Patents

Literature

14926 results about "Contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contamination is the presence of a constituent, impurity, or some other undesirable element that soils, corrupts, infects, makes unfit, or makes inferior a material, physical body, natural environment, workplace, etc.

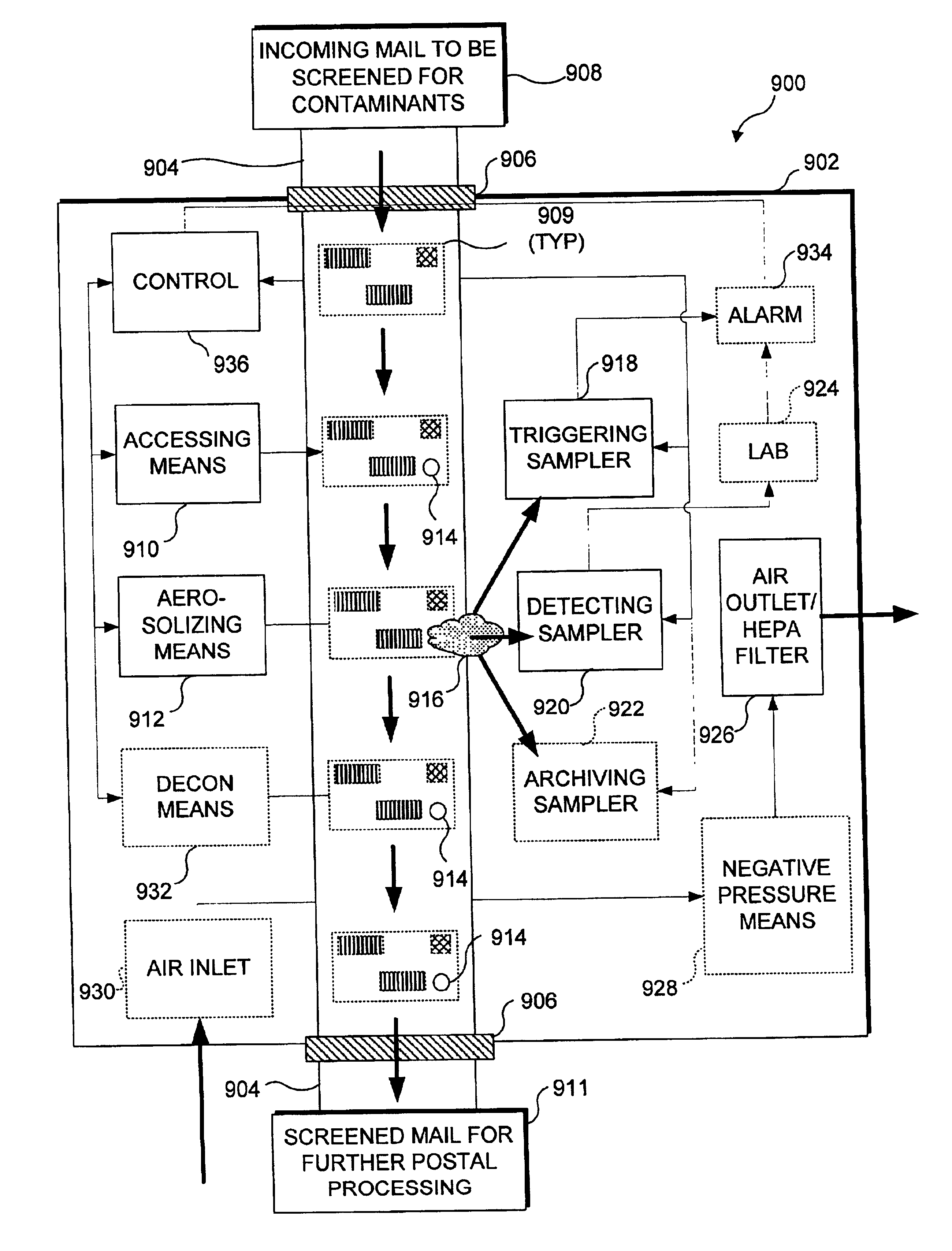

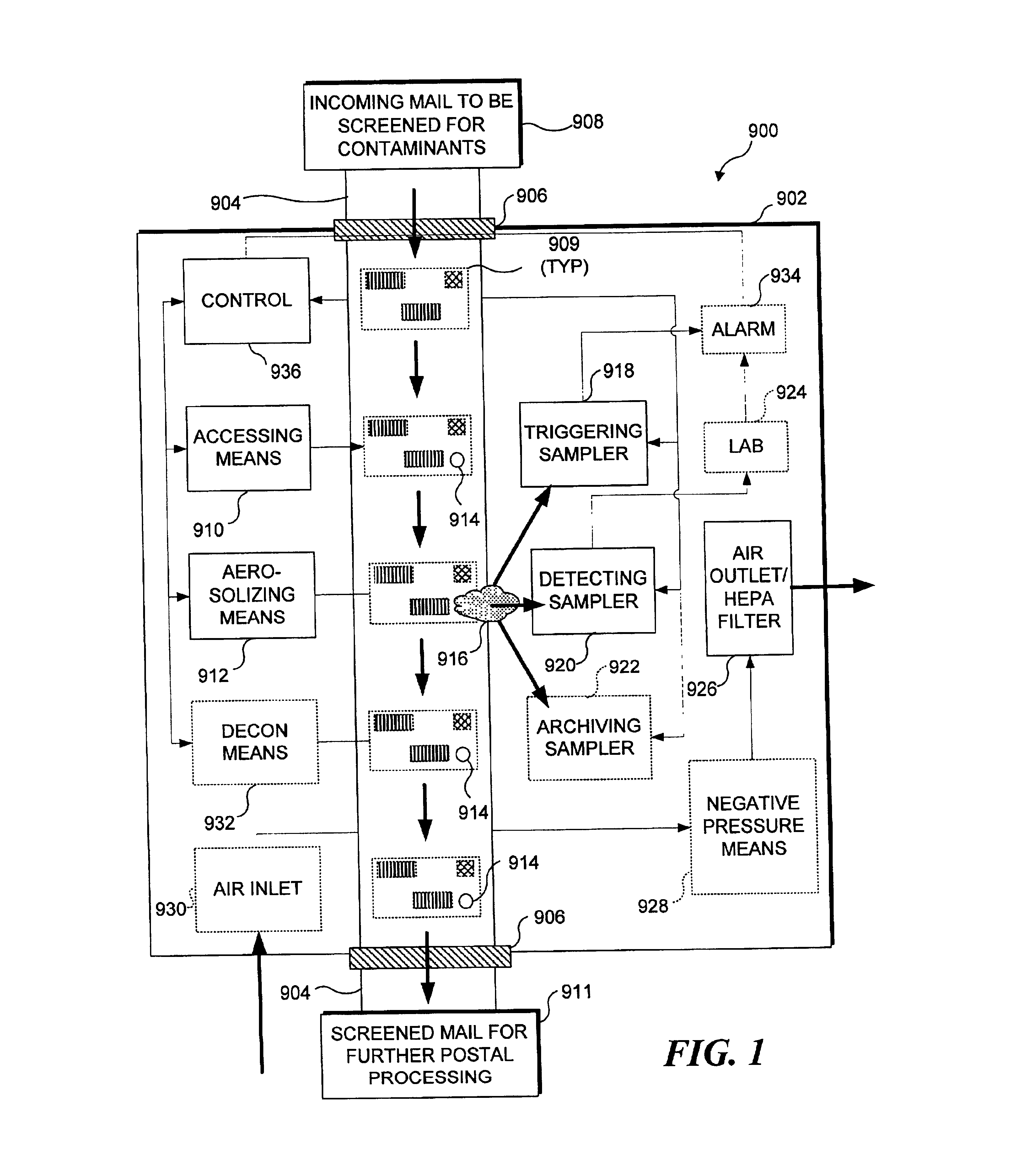

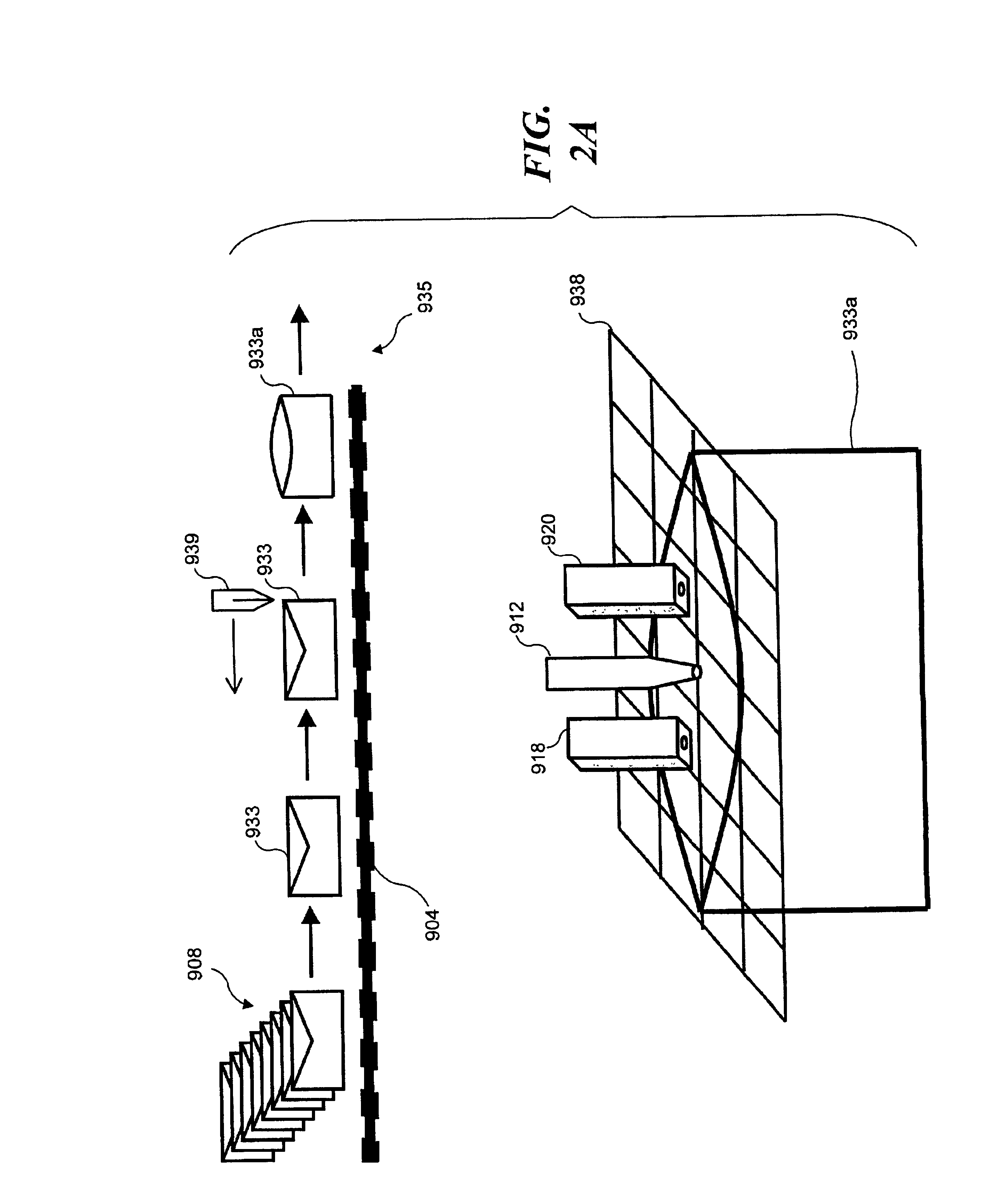

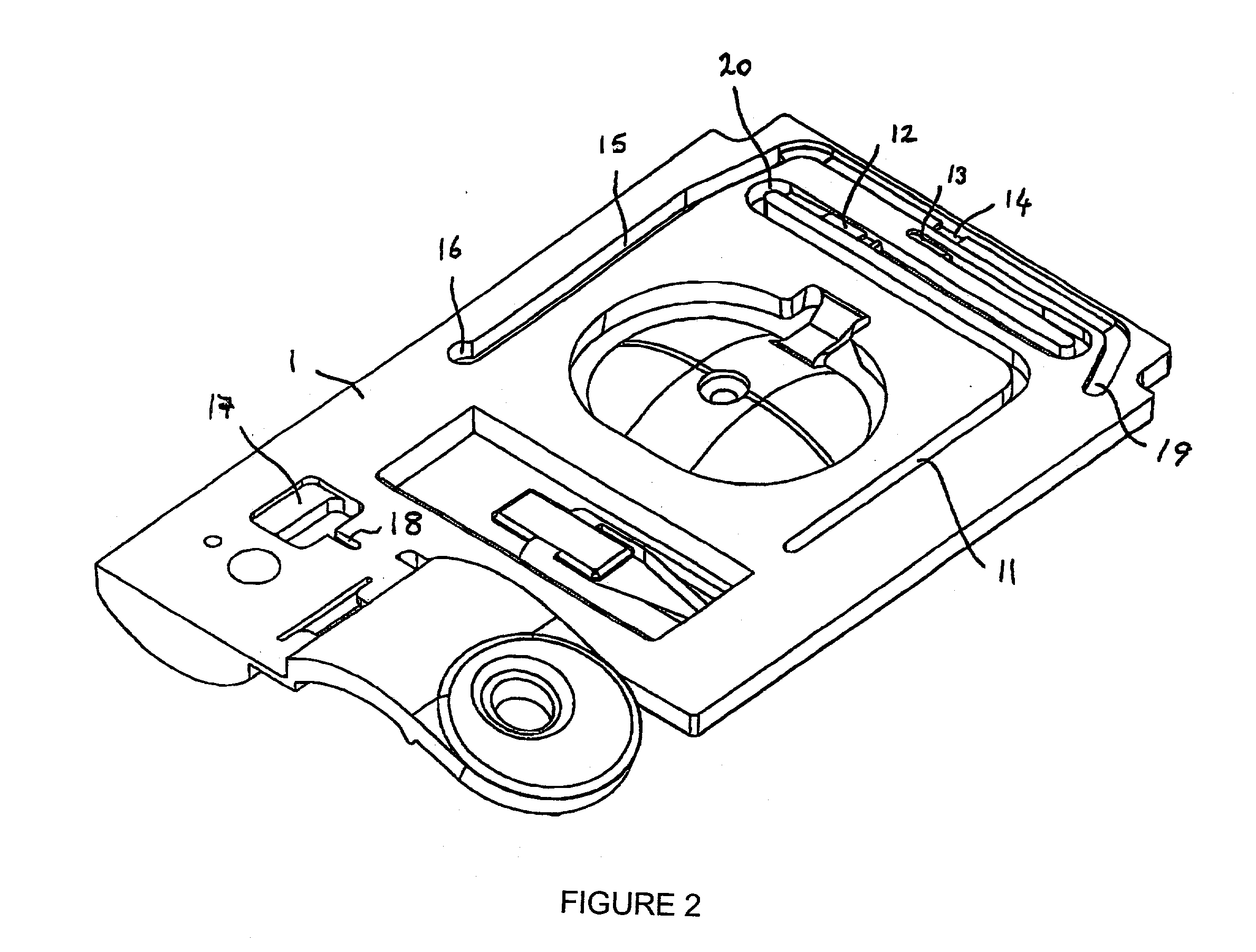

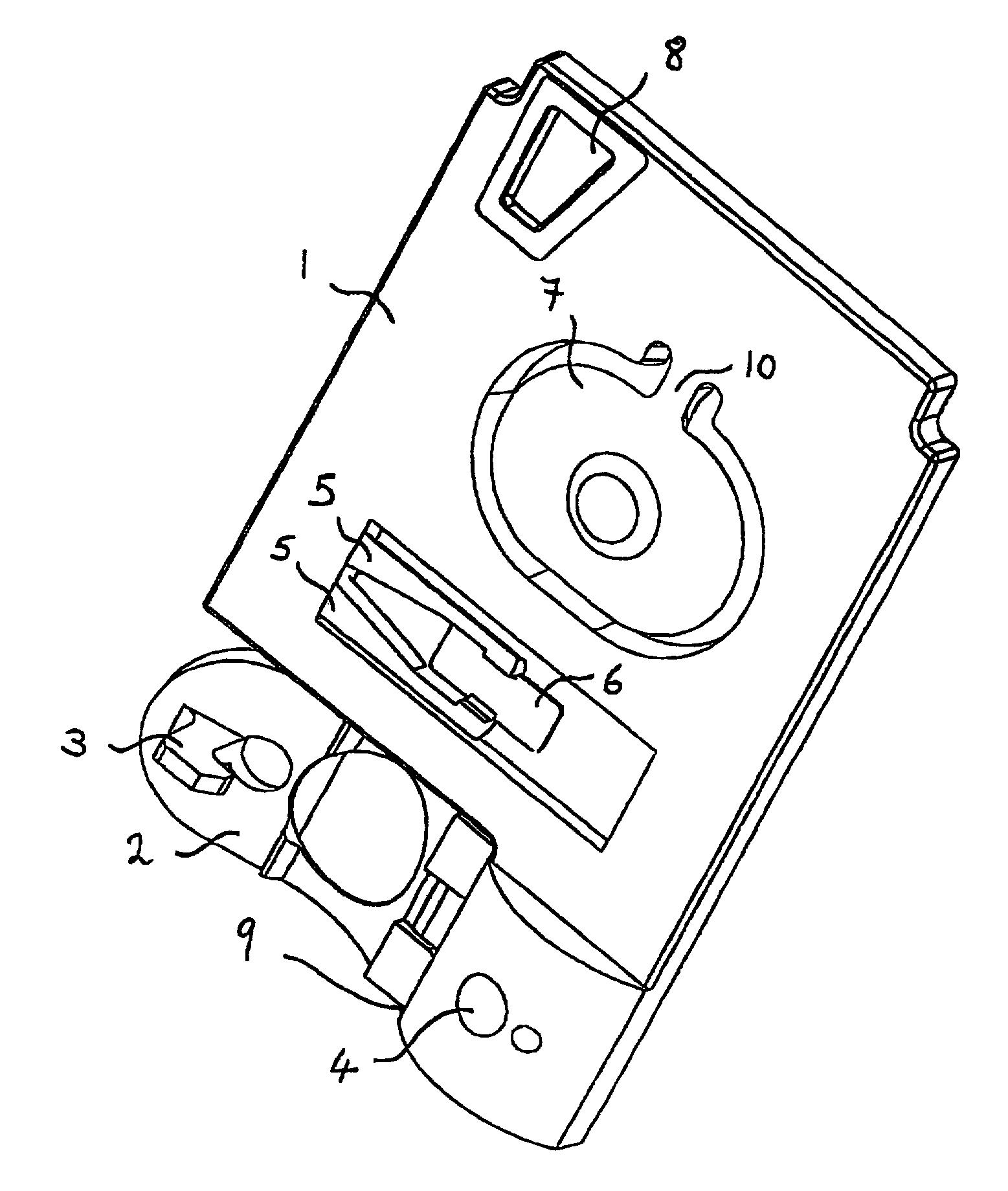

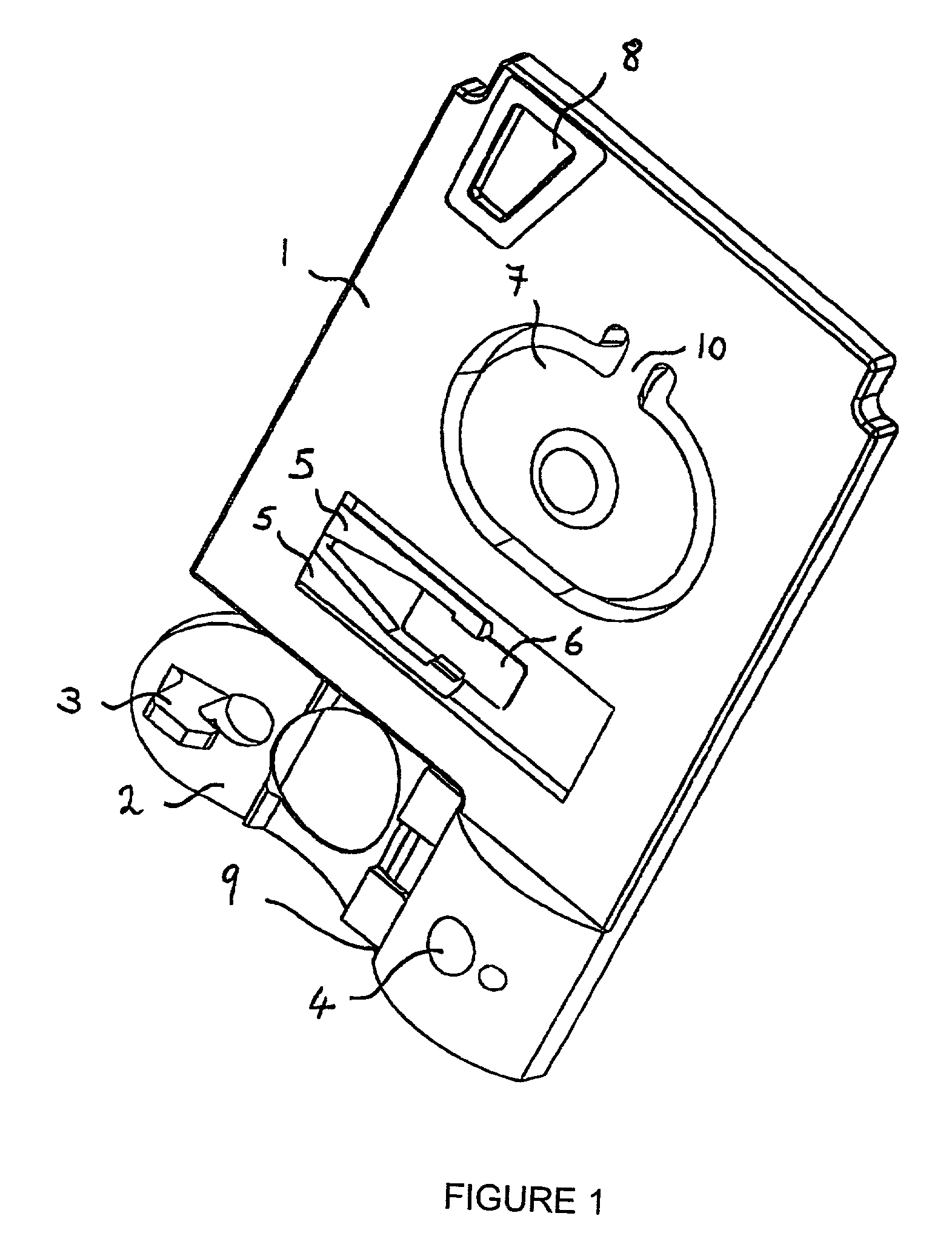

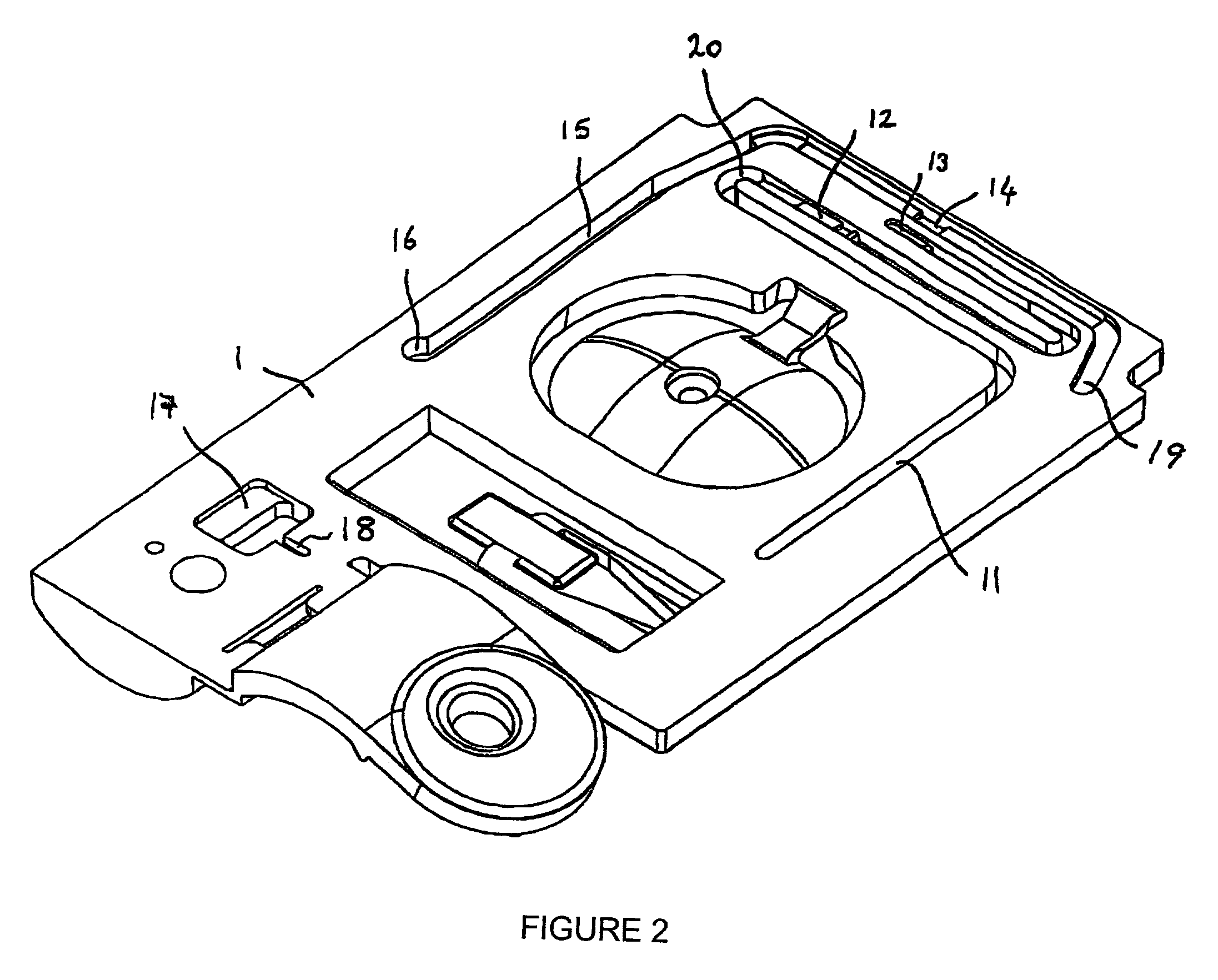

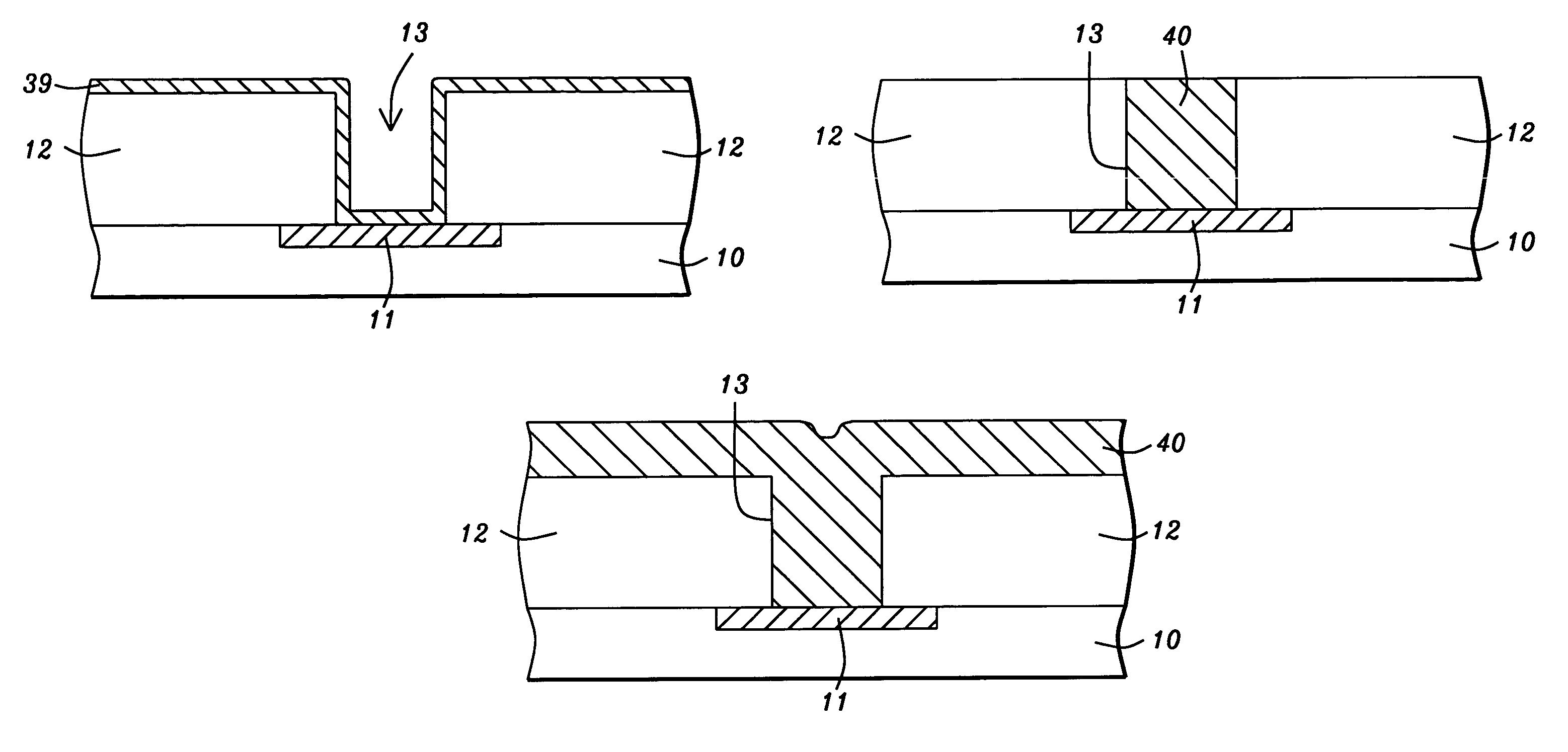

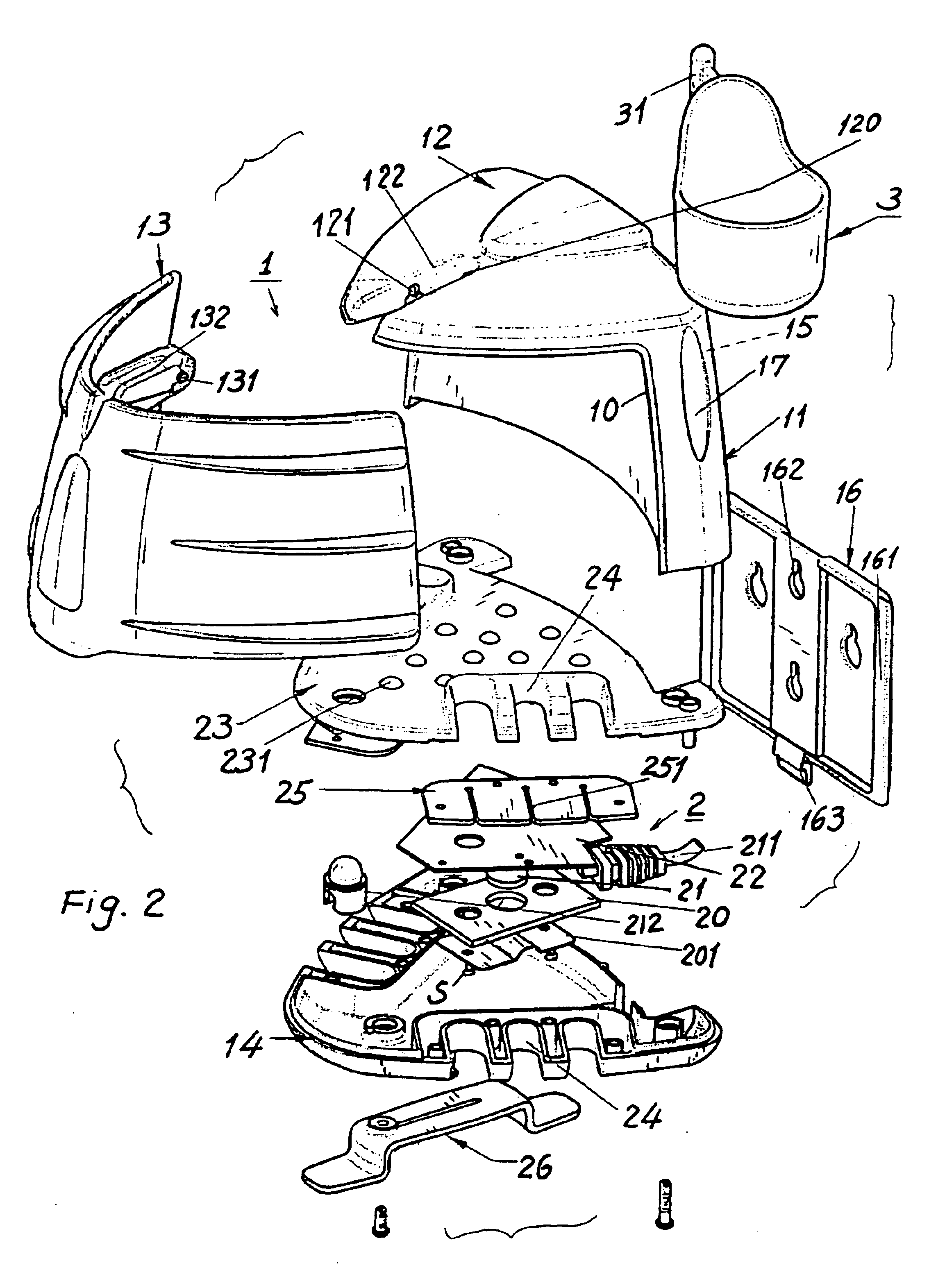

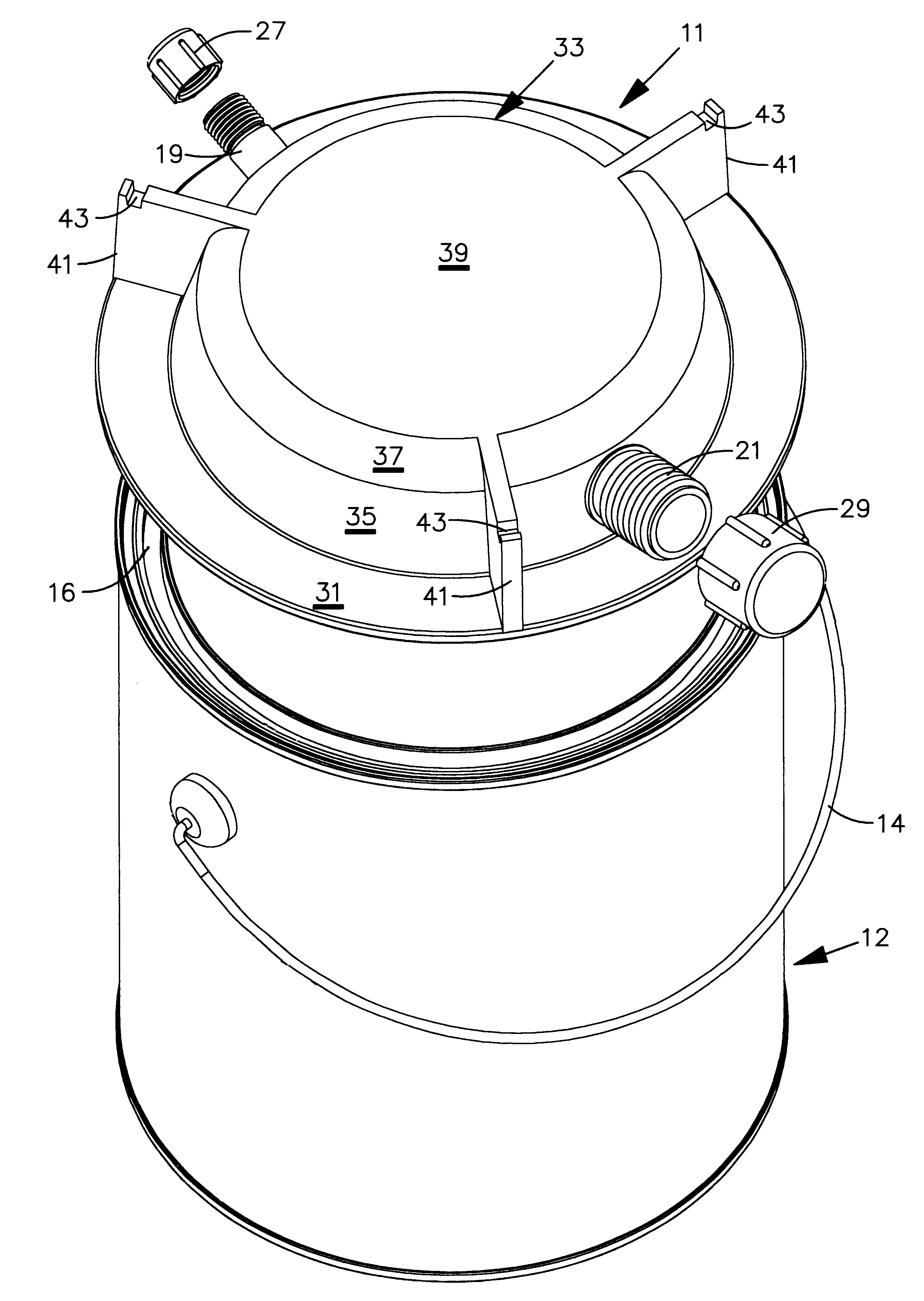

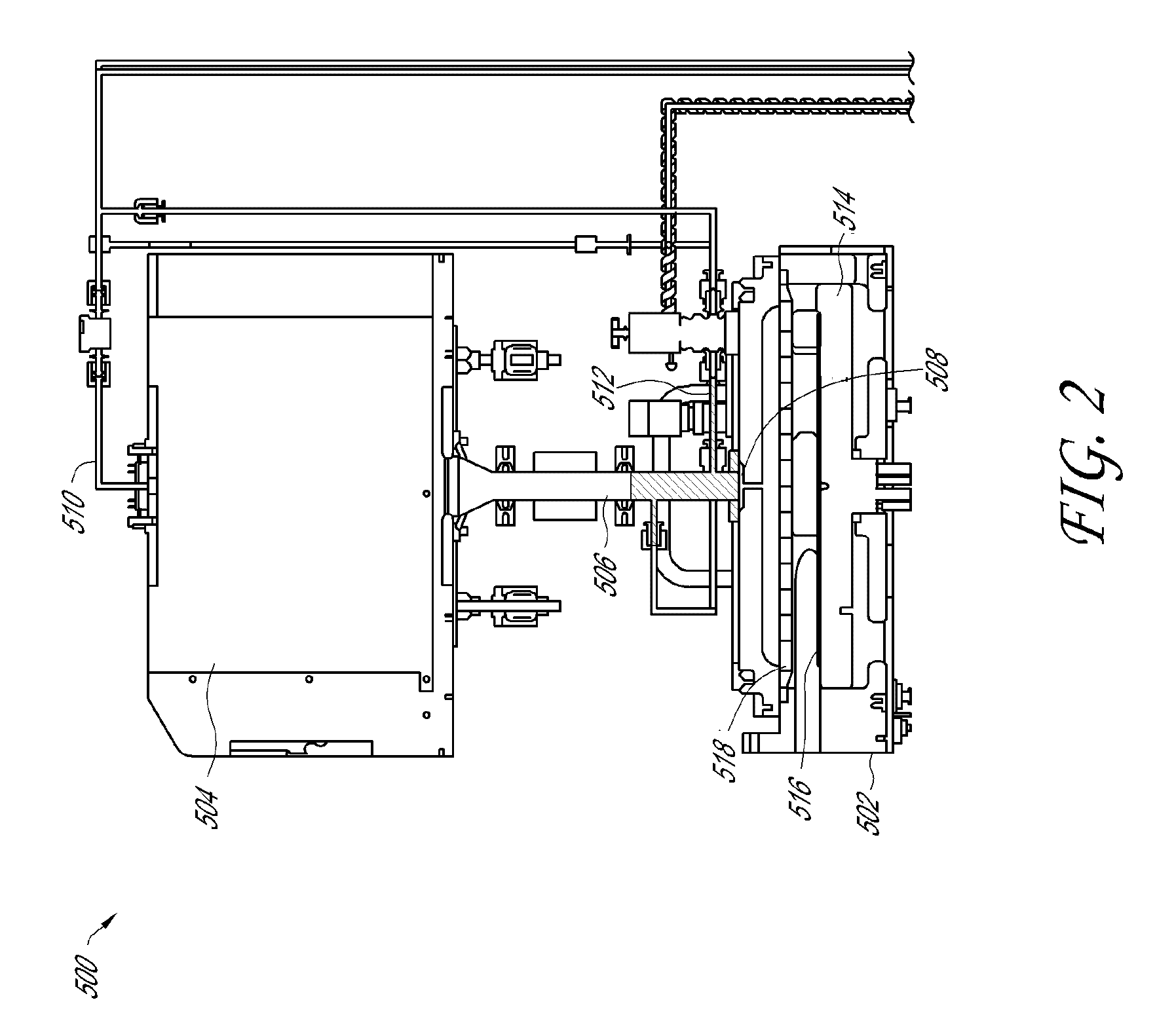

Robust system for screening mail for biological agents

InactiveUS6887710B2Lower the thresholdReduce riskAnalysing fluids using sonic/ultrasonic/infrasonic wavesLiquid dispersion analysisParticulatesEngineering

