Patents

Literature

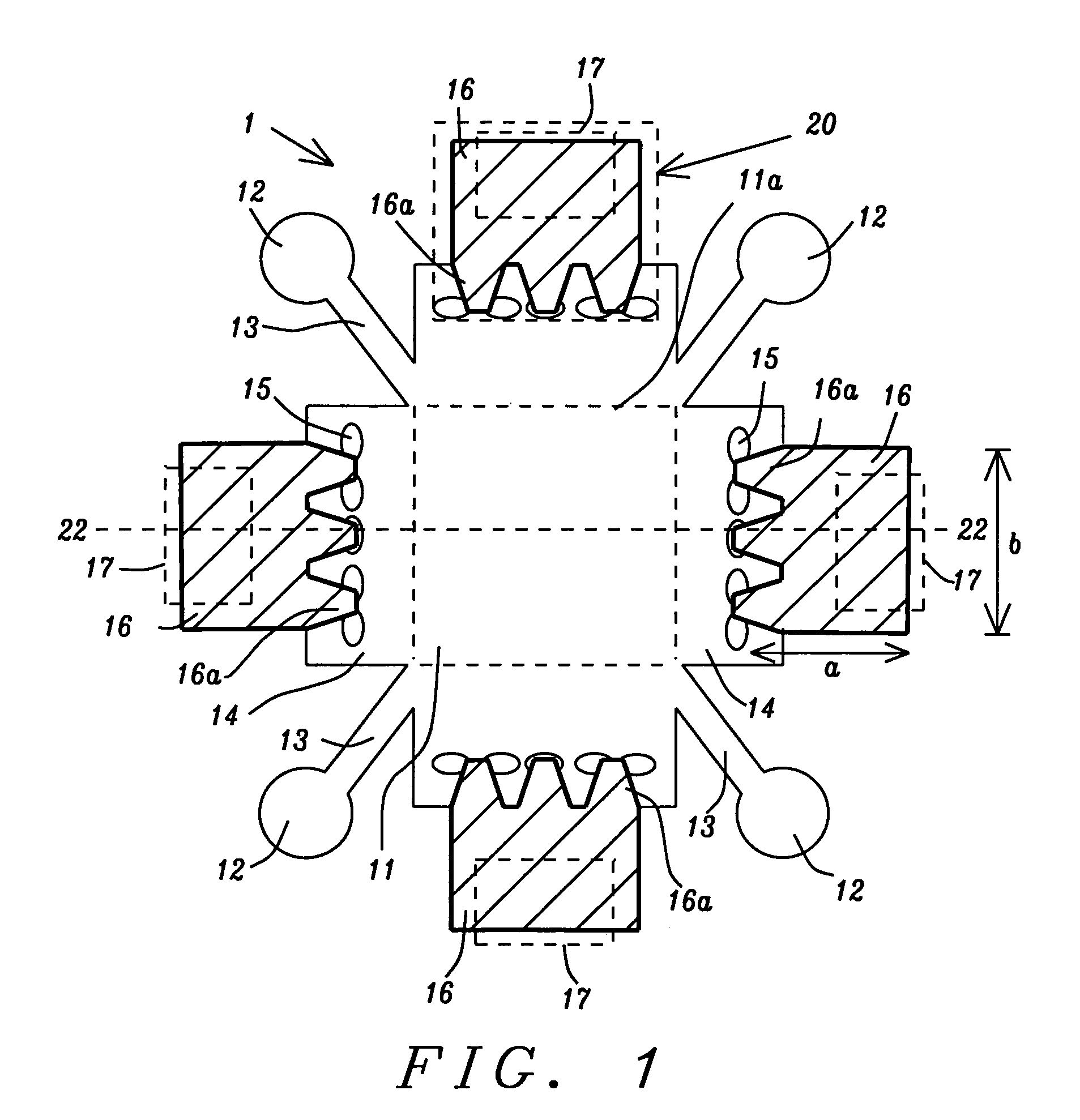

694 results about "CELLULAR SHEET" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

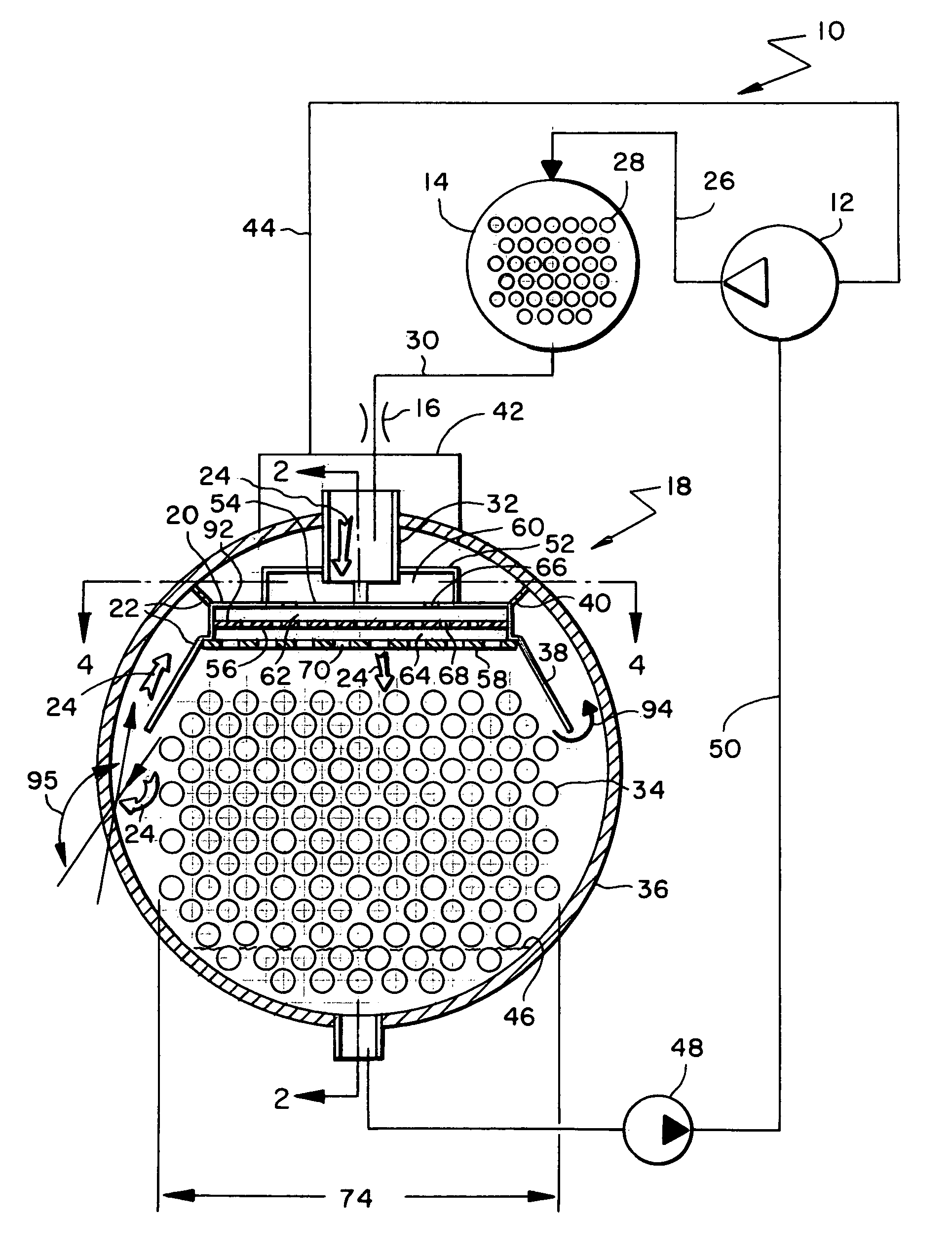

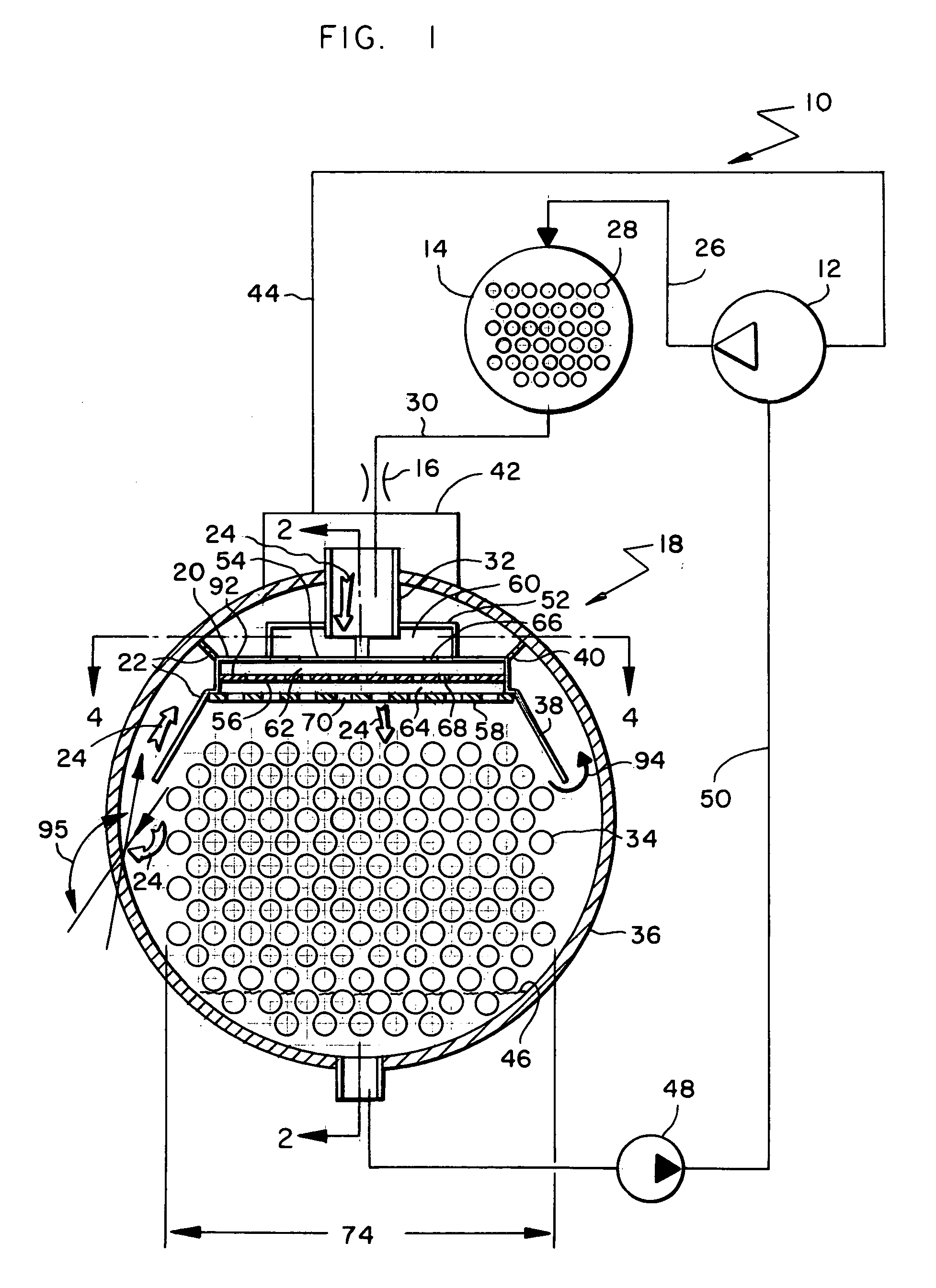

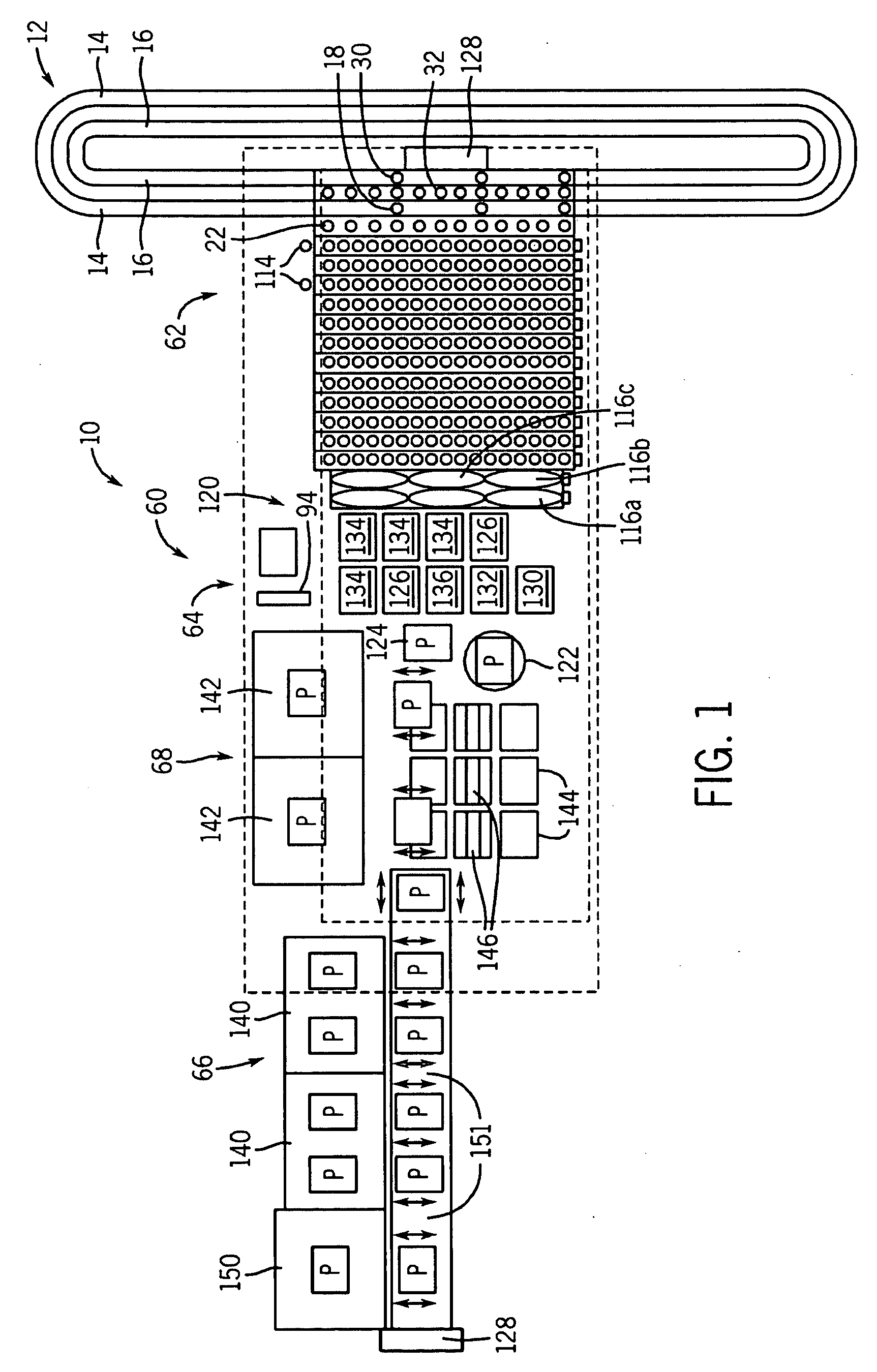

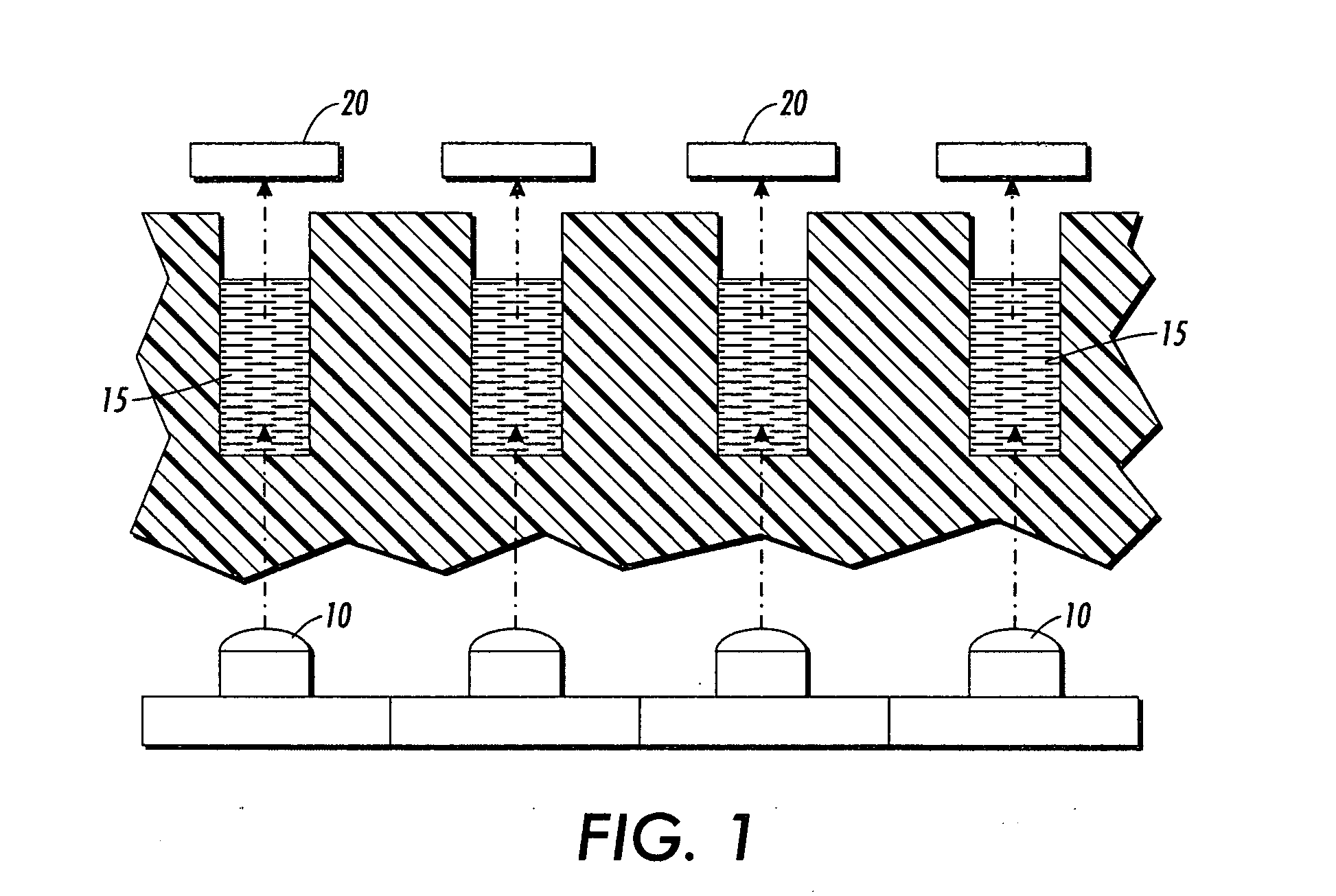

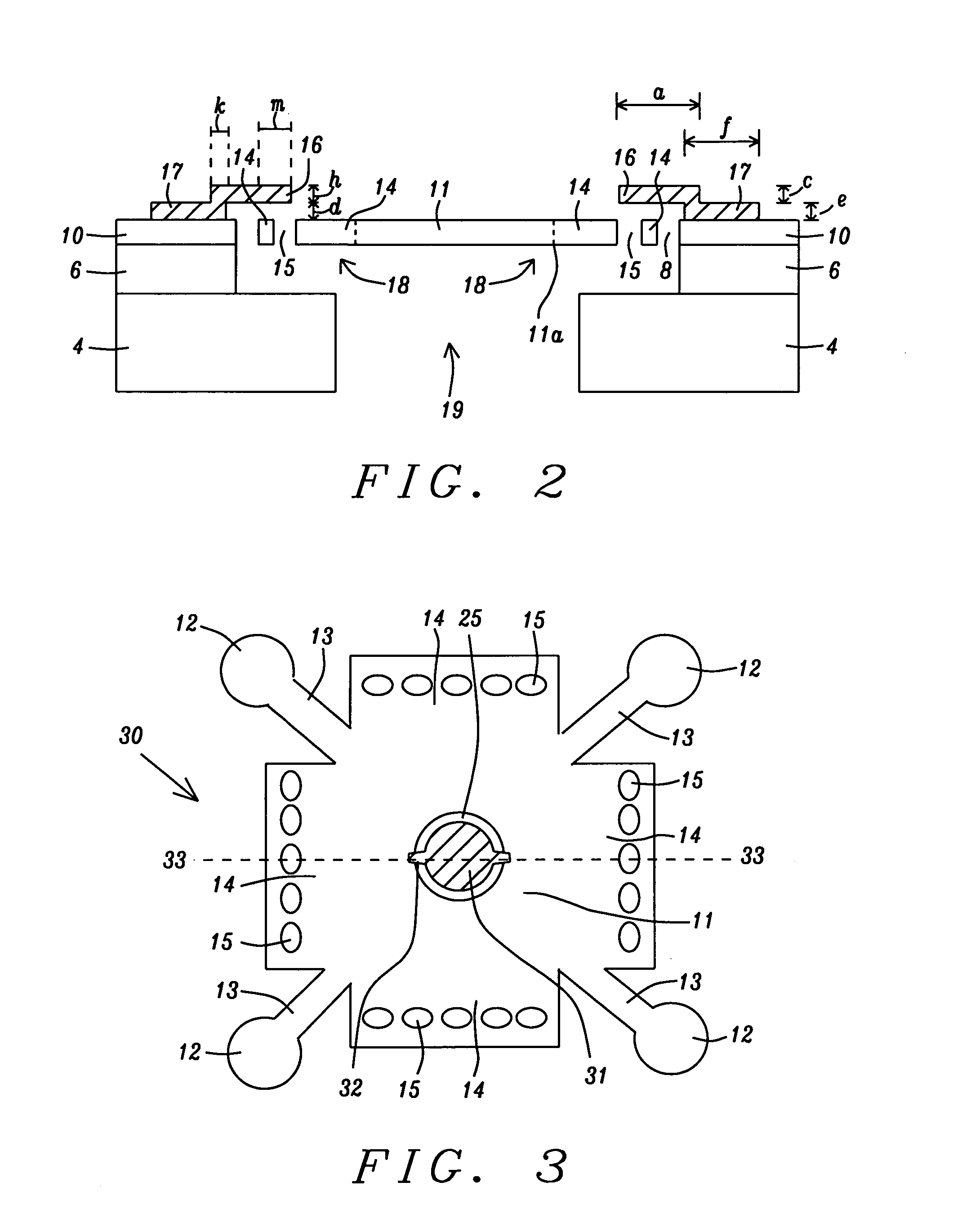

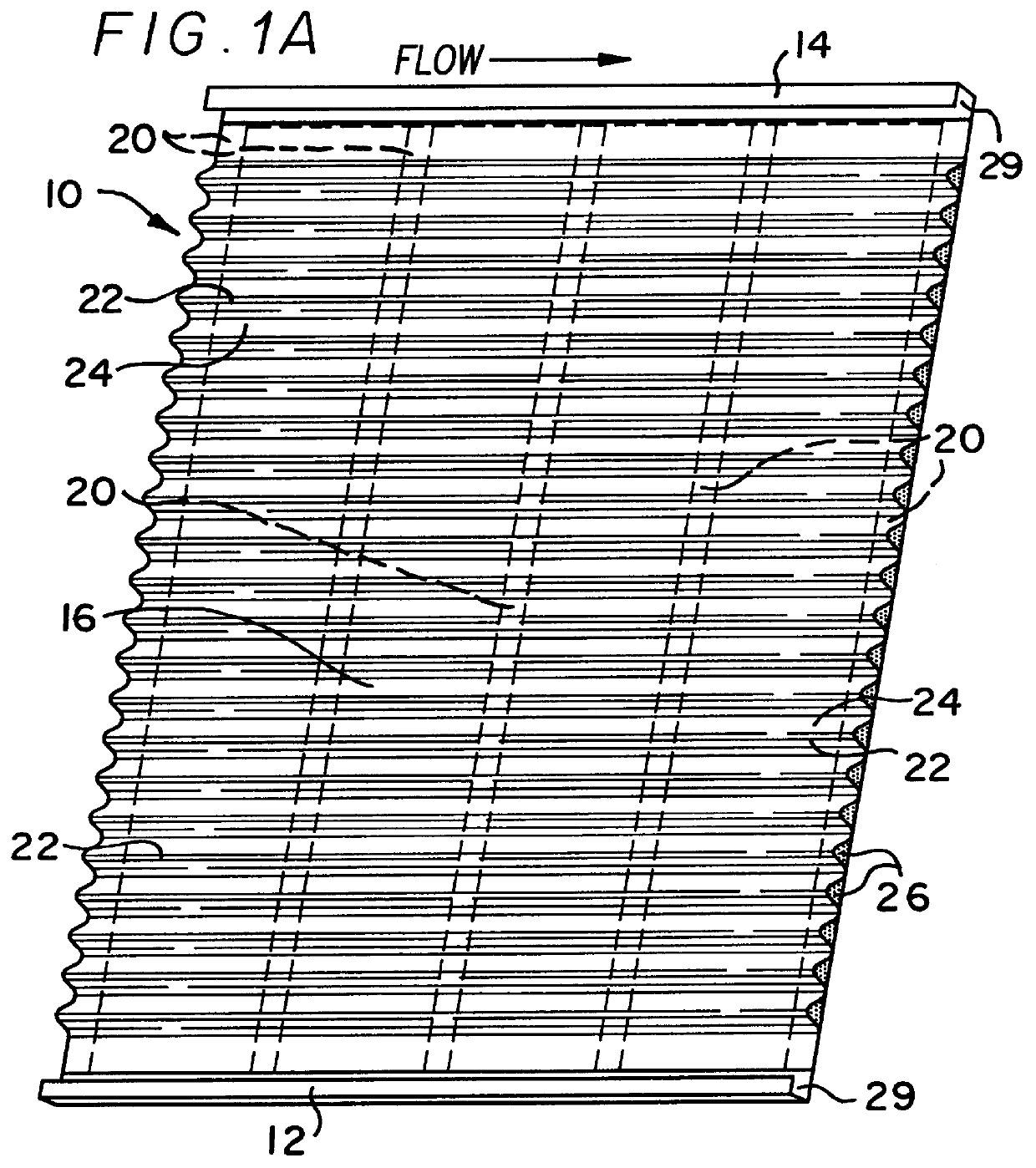

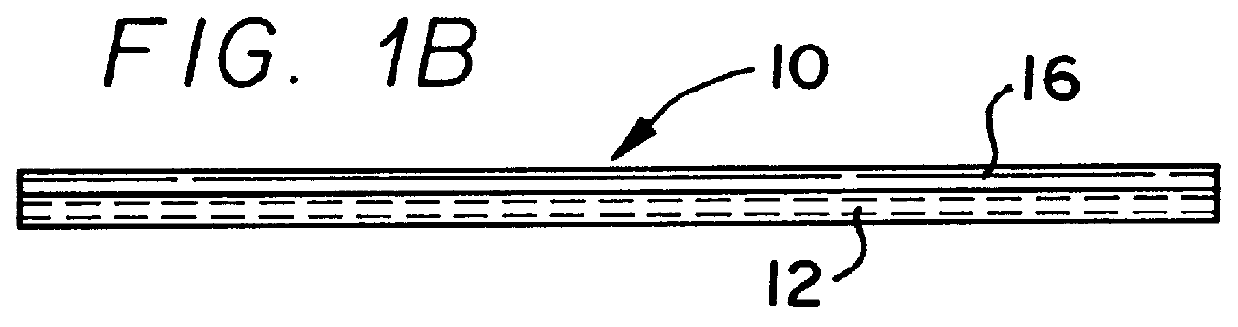

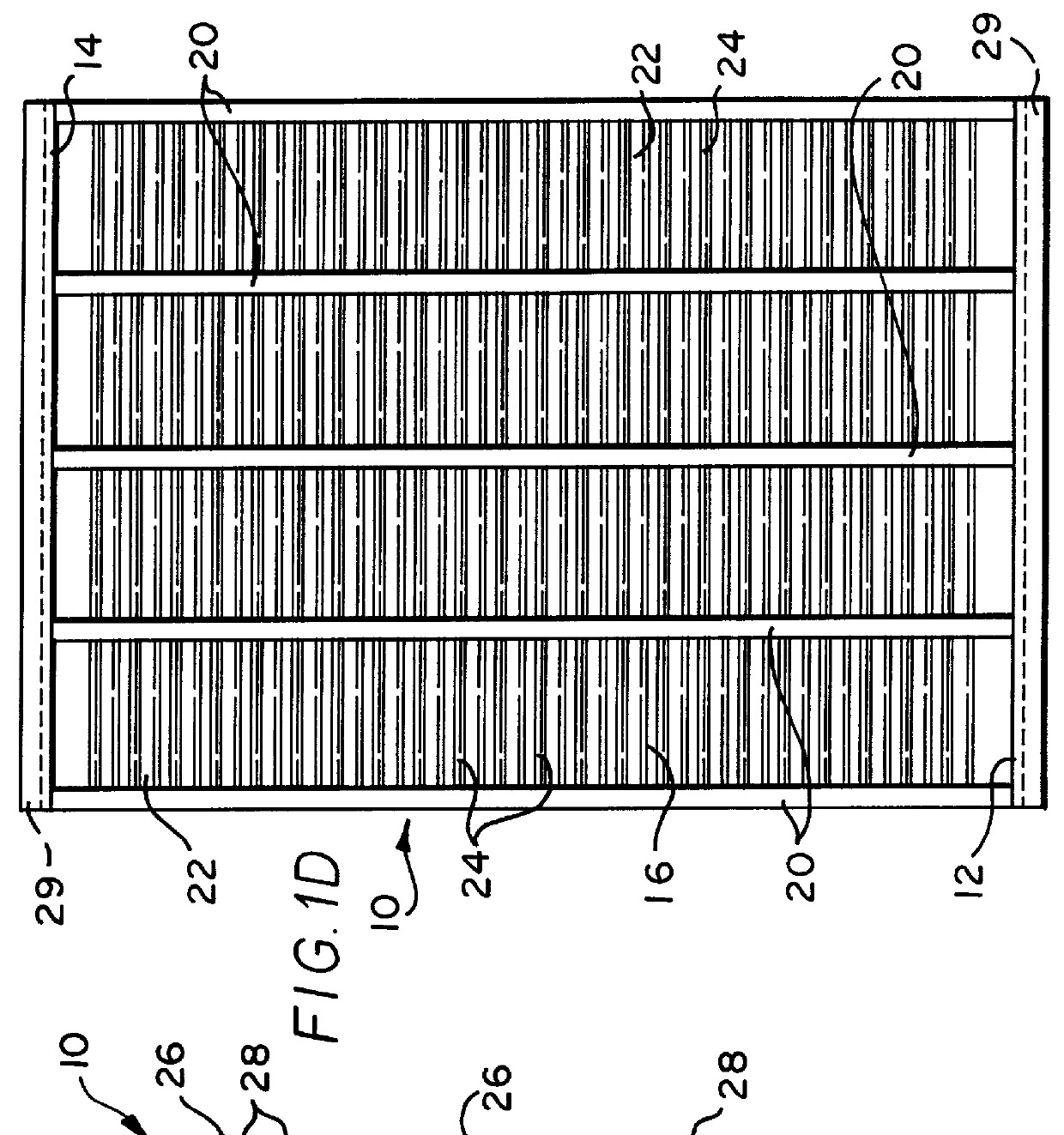

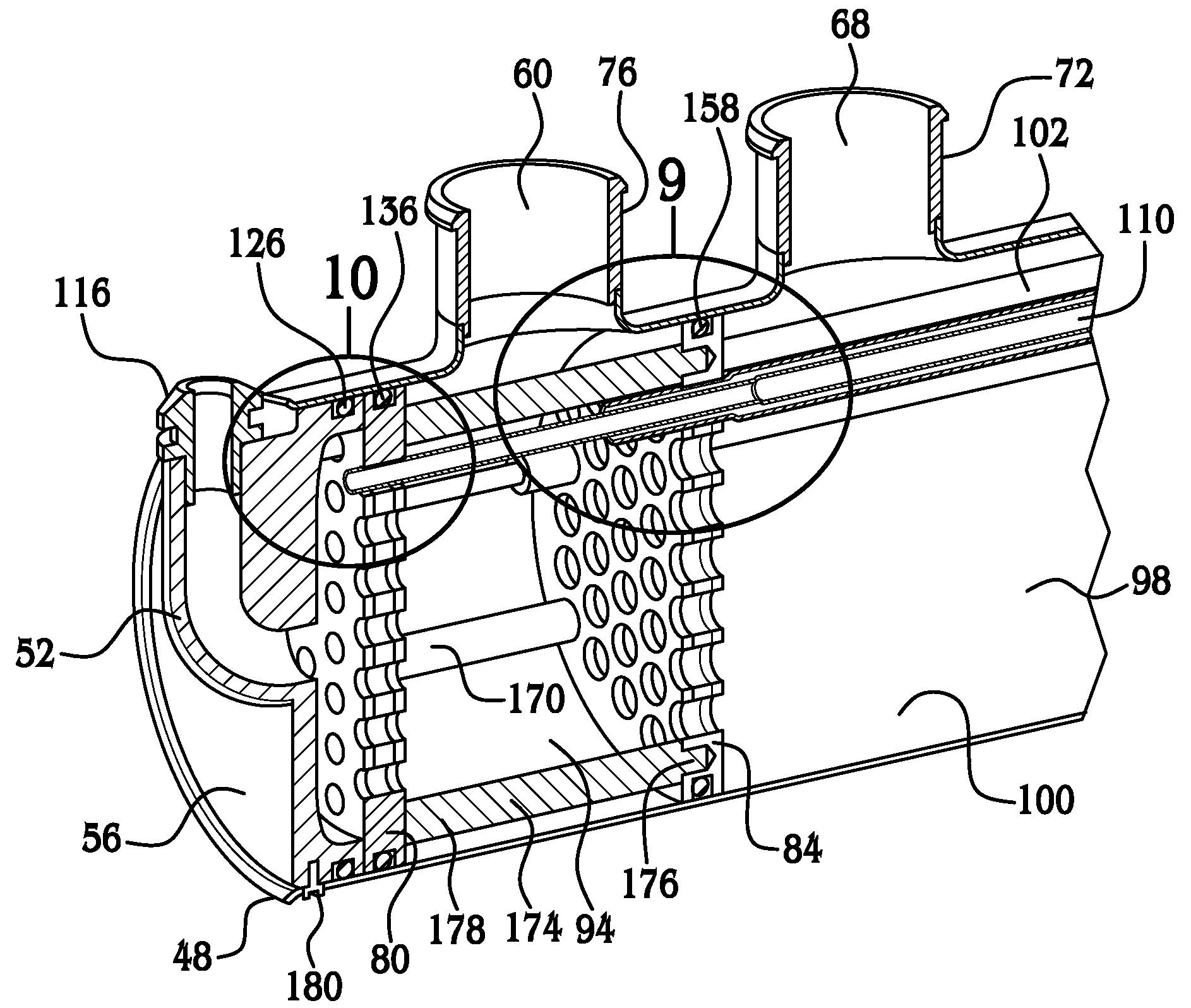

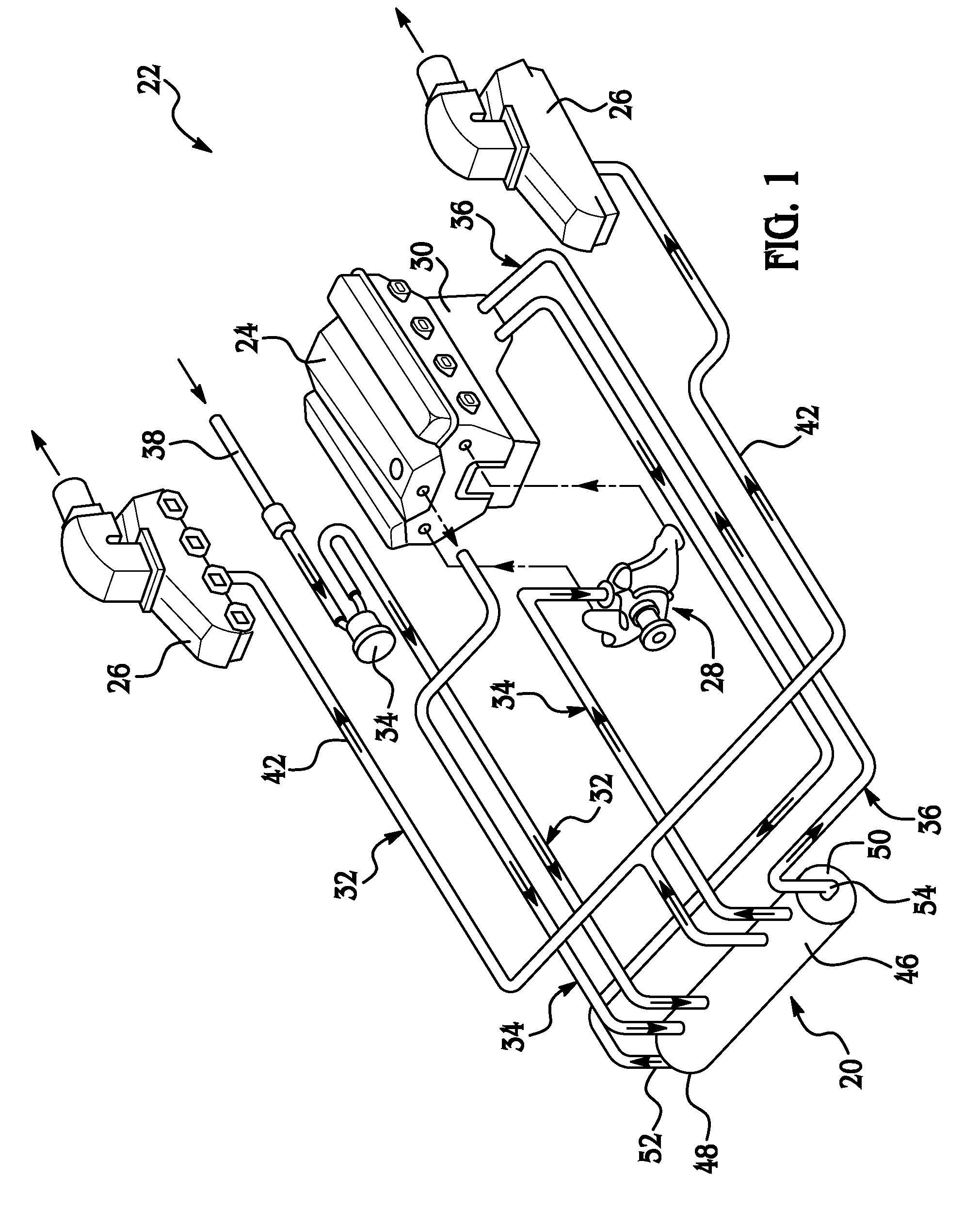

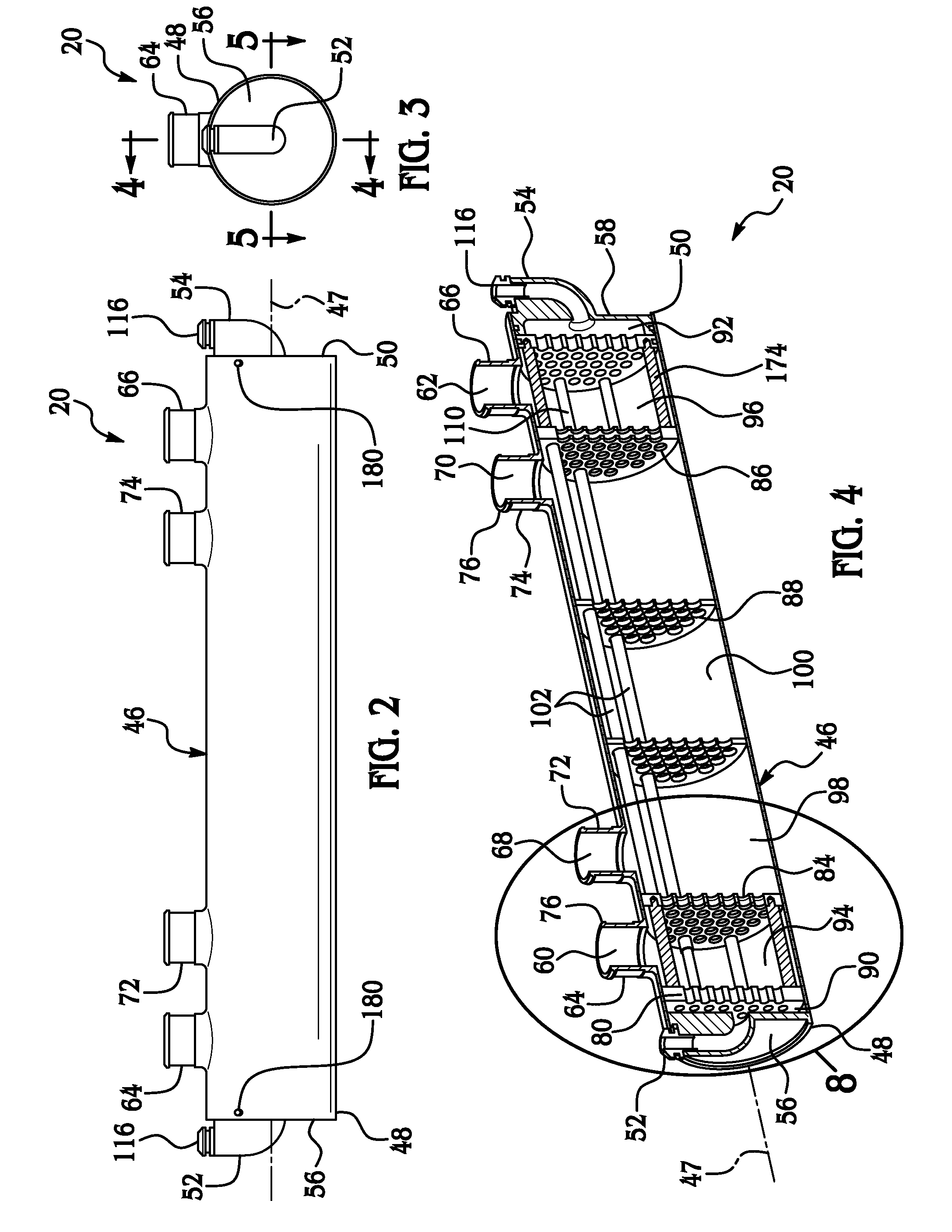

Flow distributor and baffle system for a falling film evaporator

ActiveUS6868695B1Even flow distributionEasy to separateMilk preservationEvaporators/condensersEngineeringRefrigerant

