Patents

Literature

2807results about How to "Not easily oxidized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

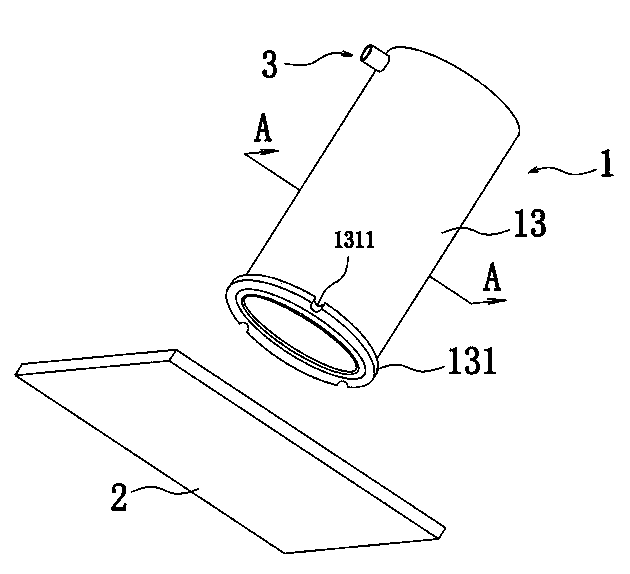

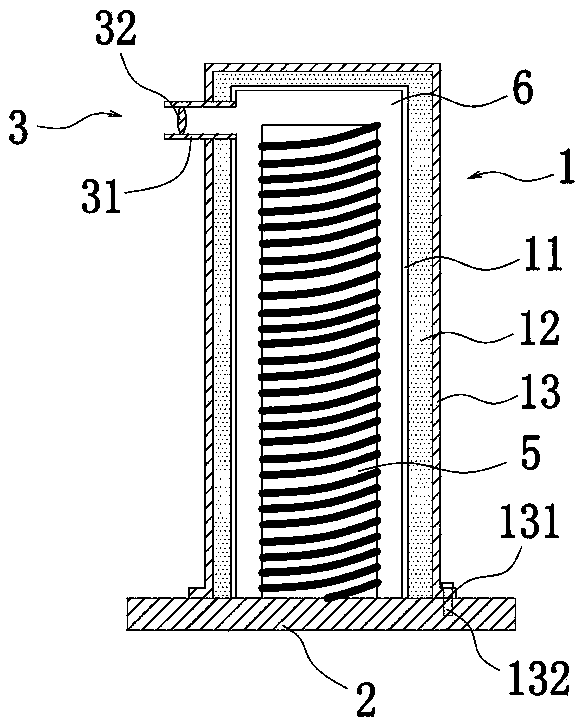

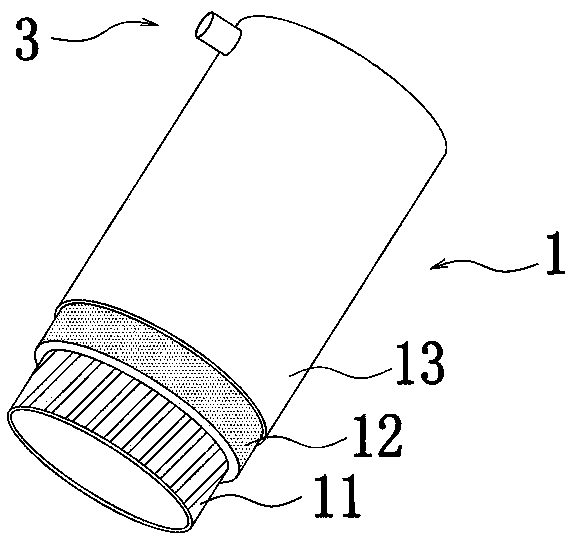

Method of Assembling An Airtight LED Light Bulb

ActiveUS20120040585A1Not easily oxidizedEasily be dampenedTube/lamp screens manufacturePoint-like light sourceNitrogenEngineering

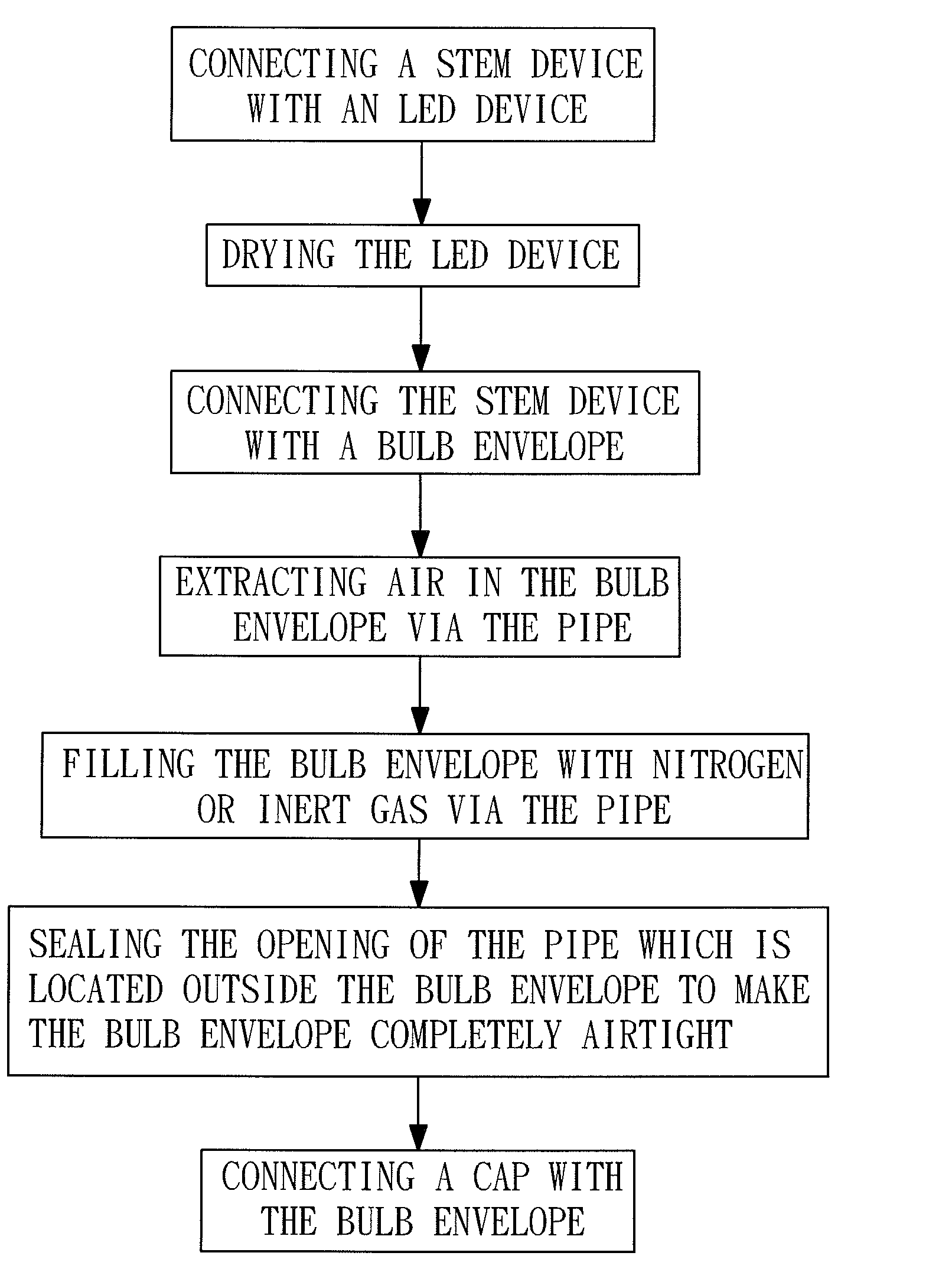

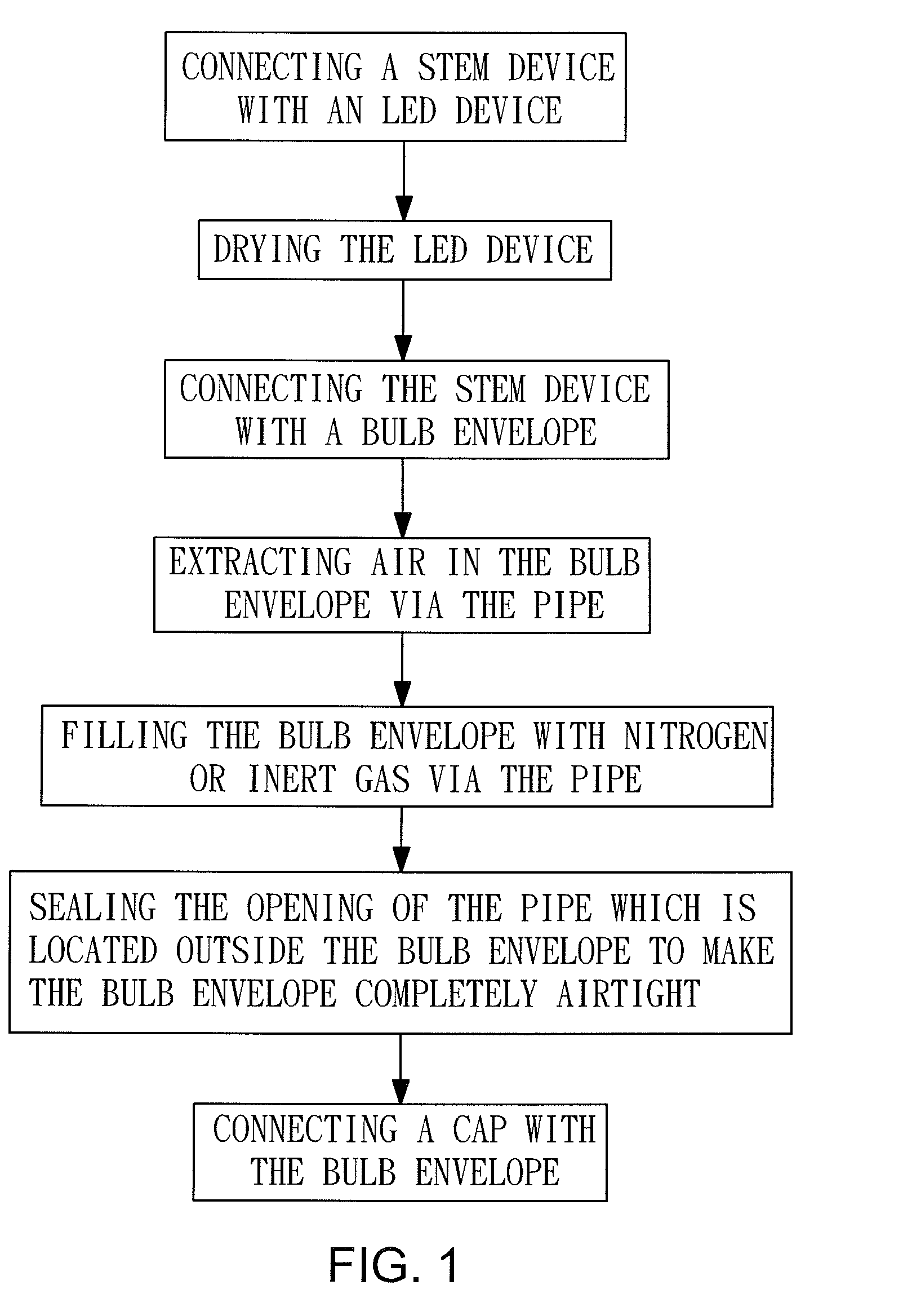

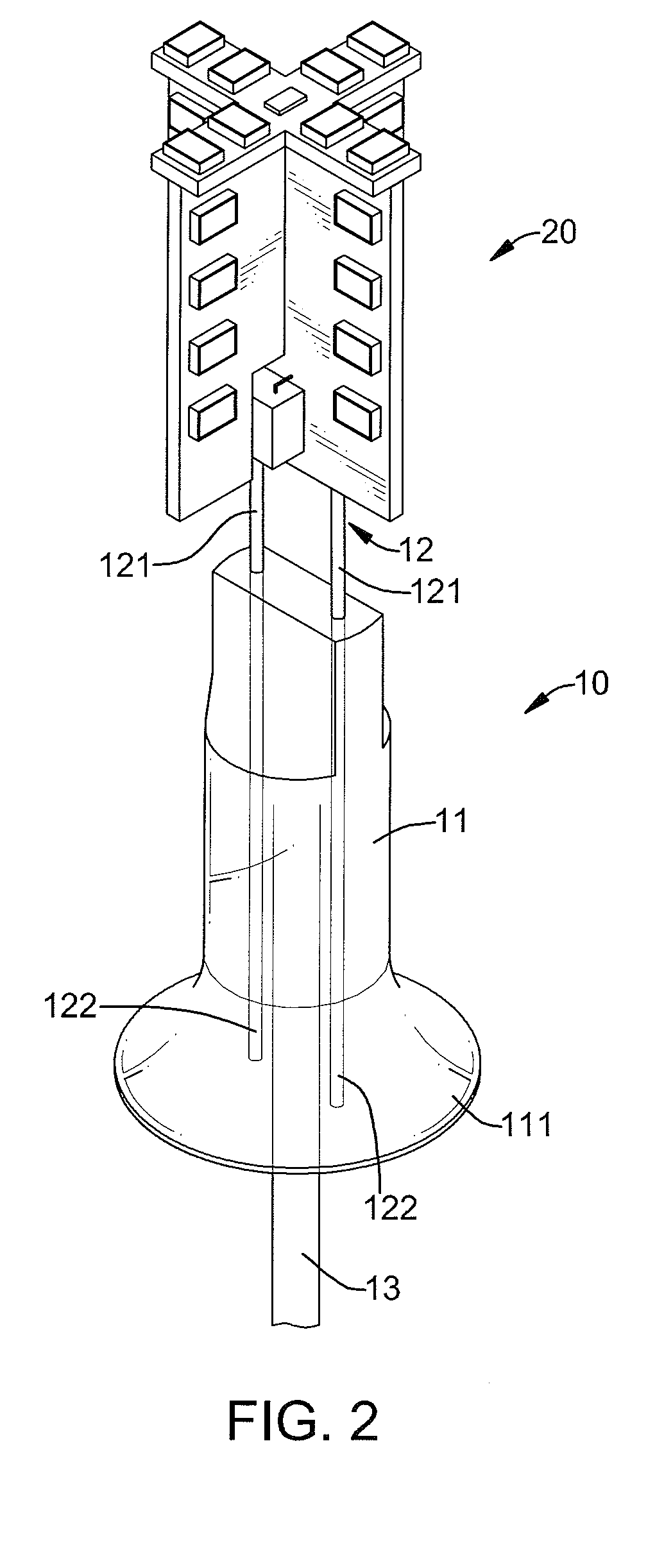

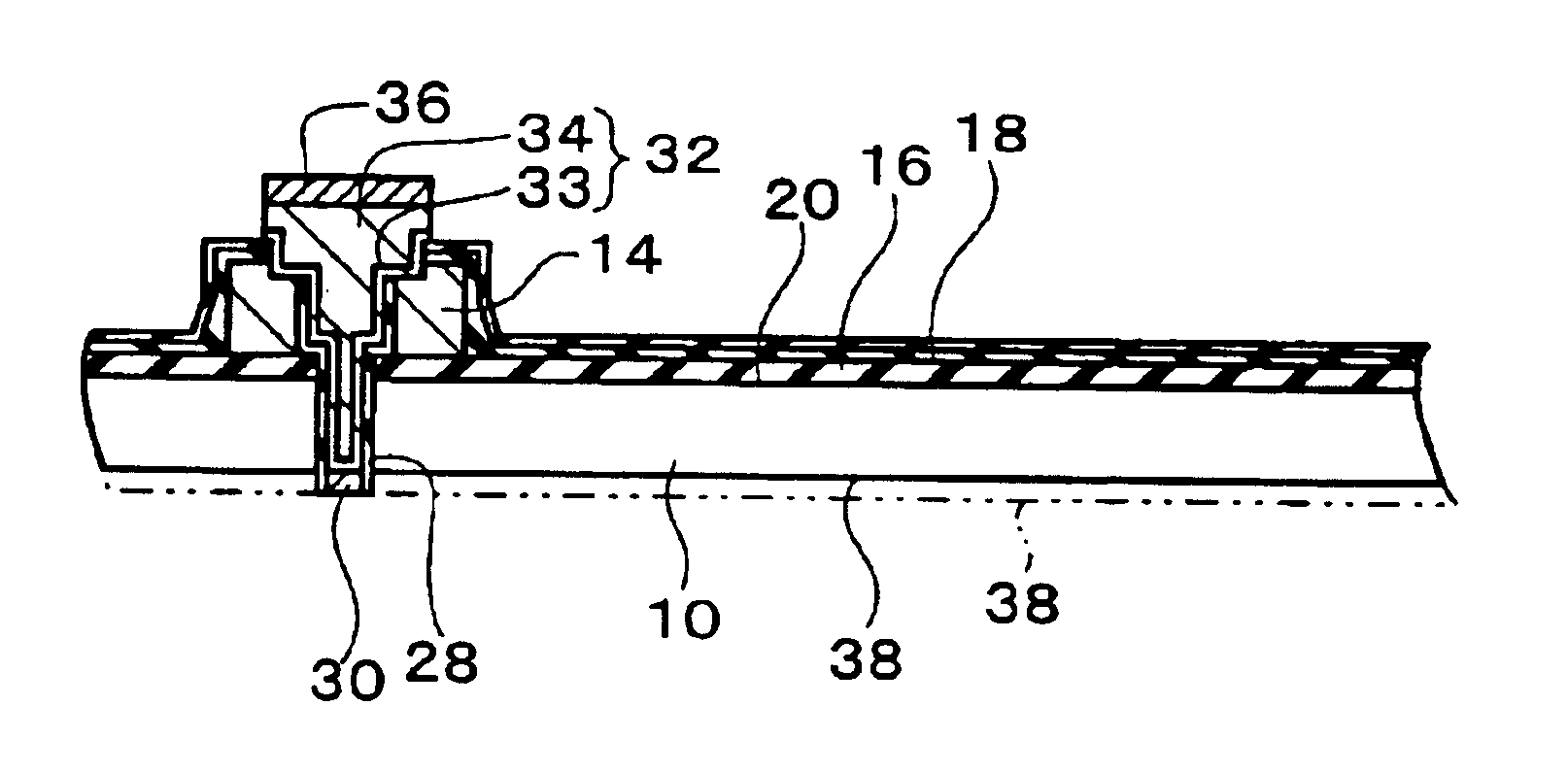

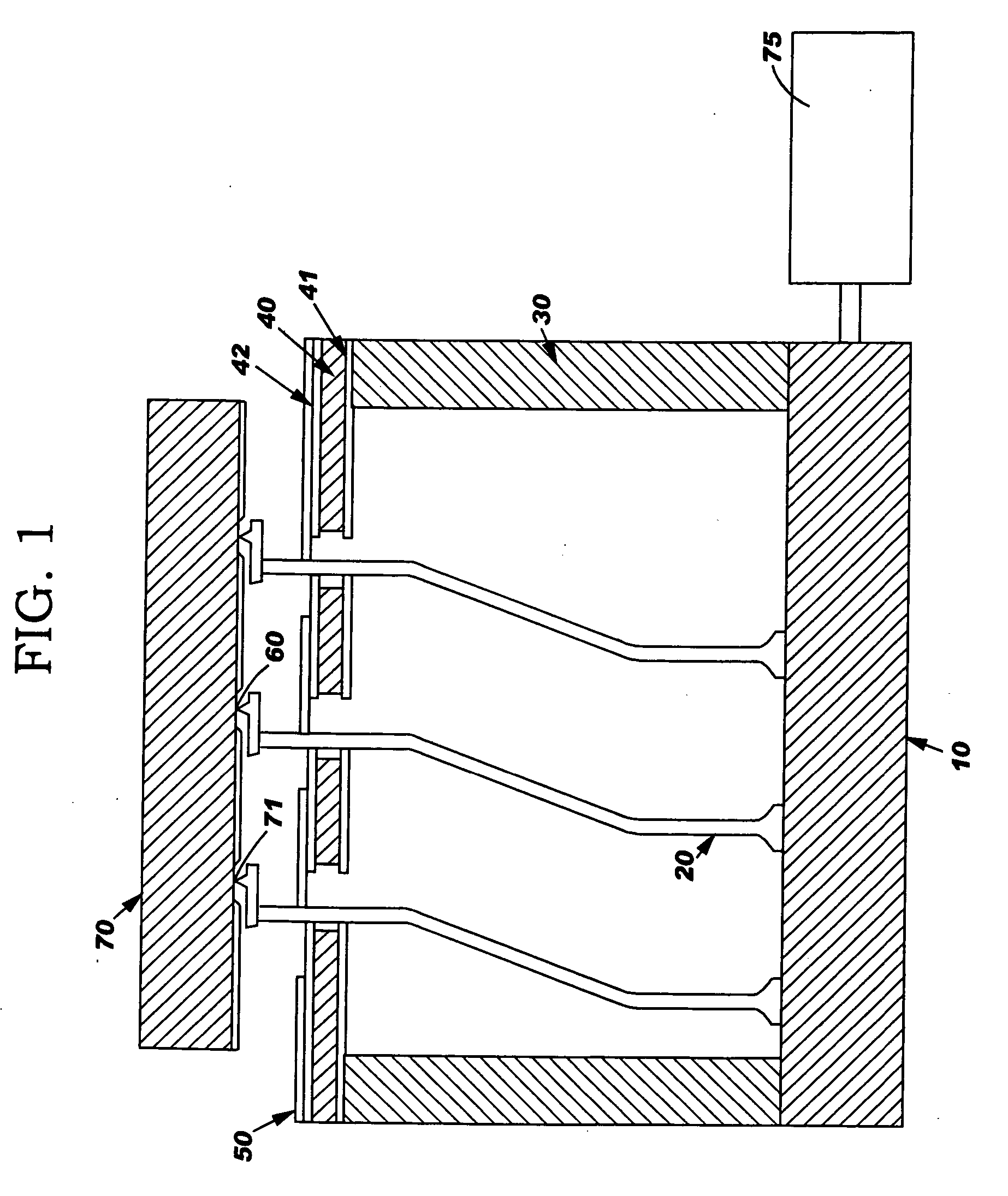

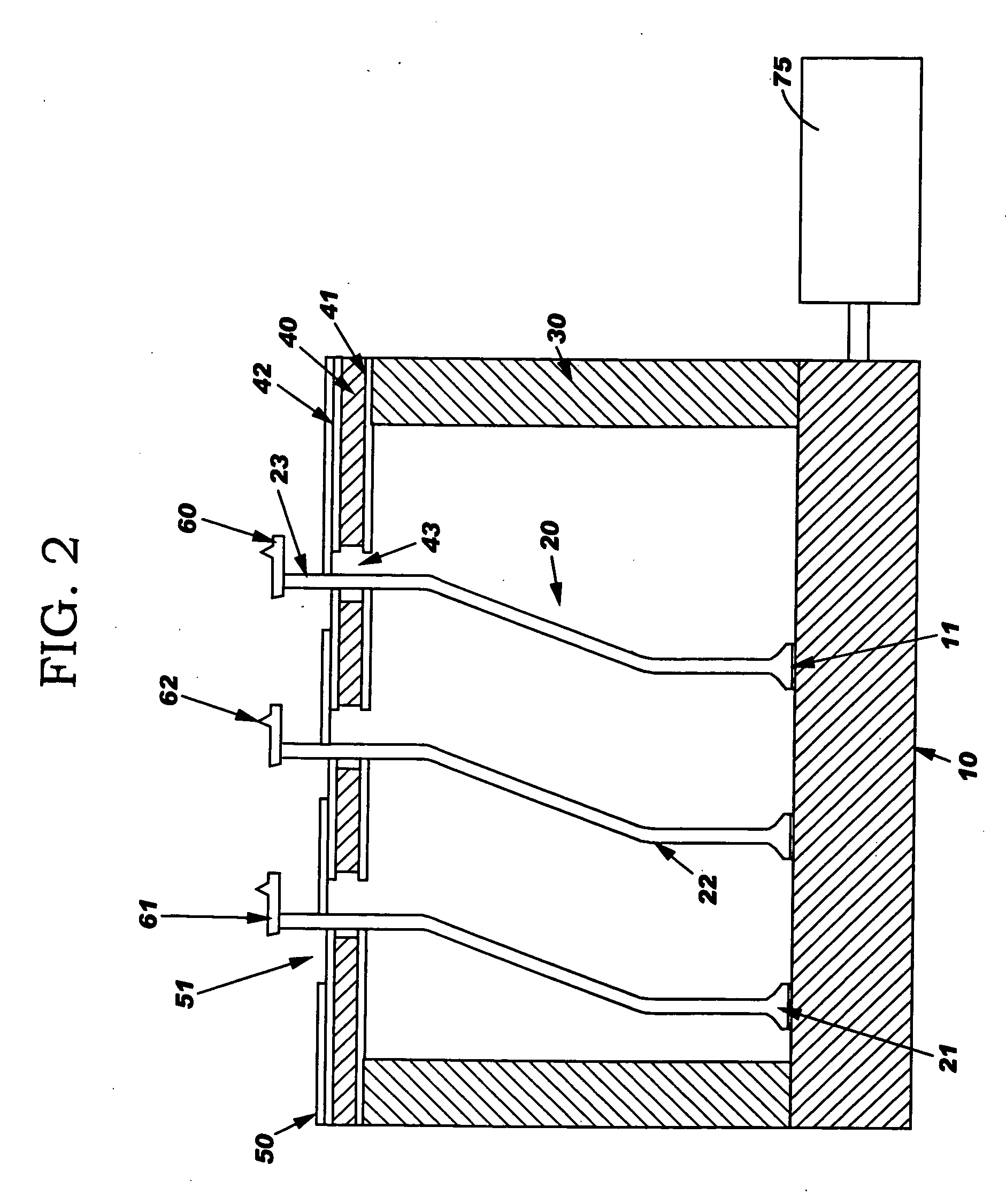

A method of assembling an airtight LED light bulb has the steps of: connecting a stem device with an LED device, drying the LED device, connecting the stem device with a bulb envelope, extracting air in the bulb envelope via a pipe, filling the bulb envelope with nitrogen or inert gas via the pipe, sealing an opening of the pipe which is located outside the bulb envelope to make the bulb envelope completely airtight and connecting a cap with the bulb envelope. Because the bulb envelope is airtight, moisture in the environment can not damage the LED device, and the steps of extracting air in the bulb envelope via the pipe and filling the bulb envelope with nitrogen or inert gas via the pipe are feasible. Consequently, the LED device will not easily be oxidized or dampened, so the lifespan of the airtight LED light bulb can be prolonged.

