Patents

Literature

1580 results about "Sheet pile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

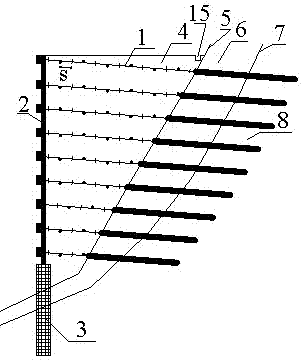

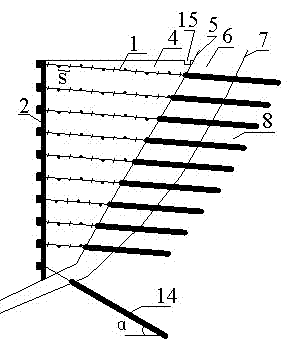

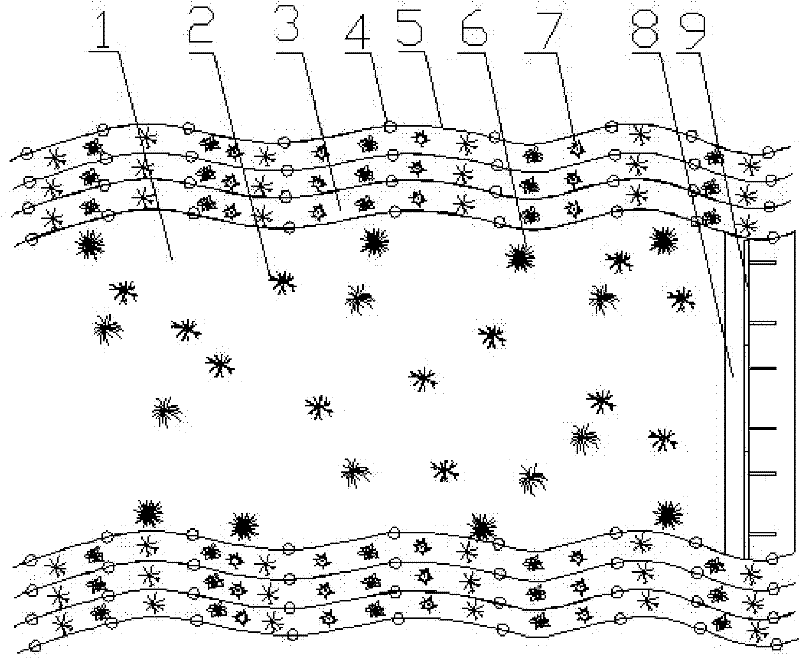

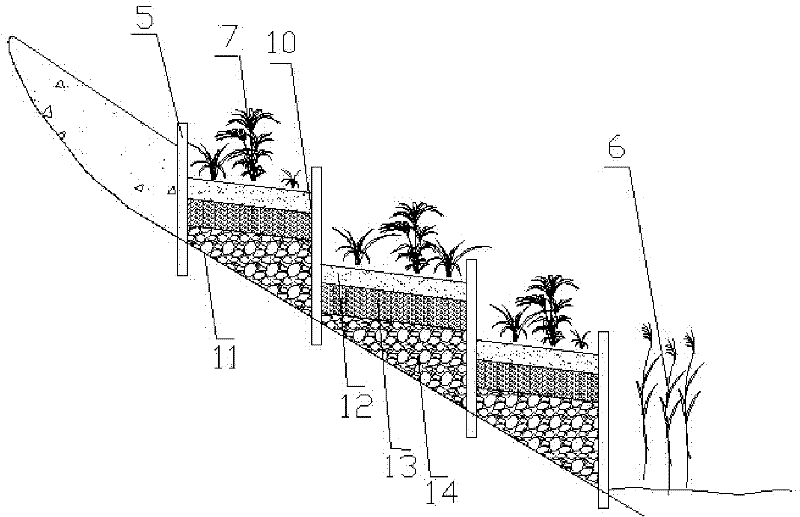

Landscape type multi-stage stepwise artificial wetland protection slope forming method

InactiveCN1632231AGood water permeabilityAvoid inconvenienceClimate change adaptationCoastlines protectionConstructed wetlandEutrophication

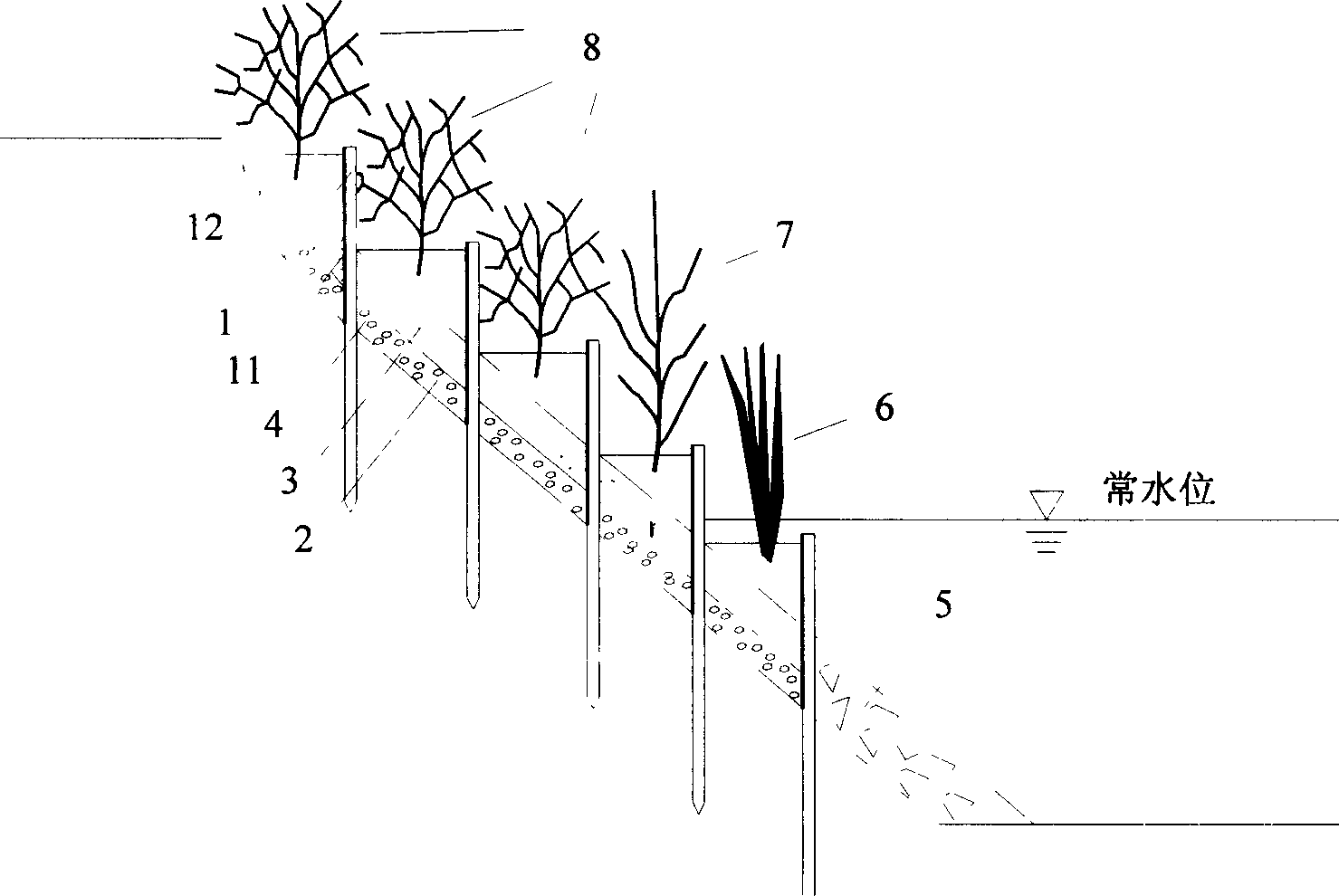

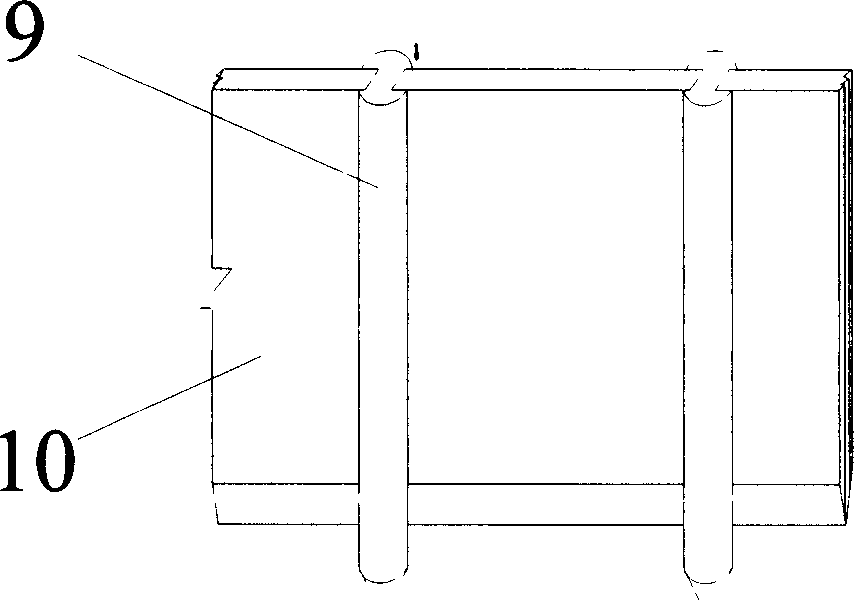

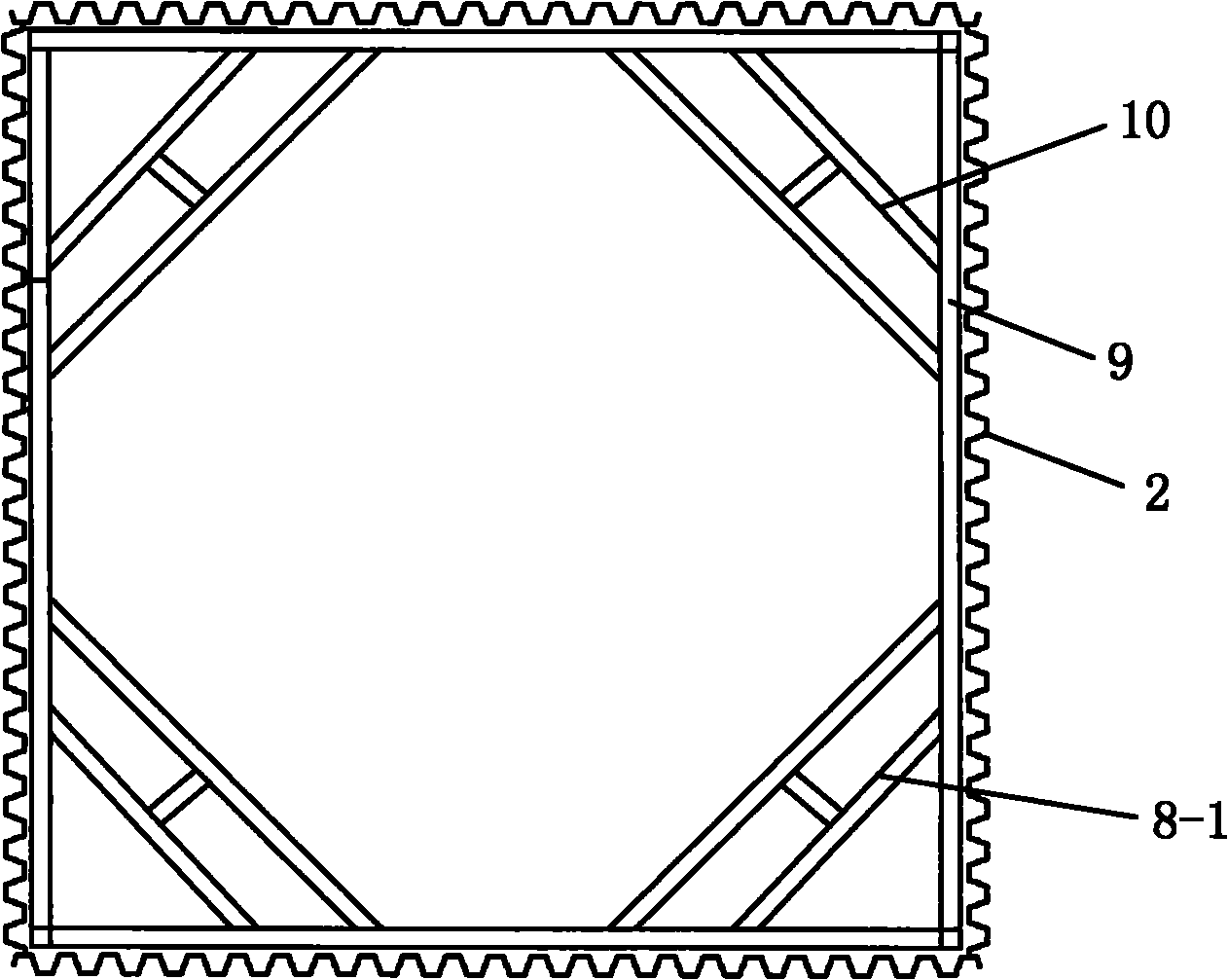

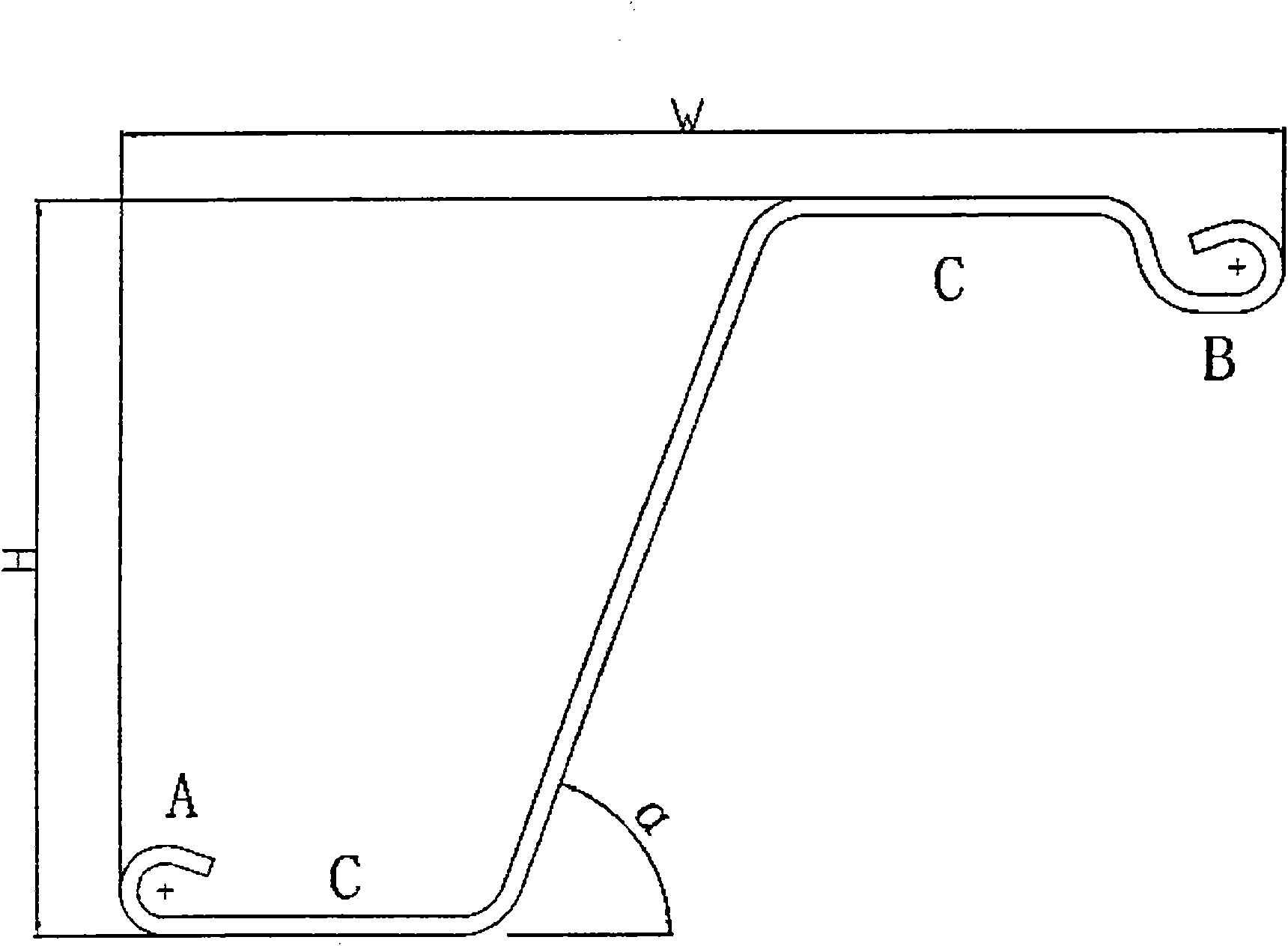

The invention relates to a slope protection forming method of a landscape-type multi-level stepped constructed wetland, which has the effect of intercepting and purifying pollutants entering river channels in the form of surface sources. Sand-free concrete piles and slabs are inserted to form pile-slab components, and a slope protection system from high to low is formed on the river bank slope from the bank slope to the river bed. Planting areas are set on the side of the pile slabs, and there are fillers inside. Geotextiles are installed on the bankside side of the slab, so that when the non-point source pollutants flow from the river bank to the river, the plants planted in the planting area absorb the eutrophication in the polluted water, and the biofilm is formed on the surface of the filler to absorb and degrade the pollutants. After this The sewage treated at the first stage continues to infiltrate or overflow, enters the second row, and goes down step by step. Finally, the sewage is purified to a greater extent and flows into the river. It solves the defects of natural, hard and ecological slope protection. The structure is simple, easy for industrial production, the construction amount is small, the land is saved, and the landscape is beautified.

Owner:HOHAI UNIV

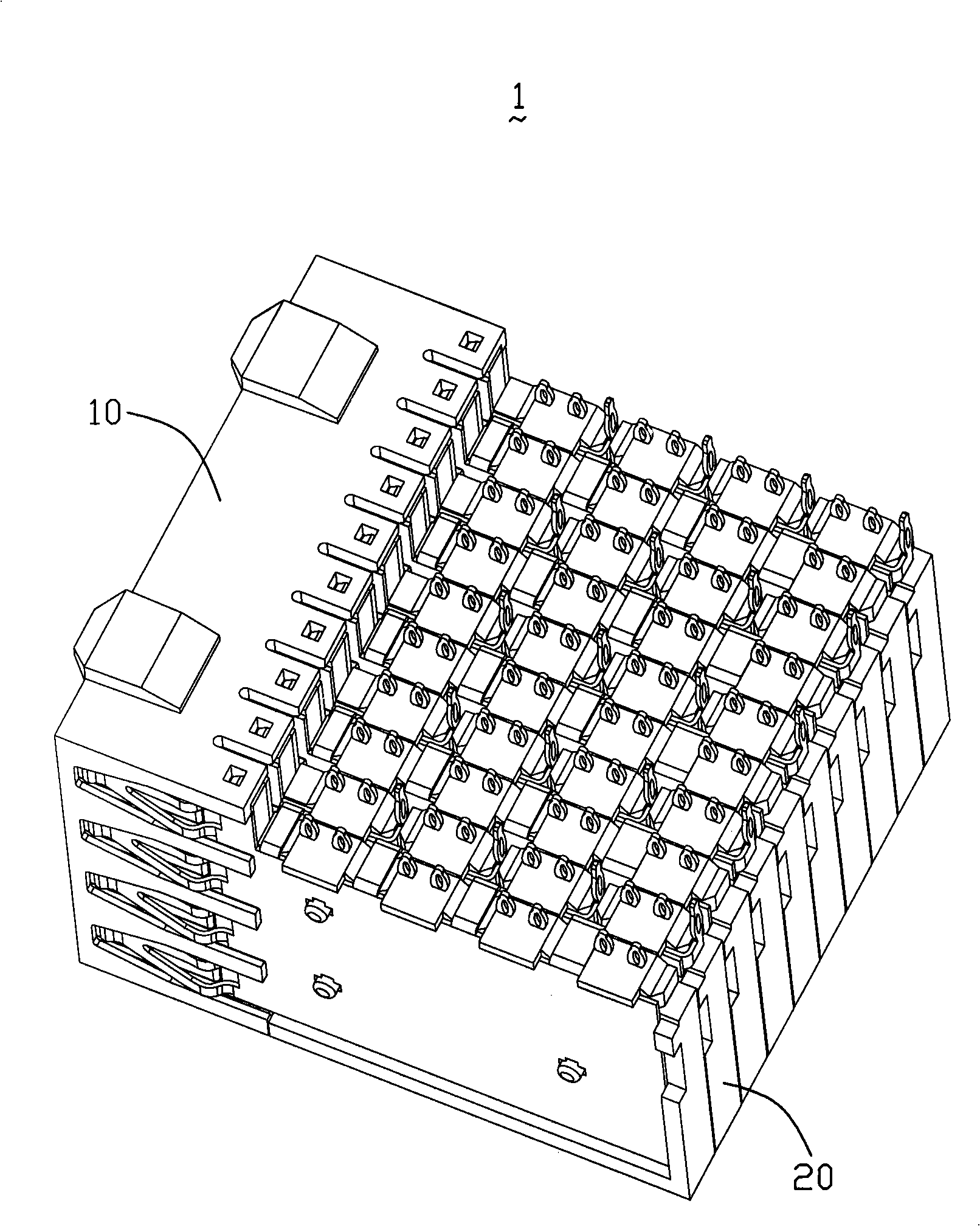

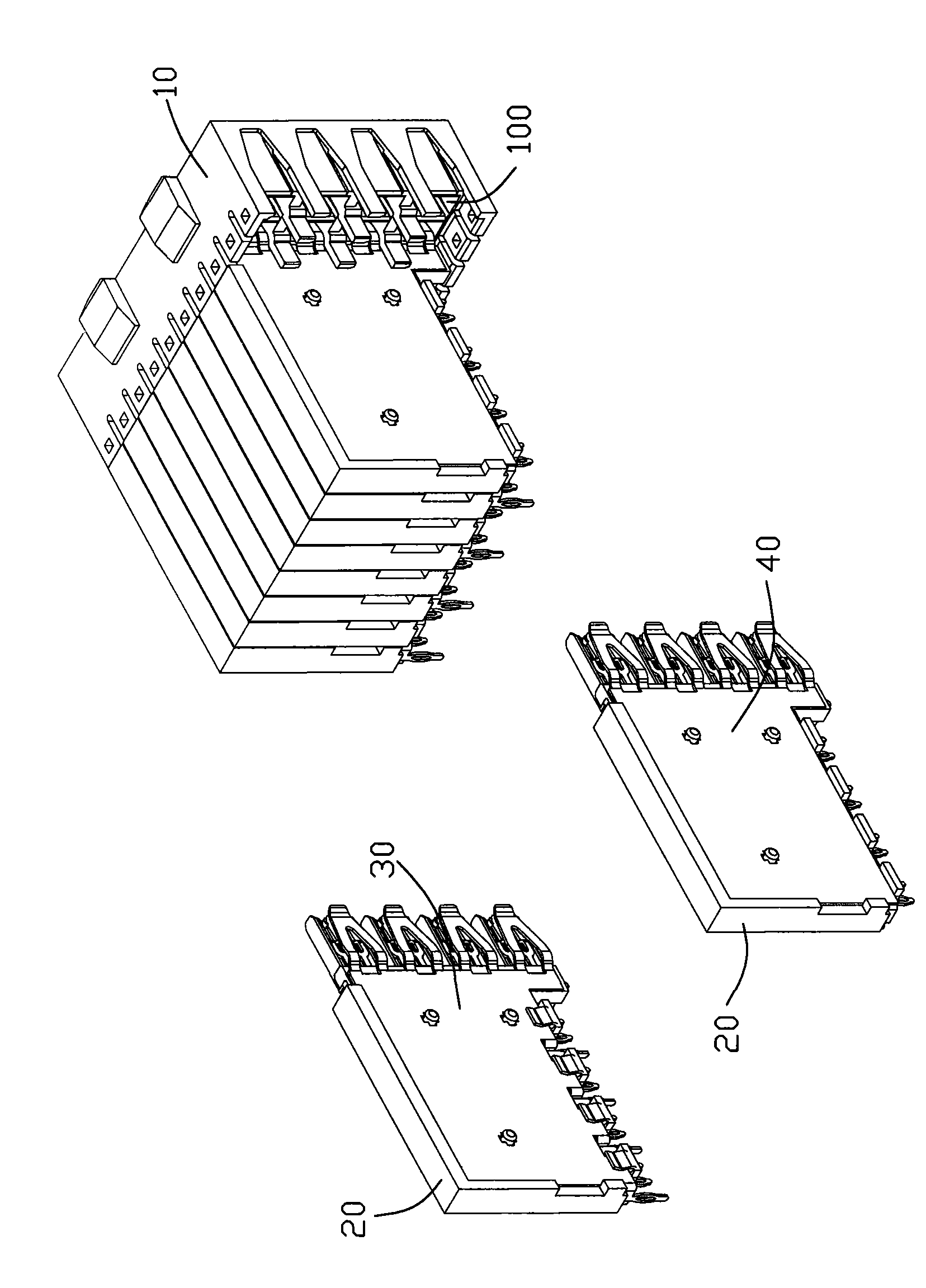

Electric connector

InactiveCN101527409AReduce the number of ground pinsOptimize layoutTwo-part coupling devicesCoupling protective earth/shielding arrangementsSheet pileElectrical and Electronics engineering

The invention relates to an electric connector. The electric connector is arranged on a circuit board; the electric connector comprises an insulation body and a plurality of terminal modules and shielding sheets piled and arranged on the insulation body; each terminal module and each shielding sheet are alternately arranged; the shielding sheet comprises a first shielding sheet and a second shielding sheet; the first shielding sheet is arranged at one side of one of the terminal modules; the first shielding sheet is provided with a plurality of earthed pins connected with the circuit board; the earthed pins are arrayed along the straight line parallel to the first shielding sheet; the second shielding sheet is arranged at one side opposite to the terminal module; and the second shielding sheet is connected with the first shielding sheet and is earthed through the first shielding sheet. With the design, the electric connector reduces the number of the pins arranged on the circuit board, thereby being convenient for circuit layout of the circuit board.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

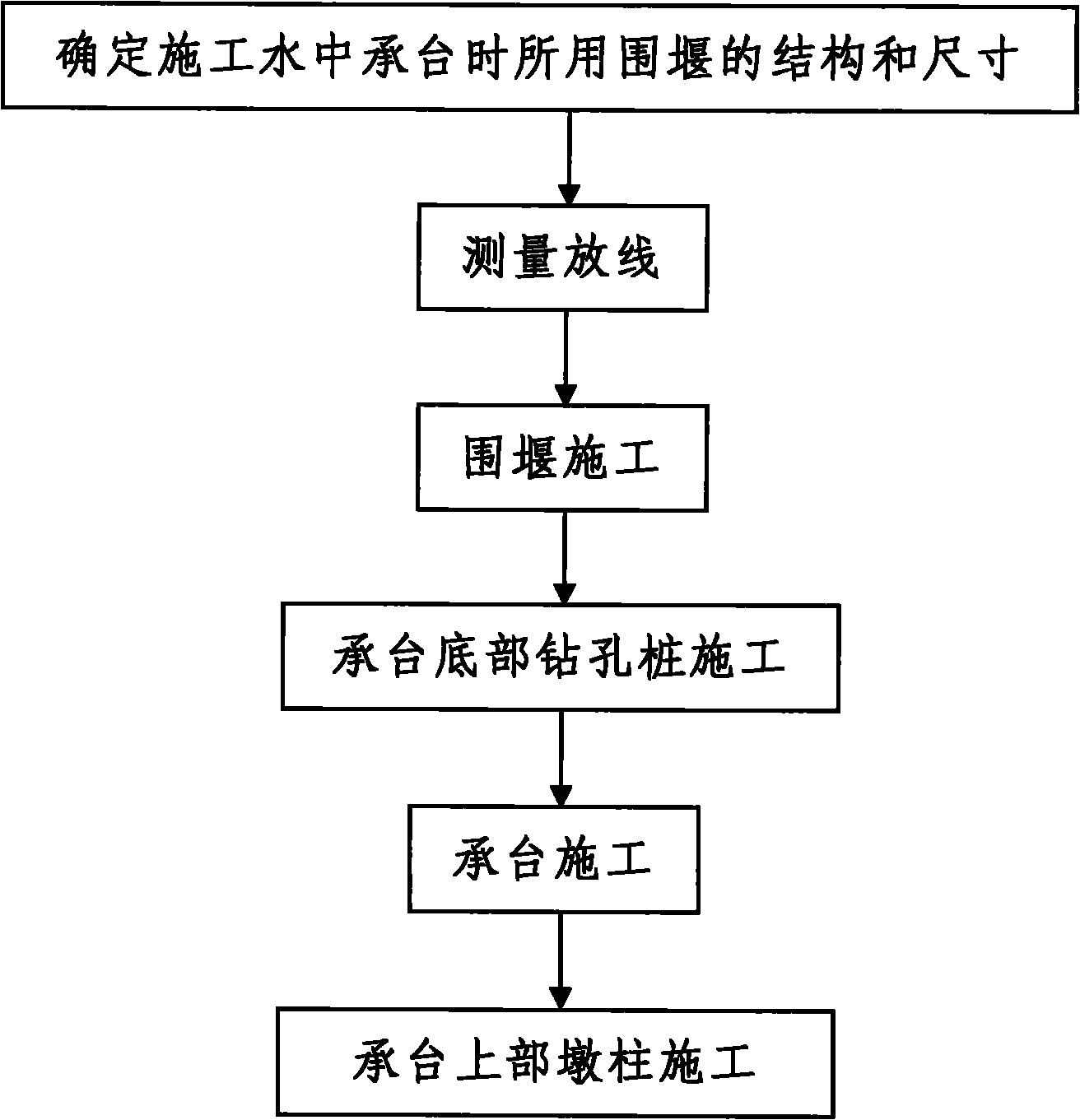

Construction technology of steel sheet pile cofferdam for Yellow River Channel internal support table construction

The invention discloses a construction technology of a steel sheet pile cofferdam for Yellow River Channel internal support table construction. A construction support table is an underwater support table arranged in a Yellow River Channel. The technology comprises the following steps of firstly, determining a structure and the size of a used cofferdam in the process of underwater support table construction; secondly, surveying and setting out; thirdly, constructing the cofferdam; fourthly, constructing a bored pile at the bottom of the support table; fifthly, constructing the support table: carrying out forming construction of the underwater support table on the top of the bored pile after construction when the bored pile construction is finished, and finishing integrative construction of the bored pile and the underwater support table; and sixthly, constructing a pier column at the upper part of the support table. The invention has the advantages of reasonable design, convenient construction and low construction cost, carrys out construction by adopting an integrative construction method of the support table and the bored pile and can efficiently solve the defects of long construction period, large investment, needs of setting up a plurality of construction platforms, large construction difficulty and the like in the successive construction process of the bored pile and the support table in the traditional construction process of the steel sheet pile cofferdam.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

