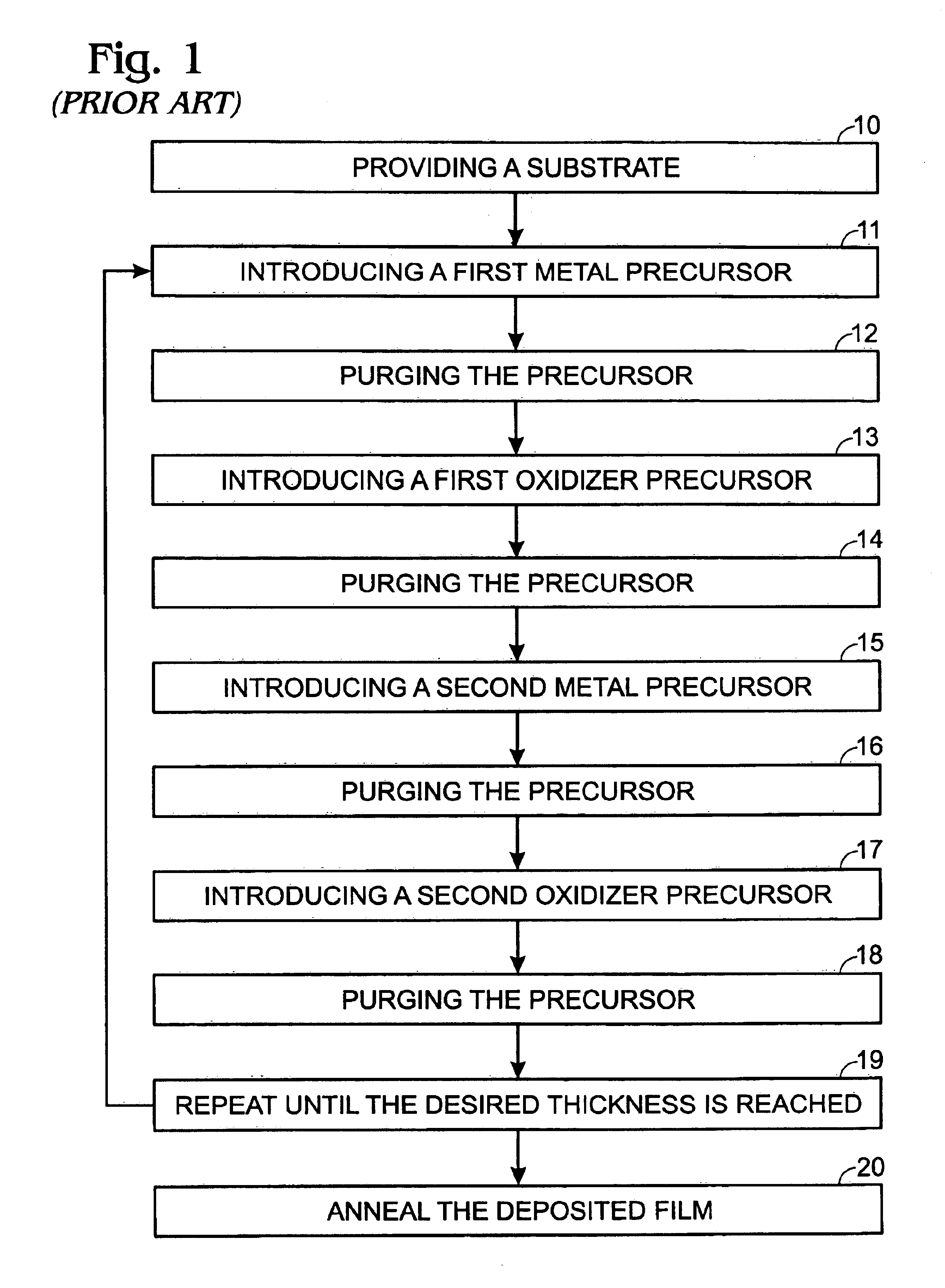

Patents

Literature

72454results about How to "Simple method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

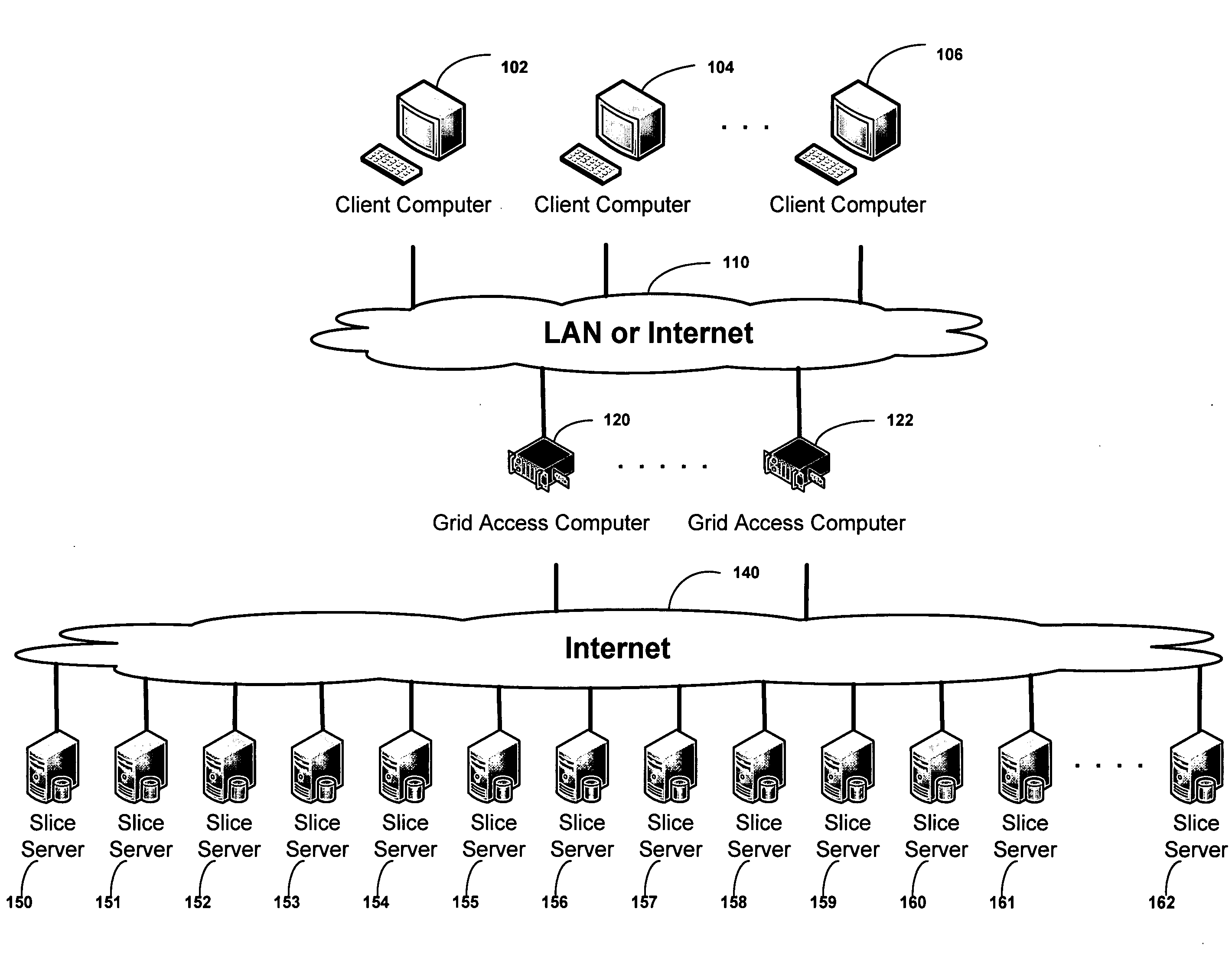

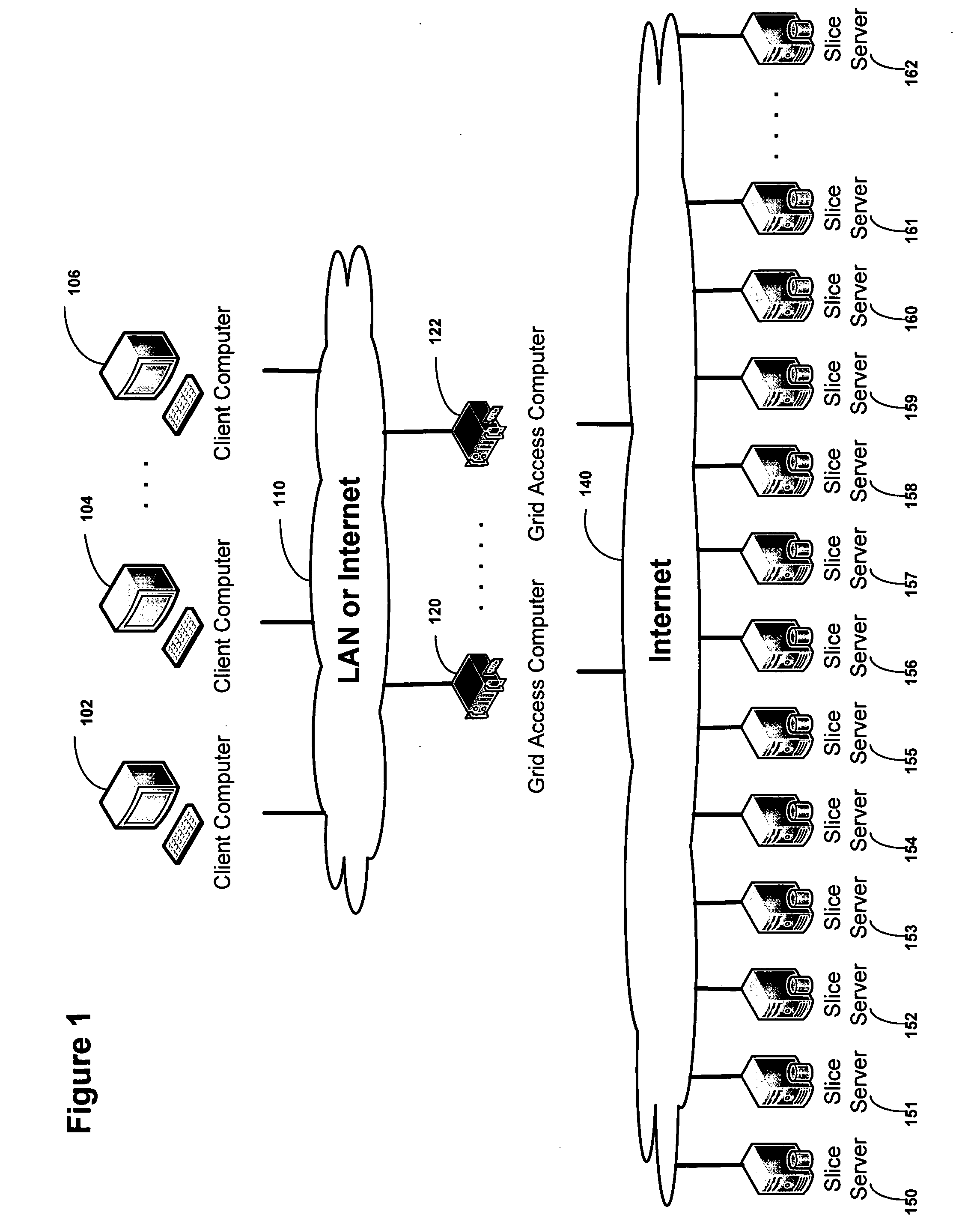

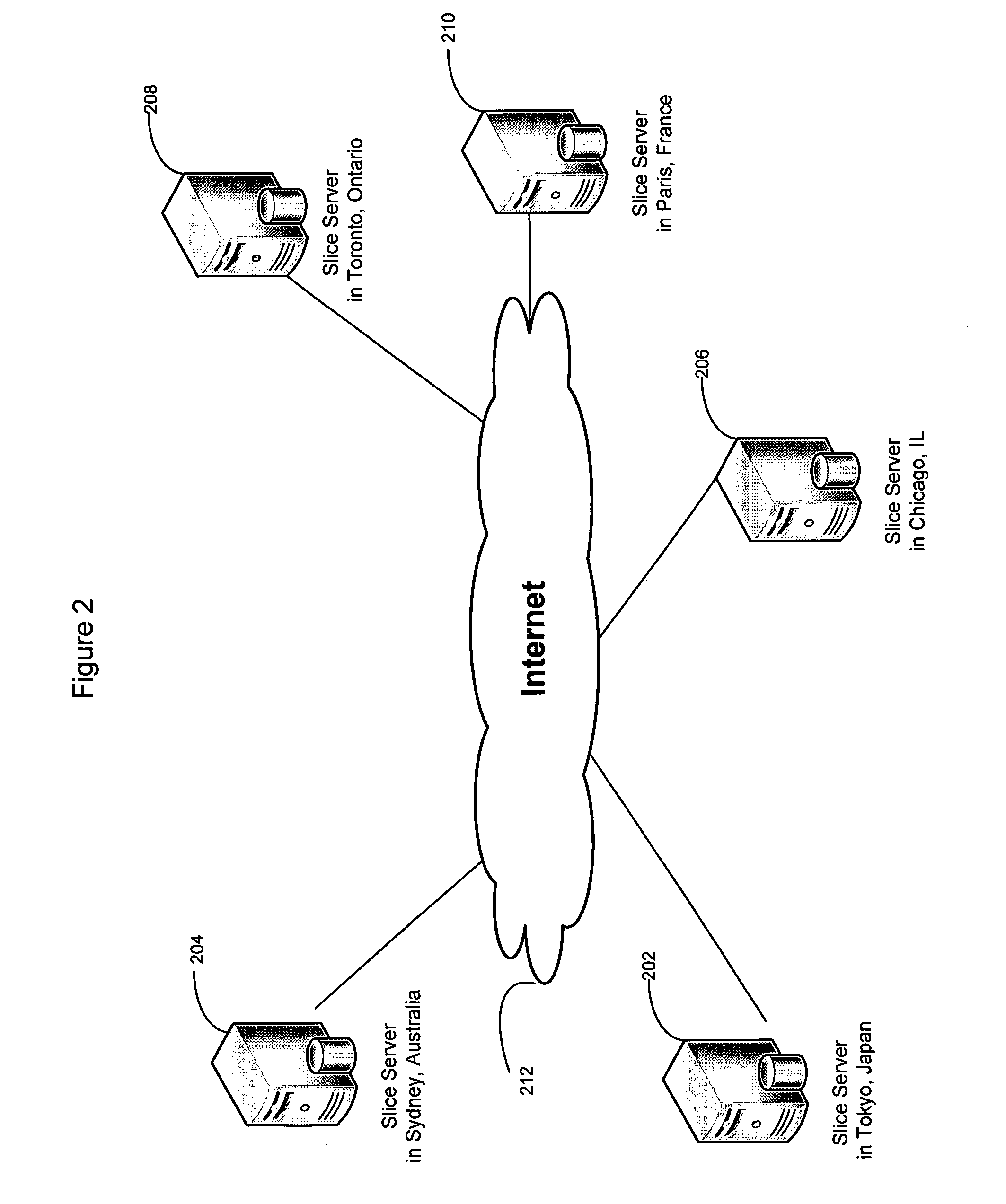

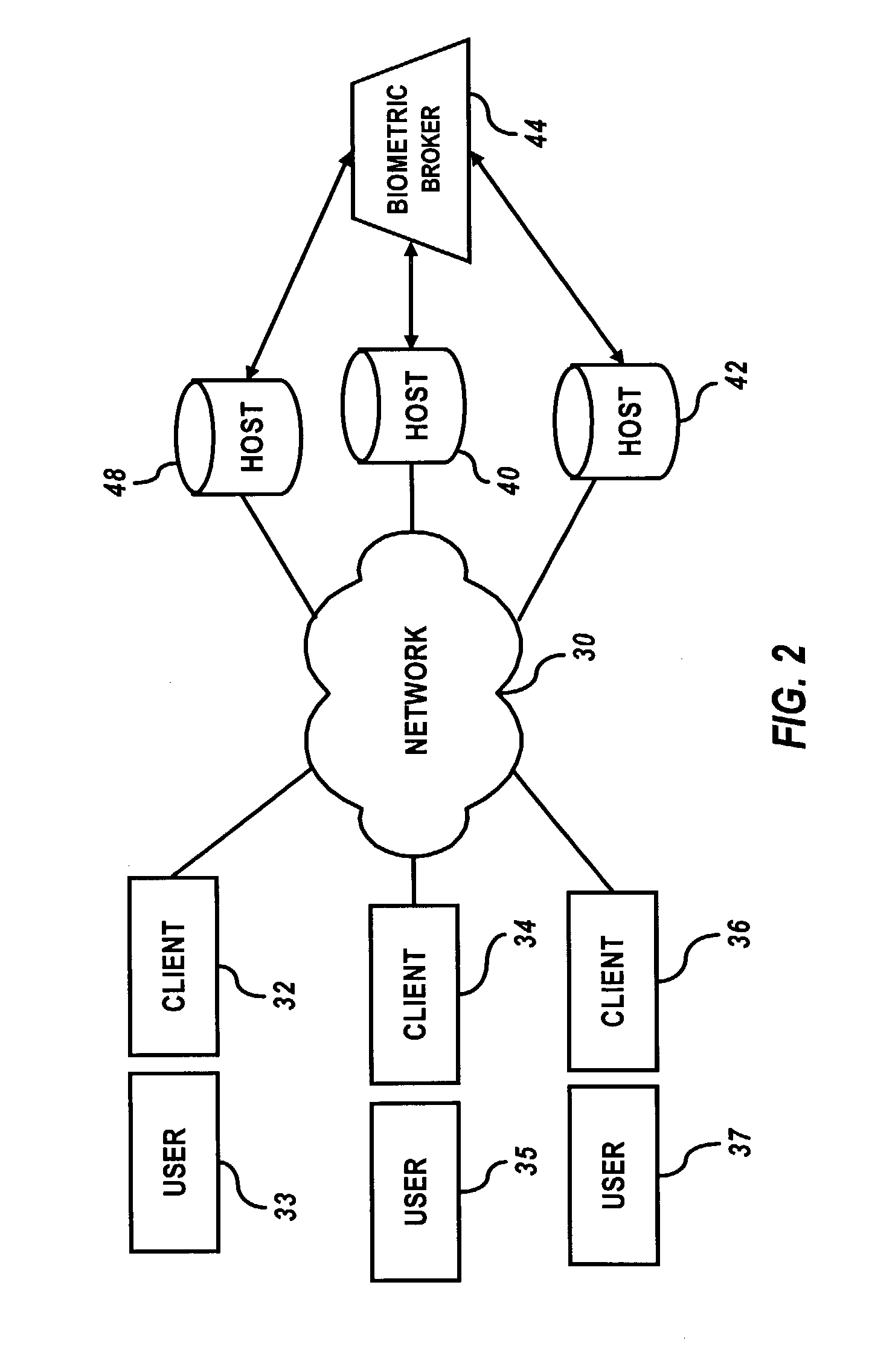

Smart access to a dispersed data storage network

ActiveUS20090094318A1Efficient accessImprove network performanceError preventionFrequency-division multiplex detailsData segmentRanking

An improved system for accessing data within a distributed data storage network (“DDSN”) is disclosed. In a system implementing the disclosed invention, traffic is routed to individual slice servers within the DDSN in accordance with objective criteria as well as user-defined policies. In accordance with one aspect of the disclosed invention, when a data segment is written to a DDSN, the segment is divided into multiple data slices, which are simultaneously transmitted to different slice servers. In accordance with another aspect of the disclosed invention, when a data segment is read from a DDSN, a list of slice servers, each containing a data slice that could be used to reconstruct the requested data segment, is assembled, and sorted in accordance with a preference rating assigned to each of the slice servers. Sufficient data slices to reconstruct the data segment are then read in accordance with the preference ranking of the slice servers.

