Patents

Literature

473 results about "Cobalt catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

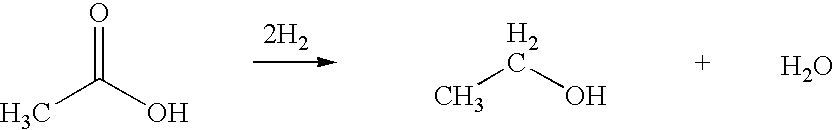

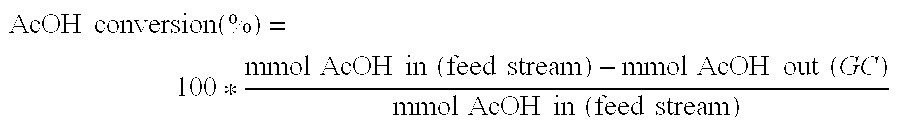

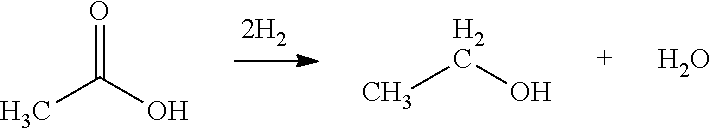

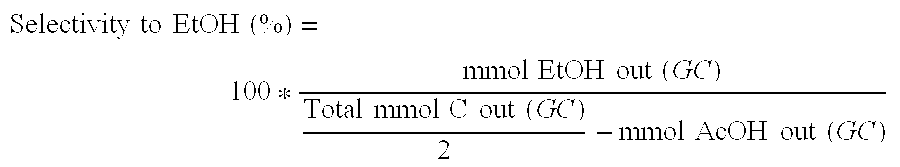

Ethanol production from acetic acid utilizing a cobalt catalyst

InactiveUS7608744B1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionAcetic acidPlatinum

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either cobalt and palladium supported on graphite or cobalt and platinum supported on silica selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

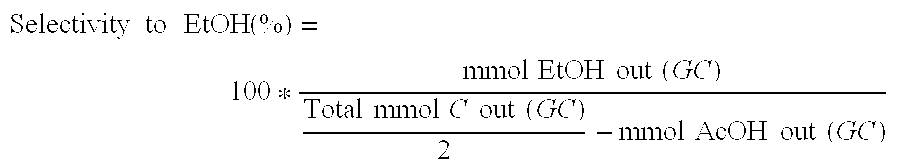

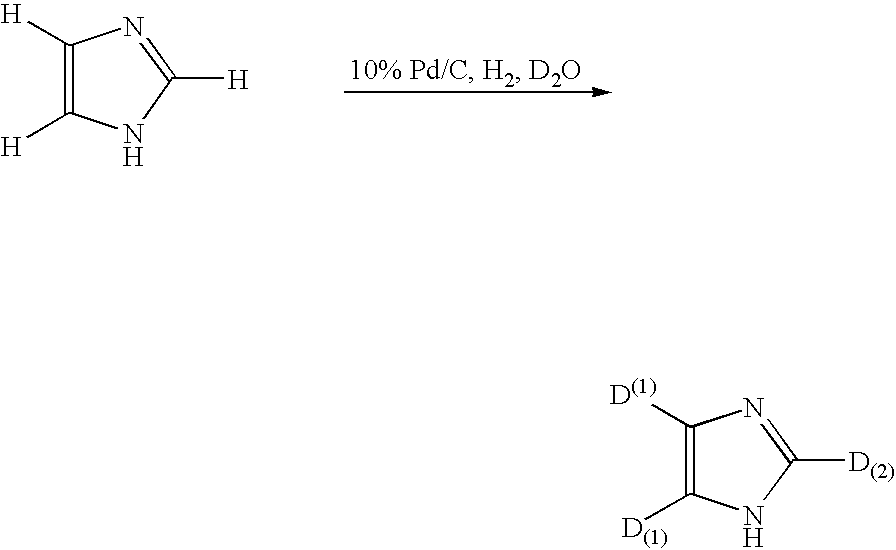

Method for deuteration of a heterocyclic ring

ActiveUS7517990B2Isotope introduction to heterocyclic compoundsSugar derivativesNickel catalystHydrogen atom

The present invention relates to a method for deuteration of a heterocyclic ring, which comprises subjecting a compound having a heterocyclic ring to sealed refluxing state in a deuterated solvent in the presence of an activated catalyst selected form a palladium catalyst, a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst. In accordance with a method of the present invention, a hydrogen atom belonging to a heterocyclic ring of a compound having a heterocyclic ring can be very efficiently deuterated because temperature of deuteration reaction can be maintained at higher than boiling point of the solvent.Further, a method for deuteration of the present invention can be applied widely to deuteration of various compounds having a heterocyclic ring which are liable to decomposition under supercritical conditions or acidic conditions, leading to industrial and efficient deuteration of a compound having a heterocyclic ring.

Owner:FUJIFILM WAKO PURE CHEM CORP

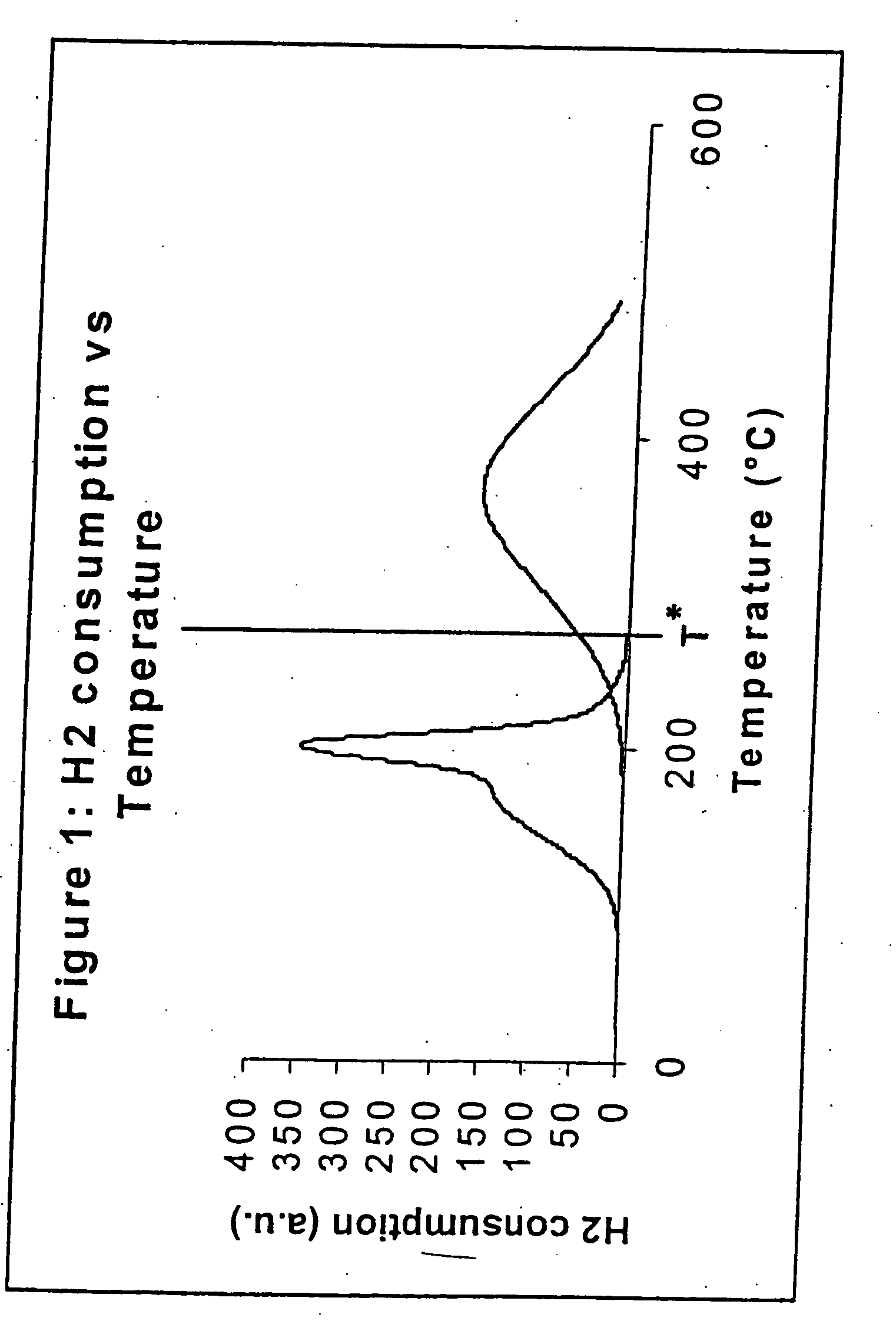

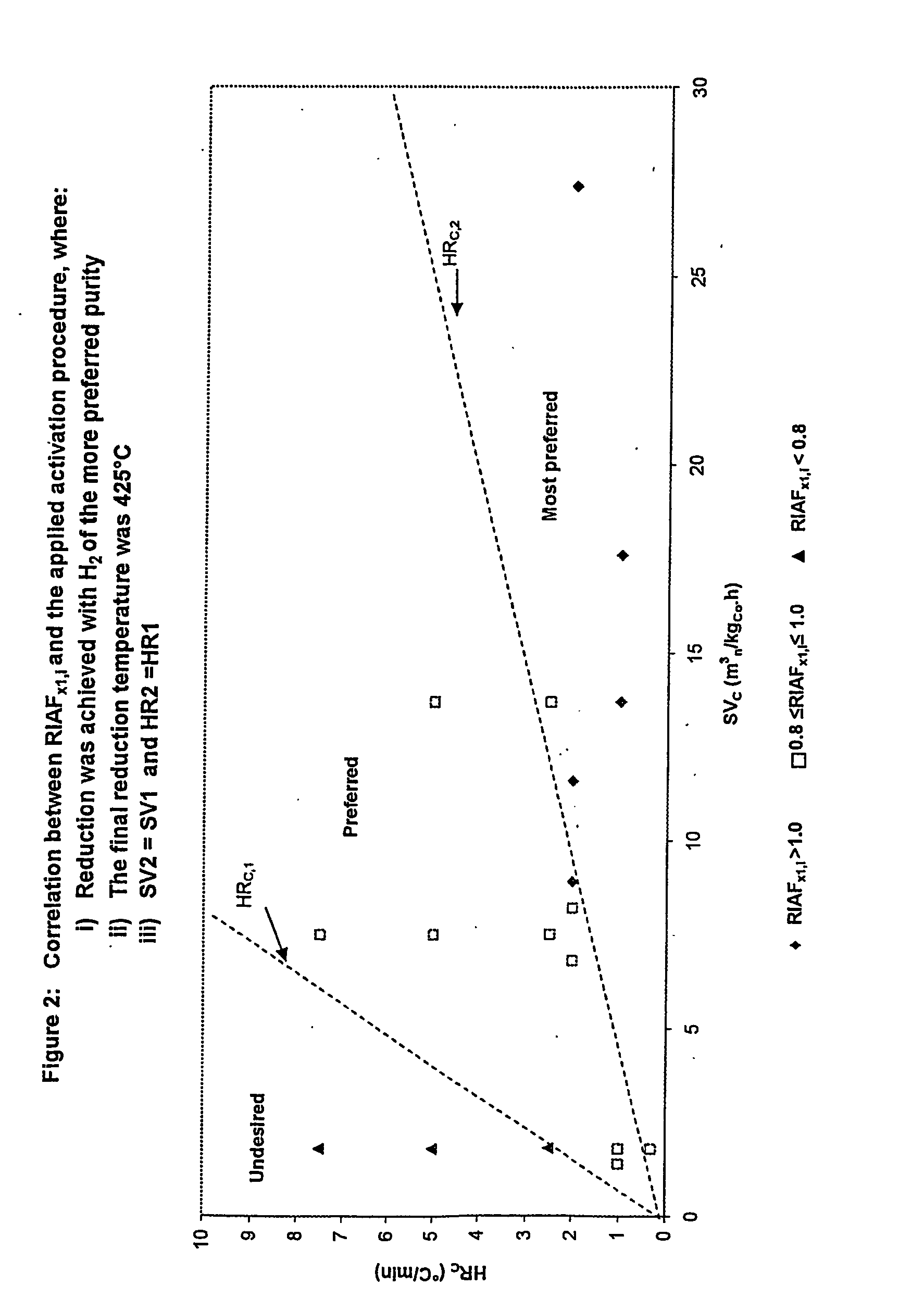

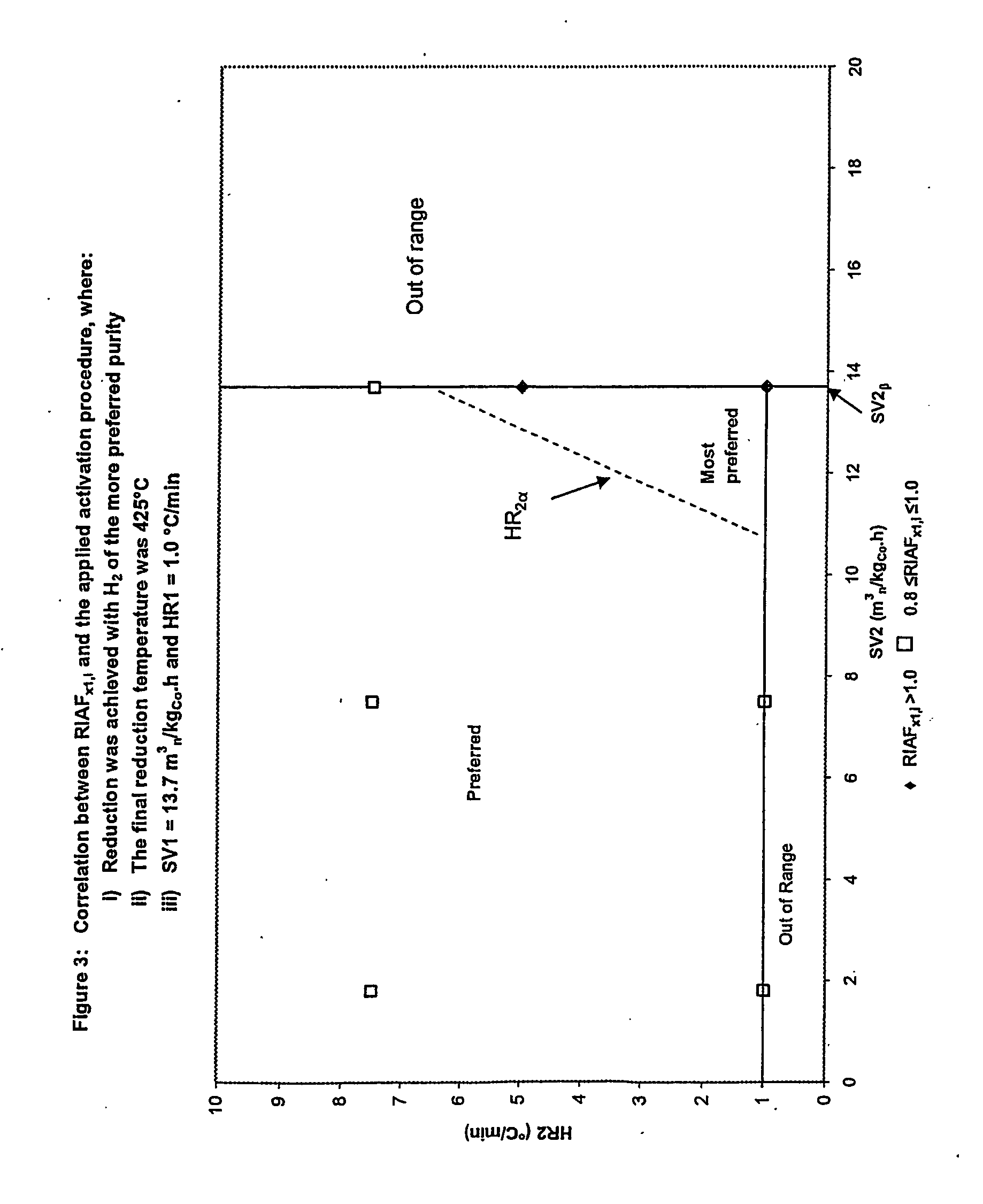

Process for activating cobalt catalysts

InactiveUS20050227866A1Improve reducibilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsParticulatesHydrogen

A particulate pre-reduction cobalt supported Fischer-Tropsch synthesis catalyst precursor which comprises a catalyst support impregnated with cobalt, is treated with a pure hydrogen reducing gas, at a first specific feed gas space velocity, SV1, and at a first heating rate, HR1, to obtain a partially reduced precursor. The support contains reducible cobalt oxide in a calcined state and having a formula-unit in which each mole of cobalt atoms is associated with more than 4 / 3 moles of oxygen atoms and displaying a reducible cobalt oxide specific surface area at least equal to that of Co3O4 spinel. The partially reduced precursor is then treated with a pure hydrogen reducing gas, at a second specific feed gas space velocity, SV2, and at a second heating rate, HR2, to obtain an activated supported Fischer-Tropsch catalyst, with SV2≦SV1 and / or HR2≧HR1; however, when SV2=SV1, HR2≠HR1 and when HR2=HR1, SV2≠SV1.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