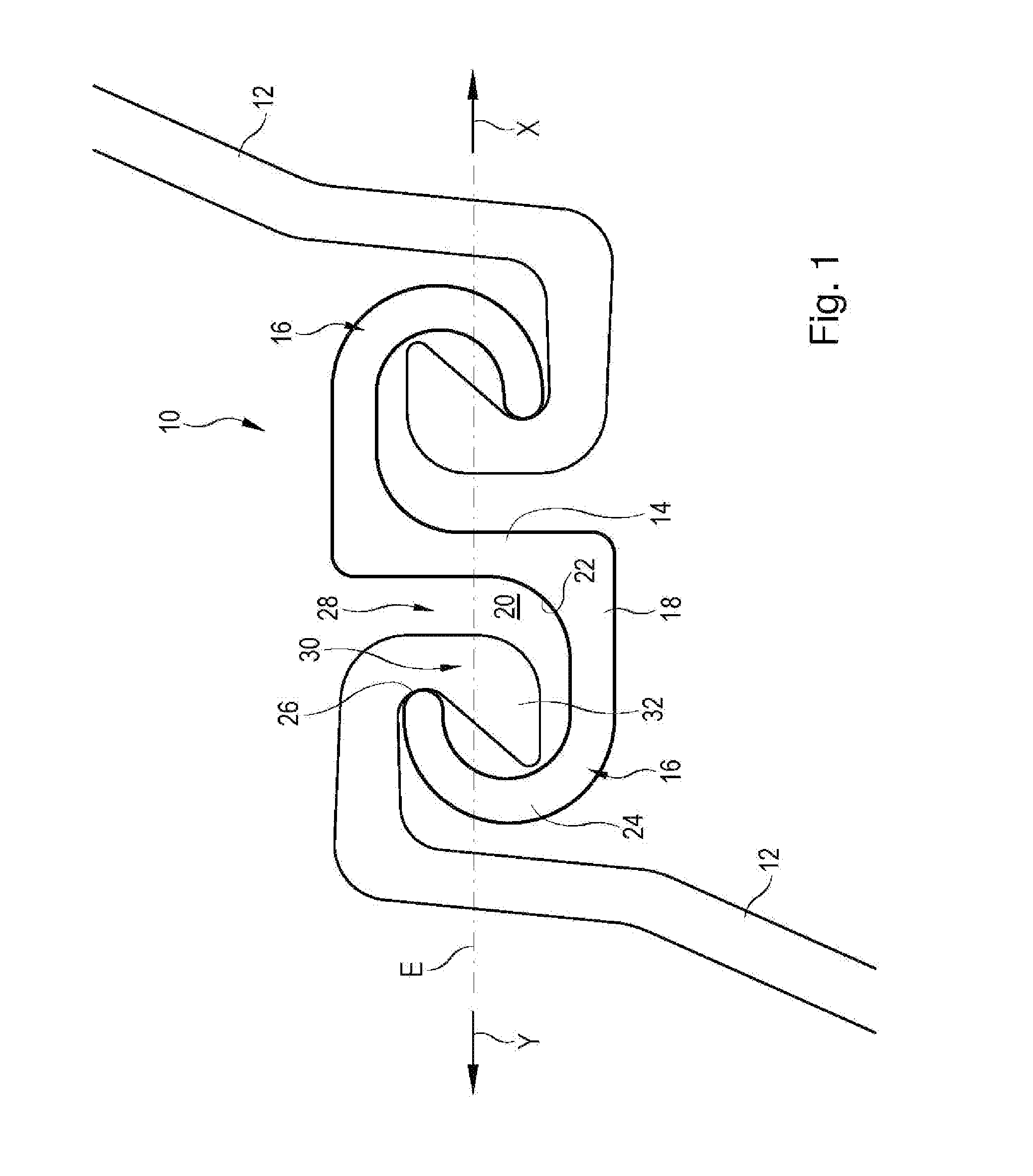

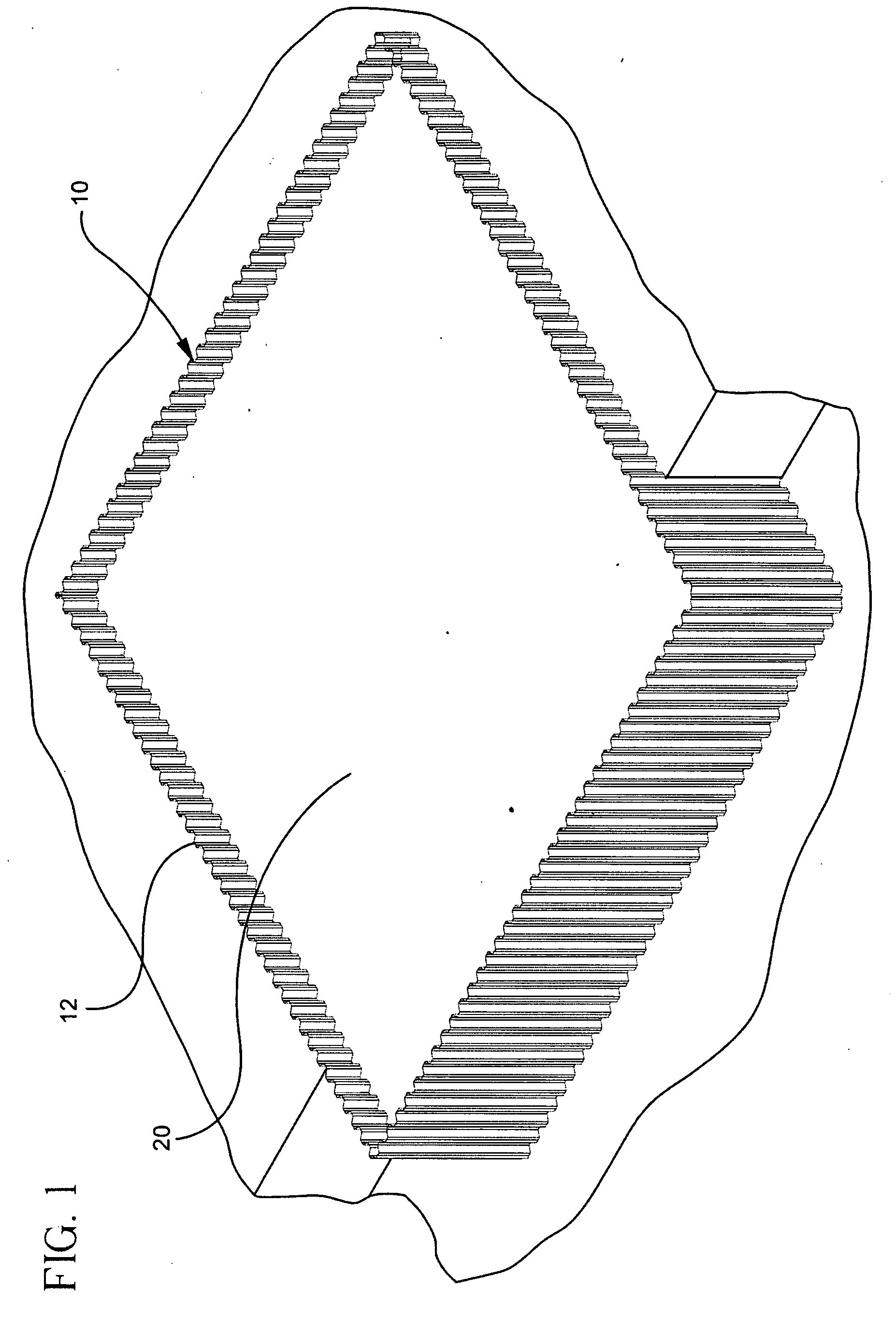

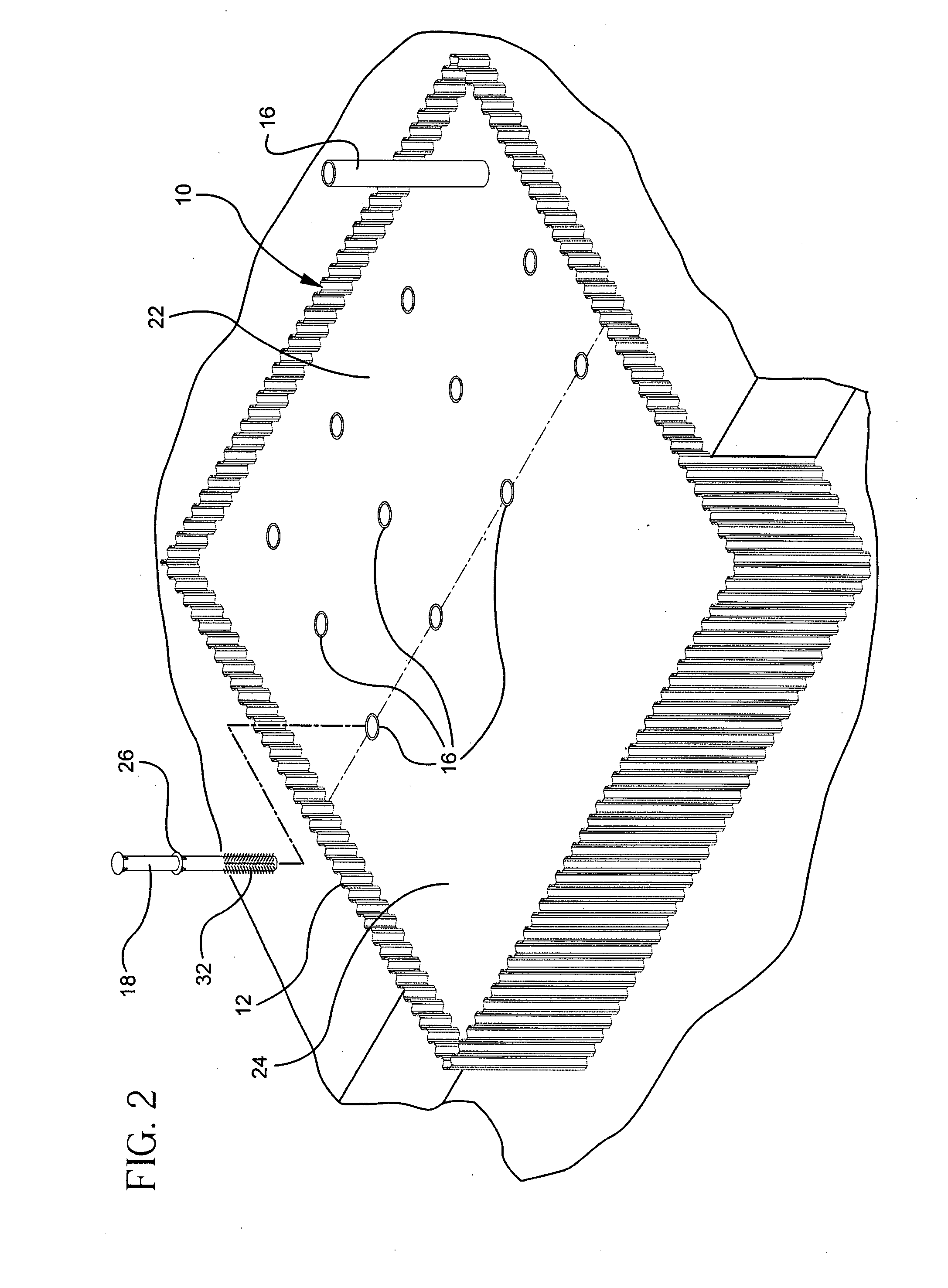

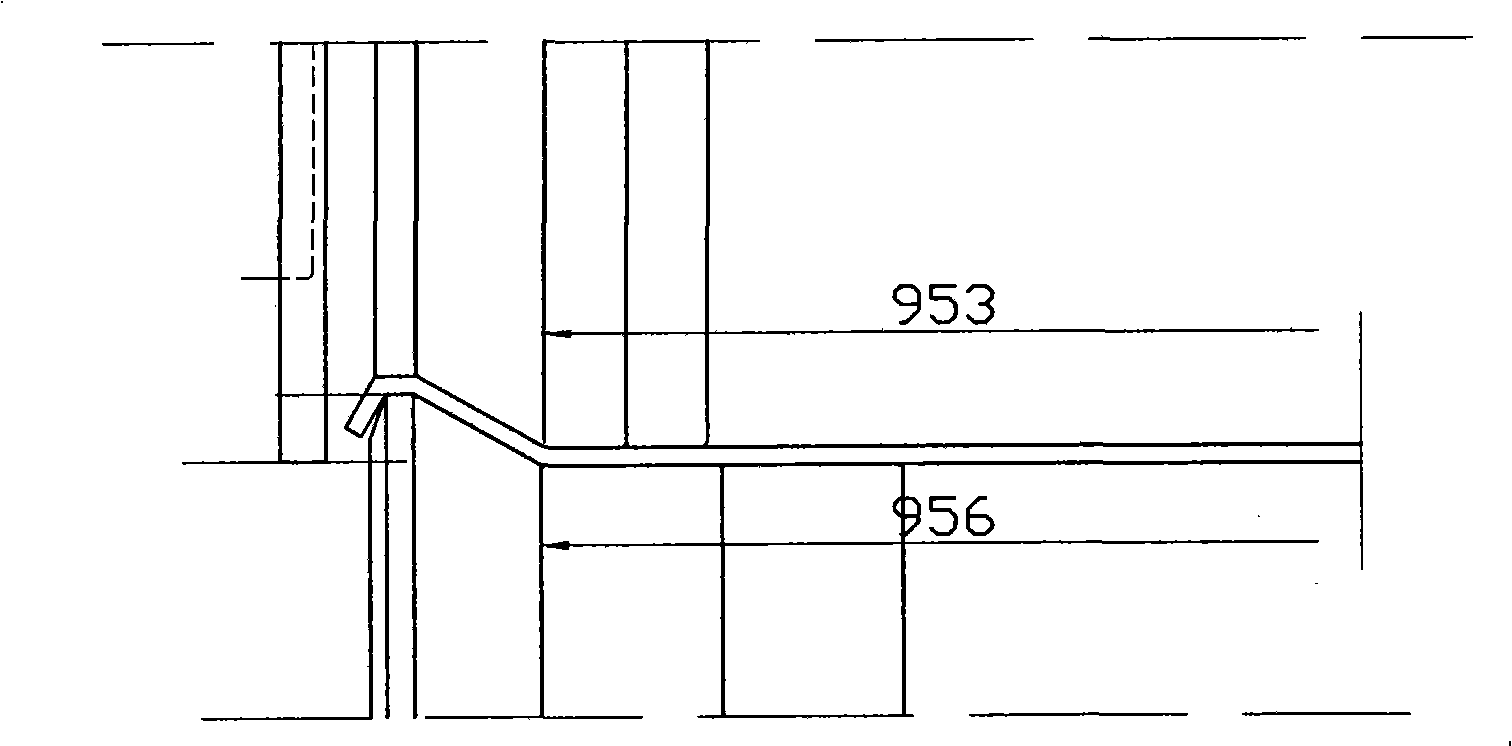

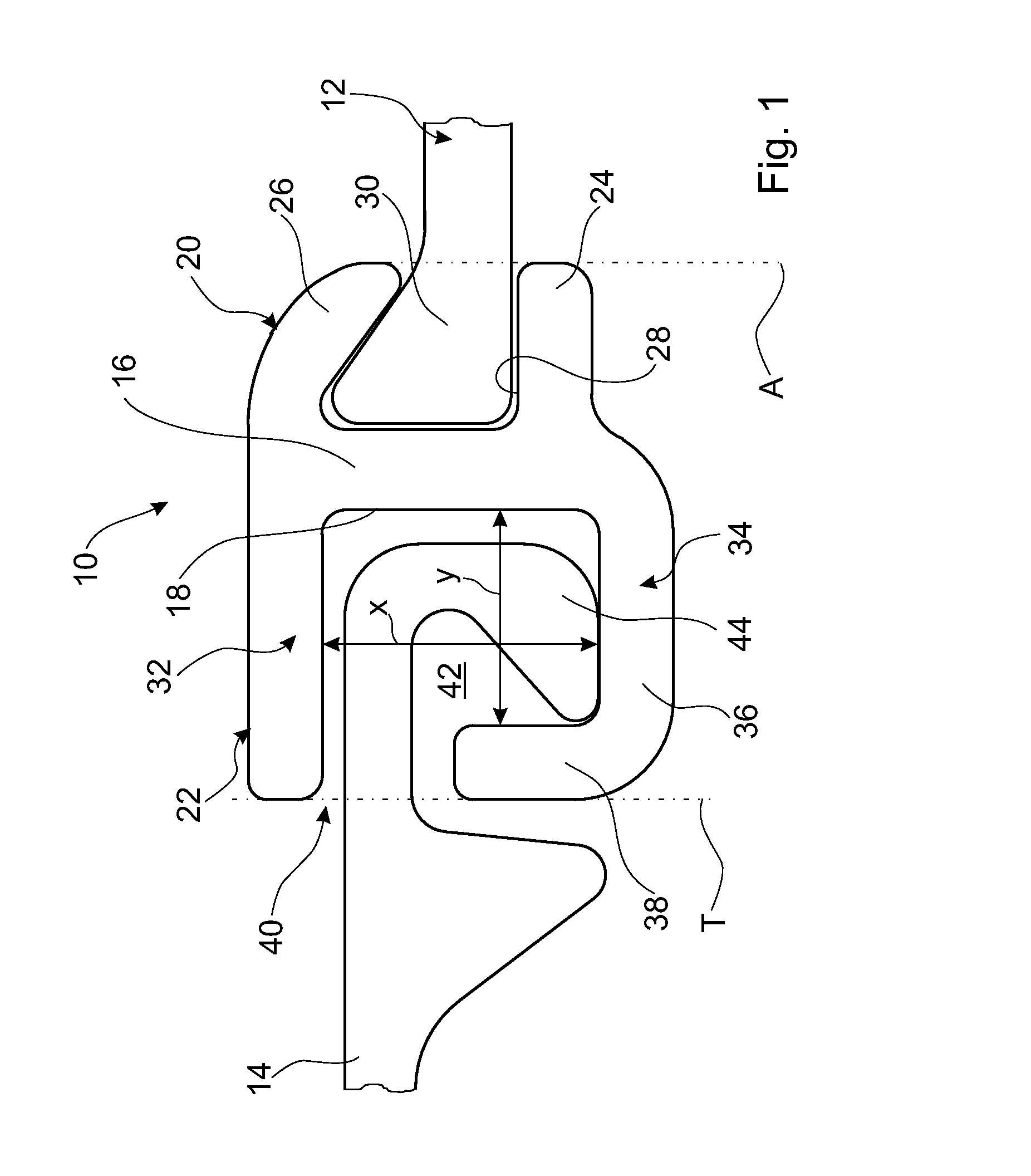

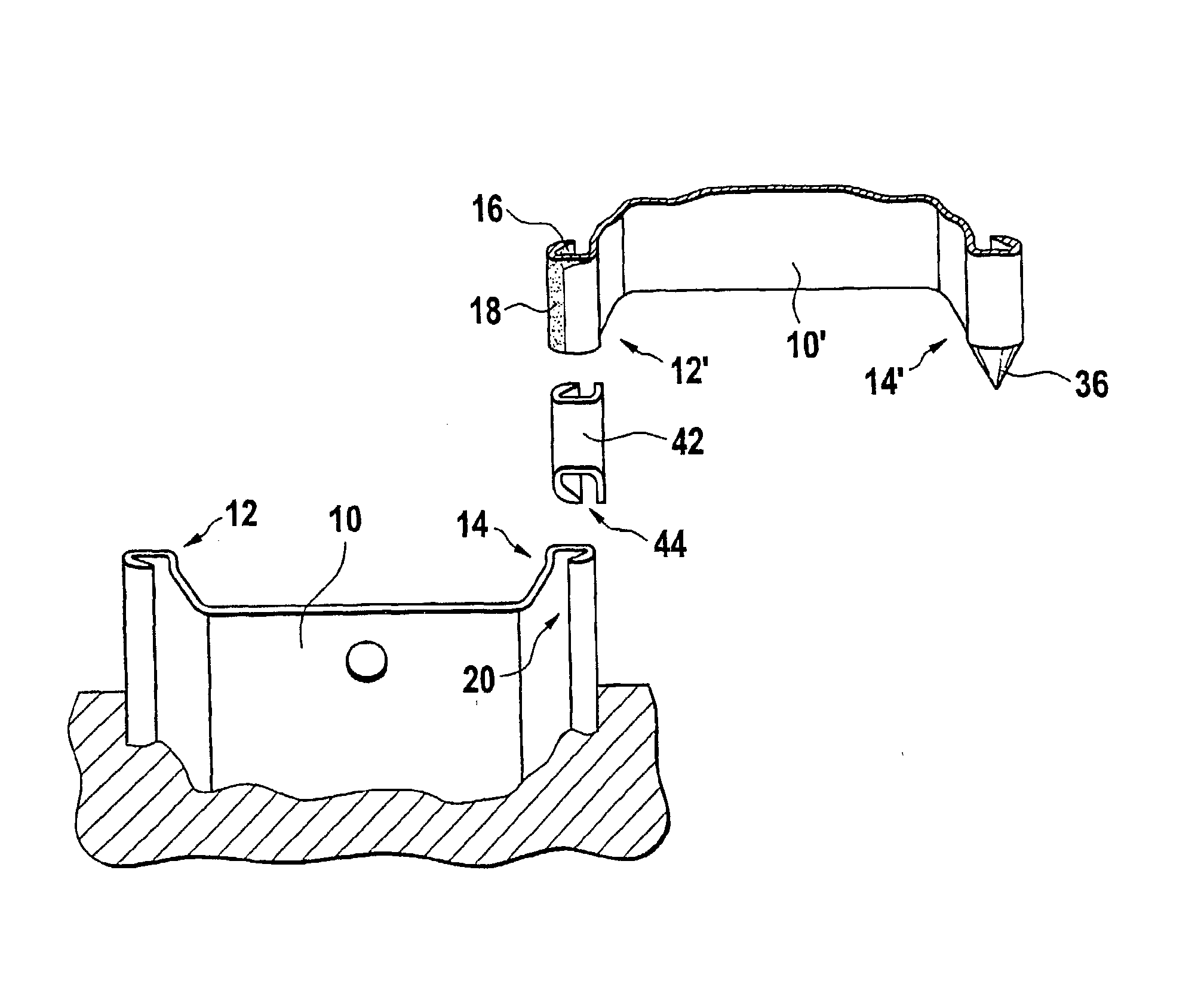

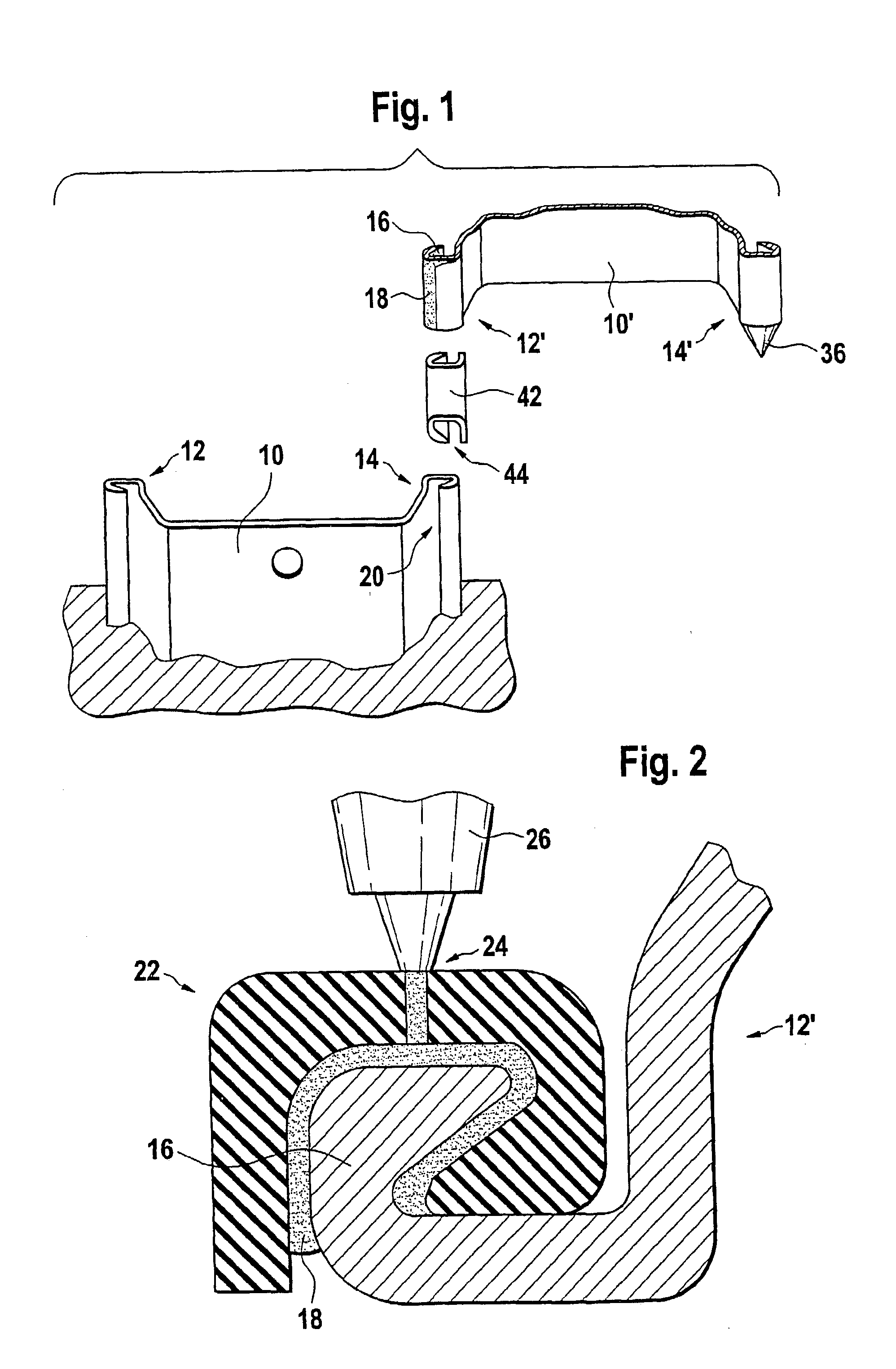

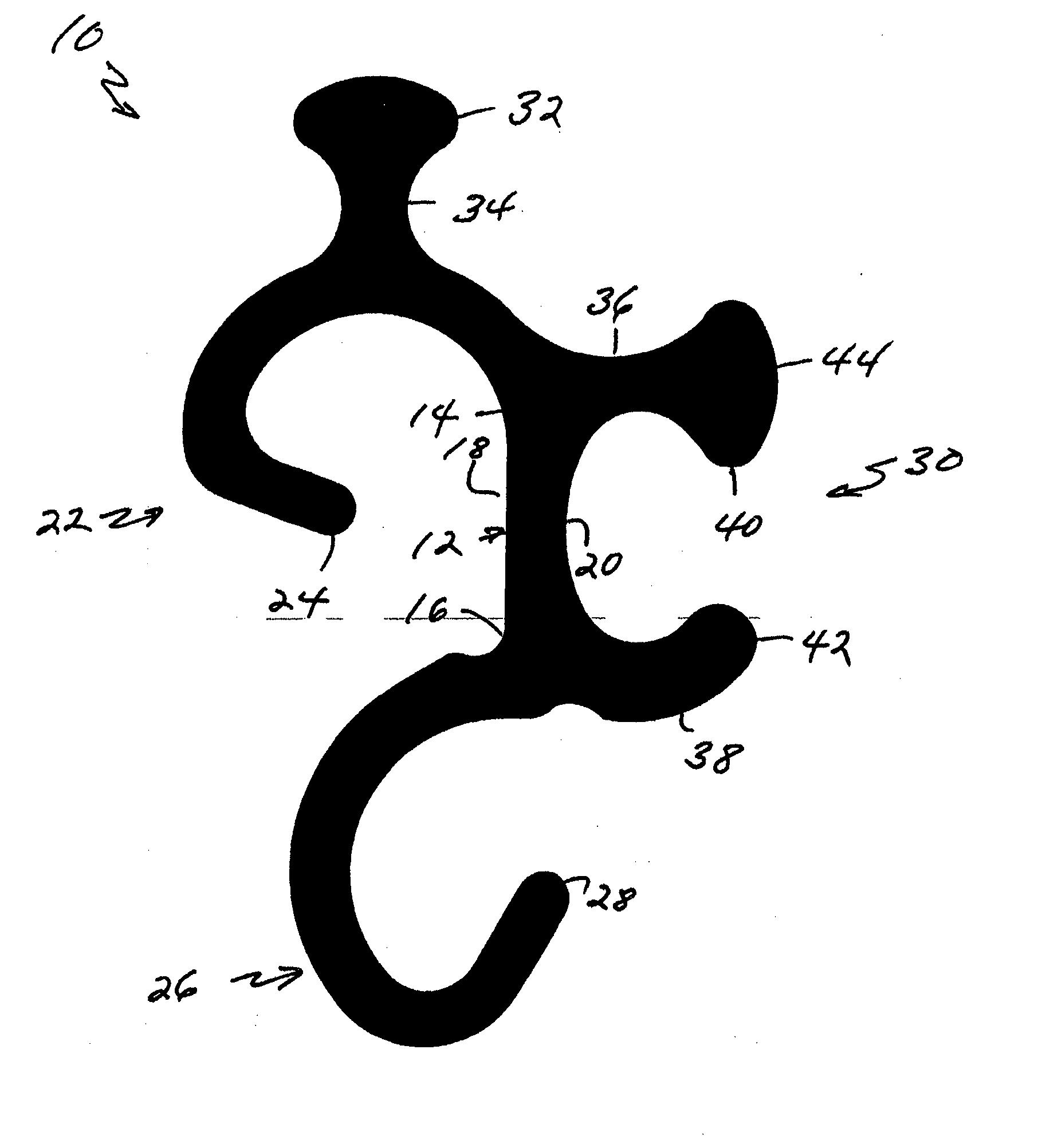

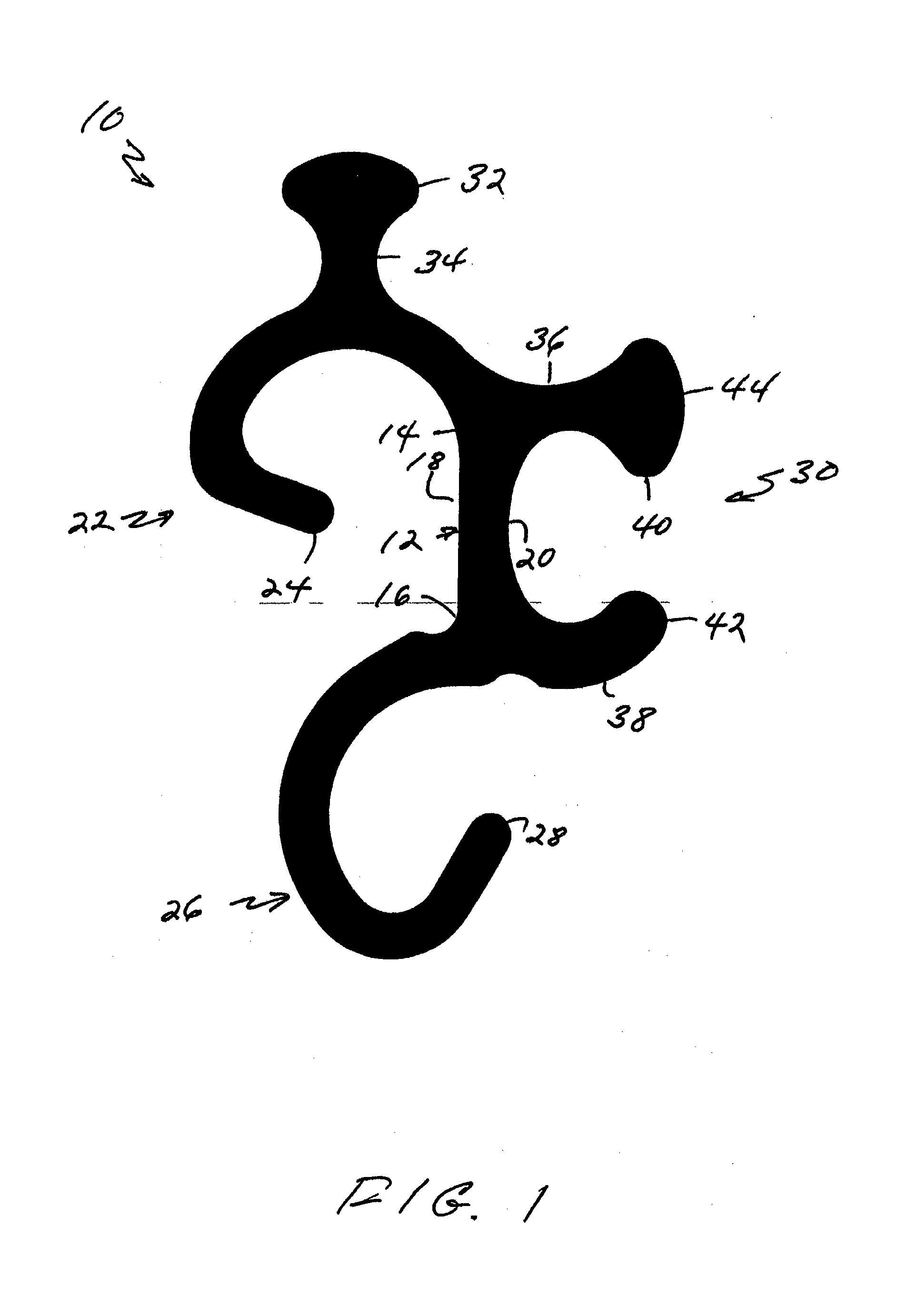

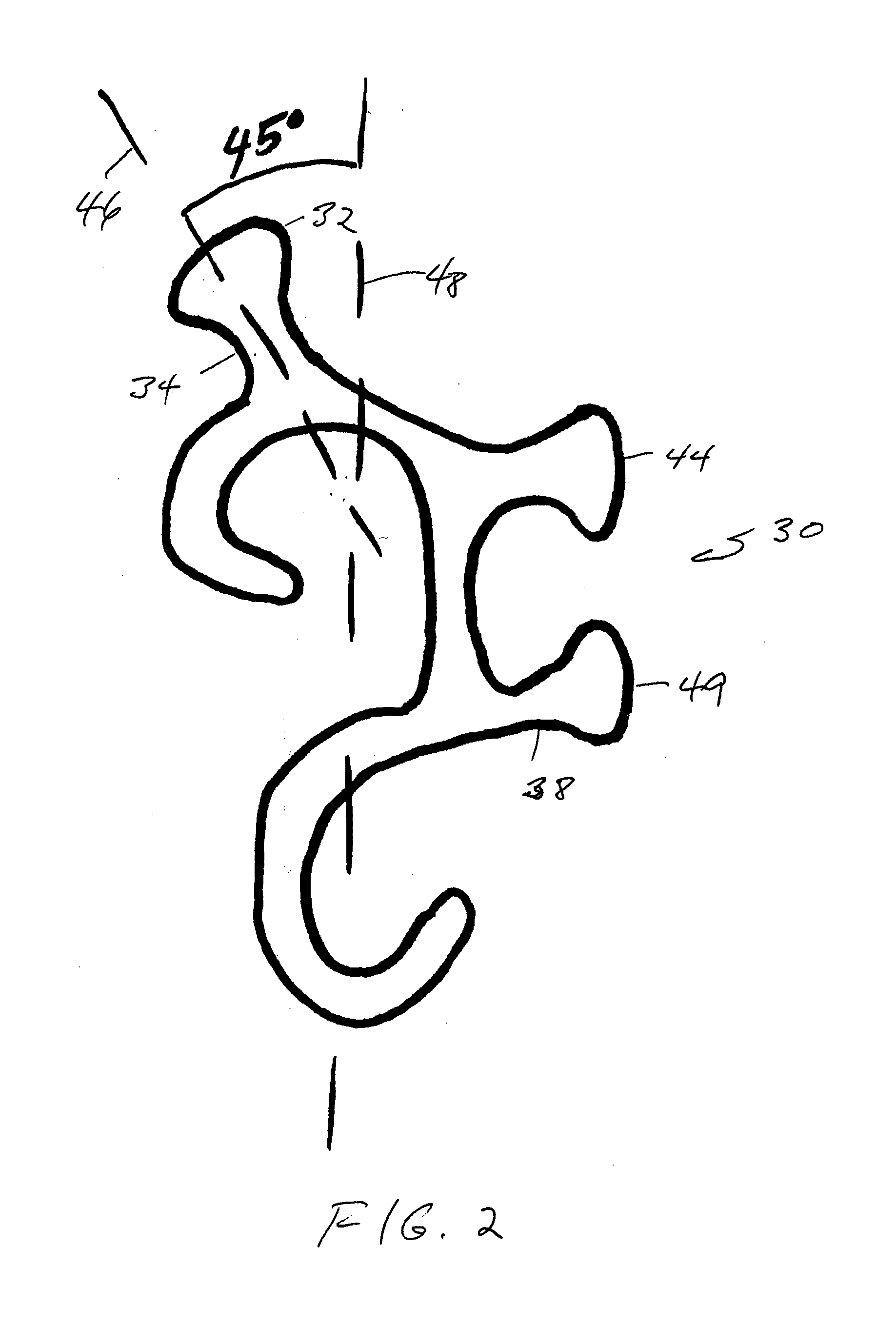

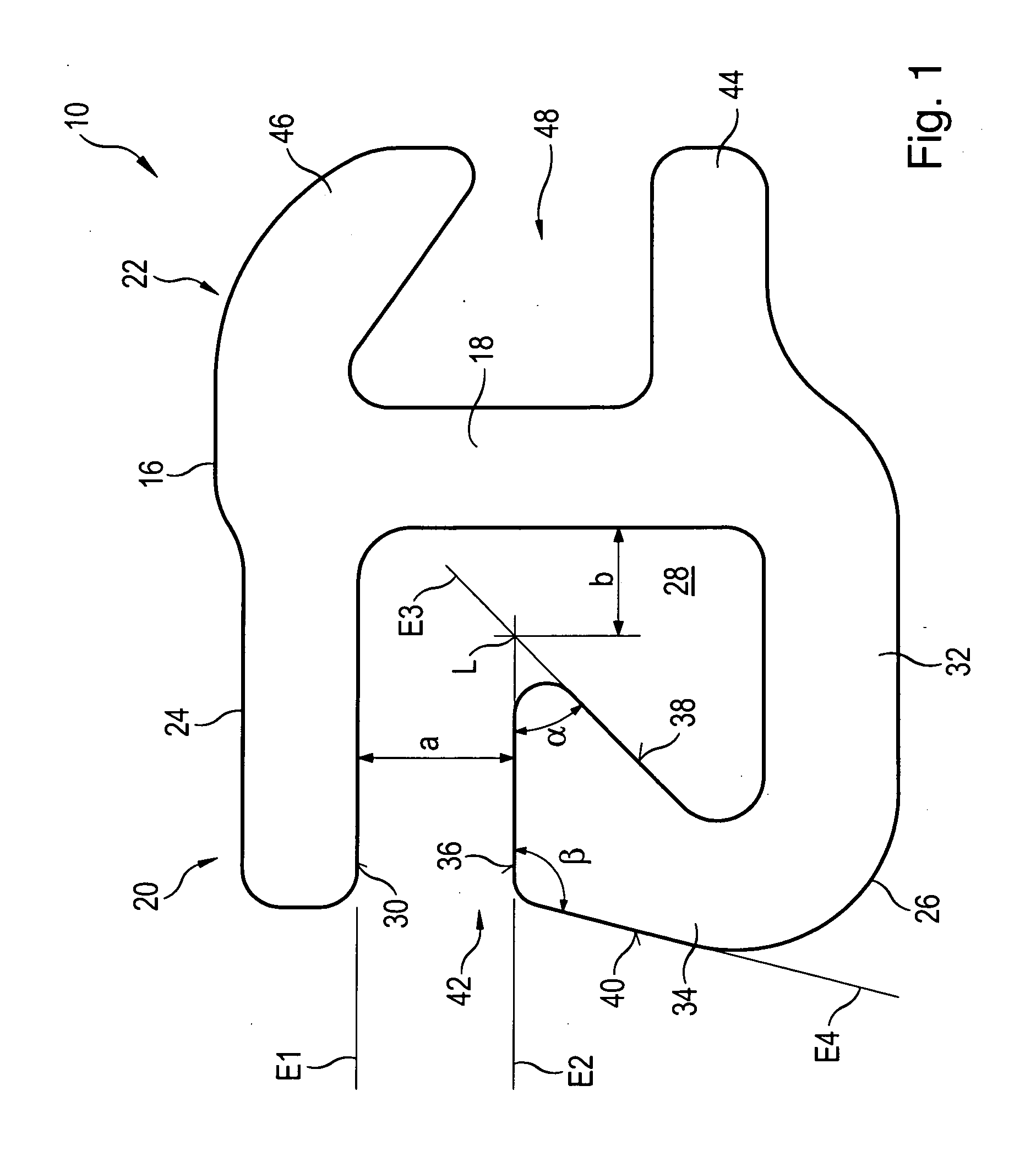

Connecting profiled element for connecting sheet piles to carrier elements

ActiveUS7527456B2Erected more easilyEasy erectionArtificial islandsScaffold connectionsEngineeringSheet pile

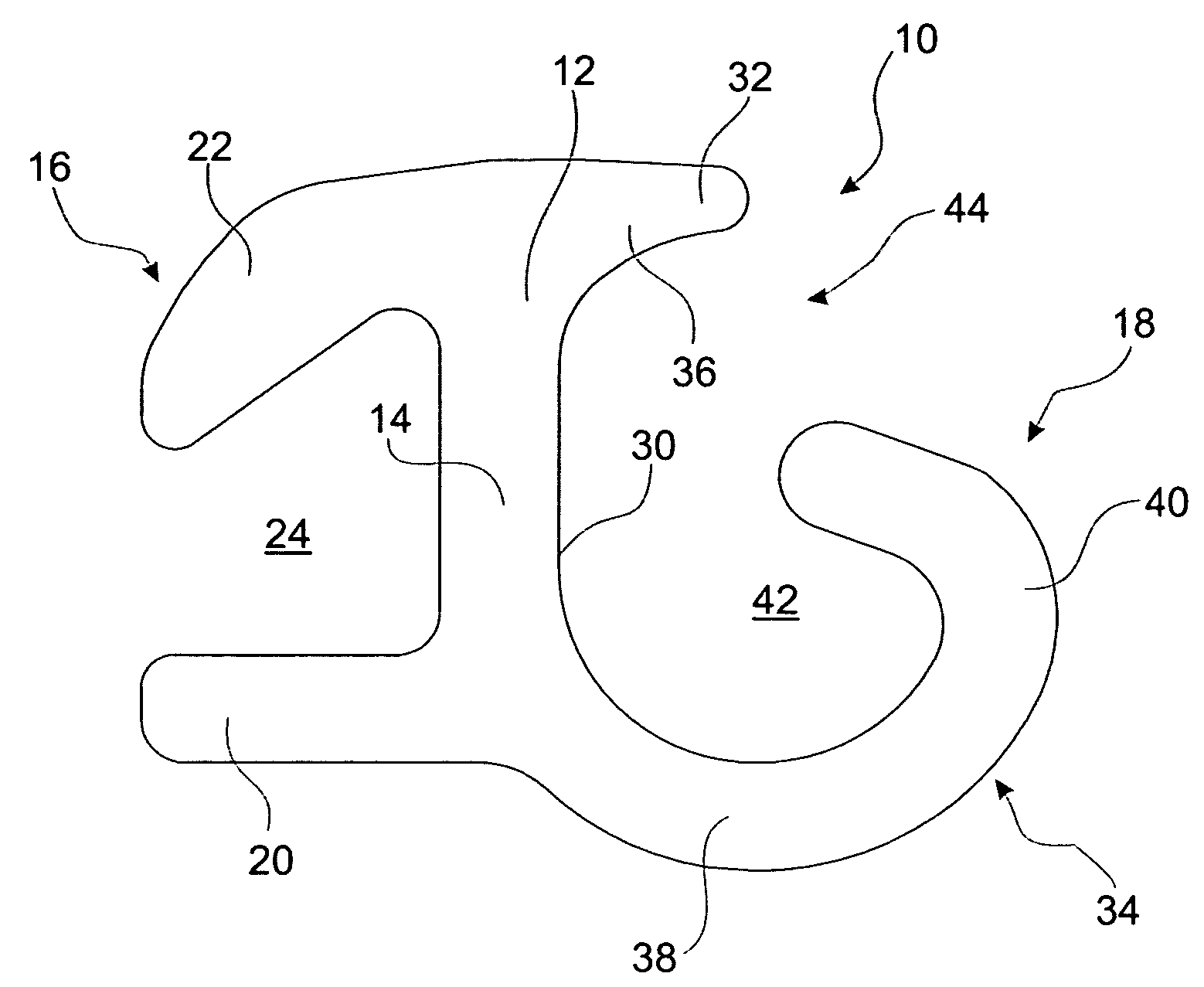

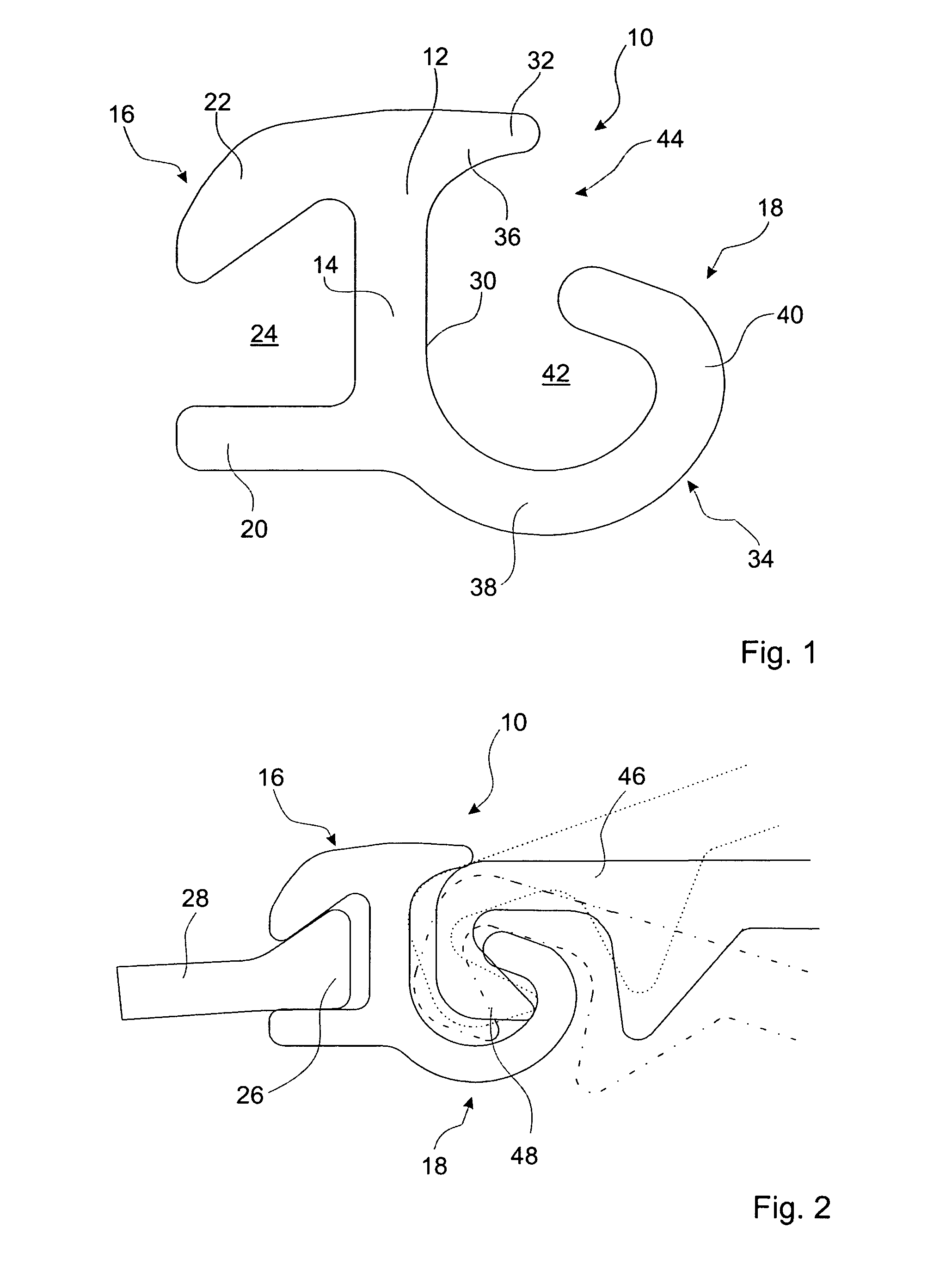

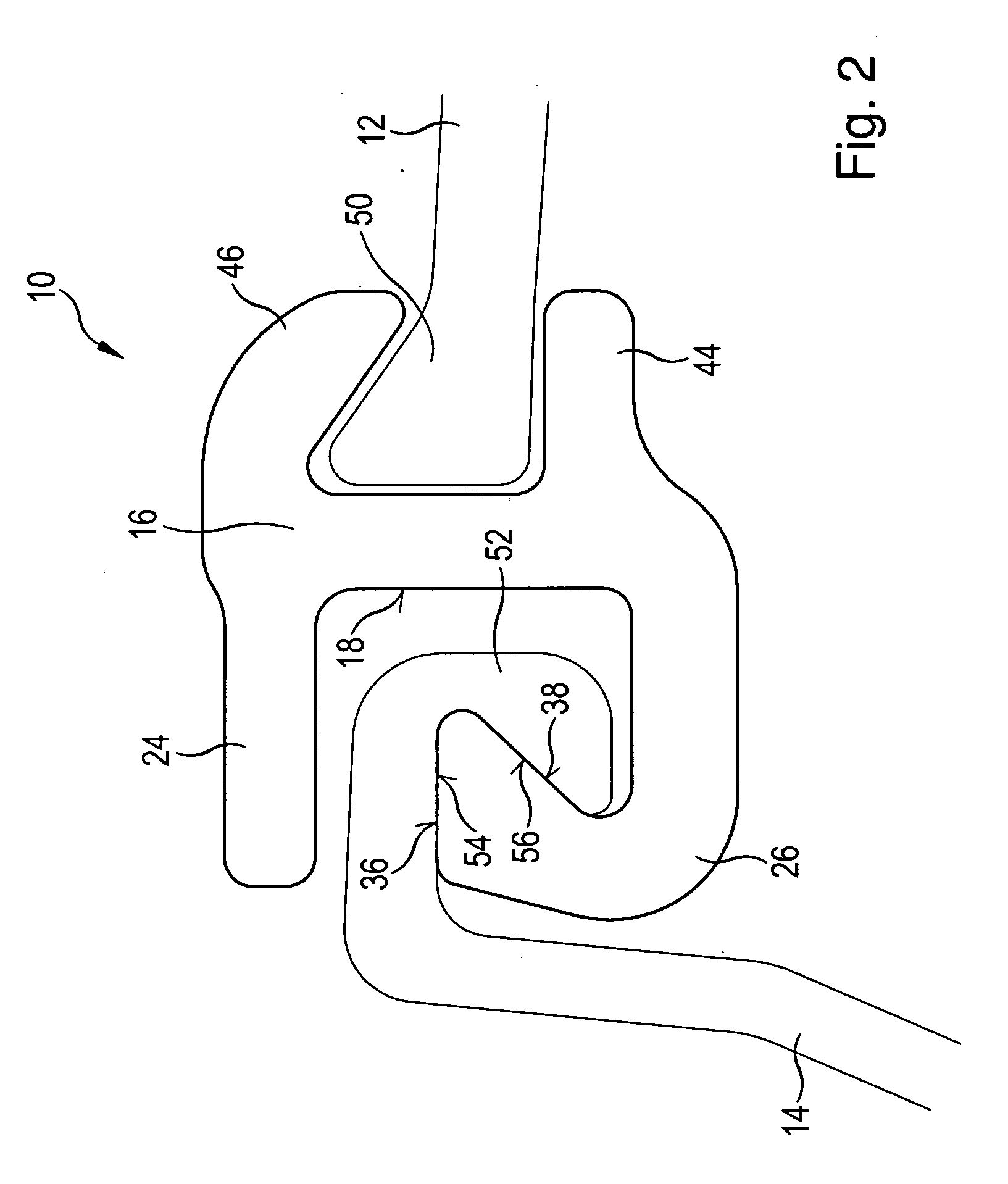

A rod-type connecting profiled element (10) for connecting sheet piles to carrier elements comprises a central strip (12) that separates two opposing connecting profiled elements (16, 18), each of which respectively forms a saw (24, 42). One connecting profiled element is embodied as a plug-in profiled element (16) for the carrier element and the other connecting profiled element is embodied as a receiving profiled element (18) for connecting a sheet pile. The central strip (12) comprises, on the side of the receiving profiled element (18), a central section (14) having a straight plane inner wall (30) to which a first short end section (32) is connected on one side, said short end section protruding past the central section (14) at an angle of approximately 90°, and being connected thereto by means of a transition section (36) having an inner wall with a cross-section that follows a quadrant. A hook strip (34) is arranged on the other side of the plane central section (14) as a second end section oriented in the same direction as the first end section (32).

Owner:SHEET PILE LLC

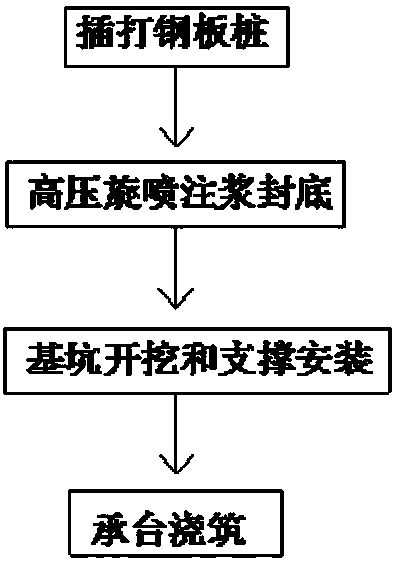

Foundation pit construction method employing steel sheet piles as support cofferdam

The invention discloses a foundation pit construction method employing steel sheet piles as a support cofferdam. The foundation pit construction method is suitable to high-water permeability sand soil geology or high-flow plasticity sludge geology and includes the steps of A, inserting and driving the steel sheet piles to form the steel sheet pile cofferdam; B, performing the ground sealing to a bottom