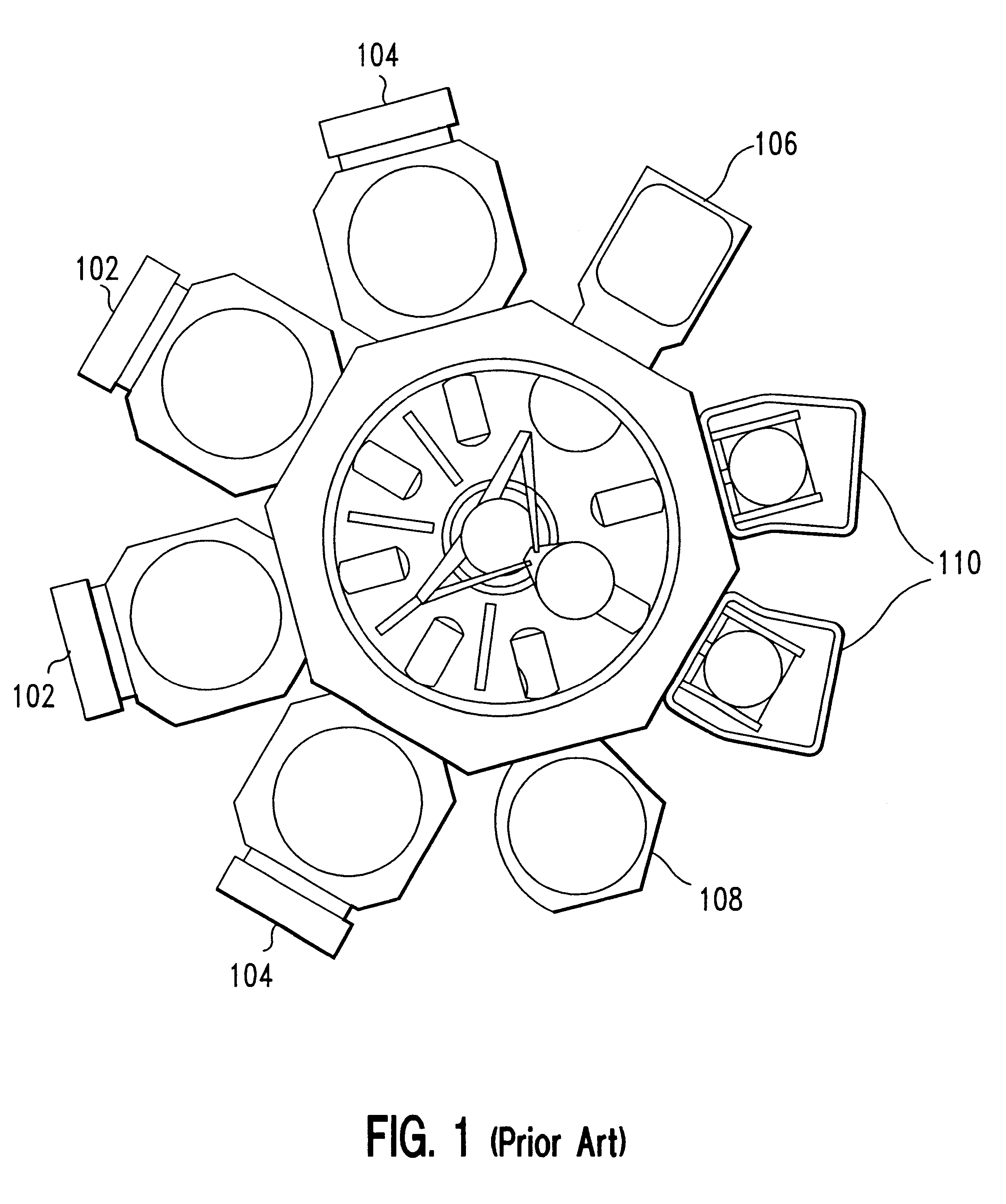

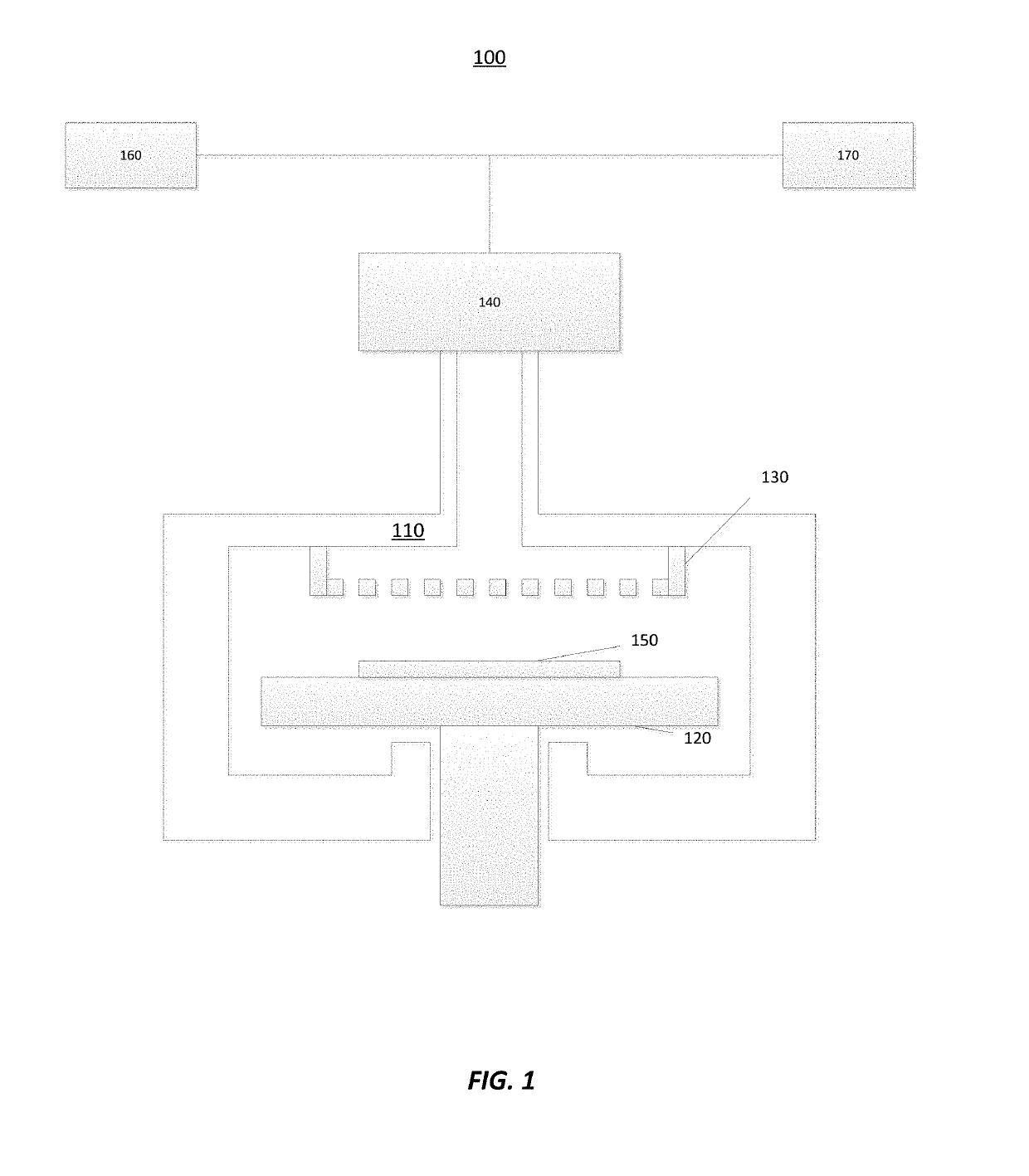

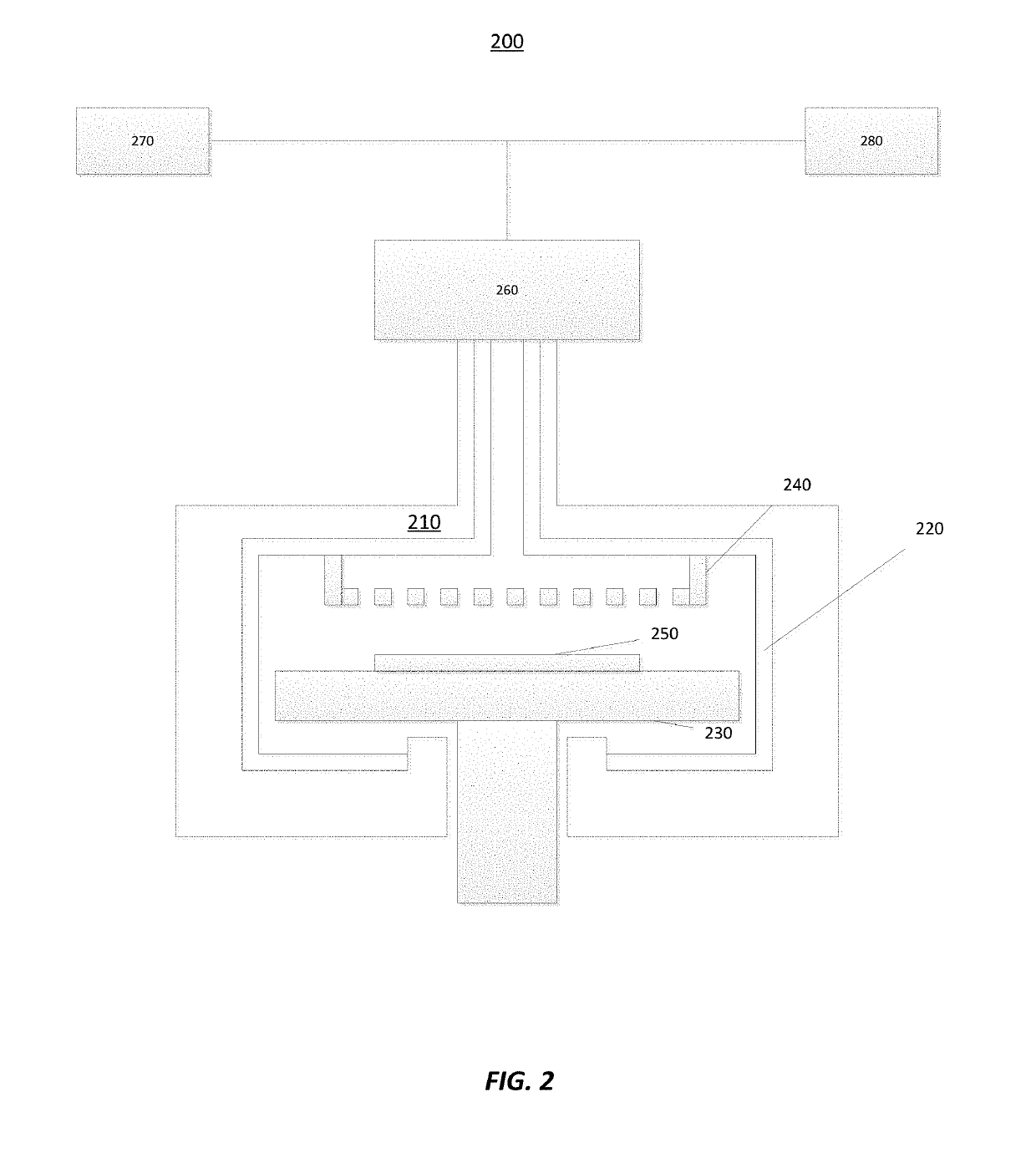

Items of mail are rapidly processed in a mail sampling system to determine if the mail is contaminated with a chemical or biological agent. The mail sampling system maintains a negative pressure in a containment chamber and includes a triggering sampler that makes a threshold determination regarding possible contamination, and a detecting sampler that obtains a sample for more detailed analysis in response to a signal from the triggering sampler. A sample of particulates collected from an item of mail is either removed for analysis or analyzed in the system to identify a contaminating agent. Optionally, the system includes an archiving sampler, which archives samples for subsequent processing and analysis, and a decontamination system, which is activated to decontaminate the mail if needed.

Owner:FLIR DETECTION

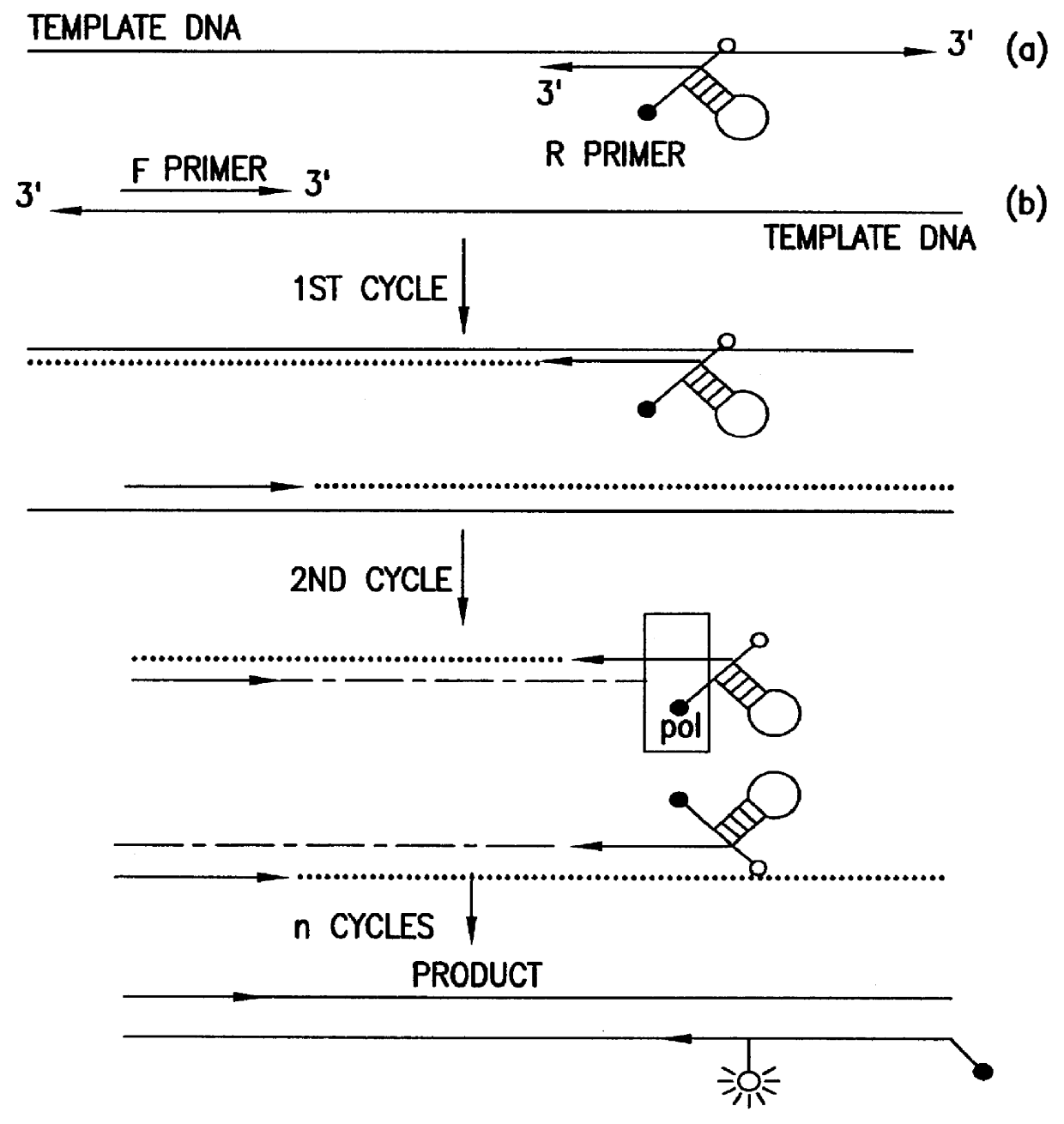

Nucleic acid amplification oligonucleotides with molecular energy transfer labels and methods based thereon

InactiveUS6117635AReduce the possibilityRapid and sensitive and reliableSugar derivativesMicrobiological testing/measurementEnergy transferFluorophore

The present invention provides labeled nucleic acid amplification oligonucleotides, which can be linear or hairpin primers or blocking oligonucleotides. The oligonucleotides of the invention are labeled with donor and / or acceptor moieties of molecular energy transfer pairs. The moieties can be fluorophores, such that fluorescent energy emitted by the donor is absorbed by the acceptor. The acceptor may be a fluorophore that fluoresces at a wavelength different from the donor moiety, or it may be a quencher. The oligonucleotides of the invention are configured so that a donor moiety and an acceptor moiety are incorporated into the amplification product. The invention also provides methods and kits for directly detecting amplification products employing the nucleic acid amplification primers. When labeled linear primers are used, treatment with exonuclease or by using specific temperature eliminates the need for separation of unincorporated primers. This "closed-tube" format greatly reduces the possibility of carryover contamination with amplification products, provides for high throughput of samples, and may be totally automated.

Owner:MILLIPORE CORP

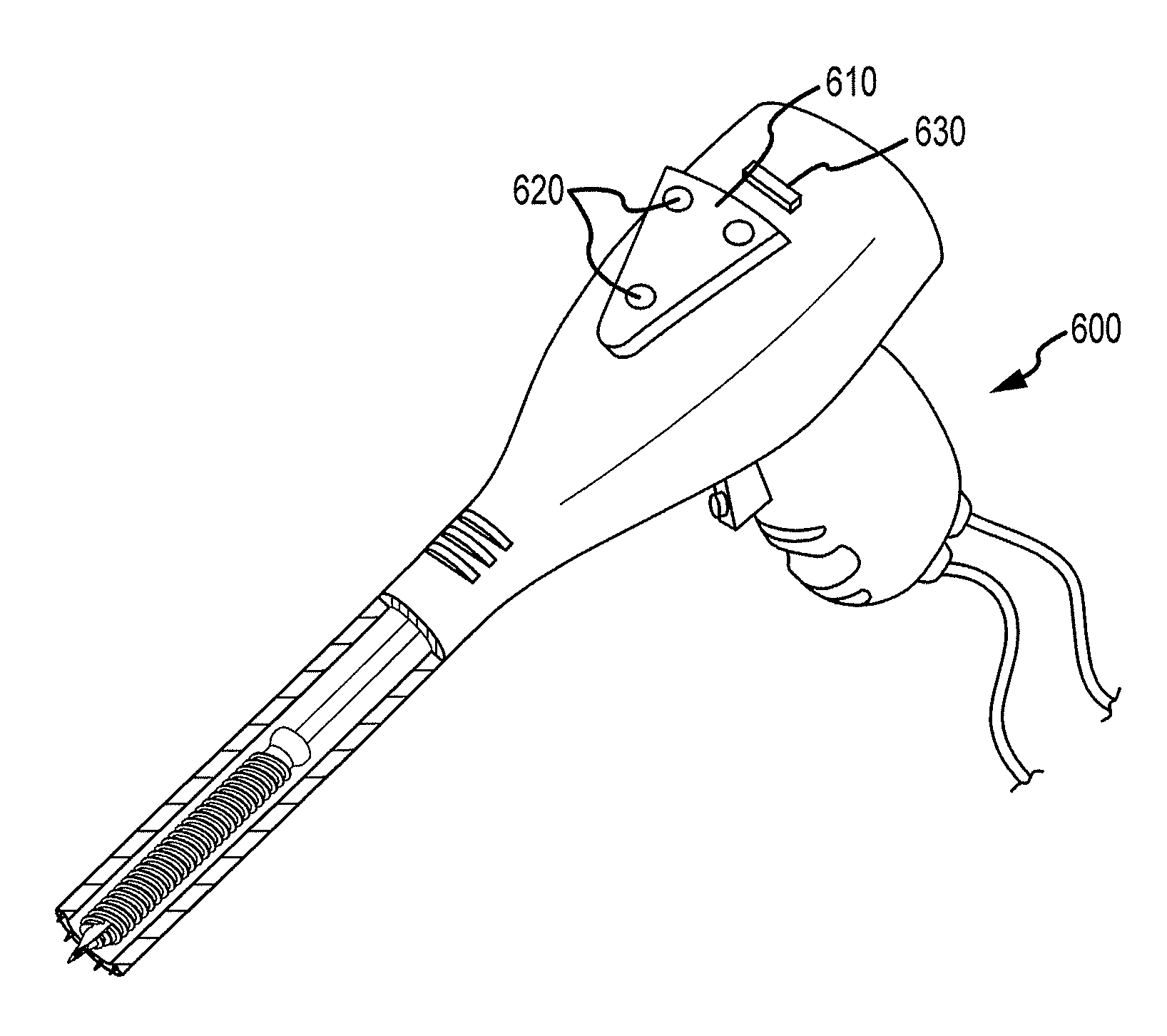

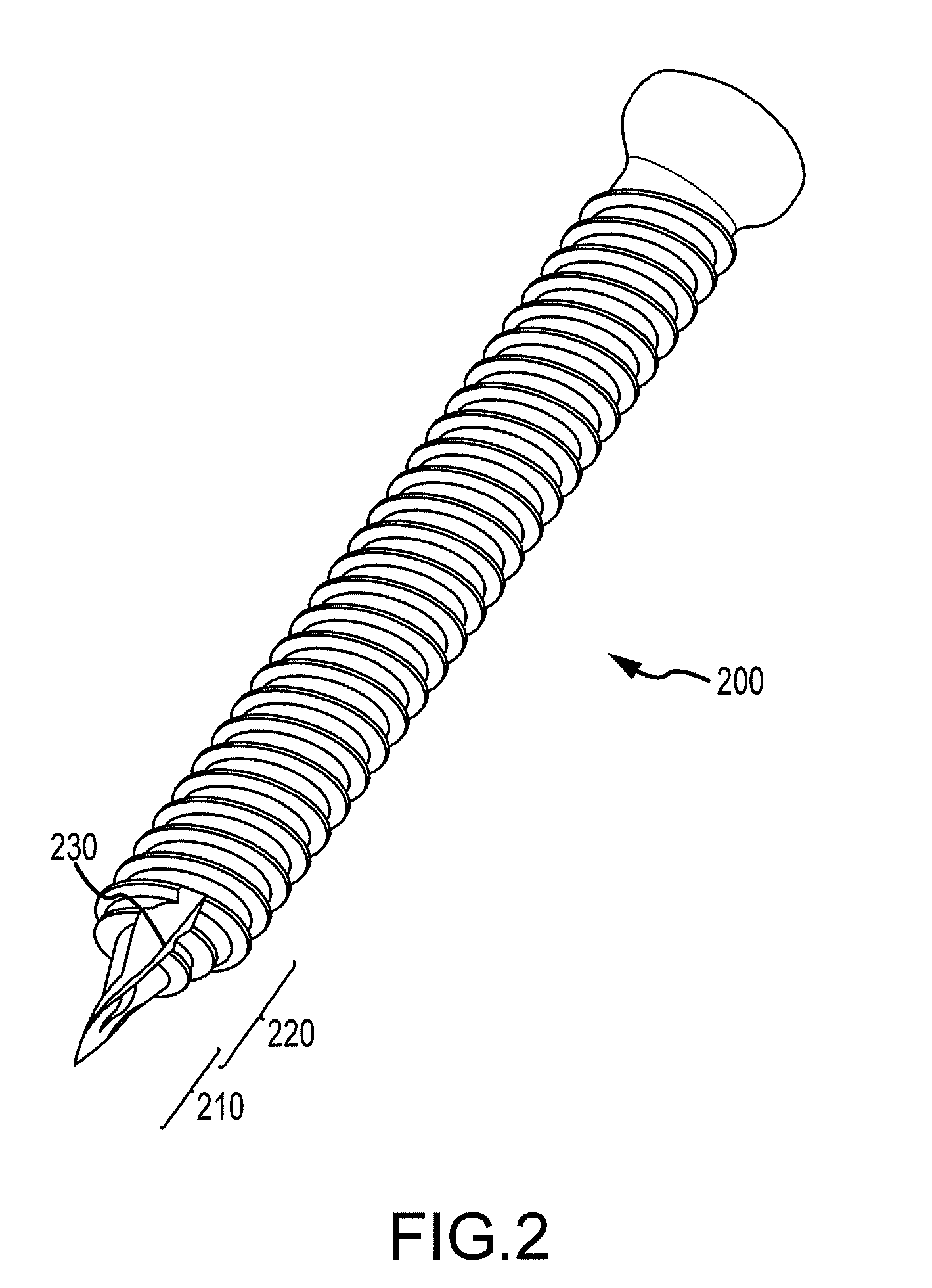

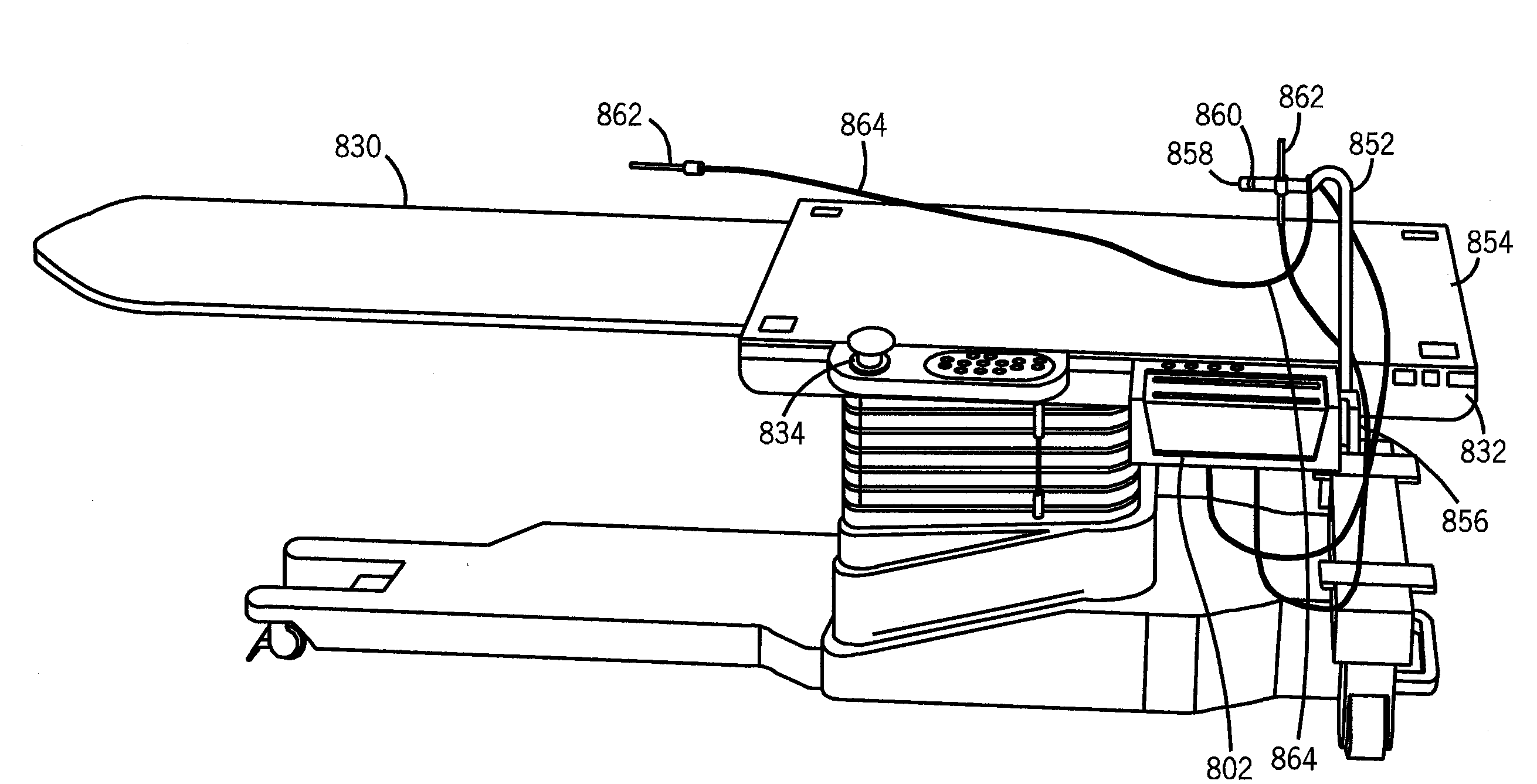

Image-guided minimal-step placement of screw into bone

ActiveUS8366719B2Procedure is time-consumeImprove accuracyInternal osteosythesisDiagnosticsScrew placementMonitoring system

The present disclosure describes a device and methods for safely and accurately placing screws into bones with a powered driving device. By employing multiple layers of fail-safe features and image-guidance systems, the powered driving device provides safe, accurate, and efficient screw placement. That is, the powered driving device may continuously monitor a screw advancement and placement and may automatically shutdown when improper placement is detected. Monitoring placement may be conducted by a microcurrent-monitoring system, by an image-guidance system, or by any other appropriate sensory system. Additionally, upon detecting that screw insertion is complete, the powered driving device may be automatically shutdown. As screw placement is continuously simulated by image-guidance in real time, multiple redundant verification steps are eliminated, providing highly accurate screw placement while decreasing clinician error, device contamination, and surgical time, the decreased surgical time associated with decreased patient-recovery time and associated medical costs.

