Patents

Literature

2011results about How to "Even contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

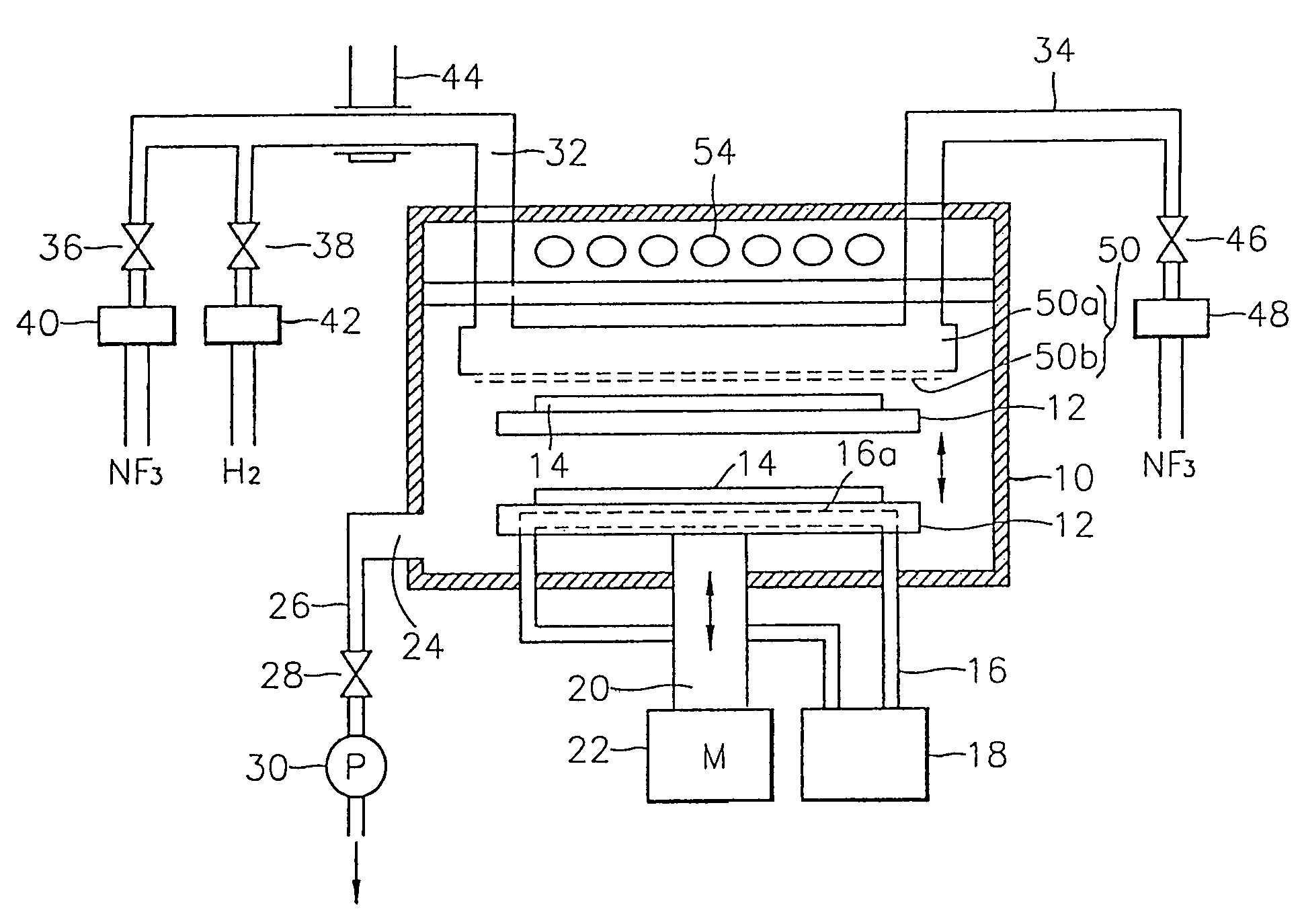

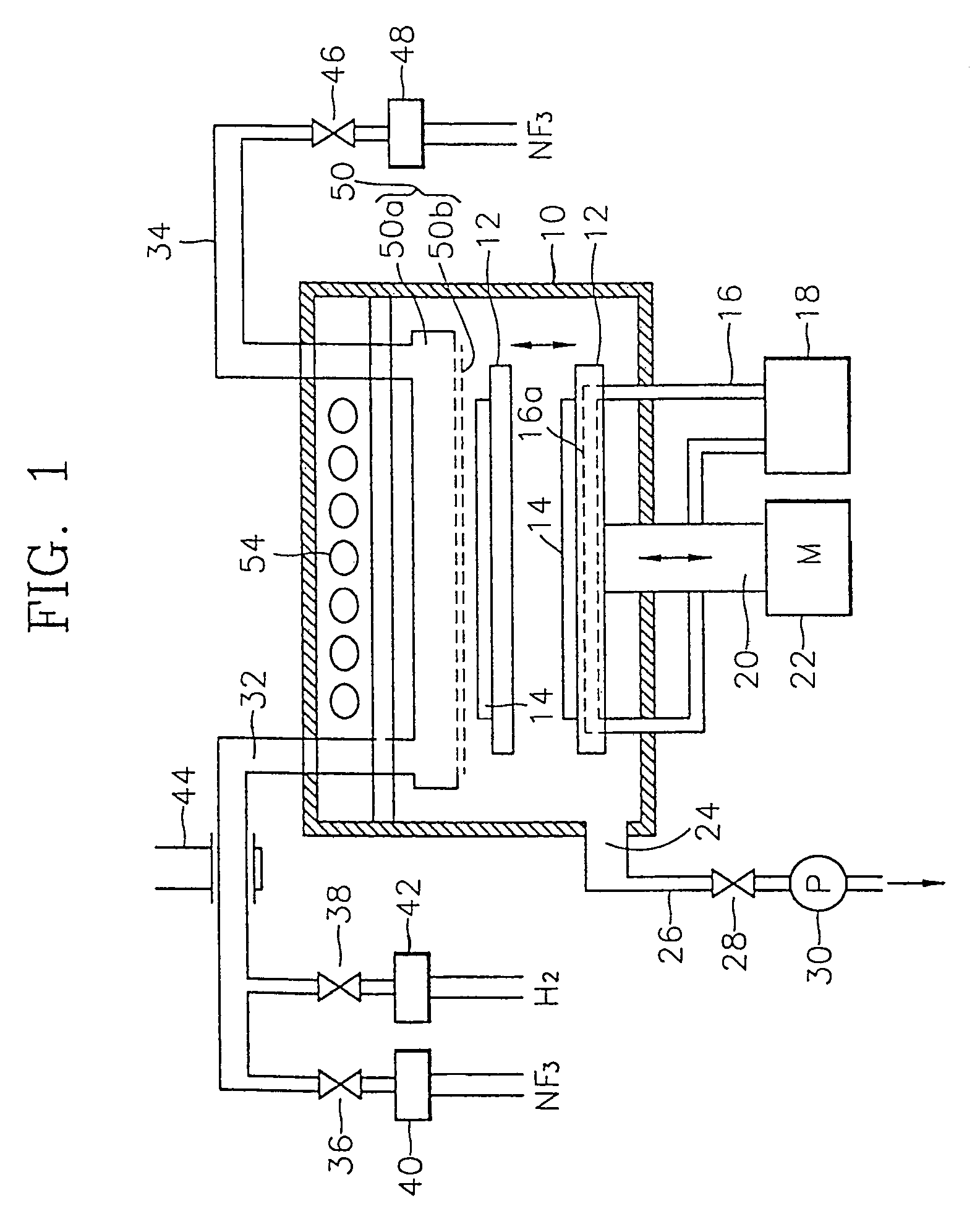

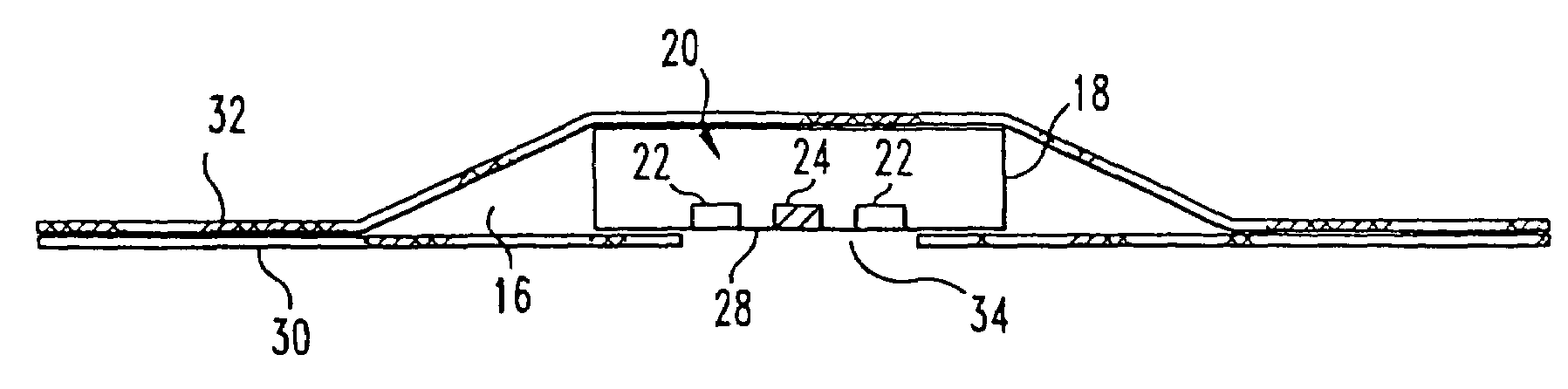

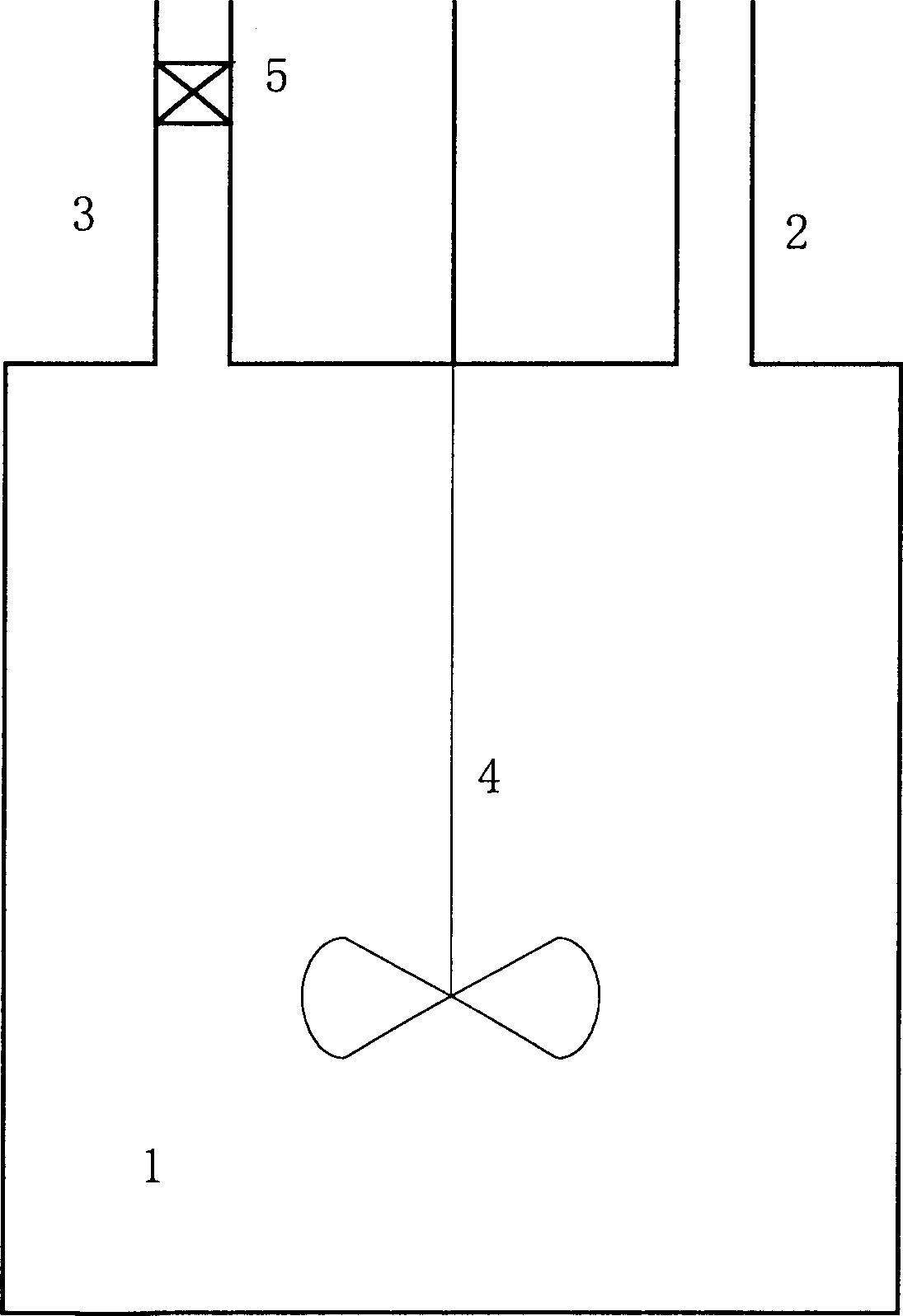

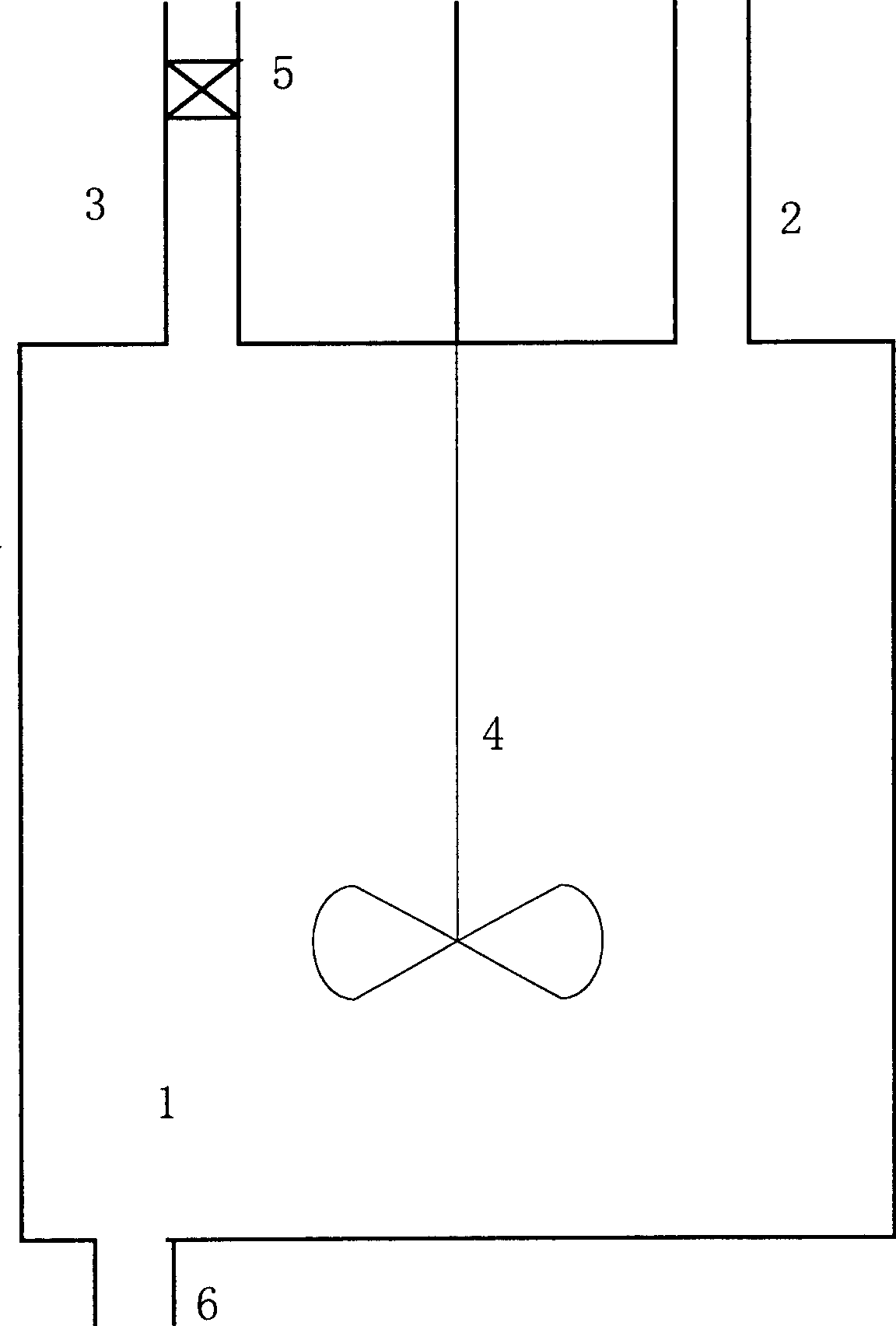

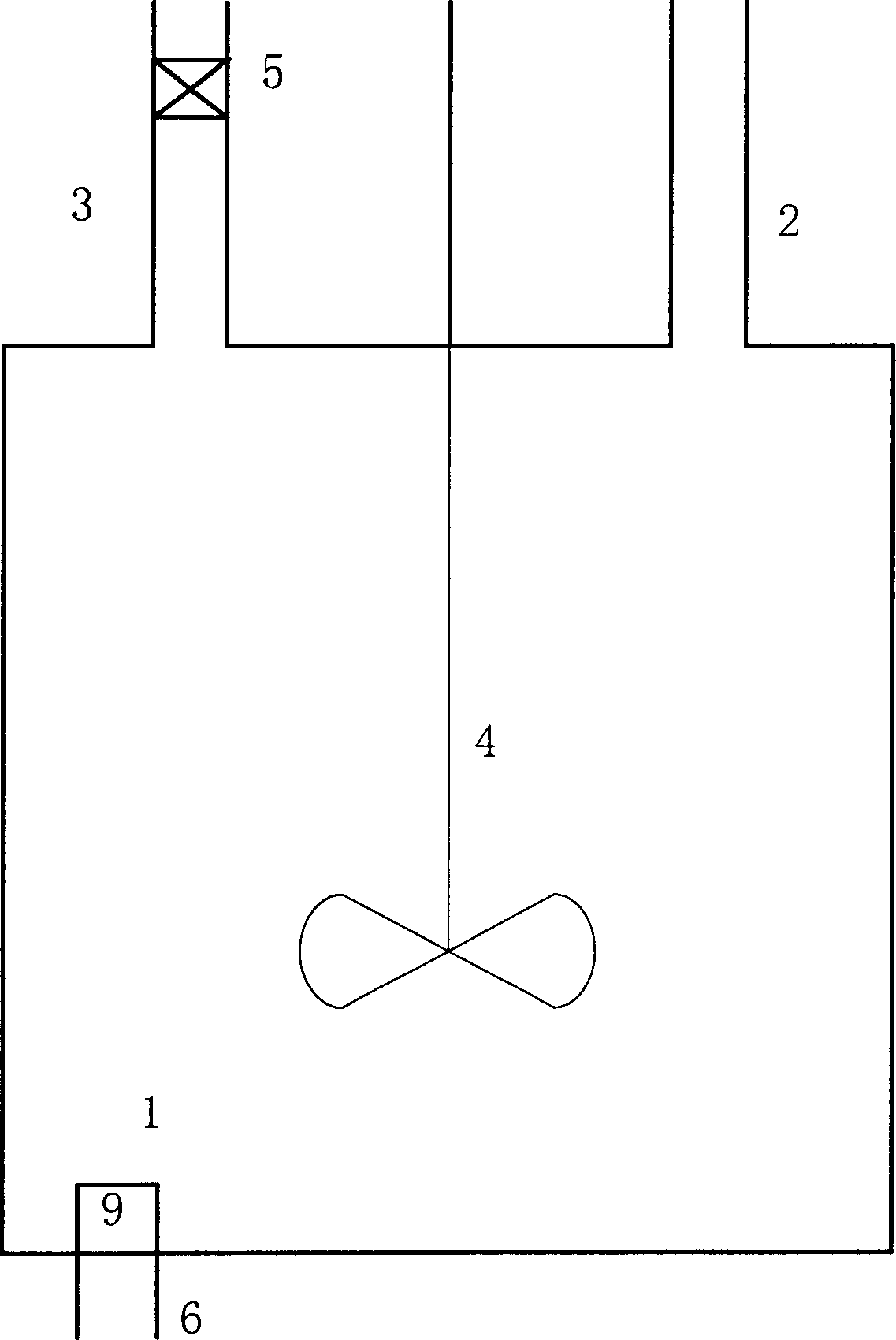

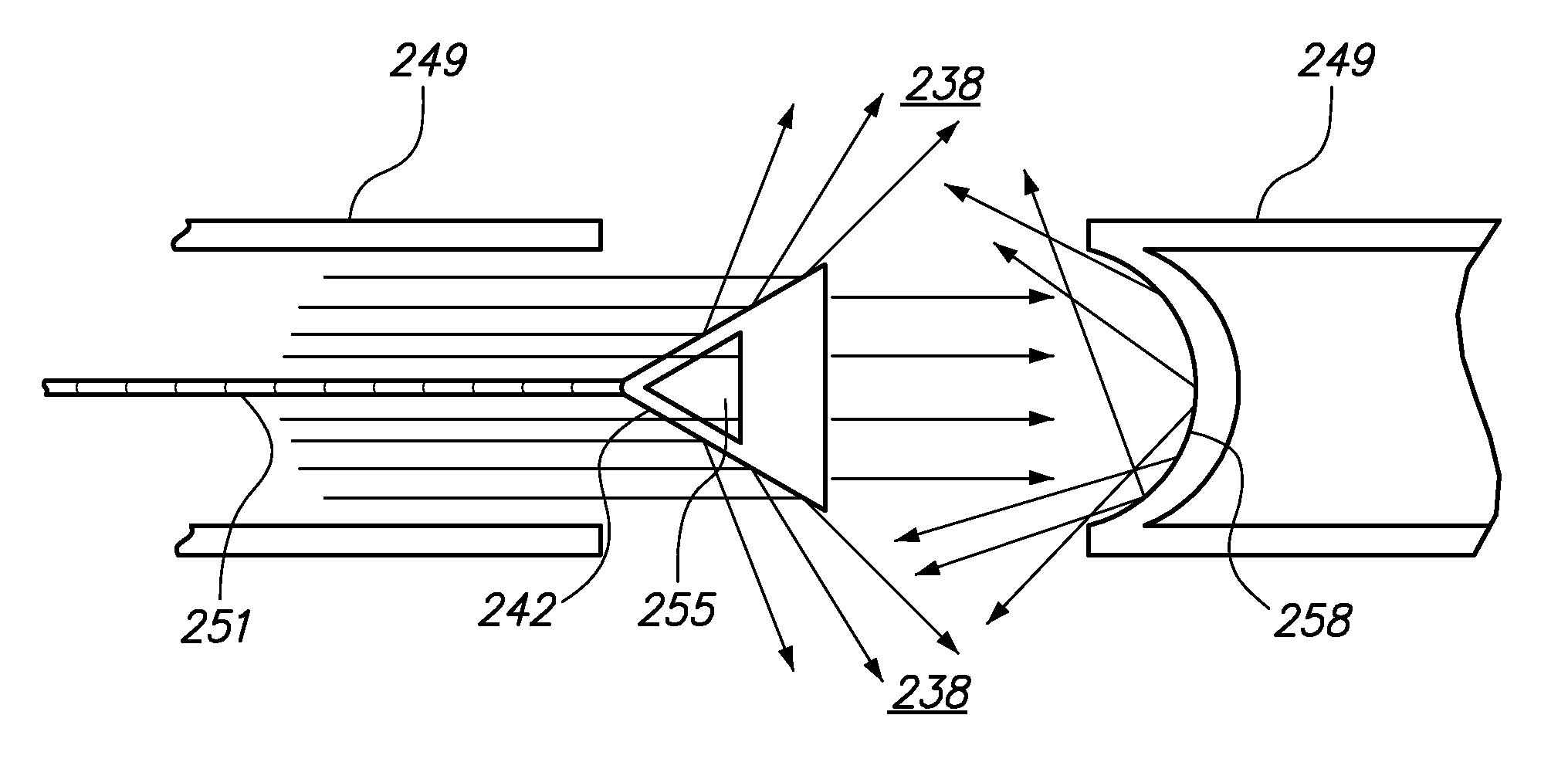

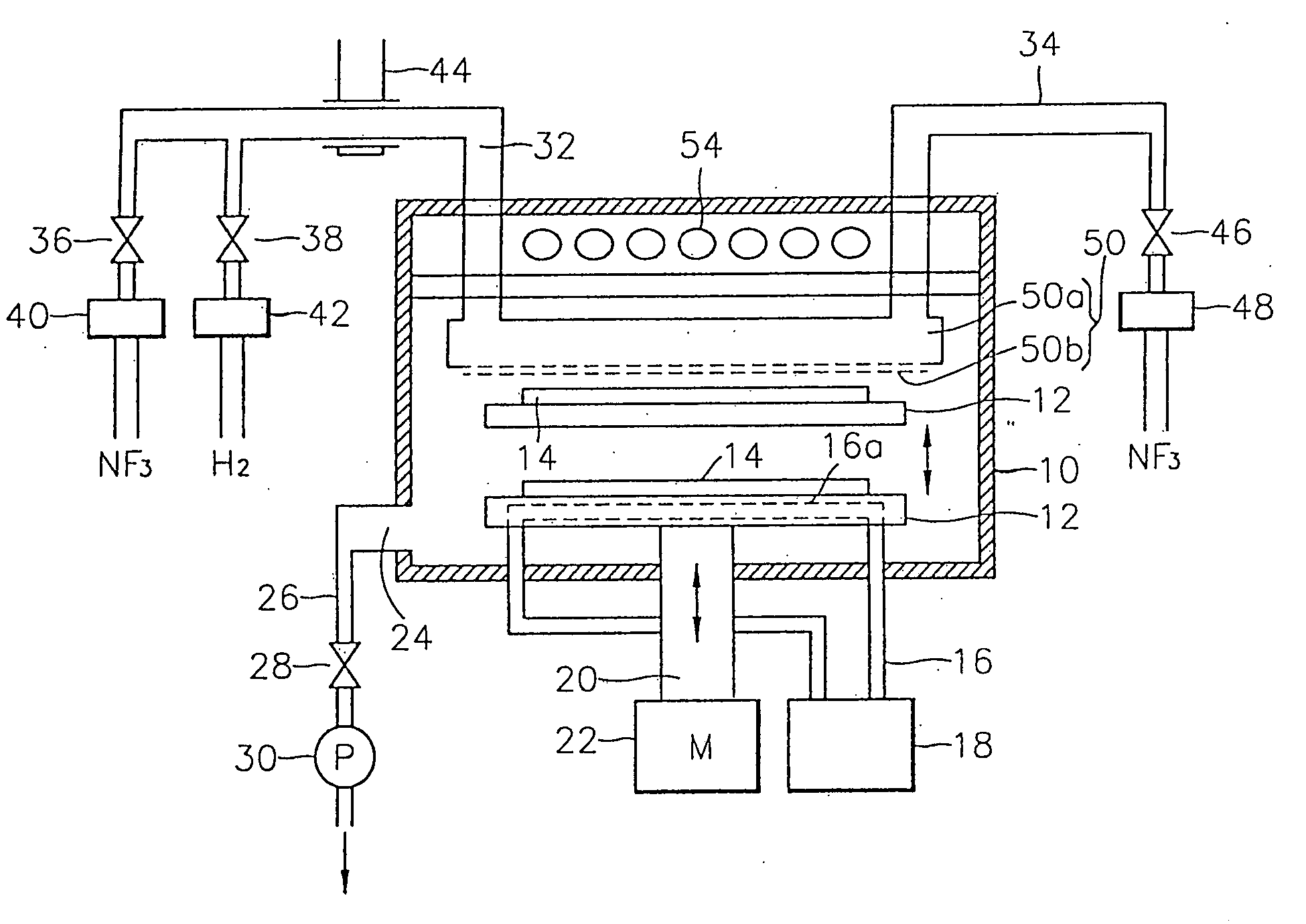

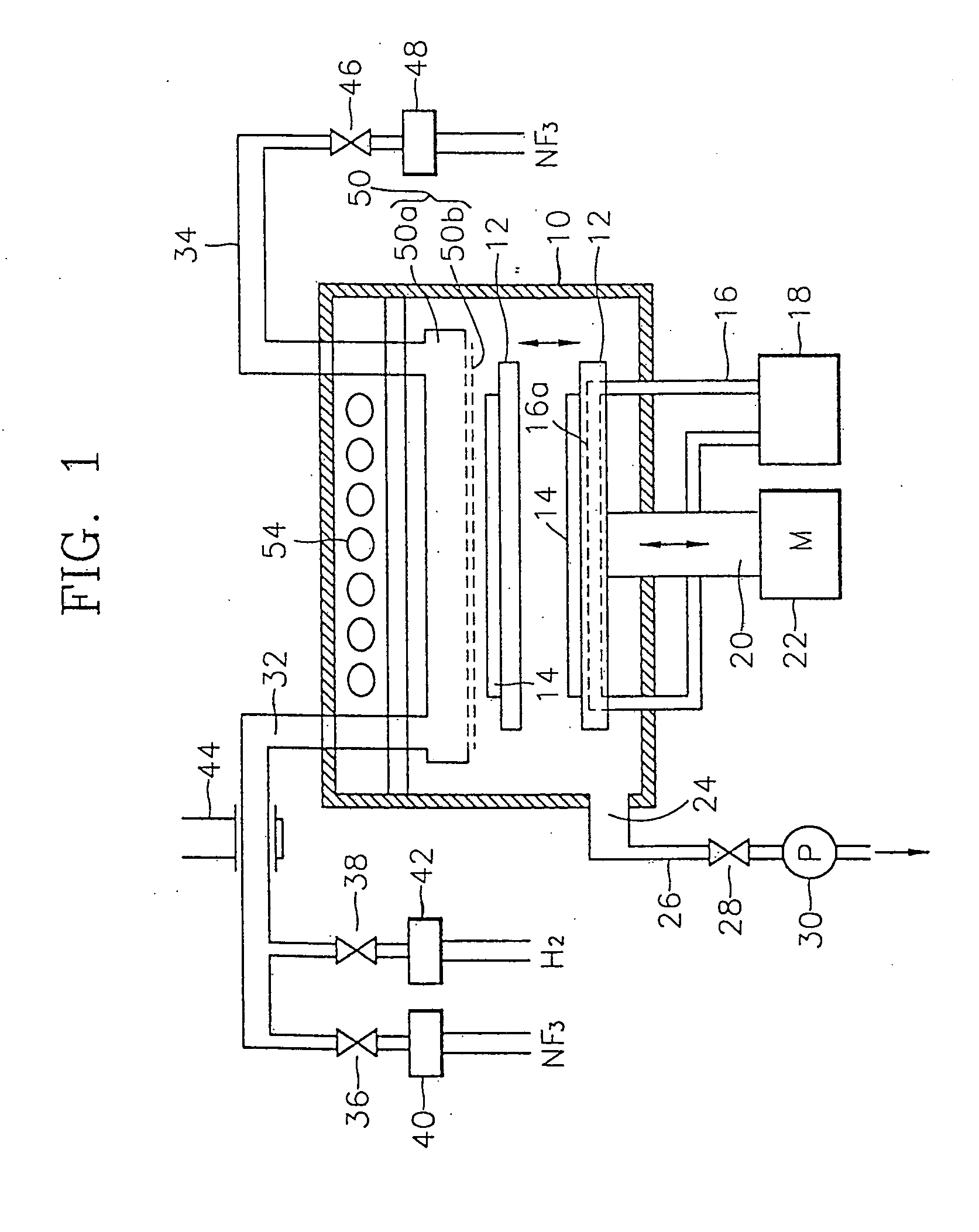

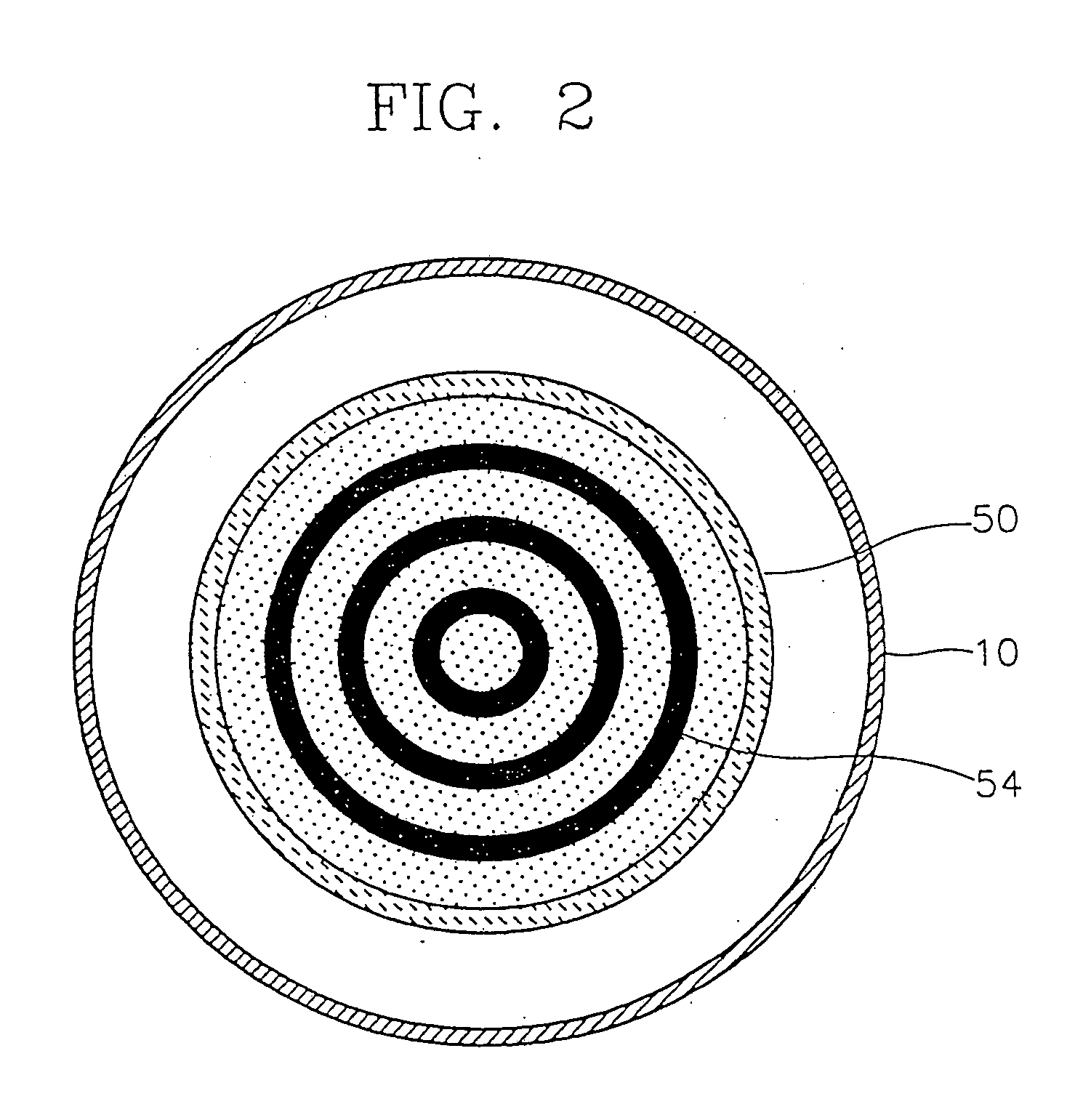

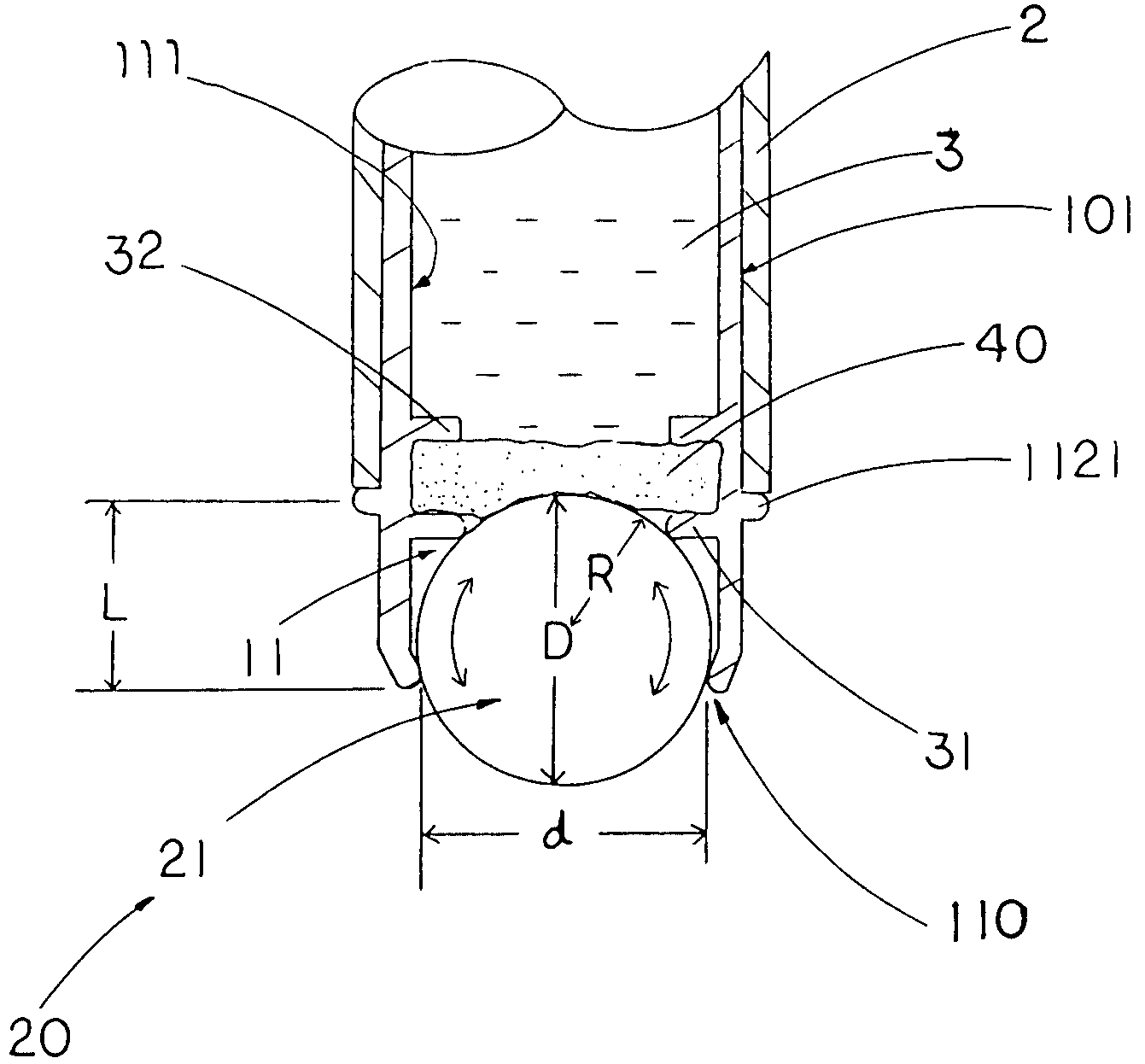

Method of removing oxide layer and semiconductor manufacturing apparatus for removing oxide layer

InactiveUS7488688B2High selectivityEven contactDecorative surface effectsSemiconductor/solid-state device manufacturingReaction layerSusceptor

A method for removing an oxide layer such as a natural oxide layer and a semiconductor manufacturing apparatus which uses the method to remove the oxide layer. A vertically movable susceptor is installed at the lower portion in a processing chamber and a silicon wafer is loaded onto the susceptor when it is at the lower portion of the processing chamber. The air is exhausted from the processing chamber to form a vacuum condition therein. A hydrogen gas in a plasma state and a fluorine-containing gas are supplied into the processing chamber to induce a chemical reaction with the oxide layer on the silicon wafer, resulting in a reaction layer. Then, the susceptor is moved up to the upper portion of the processing chamber, to anneal the silicon wafer on the susceptor with a heater installed at the upper portion of the processing chamber, thus vaporizing the reaction layer. The vaporized reaction layer is exhausted out of the chamber. The oxide layer can be removed with a high selectivity while avoiding damage or contamination of the underlying layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Sprayable water-based adhesive

