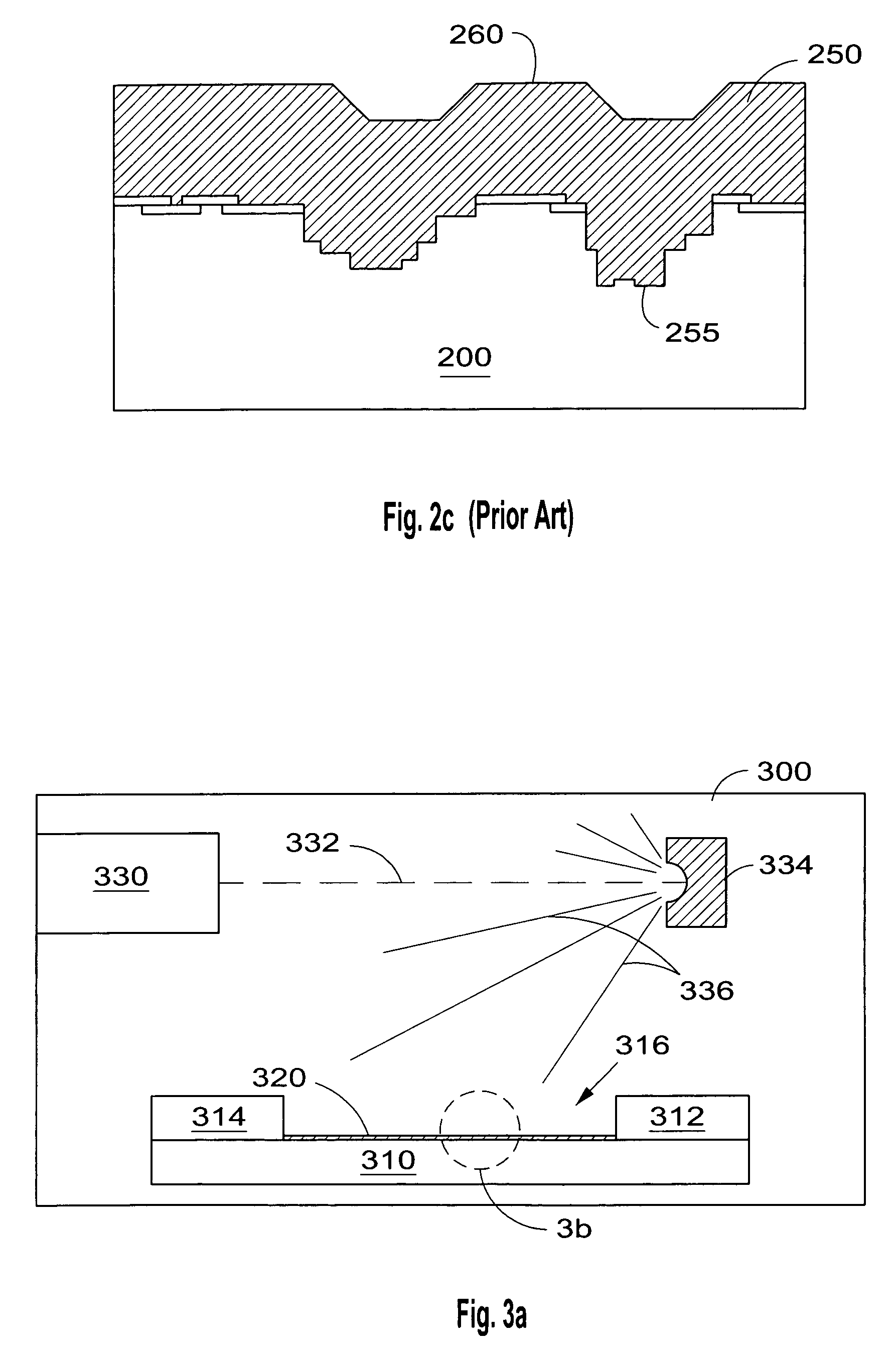

ActiveUS20080101109A1Simple structural designSolid-state devicesDigital storageElectrical resistance and conductancePhase-change memory

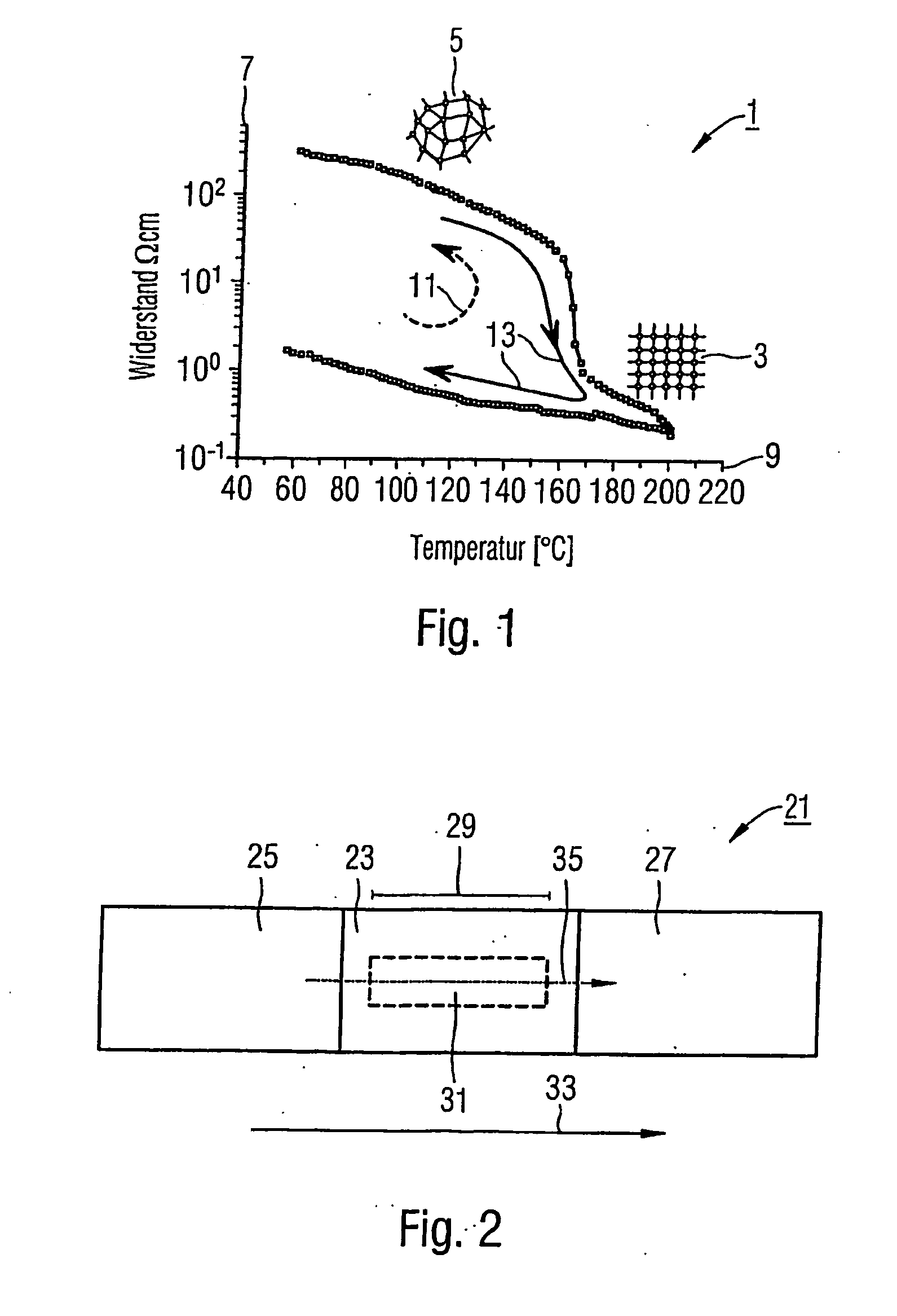

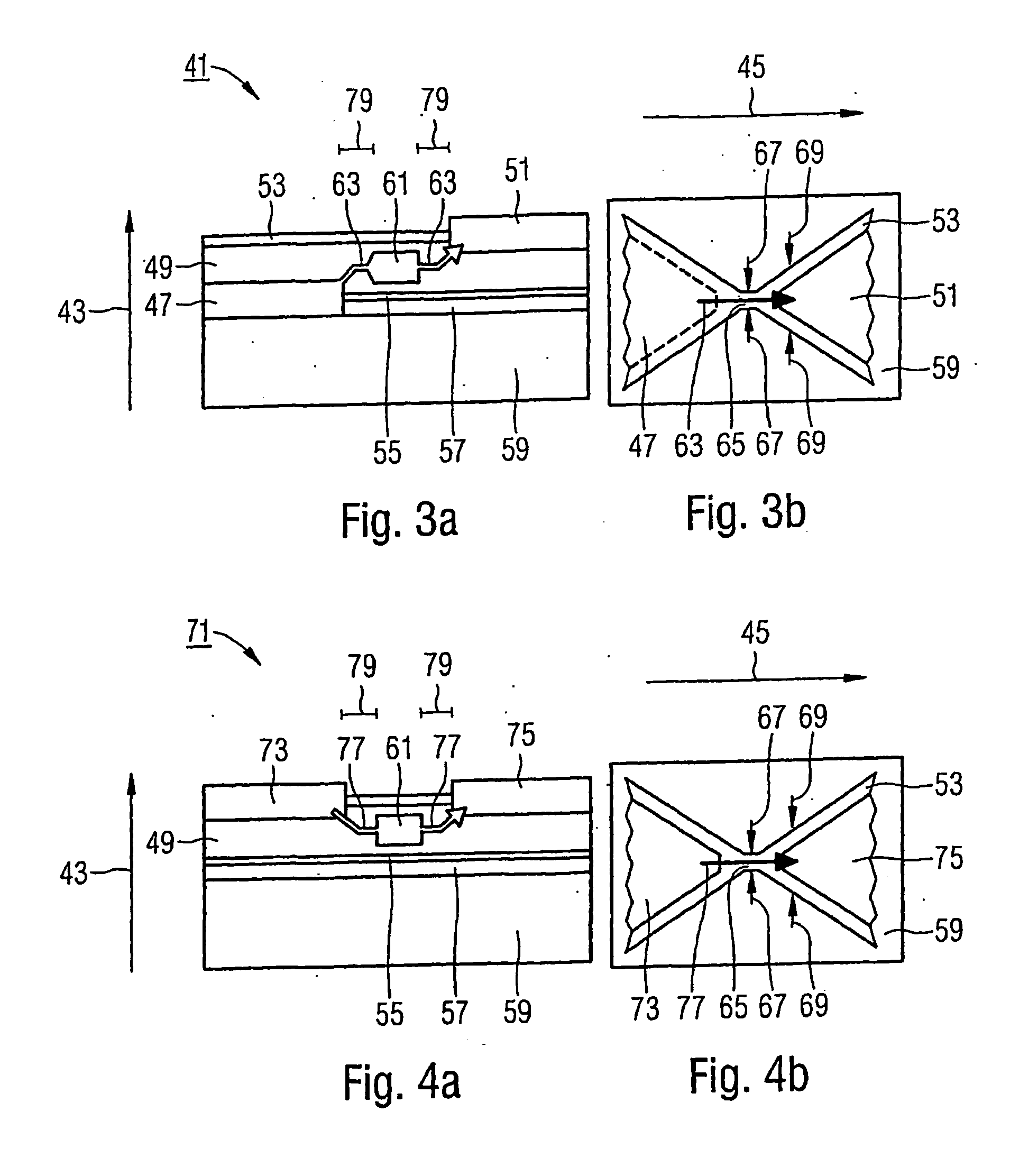

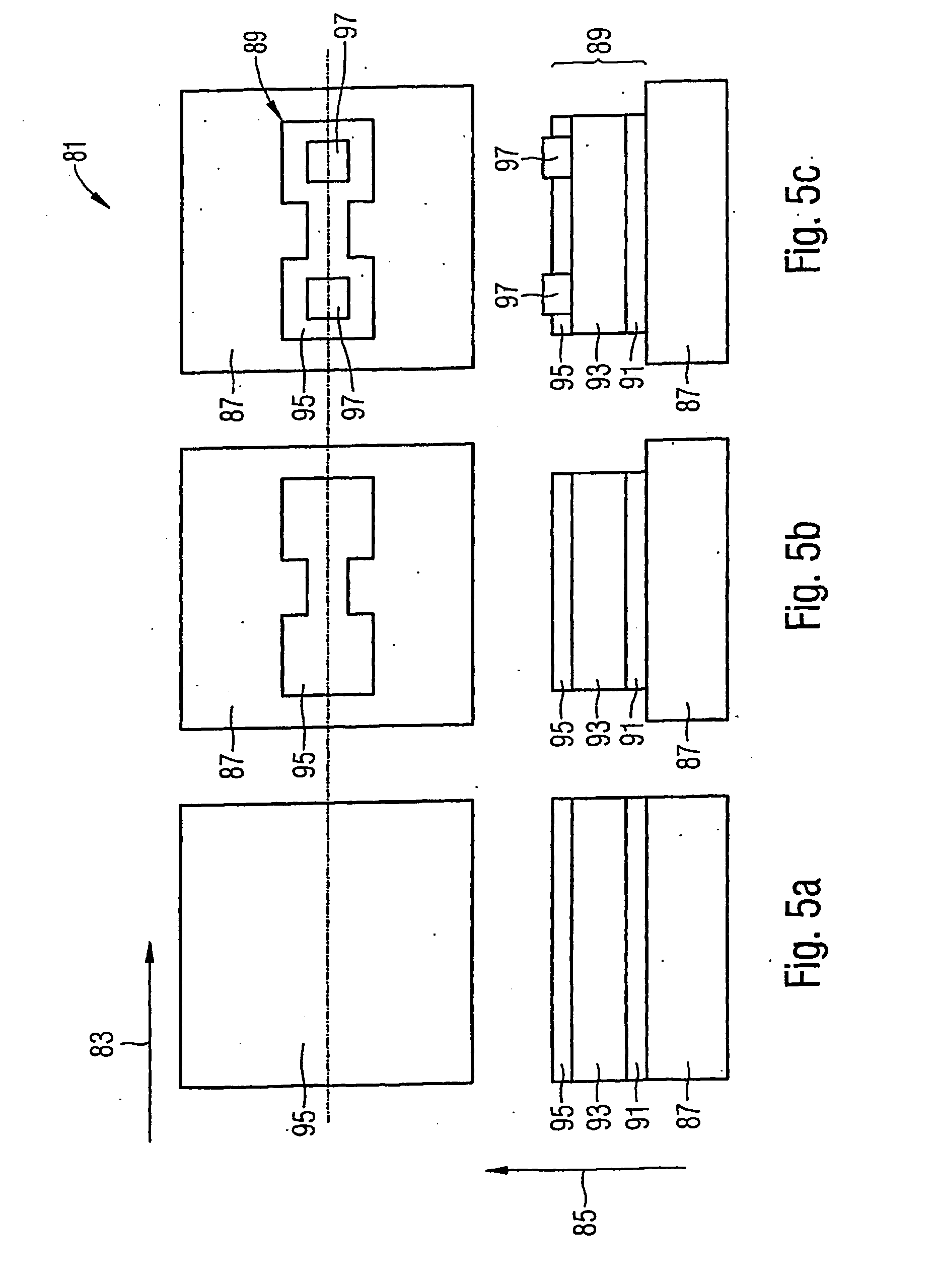

A phase change memory having a memory material layer consisting of a phase change material, and a first and second electrical contact which are located at a distance from one another and via which a switching zone of the memory material layer can be traversed by a current signal, wherein the current signal can be used to induce a reversible phase change between a crystalline phase and an amorphous phase and thus a change in resistance of the phase change material in the switching zone. The invention also relates to a phase change memory assembly, a phase change memory cell, a 2D phase change memory cell array, a 3D phase change memory cell array and an electronic component.

