Patents

Literature

2562 results about "Tube reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

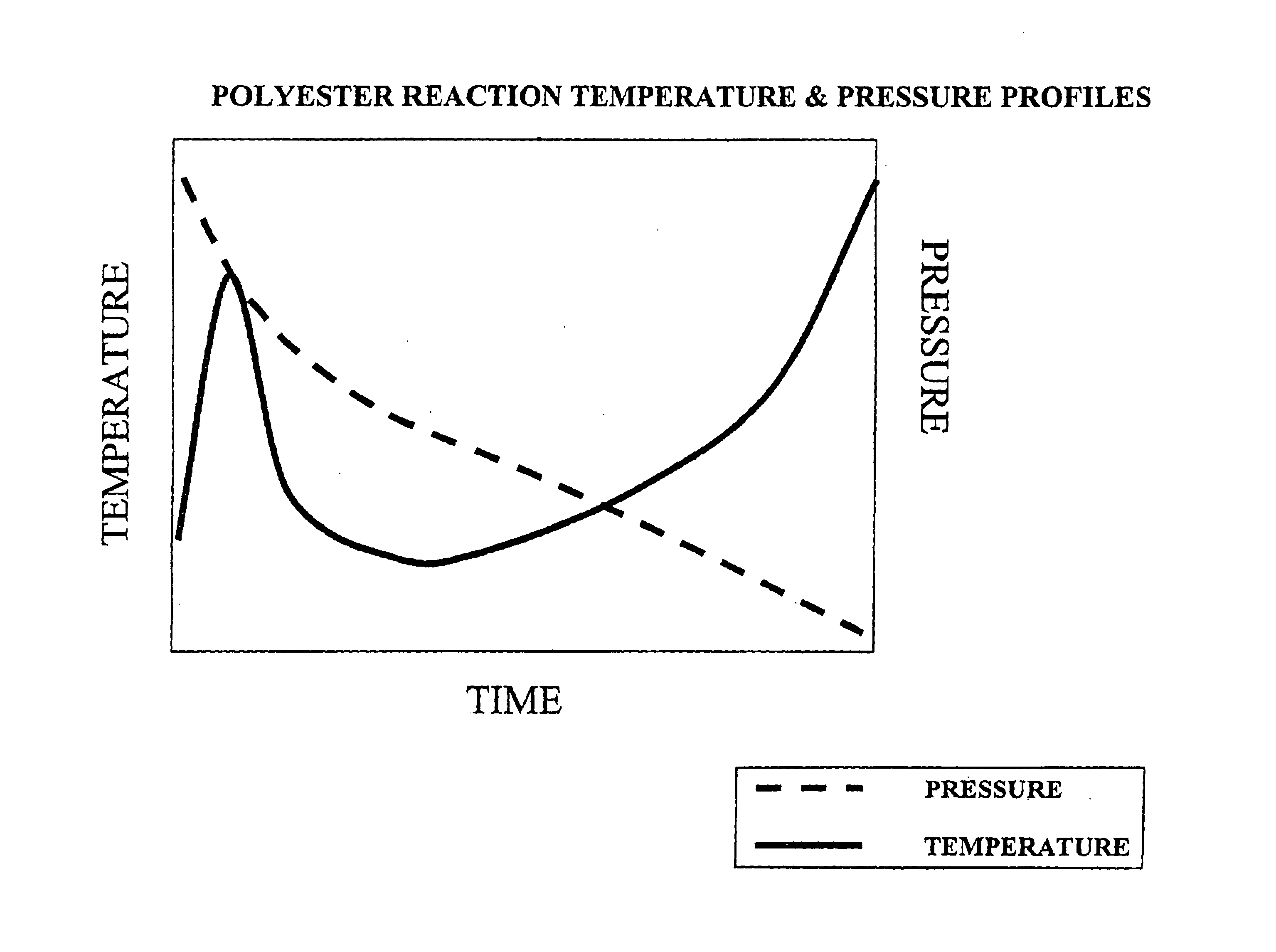

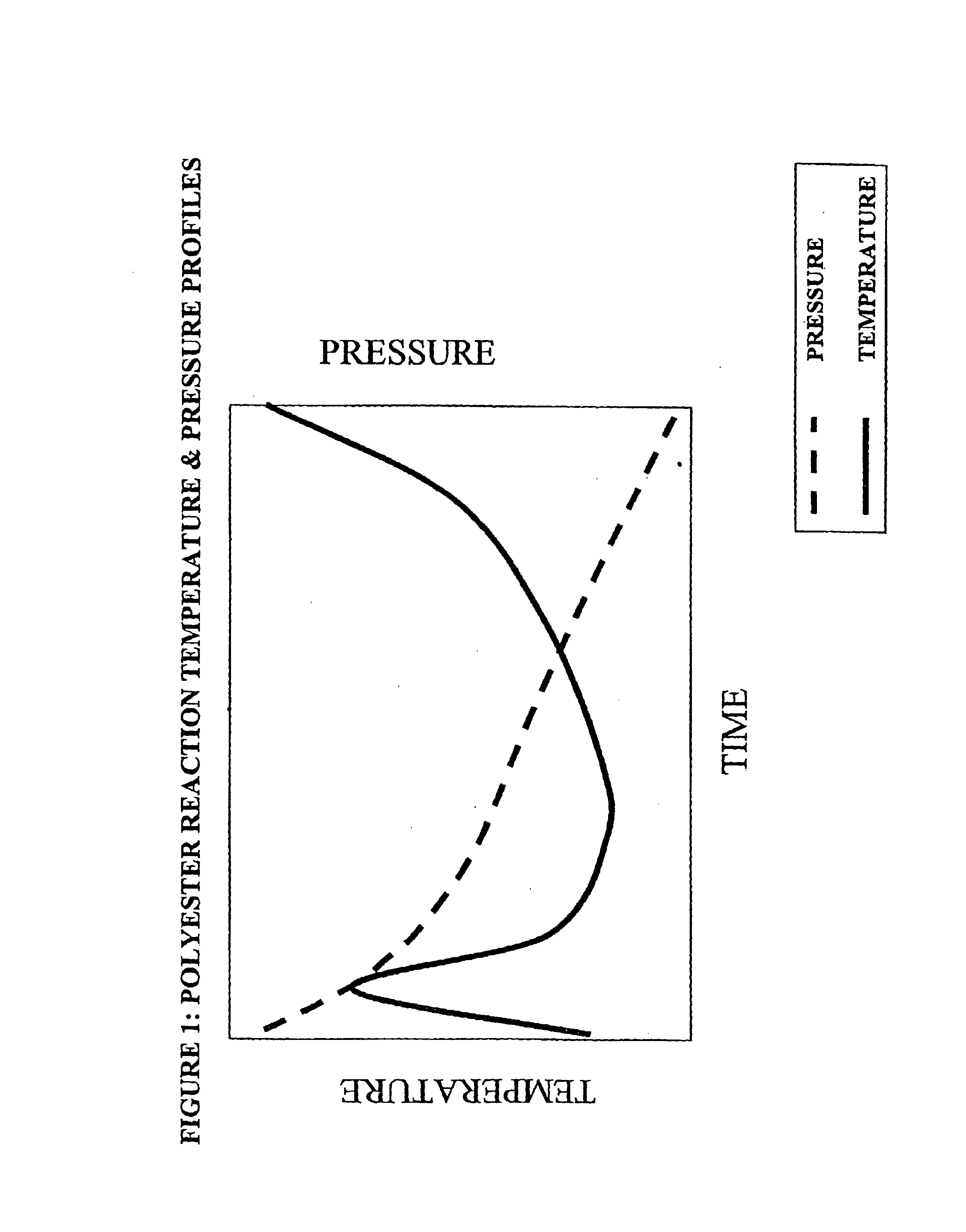

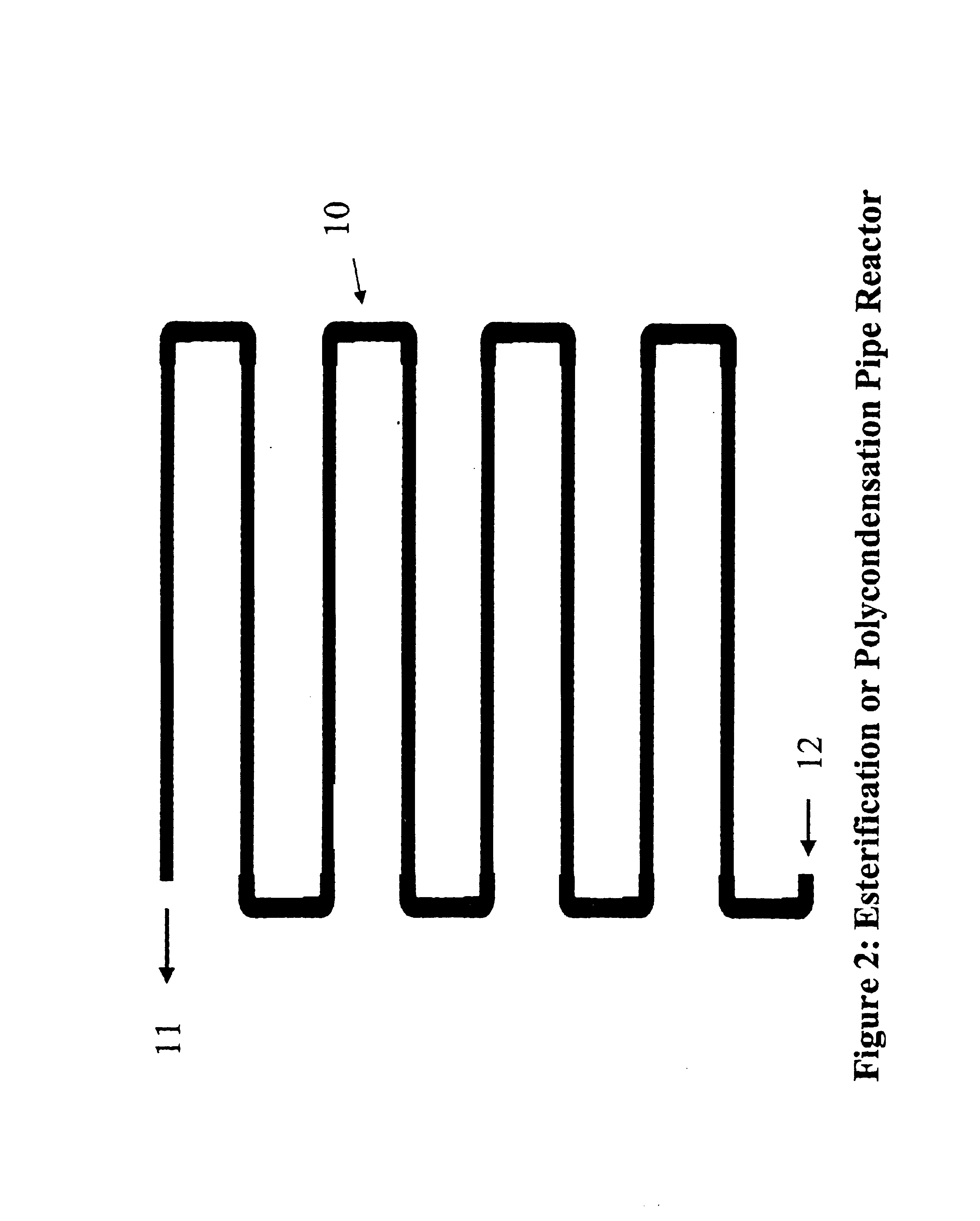

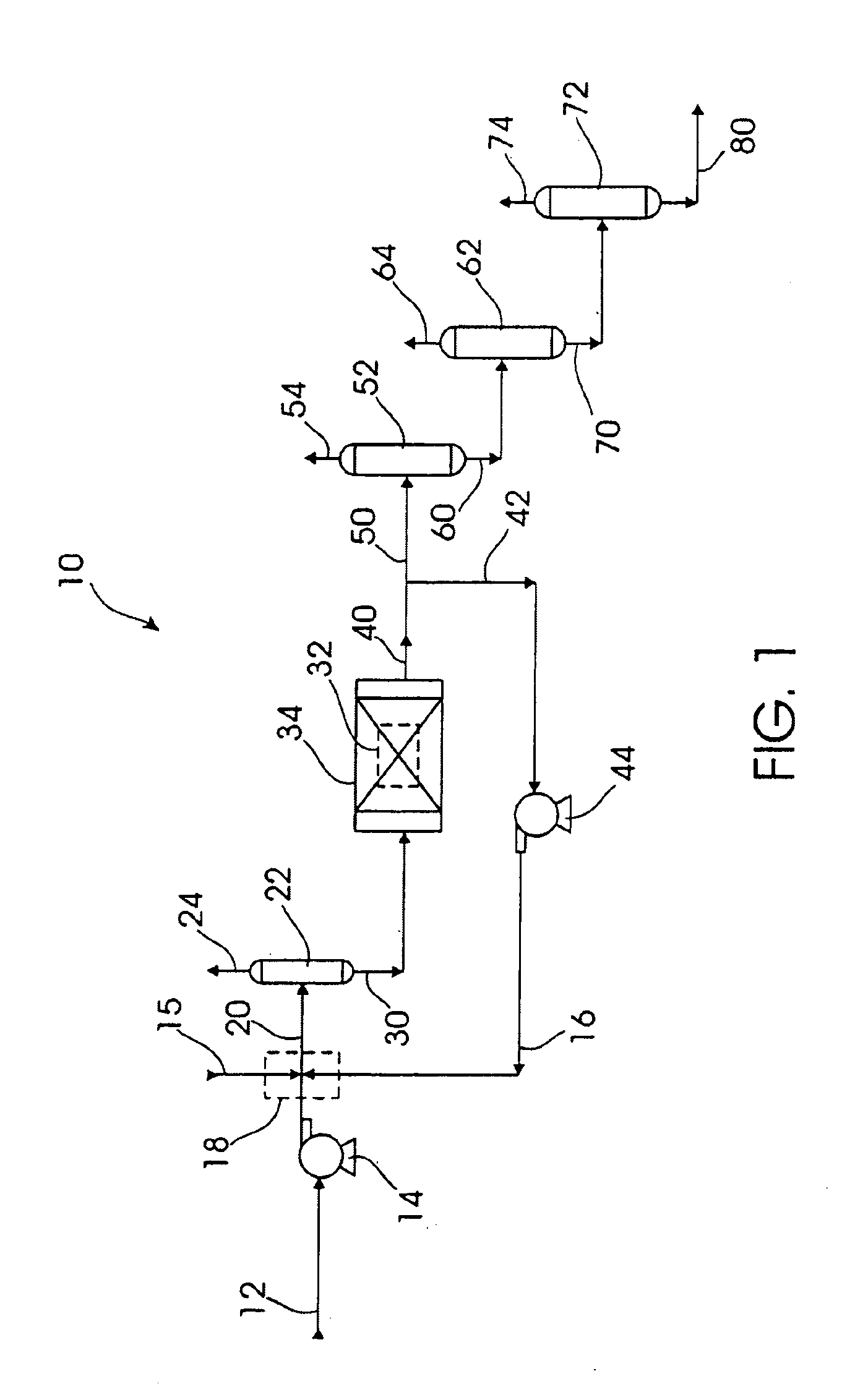

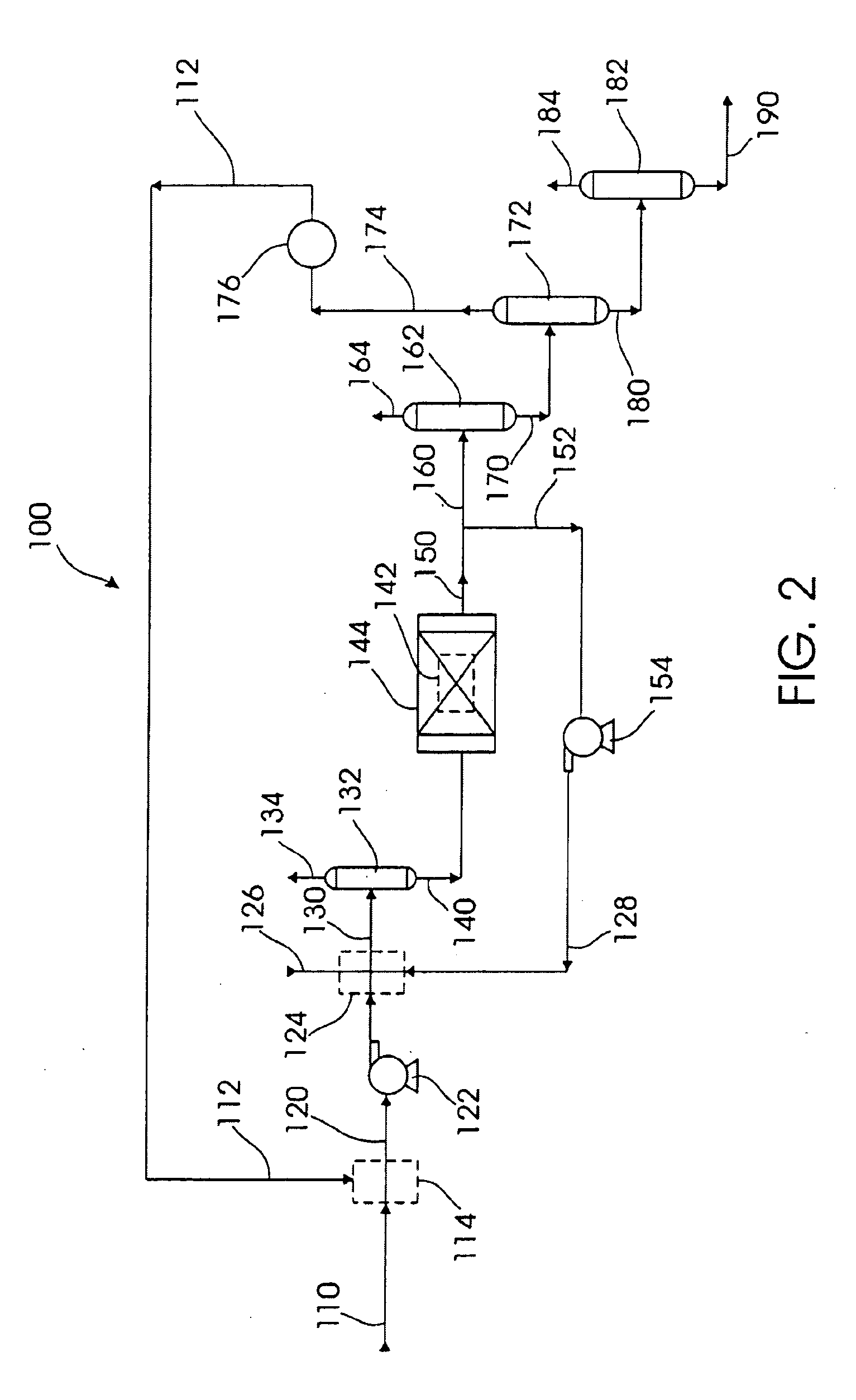

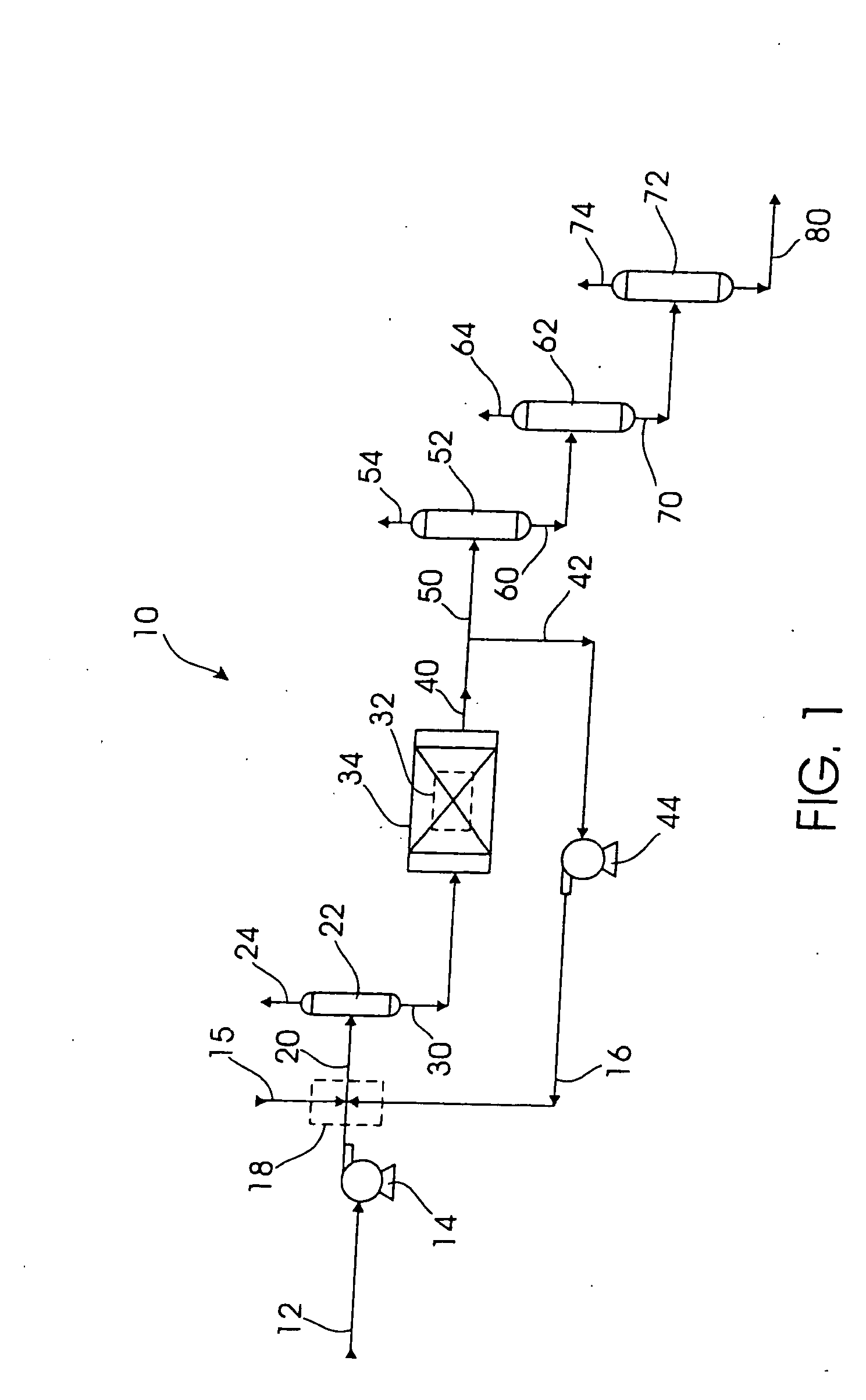

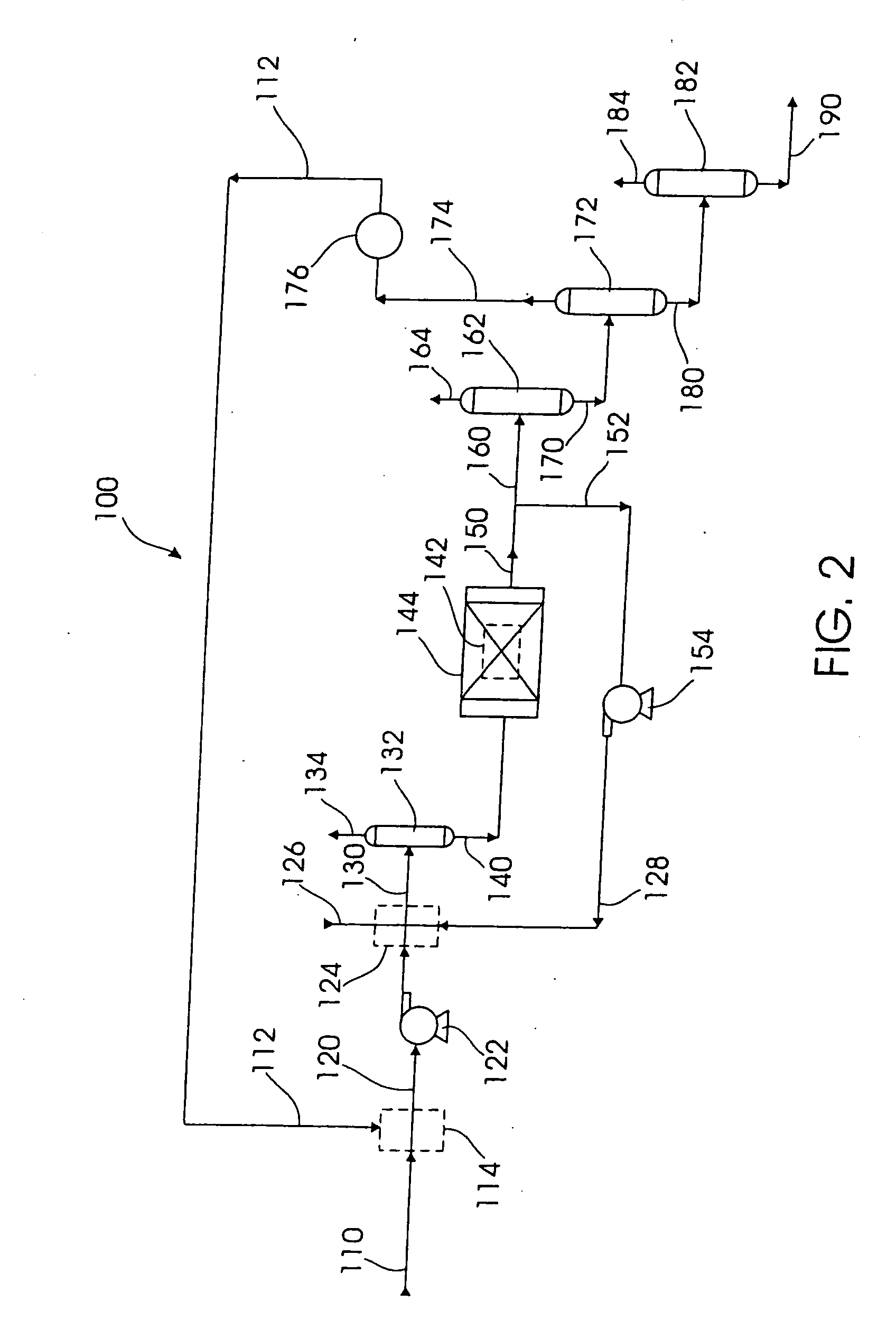

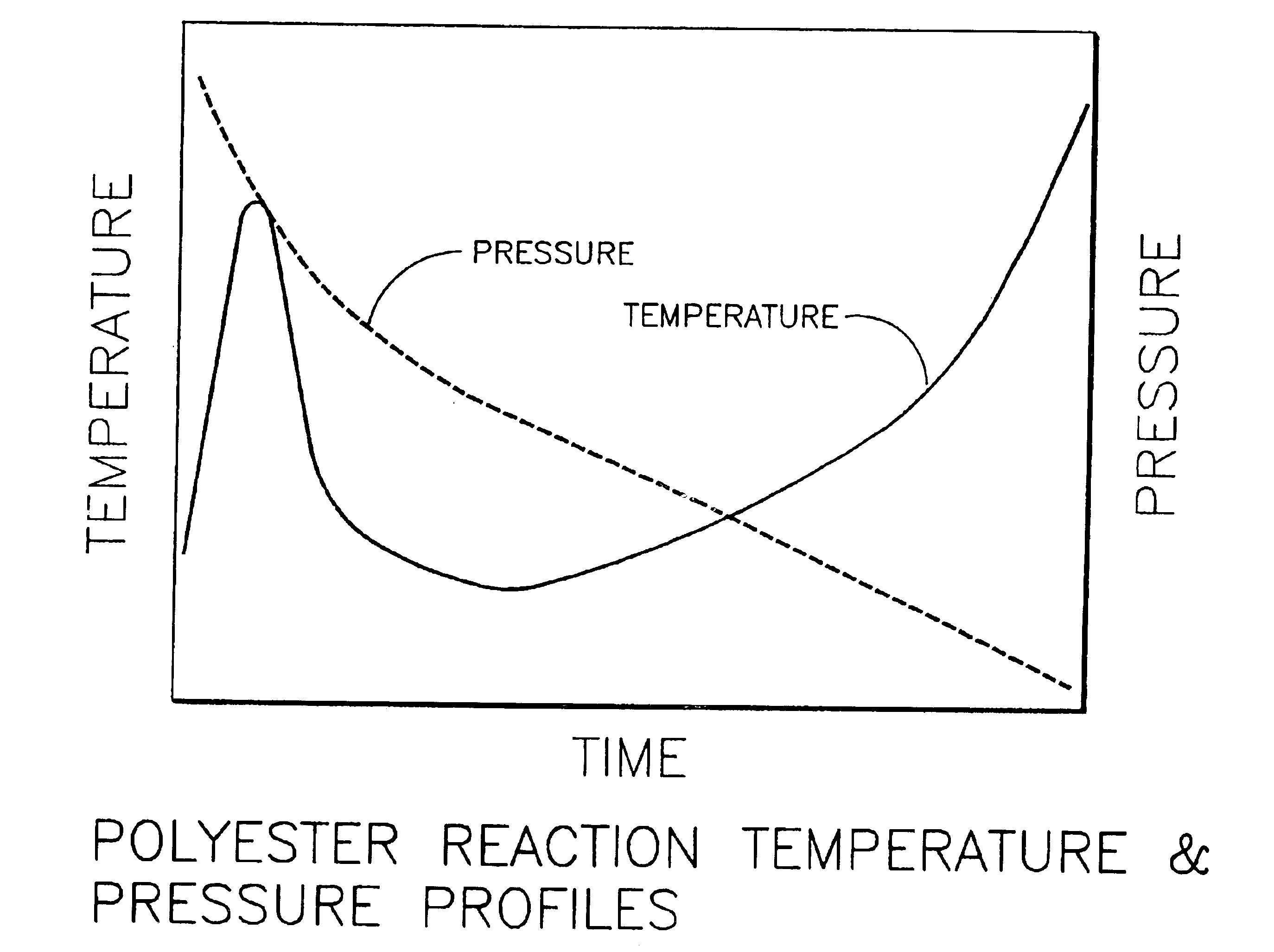

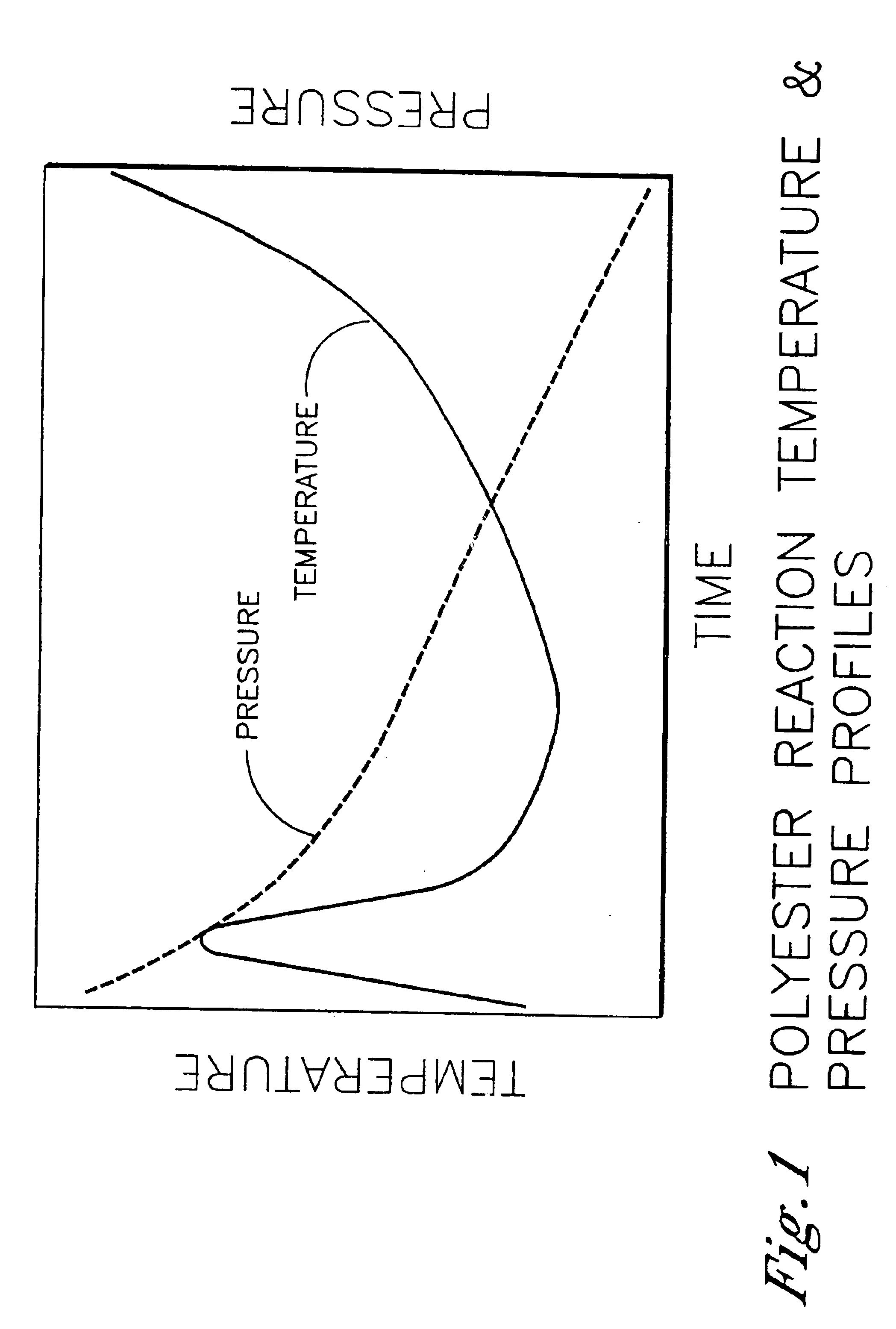

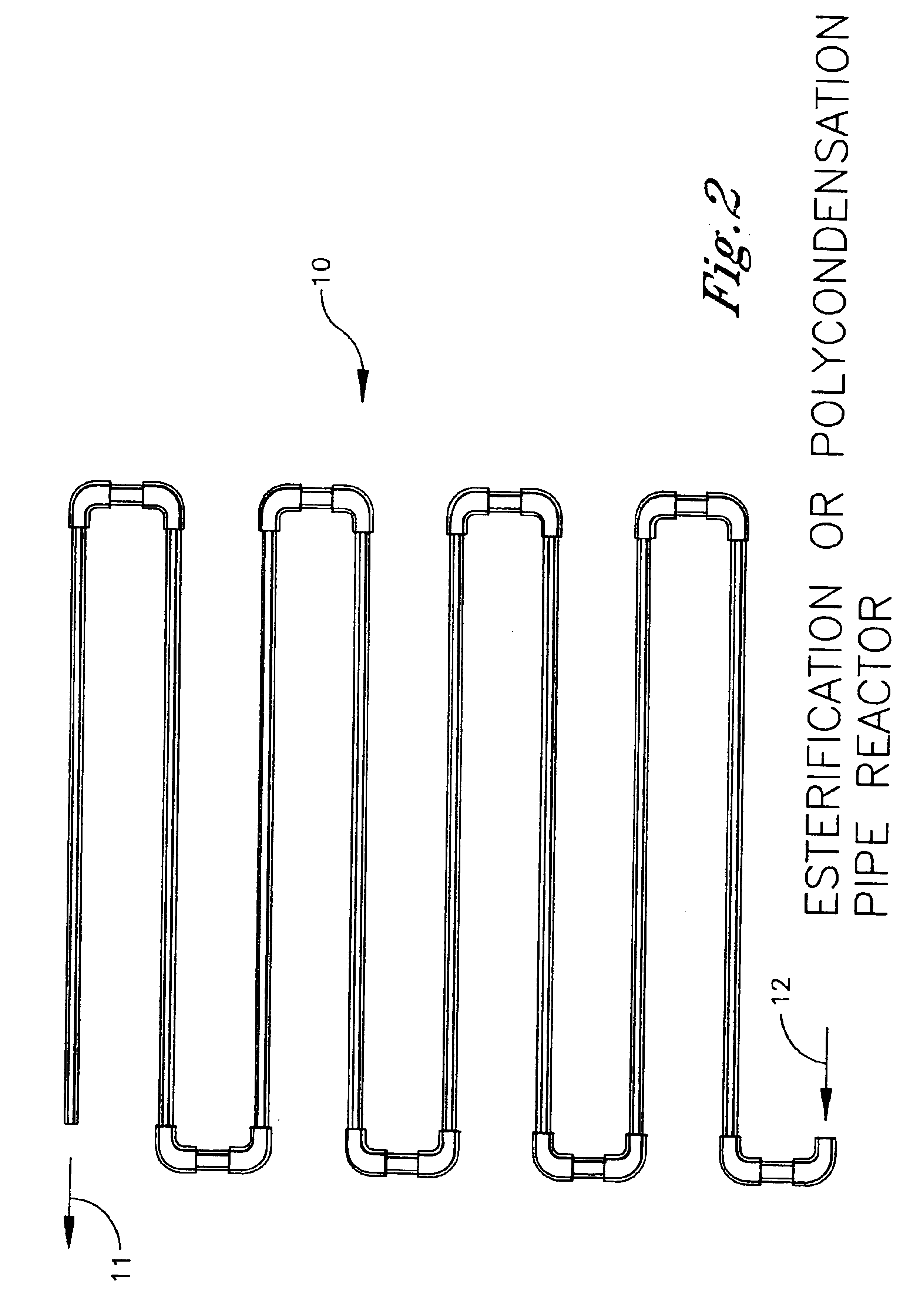

Polyester process using a pipe reactor

InactiveUS6861494B2Reduce pressureEliminate needLiquid degasificationFlow mixersProcess engineeringPolyester resin

Owner:ALPEK POLYESTER SA DE CV

Two phase hydroprocessing

