Patents

Literature

926results about "Tube/lamp screens manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

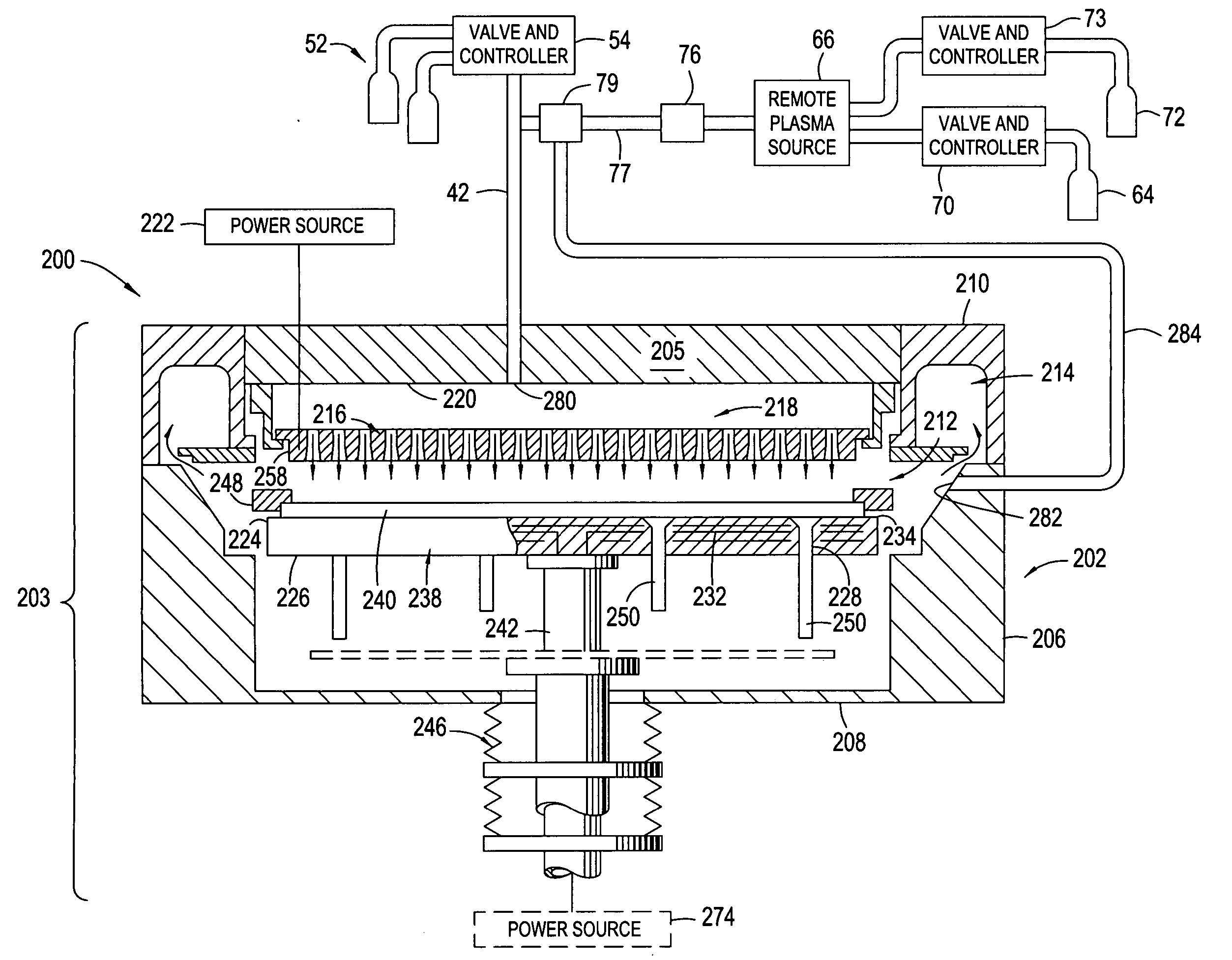

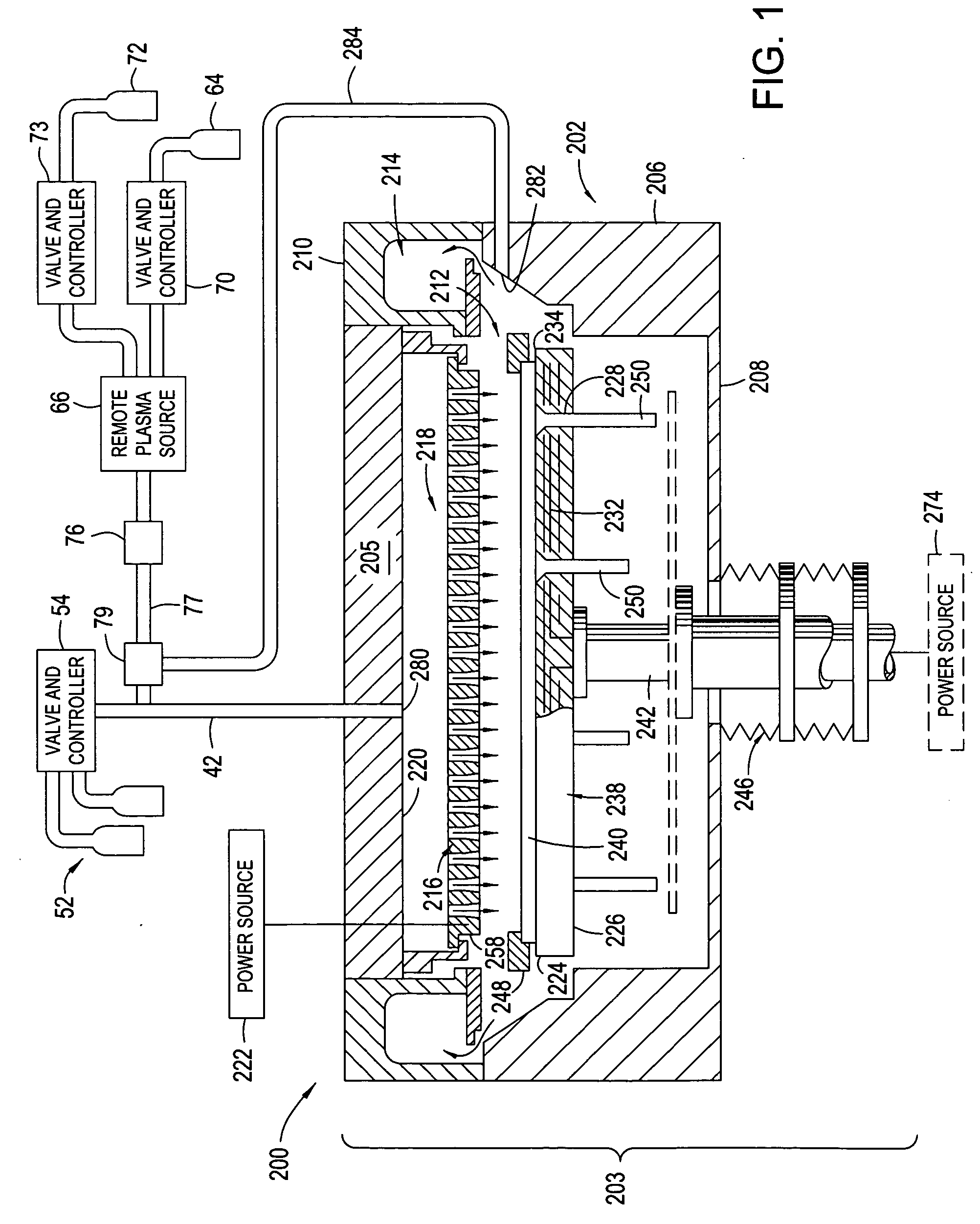

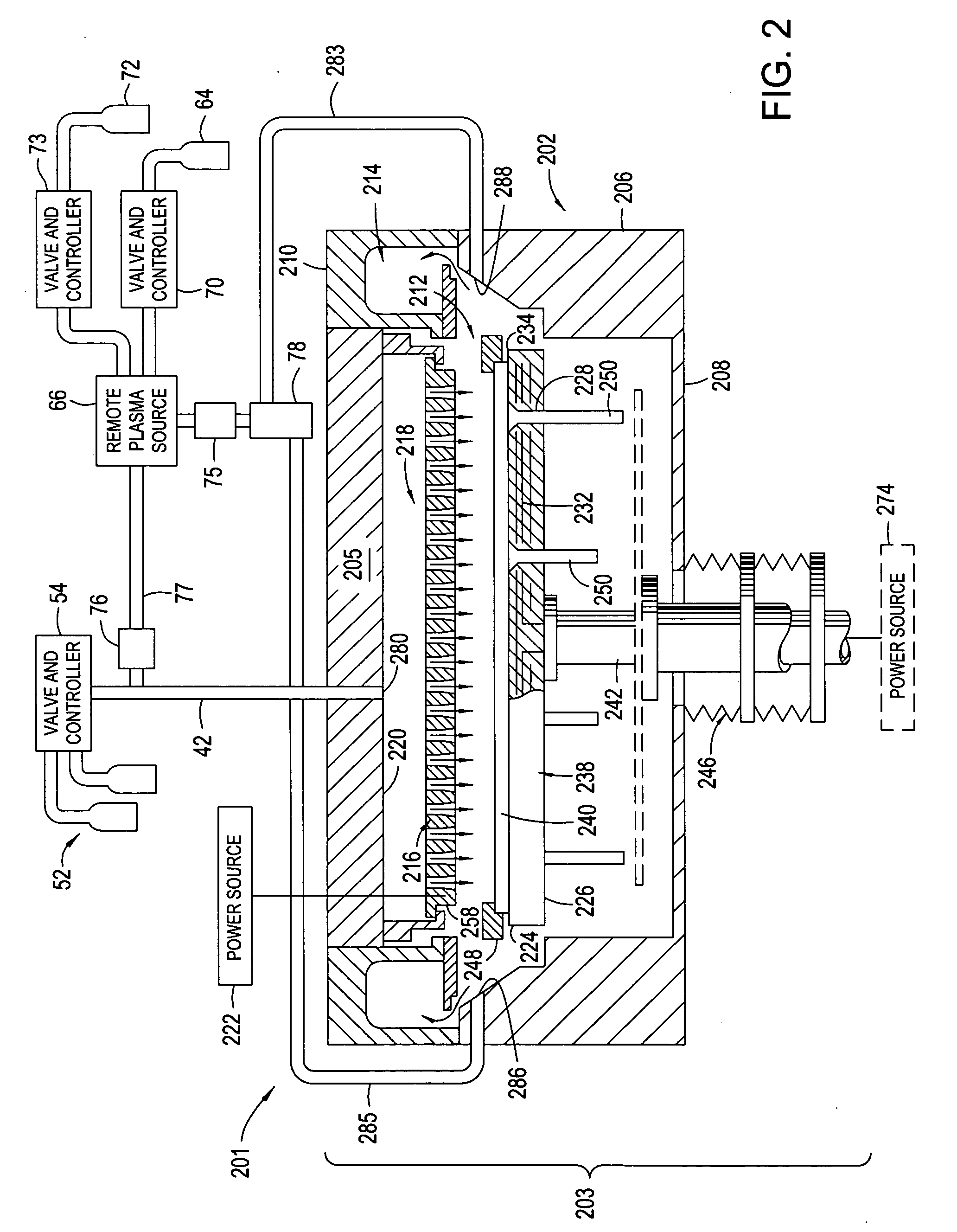

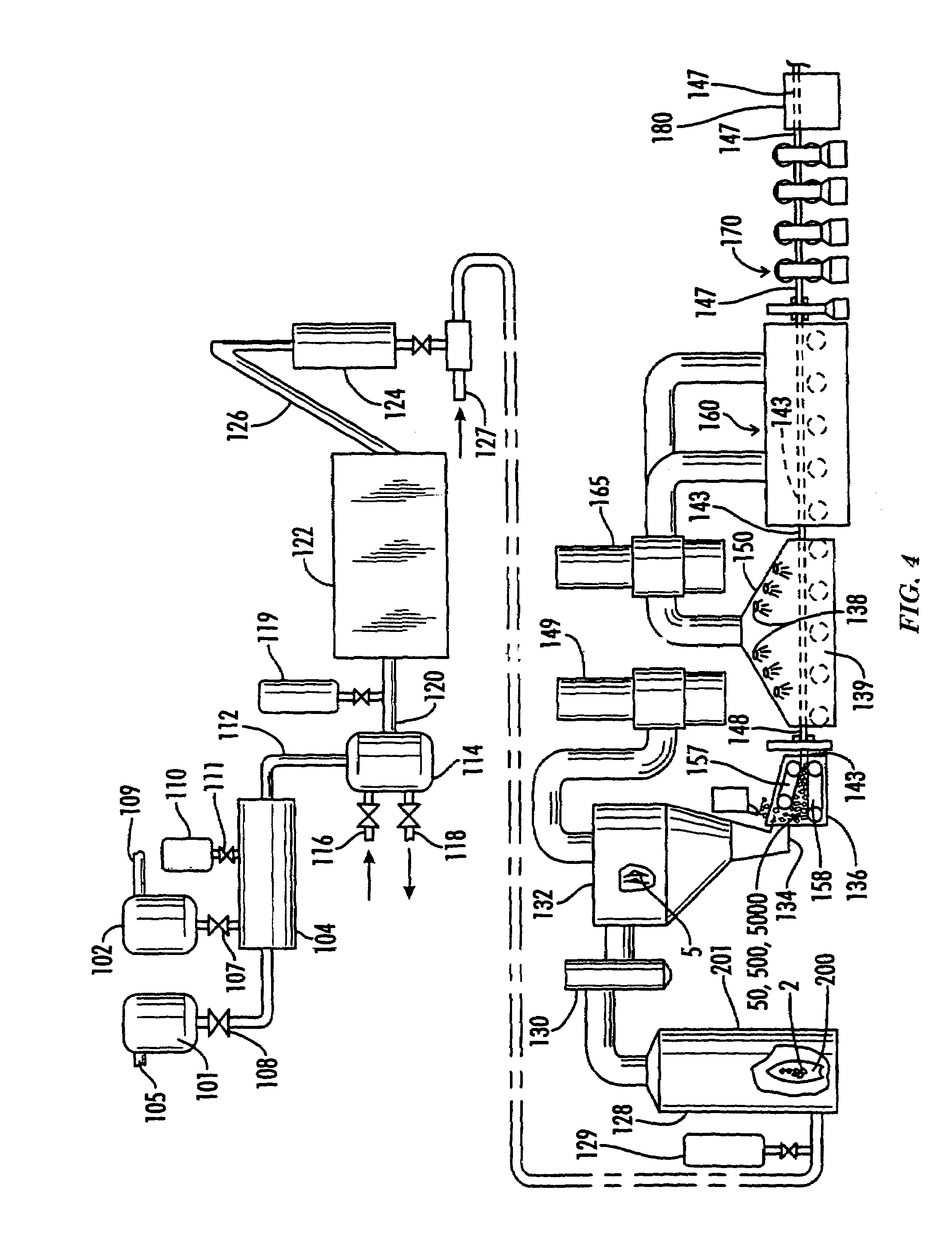

High plasma utilization for remote plasma clean

InactiveUS20060266288A1Tube/lamp screens manufactureElectric discharge tubesRemote plasmaHigh plasma

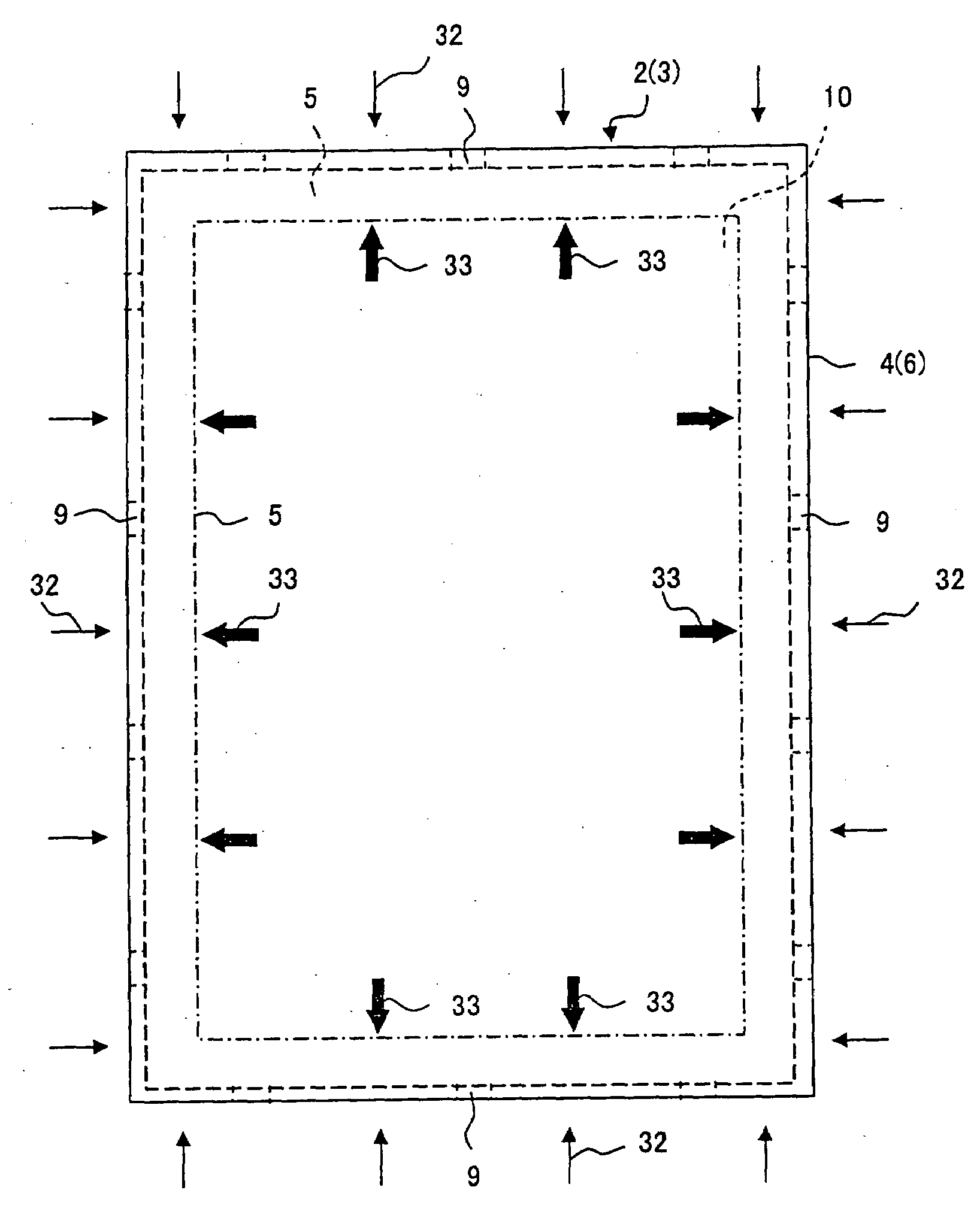

A method and apparatus for cleaning a chemical vapor deposition chamber are provided. The chemical vapor deposition chamber includes an inlet that introduces reactive species into the chamber from a remote plasma source while bypassing a gas distribution assembly of the chamber and an inlet that introduces reactive species from a remote plasma source into the chamber via the gas distribution assembly.

Owner:APPLIED MATERIALS INC

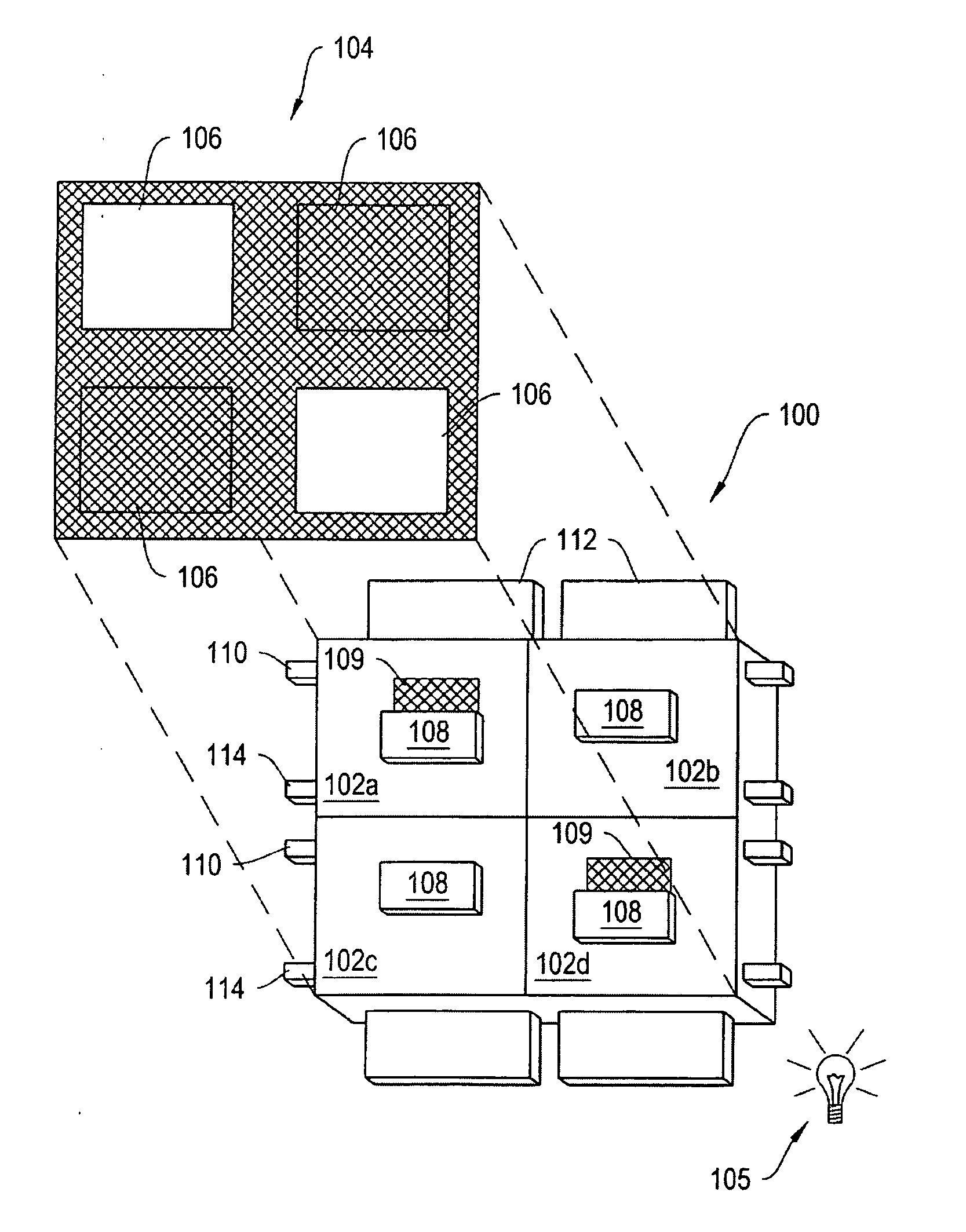

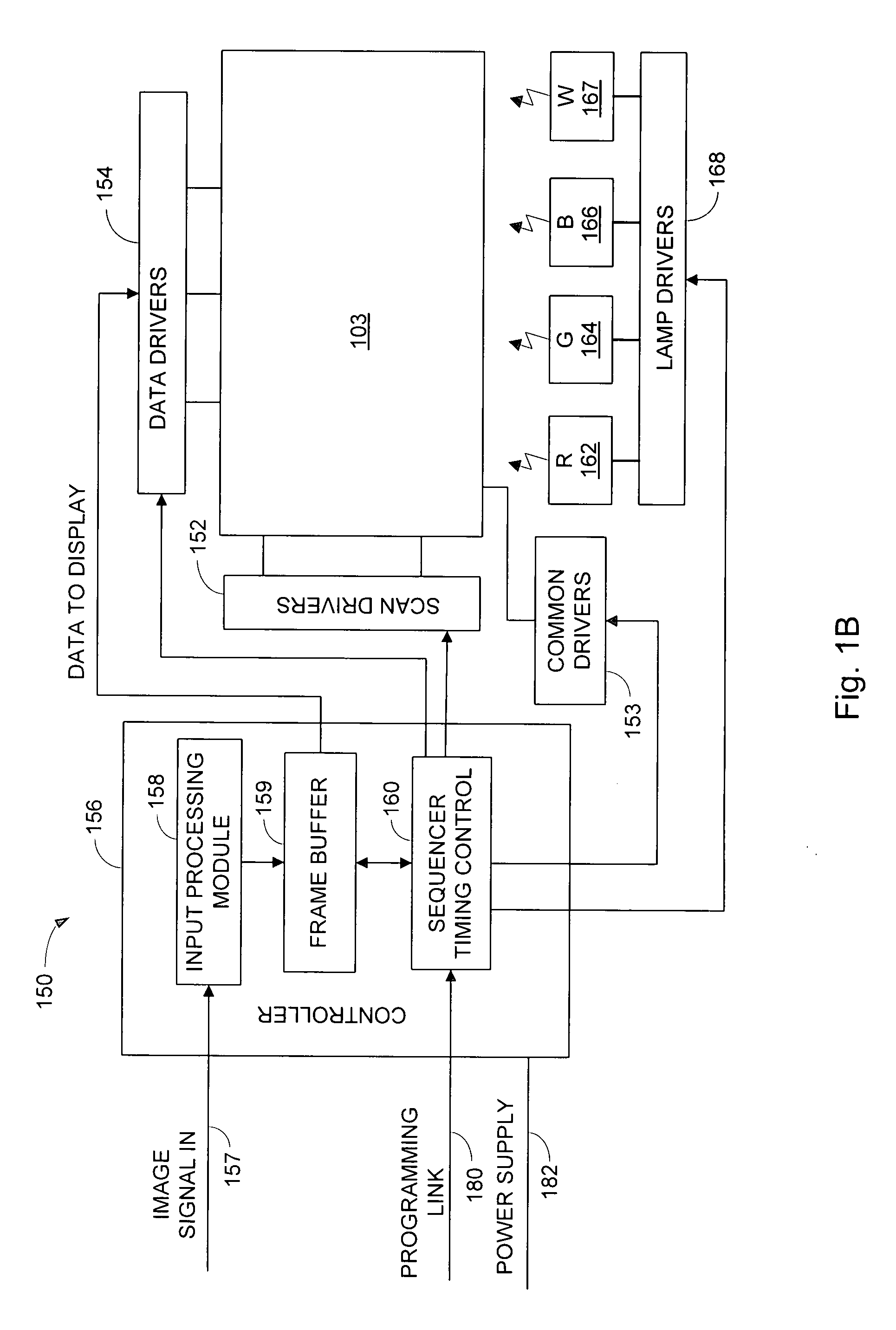

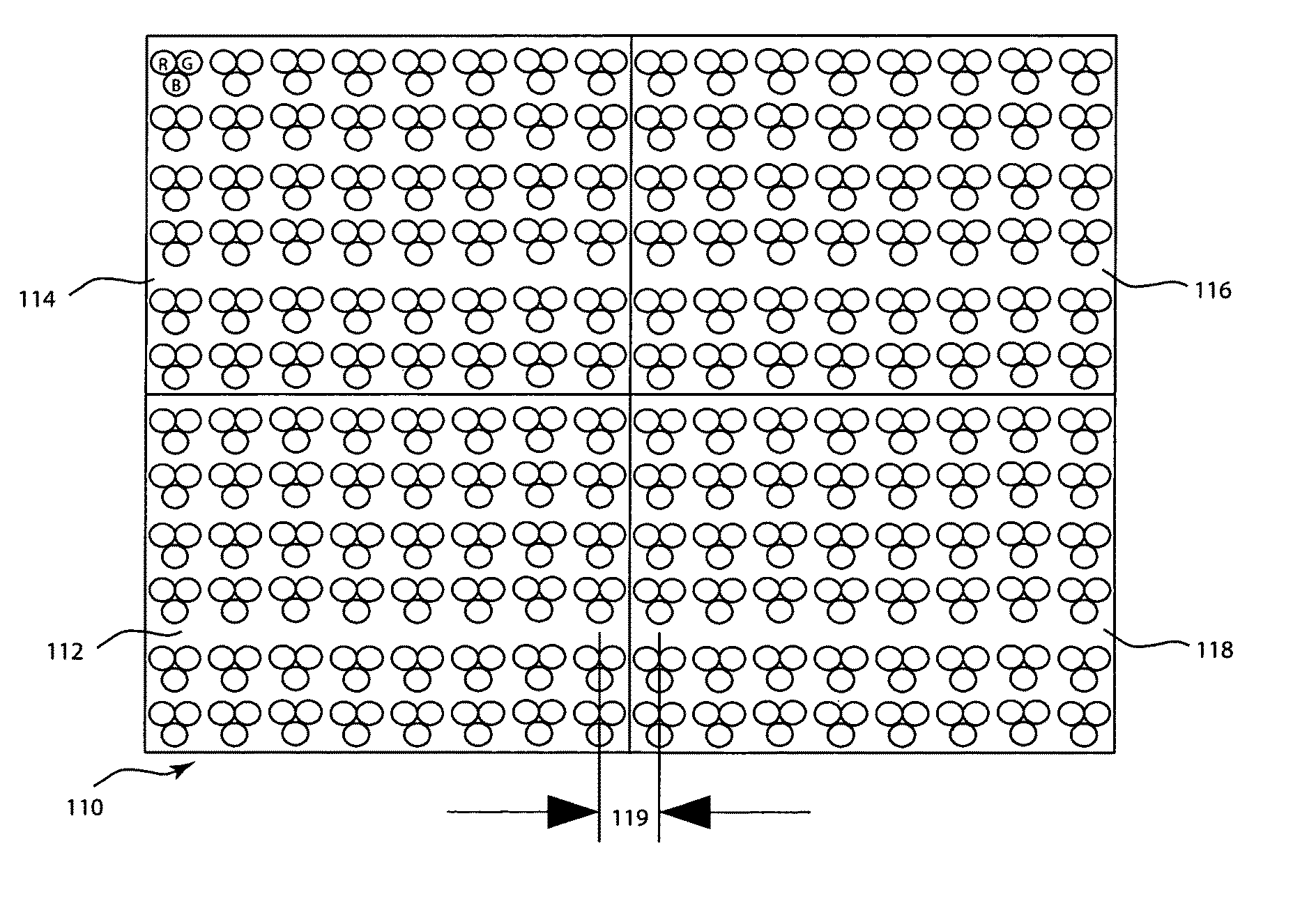

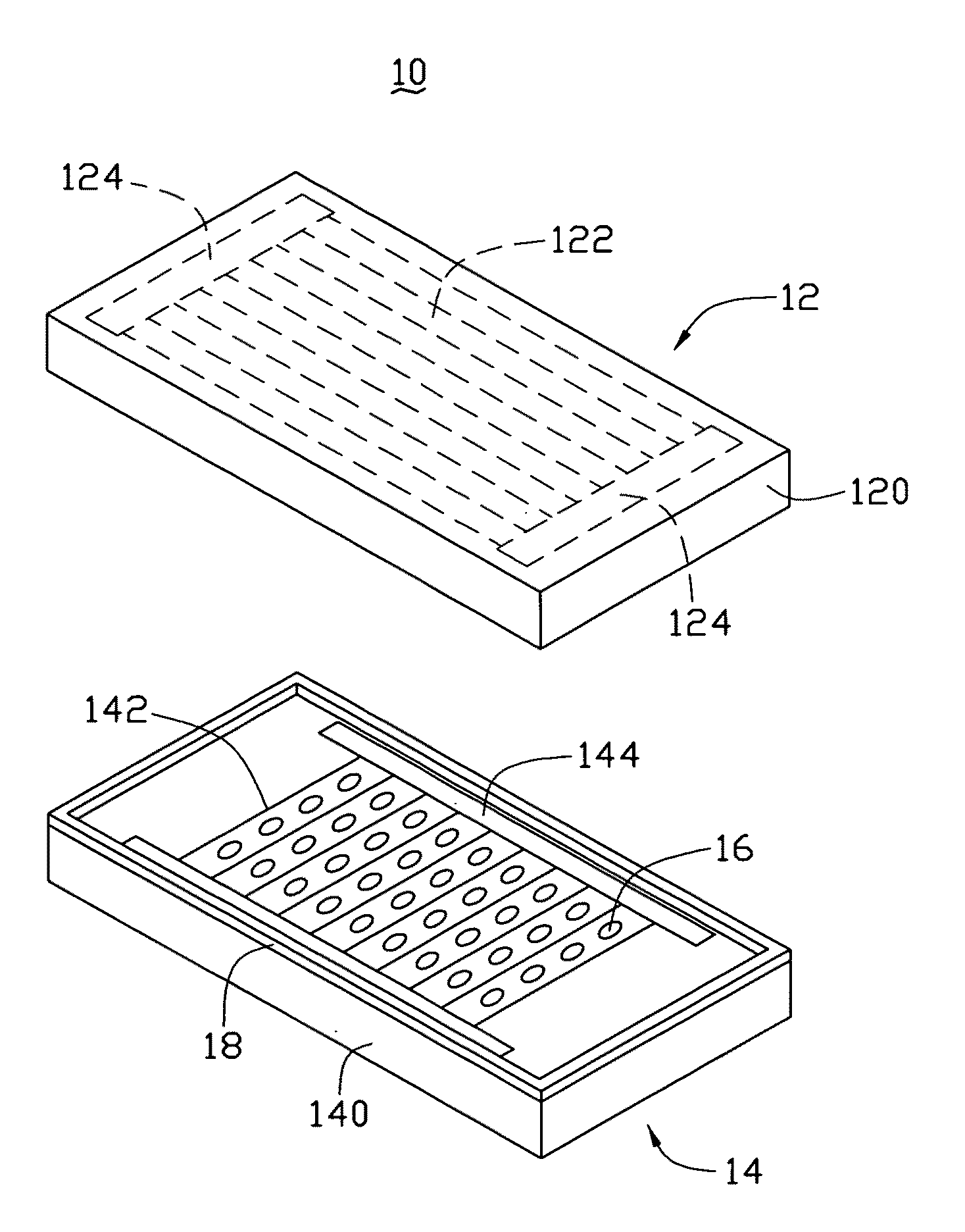

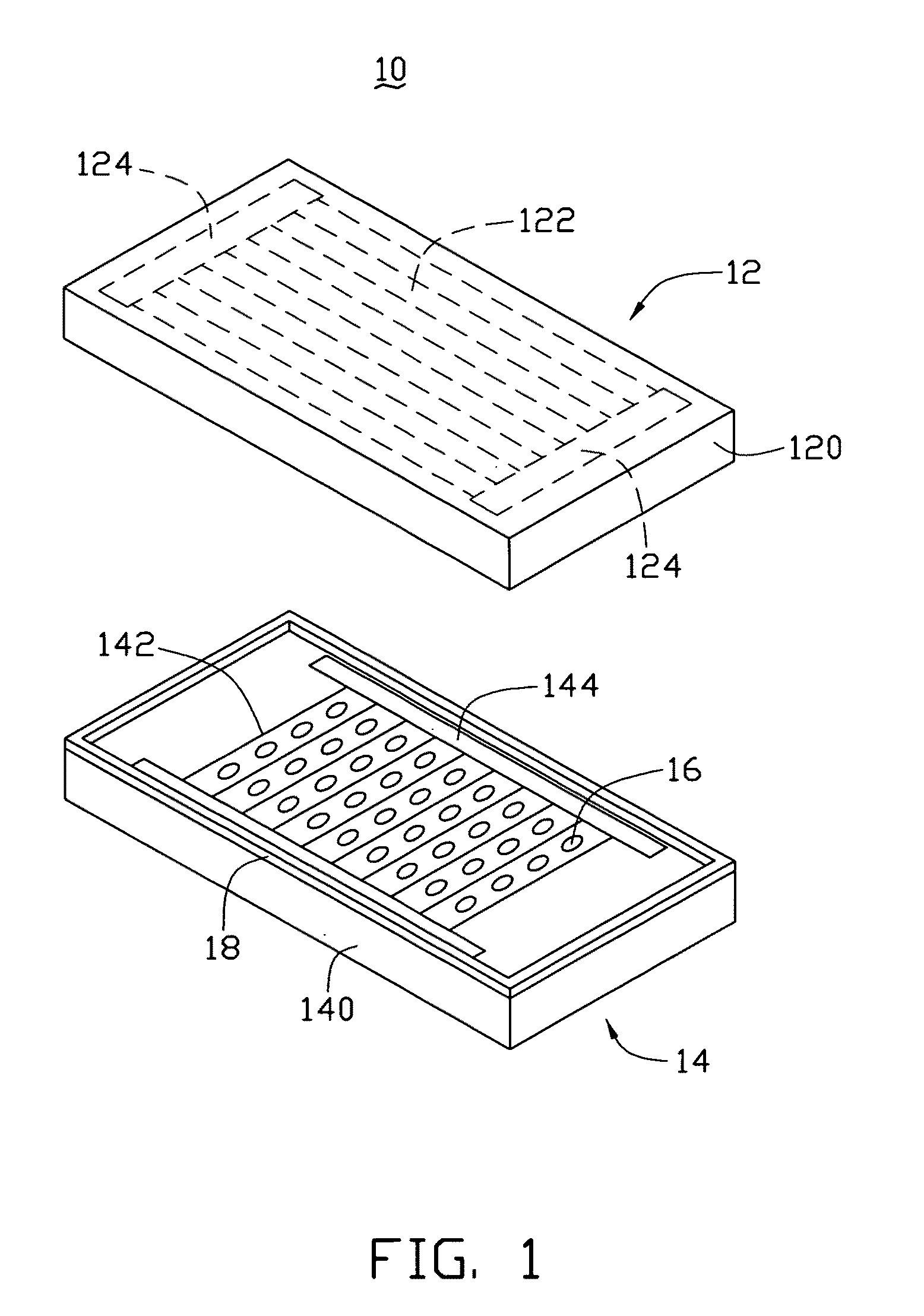

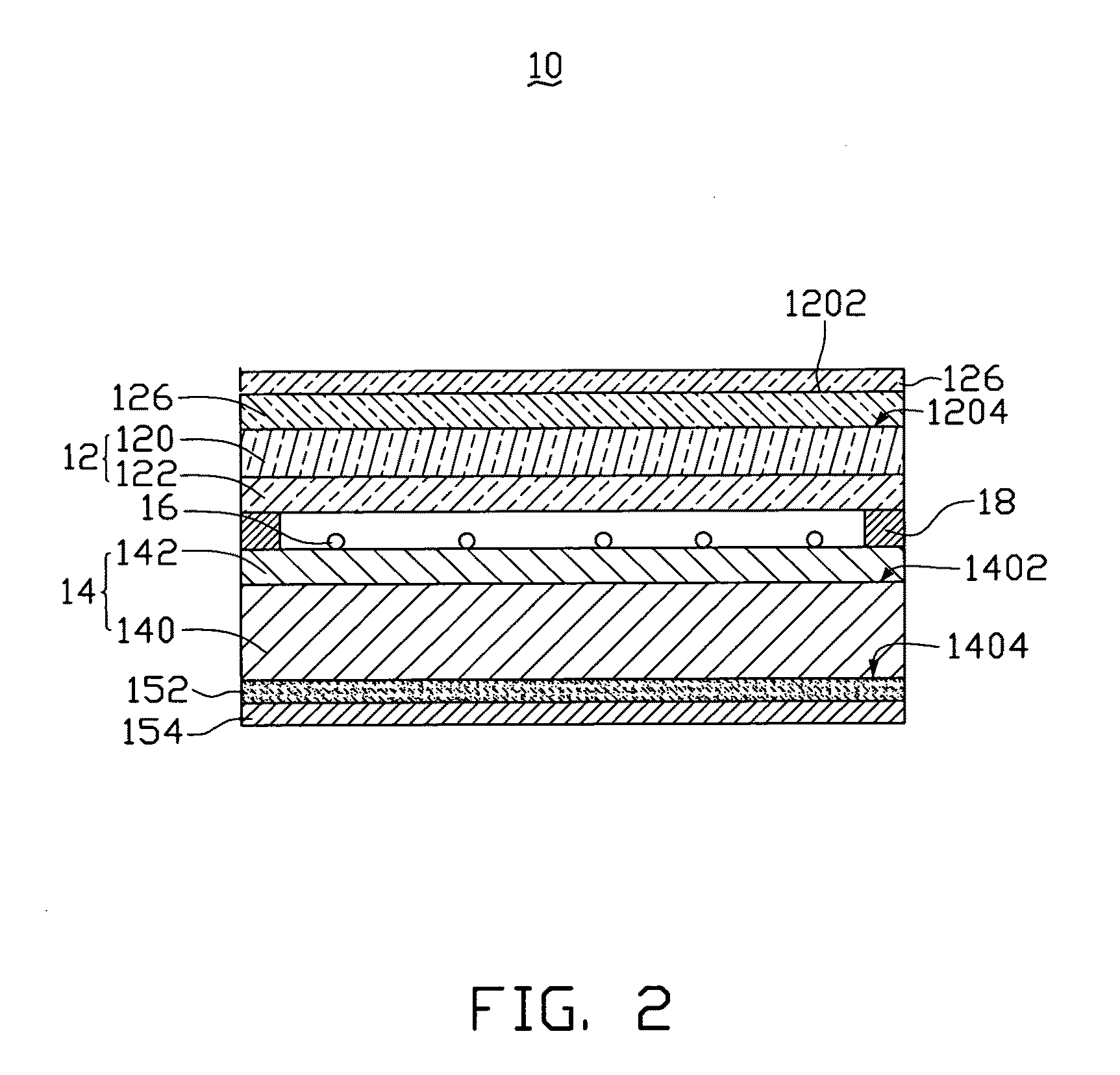

Alignment methods in fluid-filled MEMS displays

InactiveUS20080037104A1Improve electromechanical performanceGood optical performanceTube/lamp screens manufactureStatic indicating devicesDisplay deviceEngineering

This invention relates to MEMS display apparatus and methods for assembly thereof that include a plurality of light modulators having components substantially surrounded in a liquid that reduces the effects of stiction and improves the optical and electromechanical performance of the display apparatus. The invention also relates to methods for aligning components of a MEMS display to establish a correspondence between the plurality of light modulators and a plurality of apertures to regulate the transmission of light through the apparatus.

