Patents

Literature

1818results about "Microstructural device assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

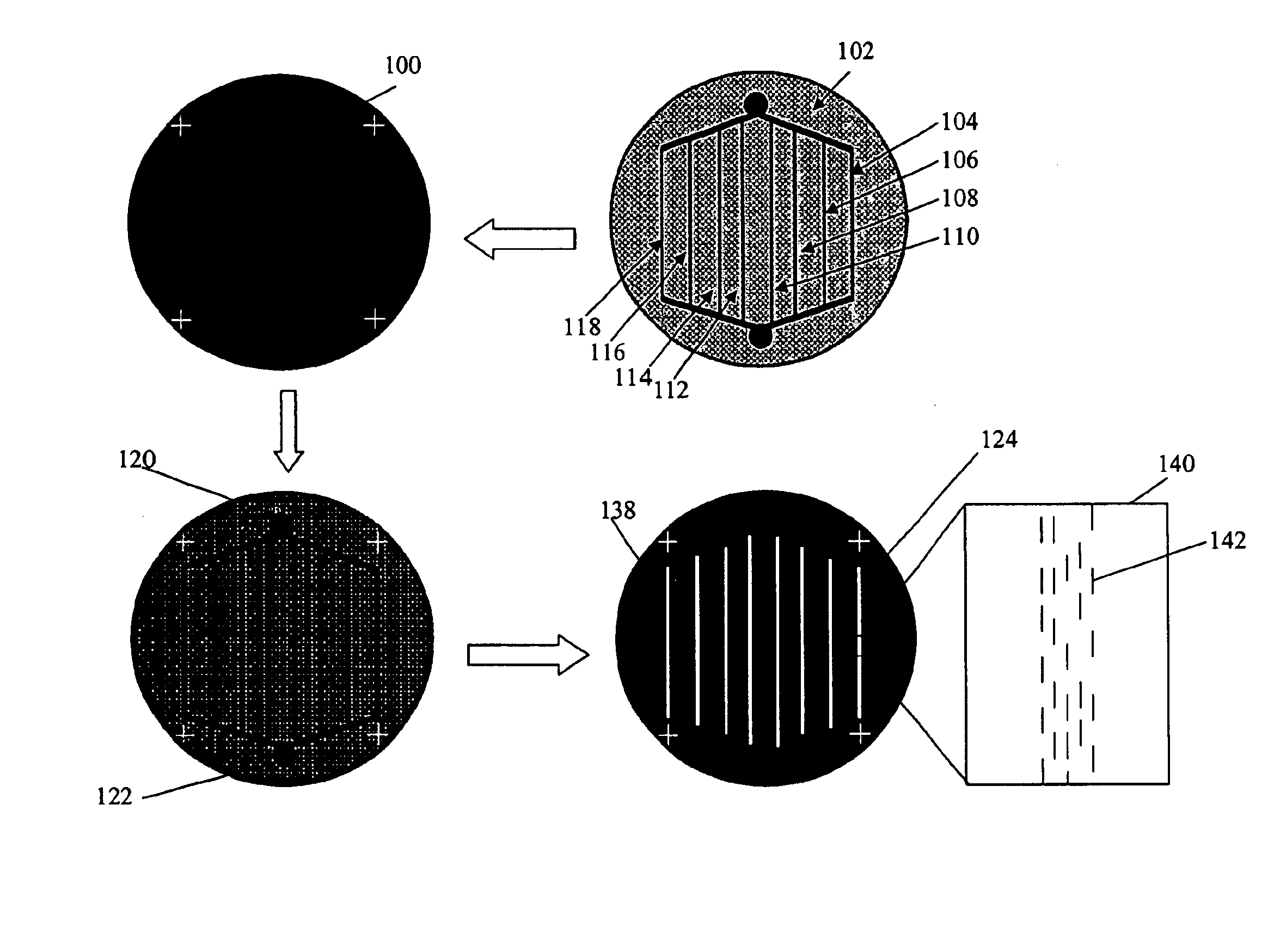

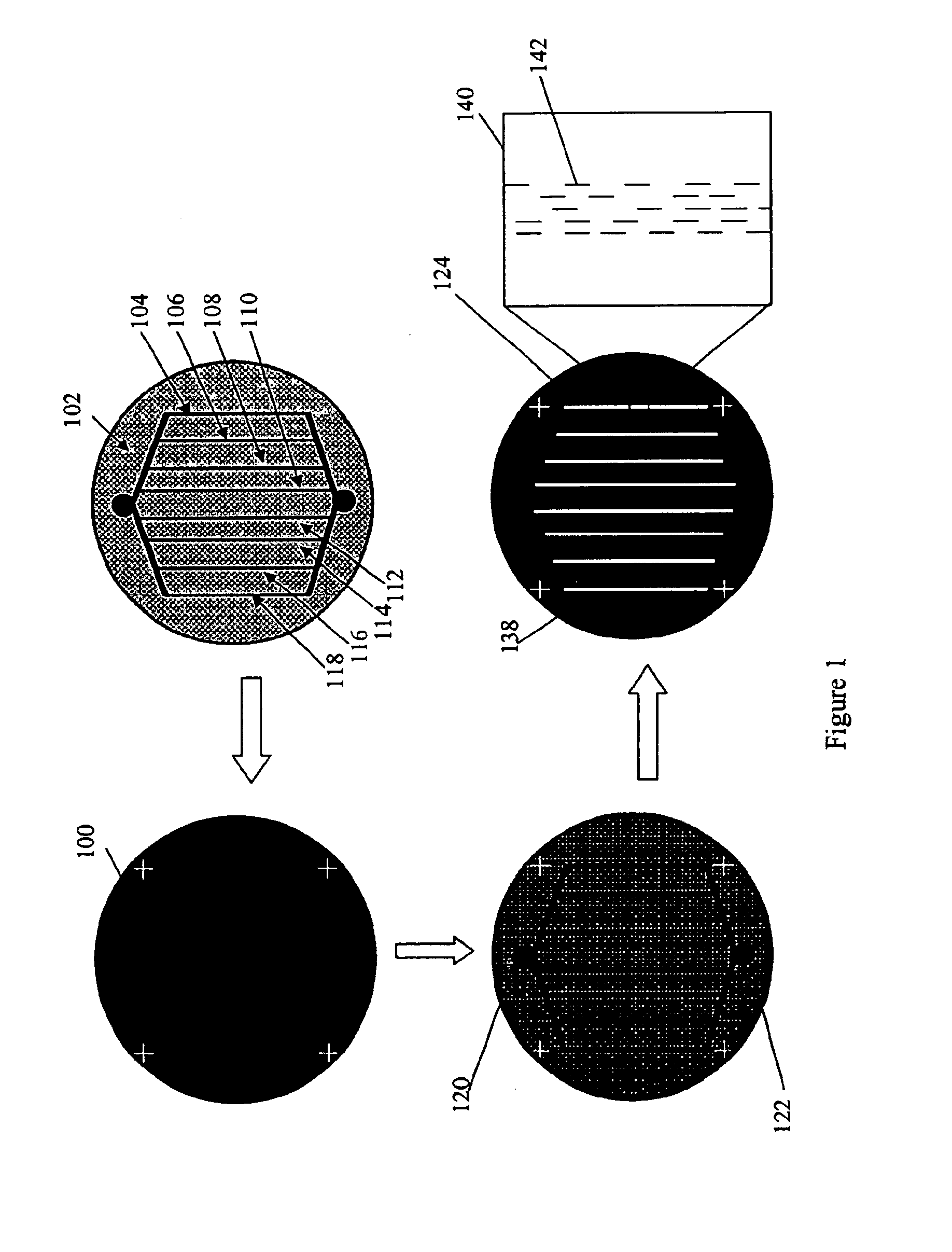

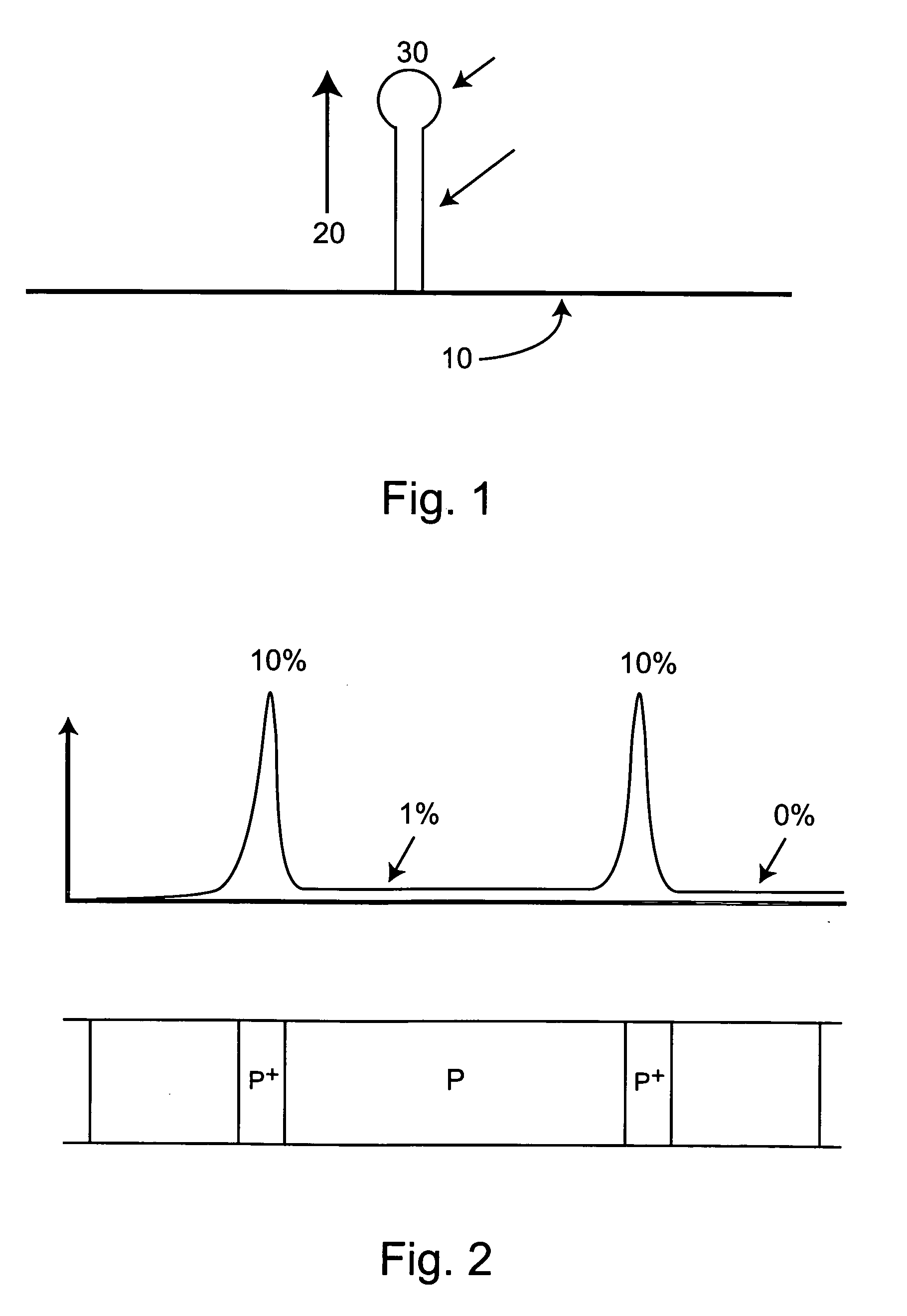

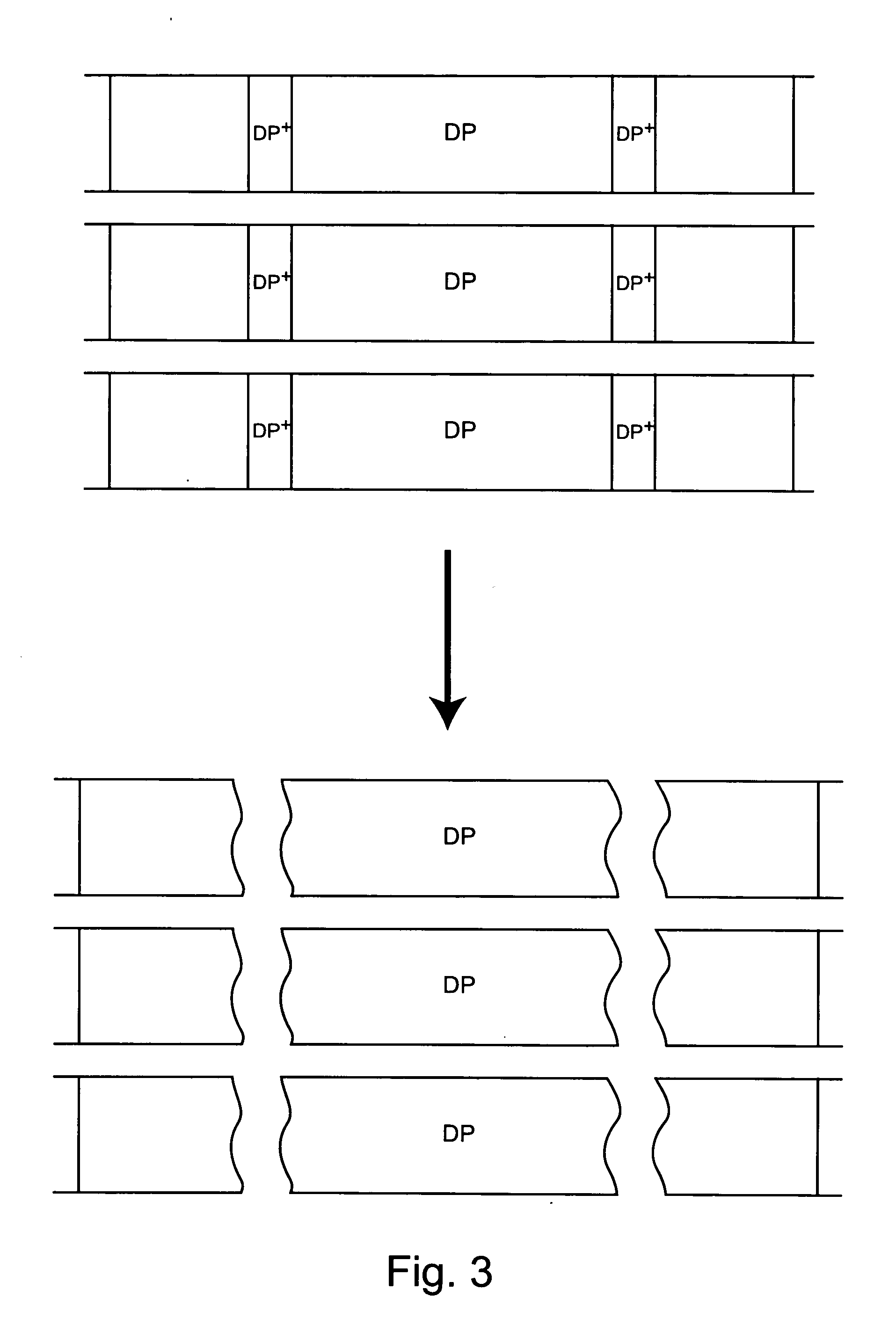

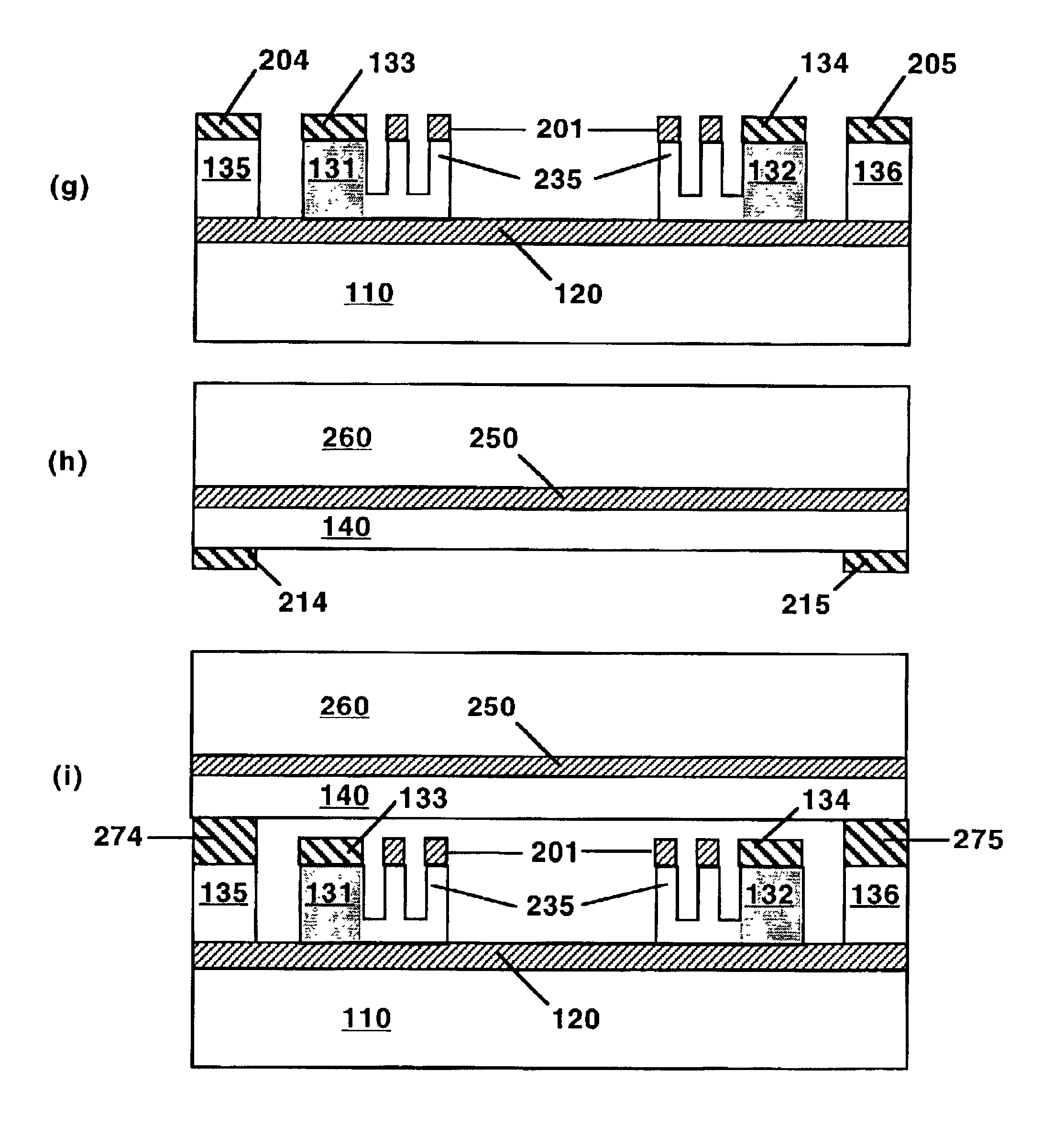

Methods of positioning and/or orienting nanostructures

Methods of positioning and orienting nanostructures, and particularly nanowires, on surfaces for subsequent use or integration. The methods utilize mask based processes alone or in combination with flow based alignment of the nanostructures to provide oriented and positioned nanostructures on surfaces. Also provided are populations of positioned and / or oriented nanostructures, devices that include populations of positioned and / or oriented nanostructures, systems for positioning and / or orienting nanostructures, and related devices, systems and methods.