InactiveUS20070224395A1Efficient use ofProlong lifeAdhesive processesRoof covering using sealantsWet bondingWater based

Water-based adhesive compositions are improved by the incorporation of hollow polymeric microspheres having outer surfaces coated with one or more barrier materials such as calcium carbonate particles. The adhesive compositions exhibit enhanced rheology, sprayability, drying time, tack and storage stability as compared to analogous adhesives that are not modified with coated hollow polymeric microspheres. Such compositions are useful as both contact adhesives as well as wet bonding one-way adhesives.

Owner:HENKEL IP & HOLDING GMBH

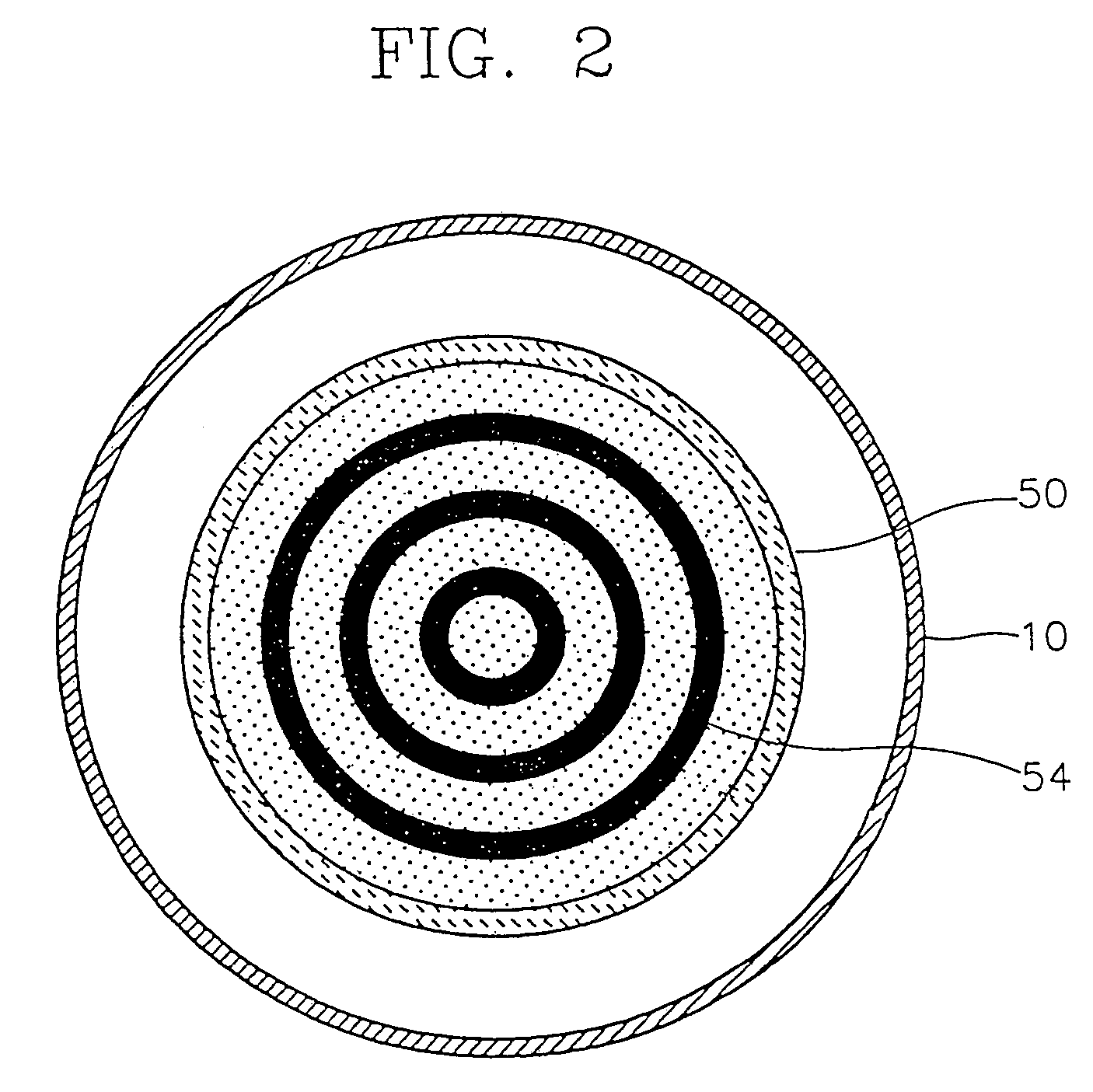

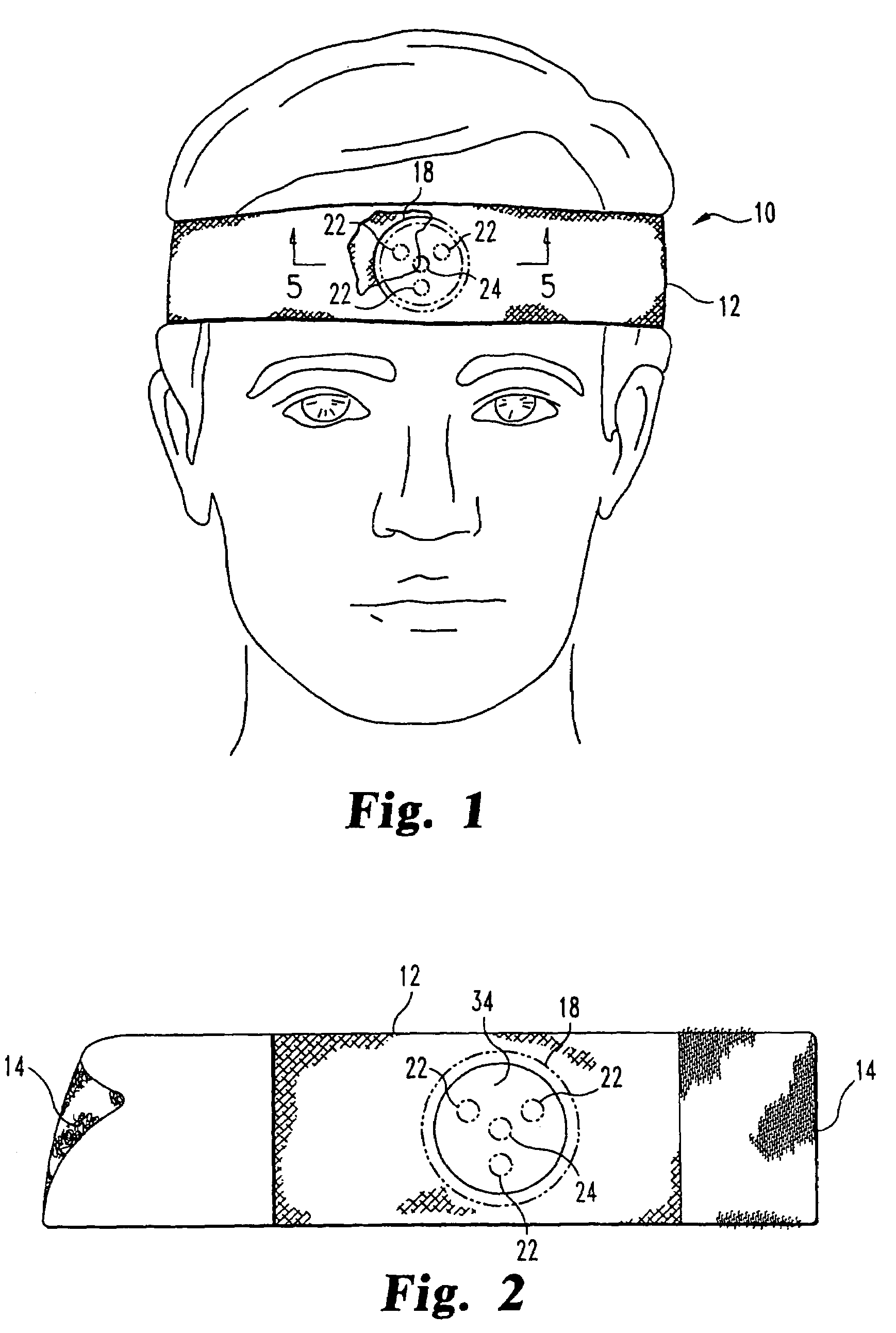

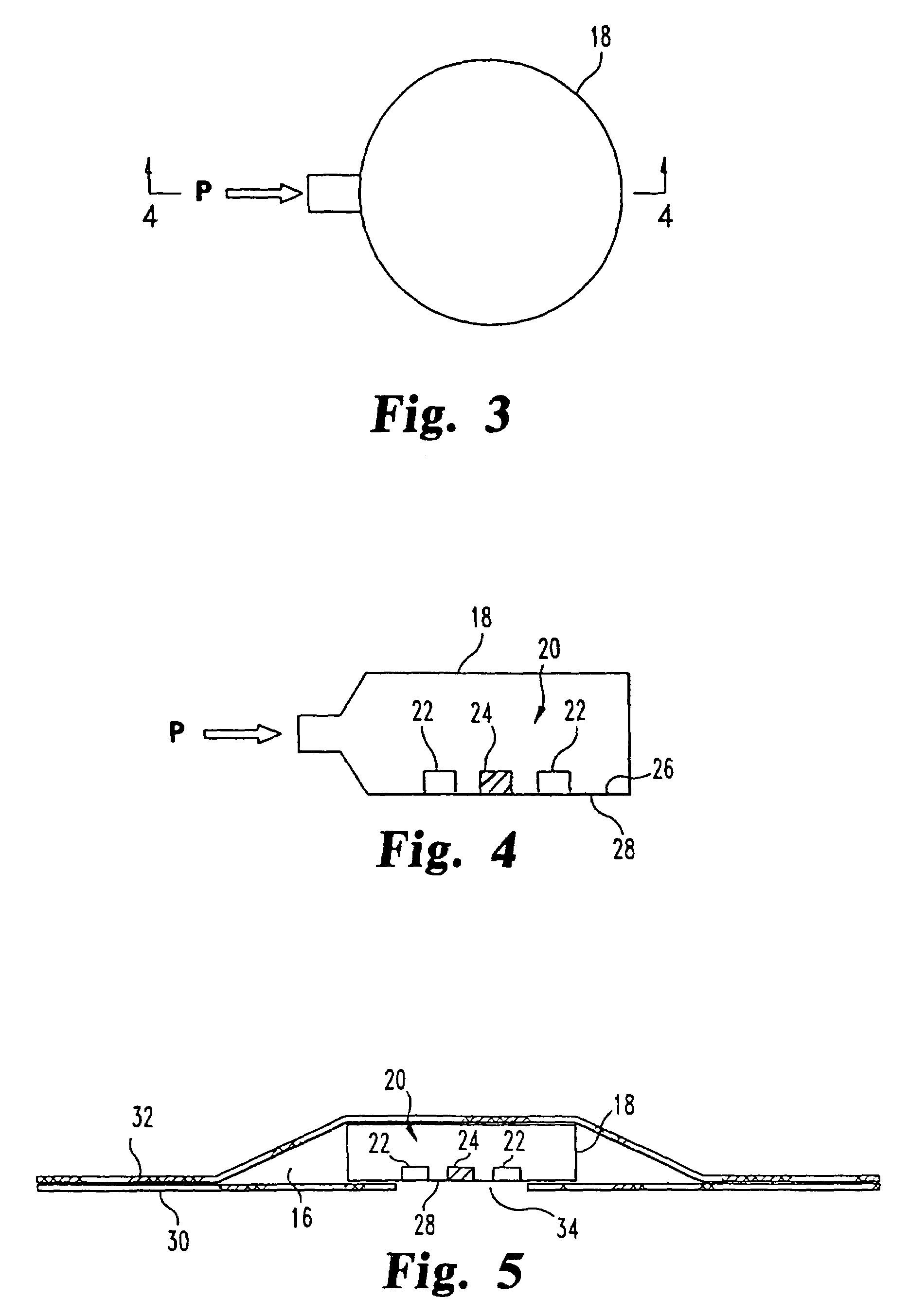

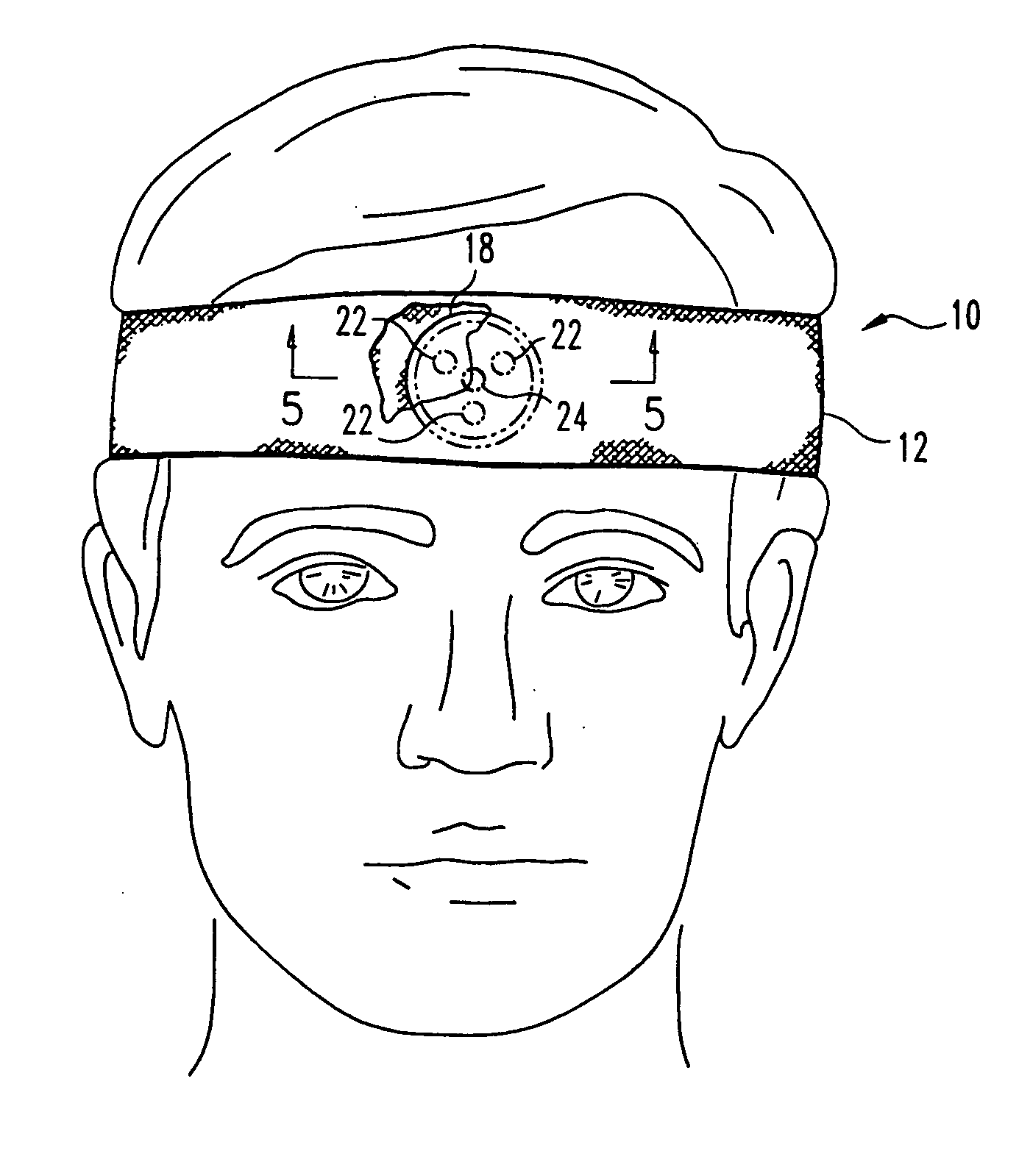

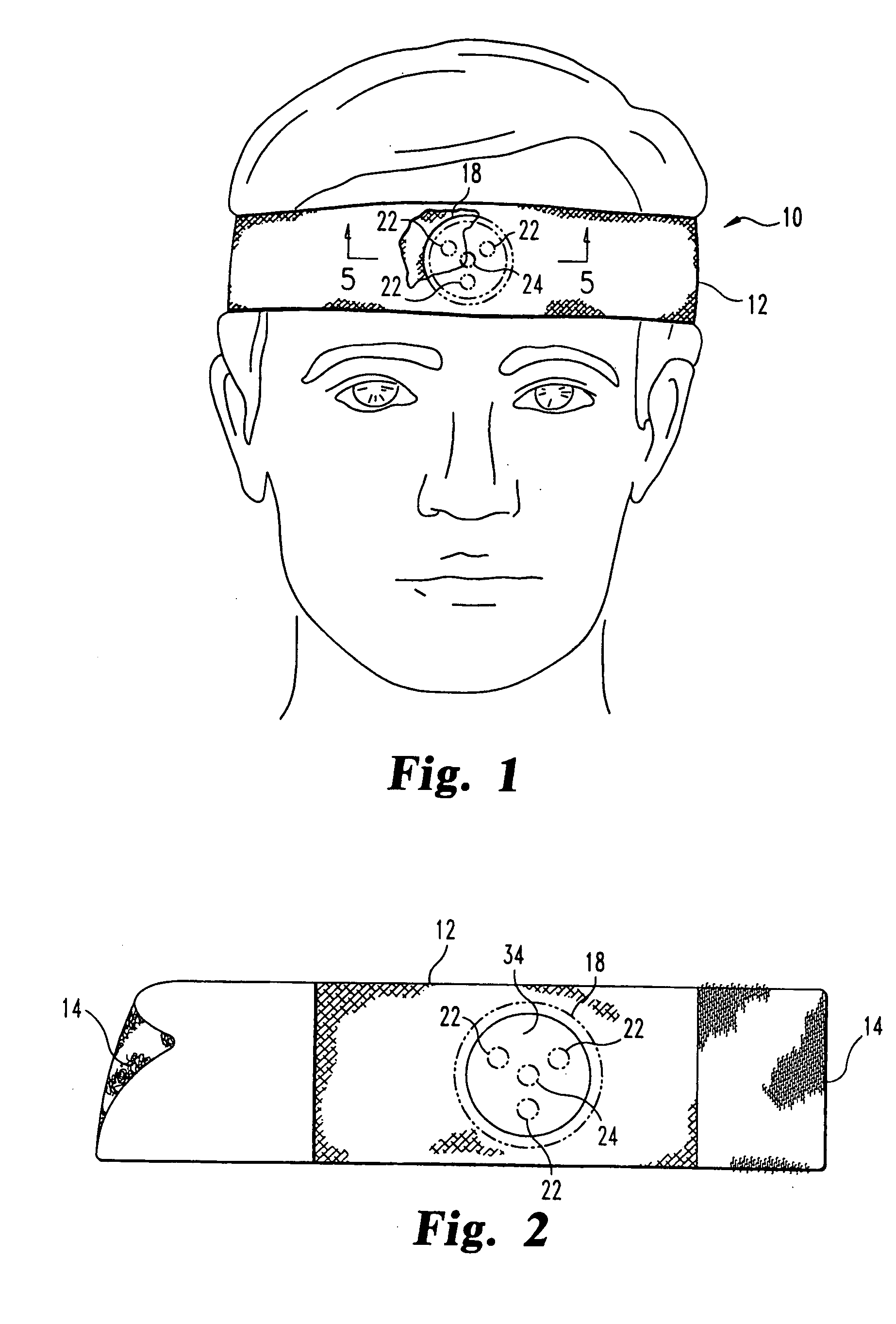

Optical noninvasive vital sign monitor

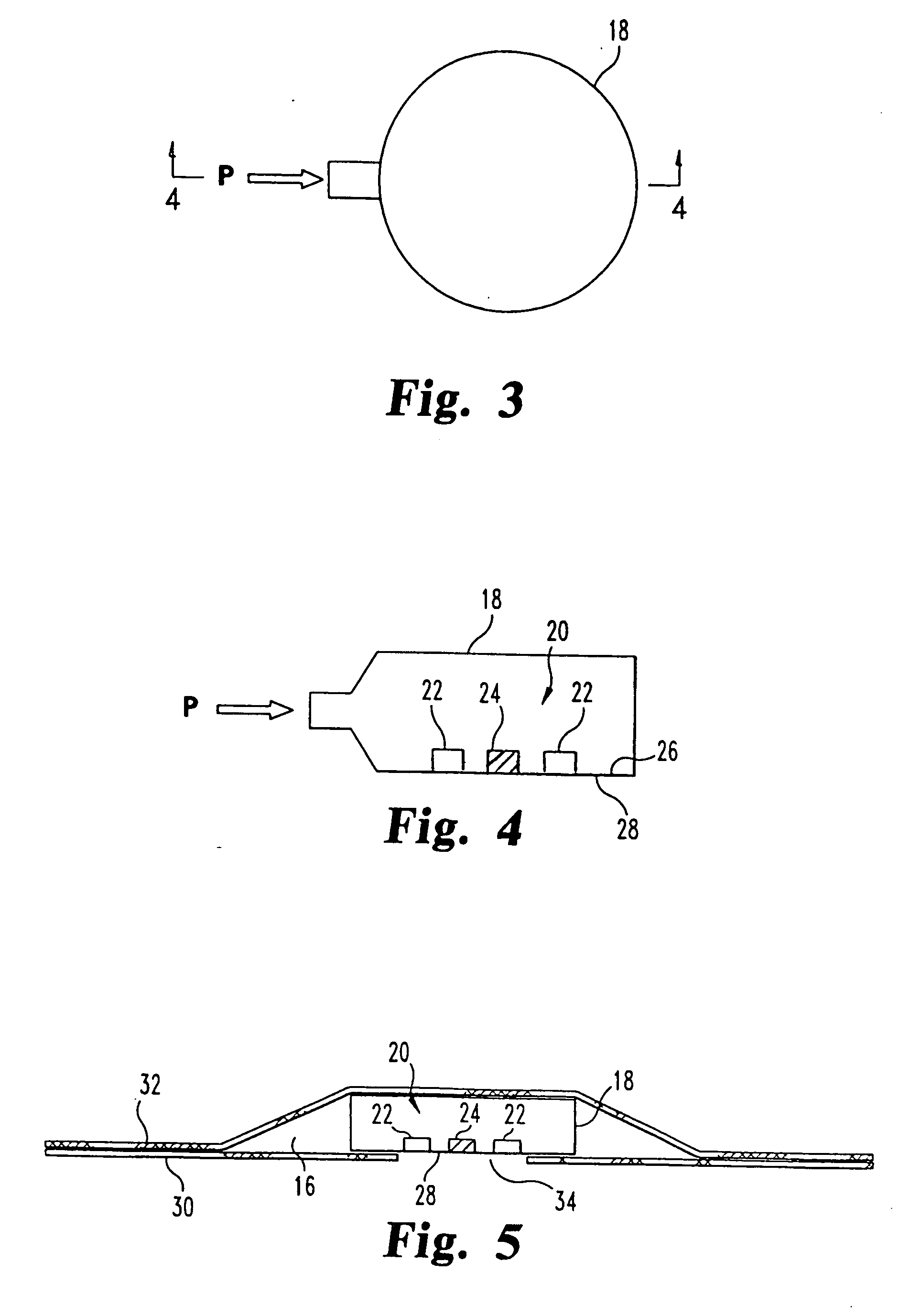

ActiveUS7164938B2Uniform pressure distributionEven contactDiagnostics using lightEvaluation of blood vesselsPhotovoltaic detectorsPhotodetector

An optical noninvasive vital sign monitor comprising a reflectance-type optical sensor within a pressurizable capsule retained by a headband, the capsule having an optically transparent or translucent inner wall adapted for placement against a subject's forehead. The optical sensor is mounted on the inside surface of the pressurizable capsule's inner wall, which contacts the subject's forehead during use, and includes a light source and a photodetector aimed toward the inside surface of the inner capsule wall. One embodiment of the vital sign monitor includes optical oscillometric circuit means responsive to an output signal from the optical sensor for determining systolic pressure, mean pressure and diastolic pressure during a transition in capsule pressure between a pressure greater than normal systolic pressure and a pressure less than normal diastolic pressure.