Owner:PURE STORAGE

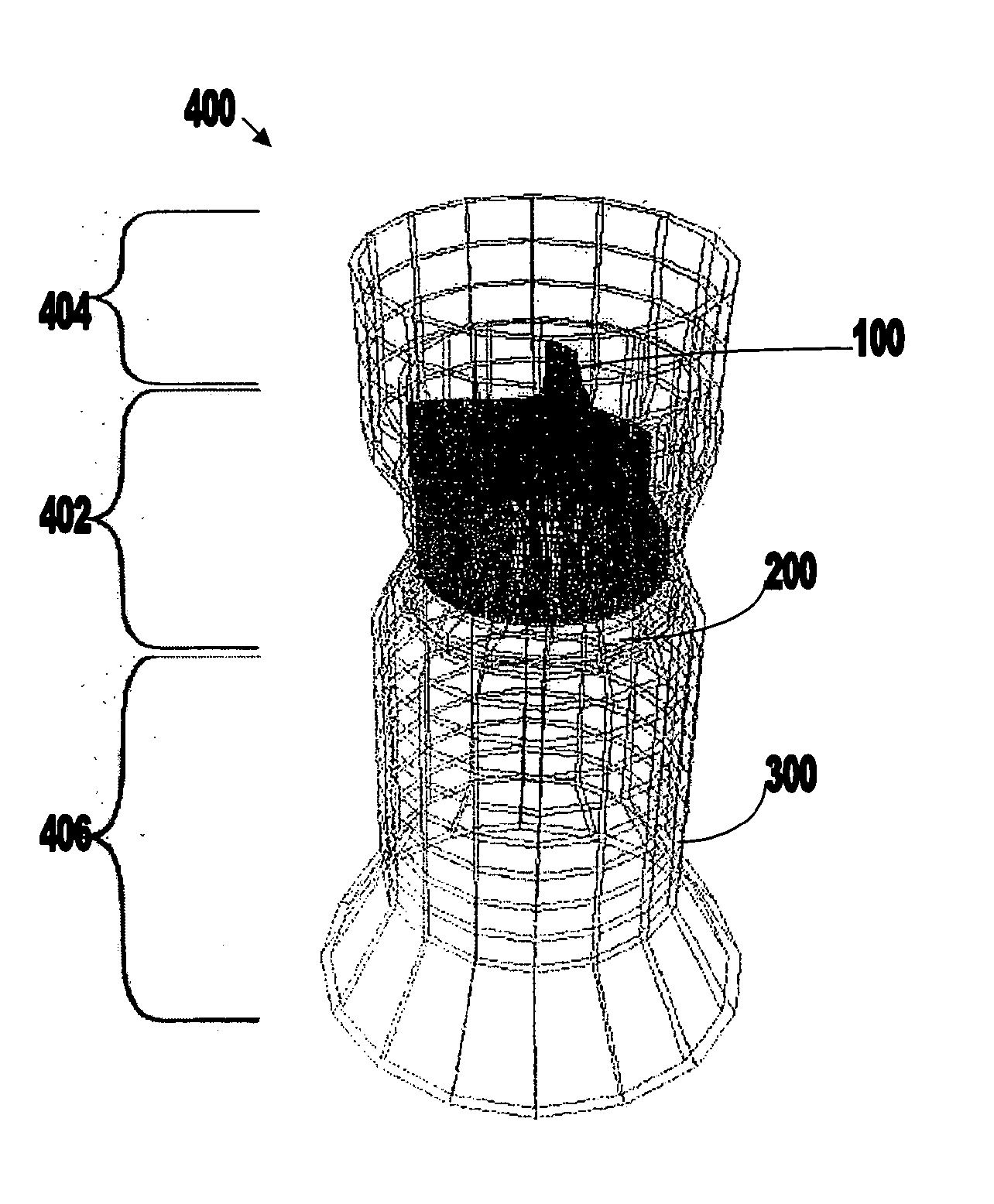

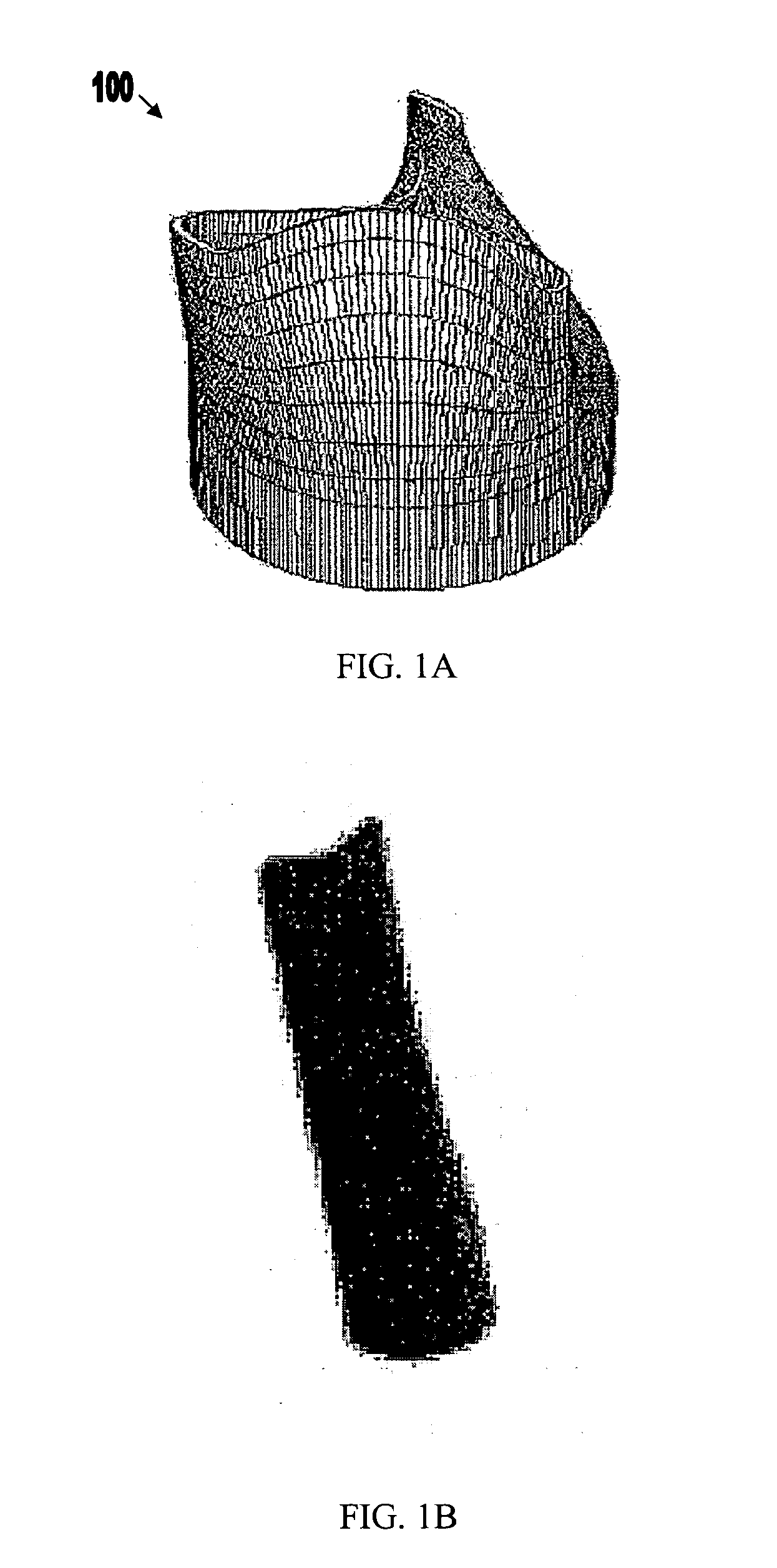

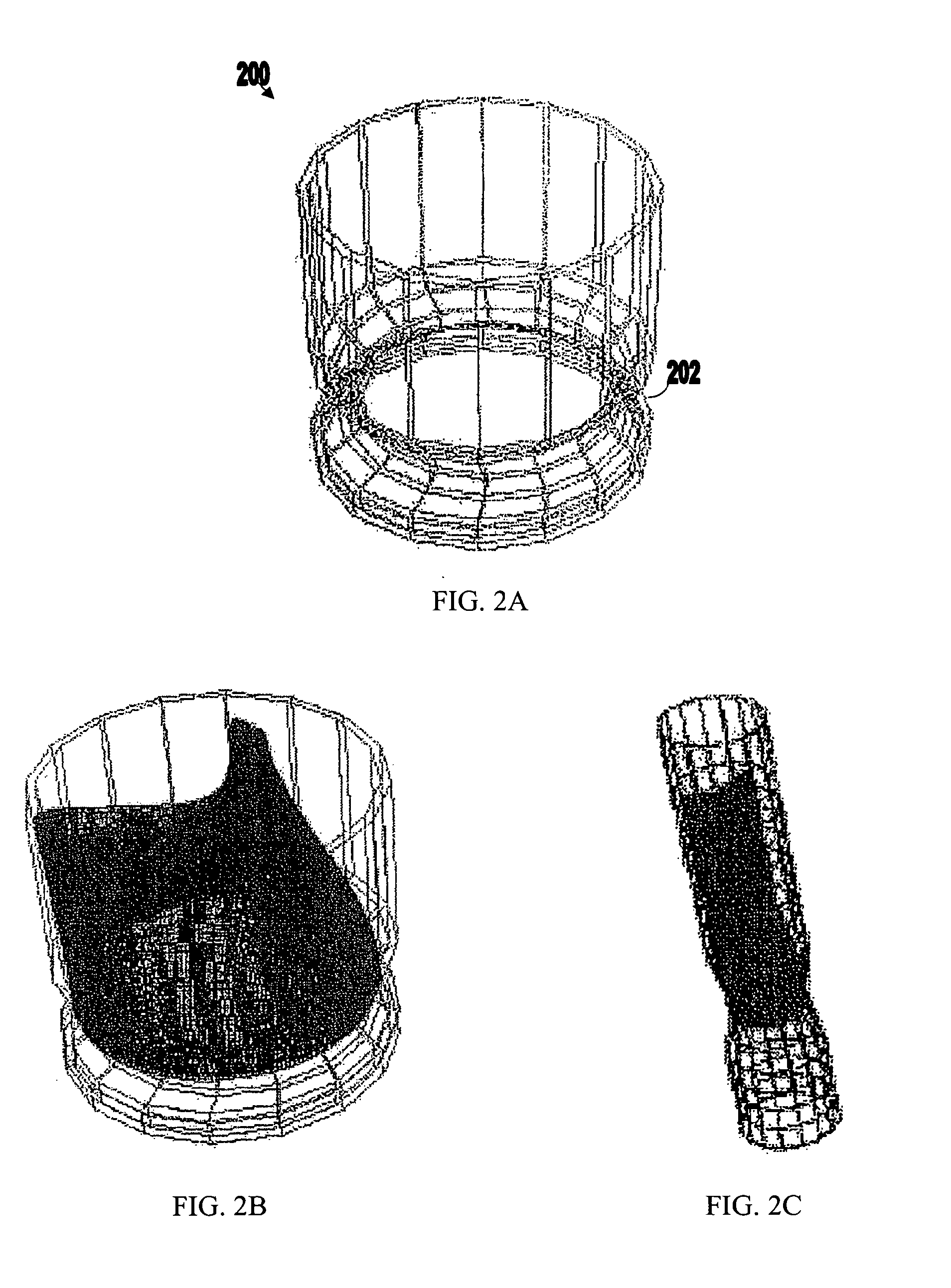

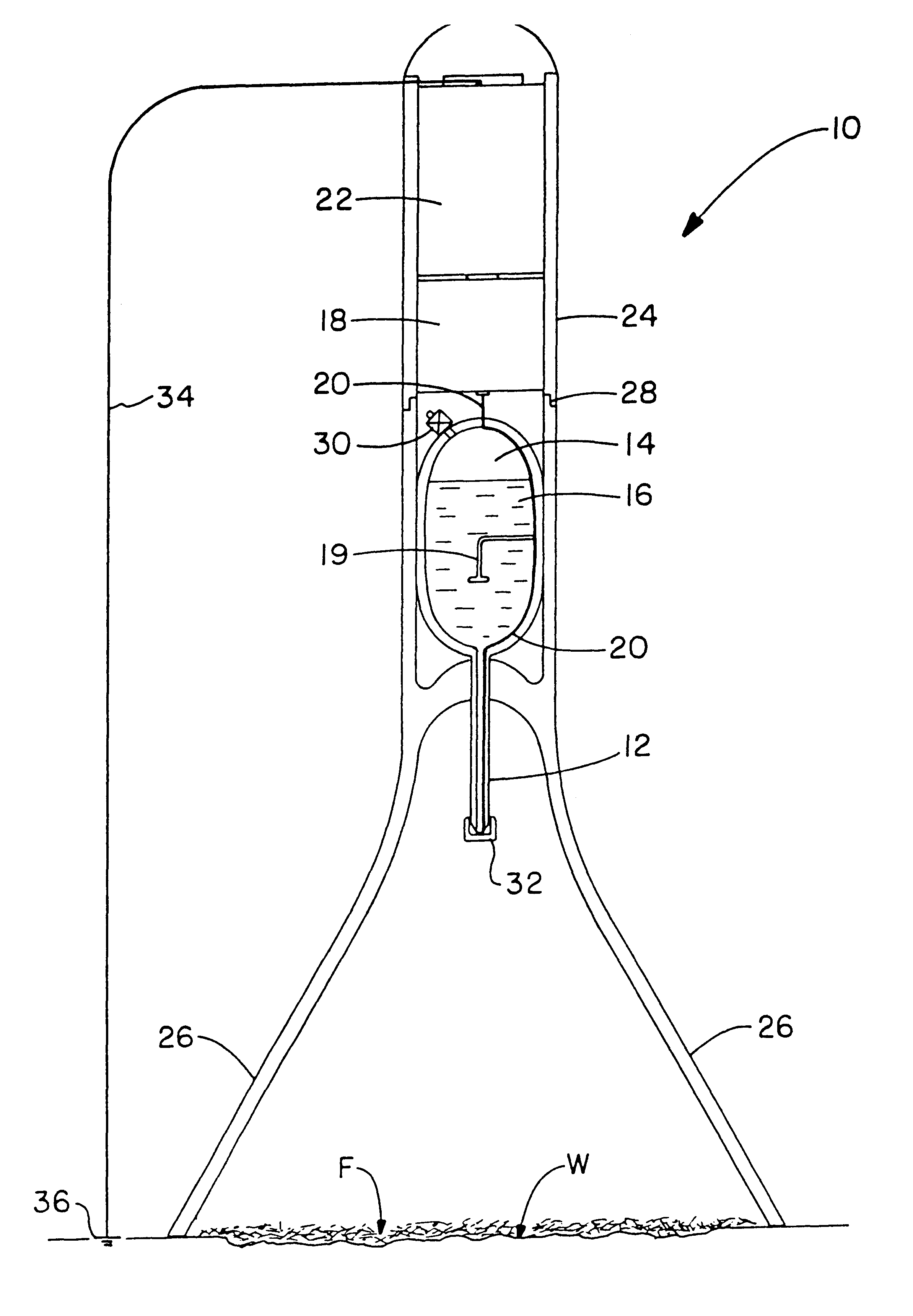

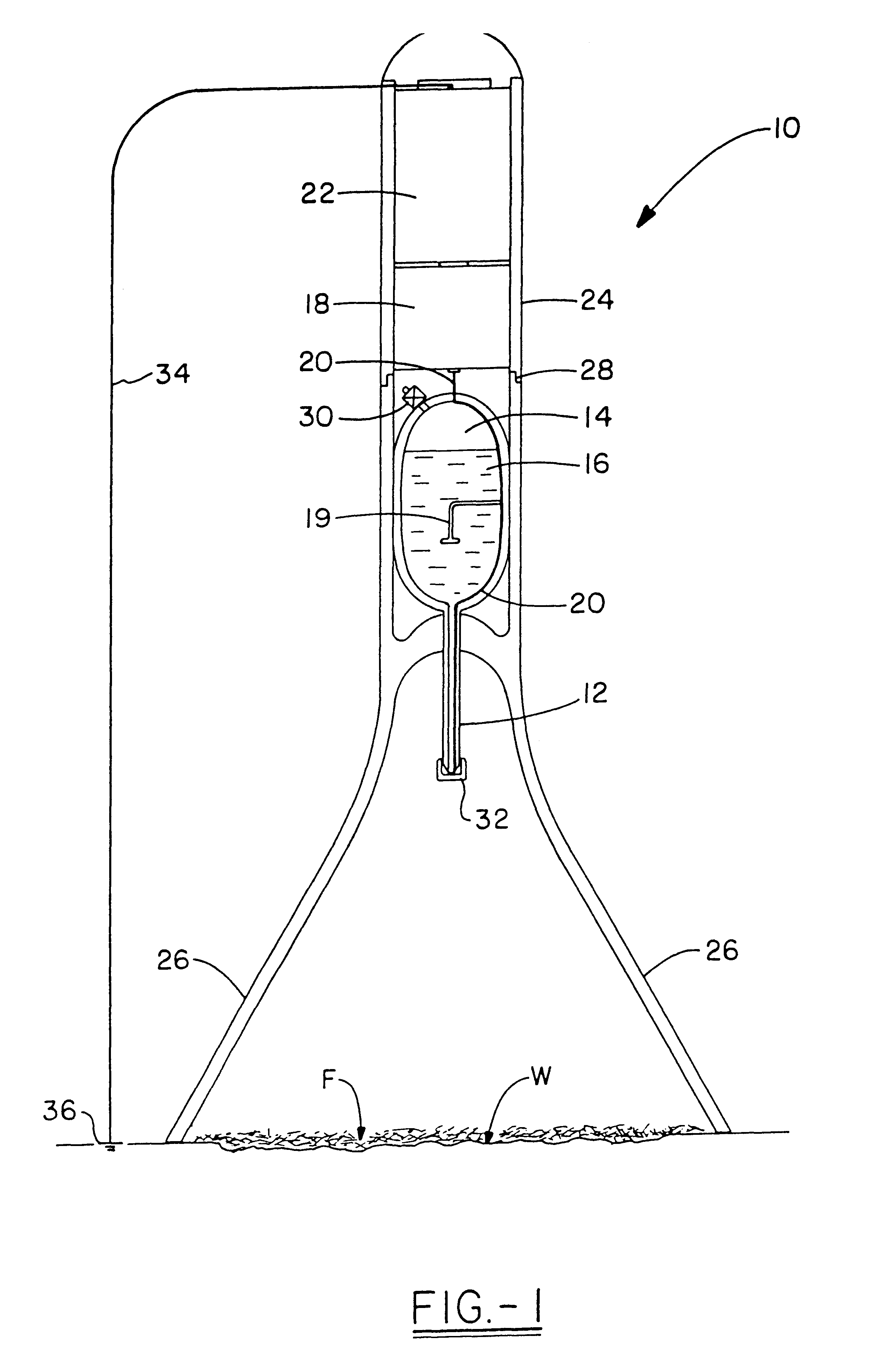

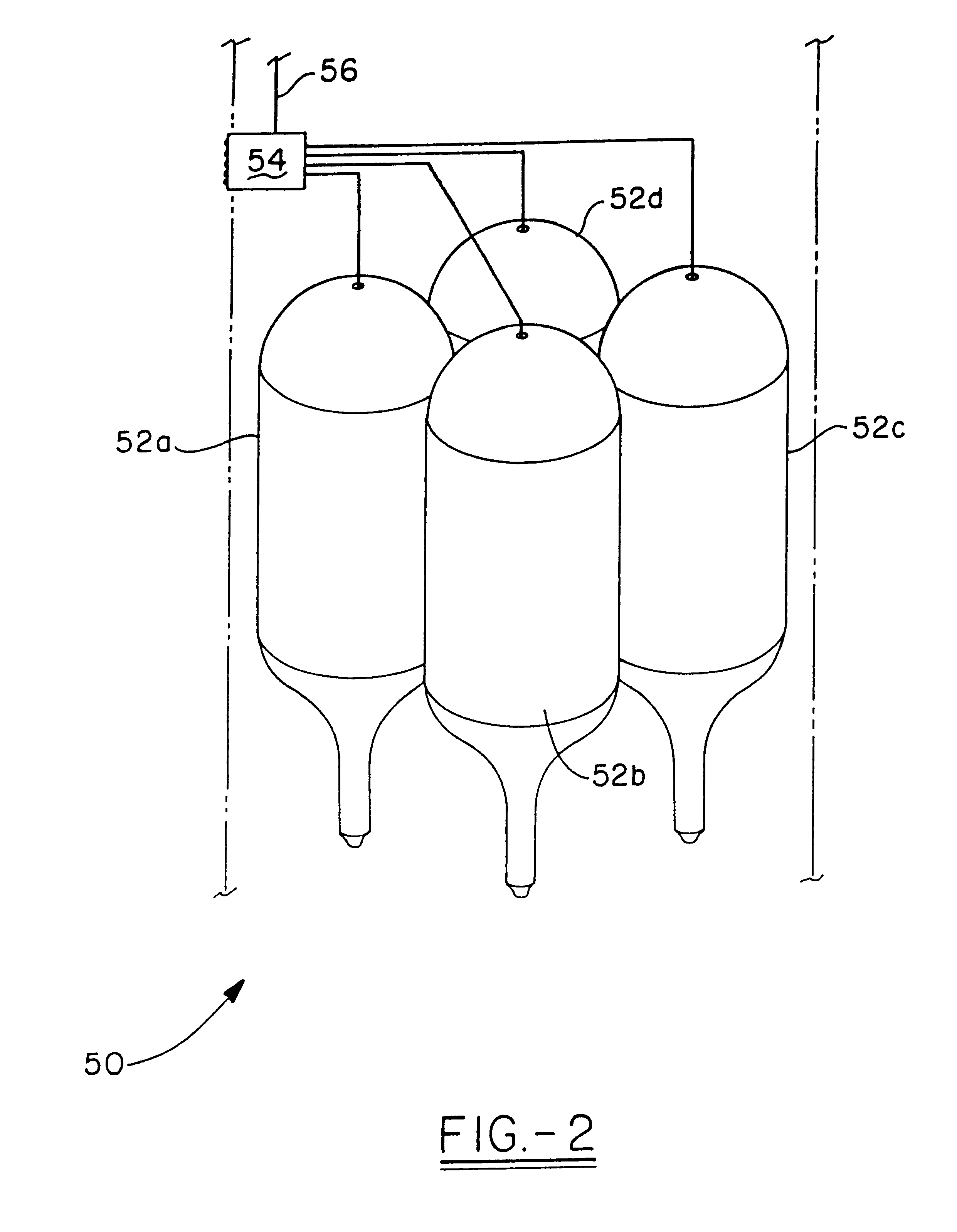

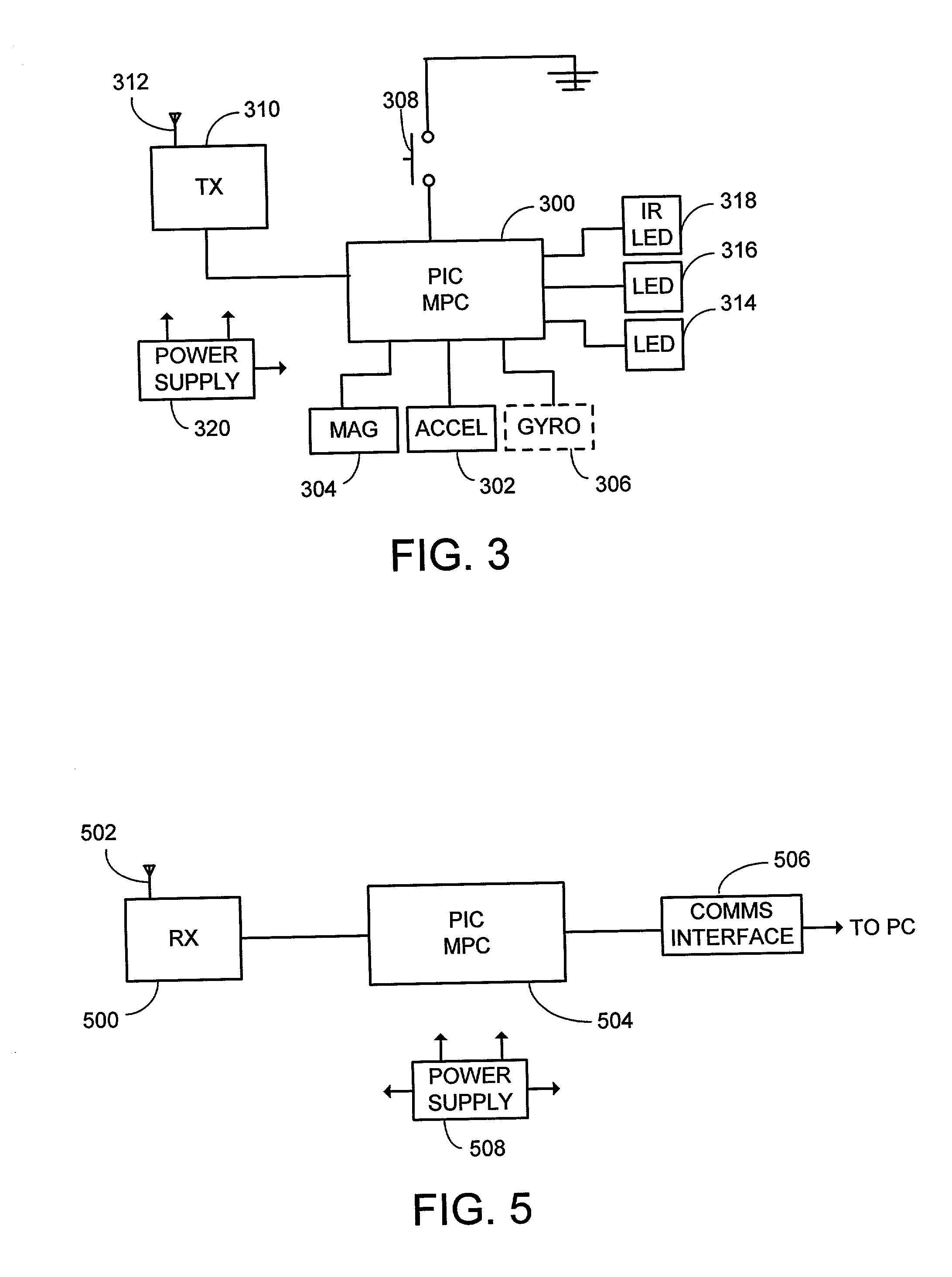

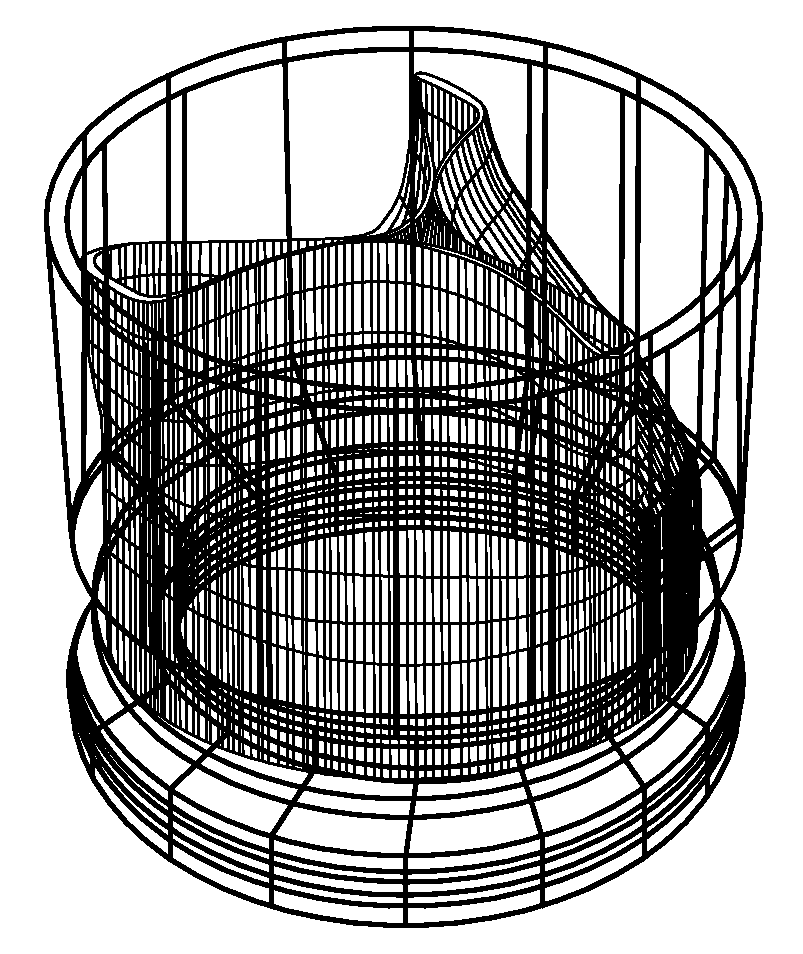

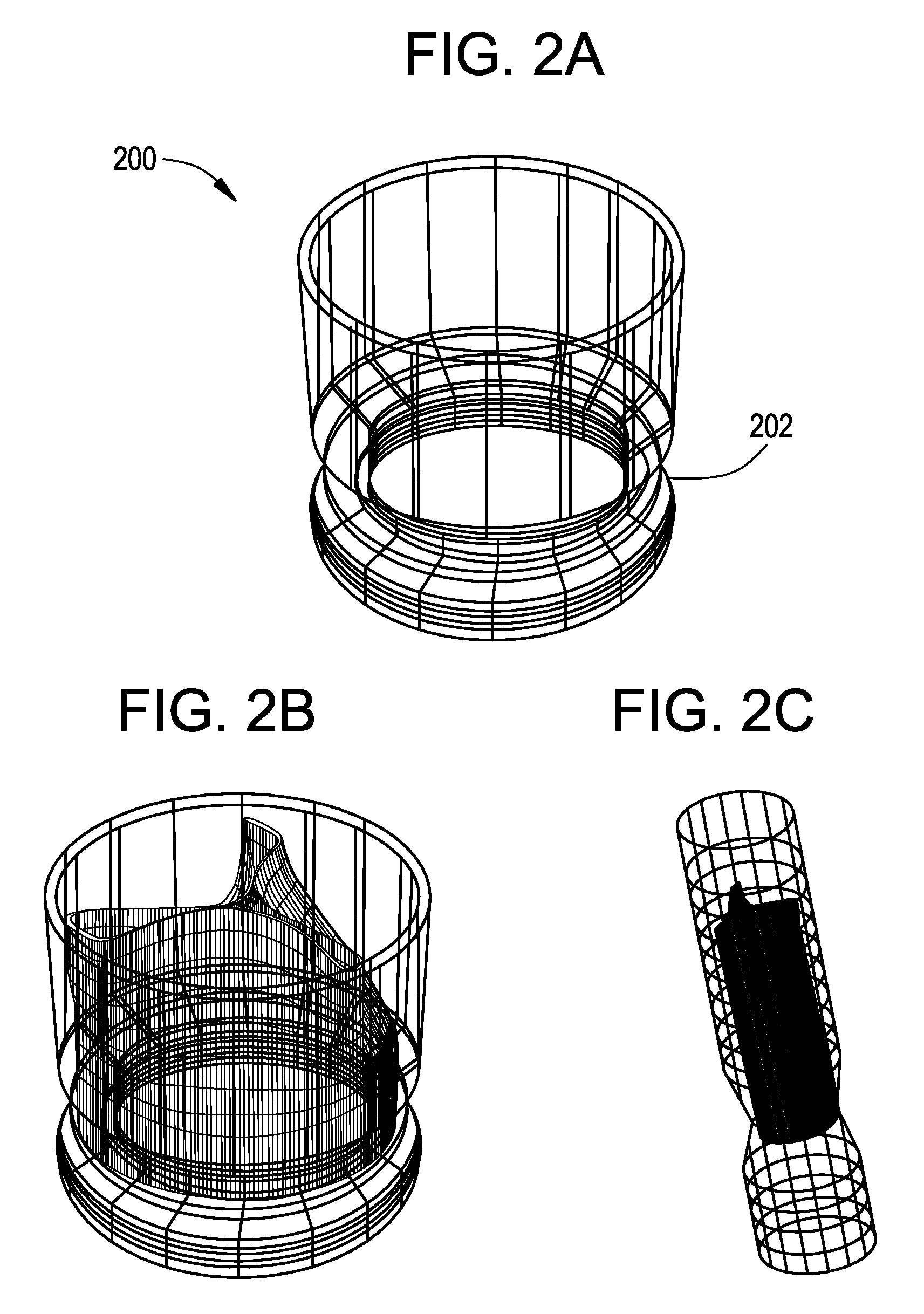

Stent-valves for valve replacement and associated methods and systems for surgery

InactiveUS20070213813A1Simple methodReduce riskStentsBalloon catheterLess invasive surgeryInsertion stent

Stent-valves (e.g., single-stent-valves and double-stent-valves), associated methods and systems for their delivery via minimally-invasive surgery, and guide-wire compatible closure devices for sealing access orifices are provided.

Owner:SYMETIS

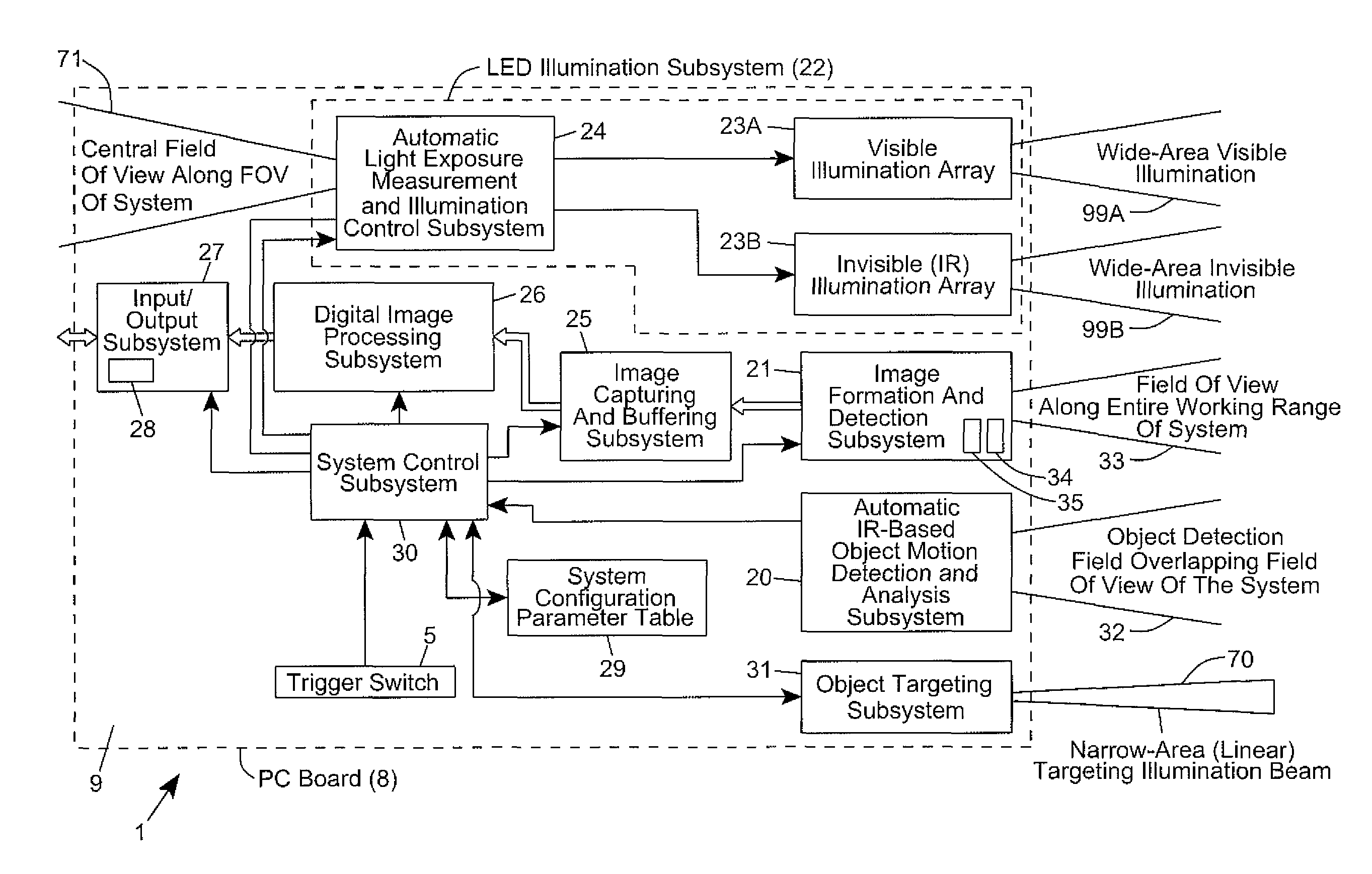

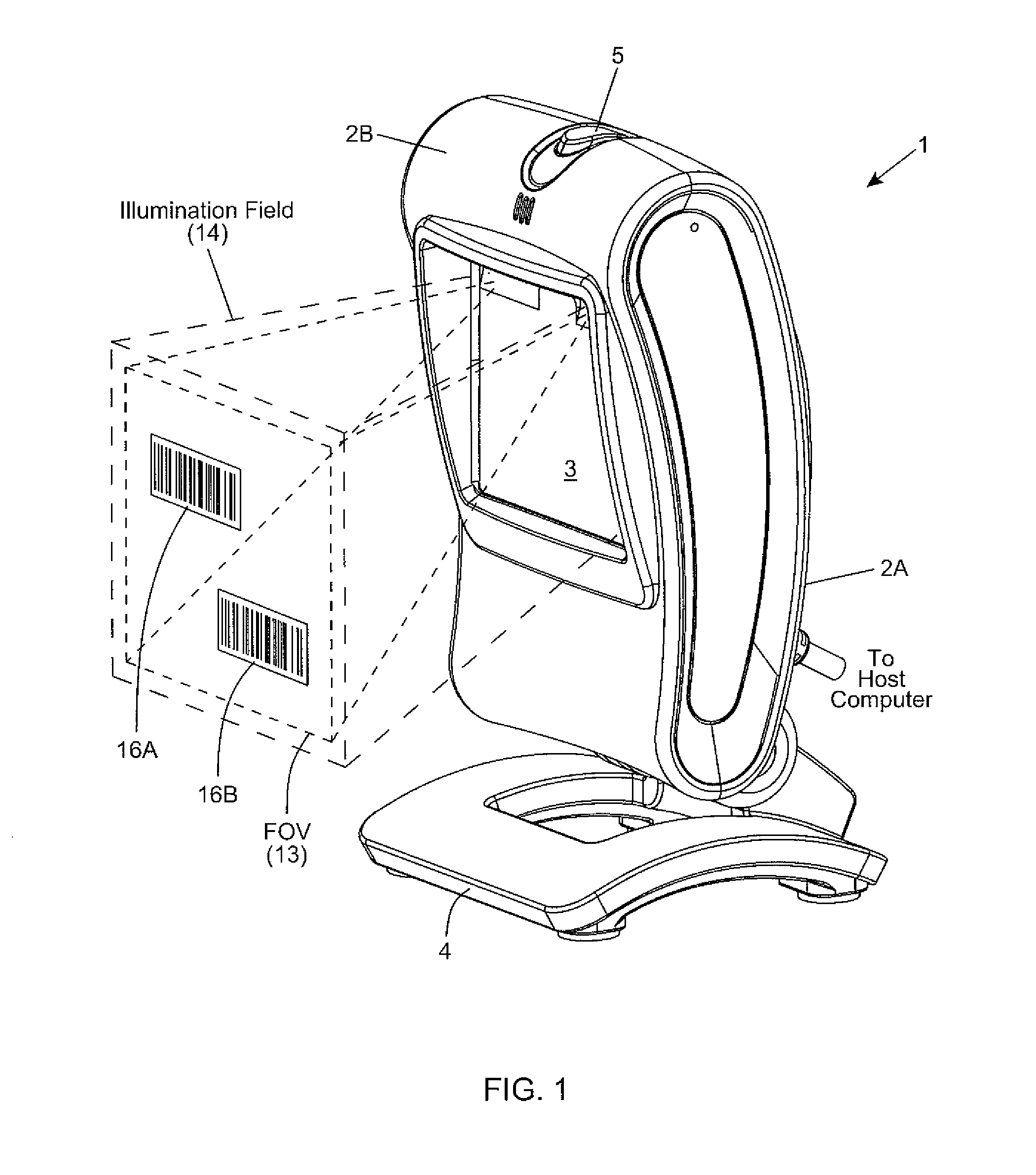

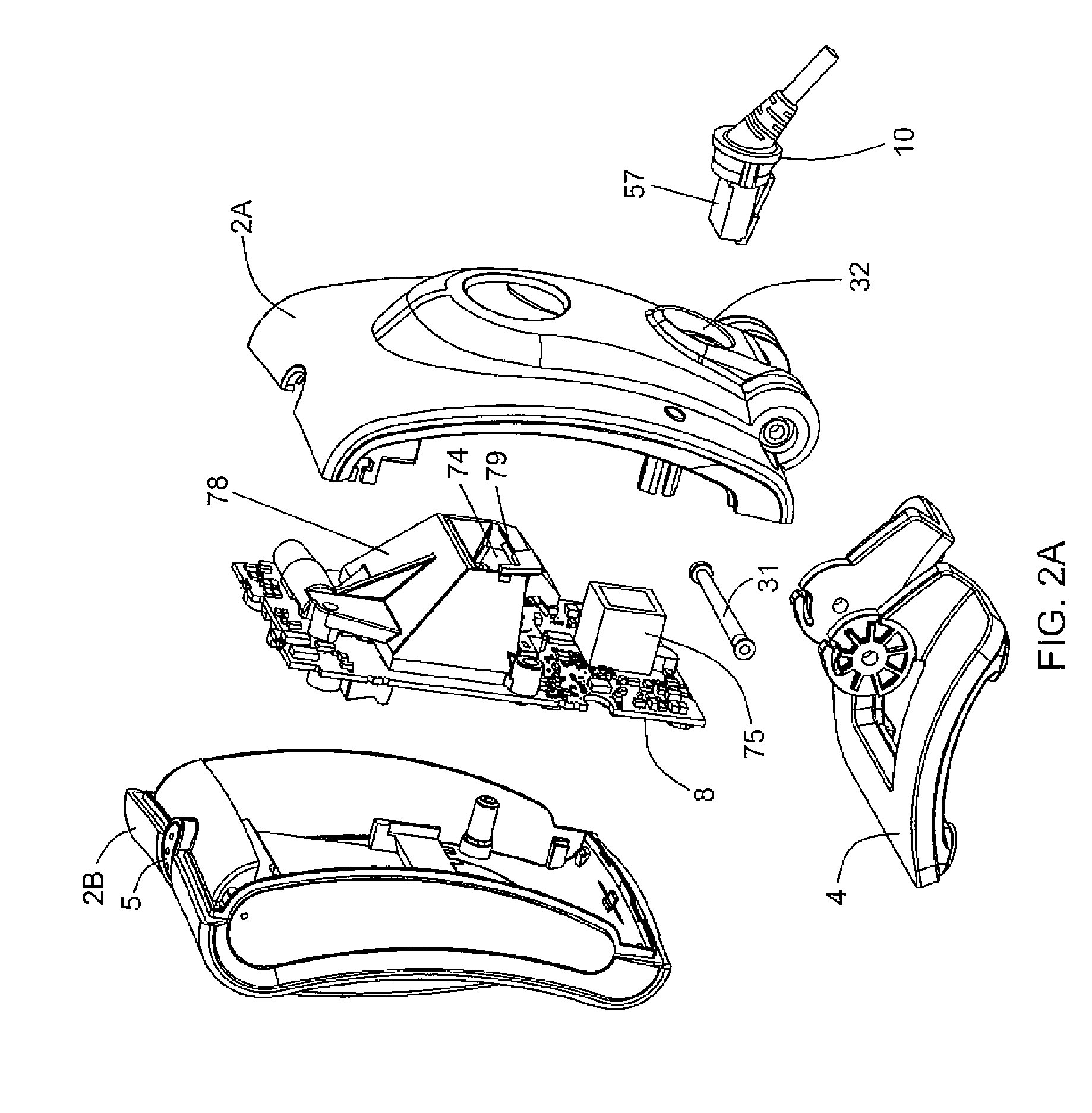

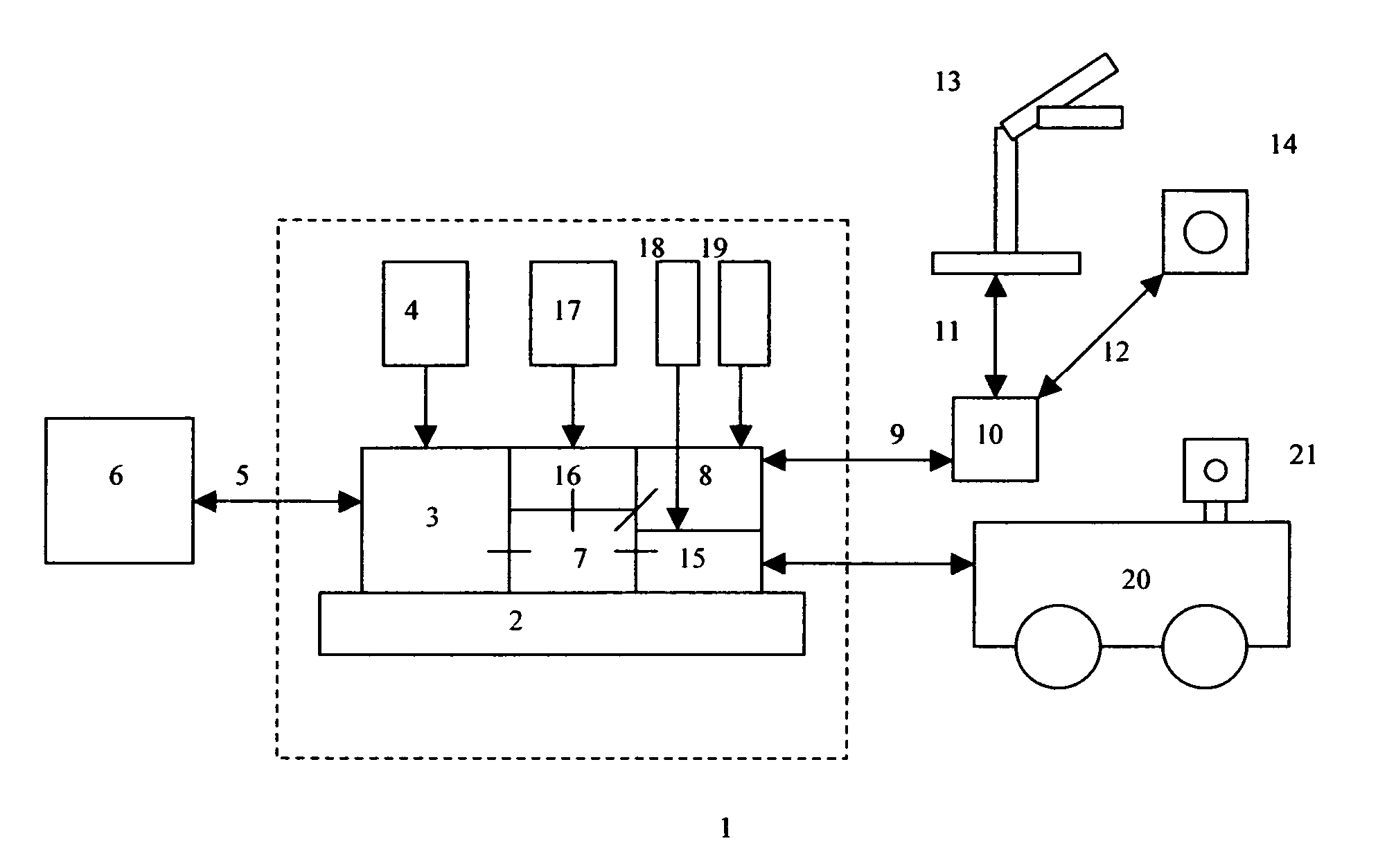

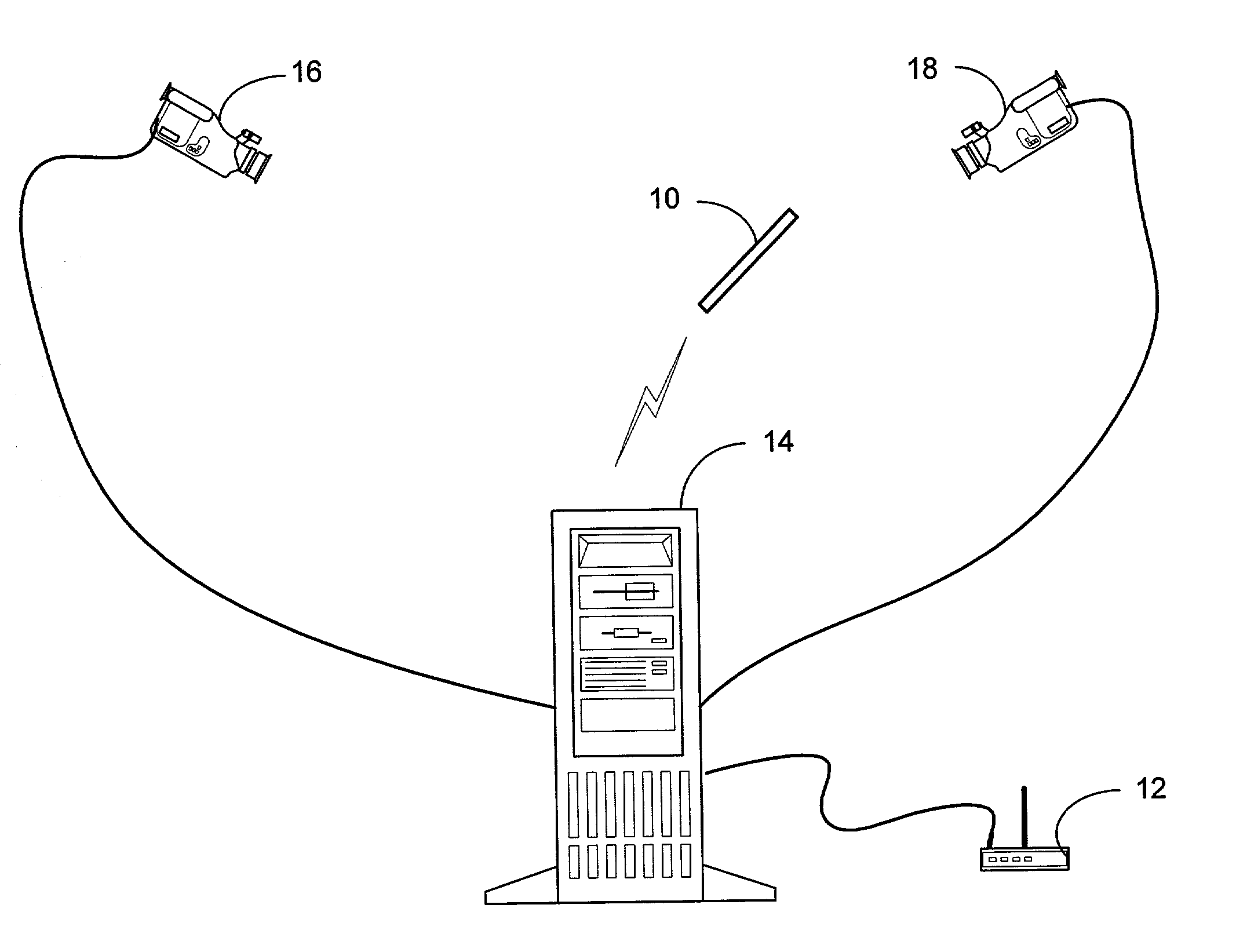

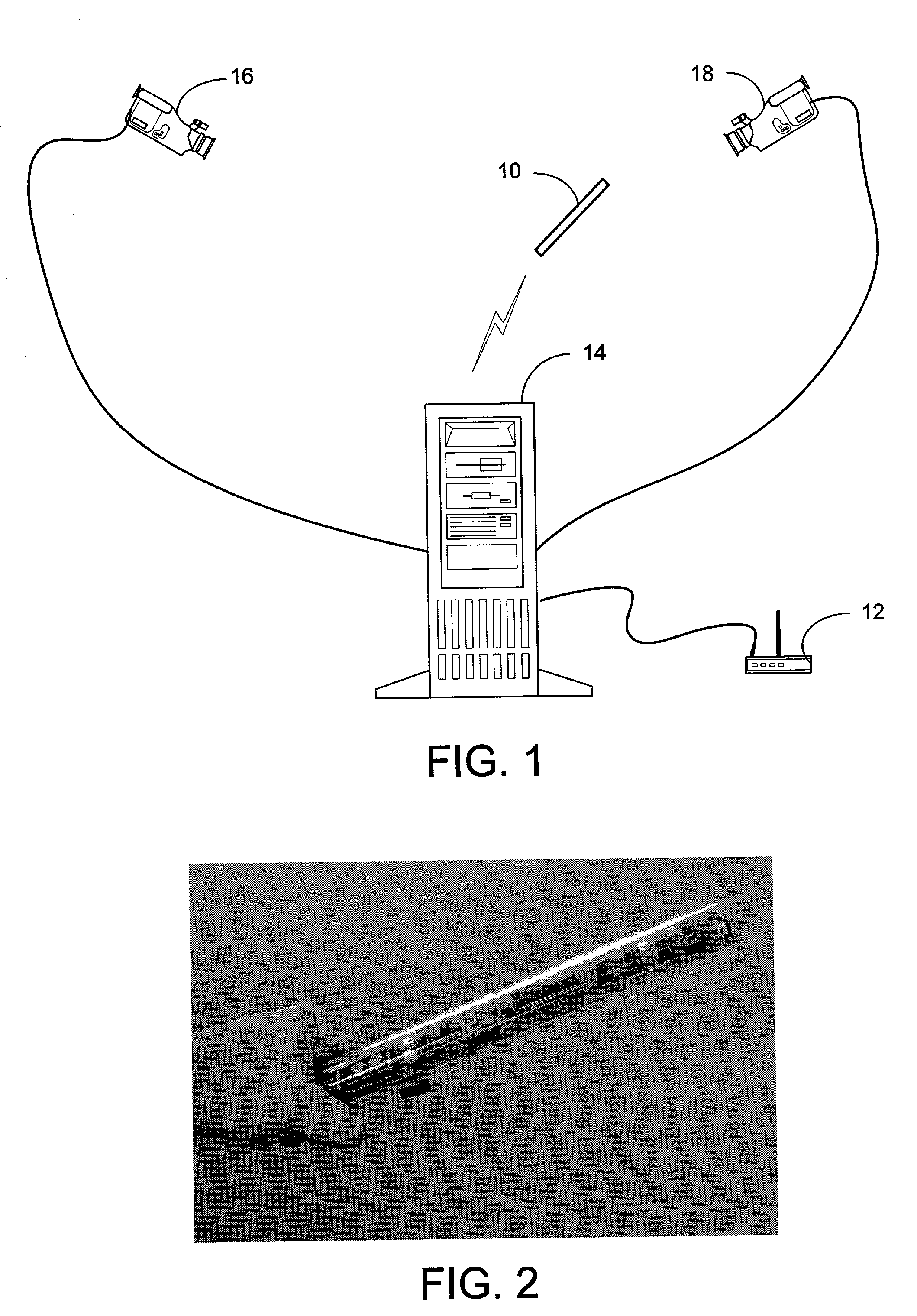

Method of and system for reading visible and/or invisible code symbols in a user-transparent manner using visible/invisible illumination source switching during data capture and processing operations

ActiveUS8408468B2Avoiding shortcoming and drawbackWithout complexityCharacter and pattern recognitionHybrid readersComputer scienceComputer graphics (images)

Method of and system for reading visible and / or invisible code symbols in a user-transparent manner using visible / invisible illumination switching during data capture and processing operations.

Owner:METROLOGIC INSTR

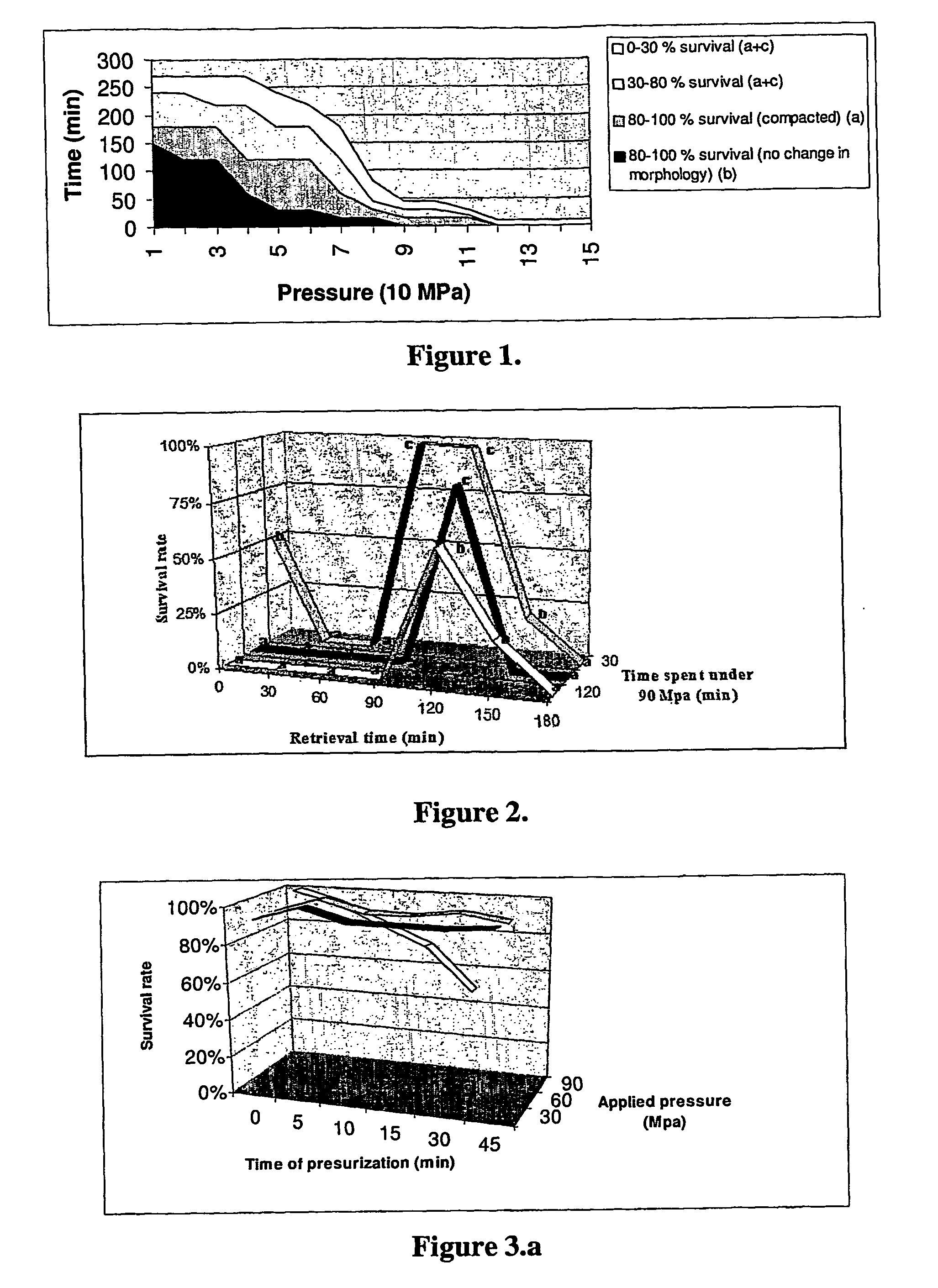

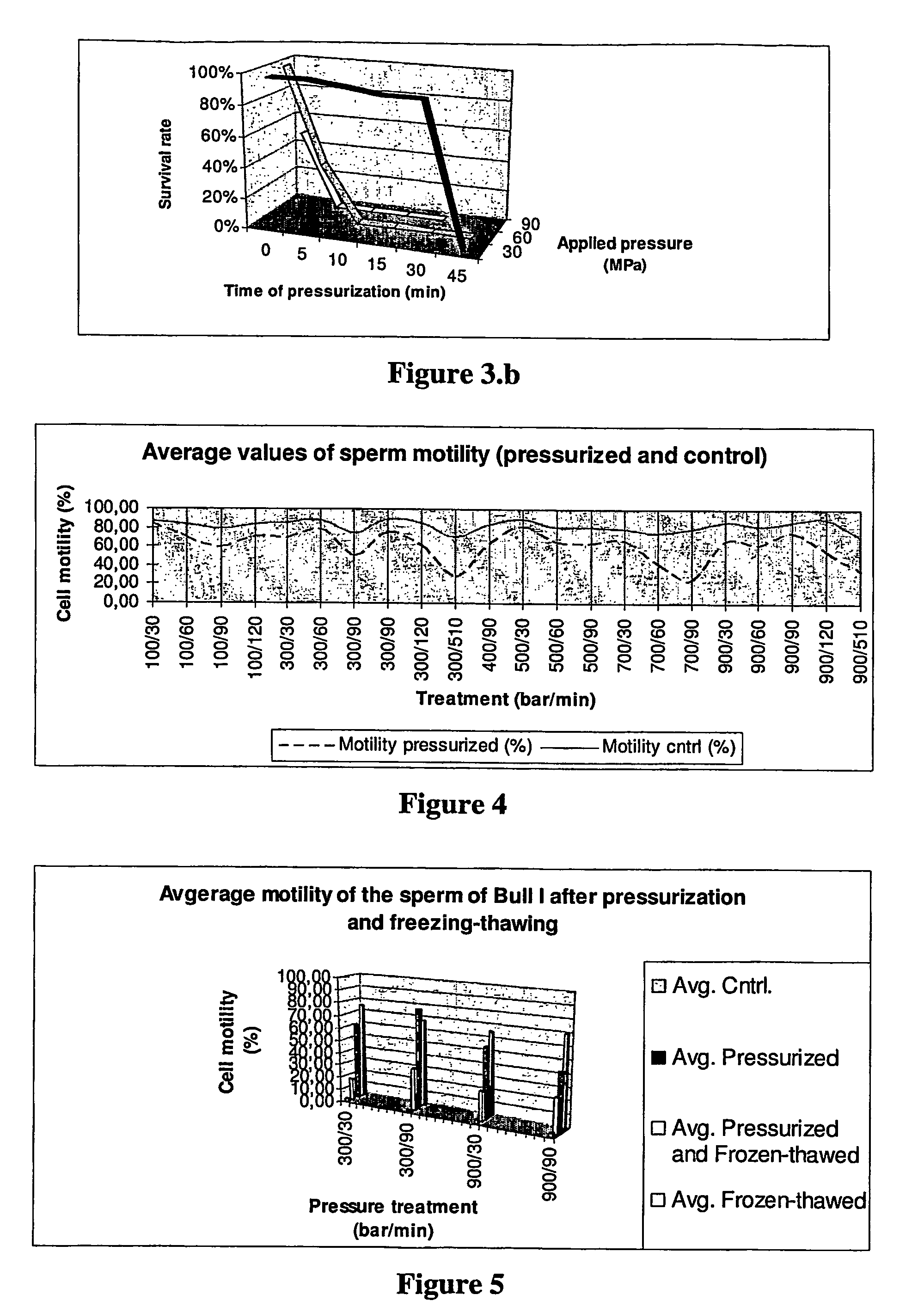

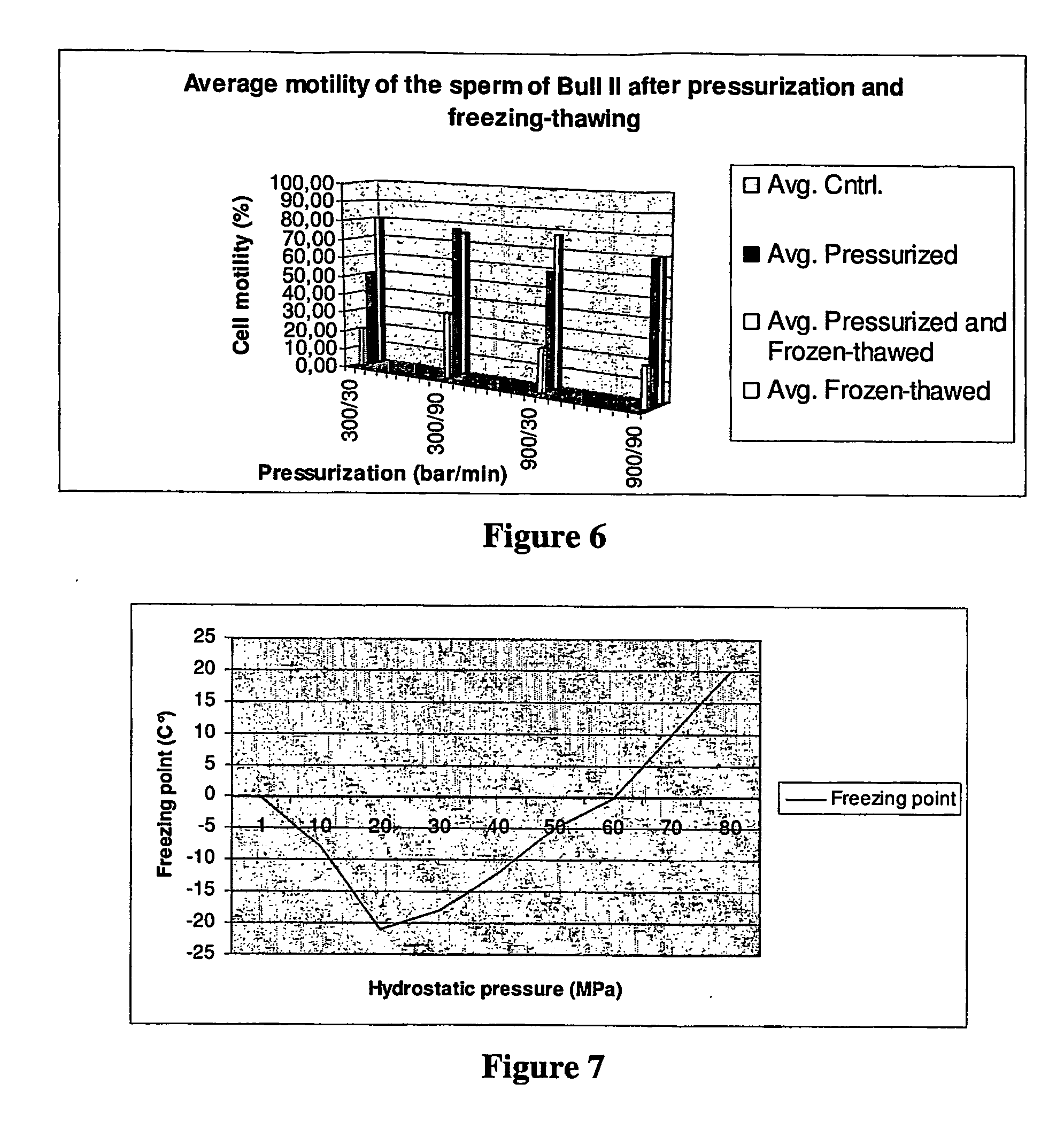

Post-thaw survival of chryopreserved biological material by hydrostatic pressure challenge

InactiveUS20070087321A1Improve survivalSimple methodDead animal preservationHydrostatic pressurePre treatment

The present invention relates to a method for improving post-thaw survival of cryopreserved biological material comprising applying hydrostatic pressure to said biological material; keeping the said biological material at the hydrostatic pressure for a predetermined time period; releasing the hydrostatic pressure; and freezing the said biological material using any protocol applicable thereto. The invention also relates to the use of a pressurizing device for the pretreatment of a biological material that is to be cryopreserved, as well as to a pressurizing device for the pretreatment of a biological material that is to be cryopreserved, said device comprising a pressure chamber for receiving biological material, means to produce said pressure, and means to maintain said pressure in said chamber.