Owner:RWTH AACHEN UNIVERSITY +1

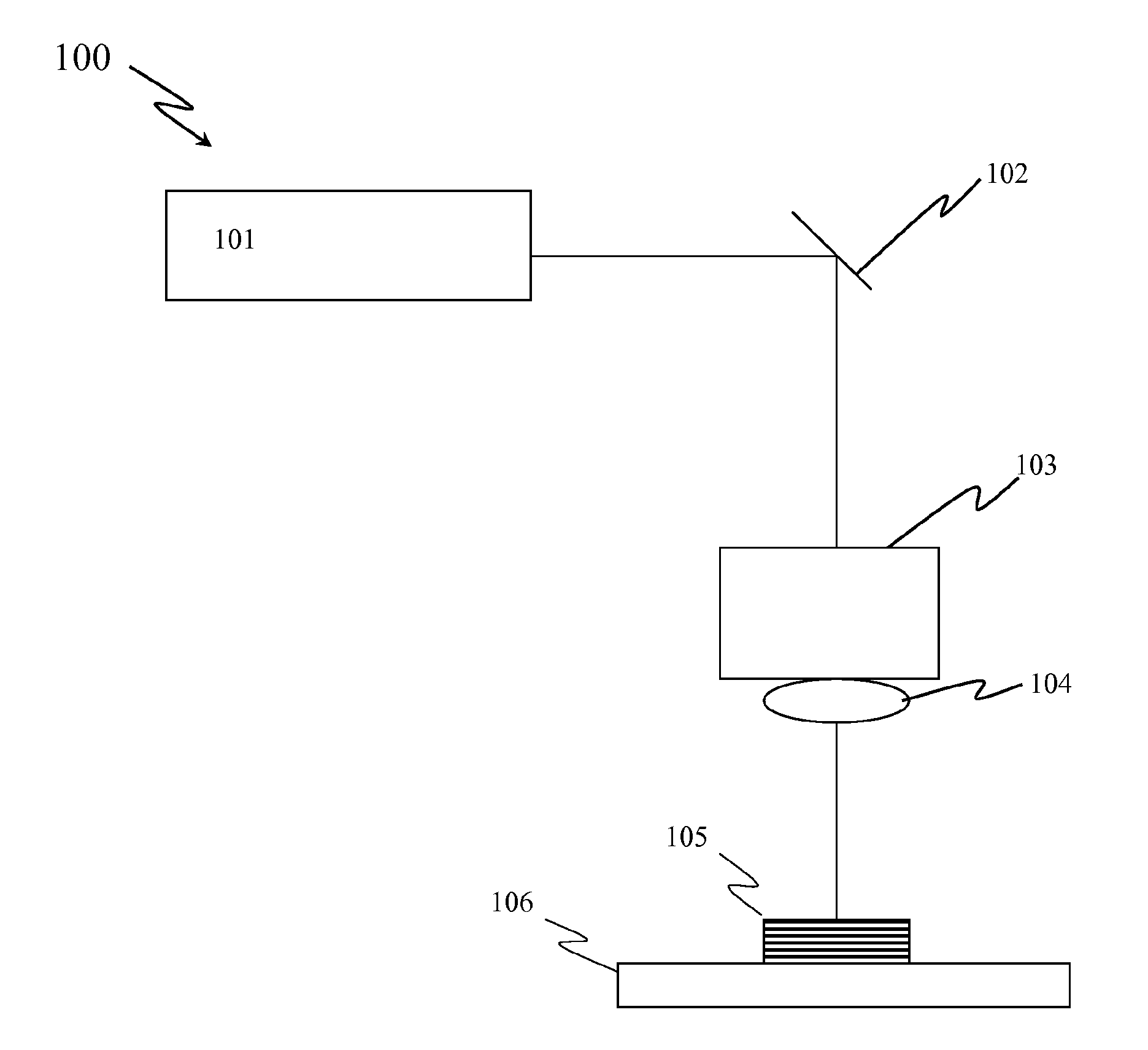

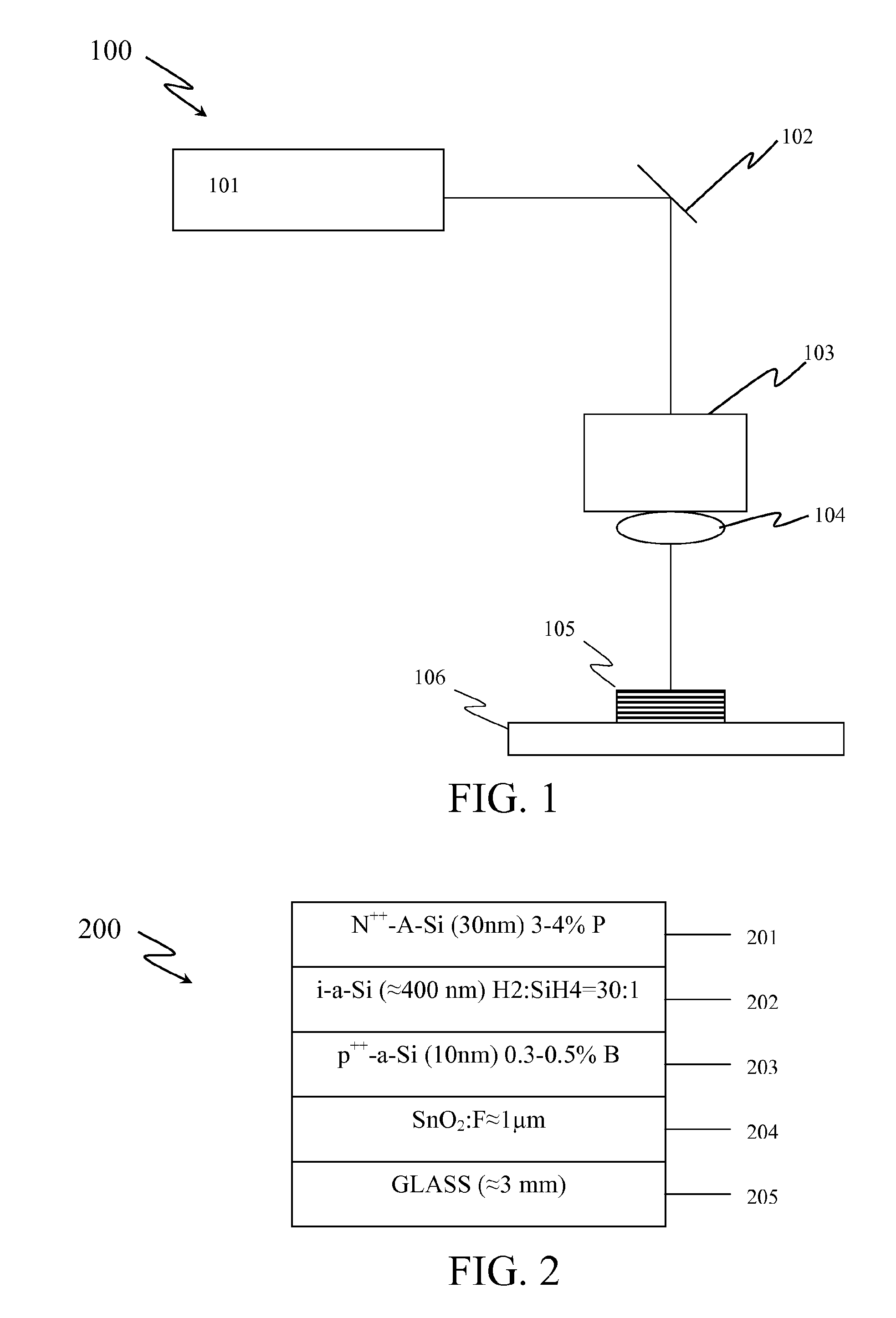

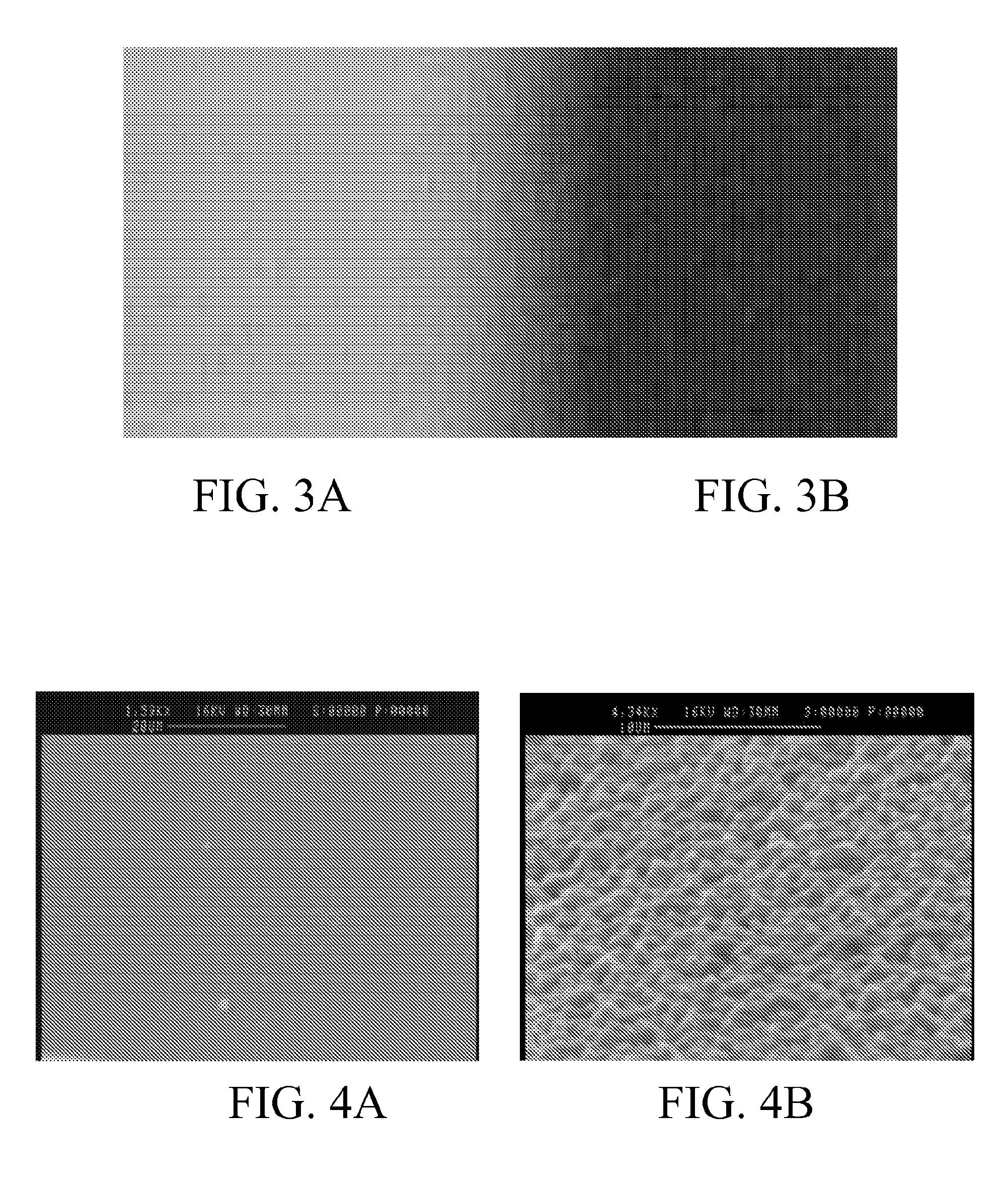

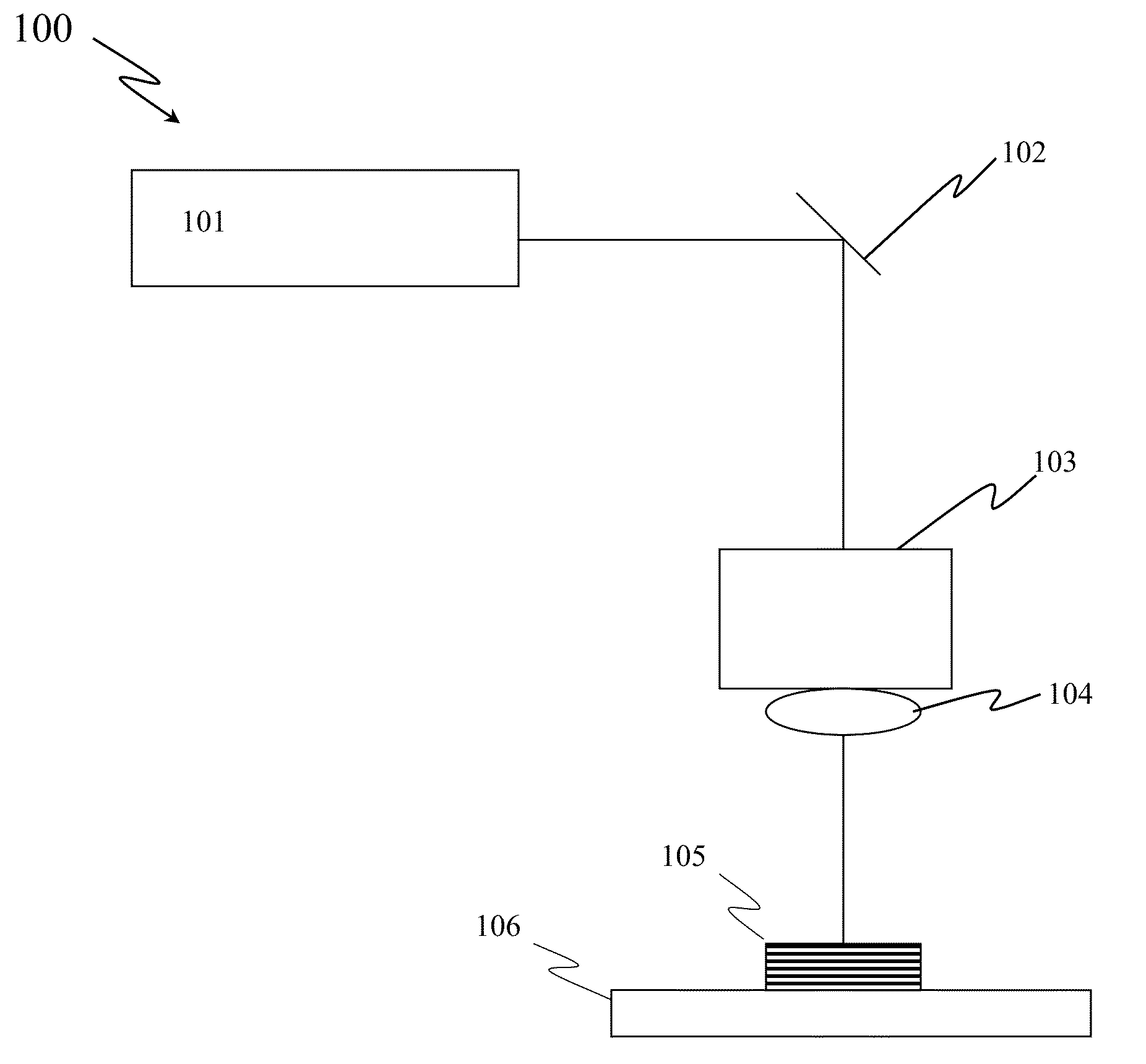

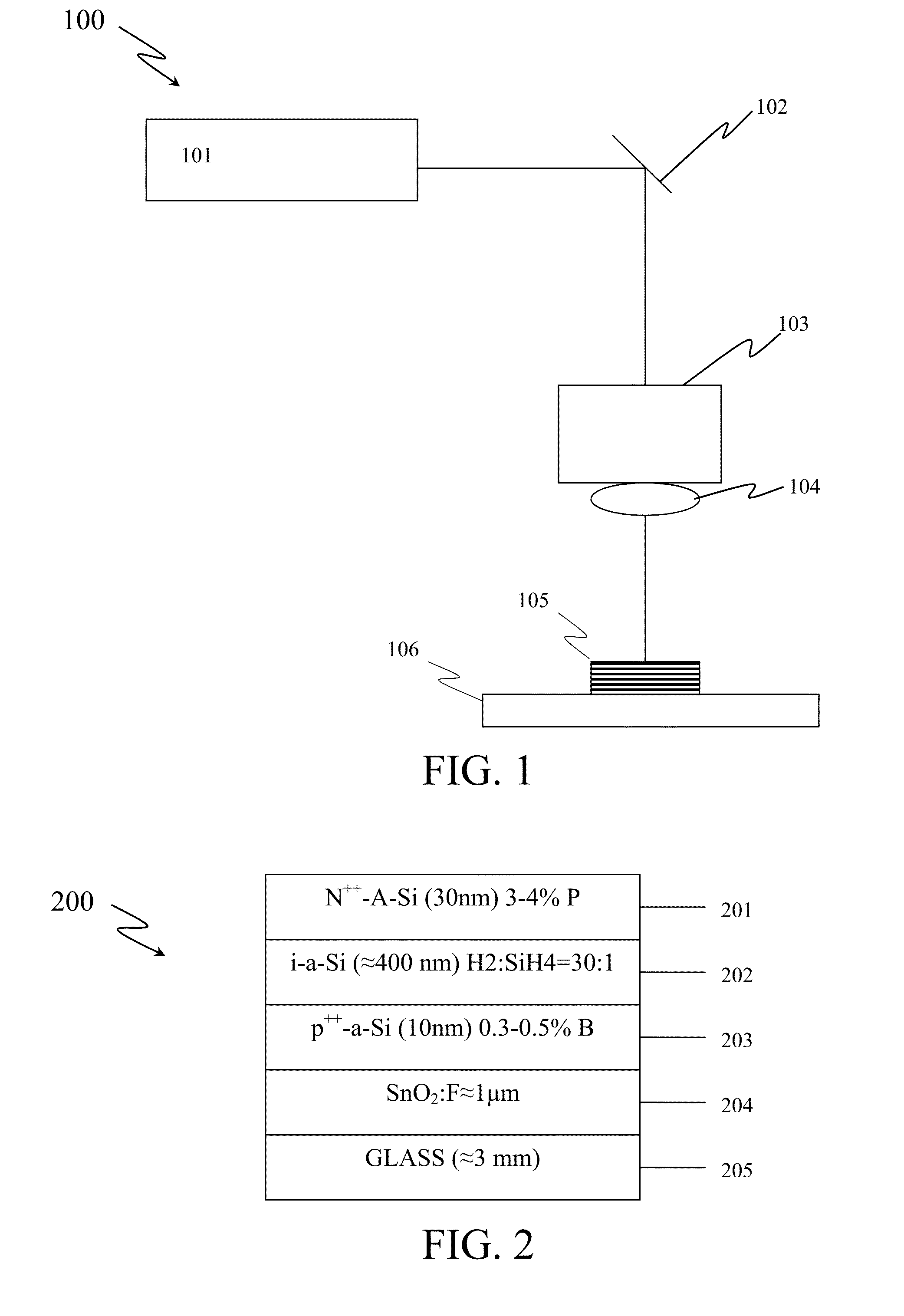

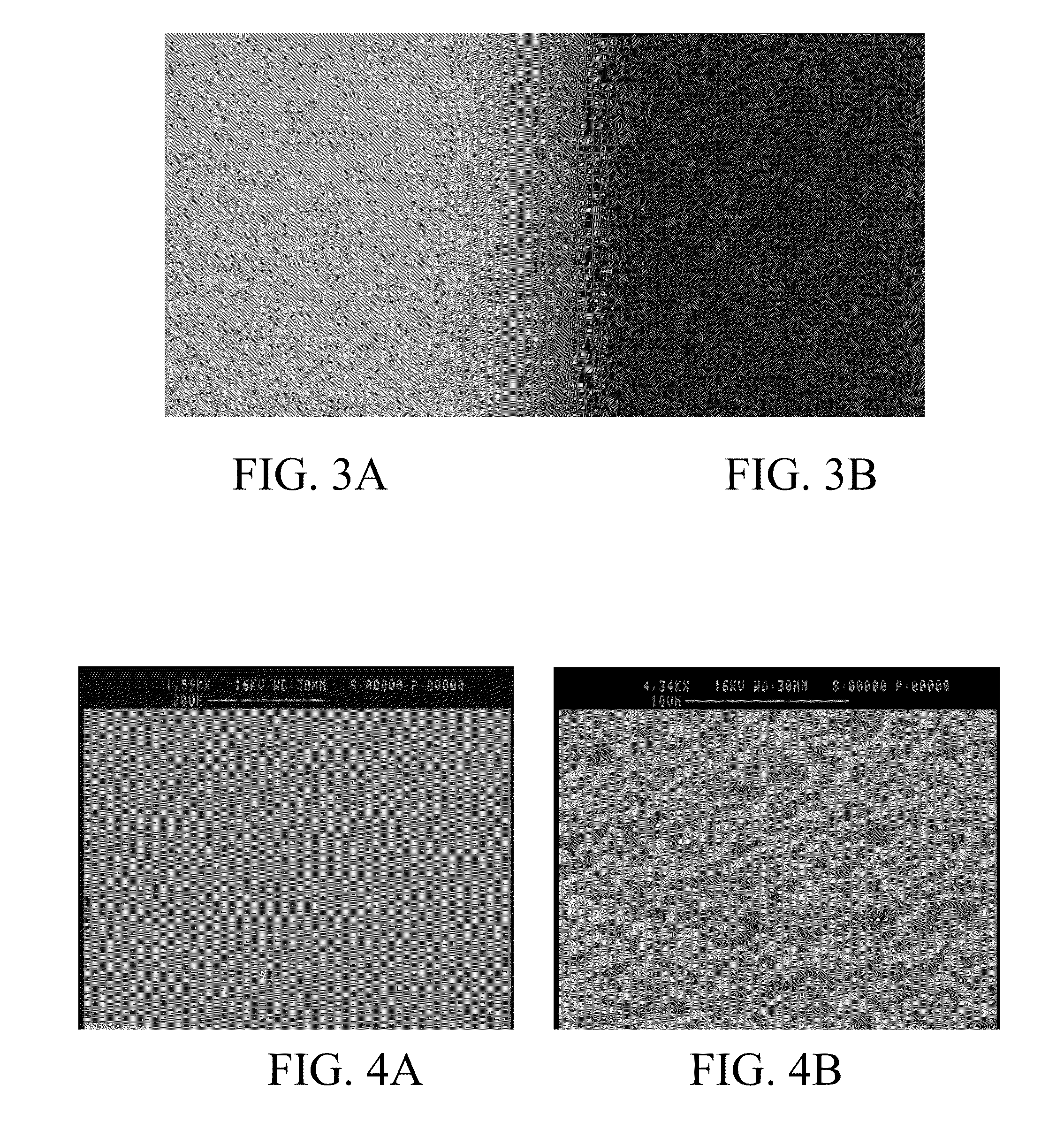

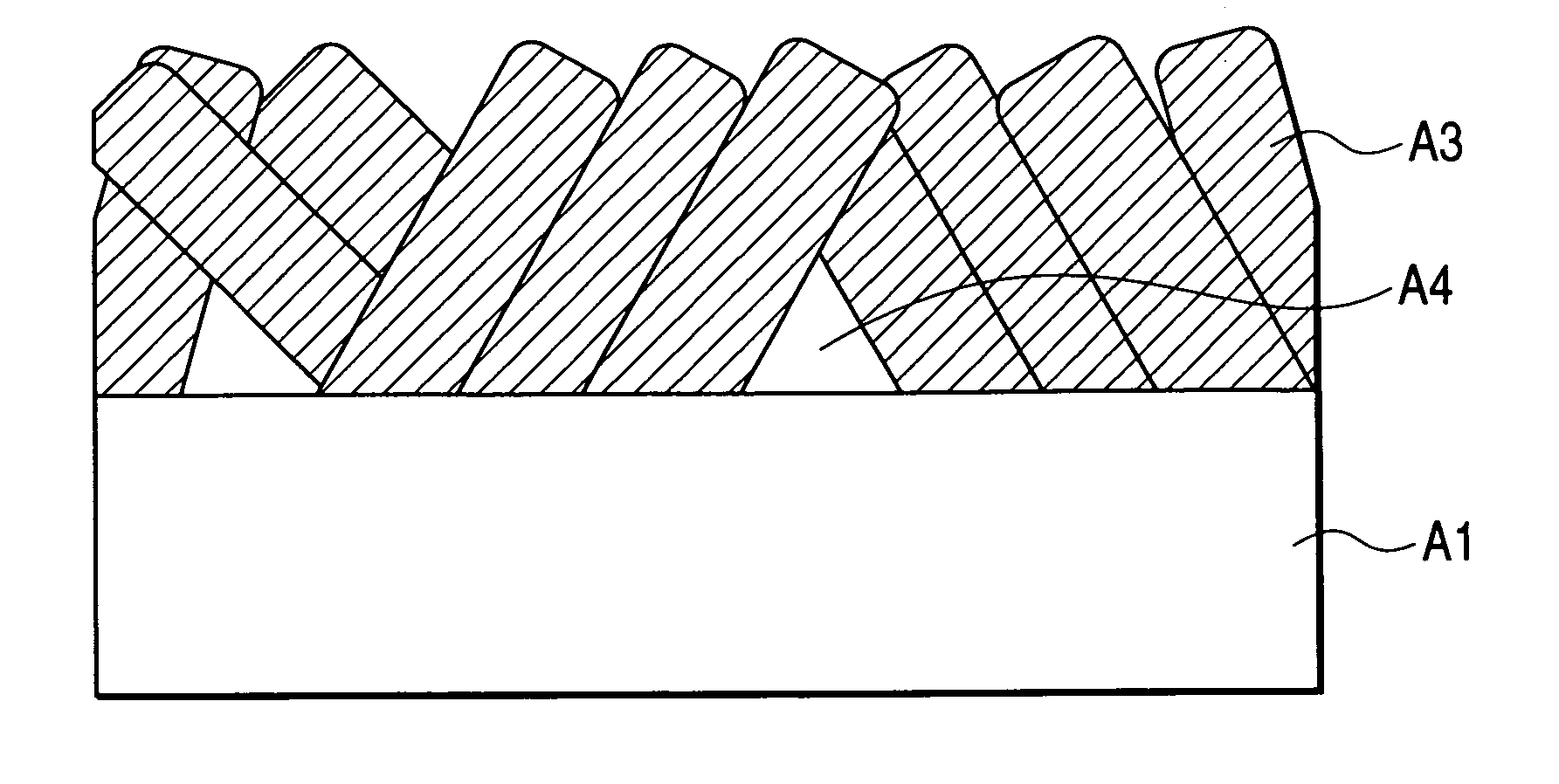

Systems and Methods of Laser Texturing of Material Surfaces and their Applications

InactiveUS20100143744A1Enhance light absorptionImprove conductivityDecorative surface effectsSemiconductor/solid-state device manufacturingAlloyElectron

The surface of a material is textured and by exposing the surface to pulses from an ultrafast laser. The laser treatment causes pillars to form on the treated surface. These pillars provide for greater light absorption. Texturing and crystallization can be carried out as a single step process. The crystallization of the material provides for higher electric conductivity and changes in optical and electronic properties of the material. The method may be performed in vacuum or a gaseous environment. The gaseous environment may aid in texturing and / or modifying physical and chemical properties of the surfaces. This method may be used on various material surfaces, such as semiconductors, metals and their alloys, ceramics, polymers, glasses, composites, as well as crystalline, nanocrystalline, polycrystalline, microcrystalline, and amorphous phases.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Amorphous soft magnetic alloy powder, and dust core and wave absorber using the same

ActiveUS20050236071A1Inorganic material magnetismInductances/transformers/magnets manufactureHigh concentrationAmorphous phase

An amorphous soft magnetic alloy powder which is produced by a water atomization method is provided. The powder contains an amorphous phase having a temperature interval ΔTx of a supercooled liquid of 20K or more; having a hardness Hv of 1000 or less; is provided with a layer with a high concentration of Si at a surface portion thereof; and being represented by the following composition formula: Fe100-a-b-x-y-z-w-tCOaNibMxPyCzBwSit And M is one or two or more elements selected from Cr, Mo, W, V, Nb, Ta, Ti, Zr, Hf, Pt, Pd, and Au.

Owner:ALPS ALPINE CO LTD

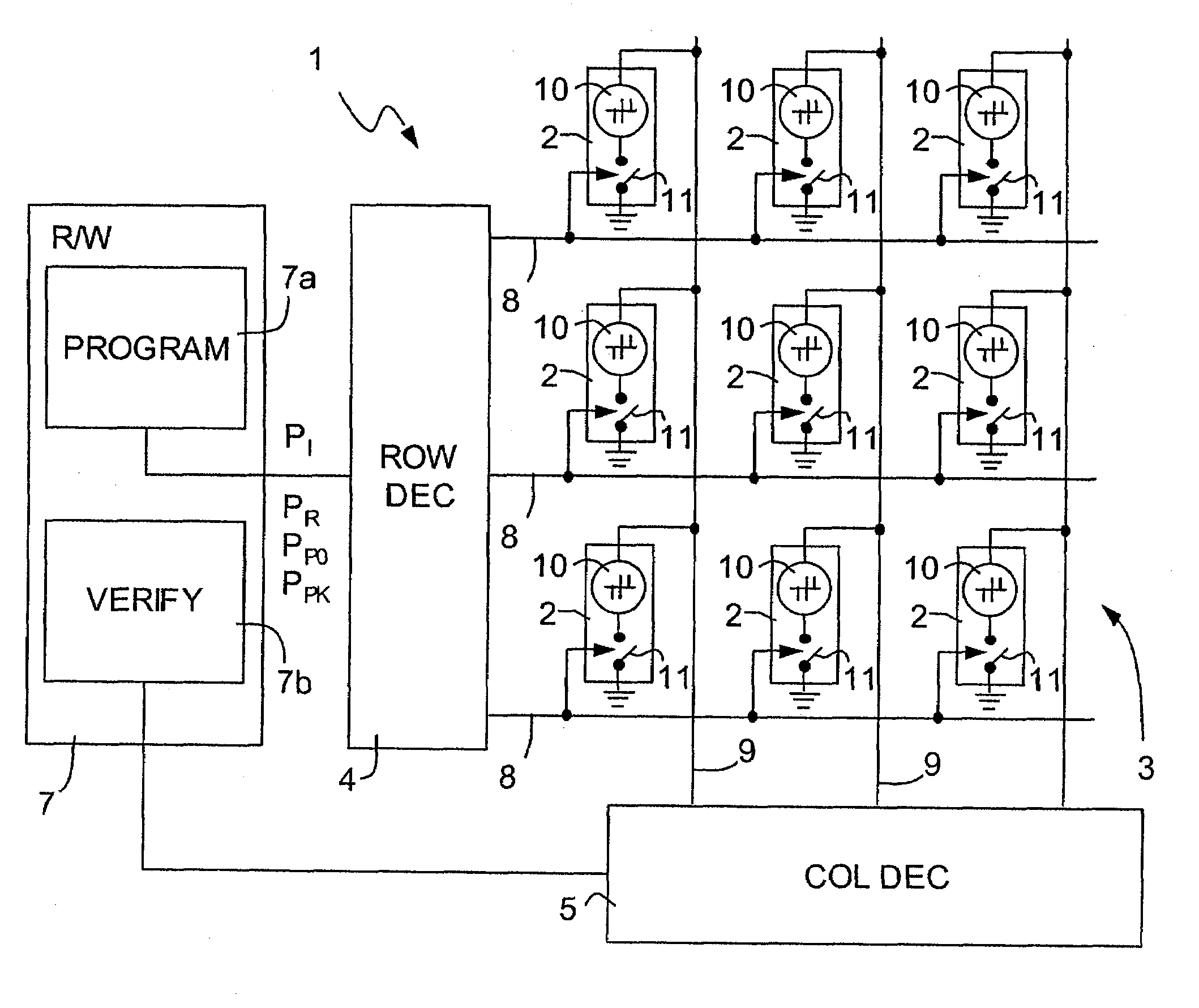

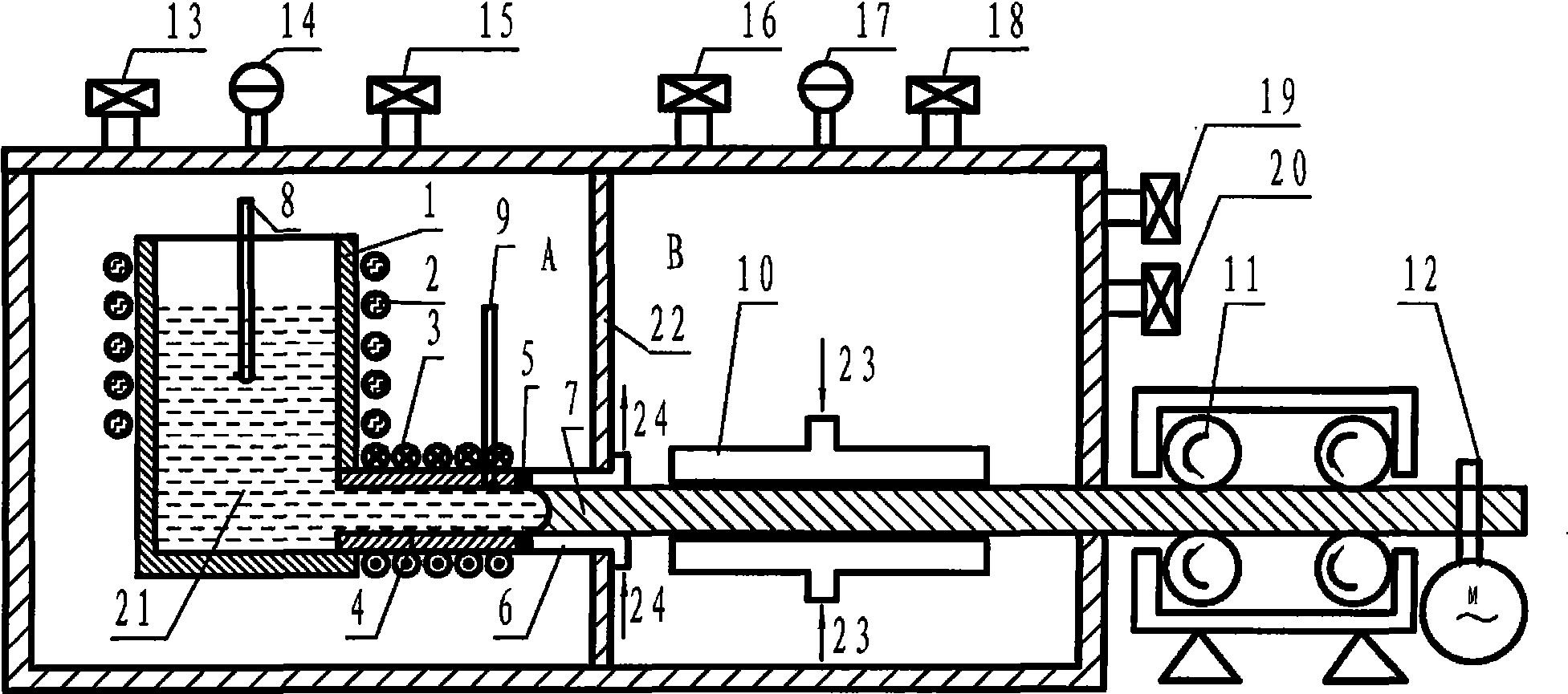

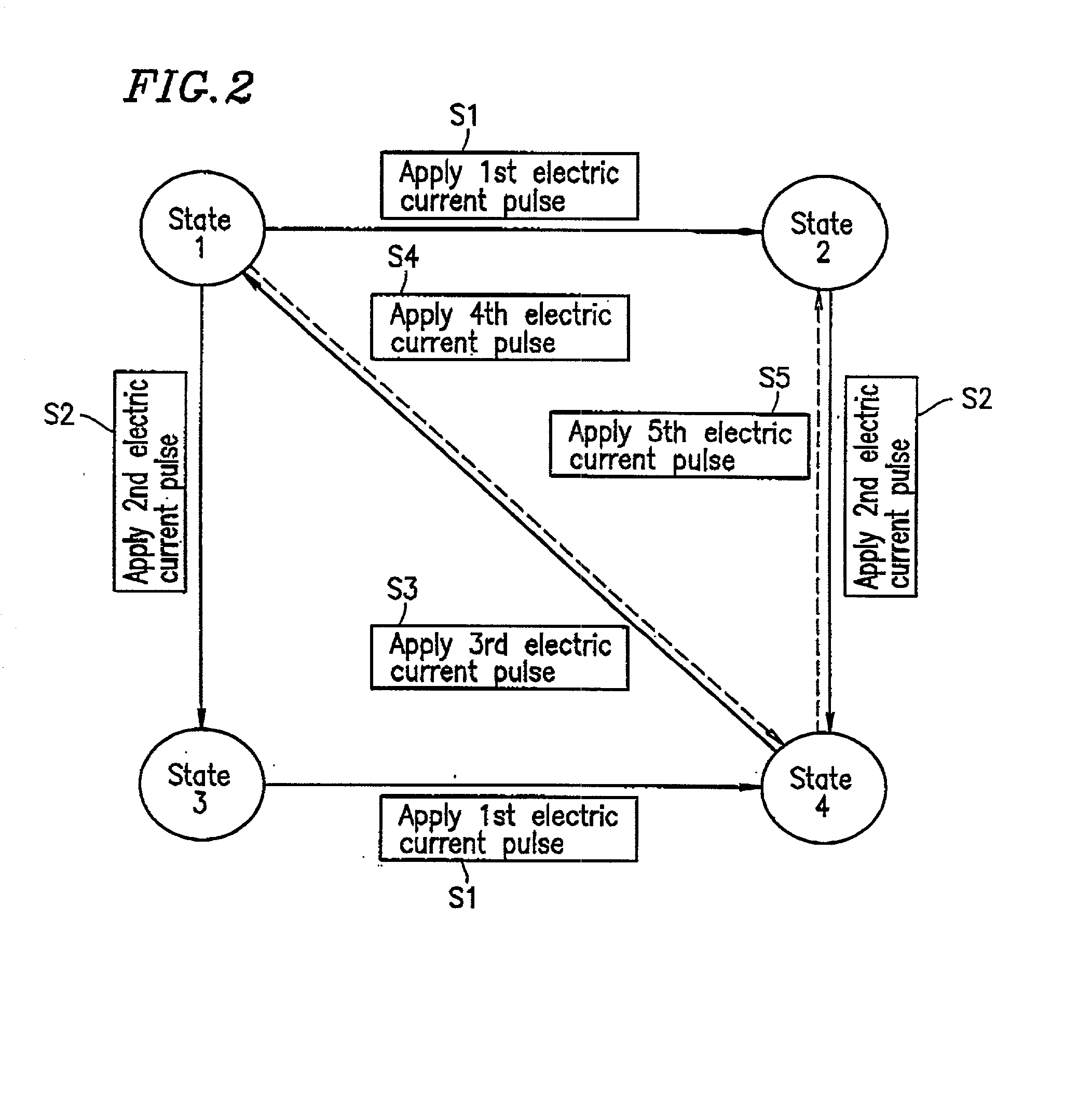

Method for multilevel programming of phase change memory cells using a percolation algorithm

ActiveUS20080151612A1Increase resistanceReduce resistanceElectric analogue storesRead-only memoriesPhase-change memoryAmorphous phase

A method and apparatus for programming a phase change memory cell is disclosed. A phase change memory cell includes a memory element of a phase change material having a first state, in which the phase change material is crystalline and has a minimum resistance level, a second state in which the phase change material is amorphous and has a maximum resistance level, and a plurality of intermediate states with resistance levels there between. The method includes using programming pulses to program the phase change memory cell in either the set, reset, or one of the intermediate states. To program in the intermediate states, a programming pulse creates a crystalline percolation path having an average diameter through amorphous phase change material and a second programming pulse modifies the diameter of the crystalline percolation path to program the phase change memory cell to the proper current level.

Owner:MICRON TECH INC

Methods of forming hafnium-containing materials, methods of forming hafnium oxide, and constructions comprising hafnium oxide

The invention includes methods of forming hafnium-containing materials, such as, for example, hafnium oxide. In one aspect, a semiconductor substrate is provided, and first reaction conditions are utilized to form hafnium-containing seed material in a desired crystalline phase and orientation over the substrate. Subsequently, second reaction conditions are utilized to grow second hafnium-containing material over the seed material. The second hafnium-containing material is in a crystalline phase and / or orientation different from the crystalline phase and orientation of the hafnium-containing seed material. The second hafnium-containing material can be, for example, in an amorphous phase. The seed material is then utilized to induce a desired crystalline phase and orientation in the second hafnium-containing material. The invention also includes capacitor constructions utilizing hafnium-containing materials, and circuit assemblies comprising the capacitor constructions.

Owner:MICRON TECH INC

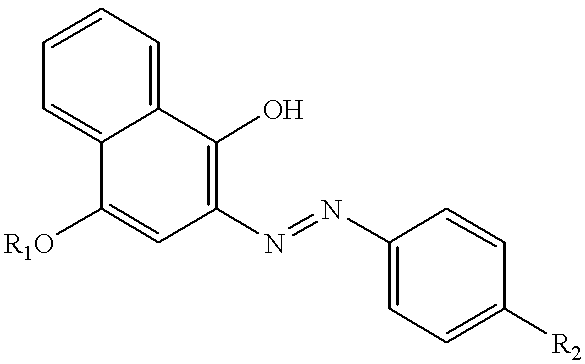

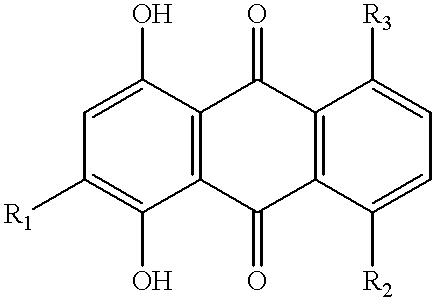

Thermal transfer recording system

InactiveUS6537410B2Improve performanceReduce volatilityInk ribbonsDecorative surface effectsAmorphous phaseCrystallization

There is described a thermal recording system which utilizes a donor element comprising a substrate and a thermal transfer material layer having a dye-containing phase which is amorphous and wherein the dye or dyes present in the amorphous phase form a continuous film. Imagewise heating of the medium transfers portions of the transfer layer to a receiver sheet, thus forming an image. The transfer layer may also include a non-dye phase comprising a thermal solvent. During the heating of the donor element, the crystalline thermal solvent melts and dissolves or liquefies at least a portion of the dye-containing phase, thereby lowering the temperature at which transfer of the transfer layer occurs.

Owner:INTELLECTUAL VENTURES I LLC

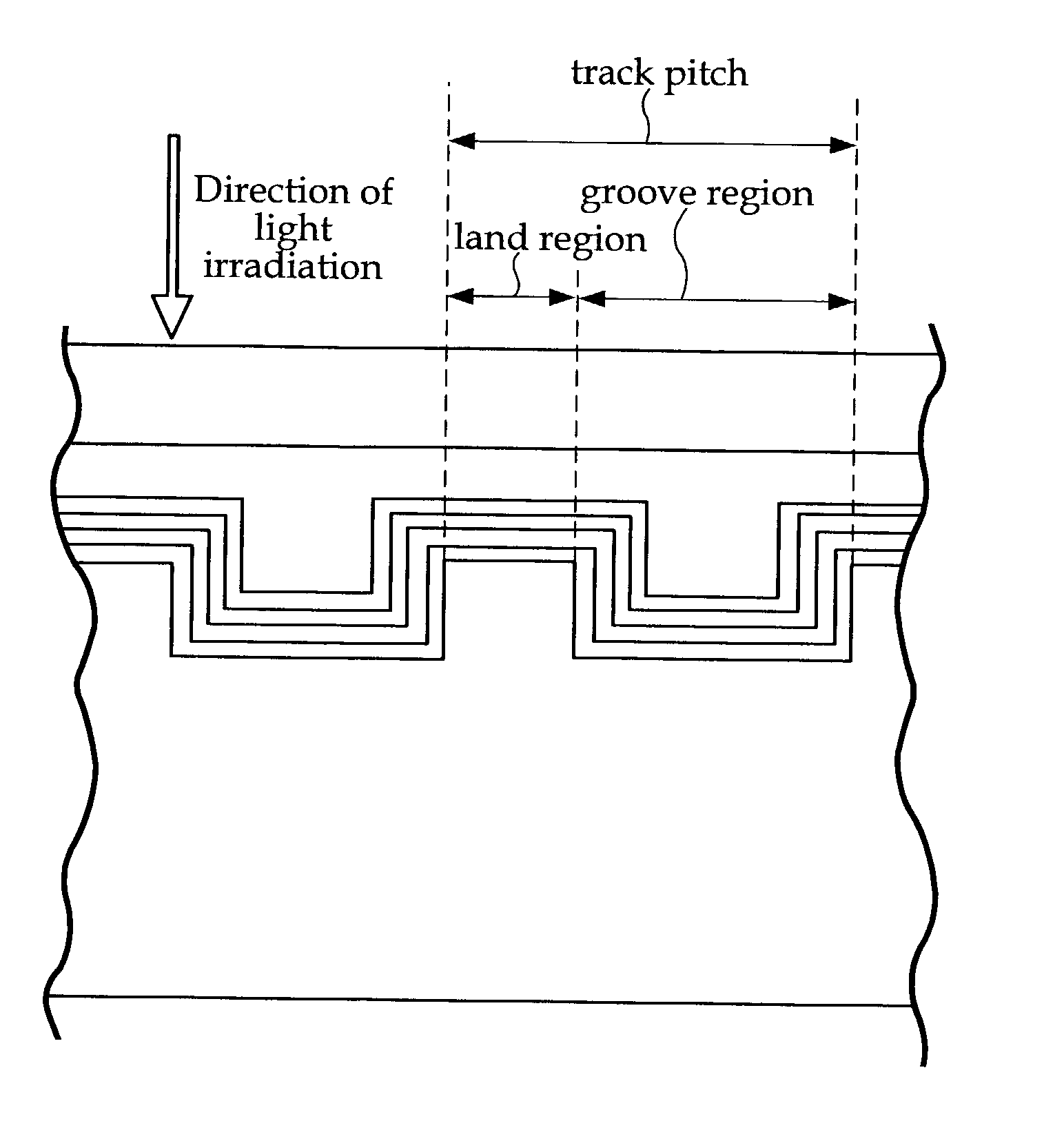

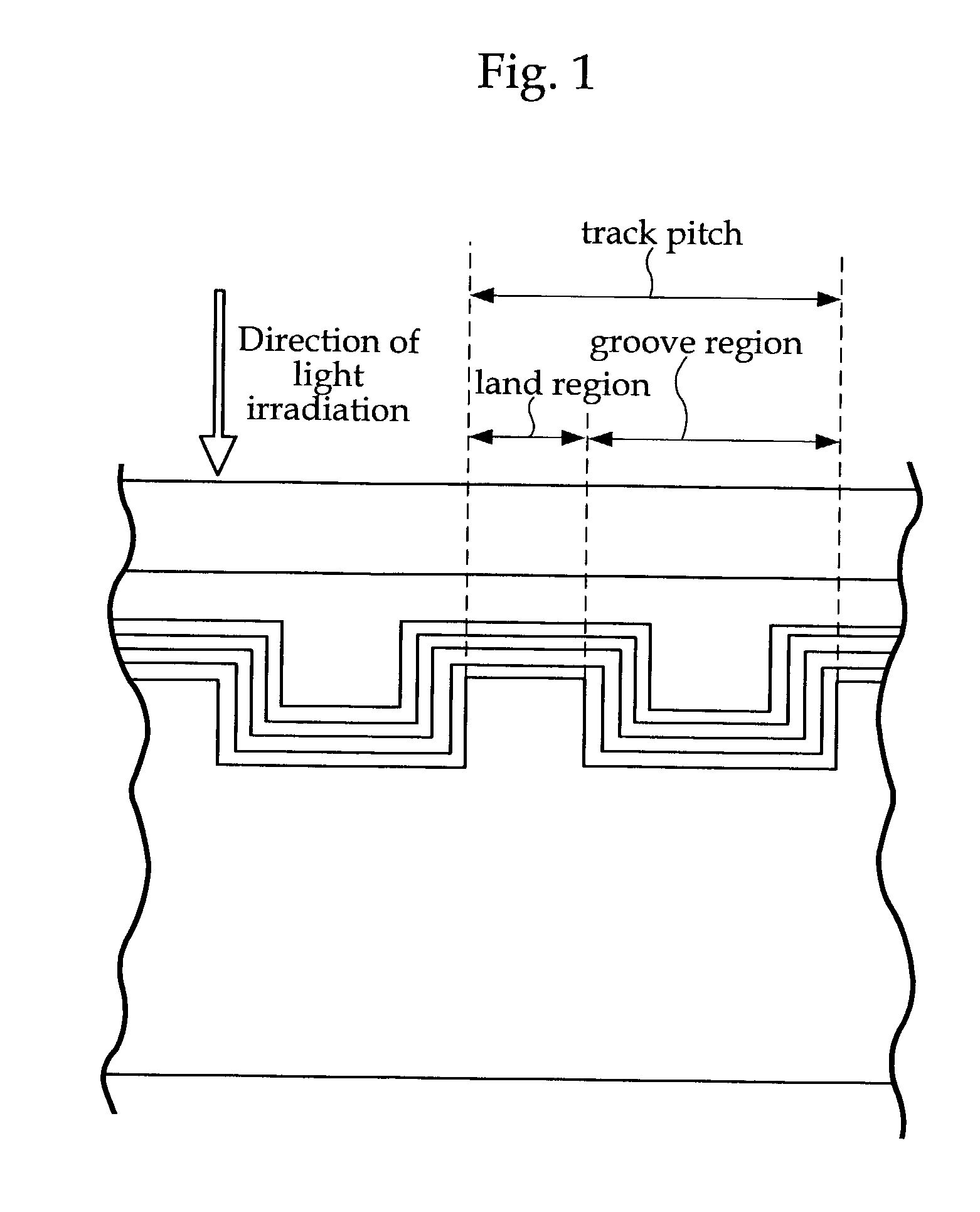

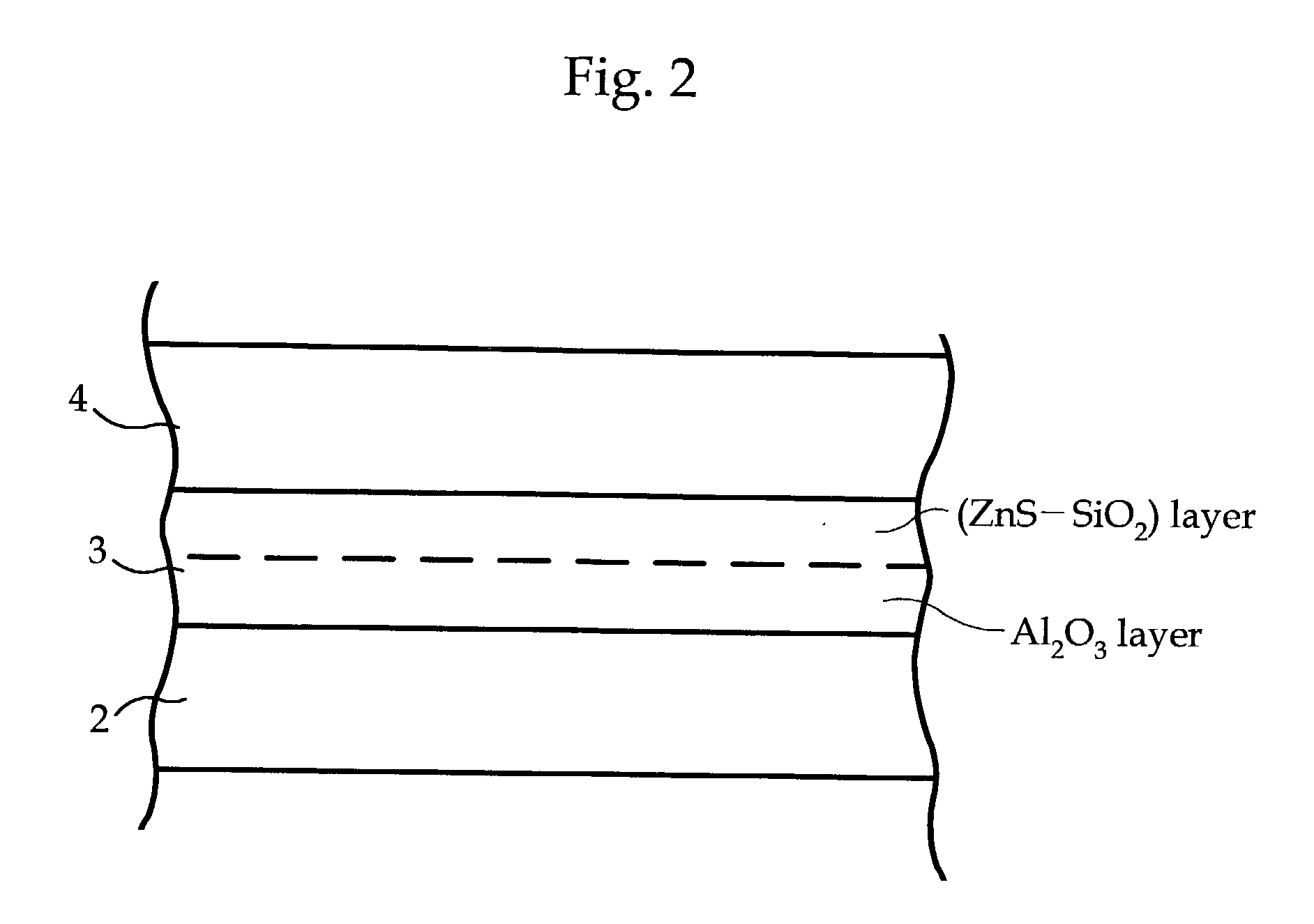

Information recording medium

InactiveUS20030081537A1Shorten speedHigh densityRadiation applicationsLayered productsLight irradiationLight reflection

An optical recording medium configured with a light reflection layer; a first protection layer; a recording layer containing a phase-change material which changes between crystalline and amorphous phases by a light irradiation; a second protection layer; and one of a cover layer and a protective coating layer disposed on a substrate in this order; and in which the light reflection layer is formed of one of an Al alloy and an Ag alloy; the first protection layer has a ZnS-SiO2 mixture layer which contains a mixture of ZnS and SiO2, and a intermediate layer having higher thermal conductivity than the ZnS-SiO2 mixture layer; the intermediate layer is formed on the side of the light reflection layer; the recording layer comprises Ge, Sb, and Te as main elements; and the second protection layer comprises a mixture of ZnS and SiO2.