Owner:ONED MATERIAL INC

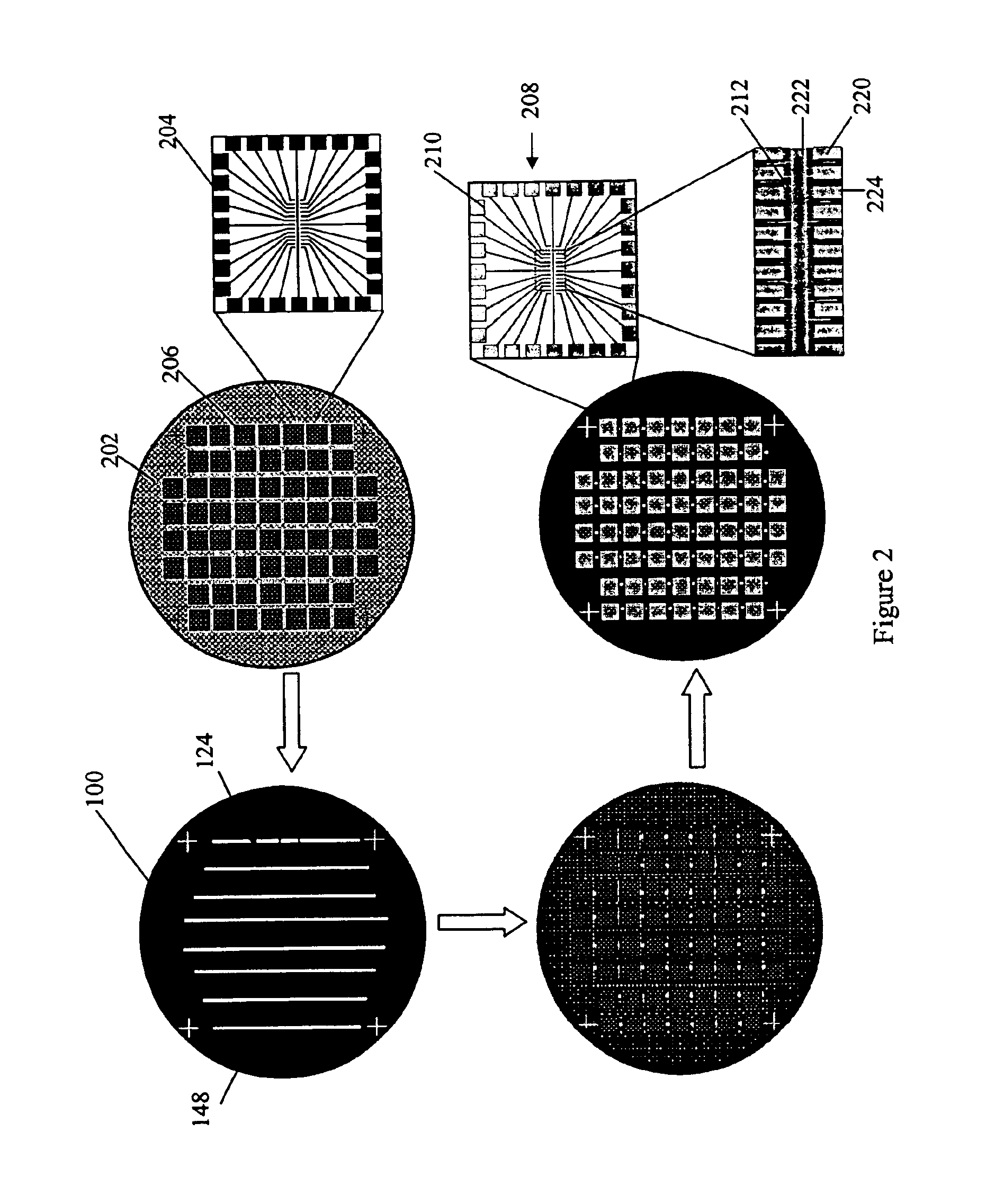

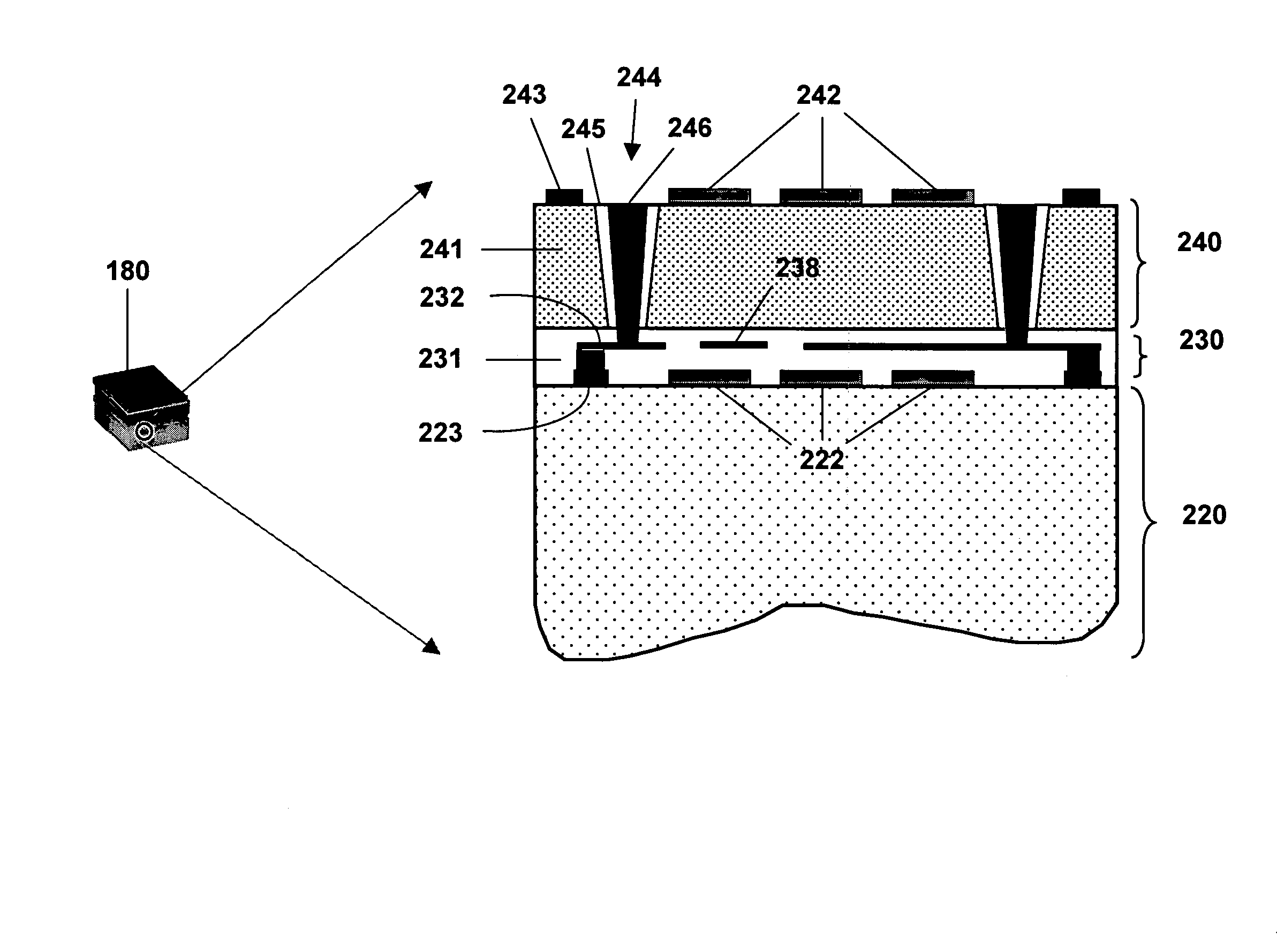

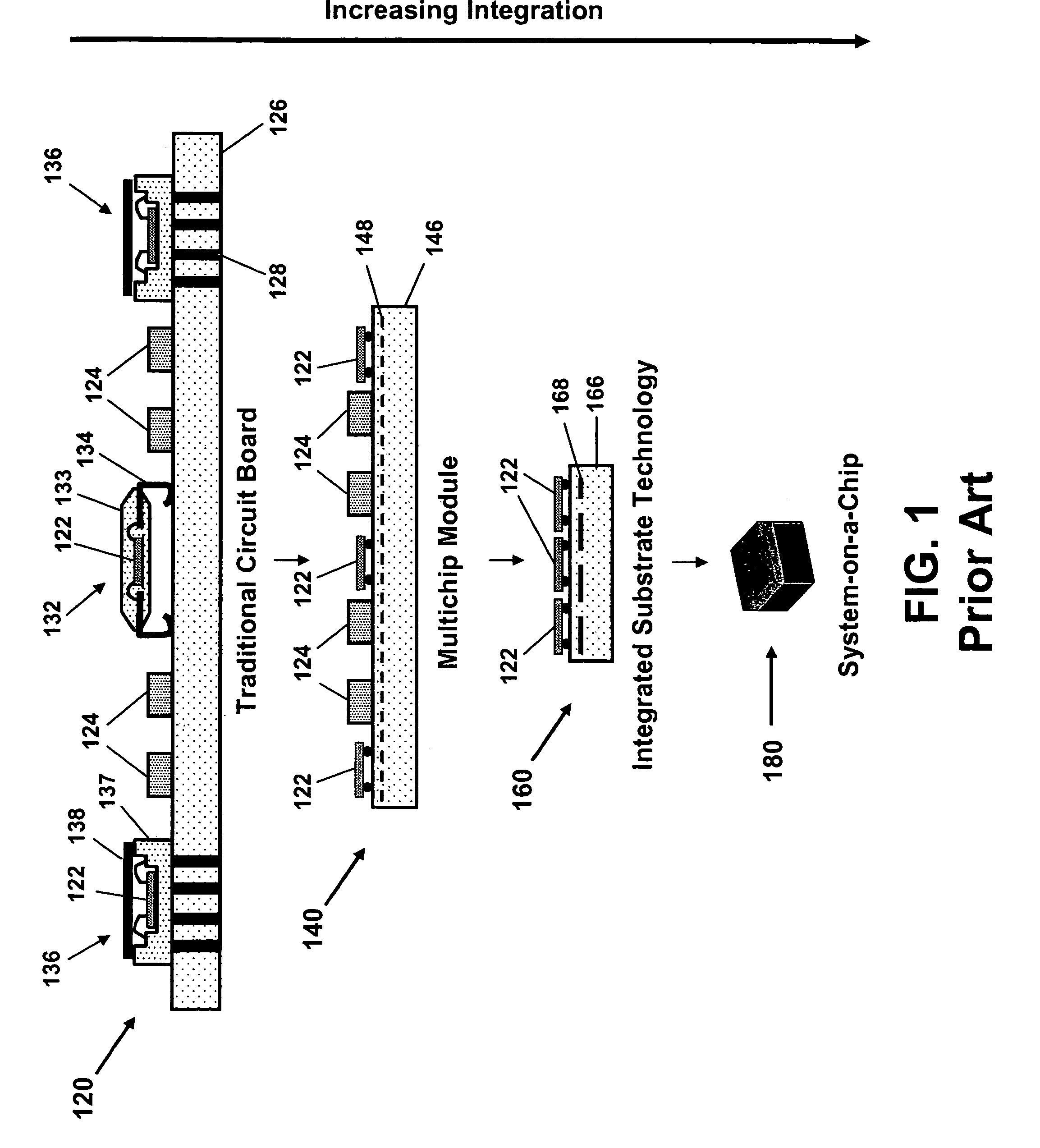

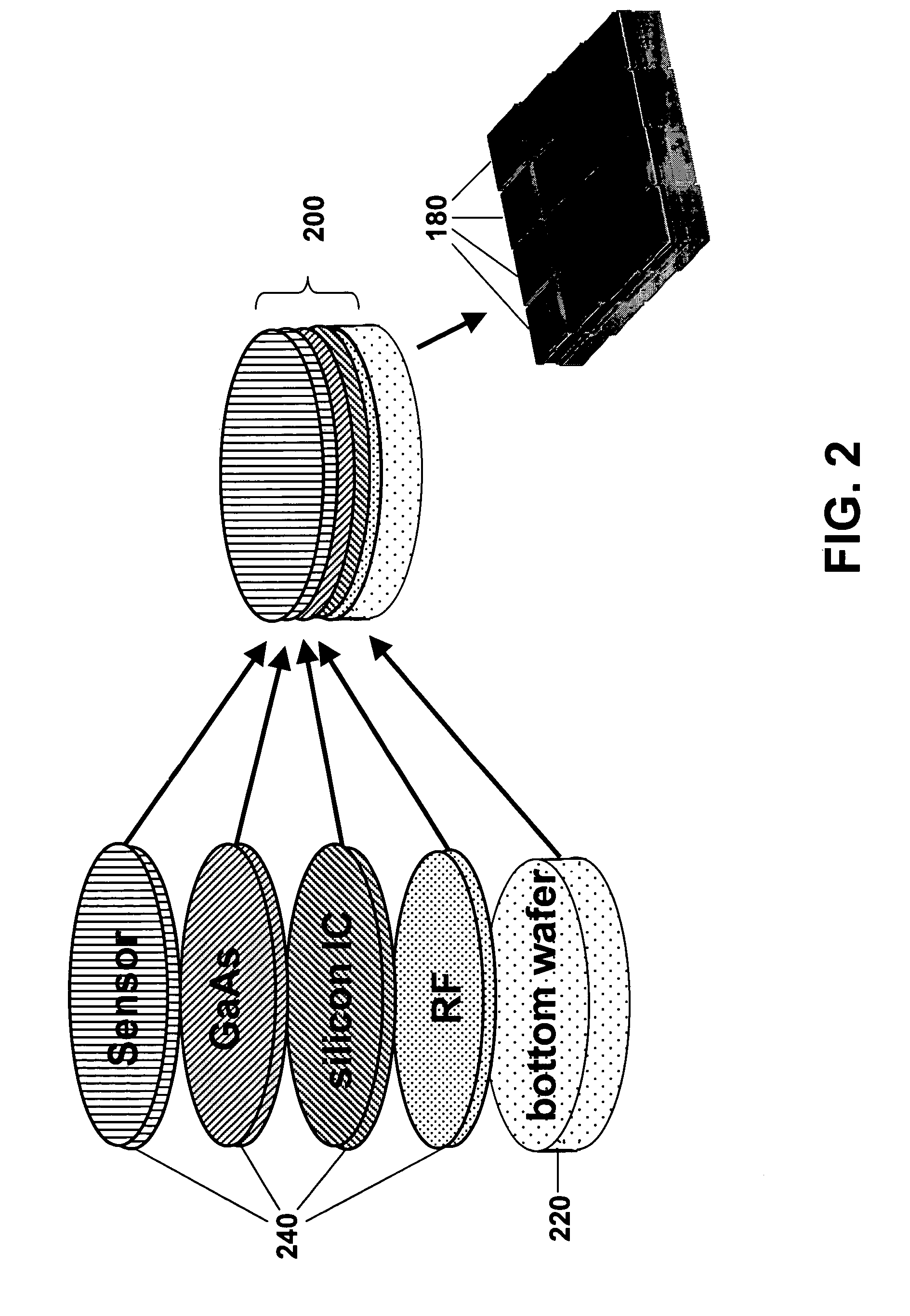

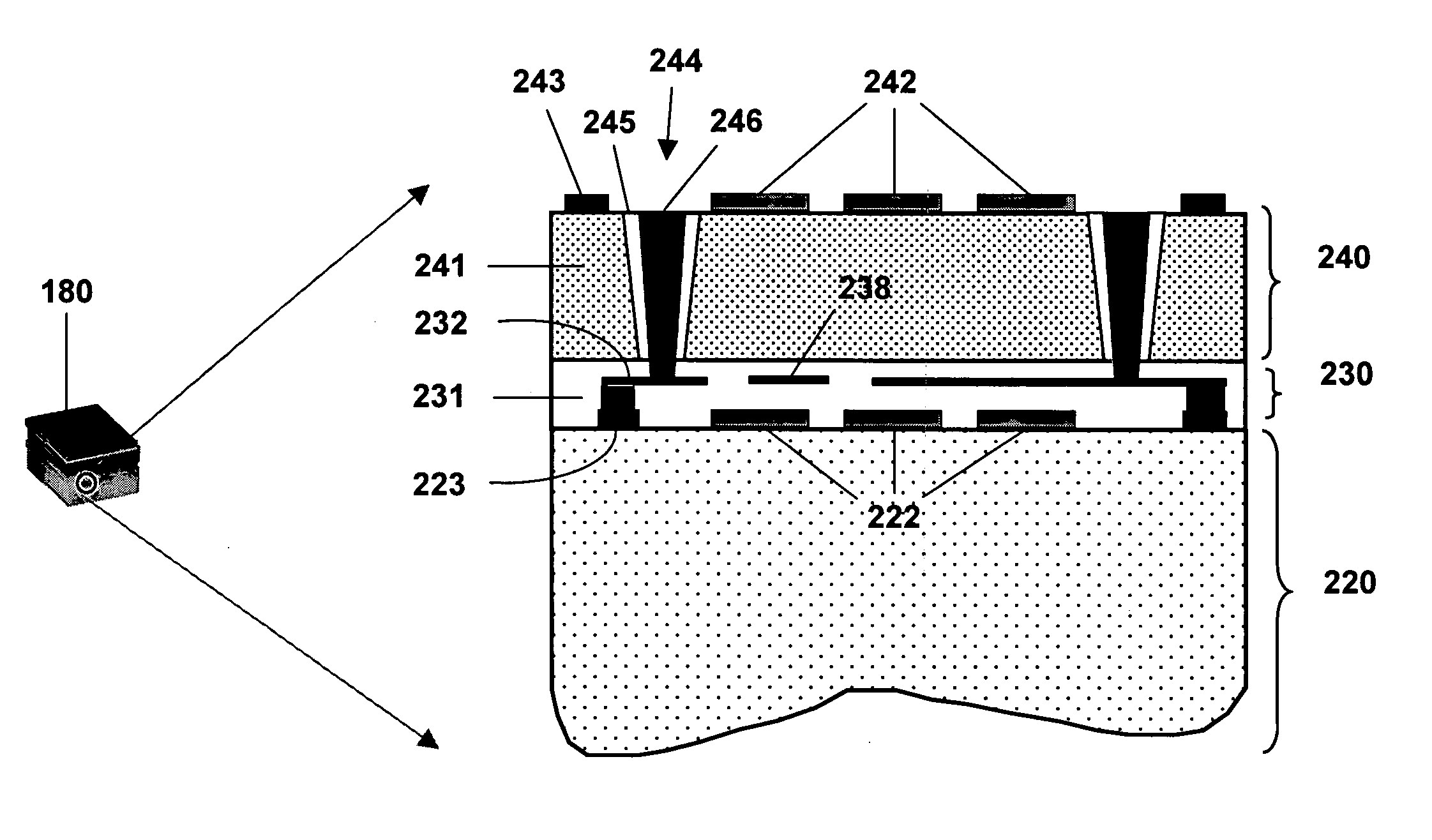

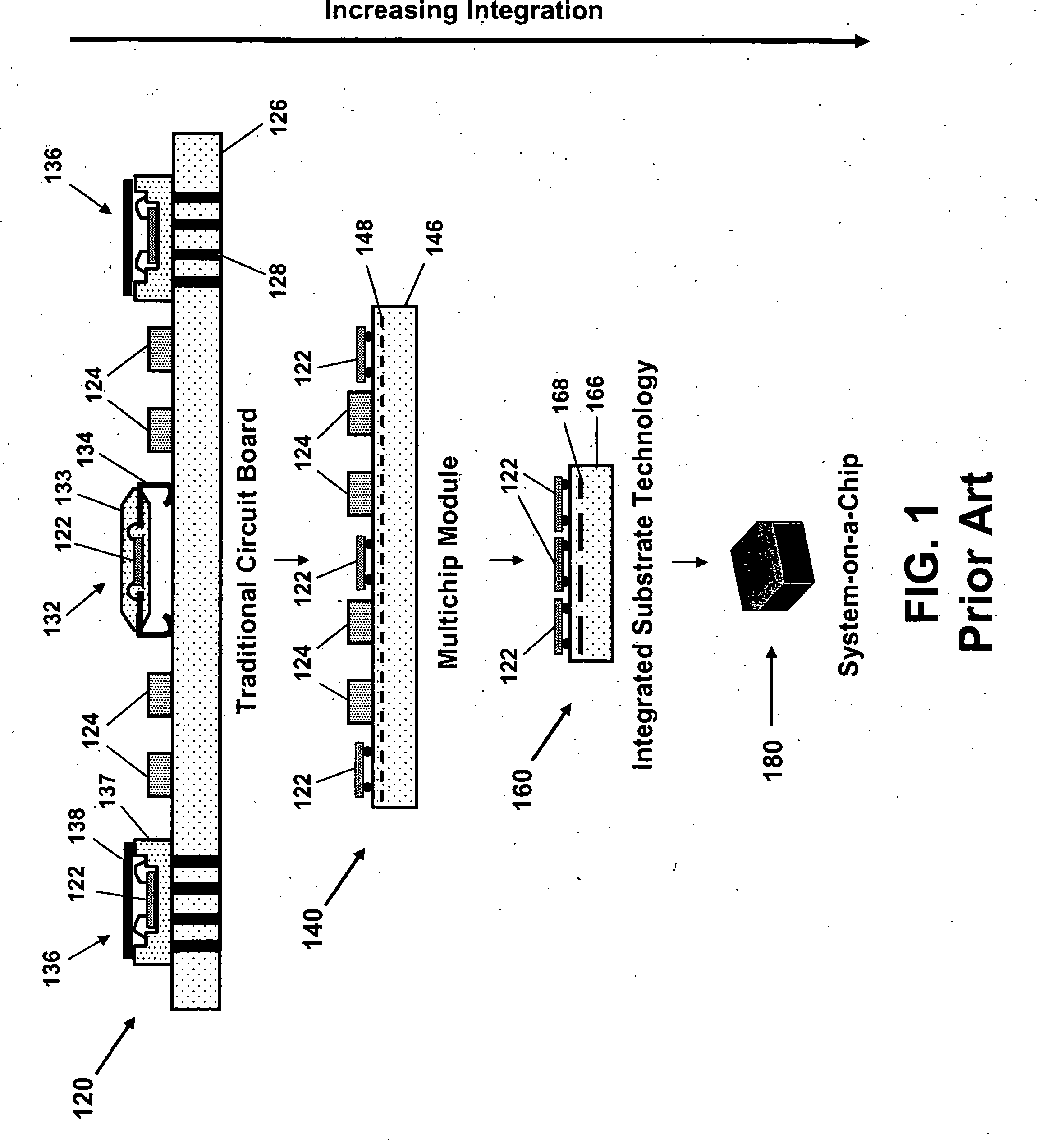

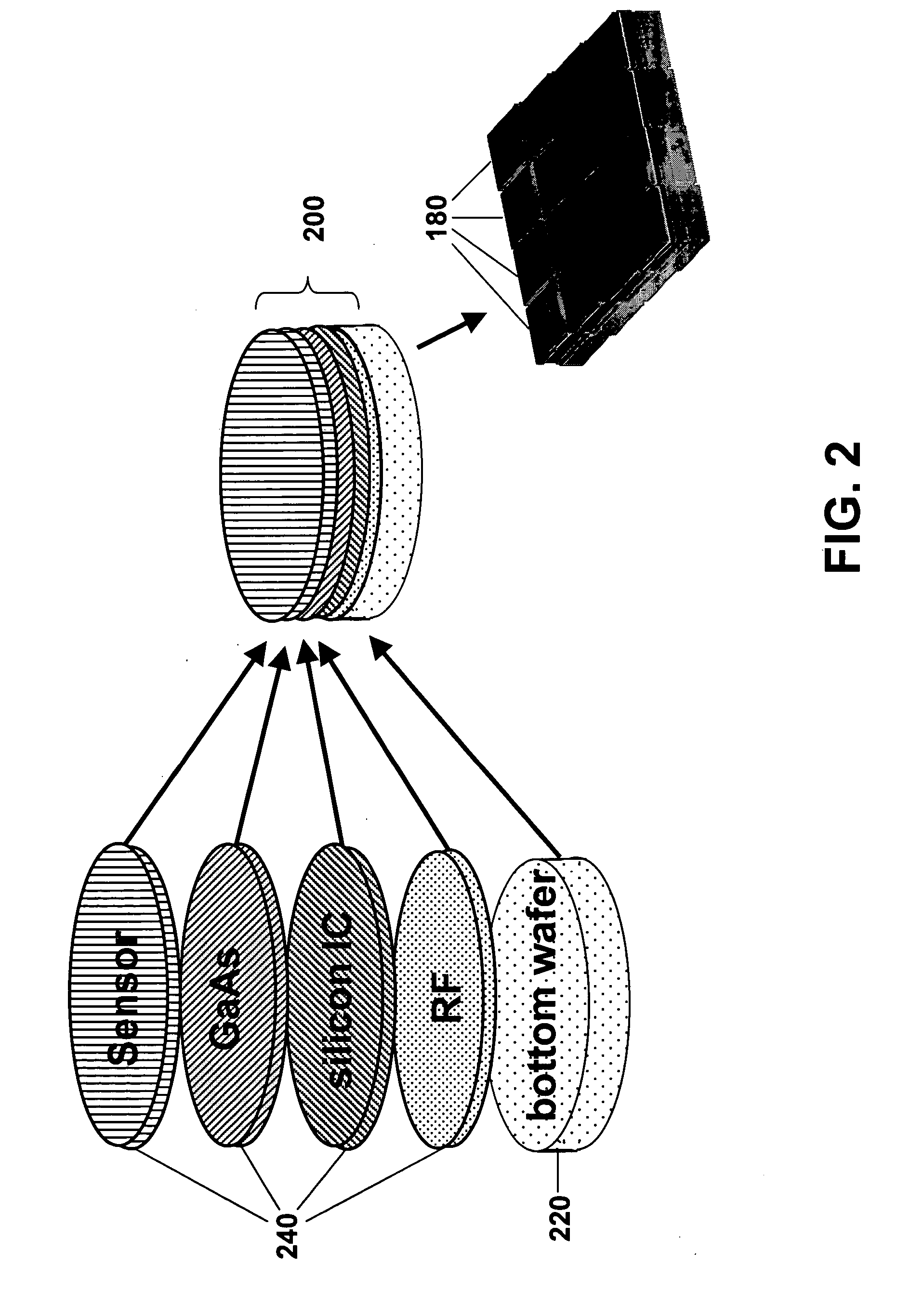

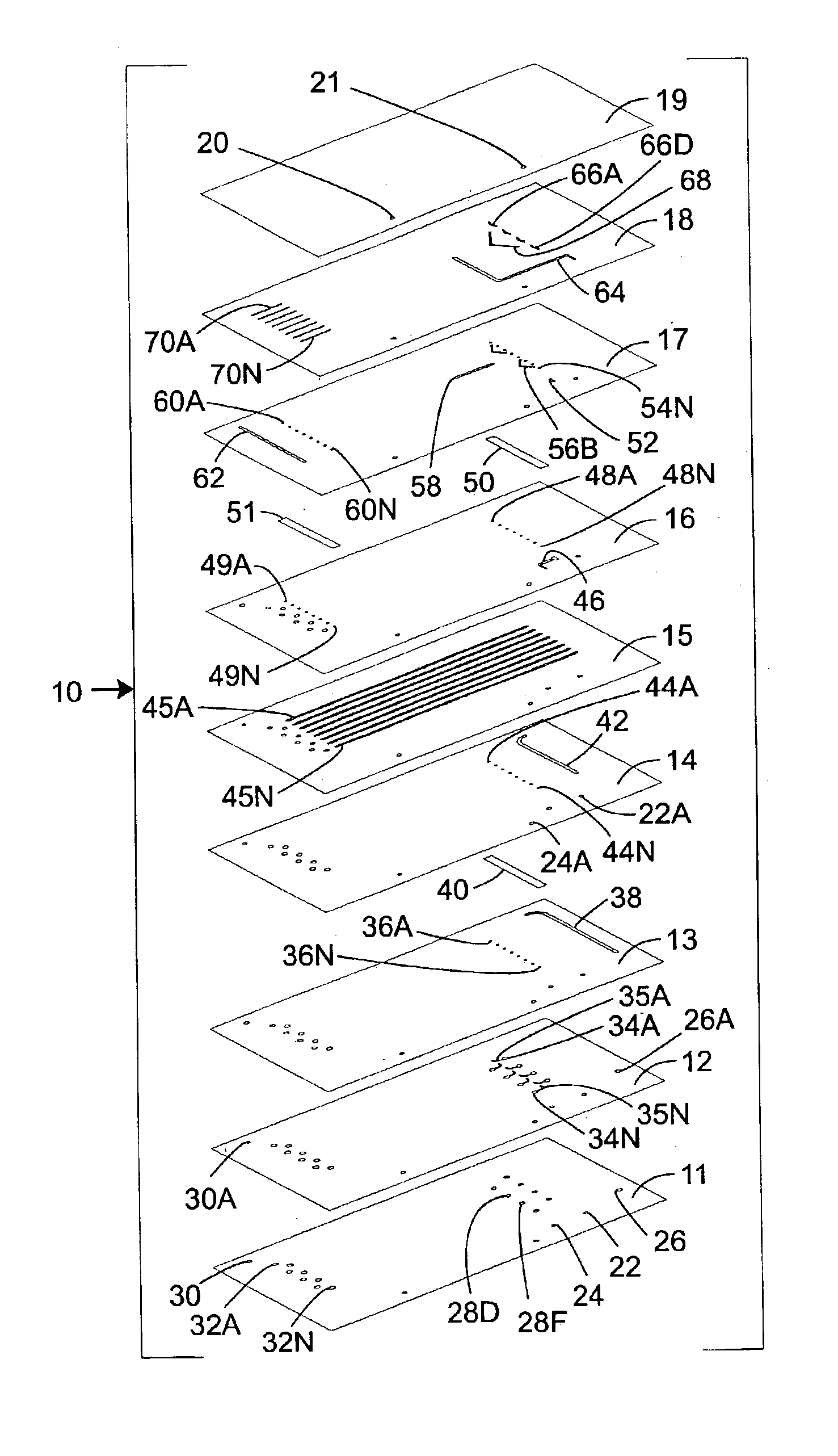

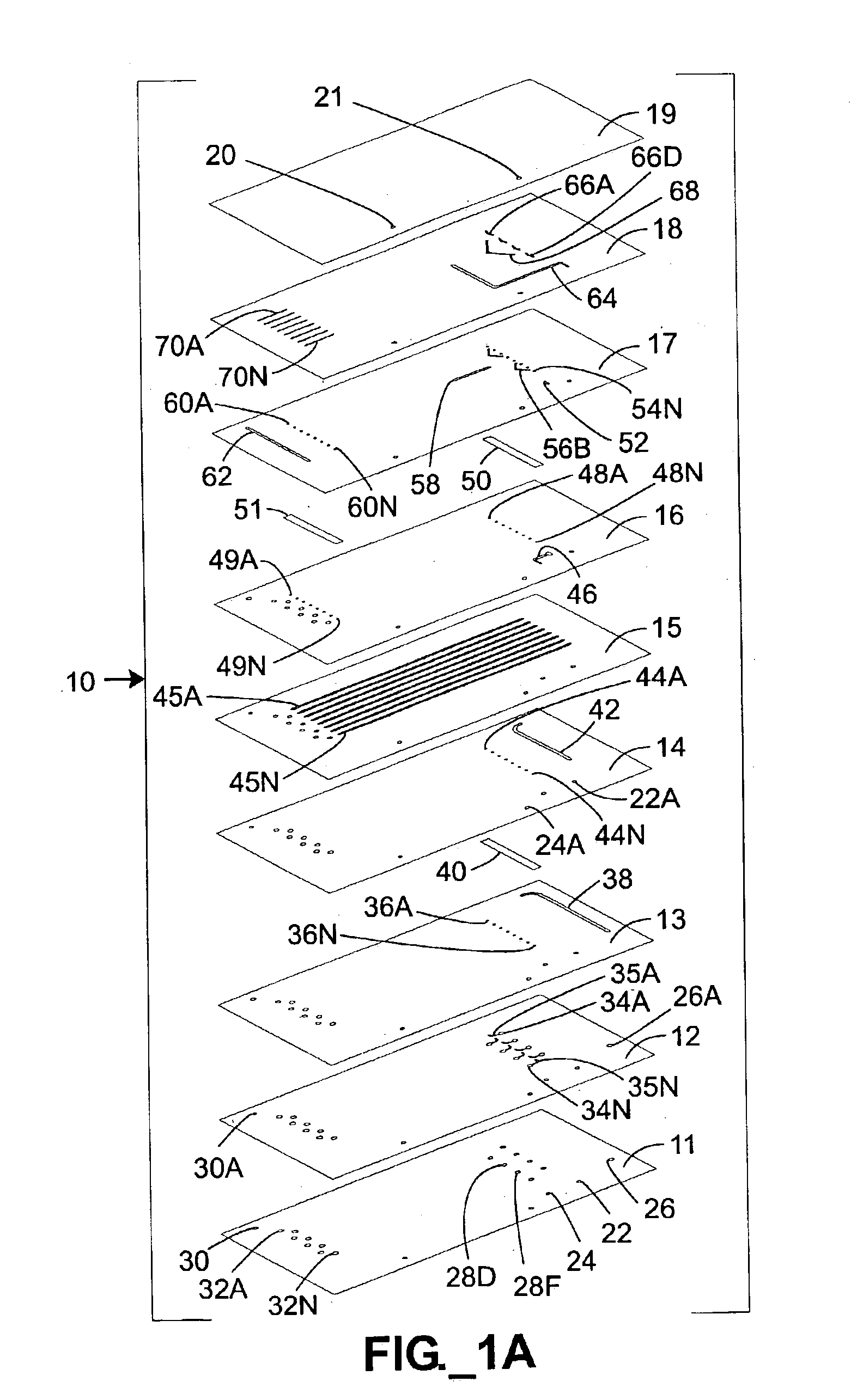

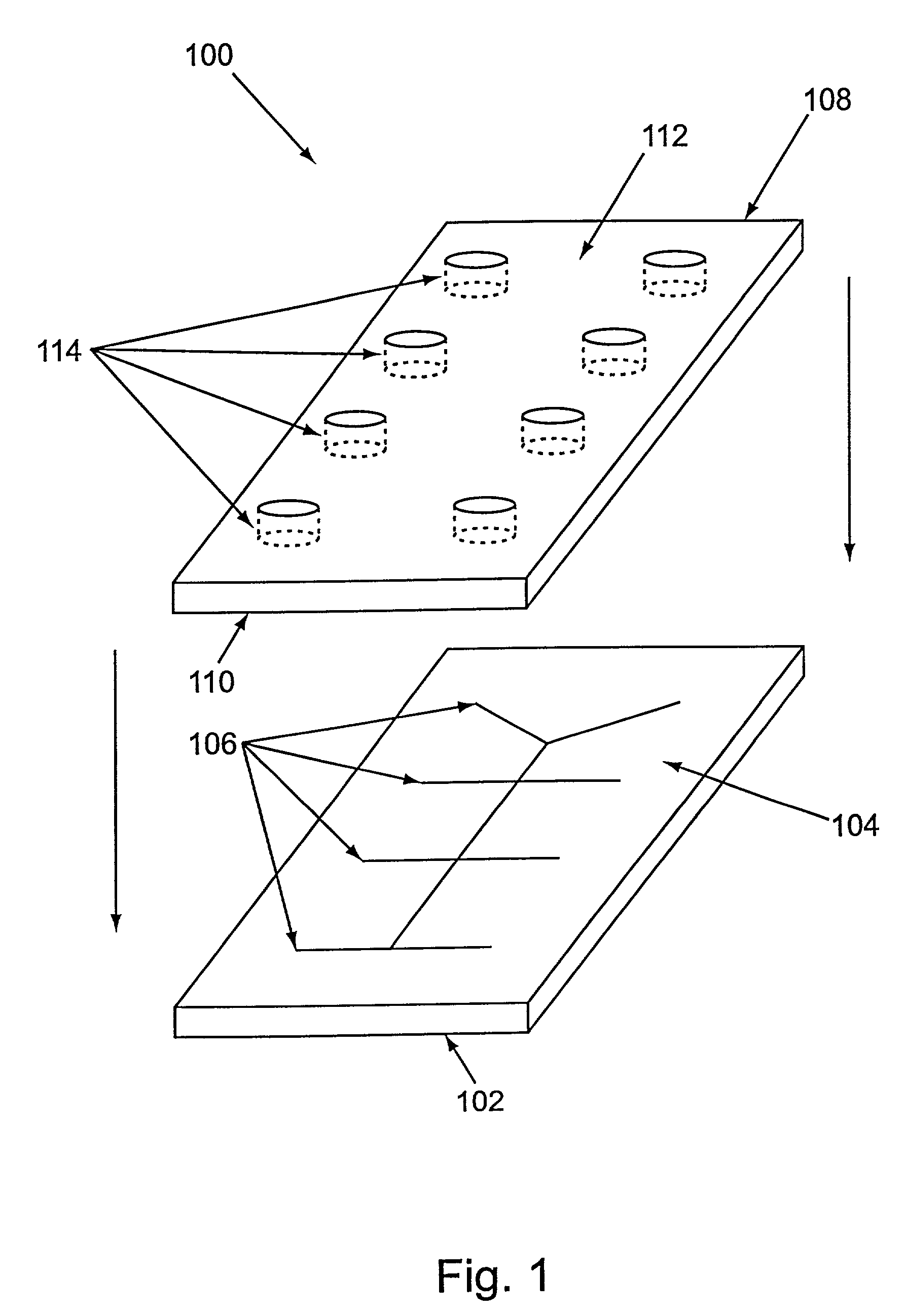

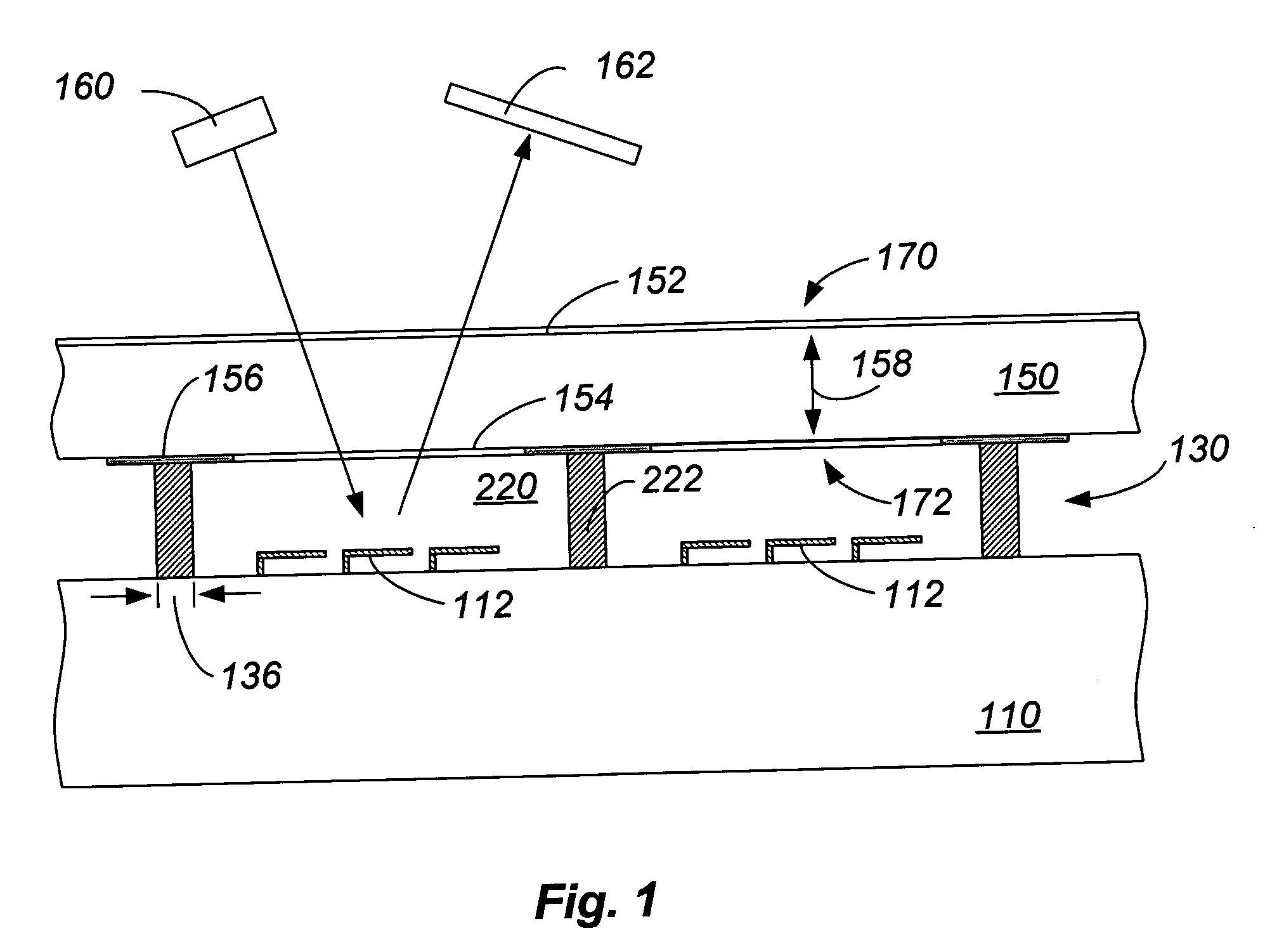

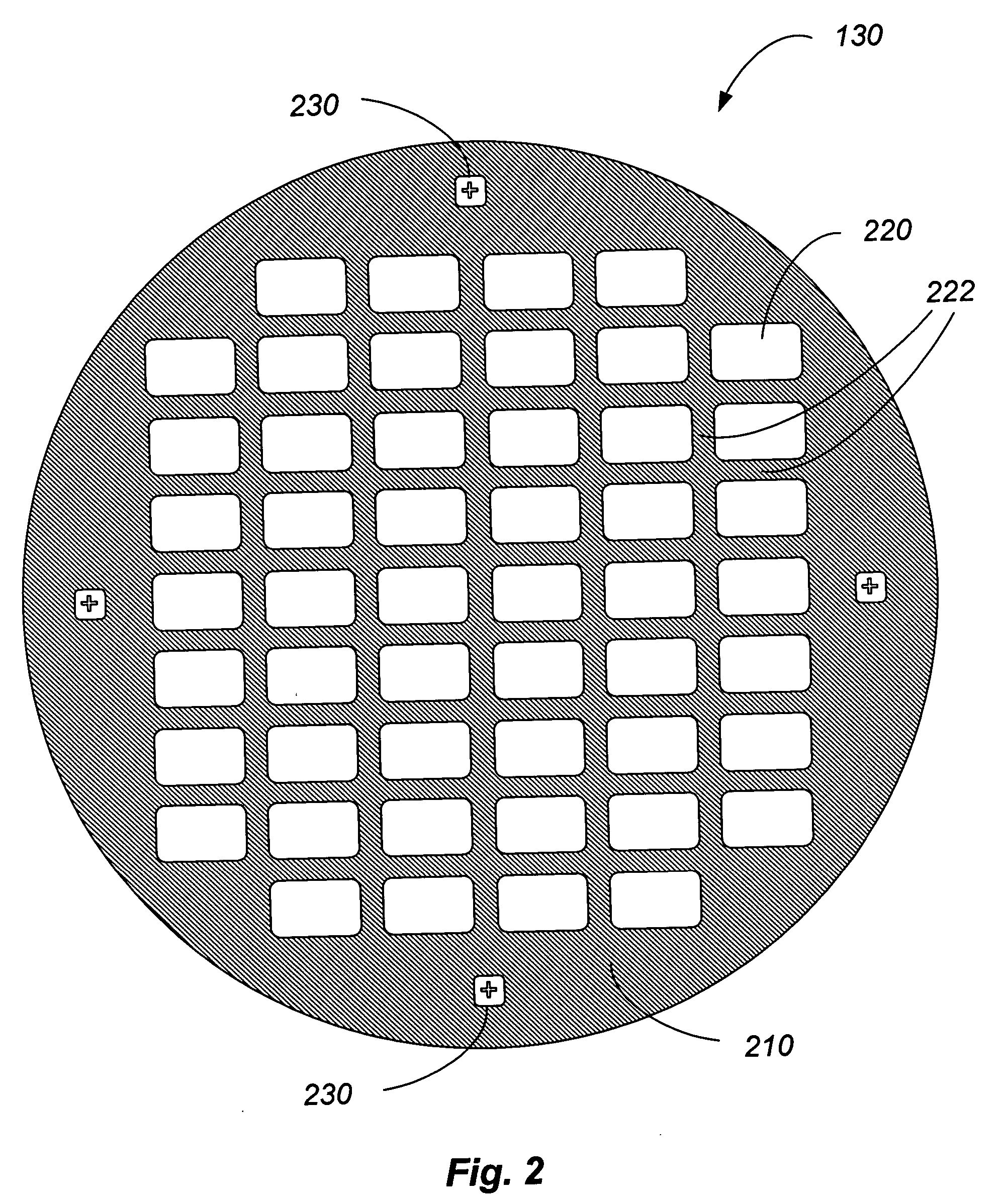

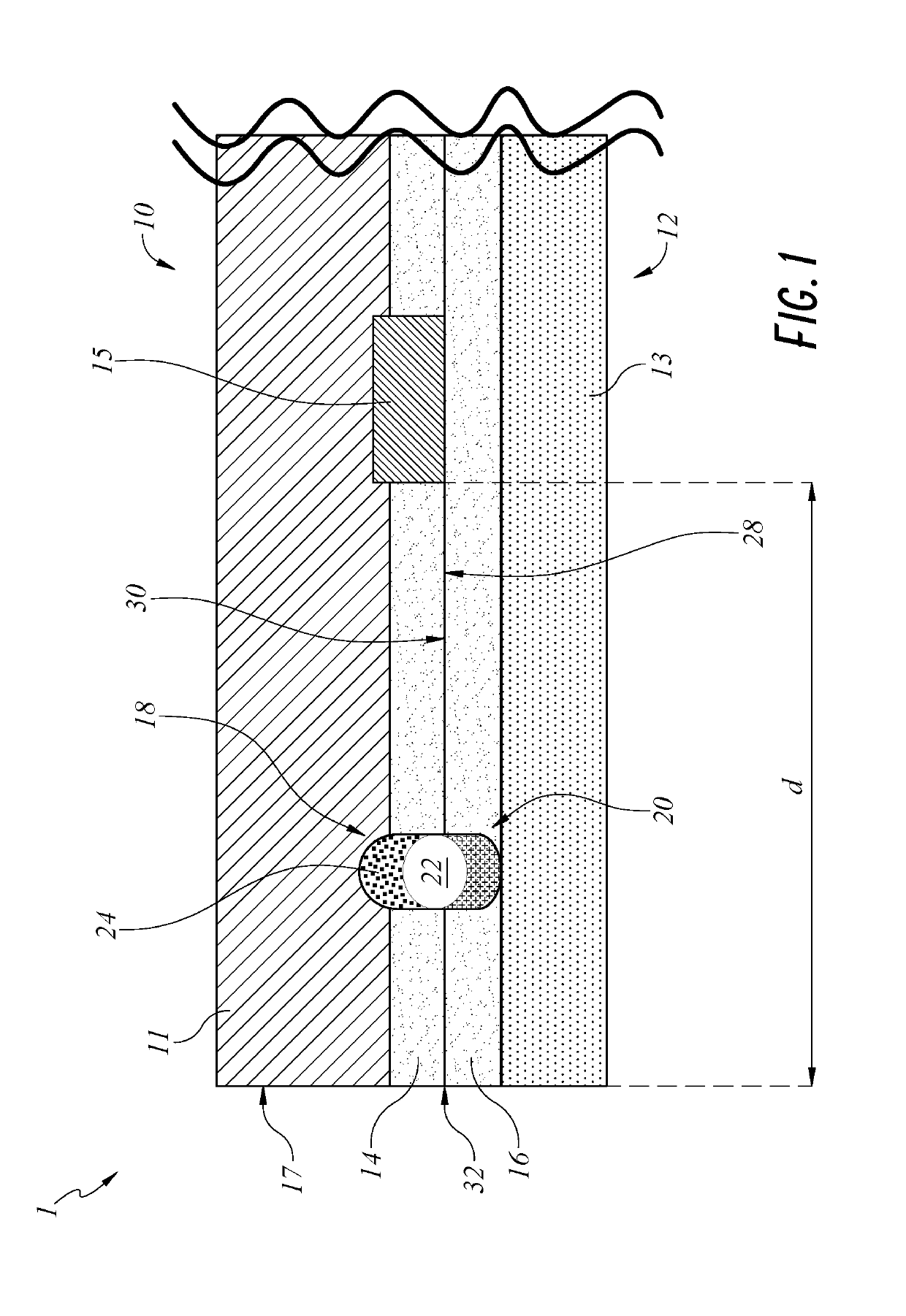

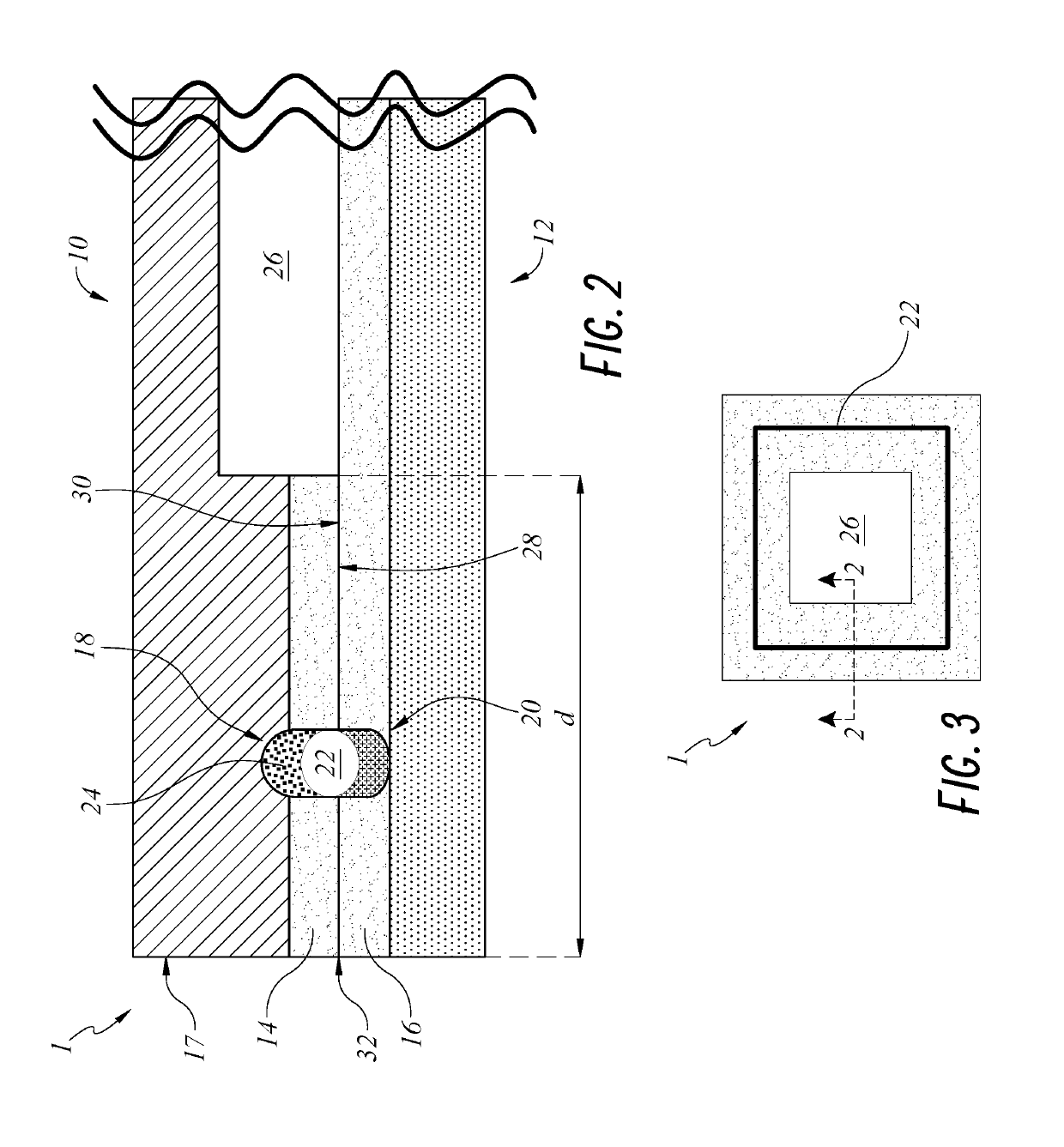

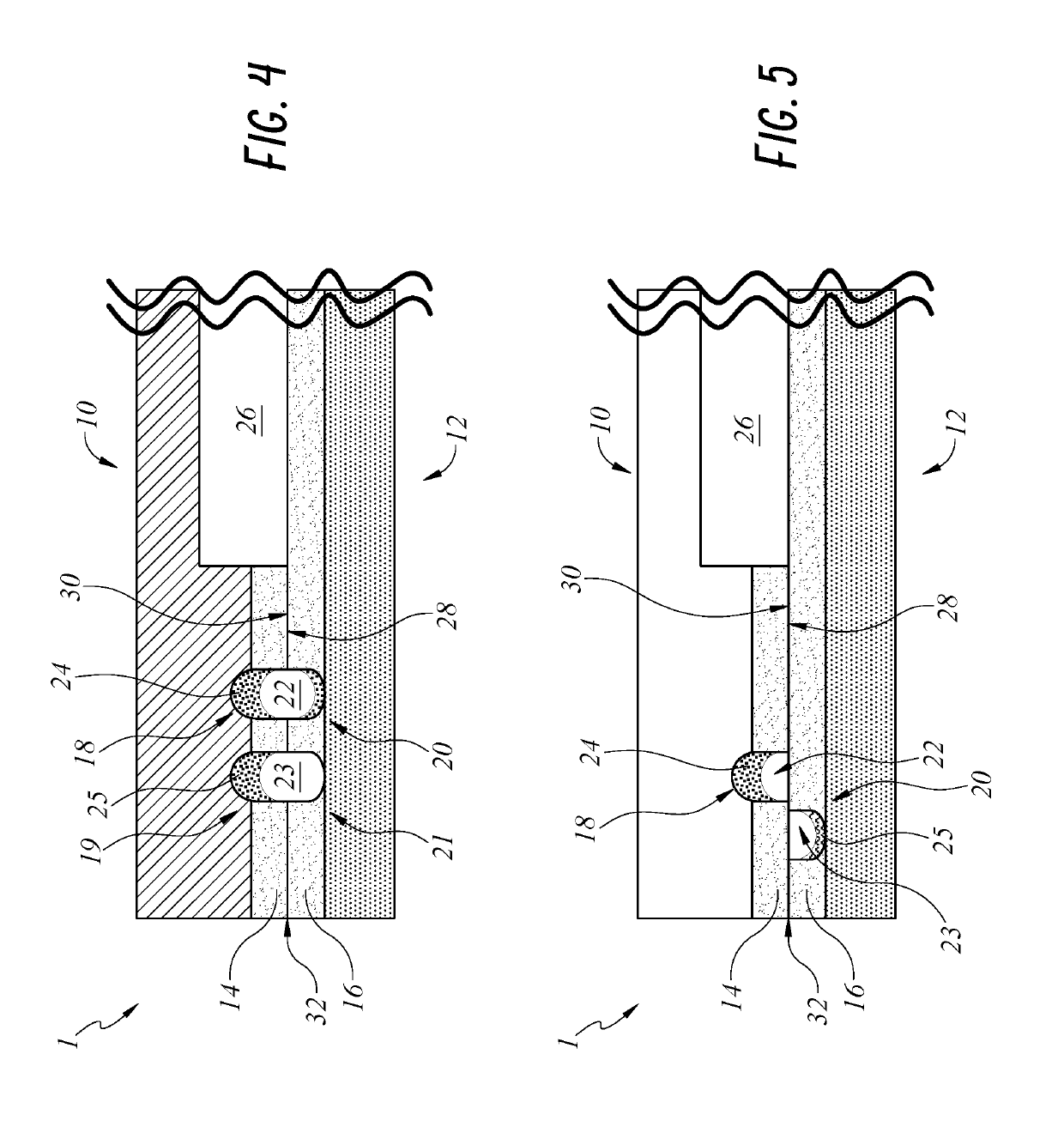

Heterogeneously integrated microsystem-on-a-chip

ActiveUS7335972B2Electronic circuit testingSemiconductor/solid-state device detailsMiniaturizationInterconnection

A microsystem-on-a-chip comprises a bottom wafer of normal thickness and a series of thinned wafers can be stacked on the bottom wafer, glued and electrically interconnected. The interconnection layer comprises a compliant dielectric material, an interconnect structure, and can include embedded passives. The stacked wafer technology provides a heterogeneously integrated, ultra-miniaturized, higher performing, robust and cost-effective microsystem package. The highly integrated microsystem package, comprising electronics, sensors, optics, and MEMS, can be miniaturized both in volume and footprint to the size of a bottle-cap or less.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