Owner:SNAPTRACK

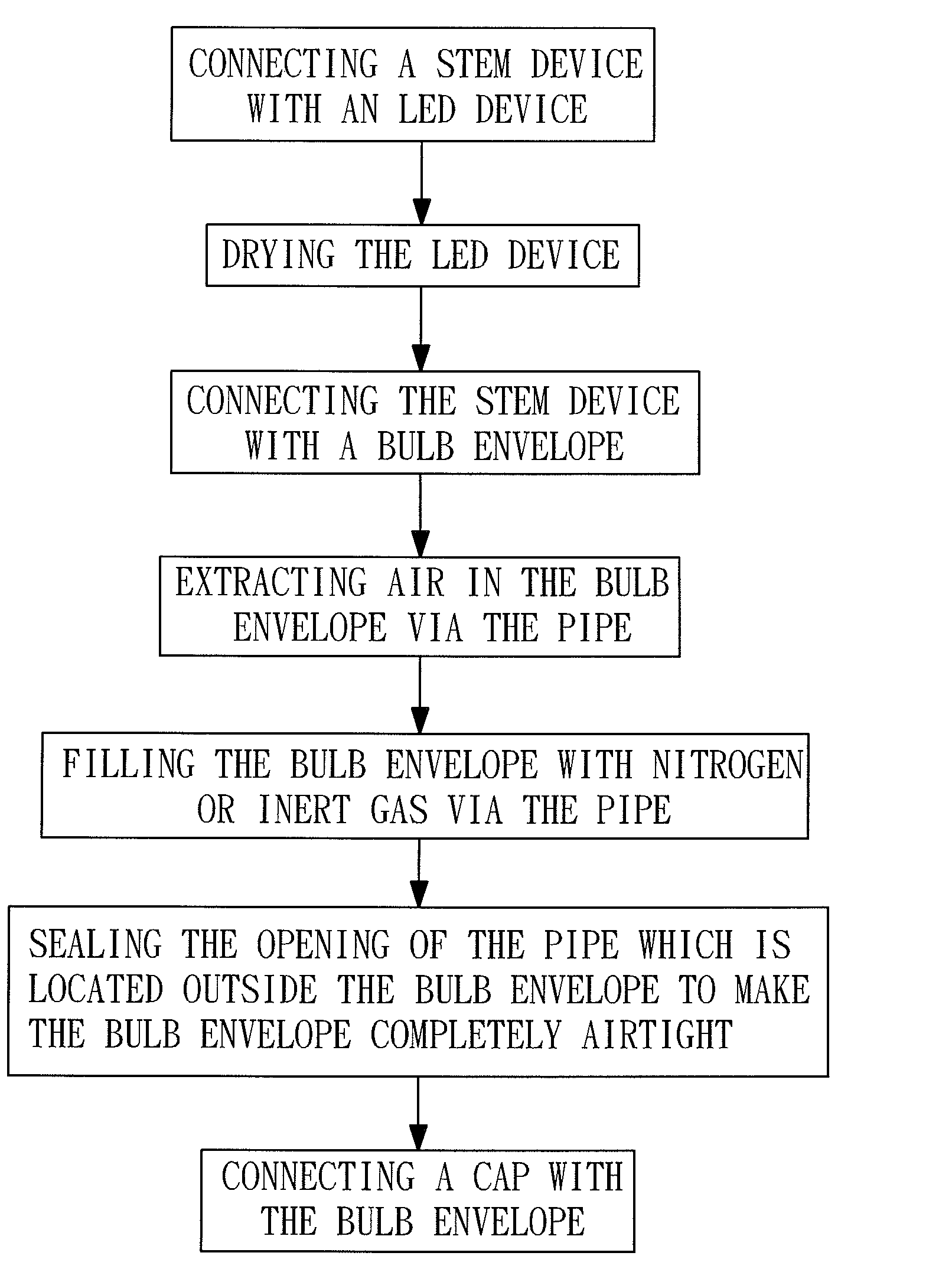

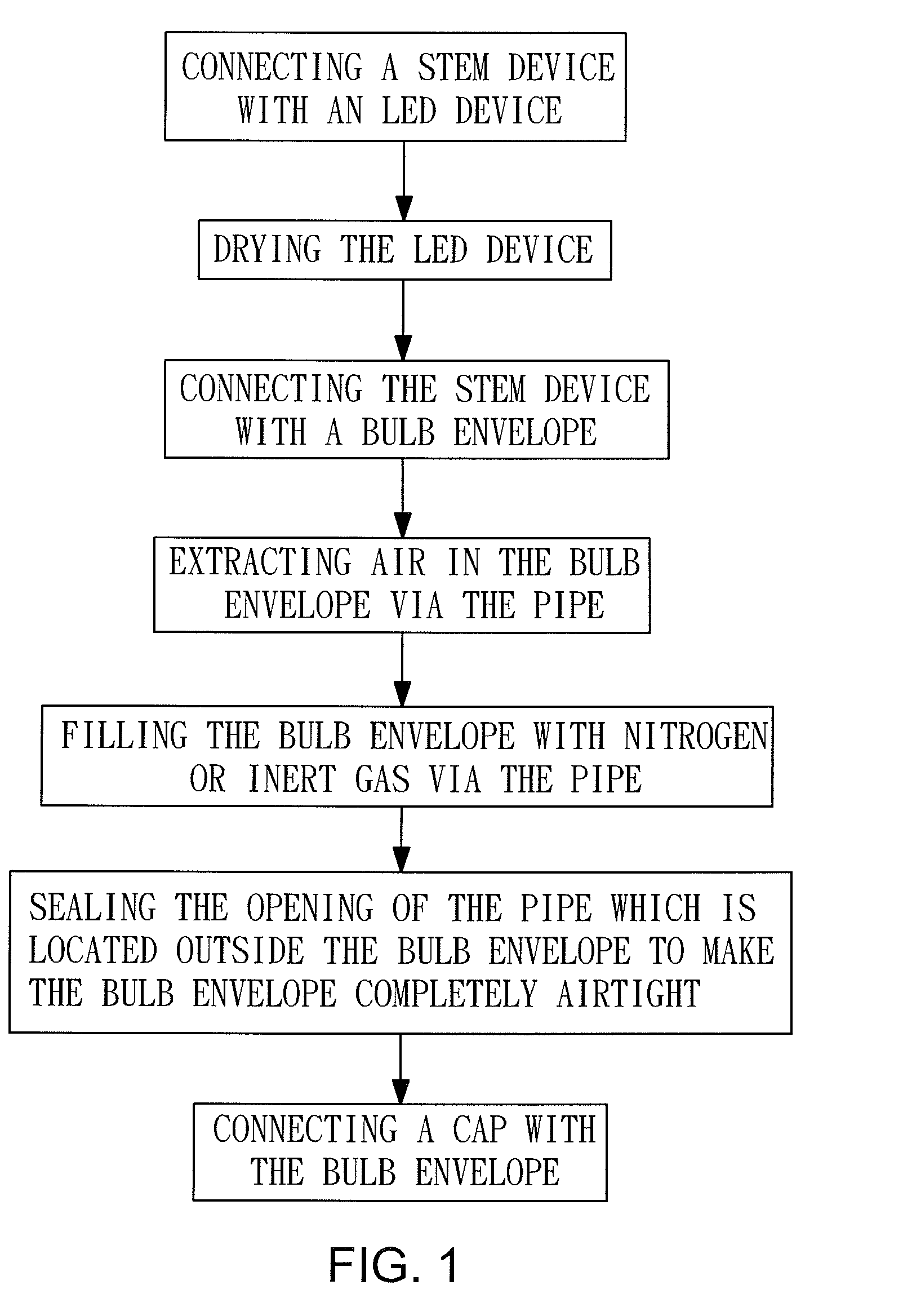

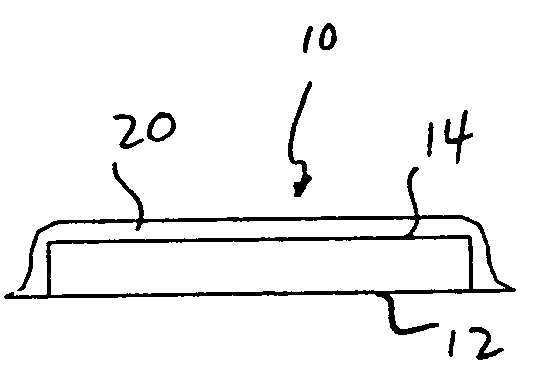

Method of Assembling An Airtight LED Light Bulb

ActiveUS20120040585A1Not easily oxidizedEasily be dampenedTube/lamp screens manufacturePoint-like light sourceNitrogenEngineering

A method of assembling an airtight LED light bulb has the steps of: connecting a stem device with an LED device, drying the LED device, connecting the stem device with a bulb envelope, extracting air in the bulb envelope via a pipe, filling the bulb envelope with nitrogen or inert gas via the pipe, sealing an opening of the pipe which is located outside the bulb envelope to make the bulb envelope completely airtight and connecting a cap with the bulb envelope. Because the bulb envelope is airtight, moisture in the environment can not damage the LED device, and the steps of extracting air in the bulb envelope via the pipe and filling the bulb envelope with nitrogen or inert gas via the pipe are feasible. Consequently, the LED device will not easily be oxidized or dampened, so the lifespan of the airtight LED light bulb can be prolonged.

Owner:LIQUIDLEDS LIGHTING

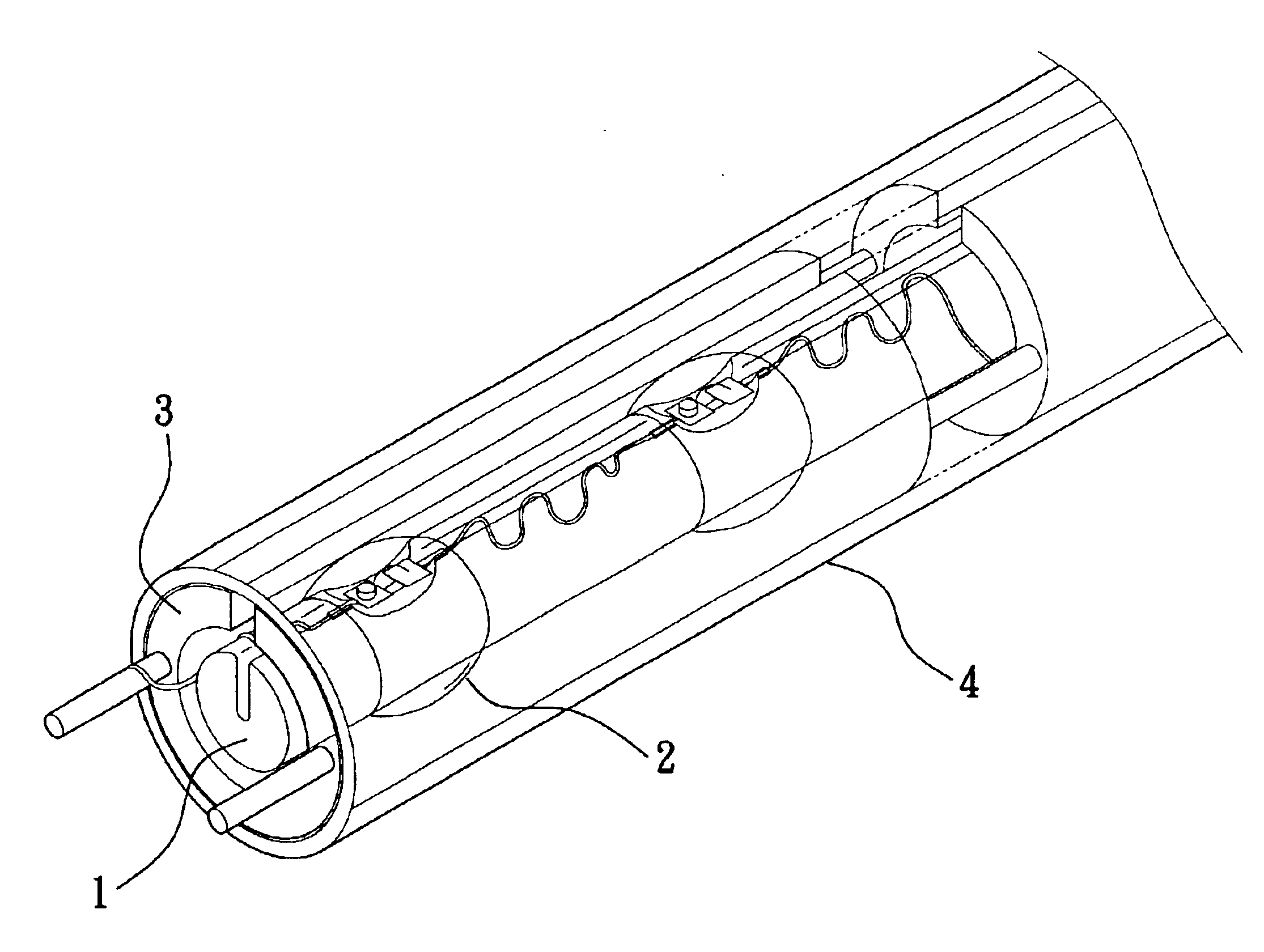

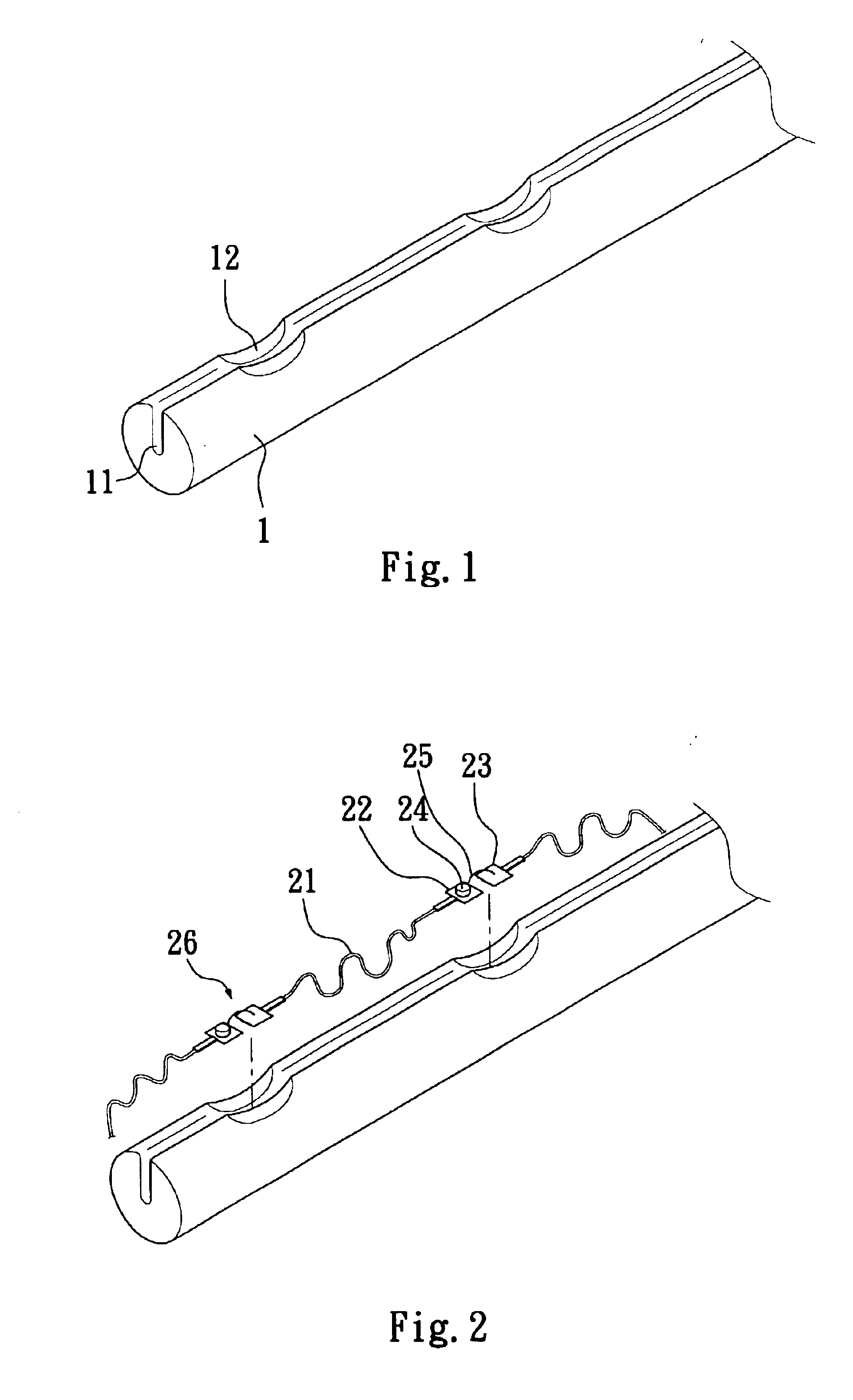

Method of producing an LED hose light

InactiveUS6857924B2Rapid positioningEasy to liftTube/lamp screens manufactureElectroluminescent light sourcesEngineeringLED lamp

A method of producing an LED hose light includes the steps of mounting a plurality of serially connected LED strings directly on a core tube, using an intermediate tube having embedded power cords for supplying power to the LED strings to enclose the core tube having the LED strings mounted thereon, so as to form an assembly of the core tube, the LED strings, and the intermediate tube, and extending the assembly of the core tube, the LED strings, and the intermediate tube through an outer tube. The LED hose light associating LED strings with the core tube is easily bendable and energy-saving and can be produced at largely reduced cost.

Owner:FU TA HAO +1

Thermionic electron emission device and method for making the same

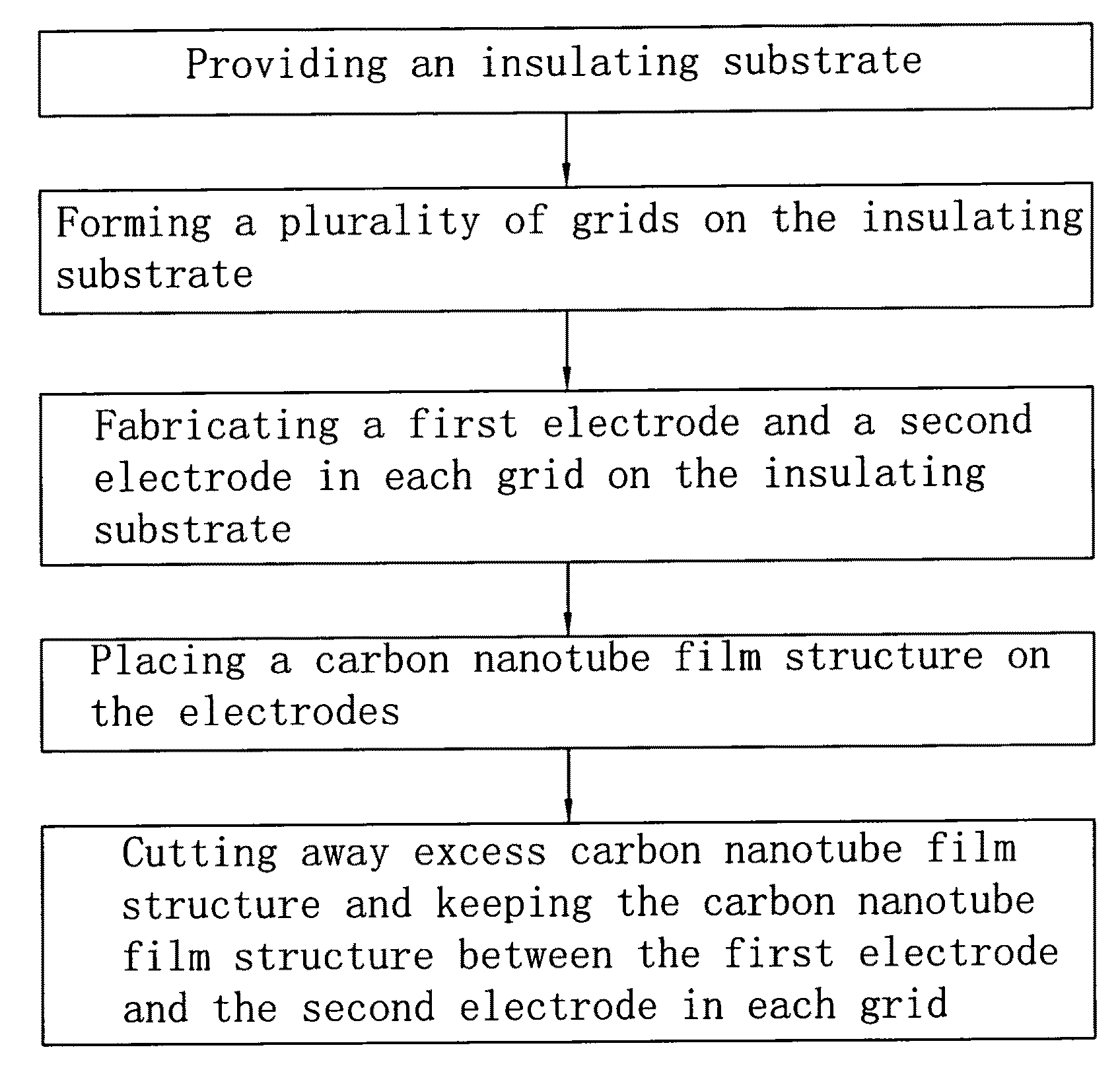

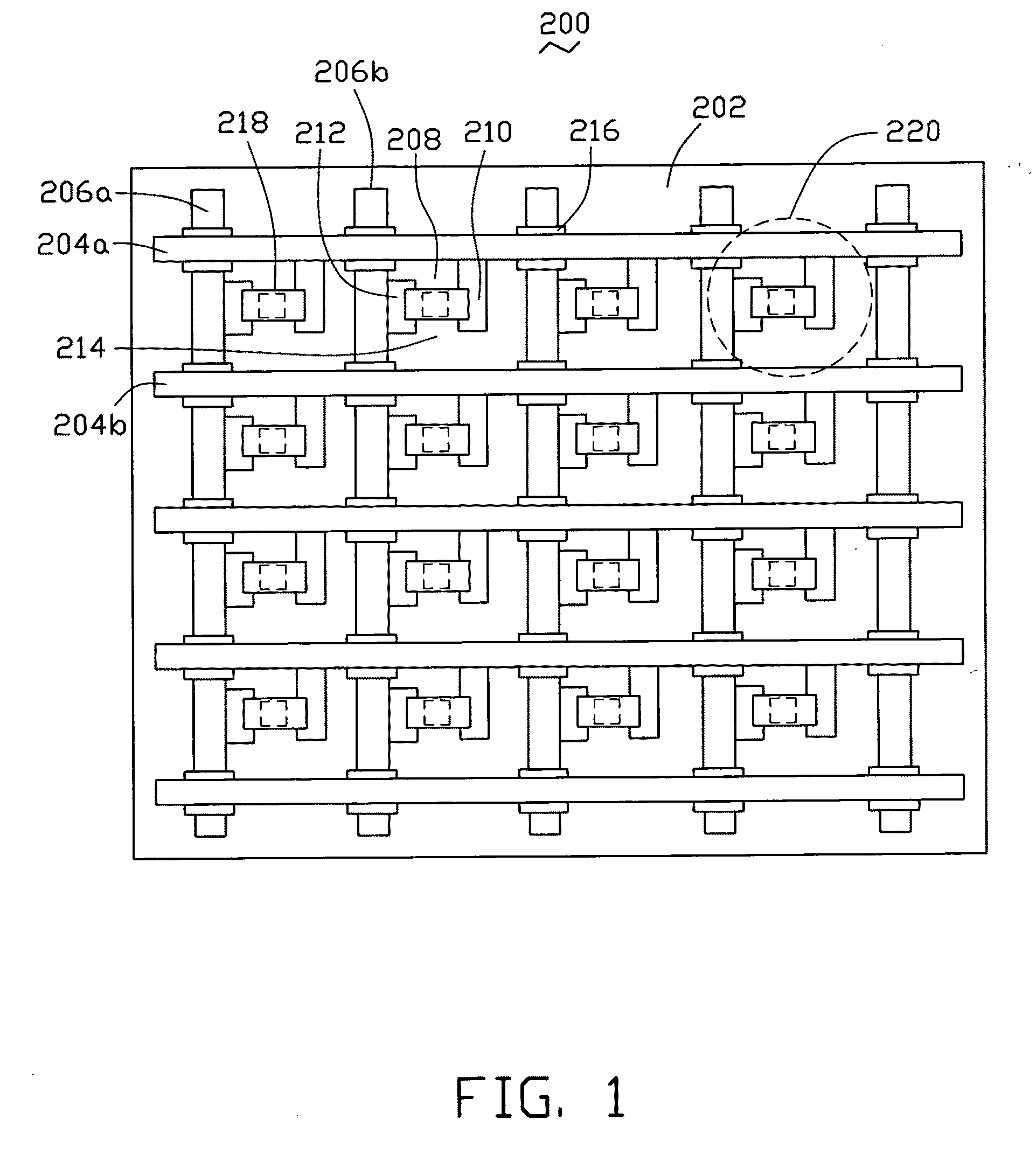

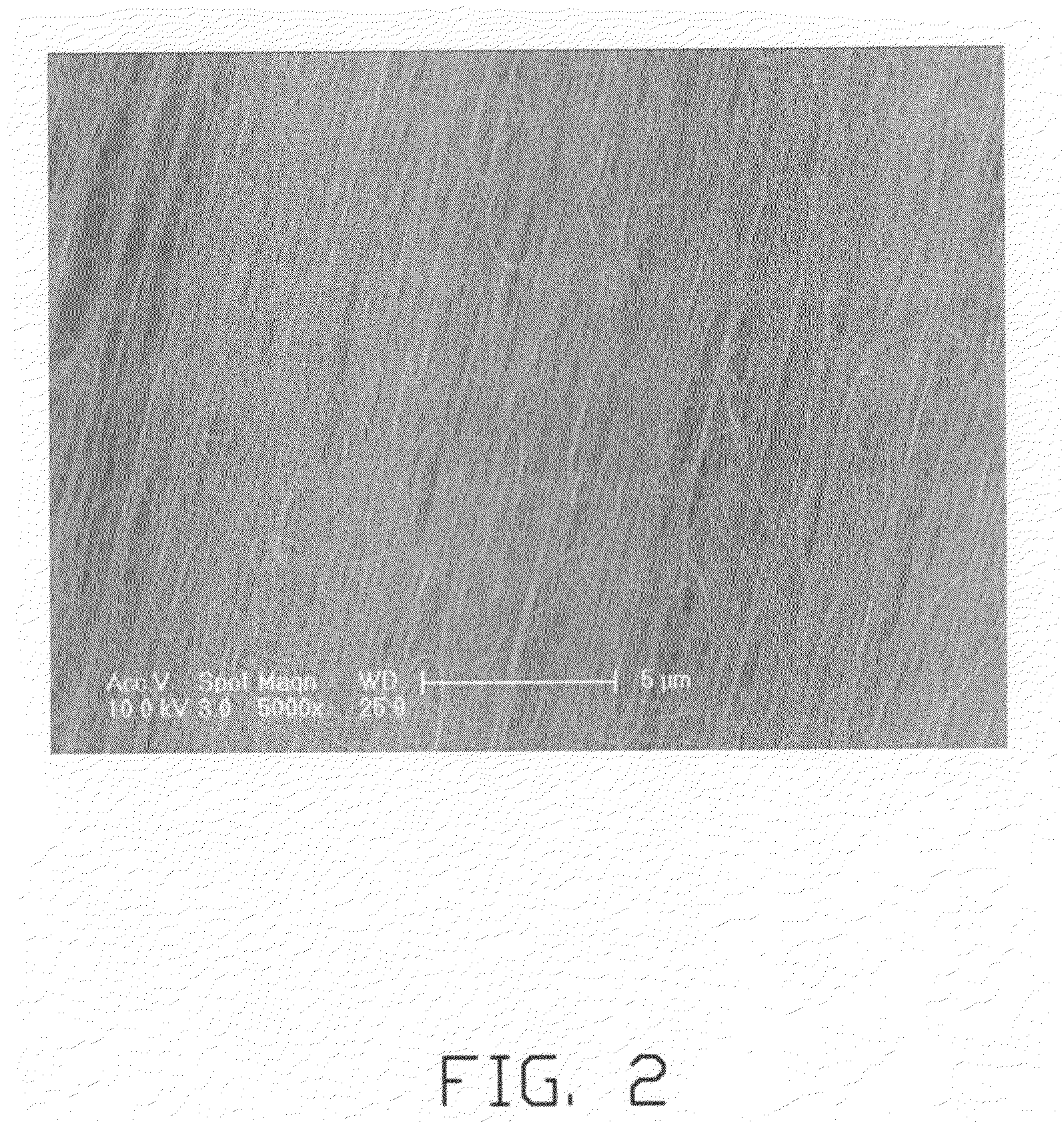

ActiveUS20090167137A1Excellent thermal electron emitting propertyIncrease brightnessTube/lamp screens manufactureControl electrodesCarbon nanotubeElectron

A thermionic electron emission device includes an insulating substrate, and one or more grids located thereon. The one or more grids include(s) a first, second, third and fourth electrode down-leads located on the periphery thereof, and a thermionic electron emission unit therein. The first and second electrode down-leads are parallel to each other. The third and fourth electrode down-leads are parallel to each other. The first and second electrode down-leads are insulated from the third and fourth electrode down-leads. The thermionic electron emission unit includes a first electrode, a second electrode, and a thermionic electron emitter. The first electrode and the second electrode are separately located and electrically connected to the first electrode down-lead and the third electrode down-lead respectively. Wherein the thermionic electron emitter includes a carbon nanotube film structure.

Owner:TSINGHUA UNIV +1

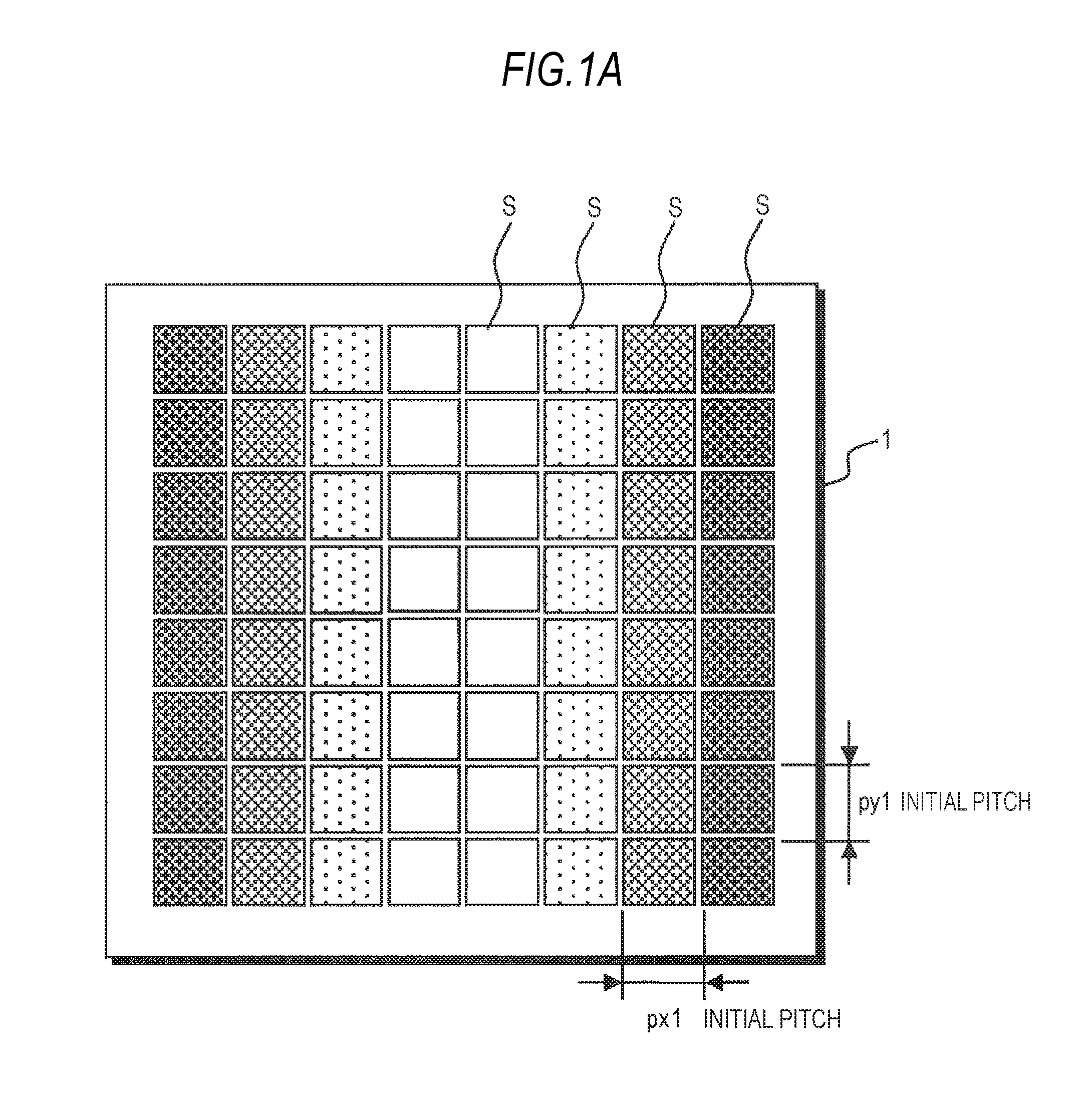

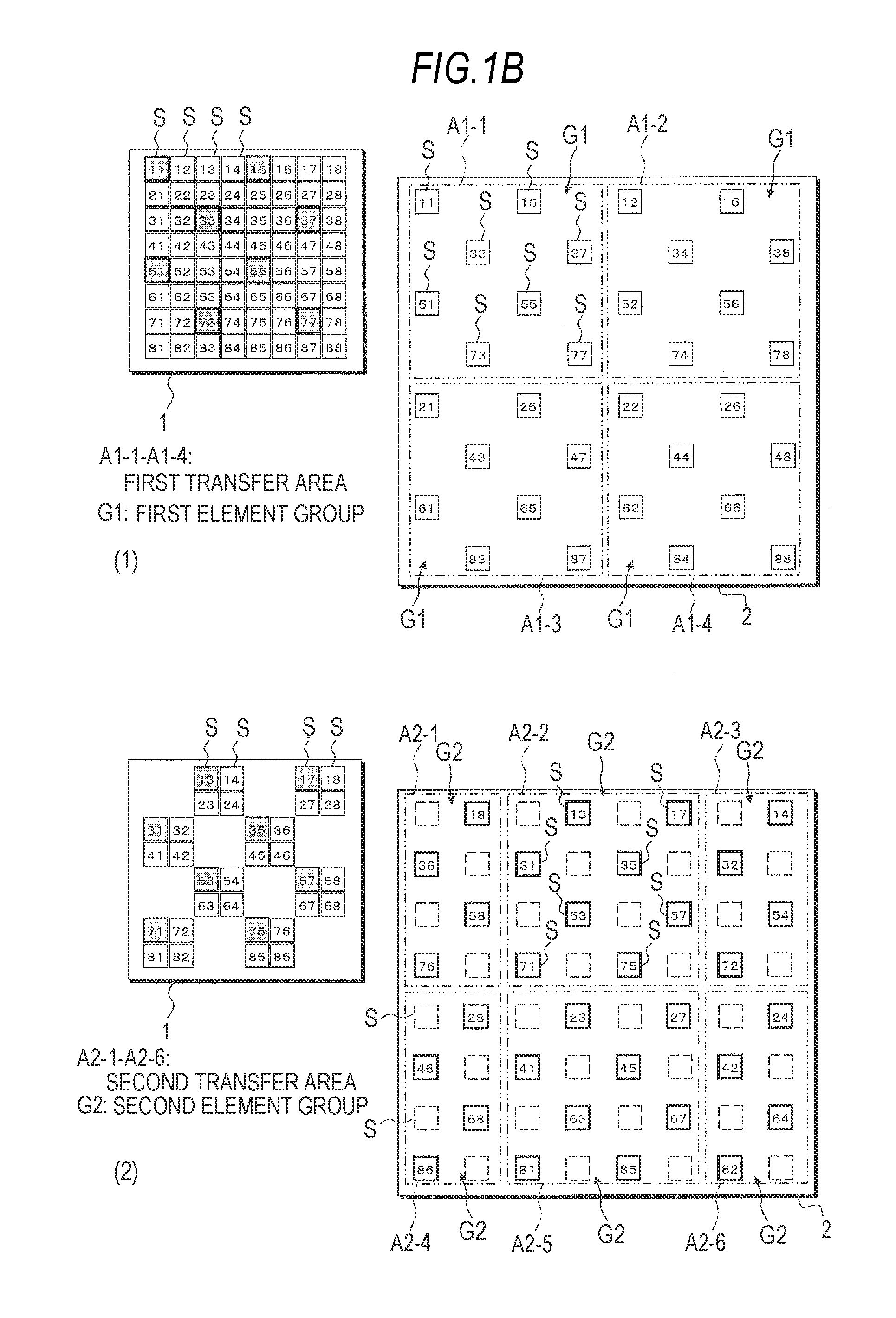

Manufacturing method of display device and display device

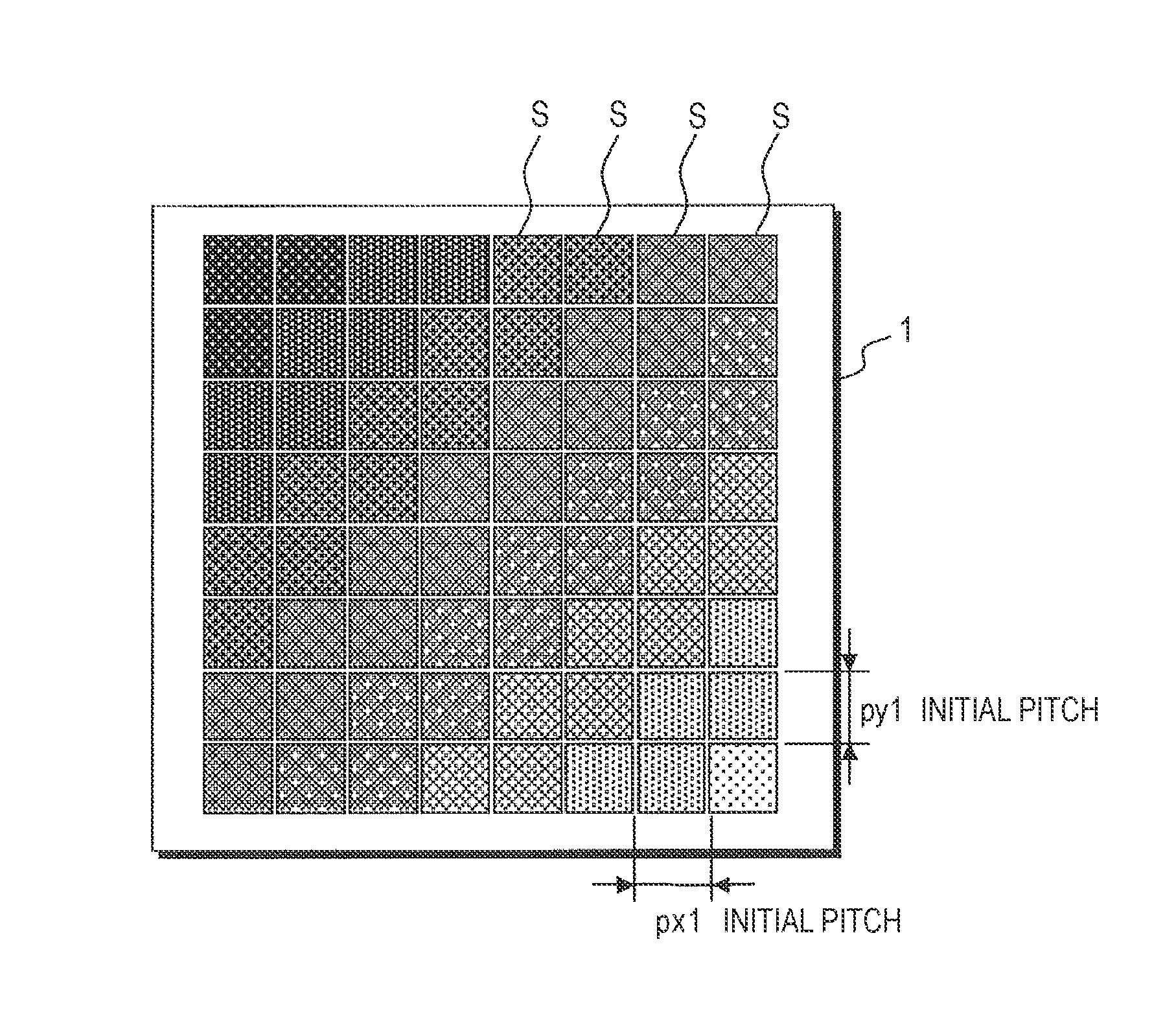

ActiveUS20100259164A1Improve picture qualityImprove display qualityTube/lamp screens manufactureDischarge tube luminescnet screensDisplay deviceEngineering

A manufacturing method of a display device, includes: a first step of collectively transferring light-emitting elements arranged at every specified number of light-emitting elements formed and arranged on a first substrate to a transfer area set on a second substrate; and a second step of transferring light-emitting elements remaining on the first substrate to between the plural light-emitting elements mounted on the second substrate in at least one of a state where the first substrate is moved with respect to the transfer area on the second substrate and a state where the first substrate is rotated in a plane.