Owner:RICOH KK

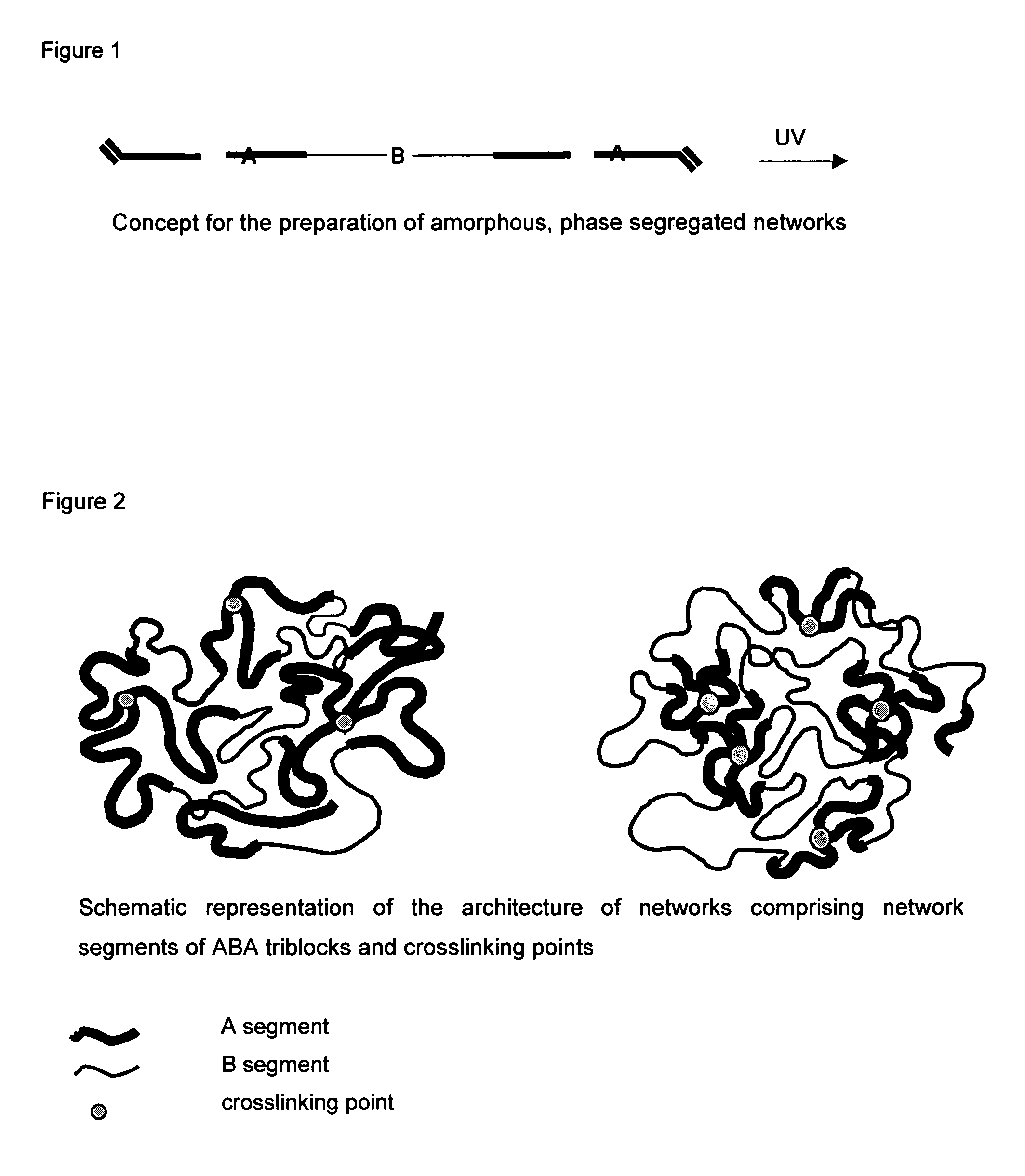

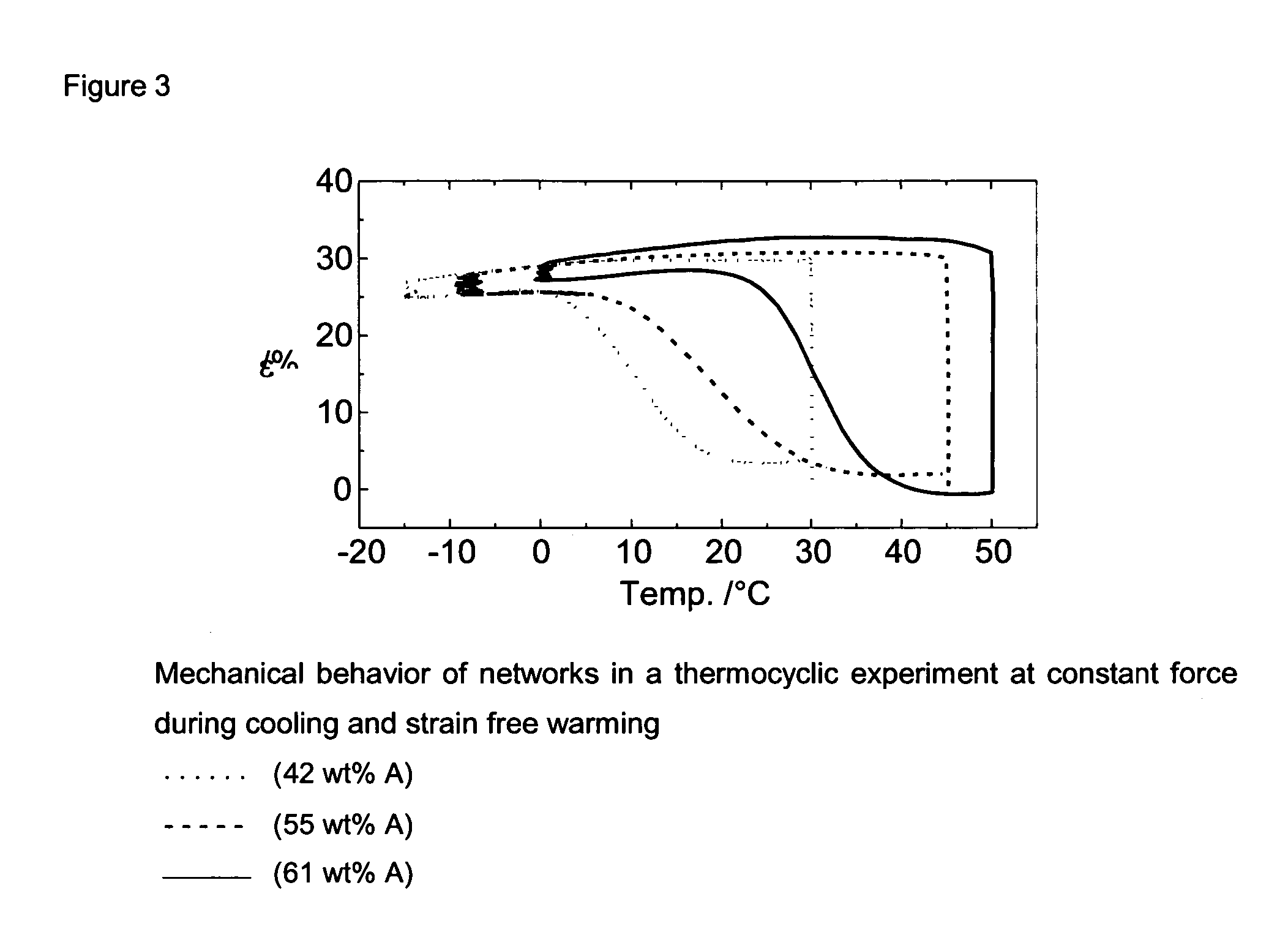

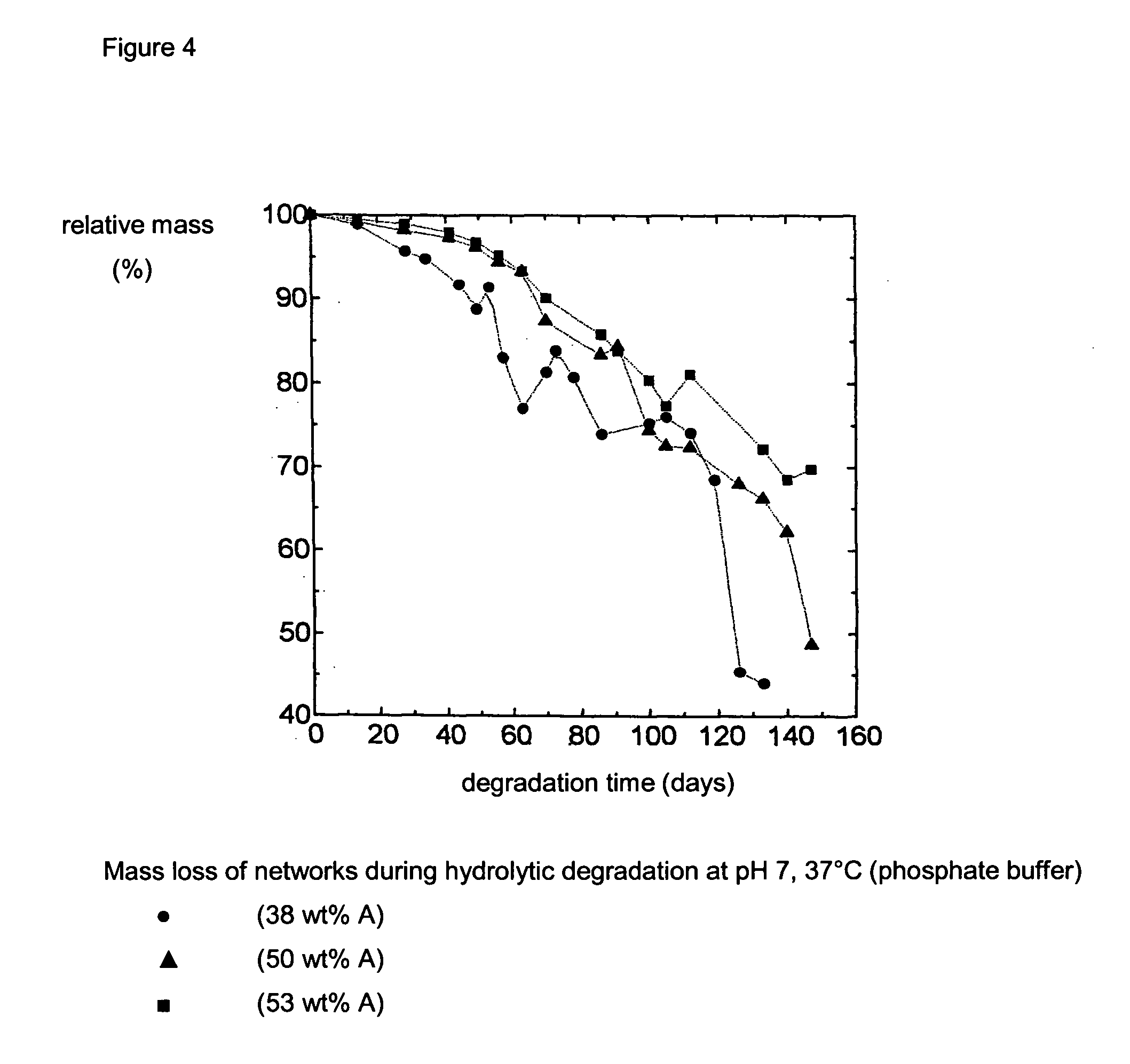

Amorphous polymer networks

The present invention relates to amorphous phase segregated networks of ABA triblock copolymers. The networks do possess good shape memory properties. The materials of the present invention are in particular suitable as materials in the medicinal field, as implants, for the target designed stimuli sensitive drug release, for ligament augmentation or as disc replacement.

Owner:MINEMOSCIENCE GMBH

Composite amorphous phase-change heat storage material and preparation method thereof

InactiveCN103525373AReduce leakageLeakage is not easy to happenHeat-exchange elementsActive agentHeat conducting

The invention relates to a composite amorphous phase-change heat storage material and a preparation method thereof, and belongs to the technical field of composite materials. The composite material is prepared from a porous material used as a support material and an inorganic hydrous salt used as a phase-change material in manners of absorbing the inorganic hydrous salt into a porous structure of the support material by virtue of the capillary adsorption action of the porous material, and self-assembly of a surfactant. The method comprises the following steps: firstly, emulsifying and dispersing the molten inorganic hydrous salt phase-change material such as calcium chloride hexahydrate by the emulsifying dispersion effect of the surfactant under an ultrasonic condition, so as to form a stable emulsion; adding expanded graphite to the emulsion to evenly disperse; putting the mixture into a vacuum oven, vacuumizing and keeping in a constant state for 30 minutes at room temperature, so as to prepare a novel composite amorphous phase-change heat storage material which is high in phase-change latent heat, good in heat-conducting property, and low in cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