face of the foundation pit to be constructed by employing a high pressure jet grouting method; C, excavating the foundation pit and mounting an inner support of the cofferdam. Compared with the conventional method that the ground sealing is performed to the foundation pit after the excavation, the foundation pit construction method has the advantages that the excavation is performed before the ground sealing, thus cofferdam collapse and piping or upwarp of the cofferdam base never occur in the case of the high-water permeability sand soil geology or the high-flow plasticity sludge geology, and the building-around settlement, caused by drainage and rainfall, is avoided to prevent ground sealing under the water.

Owner:CHINA CONSTR COMM ENG GRP UNITED

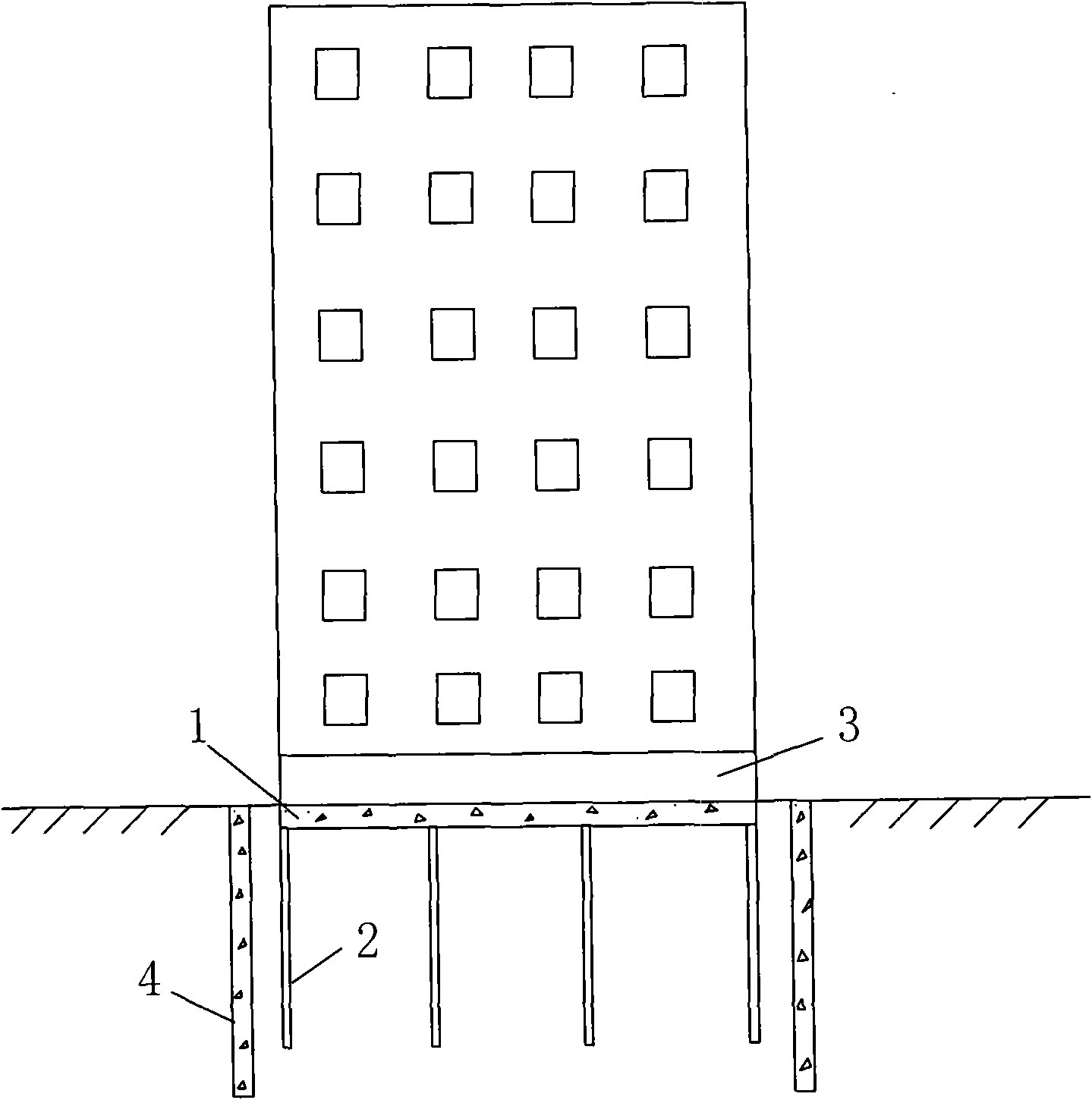

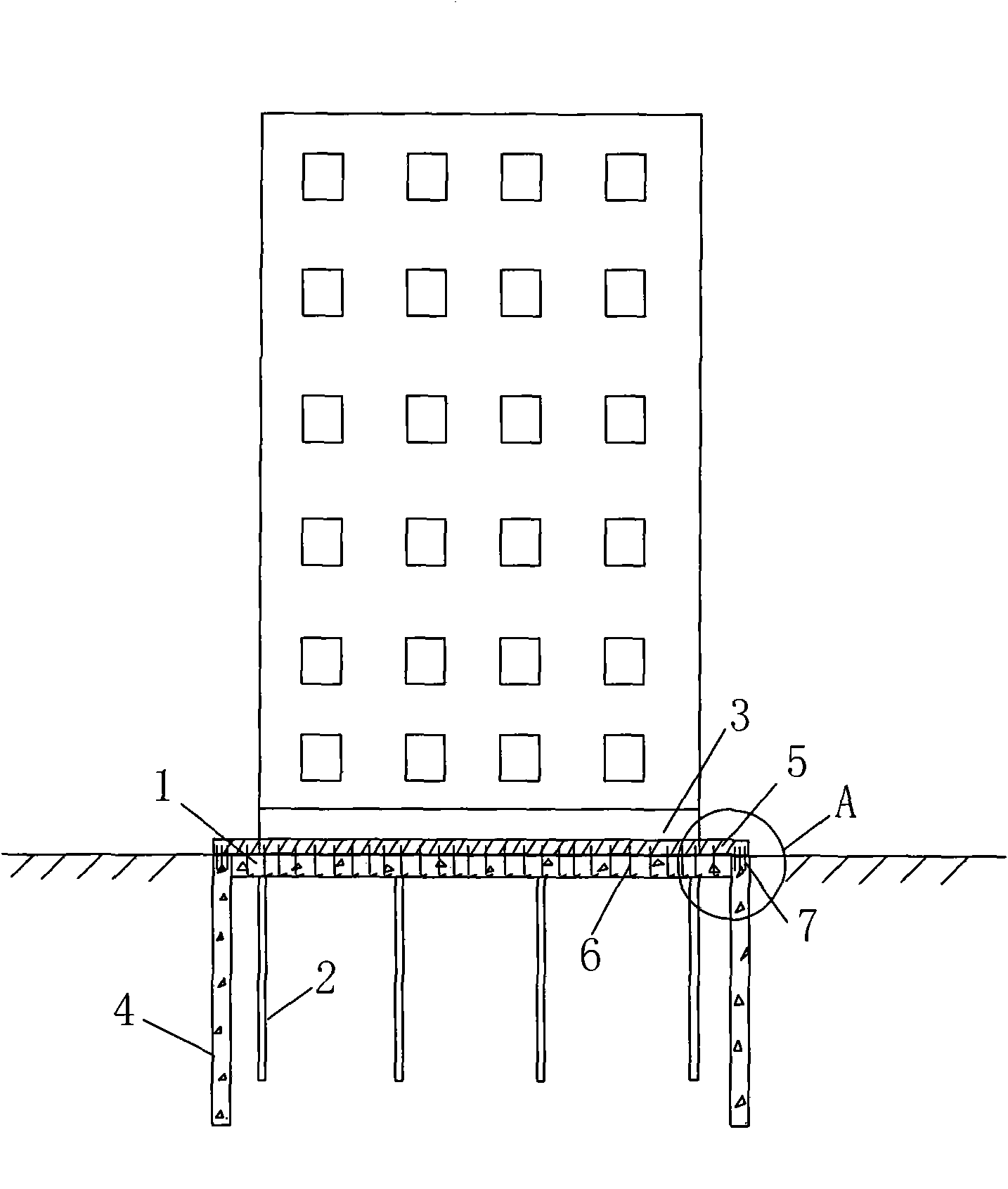

Method for constructing underground garage under old building

ActiveCN102071813AImprove securityReduce construction costsArtificial islandsBuilding repairsSlurry wallSheet pile

The invention relates to a method for constructing an underground garage, which has the characteristics that: structural stability of the original building, high construction speed and low cost are guaranteed. According to a technical scheme, the method for constructing the underground garage under the old building is characterized by comprising the following steps that: a, an underground diaphragm wall or a sheet-pile wall is poured at a position which is at least 1m away from an exterior wall around the building; b, a group of cross beams are poured at the foundation at the bottom of an overhead layer of the building, and the cross beams are integrally connected with foundation soil, the underground diaphragm wall or the sheet-pile wall to support the building; c, underground space is dug below the foundation soil of the building, an entire plate foundation layer is poured at the bottom of the underground space, and the entire plate foundation with underground piles and the underground diaphragm wall or the sheet-pile wall are integrally connected; d, a part of the underground piles are cut off between the foundation soil and the entire plate foundation and the rest underground piles are reinforced; and e, a slope is arranged on the ground and the slope is communicated with the underground space to be served as a passage for entrance and exit of vehicles.