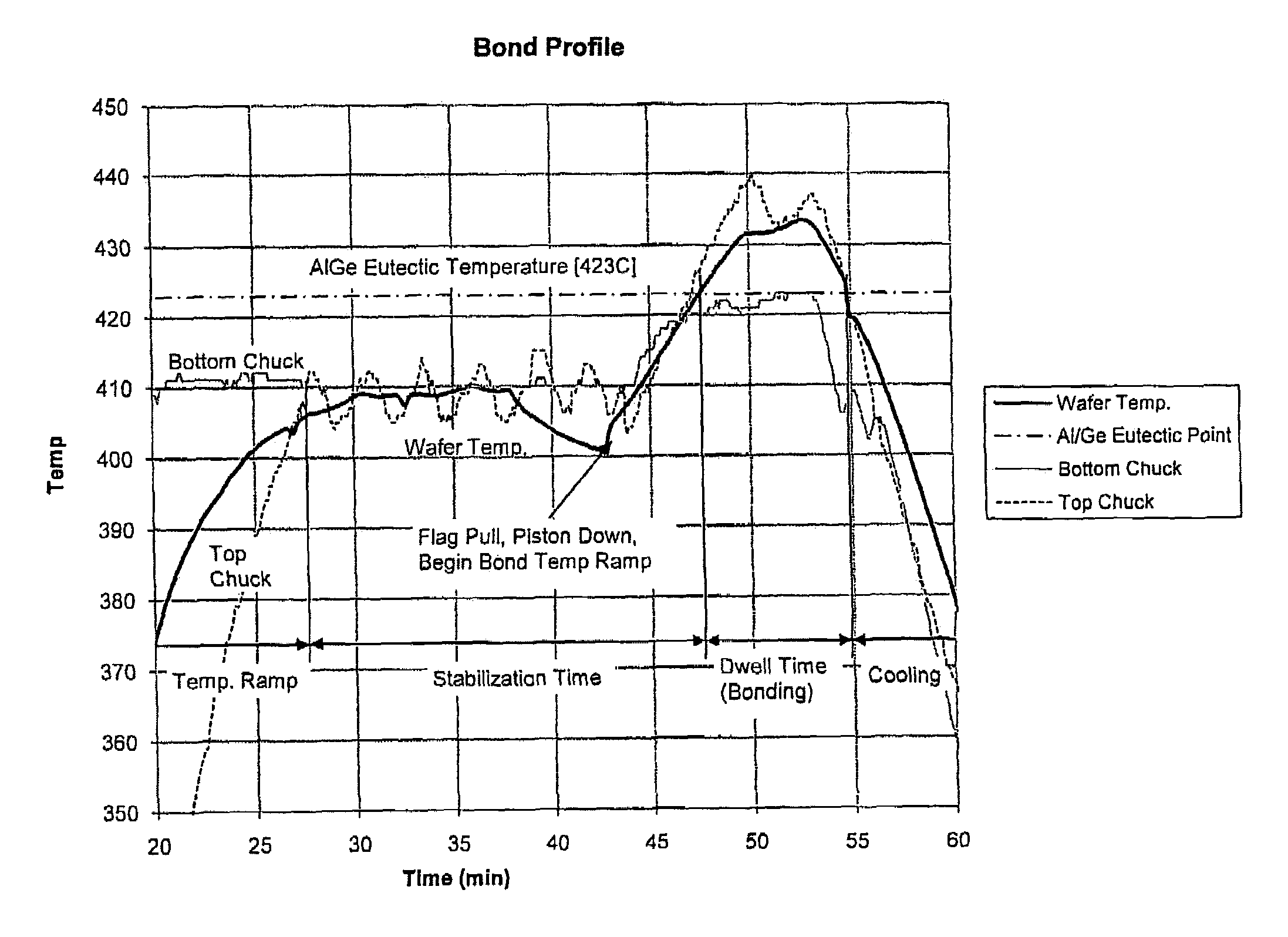

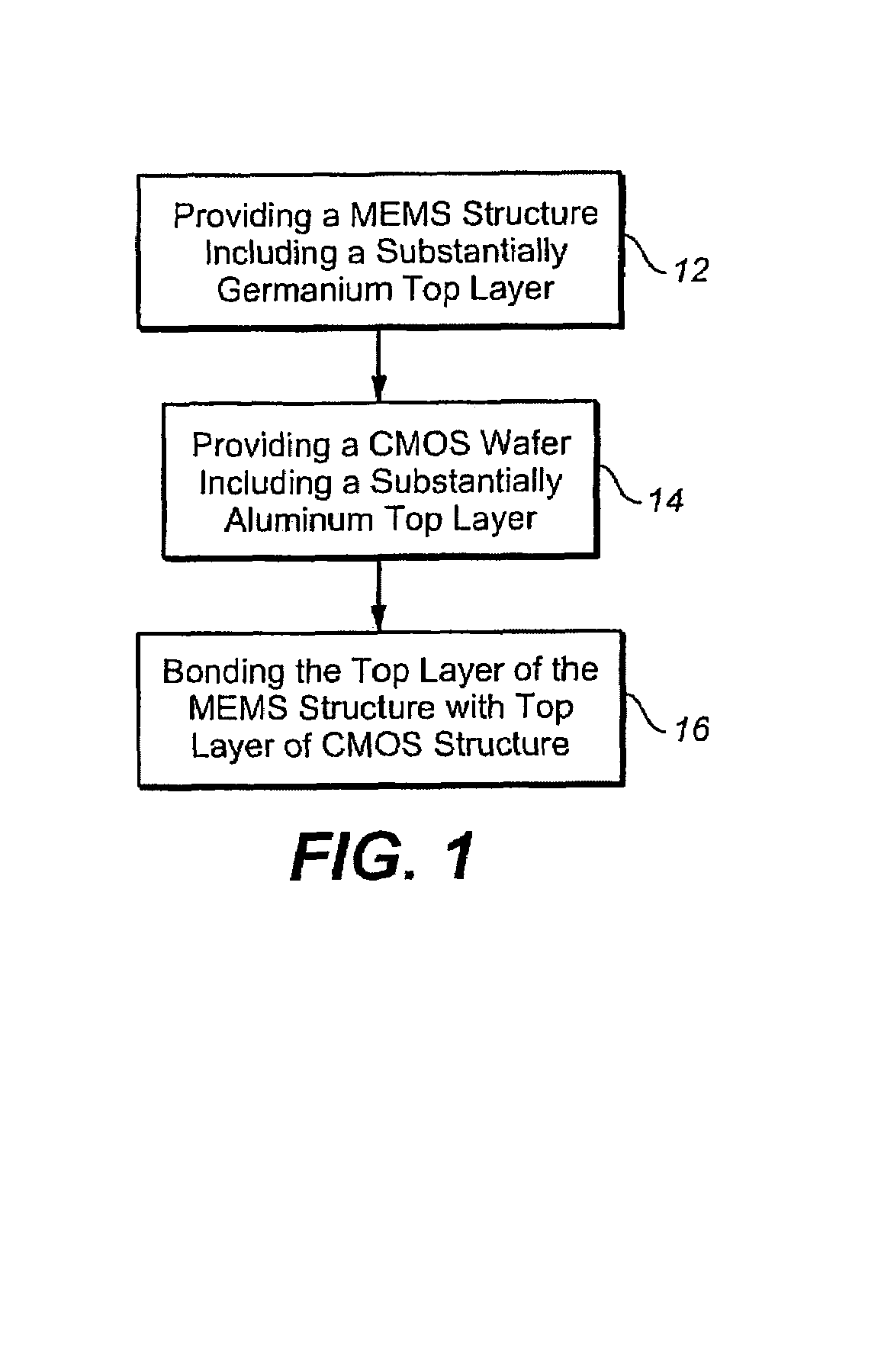

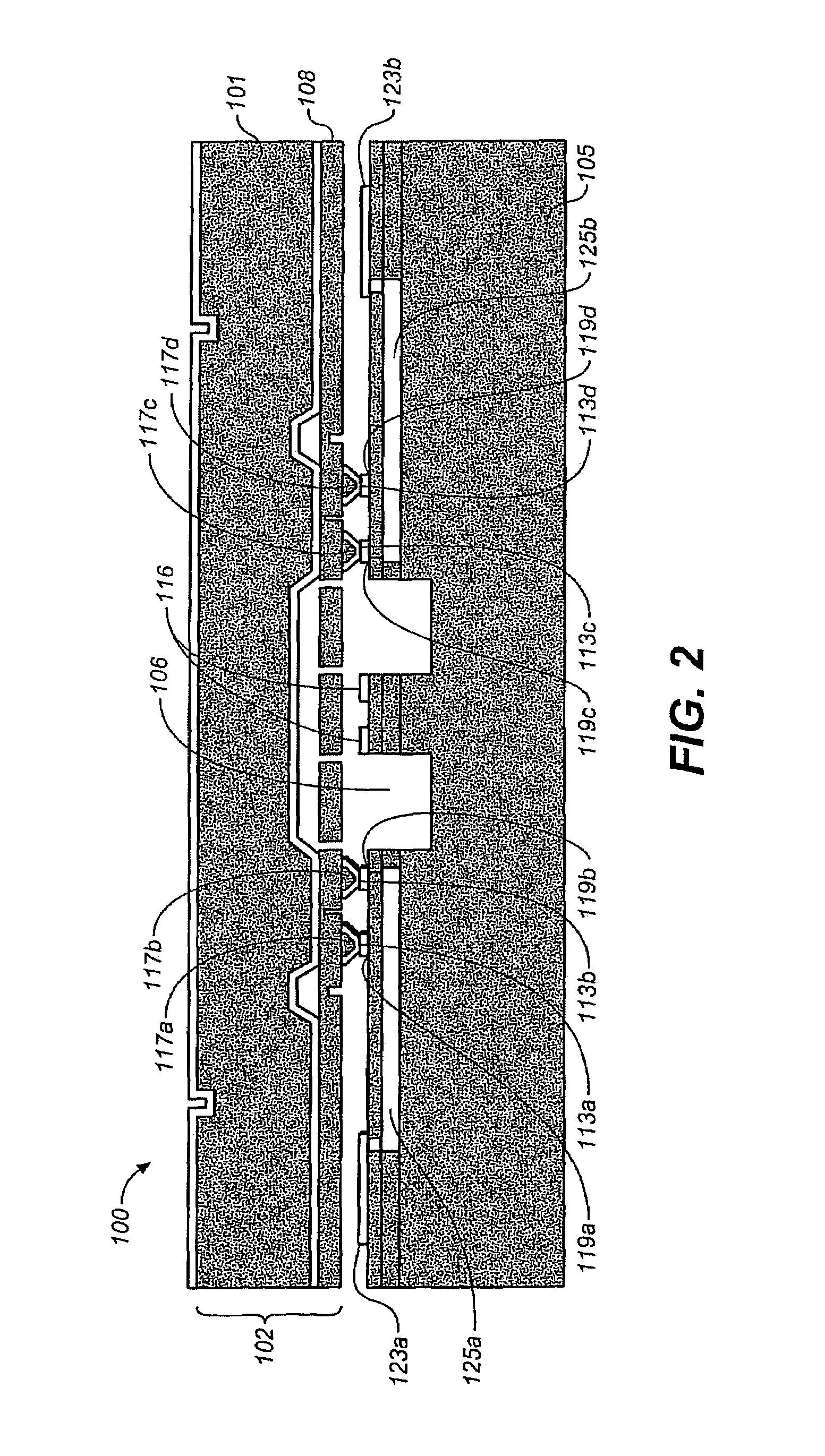

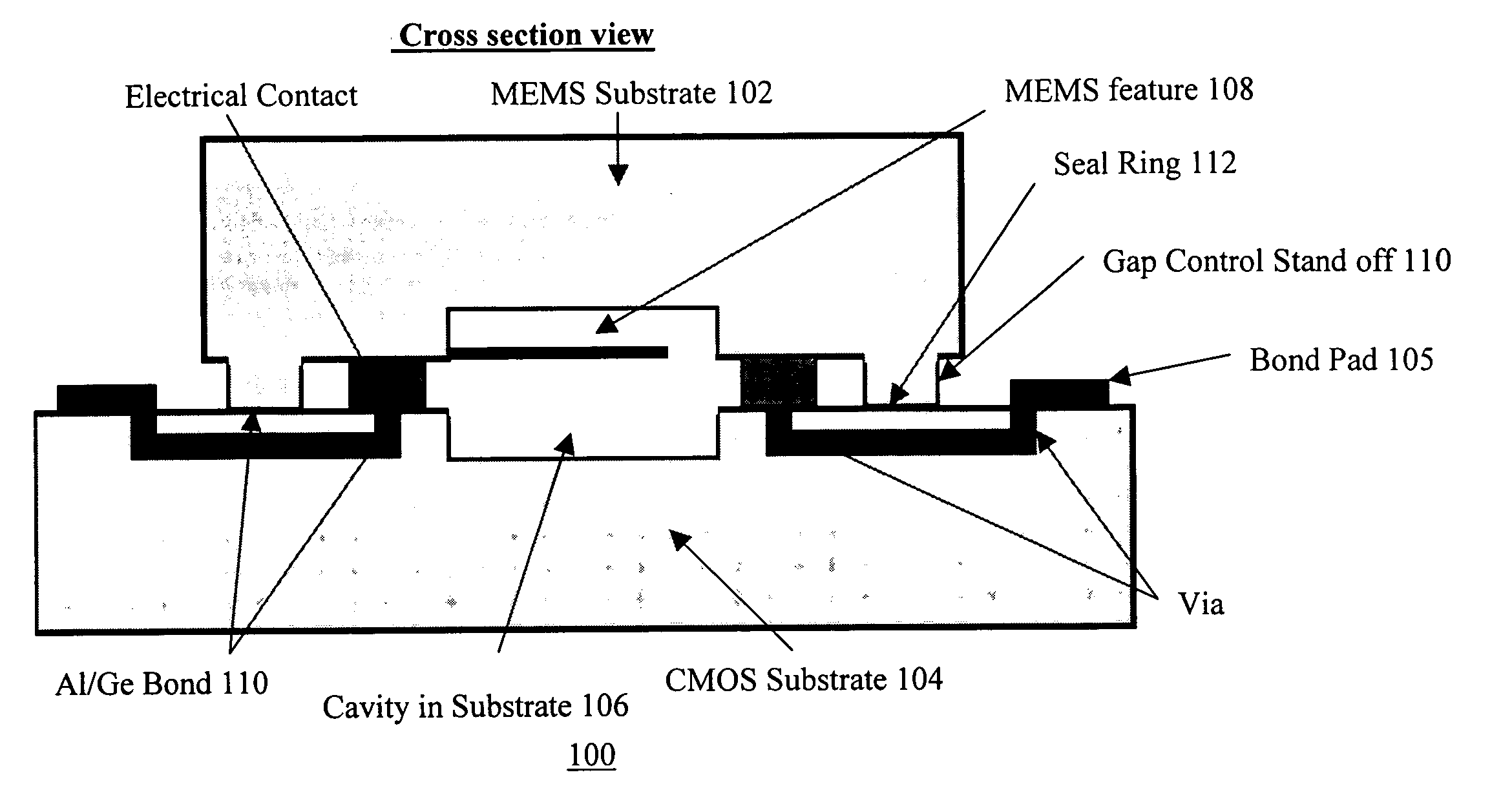

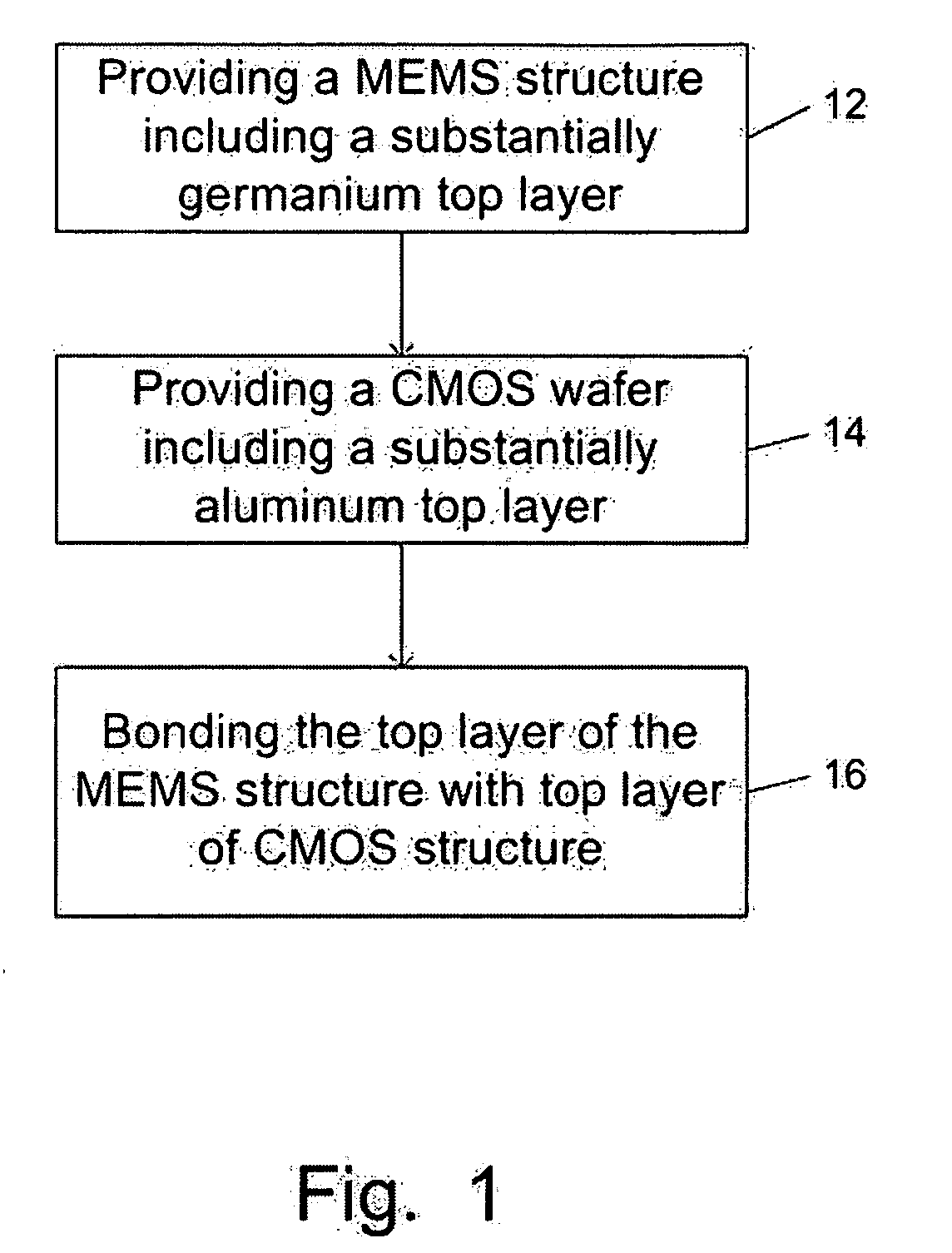

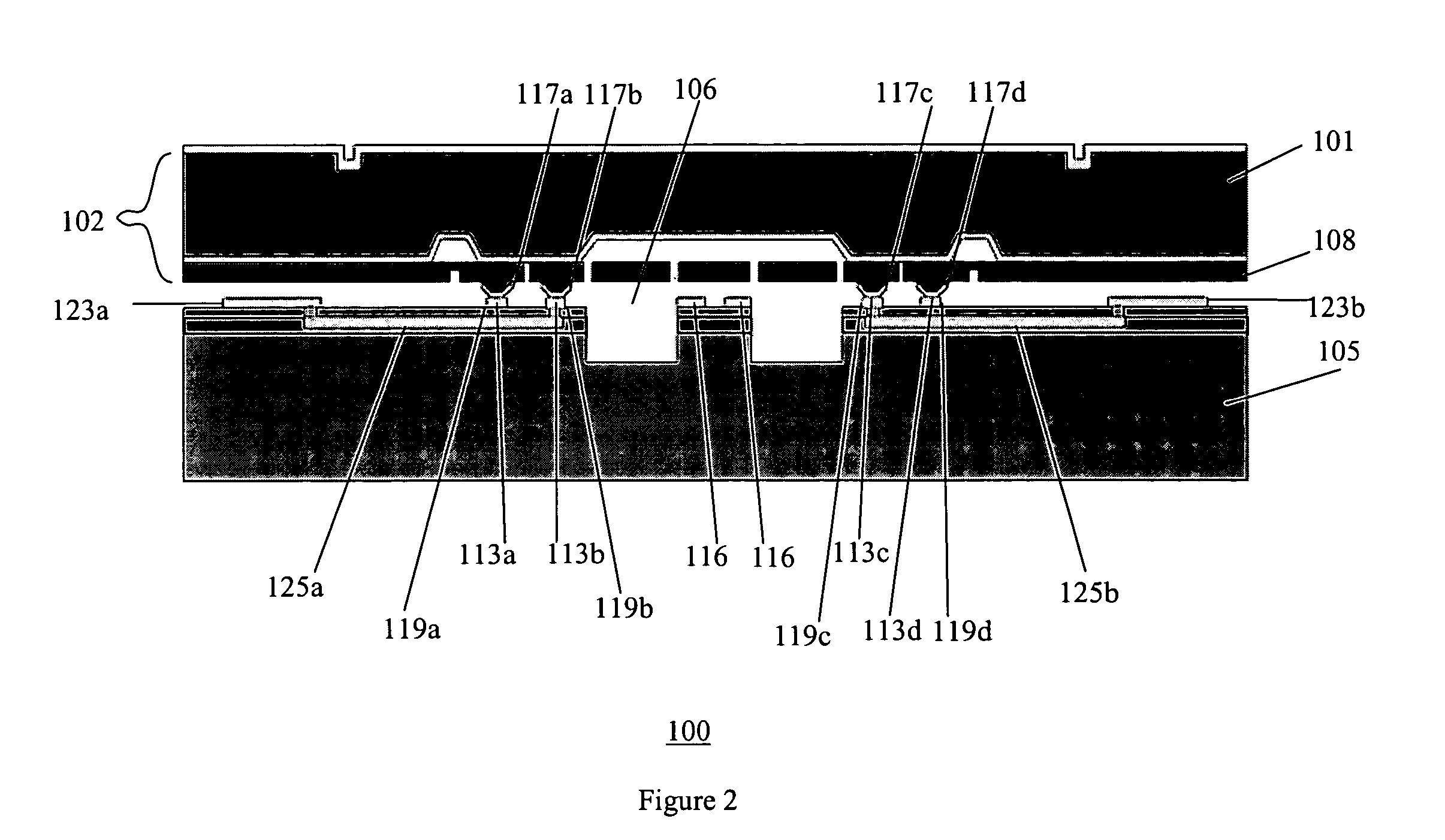

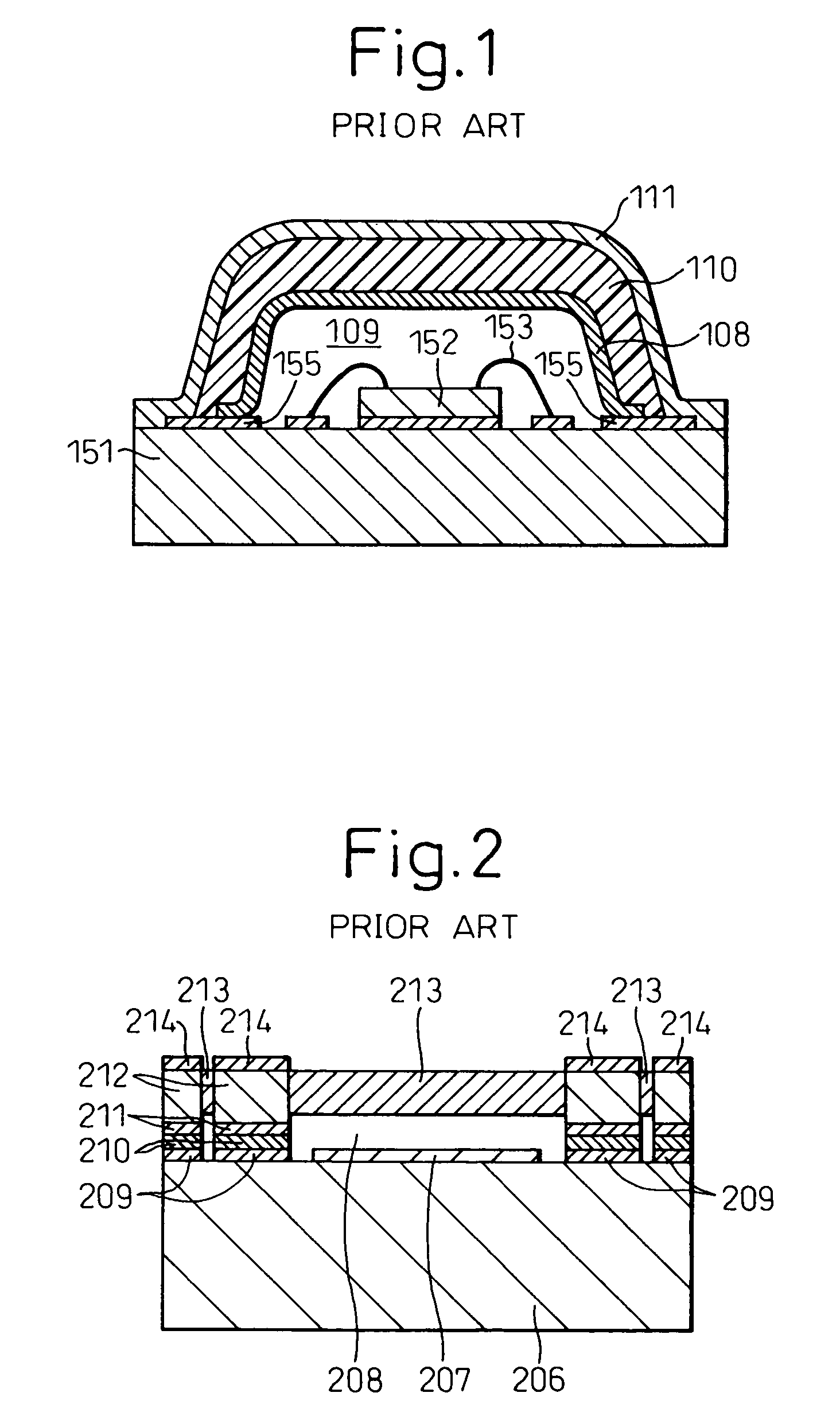

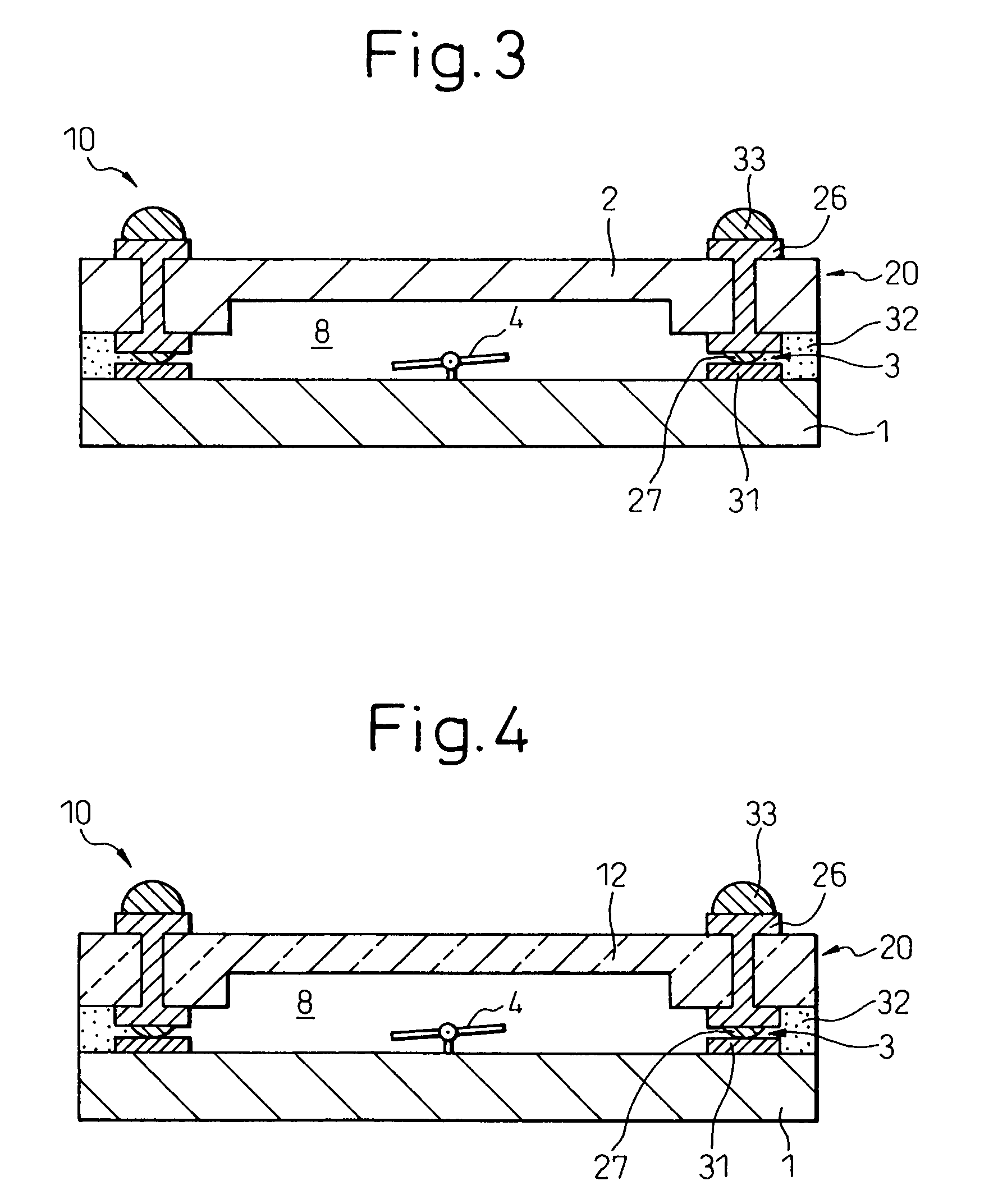

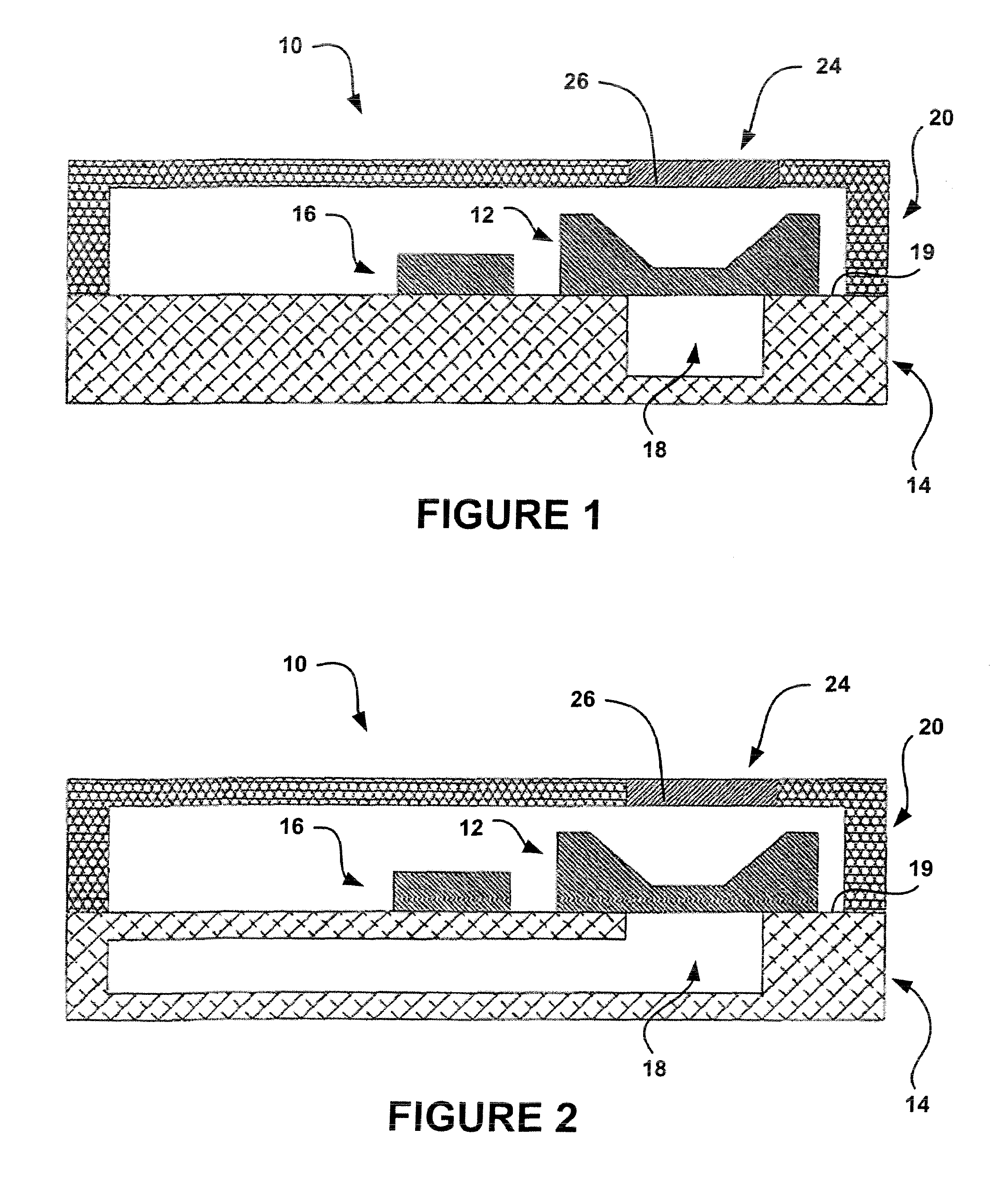

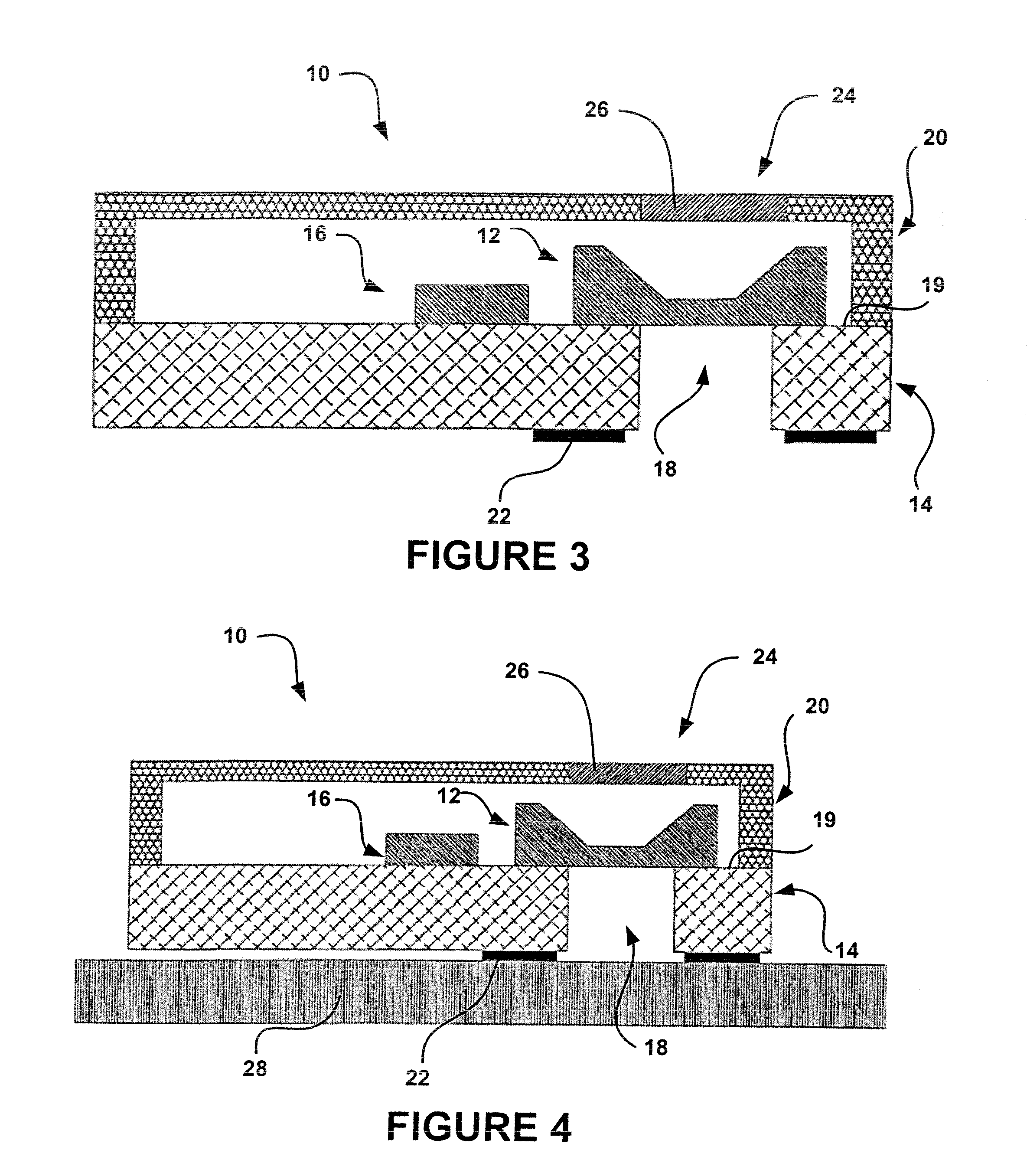

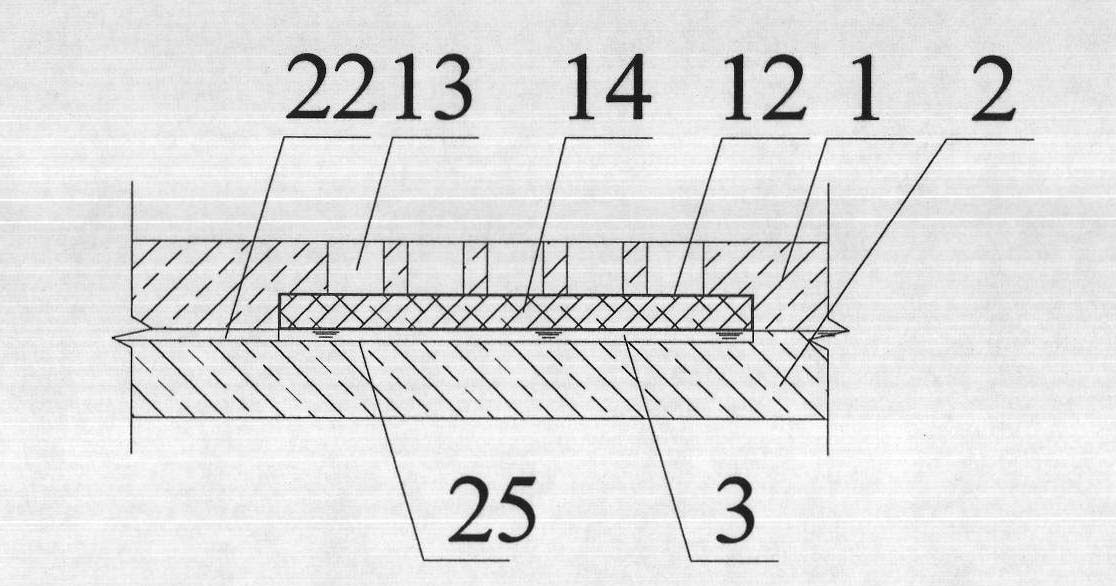

Method of fabrication of a AL/GE bonding in a wafer packaging environment and a product produced therefrom

ActiveUS7442570B2Robust and mechanical contactHighly controllableAcceleration measurement using interia forcesSemiconductor/solid-state device detailsFoundryHermetic seal

A method of bonding of germanium to aluminum between two substrates to create a robust electrical and mechanical contact is disclosed. An aluminum-germanium bond has the following unique combination of attributes: (1) it can form a hermetic seal; (2) it can be used to create an electrically conductive path between two substrates; (3) it can be patterned so that this conduction path is localized; (4) the bond can be made with the aluminum that is available as standard foundry CMOS process. This has the significant advantage of allowing for wafer-level bonding or packaging without the addition of any additional process layers to the CMOS wafer.

Owner:INVENSENSE

Method of fabrication of ai/ge bonding in a wafer packaging environment and a product produced therefrom

ActiveUS20060208326A1RobustHighly controllableAcceleration measurement using interia forcesSemiconductor/solid-state device detailsFoundryHermetic seal

A method of bonding of germanium to aluminum between two substrates to create a robust electrical and mechanical contact is disclosed. An aluminum-germanium bond has the following unique combination of attributes: (1) it can form a hermetic seal; (2) it can be used to create an electrically conductive path between two substrates; (3) it can be patterned so that this conduction path is localized; (4) the bond can be made with the aluminum that is available as standard foundry CMOS process. This has the significant advantage of allowing for wafer-level bonding or packaging without the addition of any additional process layers to the CMOS wafer.

Owner:INVENSENSE

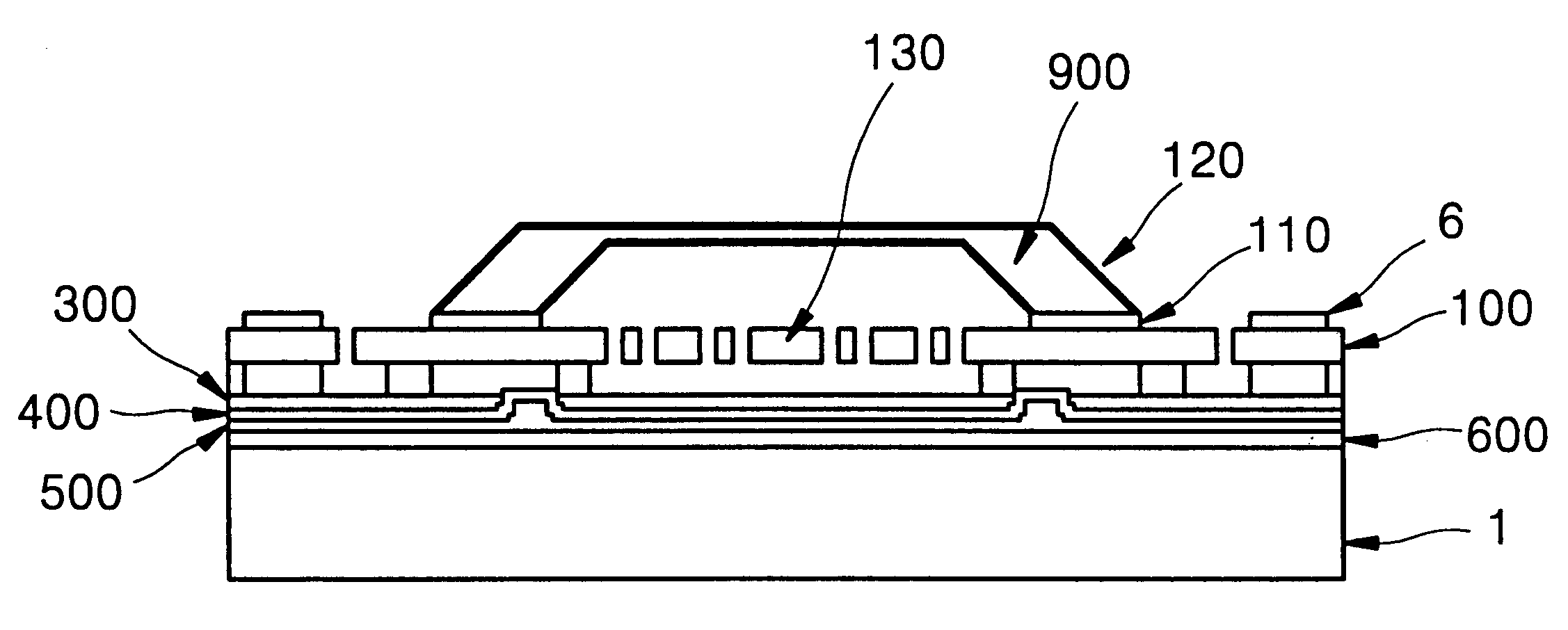

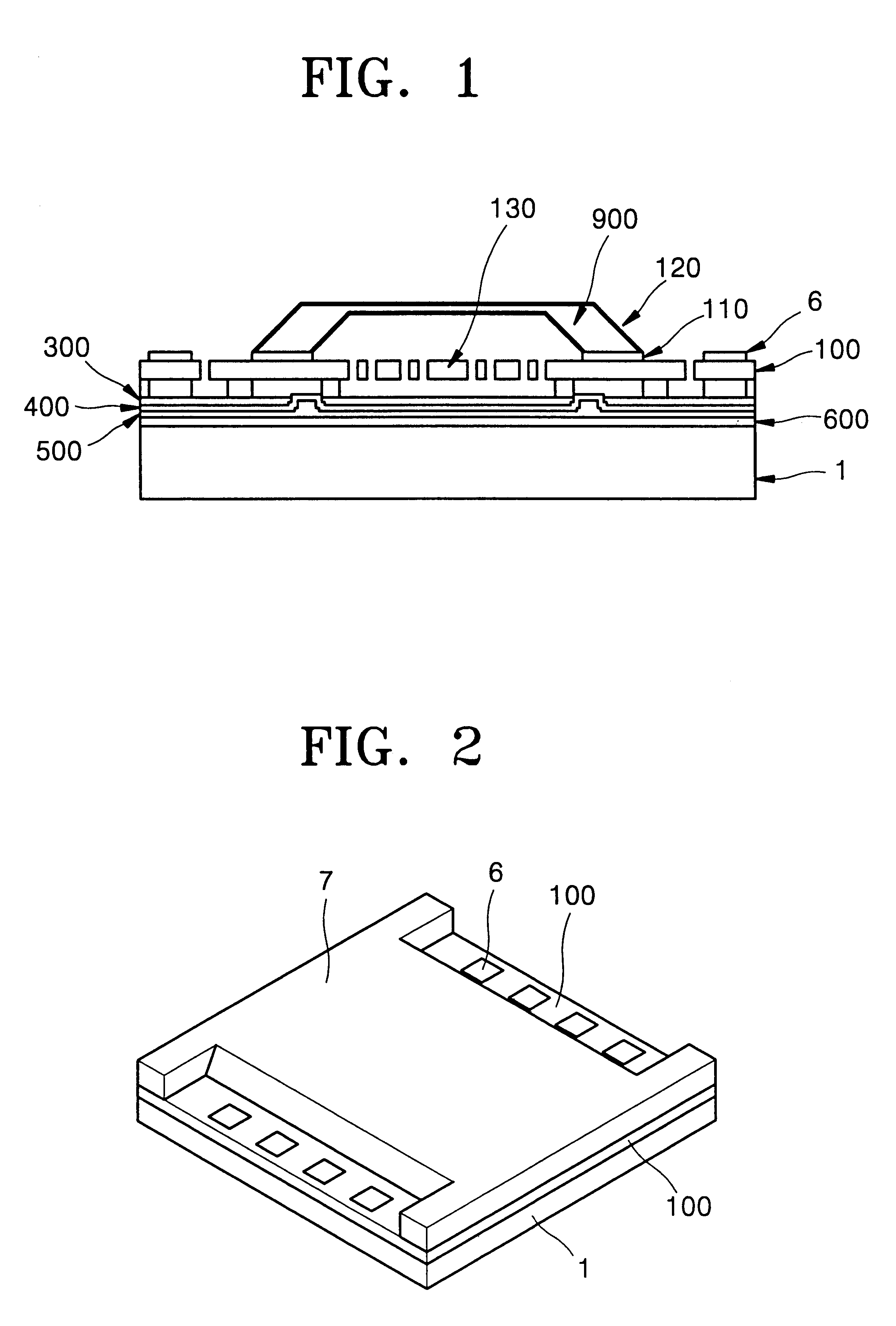

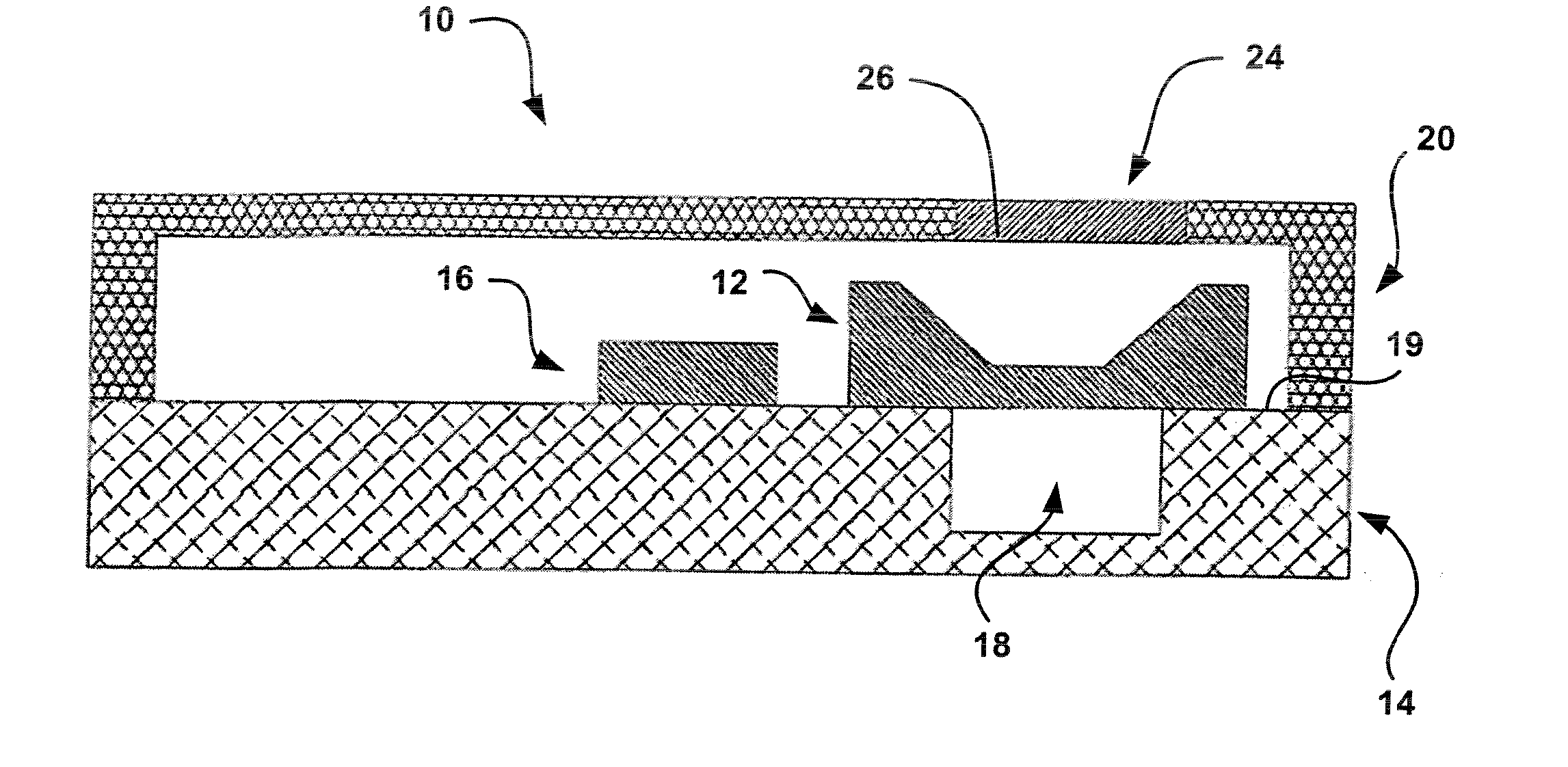

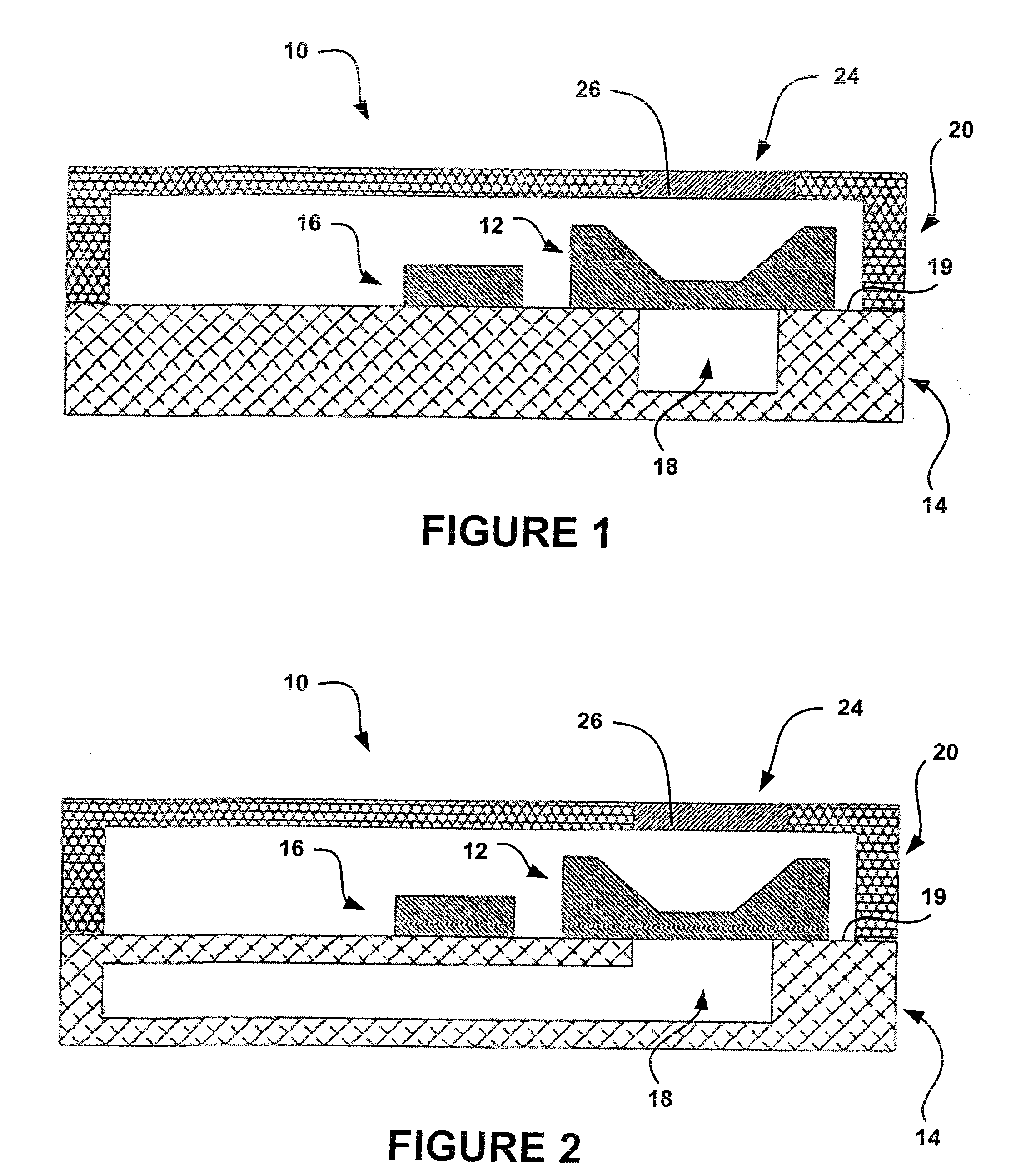

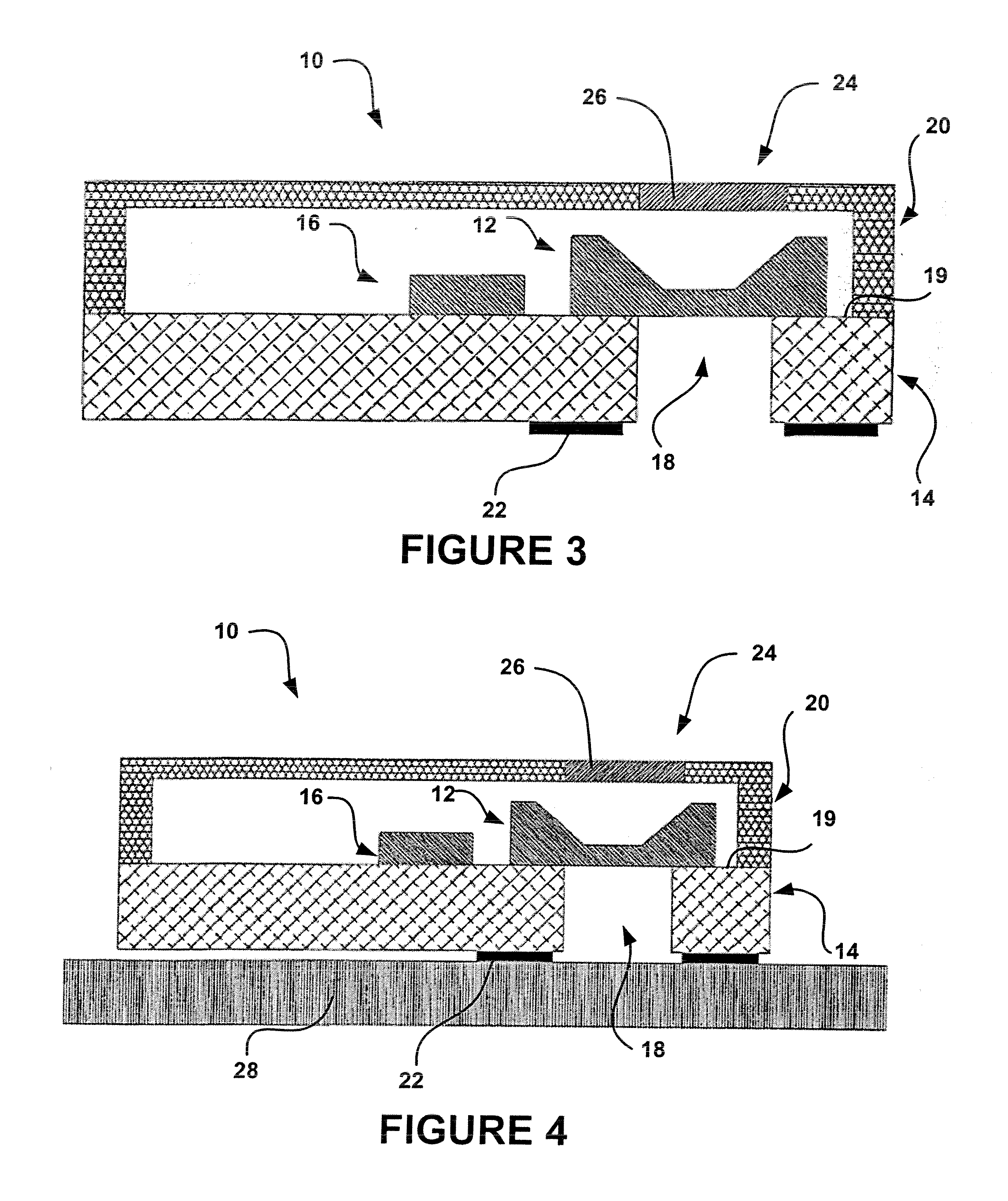

Silicon condenser microphone and manufacturing method

InactiveUS20050018864A1Piezoelectric/electrostrictive microphonesDecorative surface effectsCapacitanceTransducer

A silicon condenser microphone package is disclosed. The silicon condenser microphone package comprises a transducer unit, substrate, and a cover. The substrate includes an upper surface having a recess formed therein. The transducer unit is attached to the upper surface of the substrate and overlaps at least a portion of the recess wherein a back volume of the transducer unit is formed between the transducer unit and the substrate. The cover is placed over the transducer unit and includes an aperture.