Owner:INTEGRATED SPINAL CONCEPTS

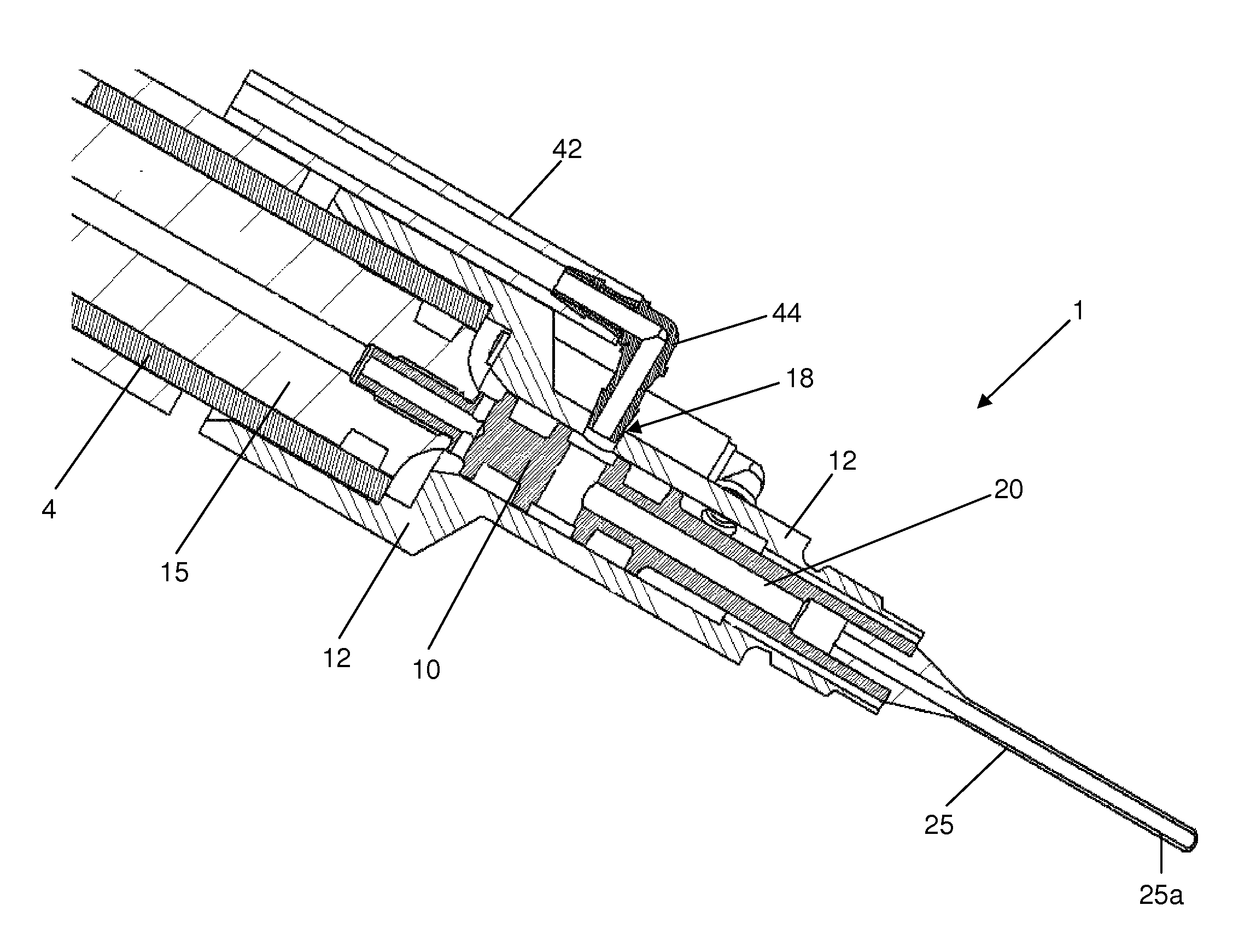

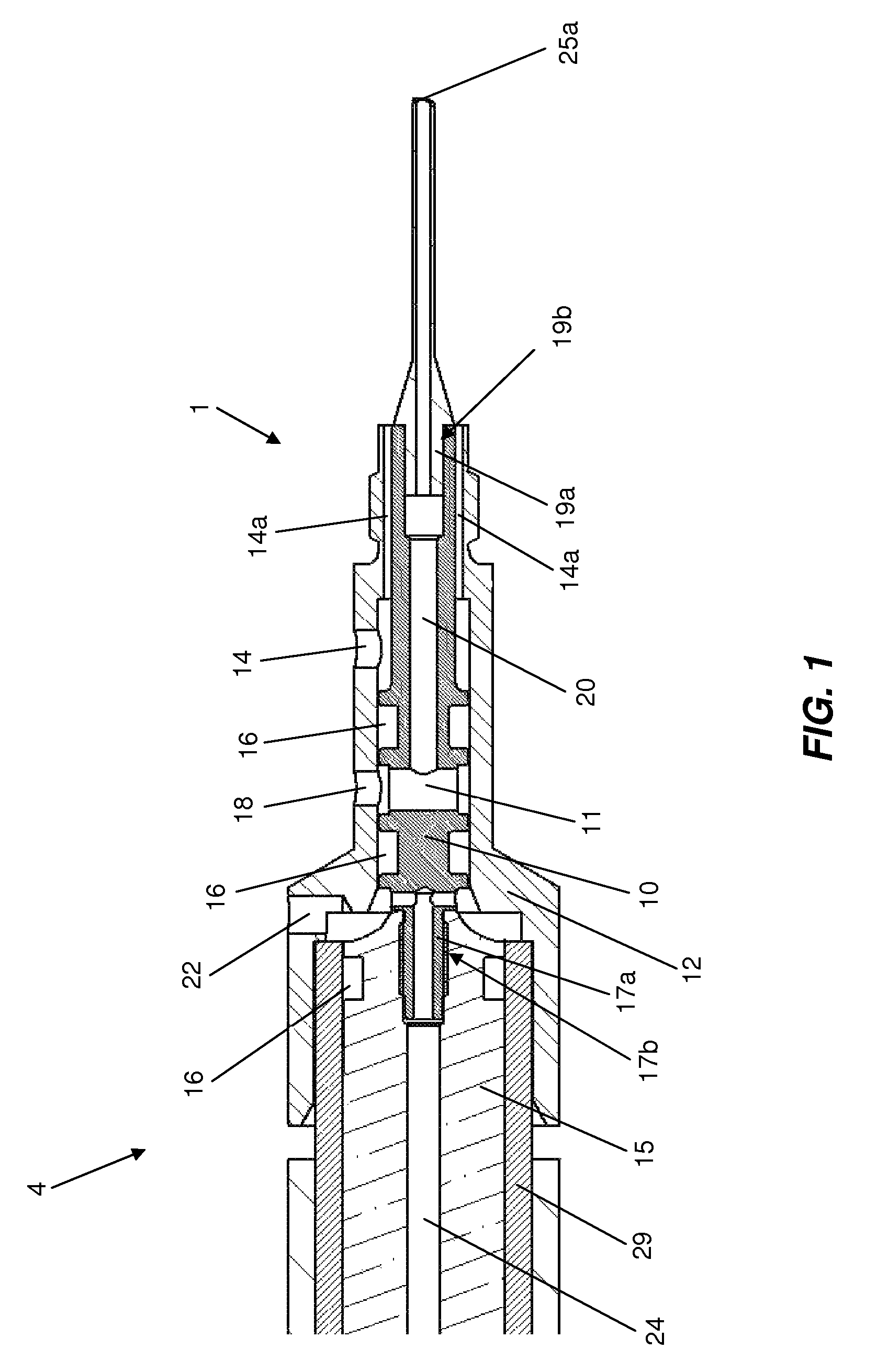

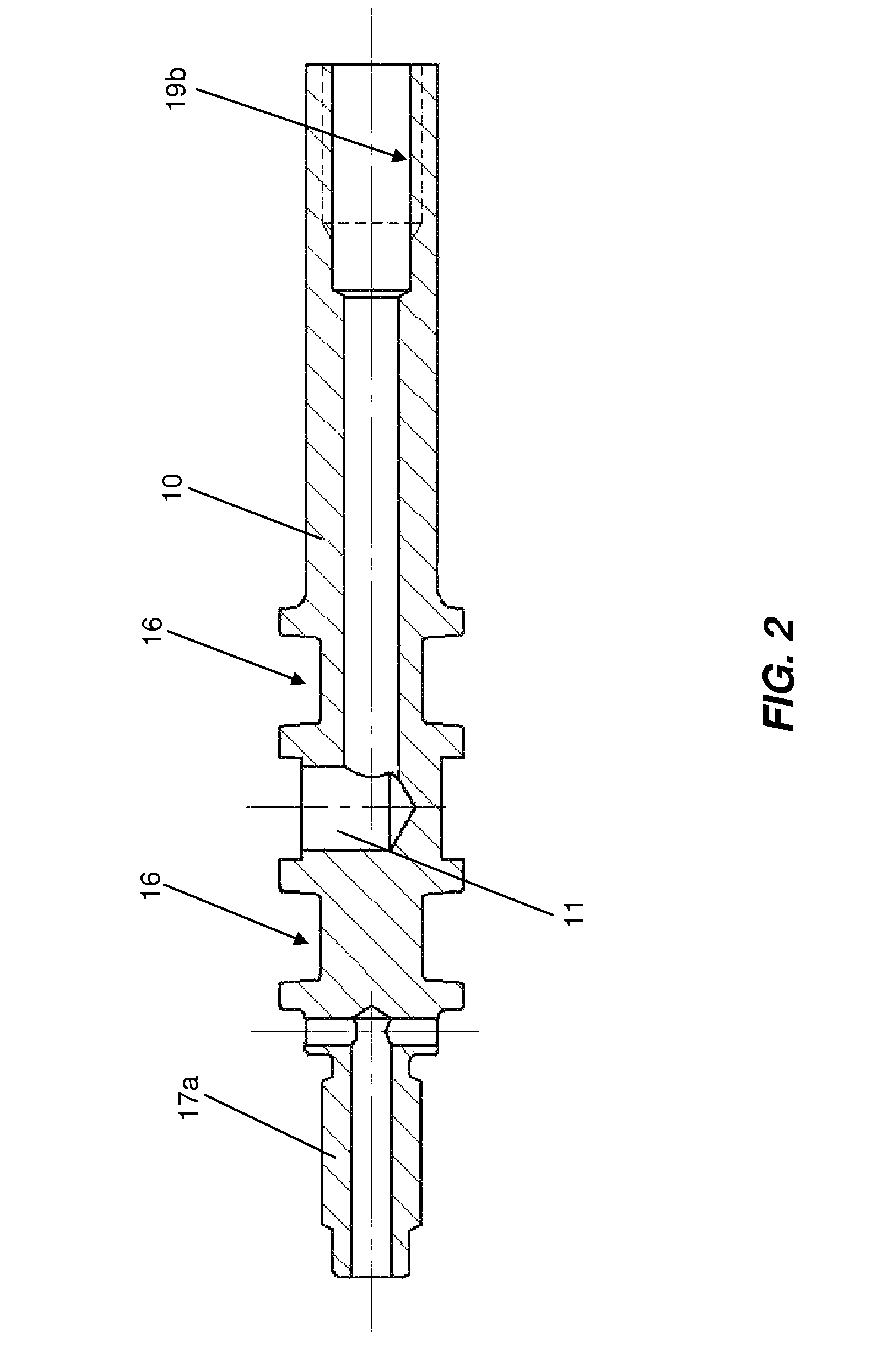

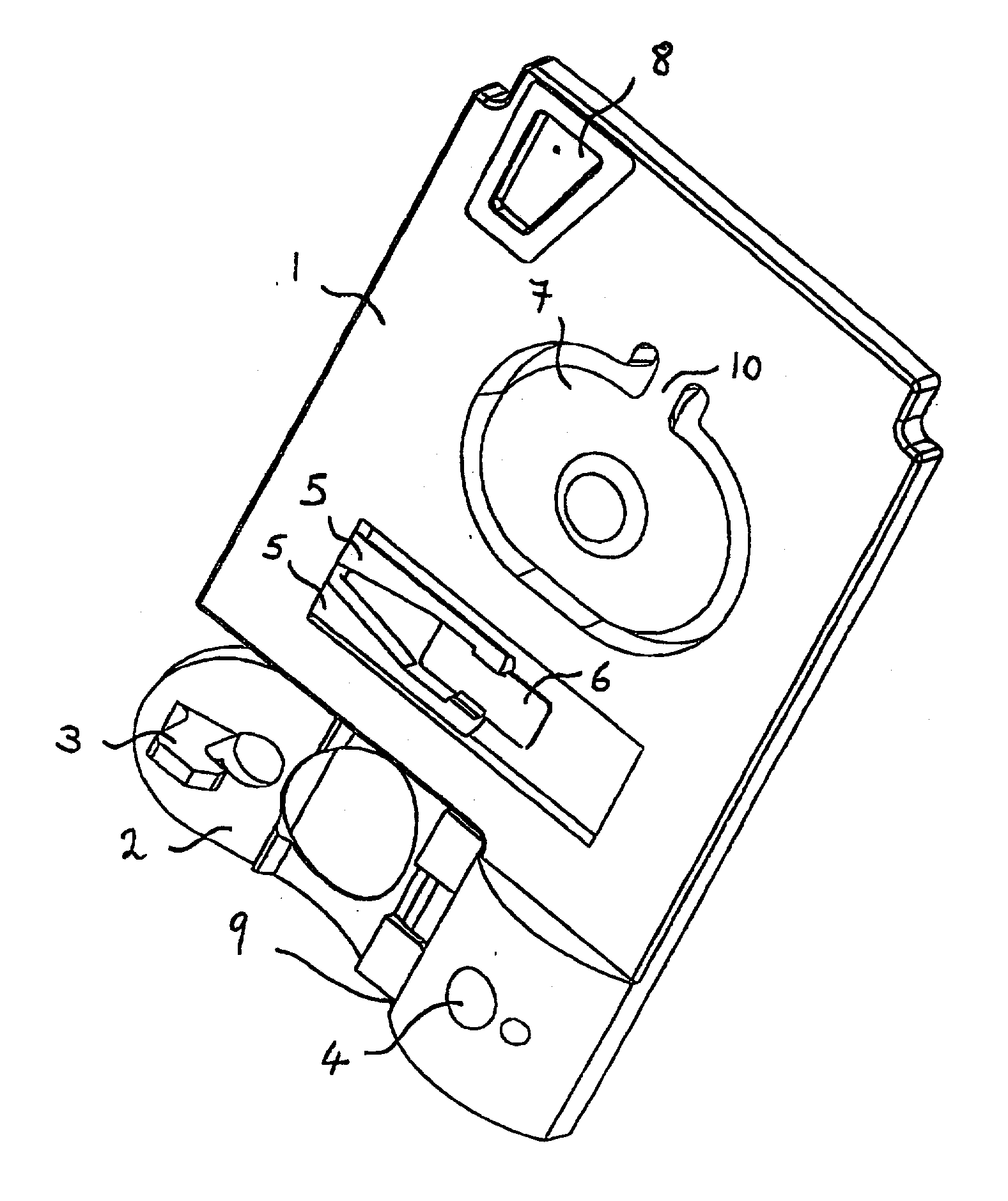

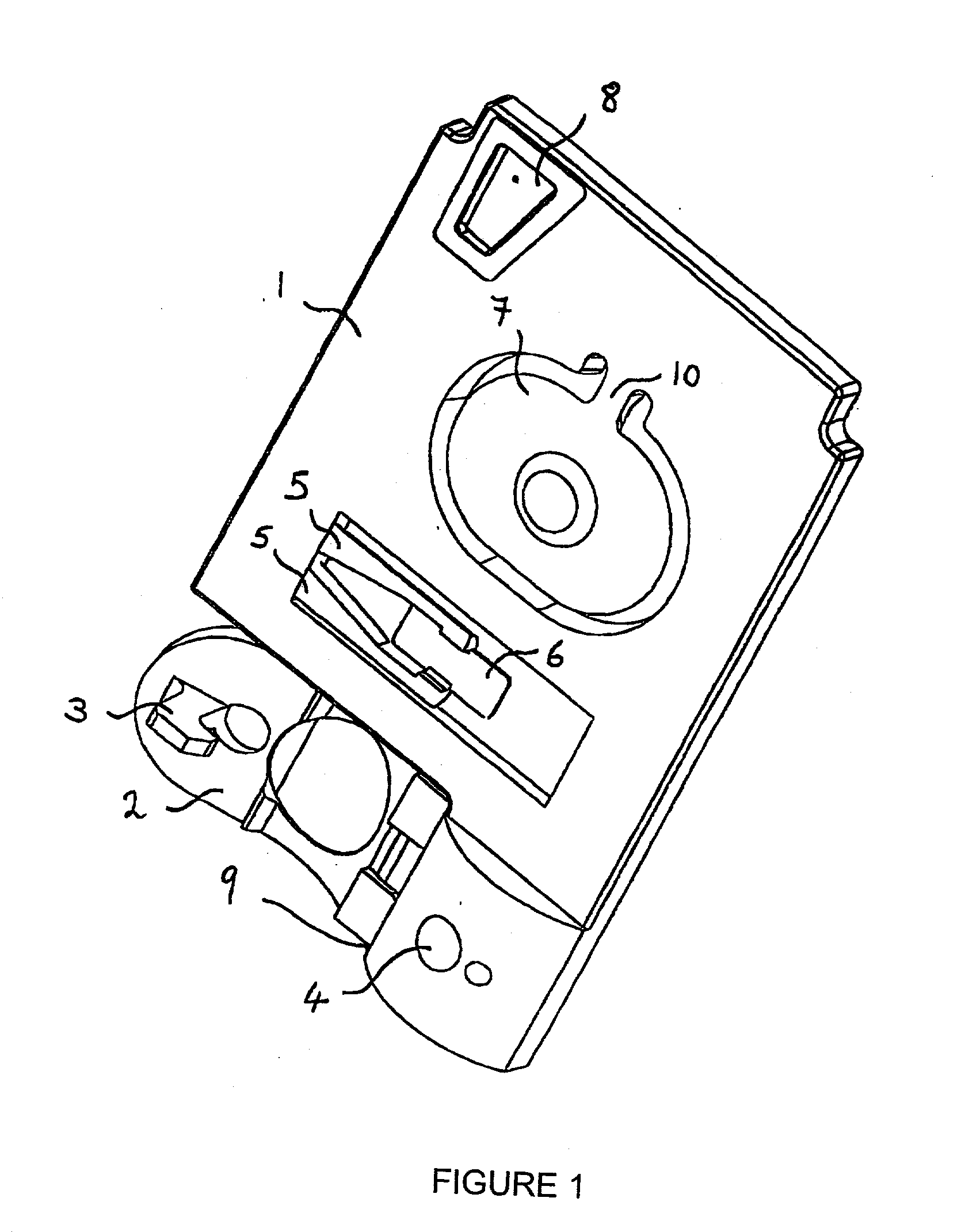

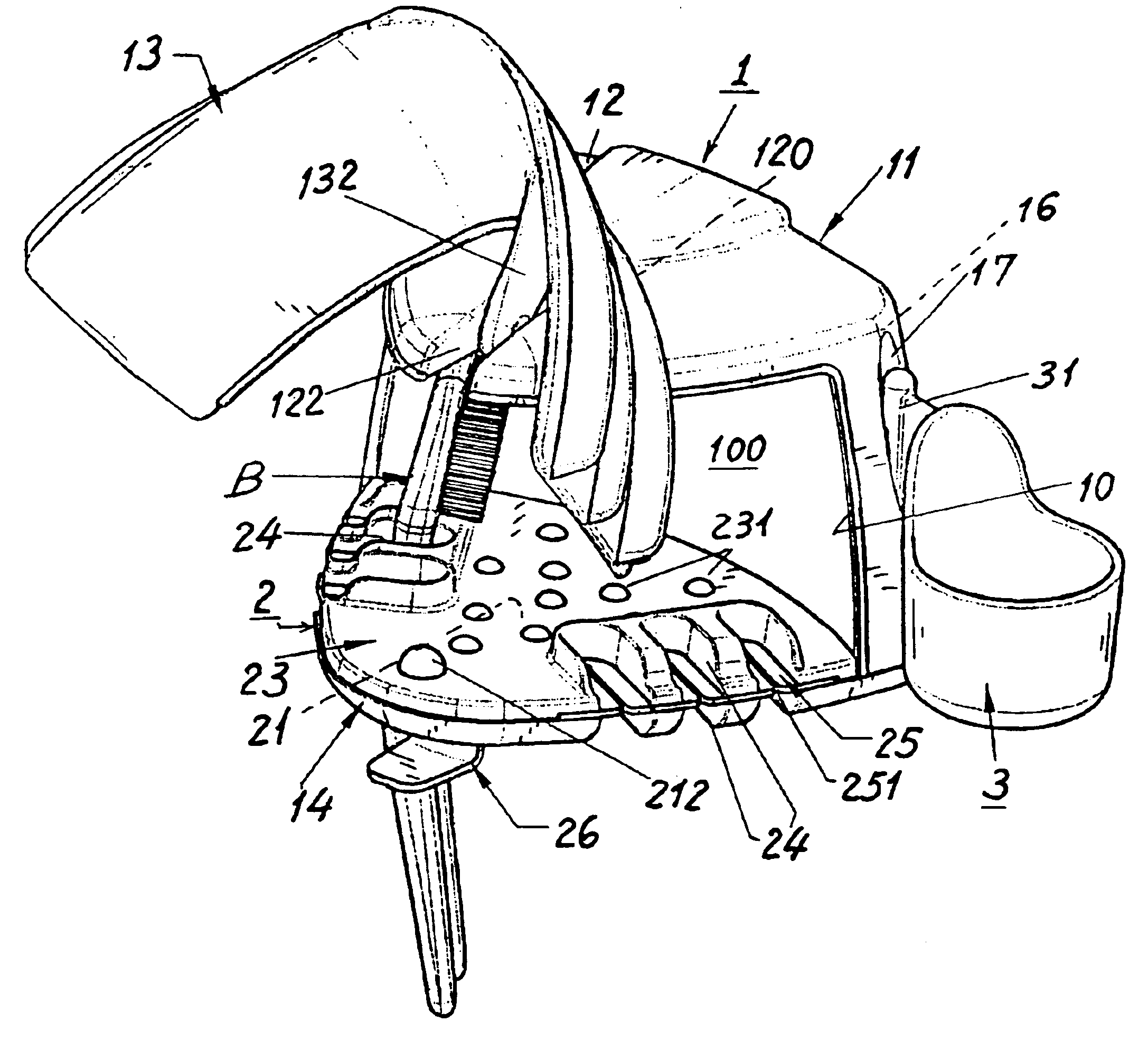

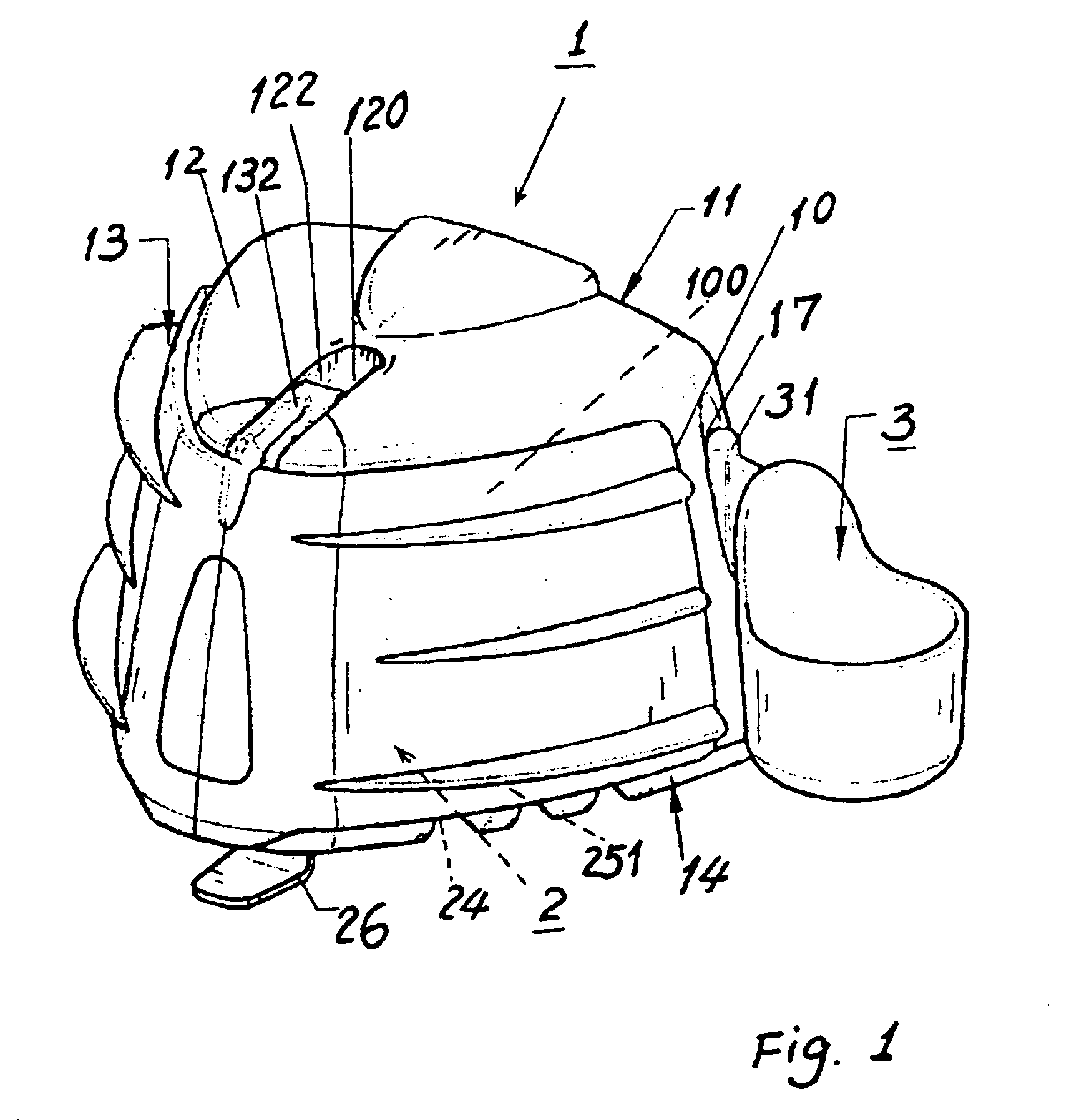

Removable adapter for phacoemulsification handpiece having irrigation and aspiration fluid paths

Current phacoemulsification handpieces require rigorous cleaning after each procedure because the aspiration and irrigation pathways for fluids are integral to the handpiece. According to the present invention, a removable horn extension and nosecone may be used with a phacoemulsification handpiece to allow for disposable fluid pathways exterior to the handpiece. This will reduce the cleaning time and effort, reduce cross-contamination, and increase the lifespan of the handpiece. Furthermore, the current invention allows different horn extensions to be used to excite different motions at the tip of the handpiece, depending on the preference of the surgeon.

Owner:ZEVEX

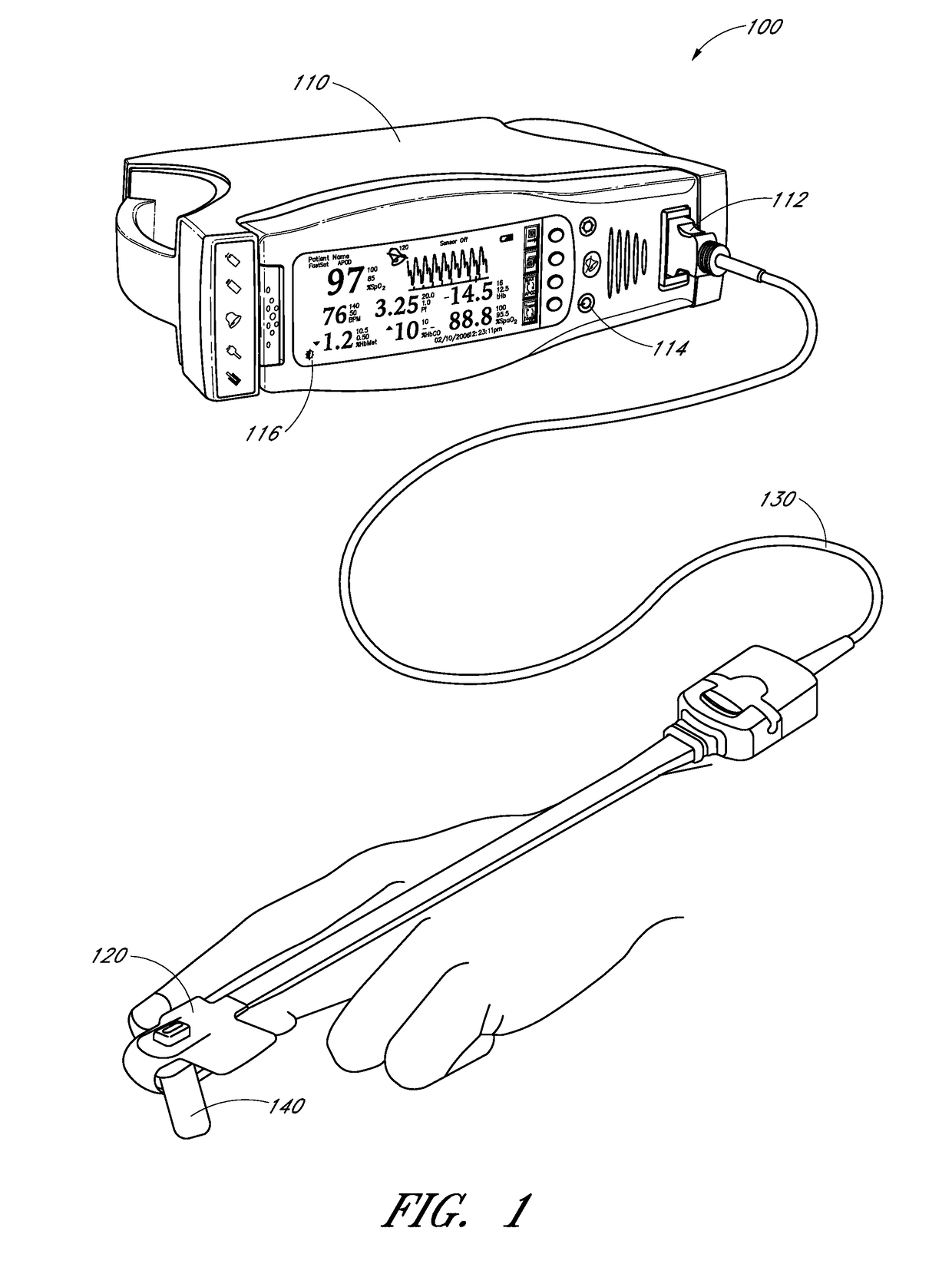

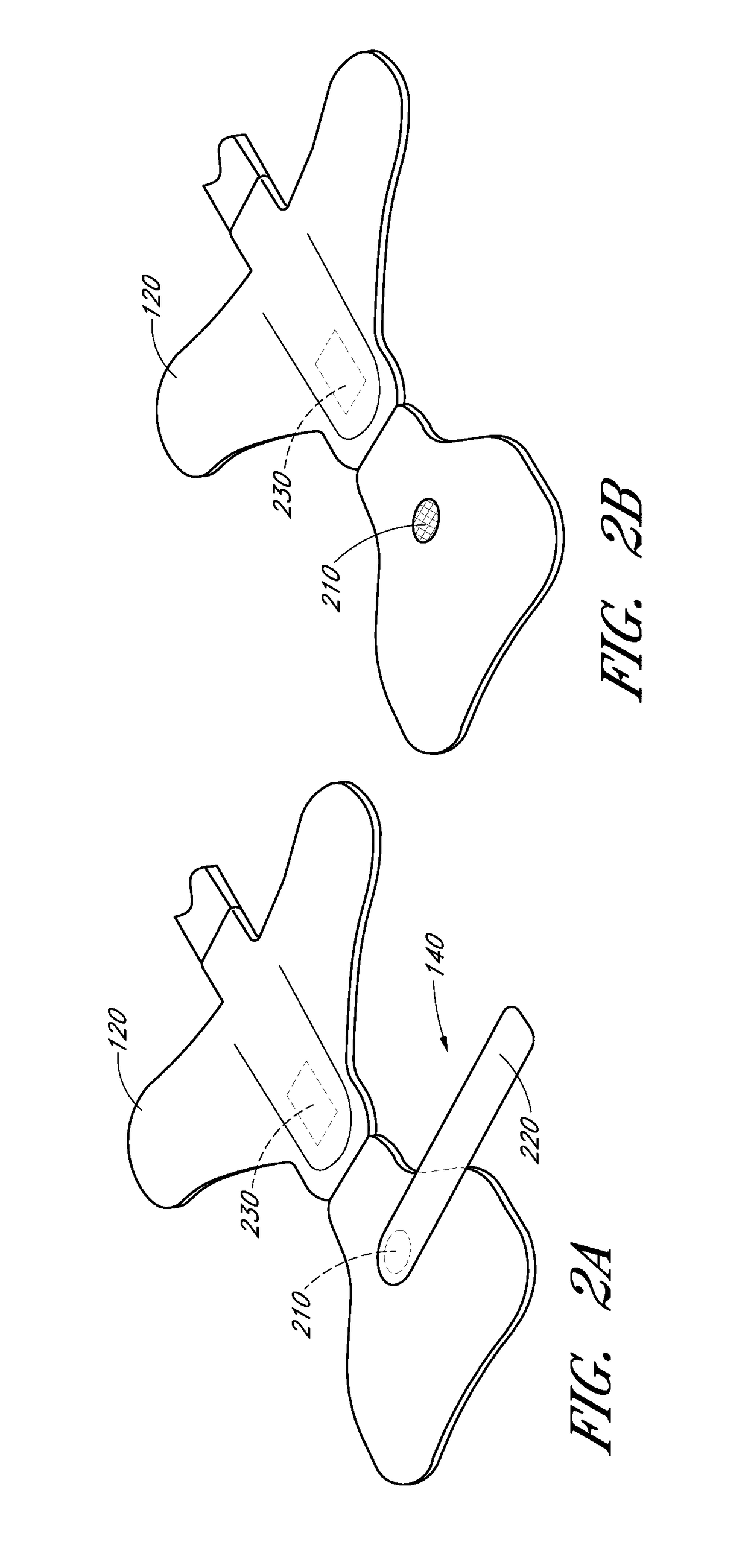

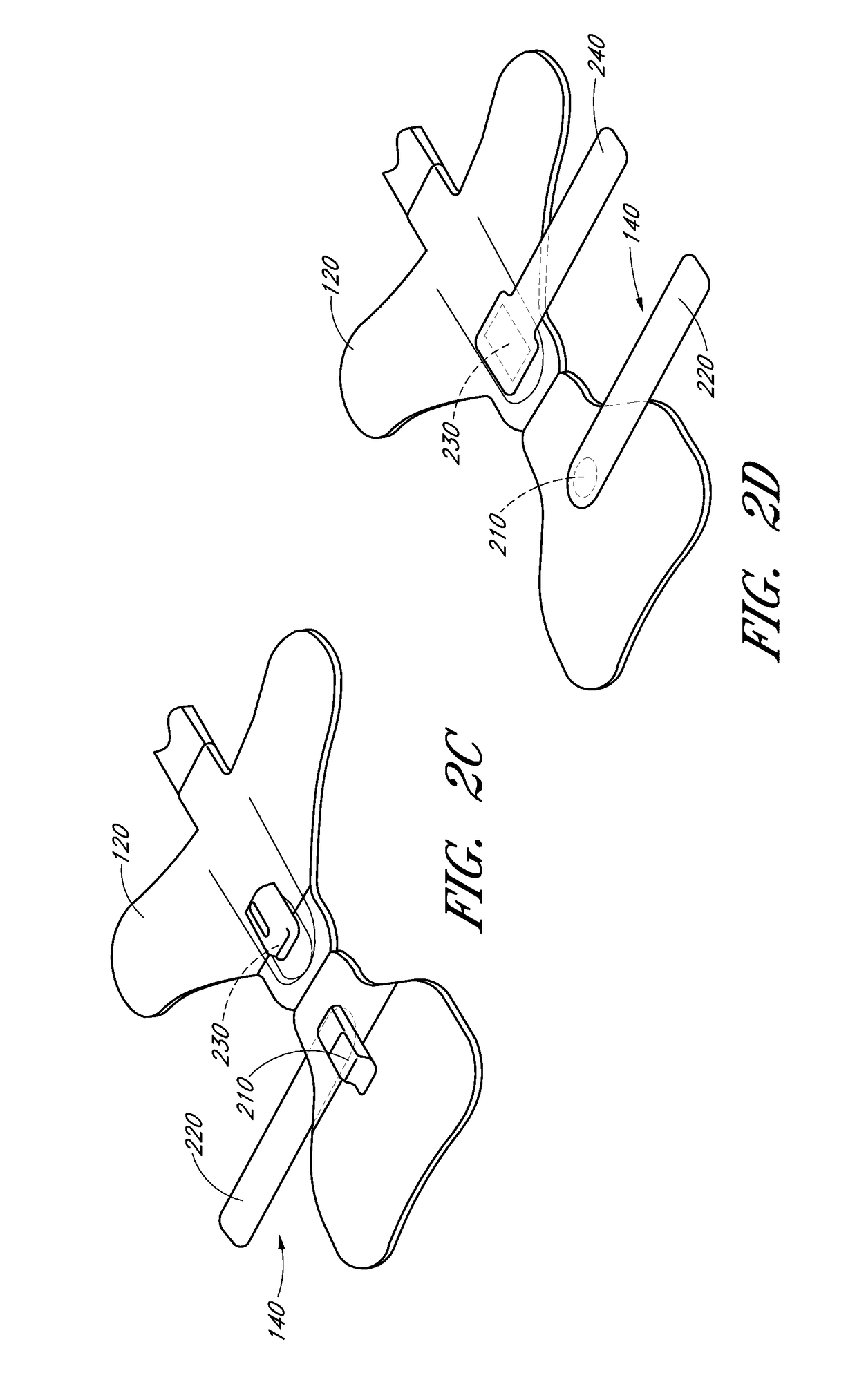

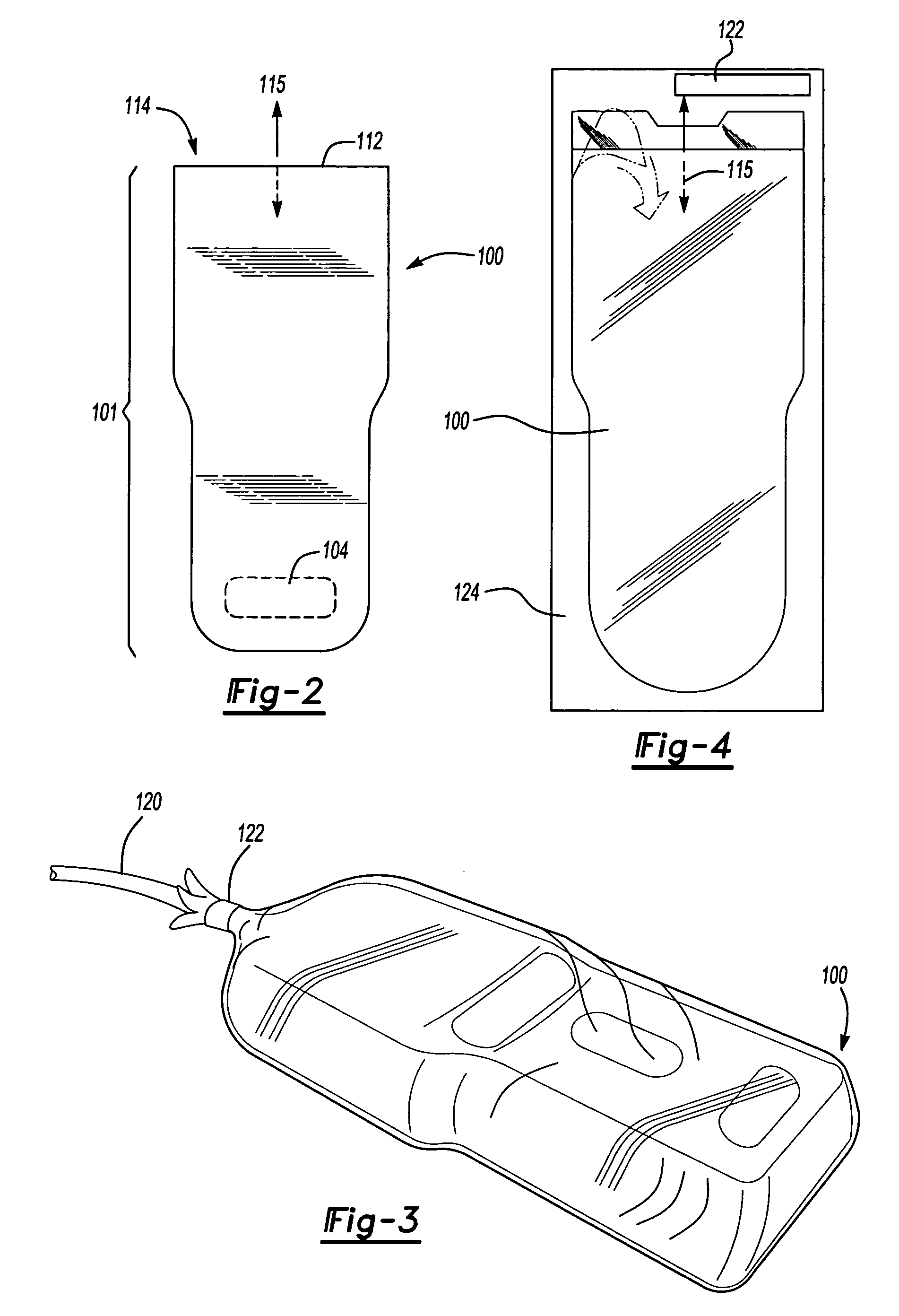

Non-invasive physiological sensor cover

ActiveUS8473020B2Reduce setup timePrevents and reduces false readingCatheterDiagnostic recording/measuringPulse oximetryEngineering

Owner:MASIMO CORP

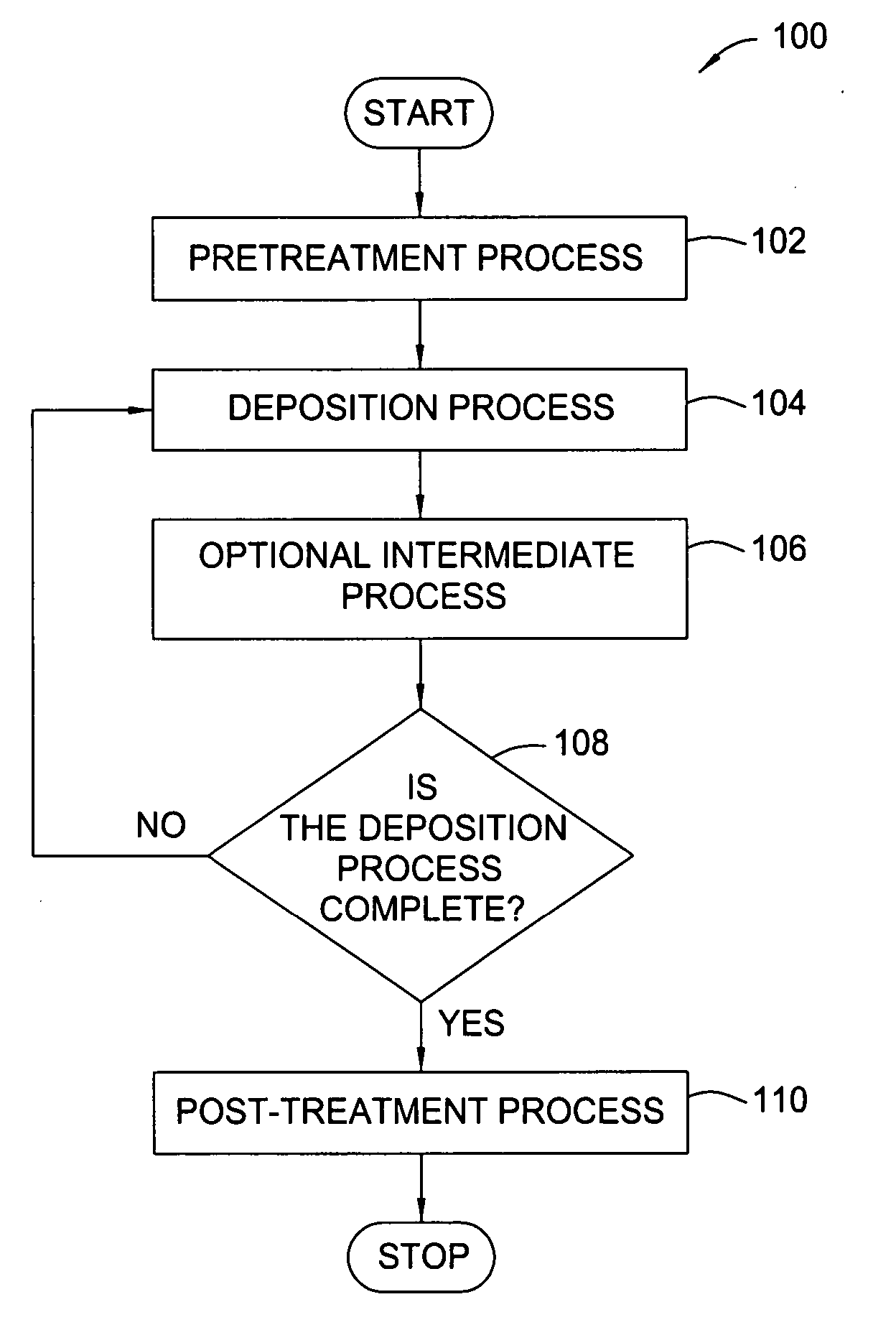

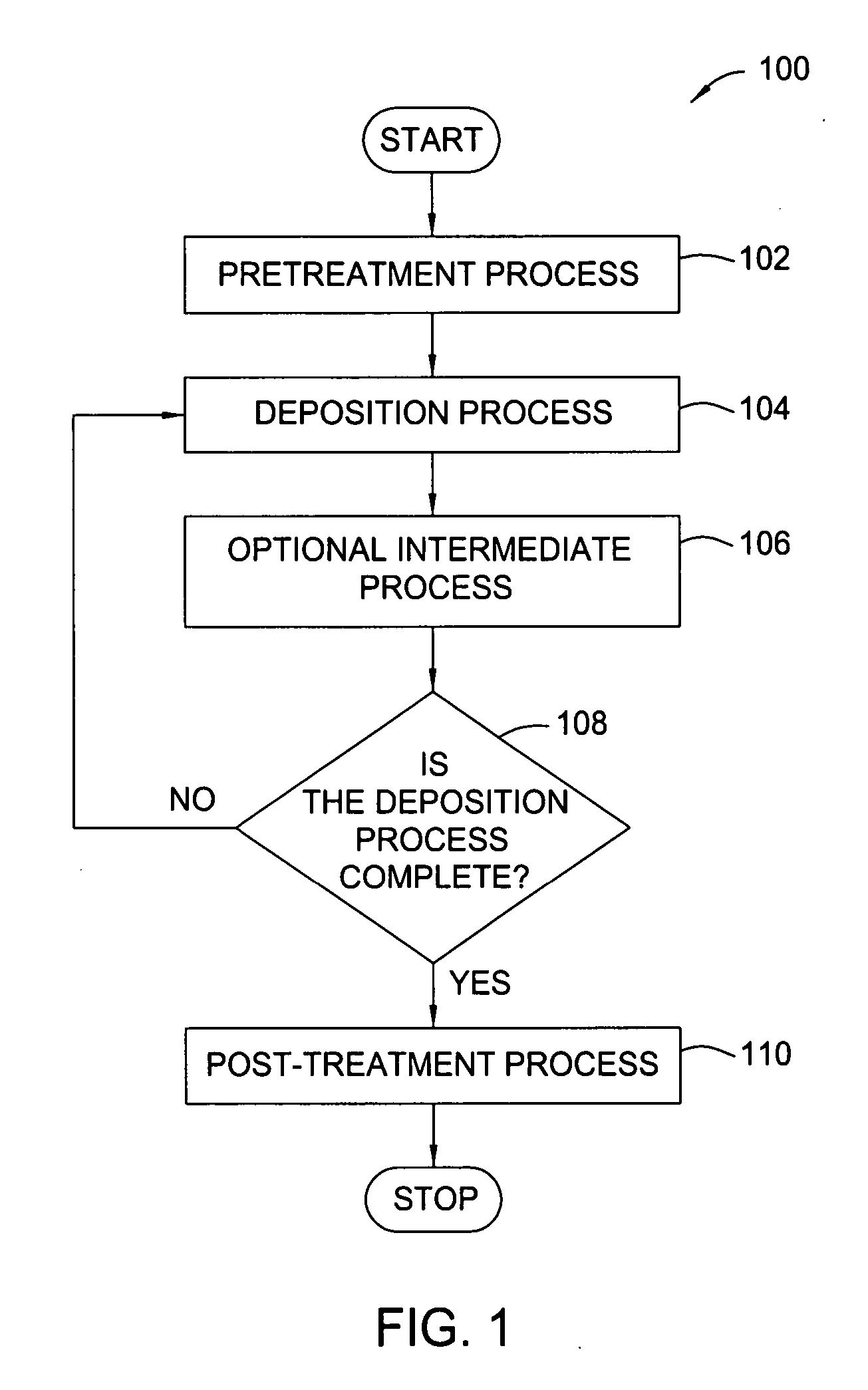

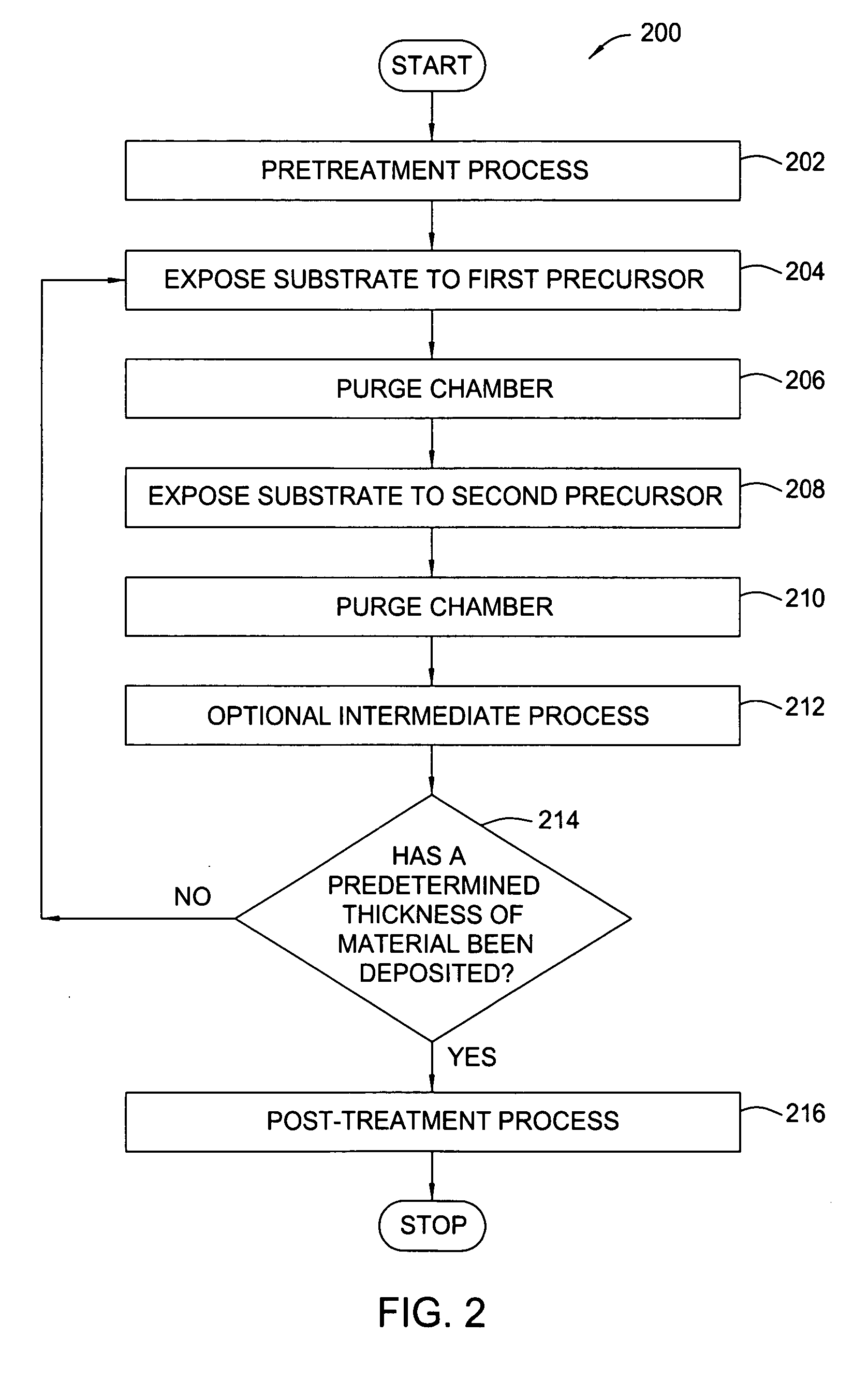

Treatment processes for a batch ALD reactor

Embodiments of the invention provide treatment processes to reduce substrate contamination during a fabrication process within a vapor deposition chamber. A treatment process may be conducted before, during or after a vapor deposition process, such as an atomic layer deposition (ALD) process. In one example of an ALD process, a process cycle, containing an intermediate treatment step and a predetermined number of ALD cycles, is repeated until the deposited material has a desired thickness. The chamber and substrates may be exposed to an inert gas, an oxidizing gas, a nitriding gas, a reducing gas or plasmas thereof during the treatment processes. In some examples, the treatment gas contains ozone, water, ammonia, nitrogen, argon or hydrogen. In one example, a process for depositing a hafnium oxide material within a batch process chamber includes a pretreatment step, an intermediate step during an ALD process and a post-treatment step.

Owner:APPLIED MATERIALS INC

Apparatus and methods for analyte measurement and immuno assay

ActiveUS20030170881A1Avoid disadvantagesBioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careOrganism

The present invention relates to an apparatus for conducting a variety of assays for the determination of analytes in liquid samples, and relates to the methods for such assays. In particular, the invention relates to a single-use cartridge designed to be adaptable to a variety of real-time assay protocols, preferably assays for the determination of analytes in biological samples using immunosensors or other ligand / ligand receptor-based biosensor embodiments. The cartridge provides novel features for processing a metered portion of a sample, for precise and flexible control of the movement of a sample or second fluid within the cartridge, for the amending of solutions with additional compounds during an assay, and for the construction of immunosensors capable of adaptation to diverse analyte measurements. The disclosed device and methods of use enjoy substantial benefits over the prior art, including simplicity of use by an operator, rapid in situ determinations of one or more analytes, and single-use methodology that minimizes the risk of contamination of both operator and patient. The disclosed invention is adaptable to the point-of-care clinical diagnostic field, including use in accident sites, emergency rooms, surgery, nursing homes, intensive care units, and non-medical environments.