InactiveUS6881326B2Eliminate needHydrogen solubility is “Physical/chemical process catalystsOrganic compound preparationSolubilityHydrogen

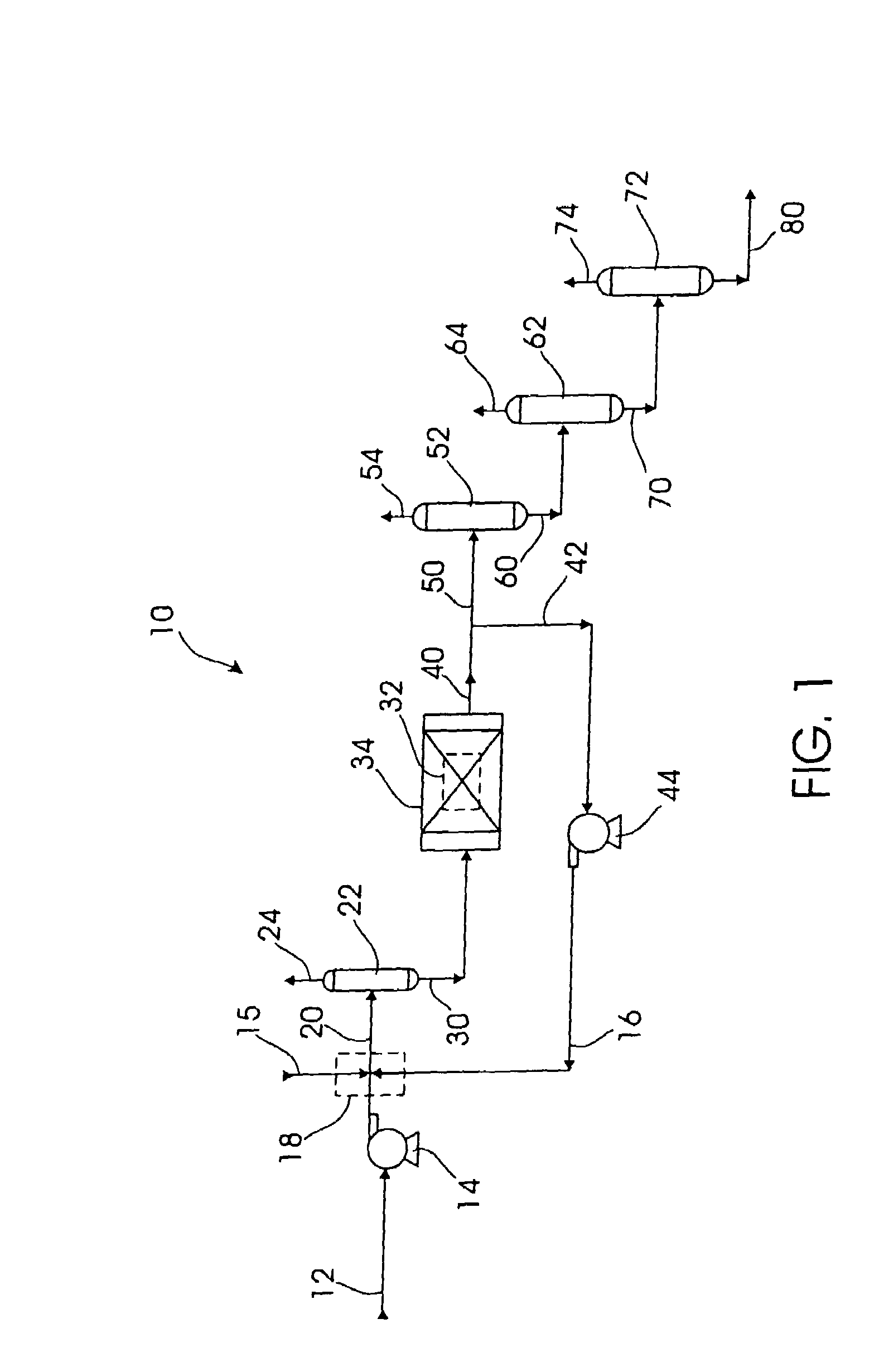

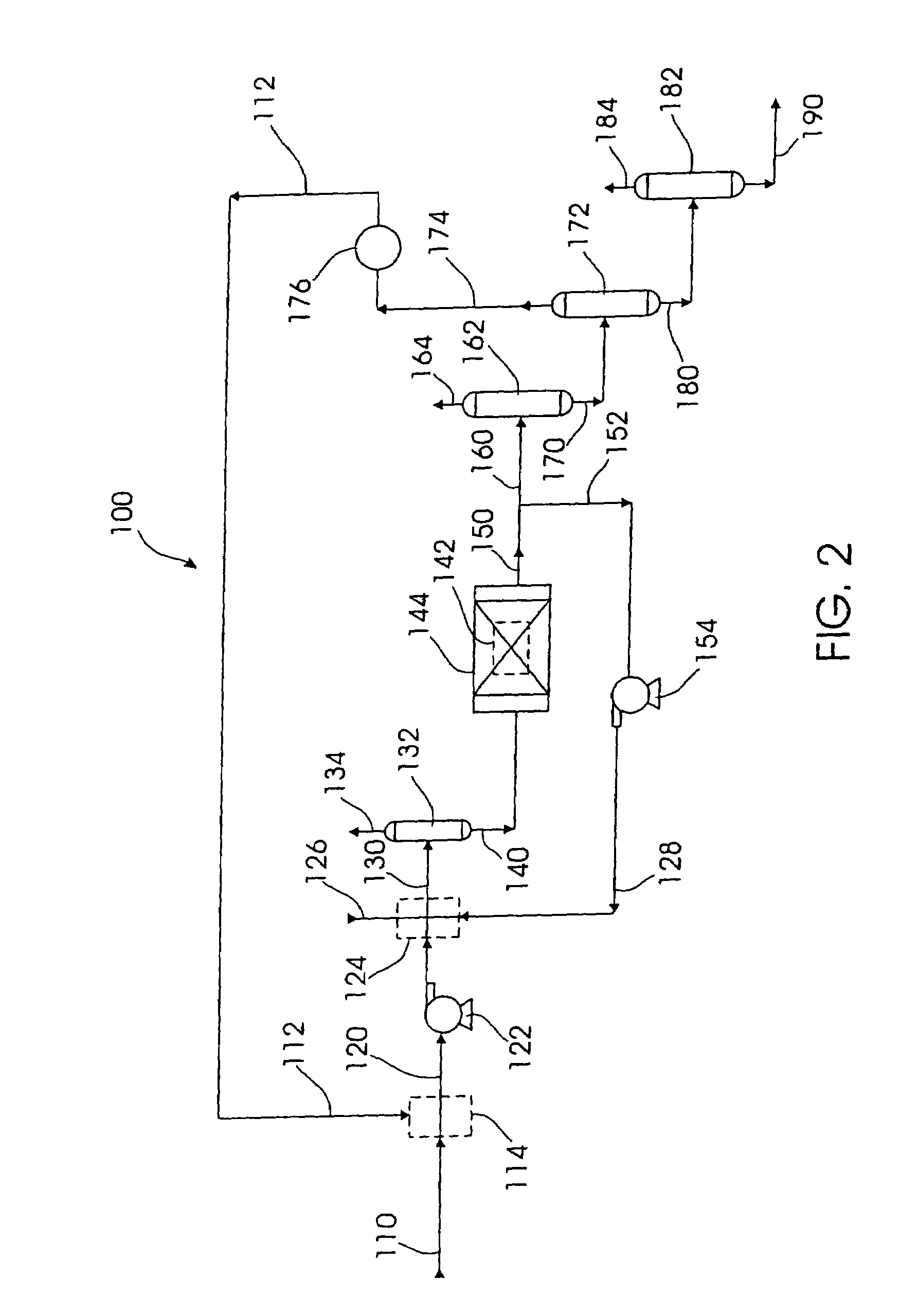

A process where the need to circulate hydrogen through the catalyst is eliminated. This is accomplished by mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is “high” relative to the oil feed. The type and amount of diluent added, as well as the reactor conditions, can be set so that all of the hydrogen required in the hydroprocessing reactions is available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required, therefore, hydrogen recirculation is avoided and trickle bed operation of the reactor is avoided. Therefore, the large trickle bed reactors can be replaced by much smaller tubular reactor.