Owner:APPL CELL TECH KORLATOLT FELELOSSEGU TARSASAG

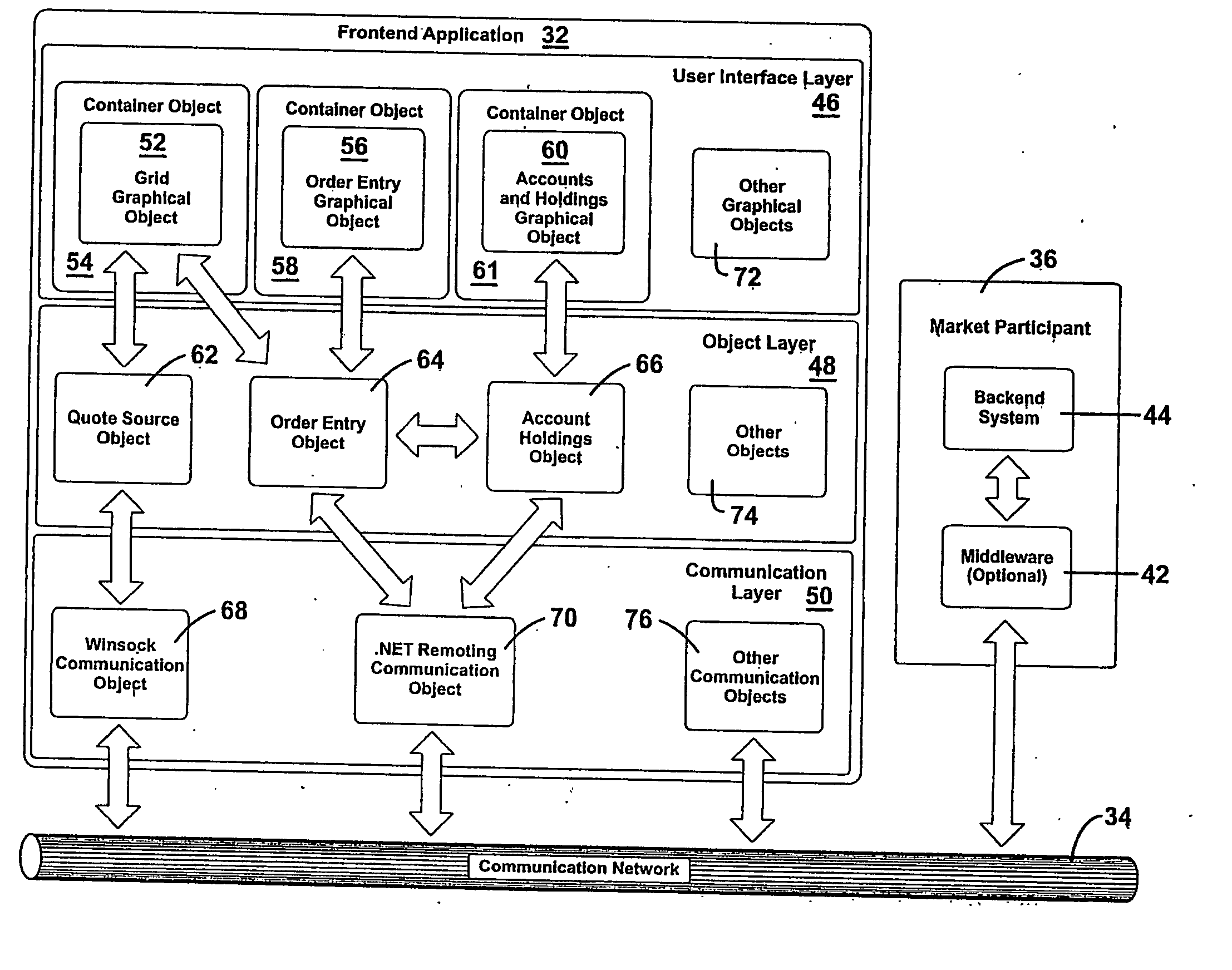

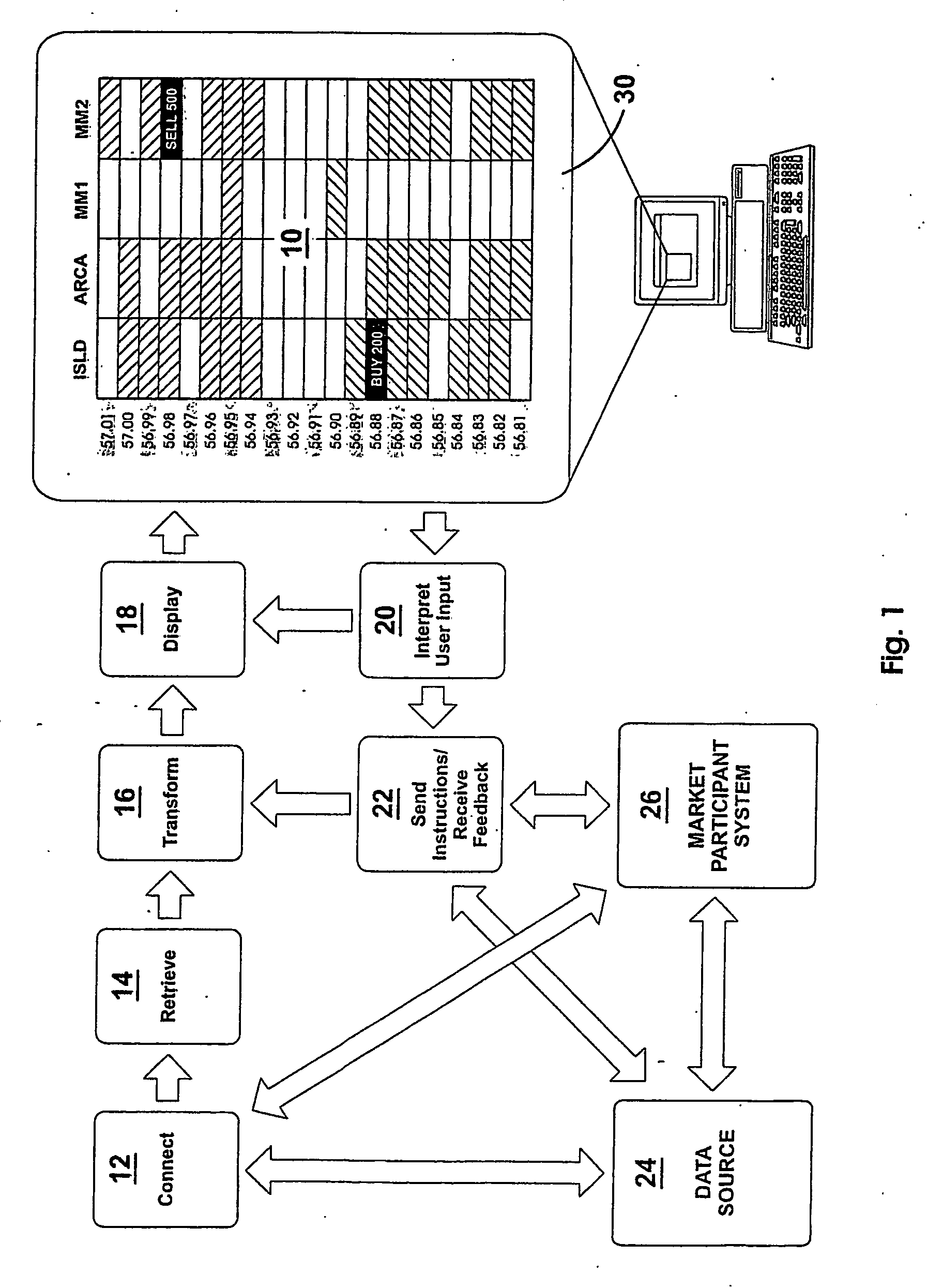

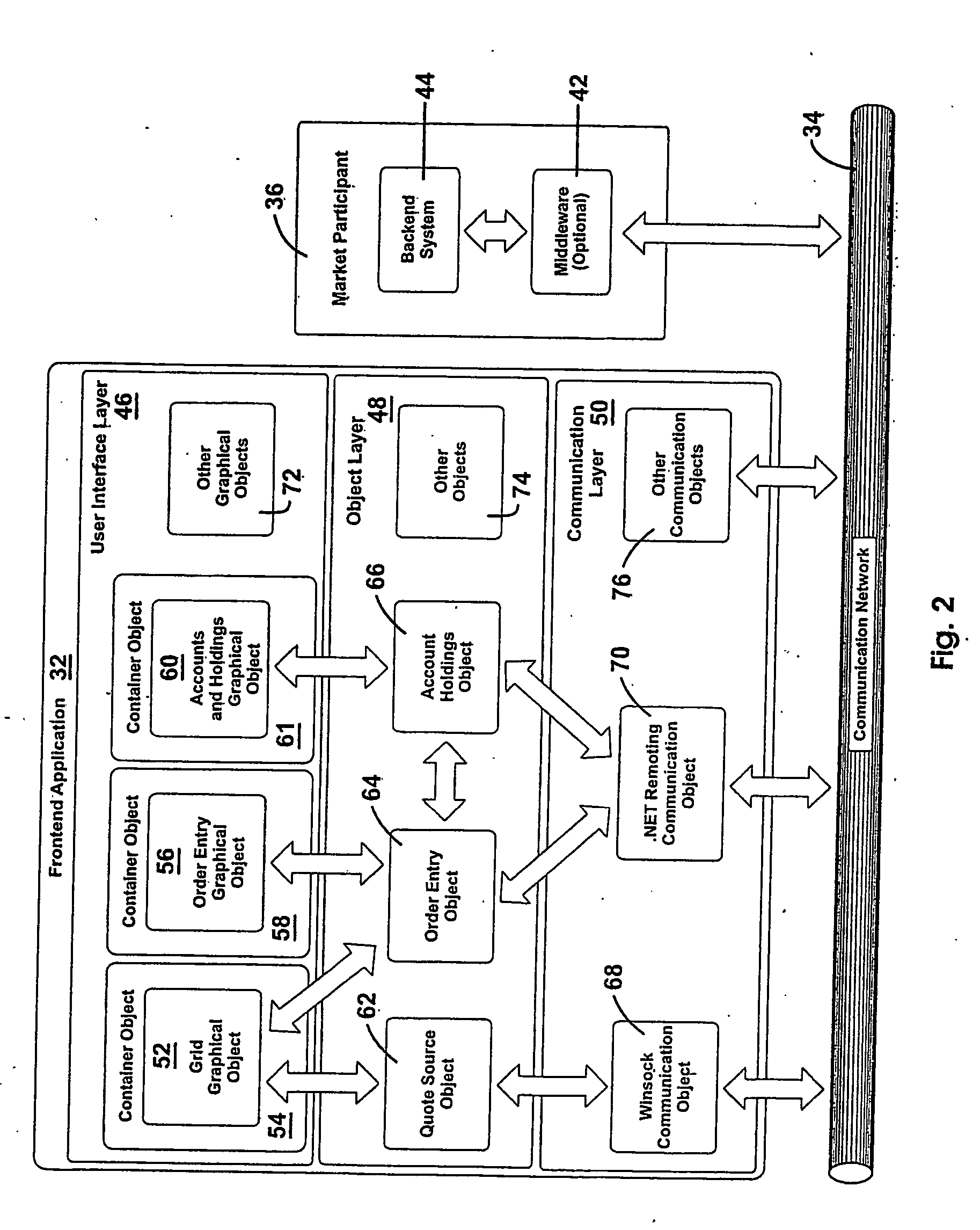

Method of buying or selling items and a user interface to facilitate the same

InactiveUS20060069635A1Easy to useFast and efficient and intuitive and user friendlySpecial service provision for substationFinanceMarket placeFinancial transaction

A method of buying or selling items having at least one market and its associated processes are disclosed. The method includes the steps of, under control of a client system, displaying information identifying at least one item and a bid and / or ask price for the item in the market; and specifying transaction conditions based on a user directed position of a moveable icon, where the transaction conditions are related to the buying or selling of the identified item in the active market. Then, in response to an action of the user sending a user transaction request at the transaction conditions displayed at the time of said action, facilitating financial transactions for the user in accordance with the transaction conditions to complete the transaction. In this manner, the item may be bought or sold by the user at the transaction conditions specified. A user interface to facilitate this method is also disclosed. A quantity recommendation system to facilitate the quantity decision of a financial transaction is further disclosed.