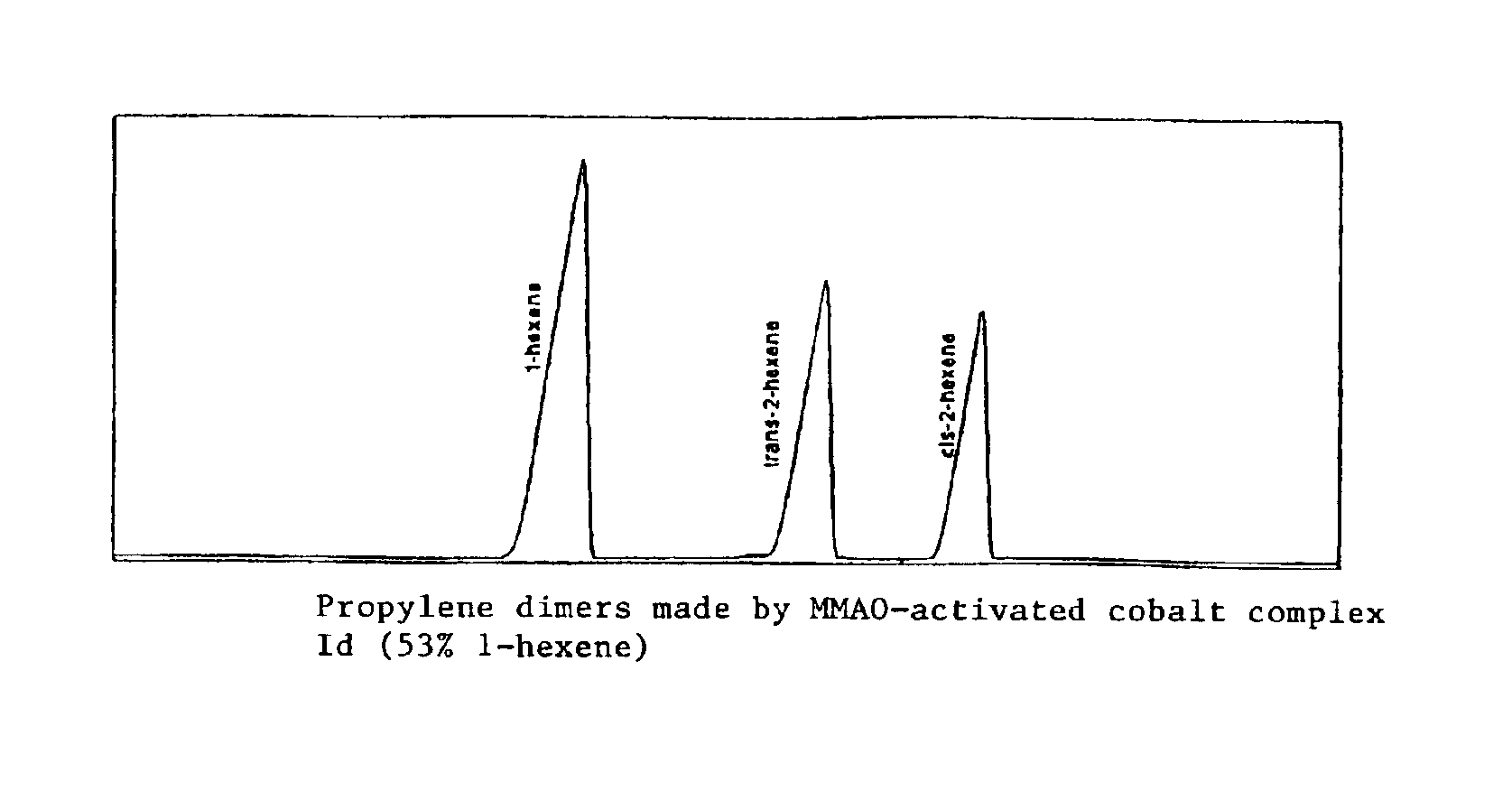

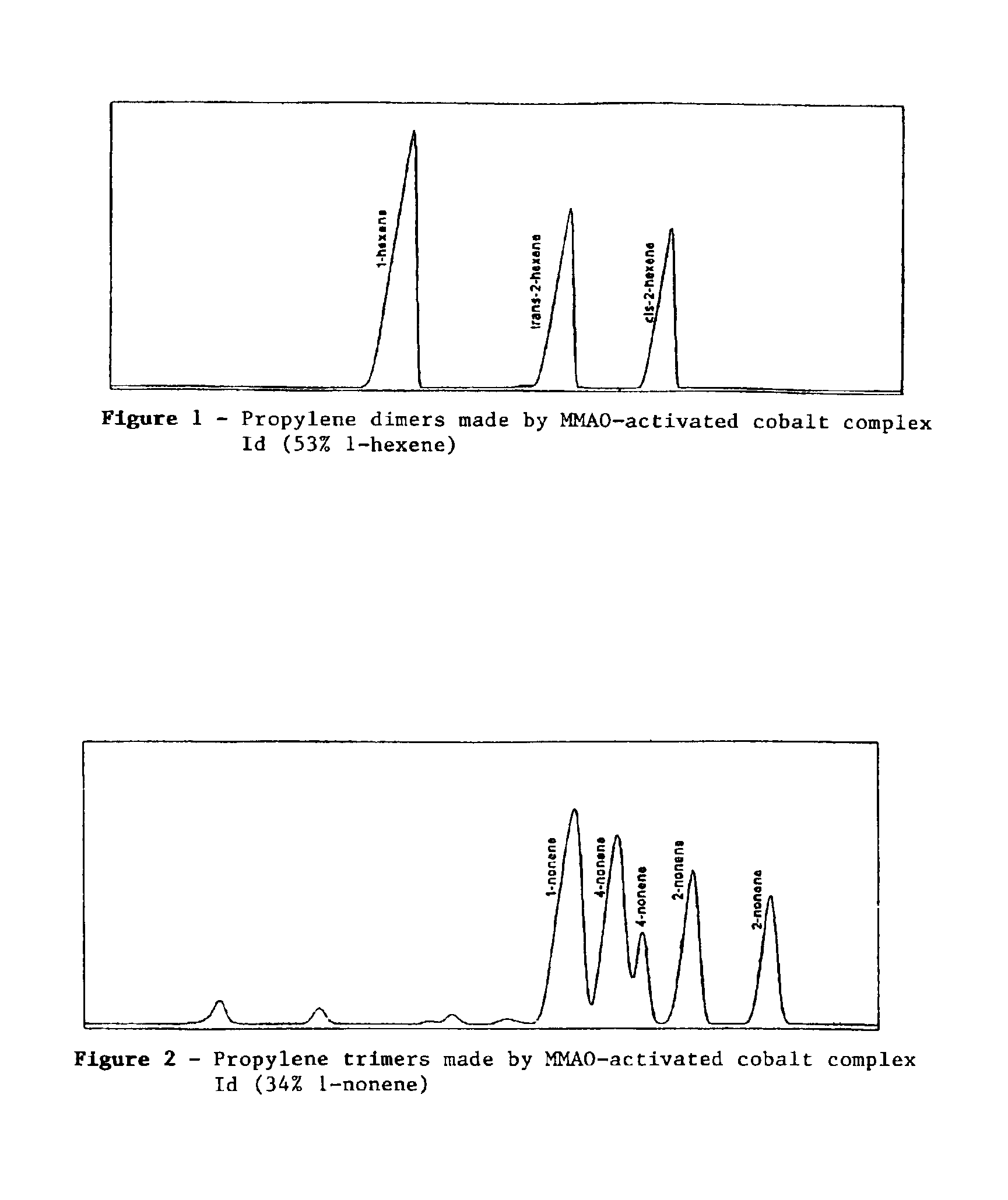

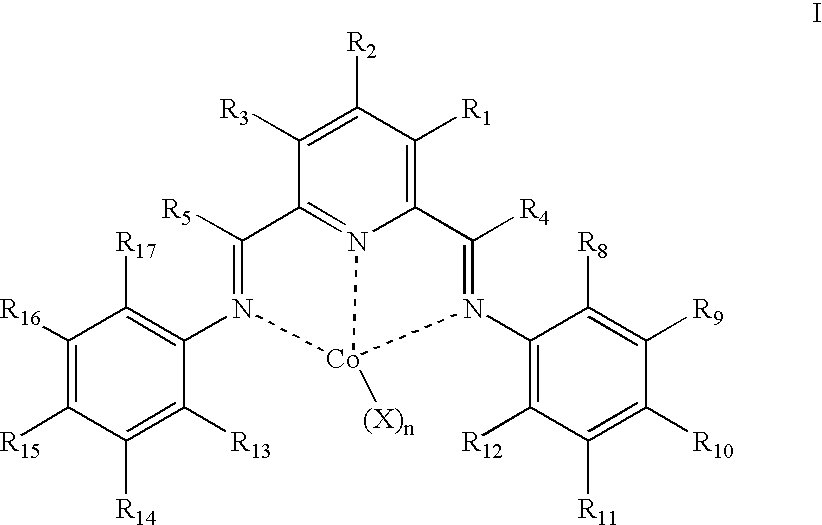

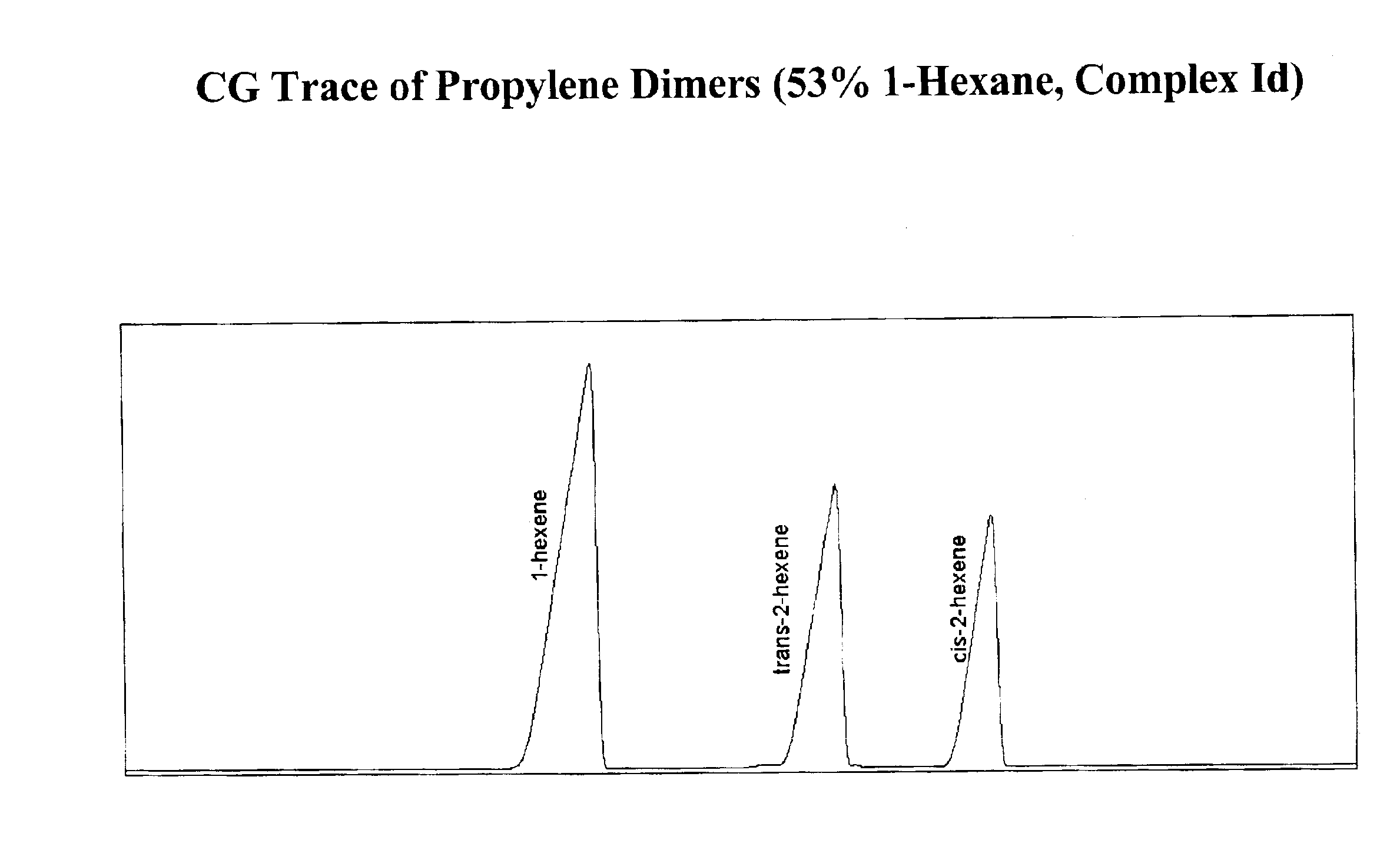

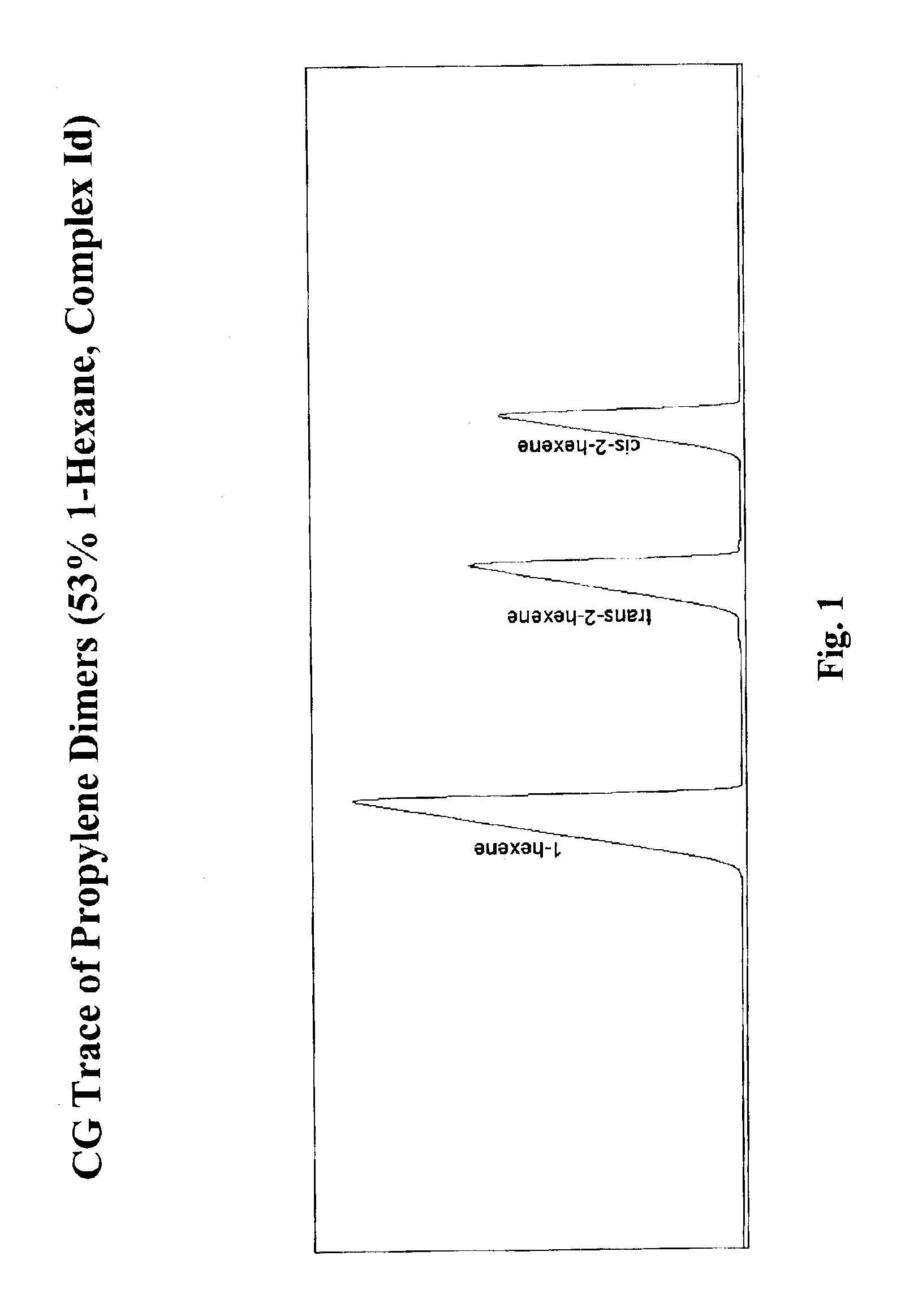

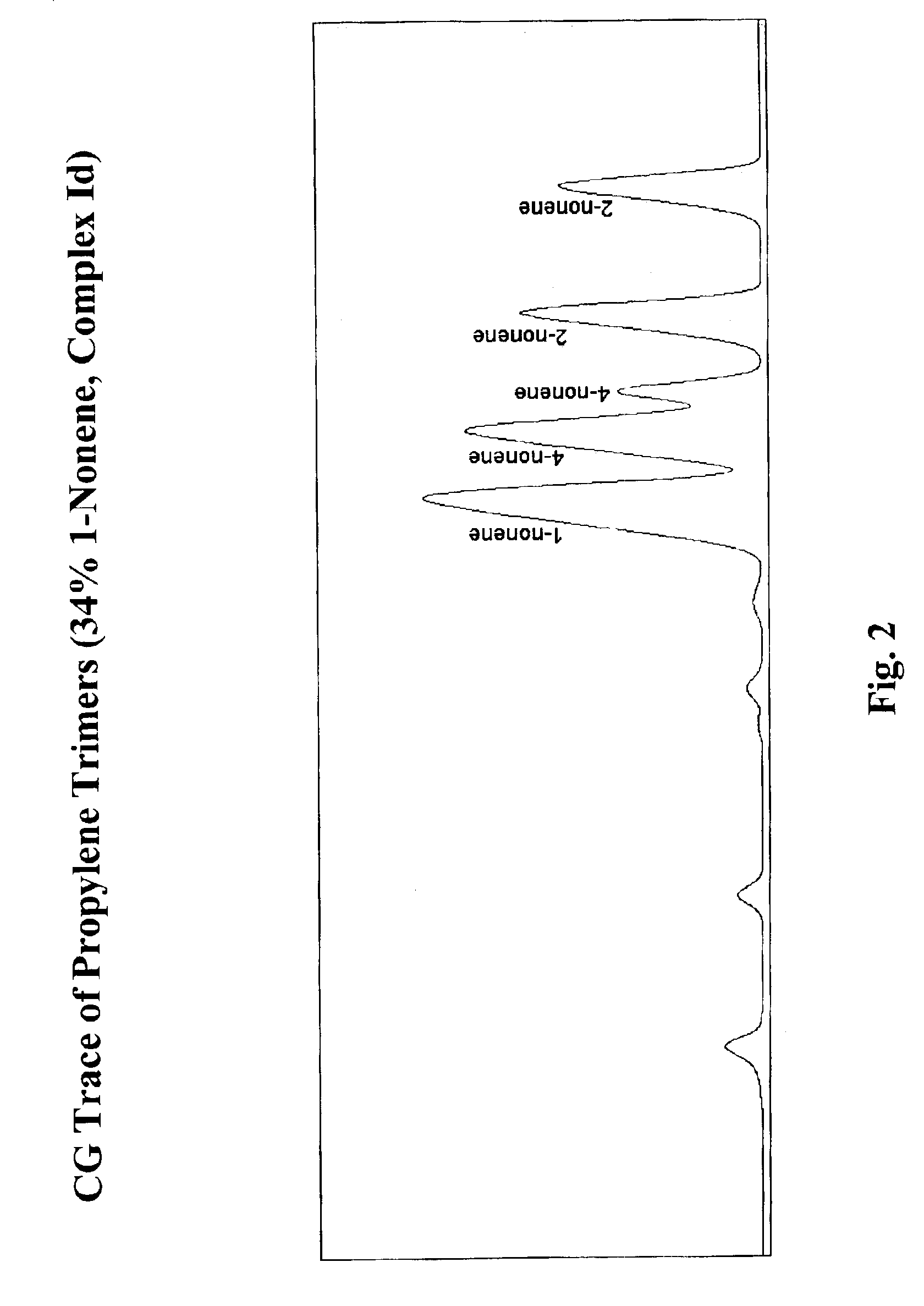

Selective isomerization and linear dimerization of olefins using cobalt catalysts

InactiveUS6911505B2Hydrocarbon by hydrogenationLiquid hydrocarbon mixtures productionIsomerizationAlpha-olefin

Processes for the production of alpha-olefins, including dimerization and isomerization of olefins using a cobalt catalyst complex are provided herein. The olefins so produced are useful as monomers in further polymerization reactions and are useful as chemical intermediates.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

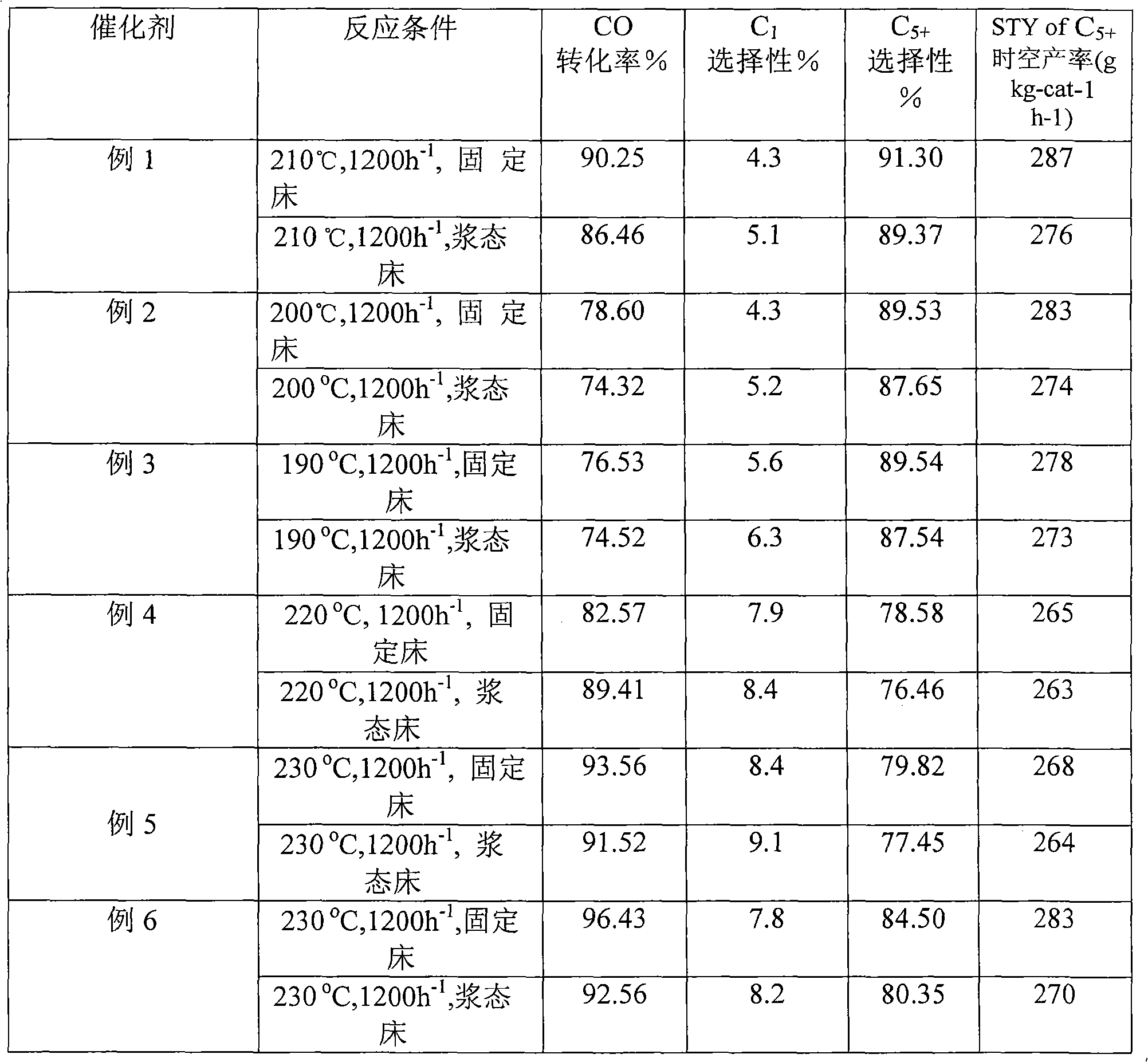

Co catalyst with controllable Fischer-Tropsch product distribution, preparing and applications thereof

InactiveCN101224425AHigh reactivityLow methane selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsCarbon numberPore diameter

A cobalt catalyst on which the distribution of Fischer-Tropsch synthesis is controllable is composed of metallic cobalt and a carrier by the weight percentage of 5-35% and 65-95% respectively. The catalyst is prepared by an impregnation method which aims at different carrier pore paths and pore diameter distribution as well as changes the interaction between the modulator cobalt and the carrier through adding a complexing agent during impregnation to achieve the even distribution of cobalt particle on the carrier surface, thus controlling the distribution of Fischer-Tropsch syntheses. The invention has the advantages of high reactivity and low selectivity of methane and achieving the selective synthesis of the products in the sections with specified carbon number.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrophobic organic modification of Co group Fischer-Tropsch synthesized catalyst, preparing and applications thereof

InactiveCN101224430AEasy to makeEasy to operateHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkaneNitrate

A Cobalt catalyst for the Fischer-Tropsch synthesis of Hydrophobic and organic modification comprises an active component, a promoter, a carrier and a grafted hydrophobic radical, wherein the weight percentages of the components are that metal cobalt takes 3-35%, porous silica gel takes 53-96%, noble metal takes 0.01-2%, and the hydrophobic radical takes 0.05-10%. The cobalt nitrate and noble metal nitrate or chloride water solution is applied to impregnate the porous silica gel to produce porous silica gel supported cobalt sample; then the hydrophobic radical on the organosilane are grafted onto the sample surface by applying a back grafting method. The invention can synthesize middle distillate oil (C5-C11 alkane) by the synthesis gas through a high selective step, shorten process flow and reduce production cost.

Owner:中科潞安能源技术有限公司

Method for Deuteration of an Aromatic Ring

ActiveUS20070255076A1Improve working environmentAmino preparation from aminesOrganic compound preparationNickel catalystHydrogen

The present invention relates to a method for deuteration of a compound having an aromatic ring, using an activated catalyst, and the method comprises reacting a compound having an aromatic ring with heavy hydrogen source in the presence of an activated catalyst selected from a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst.

