Patents

Literature

575results about How to "High saturation magnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

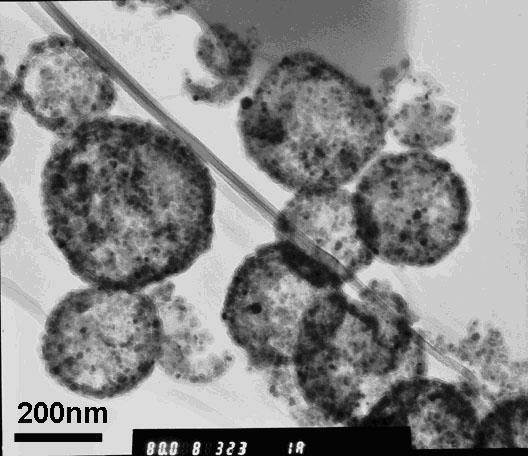

Preparation method of magnetic beads by extracting nucleic acid and application of method

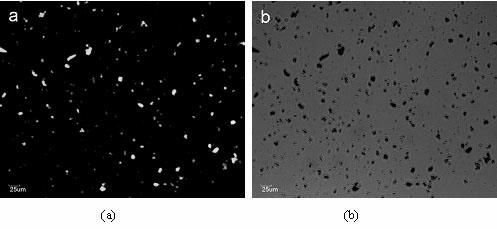

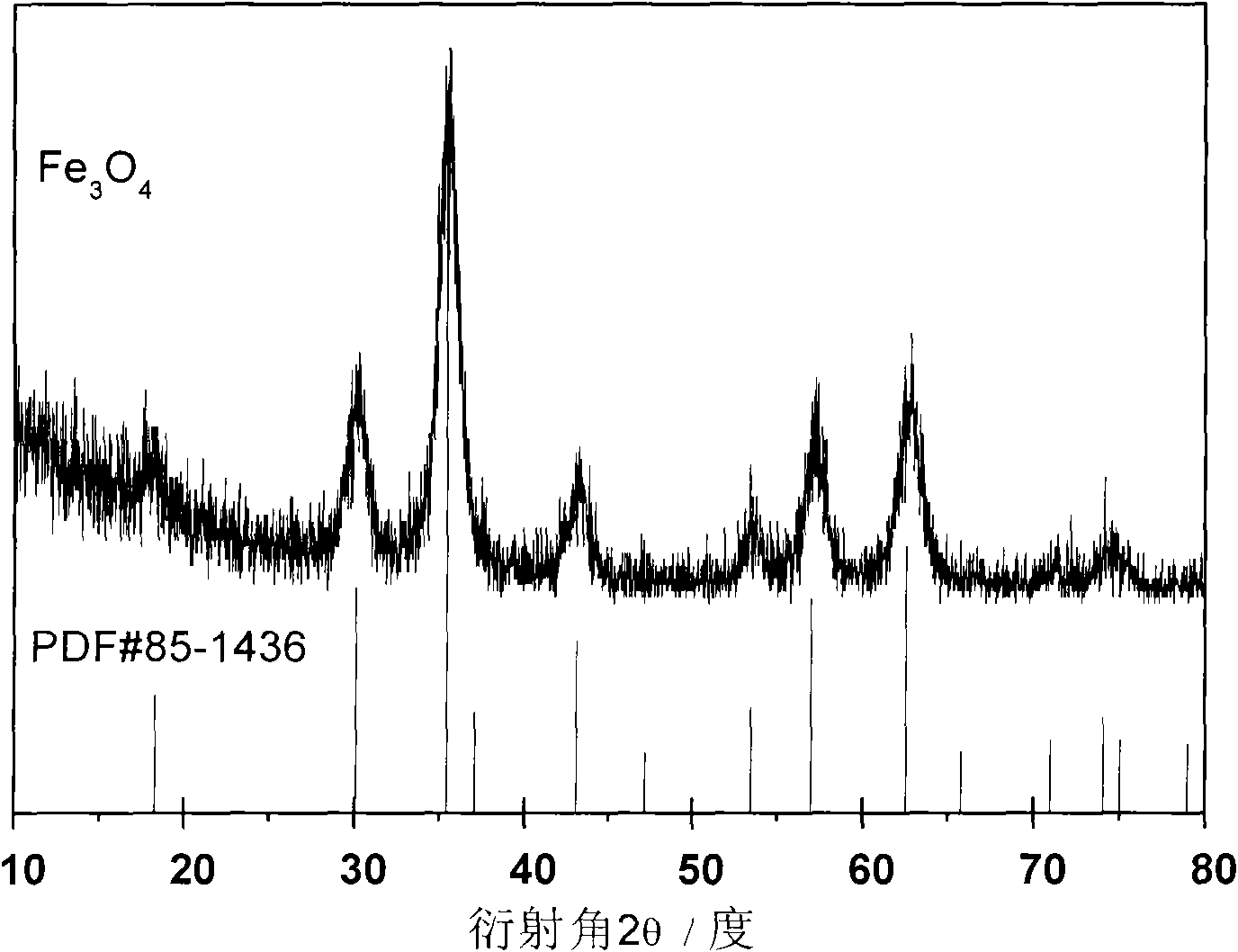

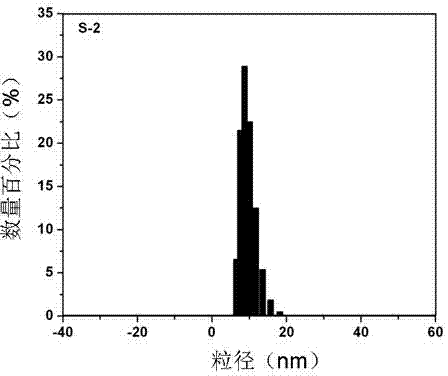

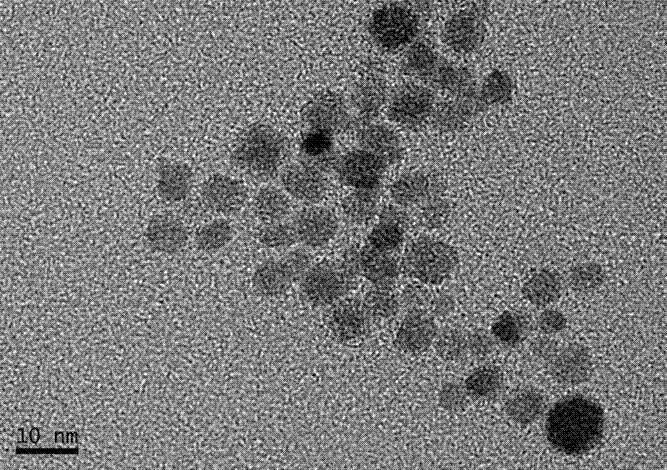

ActiveCN103908945AHigh saturation magnetizationImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMagnetic beadMagnetite Nanoparticles

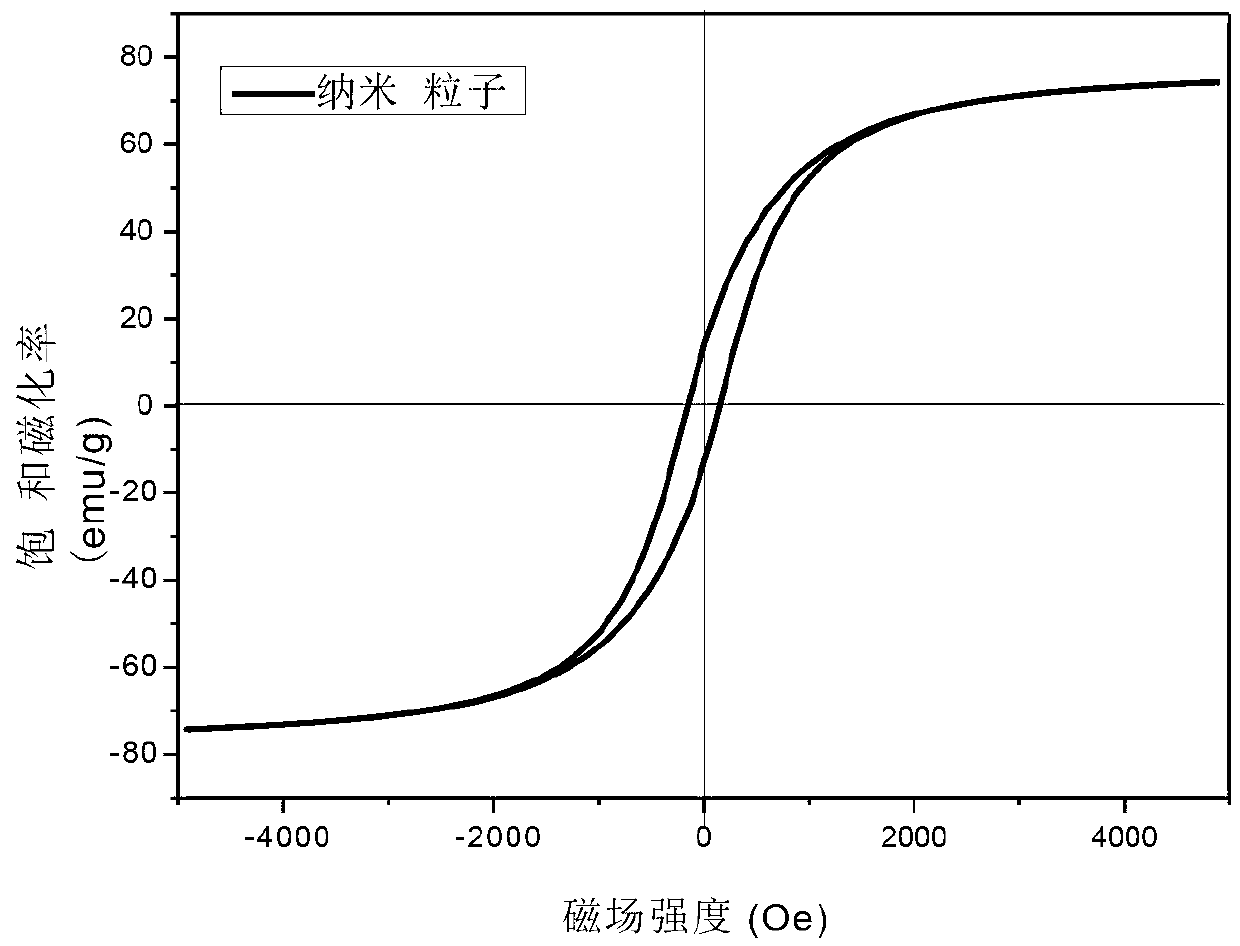

The invention discloses a preparation method of magnetic beads by extracting nucleic acid. The surfaces of magnetic nanoparticles Fe3O4 are coated with silicon hydroxyl and then are dispersed into a 0.02% NaN3 aqueous solution; the prepared silicon-based magnetic bead is of a core-shell structure and comprises a Fe3O4 nanoparticle core and a SiO2 shell layer, wherein the outer surfaces of a plurality of Fe3O4 nano-particles are coated with the SiO2 shell layer; the silicon-based magnetic bead has the secondary particle size of 400nm-1 micron, measured by a nanometer laser particle analyzer, and has the saturation magnetization of 43.0-74.5emu / g after being subjected to ultrasonic dispersion for 1h; the prepared silicon-based magnetic bead can be widely applied to nucleic acid extraction and purification of biomaterials such as fresh animal tissues, animal tissue paraffin sections, plant leaves, seeds, whole blood, free serum, hairs, fingernails, stubs, saliva, bacteria or viruses. The method is simple in process flow, convenient to operate, and low in raw material cost and is suitable for being used in industrial mass production.