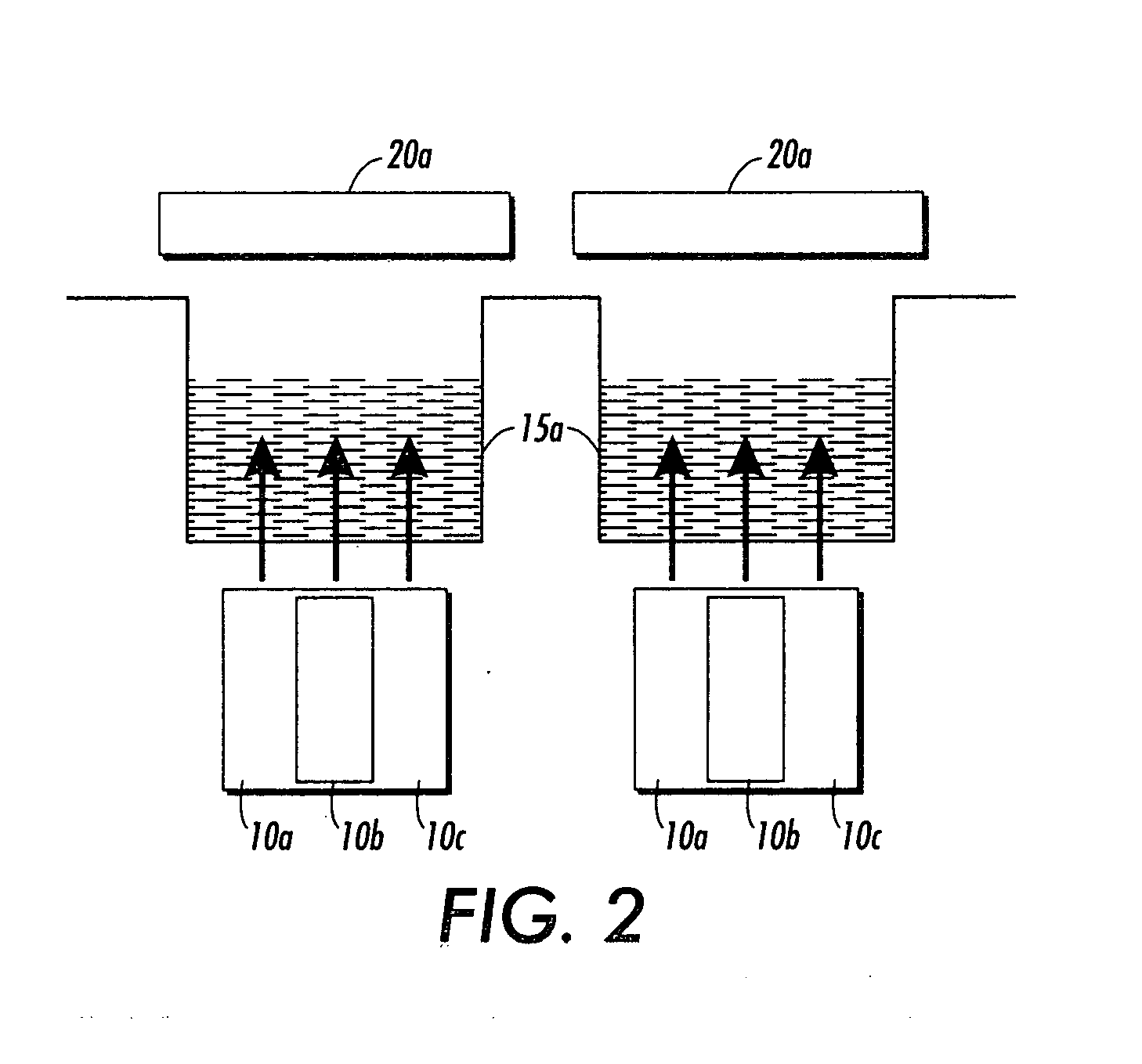

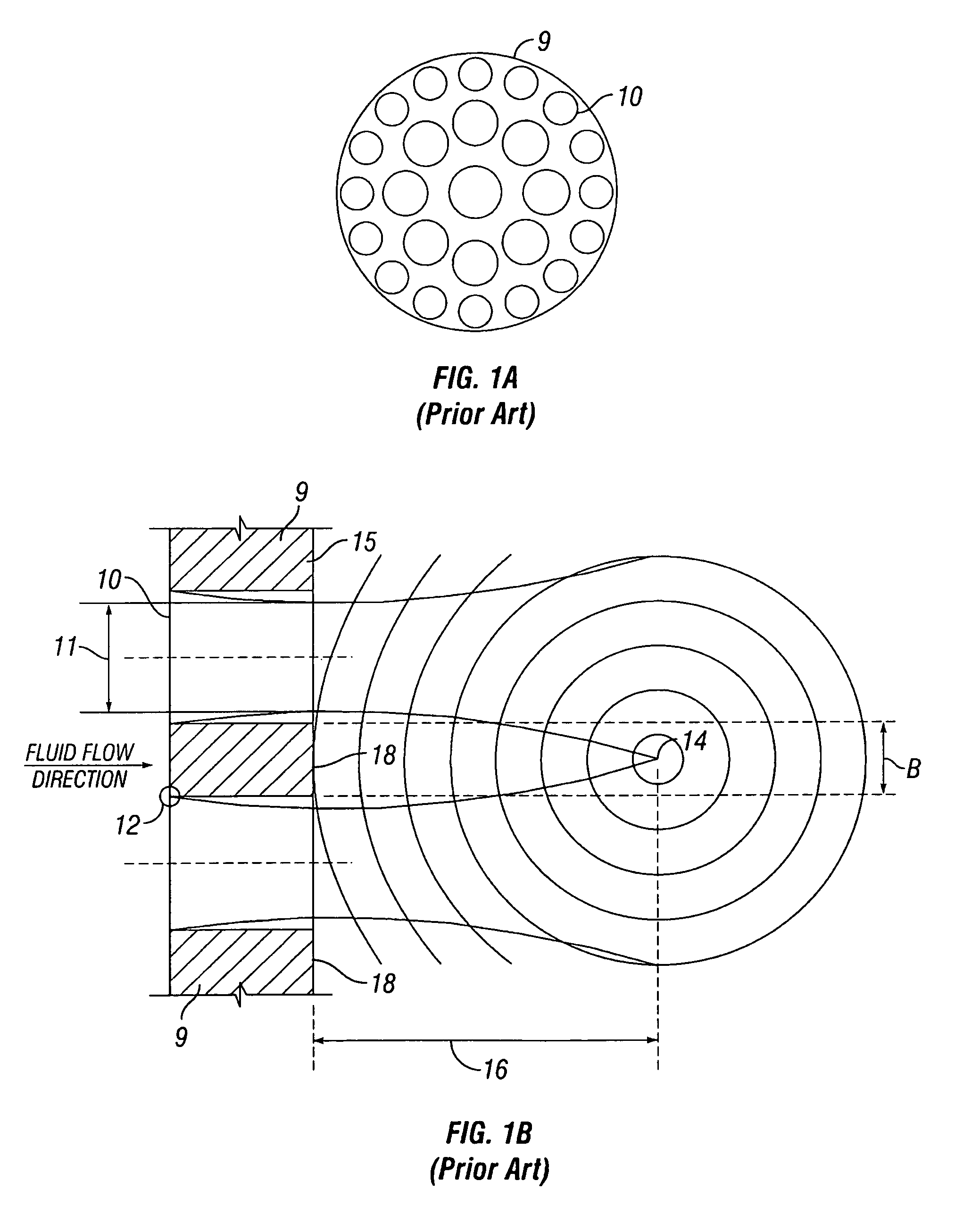

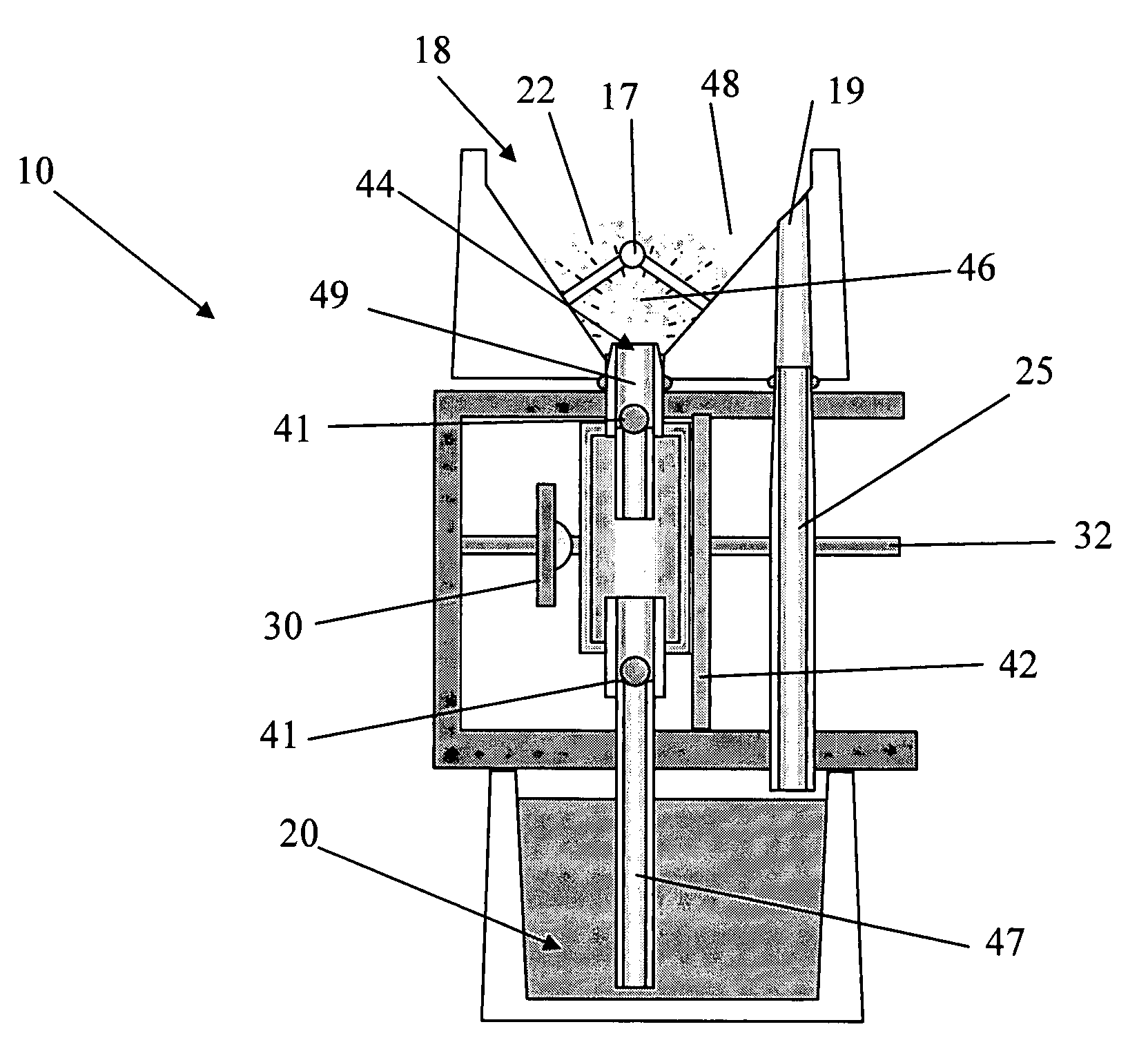

A falling film evaporator includes a flow distributor for uniformly distributing a two-phase refrigerant mixture across a tube bundle. The flow distributor includes a stack of at least three perforated plates each of which are separated by nearly full-width, full-length gaps or chambers. The flow distributor may also include a suction baffle and / or a distributor baffle. The distributor baffle extends downward to provide a hairpin turn past which refrigerant travels before exiting the evaporator. This directional change helps separate liquid from a primarily gaseous refrigerant stream. The suction baffle has various size openings to ensure that the flow rate of refrigerant through the hairpin turn is generally uniform and is maintained low enough to ensure liquid disentrainment over and along the length of the tube bundle within the evaporator.

Owner:TRANE INT INC

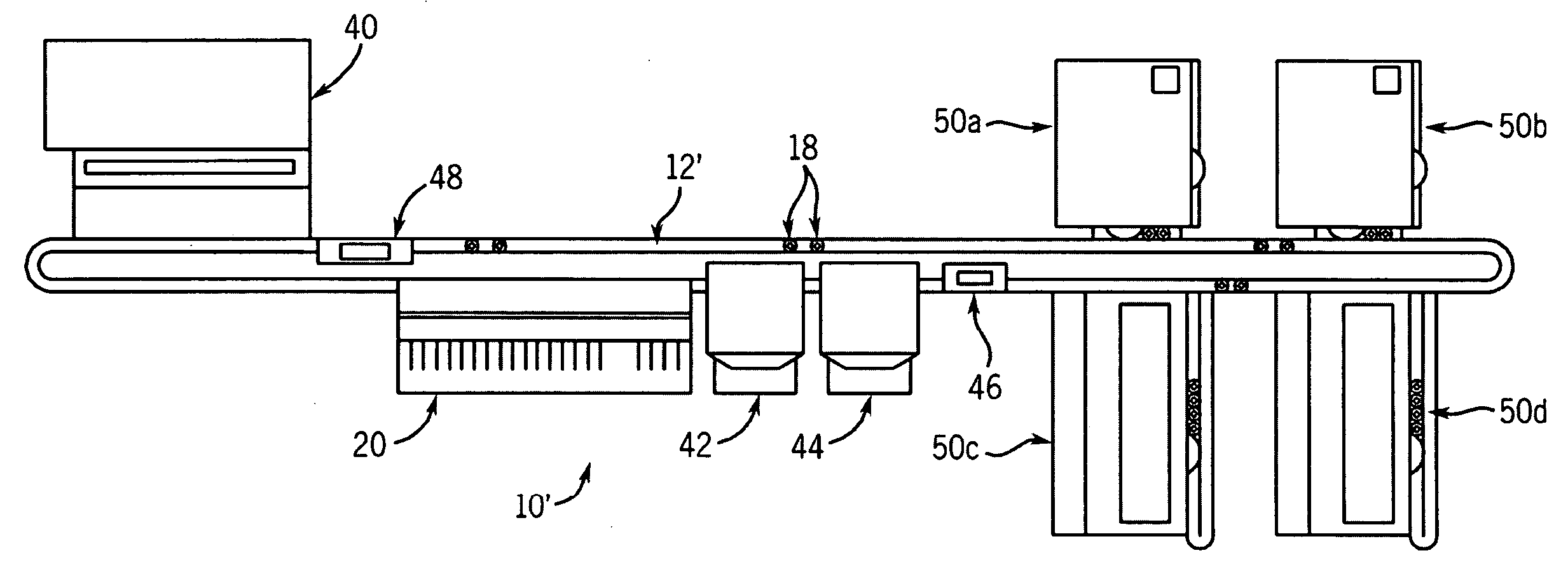

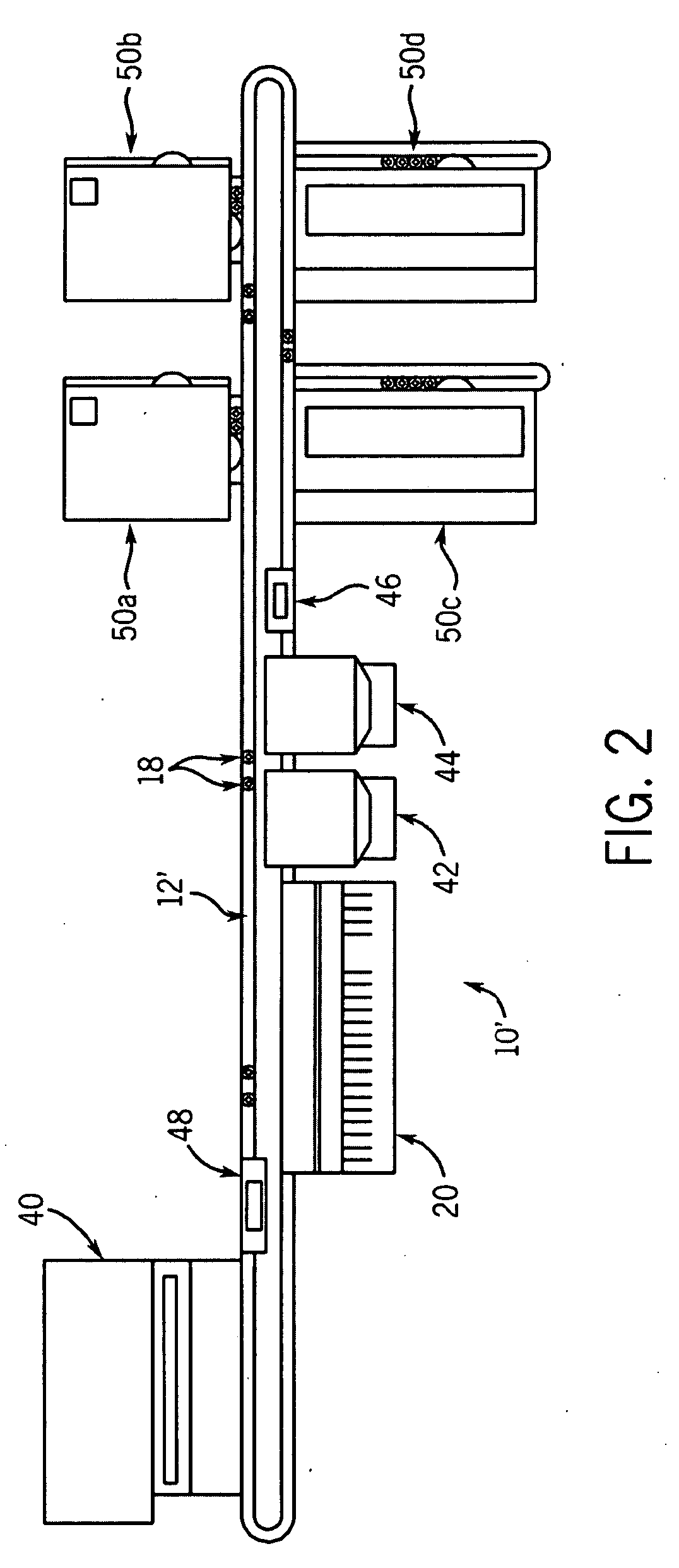

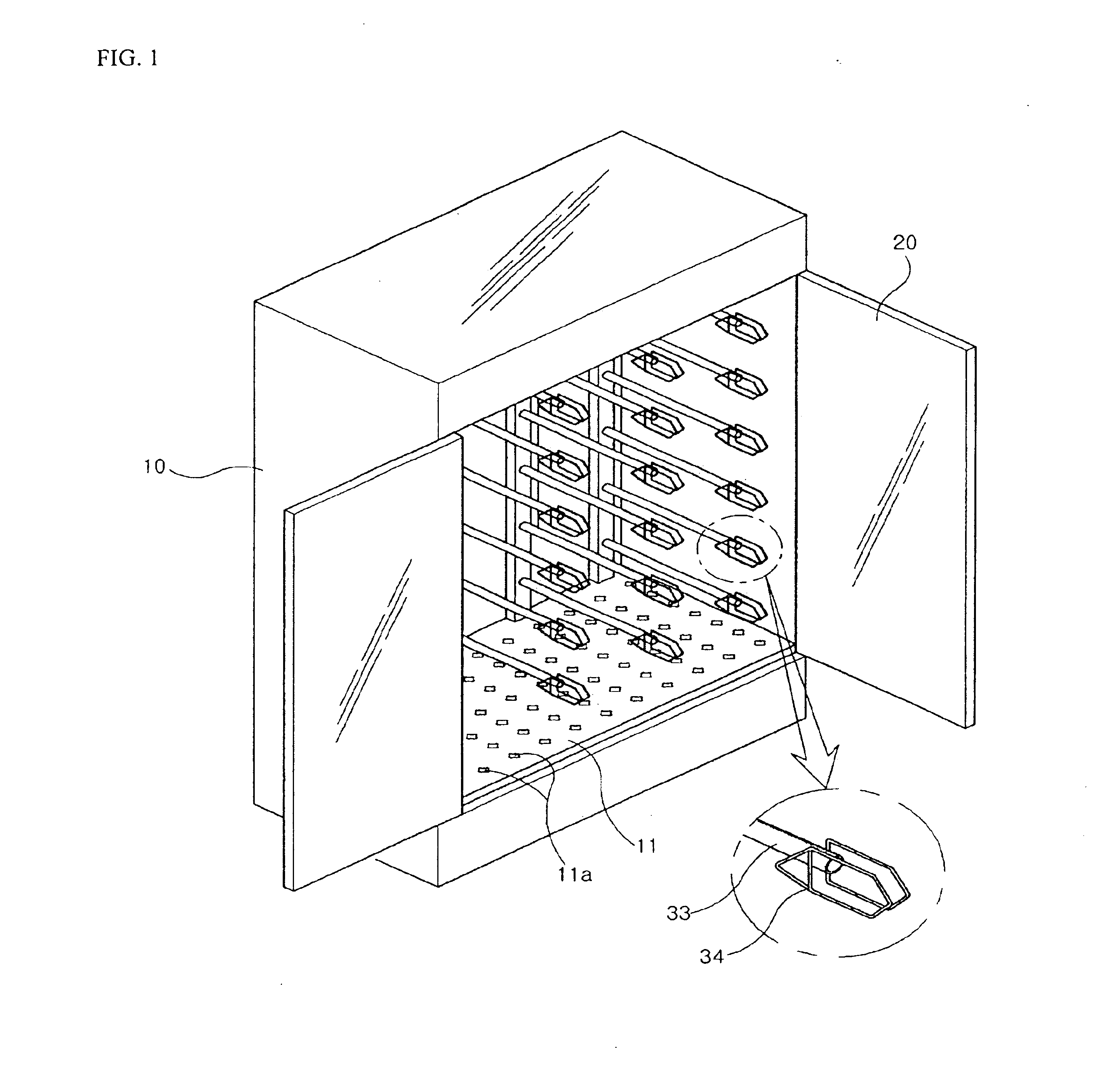

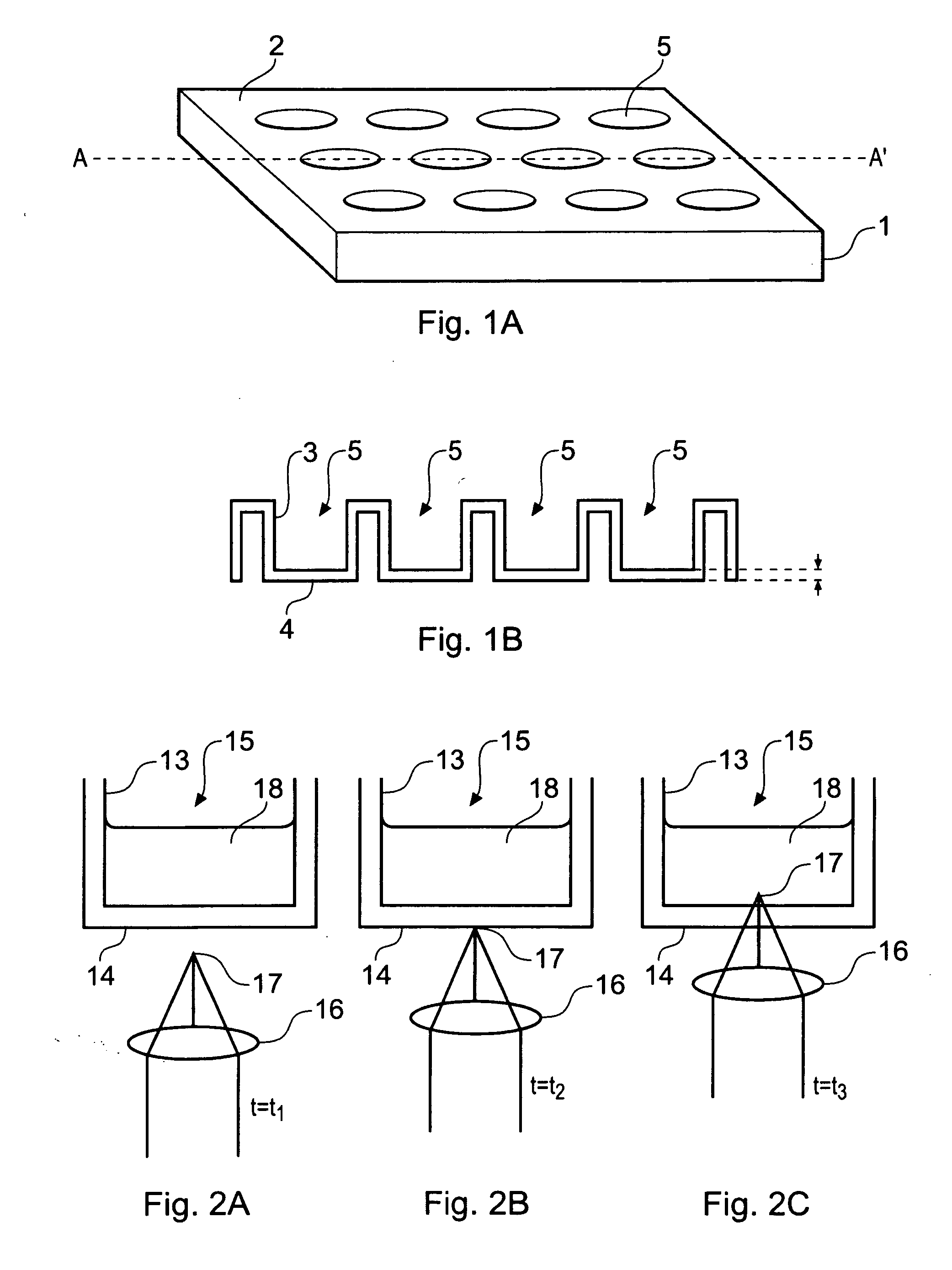

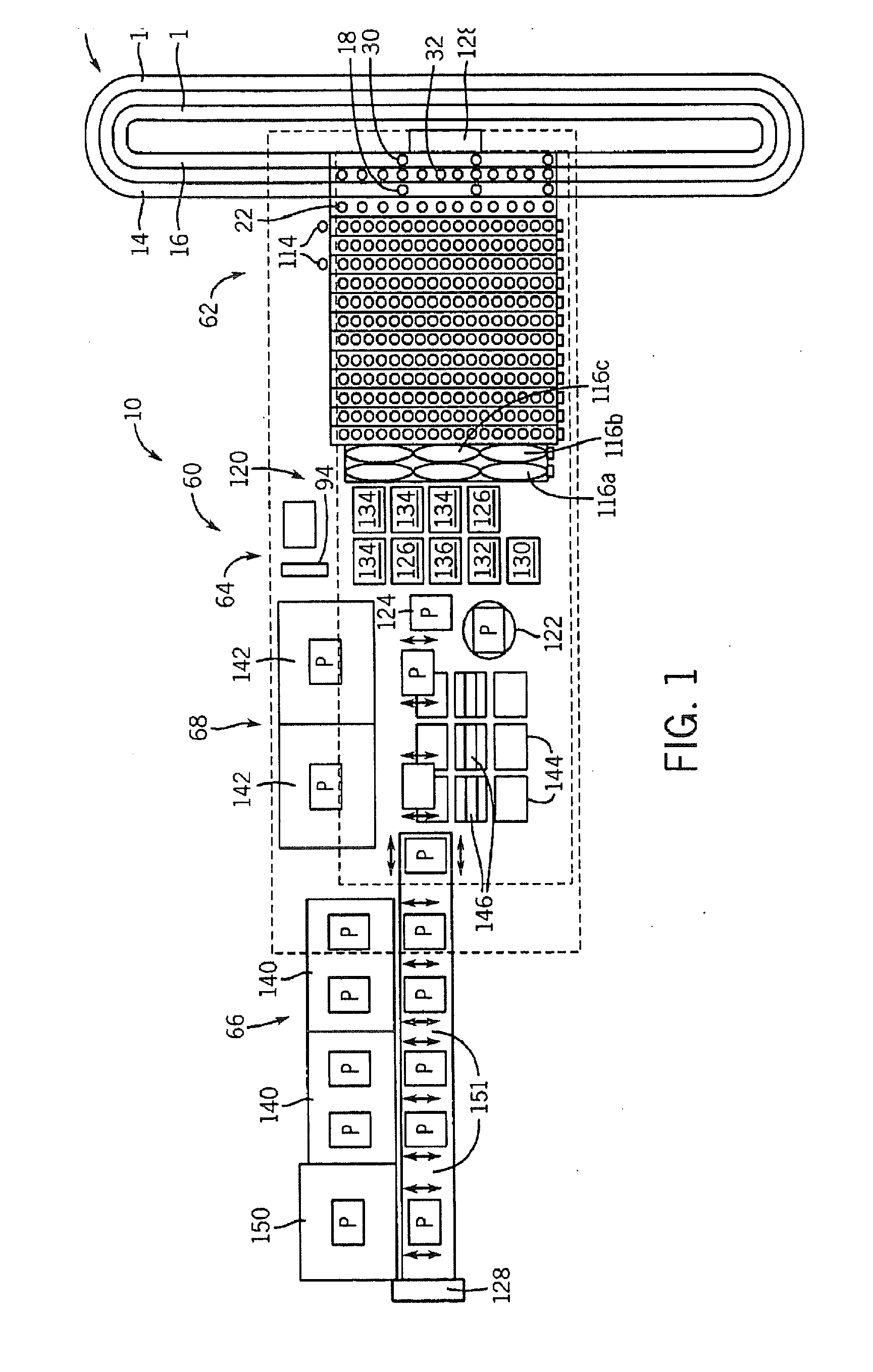

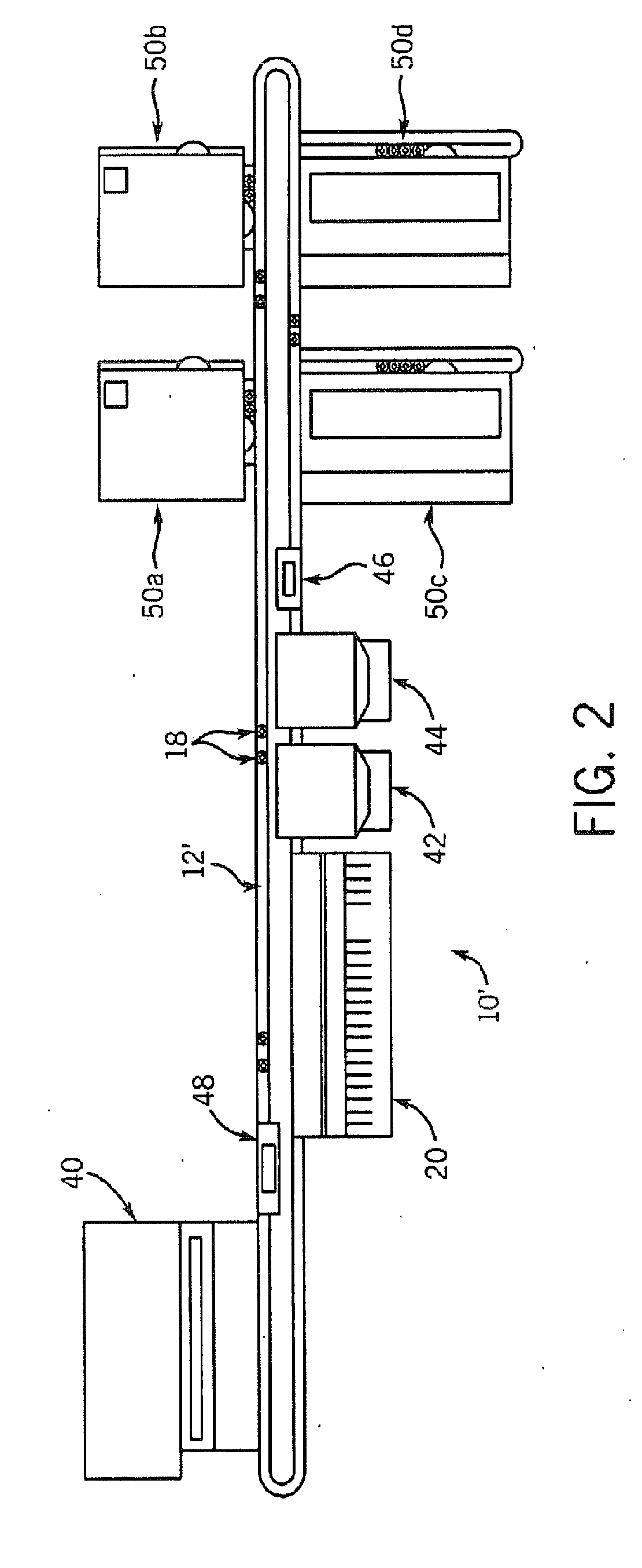

Automated analyzer for clinical laboratory

InactiveUS20090117620A1Manual loadingBioreactor/fermenter combinationsBiological substance pretreatmentsClinical chemistryMicro perforated plate

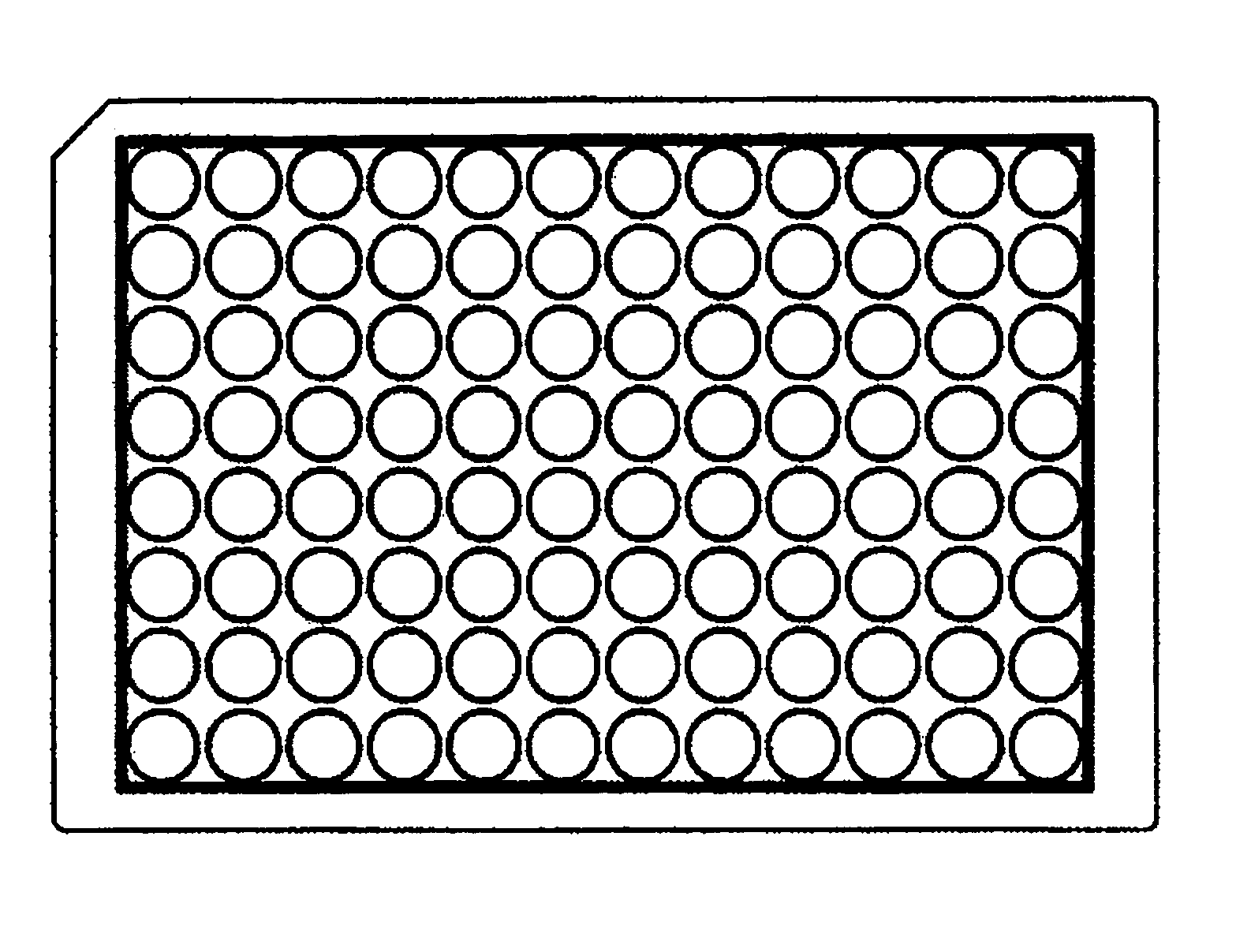

A laboratory automation system that is capable of carrying out clinical chemistry assays, immunoassays, amplification of nucleic acid assays, and any combination of the foregoing, said laboratory automation system employing at least one of micro-well plates and deep multi-well plates as reaction vessels. The use of micro-well plates as reaction vessels enables the laboratory automation system to assume a variety of arrangements, i.e., the laboratory automation system can comprise a variety of functional modules that can be arranged in various ways. In order to effectively carry out immunoassays by means of micro-well plates, a technique known as inverse magnetic particle processing can be used to transfer the product(s) of immunoassays from one micro-well of a micro-well plate to another.

