Patents

Literature

167results about How to "Reasonable design of ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

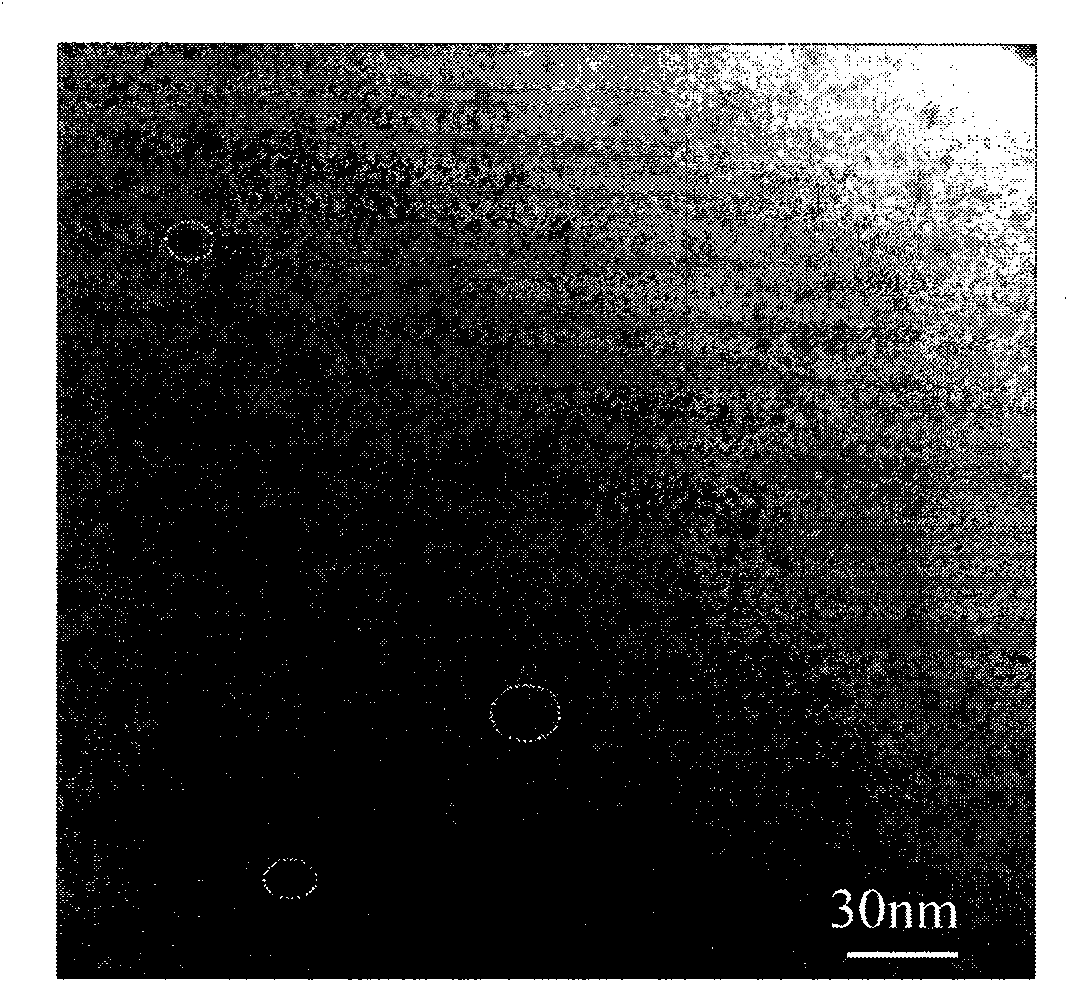

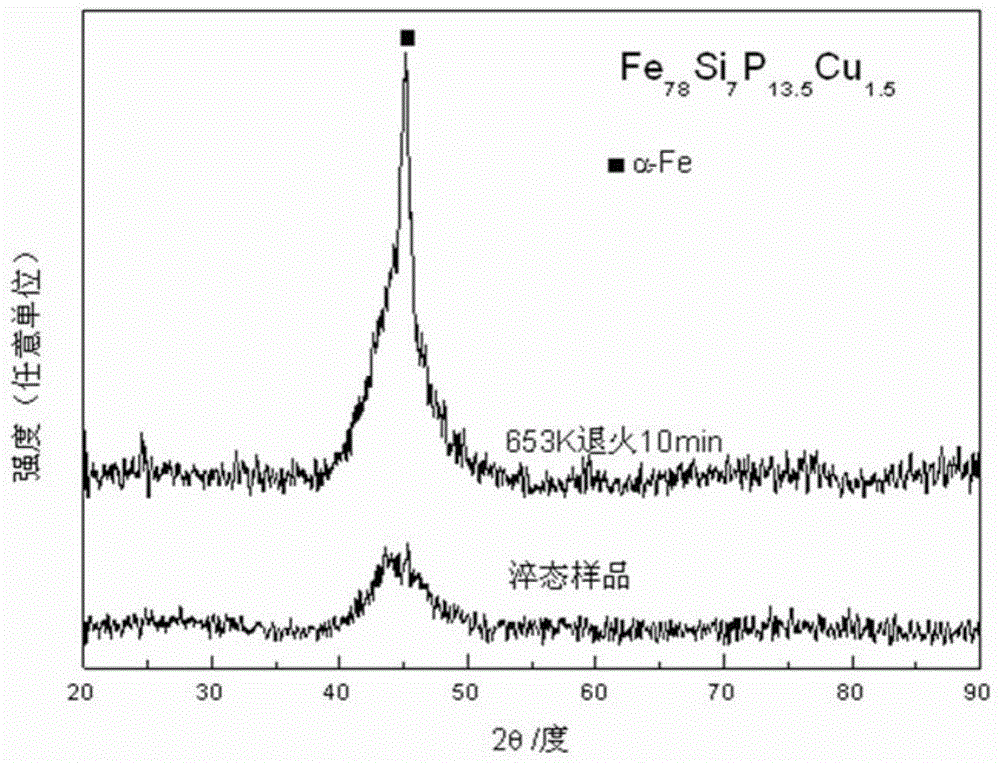

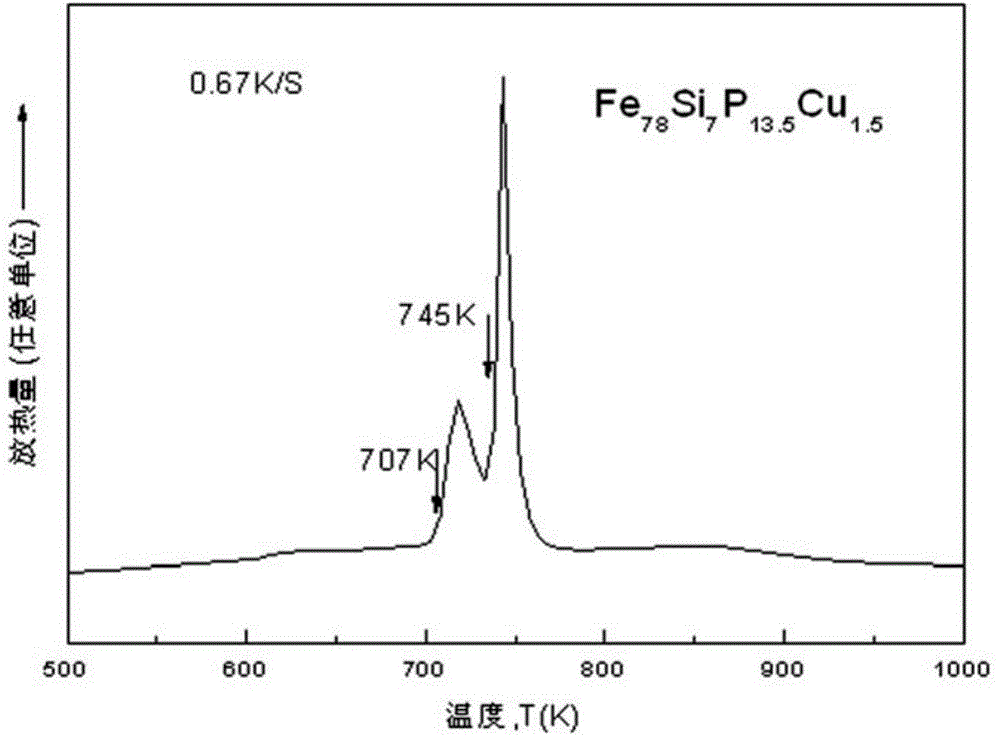

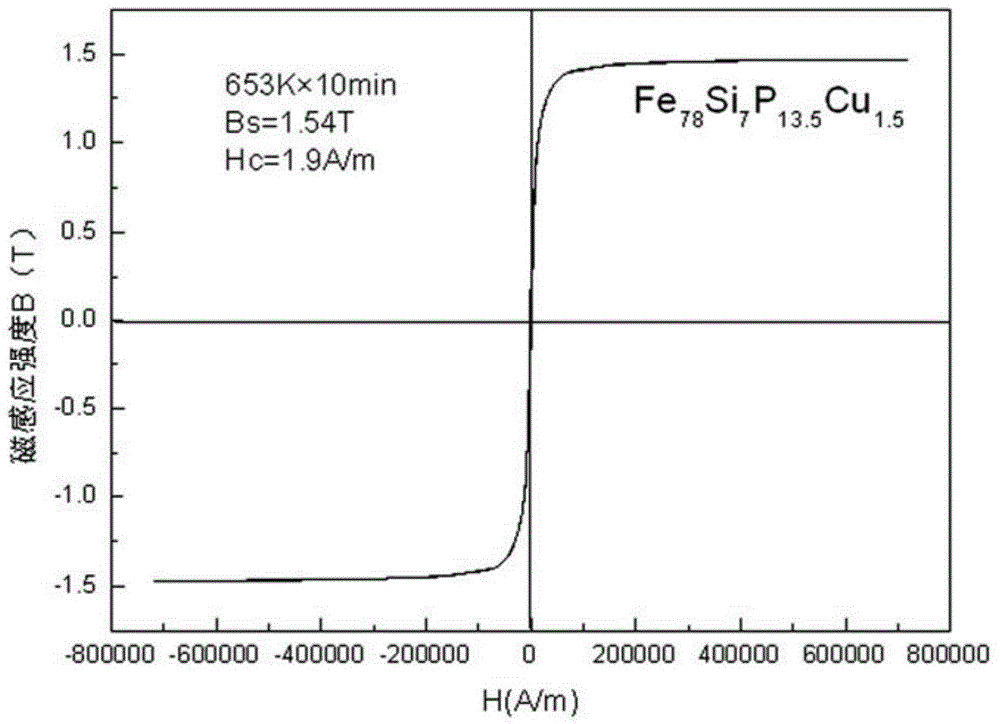

Iron-based nano-crystalline magnetically-soft alloy having high saturation magnetic induction intensity

InactiveCN101840763AReasonable design of ingredientsStrong Amorphous Formation AbilityMagnetic materialsAtomic compositionCoercivity

The invention provides an iron-based nano-crystalline magnetically-soft alloy having high saturation magnetic induction intensity. The iron-based nano-crystalline magnetically-soft alloy is characterized in that the atomic composition thereof by percentage (%) is shown in the following formula: FeTaBbCucCdMe, wherein T represents at least one selected from Zr, Ti, Ta, Hf, Nb, V, W, Mo and Cr; M represents at least one selected from P, Si, N, Sn, Ge, Ga and Al; the subscripts, i.e., a to e in the formula, indicate the atomic percentage (%) and meet the following conditions: a is larger than or equal to 0.002 and less than or equal to 5, b is larger than or equal to 2 and less than or equal to 18, c is larger than or equal to 0.02 and less than or equal to 5, d is larger than or equal to 0.002 and less than or equal to 3, and e is larger than or equal to 0.02 and less than or equal to 20; and Fe and other unavoidable impurities constitute the balancing amount. The magnetically-soft alloy of the invention has the characteristics of high glass-forming ability, high saturation magnetic induction intensity and good soft magnetic performance; and particularly, the saturation magnetic induction intensity of the annealed alloy is higher than 1.5T, and the coercive force thereof is lower than 15A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

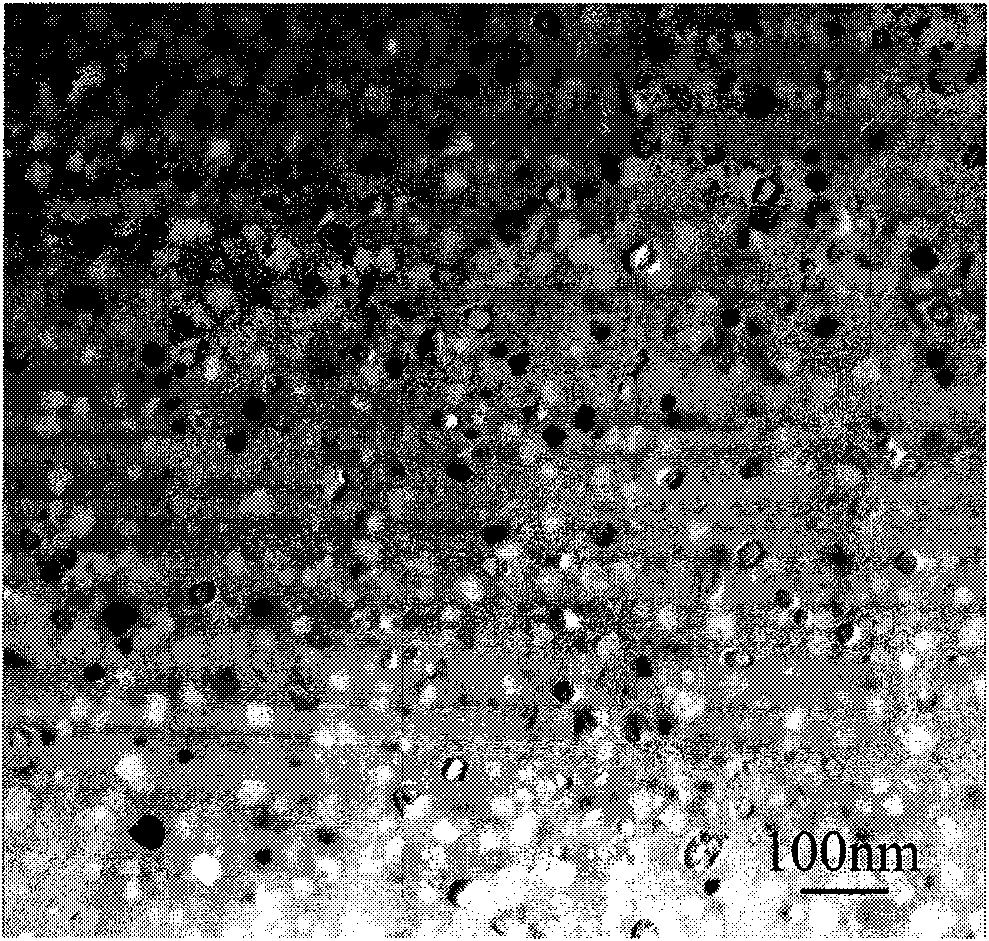

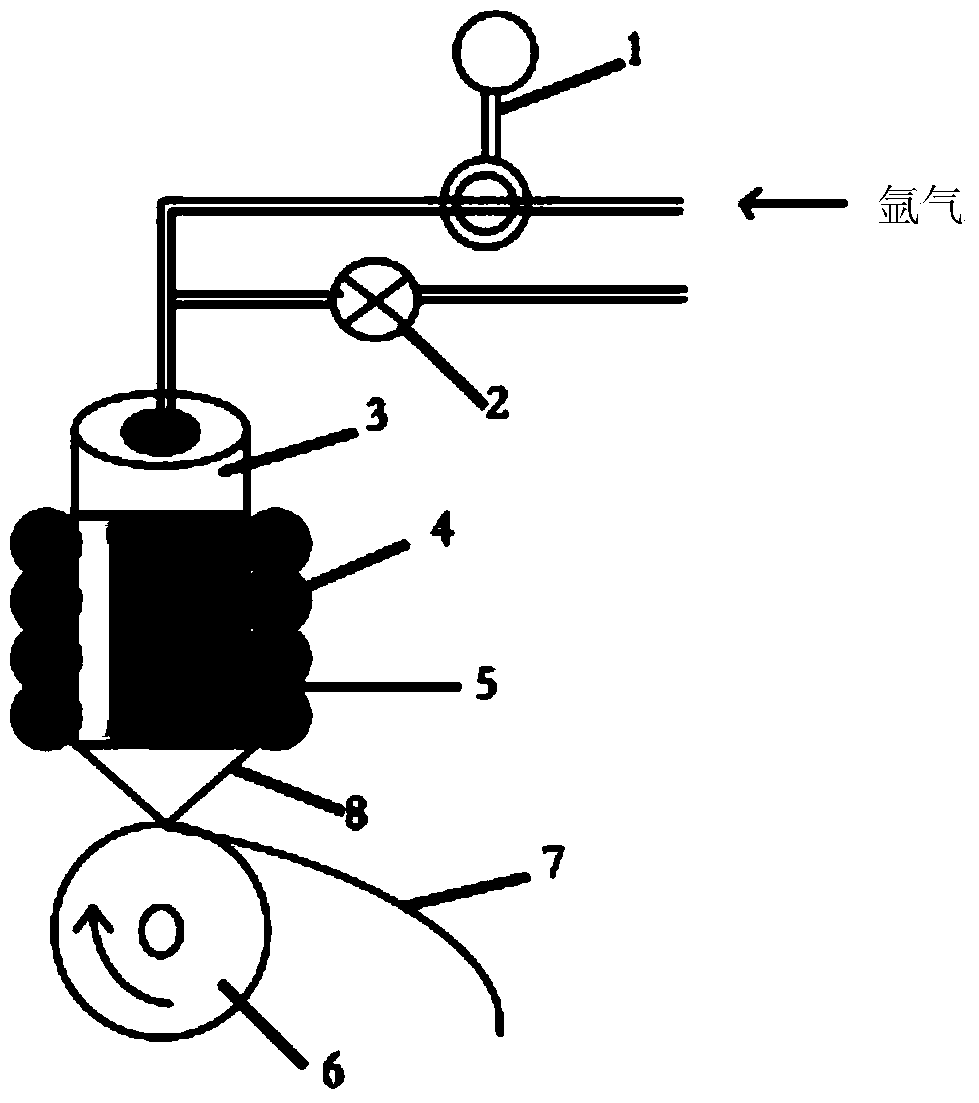

Iron-based amorphous magnetically soft alloy with uniform element distribution and preparation method thereof

