Chocolate used for external coating of cold drink, and particle-containing chocolate coat

A chocolate coating and chocolate technology, applied in the fields of application, cocoa, frozen desserts, etc., can solve the problems of unreachable coating effect, uneven particle distribution, affecting product sensory, etc., to improve appearance, control coating amount, The effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

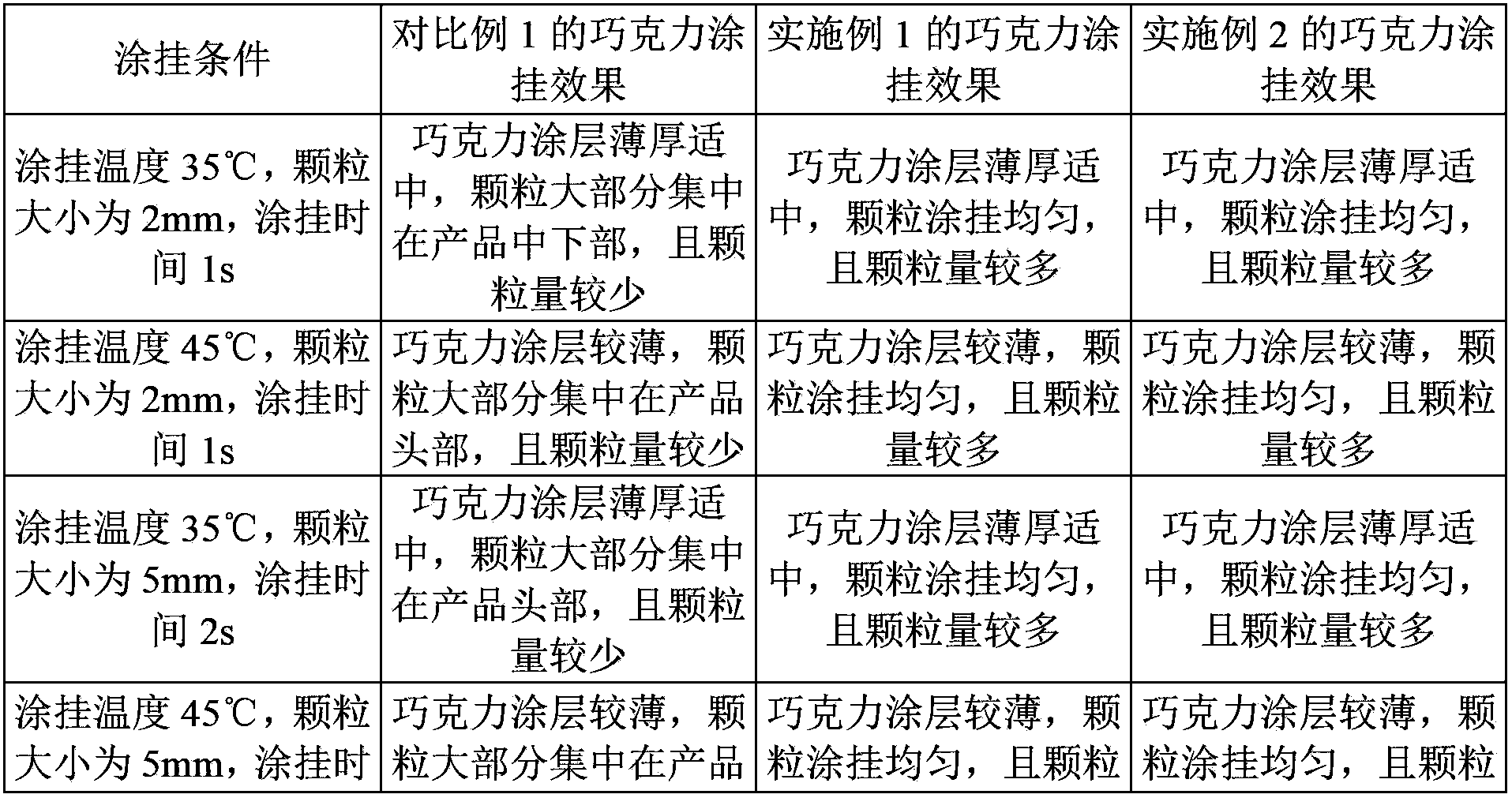

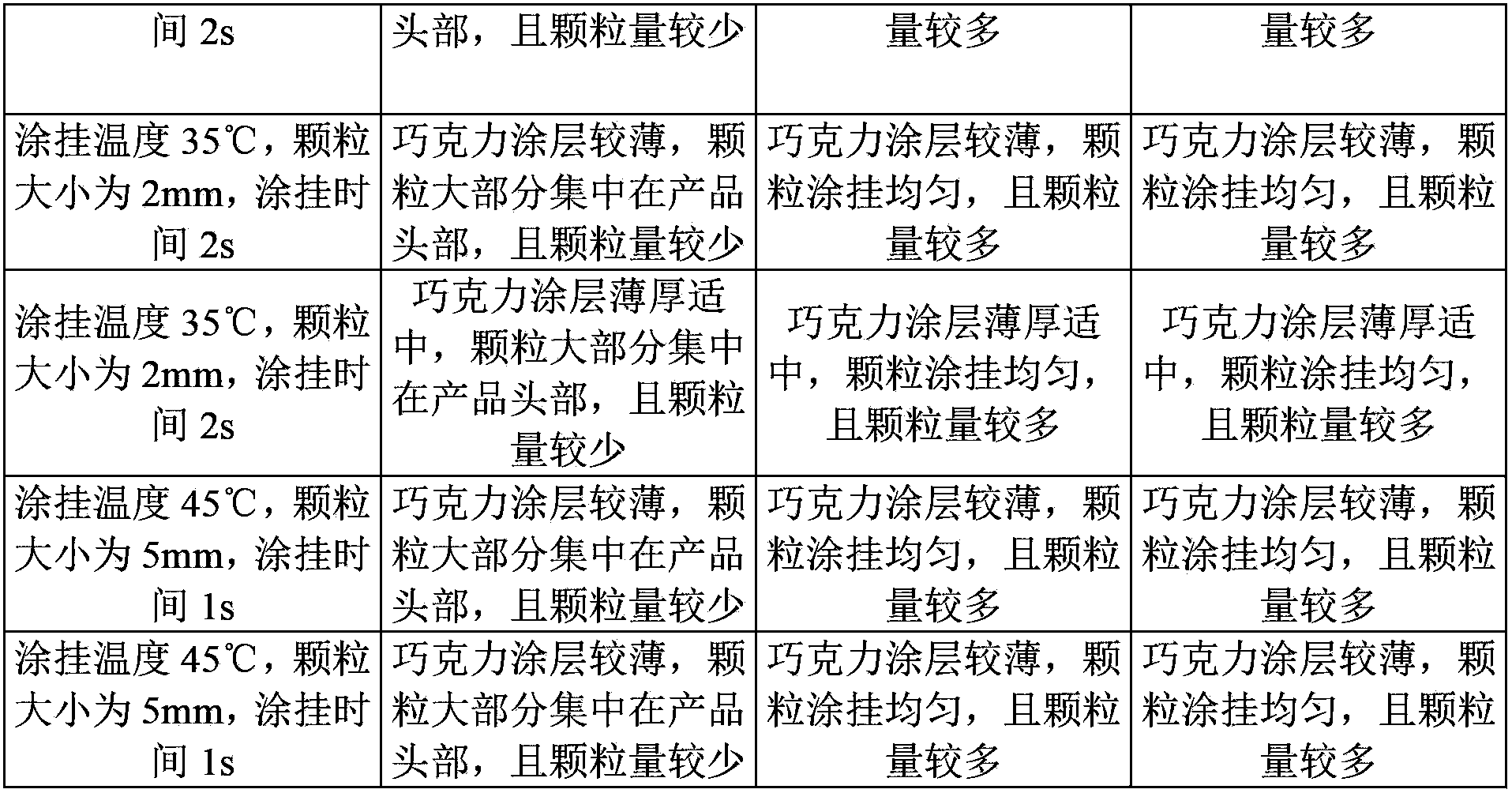

Examples

Embodiment 1

[0051] Embodiment 1 prepares the chocolate (100g) for coating and hanging of cold drinks of the present invention

[0052] The chocolate formula for cold drink coating is as follows: white sugar 33g, whole milk powder 11g, coconut oil 25g, liquid milk anhydrous cream 5g, cocoa powder 6g, natural cocoa butter 9.5g, cocoa mass 8g, emulsifier 2.5g ( Polyglyceryl ricinoleate 0.31g, lecithin 2.19g).

[0053] The preparation method comprises the following steps:

[0054]Specifically, the method for preparing the above-mentioned cold drink coating and hanging chocolate of the present invention comprises the following steps:

[0055] 1) Weighing: Accurately weigh various raw materials according to the amount added in the formula, and place them separately;

[0056] 2) Heat and melt the fats and oils required in the formula for later use, and keep the oil temperature at 40-50°C;

[0057] 3) The white granulated sugar needs to be sprayed into powdered sugar with a powder sprayer, so ...