Owner:KNOWLES ELECTRONICS INC

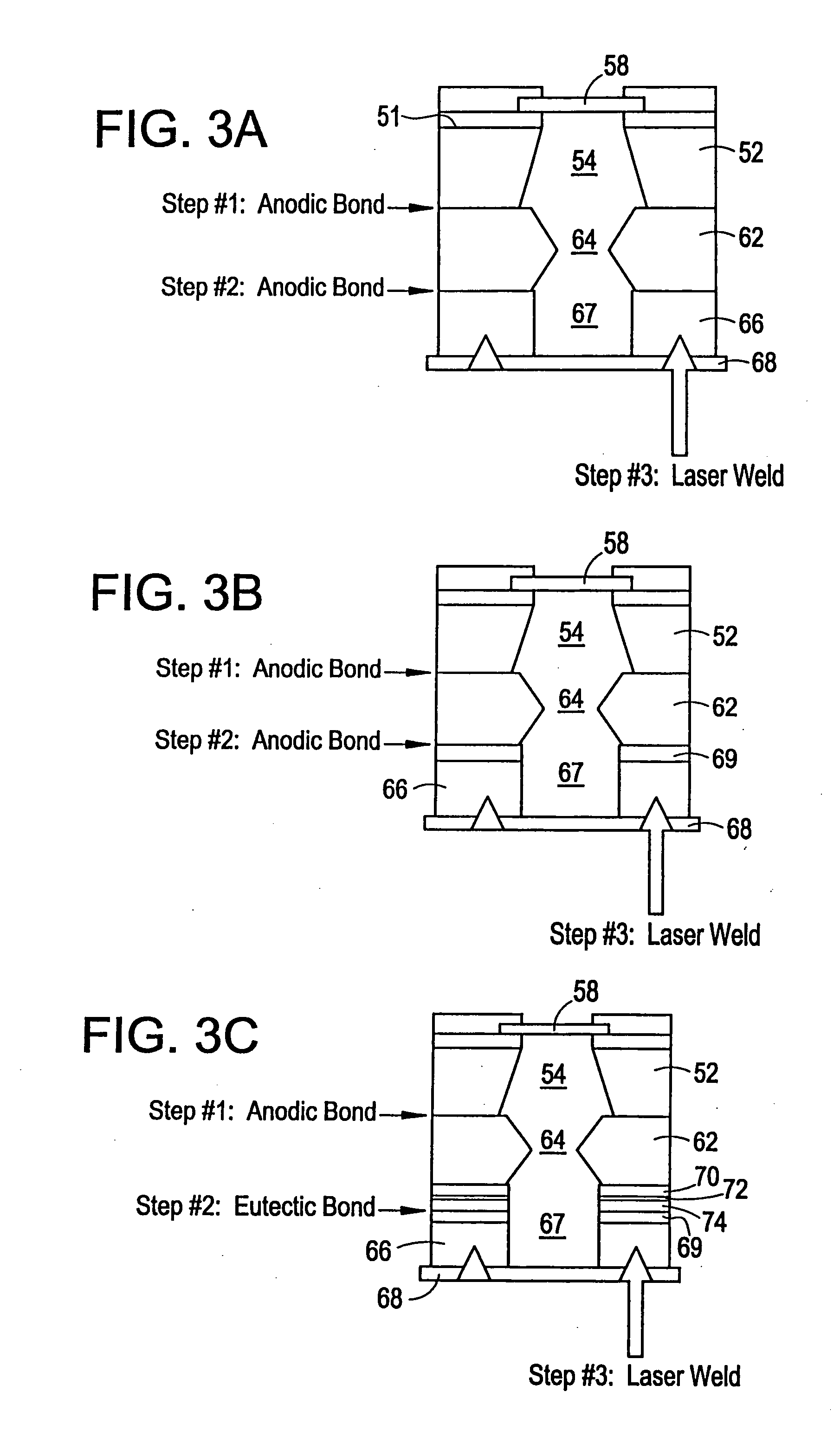

Hermetically sealed microchip reservoir devices

InactiveUS20050077584A1Fixed microstructural devicesVolume/mass flow measurementGlucose sensorsHermetic seal

Devices are provided for the controlled exposure or release of contents stored in hermetically sealed reservoirs. The devices comprise a primary substrate having a front side and a back side, and including one or more hermetic sealing materials; a plurality of reservoirs in the primary substrate positioned between the front side and the back side; reservoir contents, which comprise chemical molecules (such as drugs) or a secondary device (such as a glucose sensor), located inside the reservoirs; a hermetic sealing substrate having a surface composed of one or more hermetic sealing materials; and a hermetic seal formed between and joining the primary substrate and the hermetic sealing substrate, wherein the hermetic seal independently seals the reservoirs.

Owner:MICROCHIPS BIOTECH INC

Capacitive ultrasonic transducer, production method thereof, and capacitive ultrasonic probe

InactiveUS20070164632A1Increase sound pressureSimple methodUltrasonic/sonic/infrasonic diagnosticsTransducer detailsSound pressureUltrasonic transmission

It becomes possible to obtain high sound pressure in a high frequency domain by a capacitive ultrasonic transducer which comprises a membrane on which one electrode is formed, a cavity constructed in its backface, and a substrate on which these are mounted and supported and on whose surface an electrode is provided, on a surface in an ultrasonic transmission and reception side, characterized in that the membrane comprises two or more layers, and at least one layer of them comprises a high dielectric constant film.

Owner:OLYMPUS CORP

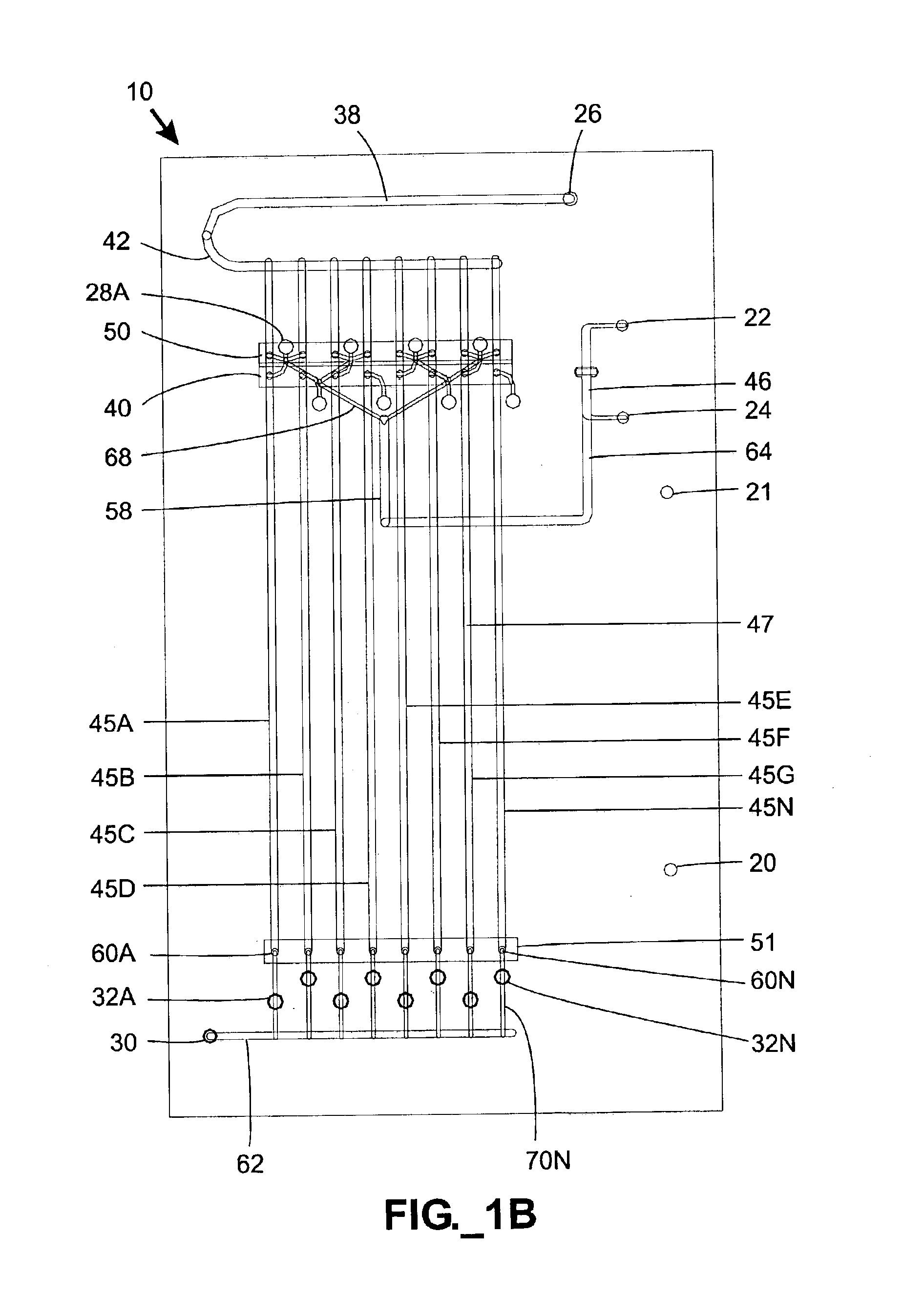

Heterogeneously integrated microsystem-on-a-chip

ActiveUS20070158787A1Semiconductor/solid-state device detailsSolid-state devicesCost effectivenessMiniaturization

A microsystem-on-a-chip comprises a bottom wafer of normal thickness and a series of thinned wafers can be stacked on the bottom wafer, glued and electrically interconnected. The interconnection layer comprises a compliant dielectric material, an interconnect structure, and can include embedded passives. The stacked wafer technology provides a heterogeneously integrated, ultra-miniaturized, higher performing, robust and cost-effective microsystem package. The highly integrated microsystem package, comprising electronics, sensors, optics, and MEMS, can be miniaturized both in volume and footprint to the size of a bottle-cap or less.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

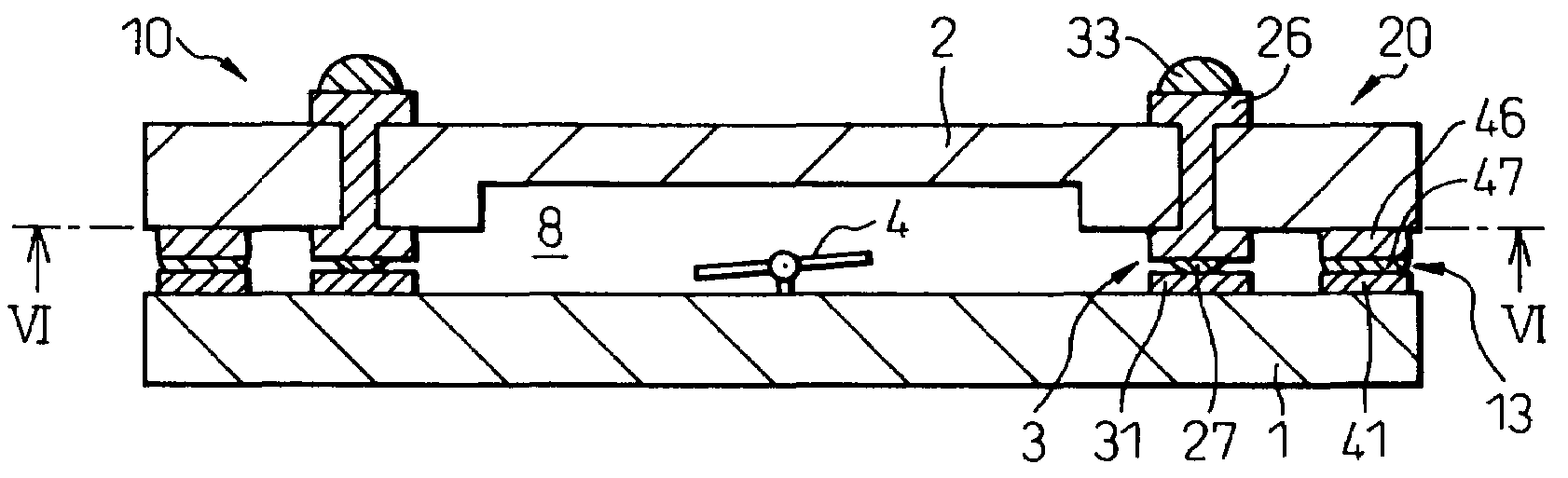

Method of fabricating micro electro mechanical system structure which can be vacuum-packed at wafer level

InactiveUS6391673B1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsVacuum packVacuum level

A method of fabricating a micro electromechanical system (MEMS) structure which can be vacuum-packaged at the wafer level is provided. The method includes the steps of forming a multilayered stack including a signal line on a first wafer; bonding a second wafer to the multilayered stack; polishing the first wafer to a predetermined thickness; forming a MEMS structure in a vacuum area of the first wafer and a pad outside the vacuum area, the MEMS structure and the pad being connected to the signal line; forming a structure in a third wafer to have space corresponding to the vacuum area of the MEMS structure; and bonding the third wafer to the polished surface of the first wafer in a vacuum state. For protection of the structure and maintaining a vacuum level required for operation, the fabricated structure is vacuum-packaged at the wafer level, thereby improving the yield of fabrication. In addition, since a special vacuum packaging process is not necessary, the fabrication can be simplified.

Owner:SAMSUNG ELECTRONICS CO LTD

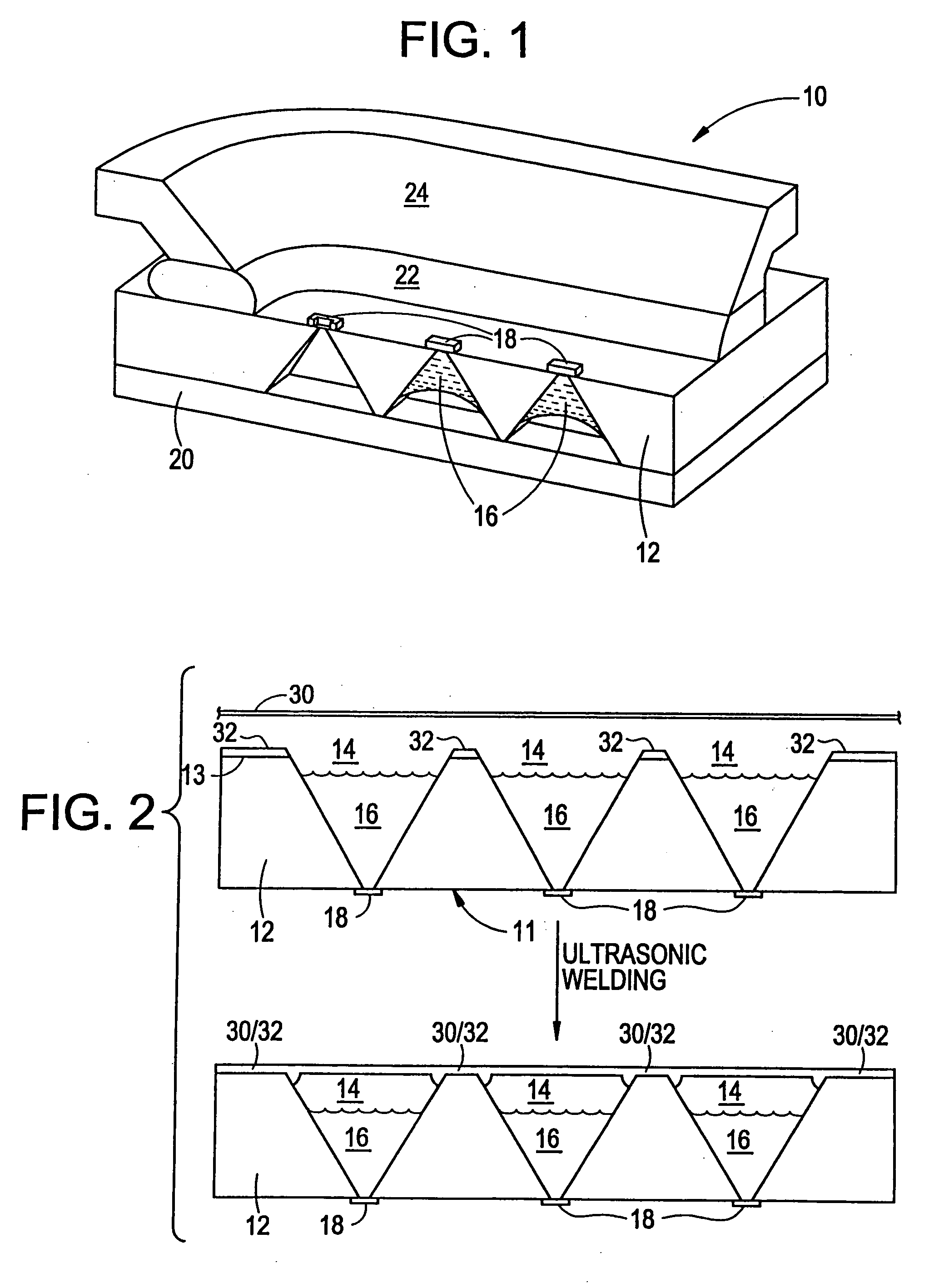

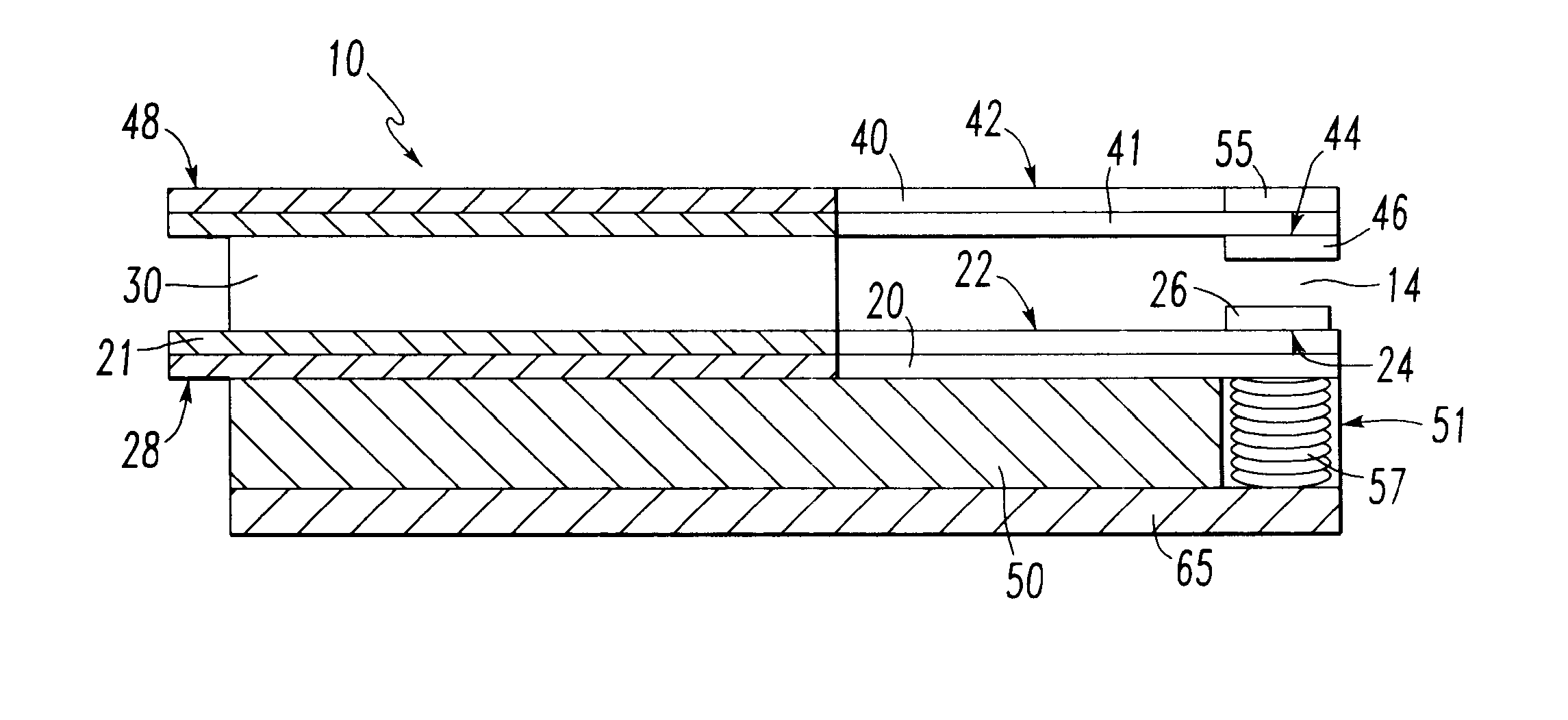

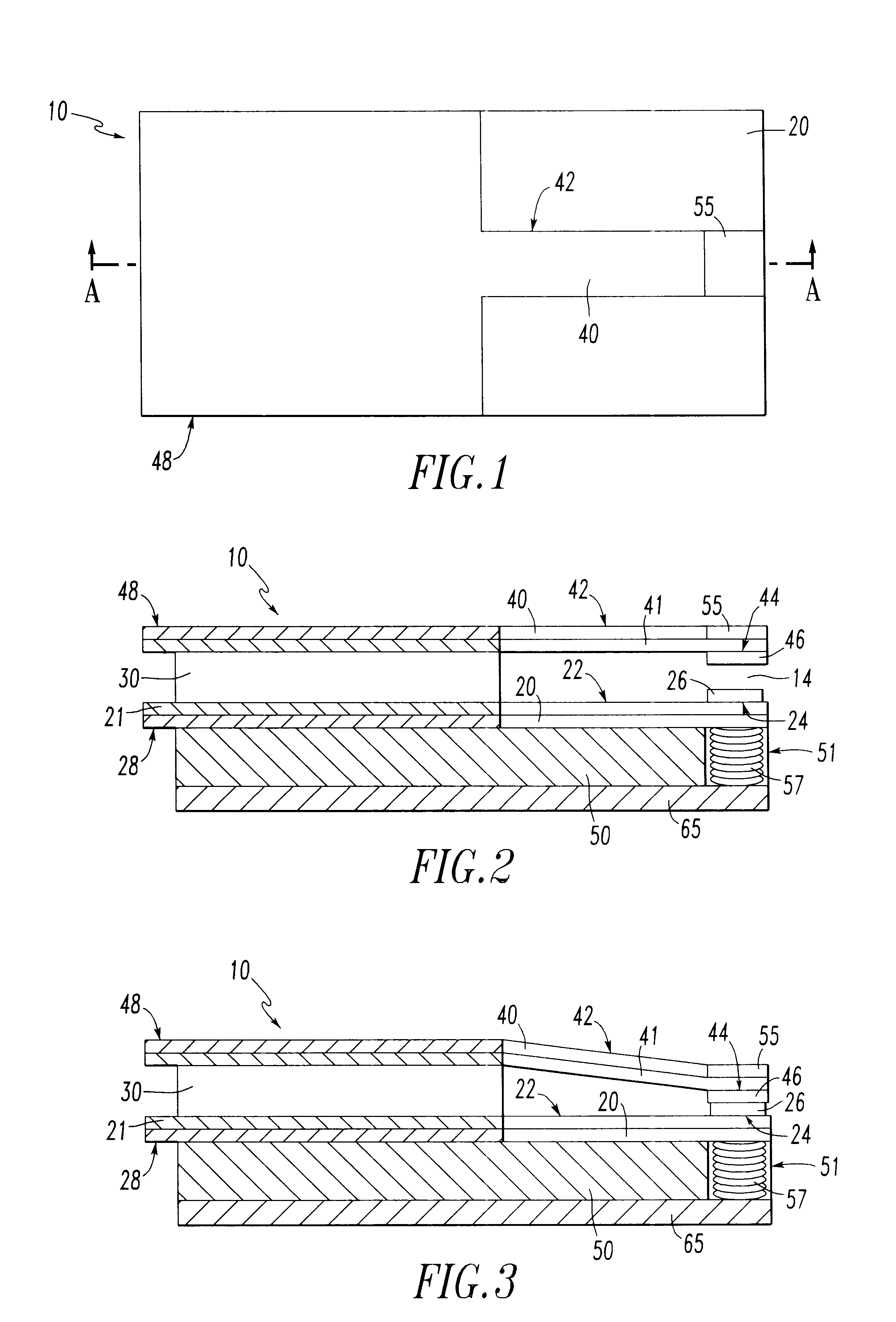

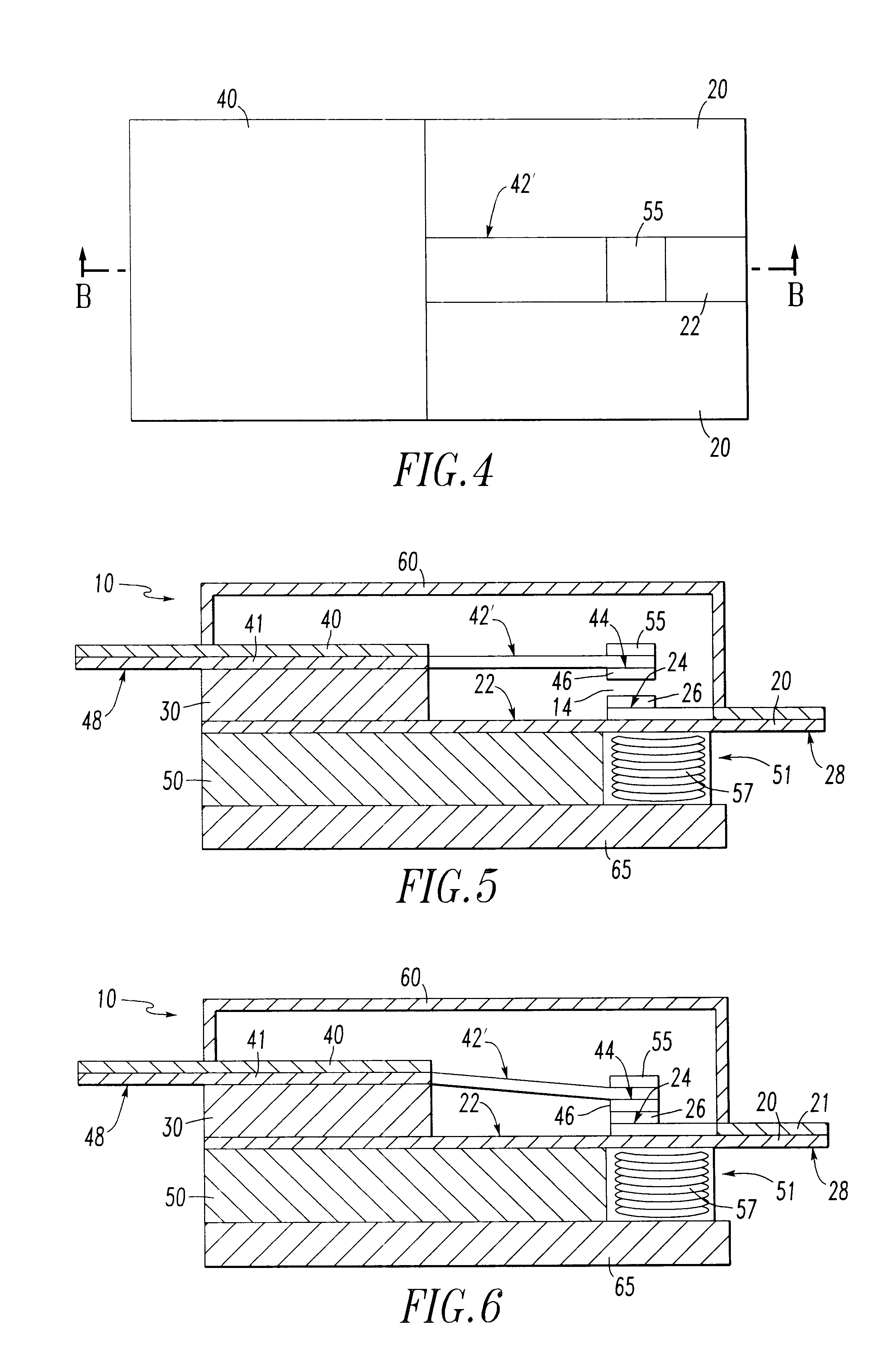

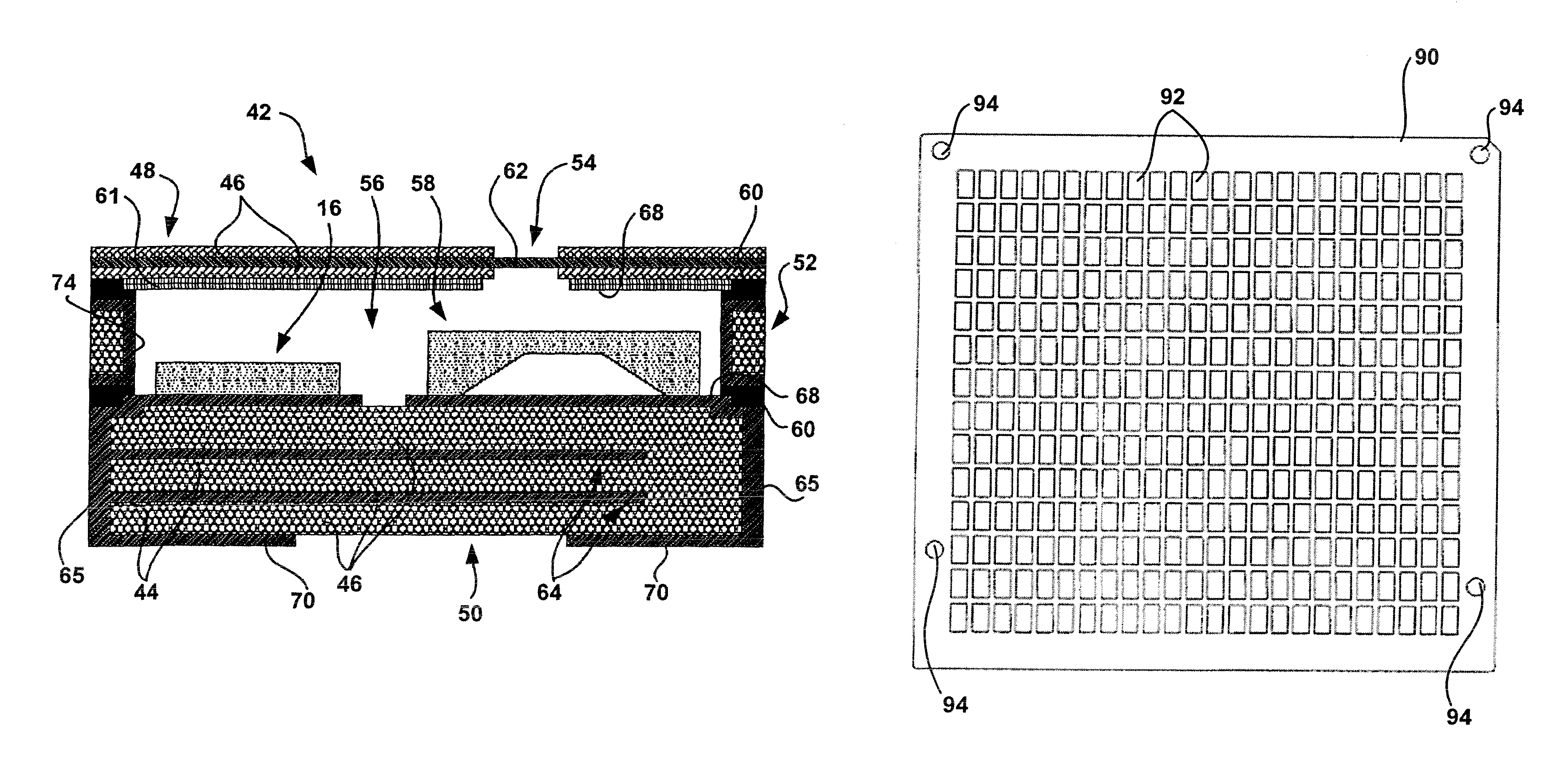

Laminate-based apparatus and method of fabrication

InactiveUS6410360B1CostDesigned withContact member manufacturingPrecision positioning equipmentDielectricManufacturing technology

The present invention discloses a laminate-based electromechanical device and a method of fabricating laminate-based electromechanical devices. The device includes two or more layers of laminate bonded together to form a unitary laminate structure. The layers of laminate include a layer of organic dielectric material that may have at least a portion of one layer of electrically conductive material adherent thereto. The layers of organic dielectric material are bonded to form a unitary laminate structure through a process of lamination. The structures that make up the electromechanical device may be formed either before or after bonding. In particular, the various electromechanical structures that make up the electromechanical device are formed from the layers of organic dielectric material and the layers of electrically conductive material adherent thereto using a predetermined sequence of additive and subtractive fabrication techniques.