Owner:PURDUE RES FOUND INC

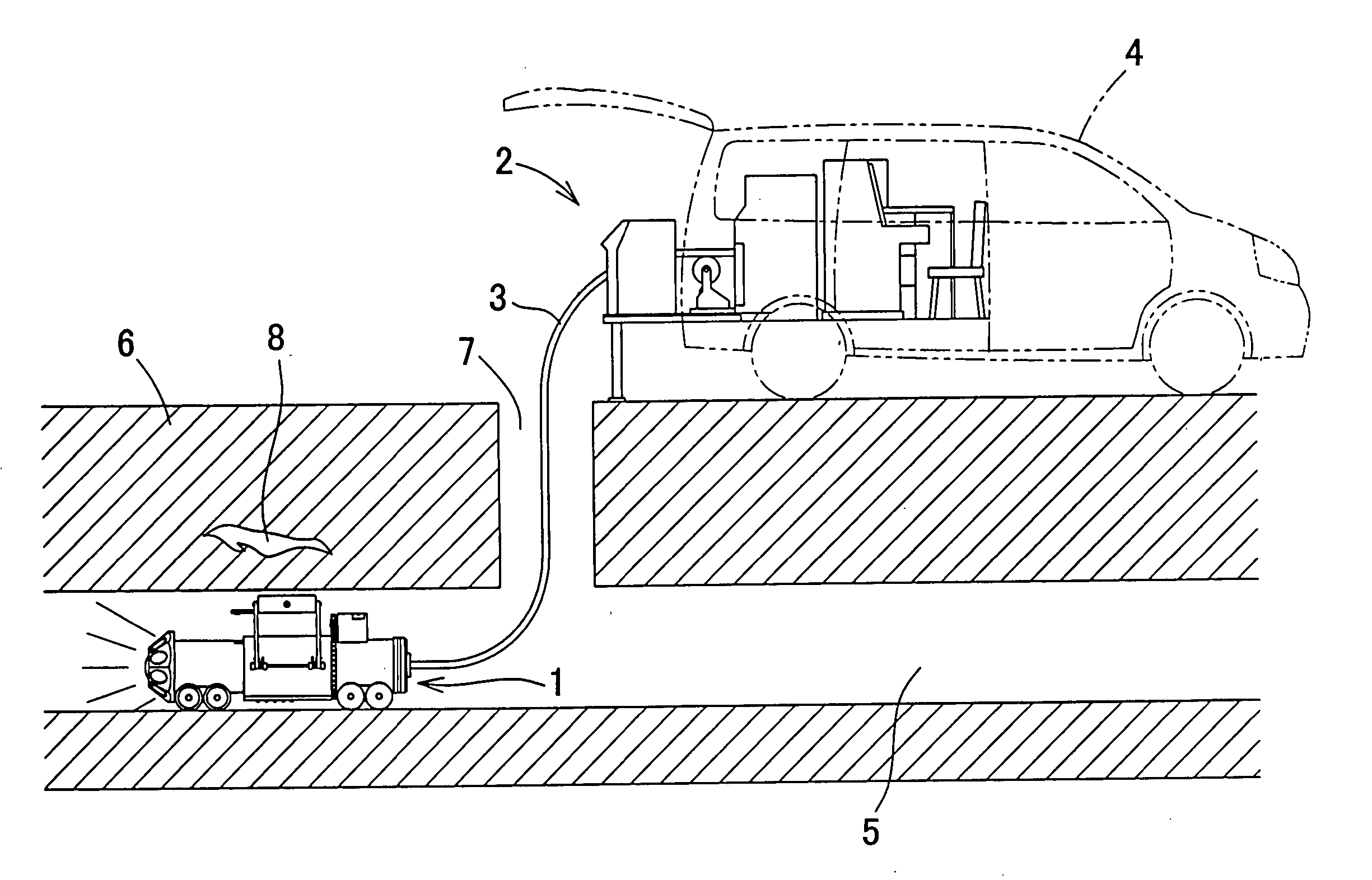

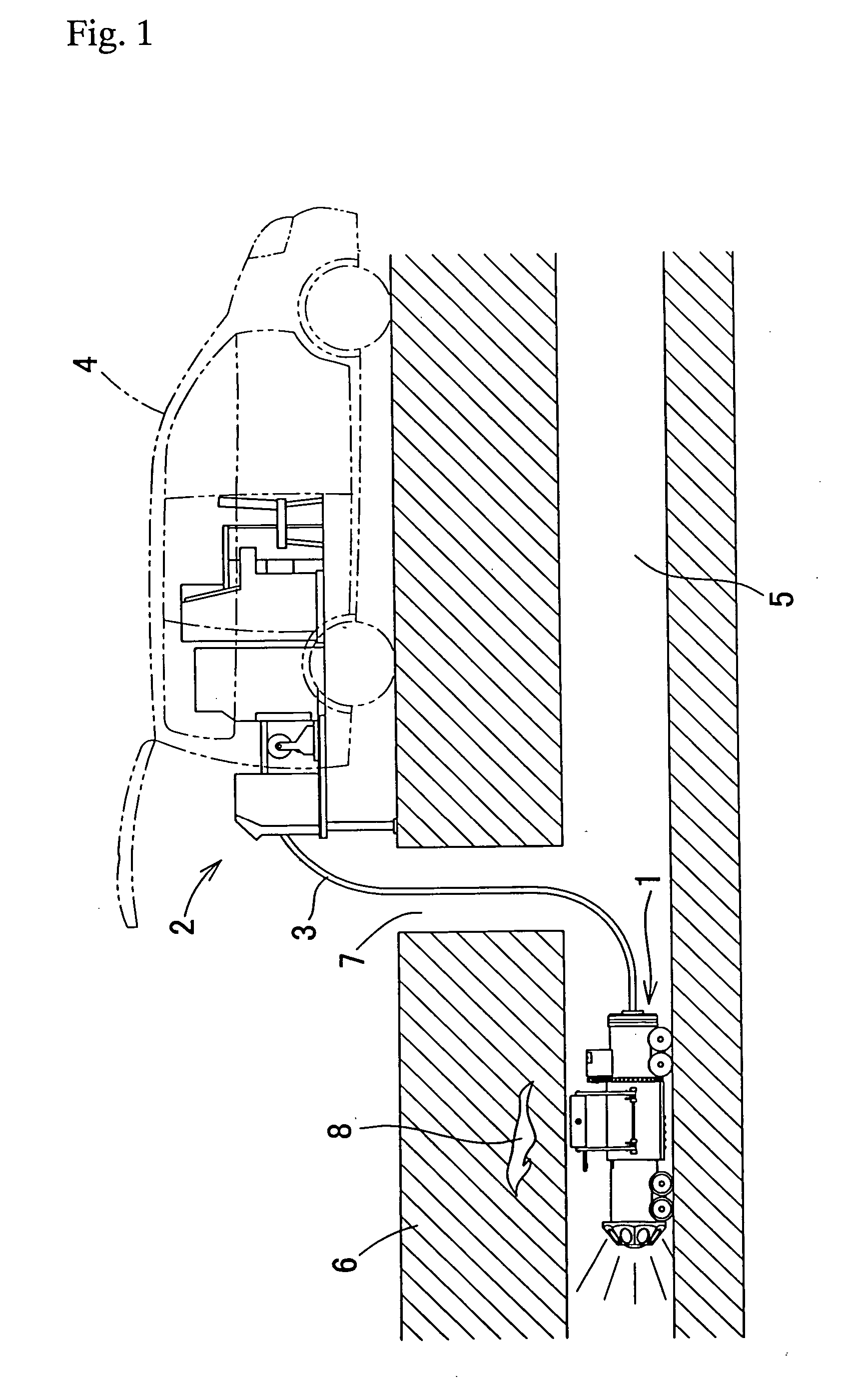

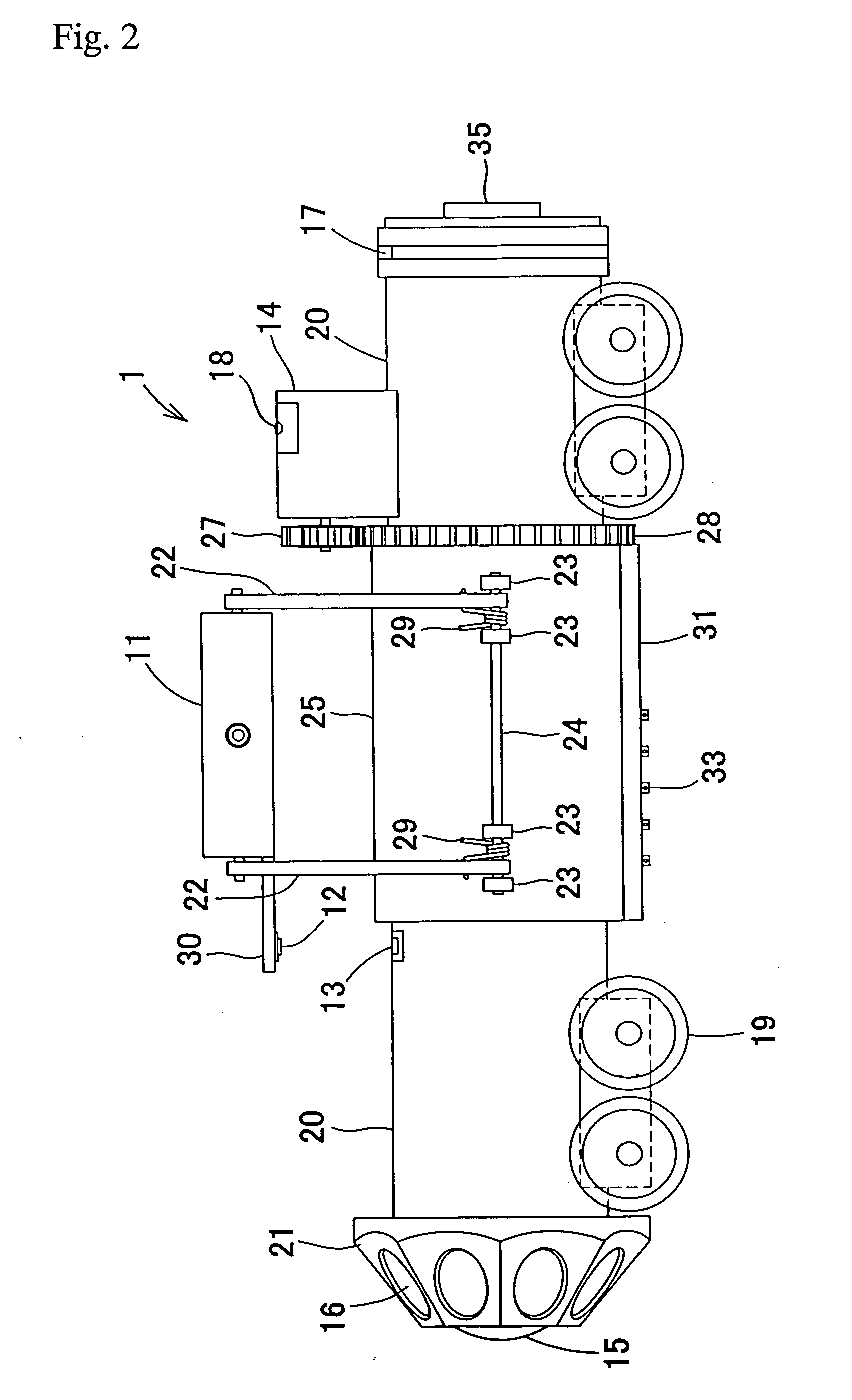

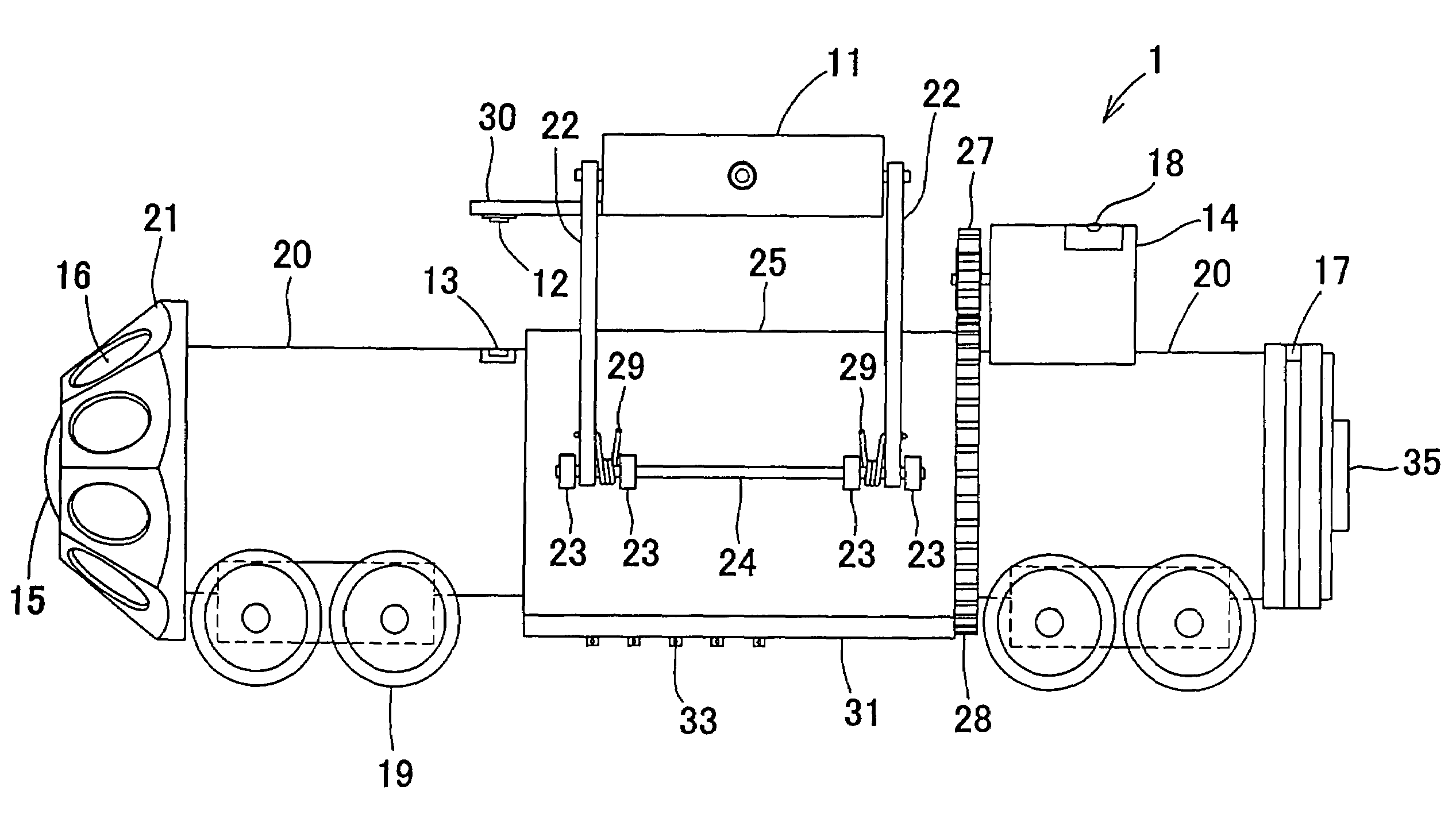

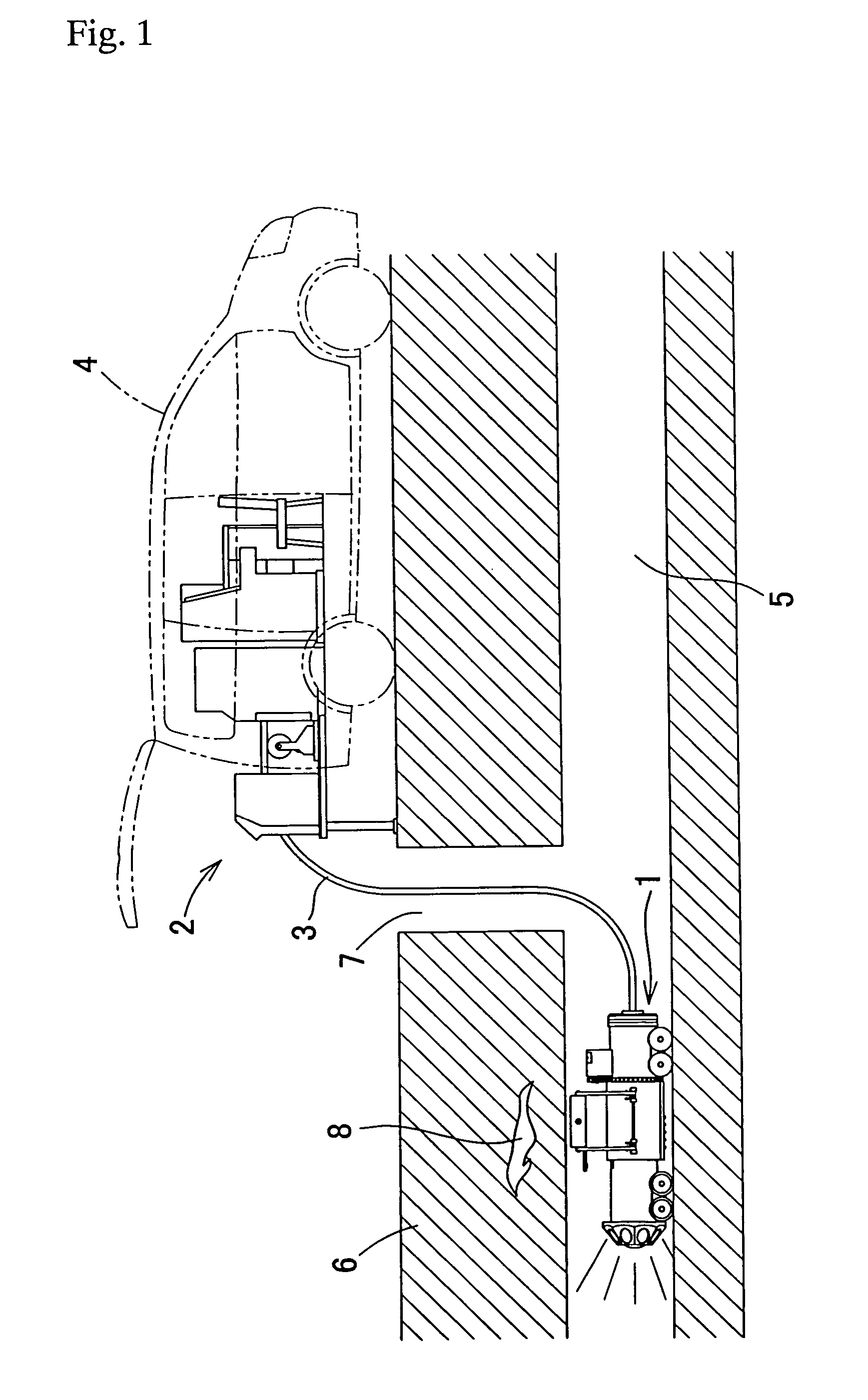

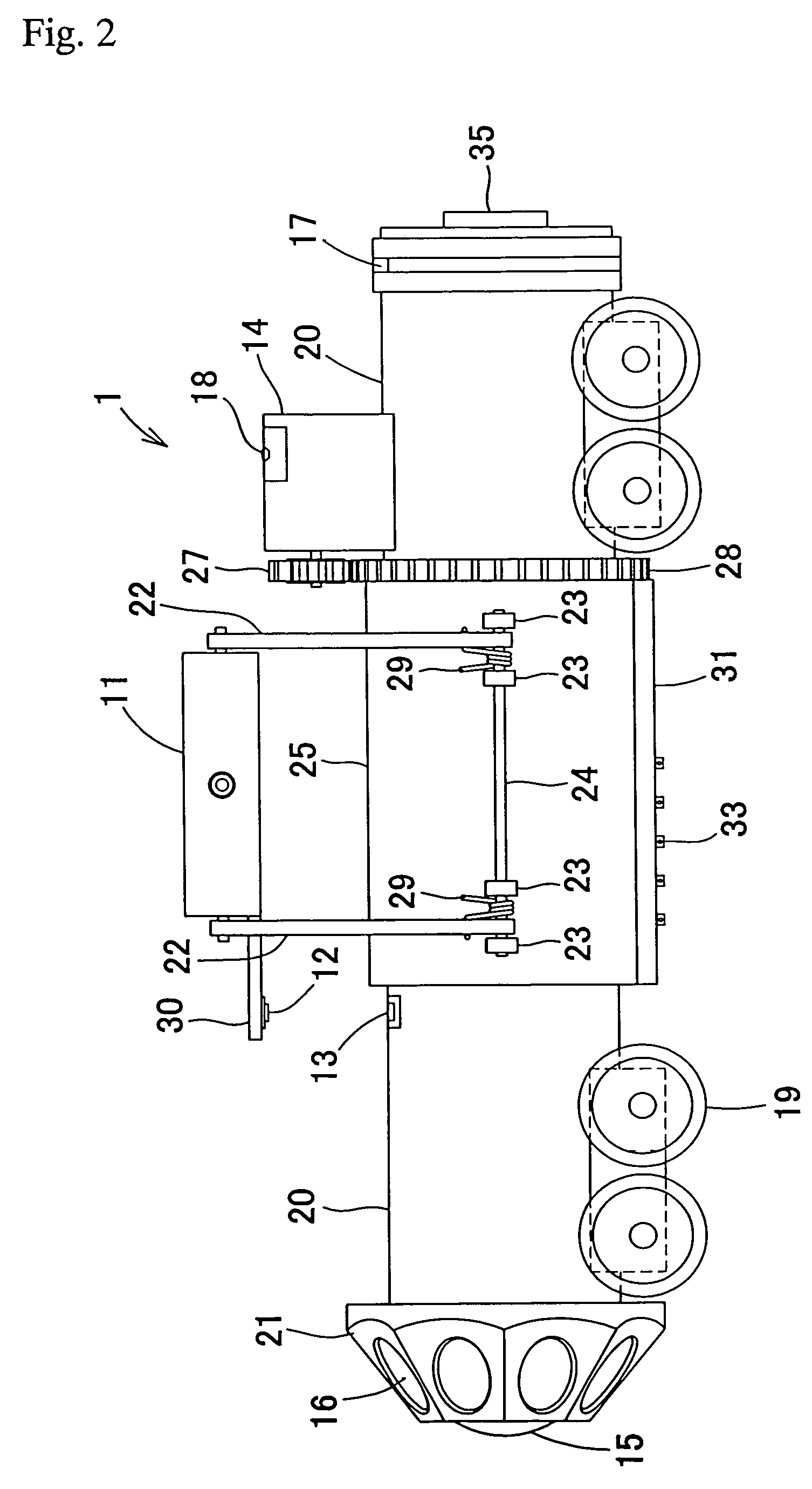

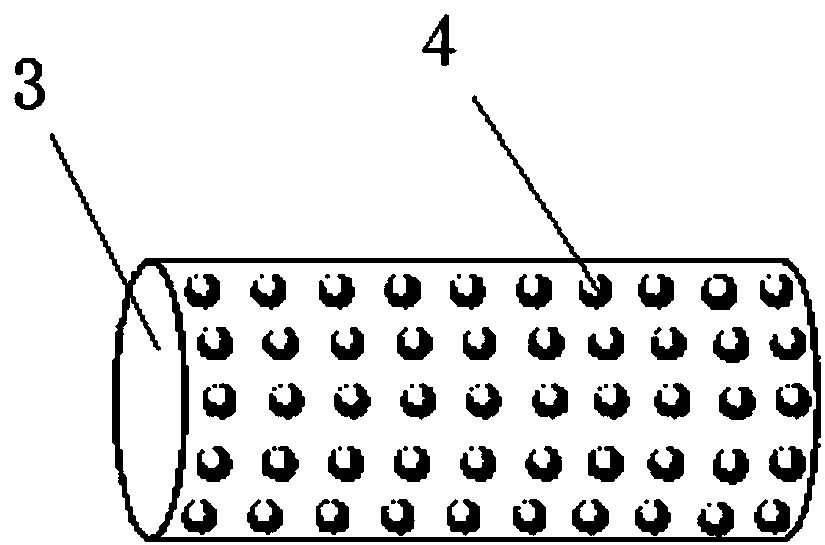

Device and method for inspecting inside of underground pipe line and method of inspecting concrete on inside of underground pipe line for deterioration

InactiveUS20050115337A1Reliably determinedAccurate measurementHollow article cleaningStructural/machines measurementFisheye lensGyroscope

A device for inspecting the inside of an underground pipe line which makes it possible to search for cavities on the outside of the underground pipe over the entire internal peripheral surface of the underground pipe, that is, not only upward of the underground pipe, but also toward both sides and downward thereof, to obtain detailed images of the inner peripheral surface of the pipe line without using a complex mechanism, and to display patterns of cracks and irregularities on the inner peripheral surface of the underground pipe by three-dimensional convergence images. The device comprises a pipe line internal self-propelled vehicle and an on-ground control unit, and the pipe line internal self-propelled vehicle is provided with a radar antenna, a camera equipped with a fisheye lens, a gyro, a laser sensor, and an infrared encoder.

Owner:BURN AM

High silicon Y-type zeolite containing rare-earth and its preparing method

ActiveCN1281493CThe initial unit cell constant is smallThe equilibrium cell constant is largeFaujasite aluminosilicate zeoliteGasolineRare earth

A rare-earth-containing high-silicon Y-type zeolite, the zeolite contains rare earths, is characterized in that the silicon-aluminum ratio of the zeolite is 5-30, the initial unit cell constant is 2.430-2.465 nanometers, and the balance unit cell constant and the initial unit cell constant The ratio is at least 0.985. The zeolite has the characteristics of small initial unit cell constant and large equilibrium unit cell constant. It has high structural stability and hydrothermal stability. The cracking catalyst containing this zeolite is not easy to deactivate. The choice of gasoline, diesel oil, dry gas and coke Good sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

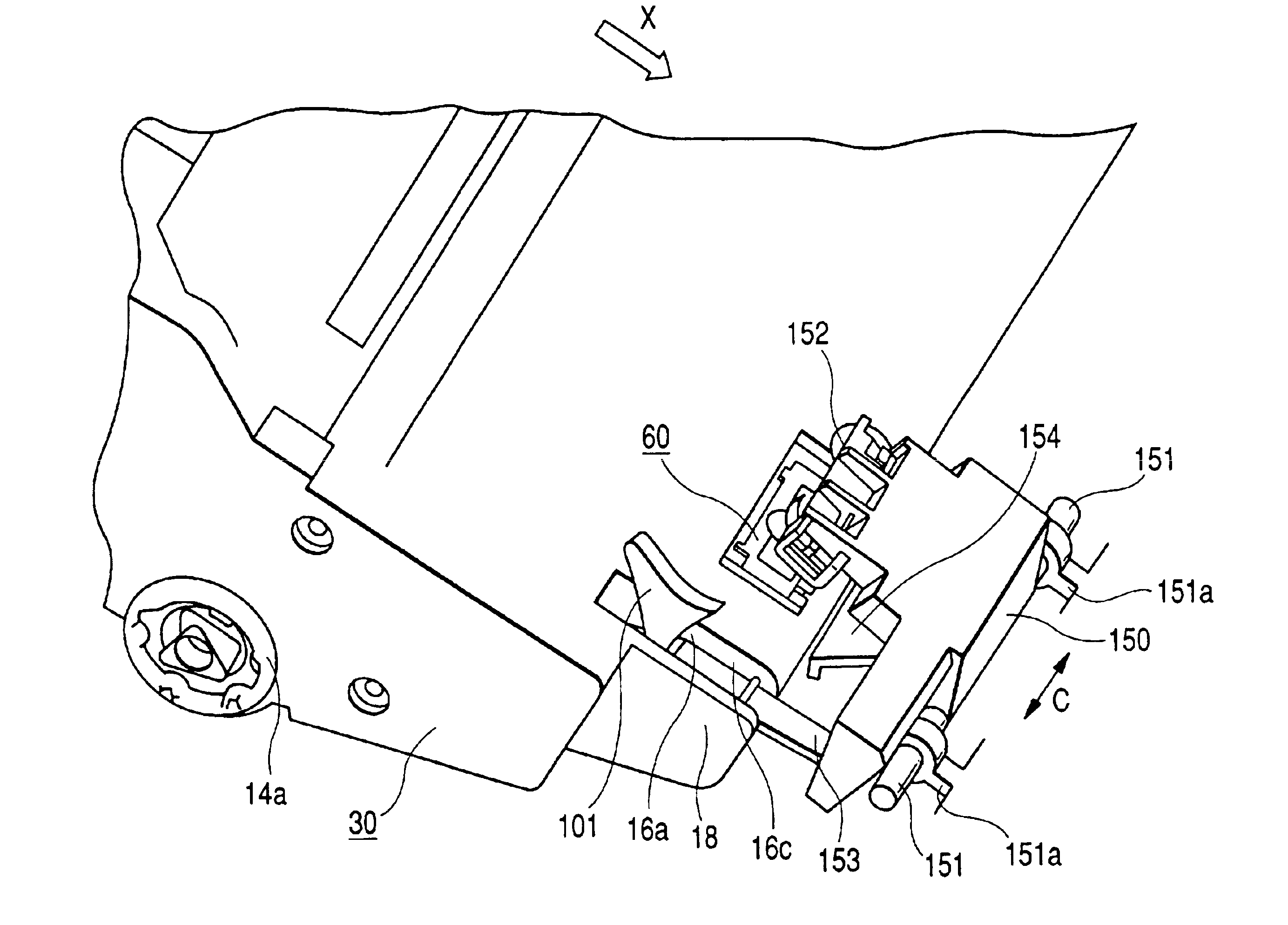

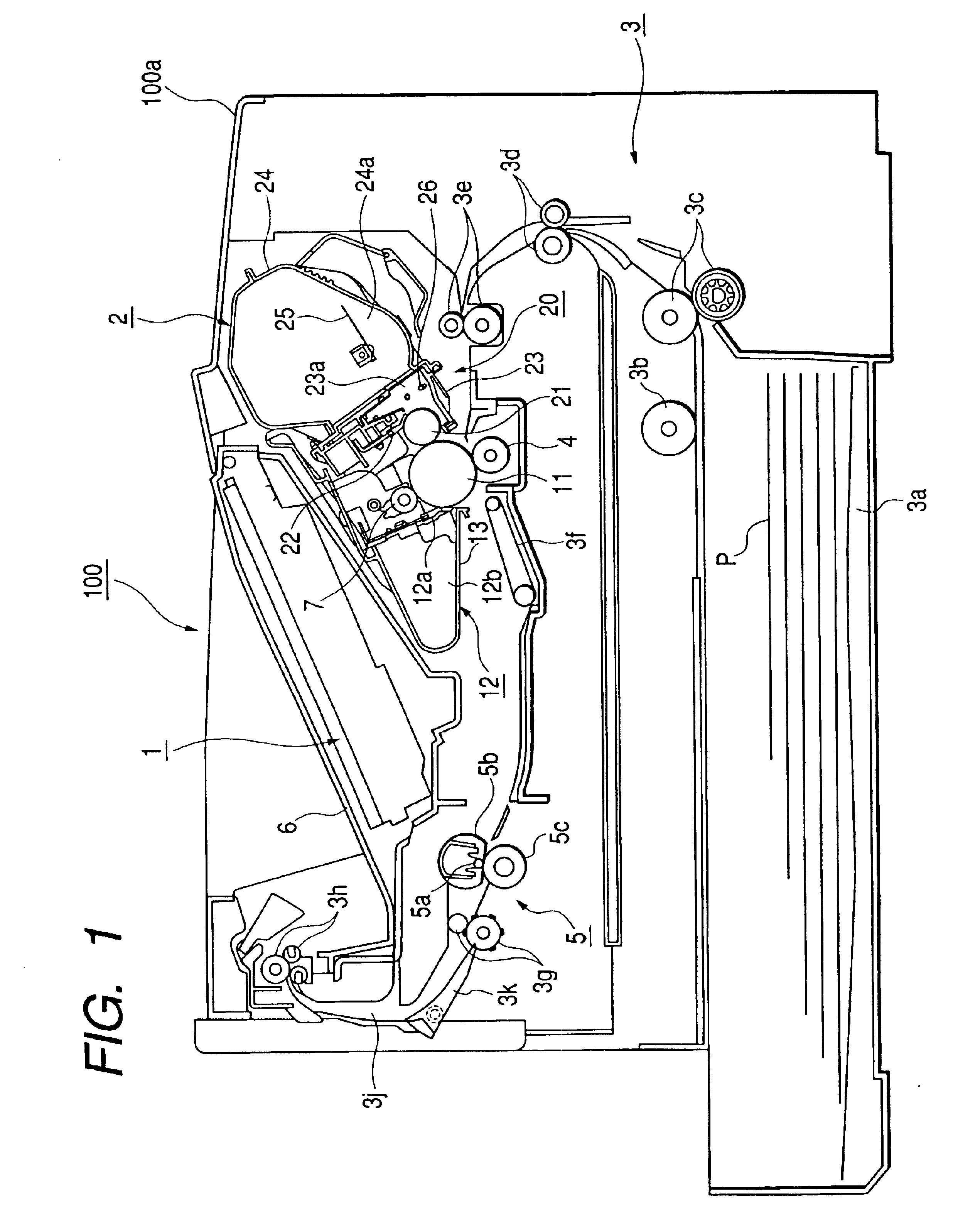

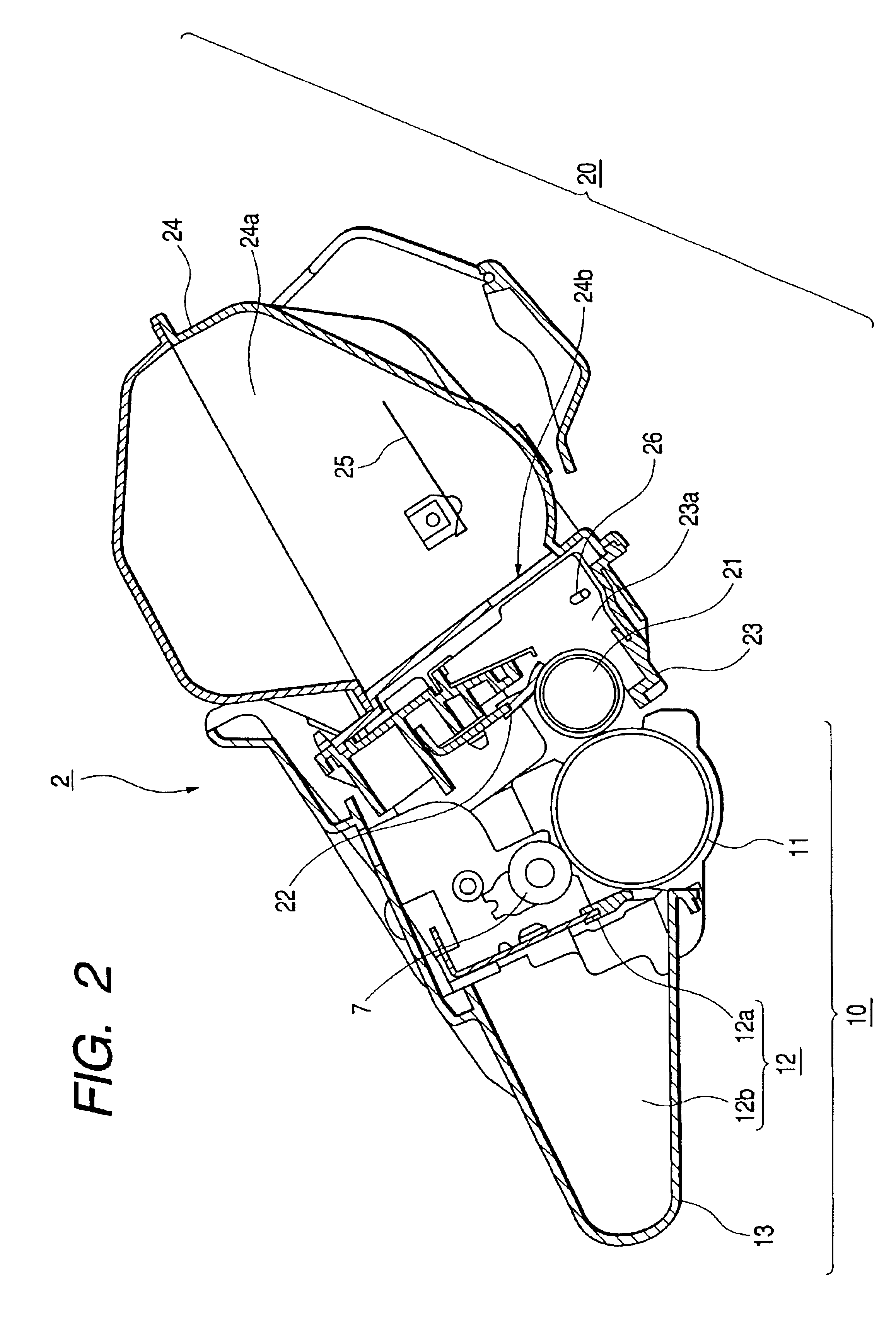

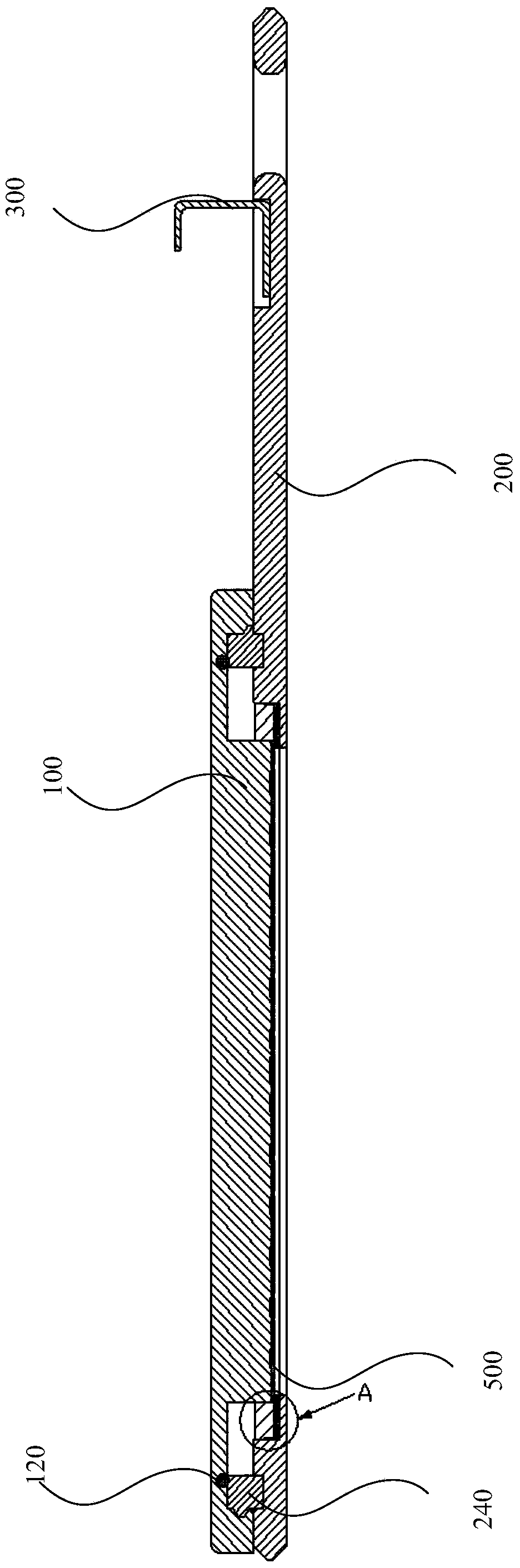

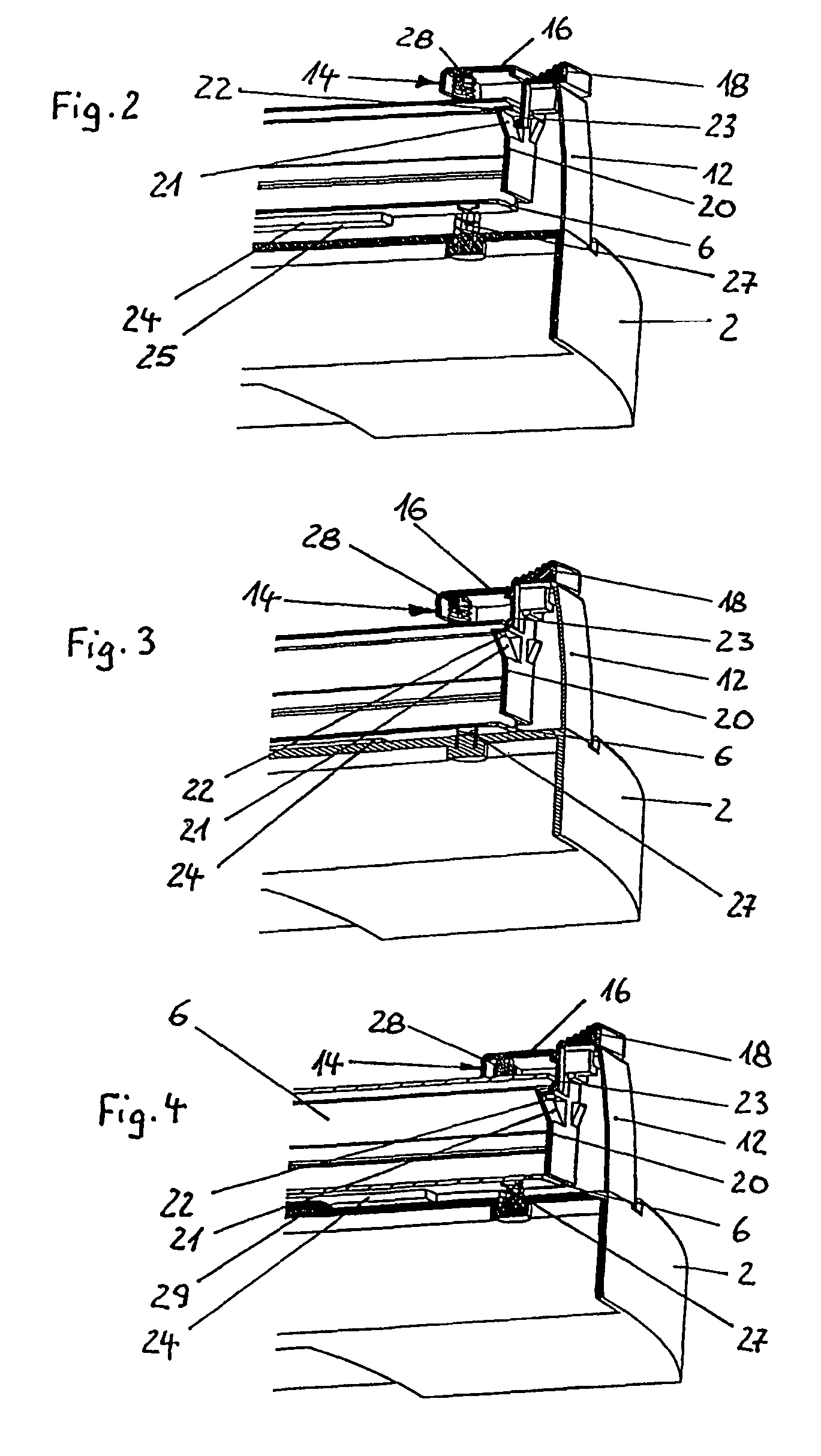

Process cartridge and electrophotographic image forming apparatus

InactiveUS6898392B2Simple structureSave spaceElectrographic process apparatusElectricityElectrical connection