ActiveCN104073749AImprove thermal stabilityHigh saturation magnetic inductionMagnetic materialsTransformerMaterials science

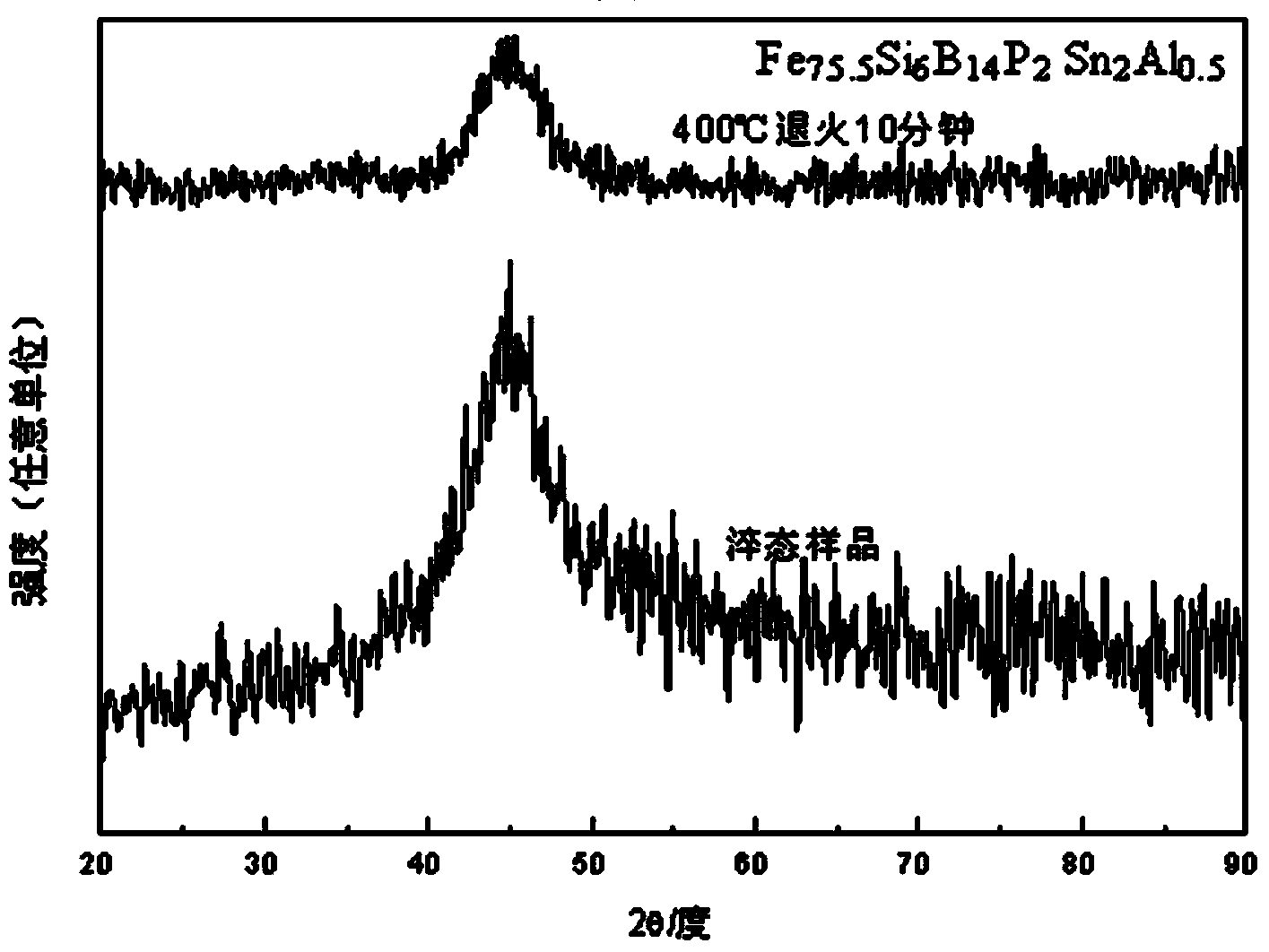

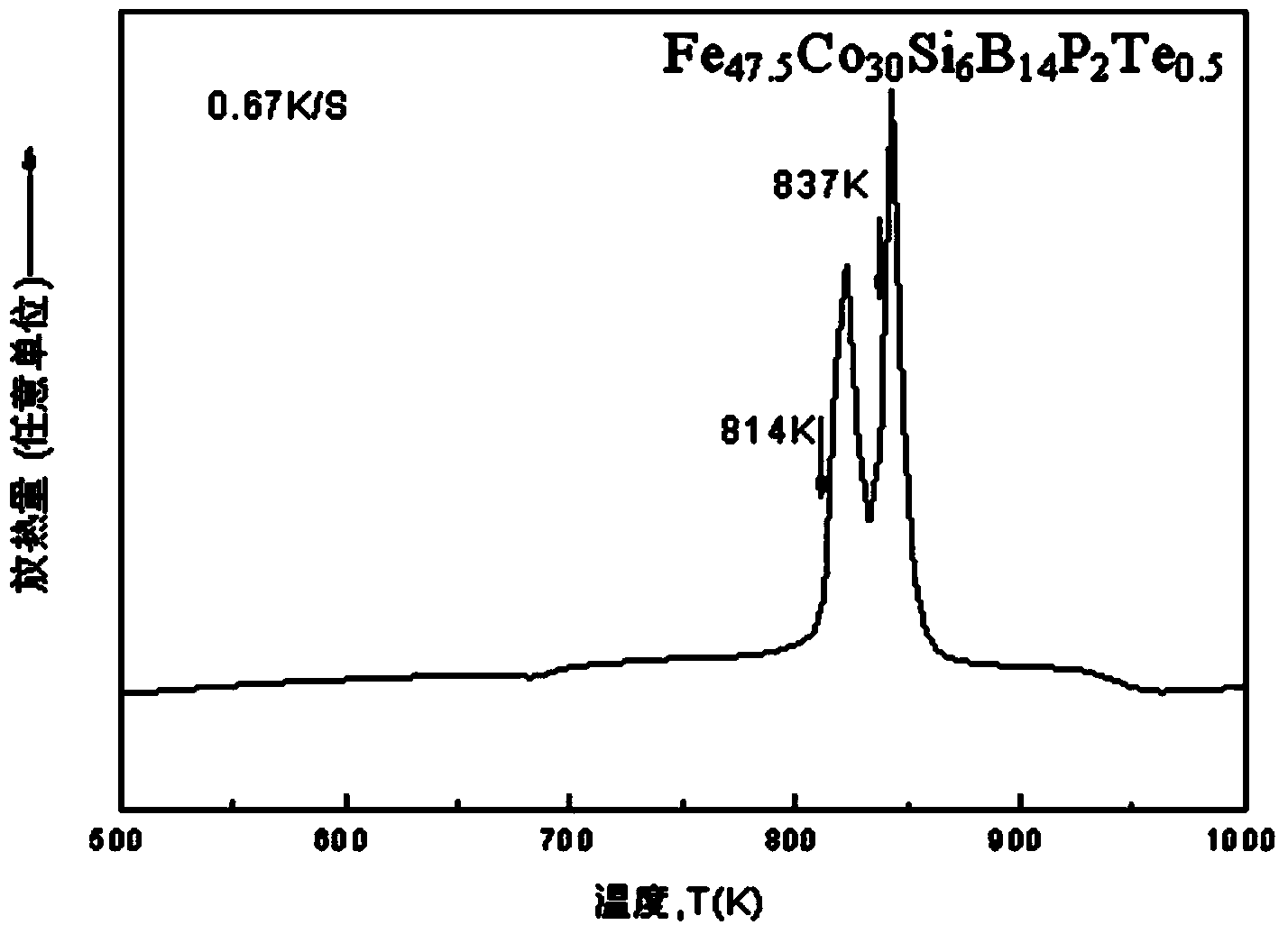

The invention discloses an iron-based amorphous magnetically soft alloy with uniform element distribution and a preparation method thereof. The expression of the alloy is FeaSibBcPdMe, a, b, c, d and e in the expression represent the atomic percent contents of corresponding components respectively, and meet the following conditions: a is not less than 70 and not greater than 84, b is not less than 2 and not greater than 10, c is not less than 5 and not greater than 18, d is not less than 0.001 and not greater than 8, e is not less than 0.0001 and not greater than 2.5, a+b+c+d+e=100%, and M is one or more of C, N, Sn, Ge, Ga, Al, S, Te, Be, Pb, Mg and Cu. The amorphous strip prepared from the alloy under a high vacuum and argon shield has the characteristic of uniform element distribution, particularly solves the problem of non-uniform distribution of element P in the amorphous alloy, has excellent magnetically soft performance, and is suitable for transformers, engines, power generators, magnetic sensors and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