Owner:RAM PRANIL

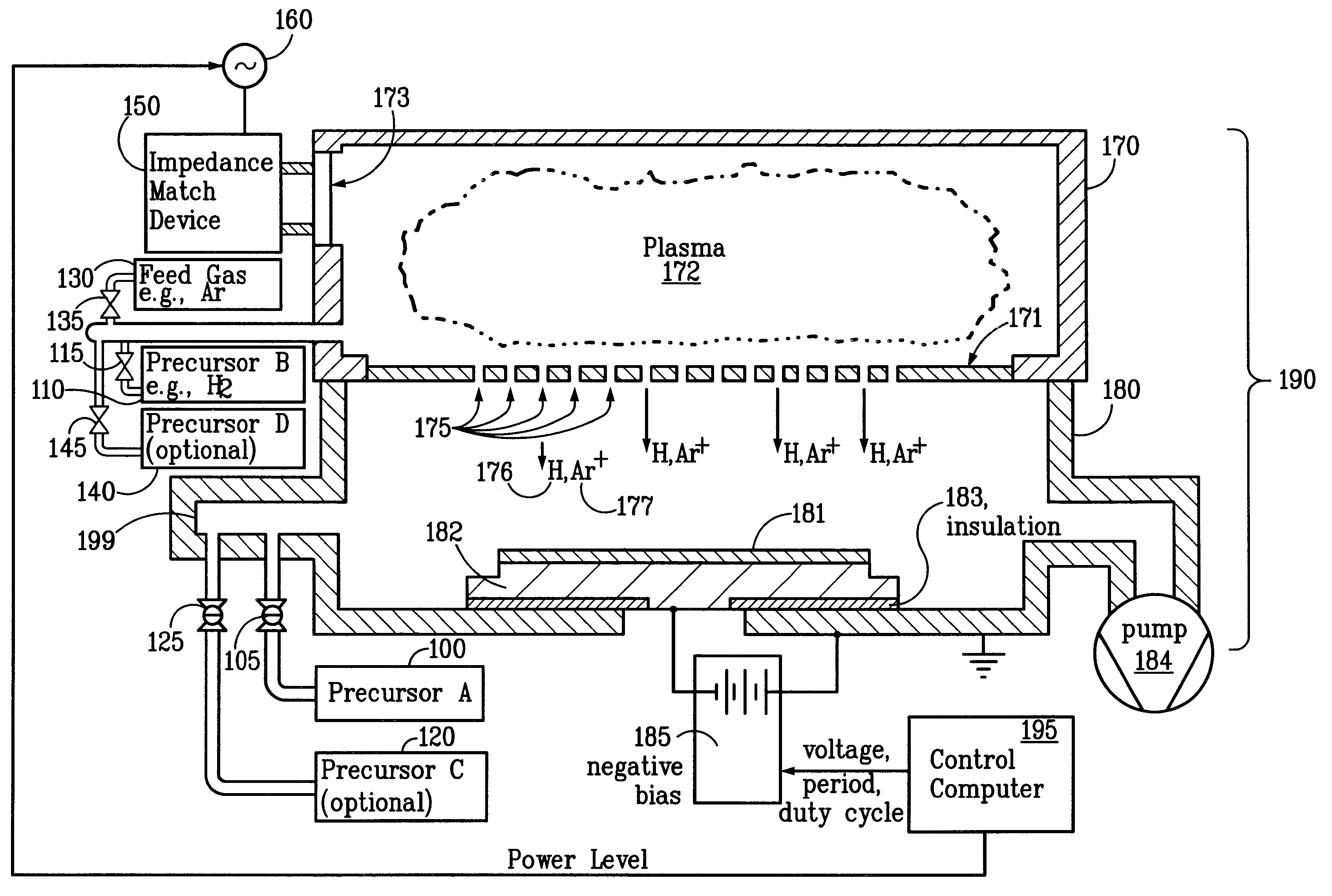

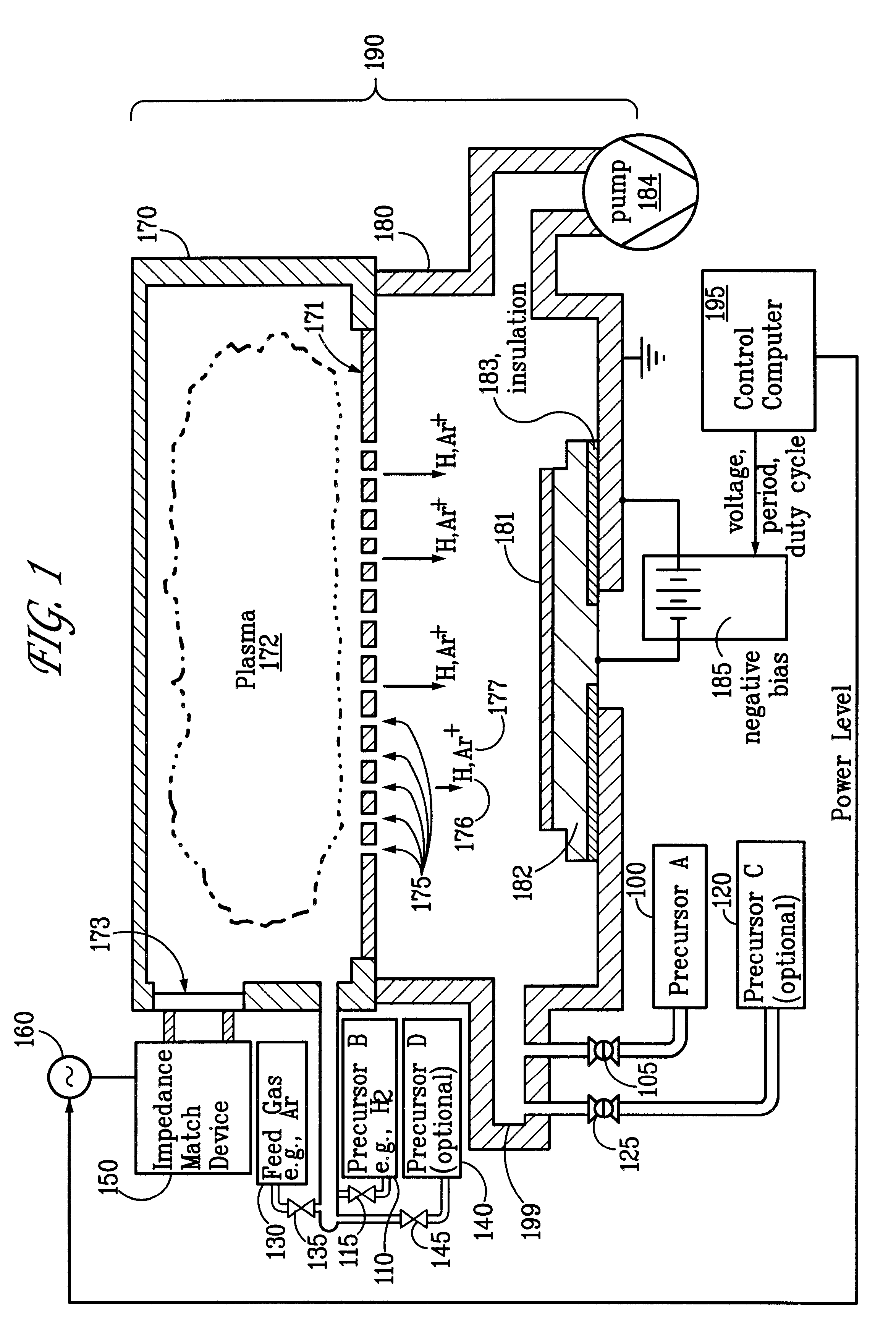

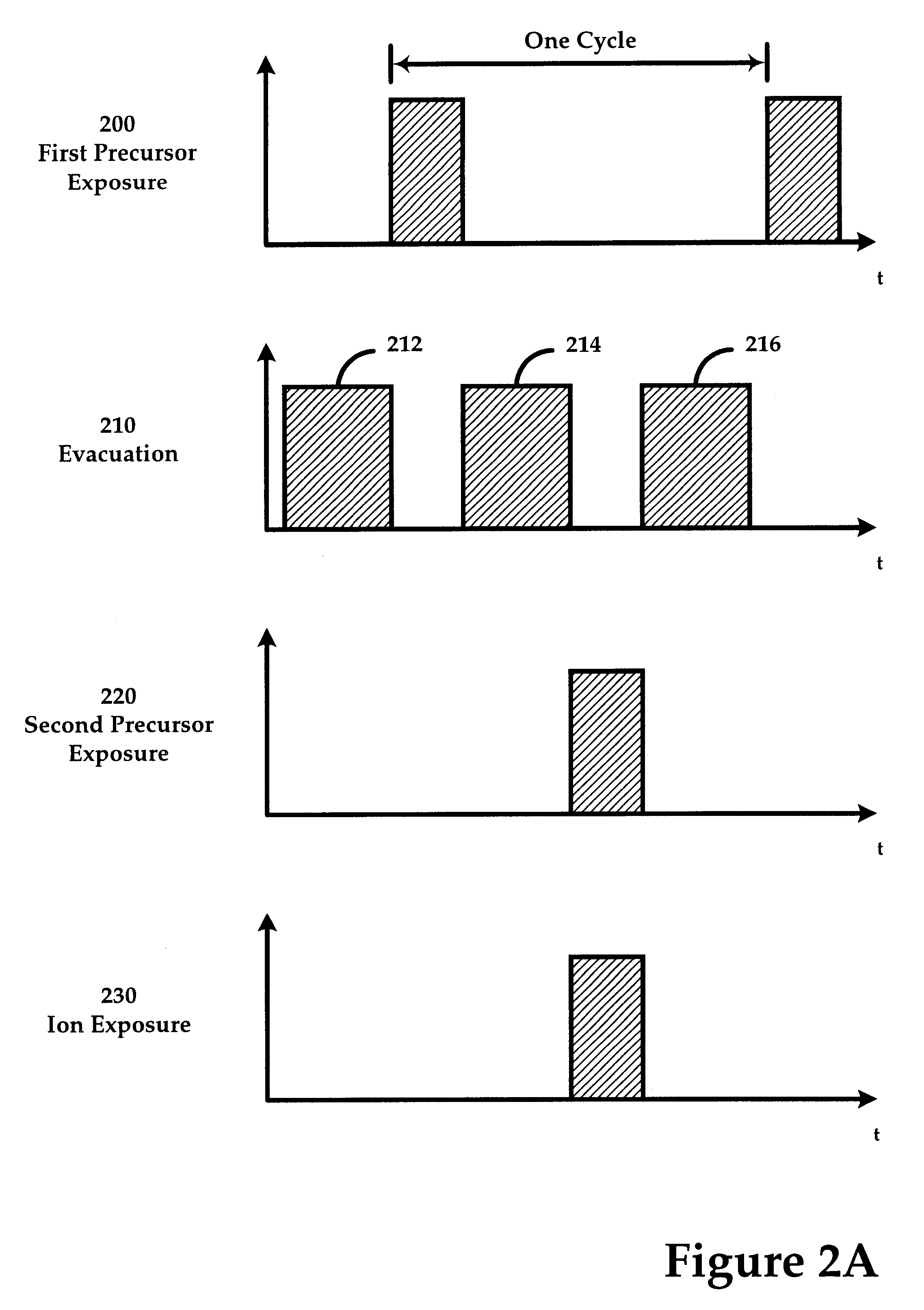

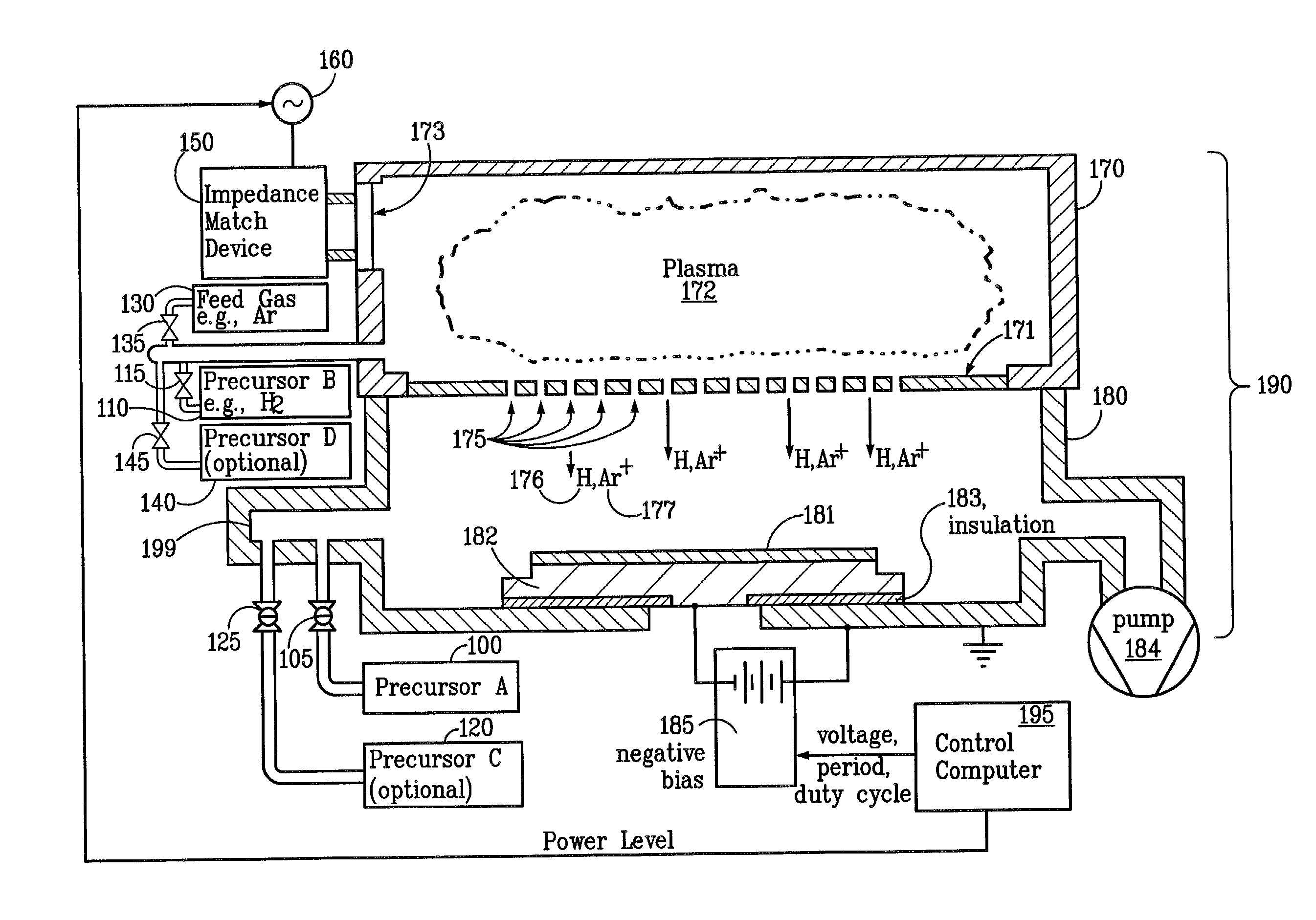

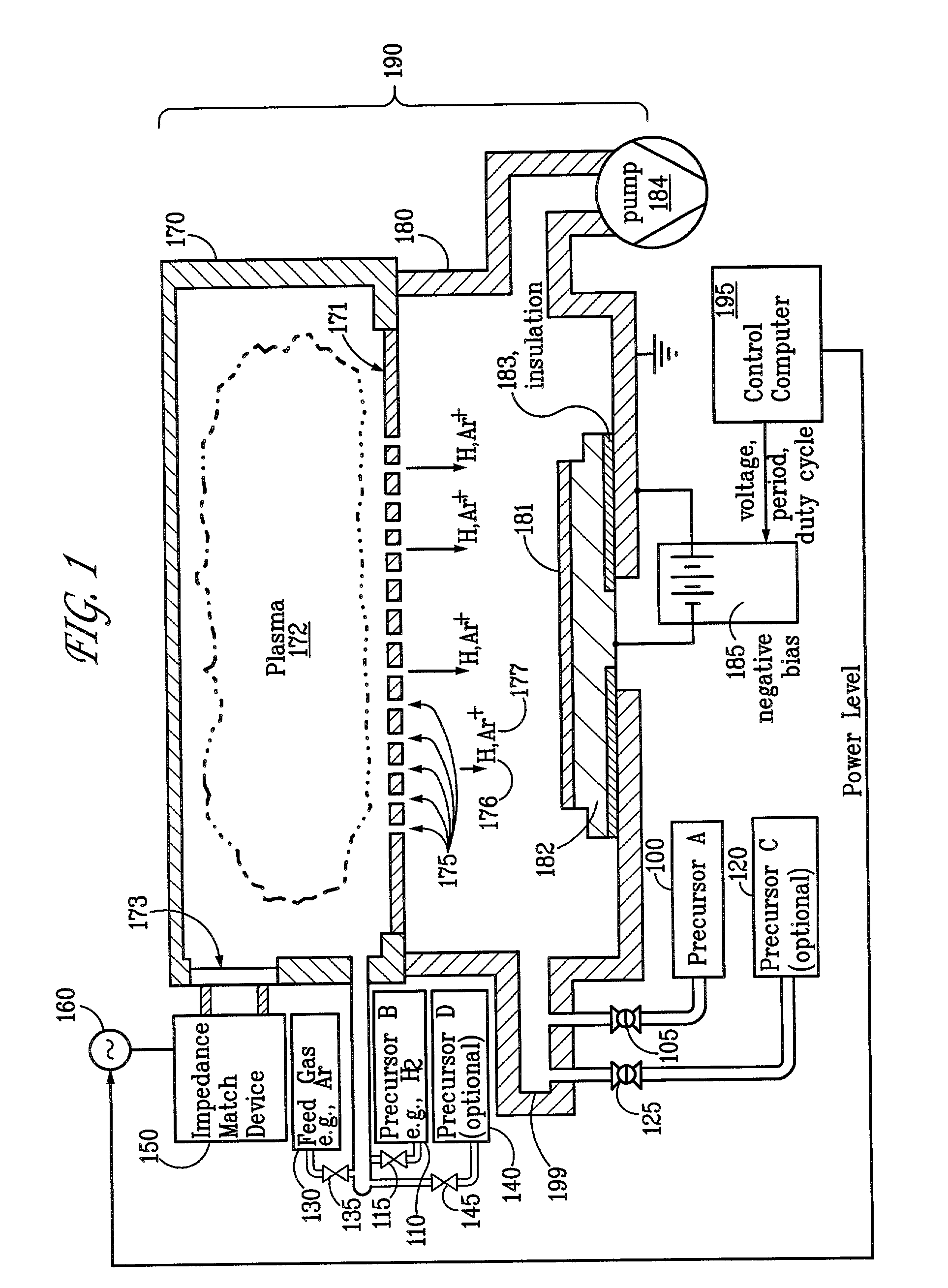

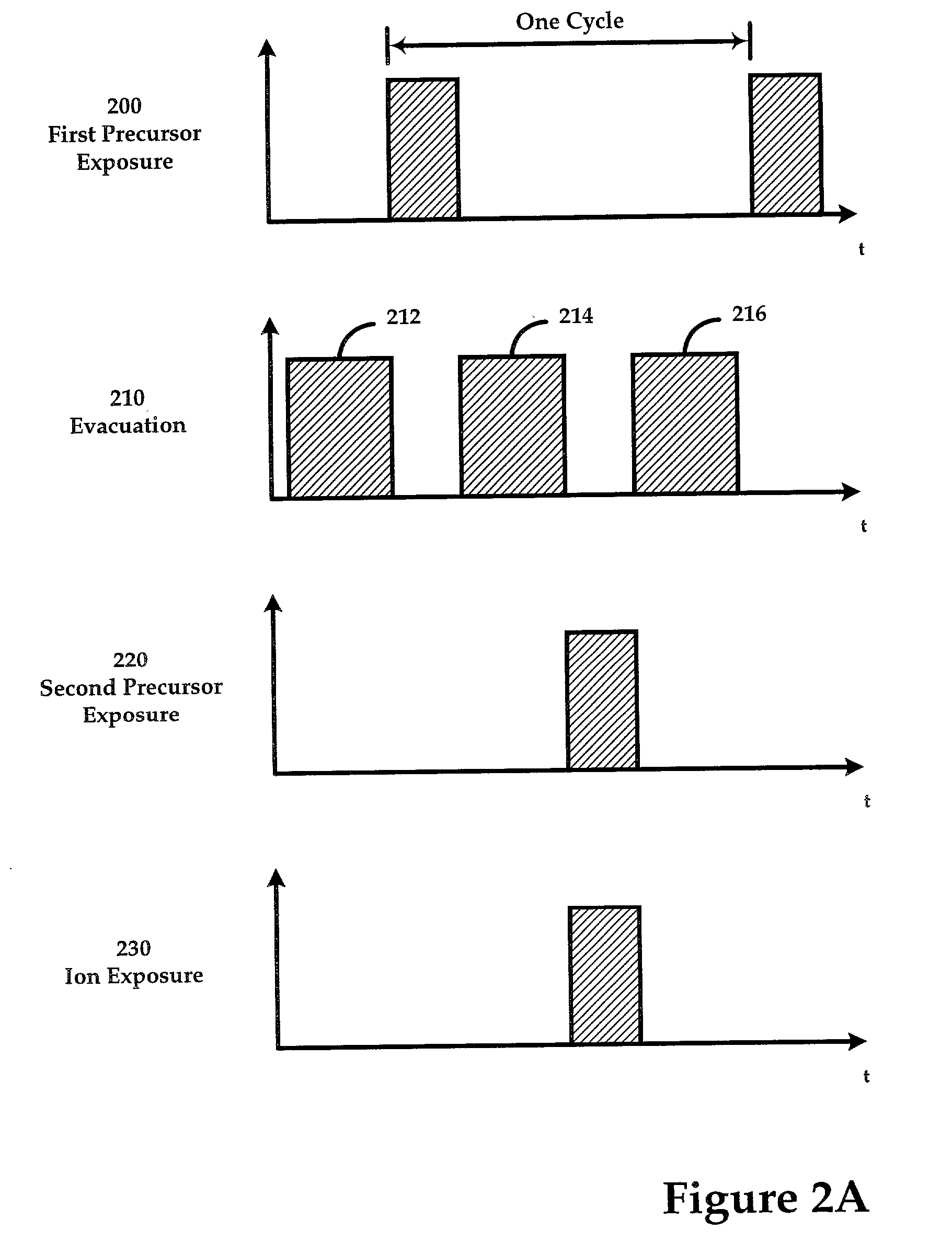

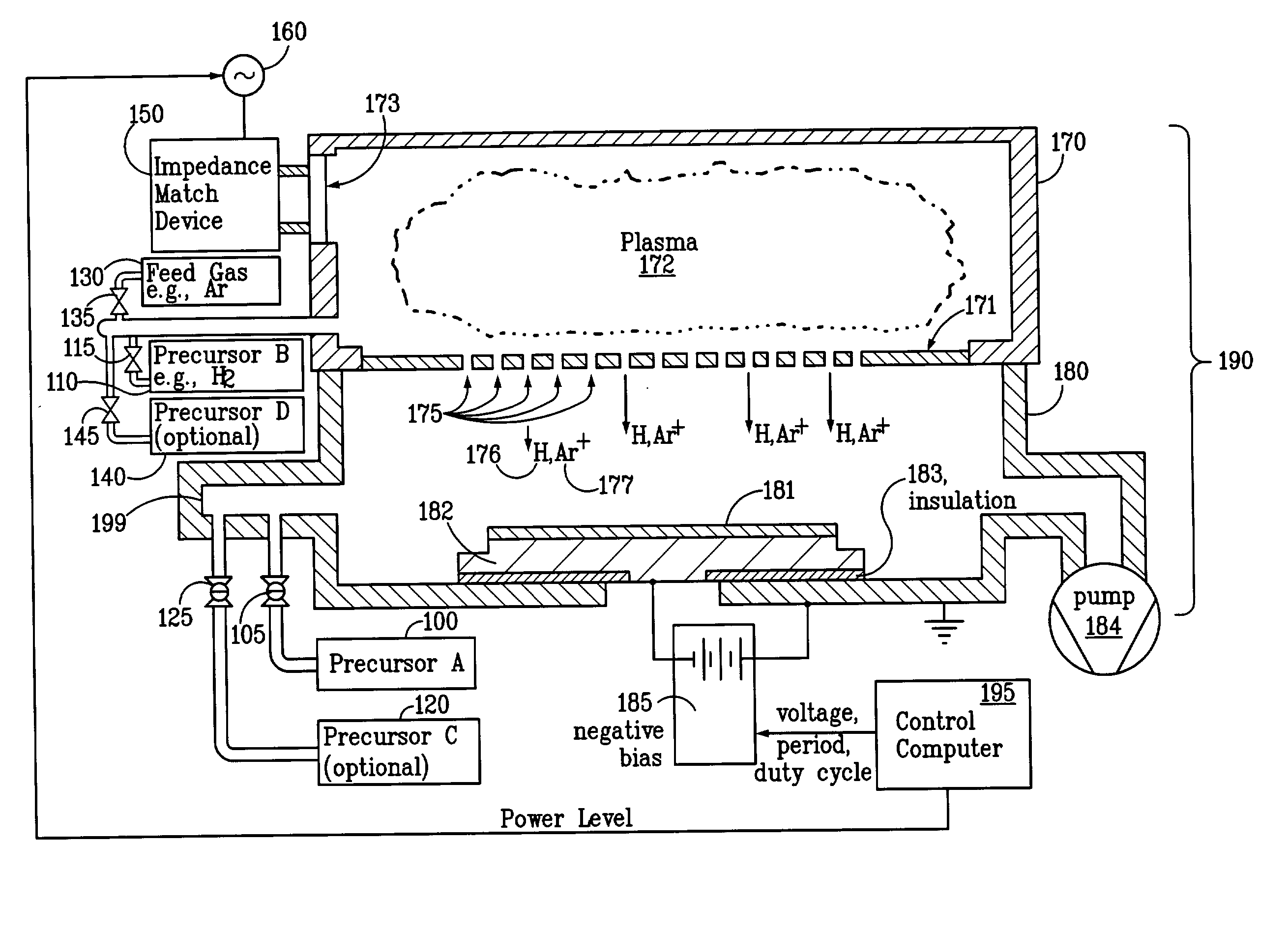

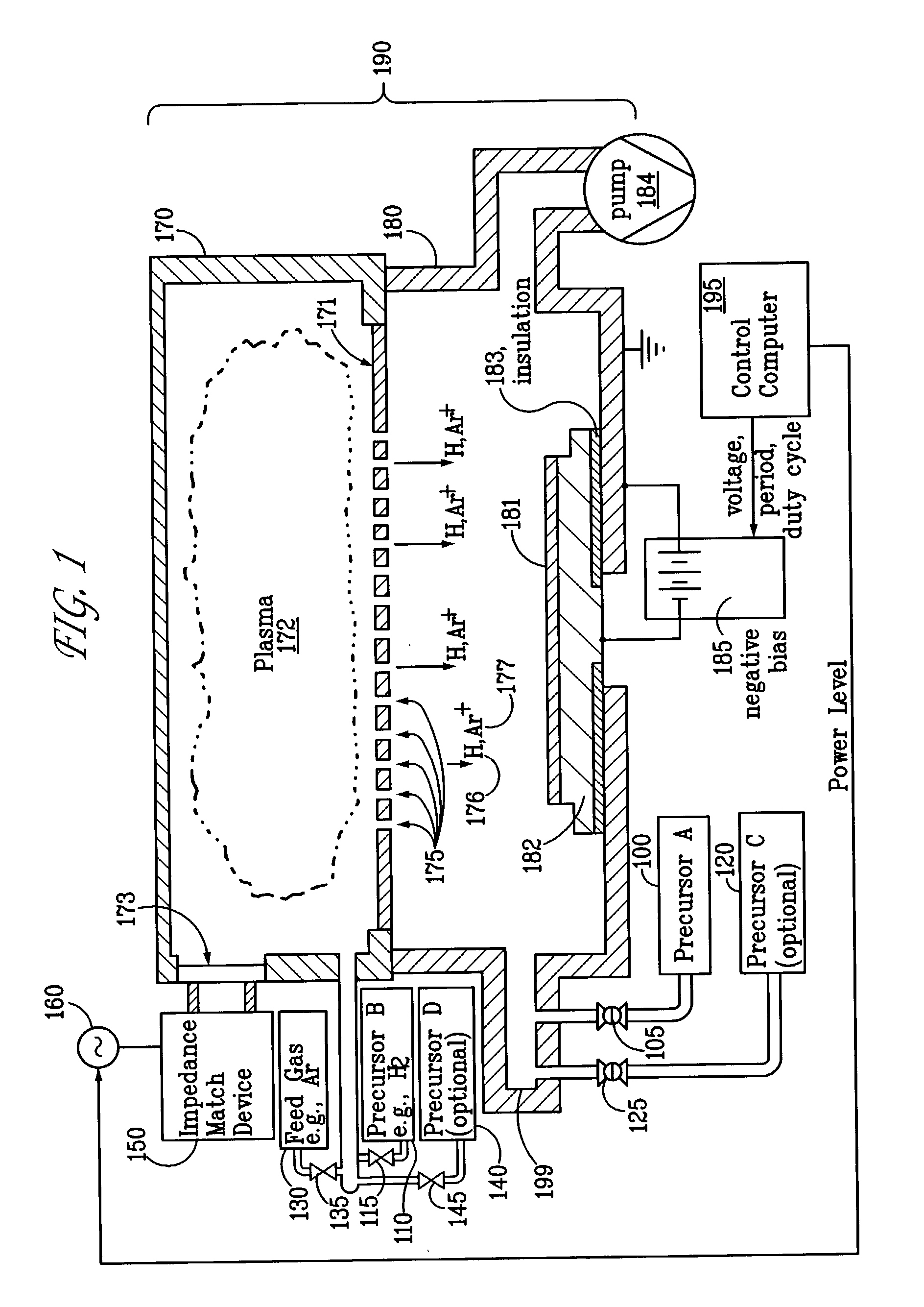

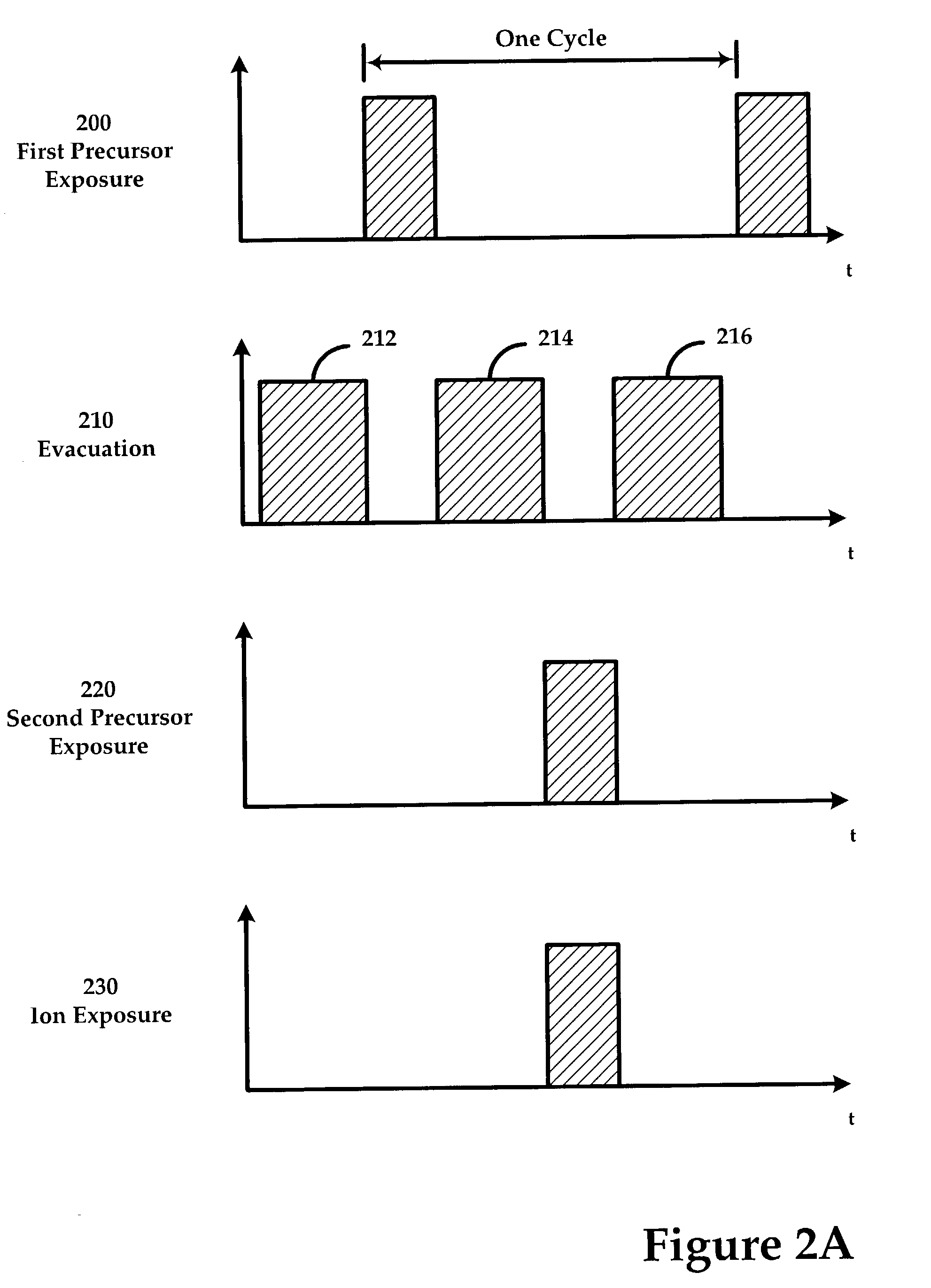

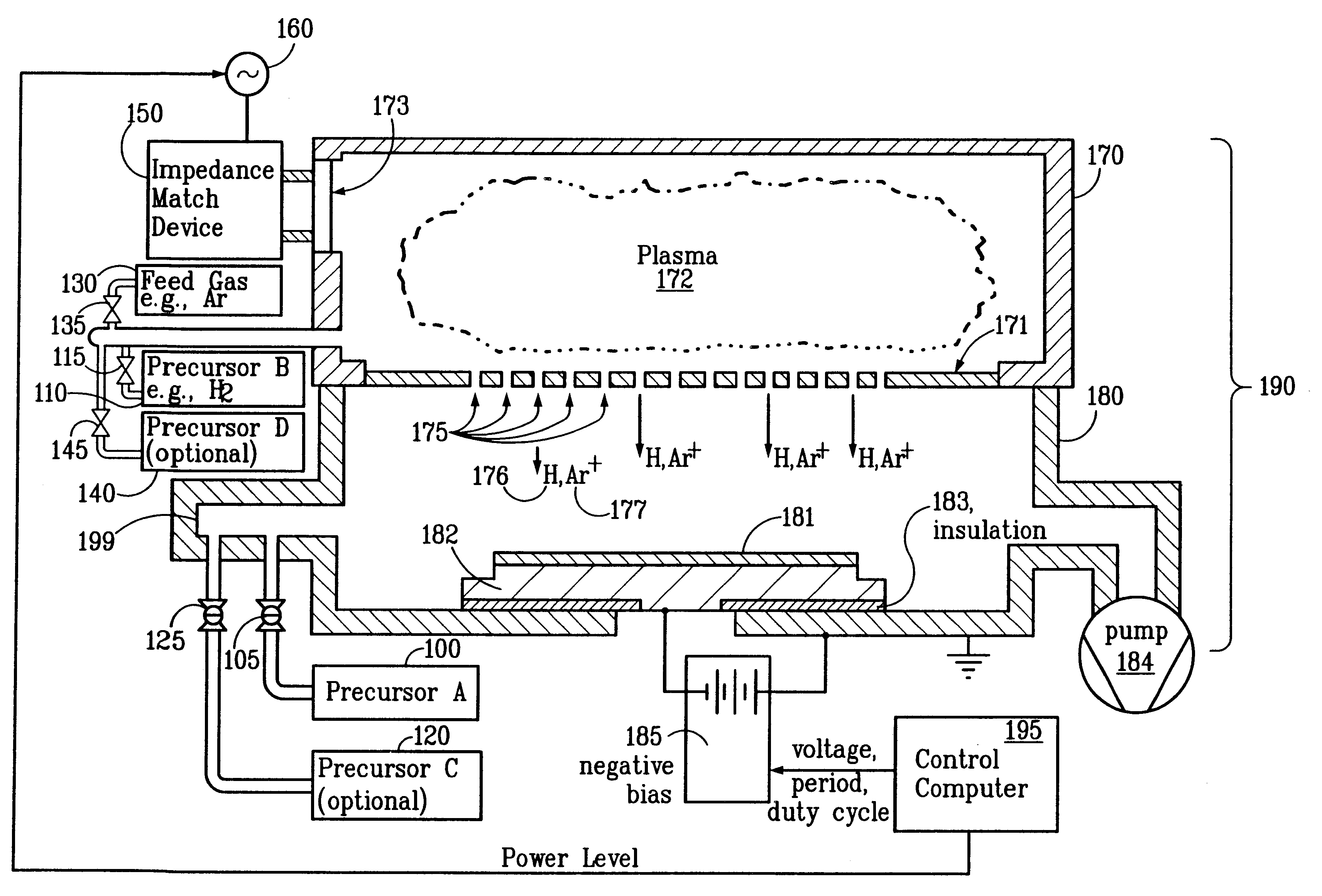

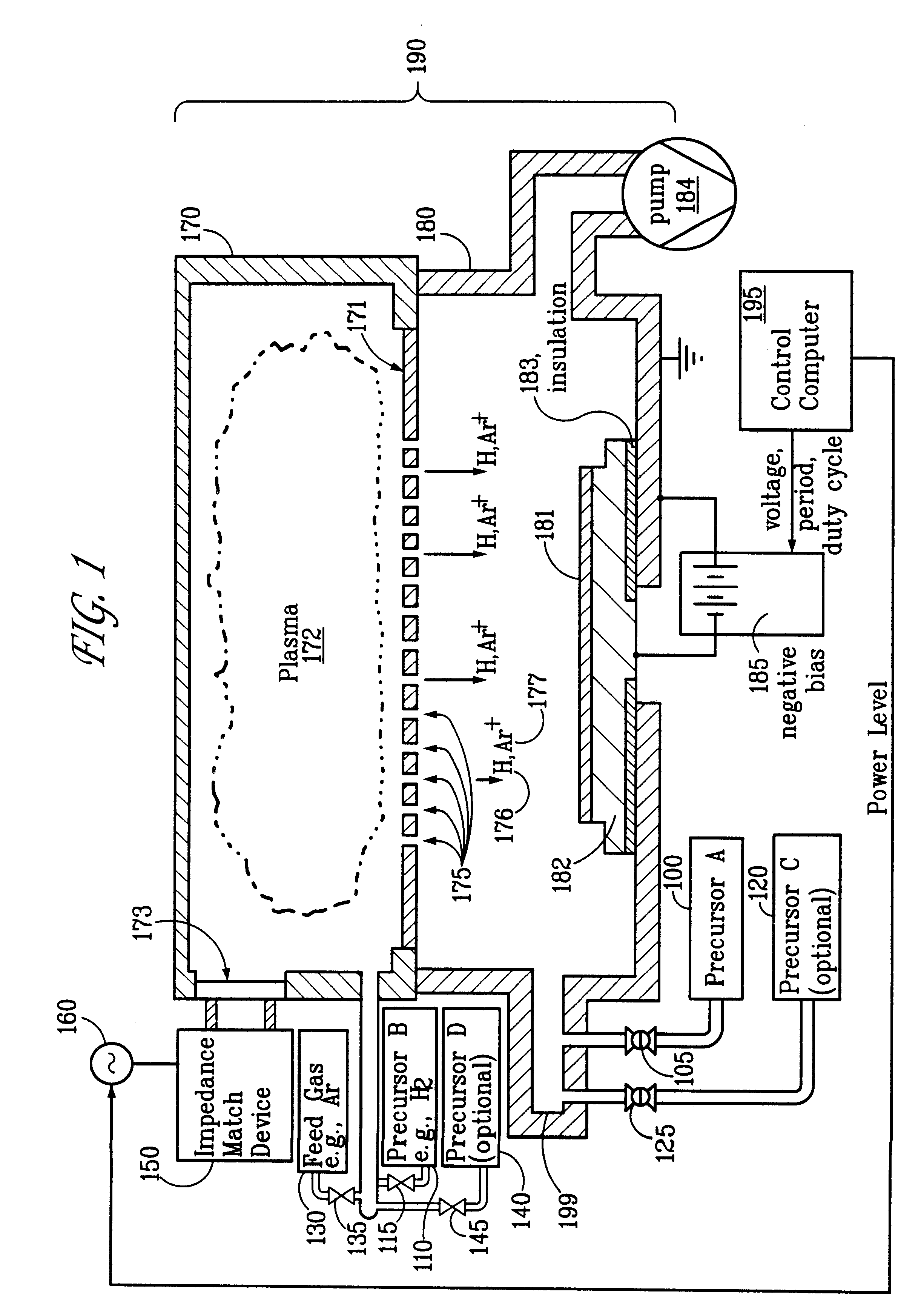

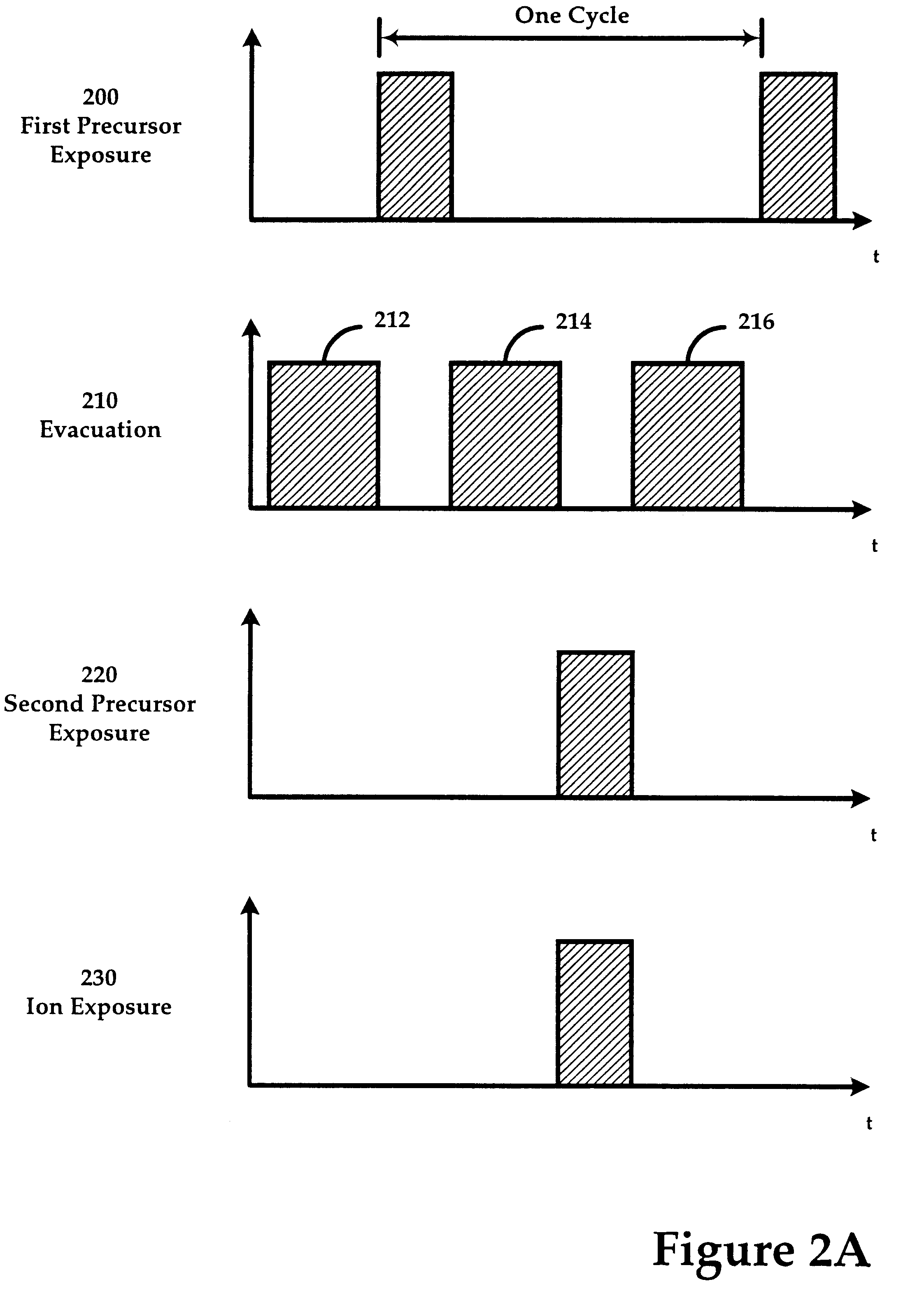

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

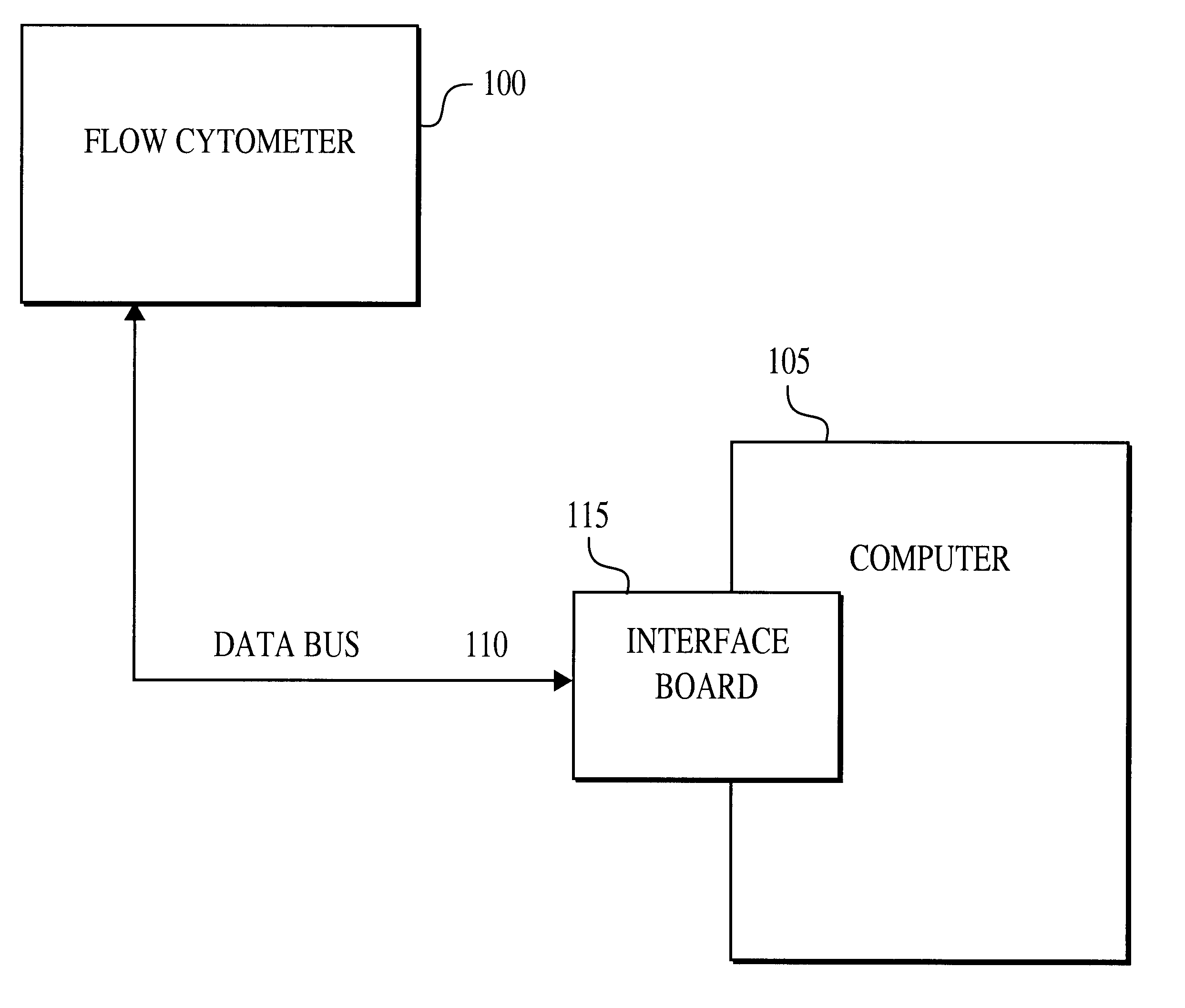

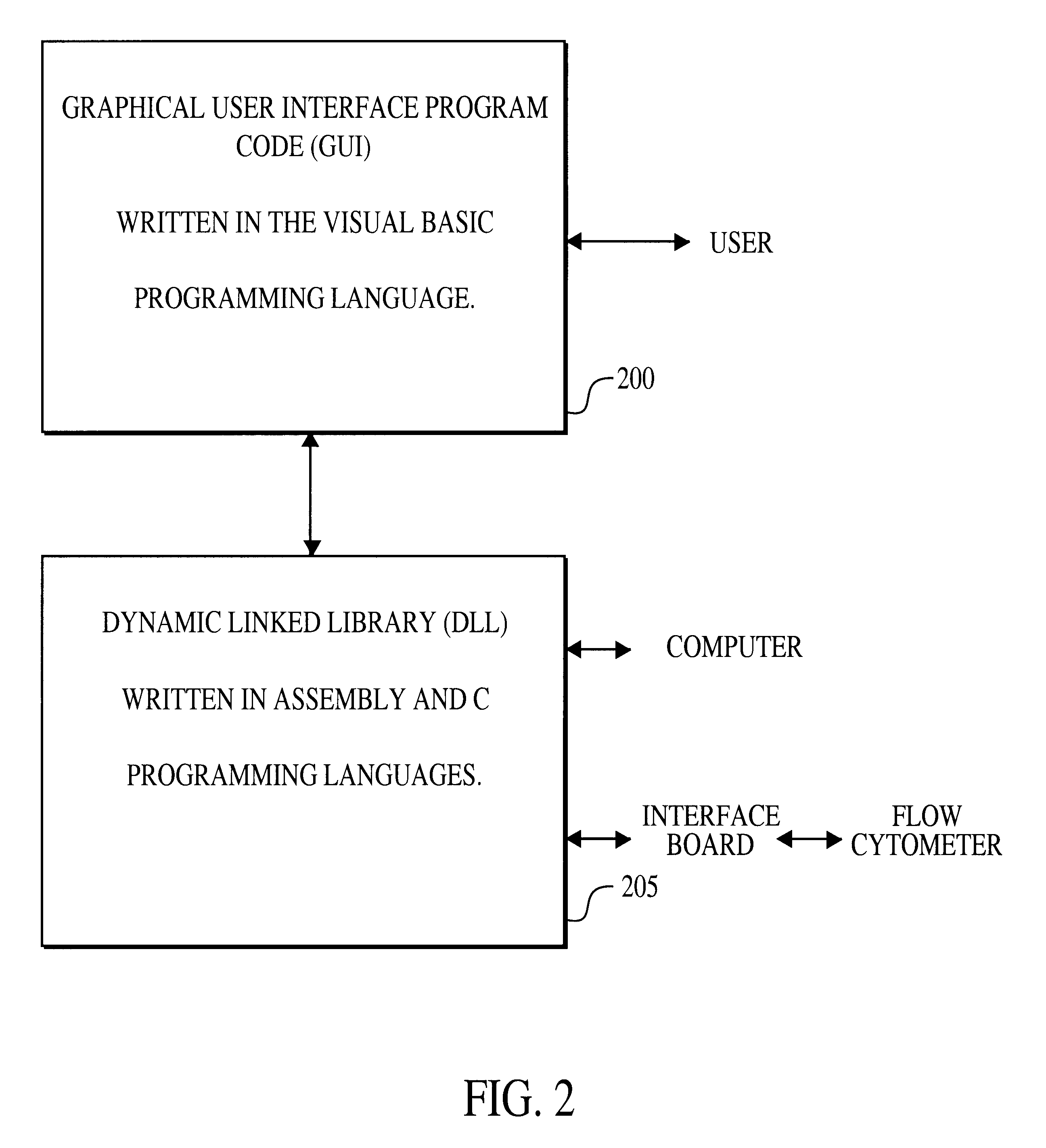

Multiplexed analysis of clinical specimens apparatus and method

InactiveUS6524793B1Simple methodSure easyMicrobiological testing/measurementEnzymologyReal time analysisDNA fragmentation

A method for the multiplexed diagnostic and genetic analysis of enzymes, DNA fragments, antibodies, and other biomolecules comprises the steps of constructing an appropriately labeled beadset, exposing the beadset to a clinical sample, and analyzing the combined sample / beadset by flow cytometry. Flow cytometric measurements are used to classify, in real-time, beads within an exposed beadset and textual explanations, based on the accumulated data obtained during real-time analysis, are generated for the user. The inventive technology enables the simultaneous, and automated, detection and interpretation of multiple biomolecules or DNA sequences in real-time while also reducing the cost of performing diagnostic and genetic assays.

Owner:LUMINEX

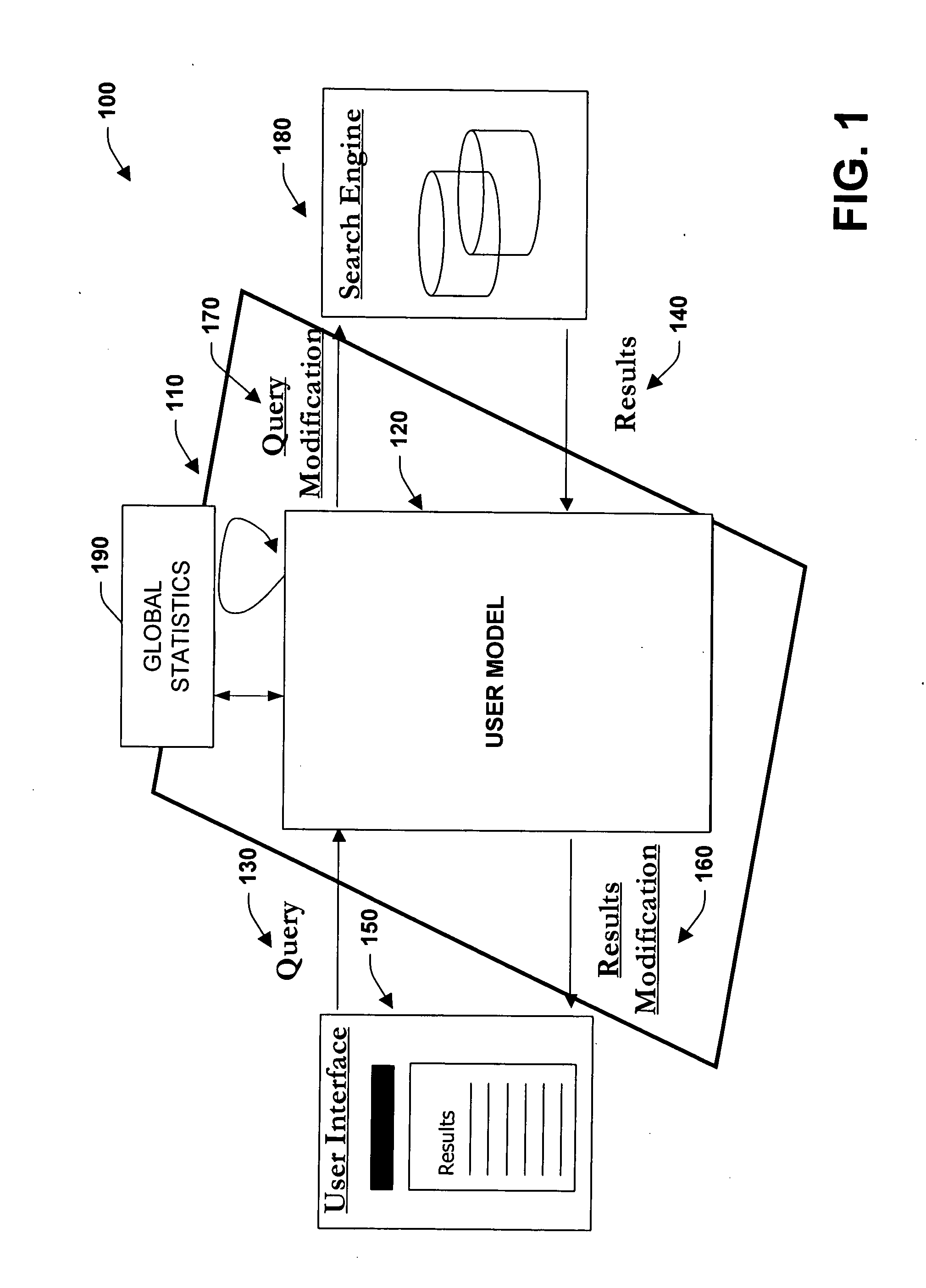

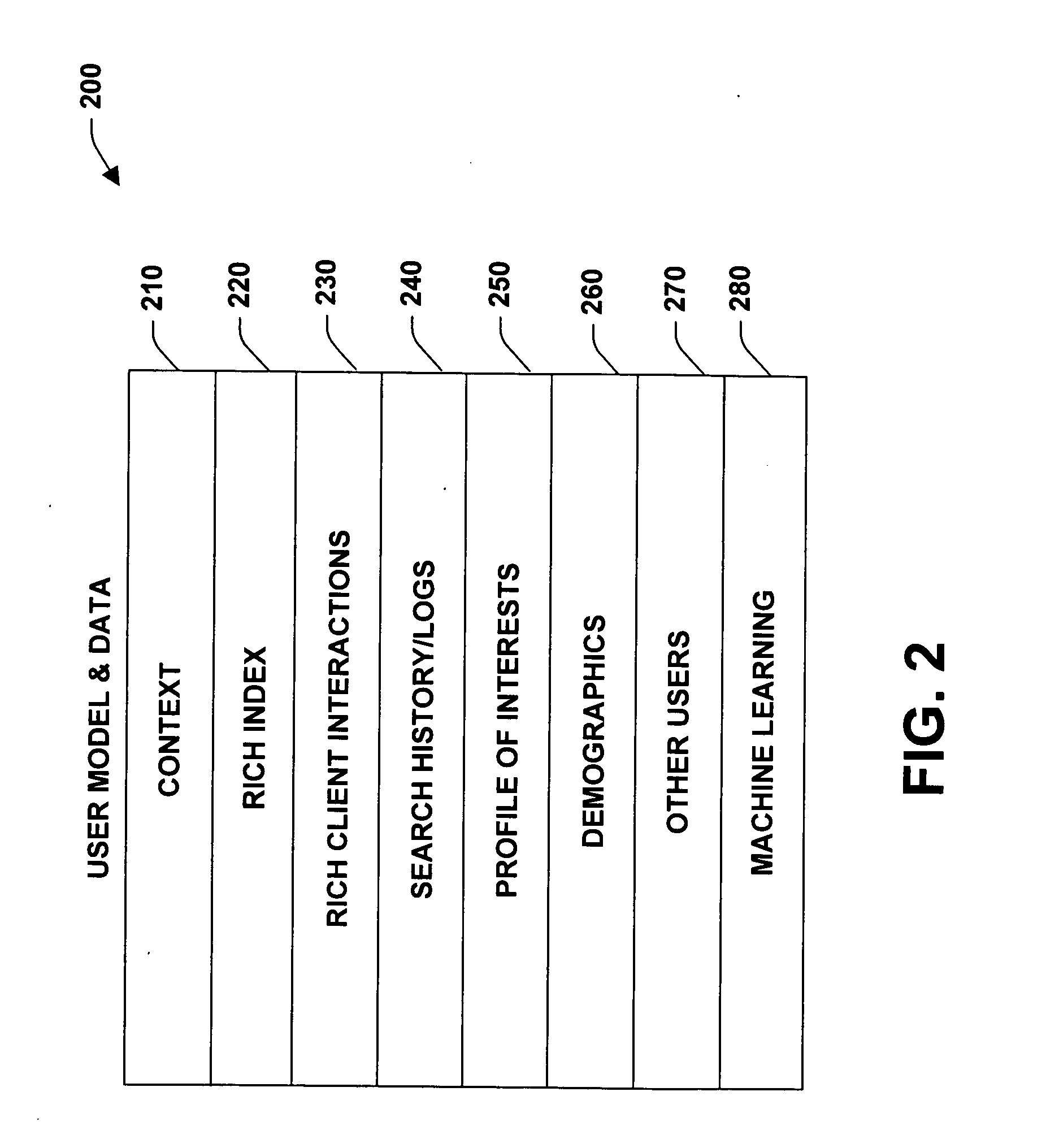

Systems, methods, and interfaces for providing personalized search and information access

InactiveUS20060074883A1Improve personalizationImprove the search experienceDigital data information retrievalSpecial data processing applicationsPersonalized searchInformation access

The present invention relates to systems and methods that employ user models to personalize generalized queries and / or search results according to information that is relevant to respective user characteristics. A system is provided that facilitates generating personalized searches of information. The system includes a user model to determine characteristics of a user. The user model may be assembled automatically via an analysis of a user's content, activities, and overall context. A personalization component automatically modifies queries and / or search results in view of the user model in order to personalize information searches for the user. A user interface receives the queries and displays the search results from one or more local and / or remote search engines, wherein the interface can be adjusted in a range from more personalized searches to more generalized searches.

Owner:MICROSOFT TECH LICENSING LLC

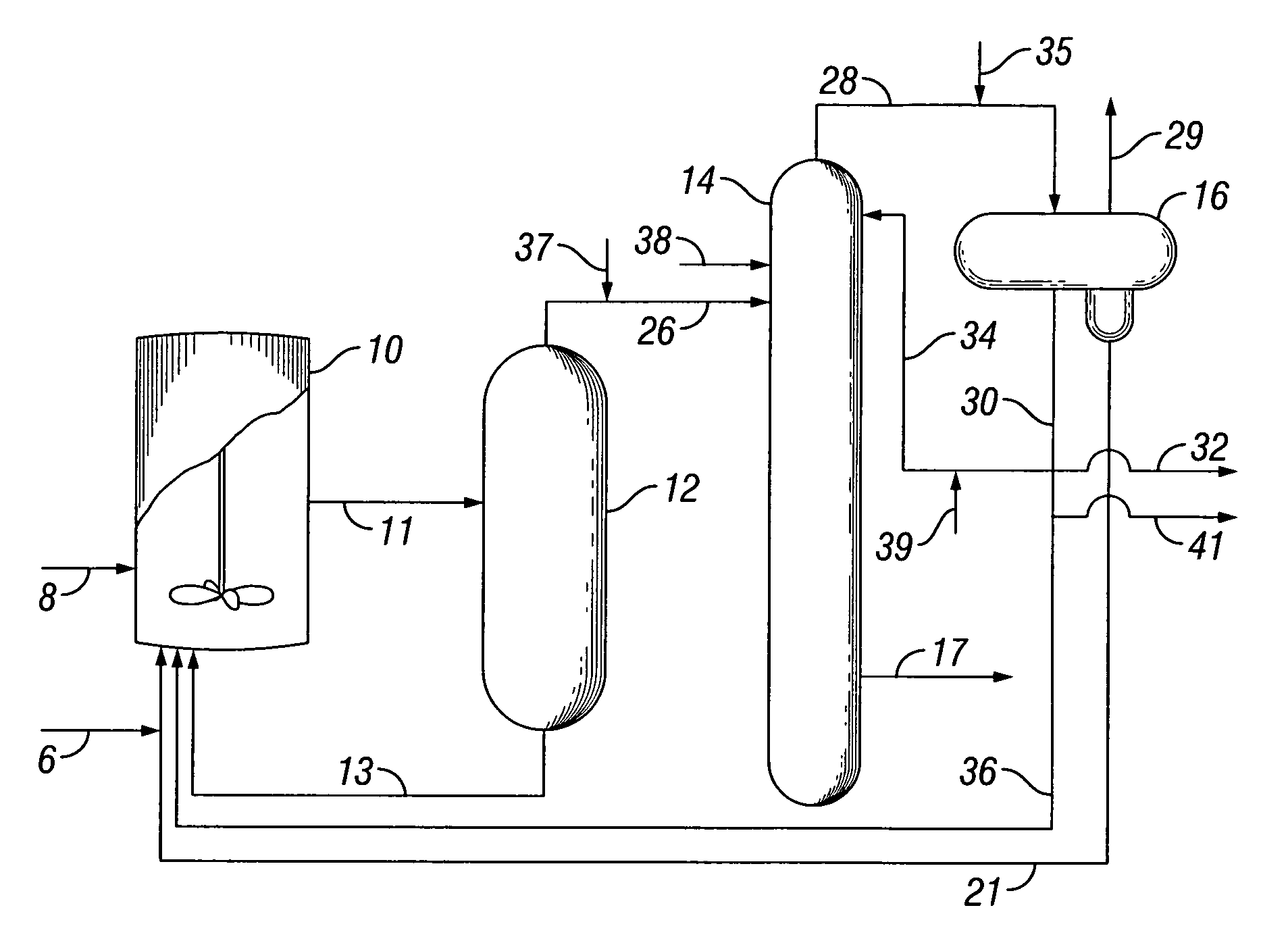

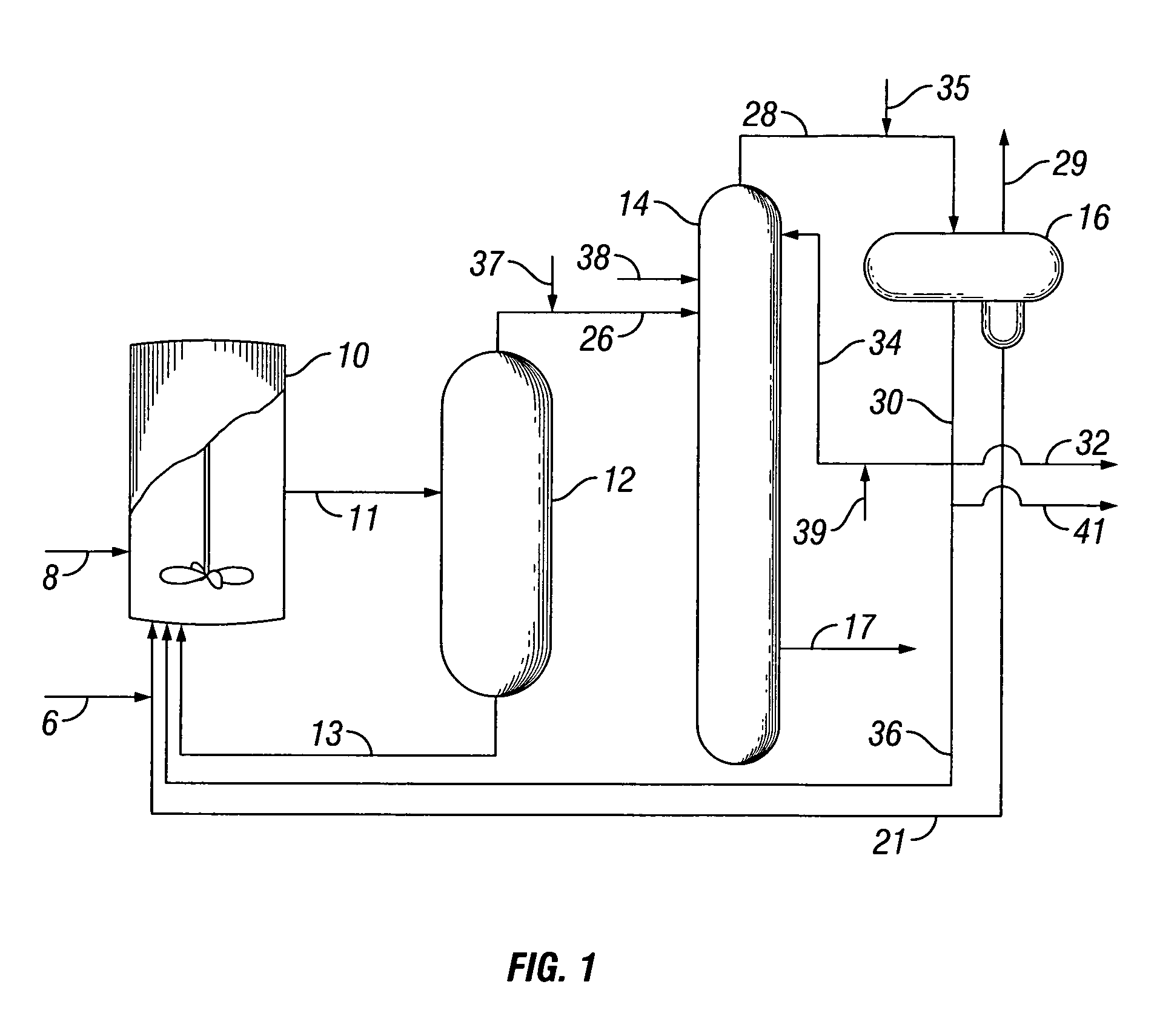

Process for producing acetic acid

ActiveUS7208624B2Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

System and method for modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020104481A1Faster efficient meanSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densitySubject matter

The present invention relates to an enhanced sequential or non-sequential atomic layer deposition (ALD) apparatus and technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method; and, 4) providing a means of improved radical generation and delivery. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. [37 C.F.R. § 1.72(b)].