Owner:GEOTECHN TECH

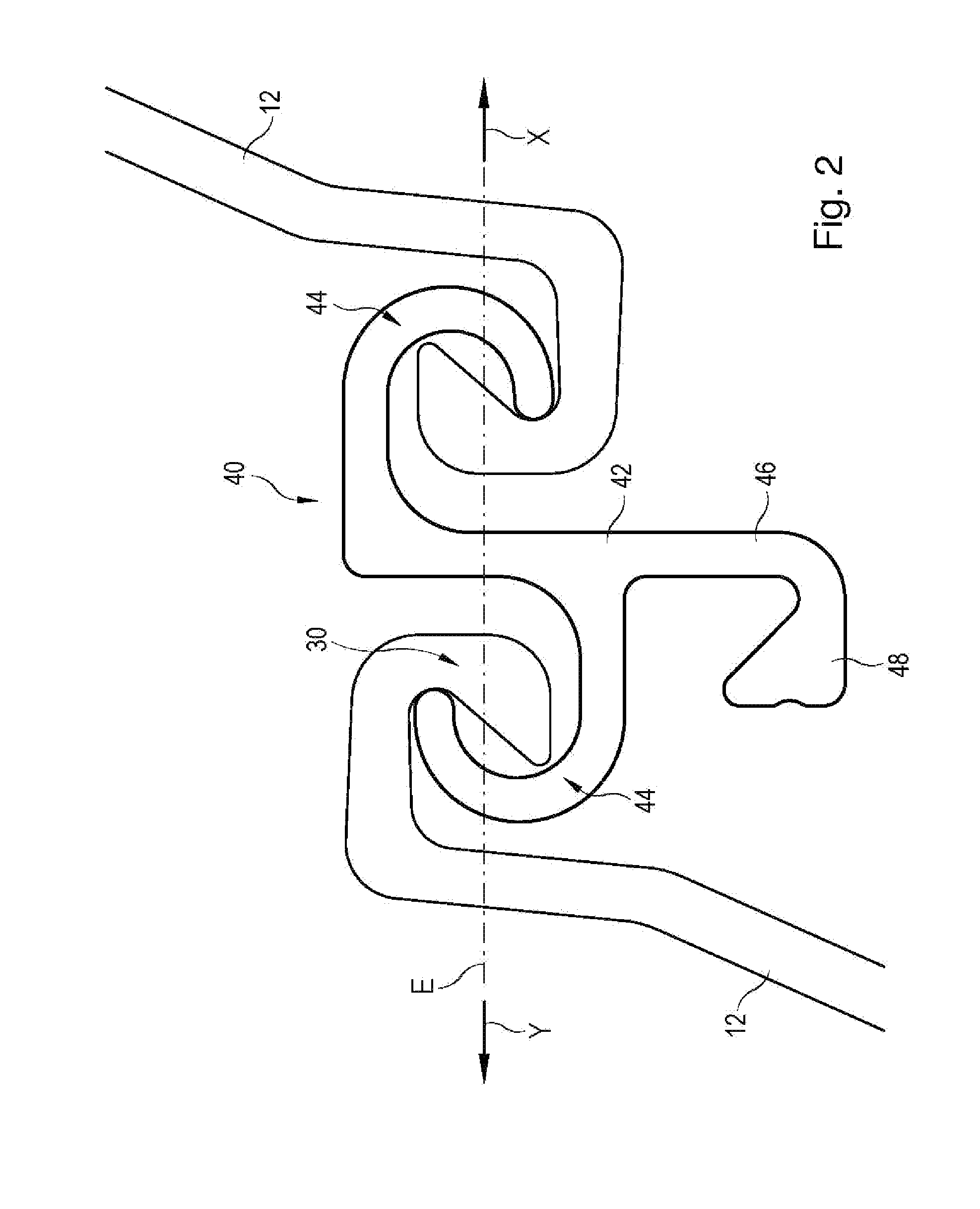

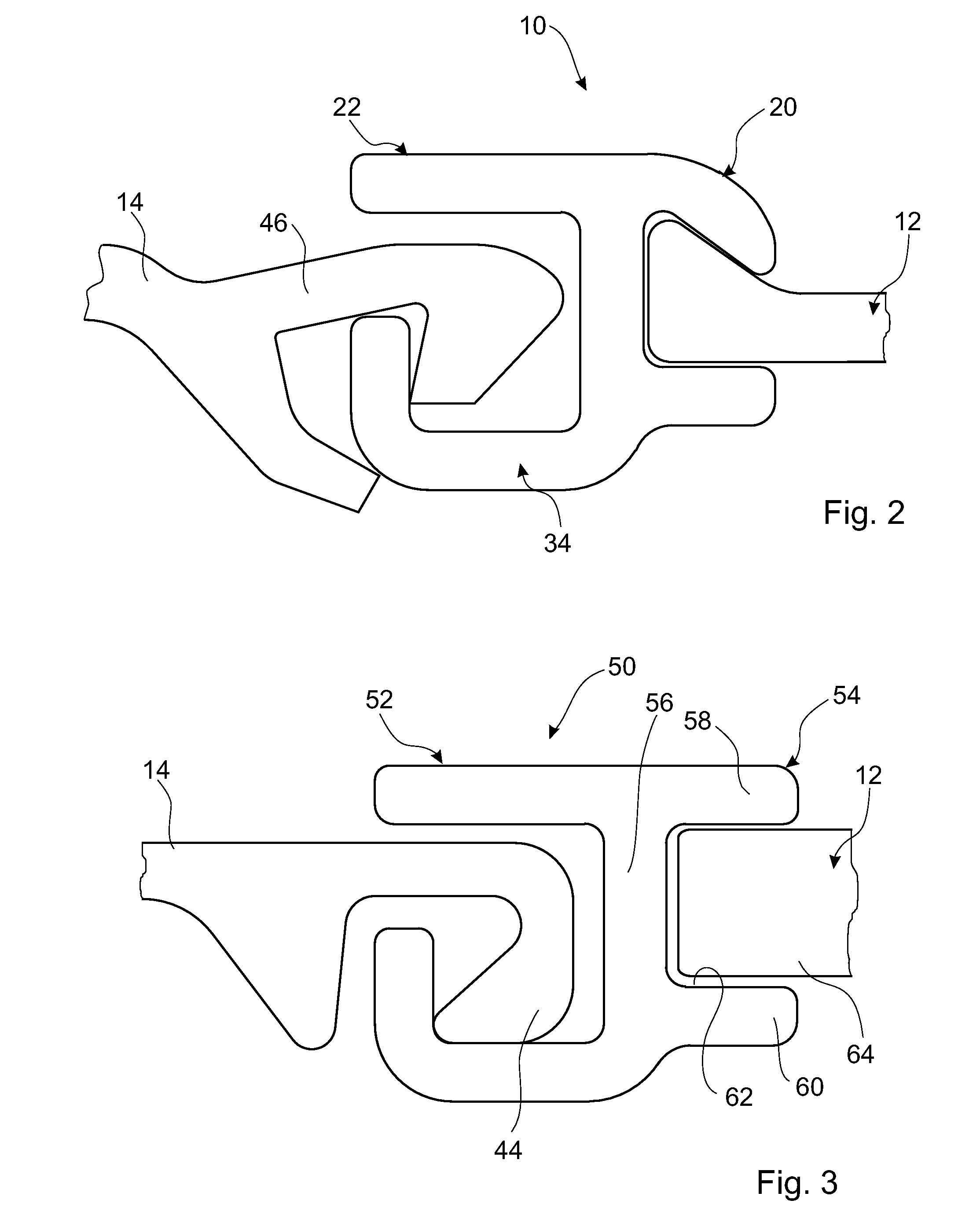

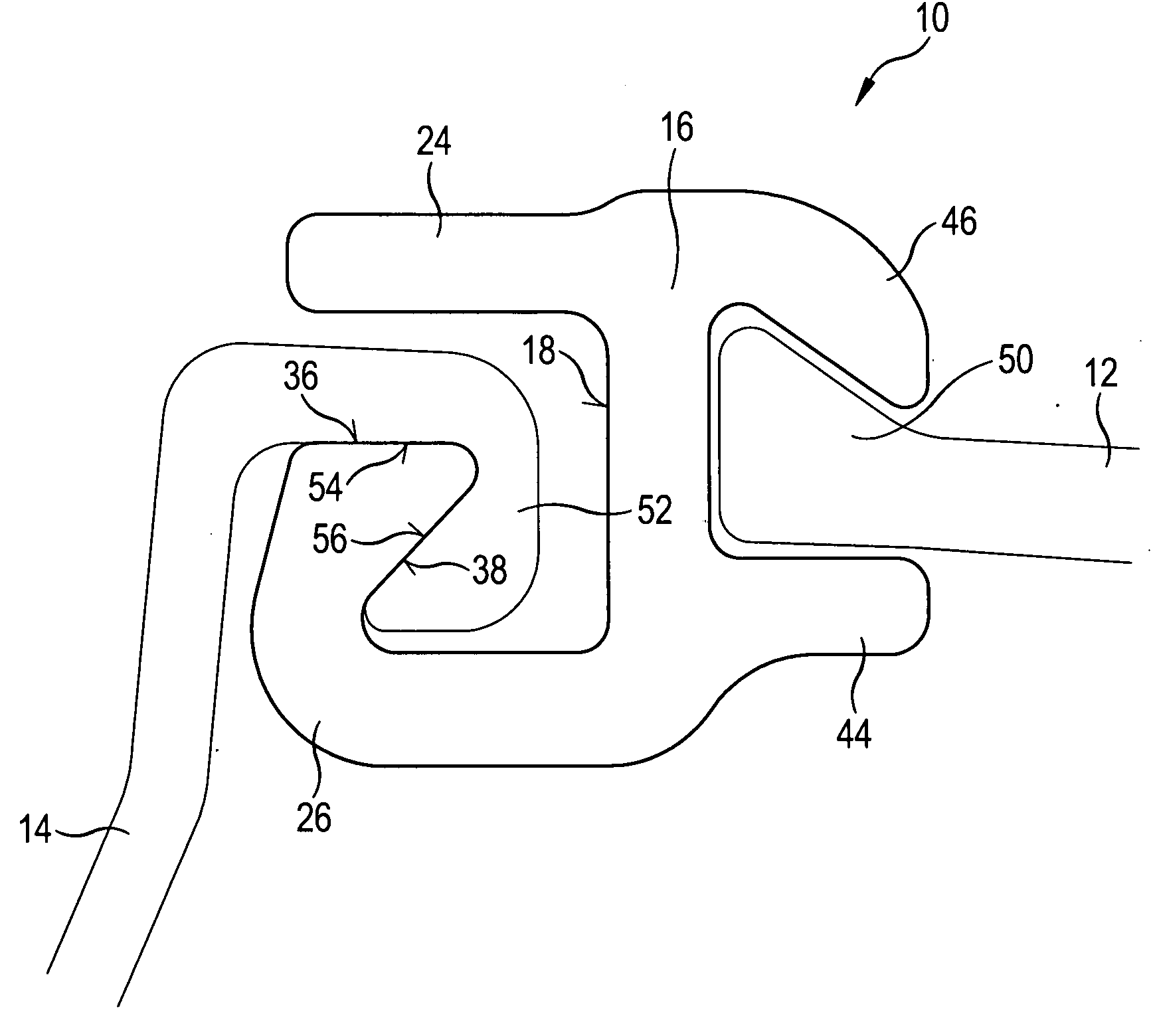

Connector for connecting sheet piles

InactiveUS20080152435A1Simple pre-assemblySufficient swivel movementSnap fastenersClothes buttonsCouplingEngineering

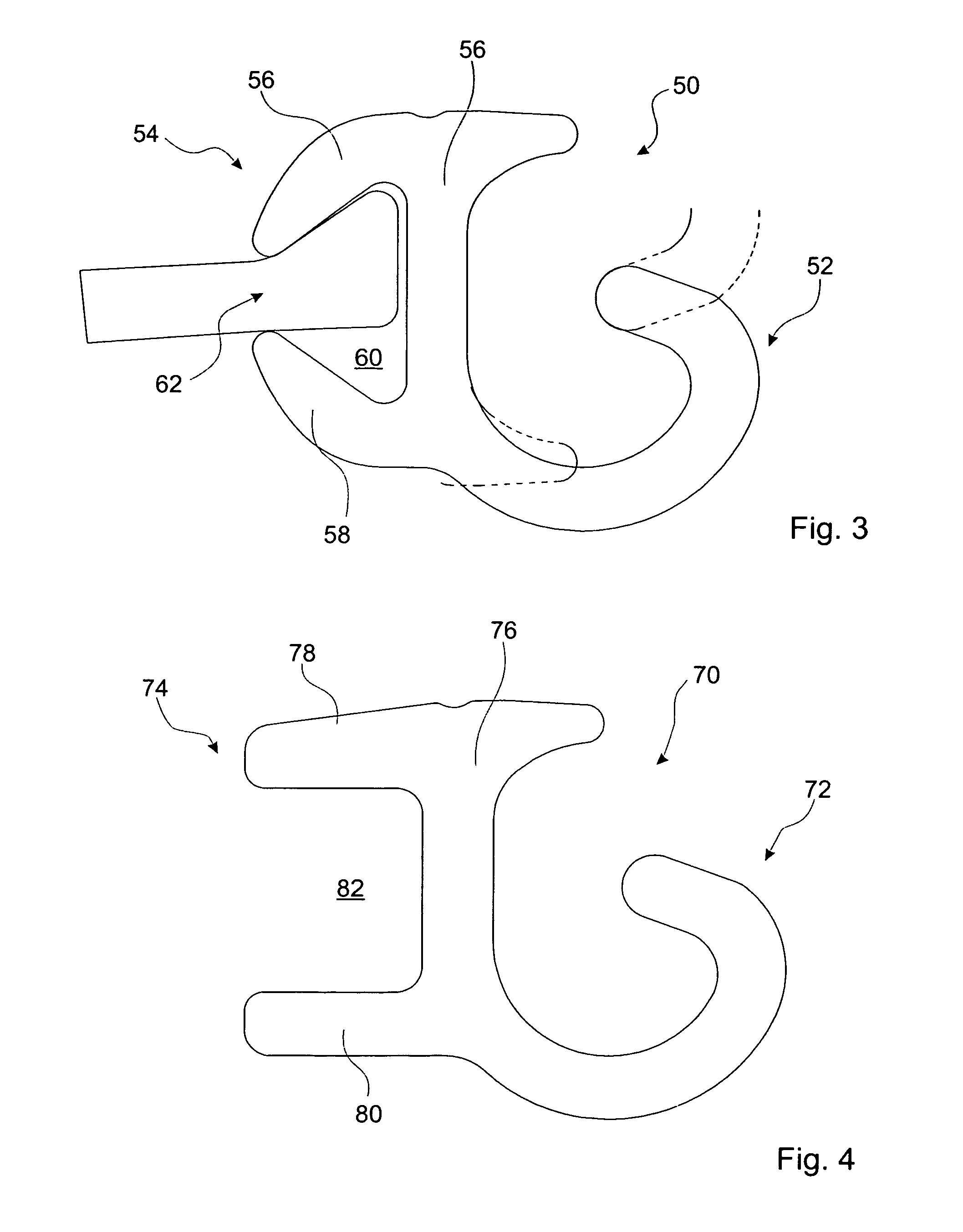

A connecting profile of substantially uniform cross-section for interconnecting sheet piles. The connecting profile includes a central strip, from which two identical hooked profiles for hooking the locks of two sheet piles in a laterally reversed manner project in opposing main coupling directions. The hooked sections of the hooked profiles extend in a mirror-inverted manner in relation to each other. The two hooked profiles are offset relative to each other on the central strip in such a way that the main coupling directions of the sheet piles hooked into the connecting profile extend at least approximately in a common plane, when the locks engaged with the hooked sections take up the largest axial distance along the main coupling directions in relation to each other.

Owner:SHEET PILE LLC

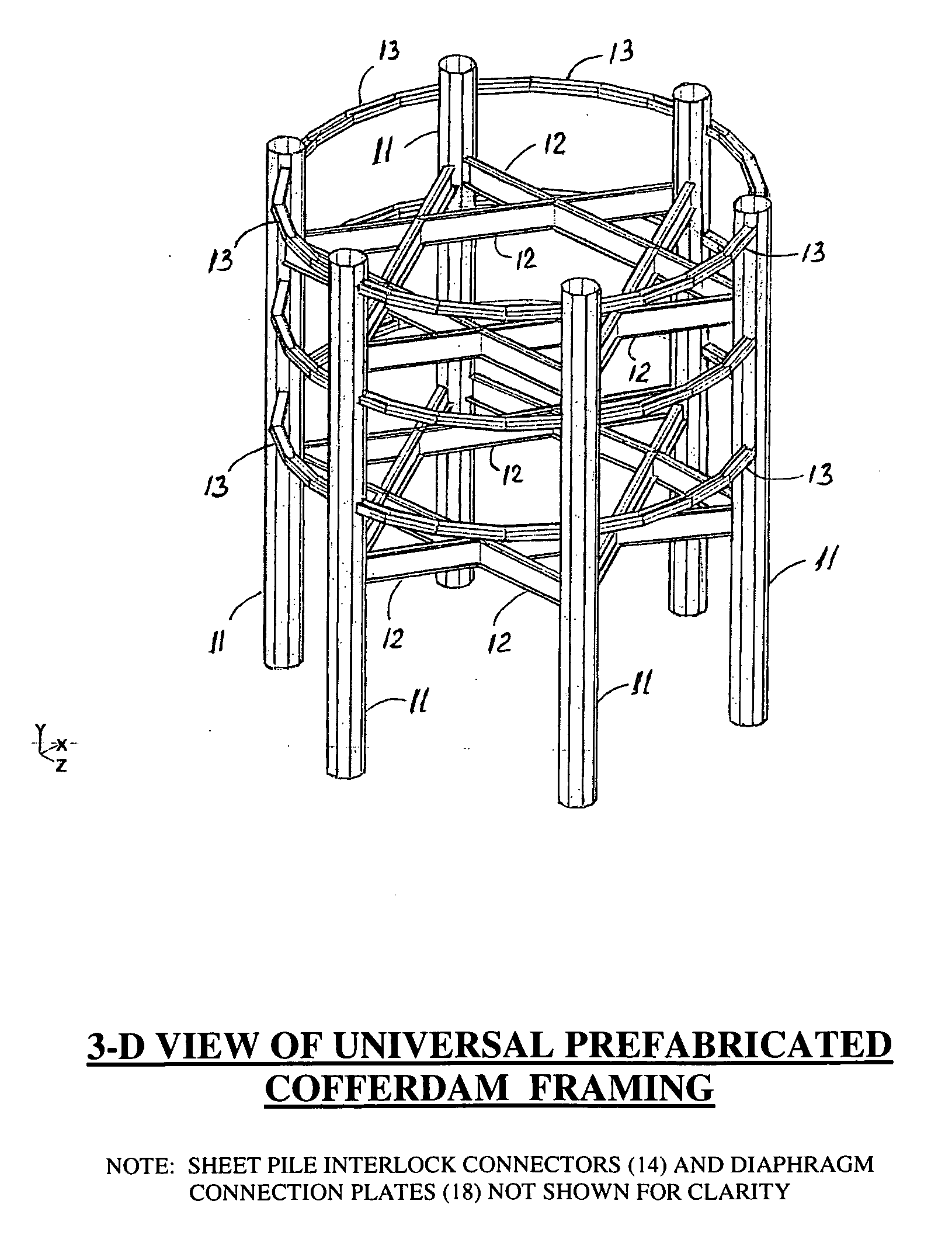

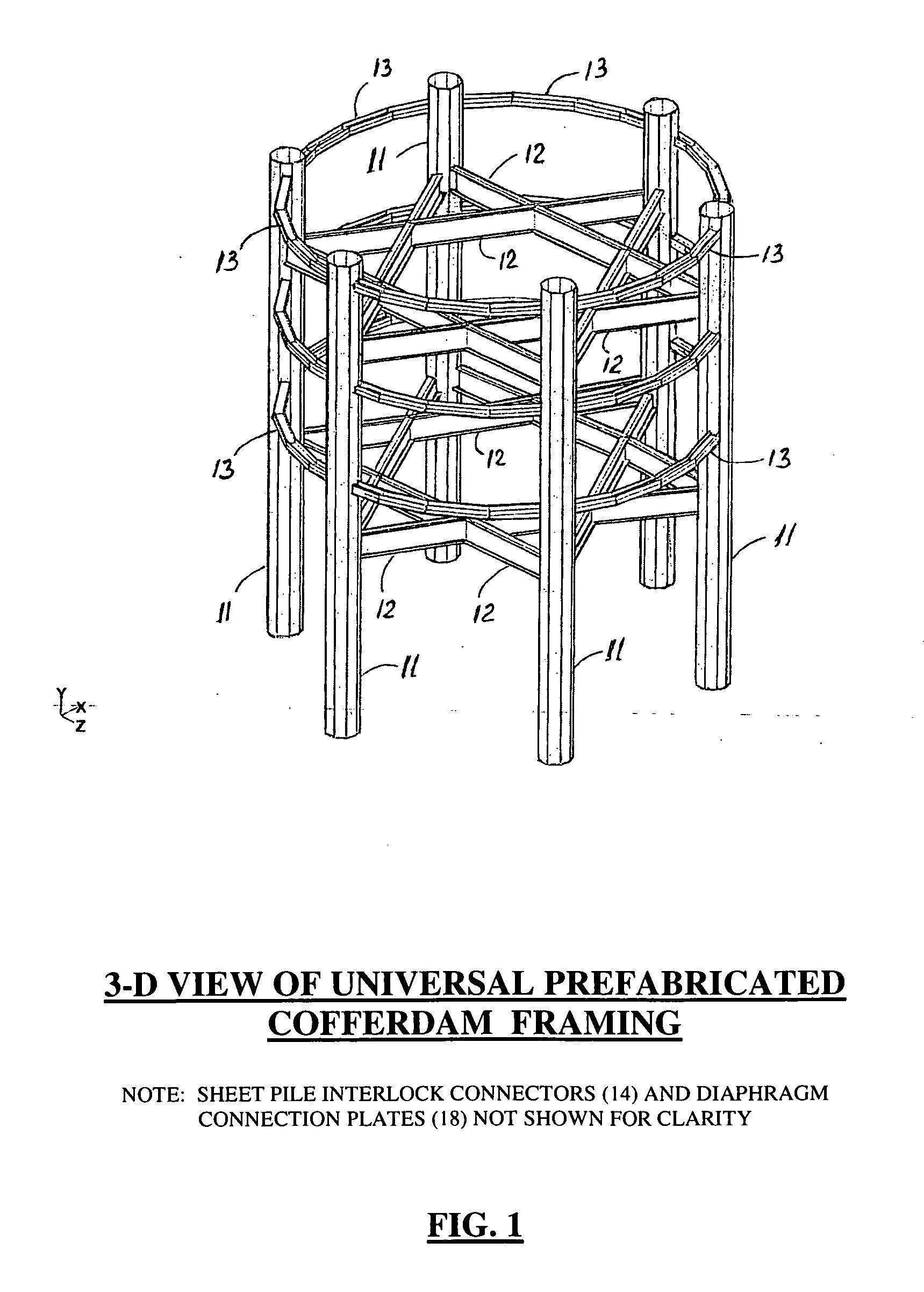

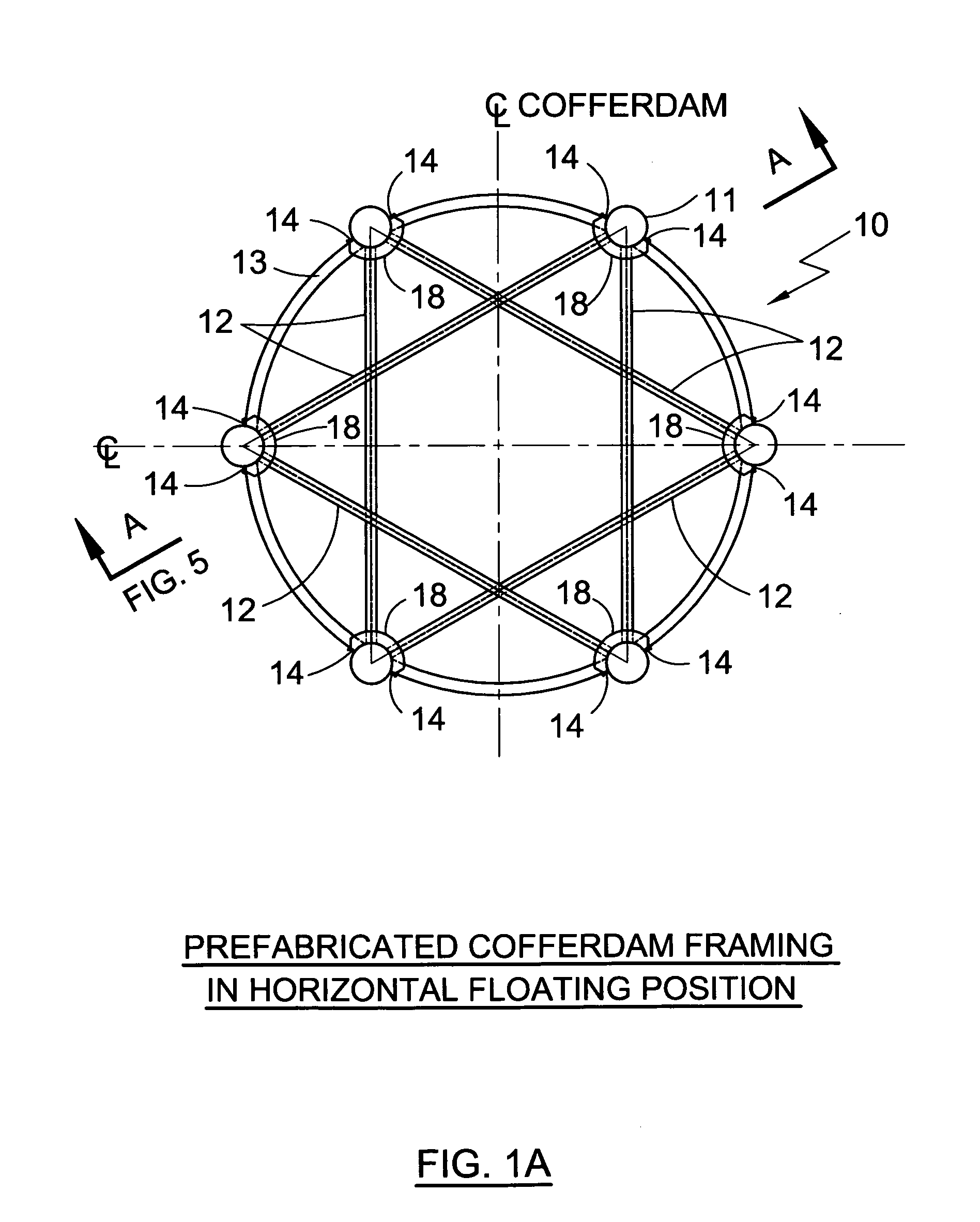

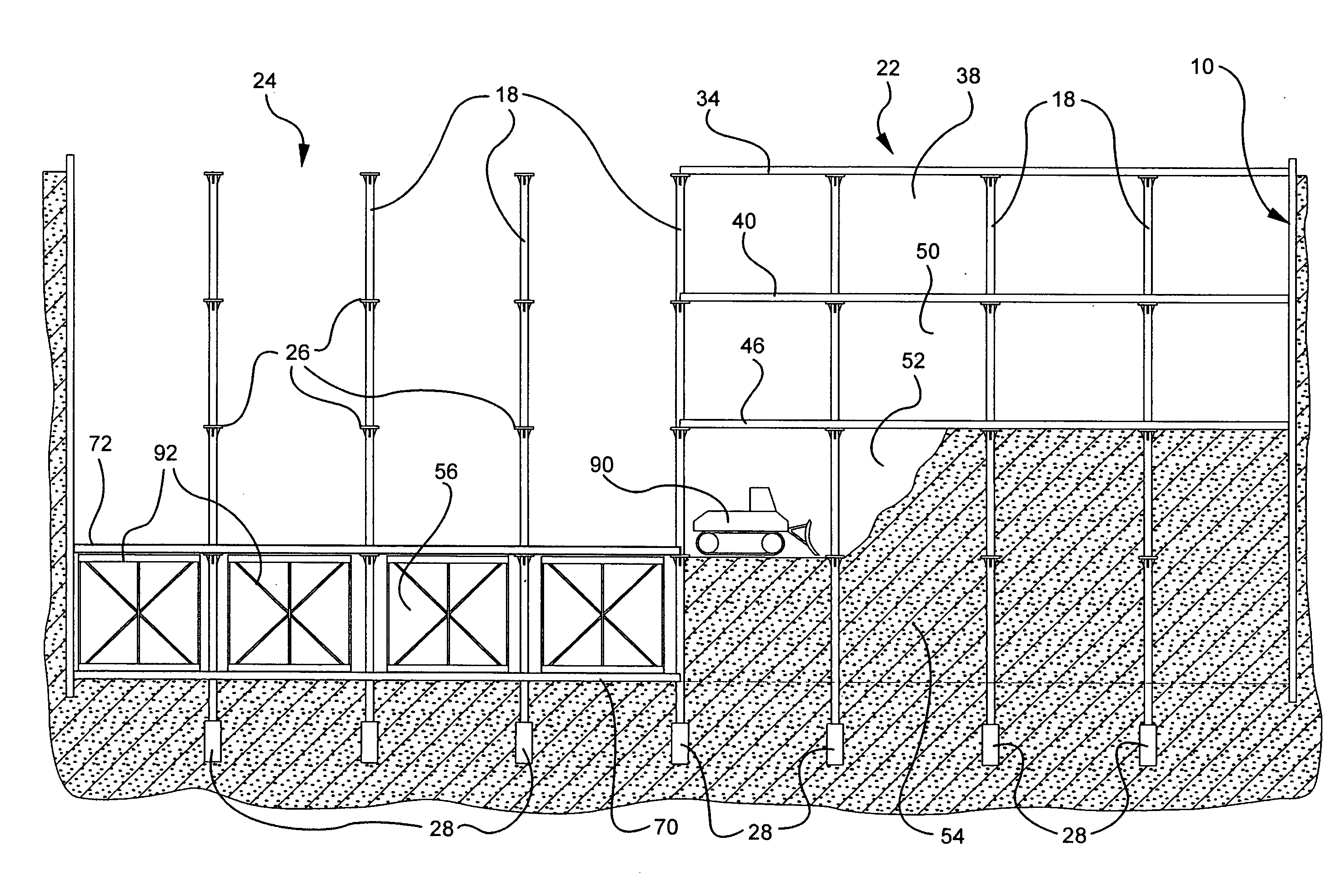

Universal Framed Cofferdam

Universal Framed Cofferdam has prefabricated skeletal steel space framing formed from multiple steel vertical pipes and two levels of horizontal diaphragm trusses rigidly connected to pipe columns. Beams of each diaphragm truss are attached to vertical pipes of the framing with rigid moment connections creating a rigid space frame of the perfectly round form that is used as a false work of the Cofferdam. Wales of the Cofferdam and short pieces of the flat sheet piling are attached to the vertical pipes forming a skeleton of the Cellular structure. The Skeleton of the Universal Framed Cofferdam is prefabricated in the convenience of the Dry Dock and than floated to the site. Buoyancy of the framing allows Cofferdam skeleton transportation without using the barge or otherwise necessary floating devices. Once brought to the site of installation Cofferdam skeleton is installed vertically in position and leveled on the bottom of the river bed. If necessary river silt can be jetted and pumped out of pipe annular space and pipe columns of framing can be simultaneously lowered in position by using vibro—hummer. After space framing installation, rock sockets are predrilled through the annular space of vertical pipes and rock anchors installed. Sheet pile skin of the Cofferdam installed between pipe columns concludes Cofferdam Can erection. Universal Framed Cofferdam Can than filled with compacted gravel and becomes a Hybrid Gravity Caisson / Columnar water front or marine structure that has the best features of the Conventional Cellular Cofferdam and of Columnar Dolphin structure. It has enhanced sliding and overturning stability provided by Rock anchors preloaded by Cofferdam granular fill and has effective mechanism that prevents concave or convex surface of rupture failure that may be suffered by conventional Cellular Cofferdams, and has mechanism that more effectively resists deep surface sliding failure of the Cofferdam base.