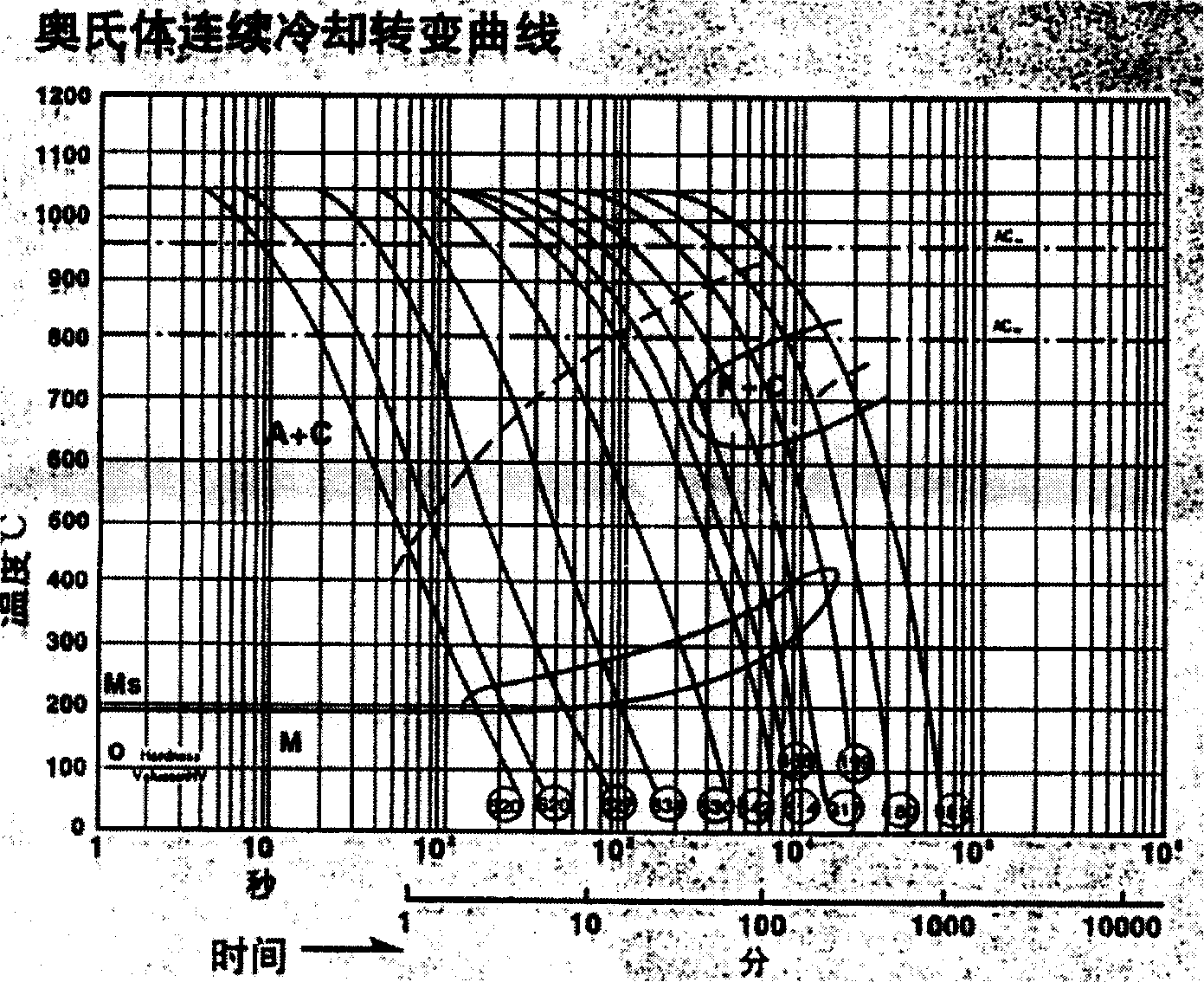

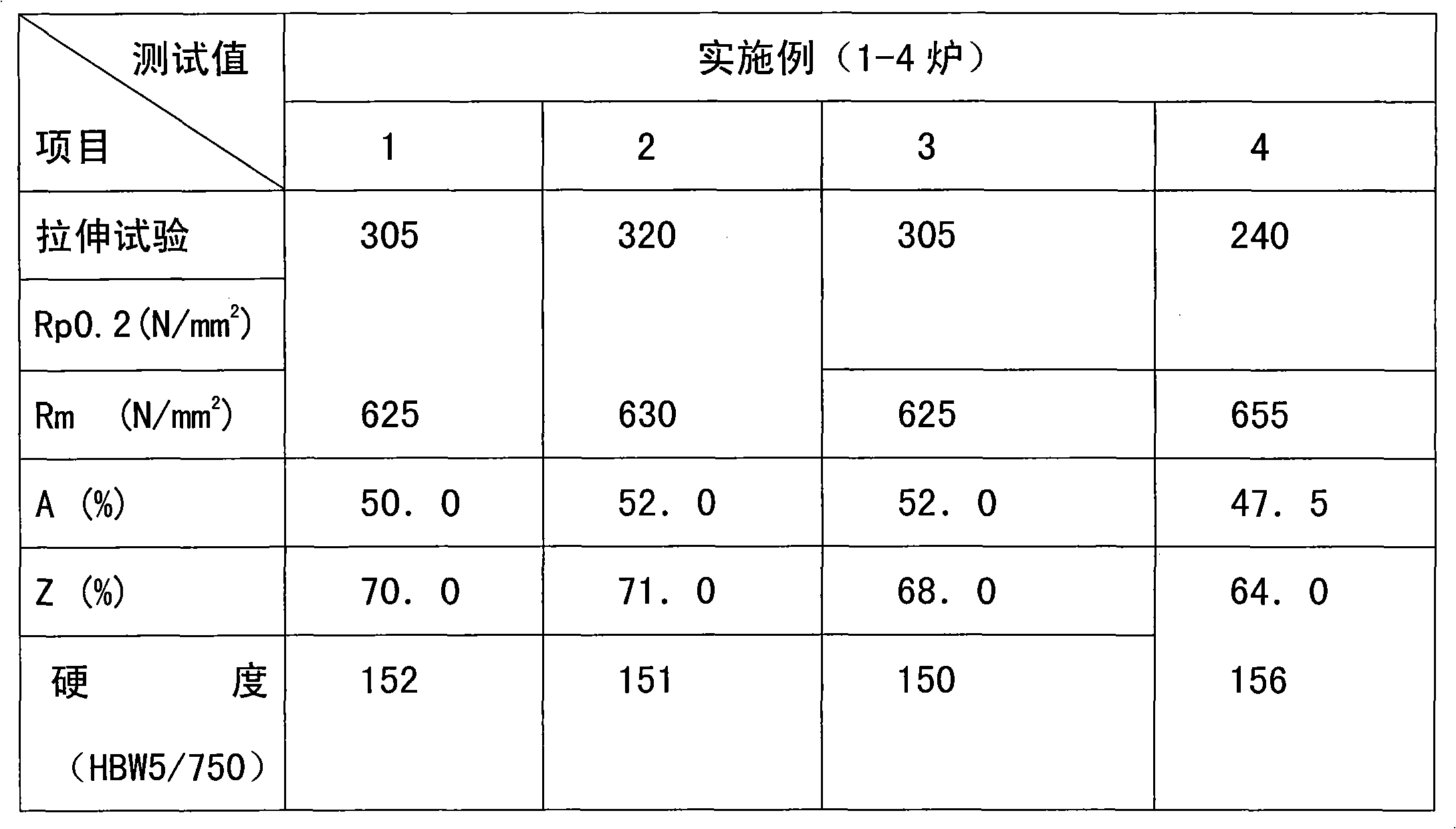

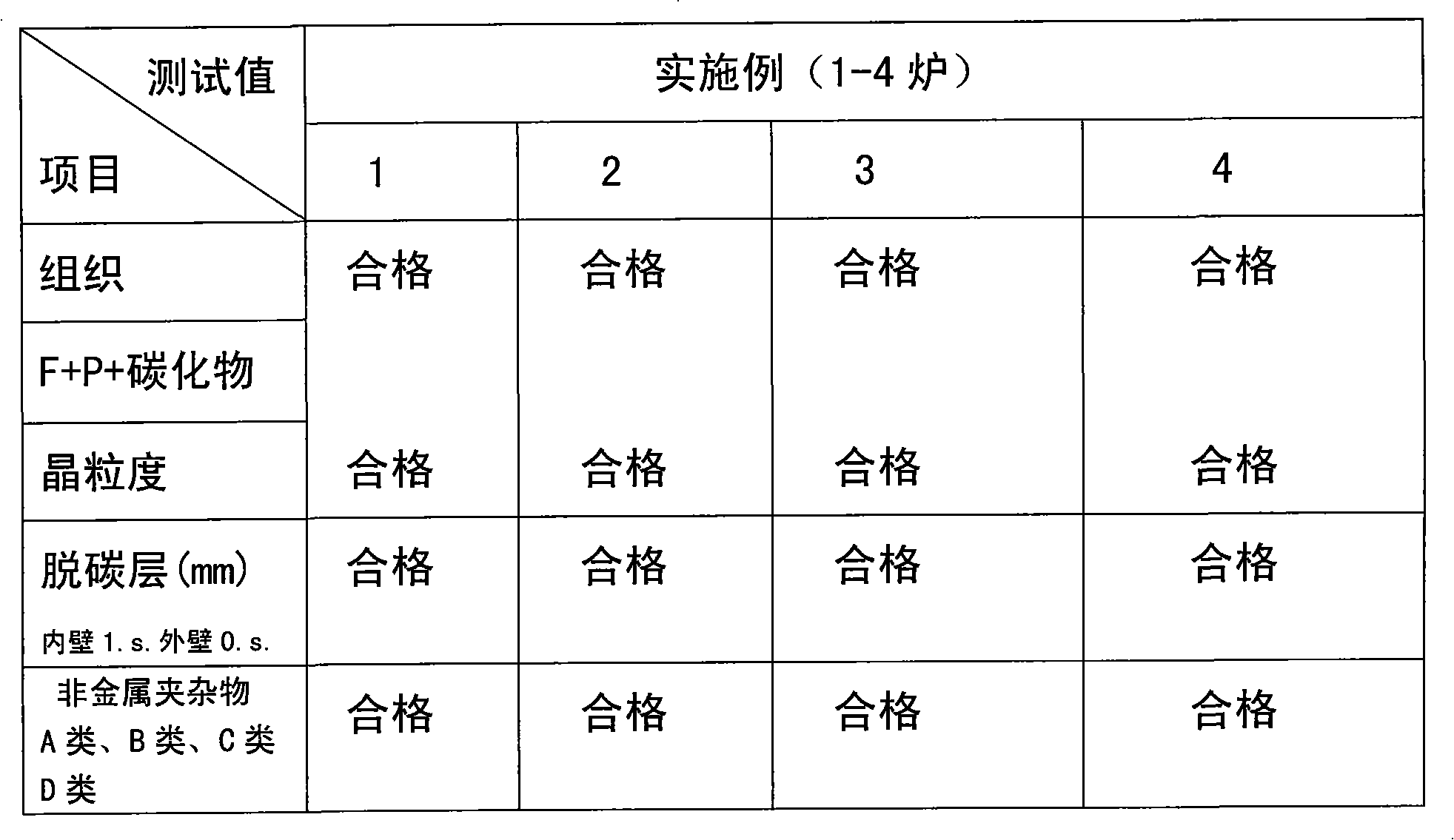

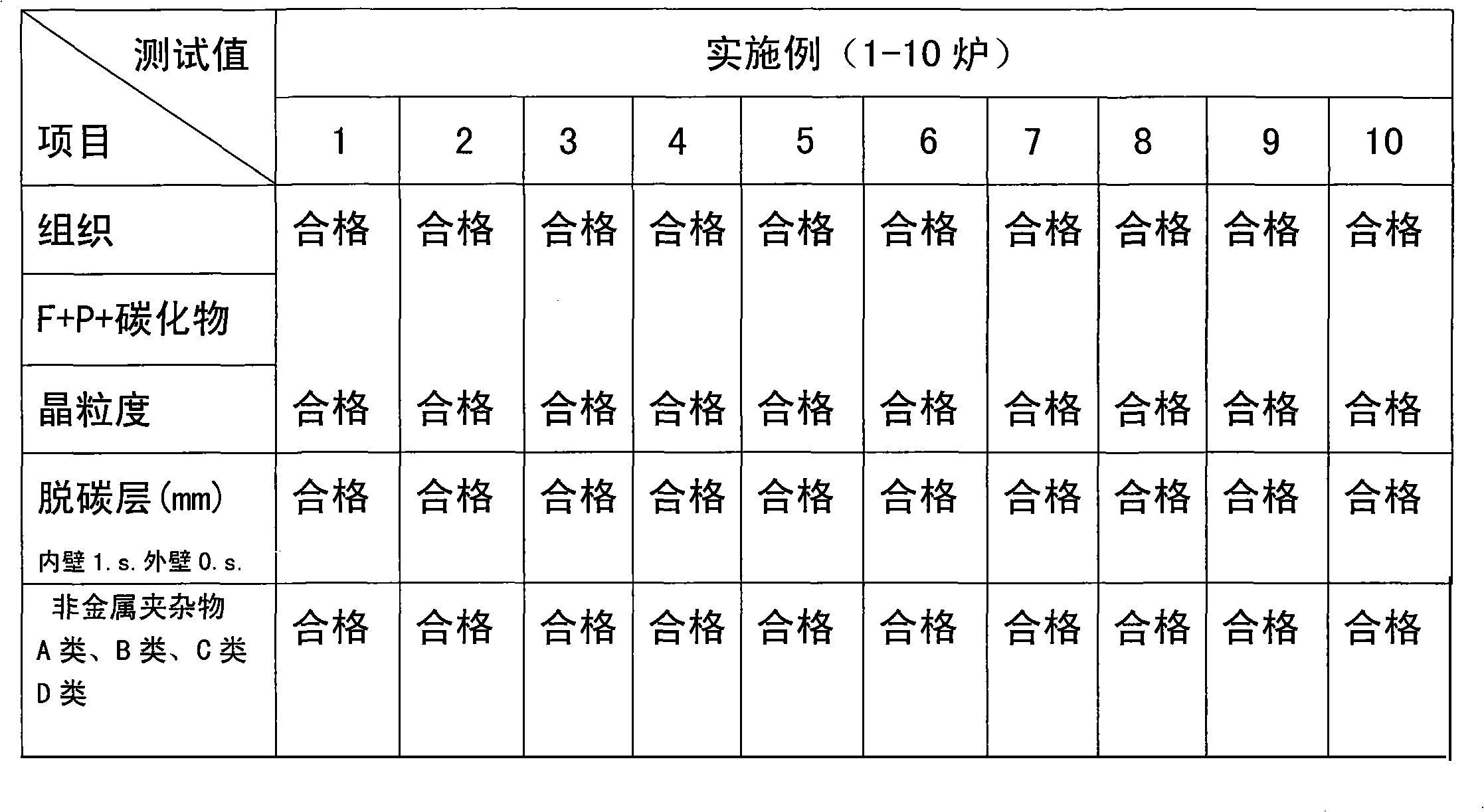

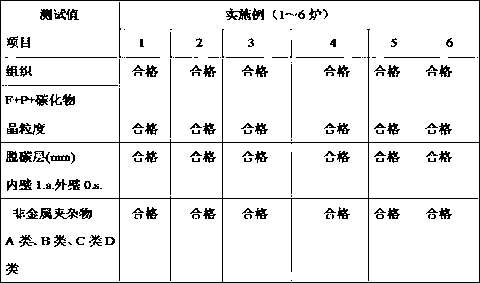

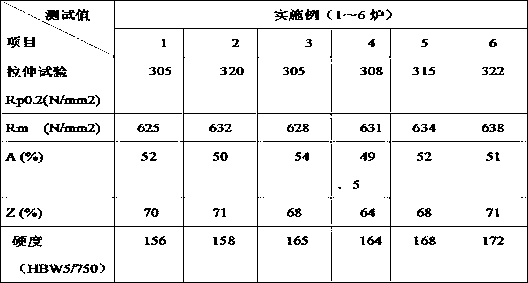

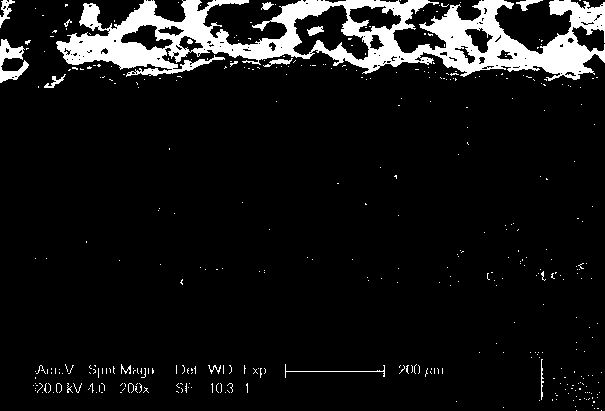

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

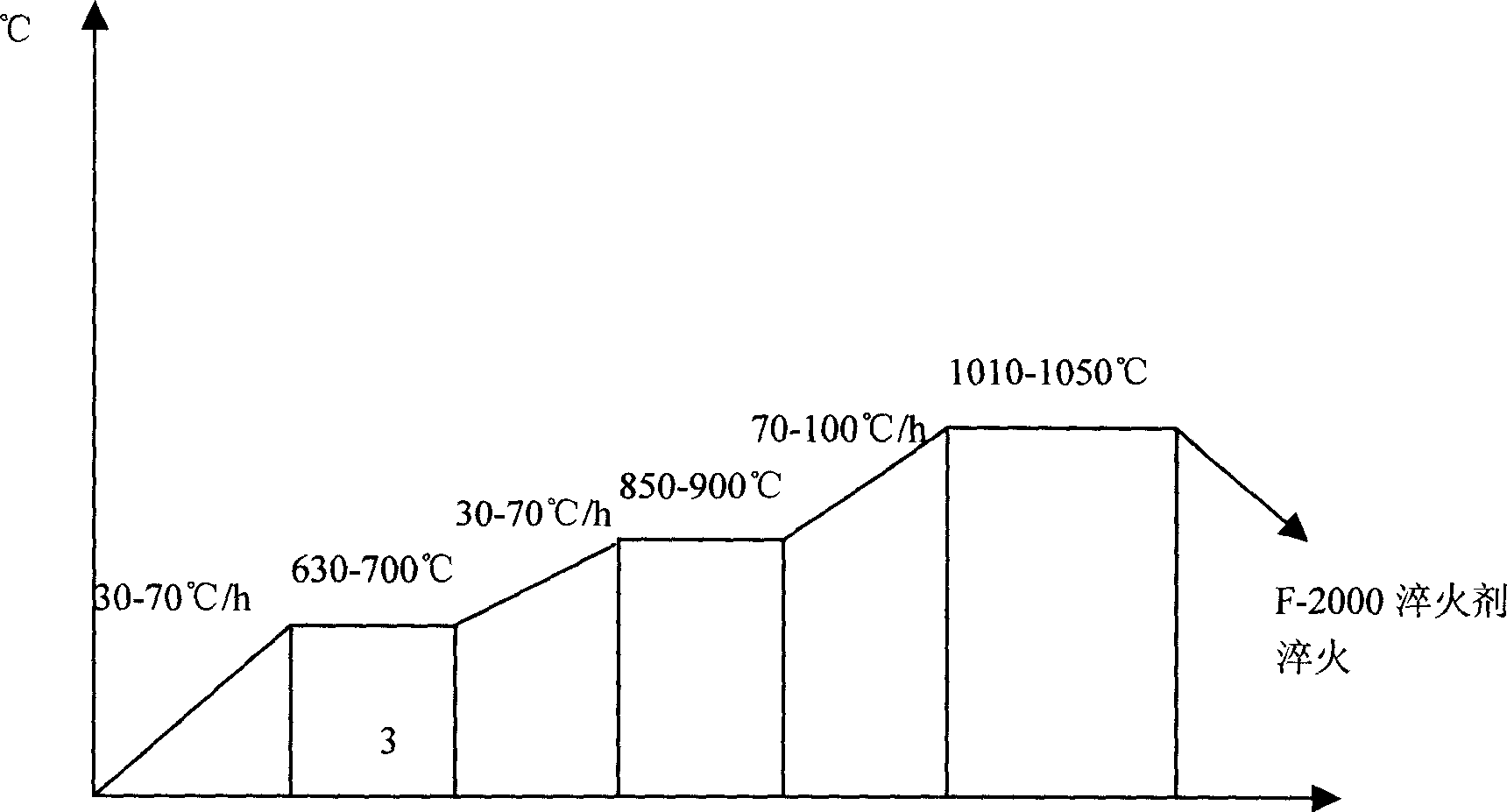

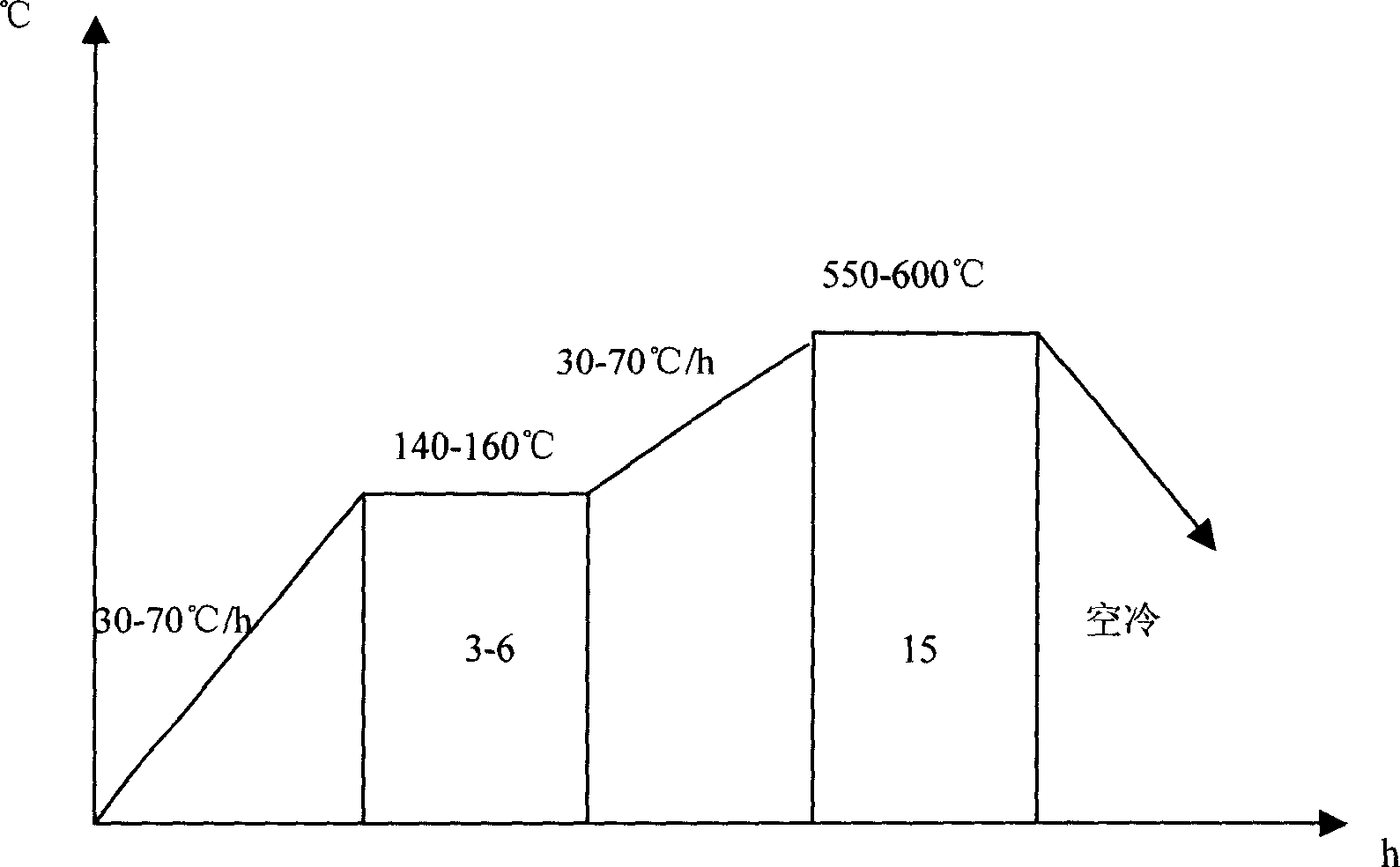

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

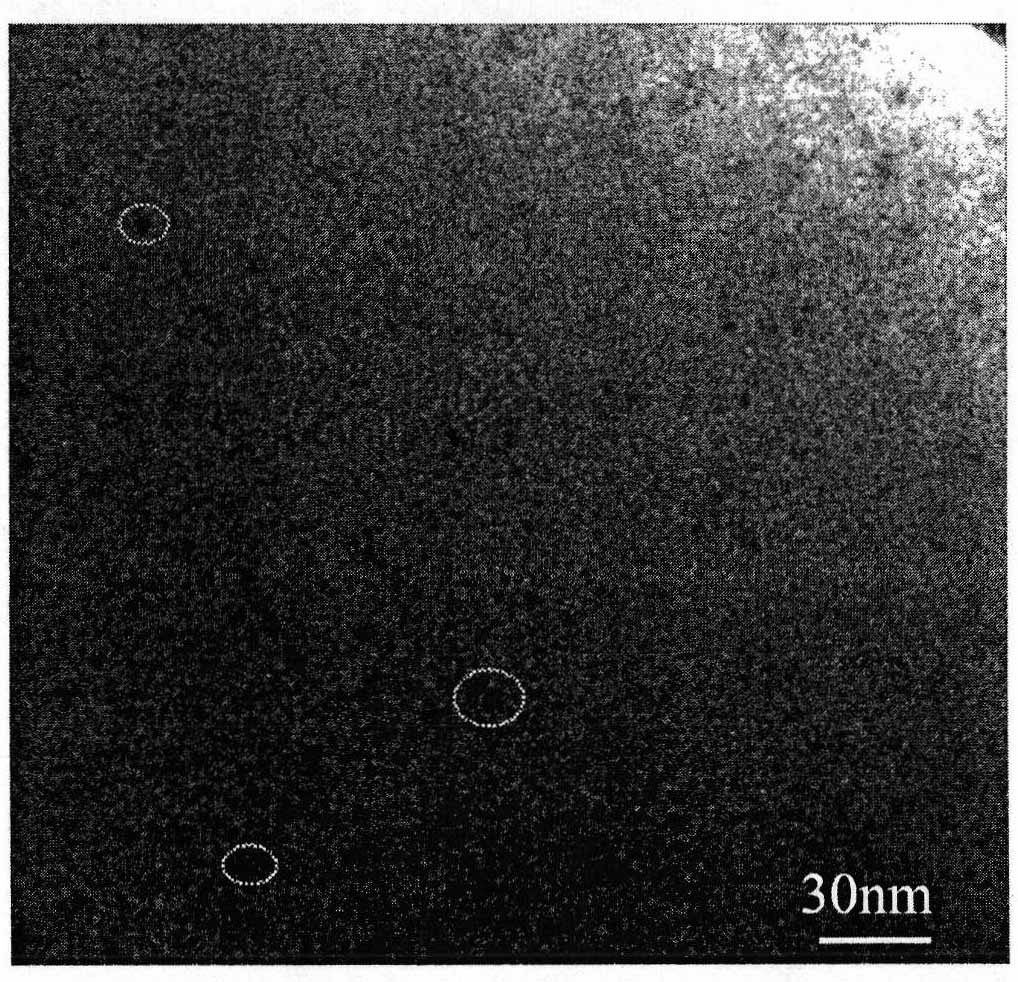

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Serial high-magnetic induction non-orieted electrical steel and its production process

The present invention relates to an electrical steel and its production, especially, the components and production process of a high-magnetic induction, low-iron loss non-oriented electrical steel. By means of regulating alloy element content, reducing gas inclusion and nitride forming element content, adding segregation element, low temperature hot rollng, once cold rolling, and annealing at thetemperature determined based on T(ann)=786.83K+61.04Si(%), the electrical steel is produced. The product of 0.50 mm thickness has a P1.5=2.70-13.00 W / Kg, B(5000)=1.76-1.82 T, and excellent cooperation between iron loss and magnetic induction. The electrical steel is suitable for use in iron core in various motors.