Owner:ABBOTT POINT CARE

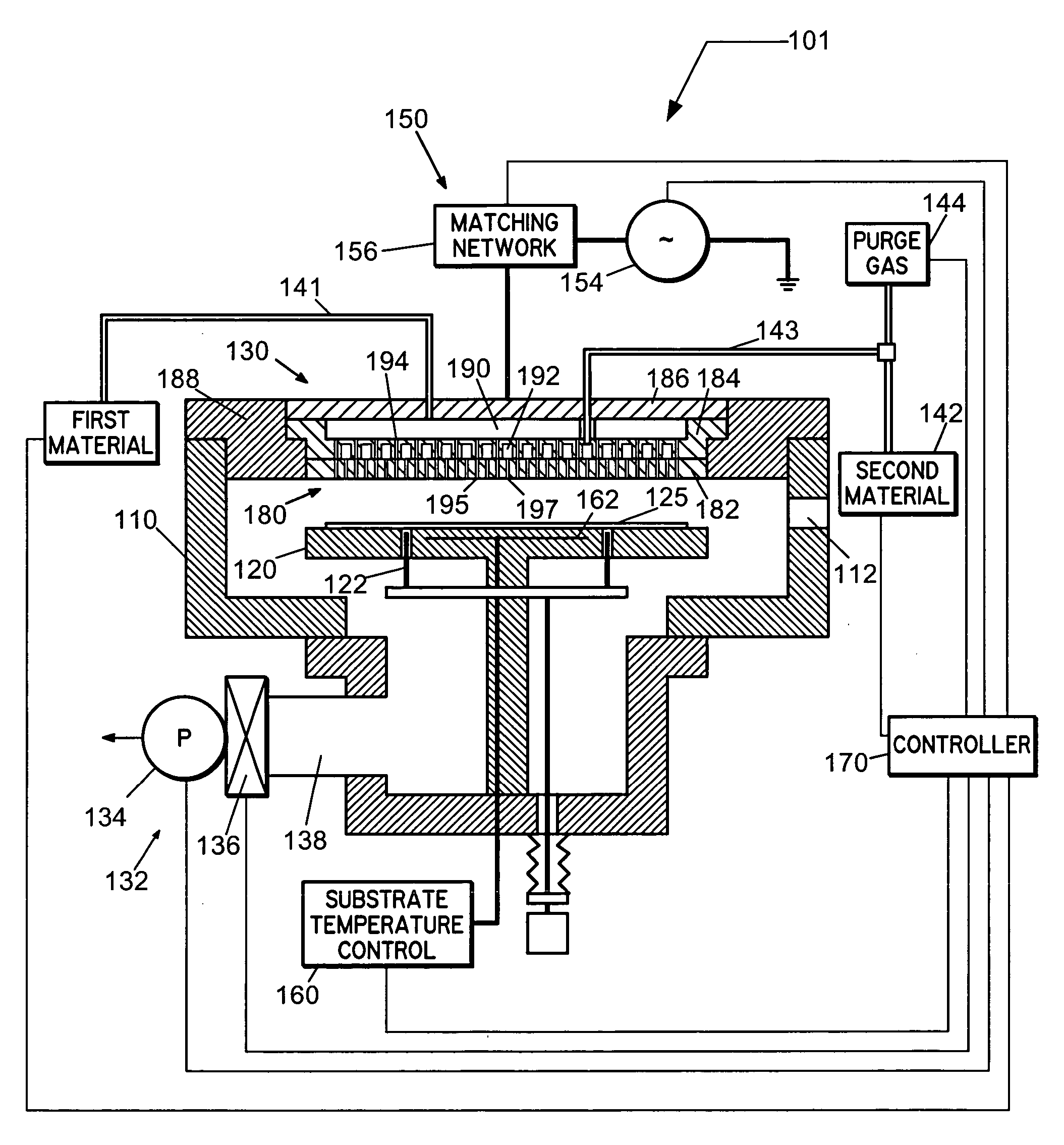

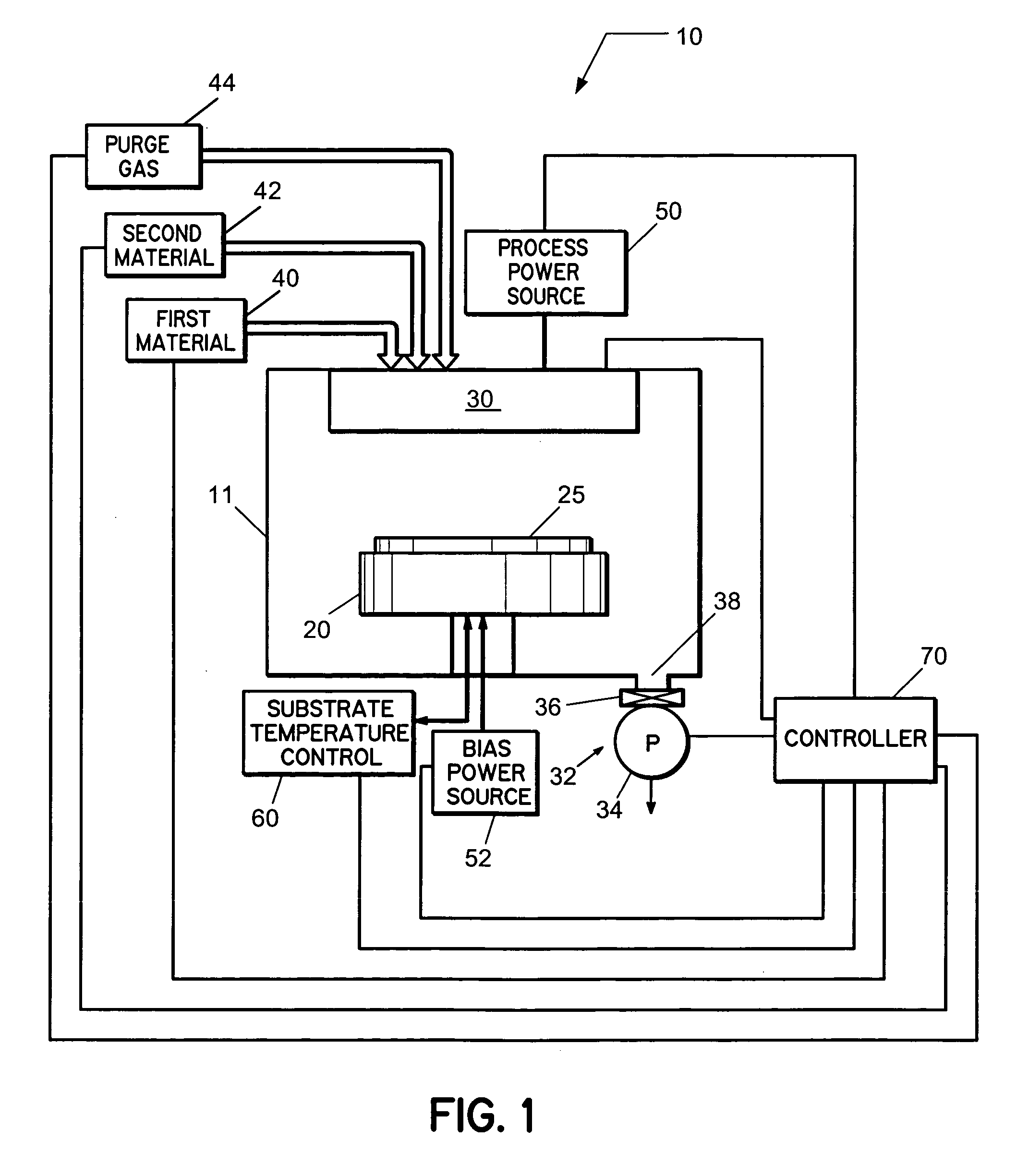

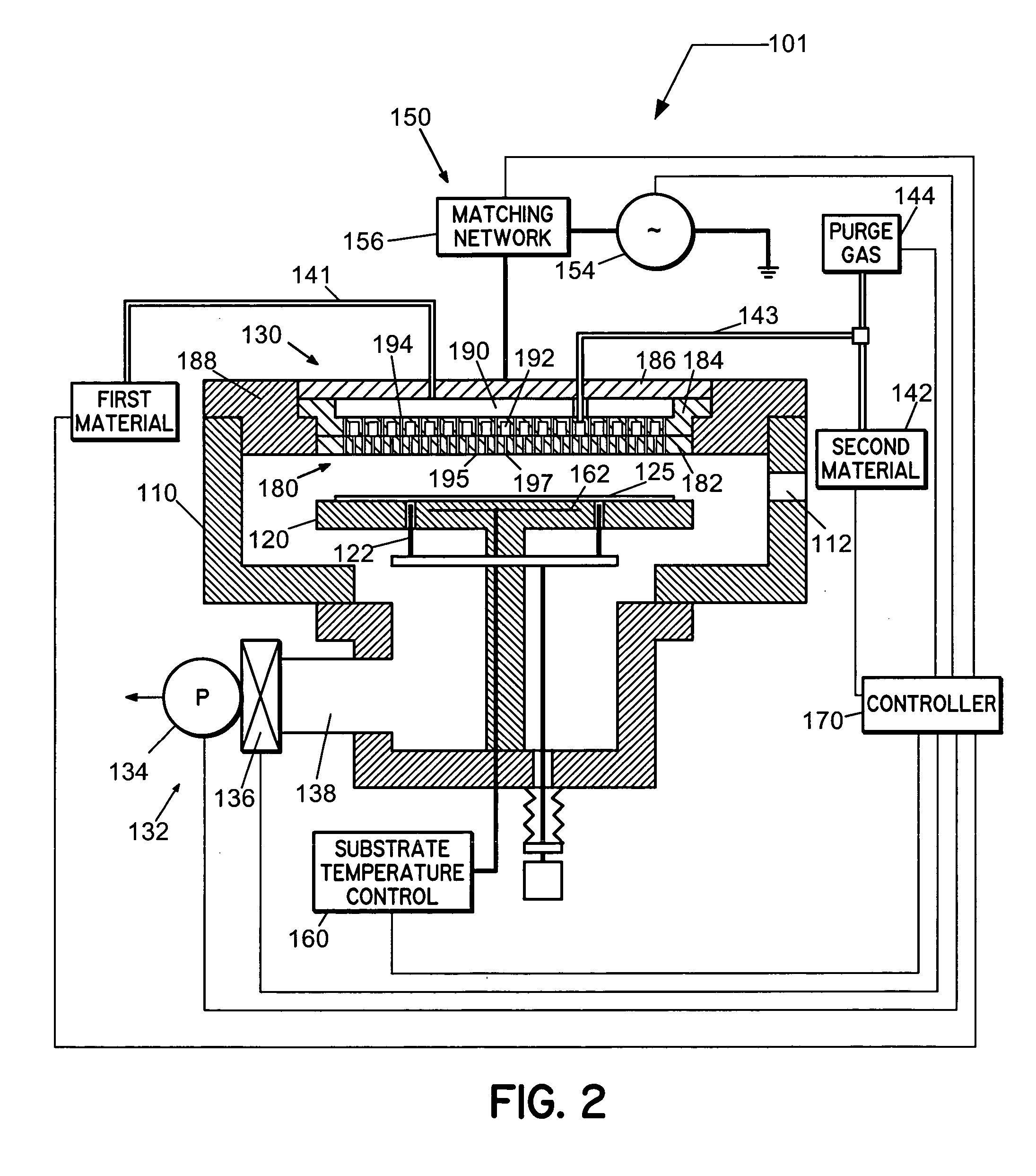

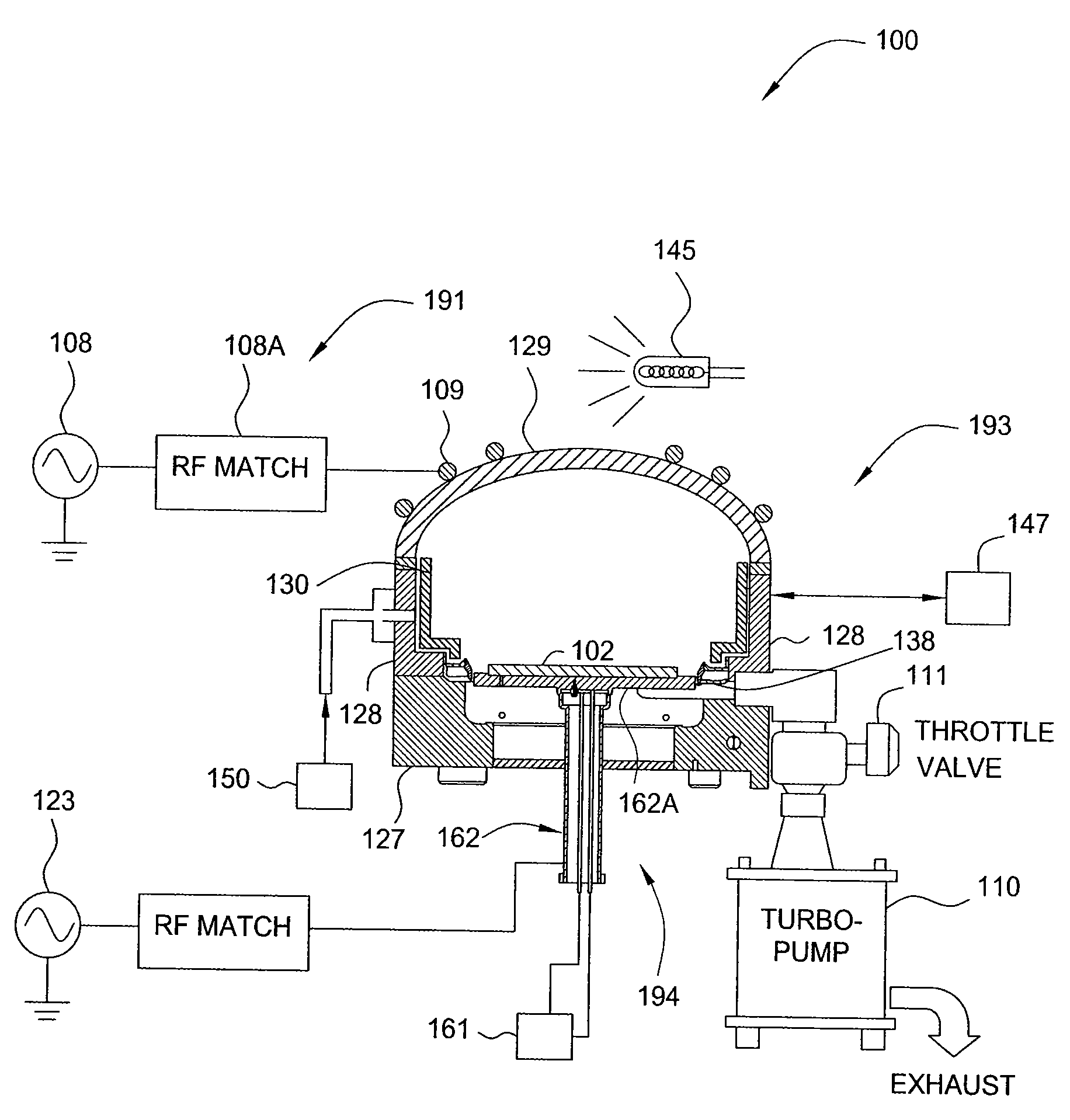

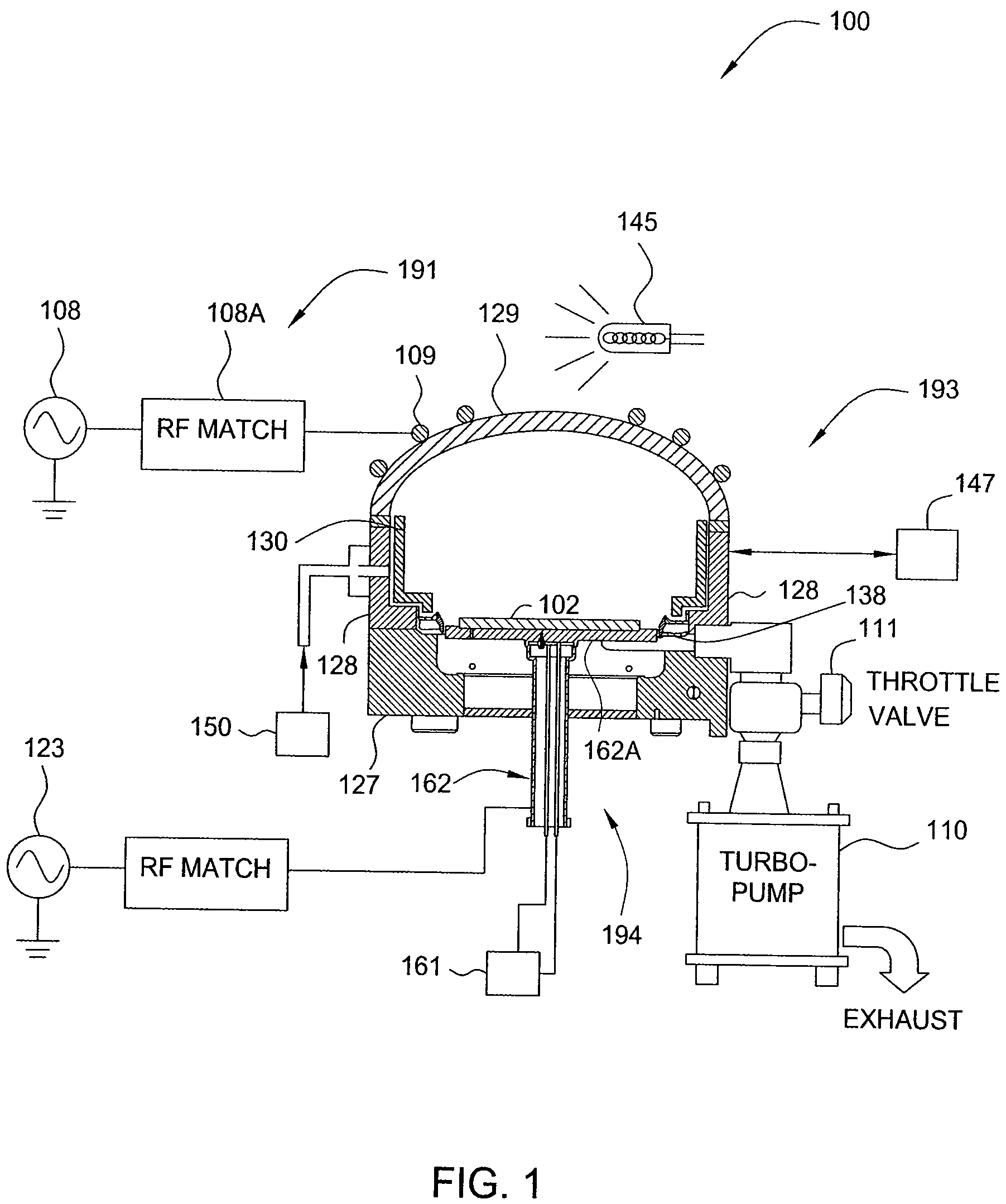

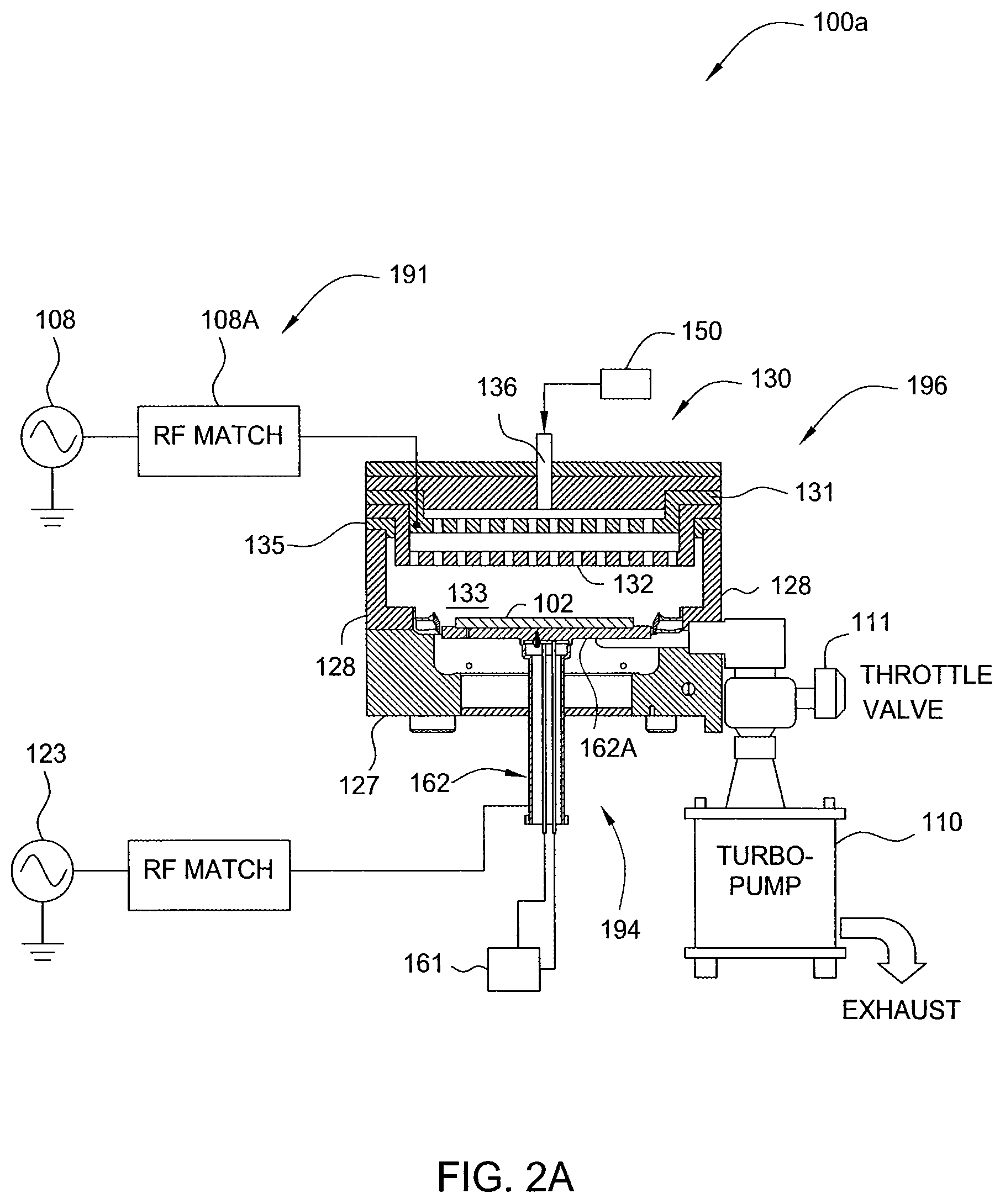

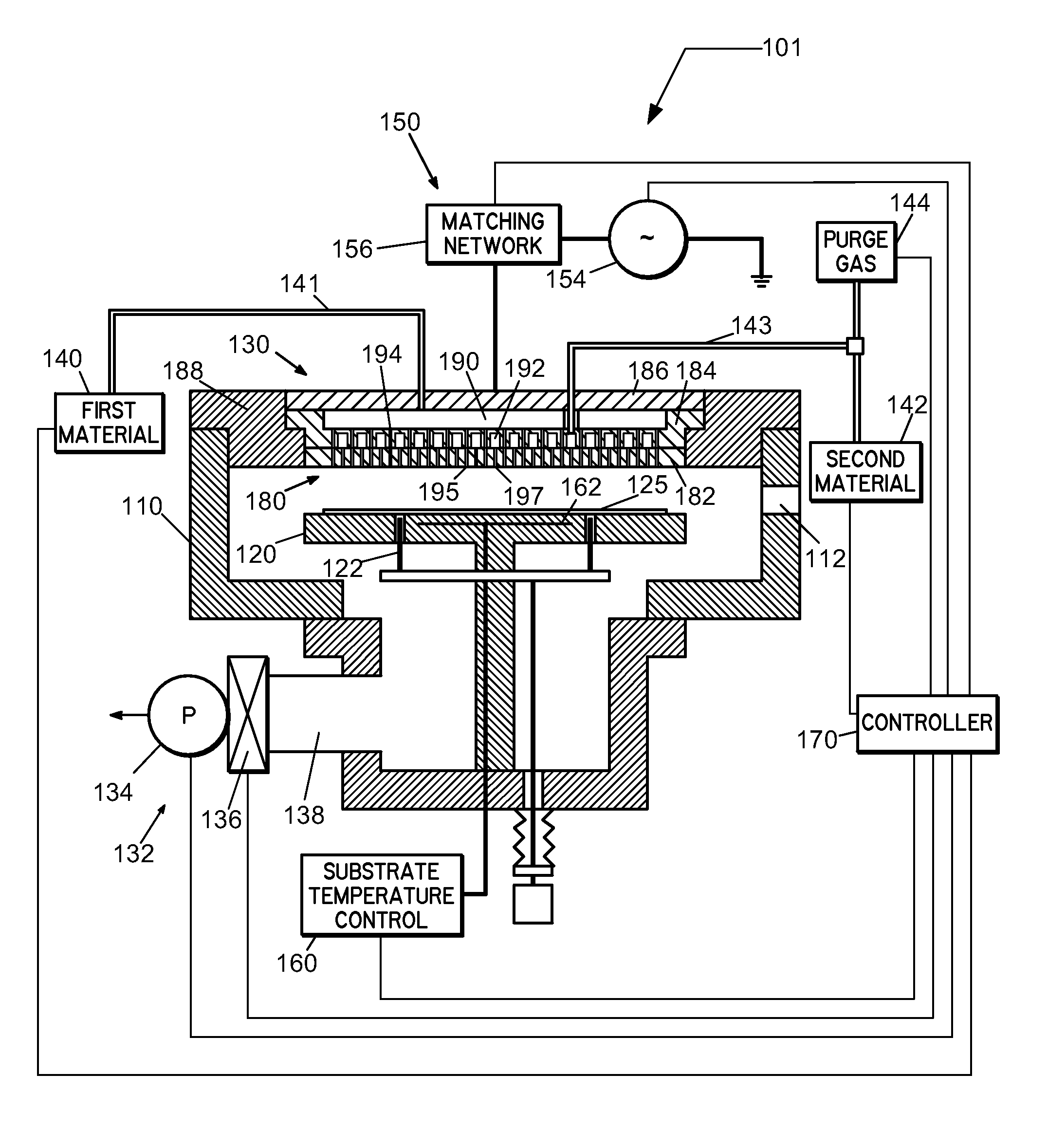

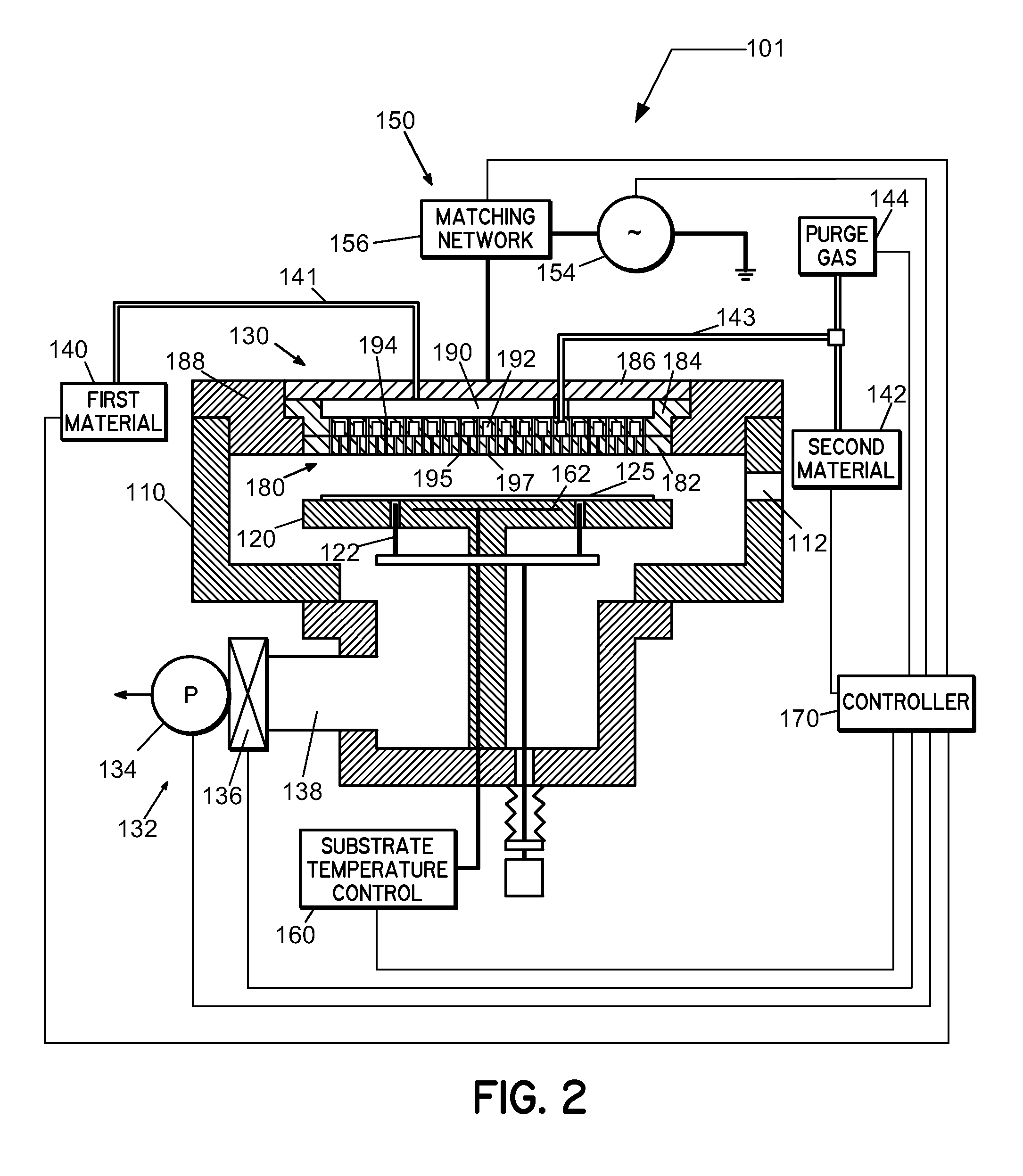

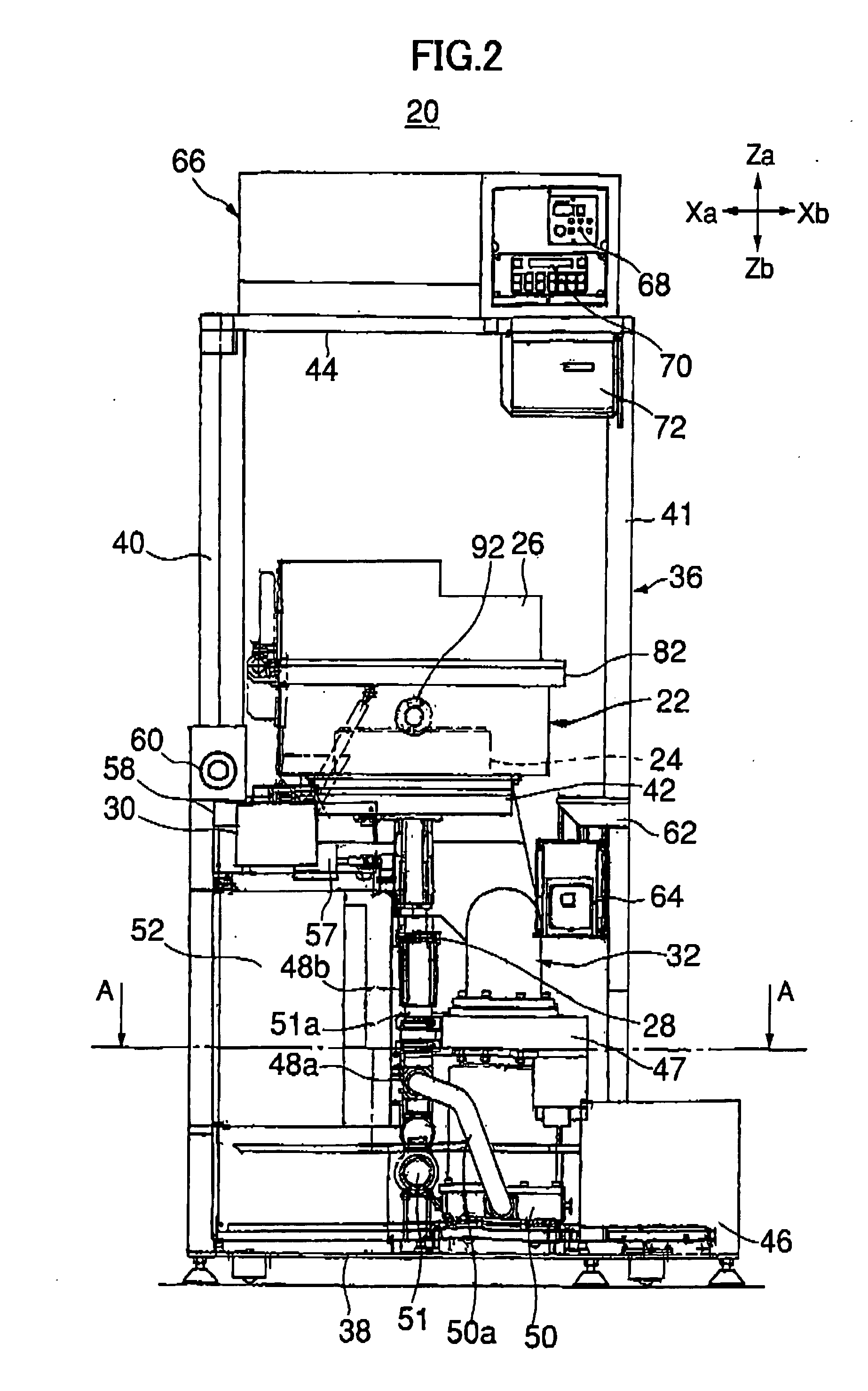

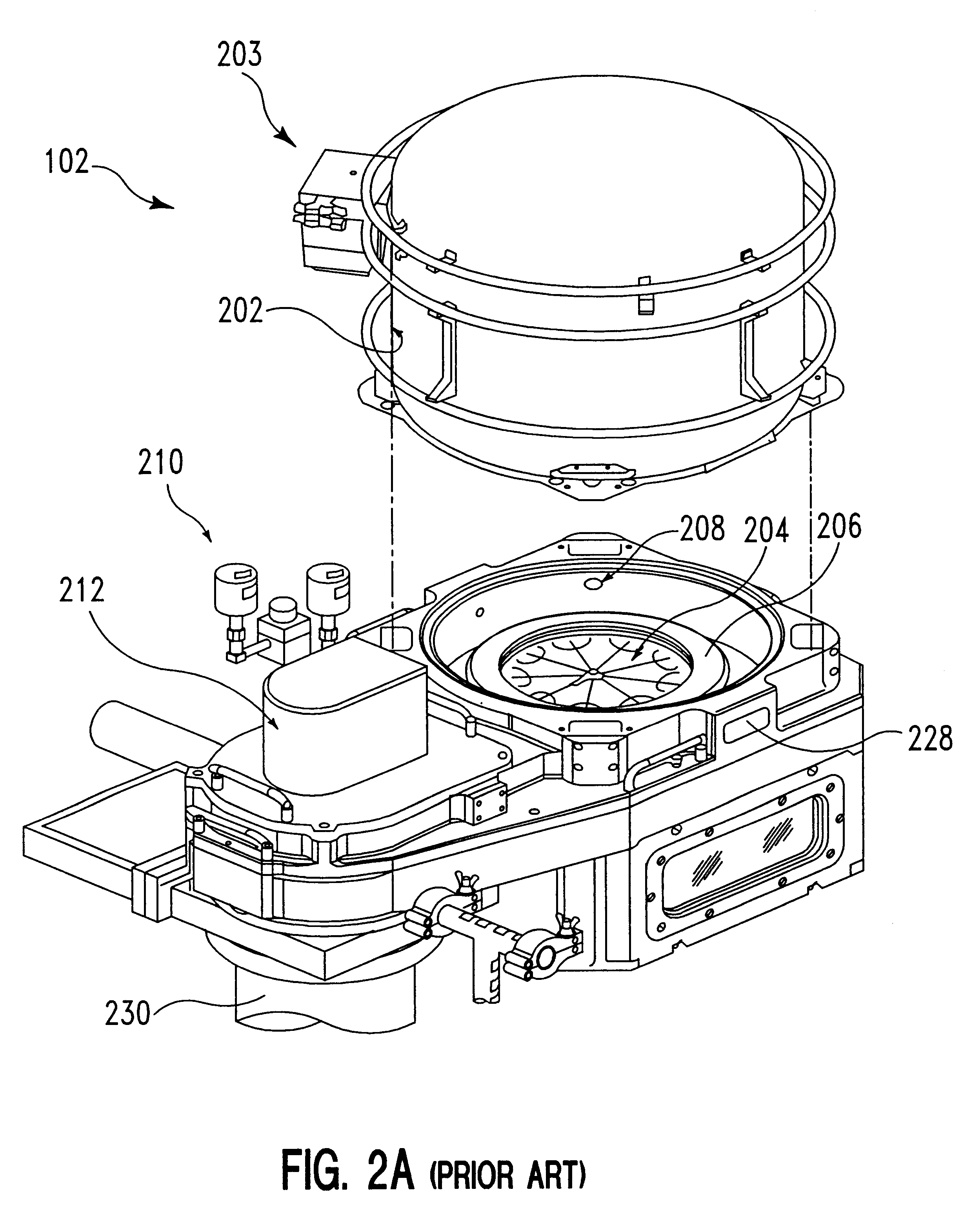

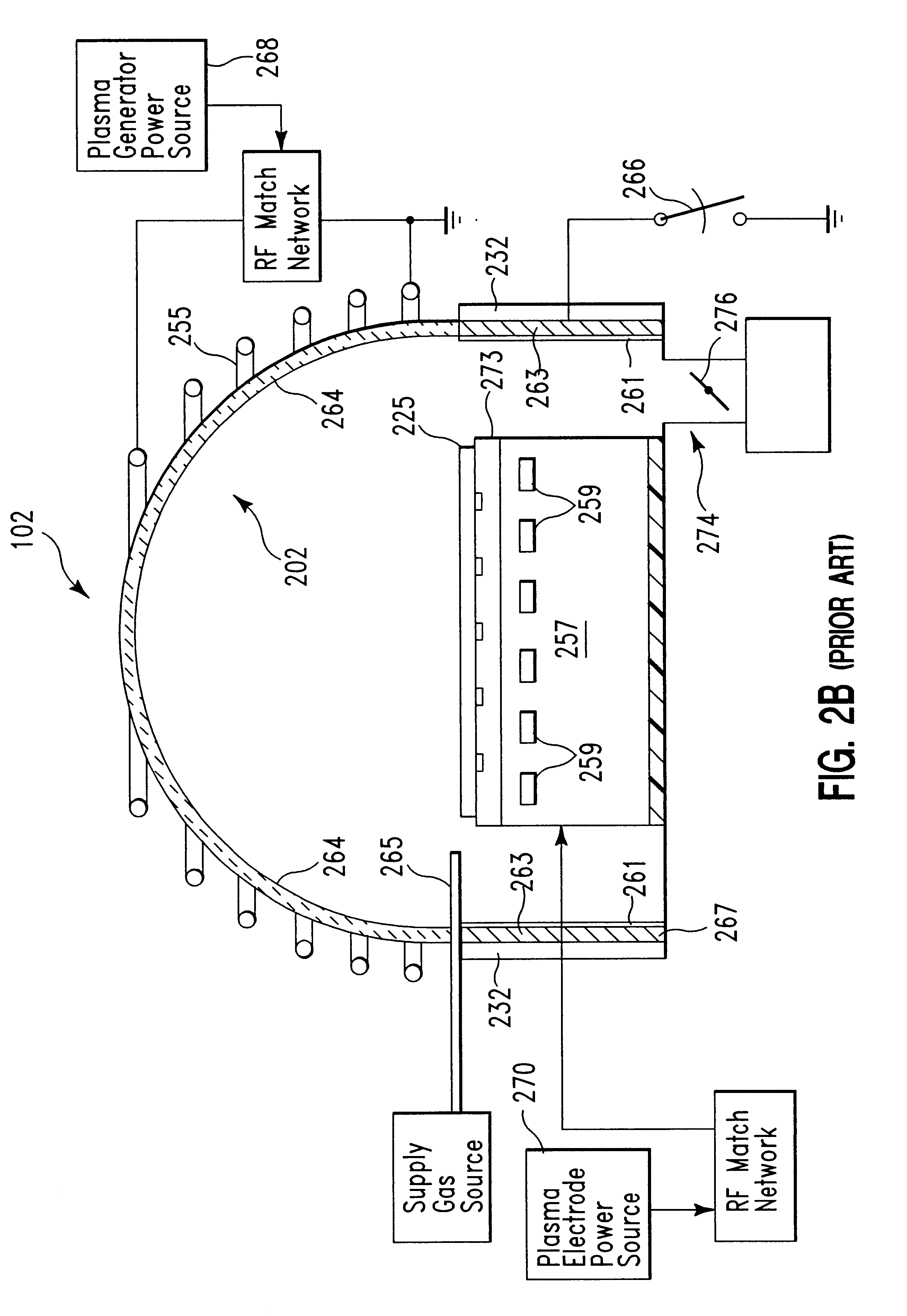

Plasma enhanced atomic layer deposition system having reduced contamination

ActiveUS20060213439A1Trend downThin film depositionLiquid surface applicatorsSemiconductor/solid-state device manufacturingAtomic layer depositionContamination

A plasma enhanced atomic layer deposition (PEALD) system is described, wherein the system comprises a processing space and a high vacuum, ultra-clean transfer space. During processing, the substrate to which the thin conformal film is formed is exposed to the processing space. During substrate transfer, the substrate is exposed to the high vacuum space. Processing gases are introduced sequentially and alternately to the process chamber and the pressures and gas flows within, to and from, and between the process chamber and the high vacuum transfer space are controlled to keep the transfer space ultra-clean.