Owner:ABBOTT LAB INC

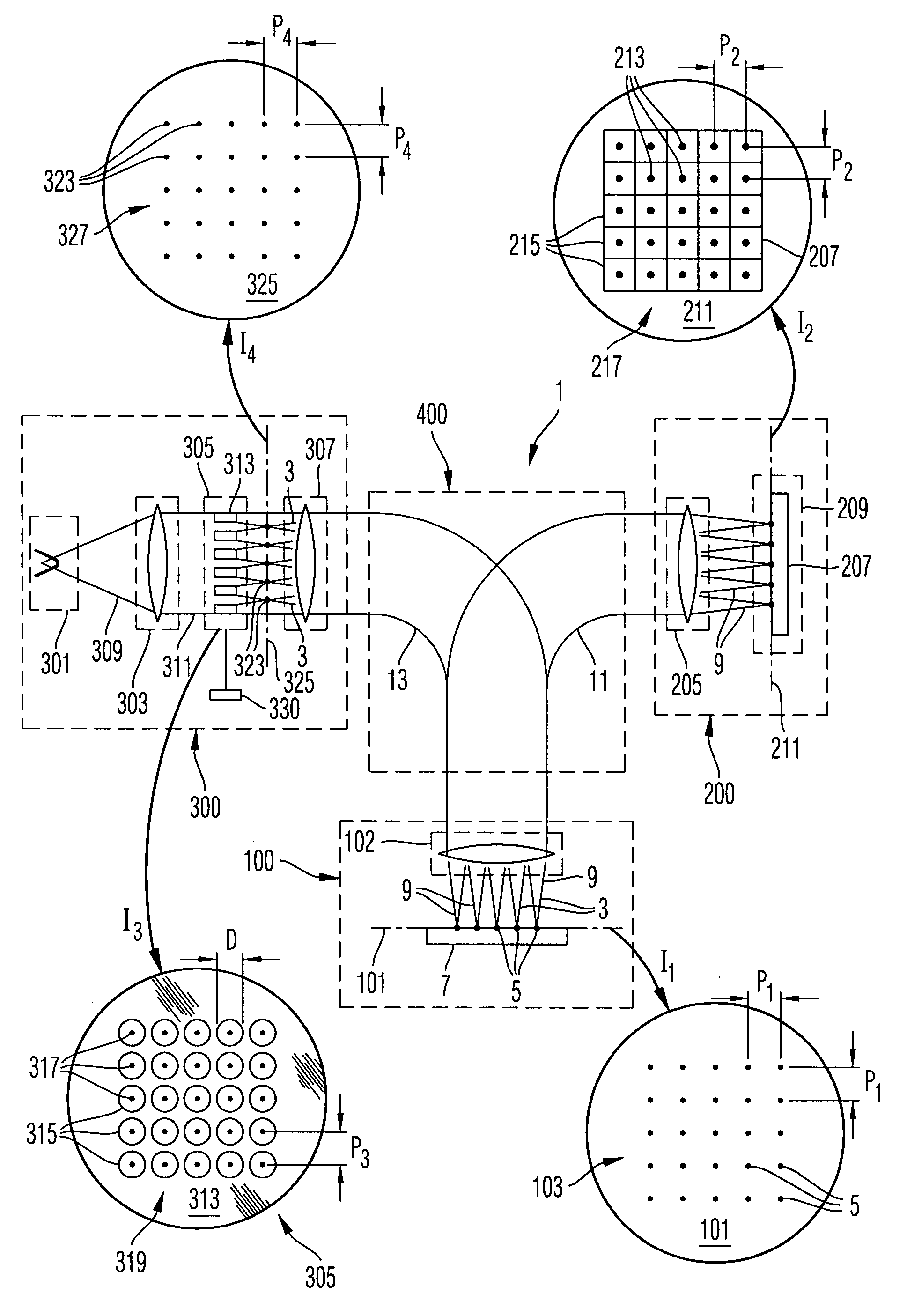

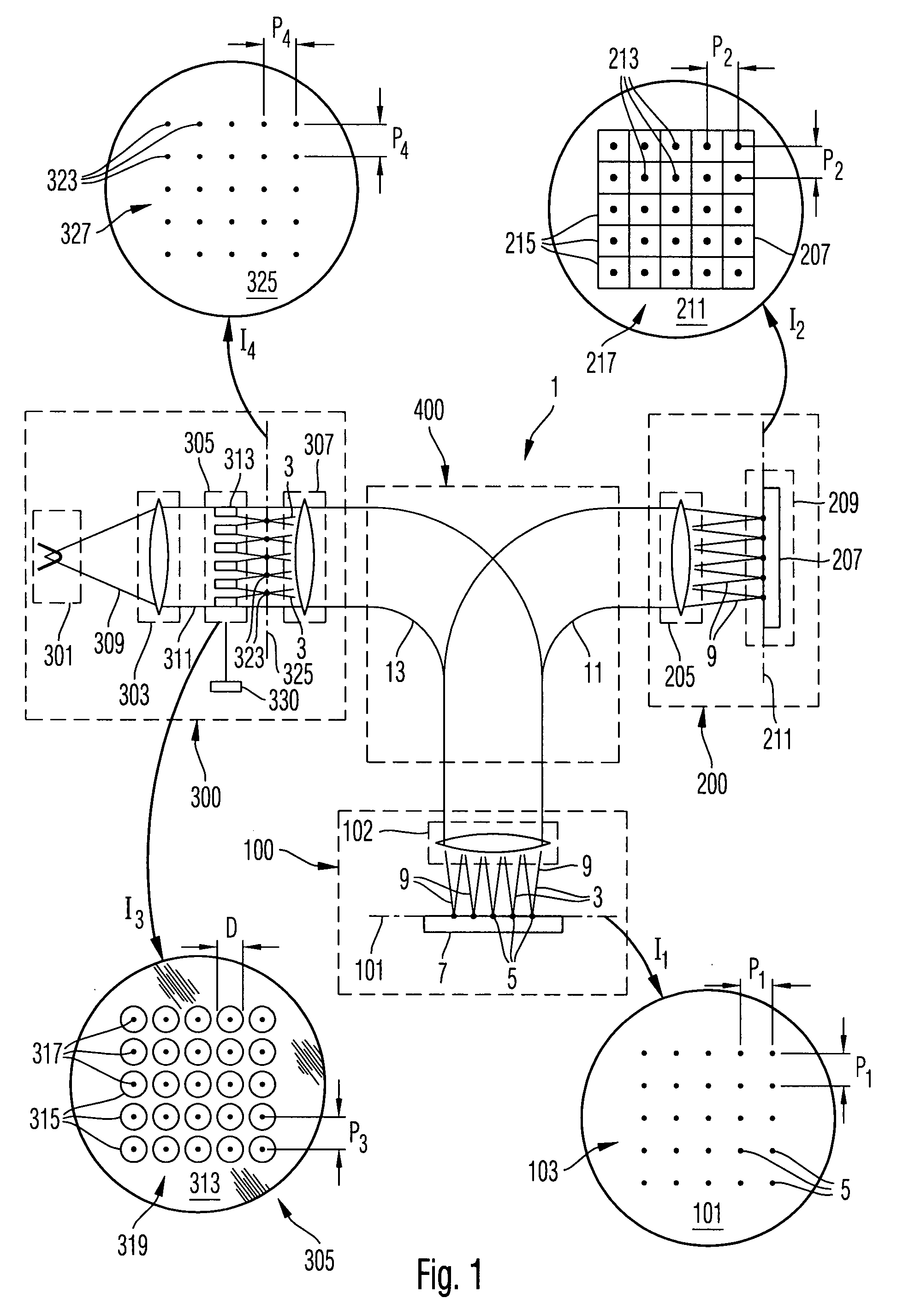

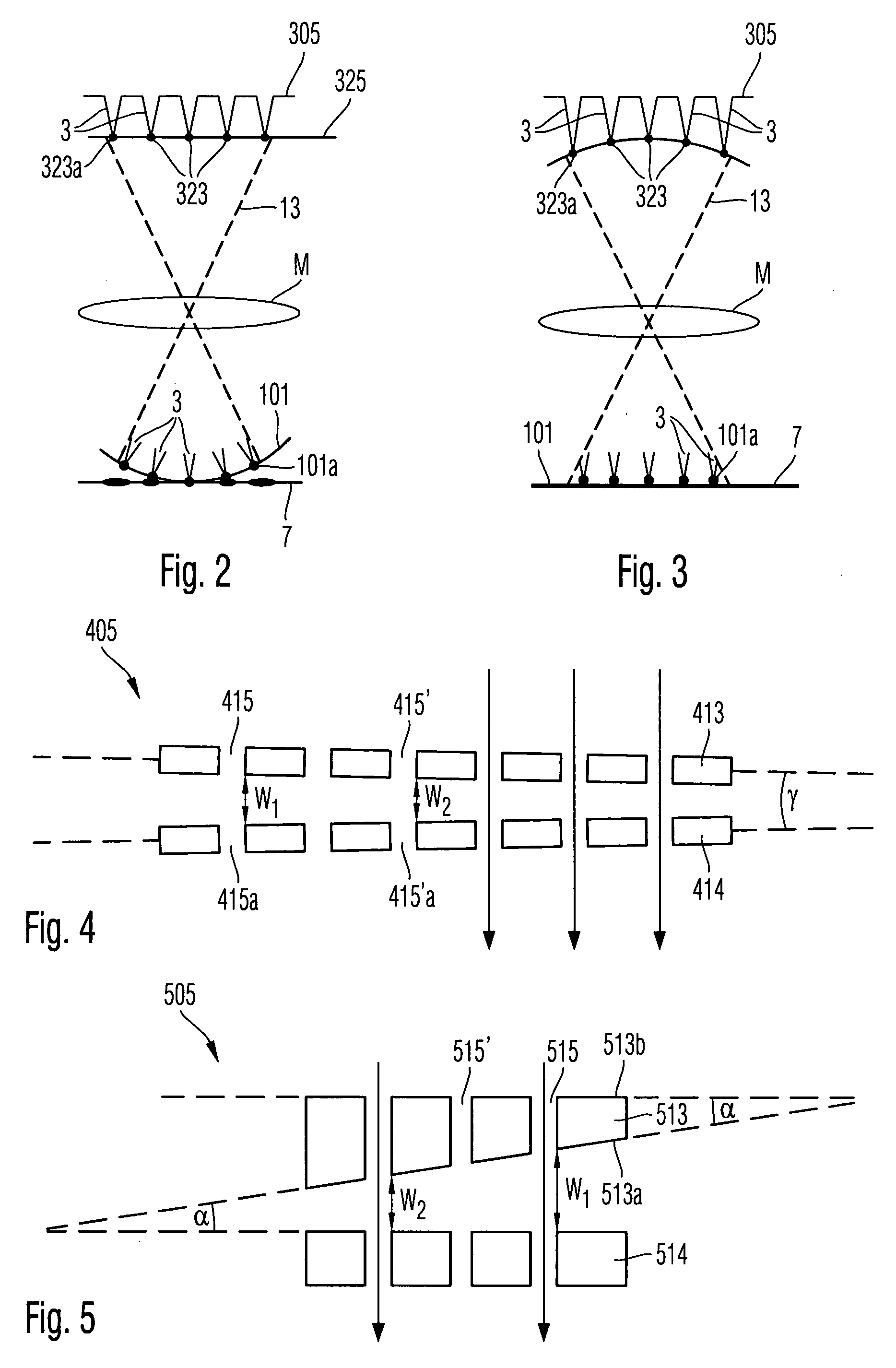

Particle-Optical Component

ActiveUS20090114818A1Reduce rateThermometer detailsMaterial analysis using wave/particle radiationEngineeringMechanical engineering

The present invention relates to a particle-optical component comprising a first multi-aperture plate, and a second multi-aperture plate forming a gap between them; wherein a plurality of apertures of the first multi-aperture plate is arranged such that each aperture of the plurality of apertures of the first multi-aperture plate is aligned with a corresponding aperture of a plurality of apertures of the second multi-aperture plate; and wherein the gap has a first width at a first location and a second width at a second location and wherein the second width is by at least 5% greater than the first width. In addition, the present invention pertains to charged particle systems and arrangements comprising such components and methods of manufacturing multi aperture plates having a curved surface.

Owner:APPL MATERIALS ISRAEL LTD +1

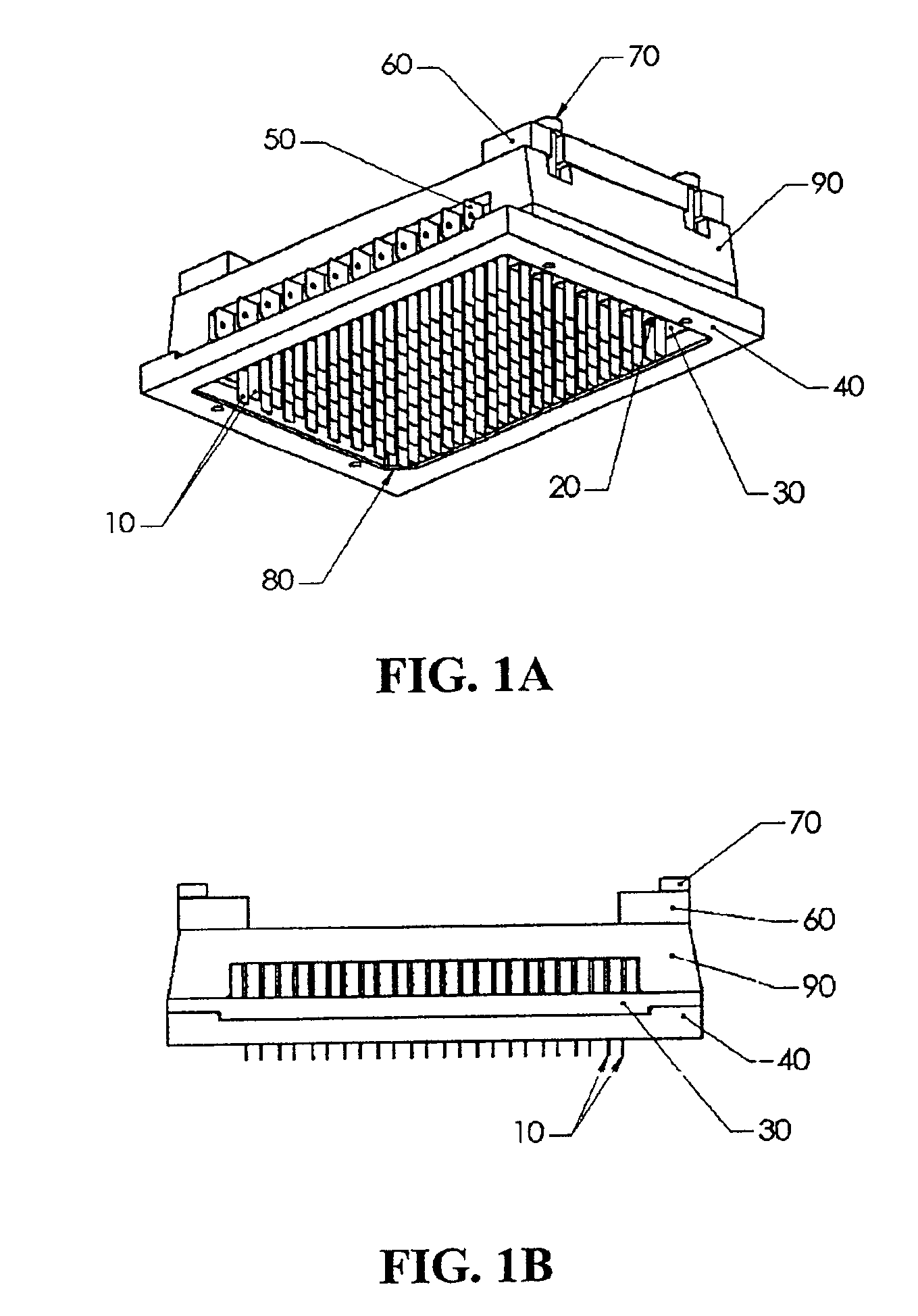

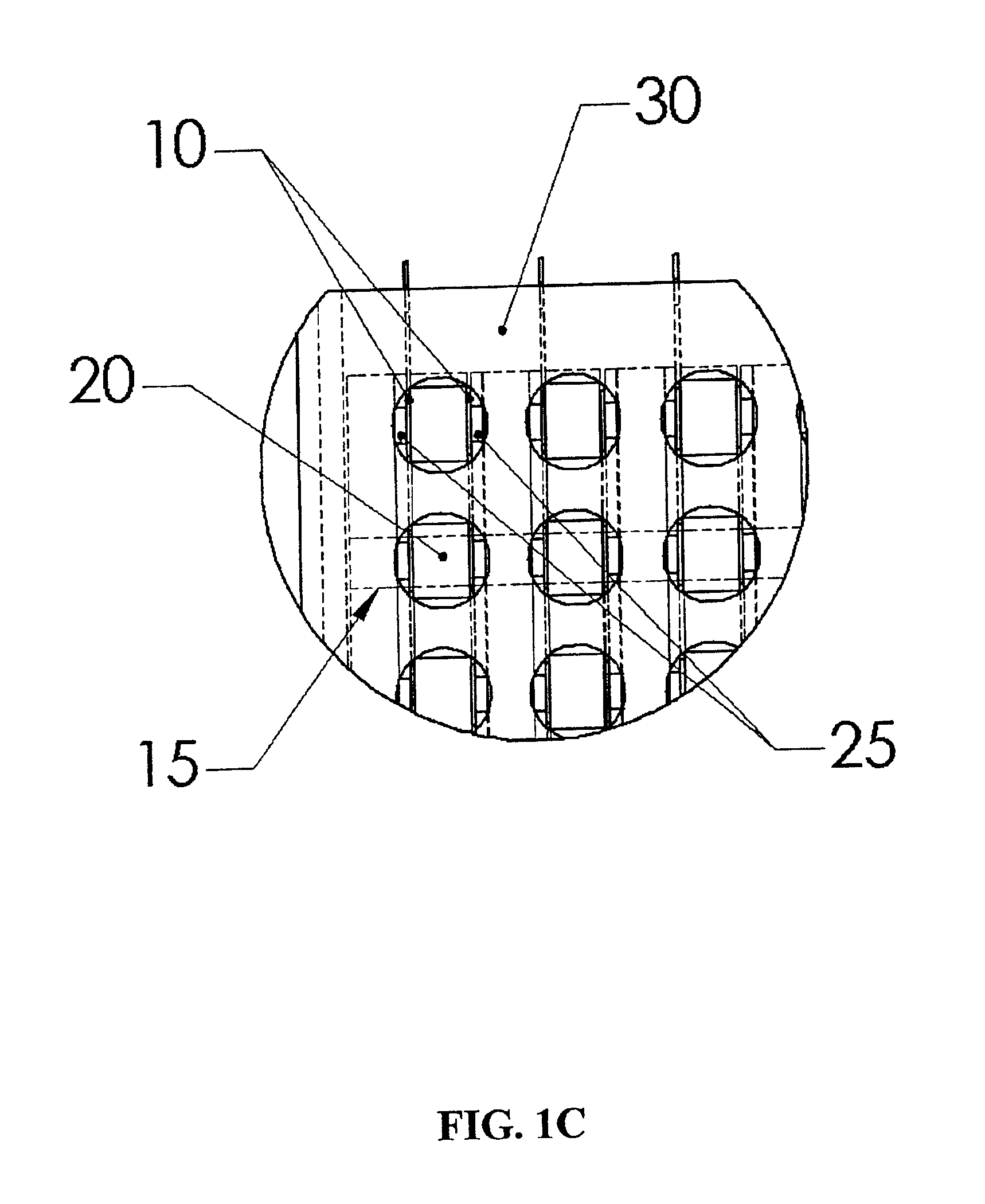

Multi-well plate and electrode assemblies for ion channel assays

InactiveUS6969449B2Immobilised enzymesBioreactor/fermenter combinationsElectrical field strengthEngineering

Plate and electrode assemblies include configurations allowing for relatively uniform electric field production. The electrodes may comprise strips of conductive material plated onto the bottom surface of sample wells or they may comprise plate electrodes extending down into the well. In some embodiments, the electric field strength varies by less than about 10% from a mean field intensity over at least about 20% of the surface area of the bottom surface of a sample well.

Owner:VERTEX PHARMA SAN DIEGO LLC

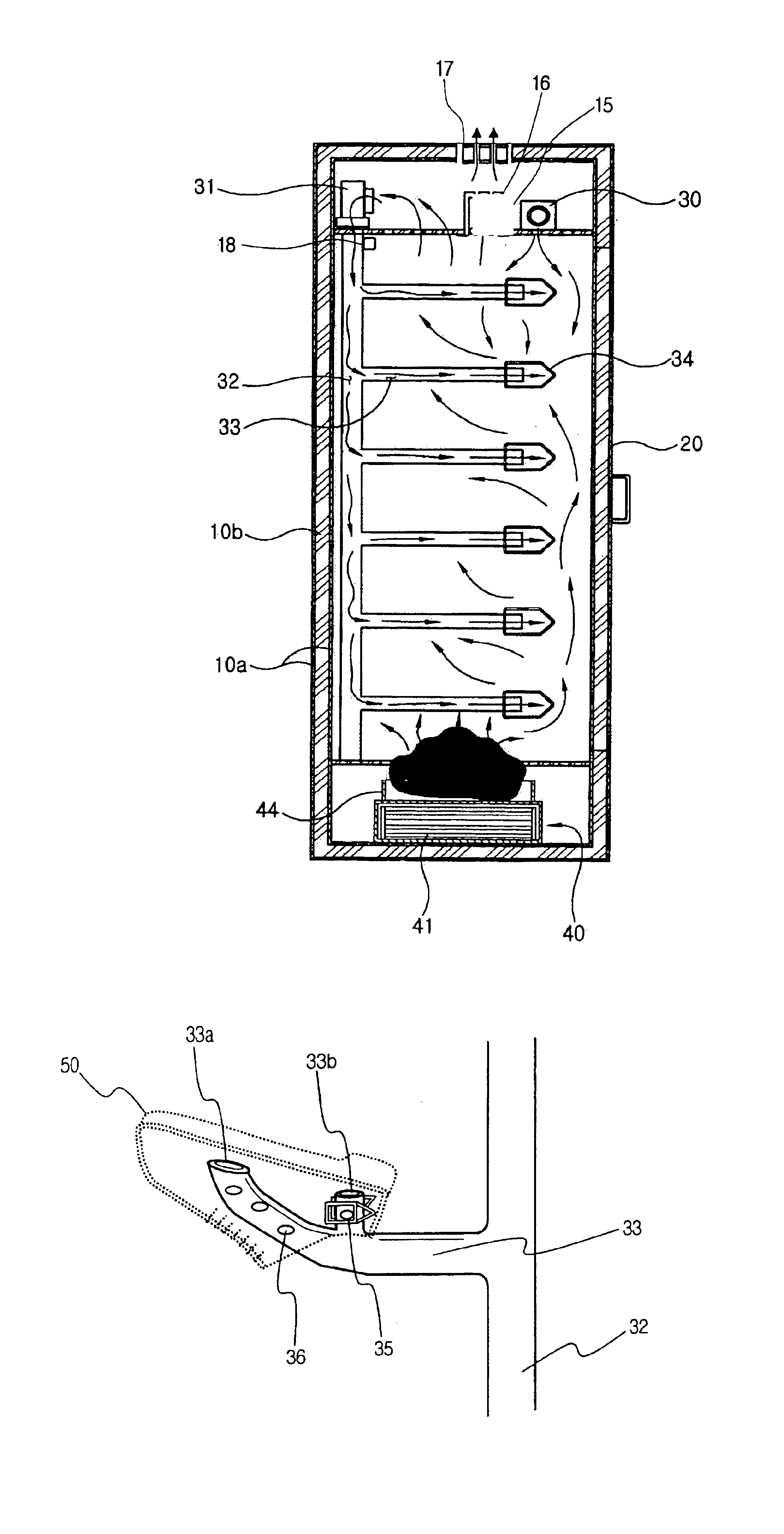

Shoe drying apparatus

InactiveUS6845569B1Short timeReduce maintenanceDrying chambers/containersDrying solid materialsEngineeringHollow core

The present invention provides a new and improved shoe drying apparatus that can dry washed and / or unwashed shoes in a short period of time by circulating ozone-containing air in the airtight interior of the apparatus and also deodorize and sanitize shoes by removing odor and bacteria from the shoes. The shoe drying apparatus comprises a housing having a front door, a first porous plate installed in the bottom interior of the housing, a sanitizing-deodorizing assembly for generating ozone-containing air (“mixed air”), a second porous plate installed in the top interior of the housing, a ventilating fan for dispersing the mixed air into the central interior of the housing, an intake fan for bringing back air present in the upper space of the second plate to the sanitizing-deodorizing assembly, a plurality of hollow main conduits extending vertically from the second plate to the first plate, a plurality of hollow auxiliary conduits extending horizontally from each main conduit, and a shoe-holding member on which a shoe is fixed for drying.

