High-hardness-toughness bainite wear-resistant cast steel as well as preparation method and application thereof

A bainite, high-hard technology, applied in the field of wear-resistant cast steel, can solve the problems of low toughness and low service life, and achieve the effects of excellent performance, easy control and reasonable composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

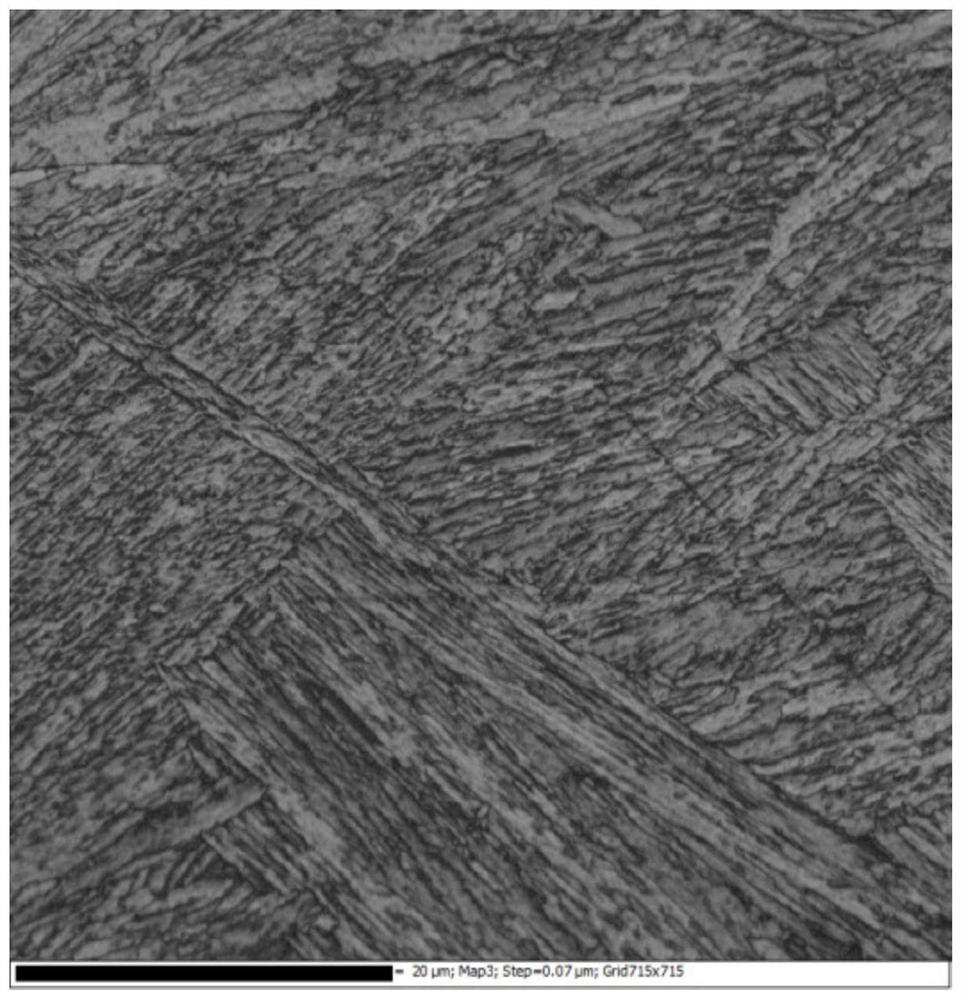

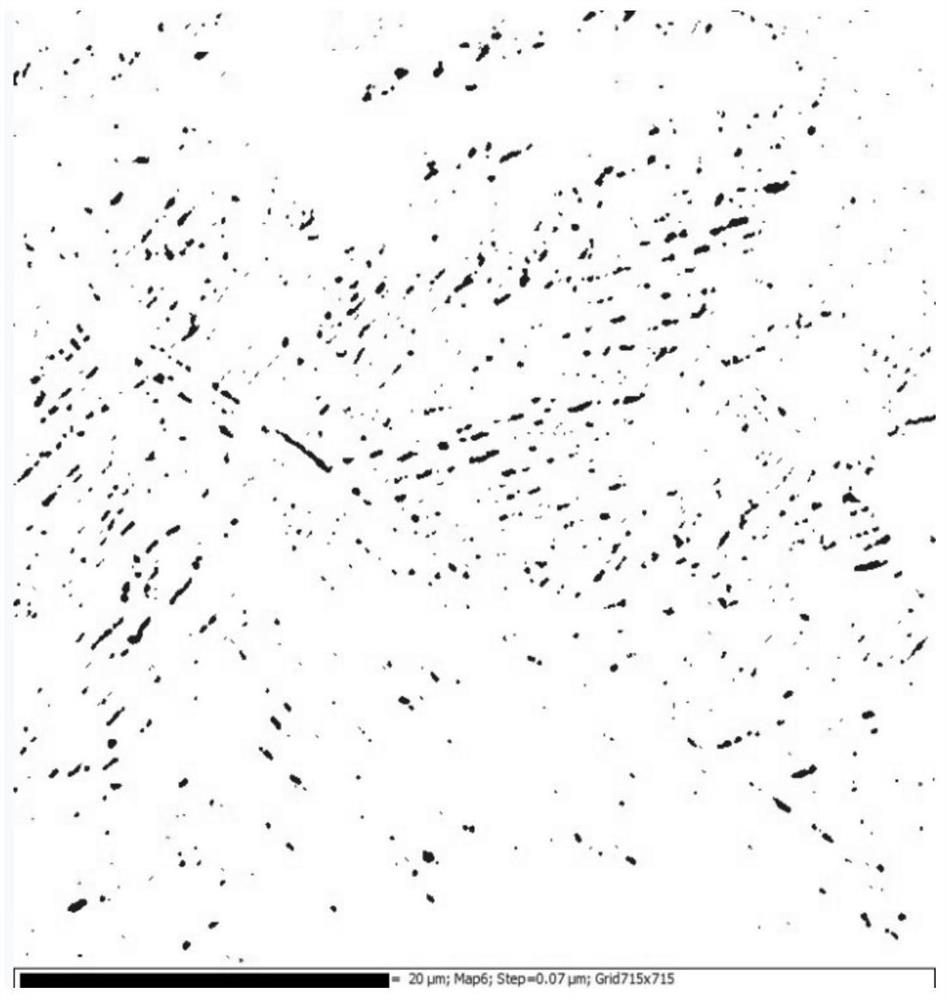

Image

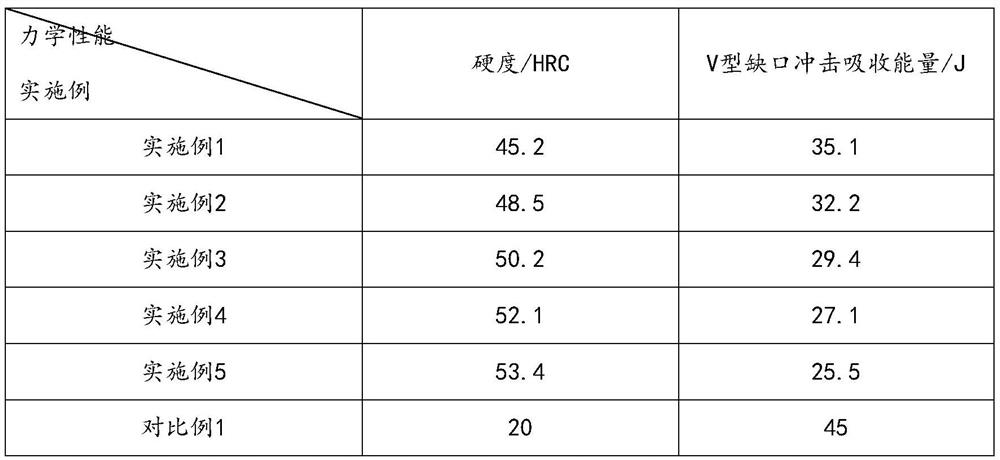

Examples

Embodiment 1

[0028] Embodiment 1, a kind of high-hardness ductile bainite wear-resistant cast steel

[0029] The chemical composition and mass content of the high-hardness ductile bainitic wear-resistant cast steel are: C: 0.25%, Si: 1.6%, Mn: 0.85%, Cr: 1.6%, Mo: 0.3%, Cu: 0.4% , RE: 0.03%, P: 0.023%, S: 0.038%, and the balance is iron and unavoidable impurities.

[0030] The preparation method of the high-hardness ductile bainitic wear-resistant cast steel comprises the following steps:

[0031] S1) Smelting: adding pig iron, scrap steel, pure iron metal and ferroalloy to an electric furnace for smelting, placing molten steel out of the furnace in a steel drum, and inoculating and modifying it with rare earth ferrosilicon alloy to obtain molten steel to be poured;

[0032] S2) casting molding: pouring the molten steel to be poured obtained in the step S1 through the gate, solidifying and cooling to obtain a casting;

[0033] S3) Normalizing: the casting obtained in step S2 is subjected...

Embodiment 2

[0036] Embodiment 2, a kind of high-hardness ductile bainite wear-resistant cast steel

[0037] The chemical composition and mass content of the high-hardness ductile bainite wear-resistant cast steel are: C: 0.30%, Si: 2.0%, Mn: 1.0%, Cr: 1.4%, Mo: 0.4%, Cu: 0.5% , RE: 0.03%, P: 0.023%, S: 0.038%, and the balance is iron and unavoidable impurities.