Owner:TOKYO ELECTRON LTD

Heat-shrinkable anti-fomitic device

Owner:M TECH INC

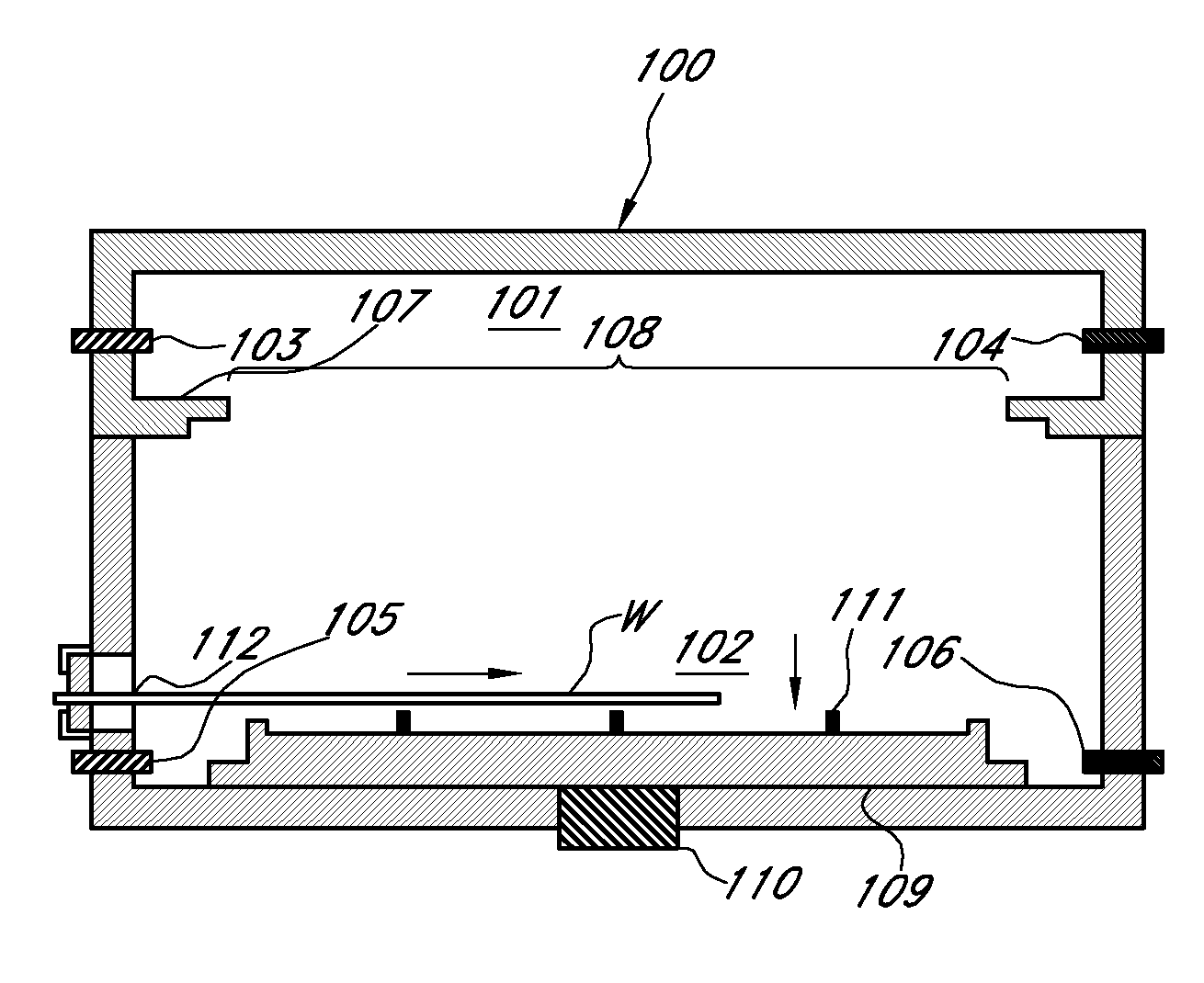

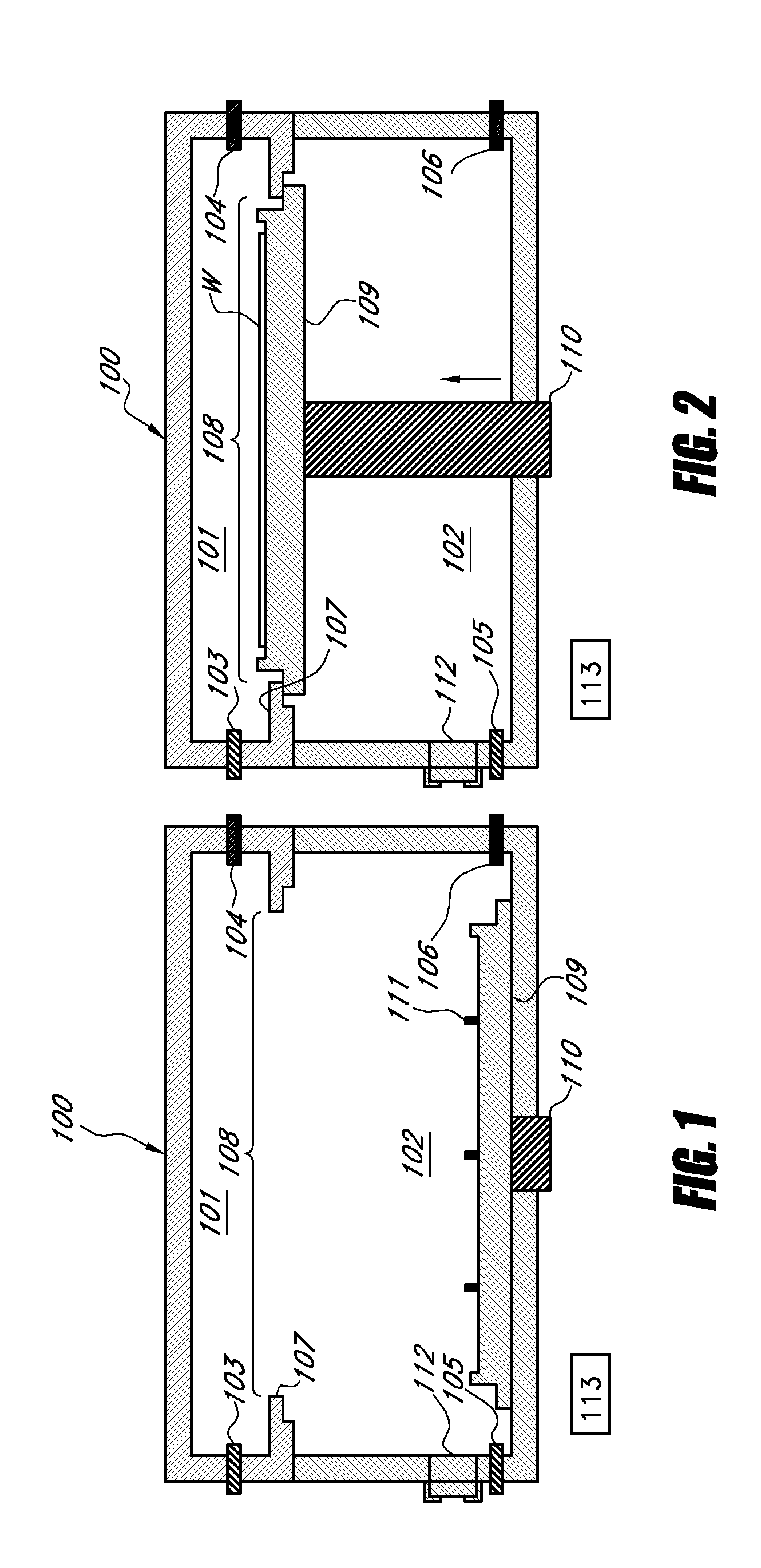

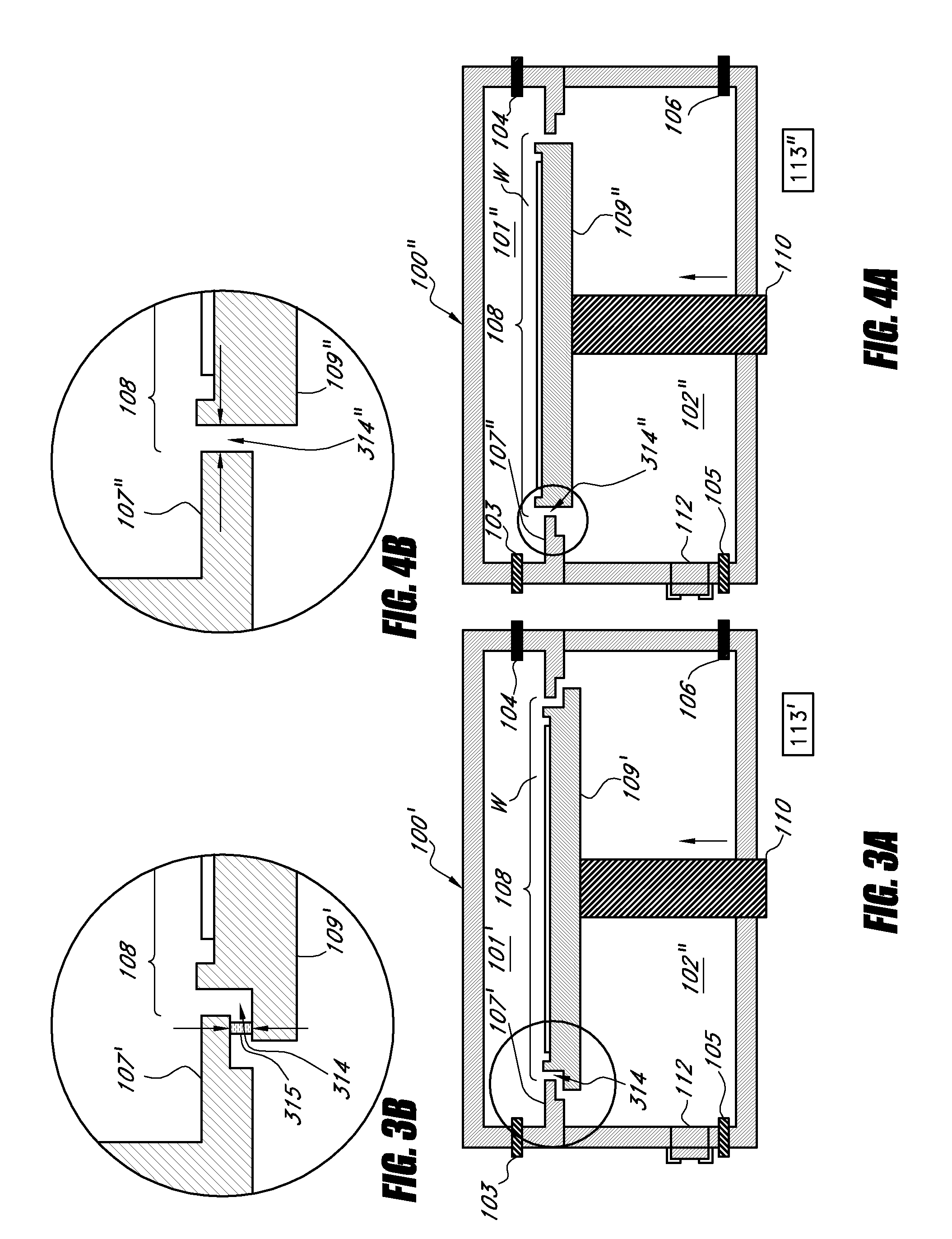

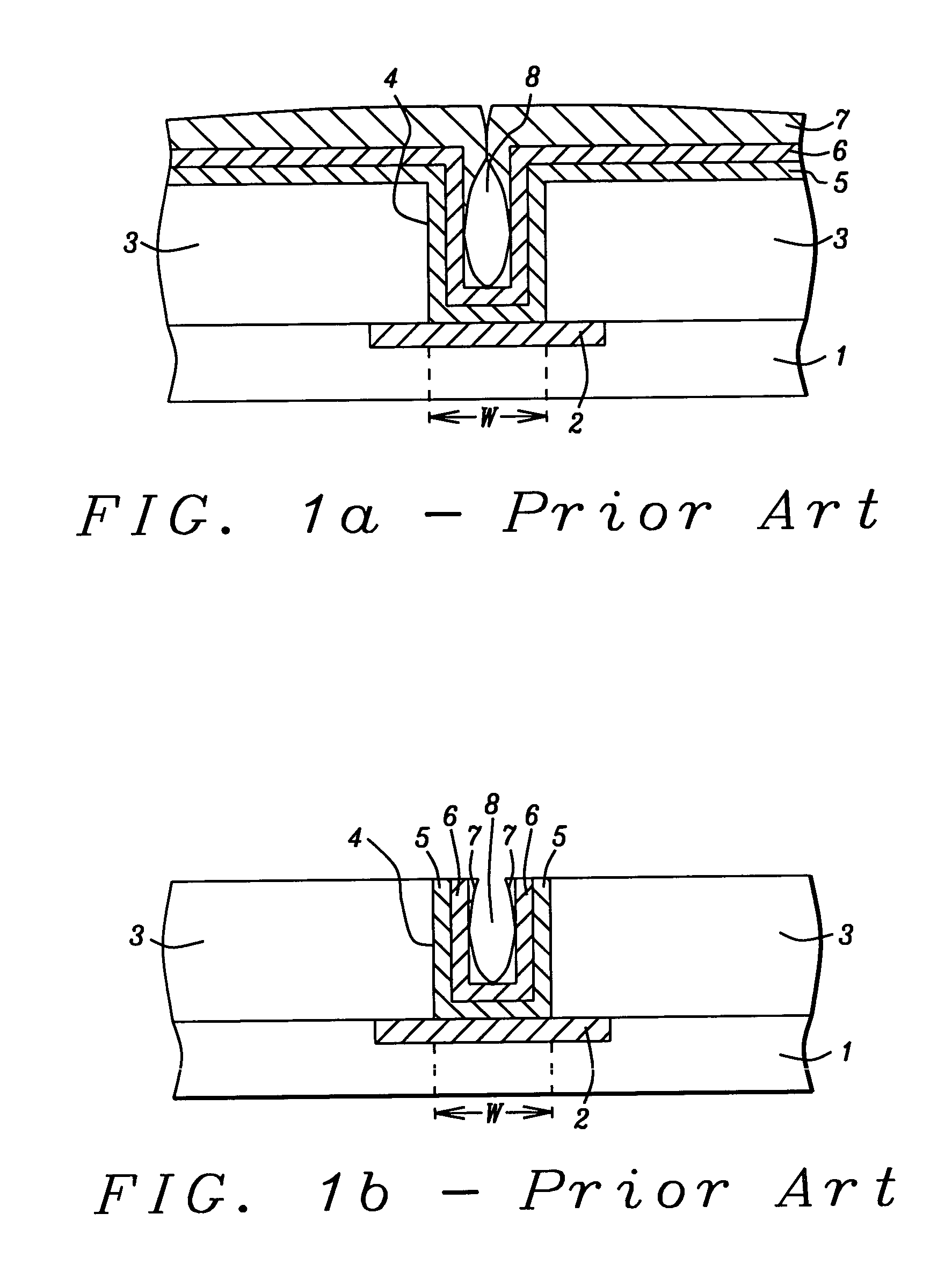

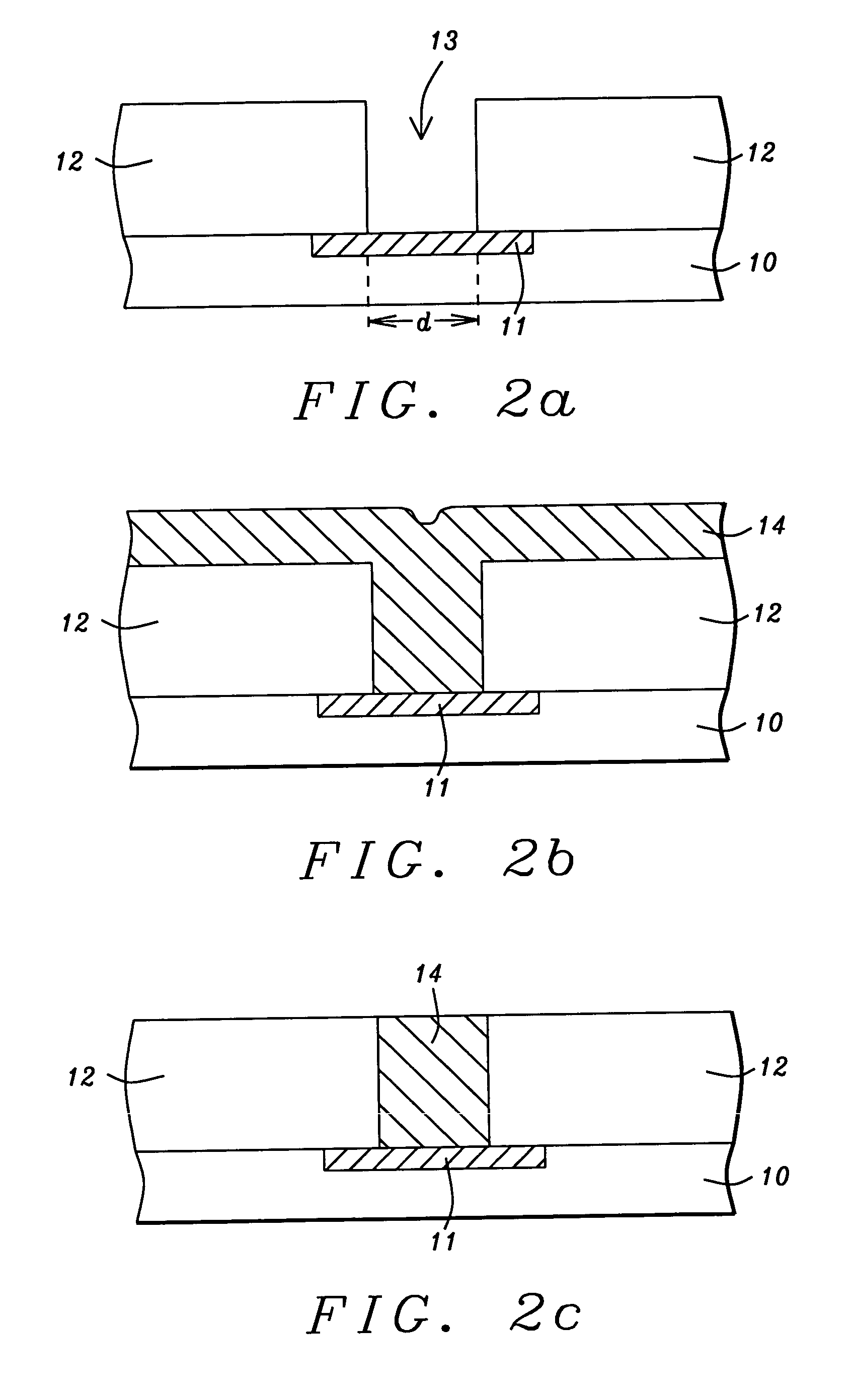

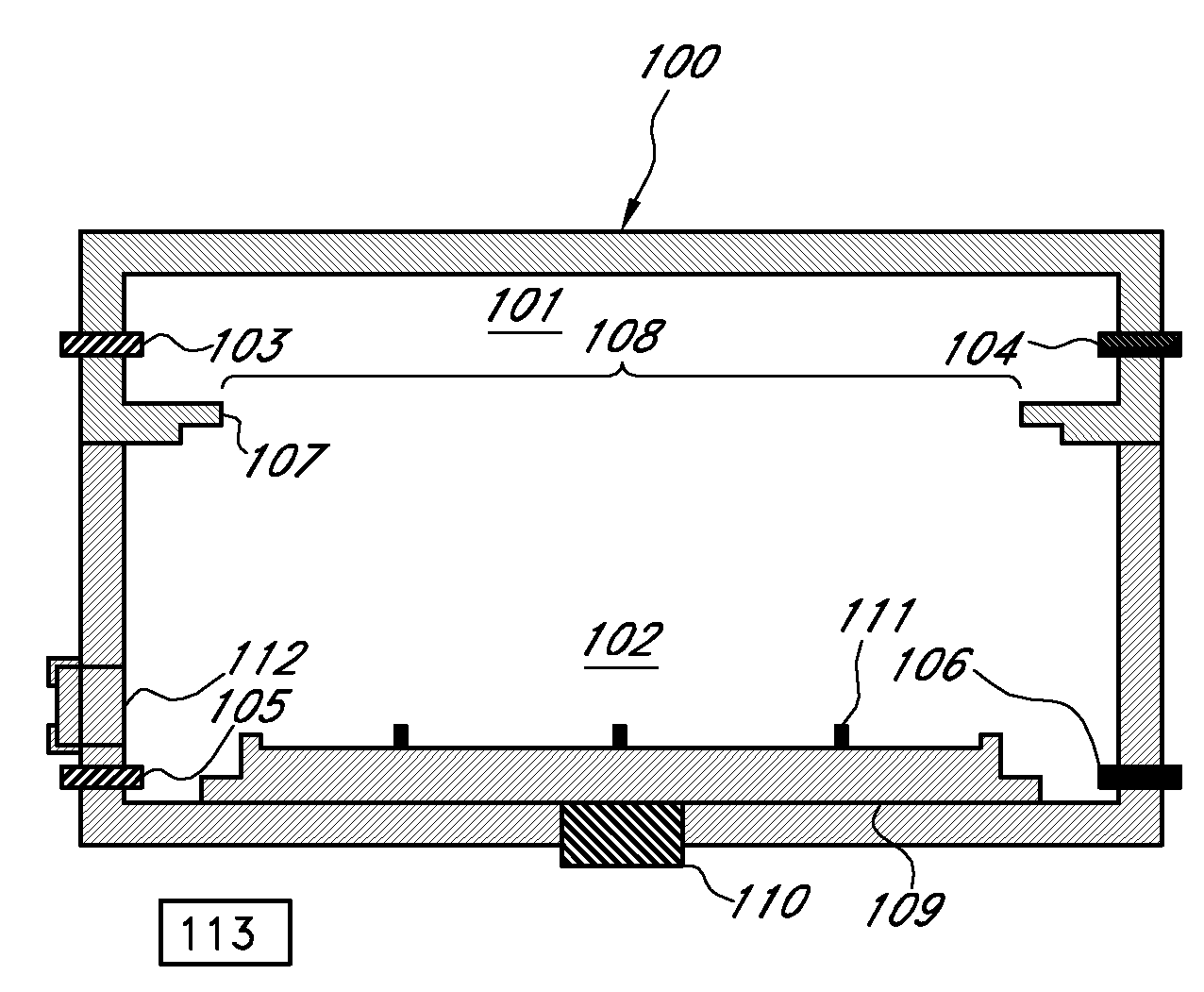

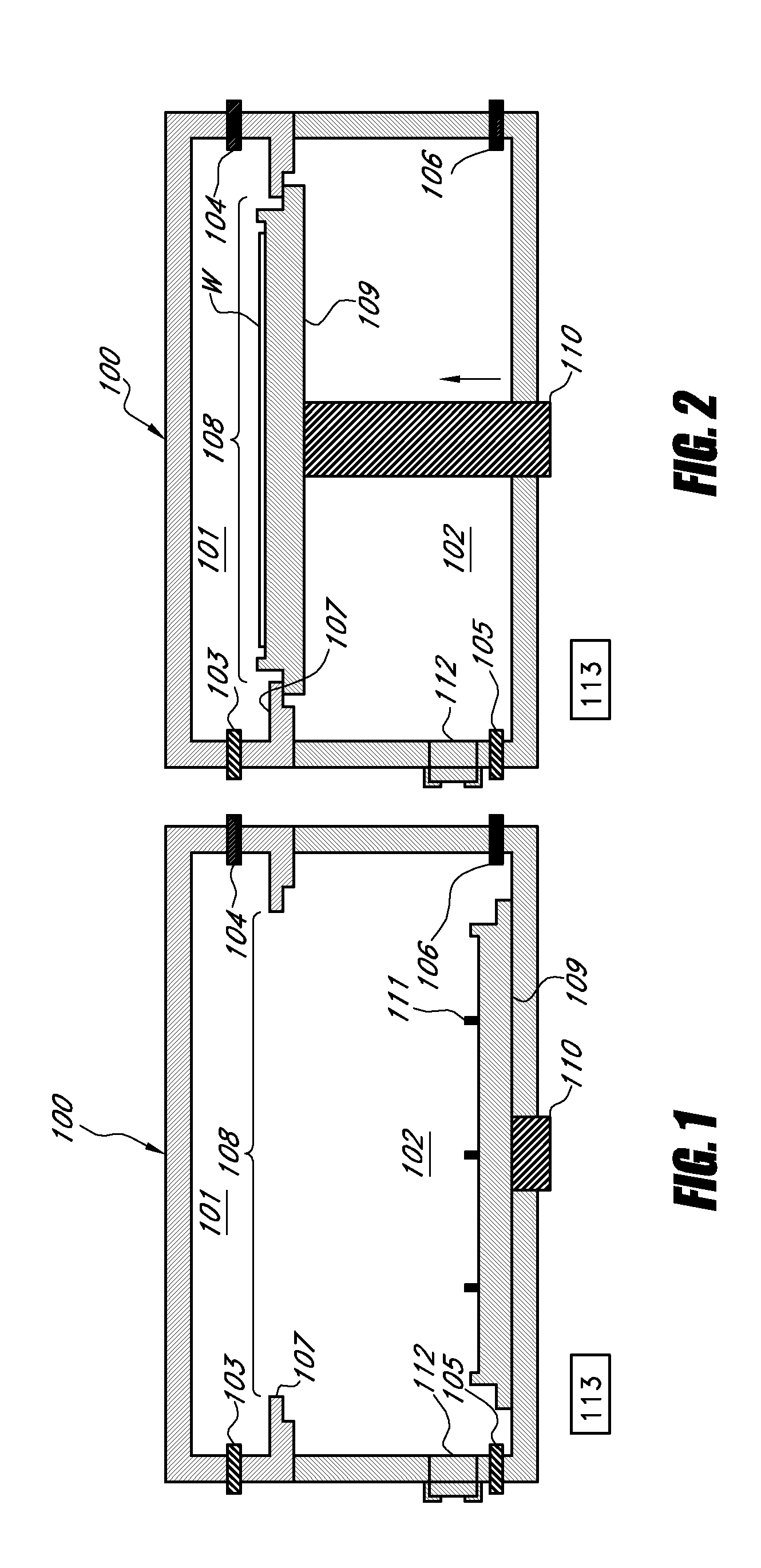

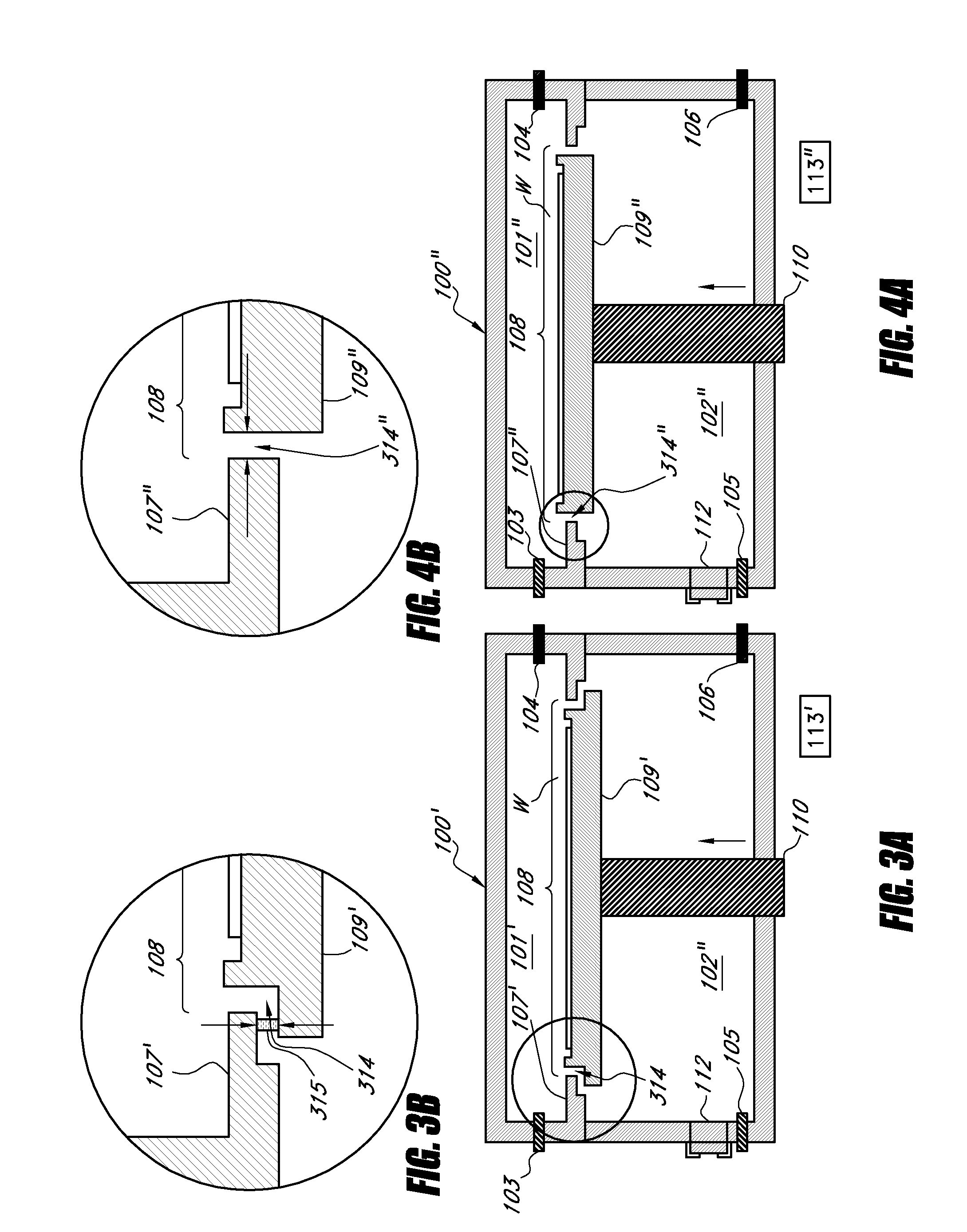

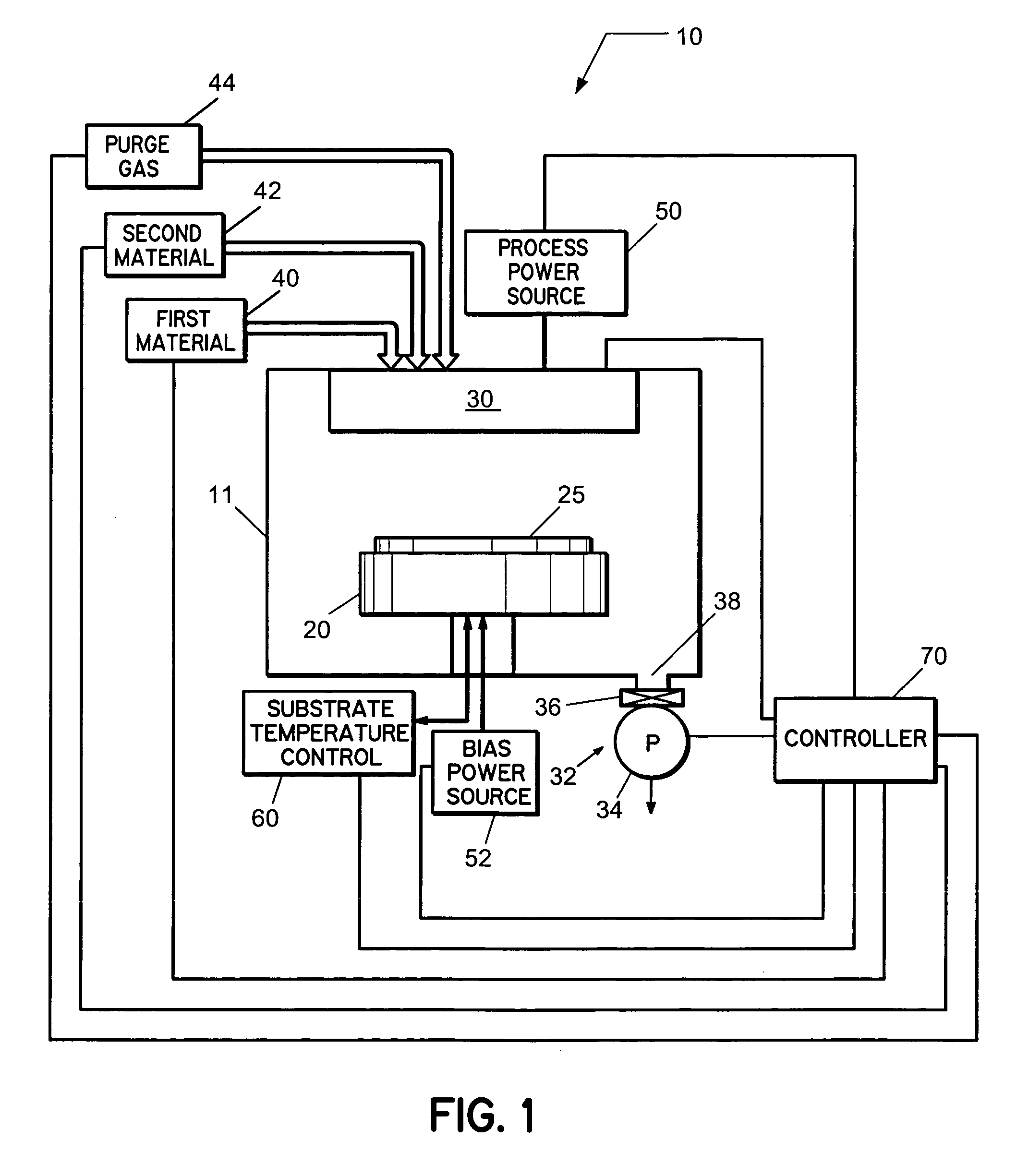

Method and apparatus for minimizing contamination in semiconductor processing chamber

ActiveUS8287648B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingPositive pressureControl system

A semiconductor processing apparatus includes a reaction chamber, a loading chamber, a movable support, a drive mechanism, and a control system. The reaction chamber includes a baseplate. The baseplate includes an opening. The movable support is configured to hold a workpiece. The drive mechanism is configured to move a workpiece held on the support towards the opening of the baseplate into a processing position. The control system is configured to create a positive pressure gradient between the reaction chamber and the loading chamber while the workpiece support is in motion. Purge gases flow from the reaction chamber into the loading chamber while the workpiece support is in motion. The control system is configured to create a negative pressure gradient between the reaction chamber and the loading chamber while the workpiece is being processed. Purge gases can flow from the loading chamber into the reaction chamber while the workpiece support is in the processing position, unless the reaction chamber is sealed from the loading chamber in the processing position.

Owner:ASM IP HLDG BV

Method and apparatus for cleaning a substrate surface

ActiveUS20090029528A1Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringContamination

The present invention generally provides apparatus and method for forming a clean and damage free surface on a semiconductor substrate. One embodiment of the present invention provides a system that contains a cleaning chamber that is adapted to expose a surface of substrate to a plasma cleaning process prior to forming an epitaxial layer thereon. In one embodiment, a method is employed to reduce the contamination of a substrate processed in the cleaning chamber by depositing a gettering material on the inner surfaces of the cleaning chamber prior to performing a cleaning process on a substrate. In one embodiment, oxidation and etching steps are repeatedly performed on a substrate in the cleaning chamber to expose or create a clean surface on a substrate that can then have an epitaxial placed thereon. In one embodiment, a low energy plasma is used during the cleaning step.