Owner:SONY CORP

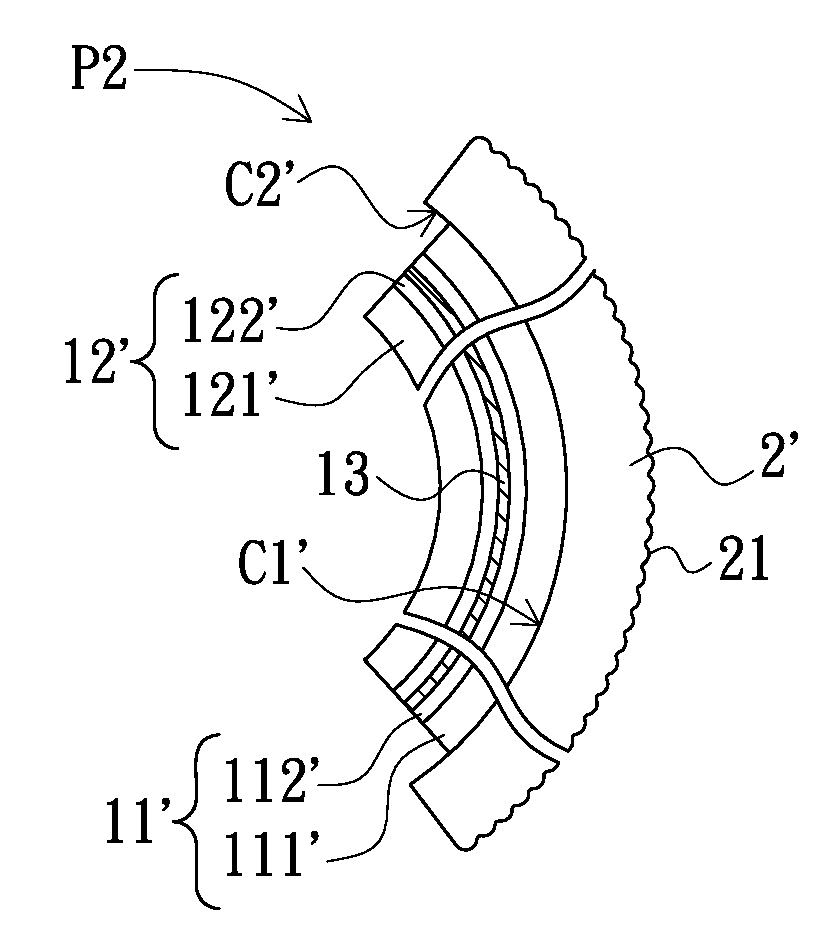

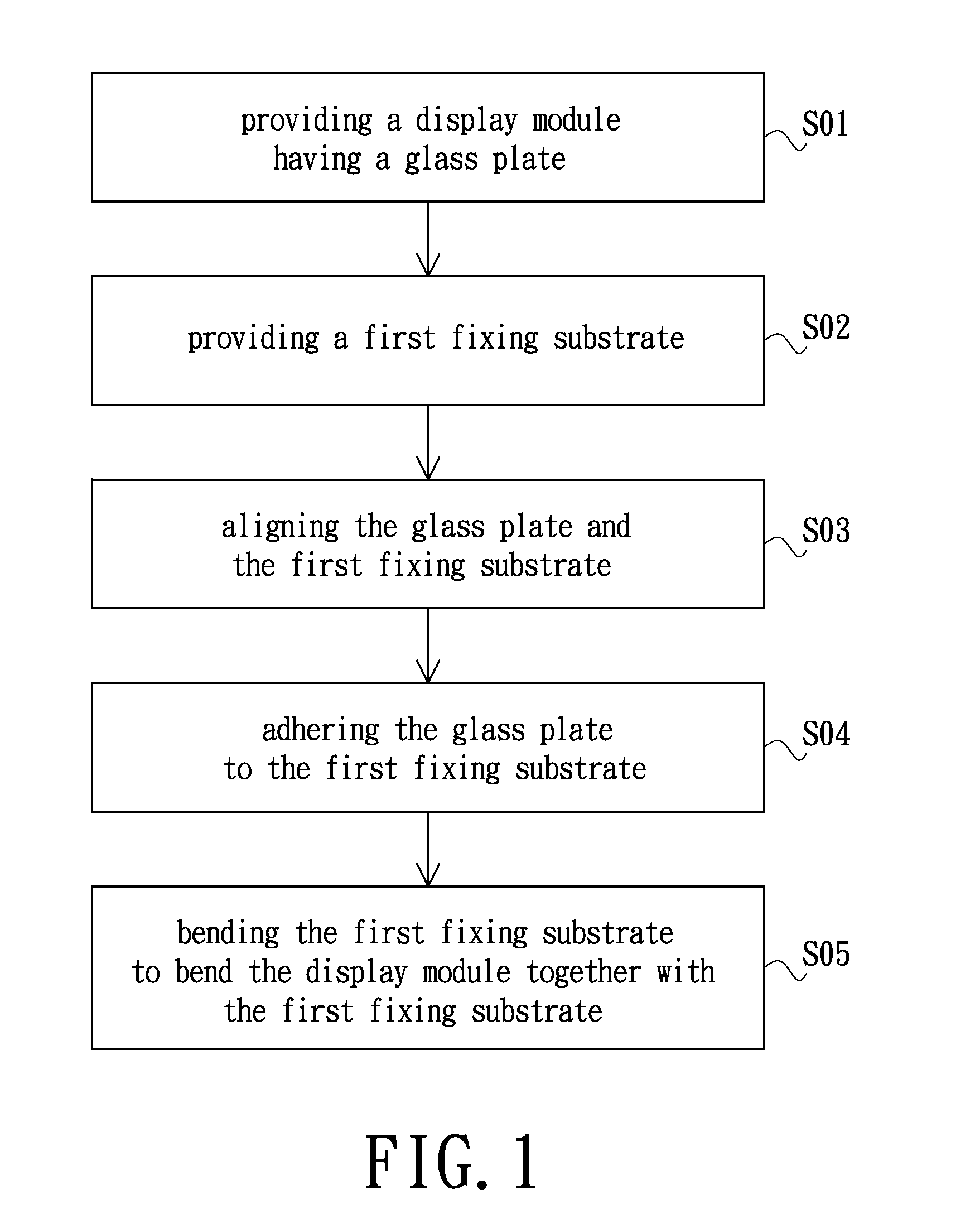

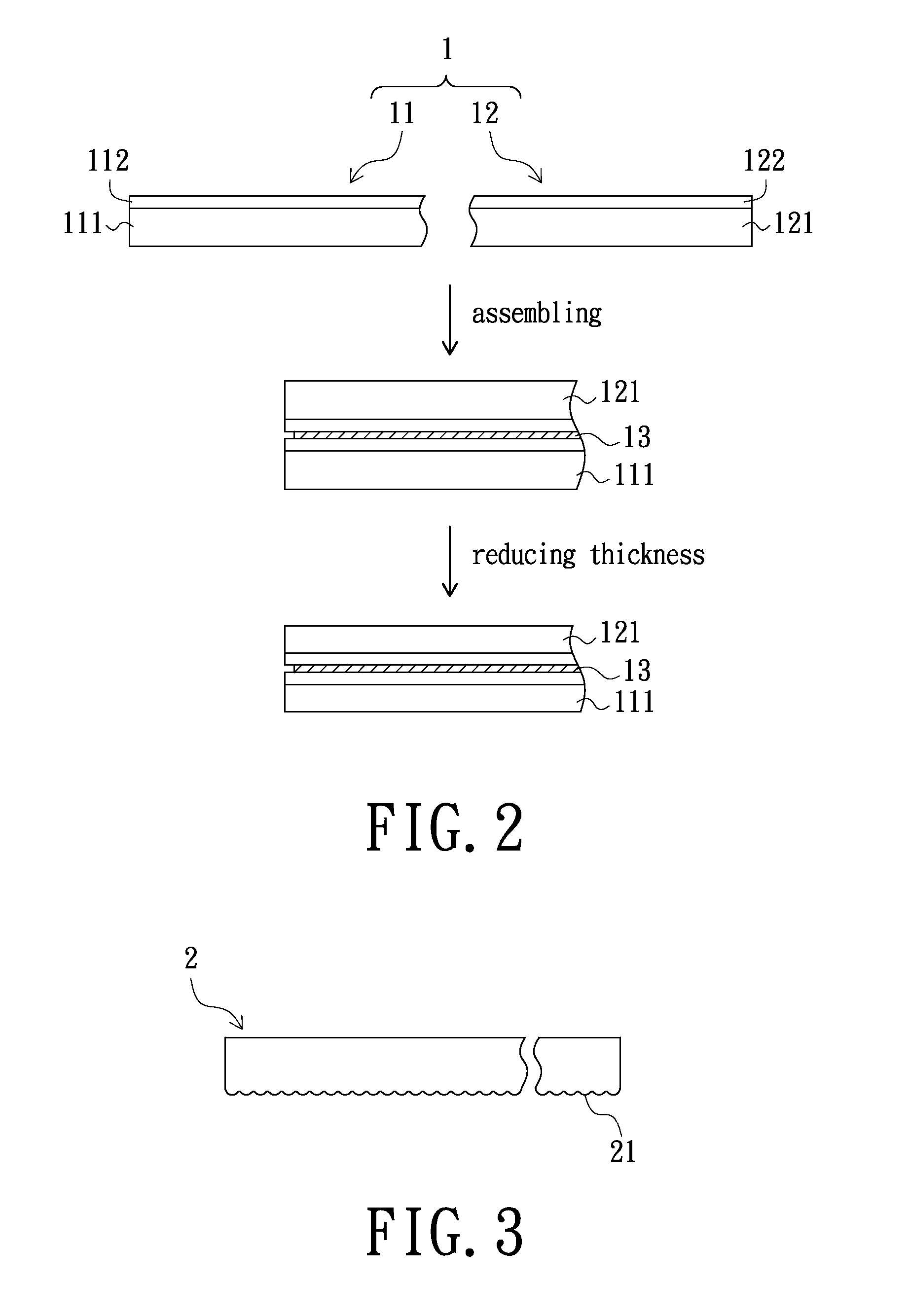

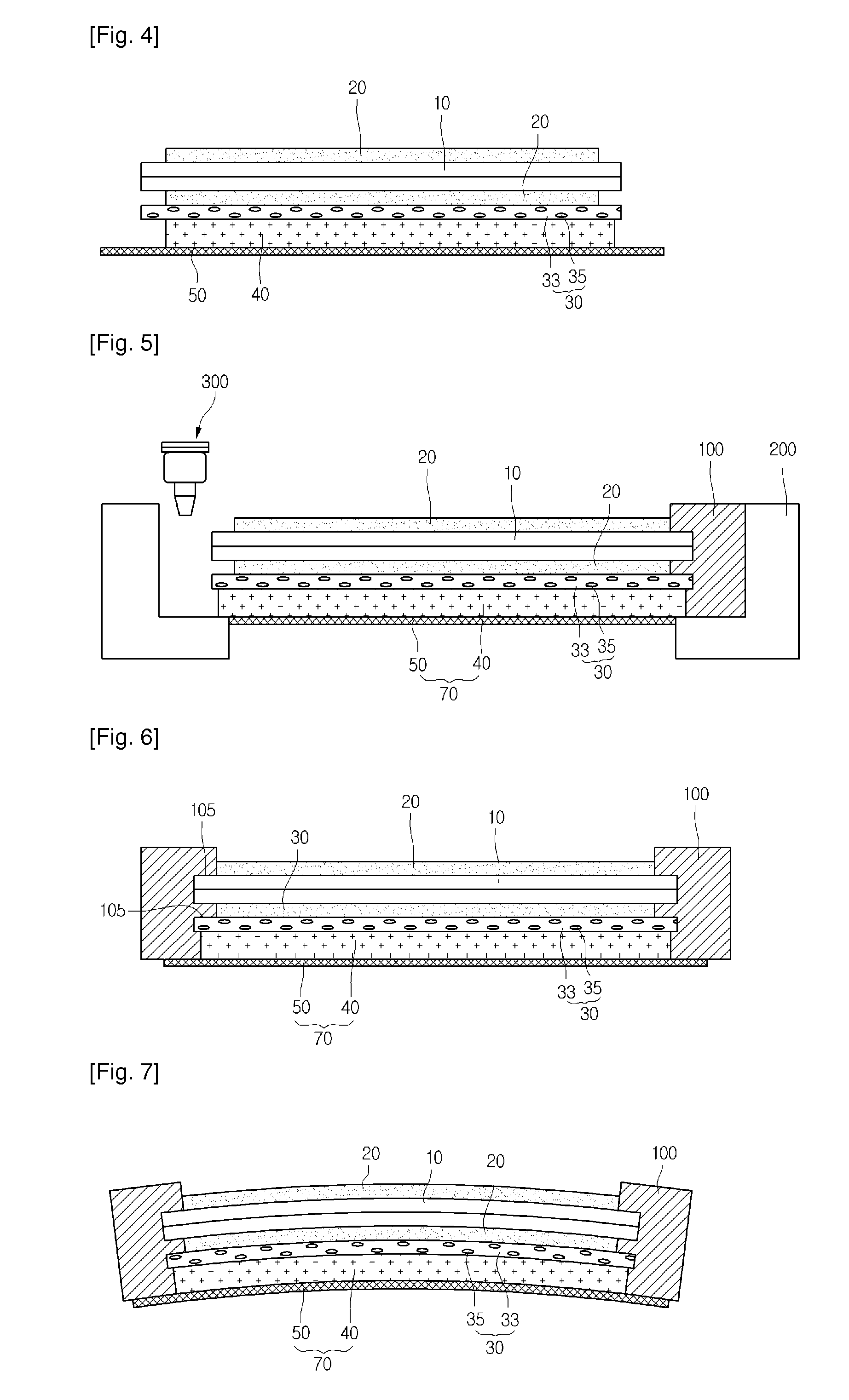

Curved Display Panel and Method for Manufacturing the same

ActiveUS20090284904A1Increase stickinessPromote generationTube/lamp screens manufactureTelevision system detailsEngineeringGlass sheet

Owner:AU OPTRONICS CORP

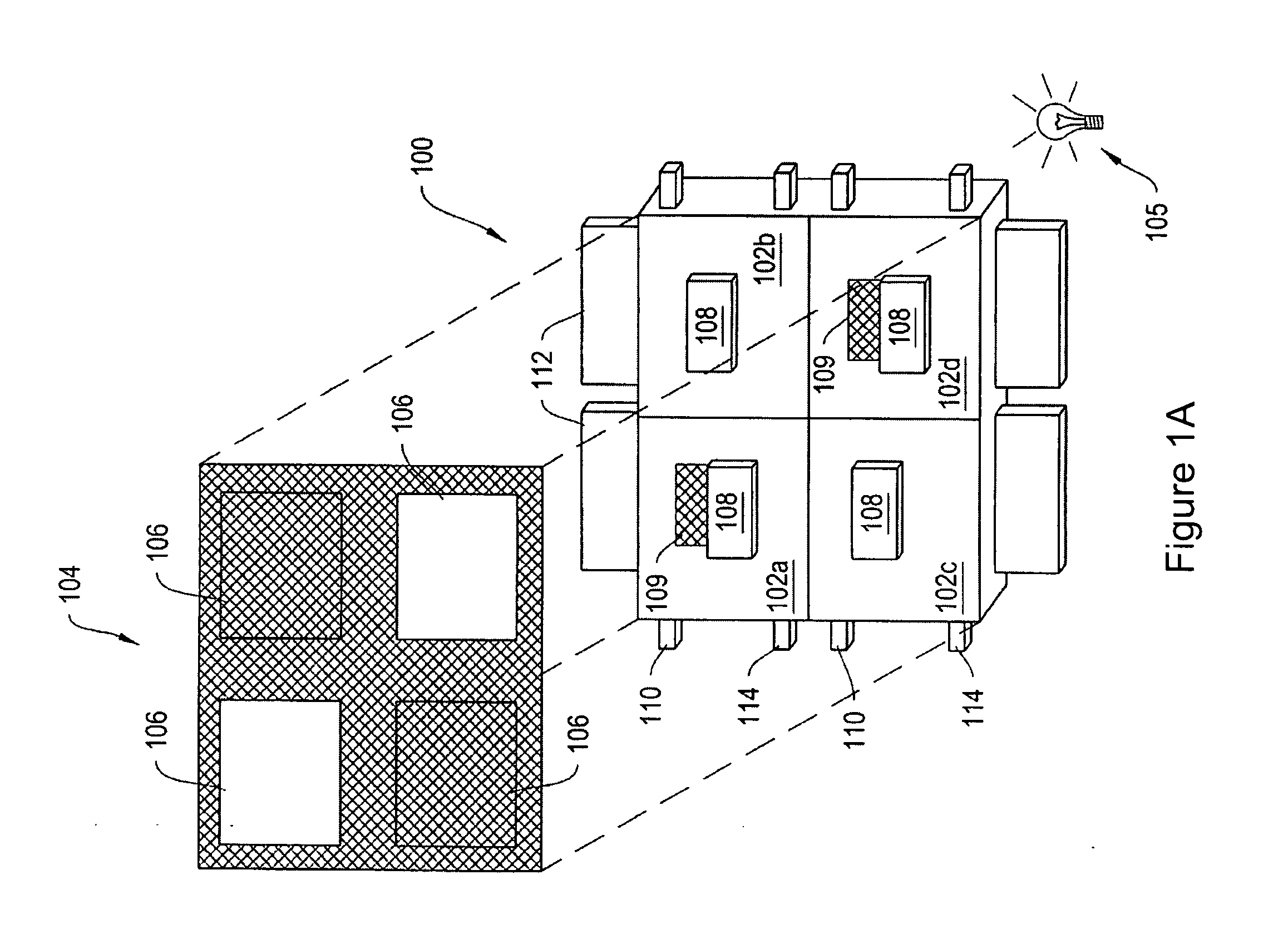

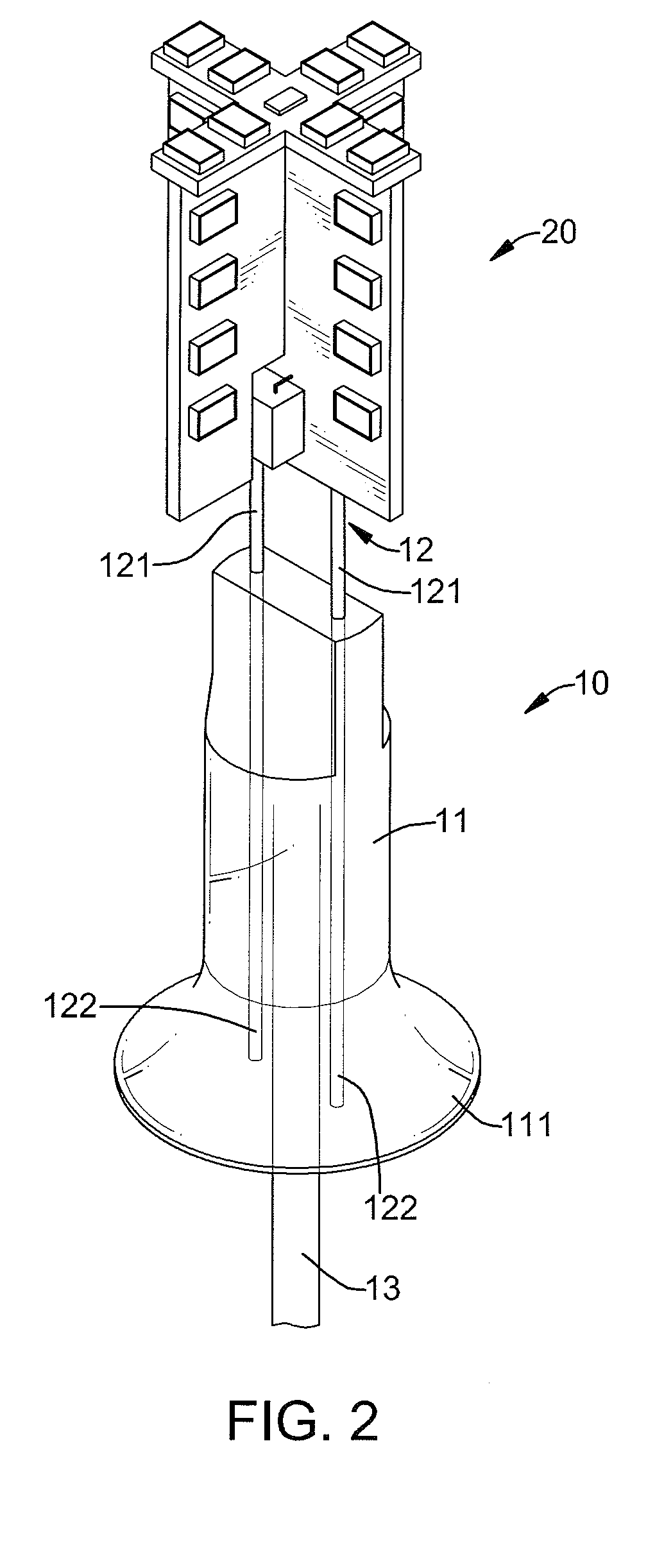

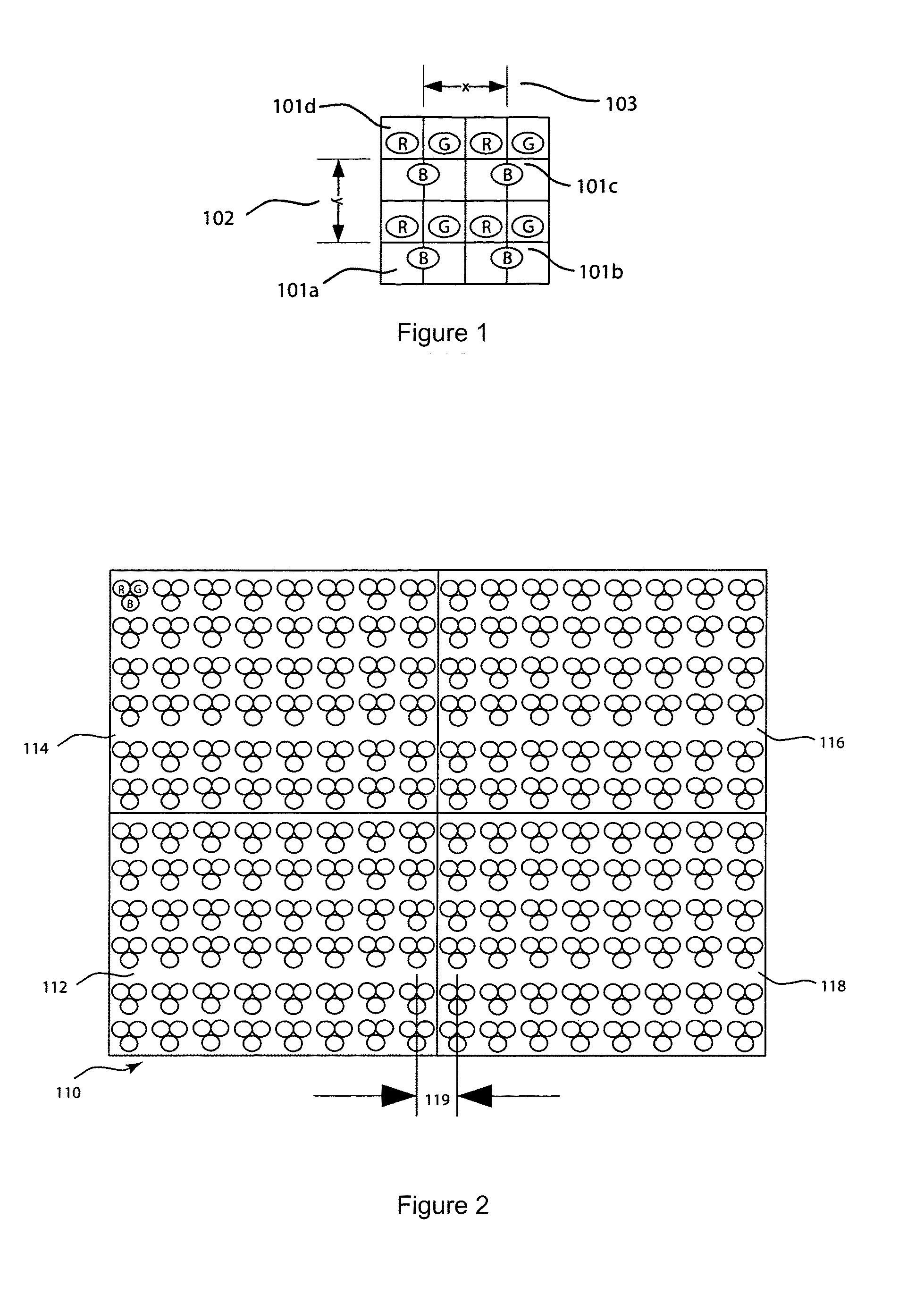

Alignment Angle Method and Apparatus for a Display

ActiveUS20090309494A1Tube/lamp screens manufactureLight source combinationsDisplay deviceEngineering

A light-emitting display system has an alignment mechanism to align or angle light-emitting tiles of the display. A first tile connects to a second tile by joining a first clamp portion on the first tile with a second clamp portion on the second tile. In an implementation, the alignment mechanism includes a replaceable angle adjustment insert that is inserted into at least one of the clamp portions, such as the first clamp portion. When the first and second clamp portions are joined, a surface of the second clamp portion presses against the insert and a desired angle between the first and second tile is formed. The insert can have any angle so that any desired angle can be formed between the first and second tiles.

Owner:BARCO INC

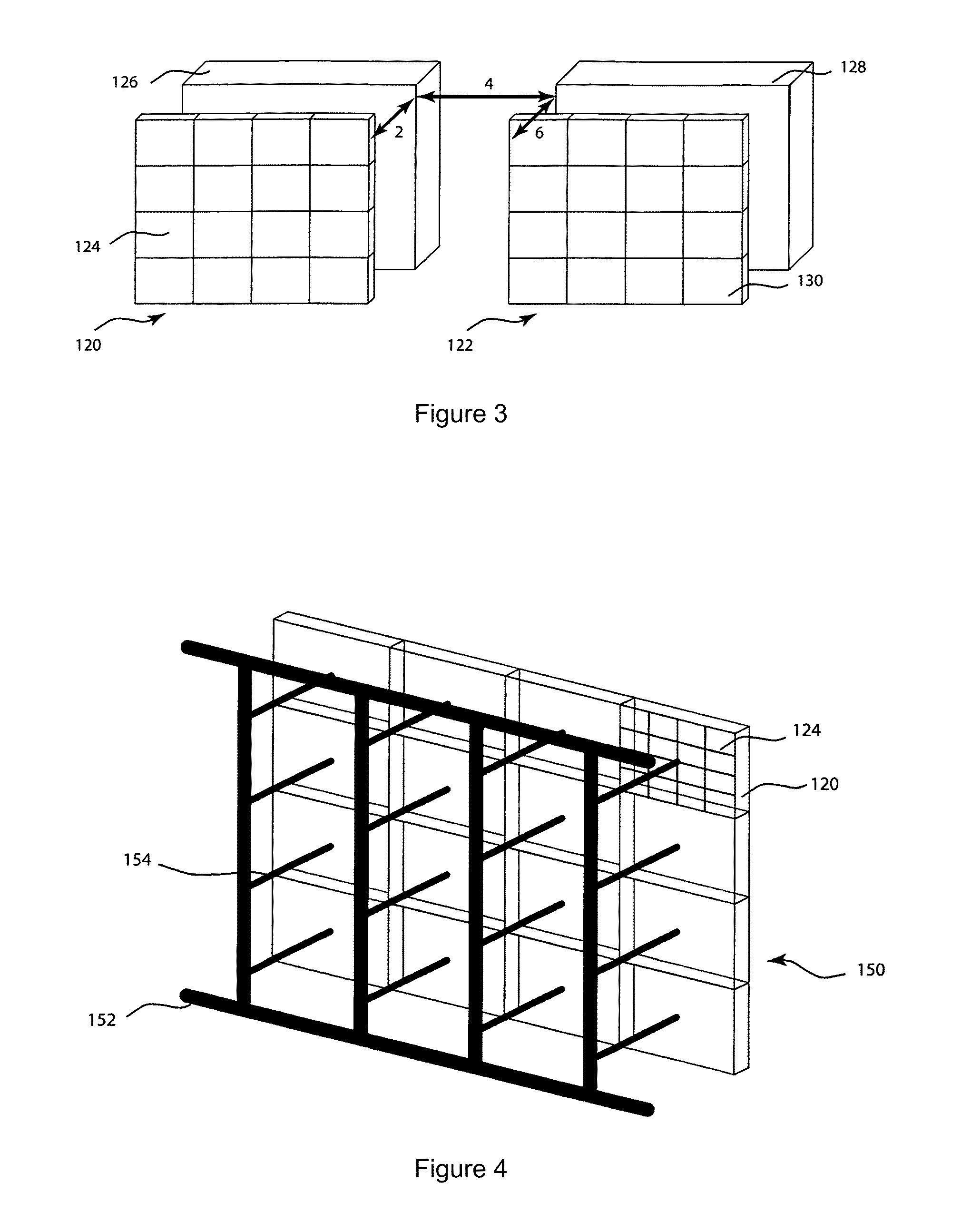

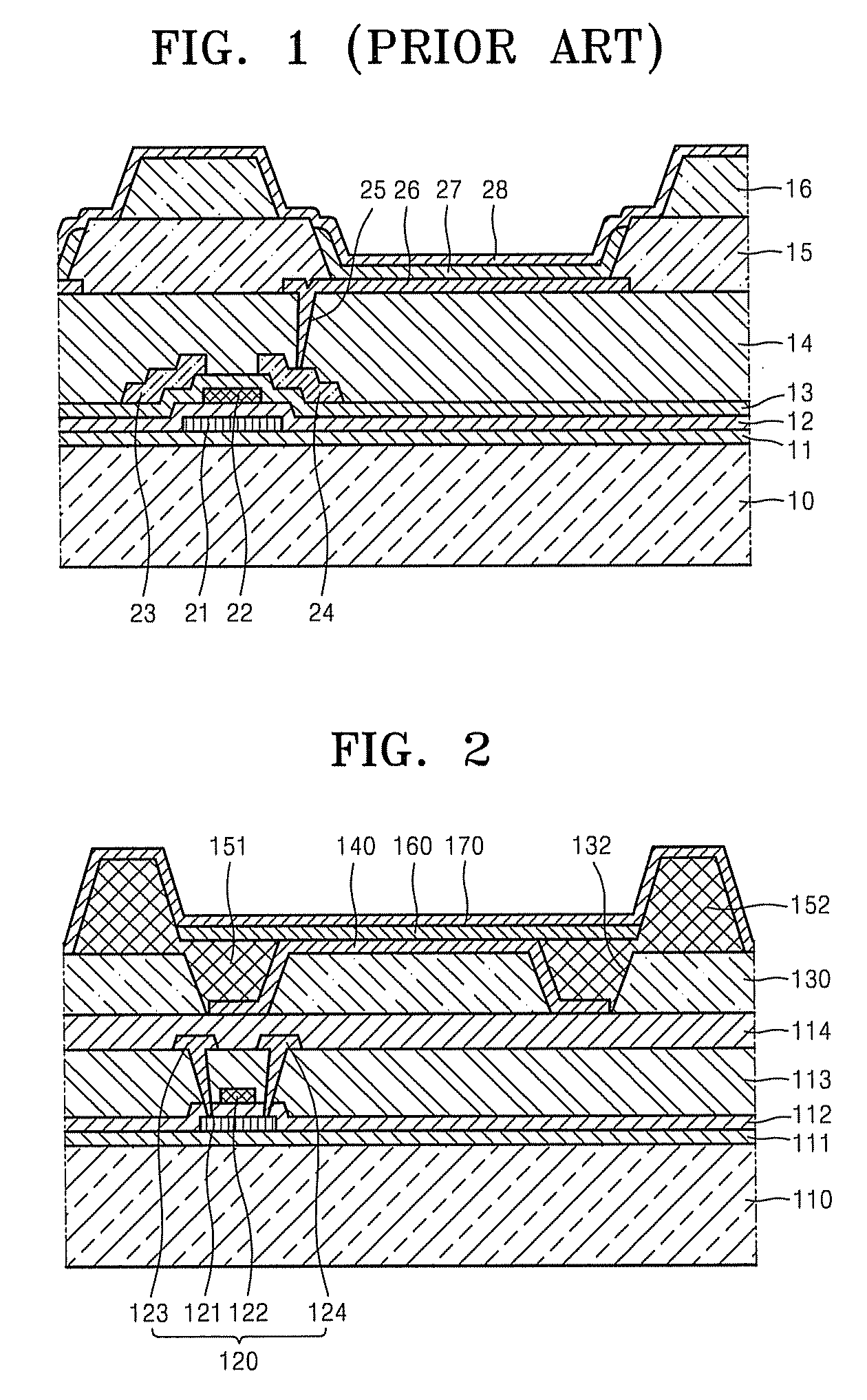

Organic electroluminescence display including a spacer and method for fabricating the same

ActiveUS20100033084A1Protection from damageTube/lamp screens manufactureDischarge tube luminescnet screensDisplay deviceEngineering

Embodiments of the present disclosure provide an organic electroluminescence display device. The display device may include a set of multi-directional spacers that are interposed between the pixels of the display. In one embodiment, the spacers are positioned in both lengthwise and crosswise directions. In another embodiment, the spacers include a first portion that is extends lengthwise between pixels and one or more portions that extend laterally from the first portion between pixels. In yet another embodiment, the spacers include portions that extend in multiple directions between pixels. The spacers may substantially surround each of the pixels and may serve as a boundary, for example, that prevents organic material for one pixel from being incorrectly deposited in another pixel. The spacers can be configured as a support structure, such as, for a metal mask during fabrication of the display device. In addition, the multi-directional aspect of the spacers may be useful in protecting the pixels from damage, such as, when a metal mask is moved during mounting or during fabrication of the display device.