[0038] The preparation method of the high-hardness ductile bainitic wear-resistant cast steel comprises the following steps:

[0039] S1) Smelting: adding pig iron, scrap steel, pure iron metal and ferroalloy to an electric furnace for smelting, placing molten steel out of the furnace in a steel drum, and inoculating and modifying it with rare earth ferrosilicon alloy to obtain molten steel to be poured;

[0040] S2) casting molding: pouring the molten steel to be poured obtained in the step S1 through the gate, solidifying and cooling to obtain a casting;

[0041] S3) Normalizing: the casting obtained in step S2 is subjected t...

Embodiment 3

[0045] Embodiment 3, a kind of high-hardness ductile bainite wear-resistant cast steel

[0046]The chemical composition and mass content of the high-hardness ductile bainite wear-resistant cast steel are: C: 0.32%, Si: 2.0%, Mn: 1.2%, Cr: 1.4%, Mo: 0.4%, Cu: 0.4% , RE: 0.04%, P: 0.024%, S: 0.035%, and the balance is iron and unavoidable impurities.

[0047] The preparation method of the high-hardness ductile bainitic wear-resistant cast steel comprises the following steps:

[0048] S1) Smelting: adding pig iron, scrap steel, pure iron metal and ferroalloy to an electric furnace for smelting, placing molten steel out of the furnace in a steel drum, and inoculating and modifying it with rare earth ferrosilicon alloy to obtain molten steel to be poured;

[0049] S2) casting molding: pouring the molten steel to be poured obtained in the step S1 through the gate, solidifying and cooling to obtain a casting;

[0050] S3) Normalizing: the casting obtained in step S2 is subjected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com