Owner:FEYGIN VITAL BORIS +1

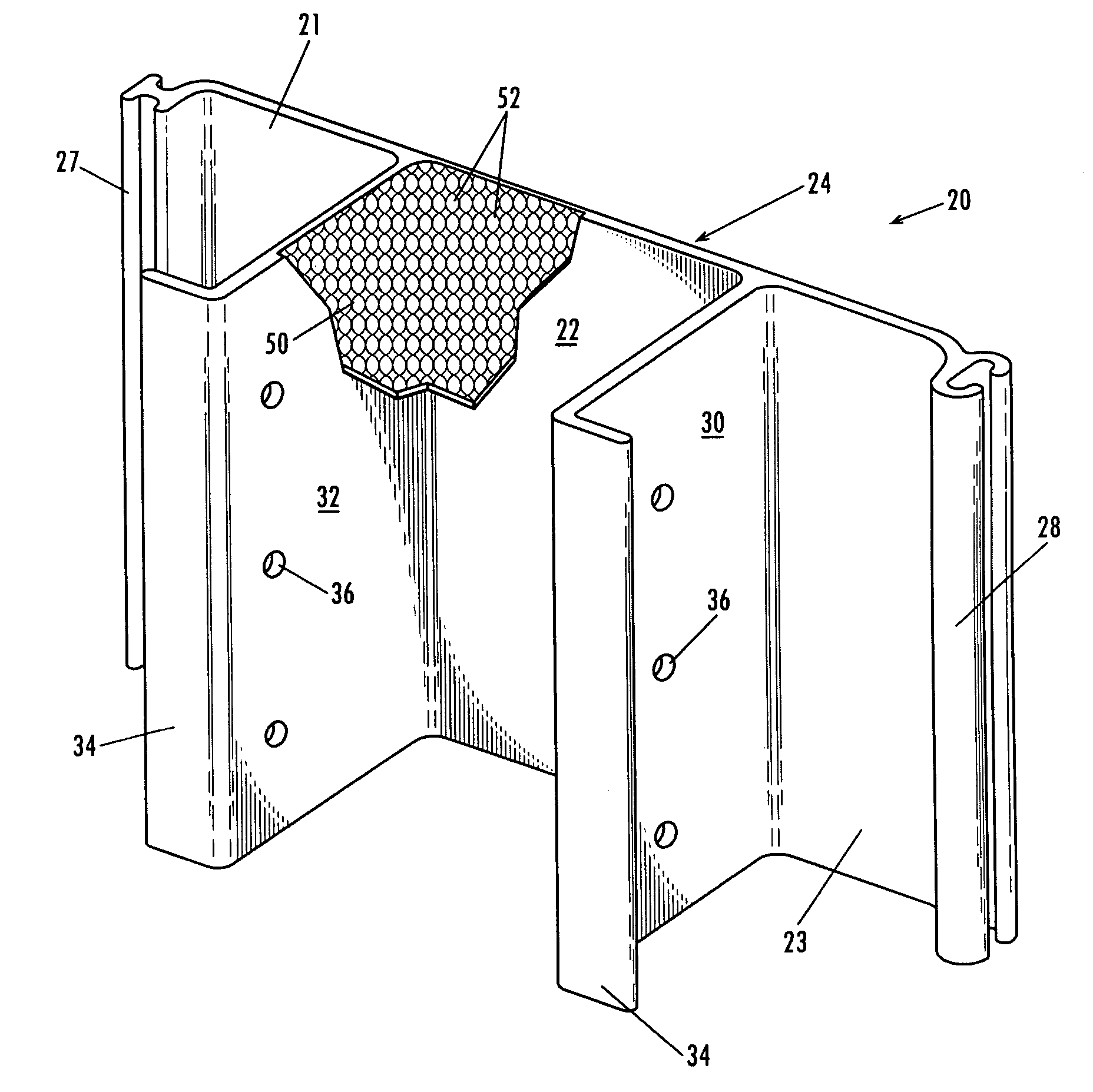

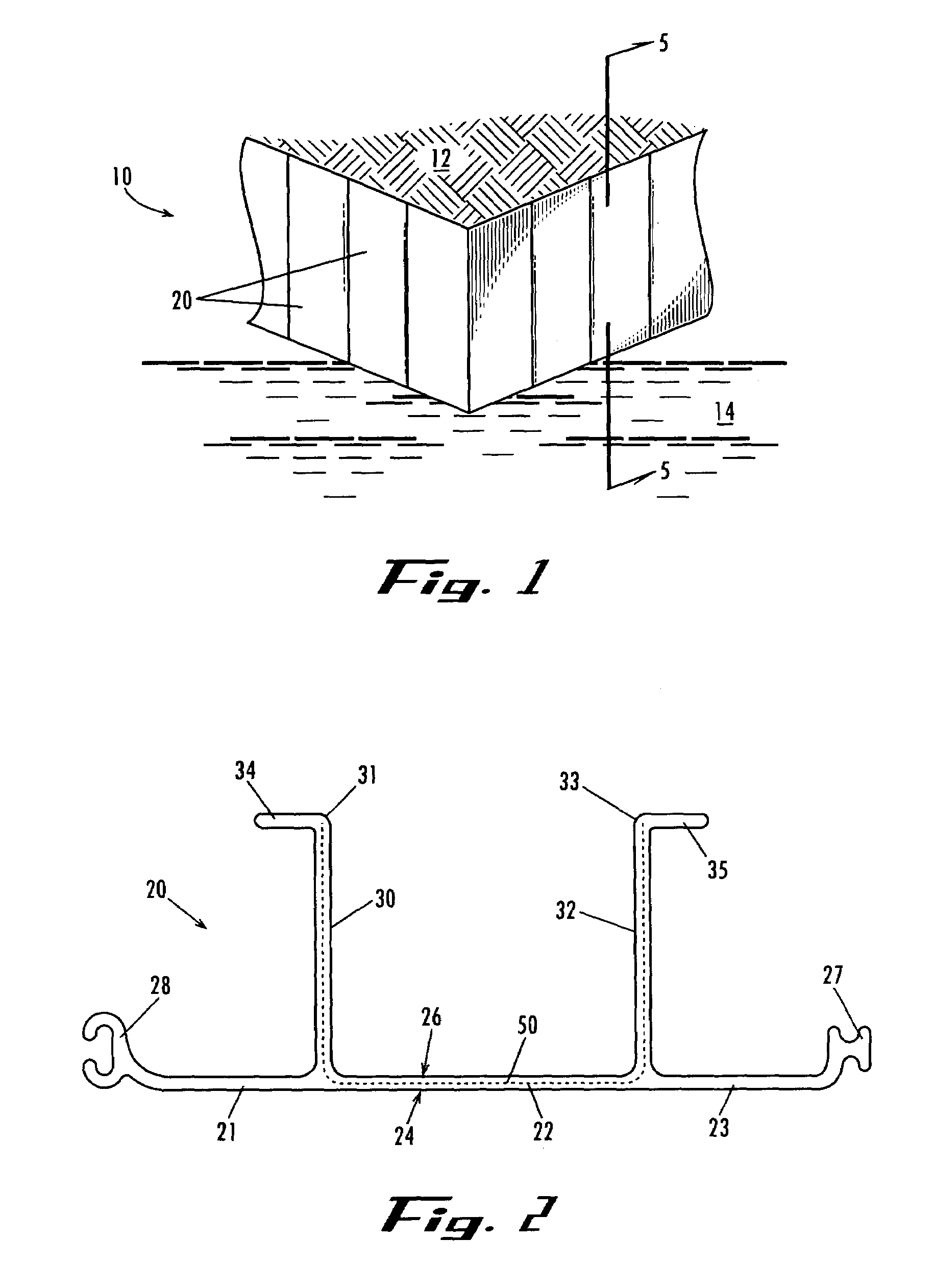

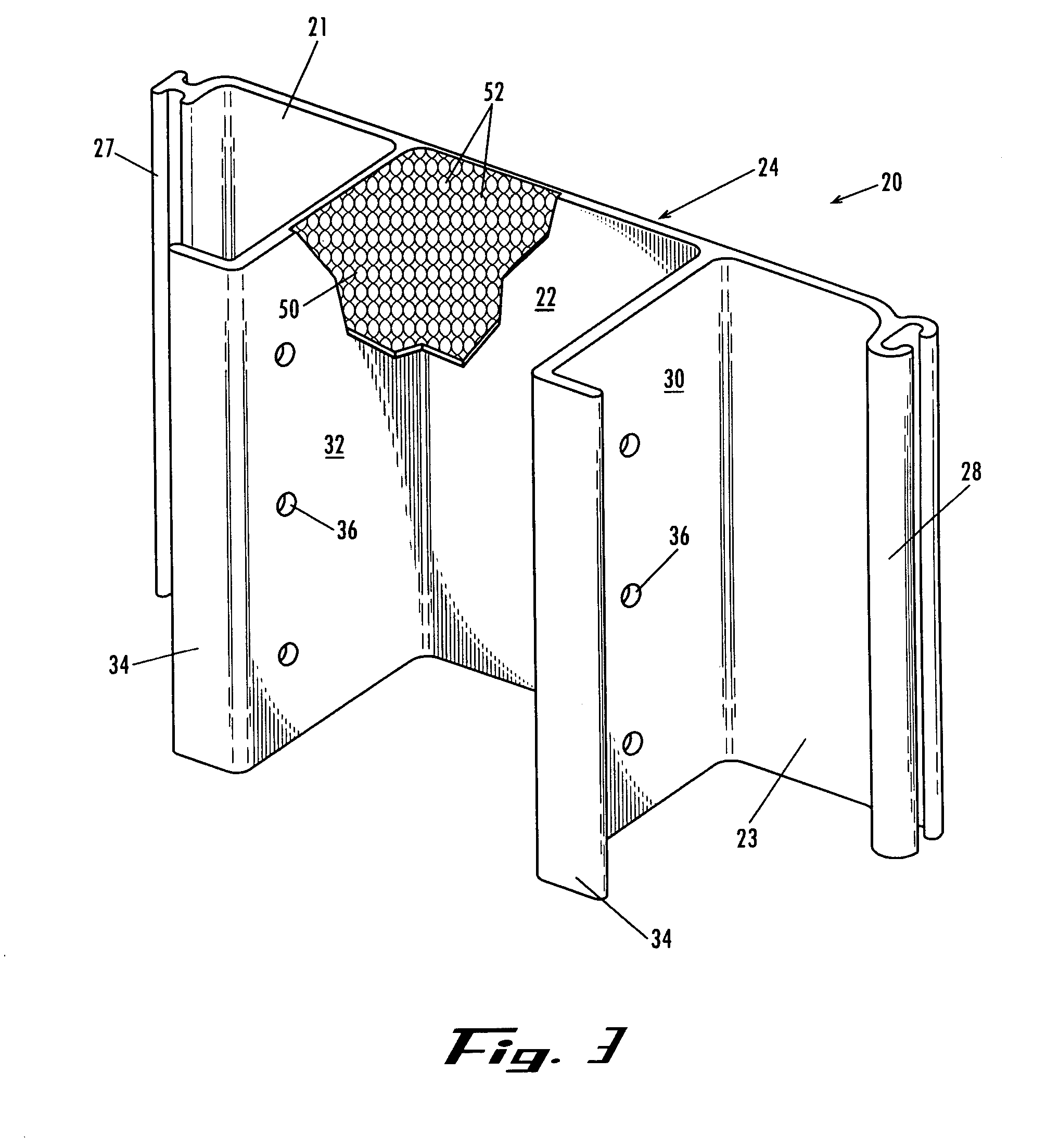

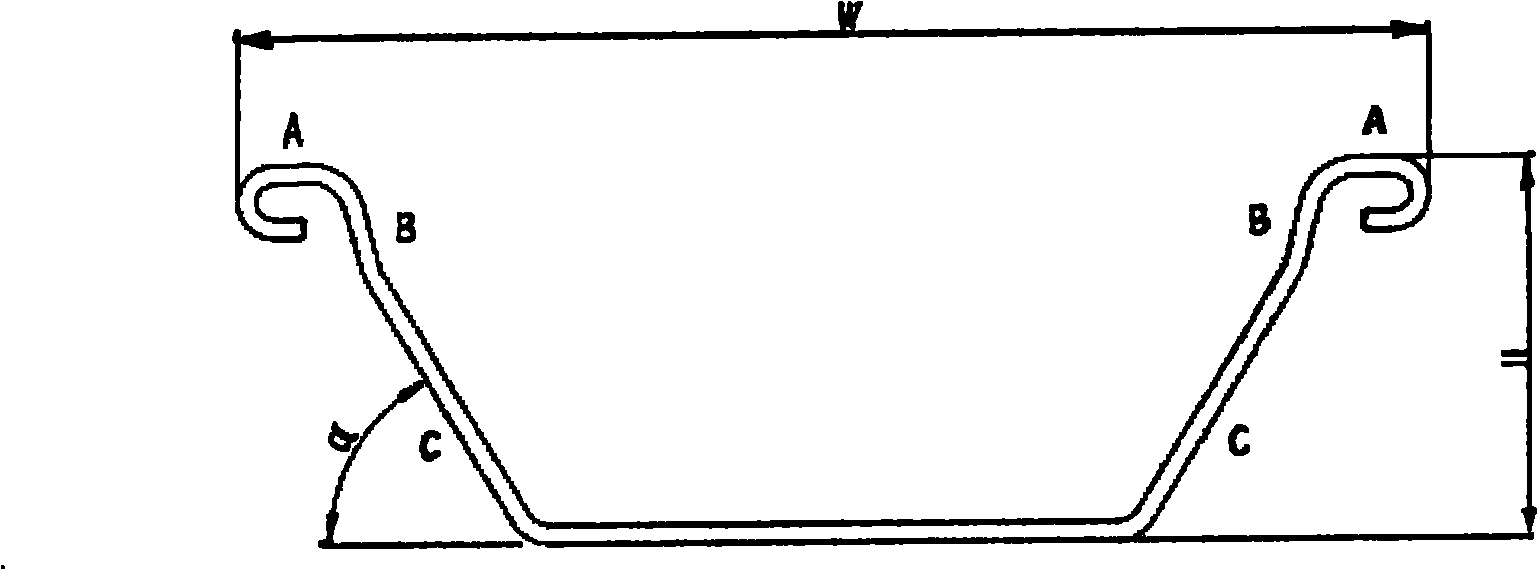

Sheet pile for forming barrier walls

A series of duplicate structural panels form a substantially flat sea wall, barrier wall, and the like, fabricated of synthetic resin material for driving into soils. The structural panel is elongated and of constant size and shape along its length, and is characterized by having been extruded lengthwise. The structural panel includes, in cross section, a central wall section having an inner surface, an outer surface, and opposed side wall sections. A male locking element is disposed on and extends laterally from one side section and a female locking element is disposed on and extends laterally from the other side wall section, the female locking element being configured to slidably receive and retain the male locking element. First and a second strengthening flanges are integrally formed on the inner surface, both substantially perpendicular to the central wall section and substantially parallel to each other. The first and second strengthening flanges extend along the length of the structural panel.

Owner:CMI CO LTD

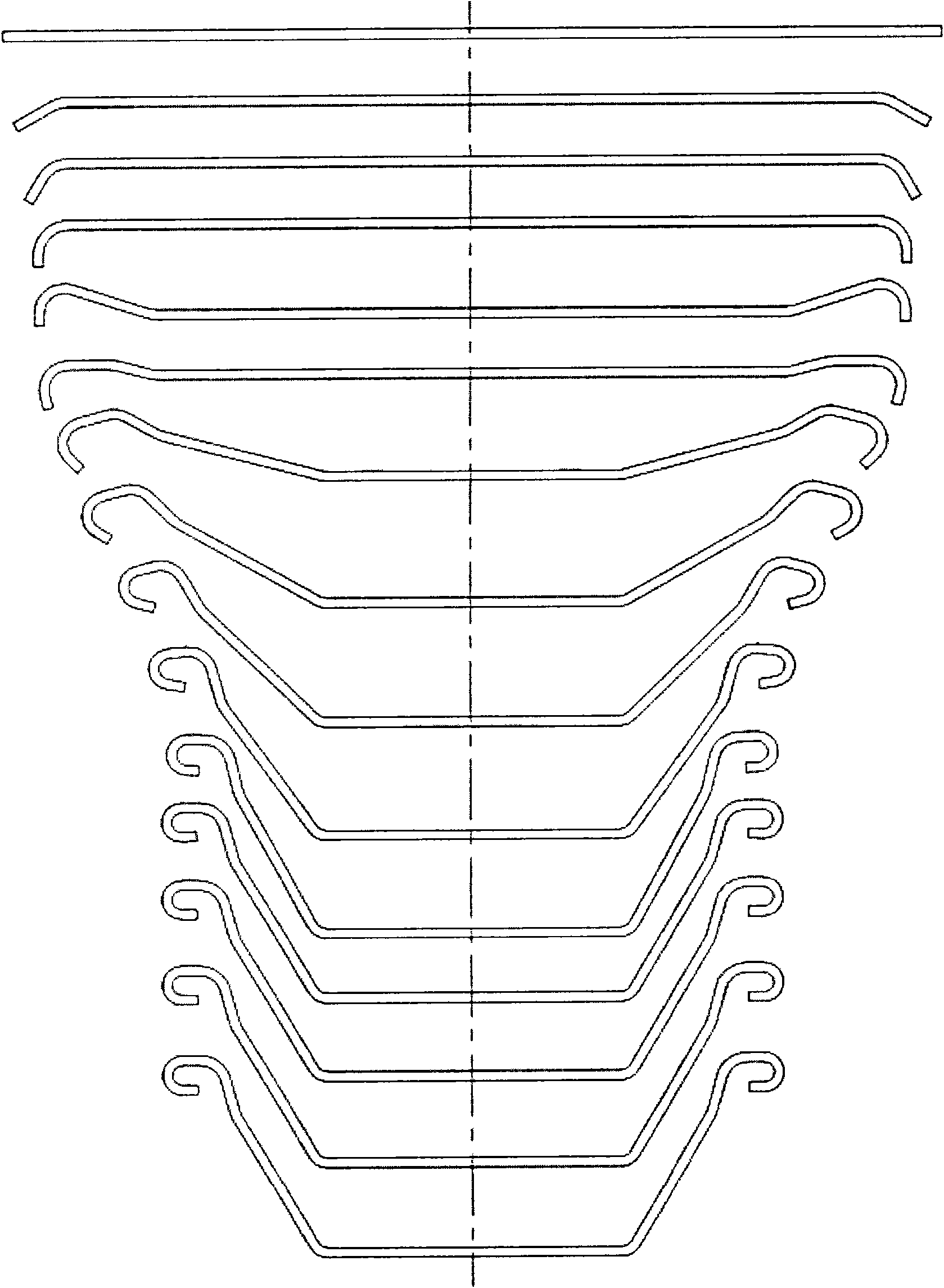

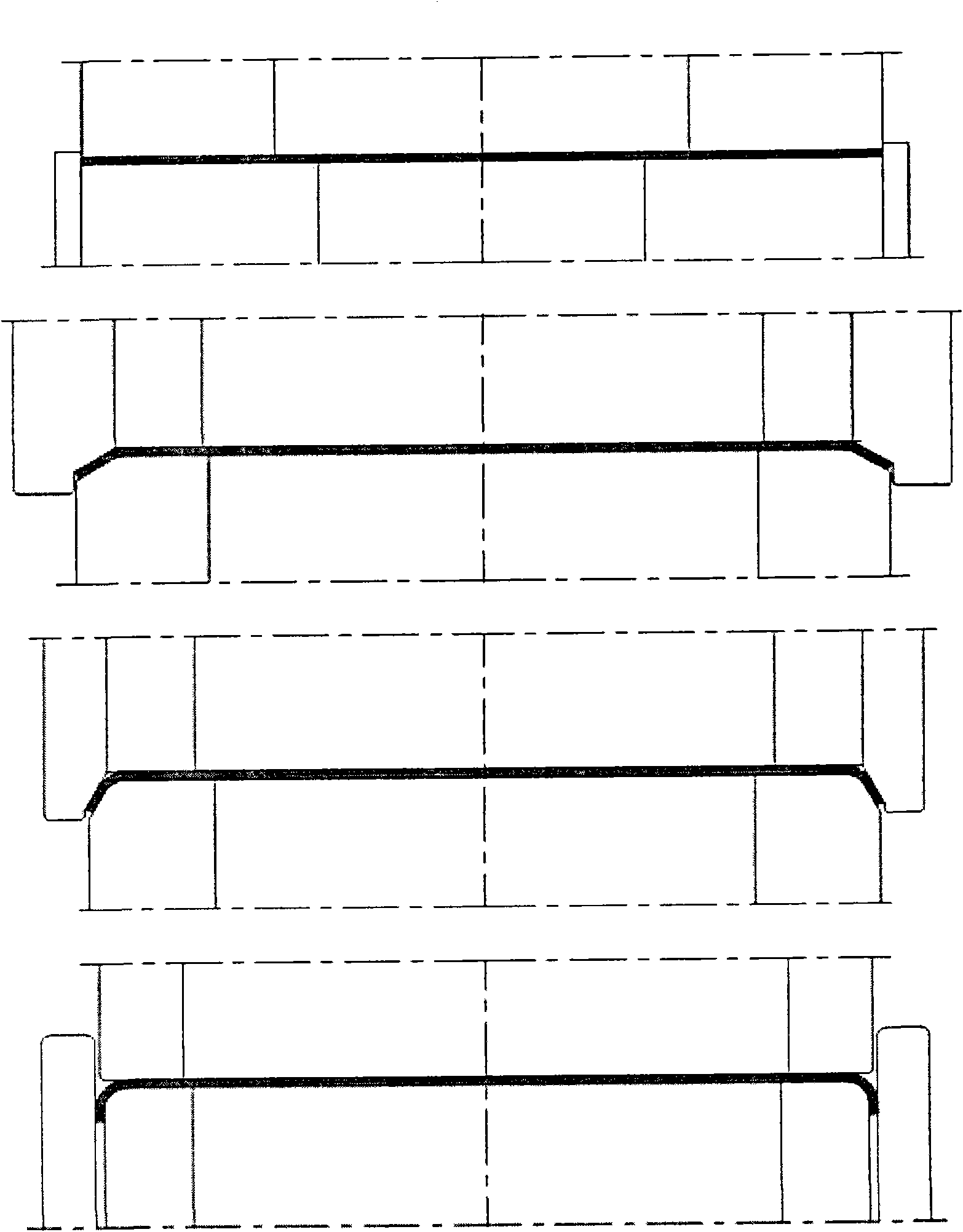

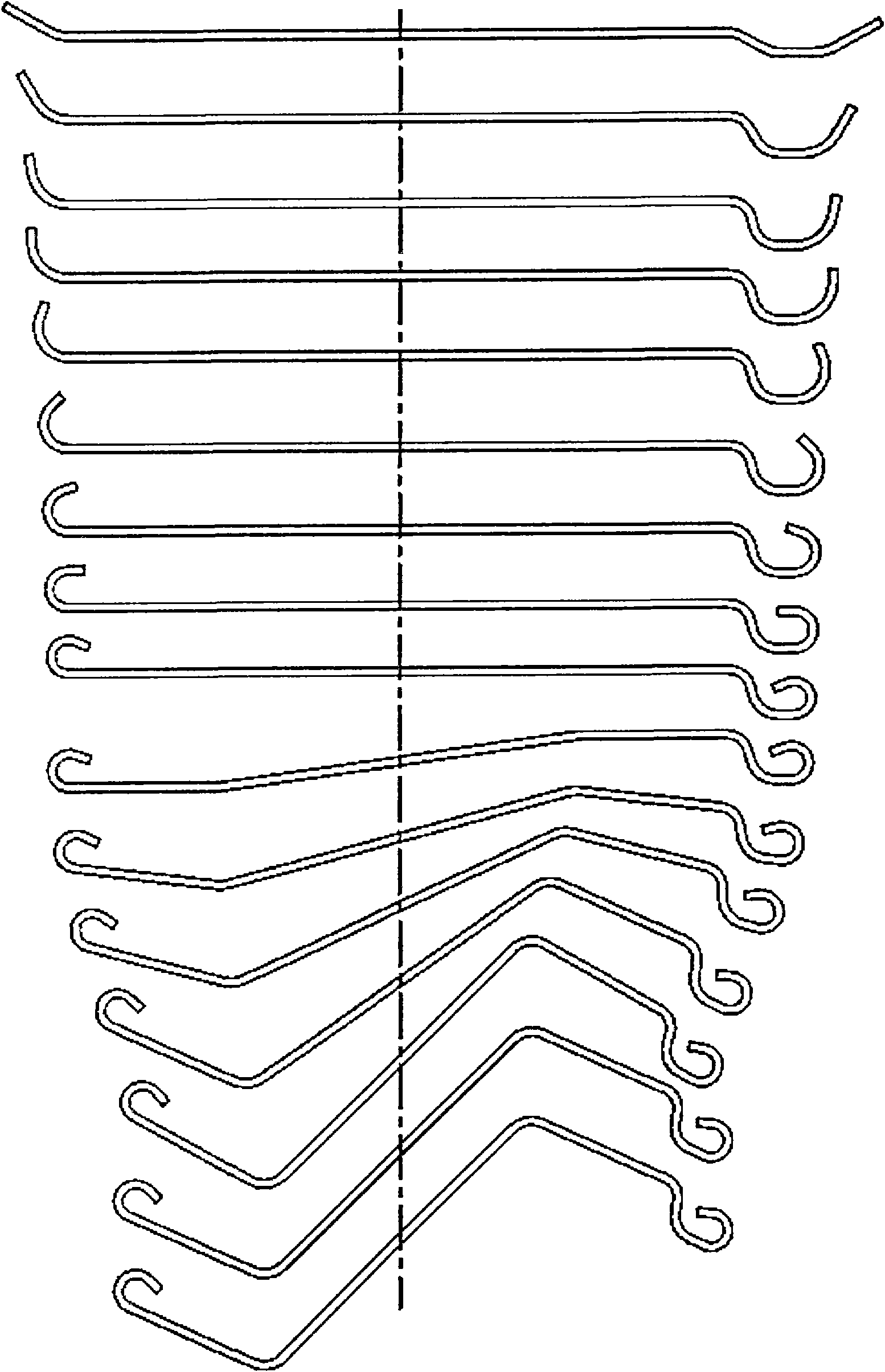

Roll type continuous cold-bending forming fabricating method for U-shaped steel sheet pile

The invention discloses a roll type continuous cold-bending forming fabricating method for a U-shaped steel sheet pile, which comprises the steps of: carrying out continuous rolling and forming by using a cold-bending machine unit and continuously overlapping lateral fore shafts to form a steel structure of sheet pile walls. The process plays an important role in controlling the product quality and improving the mate precision and the connection strength of the fore shafts of the steel sheet pile. The U-shaped steel sheet pile has rich specifications and models, and the most economical and reasonable cross section can be selected according to the actual situation of a project to realize the optimization of engineering design; and compared with a hot rolled steel sheet pile with the same performance, the U-shaped steel sheet pile saves materials of 10% to 15%, which greatly reduces the construction cost.

Owner:NANJING WANHUI STEEL SHEET PILING

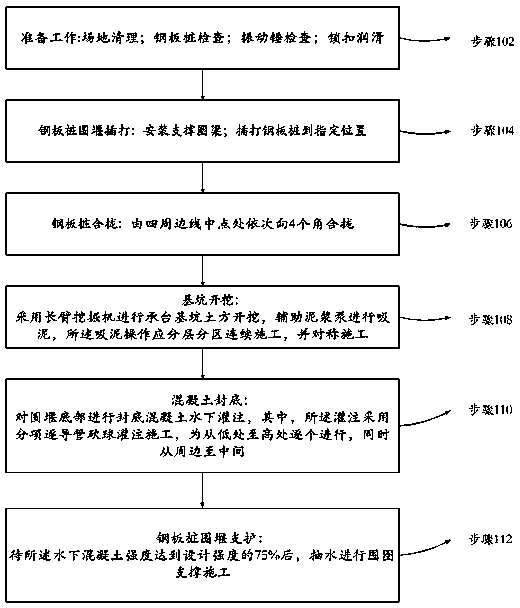

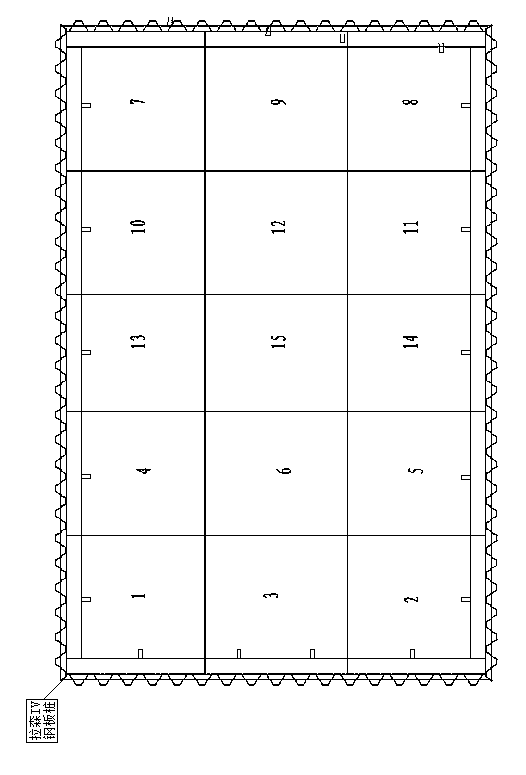

Steel sheet pile cofferdam constructing method

InactiveCN104294835ASafe and fast constructionImprove build qualityBulkheads/pilesUnderwaterCofferdam

The invention relates to the technical field of cofferdam construction, particularly to a steel sheet pile cofferdam constructing method. The method comprises (1) preparation; (2) steel sheet pile plugging and driving including mounting a first support ring beam as a guide frame for pile plugging and driving, during the pile plugging and driving, enabling the backs of steel sheet piles to be close to the guide frame, slowly lowering a lifting hook over the pile plugging and driving to ensure alignment and straightness of the steel sheet piles; (3) steel sheet pile closure including closing the steel sheet piles in the plugging order from the surrounding sides to the four corners; (4) foundation pit digging including performing cap foundation pit earth digging through a high-front shovel, and sucking soil through a mud pump in a layered, partitioned and symmetric mode; (5) concrete ground sealing including performing ground-sealing concrete underwater filling on the bottom of the cofferdam; (6) steel sheet pile cofferdam support including, when the strength of underwater concrete reaches 75% of a design strength, pumping water to achieve wailing support construction.

Owner:SINOHYDRO ENG BUREAU 4 +1

Municipal drainage pipeline construction technology

ActiveCN106978843AImprove securityImprove construction qualitySewer pipelinesArchitectural engineeringSheet pile

The invention discloses a municipal drainage pipeline construction technology. The municipal drainage pipeline construction technology is characterized by comprising the steps of measuring, paying off, piling steel sheet piles, dewatering, digging a furrow, laying a pipeline foundation, laying a pipeline, building an inspection well, conducting a closed water test, refilling the furrow and drawing out the steel sheet piles. The municipal drainage pipeline construction technology has the advantages of improving the construction quality, lowering the construction difficulty, shortening the construction period and improving the surrounding pipeline safety.

Owner:杭州之江市政建设有限公司

Manufacture method of Z-shaped steel sheet pile through continuous cold roll forming

The invention discloses a manufacture method of a Z-shaped steel sheet pile through continuous cold roll forming by continuously rolling and forming with a cold bending unit and distributing preliminary shafts at both sides of a central shaft. Web plates are continuous so as to greatly improve the modulus and the flexible rigidity of a cross section and fully exert the mechanical characteristic of the cross section. The manufacture process takes great effects in aspects, such as controlling the quality of the cold-bent Z-shaped steel sheet pile, improving the matched accuracy and the connection strength of the preliminary shafts of the steel sheet pile, and the like. The invention controls the product size and overcomes the defects generated in the processing process by performing the preliminary shafts of the cold-bent Z-shaped steel sheet pile and wholly forming the Z-shaped steel sheet pile.

Owner:NANJING WANHUI STEEL SHEET PILING

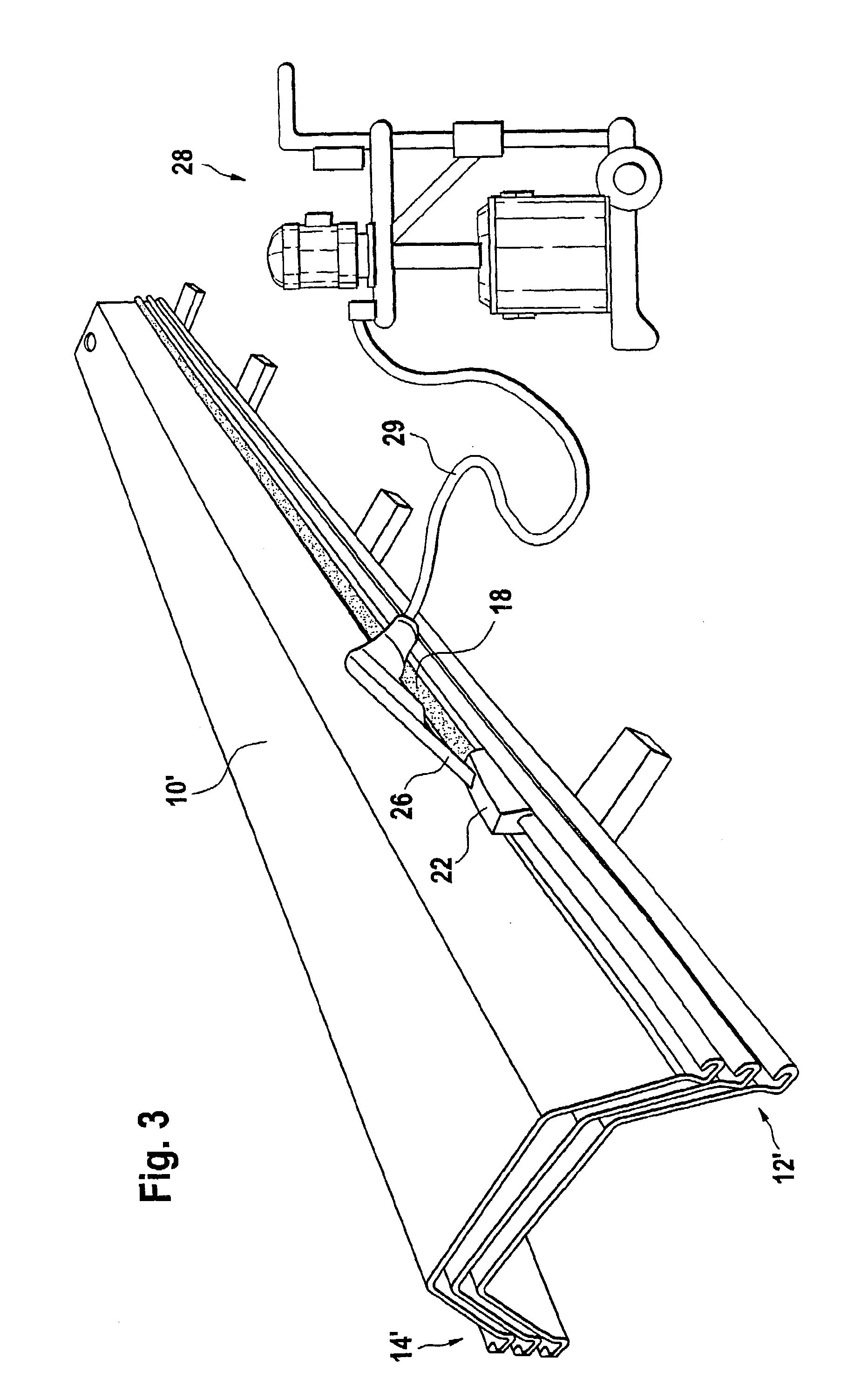

Method of construction using sheet piling sections

ActiveUS20070264087A1Minimize amount of timeArtificial islandsUnderground chambersEngineeringSheet pile

Owner:ARCELORMITTAL COMML RPS SRL

Continuous roller type cold bending shaping method for metal sheet pile

The invention relates to a continuous roll type cold-bending forming method for a steel sheet pile, including scrolling, continuous cold-bending forming and cutting; the method is characterized in that the continuous cold-bending forming refers to that the scrolled steel band is fed into a production line of a multi-pass continuous roll type cold-bending forming machine set for multi-pass continuous roll type cold-bending forming, a frame at each pass is provided with an upper rotation axis and a lower rotation axis which are equipped with inosculated dies, the upper rotation axis and the lower rotation axis rotate oppositely, one rotates along the clockwise direction, while the other rotates along anticlockwise direction; in this way, a scrolled steel plate moves forwards depending on friction force in the roll gap of rotation dies inosculated up and down after being well adjusted and enters the next pass for continue forming, when entering each pass for forming, the steel plate is forced to deform under the action of the inosculated dies, each pass completes setting forming amount, and the forming of the steel sheet pile is finally completed through a plurality of passes, thus rolling the products of the steel sheet pile in line with requirements. The method has the advantages of energy saving, environmental protection, high production efficiency and complete specification, length and size of products.

Owner:江苏顺力冷弯型钢实业有限公司

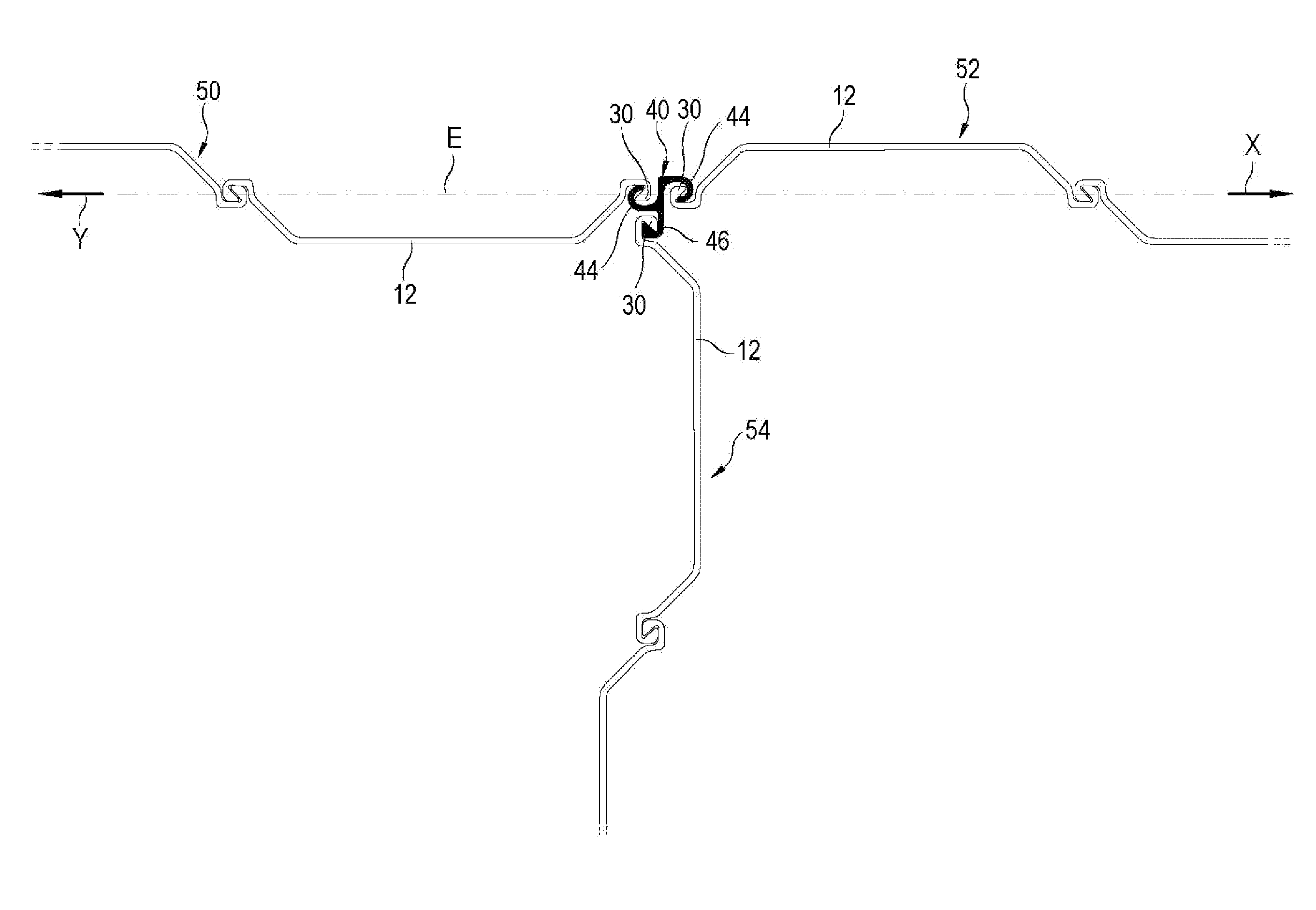

Connecting profile for connecting sheet piles to carrier elements and combined sheet pile wall comprising such a connecting profile

A connecting profile of constant cross section that couples sheet piles to carrier elements. The connecting profile exhibits a center strip, on which a coupling profile, which is to be connected to the carrier element, and an interlock profile for hooking an interlock of the sheet pile are formed. The interlock profile exhibits a supporting strip projecting from the center strip and a hook strip projecting from the center strip. The supporting strip projects at least approximately at a right angle from the center strip. The hook strip exhibits a transition section projecting at least approximately at a right angle from the center strip, and a hook section, which runs at least approximately at a right angle to the transition section in the direction of the supporting strip and which defines with the supporting strip a jaw for inserting the interlock of the sheet pile.