Owner:滁州市方舟医疗科技有限责任公司

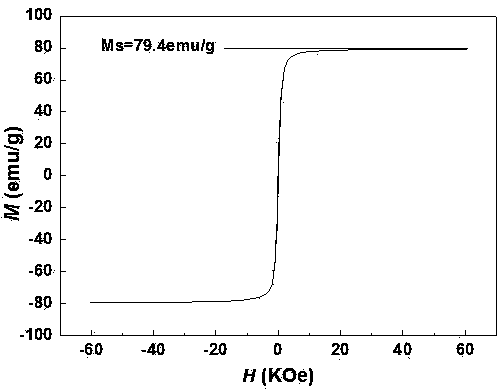

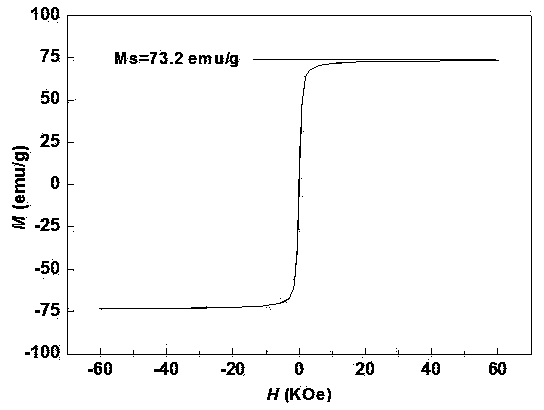

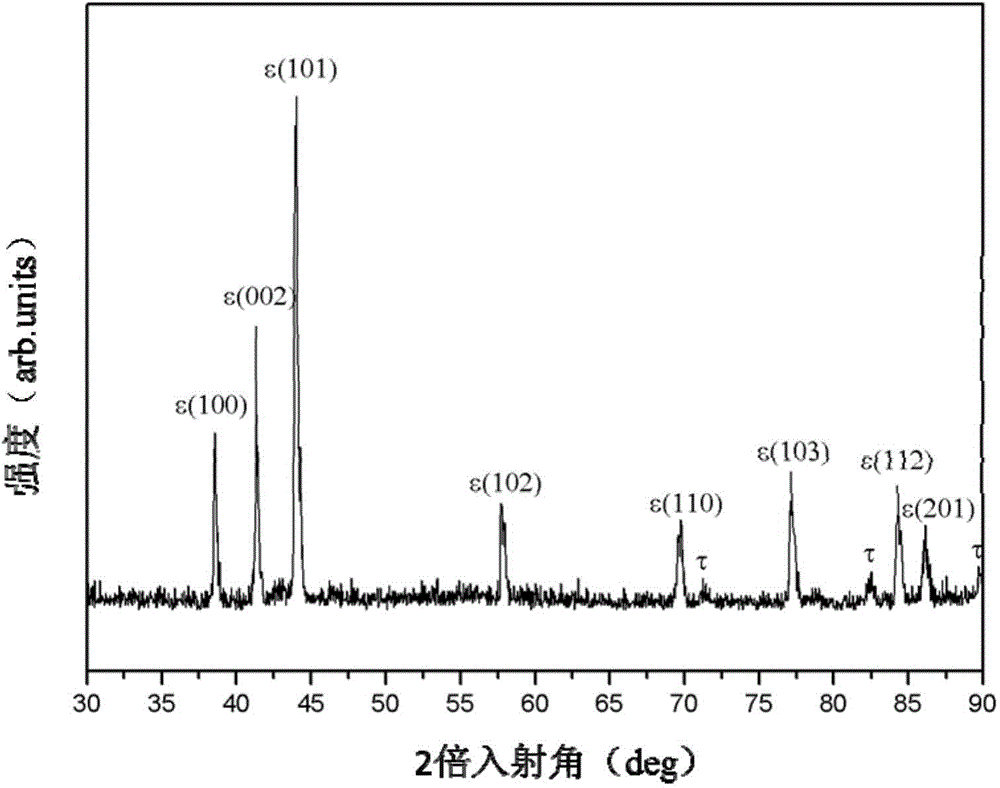

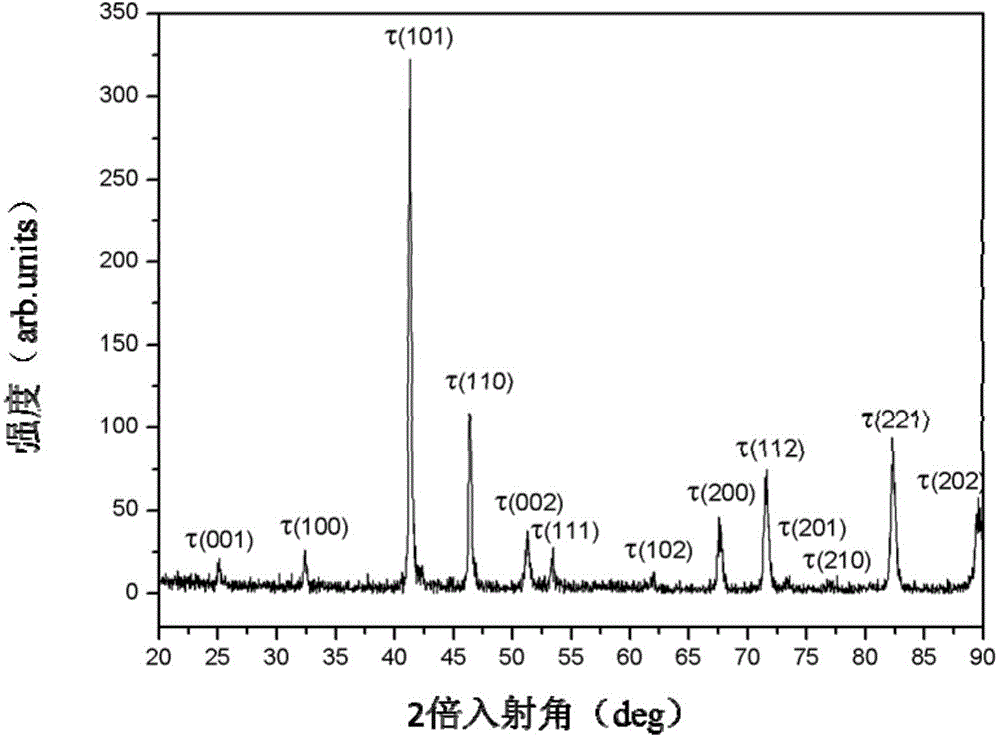

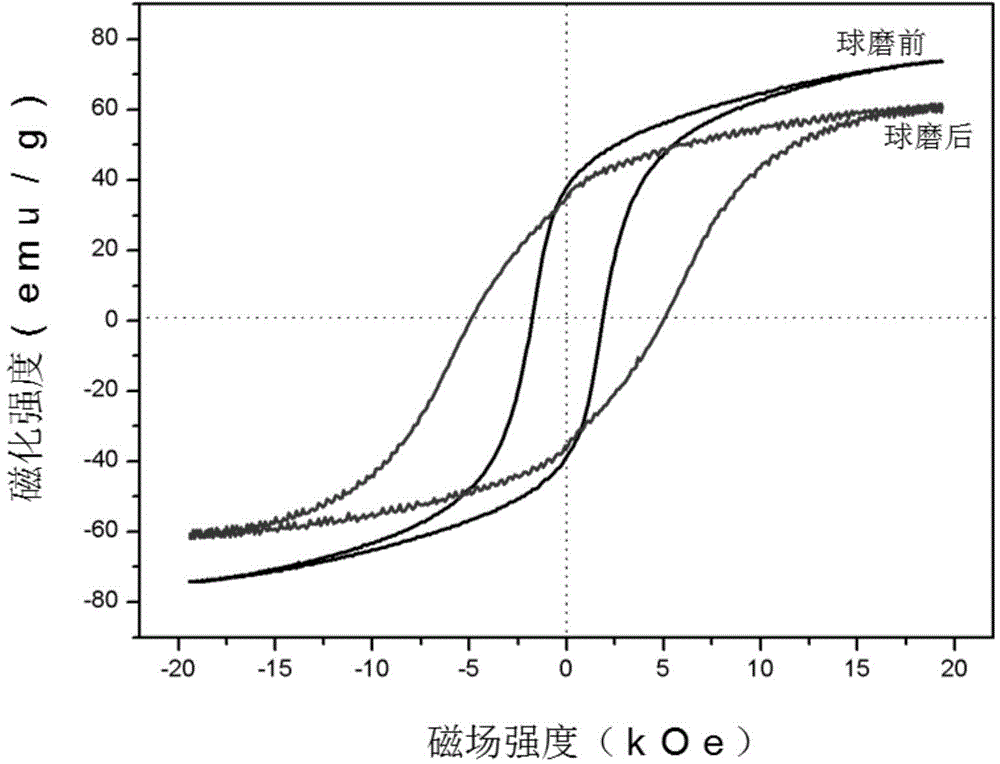

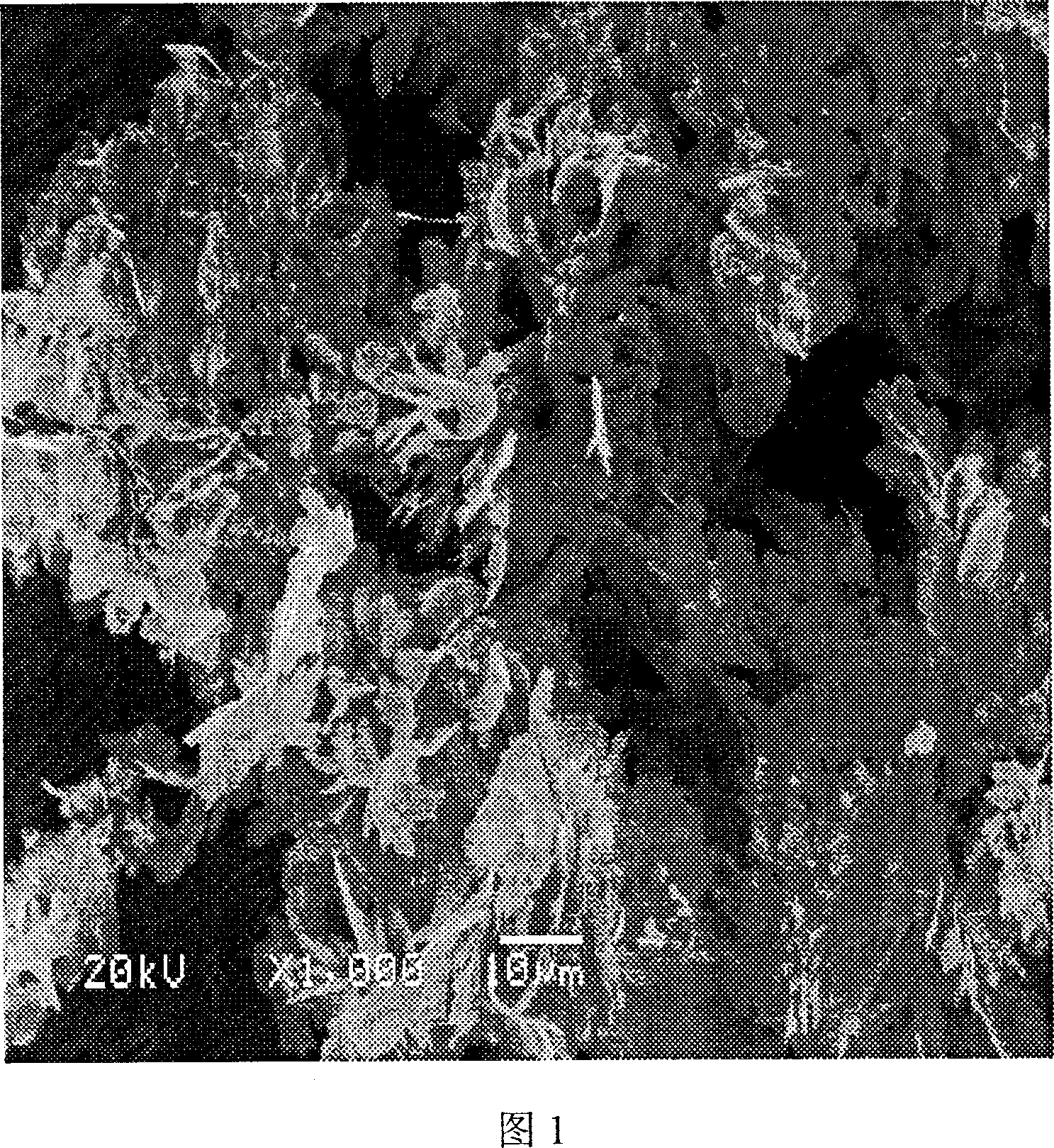

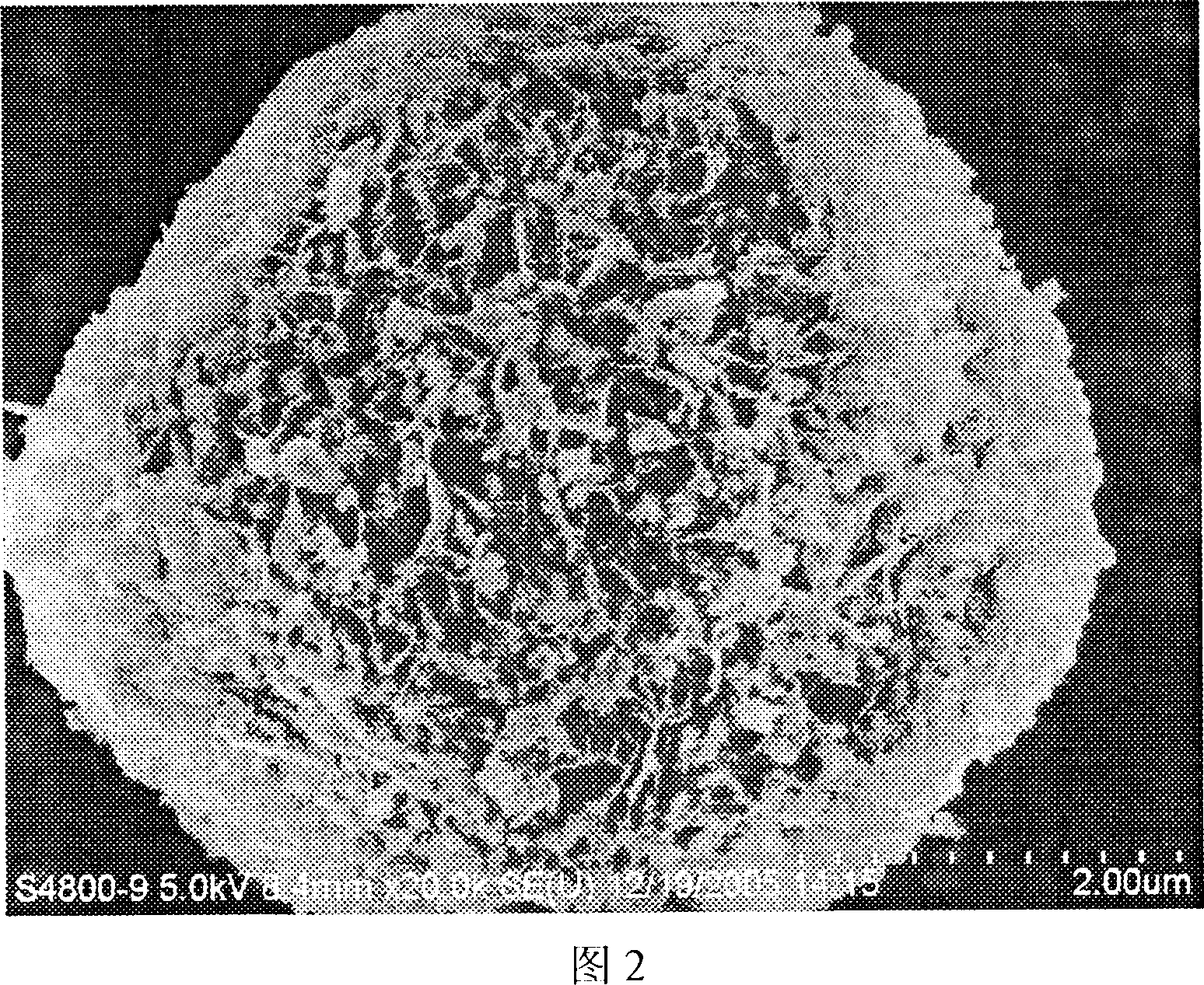

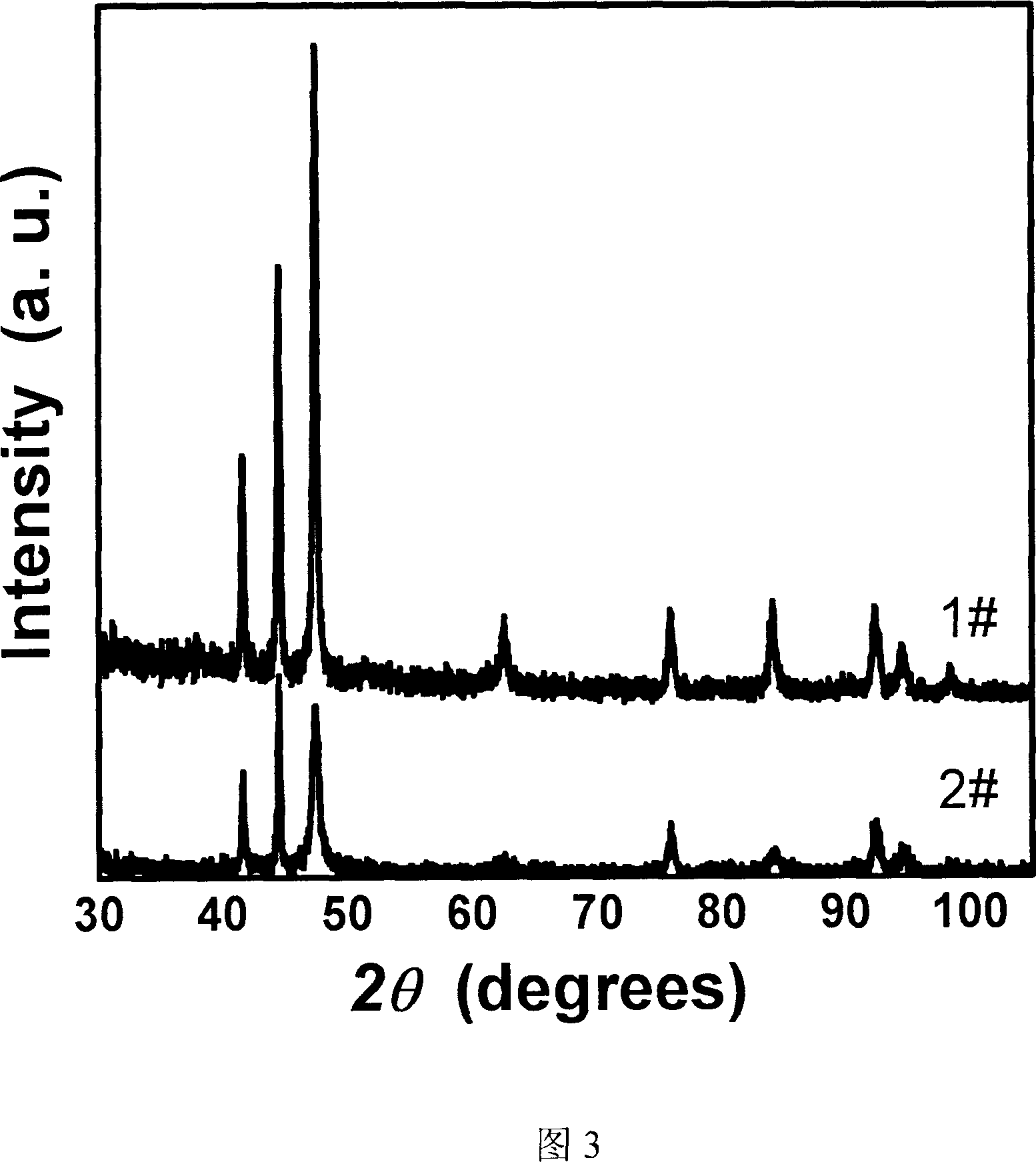

Preparation method of non-rare earth MnAl permanent magnetic alloy

InactiveCN104593625AEasy to processAccelerated corrosionMagnetic materialsElectric arc furnaceRare earth

The invention relates to a preparation method of a non-rare earth MnAl permanent magnetic alloy. The preparation method comprises the following steps: (1) preparing the compositions of a master alloy sample: preparing master alloy raw materials with Mn60-xAl40+x as a nominal composition according to the atom percentage, wherein x is equal to 0-10; (2) smelting the master alloy: adopting a non-self-consumable electric arc furnace, putting the prepared master alloy raw materials into a water cooling copper crucible, and repeatedly smelting the alloy for 3-5 times to obtain a MnAl alloy ingot with uniform compositions; (3) preparing an MnAl alloy ribbon by the MnAl alloy ingot by adopting a single-roller rapid quenching method; (4) carrying out vacuum heat treatment: carrying out vacuum heat treatment on the MnAl alloy ribbon obtained in the third step to obtain a tau-phase MnAl alloy; and (5) mechanical ball milling: ball milling the tau-phase MnAl alloy obtained in the fourth step to obtain tau-phase MnAl alloy powder, namely the non-rare earth MnAl permanent magnetic alloy with high coercivity. Compared with the prior art, according to the preparation method disclosed by the invention, the cost is low, the preparation process is simple, and the obtained MnAl permanent magnetic alloy is good in permanent magnetic property and high in coercivity.

Owner:TONGJI UNIV

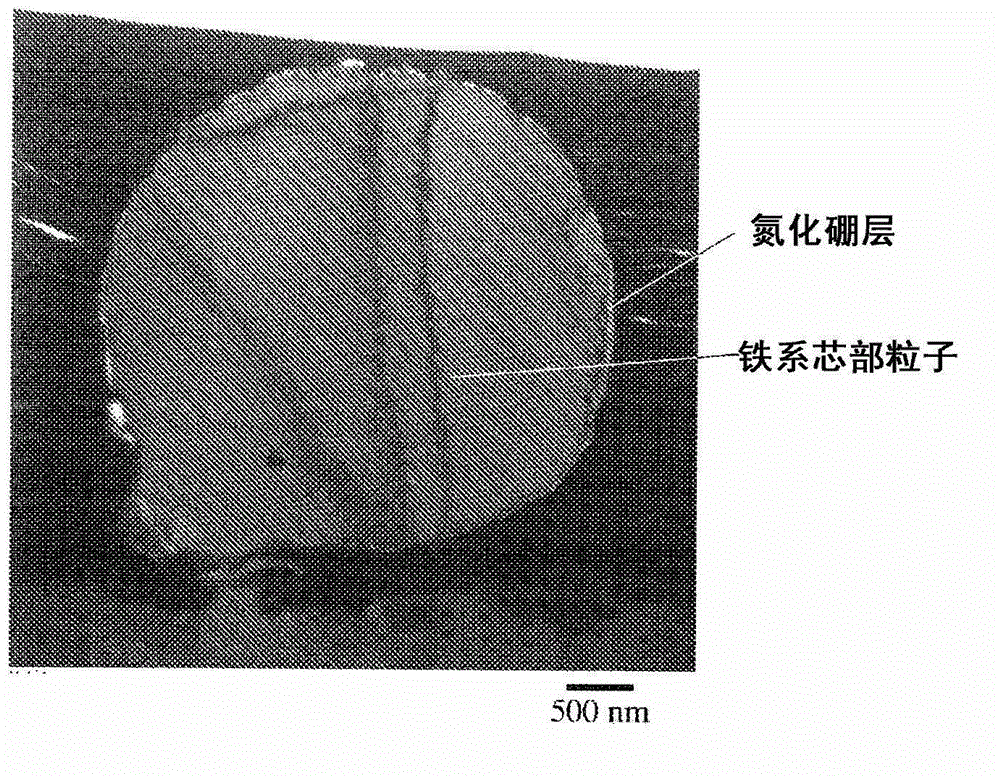

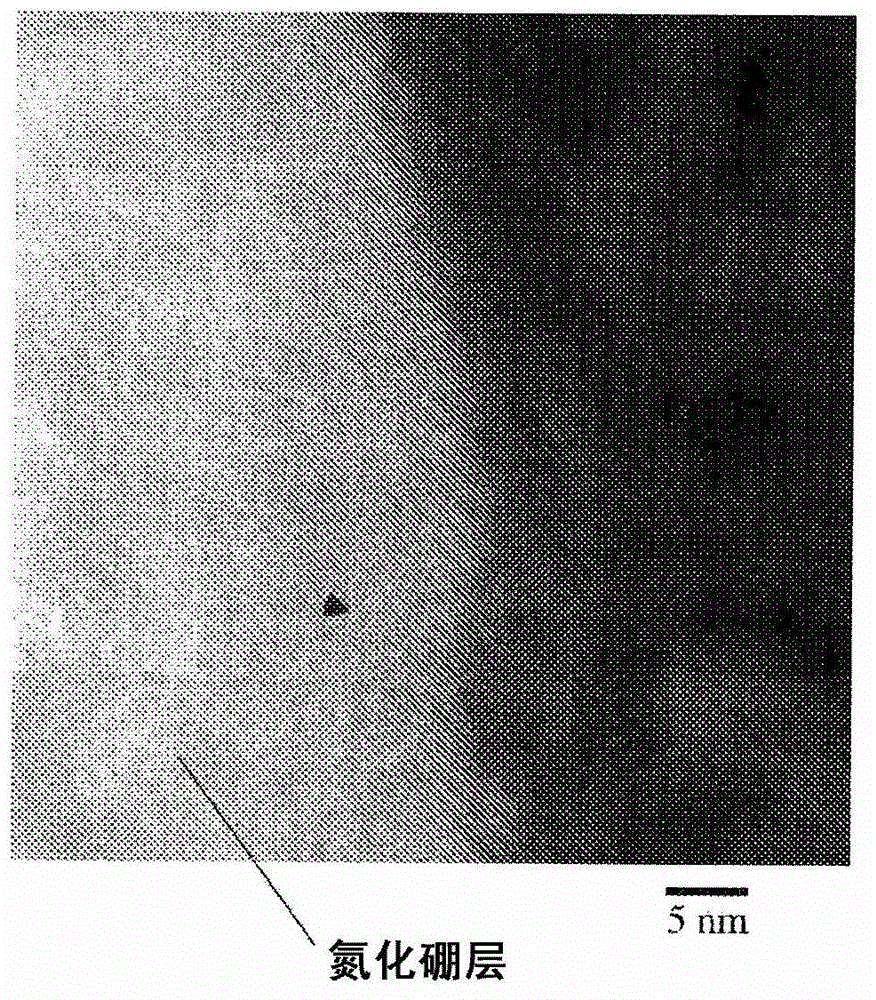

Composite soft magnetic powder, method for producing same, and powder magnetic core using same

InactiveCN103339694AHigh densityHigh saturation magnetizationTransportation and packagingMetal-working apparatusBoron nitrideNon magnetic

This composite soft magnetic powder comprises soft magnetic ferrous core particles, which have a particle size of 2-100 [mu]m, and a layer, which has boron nitride as the primary constituent and covers at least a portion of the surface of the soft magnetic ferrous core particles, the covering layer being a polycrystalline layer that comprises boron nitride microcrystalline grains having an average crystal grain size of 3-15 nm and differing crystal axis orientations and that has an average thickness that is no greater than 6.6% of the average particle size of the soft magnetic ferrous core particles. The composite soft magnetic powder is produced by means of (1) mixing an iron nitride powder having an average particle size of 2-100 [mu]m and a boron powder having an average particle size of 0.1-10 [mu]m, (2) heat treating the obtained mixed powder at a temperature of 600-850 DEG C in a nitrogen atomosphere, and (3) eliminating the non-magnetic components.