Owner:EI DU PONT DE NEMOURS & CO

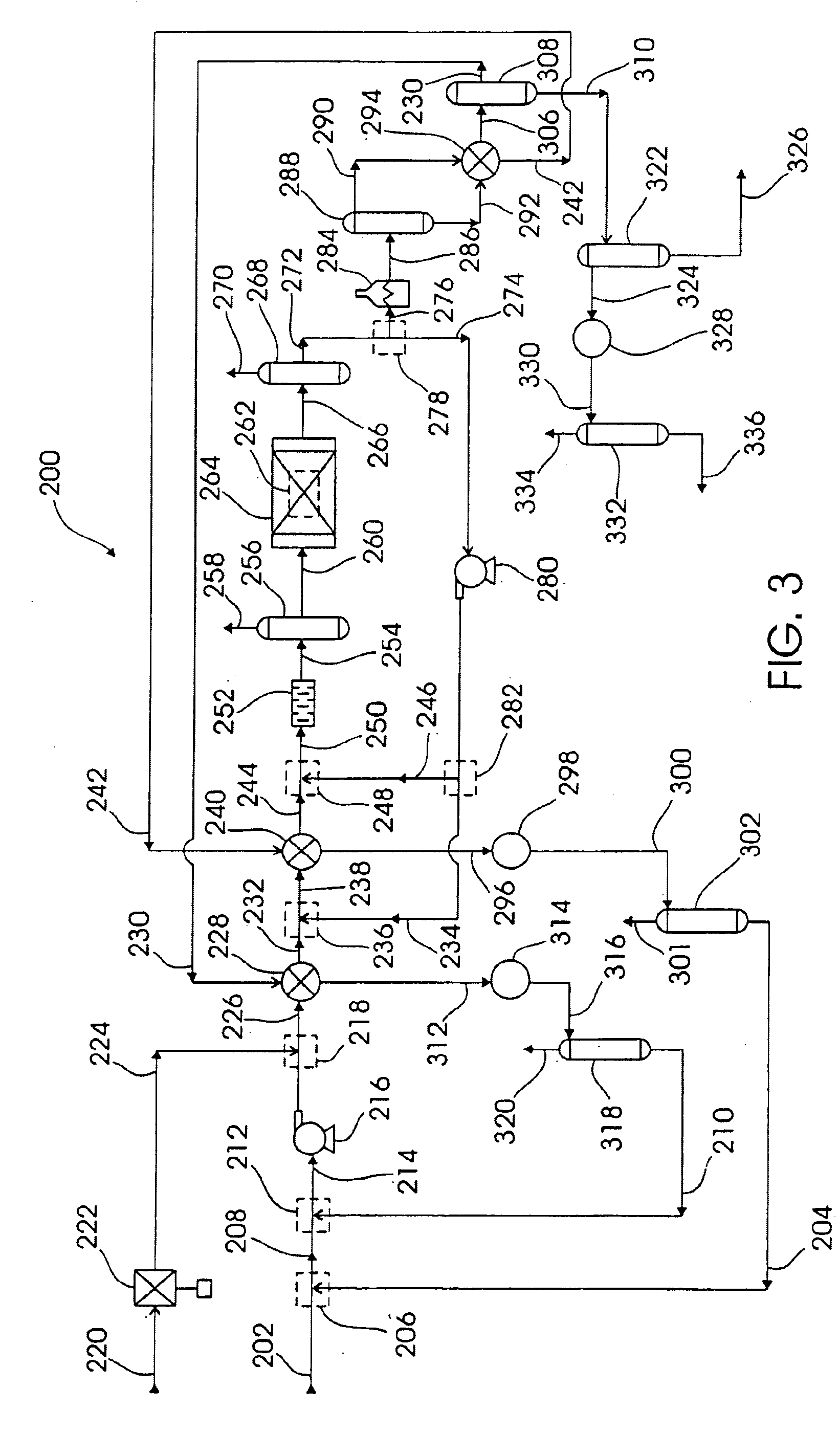

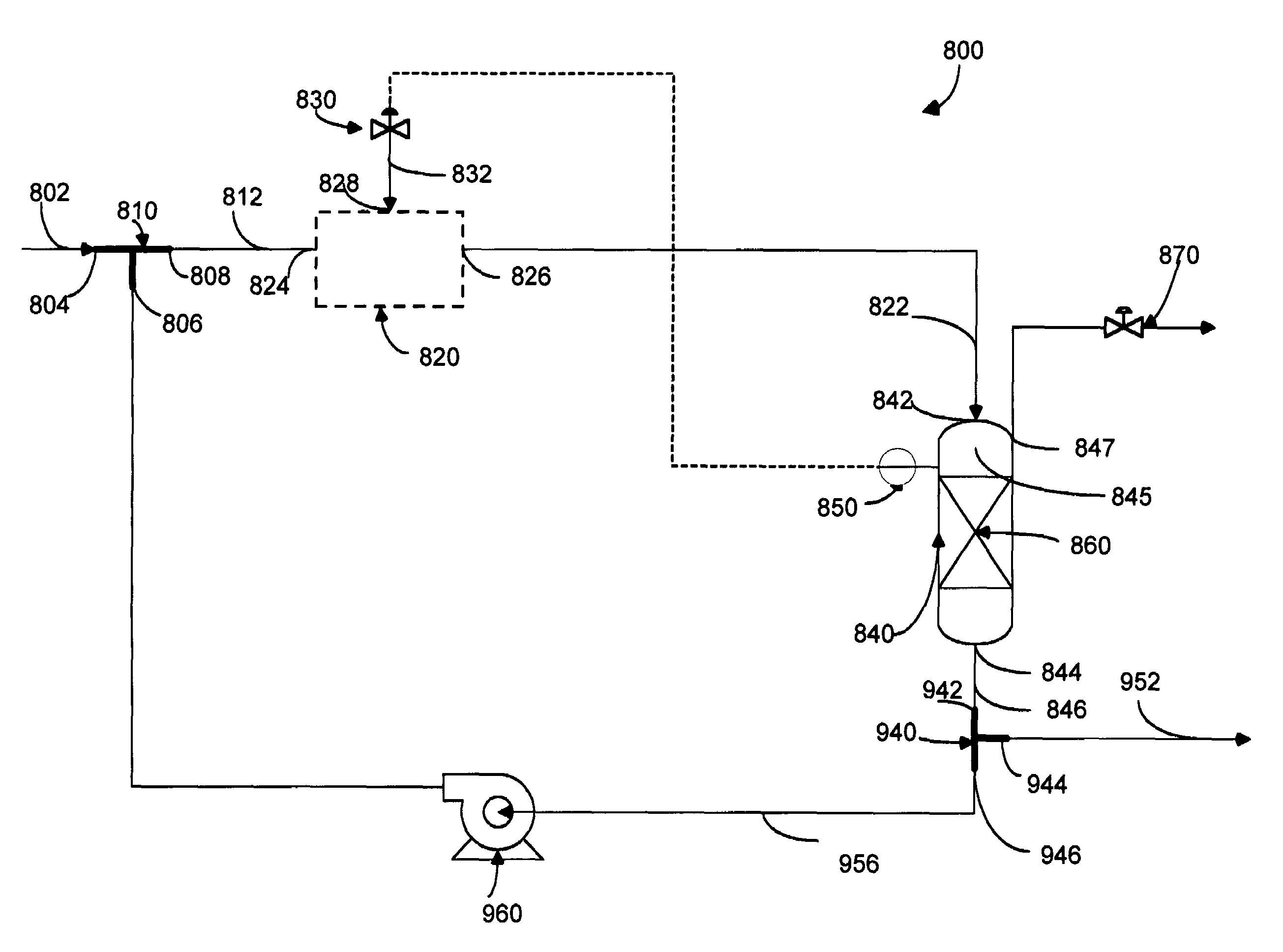

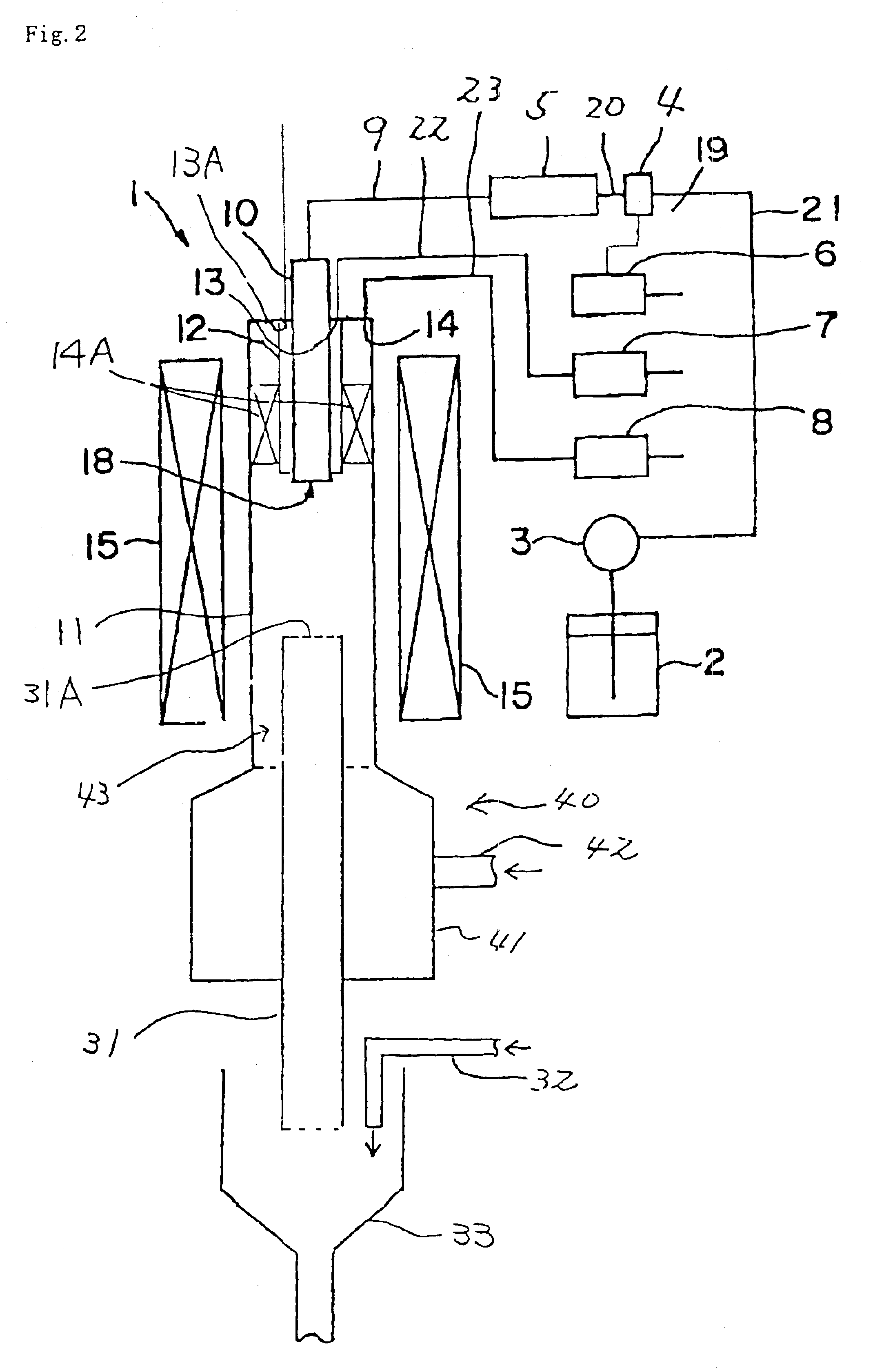

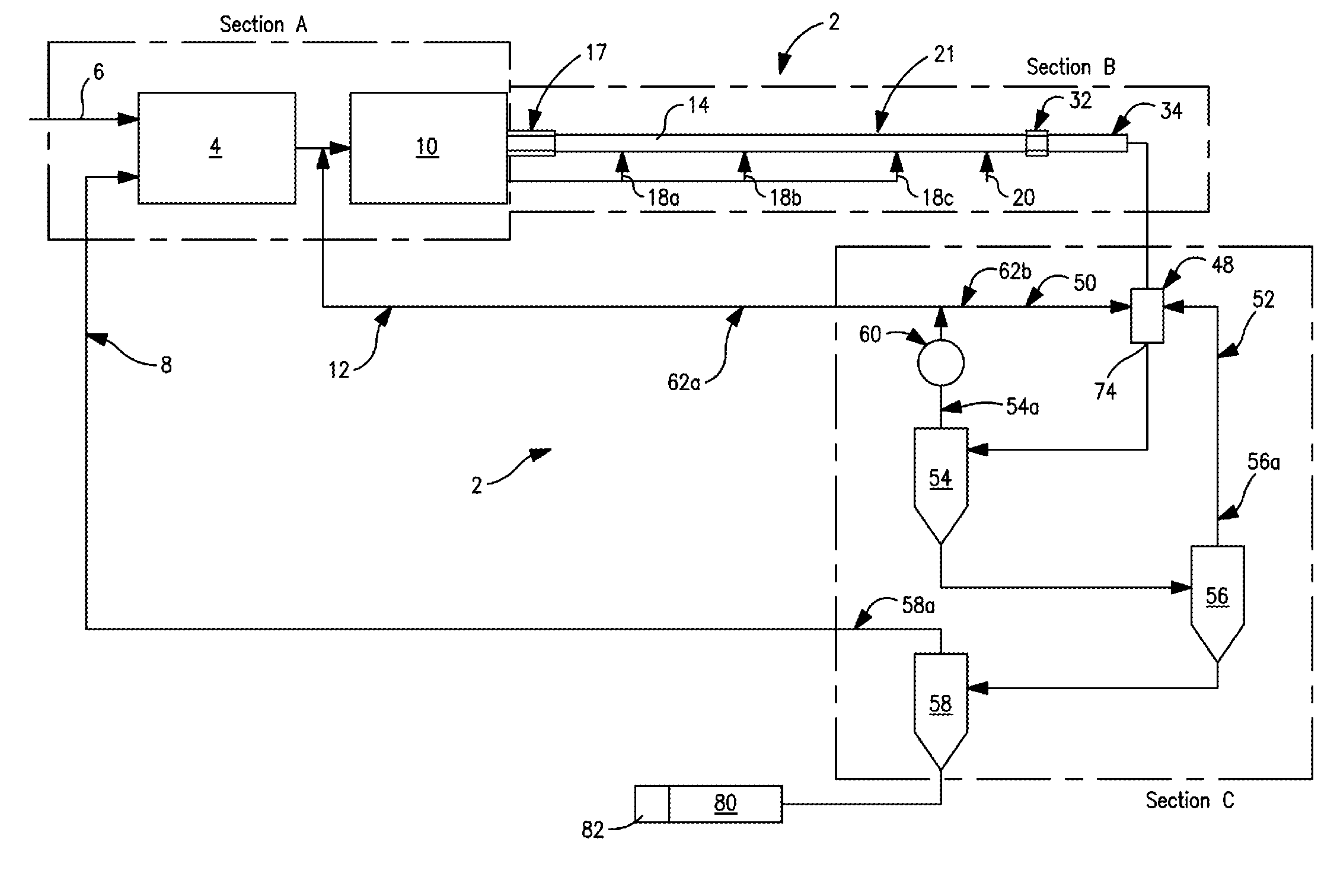

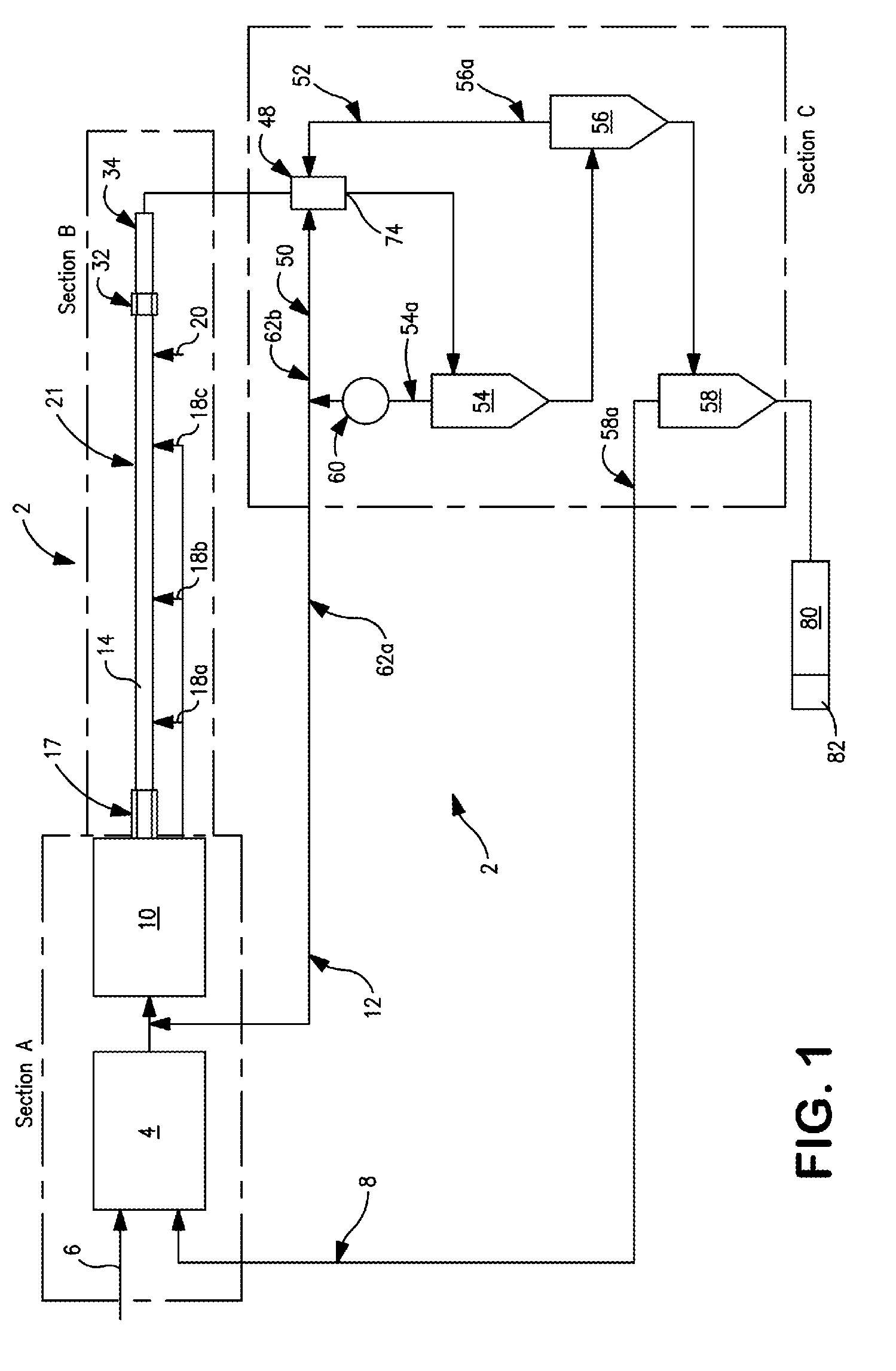

Control system method and apparatus for two phase hydroprocessing

InactiveUS20060144756A1Eliminate needHydrogen solubility is “Physical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

Polyester process using a pipe reactor

InactiveUS6906164B2Reduce pressureEliminate needLiquid degasificationFlow mixersPolyesterPolymer science

Owner:ALPEK POLYESTER SA DE CV

Method for preparing aromatic hydrocarbons by methanol-containing raw materials

InactiveCN102199069AHigh yieldAvoid inactivationHydrocarbon from oxygen organic compoundsAromatic hydrocarbonChemistry

A method for preparing aromatic hydrocarbons by methanol-containing raw materials. The methanol-containing raw materials comprise methanol and distilled gasoline. The method comprises that the methanol-containing raw materials and catalysts undergo a reaction under conditions of preparing aromatic hydrocarbons by methanol. The method provided by the invention solves the problems that in the prior arts, heat in a reactor is removed through an intermediate cooler and a multitubular reactor is utilized for heat removal or cold product gas is transmitted back to a raw material inlet to remove heat or a diluting material is added to control reaction heat. The method has the advantages of simple processes, and simple and convenient operation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

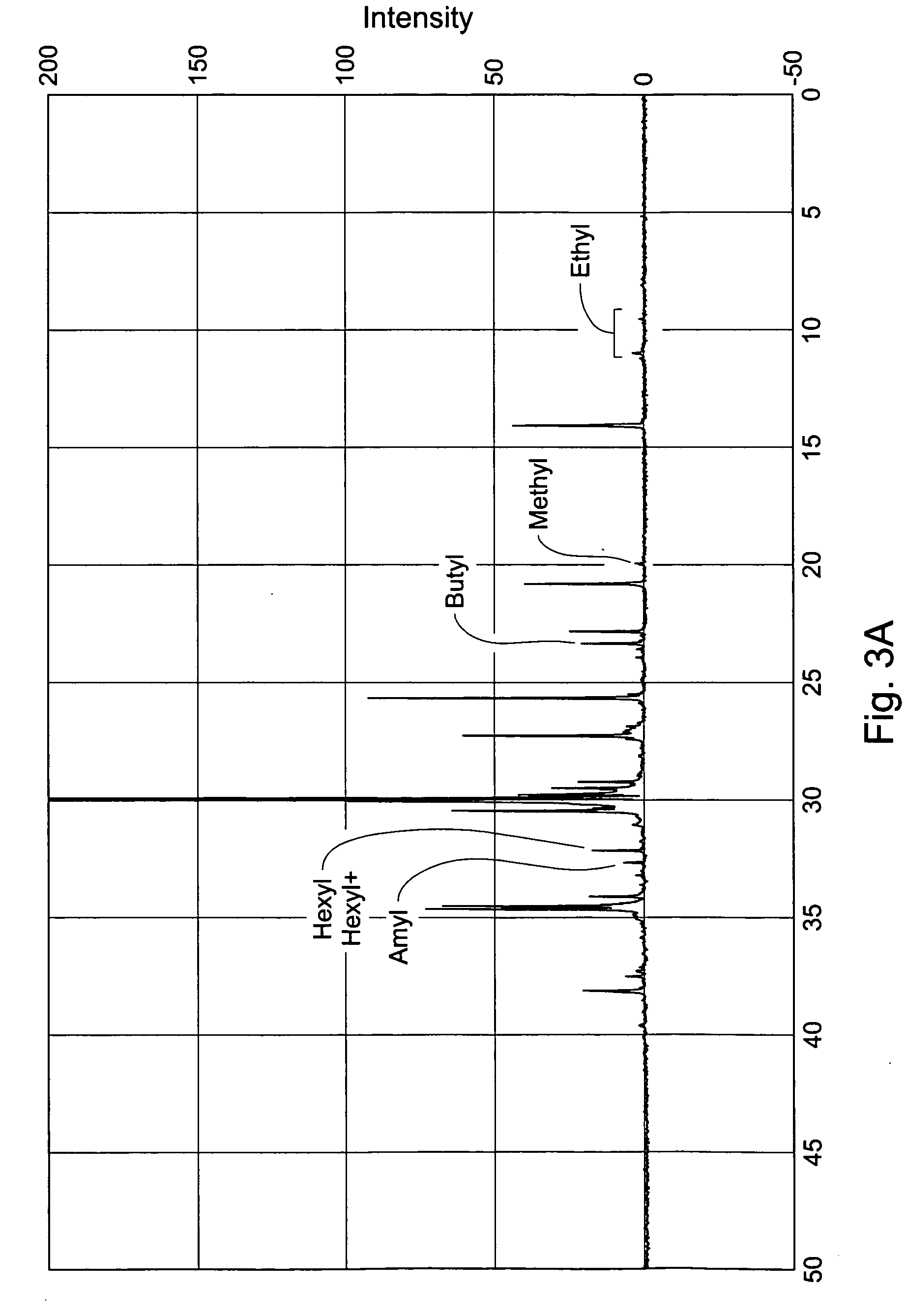

Polymers of ethylene and, optionally, copolymerizable esters, films using such polymers and stretch hood packaging processes using such films

ActiveUS20050037219A1Excellent film performanceSynthetic resin layered productsDomestic containersParticulatesMelt flow index

The invention relates to a polymer comprising units derived from ethylene, said polymer having: a) a Melt Index of from 0.05 to 20 g / 10 min as determined by ASTM-1238 Condition E; b) at least 10 per 1000 C-atoms of short chain branches, containing five carbon atoms or less, as determined by C13 NMR, and less than 3.5 mol %, of units derived from a copolymerizable ethylenically unsaturated ester, c) a density of from 0.90 to 0.94 g / cm3, preferably 0.91 to 0.935 g / cm3, especially 0.92 to 0.93 g / cm3 as determined by ASTM D1505, and d) a relaxation time as described herein of at least 10 s. Such polymers are obtainable by polymerization by free radical polymerization using a chain transfer agent that incorporates into the polymer chain such as an alpha-olefin, preferably propylene, as a chain transfer agent, preferably in a tubular reactor under circumstances to favor LCB formation in a down stream part of the tubular reactor. The polymer may be used for stretch hood film, preferably as a blown film coextruded tube comprising: a) a core of the above polymer; and b) a skin layer, on each side of the core which may be of the same or different composition, comprising at least 60 wt % of an LLDPE having density of 0.91 to 0.94 g / cm3 as determined by ASTM-D 1238 Condition E and hexane extractables less than 1.5 wt %, said skin layer containing less than 7500 ppm of anti-block particulates and said film having an elastic recovery after a 100% stretch of at least 40% and providing a normalized holding force per 100 μm thickness pre-stretch at 85% stretch after an initial stretch of 100% of at least 20 N / 50 mm at a deformation rate of less than 10% of the starting length per second.

Owner:EXXONMOBIL CHEM PAT INC

Noncatalytic manufacture of 1,1,3,3,3-pentafluoropropene from 1,1,1,3,3,3-hexafluoropropane

InactiveUS20060094911A1High selectivityPreparation by hydrogen halide split-offHydrogen fluorideHydrogen fluorideTube reactor

1,1,3,3,3-Pentafluoropropene (CF3CH═CF2, HFC-1225zc) can be produced by pyrolyzing 1,1,1,3,3,3-hexafluoropropane (CF3CH2CF3, HFC-236fa) in the absence of dehydrofluorination catalyst at temperatures of from about 700° C. to about 1000° C. and total pressures of about atmosphere pressure in an empty, tubular reactor, the interior surfaces of which comprise materials of construction resistant to hydrogen fluoride.

Owner:EI DU PONT DE NEMOURS & CO

Control system method and apparatus for two phase hydroprocessing

InactiveUS7569136B2Hydrogen solubility is “Eliminate needPhysical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

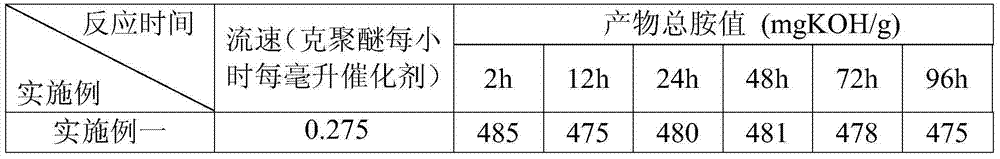

Process of producing small molecular weight polyether amine by continuous method

ActiveCN104119239AReduce the impactThe process steps are simpleOrganic compound preparationAmino-hyroxy compound preparationHydrogenMetal catalyst

The invention relates to a process of producing small molecular weight polyether amine by a continuous method. A continuous method fixed bed process is adopted, polyether, liquid ammonia and hydrogen are used as raw materials, 2-6 reactors which are fixed bed reactors or tubular reactors are connected in series and each reactor is internally filled by a Raney metal catalyst or a supported metal catalyst, respectively; under the reaction condition of certain temperature, pressure and molar proportion, the raw materials are sequentially reacted through the reactors to obtain polyether amine, the molecular weight of which is 100-1000. The process provided by the invention is simple in step. Multiple reactors and a compound catalyst system are adopted, so that the influence of generated water in the reaction to the catalyst efficiency is effectively reduced, and the yield and the conversion ratio of reaction are improved.