Owner:FUJIFILM WAKO PURE CHEM CORP

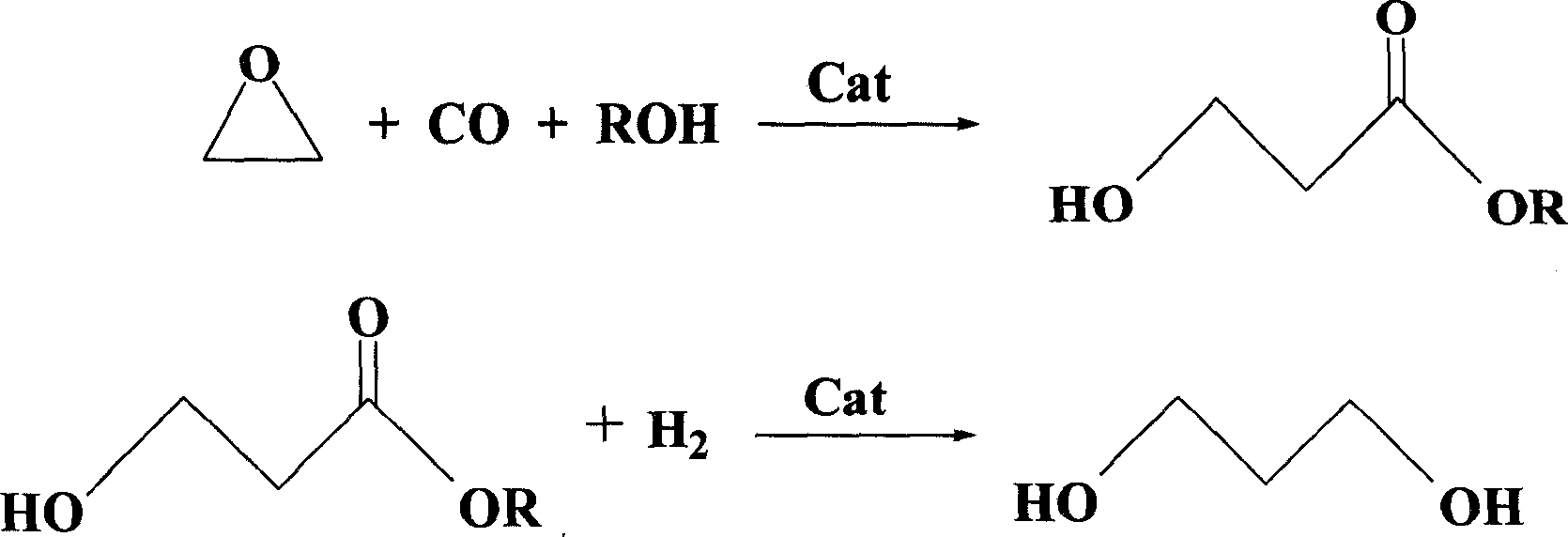

Prepn process of 3-hydroxy propionate and propylene glycol

InactiveCN101020635AHigh activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAccelerantCobalt catalyst

The present invention is process of preparing 3-hydroxy propionate and 1, 3-propylene glycol with epoxide as material. The present invention prepares 3-hydroxy propionate with epoxide, CO and alcohol under the action of cobalt catalyst and co-catalyst, and prepares 1, 3-propylene glycol under the action of 3-hydroxy propionate hydrogenating catalyst. The present invention has the advantages of simple reaction apparatus, simple operation, mild reaction condition, high catalyst activity, no environmental pollution, low production cost, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Selective isomerization and linear dimerization of olefins using cobalt catalysts

InactiveUS7001964B2Weight moreOrganic chemistryLiquid hydrocarbon mixtures productionPolymer sciencePentamer

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Nickel and cobalt plated sponge catalysts

InactiveUS20040199019A1Reduce contentImprove concentrationOrganic compound preparationHydroxy compound preparationOrganic compoundMetallic Nickel

Novel nickel and / or cobalt plated sponge based catalysts are disclosed. The catalyst have an activity and / or selectivity comparable to conventional nickel and / or cobalt sponge catalysts, e.g., Raney(R) nickel or Raney(R) cobalt catalysts, but require a reduced content of nickel and / or cobalt. Catalysts in accordance with the invention comprise nickel and / or cobalt coated on at least a portion of the surface of a sponge support. Preferably, the sponge support comprises at least one metal other than or different from the metal(s) contained in the coating. The method of preparing the plated catalysts, and the method of using the catalysts in the preparation of organic compounds are also disclosed.

Owner:WR GRACE & CO CONN

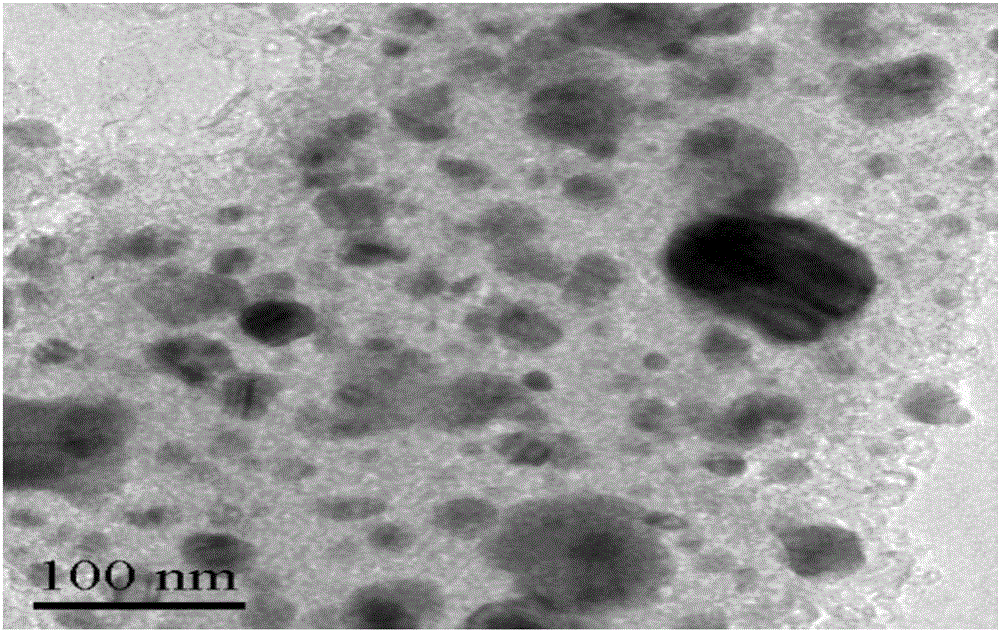

Preparation method of carbon nano-tube loaded nano-cobalt catalyst

ActiveCN103816905ALow costSimple production processMetal/metal-oxides/metal-hydroxide catalystsFiltrationCarbon nanotube

The invention discloses a preparation method of a carbon nano-tube loaded nano-cobalt catalyst. The method comprises the following steps: (1) dissolving a cobalt salt in an organic solvent and then adding a ligand to obtain a mixed liquid; (2) transferring the mixed liquid to a high-pressure kettle, performing a thermostatic heating reaction, naturally cooling to room temperature and then orderly performing filtration, washing and vacuum drying treatment on the generated crystal or powder to obtain a metal organic skeleton product Co-MOF of cobalt; and (3) roasting the metal organic skeleton product Co-MOF for 100-180 minutes at a roasting temperature of 400 DEG C to 1000 DEG C in a calcination atmosphere of argon inside a tubular furnace so as to obtain the carbon nano-tube loaded nano-cobalt catalyst. The preparation method disclosed by the invention has the advantages that the raw materials are low in cost, the production process is also simple, the reaction condition is easy to control, no template agent and surfactant are needed, the prepared product is good in consistency and environment-friendly; and the preparation method is beneficial to batch production and application of carbon nano-tube loaded nano-cobalt.