Embodiment 2

[0062] Embodiment 2 Prepare the chocolate (100g) for coating and hanging cold drinks of the present invention

[0063] The chocolate formula for cold drink coating is as follows: white sugar 37g, whole milk powder 10.5g, coconut oil 23g, liquid milk anhydrous cream 3g, cocoa powder 4g, natural cocoa butter 11g, cocoa mass 8g, emulsifier 3.5g ( Polyglyceryl ricinoleate 0.44g, lecithin 3.06g).

[0064] The preparation method comprises the following steps:

[0065] 1) Weighing: Accurately weigh various raw materials according to the amount added in the formula, and place them separately;

[0066] 2) Heat and melt the fats and oils required in the formula for later use, and keep the oil temperature at 40-50°C;

[0067] 3) The white granulated sugar needs to be sprayed into powdered sugar with a powder sprayer, so that the powdered sugar can pass through an 80-mesh sieve;

[0068] 4) Ingredients: add oil first, then add powdery raw materials in the formula except emulsifier (one...

Embodiment 3

[0072] Example 3 Preparation of chocolate (100g) for coating and hanging cold drinks of the present invention

[0073] The chocolate formula for cold drink coating is as follows: white sugar 37g, whole milk powder 9g, coconut oil 23g, liquid milk anhydrous cream 3g, cocoa powder 6g, natural cocoa butter 9g, cocoa mass 10g, emulsifier 3g (polyglycerol Ricinol ester 0.38g, lecithin 2.62g).

[0074] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com