Owner:APPLIED MATERIALS INC

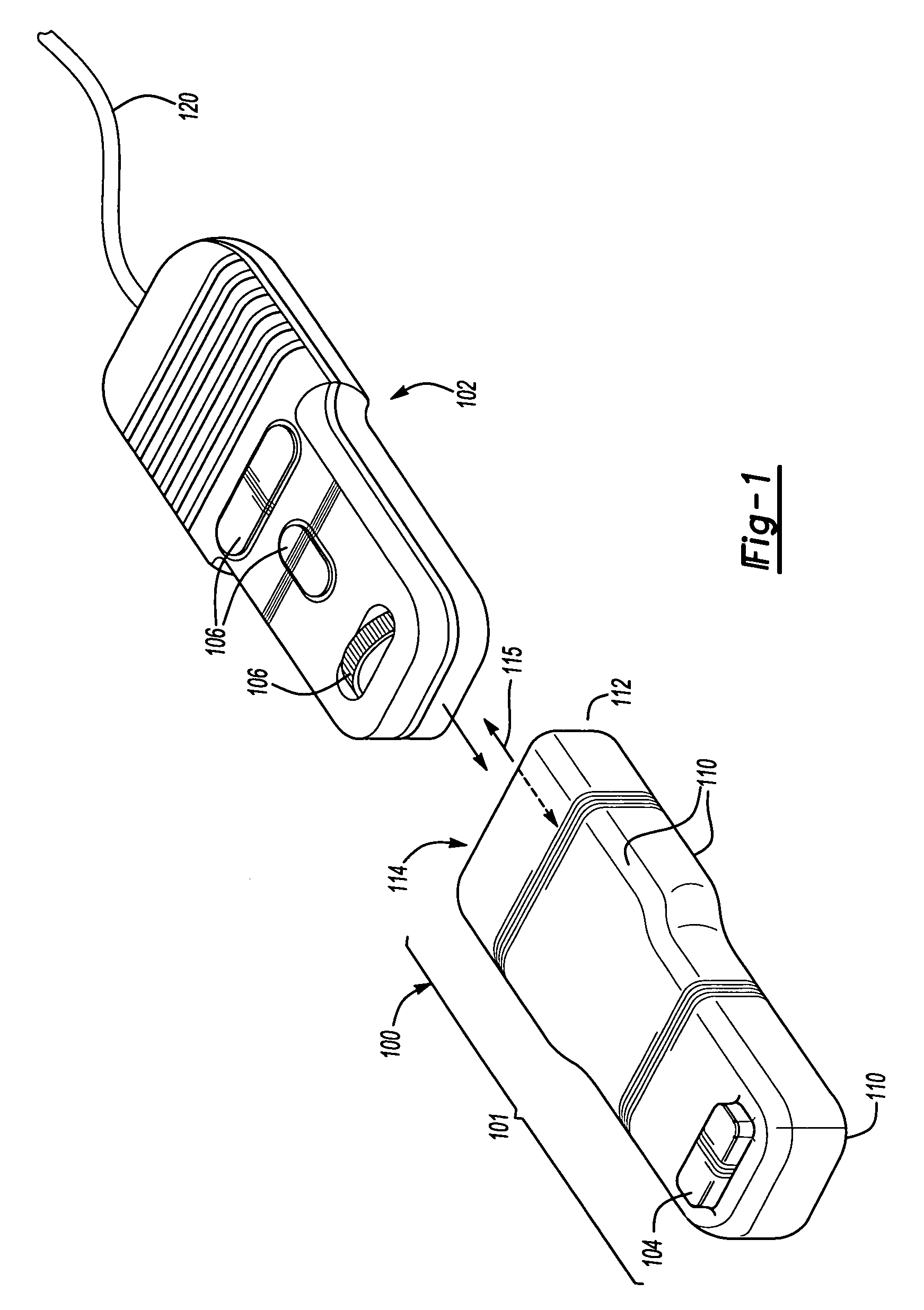

Protective shield for a patient control device

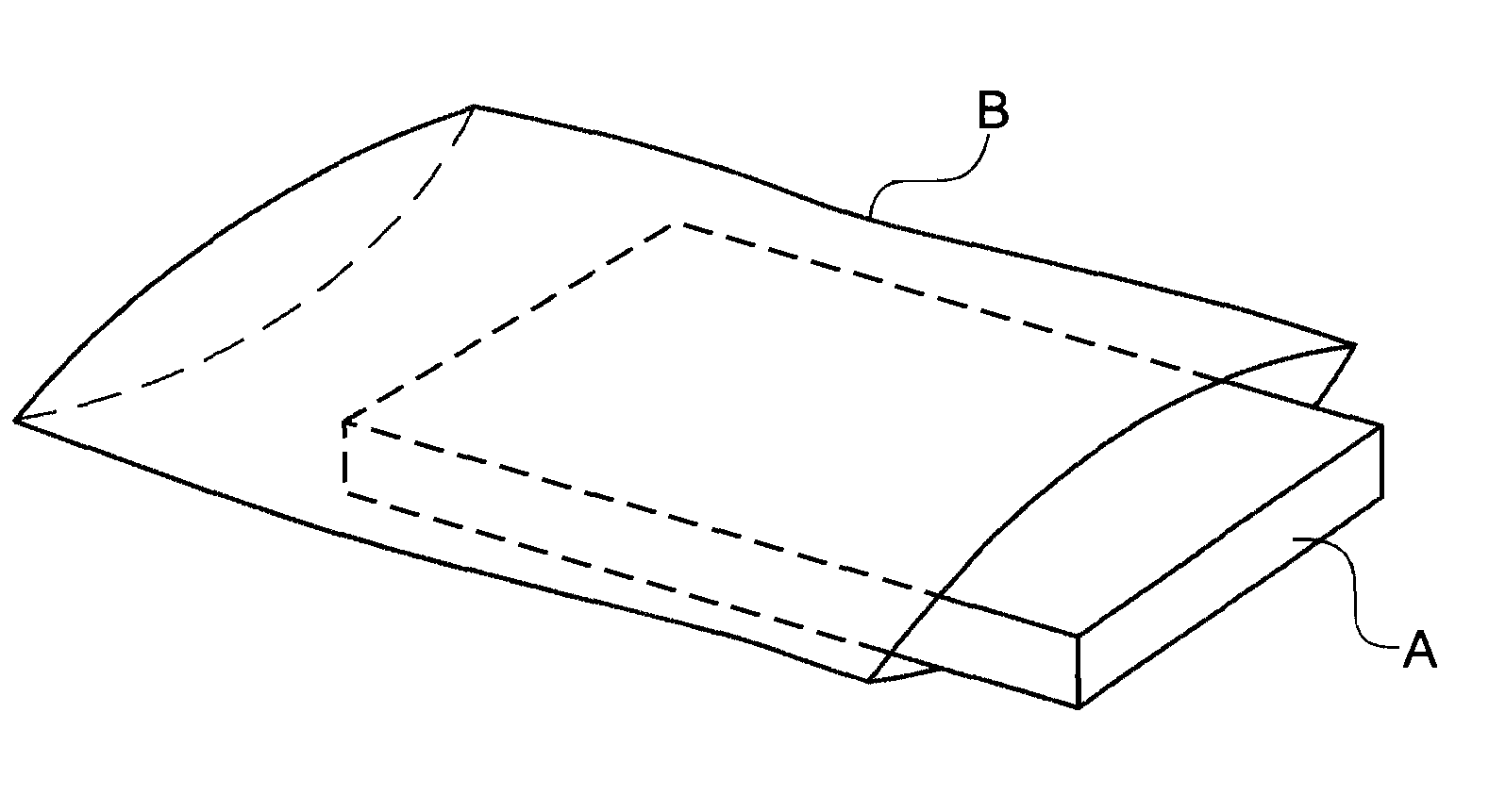

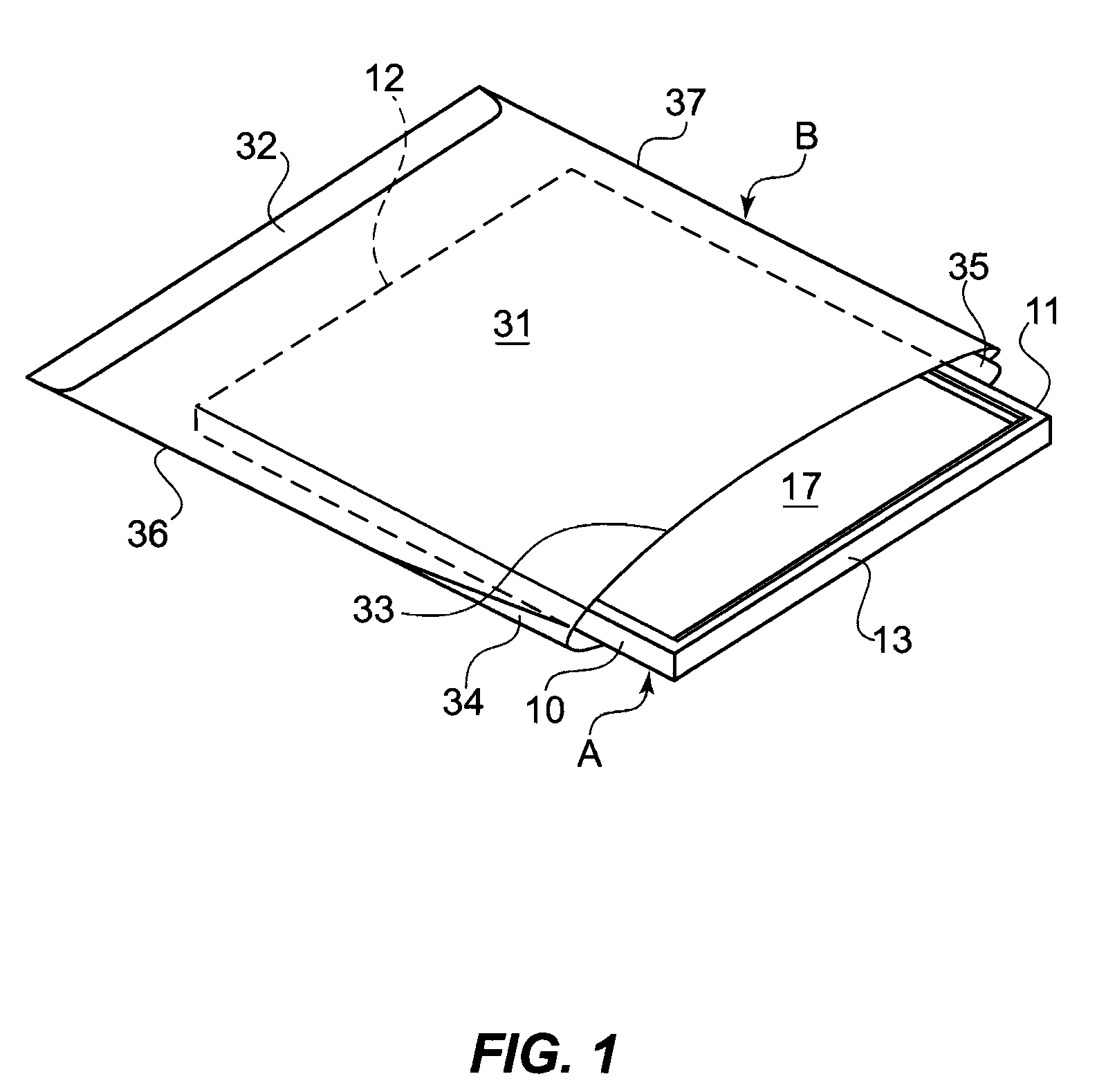

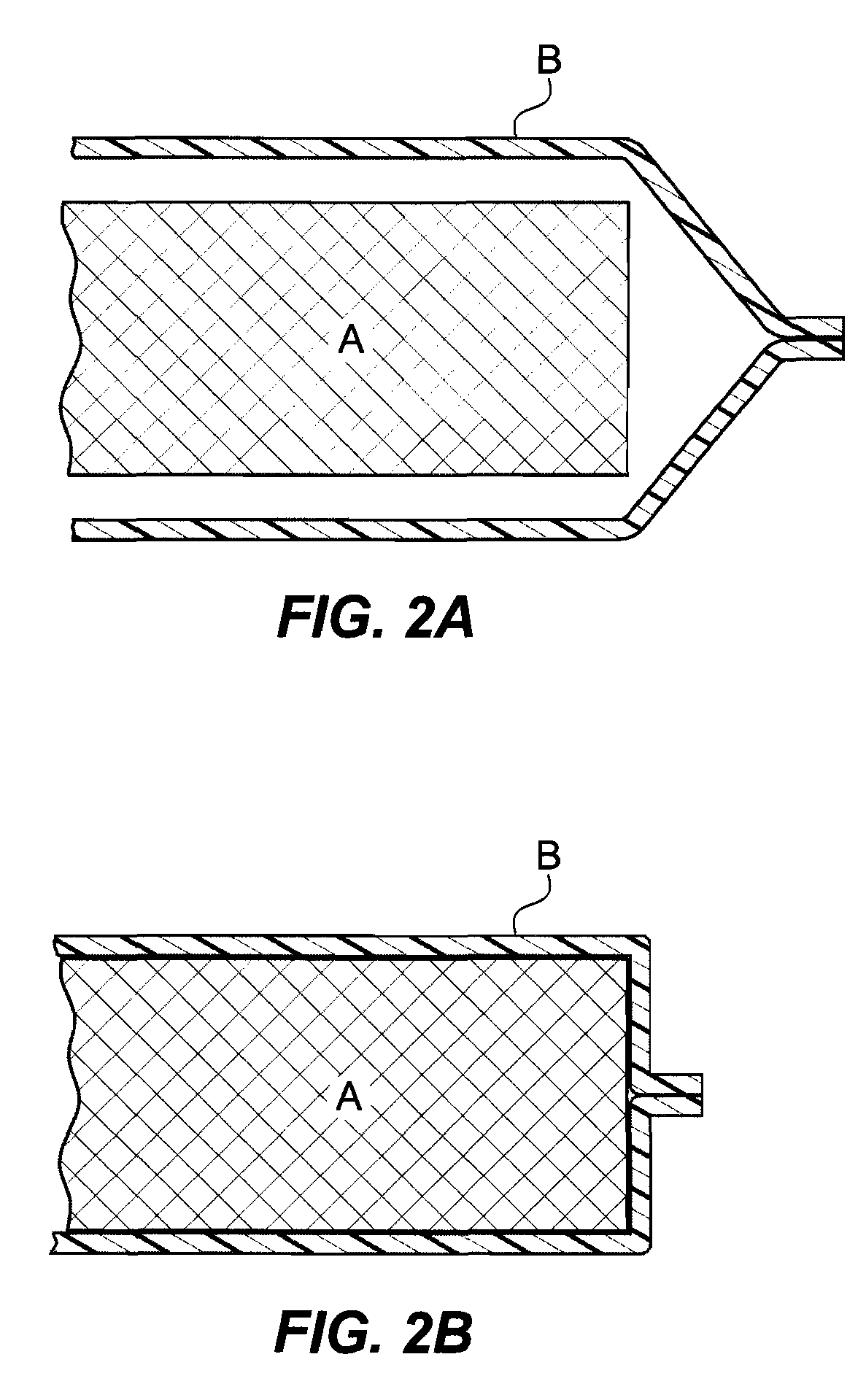

InactiveUS7011213B2Prolong lifeReduce needEnvelopes/bags making machineryWrappersContaminationElectrical and Electronics engineering

A disposable shield designed to sheath a patient control device prevents contaminants from contacting or entering the device. The shield has a bi-directional opening through which the hand-operated device is inserted and removed from the shield. A removable sealing device is used to preserve the integrity of the shield when the sealing device is removed. The shield can therefore be changed each time the device is handled by a different person, minimizing the chances of cross-contamination. The shield also extends the life of the device by preventing biological contaminants from contacting the device.

Owner:BIOTRONICS

Chamber material made of Al alloy and heater block

InactiveUS20010019777A1Not be restrictElectric discharge tubesSemiconductor/solid-state device manufacturingHigh-temperature corrosionContamination

A chamber material made of Al alloy excellent in thermal cracking resistance and chemical and / or physical corrosion resistance and capable of reducing contamination excellently and further having excellent and wide applicable brazing property in a high temperature corrosive circumstance, in which the substrate aluminum material for the chamber material made of Al alloy having an anodized film comprises 0.1 to 2.0% Si, 0.1 to 3.5% Mg, 0.02 to 4.0% Cu on the mass % basis and the balance of Al and impurity element with Cr in the impurity elements being less than 0.04%. Preferably, Fe is 0.1% or less and Mn is 0.04% or less in the impurity element and, further, the total sum of impurity elements other than Cr and Mn being restricted to 0.1$ or less. This invention can be utilized suitably to various materials used in high temperature corrosive circumstance, particularly, in high temperature corrosive gas or plasma atmosphere.

Owner:KOBE STEEL LTD

Apparatus and methods for analyte measurement and immunoassay

ActiveUS7419821B2Bioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careEngineering

Owner:ABBOTT POINT CARE

Method of manufacturing a contact interconnection layer containing a metal and nitrogen by atomic layer deposition for deep sub-micron semiconductor technology

ActiveUS7235482B2Good step coverageSafe handlingSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionContamination

An atomic layer deposition method is used to deposit a TiN or TiSiN film having a thickness of about 50 nm or less on a substrat. A titanium precursor which is tetrakis(dimethylamido)titanium (TDMAT), tetrakis(diethylamido)titanium (TDEAT), or Ti{OCH(CH3)2}4 avoids halide contamination from a titanium halide precursor and is safer to handle than a titanium nitrate. After a monolayer of the titanium precursor is deposited on a substrate, a nitrogen containing reactant is introduced to form a TiN monolayer which is followed by a second purge. For TiSiN, a silicon source gas is fed into the process chamber after the TiN monolayer formation. The process is repeated several times to produce a composite layer comprised of a plurality of monolayers that fills a contact hole. The ALD method is cost effective and affords an interconnect with lower impurity levels and better step coverage than conventional PECVD or CVD processes.

Owner:TAIWAN SEMICON MFG CO LTD

Toothbrush dryer

InactiveUS6874247B1Avoid contaminationAvoid infectionAgriculture tools and machinesWash-standsEngineeringContamination

A toothbrush dryer includes a housing formed as a heating chamber for storing toothbrush in the housing, and a heating device provided in the housing preferably at a bottom portion of the housing for warming the toothbrush for keeping a dried toothbrush for preventing bacteria, fungi or algae infection or contamination.

Owner:HSU TSANG HUNG

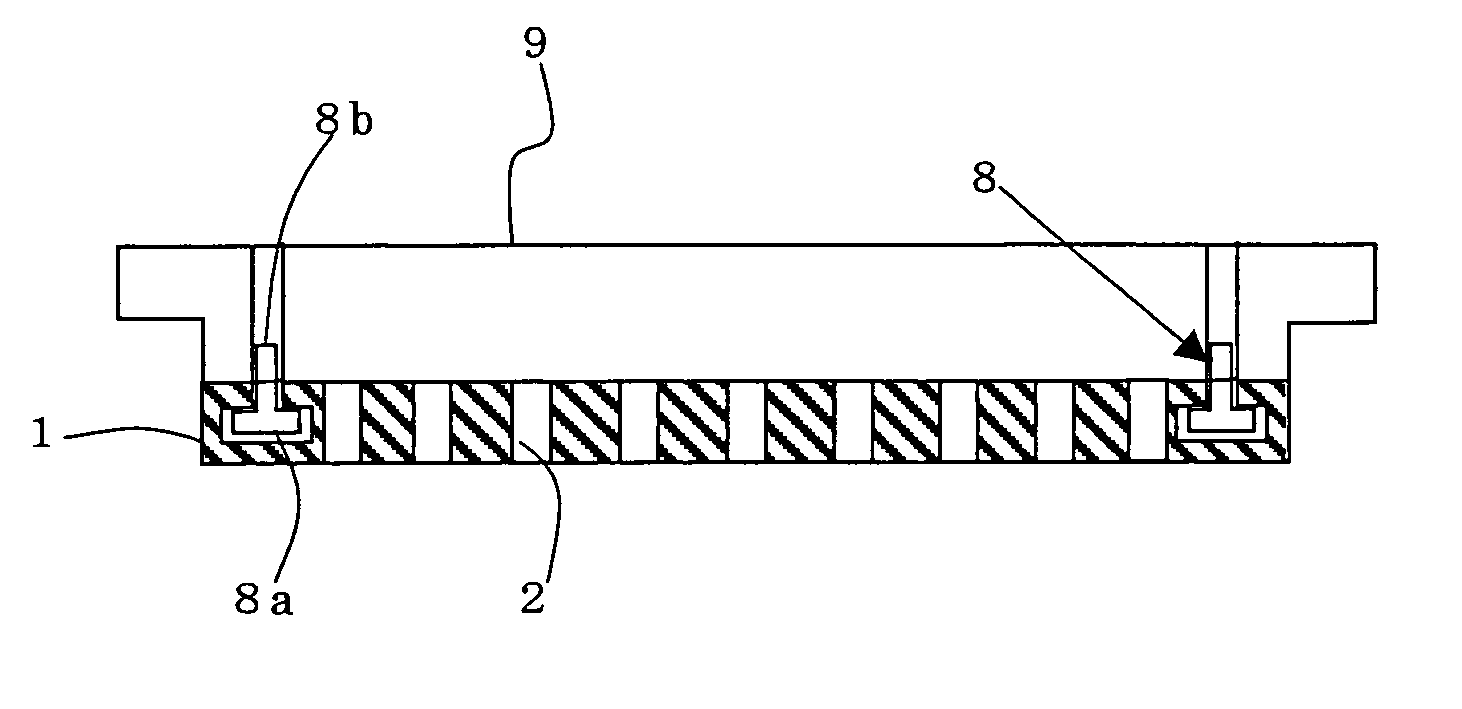

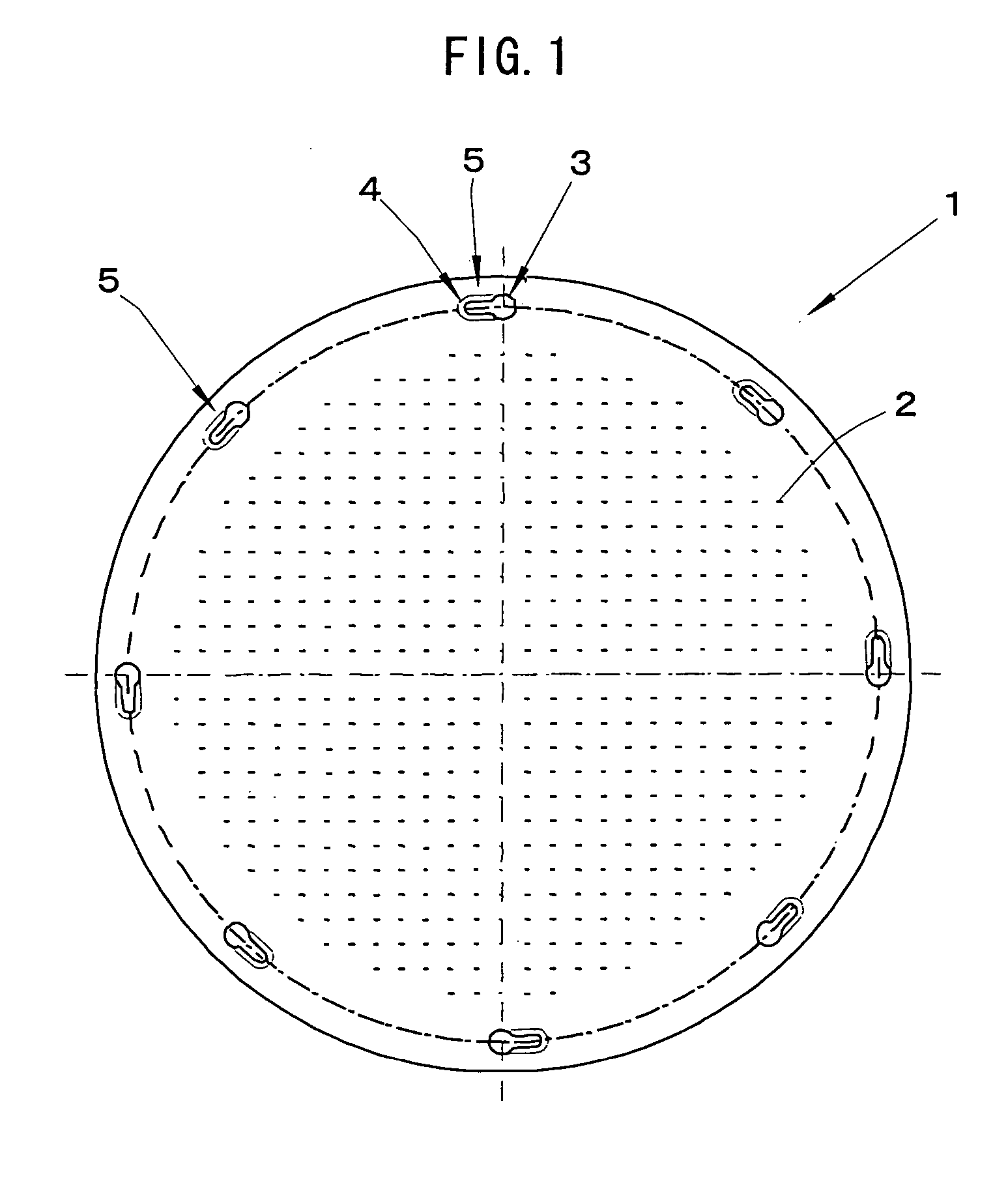

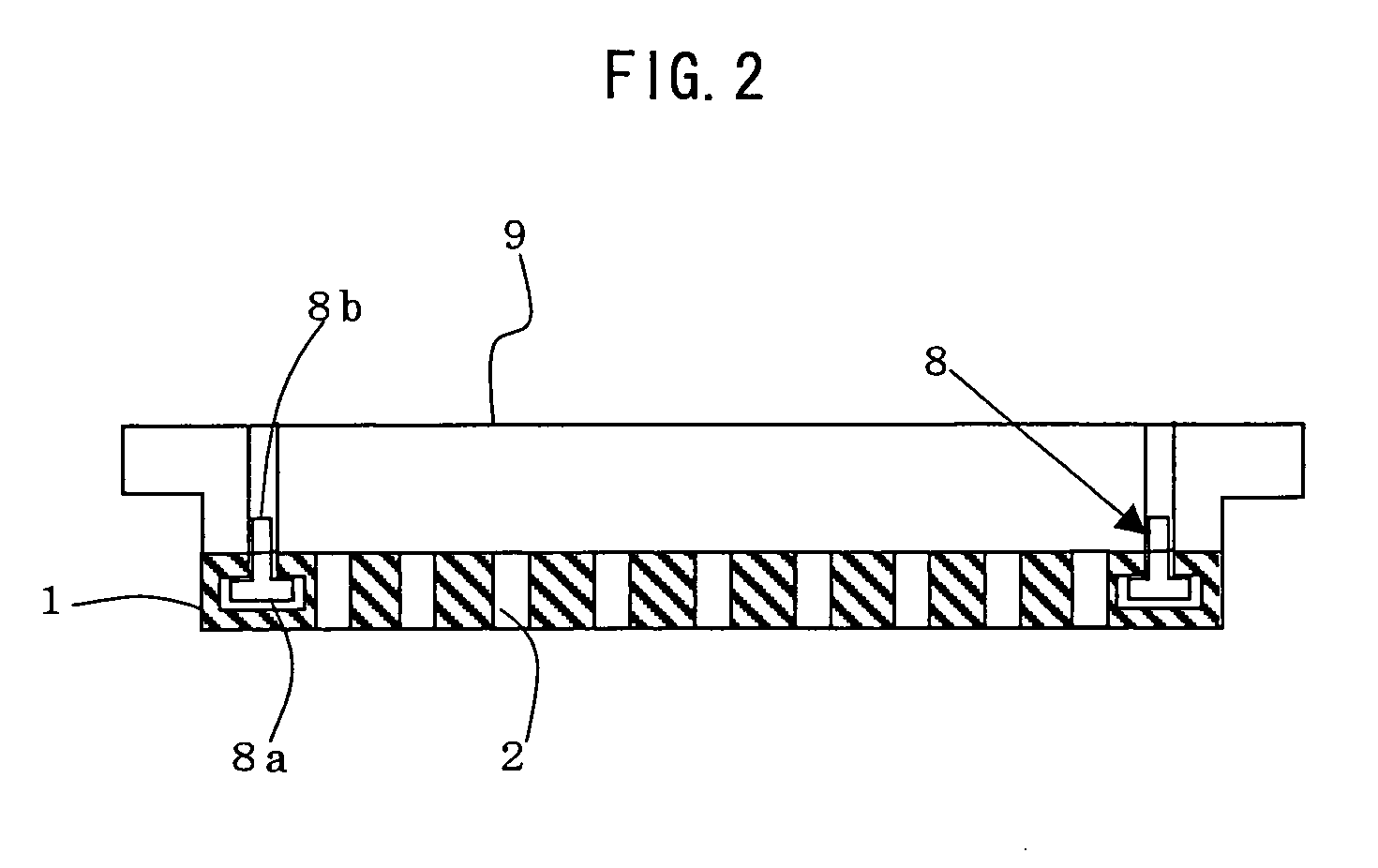

Shower plate for plasma processing apparatus and plasma processing apparatus

InactiveUS20050258280A1Easy to manufactureAvoid pollutionElectric discharge tubesMovable spraying apparatusEngineeringContamination

There is disclosed a shower plate 1, wherein the shower plate has a plurality of holes 3 for inserting the head of the fastening member and holes 4 for fitting the head are formed integrally along a concentric circle in the outside region of the gas feeding holes 2 on a side facing the supporting member, each hole for fitting extending in one direction of the concentric circle from each hole for insertion, each hole for fitting has a groove portion 4b through which the shank of the fastening member is to pass and a fitting portion 4a which is wider than the groove portion and in which the head of the fastening member is to be fitted, and the head of the fastening member fixed in the supporting member is inserted into the hole for insertion of the shower plate and the shower plate is turned so that the head of the fastening member is fitted in the fitting portion, and thereby the shower plate is supported by the supporting member without exposure of the fastening member. There can be provided a shower plate for a plasma processing apparatus, wherein effective diameter is large enough, contamination of a substrate to be treated can be prevented, it is easy to manufacture, and it is easy to fix to a supporting member.

Owner:SHIN ETSU CHEM IND CO LTD

Method and apparatus for minimizing contamination in semiconductor processing chamber

ActiveUS20100202860A1Maintain gapCreate sealLiquid surface applicatorsSemiconductor/solid-state device manufacturingPositive pressureControl system

A semiconductor processing apparatus includes a reaction chamber, a loading chamber, a movable support, a drive mechanism, and a control system. The reaction chamber includes a baseplate. The baseplate includes an opening. The movable support is configured to hold a workpiece. The drive mechanism is configured to move a workpiece held on the support towards the opening of the baseplate into a processing position. The control system is configured to create a positive pressure gradient between the reaction chamber and the loading chamber while the workpiece support is in motion. Purge gases flow from the reaction chamber into the loading chamber while the workpiece support is in motion. The control system is configured to create a negative pressure gradient between the reaction chamber and the loading chamber while the workpiece is being processed. Purge gases can flow from the loading chamber into the reaction chamber while the workpiece support is in the processing position, unless the reaction chamber is sealed from the loading chamber in the processing position.

Owner:ASM IP HLDG BV

Plasma enhanced atomic layer deposition system having reduced contamination

ActiveUS7422636B2Reduce pollutionEnhance layeringLiquid surface applicatorsSemiconductor/solid-state device manufacturingAtomic layer depositionContamination

A plasma enhanced atomic layer deposition (PEALD) system is described, wherein the system comprises a processing space and a high vacuum, ultra-clean transfer space. During processing, the substrate to which the thin conformal film is formed is exposed to the processing space. During substrate transfer, the substrate is exposed to the high vacuum space. Processing gases are introduced sequentially and alternately to the process chamber and the pressures and gas flows within, to and from, and between the process chamber and the high vacuum transfer space are controlled to keep the transfer space ultra-clean.

Owner:TOKYO ELECTRON LTD

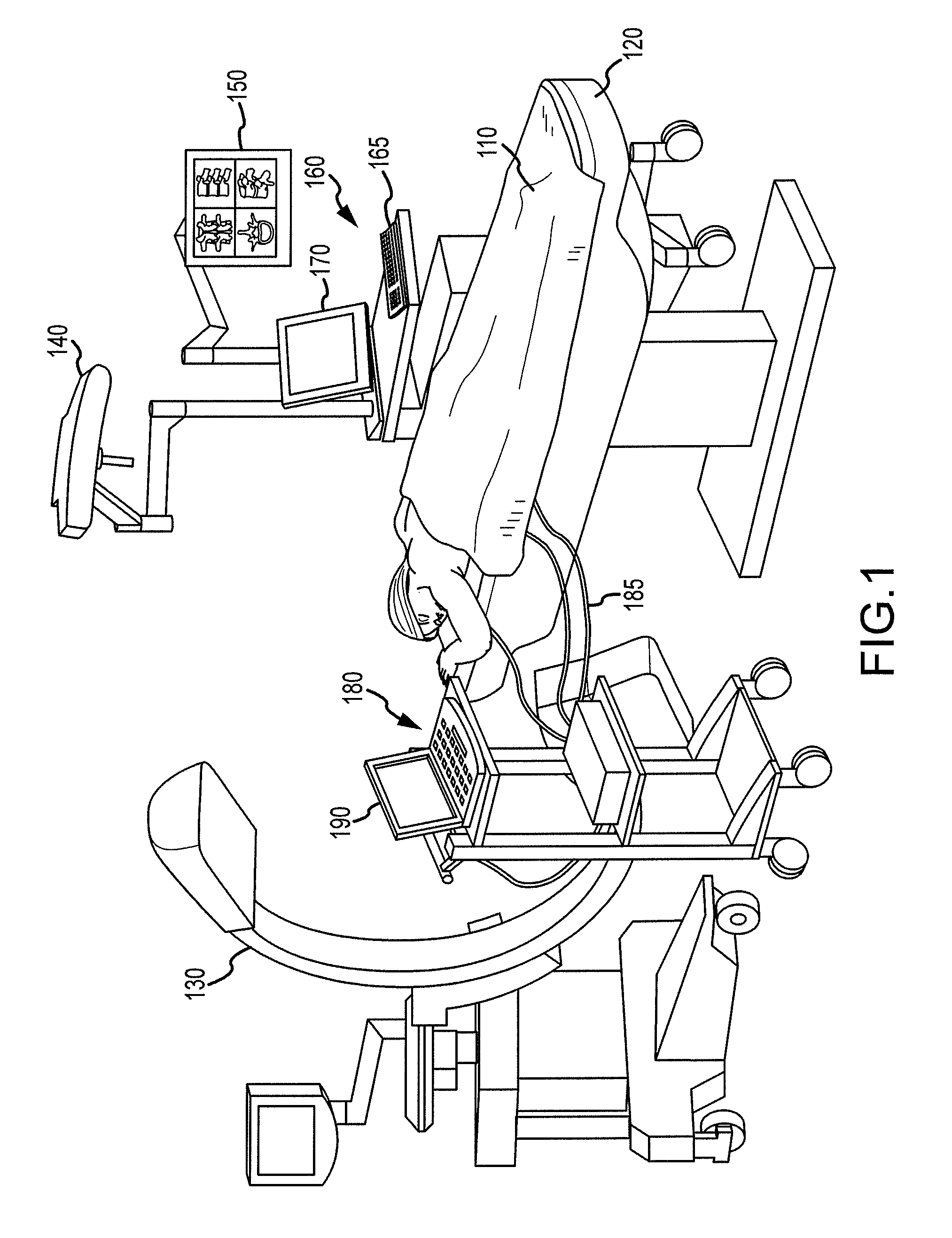

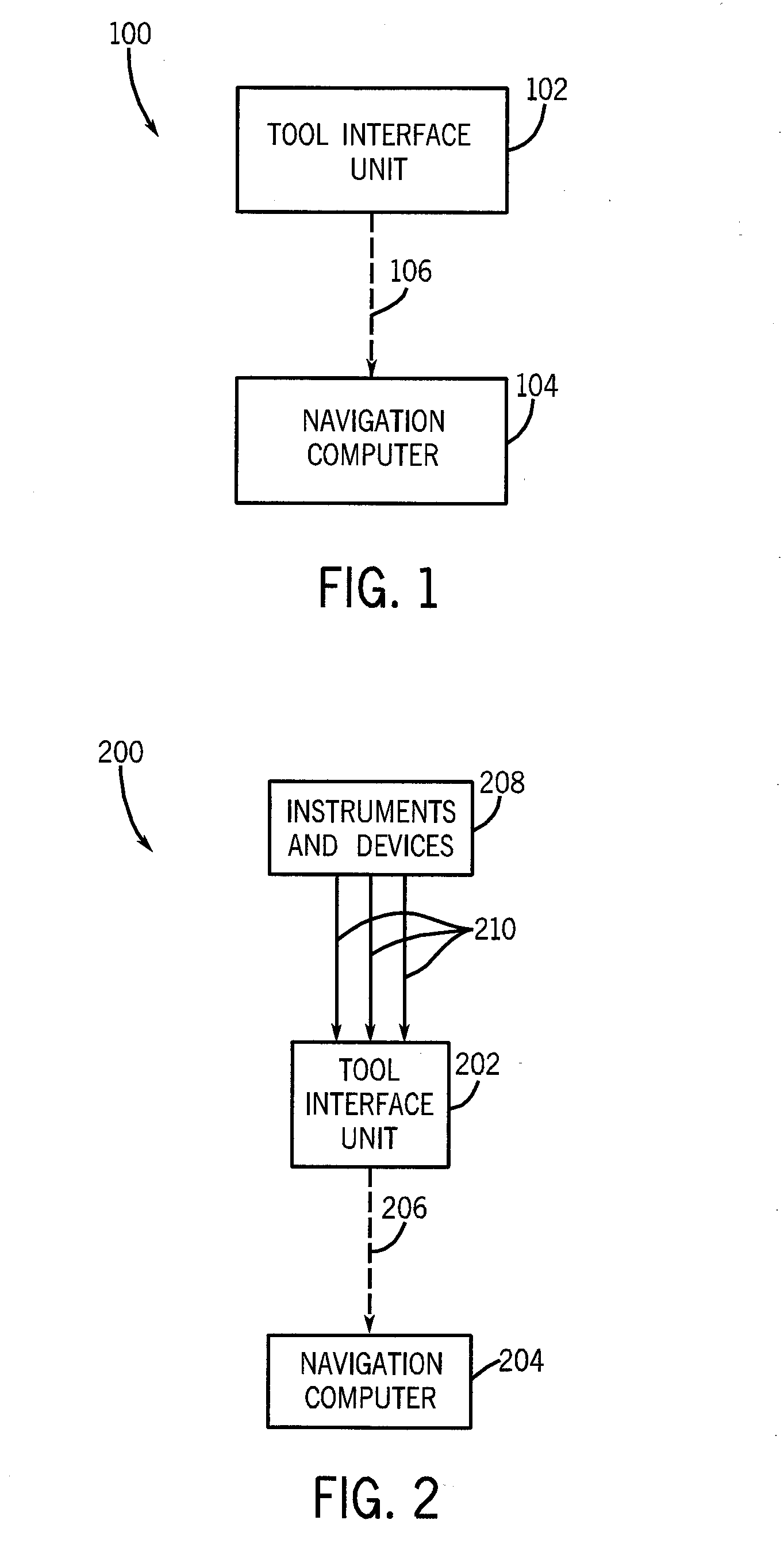

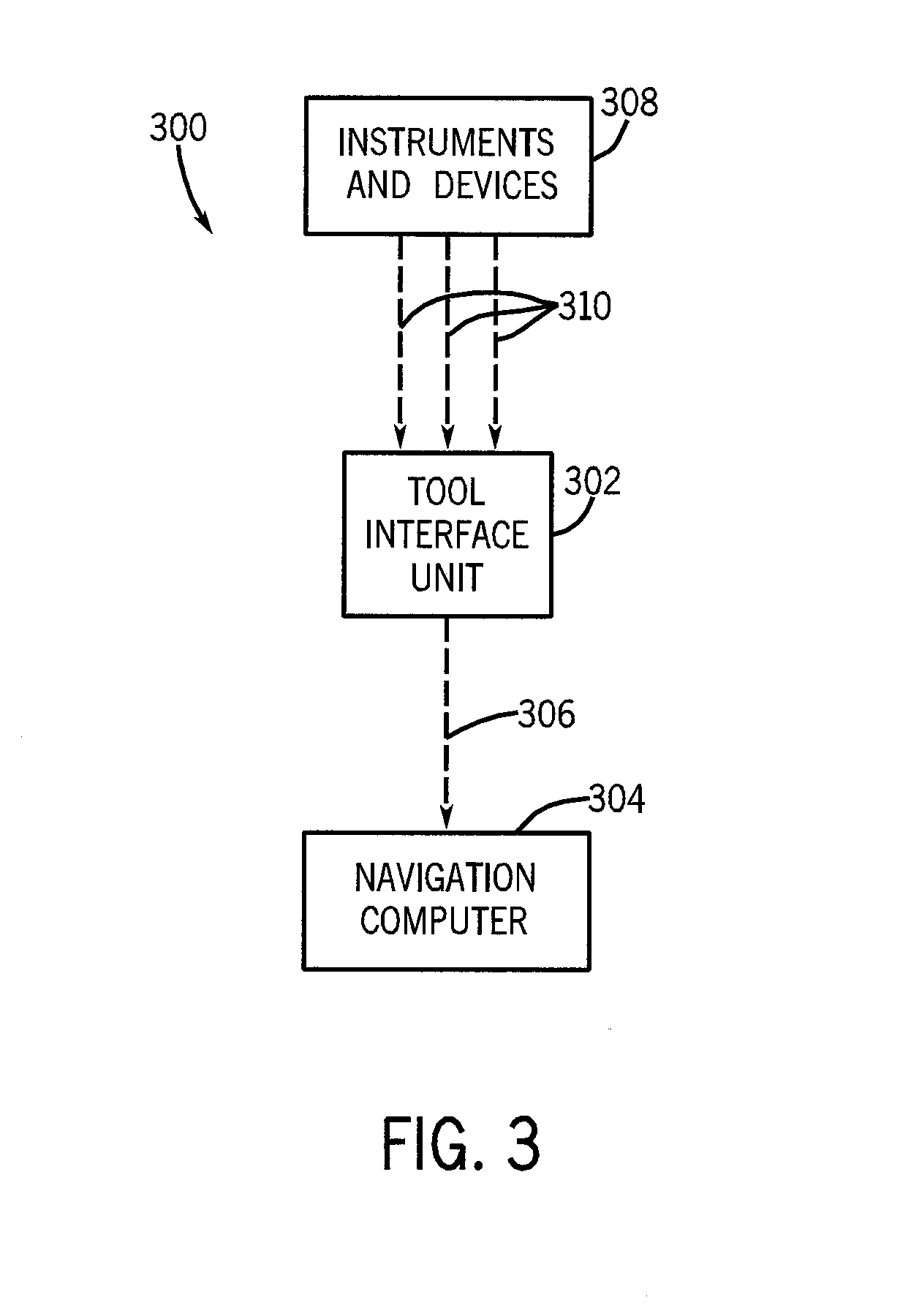

System, method and apparatus for tableside remote connections of medical instruments and systems using wireless communications

InactiveUS20080109012A1Surgical navigation systemsPatient positioning for diagnosticsSterile environmentTransceiver

System, method and apparatus are provided through which in some embodiments, a tool interface unit (TIU) of a medical navigation system or an integrated medical imaging and navigation system includes a wireless transceiver to communicate with a navigation computer in order to reduce or eliminate cabling between the TIU and the navigation computer. In some embodiments, the TIU is mounted to a side of a surgical table in order to reduce the possibility of contamination of the cables from a non-sterile environment. In some embodiments, the TIU is battery powered and includes a battery and a battery charger.