Owner:SAMSUNG DISPLAY CO LTD

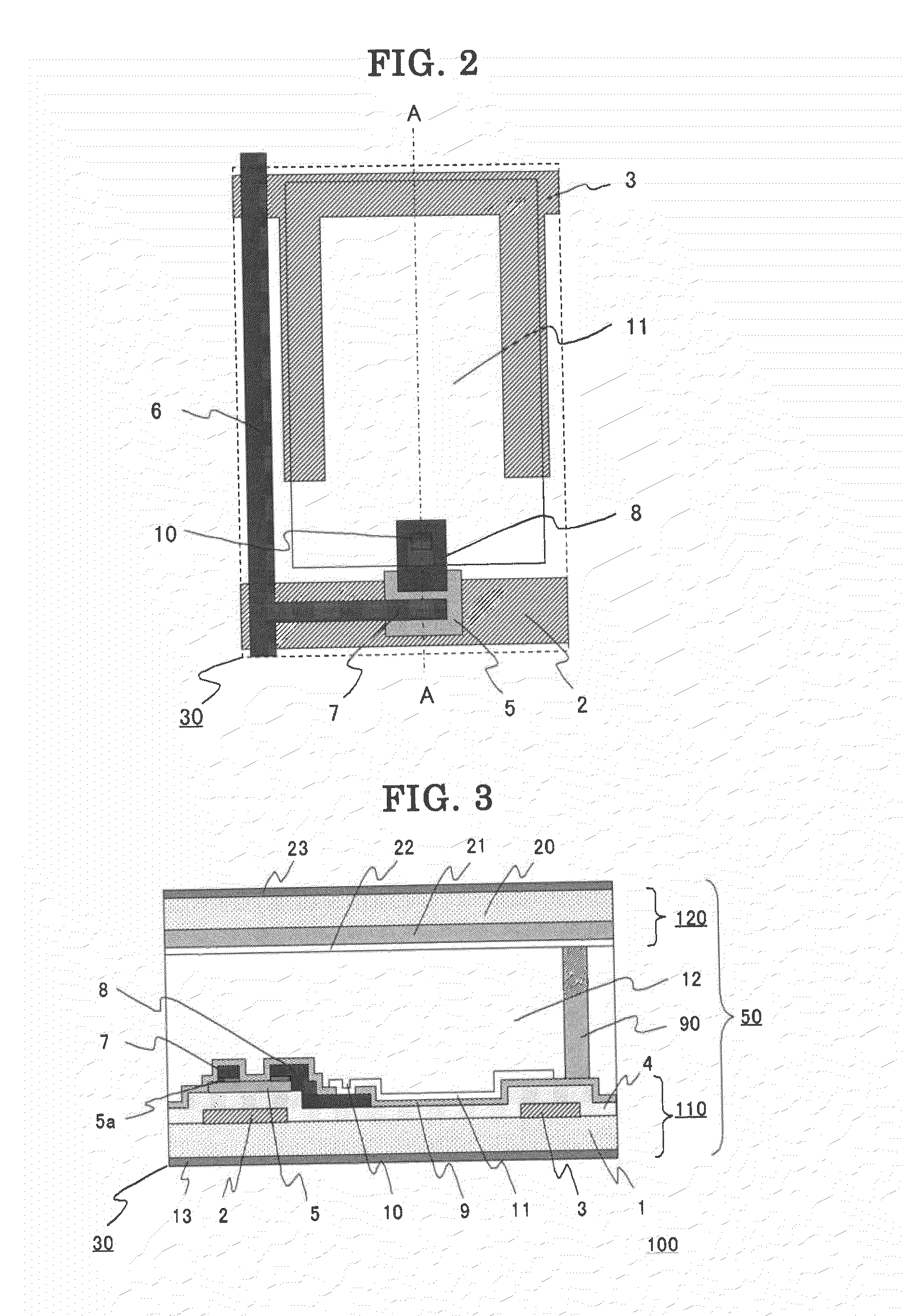

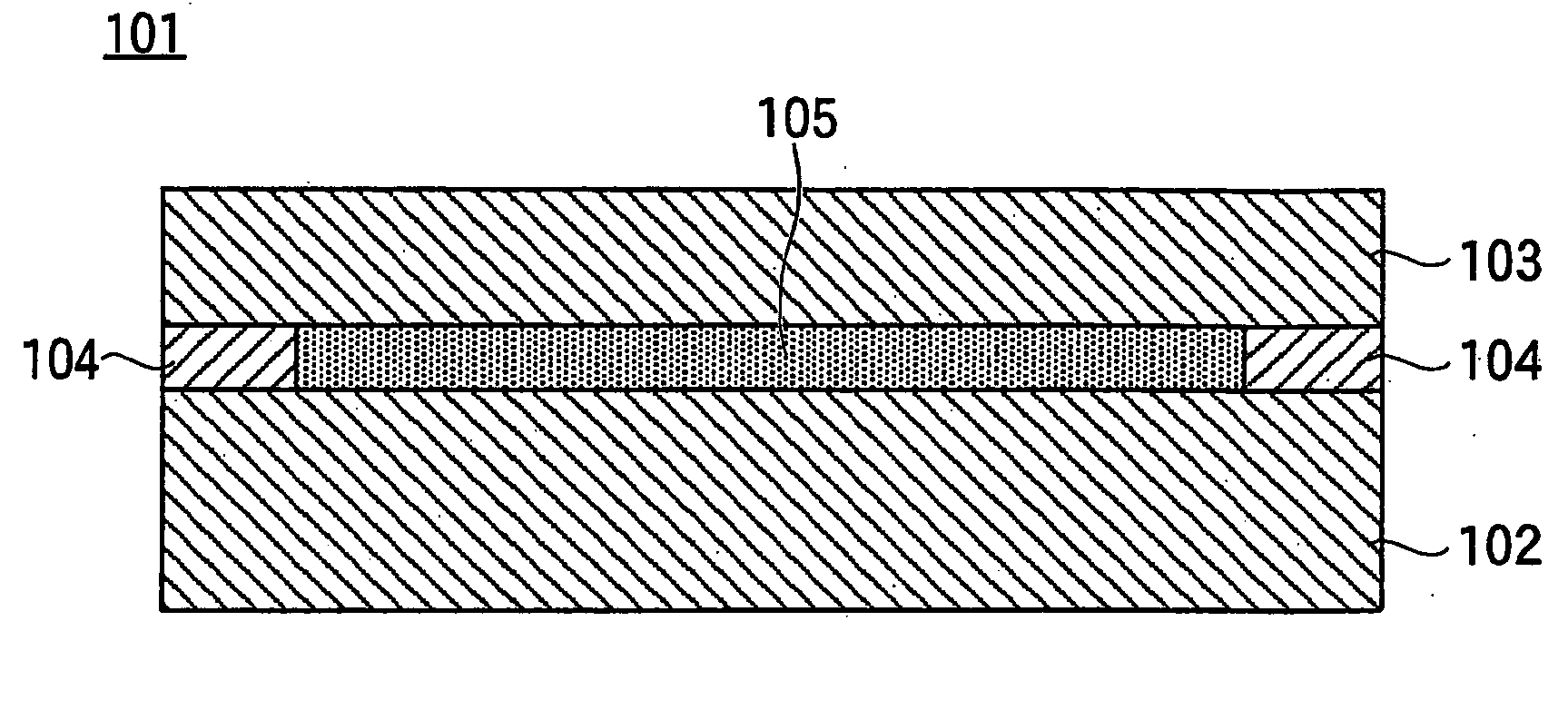

Image display device and its manufacturing method

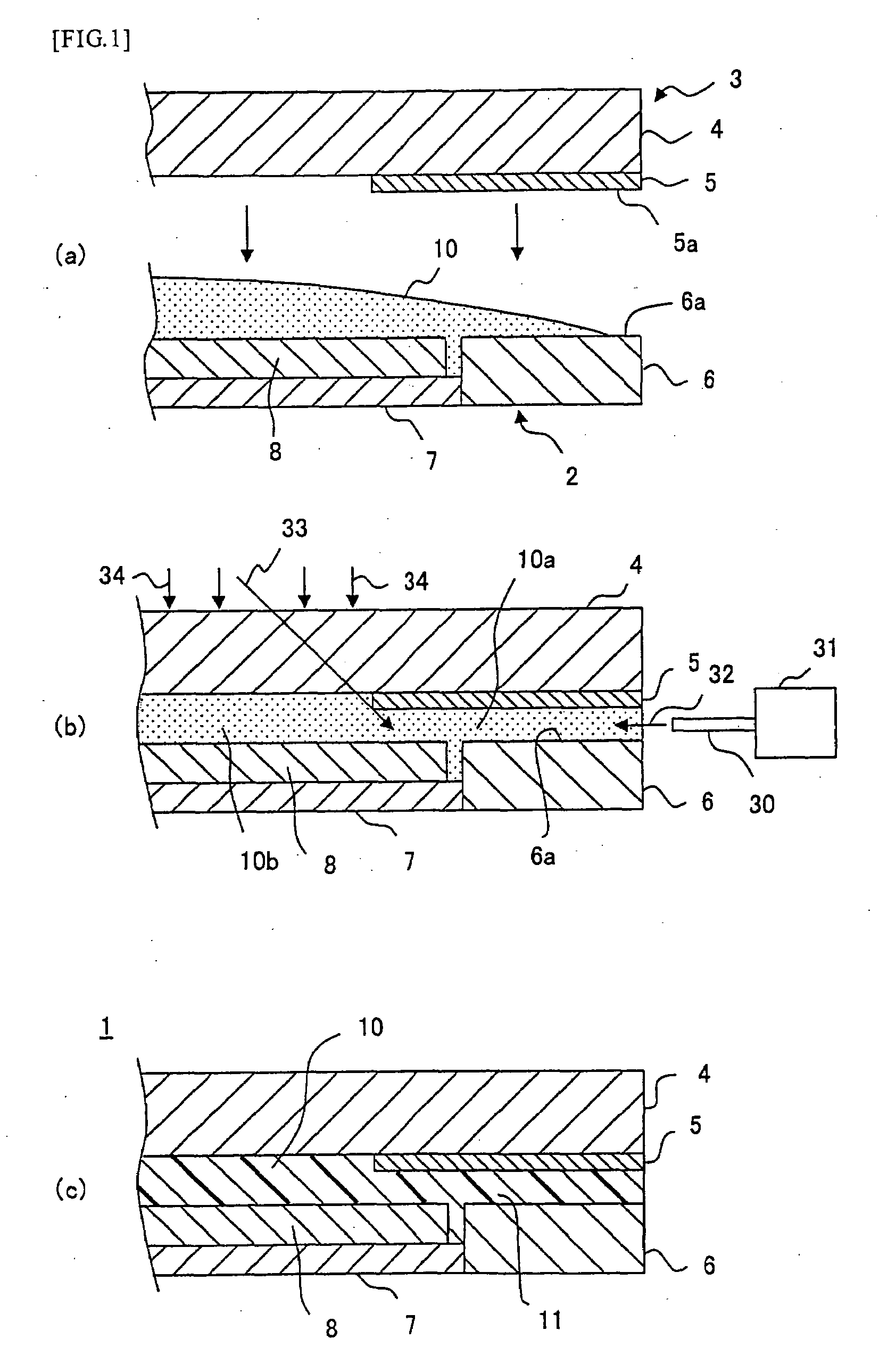

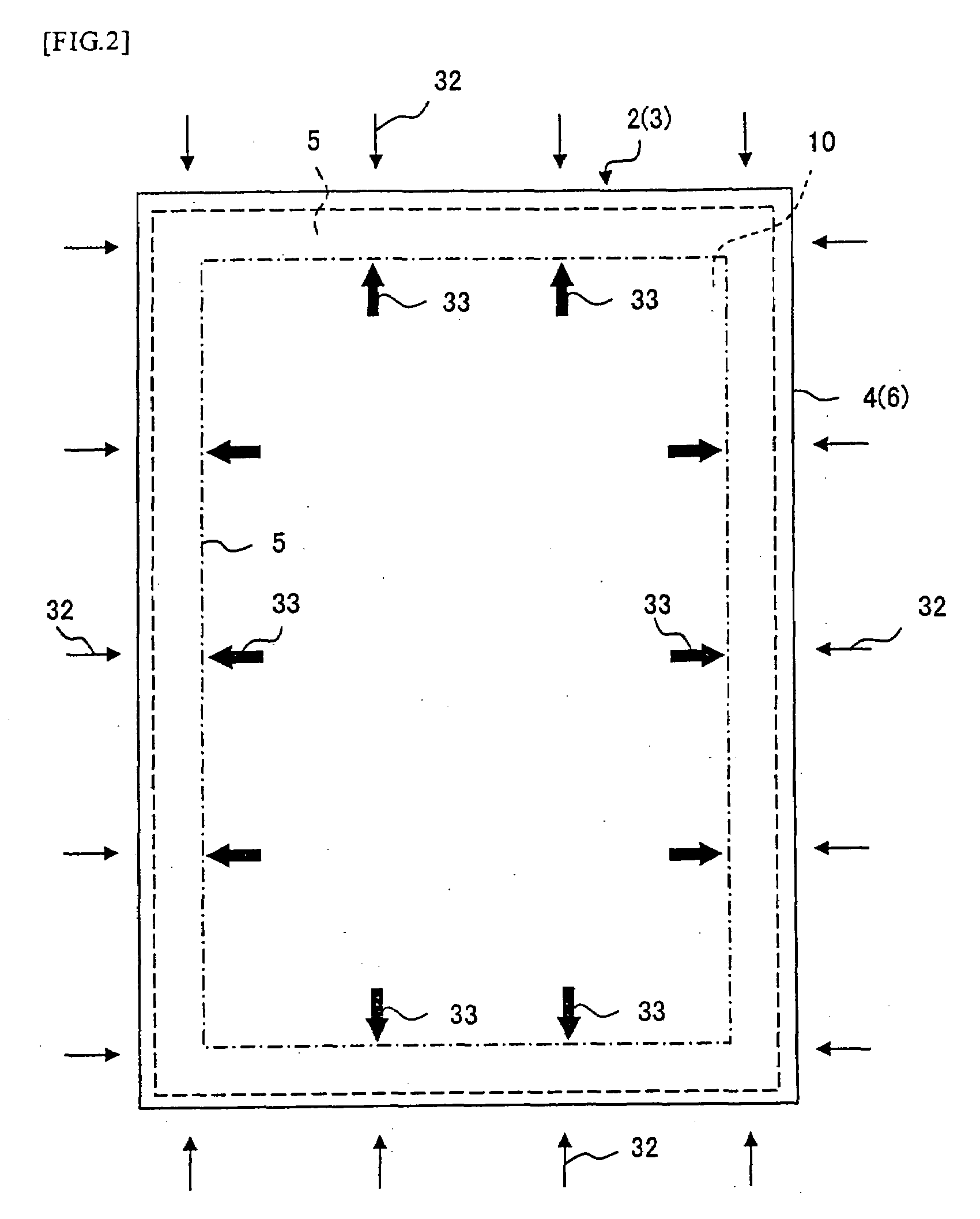

ActiveUS20090186552A1Improve reliabilityImage display is highTube/lamp screens manufactureAdhesivesLiquid-crystal displayDisplay device

It is possible to manufacture a highly reliable image display device capable of proceeding with resin cure even in the case where a protective panel is provided with a light shielding portion.A liquid crystal display unit 2 having a liquid crystal display panel 8 and a light transmissive protective panel 3 having a light shielding portion 5 are disposed face to face, a resin composition 10 is interposed between the liquid crystal display unit and the protective panel, and the resin composition is cured into a cured resin layer 11. As the resin composition 10, a light-heat-curing resin composition and containing a photopolymerization initiator and organic peroxide of thermal polymerization initiator is used. In curing the resin composition 10, cure by light (ultraviolet rays) irradiation is performed until a cure ratio of the resin composition becomes 30% or more and thereafter thermal cure is performed.

Owner:DEXERIALS CORP

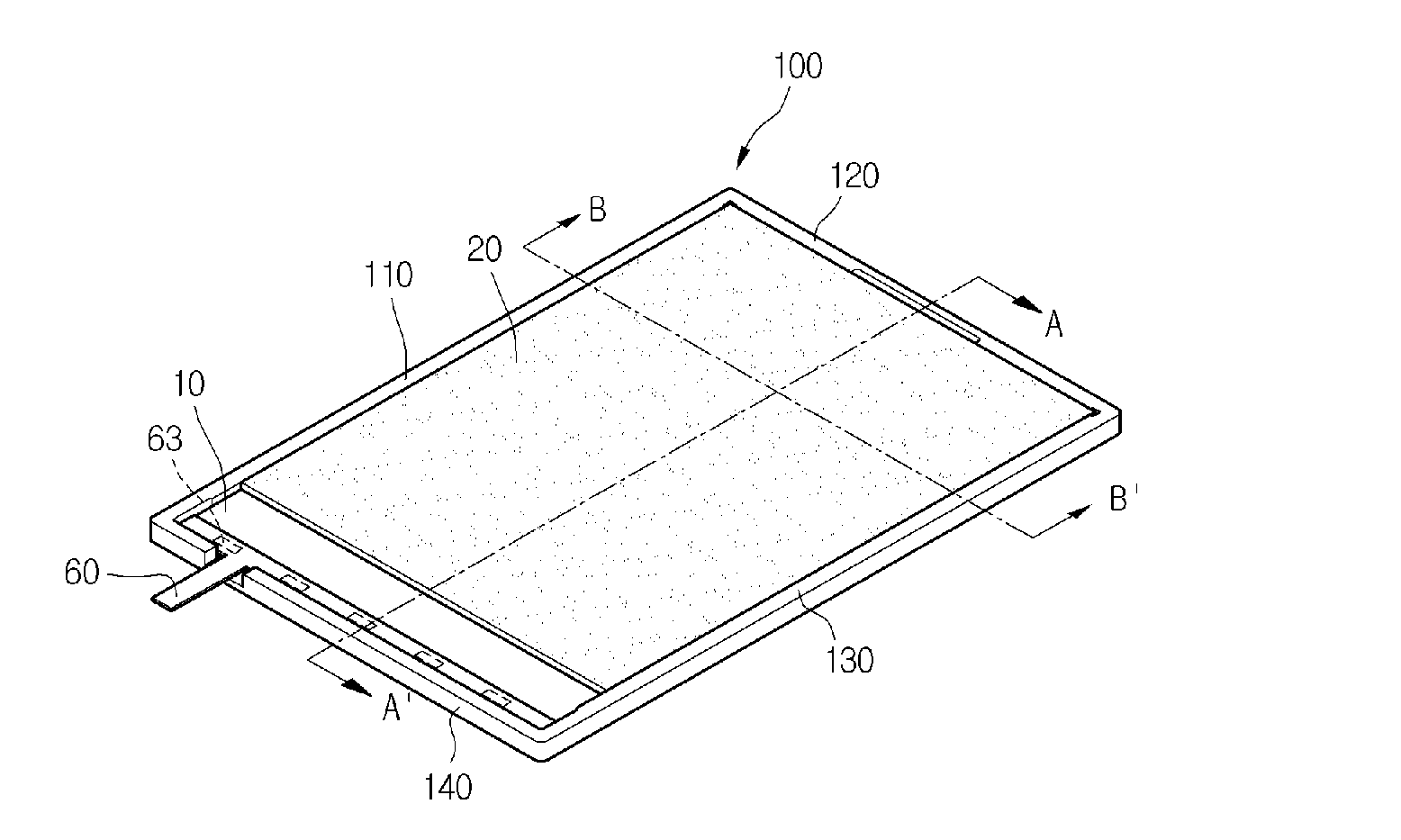

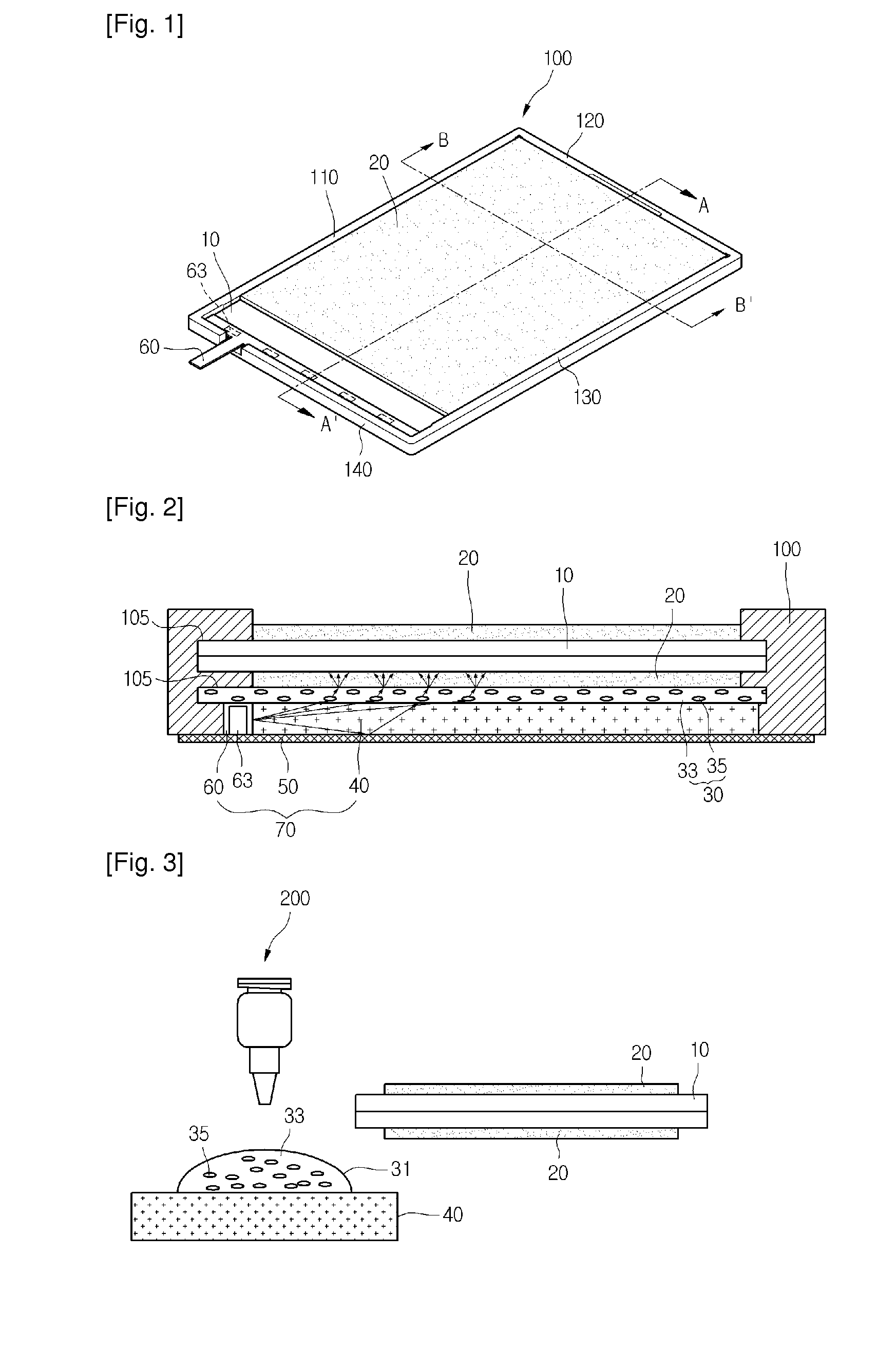

Display Device and Method for Manufacturing Thereof

ActiveUS20100171900A1Thin structureSmall sizeTube/lamp screens manufactureIlluminated signsDiffusionDisplay device

Disclosed is a display device. The display device comprises a frame receiving at least one of a liquid crystal panel and a backlight unit, an adhesive layer coupling the liquid crystal panel to the backlight unit, and wherein the adhesive layer comprises at least one of an adhesive sheet for light diffusion and a polarizer film.

Owner:LG DISPLAY CO LTD

Heat spreader for emissive display device

InactiveUS7160619B2Increase temperature differenceTube/lamp screens manufactureStatic indicating devicesDisplay deviceGraphite

A heat spreader for an emissive display device, such as a plasma display panel or a light emitting diode, comprising at least one sheet of compressed particles of exfoliated graphite having a surface area greater than the surface area of that part of a discharge cell facing the back surface of the device.

Owner:NEOGRAF SOLUTIONS LLC

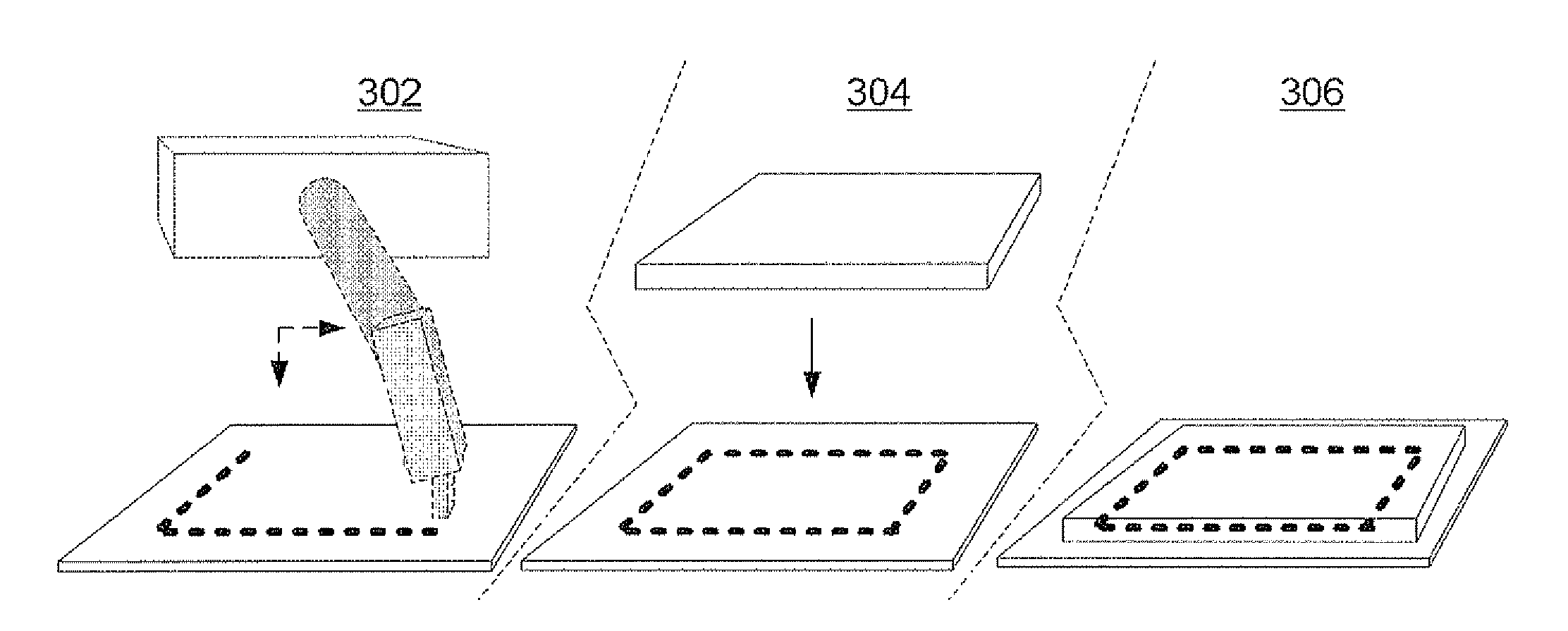

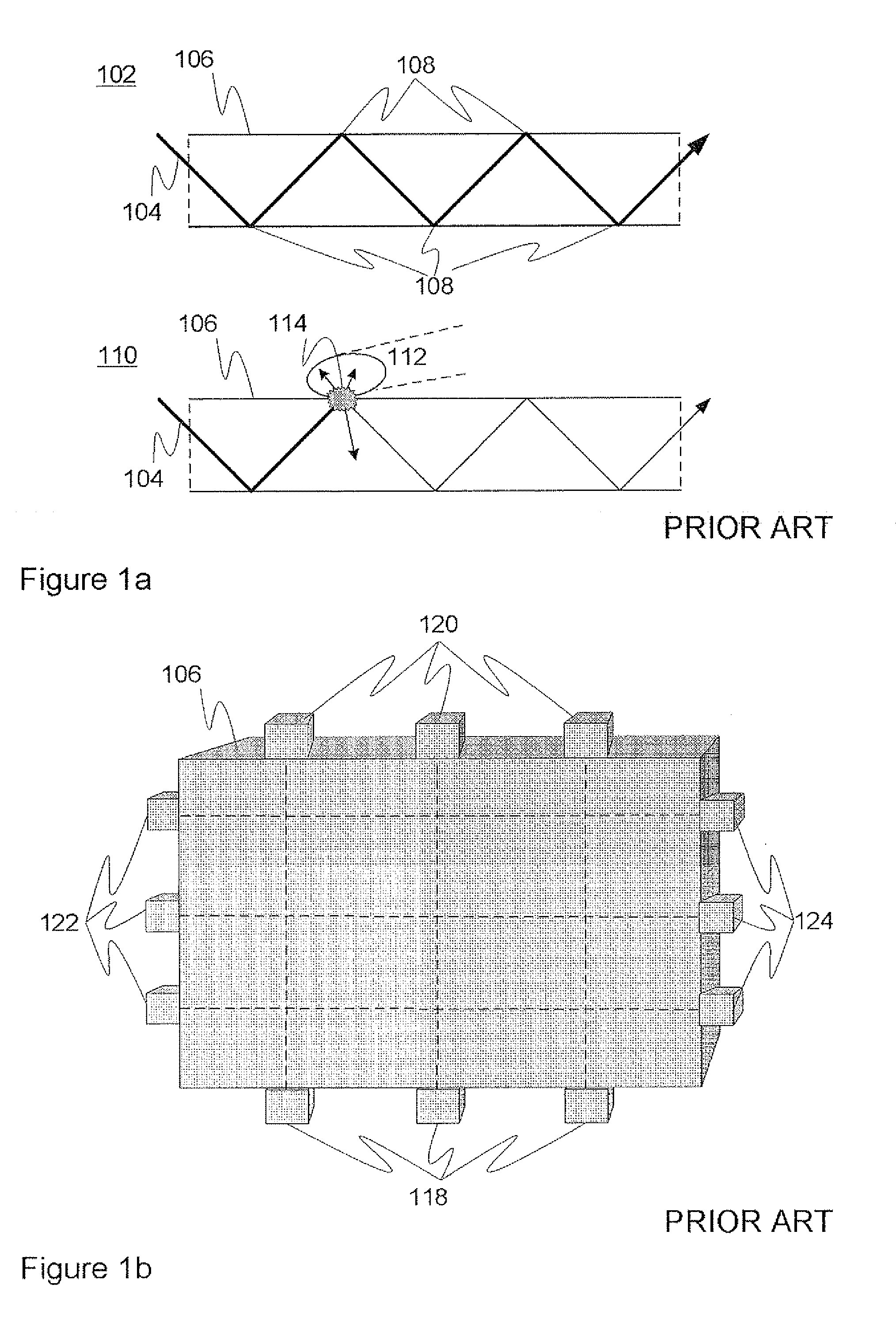

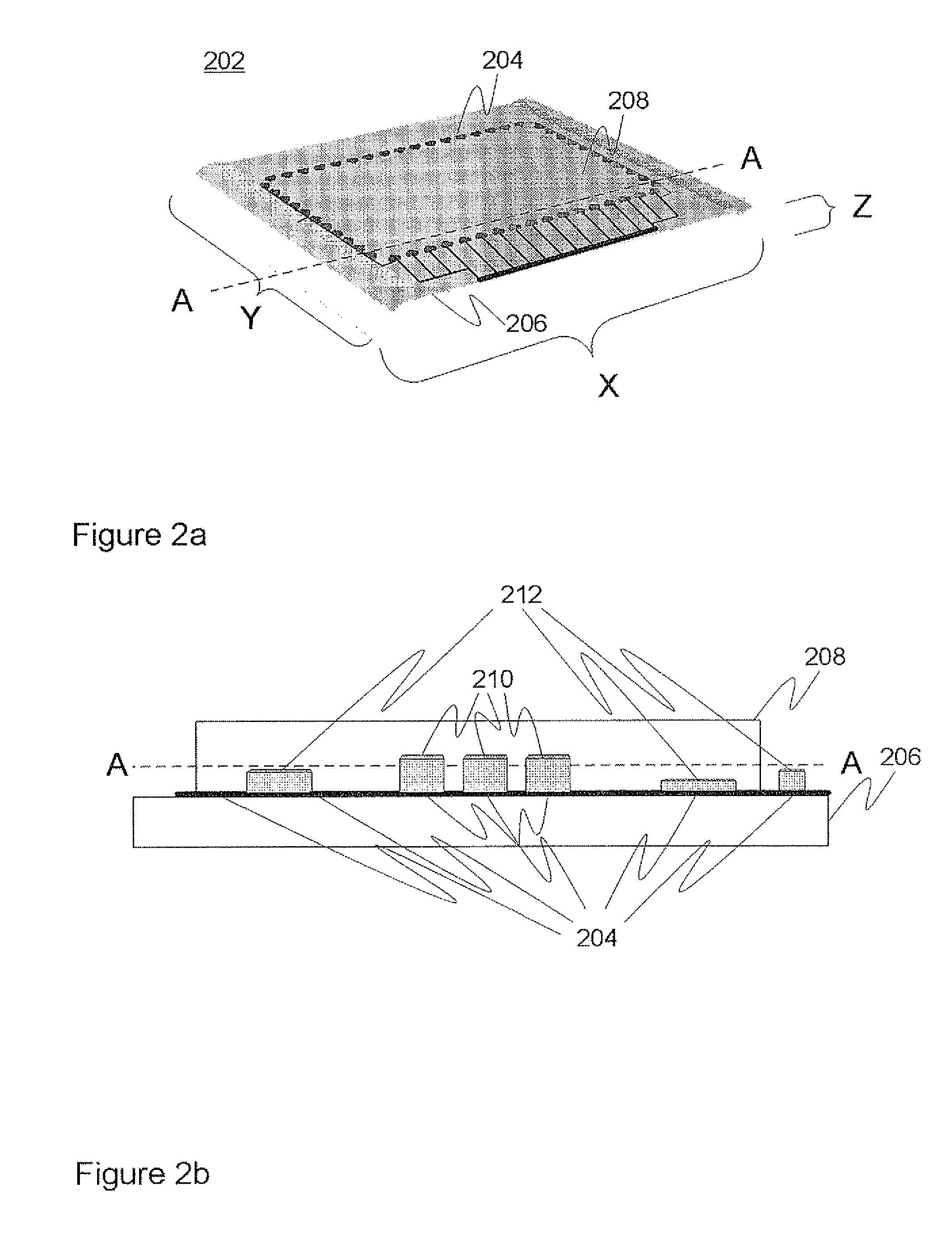

User input arrangement and related method of manufacture

InactiveUS20120038593A1Rapid industrial scale manufacturingEasy to replaceTube/lamp screens manufactureLight effect designsTotal internal reflectionUser input

Arrangement (202) for a user input device, such as a touchscreen or a touchpad, comprising a substrate (206), such as an optically substantially transparent flex film or a multilayer film, said substrate comprising support electronics (212) for providing power, control and / or communications connection to further electronic components (210), a number of emitters and detectors (210) arranged to said substrate into contact with the support electronics, for emitting and detecting light, respectively, and a lightguide (208) provided, such as laminated, onto the substrate such that said emitters and detectors are optically coupled to the lightguide material, the properties of the lightguide including the refractive index of the lightguide material being selected and the emitters and detectors being configured so as to enable, when in use, total internal reflection (TIR) -type propagation of light within the lightguide between the emitters and detectors, and recognition of a touch on the basis of a drop in the TIR performance as determined from the detected light. A related method of manufacture is presented.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