Owner:WUXI ACRYL TECH

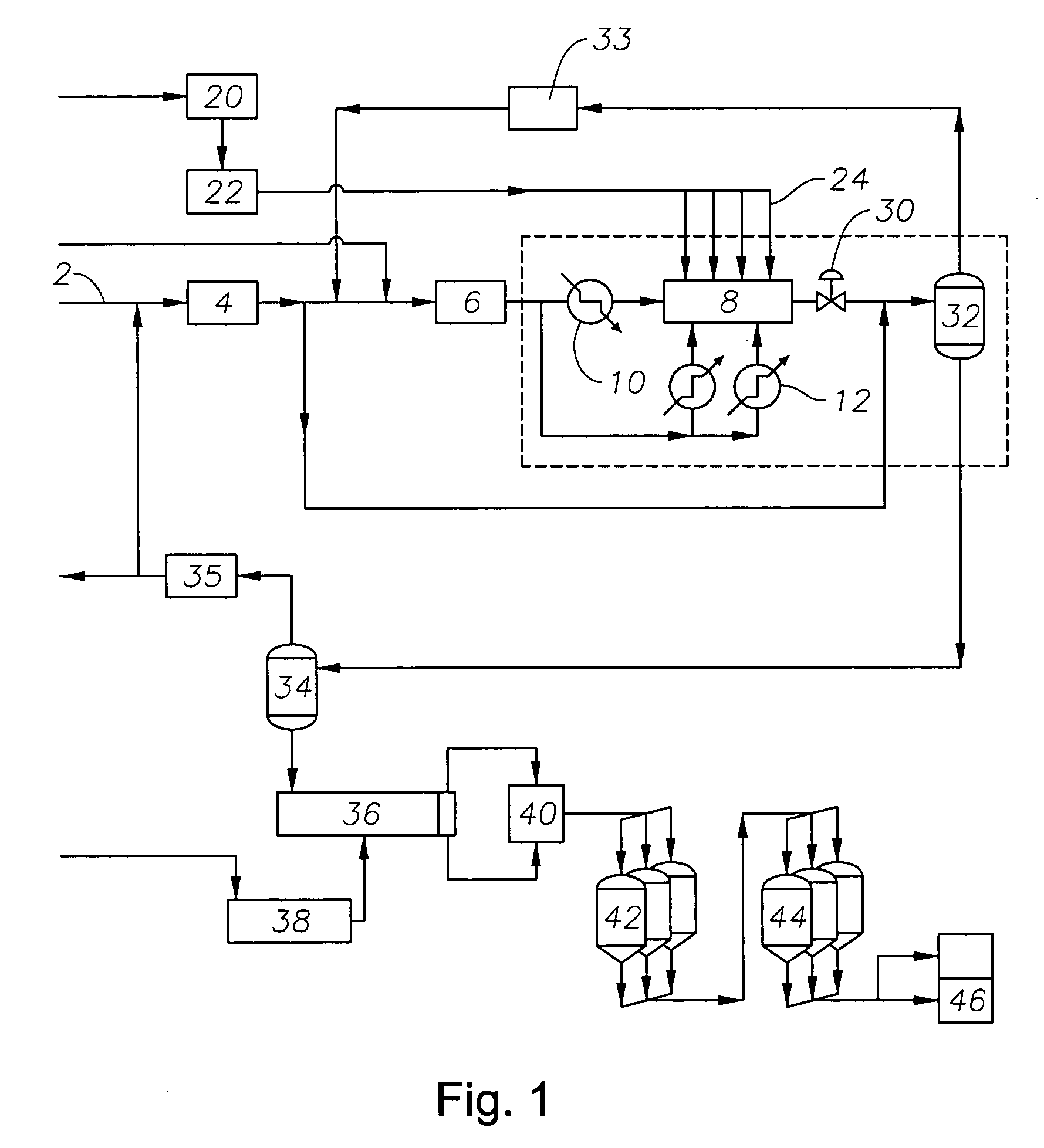

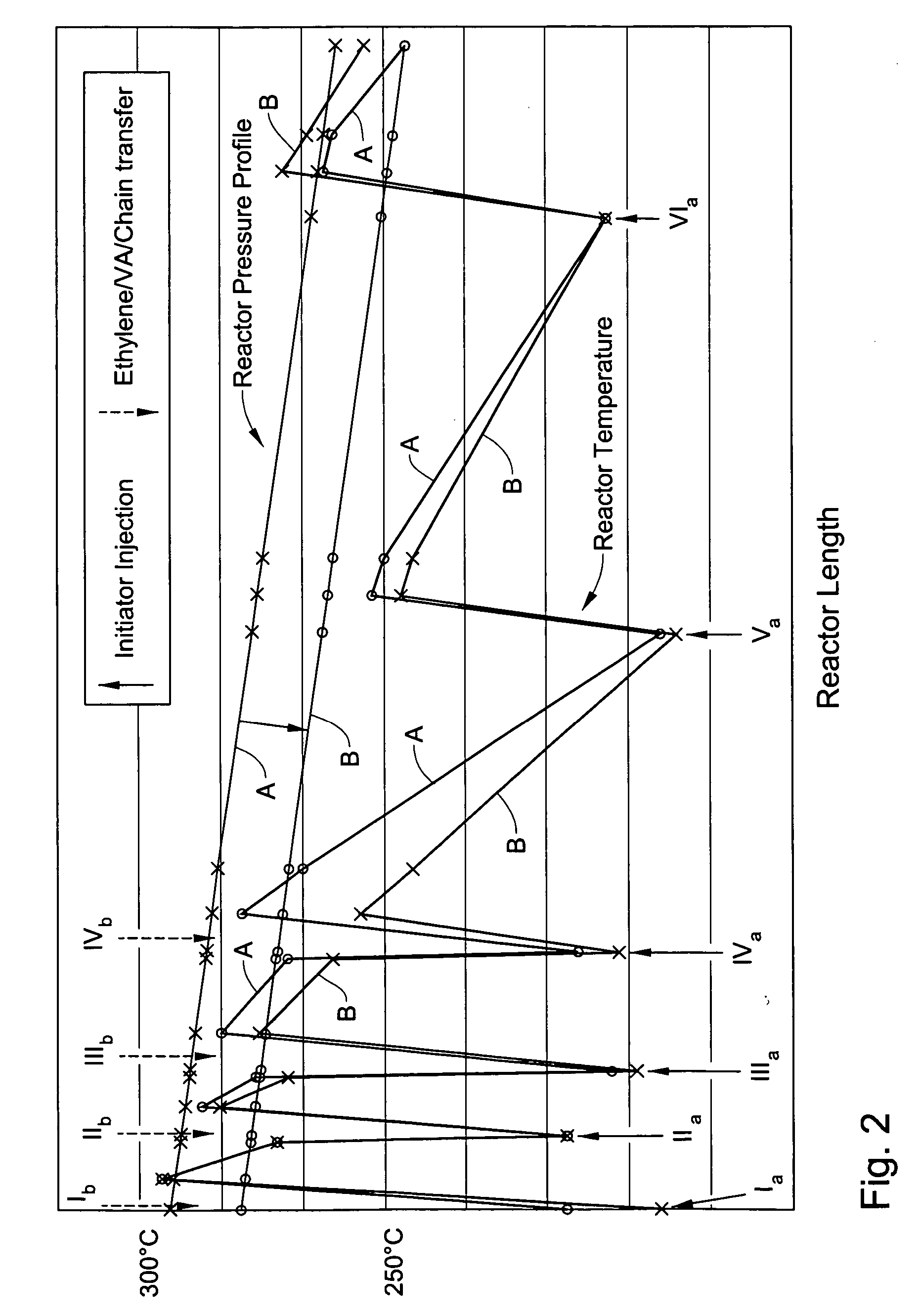

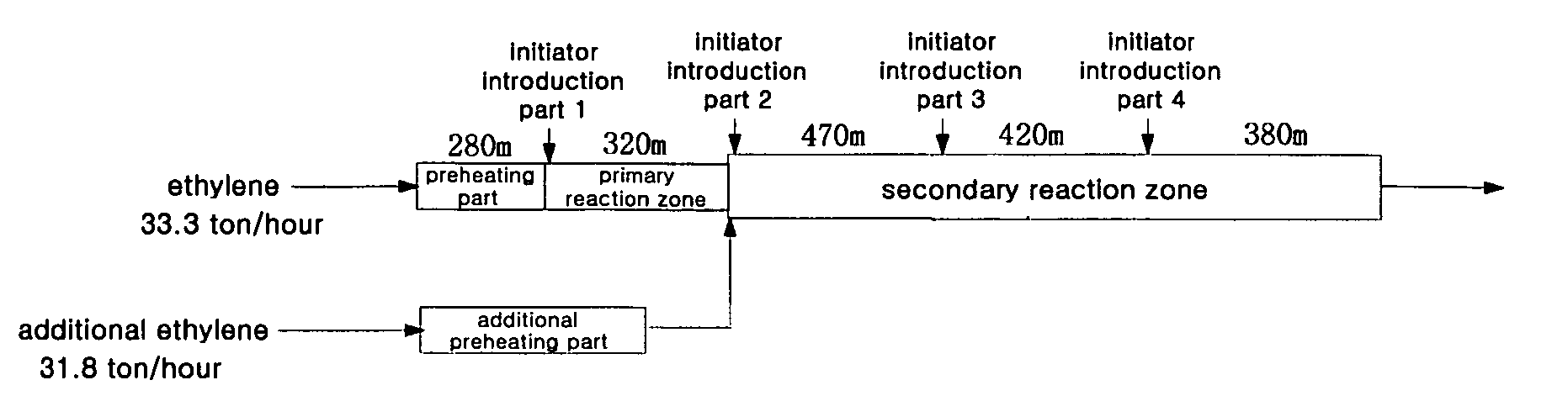

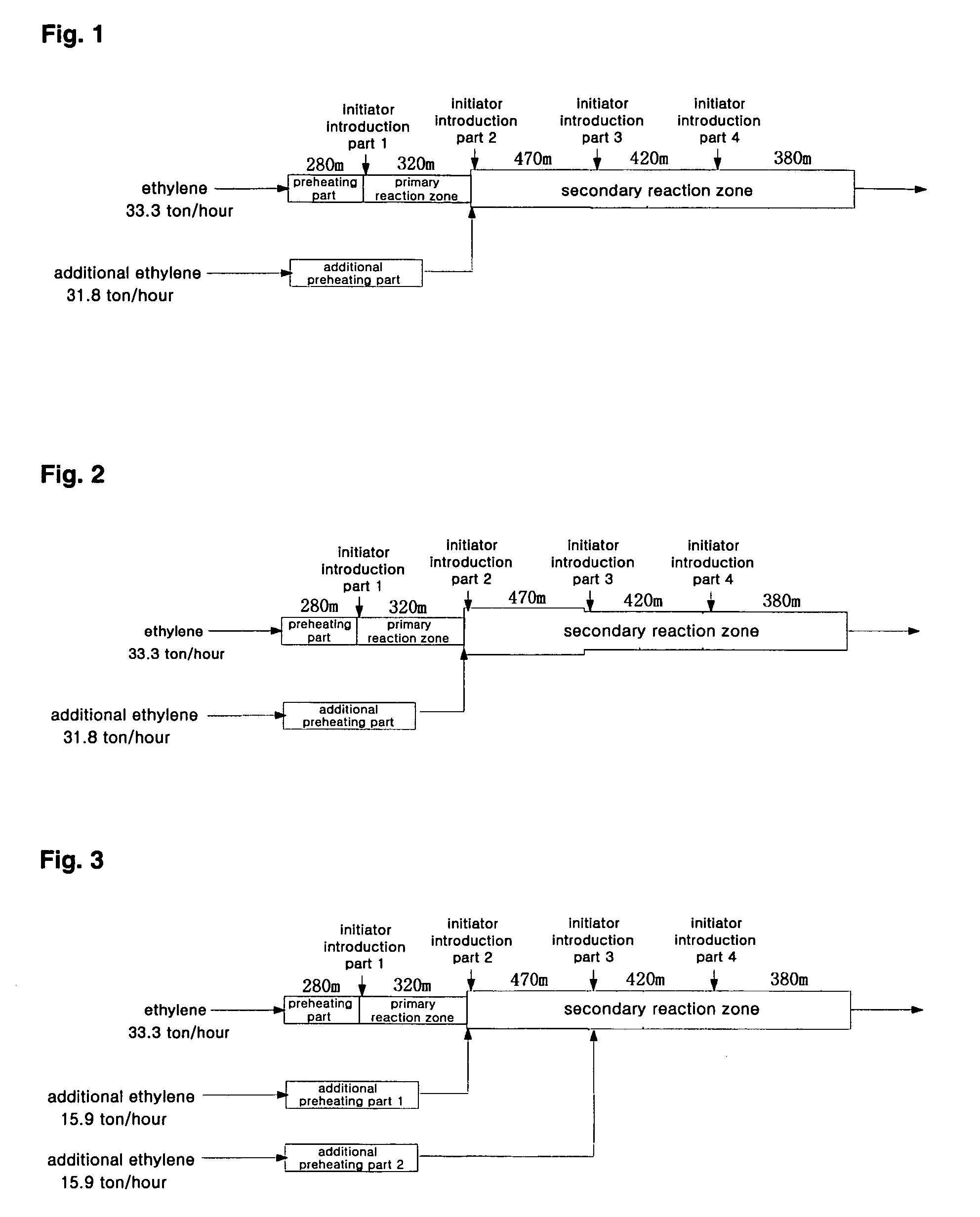

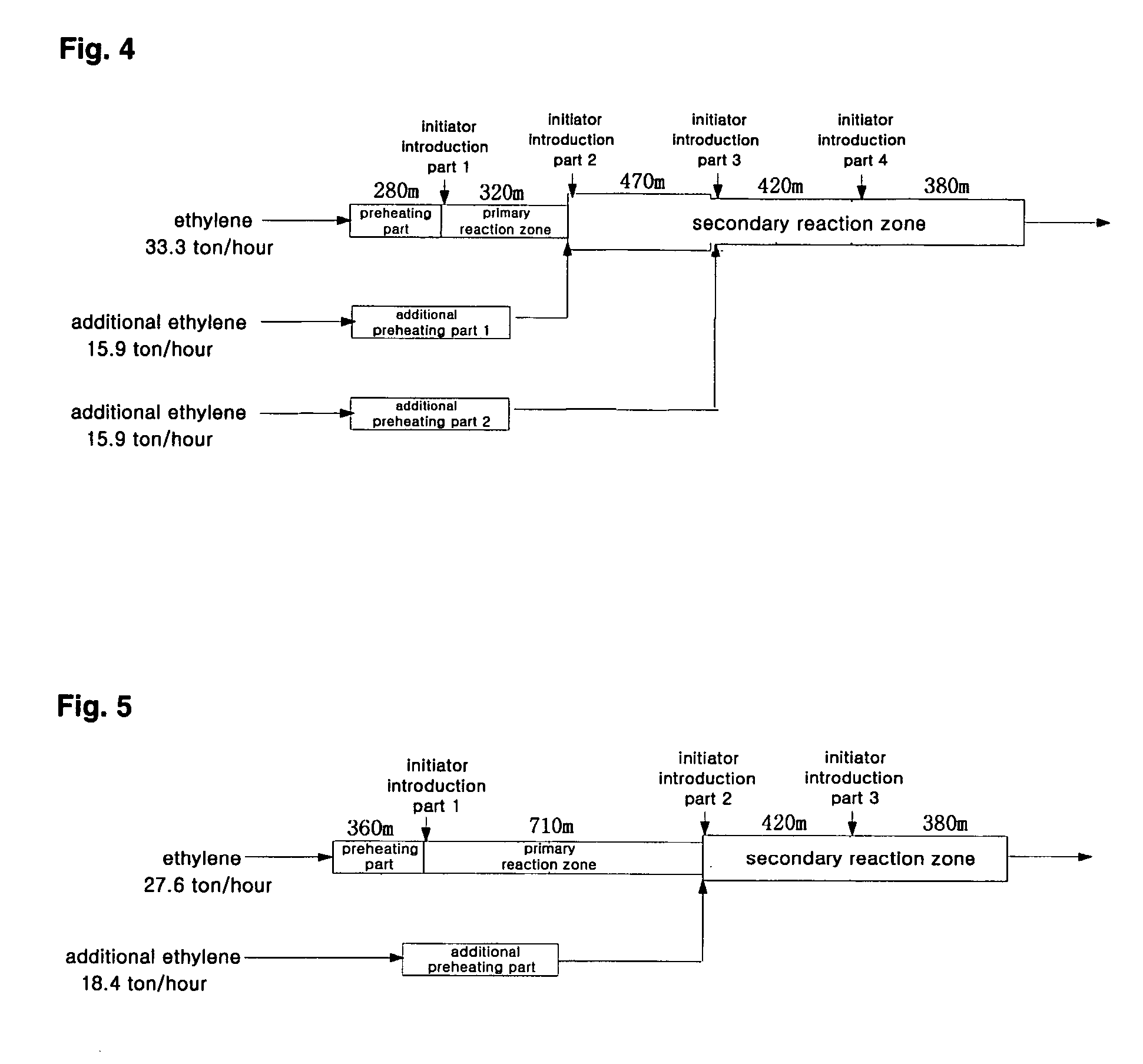

Process and apparatus for manufacturing ethylene polymers and copolymers

InactiveUS7582709B2Reliable and efficient method of manufactureEfficient heat dissipationEthylene productionChemical/physical/physico-chemical stationary reactorsPolymer scienceReaction zone

The invention relates to a process for the manufacture of ethylene polymers and copolymers in which ethylene is compressed in a primary compressor at a throughput of at least 55 tonnes / hour, mixed with recycled ethylene and further compressed in a two-stage reciprocating secondary compressor having at least 14 cylinders to a pressure of at least 2300 bar at a throughput of at least 120 tonnes / hour, heating at least a portion of that ethylene to a temperature of at least 95° C. and introducing it into a tubular reactor of diameter at least 65 mm and a length of at least 1500 m, introducing initiator in at least three reaction zones to give a conversion of at least 28% and maintaining a pressure drop over the reactor to maintain a flow velocity of at least 6 m / s.

Owner:EXXONMOBIL CHEM PAT INC

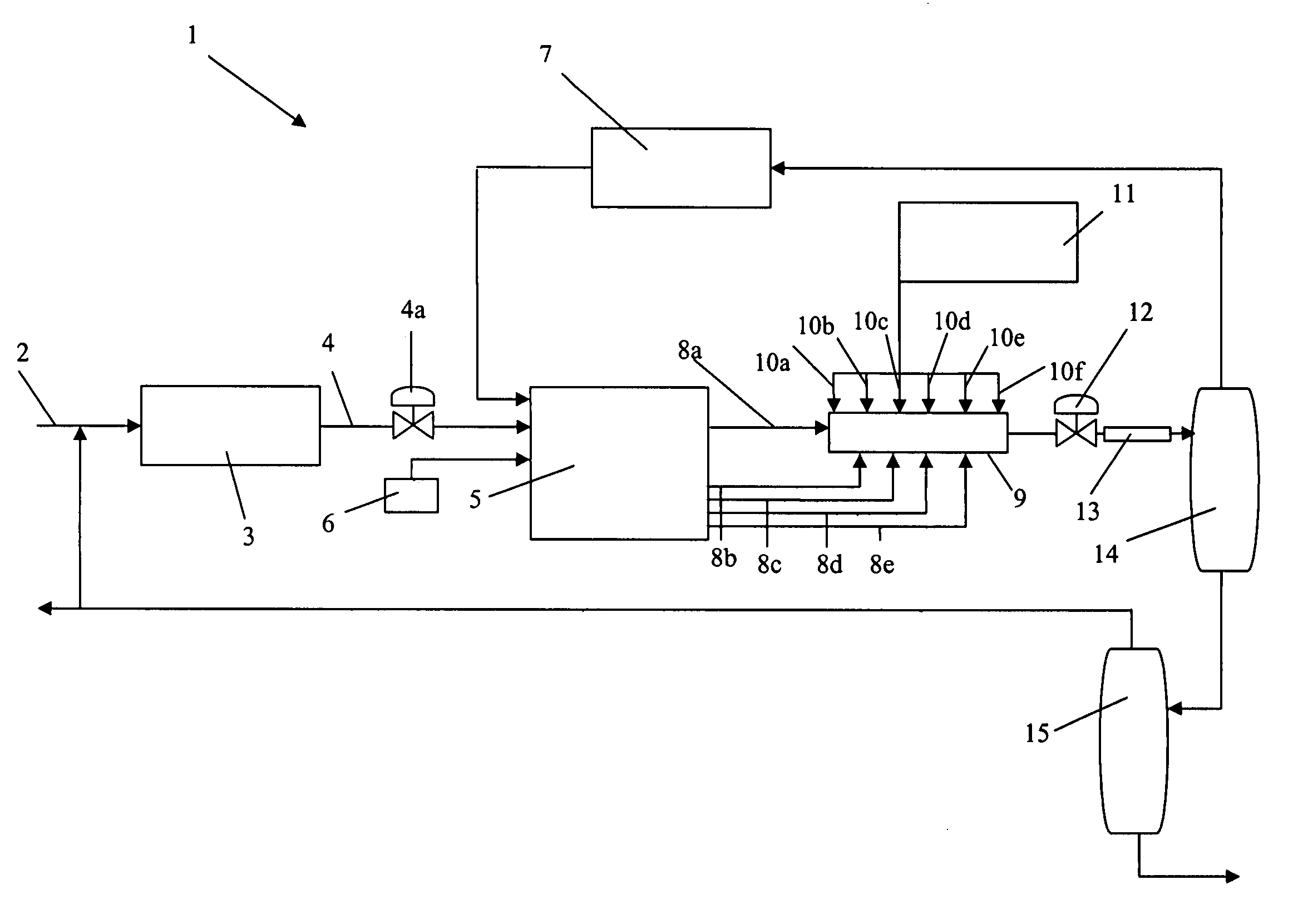

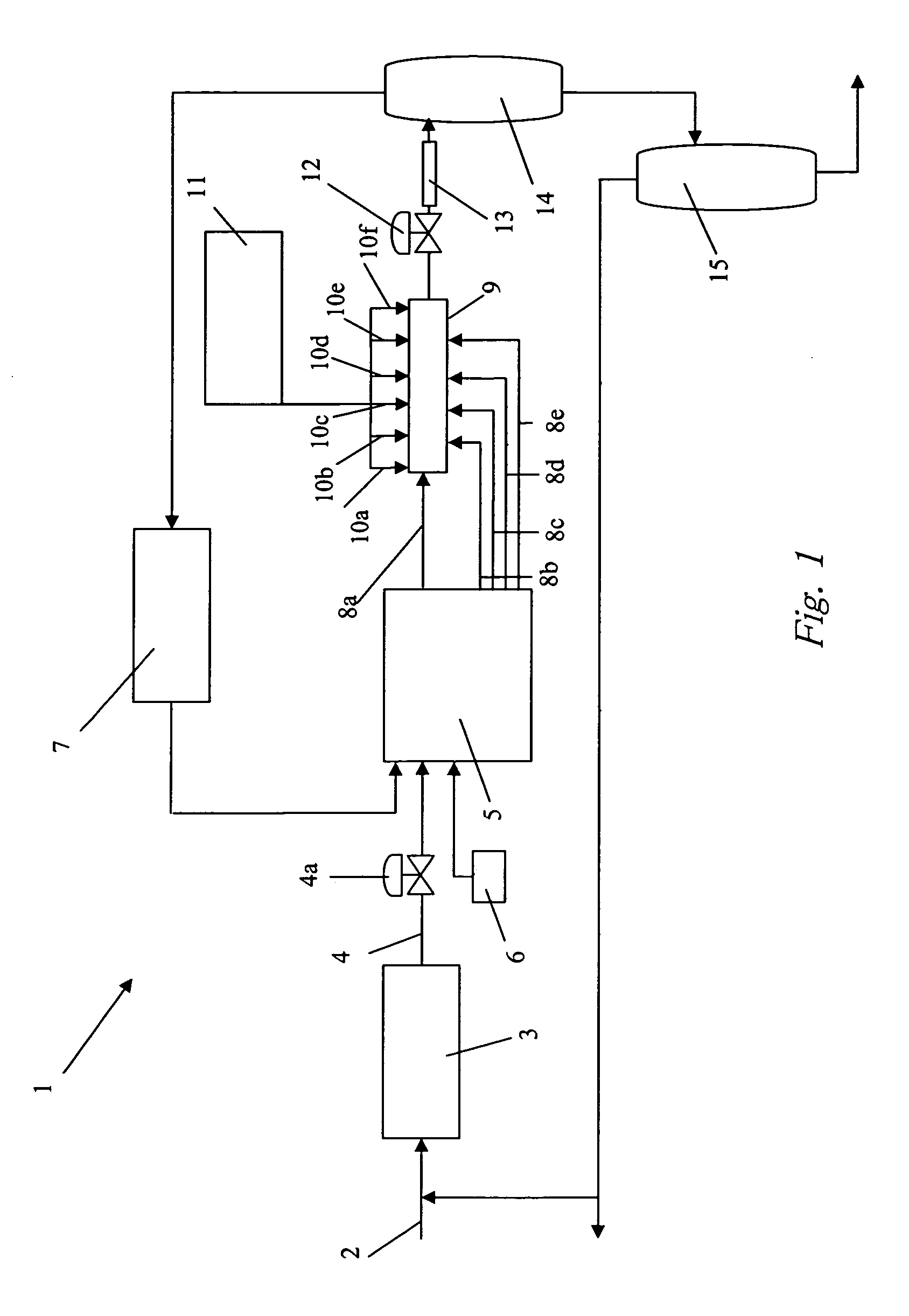

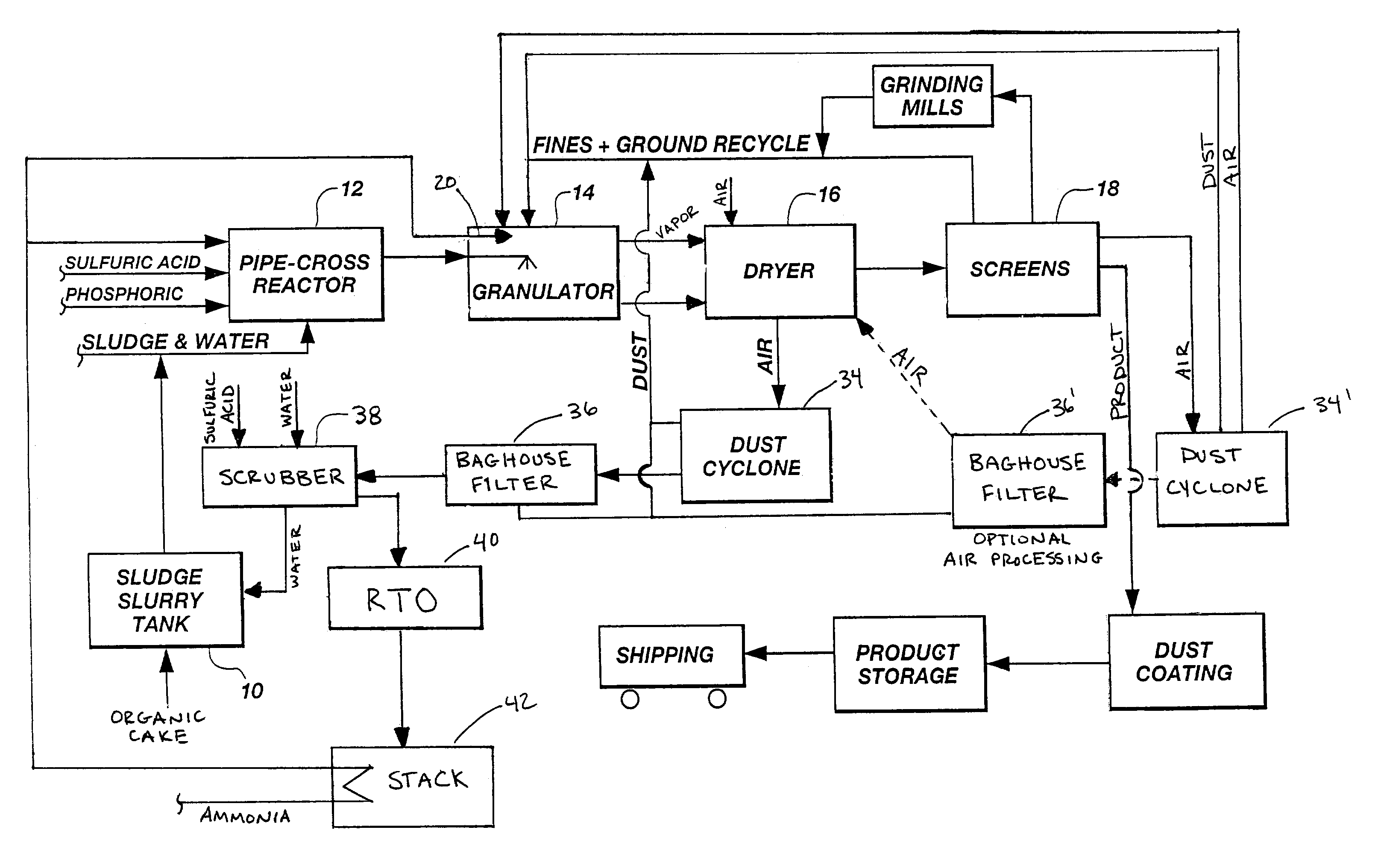

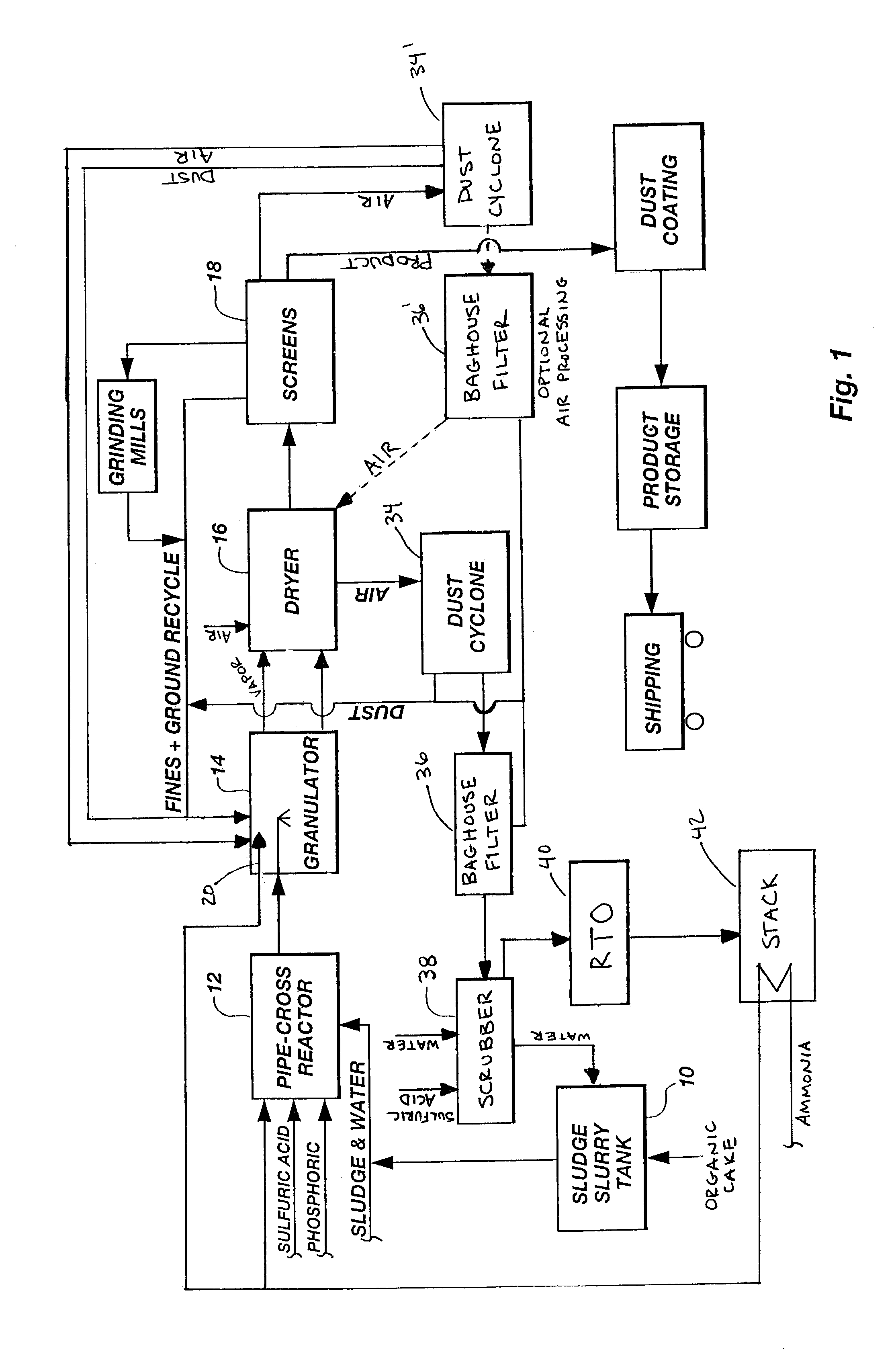

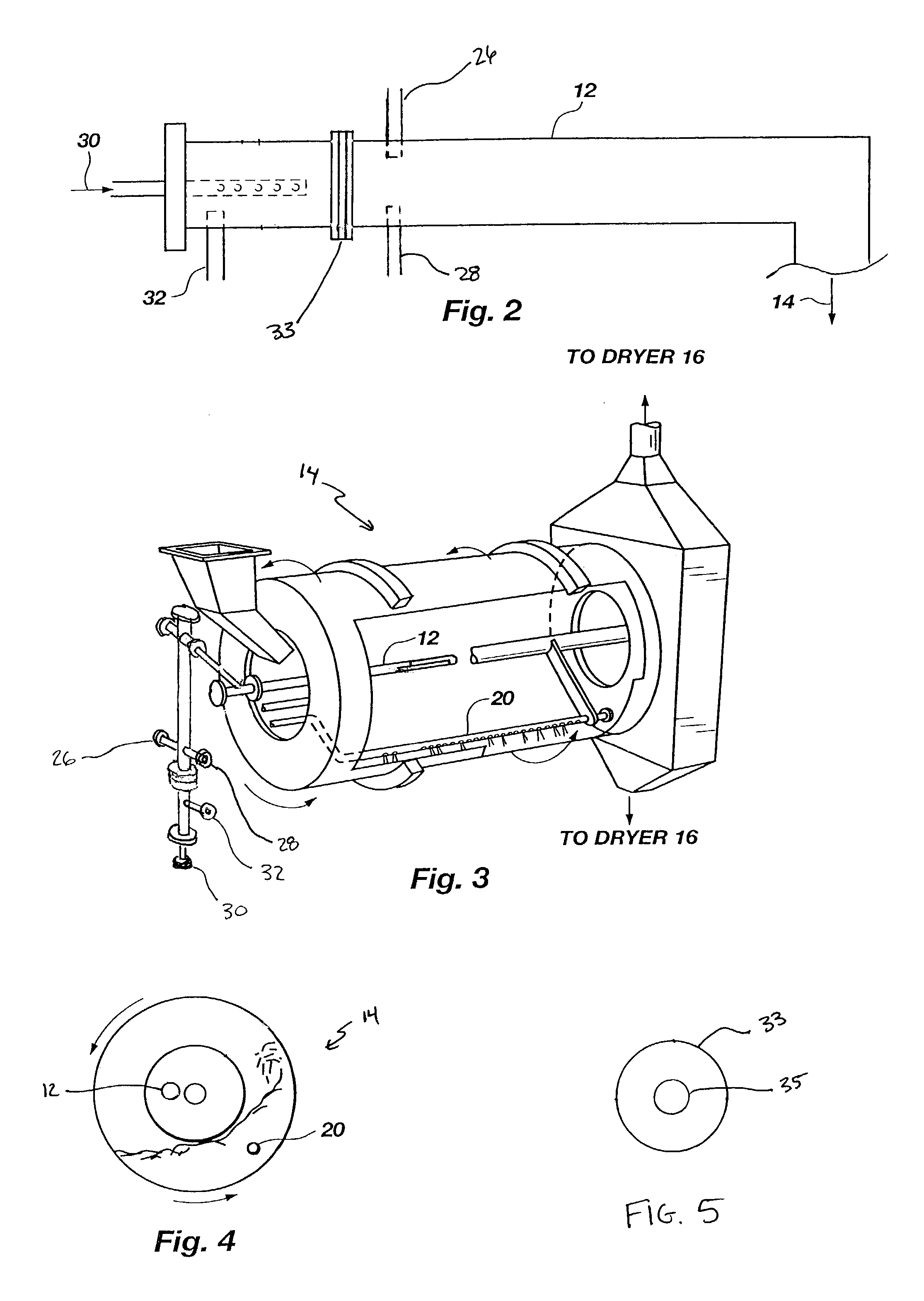

Organic recycling with a pipe-cross or tubular reactor

ActiveUS7128880B2Reduce moisture contentSimple compositionPhosphatesAnimal corpse fertilisersWater vaporSludge

The invention is directed to a process for enhancing the plant nutrient value of relatively low analysis organic waste material (e.g. sewage sludge) involves treating the waste material with an acid and base in a pipe-cross reactor or tubular to form a melt; spraying the melt onto a recycling bed of fines in a granulator and flashing off the water contained in the melt as steam; rolling the melt onto recycled fine particles in a granulator to form granulated particles; and drying these granulated particles to form an enhanced plant nutrient value composition (e.g. a fertilizer or soil conditioner having a greater NPK value than the original relatively low analysis organic waste material). The process further includes drawing off the fumes from the granulator, passing them through a dryer with the granulated particles, and subsequently oxidizing the fumes to eliminate volatile organic compounds and / or gaseous hydrocarbon pollutants be converting such into carbon dioxide and water vapor.

Owner:UNITY FERTILIZER LLC

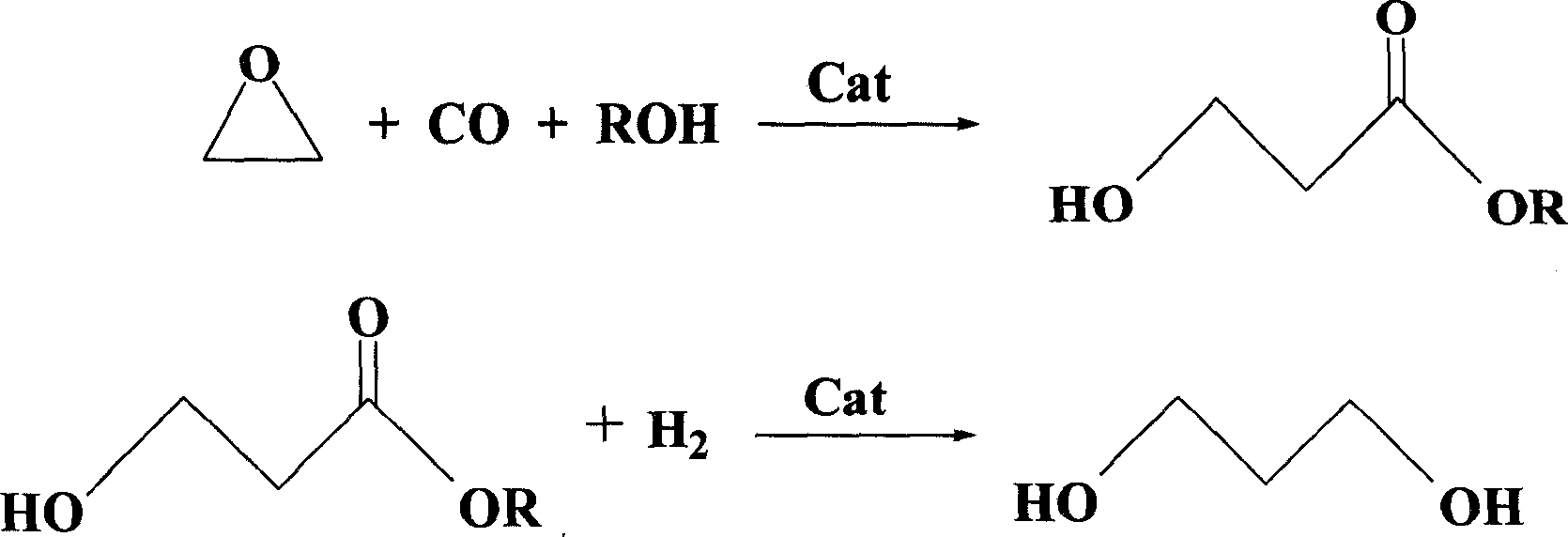

Prepn process of 3-hydroxy propionate and propylene glycol

InactiveCN101020635AHigh activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAccelerantCobalt catalyst

The present invention is process of preparing 3-hydroxy propionate and 1, 3-propylene glycol with epoxide as material. The present invention prepares 3-hydroxy propionate with epoxide, CO and alcohol under the action of cobalt catalyst and co-catalyst, and prepares 1, 3-propylene glycol under the action of 3-hydroxy propionate hydrogenating catalyst. The present invention has the advantages of simple reaction apparatus, simple operation, mild reaction condition, high catalyst activity, no environmental pollution, low production cost, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

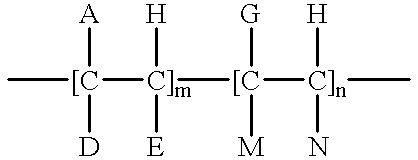

Process for the preparation of ethylene copolymers, and their use as additives to mineral oil and mineral oil distillates

InactiveUS6509424B1Liquid carbonaceous fuelsChemical/physical/physico-chemical stationary reactorsCopolymerMineral oil

The invention relates to a process for the preparation of terpolymers of ethylene and at least 2 further olefinically unsaturated compounds by polymerization in a tubular reactor fitted with at least one side branch, wherein the fresh monomer components, which are introduced into the tubular reactor via the reactor inlet (the primary stream) or via the side branch or side branches (secondary stream or secondary streams), in each of the streams contain ethylene and at most one further olefinically unsaturated compound.