Owner:LIQUIDLEDS LIGHTING

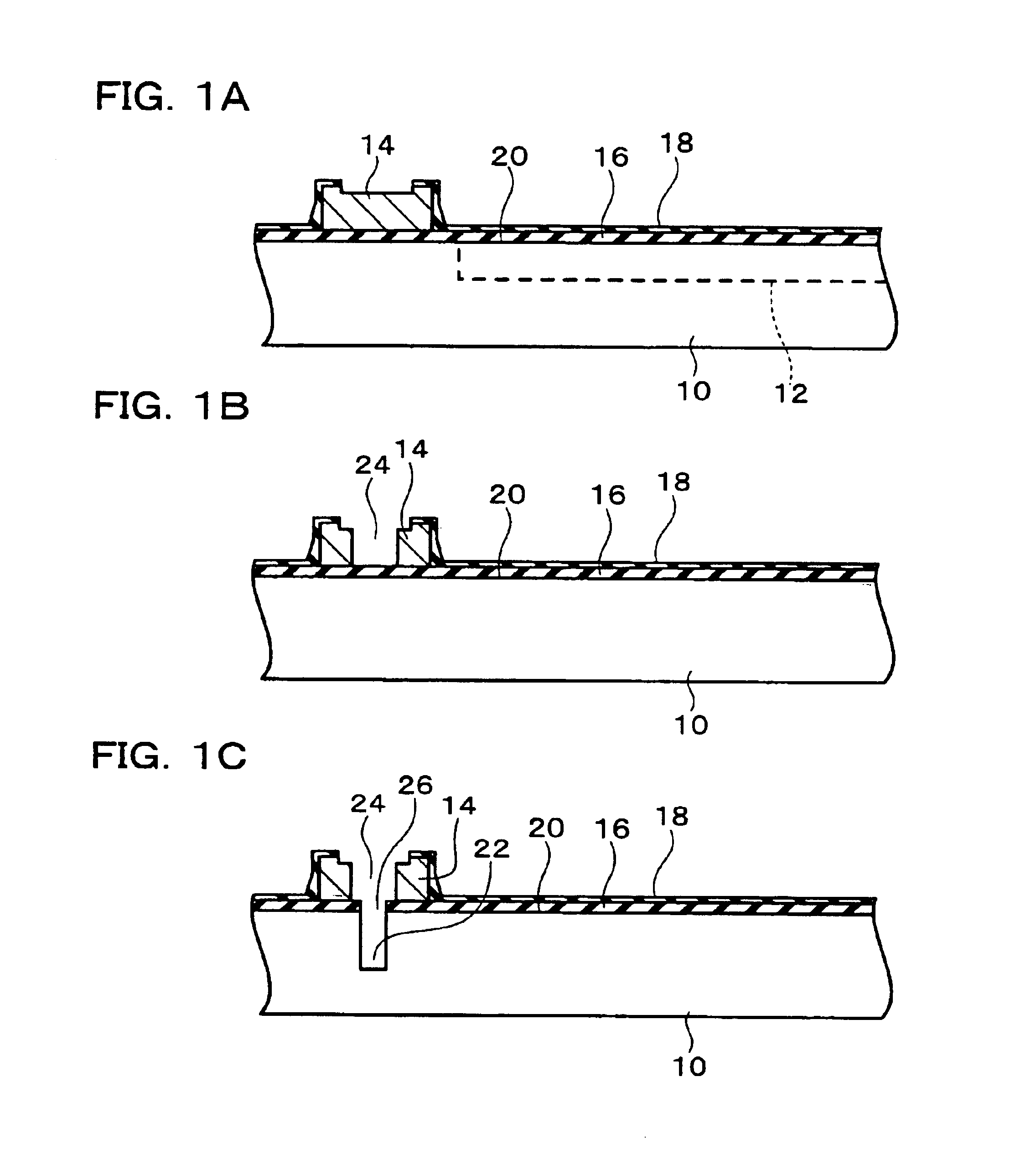

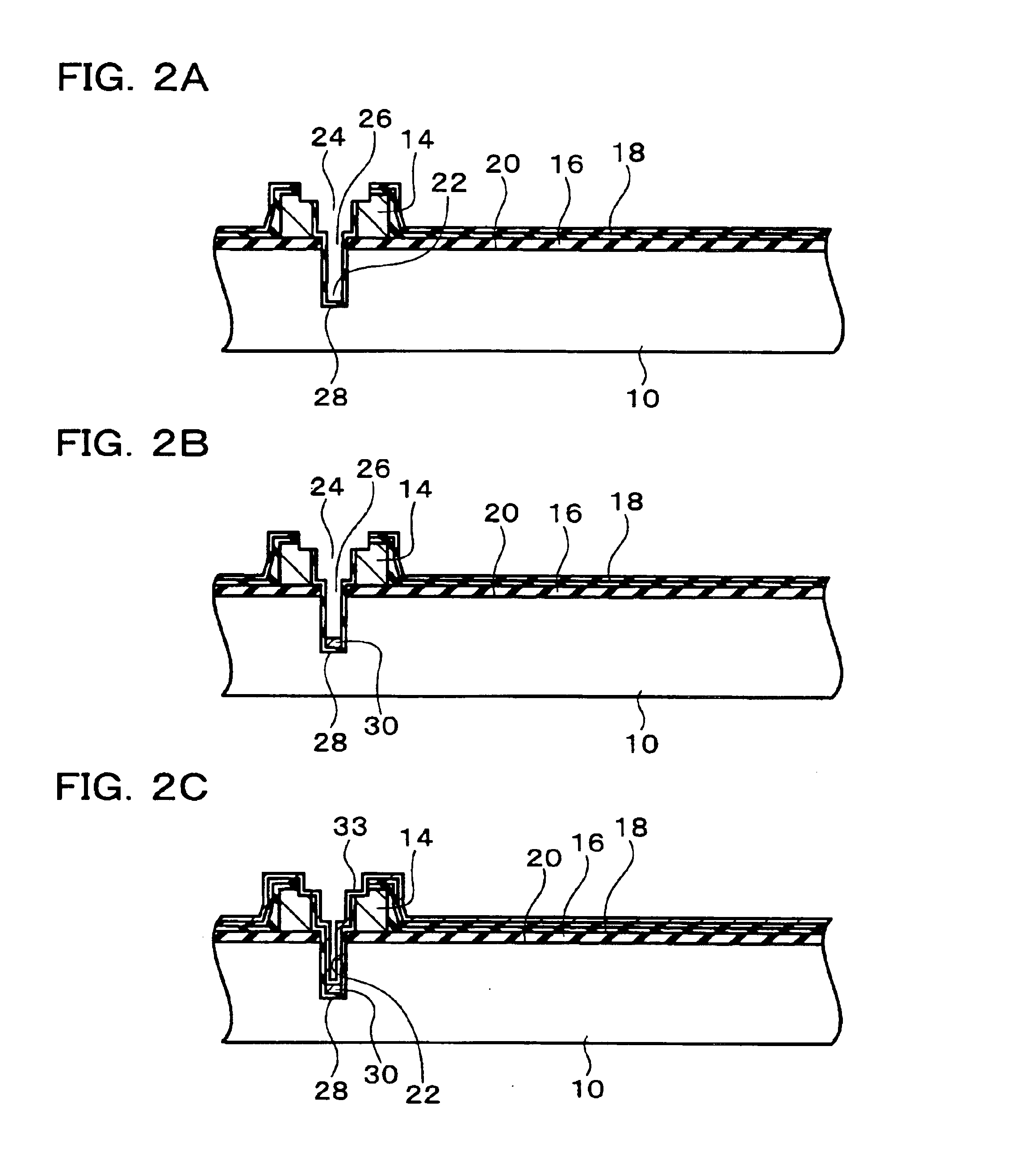

Semiconductor device and method of manufacturing the same, circuit board and electronic instrument

ActiveUS6841849B2Easily oxidizeNot easily oxidizedSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

A depression is formed from a first surface of a semiconductor substrate on which is formed an integrated circuit. An insulating layer is provided on the inner surface of the depression. A first conductive portion is provided on the inside of the insulating layer. A second conductive portion is formed on the inside of the insulating layer and over the first conductive portion, of a different material from the first conductive portion. The first conductive portion is exposed from a second surface of the semiconductor substrate opposite to the first surface.

Owner:ADVANCED INTERCONNECT SYST LTD

High polymer-based graphene composite material with positive resistance temperature coefficient and preparation method

InactiveCN102532669AReduce dosageImprove conductivityState of artElectrical resistance and conductance

The invention relates to a high polymer-based graphene composite material with positive resistance temperature coefficient, and a preparation method of the material. The composite material comprises a base body and conductive filler; the content of conductive material is 0.01-10wt%; all components are mixed uniformly and are formed through mold-pressing or extrusion / injection molding; and the formed material is irradiated after being dried, so that the high polymer-based graphene composite material with positive resistance temperature coefficient can be obtained. Compared with the prior art, the graphene composite material and the preparation method have the advantages that the manufacturing process is simple, less influence is caused to the performance of base material, oxidation is unlikely to occur, the resistivity is more stable, the circulation stability of the material is better, and NTC (Negative Temperature Coefficient) effect is not generated easily.