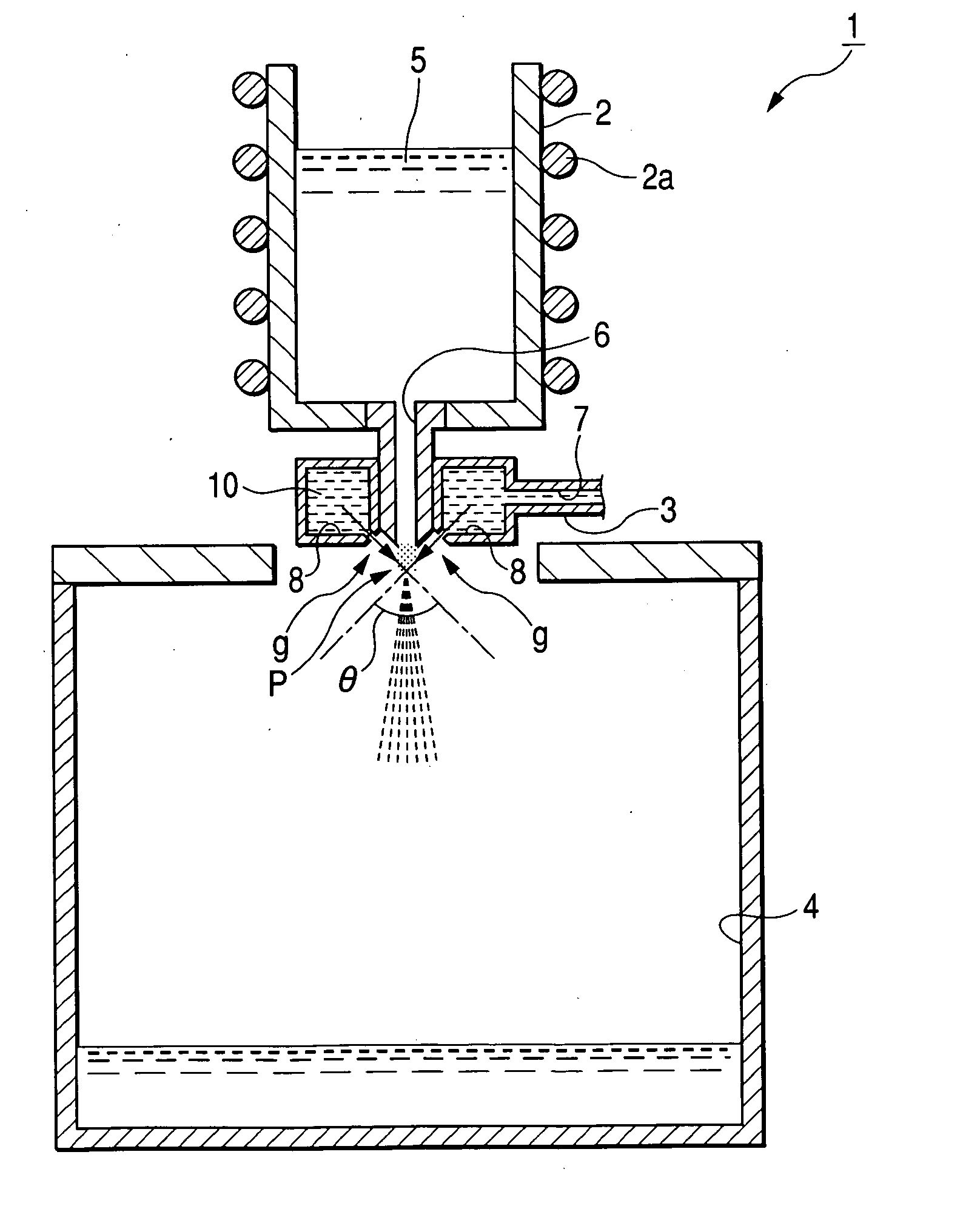

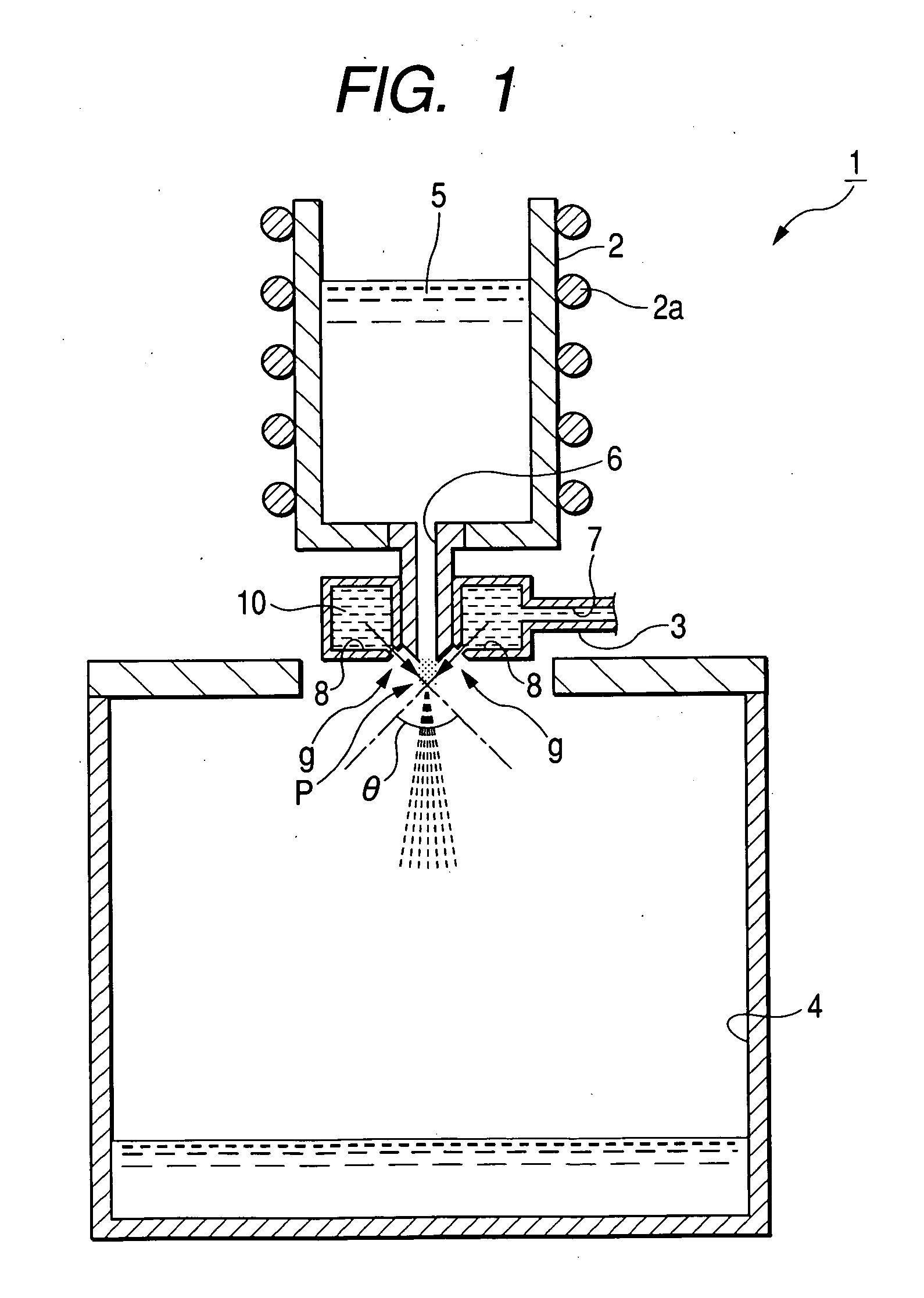

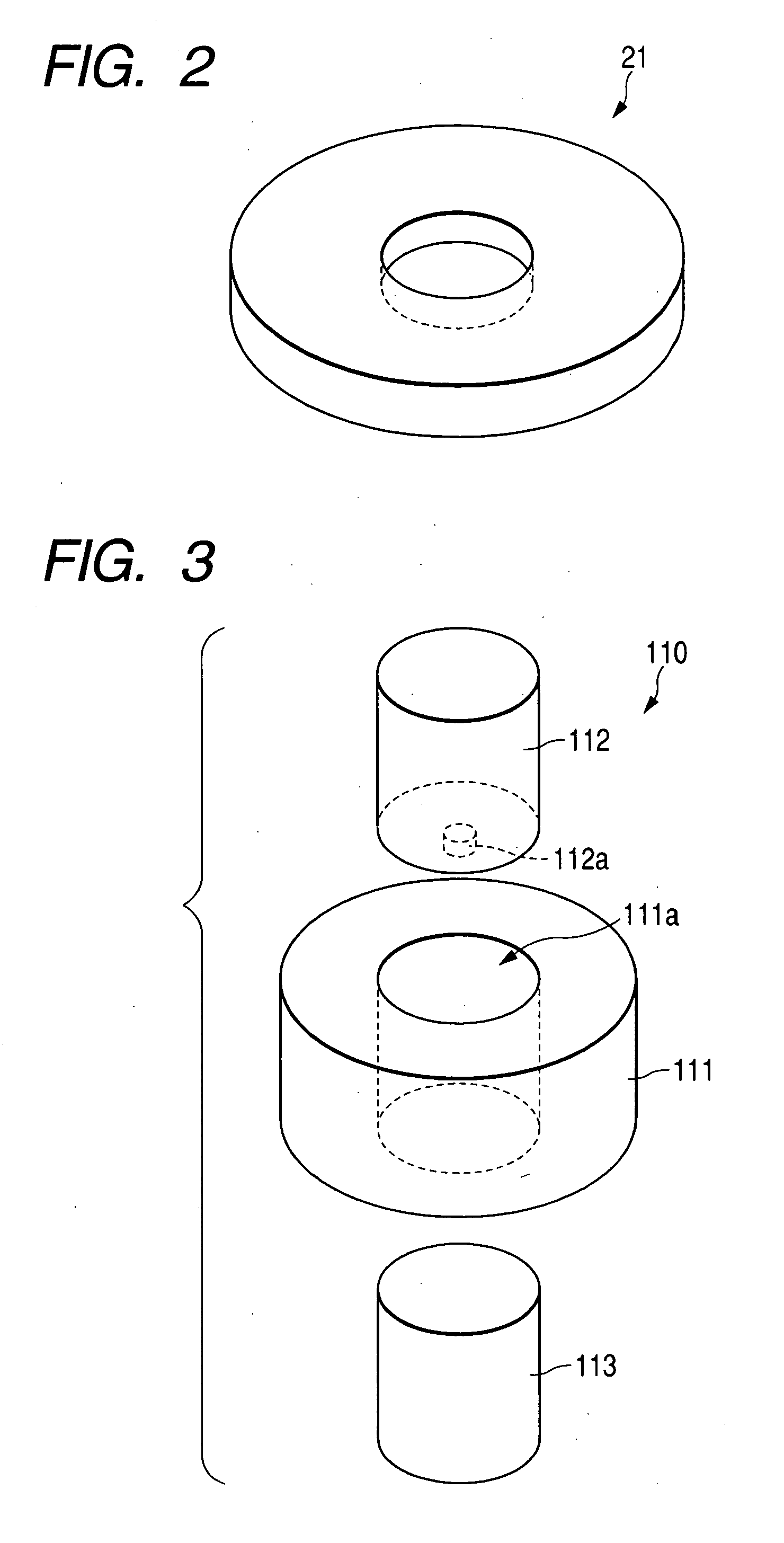

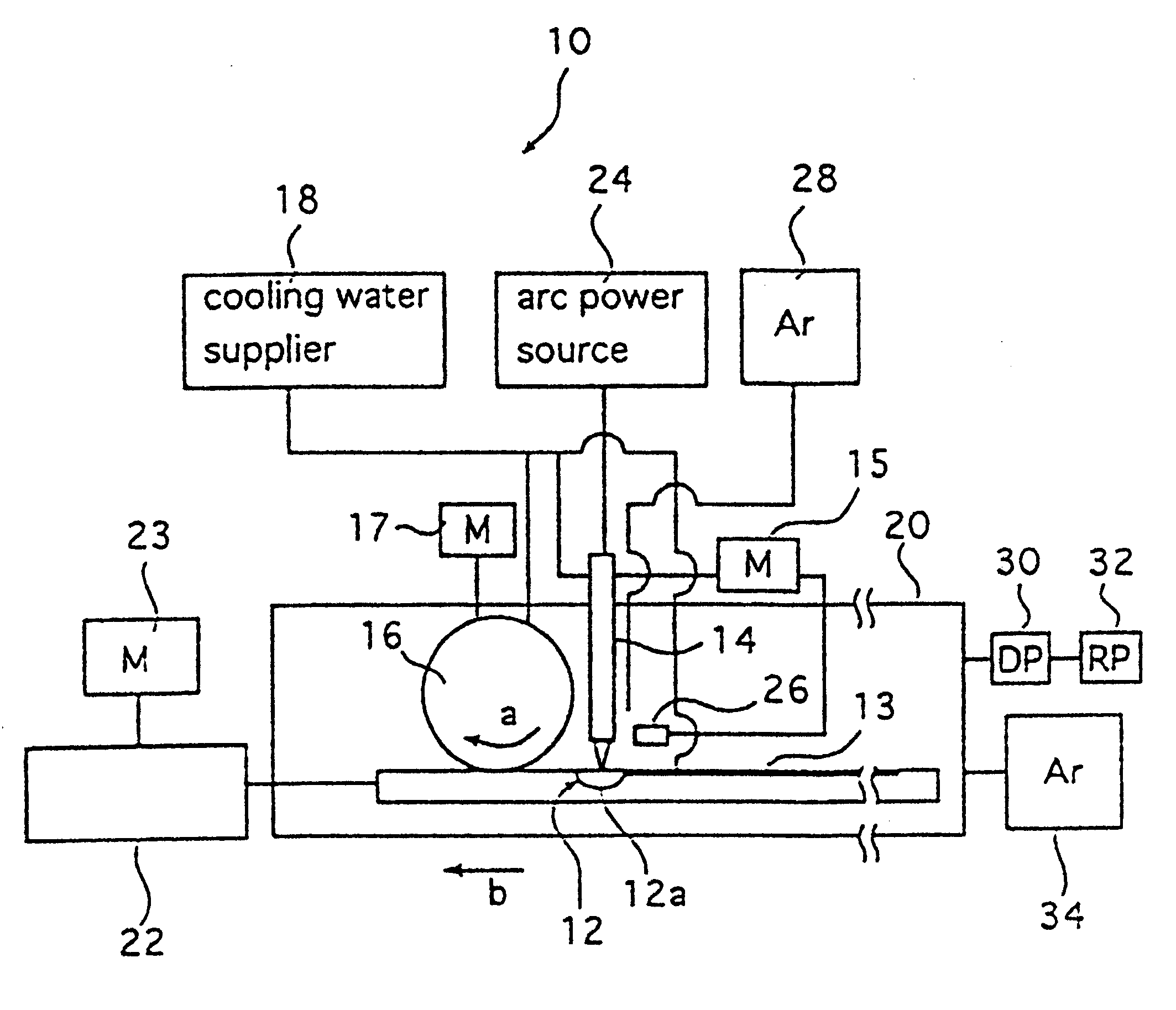

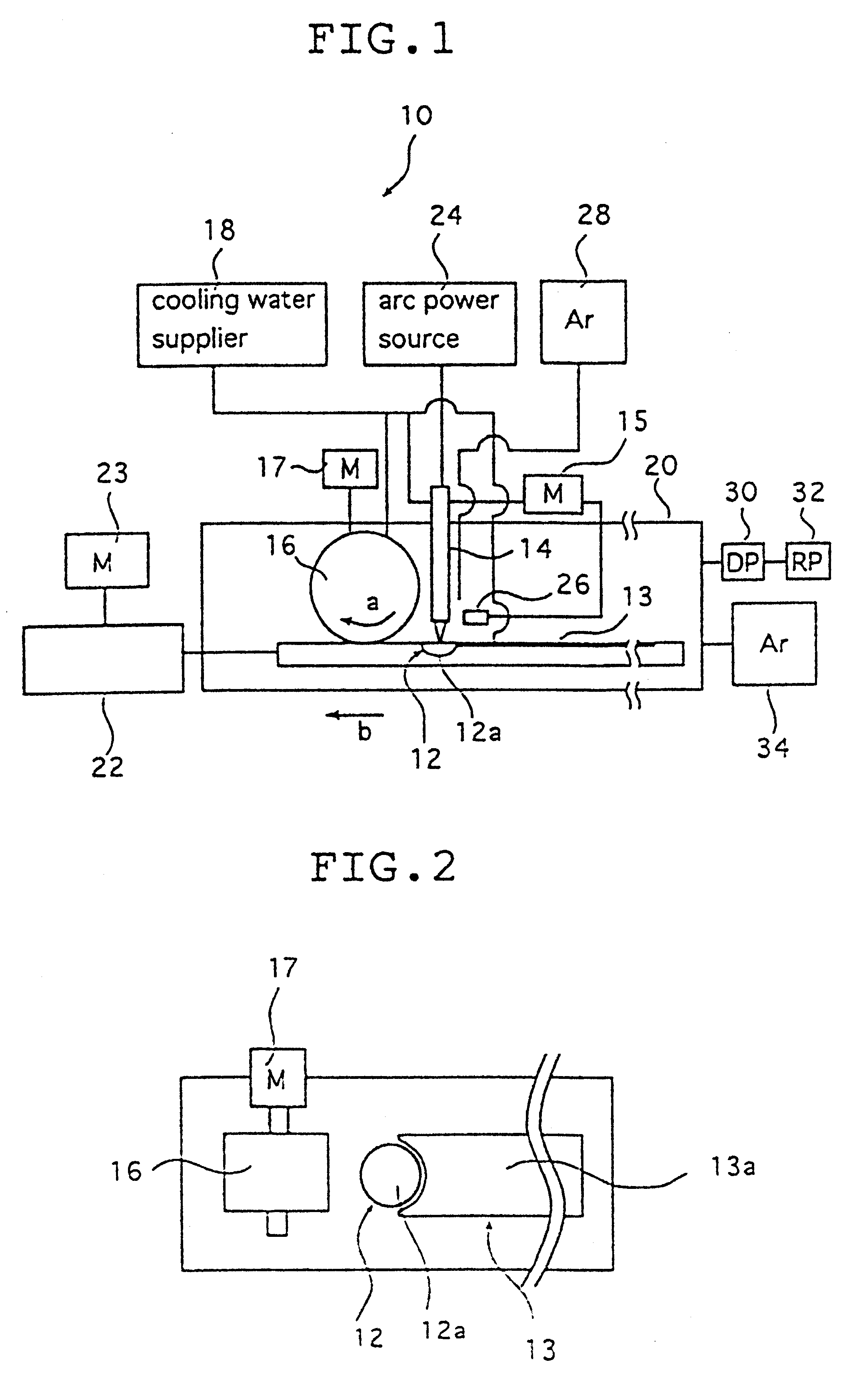

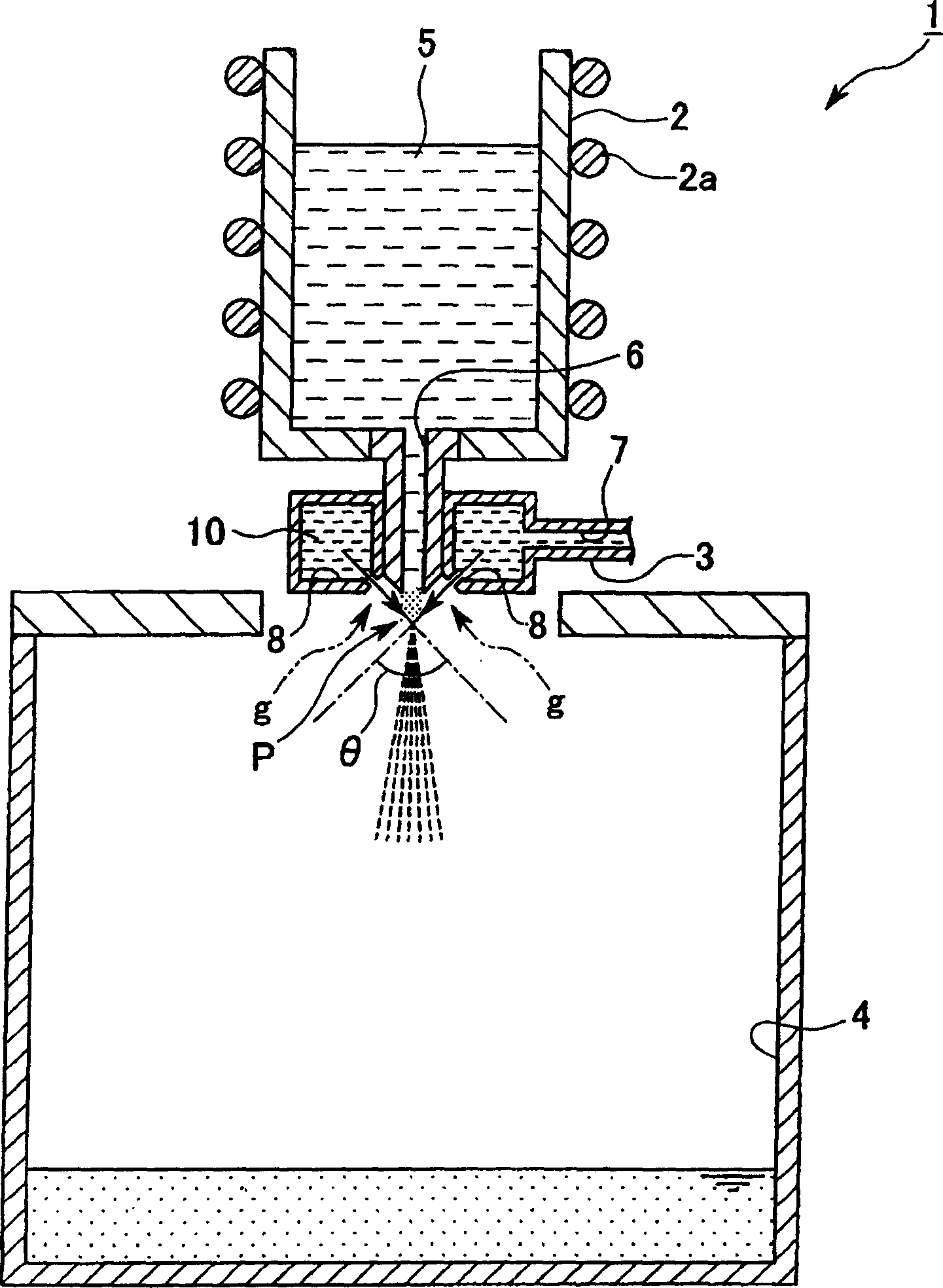

Process and apparatus for producing metallic glass

InactiveUS6427753B1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyHearth

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

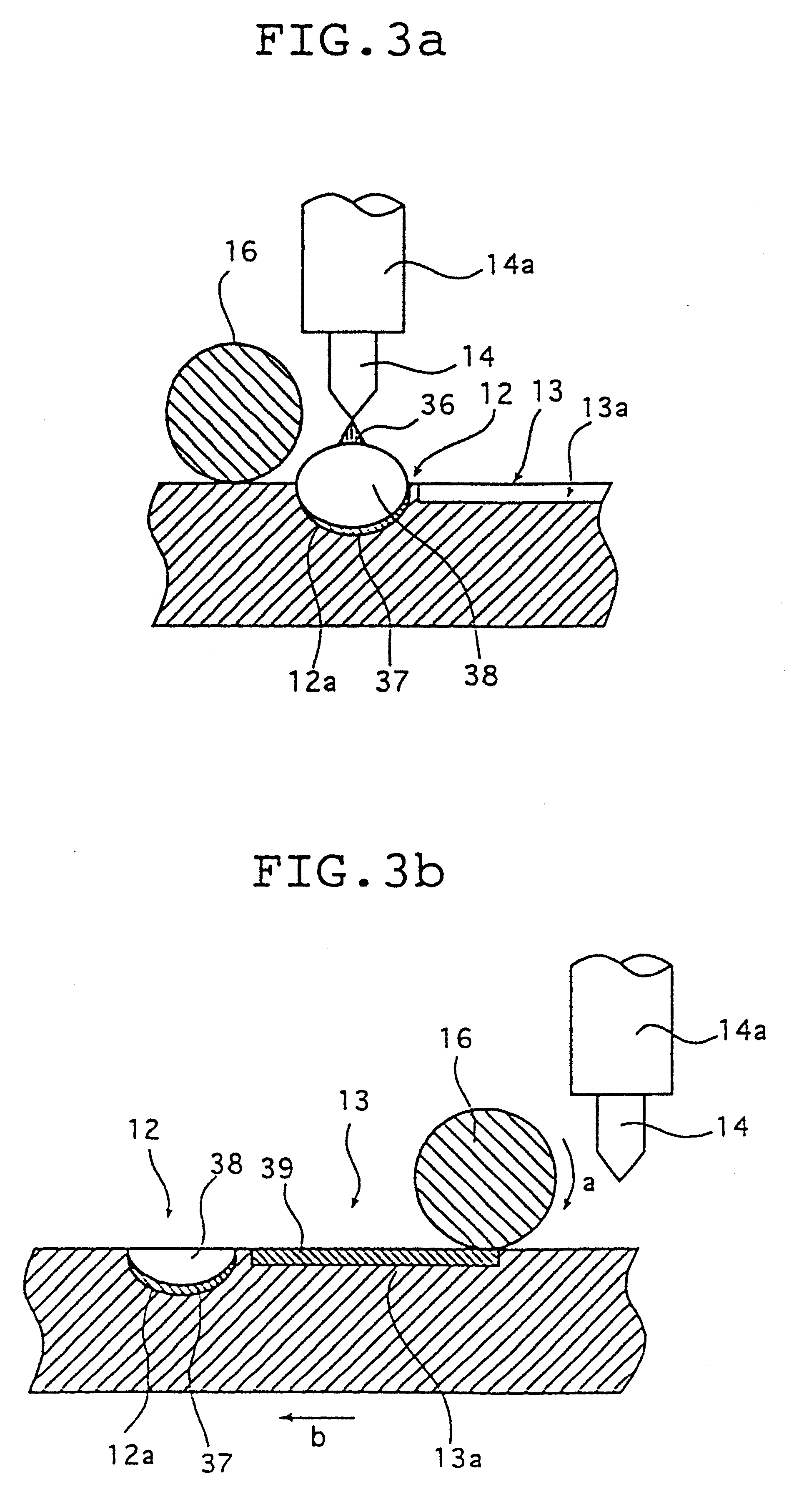

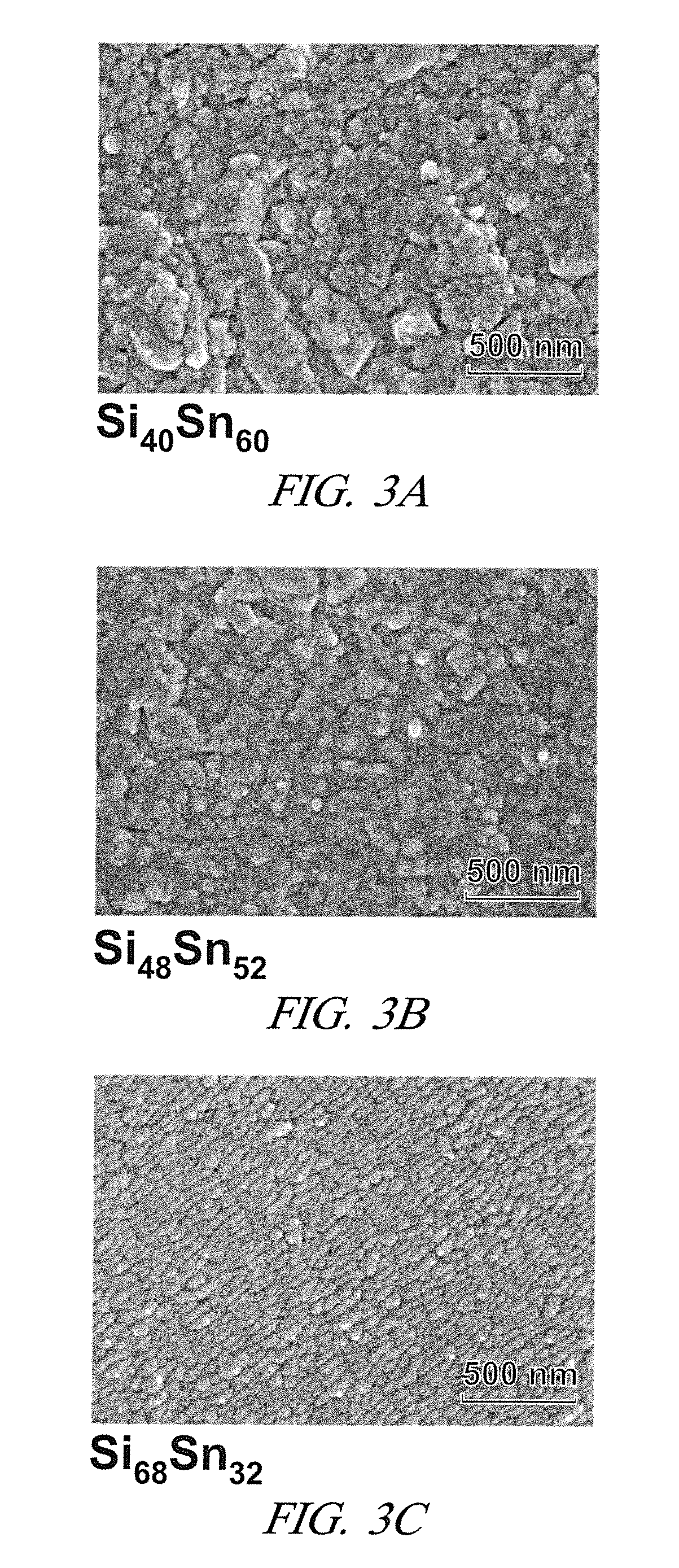

Phase separated silicon-tin composite as negative electrode material for lithium-ion batteries

ActiveUS9142830B2Reduce stressMitigate the fracture of the larger composite particlesMaterial nanotechnologyConductive materialComposite electrodeAmorphous phase

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Low-loss magnetic powder core, and switching power supply, active filter, filter, and amplifying device using the same

InactiveUS6897718B2Reduced core lossLess distortionDc-dc conversionInorganic material magnetismMetallurgyAlloy

A magnetic powder core comprises a molded article of a mixture of a glassy alloy powder and an insulating material. The glassy alloy comprises Fe and at least one element selected from Al, P, C, Si, and B, and has a texture primarily composed of an amorphous phase. The glassy alloy exhibits a temperature difference ΔTx, which is represented by the equation ΔTx=Tx−Tg, of at least 20 K in a supercooled liquid, wherein Tx indicates the crystallization temperature and Tg indicates the glass transition temperature. The magnetic core precursor is produced mixing the glassy alloy powder with the insulating material, compacting the mixture to form a magnetic core precursor, and annealing the magnetic core precursor at a temperature in the range between (Tg−170) K and Tg K to relieve the internal stress of the magnetic core precursor. The glassy alloy exhibits low coercive force and low core loss.

Owner:ALPS ALPINE CO LTD

Systems and methods of laser texturing of material surfaces and their applications

ActiveUS20130020297A1Enhance light absorptionImprove conductivityNanotechLaser beam welding apparatusAlloyElectron

The surface of a material is textured and by exposing the surface to pulses from an ultrafast laser. The laser treatment causes pillars to form on the treated surface. These pillars provide for greater light absorption. Texturing and crystallization can be carried out as a single step process. The crystallization of the material provides for higher electric conductivity and changes in optical and electronic properties of the material. The method may be performed in vacuum or a gaseous environment. The gaseous environment may aid in texturing and / or modifying physical and chemical properties of the surfaces. This method may be used on various material surfaces, such as semiconductors, metals and their alloys, ceramics, polymers, glasses, composites, as well as crystalline, nanocrystalline, polycrystalline, microcrystalline, and amorphous phases.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

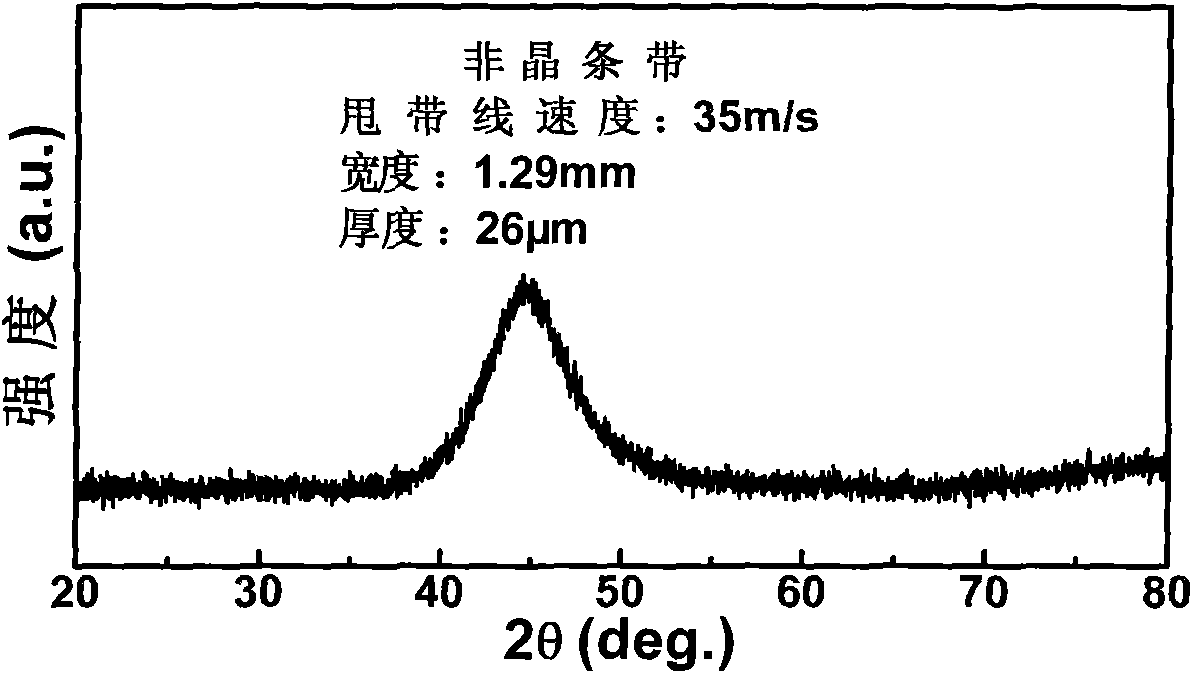

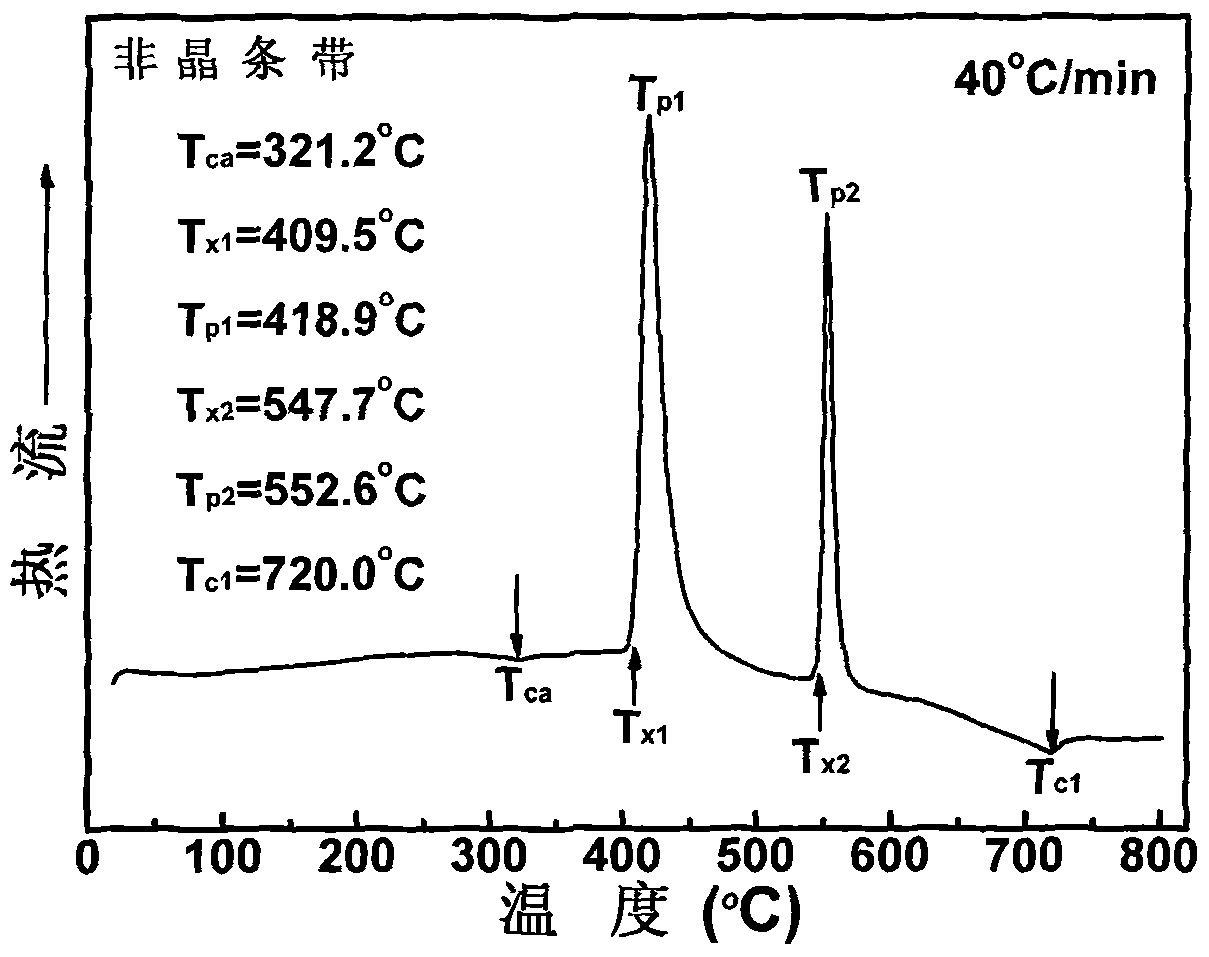

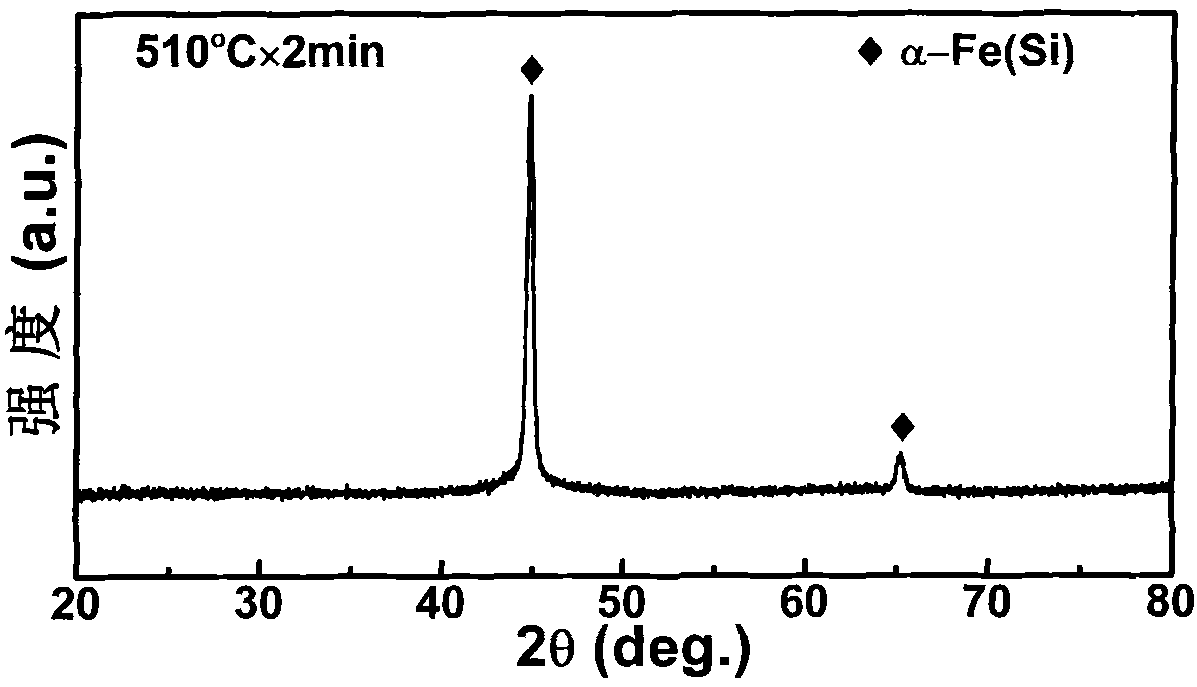

High saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material and preparation method thereof

ActiveCN101834046AHigh saturation magnetizationReduce contentMagnetic materialsMagnetizationMicrostructure

The invention relates to a high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material and a preparation method thereof. The high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material is a FexSiyBzPaCub alloy comprising ferrum, silicon, boron, phosphorus and copper, wherein x, y, z, a and b in the formula respectively represent atom percentage content of each corresponding component, x=70-90%, y=1-15%, z=1-20 %, a=1-20% and b=0.1-1%, and x+y+z+a+b=100%; the microstructure of the Fe-based nanocrystalline magnetically soft alloy is as follows: a body-centered cubic Alpha-Fe(Si) nanocrystalline phase with the size of 1-35nm and an amorphous phase rich in phosphorus and boron coexist, and the amorphous phase is the basic phase. The preparation method comprises steps of: preparing proportioned raw materials into an alloy ingot, preparing into amorphous alloy and carrying out other procedures to obtain the high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy. The invention can greatly enhance the saturation magnetization intensity of the nanocrystalline magnetically soft alloy, maintain lower coercivity and effectively reduce cost of raw materials simultaneously.

Owner:朗峰新材料启东有限公司

Highly reliable amorphous high-k gate dielectric ZrOxNy

InactiveUS7205620B2Improve surface roughnessSmooth surface roughnessVacuum evaporation coatingSemiconductor/solid-state device manufacturingEquivalent oxide thicknessGate dielectric

A gate dielectric and method of fabricating a gate dielectric that produces a more reliable and thinner equivalent oxide thickness than conventional SiO2 gate oxides are provided. Gate dielectrics formed from metals such as zirconium are thermodynamically stable such that the gate dielectrics formed will have minimal reactions with a silicon substrate or other structures during any later high temperature processing stages. The addition of nitrogen to the microstructure of the gate dielectric promotes an amorphous phase that further improves the electrical properties of the gate dielectric. The process shown is performed at lower temperatures than the prior art, which inhibits unwanted species migration and unwanted reactions with the silicon substrate or other structures. By using a thermal evaporation technique to first deposit a metal layer, the underlying substrate surface smoothness is preserved, thus providing improved and more consistent electrical properties in the resulting gate dielectric.

Owner:MICRON TECH INC

Jewelry made of precious a morphous metal and method of making such articles

Jewelry and methods of making jewelry containing a precious metal-base alloy component in bulk-solidified amorphous phase are provided.