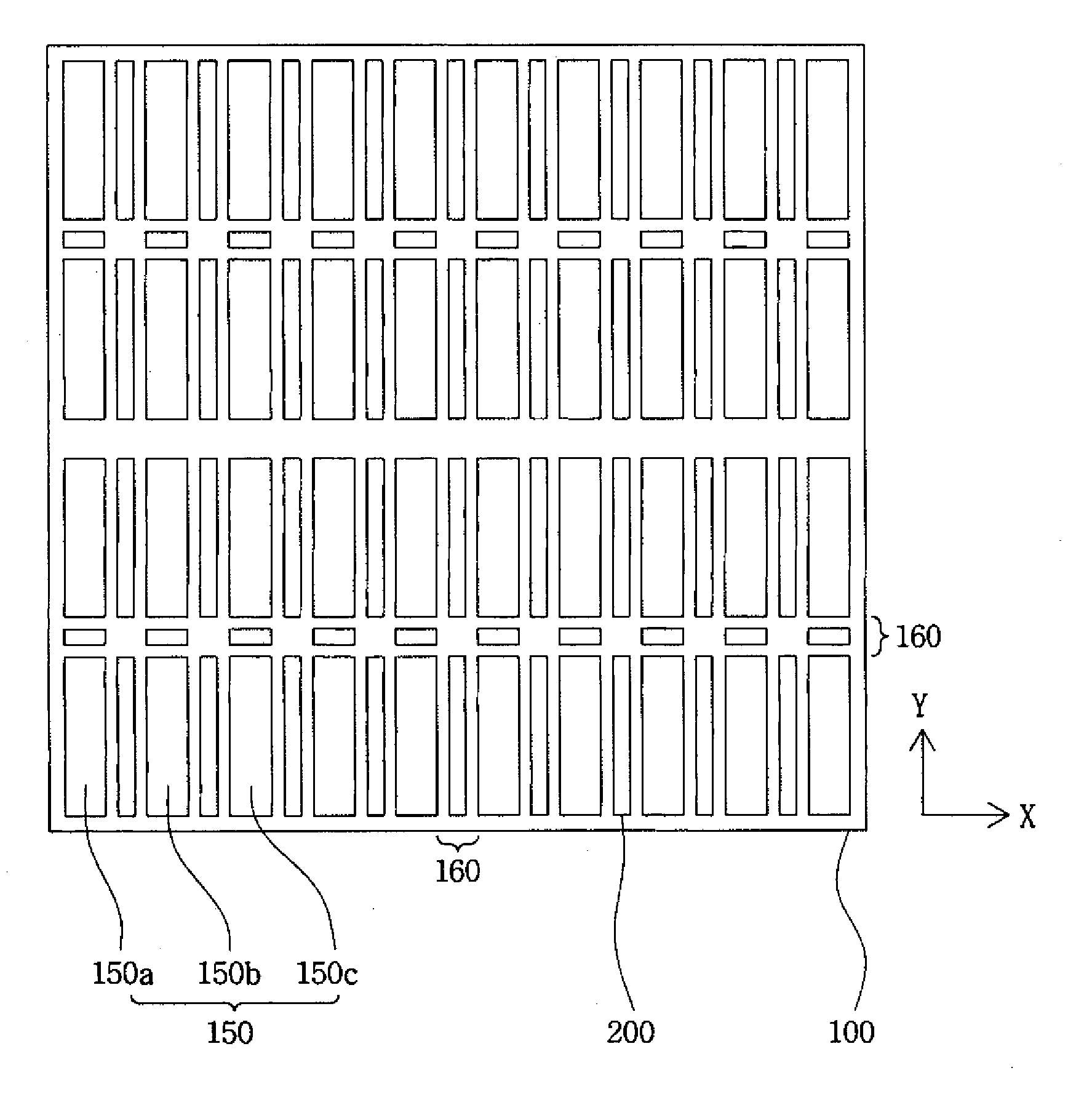

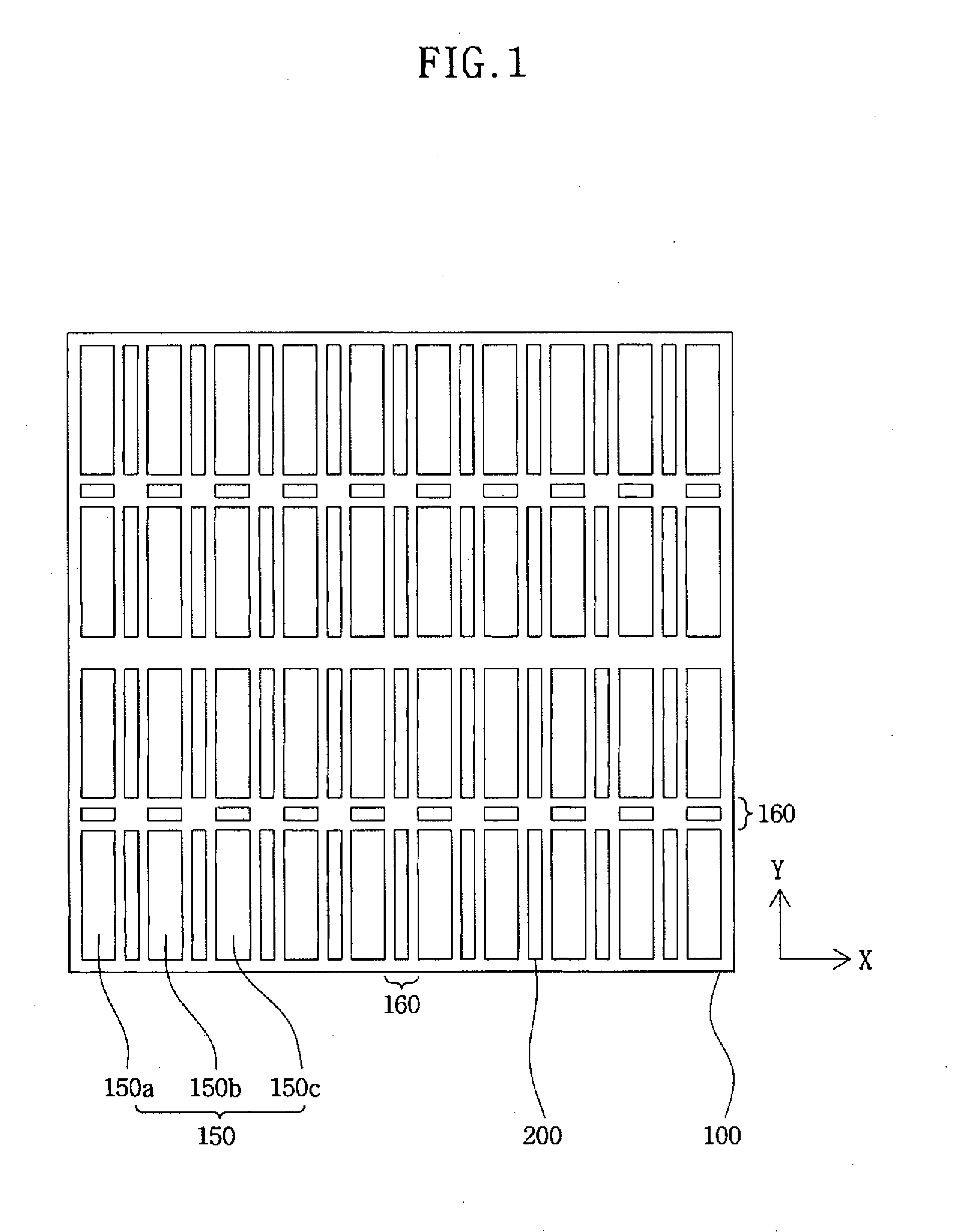

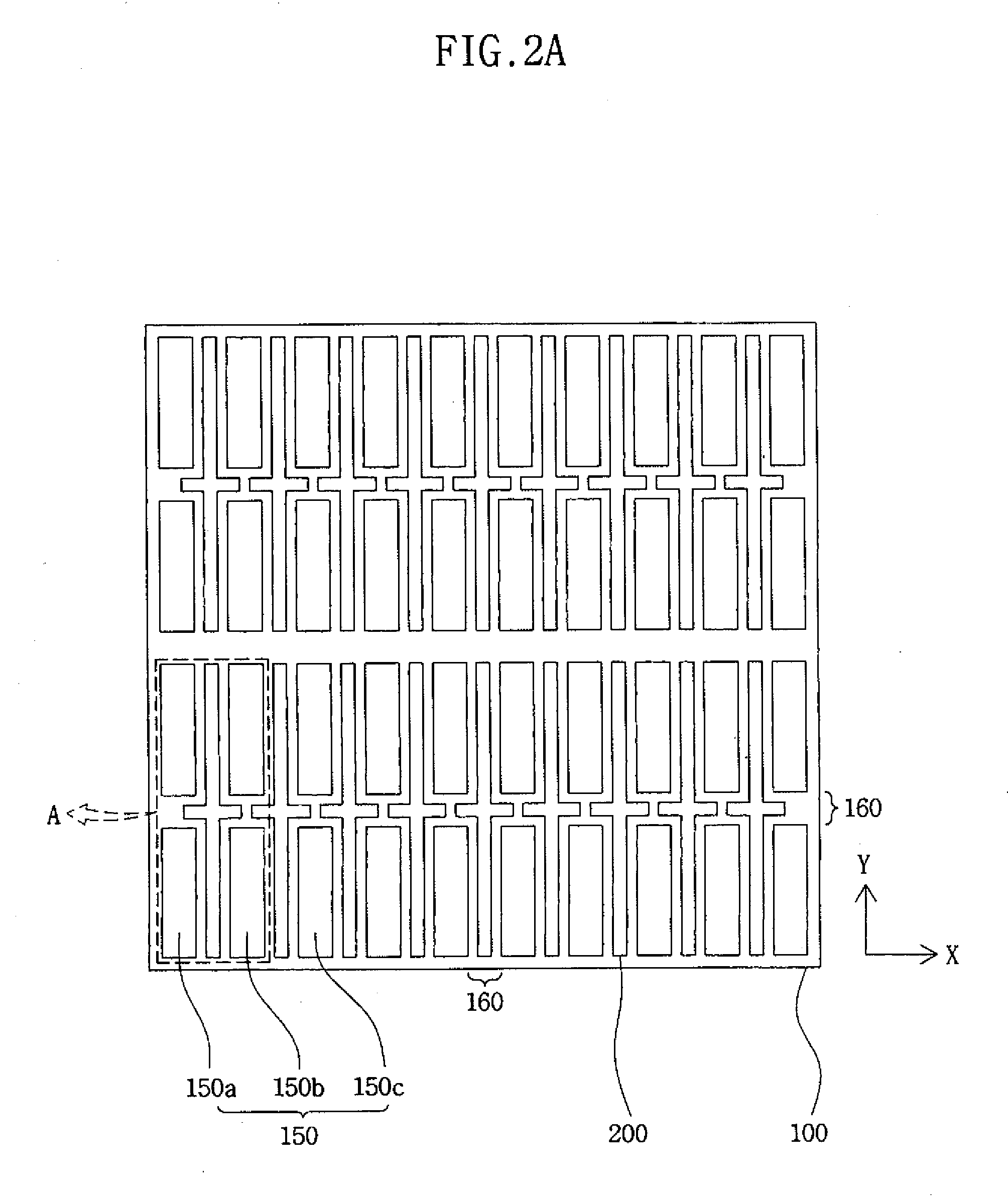

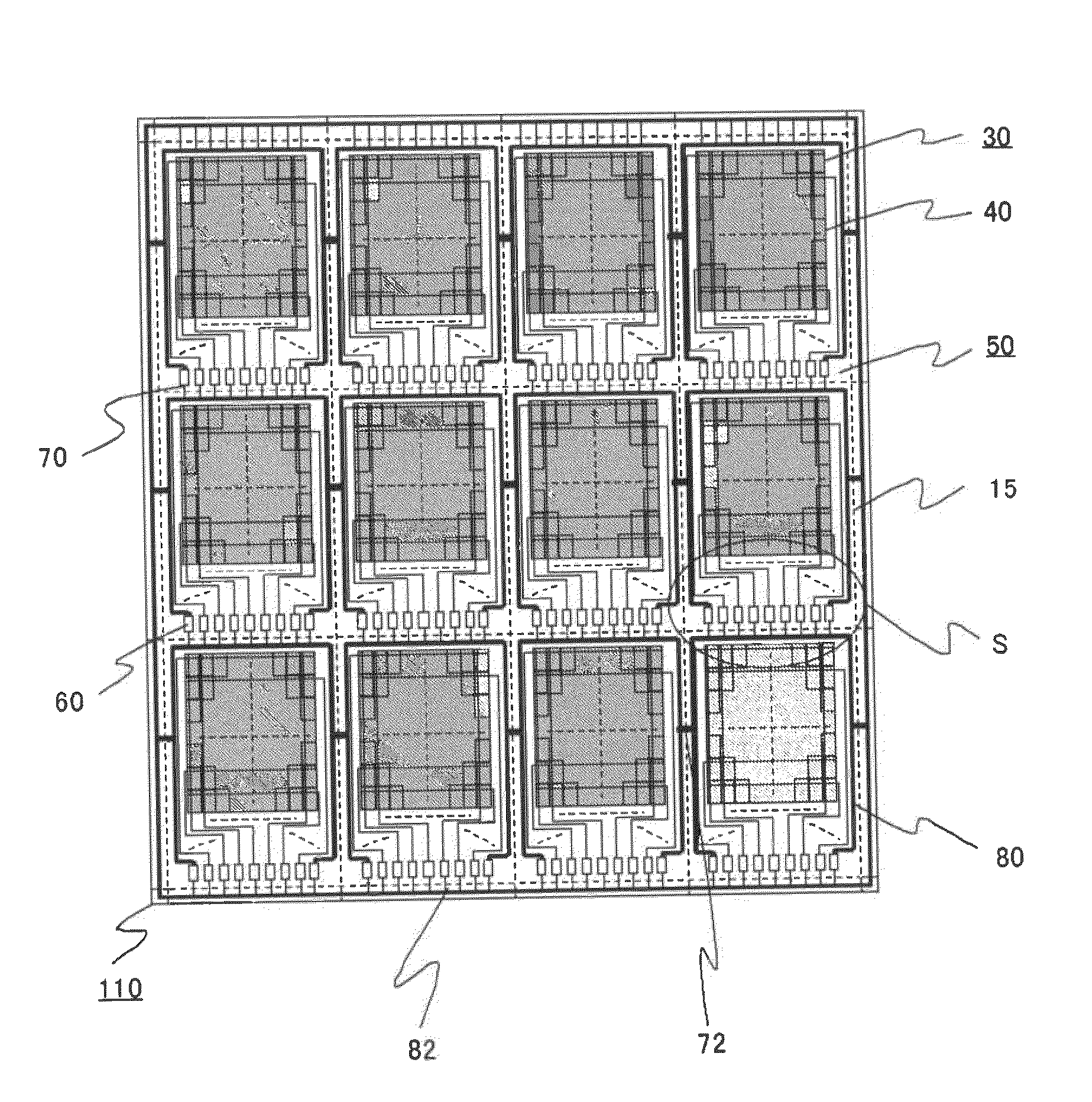

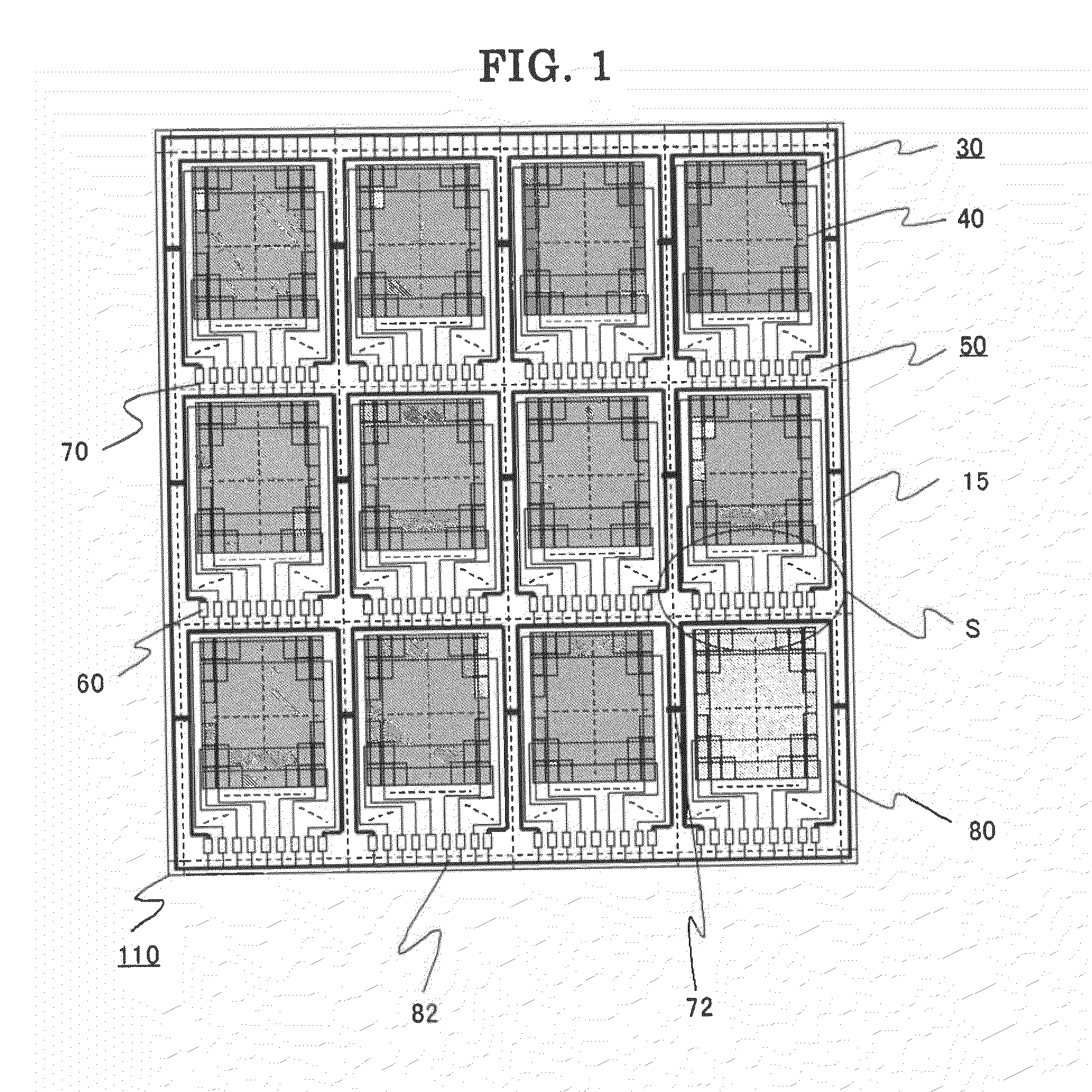

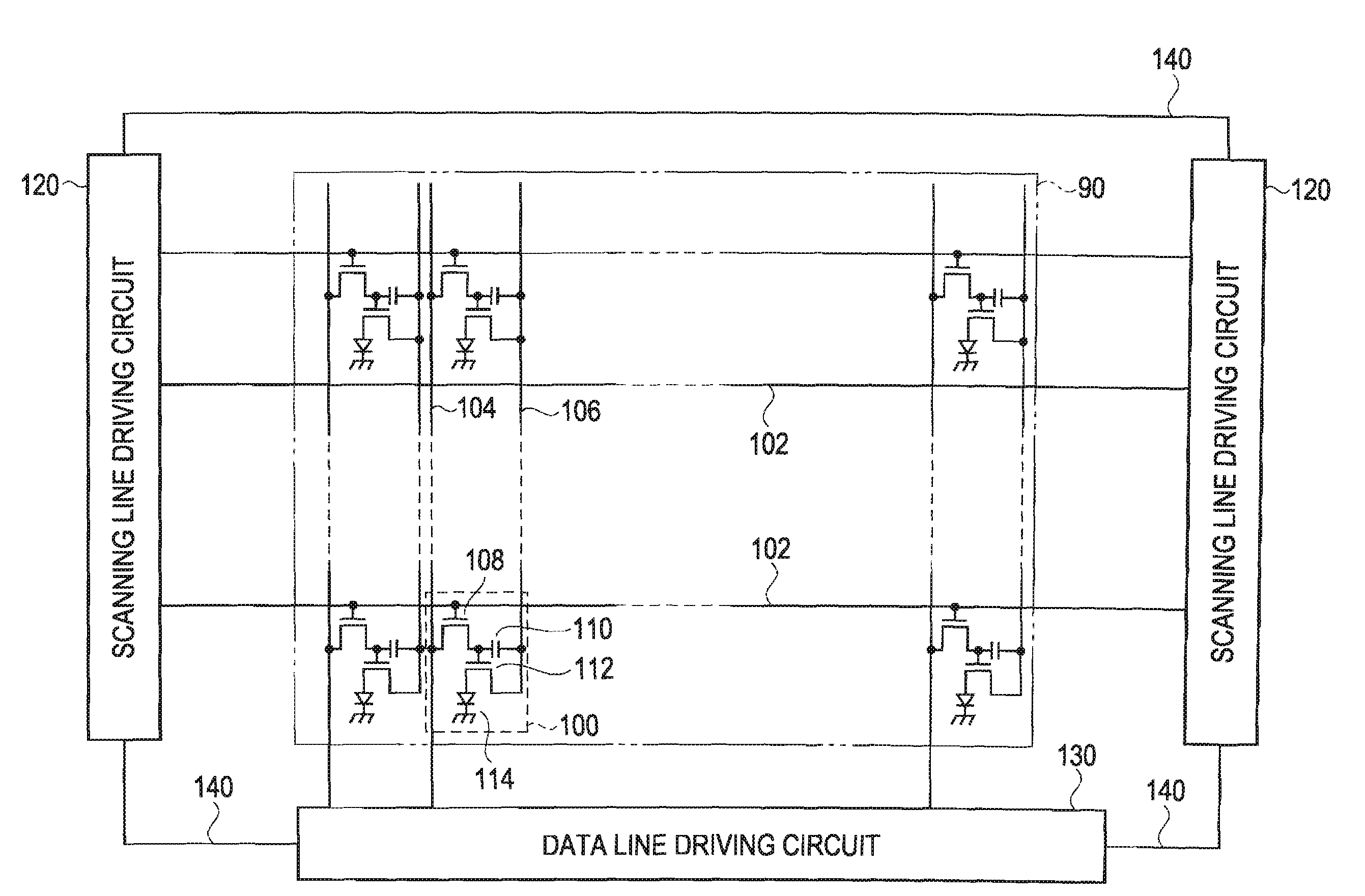

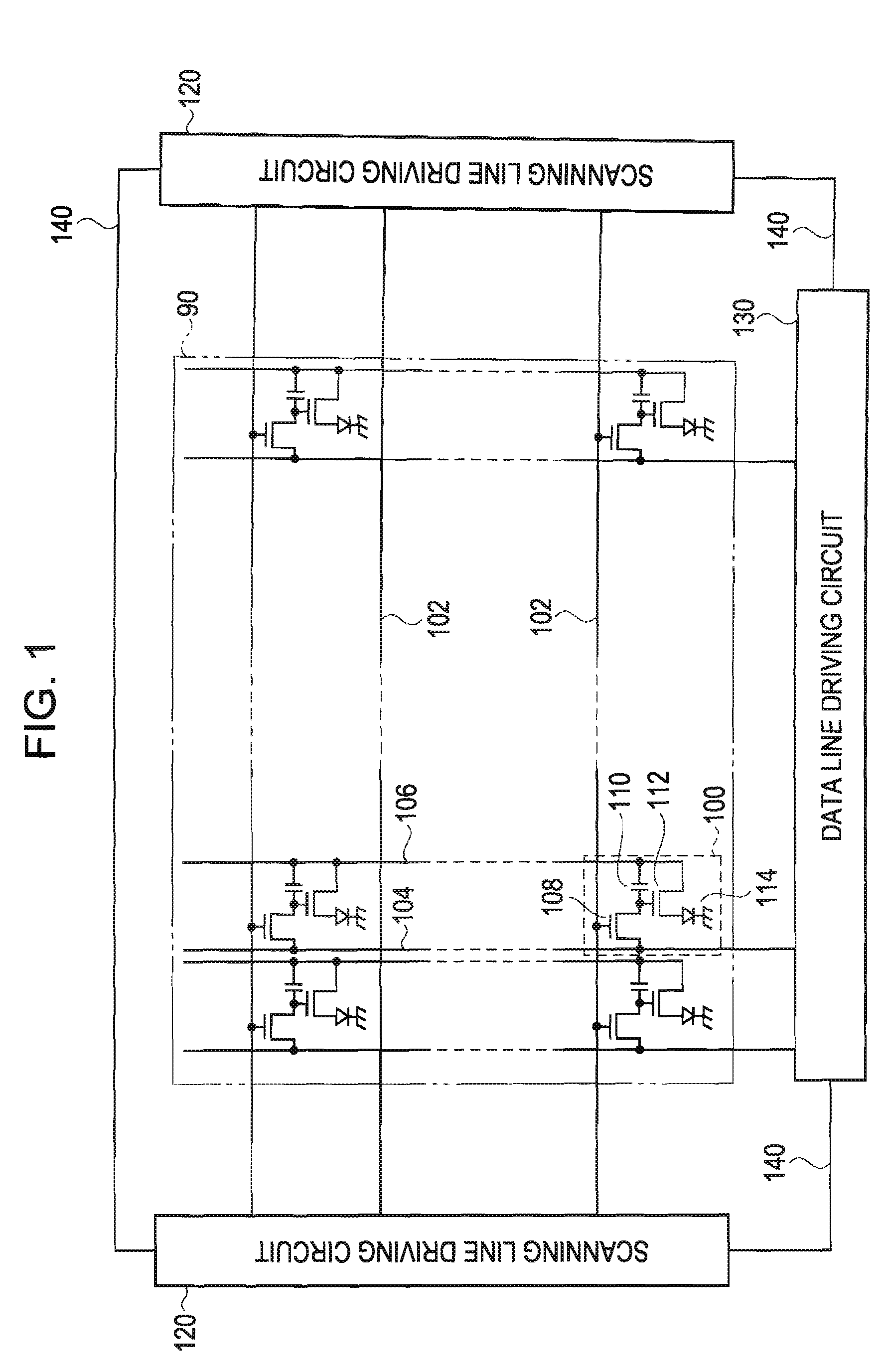

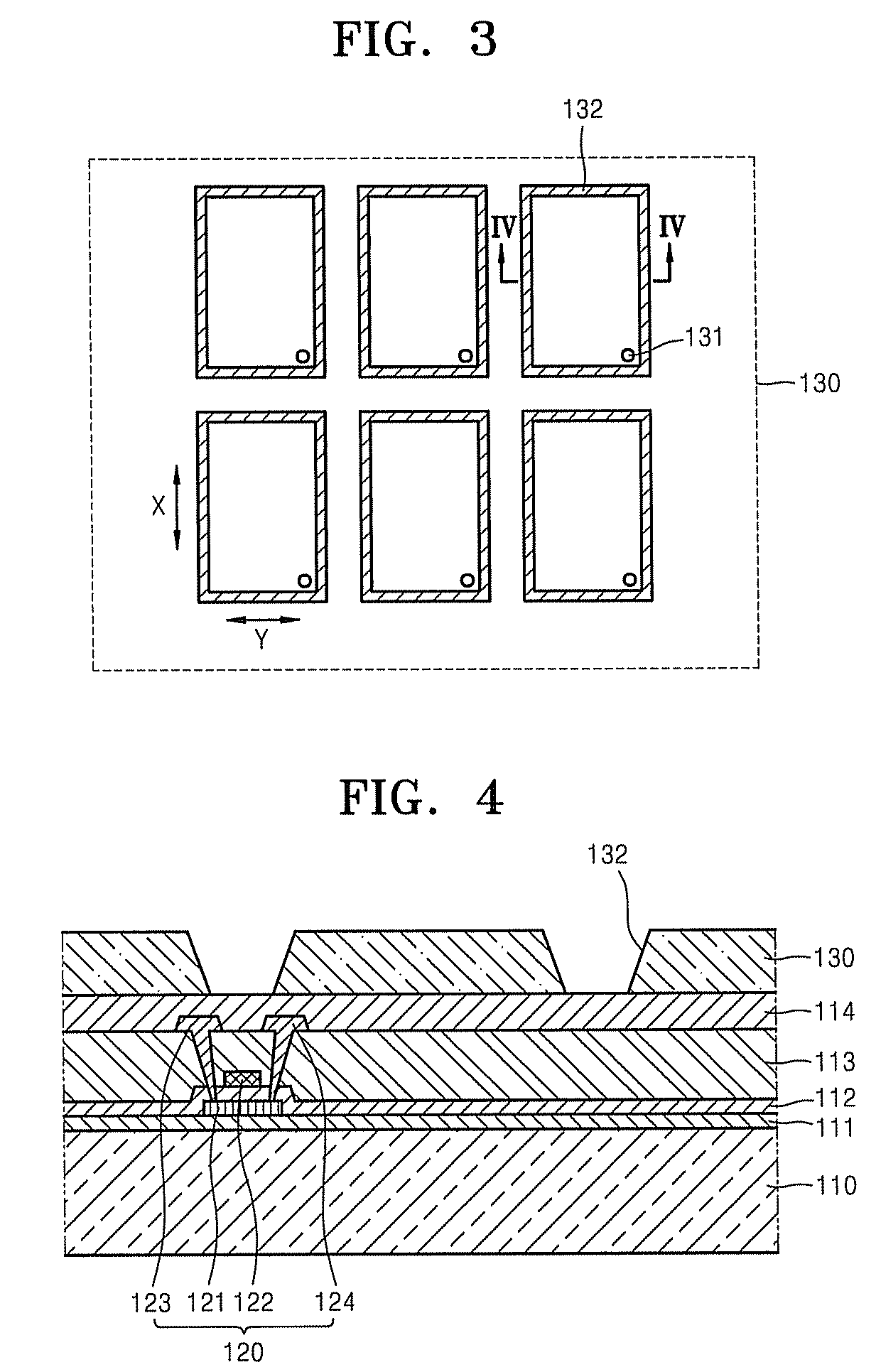

Array, substrate, and display device and its manufacturing method

ActiveUS20100163284A1Improve display reliabilityTube/lamp screens manufactureSolid-state devicesDriver circuitDisplay device

An array substrate comprises on an insulative substrate, a plurality of display areas to be portions of a plurality of display panels, in which, each display area is constituted with a plurality of pixels arranged in a matrix, and the pixels is constituted with pixel electrodes formed at intersection portions of plural scan wirings and plural signal wirings; a common wiring is formed outside each display area, for applying a reference voltage to the pixels; a plurality of external-connection terminals is formed outside each display area, to be connected with a driver circuit that drives; and comprises connection wirings located so as to intersect a cutting line along which the insulative substrate is to be cut, for connecting the external-connection terminals in one of the display panels on the insulative substrate with a common wiring in another one of the display panels adjacent to the external-connection terminals, wherein the connection wirings are formed in a conductive layer superior in corrosion resistance to the most inferior corrosion-resistance conductive layer among conductive layers constituting the array substrate.

Owner:TRIVALE TECH

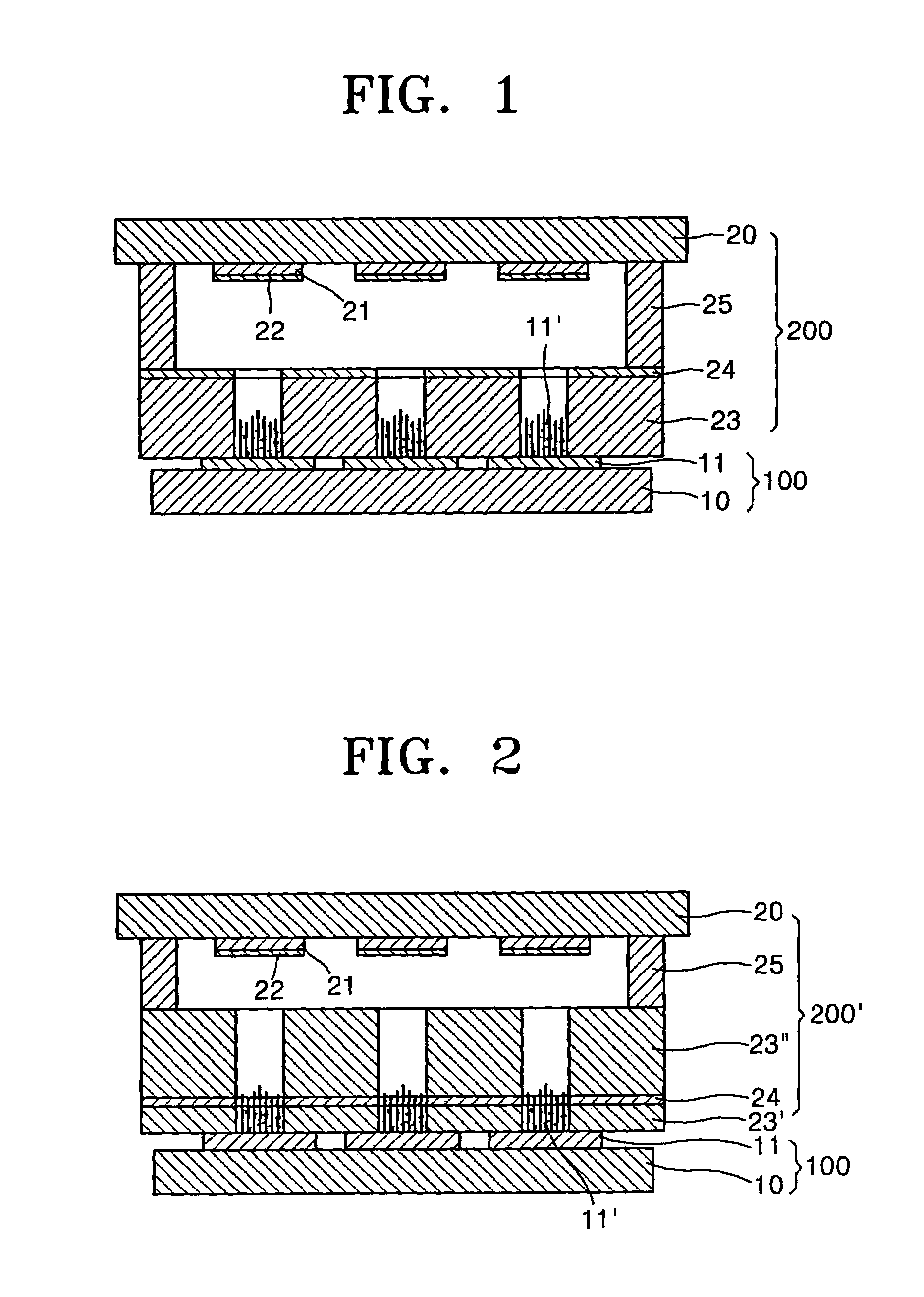

Field emission array with carbon nanotubes and method for fabricating the field emission array

InactiveUS6976897B2Simple film formationTube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersPhosphorCarbon nanotube

A field emission array adopting carbon nanotubes as an electron emitter source, wherein the array includes a rear substrate assembly including cathodes formed as stripes over a rear substrate and carbon nanotubes; a front substrate assembly including anodes formed as stripes over a front substrate with phosphors being deposited on the anodes, a plurality of openings separated by a distance corresponding to the distance between the anodes in a nonconductive plate, and gates formed as stripes perpendicular to the stripes of anodes on the nonconductive plate with a plurality of emitter openings corresponding to the plurality of openings. The nonconductive plate is supported and separated from the front substrate using spacers. The rear substrate assembly is combined with the front substrate assembly such that the carbon nanotubes on the cathodes project through the emitter openings.