Owner:SHANGHAI JIAO TONG UNIV

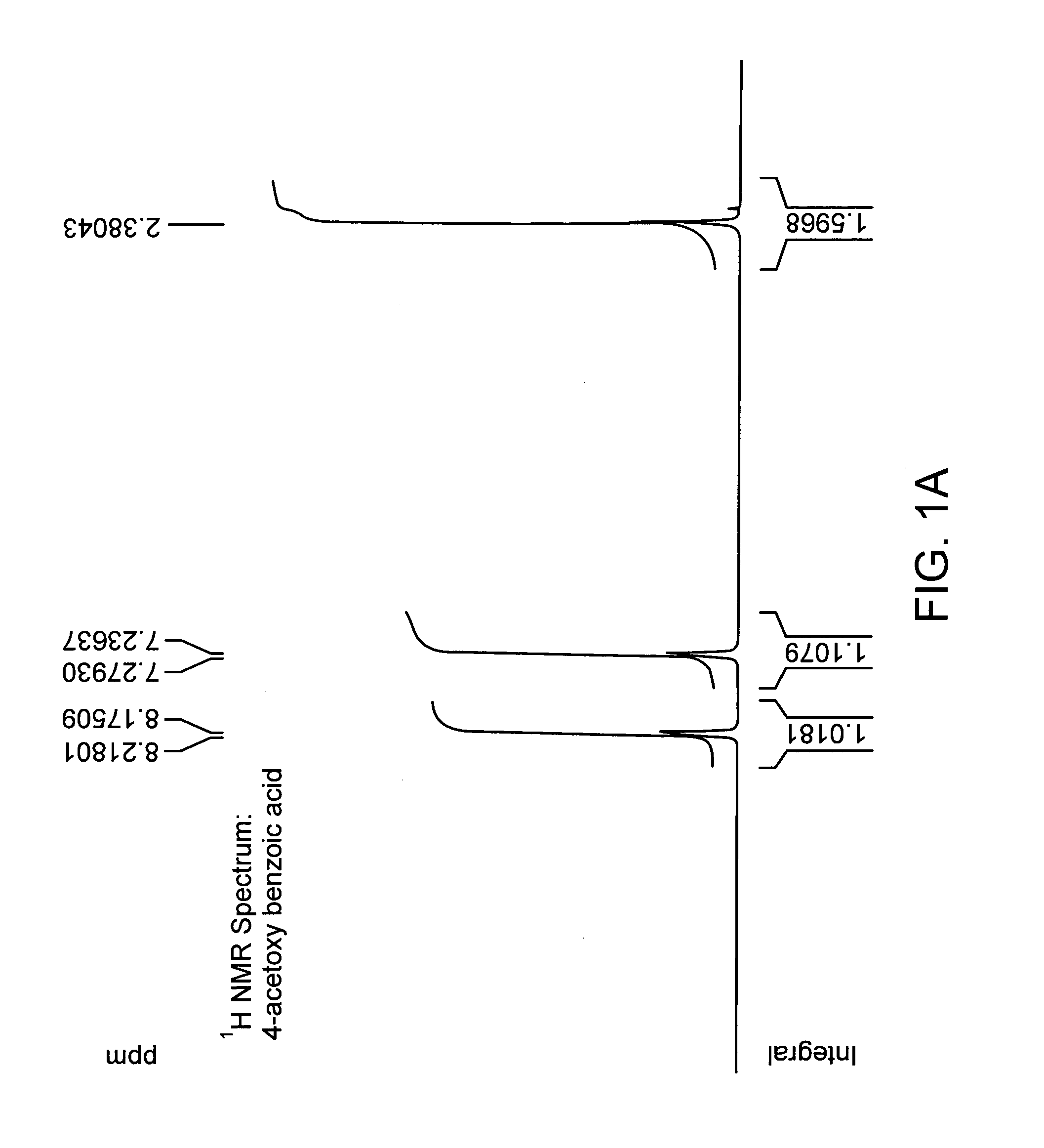

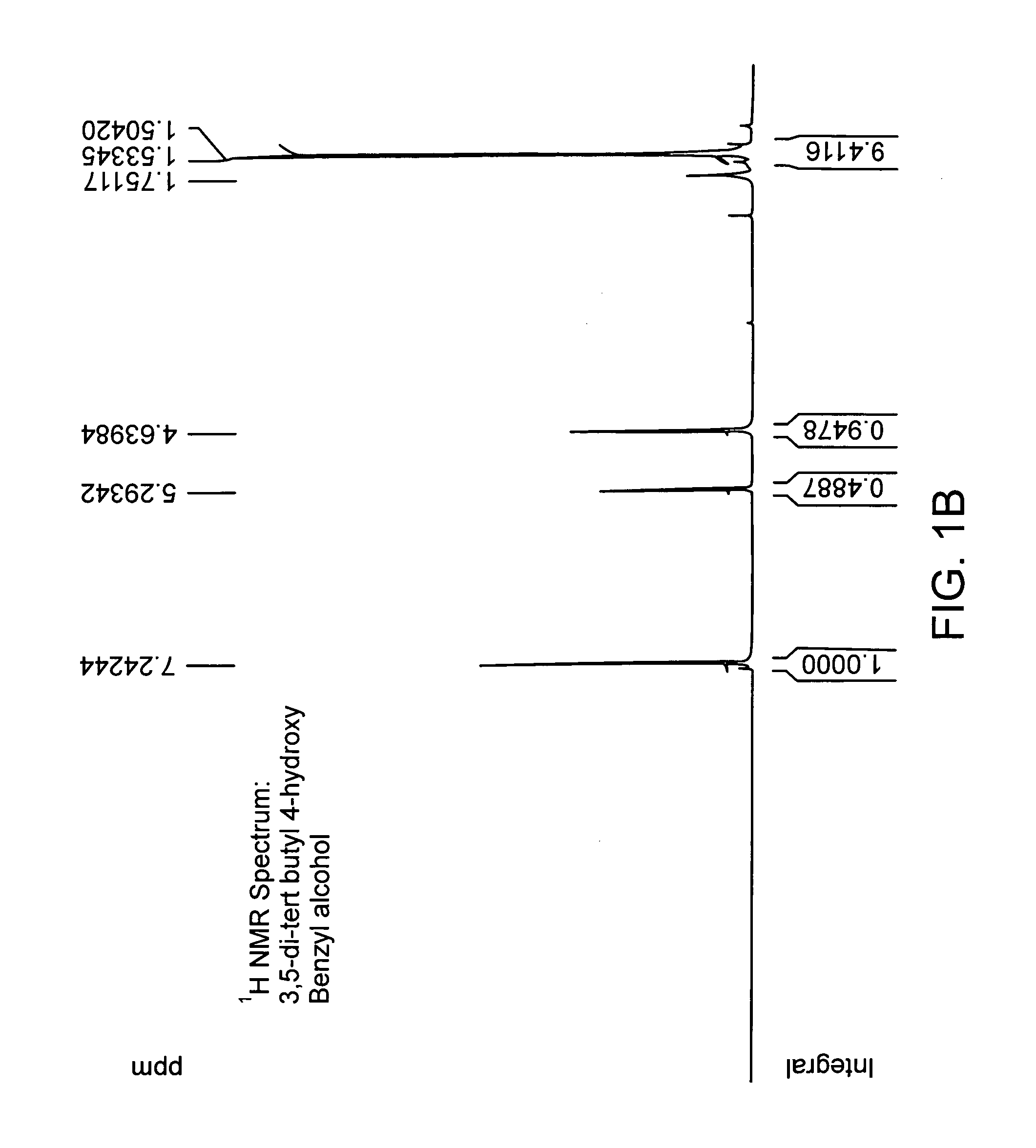

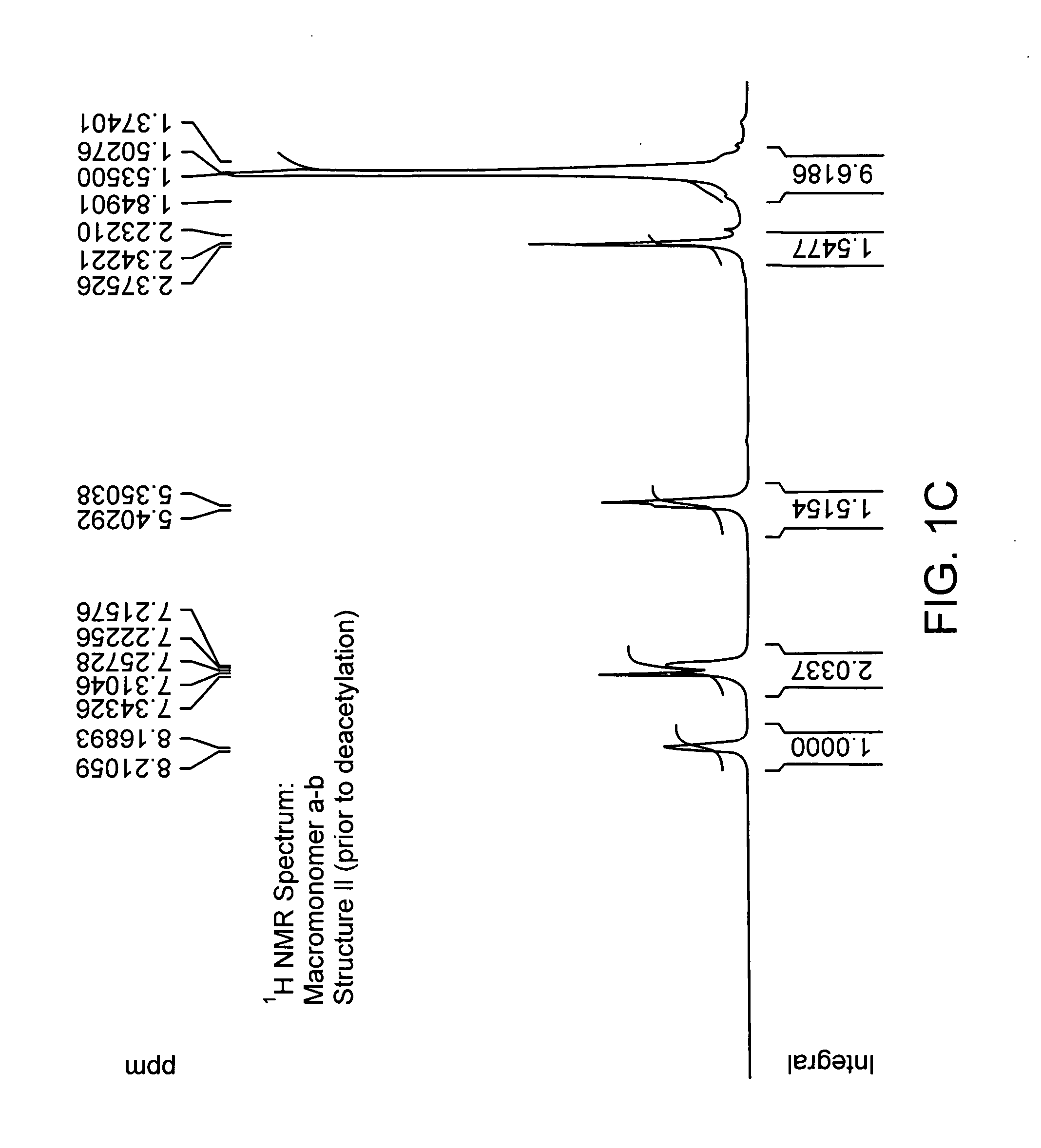

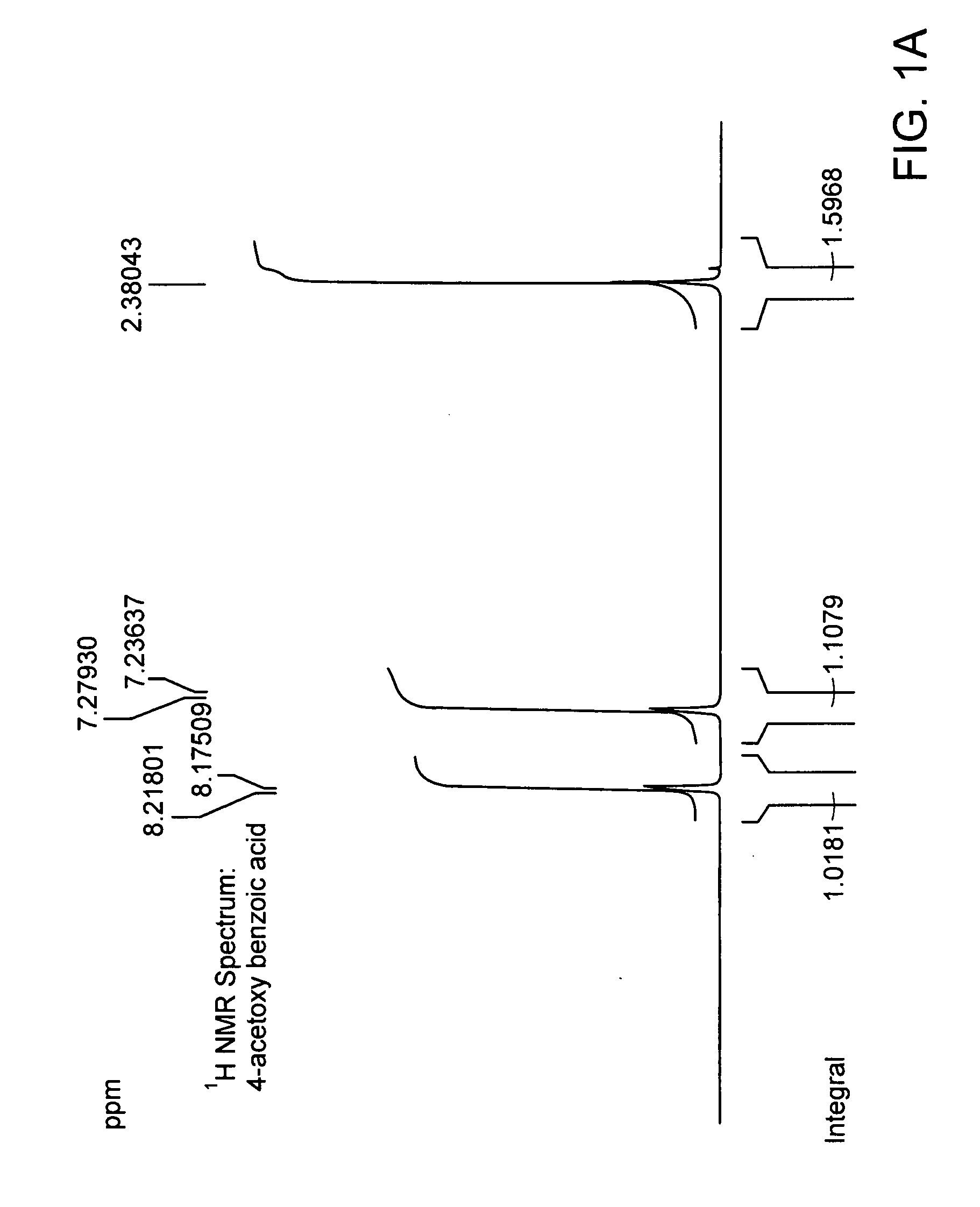

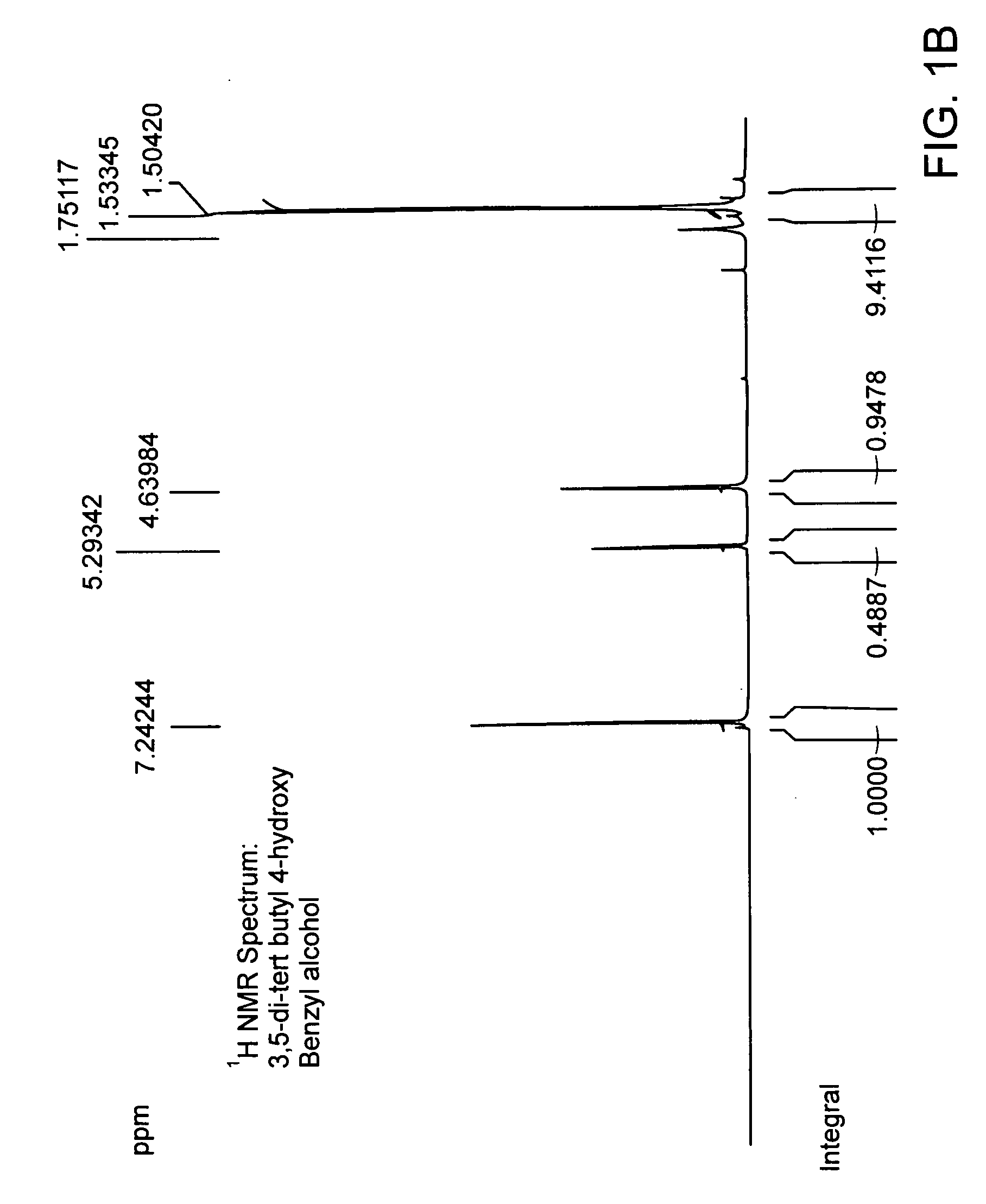

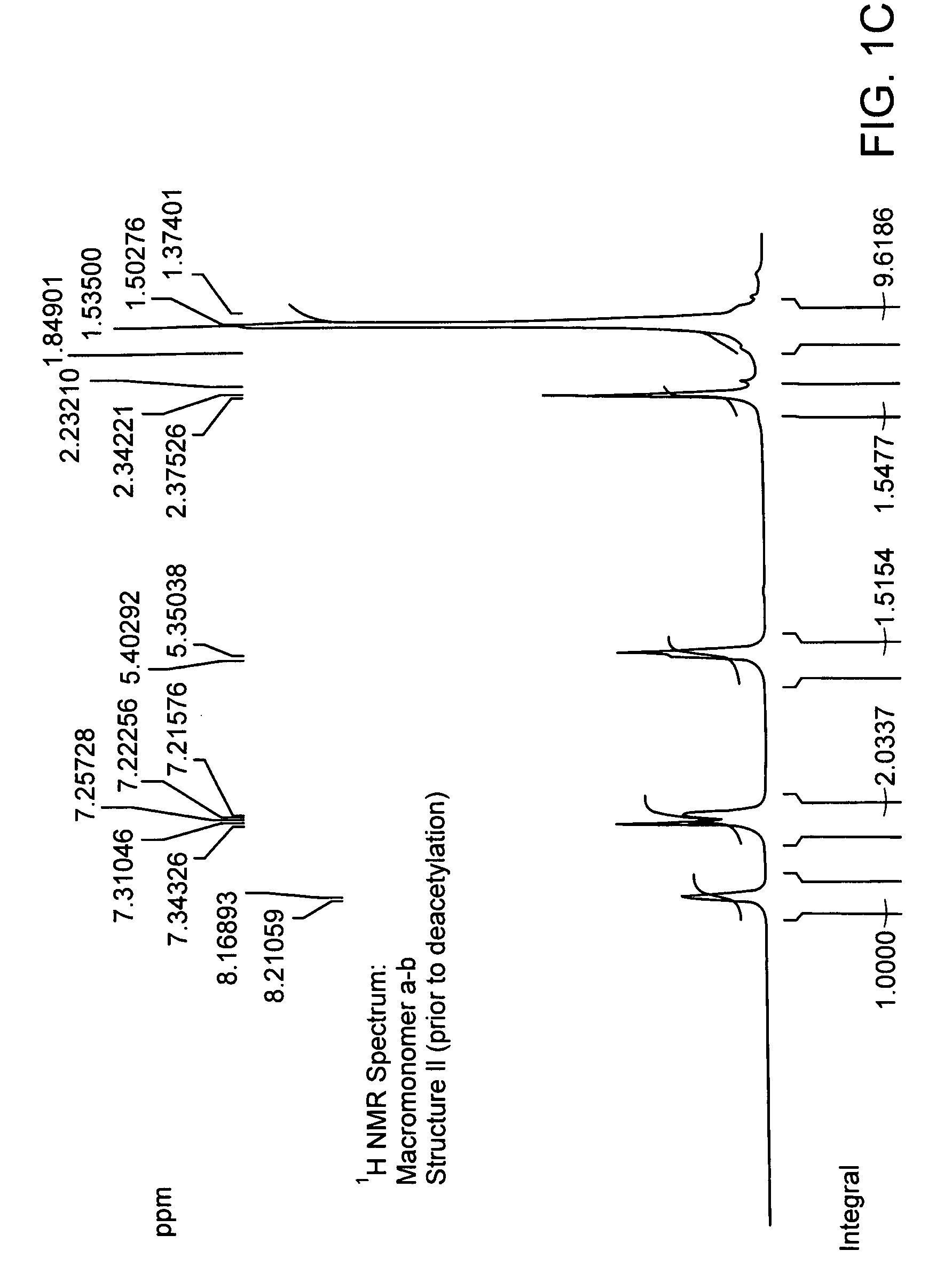

Anti-oxidant macromonomers and polymers and methods of making and using the same

InactiveUS20060041094A1Not easily oxidizedShort term and longer term stability towards oxidationOrganic compound preparationCarbonyl compound preparation by condensationAntioxidantMacromonomer

The present invention relates to macromonomer compounds possessing antioxidant properties, antioxidant polymers comprising the antioxidant macromonomers as a recurring unit, and methods of inhibiting oxidation in a substance comprising contacting the substance with the antioxidant polymers. In one embodiment, substantially all of the recurring macromonomeric units of the antioxidant polymers comprise an antioxidant moiety. In another embodiment, all of the recurring macromonomer units of the antioxidant polymers comprise an antioxidant moiety. The method of the present invention, yields antioxidant polymers with substantially all of the recurring units comprising an antioxidant moiety. These antioxidant polymers have greater bulk antioxidative properties than previously known.

Owner:POLNOX CORP

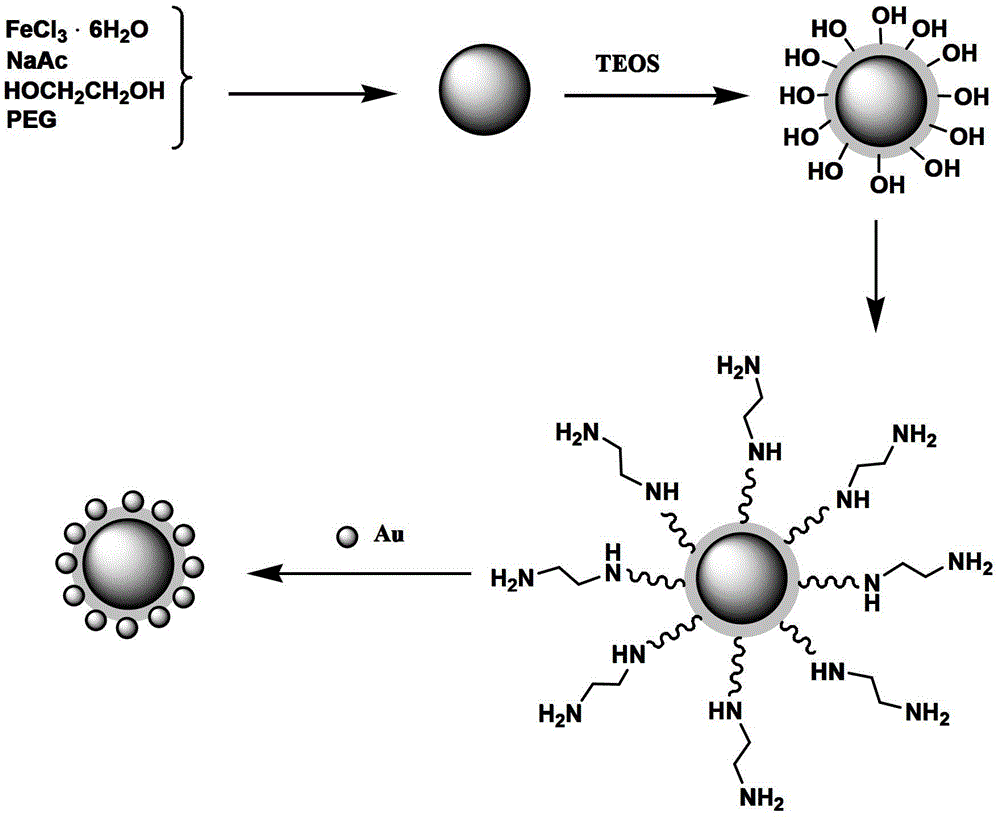

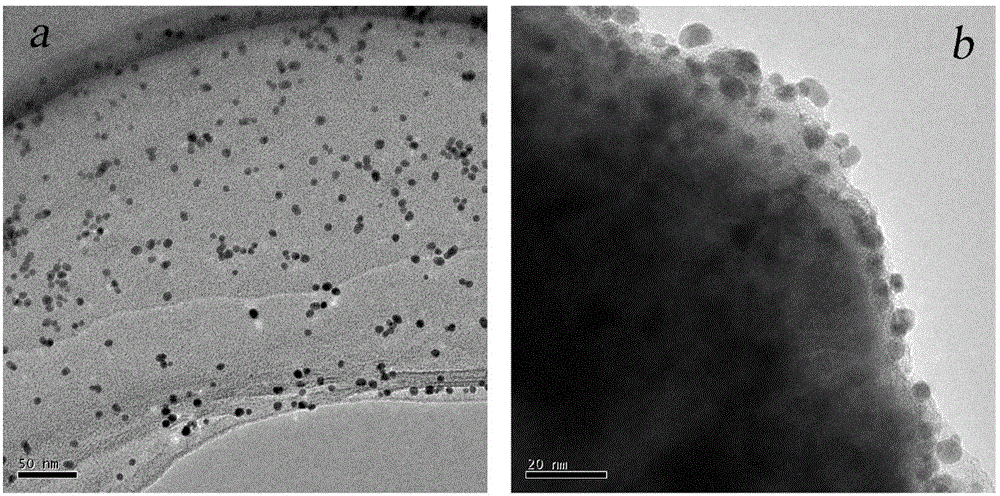

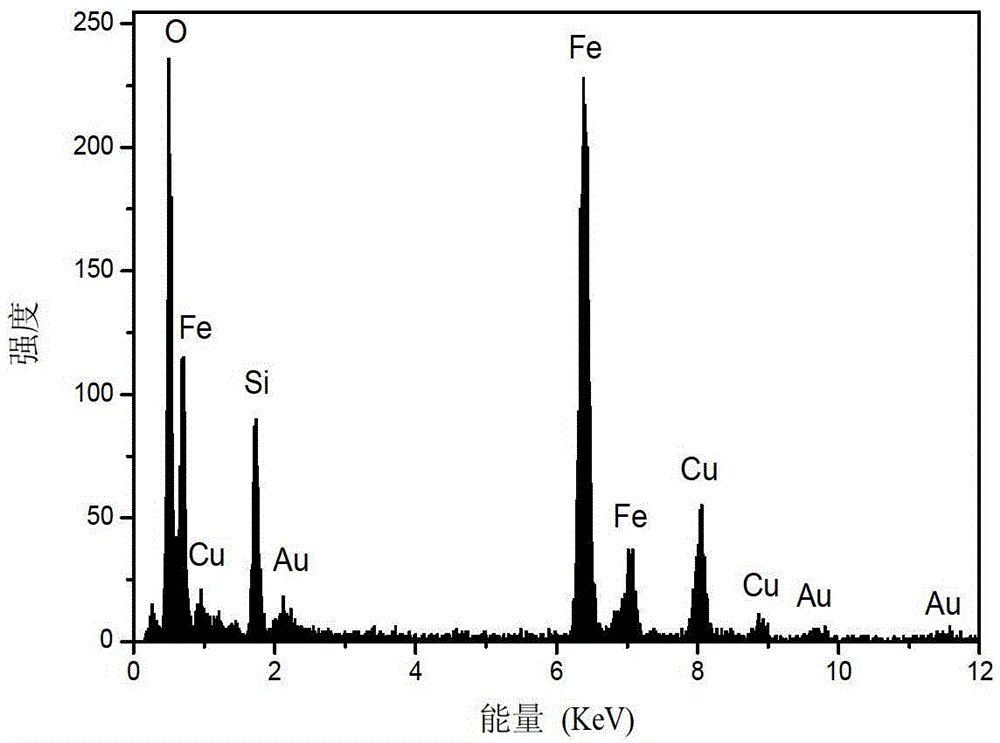

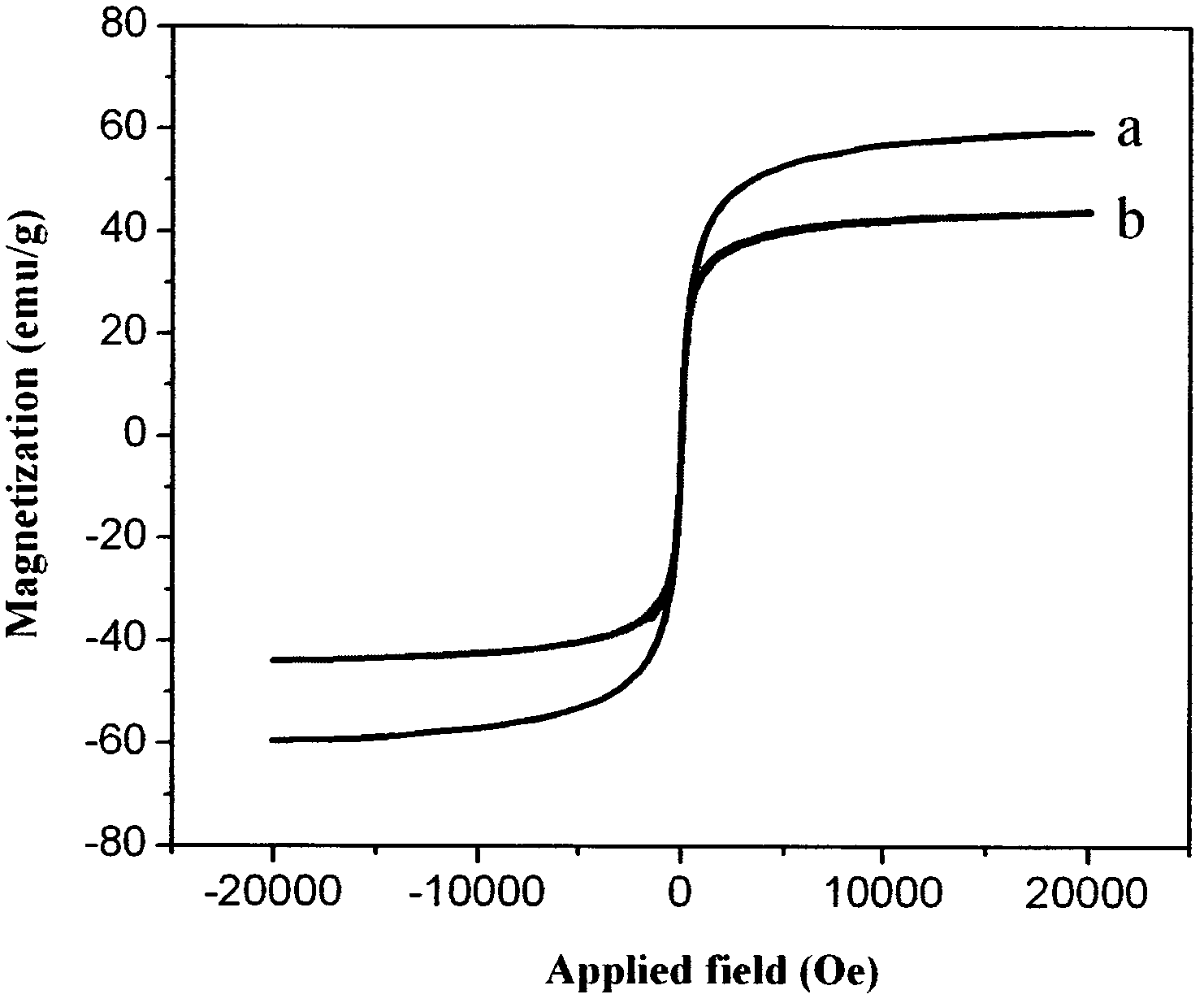

Magnetic gold nanoparticle composite material, and preparation method and application thereof

InactiveCN102974314AEasy to controlGood reproducibilityOther chemical processesAlkali metal oxides/hydroxidesMicrosphereMagnetite Nanoparticles

The invention discloses a magnetic gold nanoparticle composite material, and a preparation method and application thereof. The preparation method comprises the following steps: synthesizing ferroferric oxide magnetic microspheres, adding tetraethoxyl silicon to implement hydrolysis and polymerization on the magnetic microsphere surfaces, adding N-(2-aminoethyl)-3-aminopropyltrimethoxysilane to obtain surface-modified double-amino-group Fe3O4 / SiO2 magnetic microspheres, and compounding the surface-modified double-amino-group magnetic microspheres with gold nanoparticles. The chelation action of the double amino groups is utilized to adsorb the gold nanoparticles more firmly; and the material combines the surface selectivity of the gold nanoparticles and the superparamagnetism of the magnetic nanoparticles, can extract benzopyrene in water, and can implement quick and efficient separation.

Owner:TIANJIN UNIV

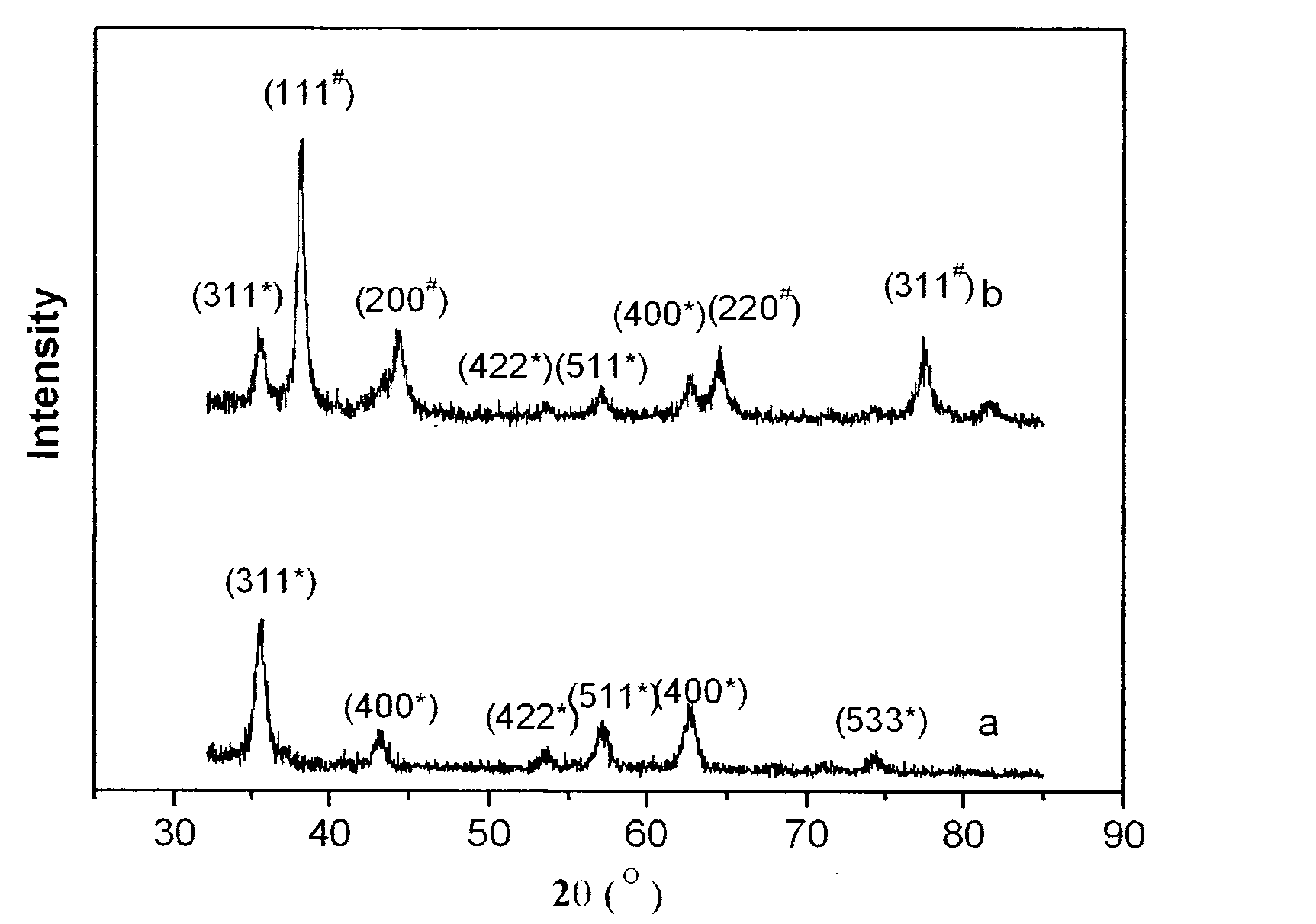

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069AImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

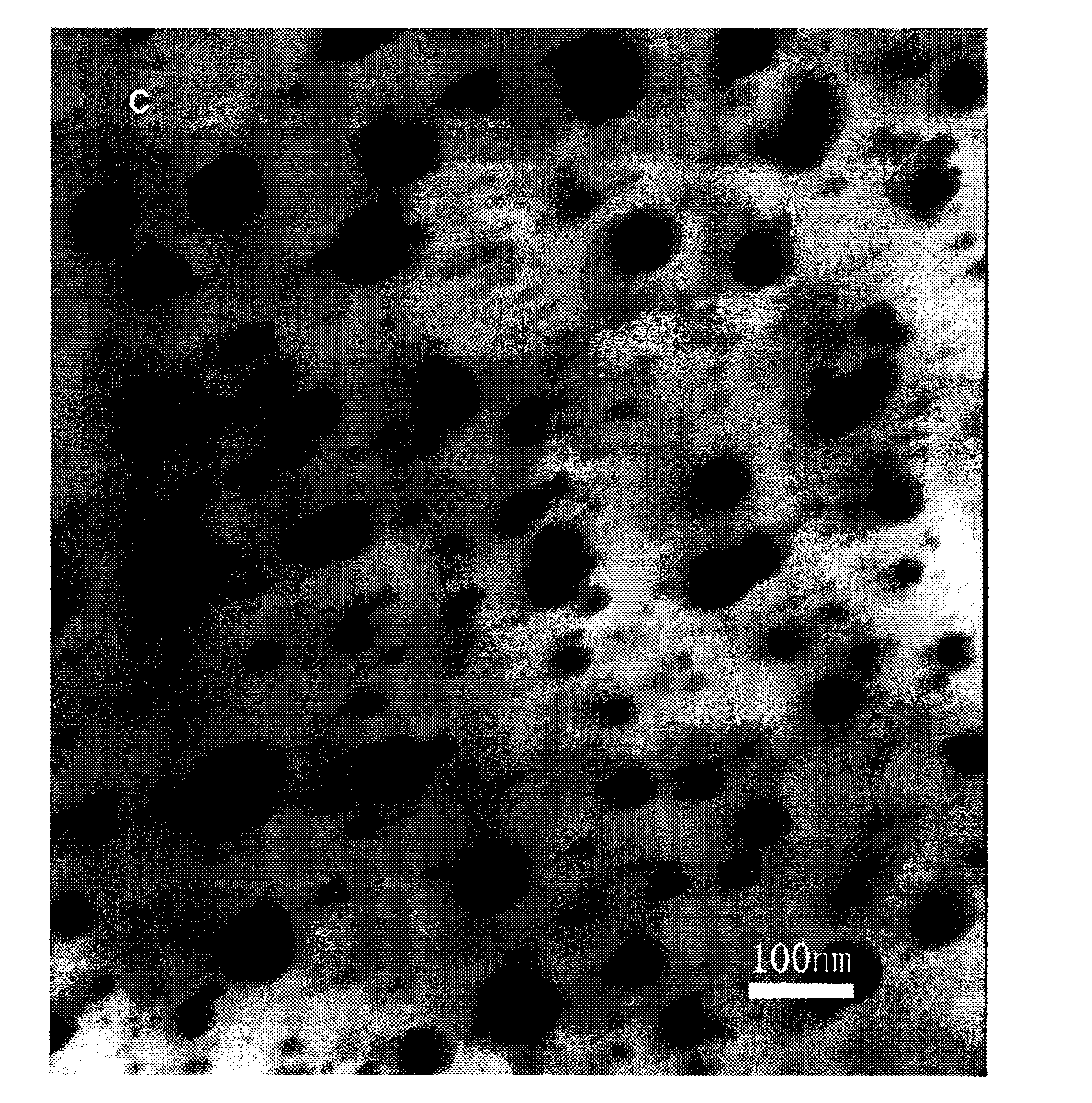

Preparation method of core-shell magnetic/gold nano particles

ActiveCN102861921AGood dispersionStrong magnetic responseMaterial nanotechnologyControlled releaseSuperparamagnetism

The invention discloses a preparation method of magnetic / gold nano particles. The preparation method comprises the following steps: firstly adopting a co-precipitation method to prepare the magnetic Fe3O4 nano particles; polymerizing the dopamine in-situ on the surfaces of the magnetic particles to obtain Fe3O4 nano particles modified by the poly dopamine; introducing polyphenol and amino groups to the surfaces of the Fe3O4 nano particles; absorbing the nano gold seeds on the surfaces of the modified magnetic particles through the static action; adopting the nano gold which is absorbed on the surfaces of the magnetic particles as the seed, adopting the polyphenol on the surfaces of the magnetic particles as a reducing agent, gradually adding the chloroauric acid liquid to gradually produce the gold layers on the surfaces of the magnetic particles to obtain the core-shell magnetic / gold nano particles. The nano particles have good water dispersion and strong magnetic respond performance. The diameters of the nano particles are 30-100 nanometers, the saturation magnetization is 30.1-38.7emu / g, and the nano particles are superparamagnetic. The nano particles have wide application prospect on the fields of targeted drug controlled release, thermal therapy, separation of protein and enzyme, etc.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

Vitamin D3 microcapsule and preparation method thereof

InactiveCN101536993AHigh embedding rateImprove thermal stabilityOrganic active ingredientsBiocideOil and greaseOil phase

The invention relates to a microcapsule and a preparation method thereof, aiming at providing a vitamin D3 microcapsule and a preparation method thereof. The vitamin D3 microcapsule comprises core material vitamin D3, oil fat, an oil-soluble emulsifier and a wall material. The preparation method comprises the following steps of: (1) adopting the core material vitamin D3, the oil fat, the oil-soluble emulsifier as oil phase for dissolving and mixing evenly; (2) adding deionized water in the wall material, stirring and dissolving as water phase; (3) adding the oil phase into the water phase, mixing, stirring evenly, then carrying out homogenization and emulsifying the obtained mixture into microcapsule; (4) carrying out spray drying to the microcapsule to form the vitamin D3 microcapsule; and (5) screening, mixing, inspecting and packing to obtain the finished product. The microcapsule and the preparation method thereof have the advantages of high embedding rate, good flowability, hard photolysis, oxidation, high heat stability, even dispersion in water and the like. The microcapsule can be widely added into food or feedstuff, is easy to be absorbed by the human body or animals, also can be used as original drug of rat poison to strengthen the stability thereof greatly.