Owner:NANKAI UNIV

One-piece solid golf ball

InactiveUS20020052253A1Improve featuresIncreased durabilityGolf ballsSolid ballsVulcanizationPolymer science

The present invention provides a one-piece solid golf ball having excellent rebound characteristics and good shot feel, while maintaining excellent processability and durability. The present invention relates to a one-piece solid golf ball formed from a rubber composition comprising a mixture consisting of polybutadiene (a) synthesized using nickel-containing catalyst and polybutadiene (b) synthesized using cobalt-containing catalyst and hydroquinone or derivatives thereof as a vulcanization stabilizer, wherein a Mooney viscosity and a weight ratio of the polybutadienes (a) and (b), an amount of the vulcanization stabilizer, a center hardness (the minimum hardness in the golf ball) and surface hardness of the golf ball, and a difference between the maximum hardness and minimum hardness in the golf ball are adjusted to a specified range.

Owner:SUMITOMO RUBBER IND LTD

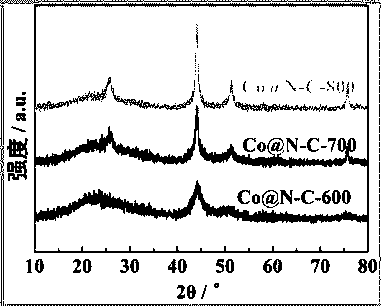

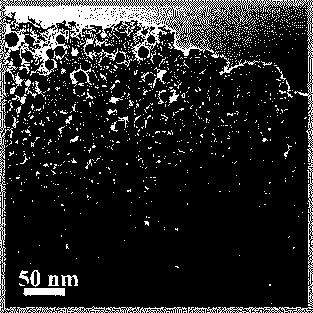

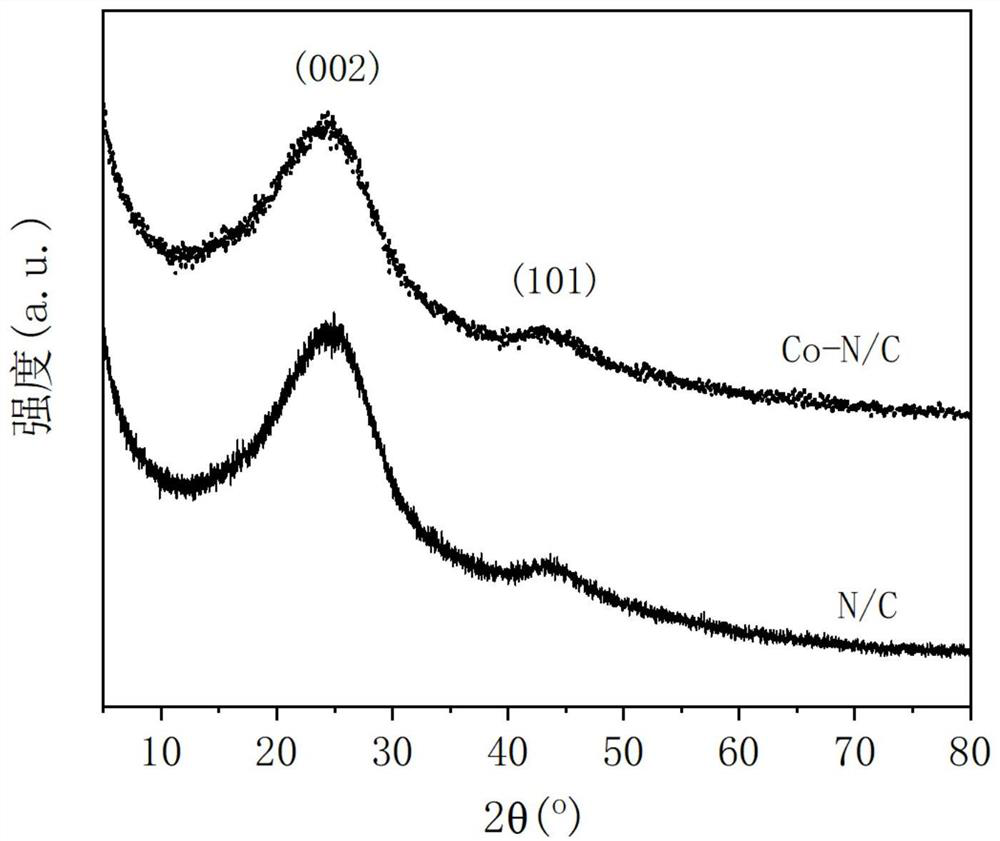

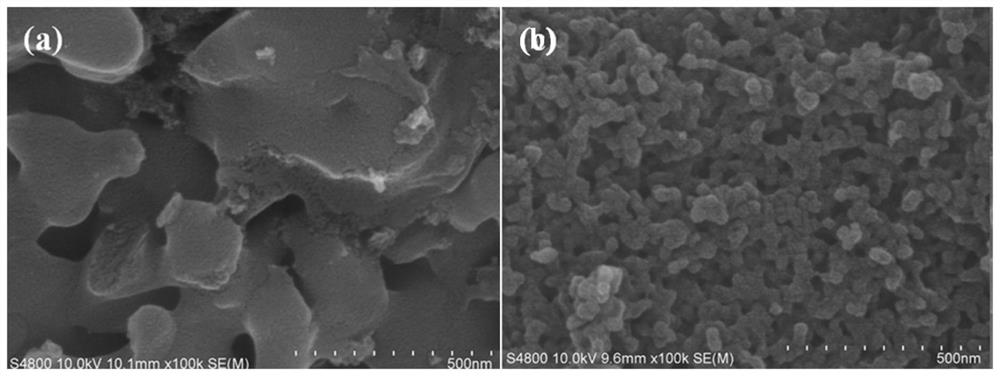

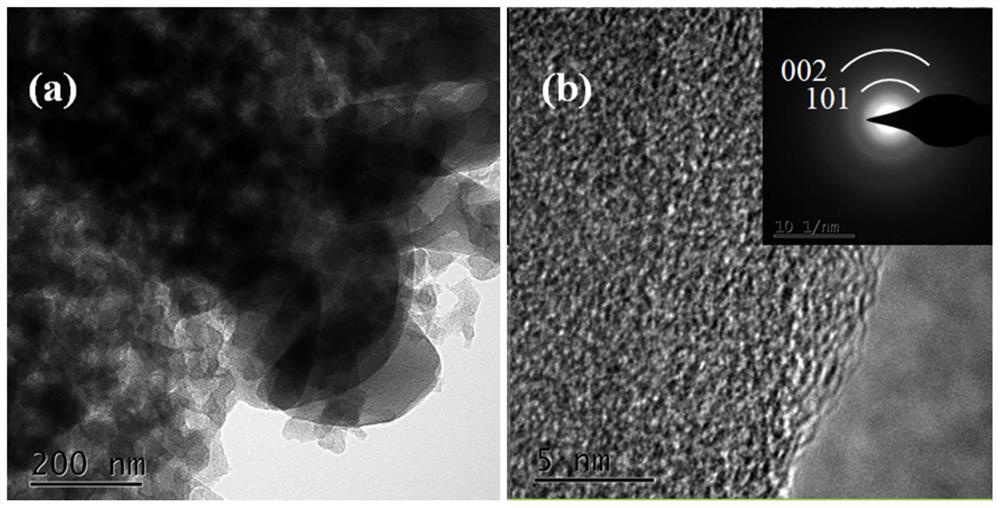

Nitrogen-doped carbon material supporting cobalt catalyst and method therewith of catalytic hydrogenation reductive amination to produce amine compounds

InactiveCN106552661AEasy to prepareReduce manufacturing costOrganic compound preparationCatalyst activation/preparationReaction temperatureNitrogen gas

The invention discloses a nitrogen-doped carbon material supporting cobalt catalyst and a method therewith of catalytic hydrogenation reductive amination to produce primary amine compounds. The catalyst is prepared through the steps of: 1) preparing a MOF material ZIF-67; and 2) under protection of nitrogen gas, calcining the MOF material ZIF-67 at 200-1000 DEG C for 1-10 h to produce the nitrogen-doped carbon material supporting cobalt catalyst Co / N-C. The method of catalytic hydrogenation reductive amination to produce the primary amine compounds with the catalyst includes the steps of: in an organic solvent, adding a carbonyl compound, ammonia water and the nitrogen-doped carbon material supporting cobalt catalyst, feeding hydrogen gas, and performing a reaction at 50-150 DEG C under 0.1-5 MPa for 0.5-20.0 h to produce the amine compounds. The preparation method of the catalyst is simple in operations. The catalyst can be used for producing the primary amine compounds in a manner of catalytic hydrogenation reductive amination. In the method, the primary amine compounds are produced with the carbonyl compound as a raw material through catalytic hydrogenation by means of the catalyst, so that the method has mild reaction conditions and is high in yield.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

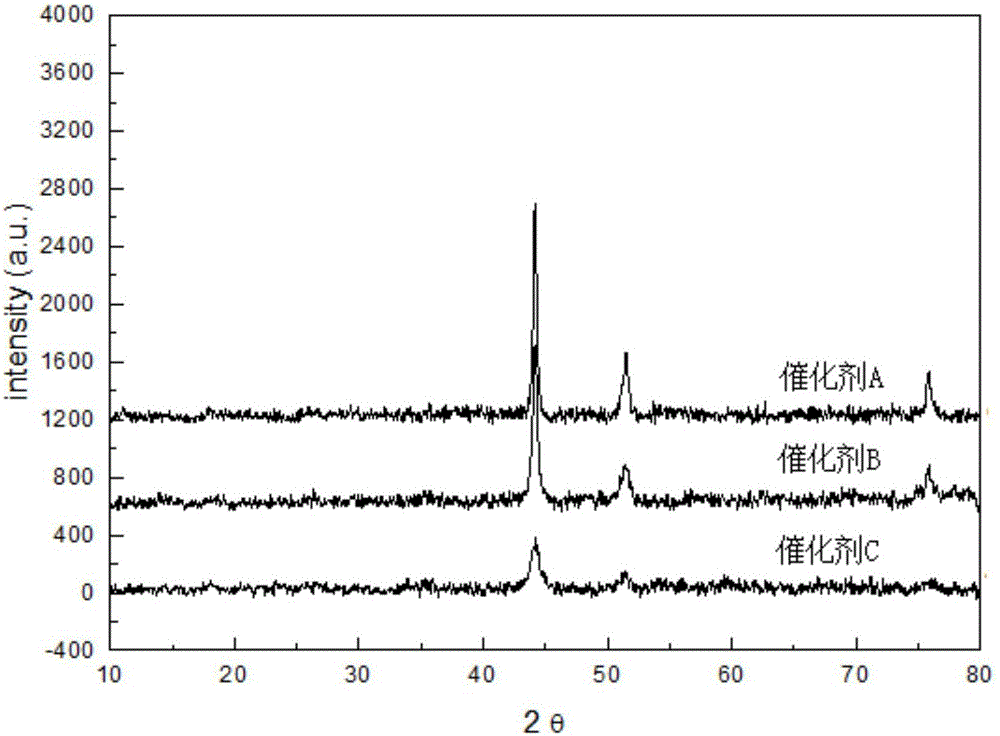

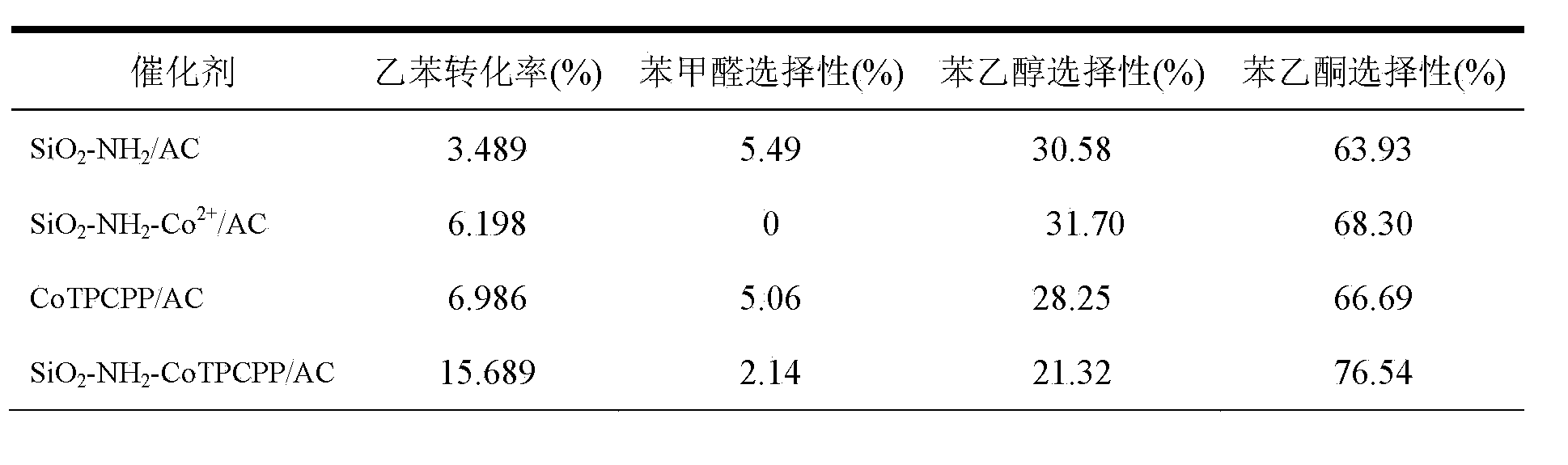

Preparation method of monatomic dispersion catalyst with high catalytic performance

InactiveCN103566935AImprove catalytic performanceImprove stabilityPreparation by oxidation reactionsOrganic compound preparationAlkaneMicrosphere

The invention belongs to the technical field of catalysis and relates to a method for preparing a monatomic cobalt catalyst by roasting silicon dioxide pellets and immobilizing metalloporphyrin. The method is realized by adopting the following technical scheme: namely stirring and dispersing nano silicon dioxide particles, dropwise adding 3-aminopropyl triethoxy silane, so as to obtain amino modified SiO2 pellets, then linking monocarboxyl metalloporphyrin (CoTPCPP) onto an amino modified SiO2 carrier through organic complexing, carbonizing porphyrin through high-temperature calcination in an inert atmosphere, and loading highly dispersed cobalt atoms onto the amino modified SiO2 pellets, thus an amino modified silicon dioxide pellet loaded monatomic cobalt catalyst is obtained. The monatomic dispersion catalyst has high catalytic activity and stability on a molecular oxygen selective ethylbenzene catalytic oxidation reaction in absence of solvent; meanwhile, a preparation method is simple, and product quality can be easily controlled, so that the monatomic dispersion catalyst is applicable to the fields of alkane selective oxidation reactions and synthesis of medical intermediates.

Owner:HUNAN UNIV

Fischer-tropsch activity for non-promoted cobalt-on-alumina catalysts

InactiveUS6271432B2Low costHigh selectivityHydrocarbon from carbon oxidesOrganic compound preparationDopantHydrogen

Cobalt catalysts, and processes employing these inventive catalysts, for hydrocarbon synthesis. The inventive catalyst comprises cobalt on an alumina support and is not promoted with any noble or near noble metals. In one aspect of the invention, the alumina support preferably includes a dopant in an amount effective for increasing the activity of the inventive catalyst. The dopant is preferably a titanium dopant. In another aspect of the invention, the cobalt catalyst is preferably reduced in the presence of hydrogen at a water vapor partial pressure effective to increase the activity of the cobalt catalyst for hydrocarbon synthesis. The water vapor partial pressure is preferably in the range of from 0 to about 0.1 atmospheres.

Owner:SASOL TECH UK

Method for synthesizing gamma-valerolactone based on catalytic hydrogenation

ActiveCN103193736AHigh activityImprove stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrogenAsymmetric hydrogenation

The invention discloses a method for synthesizing gamma-valerolactone based on catalytic hydrogenation. According to the method, levulinic acid or levulinate derivatives in a reaction solvent is / are subject to catalytic hydrogenation for 1-10 hours by adding hydrogen gas and keeping the hydrogen gas pressure at 0.5-5.0 MPa under the action of a supported cobalt catalyst and the temperature of 50-240 DEG C, and the reaction liquid is treated to obtain the gamma-valerolactone. The cobalt catalyst prepared according to the method has excellent catalytic activity and selectivity, the conversion rate of levulinic acid or levulinate is 100 percent, the yield of the gamma-valerolactone reaches up to 99 percent above; and the method has a simple operation technology, and is low in cost, safe and environment-friendly.