Owner:TELEDYNE

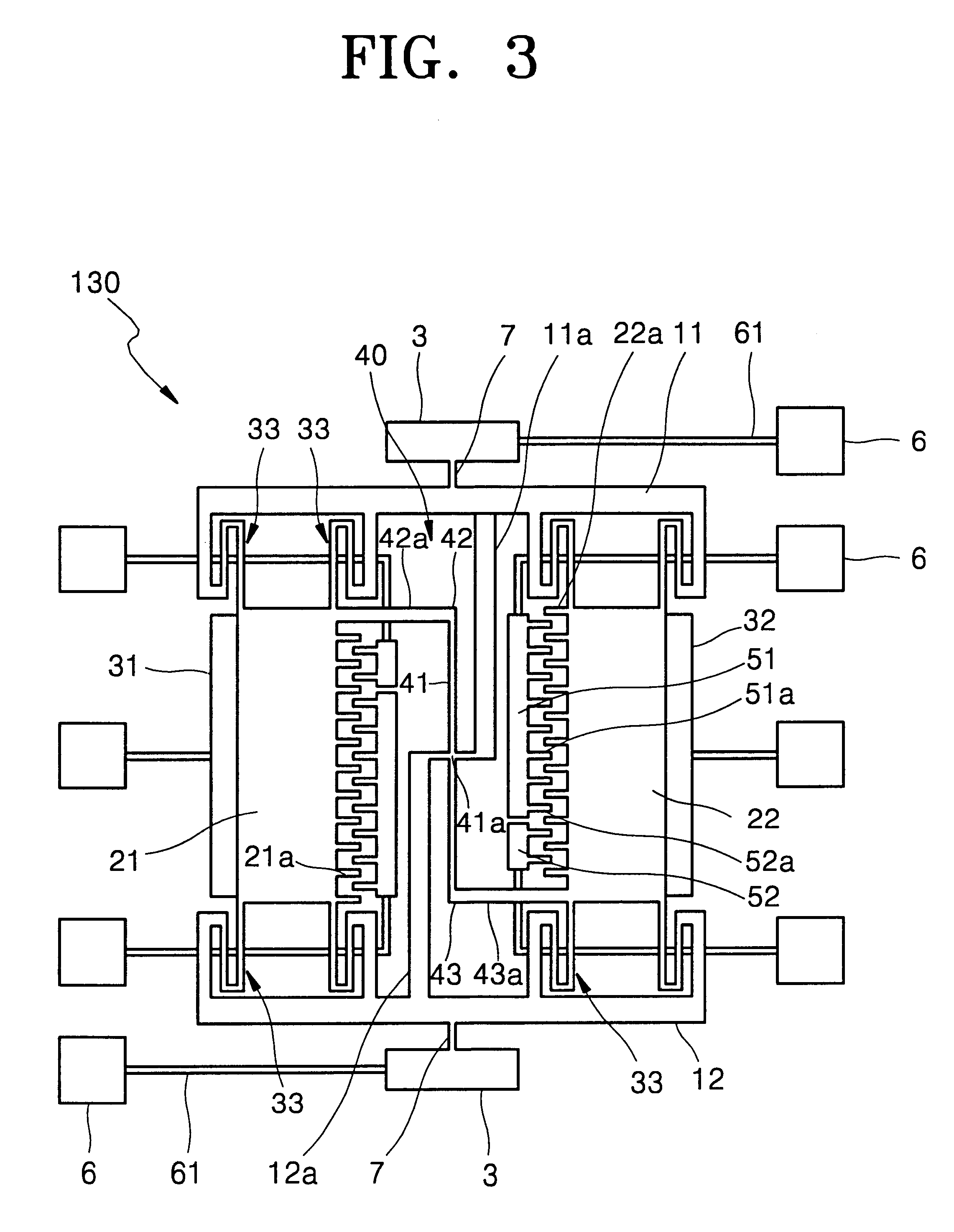

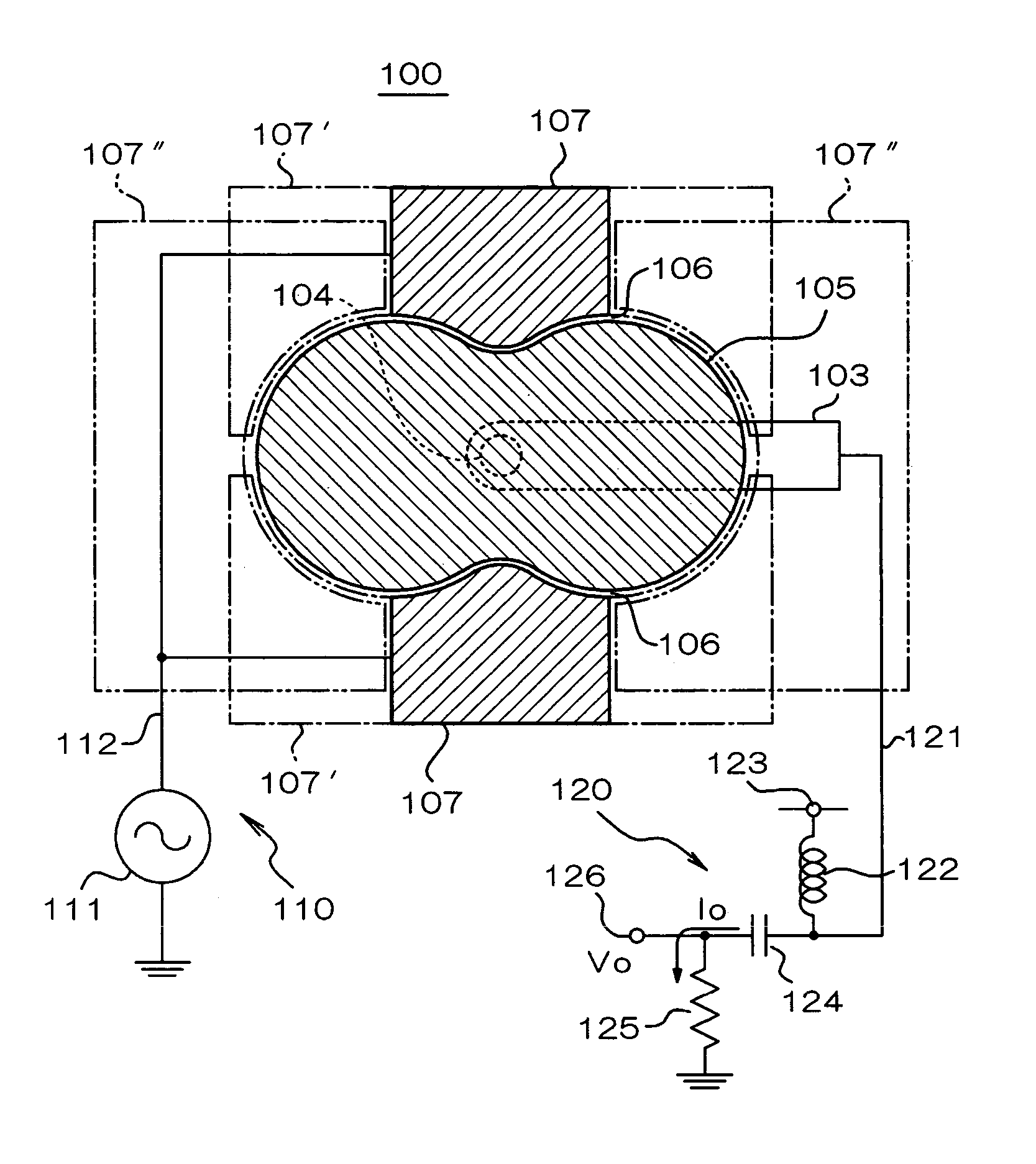

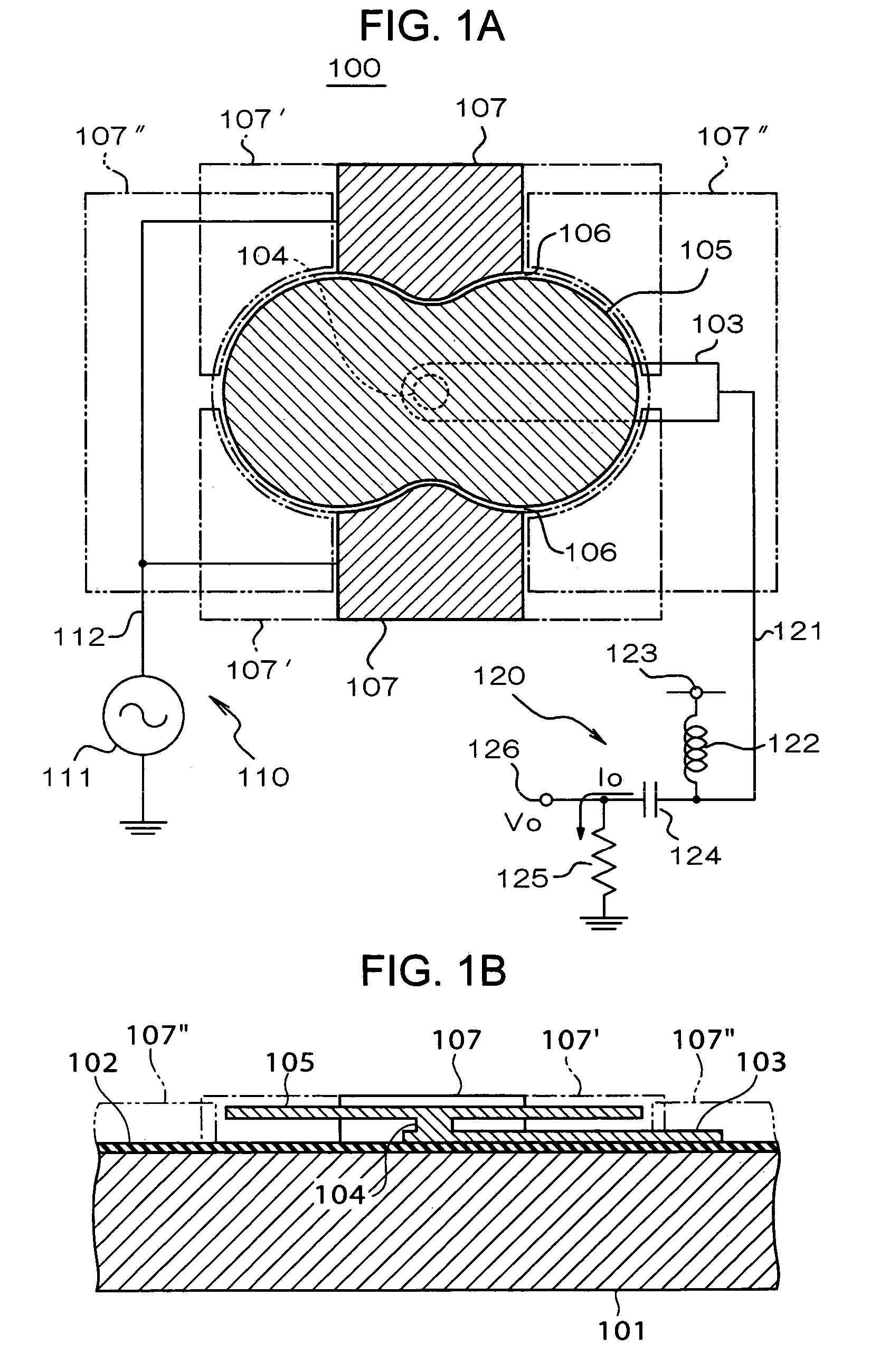

Micromechanical electrostatic resonator

InactiveUS7215061B2CapacitanceLarge capacitancePiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsCapacitanceAlternating current

Owner:SEIKO EPSON CORP

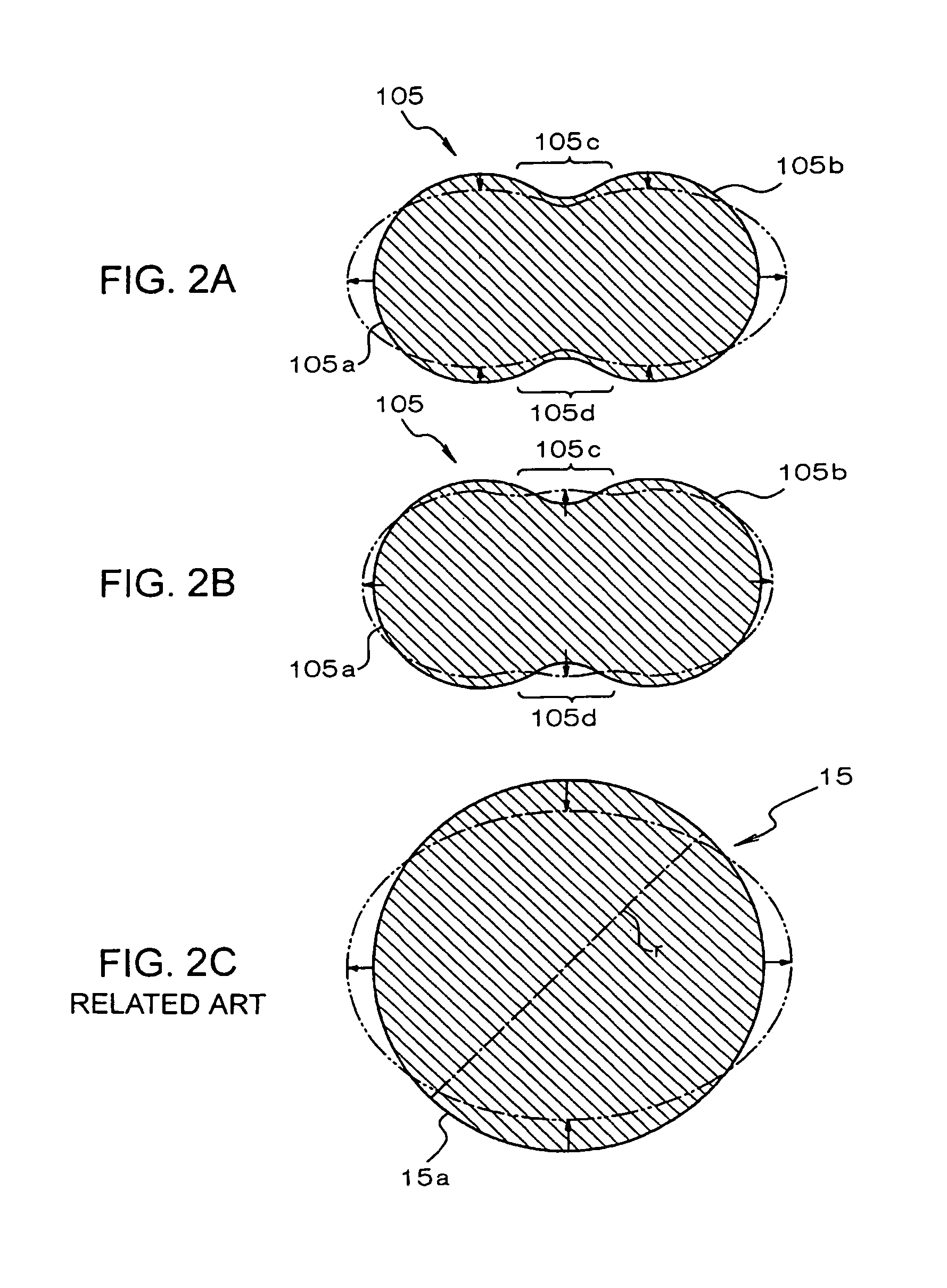

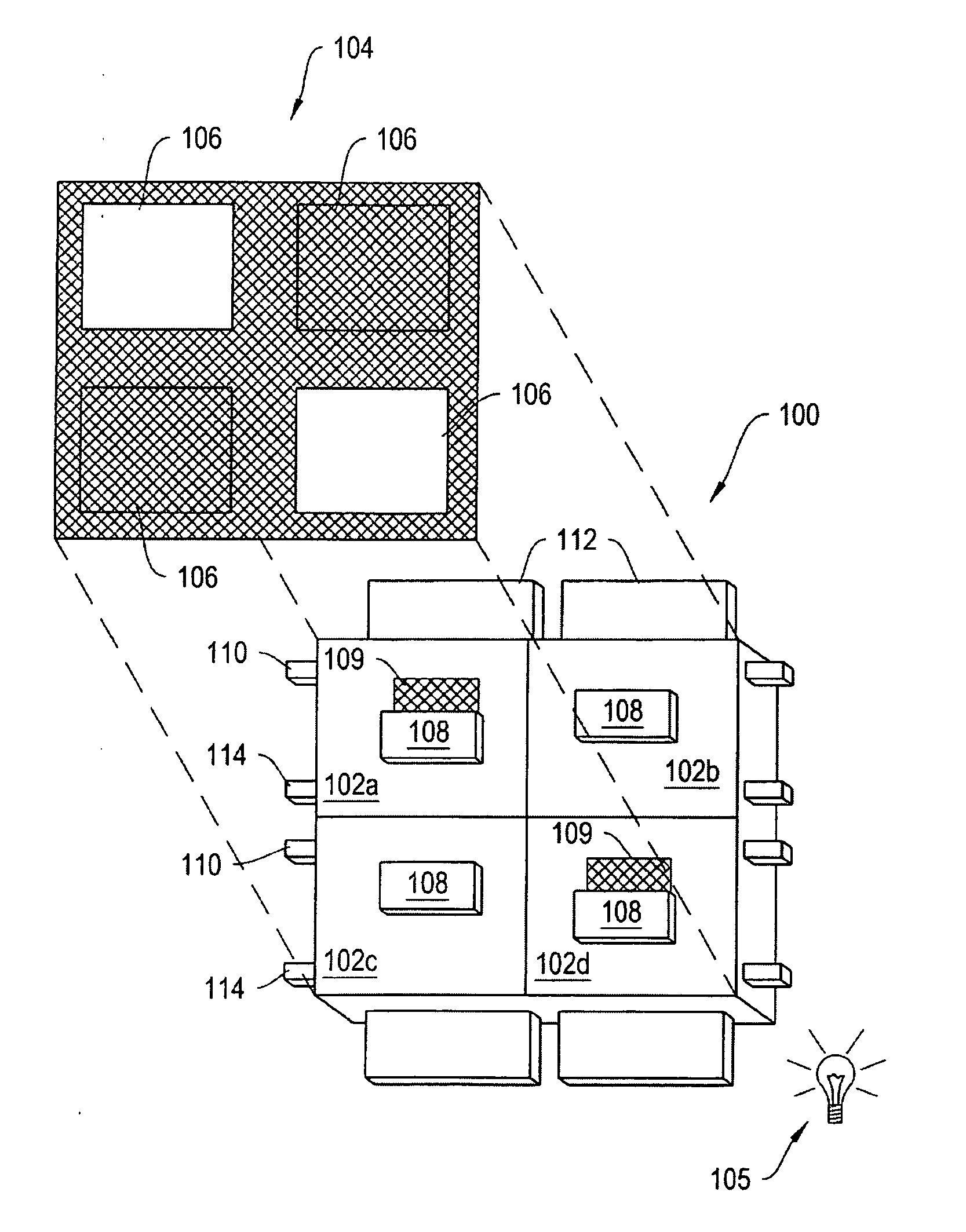

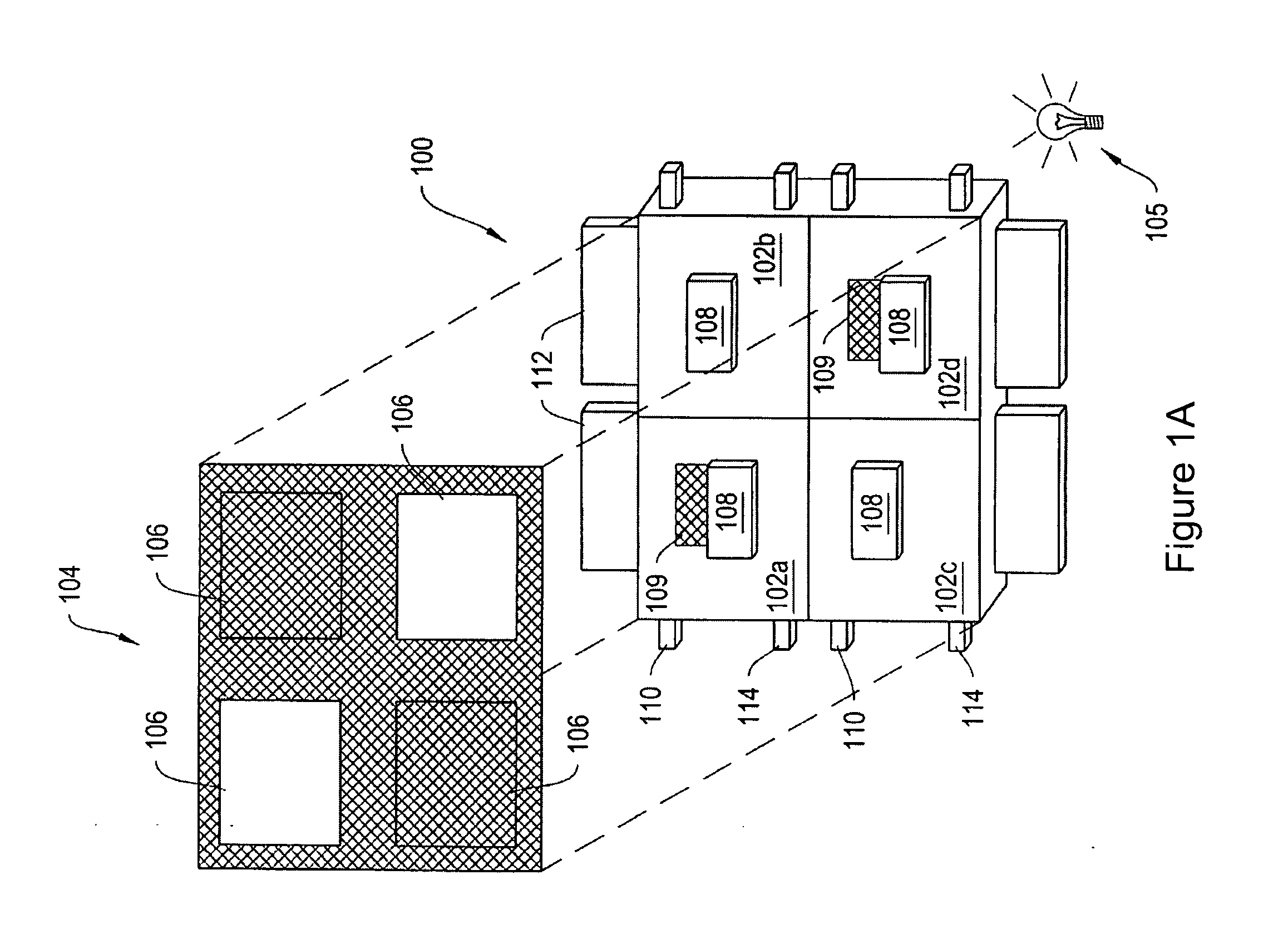

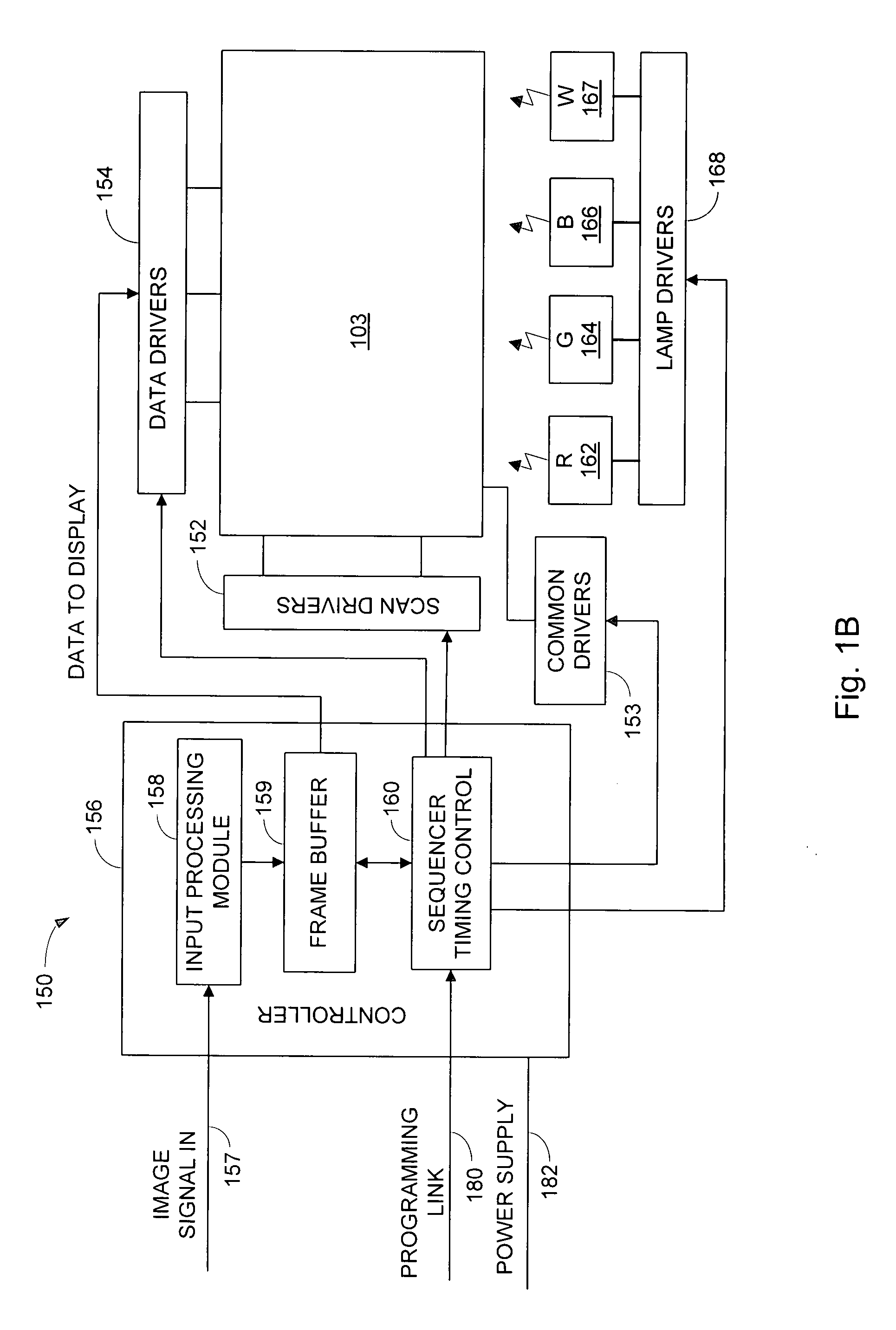

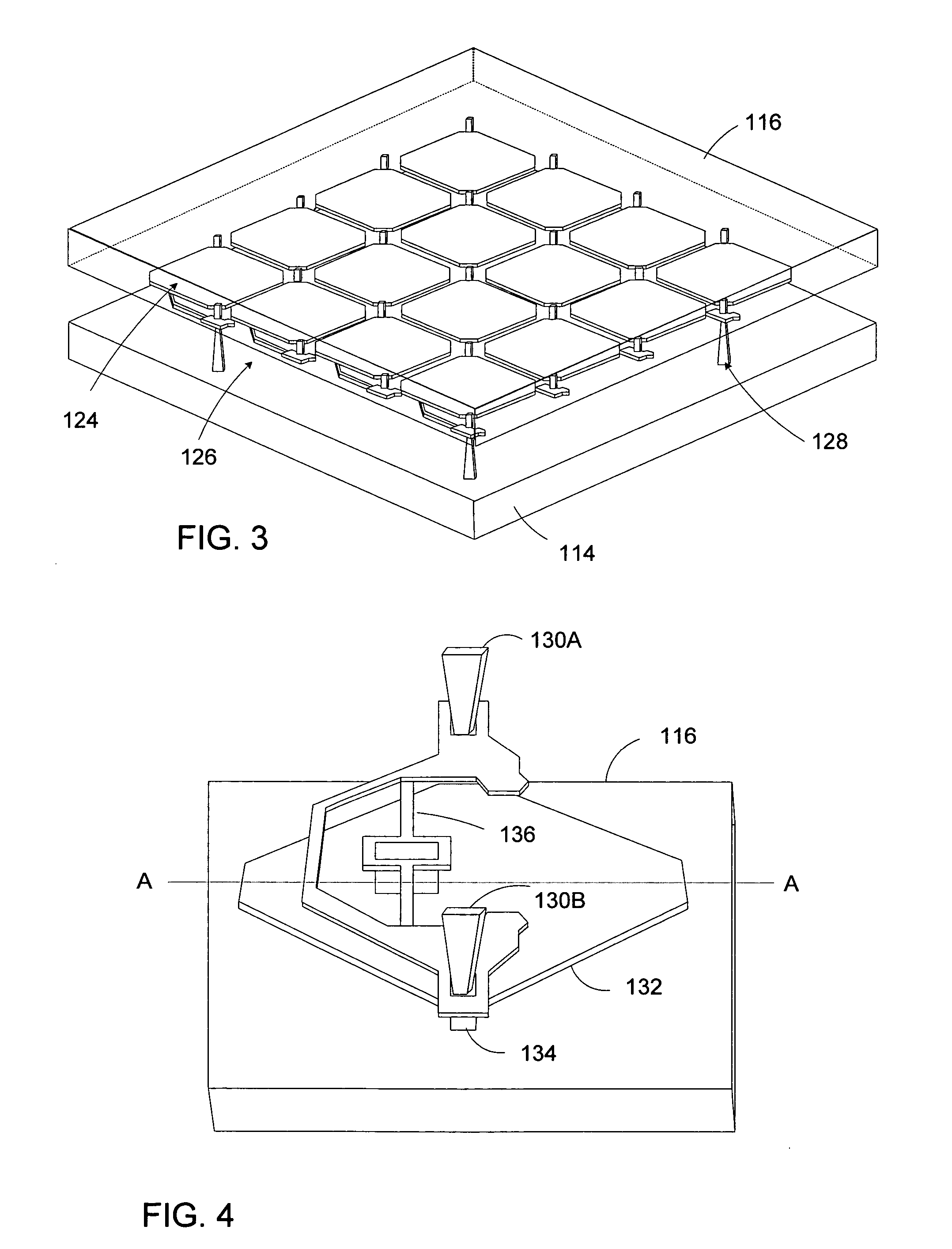

Alignment methods in fluid-filled MEMS displays

InactiveUS20080037104A1Improve electromechanical performanceGood optical performanceTube/lamp screens manufactureStatic indicating devicesDisplay deviceEngineering

This invention relates to MEMS display apparatus and methods for assembly thereof that include a plurality of light modulators having components substantially surrounded in a liquid that reduces the effects of stiction and improves the optical and electromechanical performance of the display apparatus. The invention also relates to methods for aligning components of a MEMS display to establish a correspondence between the plurality of light modulators and a plurality of apertures to regulate the transmission of light through the apparatus.

Owner:SNAPTRACK

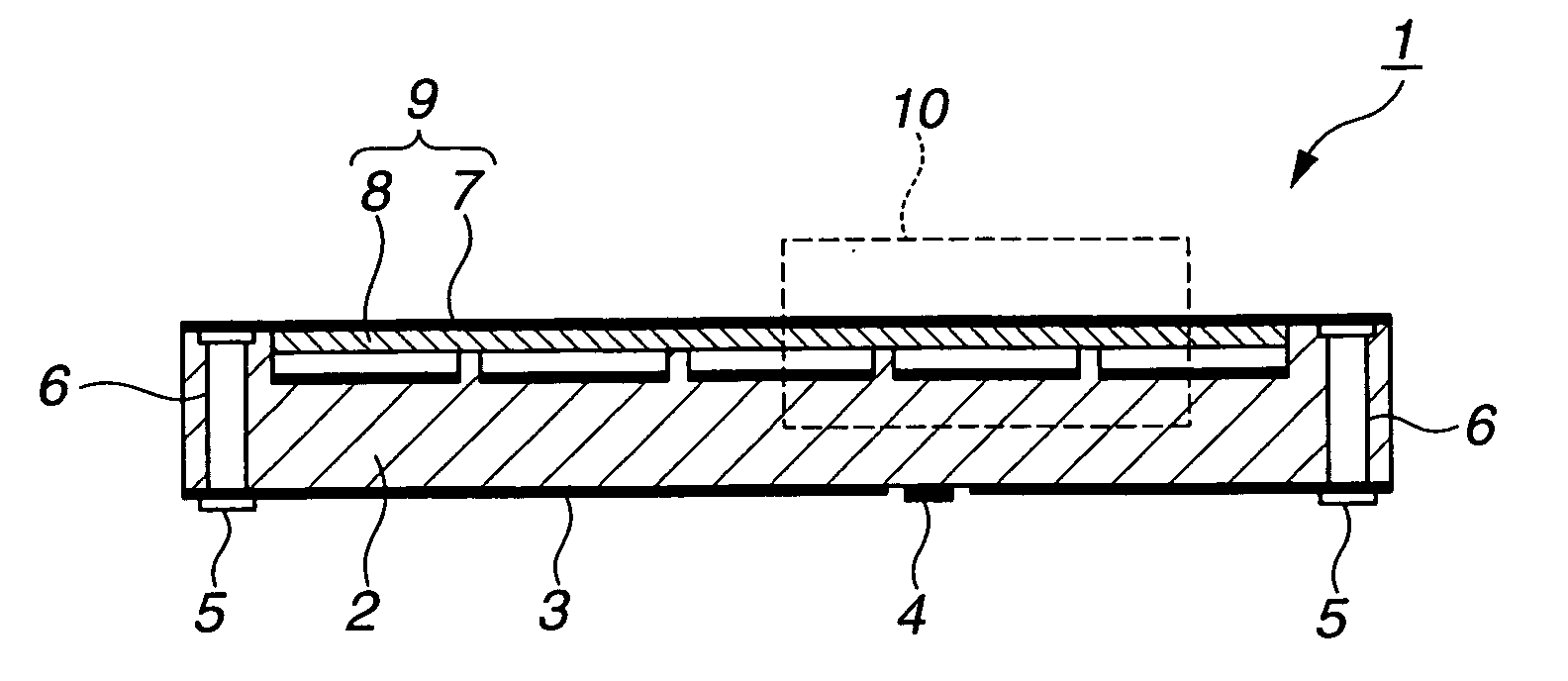

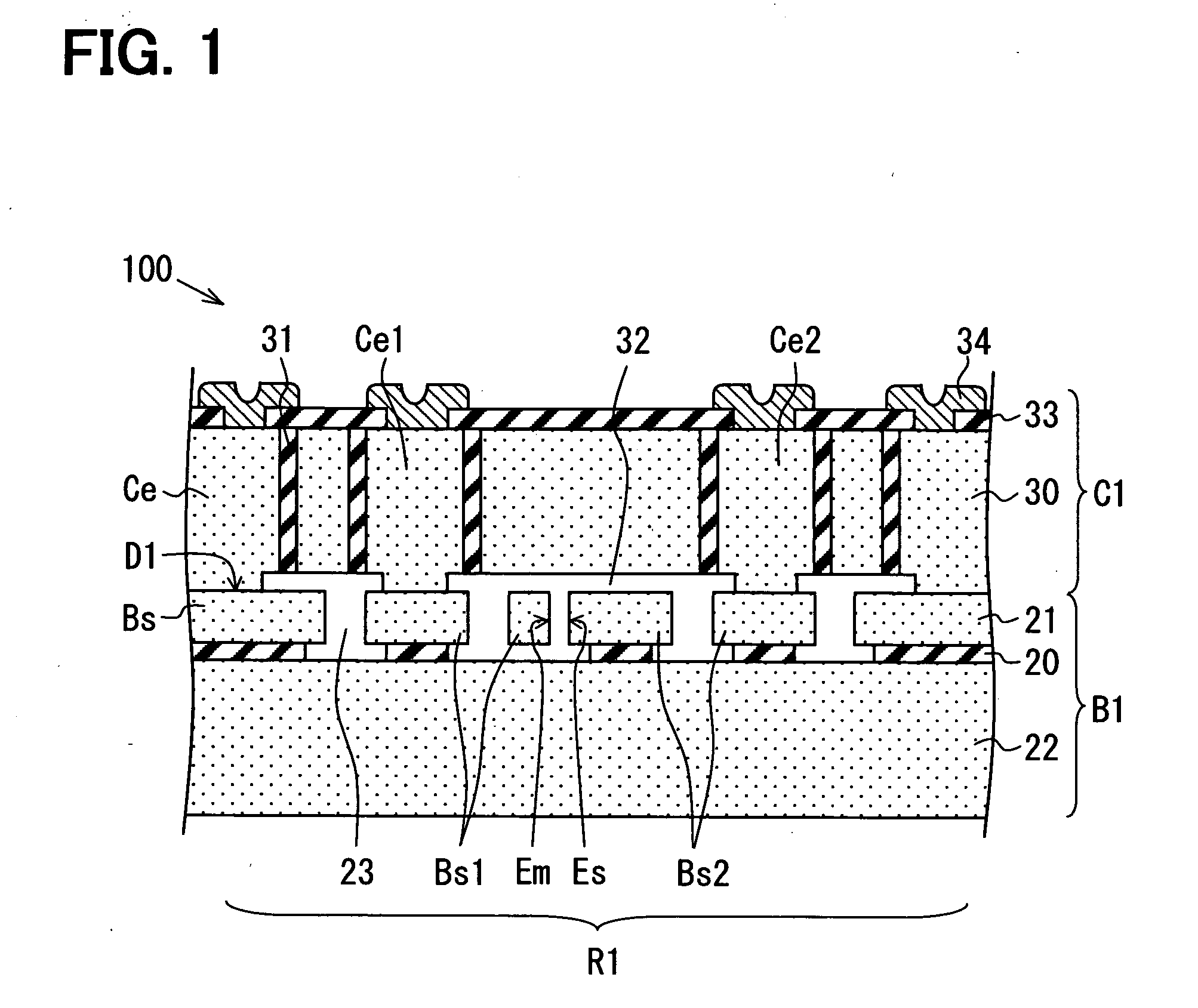

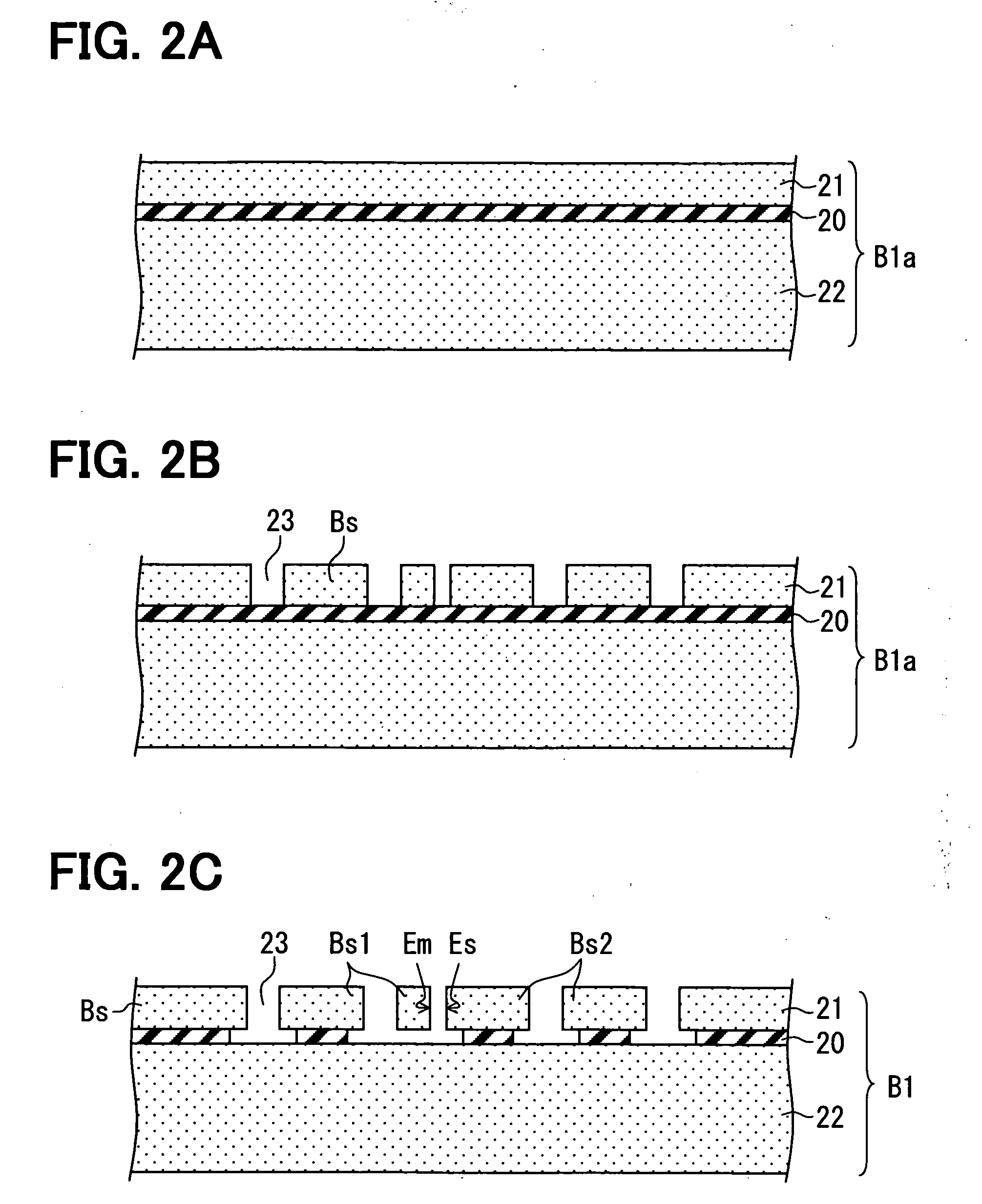

Electronic devices and its production methods

ActiveUS7456497B2Deterioration of characteristicSmall and compactFixed microstructural devicesVolume/mass flow by thermal effectsHermetic sealEngineering

An electronic device having mounted thereon an MEMS element or other functional elements, in which a device body and lid define an element-carrying space, the element-carrying space is sealed air-tight by an ultrasonic bonded part bonding the device body and the lid, and the element-carrying space having arranged inside it a system element secured to the device body and / or the lid by flip-chip connection.

Owner:SHINKO ELECTRIC IND CO LTD

Methods of making, positioning and orienting nanostructures, nanostructure arrays and nanostructure devices

InactiveUS20050230356A1Easy to controlHigh resistanceMaterial nanotechnologyNanostructure manufactureNanostructure fabricationNanostructure

Nanostructure manufacturing methods and methods for assembling nanostructures into functional elements such as junctions, arrays and devices are provided. Systems for practicing the methods are also provided.

Owner:ONED MATERIAL INC

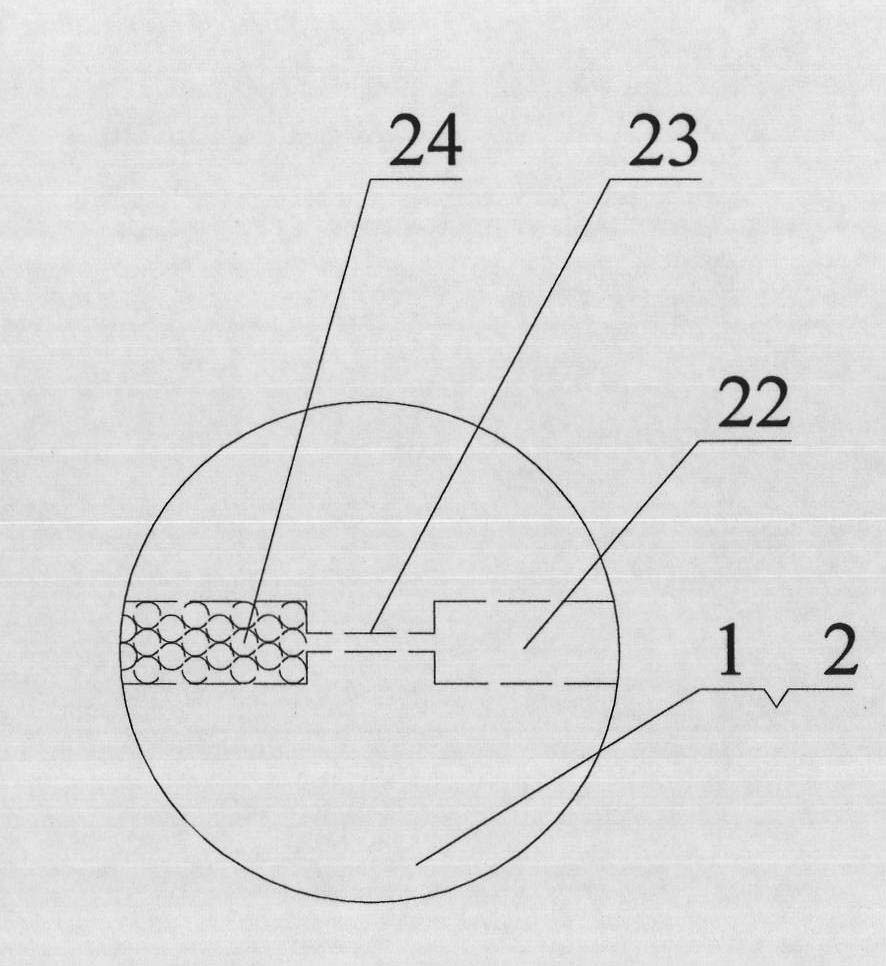

Separation column devices and fabrication methods

Pressure-driven microfluidic separation devices, such as may be used for performing high performance liquid chromatography, are provided. Multiple separation columns may be defined in a single device and packed with stationary phase material retained by porous frits. One or more splitters may be provided to distribute slurry and / or mobile phase among multiple separation columns. In one embodiment, separation devices are substantially planar and fabricated with multiple device layers. Systems and methods employing slurry for packing separation devices are also provided.

Owner:AGILENT TECH INC

Silicon condenser microphone and manufacturing method

InactiveUS7381589B2Interconnection arrangementsSemiconductor/solid-state device detailsTransducerCondenser microphone

A silicon condenser microphone package is disclosed. The silicon condenser microphone package comprises a transducer unit substrate, and a cover. The substrate includes an upper surface having a recess formed therein. The transducer unit is attached to the upper surface of the substrate and overlaps at least a portion of the recess wherein a back volume of the transducer unit is formed between the transducer unit and the substrate. The cover is placed over the transducer unit and includes an aperture.