Owner:ZHEJIANG GARDEN BIOCHEM HIGH TECH +1

Reformer of methanol-water hydrogen manufacturing equipment, and manufacturing technology of reformer

ActiveCN104229733AImprove insulation performanceReduce weightHydrogenChemical industryMethanol waterHydrogen

The invention discloses a reformer of methanol-water hydrogen manufacturing equipment, and a manufacturing technology of reformer, relating to the technical field of methanol-water hydrogen manufacturing equipment. The reformer of the methanol-water hydrogen manufacturing equipment comprises a reformer shell, wherein the reformer shell sequentially comprises a stainless steel inner shell, an insulating cotton layer and a mica outer shell from inside to outside, the diameter-thickness ratio of the reformer shell to the stainless steel inner shell is (150:0.8)-(150:2.5), the diameter-thickness ratio of the reformer shell to the insulating cotton layer is (150:10)-(150:20), and the diameter-thickness ratio of the reformer shell to the mica shell is (150:1.5)-(150:3.5). The reformer not only is high-temperature-resistant and high in strength, but also is good in insulating property, corrosion-resistant, oxidization-resistant, waterproof, non-conductive, and light in weight.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

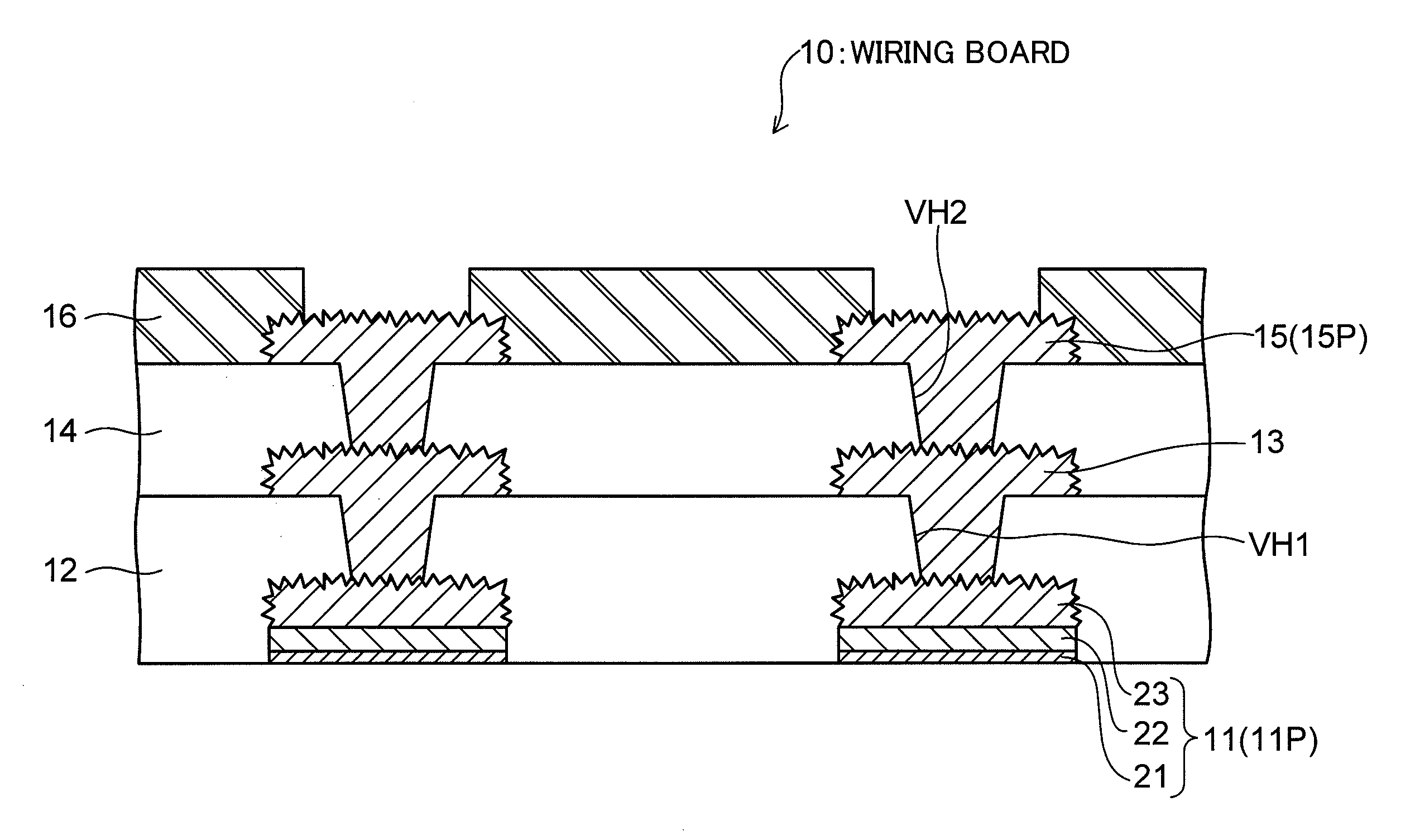

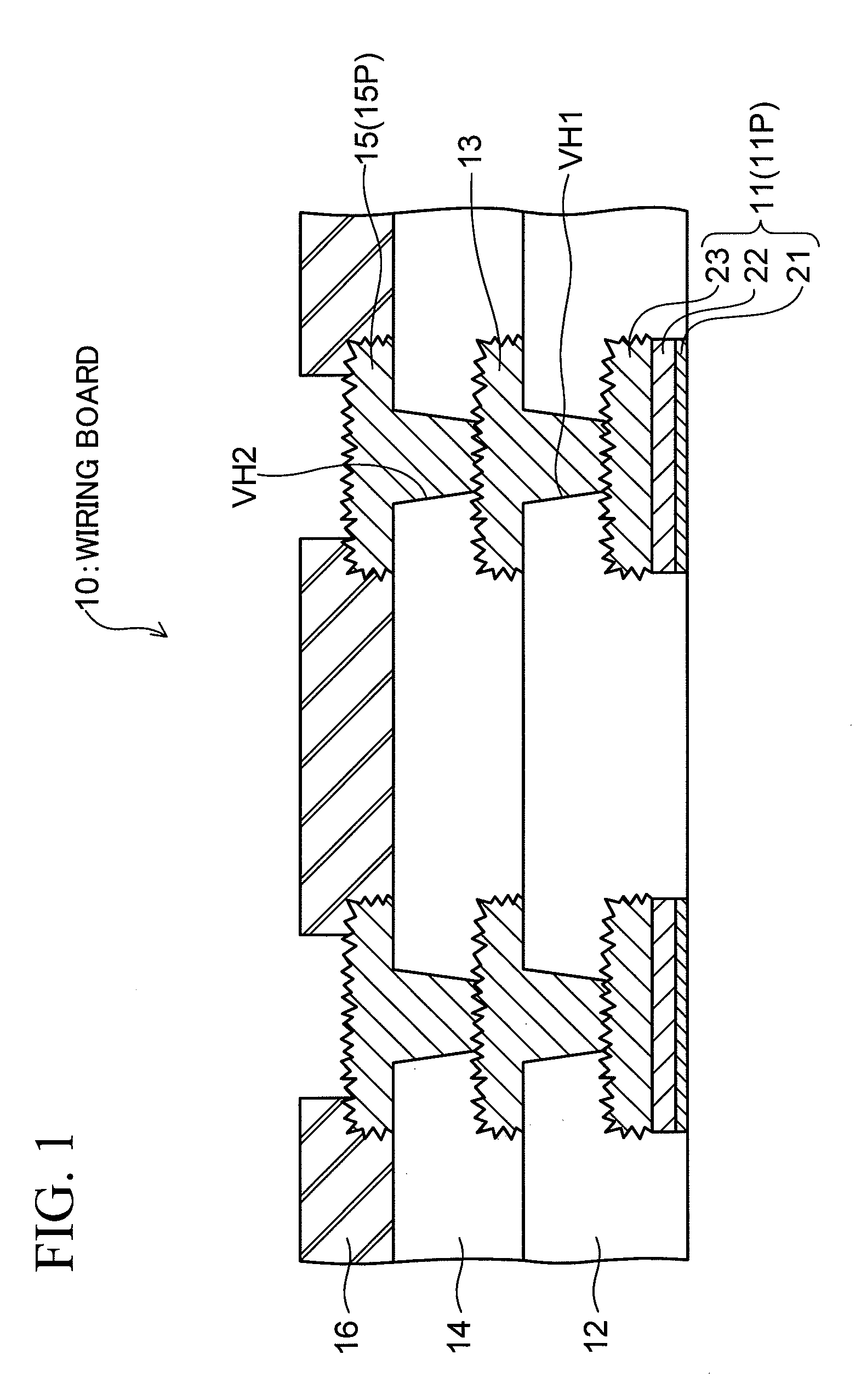

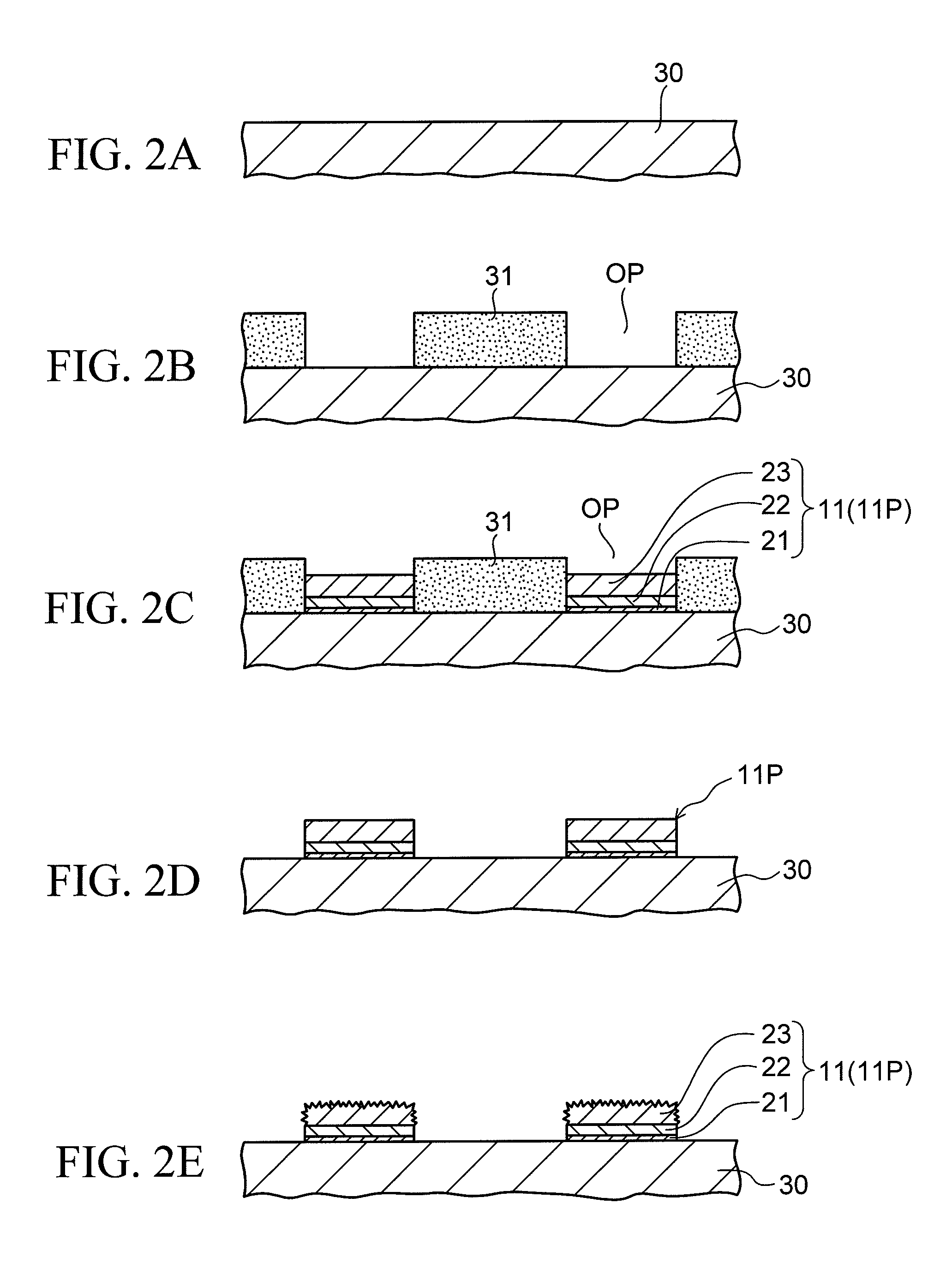

Wiring board and method of manufacturing the same

ActiveUS20100065322A1Improve tensile strengthDecreasingSemiconductor/solid-state device detailsSolid-state devicesMetalMaterials science

A wiring board includes a pad exposed from an opening portion of an outermost insulating layer. The pad includes: a first metal layer a surface of which is exposed from the wiring board; a second metal layer provided on the first metal layer and formed of a material effective in preventing a metal contained in a via inside the board from diffusing into the first metal layer; and a third metal layer provided between the second metal layer and the via, and formed of a material harder to be oxidized than that of the second metal layer. The thickness of the third metal layer is relatively thick, and is preferably selected to be three times or greater than a thickness of the second metal layer. A side surface of the third metal layer and a surface of the third metal layer to which the via is to be connected are roughed.

Owner:SHINKO ELECTRIC IND CO LTD

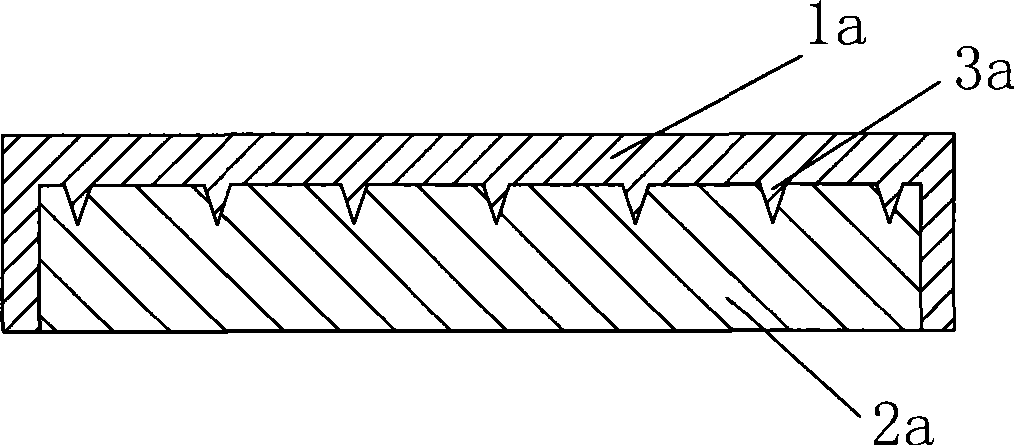

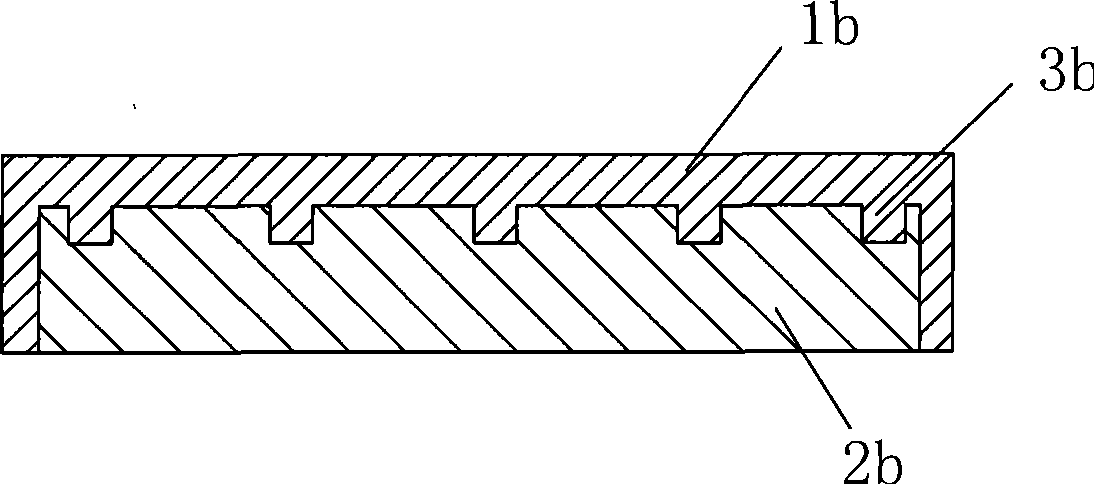

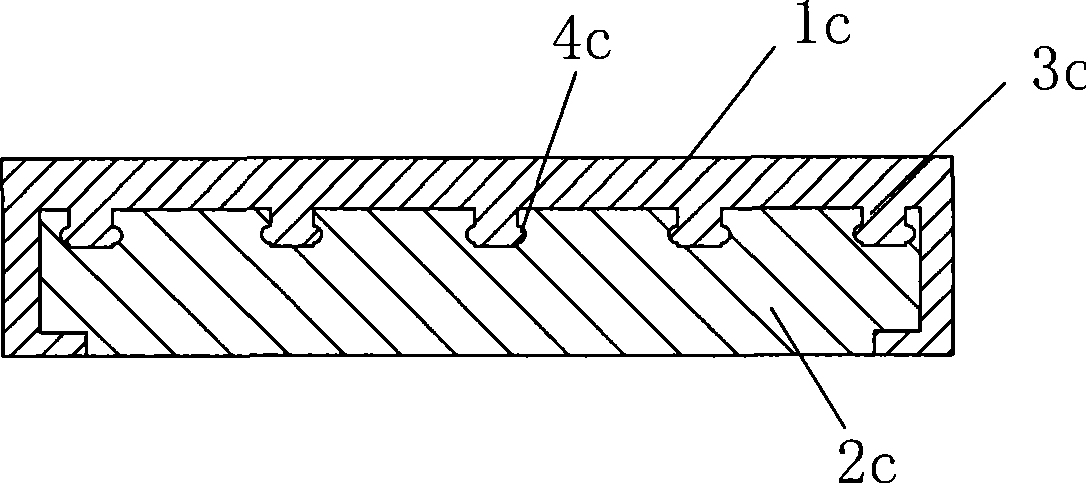

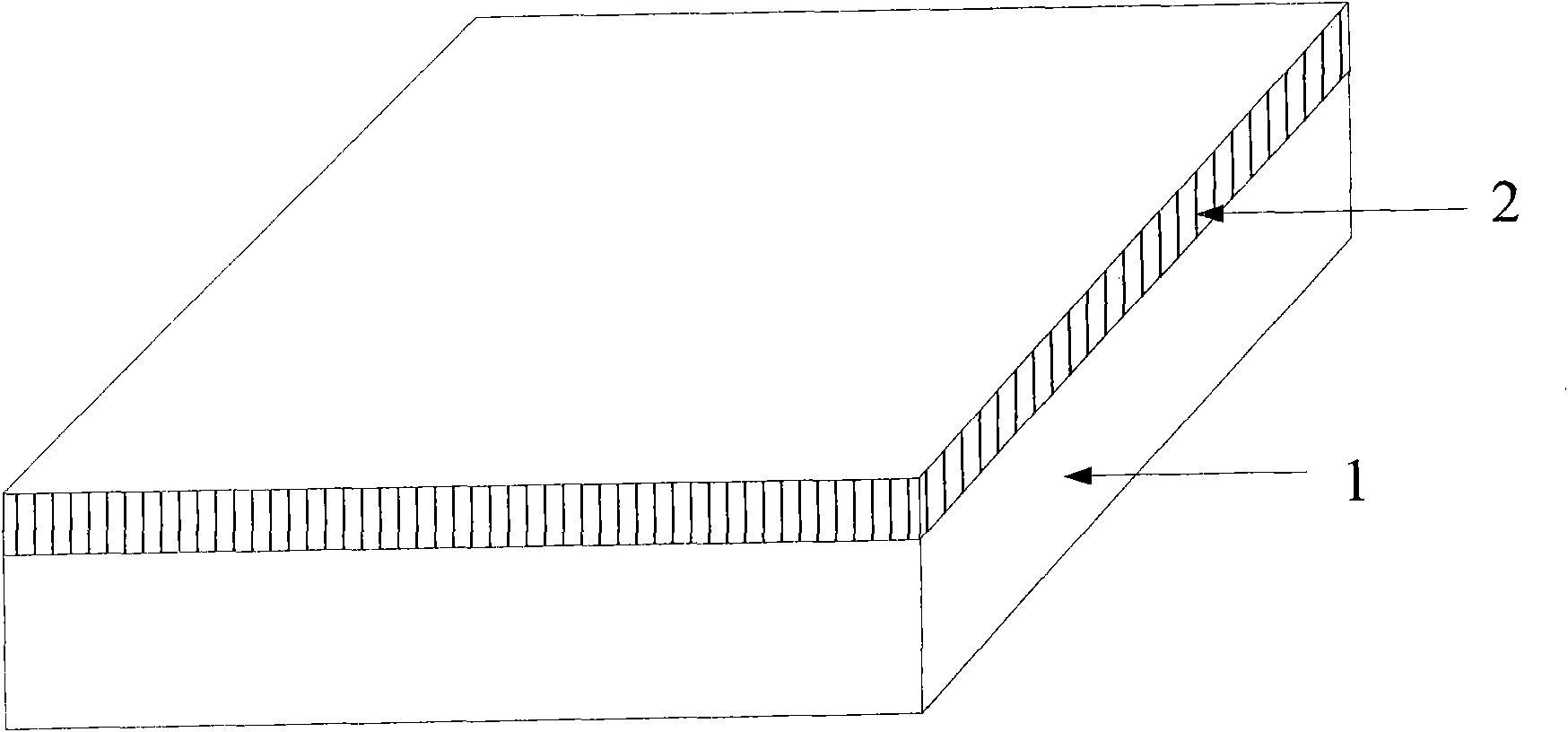

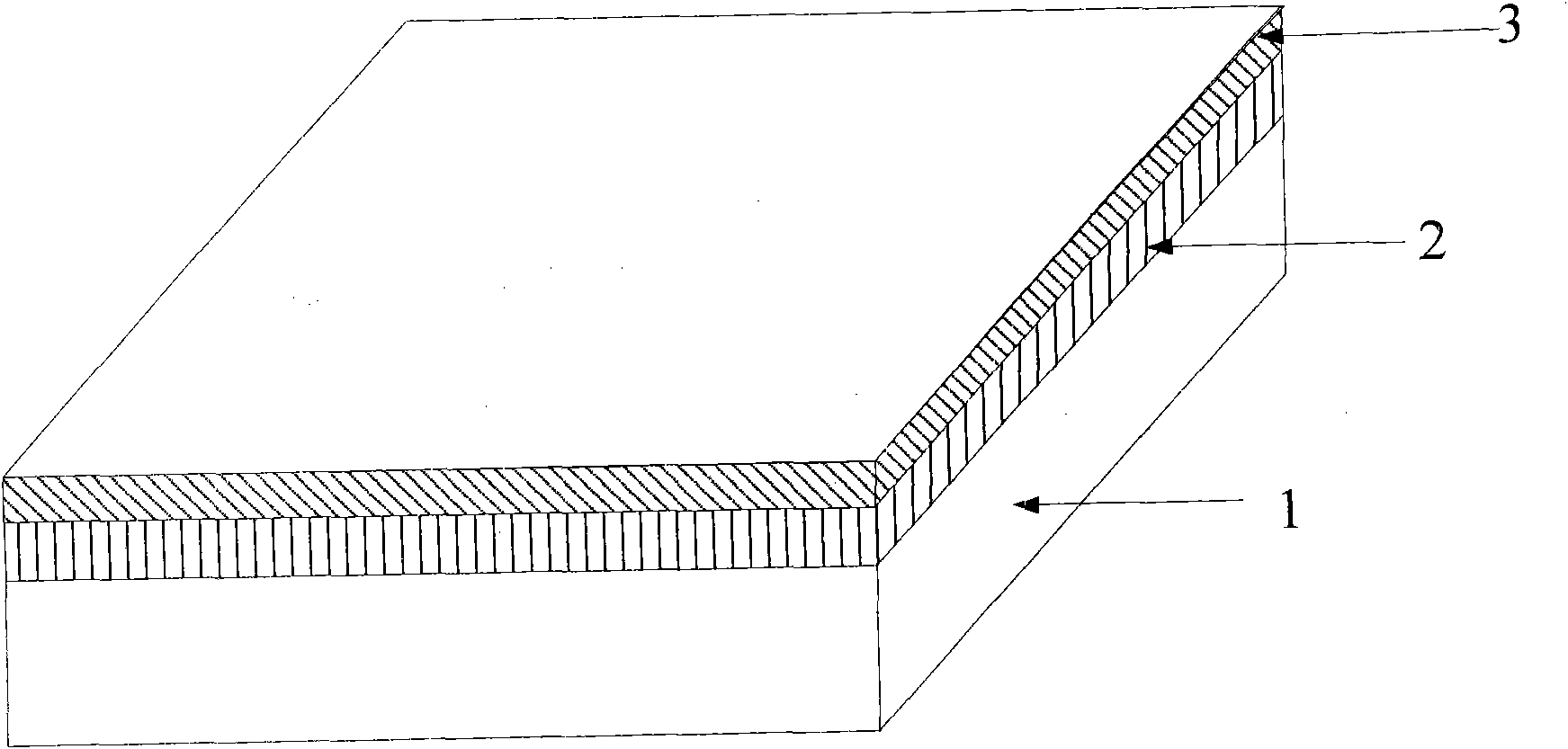

Magnalium composite board and method for producing the same

The invention discloses a magnesium-aluminum composite board and a method for manufacturing the same. The magnesium-aluminum composite board comprises at least one layer of magnesium or magnesium alloy plate and at least one layer of aluminum or aluminum alloy plate which are cast together by vacuum die-casting, and at least one two-layer joint surface which is provided with a mutually occlusive zigzag structure, namely the magnesium-aluminum composite board consists of a magnesium plate and an aluminum plate, or the magnesium alloy plate and the aluminum plate, or the magnesium plate and the aluminum alloy plate, or the magnesium alloy plate and the aluminum alloy plate by vacuum die-casting, and can be a structure with two layers, three layers or more than three layers. The method for manufacturing the composite board comprises the following steps: preheating a manufactured aluminum or aluminum alloy plate finished product as an insert of a die to certain temperature, and then putting the insert into a magnesium or magnesium alloy vacuumized die; matching the die in a vacuum pressure casting machine; pouring the molten magnesium or magnesium alloy molten; performing vacuumizing injection; and finally forming the magnesium-aluminum composite board. The joint surface of the composite board is provided with the mutually occlusive zigzag structure so that the layers are closely connected with each other sequentially and the combined strength is higher.