Owner:HITACHI METALS LTD

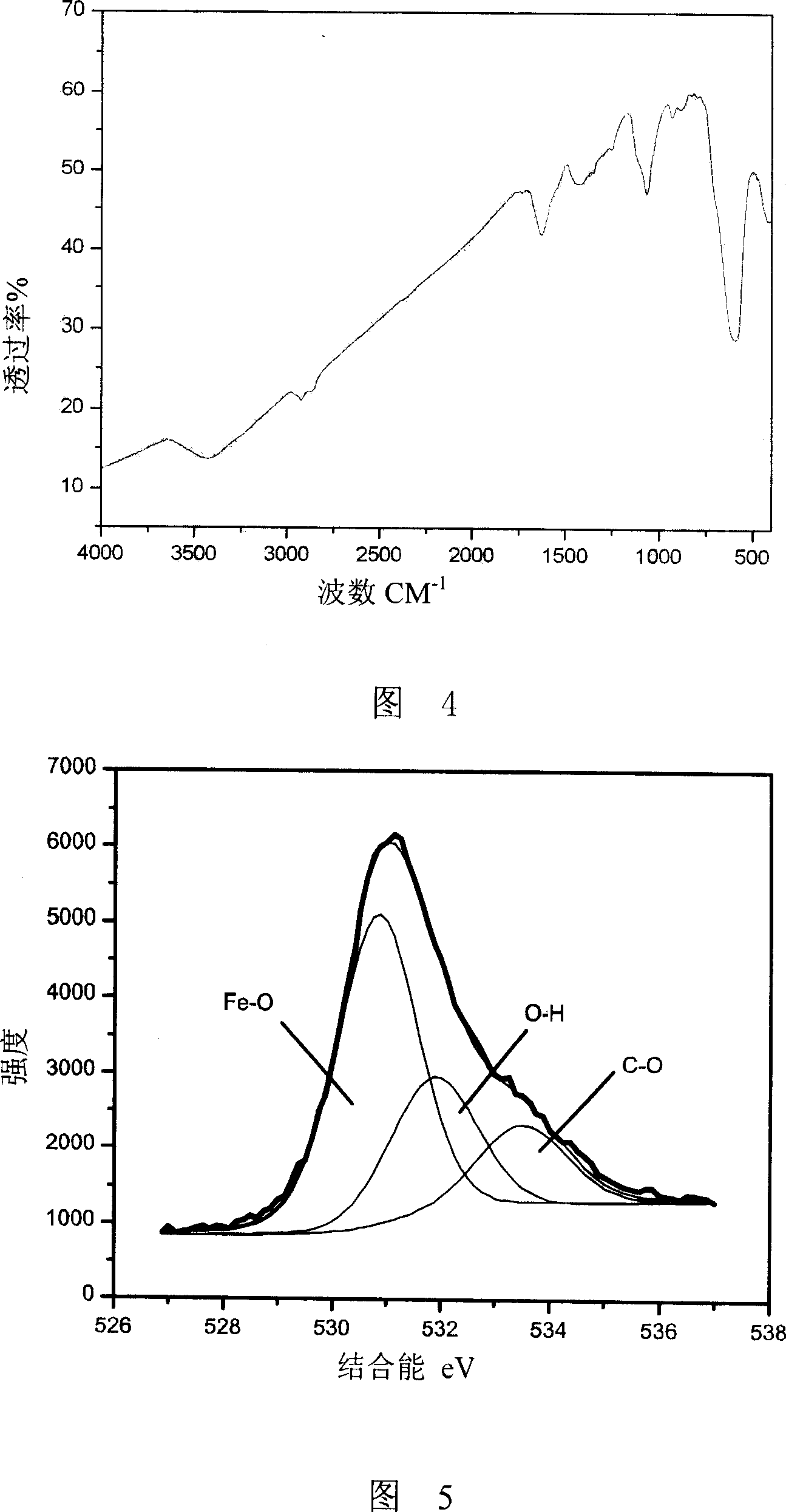

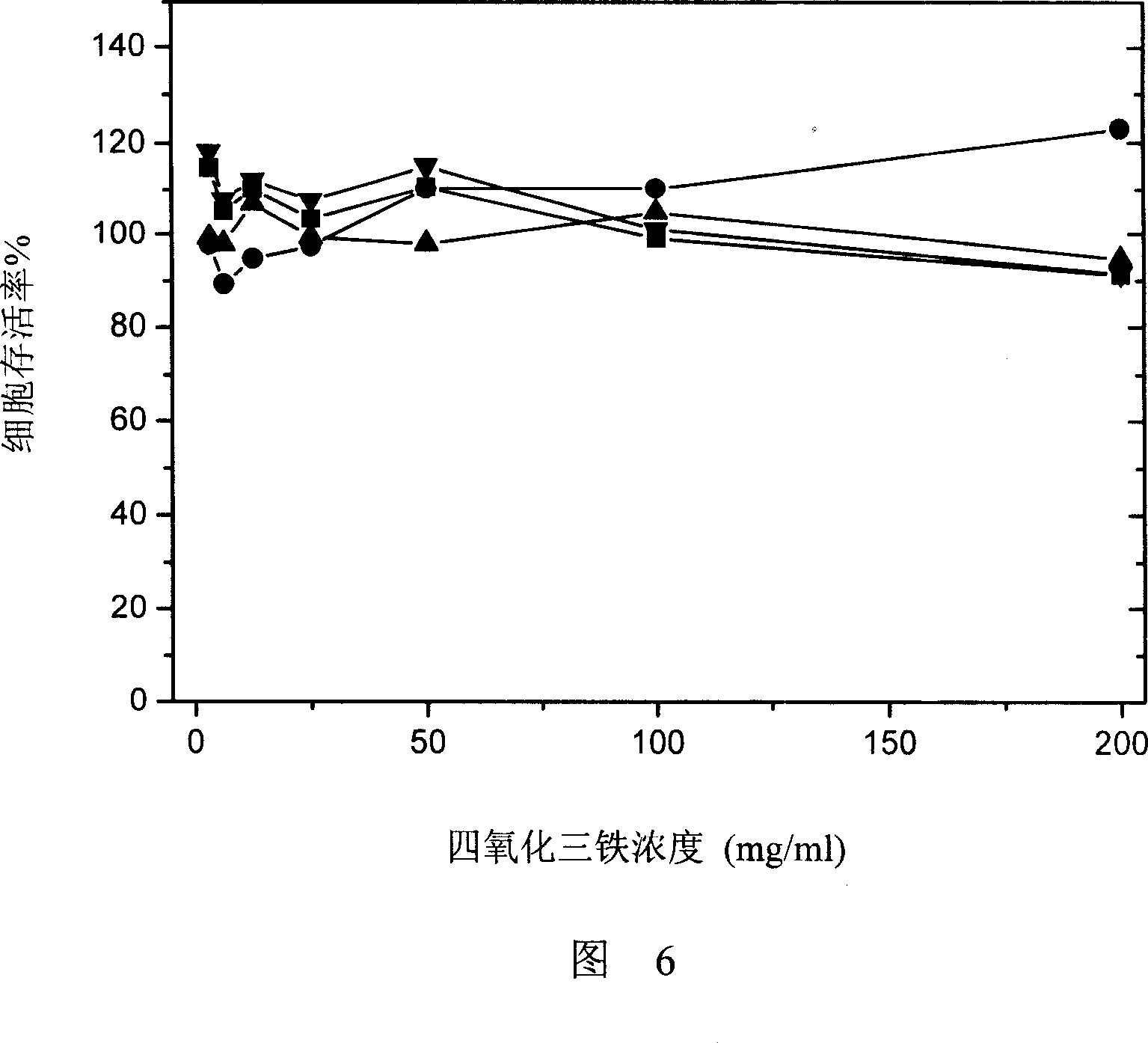

Carbon-coated ferroferric oxide core-shell nano particle and preparation method thereof

InactiveCN104001474ASmall particle sizeEasy to operateOther chemical processesAlkali metal oxides/hydroxidesOrganic dyeLithium-ion battery

The invention discloses carbon-coated ferroferric oxide core-shell nano particles and a preparation method thereof and belongs to the technical field of preparation of nano material. Deionized water is employed as a solvent; ammonia water is employed as a co-precipitation agent; and a soluble ferric salt and a soluble monosaccharide, or soluble polysaccharide, are employed as raw materials. The deionized water, the ammonia water, the soluble ferric salt and the soluble monosaccharide, or the soluble polysaccharide, are mixed together to form a homogeneous suspension liquid. The homogeneous suspension liquid, which is a mixture system, is transferred into a polytetrafluoroethylene inner liner having a stainless steel substrate. The mixture system is subjected to a reaction in a drying oven at 120-220 DEG C for 5-15 hours after the inner liner being sealed to obtain the carbon-coated ferroferric oxide core-shell particles. Particle sizes of the nano particles are 5-7 nm. The preparation method is easy, is low in cost and is free of environmental pollution. The nano particles prepared through the method have a good effect of adsorbing an organic dye and can be used in the technical fields of biological technology, medicine and anode materials of lithium ion batteries, and especially in the technical field of sewage treatment.

Owner:JIANGSU UNIV

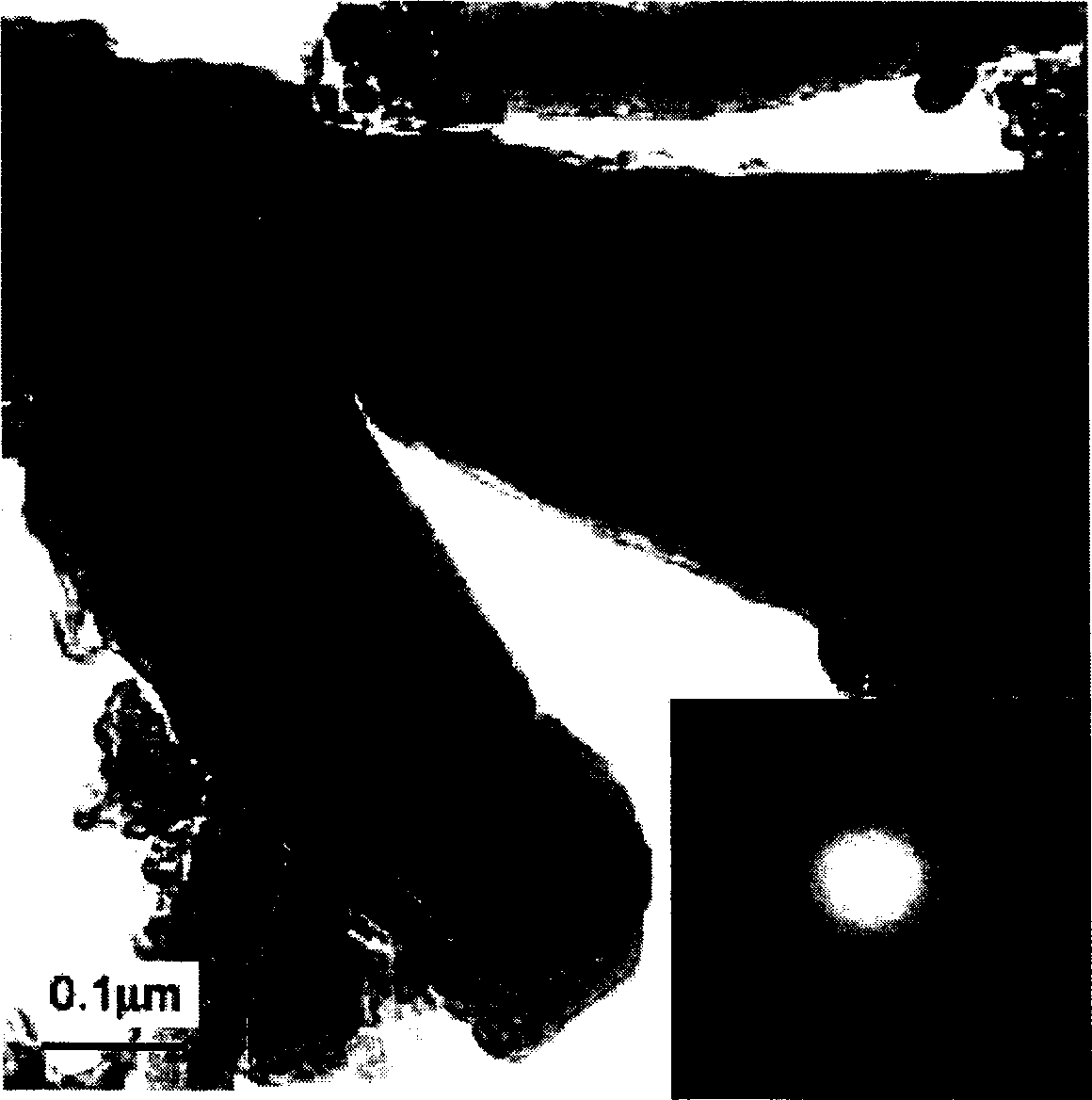

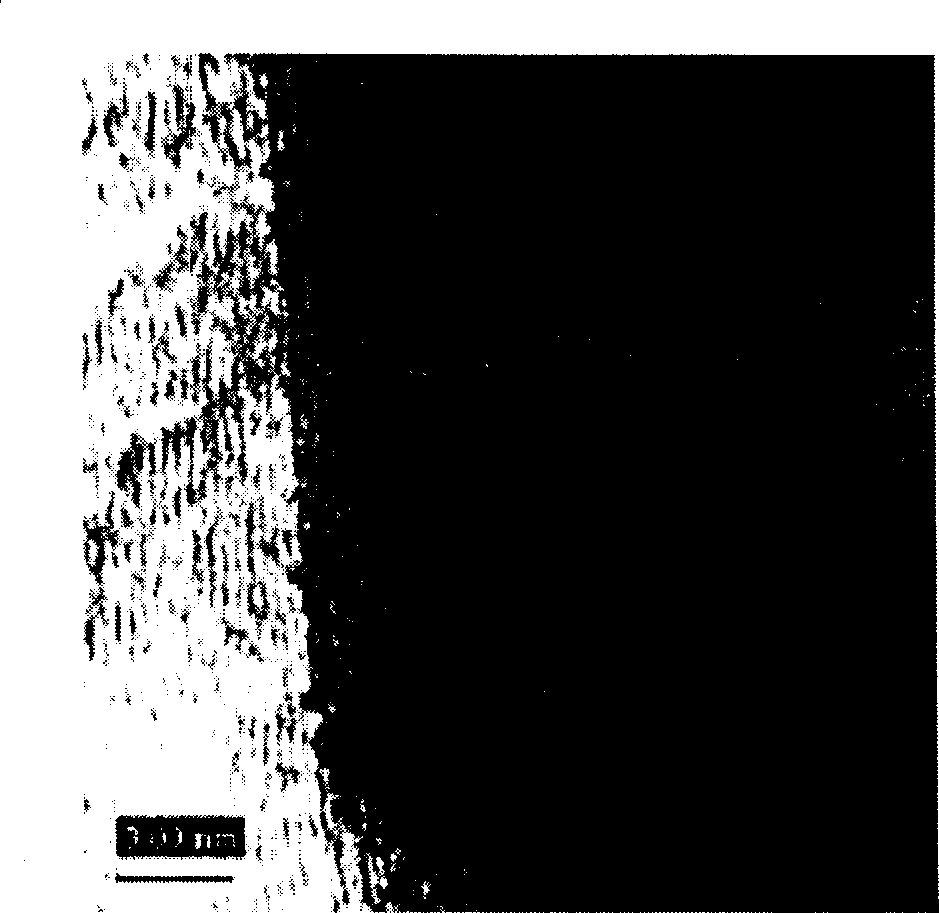

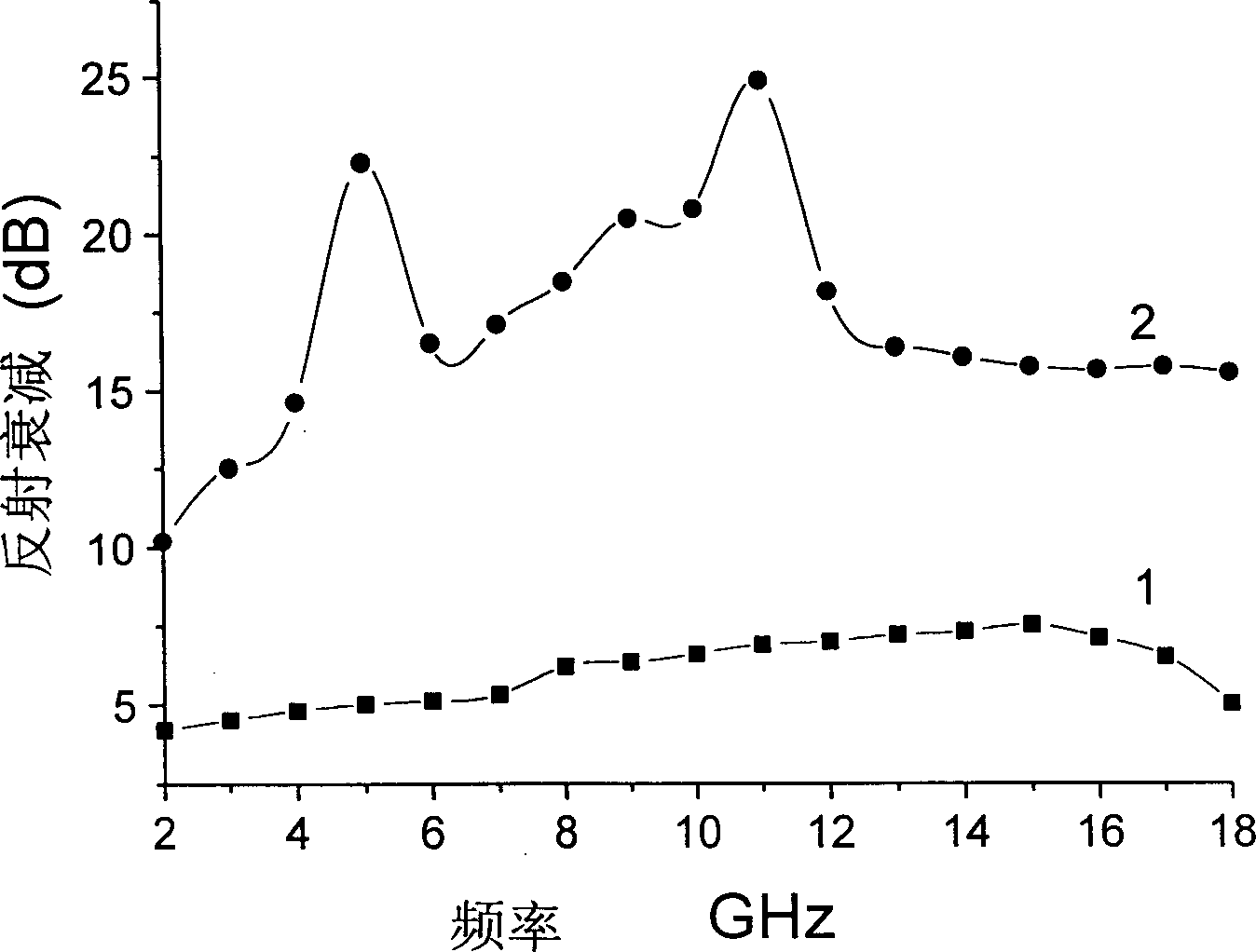

Carbon nano-tube/ferromagnetism metal nanowire composite material, mfg. method and use thereof

InactiveCN1401562AImprove oxidation resistanceImprove microwave absorption performanceMagnetic/electric field screeningRadiation-absorbing paintsEpoxyMicrowave

A composite carbon nanotube / ferromagnetic metal nanowire material is composed of carbon nanotubes and ferromagentic metal nanowires filled in said nanotubes, and is prepared through growing carbon nanotubes while filling said nanowires in the nanotubes, and crystallizing said nanowires. If said material is dispersed in the epoxy resin / alcohol solution and then solidified, a microwave absorption material or an electromagnetic shielding material is obtained.