Owner:CLARIANT PROD DEUT GMBH

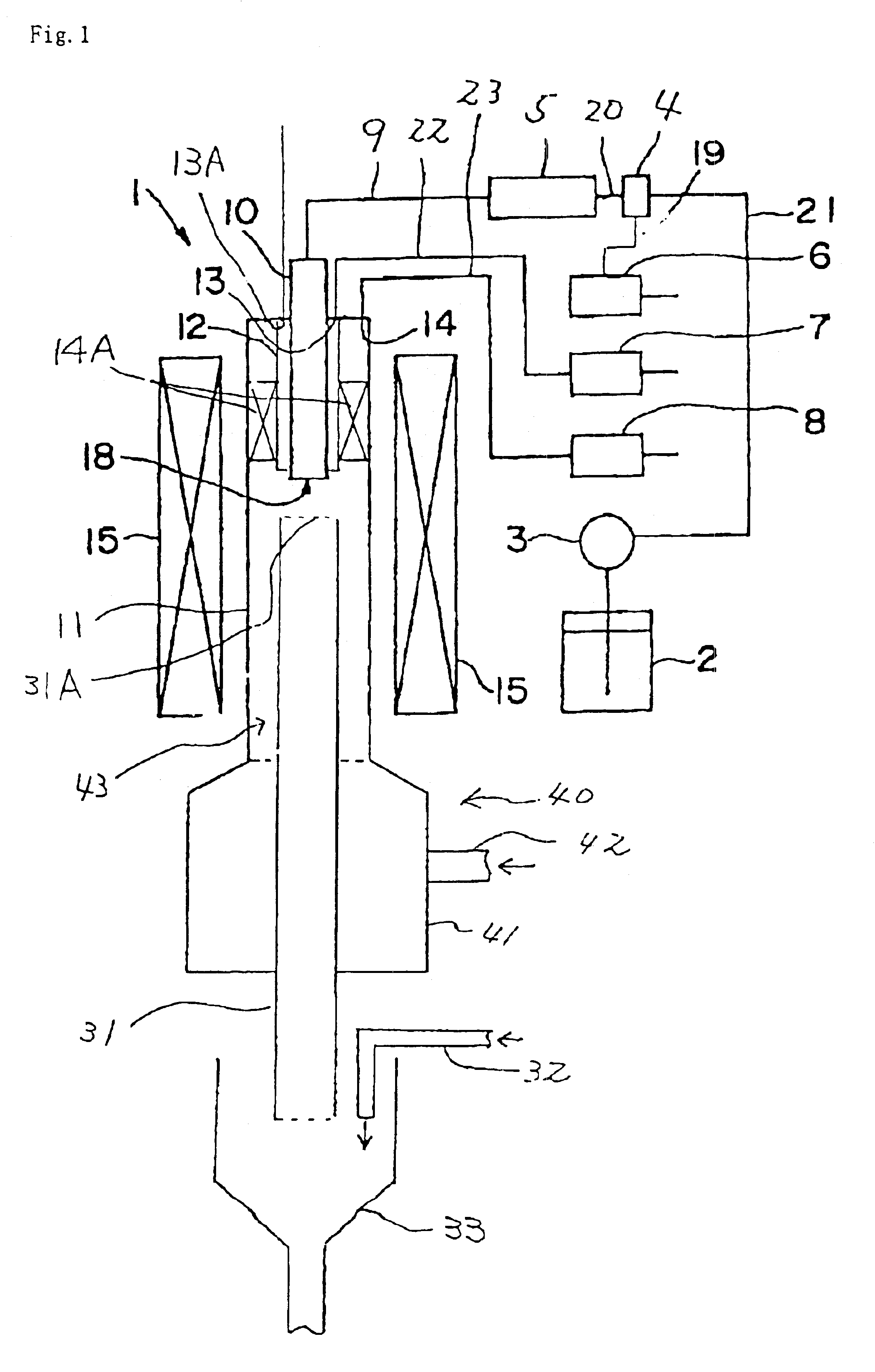

Method of ethylene polymerization for producing products having various properties with high productivity and a tubular reactor used therefor

ActiveUS20060149004A1Improve productivityMaintain physical propertiesChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical processesProduction rateReaction zone

A method for continuous ethylene polymerization under high pressure using a polymerization reaction zone comprises a primary reaction zone and a secondary reaction zone wherein the secondary reaction zone has a length of 1.5-6.5 times the length of the primary reaction zone and a cross-sectional area of 1.2-4 times the cross-sectional area of the primary reaction zone. Ethylene is fed continuously into the primary reaction zone at the starting point of the primary reaction zone. Low temperature initiator alone, or an initiator mixture containing mainly low temperature initiator is introduced into the primary reaction zone at the starting point of the primary reaction zone. Initiator alone or an initiator mixture is introduced into the secondary reaction zone at two or more different points of the secondary reaction zone. Ethylene polymer products of various physical properties are produced with high productivity, while the pressure drop is minimized.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

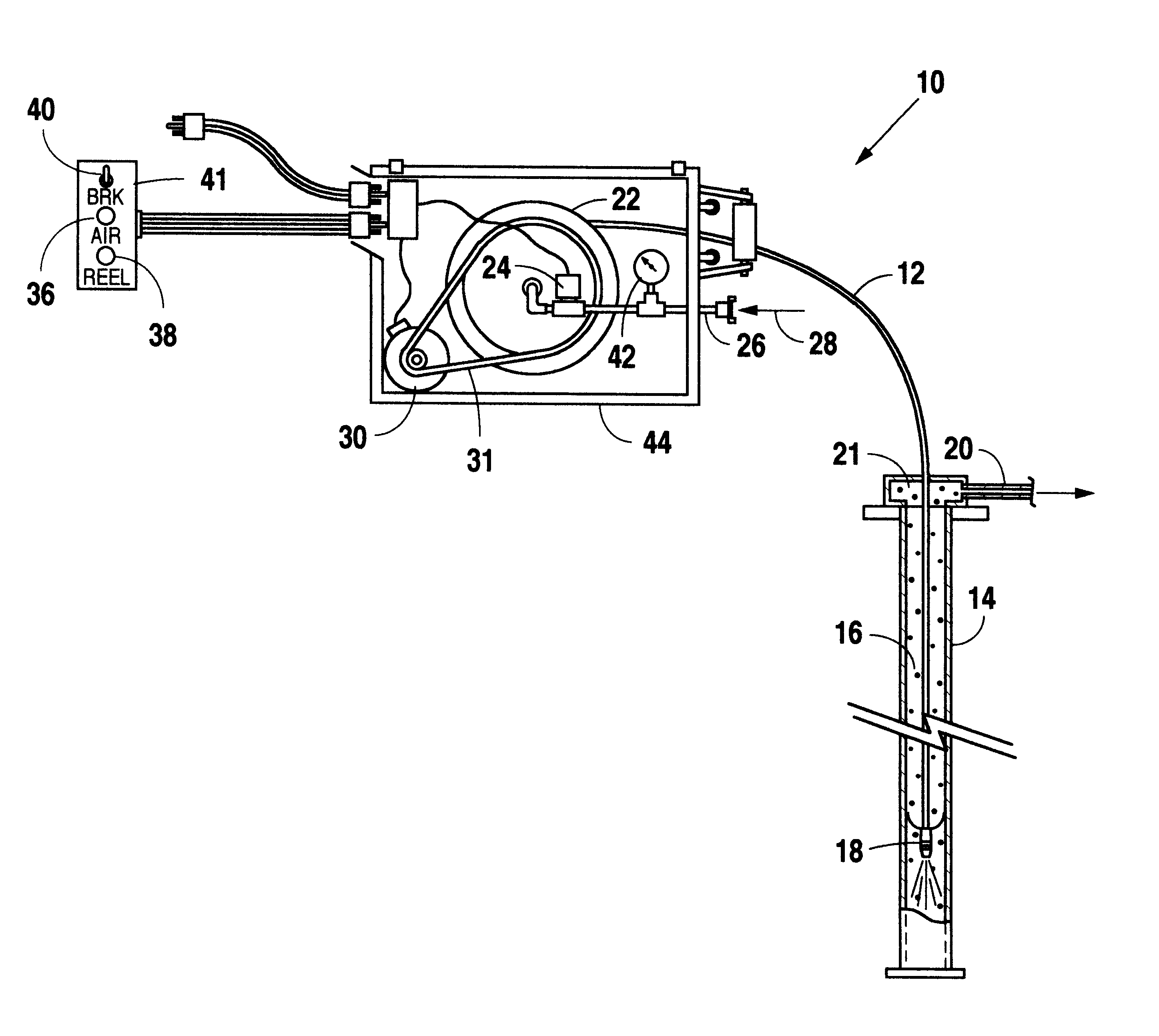

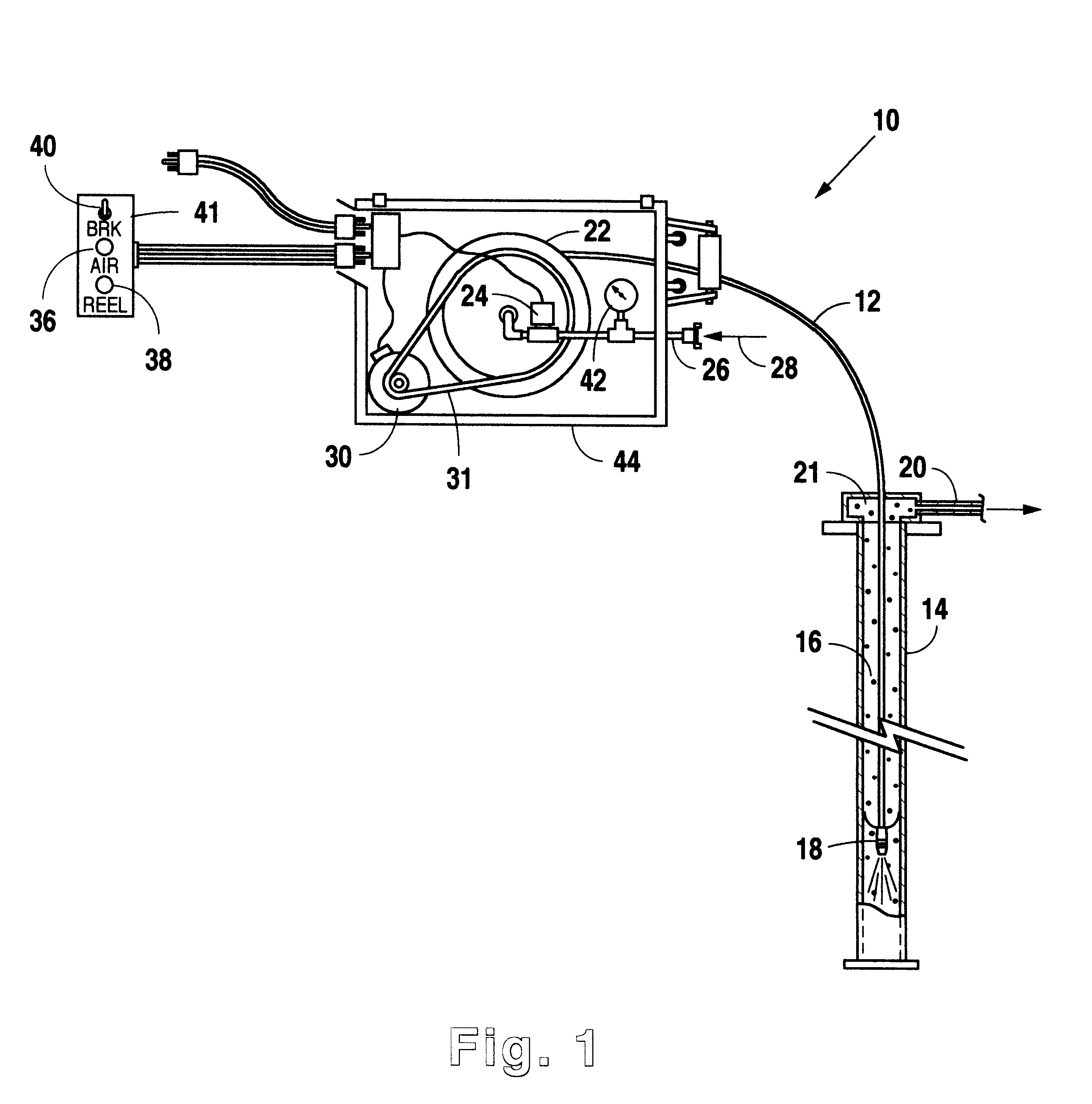

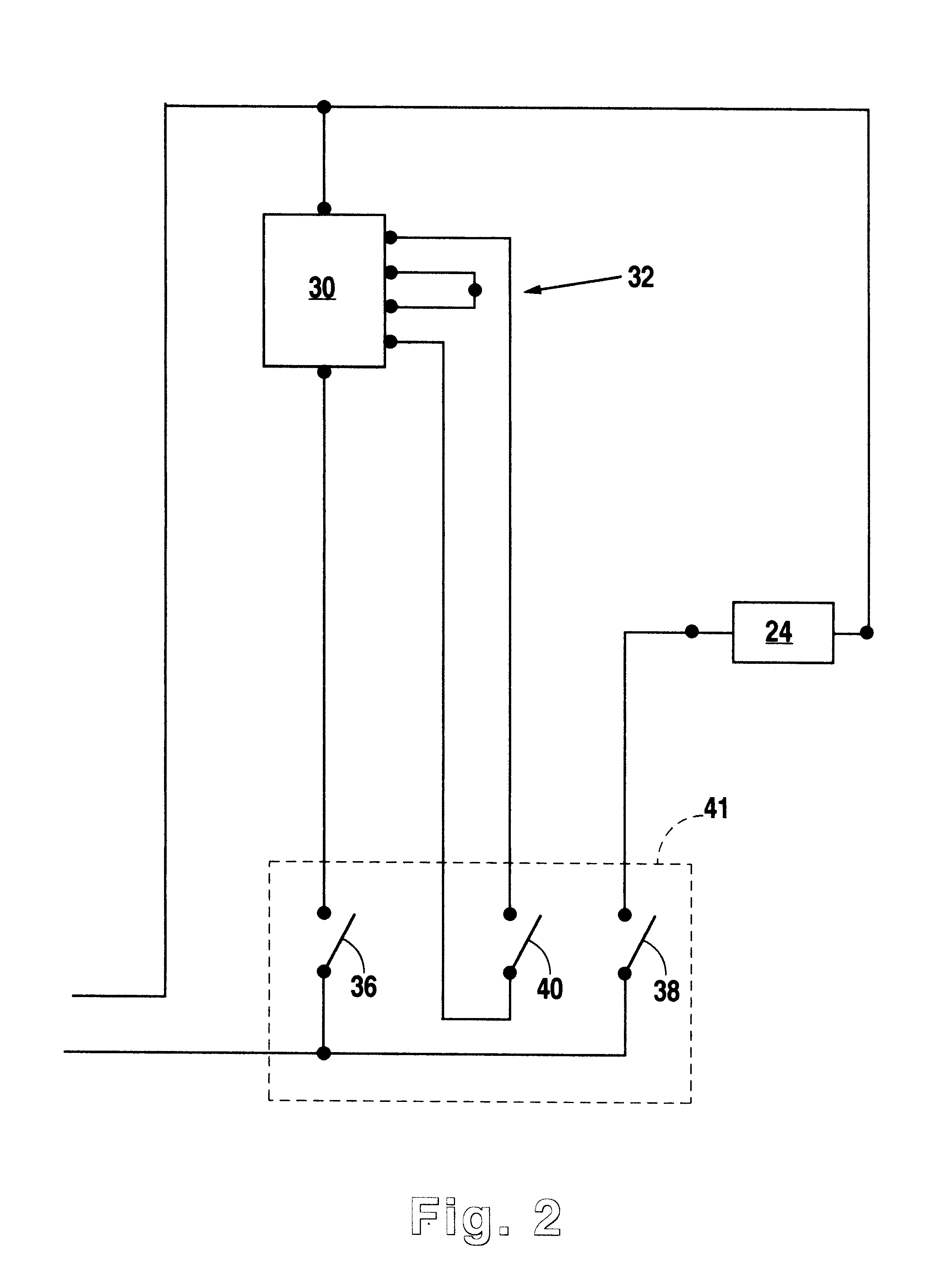

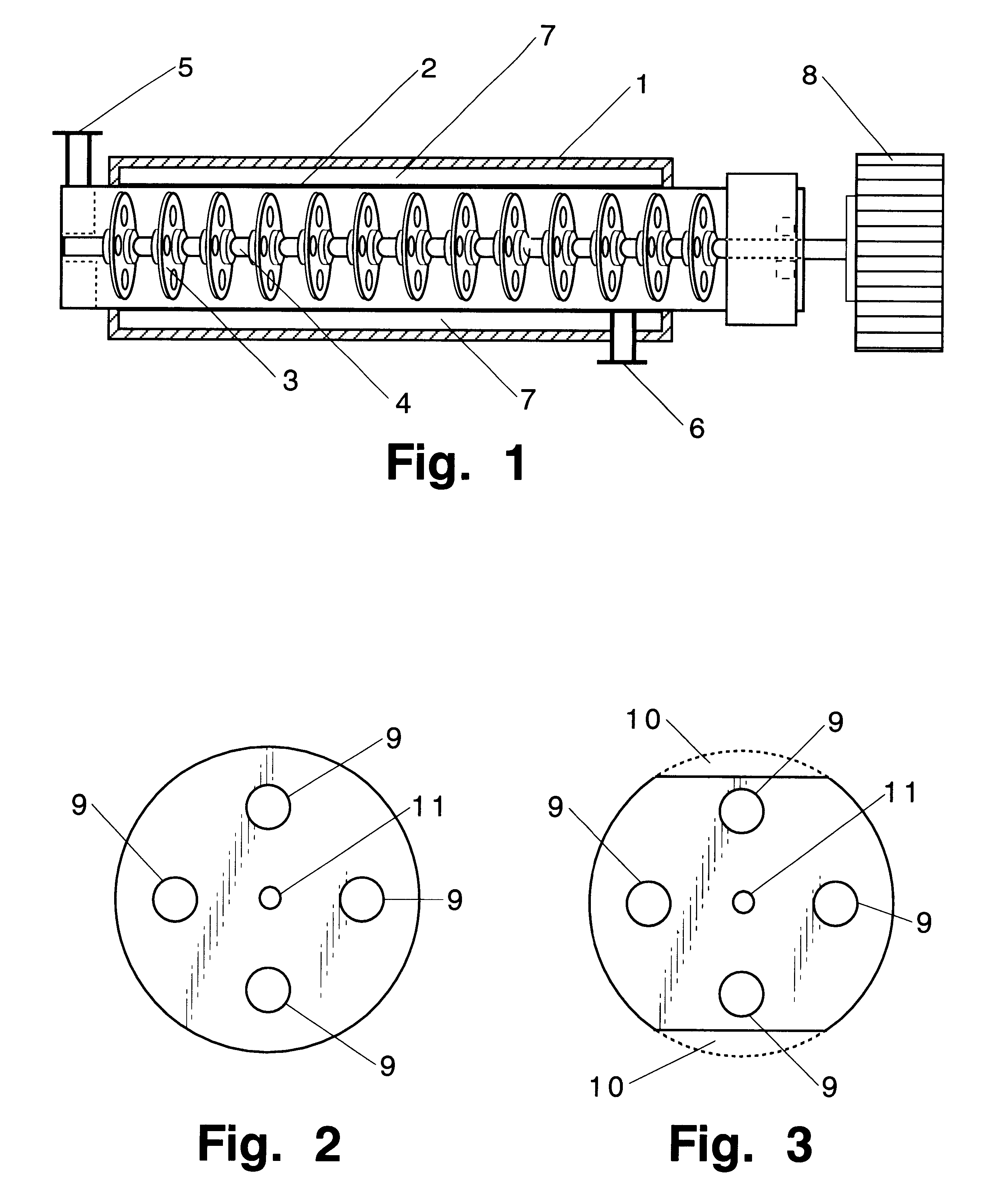

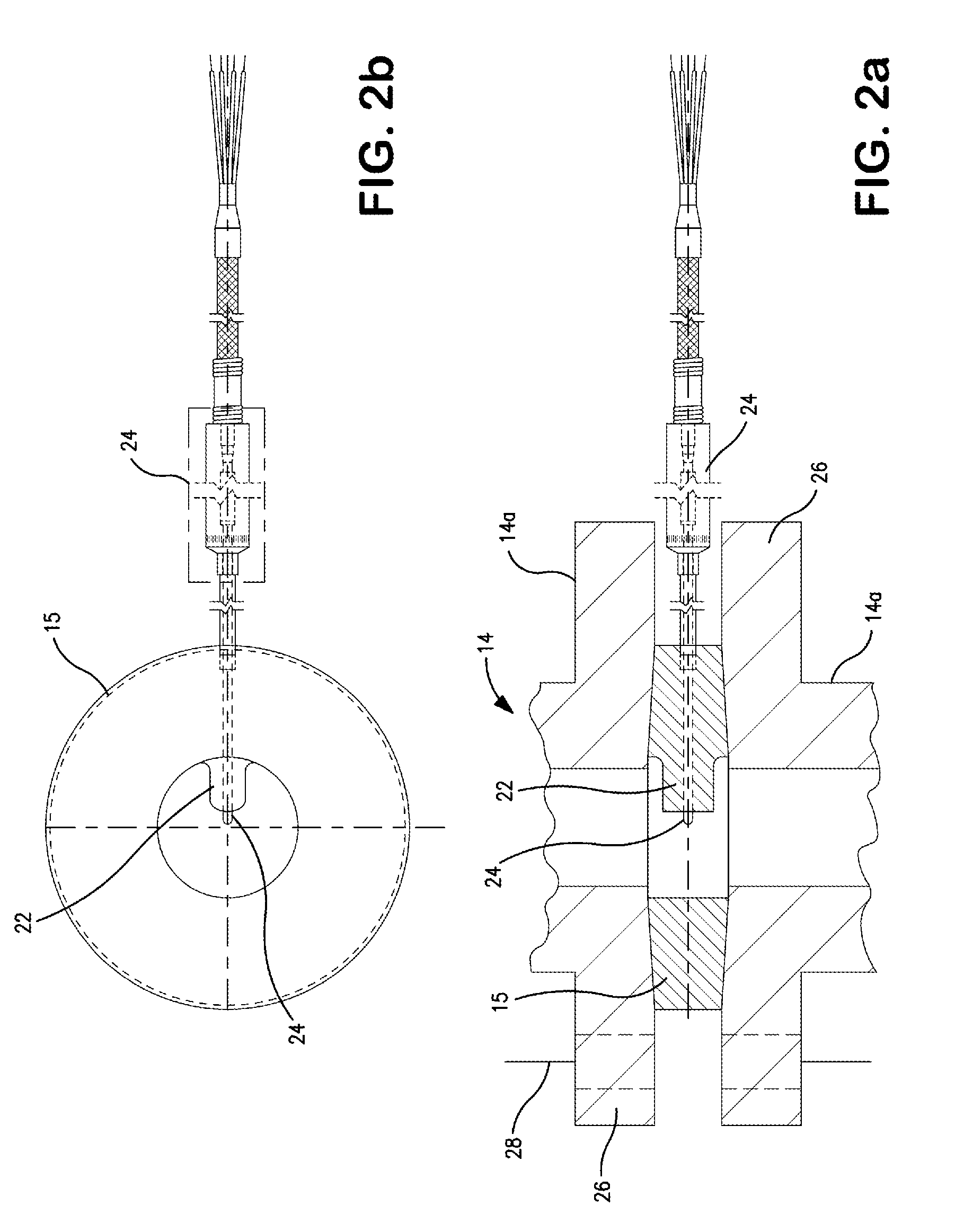

Catalyst unloading device

An electric motor is operatively connected to a reel for selectively storing, paying out, and rewinding an air lance of a device for unloading catalyst from tubular reactors. The electric motor powered reel provides improved on / off control of the air lance mounted on the reel, a braking force during withdrawal of the air lance from the reel, constant speed operation during rotation of the reel, and avoids the problem of lubricant contamination of the catalyst and reactor tubes.

Owner:PHILIP ST

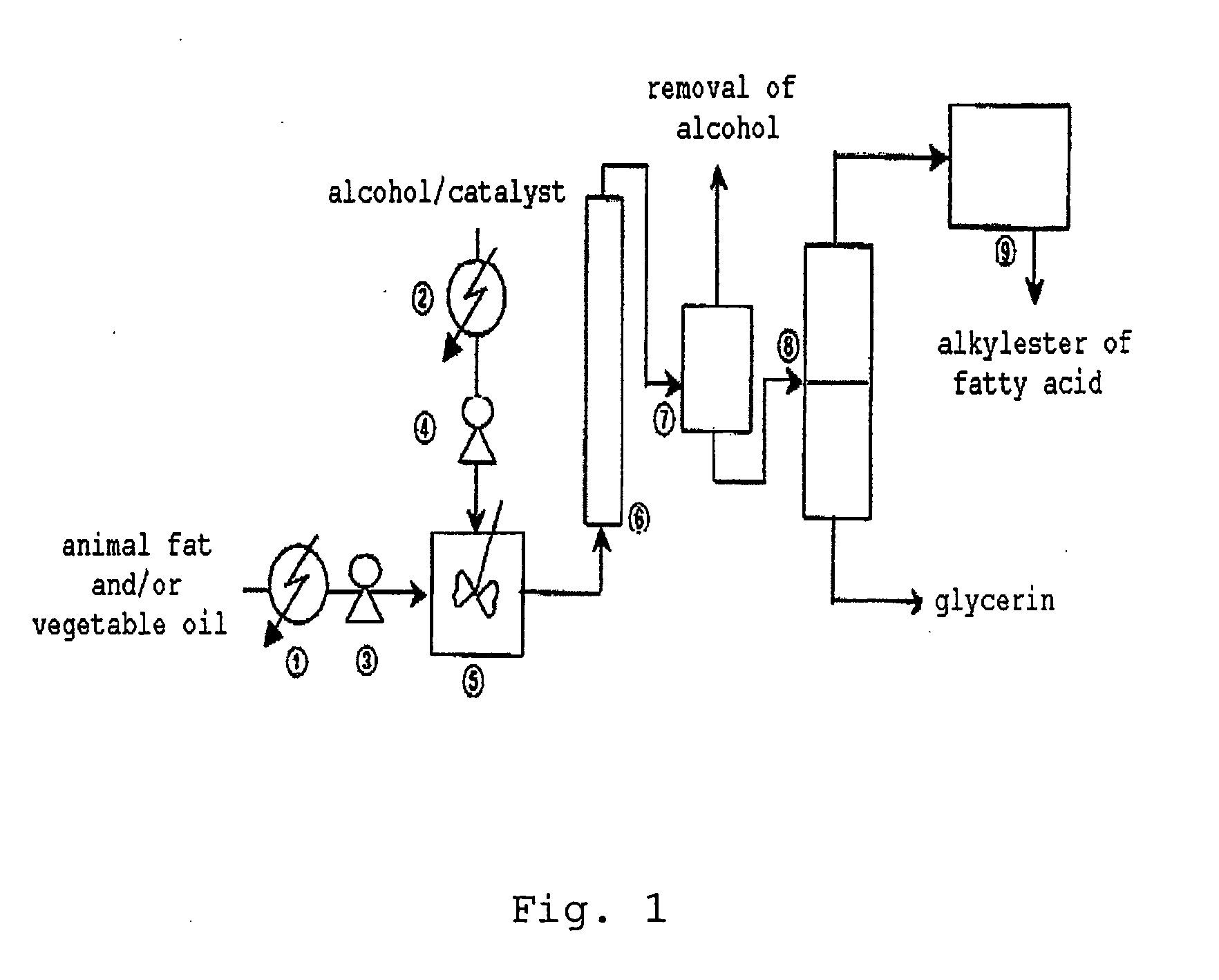

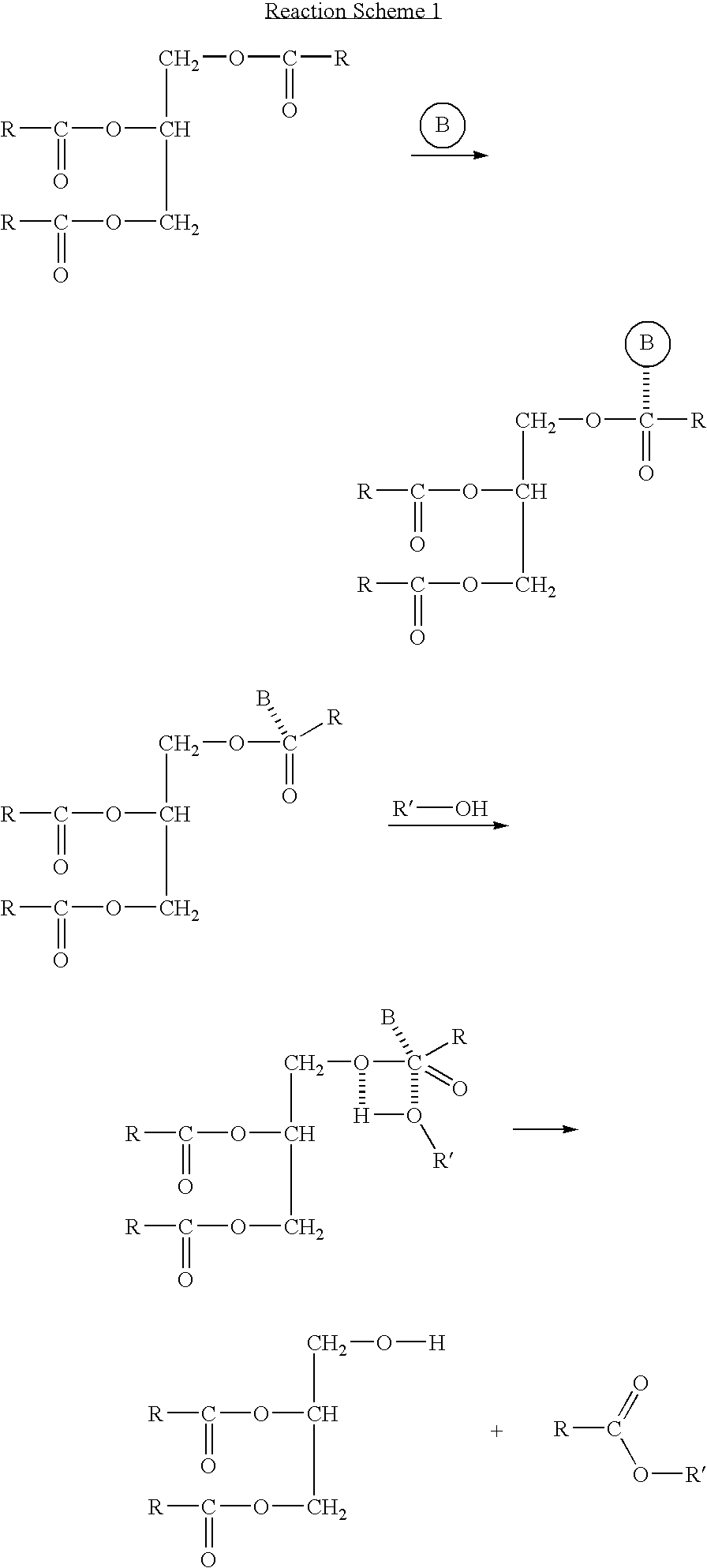

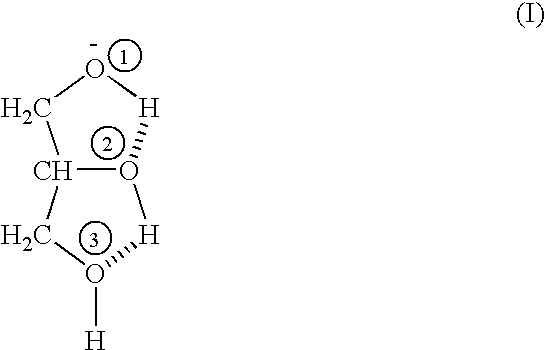

Process for producing alkylester of fatty acid in a single-phase continuous process

InactiveUS20050080280A1Phase separationFatty oils/acids recovery from wasteFatty acid esterificationAlcoholVegetable oil

The present invention relates to a process for preparing an alkylester of fatty acid with high purity via one-step continuous process by reacting an animal fat and / or vegetable oil with a lower alcohol in the presence of alkali catalyst by passing through a continuous tubular reactor while maintaining a single-phase, removing residual lower alcohol from the reaction mixture and removing residual glycerin, catalyst, etc. by phase separation. In accordance with the present invention, an alkylester of fatty acid can be produced with a high yield of 97% or more via one-step continuous process in a continuous tubular reactor without any limitation in flow types by reacting an animal fat and / or vegetable oil with a lower alcohol in the presence of alkali catalyst and carrying out a simple separating process.