Owner:CRUCIBLE INTPROP LLC

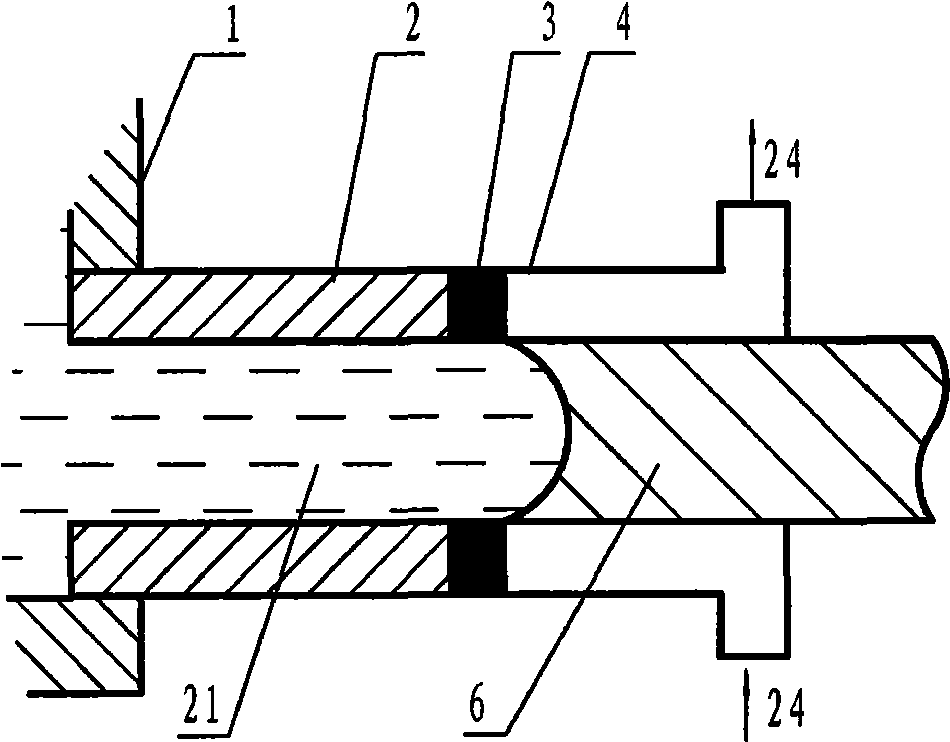

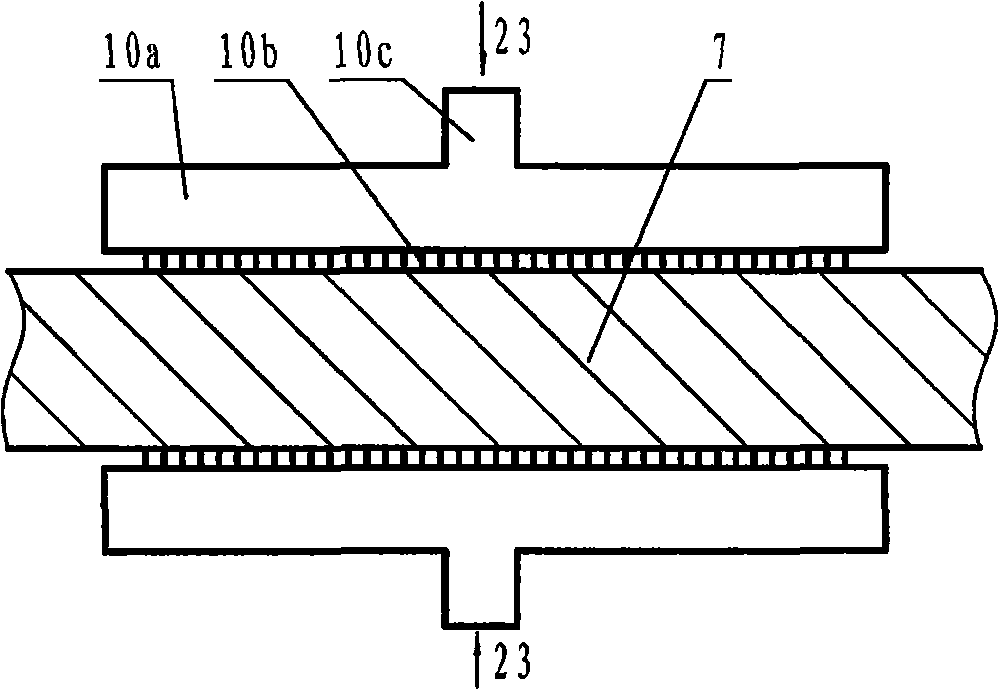

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

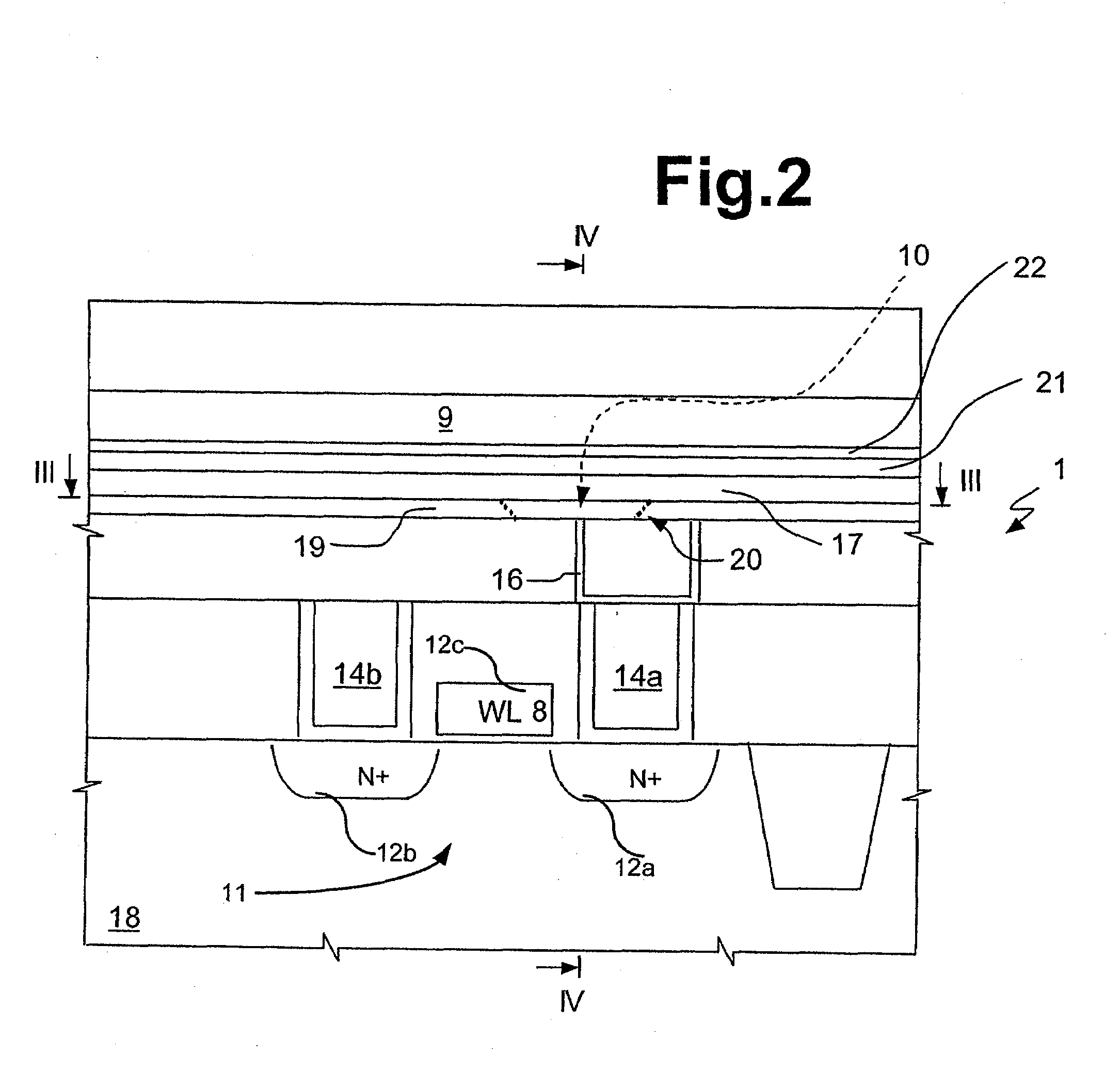

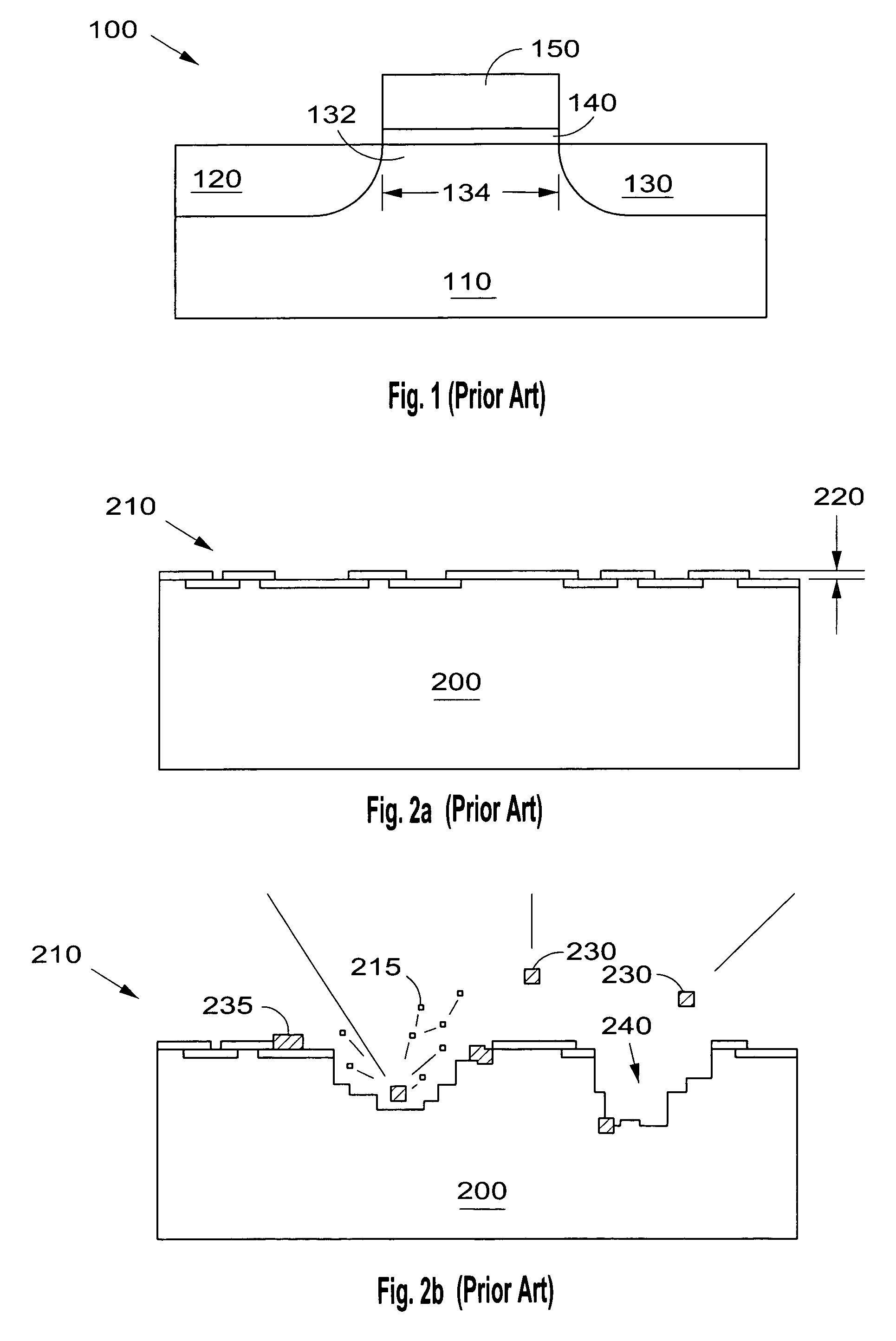

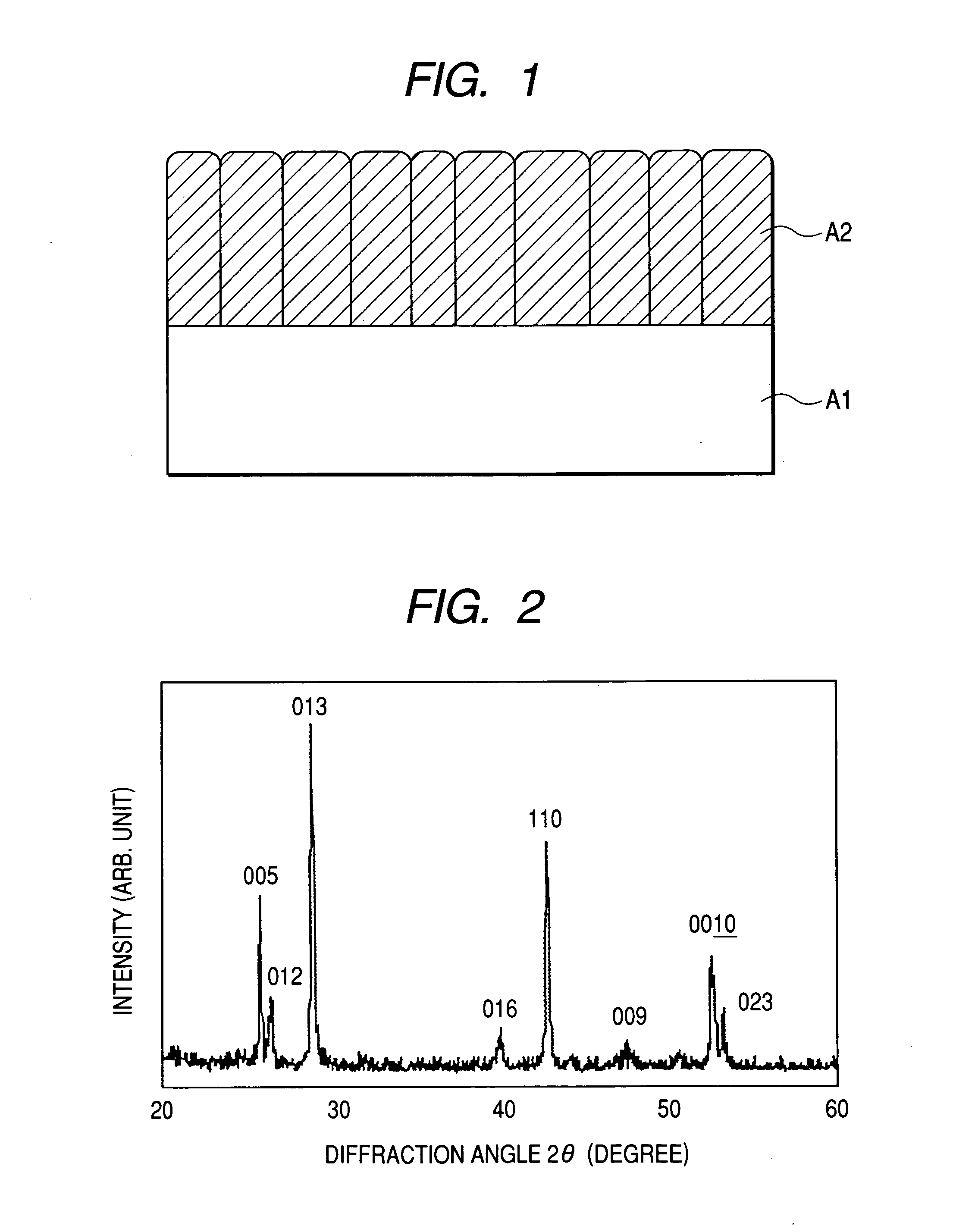

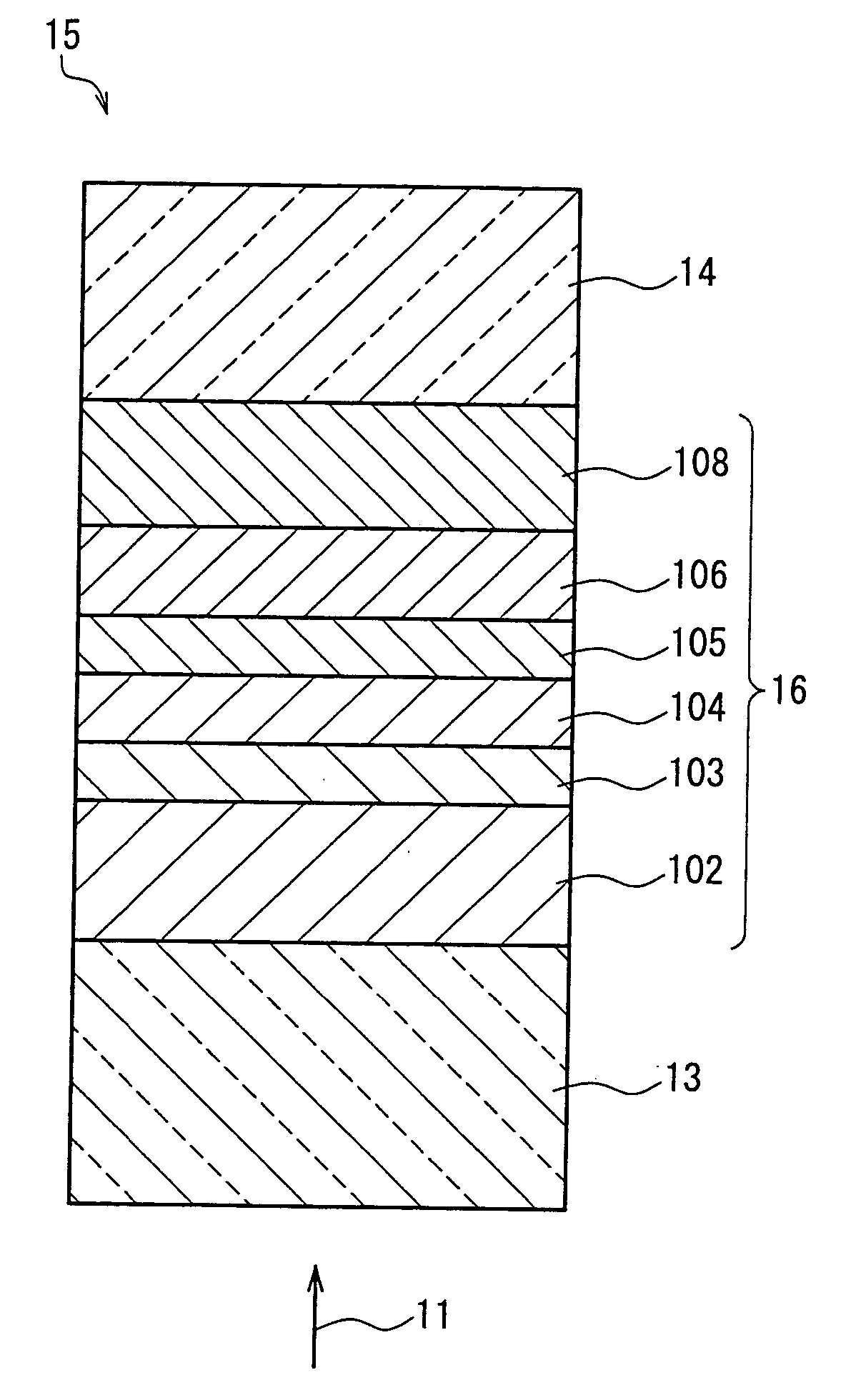

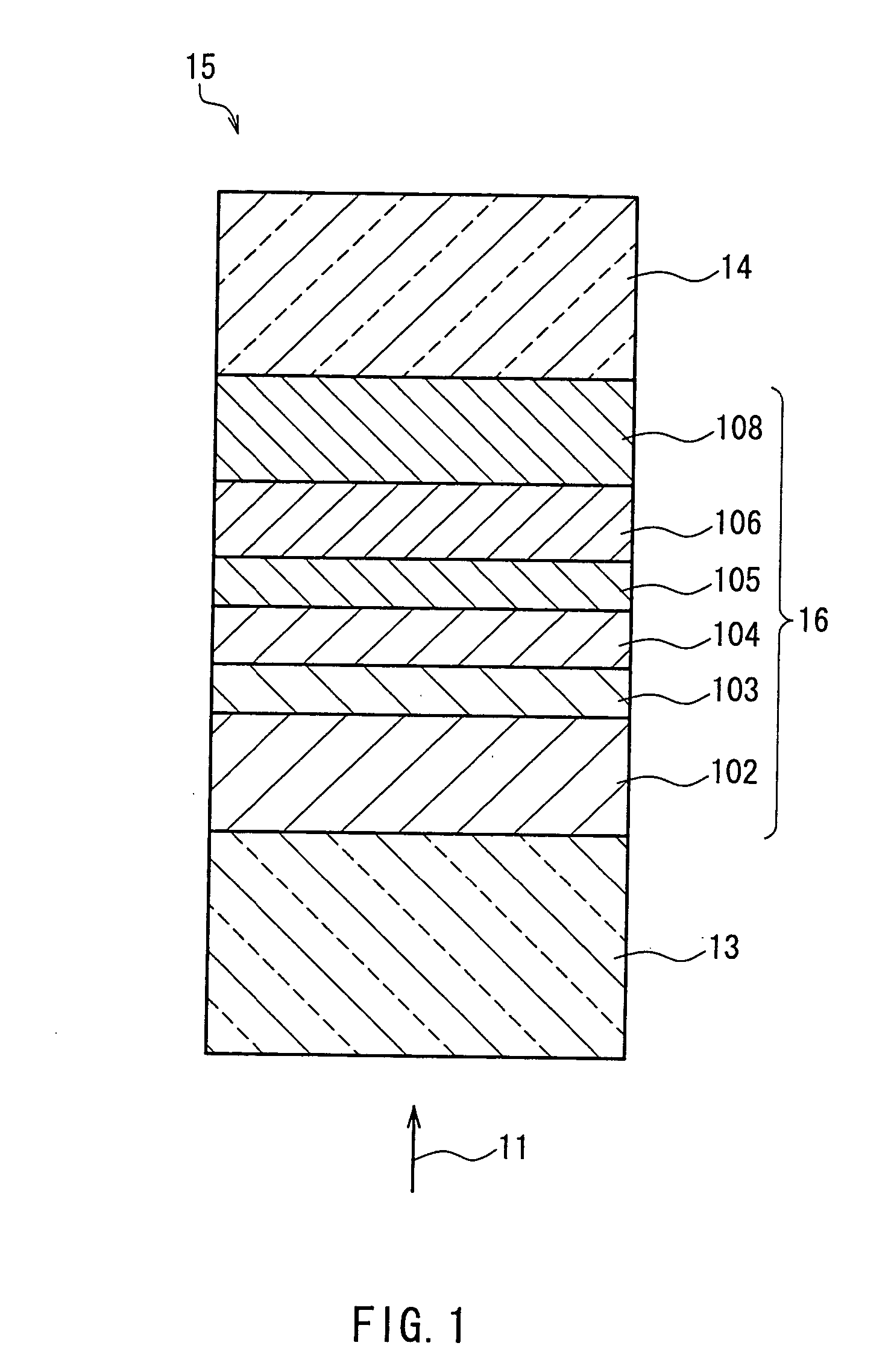

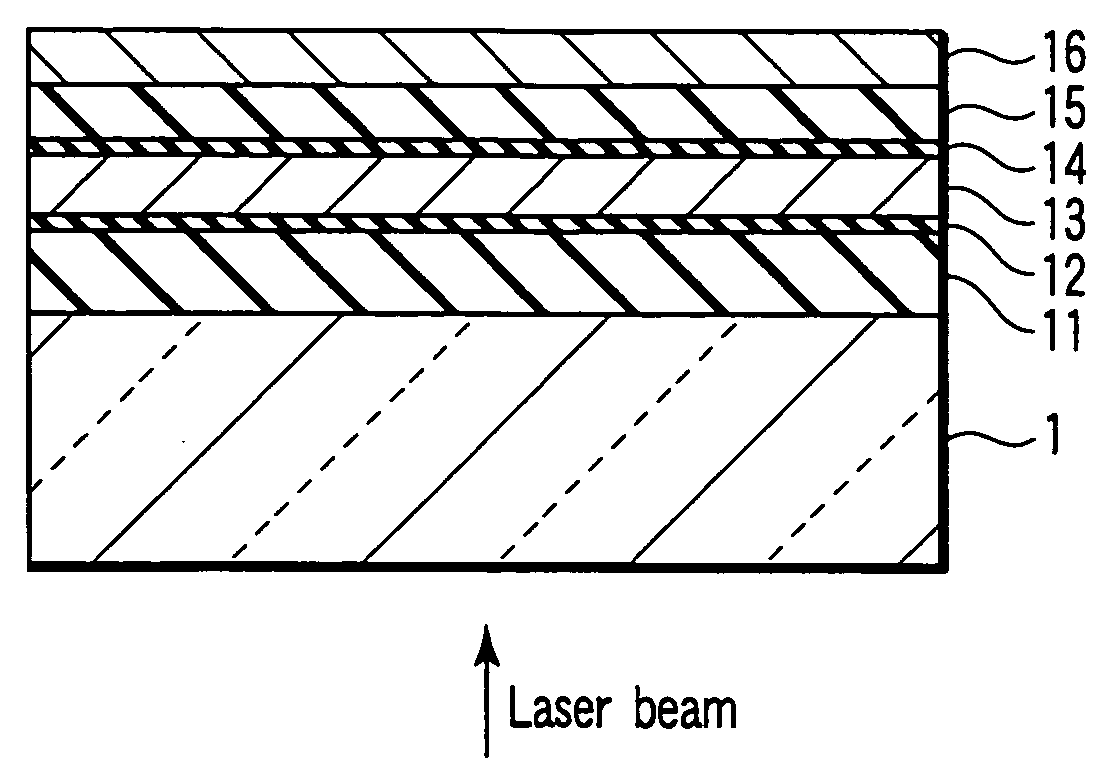

Semiconductor device and method of manufacturing the same

ActiveUS20060105556A1Non-uniform characteristicPrevent peelingVacuum evaporation coatingSolid-state devicesElectrical resistance and conductancePhase-change memory

The annealing process at 400° C. or more required for the wiring process for a phase change memory has posed the problem in that the crystal grains in a chalcogenide material grow in an oblique direction to cause voids in a storage layer. The voids, in turn, cause peeling due to a decrease in adhesion, variations in resistance due to improper contact with a plug, and other undesirable events. After the chalcogenide material has been formed in an amorphous phase, post-annealing is conducted to form a (111)-oriented and columnarly structured face-centered cubic. This is further followed by high-temperature annealing to form a columnar, hexagonal closest-packed crystal. Use of this procedure makes it possible to suppress the growth of inclined crystal grains that causes voids, since crystal grains are formed in a direction perpendicular to the surface of an associated substrate.