Owner:SHEET PILE LLC

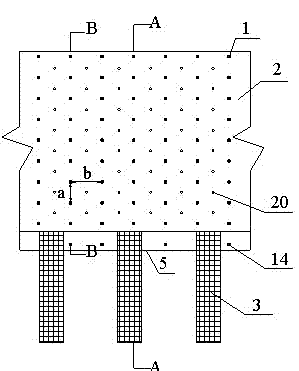

Anchor rod sheet pile combined structure and method for reinforcing high filling body on one side of slope

InactiveCN102352632AImprove frictional connection abilityAvoid disturbanceArtificial islandsExcavationsSurface layerStructural engineering

The invention discloses an anchor rod sheet pile combined structure and a method for reinforcing a high filling body on one side of a slope. The anchor rod sheet pile combined structure comprises an anchor rod (1), a concrete baffle (2) and a foundation pile (3), wherein the anchor rod (1) passes through a slope surface layer covering layer (6) to be connected with a stable bed rock (8) in a pouring slurry mode; an anchor head (9) of the anchor rod (1) is connected with the concrete baffle (2); the foundation pile (3) penetrates the stable bed rock (8) and is connected with the bottom of the concrete baffle (2); the part, in a filling body (4), of a rod body (11) of the anchor rod (1) is welded with short rods (10); the short rods (10) are arranged vertically and horizontally at intervals; the short rods (10) in the horizontal direction are welded and arranged on the upper part and the lower part of the rod body (11) at intervals; and the short rods (10) in the vertical direction are arranged on two sides of the rod body (11) at intervals. By the invention, the friction connecting capacity of the filling body and the anchor rod is greatly improved; the concrete baffle and the foundation pile are combined to form a stable and reliable system for retaining and reinforcing the high filling body on one side of the slope; the central height of the stable retaining filling body can reach 20 to 30 m; the manufacturing cost is low; and the application range is wide.

Owner:CHONGQING UNIV

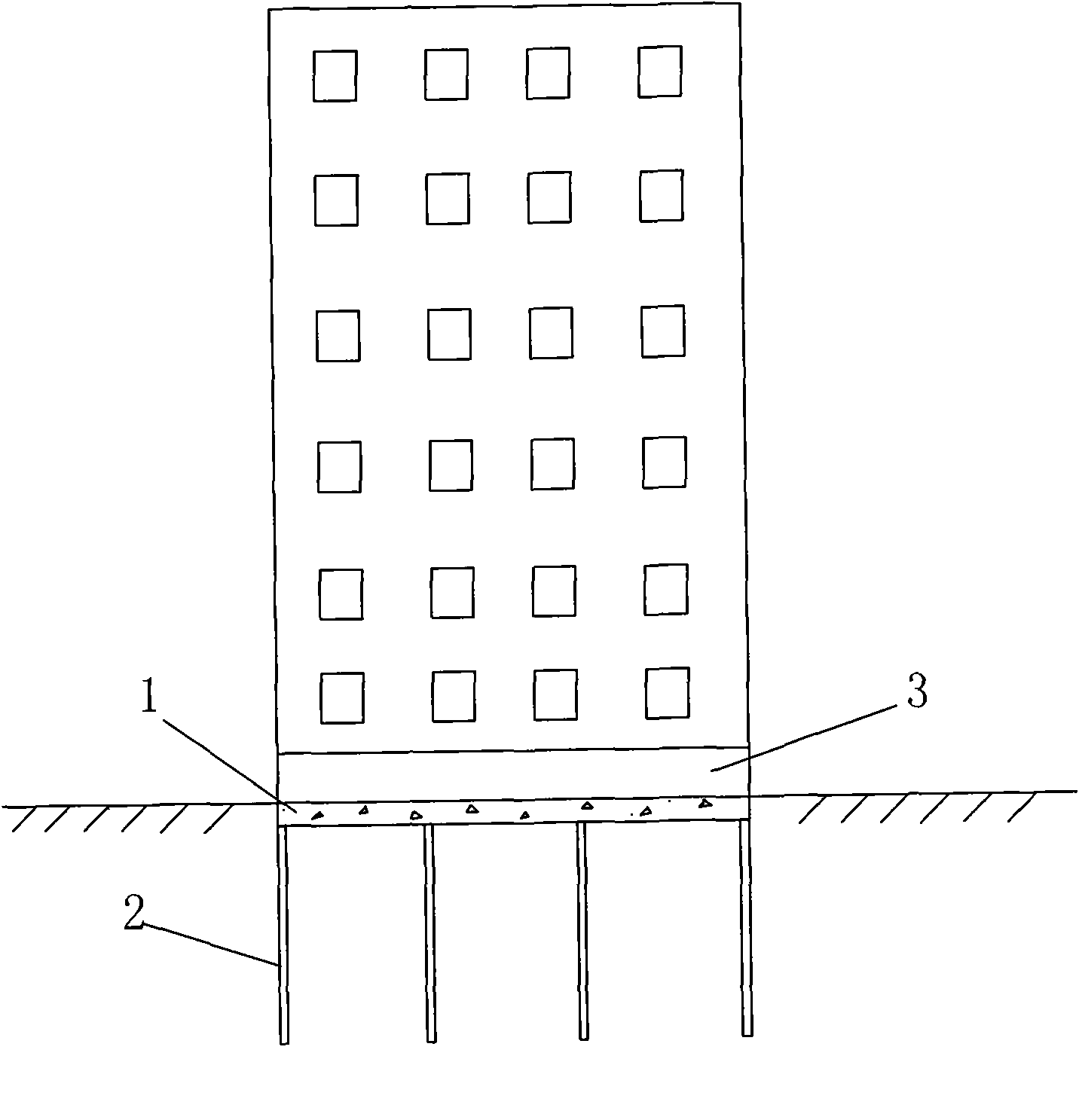

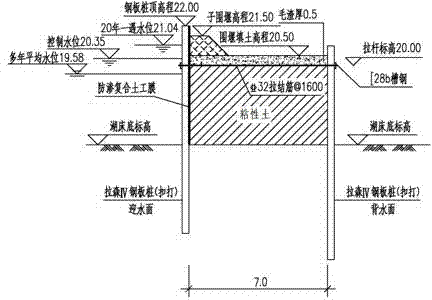

Construction method of large tube well fixed point precipitation, sealing bottom free concrete and steel sheet pile cofferdam deepwater bearing platform

InactiveCN102877420ANo quicksand phenomenonGuarantee the construction qualityFoundation engineeringBridge erection/assemblyDouble wallEngineering

The invention discloses a construction method of large tube well fixed point precipitation, sealing bottom free concrete and a steel sheet pile cofferdam deepwater bearing platform and relates to the construction method of a deepwater bearing platform of a bridge. The construction method aims to solve problems that a double wall steel cofferdam and sealing bottom concrete construction method is large in sealing bottom concrete thickness, large in steel plate pile length and large in construction difficulty. The construction method comprises the following steps of: inserting steel plate piles into a sand layer under water, connecting adjacent steel plate piles in a clamping manner so as to form a cofferdam which is higher than a water level and sealed; uniformly setting a plurality of large tube wells along an inner circle of the cofferdam; pumping out the water from a cofferdam area by using a submersible electric pump; at the same time, connecting the steel tubes or shape steels with steel plate piles which are exposed outside the water level in the horizontal direction so as to form horizontal cofferdam support beam groups, wherein the plurality of horizontal cofferdam support beam groups are arranged in the height direction; after the water in the cofferdam is completely pumped out, an underlayer is paved; and a reinforcement cage for manufacturing the deepwater bearing platform is arranged on the underlayer and concrete is cast so as to form the deepwater bearing platform.

Owner:中铁二十二局集团第一工程有限公司 +1

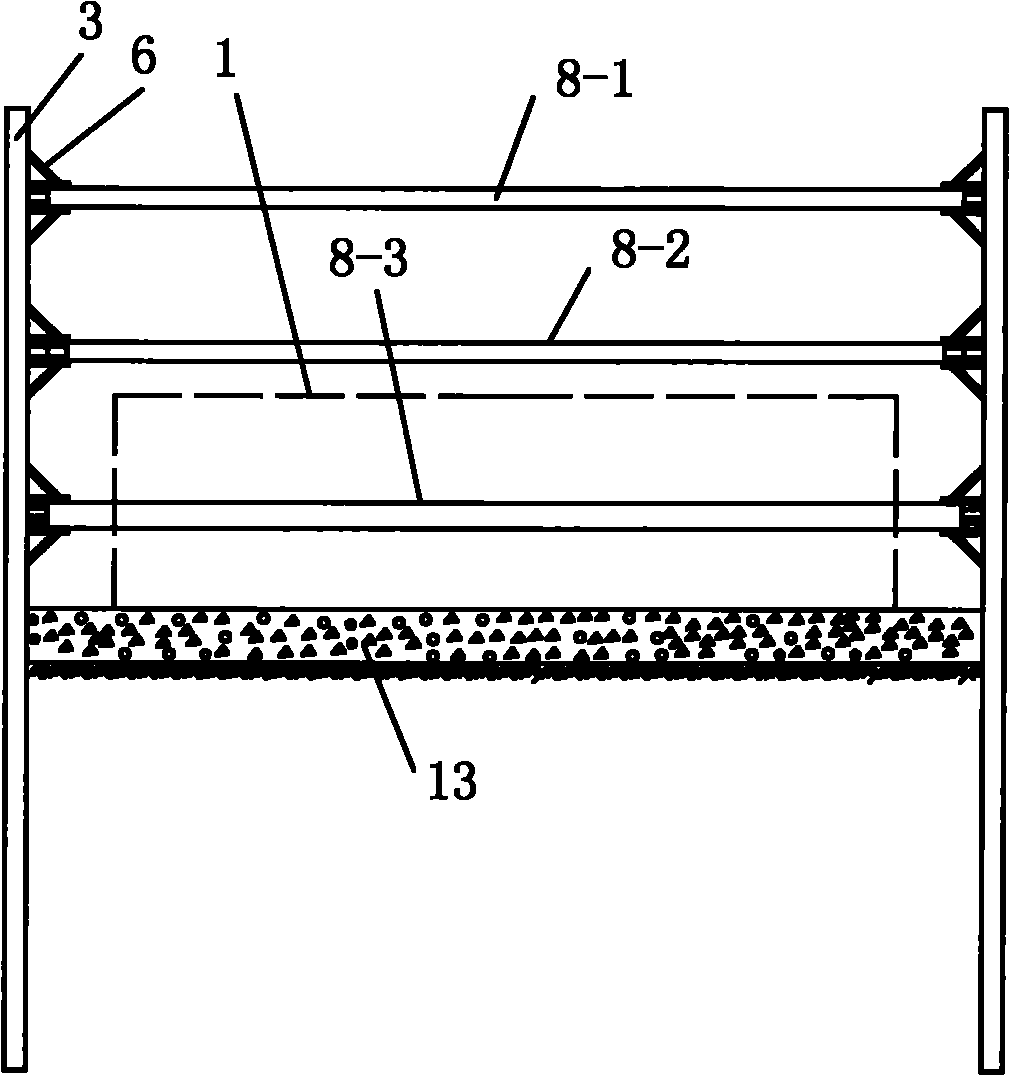

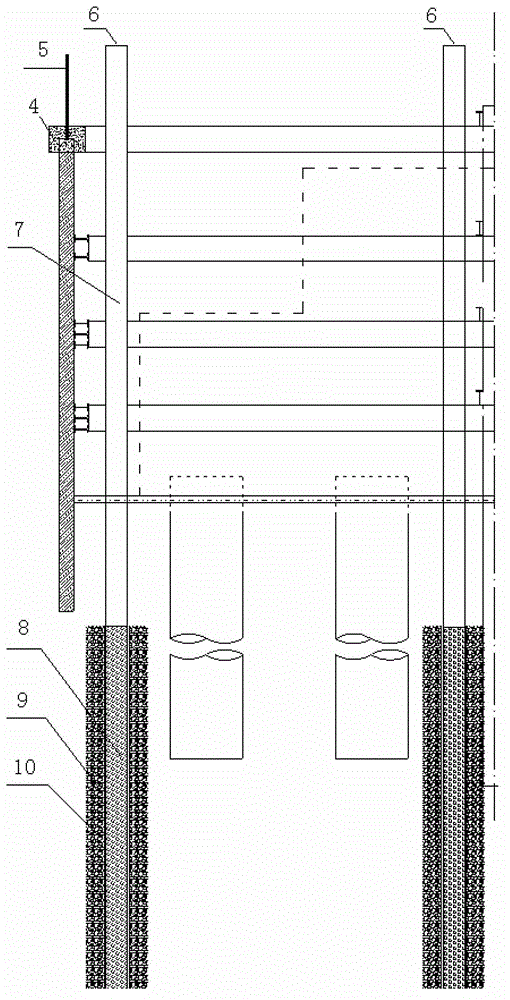

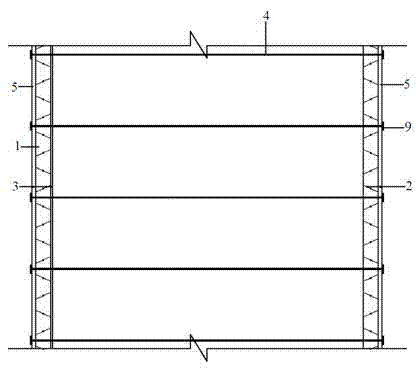

Method of constructing cofferdam after integrally lowering multiple layers of inner bracings of steel sheet pile cofferdam

ActiveCN106013192AEnsure safety and qualityGuarantee the construction qualityFoundation engineeringSludgeCofferdam

The invention discloses a method of constructing a cofferdam after integrally lowering multiple layers of inner bracings of a steel sheet pile cofferdam. The method is applied to the technical field of cofferdam construction and comprises the following steps of: heightening and constructing pile casings of the pile foundation at the bottom of a bearing platform, arranging a temporary assembly platform on the pile casings and assembling the inner bracings on the temporary assembly platform; disassembling the temporary assembly platform, arranging supporting structures at the designed elevation positions of the inner bracings on the pile casings, and lowering the inner bracings to the supporting structures; sequentially inserting steel sheet piles by using the inner bracings as inner guide till closing to form the cofferdam; and clearing sludge at the inner bottom of the cofferdam, then carrying out underwater bottom sealing by concreting, and after the strength of concrete for sealing the bottom reaches requirements, pumping water in the cofferdam dry, and constructing the bearing platform and pier bodies; and disassembling the cofferdam. The method has the beneficial effects that larger potential safety hazards caused by a conventional method of installing inner bracings and connection systems by layer-by-layer water pumping in a steel sheet pile cofferdam construction process are avoided; construction procedures are simple and easy to operate; the safety of operating personnel and the construction quality can be ensured to a greater extent; the construction period is shortened; and the construction cost is saved.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

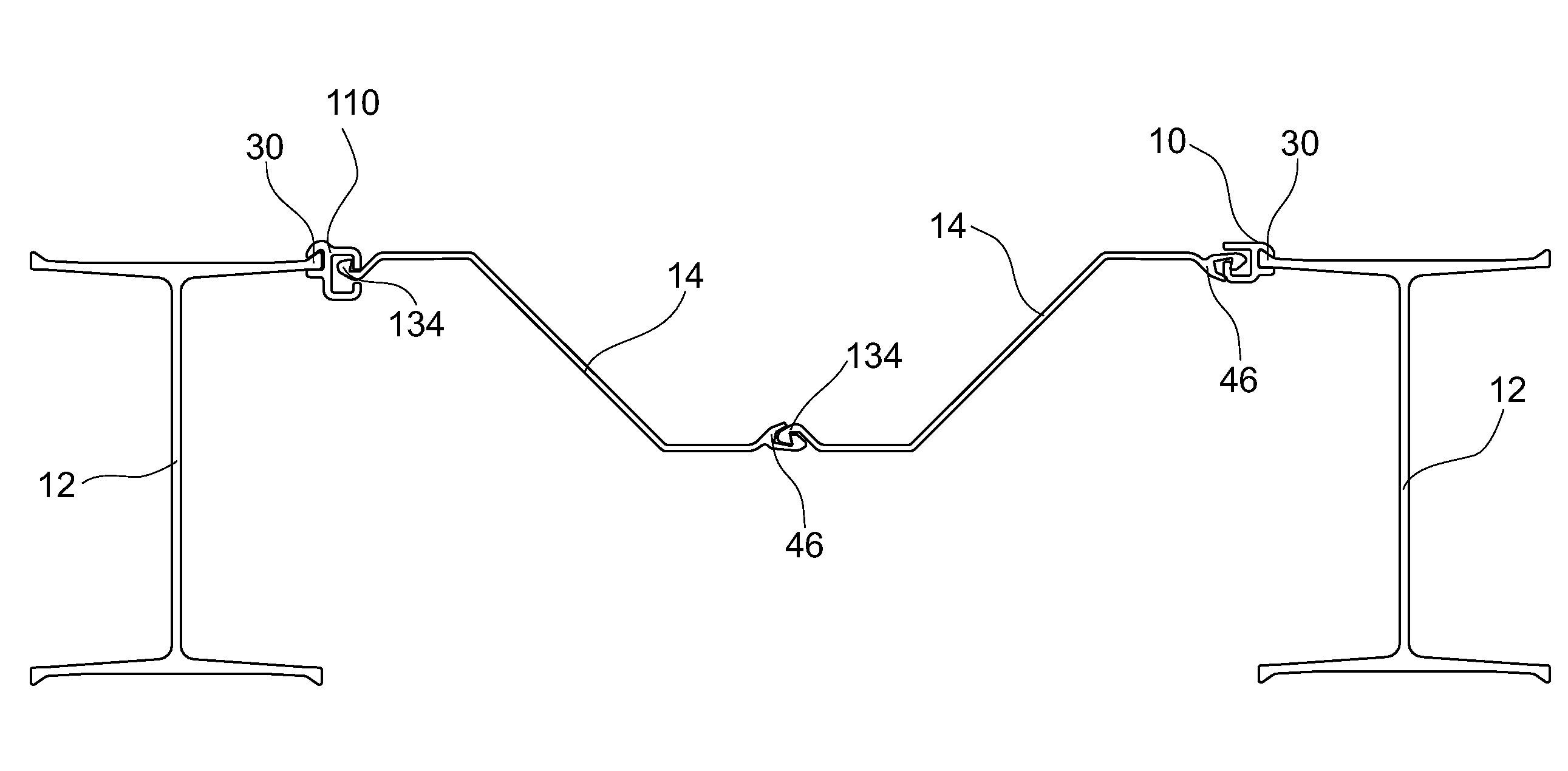

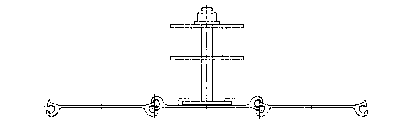

Method for building sheet pile walls

A method for building sheet pile walls comprises the steps of providing a first sheet pile (10), said first sheet pile (10) having a leading sheet pile interlock (14) with an interlock chamber (20); driving said first sheet pile (10) into the ground while protecting said interlock chamber (20) from ground material; providing a second sheet pile (10'), said second sheet pile (10') having a trailing sheet pile interlock (12') with an interlock head (16); engaging said interlock head (16) of said trailing sheet pile interlock (12') in said interlock chamber (20) of said leading sheet pile interlock (14); driving said second sheet pile (10') into the ground. The method further comprises the step of coating said interlock head (16) of said trailing sheet pile interlock (12') with fixing agent prior to engaging said interlock head (16) of said trailing sheet pile interlock (12') in said interlock chamber (20) of said leading sheet pile interlock (14).

Owner:ARCELORMITTAL COMML RPS SRL

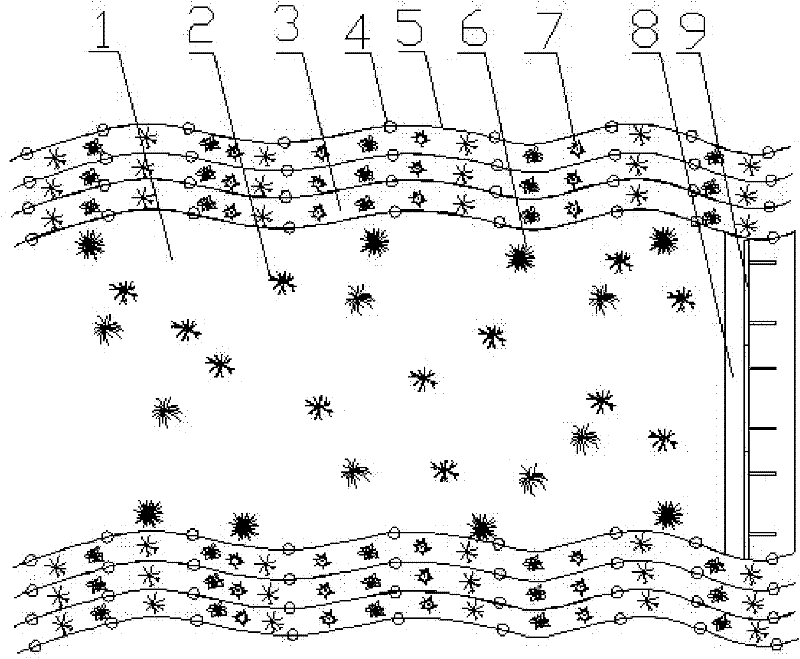

System for purifying micro-polluted water flowing to reservoirs (lakes) and repairing ecological wetlands

InactiveCN102531182ADoes not affect flood discharge capacityAvoid negative effectsClimate change adaptationSustainable biological treatmentConstructed wetlandAutomatic control

The invention discloses a system for purifying micro-polluted water flowing to reservoirs (lakes) and repairing ecological wetlands. The system comprises a hydraulic-power automatic control overturning gate, an artificial wetland and multistage stepped artificial wetland revetments, wherein the hydraulic-power automatic control overturning gate is arranged in a riverway to intercept the riverway into an upper stream and a lower stream; the artificial wetland is arranged in the riverway on the upper stream of the hydraulic-power automatic control overturning gate; the multistage stepped artificial wetland revetments are arranged on two sides of the riverway on the upper stream of the hydraulic-power automatic control overturning gate; each multistage stepped artificial wetland revetments comprise sheet pile members formed by non-fine concrete plates and piles; the sheet pile members are arranged on the bank slope of the riverway from high to low line upon line; and fillers and grown plants are filled between the two adjacent sheet pile members. The invention provides a technology for purifying micro-polluted water flowing to reservoirs (lakes) and repairing ecological wetlands. Polluted water in riverways is repaired through utilizing the ecological embankment and ecological wetland method, so that the contents of COD, BOD, TP and TN are reduced greatly.

Owner:NANJING UNIV

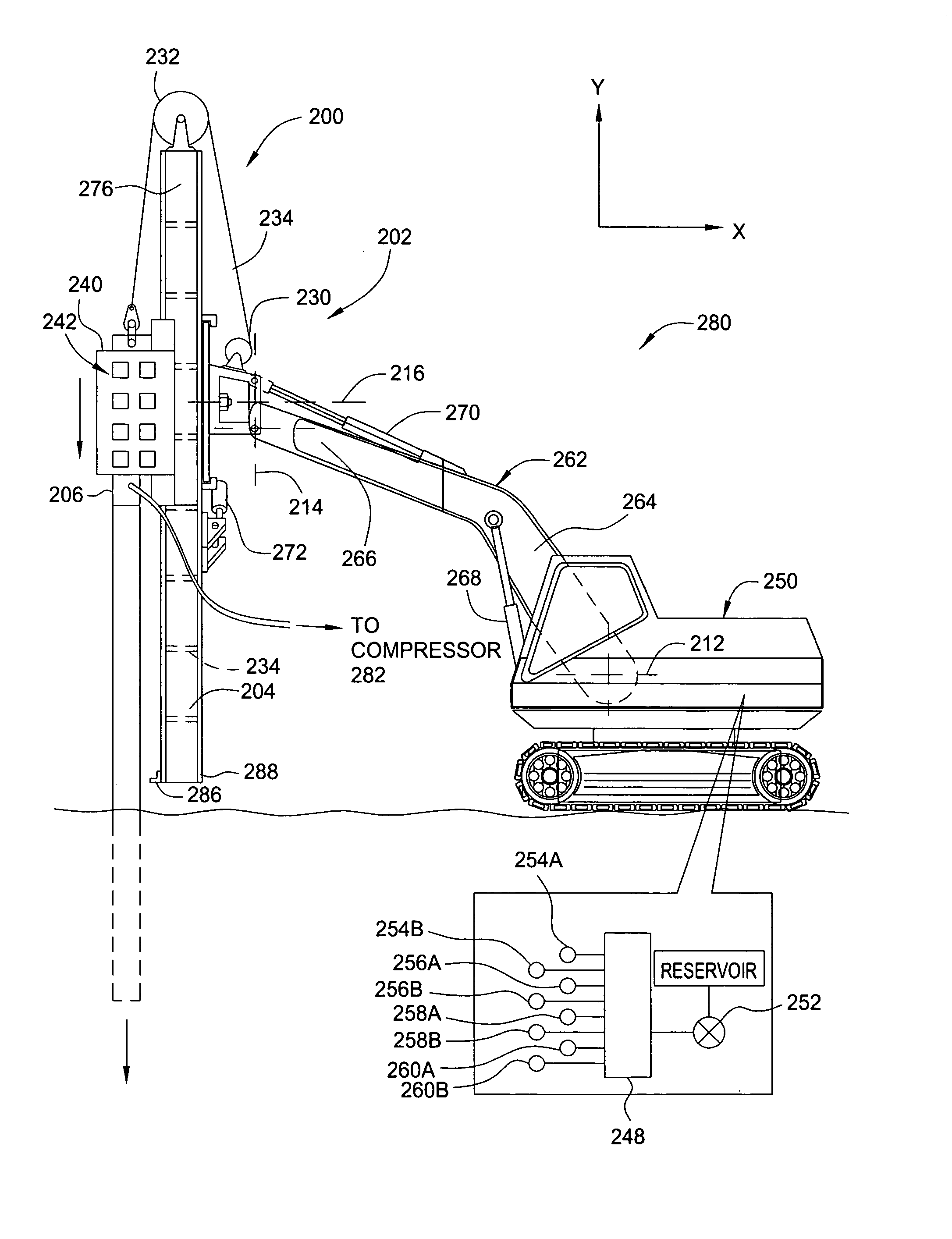

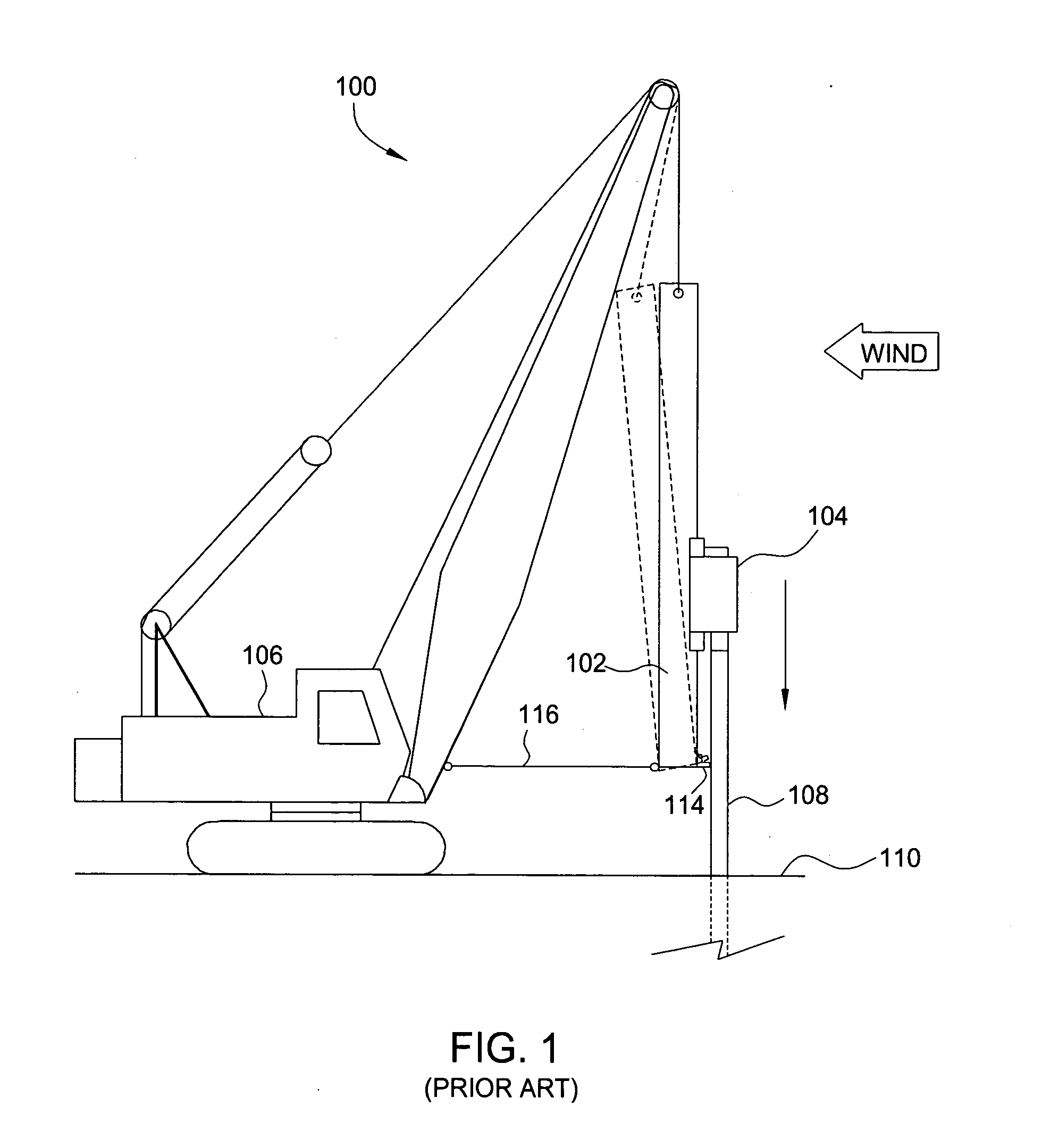

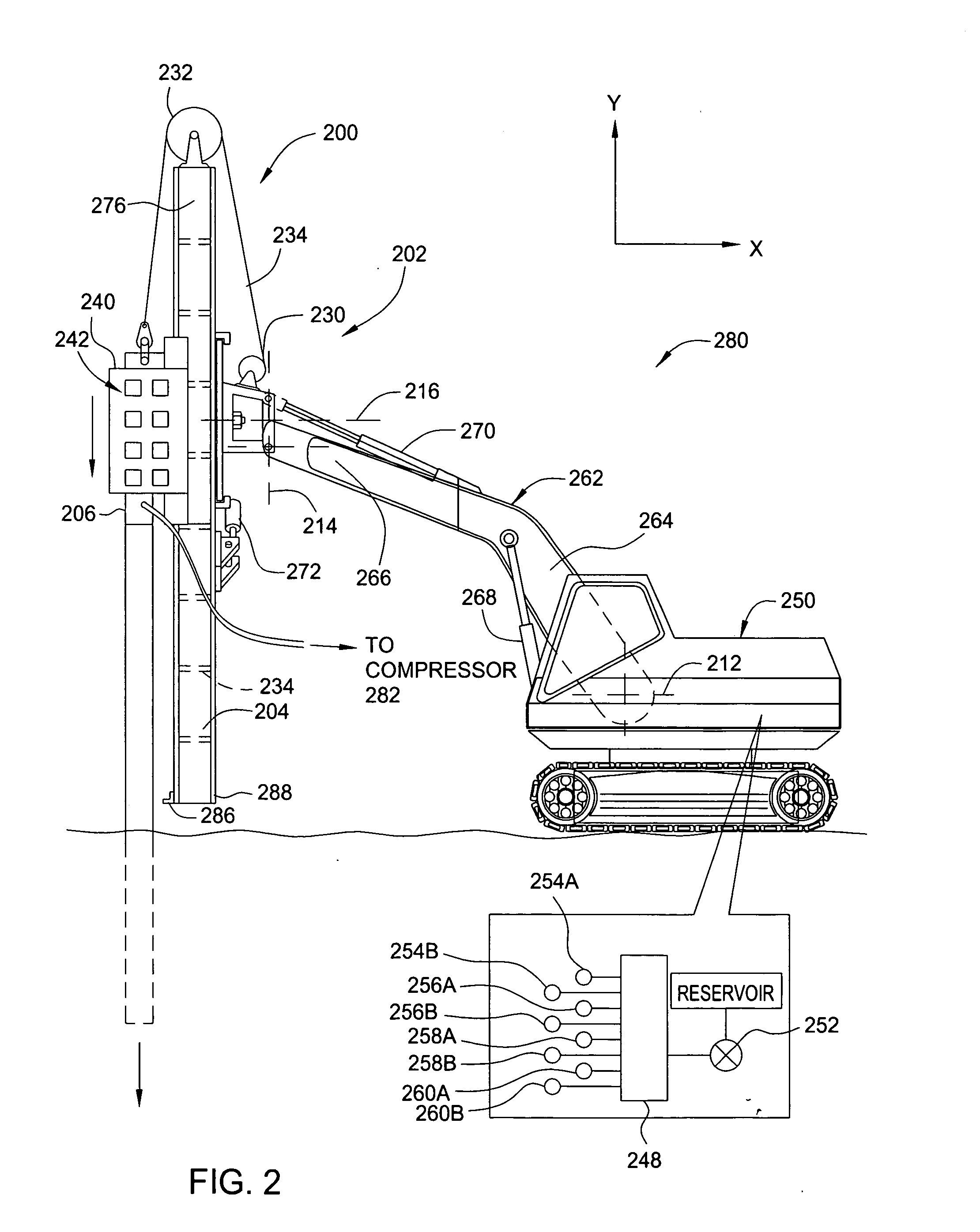

Lead alignment attachment

A construction equipment attachment for driving an object, such as a timber piles, steel piles, pipe piles, steel sheet piles, h-beam and the like, is provided. In one embodiment, the attachment includes a hammer slidably coupled to a lead, a lead mounting assembly and a hydraulic actuator coupled to the lead and the lead mounting assembly. The hydraulic actuator is adapted to control the orientation of the lead relative to the lead mounting assembly. In another embodiment, the attachment may be for a self-propelled heavy construction machine. In another embodiment, a self-propelled heavy construction machine having a lead positionable along three axes is provided.