Owner:M ENERGY

Hydrogenation method for production of hydrogen peroxide by anthraquinone process

InactiveCN102009960AUniform distributionIncrease contact areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical industryHydrogenation process

The invention discloses a hydrogenation method for production of hydrogen peroxide by the anthraquinone process, belonging to the technical field of chemical industry reaction. The method provided by the invention comprises: dispersing the gaseous phase containing hydrogen into the working solution containing the anthraquinone derivatives to obtain the gas-liquid mixing fluid containing micron bubbles, so that the gas-liquid mixing fluid passes through the pipe reactor filled with the hydrogenation catalyst at the space velocity of 3 to 1000h<-1> to finish the hydrogenation process. In the method provided by the invention, the gas-liquid micro-dispersing process and the static bed catalytic hydrogenation process are directly integrated, so that the interphase mass transfer is strengthened, and the contacts between different reactants and between the reactant and the catalyst are more sufficient and more uniform, thereby enhancing the efficiency and the controllability of the hydrogenation process and improving the economical efficiency and the security of the production of the hydrogen peroxide.

Owner:TSINGHUA UNIV

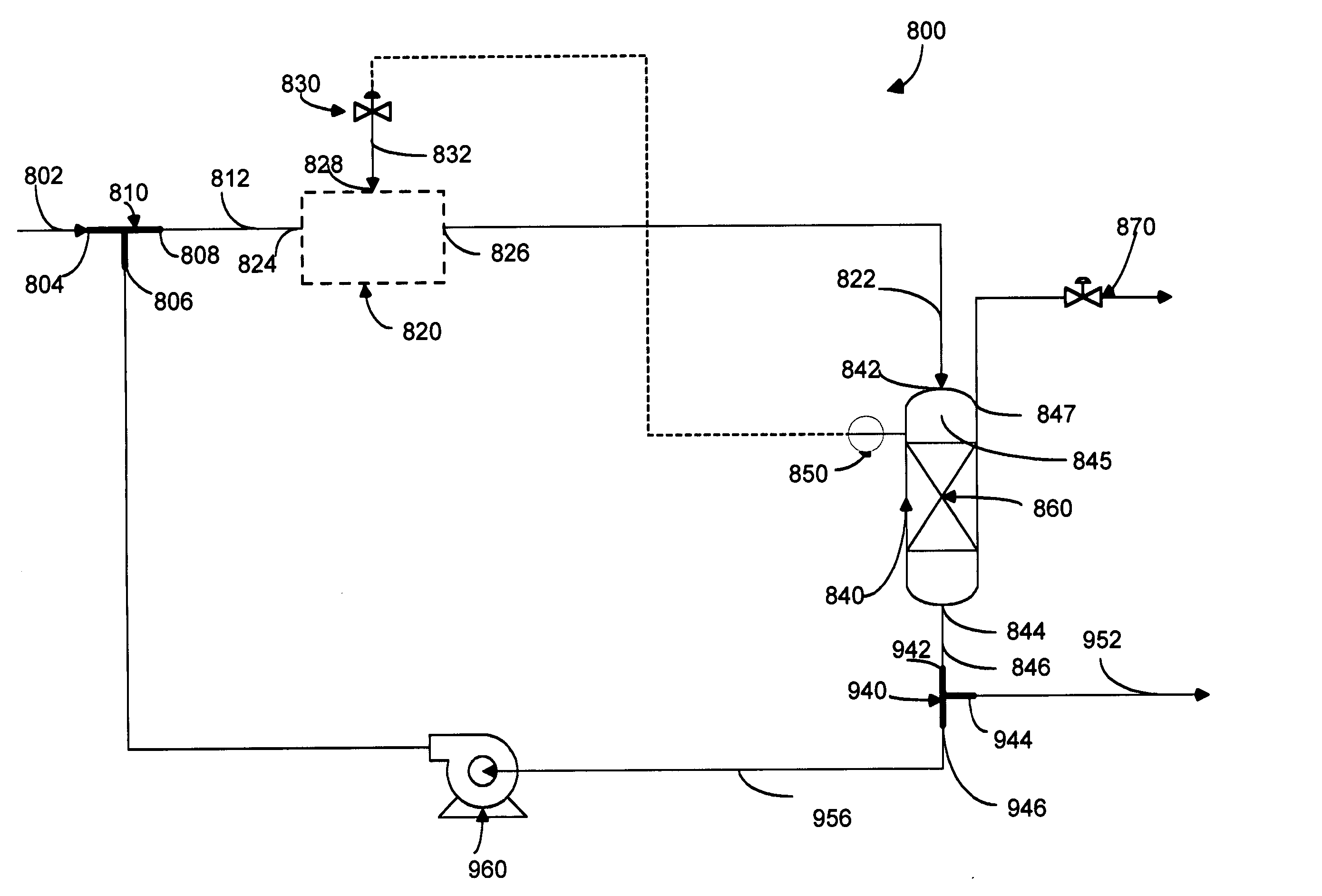

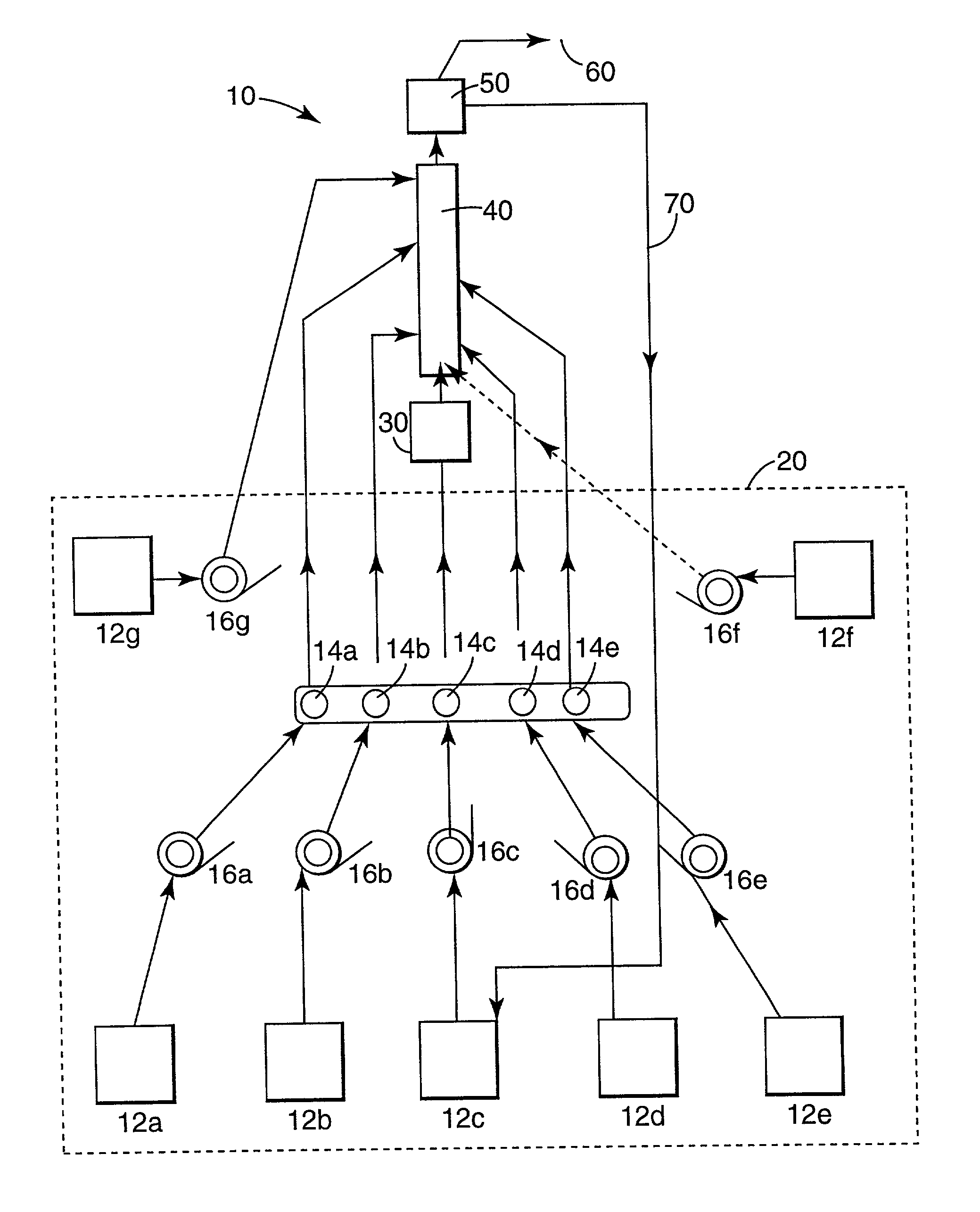

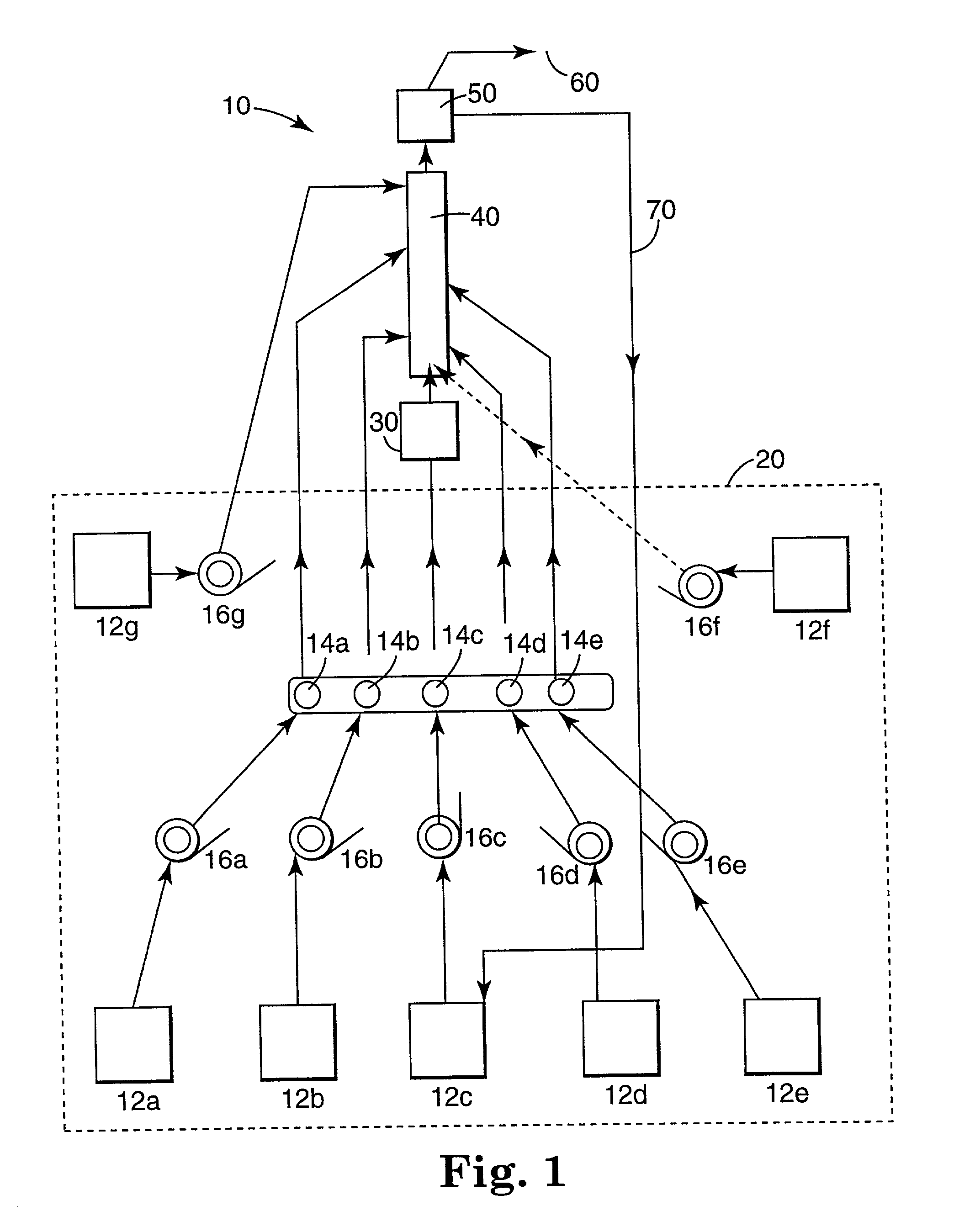

Continuous process for the production of combinatorial libraries of materials

InactiveUS20030035756A1Sequential/parallel process reactionsMacromolecular librariesStatic mixerTube reactor

A system is provided wherein a plug flow reactor is used to make combinatorial libraries of materials. Examples of plug flow reactors include stirred tube reactors, extruders, and static mixers.

Owner:3M INNOVATIVE PROPERTIES CO

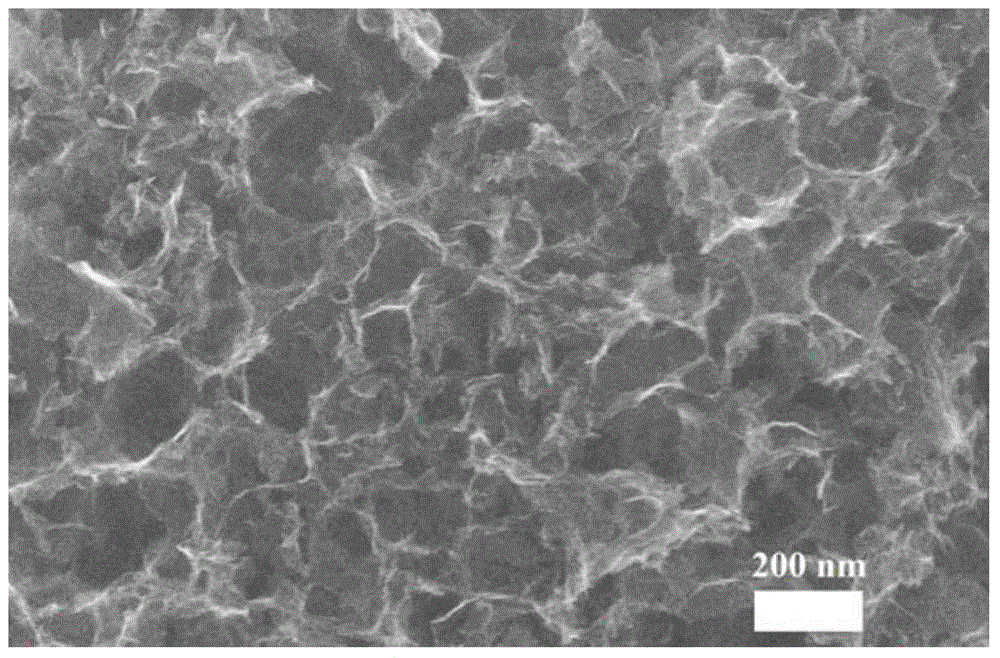

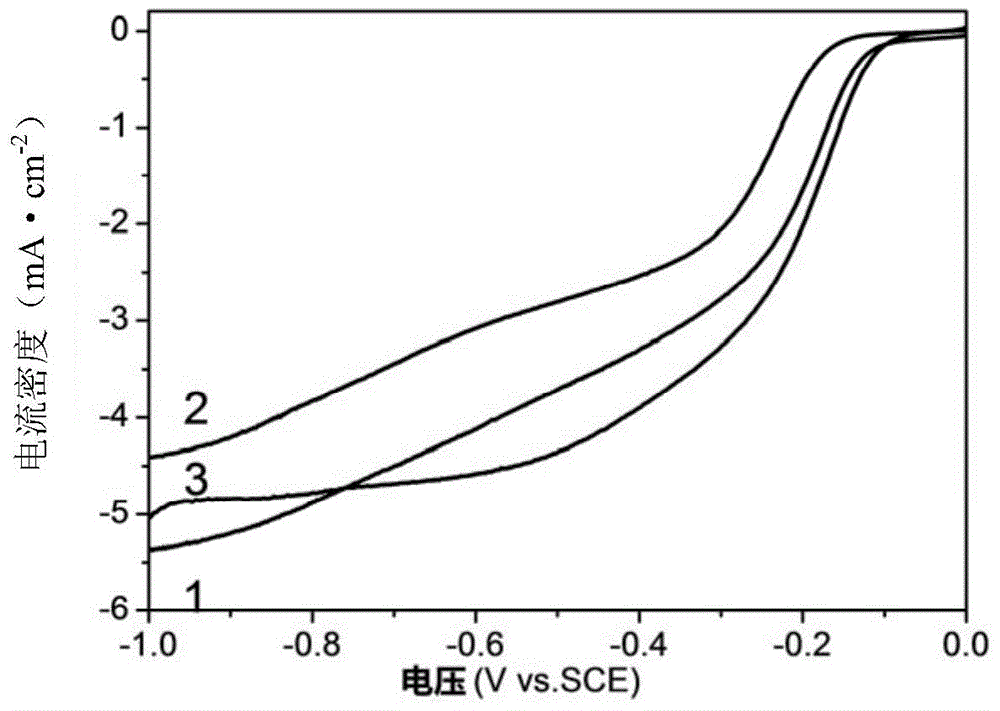

Heteroatom-doped porous graphite electro-catalyst and preparation and application thereof as well as device

ActiveCN104959134AImprove electrocatalytic performanceGood flexibilityPhysical/chemical process catalystsCell electrodesPorous grapheneAlcohol fuel

The invention belongs to the field of carbon materials and electrochemistry, and discloses a heteroatom-doped porous graphite electro-catalyst and preparation and application thereof as well as a device. The method comprises the following steps: firstly adding concentrated HNO3 into a graphite oxide aqueous solution, performing sealing, ultrasonic reaction and stewing, and pouring the solution into deionized water for centrifugation, filtering and drying to obtain graphite oxide with holes in the surface; uniformly mixing the graphite oxide with holes in the surface, a heteroatom-doped source compound and a solvent to obtain a mixture, coating the surface of a substrate with the mixture, and performing freeze drying to obtain a solid thin film; putting the substrate loaded with the solid thin film into a plasma high-temperature tubular reactor for reaction to obtain the heteroatom-doped porous graphite electro-catalyst. The prepared electro-catalyst is higher in oxygen reduction electro-catalytic performance and is higher in electrochemical performance when applied in an electrode material; the electro-catalyst can be applied to the field of proton exchange membrane fuel batteries, direct alcohol fuel batteries and metal-air battery anode materials.

Owner:SOUTH CHINA UNIV OF TECH

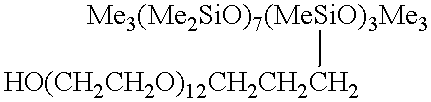

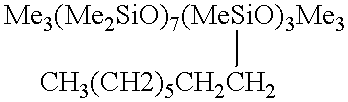

Continuous hydrosilylation method for production of a modified liquid organosilicon compound

A continuous method for performing a hydrosilylation reaction comprising effecting a hydrosilylation reaction between a liquid organosilicon compound (A) having in each molecule at least one silicon-bonded hydrogen atom and a liquid organosilicon compound (B) having in each molecule at least one aliphatic unsaturated bond in the presence of a platinum catalyst (C) continuously in a tubular reactor equipped with a stirring and plug-flow maintaining apparatus located within the reactor.

Owner:DOW TORAY CO LTD +1

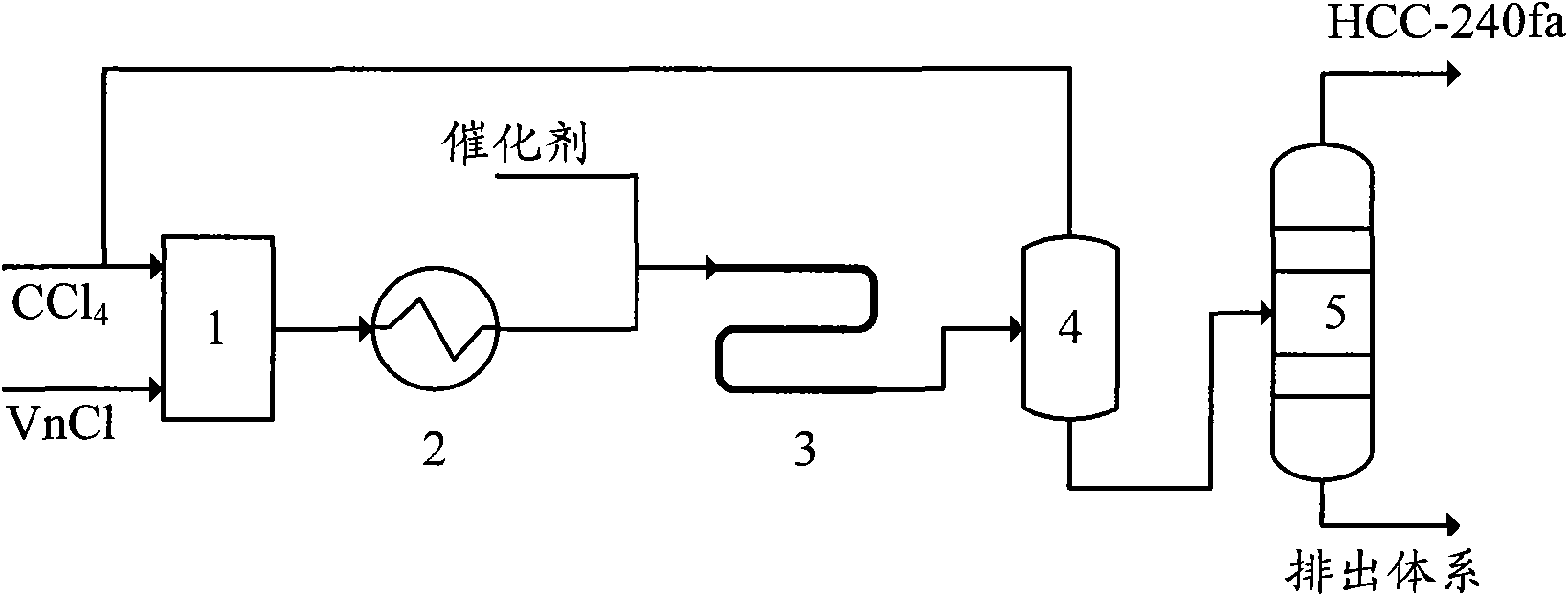

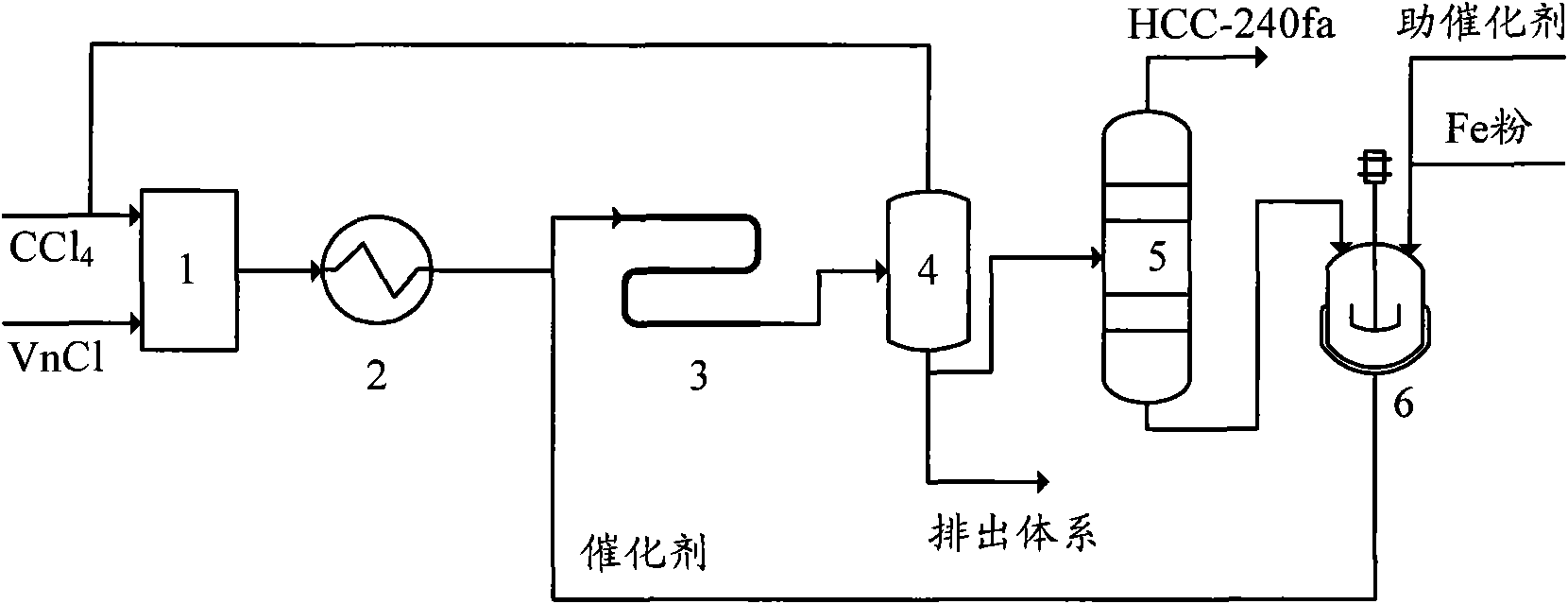

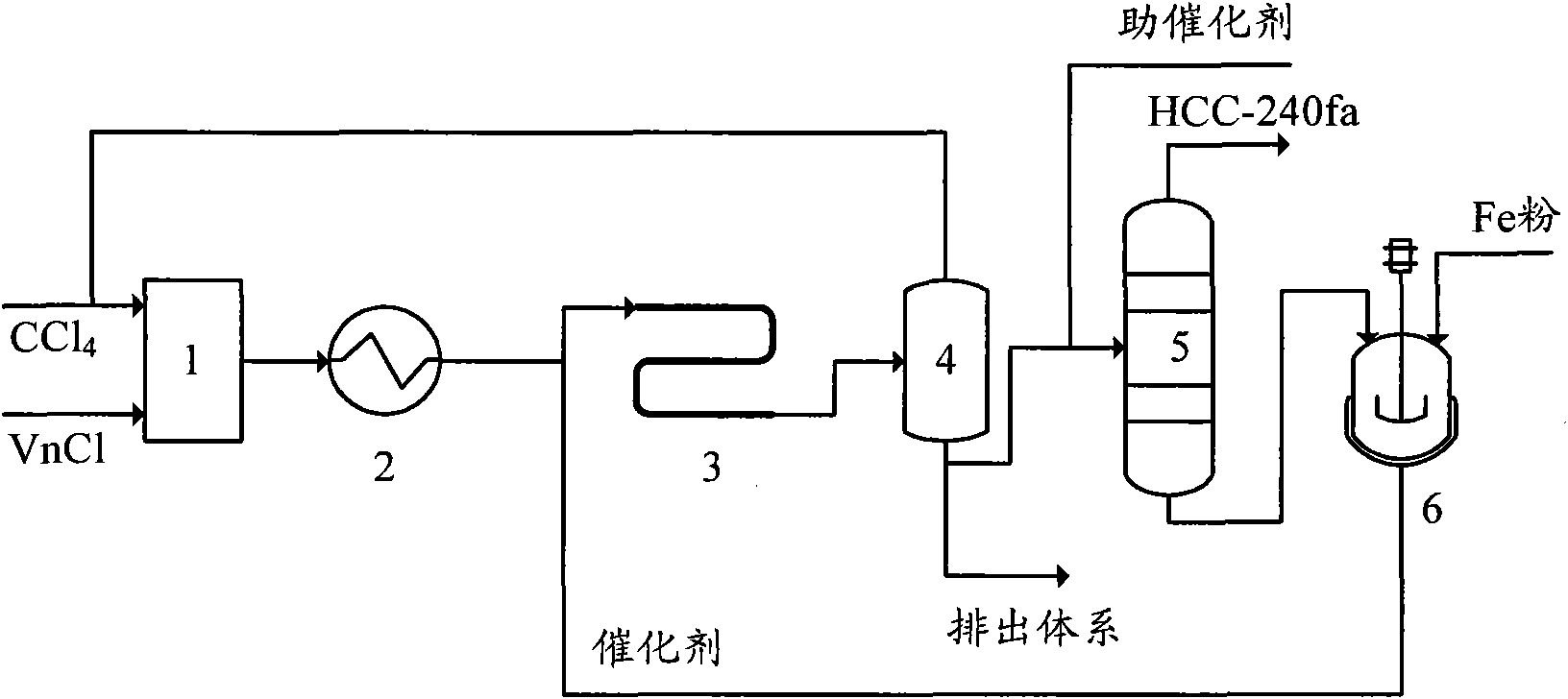

Production method of 1,1,1,3,3-pentachloropropane

InactiveCN101913980AEasy to transportAccurate measurementOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingReaction temperatureSilicon tetrachloride

The invention provides a production method of 1,1,1,3,3-pentachloropropane (HCC-240fa). The 1,1,1,3,3-pentachloropropane is synthesized by continuously reacting the materials of carbon tetrachloride and chloroethylene in a tubular reactor. The method comprises the steps of firstly mixing the carbon tetrachloride with the chloroethylene and preheating the mixture to a reaction temperature, then introducing the mixture together with a catalyst into the tubular reactor for telomeric reaction, removing the unreacted carbon tetrachloride and chloroethylene through flash evaporation, and then further distilling to obtain the HCC-240fa, wherein the unreacted carbon tetrachloride and chloroethylene are recycled and the catalyst is recycled after being subjected to the activating treatment. The invention adopts the liquid as the activated system and uses the tubular reactor for reaction, thereby ensuring simple and convenient operation as well as continuous production.