Owner:武钢集团有限公司

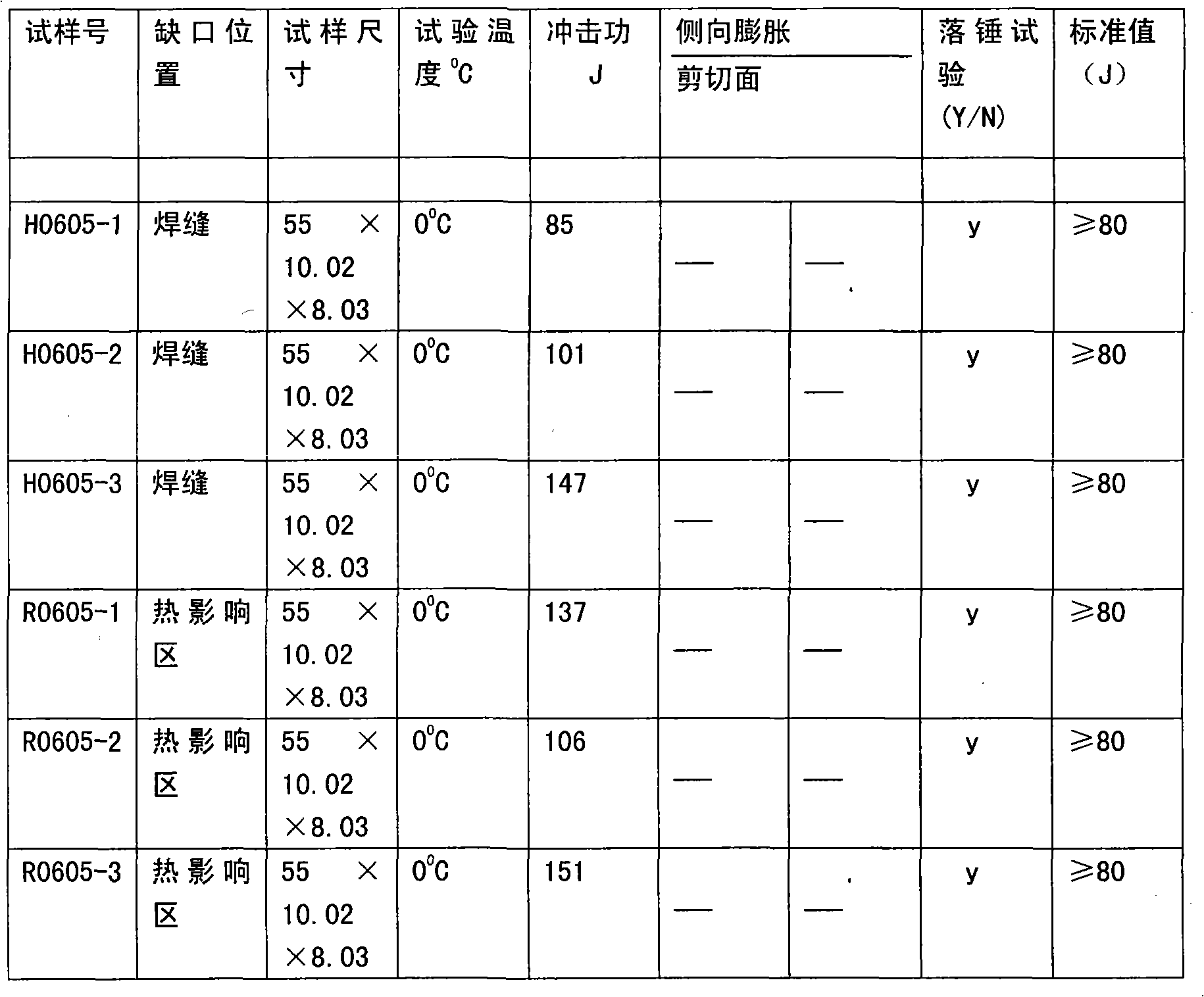

High-strength gas-defended welding wire material

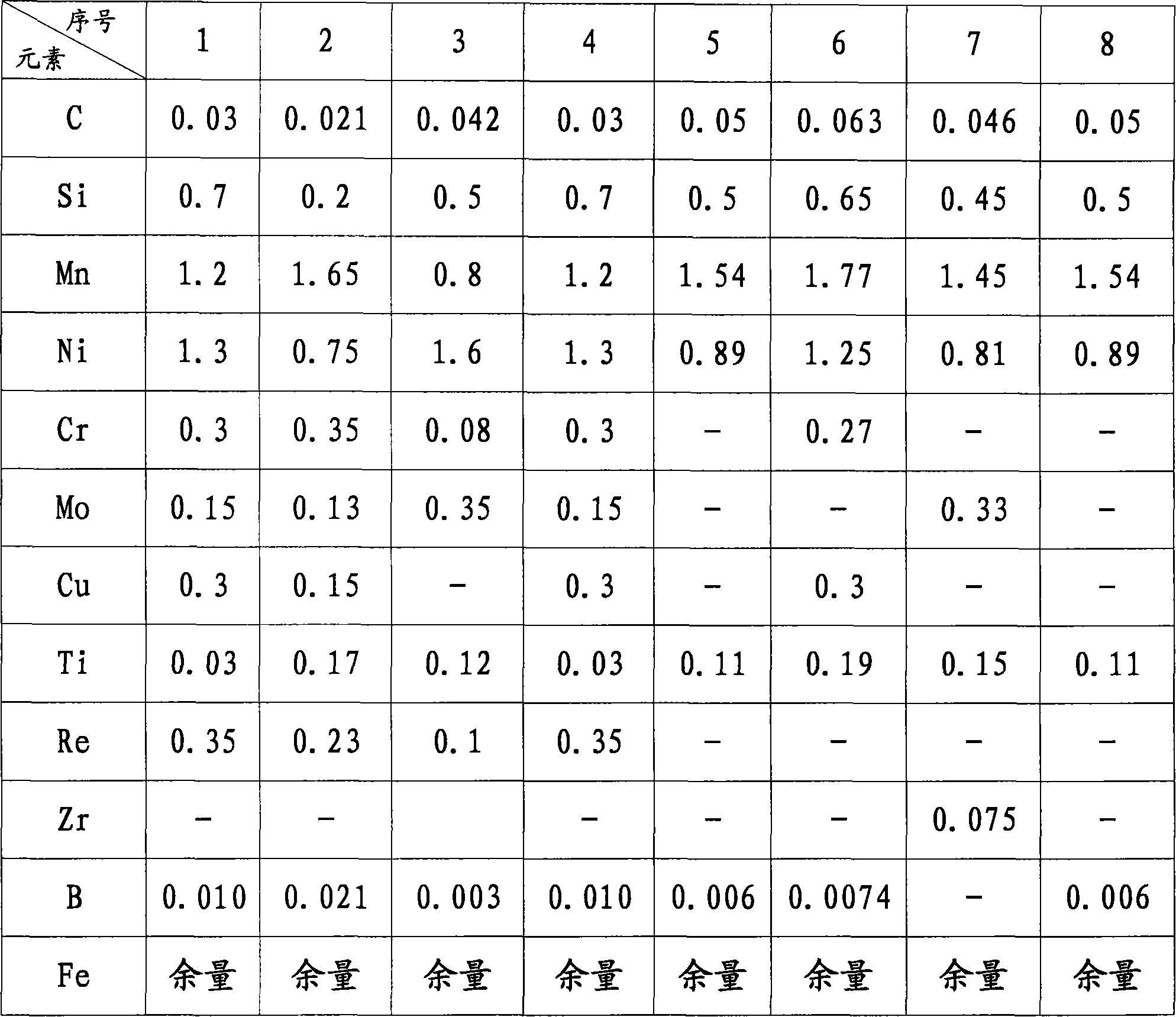

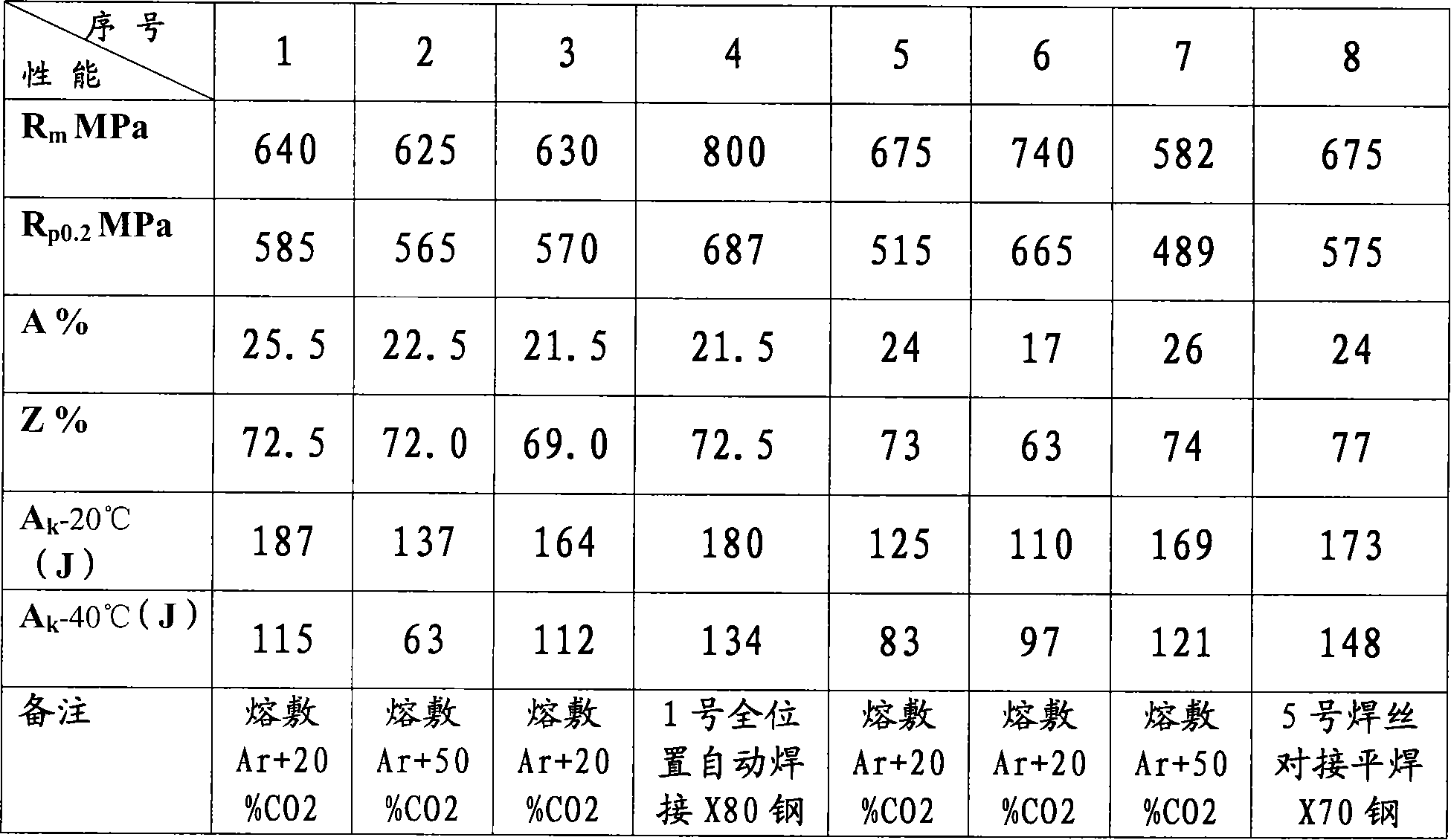

ActiveCN101116930AReasonable design of ingredientsWide range of applicationsWelding/cutting media/materialsSoldering mediaHigh intensityWeld line

The invention belongs to the full position automatic welding material making field, in particular to a high strength gas protecting welding wire of synthesis mechanics good function in the welding line by adopting the rich argon gas protecting welding. The specific ingredient weight percent of the welding wire is that C is less than 0.05 percent, Si is ranged from 0.1 percent to 0.8 percent, Mn is ranged from 0.5 percent to 2.0 percent, S is less than 0.01 percent, P is less than 0.015percent, Ni is ranged from 0.5 percent to 2.0 percent, Cr is ranged from 0.05 percent to 0.50 percent , Mo is ranged from 0.1 percent to 0.5 percent, Cu is less than 0.3 percent, Ti is ranged from 0.01 percent to 0.25 percent, Re 0.05 is ranged from percent to 0.5 percent, B is ranged from 0.001 percent to 0.030 percent and remained iron. Compared with the prior art, the invention welding wire material has fine synthesis mechanics function of reasonable, simple, economic ingredient design of the welding wire material, high strength and low temperature toughness of the welding line smelt apply metal. The invention is characterized in that the wide applicable range of CO2 content in the gas is protected and the full position automatic welding has good manufacturability.

Owner:CENT IRON & STEEL RES INST

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

Shockproof strip end-plate material of vapor generator of nuclear power plant and preparation method thereof

InactiveCN101851714AReasonable design of ingredientsLow costPressurized water reactorVapor generator

The invention discloses a shockproof strip end-plate material of a vapor generator of a nuclear power plant and a preparation method thereof, relating to a shockproof strip end-plate material of a vapor generator of a pressurized water reactor nuclear island CPR1000. The shockproof strip end-plate material is prepared from the following components in percentage by weight: 0.003-0.08 percent of C, 0.1-0.4 percent of Si, 0.3-0.8 percent of Mn, not more than 0.015 percent of P, not more than 0.01% of S, 14-17 percent of Cr, 72-78 percent of Ni, 0.05-0.5 percent of Cu, 0.05-0.5 percent of Ti, 0.05-0.5 percent of Al, 6-10 percent of Fe, 0.01-1.0 percent of Xt and the balance of inevitable impurities. The preparation method of the shockproof strip end-plate material comprises the following steps of: preparing raw materials; smelting in a vacuum refining furnace; refining electroslag; forging; thermally rolling; normalizing; and repeating the process of drawing-annealing- drawing) many times to obtain a finished product of shockproof strip end-plate material. The designed shockproof strip end-plate material of the vapor generator of the nuclear power plant has reasonable content design, excellent resistance of corrosion, fatigue and creep properties and processing performance and has very important economic meaning to improve the production efficiency, effectively prolong the service life of the vapor generator of a nuclear power plant and decrease the production cost.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

