Patents

Literature

30881results about How to "High bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

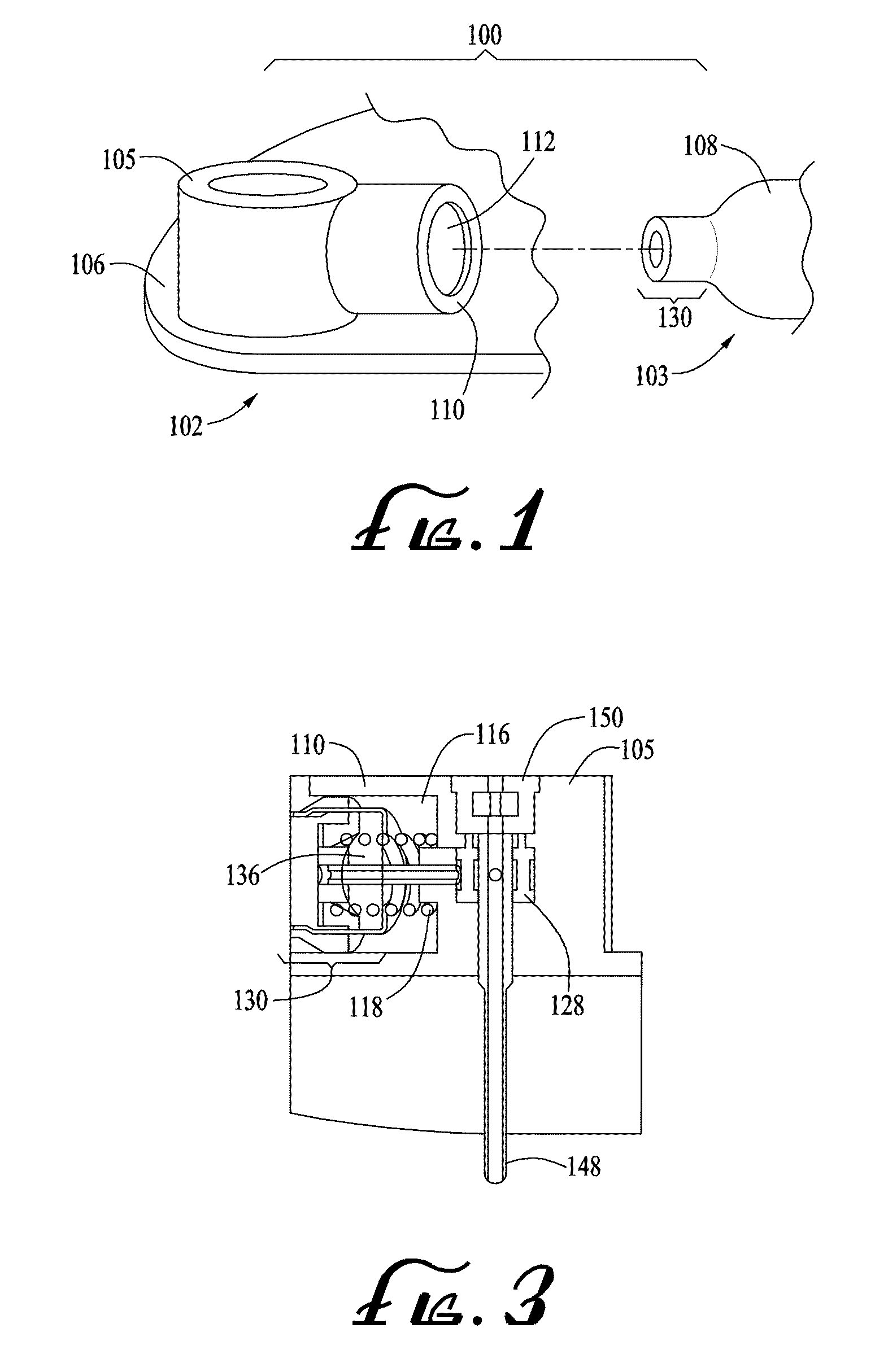

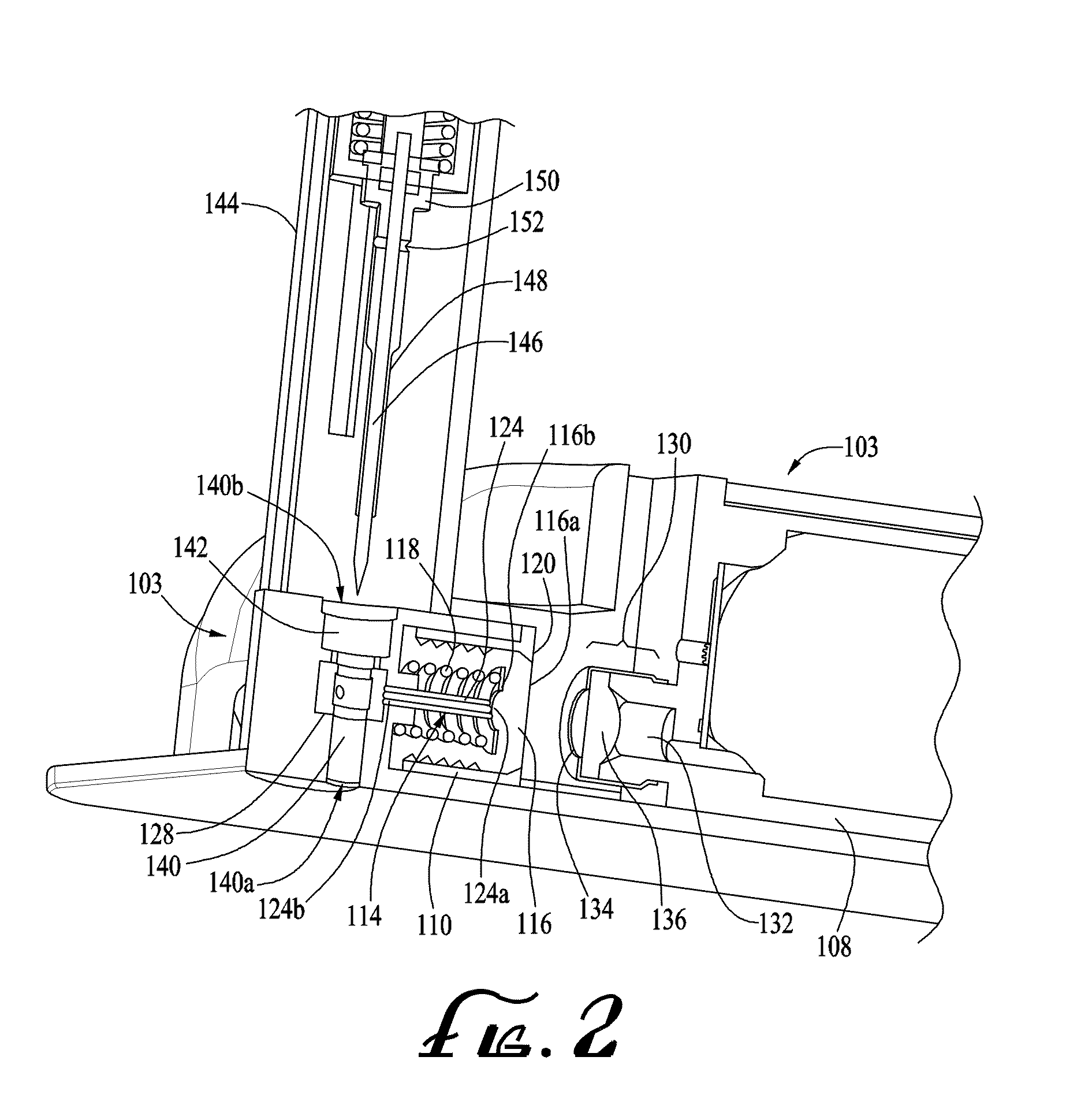

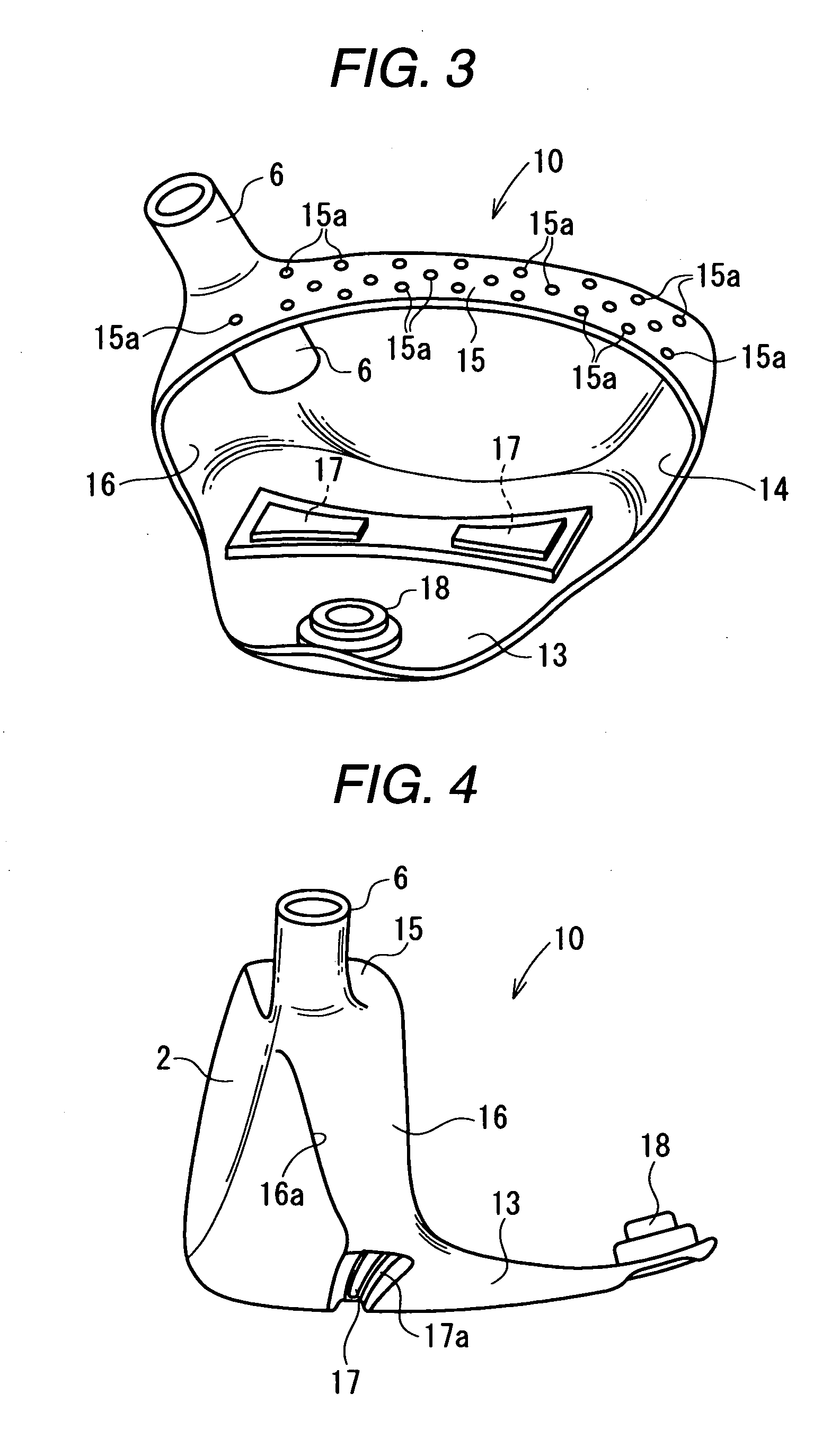