Owner:XIAN MODERN CHEM RES INST

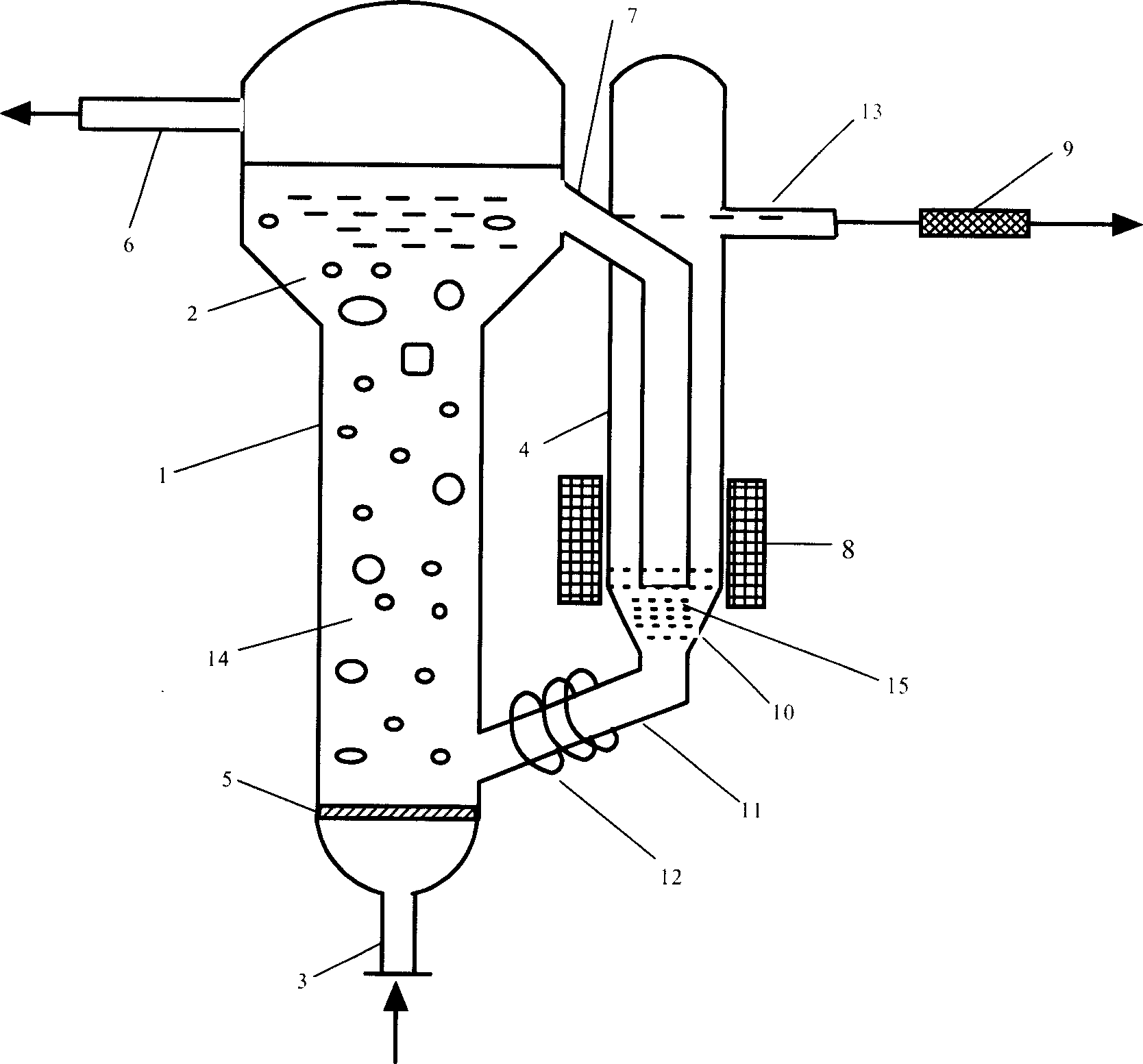

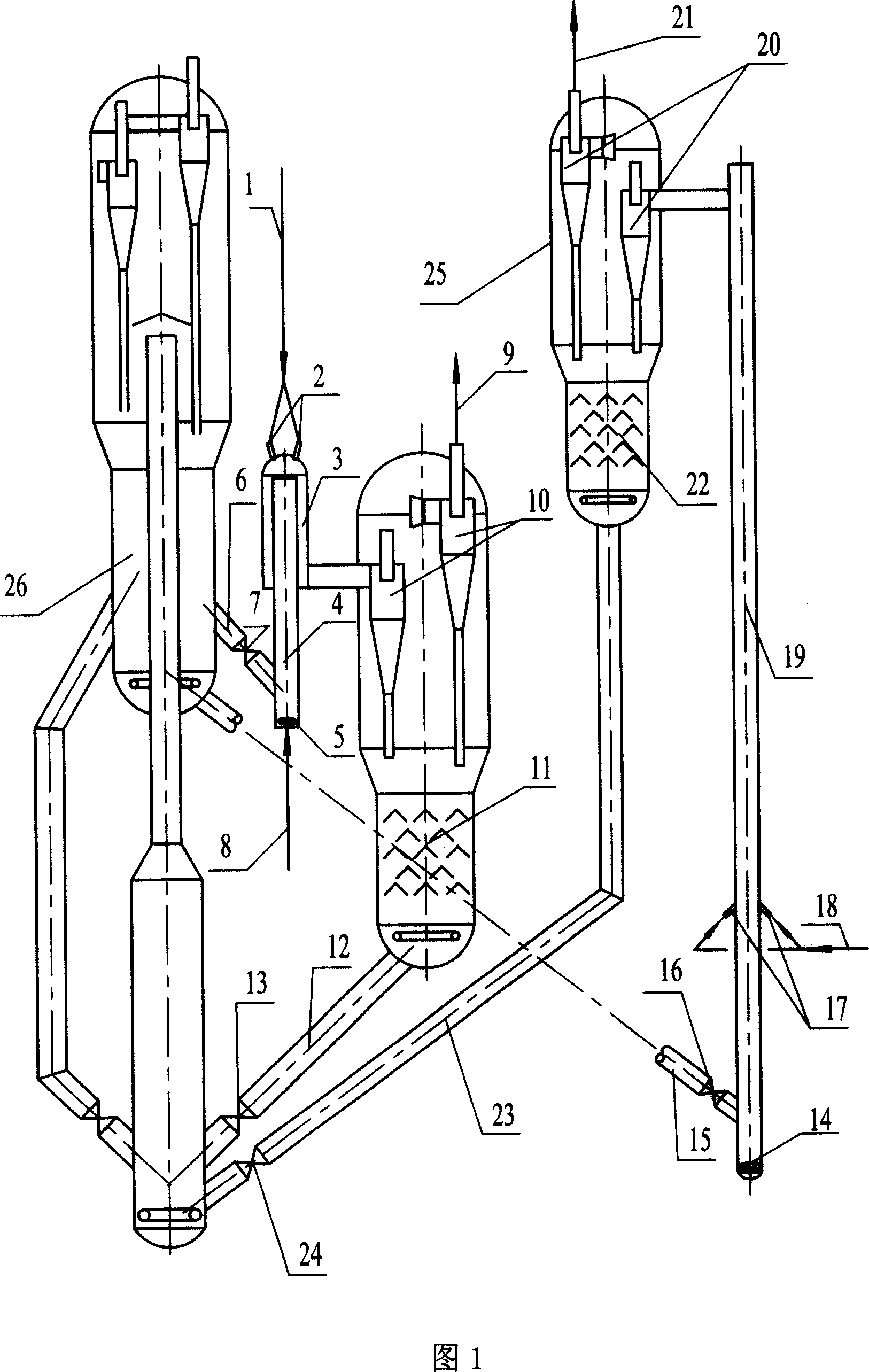

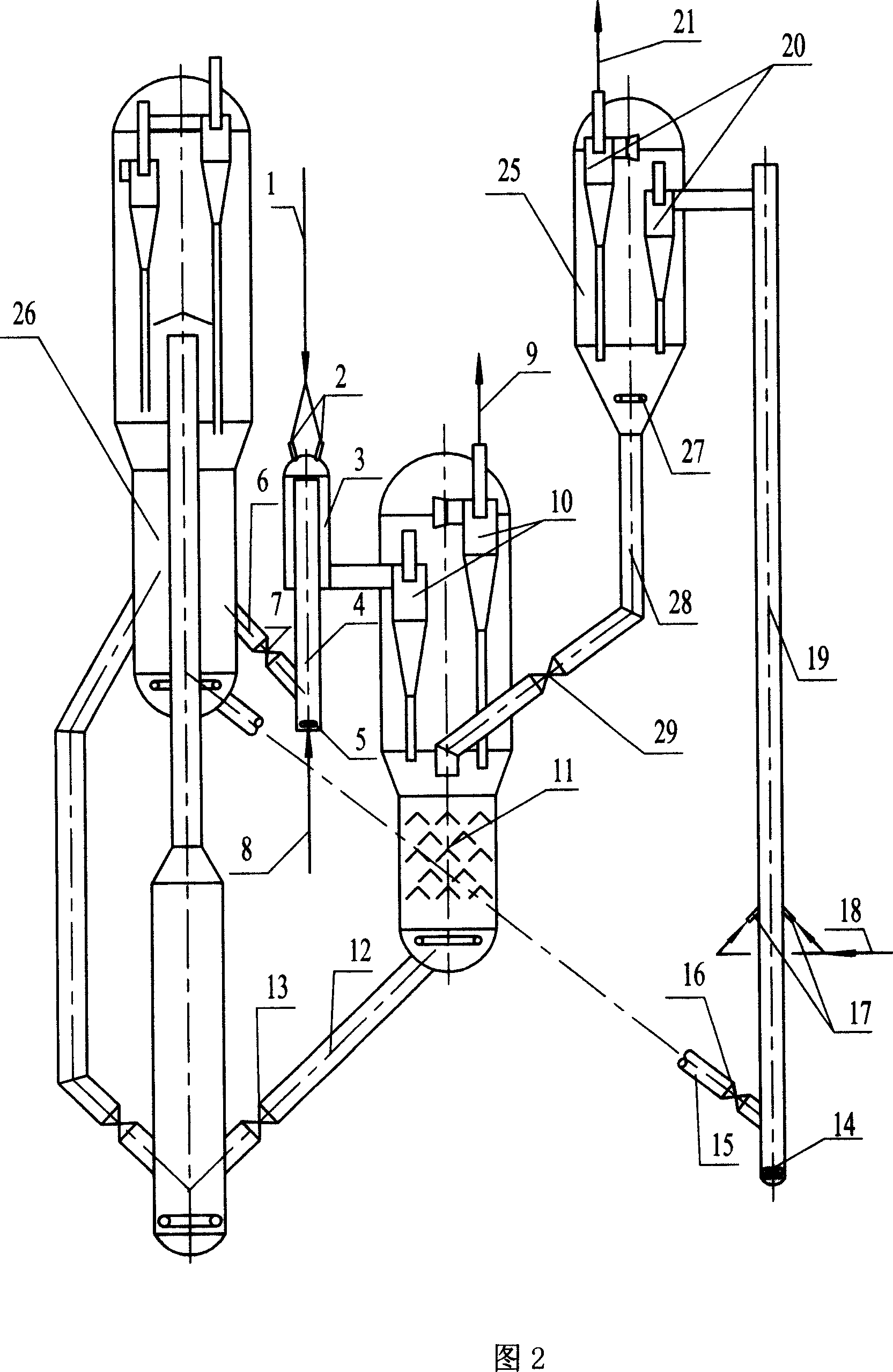

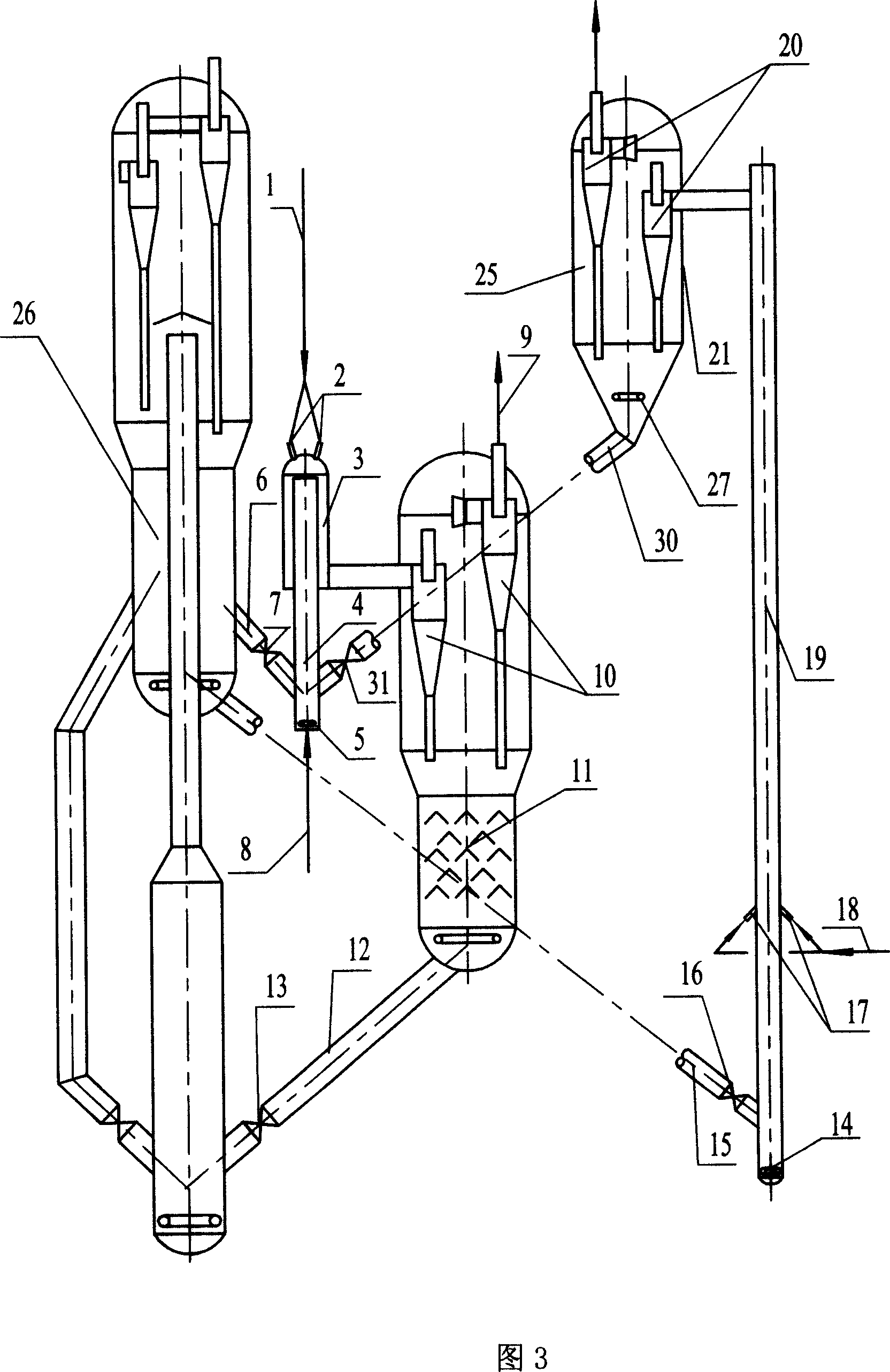

Slurry ¿Cbed reaction unit and method of use thereof

ActiveCN101116803AImprove space utilizationSave spaceHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSeparation technologyProduct gas

A slurry bed reaction equipment and method of using the same is provided, wherein the equipment comprises an ascending tube reactor 1 and a settling tube 4; the lower part of the ascending tube reactor 1 is a reacting region 14, while the upper part of the ascending tube reactor is a settling region 2 with tube diameter enlarged; the top of the settling region 2 is provided with an exhaust port 6; the bottom of the ascending tube is provided with a feed port 3 and a gas distributor 5; a pipeline 7 is used for connecting the settling region 2 with the settling tube 4, of which the opening position is arranged at the inside of the settling tube 4; the lower part of the settling tube 4 is a magnetic separation region 15, of which the lower end is communicated with the lower end of the ascending tube reactor 1 through a conical spout 10 and a reflux pipe 11; the upper part of the settling tube 4 is provided with a liquid discharging hole 13. The space utilization ratio of the reactor is improved by adopting the equipment and the separation method of the present invention; meanwhile, the separation technology combining settling, magnetic separation and filtering are adopted, making the separation part small in equipment volume, high in efficiency and space saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

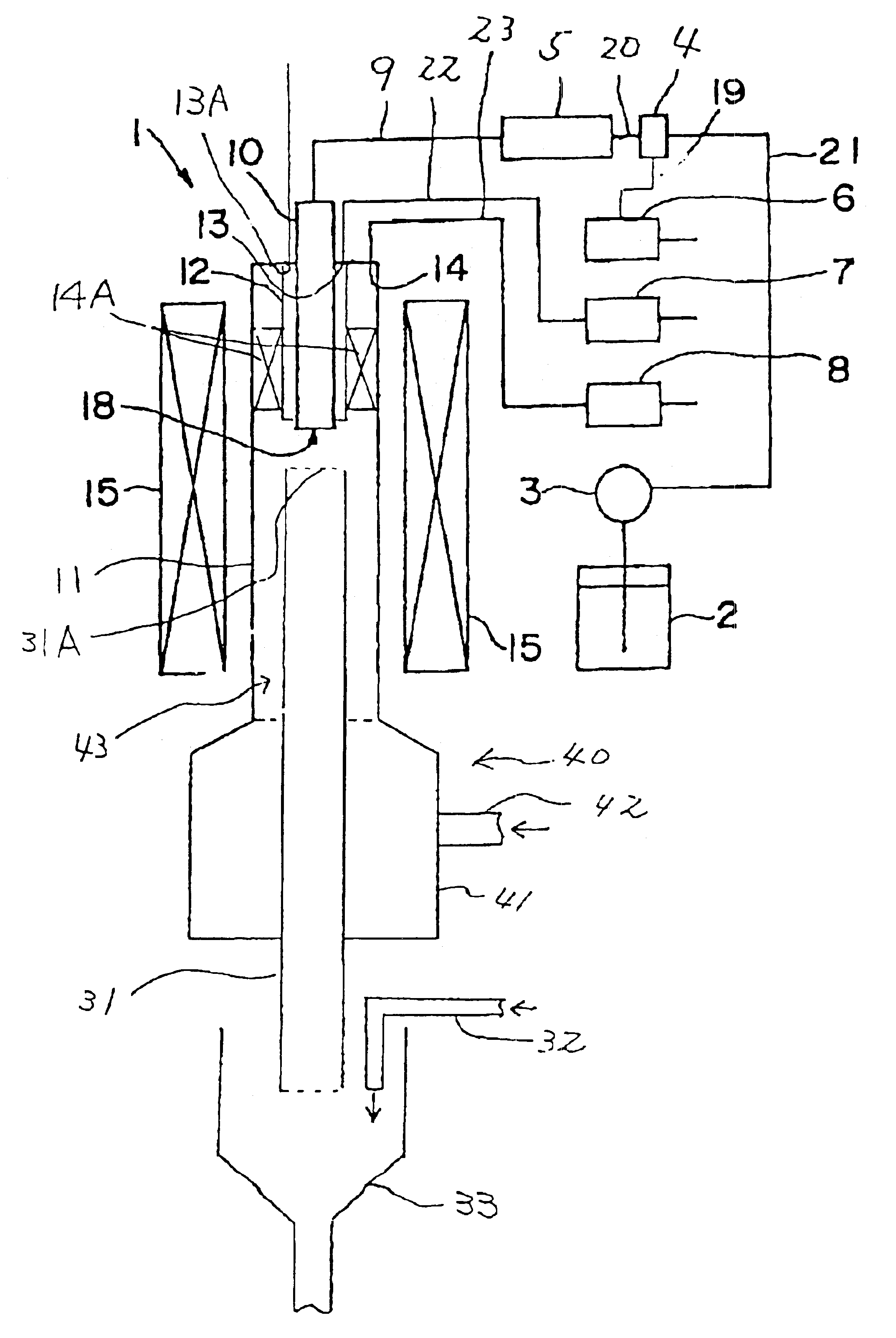

Combined catforming of high-production low carbon alkene

ActiveCN101045667AReduce backmixingHigh selectivityChemical recyclingBulk chemical productionCarbon depositAlkene

A combined catalytic converting process for preparing low-carbon olefin with high output includes such steps as contacting between heavy oil as raw material, regenerated catalyst and carbon deposited catalyst in flow-down tube reactor, cracking reaction, separating the cracked product from the catalyst to be regenerated, separating low-carbon olefin from cracked product, contacting between rest of said product and regenerated catalyst in flow-up tube reactor, reaction, separating oil gas from catalyst, separating low-carbon olefin from oil gas, and regenerating the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

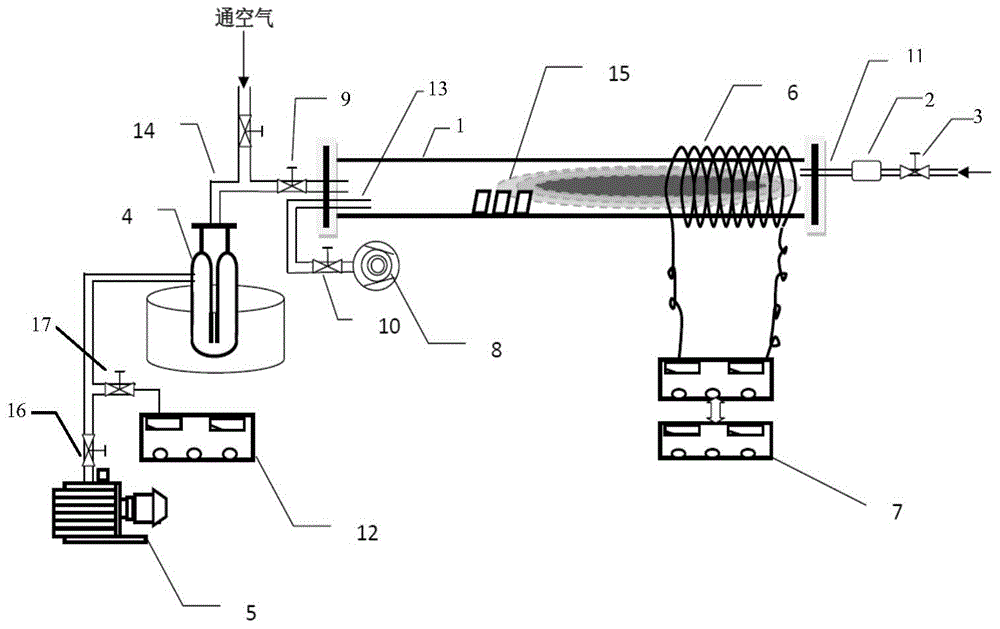

Carbon fibrous matter, production device of carbon fibrous matter, production method of carbon fibrous matter and deposit prevention device for carbon fibrous matter

Disclosed is an apparatus for production of vapor-phase growth carbon fibers. The apparatus can continuously produce these carbon fibers for a long time without blocking a furnace of tubular reactor of the apparatus. Also disclosed is a process for production of carbon fibers by means of the apparatus, a device for preventing deposition of carbon fibers on an inside of a furnace of tubular reactor, and vapor-phase growth carbon fibers produced in the apparatus.The vapor-phase growth carbon fibers include carbon nanofibers and / or carbon nanotubes. The apparatus includes a furnace of tubular reactor, at an end of which a feedstock-supplying nozzle is provided, and a discharge pipe inserted in the furnace of tubular reactor, the top end of which faces the opening of the nozzle and the bottom end discharges the carbon fibers.

Owner:NIKKISO COMPANY

Rod-shaped inserts in reactor tubes

InactiveUS7132555B2Inexpensive and easy to insertInexpensive and easy to and to removePhysical/chemical process catalystsOrganic chemistry methodsParticulatesReactor system

A process for catalytically reacting a fluid reactant mixture in a multi-tubular reactor system to form a fluid product, whereby the reactant mixture is led through at least one reactor tube containing a fixed bed of solid particulate catalyst and surrounded by a heat-exchange fluid, and whereby an upstream portion of the reactor tube is dedicated to pre-heating the reactant mixture and / or a downstream portion of the reactor tube is dedicated to post-cooling the product, characterized in that the upstream portion and / or downstream portion of the reactor tube contains a heat-exchanging essentially rod-shaped insert, the insert having a length of from 1 to 20%, preferably 1 to 5%, of the total length of the reactor tube.