Owner:PEKING UNIV

Preparation method of magnetic fluorescence dual-function silicon oxide hollow microspheres

ActiveCN102198385AHas fluorescent propertiesHigh saturation magnetizationInorganic material magnetismLuminescent compositionsAlkaneMicrosphere

The invention relates to a preparation method of magnetic fluorescence dual-function silicon oxide hollow microspheres, comprising the steps of: preparing magnetic nanometer particles by a coprecipitation method; diffusing the magnetic nanometer particles in long-chain alkane after the surfaces of the magnetic nanometer particles are modified by oleic acid; mixing the oil phase composed of alkanedispersion consisting of a styrene monomer, a superhydrophobic agent and magnetic nanometer particles, and the orthosilicic acid alkyl ester with water phase in which a surface active agent is dissolved; pre-emulsifying and finely emulsifying the mixture to obtain a fine emulsion drop system; when the drops are in free radical polymerization, adding an alkali catalyst to control the generation ofsilicon oxide and the phase separation of the organic and inorganic components of the system; in the reaction process, adding proper ammonia water and a silane coupling agent which is marked by fluorescein to obtain the hollow compound microspheres which are different in sizes, inorganic shell thicknesses and magnetic particle solid content and have stable fluorescence signals. The preparation method disclosed by the invention is simple, the raw materials are low in cost and easy to obtain; and the obtained fluorescence dual-functional hollow silicon oxide microspheres are narrow in size distribution, high in magnetic substance content and stable in fluorescence performance.

Owner:SUZHOU WIN BIO TECH CO LTD

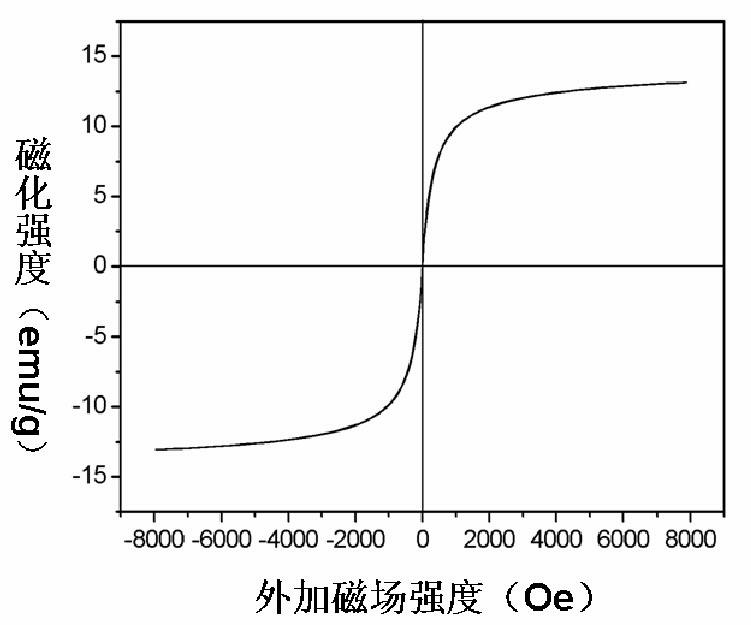

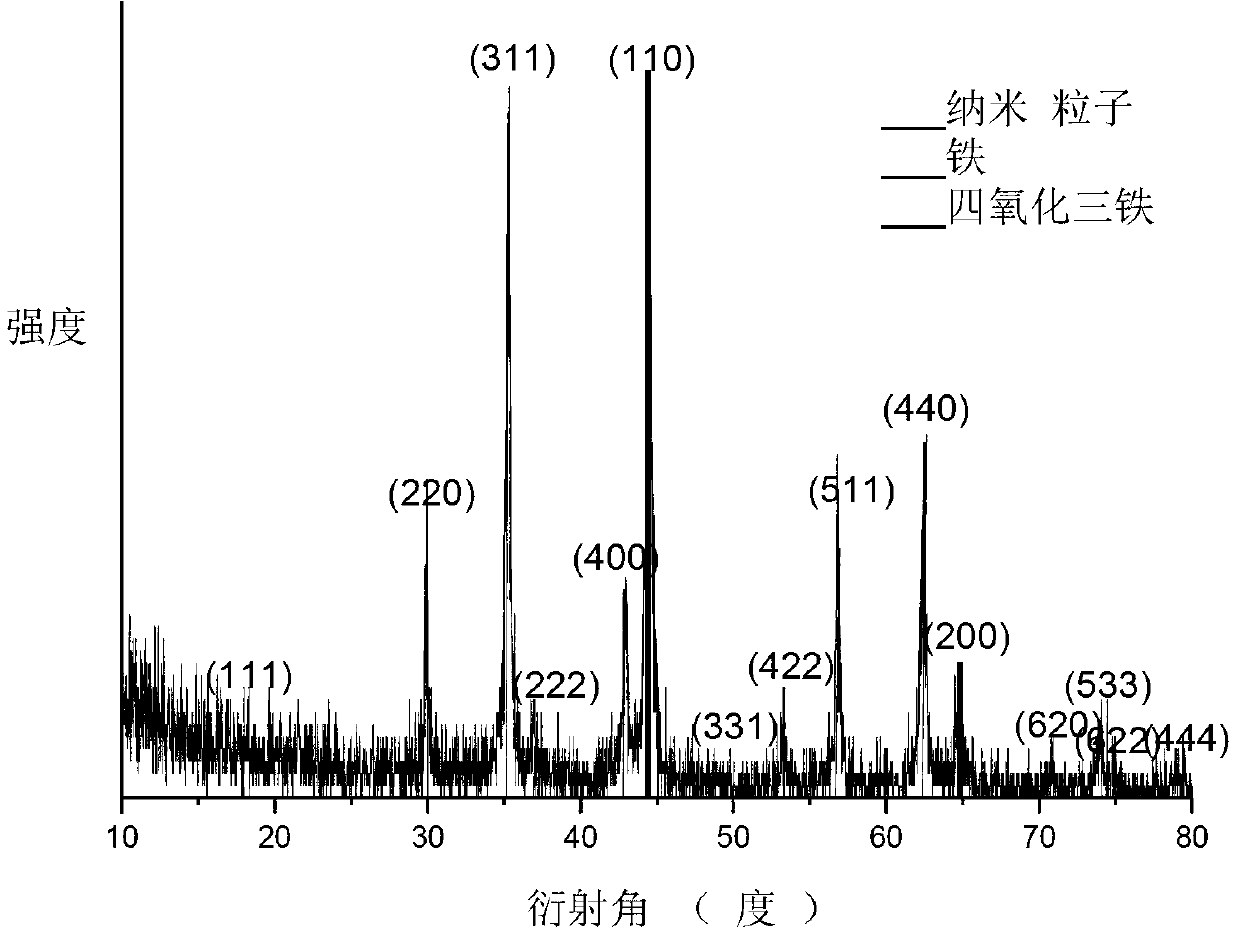

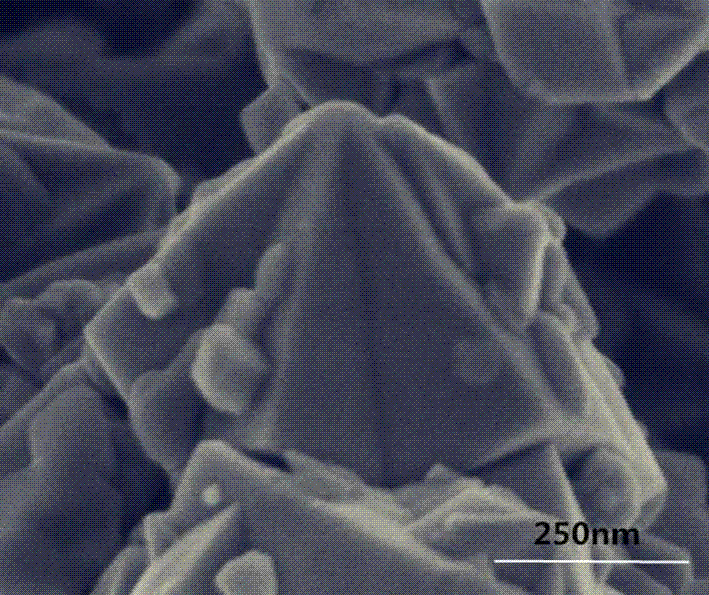

Fe@Fe3O4 nanoparticles having photothermal function, and preparation method and application thereof

ActiveCN103341165AGood dispersionGood lookingEnergy modified materialsNanotechnologySolubilityDispersity

The invention discloses Fe@Fe3O4 nanoparticles having a photothermal function, and a preparation method and an application thereof, and belongs to the field of medical science materials. The preparation method is significantly characterized by comprising: firstly, utilizing octadecene as a solvent, utilizing Fe(CO)5 as an iron source, utilizing oleyl amine as a surfactant and a stabilizer, and preparing an Fe nanomaterial having good dispersity by high temperature pyrolysis; sequentially, adding (CH3)3NO at the high temperature for oxidization to form one layer of Fe3O4 shell on the surface layer of each Fe nanoparticle, and then improving water solubility by a ligand exchange method to obtain the Fe@Fe3O4 composite material as a photothermal reagent and having high magnetization strength. The composite material has the advantages of uniform particle size, high saturation magnetization strength, and controllable morphology, and has excellent dispersion and excellent stability in aqueous solution. The reaction time is short, the raw materials are easy to get, and operation processes are convenient. On the basis of the raw materials, the Fe@Fe3O4 nanoparticles are developed to connect PEG to the surface of the material, so that the Fe@Fe3O4 nanoparticles can be applied to biological bodies. The invention provides the application of the Fe@Fe3O4 nanoparticles in the field of tumor photothermal therapy.

Owner:SHANGHAI NORMAL UNIVERSITY

Novel method of manufacturing Fe3O4/Au magnetic complex nano particle

InactiveCN101108423AOvercome costsOvercoming time consumingInorganic material magnetismNanometreChemistry

The invention discloses a new compound Fe3O4 / Au magnetic compound Nami grain method, which is characterized in that: the invention utilizes supersonic chemical method to restore gold ion on a amino or hydrosulfuryl functional magnetic Nami grain to realize the preparation of the sample. The method doesn't need purifying product, which is quick and directviewing and is a novel compound method with simple and quick operation and high yield.

Owner:HUNAN UNIV OF TECH +3

Iron base non-crystalline material and preparation method thereof

ActiveCN105986202AImprove performanceHigh saturation magnetizationVacuum evaporation coatingSputtering coatingSurface layerCrystalline materials

The invention provides an iron base non-crystalline material and a preparation method thereof. The iron base non-crystalline material has components of Fe100-a-b-cMcBbAa, wherein M is any one or more of Si, Zr, Nb, Cr, P, Al, Co, Ni and Ti, A is N and / or C, a is not less than 0.5 and not more than 2 at%, b is not less than 9 and not more than 14 at%, and c is not less than 0 and not more than 10 at%; the non-crystalline material comprises a non-crystalline basal body layer and a surface layer positioned on the non-crystalline basal body layer; and the surface layer is a FeA enriched layer. The non-crystalline basal body layer in the iron base non-crystalline material is used for providing basic performances of the iron base non-crystalline material; and through auxiliary cooperation of the performances of the surface layer, the performances of the iron base non-crystalline material can be enhanced, the saturation magnetization is improved, the coercive force is reduced, and the overall performances of the iron base non-crystalline material are improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