Owner:KIM SOO KIL

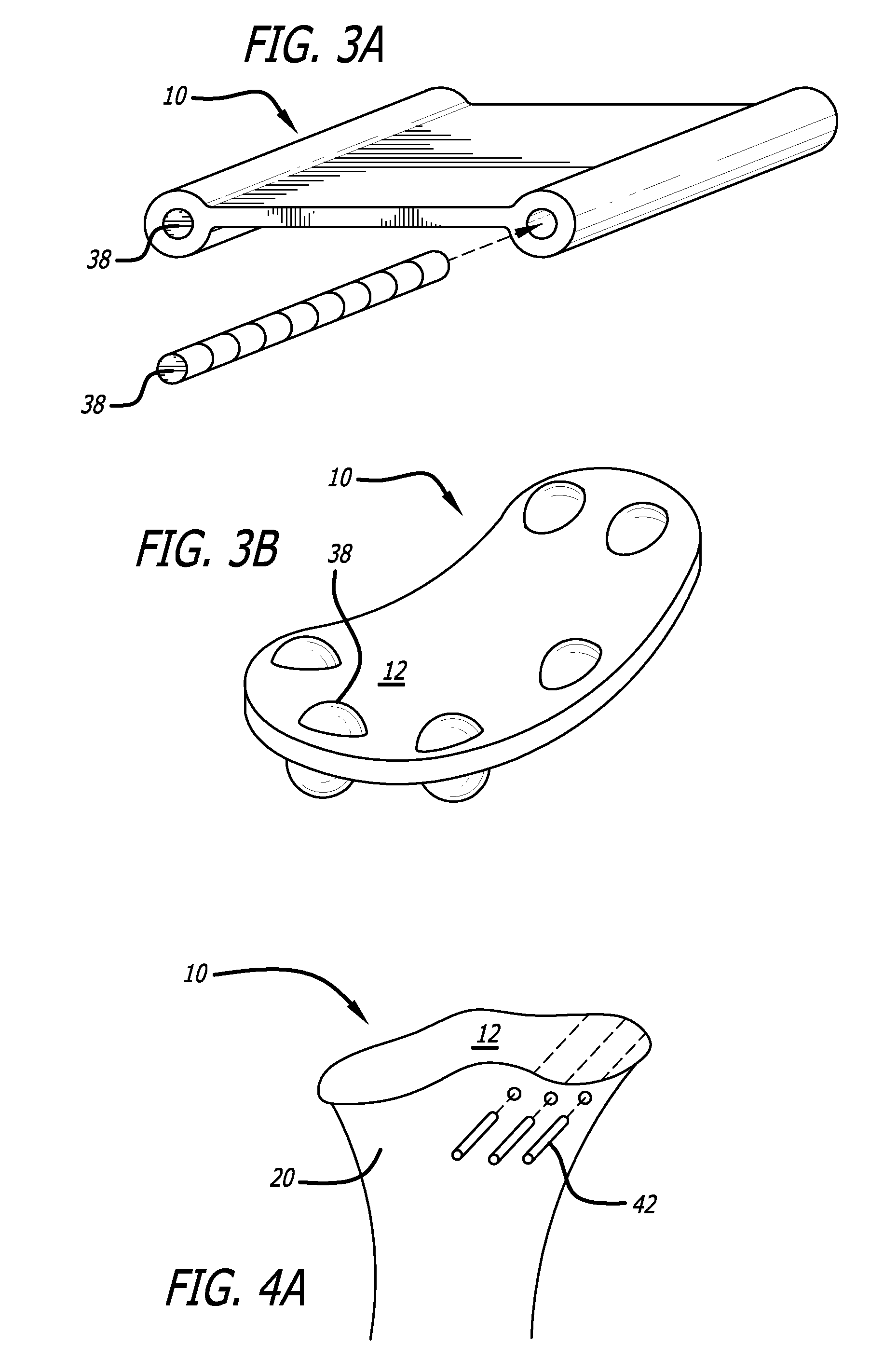

Flow conditioner for a gas transport pipe

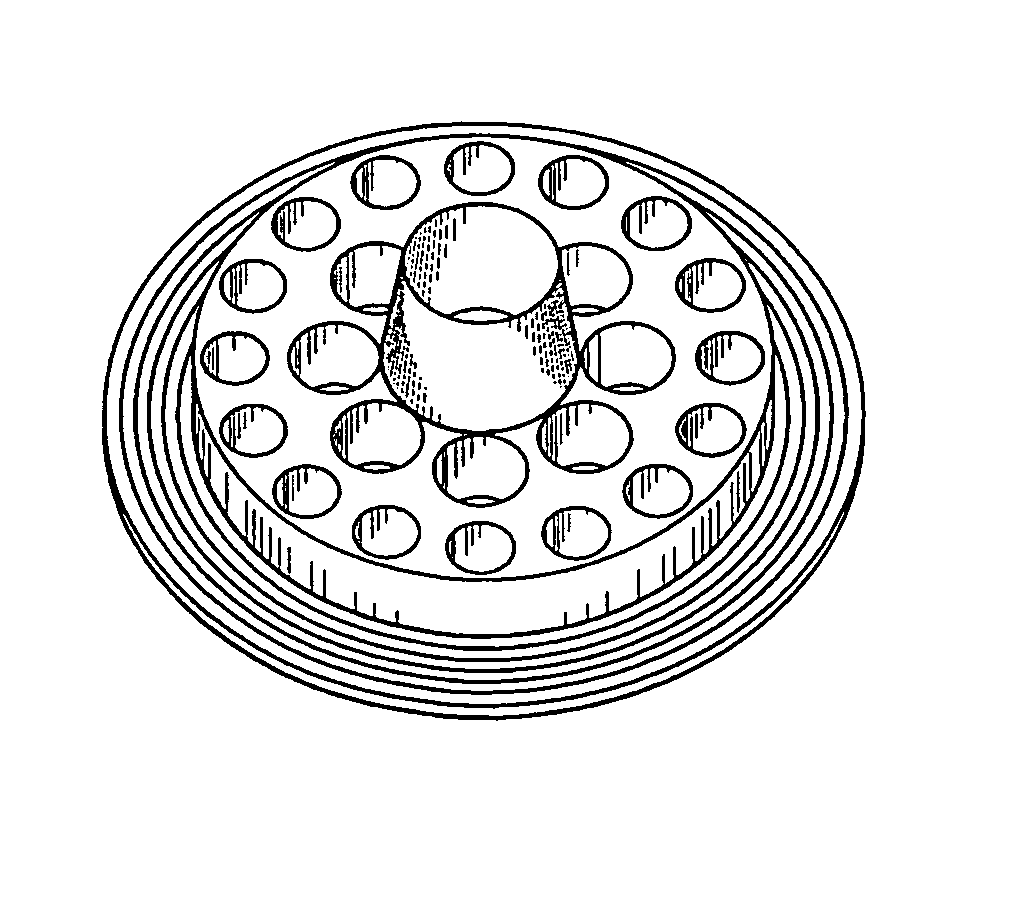

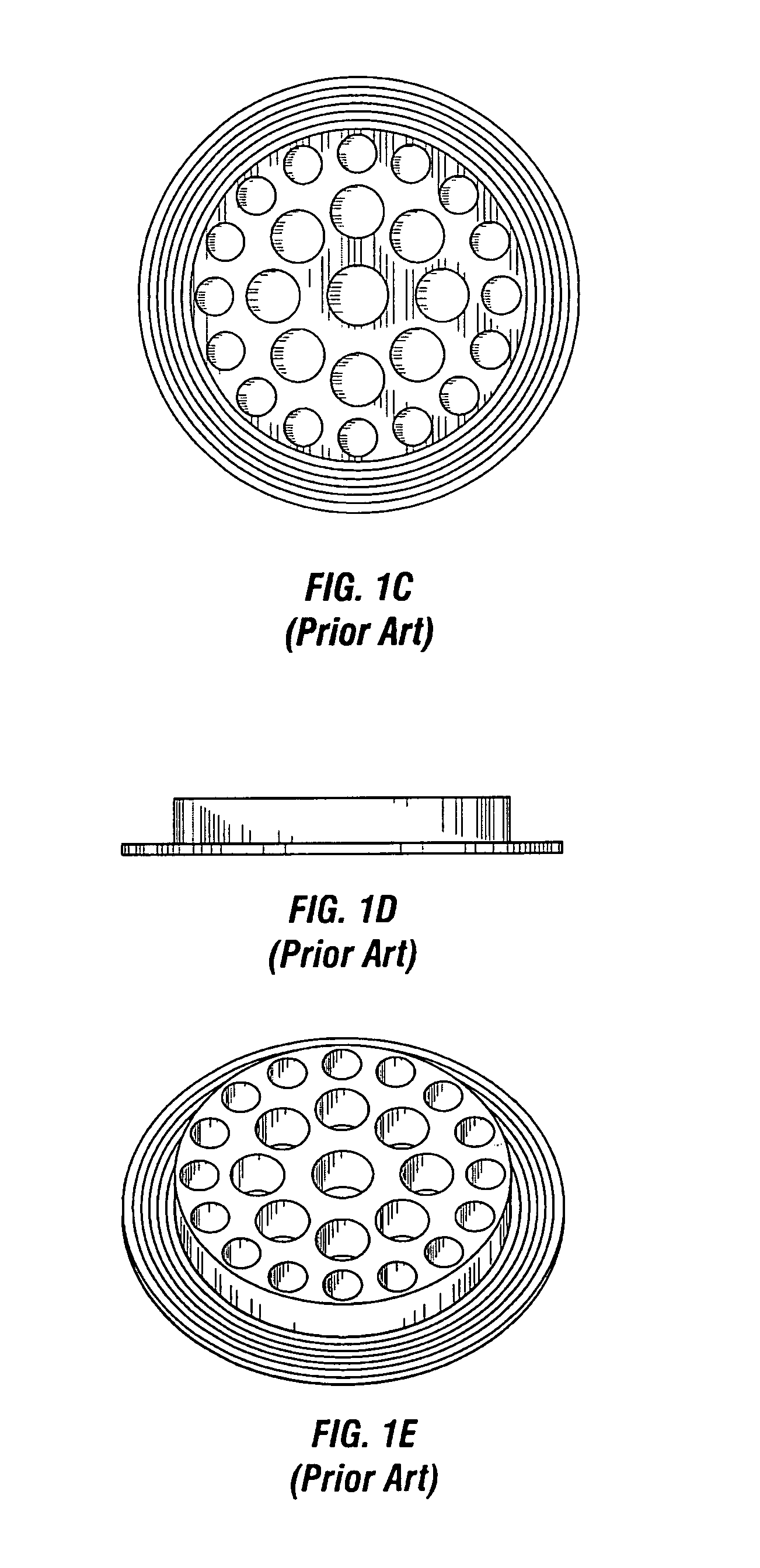

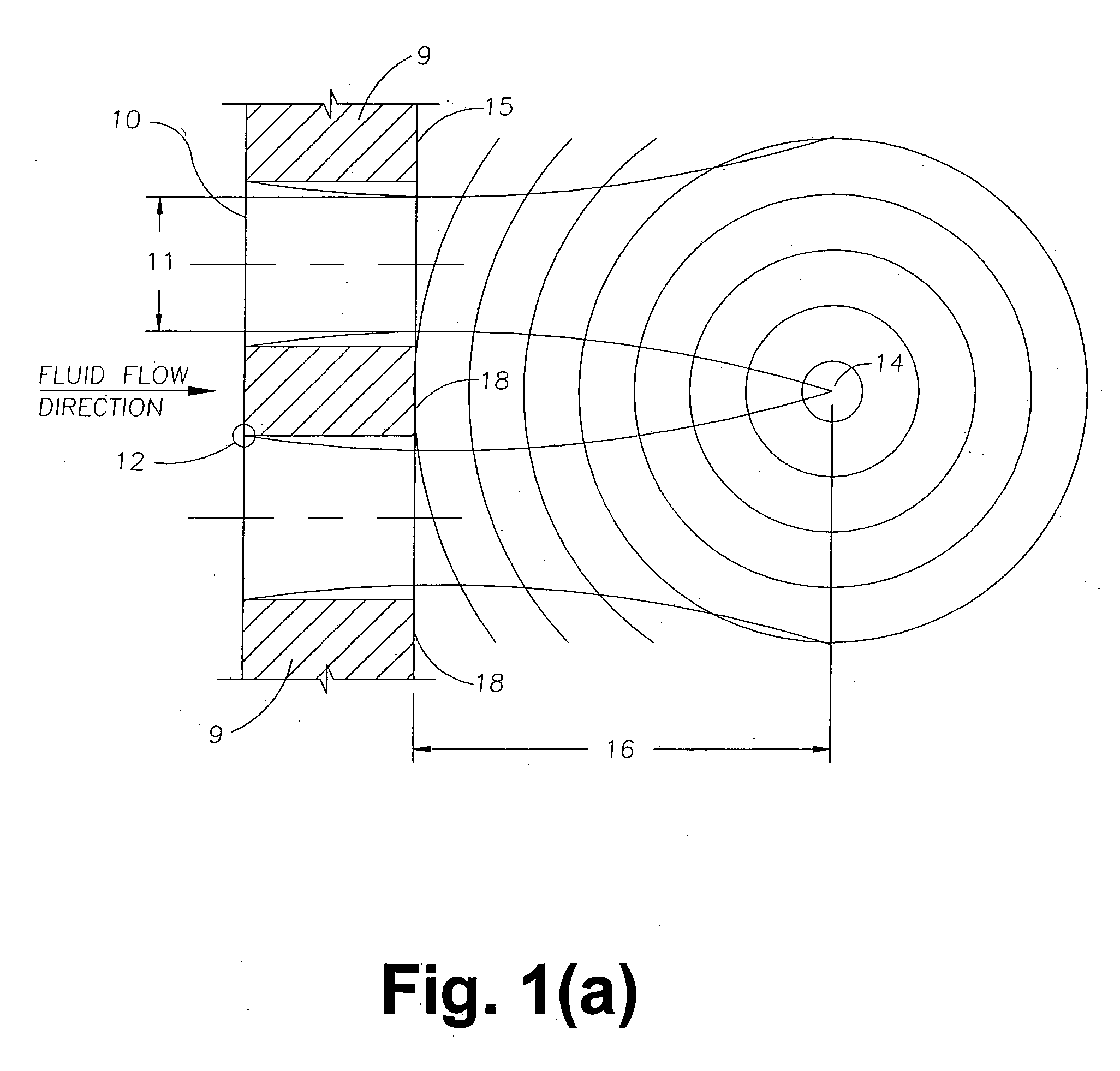

InactiveUS6145544AEliminate jet effectEliminate flow swirlFlow mixersFluid dynamicsEngineeringConcentric ring

The flow conditioner for a gas transport pipe comprises at least one perforated plate disposed essentially perpendicularly to the axis XX' of the pipe and comprising a central hole and sets of additional holes that are regularly distributed over at least three concentric rings centered on the axis of the pipe so as to define a perforated plate that is axially symmetrical. Within any one ring all of the circular holes are of the same diameter d1, d2, d3. On going away from the central hole and on passing from any one ring to an adjacent concentric ring, the diameter of the holes changes alternately in a reduction direction and in an increase direction. Each ring has a number of holes that is equal to or greater than six. The perforated plate is advantageously associated with a porous plate situated upstream from the perforated plate and parallel thereto.

Owner:GAZ DE FRANCE

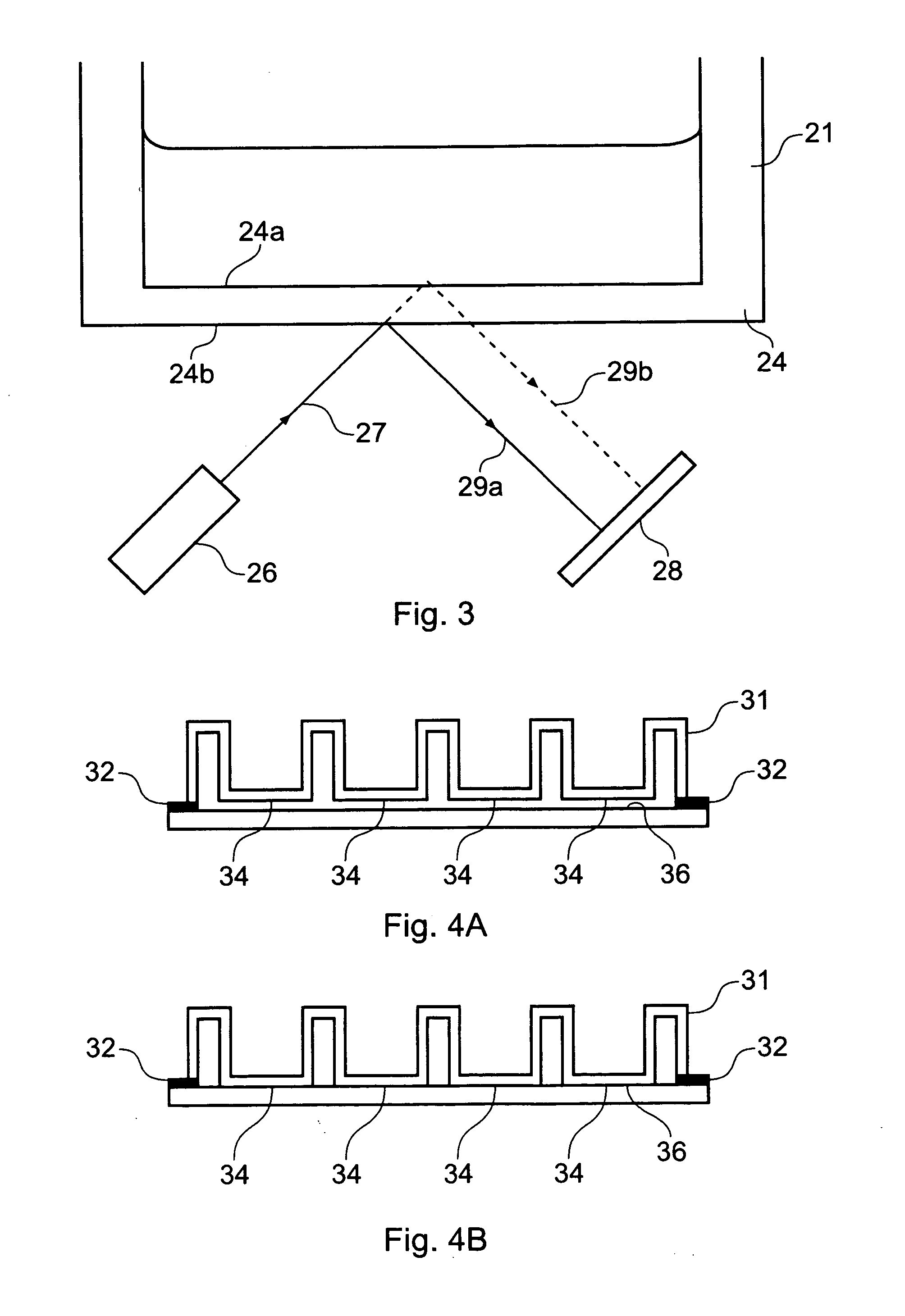

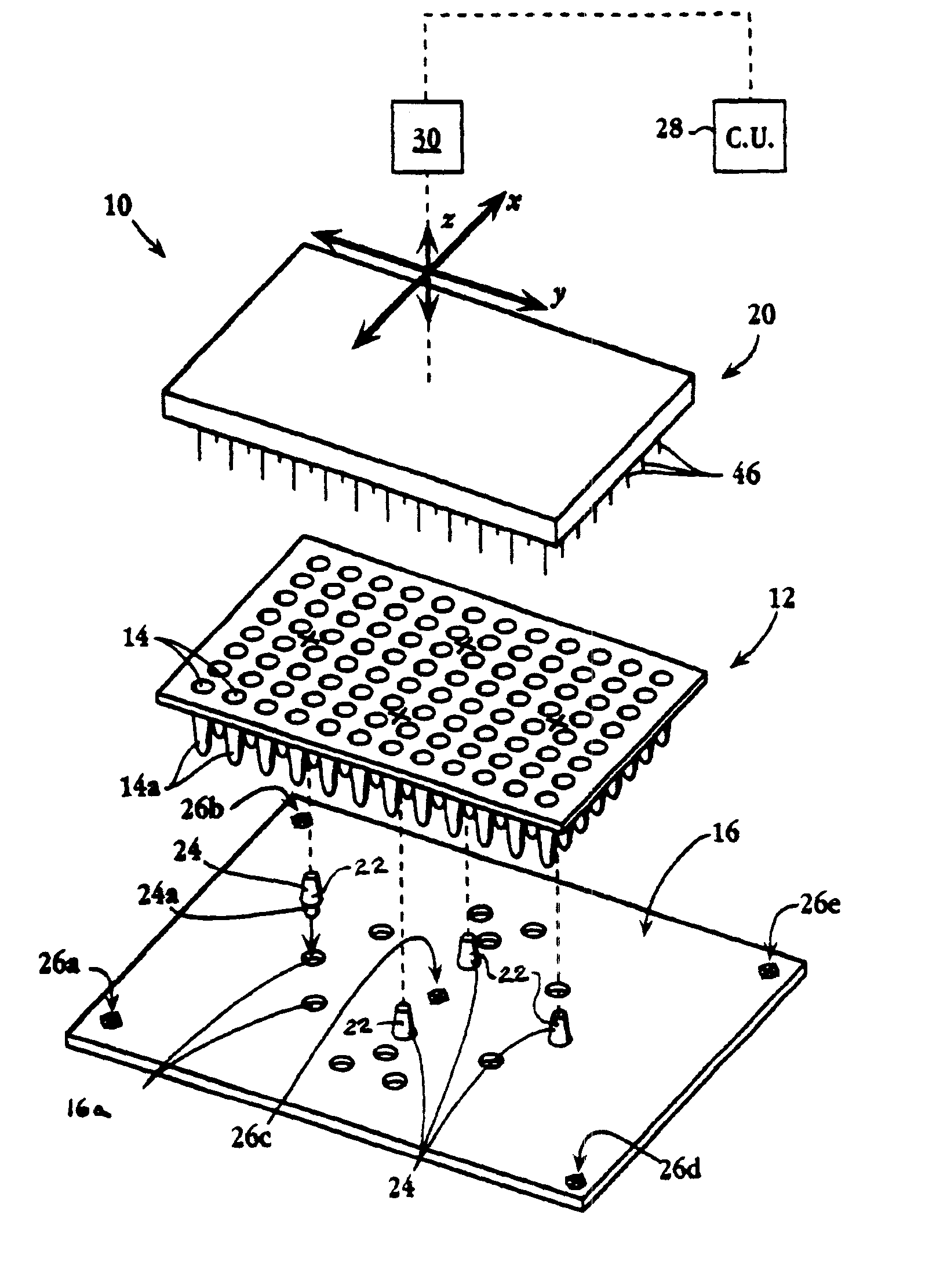

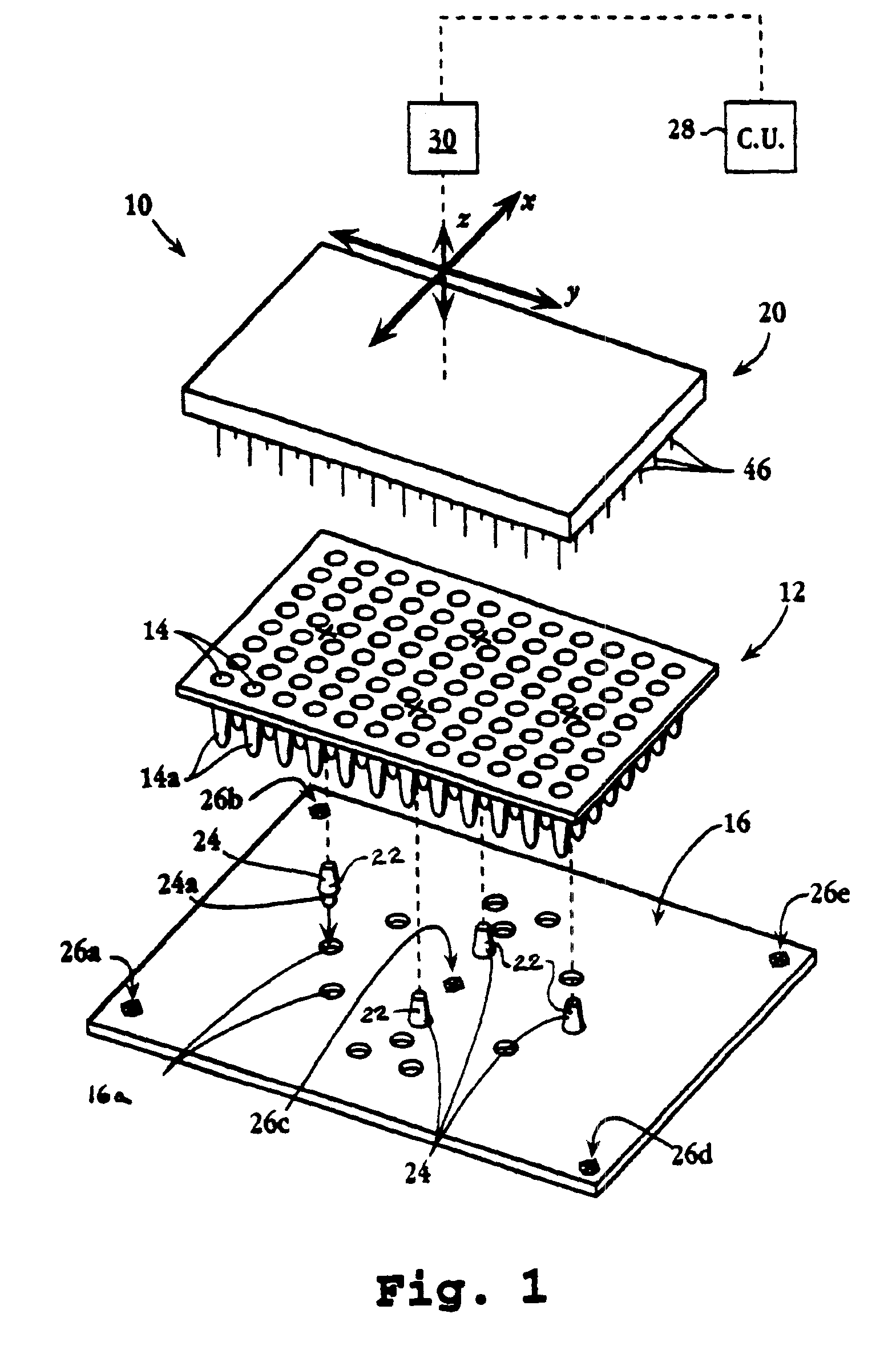

Led or laser enabled real-time PCR system and spectrophotometer

InactiveUS20050133724A1Easy to useReduce entirely avoid costRadiation pyrometryHeating or cooling apparatusPcr assayPhotovoltaic detectors

A system for conducting a polymerase chain reaction (PCR) assay upon a collection of samples is disclosed. The PCR assay is performed by absorption detection. The system includes a multi-well plate which is adapted to retain a collection of sample wells. This system includes a thermal cycler for the multi-well plate. The system additionally includes a collection of photodetectors, and a corresponding number of light sources. The light sources are positioned such that light emitted from each of the respective light sources passes through a corresponding well retained in the multi-well plate and to a corresponding photodetector. The system also includes a processor or other means for analyzing the output signals from the photodetectors. In certain versions of the system, ultra-violet light is used.

Owner:PALO ALTO RES CENT INC

Acoustic attenuation chamber

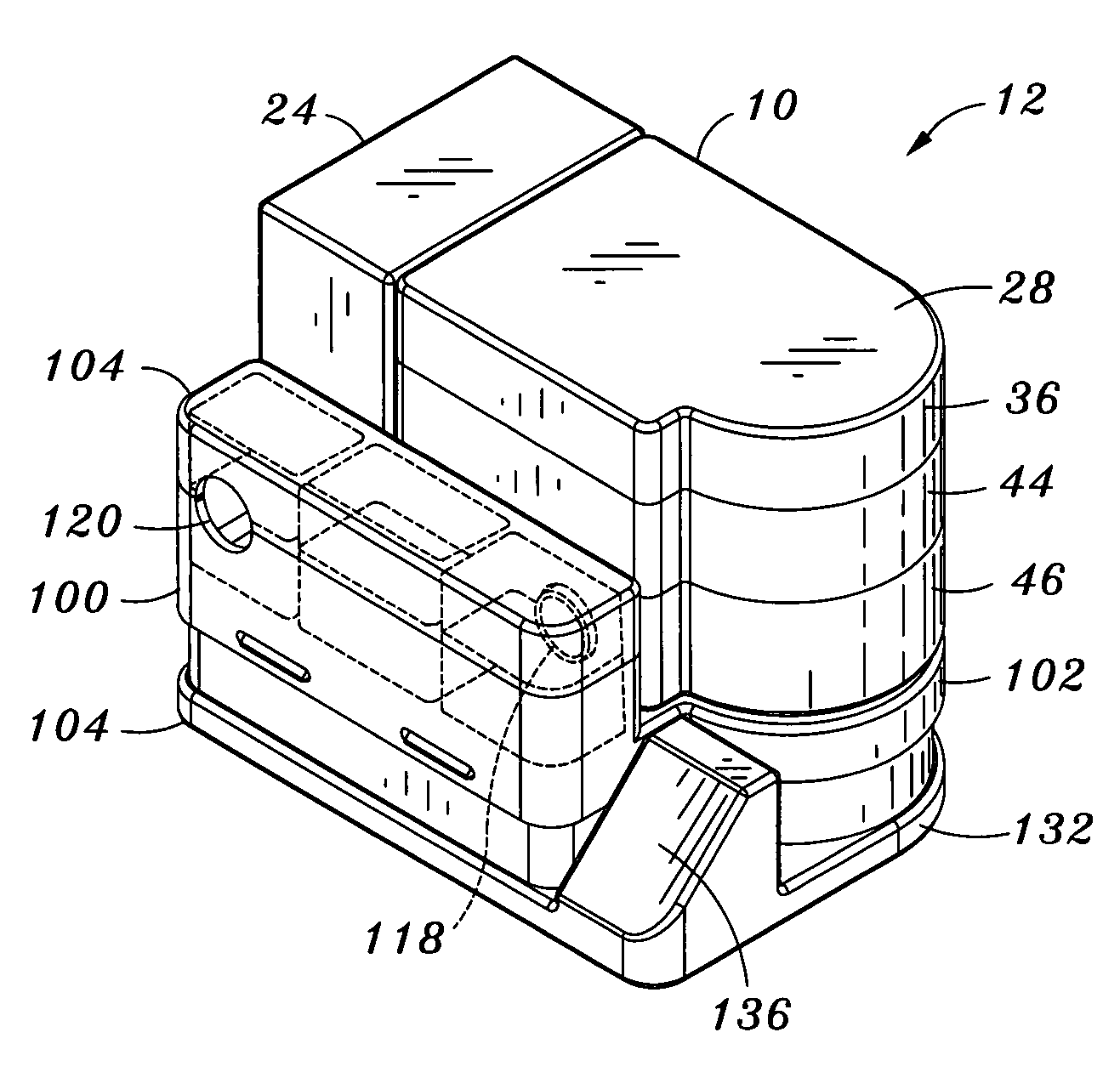

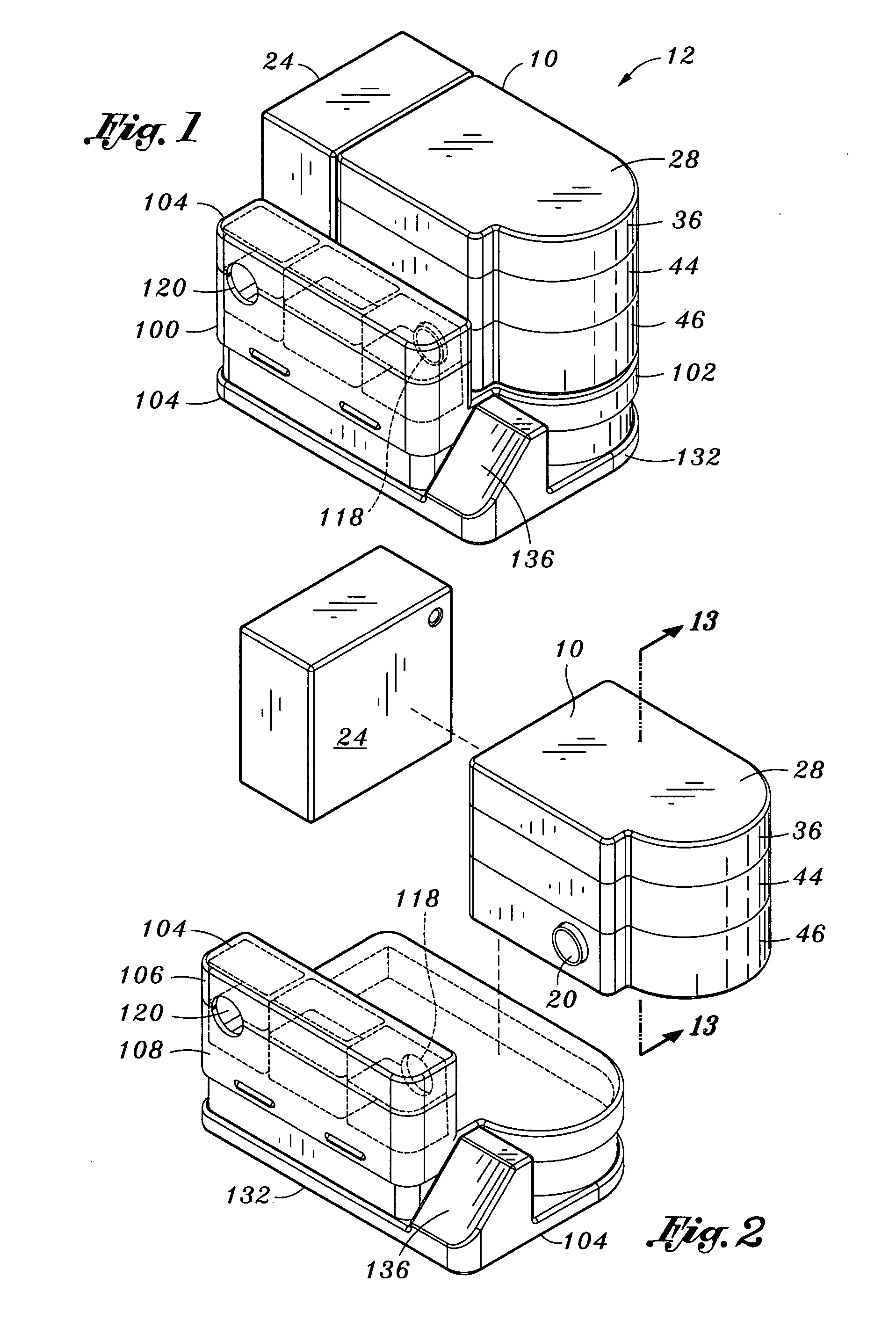

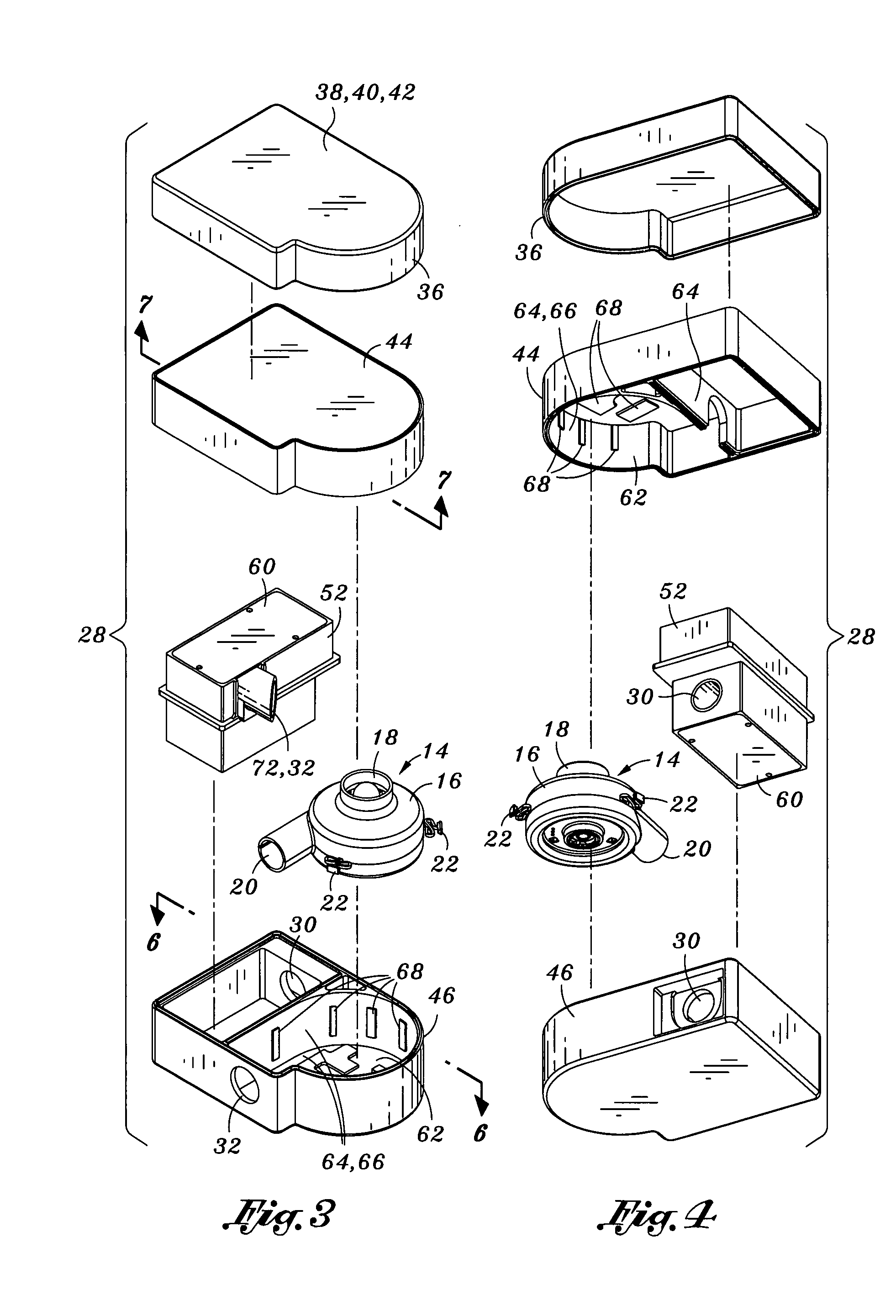

InactiveUS20080257346A1Attenuate air movement noiseHinders its propagationRespiratorsOther heat production devicesEngineeringReactive components

A silencer for a CPAP device comprises a housing assembly defining a flow path passing therethrough and including at least one of an inlet chamber, an acoustic chamber and a blower chamber. Each of the chambers has an inlet and an outlet for fluid communication therebetween. The silencer includes a combination of reactive components, resonators and dissipative elements disposed within the inlet, acoustic and blower chambers. The reactive component may be configured as a compliant-walled reactive tube. The resonator may be configured as a perforated plate defining a cavity volume. The dissipative element may comprise porous material substantially occupying the cavity volume bounded by the perforated plate in the chamber walls.

Owner:VIASYS SLEEP SYST

Backplateless silicon microphone

ActiveUS7346178B2Simple methodTransducer detailsSemiconductor electrostatic transducersParasitic capacitanceEngineering

A silicon based microphone sensing element and a method for making the same are disclosed. The microphone sensing element has a diaphragm with a perforated plate adjoining each side or corner. The diaphragm is aligned above one or more back holes created in a conductive substrate wherein the back hole has a width less than that of the diaphragm. Perforated plates are suspended above an air gap that overlies the substrate. The diaphragm is supported by mechanical springs with two ends that are attached to the diaphragm at a corner, side, or center and terminate in a rigid pad anchored on a dielectric spacer layer. A first electrode is formed on one or more rigid pads and a second electrode is formed at one or more locations on the substrate to establish a variable capacitor circuit. The microphone sensing element can be embodied in different approaches to reduce parasitic capacitance.

Owner:SHANDONG GETTOP ACOUSTIC

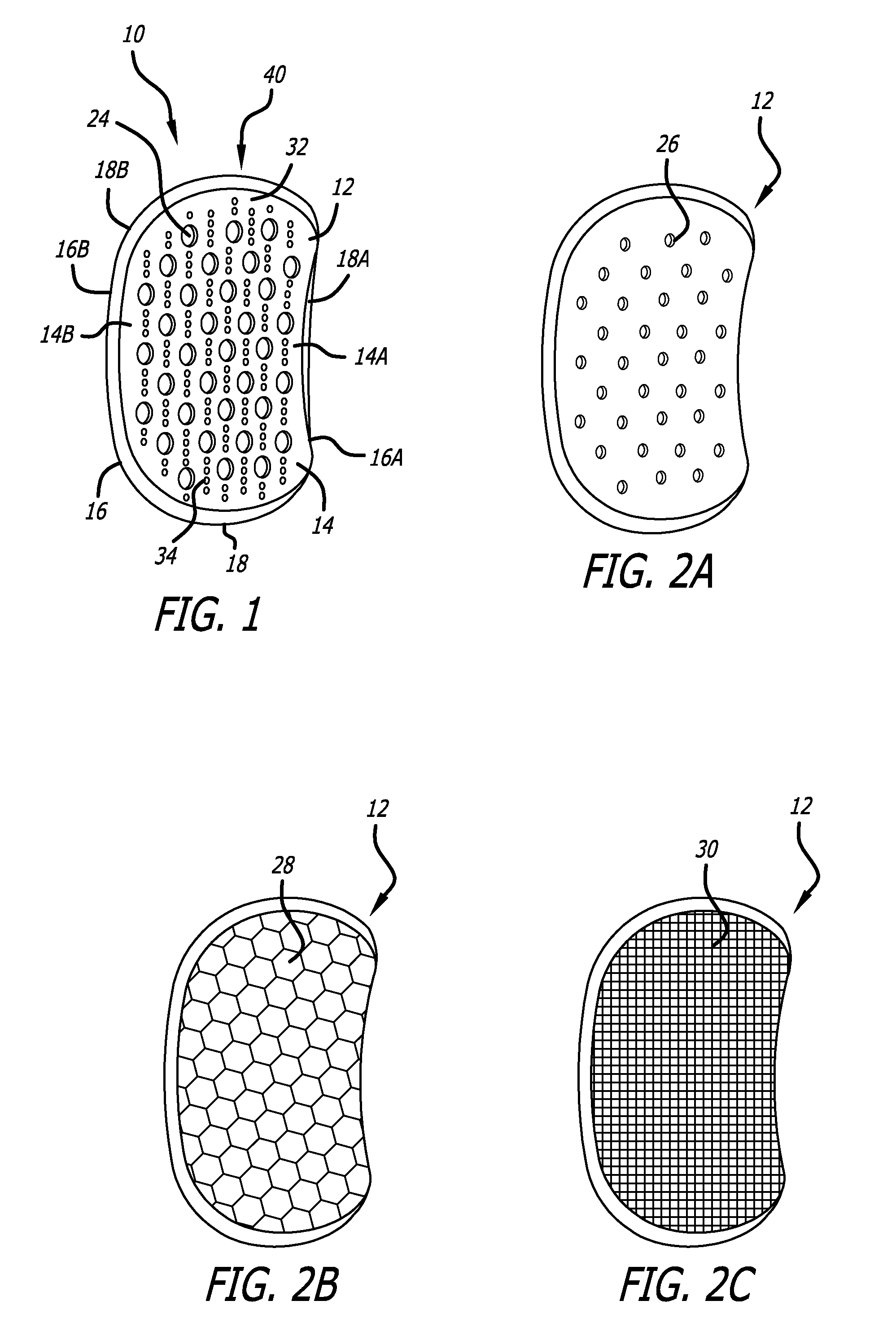

Joint support and subchondral support system

InactiveUS20100145451A1Increasing the thicknessImprove abilitiesSurgeryLigamentsVariable thicknessSupporting system

A joint support and subchondral support system for providing structural and dampening support to damaged subchondral bone in generalized or discrete arthritis includes a contoured, porous plate having a variable shaped inner surface, outer surface, and peripheral surface of variable thickness extending between the inner surface and the outer surface, suitable for insertion within the subchondral bone. The inner surface, outer surface and peripheral surface each have a concave portion and a convex portion. A guide pin hole or slot is located within the contoured, porous plate to aid in insertion and placement of the plate over at least one corresponding guide pin within the subchondral bone. The joint support and subchondral support system of the present invention is applicable to many parts of the joint as any area with cartilage disease has an adjoining subchondral component.