Owner:SAMSUNG SDI CO LTD

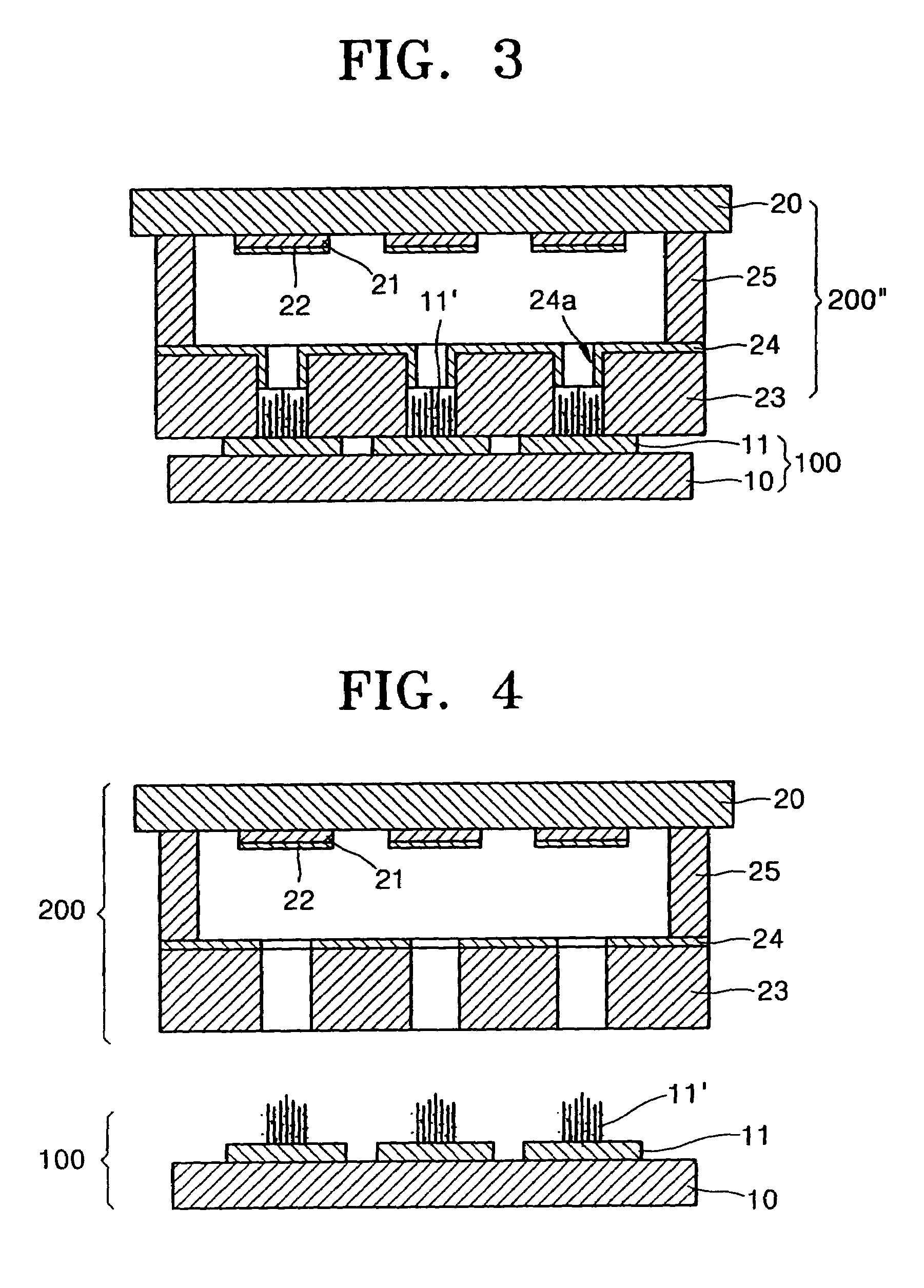

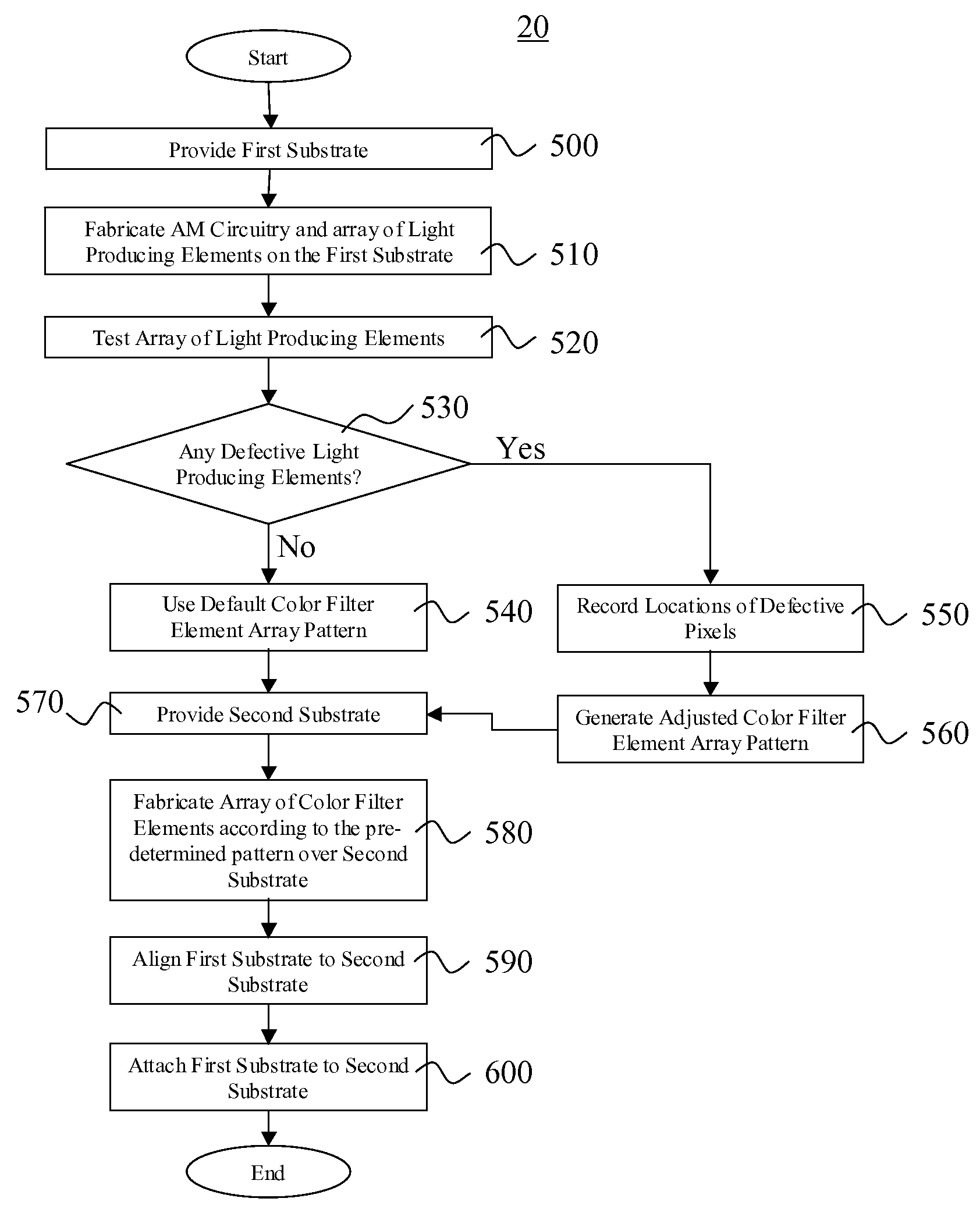

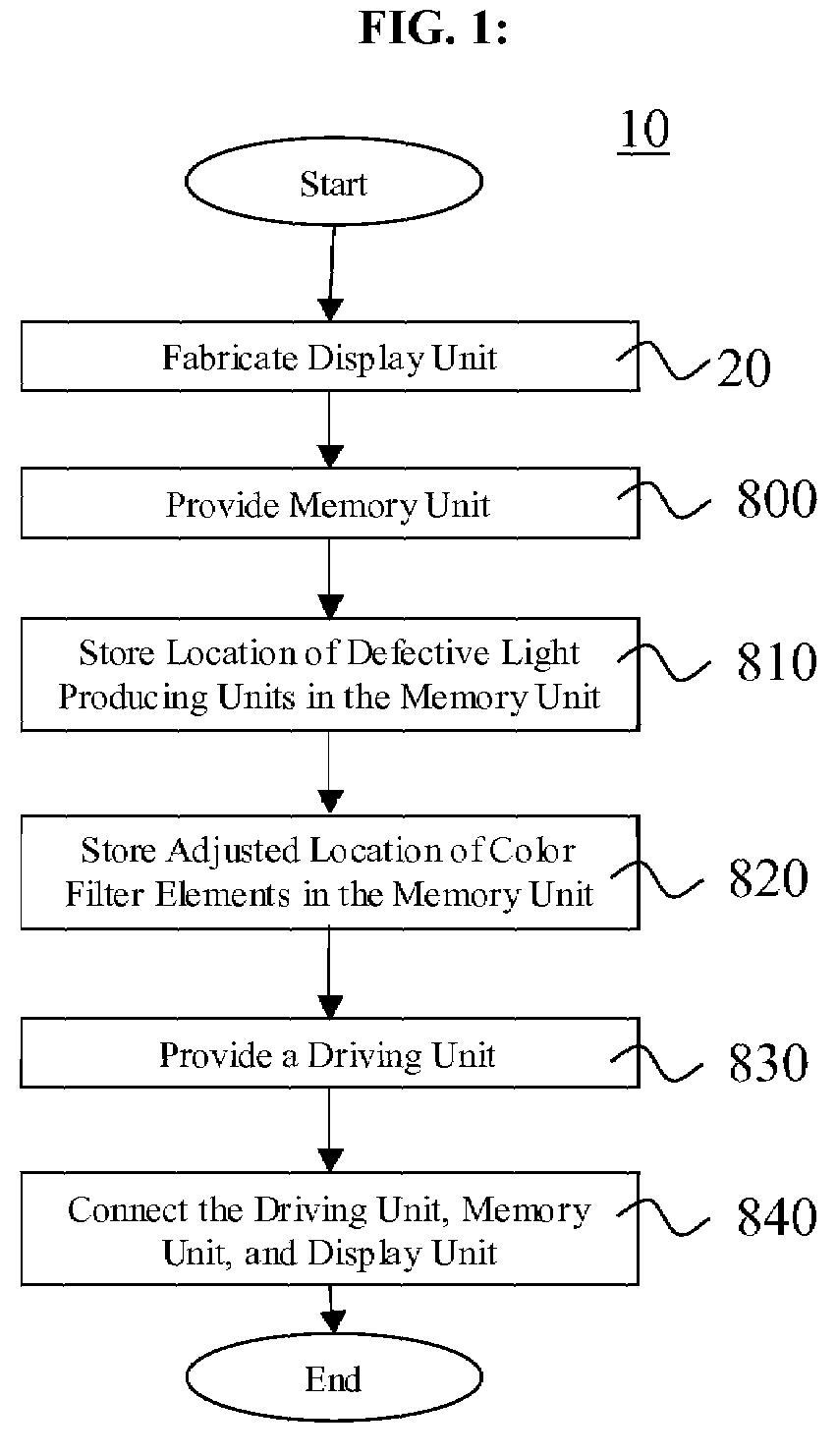

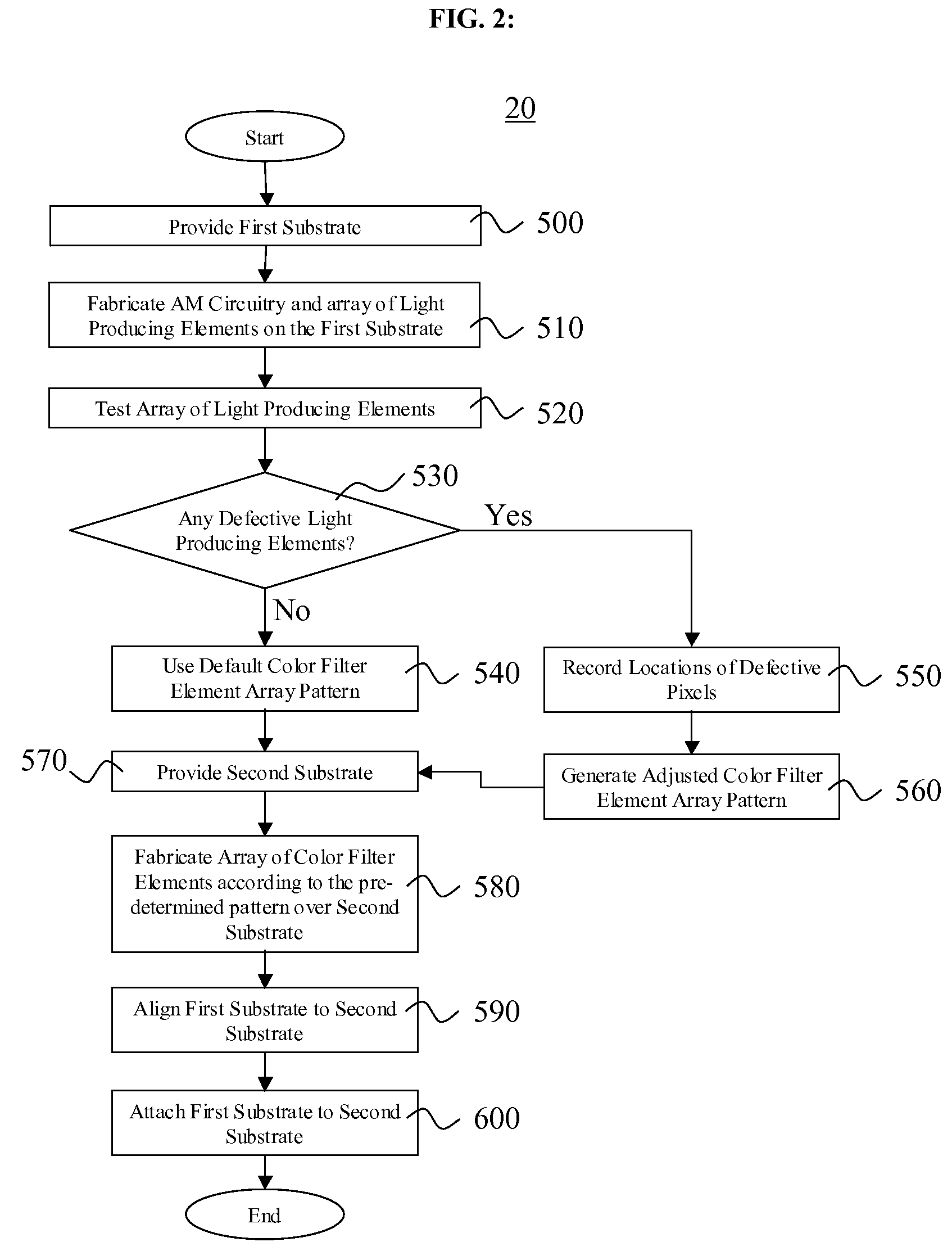

OLED display device with adjusted filter array

ActiveUS20080085652A1Downsize display deviceQuality improvementTube/lamp screens manufactureSolid-state devicesDisplay deviceOptoelectronics

A method of making an OLED display device for producing an image includes forming an array of light producing elements; testing the array of light producing elements and recording the location of defective light producing element(s); providing a default pattern of the array of color filter elements having at least two different colors; and forming an array of color filter elements in response to the recorded location of the defective light producing element(s), the location of at least one color filter element being changed from the default pattern.

Owner:GLOBAL OLED TECH

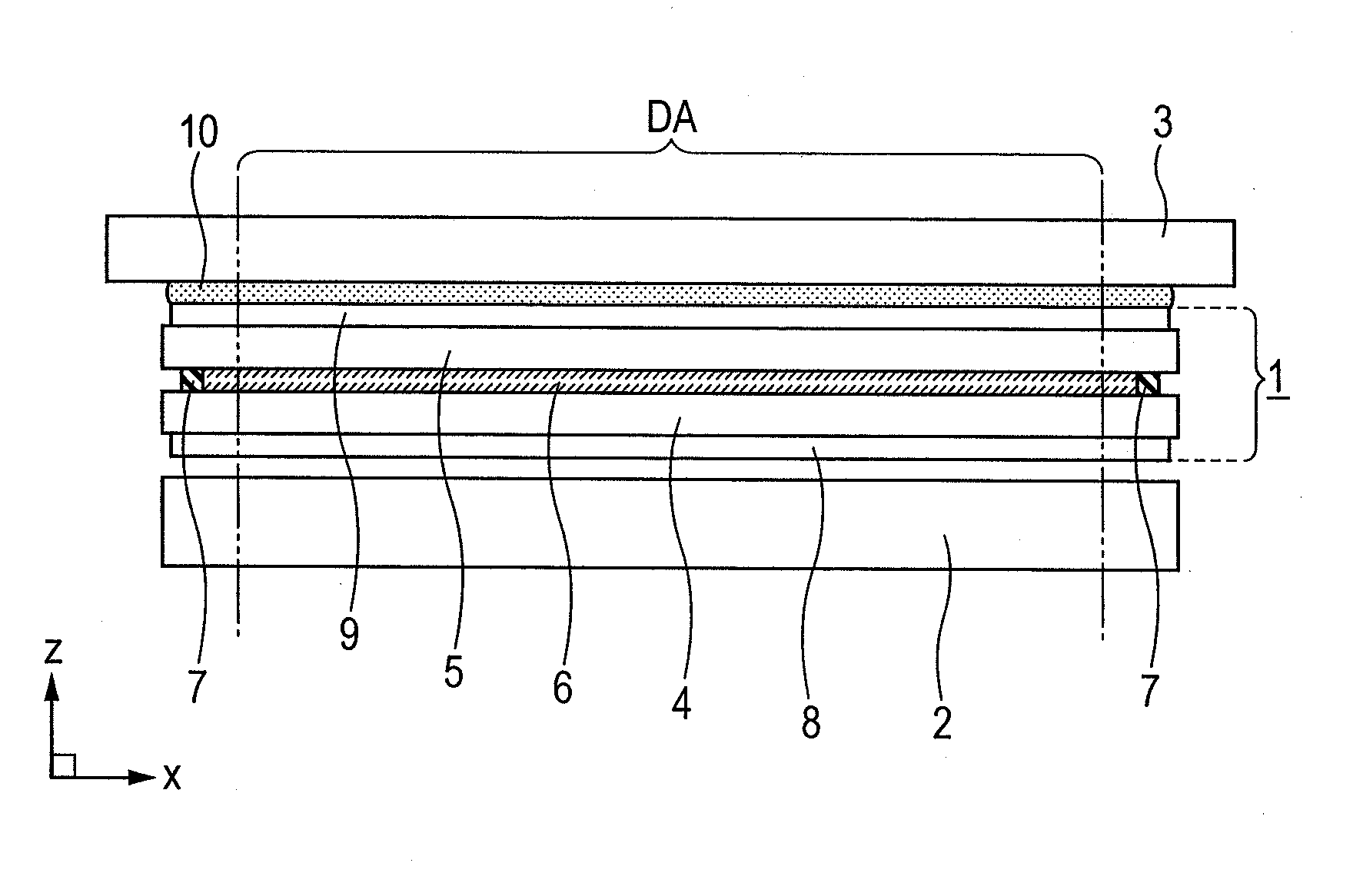

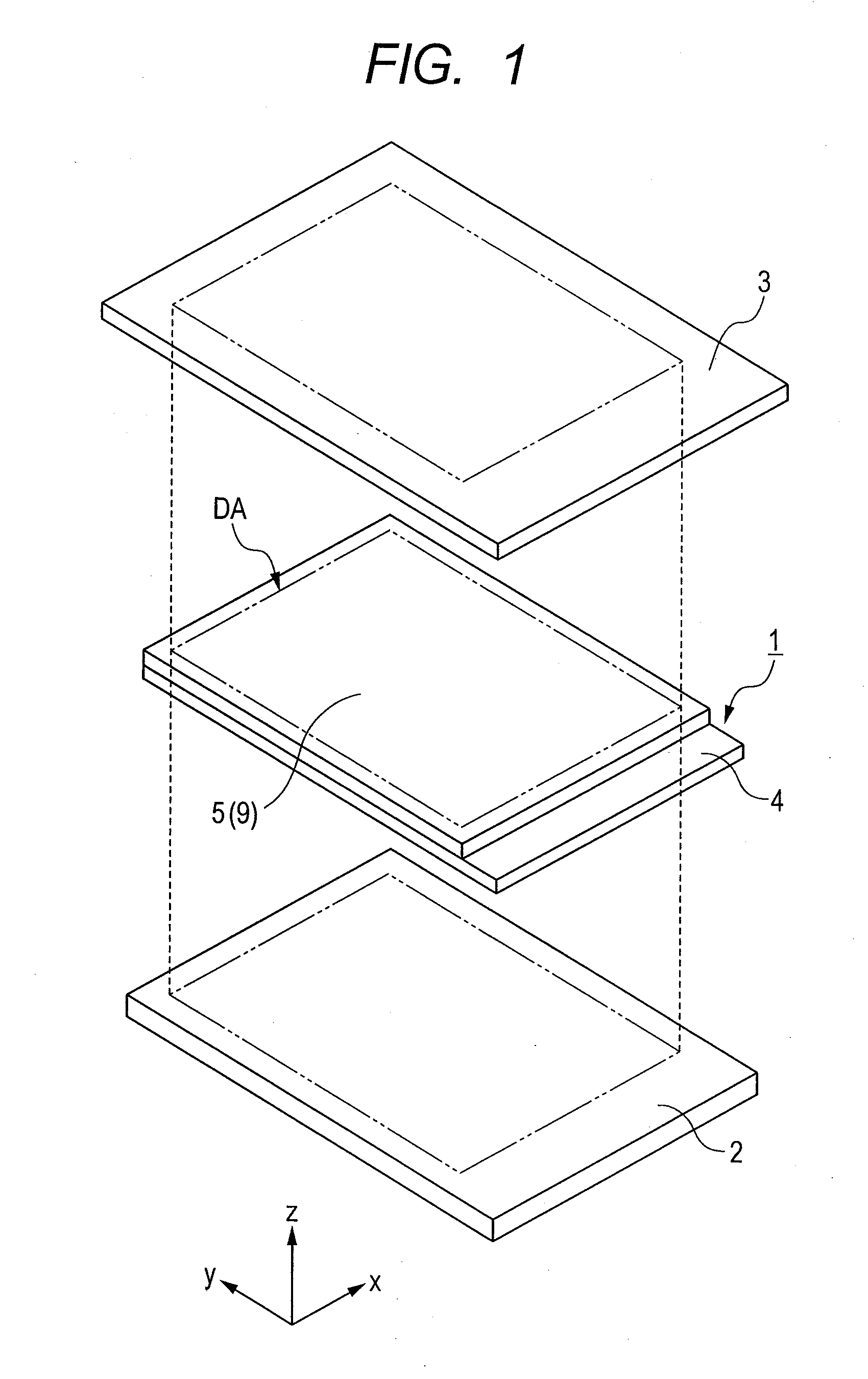

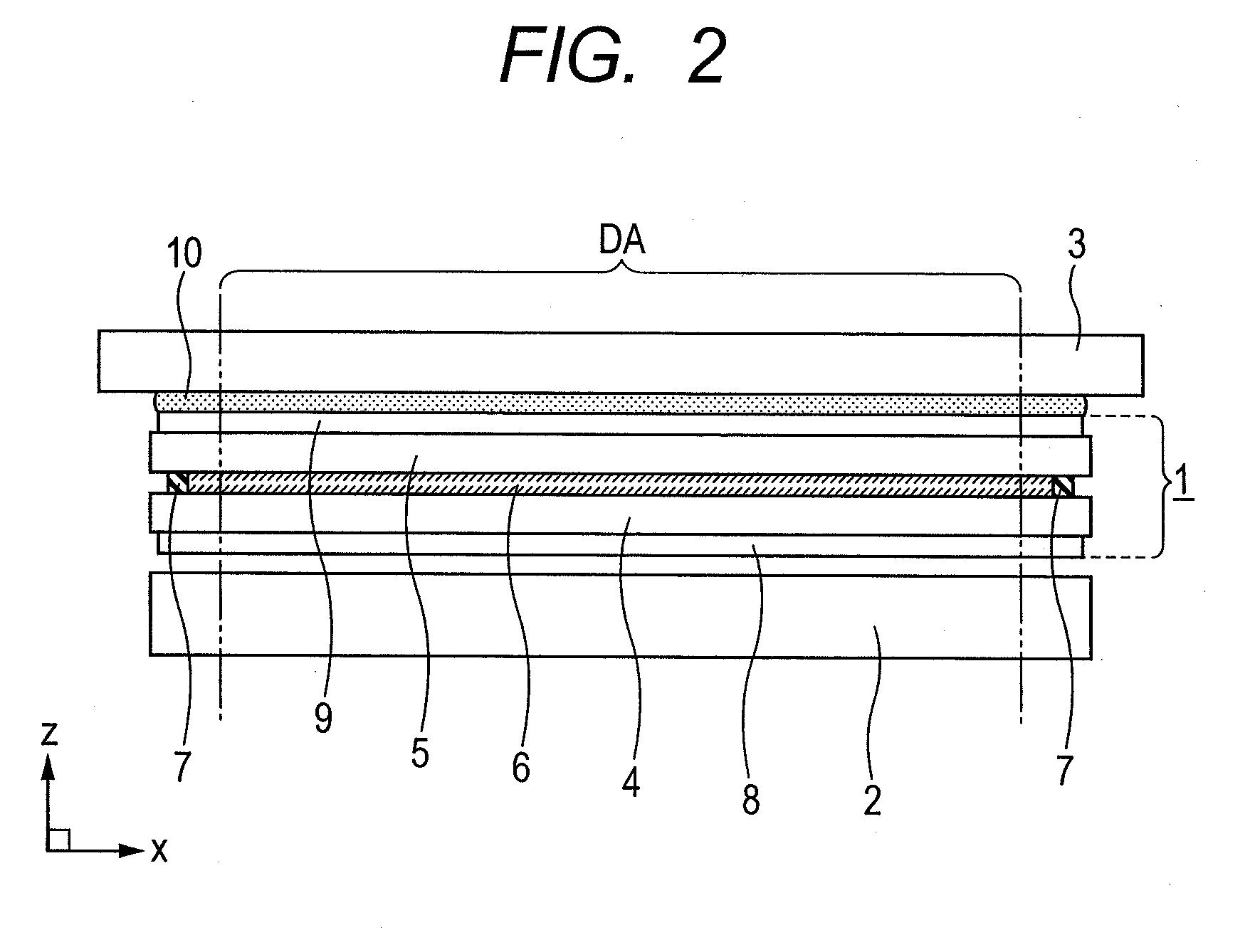

Display device and manufacturing method thereof

ActiveUS20110187960A1Sufficient effectReduce bond strengthTube/lamp screens manufactureNon-linear opticsUV curingDisplay device

Disclosed is a display device in which reliable bonding strength and high reparability are compatible when a panel-like member is bonded to a display panel.The display device comprises: a display panel; and a panel-like member bonded to the display panel with an adhesive made of an ultraviolet curable resin; wherein the adhesive includes a first adhesive portion and a second adhesive portion, the first adhesive portion being provided outside of a display area of the display panel and formed in a circular shape to surround the display area, the second adhesive portion prevailing in an area surrounded by the first adhesive portion, the first adhesive portion being different in a modulus of elasticity from the second adhesive portion, and wherein the modulus of elasticity of the second adhesive portion is smaller than the modulus of elasticity of the first adhesive portion.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

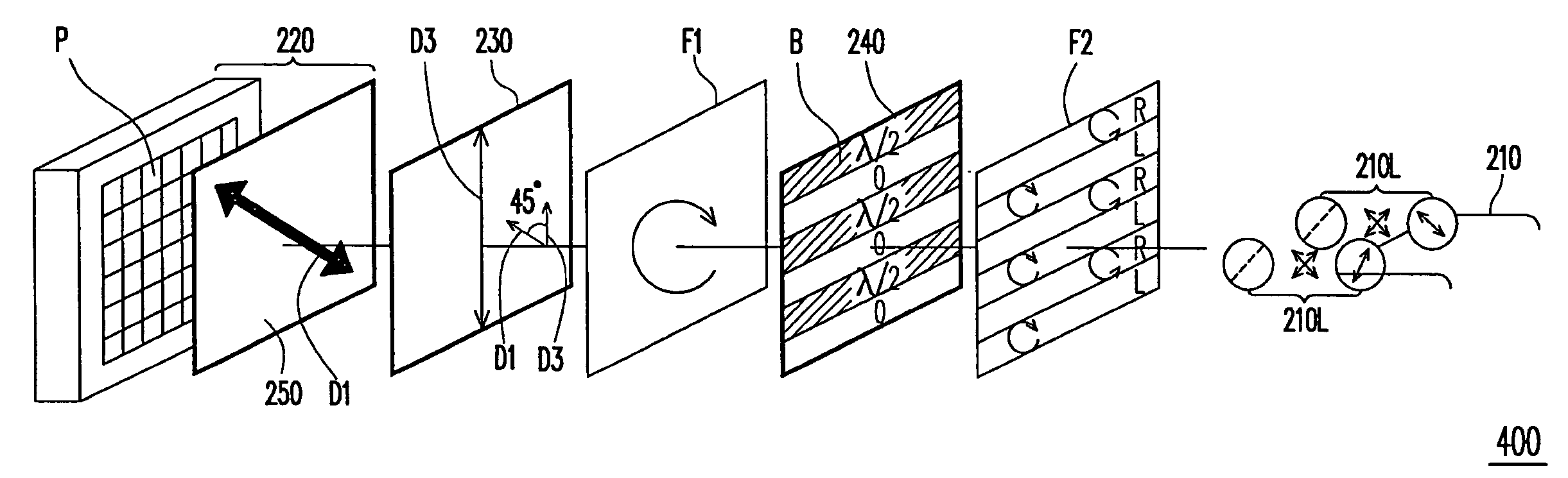

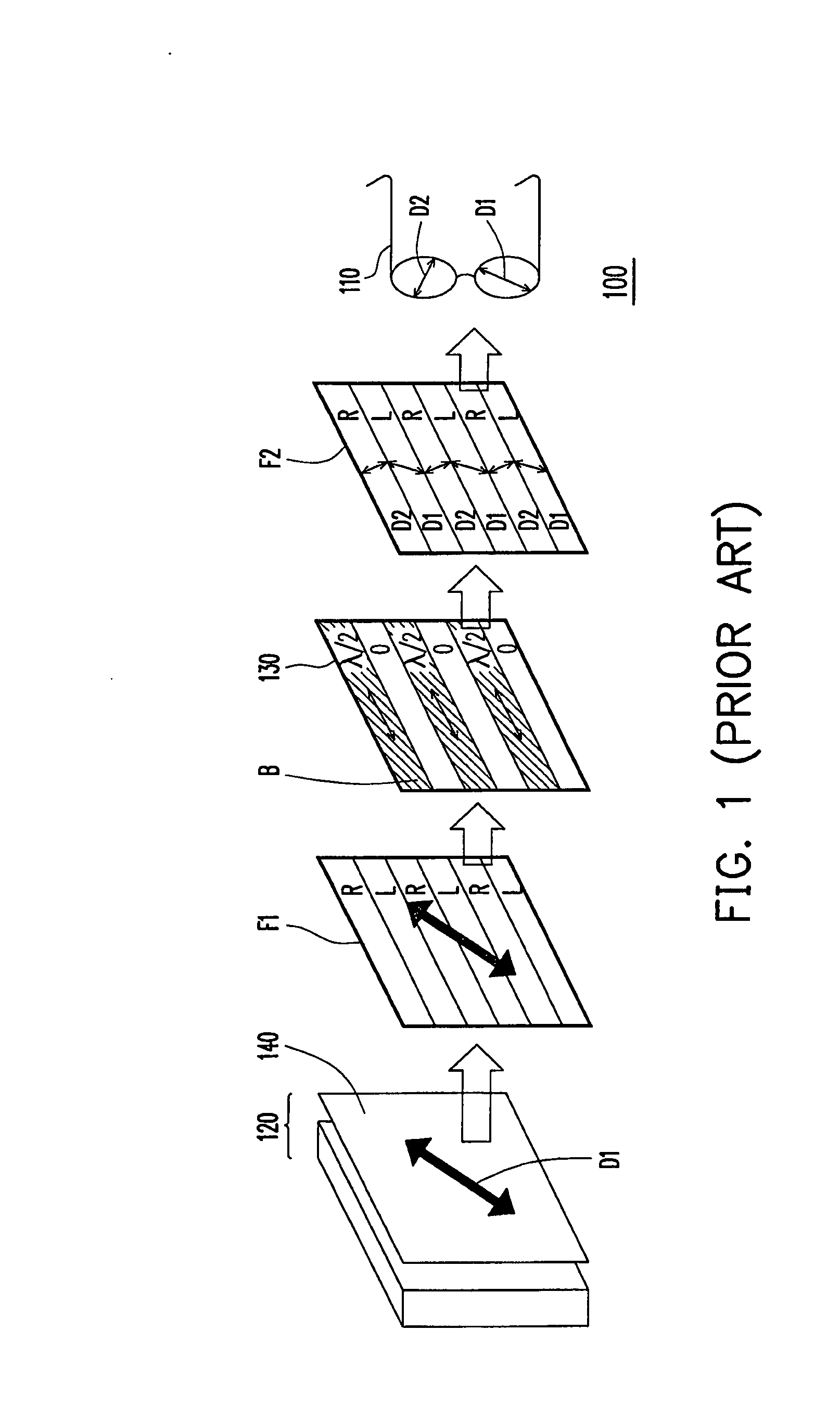

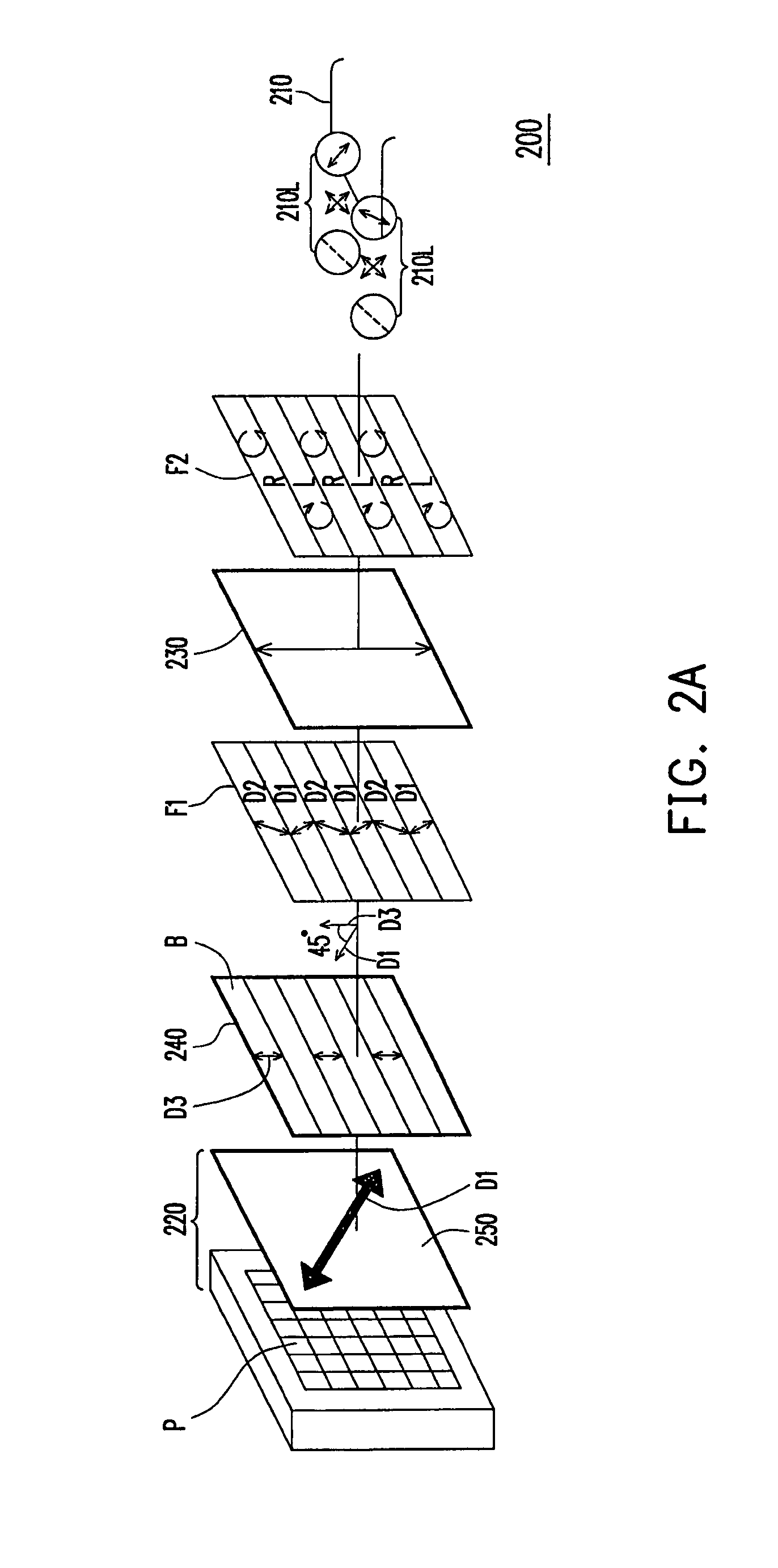

Three-dimension display and fabricating method thereof

ActiveUS20090141201A1Improve display qualityReduce manufacturing costTube/lamp screens manufactureVessels or leading-in conductors manufactureEyeglass lensesEyewear

Owner:AU OPTRONICS CORP

Image display device

ActiveUS20100097746A1Inhibition effectTube/lamp screens manufactureElectrical apparatus contructional detailsDisplay deviceEngineering

A method for manufacturing an image display device includes the step of forming a cured resin layer by interposing a photo-curable resin composition between a protection member and a display-side panel including an image display unit and a frame member and then photo-curing the photo-curable resin composition, with the photo-curable resin composition being disposed across between the image display unit and the frame member. In the manufacturing method, a high-viscosity resin composition having a viscosity of 3000 mPa·s or more and 12000 mPa·s or less is used as the photo-curable resin composition. Alternatively, after a gap between the image display unit and the frame member is sealed with a sealing film, a photo-curable resin composition is interposed between the display-side panel and the protection member.

Owner:DEXERIALS CORP

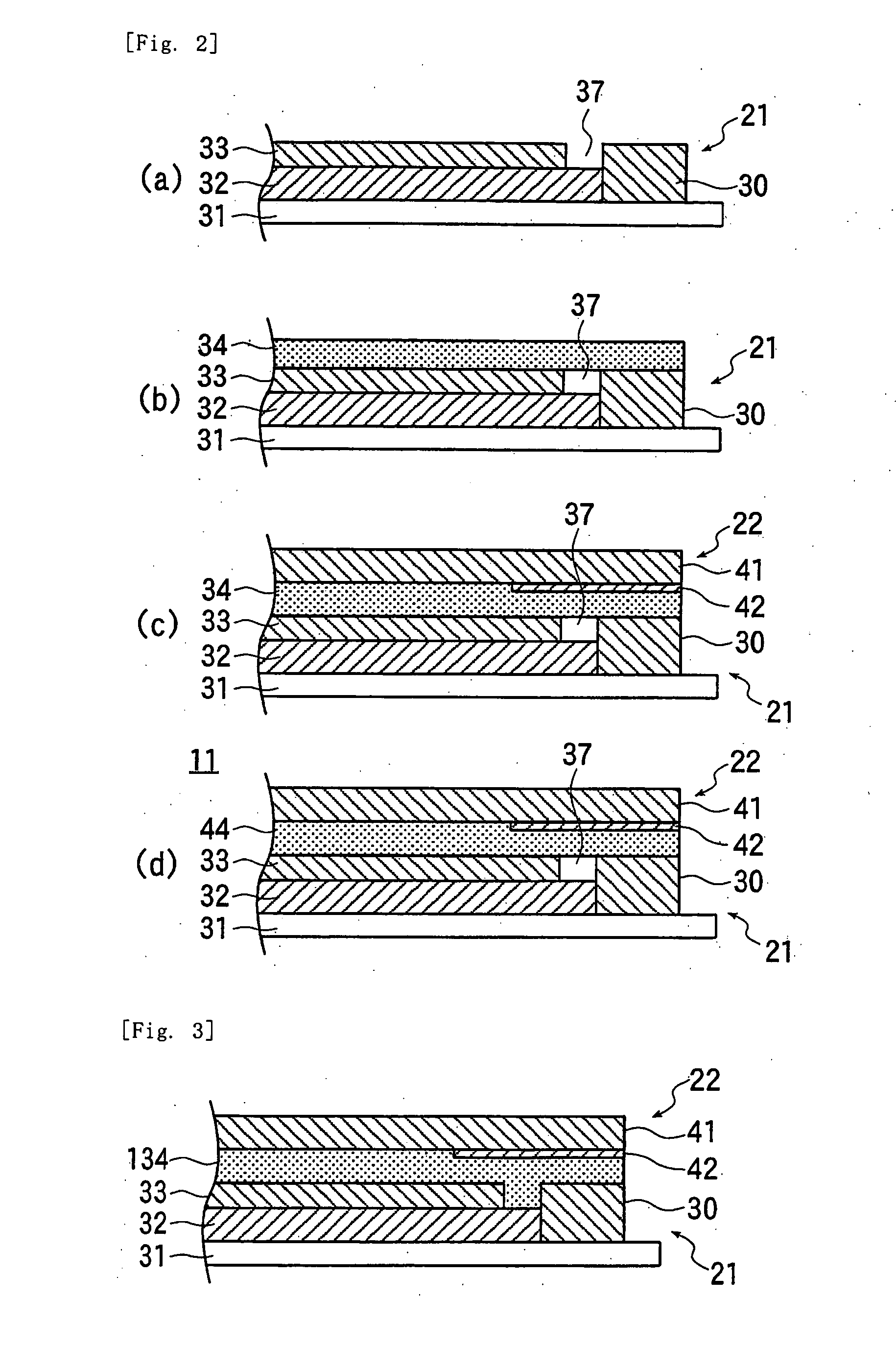

Electro-luminescence device and method of manufacturing electro-luminescence device

ActiveUS20080284331A1Improve accuracyImprove rendering capabilitiesTube/lamp screens manufactureDischarge tube luminescnet screensControl layerWater vapor

There is provided an electro-luminescence device in which a display base substrate including a display body layer having a switching element disposed in the shape of a matrix and a light emitting element having a light emitting state controlled by the switching element and a sealing layer having a gas barrier layer that is formed on the display body layer and has at least a function for blocking water vapor and a protection substrate made of a translucent material and having a surface on which at least two types of gap control layers made of different materials are stacked are bonded such that a gap control layer, disposed on the uppermost layer, of the gap control layers and the gas barrier layer are brought into contact with each other, wherein the gap control layer disposed on the uppermost layer has a Young's modulus lower than the gas barrier layer.