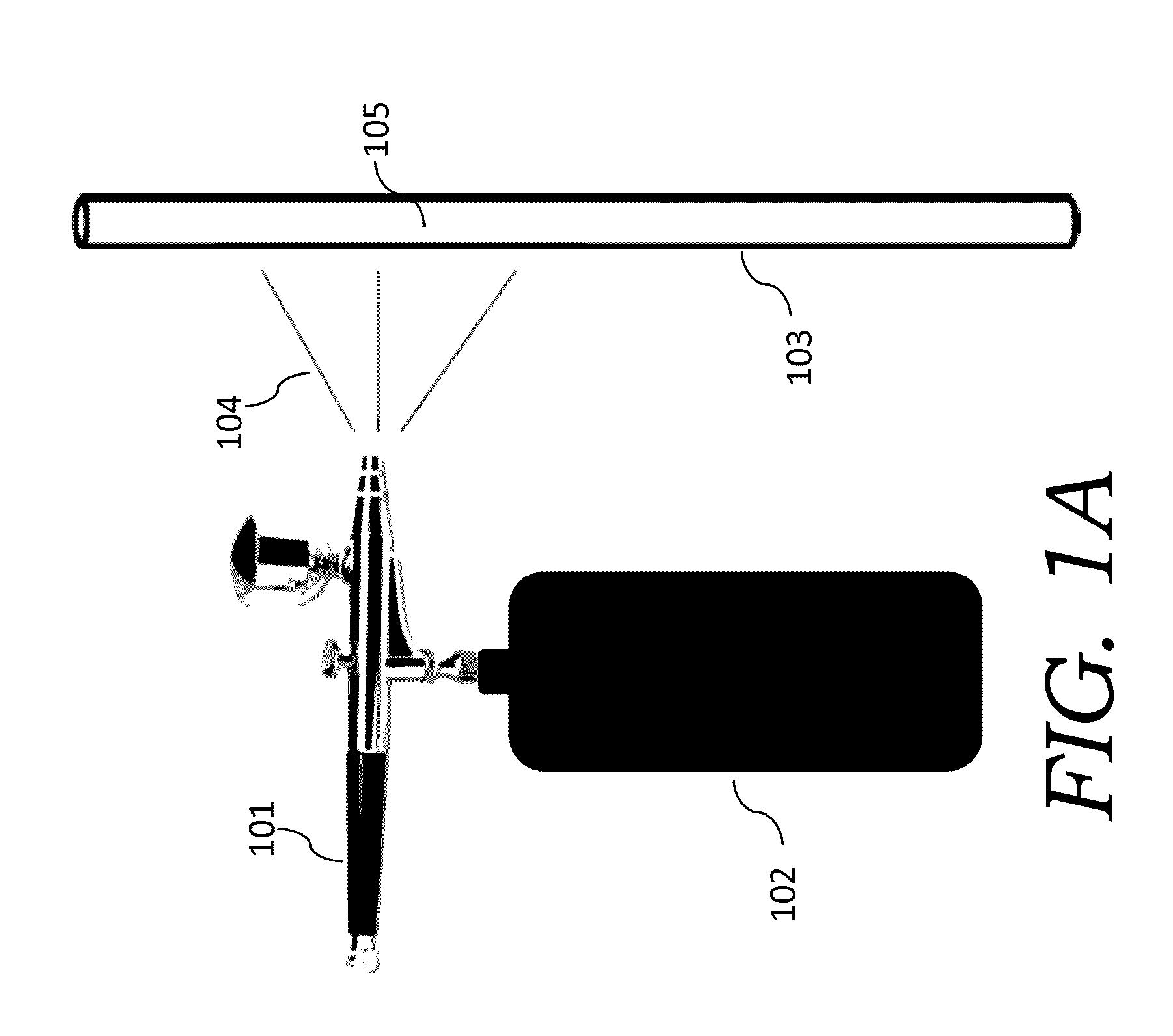

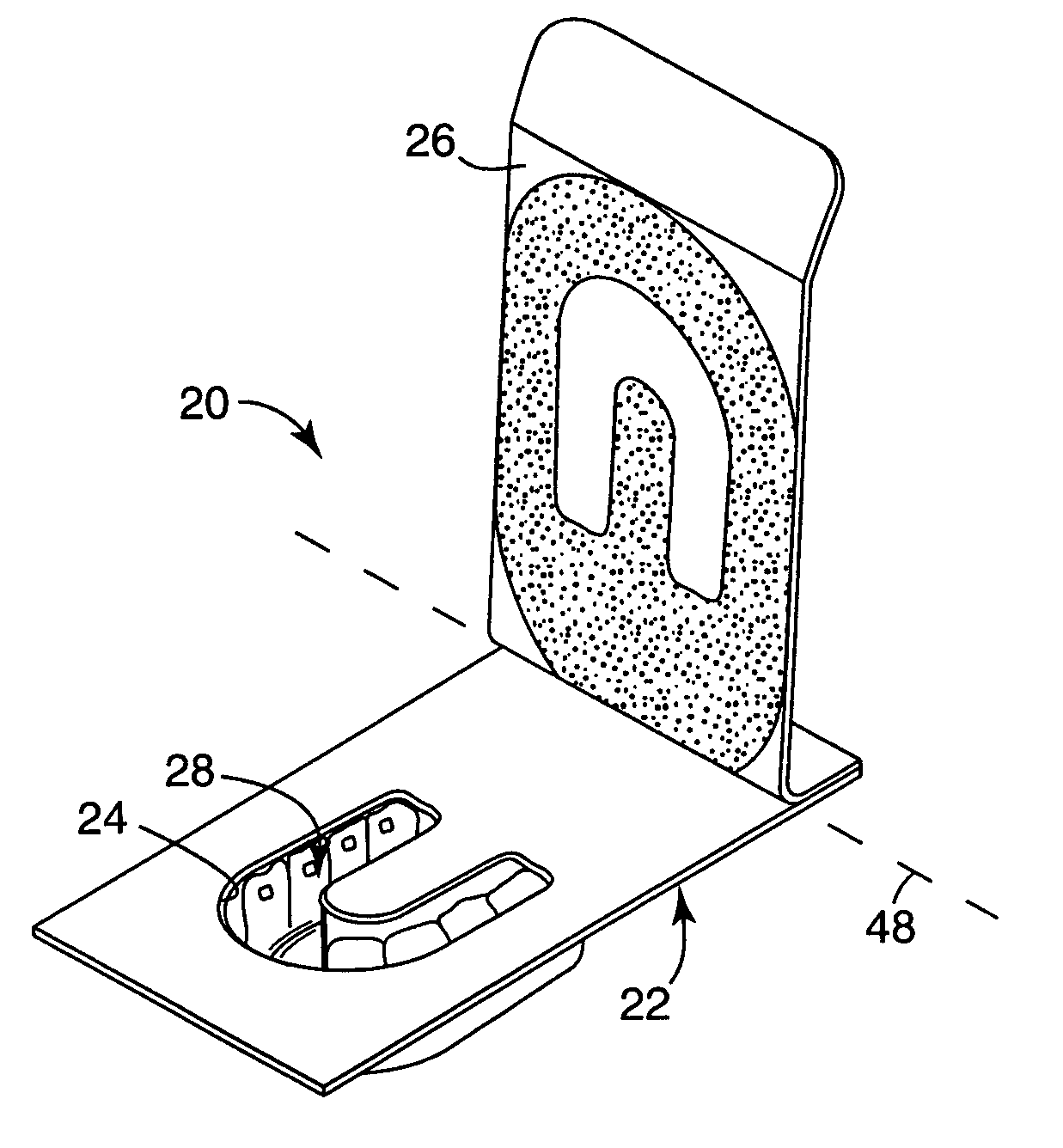

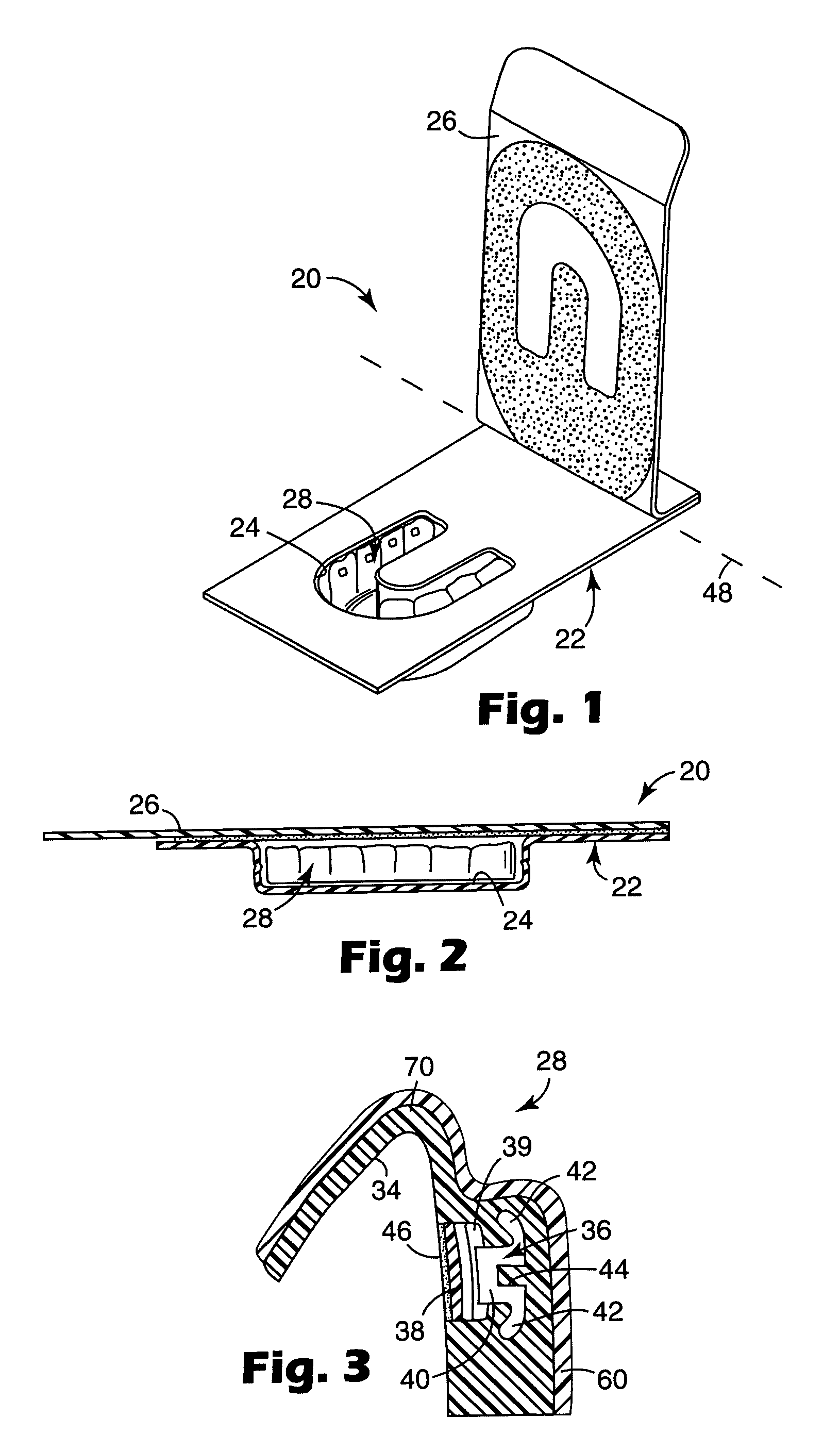

Adhesive patch systems and methods

ActiveUS20090198215A1High bonding strengthReduced adhesion strengthInfusion syringesFiltering accessoriesUltimate tensile strengthAdhesion strength

Various embodiments of the present invention are directed to patches for medical devices. In various embodiments, an adhesive patch of a medical device may have selective areas with adhesive material of varying adhesion strengths. In other embodiments, an adhesive patch of a medical device may include adhesive material that may be activated by a catalyst to increase or decrease the adhesion strength of the adhesive material. In further embodiments, a medical device may include a pierceable membrane containing an agent, the pierceable membrane positioned to be pierced by a needle and to cause some of the agent to be carried to the user-patient.