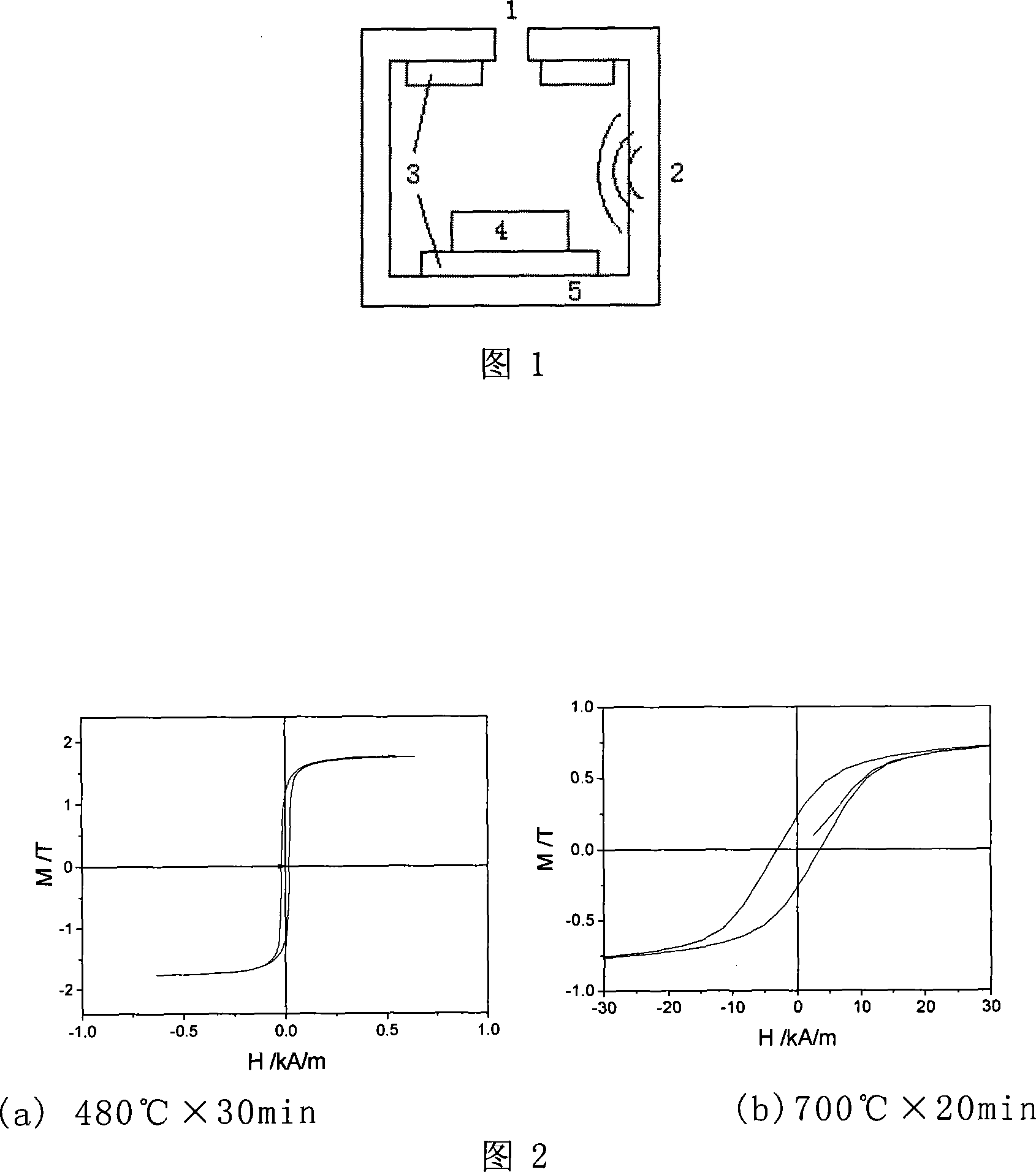

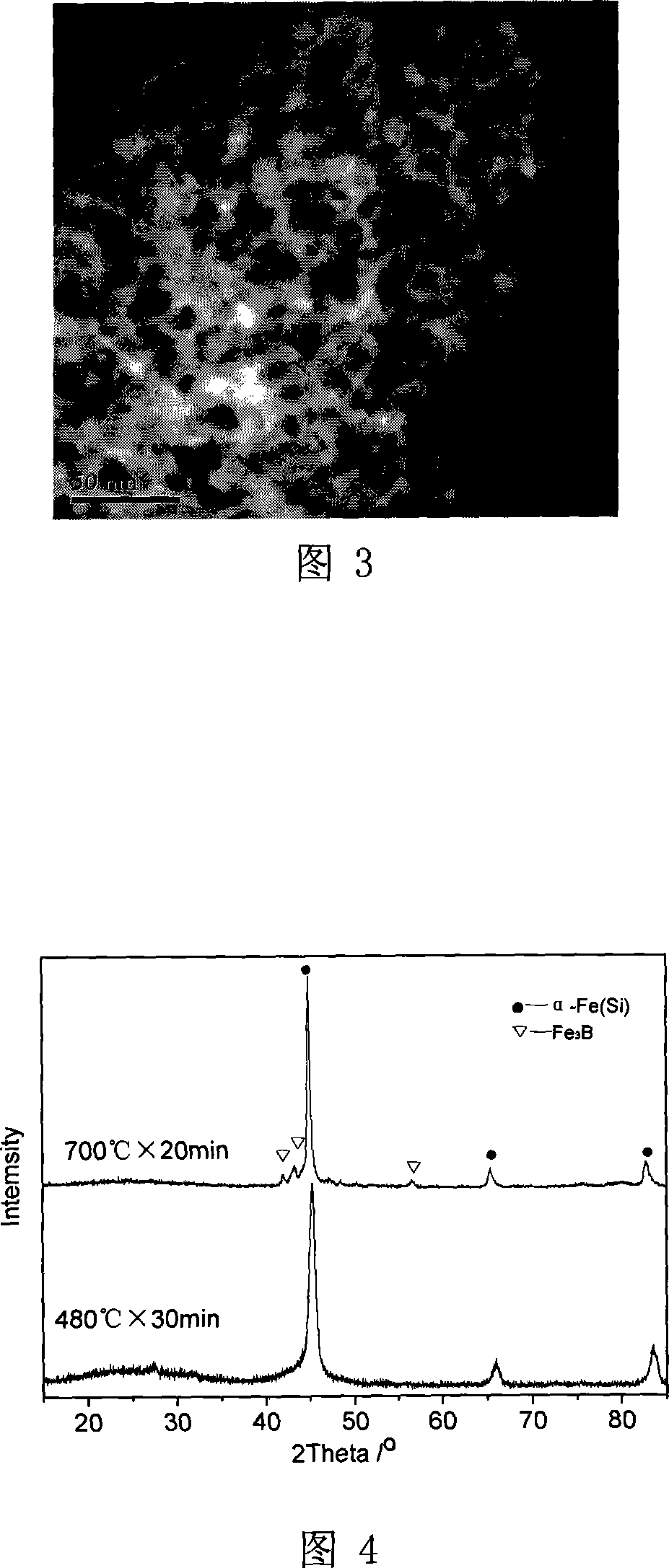

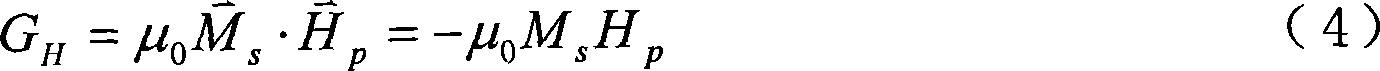

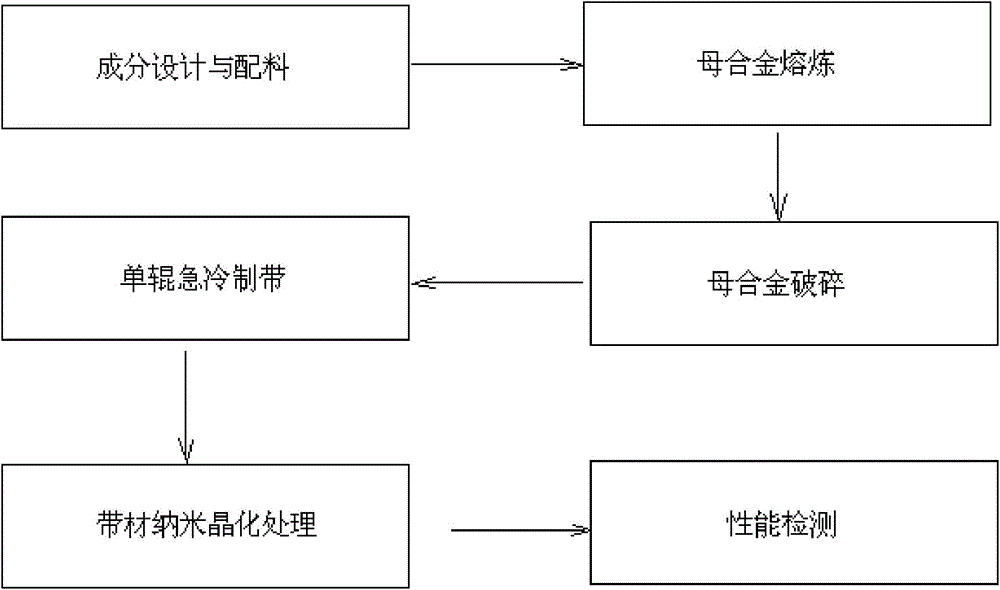

Fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy

The present invention discloses fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy. The technological process includes the following steps: 1. smelting alloy with Fe, Cu, Nb, Si and B in the ratio of Fe73.5Cu1Nb3Si13.5B9 in an induction furnace at vacuum 3-10 Pa in high purity Ar; 2. setting coarsely crushed alloy inside quartz pipe with nozzle in the bottom, setting the quartz pipe inside induction coil in a belt spinning machine, and melting the mother alloy in protecting Ar atmosphere; 3. spraying the alloy liquid under the pressure of Ar to the surface of rotating copper roller to form non-crystalline alloy belt; and 4. sealing the thin belt in quartz tube and crystallizing treatment in a microwave sintering furnace at 400-900 deg.c for 10-180 min to obtain ideal nanometer crystal structure.

Owner:CENT SOUTH UNIV

Soft magnetism composite powder and preparation method thereof

InactiveCN103177838ACoated evenlyImprove antioxidant capacityInorganic material magnetismSelf-healingPolyethylene glycol

The invention discloses soft magnetism composite powder and a preparation method of the soft magnetism composite powder. The soft magnetism composite powder is the composite powder which has two layers of inorganic insulation coating structures, the inner core of the composite powder is magnetic particles of FeSiAl or FeSi, SiO2 in a network state is coated on the outer layer of the magnetic particles, and nanocrystalline B2O3 is coated outside the SiO2. The preparation method of the soft magnetism composite powder comprises the following steps: (1) preparing magnetism SiO2 core-shell structural powder; (2) uniformly mixing the magnetism SiO2 core-shell structural powder prepared in the step (1), borate N-butyl, absolute ethanol, polyethylene glycol and deionized water, dropwise adding acetic acid, adjusting the potential hydrogen (pH) value of the mixed solution to be 5-6, stirring the mixed solution for 1-5 hours at the temperature of 40 DEG C-80 DEG C till a complete reaction is achieved, and drying the mixed solution at the temperature 40 DEG C-100 DEG C till the weight is constant; and (3) calcining the dried powder at the temperature of 400 DEG C-500 DEG C for 1-2 hours under the protective atmosphere. The soft magnetism composite powder prepared through the method has a good physical performance and a good magnetic performance. Due to the fact that a B2O3 film is coated outside the SiO2 shell layer, the magnetic powder is enabled to have a crack self-healing capability under the condition of high temperature, the electrical resistivity of a magnetic powder core is improved, and the eddy-current loss of materials is reduced.

Owner:CENT SOUTH UNIV

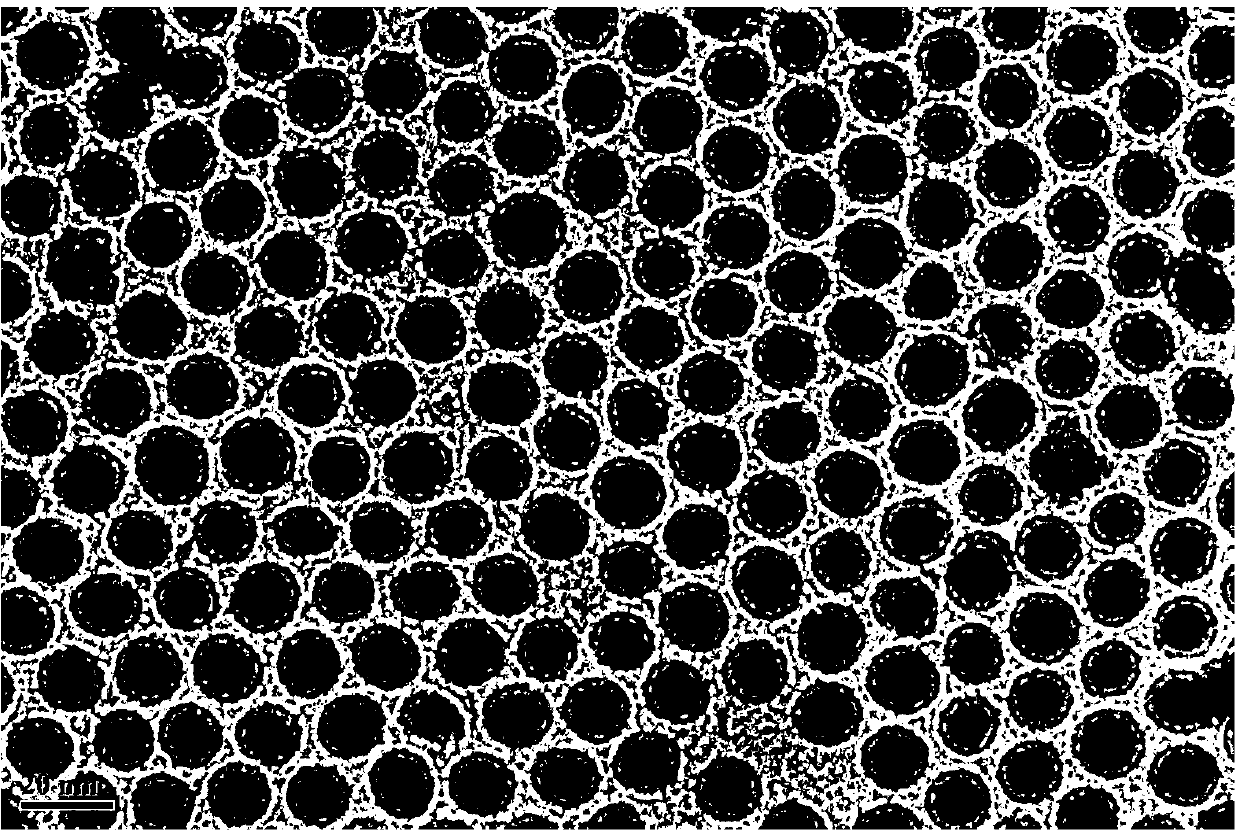

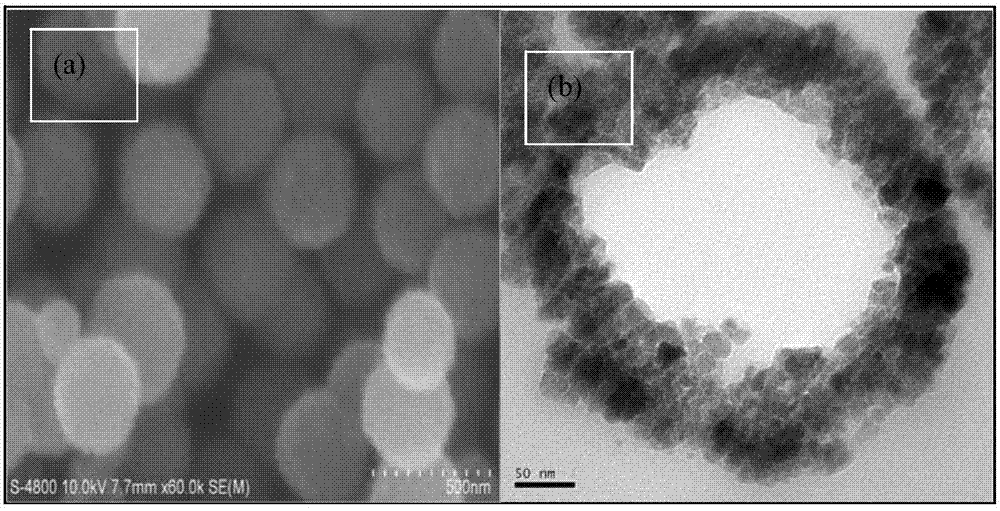

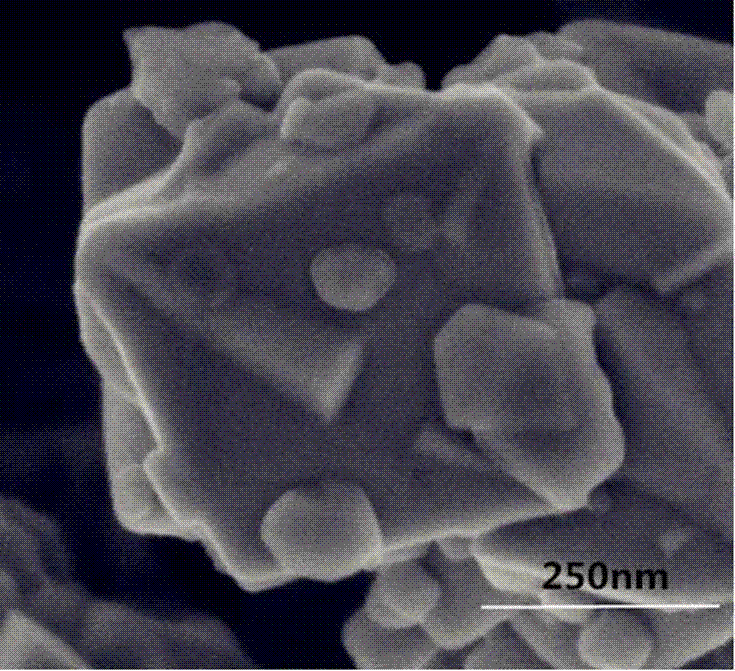

Preparation method for superparamagnetism ferroferric oxide sub-micron hollow microsphere

InactiveCN103663571ASuperparamagneticHigh saturation magnetizationInorganic material magnetismFerroso-ferric oxidesMicrospherePolyethylene glycol

The invention relates to a preparation method for a superparamagnetism ferroferric oxide sub-micron hollow microsphere. The preparation method comprises the following steps: 1) taking a reducing agent, an iron source and an alkali source, and dissolving into distilled water; 2) dissolving a surfactant into a solution obtained from step 1); 3) introducing a solution obtained from step 2) into a reaction kettle, reacting in a drying oven, performing natural cooling to room temperature for seasoning, water washing, alcohol washing, and drying in a vacuum drying box, so that the superparamagnetism ferroferric oxide sub-micron hollow microsphere is obtained. The preparation method has the following good effects: 1) according to the invention, the ferroferric oxide sub-micron hollow microsphere is compounded, and has superparamagnetism, high saturation magnetization and excellent oxidation resistance; 2) dispersing agents such as PEG (polyethylene glycol) and PVP (polyvinylpyrrolidone) are adopted to solve the problem of magnetic microsphere agglomeration, so that the ferroferric oxide sub-micron hollow microsphere with uniform particle size is obtained; 3) according to the invention, adopted raw materials is cheap, so that cost is minimized.

Owner:WUHAN UNIV OF TECH

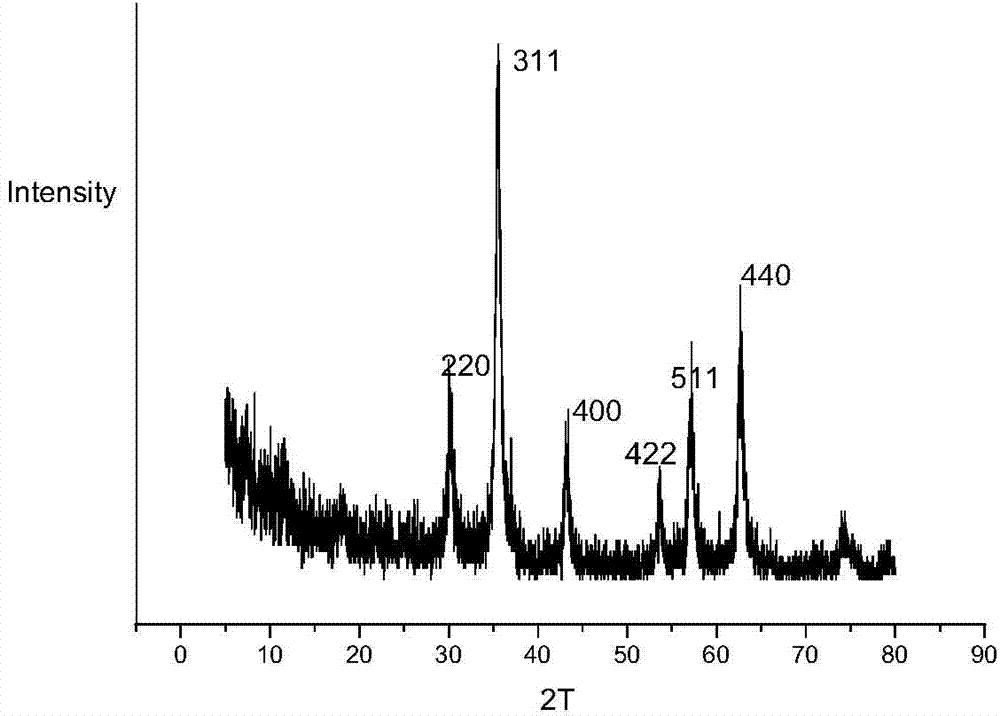

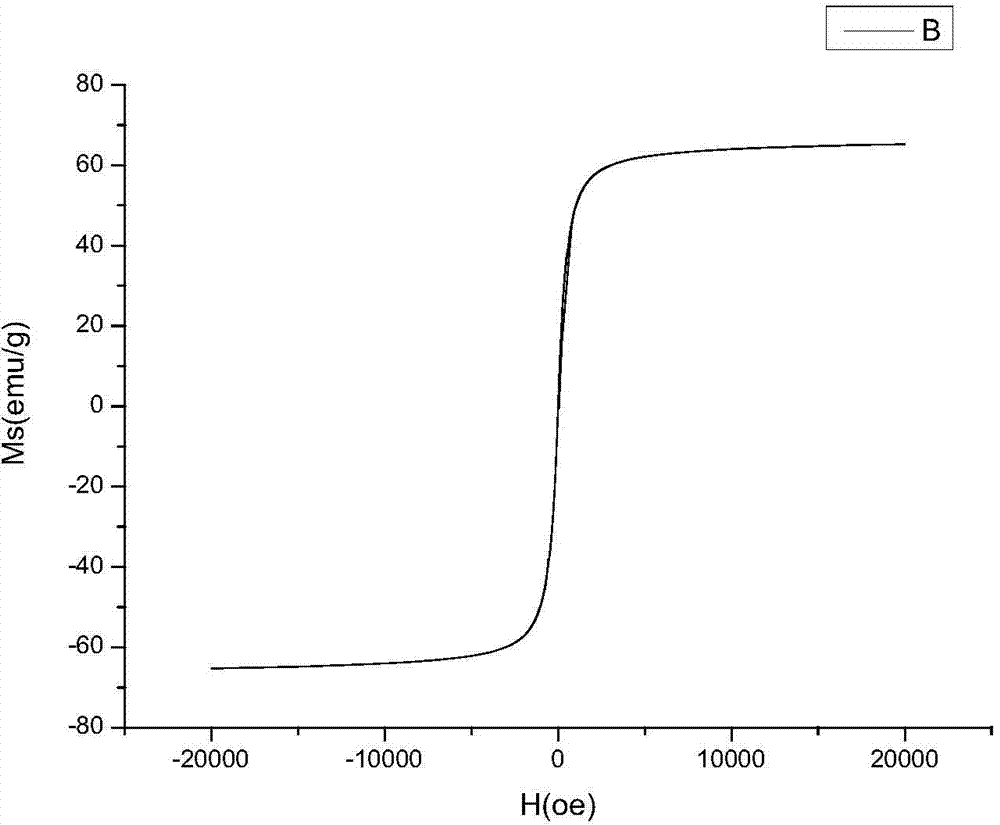

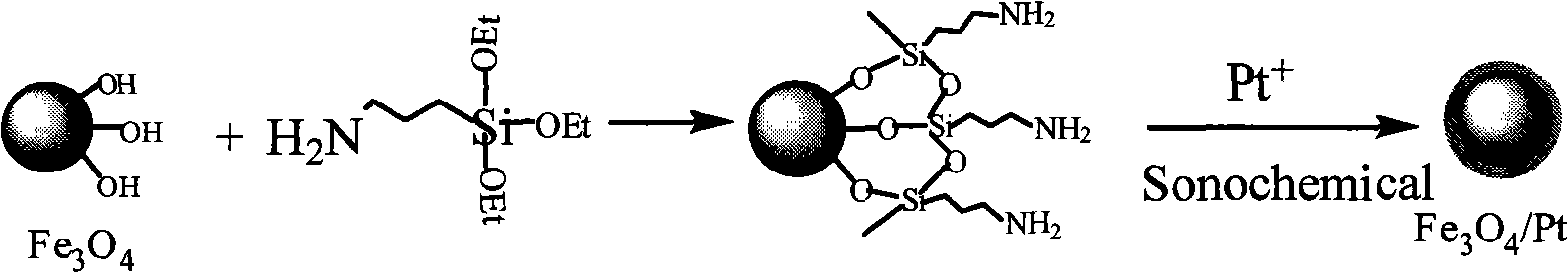

Novel method of manufacturing Fe3O4/Pt magnetic complex nano particle

InactiveCN101345111AAchieve preparationLow costInorganic material magnetismFerroso-ferric oxidesPlatinumHydrazine compound

The invention discloses a novel method used for synchronizing Fe3O4 / Pt magnetic composite nanometer particles, which is characterized in that under the ultrasonic condition, by hydrazine hydrate, platinum ion is reduced onto amido or mercapto functional magnetic nanometer particles, thus realizing the preparation of samples. The method of the invention requires no purification of product, is quick and visible, and is a novel synthesis method with simple and quick operation and high yield.