Owner:ZHEJIANG UNIV OF TECH

Multilevel hole material load cobalt catalyst, preparation method and application thereof

ActiveCN101269336AChange structureRich microporous structureHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionCarbon numberThermal stability

Owner:中科潞安能源技术有限公司

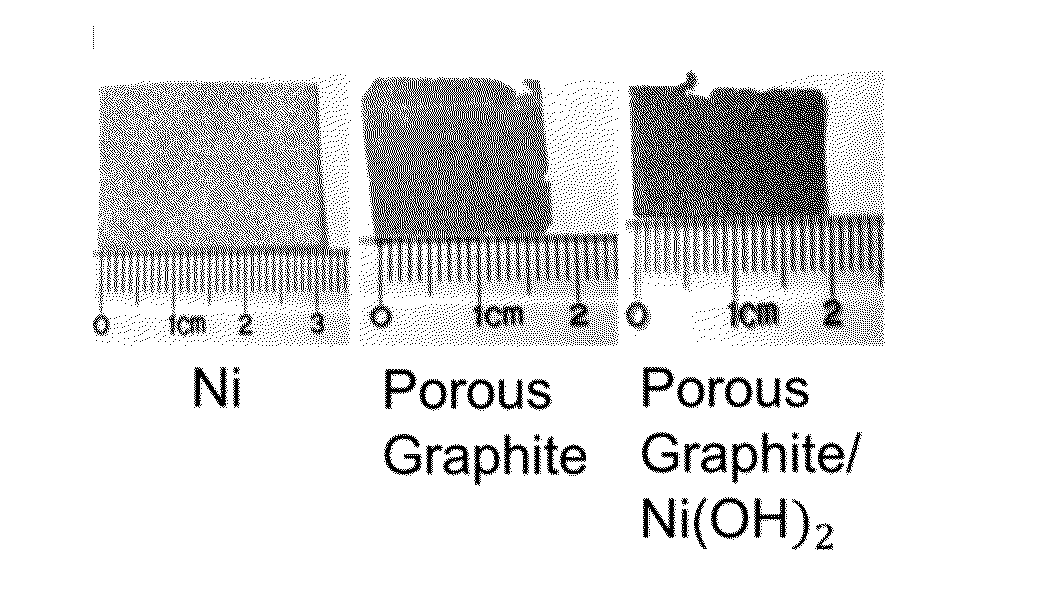

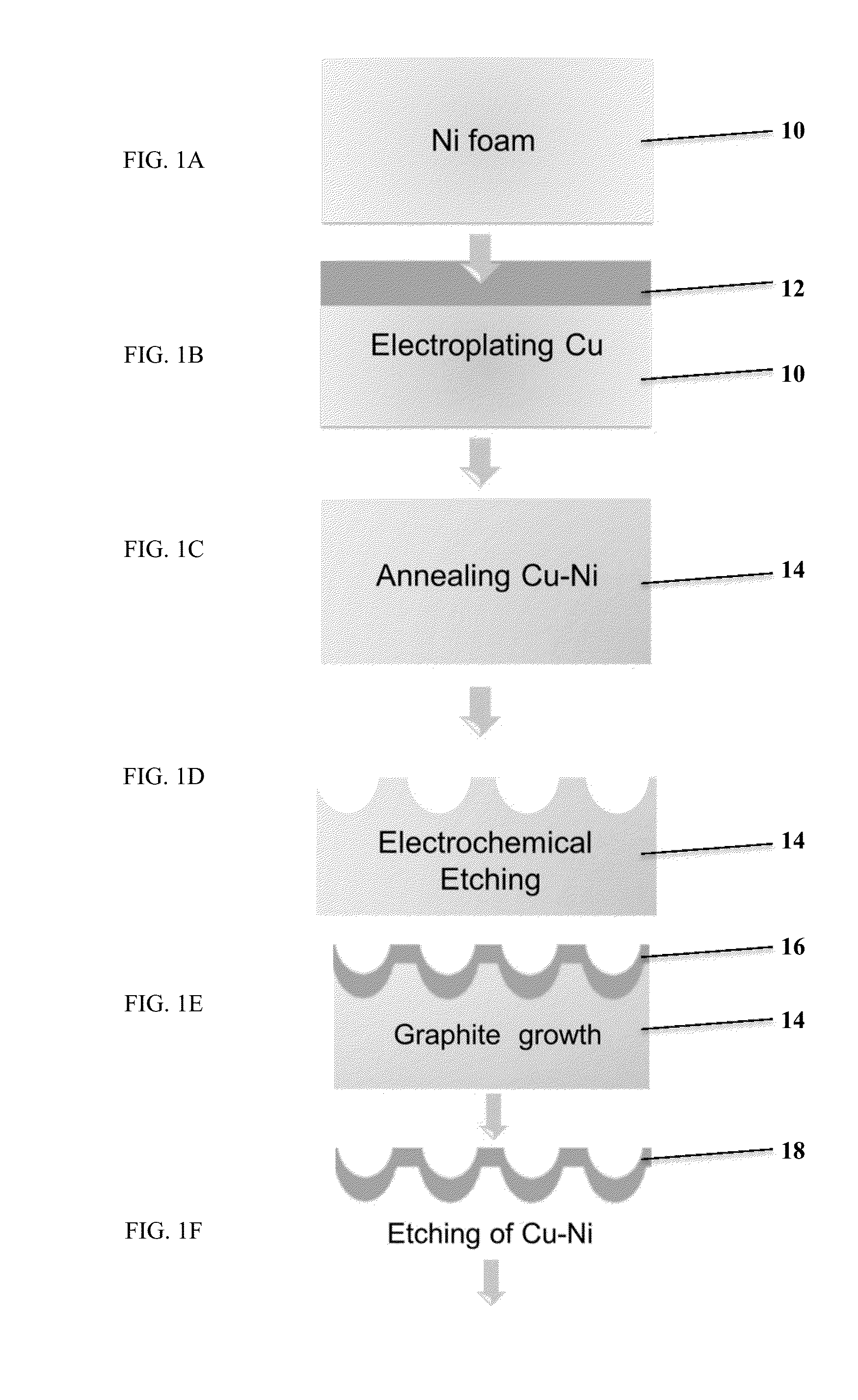

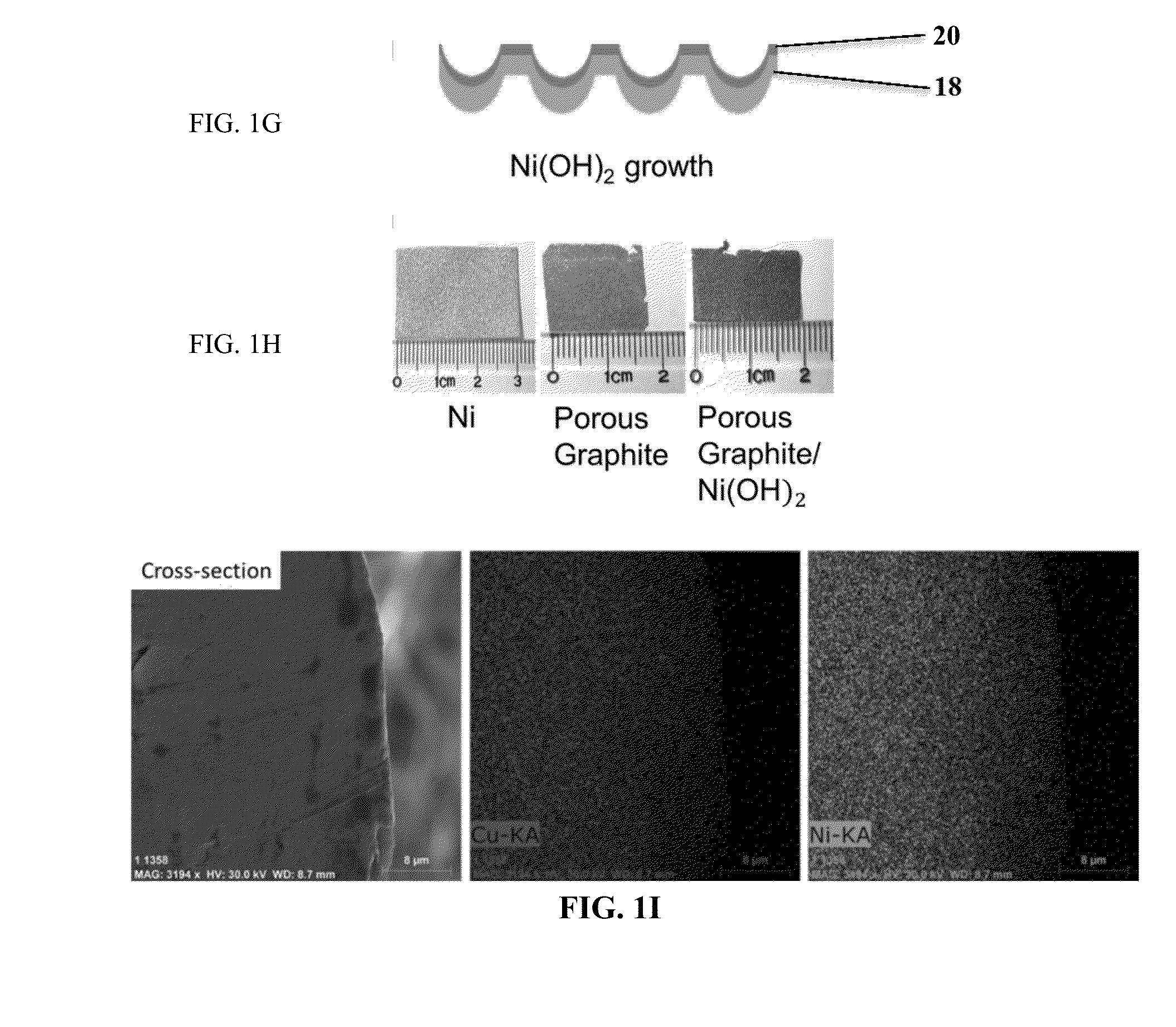

Method for manufacturing of three-dimensional freestanding porous thin-graphite with hierarchical porosity

The present invention includes an apparatus and a method of making a three dimensional graphite structure with a controlled porosity comprising: plating a metal layer on at least one of a nickel, an iron or a cobalt foam substrate; annealing the metal and the nickel, iron or cobalt foam into a porous metal-nickel, iron or cobalt catalyst, wherein the catalyst has a smooth and a porous surface; etching the smooth surface of the annealed porous metal-nickel, iron or cobalt catalyst; growing a carbonaceous layer on the porous surface of the annealed porous metal-nickel, iron or cobalt catalyst; and completely etching the porous metal-nickel, iron or cobalt catalyst to obtain the graphite layer.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Active carbon-loaded nitrogen-doped cobalt catalyst and preparation method and application thereof

ActiveCN104383953AEasy to recycleEasy to preparePhysical/chemical process catalystsWater/sewage treatment by oxidationActivated carbonWastewater

The invention discloses an active carbon-loaded nitrogen-doped cobalt catalyst and a preparation method and an application thereof. The catalyst adopts active carbon as a load carrier; a cobalt oxide and a nitrogen-containing compound are doped into the active carbon; the active carbon-loaded nitrogen-doped catalyst can be used for degrading pollutants in organic wastewater; a proper amount of bicarbonate, hydrogen peroxide and nitrogen-doped cobalt catalyst are added into the organic wastewater so as to degrade organic pollutants in the wastewater. A preparation method of the active carbon-loaded nitrogen-doped cobalt catalyst is simple, and the cost is low; the catalytic organic pollutant degrading effect is good, the degrading efficiency is high, and the metal ion dissolving rate is low; the active carbon-loaded nitrogen-doped cobalt catalyst can be repeatedly used.

Owner:WUHAN TEXTILE UNIV

Method for deuteration or tritiation of heterocyclic ring

ActiveUS20060025596A1Isotope introduction to heterocyclic compoundsSugar derivativesDecompositionPalladium catalyst

The present invention relates to a method for deuteration of a heterocyclic ring, which comprises subjecting a compound having a heterocyclic ring to sealed refluxing state in a deuterated solvent in the presence of an activated catalyst selected form a palladium catalyst, a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst. In accordance with a method of the present invention, a hydrogen atom belonging to a heterocyclic ring of a compound having a heterocyclic ring can be very efficiently deuterated because temperature of deuteration reaction can be maintained at higher than boiling point of the solvent. Further, a method for deuteration of the present invention can be applied widely to deuteration of various compounds having a heterocyclic ring which are liable to decomposition under supercritical conditions or acidic conditions, leading to industrial and efficient deuteration of a compound having a heterocyclic ring.

Owner:FUJIFILM WAKO PURE CHEM CORP

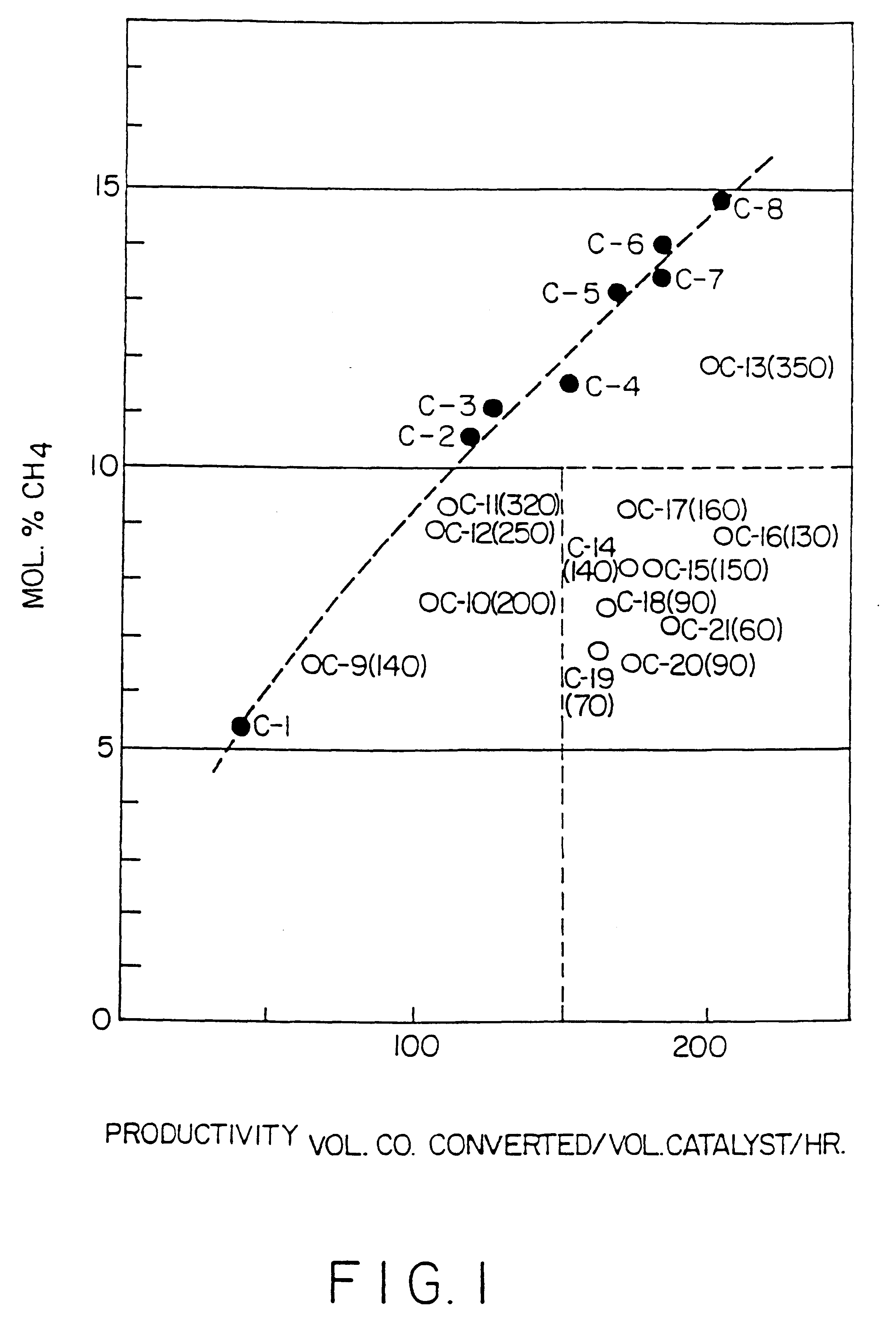

Surface supported cobalt catalysts, process utilizing these catalysts for the preparation of hydrocarbons from synthesis gas and process for the preparation of said catalysts