Owner:KNOWLES ELECTRONICS INC

Methods and devices for enhancing bonded substrate yields and regulating temperature

InactiveUS7351377B2Reduce thermal couplingReduce transportationSludge treatmentHeating or cooling apparatusBonding processEngineering

Owner:CAPLIPER LIFE SCI INC

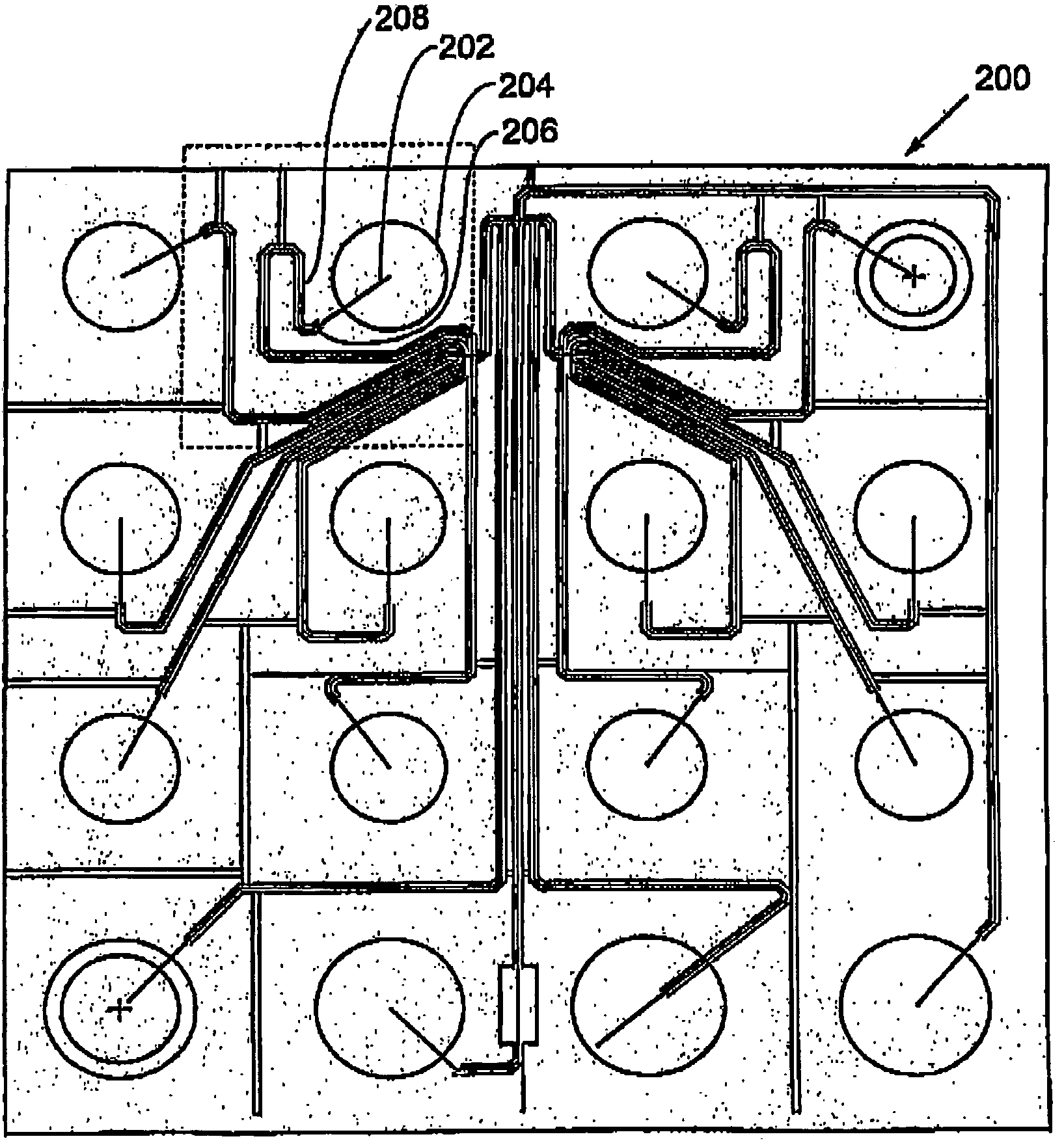

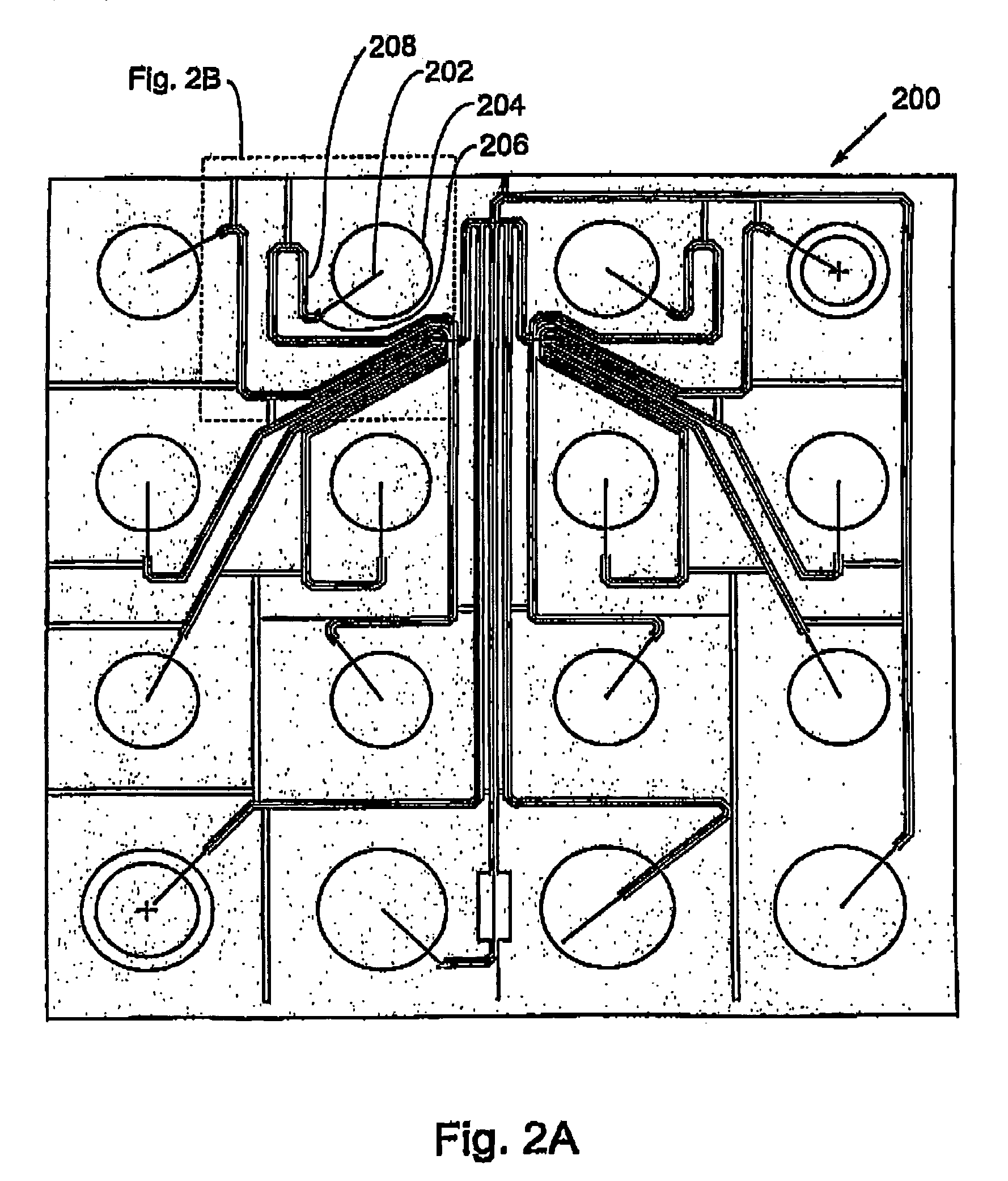

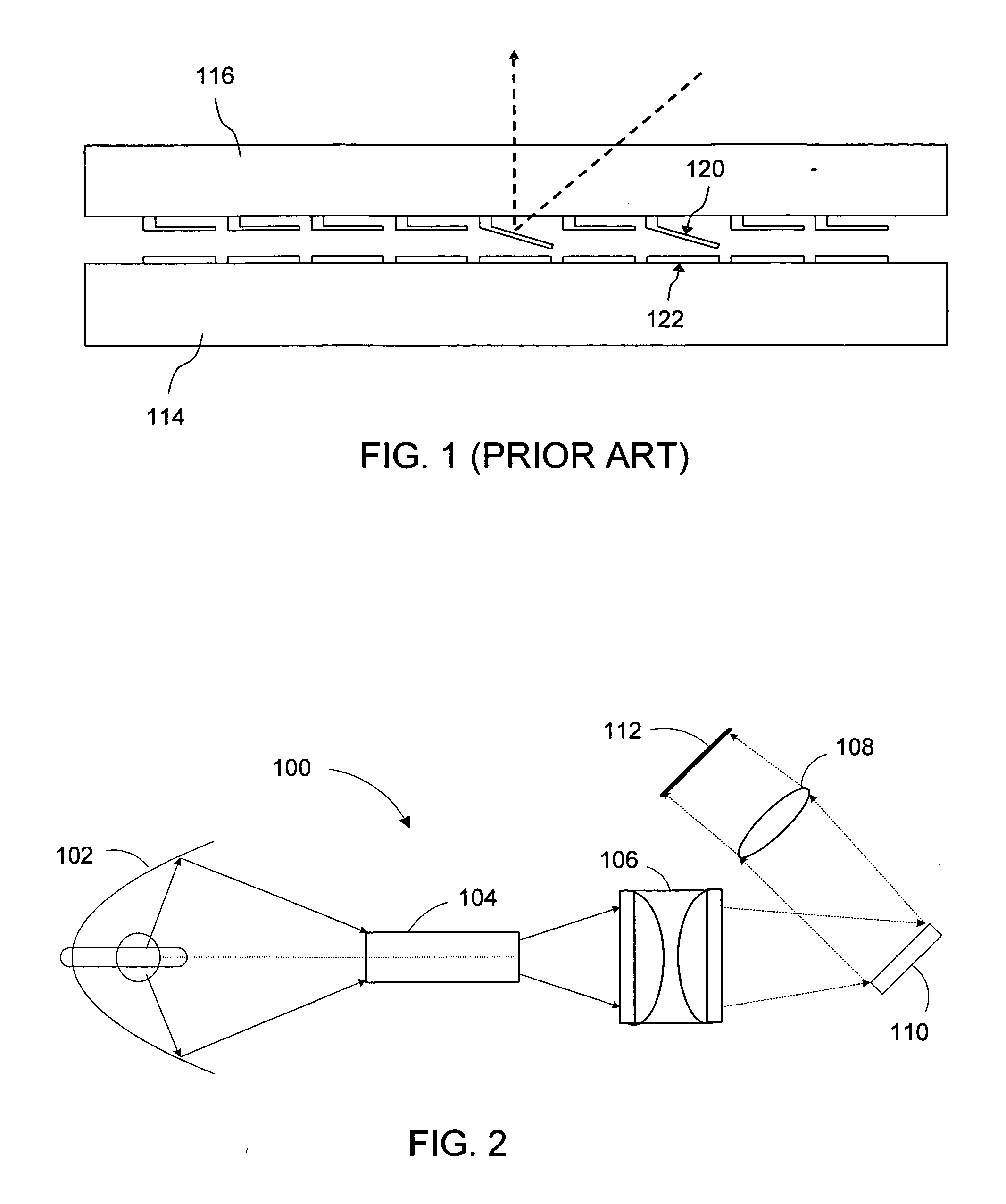

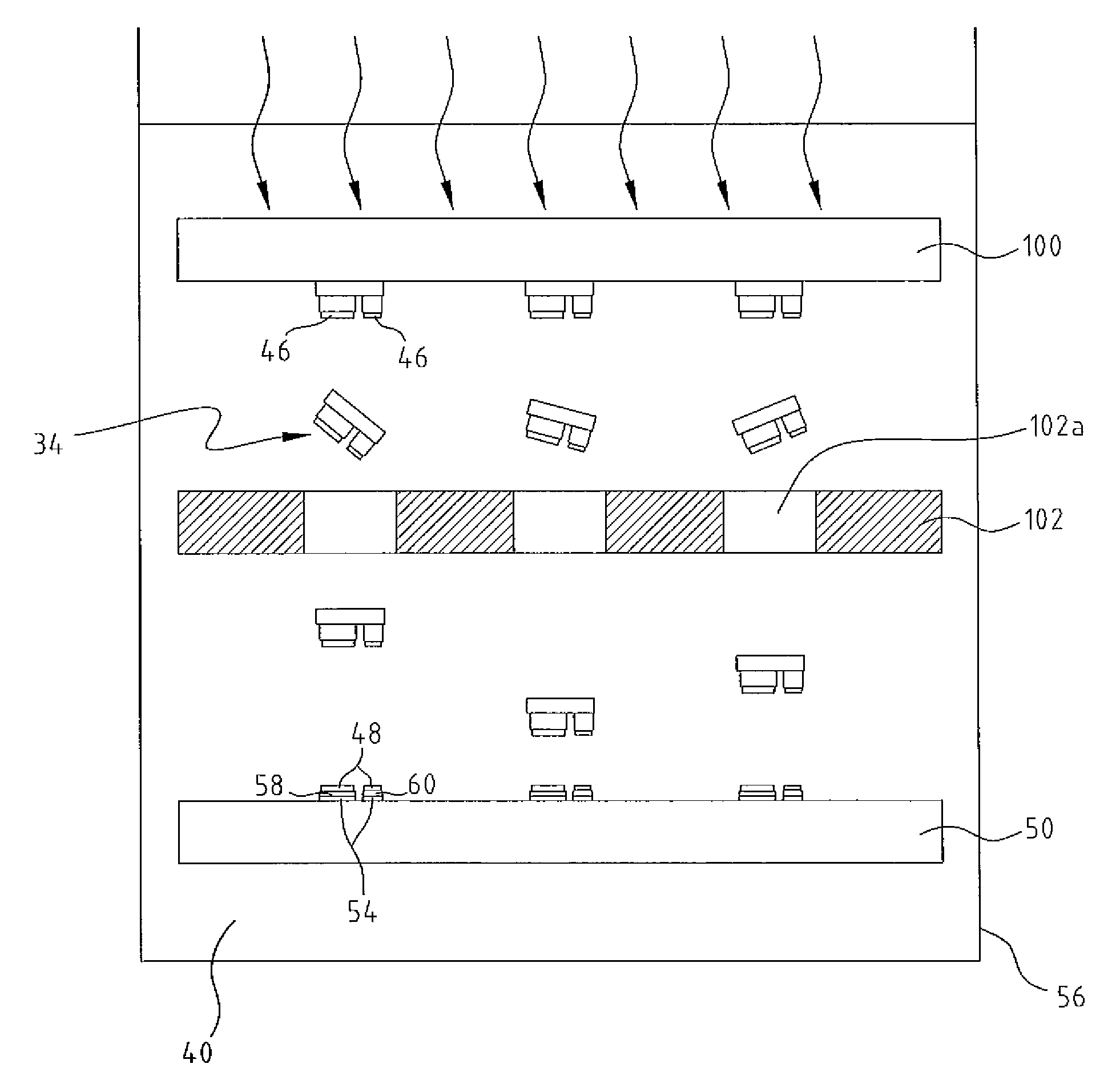

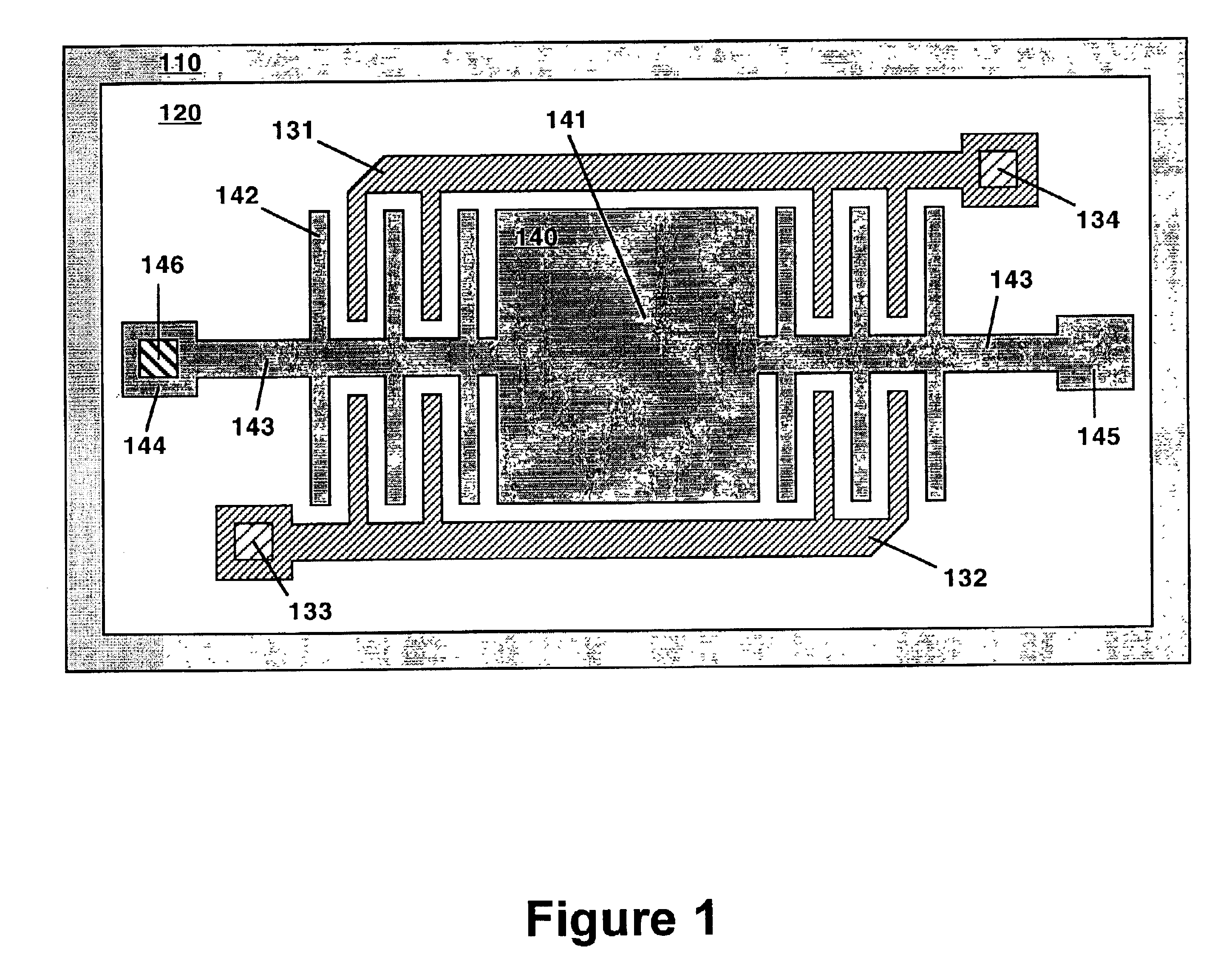

Micromirror array assembly with in-array pillars

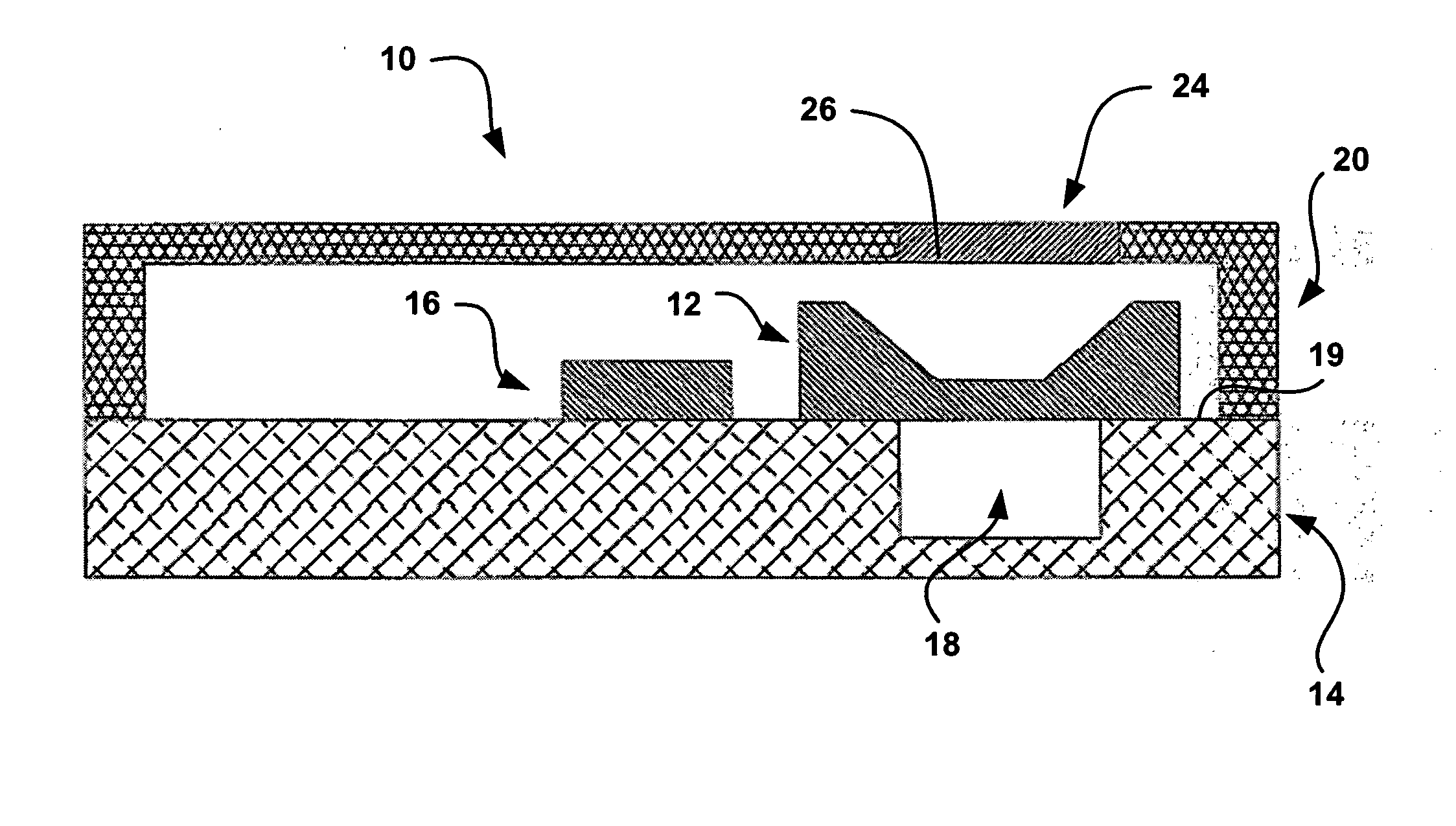

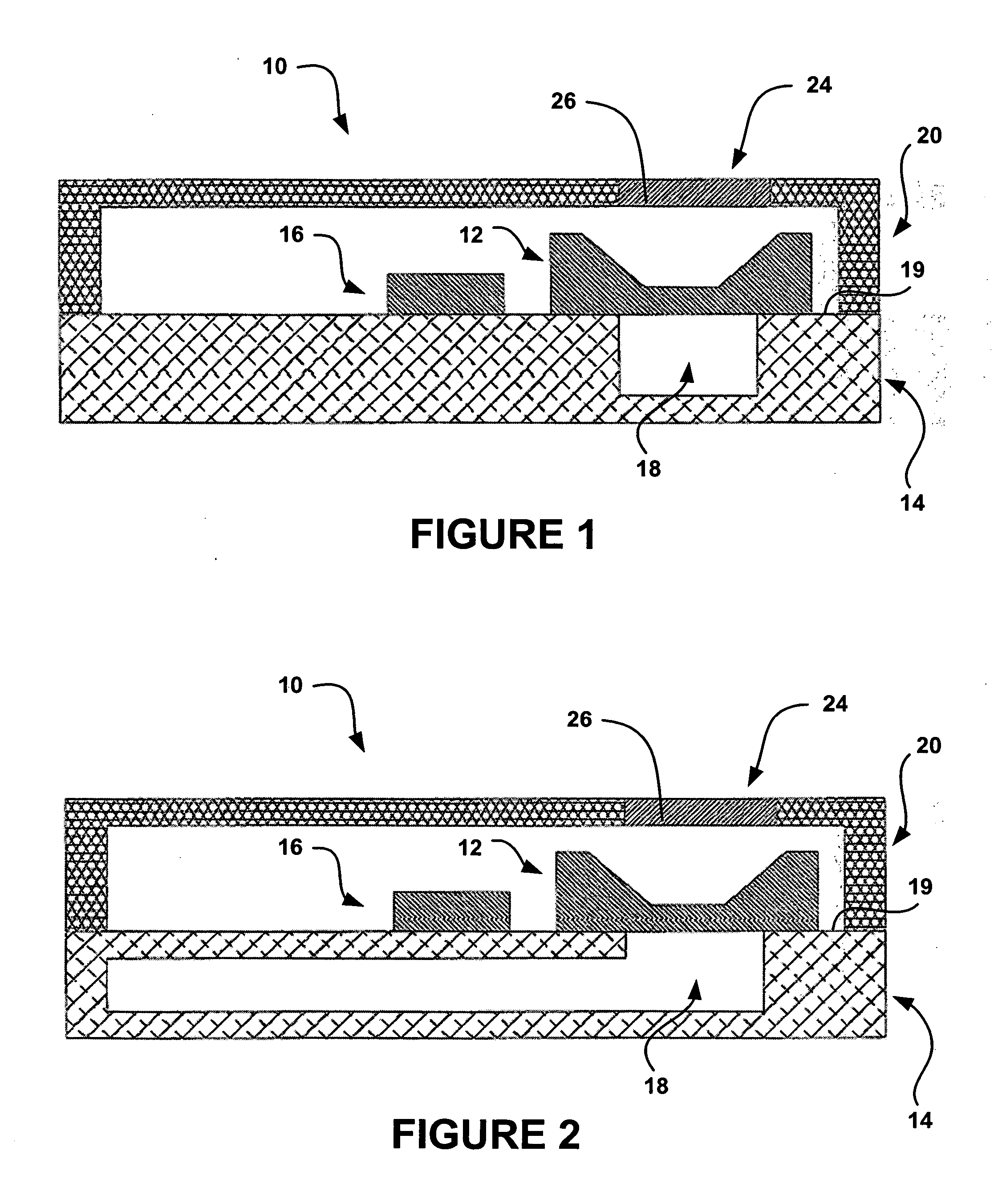

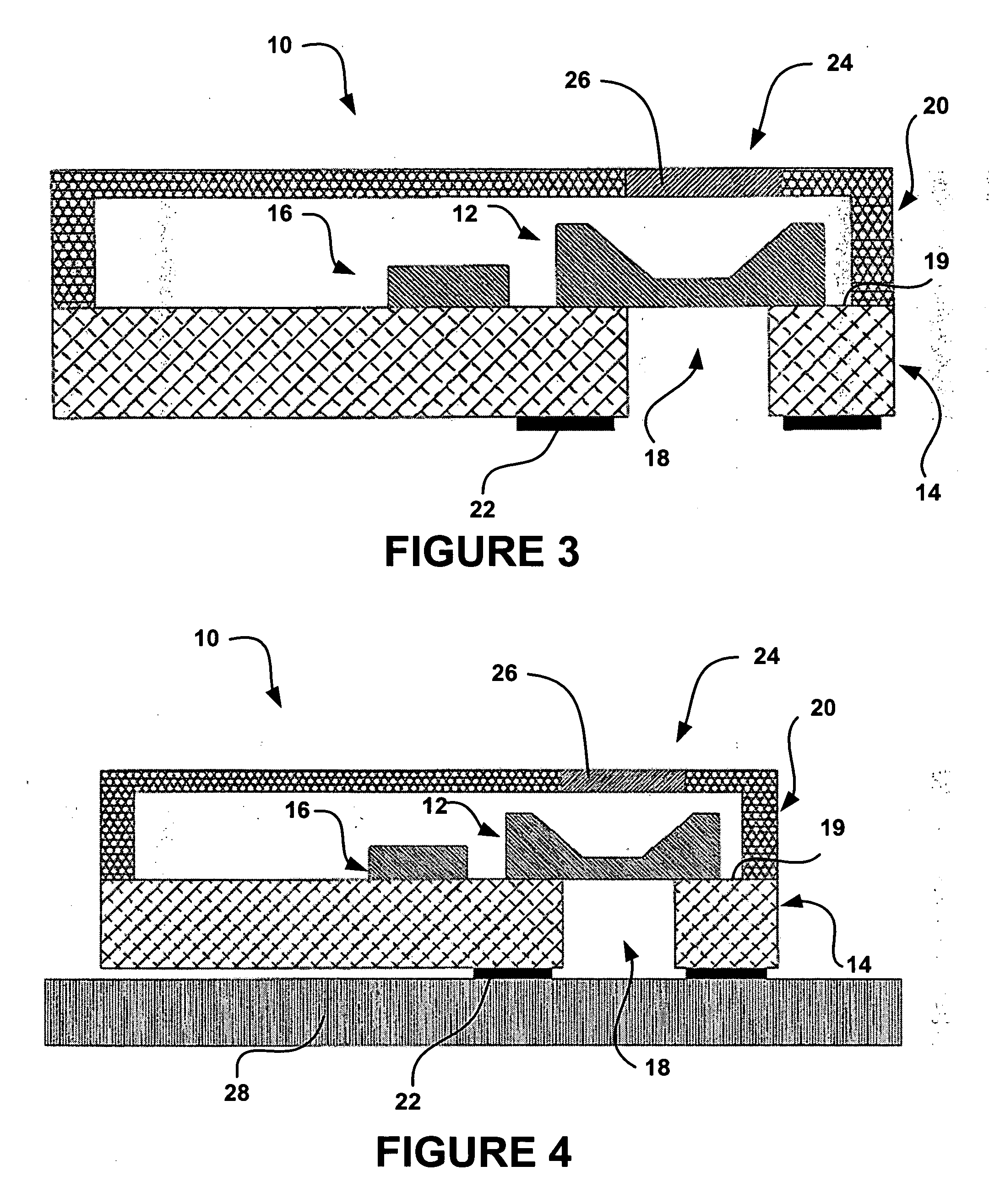

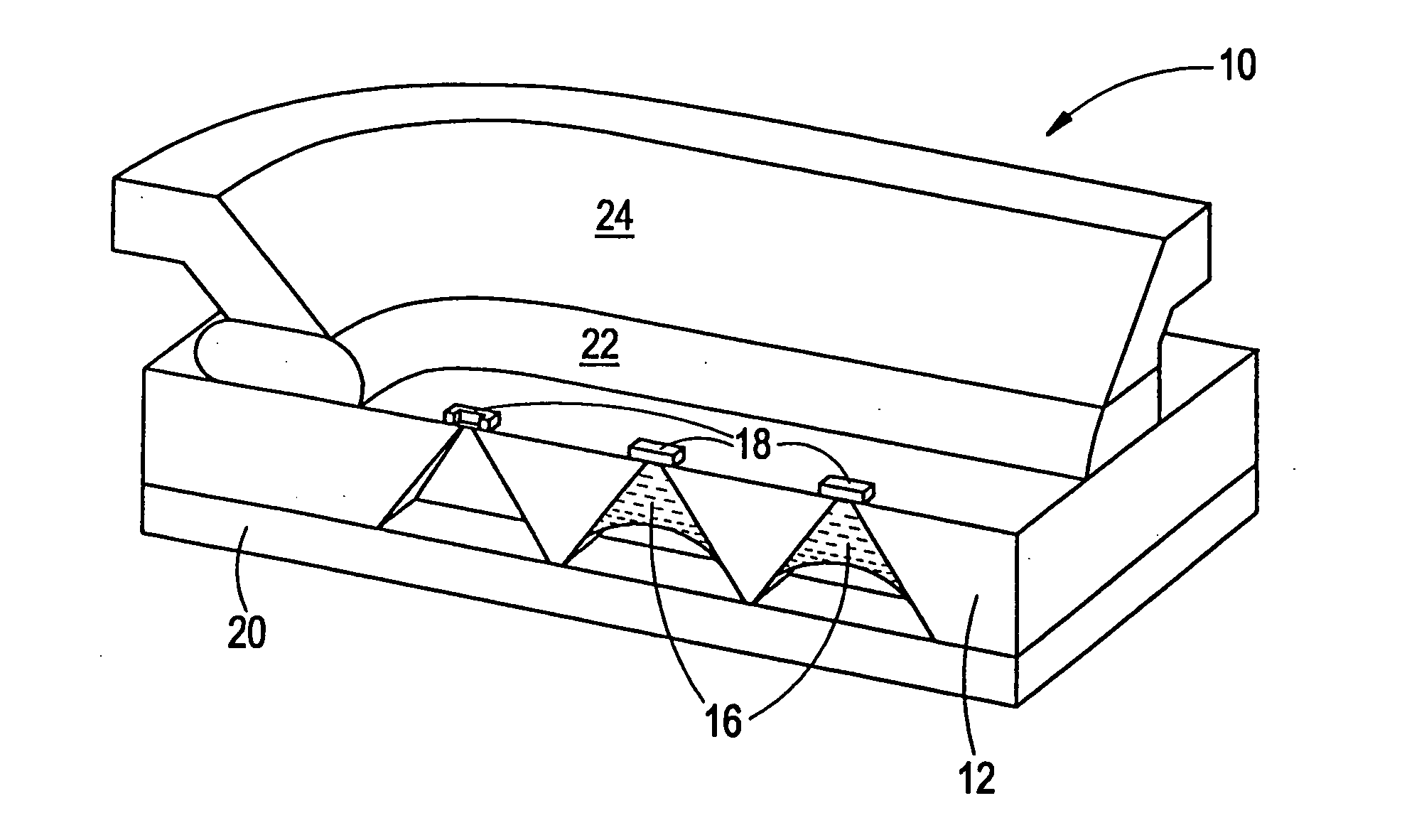

ActiveUS20050275930A1Improve air tightnessMicrostructural device assemblyAdhesivesElectricityDevice form

The present invention provides a microstructure device comprising multiple substrates with the components of the device formed on the substrates. In order to maintain uniformity of the gap between the substrates, a plurality of pillars is provided and distributed in the gap so as to prevent decrease of the gap size. The increase of the gap size can be prevented by bonding the pillars to the components of the microstructure. Alternatively, the increase of the gap size can be prevented by maintaining the pressure inside the gap below the pressure under which the microstructure will be in operation. Electrical contact of the substrates on which the micromirrors and electrodes are formed can be made through many ways, such as electrical contact areas, electrical contact pads and electrical contact springs.