Owner:ANGSTRON SYST

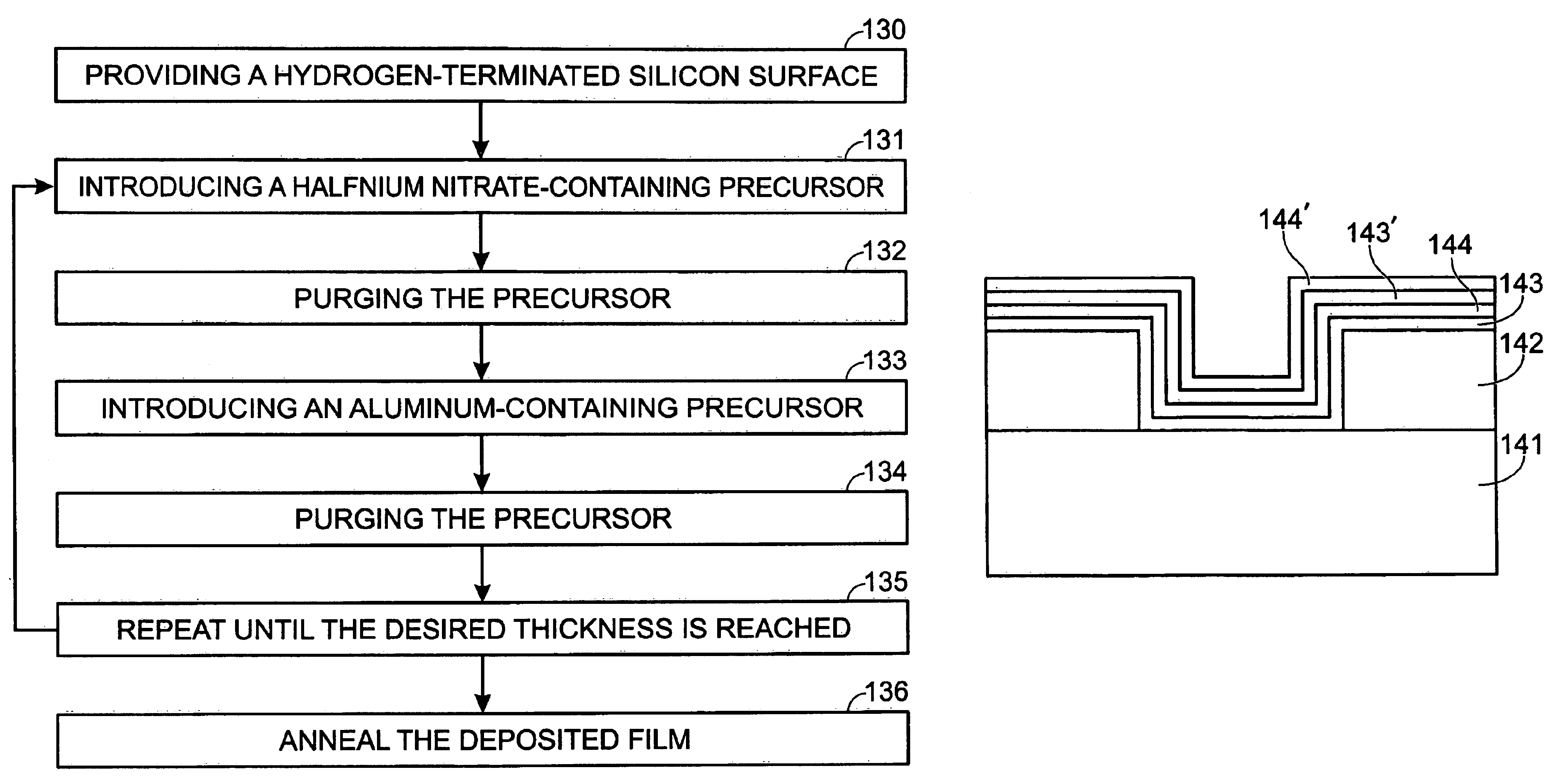

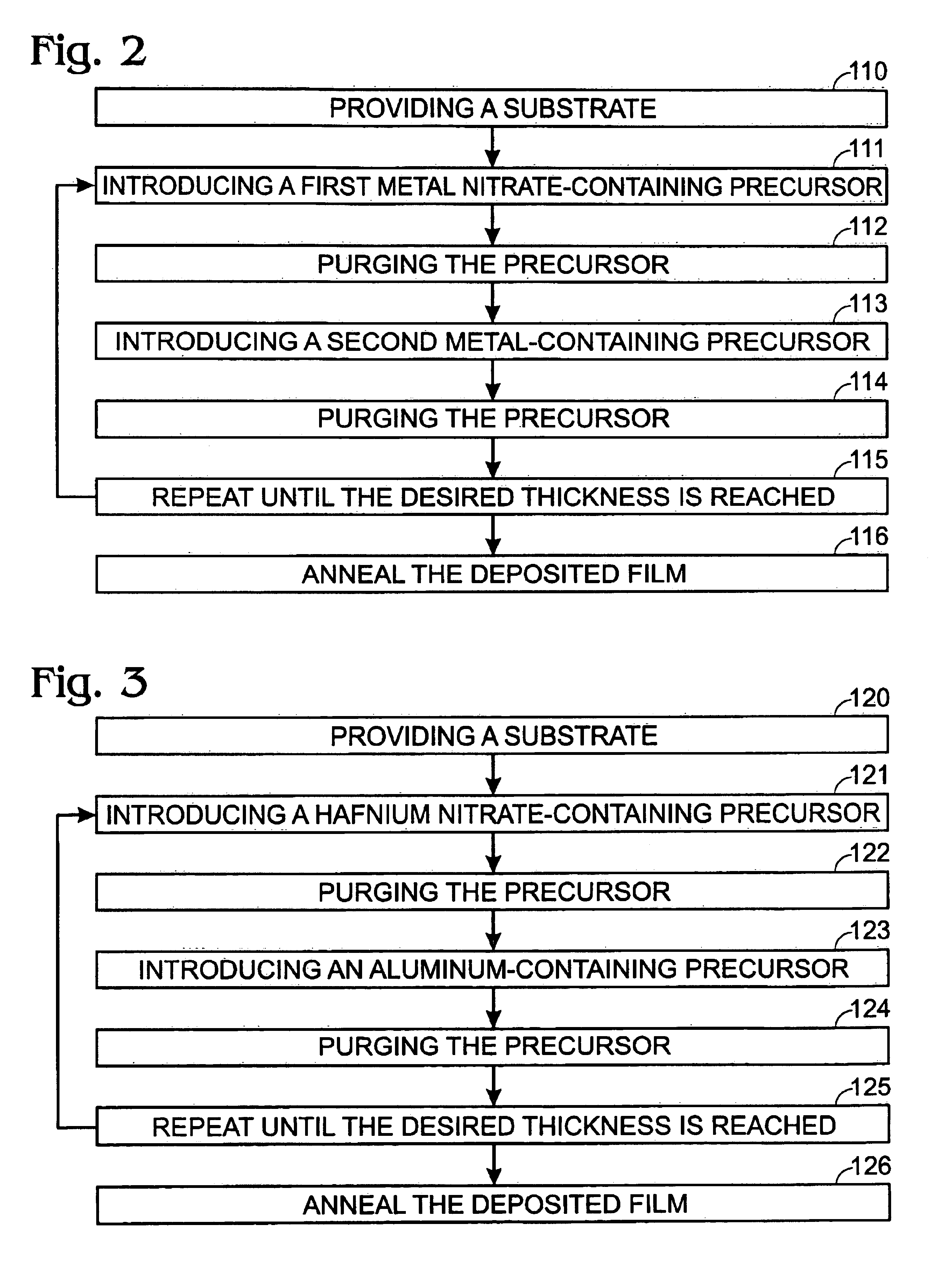

Method for depositing a nanolaminate film by atomic layer deposition

InactiveUS6930059B2Simple methodQuality improvementTransistorSemiconductor/solid-state device manufacturingGate dielectricHafnium

An atomic layer deposition method to deposit an oxide nanolaminate thin film is provided. The method employs a nitrate ligand in a first precursor as an oxidizer for a second precursor to form the oxide nanolaminates. Using a hafnium nitrate precursor and an aluminum precursor, the method is well suited for the deposition of a high k hafnium oxide / aluminum oxide nanolaminate dielectric for gate dielectric or capacitor dielectric applications on a hydrogen-terminated silicon surface.

Owner:SHARP LAB OF AMERICA INC

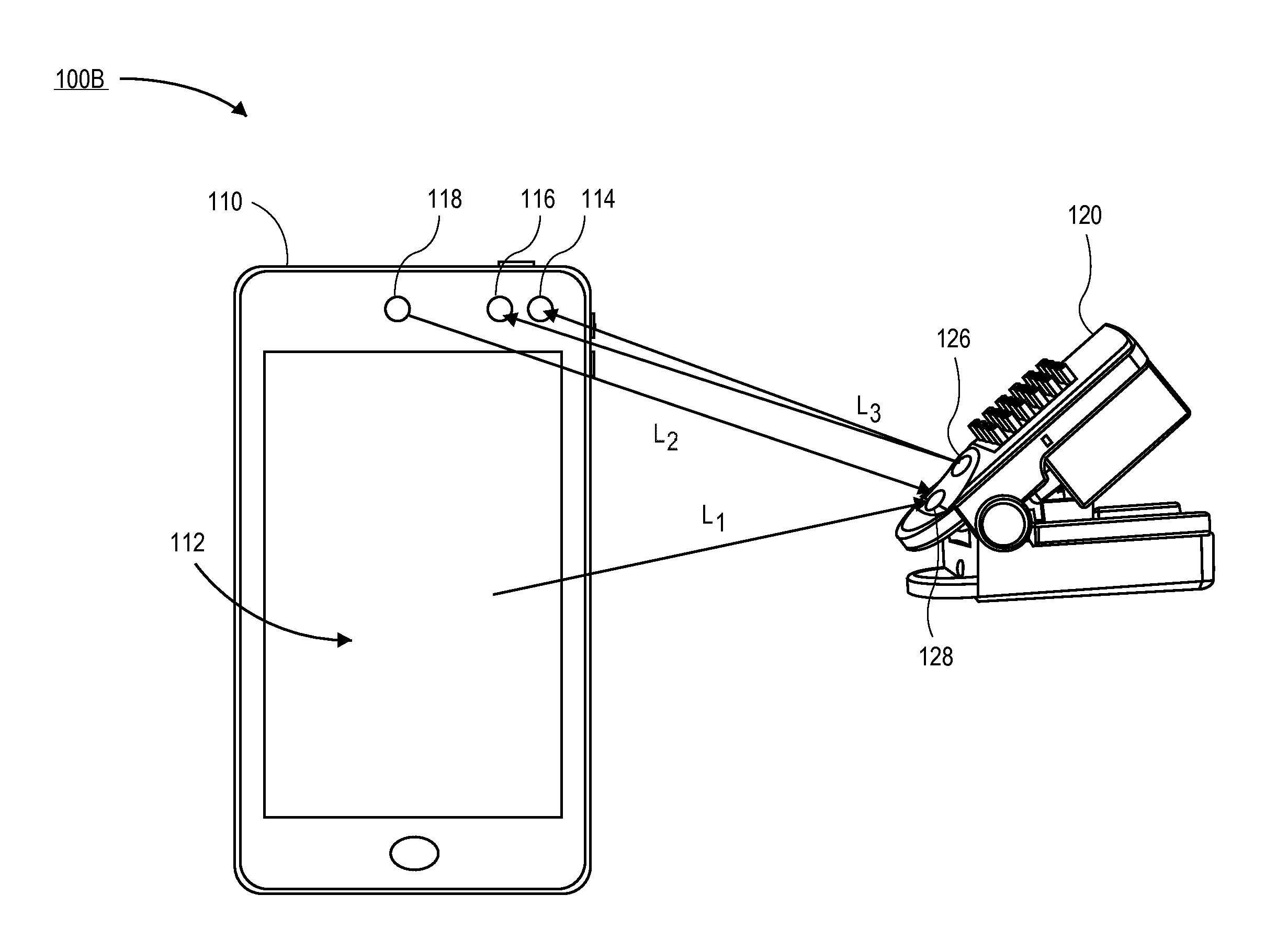

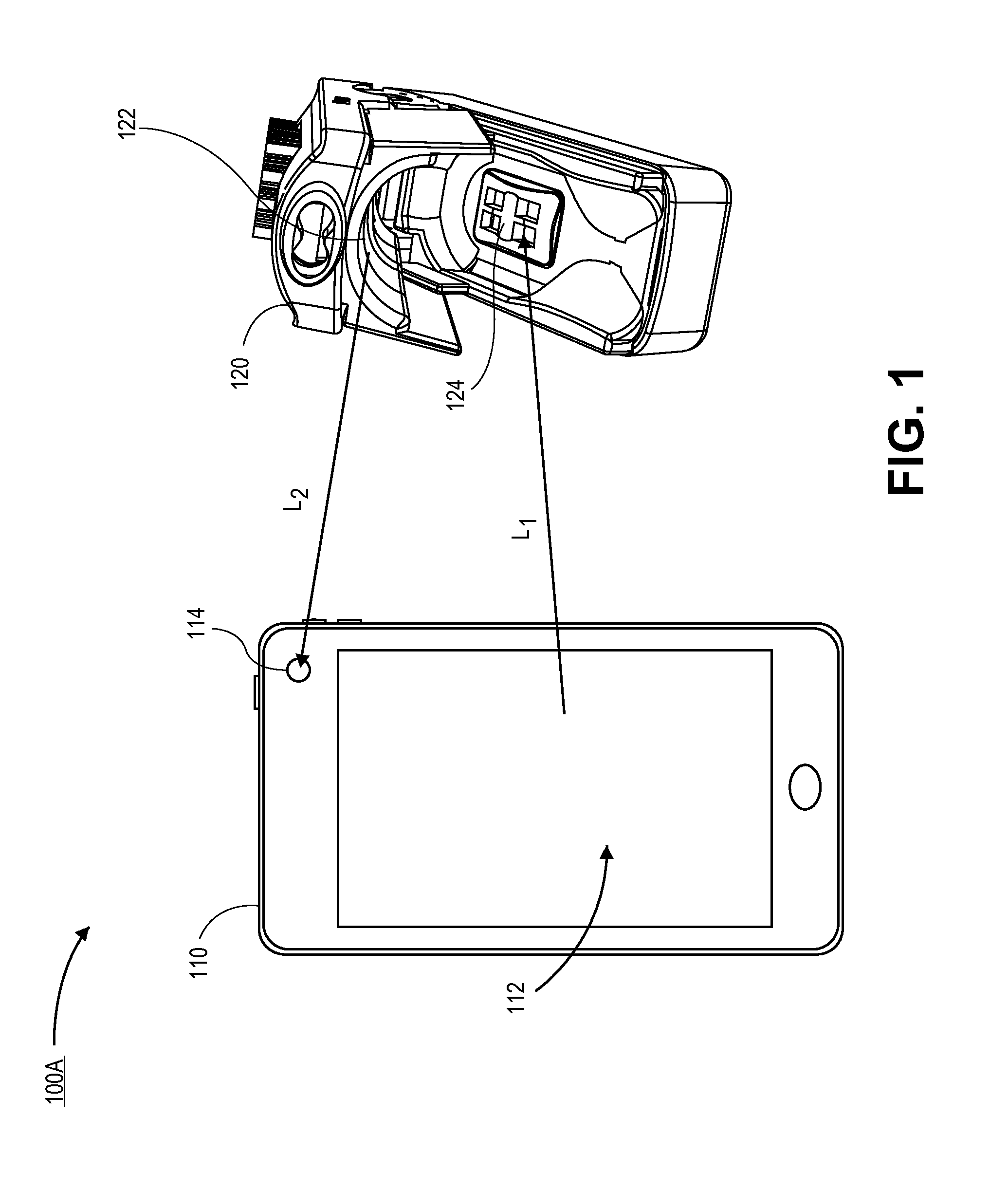

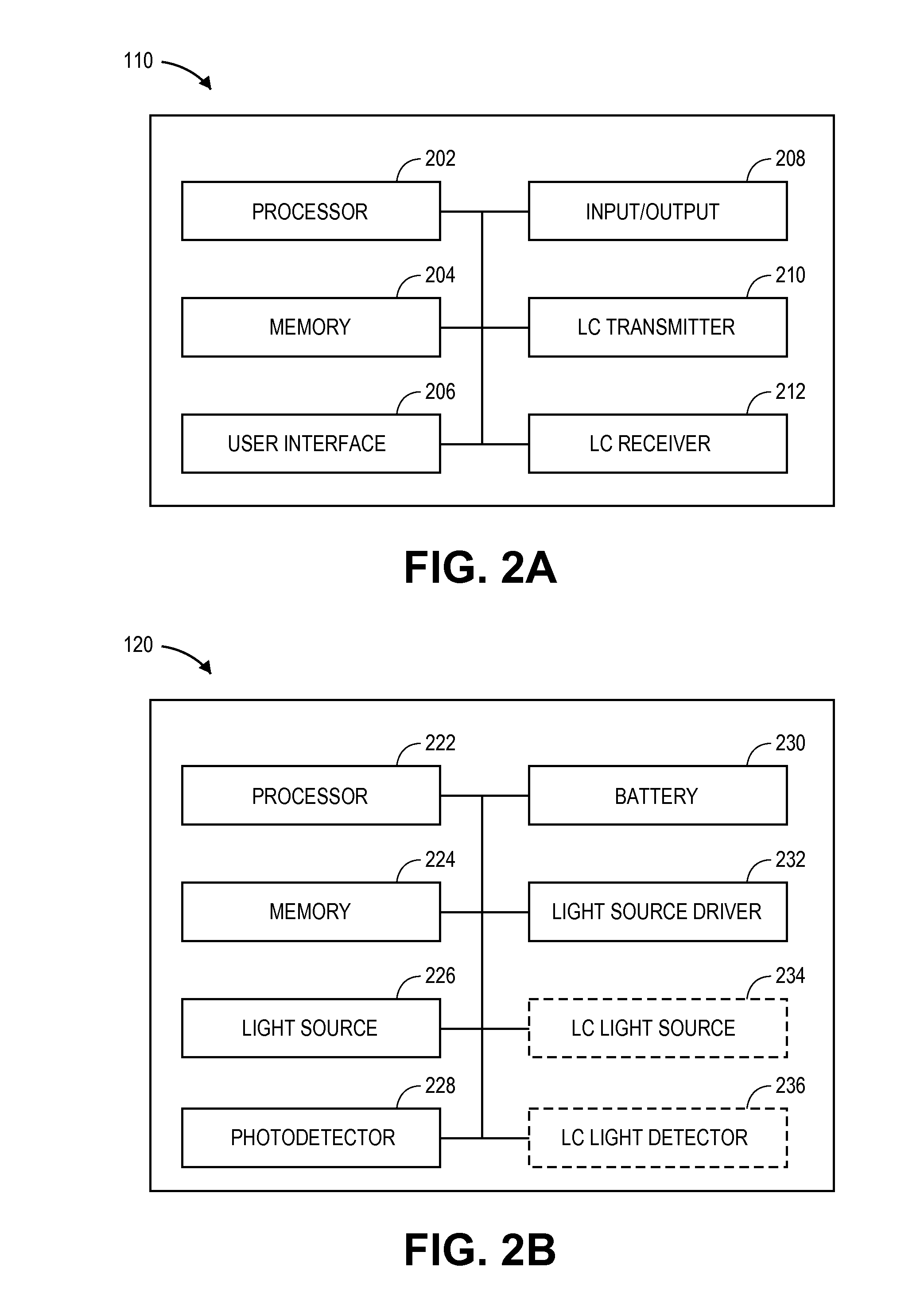

Wireless optical communication between noninvasive physiological sensors and patient monitors

InactiveUS20140275871A1Reduced portabilityReduce compactnessClose-range type systemsDiagnostic recording/measuringPatient monitorComputer science

Embodiments of the disclosure include a noninvasive physiological patient sensor and a patient monitor capable of wireless communication with one another. An optical communication path can be used to provide the communication path between the noninvasive physiological patient sensor and the patient monitor. The path can be maintained by one or more light sources and detectors traditionally associated with noninvasive optical sensors or by one or more additional dedicated light sources and detectors.

Owner:MASIMO CORP

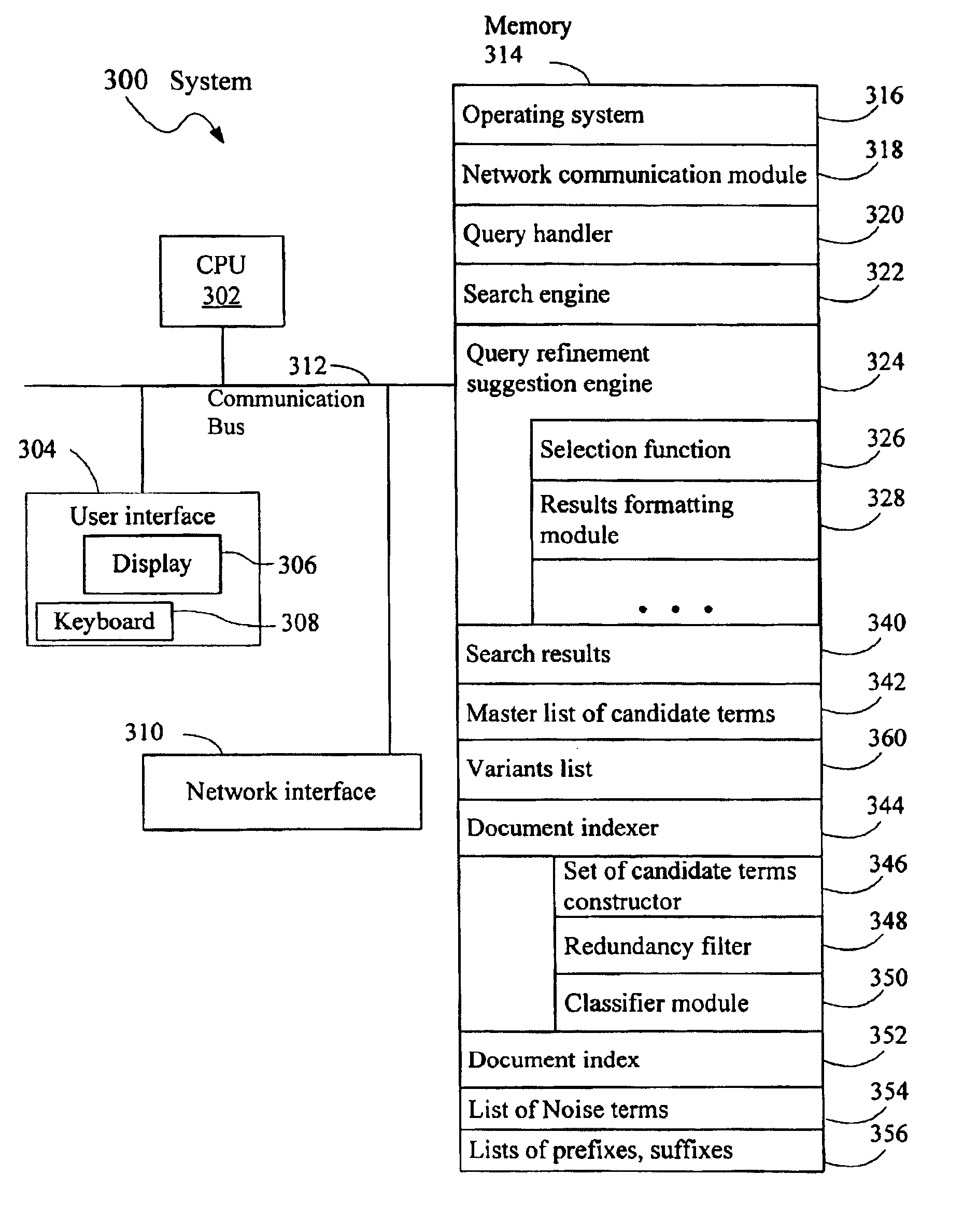

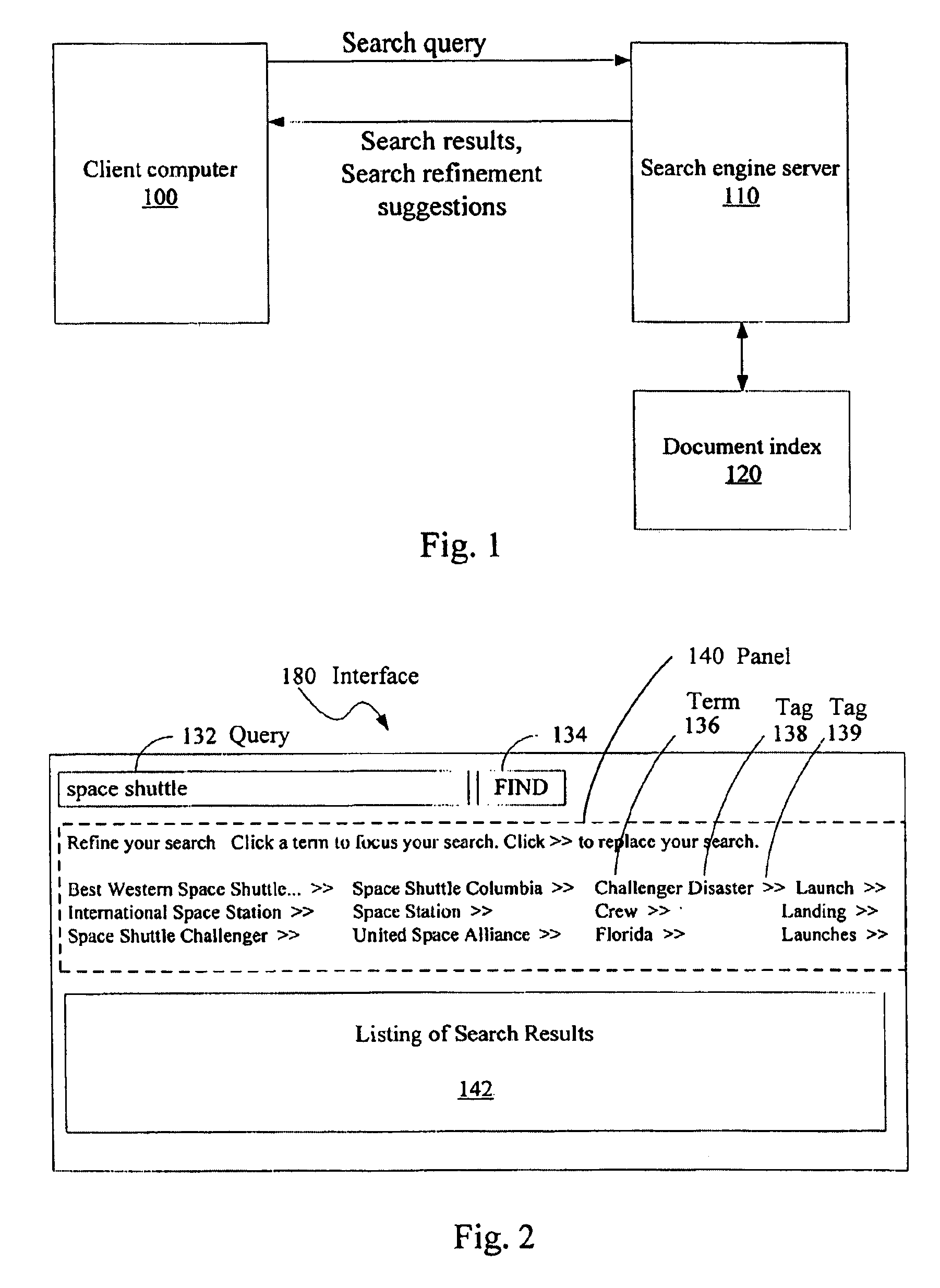

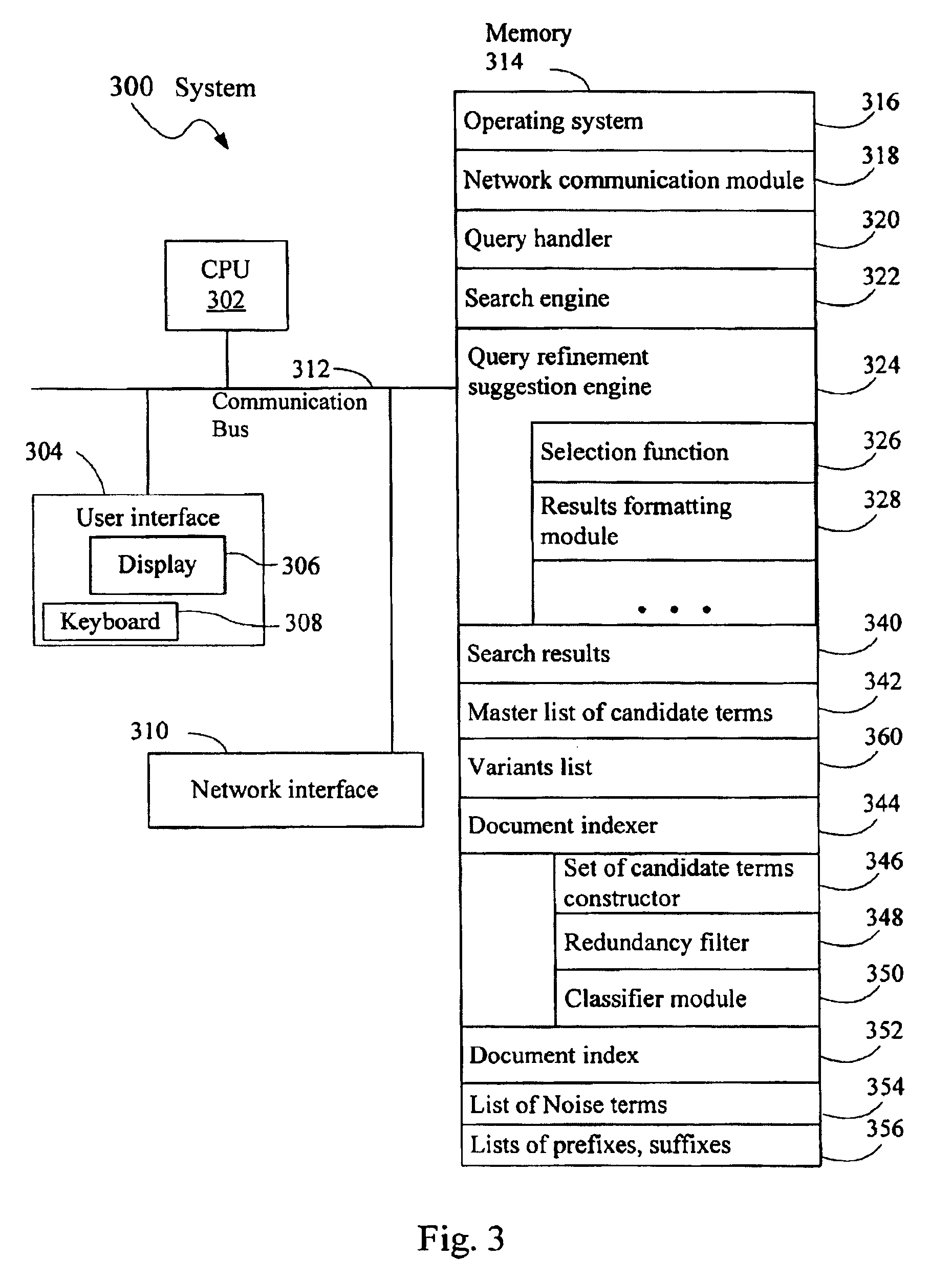

Systems and methods for interactive search query refinement

ActiveUS6947930B2Less i/o resourceLess resourcesData processing applicationsDigital data information retrievalDocument preparationInteractive search

A received query is processed so as to generate an initial group of ranked documents corresponding to the received query. Each document in all or a portion of the documents in the initial group of ranked documents is associated with a respective set of ranked candidate terms such that each candidate term in the respective set of ranked candidate terms is embedded within the document. Each respective set of ranked candidate terms is identified at a time prior to the processing of the received query. In accordance with a selection function, a subset of the candidate terms in one or more of the respective sets of candidate terms is selected. In response to the received query, the initial group of ranked documents and the subset of candidate terms are presented.

Owner:JOLLIFY MANAGEMENT

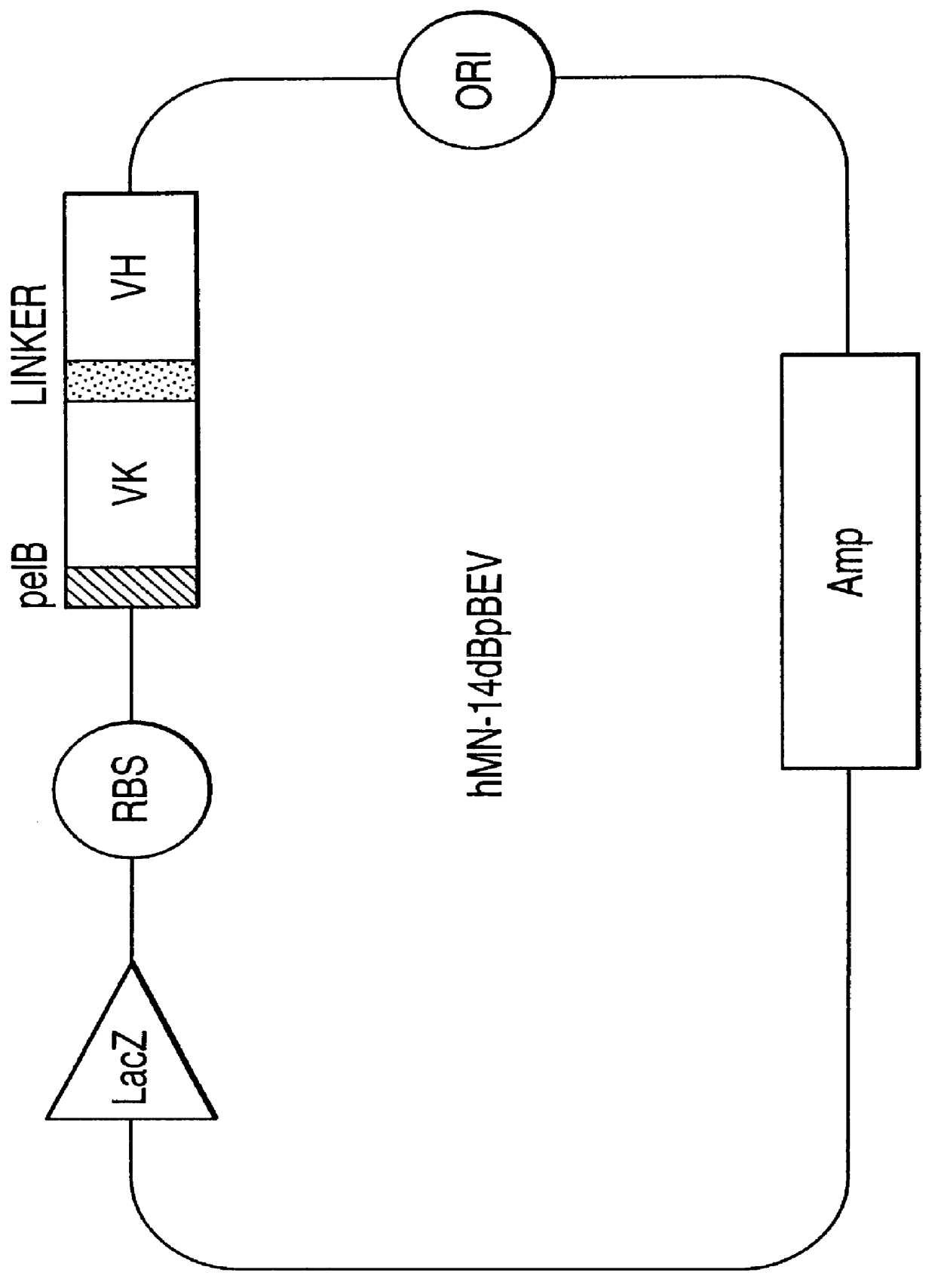

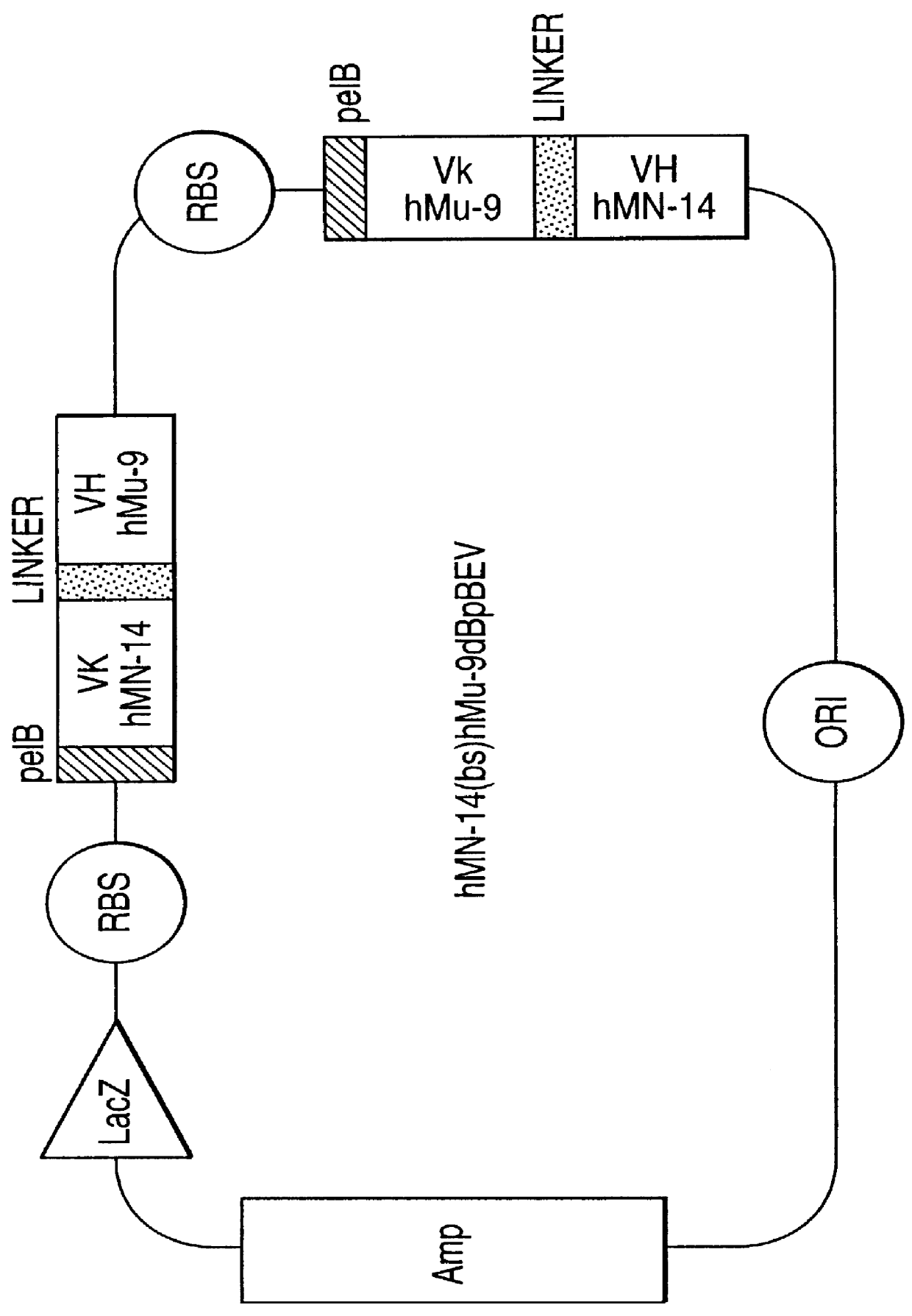

Intraoperative, intravascular, and endoscopic tumor and lesion detection, biopsy and therapy

InactiveUS6096289ADiscriminationImprove discriminationUltrasonic/sonic/infrasonic diagnosticsSurgeryNon malignantAntibody fragments

Methods are provided for close-range intraoperative, endoscopic and intravascular deflection and treatment of lesions, including tumors and non-malignant lesions. The methods use antibody fragments or subfragments labeled with isotopic and non-isotopic agents. Also provided are methods for detection and treatment of lesions with photodynamic agents and methods of treating lesions with a protein conjugated to an agent capable of being activated to emit Auger electron or other ionizing radiation. Compositions and kits useful in the above methods are also provided.