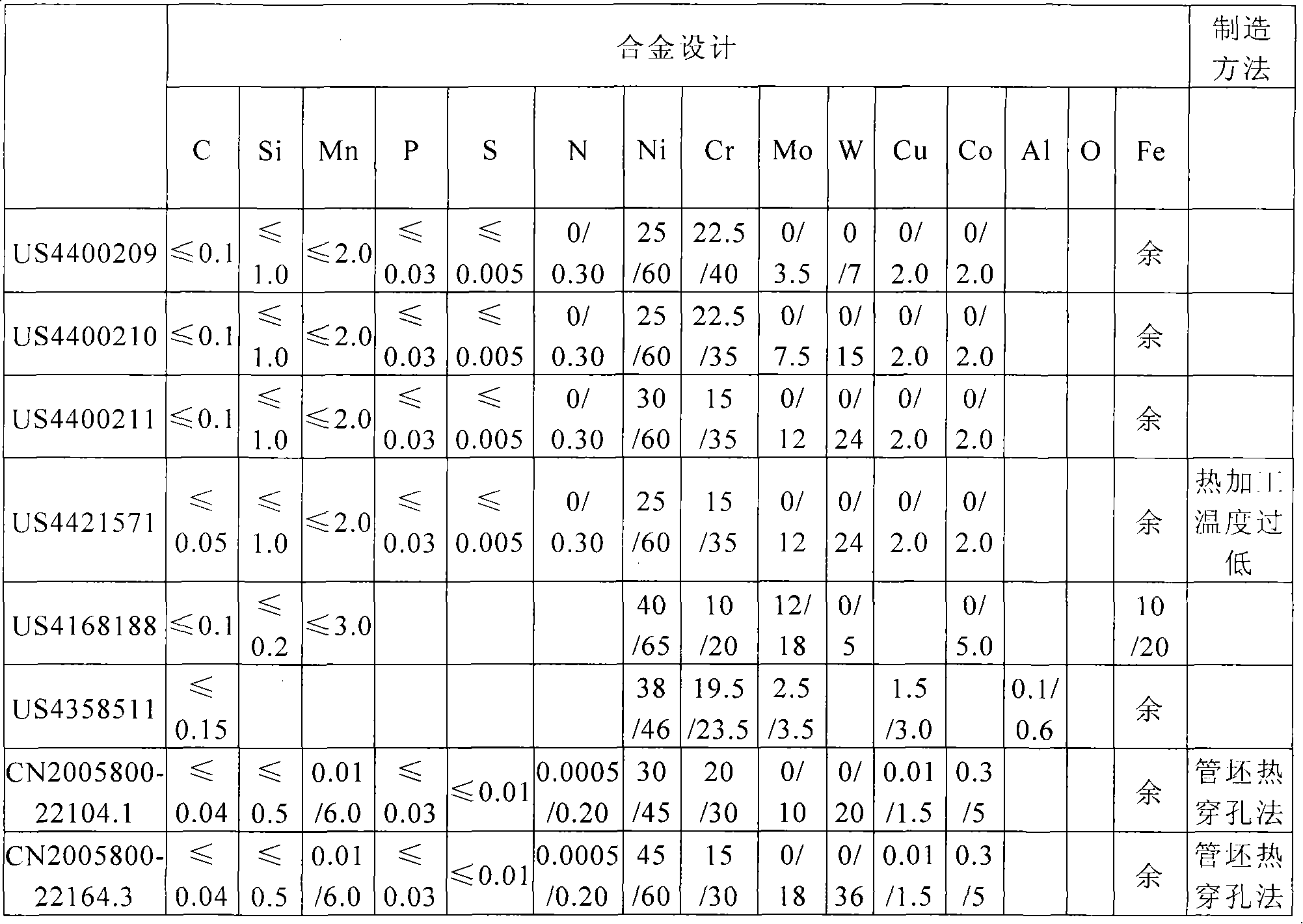

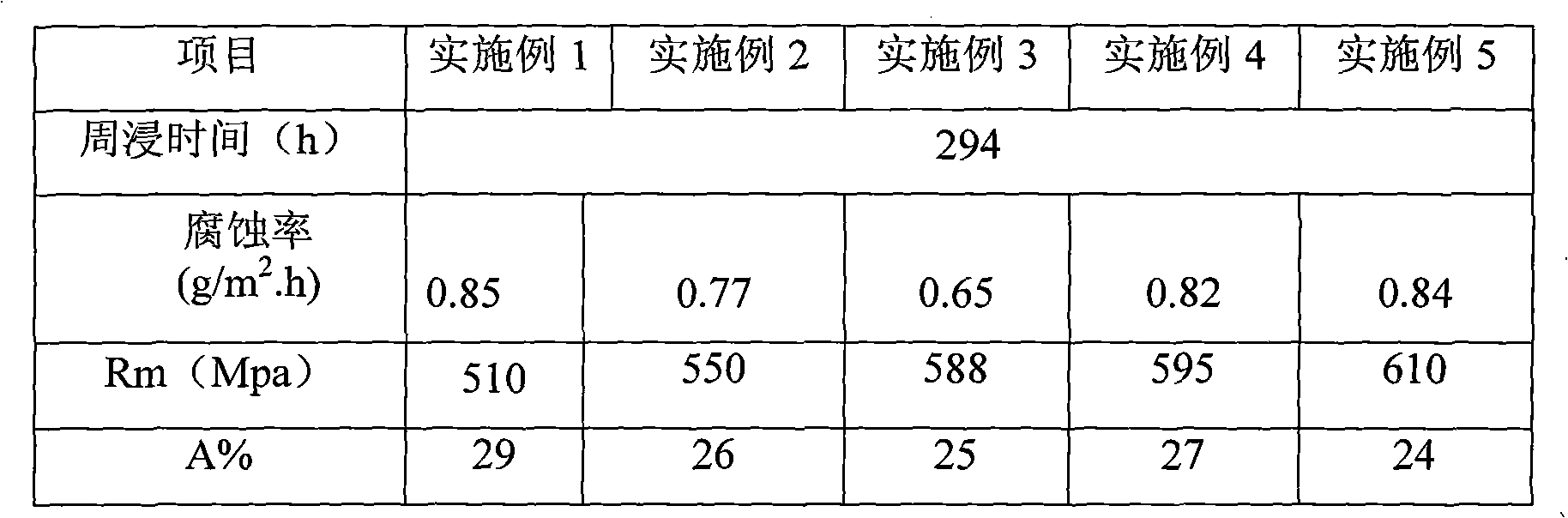

Ni-based alloy oil sleeve and manufacturing method for high-acidity deep well

ActiveCN101613833ALow costImprove high temperature corrosion resistanceDrilling rodsRoll mill control devicesSolution treatmentImpurity

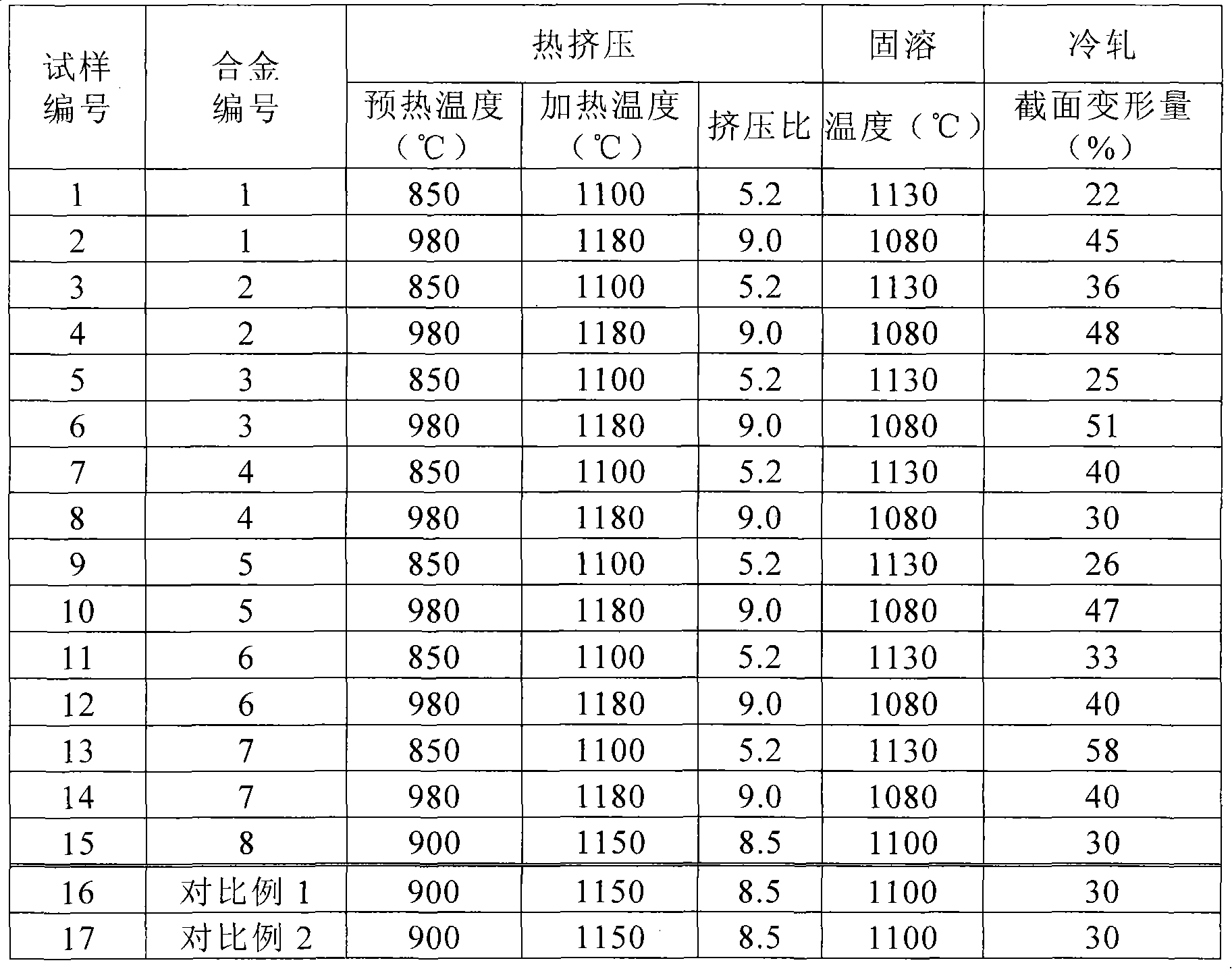

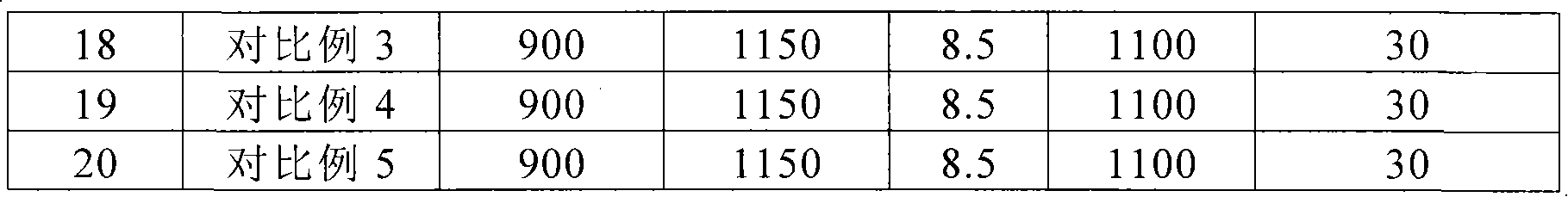

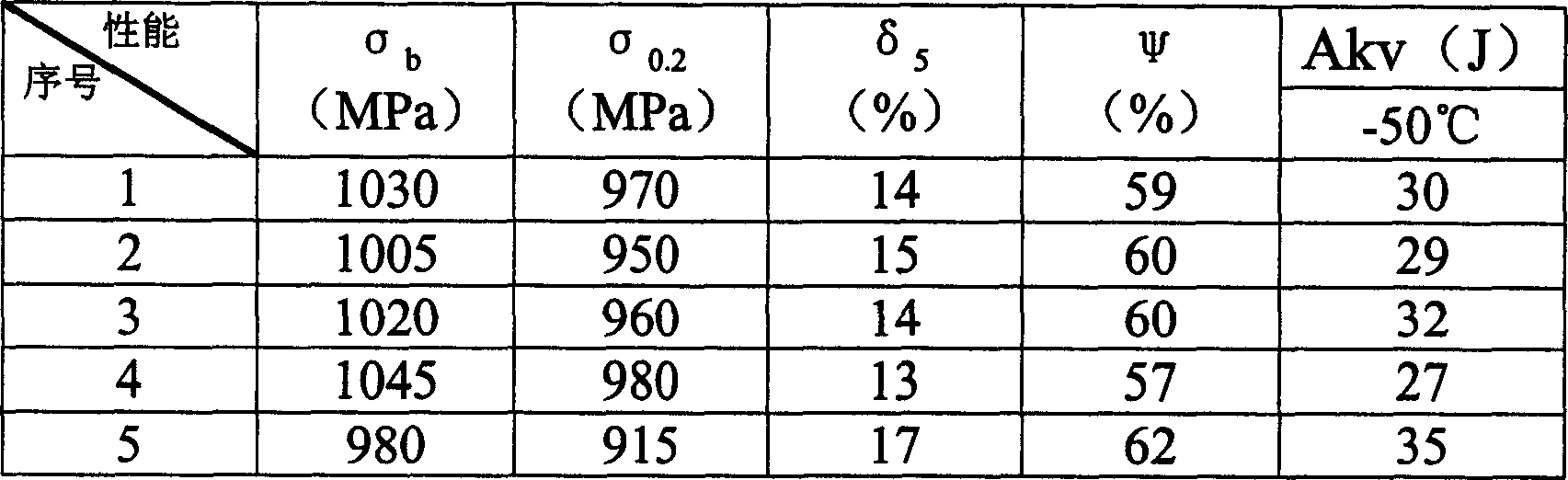

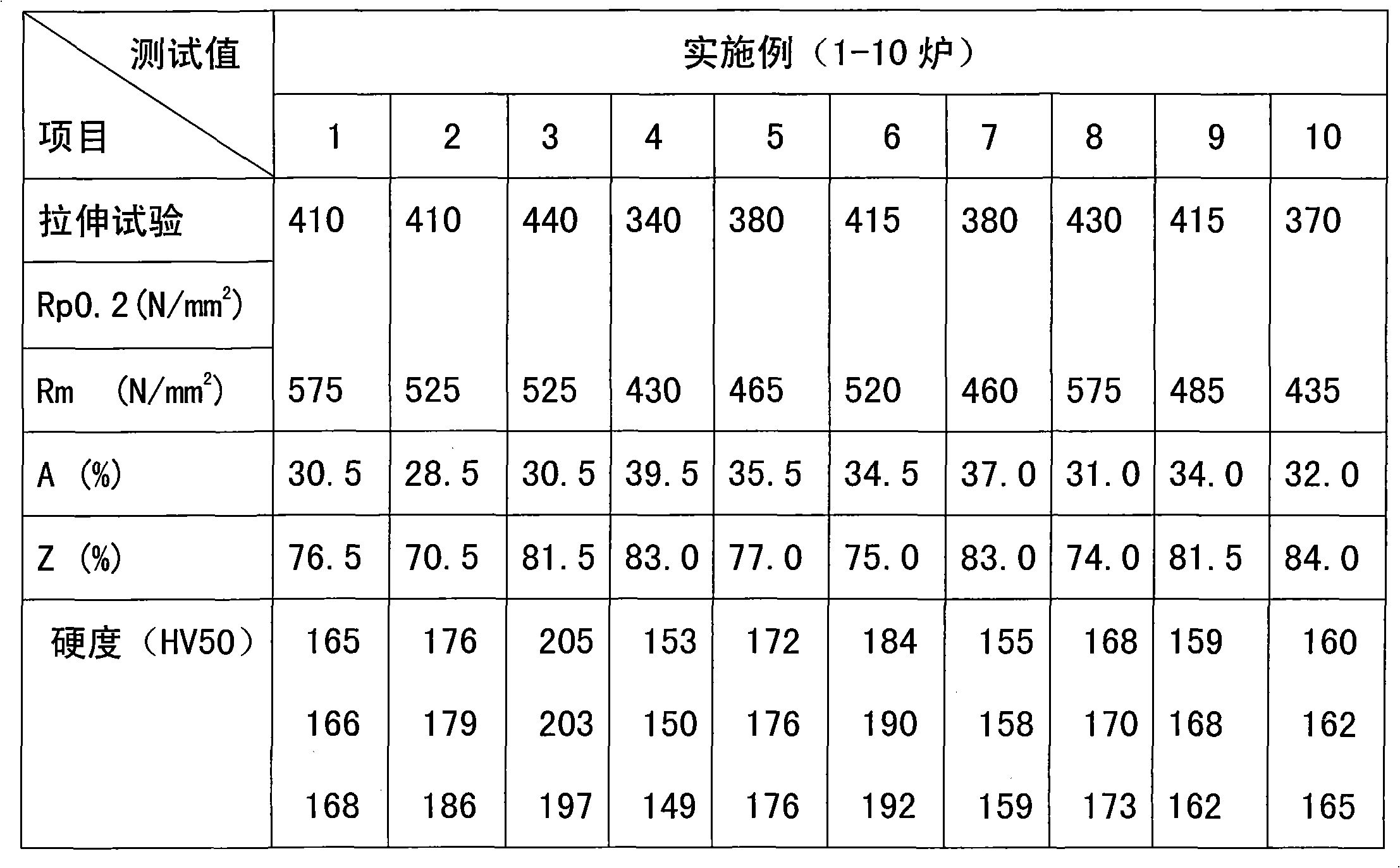

The invention relates to a Ni-based alloy oil sleeve for a high-acidity deep well, which comprises the following components in percentage by mass: less than or equal to 0.02 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, less than or equal to 0.5 percent of Si, less than or equal to 1.0 percent of Mn, 40 to 60 percent of Ni, 20 to 30 percent of Cr, 1 to 10 percent of Mo, 1 to 5 percent of W, 0 to 5 percent of Co, 0.1 to 3.0 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, less than or equal to 1.5 percent of Ti, and the balance of Fe and inevitable impurities. In the invention, the thermal extrusion processing performance and corrosion resisting performance of the alloy are effectively ensured by controlling the contents of the Al and O. The 90 to 140 ksi steel-grade Ni-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,150 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength welding electrode

InactiveCN1528555AThe ingredients are designed to be simpleReasonable design of ingredientsWelding/cutting media/materialsSoldering mediaHigh intensityMechanical property

The invention is a high-intensity welding rod used in the welding state, able to weld high intensity structural steel whose yield strength is greater than 950MPa. The chemical components of its deposited metal: C not greater than 0.07%; Si 0.1-0.6%; Mn 1.2-1.9%; Ni 2.6-3.8%; Cr 0.41-1.50%; Mo 0.66-1.6%; Ti 0.003-0.03%; the rest Fe. Its deposited metal has good synthetical mechanical property and has tensile strength greater than 1000MPa, yield strength above 950MPa and impact work greater than 27J at -50 deg.C.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Trace cobalt-containing tungsten carbide without bonding phase and preparation method thereof

The invention belongs to the field of powder metallurgy sintering, in particular refers to a trace cobalt-containing tungsten carbide without bonding phase and preparation method thereof. A hard alloy comprises components, by weight, as follows: 0.20-1.00% of Co, 0.01-0.50% of Cr3C2, 0.01-0.50% of VC and the balance of WC with grain size of 0.2-0.8 mum. The preparation method comprises the steps of: carrying out feeding and high energy ball milling according to the above raw material powder ratio, until WC powder in the ball milling powder has an average grain size refined to less than 200nm; then sintering the cemented carbide powder rapidly after the high energy ball milling by discharge plasma. The tungsten carbide base cemented carbide powder of the invention has reasonably designed components and a simple preparation method; the powder gives out heat uniformly and has fast heating and cooling speed, low sintering temperature and short sintering time to save the energy greatly; and the obtained ultrafine-grained WC cemented carbide has excellent integrated properties.