This process cartridge includes a frame body, a cartridge electrical contact, and a pushed portion provided on the frame body. The process cartridge is detachably attached to a main body of an electrophotographic image forming apparatus including a main body electrical contact, and a main body pusher. When the process cartridge is attached to the main body of the electrophotographic image forming apparatus, it is possible to achieve an electrically strong connection of the cartridge electrical contact to the main body electrical contact by the pushed portion being pushed by the main body pusher. Owing to this simple structure, it is possible to realize the electrical connection of the cartridge electrical contact to the main body electrical contact.

Owner:CANON KK

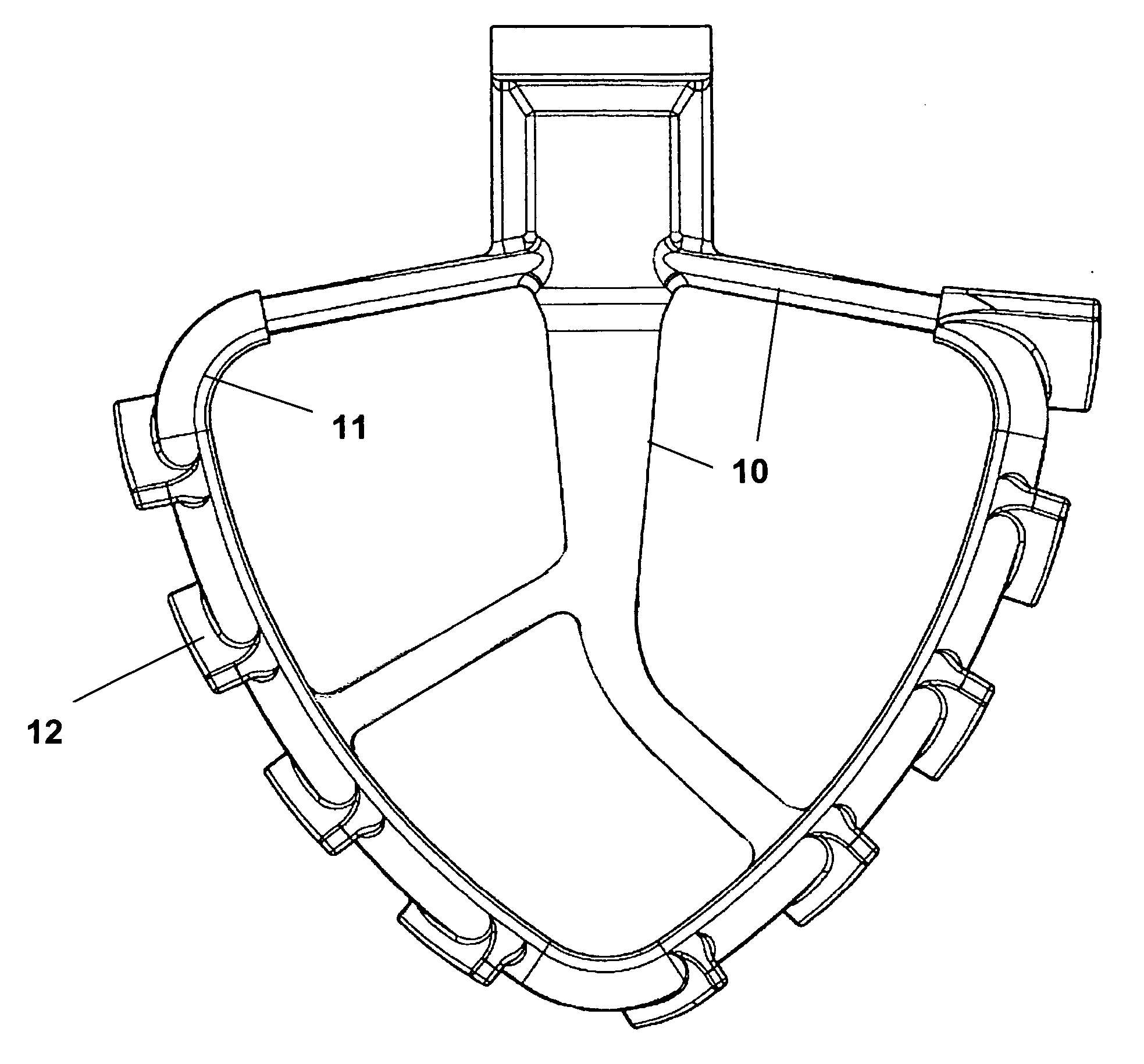

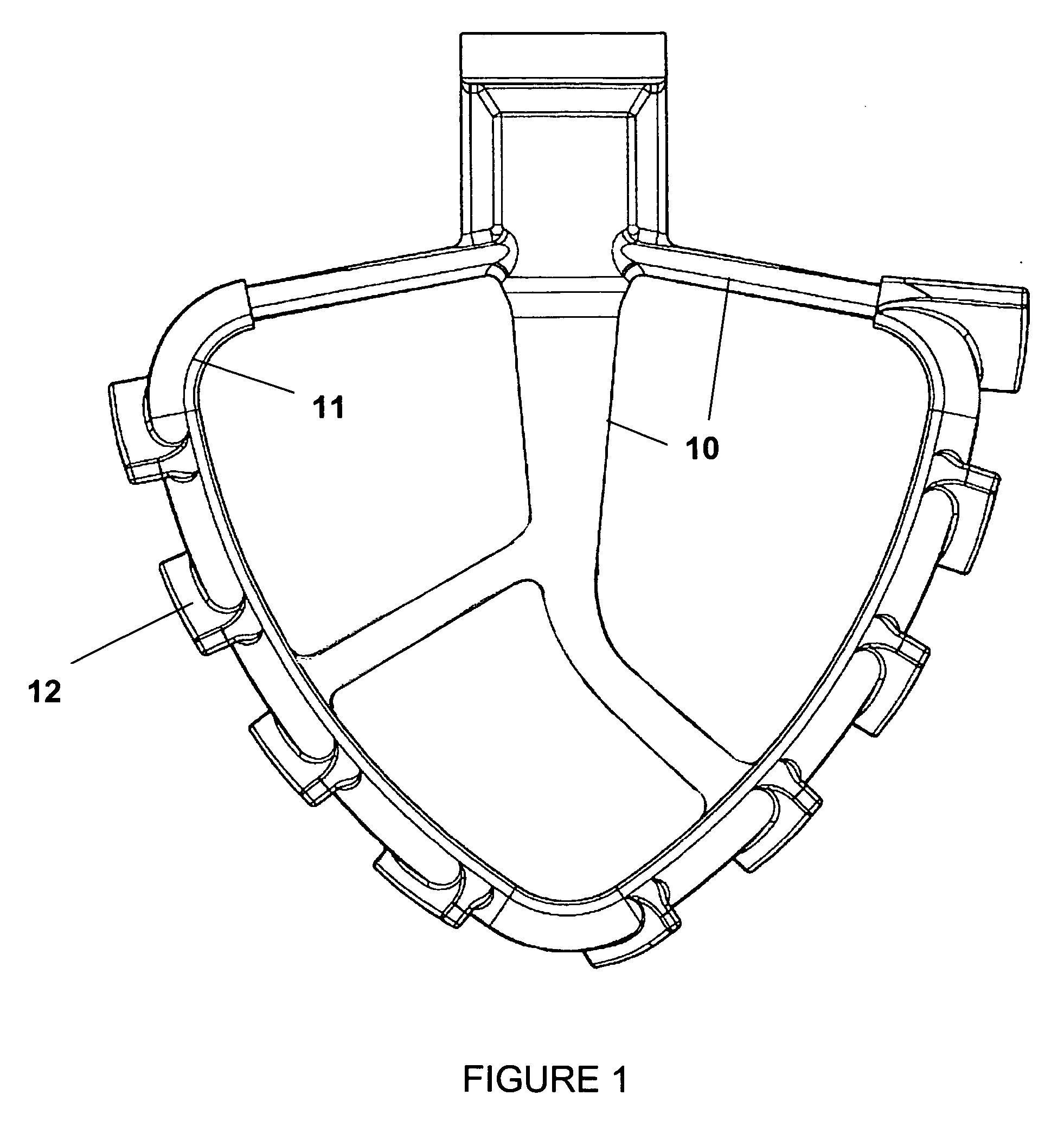

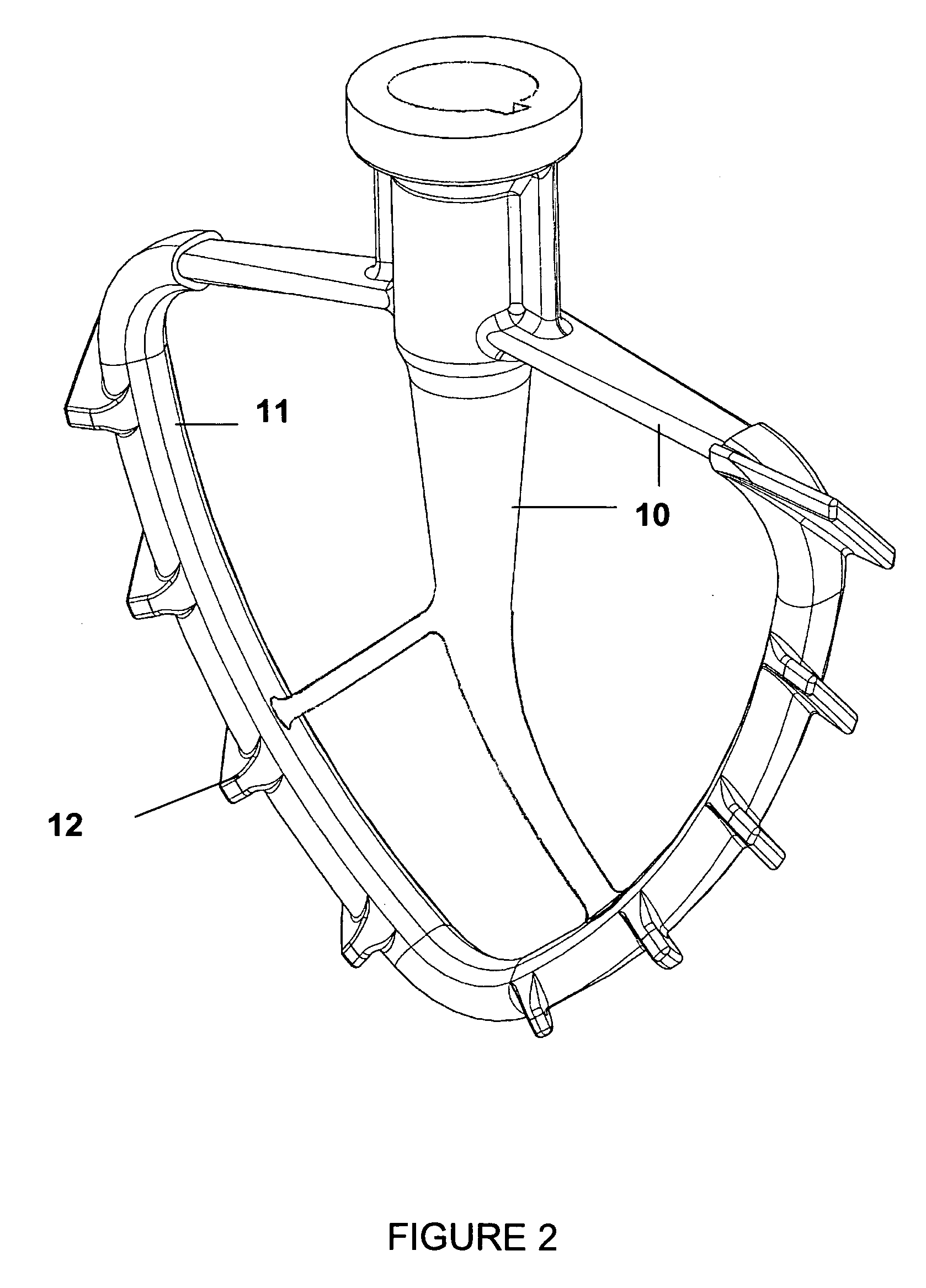

Mixer blade attachment with flexible fins

ActiveUS20060171251A1Even contactEasy to cleanRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

Owner:FRUT

Optical noninvasive vital sign monitor

ActiveUS20050283082A1Uniform pressure distributionEven contactDiagnostics using lightEvaluation of blood vesselsPhotovoltaic detectorsPhotodetector

An optical noninvasive vital sign monitor comprising a reflectance-type optical sensor within a pressurizable capsule retained by a headband, the capsule having an optically transparent or translucent inner wall adapted for placement against a subject's forehead. The optical sensor is mounted on the inside surface of the pressurizable capsule's inner wall, which contacts the subject's forehead during use, and includes a light source and a photodetector aimed toward the inside surface of the inner capsule wall. One embodiment of the vital sign monitor includes optical oscillometric circuit means responsive to an output signal from the optical sensor for determining systolic pressure, mean pressure and diastolic pressure during a transition in capsule pressure between a pressure greater than normal systolic pressure and a pressure less than normal diastolic pressure.

Owner:PURDUE RES FOUND INC

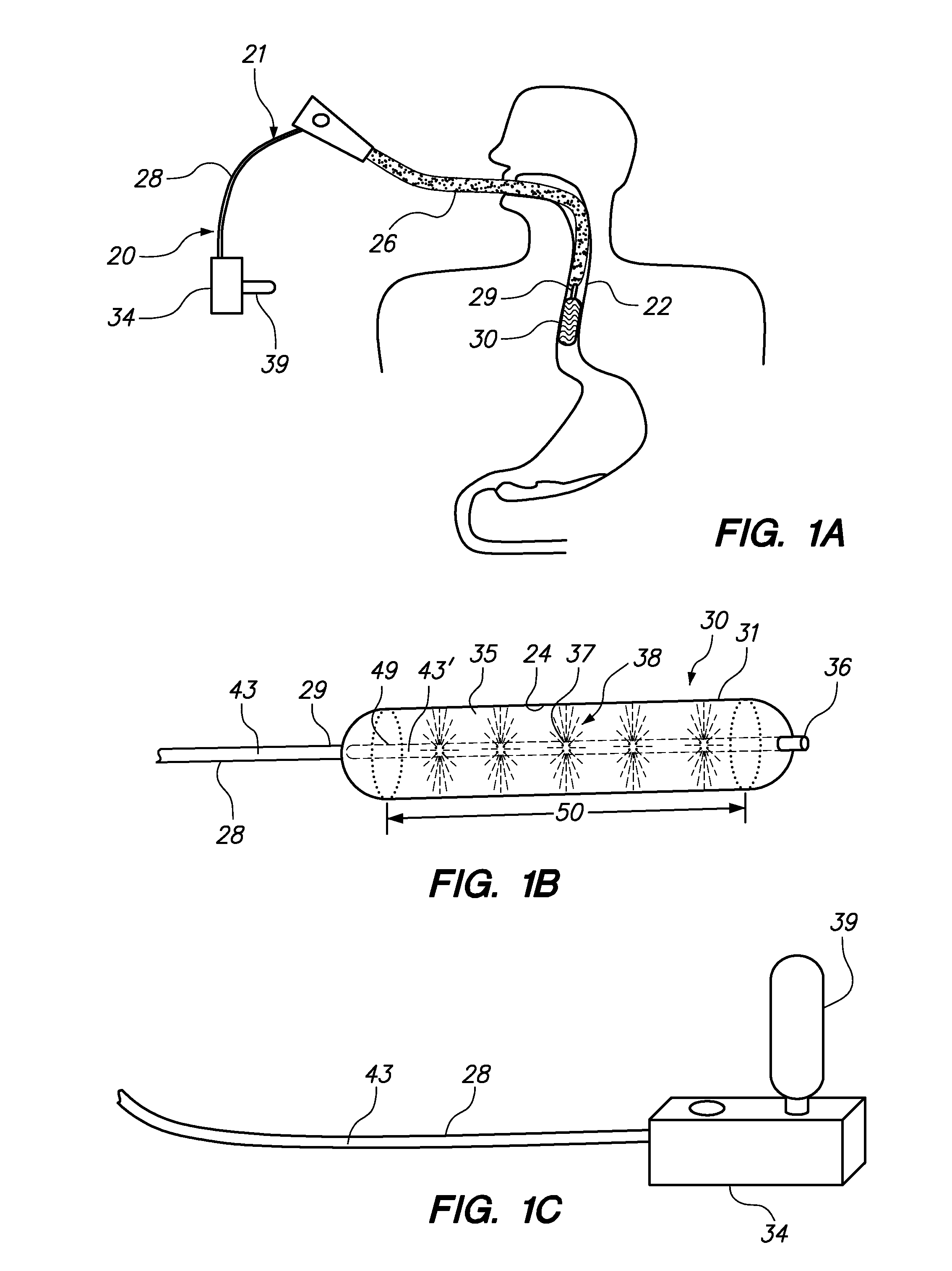

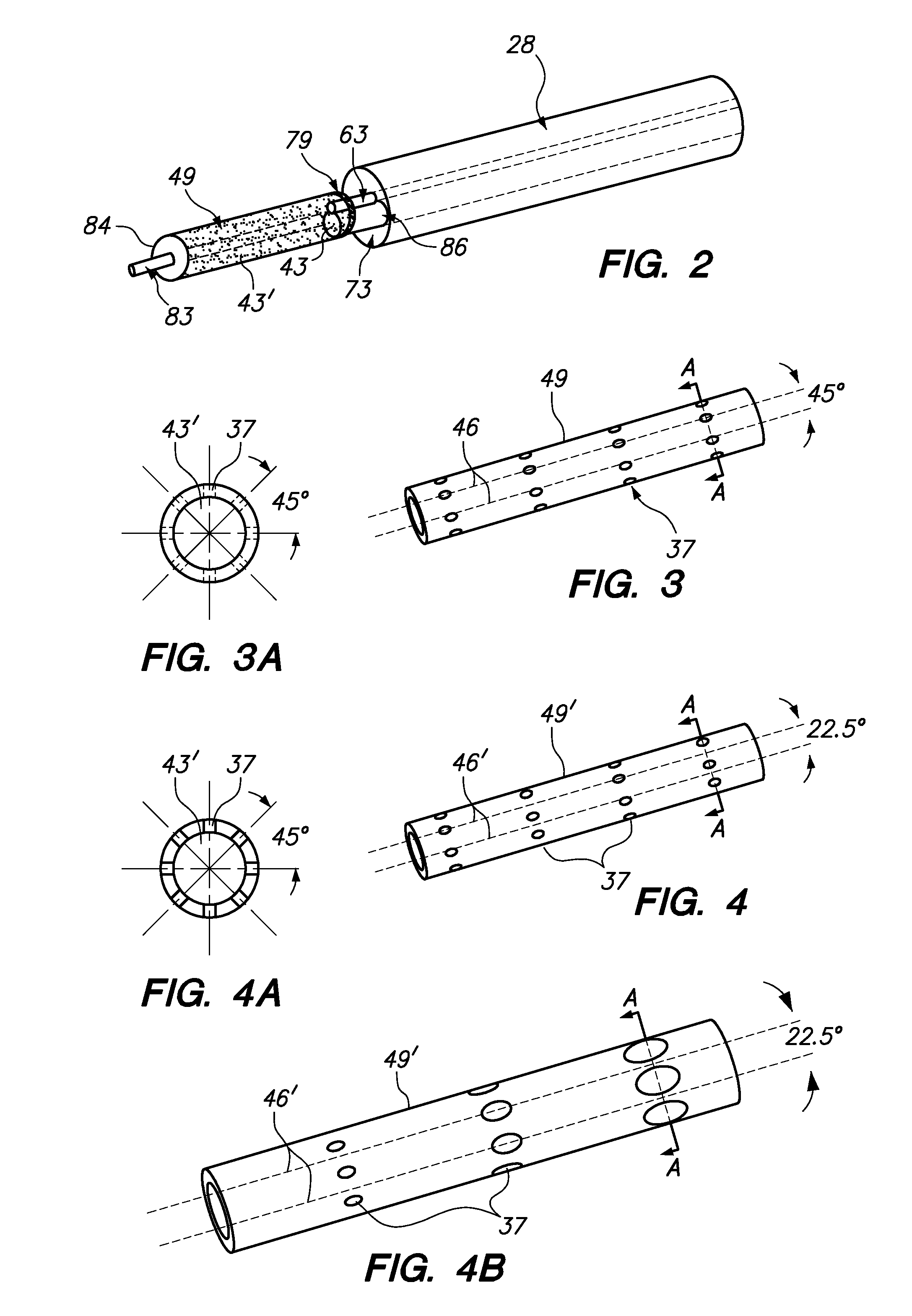

Cryogenic balloon ablation instruments and systems

A cryogenic tissue ablation instrument includes an elongate flexible body with a proximal supply port for coupling with a pressurized coolant, a supply lumen in communication with the proximal supply port, and an expandable balloon carried on the elongate body. A dispersion member coupled to the elongate body has an interior lumen in communication with the supply lumen, the dispersion member having one or more coolant dispersion apertures sized and located such that a pressurized flowable coolant will enter the balloon interior in the form of a liquid spray that contacts and provides substantially uniform cooling of the balloon.

Owner:BOSTON SCI SCIMED INC

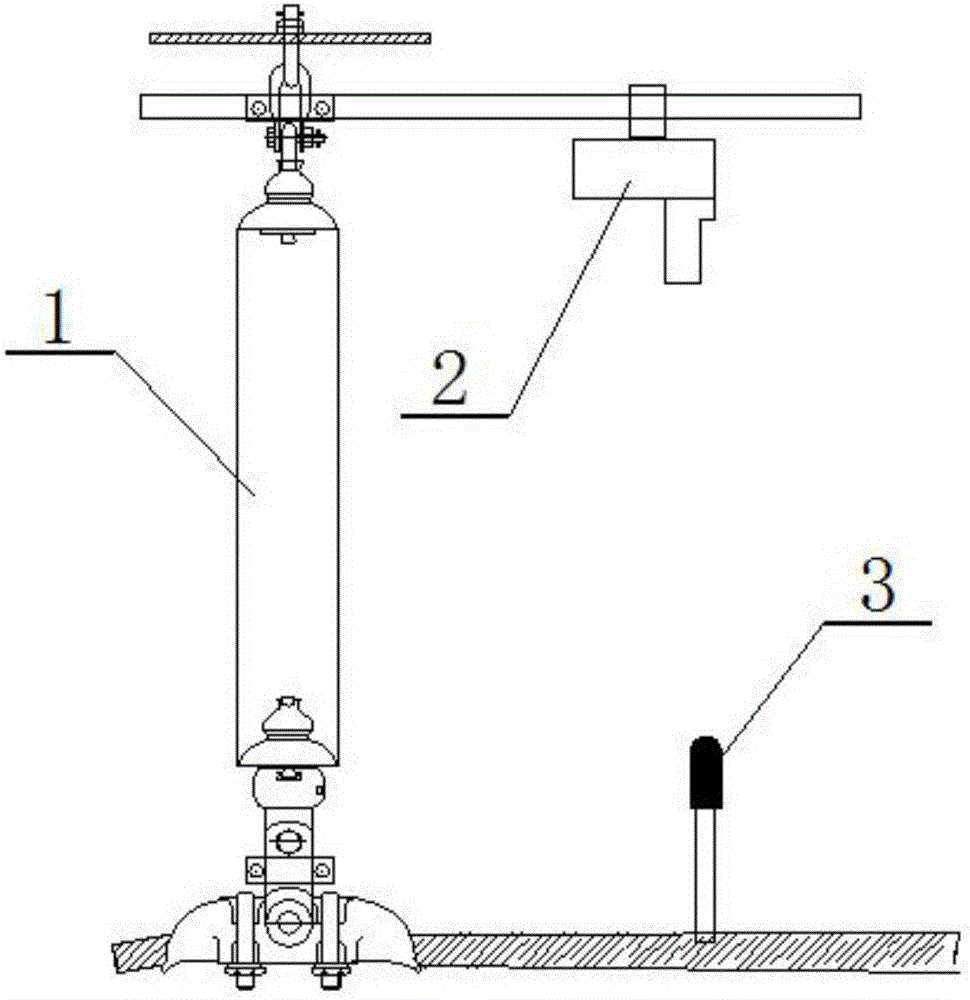

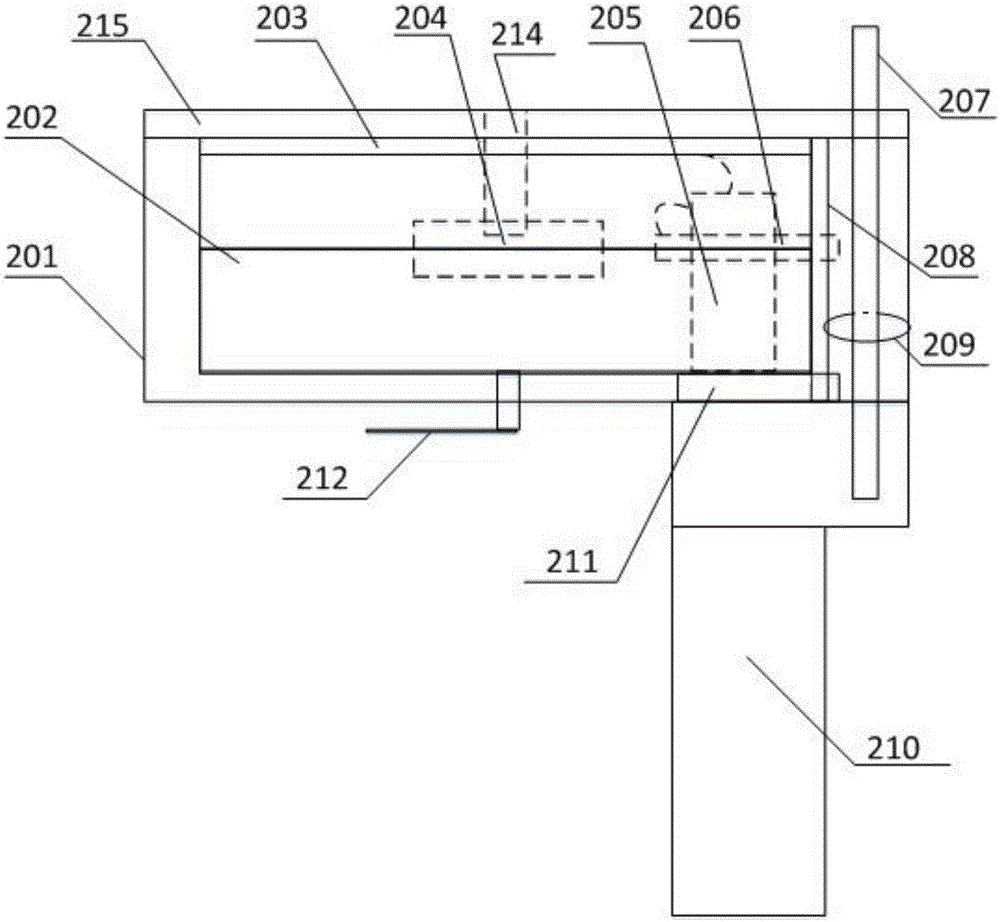

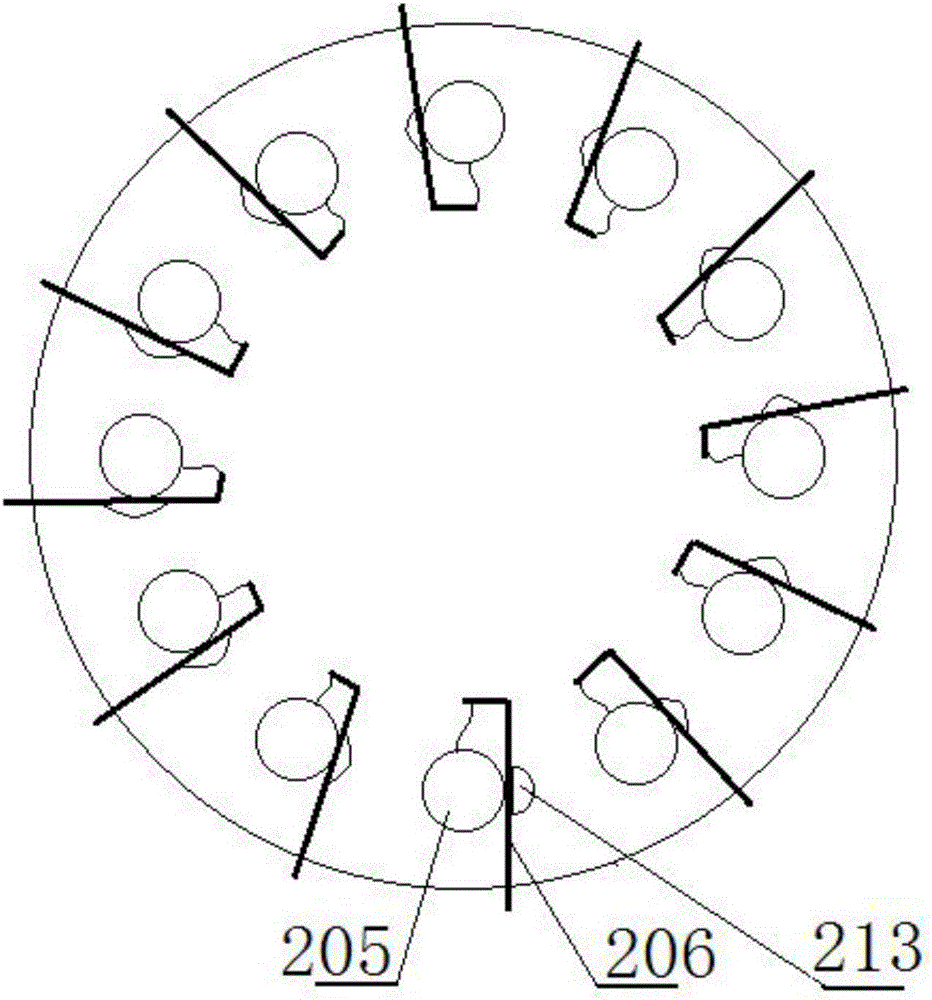

Thunder-lightening induced solid-phase arc-extinguishing lightning arrester

ActiveCN106451077AReliable rotationReliable stopSpark gap detailsDischarge by conduction/dissipationEngineeringMetal

The invention discloses a thunder-lightening induced solid-phase arc-extinguishing lightning arrester. The thunder-lightening induced solid-phase arc-extinguishing lightning arrester mainly consists of a lightning arrester shell, an arc-extinguishing rotary table, an electric conduction metal plate, a starting rod, a clamping rod, an induction coil, an arc-extinguishing barrel and a counting pointer; the arc-extinguishing rotary table is arranged inside the lightning arrester shell, and a flat spiral spring for pushing the arc-extinguishing rotary table to rotate is arranged at the central position of the arc-extinguishing rotary table; the electric conduction metal plate is arranged at the upper part of the arc-extinguishing rotary table; the arc-extinguishing rotary table is provided with a plurality of arc-extinguishing gas pills in the peripheral direction; one side of each arc-extinguishing gas pill is provided with a trigger electrode and a groove respectively, one end of each trigger electrode is connected with one of trigger ends of the corresponding arc-extinguishing gas pill through a lead, and the other ends of the trigger electrodes extend out of the edge of the arc-extinguishing rotary table; and the other of the trigger ends of the corresponding arc-extinguishing gas pill is connected with the electric conduction metal plate through a lead. The thunder-lightening induced solid-phase arc-extinguishing lightning arrester is simple in structure, reasonable in design, high in arc-extinguishing ability and stable and reliable to work, and the arc-extinguishing gas pills are changed quickly and conveniently.