Owner:IMMUNOMEDICS INC

System for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020197402A1Faster efficient meanSimple methodSemiconductor/solid-state device manufacturingSolid state diffusion coatingIonLow-k dielectric

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method.

Owner:NOVELLUS SYSTEMS

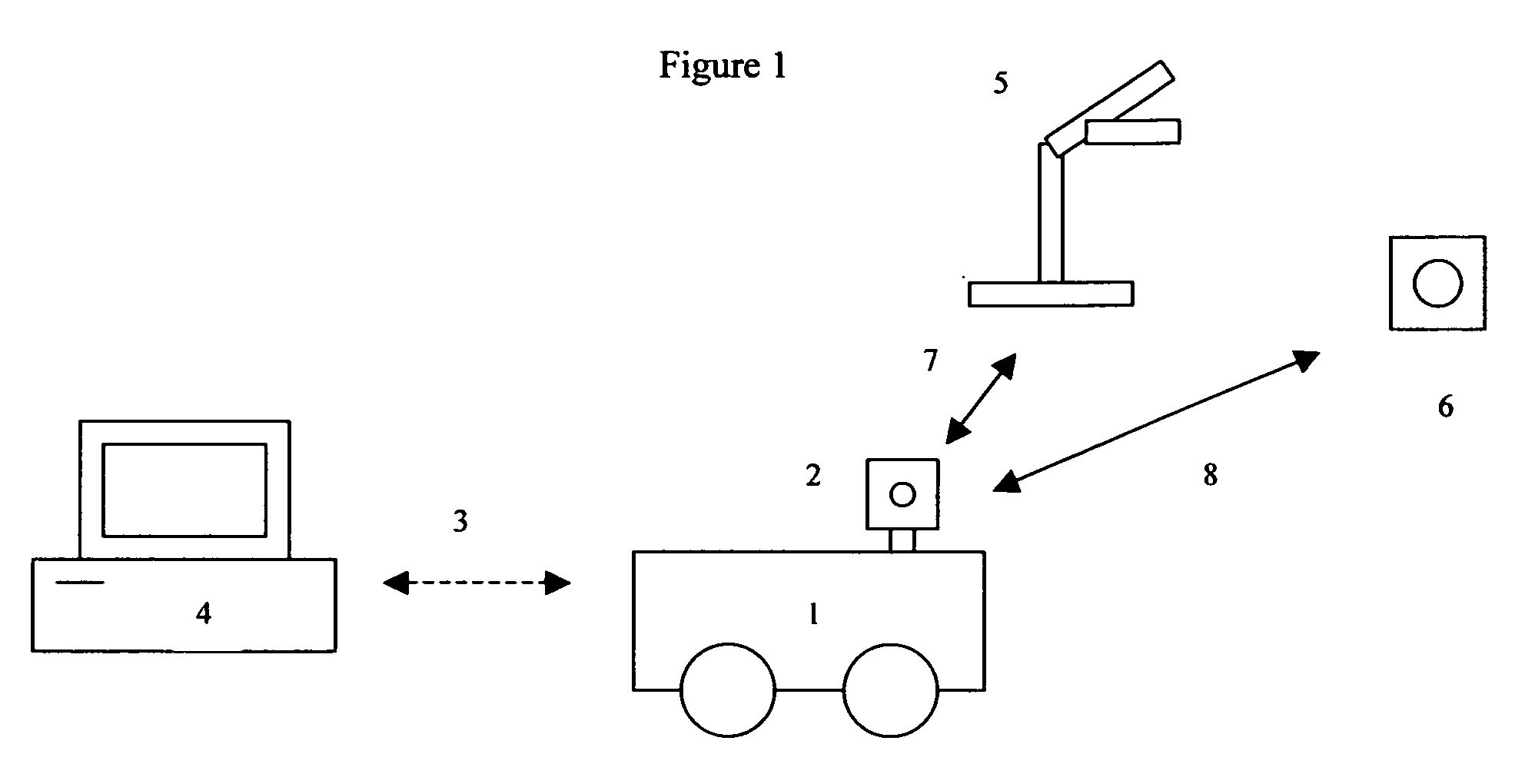

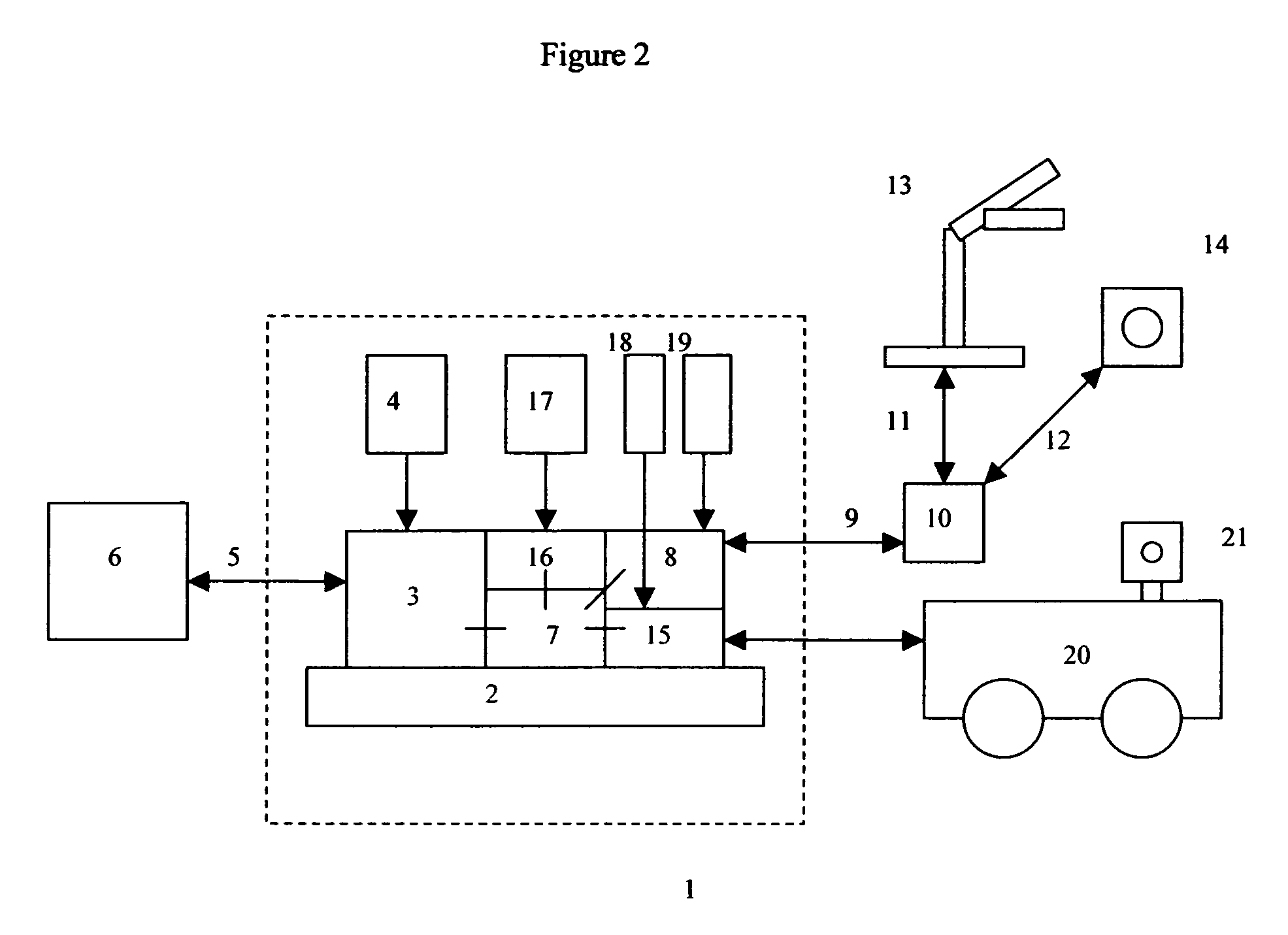

Mobile robot with wireless location sensing apparatus

InactiveUS20070061041A1Simple methodBroaden their knowledgeProgramme controlVehicle position/course/altitude controlWeb browserInternet network

A robotic navigation system for computerized mobile robot. Typically the robot, which may be in an unknown location, will have an onboard internet web server, a capability of establishing a first connection to a remote web browser on the internet for robotic control purposes, and a capability of establishing a second short range bi-directional digital radio connection to one or more nearby computerized digital radio equipped devices external to the robot. Typically at least some of these nearby digital radio equipped devices will have a known location. The robot can exchange short-range bidirectional digital radio signals with nearby devices that have a known location, and obtain location data to determine it's position. This location information can be used to assist in robotic navigation. The robot can also navigate to other objects, which also may have an unknown location, using a similar technique in which the object with an unknown location exchanges short range bidirectional digital radio signals with either the robot itself, or other digital radio linked devices with a known location (which then relay the object's location to the robot).

Owner:ZWEIG STEPHEN ELIOT

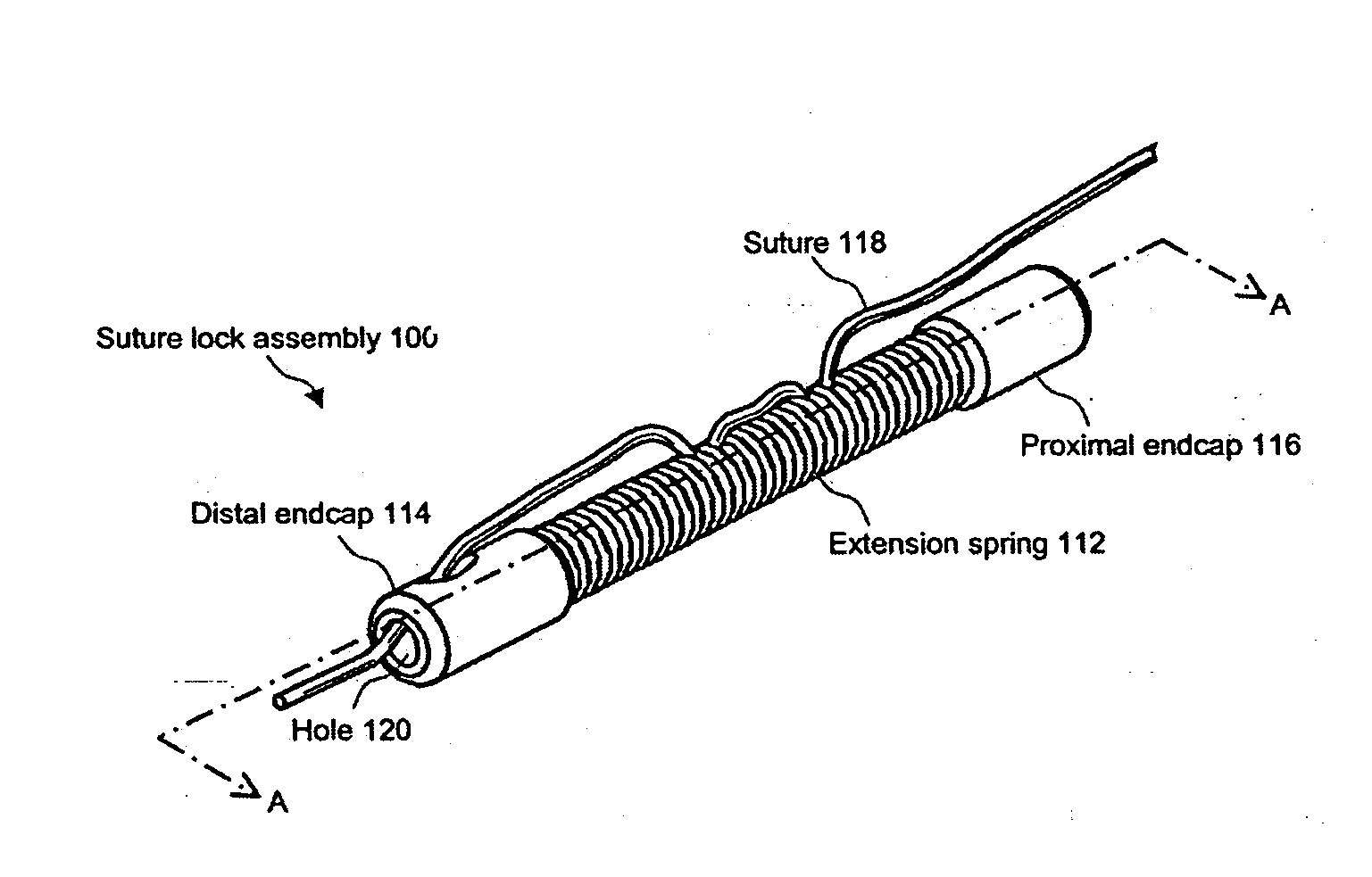

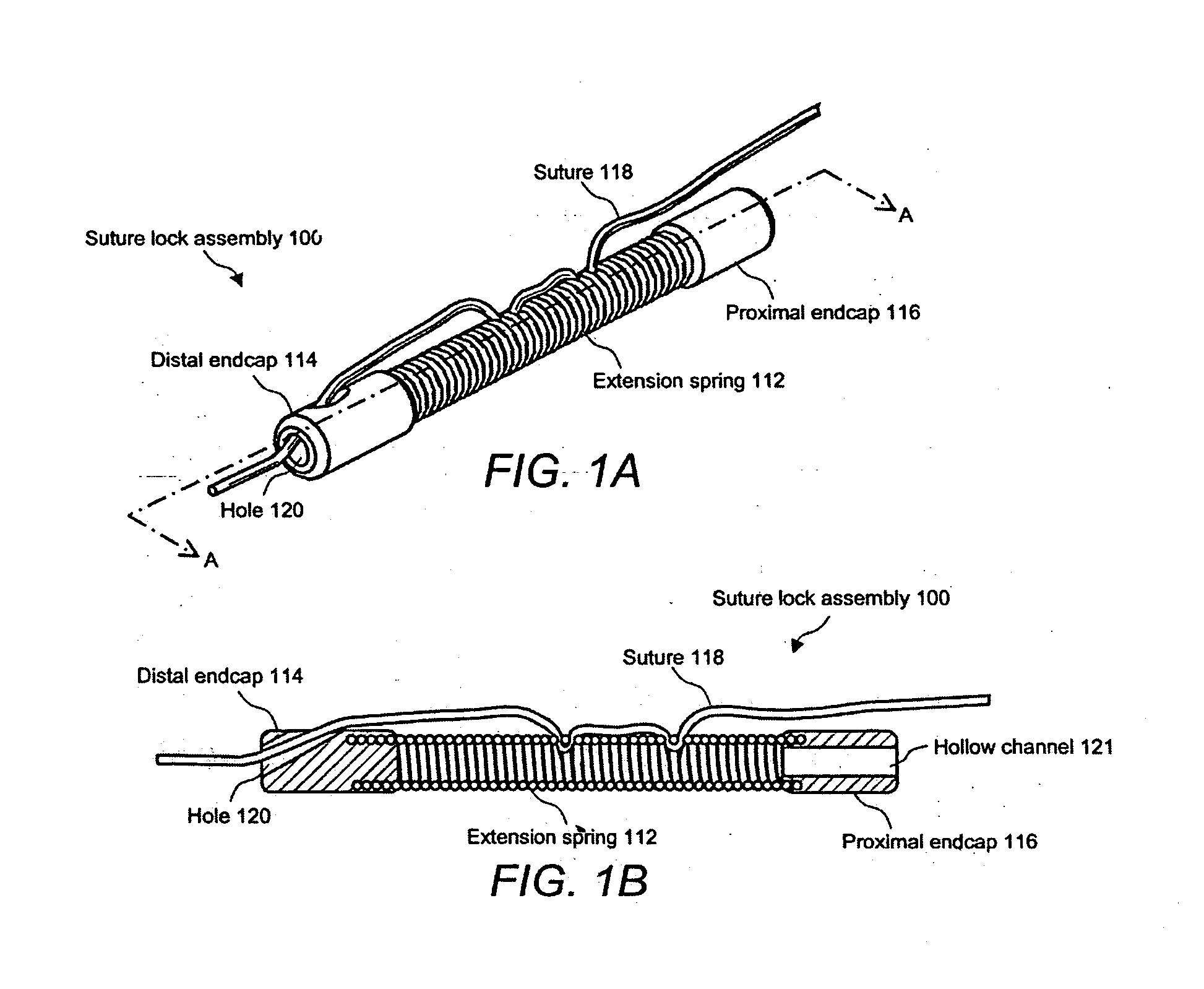

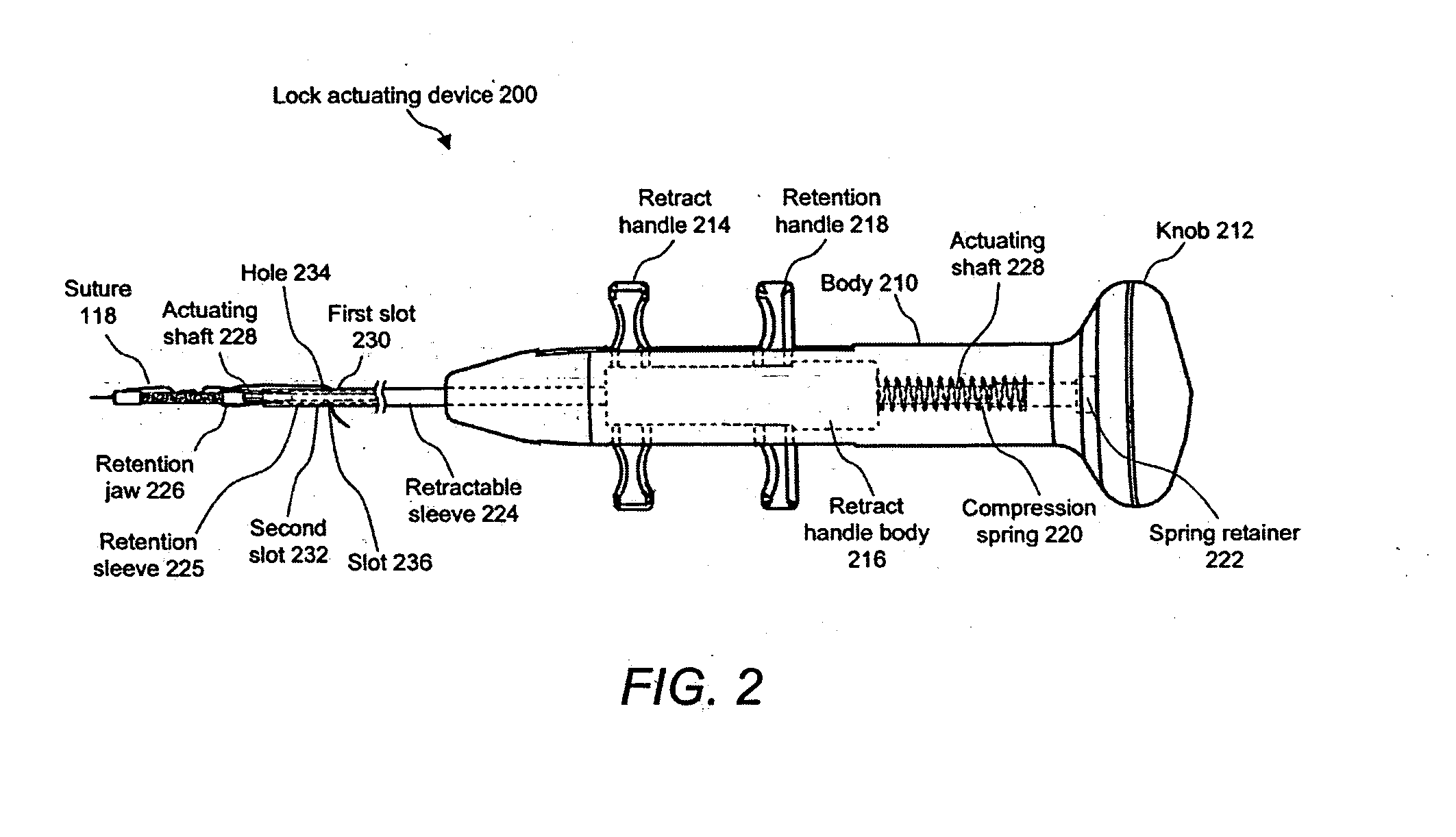

Suture locking and cutting devices and methods

InactiveUS20060004410A1Avoid more-invasiveSimple procedureSuture equipmentsSurgical needlesPosterior gastropexyGastropexy

Suture holding devices and methods are disclosed, including devices and methods useful in performing a transoral surgical procedure, such as a posterior gastropexy procedure. A device is disclosed which can be used by a physician in a medical procedure to automatically lock and cut a suture in one motion and without the need for additional cutting instrumentation, rather than perform separate locking and cutting actions.

Owner:ETHICON ENDO SURGERY INC

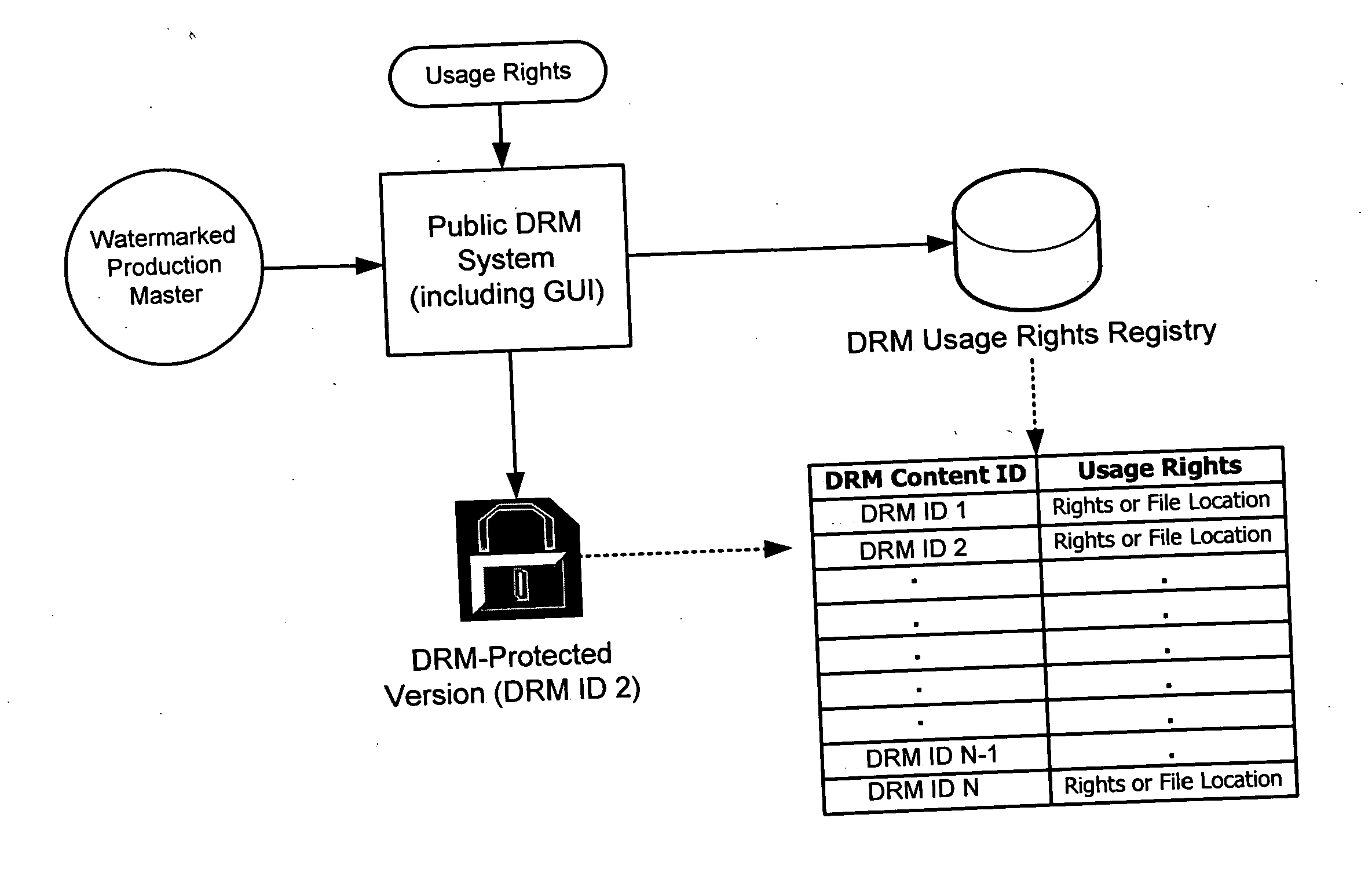

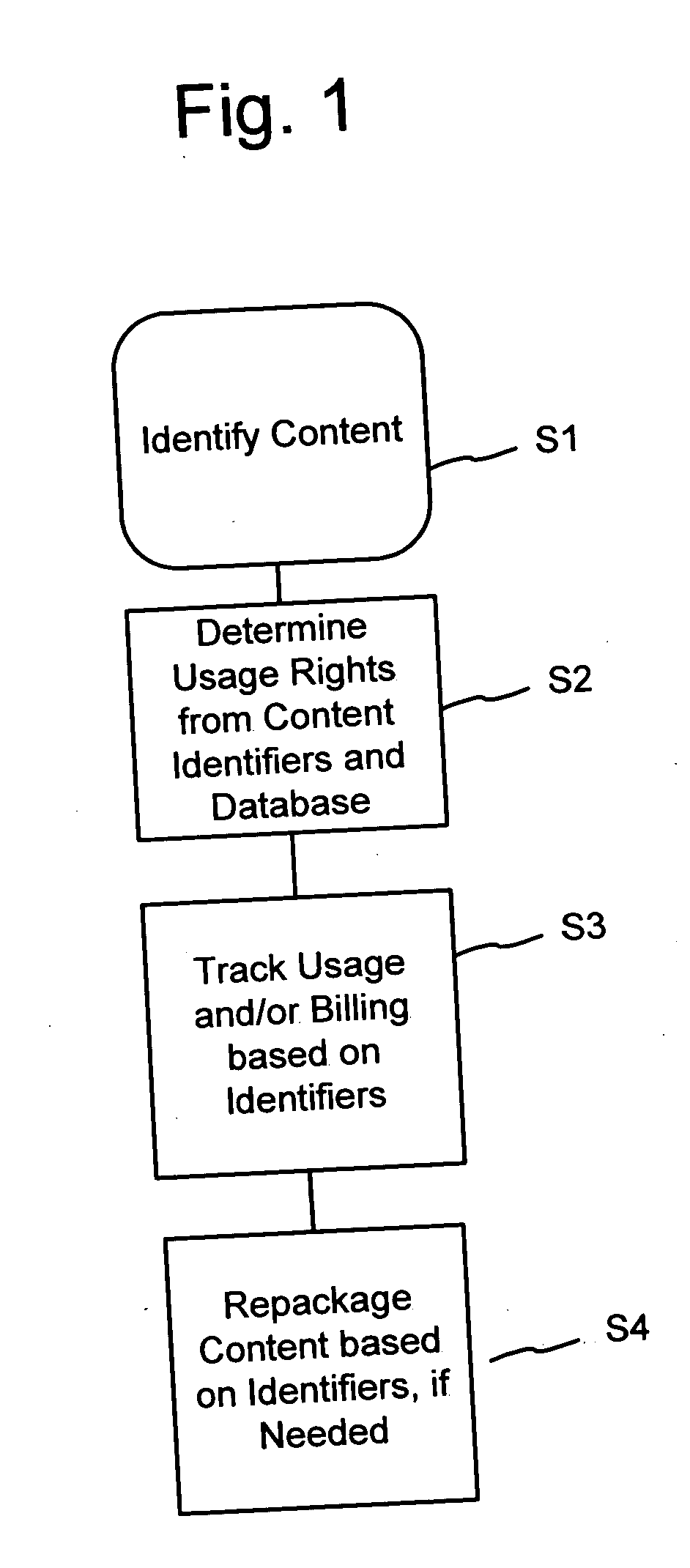

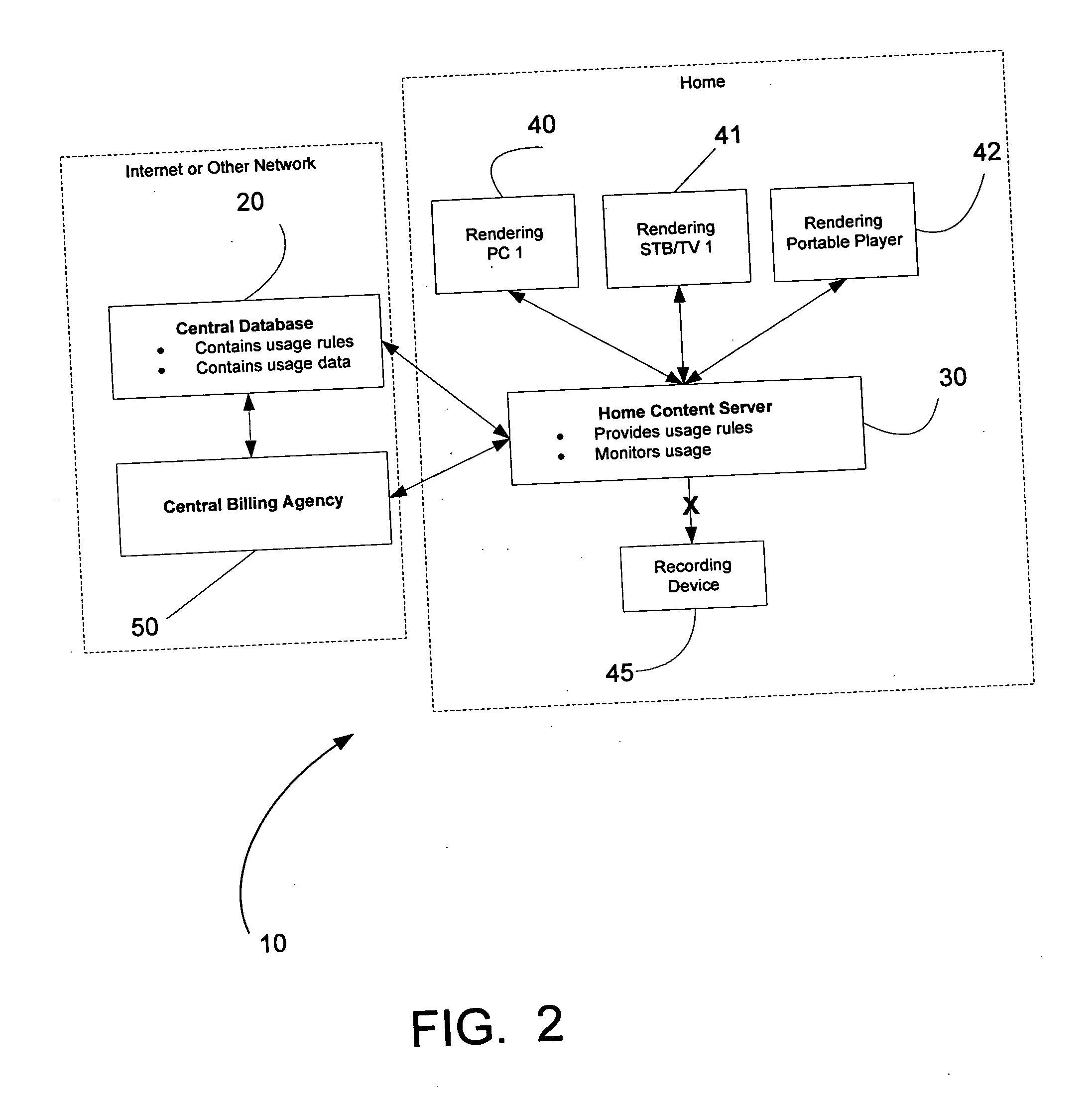

Rights management systems and methods using digital watermarking

ActiveUS20060062426A1Difficult to controlDifficult to trackUser identity/authority verificationAnalogue secracy/subscription systemsContent IdentifierRights management

A digital watermark (DWM) content identifier is steganographically embedded in content. The DWM content identifier provides a link to a rights registry storing usage rights associated with the content. In some implementations the rights registry provides an association between the DWM content identifier and a digital rights management (DRM) content identifier. The DRM content identifier is used to find associated usage rights. The DWM content identifier can also be used to transfer content from a first DRM system to a second DRM system.

Owner:DIGIMARC CORP (FORMERLY DMRC CORP)

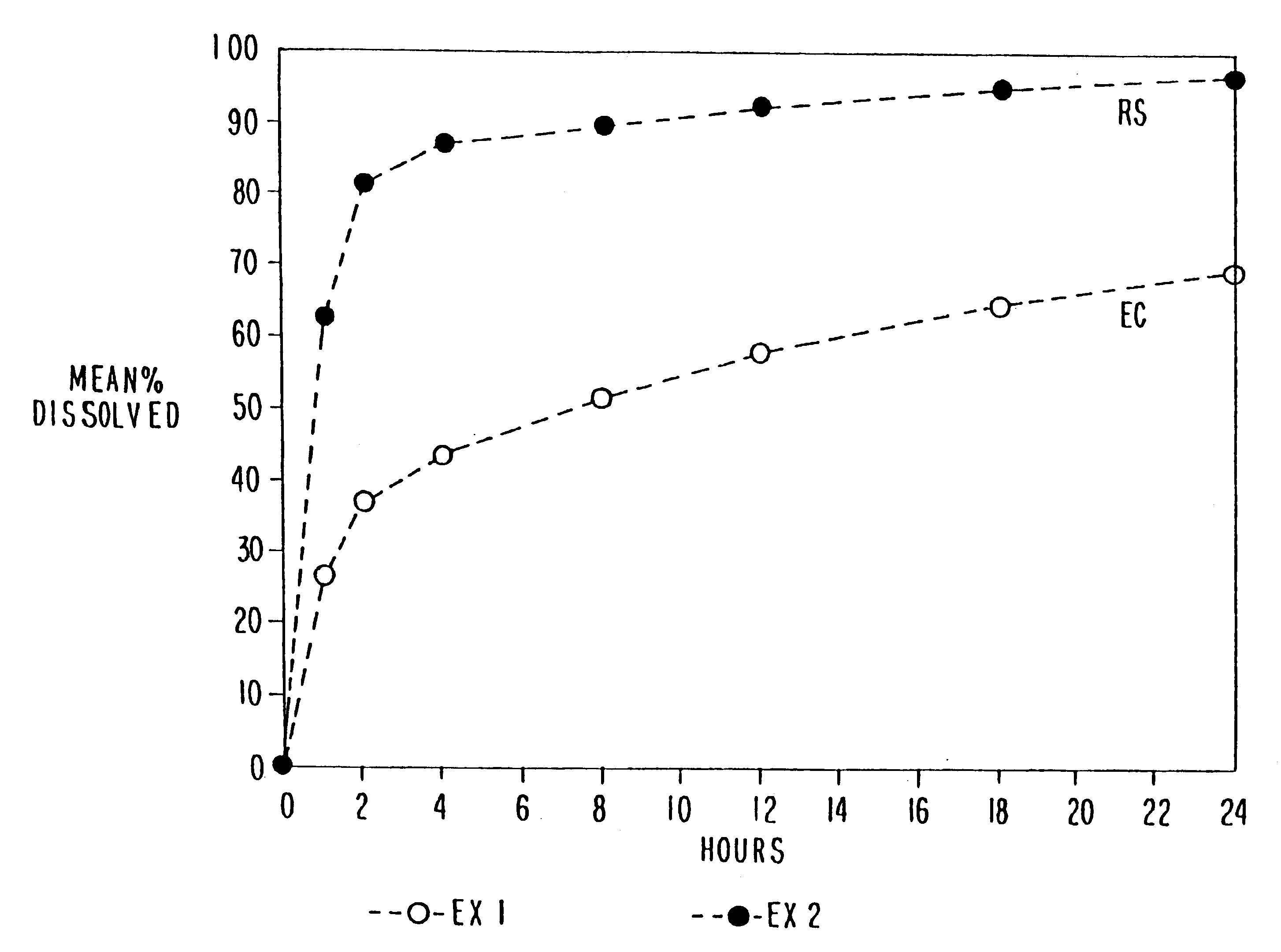

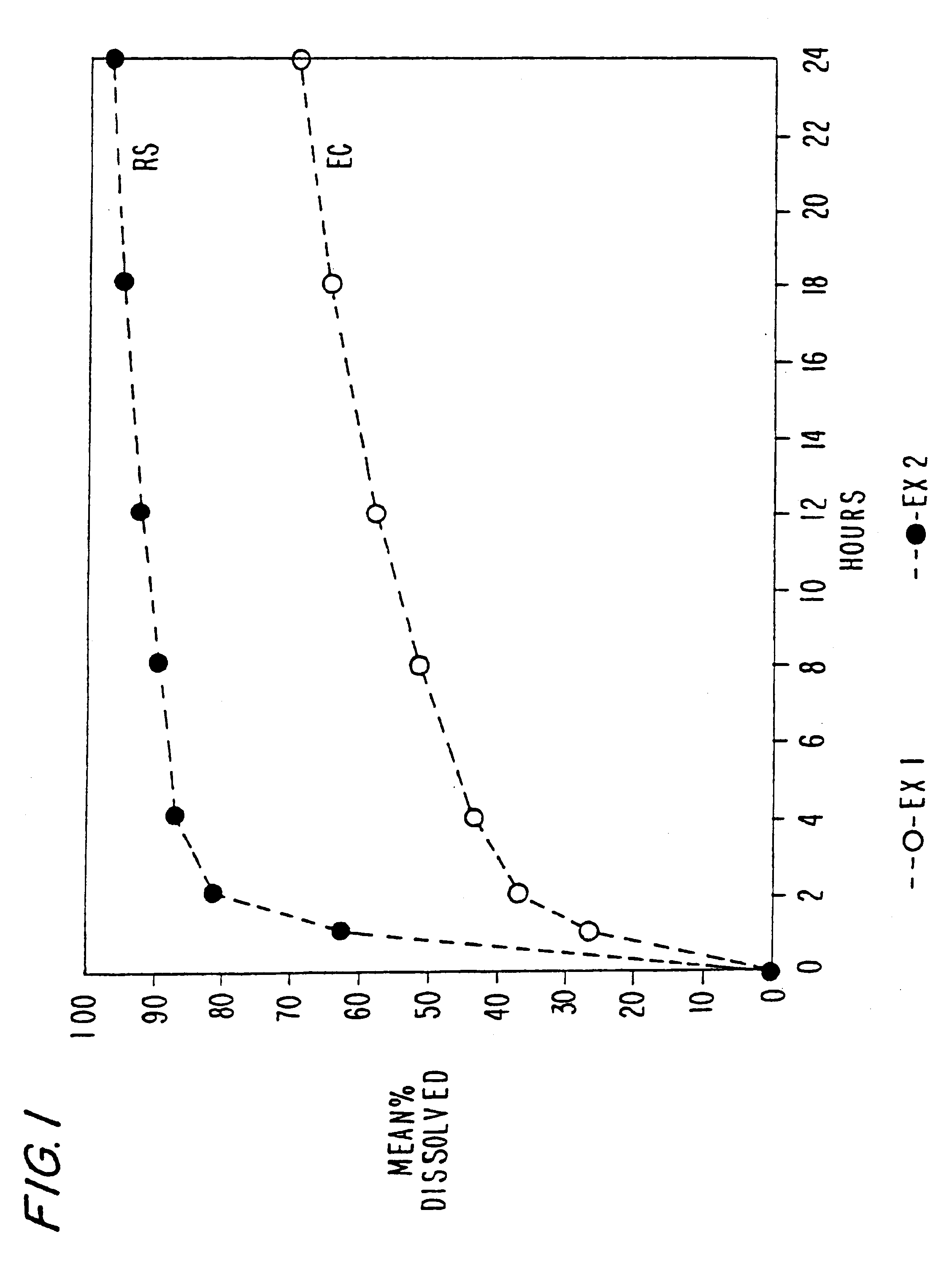

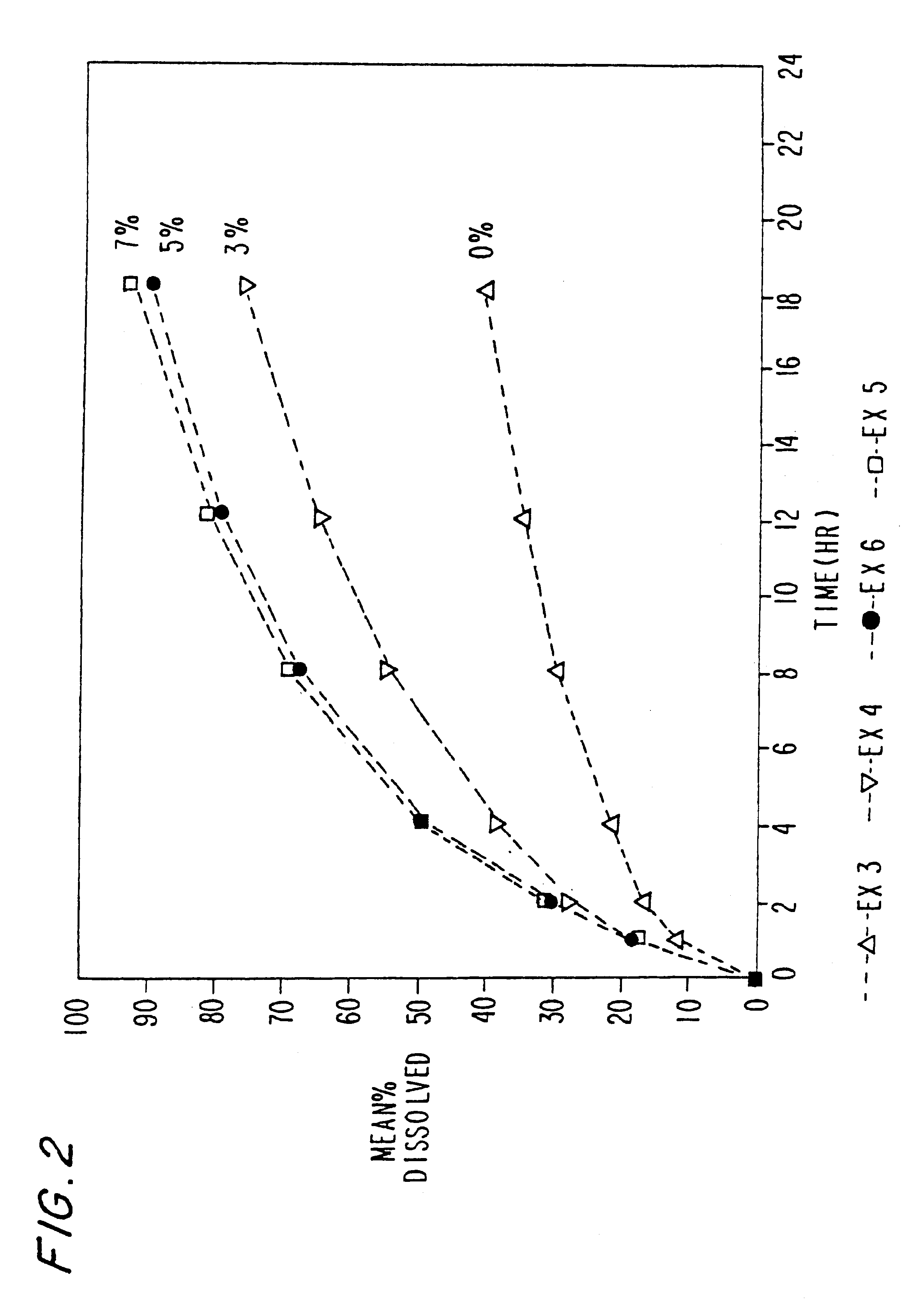

Melt-extruded orally administrable opioid formulations

InactiveUS6261599B1Sustained effectSlow and control releaseBiocideOrganic active ingredientsMelt extrusionDosage form

Bioavailable sustained release oral opioid analgesic dosage forms, comprising a plurality of multiparticulates produced via melt extrusion techniques disclosed.