Owner:RENESAS ELECTRONICS CORP

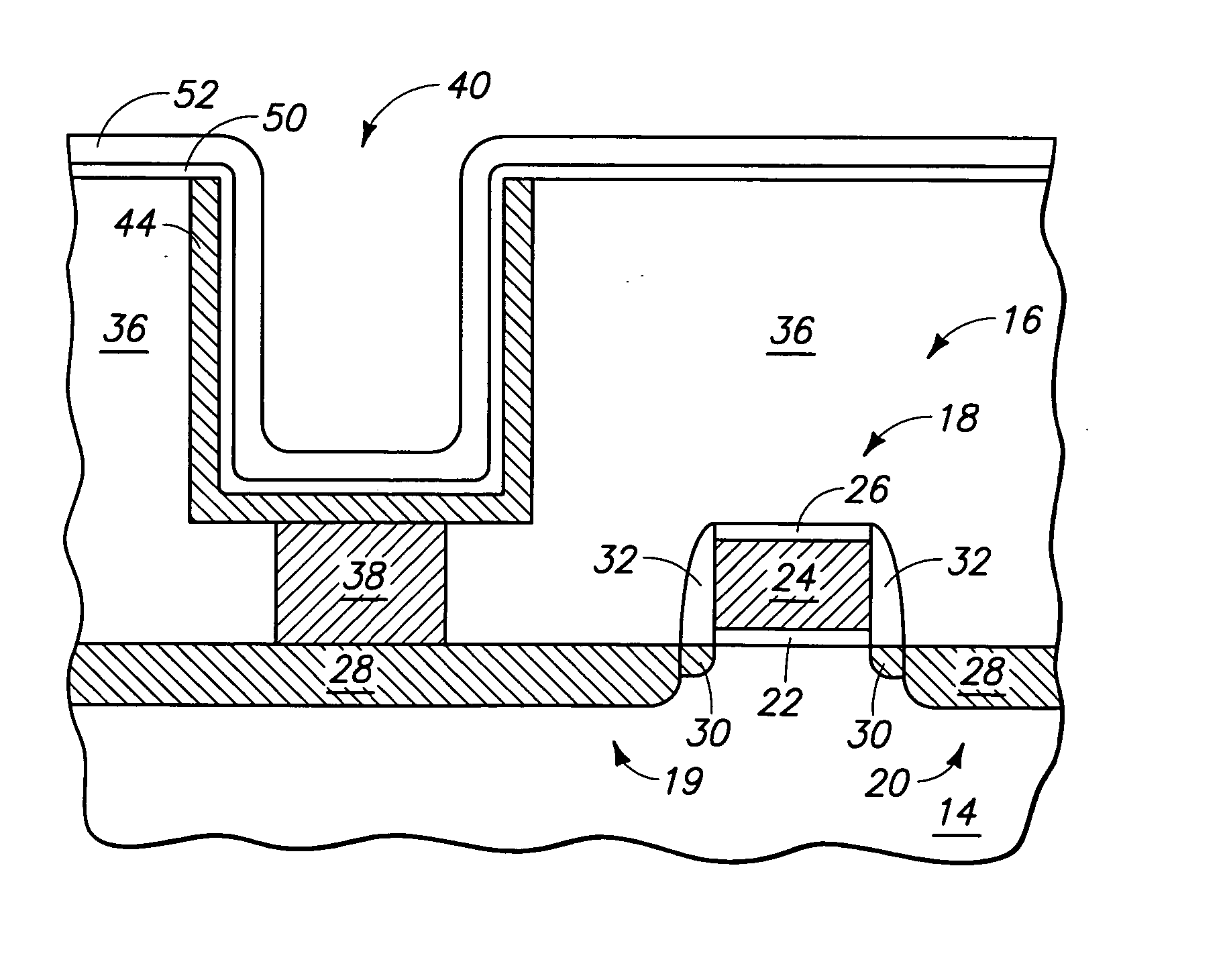

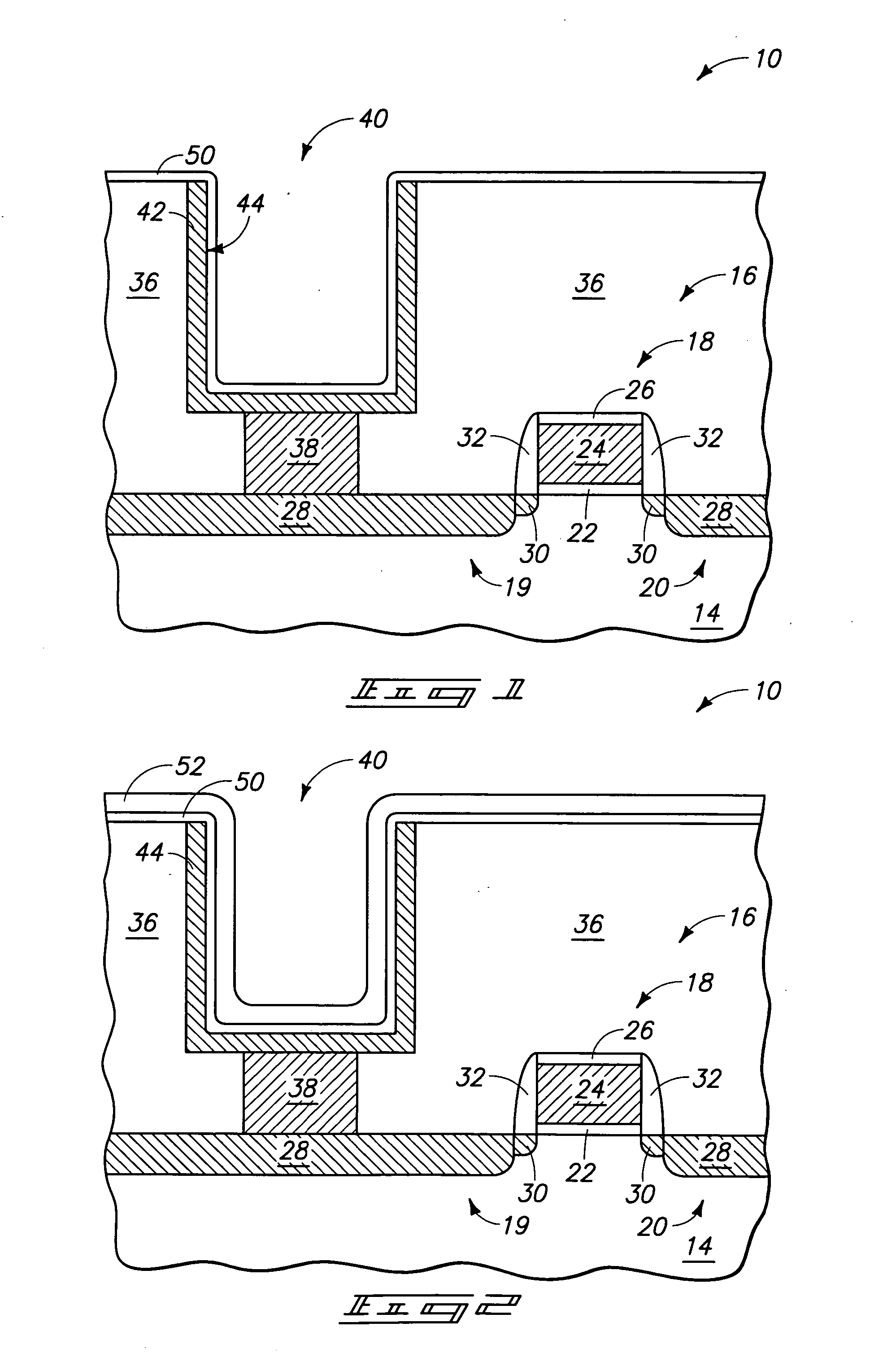

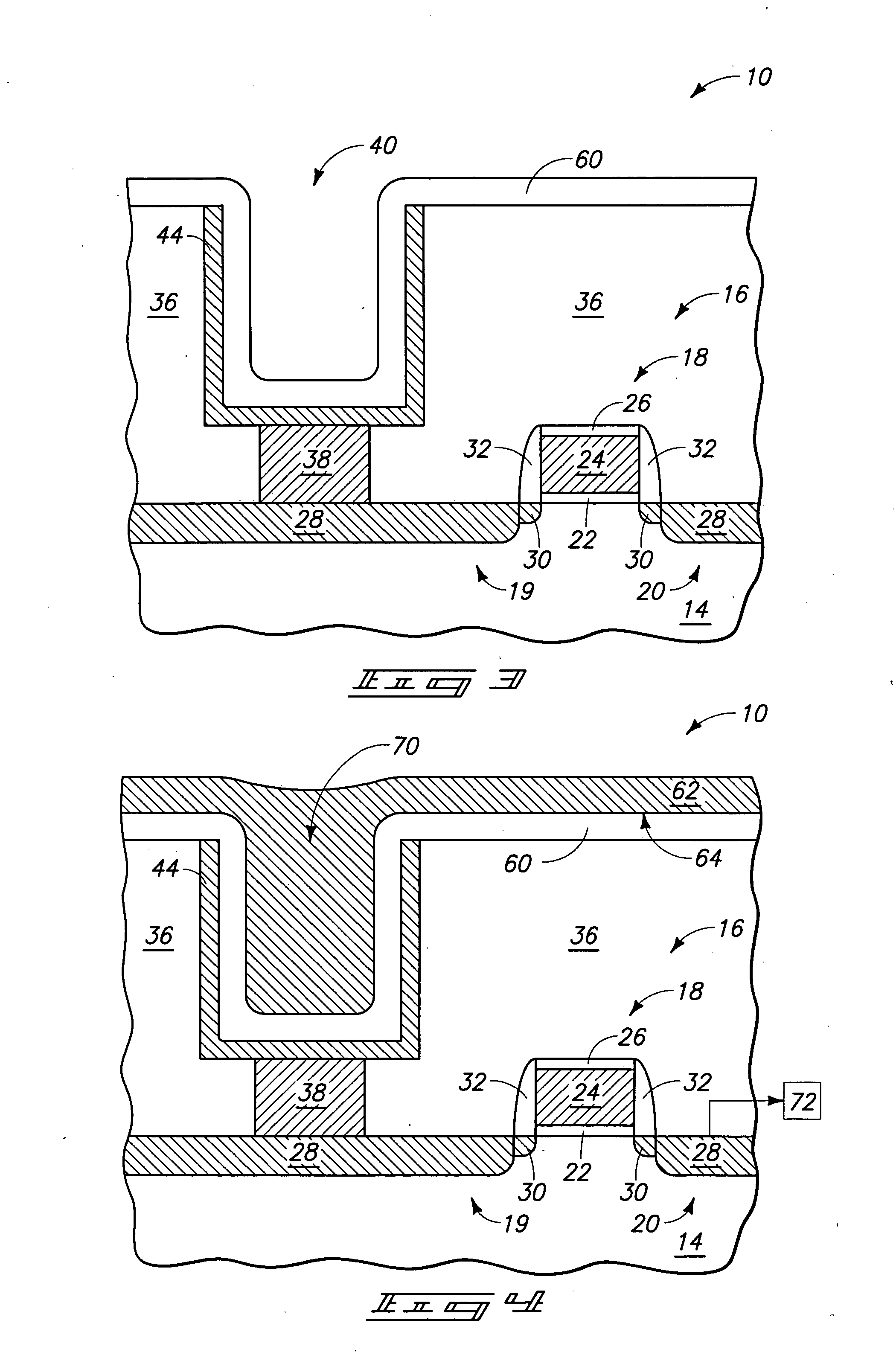

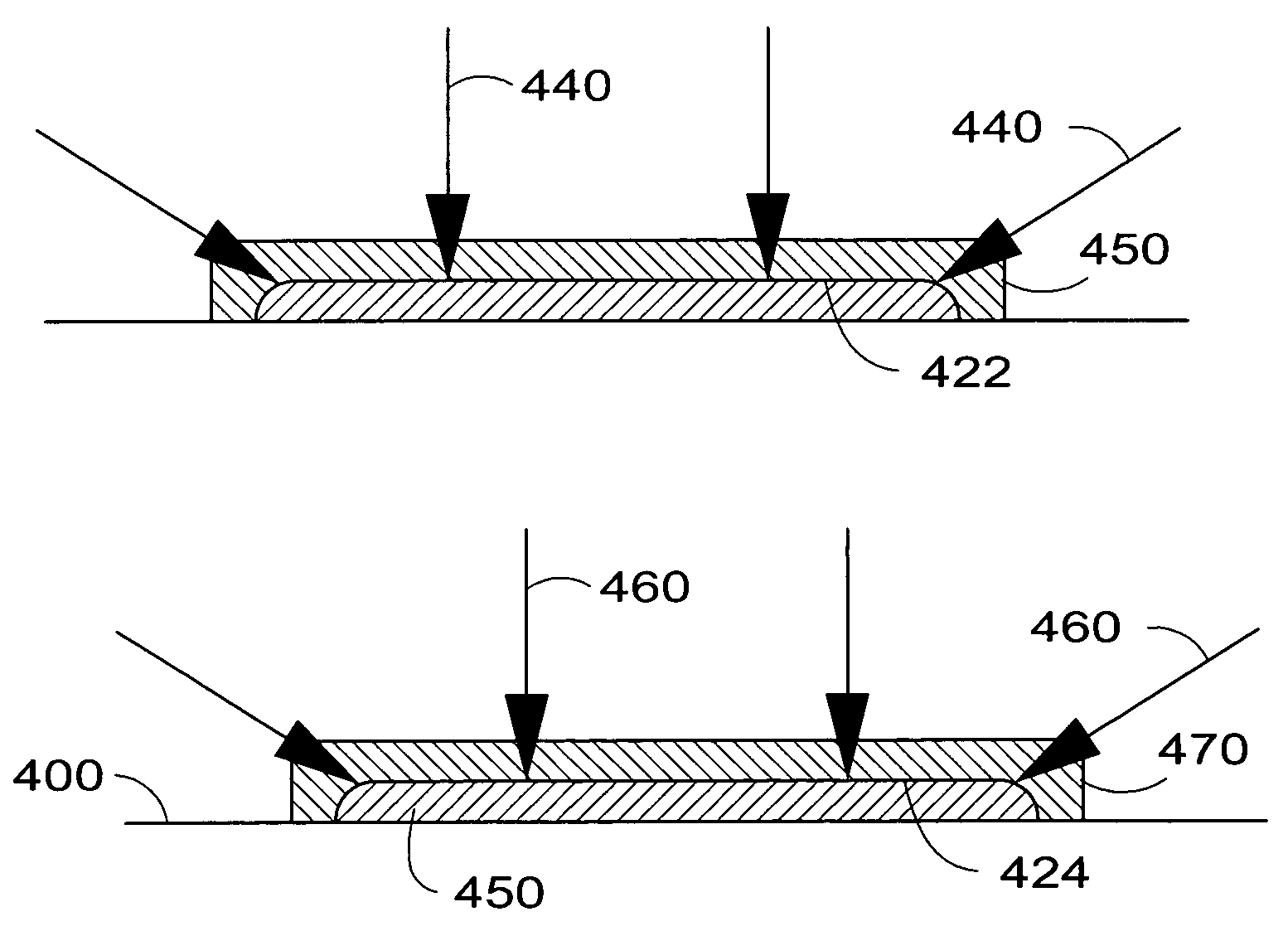

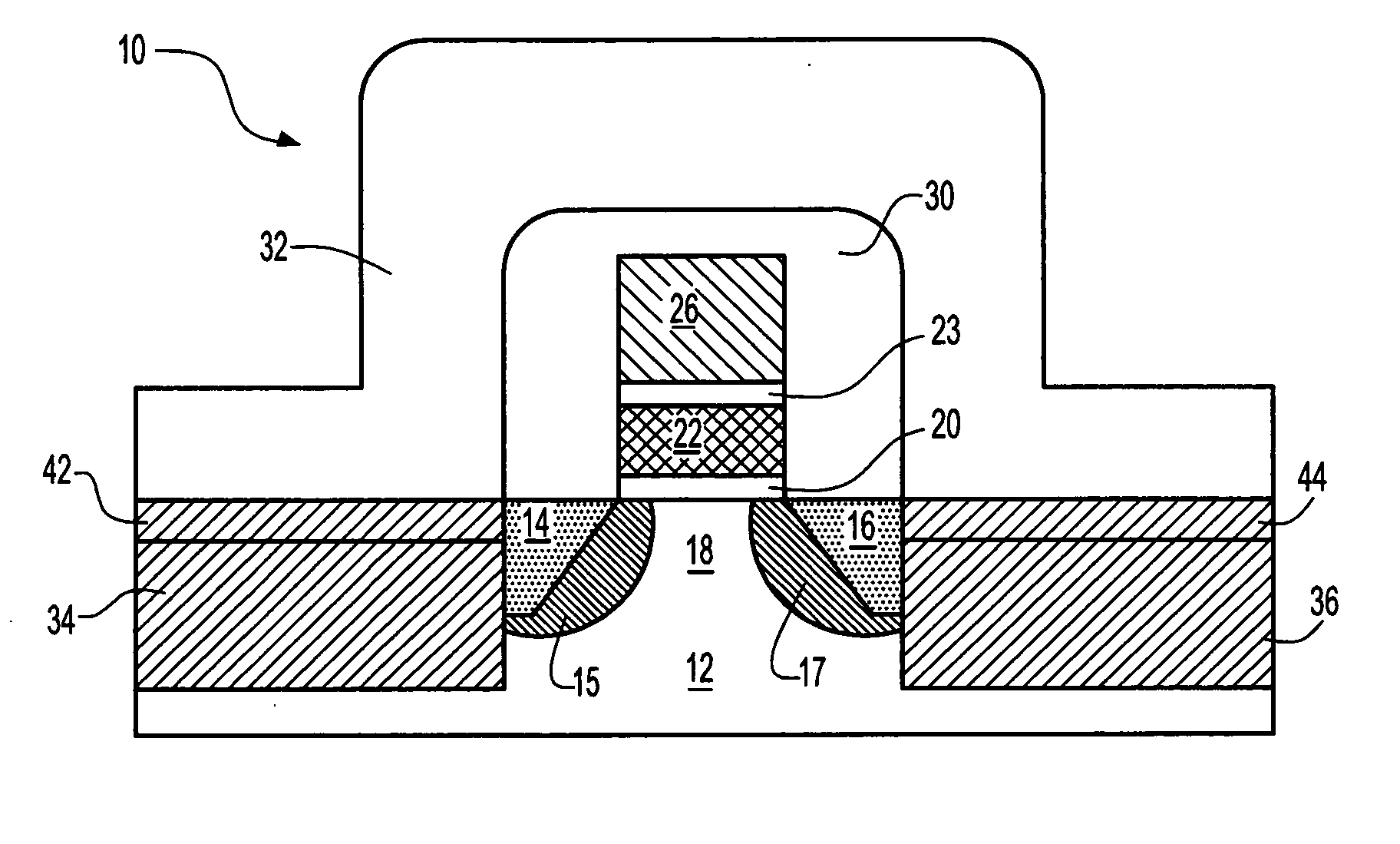

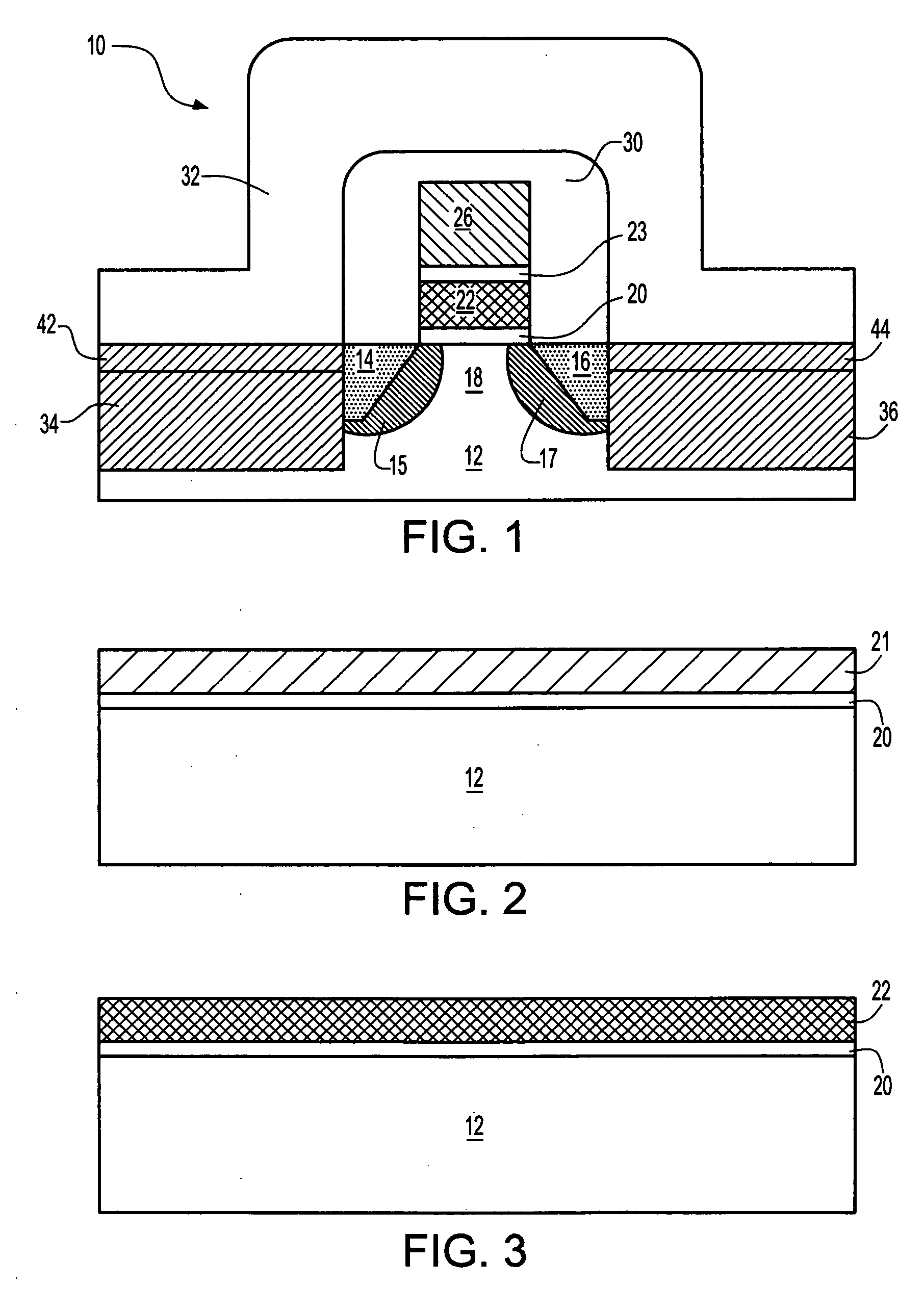

High performance mosfet comprising stressed phase change material and method of fabricating the same

The present invention relates to semiconductor devices that each comprises at least one field effect transistor (FET) containing an intrinsically stressed phase change material layer. The intrinsically stressed phase change material layer is arranged and constructed for creating stress in the channel region of the FET. Preferably, the intrinsically stressed phase change material layer is deposited over the channel region of the FET. For an n-channel FET, the intrinsically stressed phase change material layer preferably contains intrinsic compressive stress that is created by phase change, for example, from a polycrystalline phase to an amorphous phase. Alternatively, for a p-channel FET, the intrinsically stressed phase change material layer preferably contains intrinsic tensile stress that is created by phase change, for example, from an amorphous phase to a polycrystalline phase.

Owner:IBM CORP

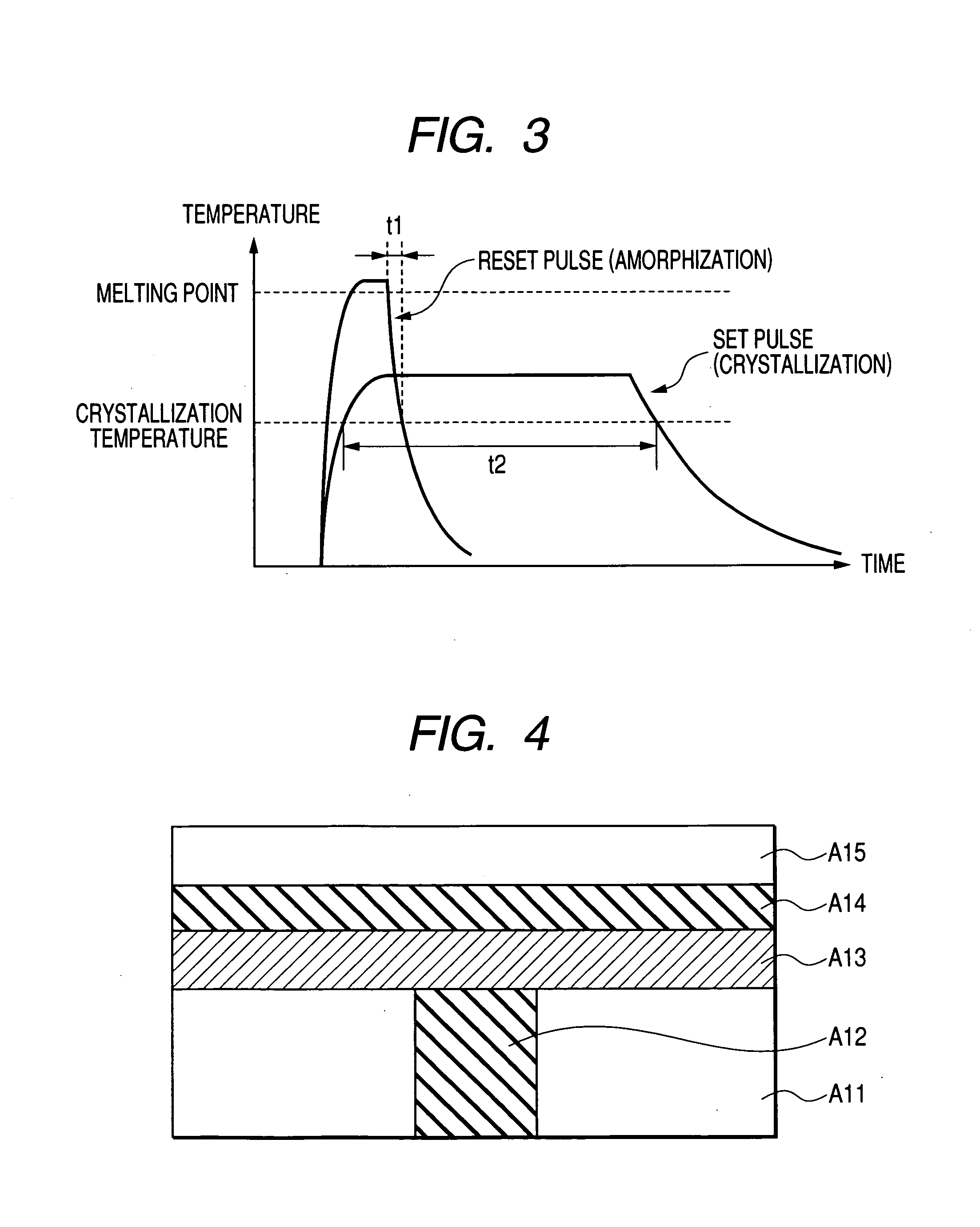

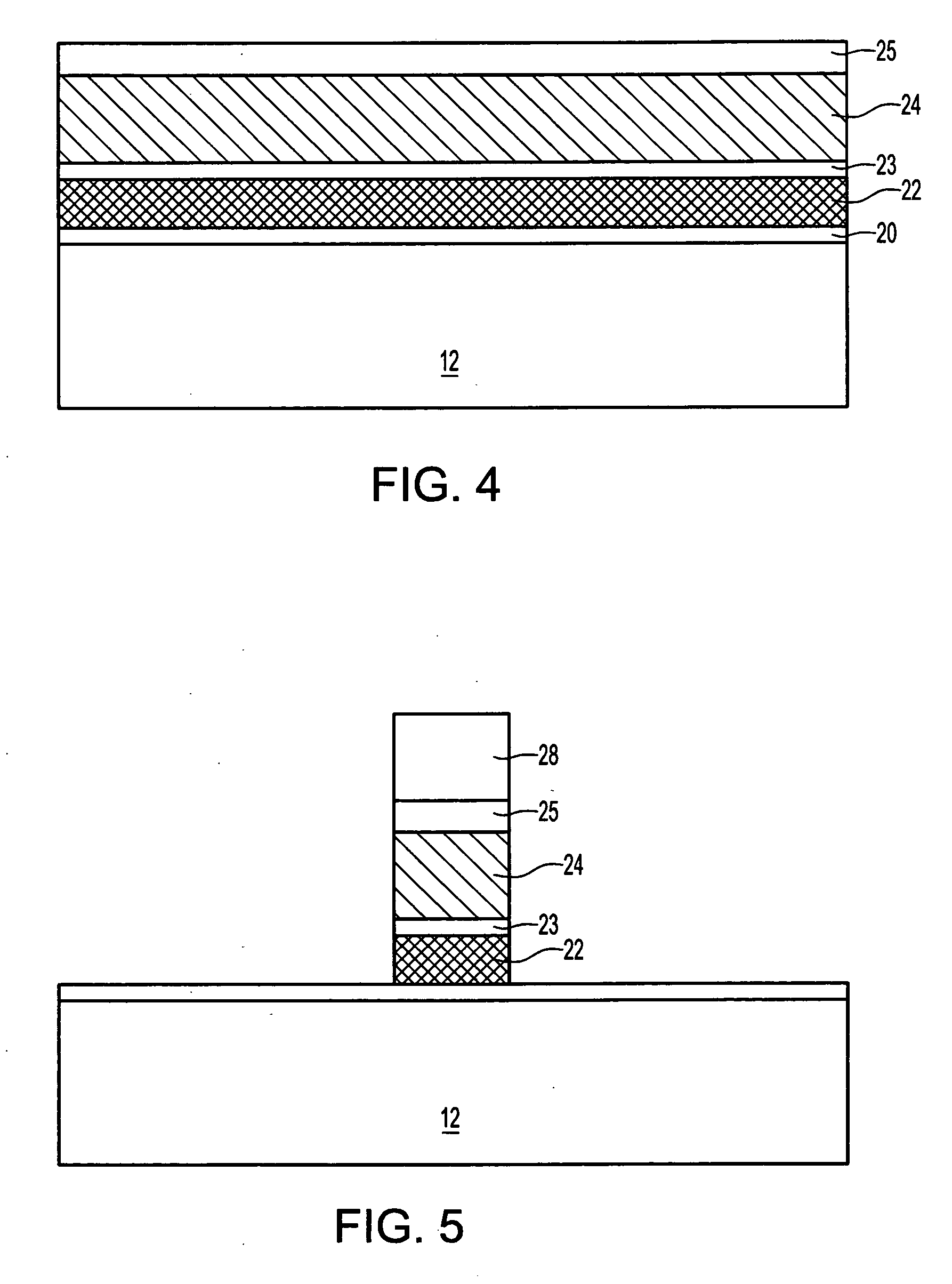

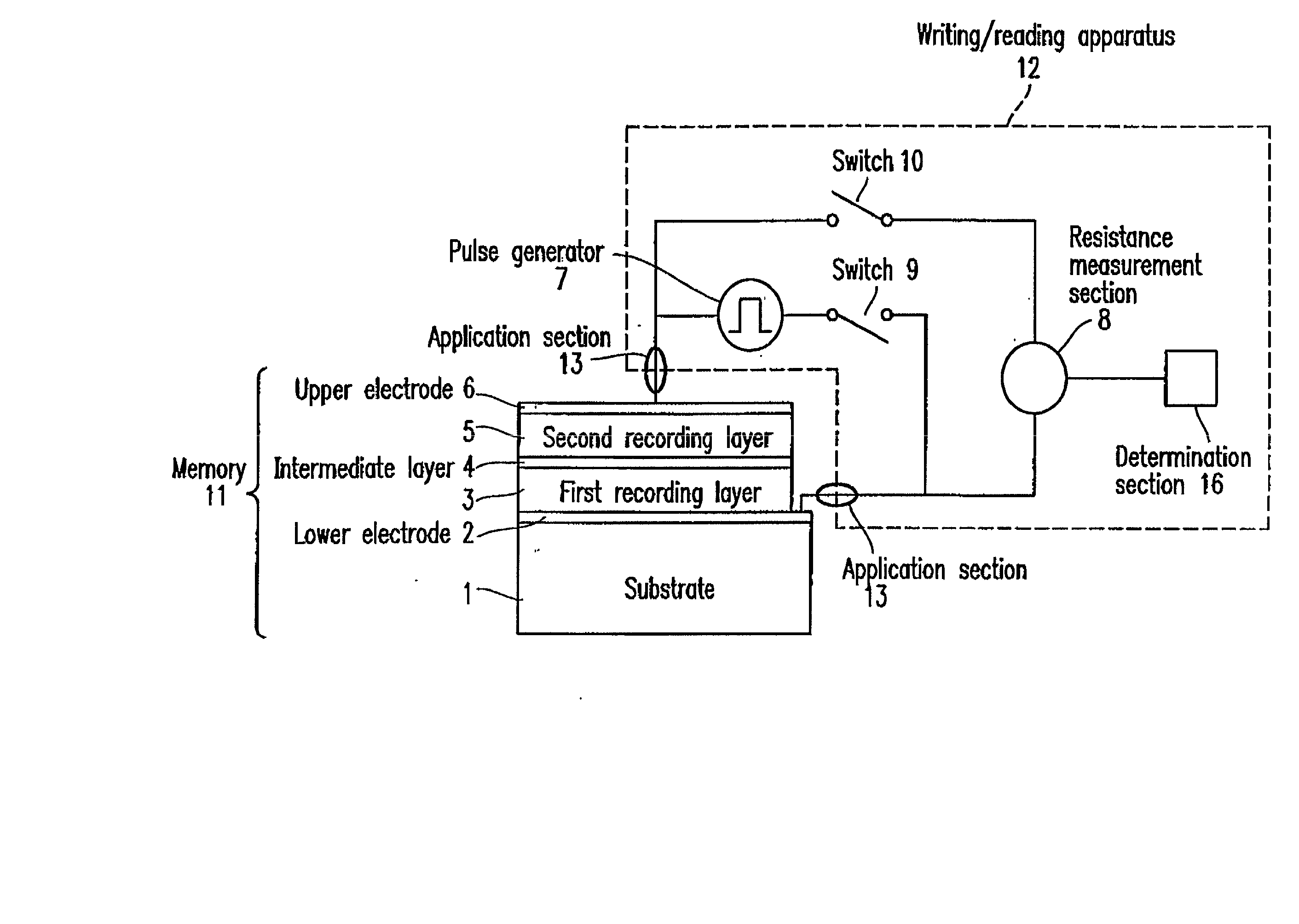

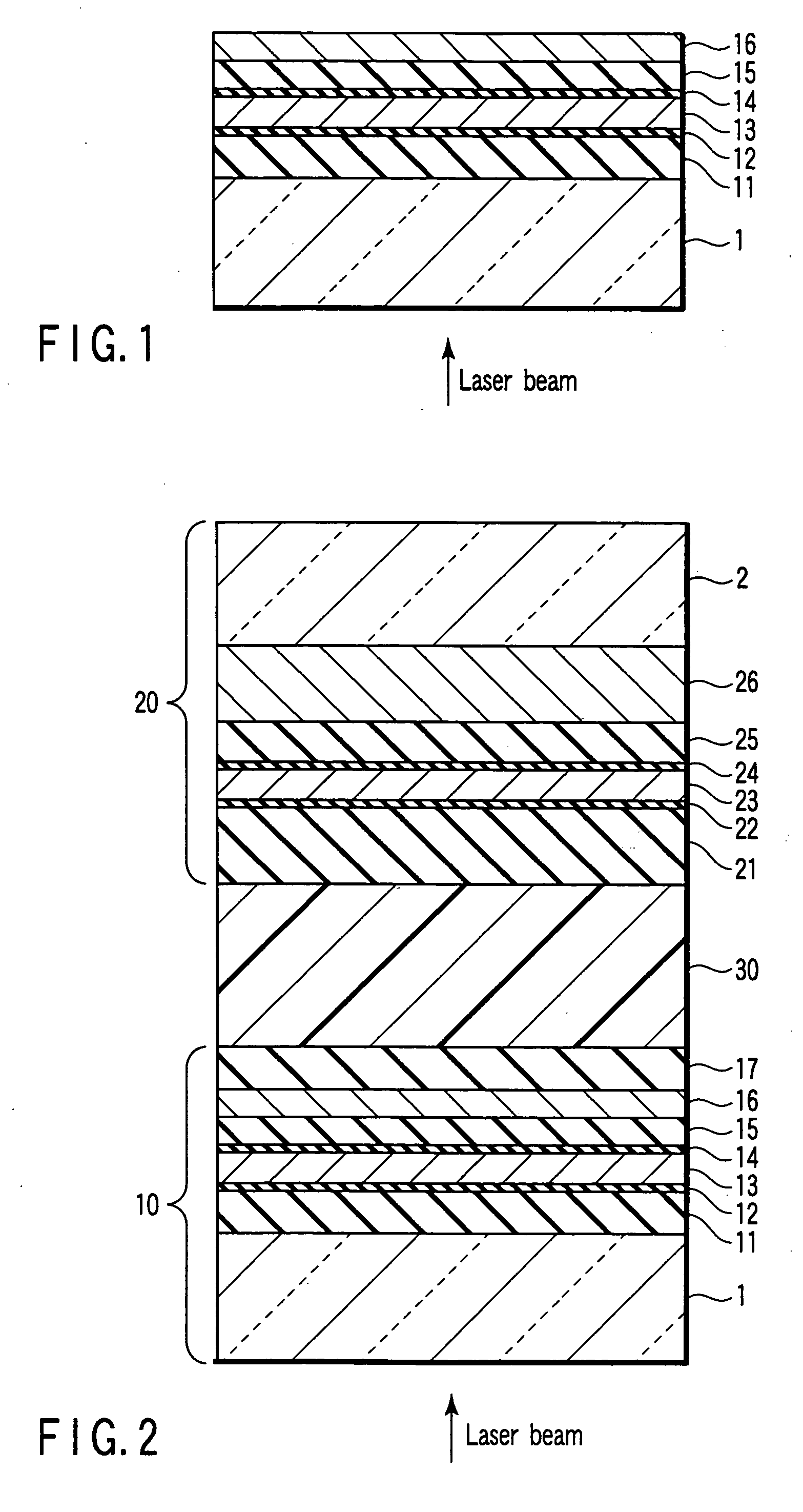

Memory, writing apparatus, reading apparatus, writing method, and reading method

InactiveUS20020131309A1Easy to implementElectrical apparatusRead-only memoriesAmorphous phaseCrystallization temperature

A memory includes: first and second recording layers for recording information by utilizing a reversible phase change between a crystalline phase and an amorphous phase which occurs due to increases in temperature caused by application of an electric current pulse. The crystallization temperatures of the first and second recording layers, Tx1 and Tx2 have the relationship Tx1<Tx2. The crystallization times of the first and second recording layers, tx1 and tx2, have the relationship tx1>tx2. Ra1+Ra2, Ra1+Rc2, Rc1+Ra2, and Rc1+Rc2are different from one another where the resistance value of the first recording layer in the amorphous phase is Ra1: the:resistance value of the first recording layer in the crystalline phase is Rc1, the resistance value of the second recording layer in the amorphous phase is Ra2 and the resistance value of the second recording layer In the crystalline phase is Rc2.