Owner:CRUZ CONSTR CORP

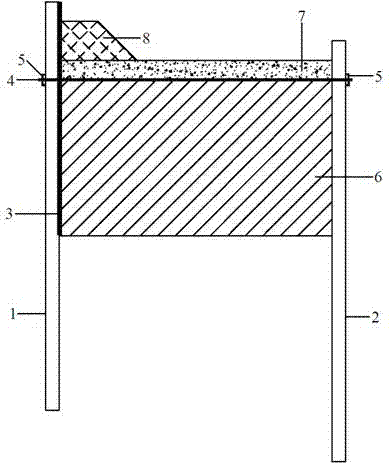

Double-layer steel sheet pile soil core composite cofferdam structure without inner support and application thereof

InactiveCN103669375ASolve the problem of large deformation of flexible structuresSolve the actual situation of easy water seepageFoundation engineeringGeomembraneCofferdam

The invention discloses a double-layer steel sheet pile soil core composite cofferdam structure without an inner support and the application of the double-layer steel sheet pile soil core composite cofferdam structure without an inner support, and belongs to the field of water conservancy projects. The double-layer steel sheet pile soil core composite cofferdam structure without an inner support comprises an upstream-face steel sheet pile and a downstream-face steel sheet pile, and the space between the steel sheet piles is filled with cohesive soil to form a cofferdam; a composite geo-membrane is laid on the portion, inside the cofferdam, of the upstream-face steel sheet pile; the upper portions of the two steel sheet piles are connected through a pull rod, middle beams are arranged outside the steel sheet piles, and the pull rod is connected with the middle beams through bolts arranged outside the corresponding middle beams. When the filling cofferdam core cohesive soil is in the same level with the pull rod, the space between the steel sheet piles is further filled with a layer of hairy residues, and a sub-cofferdam is arranged on the upstream-face steel sheet pile. The cofferdam structure can be used for building strip-shaped subsurface structures in a river or lake through the open-cut method. The cofferdam structure is stable and safe, and the problem that a steel sheet pile flexible structure is large in deformation is solved by arranging the pull rod on the tops of the two steel sheet piles; a three-level waterproofing system improves the anti-penetrability performance of the steel sheet pile cofferdam significantly.

Owner:张安政

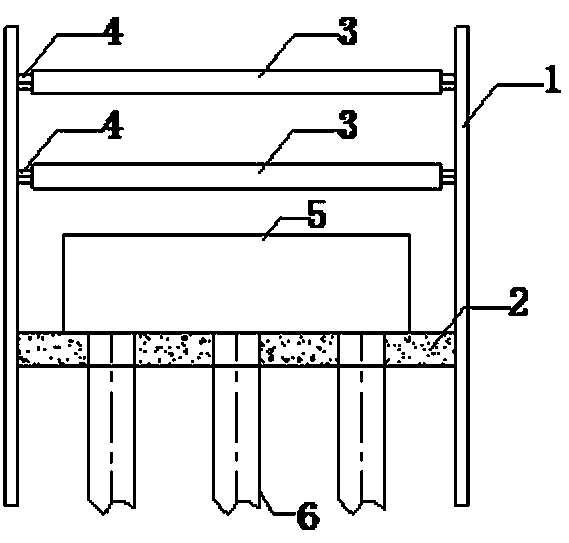

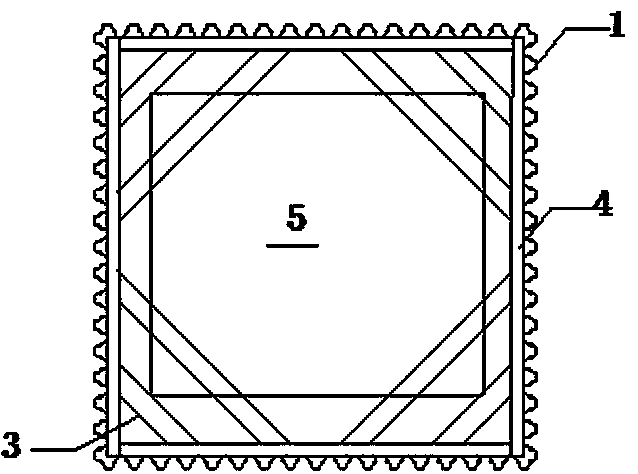

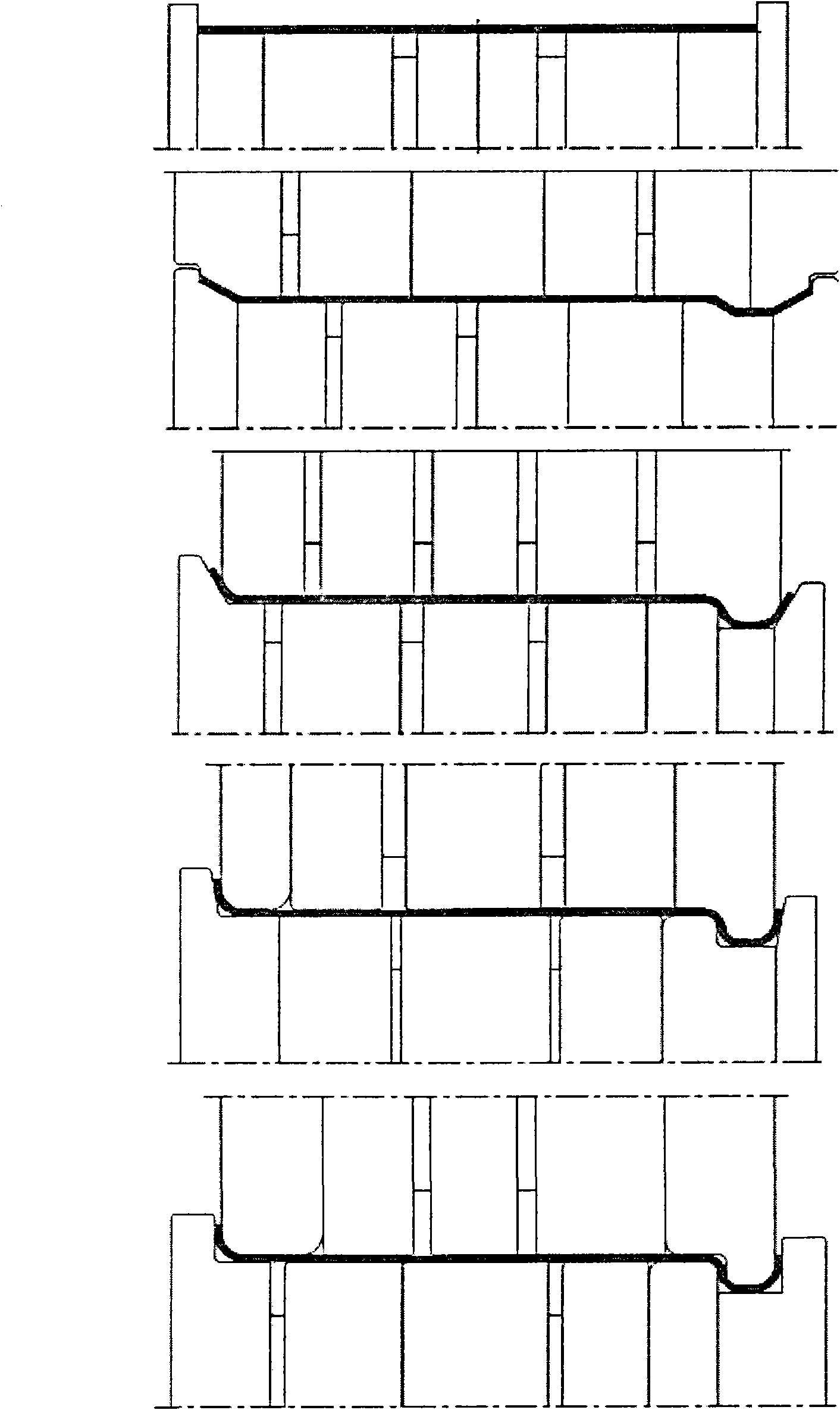

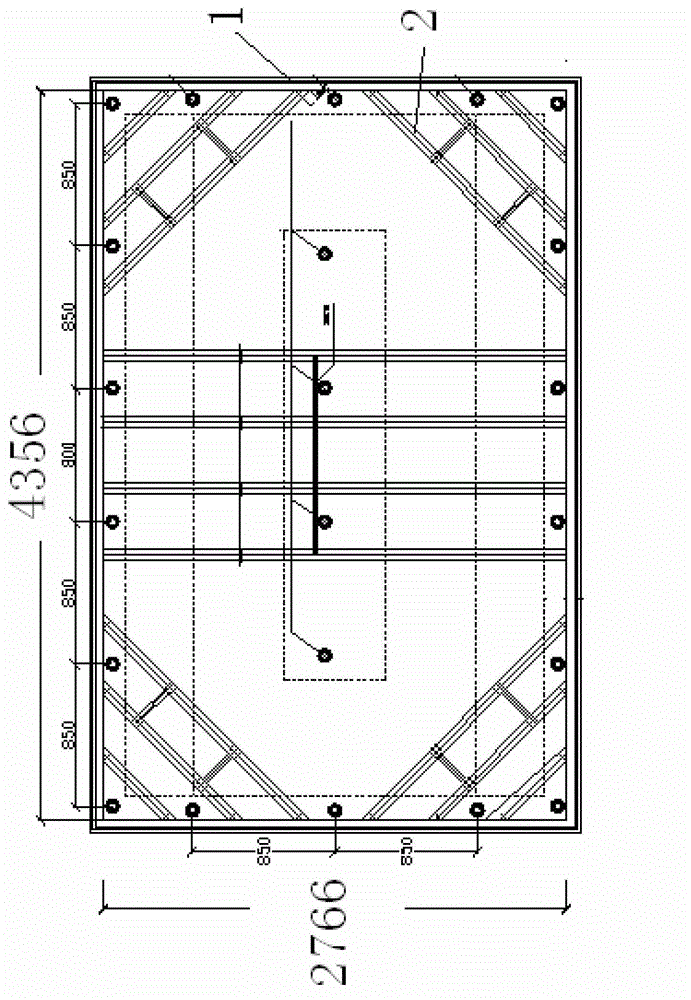

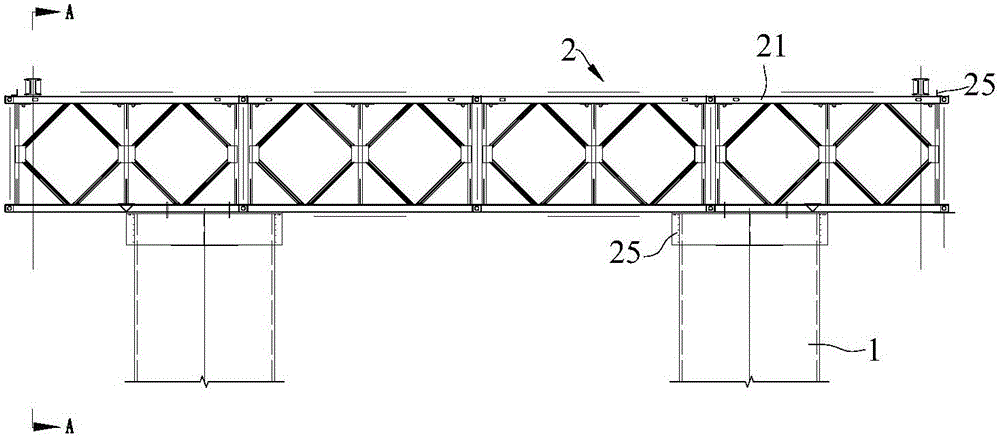

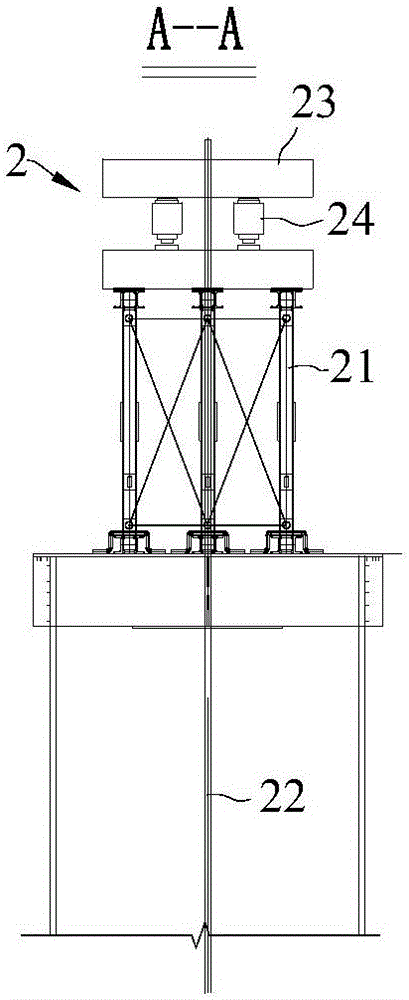

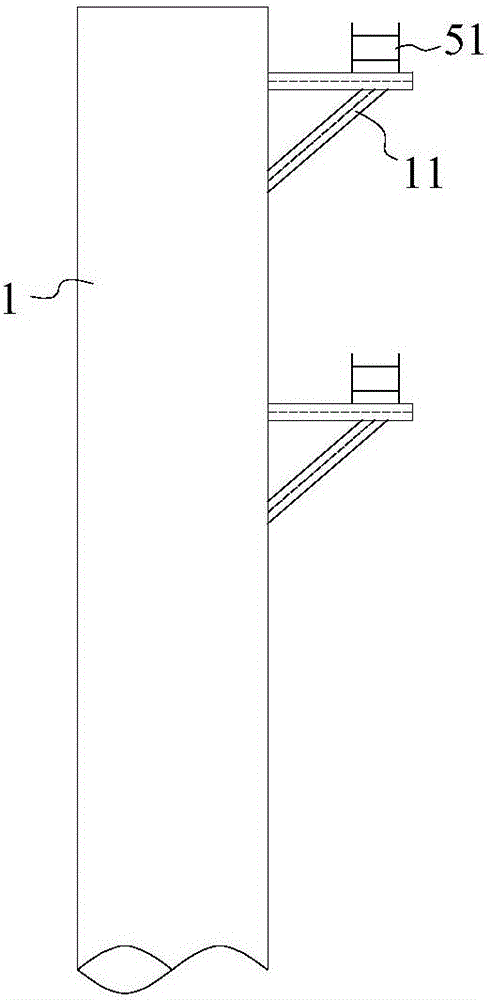

Steel sheet pile coefferdam structure and topdown construction method thereof

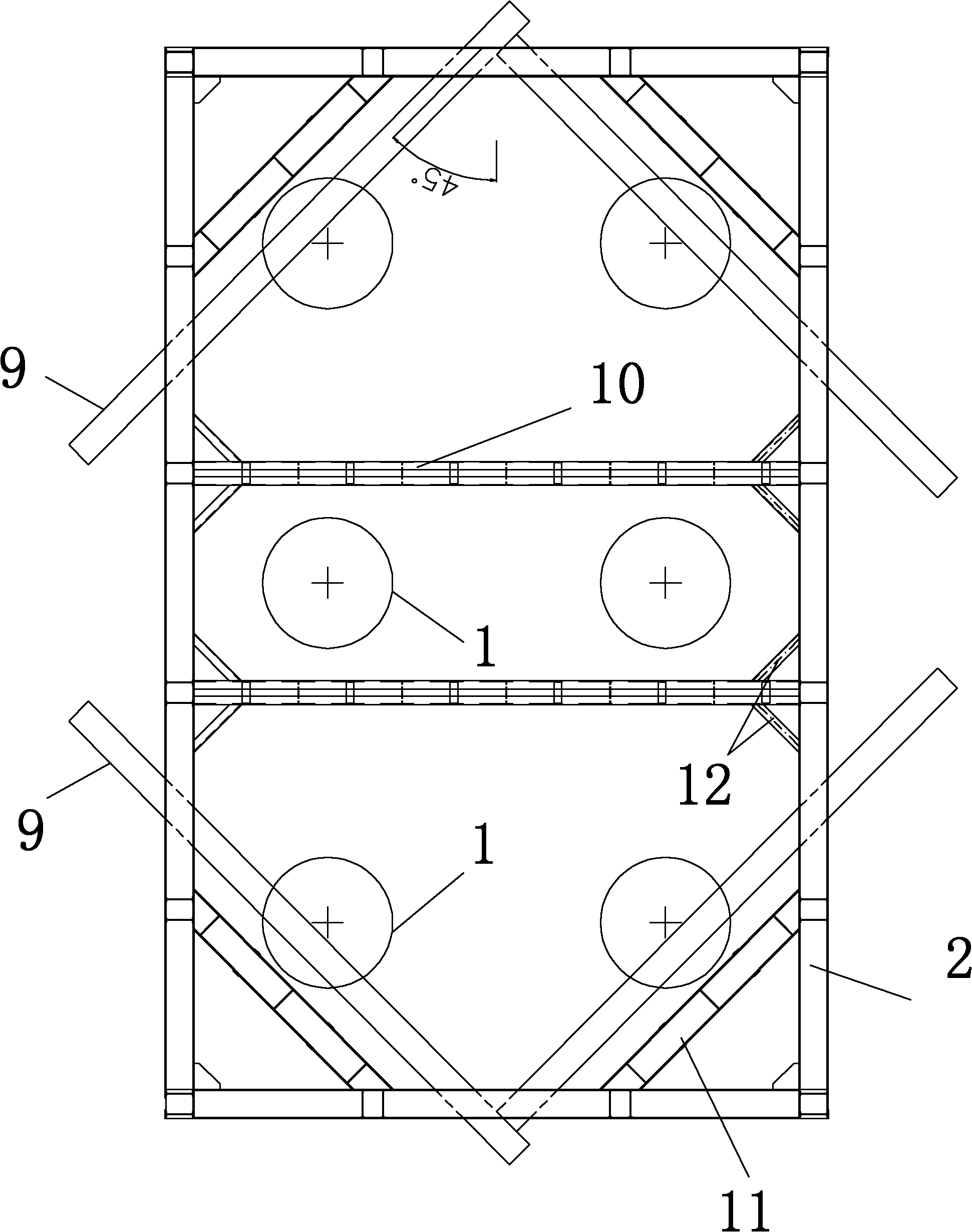

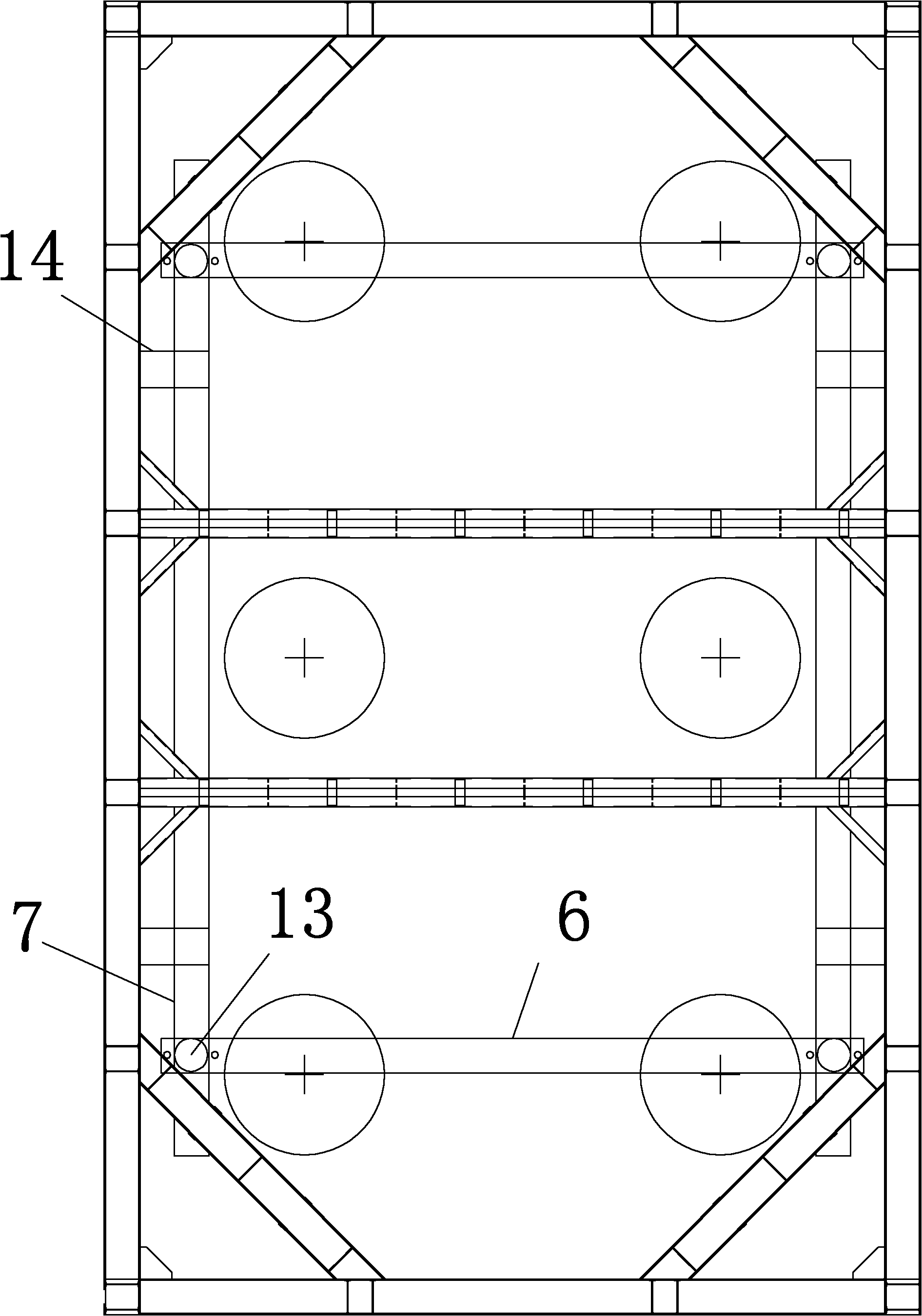

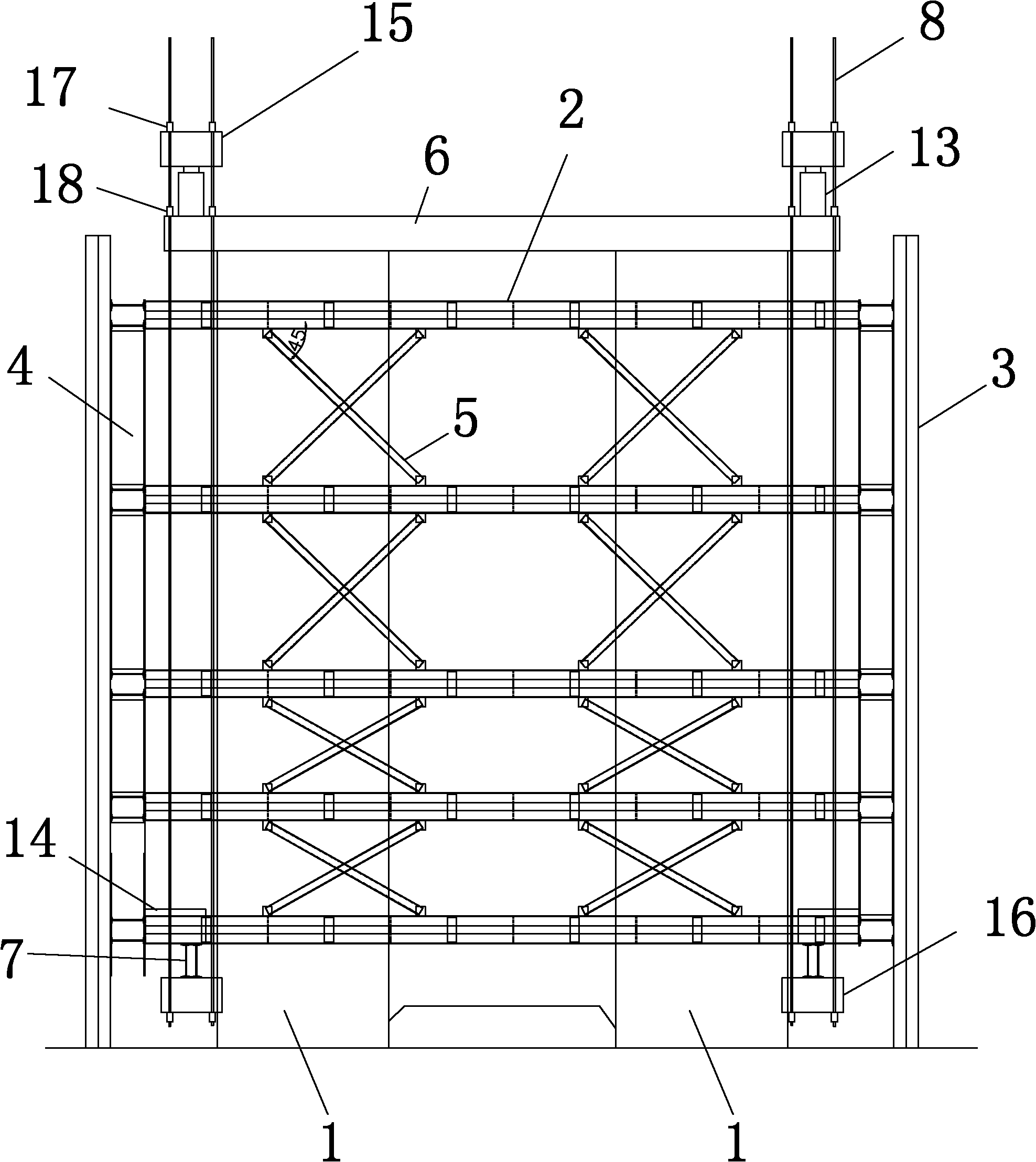

ActiveCN102191777ARealize intermittent decentralizationHigh positioning accuracyLifting devicesFoundation engineeringPurlinPile cap

The invention discloses a steel sheet pile coefferdam structure comprising a steel protecting canister, a plurality of layers of circuit purlins and steel sheet piles, wherein the steel sheet piles are inserted into the peripheries of the circuit purlins; the lower part of the steel protecting canister is welded with a bracket to form a temporary supporting platform; the circuit purlins at the upper layer and the circuit purlins at the lower layer are connected through a vertical rid and a bridging at 45 degrees; the top of the steel protecting canister is fixedly provided with an upper outrigger; the upper outrigger is provided with lifting equipment; and a lower outrigger is welded below the circuit purlins at the lowermost layer and lifted by a lifting rope of the lifting equipment. The invention also discloses a topdown construction method of the steel sheet pile coefferdam structure. In the invention, the circuit purlins, the vertical ribs and the bridging at 45 degrees are installed by utilizing a lifting system under the preconditions without using large-size lifting equipment or utilizing a large-scale prefabricating field, and therefore the quality and the stability of a steel sheet pile coefferdam are ensured; and a highrise pile cap of a pier inside water is constructed with lowest cost and smallest construction risk, therefore the feasibility and the economy of a construction technology of the steel sheet pile coefferdam inside water are enhanced.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

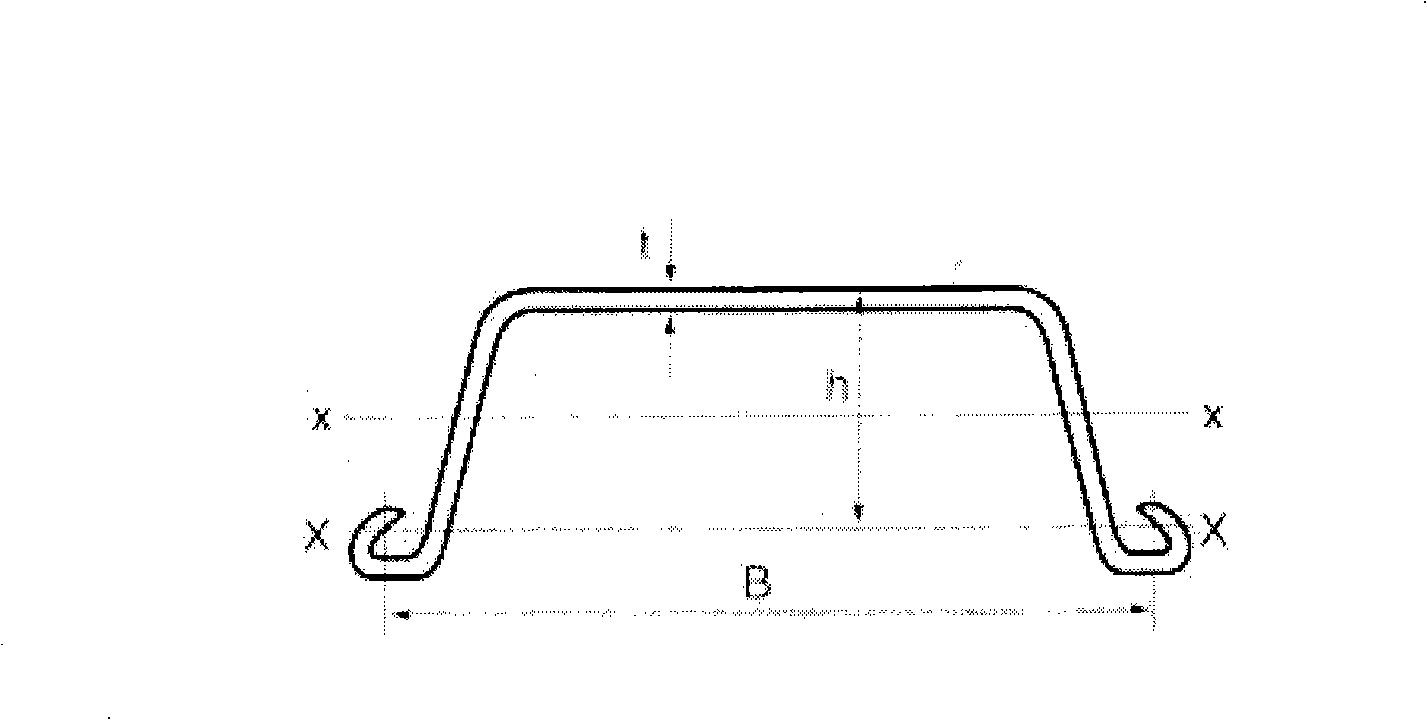

Hot-rolled U shaped metal sheet pile and microalloying production method

InactiveCN101403069AImprove performanceSimple production processTemperature control deviceChemical compositionMetal sheet

The invention relates to a hot-rolled U-shaped steel sheet pile and a micro-alloying production method thereof, which belong to the field of iron and steel metallurgy and materials. The chemical components of the steel have the following mixture ratio by weight percent: 0.12-0.26 of C, 0.6-1.8 of Mn, 0.25-0.60 of Si, 0.020 or less of P, 0.020 or less of S, 0.010-0.050 of Als, 0.01-0.20 of V and 0.005 or less of N. The method sequentially comprises the steps of converter or electric furnace smelting, secondary refining, continuous casting, heating and rolling. The invention enhances the comprehensive performance of the steel sheet pile, improves the welding performance of the steel sheet pile, improves the utility ratio of the steel sheet pile and has simple production technology.