Owner:HUNAN UNIV OF TECH +3

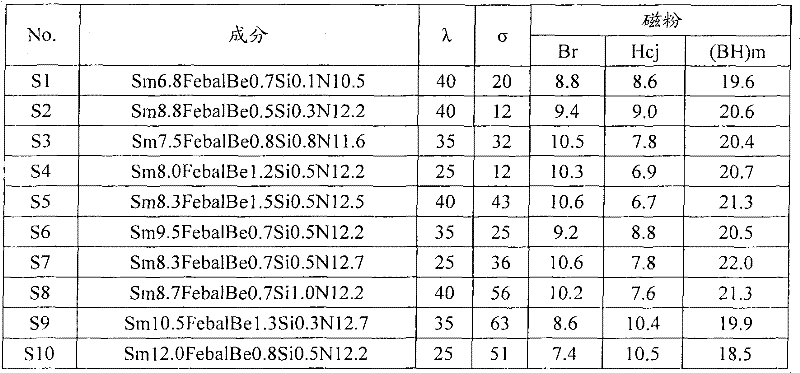

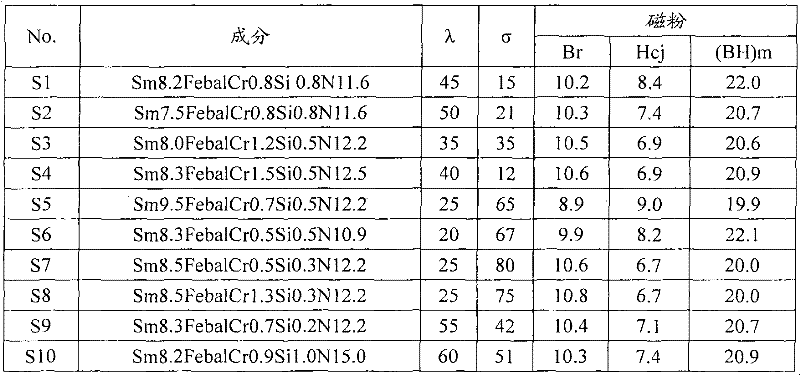

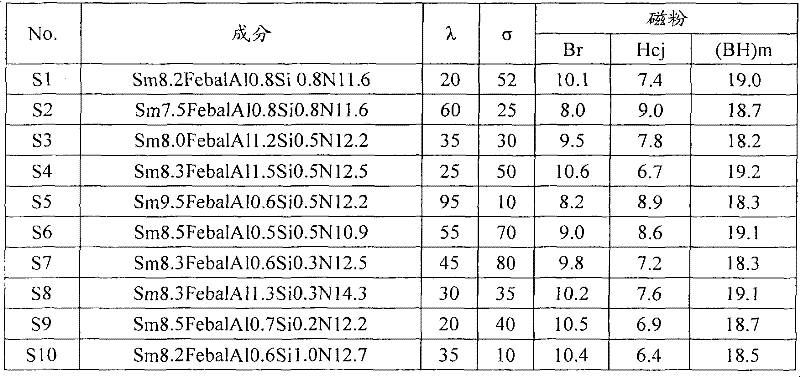

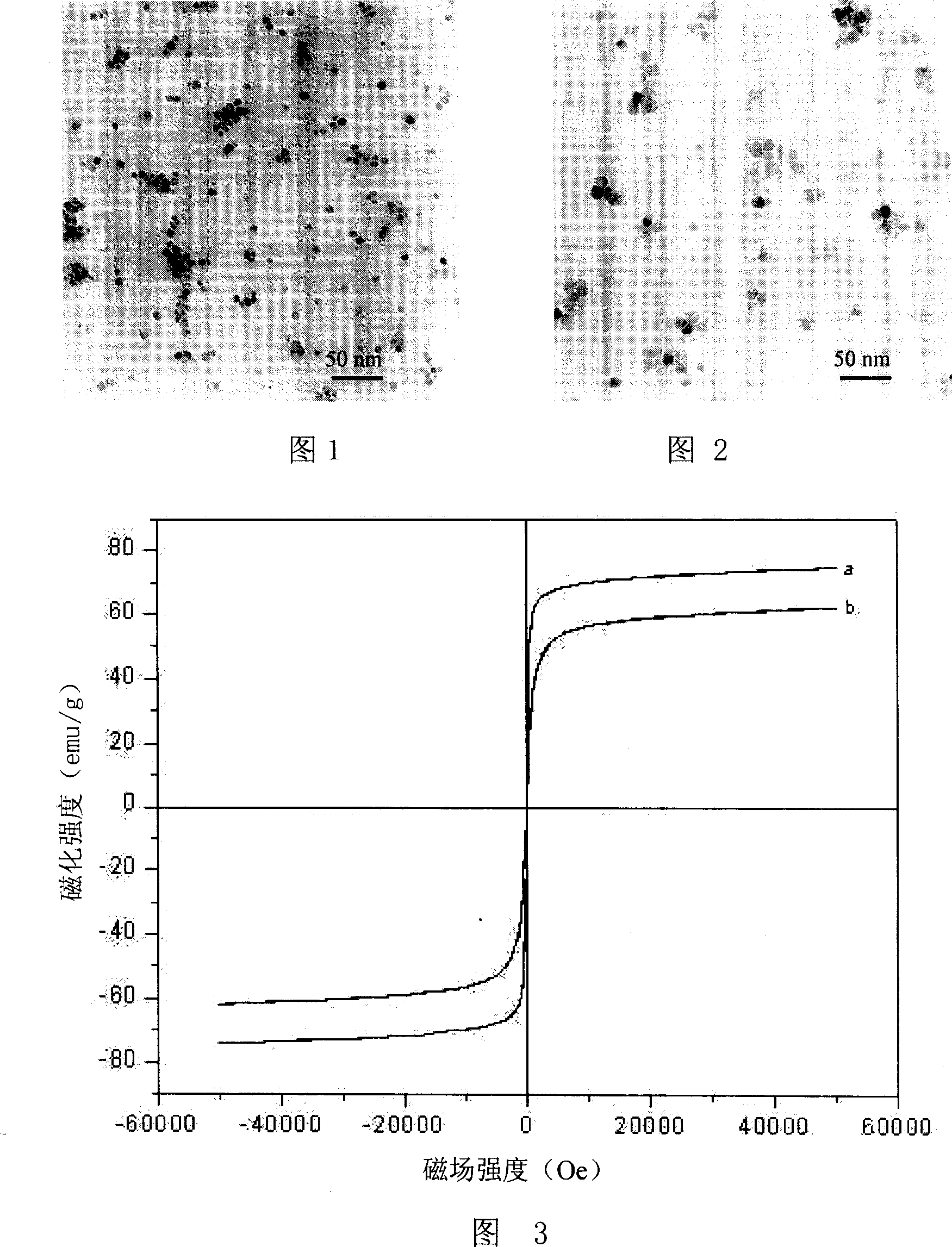

Rare earth permanent magnetic powder and bonded magnet

ActiveCN102208234AImprove liquidityHigh saturation magnetizationInorganic material magnetismThin material handlingRare earthNanocrystal

The invention discloses a rare earth permanent magnetic powder which takes Sm, Fe, M, N and Si as main components, and takes a TbCU7 structure as a main phase, the M is at least one of the Be, Cr, Al, Ti, Ga, Nb, Zr, Ta, Mo and V. The Si element is added in the rare earth permanent magnetic powder to add the glass forming ability of a samarium-ferro alloy, and the M element with a certain amount is compounded and added to increase the wetting property of an alloy solution; and therefore, the alloy solution is more convenient to be ejected from a smelting device. The samarium element content in the rare earth permanent magnetic powder is in a 1-12 at% range, the content of the M is in a 0.1-1.5 at% range, the content of N is in a 10-15 at% range, the content of Si is in a 0.1-1.5 at% range, and the rest is ferrum. An average grain size of the rare earth permanent magnetic powder is 10-100 microns; and the rare earth permanent magnetic powder is composed of a nano-crystal with an average size of 10-120 nm and amorphous structure.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Superparamagnetism magnetic resonance contrast medium, and its preparing method

InactiveCN101002951AHigh crystallinityHigh saturation magnetizationEmulsion deliveryIn-vivo testing preparationsPolyolResonance

A superparamagnetic MRI contrast medium is a Fe3O4 nanoparticl coated by polyol moleculae. Its preparing process includes such steps as high-temp reaction of Fe contained compound in polyol solution, cooling, depositing, separating, dispersing it in water, filtering, and sterilizing. It has high crystalline level, high saturated magnetic intensity and high imaging effect.

Owner:HARBIN INST OF TECH

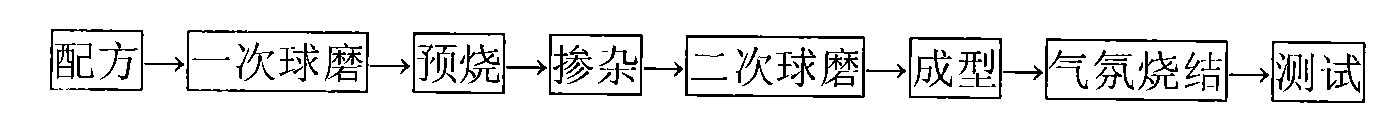

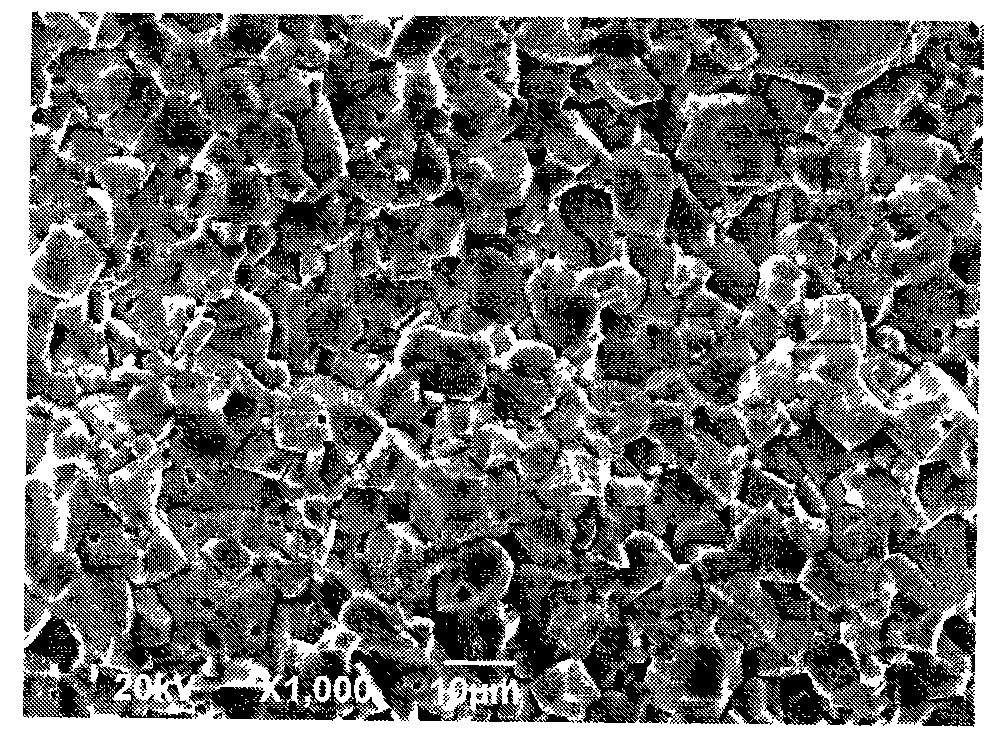

Low-loss LiZn ferrite material for phase shifter and preparation method thereof

InactiveCN101552072ALow coercivityReduce dielectric lossInorganic material magnetismDielectric lossMagnetization

A low-loss LiZn ferrite material for a phase shifter relates to the technical field of preparation of ferrite materials. The low-loss LiZn ferrite material consists of main materials, additives and binding agents, calculated by Fe2O3, ZnO, Mn3O4 and Li2CO3, the main materials comprise 64-71 mol percent of Fe2O3, 15-22 mol percent of ZnO, 0.8-1.5 mol percent of Mn3O4 and 9.9-12 mol percent of Li2CO3; relative to the main materials, the additives are calculated by Bi2O3, BST and Nb2O5, and the proportion is 0.5-3.0 wt percent of Bi2O3, 0.1-0.5 wt percent of BST and 0.05-0.4 wt percent of Nb2O5. The invention reduces the coercivity and the dielectric loss, and improves the saturation magnetization, thus realizing the low temperature preparation of the LiZn ferrite material with low coercivity, low dielectric loss and high saturation magnetization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-saturation-magnetization iron-base amorphous nanocrystal soft magnetic alloy and preparation method thereof

InactiveCN104561841ASolve the problem of low saturation magnetic inductionHigh saturation magnetizationFurnace typesMagnetic materialsMagnetization transferHigh saturation magnetization

The invention relates to a high-saturation-magnetization iron-base amorphous nanocrystal soft magnetic alloy and a preparation method thereof. The alloy is expressed as FeaMbCucSixByPz, wherein M is one or more of Al, Cr, Mn, Ti and V; and 68<=a<=90, 0<=b<=6, 0<=c<=2, 3<=x<=20, 4<=y<=20, 0<=z<=10, and a+b+c+x+y+z=100. Compared with the prior art, the product has the advantages of high saturation magnetization and the like.

Owner:SHANGHAI HANTAO NANO TECH

Process for preparing nano granule with high shape anisotropic property

The invention relates to a method for producing magnetic nanometer particles, with shape aeolotropism and magnetic crystal aeolotropism, or multi aeolotropism. Wherein, it can be used to prepare single-phase stack hexagonal (HCP) cobalt nanometer particles and binary or ternary alloy nanometer particles of iron, cobalt and nickel. The invention processes at 90-200Deg. C and more than one pressure reacts the metal salt or cobalt with water.

Owner:天津佰腾生产力促进中心有限公司

Fe-based amorphous alloy material and method of producing the same

The invention provides an amorphous alloy material with Fe as the main component and a preparation method thereof. The amorphous alloy material of the invention comprises the chemical components with the following parts by weight: Fe: 91.0-93.5; Si: 5.2-6.6; B: 2.5-3.3; Cr: 0.05-0.25; Cu: 0.010-0.030; and C: 0.05-0.20. The Fe-based amorphous alloy belt material has simple design in components, and good mechanical property and fine processability of the material; moreover, yield is over 90%. In addition, the manufactured Fe-based amorphous alloy belt material has high comprehensive magnetic property; and coreloss of a transformer manufactured by the amorphous alloy material is greatly reduced. The Fe-based amorphous alloy belt material enjoys wide application and low use cost and serves to save energy and protect the environment.

Owner:北京晶鑫联合新材料科技有限公司

Preparation method of FeCo alloy absorbing material

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Inhomogeneous nucleation insulation coating processing method of metal soft magnetic composite material

ActiveCN104028747APrecise thickness controlPrecise control of its chemical compositionInorganic material magnetismInsulation layerSpray coating

The invention discloses an inhomogeneous nucleation insulation coating processing method of a metal soft magnetic composite material. The method includes the following steps that (1) particle size distribution is conducted on metal magnetic powder after sieving is conducted; (2) insulation coating is conducted on the distributed metal powder through an inhomogeneous nucleation method, and then the metal powder is dried; (3) the dried magnetic powder and a binding agent are evenly fixed, a release agent is added to conduct dry pressing and forming, and the mixture is pressed to form blank samples; (4) heat preservation is conducted on the blank samples for half an hour to two hours in a protective atmosphere, and air cooling and spray coating are conducted to obtain the target product. The composite powder prepared through the inhomogeneous nucleation method is even and compact in coating and controllable in coating layer thickness, and has high oxidation resistance, high resistivity, high saturation magnetization intensity, the good magnetic property and the good mechanical property; the surface of the metal magnetic powder is evenly coated with an A12O3 insulation layer through the inhomogeneous nucleation method, so that the coating effect is superior to that of an existing method, the operability is high and volume production is facilitated.