Owner:江西长裕硬质新材料有限公司

Shockproof strip material of nuclear power station steam generator, and preparation method thereof

The invention discloses a shockproof strip material of a nuclear power station steam generator, and a preparation method thereof, in particular to a shockproof strip material of a pressurized water reactor nuclear island CPR 1000 steam generator. The shockproof strip material comprises the components by weight percent: 0.02-0.07% of C, 0.2-1.0% of Si, 0.3-0.8% of Mn, less than or equal to 0.04% of P, less than or equal to 0.03% of S, 11.5-13.5% of Cr, 0.2-0.6% of Ni, less than or equal to 0.05% of N, 0.01-1.0% of Xt as well as balance Fe and unavoidable impurities. The preparation method of the shockproof strip material comprises: preparation of the raw materials, smelting by a vacuum refining furnace, refining the electroslag, forging, hot rolling, normalizing, multi-channel (drawing-annealing-drawing), and thereby obtaining the finished product of the shockproof strip material. The shockproof strip material of the nuclear power station steam generator is reasonable in component design, has excellent corrosion resistance, anti-fatigue property, creep resistance and processing performance, and has important economic significance for improving the production efficiency, prolonging the service life of the nuclear power station steam generator and reducing the production cost.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Preparation method for nickel-based superalloy for exhaust valve

InactiveCN102808111AImprove mechanical propertiesReduce chemical composition deviationExhaust valveRoom temperature

Owner:NANTONG WEALTH MASCH TECH CO LTD

Anti-vibration alloy material for nuclear power station steam generator and preparation process thereof

The invention discloses an anti-vibration alloy material for a nuclear power station steam generator. The anti-vibration alloy material is used for fabricating anti-vibration strips, retaining rings and retaining strips of nuclear power station steam generators and comprises the following components by weight percent: C 0.015 to 0.030%, Si 0.05 to 0.5%, Mn 0.05 to 0.50%, P <= 0.015%, S <= 0.010%, Cr 28.0 to 31.0%, Ni 58.0 to 63%, Cu 0.001 to 0.20%, Ti 0.005 to 0.5%, Al 0.005 to 0.5%, Fe 7.0 to 11.0%, Re 0.01 to 1.0%, Nb 0.001 to 0.10% and Mo 0.001 to 0.10%, with the balance being unavoidable impurities. A preparation process for the material comprises the following steps: A, preparation of raw materials according to weight percent of the components of the anti-vibration alloy material; B, cleaning and drying of the surfaces of the prepared raw materials and high vacuum smelting of the raw materials in a vacuum smelting furnace according to a melting order; C, re-melting and refining of electroslag; D, forging; E, hot rolling; F, vacuum solid solution heat treatment; G, surface processing of bars; and H, multi-pass drawing, annealing, drawing and linear cutting. A finished product of the anti-vibration material is obtained after the above-mentioned steps; design of the components of the material is reasonable, and the preparation process is advanced.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Powder core wire as well as preparation method and application thereof

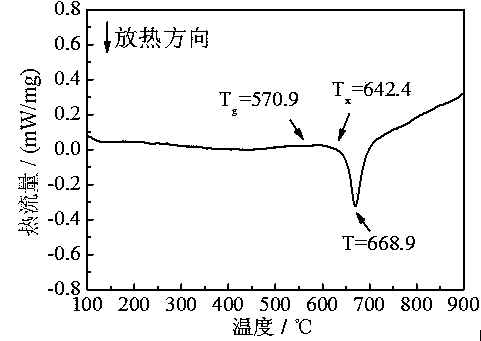

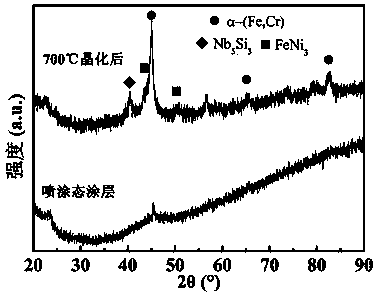

ActiveCN104032251AEnhanced Amorphous Formation AbilityImprove corrosion resistanceMolten spray coatingVulcanizationSand blasting

The invention discloses a powder core wire as well as a preparation method and application thereof. The powder core wire is prepared by coating a powder core in a stainless steel strip; the powder core is prepared by mixing seven element powder in percentage by weight: 30-50% of Cr, 2-10% of B, 1-5% of Al, 1-5% of Si, 3-15% of Nb, 2-10% of Mo and the rest amount of Fe; the skin of the powder core wire selects the stainless steel strip; the weight ratio of the powder core to the stainless steel strip is (0.43-0.67): 1; when a coating layer is prepared by adopting an electric arc spraying technology, oil and rust on the surface of a matrix are removed firstly; and then, the pretreatment such as sand blasting is performed. The powder core wire can obtain the coating layer with low porosity, high hardness and excellent high-temperature oxidization and sulphuration corrosion resistance, and is suitable for such high-temperature structural members as a boiler pipe, a roller and an engine cylinder body.

Owner:HOHAI UNIV

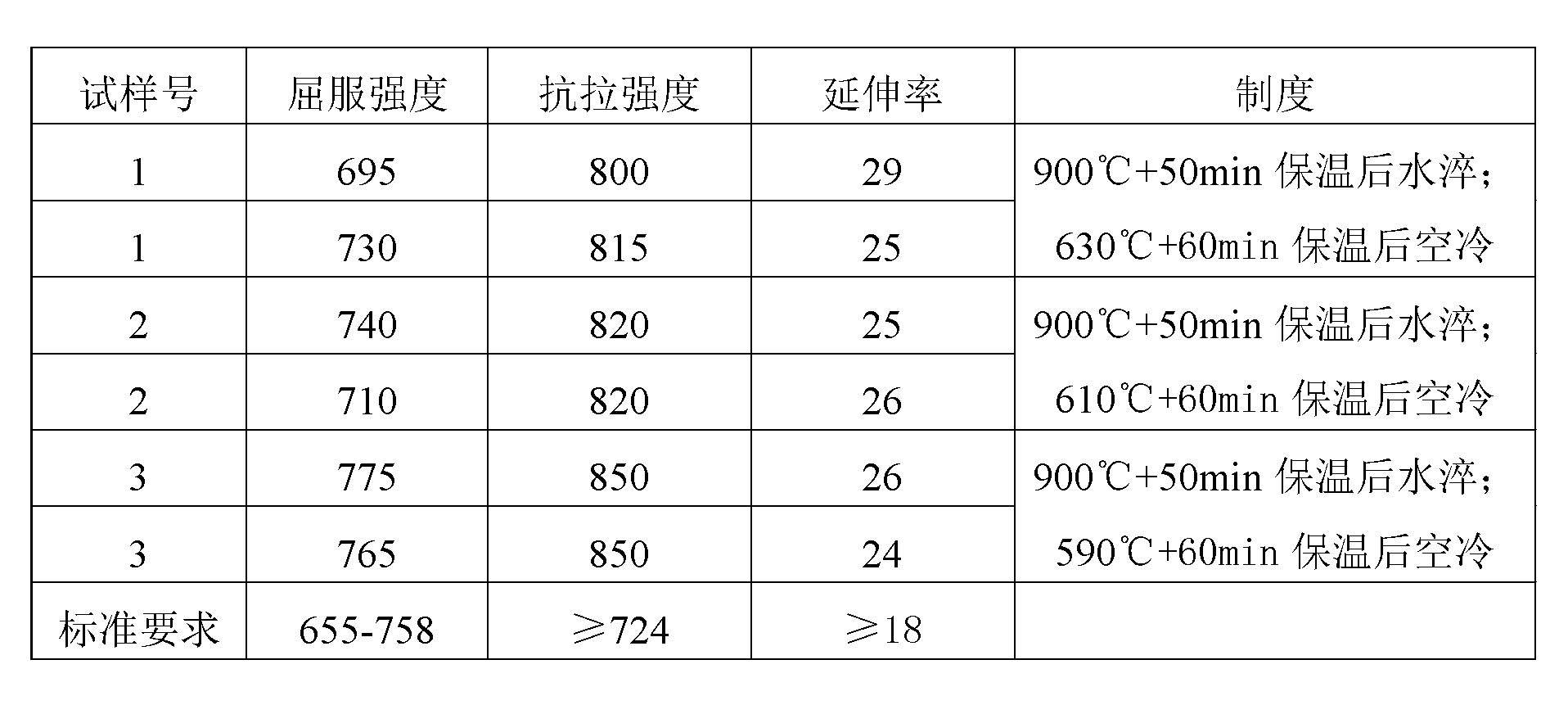

Method for manufacturing oil casings made of R95-grade steel containing rare earth

InactiveCN102936691AImprove plasticityImprove impact toughnessFurnace typesProcess efficiency improvementRare-earth elementTempering

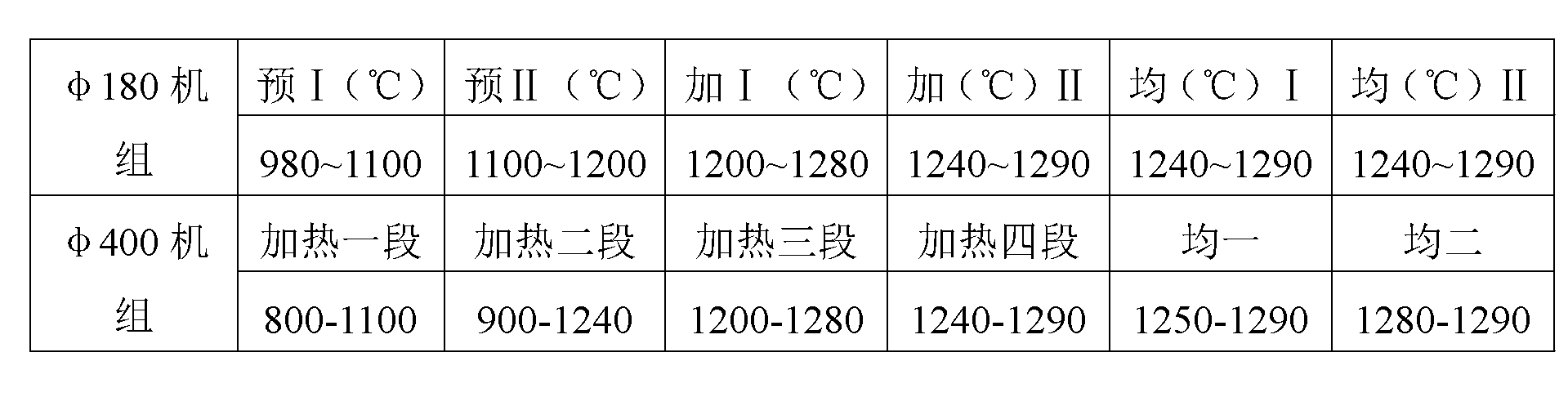

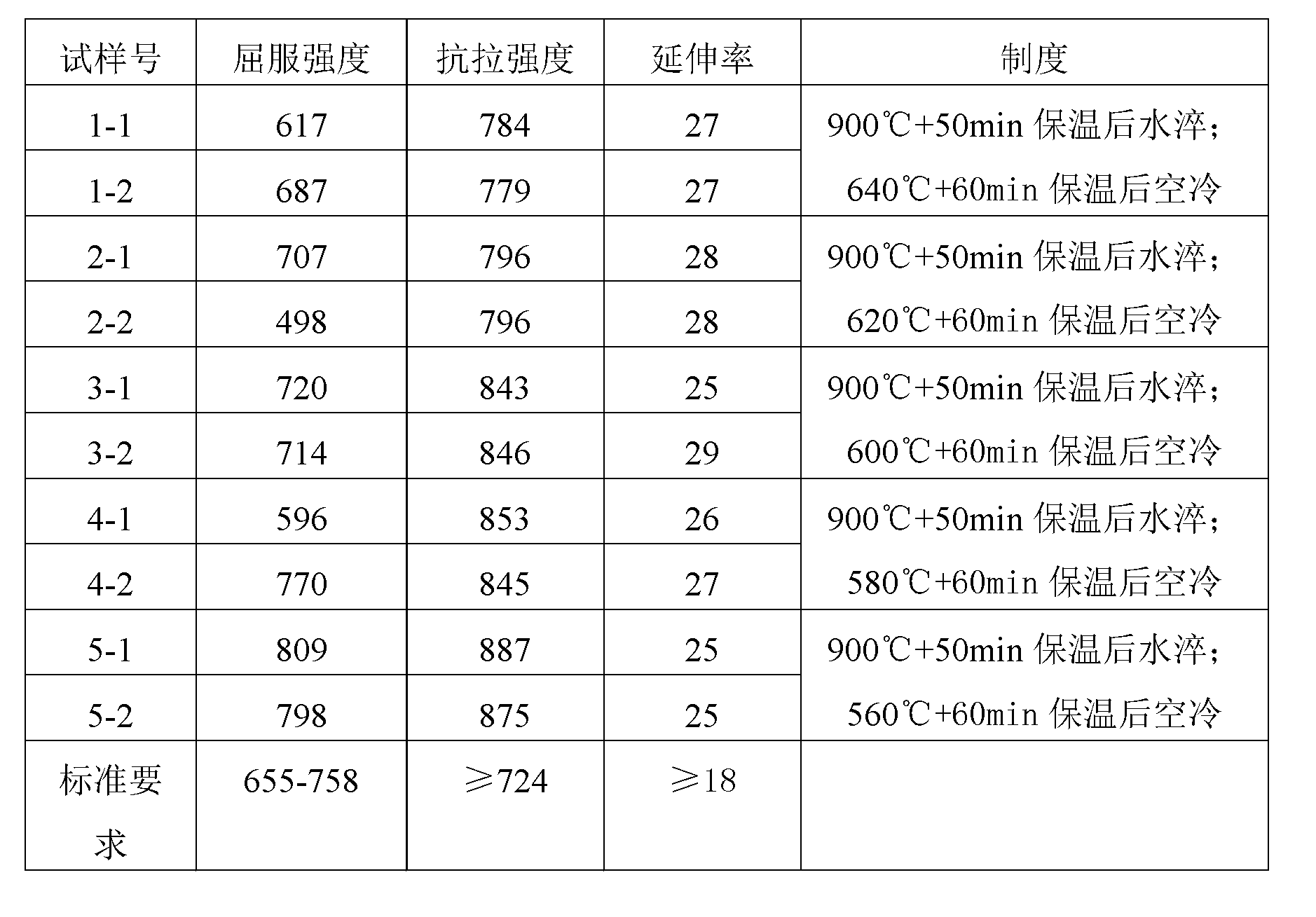

The invention relates to a method for manufacturing oil casings made of R95-grade steel containing rare earth. The method is characterized in that each casing blank comprises, by weight, from 0.24% to 0.30% of C, from 0.15% to 0.35% of Si, from 1.35% to 1.55% of Mn, lower than or equal to 0.020% of P, lower than or equal to 0.010% of S, from 0.30% to 0.40% of Cr, from 0.02% to 0.04% of Al, from 0.0007% to 0.0110% of rare earth elements RE and the balance Fe which is a matrix. A casing heat treatment regime includes that the temperature is 910 DEG C+ / -20 DEG C and is kept for 50 minutes, and then water quenching is performed; and the tempering temperature is 630 DEG C+ / -20 DEG C and is kept for 80 minutes, then air cooling production is carried out, and the steel casings with optional sizes can meet standard requirements. The method has the advantages that the 27Mn2CrRe steel containing carbon manganese steel and the rare earth is reasonable in material constitution design, and is low in cost due to the fact that materials for manufacturing the casings do not contain precious metal elements such as molybdenum; the water quenching and tempering are combined in a heat treatment process, and the water quenching does not affect environments and is low in cost, so that the plasticity of the steel is greatly improved on the premise that the strength of the obtained oil casings made of the R95-grade steel is guaranteed, the impact toughness of the steel casings is improved, and the steel casings are excellent in high-temperature mechanical property and can meet service requirements on oil casings under different working conditions.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