Owner:PURDUE PHARMA LP

Continuous method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6416822B1Faster efficient meanSimple methodPretreated surfacesSemiconductor/solid-state device manufacturingHigh densityVolumetric Mass Density

The present invention relates to an enhanced non-sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method.

Owner:NOVELLUS SYSTEMS

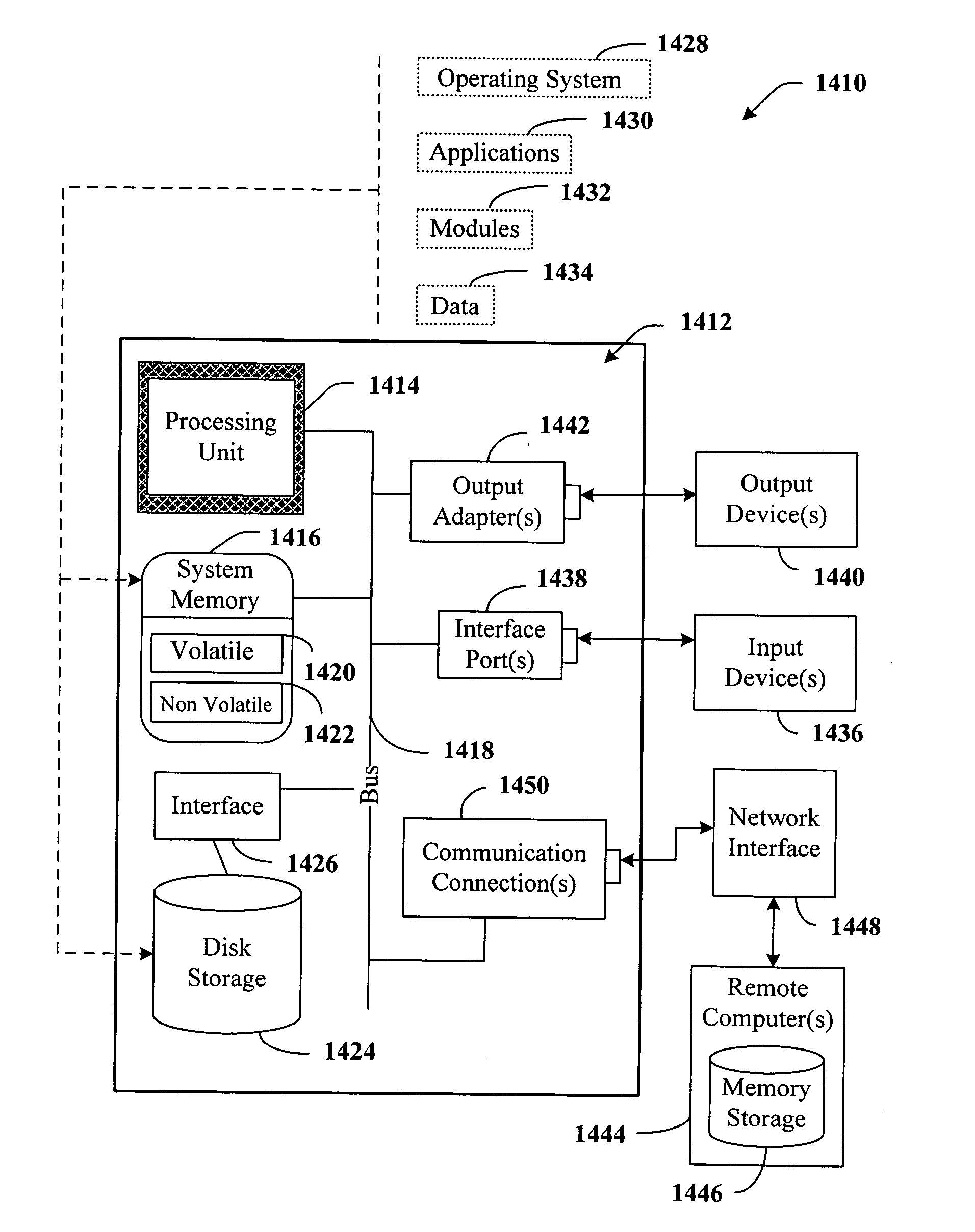

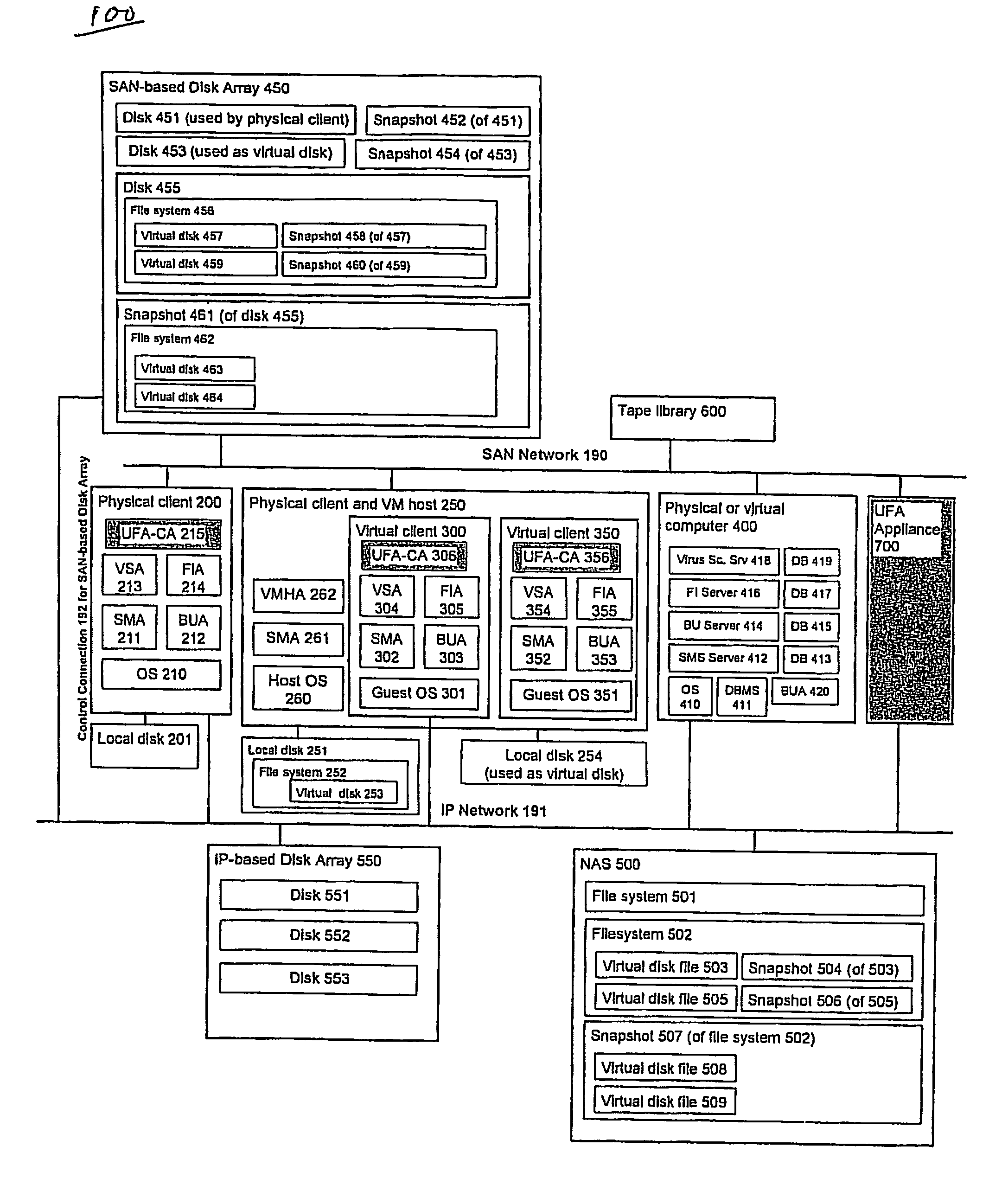

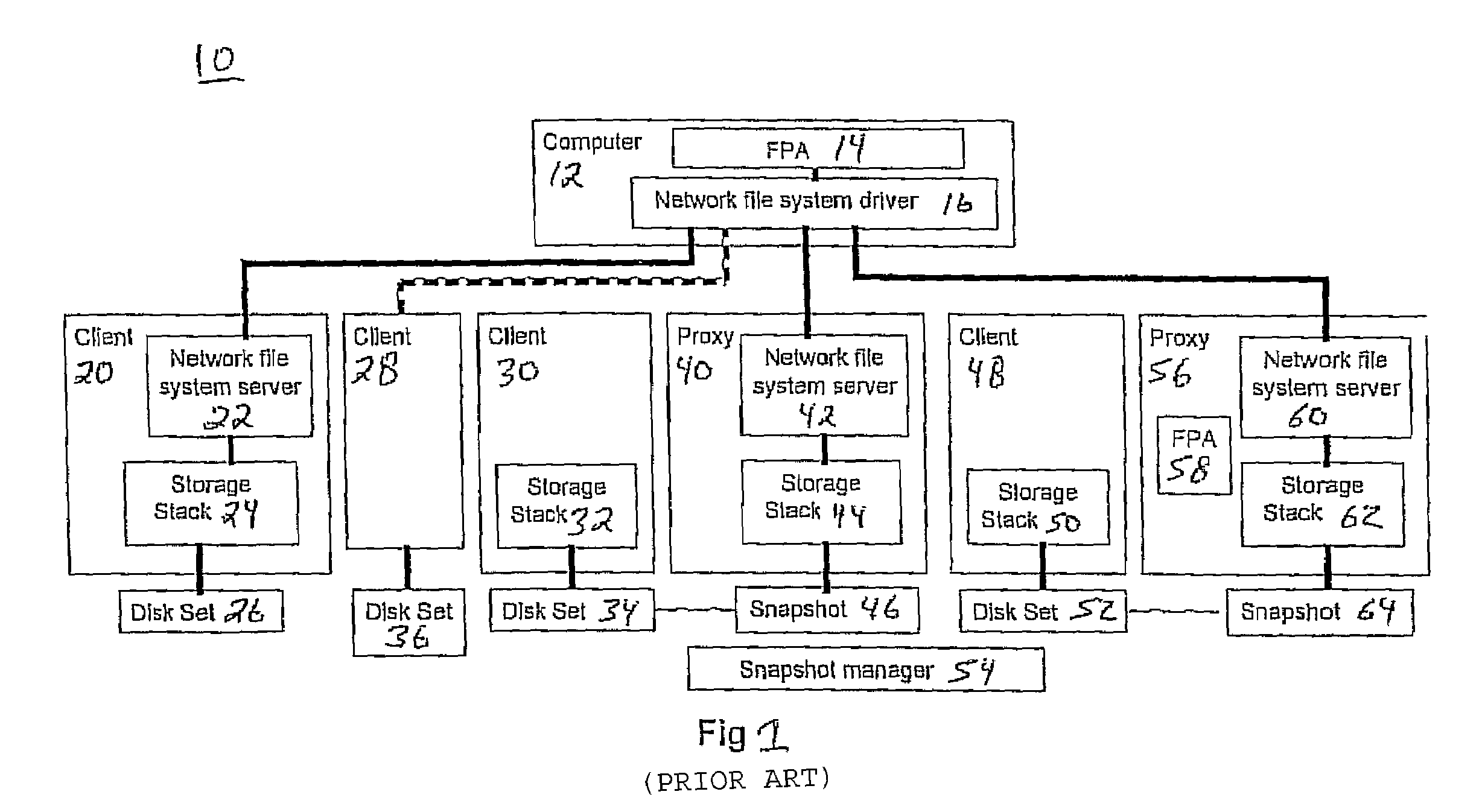

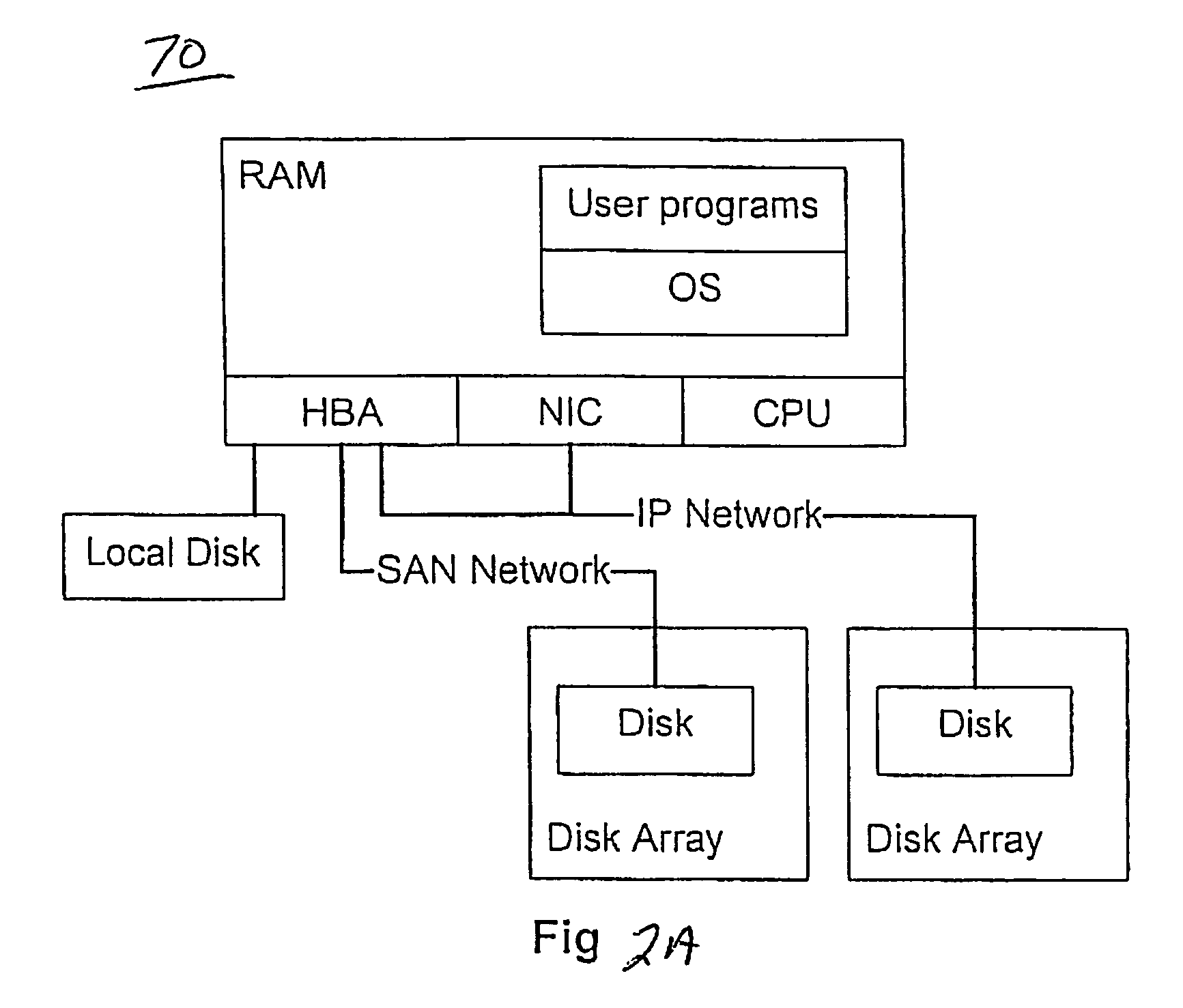

Universal file access architecture for a heterogeneous computing environment

ActiveUS7606868B1Simple methodReduce the numberMultiple digital computer combinationsSoftware simulation/interpretation/emulationClient-sideService provision

An architecture and system are described that provide a unified file access service within in a managed computing environment composed of diverse networks, computing devices, and storage devices. The service provides mechanisms for remotely accessing the file systems of any managed computer or disk snapshot, independently of the computer's current state (powered on, suspended or powered off), its location within the environment, its hardware type (virtual vs. physical), its operating system type, and its file system formats. The system isolates centralized FPAs from the details of clients, proxies and storage elements by providing a service that decomposes offloaded file system access into two steps. A FPA or a requester acting on behalf of the FPA first expresses the disk set or the computer containing the file systems it wishes to access, along with requirements and preferences about the access method. The service figures out an efficient data path satisfying the FPA's needs, and then automatically configures a set of storage and computing resources to provide the data path. The service then replies with information about the resources and instructions for using them. The FPA then accesses the requested file systems using the returned information.

Owner:VMWARE INC

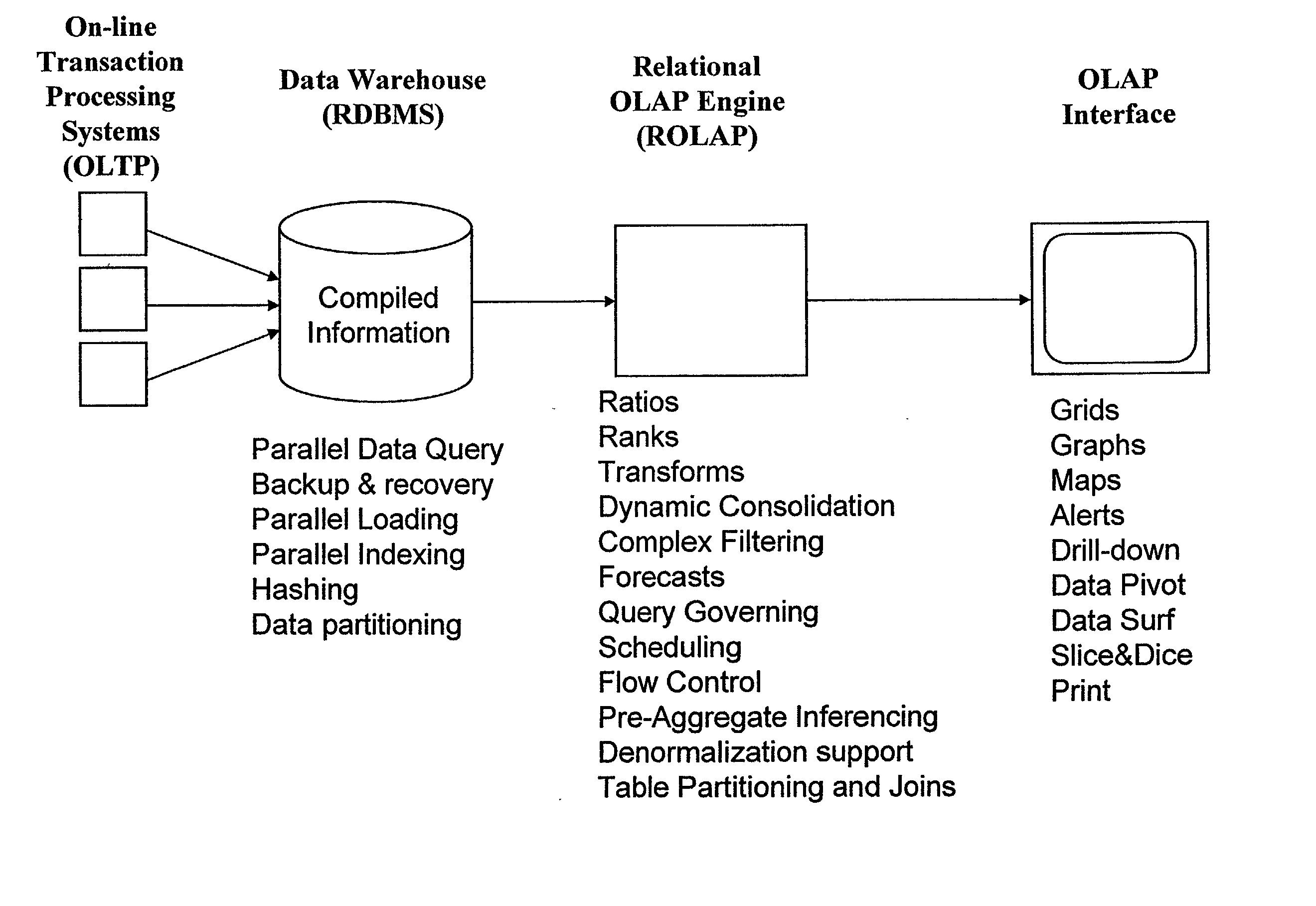

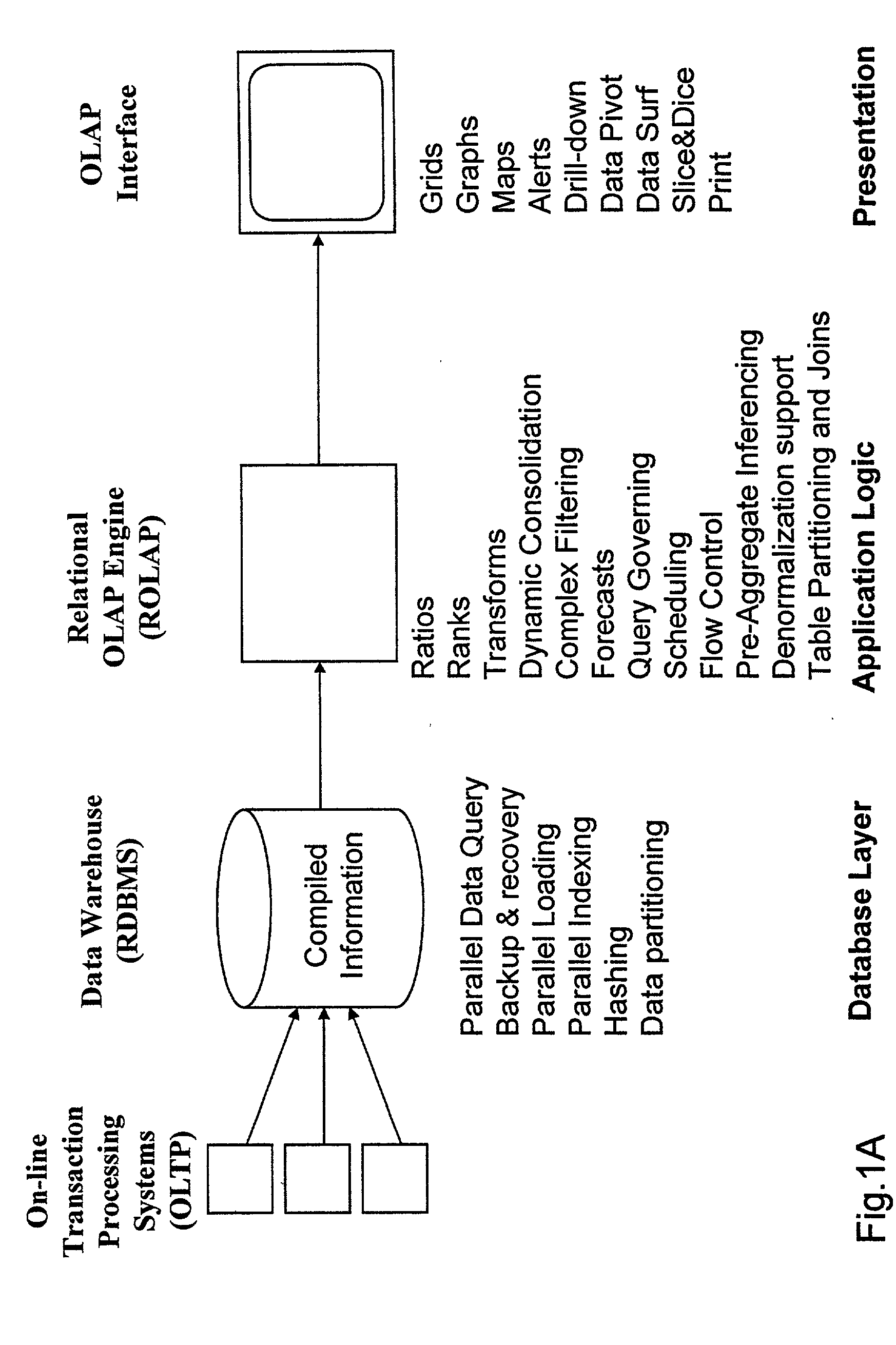

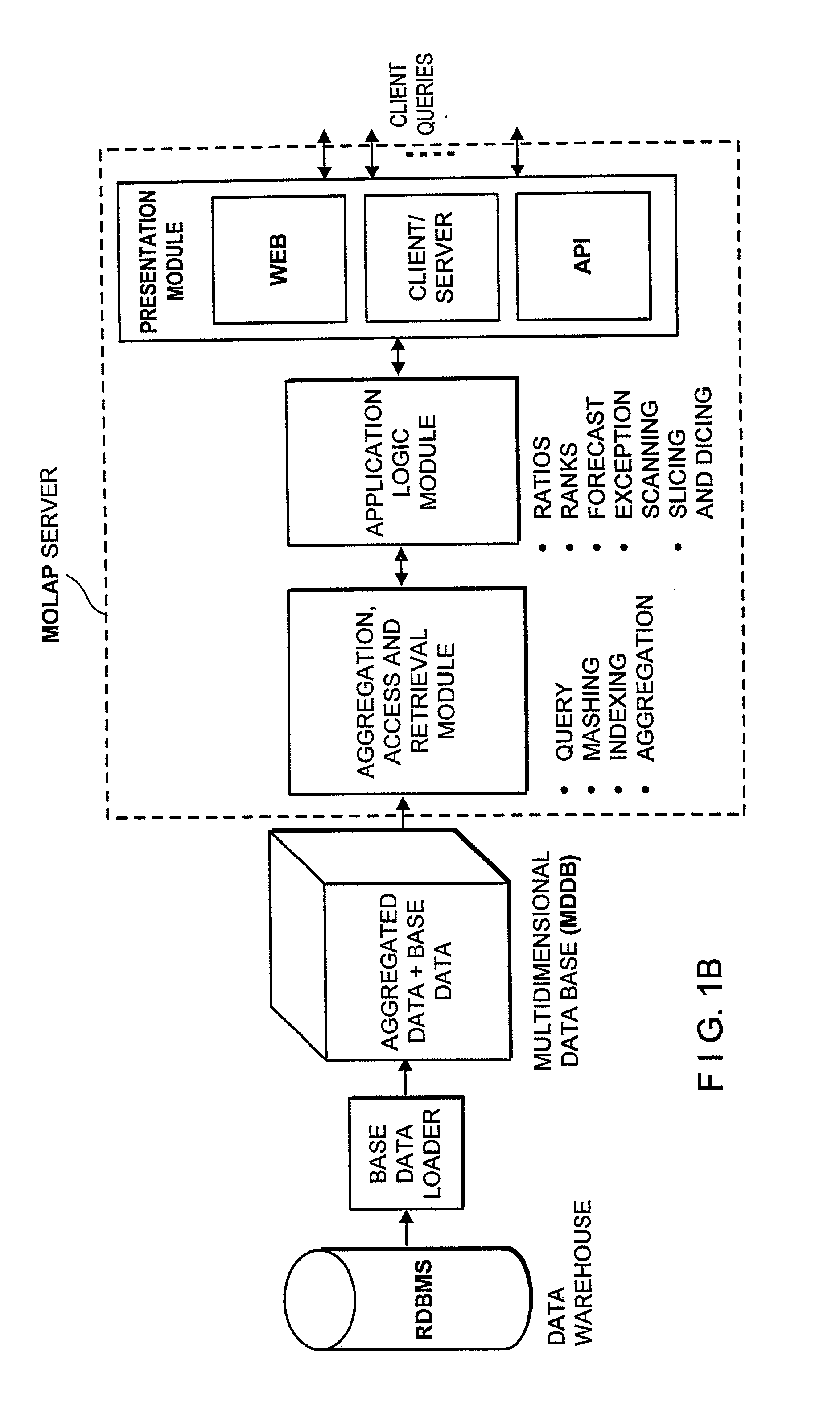

Data aggregation server for managing a multi-dimensional database and database management system having data aggregation server integrated therein

InactiveUS20020029207A1Reduce the burden onImprove system performanceData processing applicationsDigital data processing detailsData aggregatorThe Internet

Improved method of and apparatus for aggregating data elements in multidimensional databases (MDDB). In one aspect of the present invention, the apparatus is realized in the form of a high-performance stand-alone (i.e. external) aggregation server which can be plugged-into conventional OLAP systems to achieve significant improments in system performance. In accordance with the principles of the present invention, the stand-alone aggregation server contains a scalable MDDB and a high-performance aggregation engine that are integrated into the modular architecture of the aggregation server. The stand-alone aggregation server of the present invention can uniformly distribute data elements among a plurality of processors, for balanced loading and processing, and therefore is highly scalable. The stand-alone aggregation server of the present invention can be used to realize (i) an improved MDDB for supporting on-line analytical processing (OLAP) operations, (ii) an improved Internet URL Directory for supporting on-line information searching operations by Web-enabled client machines, as well as (iii) diverse types of MDDB-based systems for supporting real-time control of processes in response to complex states of information reflected in the MDDB. In another aspect of the present invention, the apparatus is integrated within a database management system (DBMS). The improved DBMS can be used to realize achieving a significant increase in system performance (e.g. deceased access / search time), user flexibility and ease of use. The improved DBMS system of the present invention can be used to realize an improved Data Warehouse for supporting on-line analytical processing (OLAP) operations or to realize an improved informational database system, operational database system, or the like.

Owner:YANICKLO TECH LIABILITY +1

Electrospun fibers and an apparatus therefor

InactiveUS6753454B1Optimal spacingMaintain spacingNanotechFilament/thread formingFiberPolymer solution

A novel fiber comprising a substantially homogeneous mixture of a hydrophilic polymer and a polymer which is at least weakly hydrophobic is disclosed. The fiber optionally contains a pH adjusting compound. A method of making the fiber comprises electrospinning fibers of the substantially homogeneous polymer solution. A method of treating a wound or other area of a patient requiring protection from contamination comprises electrospinning the substantially homogeneous polymer solution to form a dressing. An apparatus for electrospinning a wound dressing is discosed.

Owner:AKRON THE UNIV OF +2

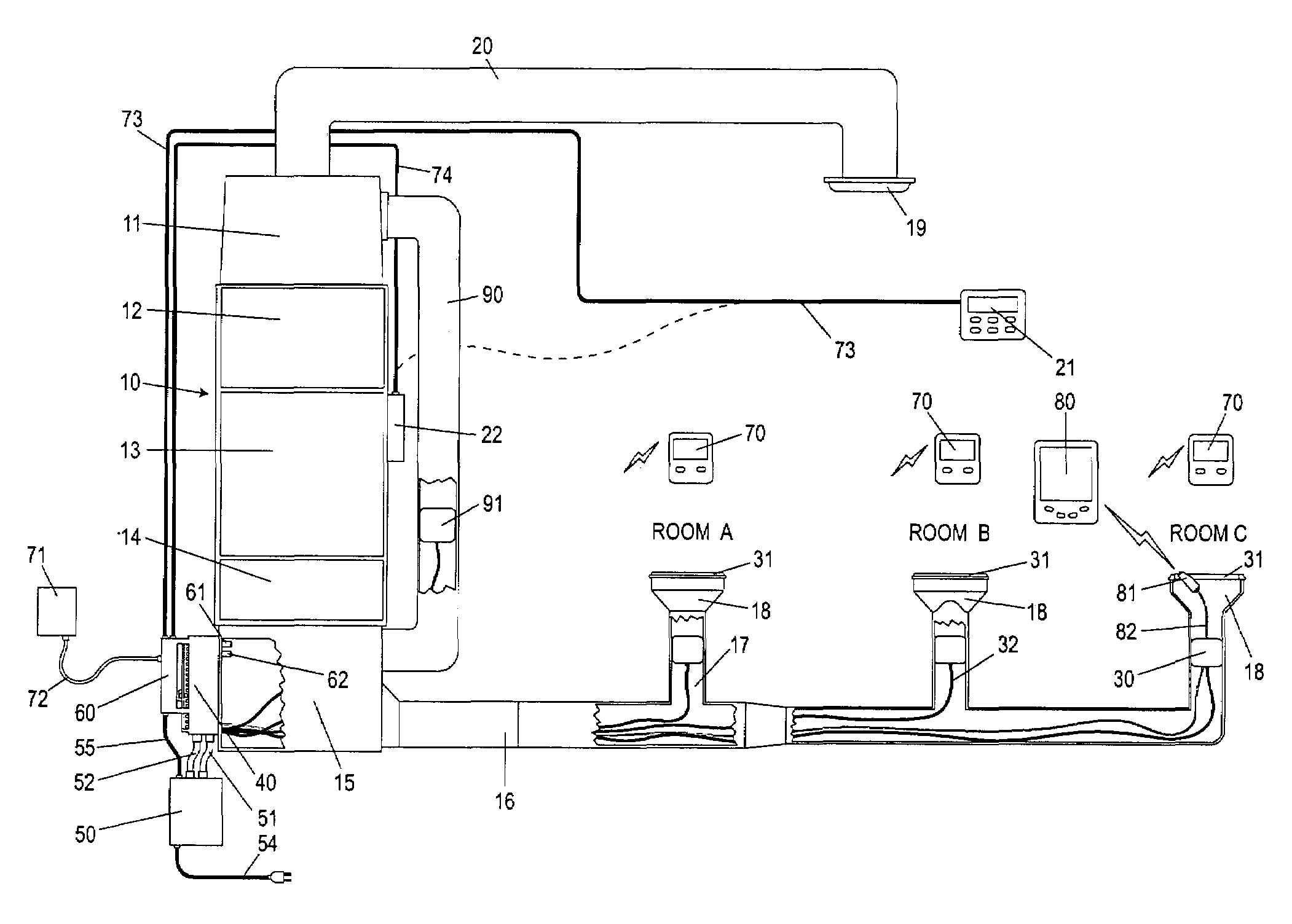

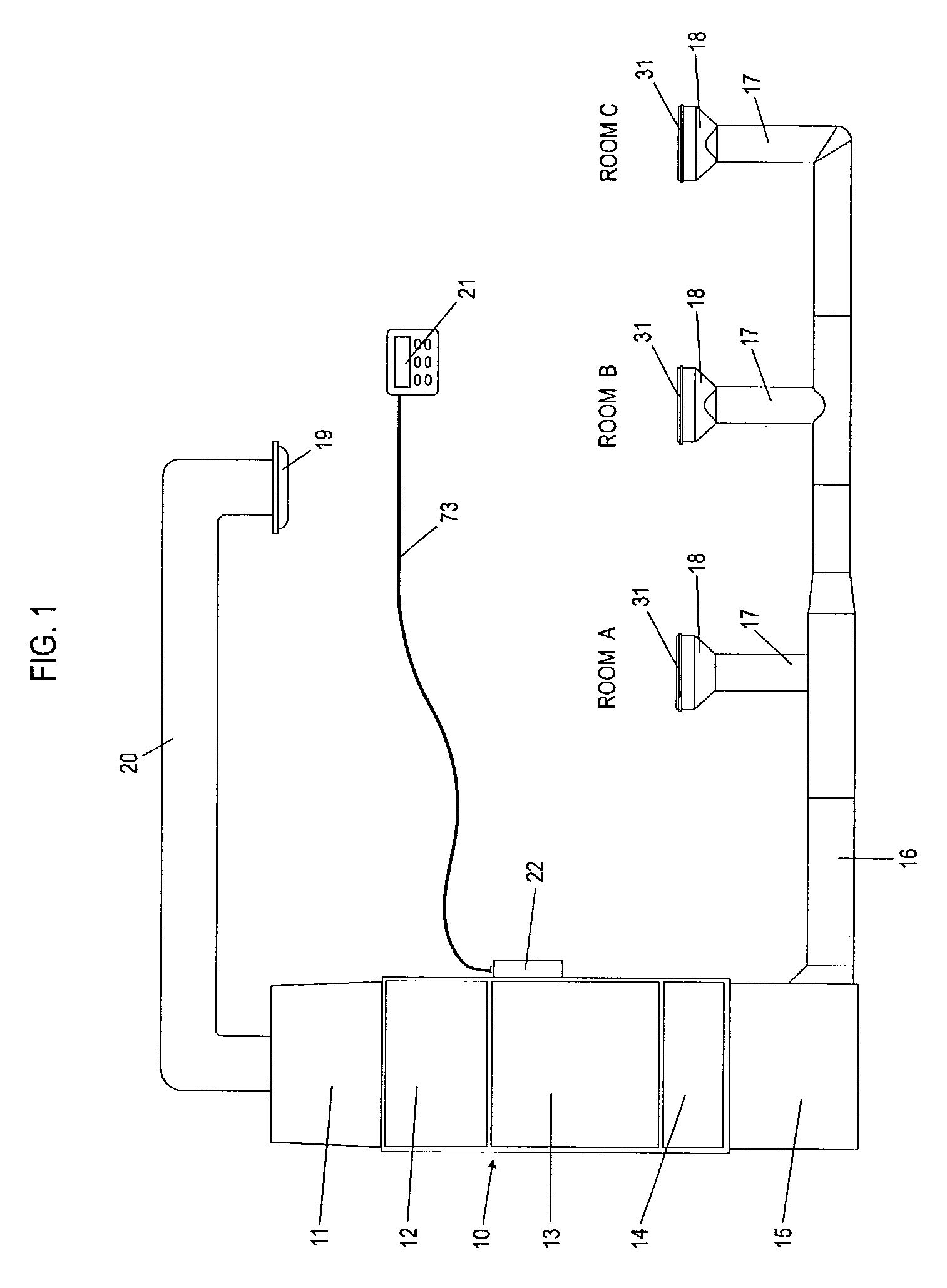

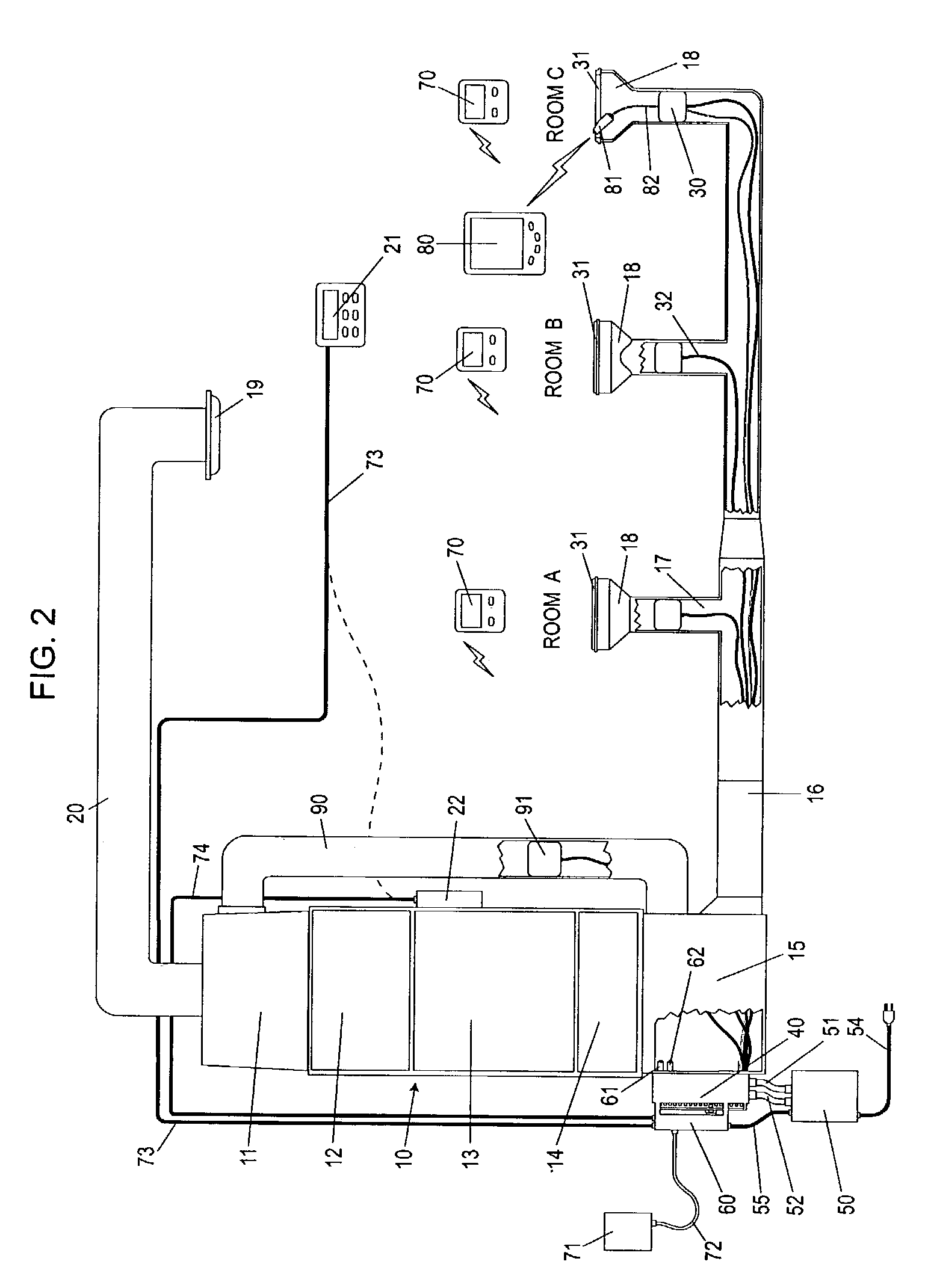

Forced-air zone climate control system for existing residential houses

ActiveUS6983889B2Improve comfortLow costLighting and heating apparatusTemperatue controlTemperature controlControl system