Owner:DEE DEREK

Silicon microphone with impact proof structure

ActiveUS20080031476A1Avoid breakingPiezoelectric/electrostrictive microphonesTransducer detailsDielectric layerMechanical engineering

Improved impact proof capability of a silicon microphone sensing element is achieved with a stopper element that limits the maximum vibration of moveable parts. The stopper has a lower anchor portion and upper finger portion that is elevated a certain distance above the diaphragm and overhangs the outer edges of the perforated plates. The stopper is formed on a stack consisting of a lower substrate, a middle dielectric layer, and an upper membrane layer. There is a back hole in the substrate and an air gap in the dielectric layer to allow sound to impinge on the diaphragm. The number of fingers and composition of the stopper is variable. Optionally, the stopper has a center support design and is formed on a center anchor within an opening in the diaphragm. An upper finger region overhangs the diaphragm near the center opening and thereby prevents breakage due to large vibrations

Owner:SHANDONG GETTOP ACOUSTIC

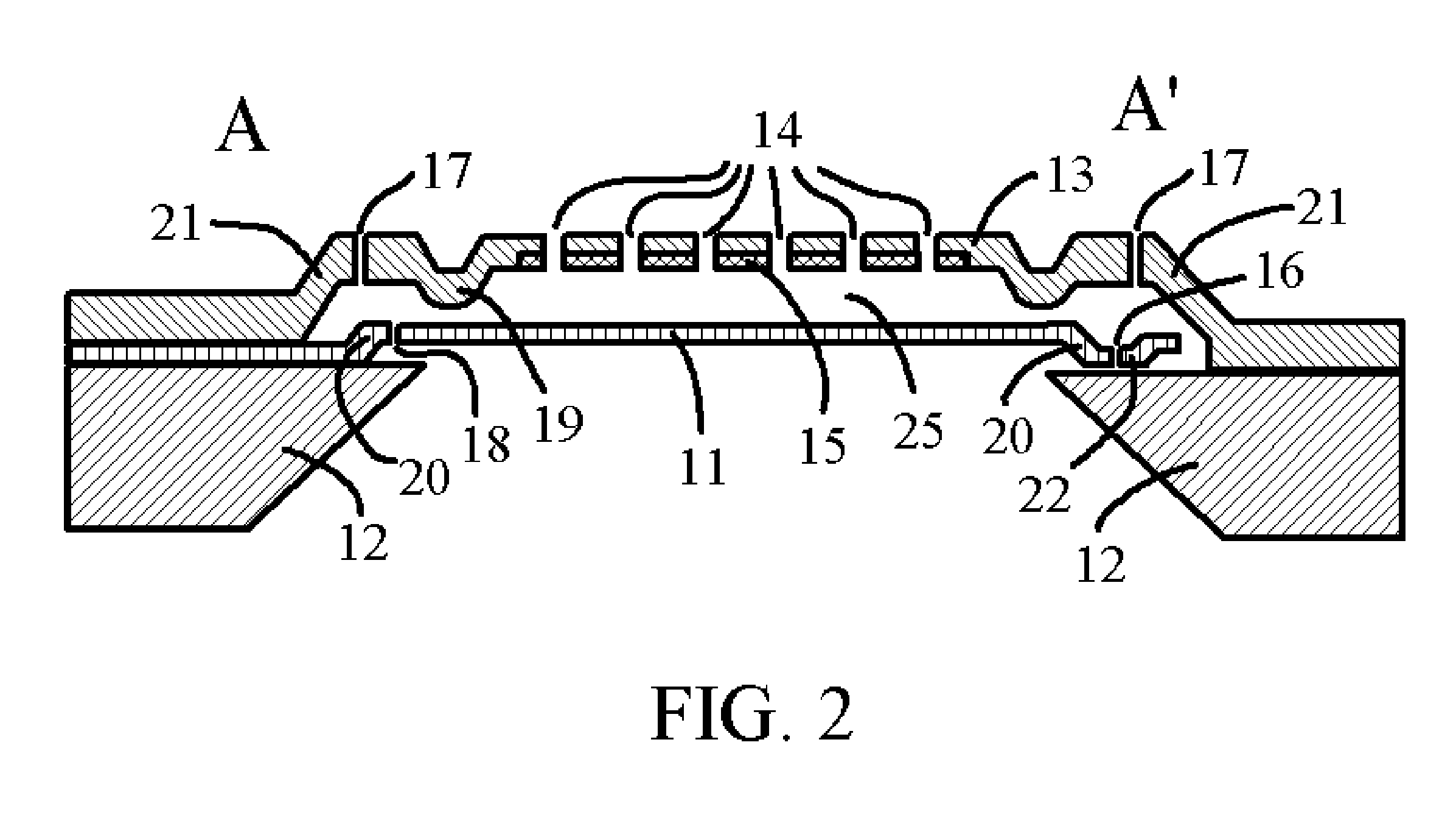

Screen apparatus for vibratory separator

InactiveUS6032806AEasy to insertQuickly and easily repairedSievingScreeningEngineeringMechanical engineering

A screen is disclosed which, in certain aspects, has screening material between opposed frame sides and one or more lower strips beneath the screen. In one aspect these strips are only inteconnected via their ends and not along their lengths. In certain aspects, a plurality of lower strips are bonded to the screen and extend across the screen from one frame side to the other. In one aspect one or more of the strips has one, two, or more humps or ridges corresponding to one or more corrugations in a corrugated perforated plate and / or corrugated screen assembly which is on the plate or, with no plate present, on the strips. In another aspect instead of the strips a solid corrugated perforated plate is used. In one aspect openings or perforations through the plate are triangular. In one aspect the screen is undulating screening material and lower portions of the screening material are bonded to a plate or to strips. Optionally screen mounting hooks or frame edges or screen edges may be used with such screens. A screening apparatus or shale shaker is disclosed which uses such plates and screens.

Owner:VARCO I P INC

Tubular heat exchanger

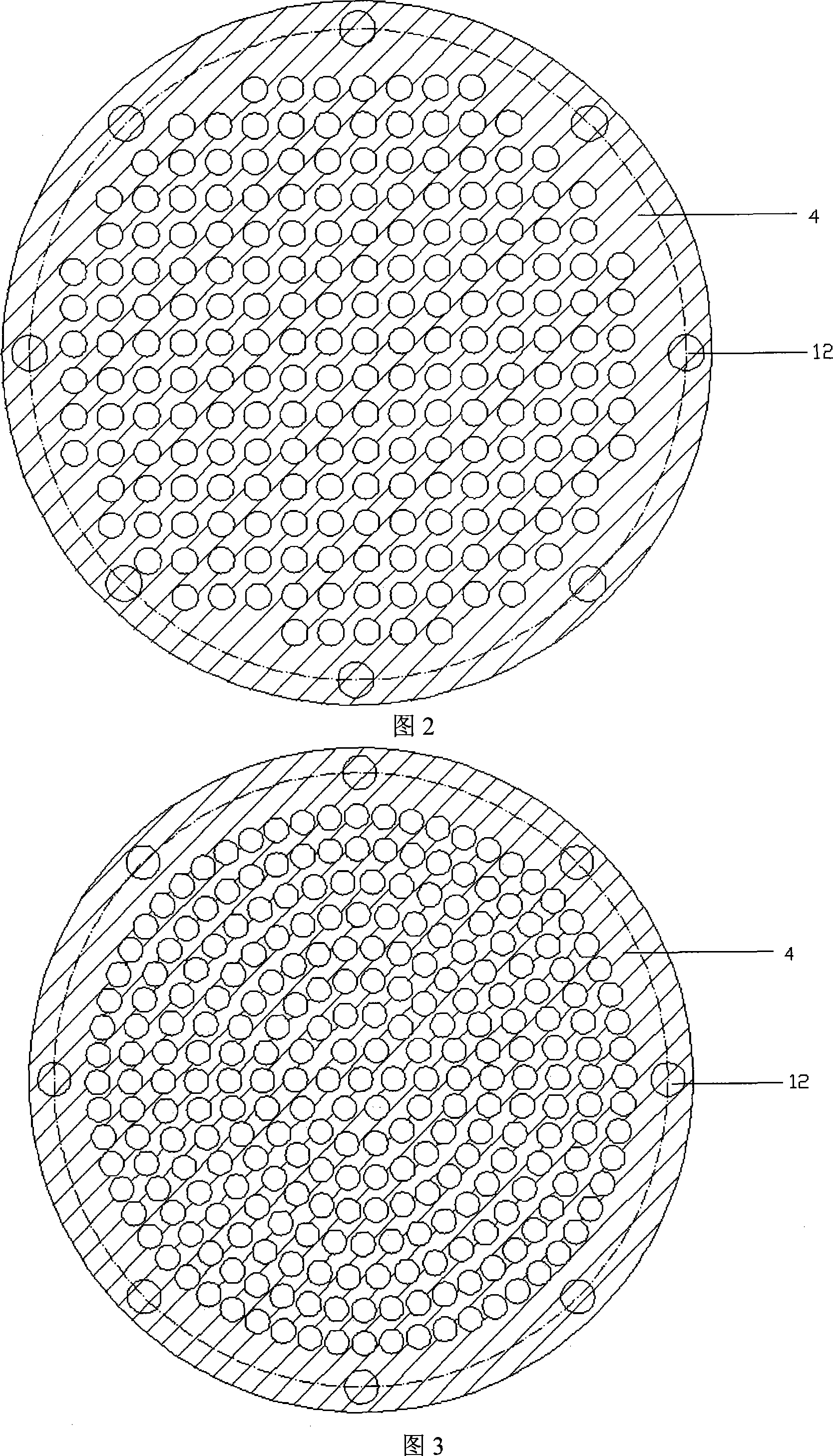

InactiveUS20090008074A1Easy to replaceOmissionStationary conduit assembliesHeat exchanger casingsEngineeringMechanical engineering

A tubular heat exchanger preferably of a multi-pass design, has a cylindrical shell with open ends that are releasable covered and sealed by preferably two end caps. Located removably in the shell and axially between the end caps is a core having a plurality of outer tubes and preferably a plurality of inner tubes with each one of the inner tubes extending through a respective one of the outer tubes. A plurality of perforated plates disposed in the shell are sealed releasably to respective ends of the inner and outer tubes thereby forming a plurality of liquid tight chambers for the flow of a plurality of segregated mediums and the transfer of heat therebetween.

Owner:VAMVAKITIS DIMITRI L +3

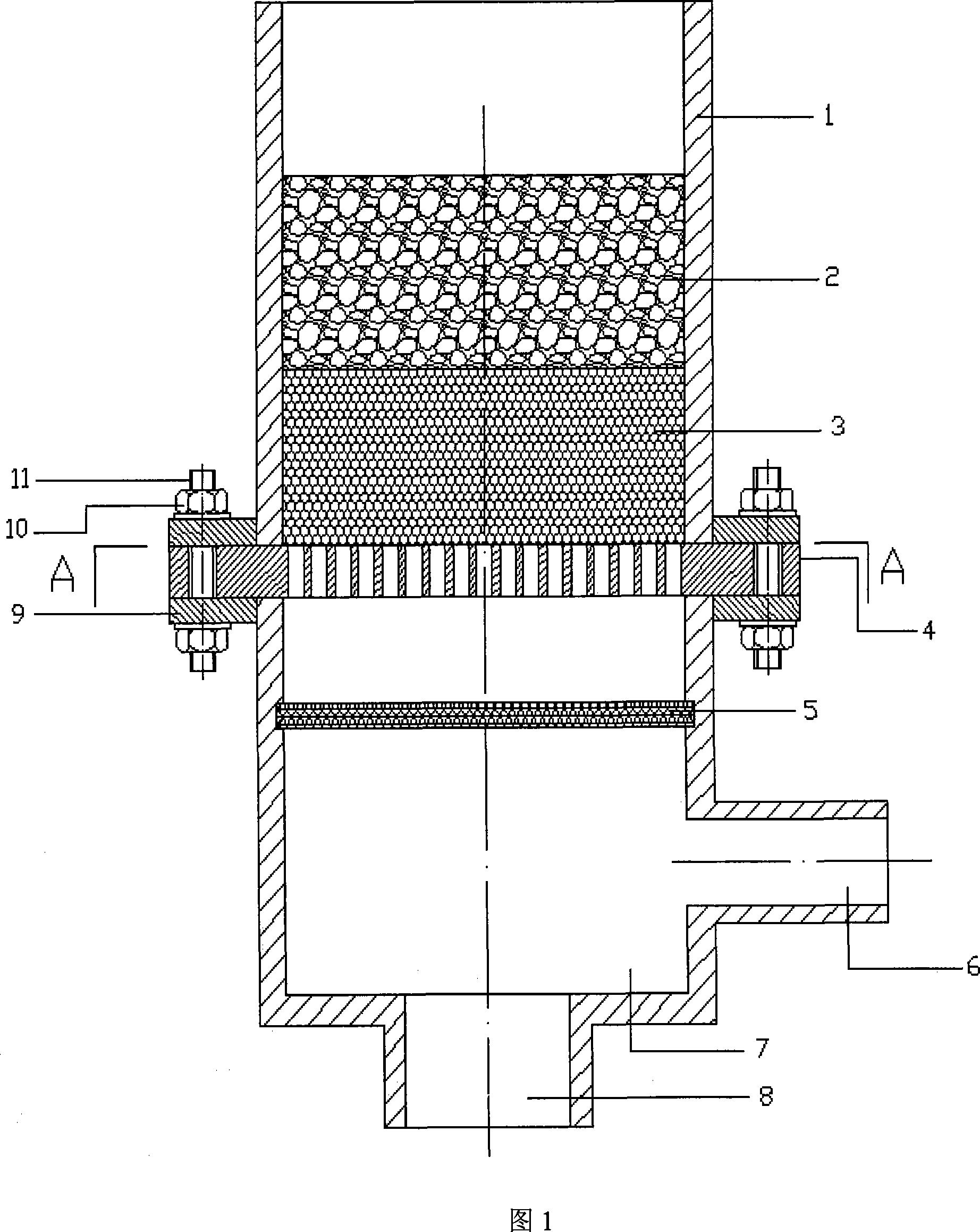

Sectional type porous ceramic dielectric gas fuel combusting device

InactiveCN101158469AImprove securityWide calorific value rangeGaseous fuel burnerDielectricCombustor

The invention relates to a multi-stage multi-aperture ceramic dielectric gas fuel inflamer which includes an inflamer shell, a dust-removing wire netting or a metal brush, an air pipeline, a premixing chamber and a fuel gas pipeline. The invention is mainly characterized in that the inflamer shell is divided into an upper part and a lower part with a multi-aperture plate as a boundary. The inner part of the empty cavity at the upper part of the inflamer shell is sequentially provided with a ceramic multi-aperture dielectric of the large-aperture area which is arranged above a ceramic multi-aperture dielectric of the small-aperture area and the ceramic multi-aperture dielectric of the small-aperture area is arranged on the multi-aperture plate. The dust-removing wire netting or the metal brush is arranged under the multi-aperture plate and in the inflamer shell. The multi-aperture plate is imbedded into the middle of the upper and lower parts of the inflamer shell. The surrounding of the multi-aperture plate extends to the outside of the inflamer shell. The invention has the advantage that the multi-stage multi-aperture ceramic dielectric gas fuel inflamer has a higher thermal value range, thereby both the gas of a low thermal value or bum gas fuel and the gas of a higher thermal value can be burnt. The multi-aperture plate added in the inflamer has played a good role of radiating and can effectively prevent backfire or explosion.

Owner:NORTHEASTERN UNIV

Silencer for perforated plate flow conditioner

Owner:SAWCHUK BLAINE DARREN +1

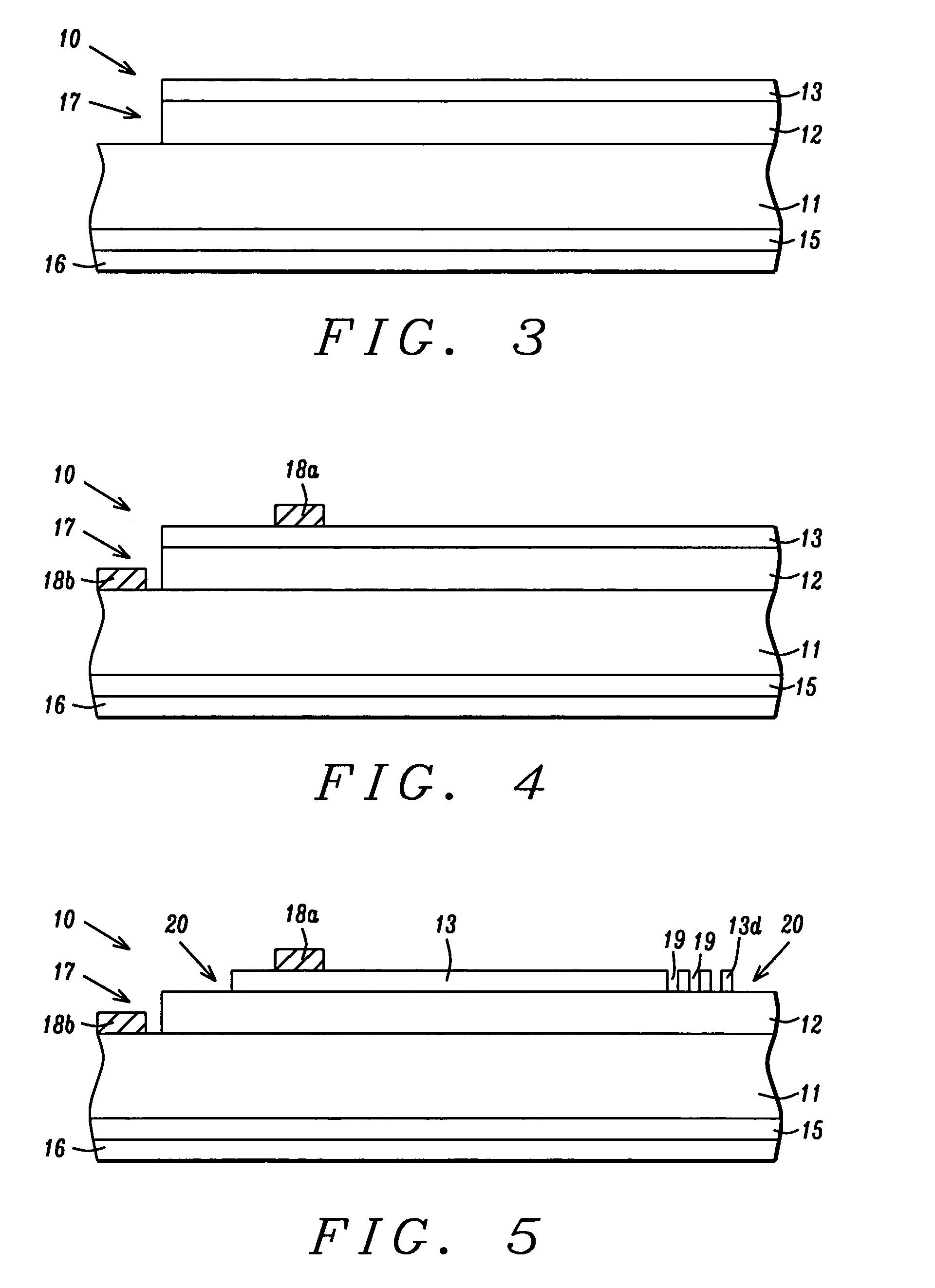

Three-dimensional tissue equivalent using macromass culture

The present invention provides a three-dimensional tissue equivalent for in-vivo and in-vitro uses. The three dimensional tissue equivalent of the present invention is a non-contractile cellular sheet cultured over a porous scaffold using a macromass culturing technique, for example where the cellular sheet is entirely on one side of a porous sponge. In one embodiment, the present invention provides a dermal wound dressing that comprises a high density cellular sheet of dermal fibroblast cells.

Owner:RELIANCE LIFE SCI PVT

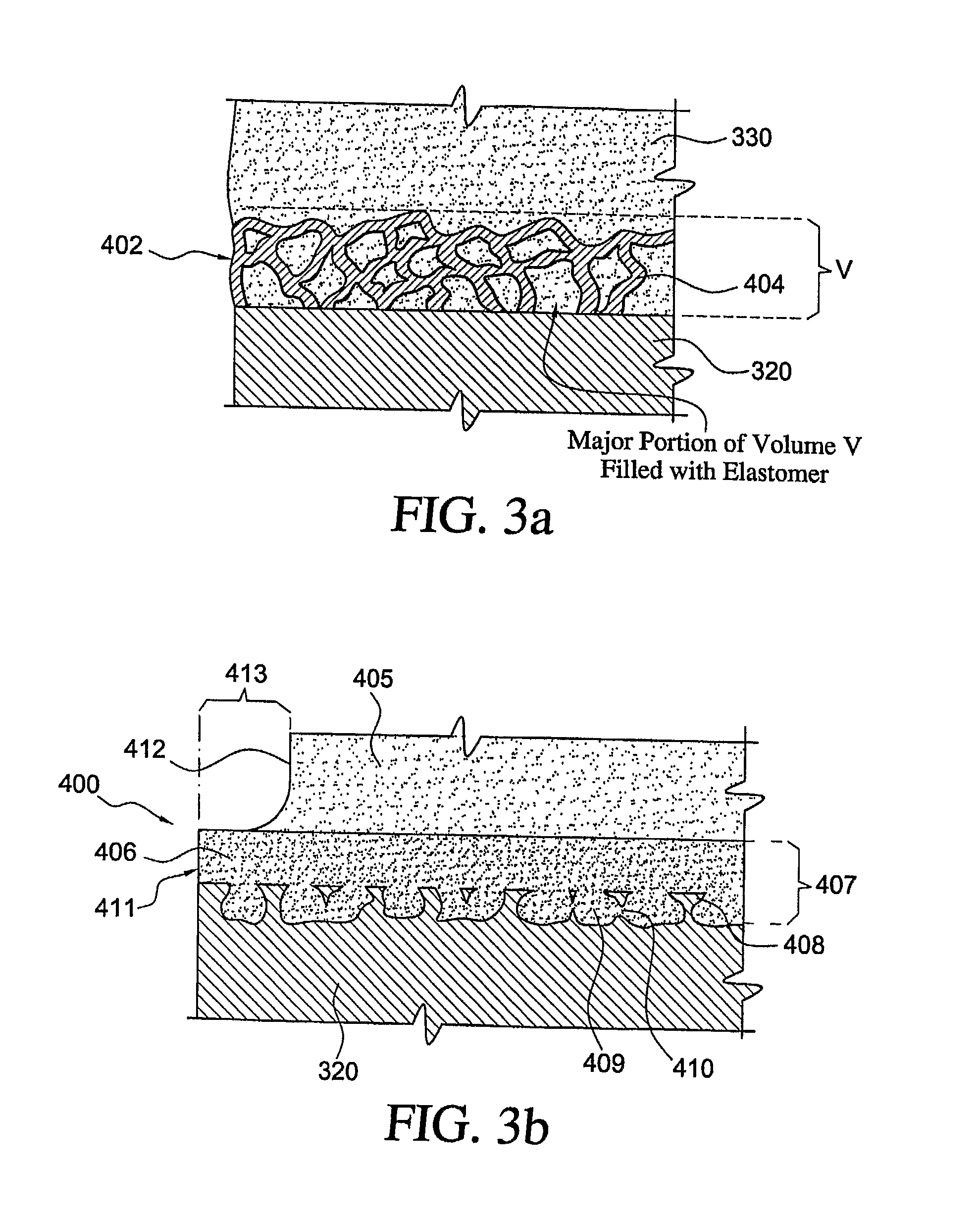

Fixation of Elastomer to Rigid Structures

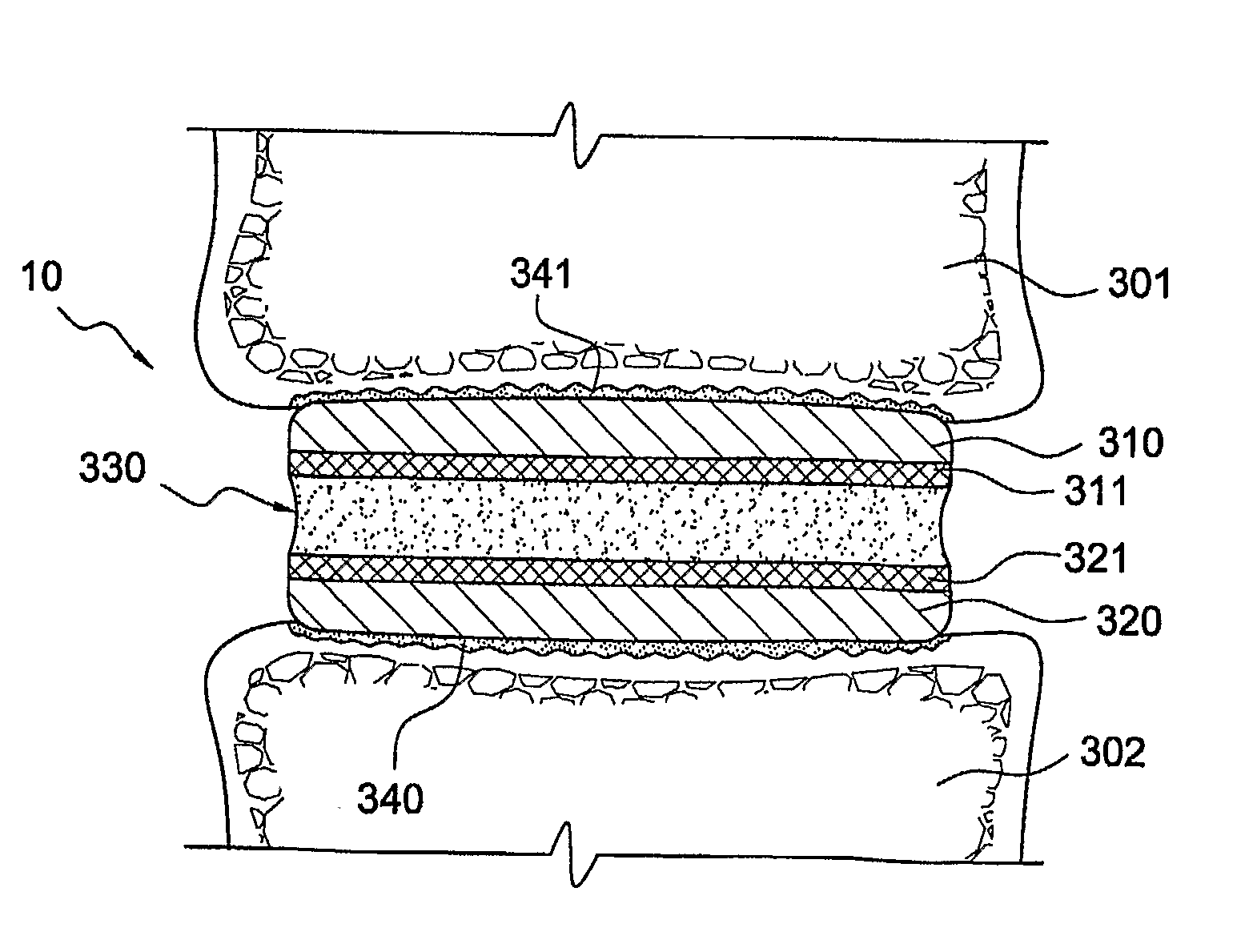

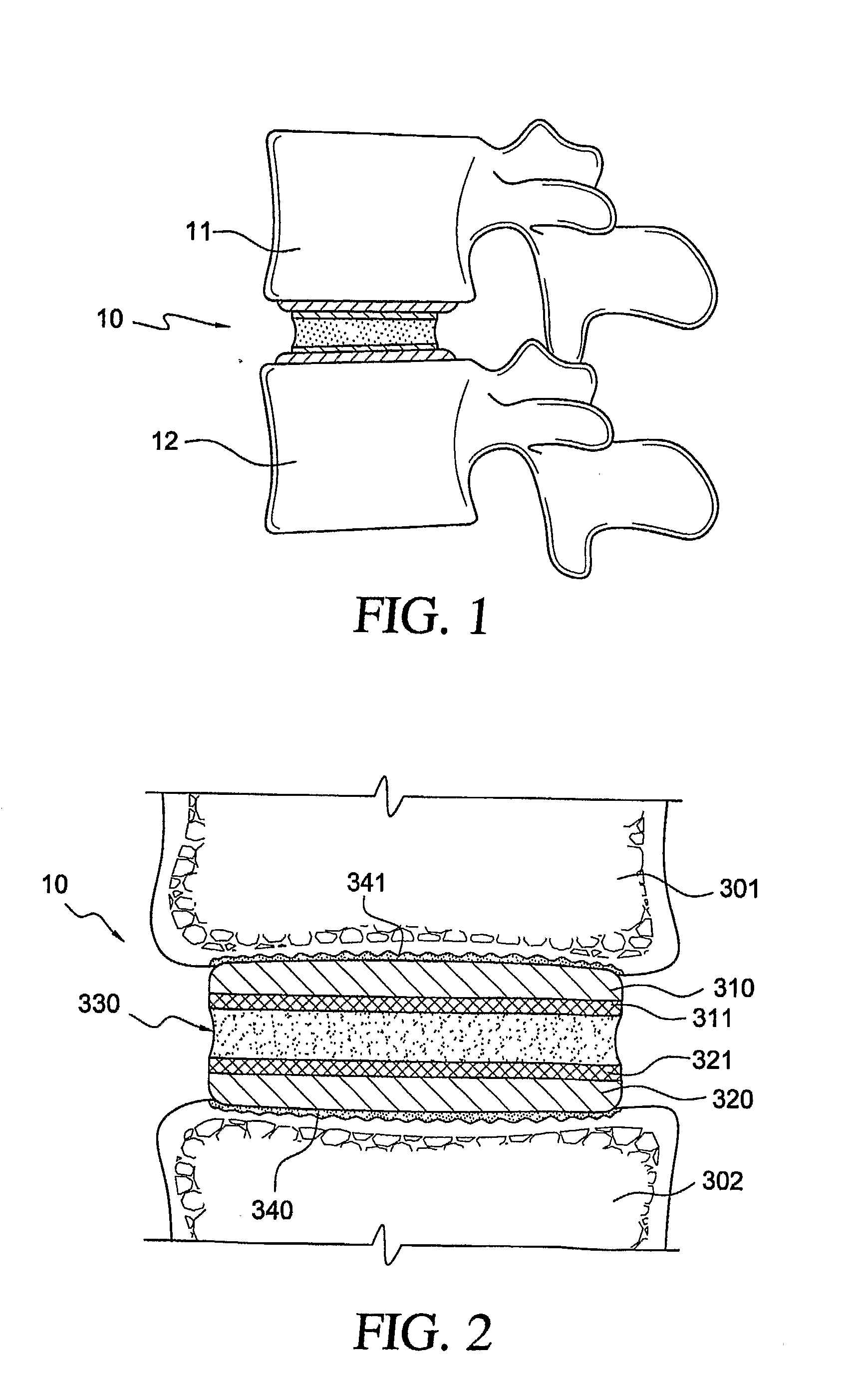

A surgical implant, especially an artificial intervertebral disc, includes a rigid substrate (513) having a porous attachment structure (512) that covers a portion of the substrate and an elastomeric body (510) that is fastened to the substrate by impregnating the porous attachment structure. The porous attachment structure has a net porosity greater than 21.5%. The porous attachment structure may be, for example, a perforated plate or a screen spaced from a substrate surface, or a layer of trabecular metal or an open-cellular material.

Owner:K2M

Capacitive micromachined acoustic transducer

ActiveUS7152481B2Wide bandwidthHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsMembrane anchorTransducer

A micromachined capacitive acoustic transducer including an electrode formed by a perforated plate and another electrode formed by a shallowly corrugated membrane anchored at one or more positions on the substrate which also supports the said perforated plate is described. Also disclosed includes: a fixed perforated plate; a movable shallowly corrugated membrane having holes to form acoustic filter to a certain frequency or a range of frequencies spaced from the perforated plate that is anchored in one or more location but loose at other locations; a support structure in the perforated plate maintaining the minimum separation between the membrane and the perforated plate near the perimeter.