Owner:PANASONIC CORP

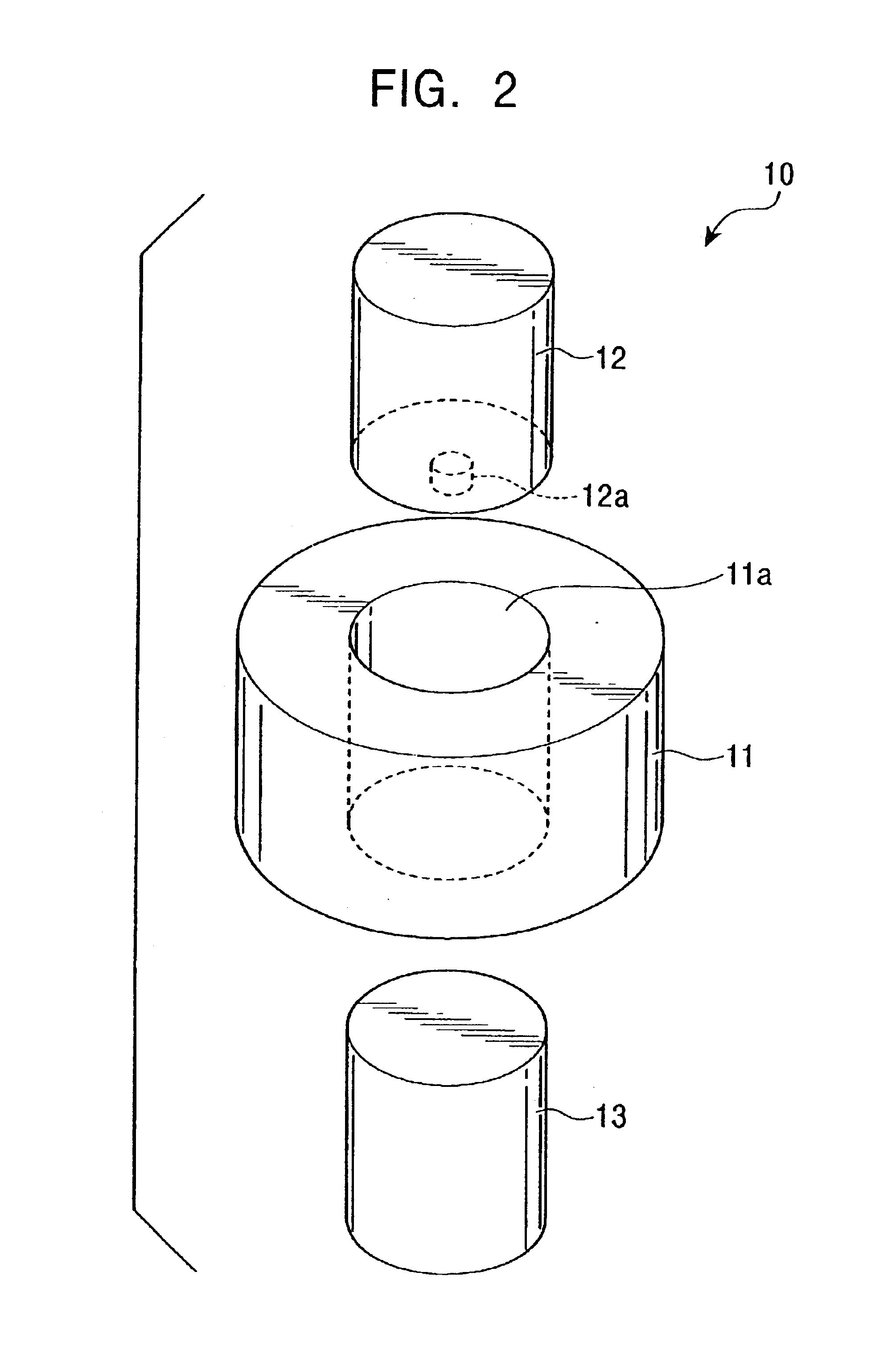

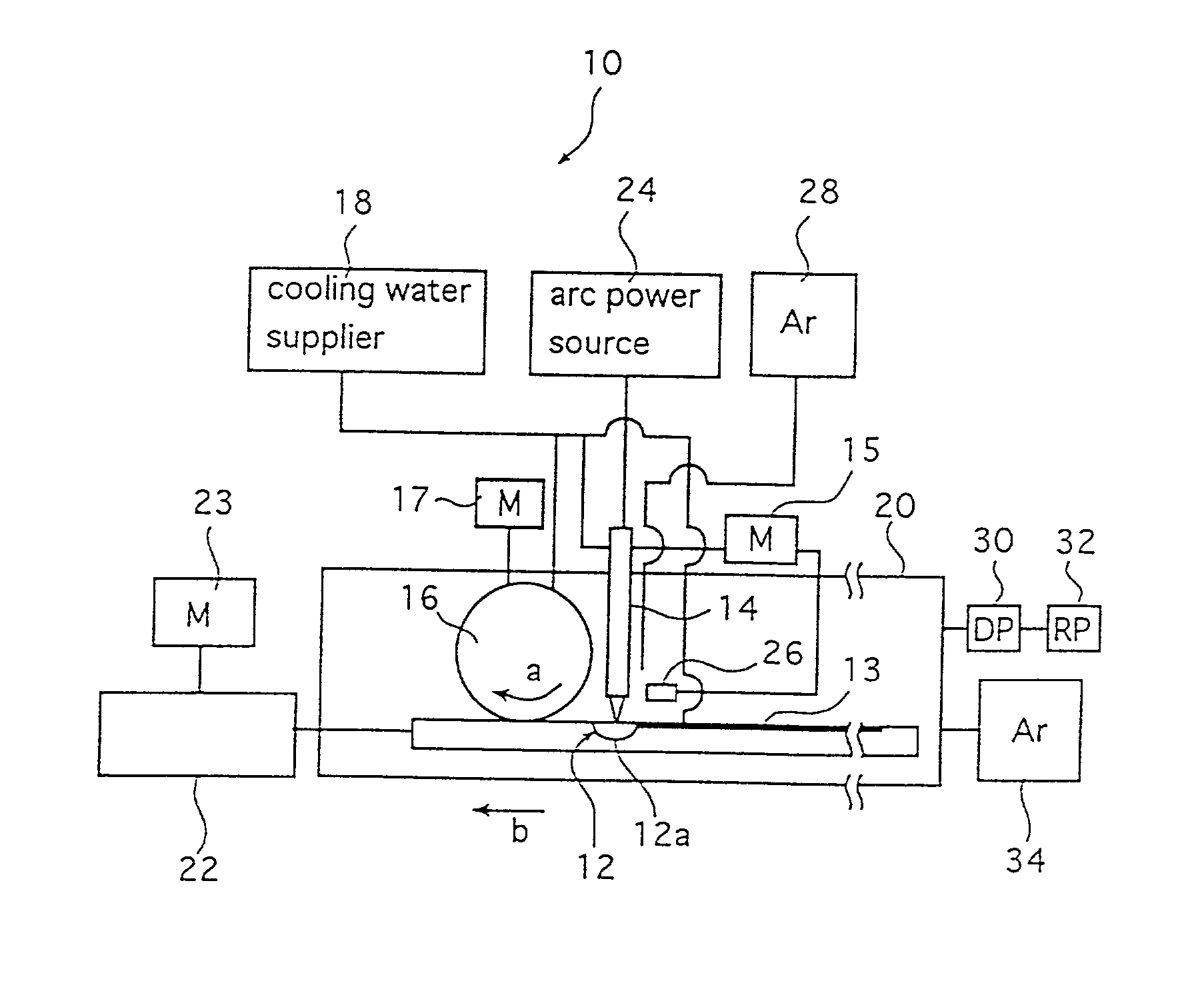

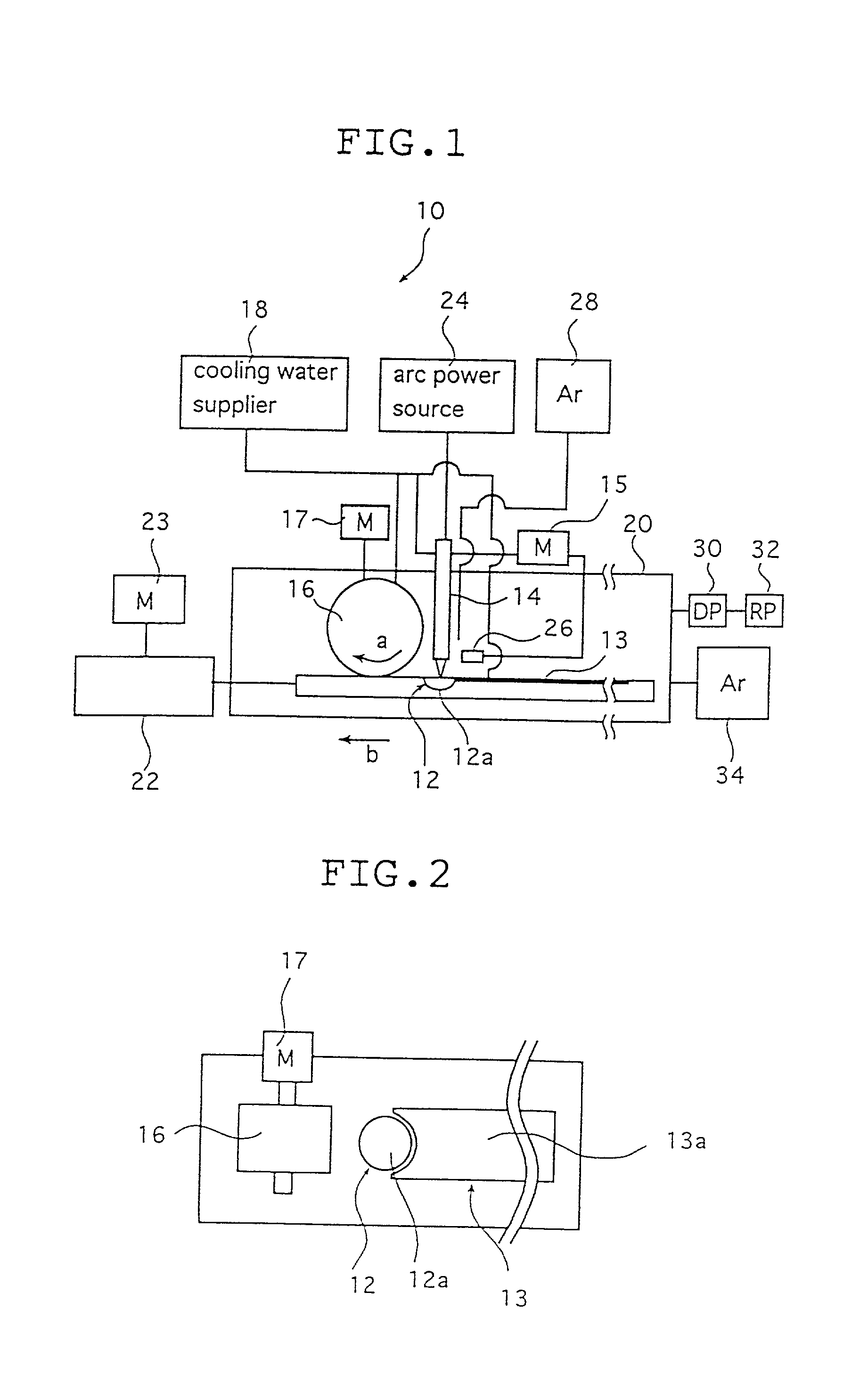

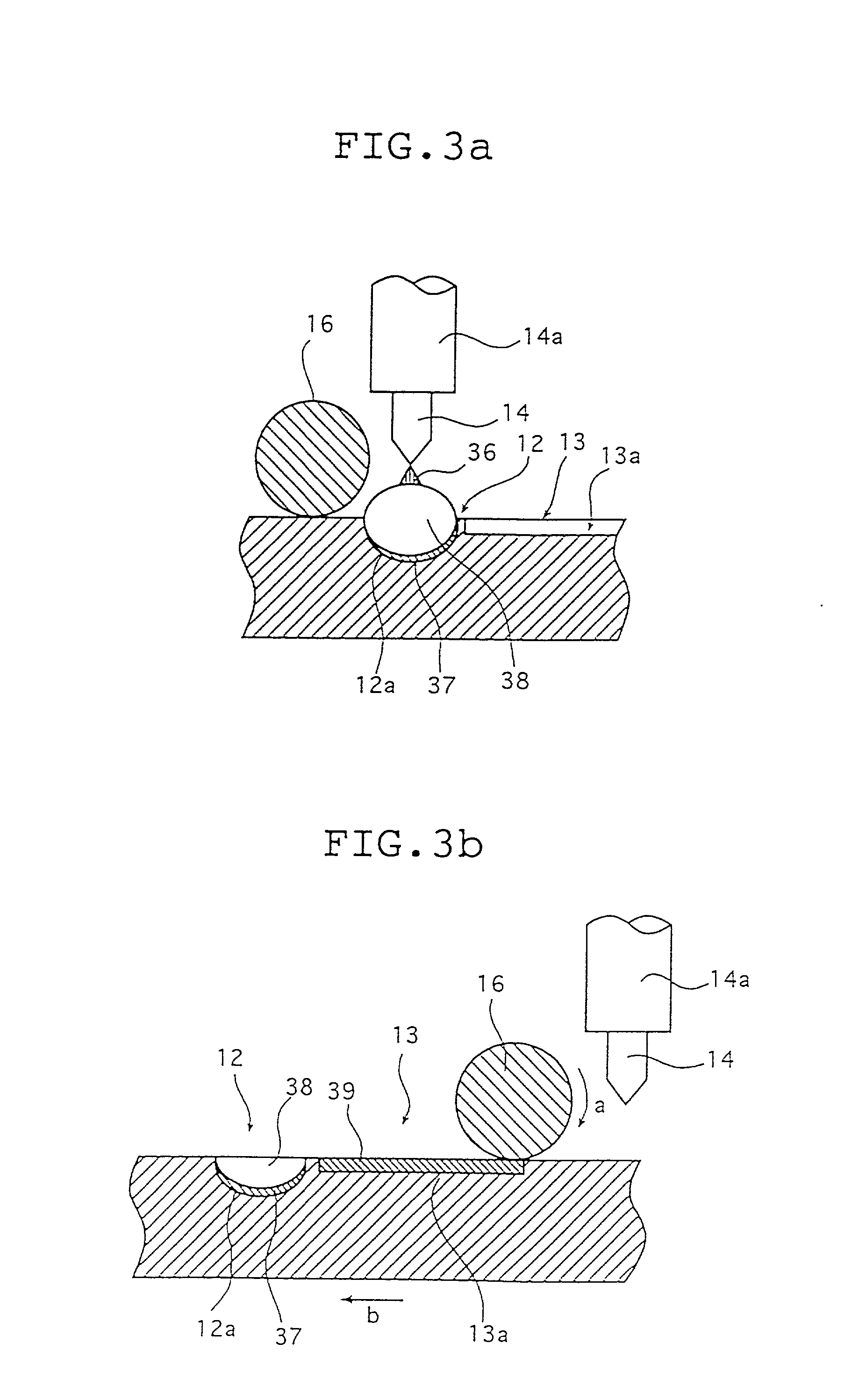

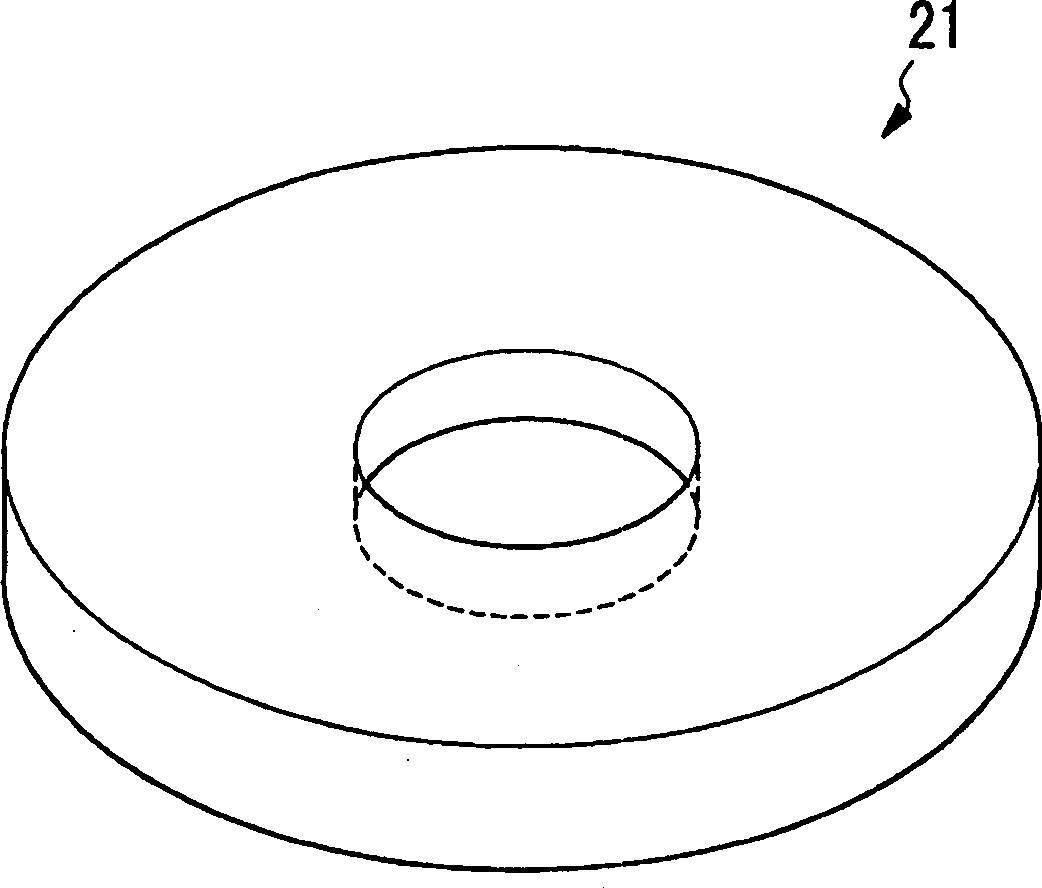

Process and apparatus for producing metallic glass

InactiveUS20020100573A1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyAlloy

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

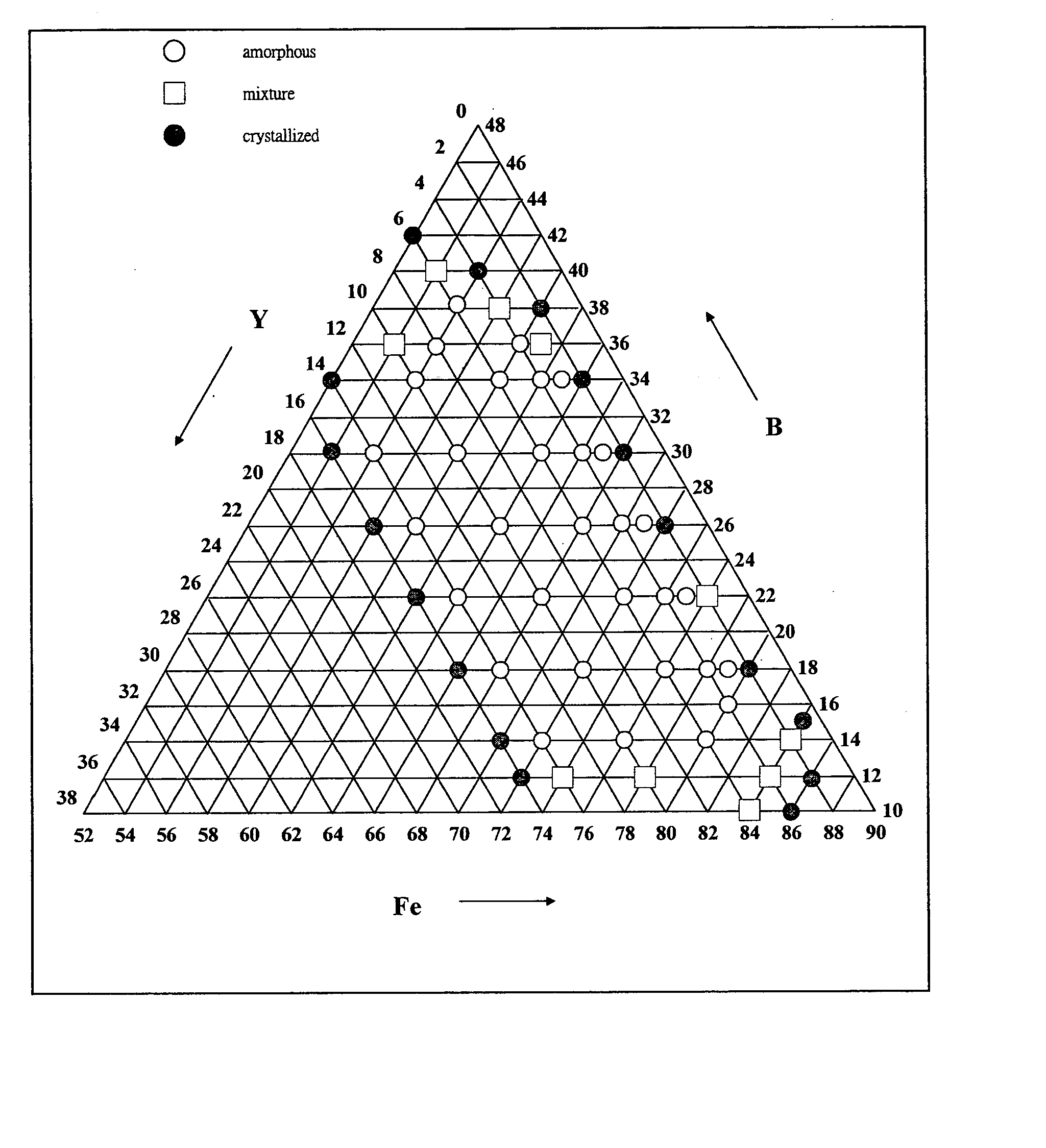

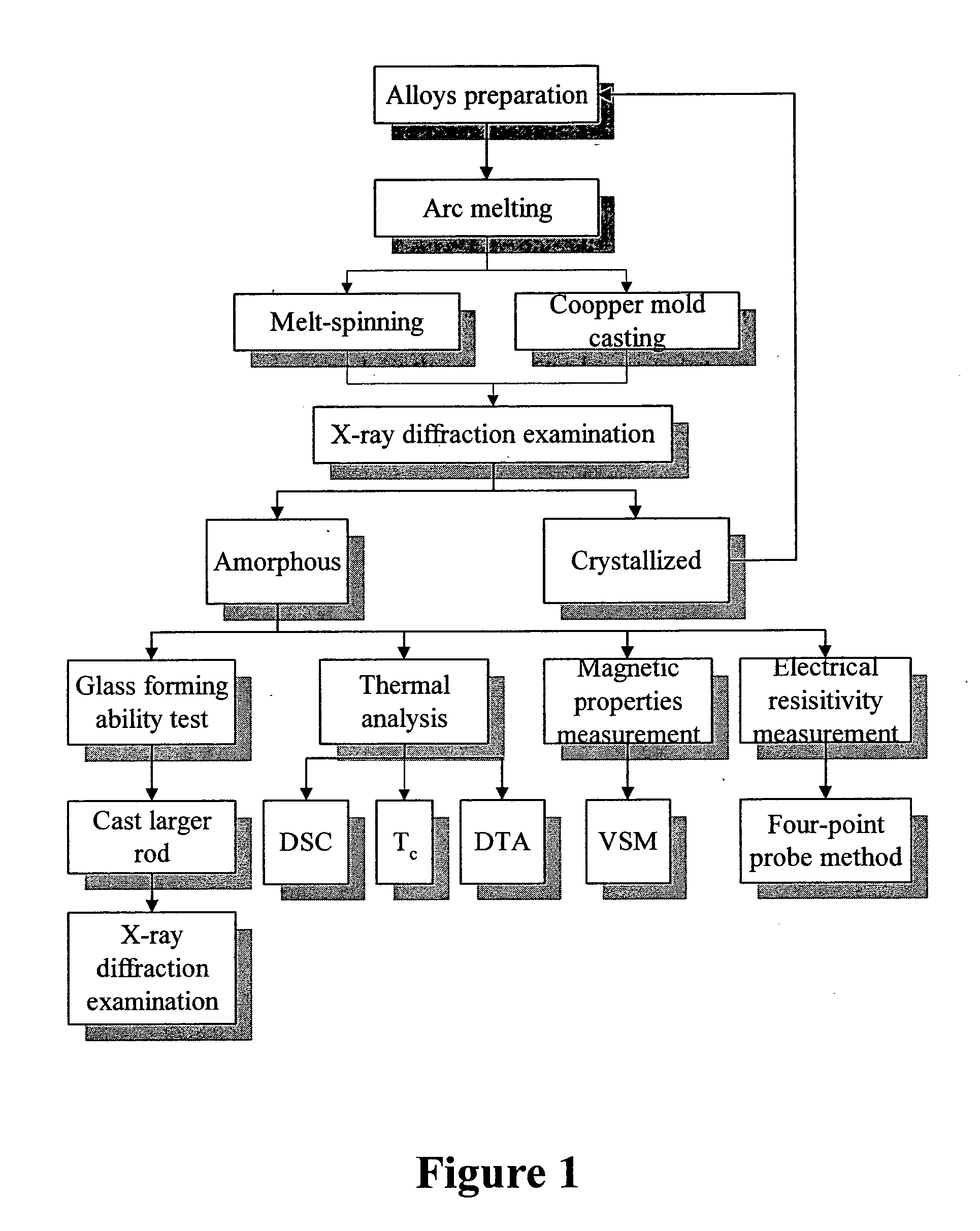

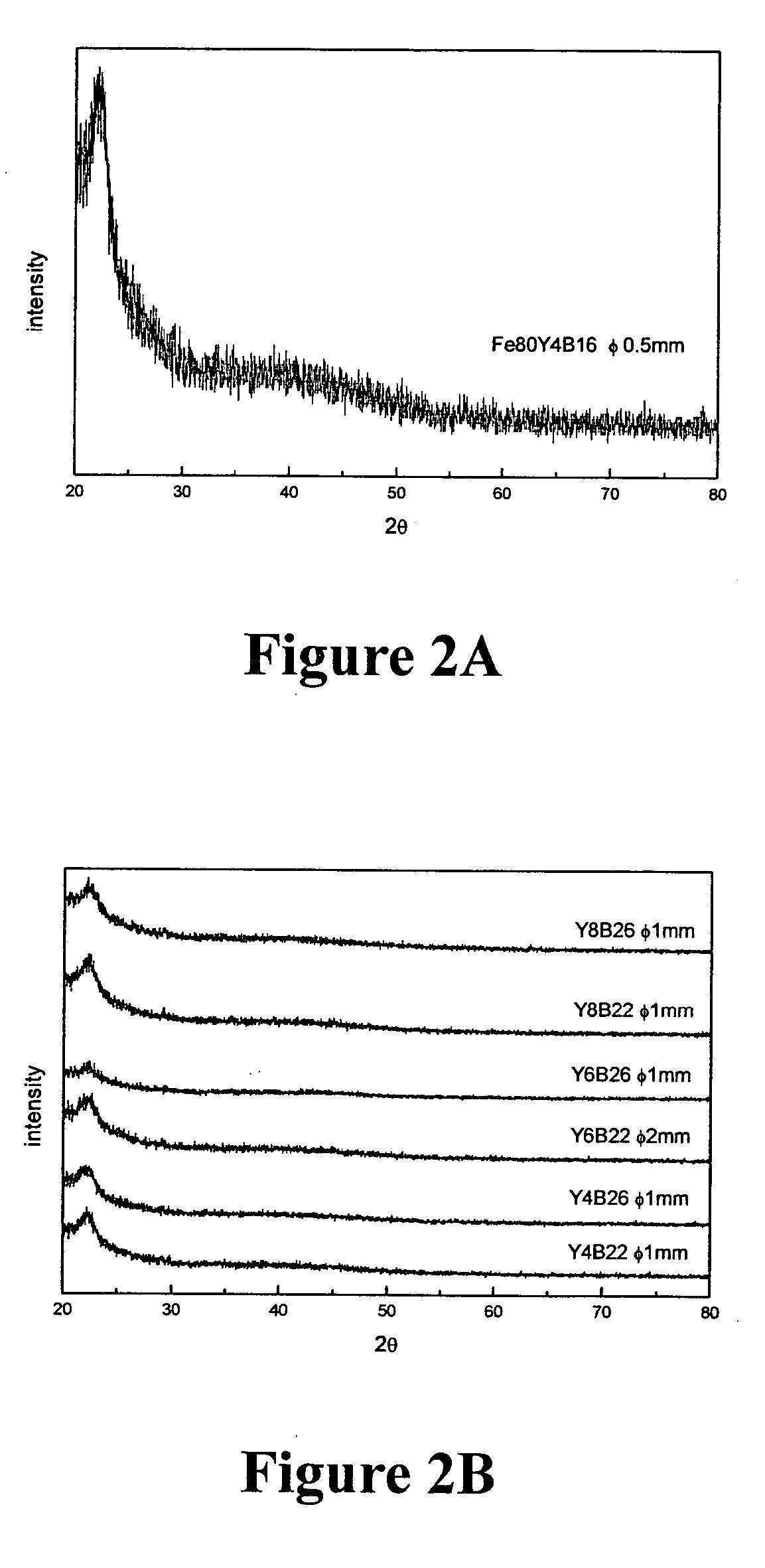

Ternary and multi-nary iron-based bulk glassy alloys and nanocrystalline alloys

InactiveUS20050263216A1High glass forming abilityIncreased electrical resistivityMagnetic materialsAmorphous phaseAtomic radius

Disclosed in this invention is a family of ternary and multi-nary iron-based new compositions of bulk metallic glasses which possess promising soft magnetic properties, and the composition selection rules that lead to the design of such new compositions. The embodiment alloys are represented by the formula MaXbZc, where M represents at least one of ferromagnetic elements such as iron and may partly be replaced by some other substitute elements; X is an element or combinations of elements selected from those with atomic radius at least 130% that of iron and in the mean time is able to form an M-rich eutectic; and Z is an element or combinations of elements selected from semi-metallic or non-metallic elements with atomic radius smaller than 86% that of iron and in the meantime is able to form an M-Z eutectic; a, b, c are the atomic percentage of M, X, Z, respectively, and a+b+c=100%. When 1%<b<15% and 10%<c<39%, the alloys show a bulk glass forming ability to cast amorphous ribbons / sheets at least 0.1 mm in thickness. When 3%<b<10% and 18%<c<30%, the alloys show a bulk glass forming ability to cast amorphous rods at least 1 mm in diameter. The amorphous phase of these as-cast sheets / rods is at least 95% by volume. This invention also discloses the existence of nano-crystalline phase outside of the outer regime of the bulk glass forming region mentioned above.

Owner:NATIONAL TSING HUA UNIVERSITY

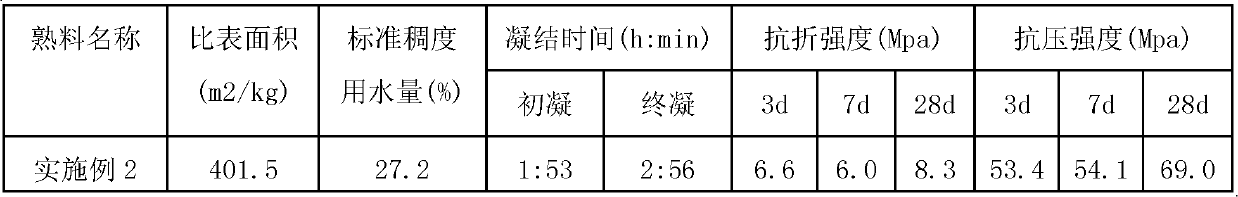

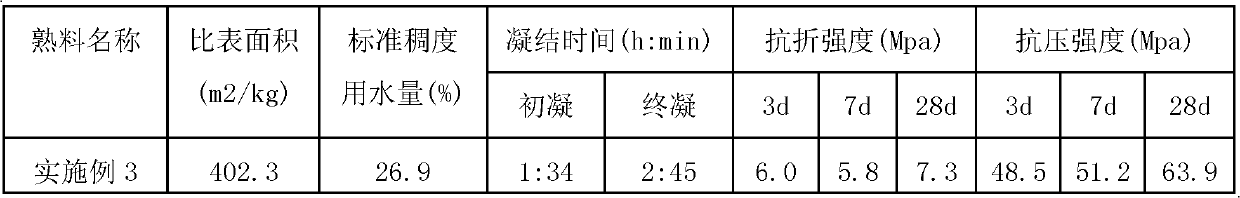

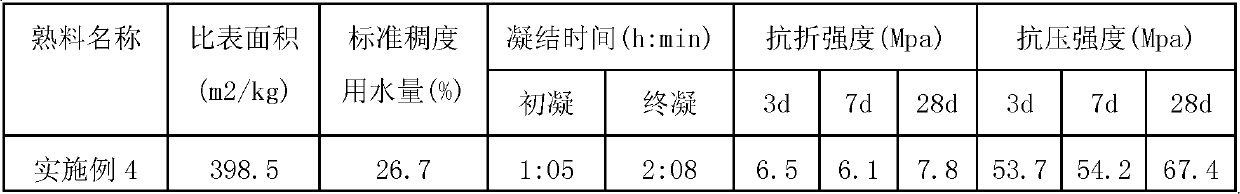

Active belite-sulphate aluminum cement clinker and preparation method for active belite-sulphate aluminum cement clinker

ActiveCN102584045AChange work performanceReduce manufacturing costCement productionAmorphous phaseMaceral

The invention discloses active belite-sulphate aluminum cement clinker, which comprises the following mineral compositions in weight percentage: 25-30 percent of beta-type C2S, 25-30 percent of a-type C2S, 28-40 percent of C4A3S`, 4-12 percent of C4AF and 4-8 percent of amorphous-phase substance. The control of different forms and the change of number of the C2S in the clinker are controlled mainly through special setting on clinker ingredient rate values. The invention also discloses a preparation method for the active belite-sulphate aluminum cement clinker. Compared with traditional common silicate cement clinker, the active belite-sulphate aluminum cement clinker has the advantages that more industrial solid waste residues are used in raw materials by the active belite-sulphate aluminum cement clinker, and thereby, the production cost is reduced, the use proportion of limestone is greatly reduced, and the carbon dioxide emission in clinker production is obviously reduced. Under the condition that the water demand and the setting time of the obtained clinker are basically the same as that of the common silicate cement clinker, the strength of the obtained clinker is superior to that of the common silicate cement clinker.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Information recording medium and medium for manufacturing the same

InactiveUS20050074694A1Decrease in recording sensitivityDecrease in signal intensitySenses disorderRadiation applicationsInformation layerAmorphous phase

An information recording medium includes a substrate and an information layer formed on the substrate. The information layer includes a recording layer whose phase can be changed between a crystalline phase and an amorphous phase by irradiation with a laser beam or application of electric energy; a Cr-containing layer including at least Cr and O, arranged in contact with a first surface of the recording layer; and a Ga-containing layer including at least Ga and O, arranged in contact with a second surface of the recording layer.

Owner:PANASONIC CORP

Soft-magnetic powder core and method of preparing the same

ActiveCN101226802AReduce permeabilityReduce AC lossInorganic material magnetismSoft magnetAmorphous phase

The invention relates to magnetic powder cores of soft magnet and a process of preparation thereof, belonging to the technical field of magnetic material. The magnetic powder cores of soft magnet is made from the following magnetic powders, a principal phase formed by one or a plurality of Fe based, Fe-Si based, Fe-B based, Fe-Si-B based and Fe-Al-B based and an amorphous phase which is inlaid in the principal phase and formed by one or plurality of Fe, C, Cu, Nb, Zr and Hf form nanocrystalline powders, wherein the principal phase is amorphous or in nanocrystalline state with average grain size of 3-100 nm. The prepared magnetic powder has the advantages of low eddy current loss, perfect direct current superposition property, suitable for higher frequency and the like.