Owner:武汉钢铁有限公司

Universal connecting element for sheet pile wall components

A universal connecting element which is capable of connecting sheet pile wall components, such as sheet piles, beam piles and other sheet pile connectors, that have various types of interlocks such as Larssen locks, cold formed hooks and knob and claw locks. The connecting element includes a reverse “S” shaped profile to which has been added either a neck and head strip, for connection with a claw strip, or a claw strip, for connection with a head strip, or both.

Owner:SHEET PILE LLC

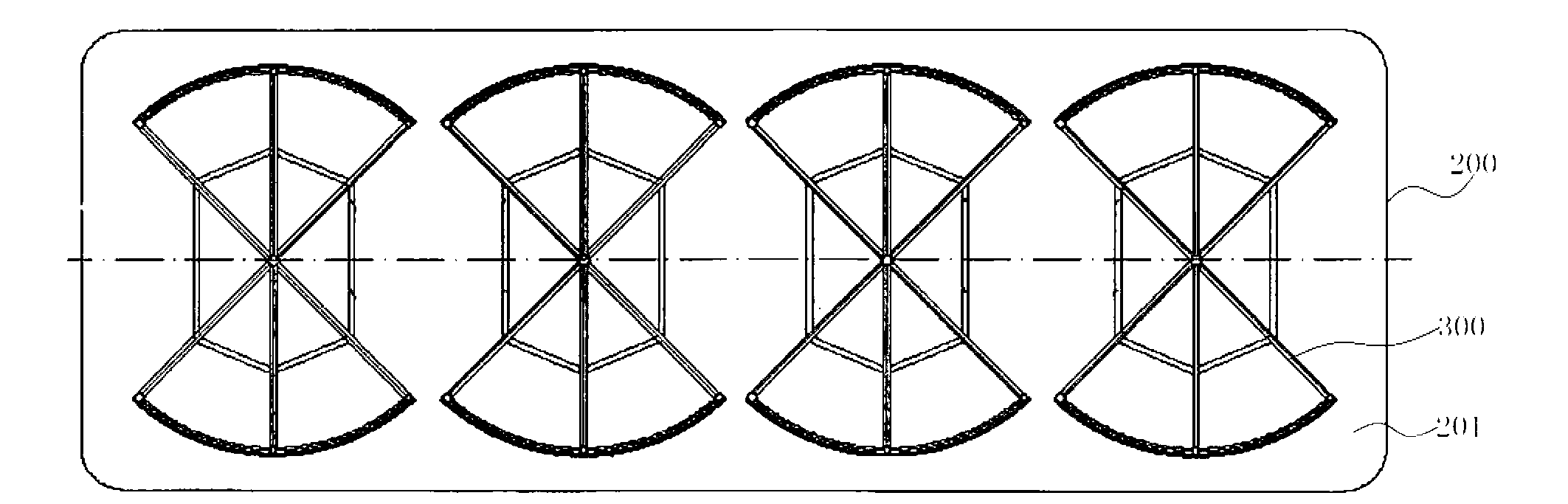

Transportation method for pre-assembled main cellular sheet pile 1/4 cylinders of cellular steel sheet piles

ActiveCN103233452ASolve construction difficultiesSave land areaArtificial islandsUnderwater structuresSheet pileCELLULAR SHEET

The invention discloses a transportation method for pre-assembled main cellular sheet pile 1 / 4 cylinders of cellular steel sheet piles. The method comprises the steps of (1) arranging transport supports on transport ships, wherein the supports are fixed on decks of the transport ships and loaded in a two-side longitudinal symmetrical mode; (2) assembling main cellular sheet pile 1 / 4 cylinders on the transport supports by using steel sheet piles to obtain corresponding 1 / 4 circular steel sheet pile assembly sheets; and (3) hauling the transport ships with the 1 / 4 circular steel sheet pile assembly sheets arranged through towage ships to construction sites. According to the transportation method, problems in the prior art can be solved effectively, and the shipping stability and safety of the ships are guaranteed.

Owner:CCCC THIRD HARBOR ENG

Connection element for connecting sheet piles to carrier elements as well as a combination sheet pile wall with such connection elements

A connection element for connecting a sheet pile to a carrier element, with a base strip (16) to be fastened to a carrier element (14), is provided with an interlock profile (20) for engaging the sheet pile (14). The interlock profile (20) exhibits a lock chamber (28) that is defined by the base strip (16), a support strip (24) that protrudes from the base strip (16) and a hook strip (26) that protrudes from the base strip (16), whereby the hook strip (16) exhibits a straight extending transition section (32) protruding from the base strip (16) and a hook section (34) that follows said transition section and points in the direction of the support strip (34). The hook section exhibits a first support surface (26) that faces an inner surface (30) of the support strip (24), whereby the first support surface (36) and at least that section of the inner surface (30) of the support strip (24) that directly faces the first support surface (26) are located in parallel converging planes (E1, E2) and together define the jaw (42) of the lock chamber (28). The first support surface (36) transitions under an acute angle (α) into a second support surface (38) that defines the lock chamber (28).

Owner:SHEET PILE LLC

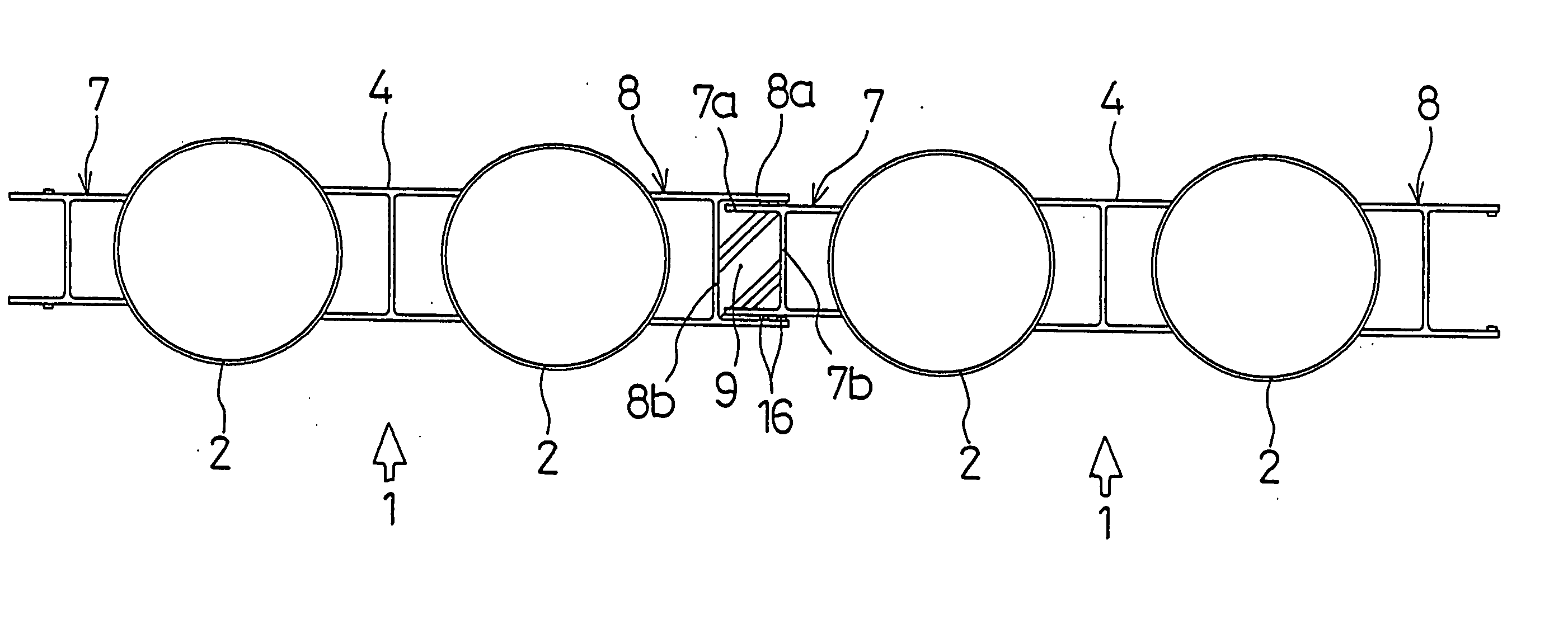

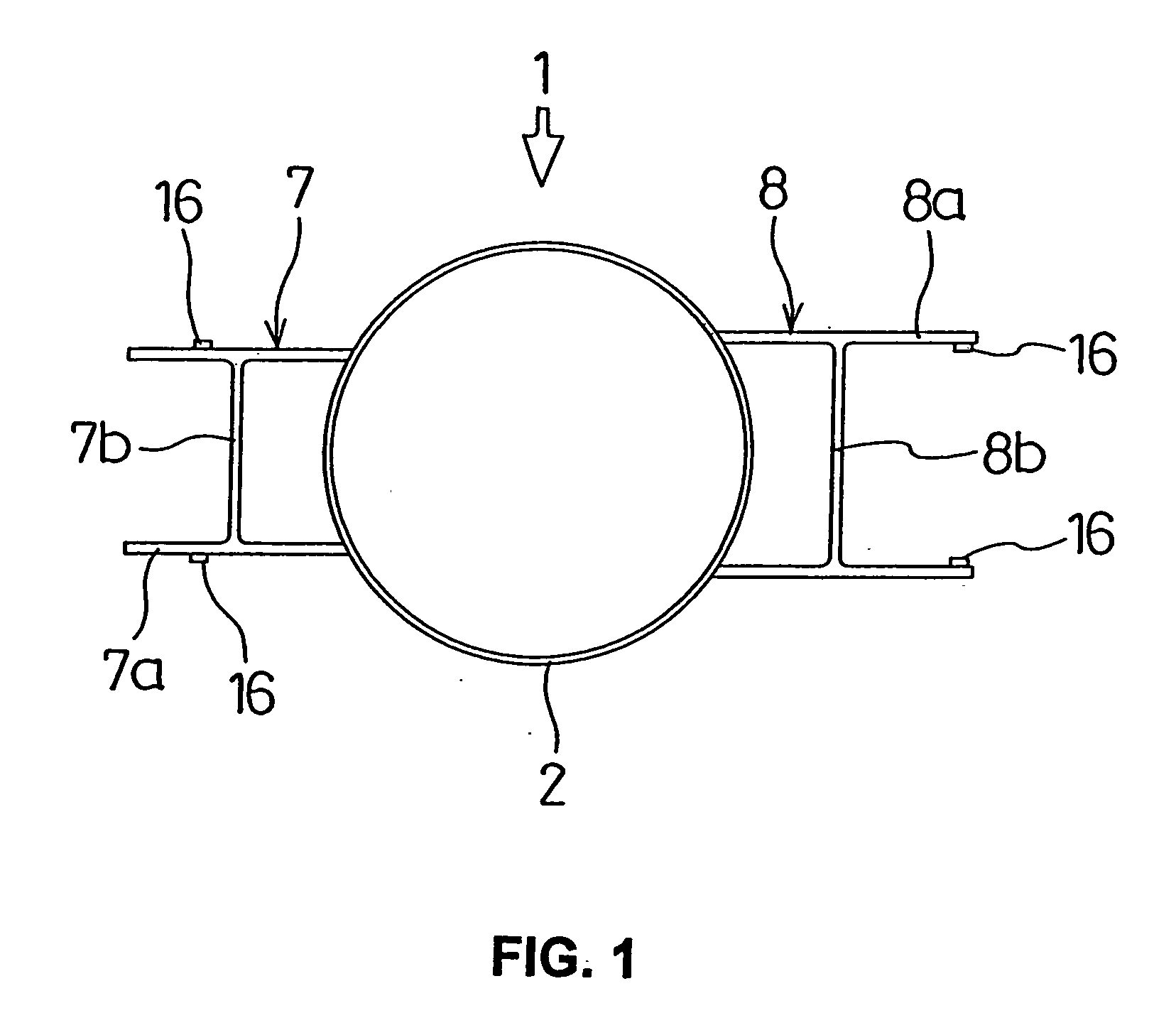

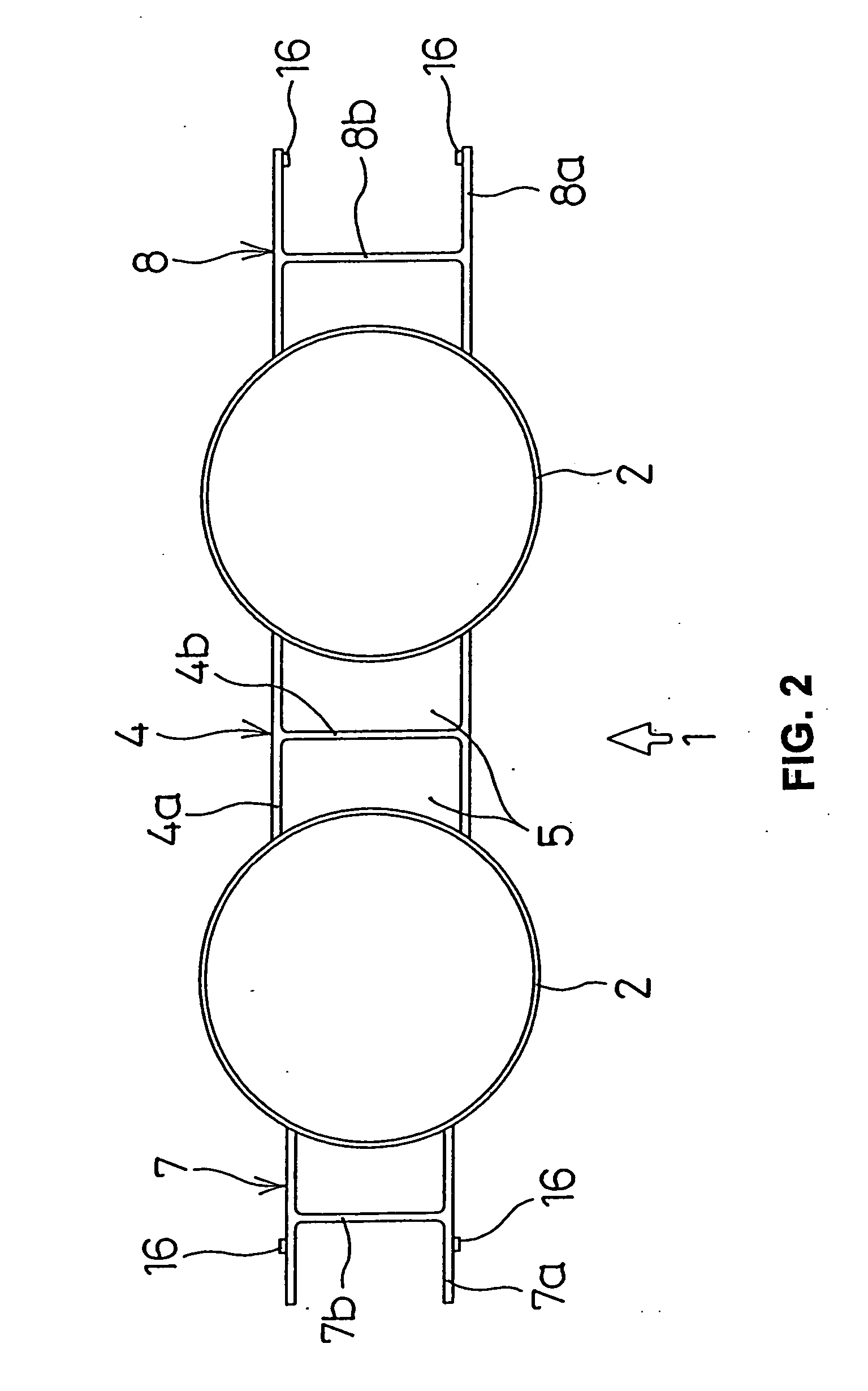

Steel-pipe sheet pile and coupling structure of steel-pipe sheet piles

InactiveUS20050254905A1Improve the water-stop effectGood stopping effectArtificial islandsFencingEngineeringSheet pile

A steel-pipe sheet pile including a steel pipe and joints for coupling the steel pipe to another steel pipe and multiple steel pipes arranged in a building direction of a steel-pipe sheet pile wall, wherein the joints include a male joint and a sale joint each made of an H-shaped steel-beam coupled at flange edges to the steel pipe, and wherein the male joint is slightly smaller in size relative to the female joint so that the male joint can be fitted in a space defined by flange inside surfaces and web surface of a female joint of a neighboring steel-pipe sheet pile. The inside surfaces of the flanges of the female joint and the outside surfaces of the flanges of the male joint are provided with projections, respectively. The steel-pipe sheet pile is a jointed steel-pipe sheet pile including multiple steel pipes integrally coupled to one another via H-shaped steel-beams as tying members of H-shaped transverse cross-sections, respectively, such that each tying member has flange edges coupled to peripheral surfaces of the associated steel pipes to be plurally arranged in a building direction of a steel-pipe sheet pile wall.

Owner:DATA TOO

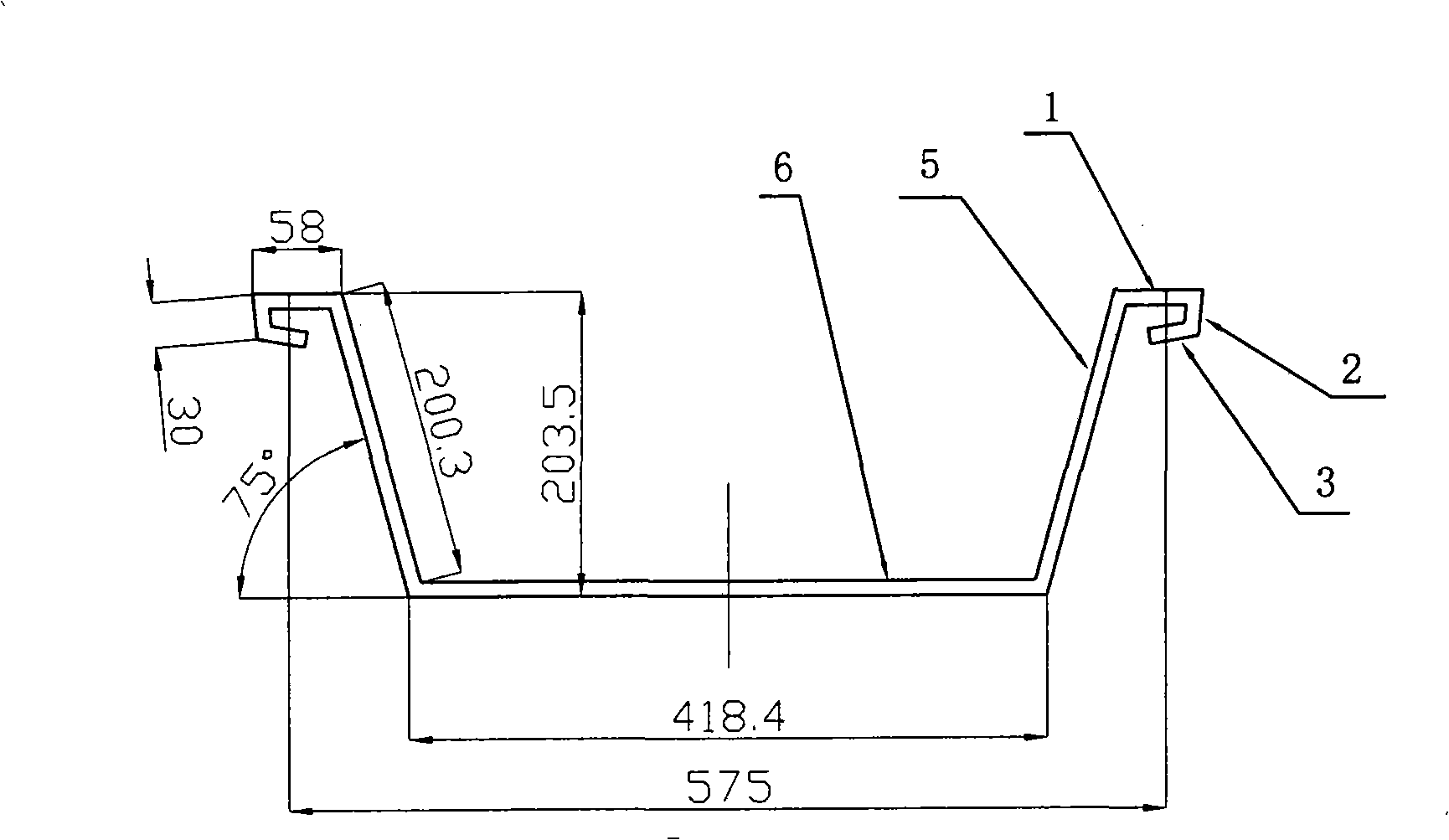

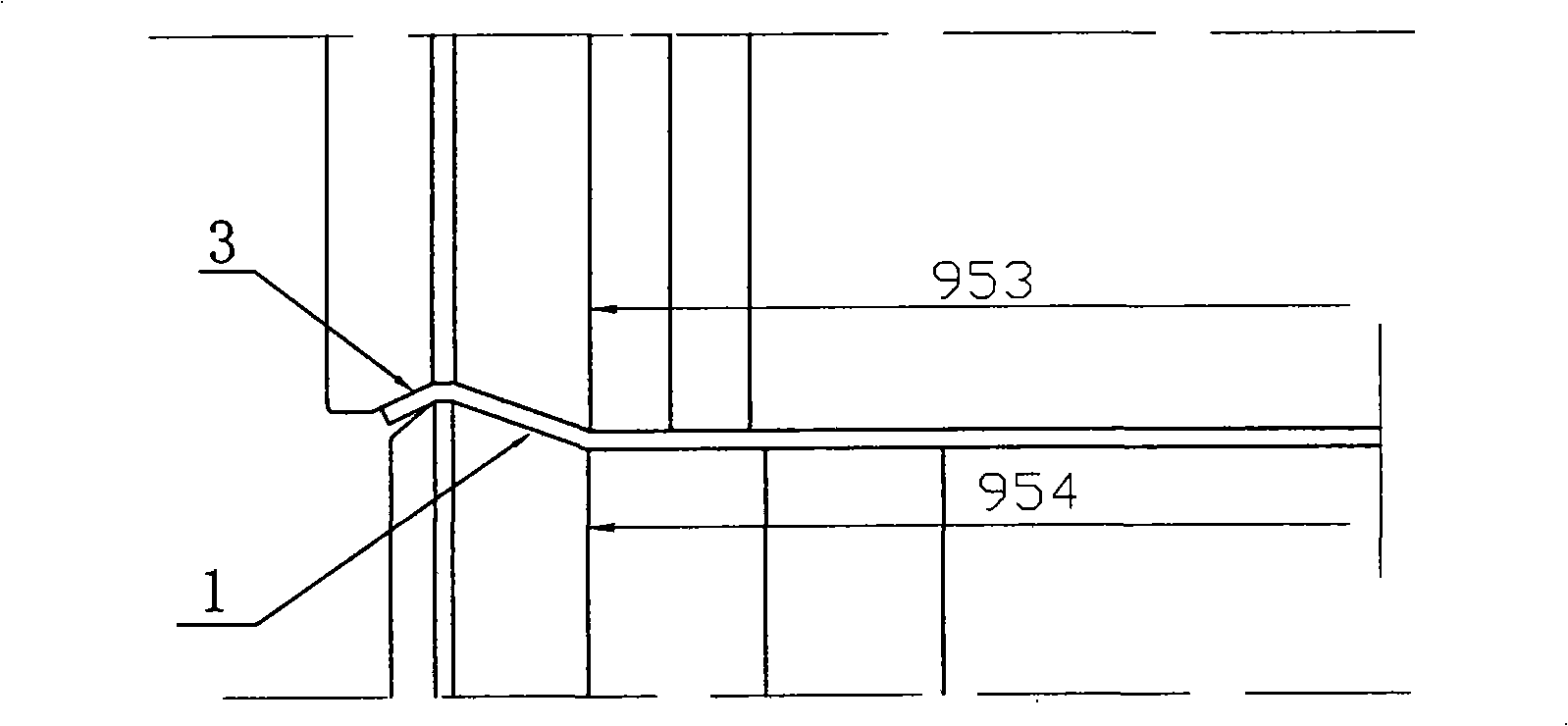

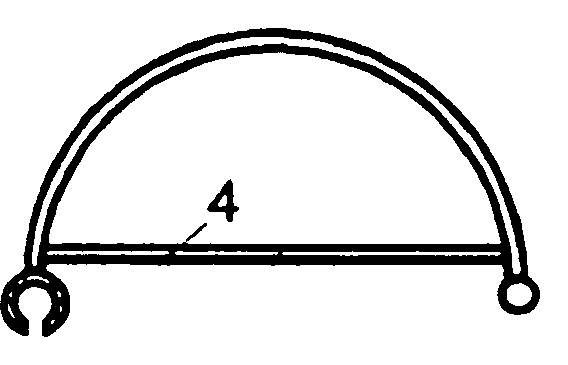

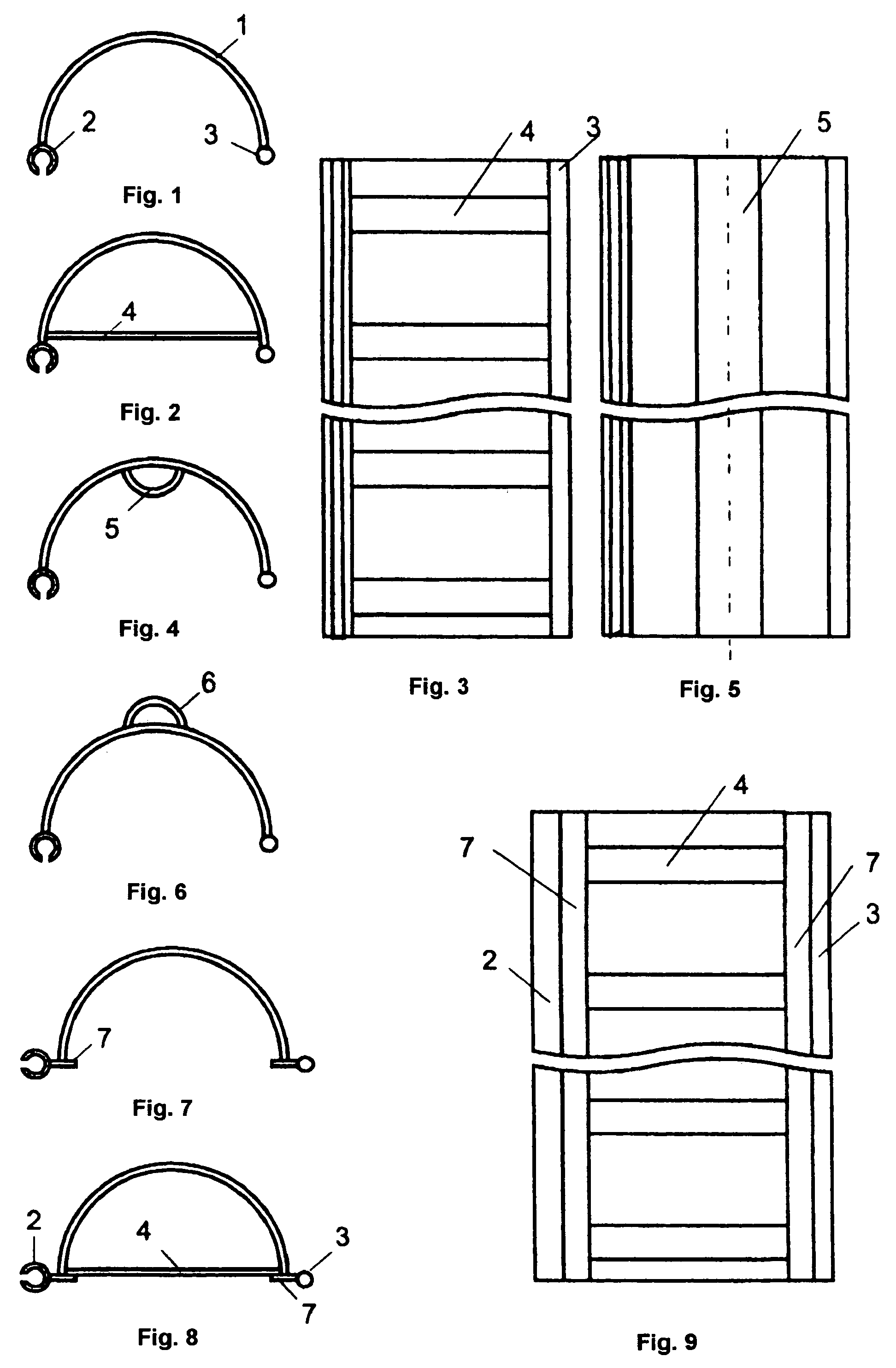

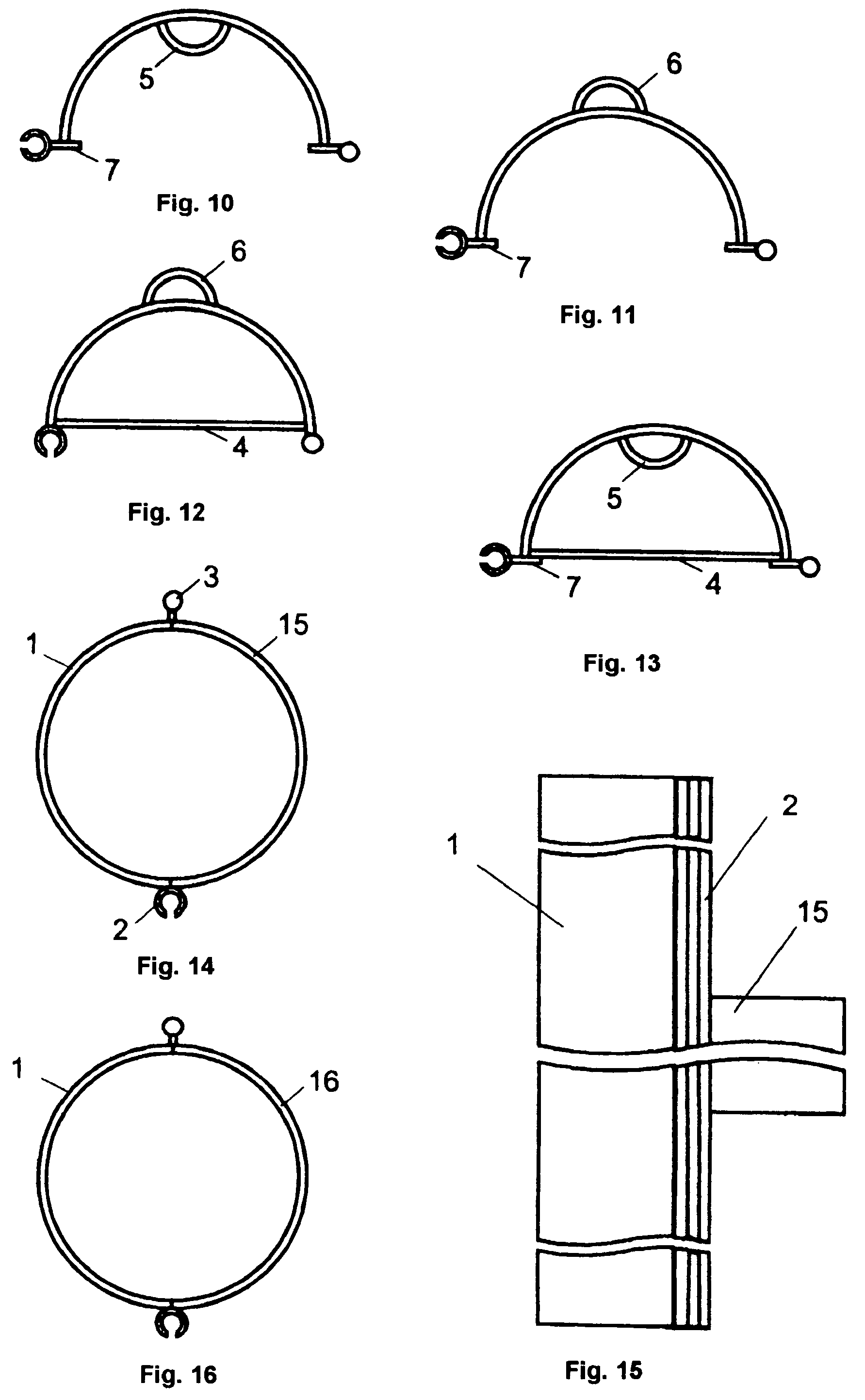

Grooved sheet pile and method for production thereof

InactiveUS7175369B2Simplify the manufacturing processVariability of their designArtificial islandsExcavationsUltimate tensile strengthSheet pile

To simplify the production and expand the variability of structures to use, a grooved sheet pile having a trough-type body is produced by cutting a cylindrical segment (referred to as a troughlike element) (1) from a round tube along its length and fixing locking elements (2) and (3) to side edges of the troughlike element. The troughlike element (1) can be reinforced by attaching reinforcing elements (4) thereto and / or providing annular elements (15), (16). The troughlike element (1) has a section made of material of higher strength and / or corrosion-resistant and / or thickened material. The troughlike elements (1) can be arranged in parallel and fixed to each other to make a panel.

Owner:SHEET PILE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com