Owner:青岛地恩地材料科技有限公司

Method for preparing magnetic active carbon composite material for water processing

InactiveCN101502789APreserve the open cell structureImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionMagnetite NanoparticlesHigh pressure

The invention provides a method for preparing a magnetic active carbon composite material for water treatment in the technical field of environmental purification. The method comprises the following steps: mixing active carbon and corresponding metal salt solution, and generating magnetic nano granules in pore canals of the active carbon in situ by using the characteristics of instantaneous high temperature, high pressure, high cooling speed and the like generated by ultrasonic waves; and filtering and drying the obtained compound, and treating the compound at high temperature to form the magnetic active carbon composite material, wherein the magnetic material accounts for 15 to 50 percent in the whole material in terms of weight percentage, and the active carbon material accounts for 85 to 50 percent. The invention provides a new method for generating magnetic nano particles in the pore canals of the active carbon; and the prepared magnetic active carbon keeps larger specific surface area, reserves the open pore canals from the active carbon, removes organic substances and inorganic heavy metal ions in water treatment, and is easy for magnetic separation and convenient to recover.

Owner:SHANGHAI JIAO TONG UNIV

Mirco algal food nutrient intensifying agent prescription and its preparing process

InactiveCN1653938ABalanced nutritionReasonable ratioAnimal feeding stuffAccessory food factorsShrimpAdditive ingredient

The present invention is one kind of nutrient reinforcing agent for artificial fry raising of marine animal, and relates to the recipe and preparation process of micro algae bait nutrient reinforcing agent. The microalgae bait nutrient reinforcing agent consists of several kinds of micro algae containing different nutritious components and has grain size of 5-20 microns. It contains great amount of DHA, ARA and natural astaxanthin, and can raise the immunity and survival rate of raised marine animal. It can meet the requirement of hatched fries of fishes, shrimps and shells in feed. For example, when the microalgae bait nutrient reinforcing agent is used in raising turbot, it can raise the survival rate and lower the albinism rate greatly.

Owner:QINGDAO SAMUELS INDAL & COMML

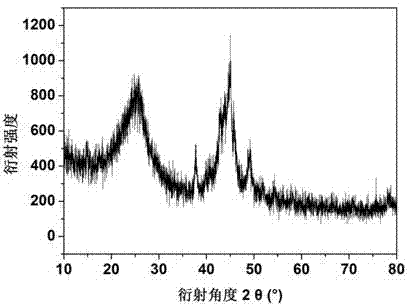

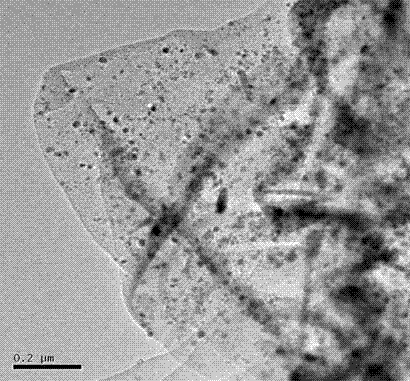

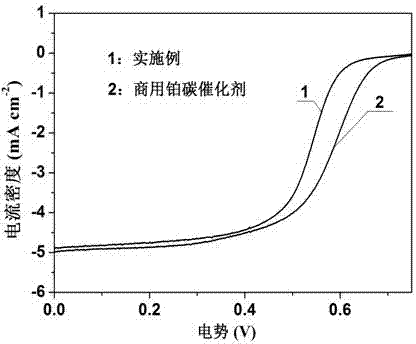

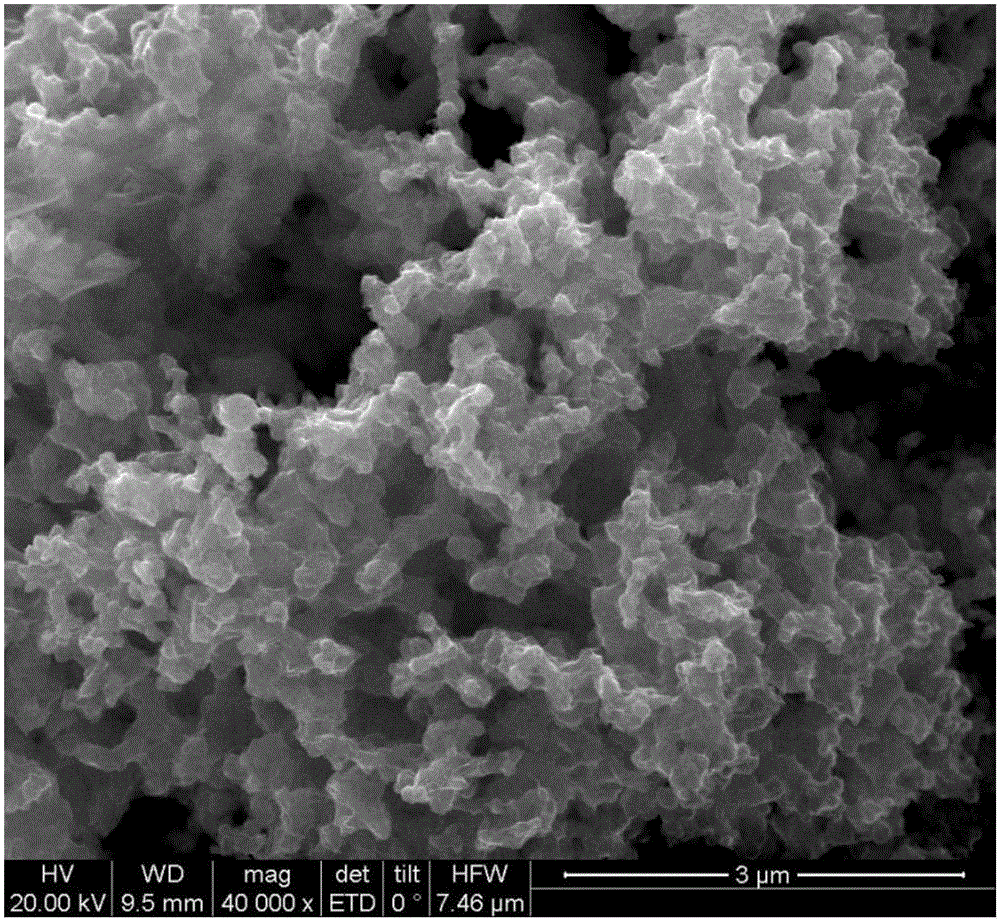

Preparation method and application of nitrogen-doped porous carbon nano sheet composite material

The invention discloses a preparation method of a nitrogen-doped porous carbon nano sheet composite material. The preparation method comprises the steps of performing high-temperature carbonization treatment on a mixture which consists of melamine and adjacent phenanthroline iron and serves as a precursor in a tubular furnace under an inert gas environment, and then removing dissolved iron compounds from an acidic solution to obtain a porous carbon nano sheet layer with carbon-coated iron carbide nano particles. The preparation method has the advantages that the technology is simple, the raw materials are cheap, and operation is easy to implement; in the prepared composite material, iron carbide is uniformly dispersed in the carbon nano sheet layer, so that the composite material is high in specific surface area and pore volume; iron carbide nano particles are completely coated by graphitized carbon, so that oxidization and corrosion are hardly caused; the composite material is stable in acidic electrolyte, and the battery activity can be effectively improved; when used as an electrocatalyst, the composite material is relatively high in electrocatalysis efficiency; the preparation method has an important value and significance in the field of preparation of doped carbon nano composite materials and electrocatalysis of proton membrane fuel batteries.

Owner:NANKAI UNIV

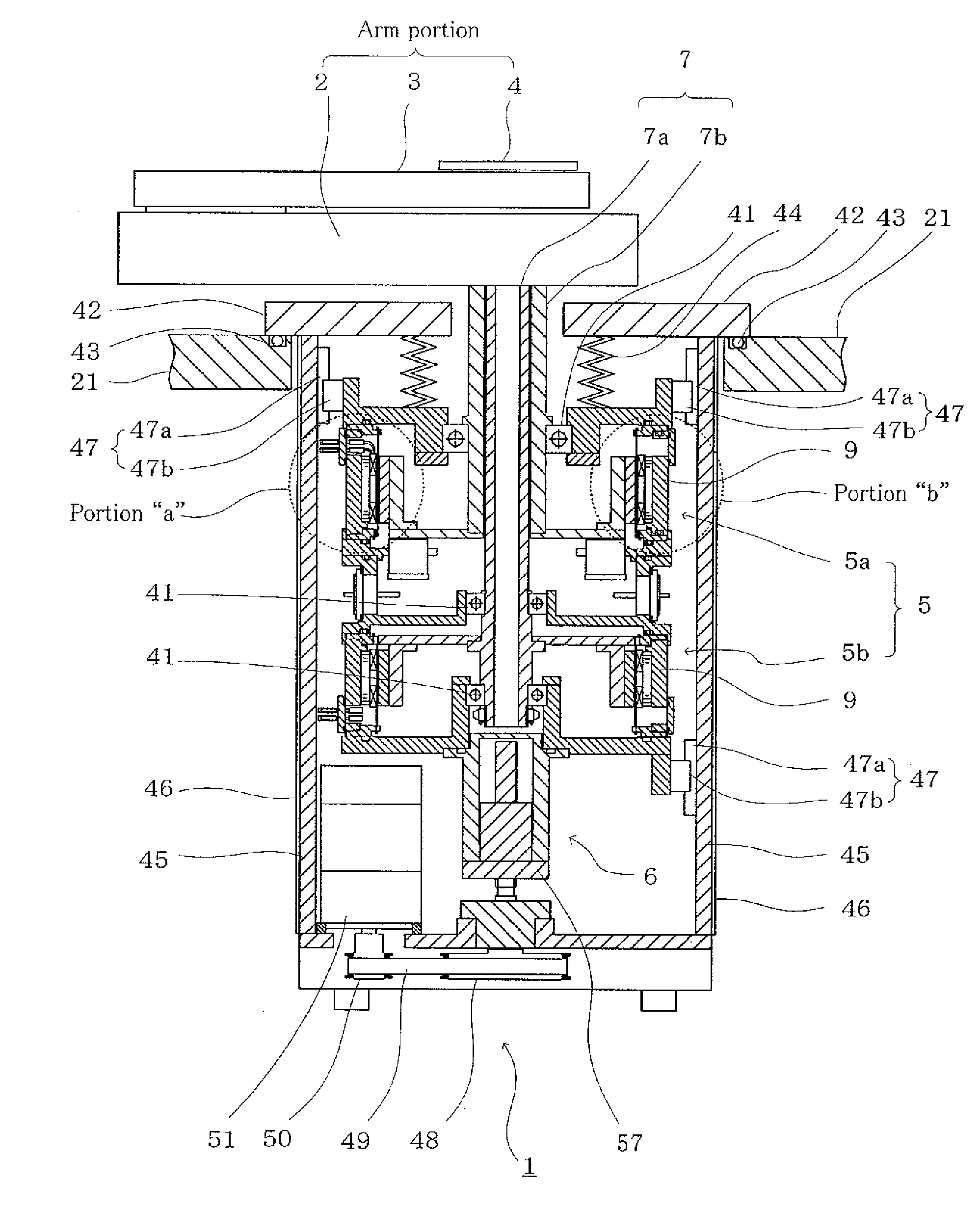

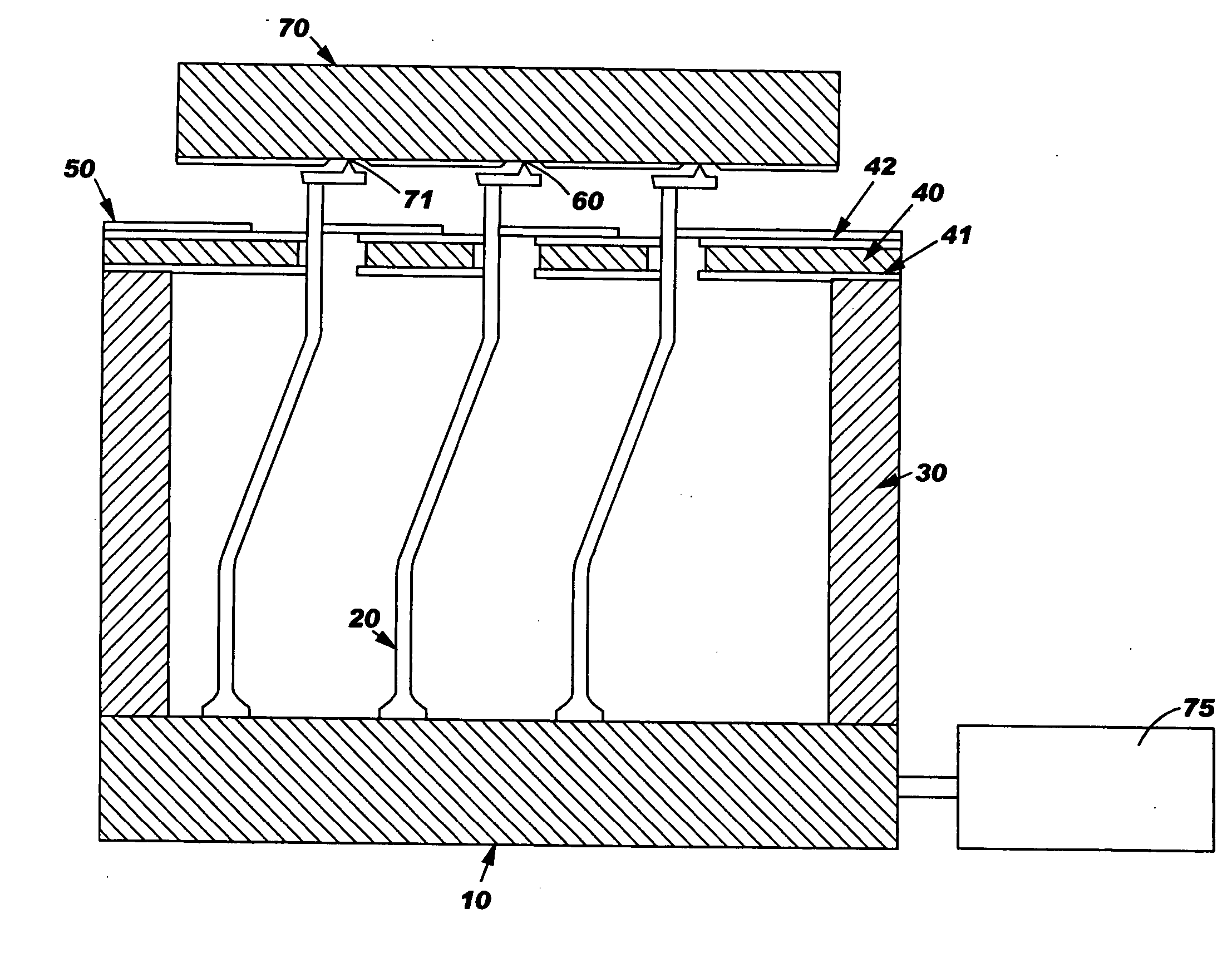

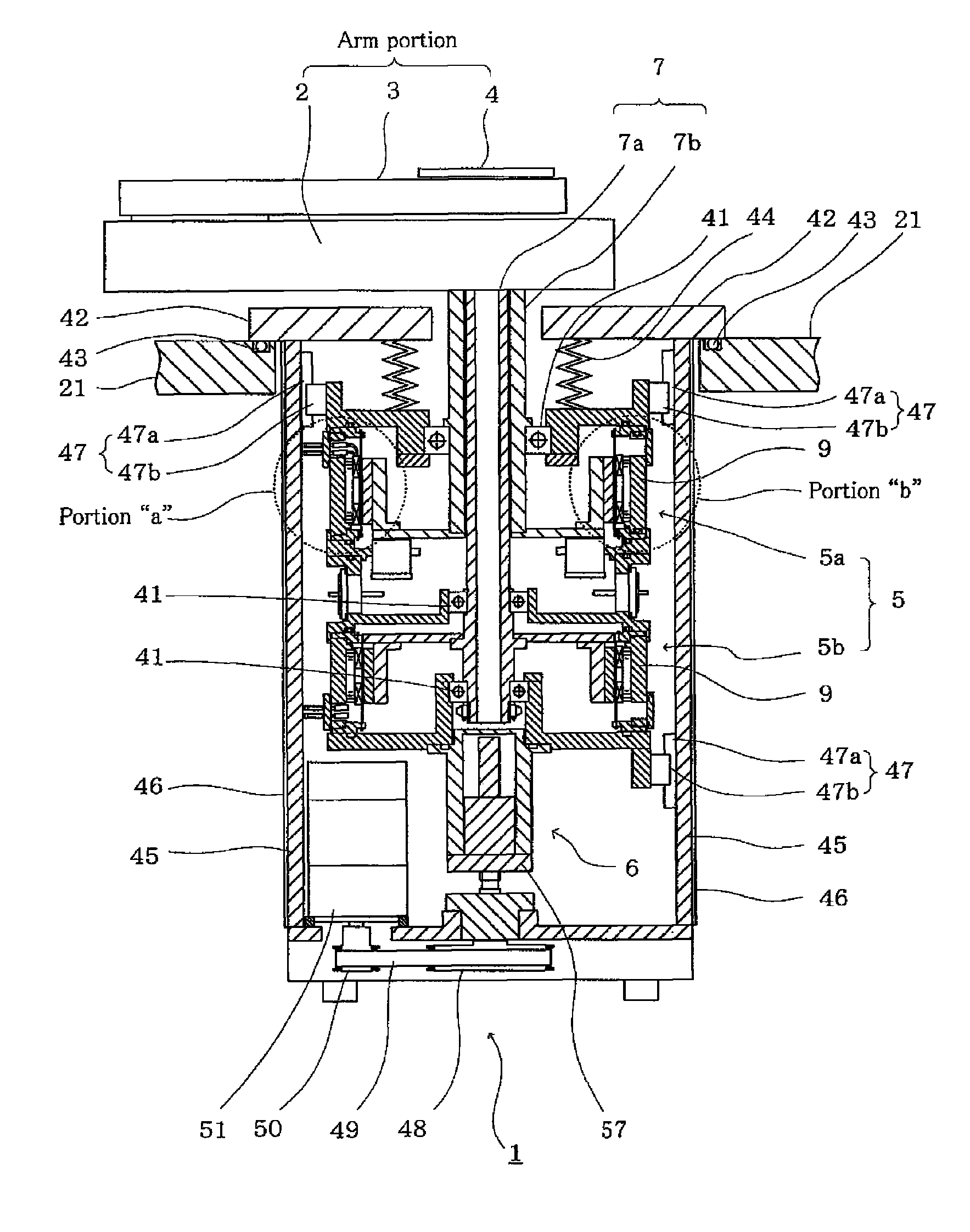

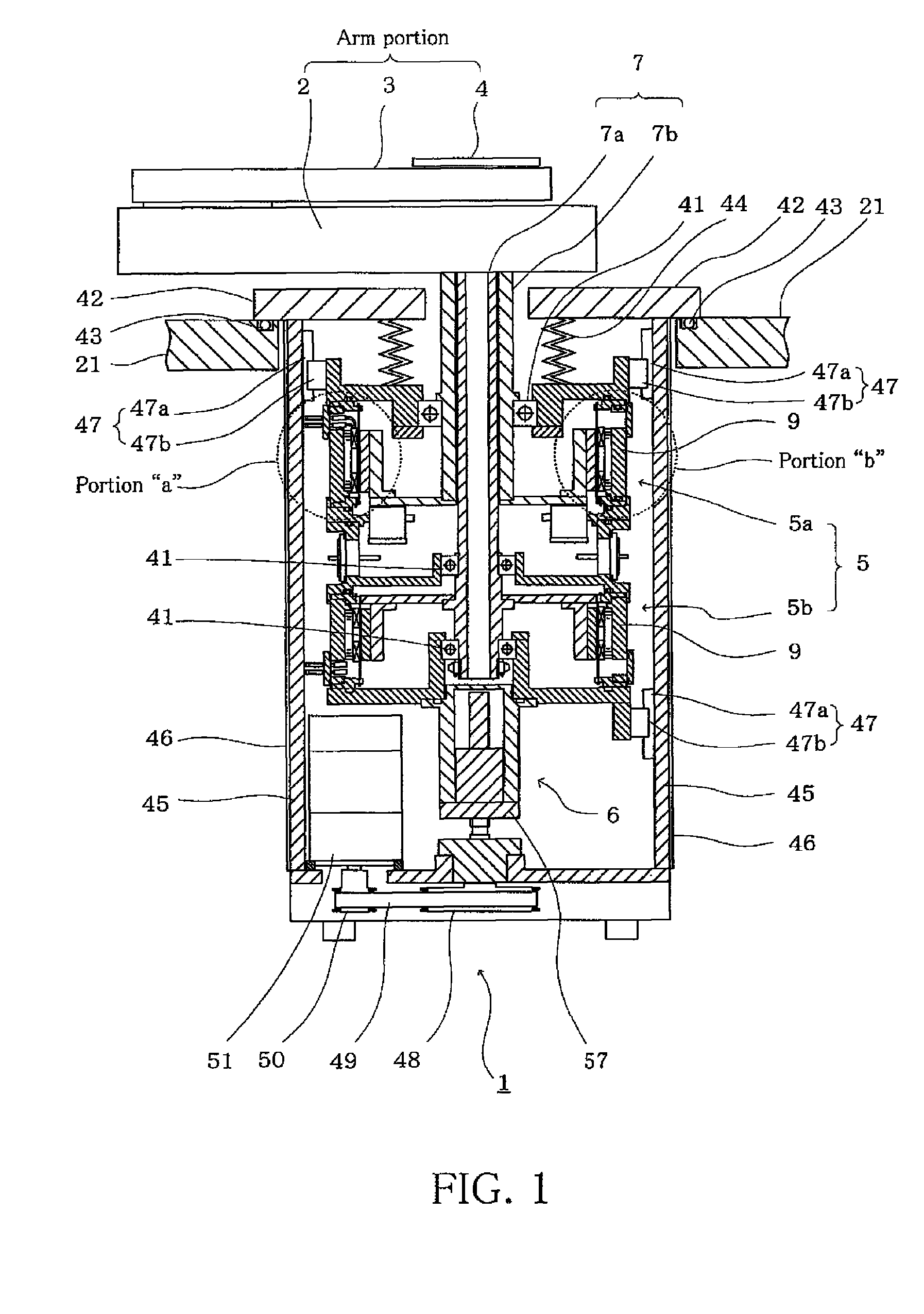

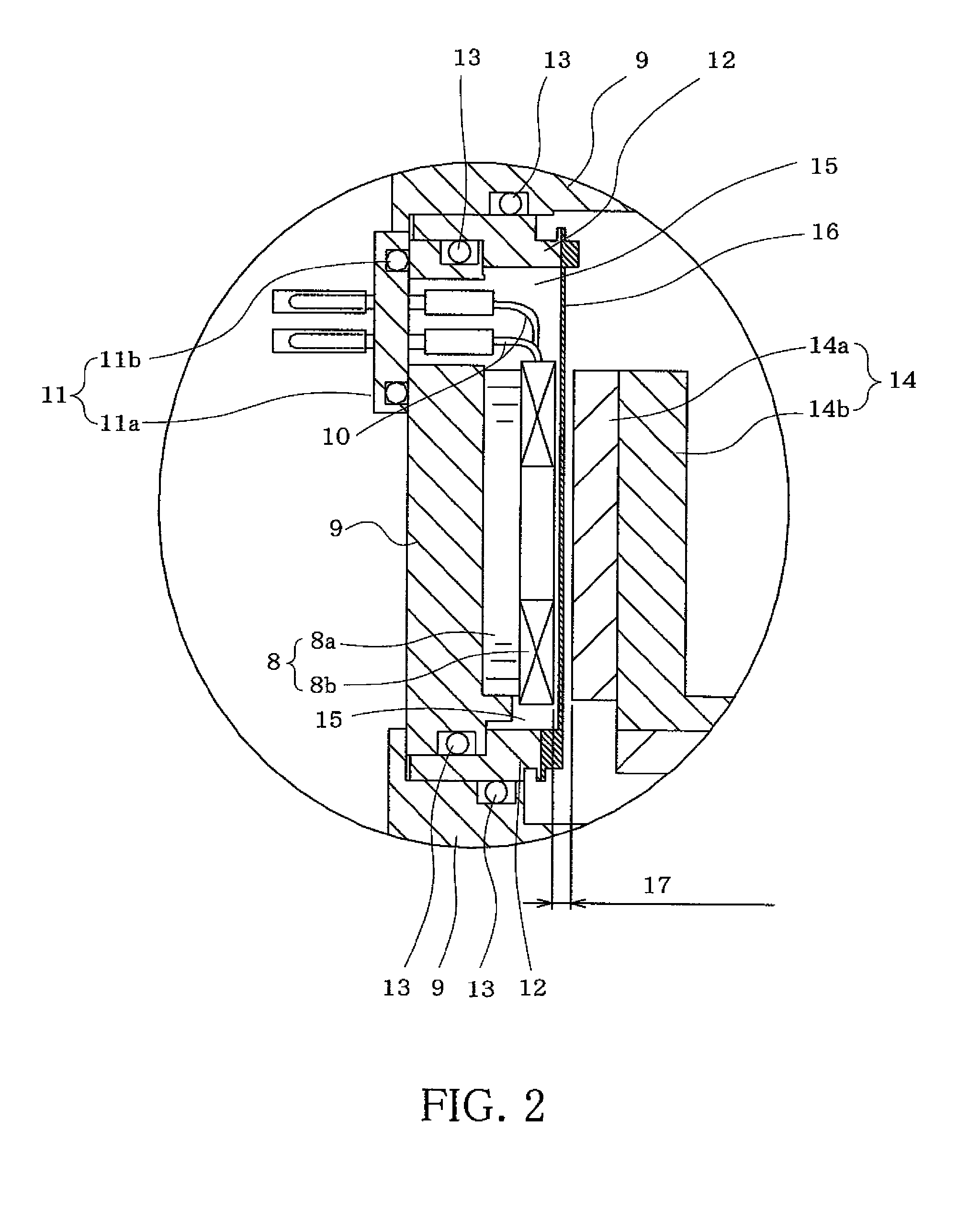

Vacuum robot, vacuum motor for vacuum robot, and production method of said vacuum motor