Owner:TEXAS INSTR INC +1

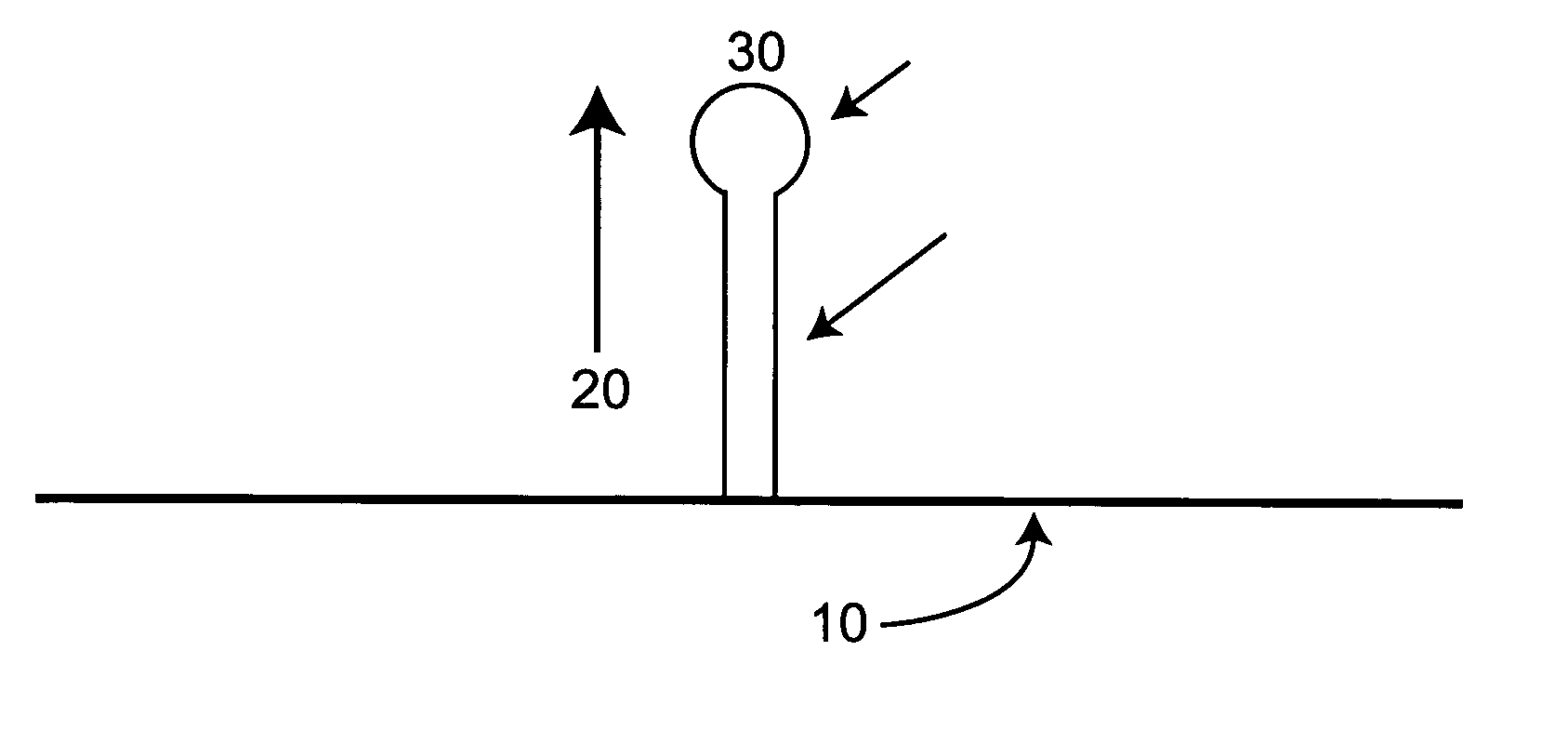

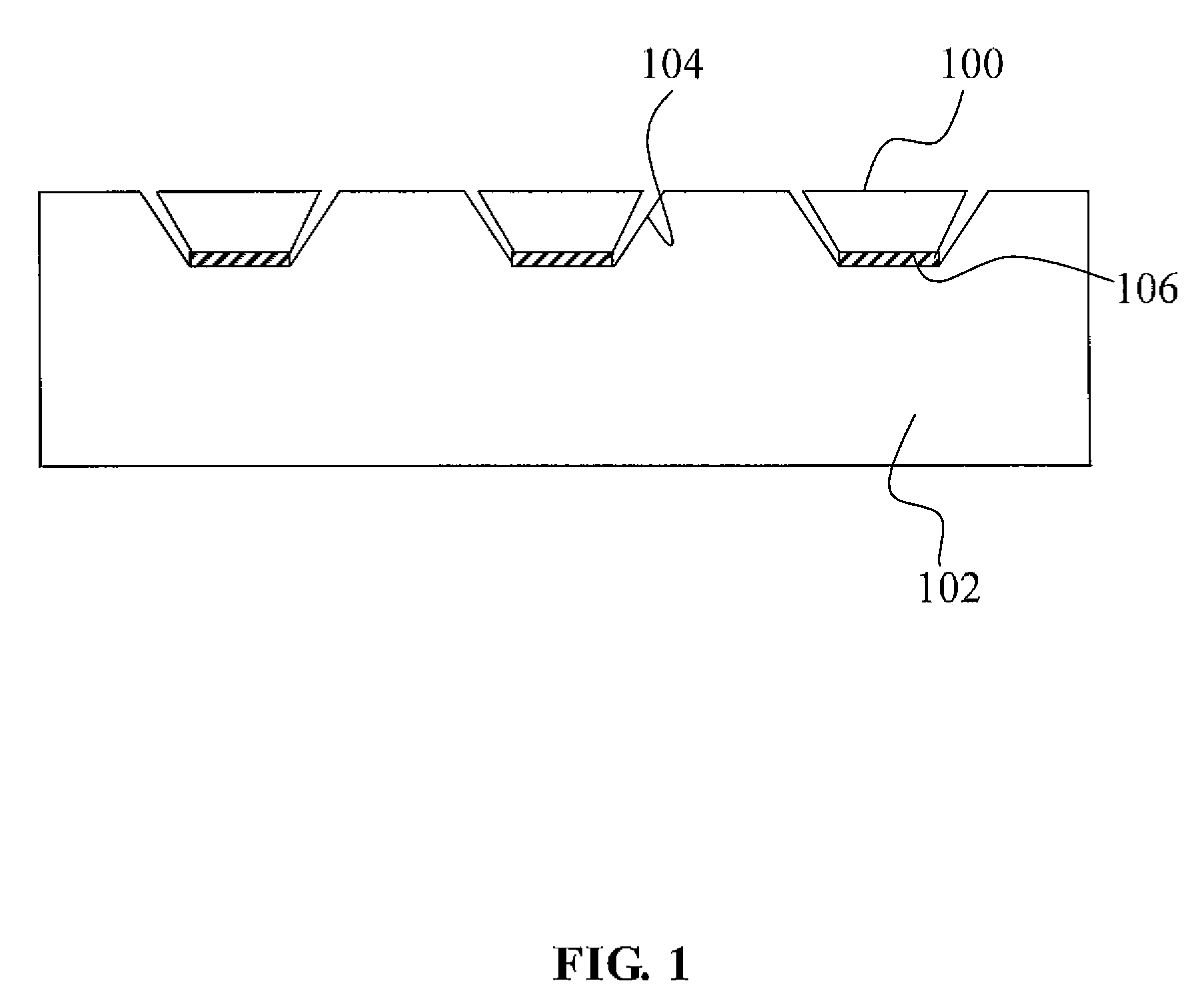

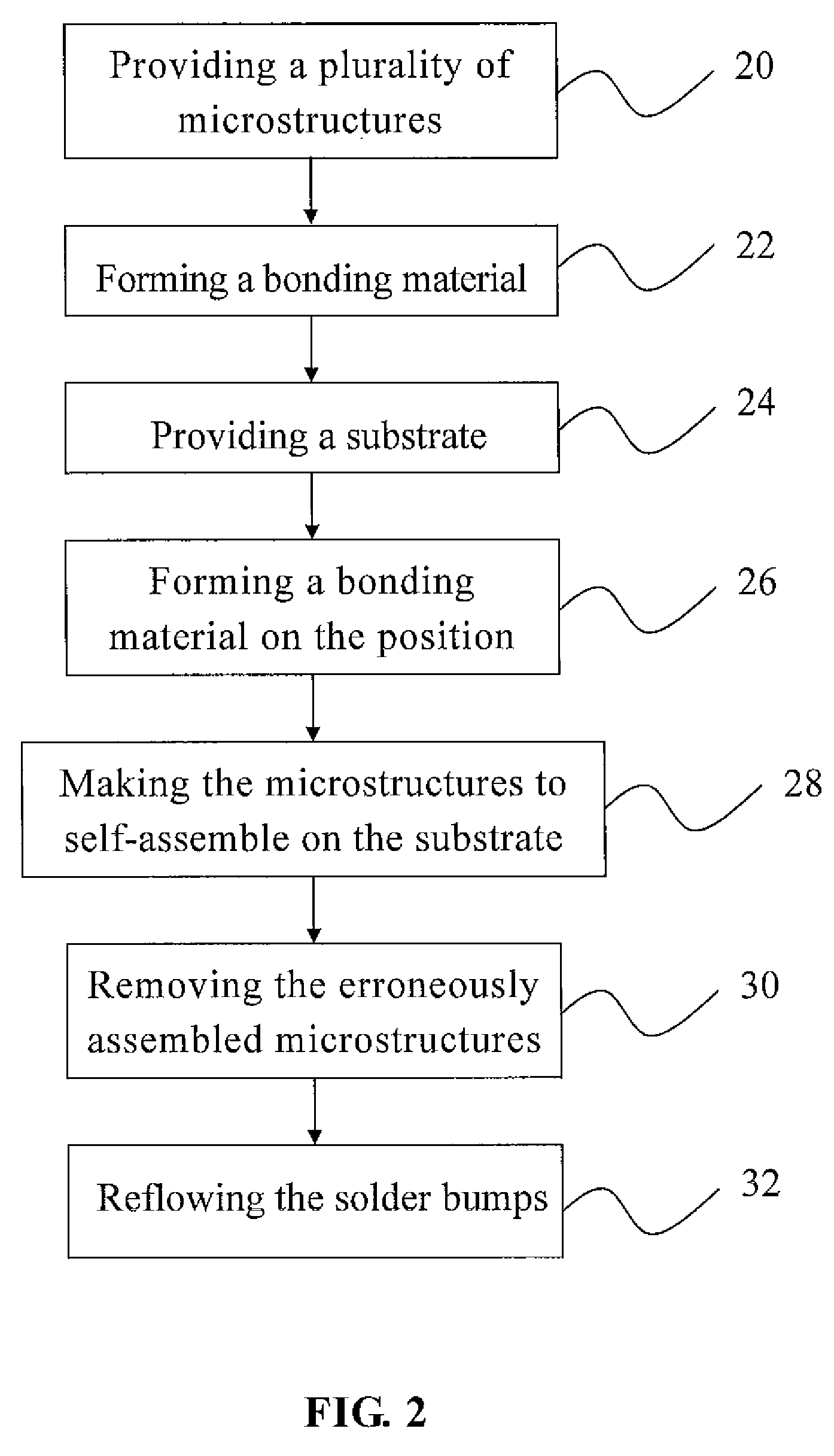

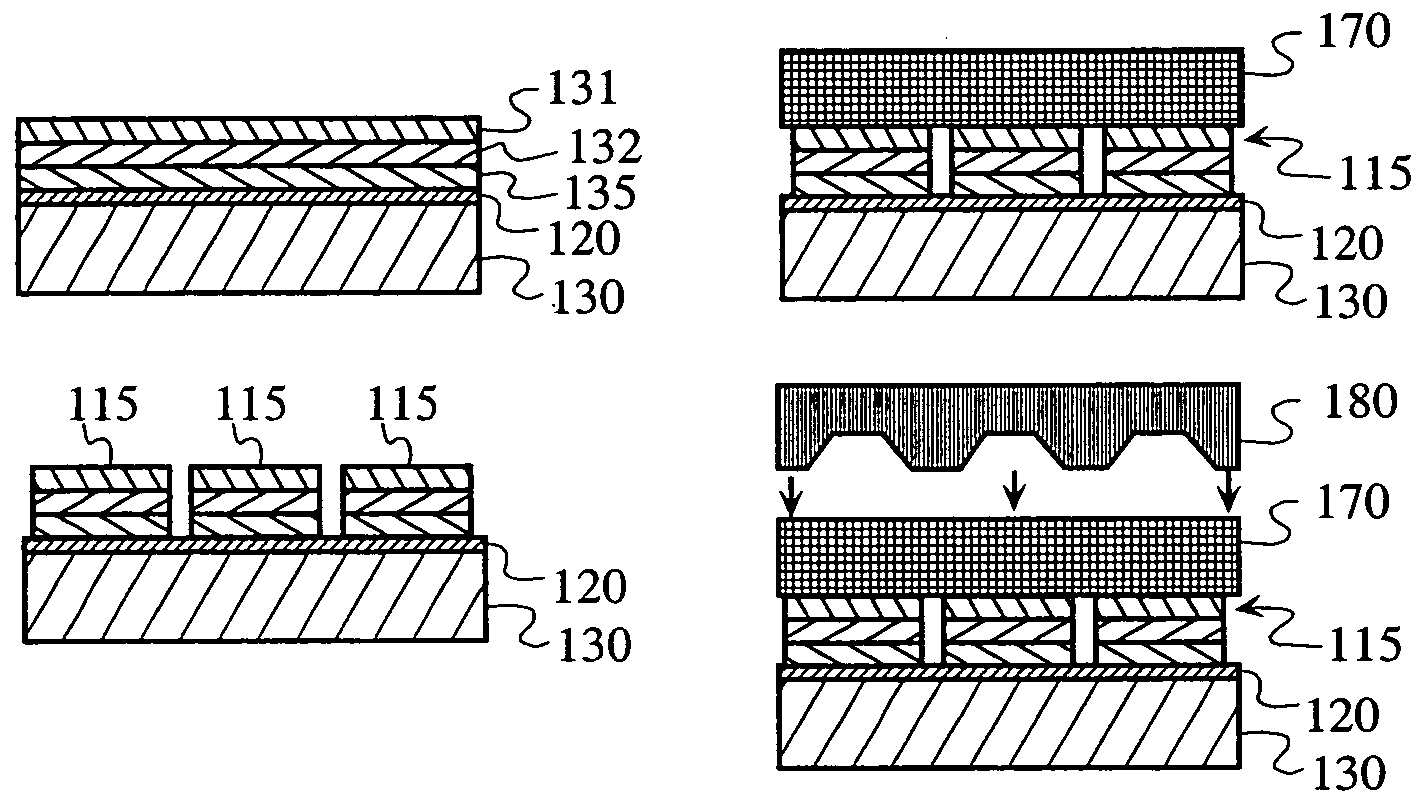

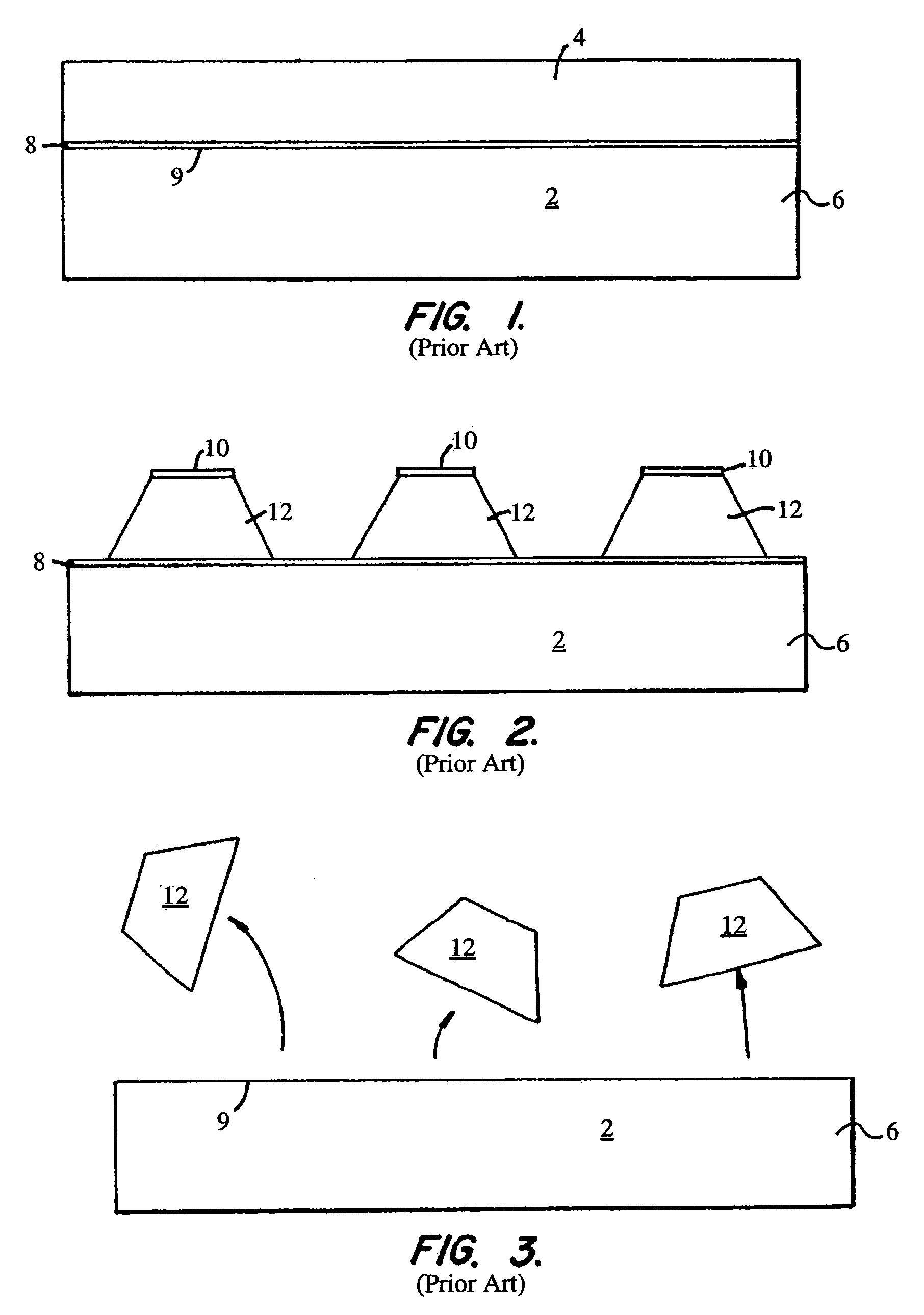

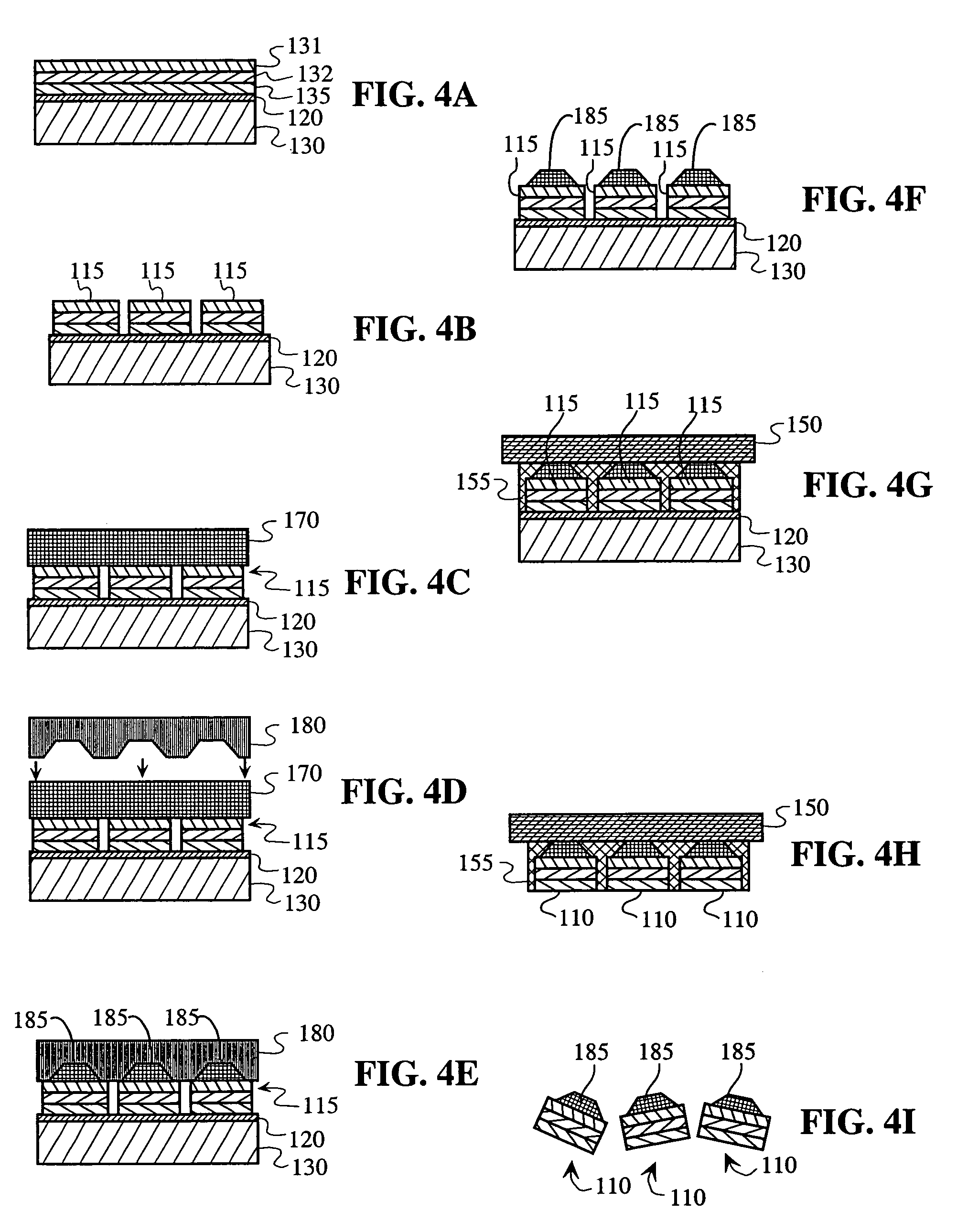

Method for self-assembling microstructures

InactiveUS20080023435A1Precise positioningImproved and easy processSolid-state devicesMicrostructural device assemblyPresent methodElectrical connection

A method for self-assembling a plurality of microstructures onto a substrate comprising using a bonding material to make the microstructure assembled onto the substrate by a physical attraction force The microstructures are self-aligned with the substrate, and further permanently fixed on and electrical connection with the substrate by the solder bumps between the microstructures and the substrate, which is formed by the solder bumps via reflow process. There is no need for the using of the conventional pick-and-place device in the present method. The present method could be applied to light emitting diodes, RFID tags, micro-integrated circuits or other types of microstructures.

Owner:NAT TAIWAN UNIV

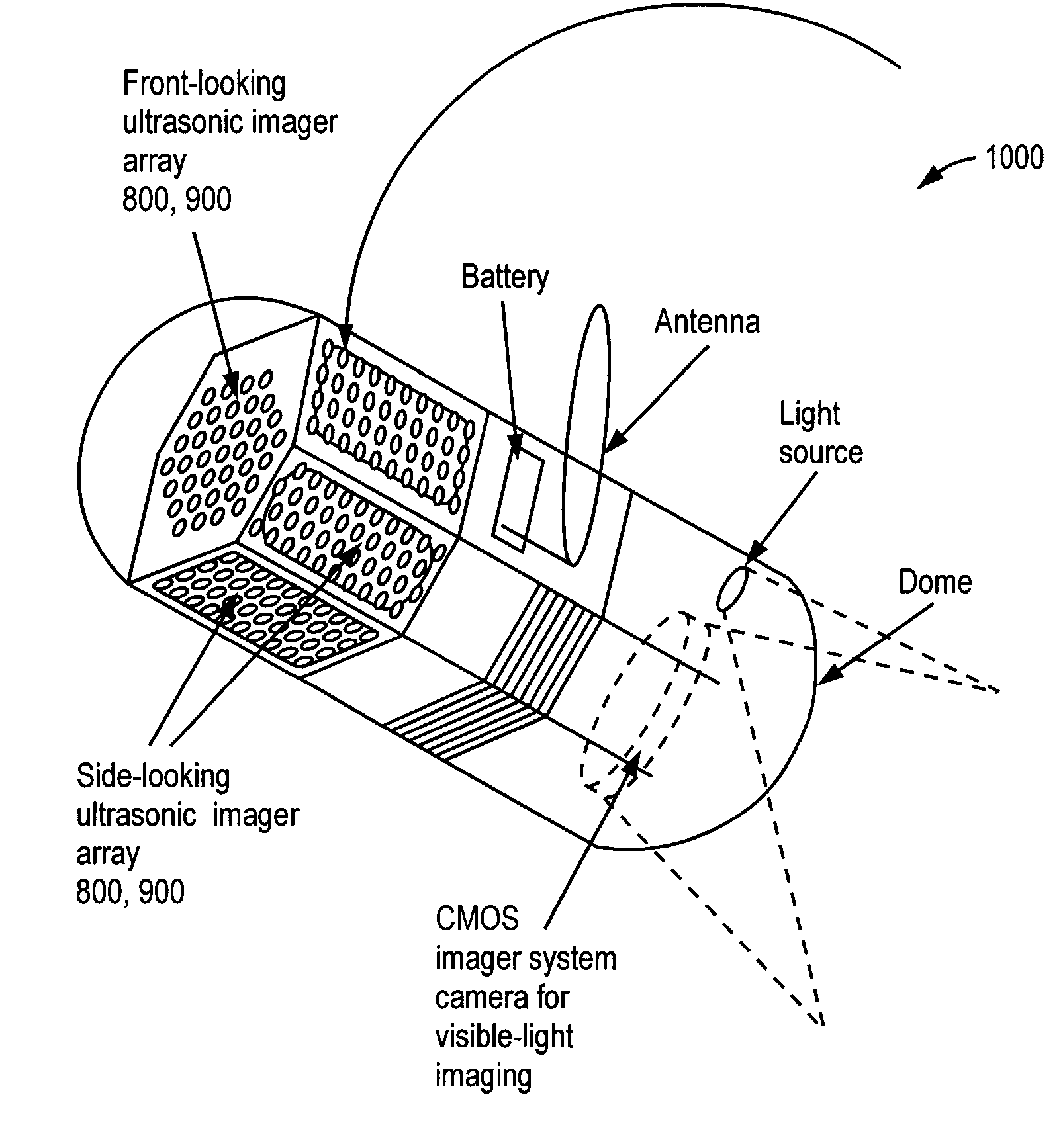

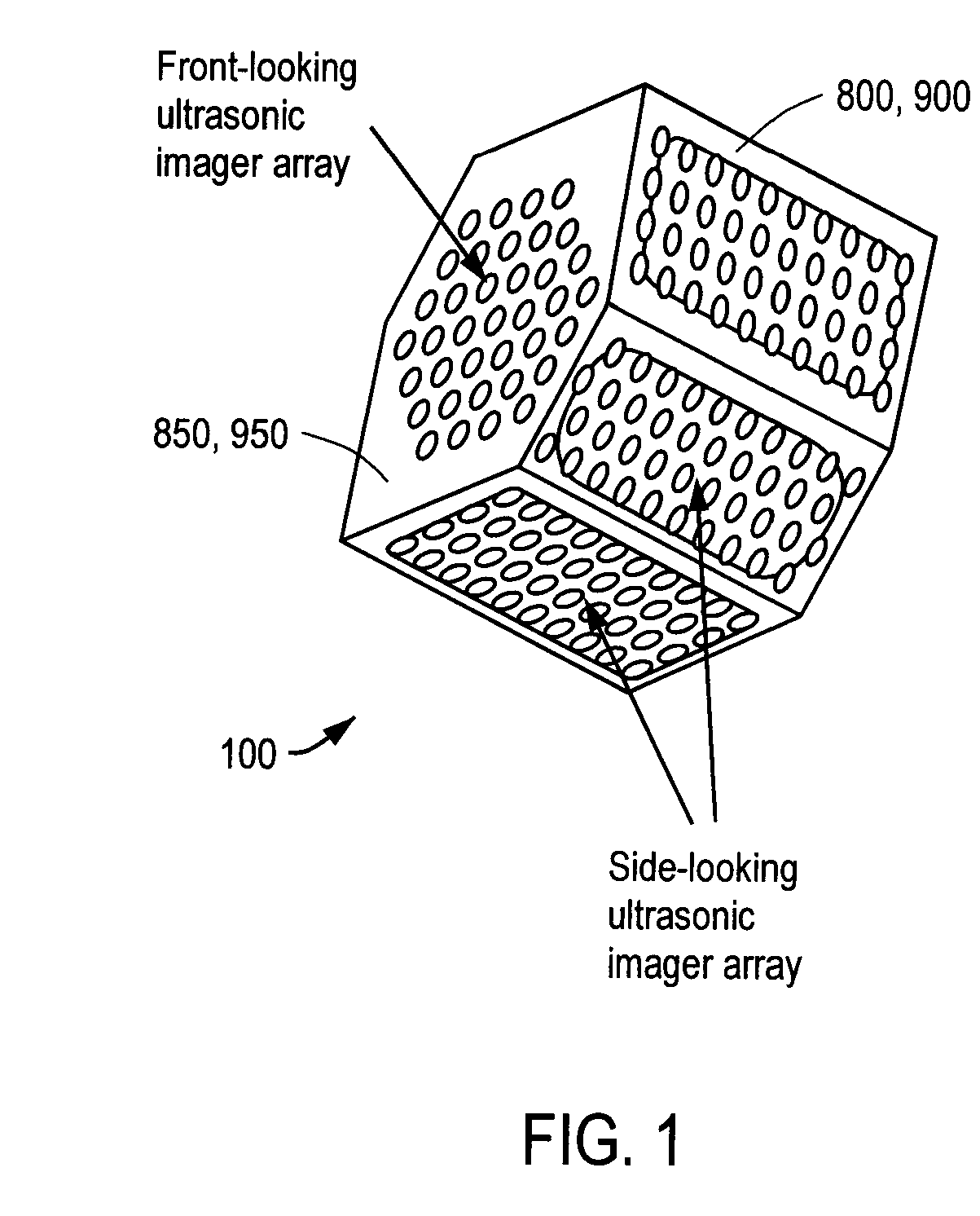

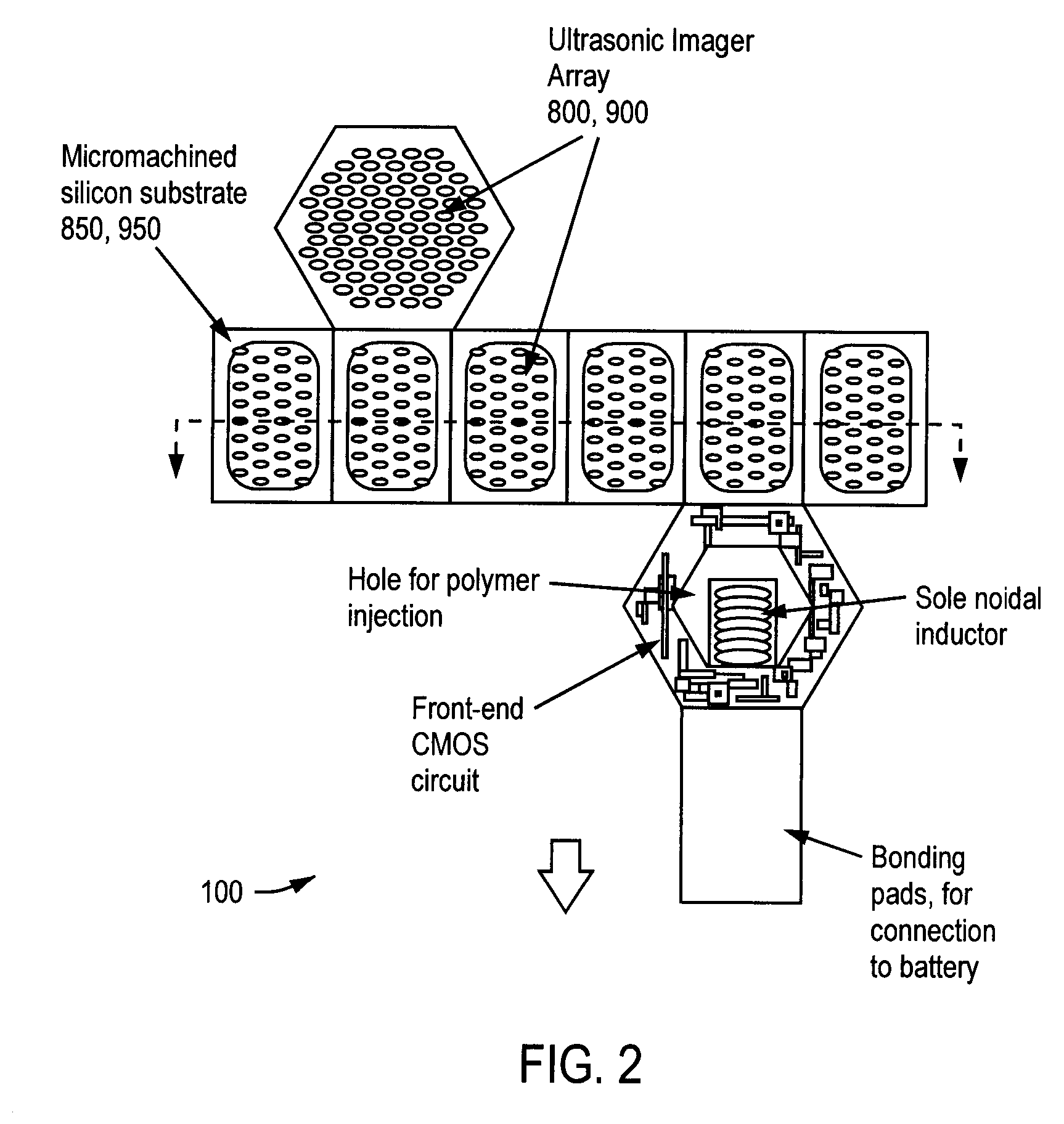

Three-Dimensional, Ultrasonic Transducer Arrays, Methods of Making Ultrasonic Transducer Arrays, and Devices Including Ultrasonic Transducer Arrays

ActiveUS20070264732A1Avoid cavitiesUltrasonic/sonic/infrasonic diagnosticsEndoscopesSurface layerMedical imaging

Medical imaging devices may comprise an array of ultrasonic transducer elements. Each transducer element may comprise a substrate having a doped surface creating a highly conducting surface layer, a layer of thermal oxide on the substrate, a layer of silicon nitride on the layer of thermal oxide, a layer of silicon dioxide on the layer of silicon nitride, and a layer of conducting thin film on the layer of silicon dioxide. The layers of silicon dioxide and thermal oxide may sandwich the layer of silicon nitride, and the layer of conducting thin film may be separated from the layer of silicon nitride by the layer of silicon dioxide.

Owner:STC UNM

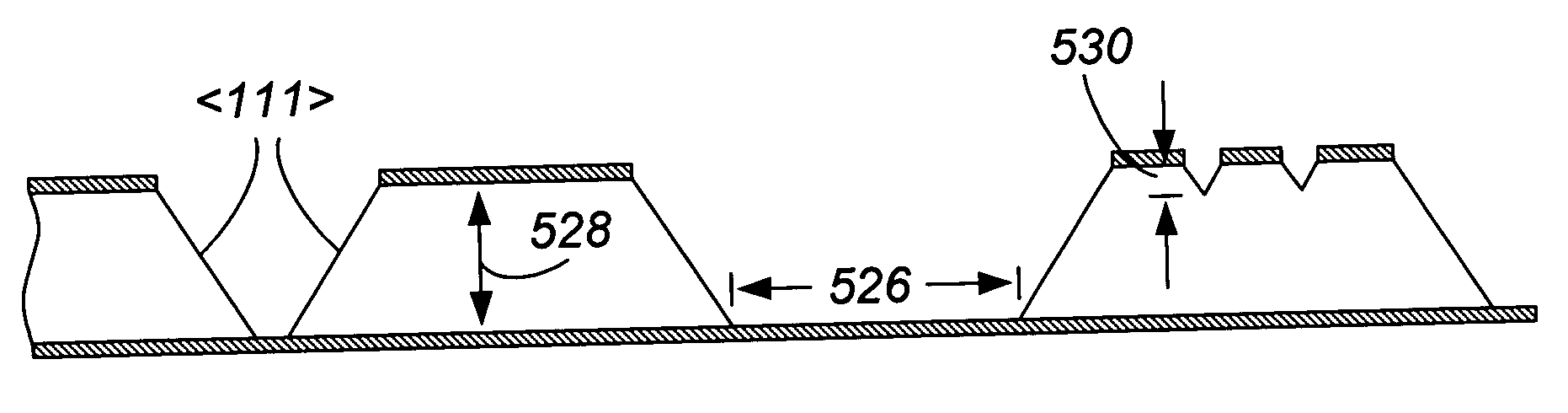

Triple alignment substrate method and structure for packaging devices

ActiveUS20060270179A1Easy to useHigh device yieldSemiconductor/solid-state device detailsSolid-state devicesSelf limitingEtching

A method for aligning multiple substrates. The method includes providing a handle substrate, providing a spacer substrate, and forming a plurality of first alignment marks on a first surface of the handle substrate. The method also includes forming a plurality of self-limiting alignment marks on a first surface of the spacer substrate and forming a plurality of openings in the spacer substrate, each of the plurality of openings surrounded by standoff regions. The method further includes aligning the first surface of the handle substrate and the first surface of the spacer substrate using the first alignment marks and the self-limiting alignment marks and bonding the handle substrate to the spacer substrate to form a composite substrate structure. In a specific embodiment, the plurality of self-limiting alignment marks and the plurality of openings are formed using an anisotropic wet etching process that preferentially etches the spacer substrate.

Owner:MIRADIA INC

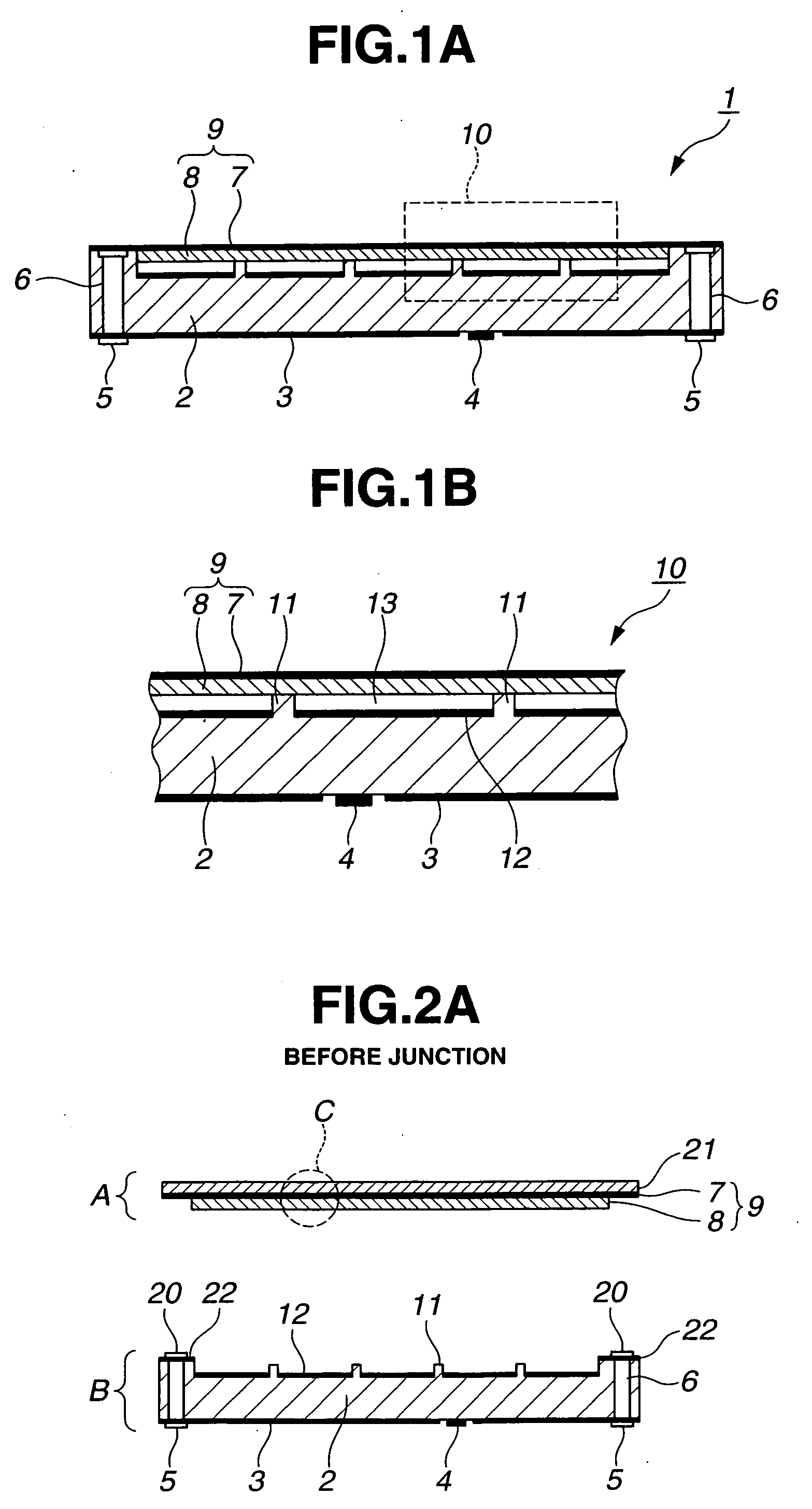

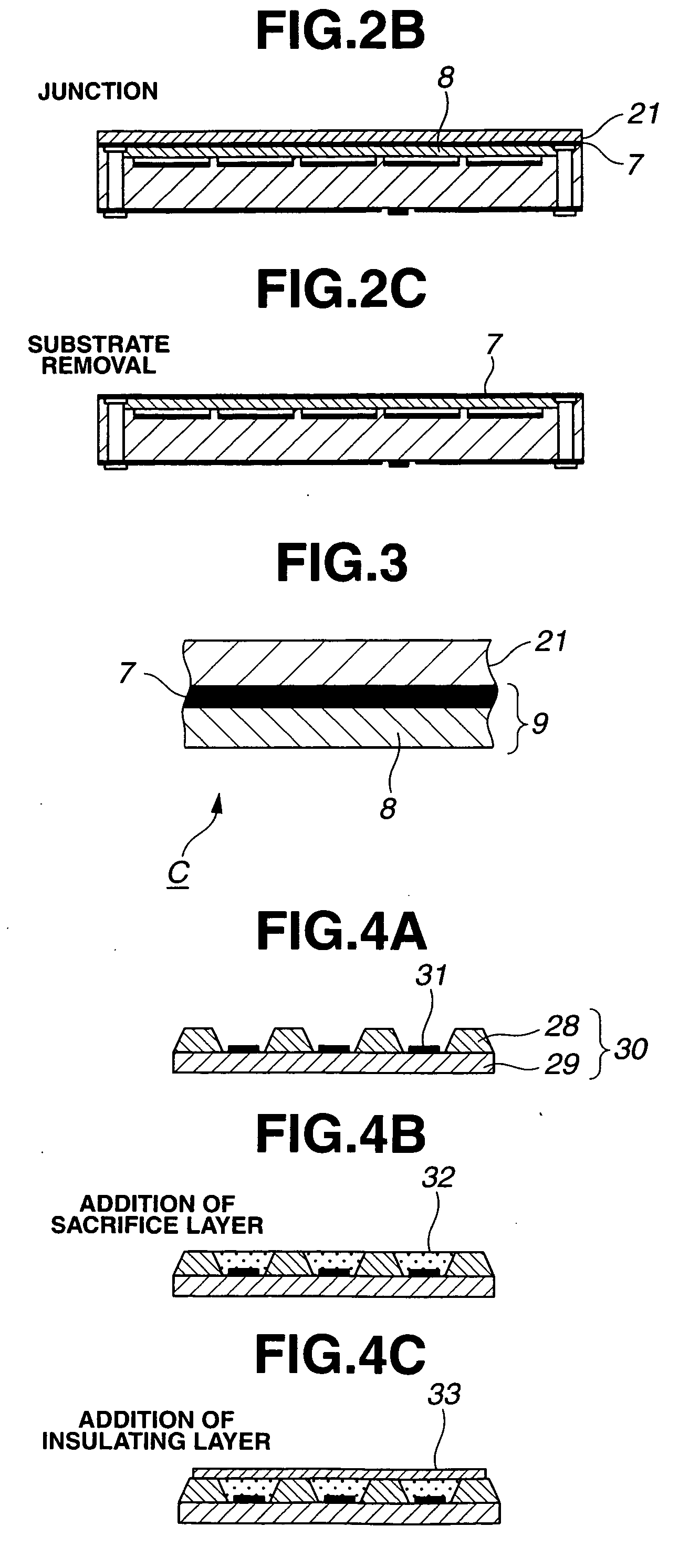

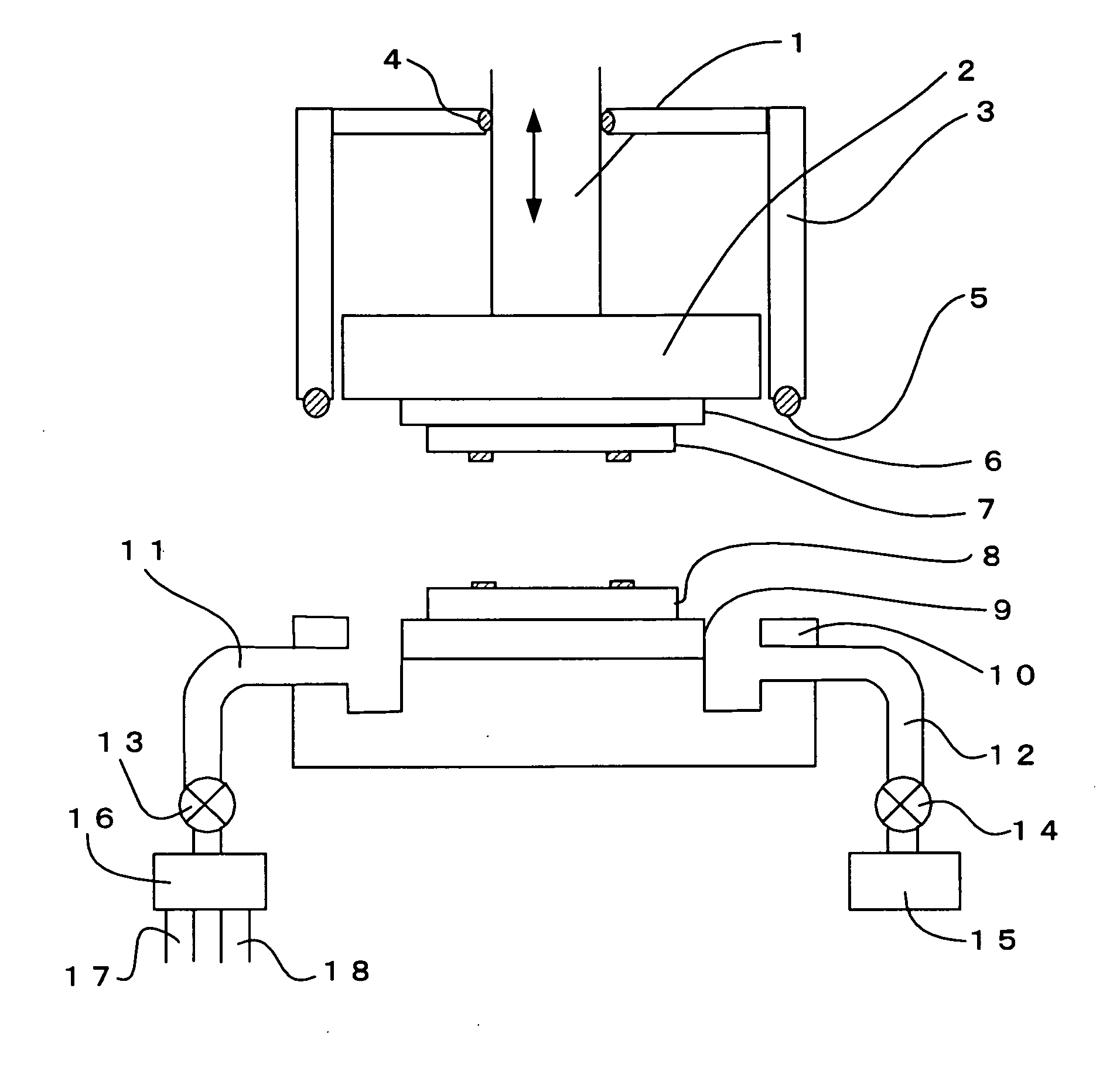

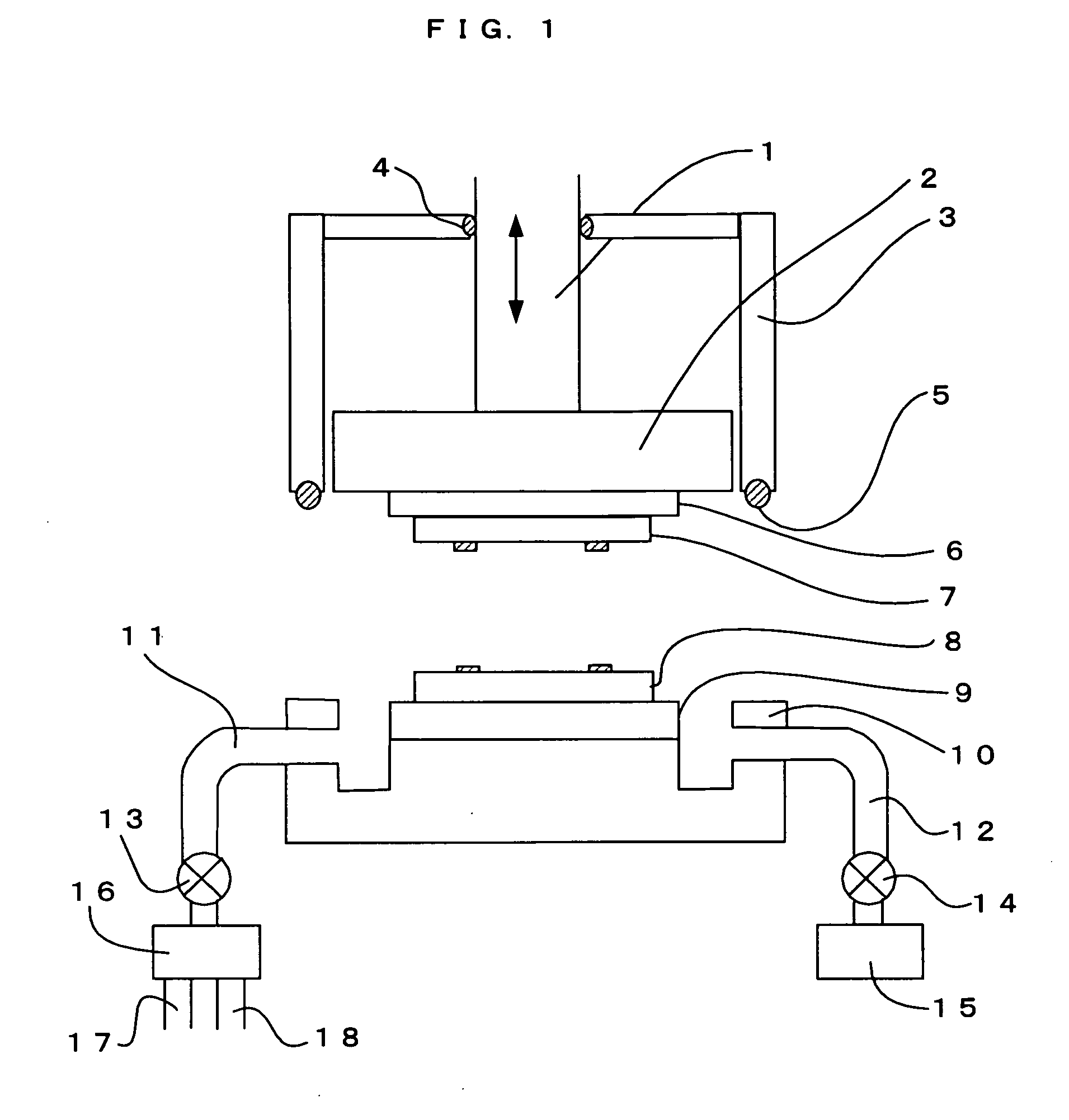

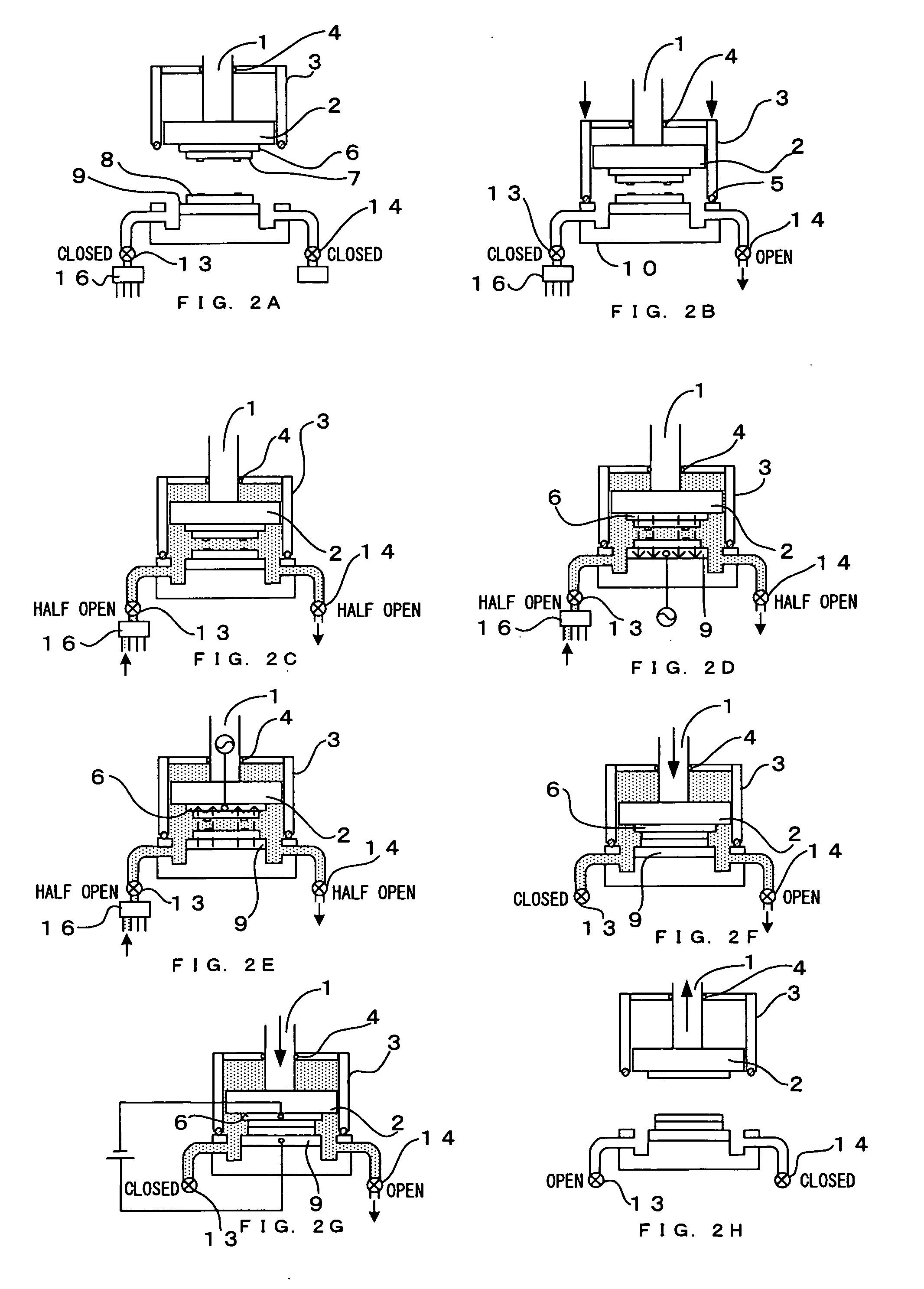

Bonding method, device produced by this method, and bonding device

ActiveUS20070111471A1High bonding strengthIncrease productivitySemiconductor/solid-state device manufacturingMicrostructural device assemblyThermal expansionEngineering

Conventional heat bonding and anodic bonding require heating at high temperature and for a long time, leading to poor production efficiency and occurrence of a warp due to a difference in thermal expansion, resulting in a defective device. Such a problem is solved. An upper wafer 7 made of glass and a lower wafer 8 made of Si are surface-activated using an energy wave before performing anodic bonding, thereby performing bonding at low temperature and increasing a bonding strength. In addition, preliminary bonding due to surface activation is performed before main bonding due to anodic bonding is performed in a separate step or device, thereby increasing production efficiency, and enabling bonding of a three-layer structure without occurrence of a warp.