Owner:ZHEJIANG UNIV

High-performance gamma-Fe2O3 magnetofluid and preparation method thereof

InactiveCN104064315AHigh solid contentHigh saturation magnetizationMagnetic liquidsFerric oxidesFerrous saltsMagnetite Nanoparticles

The invention relates to high-performance gamma-Fe2O3 magnetofluid and a preparation method of the high-performance gamma-Fe2O3 magnetofluid, and belongs to the technical field of nanoscale science and technology and material preparation. The preparation method is characterized in that magnetic nanometer particles are prepared through a chemical coprecipitation method, after ferrous salt solutions and ferric salt solutions are evenly mixed, superfluous alkaline solutions are added till complete reaction is finished, then moderate surfactants are added and surface modification treatment is conducted, and finally the magnetic nanometer particles are obtained after sediment is conducted; after the magnetic Fe3O4 nanometer particles are cleaned and dried, the gamma-Fe2O3 magnetic particles are obtained after the cleaned and dried gamma-Fe2O3 magnetic particles are subjected to oxidation at a certain temperature in a certain time period; quantitative surfactants and carrier liquids are added to a gamma-Fe2O3 magnetic particle solution , dispersion is conducted, and the high-performance gamma-Fe2O3 magnetofluid is obtained. The high-performance gamma-Fe2O3 magnetofluid prepared through the preparation method is simple in process and high in specific magnetization, and industrial batch production can be achieved conveniently.

Owner:UNIV OF SCI & TECH BEIJING

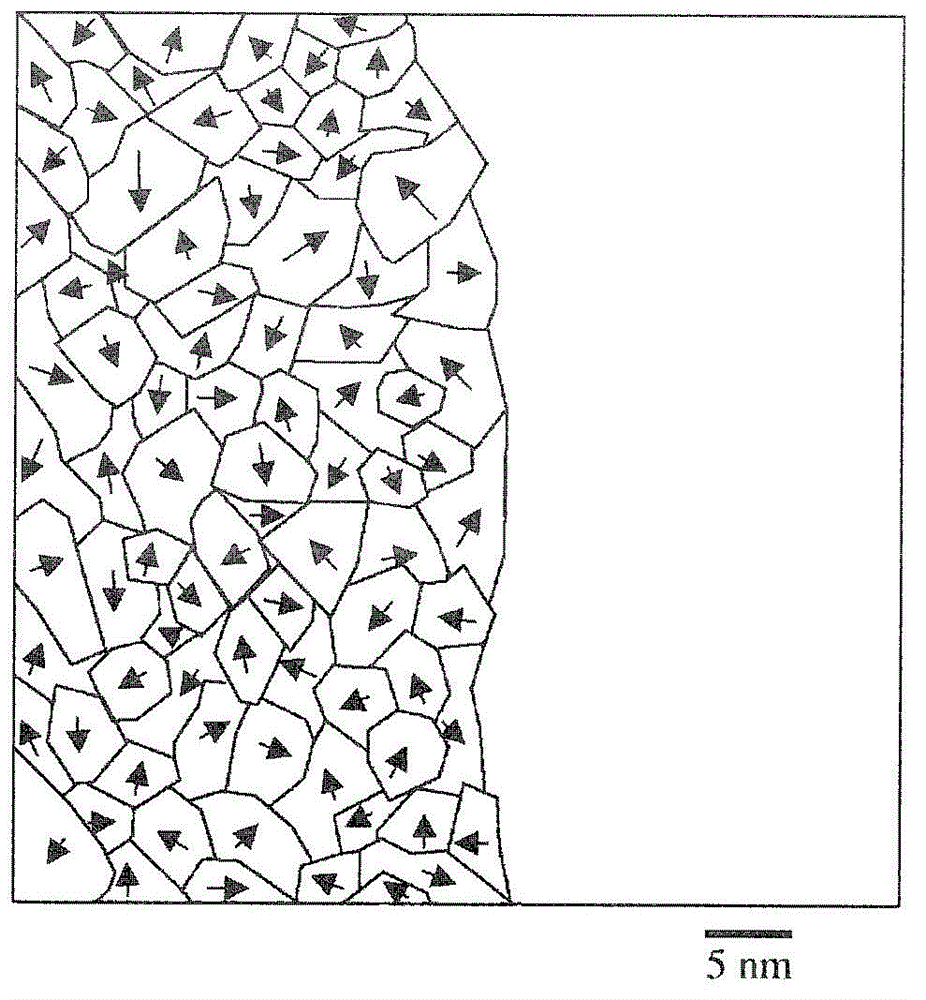

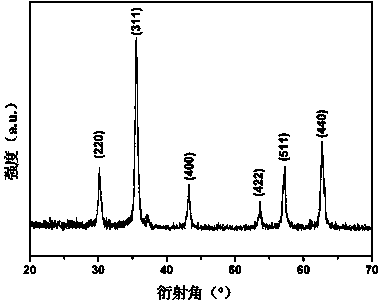

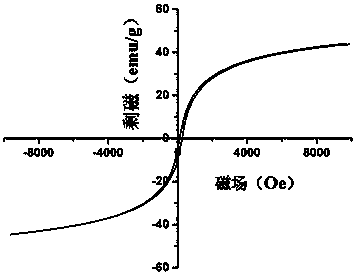

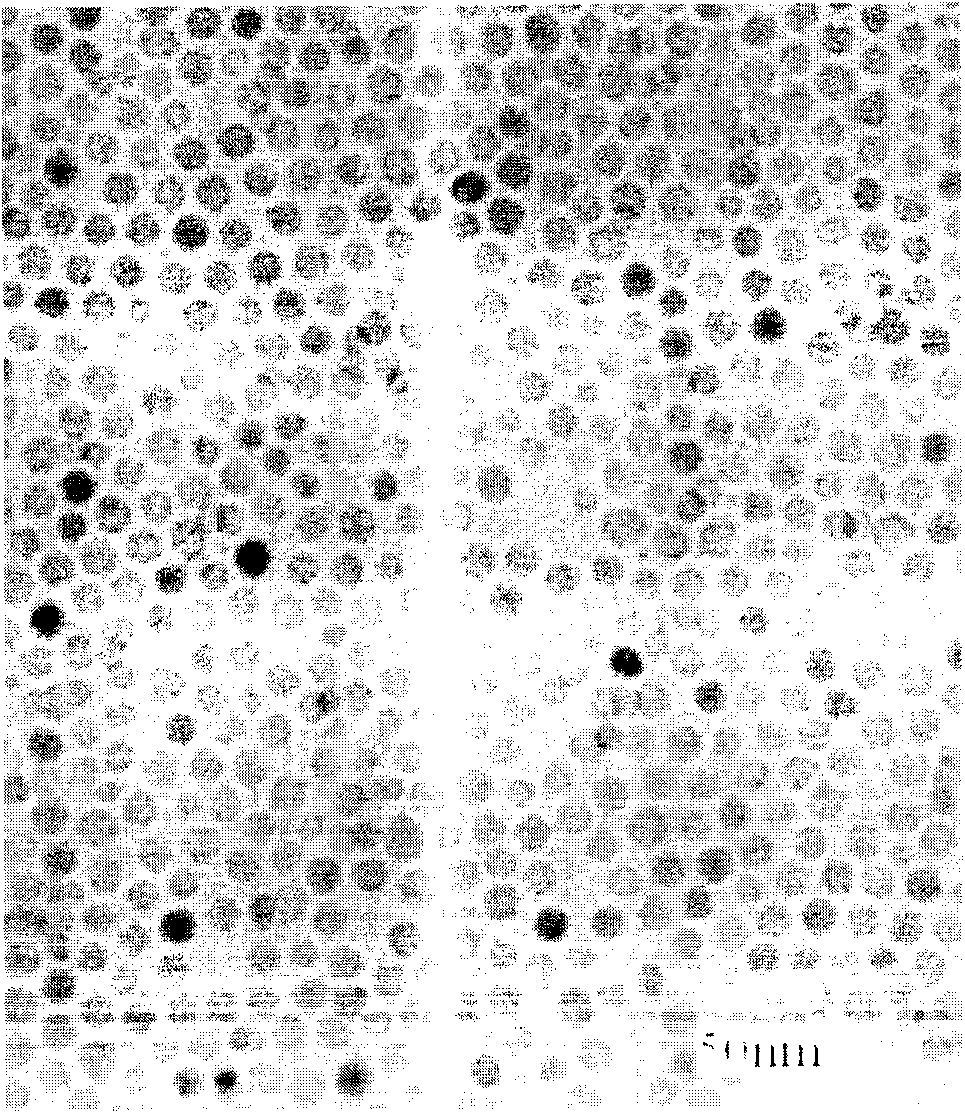

Method for preparing monodisperse Fe3O4 magnetic nanoparticles

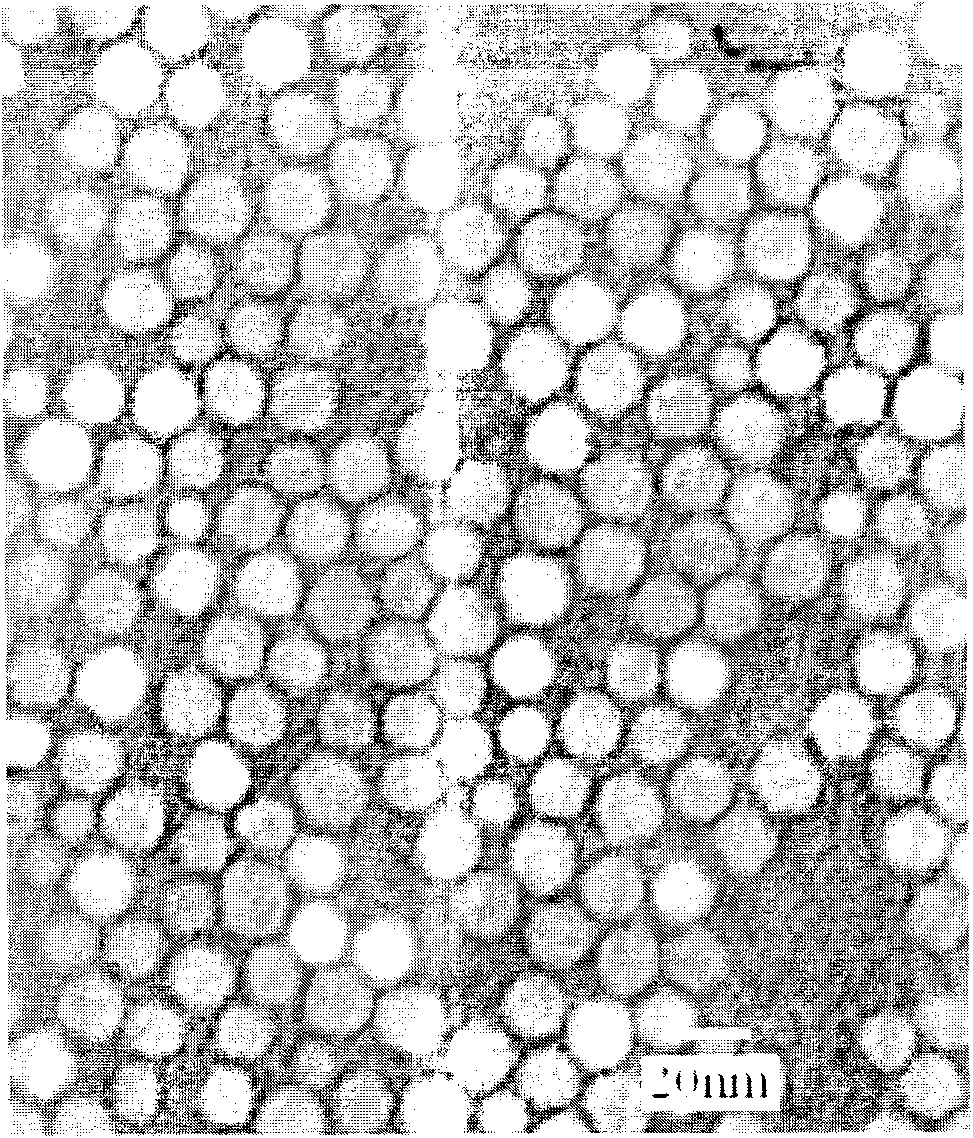

InactiveCN101538068AUnprotectedSmall sizeInorganic material magnetismFerroso-ferric oxidesMagnetic markerSuperparamagnetism

The invention provides a method for preparing monodisperse Fe3O4 magnetic nanoparticles. Precursor is Fe2O3 or iron oxide yellow which has the chemical formula of Fe2O3.H2O; stabilizing agent is oleic acid; high temperature organic solvent is 1-octadecylene (b. p. 318DEG C); precipitating agent is prepared by mixing any two of toluene, dimethyl benzene, ethanol, isopropanol and acetone according to the volume ratio of 1:4-2:3; the mol ratio between the precursor and the stabilizing agent is 1:4-1:9; the mol ratio between the precursor and the high temperature organic solvent is 1:10; inert gas protection is not needed, and the Fe3O4 magnetic nanoparticles which have small sizes, monodisperse, narrow distribution, high saturation magnetization intensity and superparamagnetism. The method can be widely applied to biomedicine fields such as magnetic resonance imaging, biological magnetic separation, magnetic target drug carrier, biological magnetic marker and the like, and the high technical fields such as magnetic sealing, aerospace lubrication, magnetic anti-counterfeiting ink material, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

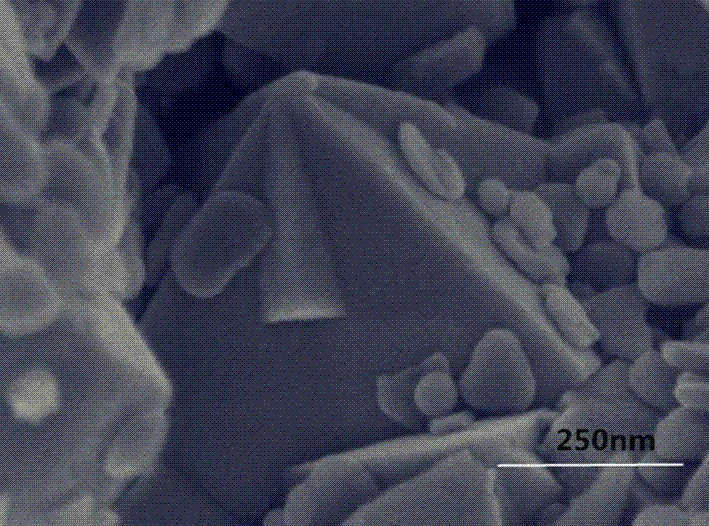

Mn element and Zn element-doped super-paramagnetic ferrite nanoparticles and preparation method thereof

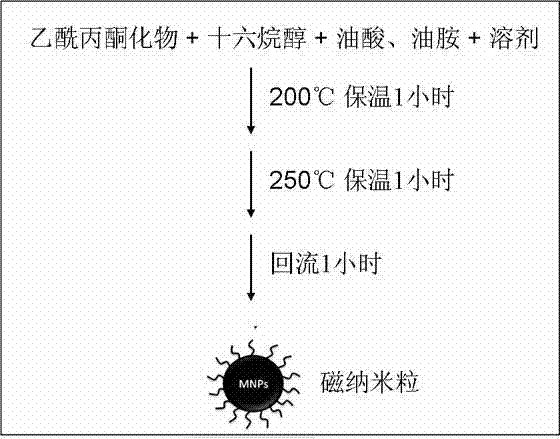

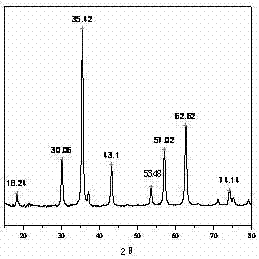

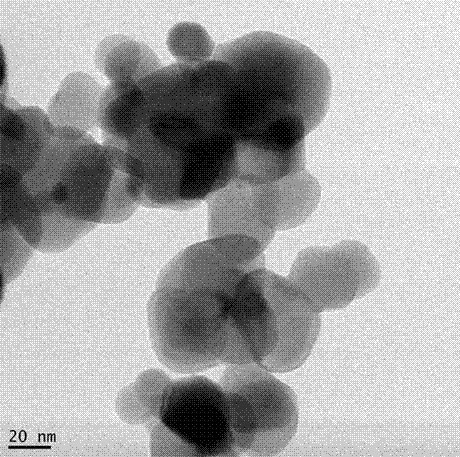

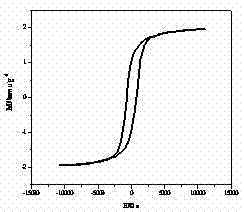

ActiveCN102786299AControlling Saturation MagnetizationRegular shapeMaterial nanotechnologyHexadecaneActive agent

The invention discloses Mn element and Zn element-doped super-paramagnetic ferrite nanoparticles and a preparation method thereof. Manganese element is added or manganese element and zinc element are simultaneously added into a face-centered cubic crystal structure of ferriferrous oxide nanoparticles by using a method of decomposing metal precursor compound at a high temperature; the magnetic performance of the prepared super-paramagnetic nanoparticles is improved by changing the doping amount and the distribution of the metal element; and primarily, the saturation magnetization is improved. The preparation method specifically comprises the following steps of: mixing acetylacetones of Fe and Mn as well as Zn with 1,2-hexadecanol; performing high-temperature decomposition in high-boiling-point solvent by taking oleic acid and oleylamine as surfactants; or performing high-temperature decomposition on composite oleate of Fe, Mn and Zn by taking the oleic acid as the surfactant; heating and preserving heat in stages in argon or nitrogen protective atmosphere to guarantee growth of nanoparticle nuclear; and cooling to room temperature after reaction is finished and settling and centrifuging to finally obtain the super-paramagnetic ferrite nanoparticles which are uniformly dispersed in normal hexane solution.