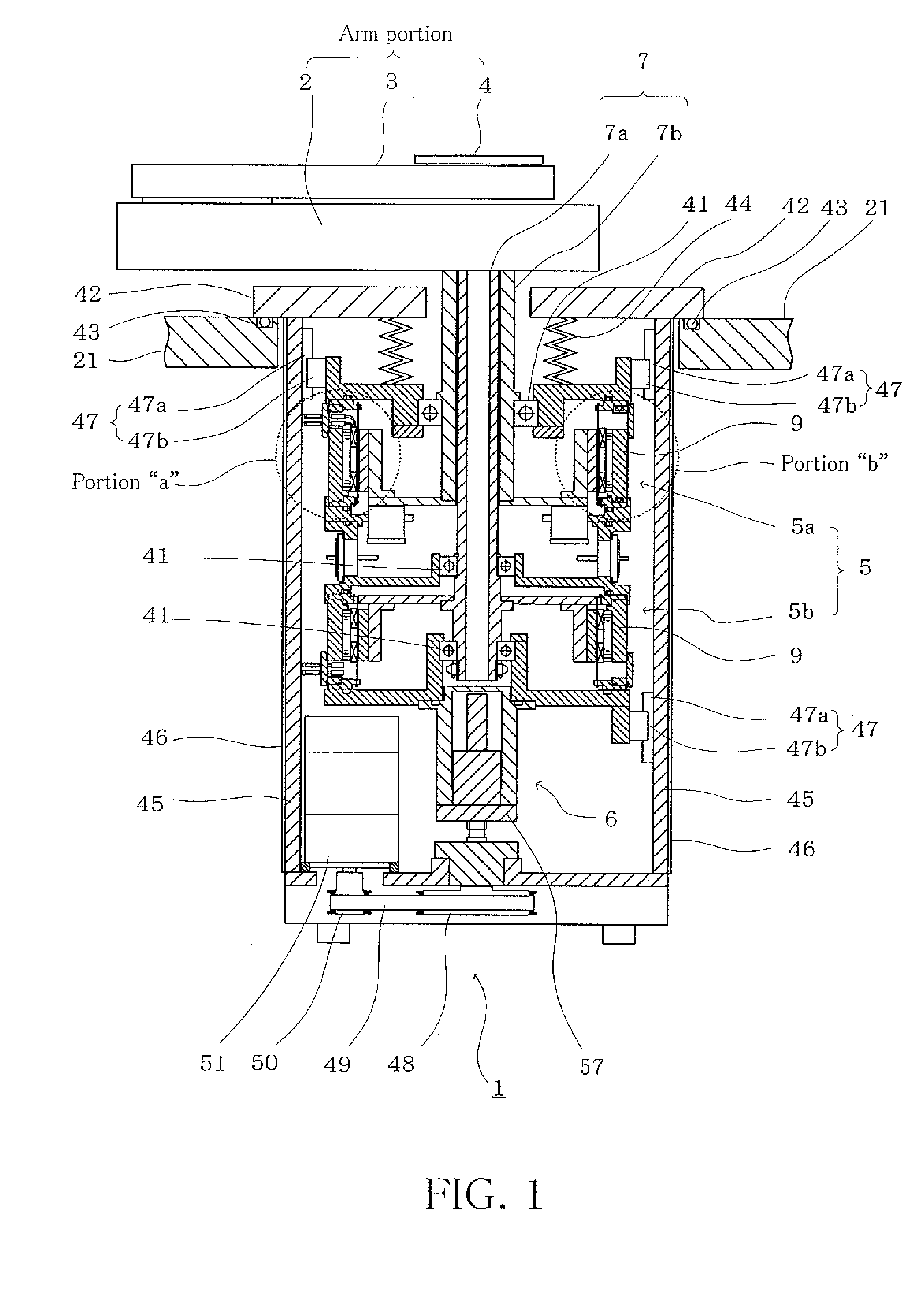

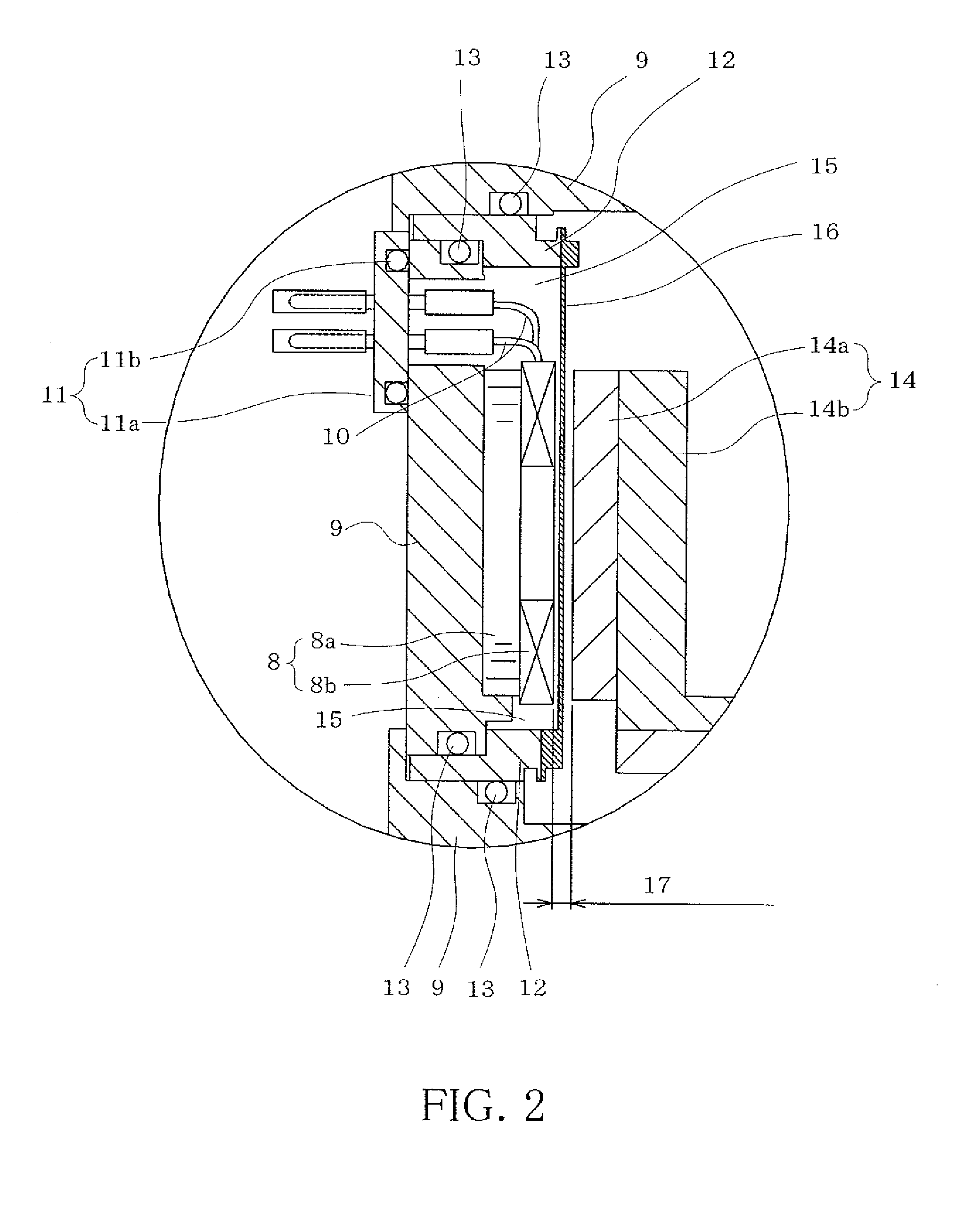

InactiveUS20070280813A1Improve reliabilityReduce gapProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingAtmospheric pressureElectric motor

A vacuum robot includes an arm portion on which a work is to be disposed under a reduced pressure environment and a motor portion for rotatably driving the arm portion, the vacuum robot being configured to transfer the work by causing a rotational movement of the arm portion by the motor portion. The motor portion comprises a rotor portion connected to the arm portion, a stator portion disposed at an external periphery of the rotor portion, a housing disposed under an atmospheric pressure environment, and a thin cylindrical can disposed in an electromagnetic gap formed between the rotor portion and the stator portion and secured to the housing so that the stator portion is air-tightly encapsulated in a space formed by the housing and the can. The space is maintained in a depressurized state by a seal.

Owner:YASKAWA DENKI KK

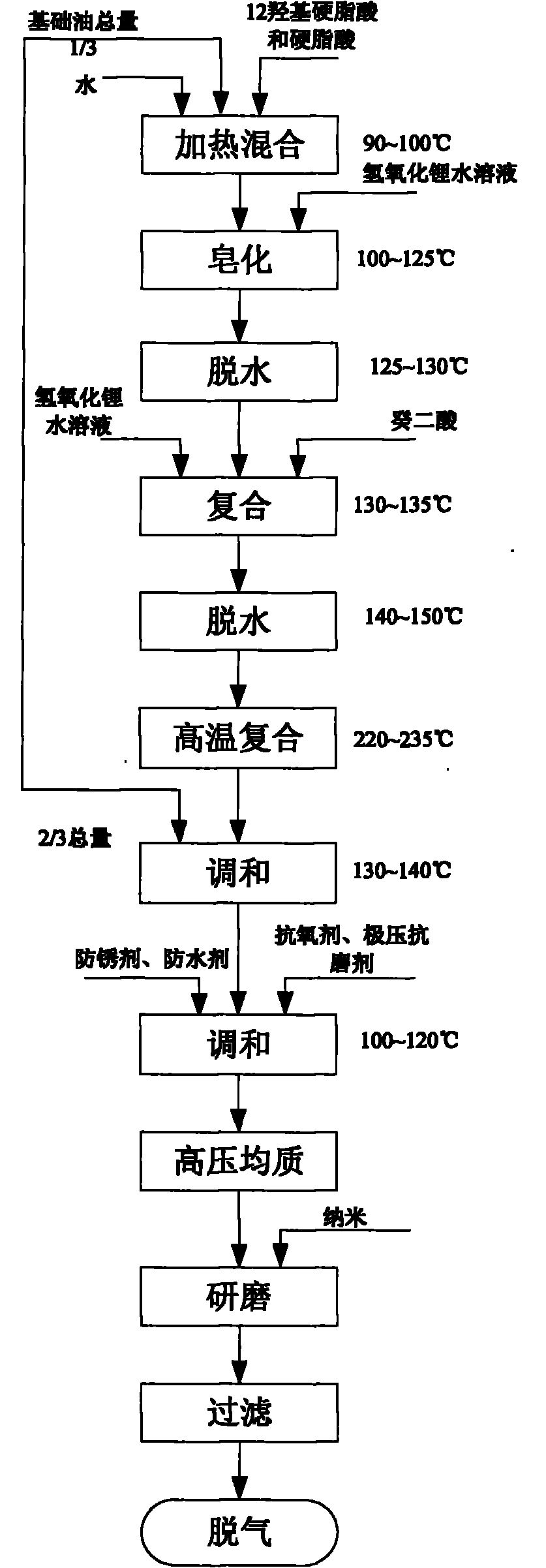

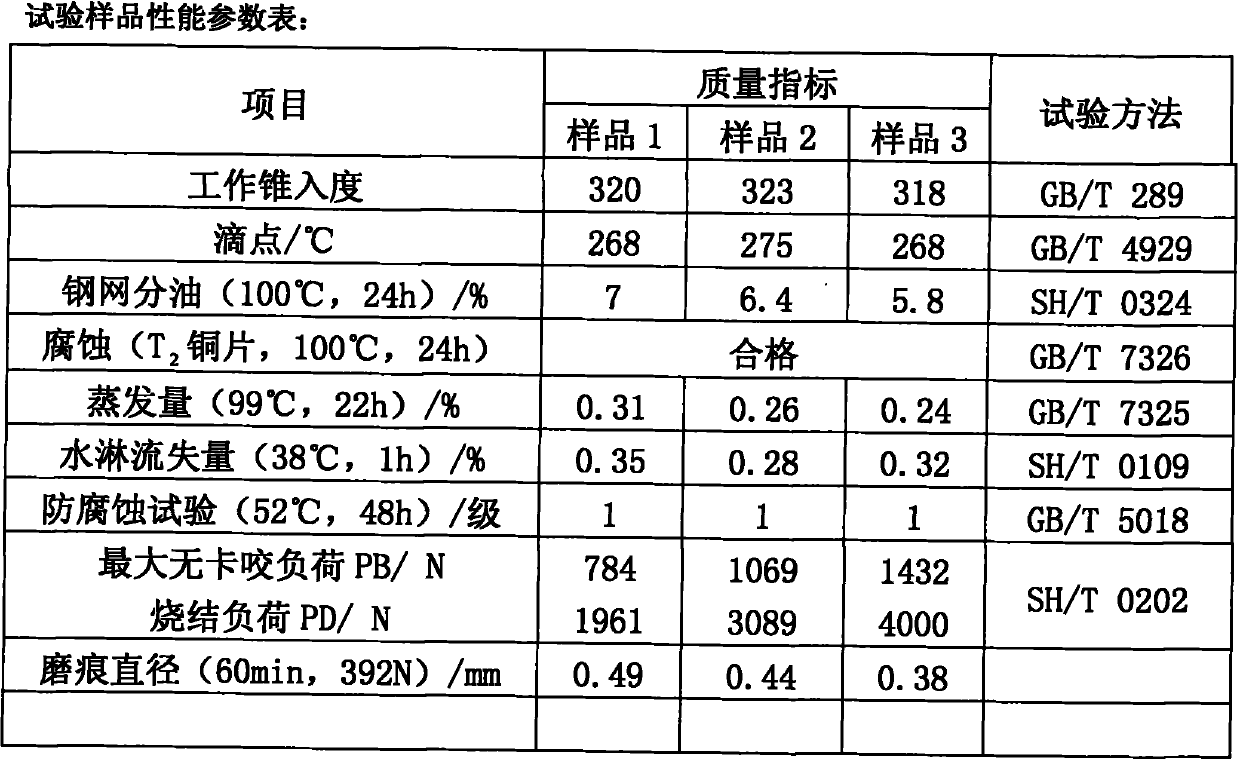

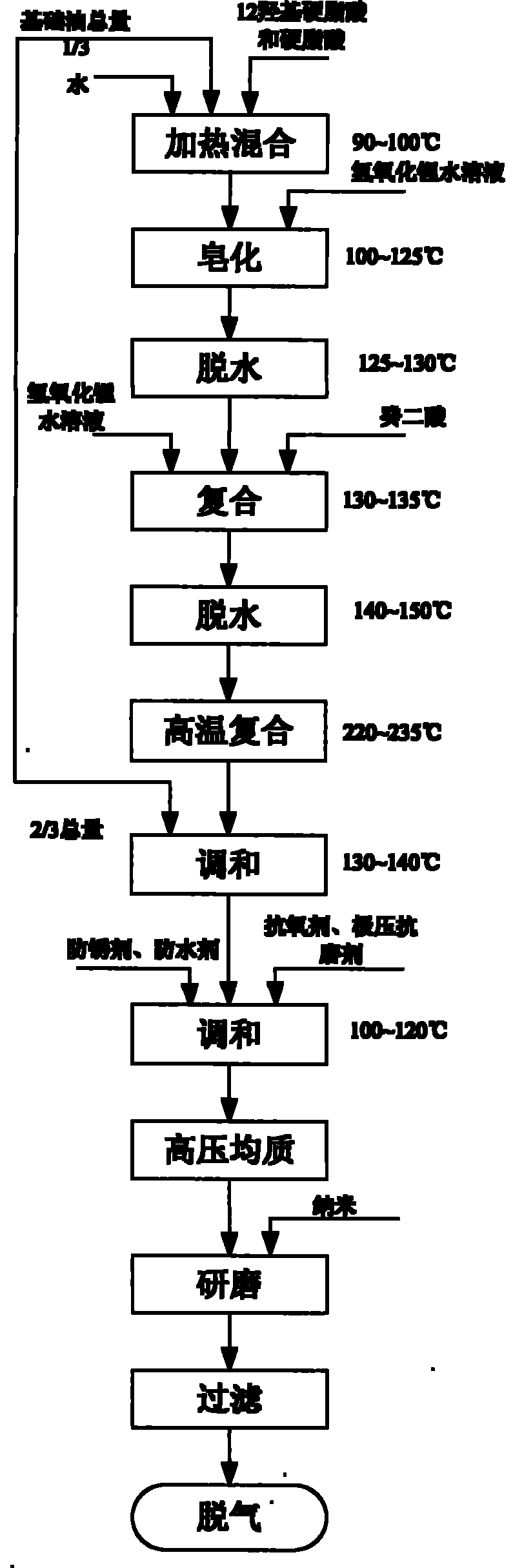

Hub bearing lubricating grease and preparation method thereof

InactiveCN102140382AGood extreme pressure and anti-wear propertiesImprove adhesionLubricant compositionLithium soapHigh resistance

The invention discloses a hub bearing lubricating grease and a preparation method thereof. In the lubricating grease, composite lithium soap is taken as a thickening agent, an antirusting agent, an antioxidant, an extreme-pressure anti-wear agent and a waterproofing agent are added, and a nanometer additive and the like are added according to different proportions. The lubricating grease is prepared by the processes including saponifying, dehydrating, blending, shearing, homogenizing, grinding, filtering, degassing and the like. A lubricating grease composition has the advantages of high dropping point, high wear resistance, high extreme pressure resistance, high high-low temperature performance and the like, has high water resistance and rust resistance, and is suitable for lubricating the automobile bush bearings under harsh working conditions.

Owner:SOUTH CHINA UNIV OF TECH

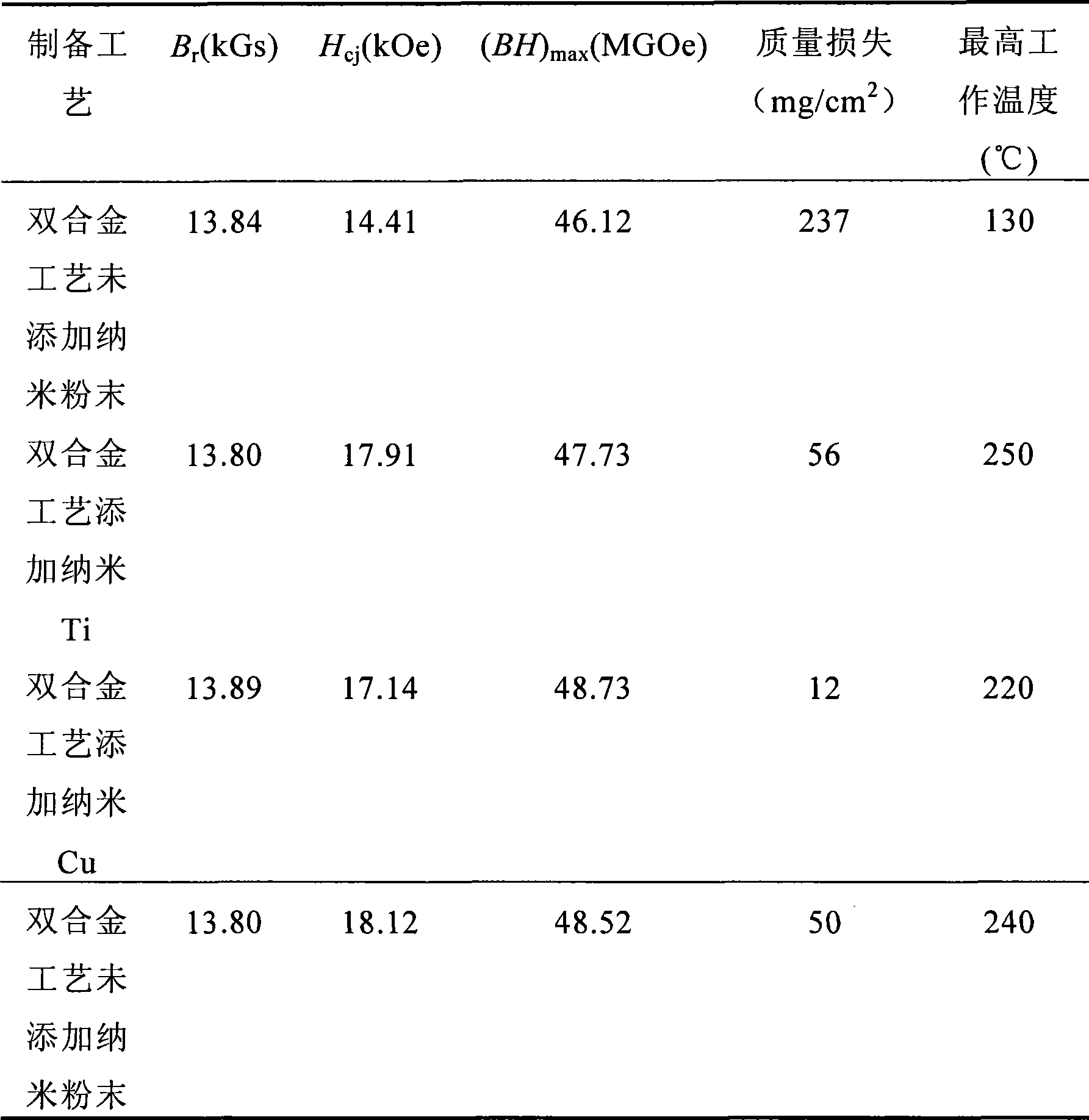

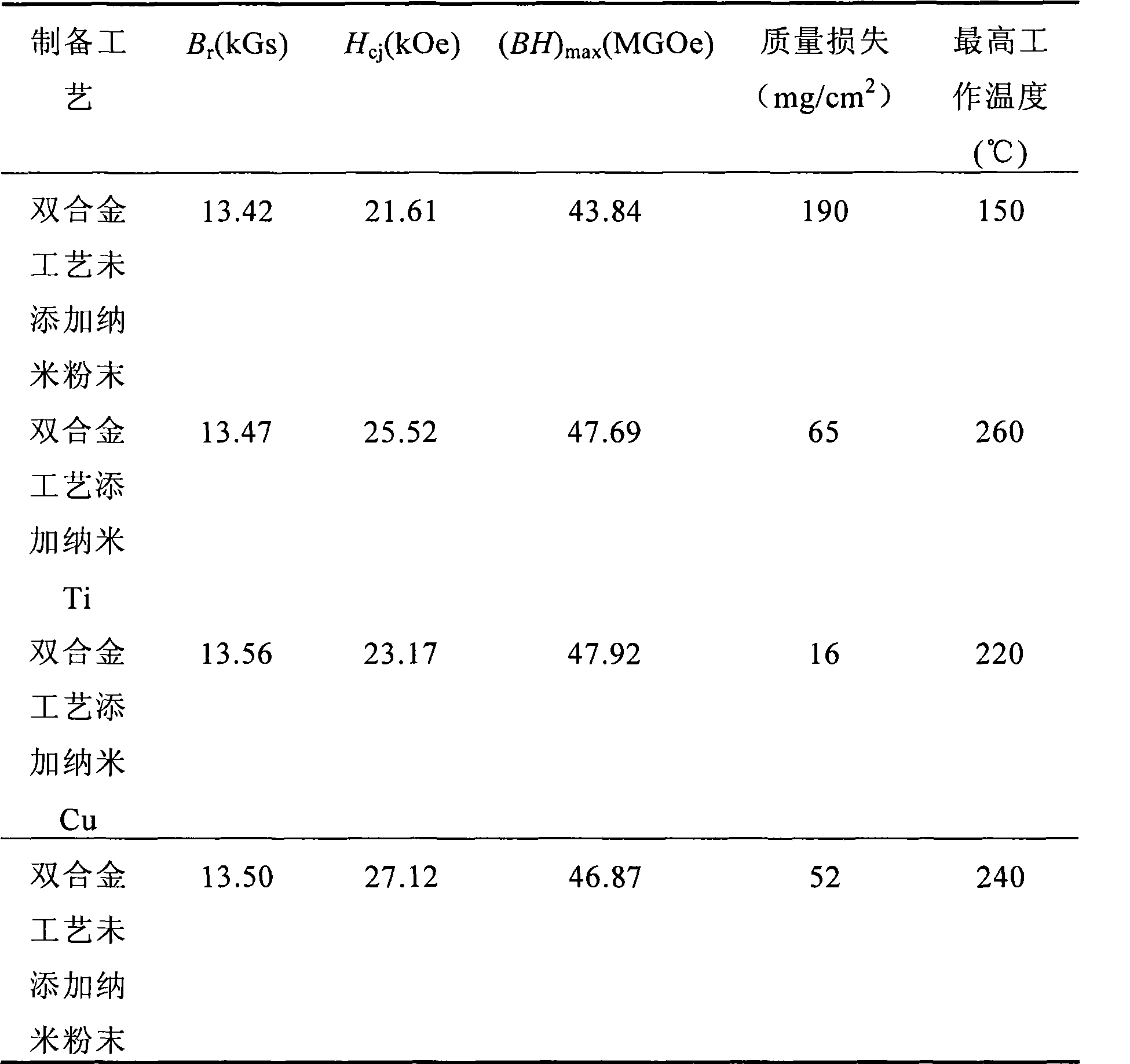

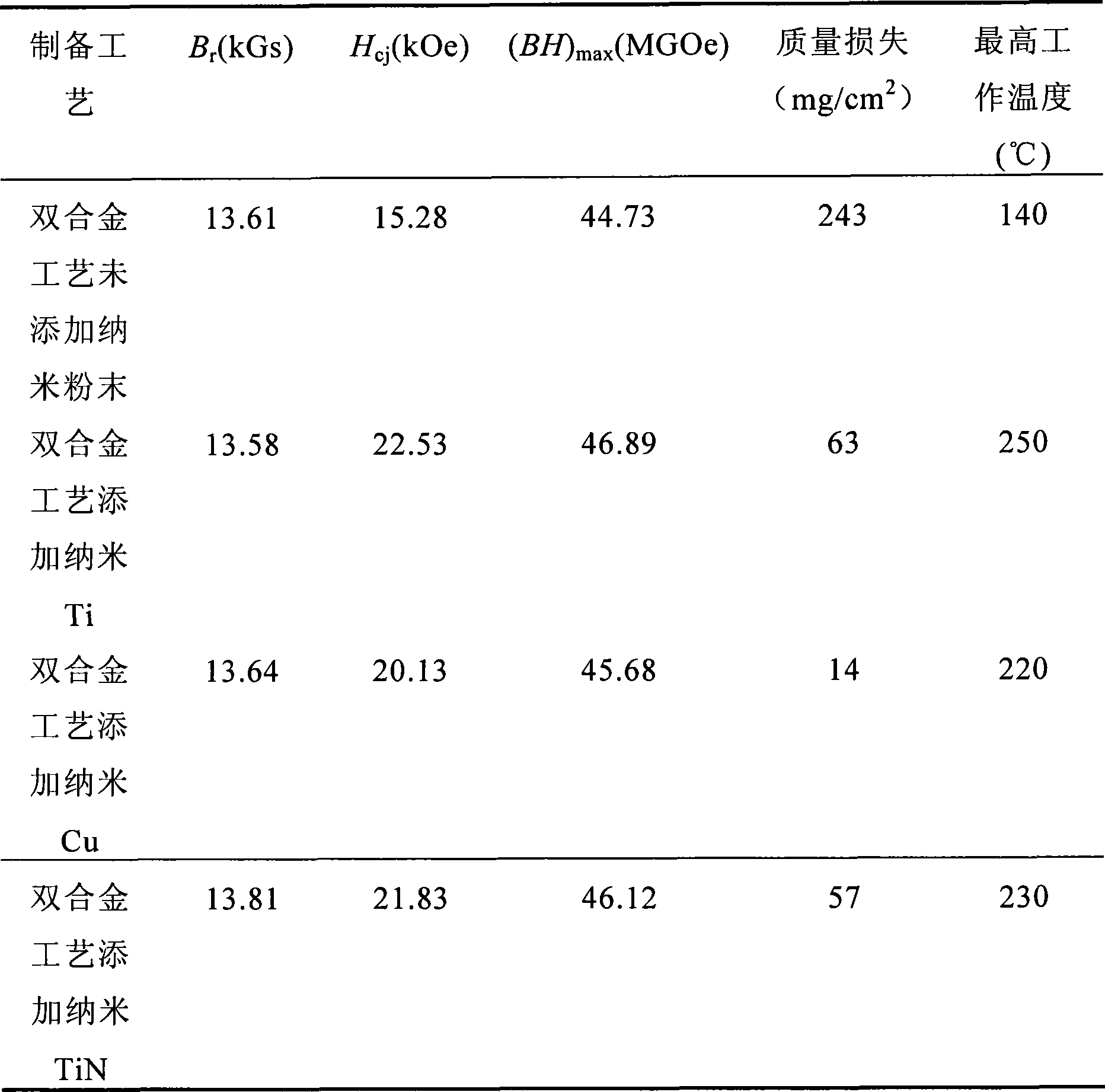

Sintered NdFeB permanent magnet with high working temperature and high corrosion resistance

InactiveCN101499346AIncrease coverageImprove microstructureInorganic material magnetismAlloyGrain boundary

The invention provides a sintered Nd-Fe-B (neodymium iron boron) permanent magnet combination with high working temperature and high corrosion resistance; the composition of the magnet comprises 80-95% of main phase alloy powder and 5-20% of nano-modified grain-boundary-phase alloy powder, taking the total weight of the permanent magnet combination in calculation; the main phase alloy powder is calculated by atomic percentage, and the composition comprises NdaFe100-a-b-cBbMc, wherein a is no less than 11 but no more than 16, b is no less than 5.4 but no more than 6.6, and c is no less than 0 but no more than 6, and M is one or more types of elements Dy, Tb, Nb, Co, Ga, Zr, and Al; and the average particle diameter of the main phase alloy powder is 3-8 mu m. The invention also provides a sintered Nd-Fe-B permanent magnet which simultaneously has high working temperature and high corrosion resistance.