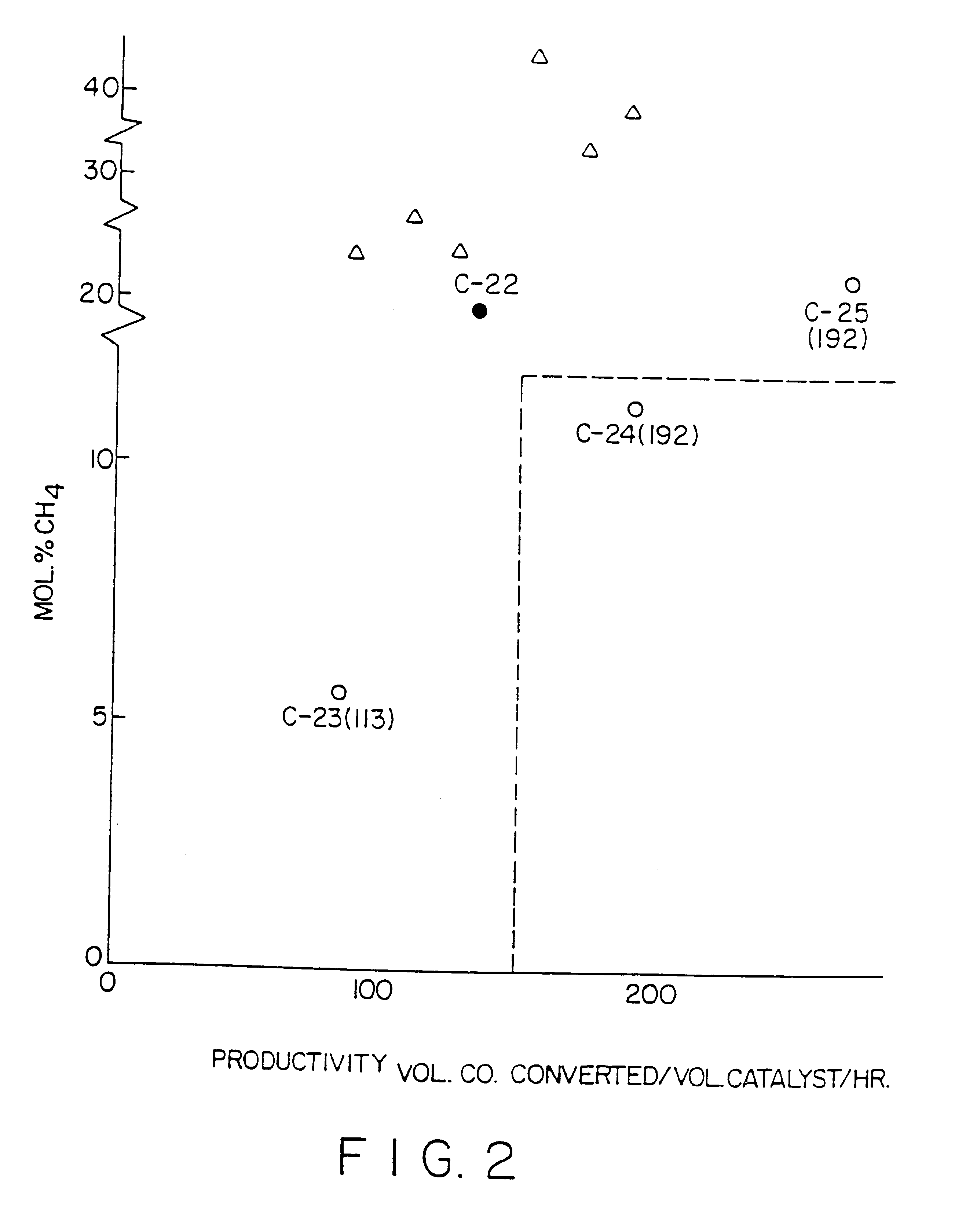

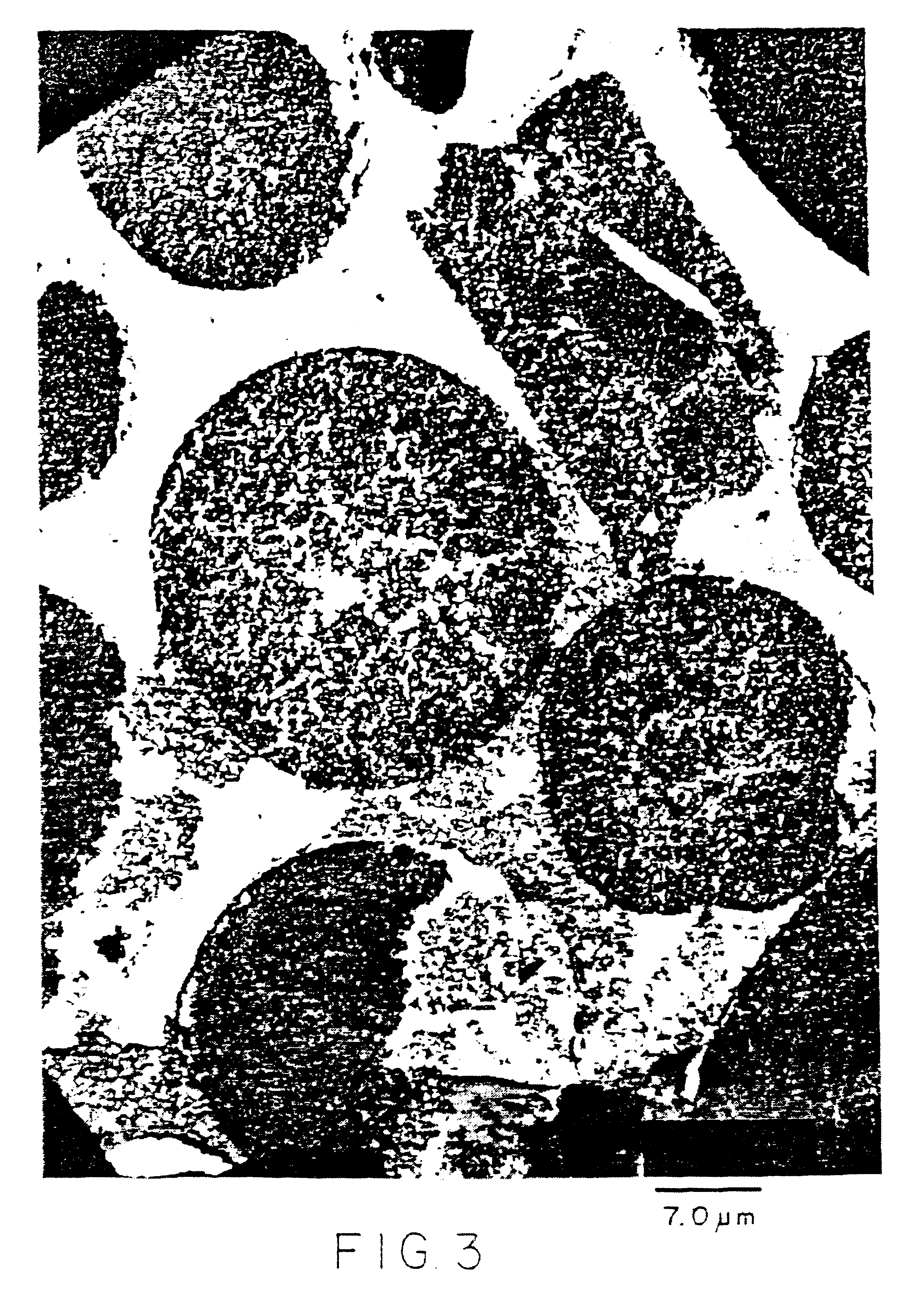

InactiveUSRE37406E1Improve productivityLow methane selectivityHydrocarbon from carbon oxidesOrganic compound preparationParticulatesRhenium

A supported particulate cobalt catalyst is formed by dispersing cobalt, alone or with a metal promoter, particularly rhenium, as a thin catalytically active film upon a particulate support, especially a silica or titania support. This catalyst can be used to convert an admixture of carbon monoxide and hydrogen to a distillate fuel constituted principally of an admixture of linear paraffins and olefins, particularly a C10+ distillate, at high productivity, with low methane selectivity. A process is also disclosed for the preparation of these catalysts.

Owner:EXXON RES & ENG CO

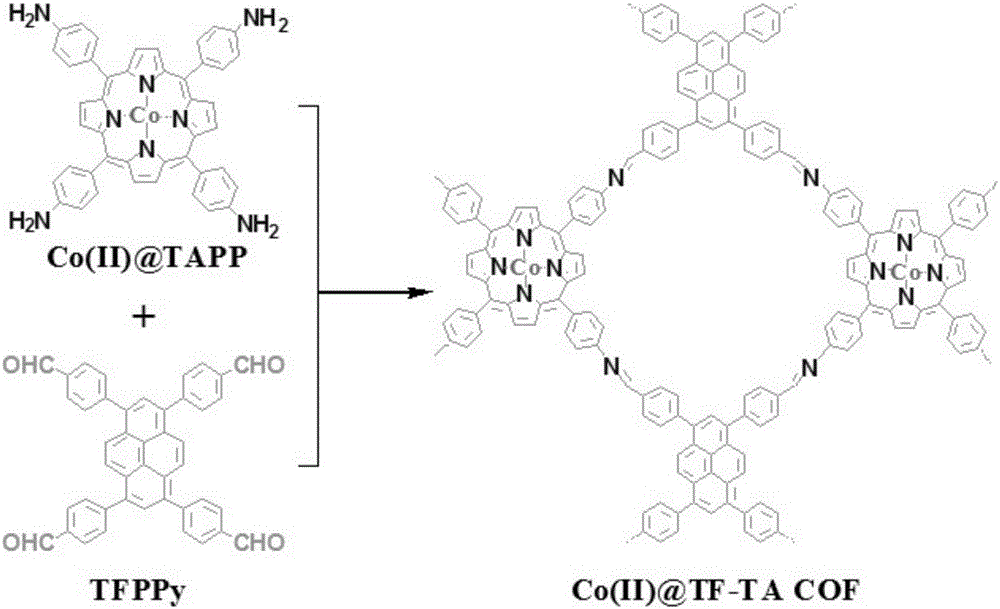

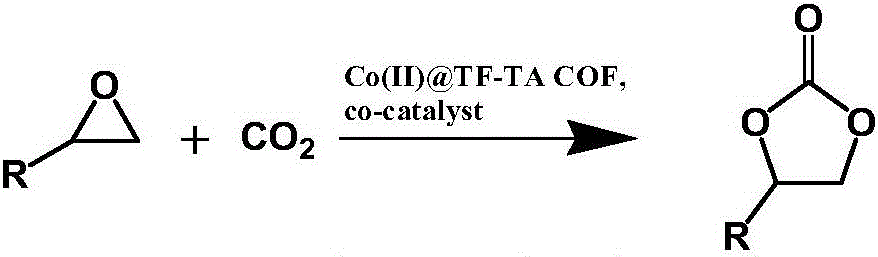

Covalent organic frameworks-supported cobalt catalyst and preparation and application thereof

ActiveCN107433205ASimple and fast operationProcess stabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical compoundPorphyrin

The invention discloses preparation of a novel heterogenous catalyst Co (II) (at) TF-TA COF: covalent organic frameworks (COFs)-supported metallic cobalt is used for catalyzing carbon dioxide and an epoxy compound for synthesis of a cyclic carbonate compound. Structural unit of the material contains a cobalt-porphyrin compound which can be used for catalyzing a reaction between carbon dioxide and an epoxy compound. In addition, the COFs have large specific surface area and an open porous structure, which can enhance adsorption capacity of carbon dioxide. Thus, the Co (II) (at) TF-TA COF can simultaneously realize adsorption of carbon dioxide gas and catalytic conversion for generation of cyclic carbonates. The type of a reaction substrate is extensible; reaction yield is high; the catalyst can be recycled; operation is simple; and added value of a product is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

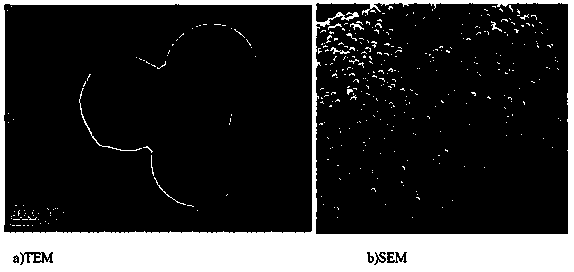

Preparation method and application of nitrogen-doped porous carbon-loaded cobalt catalyst

InactiveCN105498823ASimple methodIncreased Cobalt LoadingPhysical/chemical process catalystsHydrogen productionPorous carbonSynthesis methods

The invention discloses a preparation method of a nitrogen-doped porous carbon-loaded cobalt catalyst. The preparation method includes: adding N, N-bis(salicylidene) ethylene dimino cobalt (II) or bi(3-methoxysalicylaldehyde) ethylenediamine cobalt chloride into a crucible, placing into a tubular furnace, and heating to 400-900 DEG C for calcining for 1-10 h in a hydrogen-argon mixed atmosphere; cooling to room temperature to obtain the nitrogen-doped porous carbon-loaded cobalt catalyst which is used for hydrolytic dehydrogenation of ammonia borane. The preparation method has the advantages that the catalyst is prepared by adopting a one-step pyrolysis synthesis method, the preparation method is simple, cobalt loading quantity is greatly increased, and industrial production is facilitated; the catalyst is used for catalyzing hydrolytic dehydrogenation of ammonia borane, maximum dehydrogenation rate reaches 1383 mL H2min-1gCo-1, and activation energy is 31.0kJ / mol; especially, after cobalt nanoparticles are embedded in nitrogen-doped porous carbon, circulating stability is improved greatly.

Owner:NANKAI UNIV

Method for degrading organic pollutants in water by using nitrogen-doped porous carbon anchored monatomic cobalt catalyst to activate persulfate

InactiveCN112408577AEfficient degradationIncrease productionPhysical/chemical process catalystsWater contaminantsPtru catalystPorous carbon

The invention discloses a method for degrading organic pollutants in water by using a nitrogen-doped porous carbon anchored monatomic cobalt catalyst to activate persulfate. The method comprises the following steps: mixing the nitrogen-doped porous carbon anchored monatomic cobalt catalyst, persulfate and organic pollutant-containing water, and carrying out degradation reaction to degrade organicpollutants in water, wherein the nitrogen-doped porous carbon anchored monatomic cobalt catalyst comprises nitrogen-doped porous carbon, and monatomic cobalt is doped in the nitrogen-doped porous carbon. The method for degrading the organic pollutants in the water by utilizing a nitrogen-doped porous carbon anchored monatomic cobalt catalyst to activate persulfate has the advantages of strong water quality interference resistance, high degradation efficiency, environmental protection and the like, can efficiently remove the organic pollutants in the water, and is high in use value and good inapplication prospect.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