Owner:BONDTECH

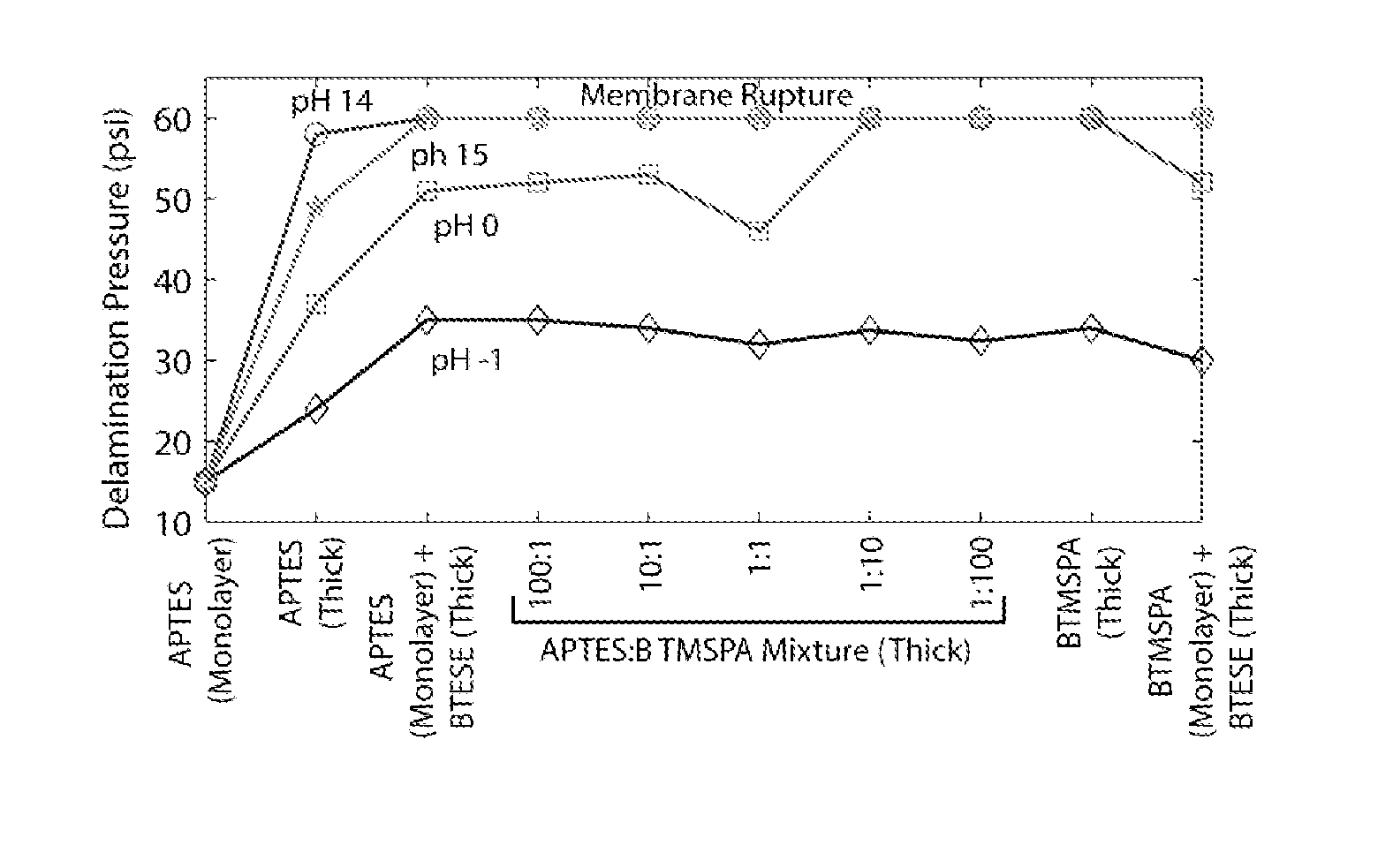

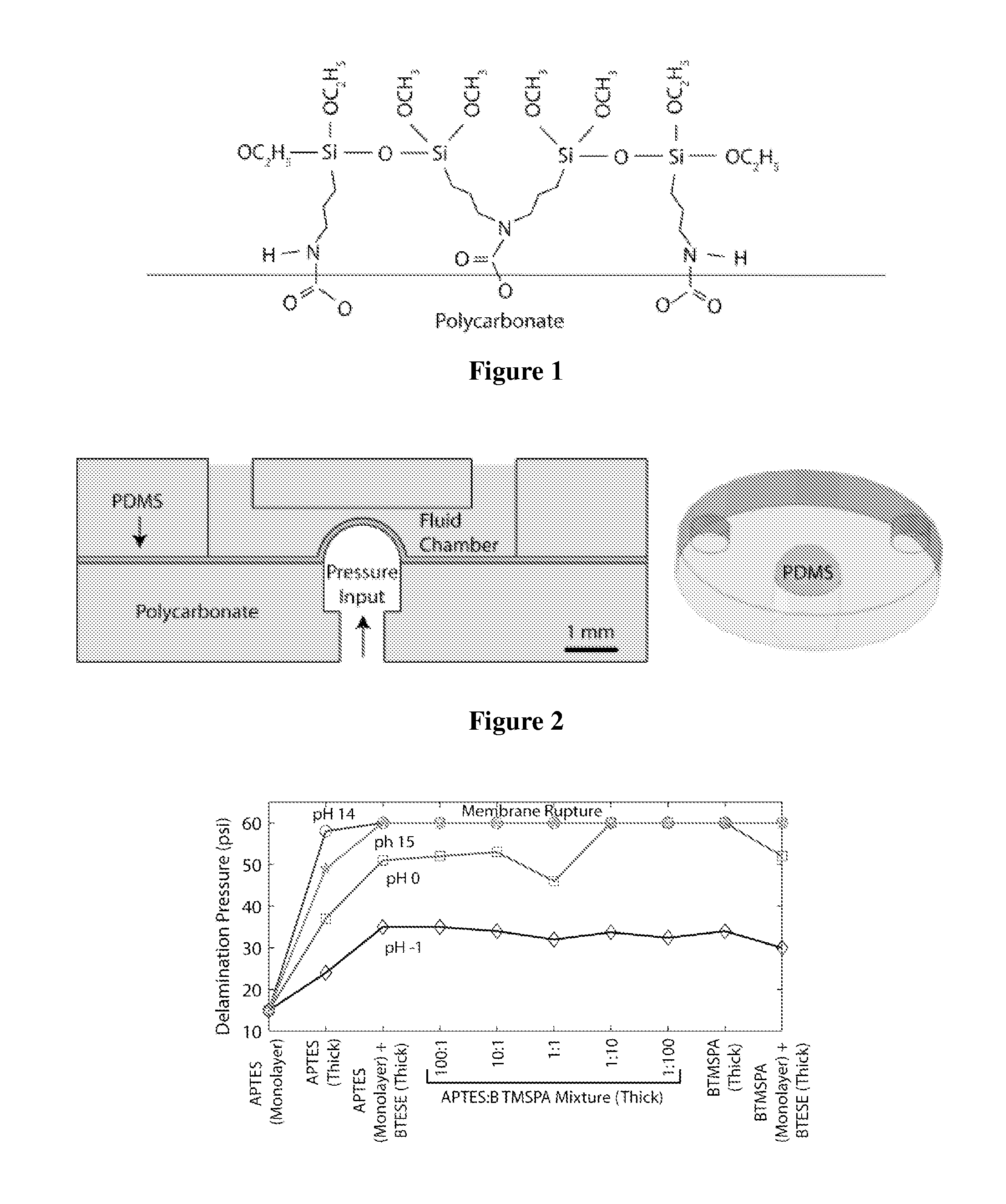

Method of hydrolytically stable bonding of elastomers to substrates

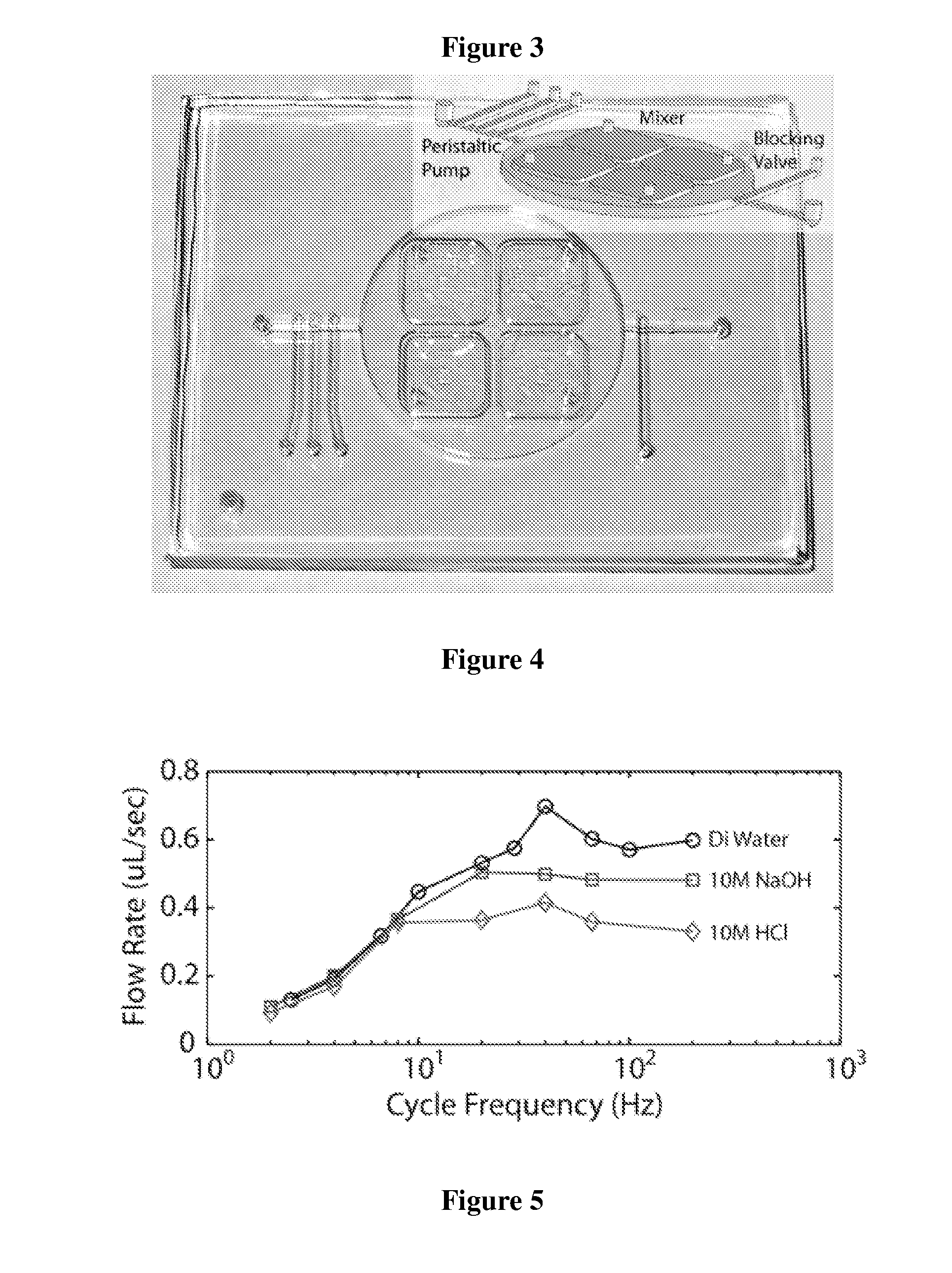

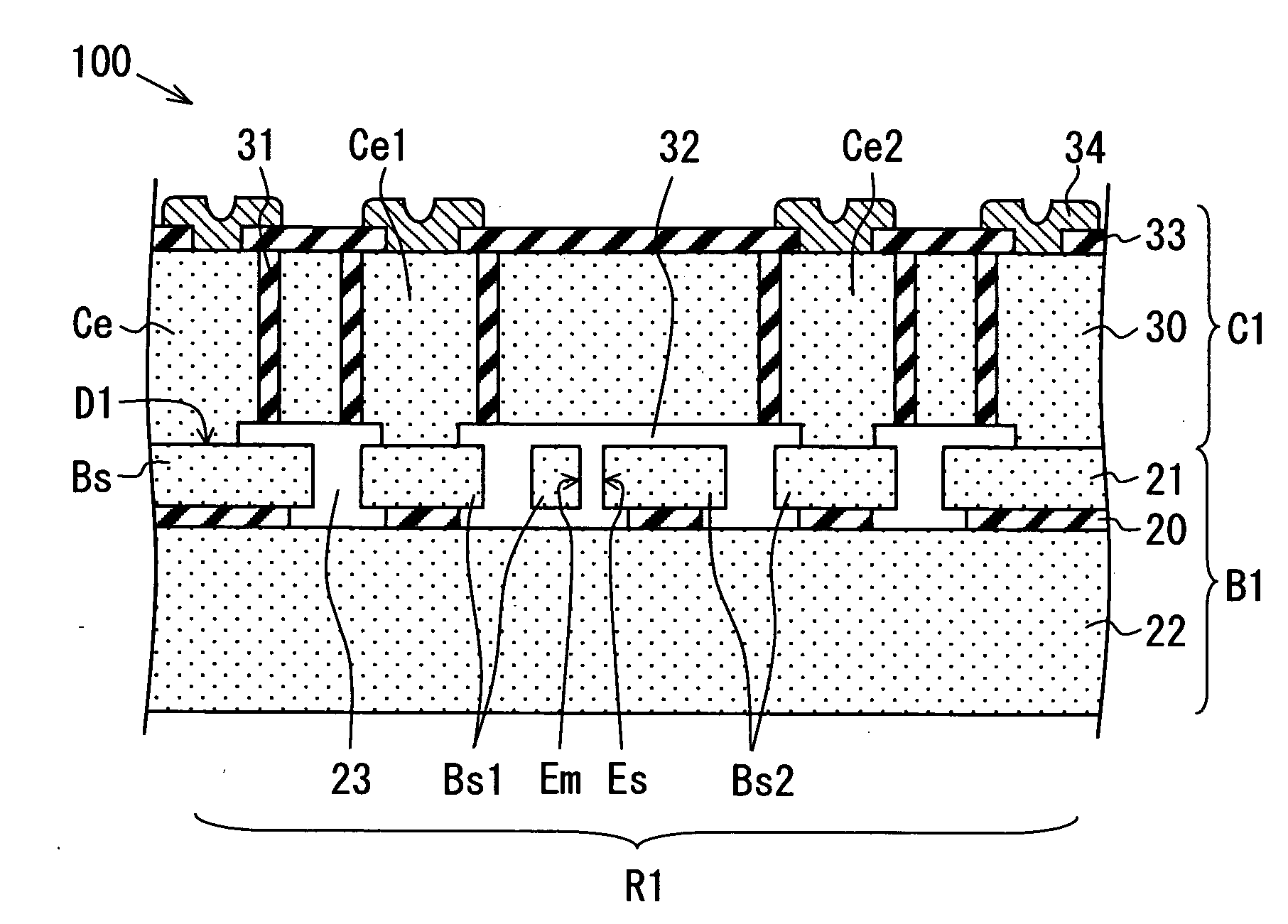

ActiveUS20110195260A1Hydrolytic stabilityAdhesive processesLaboratory glasswaresElastomerPeristaltic pump

Active devices such as pumps and mixers have been fabricated in plastic-PDMS hybrid devices. By utilizing functionalized bis-silane primers, bond strength between Polycarbonate or PMMA and PDMS improved in dry and aqueous environments. Plastic-primer-PDMS layers exposed to acid and base solutions at 70° C. for 2 hours showed no signs of delamination at 30 psi for pH −1 to 15 and 60 psi for pH 0 to 15. A peristaltic pump fabricated in polycarbonate achieved consistent flow rates up to peristaltic cycle frequencies of 10 Hz in water, 1OM HCl, and 1OM NaOH solutions.

Owner:MASSACHUSETTS INST OF TECH

Semiconductor device and method for manufacturing the same

InactiveUS20080290490A1Reduce equipment costsSecure strengthPrecision positioning equipmentSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor device includes: a first substrate made of semiconductor and having first regions, which are insulated from each other and disposed in the first substrate; and a second substrate having electric conductivity and having second regions and insulation trenches. Each insulation trench penetrates the second substrate so that the second regions are insulated from each other. The first substrate provides a base substrate, and the second substrate provides a cap substrate. The second substrate is bonded to the first substrate so that a sealed space is provided between a predetermined surface region of the first substrate and the second substrate. The second regions include an extraction conductive region, which is coupled with a corresponding first region.

Owner:DENSO CORP

Oriented self-location of microstructures with alignment structures

InactiveUS7223635B1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectronic equipment

Owner:HRL LAB

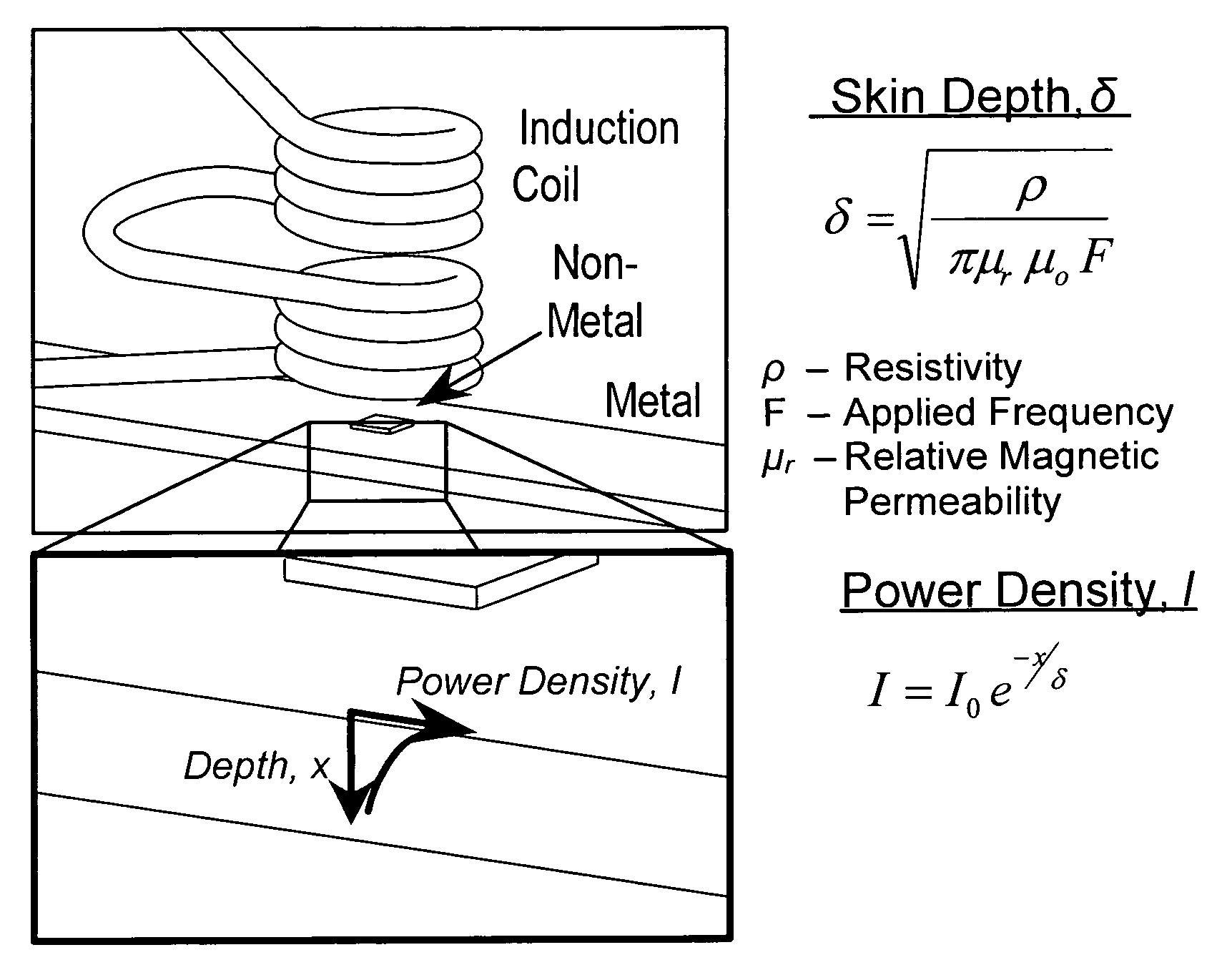

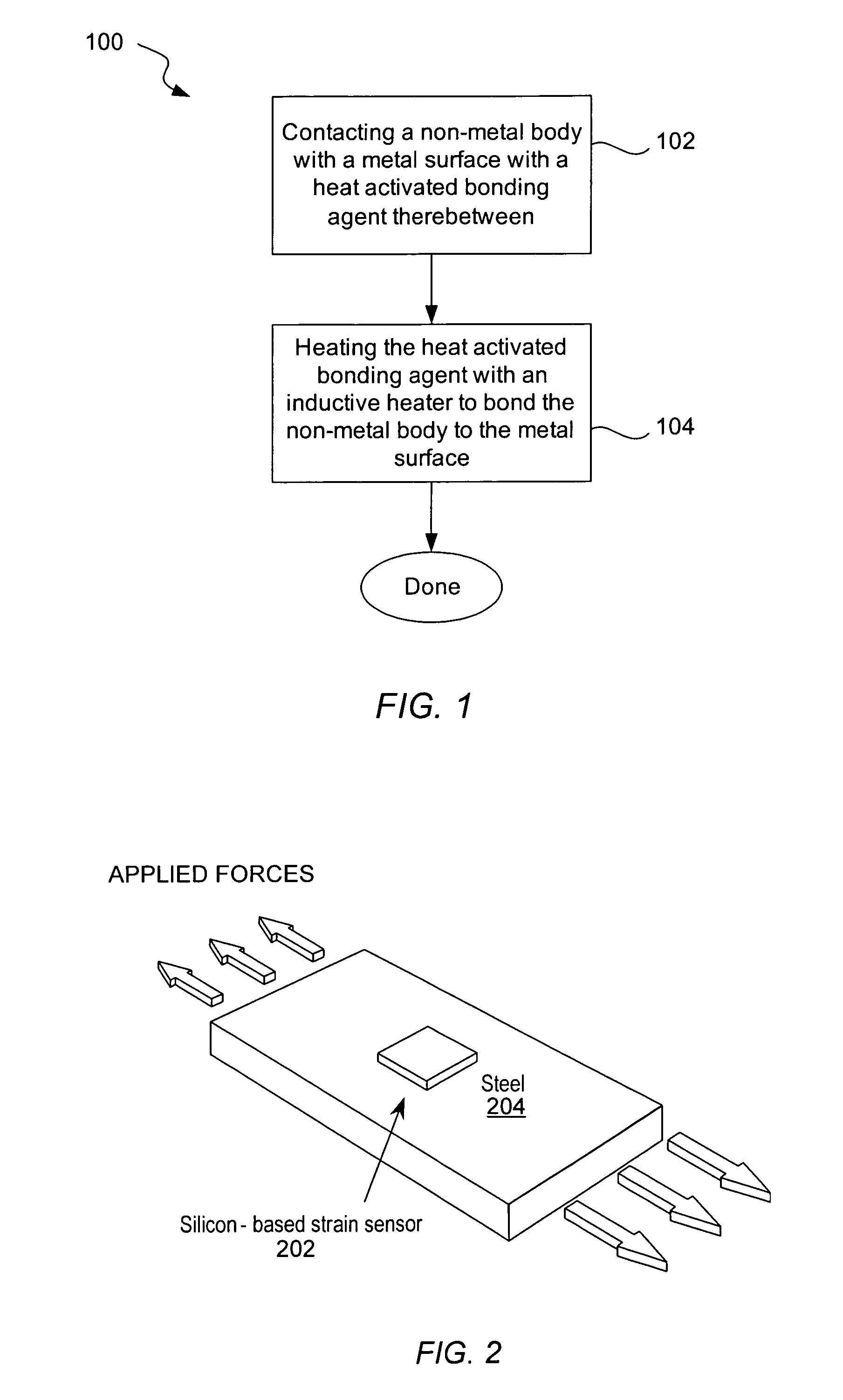

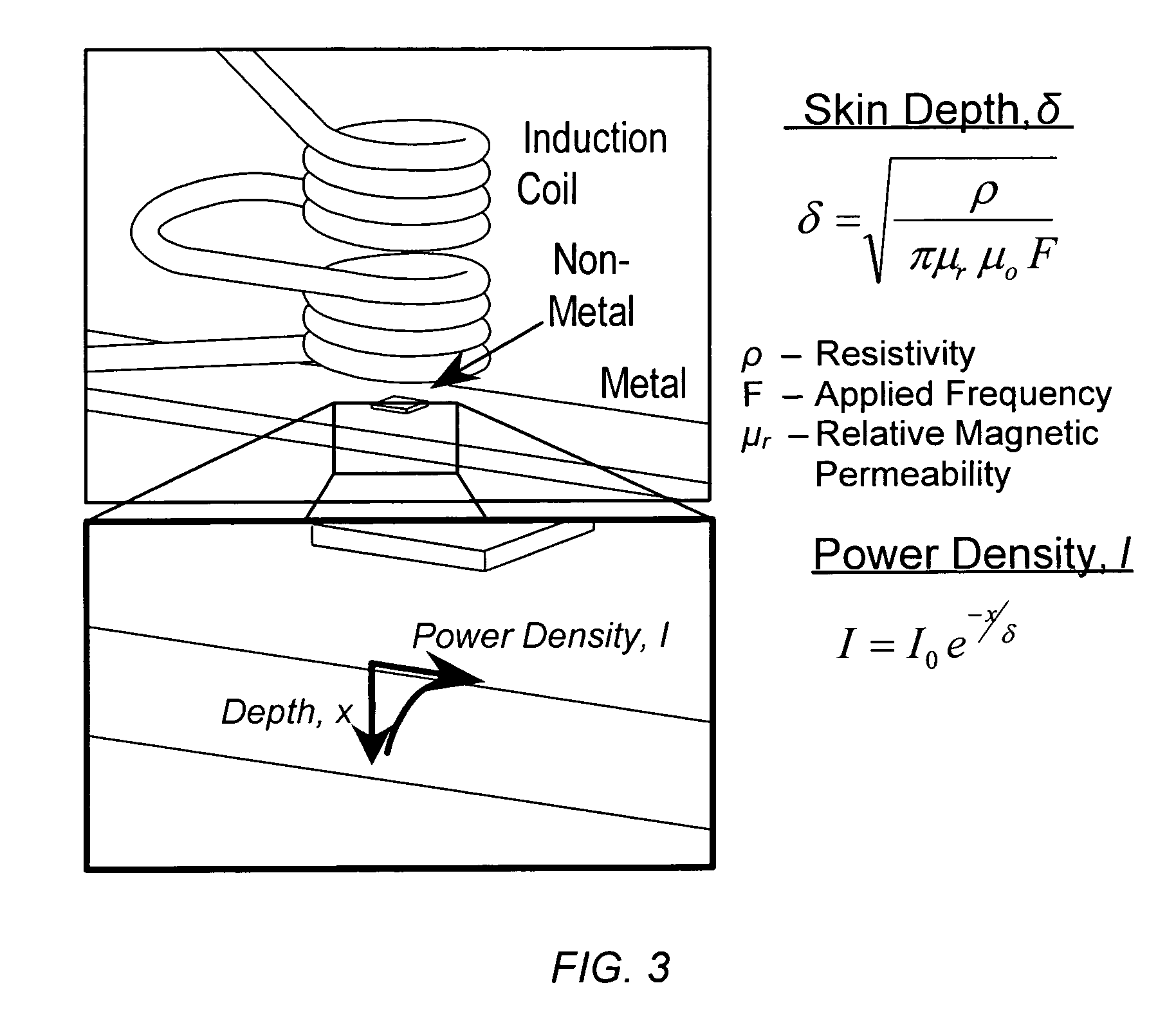

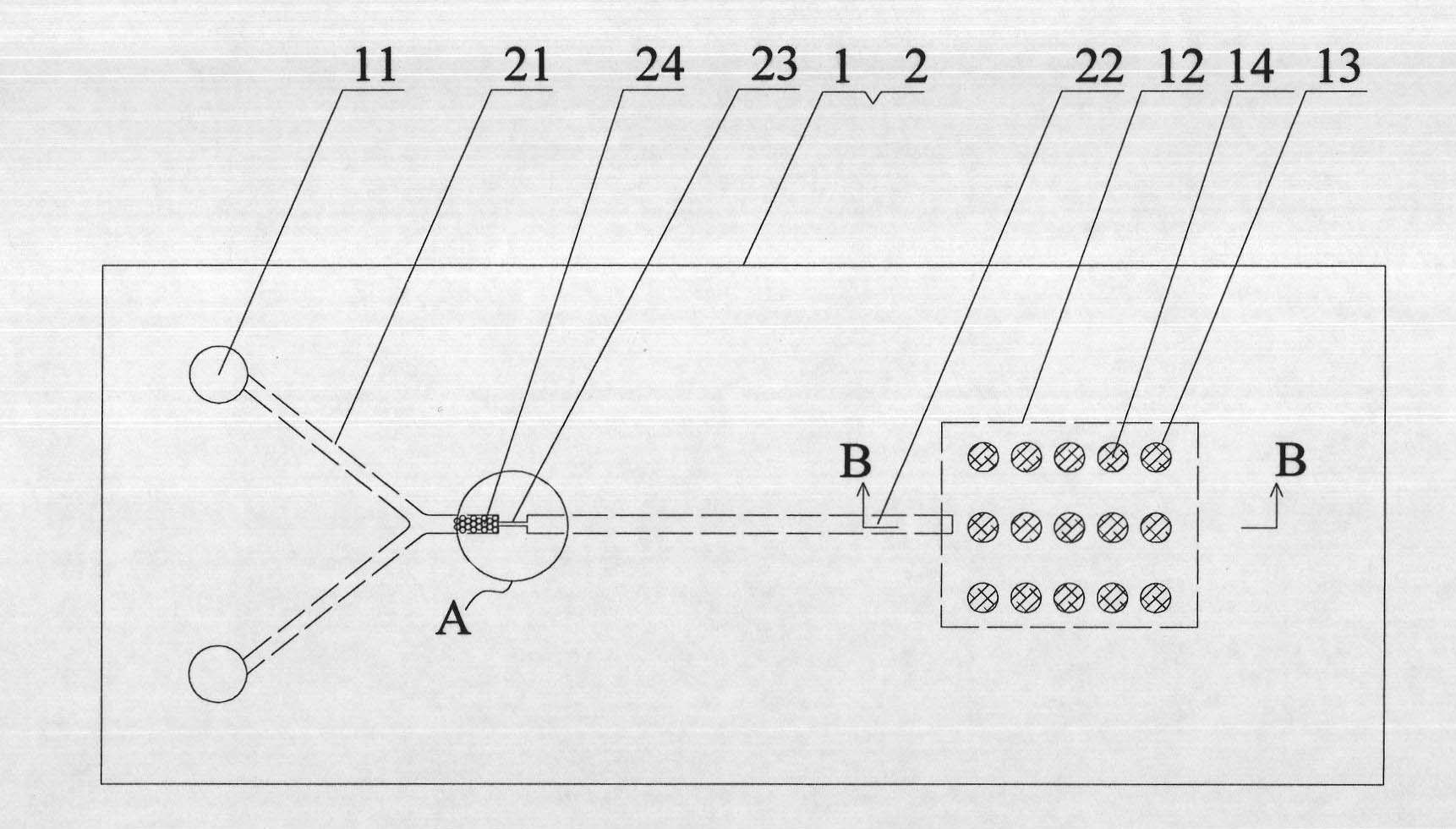

Bonding a non-metal body to a metal surface using inductive heating

InactiveUS7452800B2Change propertiesQuickly and effectively bondSolid-state devicesForce measurementMechanical componentsMems sensors

A bonding technique suitable for bonding a non-metal body, such as a silicon MEMS sensor, to a metal surface, such a steel mechanical component is rapid enough to be compatible with typical manufacturing processes, and avoids any detrimental change in material properties of the metal surface arising from the bonding process. The bonding technique has many possible applications, including bonding of MEMS strain sensors to metal mechanical components. The inventive bonding technique uses inductive heating of a heat-activated bonding agent disposed between metal and non-metal objects to quickly and effectively bond the two without changing their material properties. Representative tests of silicon to steel bonding using this technique have demonstrated excellent bond strength without changing the steel's material properties. Thus, with this induction bonding approach, silicon MEMS devices can be manufacturably bonded to mechanical steel components for real time monitoring of the conditions / environment of a steel component.

Owner:RGT UNIV OF CALIFORNIA

Micro fluid control chip and preparation method and application thereof

InactiveCN101817495AReduce volumeVolume stabilityPrecision positioning equipmentSolid-state devicesFluid controlVolumetric Mass Density

The invention belongs to the technical field of micro fluid control, particularly disclosing a micro fluid control chip and a preparation method and application thereof. One side of the chip is provided with a plurality of sample introduction holes, each sample introduction hole is communicated with a sample introduction runner; after meeting, each sample introduction runner is communicated with a main runner; the main runner is provided with a narrow runner; a micro-sphere of which the size is 0.5-1.5 mm is filled in front of the inlet of the narrow runner; the outlet of the main runner is communicated to a waste liquid tank arranged at the other side of the chip. The preparation method mainly comprises: firstly preparing a PDMS substrate; then, preparing a PDMS cover plate with an upper groove; sticking the substrate onto the cover plate to obtain a semi-finished product of the chip; carrying out modified treatment on each runner in the semi-finished product of the chip; finally, putting the micro-sphere in, controlling the charge quantity, and finishing production. The micro fluid control chip of the invention has high solution mixing efficiency, stable solution flow rate, small volume, convenient carrying and relatively simple manufacturing; when being used for detecting the density of triphosadenine, the micro fluid control chip has the advantages of high sensitivity, favourable detection effect and the like and can not be affected by environment humidity.

Owner:HUNAN UNIV

Bonded structures

ActiveUS20190198409A1Precision positioning equipmentSemiconductor/solid-state device detailsBond interfaceEngineering

A bonded structure is disclosed. The bonded structure can include a first element that has a first bonding surface. The bonded structure can further include a second element that has a second bonding surface. The first and second bonding surfaces are bonded to one another along a bonding interface. The bonded structure can also include an integrated device that is coupled to or formed with the first element or the second element. The bonded structure can further include a channel that is disposed along the bonding interface around the integrated device to define an effectively closed profile The bonded structure can also include a getter material that is disposed in the channel. The getter material is configured to reduce the diffusion of gas into an interior region of the bonded structure.

Owner:INVENSAS BONDING TECH INC

Silicon Condenser Microphone and Manufacturing Method

InactiveUS20070201715A1Piezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersTransducerEngineering

A silicon condenser microphone package is disclosed. The silicon condenser microphone package comprises a transducer unit, substrate, and a cover. The substrate includes an upper surface having a recess formed therein. The transducer unit is attached to the upper surface of the substrate and overlaps at least a portion of the recess wherein a back volume of the transducer unit is formed between the transducer unit and the substrate. The cover is placed over the transducer unit and includes an aperture.

Owner:KNOWLES ELECTRONICS INC

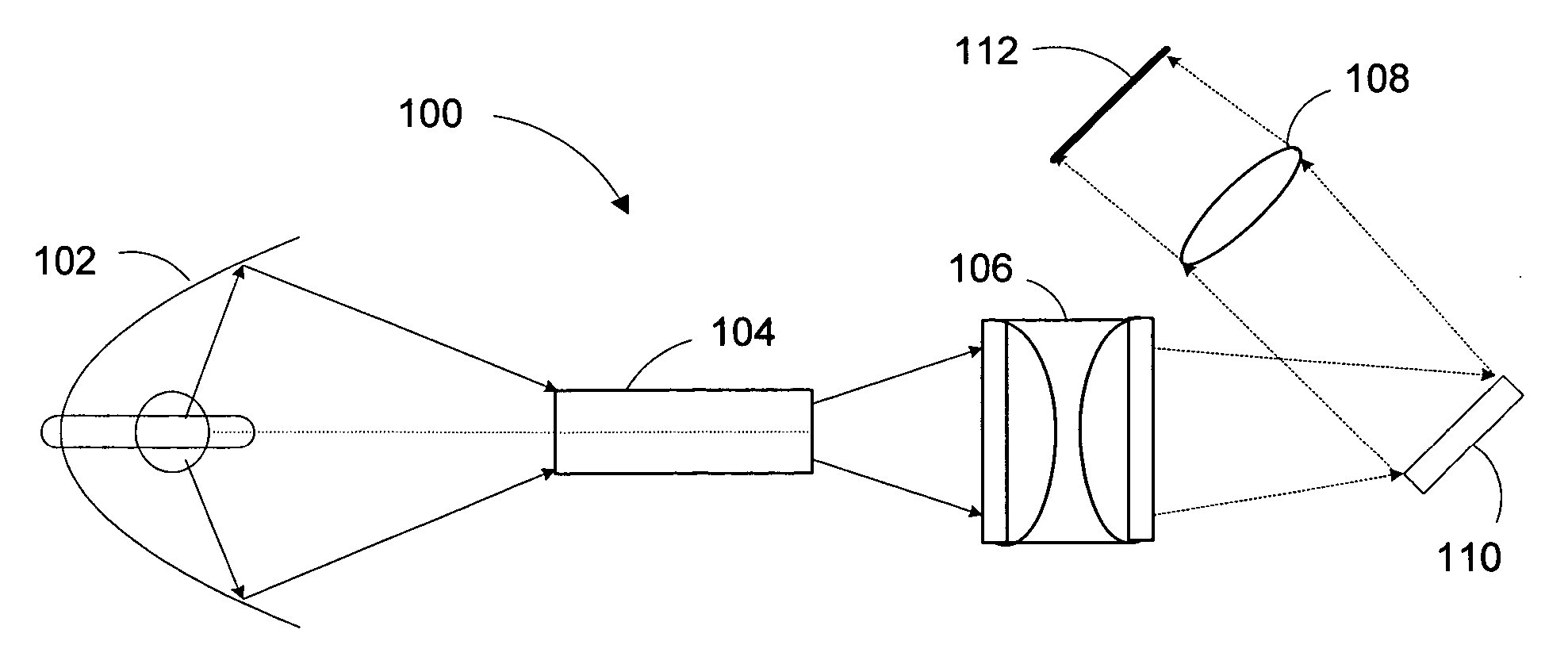

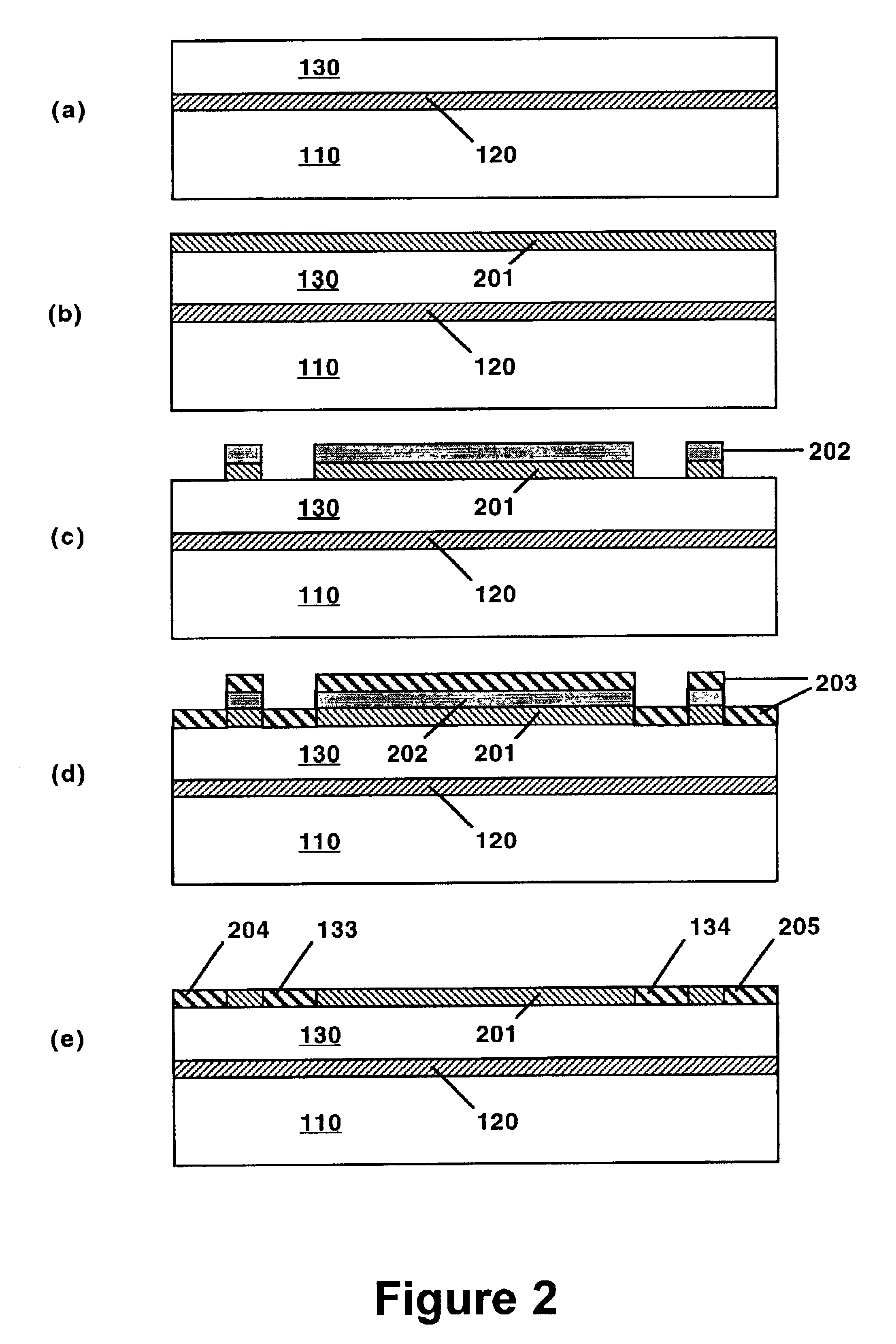

Process for high yield fabrication of MEMS devices

ActiveUS6872319B2Thickness minimizationExceptionally precise layer to layer alignmentSemi-permeable membranesPrecision positioning equipmentEngineeringSilicon

A MEMS fabrication process eliminates through-wafer etching, minimizes the thickness of silicon device layers and the required etch times, provides exceptionally precise layer to layer alignment, does not require a wet etch to release the moveable device structure, employs a supporting substrate having no device features on one side, and utilizes low-temperature metal-metal bonding which is relatively insensitive to environmental particulates. This process provided almost 100% yield of scanning micromirror devices exhibiting scanning over a 12° optical range and a mechanical angle of ±3° at a high resonant frequency of 2.5 kHz with an operating voltage of only 20 VDC.

Owner:TELEDYNE SCI & IMAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com