Owner:ZHEJIANG UNIV +1

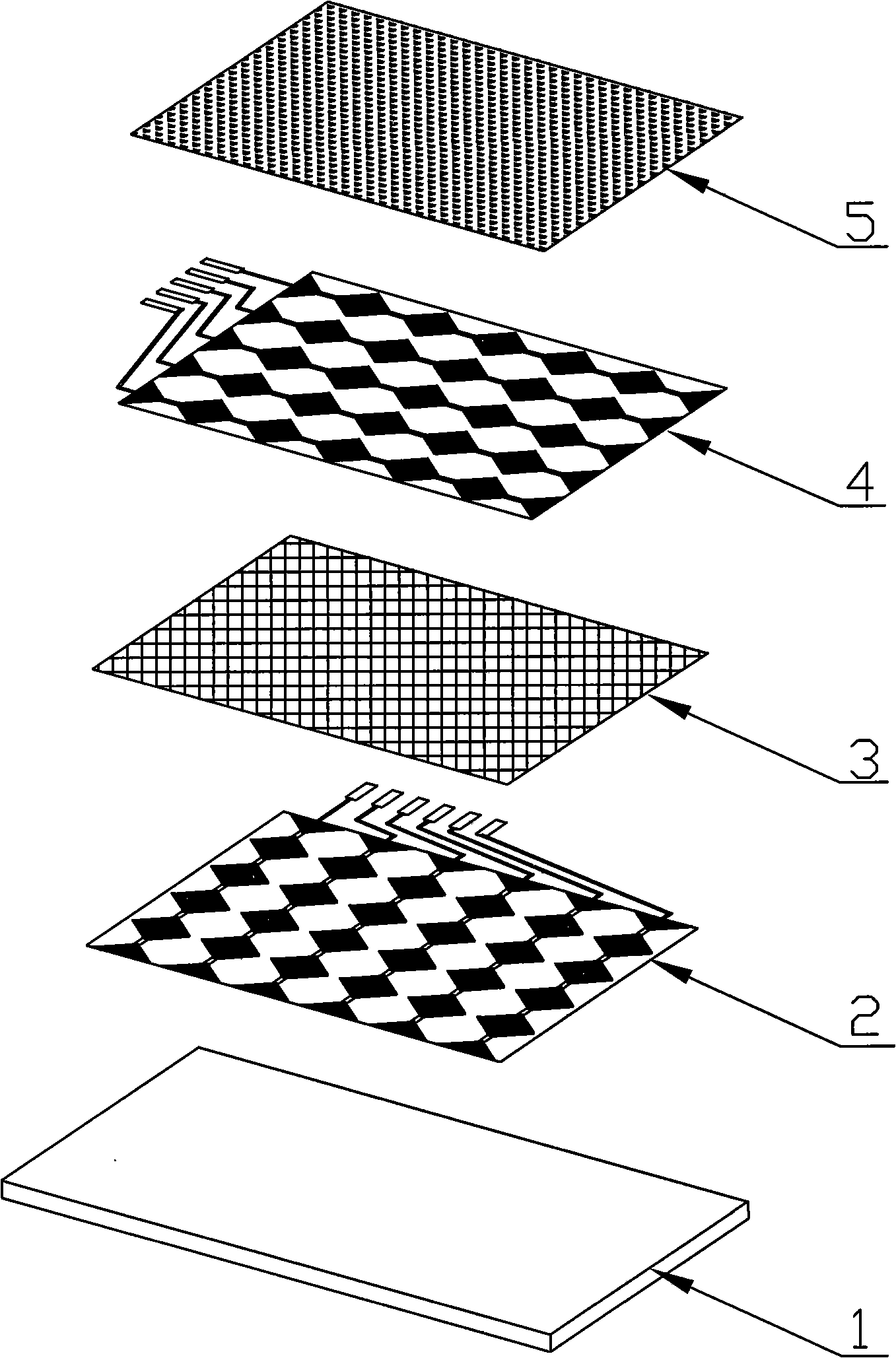

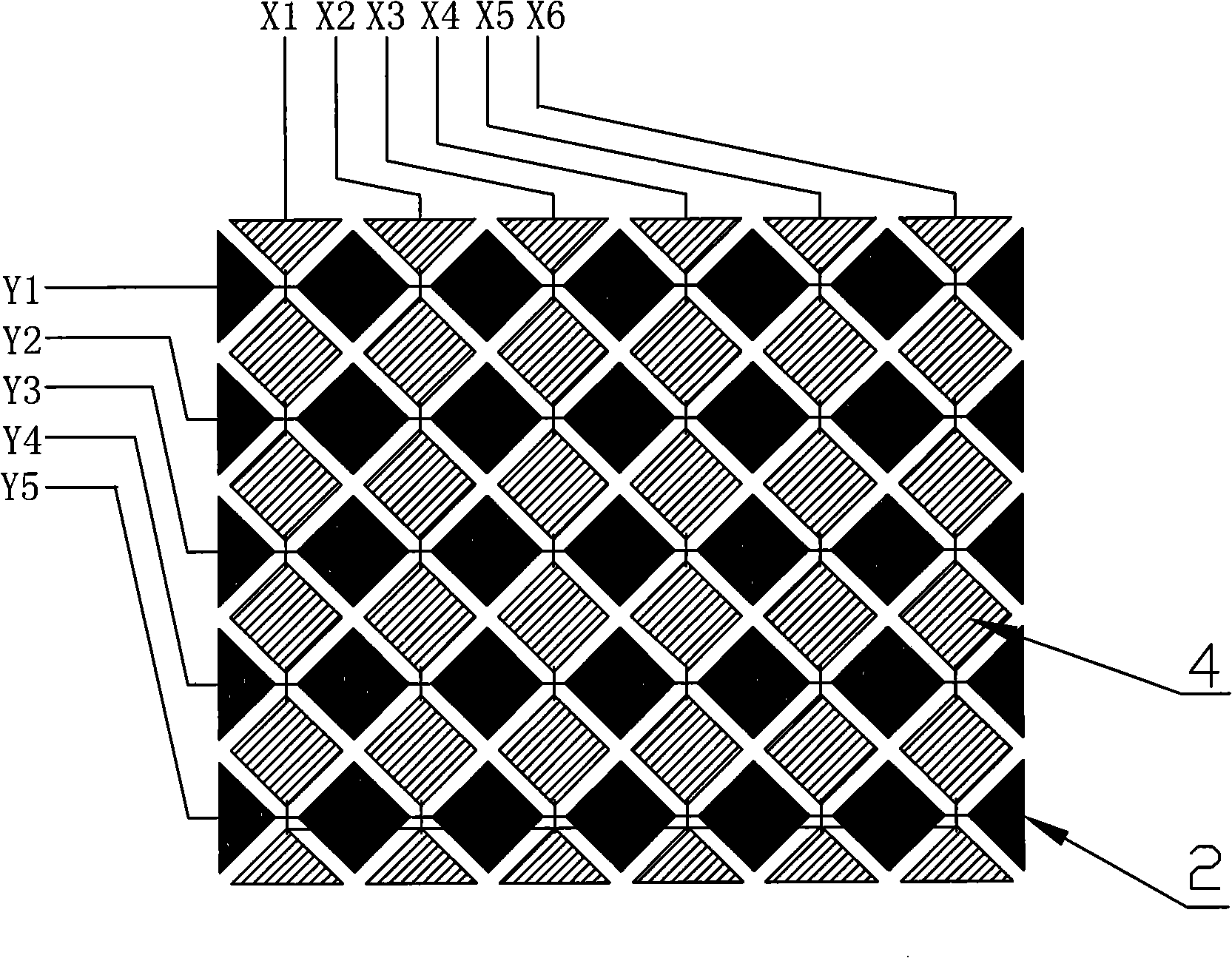

Non-contact capacitance induction touch panel

InactiveCN101271373ANo wearExtended service lifeInput/output processes for data processingCapacitanceTouchscreen

The invention discloses a non-contact capacitance induction touch screen, including a baseplate glass. One surface of the baseplate glass is plated by a horizontally connected ITO electrode matrix along the reticular Y direction; the ITO electrode matrix along the reticular Y direction is plated by an insulating layer; the insulating layer is plated by a longitudinally connected ITO electrode matrix along the X direction which is approximately complemented with the blank part of the ITO electrode matrix along the reticular Y direction. The non-contact capacitance induction touch screen provided by the invention, with built-in double-layer ITO design and an additional control processor, can achieve continuous hand-writing simulation control and operation. With no wear and tear, long service life, high luminousness, small thickness, low cost and easy operation, the touch screen can be rapidly applied to various screens of high-end and low-end electronic products of all sizes and all types, thus facilitating humanized design and industrial output.

Owner:MATRIX CRYSTAL

Preparation method of plant unbleached impregnated specimen

InactiveCN102524245APrevent browningSimplified fixed killing proceduresDead plant preservationBiotechnologyEngineering

The invention provides a preparation method of a plant unbleached impregnated specimen. In the invention, the fixative of the operation process adopts a composite biocidal formula and simplifies the fixing and biocidal procedures, and the operation is simple; and the preservation solution for preserving the plant specimens adopts nontoxic and inexpensive biological extracts, such as garlic extract, ginger extract, carboxylation chitosan and the like, and solves the problem of environmental pollution when preserving and storing the plant specimens. The preparation method of invention can be applied to the impregnation and preservation of monochromatic plants, such as green, yellow, red, white plants and the like, multi-color plants and whole plant specimen, and provides a novel way for preparing the plant unbleached impregnated specimens.

Owner:HENAN UNIV OF SCI & TECH

Anti-oxidant macromonomers and polymers and methods of making and using the same

InactiveUS20080311065A1Not easily oxidizedShort term and longer term stability towards oxidationCosmetic preparationsBiocideMacromonomerAnti oxidant

Owner:POLNOX CORP

Method for preparing semi aromatic copolymer nylon

ActiveCN103923313ALow polymerization temperatureLow polymerization pressurePolymer scienceOrganic chemistry

The invention relates to a method for preparing semi aromatic copolymer nylon, belonging to the technical field of preparation materials for high temperature resistant nylon with high strength and high stability. According to the method, nylon salt is firstly synthesized, then semi aromatic copolymer nylon prepolymer is mainly synthesized at lower temperature and lower pressure, the semi aromatic copolymer nylon prepolymer is prevented from yellowing due to oxidization at high temperature in discharging so as to affect the quality, due to the requirement of lower pressure, the requirement on preparation equipment is lowered, and the production cost is greatly lowered.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method for preparing colorful film for protecting solar cell thin grid line metal electrode by adopting mask

InactiveCN101834230ANot easily oxidizedGuaranteed electrical conductivityFinal product manufactureSemiconductor devicesButt jointMetal electrodes

The invention relates to a method for preparing a colorful film for protecting a solar cell thin grid line metal electrode by adopting a mask. In the method, after a solar cell is prepared, a mask is utilized to cover a main grid line metal electrode on the front surface of the solar cell, a film is coated on the area which is not covered by the mask for the second time, and a dielectric layer for protecting the thin grid line metal electrode is prepared to form a structure comprising the dielectric layer, the thin grid line metal electrode and a passivation layer. The method can protect the thin grid line metal electrode against easy oxidation, and the main grid line metal electrode can be normally connected by welding rods. The passivation effect of the front surface can be enhanced through optimizing the passivation layer; the reflectivity of the front surface of the solar cell can be reduced and color regulation can be realized through regulating the dielectric layer; and characters, figures, graphics and the like can be displayed on the front surface of the solar cell through changing a mask pattern. In addition, the secondary film coating method is convenient to be in butt joint with the traditional crystalline silicon solar cell preparation process and is easy for industrialization.

Owner:SUN YAT SEN UNIV

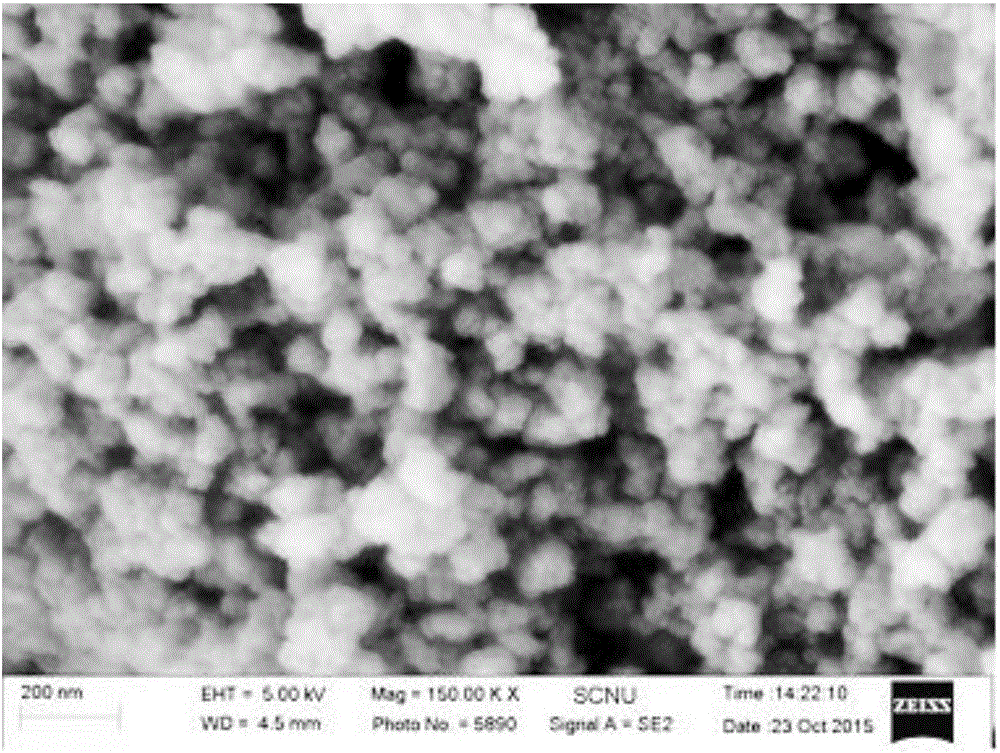

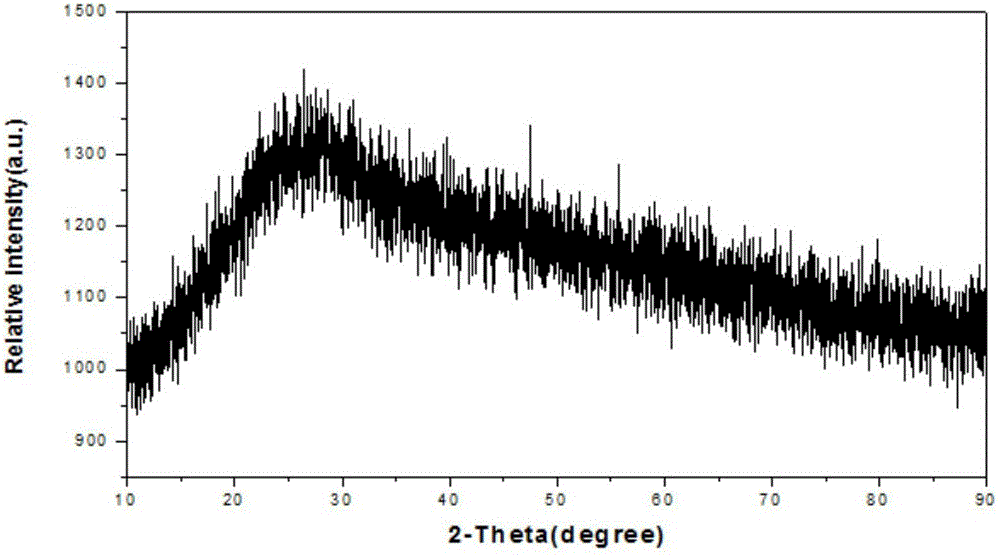

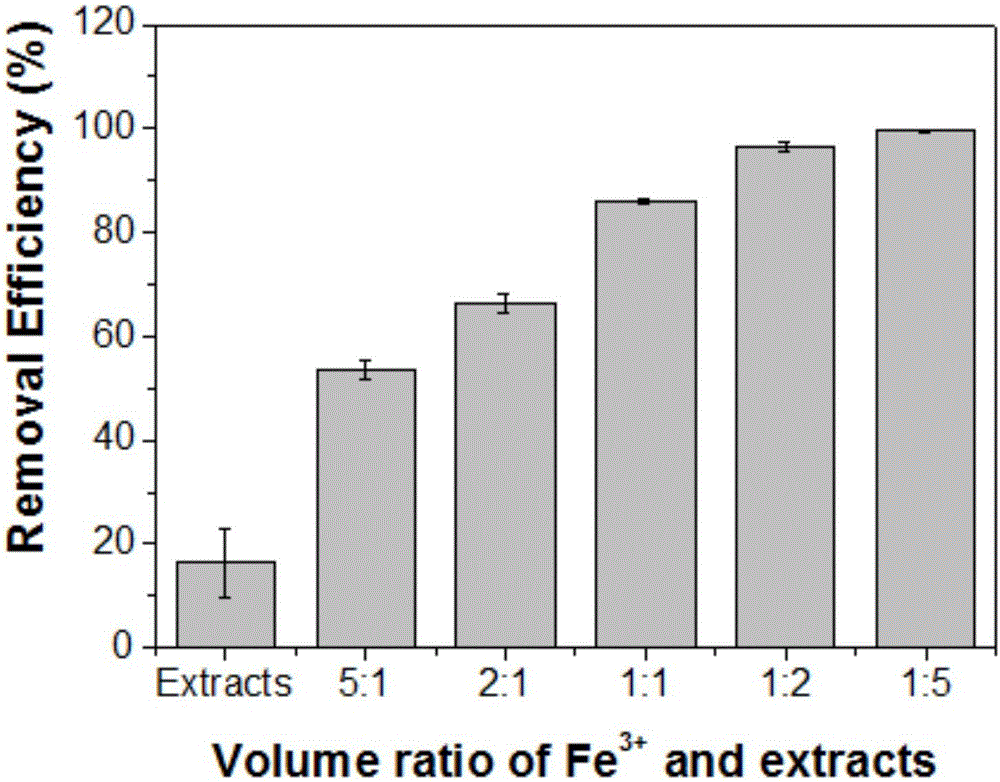

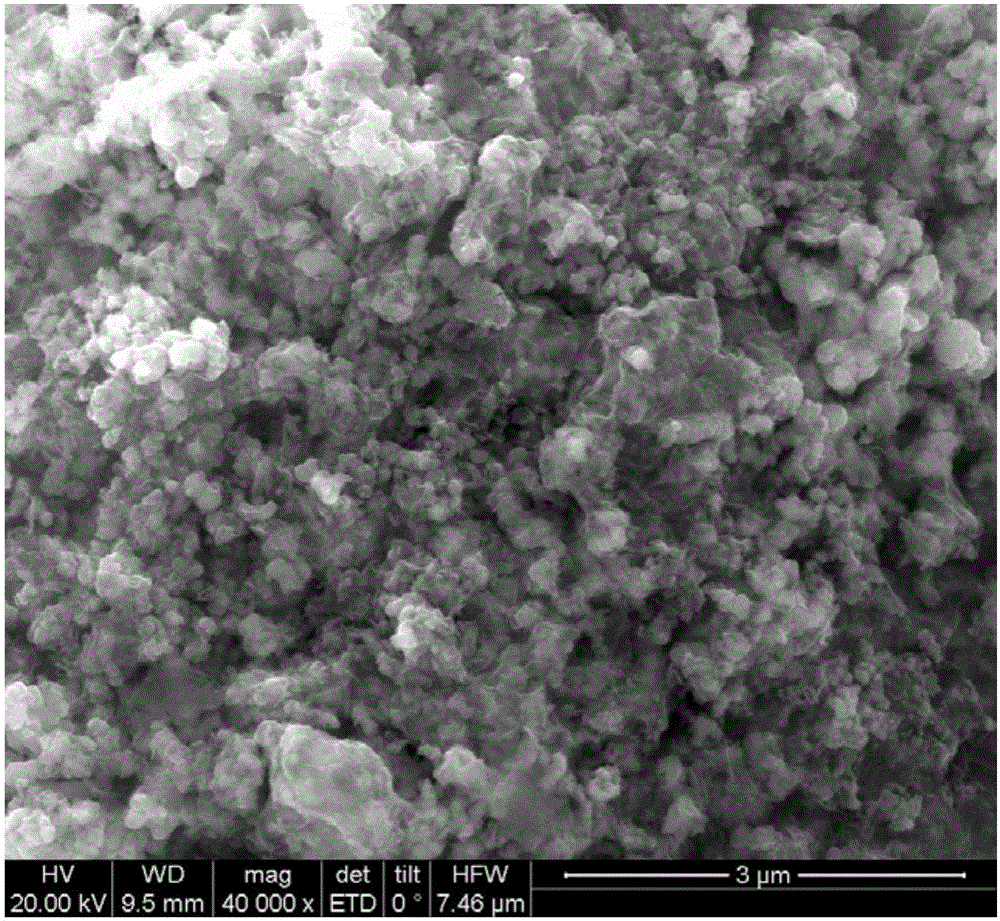

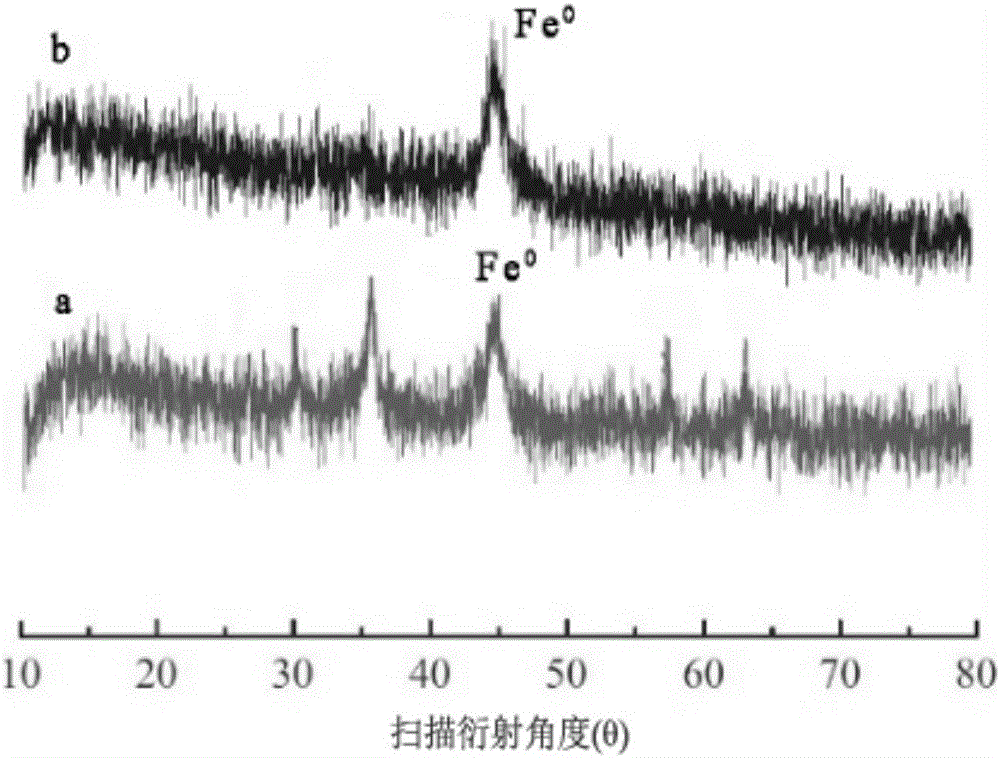

Method for green synthesis of nanoscale zero-valent iron through water hyacinth extraction liquid and application

InactiveCN106180755ASimple methodReduce energy consumptionTransportation and packagingWater contaminantsSynthesis methodsRepair material

The invention discloses a preparing method for green synthesis of nanoscale zero-valent iron through water hyacinth extraction liquid and application. Water hyacinth stem and leaf extraction liquid serves as a reduction agent to reduce iron ions or ferrous ions to the zero-valent iron, a chromium pollution water green repairing material-green synthesis nanoscale zero-valent iron particles are obtained through preparing. The synthesis method is low in synthesis cost, small in energy consumption, simple in process, and free of a special device, the used reduction agent is the water hyacinth stem and leaf extraction liquid, wastes are utilized, and the synthesized particles are easily agglomerated and have the beneficial effects of being good in flowability, large in specific surface area, high in stability and the like. The repairing material prepared through the method is suitable for repairing the chromium pollution water and is high in repairing efficiency.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Pig tin series leadless alloy soldering paste and preparation method thereof

InactiveCN101380699ANot easily oxidizedAvoid solder joints that cannot formWelding/cutting media/materialsSoldering mediaRare-earth elementRosin

The invention discloses a tin-zinc series lead-free alloy soldering paste and a manufacturing method thereof. According to the weight percentage, the tin-zinc series lead-free alloy soldering paste consists of 85 to 90 percent of solder alloy powder as well as 10 to 15 percent of scaling powder; wherein, the solder alloy powder consists of 8 to10 percent of zinc, 0.005 to 1.0 percent of rare earth element, 0.001 to 0.1 percent of aluminum as well as tin according to the weight percentage; the total amount of each component is 100 percent; wherein, the scaling powder consists of 15 to 60 percent of modified rosin, 3 to 20 percent of activator, 1 to 10 percent of paste forming agents, 2 to 10 percent of thixotropic agents, 0.1 to 3 percent of azimino-benzene, 0.1 to 8 percent of trichloride isocyanuric acid as well as organic solvent according to the weight percentage; the total amount of each component is 100 percent. The solder alloy powder and the scaling powder are respectively prepared and then mixed uniformly for preparing the tin-zinc series lead-free soldering paste. The lead-free soldering paste has excellent wettability, is hard to be oxidized, has good welding performance and is suitable for an SMT technique flow.