Owner:GENERAL ELECTRIC CO

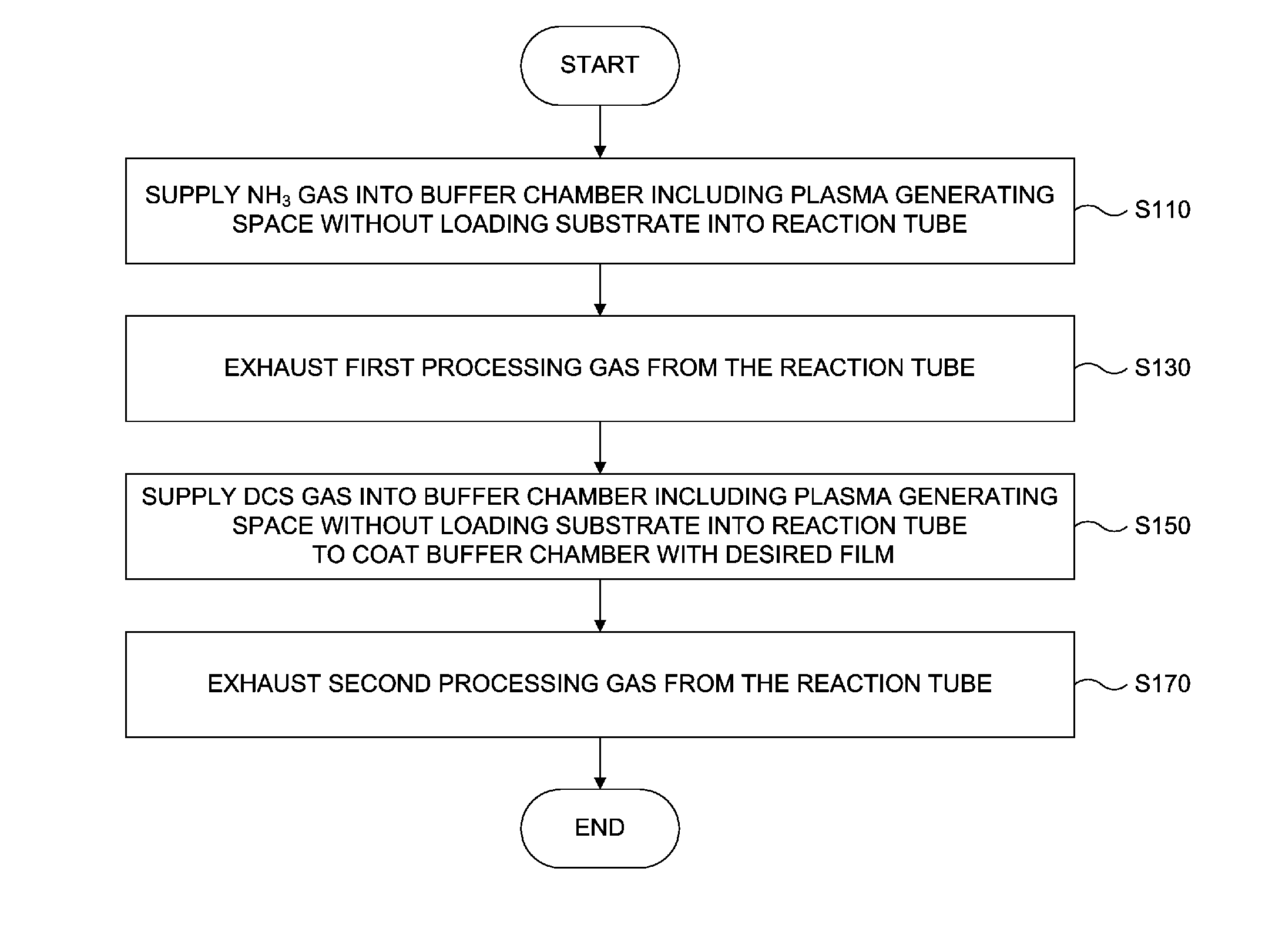

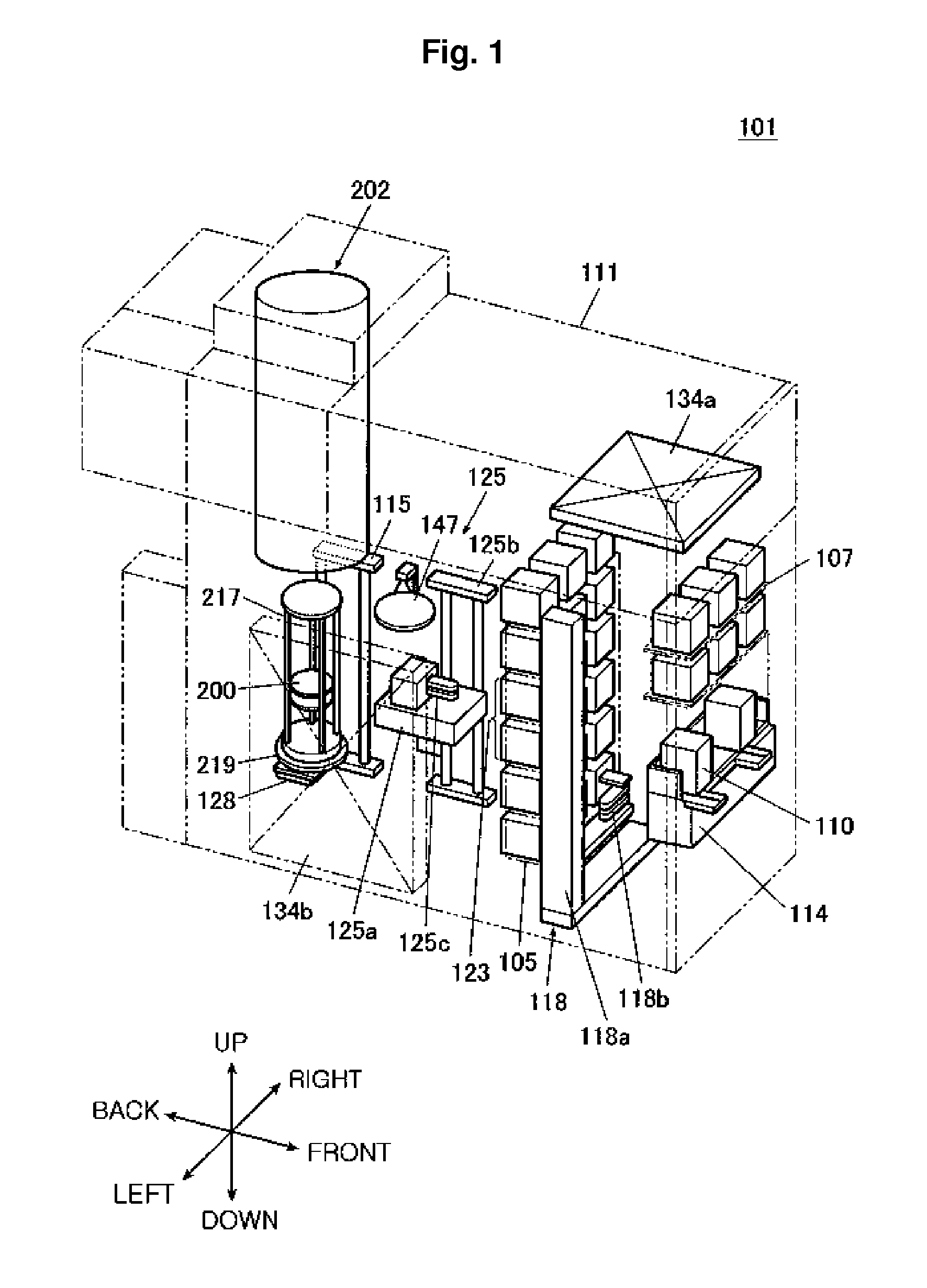

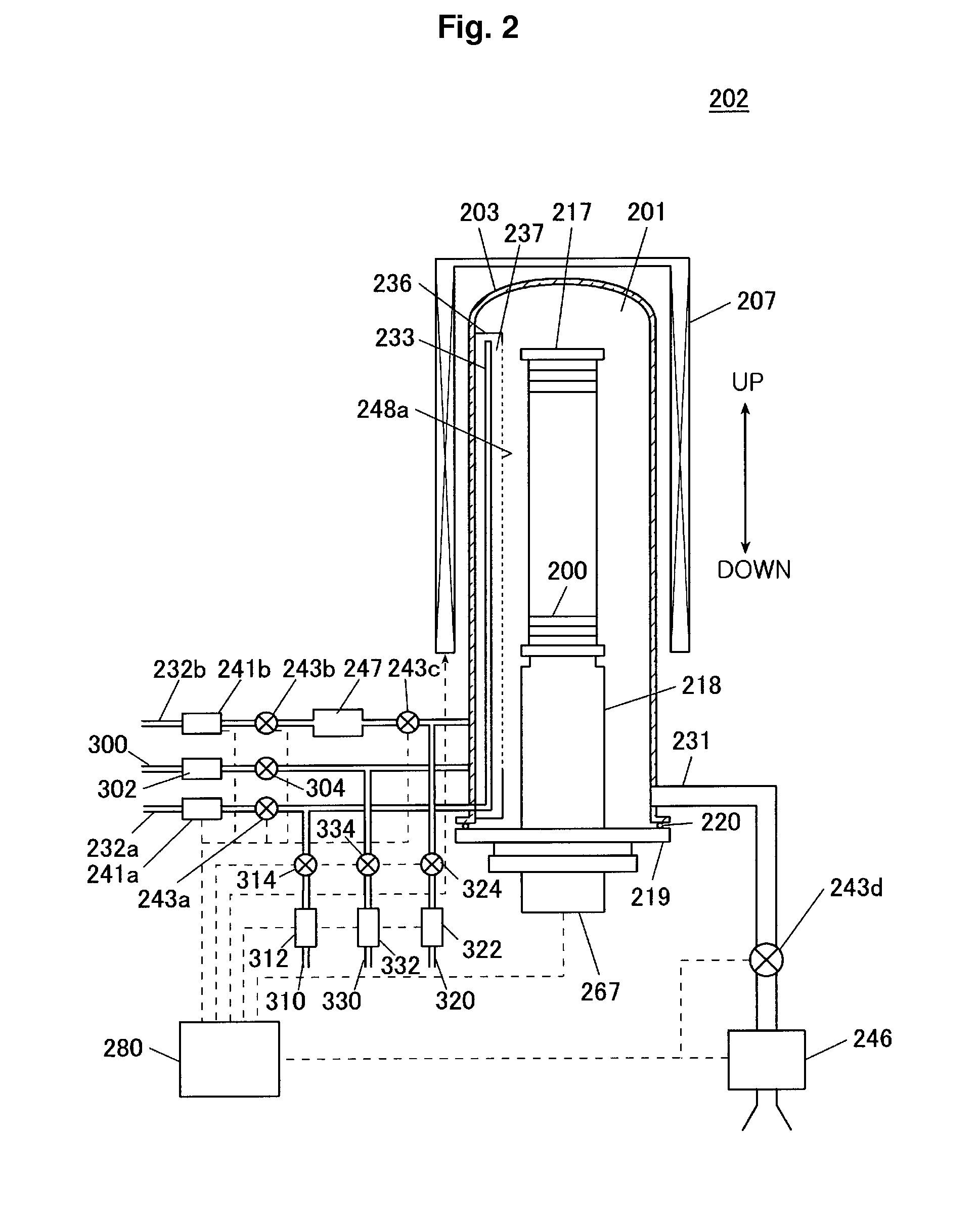

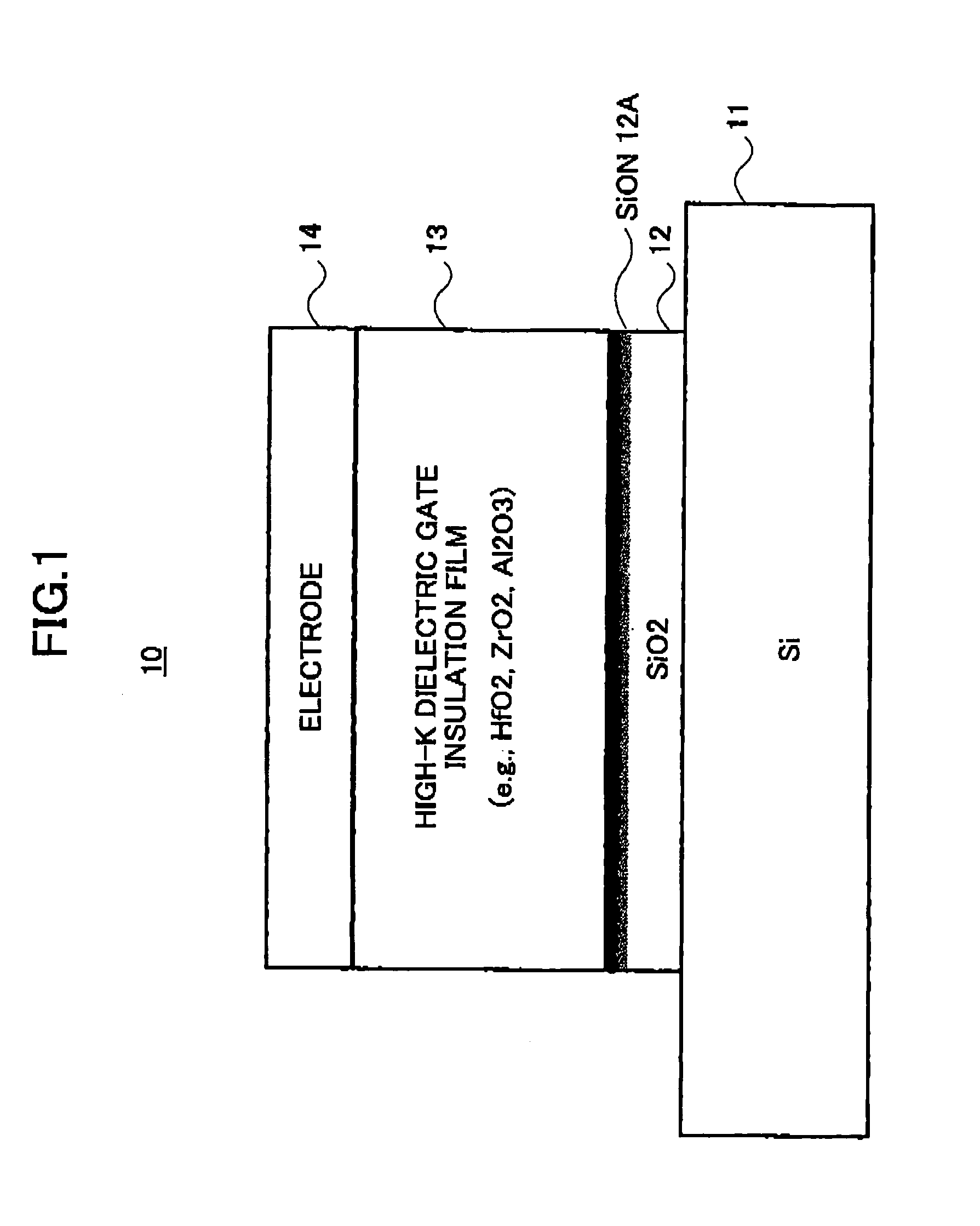

Coating method for coating reaction tube prior to film forming process

InactiveUS20120122319A1Prevent and restrainElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringContamination

Contamination of a substrate can be prevented or suppressed. A substrate processing apparatus includes a reaction tube having an inner space divided by a barrier wall into a film forming space and a plasma generating space. When a desired film is formed on a substrate placed inside the reaction tube, first and second processing gases are supplied to the reaction tube through nozzles. On the other hand, when a part of the reaction tube constituting the plasma generating space is coated with a film, second and third processing gases are supplied to the plasma generating space through the nozzle.

Owner:SHIMIZU HIRONOBU

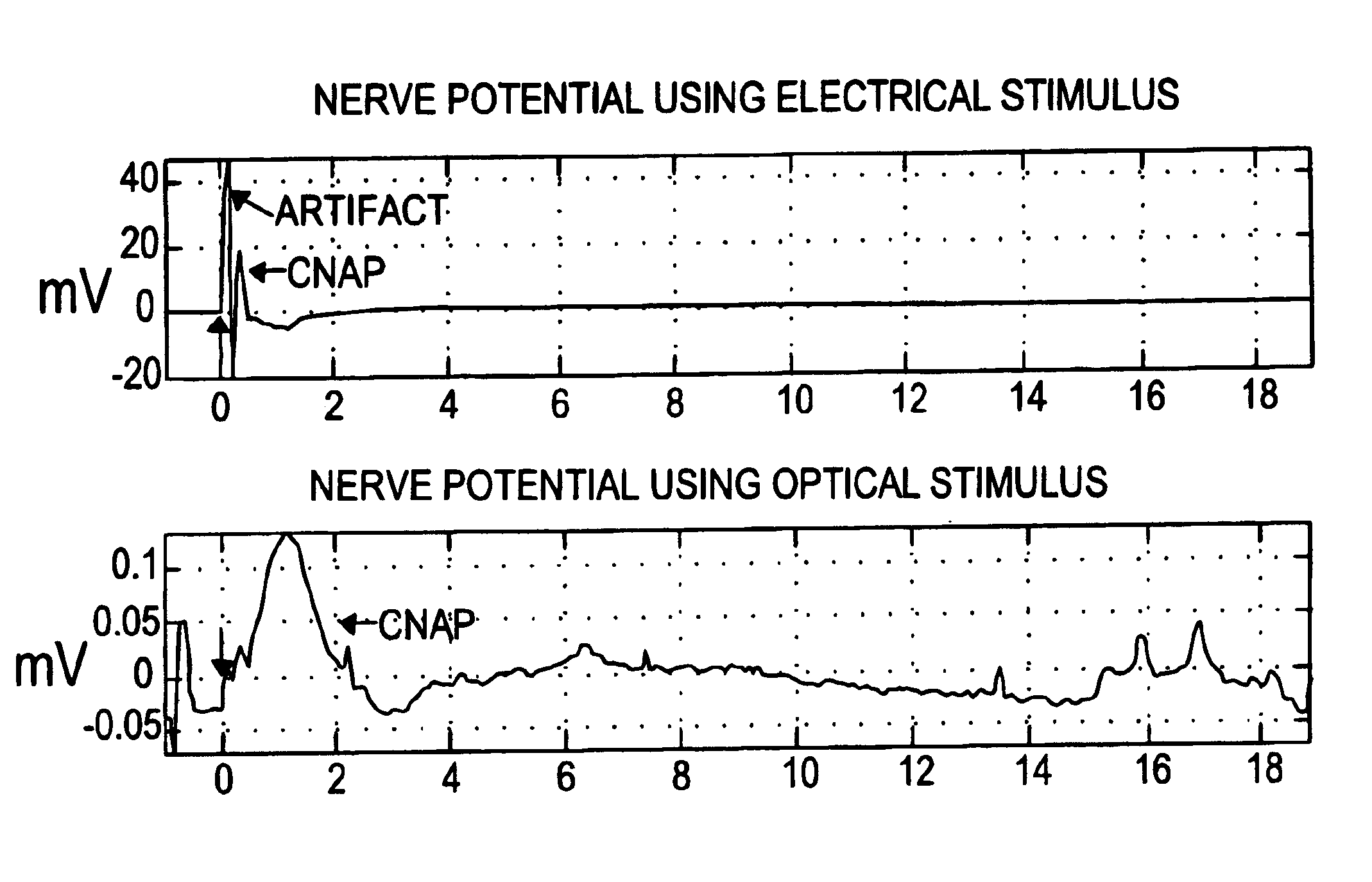

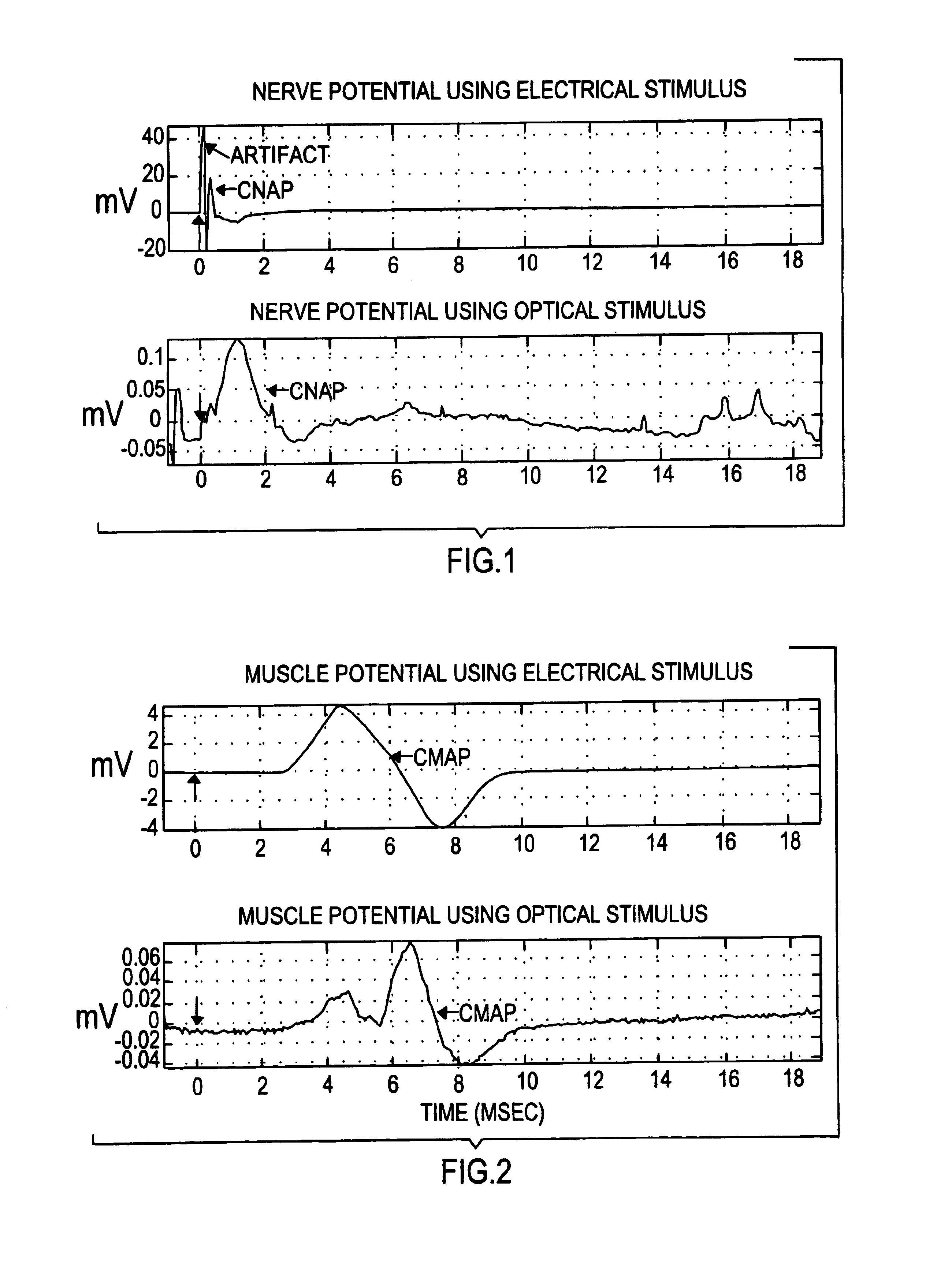

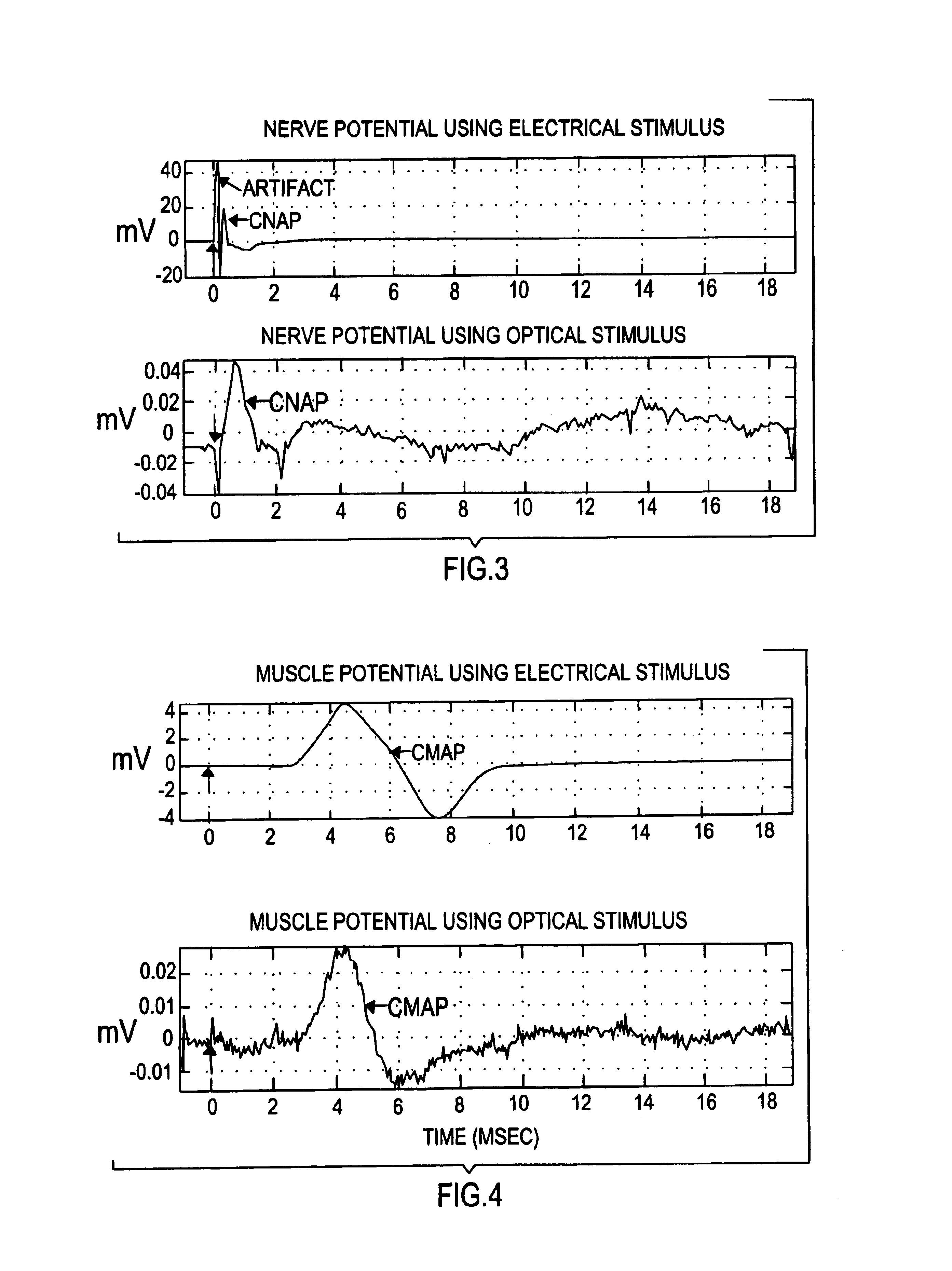

Methods and devices for optical stimulation of neural tissues

InactiveUS6921413B2Increasing electrical field sizeHighly specificElectrotherapySurgeryPHYSICAL MANIPULATIONSOptical stimulation

The present invention provides methods of directly stimulating neural tissue with optical energy. By stimulating neural tissue at wavelengths, laser pulses, and spot sizes disclosed herein, nerve stimulation may be used to uniquely stimulate neural tissue in way not afforded by other means of stimulation. It can allow basic scientists to study the properties of individual neurons or populations of neurons without piercing tissue with fragile microelectrodes. Furthermore, responses of neural tissue can be studied in a pure fashion without contamination by electrical artifact commonly seen with electrical stimulation. With respect to clinical uses, optical stimulation can be used to map function in subsections of peripheral nerves as an aid to operative repair. Finally, stimulation with optical energy does not require physical contact with the nerve which may be an advantage clinically when physical manipulation of neural tissue is not desired.

Owner:VANDERBILT UNIV

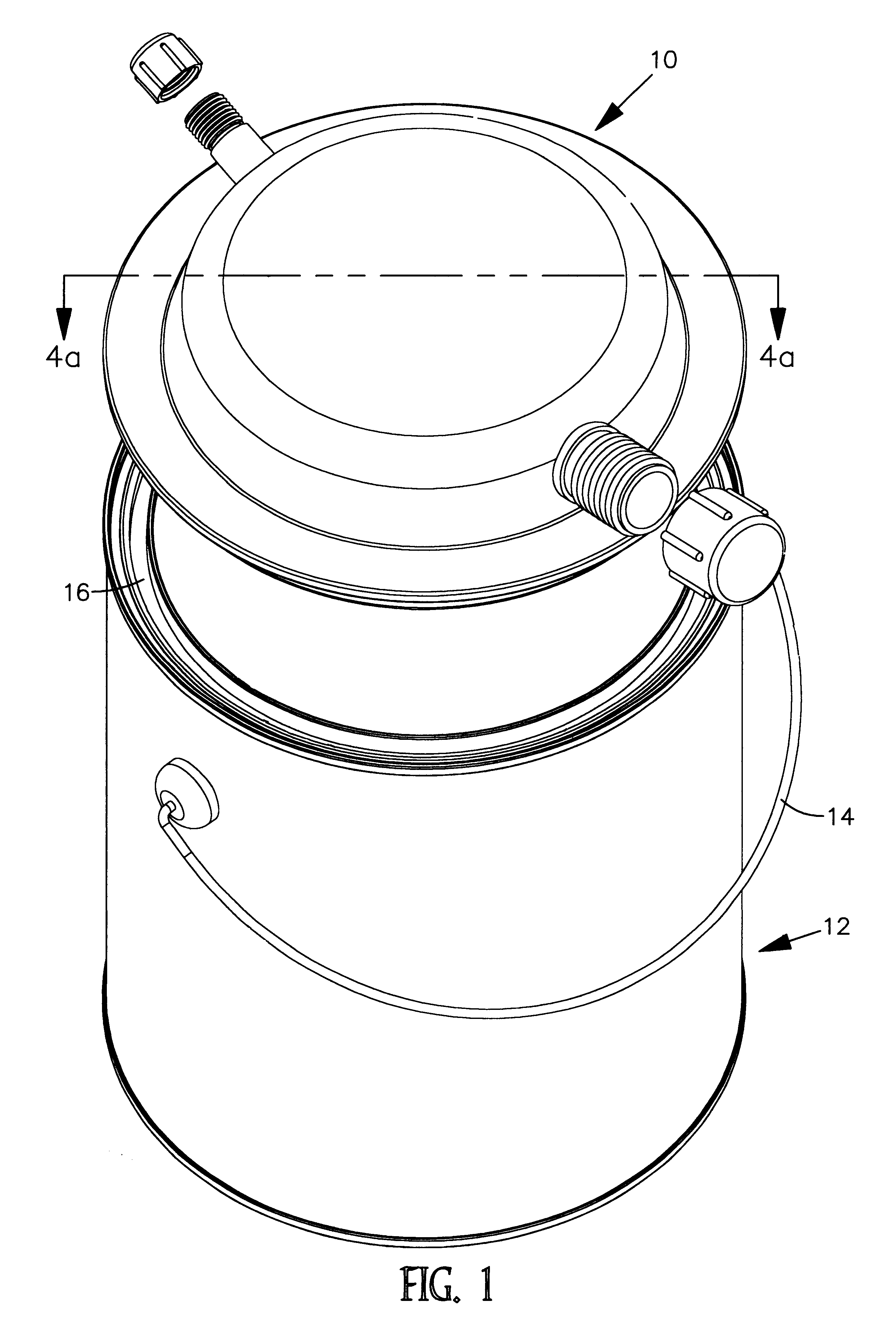

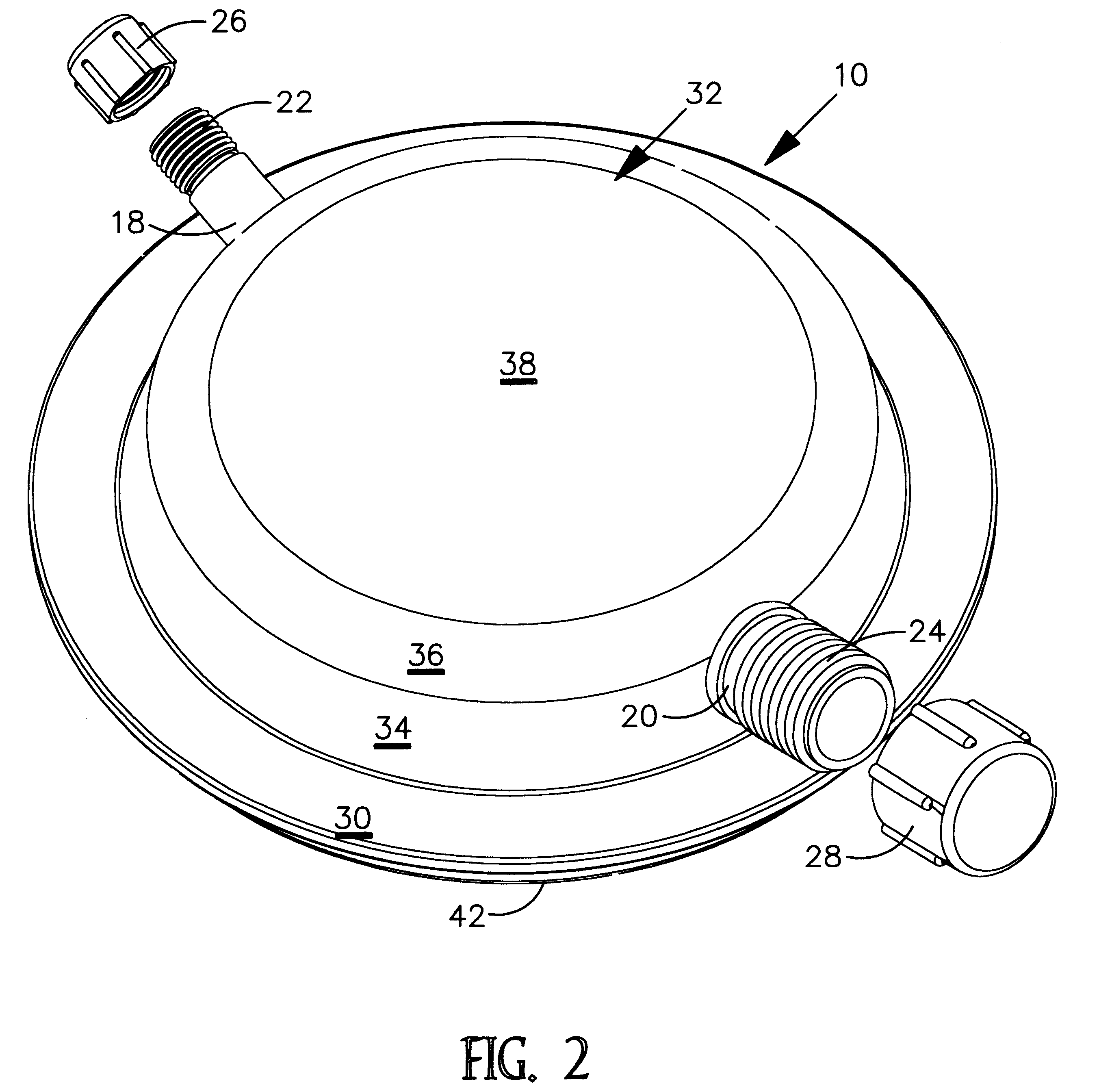

Stackable container cover

InactiveUS6269977B1Safely and conveniently sealsPackage recyclingLiquid flow controllersEvaporationEngineering

A stackable and reusable, container cover is disclosed for safe, sealed, and protected confinement of fluid contents therein to prevent, among other matters, spillage, contamination, evaporation and hardening of the fluid contents. The cover consists of a single molded disc shaped device with an elevated flat surface, platform for supporting another container thereon. The cover also provides for multiple and different sized spouts for various and particular flow rates and flow confinements, and angled in such manner for easy drip less pouring. In addition, the cover provides for a significant step in providing a very convenient snap on, attachment, and snap off, detachment means for reuse of the cover on yet another container.

Owner:MOORE KIM IRA

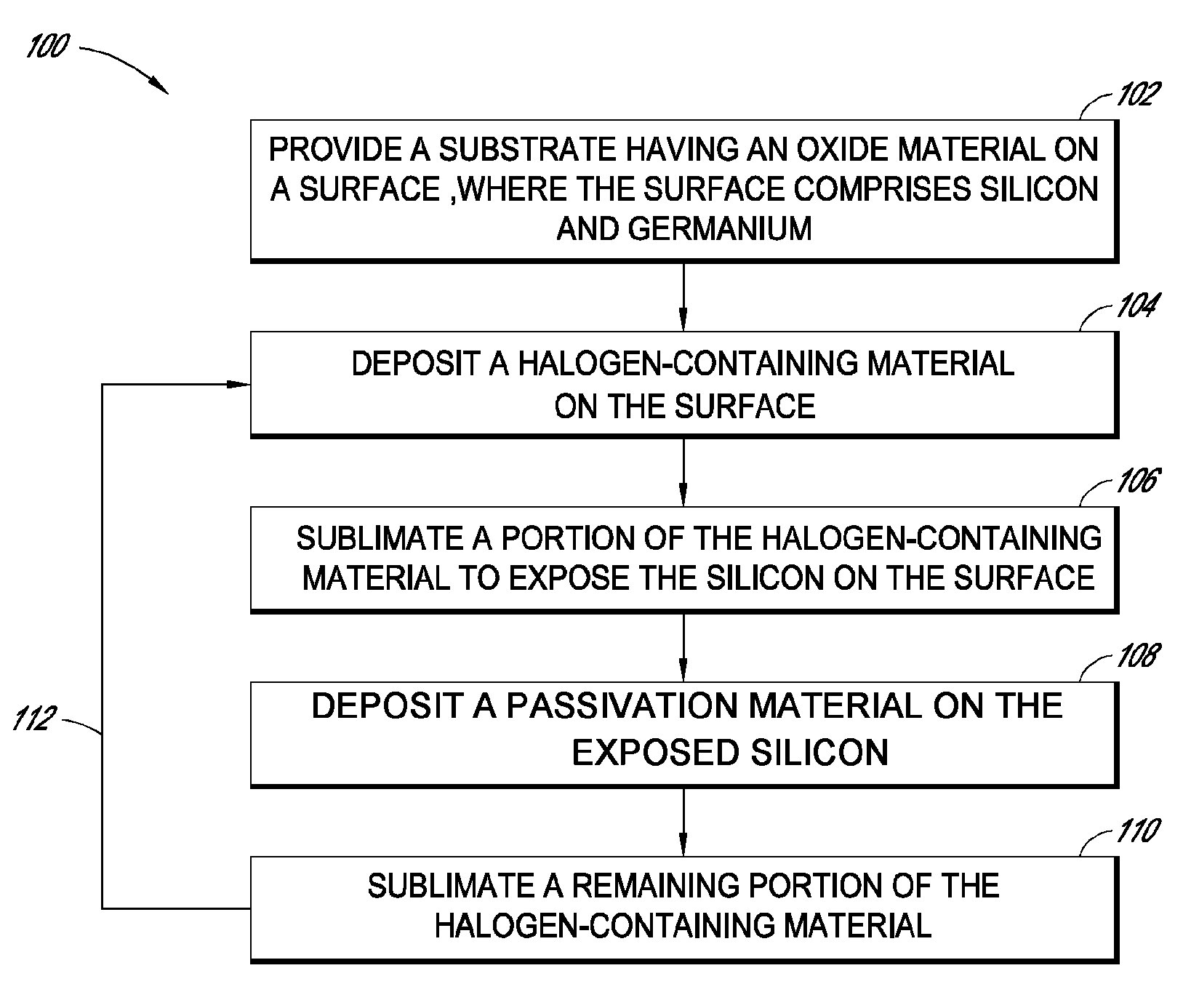

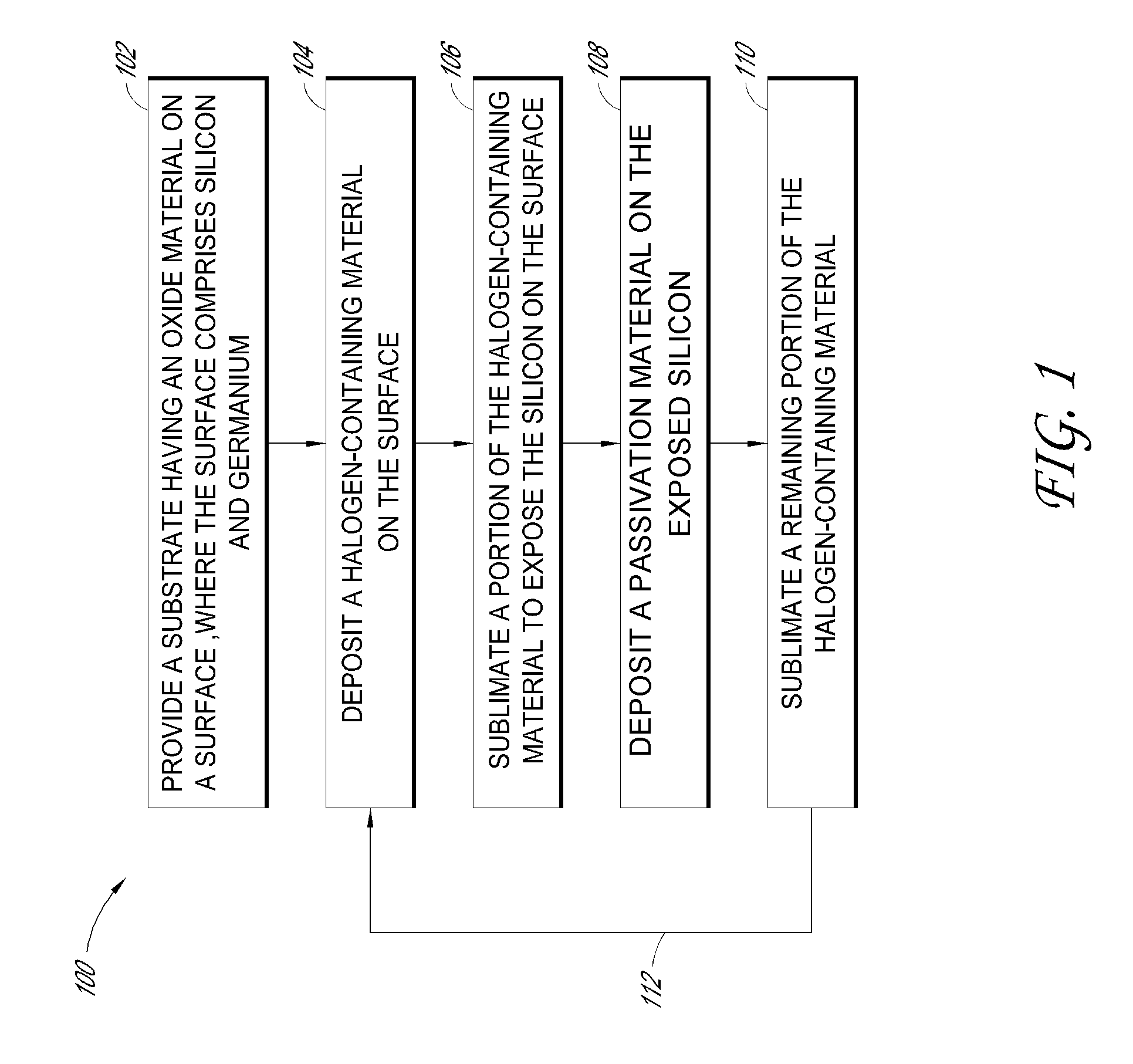

Germanium oxide pre-clean module and process

ActiveUS9474163B2Printed circuit liquid treatmentSemiconductor/solid-state device manufacturingChemical speciesHalogen

In some embodiments, a method for integrated circuit fabrication includes removing oxide material from a surface of a substrate, where the surface includes silicon and germanium. Removing the oxide material includes depositing a halogen-containing pre-clean material on a silicon oxide-containing surface and sublimating a portion of the halogen-containing pre-clean material to expose the silicon on the surface. A passivation film is deposited on the exposed silicon. The passivation film may include chlorine. The passivation film may prevent contamination of the silicon surface by chemical species from the later sublimation, which may be at a higher temperature than the earlier sublimation. Subsequently, a remaining portion of the halogen-containing pre-clean material and the passivation film are sublimated. A target material, such as a conductive material, may subsequently be deposited on the substrate surface.