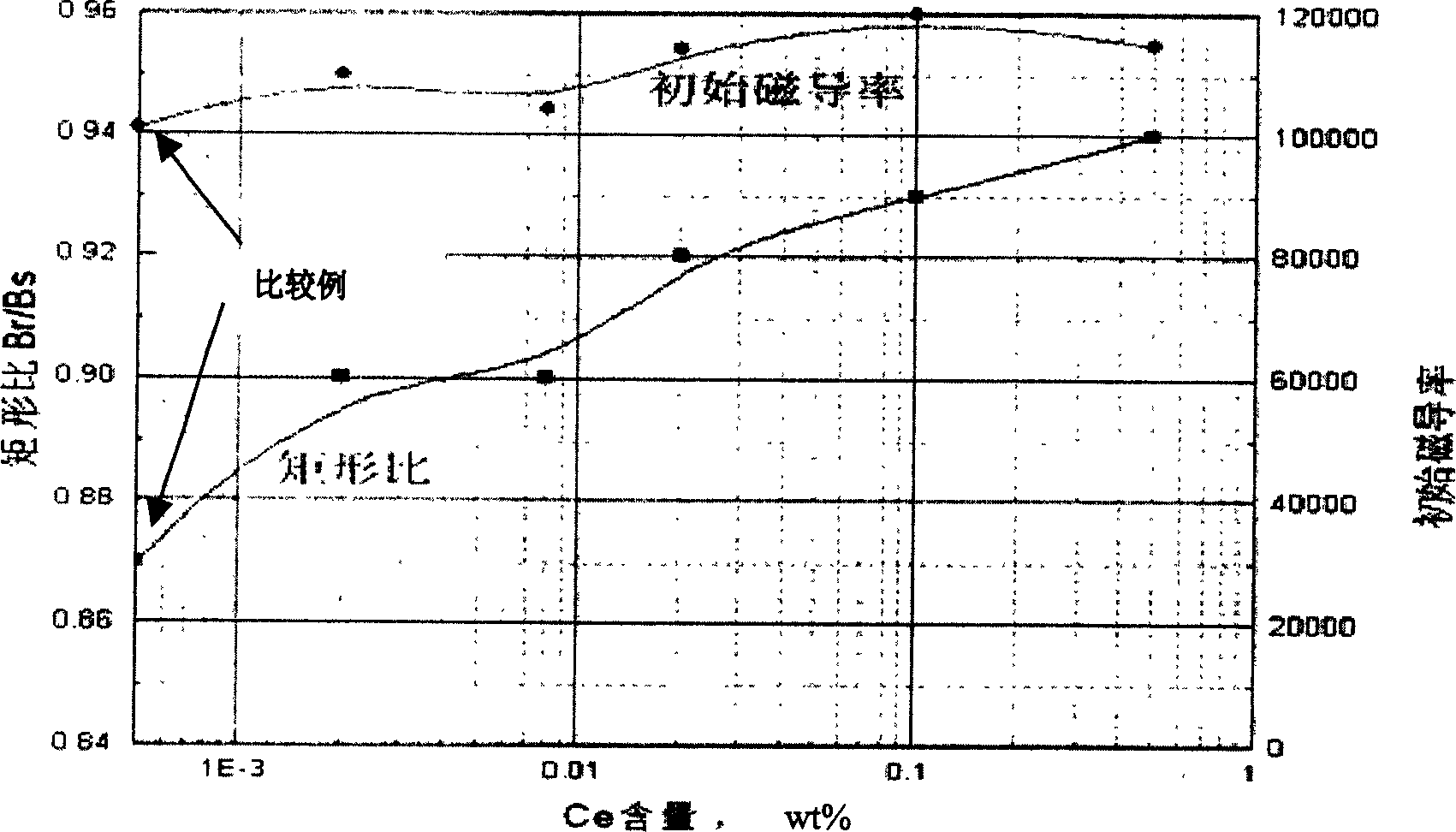

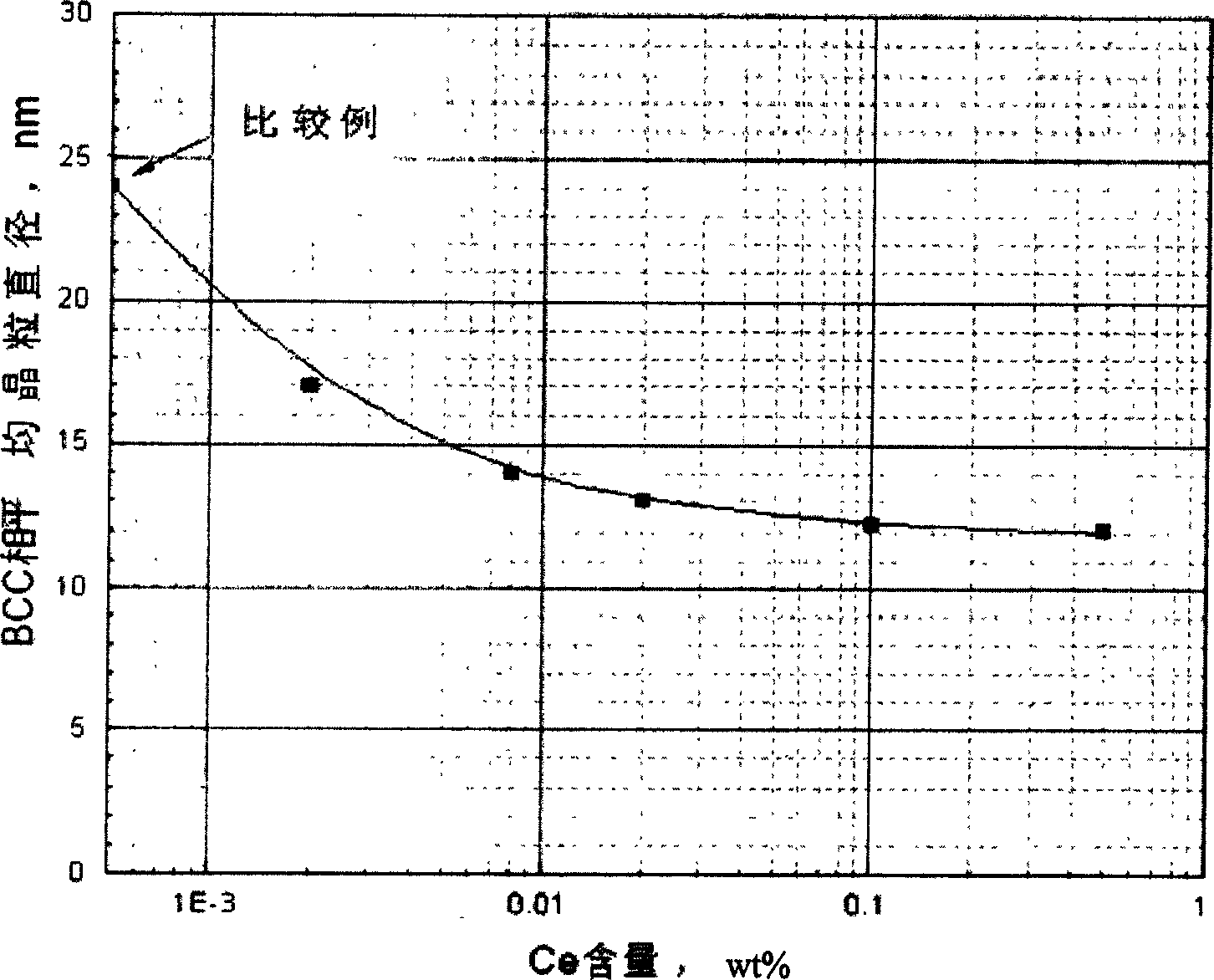

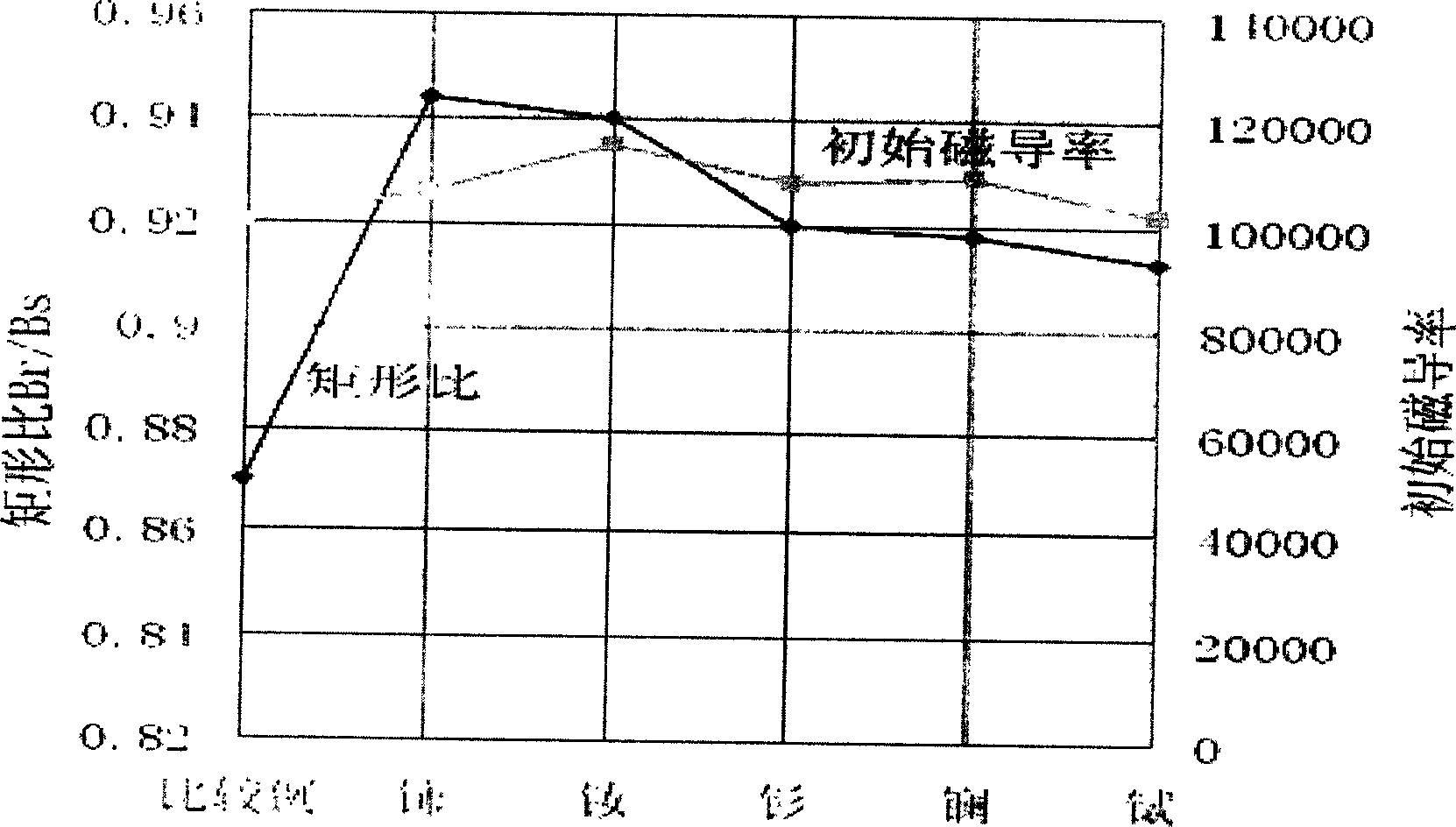

Trace rare earth element-containing iron-based nanocrystalline alloy

InactiveCN1621552ASimple preparation processImprove magnetic propertiesRare-earth elementChemical composition

The present invention belongs to the field of preparation purify iron-base non-crystal and nanometer crystal alloy material, and is especially one kind of iron-base non-crystal and nanometer crystal alloy material with mixed non-crystal and nanometer crystal and non-crystal texture and containing small amount of RE element. The non-crystal and nanometer crystal alloy material has the chemical components including Si 7-9 wt%, B 1.5-2.5 wt%, Cu 1-2 wt% Mo and / or Nb plus Co 4-9 wt%, and Ce as RE element 0.001-0.5 wt%, except Fe. The iron-base non-crystal and nanometer crystal alloy material has reasonable composition, simple preparation process, and high comprehensive performance.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

700MPa-tensile strength steel for large heat input welding structure and manufacturing method thereof

InactiveCN102312173AHigh strengthImprove toughnessTemperature control deviceHeat-affected zoneNiobium

The invention provides 700MPa-tensile strength steel for a large heat input welding structure and a manufacturing method thereof. The 700MPa-tensile strength steel for the large heat input welding structure comprises the components: 0.04-0.08 percent of carbon (C), 0.05-0.5 percent of silicon (Si), 1.40-1.85 percent of manganese (Mn), 0.2-0.4 percent of chromium (Cr), 0.010-0.060 percent of niobium (Nb), 0.005-0.03 percent of titanium (Ti), 0.02-0.04 percent of vanadium (V), 0.10-0.30 percent of copper (Cu), 0.10-0.40 percent of nickel (Ni), 0.10-0.30 percent of molybdenum (Mo), 0.0020-0.0050 percent of zirconium (Zr), 0.015-0.050 percent of aluminum (Al) and the balance of ferrum (Fe) and inevitable impurities. The manufacturing method comprises smelting, continuous casting and rolling. The temperature of heating before rolling is 1150-1230 DEG C; the rolling temperature of a recrystallization zone is not lower than 1000 DEG C; the rolling temperature of a non-recrystallization zone is 830-930 DEG C; the time of relaxation after rolling is 10-120s; the cooling speed is 3-30 DEG C / S; the final cooling temperature is 380-500 DEG C; and then, air cooling and tempering are carried out. The 700MPa-tensile strength steel for the large heat input welding structure has a reasonable component design and a simple process; thermal refining is not needed; the welding performance of a product is good; preheating is not needed before welding; thermal treatment is not needed after welding; and a heat affected zone has very high toughness.

Owner:ANGANG STEEL CO LTD

Low boron alloyed steel by hot rolling

The invention was about one kind of low Boracium alloyed steel that use for hot rolling (low yield strength <=280 Mpa / cmm2). It has a special use for cold roll steel material and hot roll punching steel material. The hot roll steel that has a low B has the mass ratio of ingredient: C<=0.01%, Si 0.01-0.10%, Mn 0.10-1.0%, S 0.001-0.020%, P<=0.020%, B 0.0003-0.015%, Al 0.03-0.06%, N 0.003-0.009%, the residue is impurity Fe. Its advantages include good ingredient in design; lower cost; good property for cold roll; good punching.

Owner:CENT IRON & STEEL RES INST

High-strength, low-alloy and high-carbon steel wire rod and production method thereof

ActiveCN102312169AReasonable design of ingredientsReasonable designManufacturing convertersMetal rolling arrangementsProcess systemsSulfur content

The invention provides a high-strength, low-alloy and high-carbon steel wire rod and a production method thereof. The high-strength, low-alloy and high-carbon steel wire rod comprises the following components: 0.86-1.0 percent of carbon (C), 0.1-2.0 percent of silicon (Si), 0.3-1.0 percent of manganese (Mn), 0.1-1.0 percent of chromium (Cr), not greater than 0.020 percent of phosphorus (P), not greater than 0.015 percent of sulfur (S), not greater than 0.1 percent of inevitable impurities and the balance of ferrum. The production method comprises the following steps: (1) molten iron desulfuration pretreatment: sulfur content is controlled to be under 0.005 percent; (2) converter melting: phosphorus content in steel is not greater than 0.010 percent, and the temperature of converter final molten steel is 1570-1680 DEG C; (3) low-frequency (LF) refining: the temperature is 1550-1620 DEG C; (4) continuous casting: a low-superheat degree casting process system is used; the superheat degree of tundish molten steel is not greater than 25 DEG C; and the dimension of a casting blank is (200-400mm)*(300-500mm); and (5) tandem rolling and wire stock rolling: the diameter of the wire rod is 5.5-8mm, and the supercooling degree of the wire rod is 50-75 DEG C in the phase change process. In the wire rod produced by adopting the process of the invention, the tensile strength is not less than 1300MPa, the area reduction index is not less than 35 percent, and the drawing requirement of a user is met.