Owner:EMME E2MS

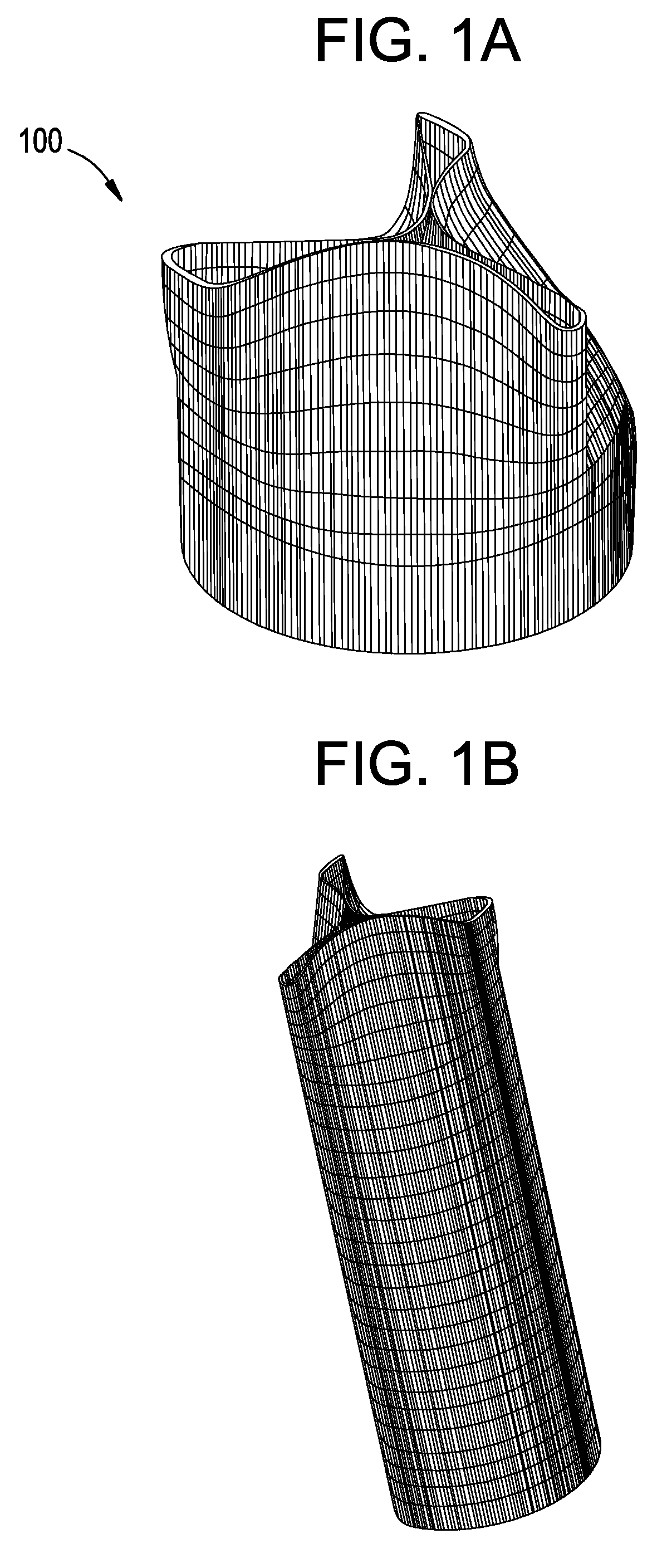

System and process for controlling electronic components in a ubiquitous computing environment using multimodal integration

ActiveUS6990639B2Increase choiceMade robustTransmission systemsCathode-ray tube indicatorsPointing deviceElectronic component

Owner:MICROSOFT TECH LICENSING LLC

Stent-valves for valve replacement and associated methods and systems for surgery

InactiveUS20090171447A1Simple methodReduce riskStentsBalloon catheterLess invasive surgeryGuide wires

Stent-valves (e.g., single-stent-valves and double-stent-valves), associated methods and systems for their delivery via minimally-invasive surgery, and guide-wire compatible closure devices for sealing access orifices are provided.

Owner:JENAVALVE TECH INC

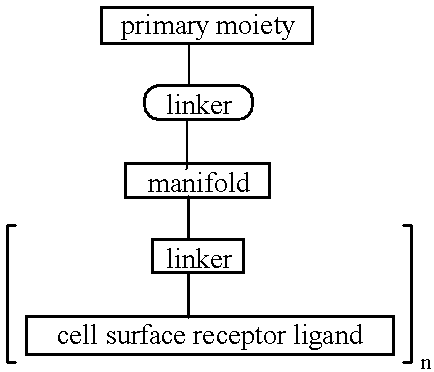

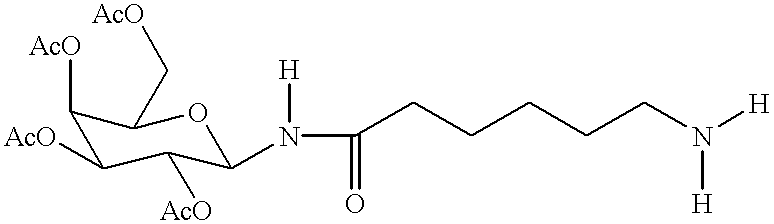

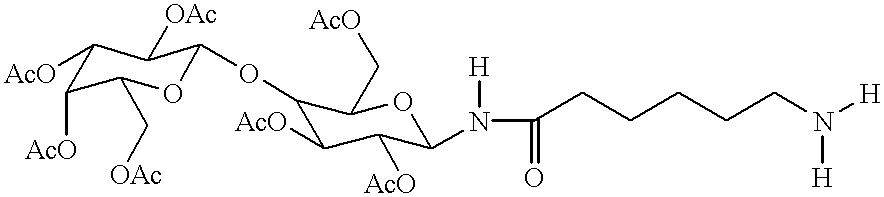

Targeted oligonucleotide conjugates

InactiveUS6300319B1Simple methodReduce interferenceBiocideOrganic active ingredientsReceptor degradationOligonucleotide

The present invention provides improved ingress of therapeutic and other moieties into cellular targets. In accordance with preferred embodiments, complexes are provided which carry primary moieties, chiefly therapeutic moieties, to such target cells. Such complexes preferably feature cell surface receptor ligands to provide specificity. Such ligands are preferably bound to primary moieties through polyfunctional manifold compounds.

Owner:IONIS PHARMA INC

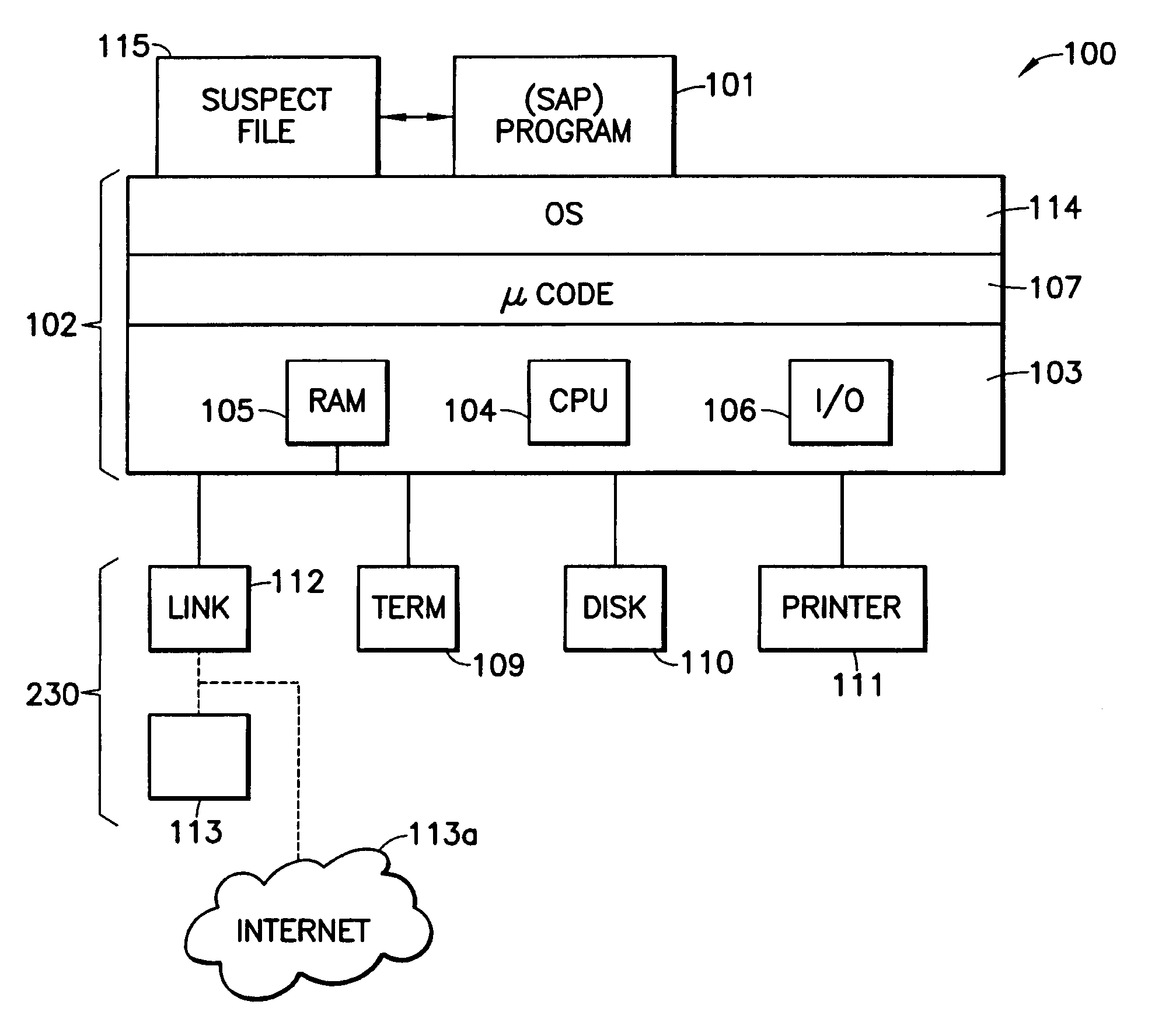

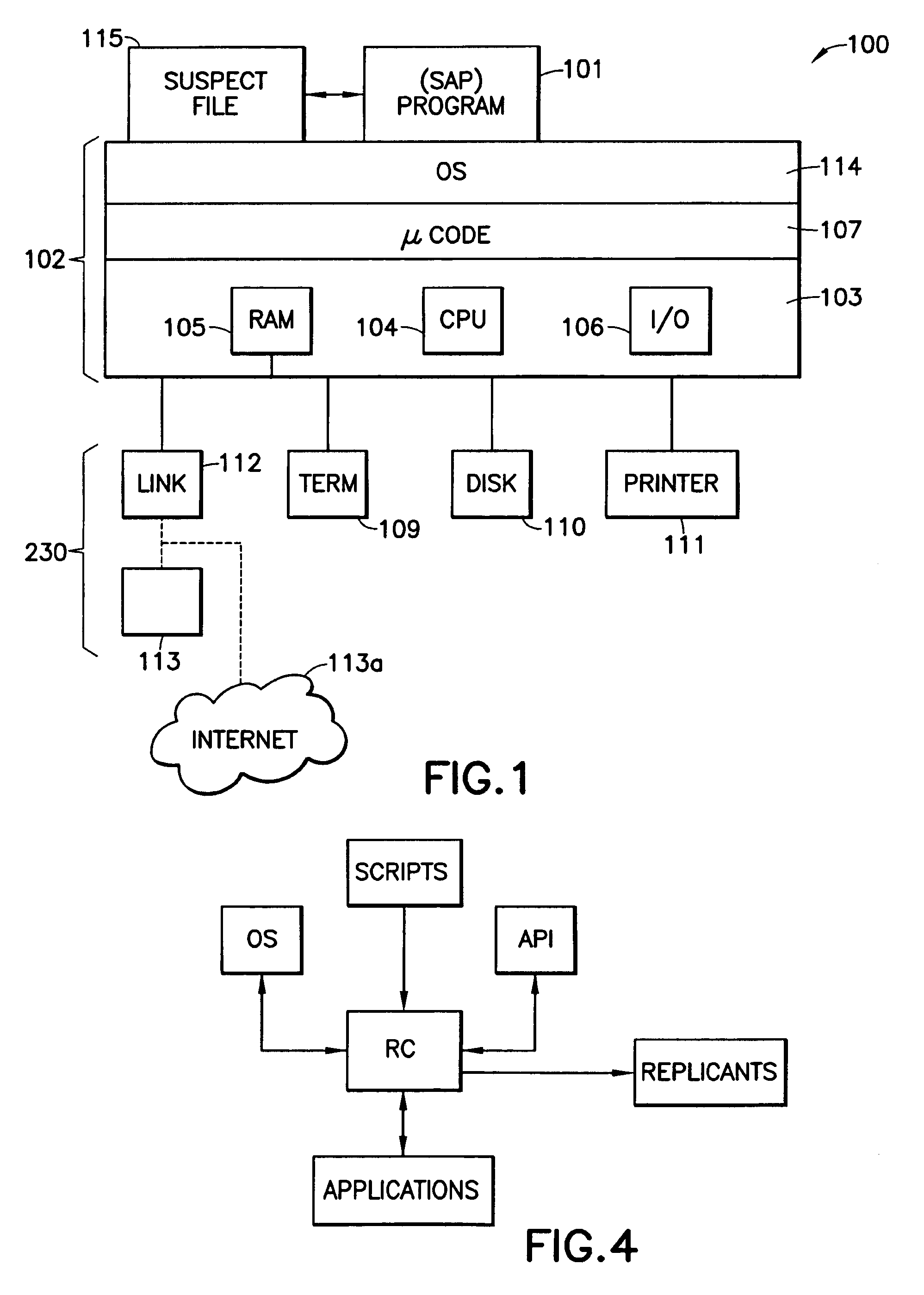

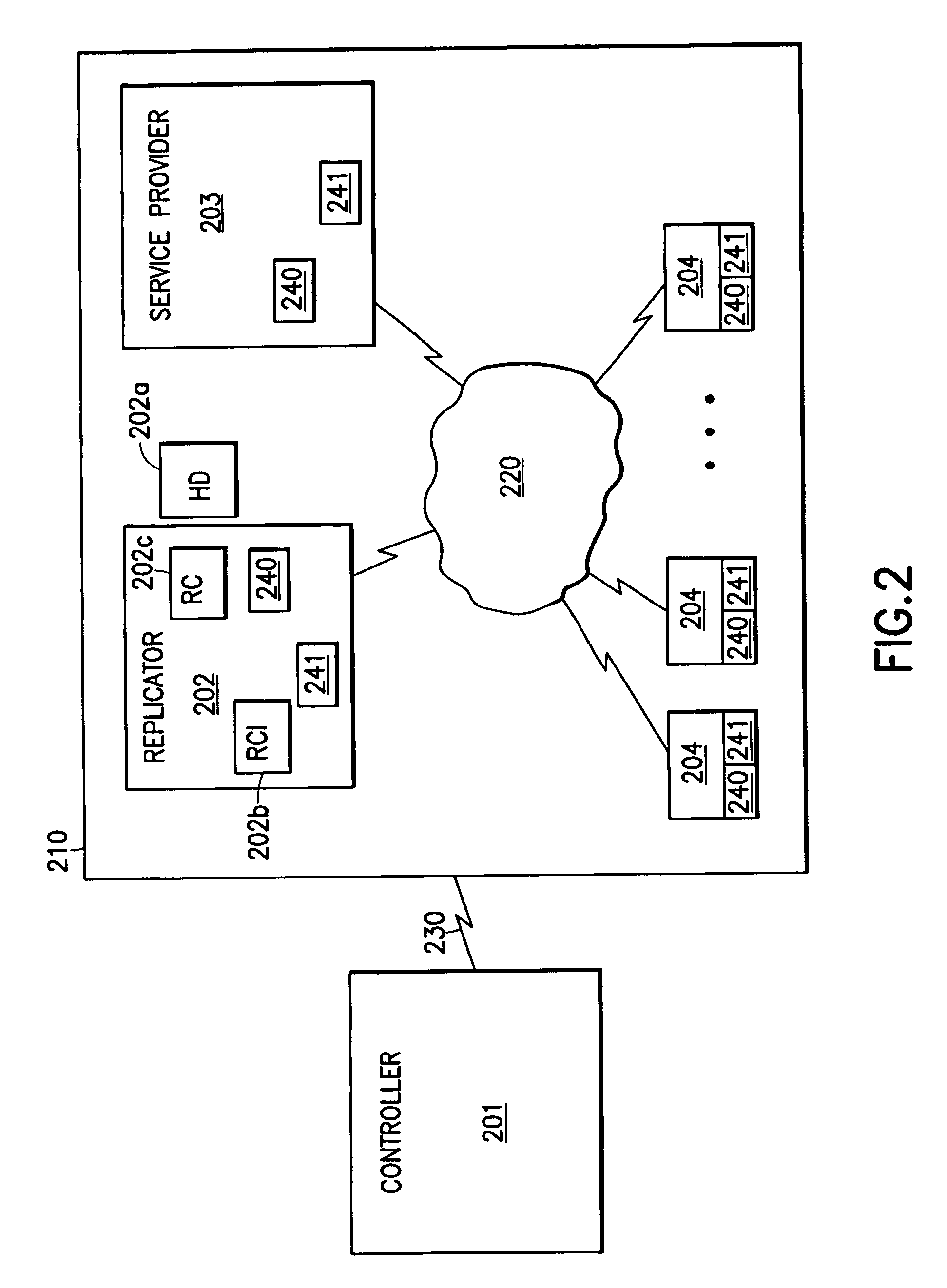

Method and apparatus for replicating and analyzing worm programs

InactiveUS6981279B1Simple methodEffective limitMemory loss protectionDigital data processing detailsThe InternetEmbedded system

A system and a method are disclosed for dynamically analyzing software, some of whose potentially-important behaviors (such as worm-like behavior) may only be displayed when the software is executed in an environment where it has, or appears to have, access to a production network and / or to the global Internet. The software can be executed in a real or an emulated network environment that includes a monitoring component and an emulation component. The monitoring component serves to capture and / or record the behaviors displayed by the software and / or other components of the system, and the emulation component gives the software being analyzed the impression that it is executing with access to a production network and / or to the global Internet. The software being analyzed is effectively confined to the analysis network environment, and cannot in fact read information from, or alter any information on, any production network or the global Internet.

Owner:TREND MICRO INC

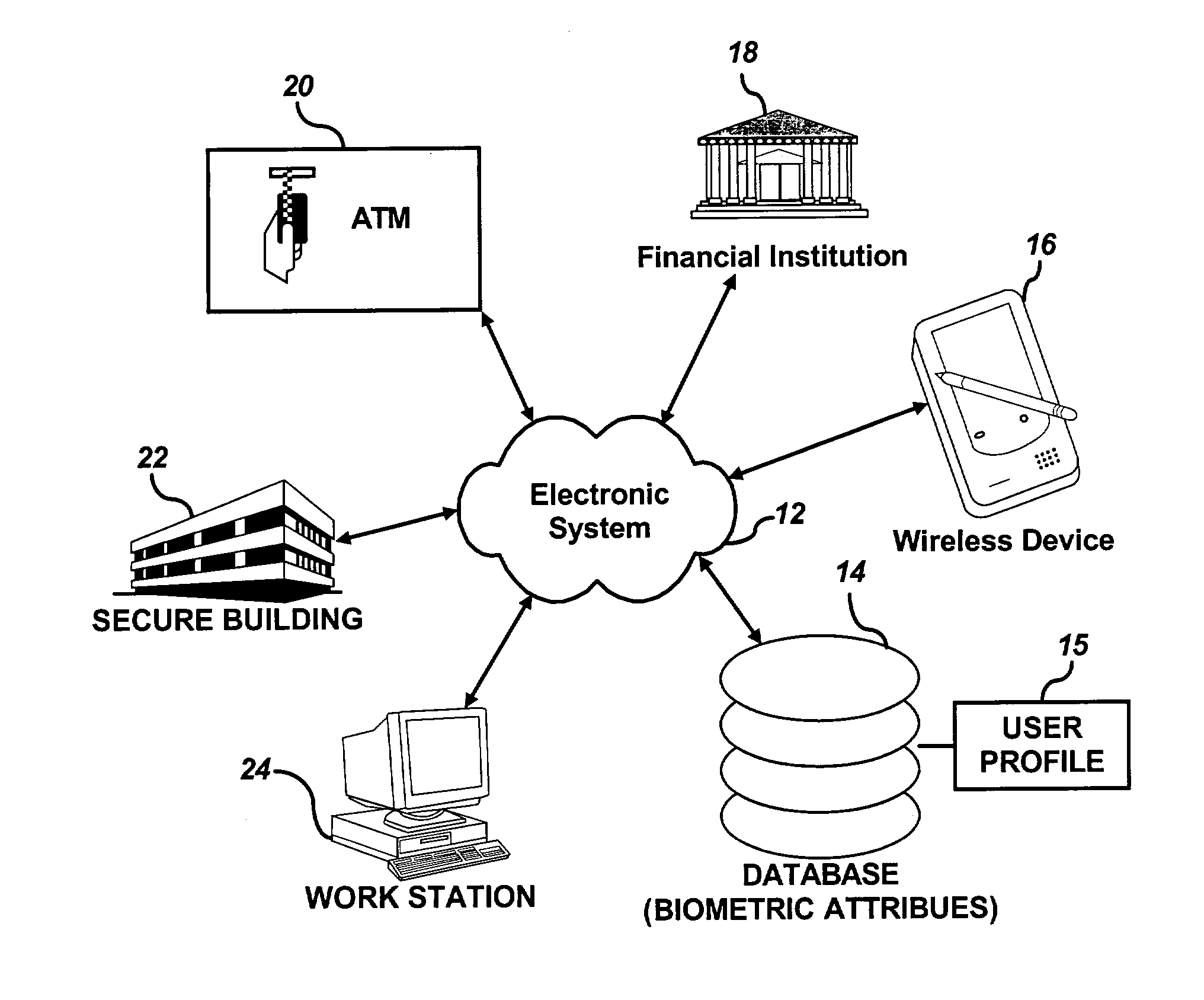

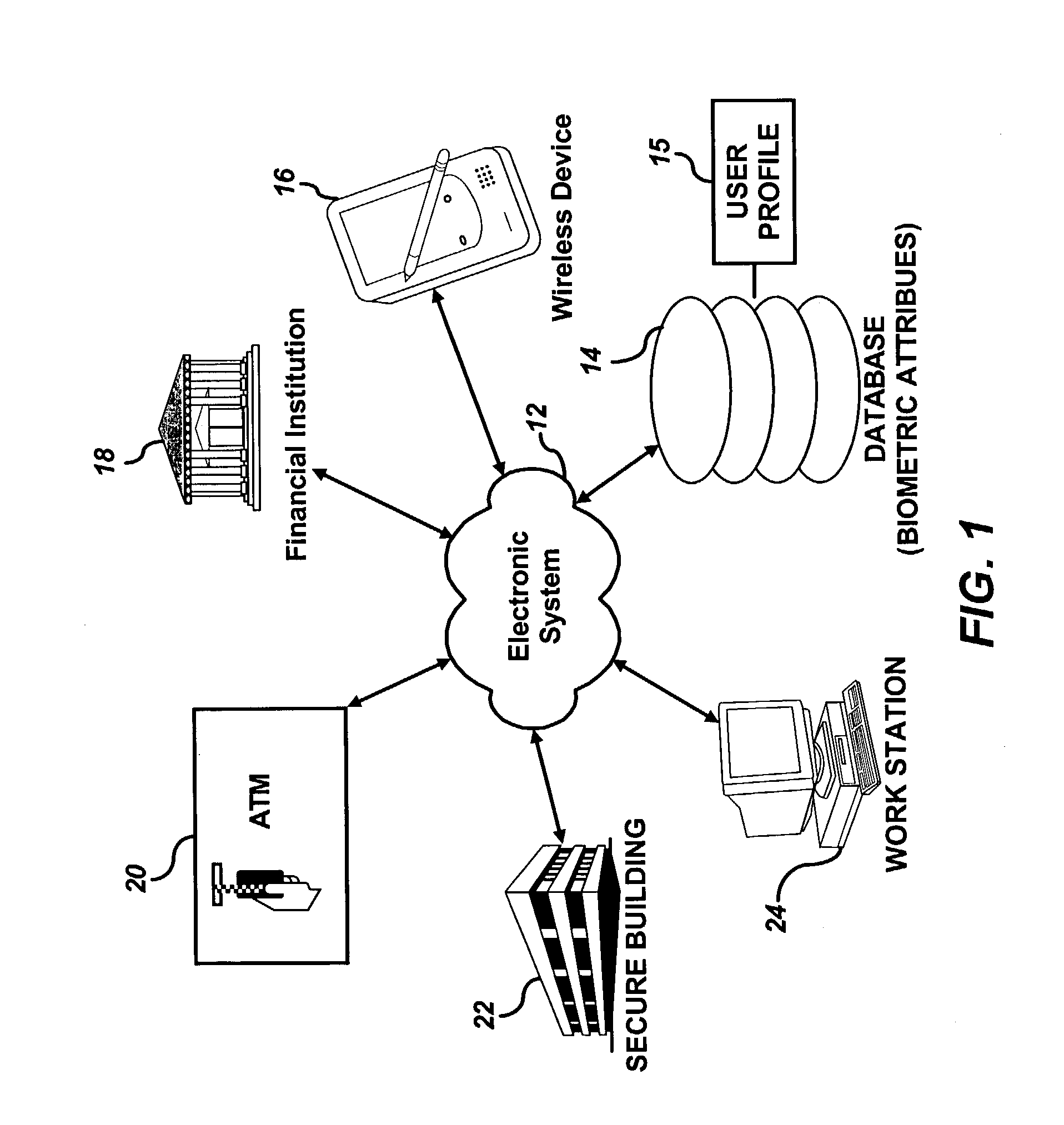

Random biometric authentication utilizing unique biometric signatures

InactiveUS20030163710A1Accurate authenticationSecure user accessDigital data processing detailsUser identity/authority verificationUser inputLayer thickness

A user can be challenged to provide at least one randomly selected biometric attribute. The randomly selected biometric attribute input by the user is automatically compared to a plurality of biometric attributes of the user contained in a user profile. The user can then be authenticated if the randomly selected biometric attribute input by the user matches at least one of the plurality of biometric attributes of the user contained in the user profile. Biometric attributes analyzed according to the methods and systems of the present invention, include, but are not limited to, for example, fingerprints, iris, retina, and / or tissue characteristics, such as skin morphology, skin layer thickness, collage density and orientation, tissue hydration, optical patent length differences, etc.

Owner:IP VENUE LLC

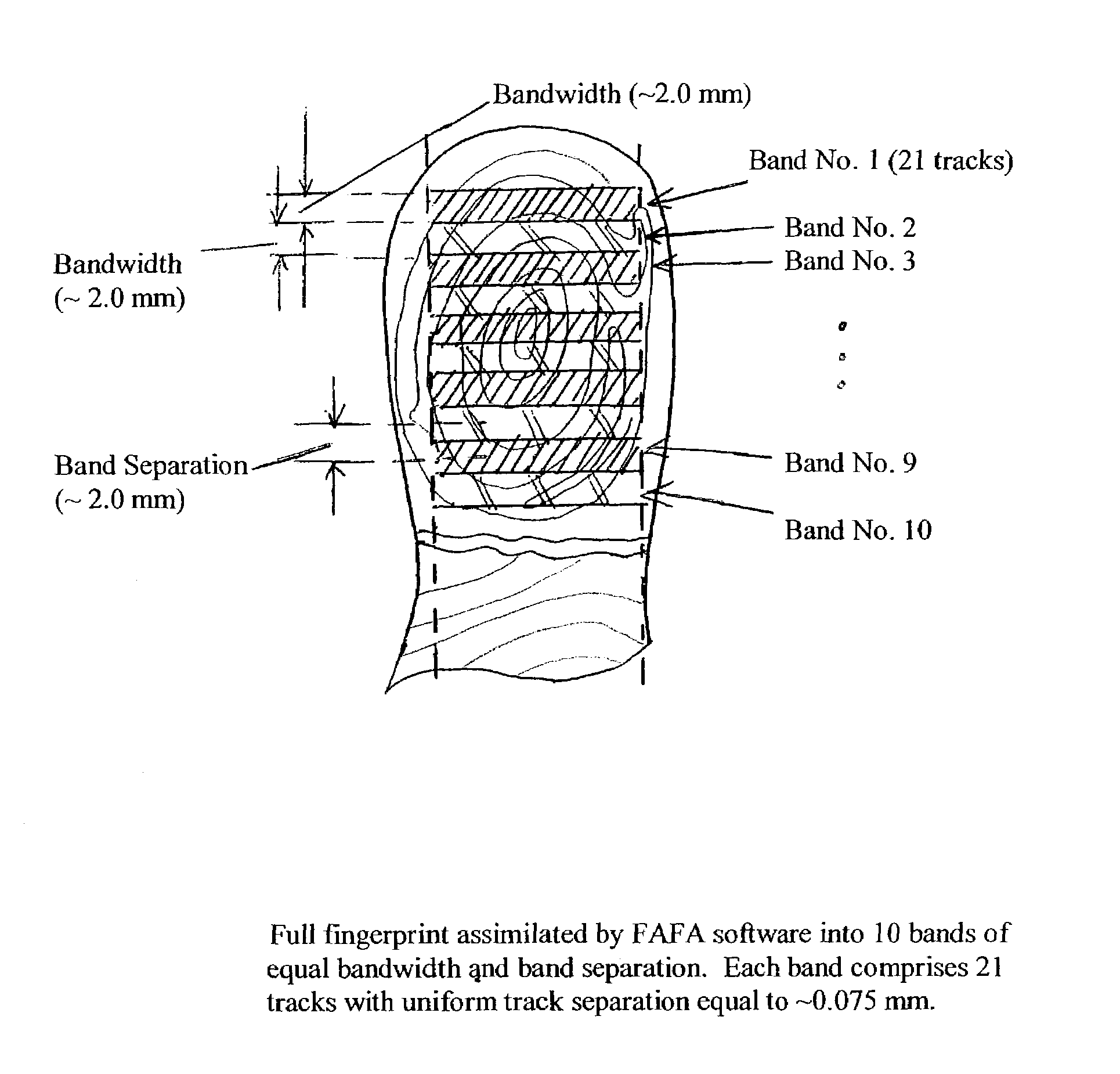

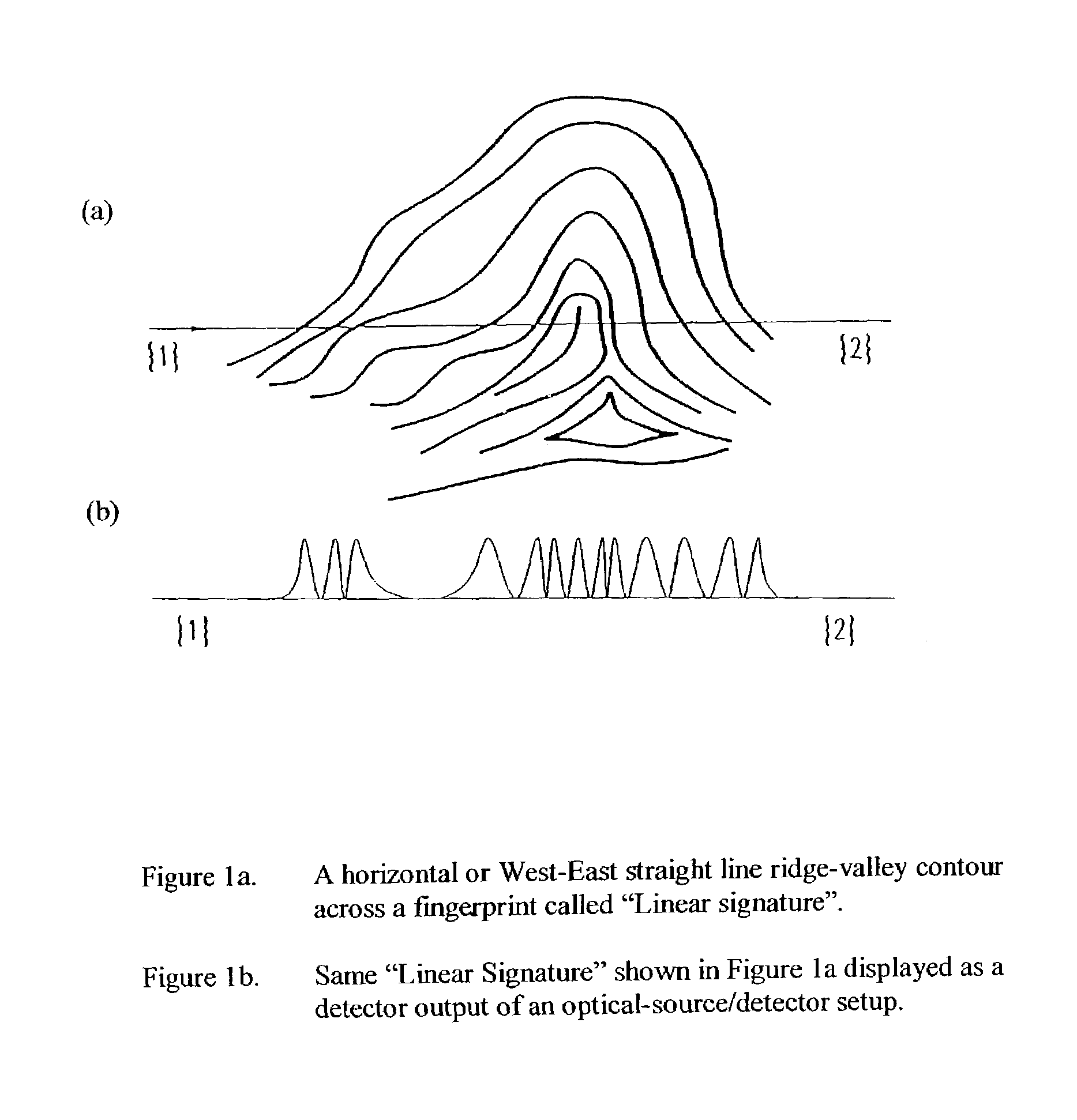

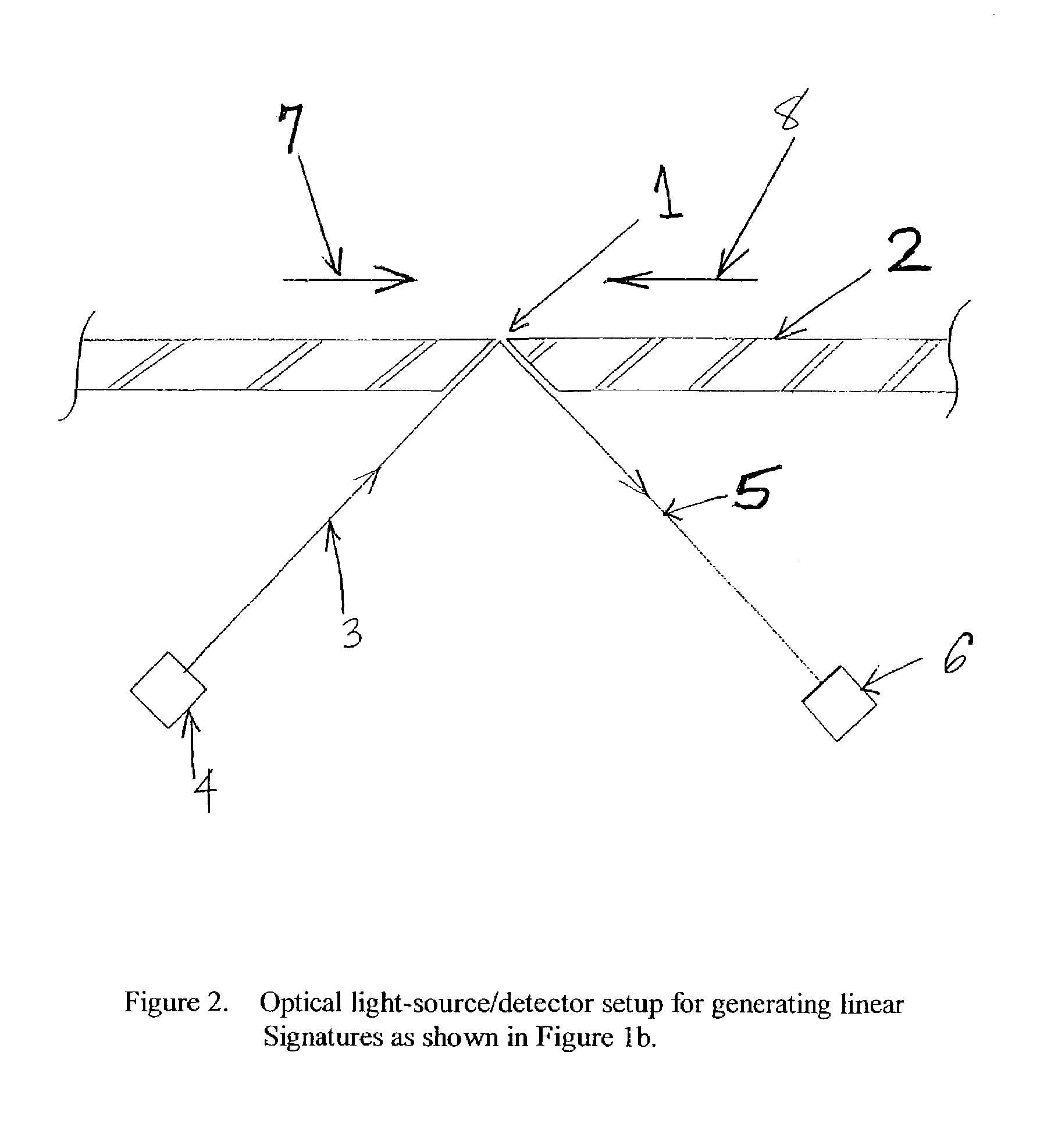

Method for authenticating an individual by use of fingerprint data

InactiveUS7136514B1Simple methodElectric signal transmission systemsImage analysisFast Fourier transformBiometrics

A method for authenticating an individual by use of fingerprint data that involves two different broad steps. The first step is to obtain a biometrics fingerprint signature template (“BFST”) for an individual in an enrollment process by selecting a plurality of bands for the BFST and obtaining a plurality of tracks corresponding to each of the plurality of bands by use of an enrollment frame of a selected finger of the individual, wherein the plurality of bands are spatially referenced to the enrollment frame and can be spatially referenced to a reference barrier. The second step is to authenticate (or not) a candidate finger against one or more BFST in an authentication process in which a swipe direction and an access code for the individual are selected, a plurality of candidate tracks are obtained from the candidate finger through use of the reference barrier in an authentication unit so that each of the plurality of candidate tracks is spatially referenced so as to be within a corresponding one of the plurality of bands, calculating a similarity index for each of the plurality of candidate tracks and each of the plurality of tracks for the band to which the candidate track corresponds by use of a Fast Fourier-transform fingerprint algorithm, and multiplying each maximum similarity index obtained for each of the plurality of candidate tracks to obtain a match index which indicates a match if it exceeds a preselected threshold.

Owner:WONG JACOB Y

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com