Owner:NEOMEMS TECH INC WUXI CHINA

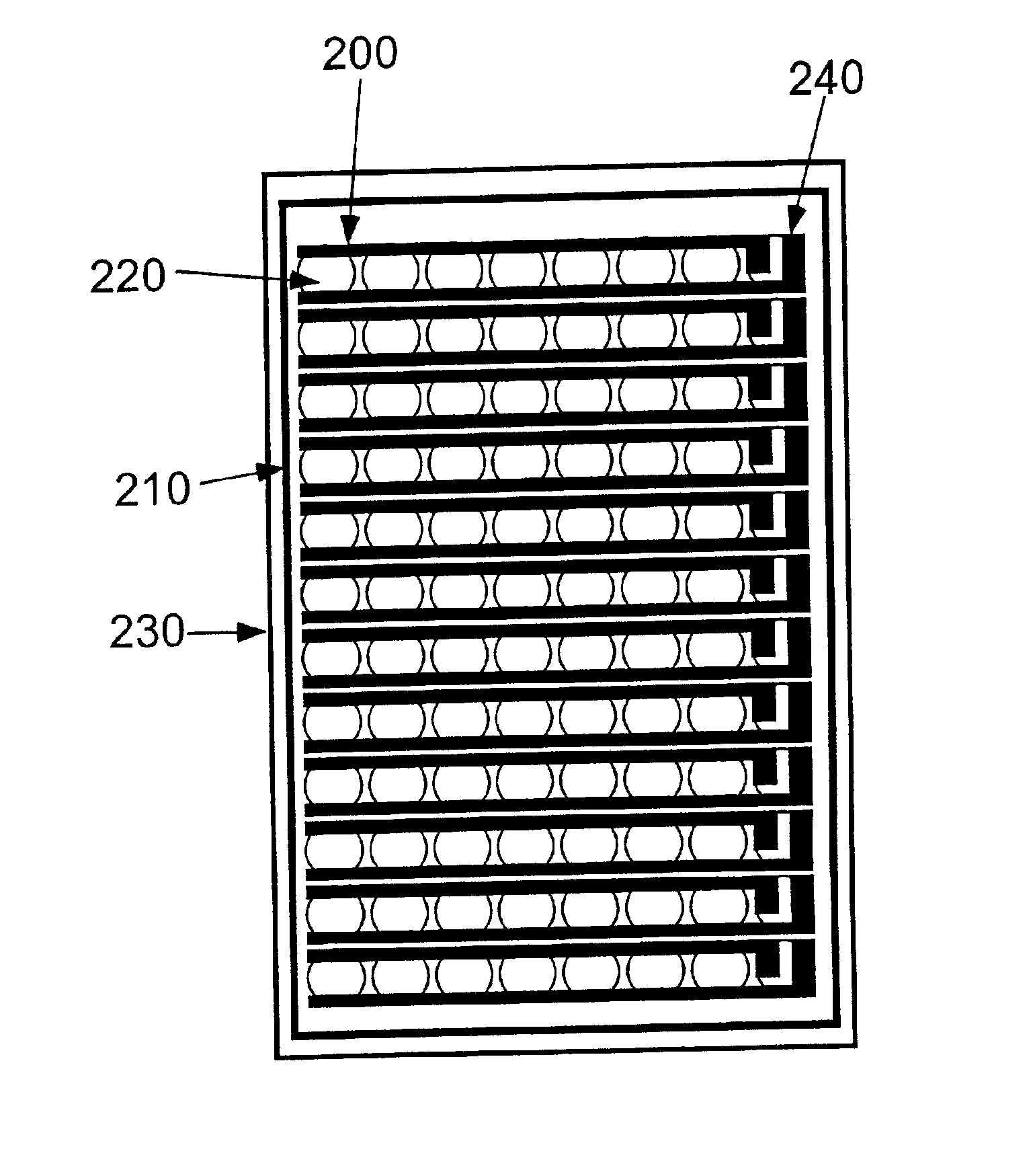

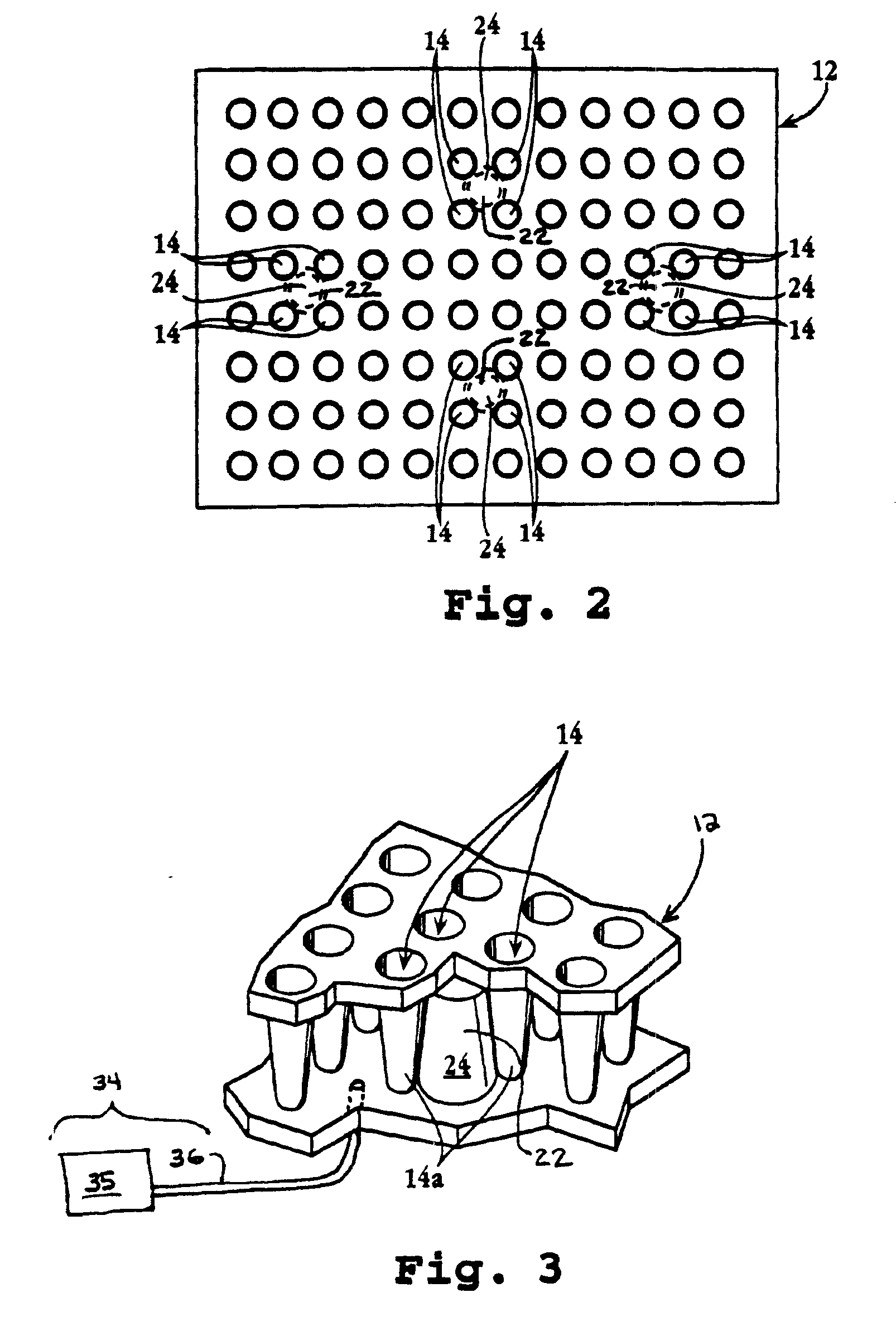

Perfusion bioreactors for culturing cells

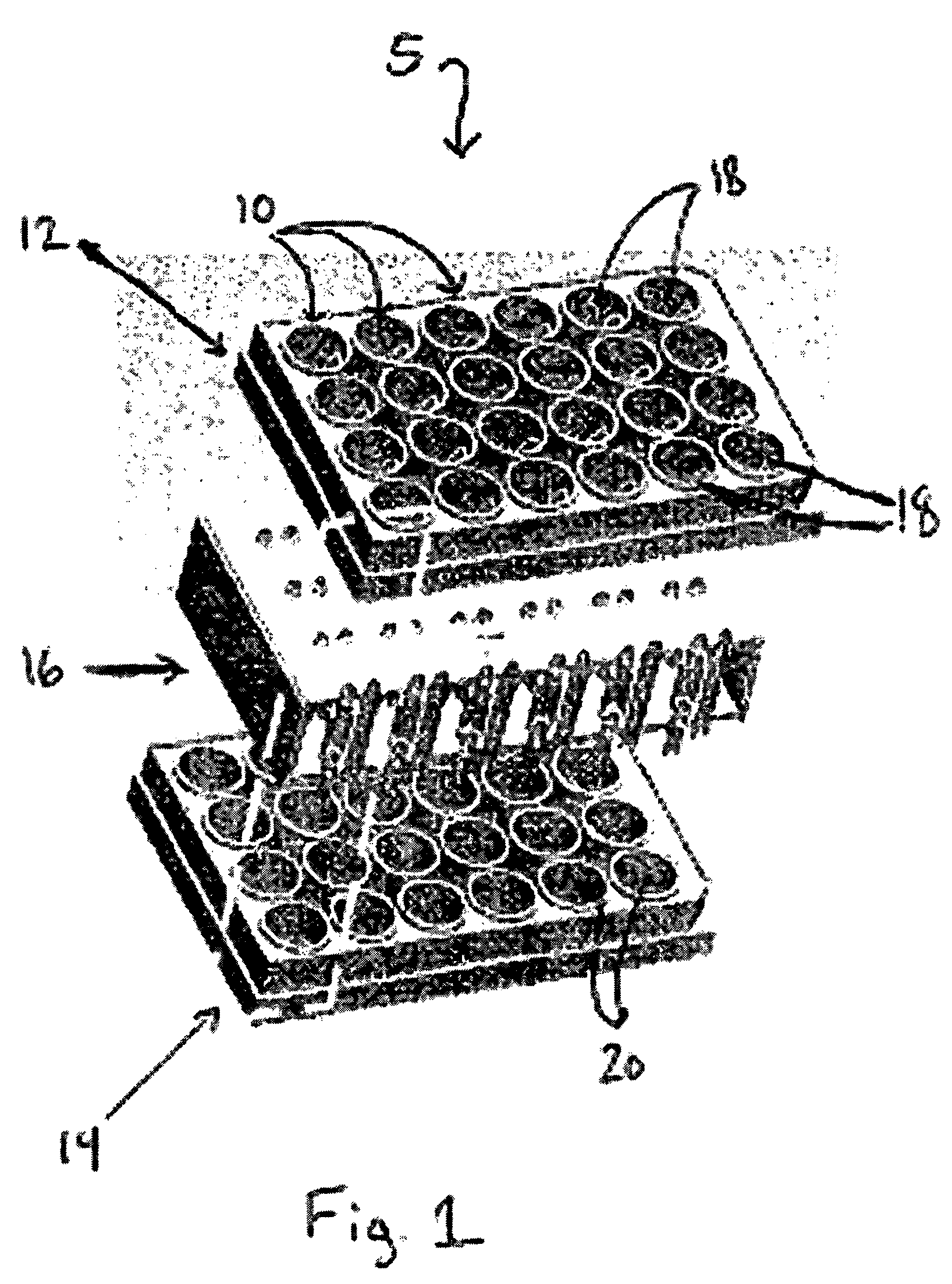

ActiveUS7767446B2Bioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion bioreactorCulture cell

A bioreactor system comprising a multi-well platform including an array of bioreactor units. The bioreactor system comprises a perfusion unit and a fluid source unit fluidly interconnected by a pumping unit. The perfusion unit comprises a multi-well plate including a plurality of main chambers configured to house or contain a cell culture and in each bioreactor unit an independent cell study or experiment may be performed.

Owner:ORGANOVO

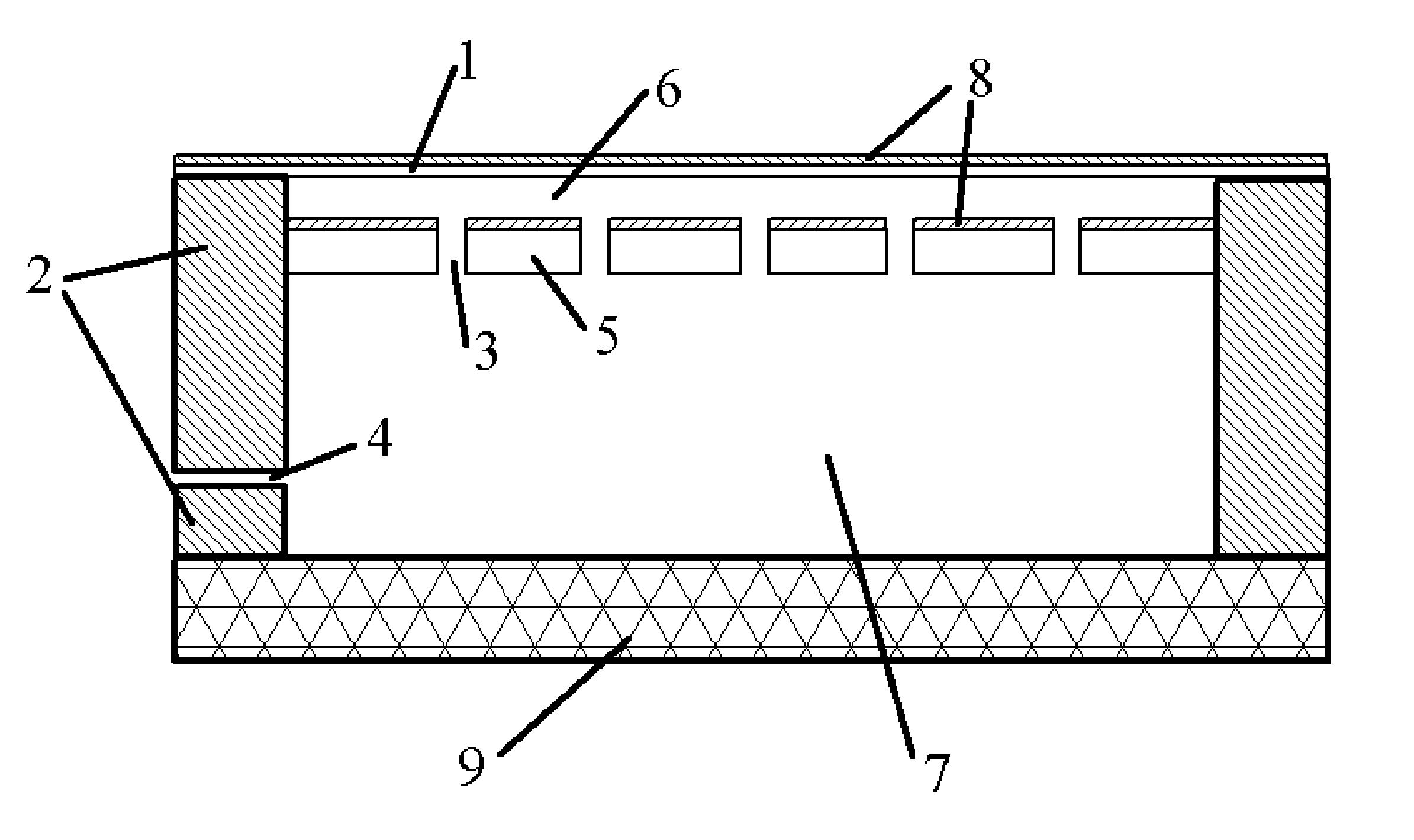

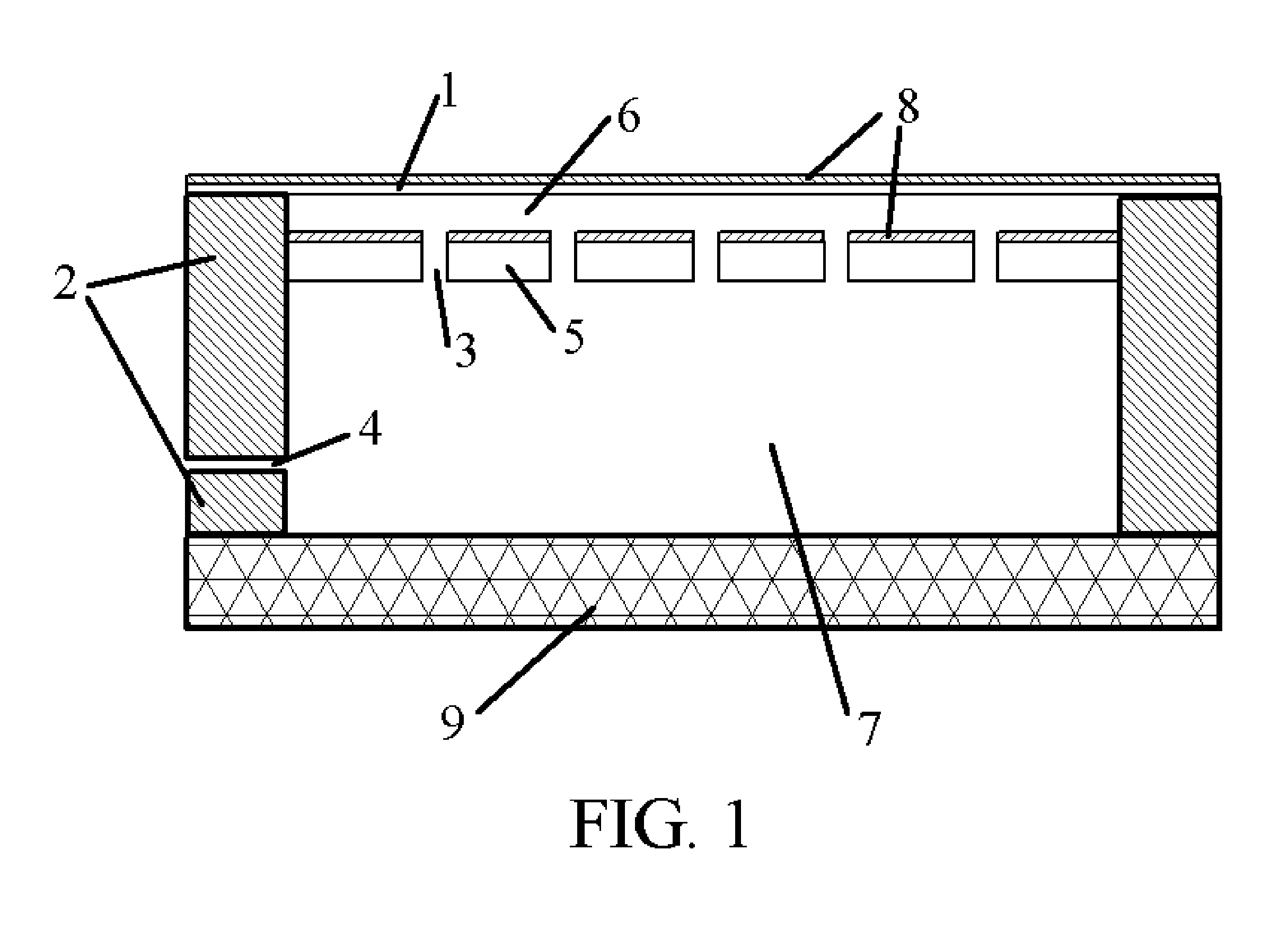

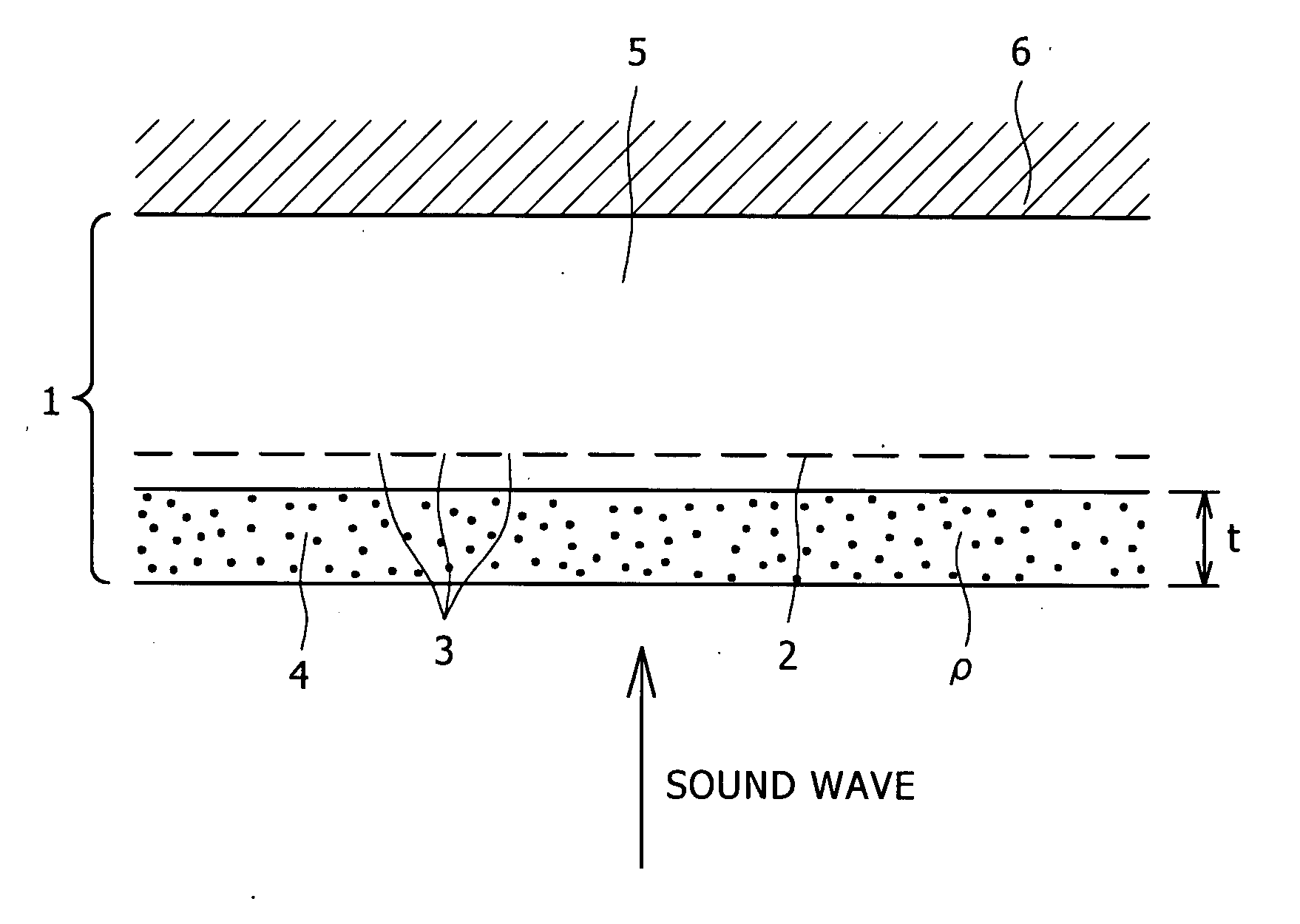

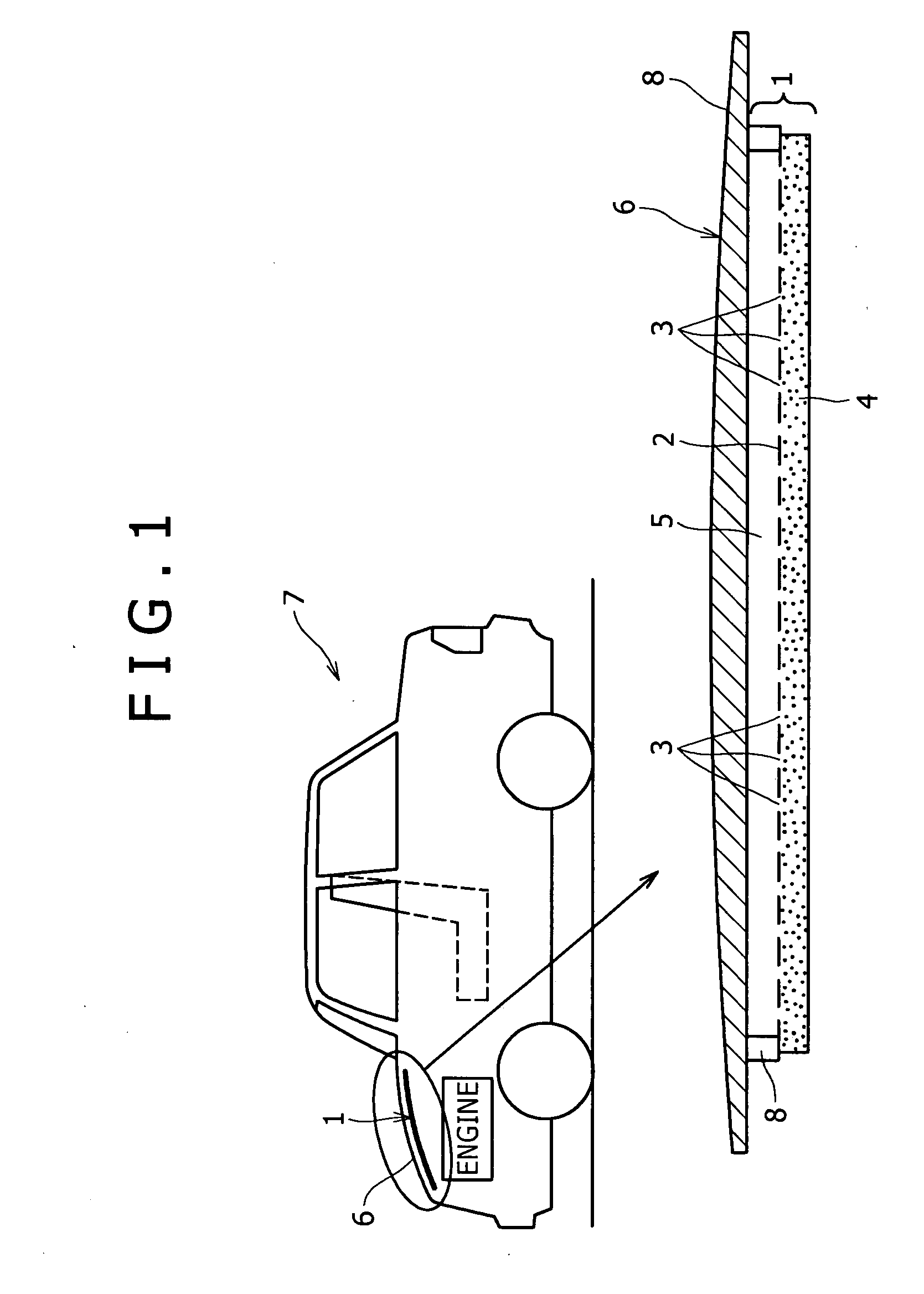

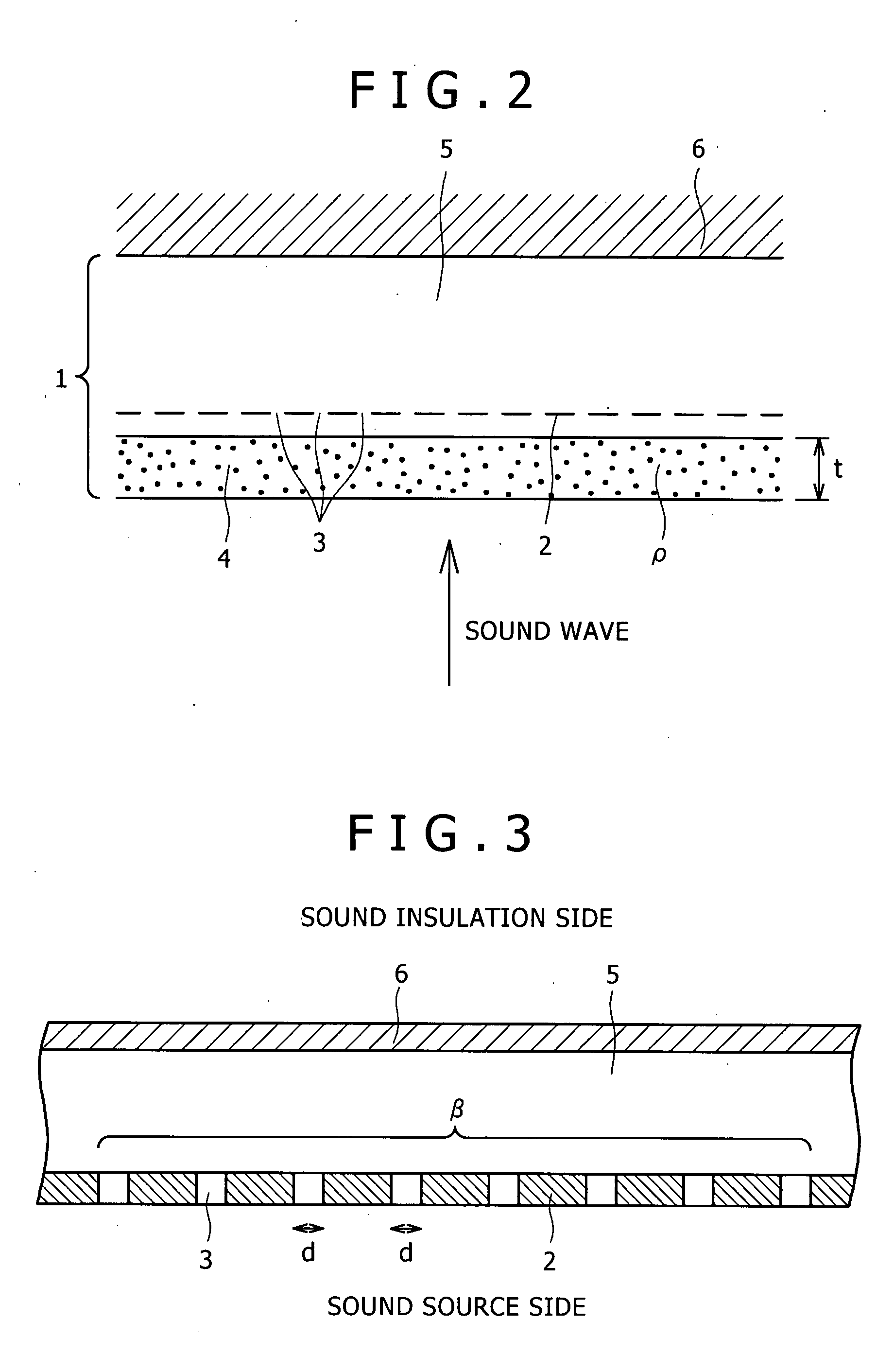

Sound Absorbing Structure

InactiveUS20080128201A1Easy to processImprove sound absorptionLayered productsVehicle componentsFiberSound sources

A sound absorbing structure having excellent in sound absorbing performance, which is capable of achieving 0.4 or higher in the sound absorbing coefficient even in the case where a perforated panel is a thin plate such as aluminum foil within a range where a reduction in the weight of a vehicle body is not impaired and through holes have a large hole diameter in order to make the processing of providing a large number of through holes in the perforated panel. The sound absorbing structure 1 is the sound absorbing structure 1 for suppressing noise generated on a sound source side, which is equipped with: a perforated panel 2 having a large number of through holes 3 and a fiber material 4, which are provided so as to face the sound source side and provided so as to overlap with each other; and an air layer 5 provided behind the perforated panel 2, in which the density and the thickness of the fiber material 4 and the hole diameter and the aperture rate of the through holes 3 of the perforated panel 2 severally have a specific relationship.