Owner:MEDTRONIC MIMIMED INC

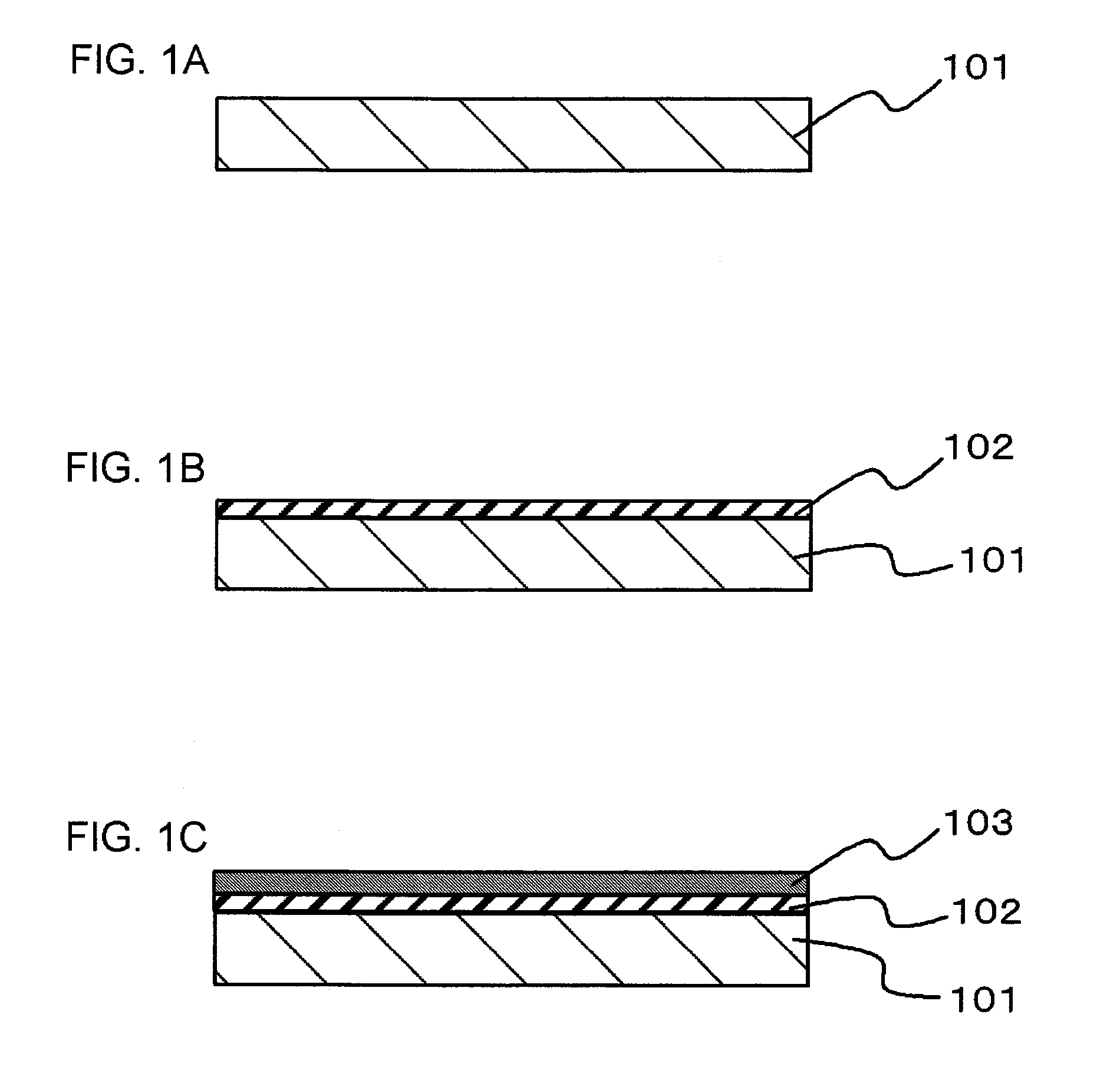

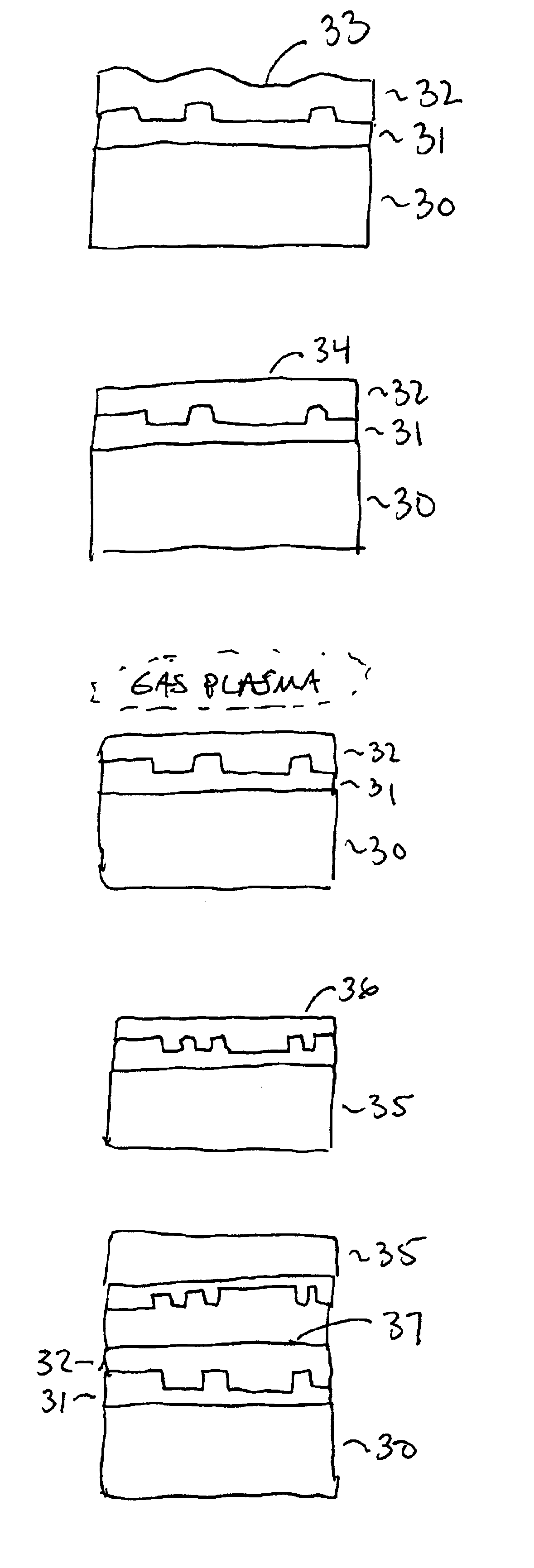

Method of manufacturing semiconductor device

InactiveUS20110171775A1Without deteriorating reliability of deviceHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorPlasma polymerization

A method of manufacturing a semiconductor device includes forming a first insulating film over an underlying film by plasma polymerization of cyclic siloxane, and forming a second insulating film on the first insulating film by plasma polymerization of the cyclic siloxane continuously, after forming the first insulating film. The deposition rate of the first insulating film is slower than the deposition rate of the second insulating film.