Owner:SHELL USA INC

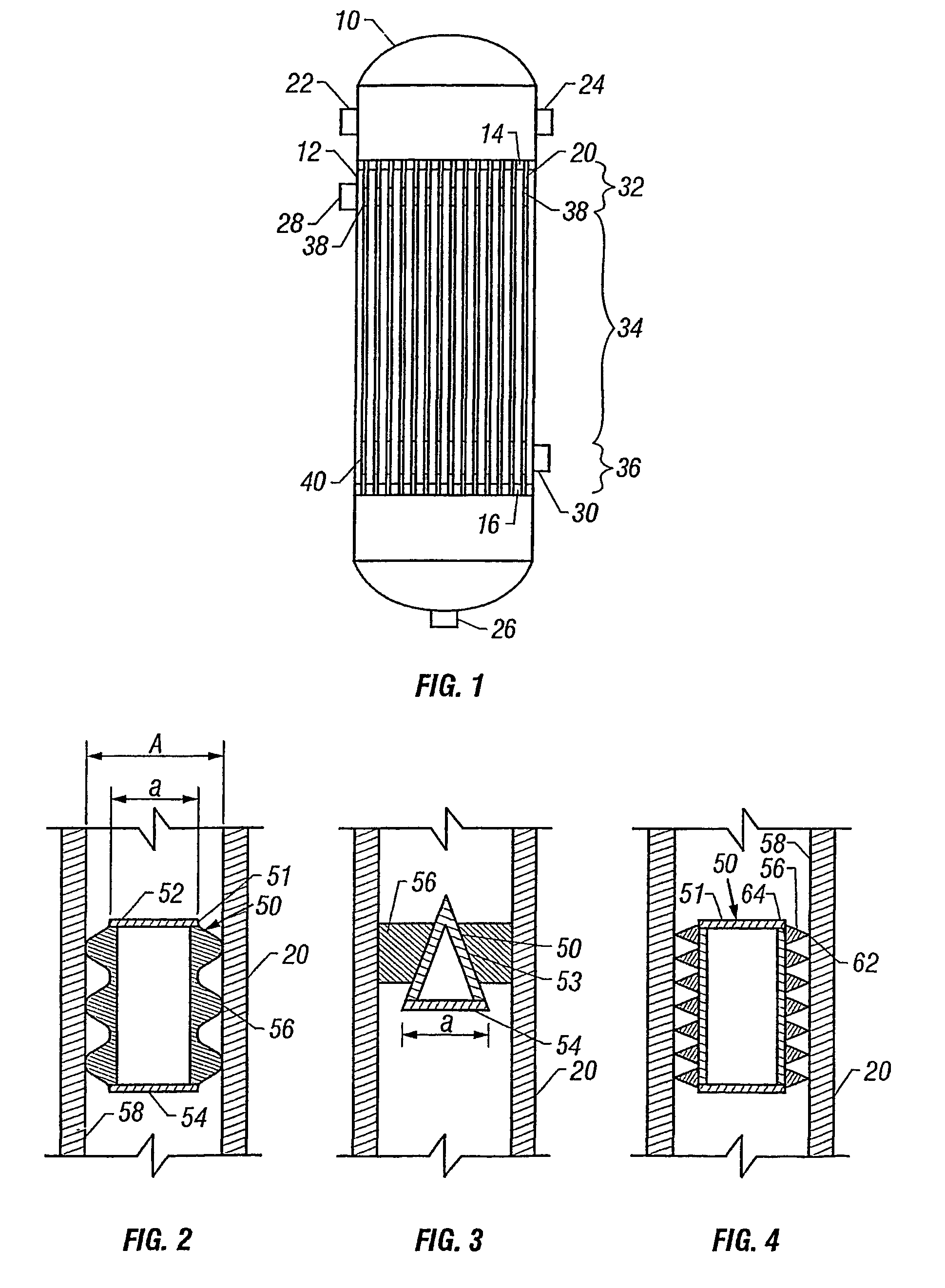

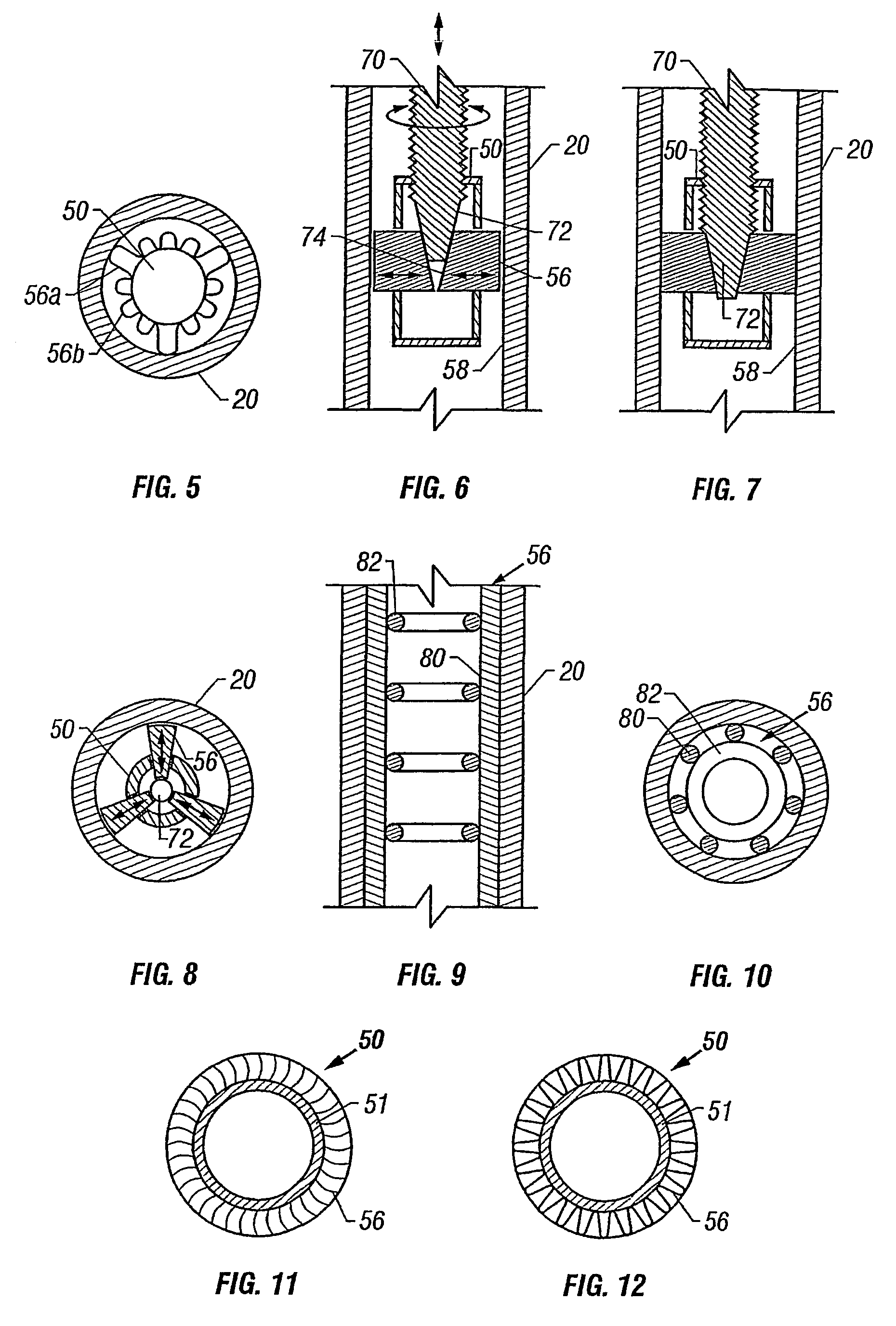

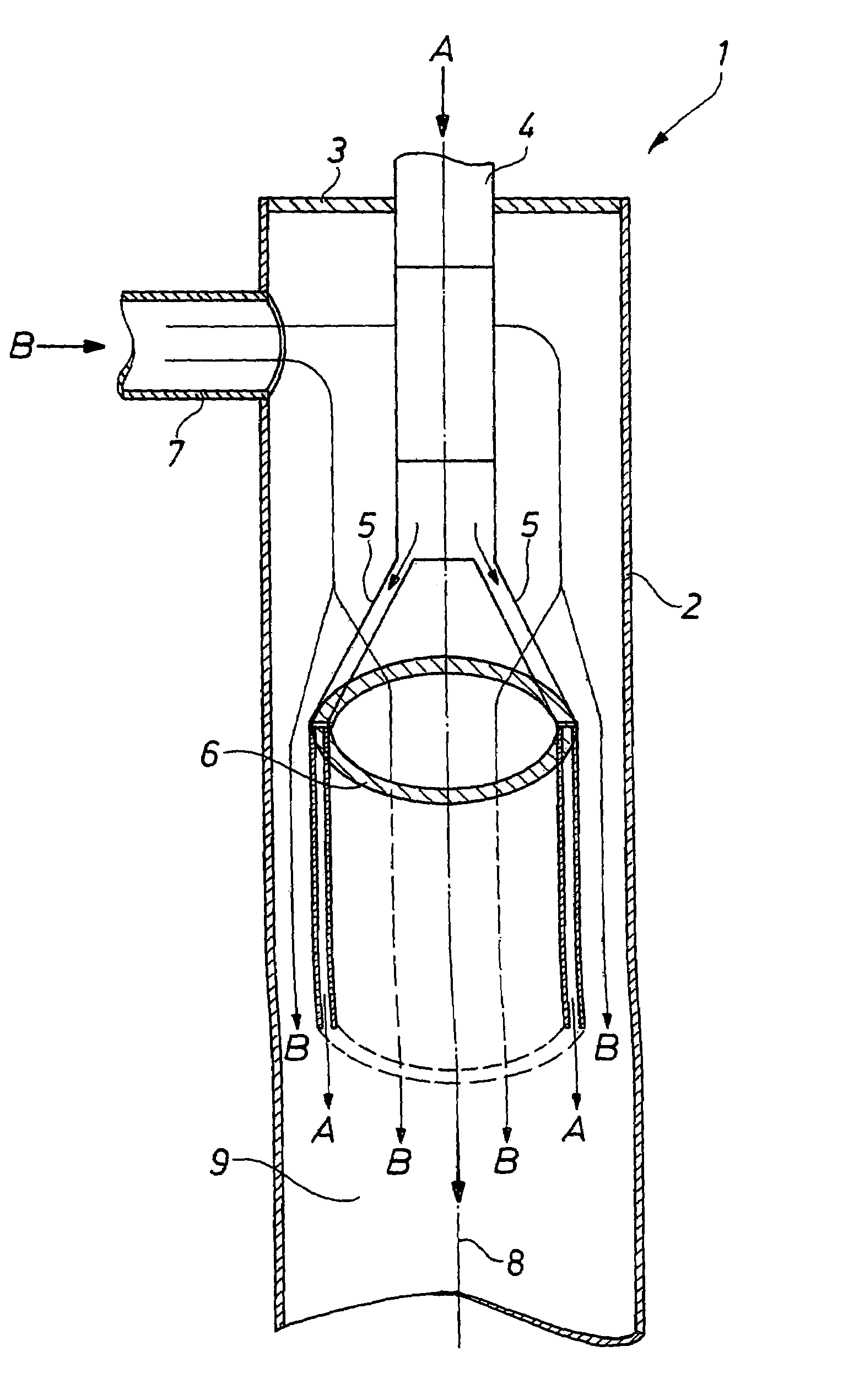

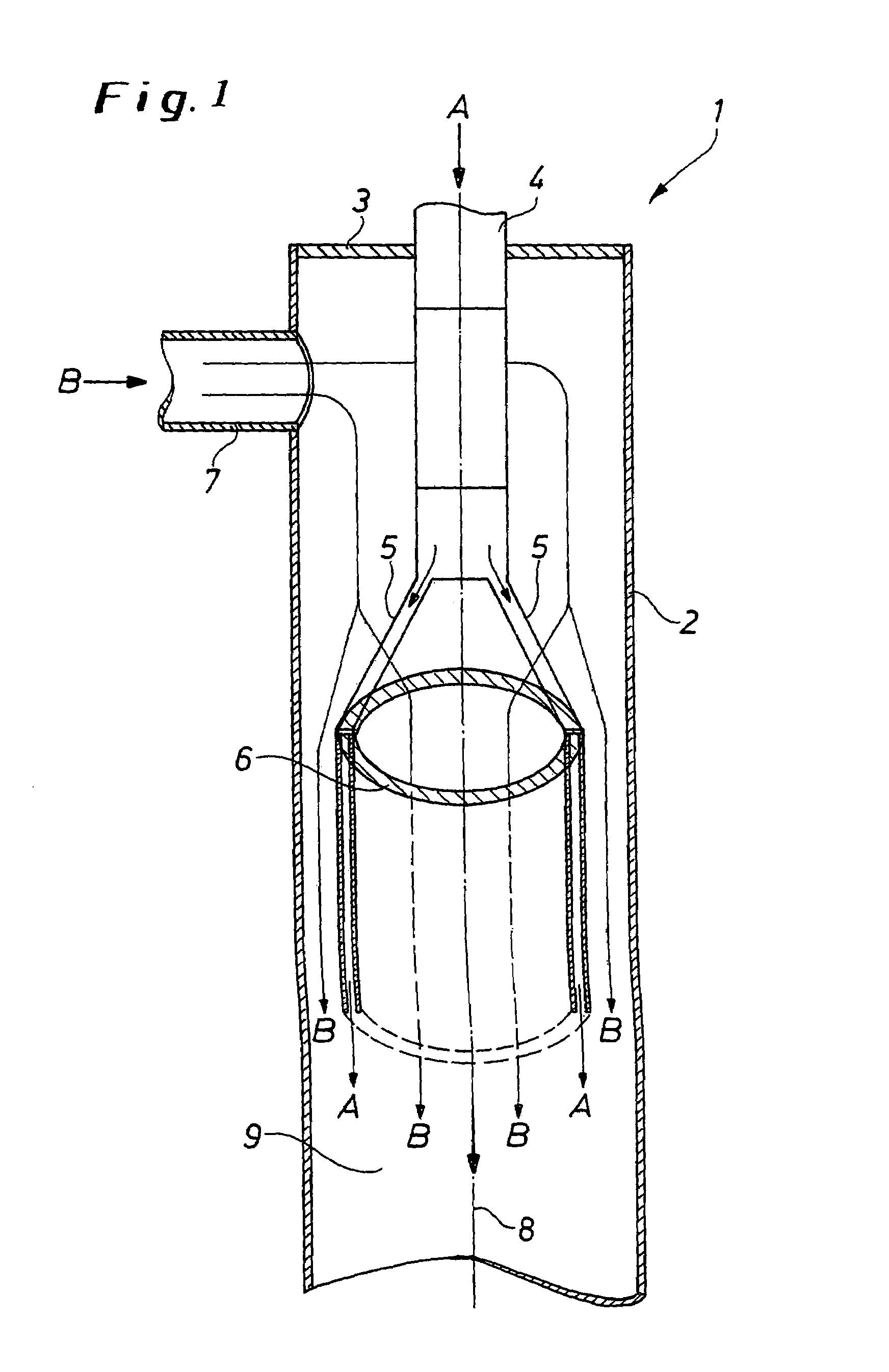

Tubular reactor with expandable insert

A tubular reactor having an insert for improving heat transfer characteristics of the tubular reactor. The insert comprises a catalyst and metal structures consecutively arranged in a lengthwise direction of the tube. The metal structures have radially expandable side walls and orifices for squeezing fluid between the metal structures and the tube wall. The radially expandable side walls form hollows between the radially expandable side walls and the tube wall of the tubular reactor. The radially expandable side walls deform responsive to the fluid pressure difference between the inside of the metal structure and the outer space between the metal structure and the tube wall thereby maintaining the gap between the orifice opening and the tube wall to adjust for tube creep.

Owner:AIR PROD & CHEM INC

Multi reactor process

This invention relates to the polymerization of ethylene polymers using a continuously stirred tank reactor (CSTR) that is connected in series to a tubular reactor. The tubular reactor receives a polymer solution from the CSTR. Further polymerization in the tubular reactor improves production efficiencies, particularly with respect to lowering the amount of energy required to recover the polymer and residual comonomer from the solution. The use of tempered i.e. (heated) ethylene in the tubular reactor has been discovered to mitigate gel problems and lower / reduce levels of hexane extractables.

Owner:NOVA CHEM (INT) SA

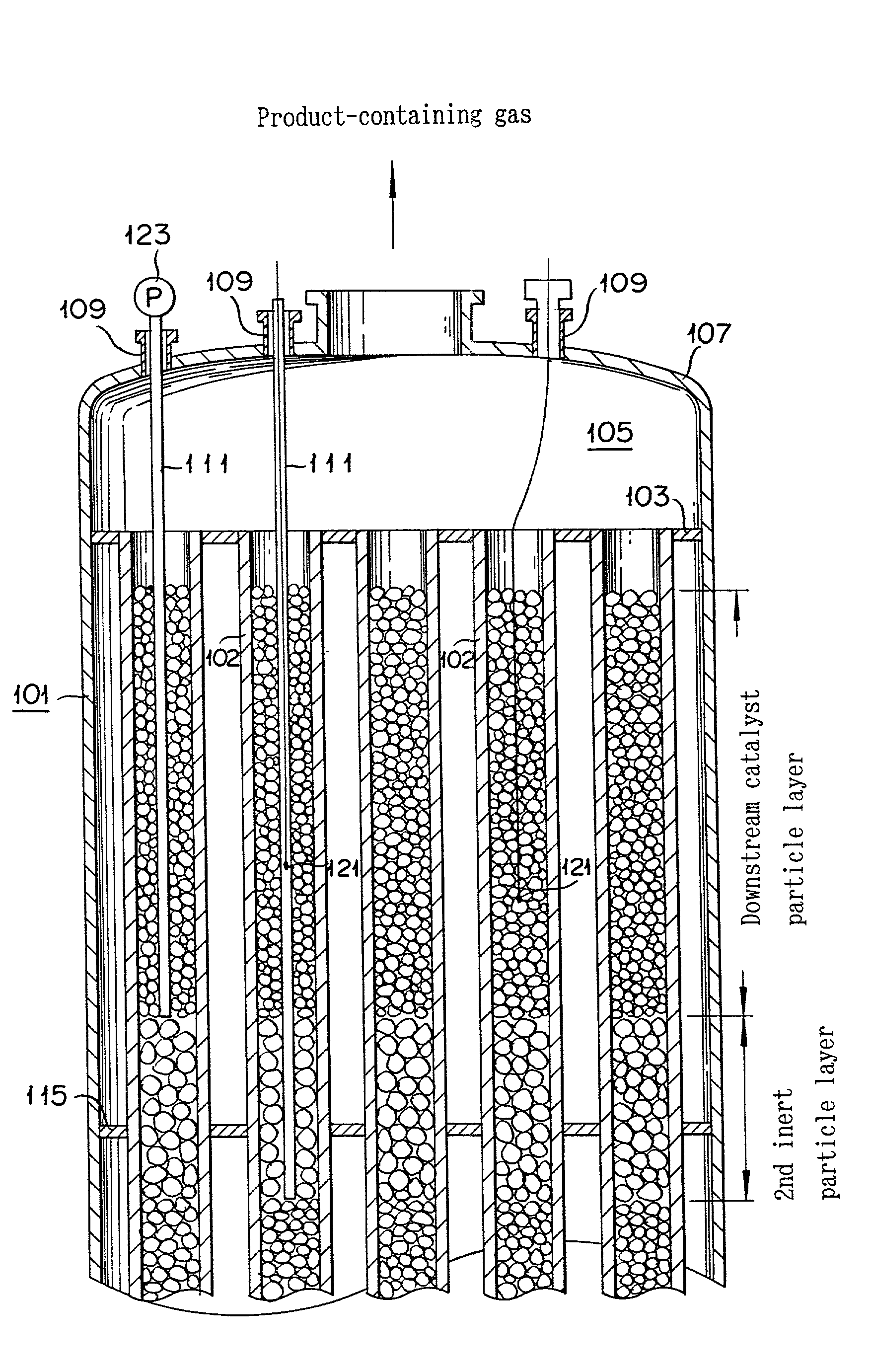

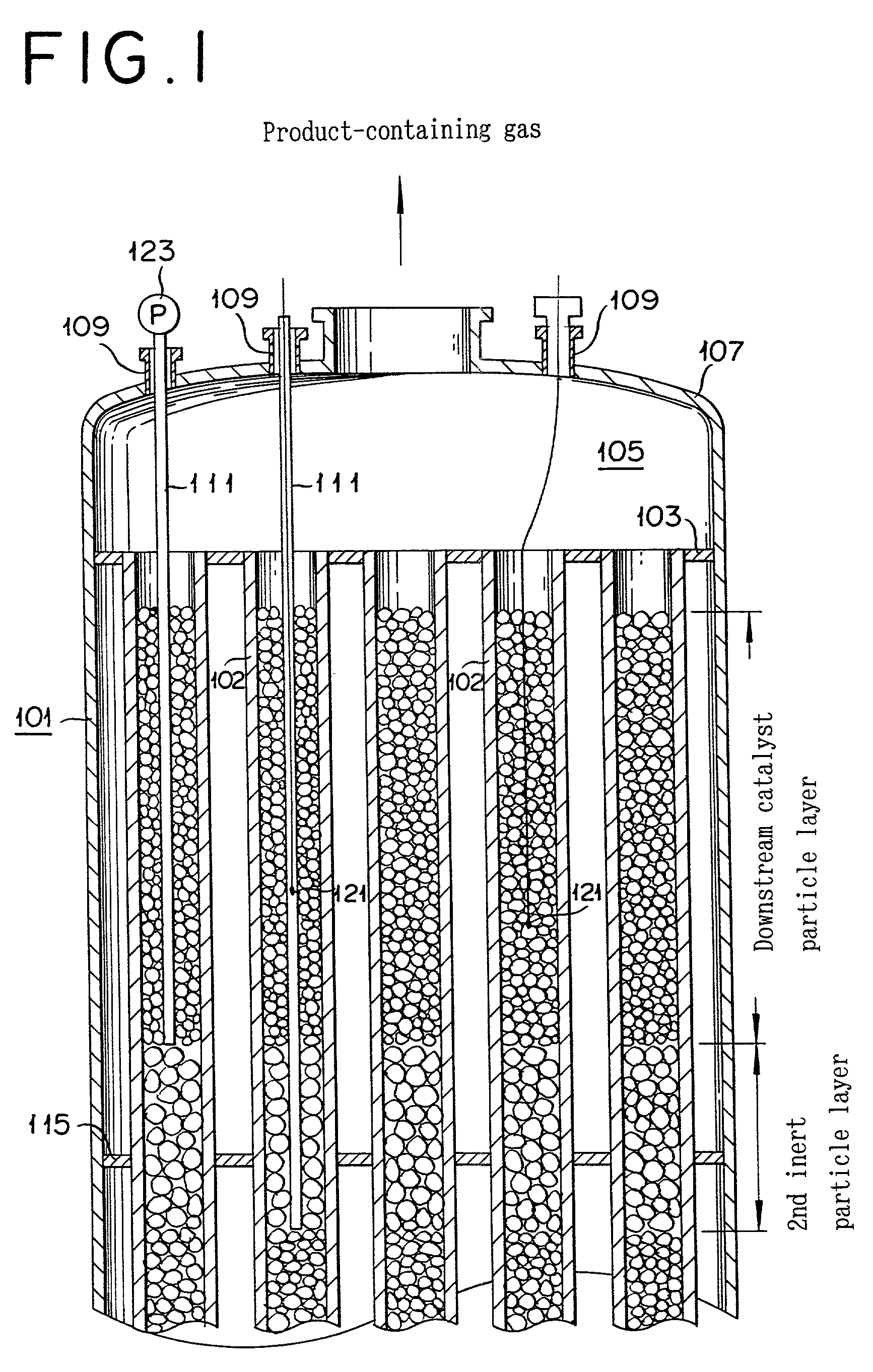

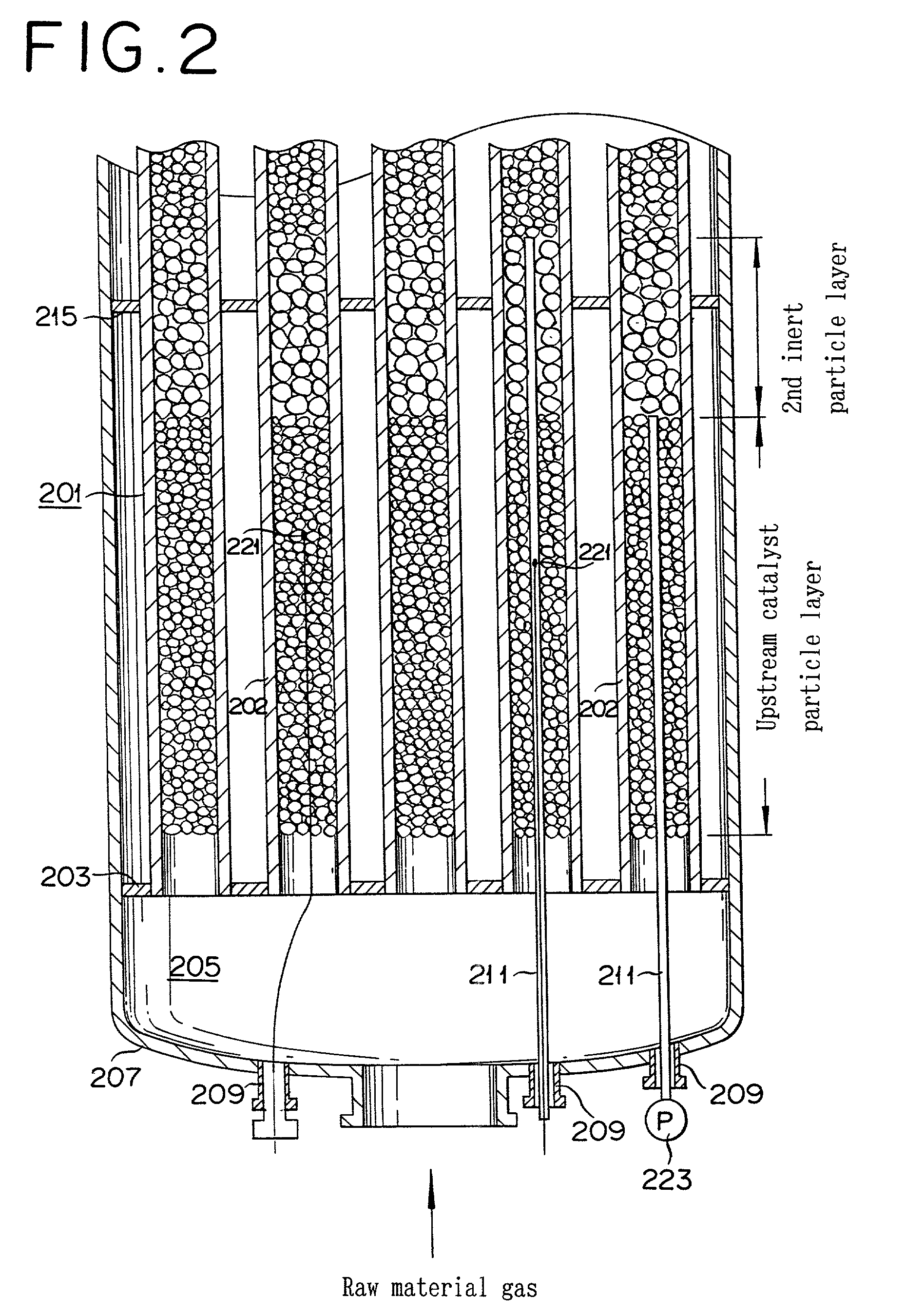

Reactor filled with solid particle and gas-phase catalytic oxidation with the reactor

InactiveUS20030006026A1Accurate pressureAccurate temperatureOrganic compound preparationOrganic chemistry methodsGas phaseCatalytic oxidation

A shell-and tube reactor including at least one reaction tube with a measuring means, substantially same solid particles being filled in the reaction tubes with or without the measuring means, a length of the filled solid particle layer, and a pressure drop thereof while passing a gas through the reaction tube, per each reaction tube, being substantially the same, respectively. By measuring the temperature of the catalyst particle layer, such a temperature as a representative can be gasped.

Owner:NIPPON SHOKUBAI CO LTD

Process for the preparation of diisocyanates

The invention relates to a process for the preparation of isocyanates in the gas phase, in which the possibilities for back-mixing and byproduct formation are reduced by improving the mixing of the starting materials in a tubular reactor.

Owner:COVESTRO DEUTSCHLAND AG

High pressure polymerization process

ActiveUS8445606B2Improve efficiencyLow costChemical/physical/physico-chemical stationary reactorsPolymer scienceEngineering

The invention relates to high pressure tubular reactor olefin polymerization plants having improved specific energy consumption. The plants may be newly constructed or made by de-bottlenecking an existing plant. The tube of the tubular reactor may have improved arrangements for cooling to increase conversion and optimized polymer-recycle gas separation arrangements using a jet pump for recycling unreacted monomer while permitting haze to be maintained. The improved cooling arrangements include a reduced pressure cooling zone forming the tail end of the tube and / or a shortened heating zone for the front feed and allowing more monomer to be fed as a side feed.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com