Owner:KOBE STEEL LTD

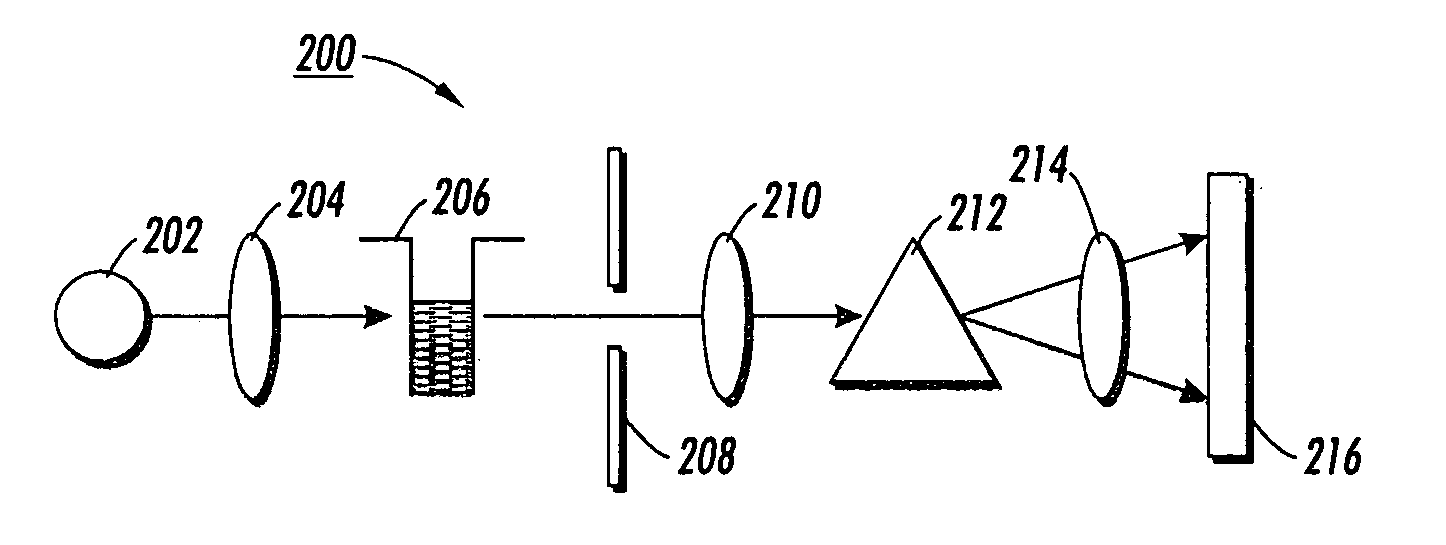

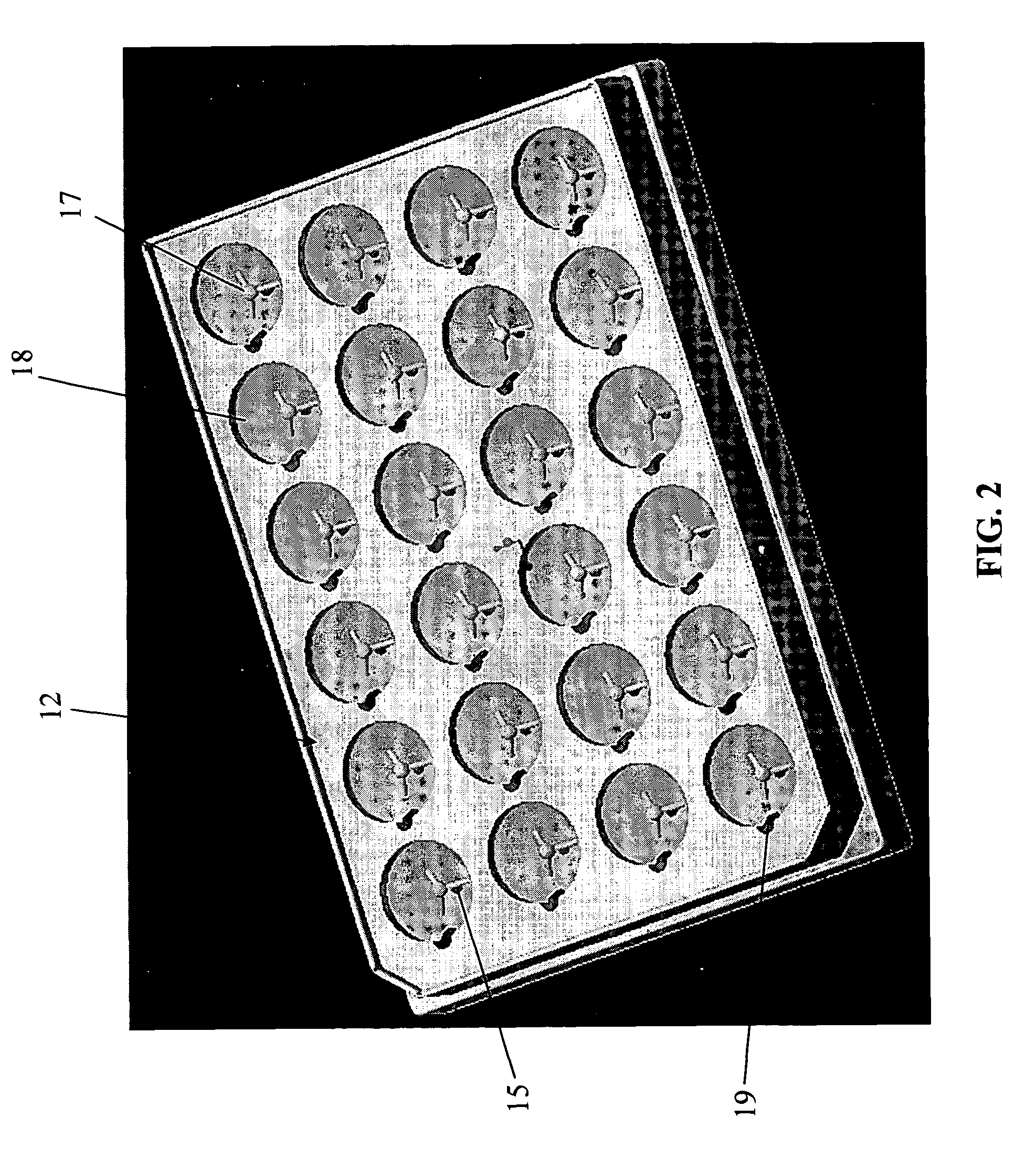

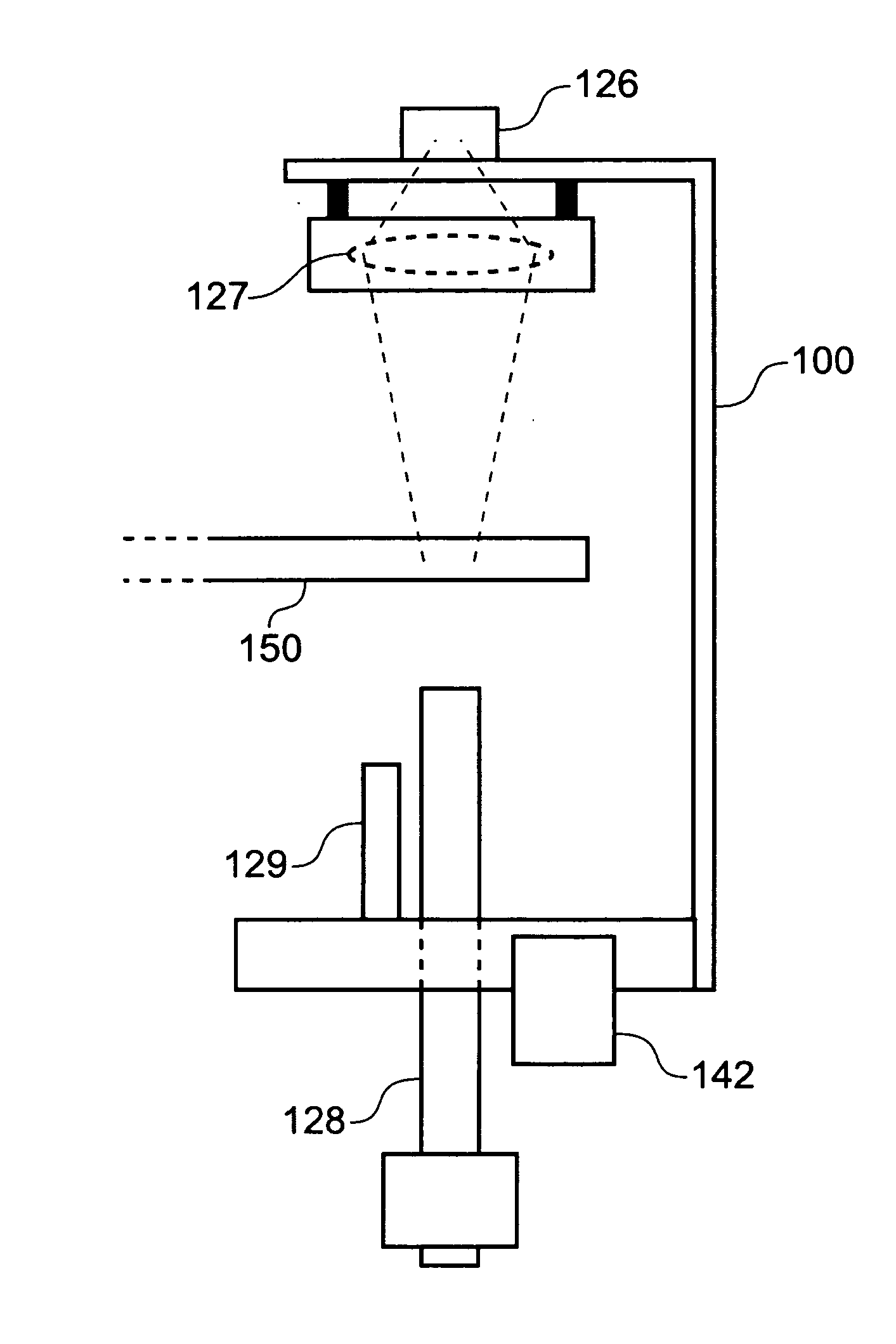

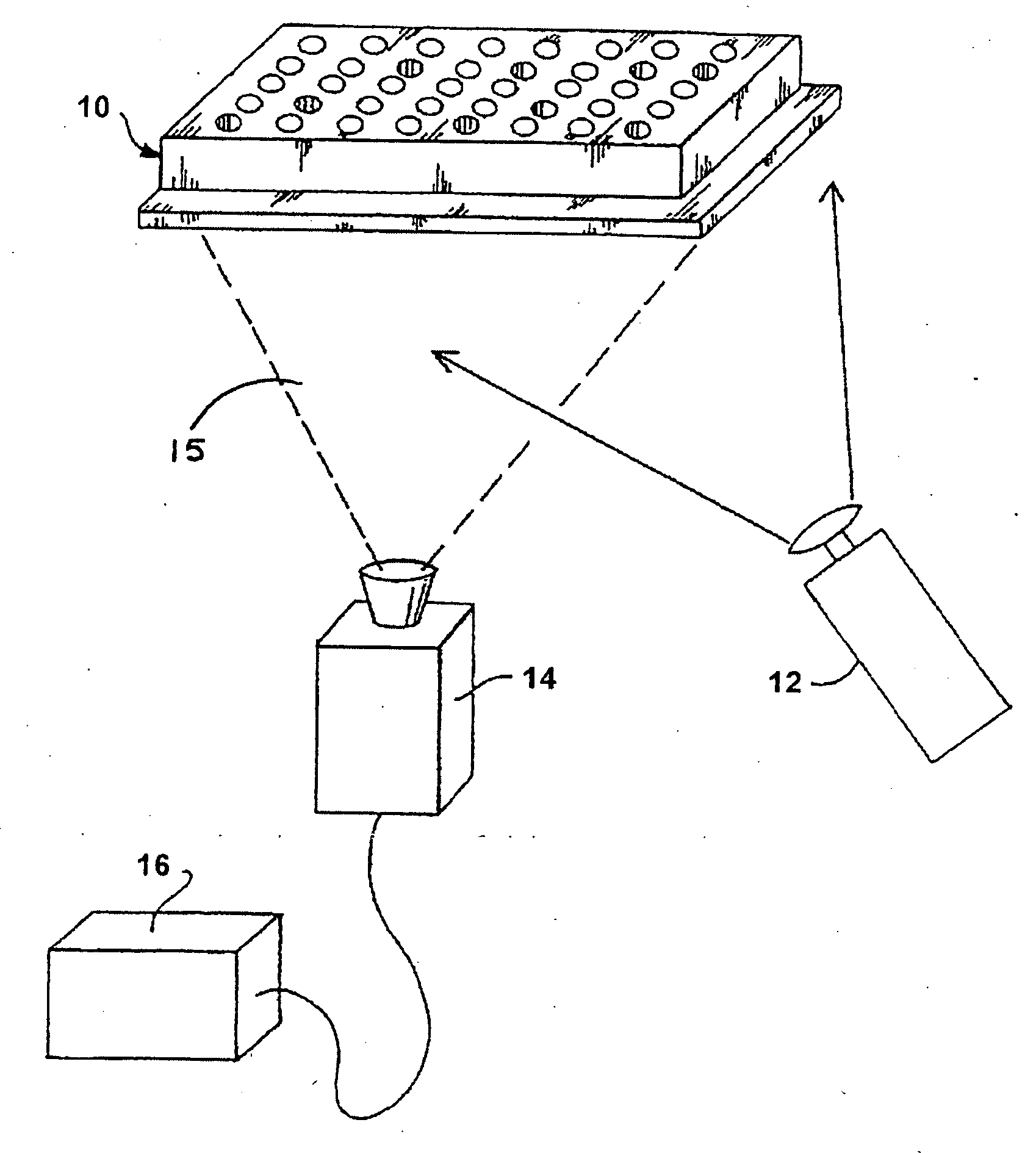

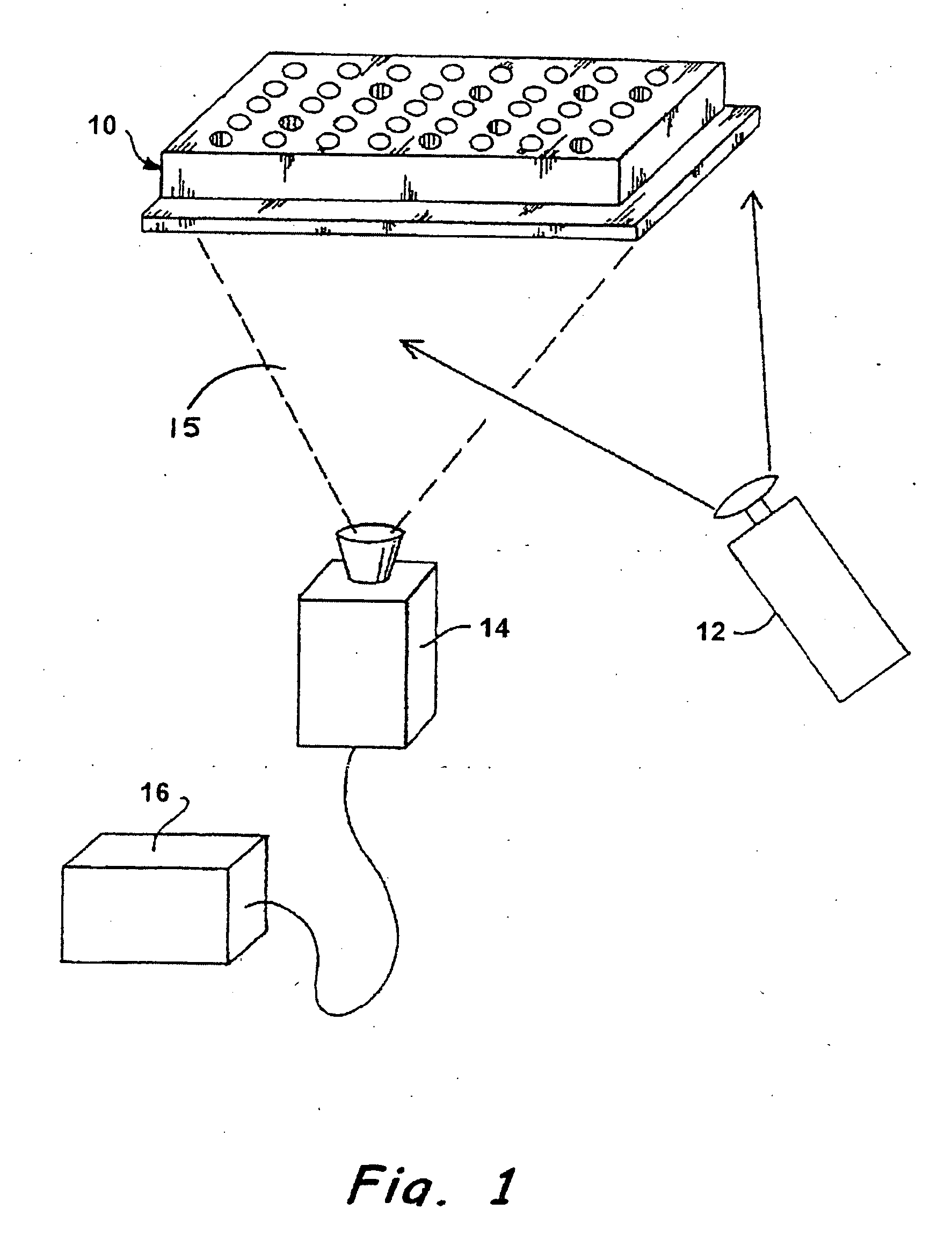

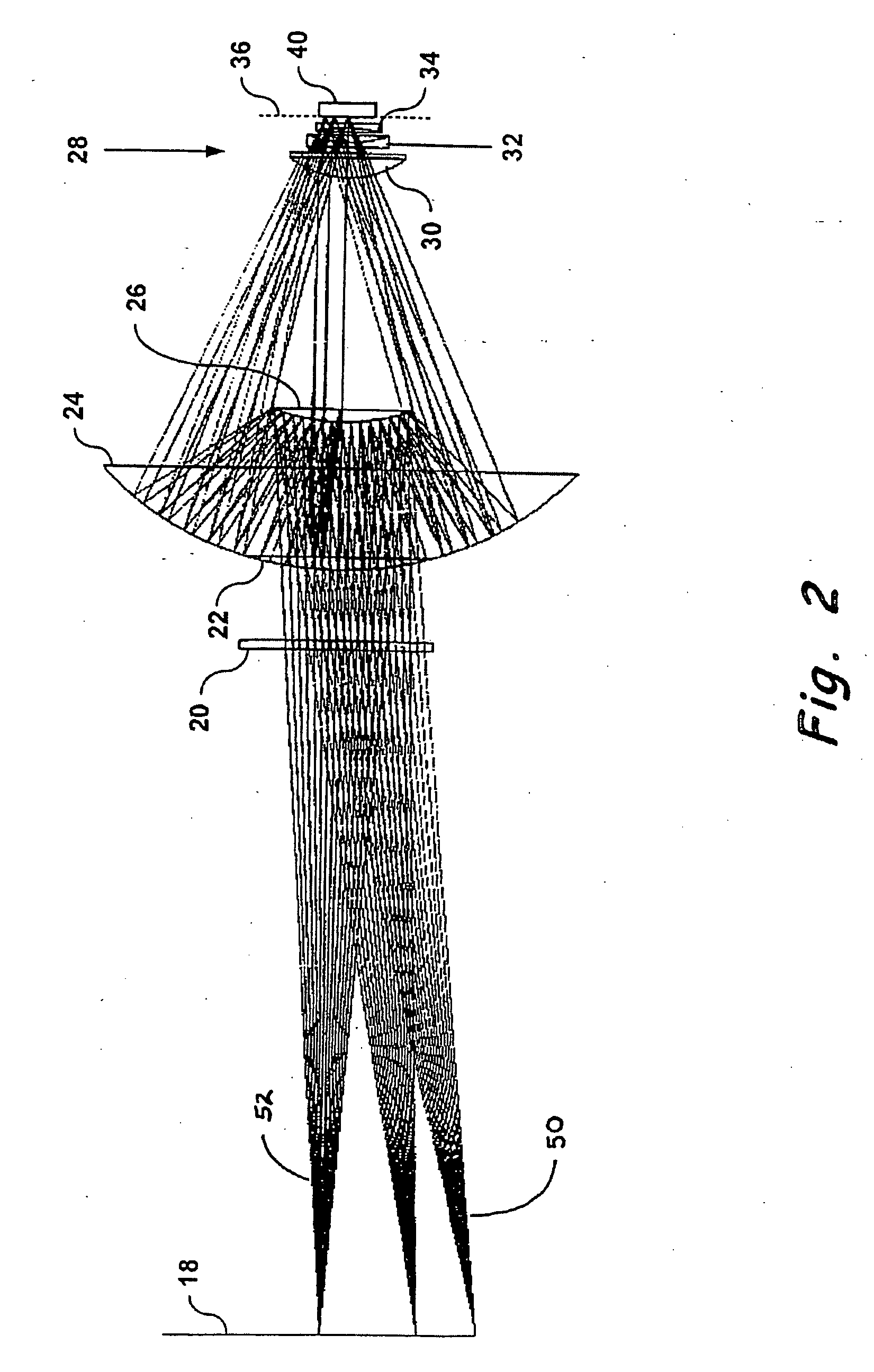

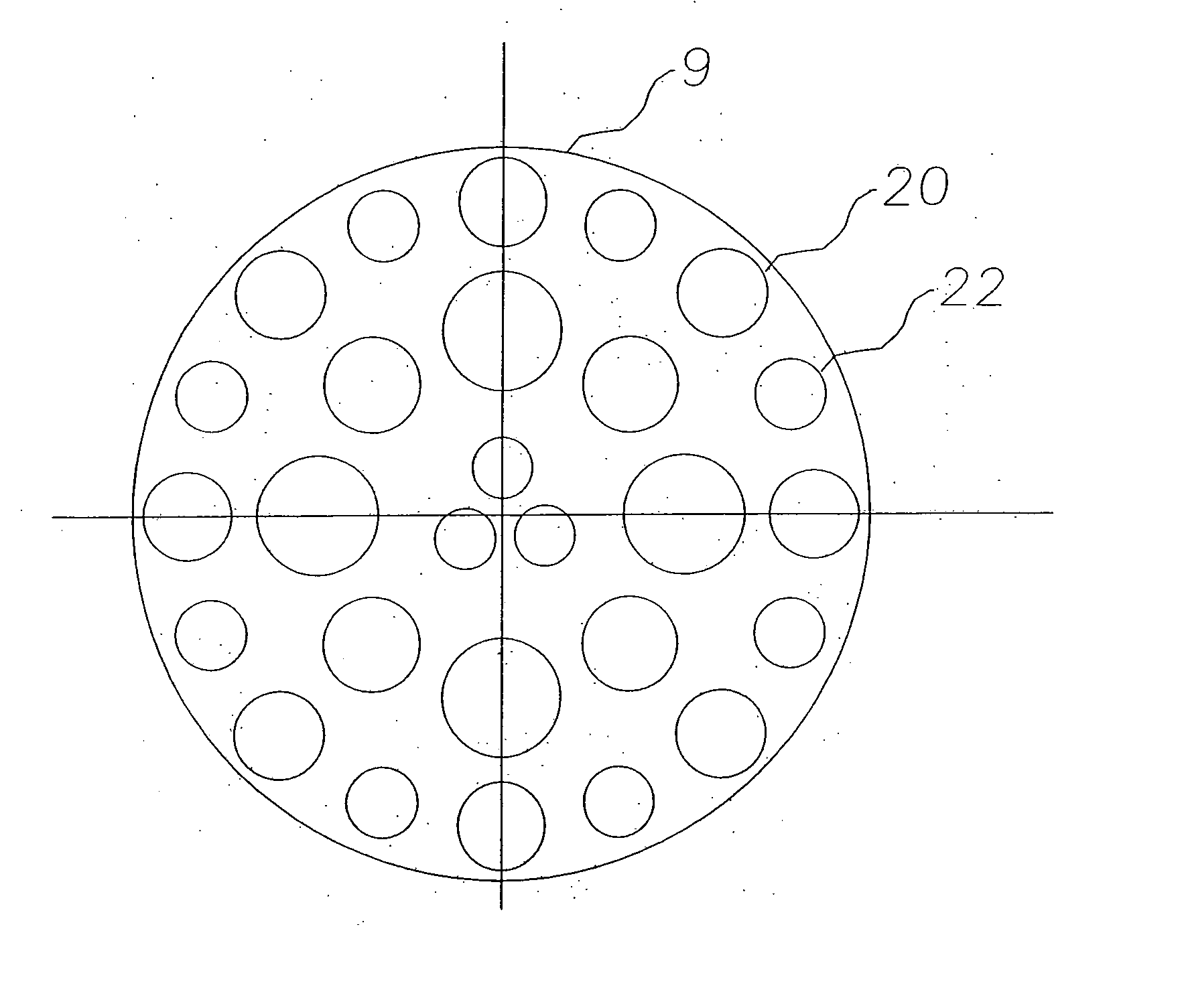

Methods and apparatus for optical analysis of samples in biological sample containers

ActiveUS20080297774A1Accurately knowAccurately determineRadiation pyrometrySpectrum investigationFast scanningCELLULAR SHEET

An apparatus and method for optically analyzing samples in a biological sample container containing samples arranged at different locations on the base of the container. An optical acquisition device is provided comprising a detector and an objective. The position of the upper and lower surfaces of the base at each of the sample locations is determined by a confocal polychromatic displacement sensor. Light is collected from each of the sample locations by adjusting the focal plane to be coincident with, or vertically offset from, the upper surface of the base, as determined from the displacement sensor. This allows for rapid scanning of large numbers of samples in a multi-well plate or other biological sample containers.

Owner:GENETIX LTD

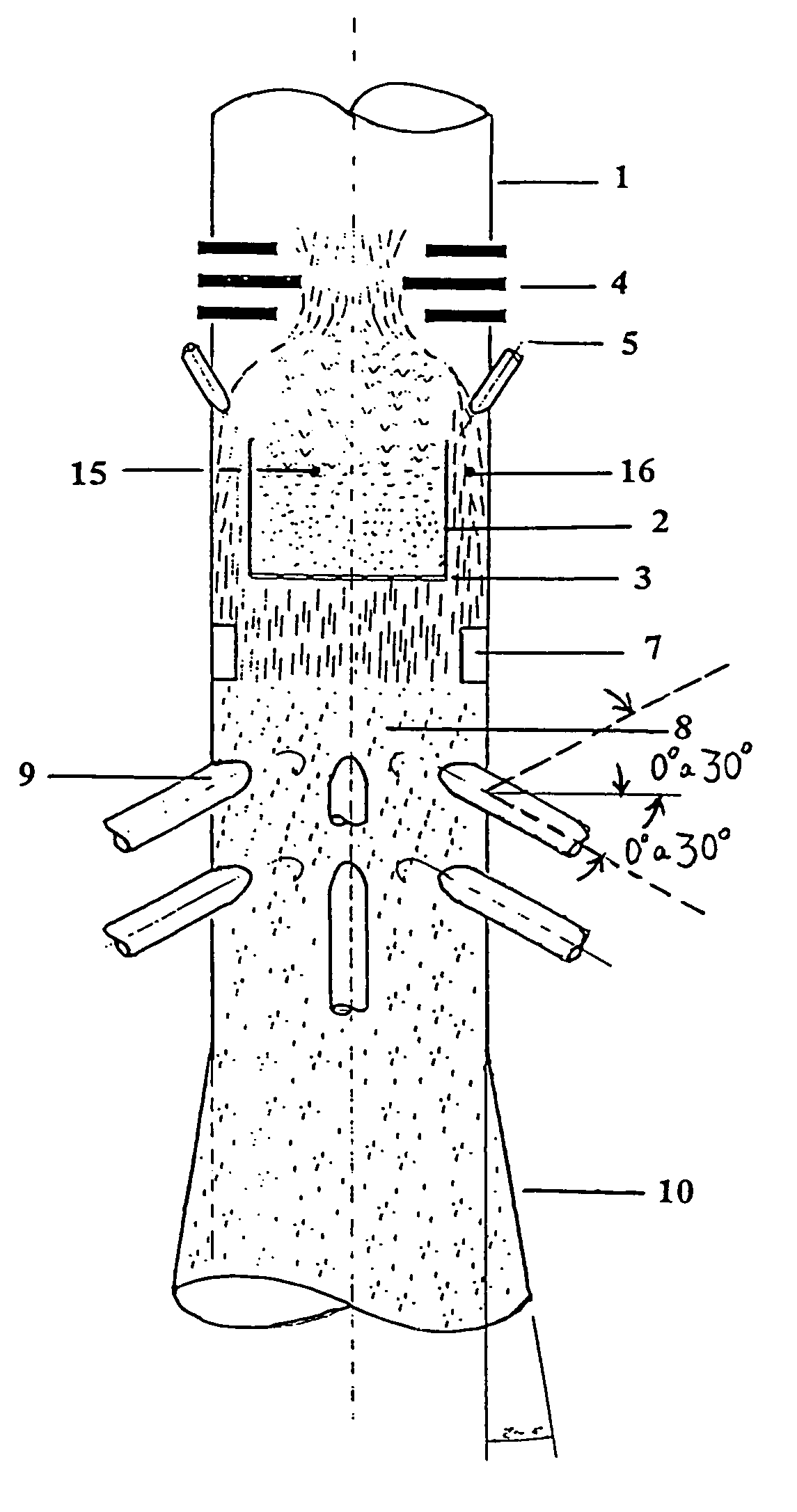

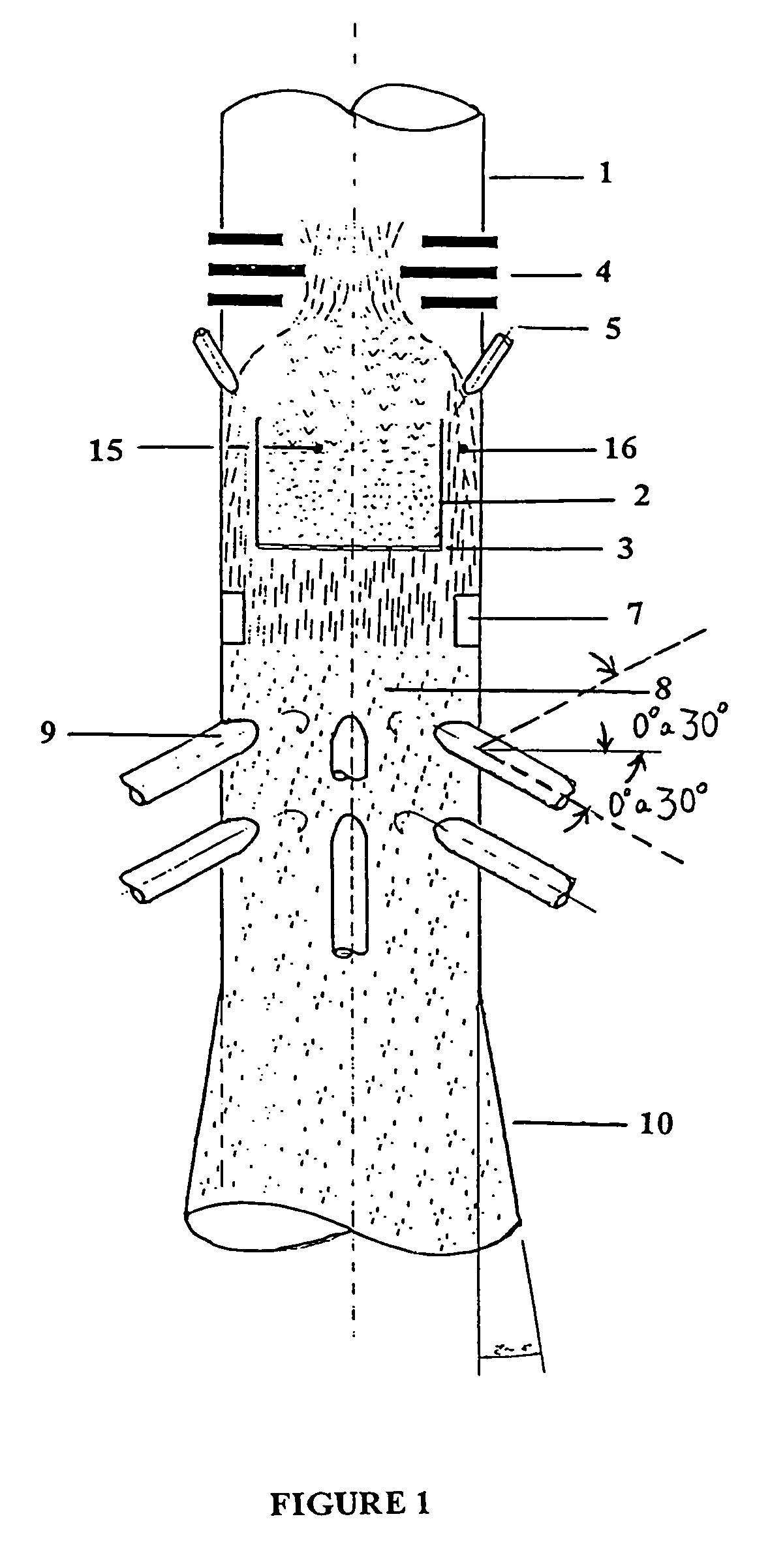

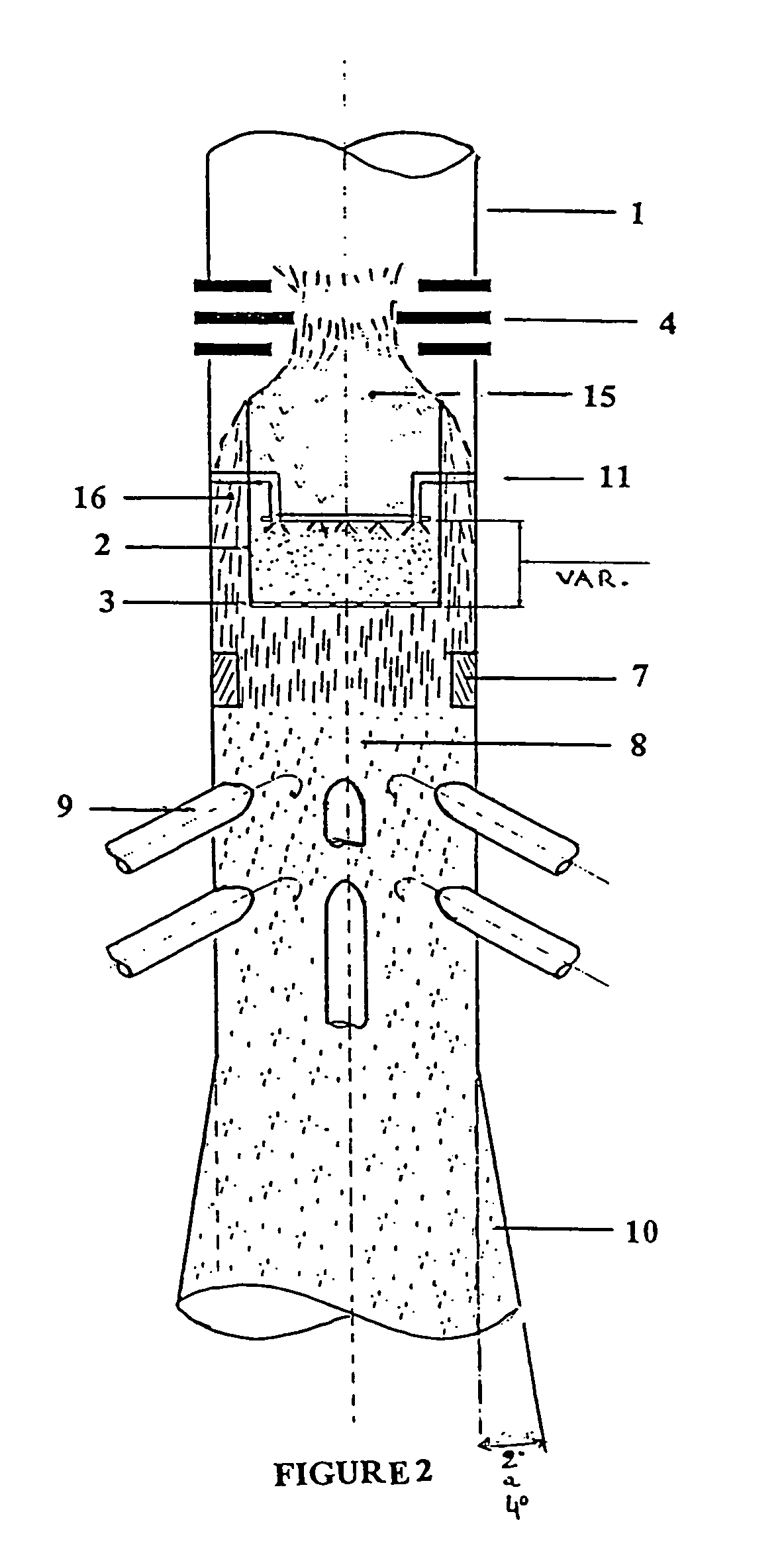

Multifunctional entry device for a downward flow tube reactor

InactiveUS7531142B2Easy maintenanceImprove condition of distributionCombination devicesAuxillary pretreatmentParticulatesVertical tube

A device and a method for operating it for application in a vertical tube reactor with downward flow (downer), has the aim of ensuring the intimate mixing of the solid particulate catalyst with a reagent fluid. Homogeneous distribution of catalyst is due to the use of a plate having perforations. Said perforated plate normally allows the passage of a portion of the stream of catalyst. The other portion overflows the edge of the plate, flowing in the form of an annular curtain, near the inner surface of the surrounding tube of the device. After passing beyond the perforated plate, the curtain-flow undergoes a deflection produced by an annular screen, to be mixed with the stream originating from the orifices in the perforated plate. A hydrocarbon charge is injected below the perforated plate, forming a certain angle with respect to the direction of the downward flow of catalyst, by means of inlets distributed uniformly about cross sections of the surrounding tube. After the mixing region, the diameter of the device, when smaller than the diameter of the associated tube reactor, expands slightly.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

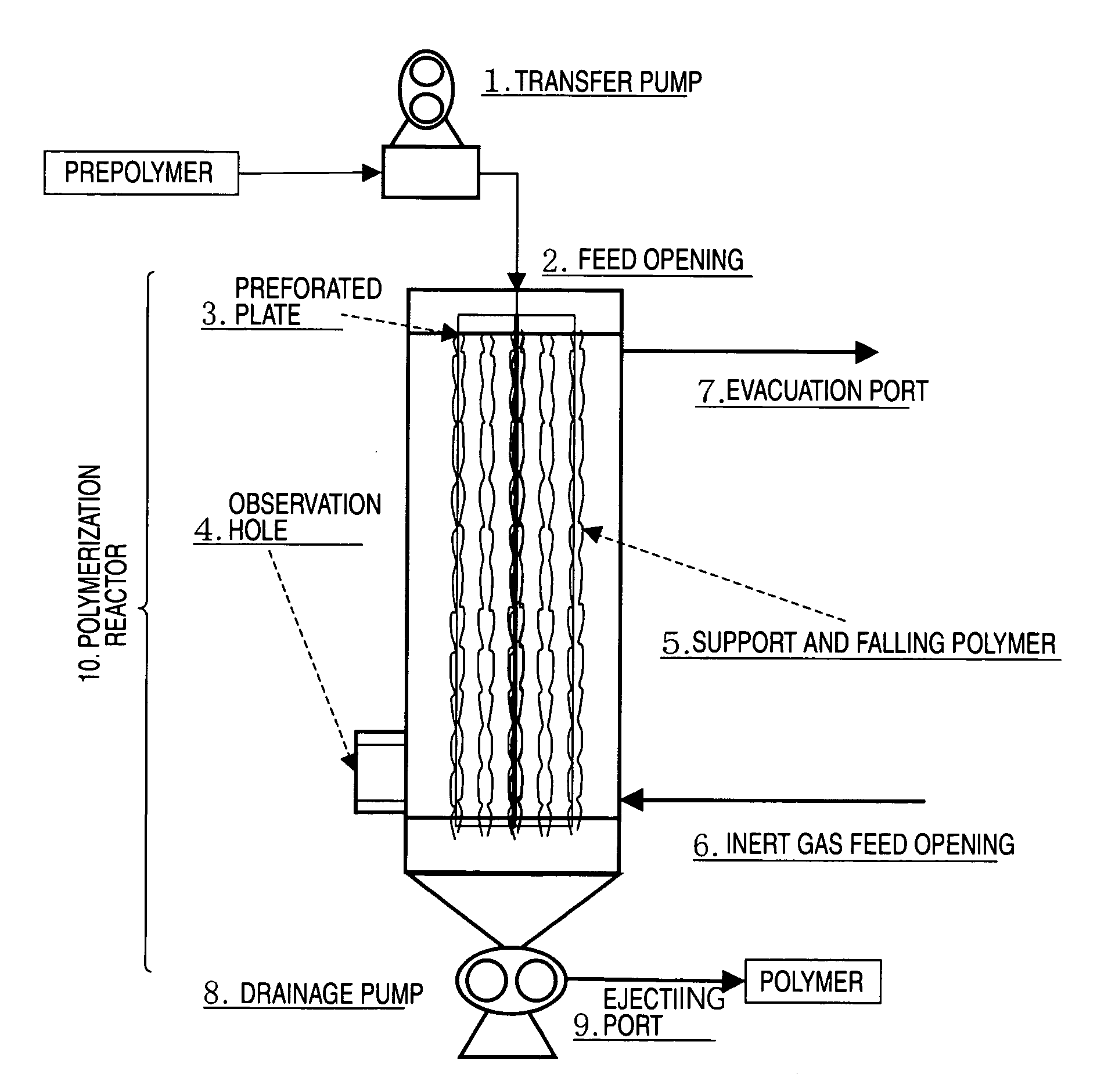

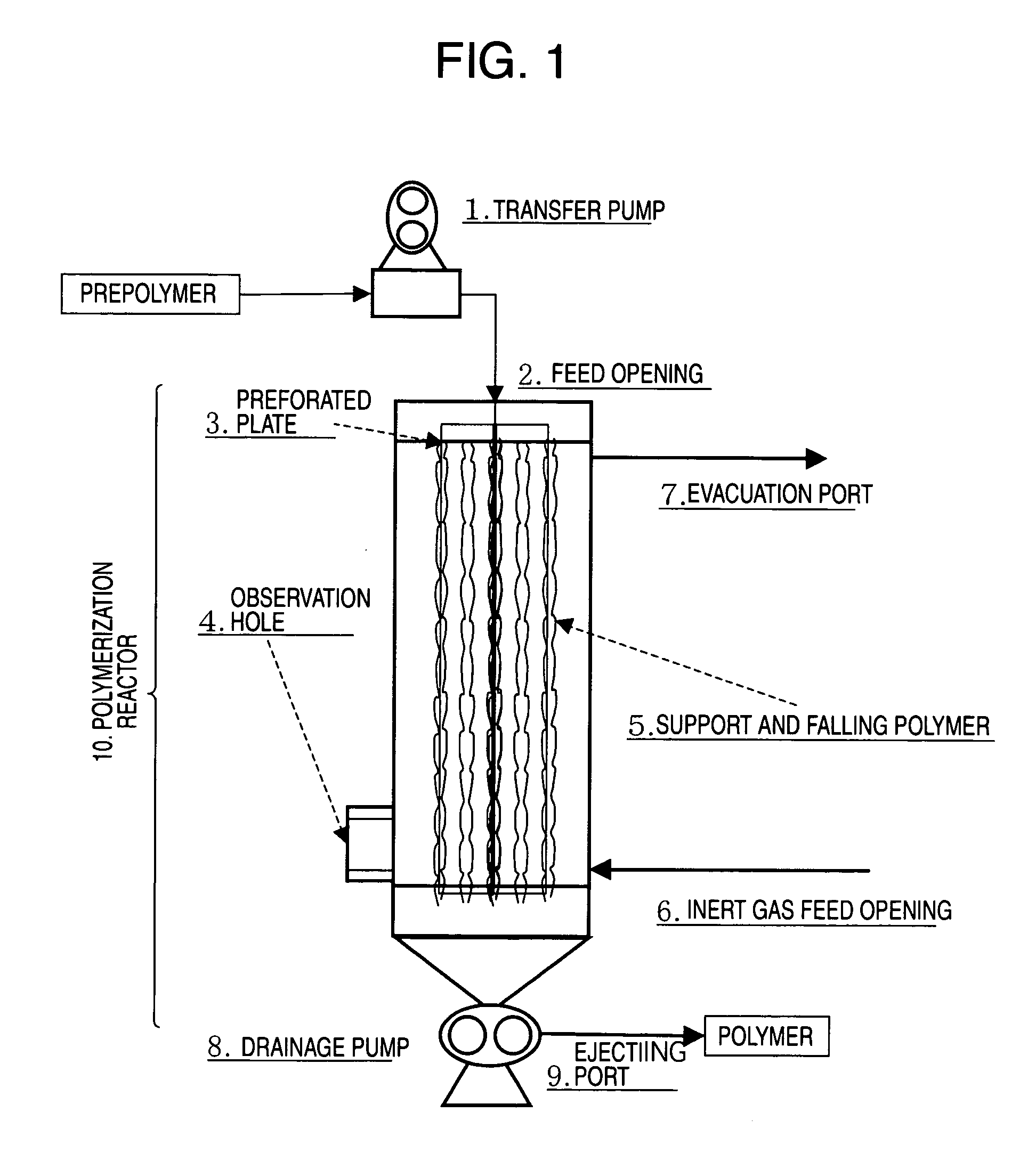

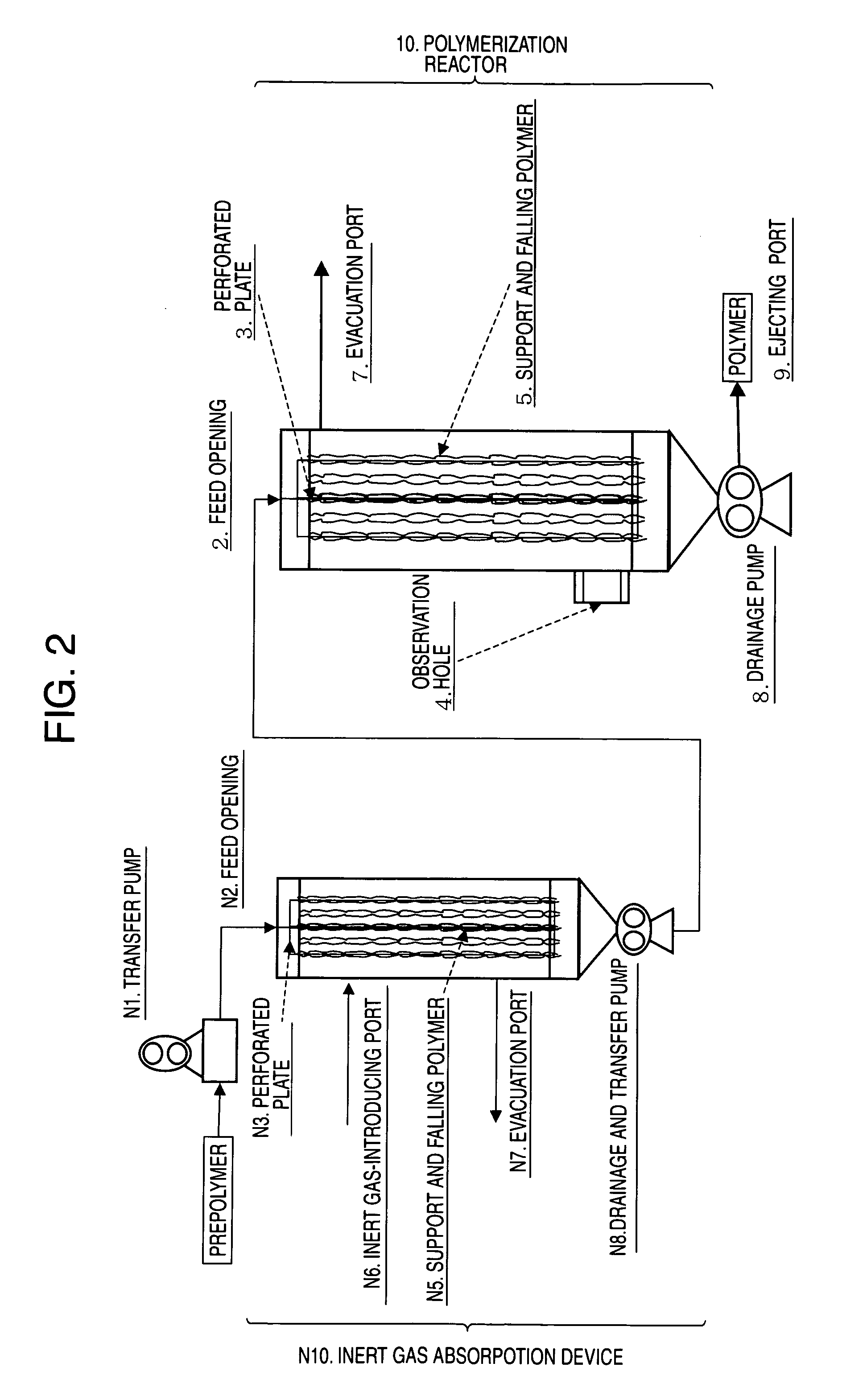

Process for Producing Polyalkylene Terephthalate, Process for Producing Polyalkylene Terephthalate Molding and Polyalkylene Terephthalate Molding

ActiveUS20080274320A1Low costIncrease production capacitySuture equipmentsLayered productsMolten statePolymer science

The present invention provides a method of producing polyalkylene terephthalate, which comprises: introducing a prepolymer of polyalkylene terephthalate that is in a molten state comprising 70 mol % or more of ethylene terephthalate or 1,4-butylene terephthalate repeating units and having an intrinsic viscosity [η] between 0.2 and 2 dl / g through a feed opening to a polymerization reactor; discharging the introduced prepolymer from holes of a perforated plate; and polymerizing the prepolymer under reduced pressure, while allowing the prepolymer to fall along the surface of a support that is open towards the outside at a temperature between the [crystalline melting point−10° C.] of the prepolymer or higher and the [crystalline melting point+30° C.] of the prepolymer or lower under the conditions represented by a formula S1 / S2>1, wherein S1 is the surface area of falling polyalkylene terephthalate, and S2 is the area where the support is in contact with polyalkylene terephthalate.