Owner:SEIKO EPSON CORP

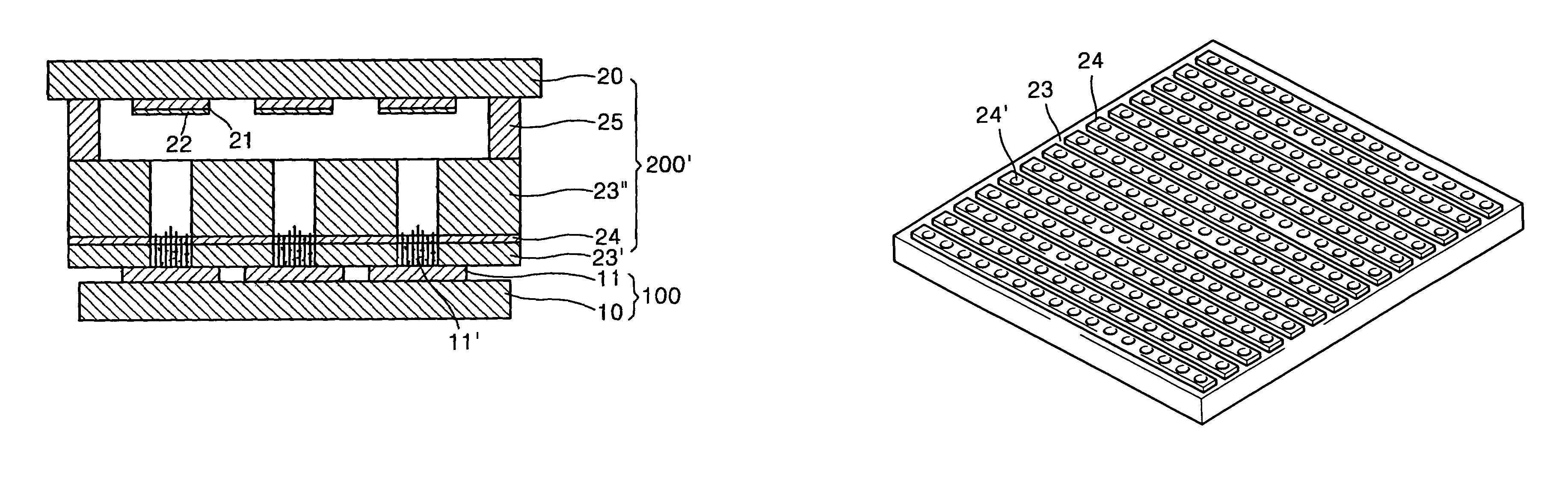

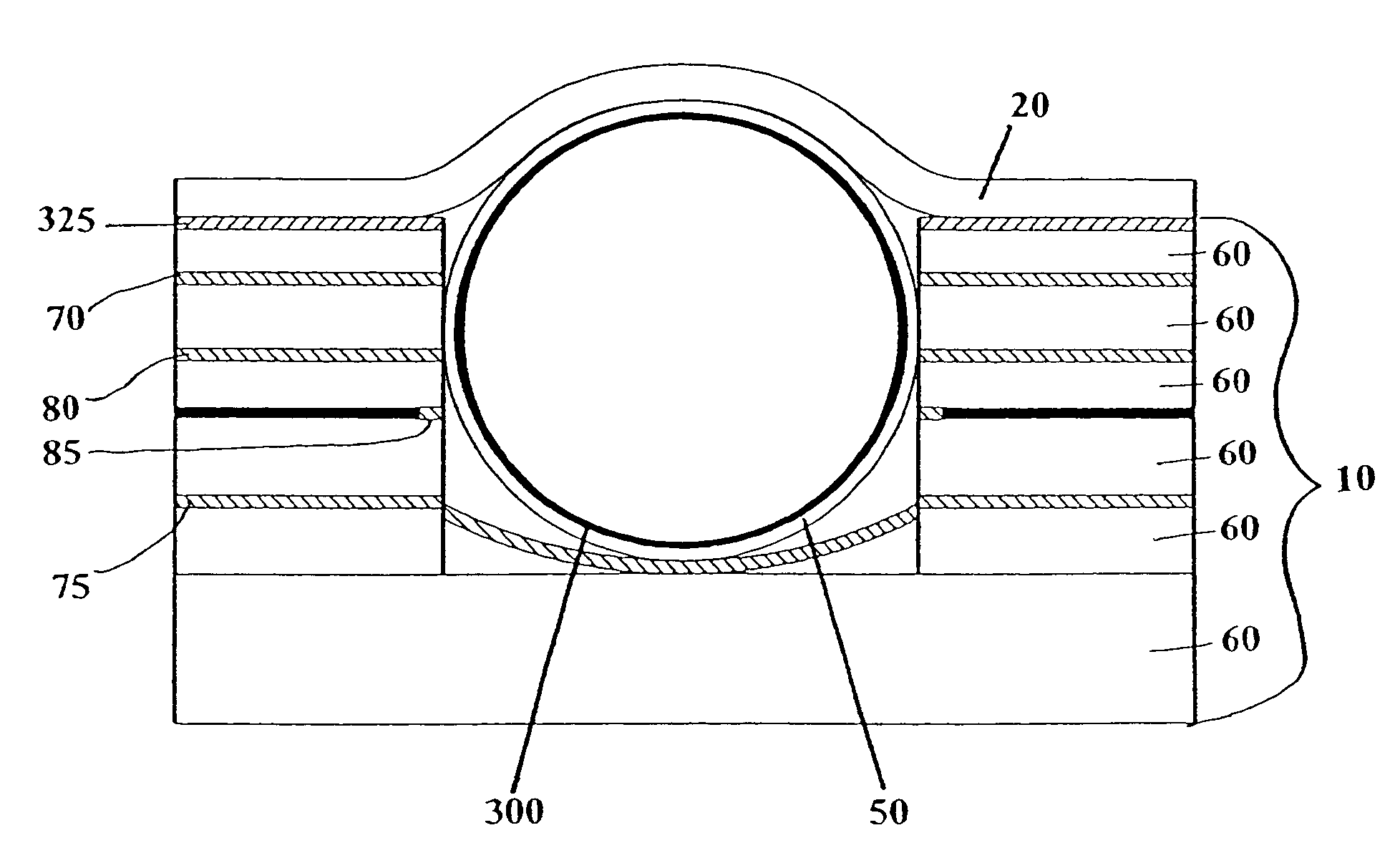

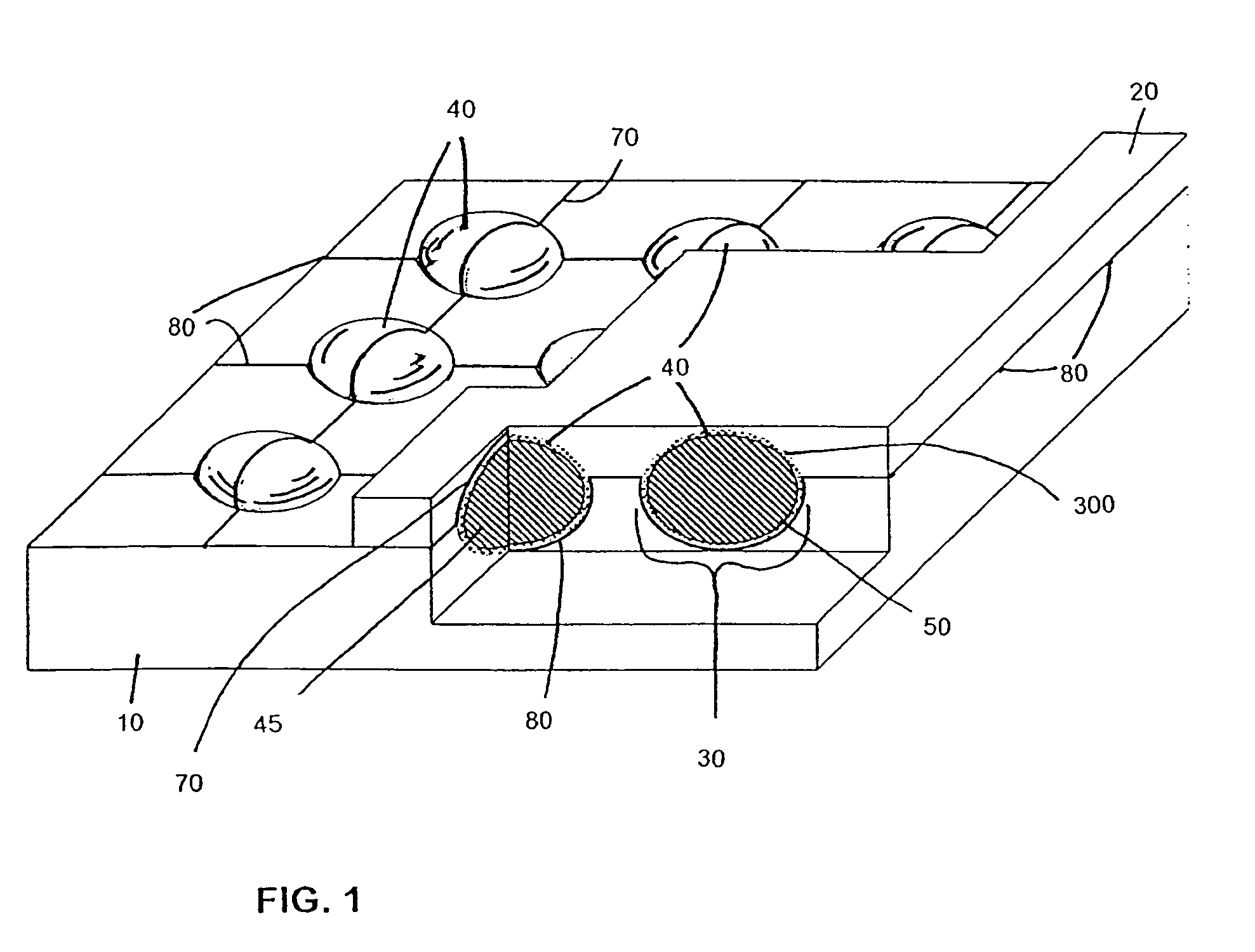

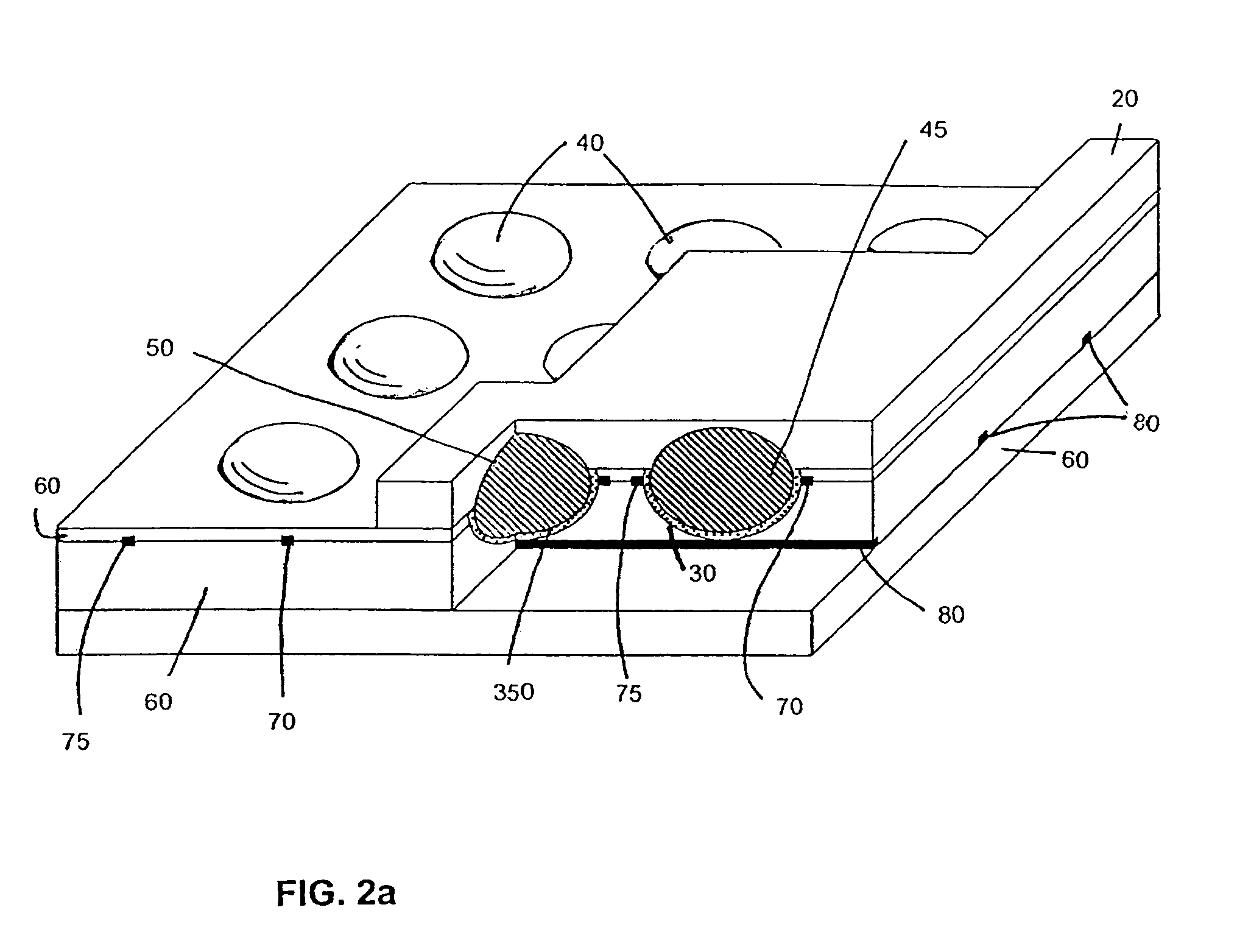

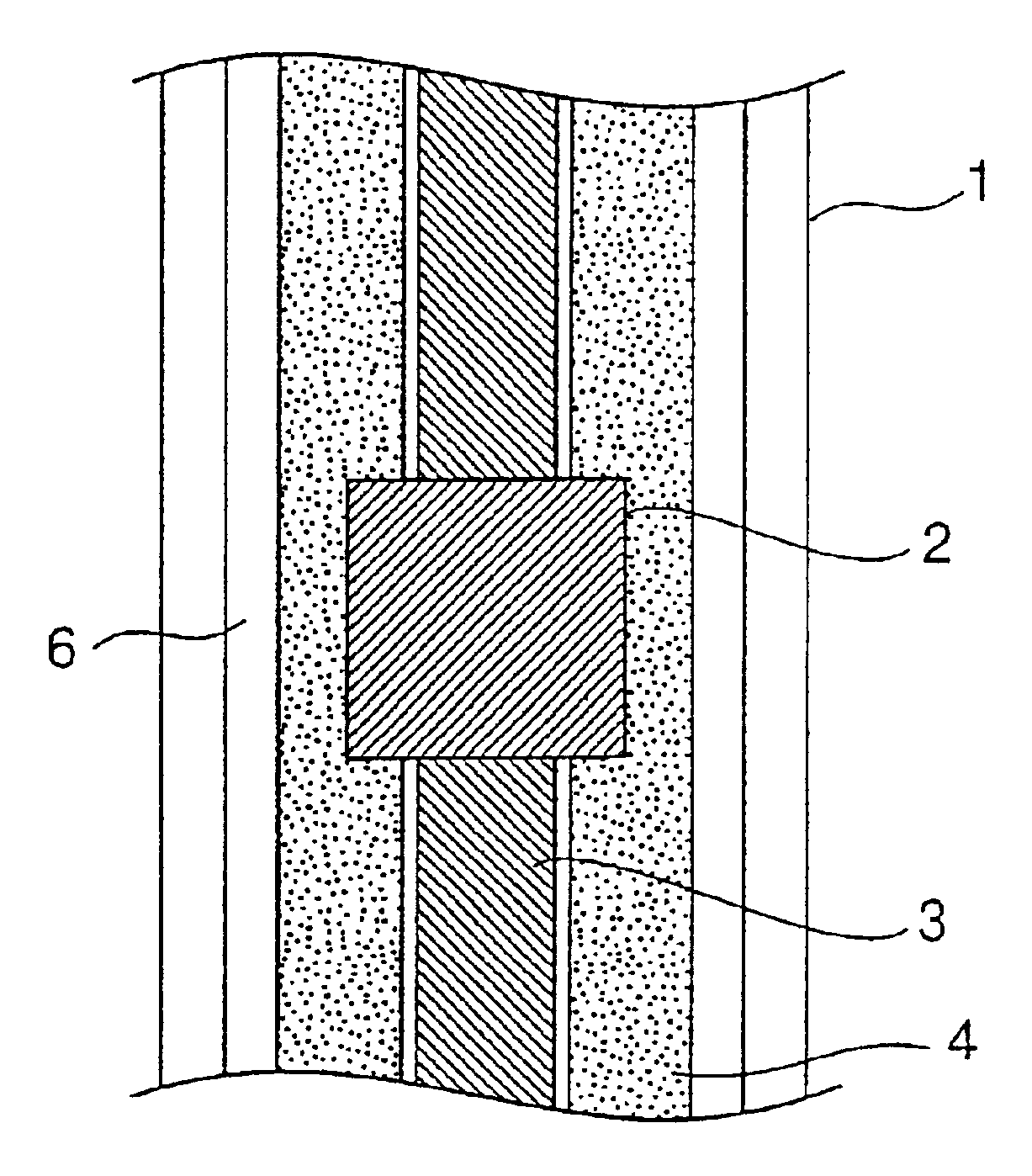

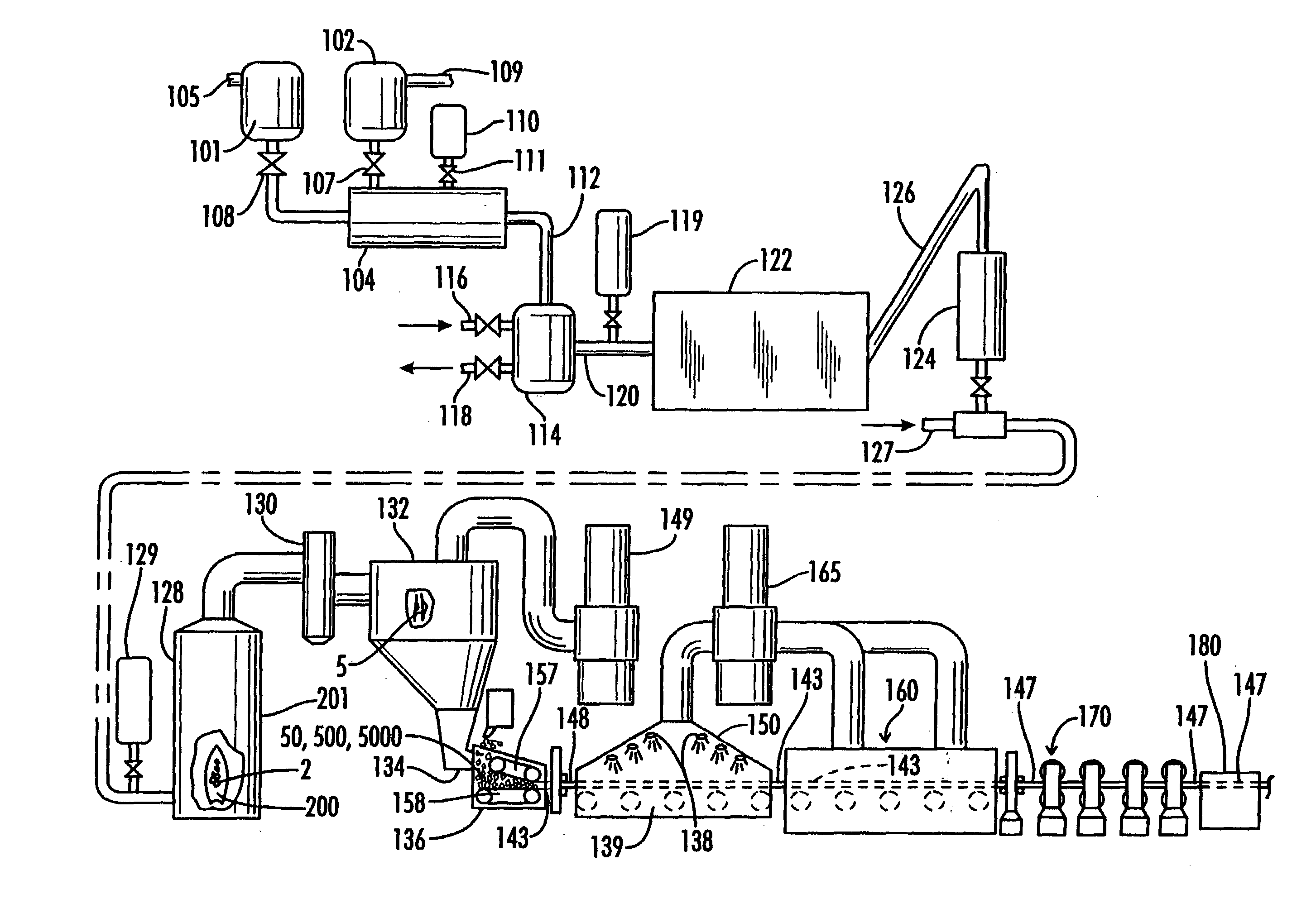

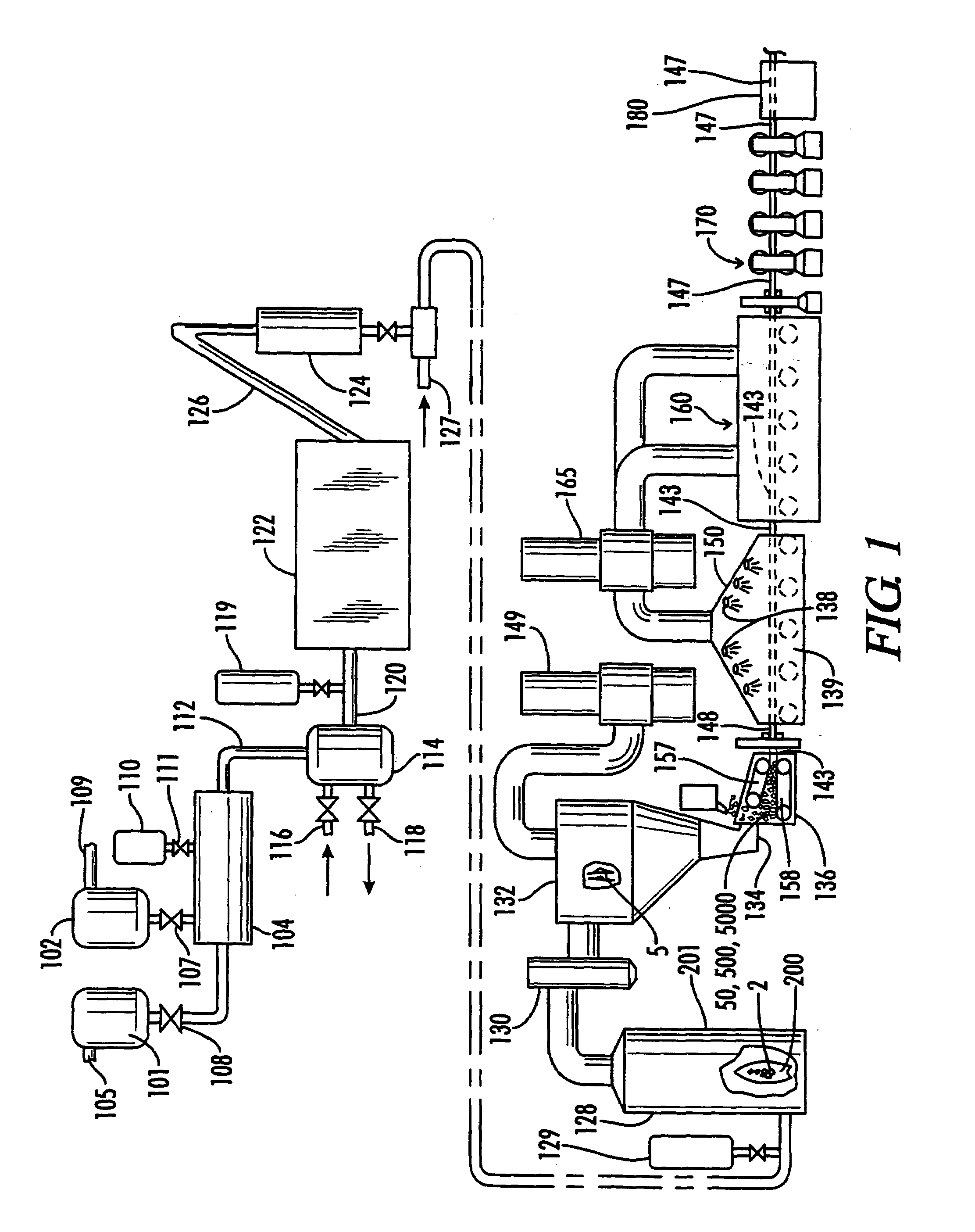

Liquid manufacturing processes for panel layer fabrication

InactiveUS7025648B2Tube/lamp screens manufactureTelevision system detailsDielectric substrateWaveguide

A method for manufacturing a light-emitting panel sandwiches a plurality of micro-components between two flexible substrates in a web configuration. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. The micro-components are disposed in sockets formed at pre-determined locations in a first dielectric substrate so that they are adjacent to electrodes imprinted in the first substrate. Dielectric layers and the conductors for acting as electrodes are formed using liquid processes or combined liquid and sheet processes, where liquid materials are applied to the surface of the underlying layer, then cured to complete the formation of layers. The assembled layers are coated with a protective coating and may include an RF shield. In one embodiment, patterning of the conductors is achieved by applying conductive ink using an ink jet process. In another embodiment, the conductors may be patterned photolithographically using a leaky optical waveguide as a contact mask.

Owner:LEIDOS

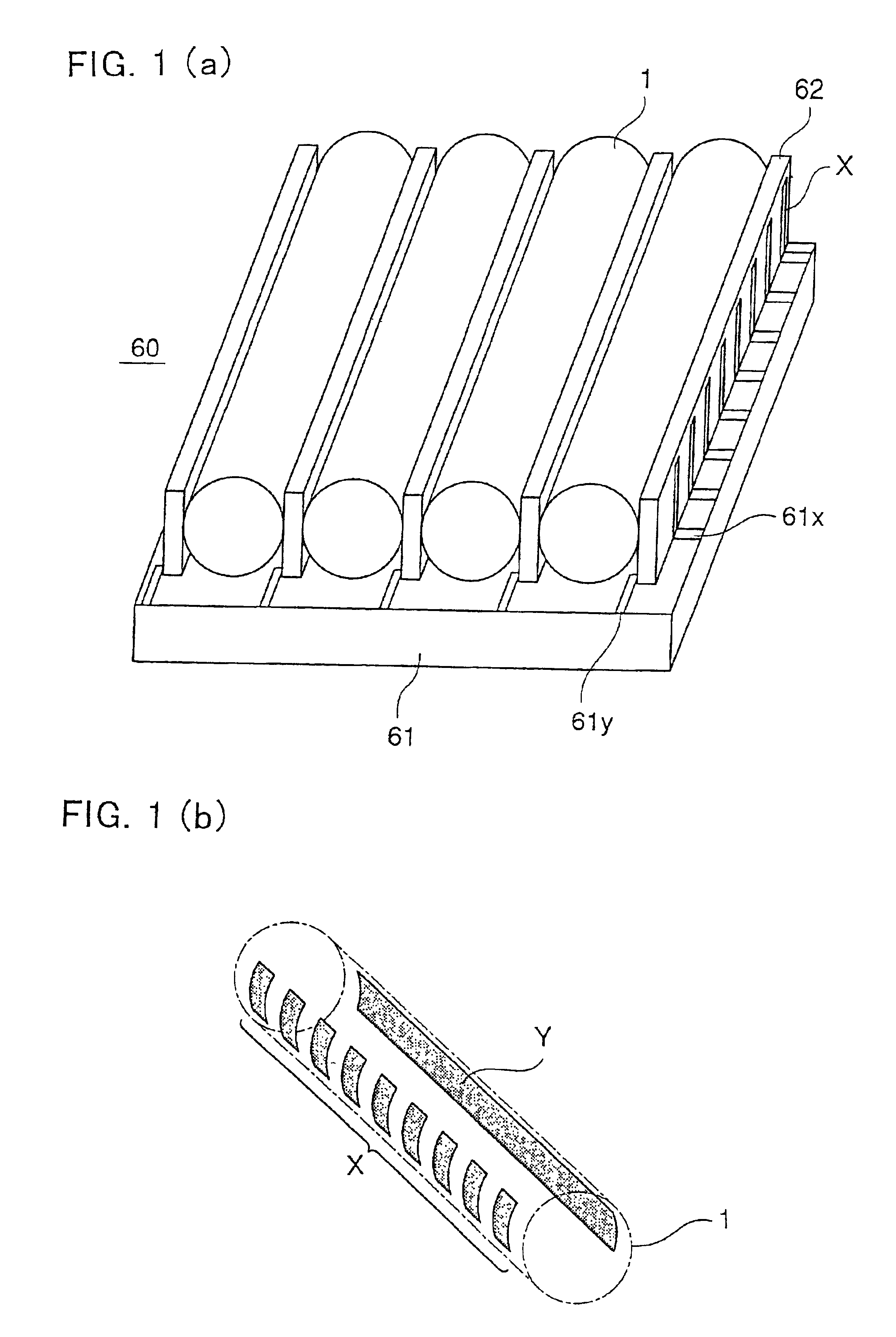

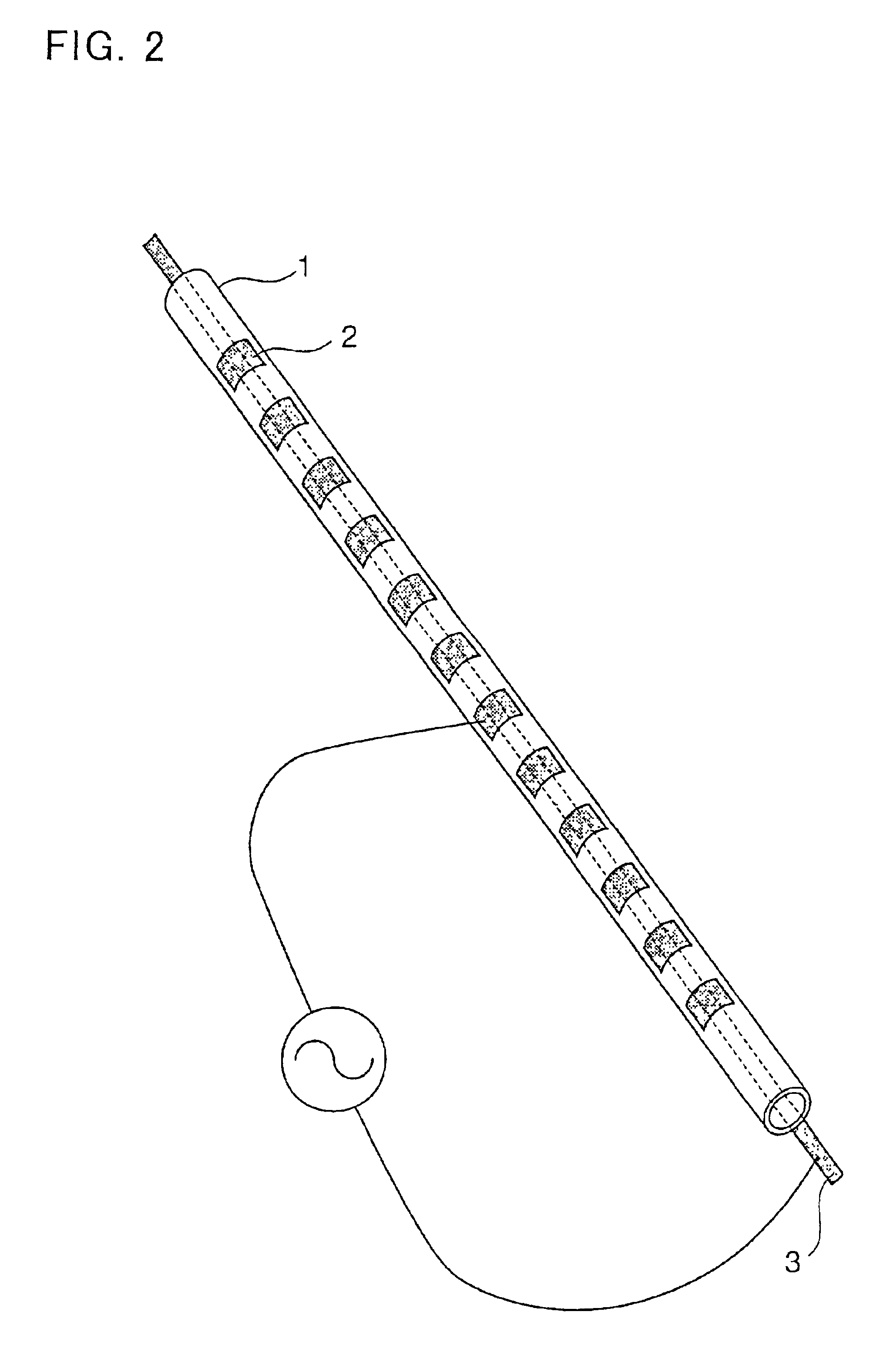

Gas discharge tube and method for forming electron emission layer in gas discharge tube

InactiveUS6932664B2Reduce unevennessImprove discharge characteristicsTube/lamp screens manufactureGas-filled discharge tubesEngineeringElectron

Owner:SHINODA PLASMA

Heat spreader for emissive display device

InactiveUS7150914B2Increase temperature differenceTemperature differenceTube/lamp screens manufactureMaterial nanotechnologyDisplay deviceGraphite

A heat spreader for an emissive display device, such as a plasma display panel or a light emitting diode, comprising at least one sheet of compressed particles of exfoliated graphite having a surface area greater than the surface area of that part of a discharge cell facing the back surface of the device.

Owner:NEOGRAF SOLUTIONS LLC

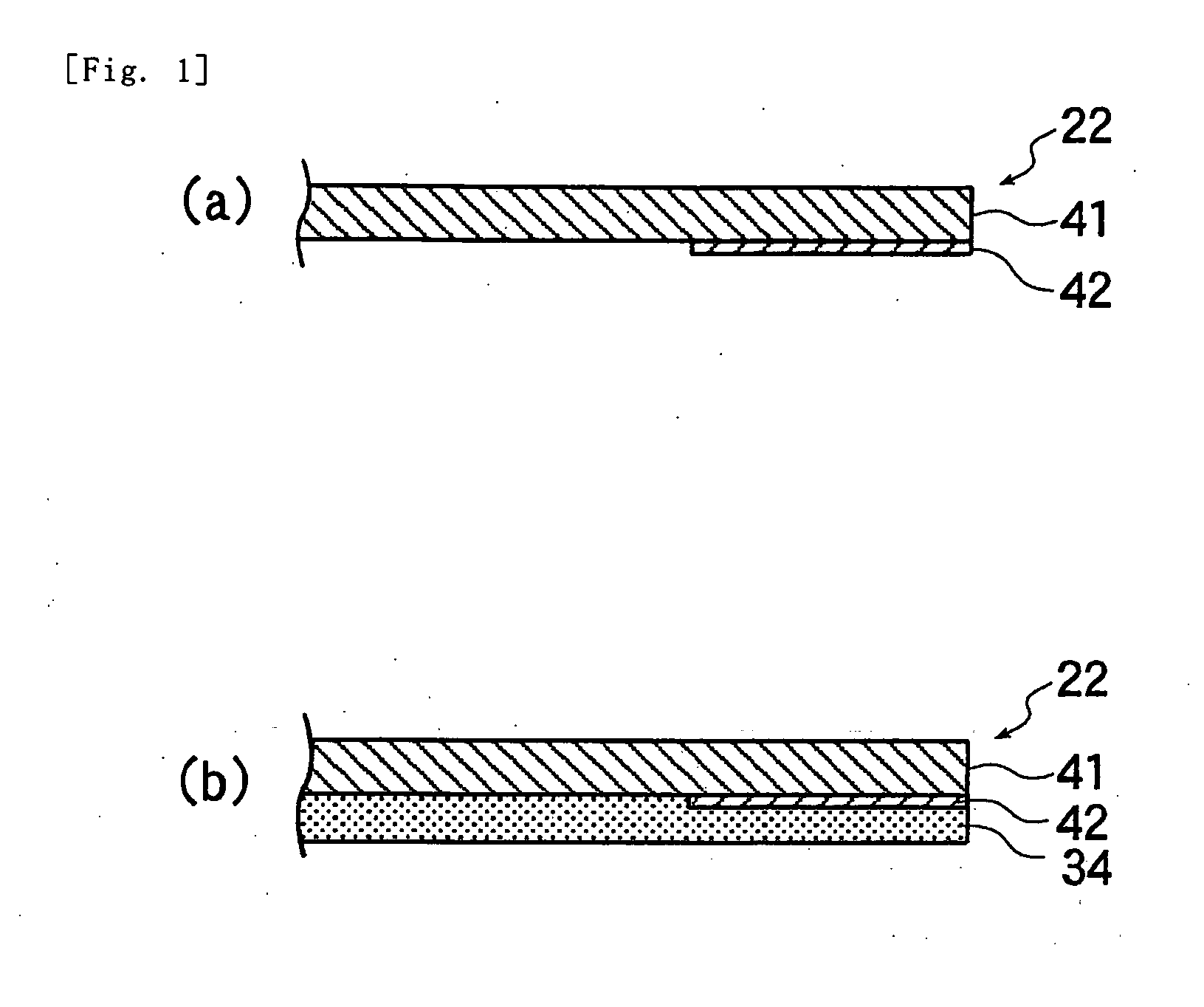

Method for making liquid crystal display adopting touch panel

ActiveUS20100041297A1Tube/lamp screens manufactureNanoinformaticsLiquid-crystal displayCarbon nanotube

A method for making a liquid crystal display screen is provided. A touch panel including at least one carbon nanotube structure layer is prepared. A first polarizer is applied on a surface of the touch panel. A thin film transistor panel including a number of thin film transistors is prepared. A liquid crystal layer is placed between the first polarizer and the thin film transistors.

Owner:TSINGHUA UNIV +1

Heat spreader for plasma display panel

InactiveUS7138029B2Good thermal contactLiquid crystal compositionsTube/lamp screens manufactureThermodynamicsAdhesive

Owner:NEOGRAF SOLUTIONS LLC

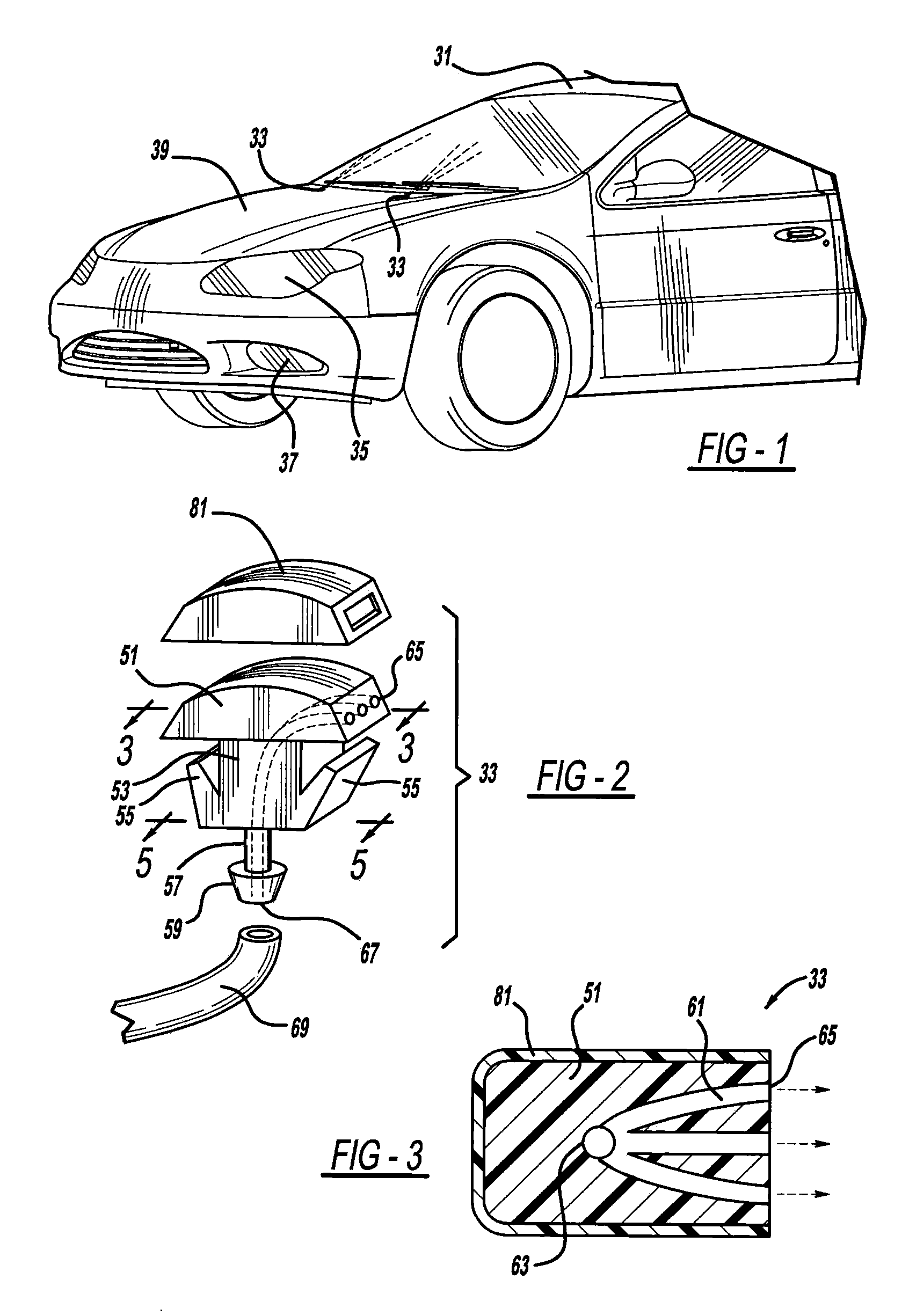

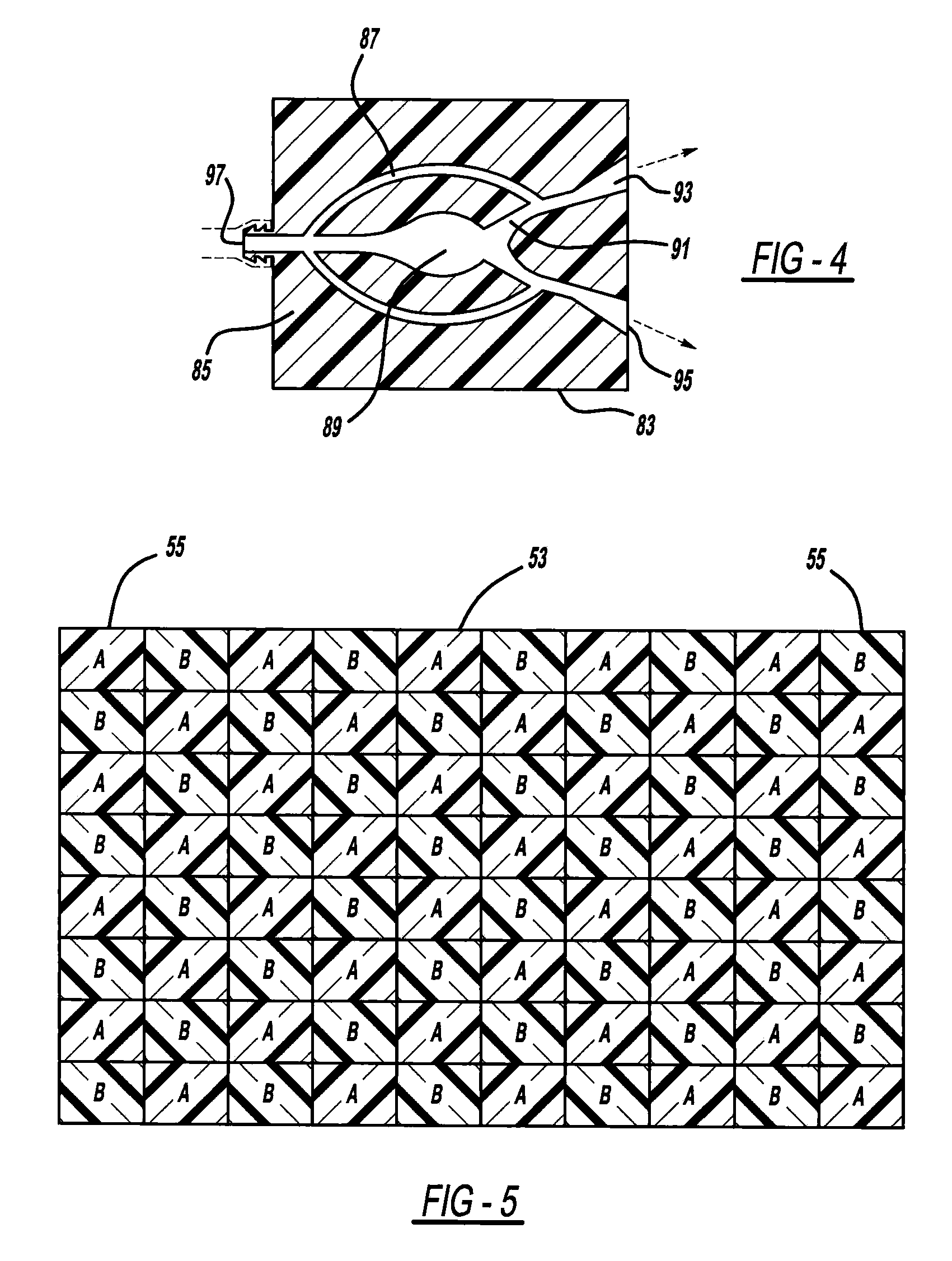

Process of making a component with a passageway

A component is provided that includes at least one passageway. In another aspect, a component, such as a lamp or a vehicular washer jet, is made of layers of material, a light curable material and / or multiple built-up materials. Another aspect uses a three-dimensional printing machine to emit material from an ink jet printing head to build up a component.