Owner:王巨丰 +1

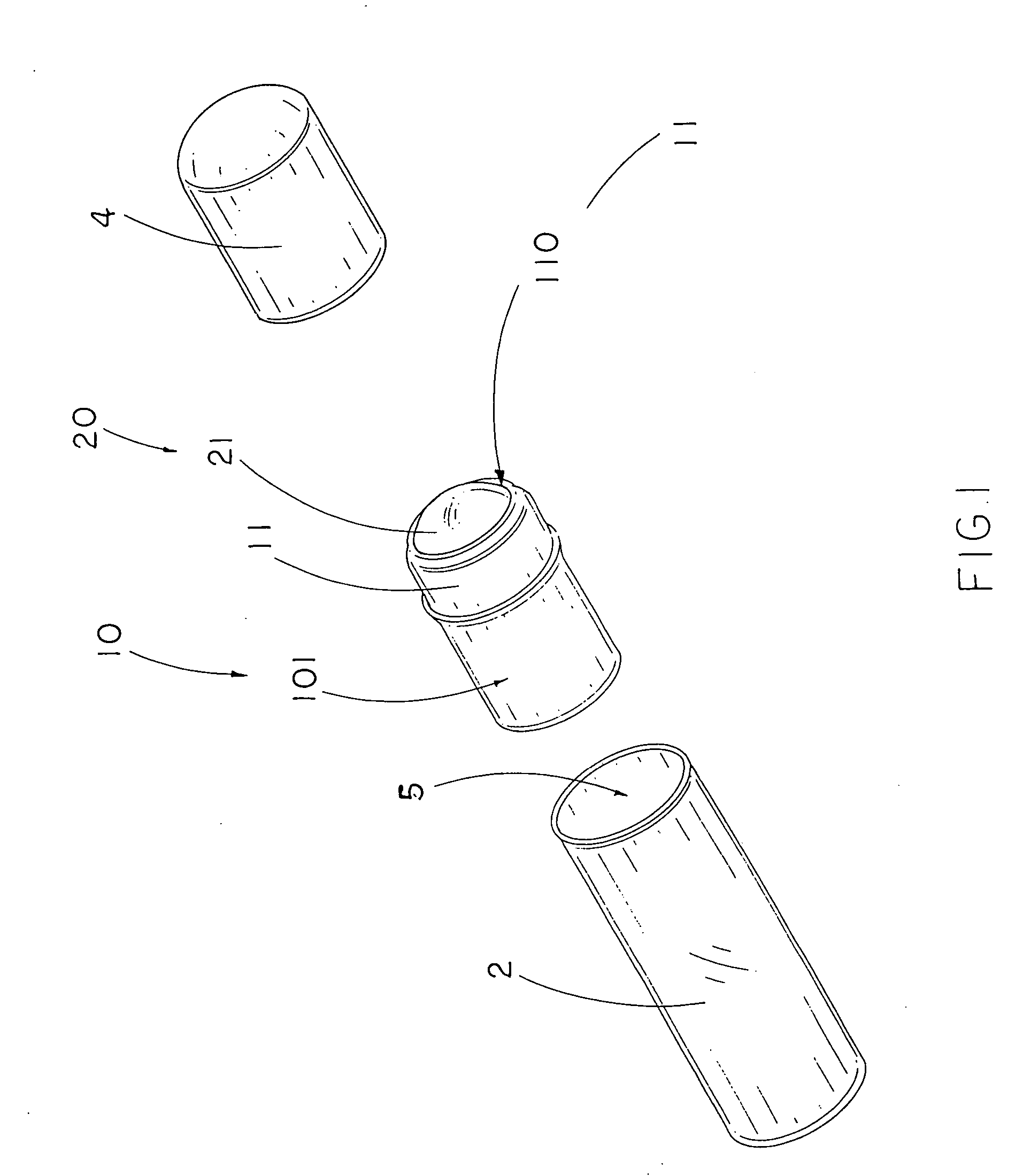

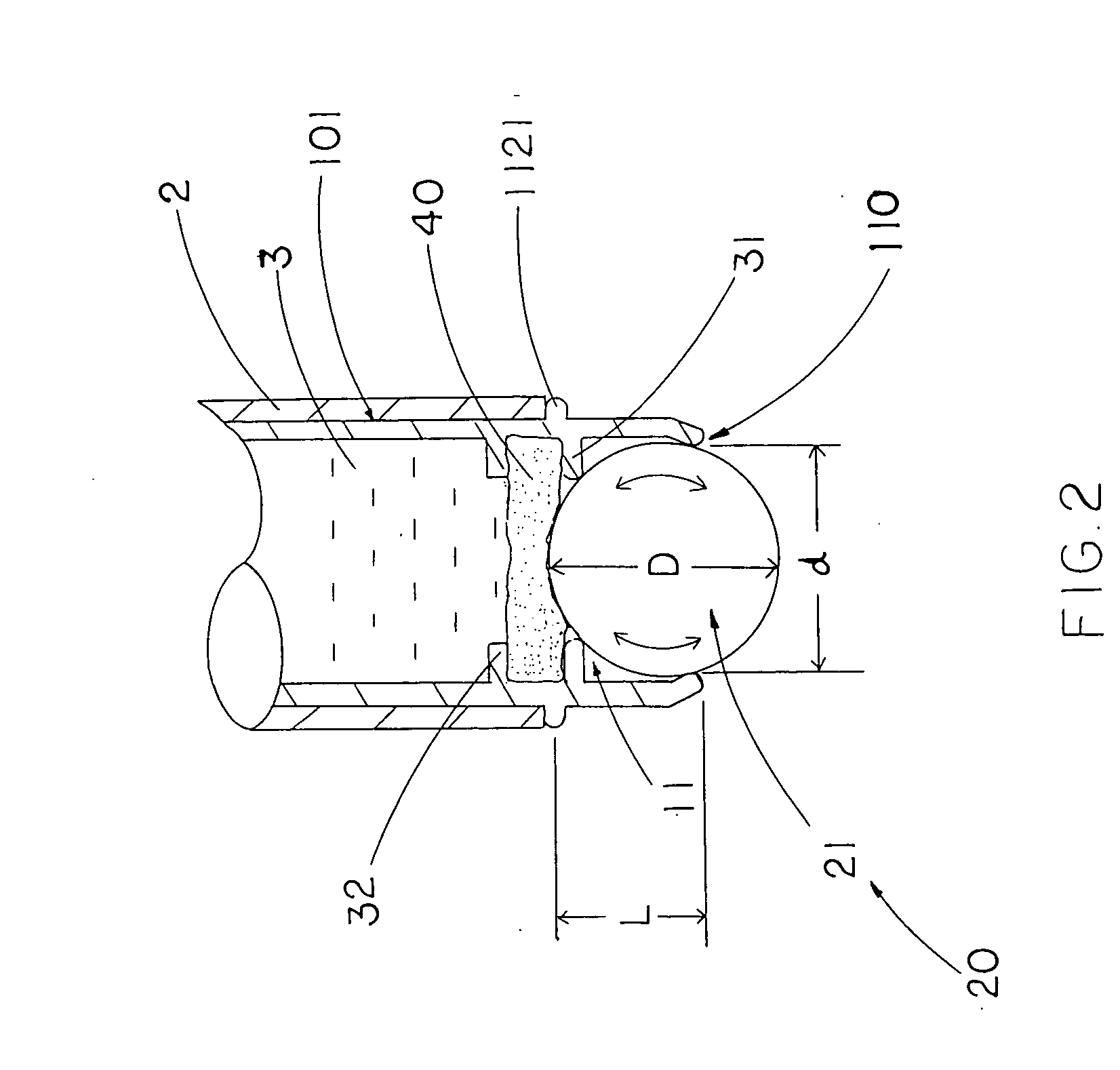

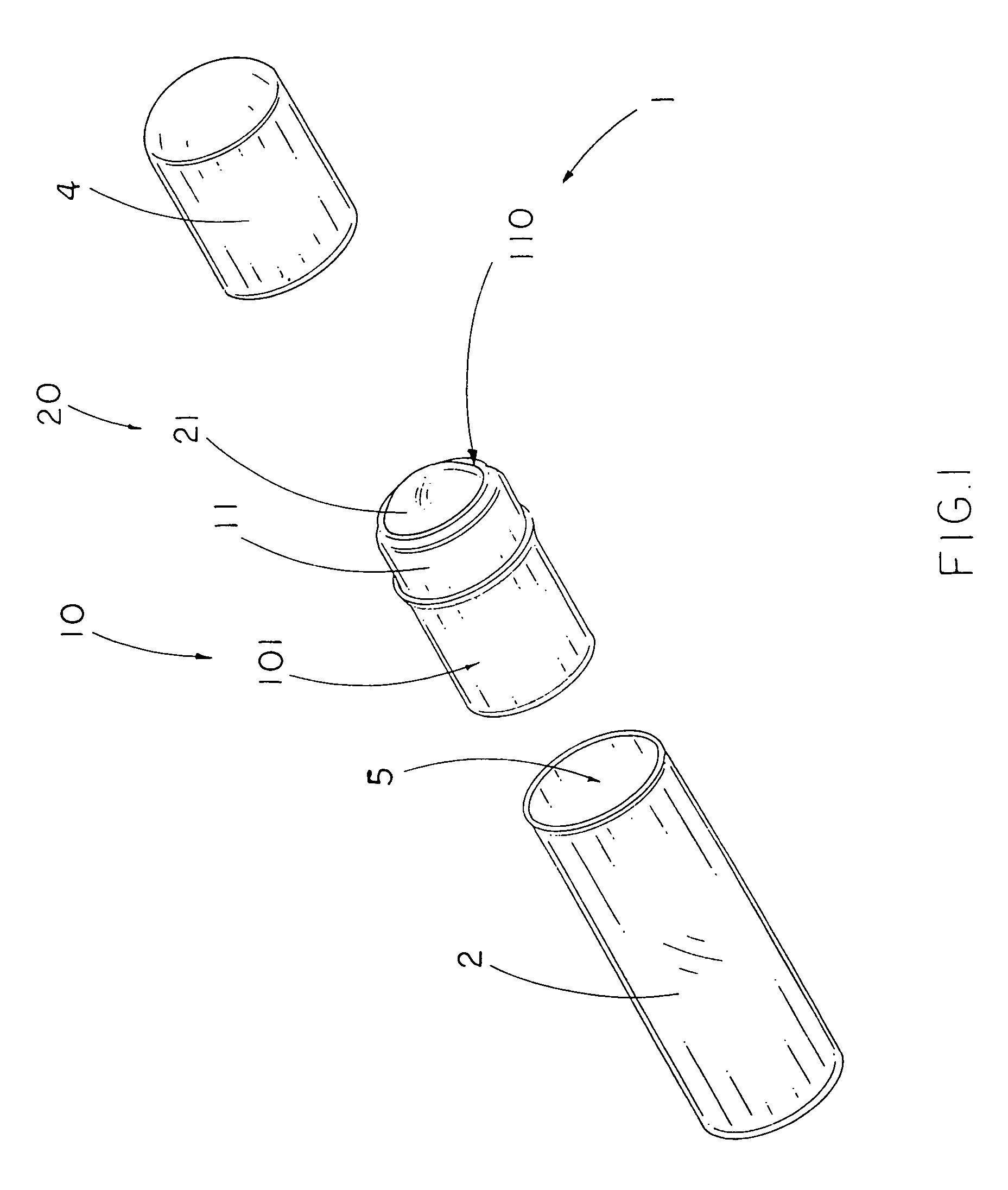

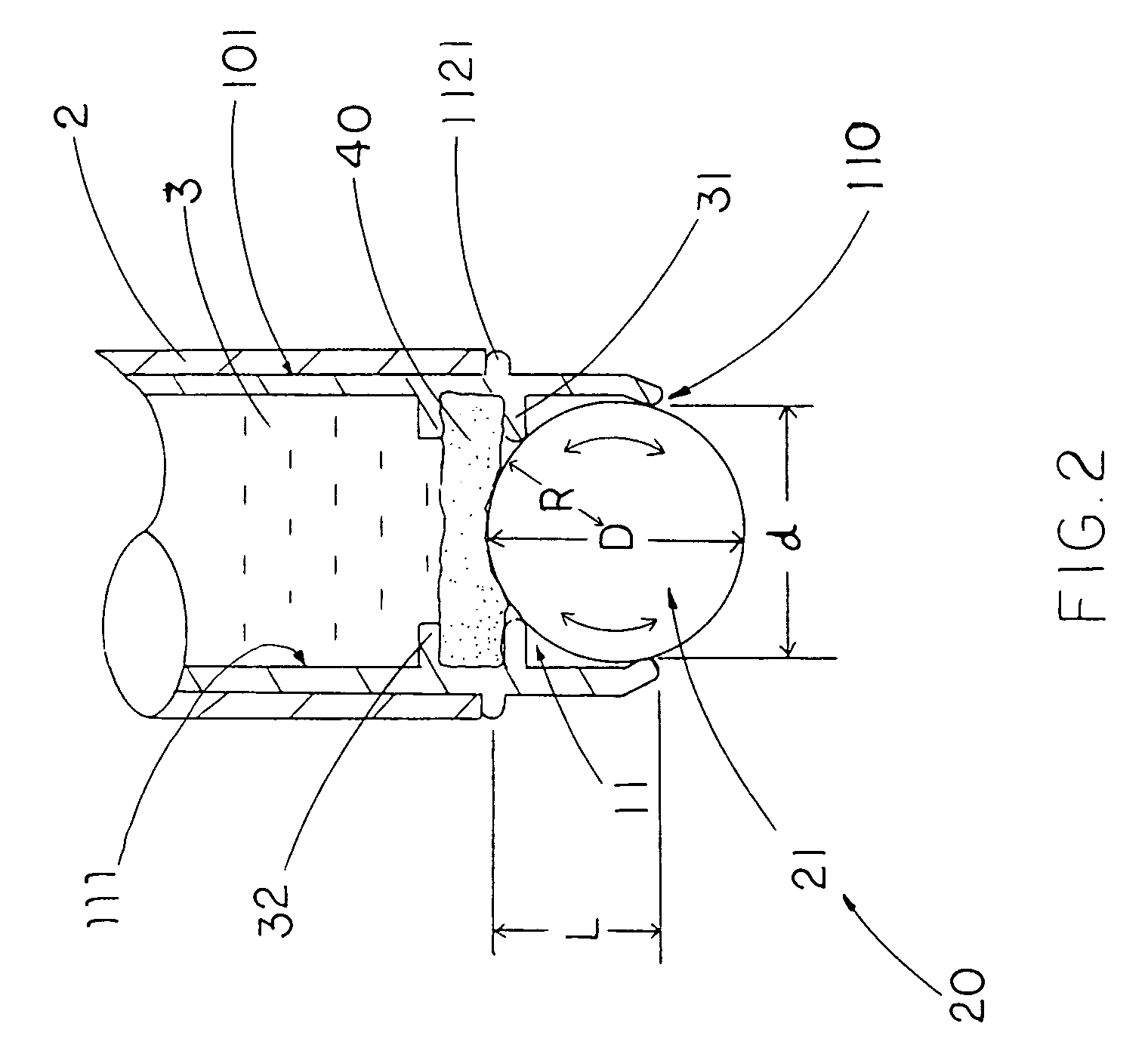

Dispenser head for fluid container

InactiveUS20060222445A1Reduce manufacturing costLow costPropelling pencilsBall-point pensEngineeringMechanical engineering

Owner:CHUANG KAIWIN

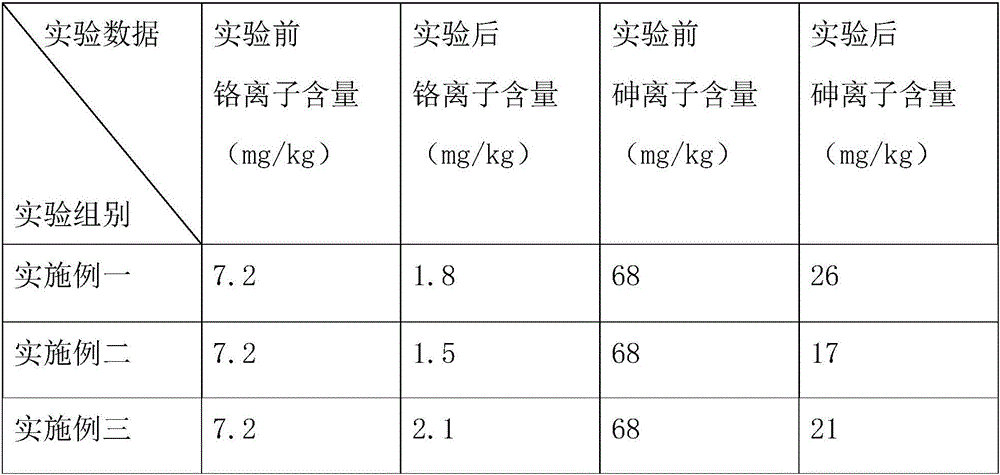

Preparation method of modified micron zero-valent iron and application method of modified micron zero-valent iron in remediation of heavy metal contaminated soil

ActiveCN106180735AAvoid secondary pollutionGood dispersionContaminated soil reclamationSoil treatmentSlag

The invention discloses a preparation method of modified micron zero-valent iron and an application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil. The preparation method of the modified micron zero-valent iron comprises the steps of cleaning of iron raw materials, preparation of micro iron, ultrafine grinding and modifying treatment. A modifying agent composed of water, xanthan gum, sulfide, a stabilizing agent, zeolite and blast furnace slag is adopted in the step of modifying treatment. The preparation method of the modified micron zero-valent iron has the beneficial effects that the production process of the modified micron zero-valent iron is simple, and the effect similar or superior to micron zero-valent iron is achieved while the cost is reduced; and in addition, the reaction activity is controlled, the oxidation rate is decreased, excellent stability is obtained, and the acting time of the micron zero-valent iron is longer. By the adoption of the application method of the modified micron zero-valent iron, the remediation cost of heavy metal contaminated underground water is further reduced. According to the preparation method of the modified micron zero-valent iron and the application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil, organic fertilizer is added in the soil treatment process so that the fertility of soil can be improved, the structure of soil can be improved through humic acid produced by the organic fertilizer, heavy metal elements, such as lead, chromium and arsenic, in underground water can be removed, and the concentration of pollutants such as nitrate and perchlorate can be reduced.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

Device and method for inspecting inside of underground pipe line and method of inspecting concrete on inside of underground pipe line for deterioration

InactiveUS7131344B2Improve accuracyImprove detection accuracyHollow article cleaningStructural/machines measurementCamera lensFisheye lens

A device for inspecting the inside of an underground pipe line which makes it possible to search for cavities on the outside of the underground pipe over the entire internal peripheral surface of the underground pipe, that is, not only upward of the underground pipe, but also toward both sides and downward thereof, to obtain detailed images of the inner peripheral surface of the pipe line without using a complex mechanism, and to display patterns of cracks and irregularities on the inner peripheral surface of the underground pipe by three-dimensional convergence images. The device comprises a pipe line internal self-propelled vehicle and an on-ground control unit, and the pipe line internal self-propelled vehicle is provided with a radar antenna, a camera equipped with a fisheye lens, a gyro, a laser sensor, and an infrared encoder.

Owner:BURN AM

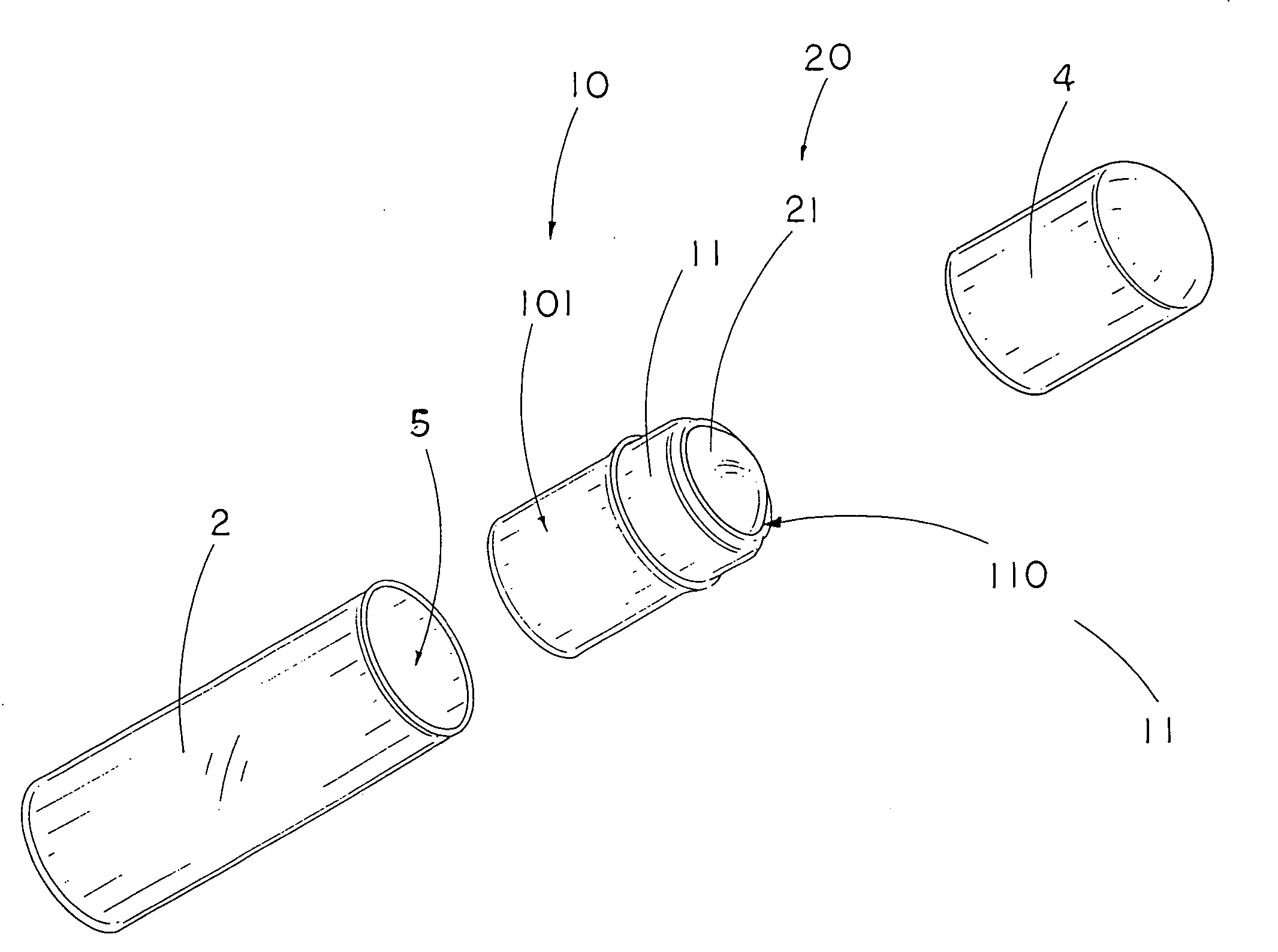

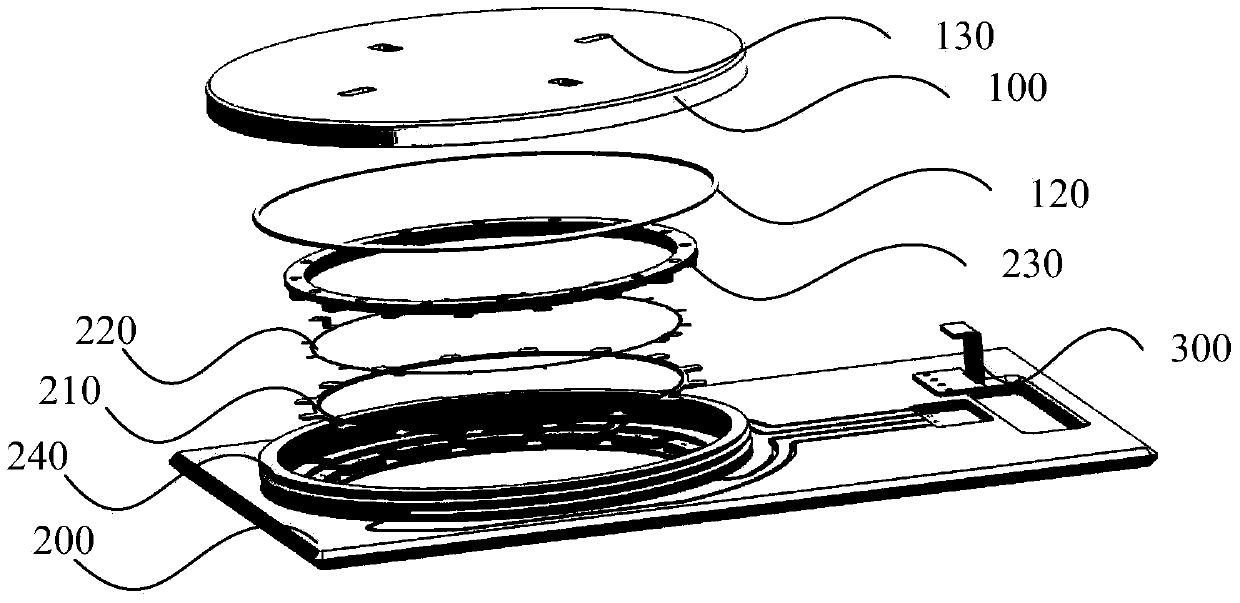

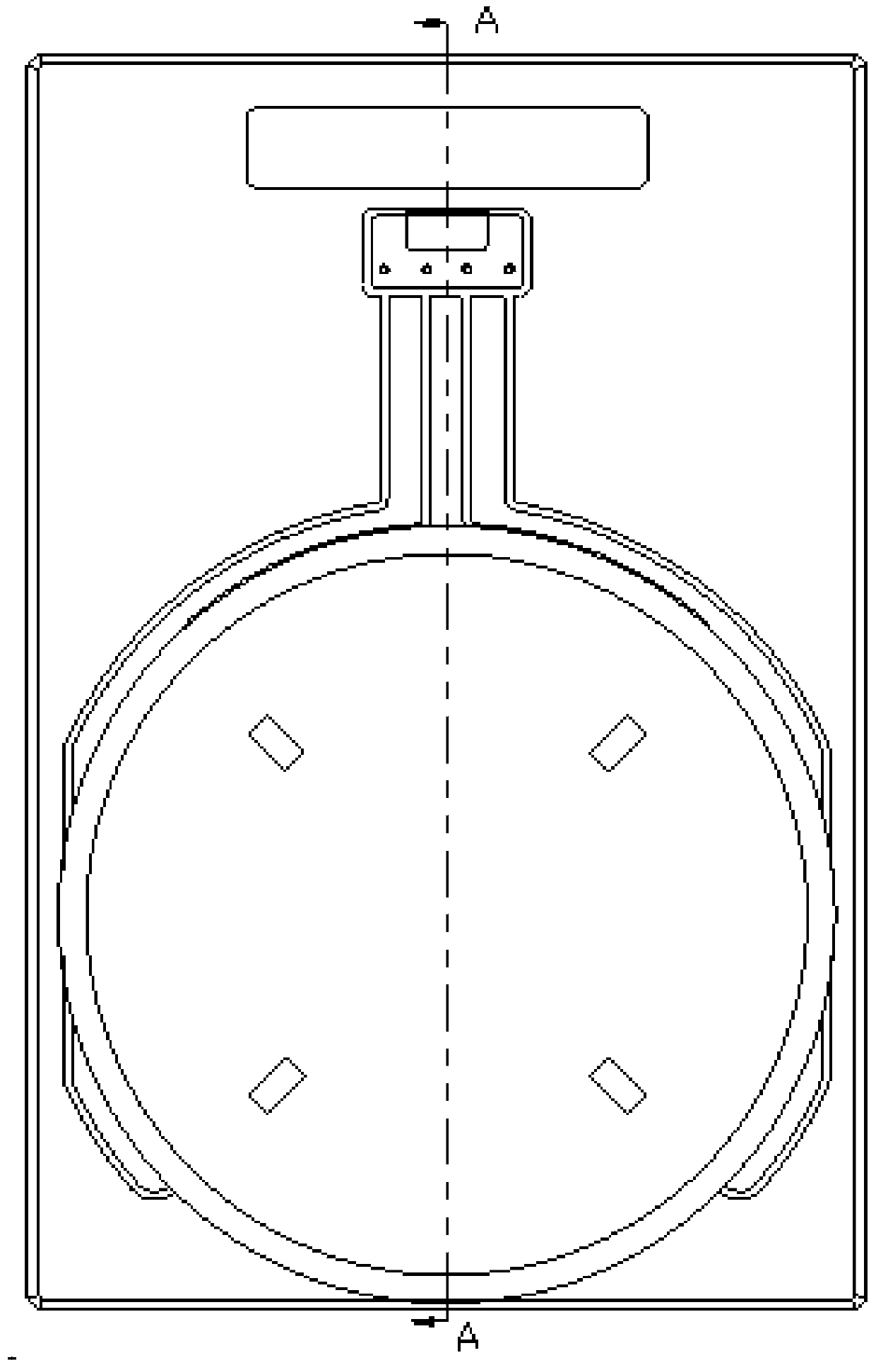

Hanging tool for wafer electroplating

ActiveCN103469271AUniform platingContact withElectrolysis componentsSemiconductor devicesEngineeringElectroplating

The invention discloses a hanging tool for wafer electroplating. The hanging tool comprises an upper cover, a lower plate and a metal conductive ring, wherein an inner thread is arranged on the inner wall of the upper cover, a wafer groove is formed in the lower plate, an electroplating hole is formed in the middle of the wafer groove, and an outer thread engaged with the inner thread is arranged on the outer wall of the wafer groove; a platform is arranged between the inner wall of the wafer groove and the electroplating hole; the metal conductive ring is arranged on the platform. The upper cover of the hanging tool for the wafer electroplating is locked in a rotary mode, and the need of manually disassembling screws is eliminated, so that the hanging tool is convenient to operate, uniform in force, good in electrical conductivity and sealing performance and uniform in water coating, thereby greatly saving the manpower and reducing the wafer scrapping risk.