Owner:XIAN UNIV OF TECH

Electrical connector design and contact geometry and method of use thereof and methods of fabrication thereof

InactiveUS20060046528A1Increased durabilityImprove reliabilityElectrical measurement instrument detailsCoupling device detailsElectronic structureElectrical conductor

A probe or an electrical connector comprises a substrate with a surface having a plurality of electrical contact locations. A shaped elongated electrical conductor has a first end coupled to one of the electrical contact locations and a second end thereof which projects away from the electrical contact location and through an aperture in a sheet of material. The sheet is disposed to be spaced apart from the surface of the substrate. At the second end of the elongated electrical conductor there is a tip structure, which is larger than the aperture in the sheet of material. The tip structure has a pointed portion thereof. The tip structure is disposed against contact locations of a contact surface. The electronic structure is moved towards the contact surface permitting the tip structure to penetrate into the surface of the electrical contact location thereon and to move, wipe, or vibrate across the surface thereof as the shaped elongated electrical conductor flexes as a result of being compressed by the movement of the electronic structure toward the contact surface.

Owner:IBM CORP

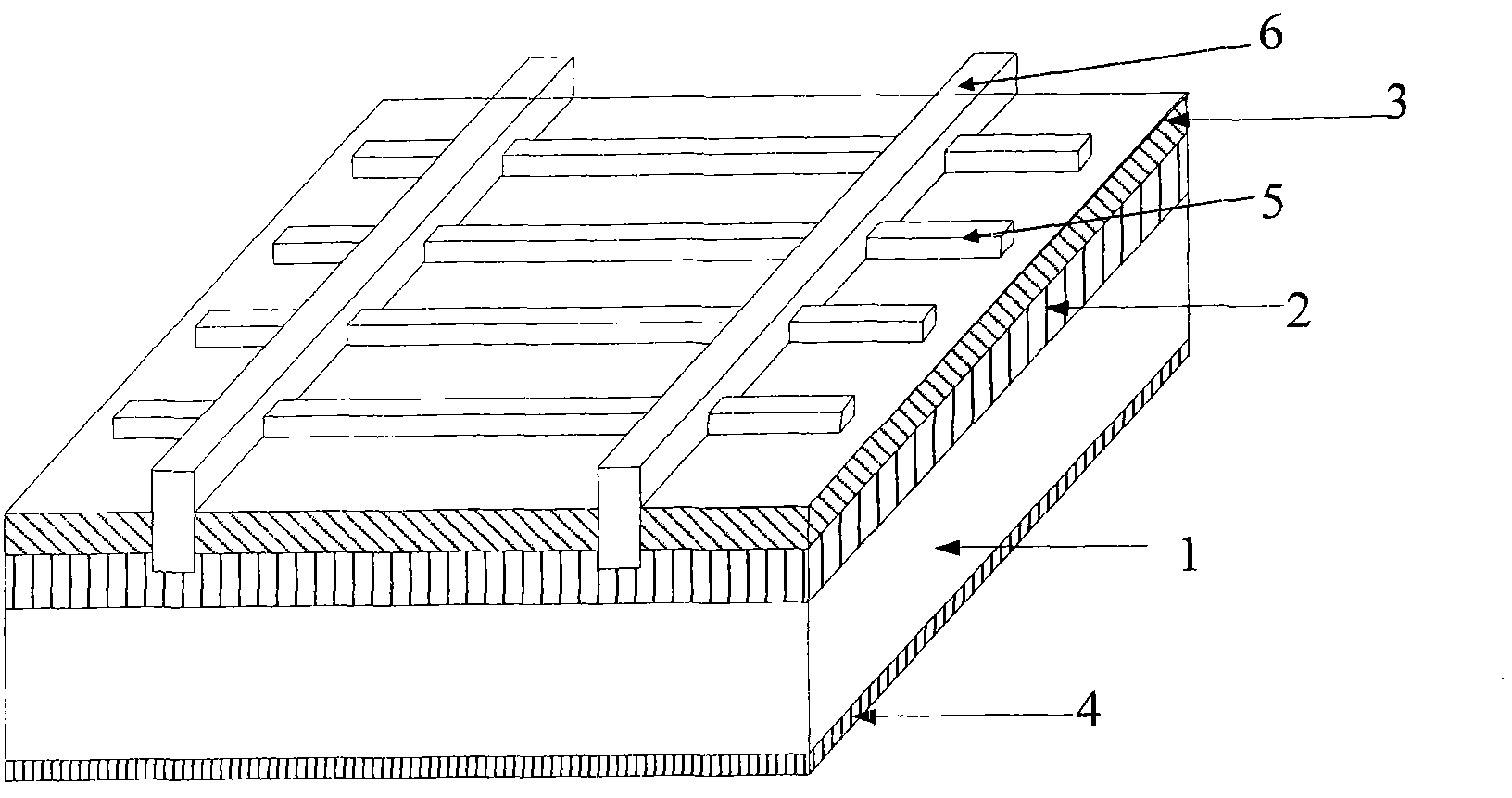

Internal combustion engine variable geometry turbine supercharger nozzle ring components

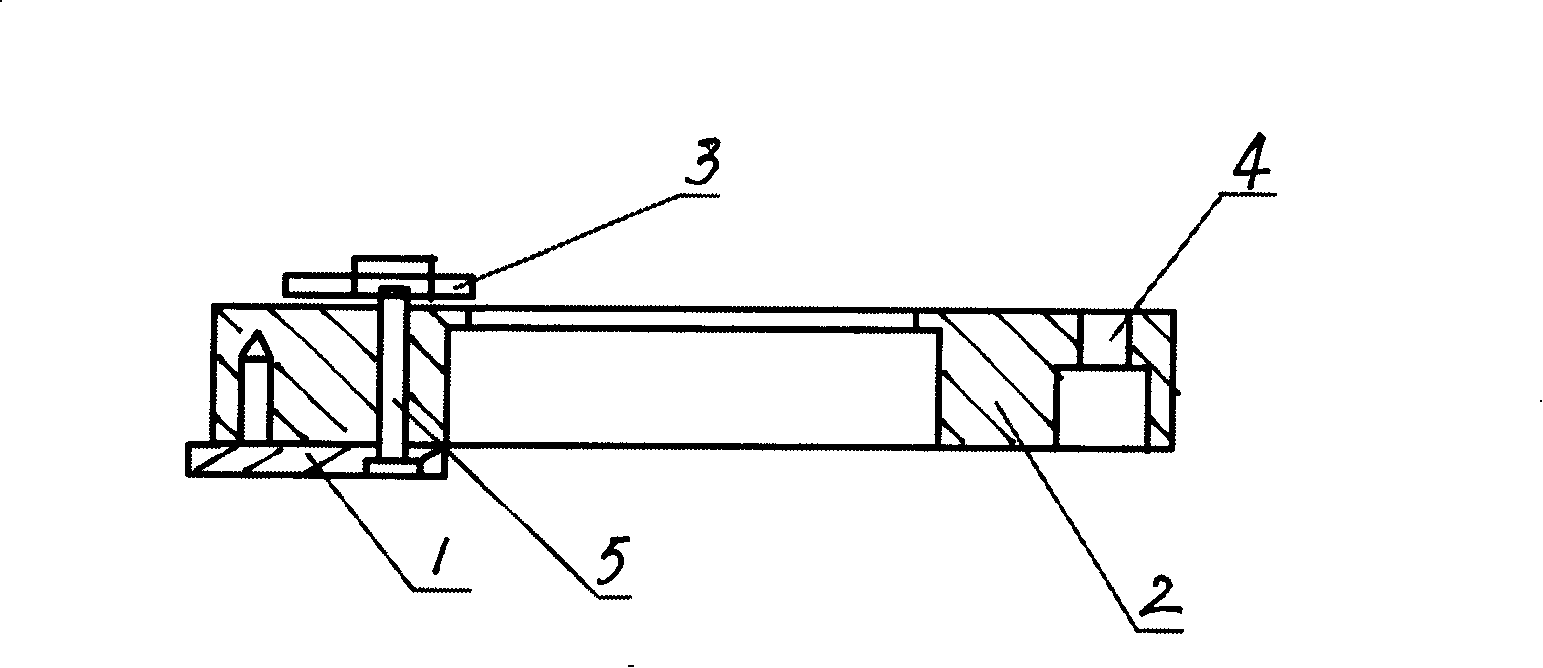

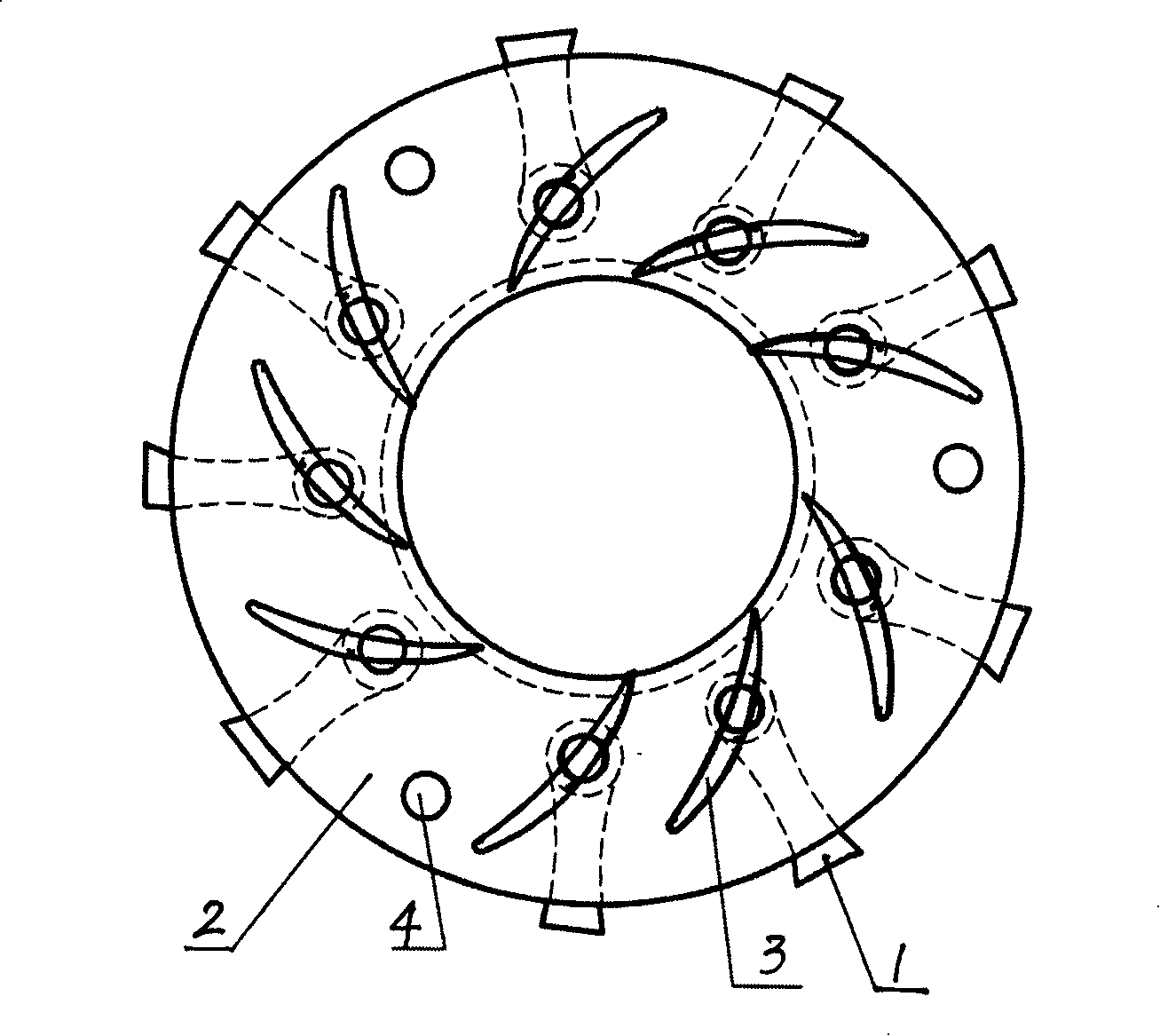

ActiveCN101191425AExtended service lifeIncrease output powerInternal combustion piston enginesEngine componentsVariable geometry turbineEmission standard

The invention discloses an internal-combustion engine variable geometry turbocharger nozzle ring component, comprising forks(1), a mounting plate(2) and a blade(3), wherein the side surface of the mounting plate(2) is provided with a plurality of groups of blades(3) which are evenly spaced and arranged on the same circumference and are in the same direction, each group of blades which consists of at least three blades(3) and can be mutually opened and folded simultaneously; the other side of the mounting plate is provided with forks(1) which are connected with corresponding blades; because the blades are the three dimensional curved surface, air inlet passages for blades are continuously changed, the air input of the turbocharger is also continuously changed according to the working condition of the engine, thereby the engine can get proper amount of pressurized air under all conditions, which makes that the engine always runs under a reasonable condition, thereby realizing that the turbocharger increases the output power of the engine by 30 to 100 percent, reducing the emission of harmful gas by more than 10 percent, realizing that the fume emission reaches the emission standard of the European IV, lowering oil consumption by 5 to 10 percent and improving the economical efficiency of the automobile.

Owner:PINGXIANG DEBO TECH CO LTD

Vacuum robot, vacuum motor for vacuum robot, and production method of said vacuum motor

InactiveUS7950890B2Improve reliabilityReduce gapProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingEngineeringAtmospheric pressure

A vacuum robot includes an arm portion on which a work is to be disposed under a reduced pressure environment and a motor portion for rotatably driving the arm portion, the vacuum robot being configured to transfer the work by causing a rotational movement of the arm portion by the motor portion. The motor portion comprises a rotor portion connected to the arm portion, a stator portion disposed at an external periphery of the rotor portion, a housing disposed under an atmospheric pressure environment, and a thin cylindrical can disposed in an electromagnetic gap formed between the rotor portion and the stator portion and secured to the housing so that the stator portion is air-tightly encapsulated in a space formed by the housing and the can. The space is maintained in a depressurized state by a seal.

Owner:YASKAWA DENKI KK

Coated type nanoscale zero-valent iron as well as preparation method and application thereof

ActiveCN106000335APrevent oxidationHigh reactivitySludge treatmentOther chemical processesFerricMaterials science

The invention discloses coated type nanoscale zero-valent iron as well as a preparation method and an application thereof. The coated type nanoscale zero-valent iron comprises nanoscale zero-valent iron and sodium alginate, wherein the nanoscale zero-valent iron is coated with sodium alginate, and a mass ratio of sodium alginate to the nanoscale zero-valent iron is (0.1-0.4):1. The preparation method of the coated type nanoscale zero-valent iron comprises the step that the nanoscale zero-valent iron and a sodium alginate solution are mixed and subjected to ultrasonic treatment, and the coated type nanoscale zero-valent iron is obtained. The coated type nanoscale zero-valent iron can be used for treating sediment with heavy metal pollution, is simple and convenient to operate, good in stabilizing effect, good in mobility, low in repair cost, clean and pollution-free, has no toxic and harmful effects on the environment and has broad application prospect in the technical field of treatment of heavy metal pollution of the sediment.

Owner:HUNAN SANYOU ENVIRONMENTAL TECH CO LTD

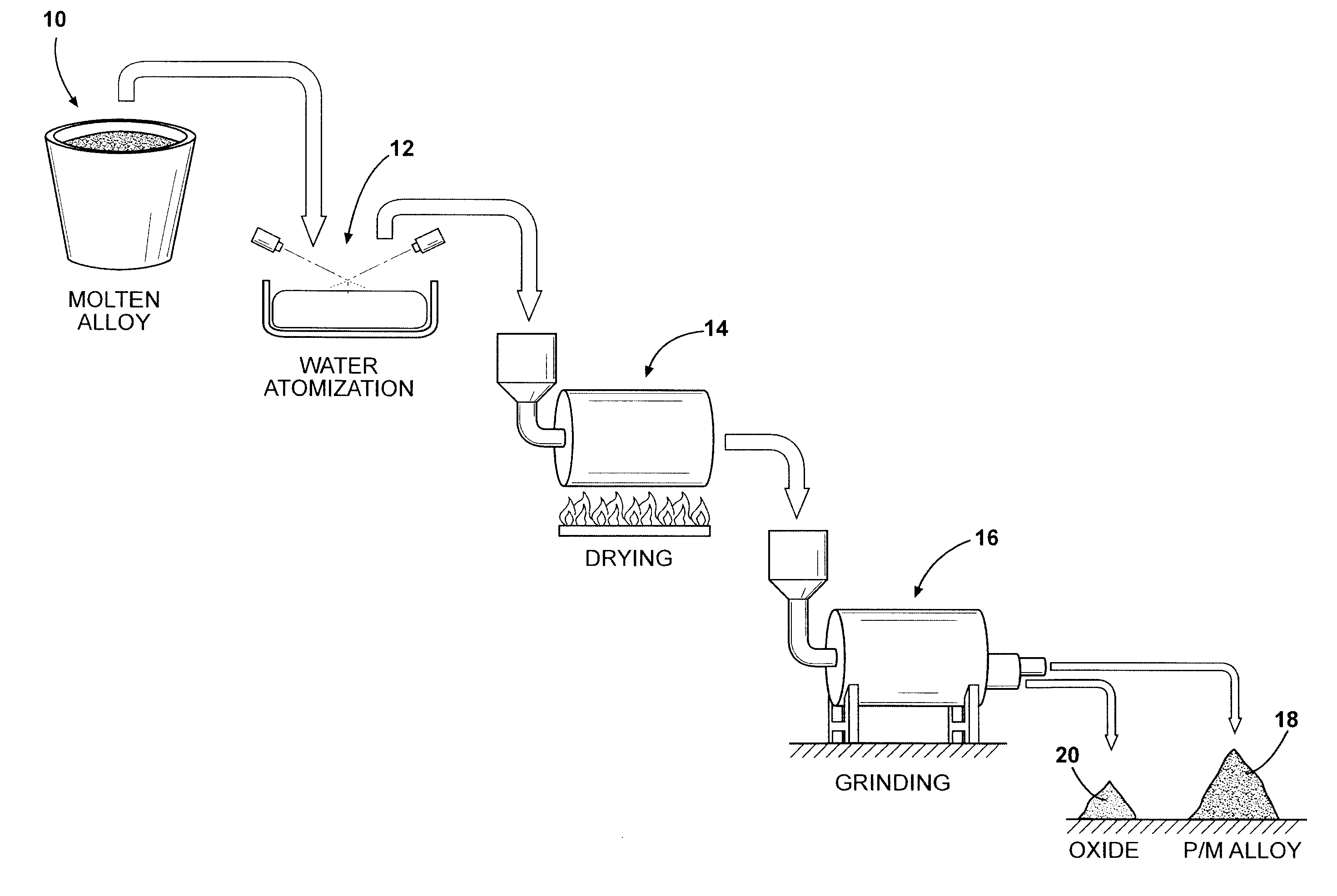

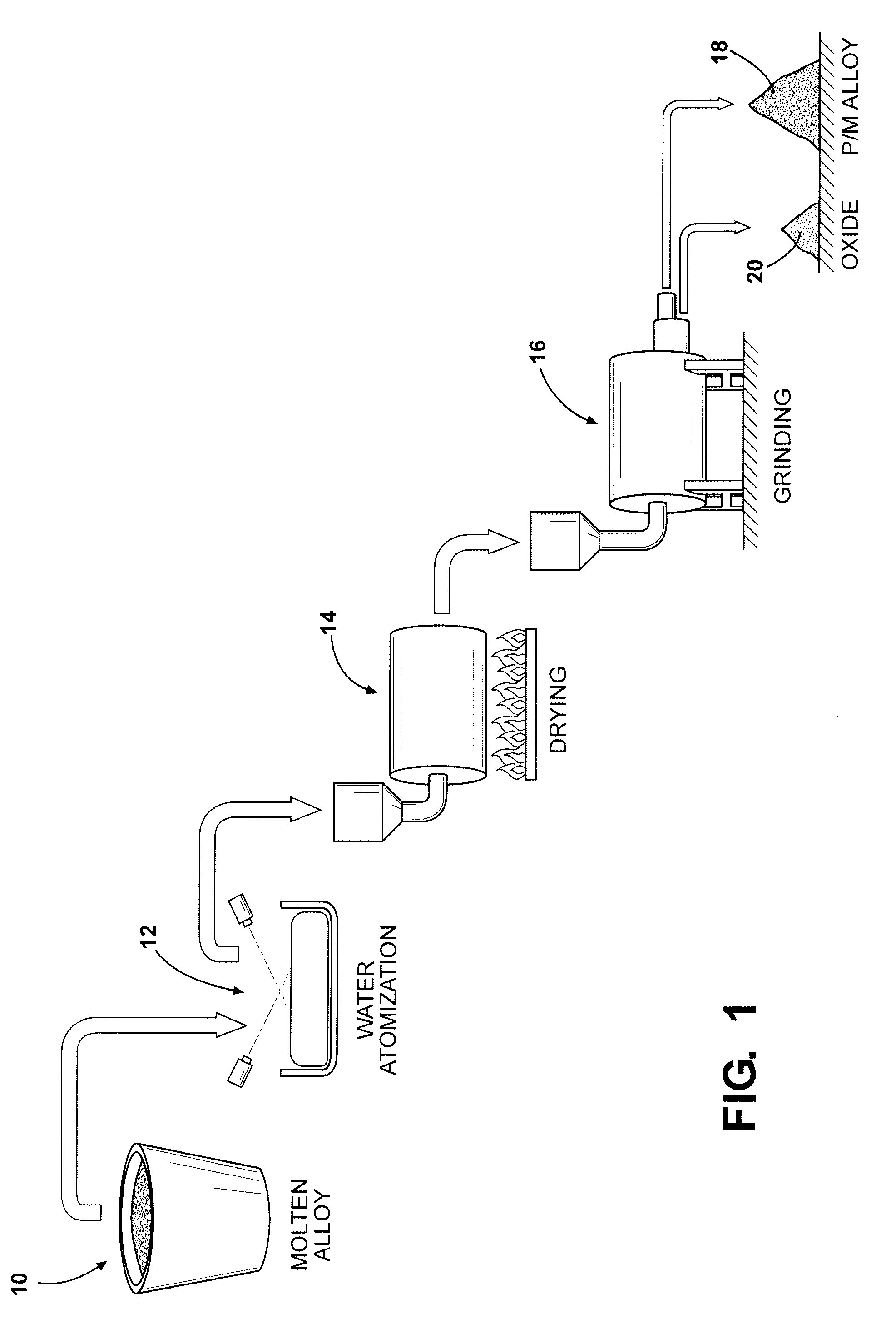

Powdered metal alloy composition for wear and temperature resistance applications and method of producing same

A powder metal steel alloy composition for high wear and temperature applications is made by water atomizing a molten steel alloy composition containing C in an amount of at least 3.0 wt %; at least one carbide-forming alloy element selected from the group consisting of: Cr, V, Mo or W; an O content less than about 0.5 wt %, and the balance comprising essentially Fe apart from incidental impurities. The high carbon content reduces the solubility of oxygen in the melt and thus lowers the oxygen content to a level below which would cause the carbide-forming element(s) to oxidixe during water atomization. The alloy elements are thus not tied up as oxides and are available to rapidly and readily form carbides in a subsequent sintering stage. The carbon, present in excess, is also available for diffusing into one or more other admixed powders that may be added to the prealloyed powder during sintering to control microstructure and properties of the final part.

Owner:CORP DE LECOLE POLYTECHNIQUE DE MONTREAL +1

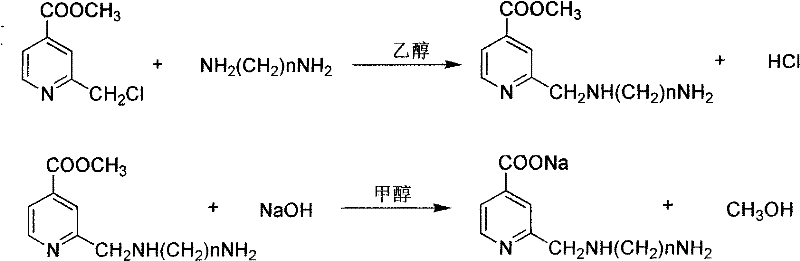

Preparation method of anionic aqueous polyurethane dispersoid for fabric coating and decoration

The invention relates to a preparation method of an anionic aqueous polyurethane dispersoid for fabric coating and decoration. The preparation method is operated according to the following steps that: (a) polyether polyol, polyester polyol and diisocyanate are subjected to polymerization reaction for 2 to 4 hours at 70 to 90 DEG C under the effect of catalysts; (b) acetone solvents and diamine hydrophilic chain extenders containing picolinic acid structures are added for taking reaction for 5 to 30 minutes at 40 to 65 DEG C, and polyurethane prepolymers are prepared; (c) the temperature is lowered to 20 to 40 DEG C, low-molecular-weight chain extenders and water are added and are emulsified through being stirred at high speed; (d) the acetone solvents are removed through reduced pressure distillation, and the anionic aqueous polyurethane dispersoid for fabric coating and decoration is obtained. Because diamine containing the picolinic acid structures is used as hydrophilic chain extenders, the regular pyridine ring structure is contained, the crystallization performance and the initial bonding intensity can be improved, meanwhile, a pyridine ring is an electron deficiency system, the color deepening caused by oxidation cannot easily occur, and the product has the yellowing resistance performance.

Owner:JIAXING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com