Owner:ANGANG STEEL CO LTD

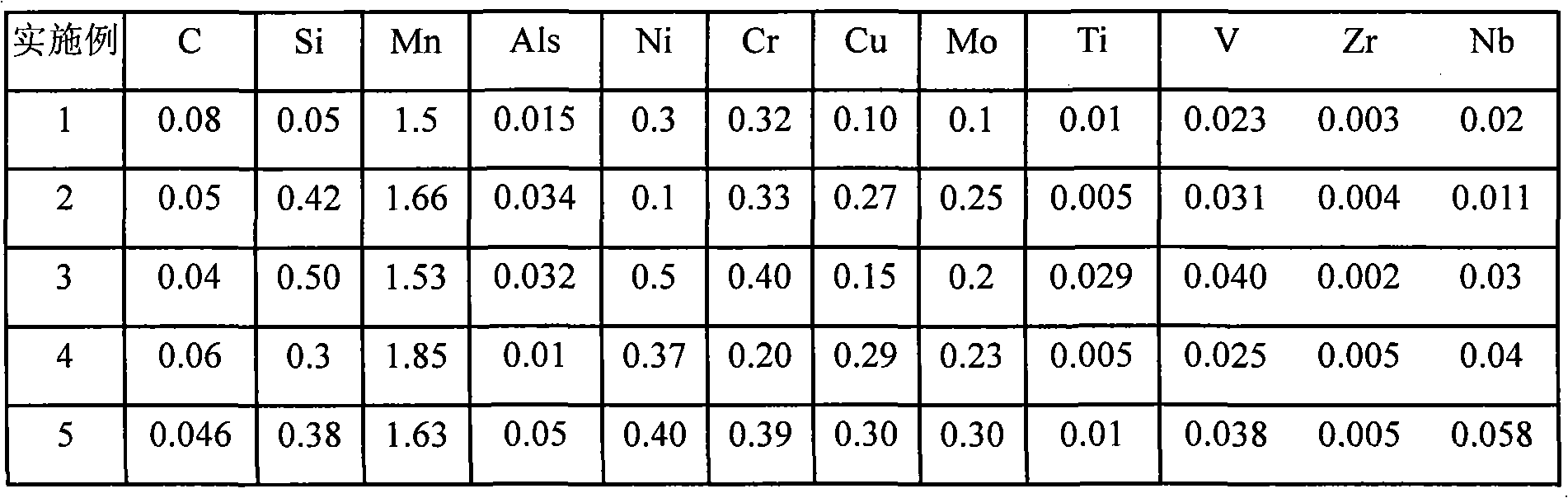

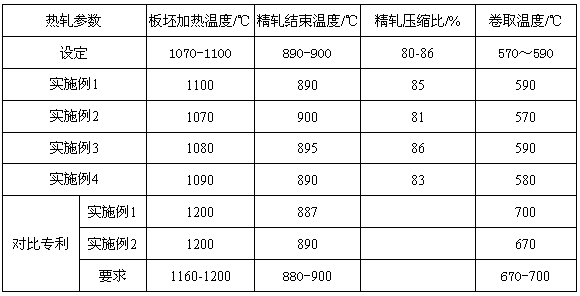

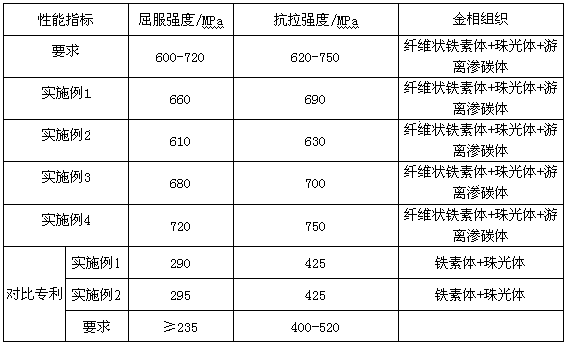

Inboard plate high strength steel and production method thereof

The invention relates to a high strength steel and a production method thereof, and specially relates to an inboard plate high strength steel and a production method thereof. The invention aims to solve the technical problems that the cost of high strength steel is high because of the large using amount of alloy elements and the yield strength of cheap inboard plate cannot meet the requirements. The high strength steel is characterized by being composed of the following elements in percentage by weight: 0.04 to 0.06% of carbon, 0.005 to 0.03% of silicon, 0.15 to 0.25% of manganese, not more than 0.016% of phosphor, not more than 0.015% of sulfur, 0.002 to 0.003% of boron, 0.025 to 0.05% of aluminum, and the balance being Fe and inevitable impurity elements. The steel is used to manufacture inboard plates, the yield strength Rel is 600 to 720 MPa, the tensile strength Rm is 620 to 750 MPa, and the microstructure of the steel is a composite of fibrous ferrite, pearlite, and free cementite.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Vanadium-titanium ferrite ductile iron automobile hub and production process thereof

The invention relates to the field of cast iron alloys, and particularly relates to a vanadium-titanium ferrite ductile iron automobile hub and a preparation method thereof. The automobile hub is made of vanadium-titanium ferrite ductile iron, and the vanadium-titanium ferrite ductile iron comprises the following chemical compositions in percentage by mass: 3.3-3.6% of C, 3.0-3.4% of Si, 0.0-0.4% of Mn, less than or equal to 0.06% of P, less than or equal to 0.02% of S, 0.12-0.18% of V, 0.05-0.10% of Ti, 0.0-0.08% of Cr, 0.040-0.060% of RE, 0.040-0.060% of Mg, and the balance of Fe and other trace elements and impurities. The vanadium-titanium ferrite ductile iron automobile hub disclosed by the invention is 550-650 MPa in strength and 12-15% in elongation percentage. Comprehensive properties of the vanadium-titanium ferrite ductile iron automobile hub disclosed by the invention are significantly better than those of common ferrite ductile iron automobile hubs.

Owner:陈国

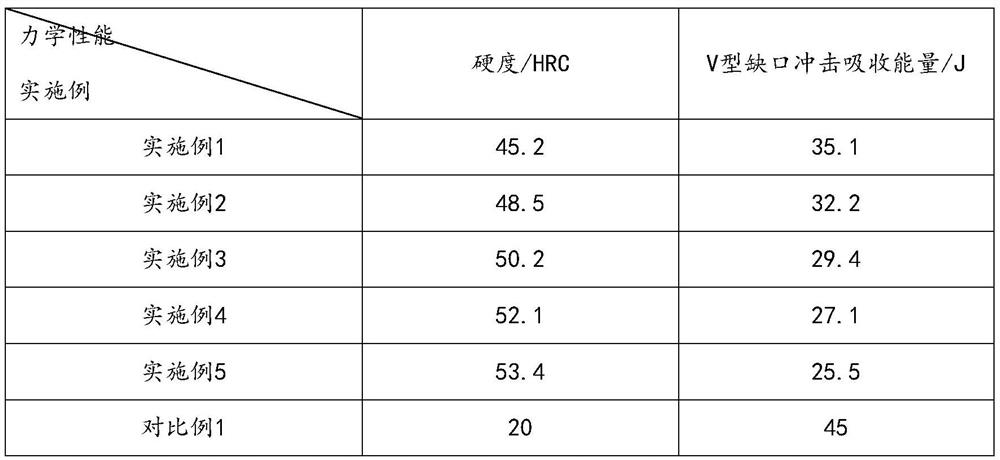

High-hardness-toughness bainite wear-resistant cast steel as well as preparation method and application thereof

ActiveCN112593157AReasonable design of ingredientsReduce manufacturing costGrain treatmentsQuenching agentsHardnessToughness

The invention belongs to the technical field of wear-resistant cast steel, and particularly relates to high-hardness-toughness bainite wear-resistant cast steel and a preparation method and application thereof. The high-hardness-toughness bainite wear-resistant cast steel comprises the following chemical components in percentage by mass: 0.25-0.44% of C, 1.2-2.2% of Si, 0.8-1.5% of Mn, 1.0-1.9% ofCr, 0.3-0.6% of Mo, 0.3-0.6% of Cu, 0.03-0.08% of RE, less than or equal to 0.032% of P, less than or equal to 0.040% of S and the balance of Fe and inevitable impurities. The high-hardness--toughness bainite wear-resistant cast steel has high hardness and high toughness, particularly has matched hardness and toughness, has performance superior to that of in-service bainite cast steel, and is particularly suitable for manufacturing wear-resistant parts of large semi-autogenous mill lining plates and the like under the large-impact abrasive wear working condition.

Owner:JINAN UNIVERSITY

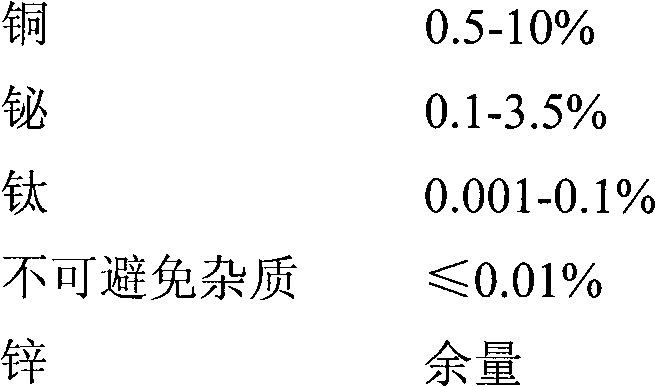

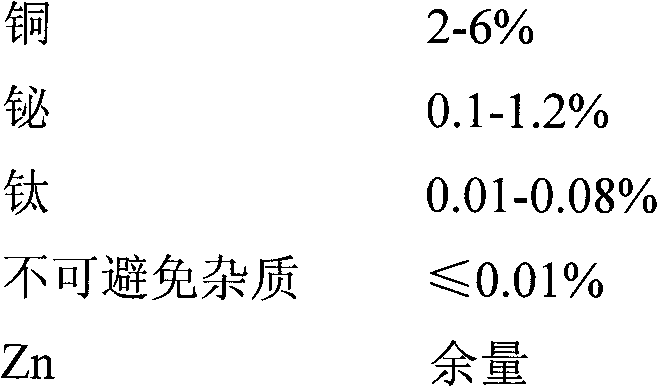

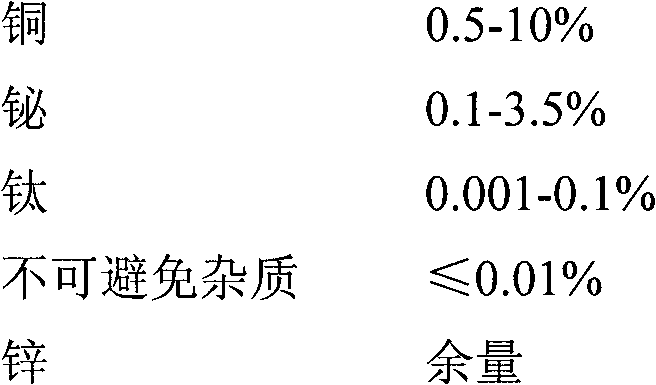

Easy-cutting zinc-copper-base wrought zinc alloy and preparation method thereof

The invention relates to an easy-cutting zinc-copper-base wrought zinc alloy and a preparation method thereof. The easy-cutting zinc-copper-base wrought zinc alloy is characterized by comprising the following components in percentage by weight: 0.5-10% of copper, 0.1-3.5% of bismuth, 0.001-0.1% of titanium, at most 0.01% of inevitable impurity and the balance of zinc. The alloy fusion casting technique comprises the following steps: smelting in a line frequency furnace, intermediate frequency or reverberatory furnace, and carrying out continuous casting or metal mold casting to obtain a casting blank; and carrying out hot extrusion at 180-400 DEG C, and finally carrying out cold drawing to obtain various sizes of rods, wires and section products. The obtained products can be used in the fields of automatic lathes, drill presses, instrument lathes and the like. Compared with the prior art, the alloy provided by the invention has the characteristics of favorable cutting property, moderate mechanical properties and the like, and is easy for processing and electroplating.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Soft magnetic structural steel resisting salt fog corrosion and its making process

The present invention relates to soft magnetic structural steel, and is especially one kind of soft magnetic structural steel resisting salt fog and its making process. The present invention solves the technological problem of raising the salt fog corrosion resistance of soft magnetic structural steel. The soft magnetic structural steel consists of C 0.020-0.040 wt%, Si 1.40-1.60 wt%, Mn 0.40-0.80 wt%, P not more than 0.015 wt%, S not more than 0.005 wt%, Als 0.040-0.060 wt%, Cu 0.20-0.50 wt%, Ti 0.035-0.055 wt%, N not more than 0.0035 wt%, Ni 0.80- 1.20 wt%, and Ca or REM 10-60ppm, except Fe and inevitable impurities. Its making process includes continuous casting, re-crystallization controlling rolling, accelerated cooling or intermittent direct quenching, and subsequent slow cooling step. The present invention is especially suitable for use as side guide plate in magnetic suspension train track beam in high salt fog area.

Owner:BAOSHAN IRON & STEEL CO LTD

Insert material for heat-resisting ductile iron stamping die

The invention discloses an insert material for a heat-resisting ductile iron stamping die, aiming at overcoming the problem that the conventional die steel has high cost and providing a die material of a thicker steel plate which is stamped and formed under high temperature. The die material comprises the following components in percentage by weight: 2.4 to 2.9 percent of C, 4 .0 to 6.0 percent of Si, 0.3 to 1.2 percent of Mn, 0.3 to 1.2 percent of Cr and the balance of Fe. A preparation method of the die material comprises the following steps of: smelting by adopting an alkaline medium-frequency induction furnace, firstly clearing pig iron and steel scraps in the furnace, then adding alloys, adjusting the content of the alloys, taking away the furnace slag on the surface of iron liquid after iron alloy is cleared, and finally discharging from the furnace and pouring. The material has the properties of more than 505MPa of tensile strength and below 0.20g / m<2>h of oxidation speed after the heat preservation for 150 hours at 800 DEG C, belongs to a heat-resisting material, and has below 1.2mm of fatigue crack length after circulating 2000 times at 25 to 800 DEG C, thereby being superior to the performance of heat-resisting gray pig iron.

Owner:JILIN UNIV

Ultra-low-carbon martensite wear-resistant automatic welding wire

ActiveCN101767254AExcellent match of comprehensive mechanical propertiesComprehensive mechanical properties matchingWelding/cutting media/materialsSoldering mediaImpellerWater turbine

The invention relates to an ultra-low-carbon martensite wear-resistant automatic welding wire. The welding wire comprises the following components by weight percent: 0.030% or less of C, 0.40-0.80% of Si, 0.80-1.20% of Mn, 0.020% or less of P, 0.010% or less of S, 12.0-16.50% of Cr, 3.80-5.50% of Ni, 0.40-0.80% of Mo, 0.035% of N, 0.010-0.10% of Re, 0.010% or less of Ca and the balance Fe and other unavoidable impurities. The preparation technology of the invention is basically the same of that of the existing technologies. The preparation technology comprises the following steps: mixing materials according to the design components of the invention, smelting in a vacuum refining furnace, striking and forging, performing hot rolling, normalizing and tempering under high temperature, performing multi-pass drawing, tempering and drawing, and when the welding wire is drawn to have a diameter of 2.2 mm, continuously drawing to obtain the welding wire with a diameter of 1.2mm or 1.6 mm (according to the design demand of the user) and a tensile strength of 1400MPa. The welding wire is applicable to the resurfacing welding preparation and repair of large hydropower stations, parts of water turbines such as revolving shafts, impellers and blades and marine ships. The weld joint has high wear resistance and corrosion resistance; and the welding wire material of the invention has good weldability and processability and high working efficiency and can be welded automatically.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Steel for acid soil corrosion-resistant hot rolling U-shaped steel sheet pile and production method thereof

InactiveCN101838773AGood corrosion performanceMeet the requirements of corrosion resistanceTemperature control deviceSlagSheet pile

The invention relates to steel for an acid soil corrosion-resistant hot rolling U-shaped steel sheet pile and a production method thereof. The steel comprises the following components by weight percent: 0.13-0.28% of C, 0.6-1.5% of Mn, 0.10-0.6% of Si, less than or equal to 0.020% of S, less than or equal to 0.02% of P, 0.5-1.2% of Cr, 0.15-0.3% of Mo and the balance of Fe and unavoidable impurities. The method comprises the following steps: melting: adopting less than 0.005% of [Al] to deoxidize, adding lime at a time when discharge is started, wherein the thickness of the slag blanket is 6-15mm; continuous casting: preheating a continuous casting bloom to 300 DEG C, and then heating to 1150-1300 DEG C, and preserving the temperature for 10-30 minutes, wherein the pouring temperature is 1570-1580 DEG C, the degree of superheat is 15-35 DEG C, the casting speed is 1.0-2.0meter / miniute, the thickness of the casting powder is 2-5 millimetres; and rolling: the starting rolling temperature is 1100-1250 DEG C and the finishing rolling temperature is 850-920 DEG C.

Owner:WUHAN IRON & STEEL (GROUP) CORP

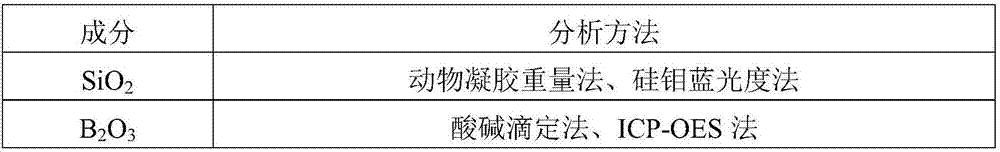

Superhard grinding tool ceramic bonding agent, preparation method of superhard grinding tool ceramic bonding agent and superhard grinding tool ceramic bonding agent standard sample

InactiveCN107443262AReasonable design of ingredientsAccurate valuePreparing sample for investigationAbrasion apparatusStandard samplesStandard curve

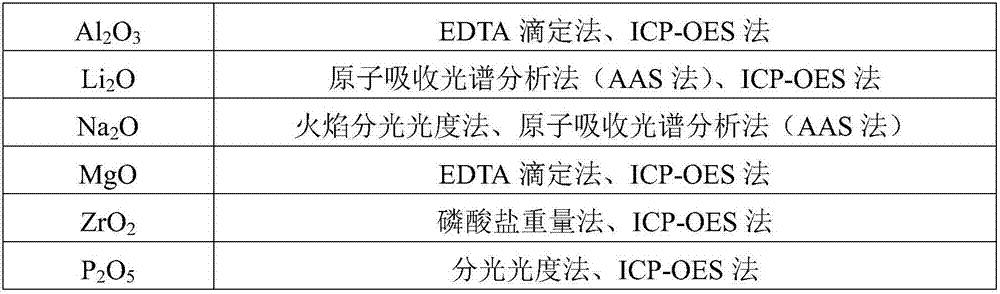

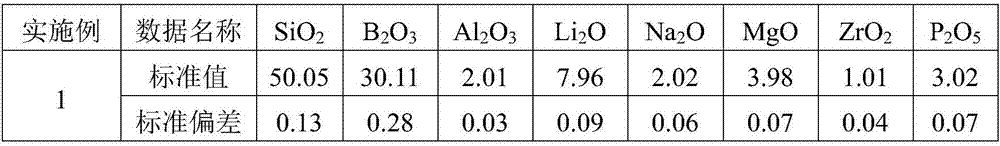

The invention relates to a superhard grinding tool ceramic bonding agent, a preparation method of the superhard grinding tool ceramic bonding agent and a superhard grinding tool ceramic bonding agent standard sample, and belongs to the technical field of chemical component detection samples and preparation thereof. The superhard grinding tool ceramic bonding agent is prepared from, by mass percent, 50%-70% of SiO2, 5%-30% of B2O3, 2%-8% of Al2O3, 2%-8% of Li2O, 2%-8% of Na2O, 0.5%-4% of MgO, 0.5%-5% of ZrO2 and 1%-5% of P2O5. The superhard grinding tool ceramic bonding agent can be used for the standard sample of superhard grinding tool ceramic bonding agent detection and analysis. The superhard grinding tool ceramic bonding agent standard sample is reasonable in component design and accurate in definite value; the problem that no superhard grinding tool ceramic bonding agent standard sample exists at present is solved; a qualified standard curve can be drawn on a modern advanced instrument; and efficient and accurate detection on the superhard grinding tool ceramic bonding agent is achieved.

Owner:郑州国机精工发展有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com