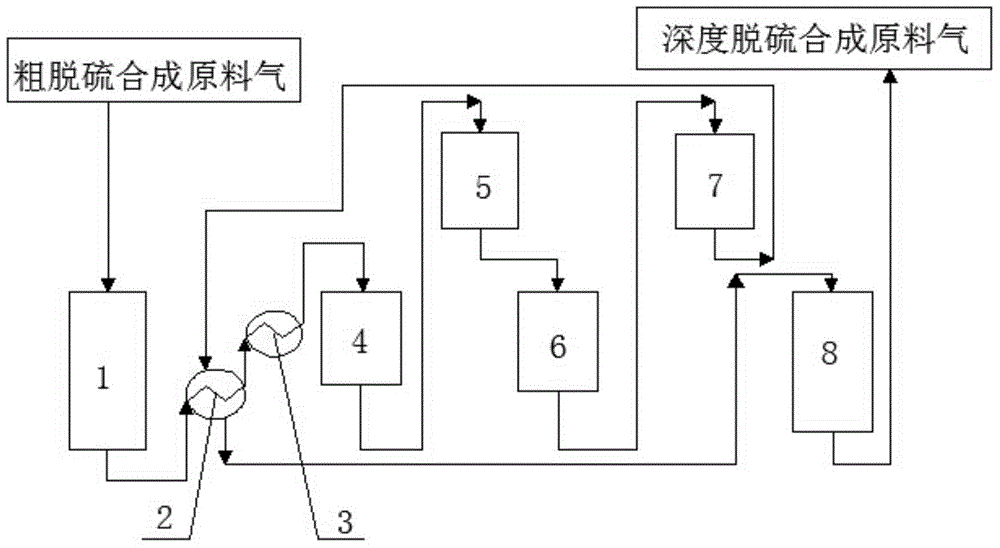

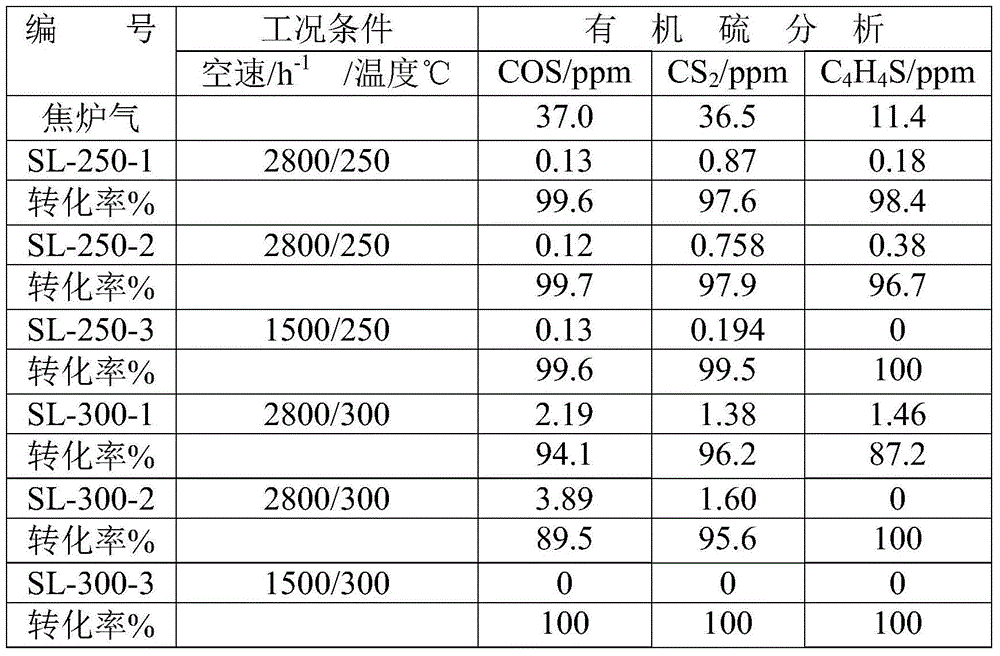

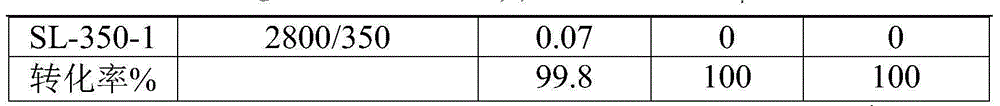

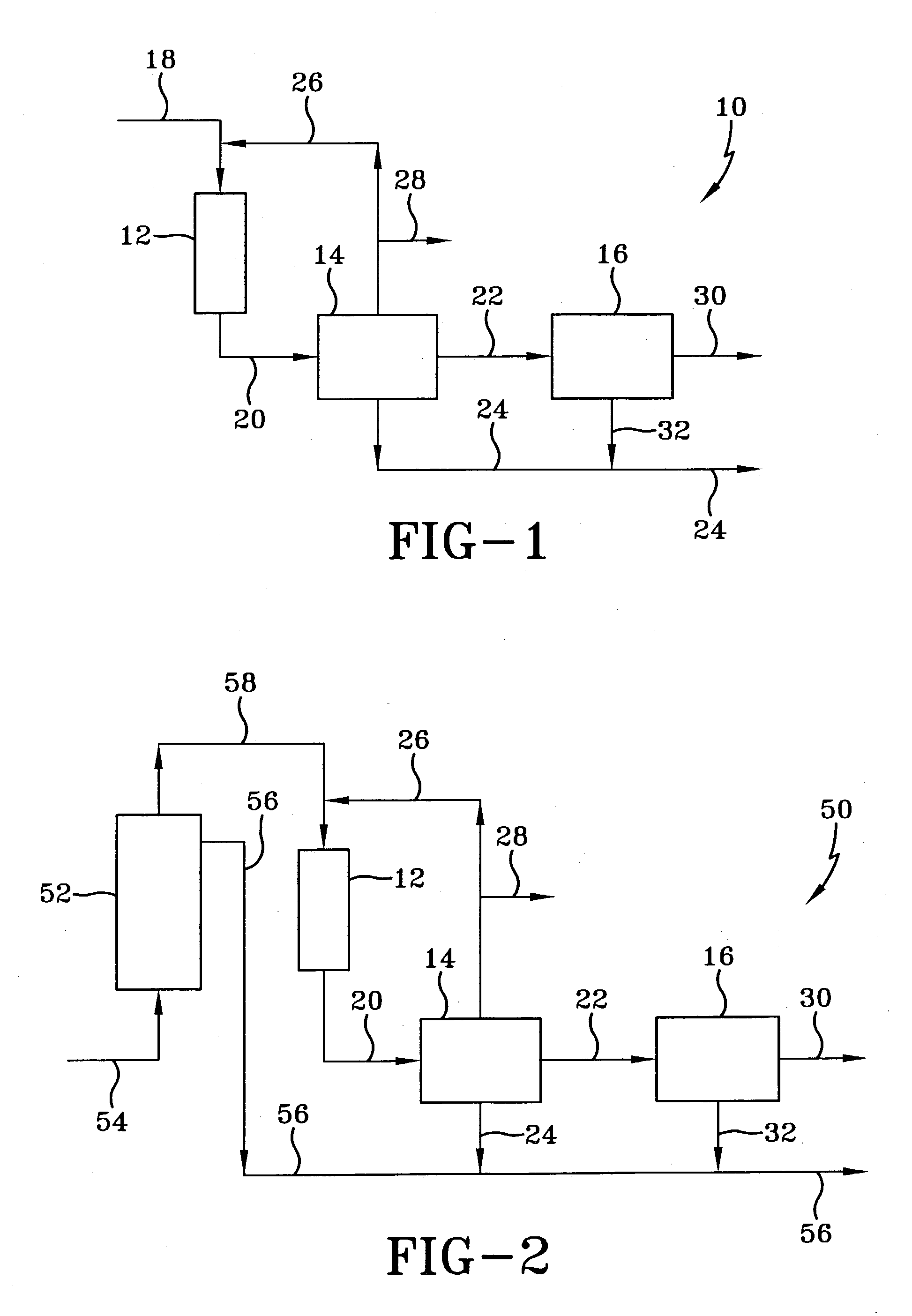

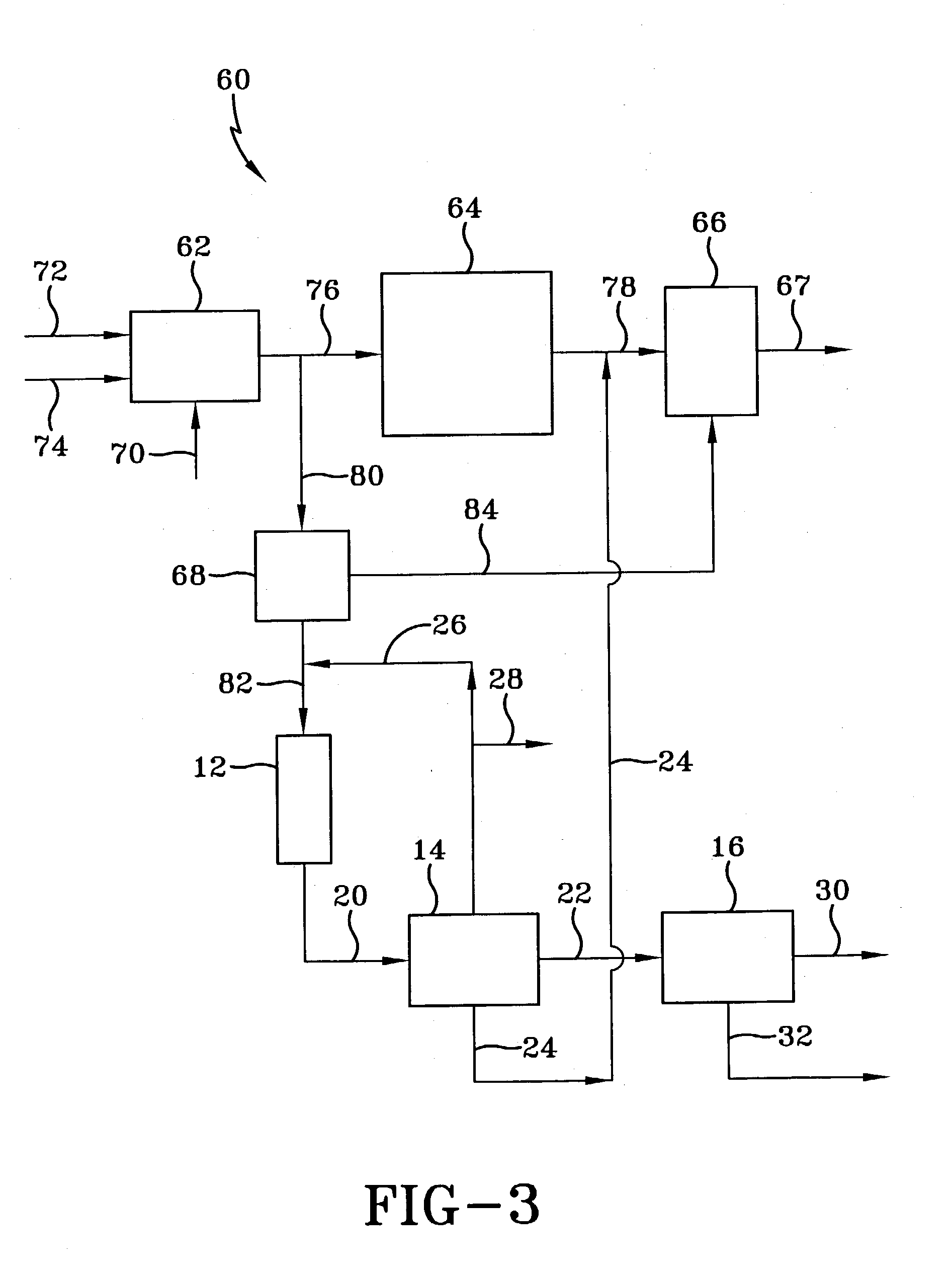

Synthetic raw material gas deep fine desulfurization process and fine desulfurization device

InactiveCN104437032AReduce energy consumptionExtend your lifeDispersed particle separationPetroleumMaterials science

The invention discloses a deep desulfurization method for preparing a synthetic raw material gas by taking a coal-based natural gas, a petroleum refining gas, a coke oven gas, a steel mill converter gas and the like as raw materials. The method comprises the step of enabling the raw material gas which is treated by rough desulfurization and contains hundreds of parts per million (ppm) of H2S and hundreds of ppm of organic sulfur (including COS, CS2, sulfur alcohol, sulfur ether, thiophene and the like) to pass through a plurality of stages of titanium-based molybdenum-cobalt catalysts, a plurality of stages of zinc oxide desulfurizing agents and a stage of multifunctional fine desulfurizing agent to enable the total sulfur to be less than or equal to 0.01ppm. Compared with the existing desulfurization accuracy (0.1ppm), the desulfurization accuracy of the deep desulfurization method enables the degree of purification to be increased by one order of magnitude and enables the service life of a methyl alcohol catalyst to be doubled. The invention also discloses a medium-temperature fine desulfurization device used by the synthetic raw material gas deep fine desulfurization method. For the industrial community, after the method and the device are used, the starting and stopping times of the device can be reduced, the raw material and the power consumption are reduced, the yield of the device is increased, and an effective measure capable of saving energy, reducing emission and increasing yield can be provided.

Owner:SANLONG CATALYST

Linear alpha olefins from natural gas-derived synthesis gas over a nonshifting cobalt catalyst

InactiveUS20040127582A1Hydrocarbon from carbon oxidesOrganic compound preparationWater vaporAlpha-olefin

Linear alpha olefins having from four to twenty carbon atoms and low amounts of oxygenates are synthesized, by producing a synthesis gas containing H2 and CO from natural gas and passing it over a non-shifting cobalt catalyst at reaction conditions of temperature, % CO conversion, and gas feed H2:CO mole ratio and water vapor pressure, effective for the mathematical expression 200-0.6T+0.03PH2O-0.6XCO-8(H2:CO) to have a numerical value greater than or equal to 50. This process can be integrated into a conventional Fischer-Tropsch hydrocarbon synthesis process producing fuels and lubricant oils.