Owner:SICHUAN UNIV

Preparation method of CoFe2O4 magnetic nano material

InactiveCN102923785AHigh saturation magnetizationSynthetic process conditions are mildMaterial nanotechnologyIron compoundsReaction temperaturePhysical chemistry

The invention provides a preparation method of a CoFe2O4 magnetic material. The preparation method comprises steps as follows: preparing a certain amount of ferric nitrate Fe(NO3)3.9H2O and a certain amount of cobalt nitrate Co(NO3)2.6H2O into a mixed solution; slowly adding to a NaOH solution with a certain concentration at a certain temperature; then agitating the reaction solution under reinforcement; maintaining the reaction temperature for a period of time; then filtering and washing until the filtrate is neutral; drying the product; grinding to obtain black brown precursors; and thermally processing the precursors for 1 hour at a certain temperature, so as to obtain the CoFe2O4 magnetic nano material.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

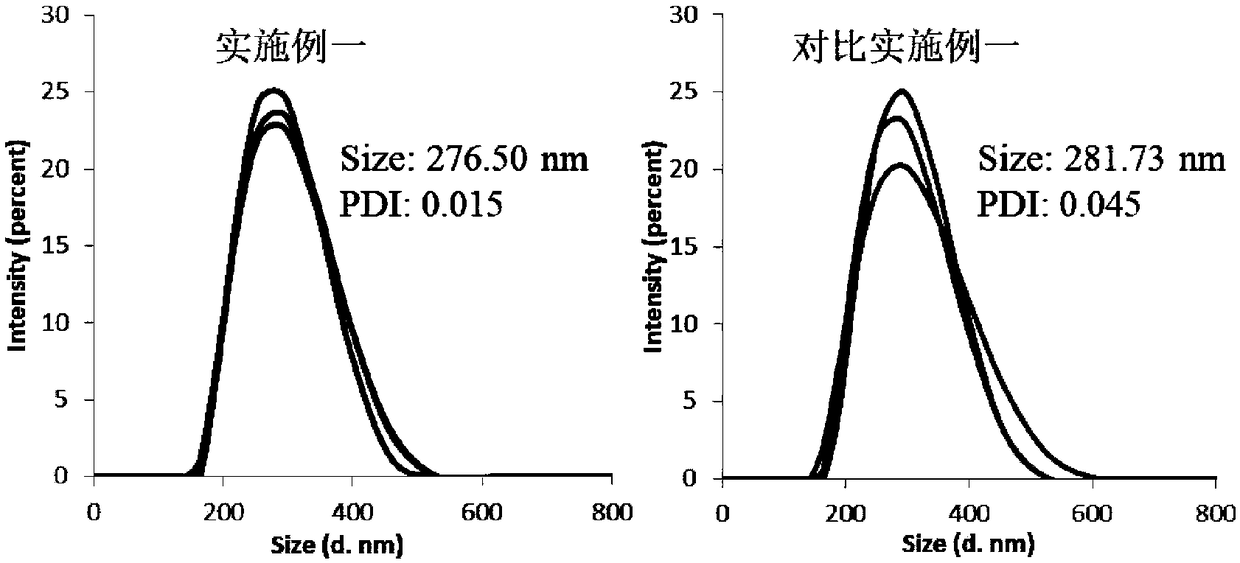

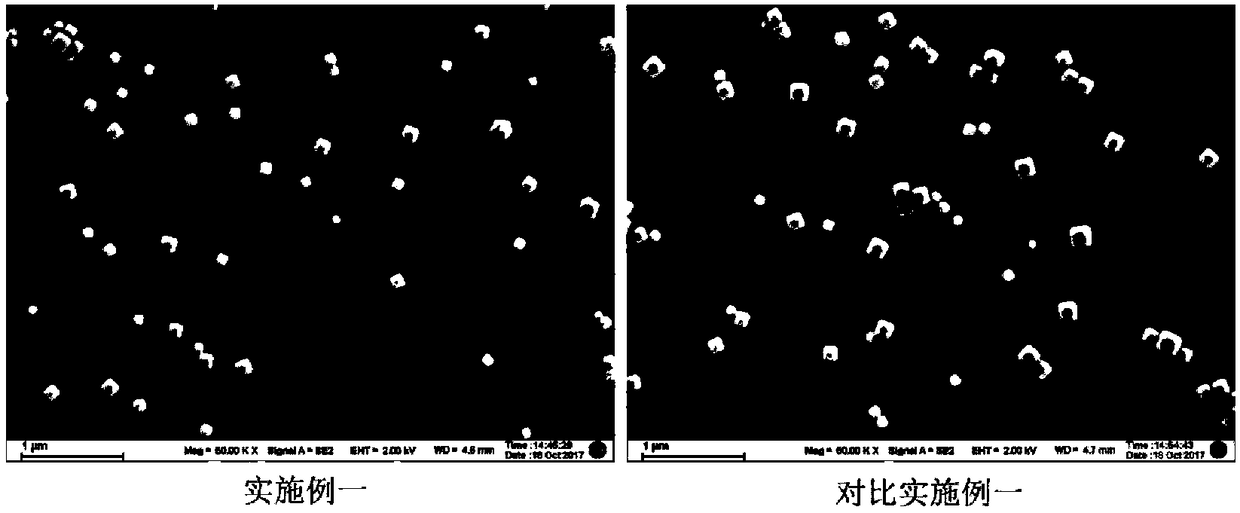

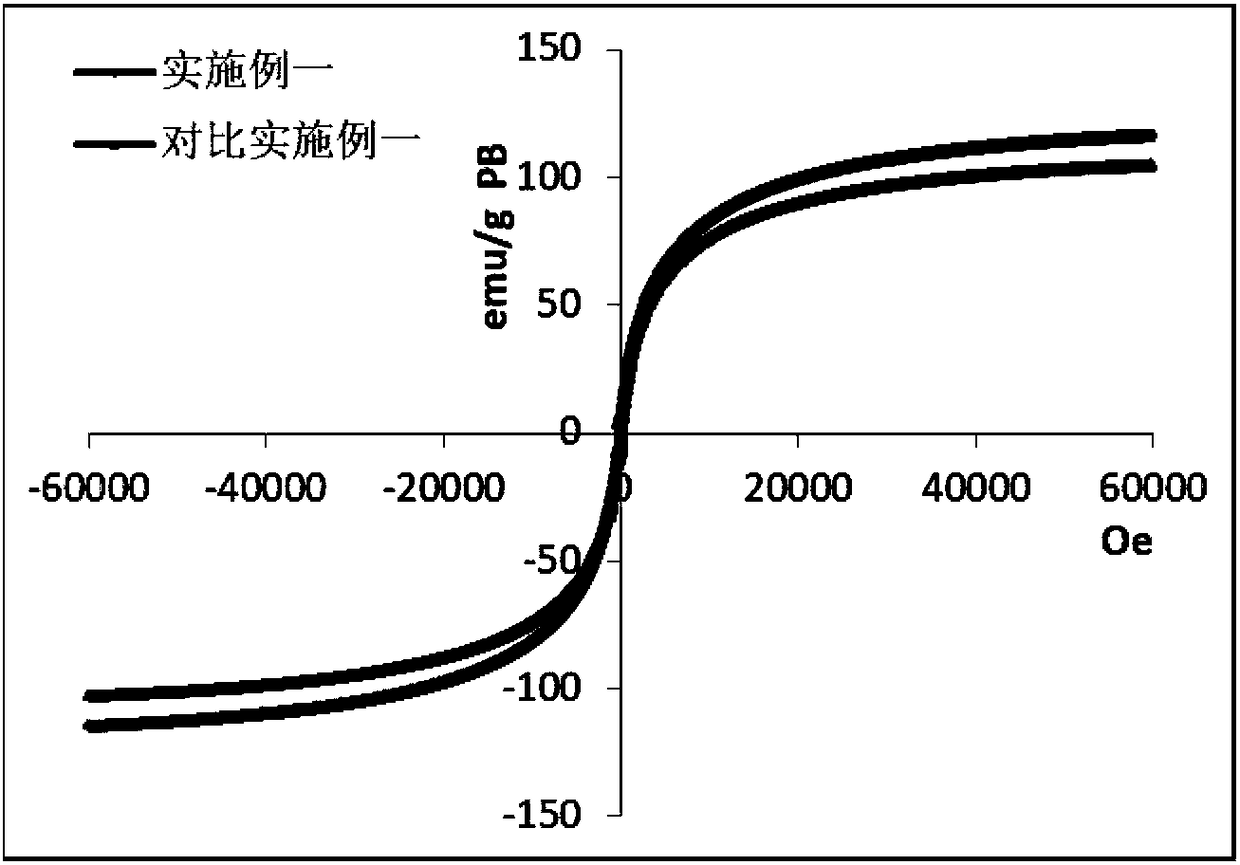

Preparation method of PVP modified prussian blue nanometer material

ActiveCN108324733AQuality improvementUniform particle size distributionHeavy metal active ingredientsAntinoxious agentsFreeze-dryingPrussian blue

The invention provides a preparation method of a PVP modified prussian blue nanometer material. The method concretely comprises the following steps of (1) dissolving PVP and precursors into water formixing; (2) adding hydrochloric acid for regulating the pH to an acid state; (3) performing reaction under the electromagnetic induction heating; (4) performing ethanol water centrifugal washing, dialysis and freeze drying to obtain a finished product. According to the method, magnetic inner heat is used for replacing an ordinary external heating mode; in a shorter reaction time, the high-qualityprussian blue nanometer material can be obtained. The PVP modified prussian blue nanometer material prepared by the method has the advantages of small polydispersity coefficient, uniform particle dimension distribution, higher magnetism and higher nanometer enzymatic activity.

Owner:SOUTHEAST UNIV

High-bonding-strength insulated coating treatment method of metal soft magnetic composite material

The invention discloses a high-bonding-strength insulated coating treatment method of a metal soft magnetic composite material. The method comprises the following steps: (1) sieving metal magnetic powder, and performing particle size distribution; (2) performing insulated coating on the distributed metal magnetic powder by using a sol-gel method, and then drying the metal magnetic powder; (3) uniformly mixing the dried magnetic powder and an adhesive, adding a release agent, and performing dry pressing to obtain a magnetic ring; (4) performing heat preservation, air cooling and spraying on the magnetic ring in protective atmosphere to obtain a target product. The bonding strength of composite powder prepared by using the sol-gel method and magnetic powder particles is high, the powder is coated uniformly and densely, and a coating layer is controllable in thickness, good, oxidation resistance and high saturation magnetization intensity are achieved, excellent in magnetic property and mechanical property, high in bonding strength, and not prone to disengagement; the coating effect is superior to that of an existing method; the method is high in operability and facilitates batch production; the resistivity of soft magnetic metal particles is effectively improved, and the magnetic core loss of the soft magnetic composite material is greatly reduced.

Owner:ZHEJIANG UNIV

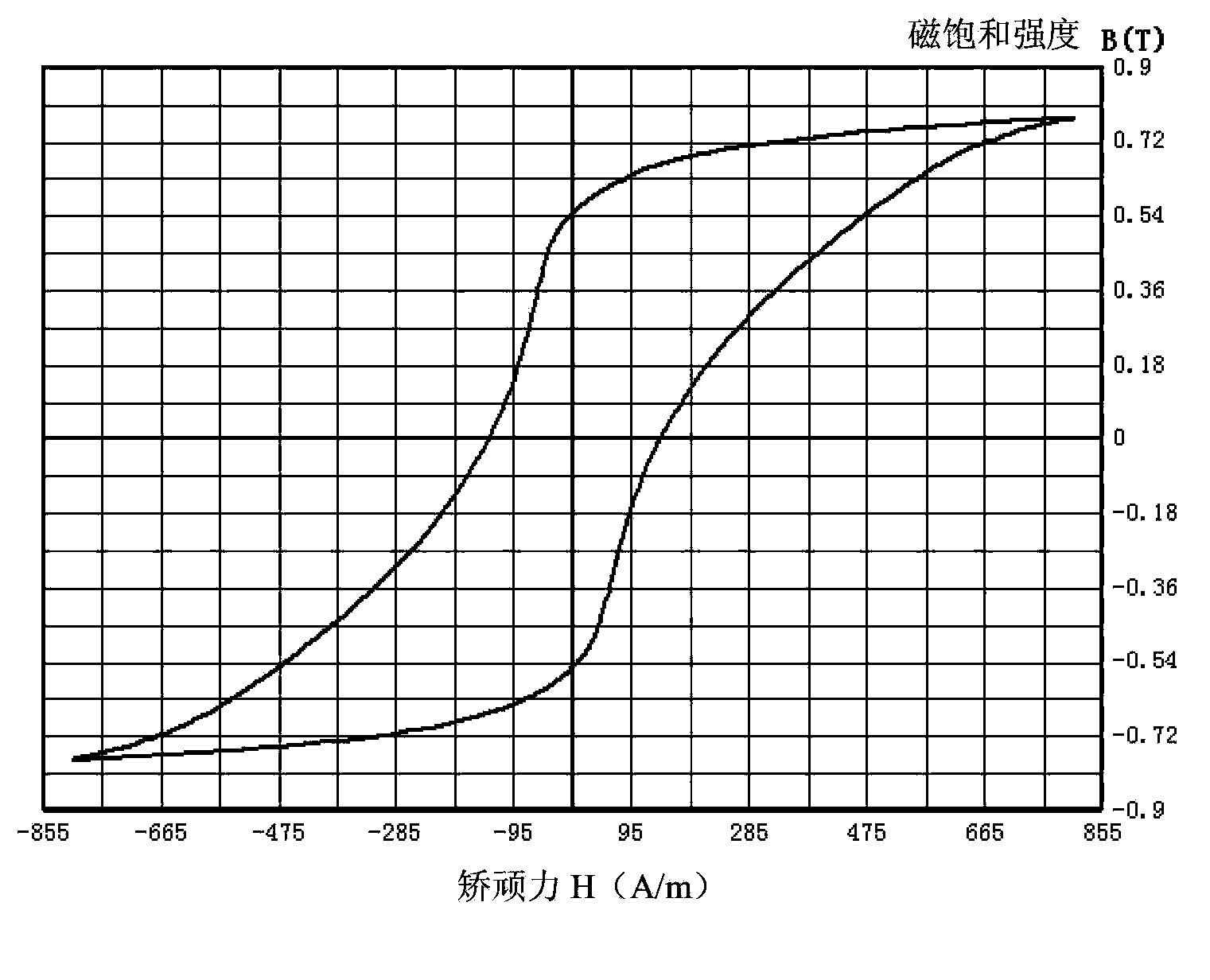

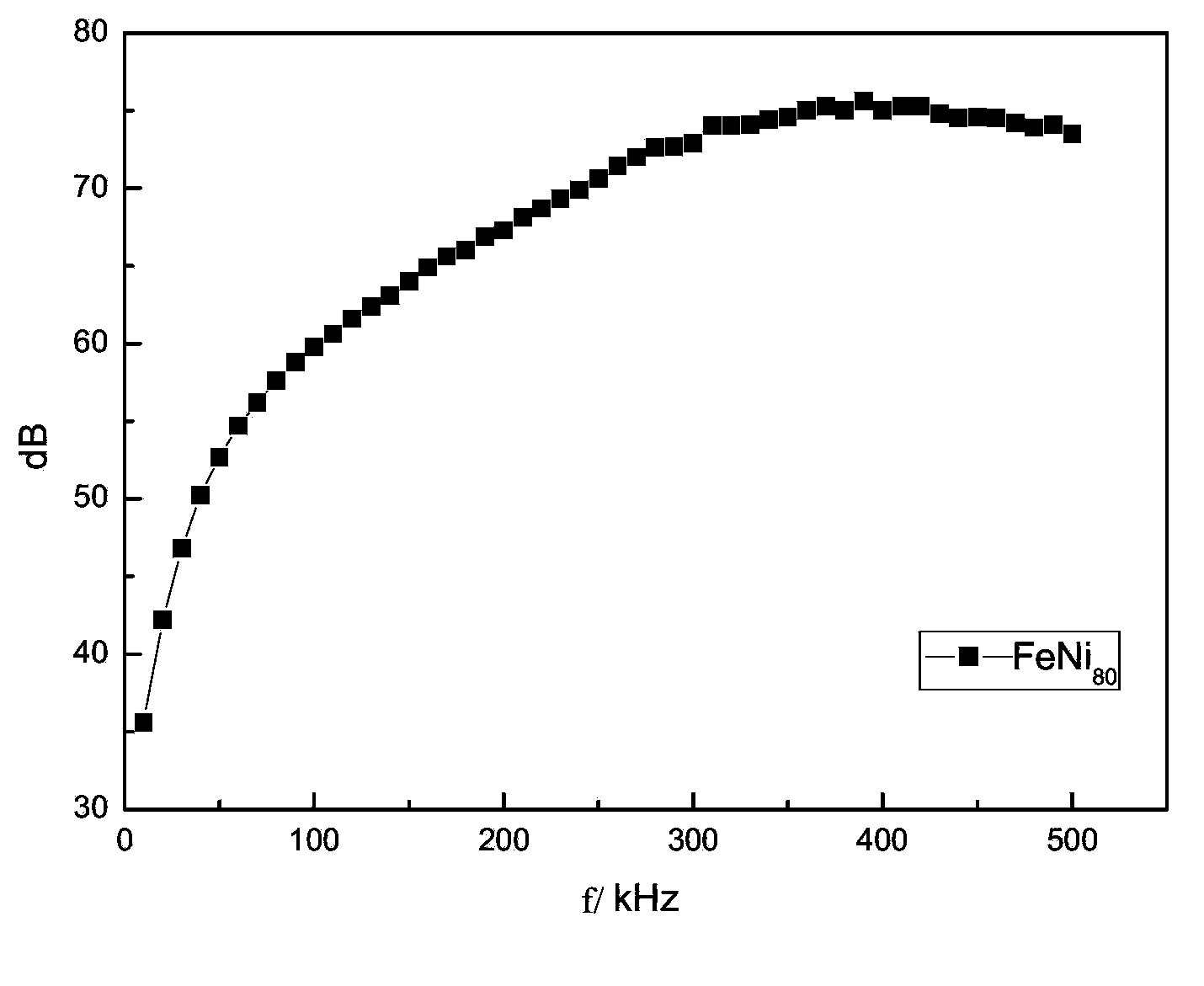

Electroplating Fe-Ni alloy magnetic shielding material and preparation method thereof

An electroplating Fe-Ni alloy magnetic shielding material and a preparation method thereof. The magnetic shielding material is a composite shielding film material comprising a plurality of Cu thin films or Ni thin films and a plurality of Fe-Ni alloy plating layers, wherein the Fe-Ni alloy plating layers have nickel content of 50%-85%. The magnetic shielding material has high saturation magnetization intensity, and low residual magnetization intensity and coercive force, and has certain magnetic shield performance in a low frequency magnetic field and a static magnetic field. The preparation method comprises the following steps: (1) cleaning the surface of a substrate; (2) depositing the Cu thin films or Ni thin films on the substrate; (3) electroplating the substrate in an electroplating liquid for electroplating the Fe-Ni alloy plating layers; (4) placing the substrate electroplated with the Fe-Ni alloy plating layers in a resistance furnace, fast heating temperature to 300 DEG C, insulating under the protection of hydrogen for 4 h, and finally cooling in hydrogen atmosphere with the furnace to carry out a low temperature annealing treatment; and (5) repeating the steps (2)-(4) to obtain the required Fe-Ni alloy magnetic shielding material.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method of magnetic nano ferroferric oxide modified hollow glass microsphere

ActiveCN102993781AHigh saturation magnetizationGood combination fastnessOther chemical processesPigment treatment with macromolecular organic compoundsIonNanometre

The invention discloses a preparation method of a magnetic nano ferroferric oxide modified hollow glass microsphere. The method comprises the steps of removing oil of a hollow glass microsphere; soaking the hollow glass microsphere with oil removed in a coarsening solution to react, filtering and subsequently washing, and drying; dipping the hollow glass microsphere in a coupling agent solution to react, filtering and subsequently washing, drying and baking; dipping the hollow glass microsphere in a chitosan solution, stirring and filtering, subsequently prebaking and baking; soaking the dried hollow glass microsphere in a sodium hydroxide solution, filtering and then washing; and finally dipping the hollow glass microsphere in a ferrous chloride mixture solution, transferring to a high-pressure reaction kettle, sealing and then carrying out insulation treatment, and filtering the hollow glass microsphere after finishing reacting; and washing respectively by using absolute ethyl alcohol and deionized water and drying. The preparation method saves the raw material and is easy and simple to operate; through the modification on the surface of the hollow glass microsphere, the problems of no magnetism, poor coating fastness, weak magnetism and the like of the hollow glass microsphere are solved.

Owner:JIAXING HENENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com