Owner:A RAYMOND & CO

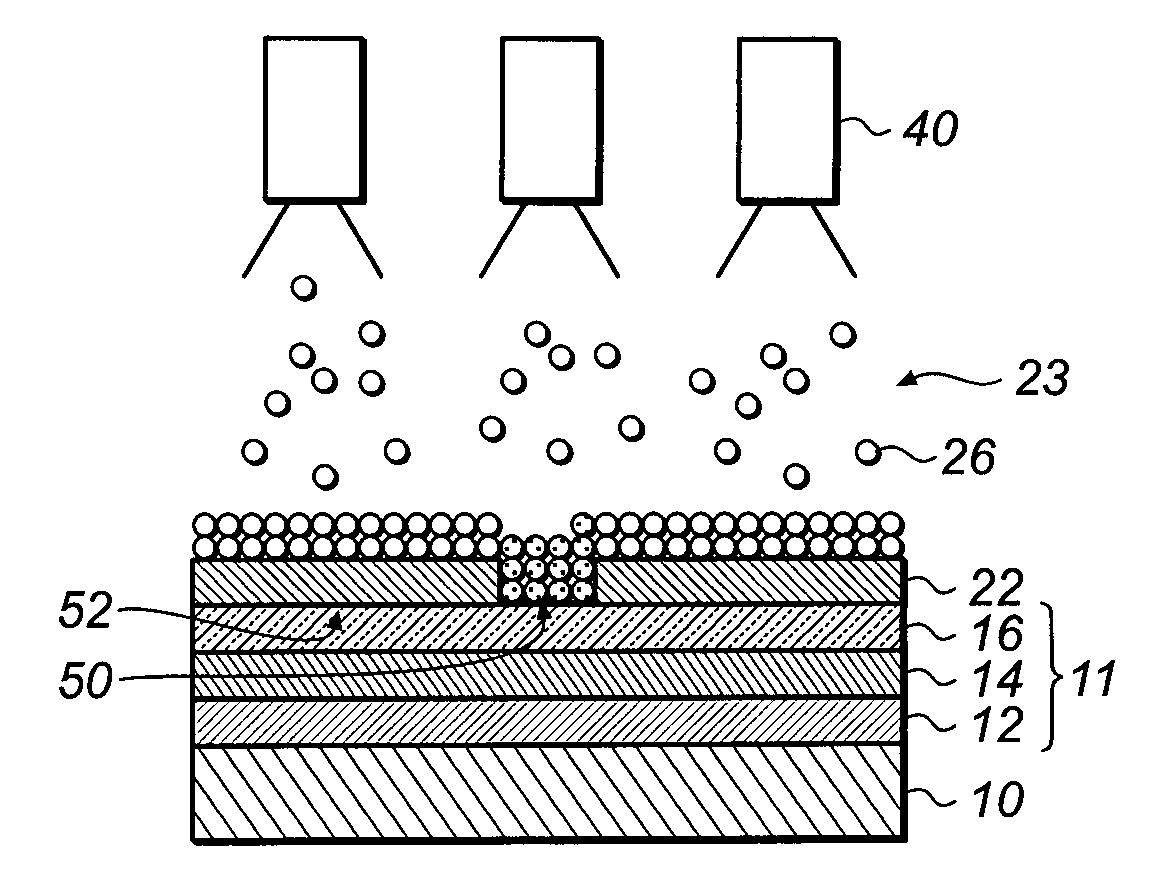

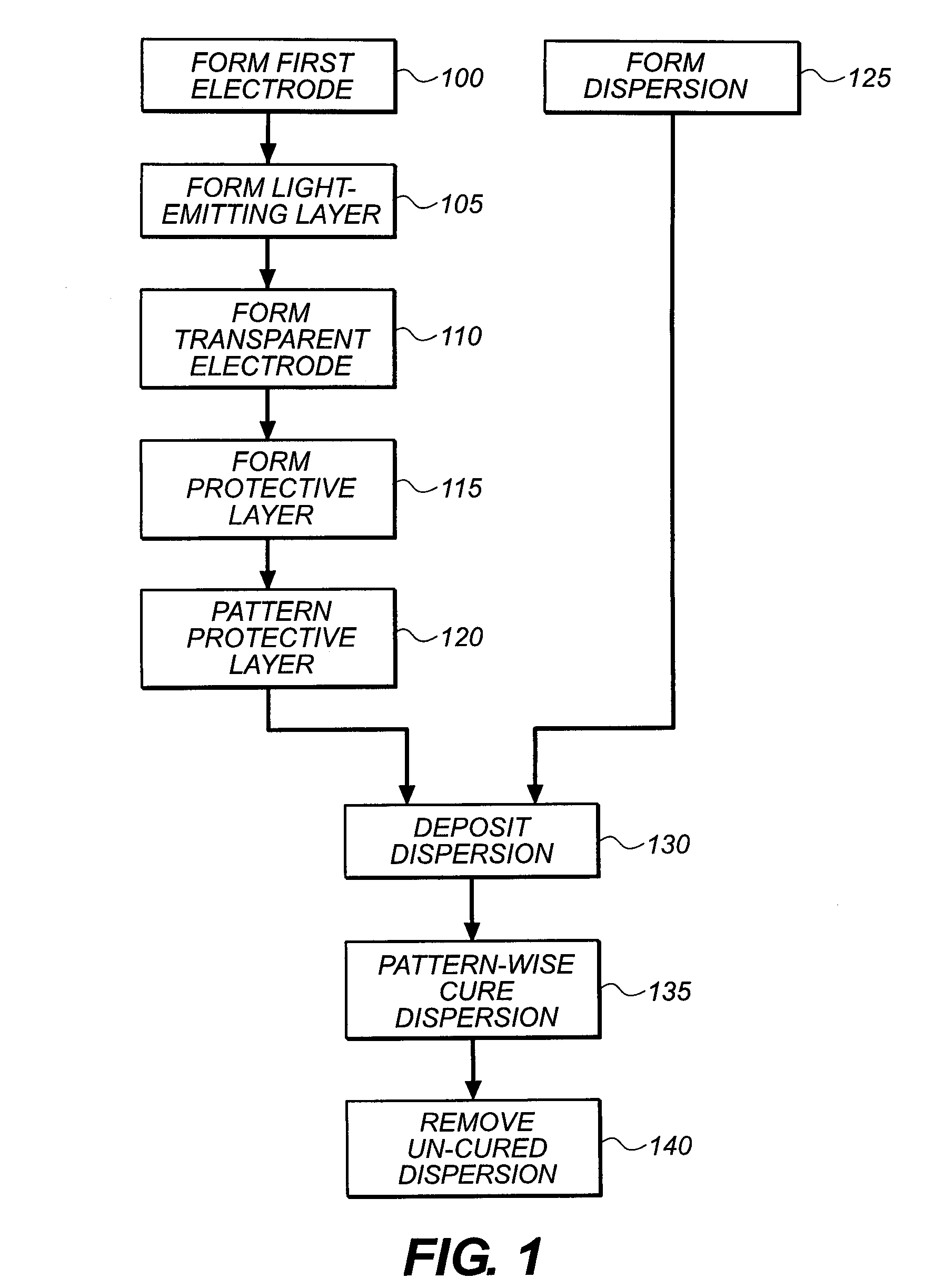

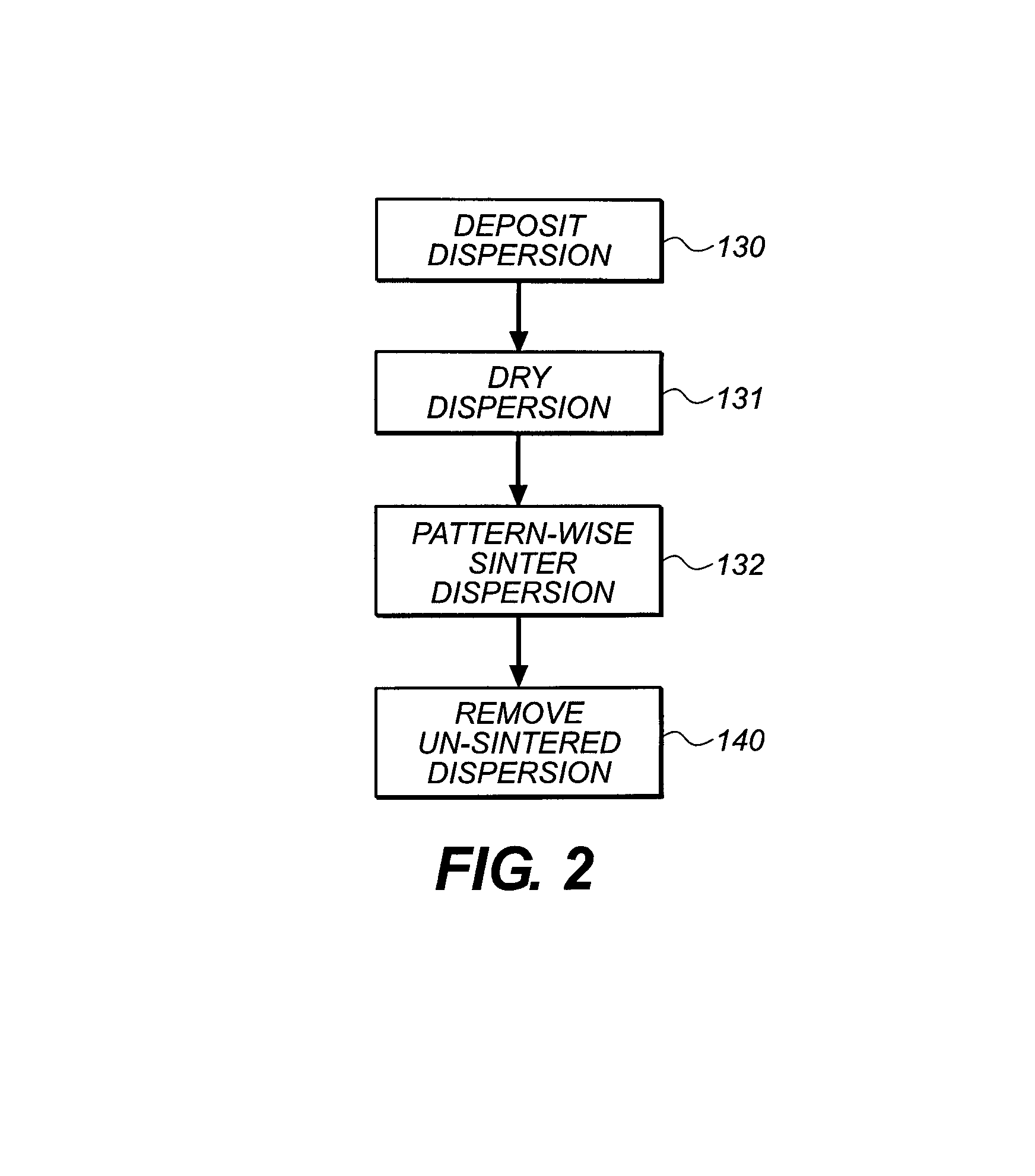

Device and method for improved power distribution for a transparent electrode

ActiveUS7722422B2Tube/lamp screens manufactureDischarge tube luminescnet screensElectrically conductiveElectrode

A method for improving power distribution of a transparent electrode that includes forming an LED over a substrate; the LED including a first electrode, a transparent electrode, and one or more light-emissive layers formed there-between. A patterned protective layer is formed on the transparent electrode; the patterned protective layer having open areas wherein the protective layer is not present, and covered areas wherein the protective layer is present. A solution having curable conductive precursor components is deposited over the open areas onto the transparent electrode. The precursor components of the solution are pattern-wise cured to form patterned electrically conductive areas on the transparent electrode in the open areas, and any uncured precursor components of the solution are removed.

Owner:GLOBAL OLED TECH

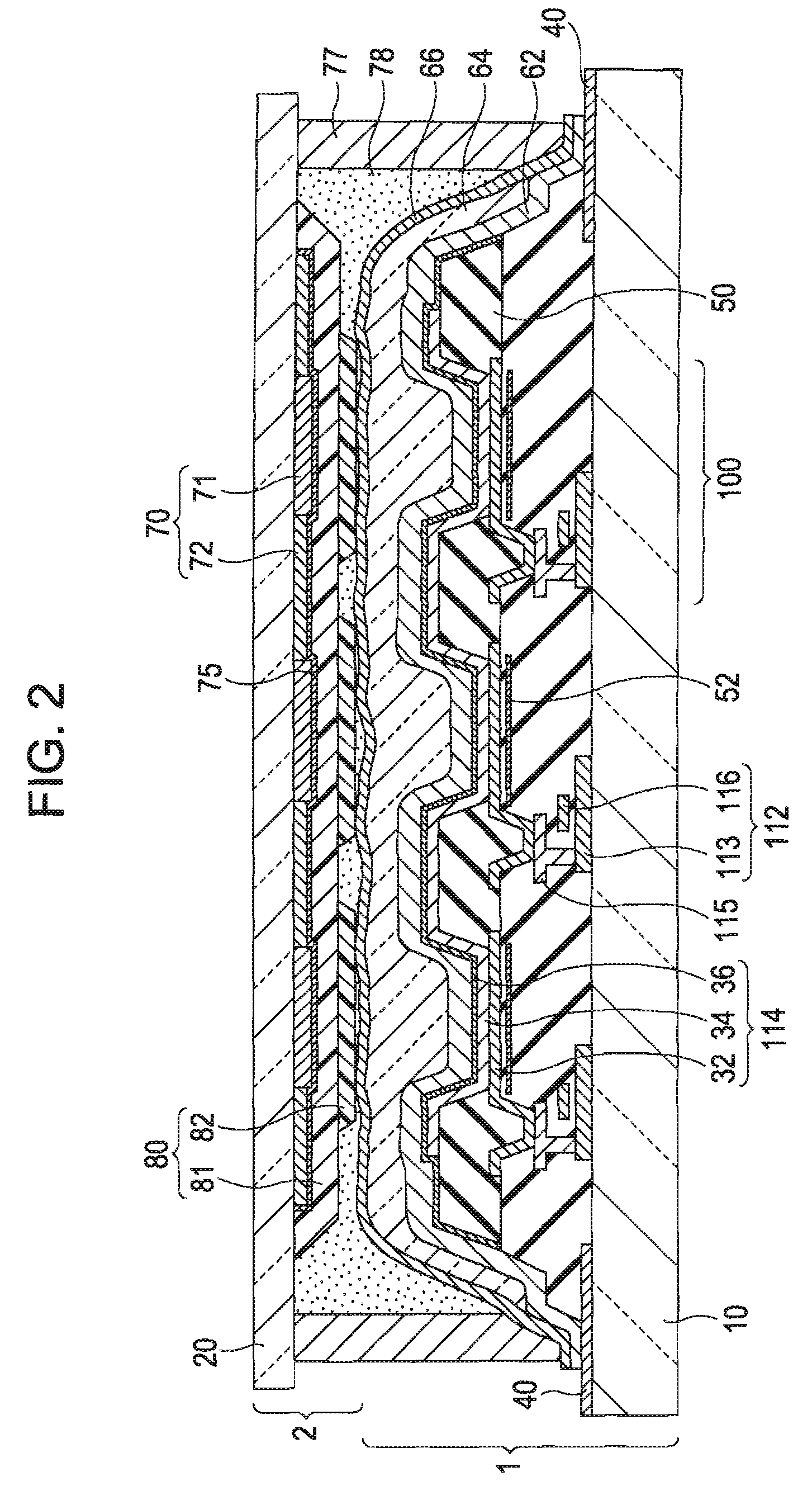

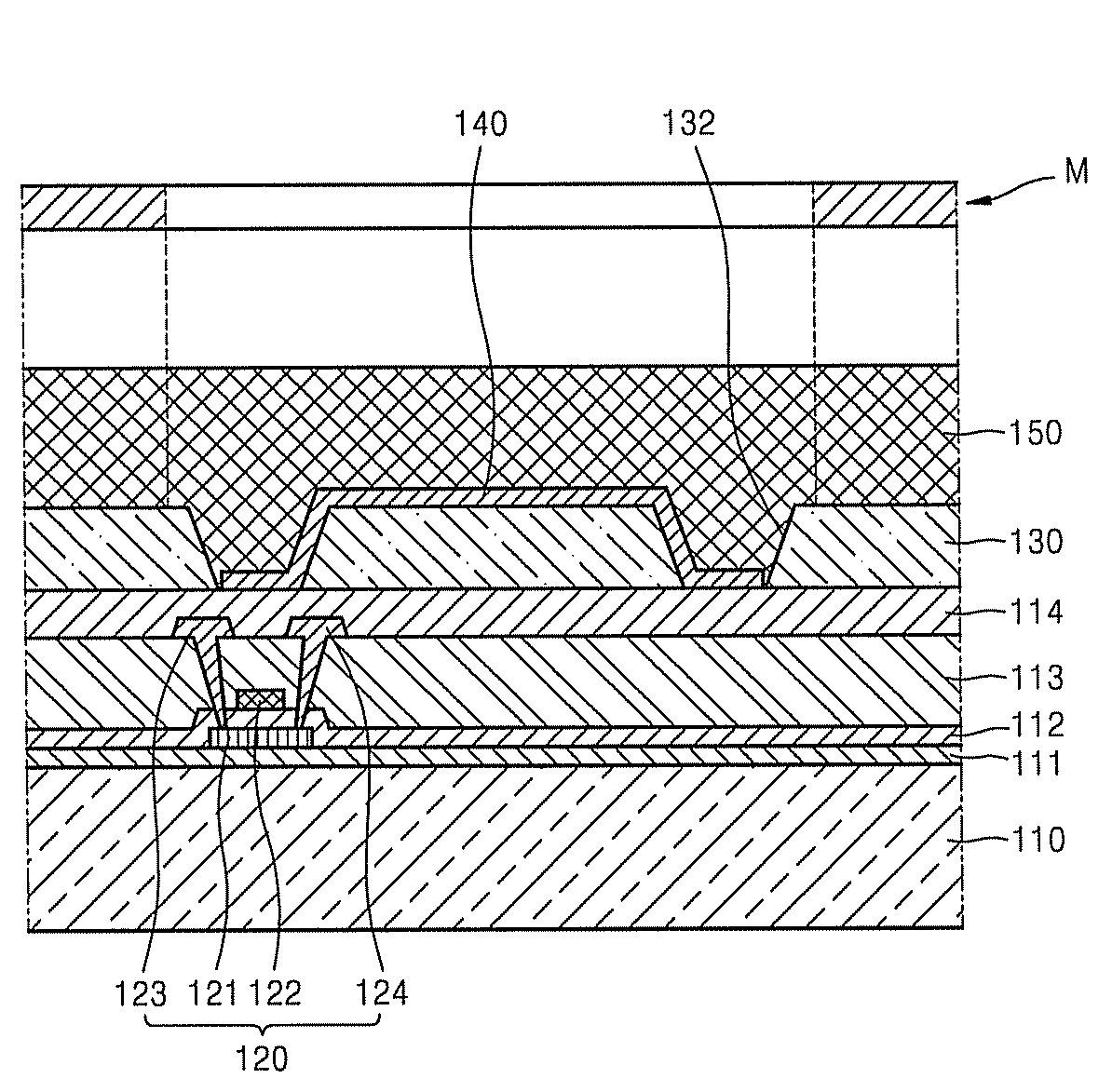

Organic light emitting display apparatus and method of manufacturing the same

ActiveUS20090039773A1Easy to useLow costTube/lamp screens manufactureDischarge tube luminescnet screensClosed loopOptoelectronics

An organic light emitting display apparatus including: a substrate; a thin film transistor formed on the substrate; a planarization layer formed on the substrate to cover the thin film transistor and comprising a closed-loop groove; a pixel electrode that contacts the thin film transistor and is formed on the planarization layer; a pixel defining layer formed to fill the closed-loop groove; a spacer formed on the planarization layer and disposed outside the pixel electrode; an organic light emitting layer formed on the pixel electrode; and an opposite electrode covering the organic light emitting layer.

Owner:SAMSUNG DISPLAY CO LTD

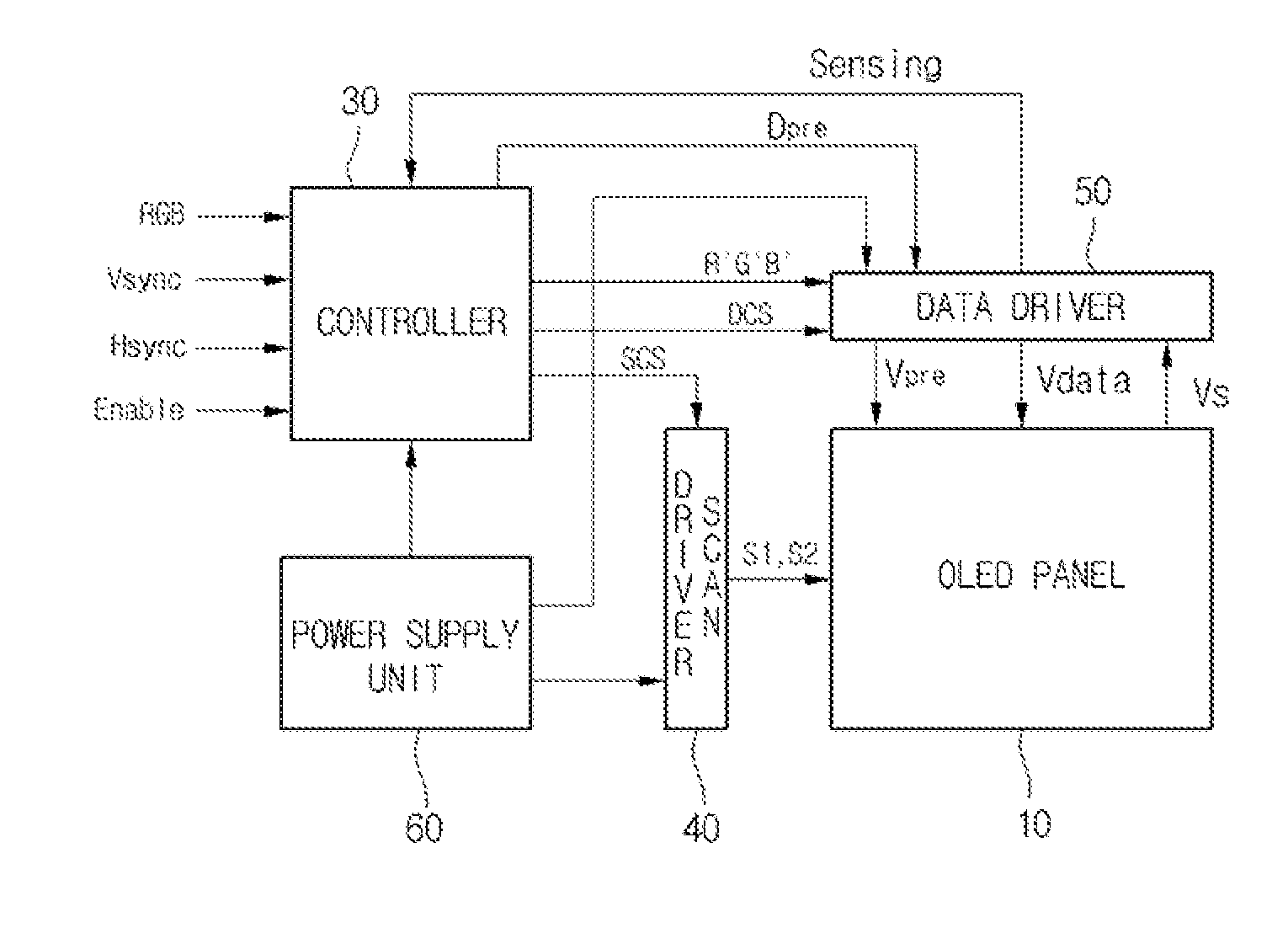

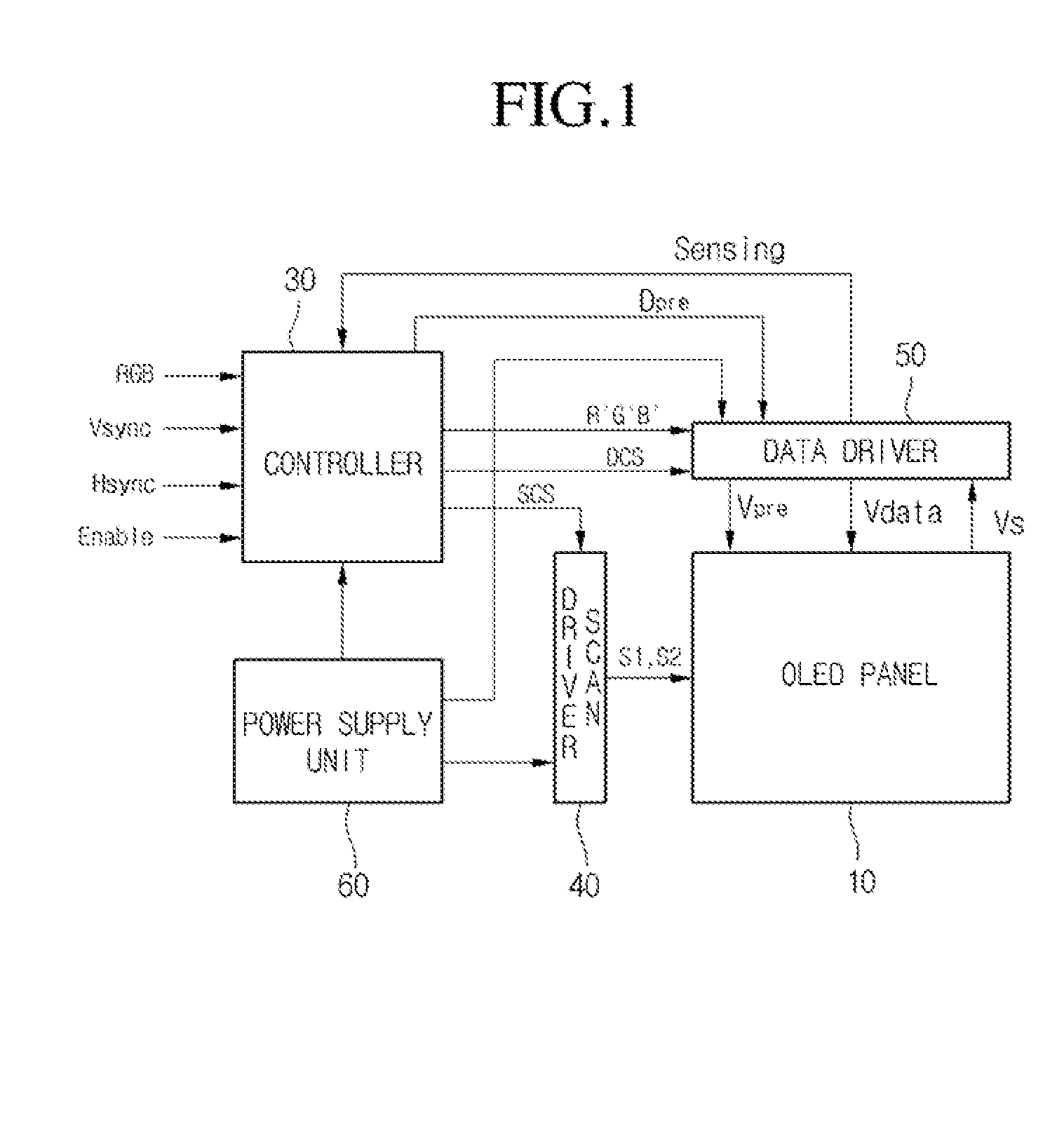

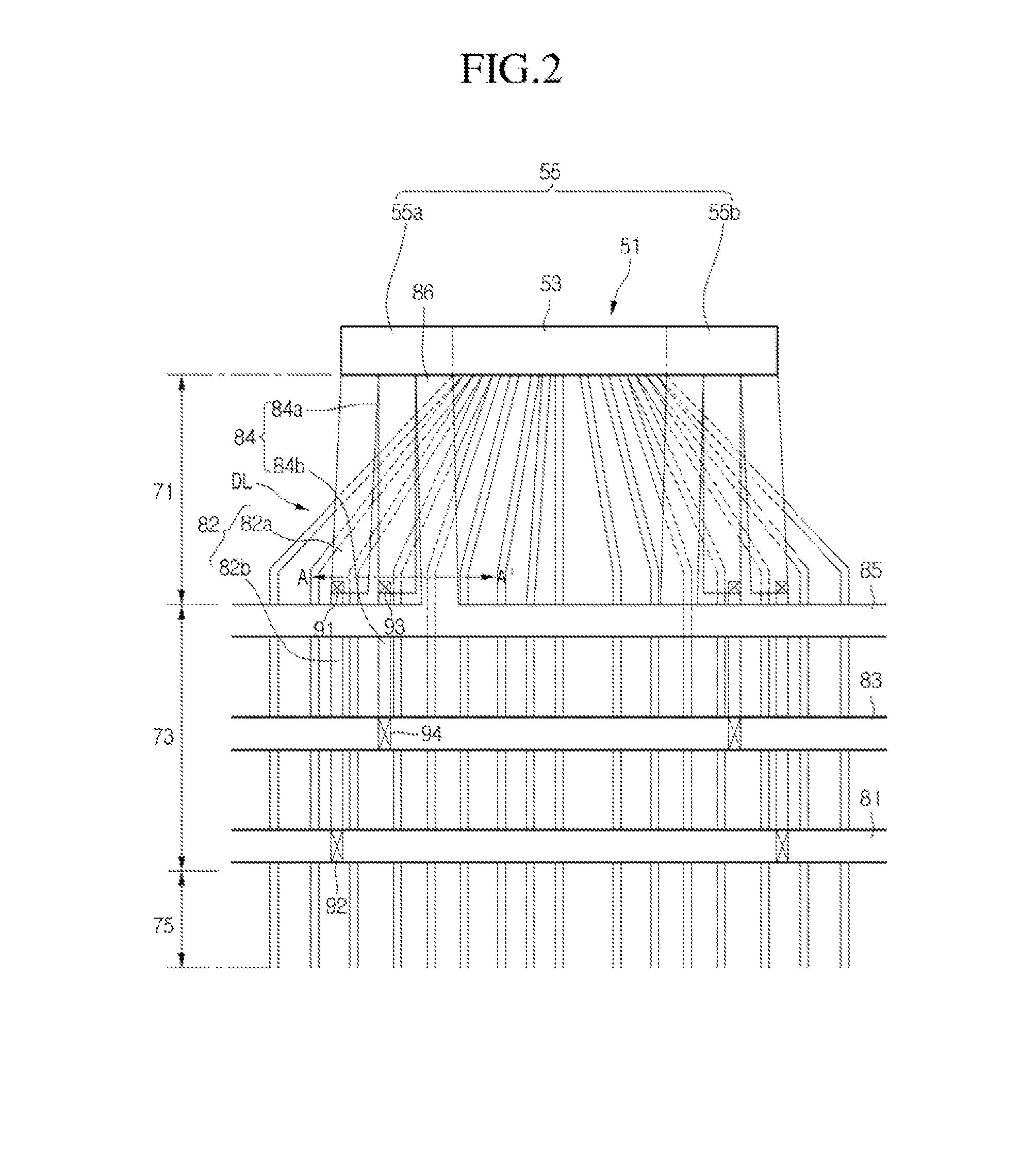

Organic Light Emitting Display

ActiveUS20130106817A1Improve display qualityMinimizing capacitance deviationTube/lamp screens manufactureElectroluminescent light sourcesCapacitanceData lines

An OLED device is disclosed that enhances display quality by minimizing capacitance deviation between data lines of the OLED device. The capacitance deviation may be minimized by utilizing an expansion portion of a power line of the OLED device. The capacitance deviation may also by minimized by utilizing an overlap pattern that overlaps a plurality of the data lines.

Owner:LG DISPLAY CO LTD

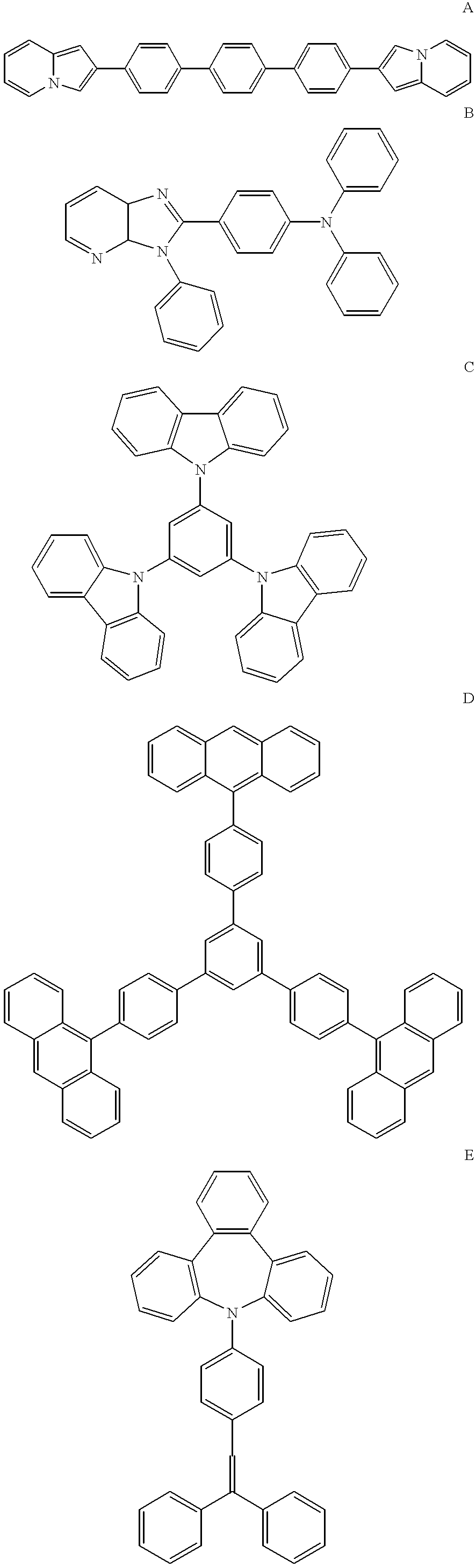

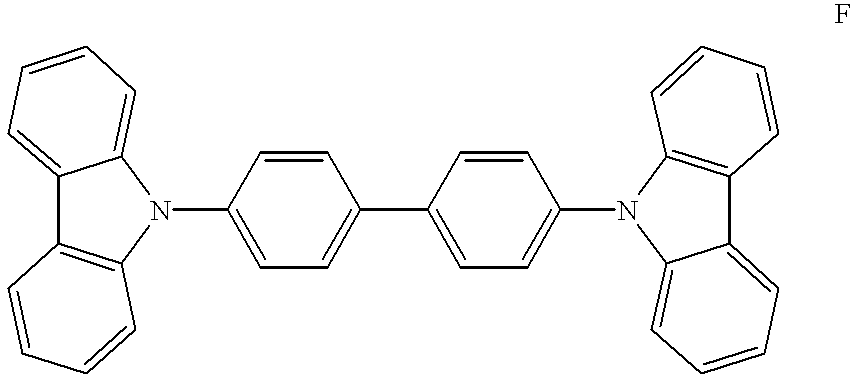

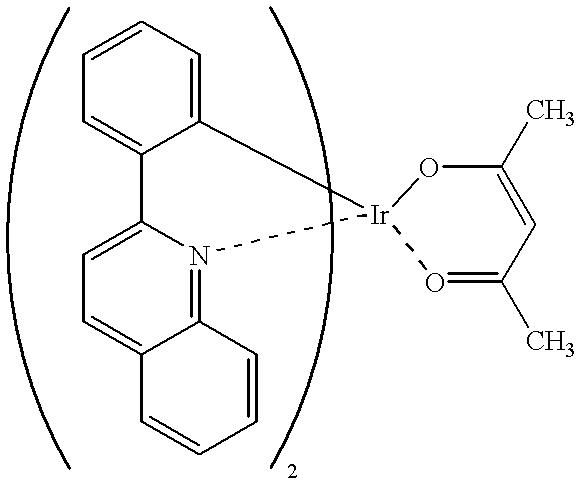

Method for selecting combination of host material and light-emitting material, and organic light-emitting device using combination selected thereby

InactiveUS6626722B2High light emitting efficiencyAvoid difficult choicesTube/lamp screens manufactureDischarge tube luminescnet screensPhoto irradiationOrganic light emitting device

A method for selecting a combination of a host material and a light-emitting material to be used for a light-emitting layer of an organic light-emitting device, involving the steps of: (a) disposing a mixture film containing a host material and a light-emitting material on a substrate; and (b) evaluating the mixture film with respect to light-emitting properties while irradiating a light that is absorbed by the host material to the mixture film. An organic light-emitting device with a light-emitting layer containing the combination of the host material and the light-emitting material selected by the method is also provided.

Owner:FUJIFILM HLDG CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com