Owner:CHINA JILIANG UNIV +1

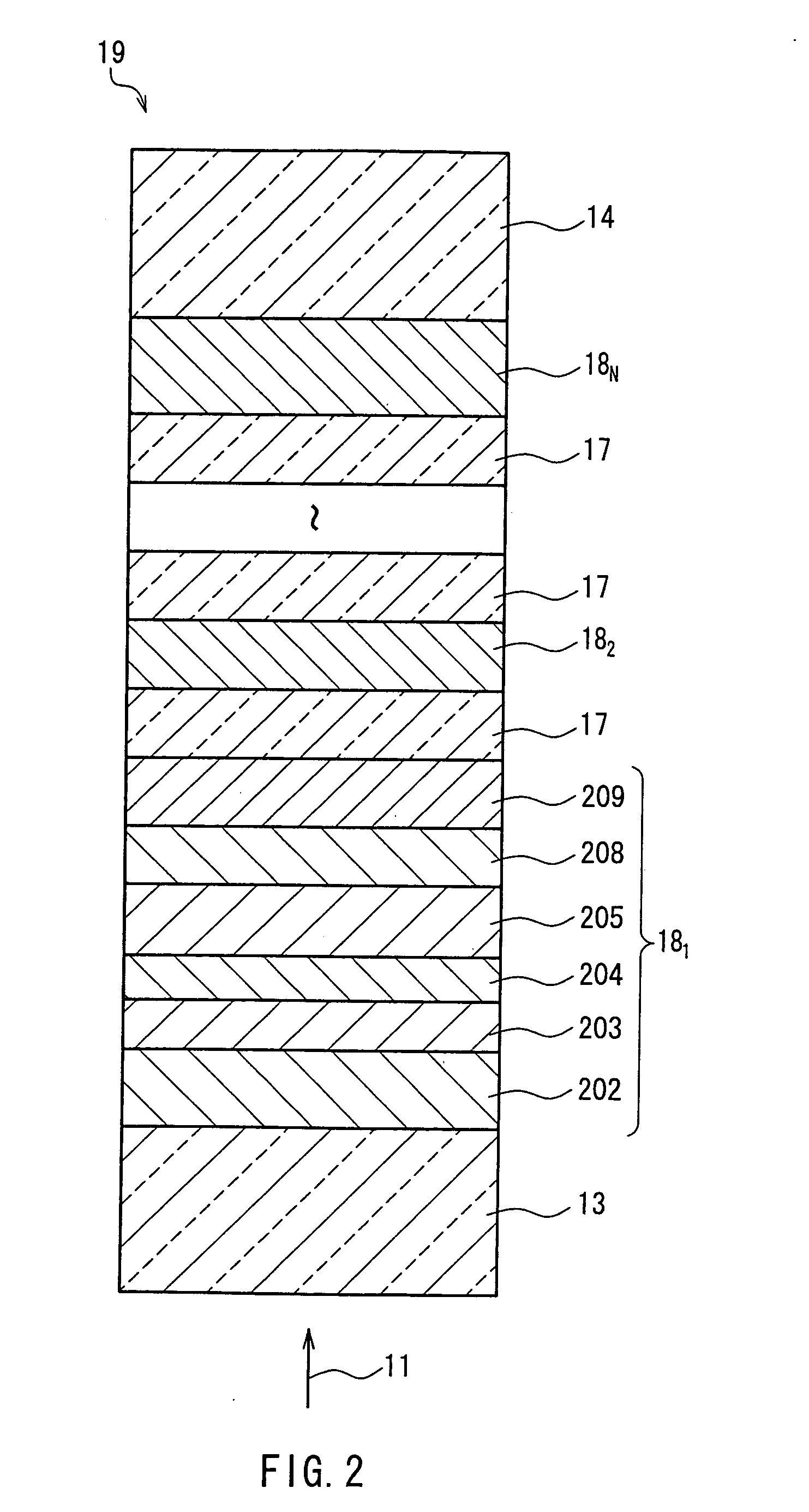

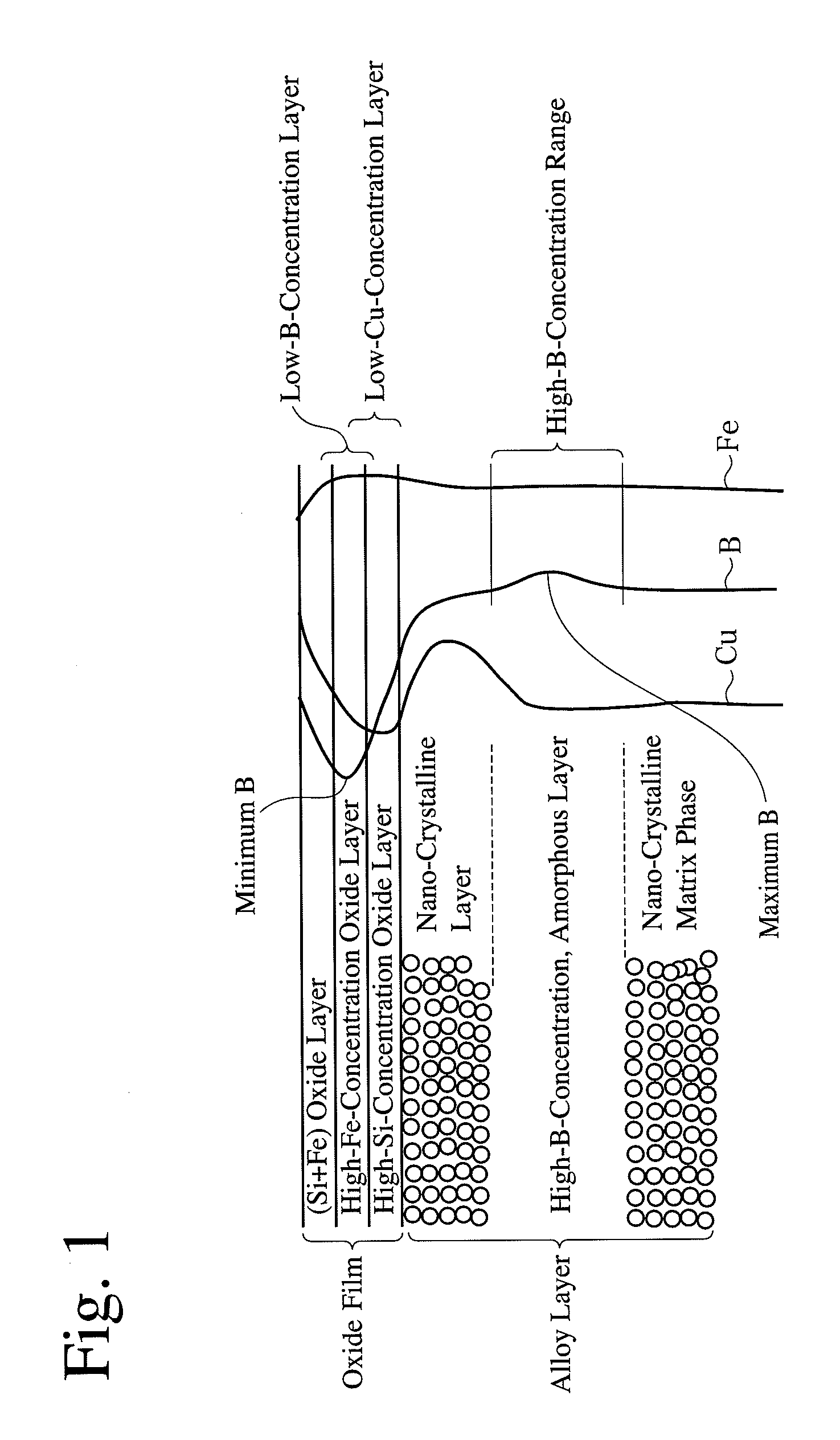

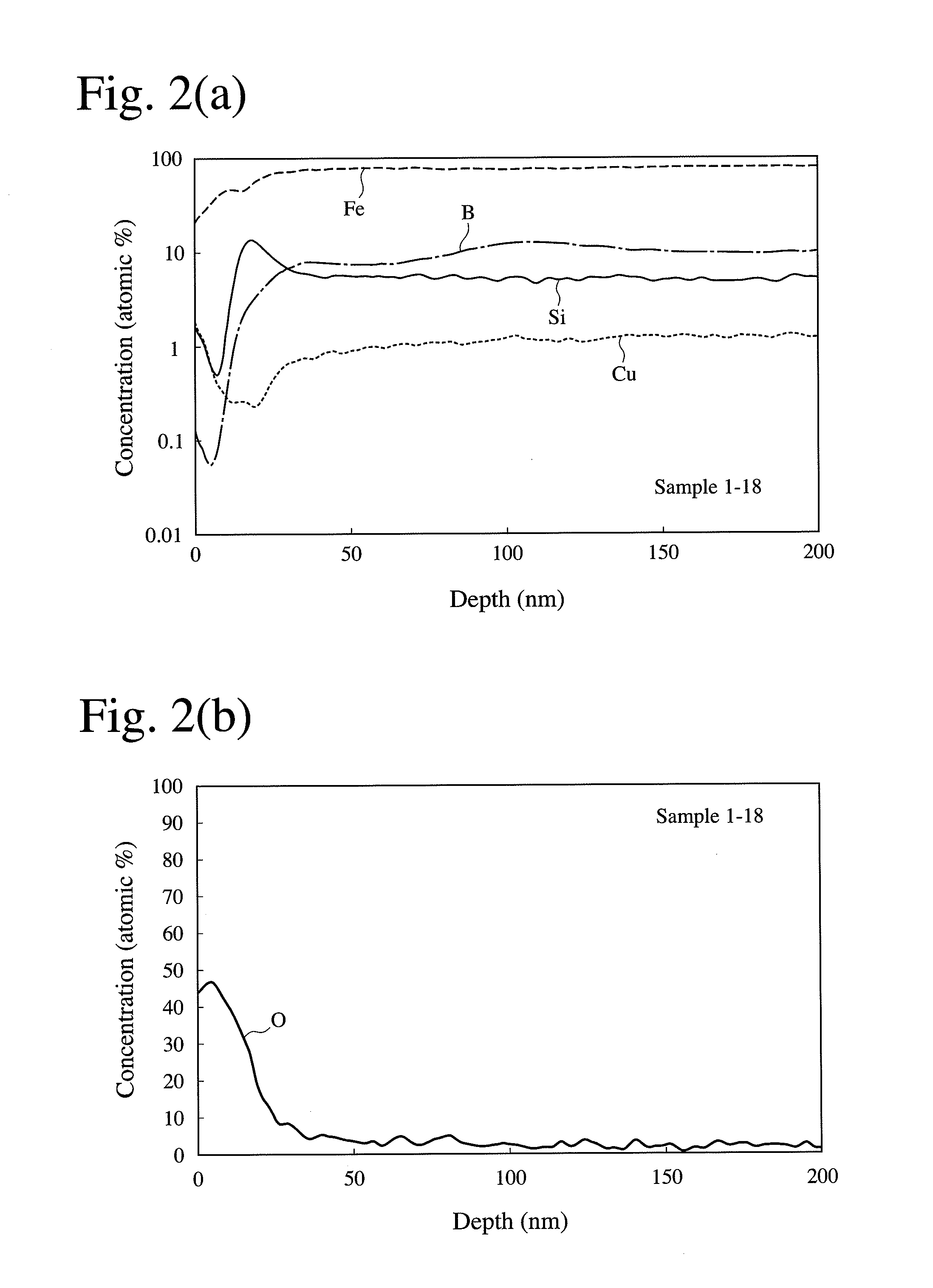

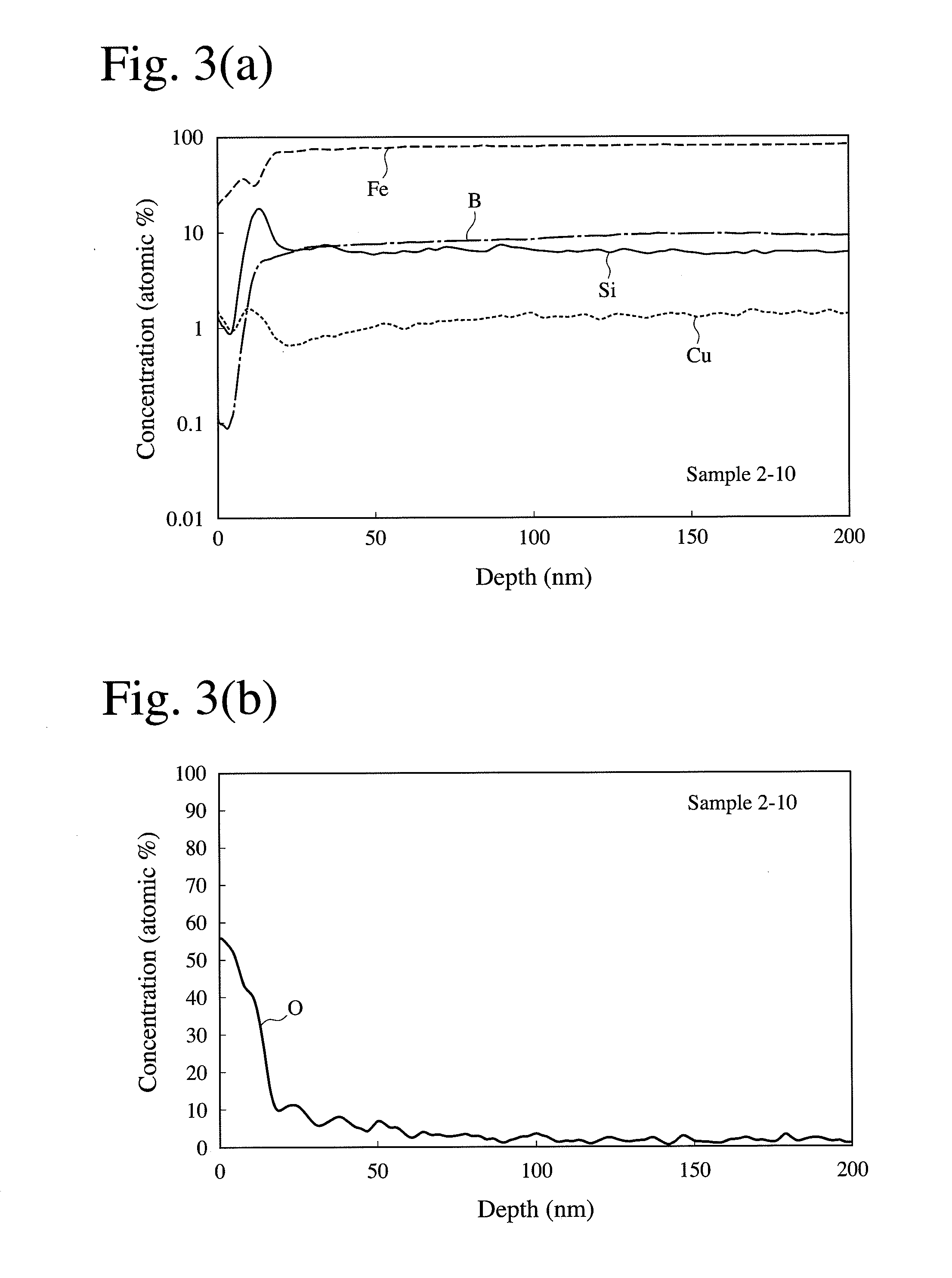

Soft magnetic alloy ribbon and its production method, and magnetic device having soft magnetic alloy ribbon

ActiveUS20110272065A1High saturated magnetic flux densityLow core lossMaterial nanotechnologyNanomagnetismAmorphous phaseQuenching

A method for producing a soft magnetic alloy ribbon having a composition represented by Fe100−x−y−zAxByXz, wherein A is Cu and / or Au, X is at least one element selected from the group consisting of Si, S, C, P, Al, Ge, Ga and Be, and x, y and z are numbers (by atomic %) meeting the conditions of 0<x≦5, 10≦y≦22, 1≦z≦10, and x+y+z≦25, and comprising a matrix phase in which fine crystal grains having an average diameter of 60 nm or less are dispersed at a volume fraction of 50% or more, part of an oxide film formed on the surface being a layer having a lower B concentration than the average B concentration of the matrix phase; comprising the steps of (1) ejecting an alloy melt having the above composition onto a rotating cooling roll for quenching, to form a primary fine-crystalline alloy ribbon having a matrix phase, in which fine crystal nuclei having an average diameter of 30 nm or less are dispersed at a volume fraction of more than 0% and less than 30% in an amorphous phase; and then (2) annealing the primary fine-crystalline alloy ribbon in an atmosphere having an oxygen concentration of 6-18%.

Owner:HITACHI METALS LTD

Phase-change optical recording medium

A phase-change optical recording medium has a recording film that brings about reversible phase-change between a crystalline phase and an amorphous phase upon irradiation with light and an interface film formed in contact with at least one surface of the recording film and comprising hafnium (Hf), silicon (Si), oxygen (O) and carbon (C).

Owner:KK TOSHIBA

Noncrystalline soft magnetic alloy powder and dust core, electricwale absorber using the same

ActiveCN1487536AExcellent soft magnetic propertiesSpeed up coolingInorganic material magnetismCores/yokesMetallurgyAmorphous phase

Provided is amorphous soft magnetic alloy powder which has high saturation magnetization and low core loss and which is almost spherical and manufactured by water atomization method, and to provide a green compact core and radio wave absorber using the same. This amorphous soft magnetic alloy powder is formed substantially spherical by the water atomization method. The powder mainly consists of Fe and contains at least P, C and B, and is formed of amorphous soft magnetic alloy powder consisting of an amorphous phase with a temperature interval DeltaTx of the supercooled liquid of >= 20K. A green compact core is formed by solidifying the granulated mixture of this amorphous soft magnetic alloy powder, insulator and lubricant. The radio wave absorber is formed by mixing the amorphous soft magnetic alloy powder the particles of which is flattened and insulator.

Owner:ALPS ALPINE CO LTD

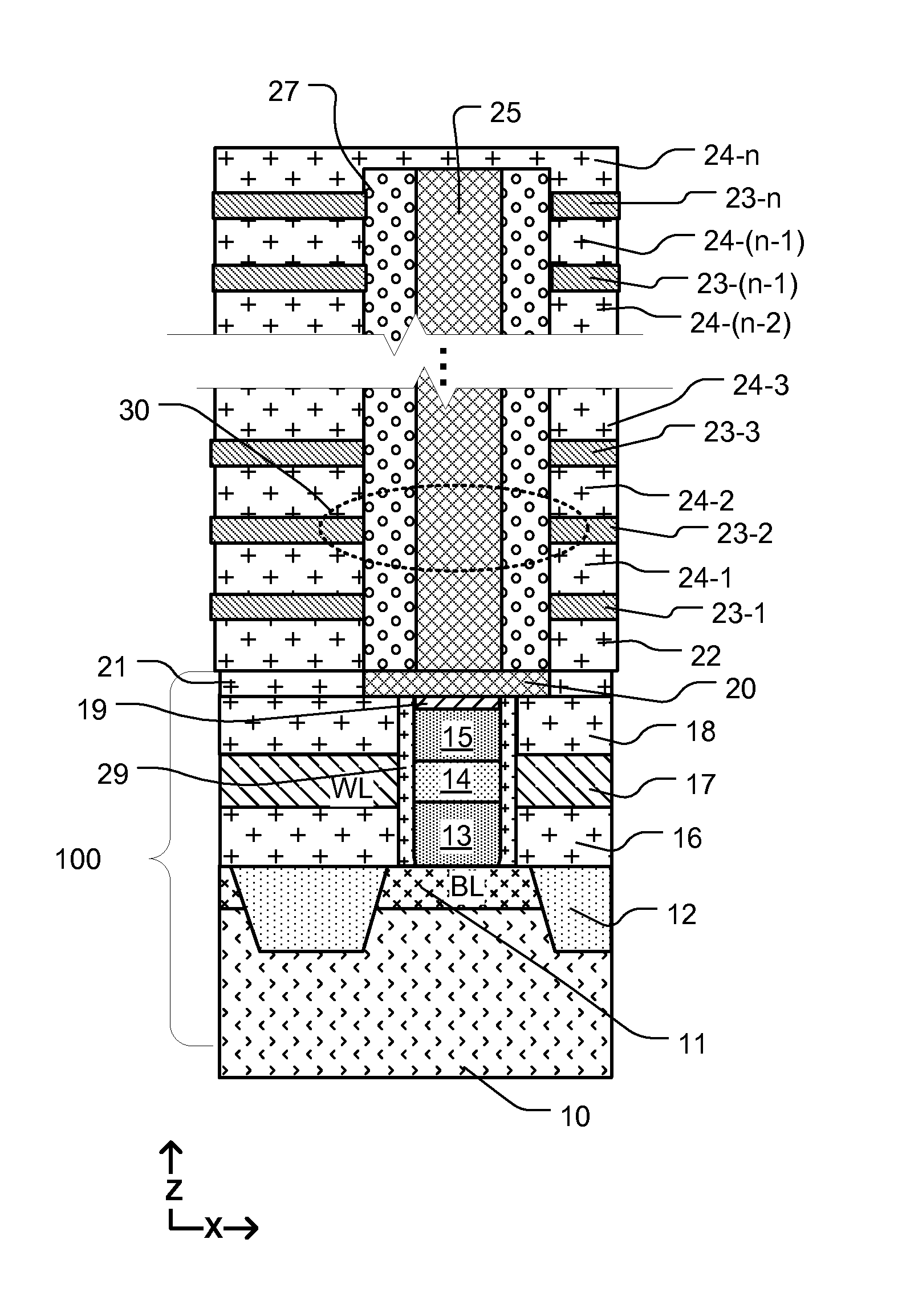

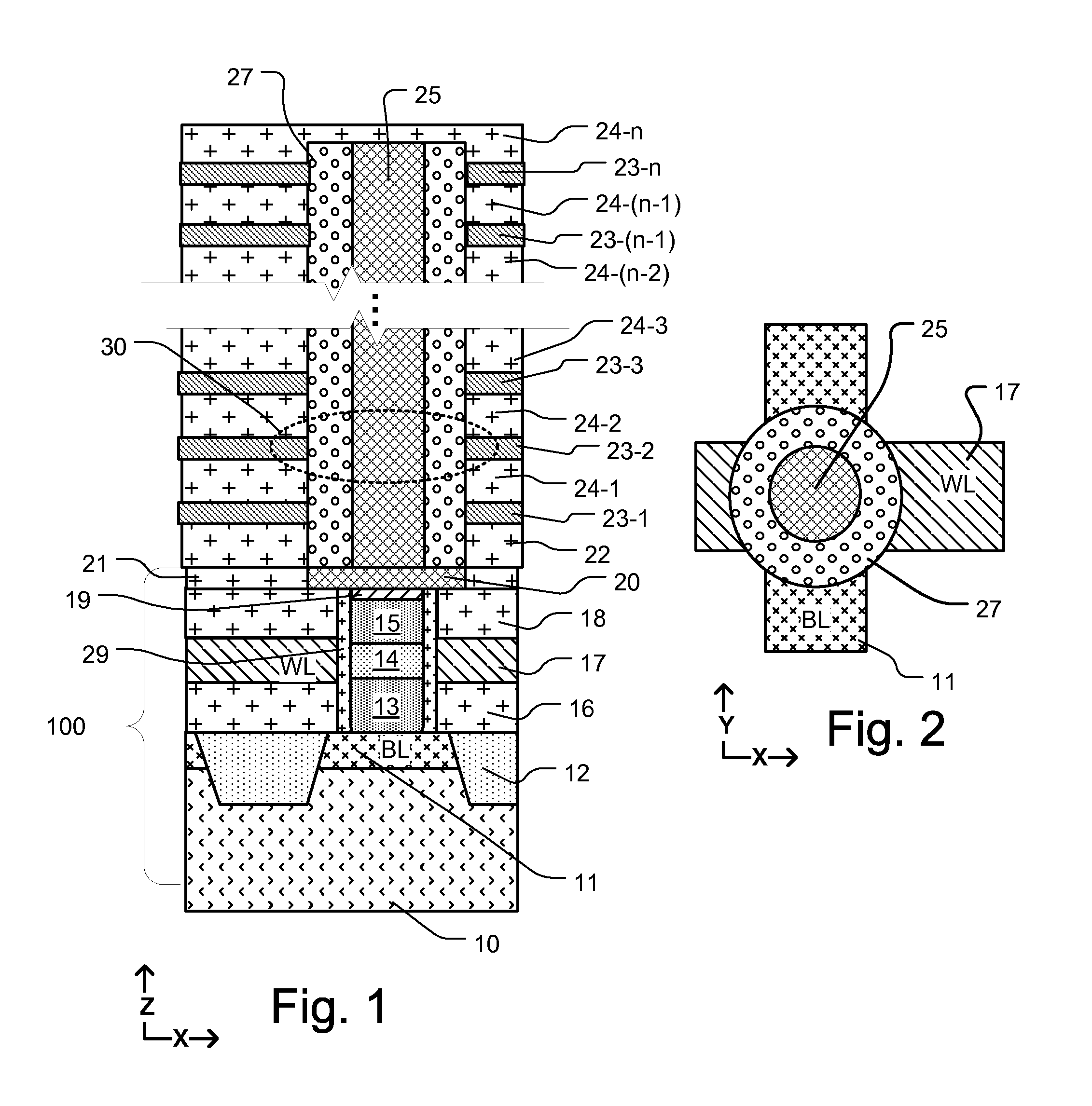

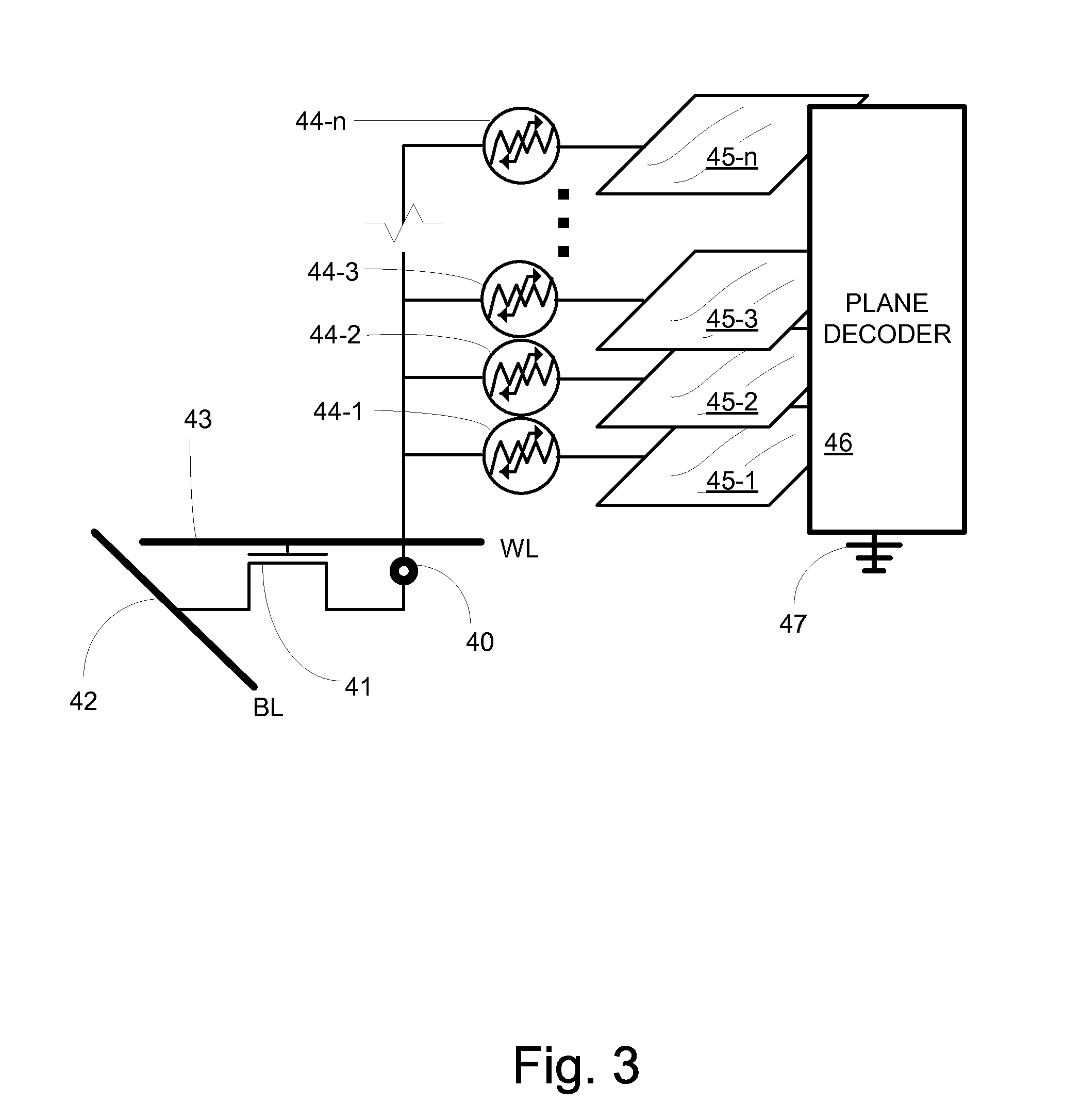

Integrated circuit 3D phase change memory array and manufacturing method

ActiveUS20140198553A1Semiconductor/solid-state device manufacturingDigital storagePhase-change memoryAmorphous phase

A 3D phase change memory device can store multiple bits per cell represented by a plurality of non-overlapping ranges of resistance all of which are established by different resistance ranges corresponding to respective amorphous phase thickness of the phase change memory material. An array of access devices can underlie a plurality of conductive layers, separated from each other and from the array of access devices by insulating layers. An array of pillars extending through the plurality of conductive layers contact corresponding access devices. The phase memory material is between the pillars and conductive layers. Circuitry is configured to program data in the memory cells using programming pulses having shapes that depend on the resistance range of the cell before programming and the data values to be stored.

Owner:MACRONIX INT CO LTD

Iron-based nanometer crystal magnetically soft alloy and preparation method thereof

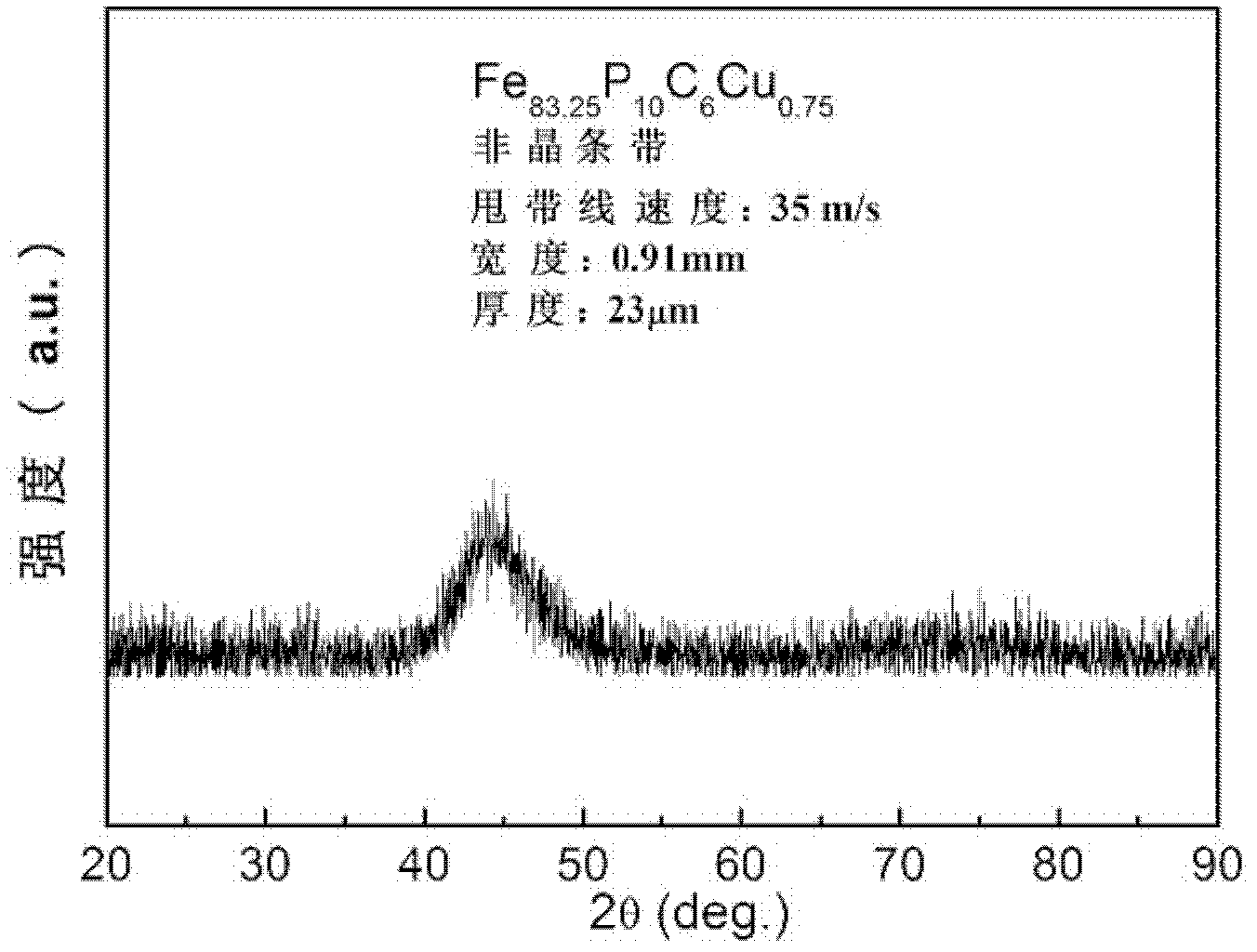

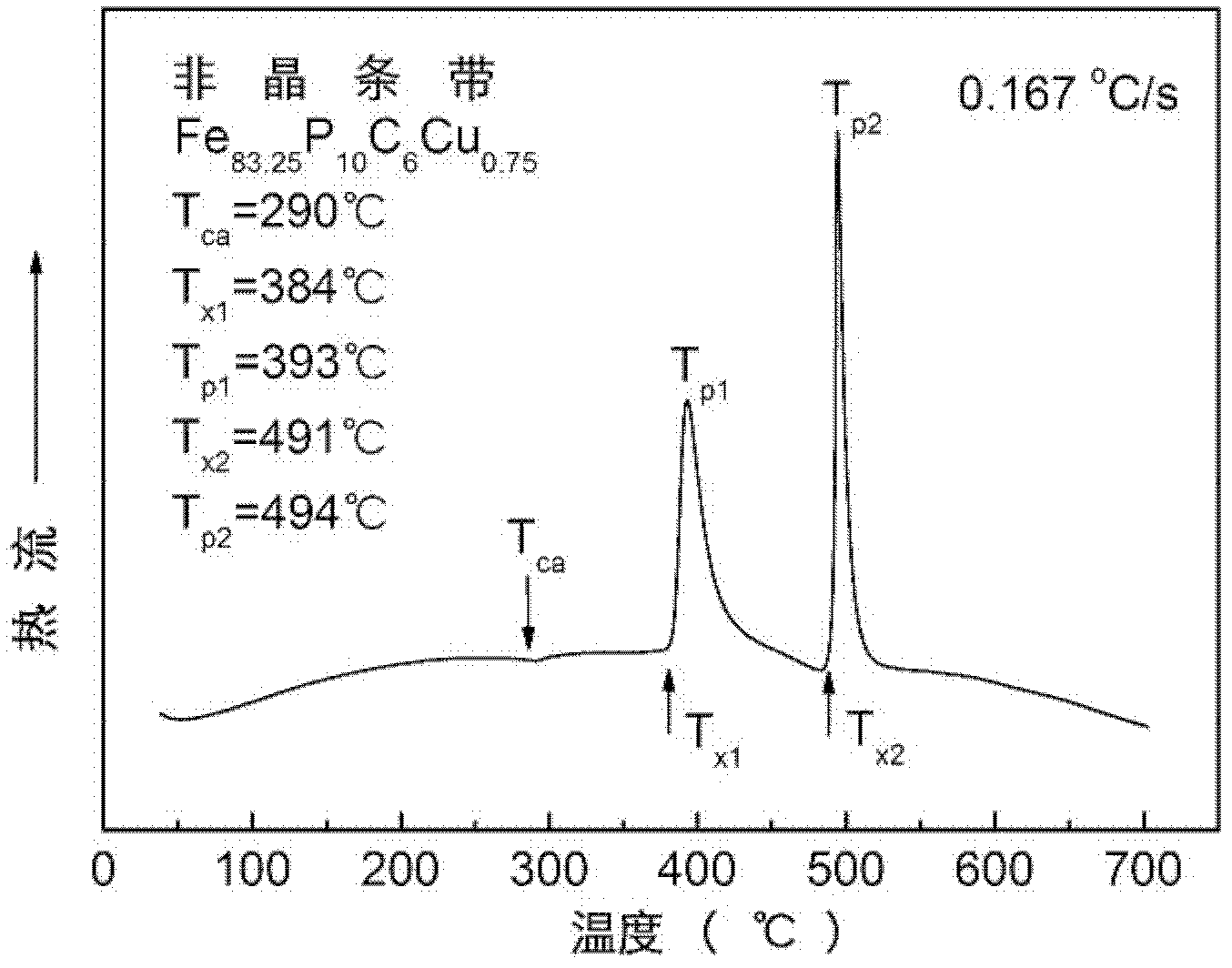

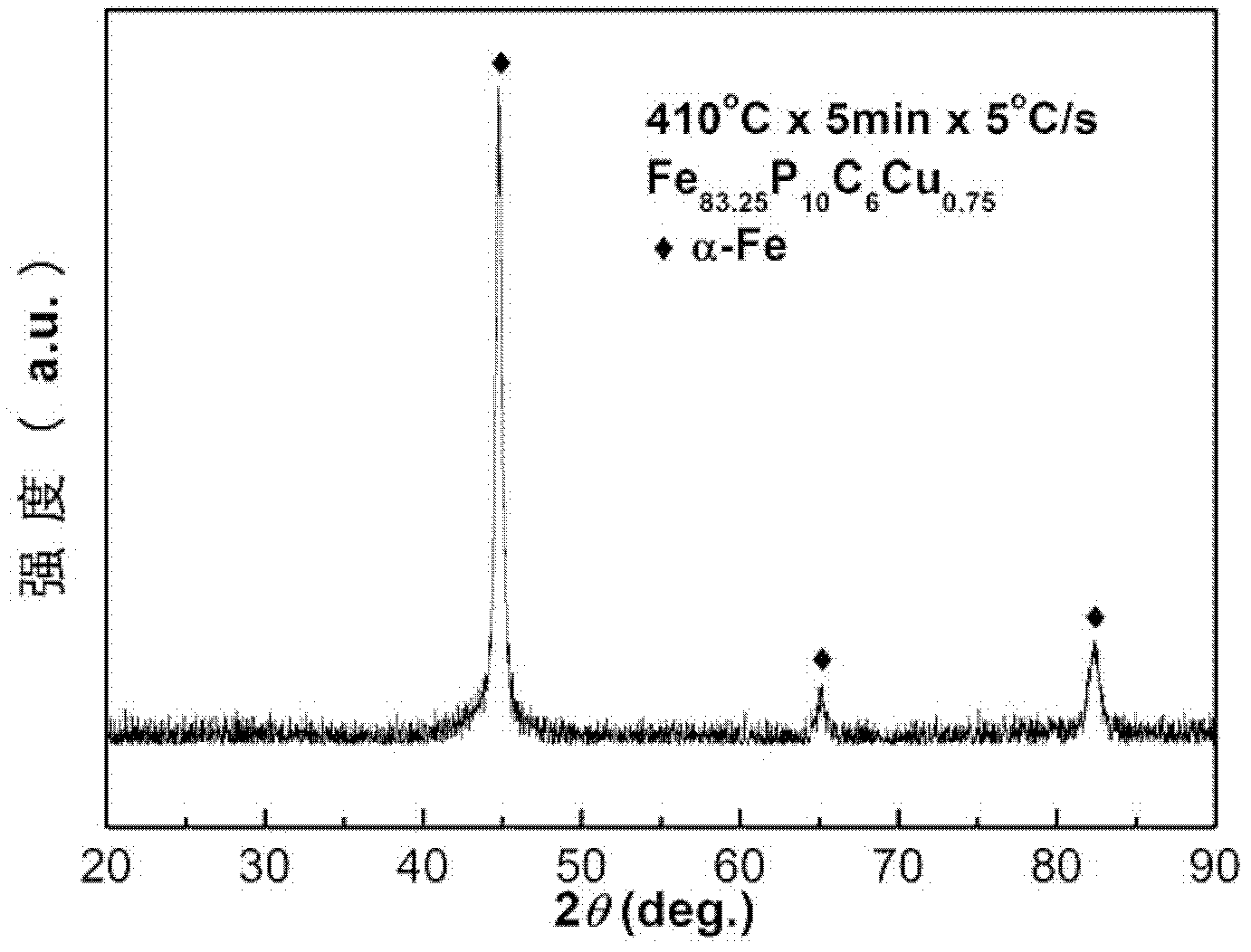

ActiveCN102543347AReduce processing costsHigh saturation magnetic inductionMagnetic materialsAmorphous phaseAlloy

The invention discloses a novel iron-based nanometer crystal magnetically soft alloy and a preparation method thereof. The molecular formula of the iron-based nanometer crystal magnetically soft alloy is FexPyCzMaCub, wherein the M in the molecular formula is one or more than one of B, Si, Al, Cr, Mn, Mo and Ge; x,y,z,a and b respectively represent atom percentage composition of each corresponding component, wherein 70<=x<=90, 1<=y<=20, 1<=z<=20, 0<=a<=10, 0.1<=b<=2, and x+y+z+a+b=100; and a microstructure is coexistence of a body-centered stand alpha-Fe nanometer crystalline phase the size of which is 5-40 nm and a rich phosphatic and carbon amorphous phase. Compared with the existing nanometer crystal magnetically soft alloy, the alloy disclosed by the invention meanwhile has the advantages of high saturation induction density, low coercive force, low iron loss and high magnetic permeability; and in addition, precious metals such as Nb, Zr, Co, Ni, Y and the like are not contained, thus the processing cost is greatly reduced and the application prospect is good.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com