Owner:ASAHI KASEI CHEM CORP

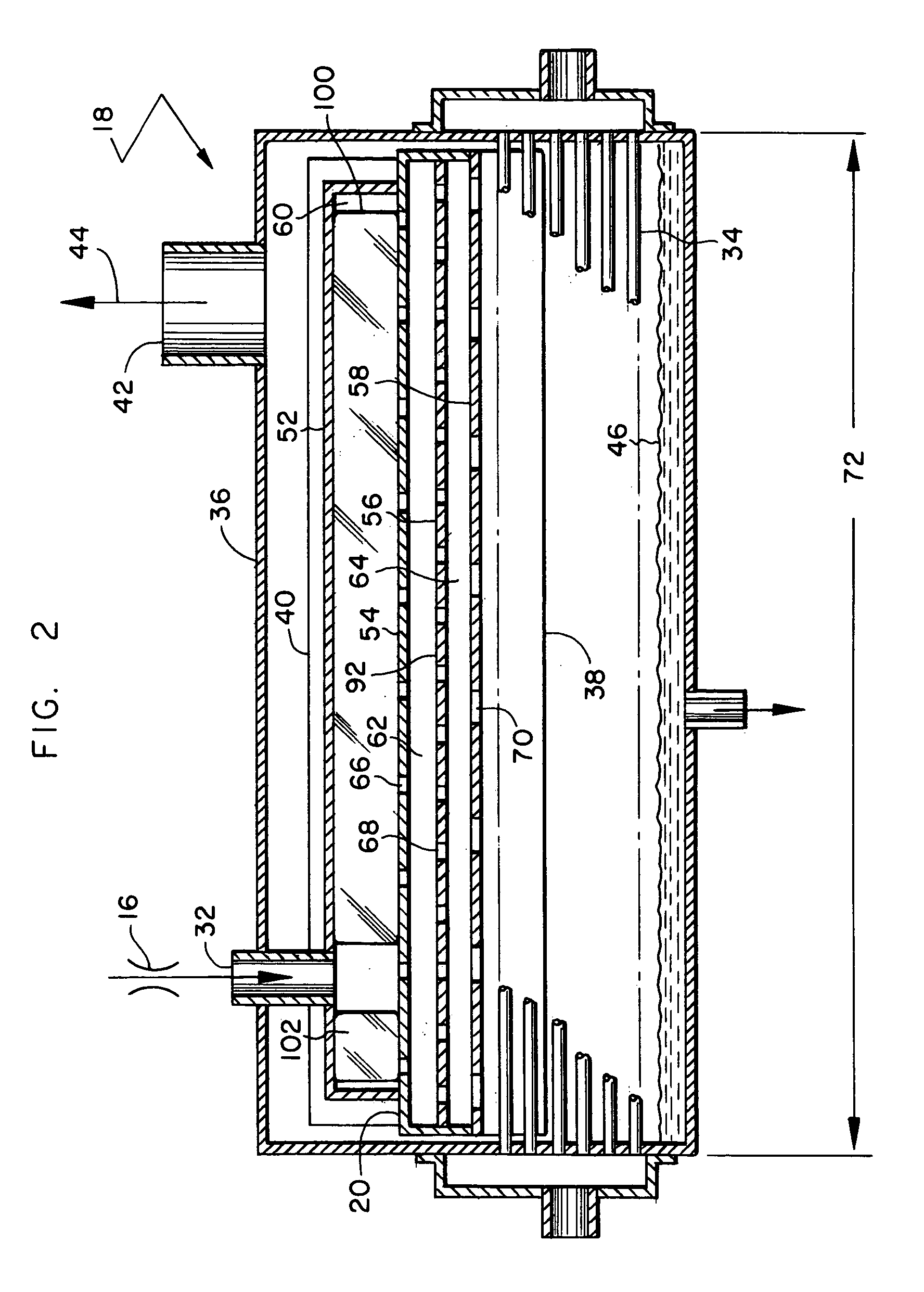

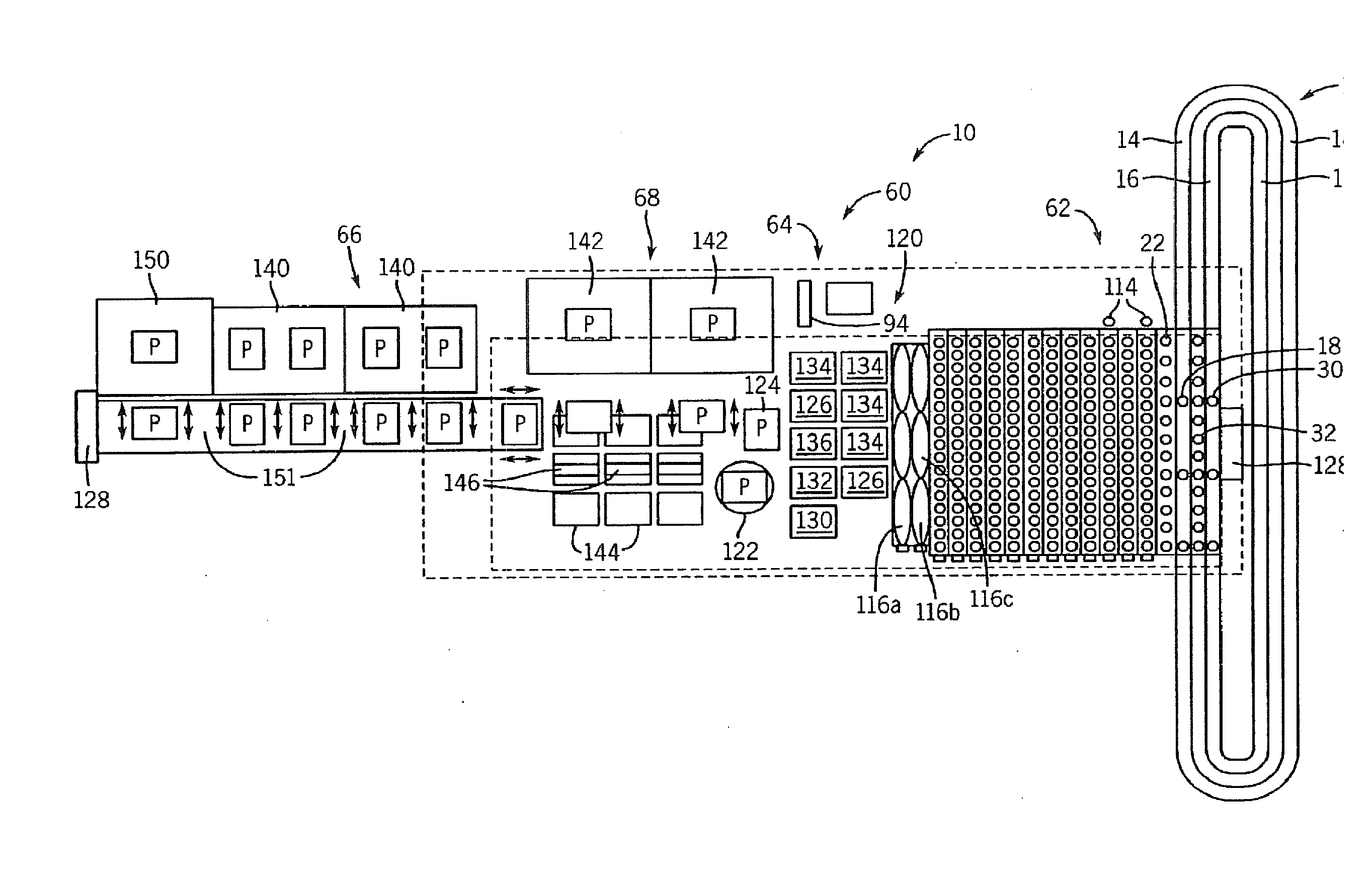

Automated analyzer for clinical laboratory

ActiveUS20120282684A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicro perforated plateClinical chemistry

A laboratory automation system that is capable of carrying out clinical chemistry assays, immunoassays, amplification of nucleic acid assays, and any combination of the foregoing, said laboratory automation system employing at least one of micro-well plates and deep multi-well plates as reaction vessels. The use of micro-well plates as reaction vessels enables the laboratory automation system to assume a variety of arrangements, i.e., the laboratory automation system can comprise a variety of functional modules that can be arranged in various ways. In order to effectively carry out immunoassays by means of micro-well plates, a technique known as inverse magnetic particle processing can be used to transfer the product(s) of immunoassays from one micro-well of a micro-well plate to another.

Owner:ABBOTT LAB INC

Pattern adhesive seal products and method of production

The present invention is drawn to a method of making a sealing product, by a) selecting an a sealing material of an optimum film, mat or multi-well plate surface material for a specific sealing application; b) treating the sealing material; and c) directly coating the sealing material with an adhesive in a pattern format using Gravure, screen, rotary screen, flexographic, pad printing or dry transfer techniques. The present invention is further drawn to a sealing product made using the aforementioned method.

Owner:RAZAVI ALI

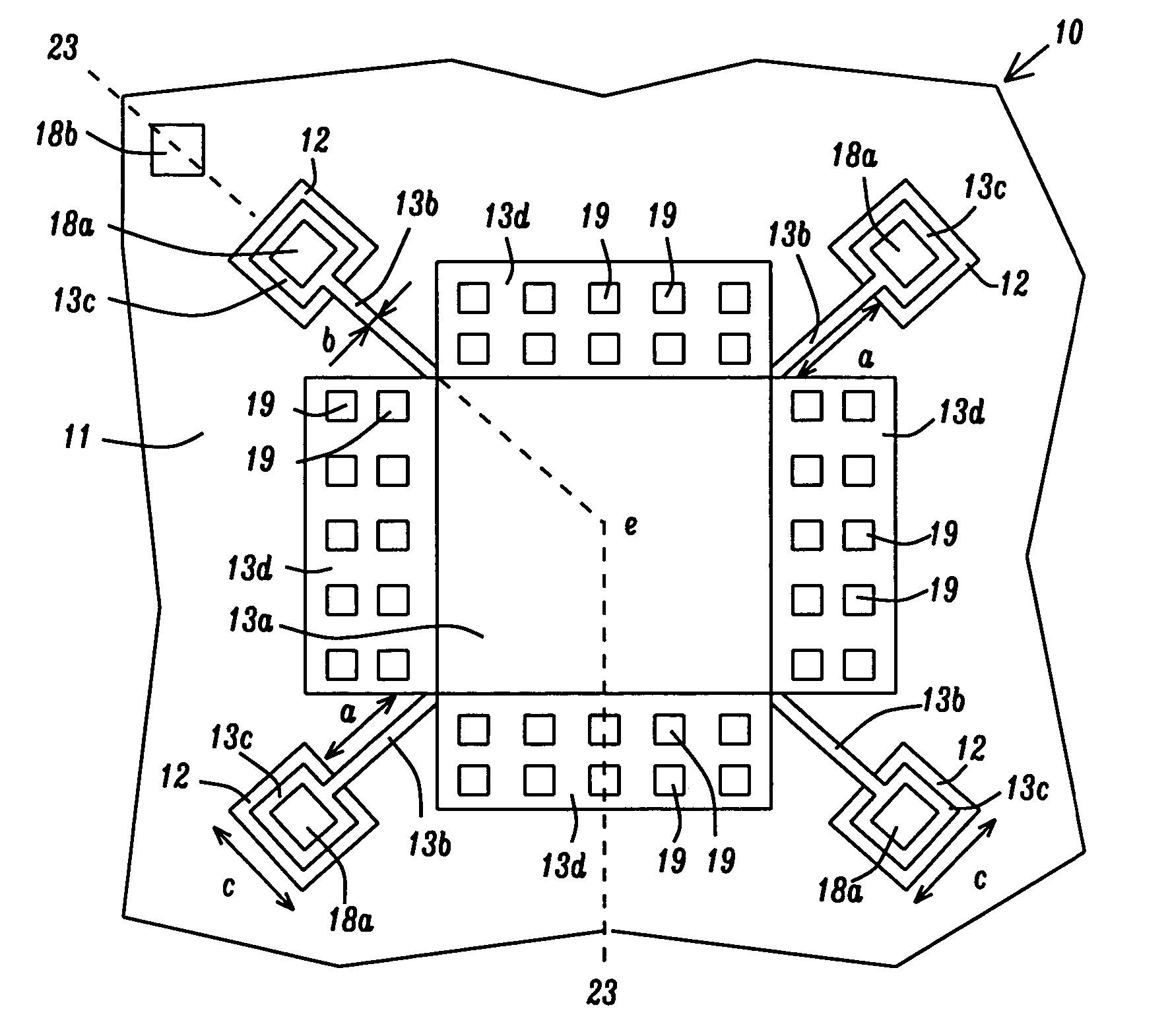

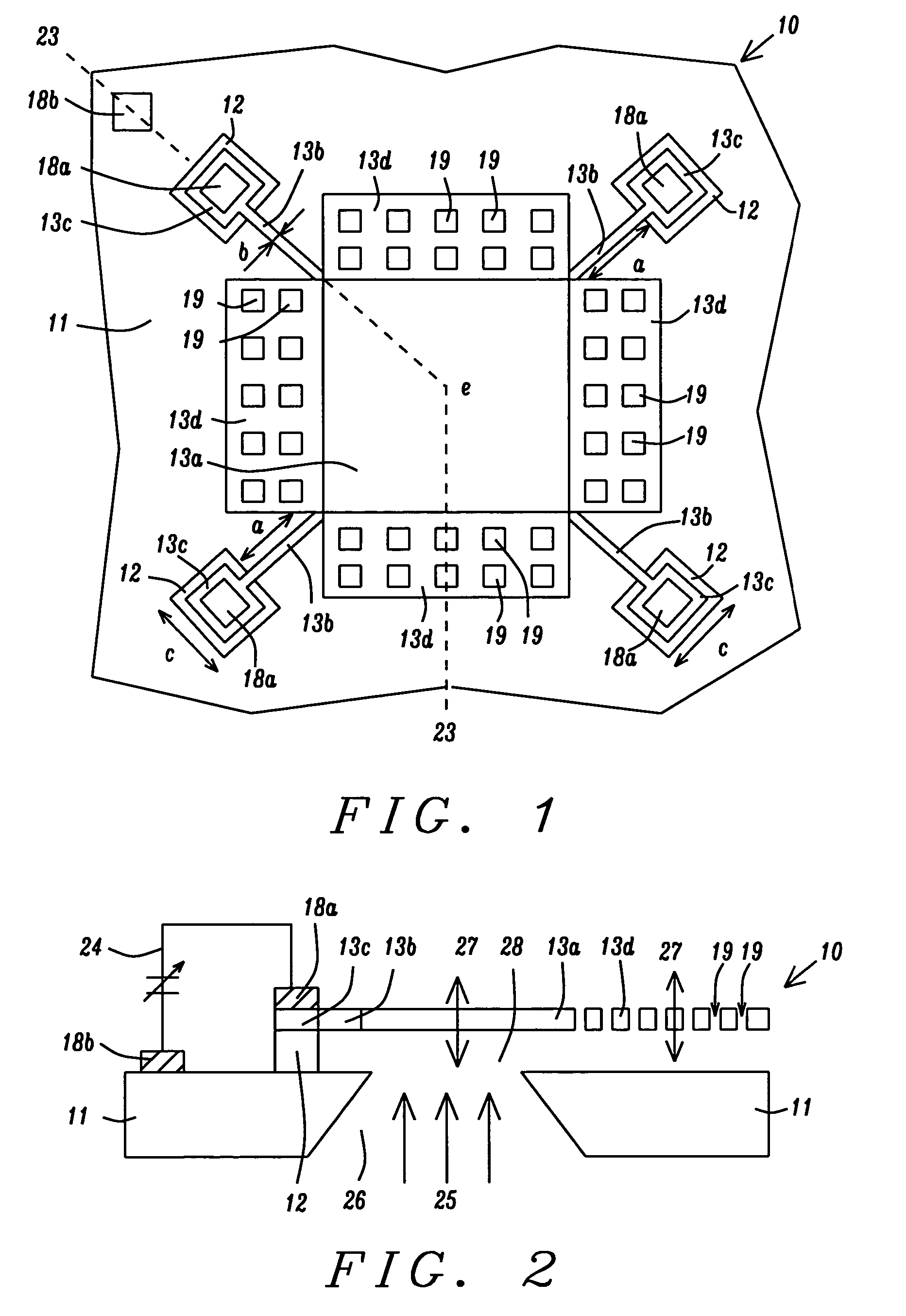

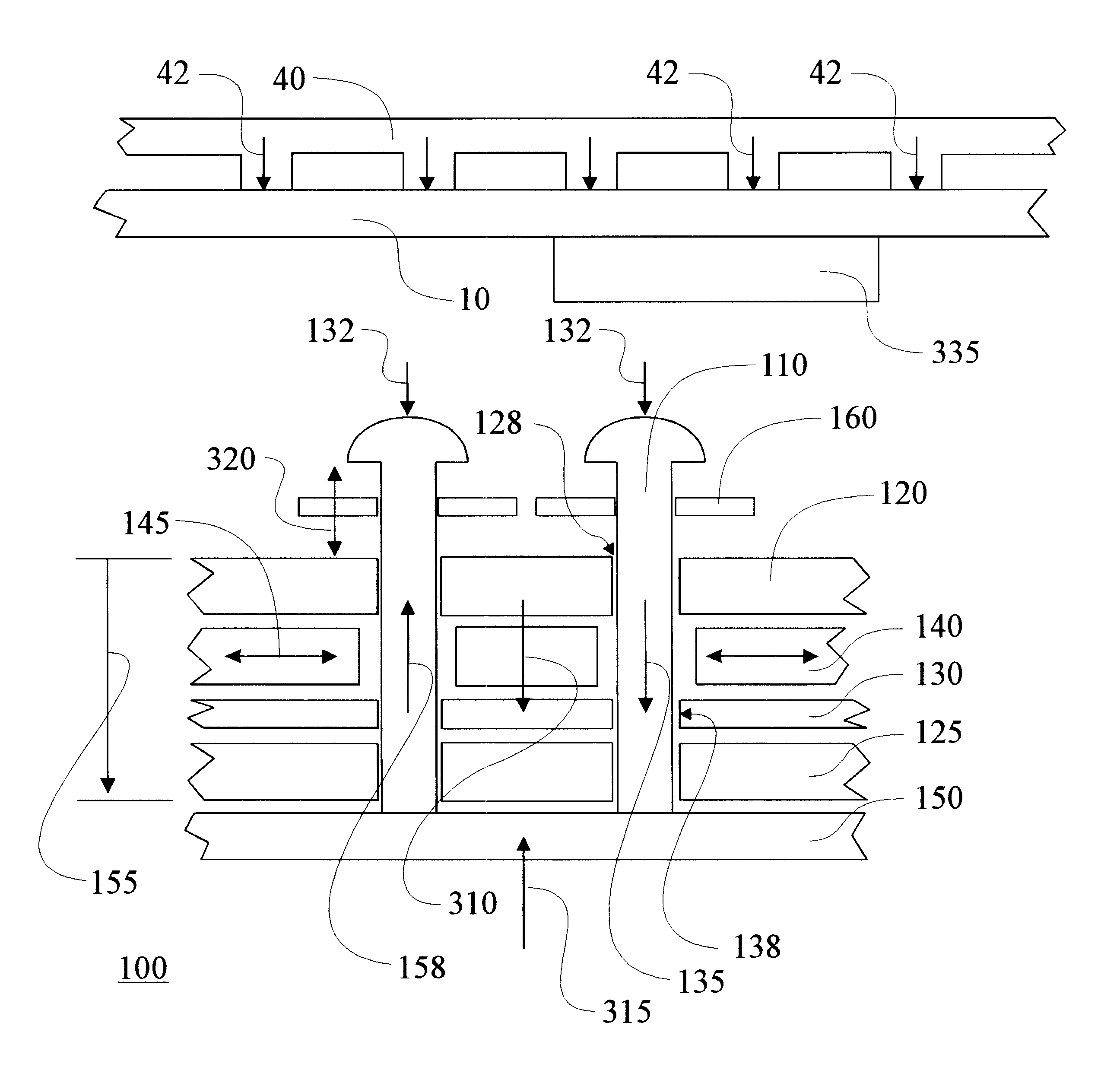

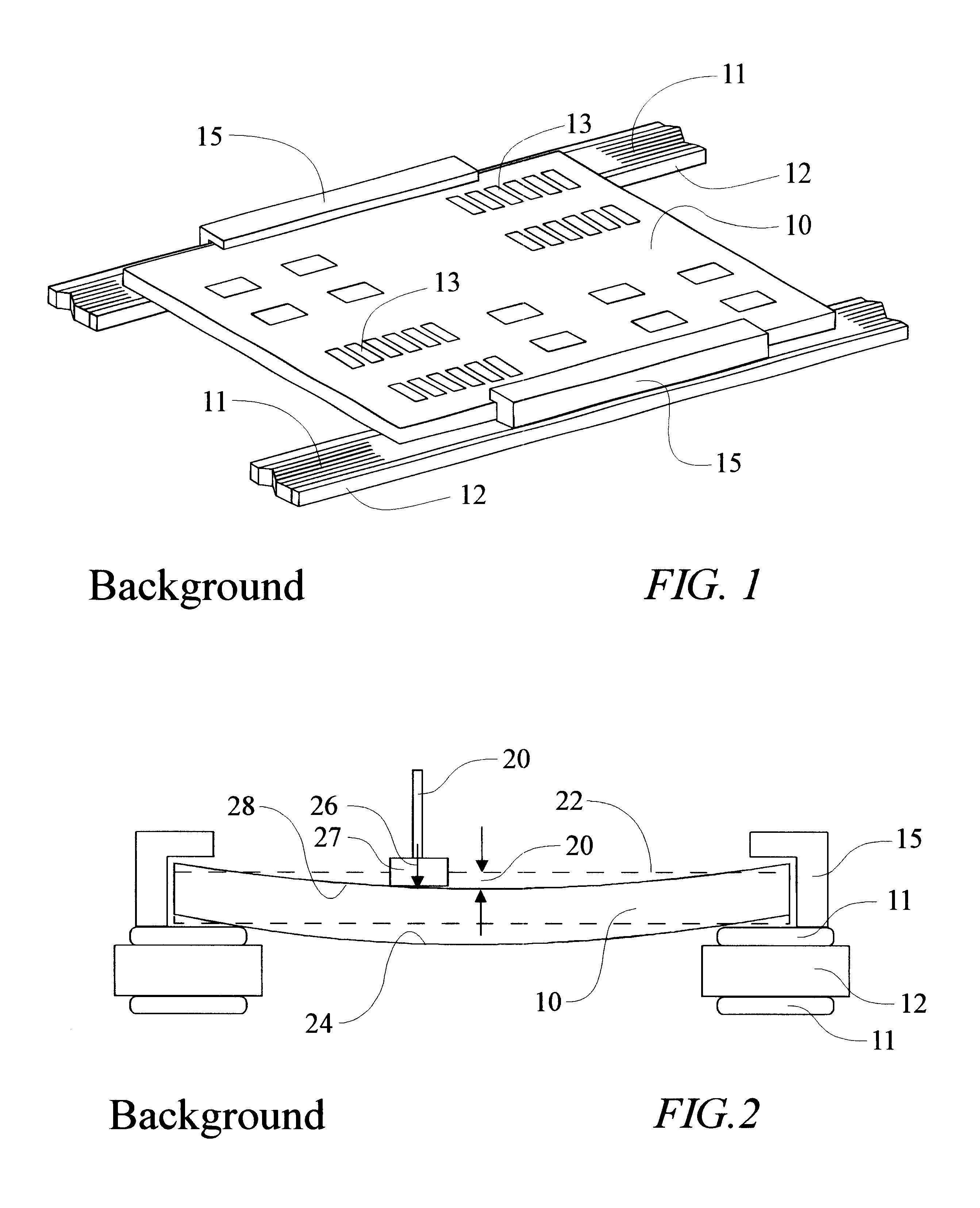

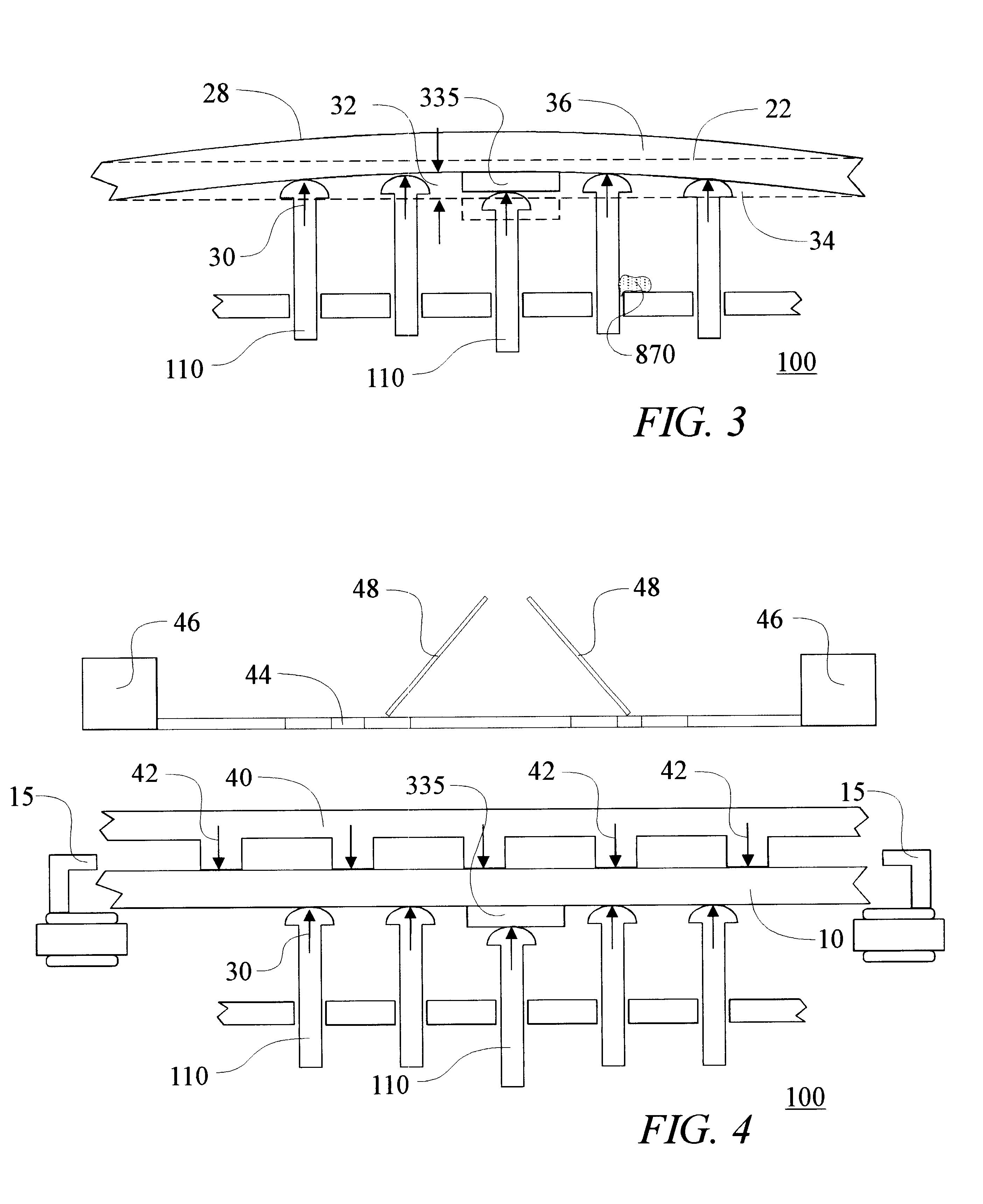

Flexible, self conforming, workpiece support system and accessories

InactiveUS6695298B1Increase resistanceEnhanced magnetic forceLarge fixed membersPositioning apparatusForeign matterSupporting system

An apparatus and accessories are disclosed for a flexible support apparatus 100, 900 using elongated support members 110 to support a face of a workpiece 10 and respective protrusions 335. The elongated support members 110 are arranged through at least one plane of perforated material 120, where the elongated support members 110 are profiled against the workpiece 10 and respective protrusions 335. The profile of the elongated support members 110 is created by contacting forces 132 generated by bringing the workpiece 330 and the plurality of elongated support members 110 together. A holding force is then applied to the elongated support members 110 to support the workpiece 10 against forces applied by a workstation. Fluid 902 is used to raise expansion members to raise the plurality of elongate support members 110. A perforated plate 920 is used to control the flow of fluid 902 between a fluid cavity 910 and the plurality of expansion members 904. Accessories to improve performance and reliability include a protective collar for protection from foreign materials 870 (solder paste) and a reinforcing member 40, 44 to reinforce thin, flexible workpieces 10.

Owner:GALAHAD

Reflective optic system for imaging microplate readers

A reflective light imaging system for use in high-throughput screening of samples disposed in multiple-well plates. The system can include a set of mirrors and lenses. The first mirror has a central aperture through which light from the object passes. The first mirror has a concave reflective surface that faces the image plane. The next element is a second mirror with a convex reflective surface. The system can include an aberration corrective system positioned between the second mirror and the image plane, and an optical sensor near the image plane. Light from an object passes through the central aperture of the first mirror and is reflected off the convex surface of the second mirror. The light then strikes the reflective surface of the first mirror. The light from the first mirror is then collected by the aberration correction system and transmitted toward the image plane.

Owner:MOLECULAR DEVICES

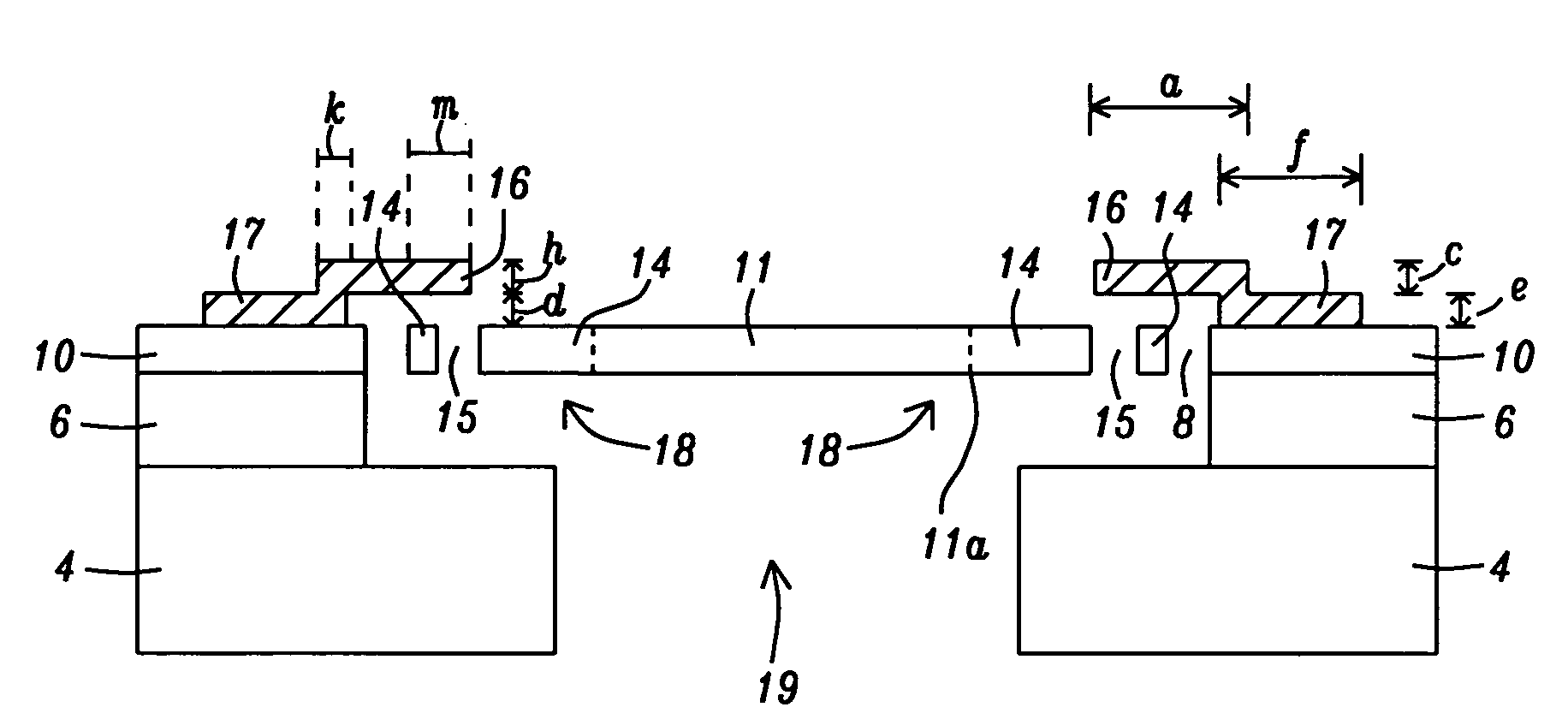

Non-linear noise suppressor for perforated plate flow conditioner

InactiveUS20060096650A1Volume/mass flow measurementValve members for absorbing fluid energySuppressorEngineering

A perforated plate flow conditioner includes a central hole; and at least one outer array of alternating large outer holes and small outer holes, wherein the difference between the diameters of the holes in the array is between 0.25% and 25% of the large hole diameter. In an alternate embodiment, the conditioner further includes an inner array of alternating large inner holes and small inner holes, and wherein no two adjacent holes have the same diameter. In another alternate embodiment, the conditioner has no central hole, and has an array of alternatingly-sized holes.

Owner:SAWCHUK BLAINE DAREN +1

Apparatus for the precise location of reaction plates

InactiveUS6878341B2Consistent DimensionsWithdrawing sample devicesMaterial analysis by optical meansPipetteSupport surface

Generally, the present invention provides a device and method for accurately locating a multi-well plate at a plate-support location, e.g., a work surface, of an automated laboratory machine, such that one or more acting members of the machine, such as an array of pipette tips, optical sensors, or the like, can accurately address and operate on the individual wells. Interior and / or exterior surface regions of one or more wells of a multi-well plate are used as the primary plate features engaged by locating structure of the machine. In one particular embodiment one or more upwardly tapered projections extend from a plate-support surface of a plate-handling machine for mating engagement with the exterior surface regions of one or more wells. In another embodiment, the exterior surface regions along one or more well bottoms are engagingly received within bores, or other receiving structure, formed on the place-support surface of a machine. In a further embodiment, one or more downwardly extending projections depend from an acting-member support, along with the acting members of a machine. Introduction of the projections into some of the wells of a multi-well plate serves to align the acting members with the plate's other wells.

Owner:APPL BIOSYSTEMS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com