Owner:江苏矽智半导体科技有限公司

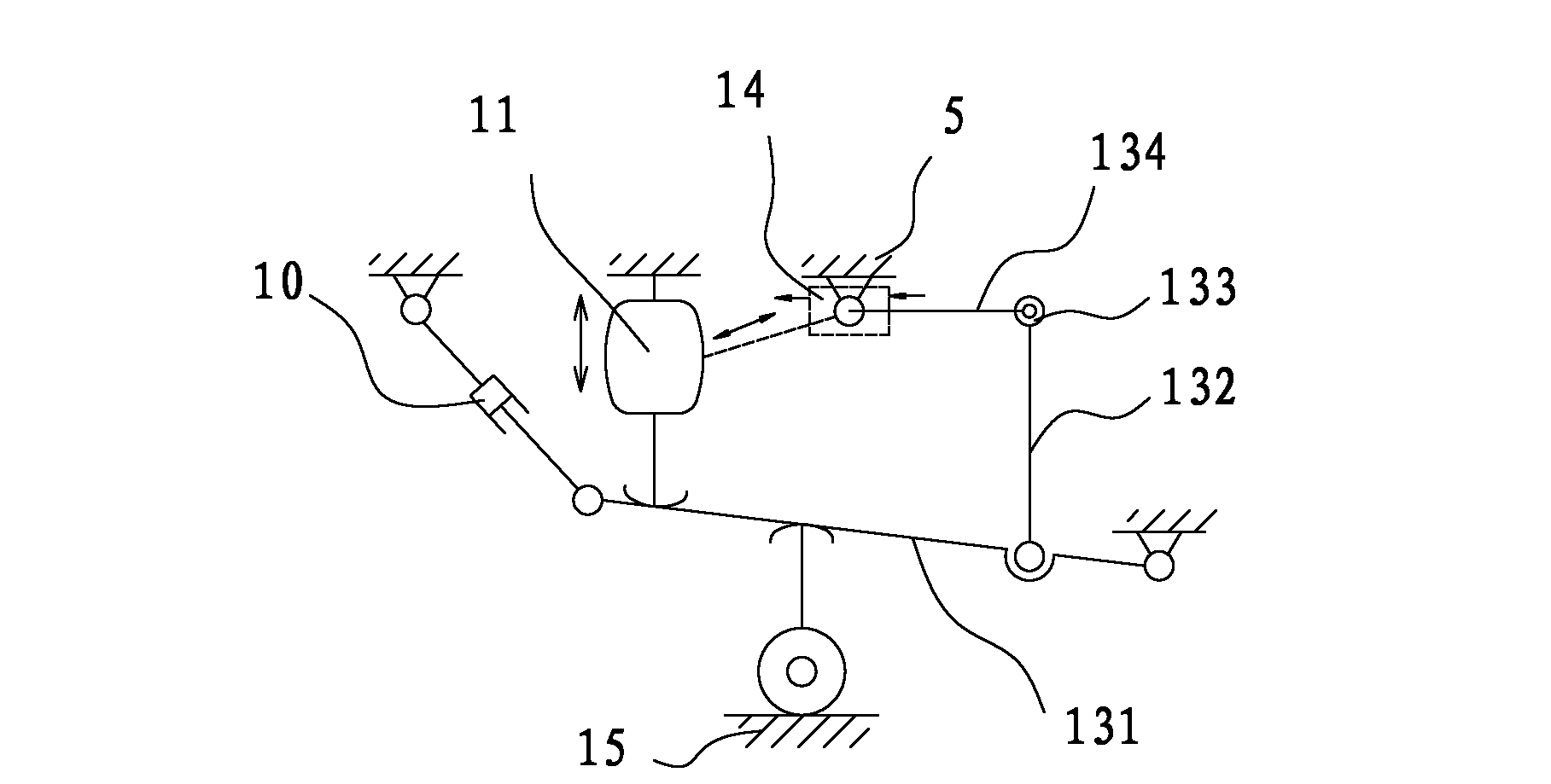

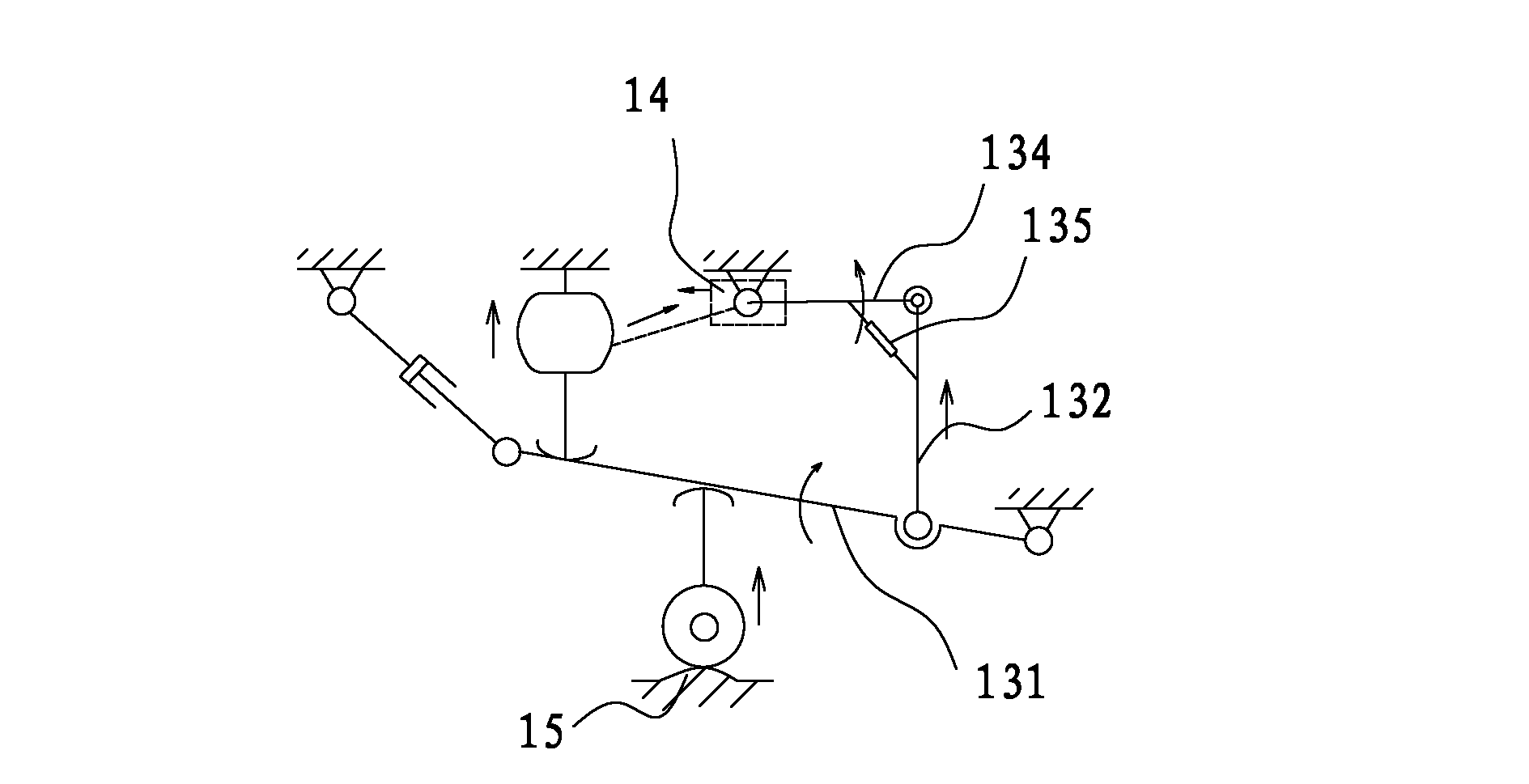

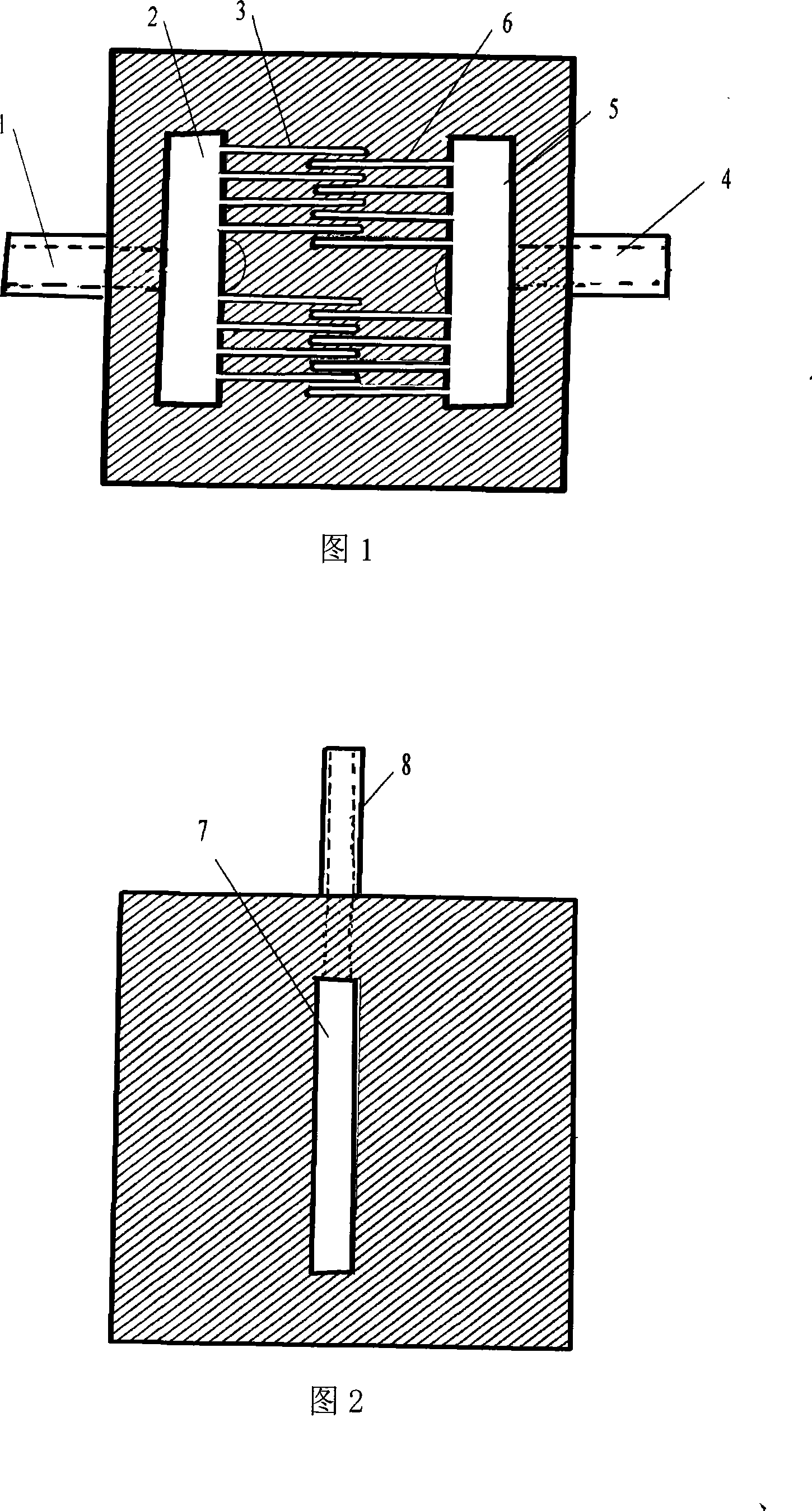

Method of removing oxide layer and semiconductor manufacturing apparatus for removing oxide layer

InactiveUS20050087893A1High selectivityEven contactDecorative surface effectsSemiconductor/solid-state device manufacturingReaction layerSusceptor

A method for removing an oxide layer such as a natural oxide layer and a semiconductor manufacturing apparatus which uses the method to remove the oxide layer. A vertically movable susceptor is installed at the lower portion in a processing chamber and a silicon wafer is loaded onto the susceptor when it is at the lower portion of the processing chamber. The air is exhausted from the processing chamber to form a vacuum condition therein. A hydrogen gas in a plasma state and a fluorine-containing gas are supplied into the processing chamber to induce a chemical reaction with the oxide layer on the silicon wafer, resulting in a reaction layer. Then, the susceptor is moved up to the upper portion of the processing chamber, to anneal the silicon wafer on the susceptor with a heater installed at the upper portion of the processing chamber, thus vaporizing the reaction layer. The vaporized reaction layer is exhausted out of the chamber. The oxide layer can be removed with a high selectivity while avoiding damage or contamination of the underlying layer.

Owner:SAMSUNG ELECTRONICS CO LTD

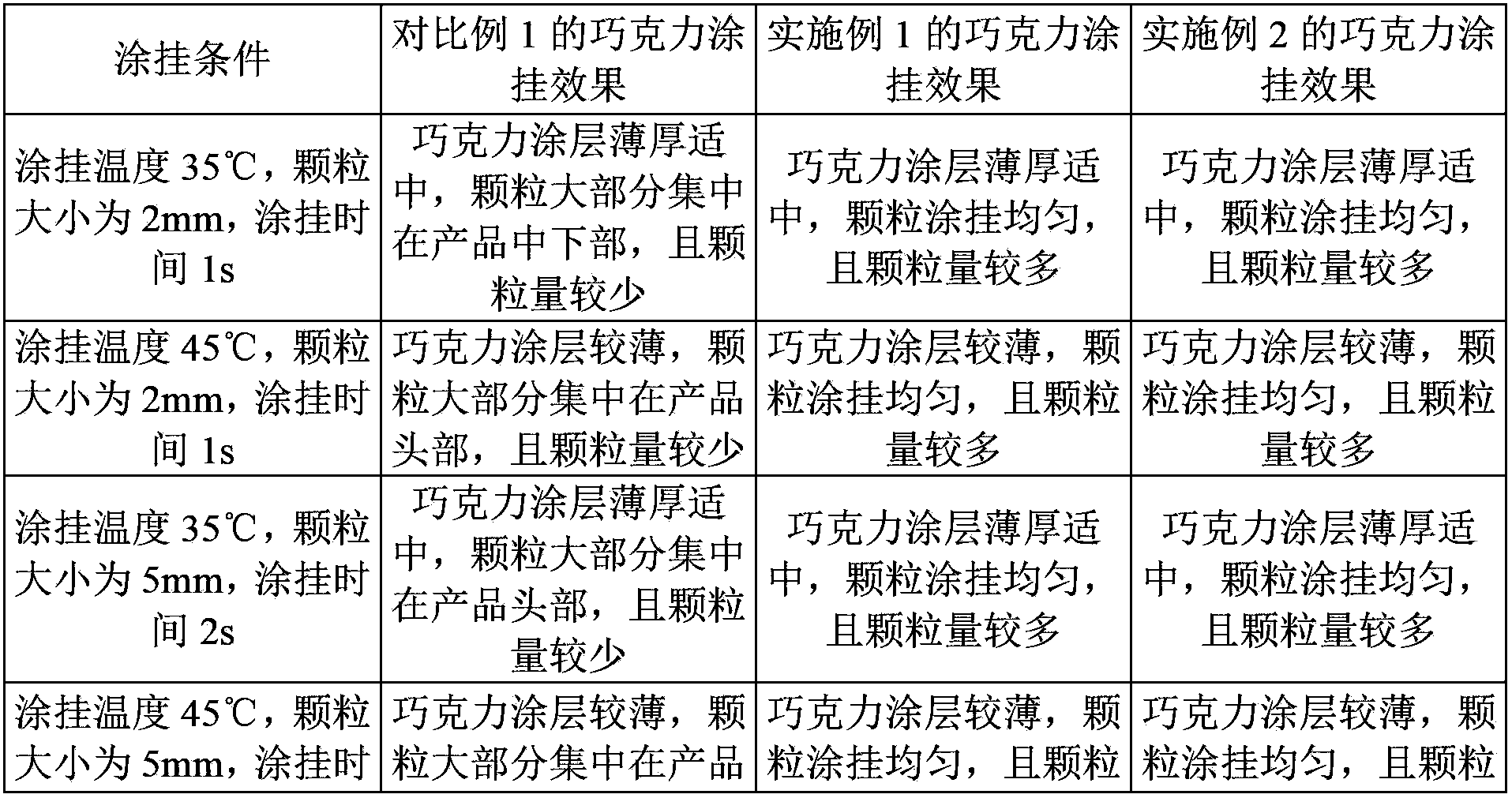

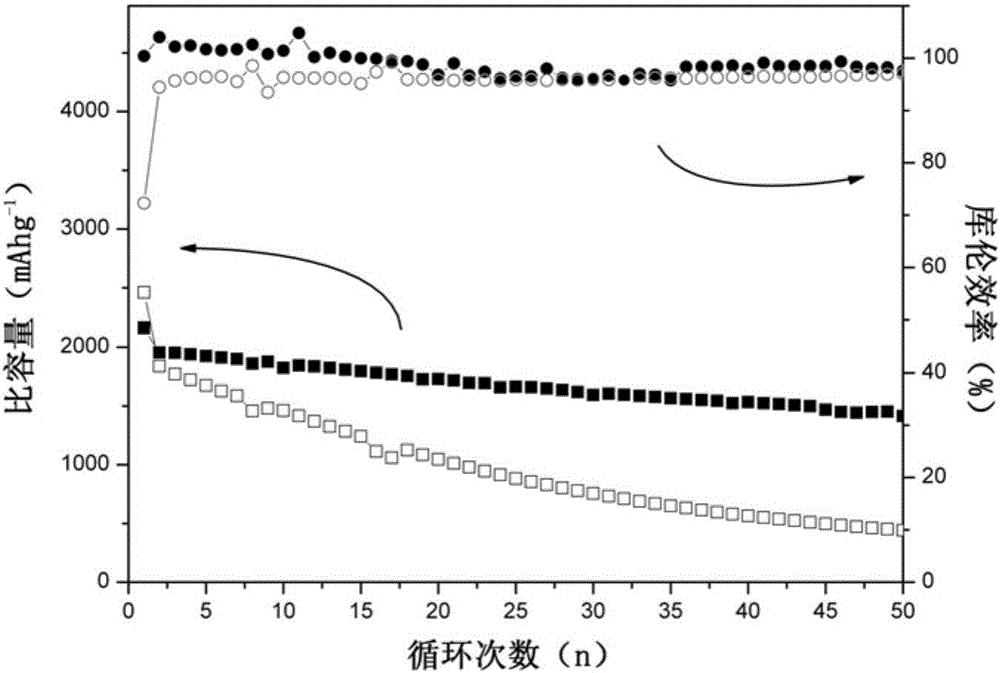

Chocolate used for external coating of cold drink, and particle-containing chocolate coat

The invention relates to the food field, and concretely relates to a chocolate used for the external coating of a cold drink, and a particle-containing chocolate coat. The chocolate used for the external coating of a cold drink comprises 33-37wt% of white granulated sugar, 9-11wt% of whole milk power, 23-25wt% of coconut oil, 3-5wt% of anhydrous cream, 4-6wt% of cocoa powder, 9-11wt% of natural cocoa butter, 8-10wt% of cocoa liquor, and 2.5-3.5wt% of an emulsifier, wherein the sum of the weight percentages of all the above components is 100%. Particles can suspend in the chocolate, so the particles can be uniformly distributed in the surface of a product in the coating process, the proper mouthfeel of the externally coated chocolate is guaranteed, and the coating amount of the chocolate can be effectively controlled in order to realize an ideal coating effect.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

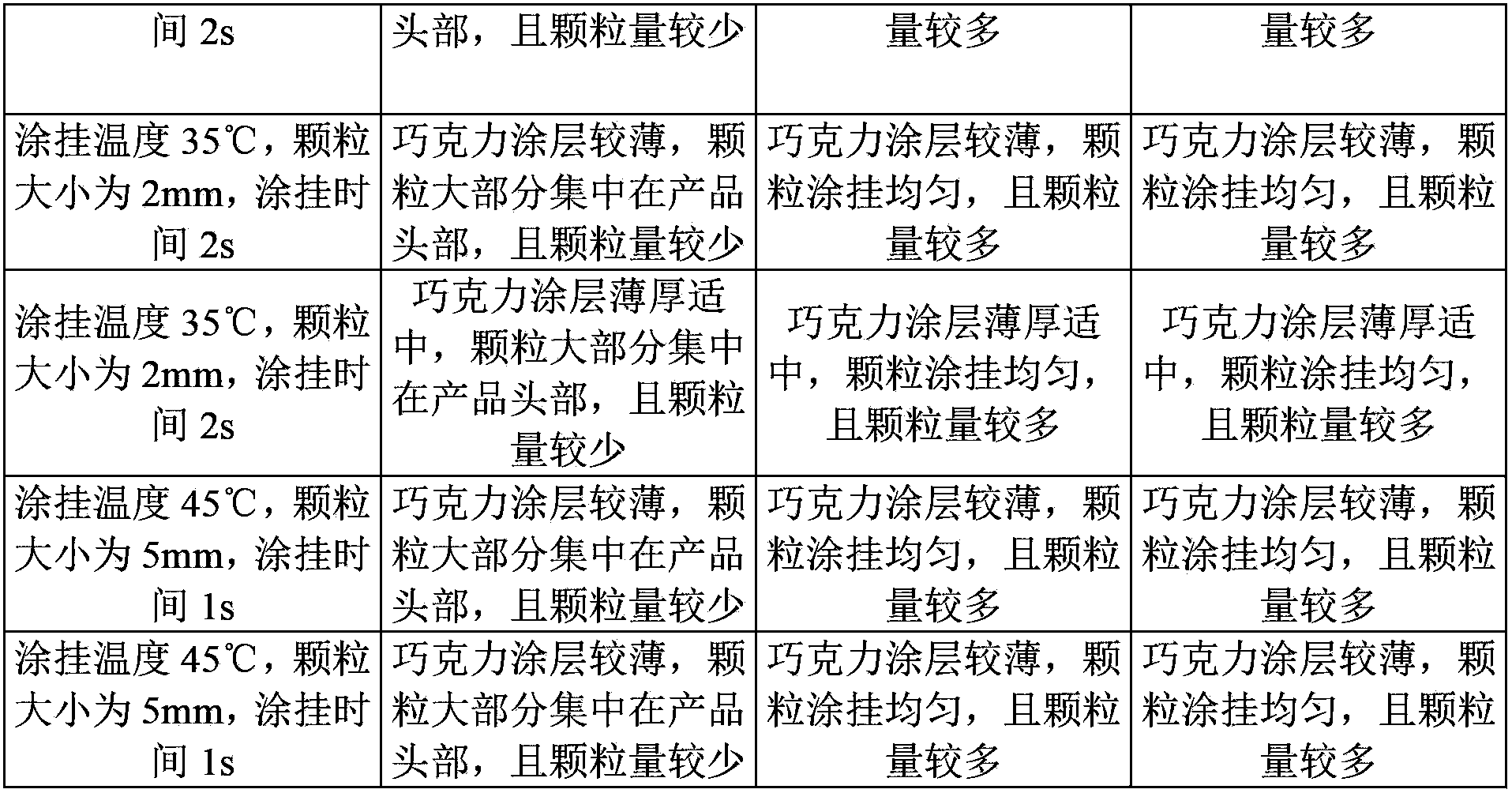

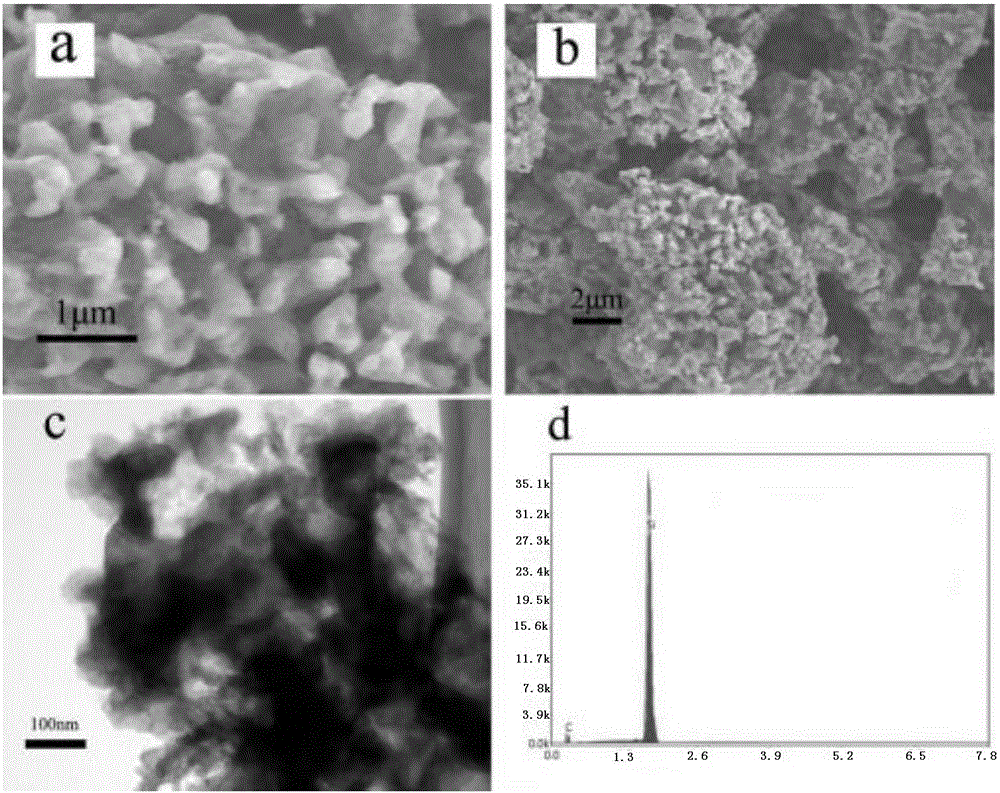

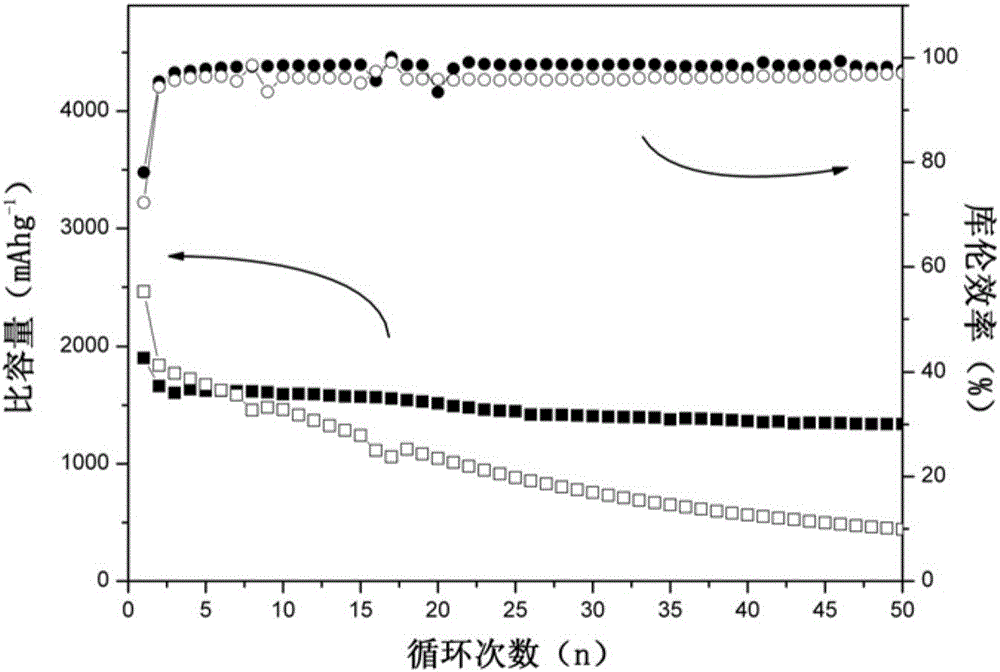

Porous silicon-carbon composite material and preparation method and application thereof

ActiveCN105826527AImprove cycle stabilitySimple processCell electrodesSecondary cellsCarbon compositesMagnesium silicide

The invention discloses a preparation method of a porous silicon-carbon composite material.The preparation method specifically comprises the steps that magnesium silicide powder is placed in a CO2-Ar mixed atmosphere to be subjected to heat treatment at the temperature of 700 DEG C-900 DEG C and then subjected to acid pickling and aftertreatment to obtain the porous silicon-carbon composite material, wherein the volume fraction of CO2 in the CO2-Ar mixed atmosphere is 10%-90%.According to the preparation method, the technology is simple, repetition is easy to achieve, and large-scale industrialized production can be achieved.When the porous silicon-carbon composite material prepared through the method is applied to a lithium ion battery by serving as a negative electrode material, the circulating stability of the lithium ion battery can be significantly improved.

Owner:ZHEJIANG UNIV

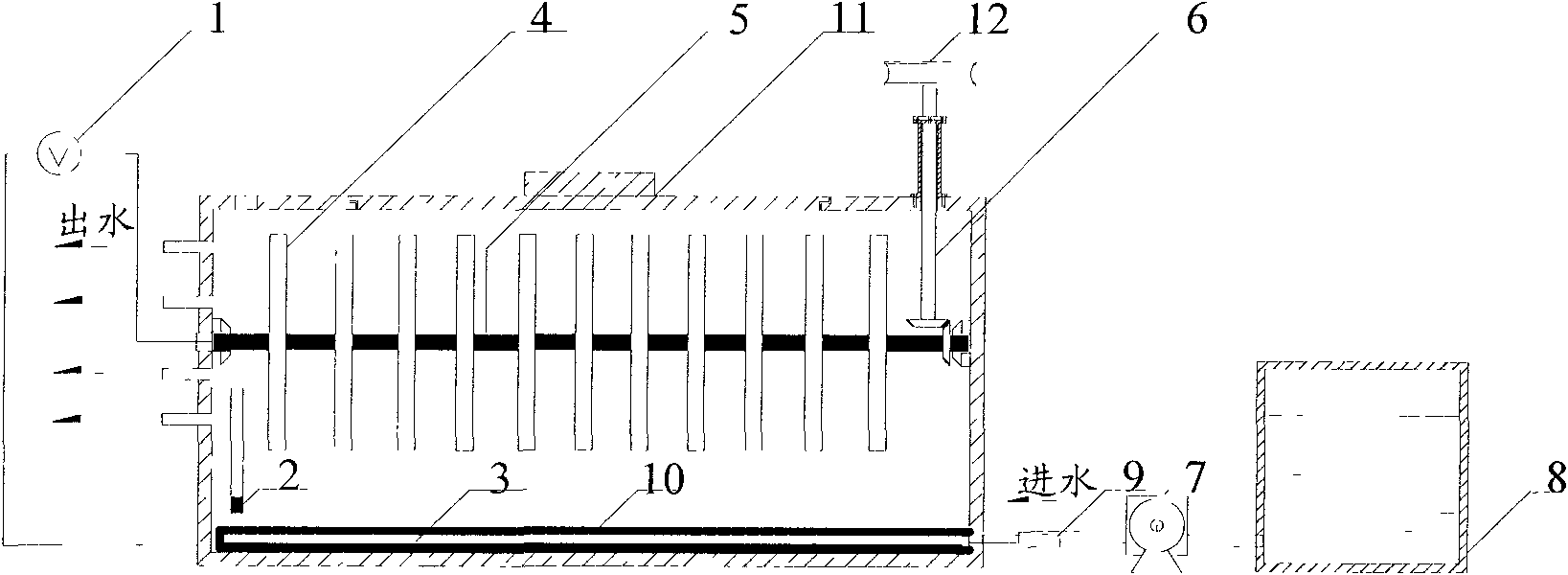

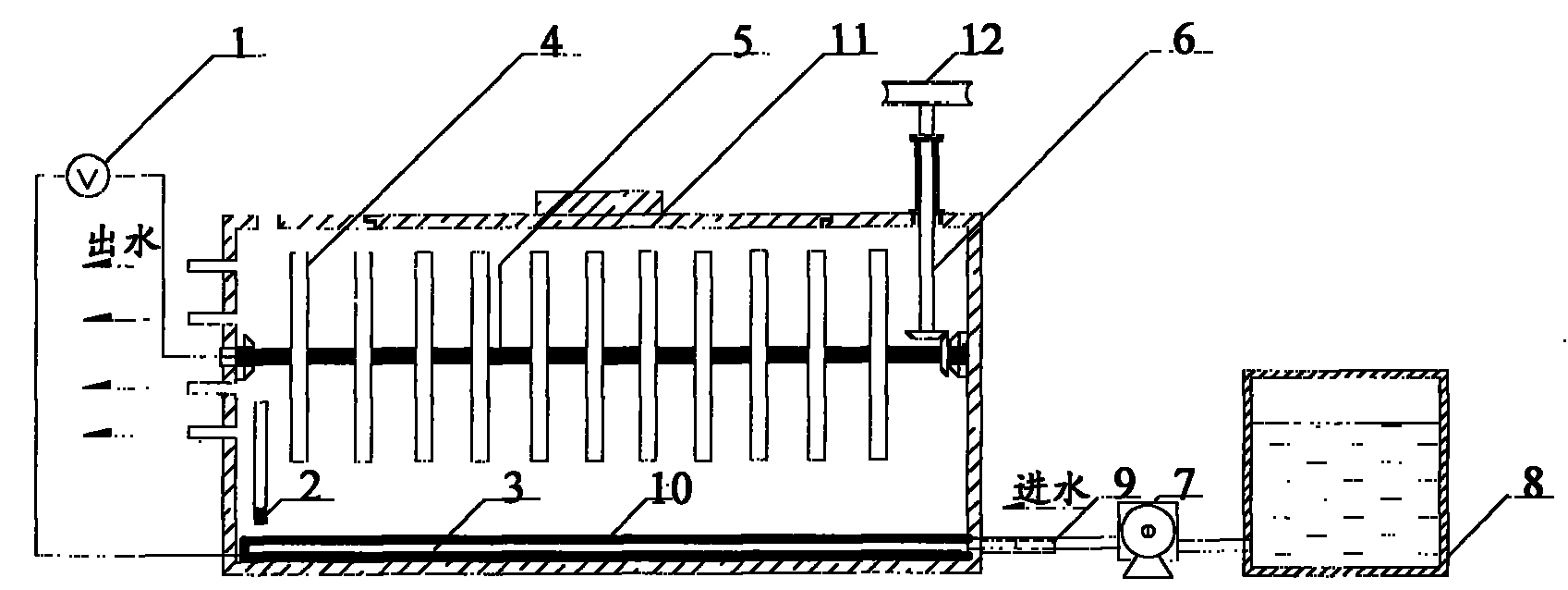

Rotating biological-cathode microbiological fuel cell and sewage treatment method thereof

InactiveCN101817587AEven contactBiochemical fuel cellsTreatment with aerobic and anaerobic processesFiberCarbon fibers

The invention relates to a rotating biological-cathode microbiological fuel cell and a sewage treatment method thereof, and belongs to the technical field of sewage treatment and resource recycling in environment engineering. The invention is characterized in that a cathode is made of carbon fibers and fixed to a circular ring. The outer layer of the rotating cathode biomembrane mainly comprises aerobic nitrifiers for completing the short-range nitrification of ammonia nitrogen. In the inner layer of the cathode biomembrane, nitrite nitrogen and nitrate nitrogen are used as electron acceptors, an electrode is an electron donor and used for denitrification. The structure of a reactor realizes controllable rotation speed of the cathode, controllable distance between the cathode and the anode, and controllable submerging proportion of the cathode biomembrane, and has the advantages of flexible operation, and convenient regulation and control. The rotating biological-cathode microbiological fuel cell can realize control on dissolved oxygen in a single-chamber reactor; and thus, the invention reduces the internal resistance of the cell, accelerates the biomembrane renewing, realizes the short-range nitrification and denitrification, synchronously completes decarburization and denitrification with low consumption and high efficiency, and extracts chemical energy from pollutants to form electric energy output.