Owner:EXXON RES & ENG CO

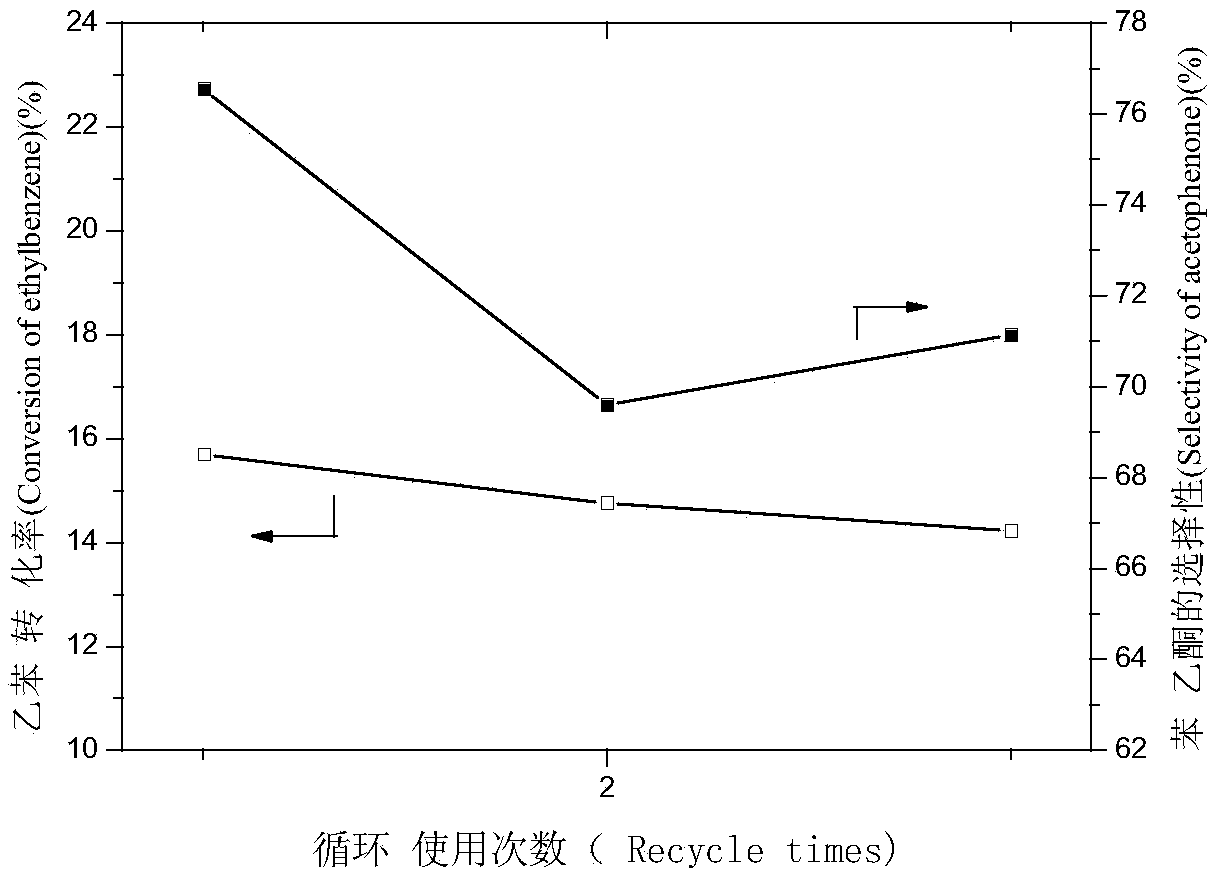

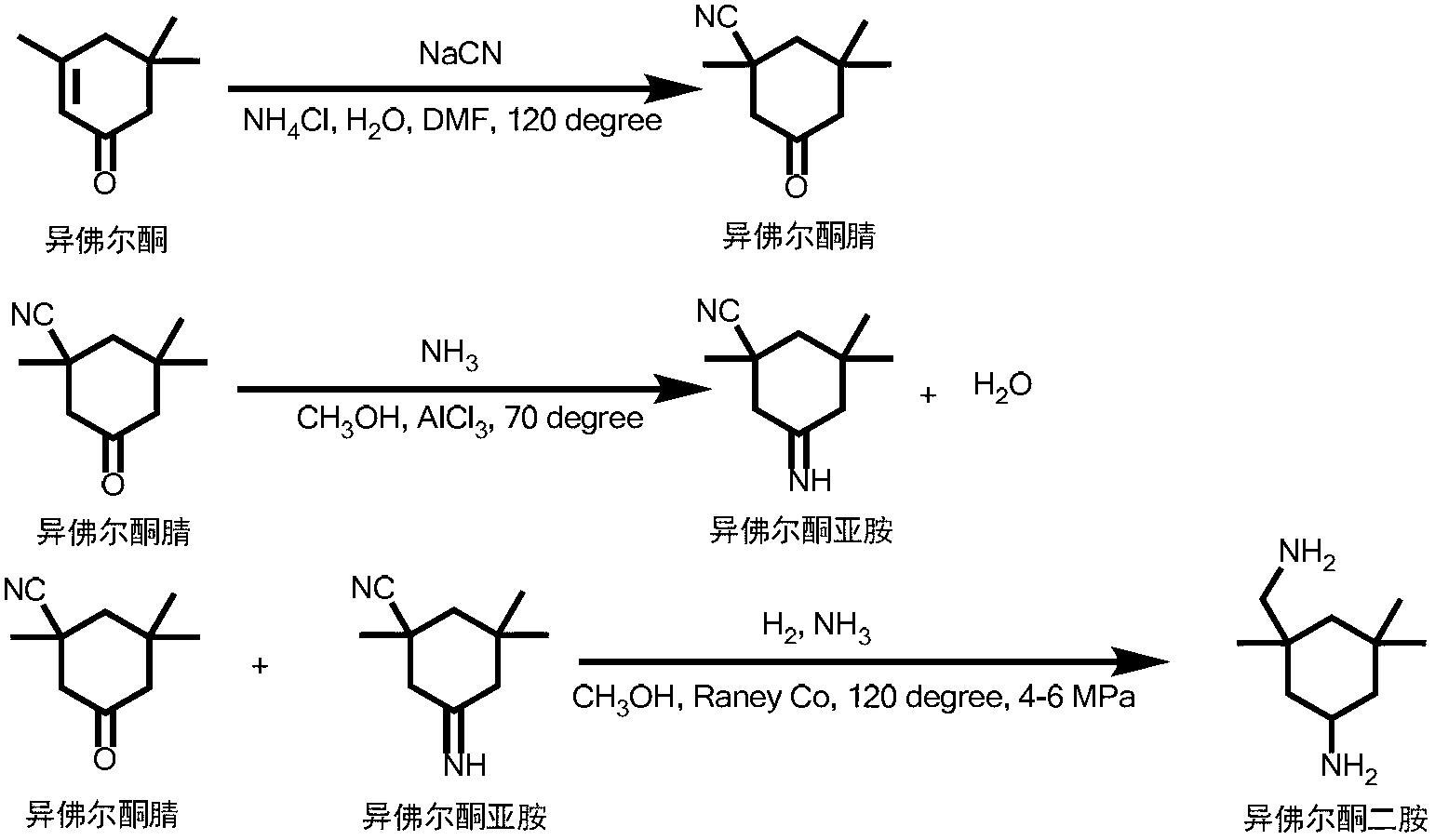

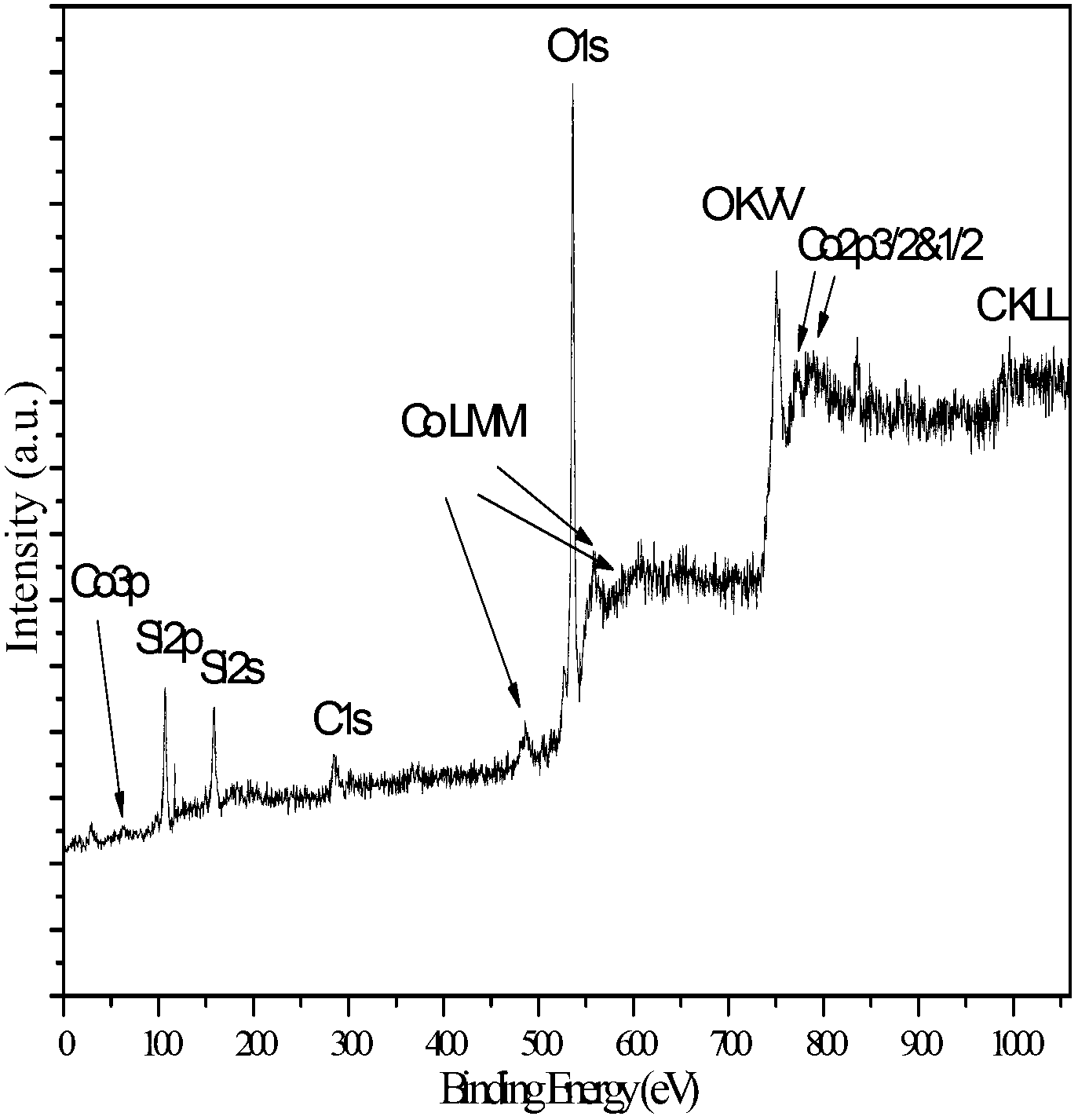

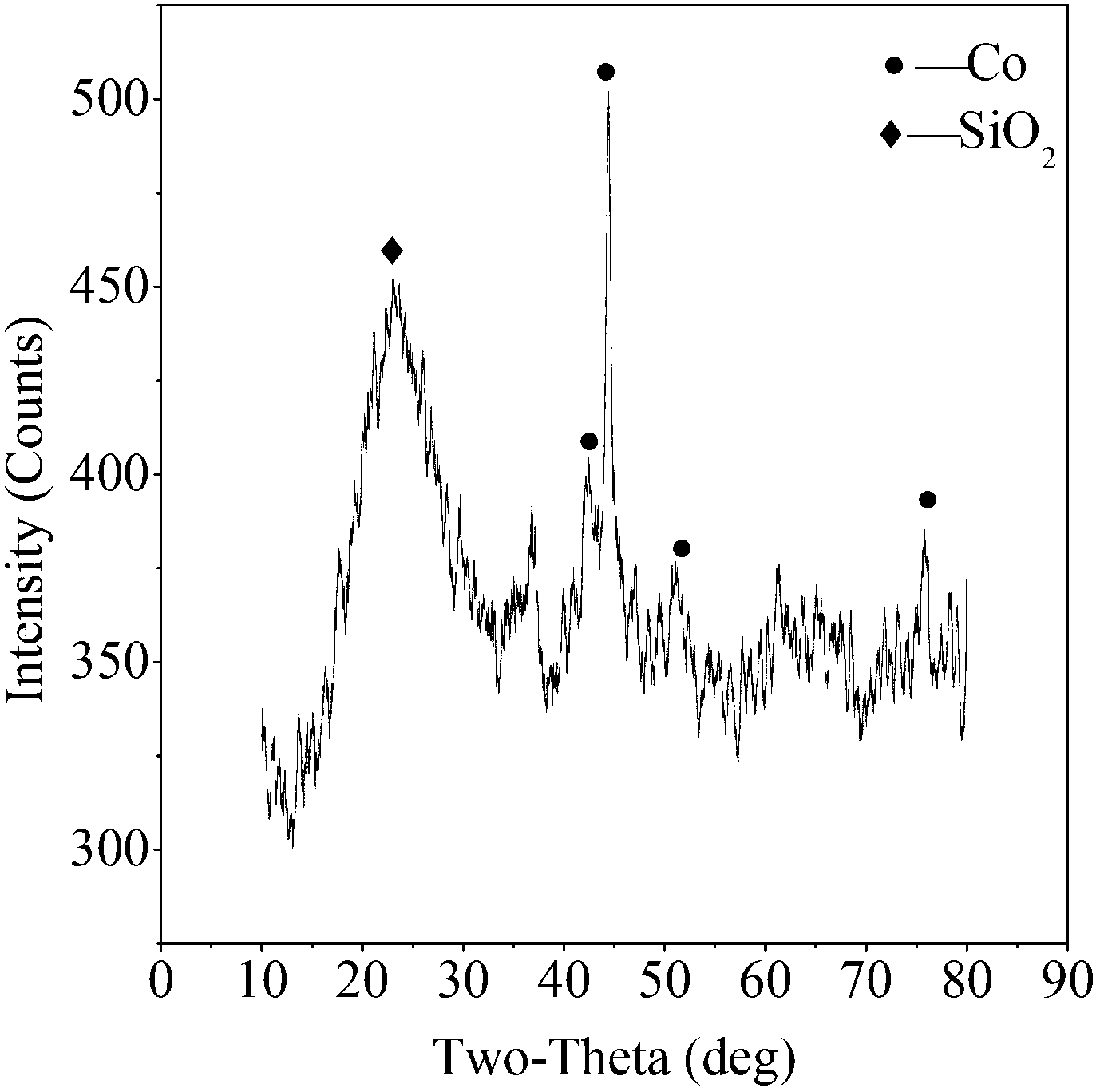

Method for preparing isophorone diamine

InactiveCN103265437AUniform dispersionHigh activityOrganic compound preparationAmino compound preparationHydrogenOrganic solvent

The invention discloses a method for preparing isophorone diamine, wherein the method comprises: using phorone nitrile as a raw material, under an effect of a metal cobalt catalyst, ammonia gas and hydrogen are orderly introduced into an organic solvent, and are reacts under stirring for 1-8h at 40-180 DEG C in a pressure condition of 1-10 MPa, and after reaction, a reaction mixture is post-treated to obtain the isophorone diamine. Uniformly-dispersive and high active metal cobalt catalyst is prepared by a sol-gel method, and when the catalyst is used for preparing isophorone diamine, a conversion rate of IPN can reach 100%, and the yield of IPAD is 78.5-98.3%. The catalyst has a long service life, and after the catalyst repeats eight-time by simple filtration after catalytic reaction, the conversion rate of IPN reduces 6.3%, yield of IPDA reduces 7.8%, and catalyst activity is almost not changed.

Owner:ZHEJIANG UNIV

Process for increasing cobalt catalyst hydrogenation activity via aqueous low temperature oxidation

InactiveUS6465529B1Improve catalytic performanceImprove performanceLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesCobalt metalHydrogenation reaction

An aqueous low temperature oxidation (ALTO) process wherein a catalyst or catalyst precursor constituted of a solids support, or powder component, and a metal, or metals component, inclusive of cobalt, is oxidized, reduced and rendered catalytically active for conducting carbon monoxide hydrogenation reactions. The cobalt catalyst or cobalt catalyst precursor is thus contacted at low temperature with an oxidant in the presence of water (e.g., water to which an oxidant is added), sufficient to oxidize the cobalt metal, or metals component of the catalyst or catalyst precursor. On reduction, the hydrogenation activity of the cobalt catalyst is increased. All or a portion of the cobalt metal of the catalyst precursor is oxidized to form a Co2+ cationic or oxo-anionic species at least during the initial phase of the reaction. On reduction, as may be produced by contact and treatment of the oxidized catalyst or catalyst precursor with hydrogen, or a hydrogen-containing gas, the catalytic metal, or metals component of the catalyst, is reduced to metallic metal, e.g., Co, and the catalyst thereby activated, and / or the catalytic activity increased.

Owner:EXXON RES & ENG CO

Ethanol Production from Acetic Acid Utilizing a Cobalt Catalyst

InactiveUS20110282109A1Organic compound preparationOxygen compounds preparation by reductionIridiumRhenium

A process for the selective and direct formation of ethanol from acetic acid comprising contacting a feed stream containing acetic acid and hydrogen in vapor form at an elevated temperature with a hydrogenation catalyst comprising cobalt and one or more metals selected from the group consisting of palladium, platinum, rhodium, ruthenium, rhenium, iridium, chromium, copper, tin, molybdenum, tungsten, vanadium, zinc and iron on a catalyst support.

Owner:CELANESE INT CORP

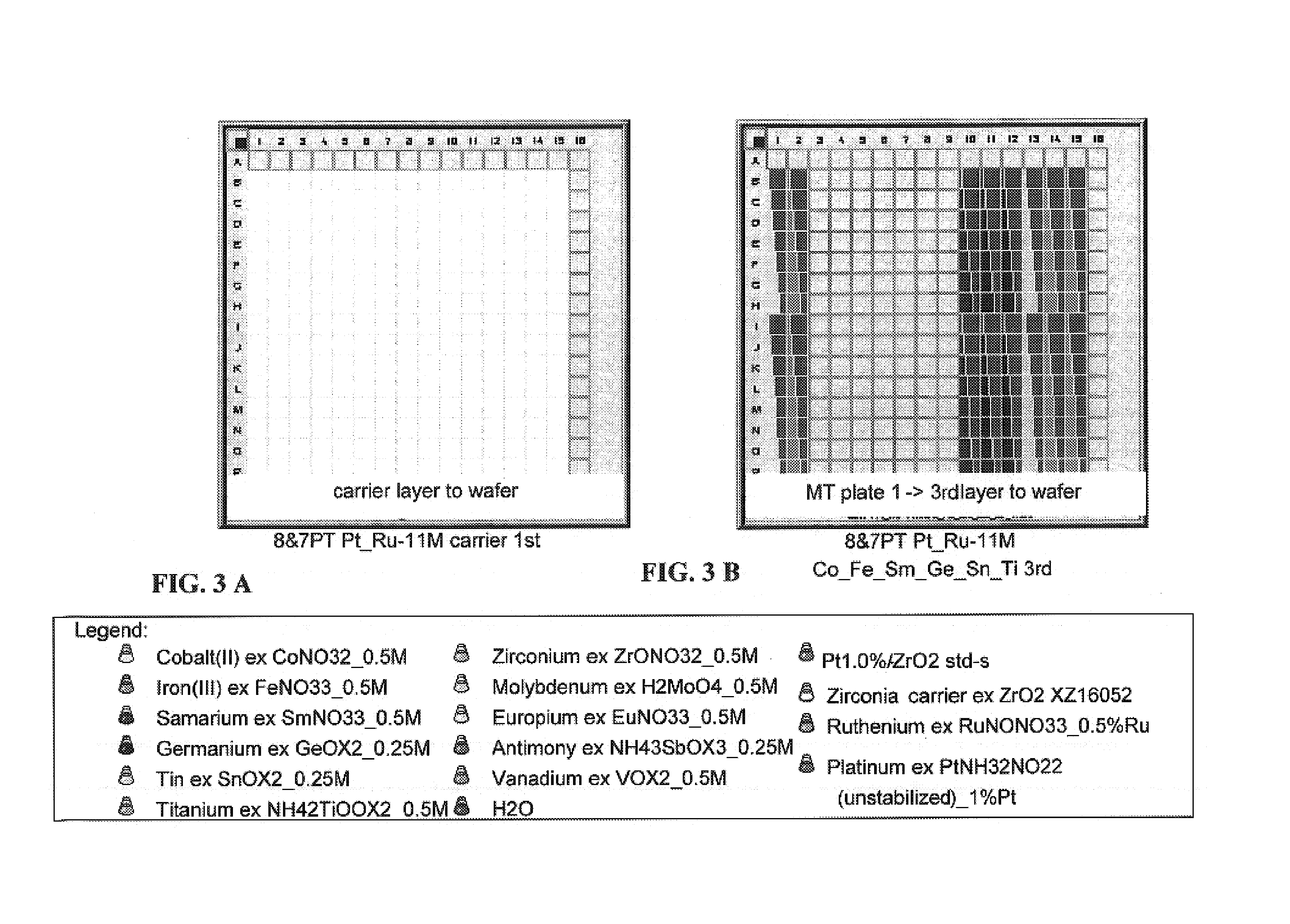

Platinum-free ruthenium-cobalt catalyst formulations for hydrogen generation

ActiveUS7160534B2Maintain good propertiesHydrogenSequential/parallel process reactionsPlatinumRuthenium

A method and catalysts and fuel processing apparatus for producing a hydrogen-rich gas, such as a hydrogen-rich syngas are disclosed. According to the method, a CO-containing gas, such as a syngas, contacts a platinum-free ruthenium-cobalt water gas shift (“WGS”) catalyst, in the presence of water and preferably at a temperature of less than about 450° C., to produce a hydrogen-rich gas, such as a hydrogen-rich syngas. Also disclosed is a platinum-free ruthenium-cobalt water gas shift catalyst formulated from:a) Ru, its oxides or mixtures thereof;b) Co, Mo, their oxides or mixtures thereof; andc) at least one of Li, Na, K, Rb, Cs, Ti, Zr, Cr, Fe, La, Ce, Eu, their oxides and mixtures thereof. The WGS catalyst may be supported on a carrier, such as any one member or a combination of alumina, zirconia, titania, ceria, magnesia, lanthania, niobia, zeolite, perovskite, silica clay, yttria and iron oxide. Fuel processors containing such water gas shift catalysts are also disclosed.

Owner:HONDA MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com