Owner:ASM IP HLDG BV

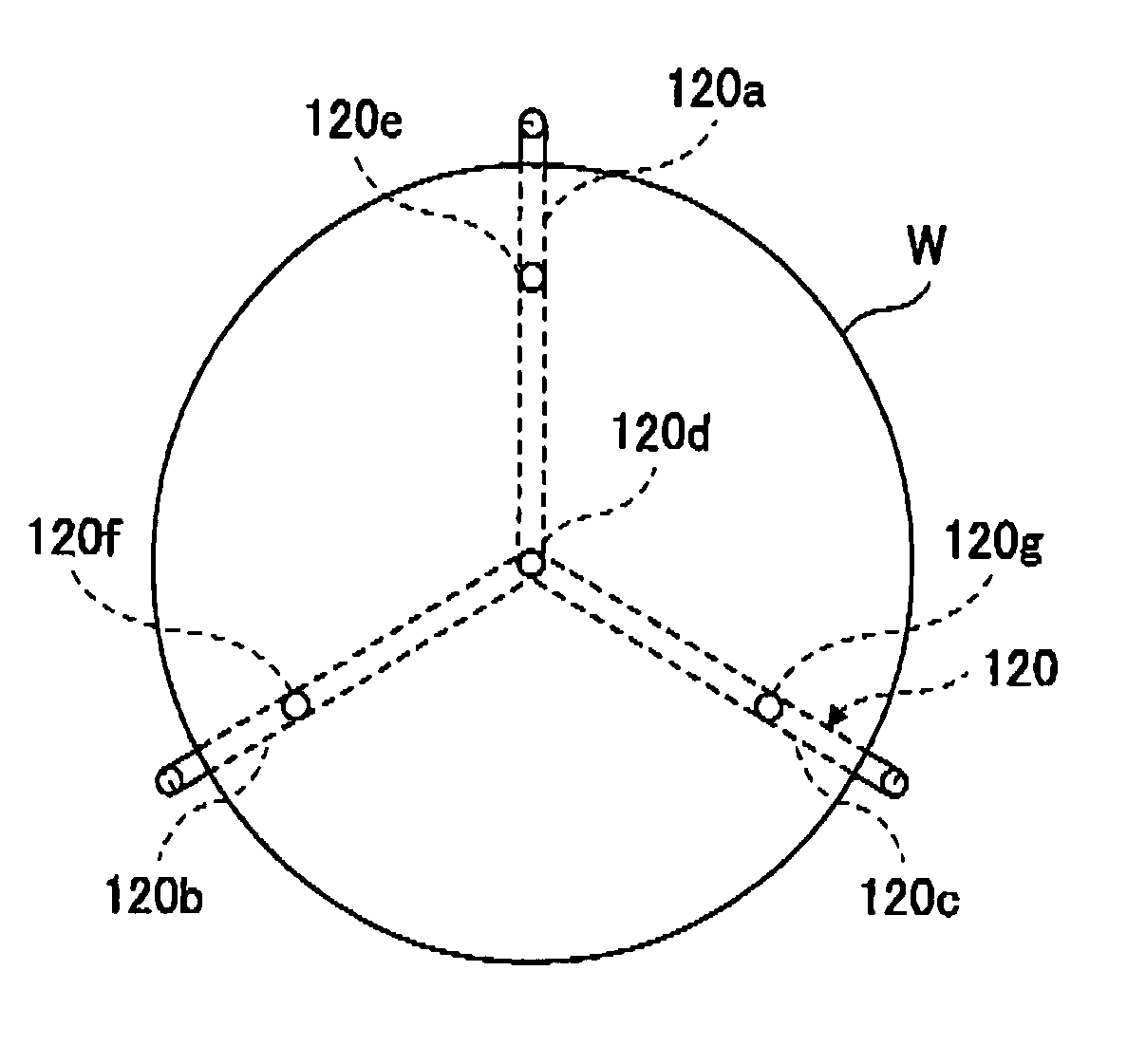

Substrate processing apparatus

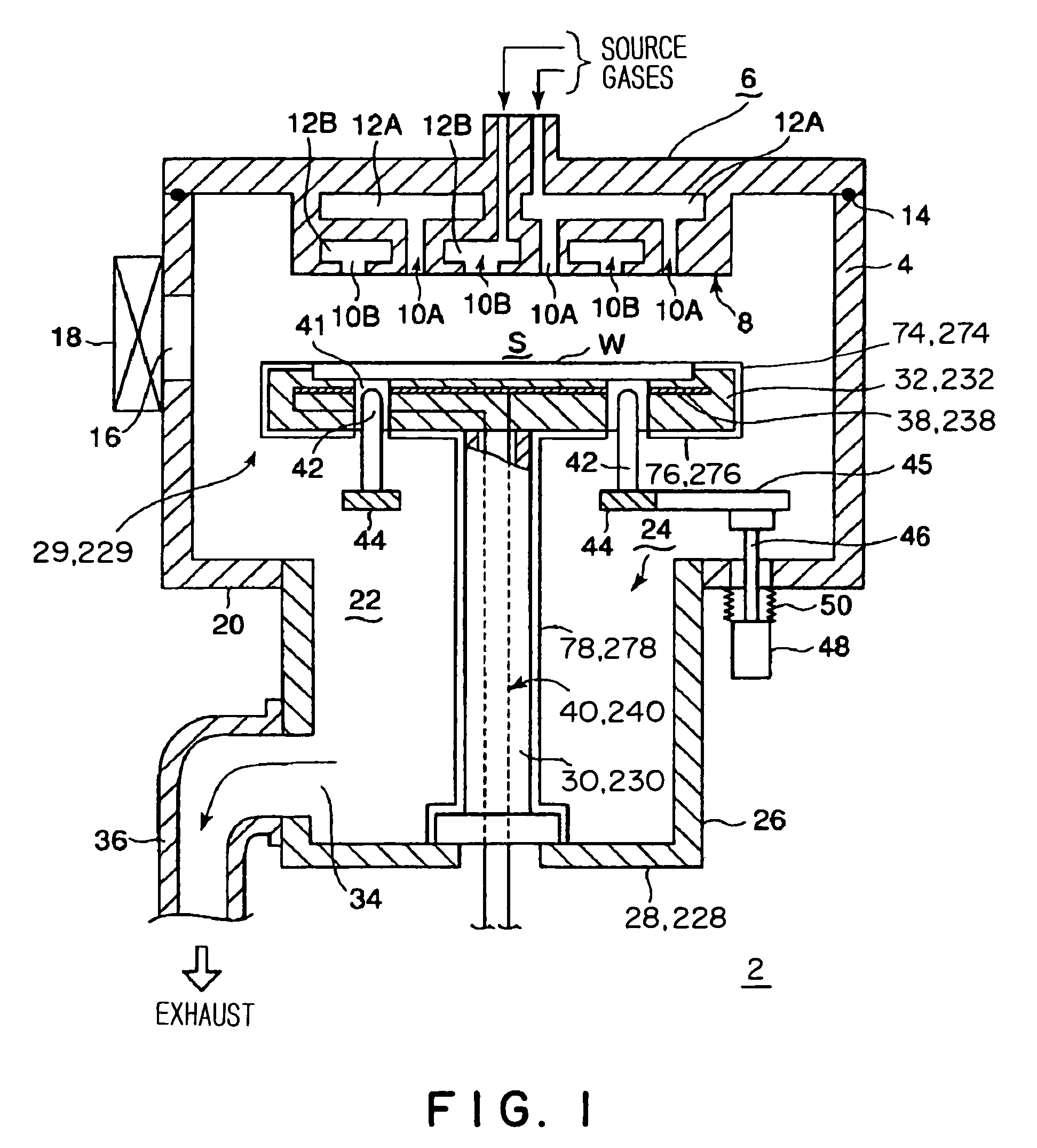

ActiveUS20060048710A1Avoid pollutionUniform temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

The substrate processing apparatus according to the present invention is aimed to stably and efficiently perform a deposition process on a substrate W. The substrate processing apparatus supports the substrate W in a position facing a heater portion and thus rotates a holding member holding the substrate W. Furthermore, the heating portion houses a SiC heater and a heat reflecting member in an internal portion of a quartz bell jar made of transparent quartz, and depressurizes an internal space of a processing vessel and an internal space of the quartz bell jar at the same time; thereby allowing the thickness of the quartz bell jar to be thinner, and thus improving thermal conductivity of heat from the SiC heater and preventing contamination by the SiC heater.

Owner:TOKYO ELECTRON LTD

Method of cleaning a semiconductor device processing chamber after a copper etch process

The present invention is a method for removing deposited etch byproducts from surfaces of a semiconductor processing chamber after a copper etch process. The method of the invention comprises the following general steps: (a) an oxidation step, in which interior surfaces of the processing chamber are contacted with an oxidizing plasma; (b) a first non-plasma cleaning step, in which interior surfaces of the processing chamber are contacted with an H+hfac-comprising gas; and (c) a second cleaning step, in which interior surfaces of the processing chamber are contacted with a plasma containing reactive fluorine species, whereby at least a portion of the copper etch byproducts remaining after step (b) are volatilized into gaseous species, which are removed from the processing chamber. The method of the invention is preferably performed at a chamber wall temperature of at least 150° C. in order to achieve optimum cleaning of the chamber at the chamber operating pressures typically used during the cleaning process. The dry cleaning method of the invention can be performed between wafer processing runs without opening the processing chamber, thereby minimizing potential contamination to the chamber as well as chamber downtime.

Owner:APPLIED MATERIALS INC

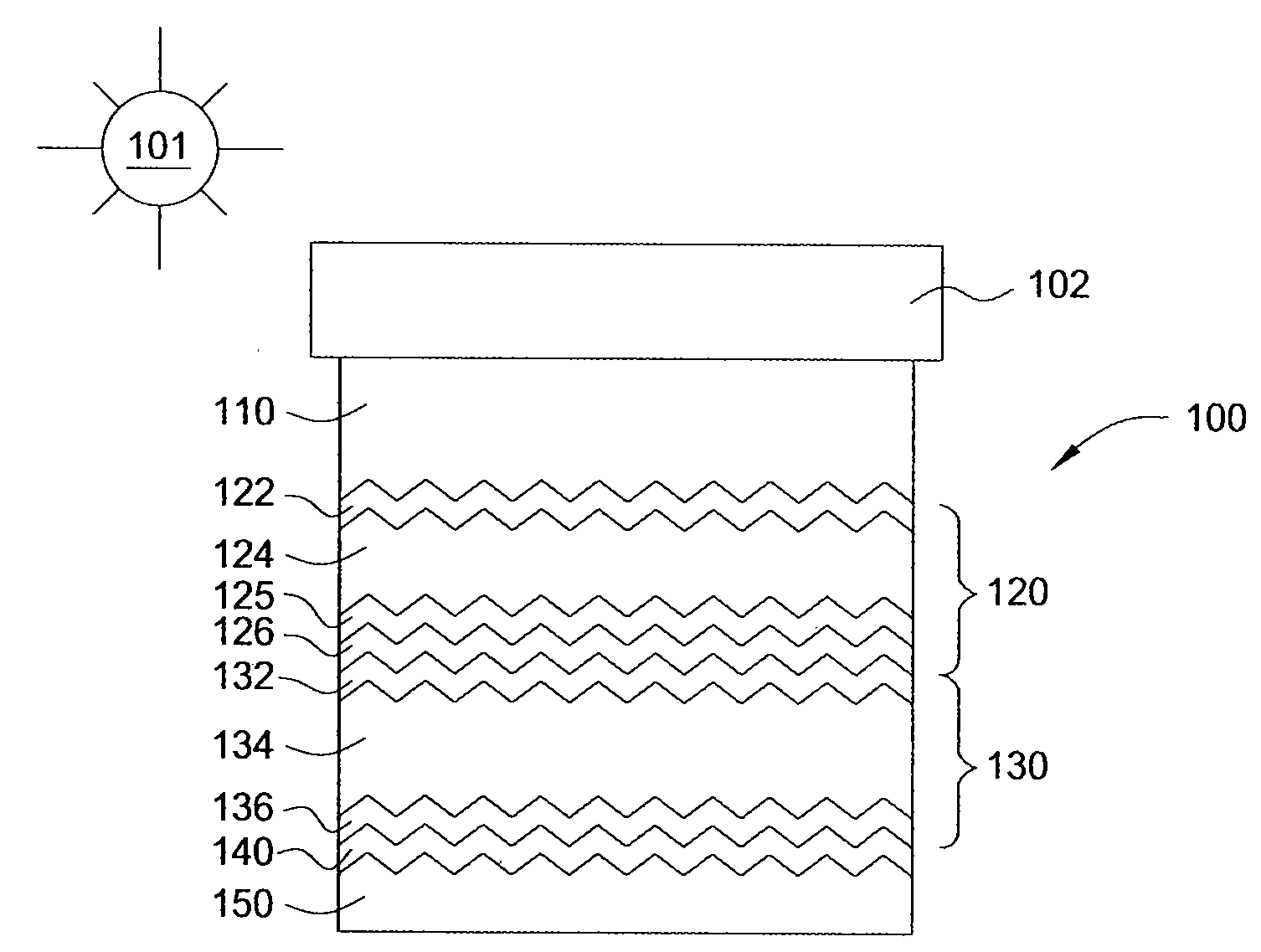

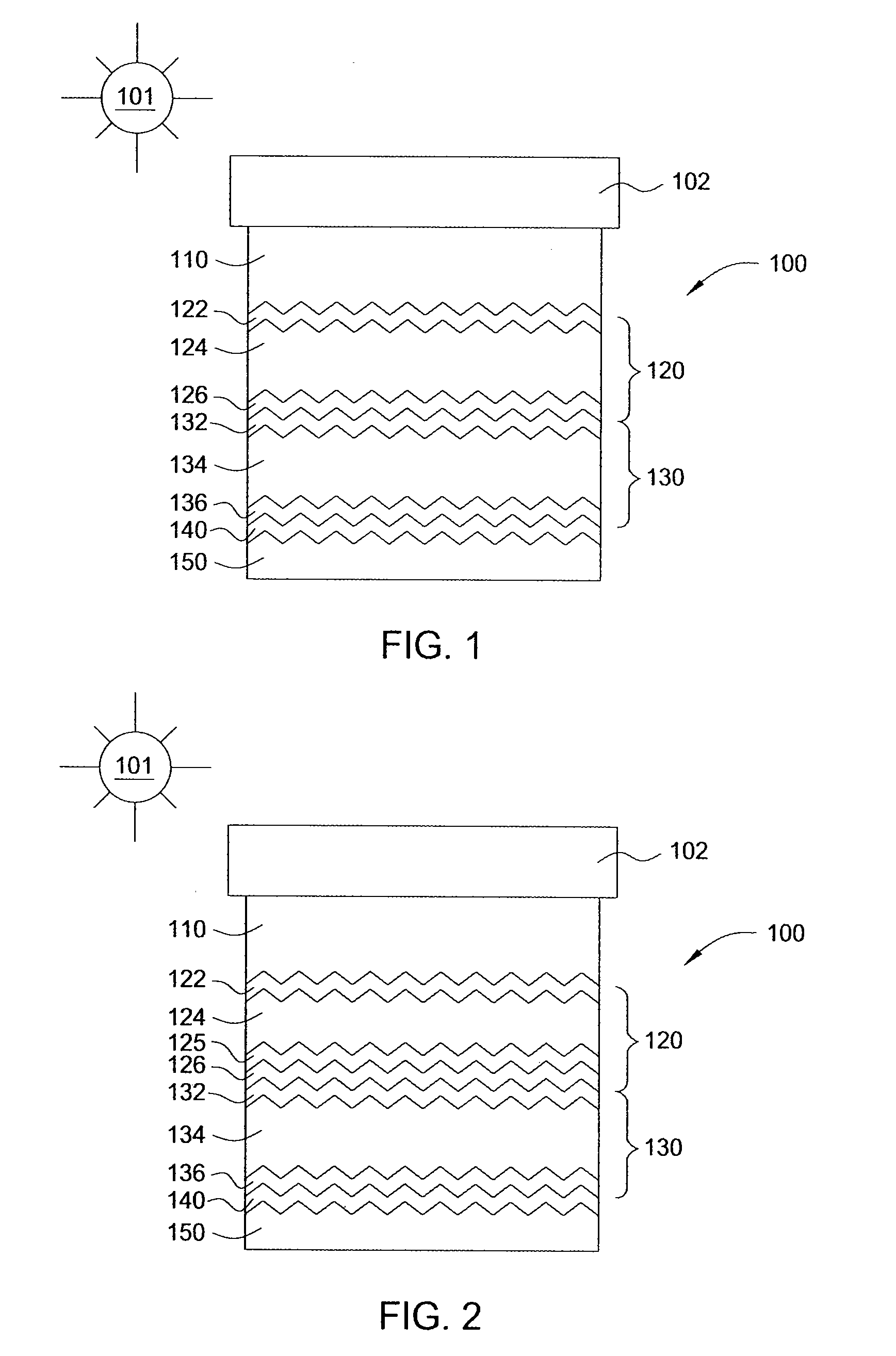

Solar cells and methods and apparatuses for forming the same including i-layer and n-layer chamber cleaning

InactiveUS20090093080A1Reduce pollutionFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringContamination

Embodiments of the present invention generally provide an apparatus and method for forming an improved thin film single or multi-junction solar cell in a substrate processing device. One embodiment provides a system that contains at least one processing chamber that is adapted to deposit one or more layers that form a portion of a solar cell device. In one embodiment, a method is employed to reduce the contamination of a substrate processed in the processing chamber by performing a cleaning process on the inner surfaces of the processing chamber prior to depositing the one or more layers on a substrate. The cleaning process may include depositing a layer, such as a seasoning layer or passivation layer, that tends to trap contaminants found in the processing chamber. Other embodiments of the invention may provide scheduling and / or positioning the cleaning processing steps at desirable times within a substrate processing sequence to improve the overall system substrate throughput.

Owner:APPLIED MATERIALS INC

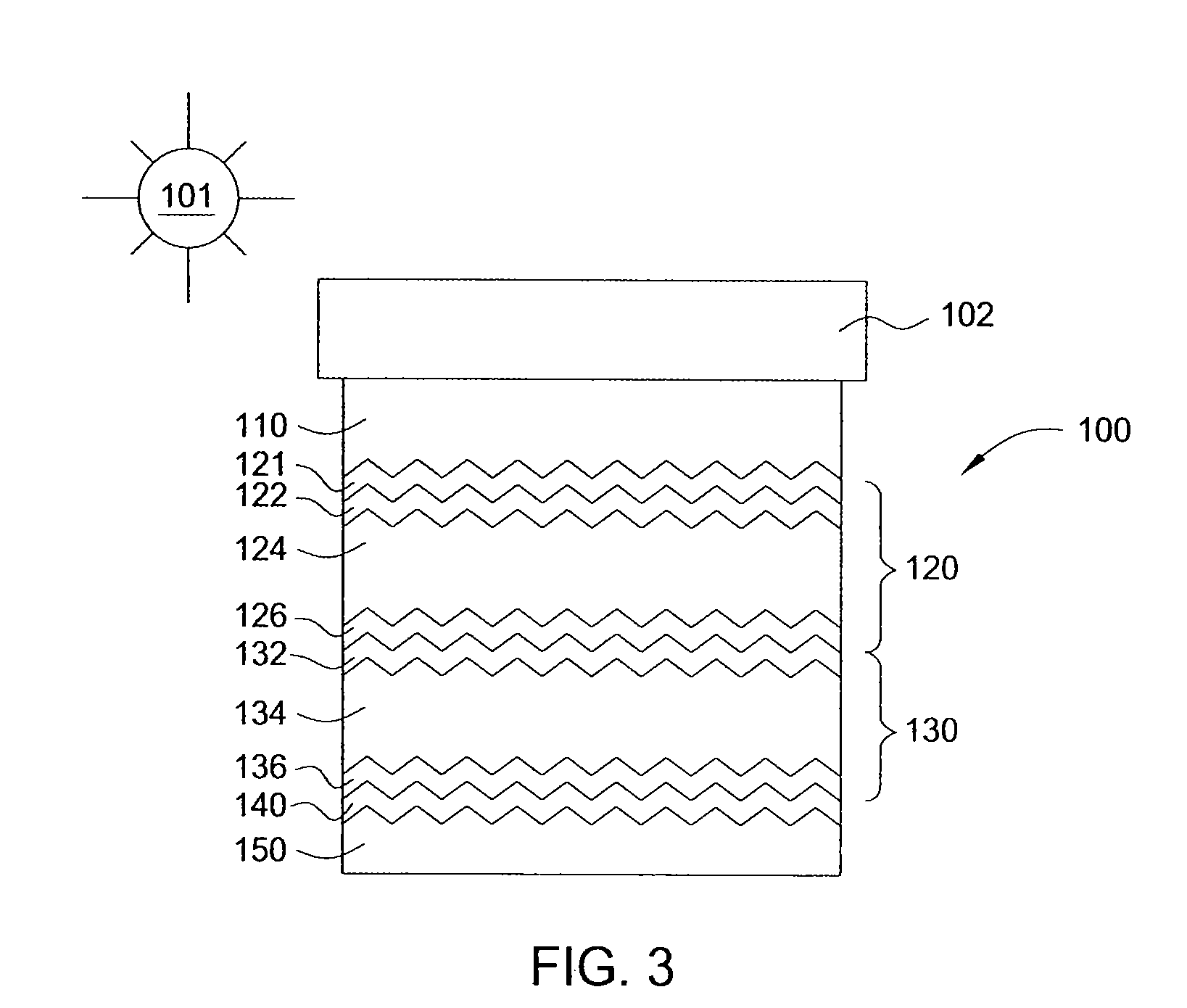

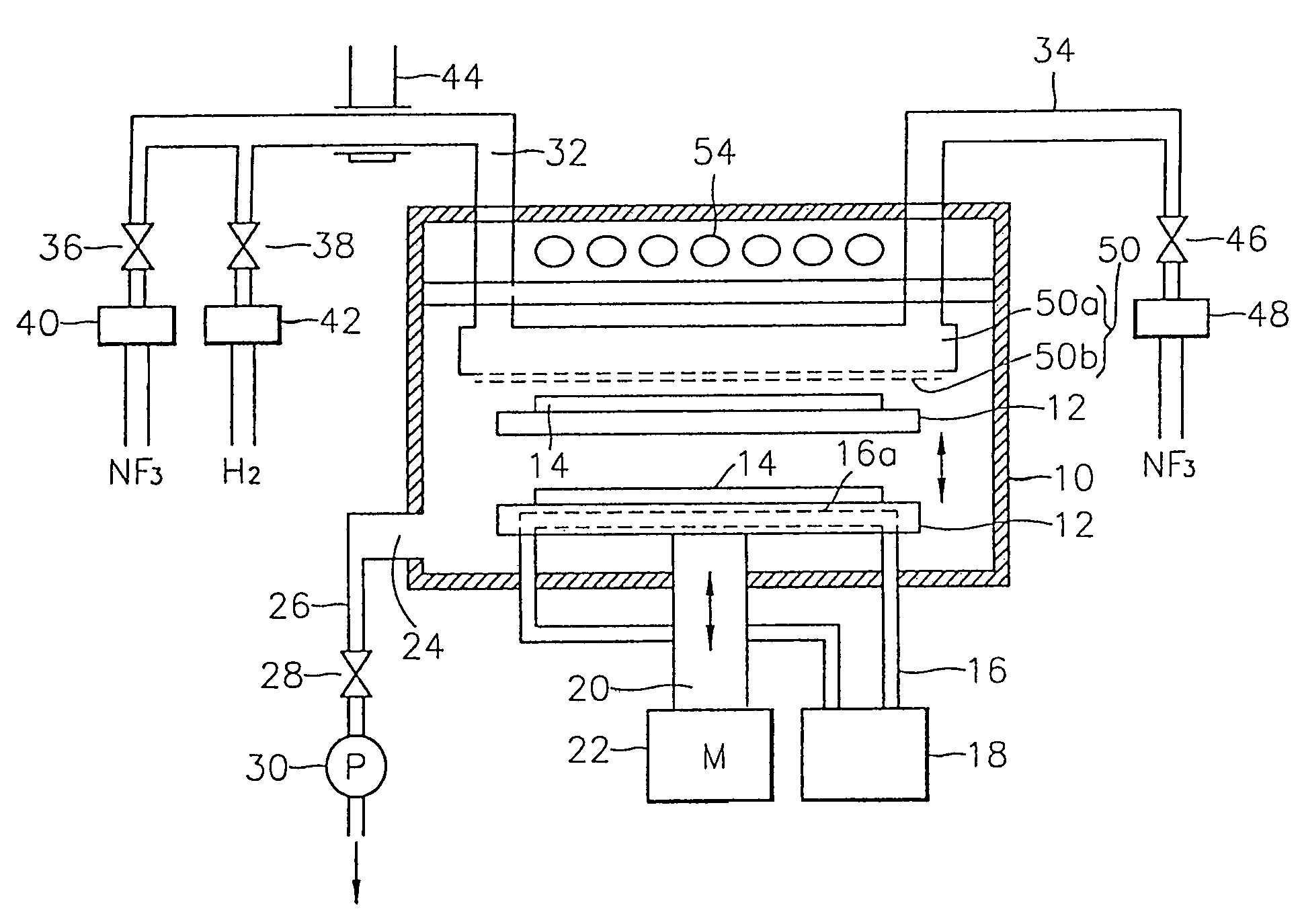

Method of removing oxide layer and semiconductor manufacturing apparatus for removing oxide layer

InactiveUS7488688B2High selectivityEven contactDecorative surface effectsSemiconductor/solid-state device manufacturingReaction layerSusceptor

A method for removing an oxide layer such as a natural oxide layer and a semiconductor manufacturing apparatus which uses the method to remove the oxide layer. A vertically movable susceptor is installed at the lower portion in a processing chamber and a silicon wafer is loaded onto the susceptor when it is at the lower portion of the processing chamber. The air is exhausted from the processing chamber to form a vacuum condition therein. A hydrogen gas in a plasma state and a fluorine-containing gas are supplied into the processing chamber to induce a chemical reaction with the oxide layer on the silicon wafer, resulting in a reaction layer. Then, the susceptor is moved up to the upper portion of the processing chamber, to anneal the silicon wafer on the susceptor with a heater installed at the upper portion of the processing chamber, thus vaporizing the reaction layer. The vaporized reaction layer is exhausted out of the chamber. The oxide layer can be removed with a high selectivity while avoiding damage or contamination of the underlying layer.

Owner:SAMSUNG ELECTRONICS CO LTD

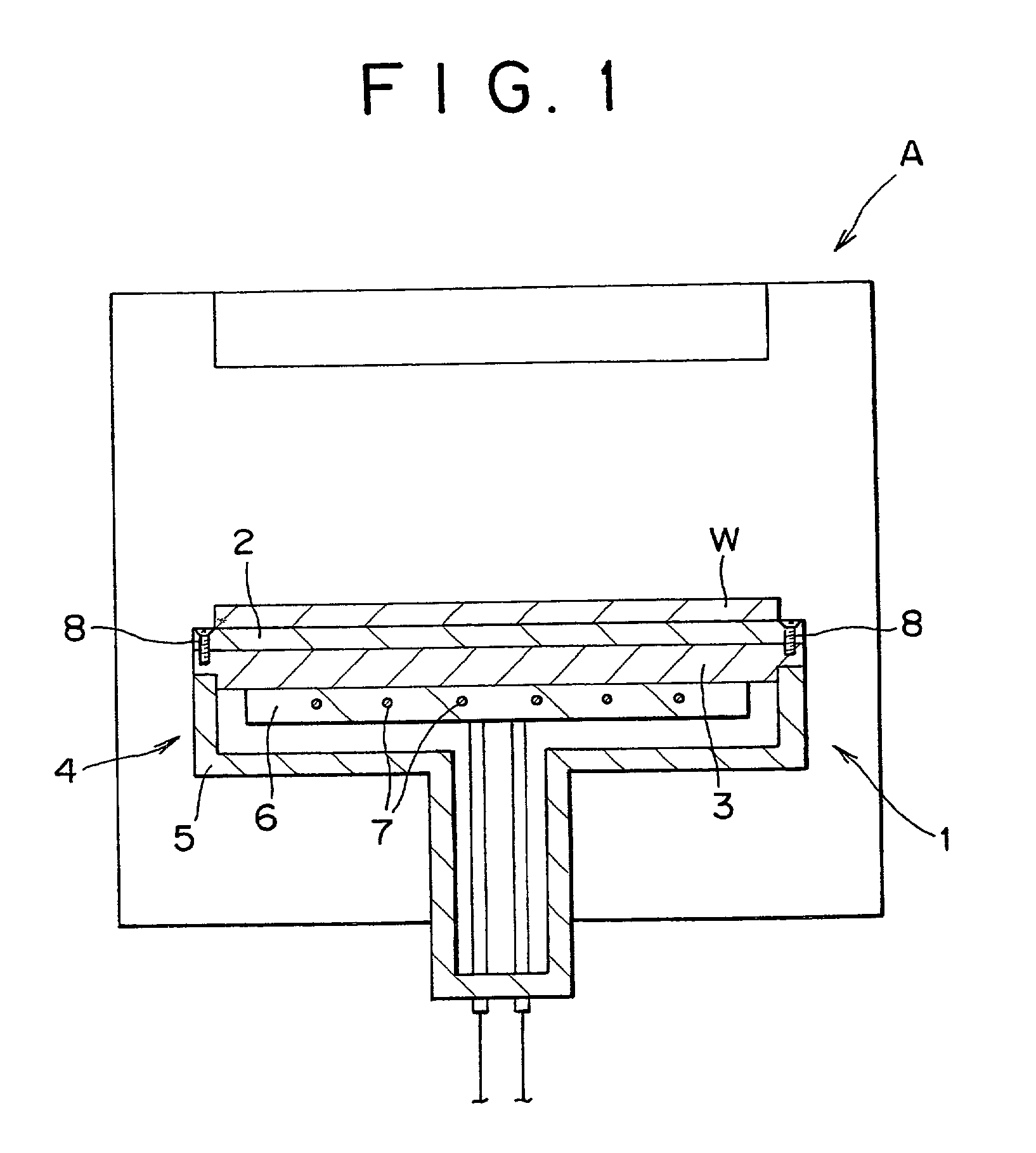

Loading table and heat treating apparatus having the loading table

ActiveUS7718930B2Thermal diffusionPrevent heat from spreadingDrying solid materials with heatMuffle furnacesEngineeringContamination

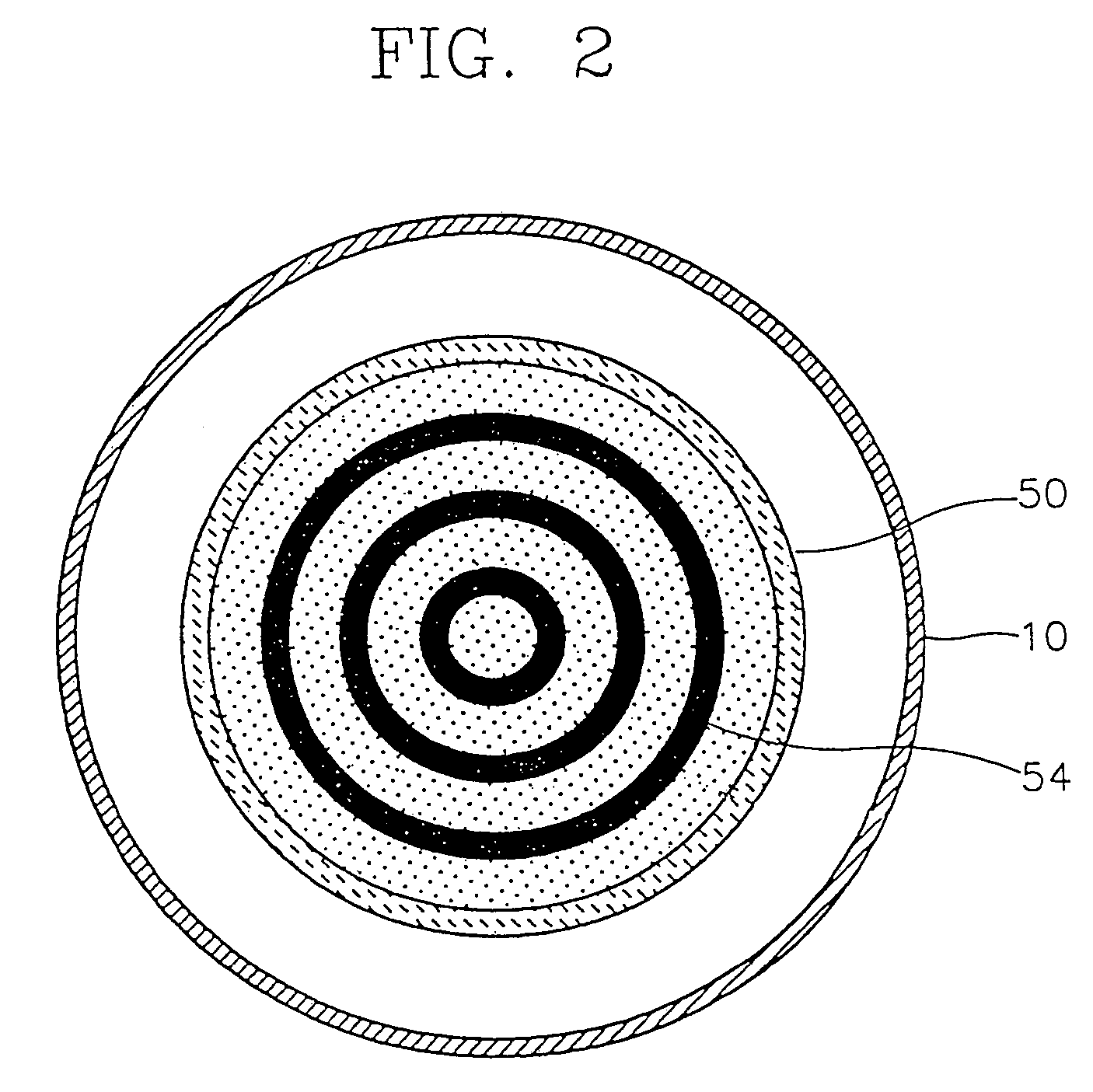

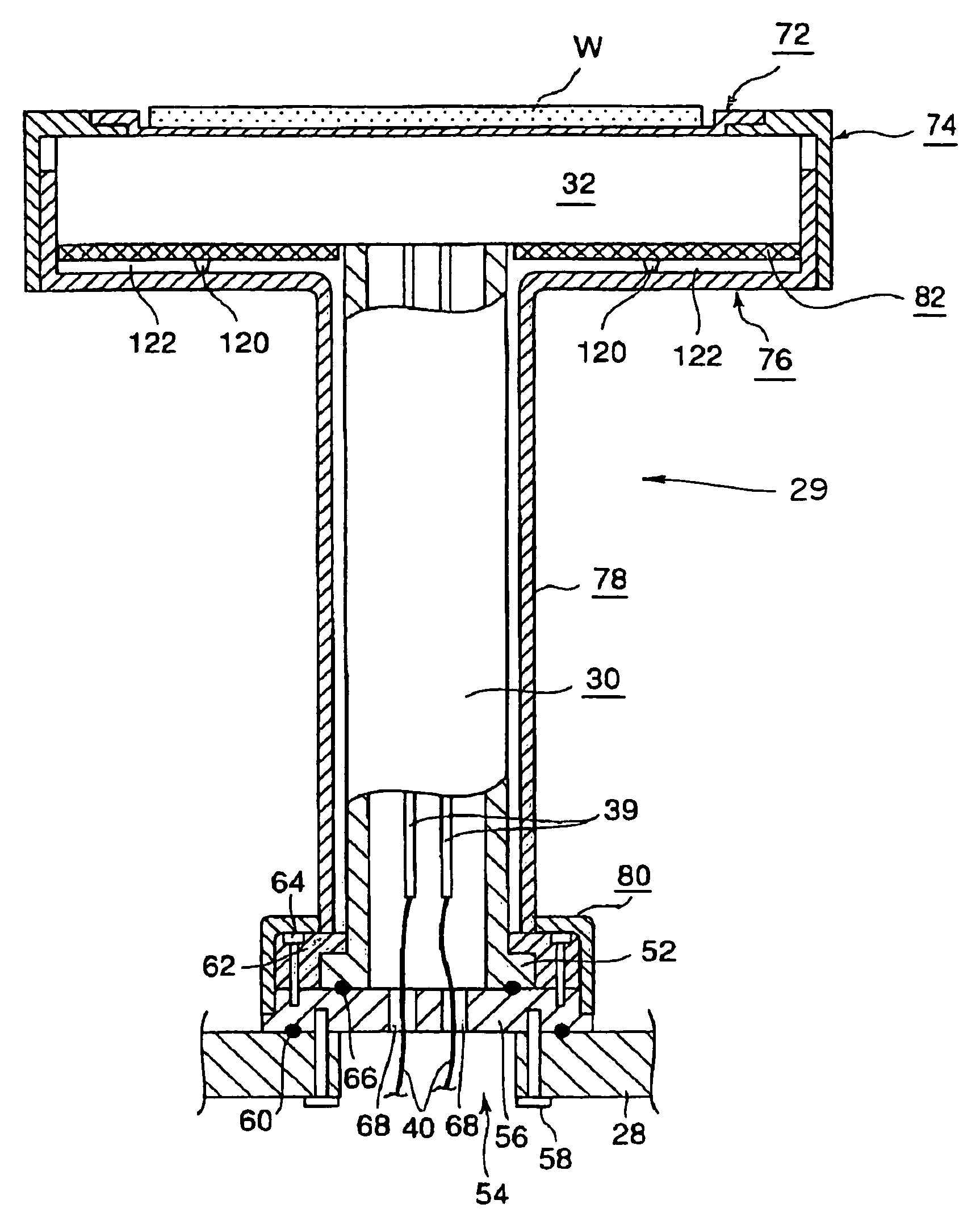

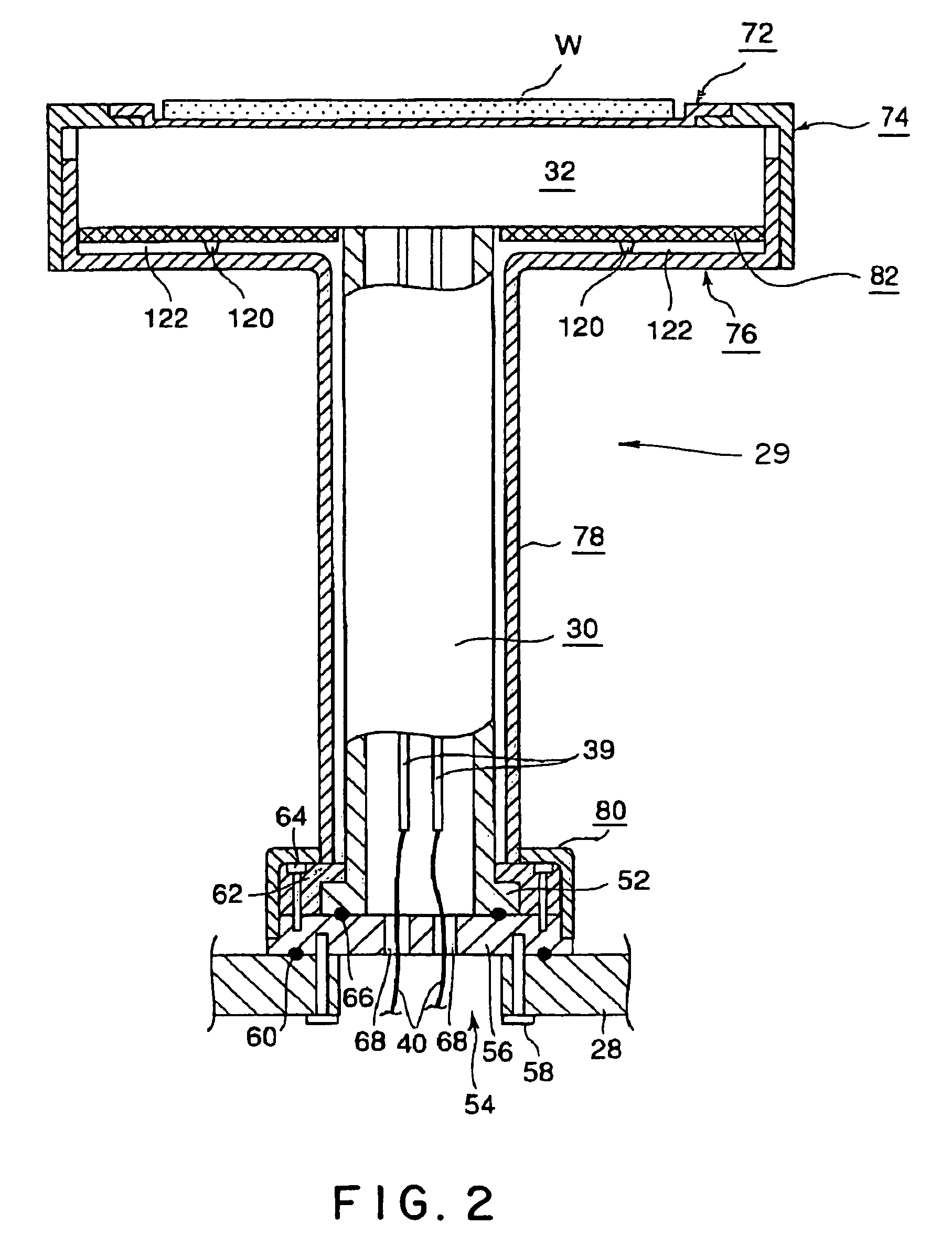

A thermal processing system has a processing vessel 4, a support post 30 stood on the bottom wall of the processing vessel 4, and a support table 32 internally provided with a heating means 38 and supported on the support post 30. A workpiece W is placed on the upper surface of the support table 32 and is subjected to a predetermined thermal process. The upper, the side and the lower surface of the support table 32 are covered with heat-resistant covering members 72, 74 and 76 to prevent the thermal diffusion of metal atoms causative of contamination from the support table 32. thus, various types of contamination, such as metal and organic contamination, can be prevented.

Owner:TOKYO ELECTRON LTD

Reactor, system including the reactor, and methods of manufacturing and using same

ActiveUS20190287769A1Electric discharge tubesSemiconductor/solid-state device manufacturingForming gasContamination

A reactor for processing substrates and methods for manufacturing and using the reactor are disclosed. Specifically, the reactor can include a material that forms gas compounds. The gas compounds are then easily removed from the reactor, thus reducing or avoiding contamination of the substrates in the reactor that would otherwise arise.

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com