Owner:DALIAN UNIV OF TECH

Dispenser head for fluid container

InactiveUS7293930B2Reduce manufacturing costLow costBall-point pensPackaging toiletriesEngineeringMechanical engineering

Owner:CHUANG KAIWIN

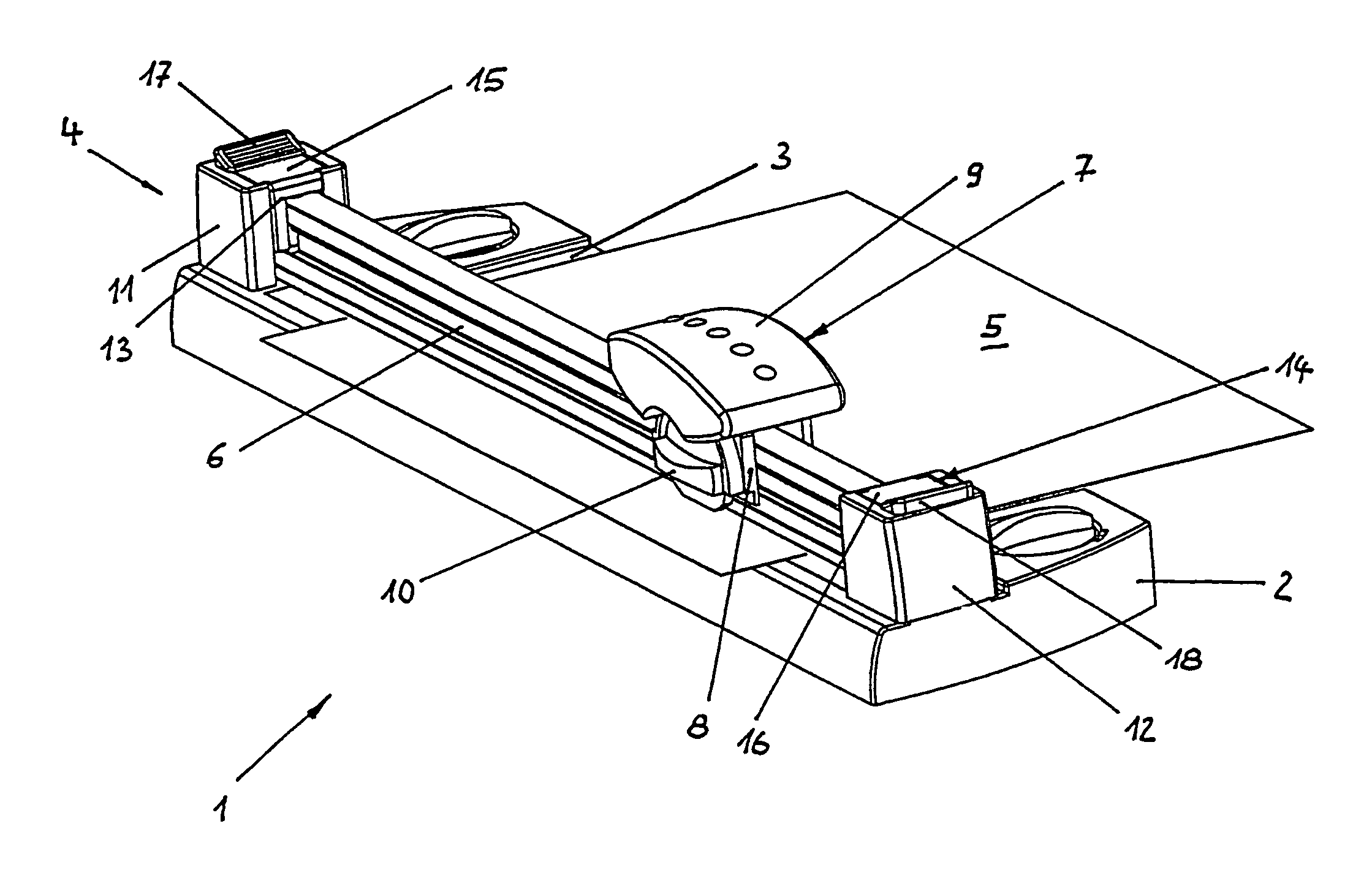

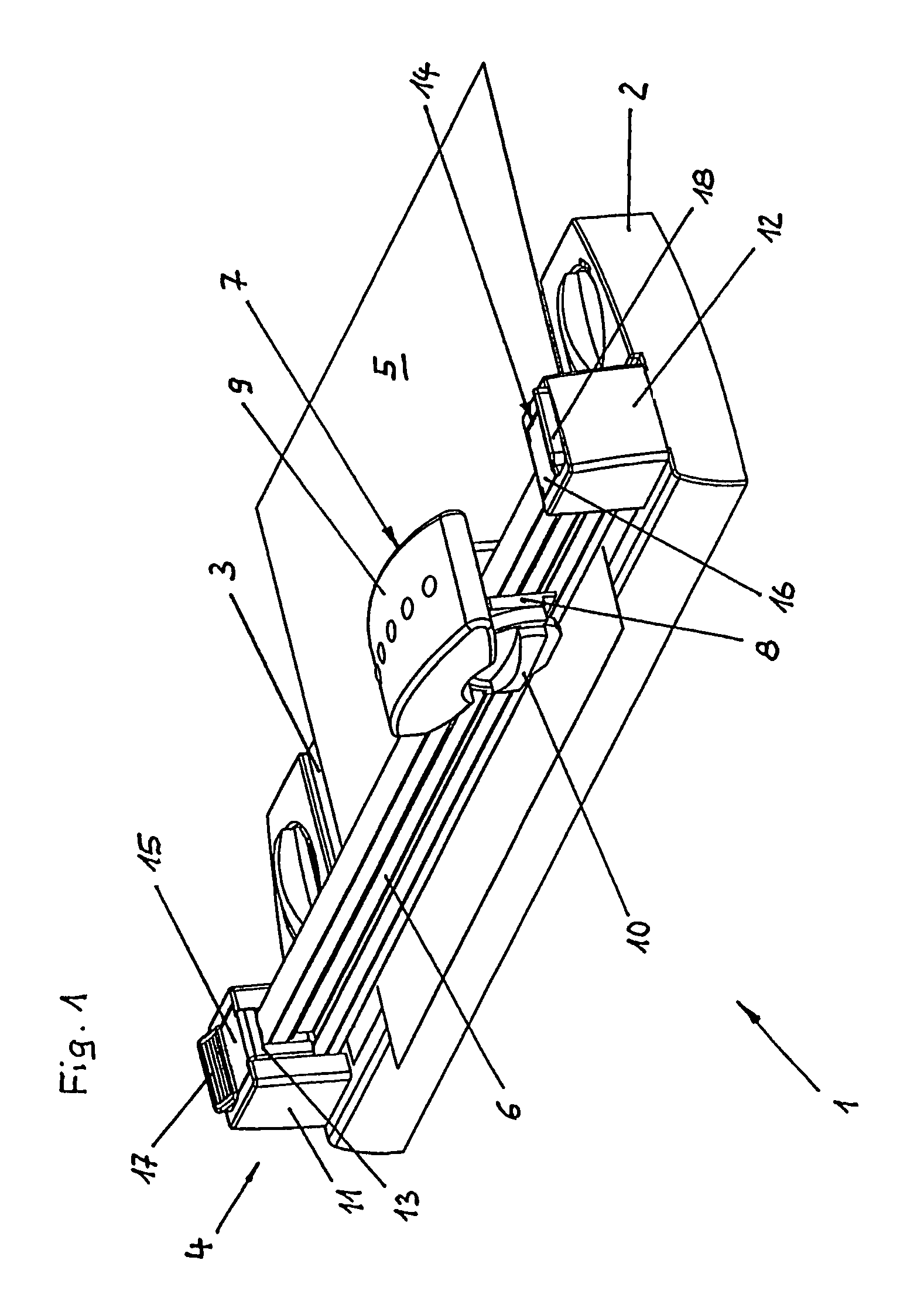

Rotary cutting unit for trimming sheet material

InactiveUS7878099B2Simple designEven contactShearing machinesMetal working apparatusEngineeringSheet material

Owner:MONOLITH

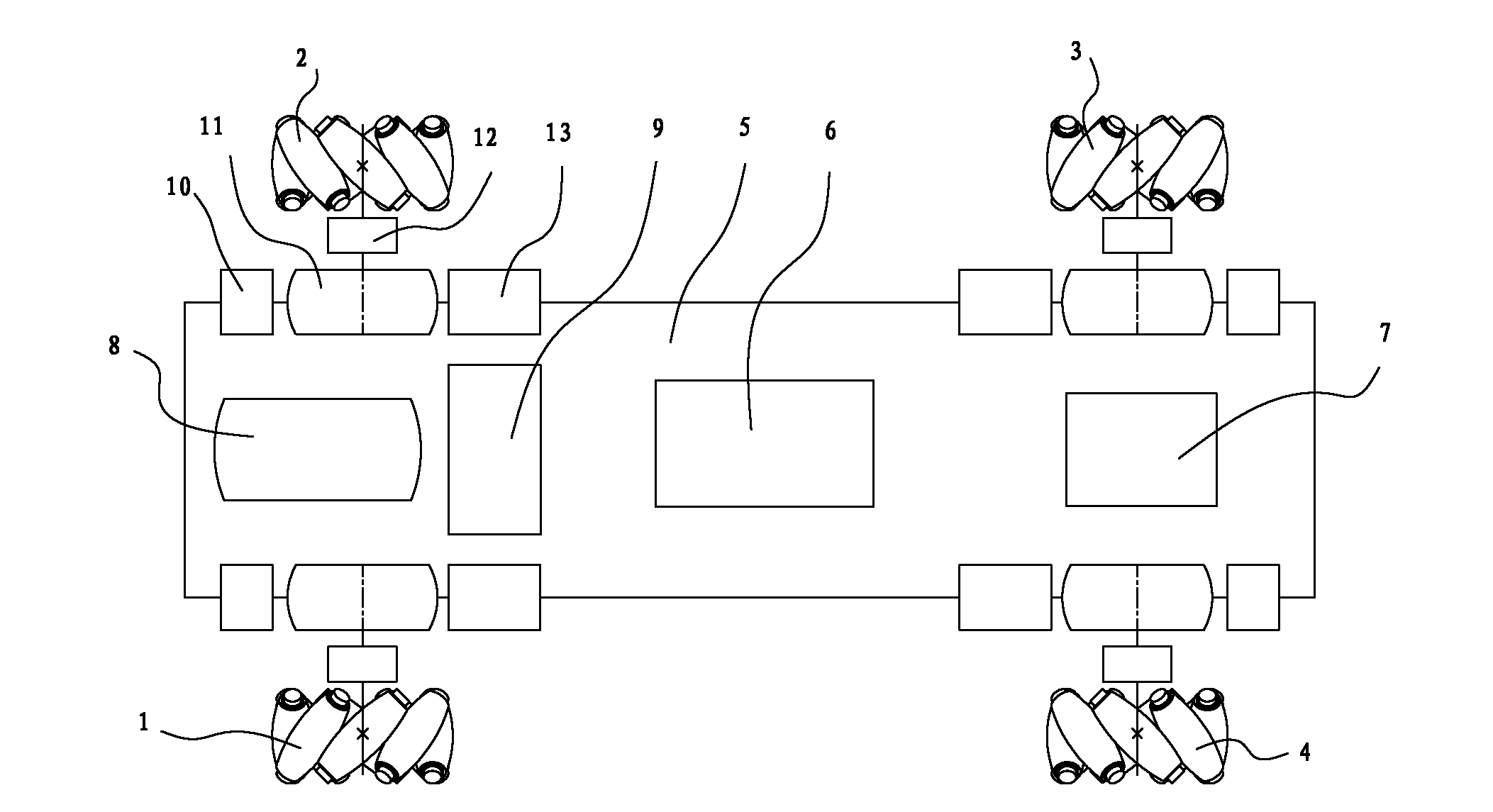

Mecanum wheel omnidirectional mobile vehicle and working method thereof

The invention provides a Mecanum wheel omnidirectional mobile vehicle and a working method of the Mecanum wheel omnidirectional mobile vehicle, relates to an omnidirectional mobile vehicle provided with a Mecanum wheel and a working method of the omnidirectional mobile vehicle which are particularly applicable to realizing omnidirectional movement of the vehicle in a narrow space, and provides the Mecanum wheel omnidirectional mobile vehicle with four wheels uniformly grounded and having capability of keeping a frame horizontal to the greatest extent and the working method of the Mecanum wheel omnidirectional mobile vehicle. The Mecanum wheel omnidirectional mobile vehicle comprises a frame, a power supply, a controller and Mecanum wheels, wherein the Mecanum wheels are connected to the bottom of the frame through an air bag suspending device; the air bag suspending device comprises a damper, an air bag, an air supply, an air valve and a height adjusting device; tops of the damper andthe air bag are fixedly connected to the bottom of the frame; an axle of the Mecanum wheels is connected to the bottom ends of the damper and the air bag; and the air bag is connected with the air supply through the air valve. According to the Mecanum wheel omnidirectional mobile vehicle, closed-loop control is performed over the horizontality of the frame and the distance from the frame to the wheels, so that the wheels provided by the invention are adaptable to the application requirements of special industry.

Owner:YANGZHOU WANFANG ELECTRONICS TECH

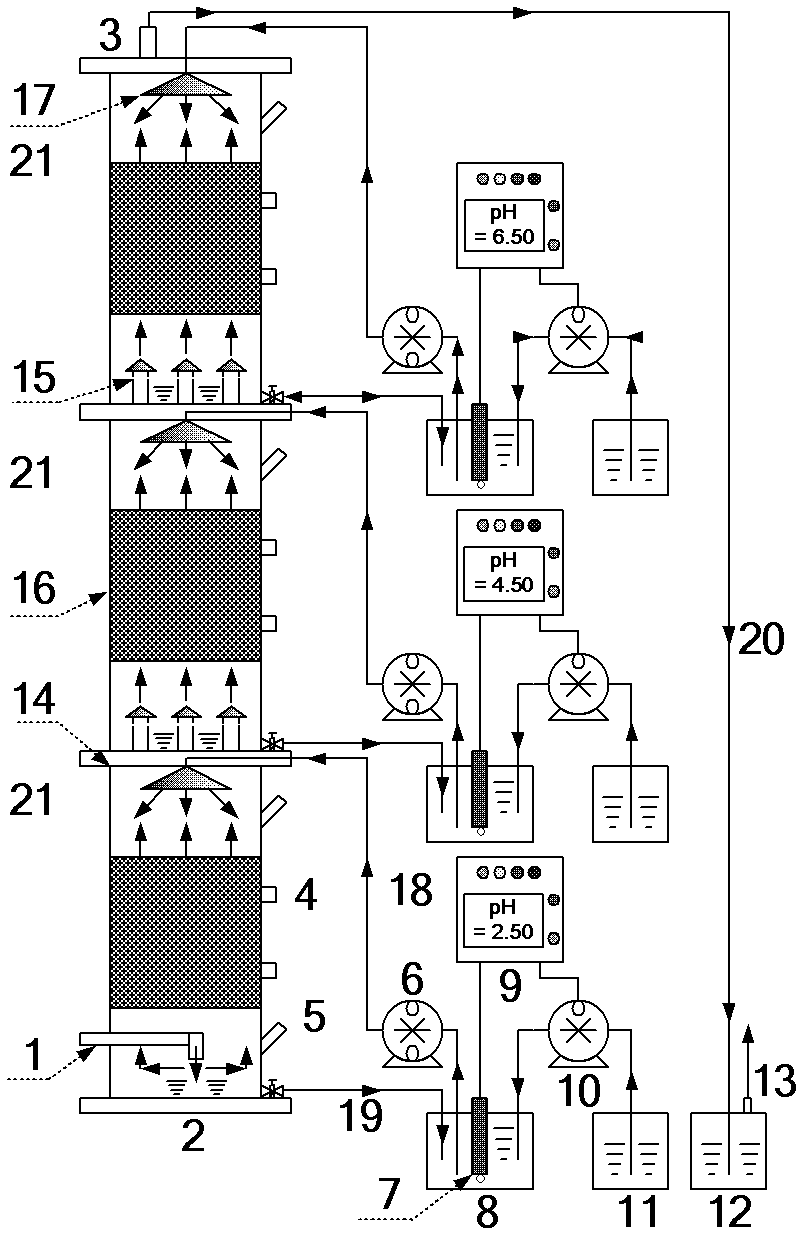

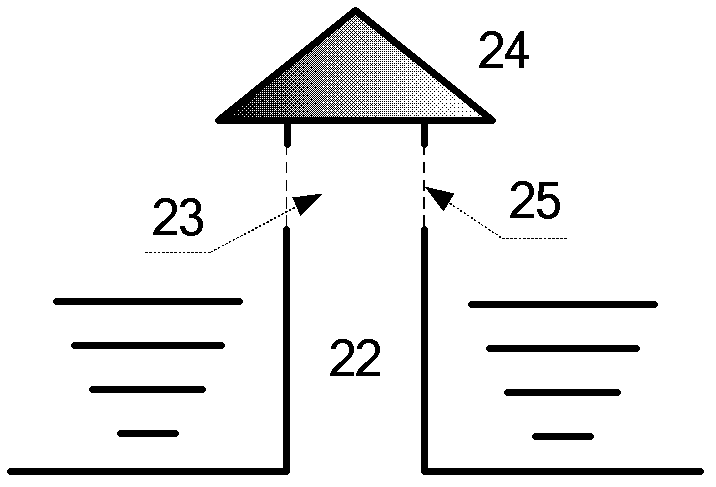

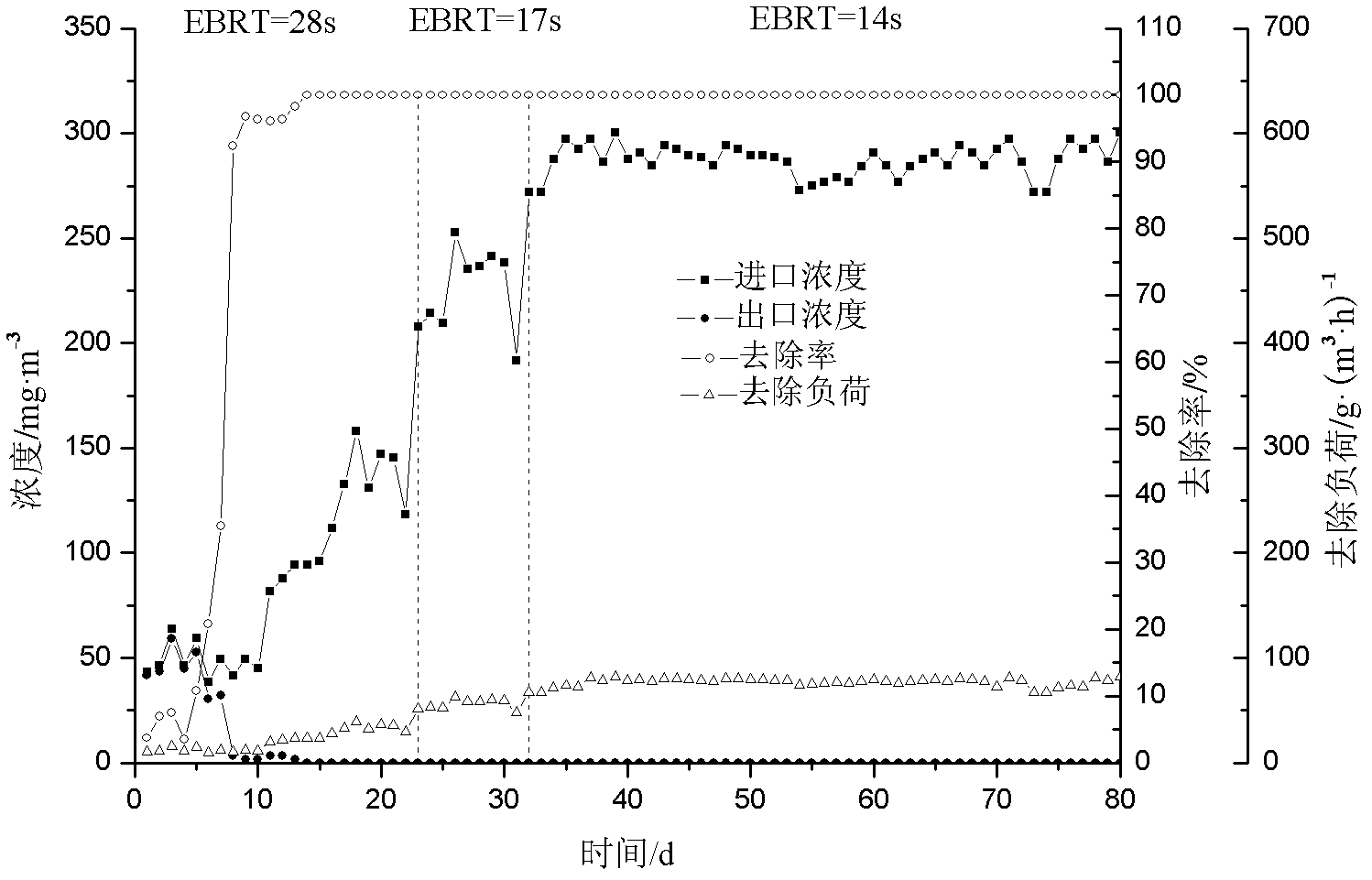

A method for treating waste gas with a biological trickling filter tower and its special device

InactiveCN102284245AImprove blockageEven contactDispersed particle separationAir quality improvementTemperature controlTrickling filter

The invention discloses a method for treating waste gas with a biological trickling filter tower: the waste gas is passed through the bottom of the biological trickling filter tower, treated by the biological trickling filter tower, and the treated waste gas is discharged from the top, and the biological trickling filter tower is composed of The bottom of the tower with exhaust gas inlet, the tower body, and the top of the tower equipped with exhaust gas outlet are composed. The tower body is composed of several biological treatment units stacked from bottom to top, and the biological treatment units on adjacent layers are arranged There is a liquid interlayer, and the air vents for the adjacent layers are arranged on the liquid interlayer, and each layer of biological treatment units is independently equipped with a nutrient solution spray system and a temperature control device from top to bottom. Biological packing layer and nutrient solution receiving pool; the invention increases the processing load of the unit packing; improves the plugging problem of the packing layer, avoids the occurrence of channeling phenomenon, and has uniform and sufficient gas-liquid contact; packing replacement and backwashing are more convenient; the process Economical, suitable for the purification treatment of complex volatile organic mixed pollutants.

Owner:ZHEJIANG UNIV OF TECH

ITO-Ag-ITO etching liquid for AM-OLED display screen and preparation method

ActiveCN105176533AAdjust densityConsistent etch rateSurface treatment compositionsAcetic acidO-Phosphoric Acid

The invention discloses ITO-Ag-ITO etching liquid for an AM-OLED display screen and a preparation method. The etching liquid is prepared from phosphoric acid, acetic acid, nitric acid, additives, surfactants and pure water. The preparation method of the etching liquid comprises the steps that the rotating speed of a stirrer of a dosing tank is kept at normal temperature and pressure, the pure water, the phosphoric acid, the acetic acid, the nitric acid, the additives, the surfactants and the balance pure water are sequentially added into the dosing tank, and after full stirring is conducted, the ITO-Ag-ITO etching liquid is prepared by introducing a fully-stirred mixture into a filter for filtration. According to the ITO-Ag-ITO etching liquid for the AM-OLED display screen and the preparation method, the ITO-Ag-ITO etching liquid is small in particle size and high in purity, the etching rate to different metal is basically the same, and reaction is stable; the etching rate can be controlled by adjusting the concentrations of the phosphoric acid and the nitric acid, the surface of a substrate etched through the etching liquid is clean and tidy, residues do not exist, the intermetallic layering phenomenon does not exist, remaining lines are flat and smooth, and the etching angle is kept between 70 degrees to 90 degrees.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

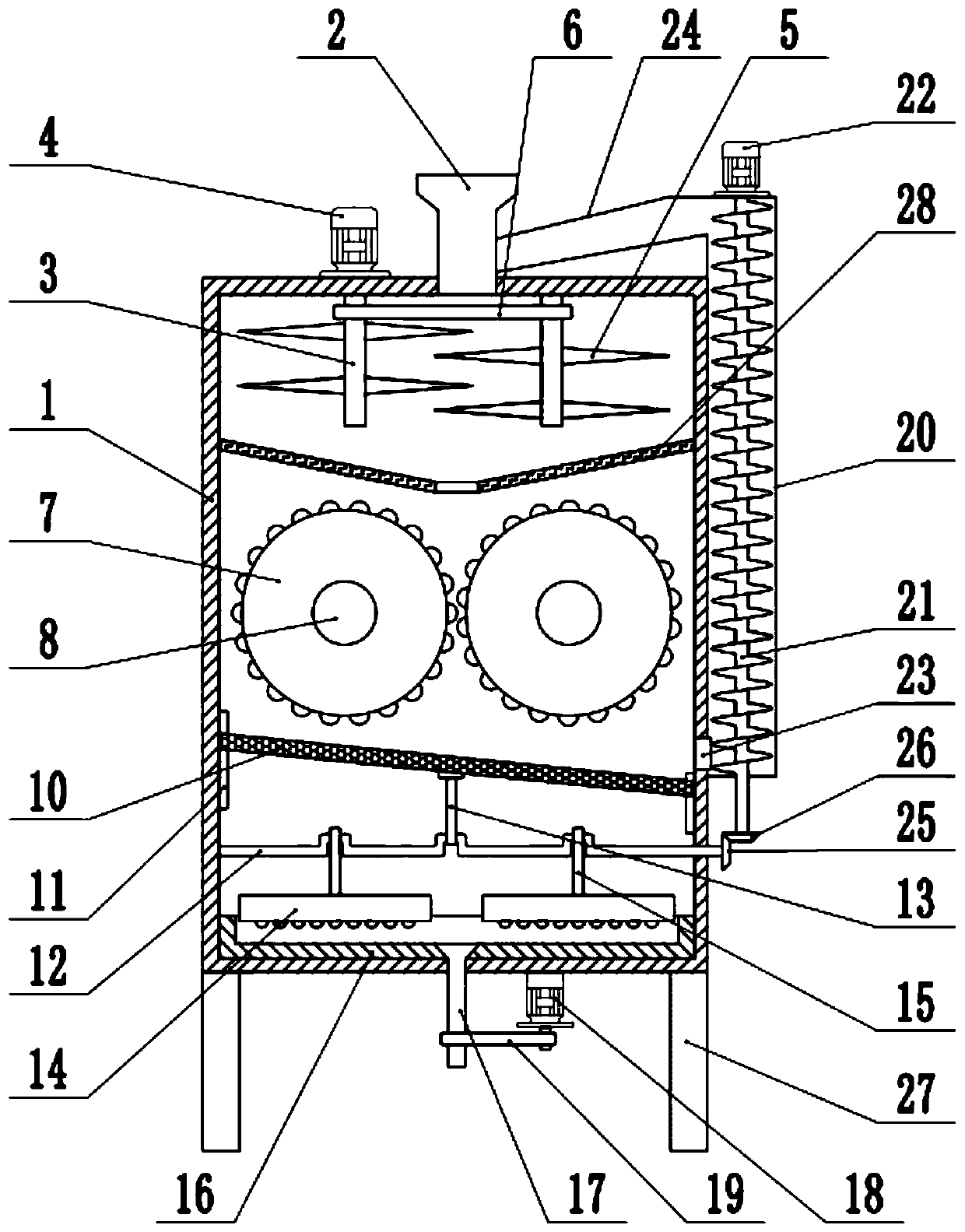

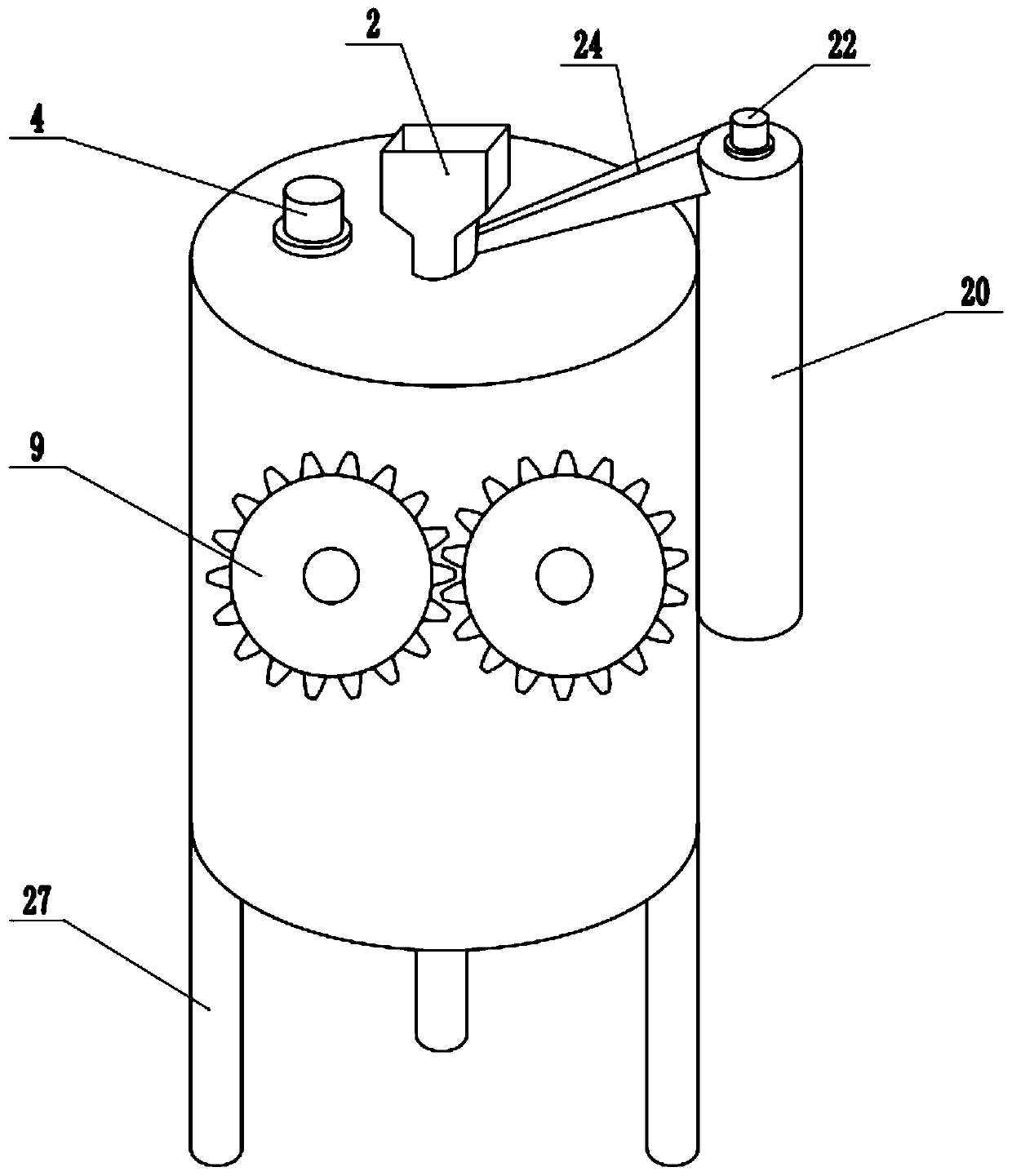

Self-circulation smashing and grinding device for rice processing

InactiveCN110227591AEven contactImprove screening efficiencyCocoaGrain treatmentsEngineeringProduct processing

The invention relates to the field of agriculture product processing equipment, in particular to a self-circulation smashing and grinding device for rice processing. The self-circulation smashing andgrinding device for rice processing comprises a shell, a smashing shaft, a smashing blade, a first driving belt and a grinding plate, wherein a smashing mechanism is arranged in the shell; a guiding plate is arranged under the smashing mechanism; a rice milling mechanism s arranged under the guiding plate; a sieve plate is arranged under the rice milling mechanism; a crankshaft is arranged under the sieve plate; a sieve plate connecting rod is hinged to the lower surface of the sieve plate; the lower end of the sieve plate connecting rod is arranged on the crankshaft in a sleeving way; the grinding plate is arranged on the bottom part of the shell; and a circulation mechanism is arranged on the outer side wall of the shell. The smashing mechanism is used for preliminarily smashing rice, the rice milling mechanism is used for crushing the rice so as to carry out rice milling operation, the crushed rice falls onto the sieve plate, the rice is screened by utilizing the sieve plate, and the sieve plate vibrates up and down in the screening process, so that the screening efficiency is improved; and non-completely smashed rice enters a circulation cylinder through a circulation feed inlet so as to be circularly smashed.

Owner:邓博文

Micro-contact mixer

ActiveCN101234324AShort mass transfer distanceLarge mass transfer areaMixing methodsChemical/physical/physico-chemical processesChemical industryChemical process

The invention relates to a high performance double multiple thin layer micro-contact mixer used for rapid mix, mass transfer and reaction of fluids in the chemical process, which belongs to the field of reaction and separation devices of chemistry and chemical engineering. The micro-contact mixer is formed by inserting an upper cavity chamber and a lower cavity chamber into an integral shell or by lapping closely connected shell components; a fluid inlet pipe of material A and a distribution chamber are communicated with a fluid parallel channel of material A; a fluid inlet pipe of material B and a distribution chamber are communicated with a fluid parallel channel of material B, thus forming the lower cavity chamber; a fluid mixing chamber and a mixed fluid outlet pipe are communicated to form the upper cavity chamber; two fluids enter the mixer from the inlet pipe through the distribution chamber respectively to make multiple thin layer contact in the fluid mixing chamber to realize rapid mix, mass transfer and reaction. The micro-contact mixer has the advantages of high mass transfer efficiency, high operational elasticity, uneasy blocking, easy processing and manufacturing and has good prospects in mixing and reaction fields such as the chemistry, chemical engineering, petrol-chemical industry, medicine and food.

Owner:TSINGHUA UNIV

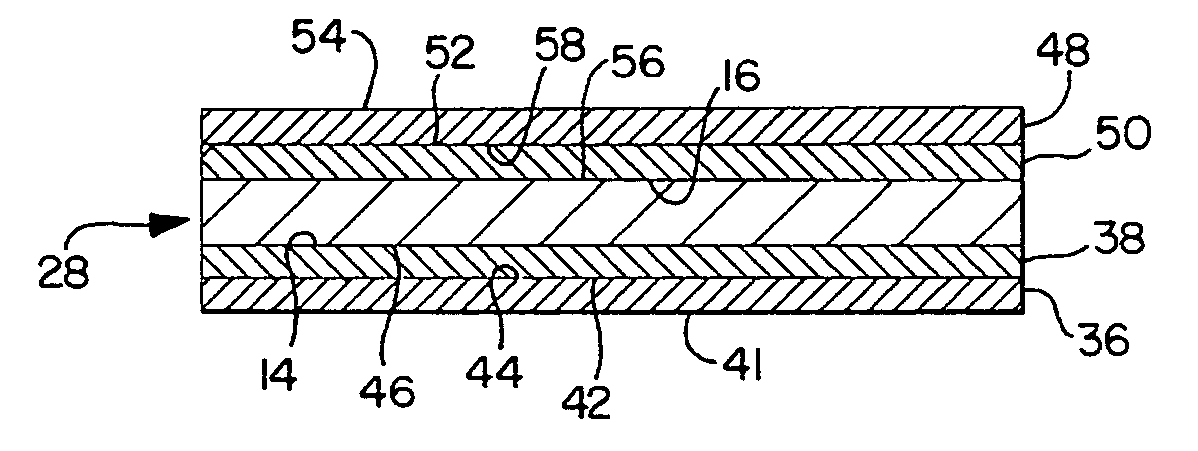

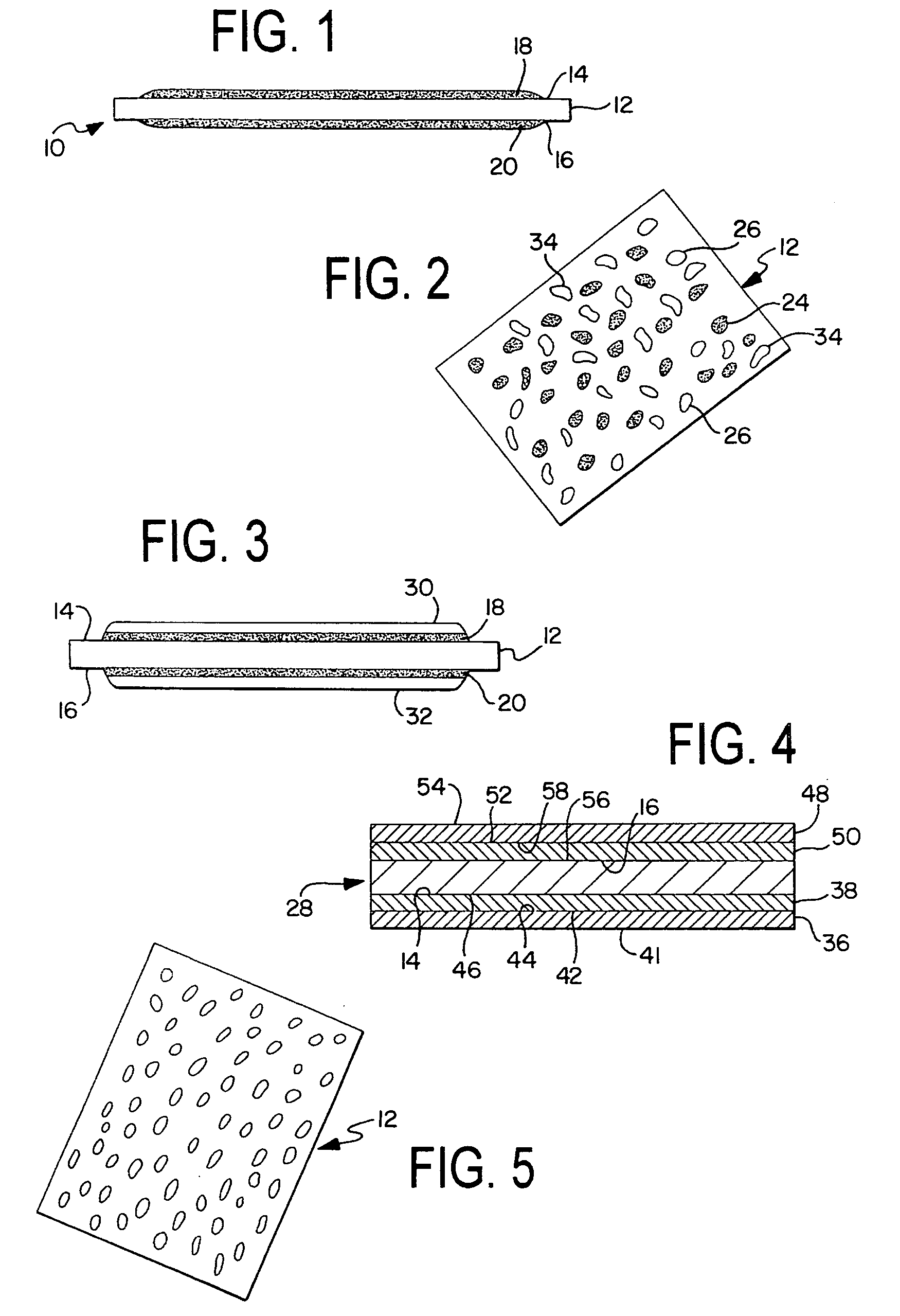

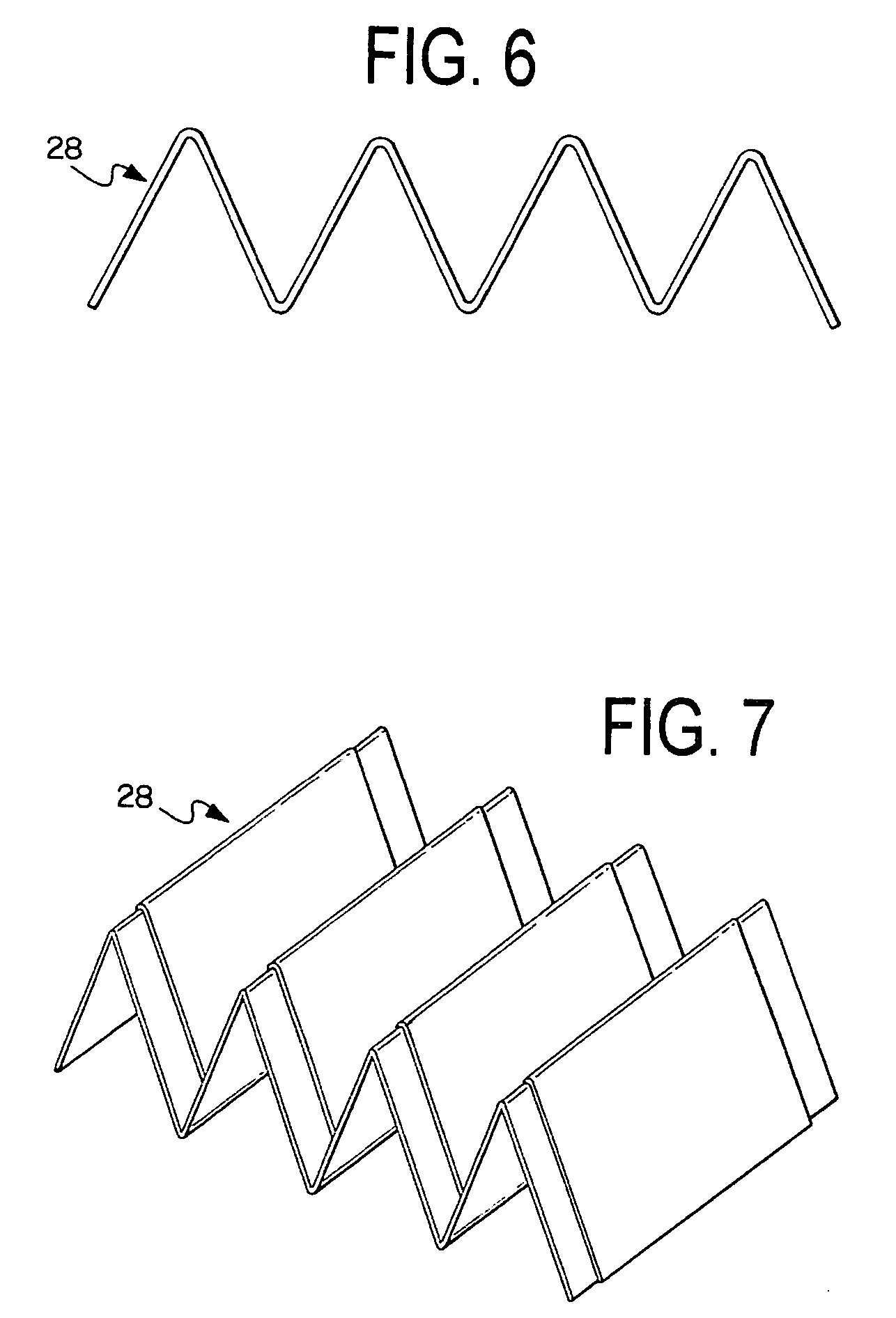

Adhesive-treated electrode separator and method of adhering an electrode thereto

InactiveUS20050260490A1Reduce the amount requiredMaximize electrode efficiencyCell seperators/membranes/diaphragms/spacersPrimary cellsAdhesiveSolvent

An adhesive-treated porous separator and a method of adhering an electrode to the adhesive-treated separator without substantially occluding the pores of the separator. The adhesive-treated separator membrane comprises a porous separator having an anode side and a cathode side, a first adhesive formulation coated on the anode side, and a second adhesive formulation coated on the cathode side. The first and second adhesive formulations each include an adhesive component, a solvent, and an occlusion prevention component. The method of adhering the electrode to the adhesive-treated separator includes the steps of providing the first adhesive formulation and the second adhesive formulation, providing a porous separator having an anode side and a cathode side; coating the anode side of the separator with the first adhesive formulation and coating the cathode side of the separator with the second adhesive formulation such that the occlusion prevention component substantially fills the pores of the separator; precluding occlusions in the pores of the separator so as to substantially free the pores of occlusions; and laminating an anode to the anode side and a cathode to the cathode side of the separator.

Owner:ELDOR CORP SPA

Production of instant water-gas slurry

InactiveCN101029260AEasy to oxidizeNot easily oxidizedLiquid carbonaceous fuelsLump/pulverulent fuel preparationMixed materialsBall mill

Production of quick-dissolving powdered water gas slurry is carried out by mixing various additive solutions with raw material coal proportionally, delivering mixed materials into ball mill, and dry grinding to obtain the final product. It has better stability, shorter working time, less producer and consumption and higher efficiency.

Owner:陕西升基利科技有限公司

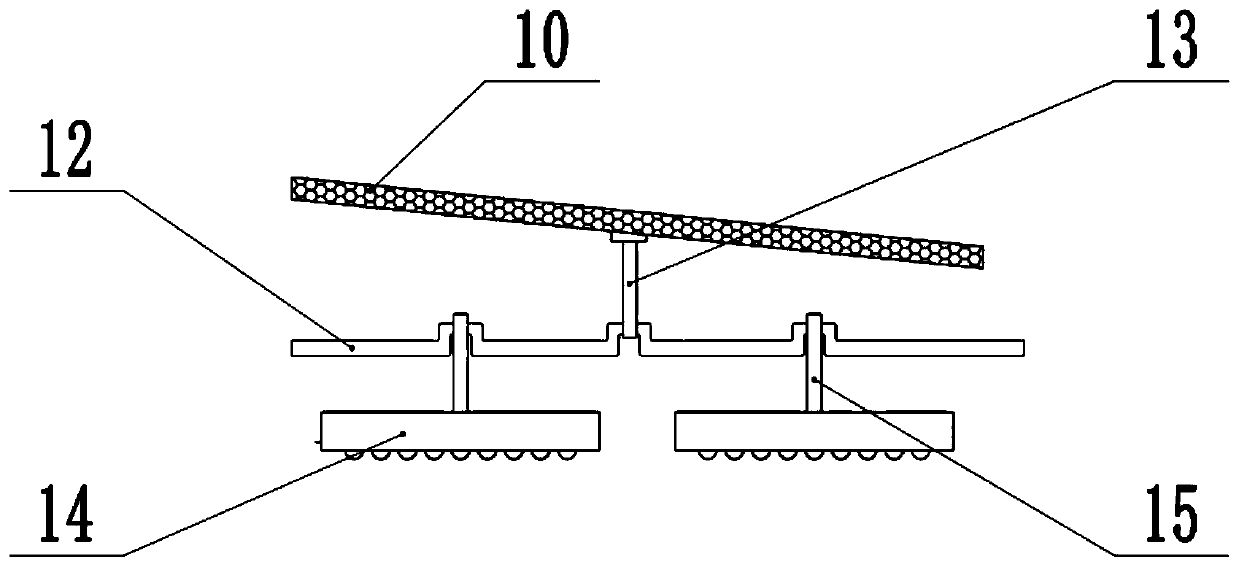

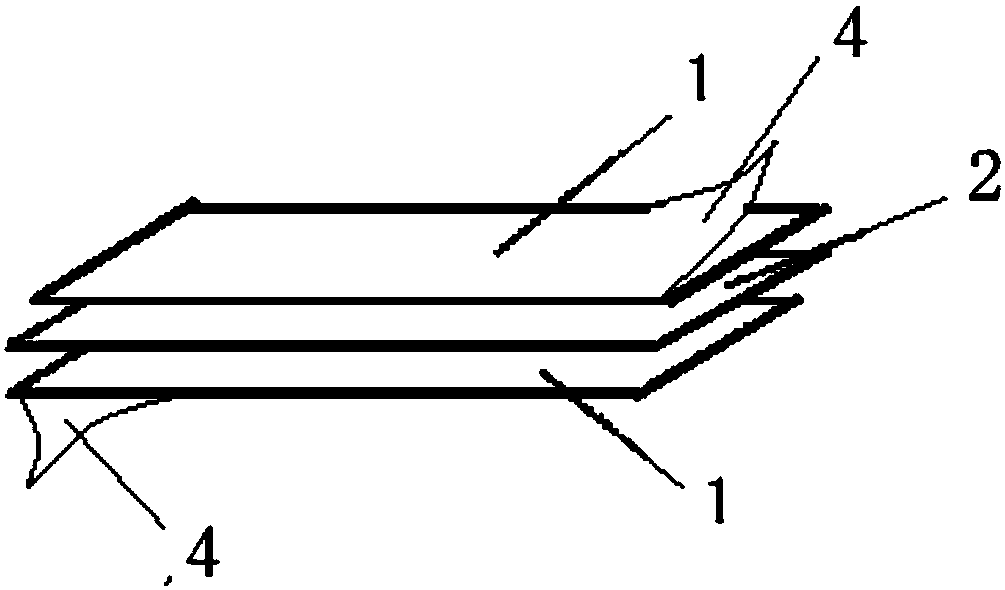

Preparation method of lithium-copper composite negative electrode foil piece

ActiveCN107819104AImprove machinabilityEven contactElectrode rolling/calenderingSecondary cellsLithium metalCopper foil

The invention relates to a preparation method of a lithium-copper composite negative electrode foil piece. An intermittent local pressure enhancement method is adopted for uniformly adhering lithium metal foil pieces on the surface of a copper foil, and a lithium-copper composite negative electrode foil piece is formed. The preparation method comprises the following concrete steps: clamping the copper foil between the lithium metal foil pieces to form a lithium foil / copper foil / lithium foil sandwich layer; adopting common rolling equipment, starting a traction system, and enabling the lithiumfoil / copper foil / lithium foil sandwich layer to pass through a grinding roller, so as to form intermittent local pressure on the lithium foil / copper foil / lithium foil sandwich layer, wherein the pressure range is 0.05-5MPa, and a pre-compounded lithium foil / copper foil / lithium foil sandwich slice is formed; and enabling the pre-compounded lithium foil / copper foil / lithium foil sandwich slice to pass through the grinding roller again, and applying pressure for shaping, wherein the pressure range is 0.02-5MPa, so that the lithium-copper composite negative electrode foil piece is obtained. The preparation method provided by the invention has the beneficial effects that layer-to-layer contact of the prepared lithium-copper composite negative electrode foil piece is uniform, contact of a lithiummetal negative electrode with the copper foil is further improved, and the problem that the lithium metal foil piece and the copper foil are infirmly bonded is avoided, so that outage of lithium metal in a working process of a battery is prevented.

Owner:TIANJIN LISHEN BATTERY +1

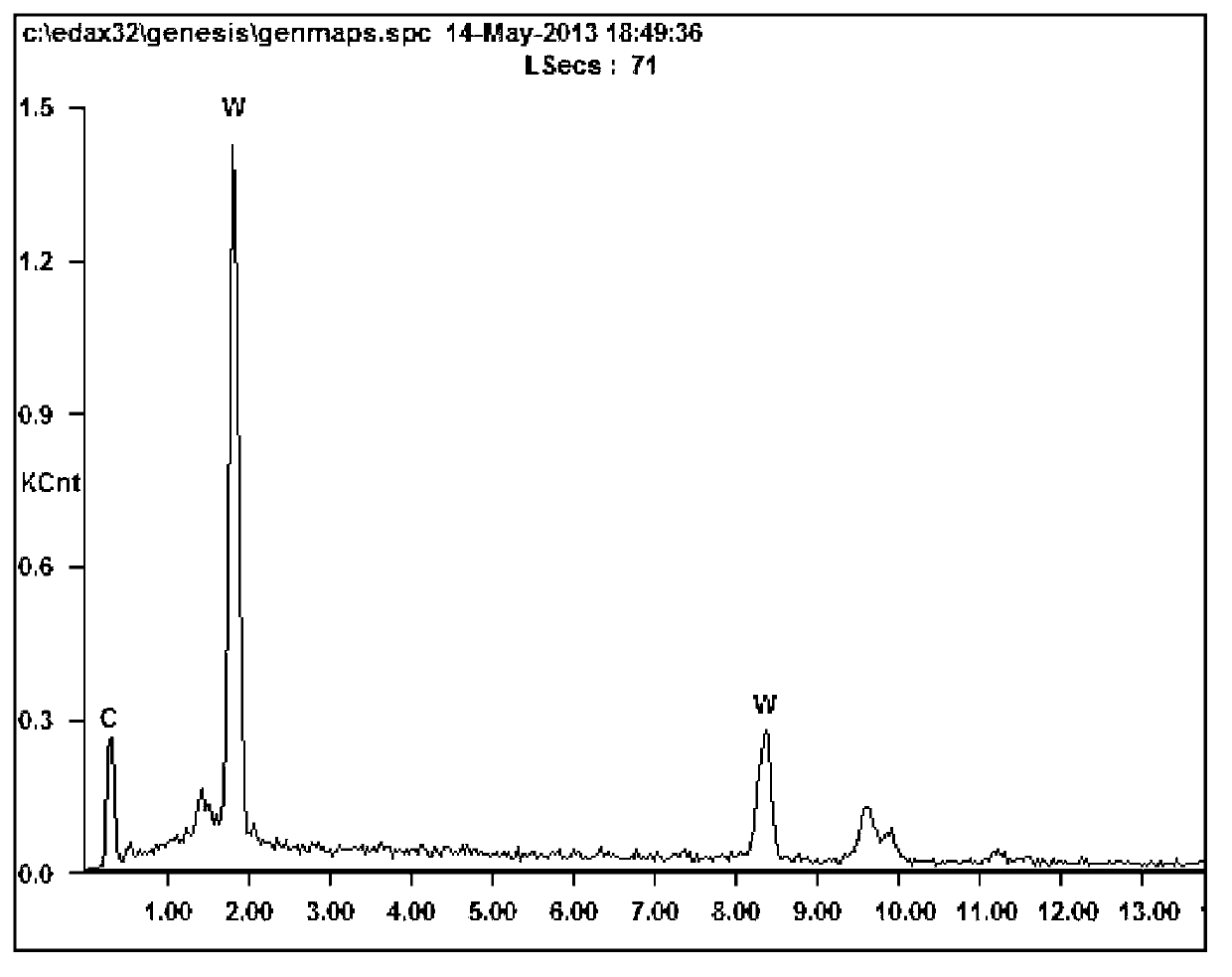

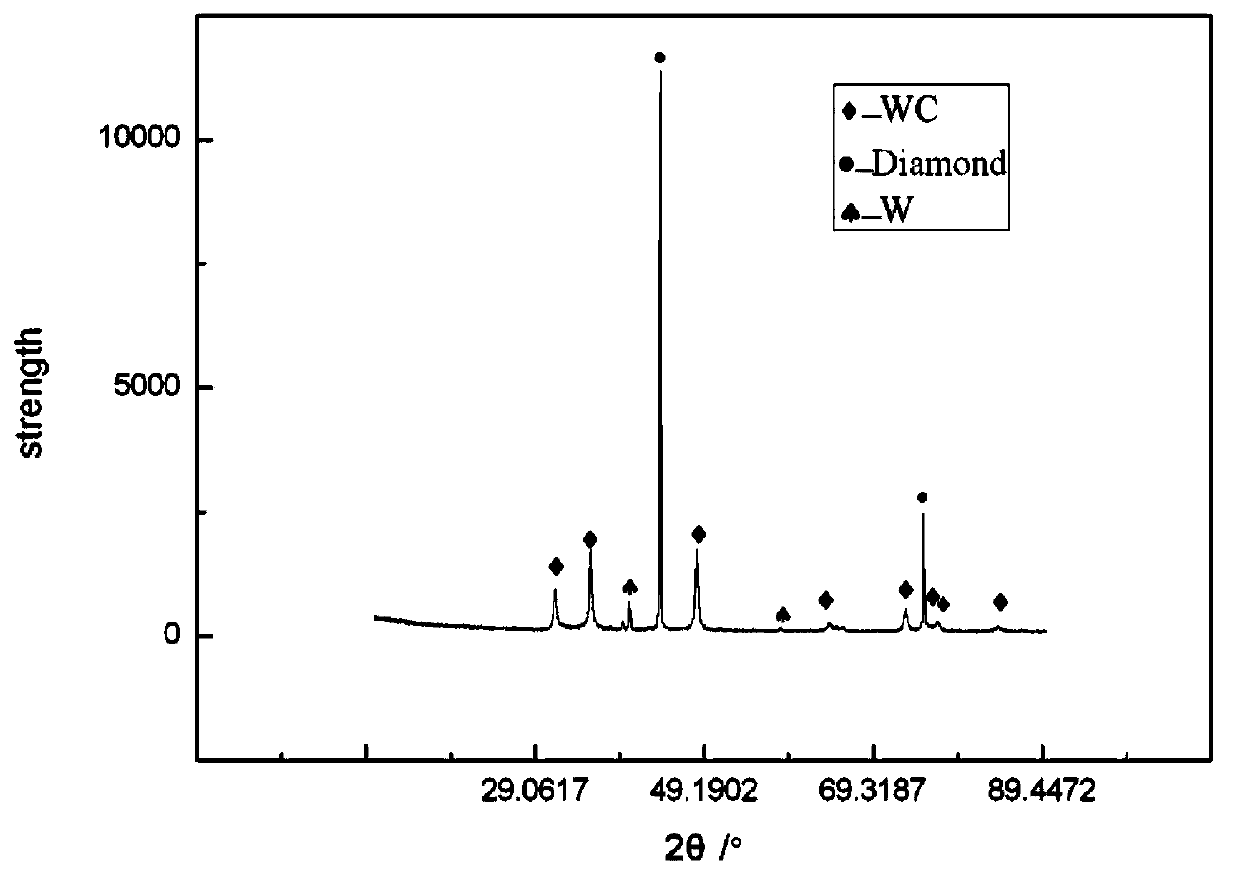

Method for plating tungsten on diamond surface

InactiveCN103388142AImprove adsorption capacityFacilitate depositionHeat inorganic powder coatingCarbideUltrasonic oscillation

The invention relates to a method for plating tungsten on a diamond surface. In the invention, a salt-bath tungsten plating method is adopted. The method comprises the following steps of removing greasy dirt on the surface of a diamond particle, mixing with tungsten powder in a crucible after coarsening and carrying out sensitization-activation treatment; carrying out high-temperature salt-bath tungsten plating in a fused salt environment; and then cleaning and drying through a clear water boiling method to obtain an finished product, wherein the method for removing greasy dirt and coarsening is as follows: placing the diamond particle in diluted alkaline and carrying out ultrasonic oscillation cleaning, and cleaning by deionized water; soaking and cleaning by diluted acid; washing to neutral by water; adding into a nitric acid solution for boiling for 3-10 minutes, carrying out coarsening treatment and washing to neutral by deionized water, and carrying out sensitization-activation treatment; and cleaning by deoionized water and drying after cleaning by alcohol for acetone, wherein the salt-bath tungsten plating is carried out in a vacuum furnace. The method for plating tungsten on the diamond surface can be used for effectively plating a layer of compact and uniform coating on the surface of the diamond particle; the phase is mainly composed of WC (Wolfram Carbide) and W (Wolfram), so that toxic substances are not generated in the process. Moreover, the process is simple and the cost is low.

Owner:SOUTHEAST UNIV

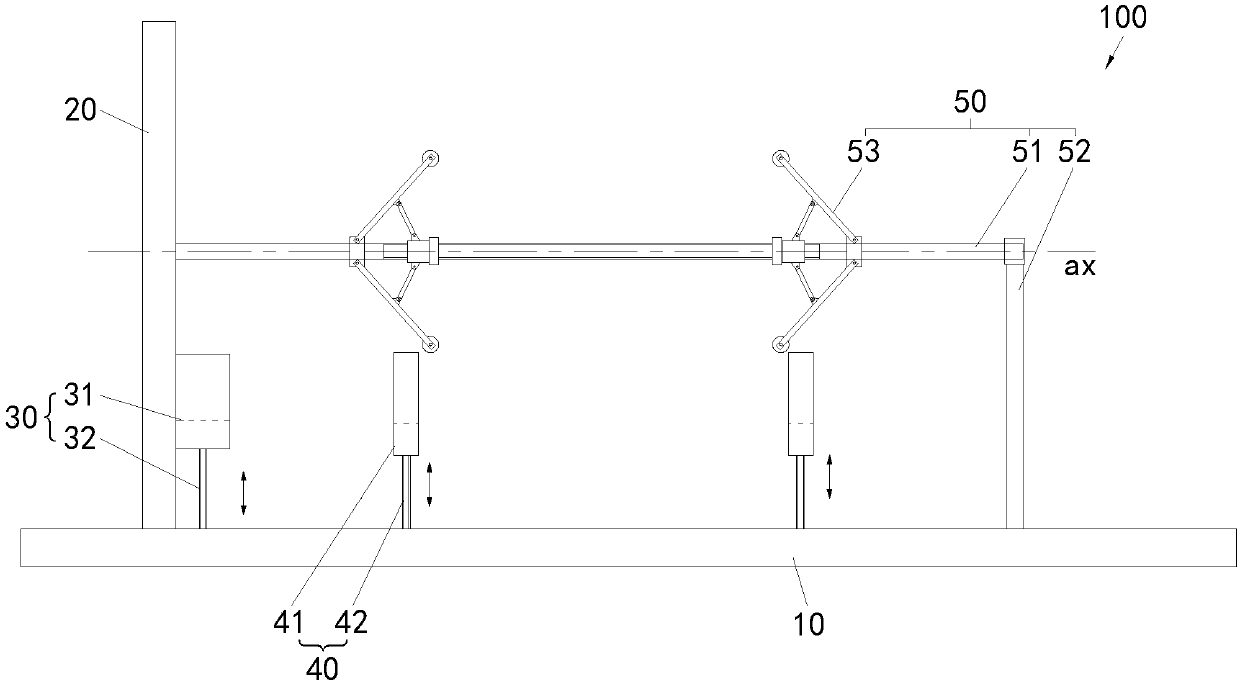

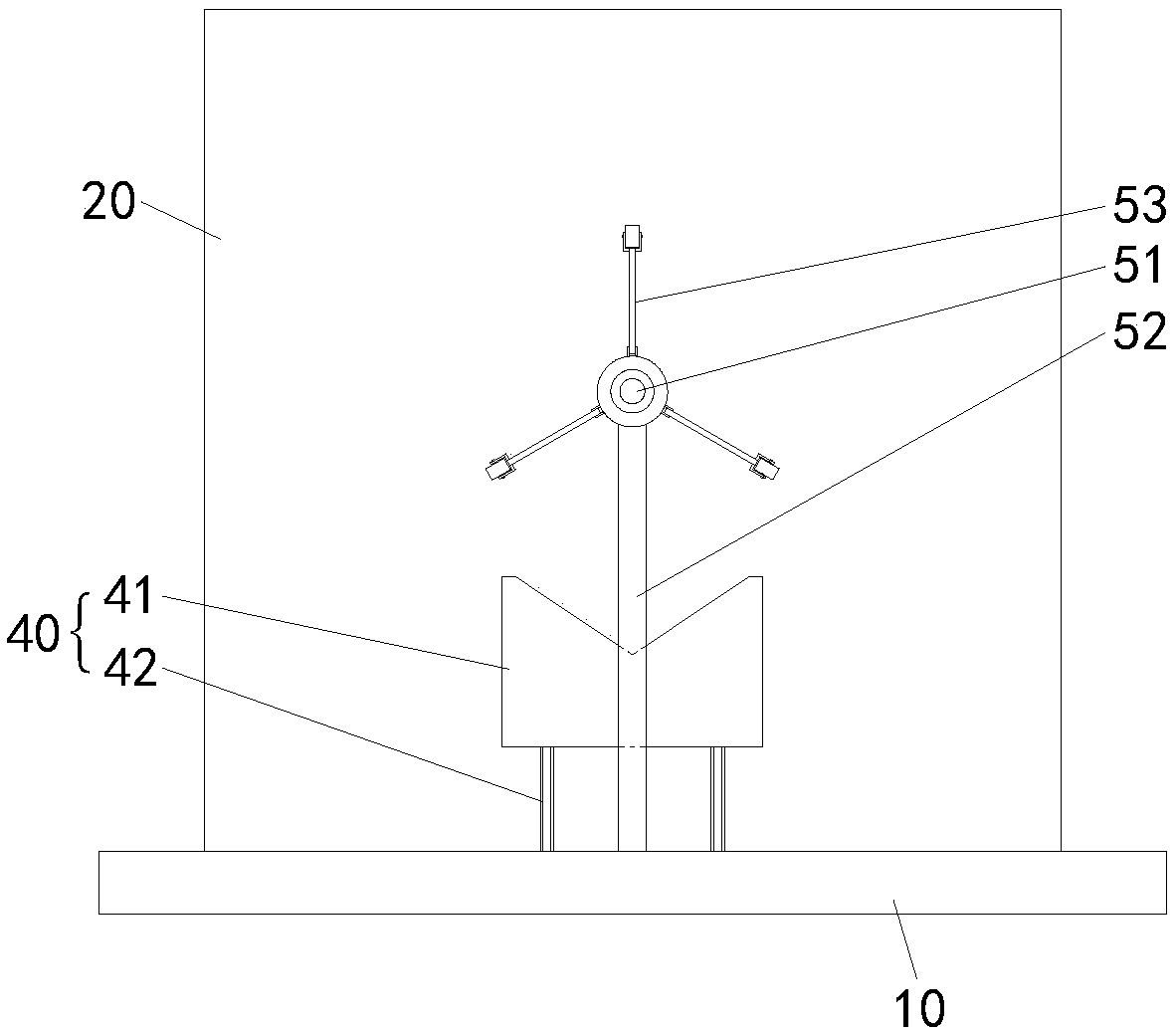

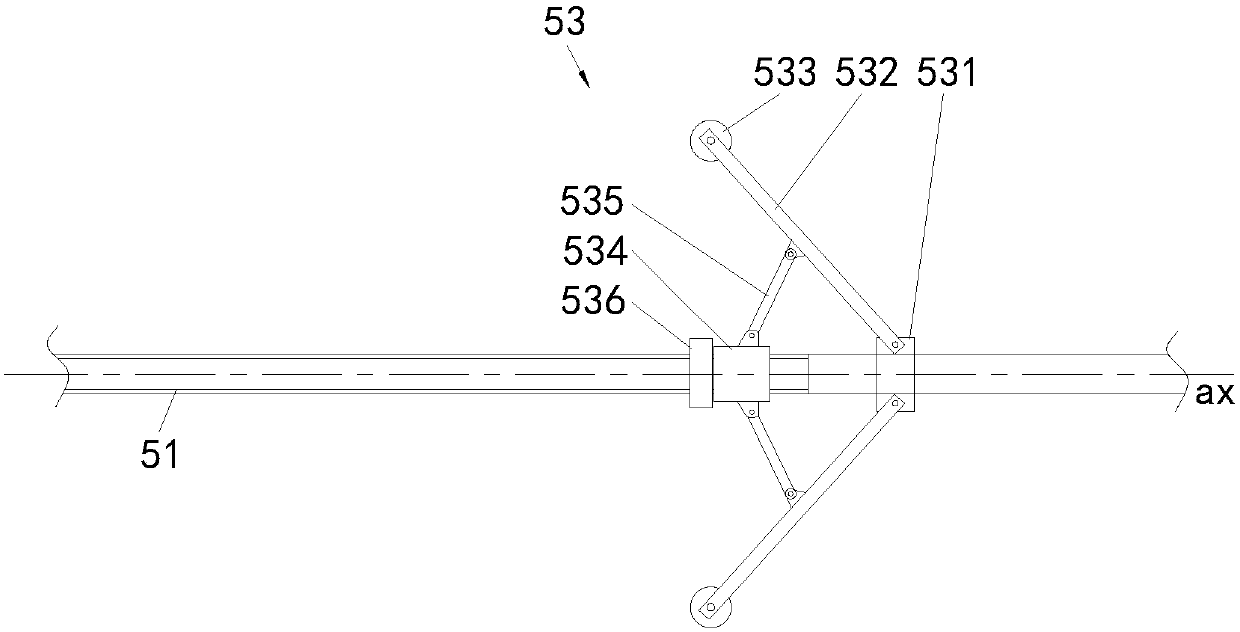

Prefabrication platform and prefabrication method for jacketed pipe

PendingCN107855721AEasy to penetrate and installGuaranteed verticalityWelding/cutting auxillary devicesAuxillary welding devicesFiberCompound (substance)

The invention discloses a prefabrication platform and a prefabrication method for a jacket pipe and relates to the technical field of petrochemical engineering and chemical fiber equipment installation. The prefabrication platform and the prefabrication method for the jacketed pipe are provided to solve the problems that according to existing prefabrication construction for a straight pipe sectionof a major-diameter jacketed pipe, operation is relatively complex, and the working efficiency is low. The prefabrication platform is composed of a flange plate positioning frame, an inner pipe positioning assembly and a plurality of outer pipe positioning assemblies. A first adjusting rod arranged on the bottom of a positioning base can adjust the height of a flange plate. The inner pipe positioning assembly is composed of a center rod perpendicularly fixed to a back plate, an extensible and retractable guide wheel supporting frame arranged on the center rod in a sleeving manner and a supporting frame connected to the other end of the center rod, wherein the extensible and retractable guide wheel supporting frame is composed of a fixing casing pipe arranged on the center rod in a sleeving manner, supporting rods which are evenly distributed in the radial direction of the axis of the center rod and hinged to the fixing casing pipe and extensible and retractable supports, one end of each extensible and retractable support is hinged to the corresponding supporting rod, the other end of each extensible and retractable support is hinged to the center rod, and the other end of each supporting rod is provided with a guide wheel. The outer pipe positioning assembly comprises an outer pipe support and a second adjusting rod which are detachably connected.

Owner:SHANGHAI INSTALLATION ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com