Owner:RENESAS ELECTRONICS CORP

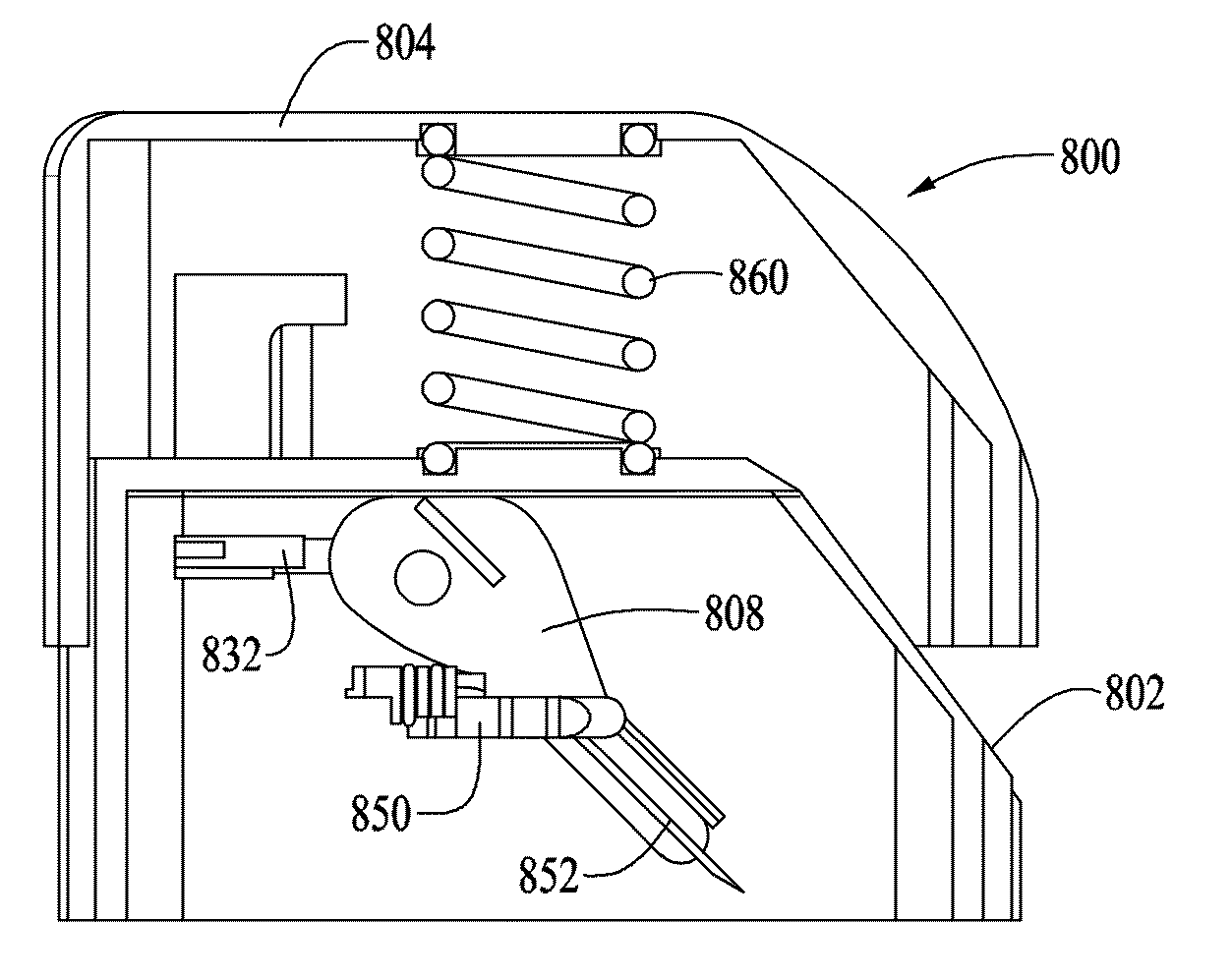

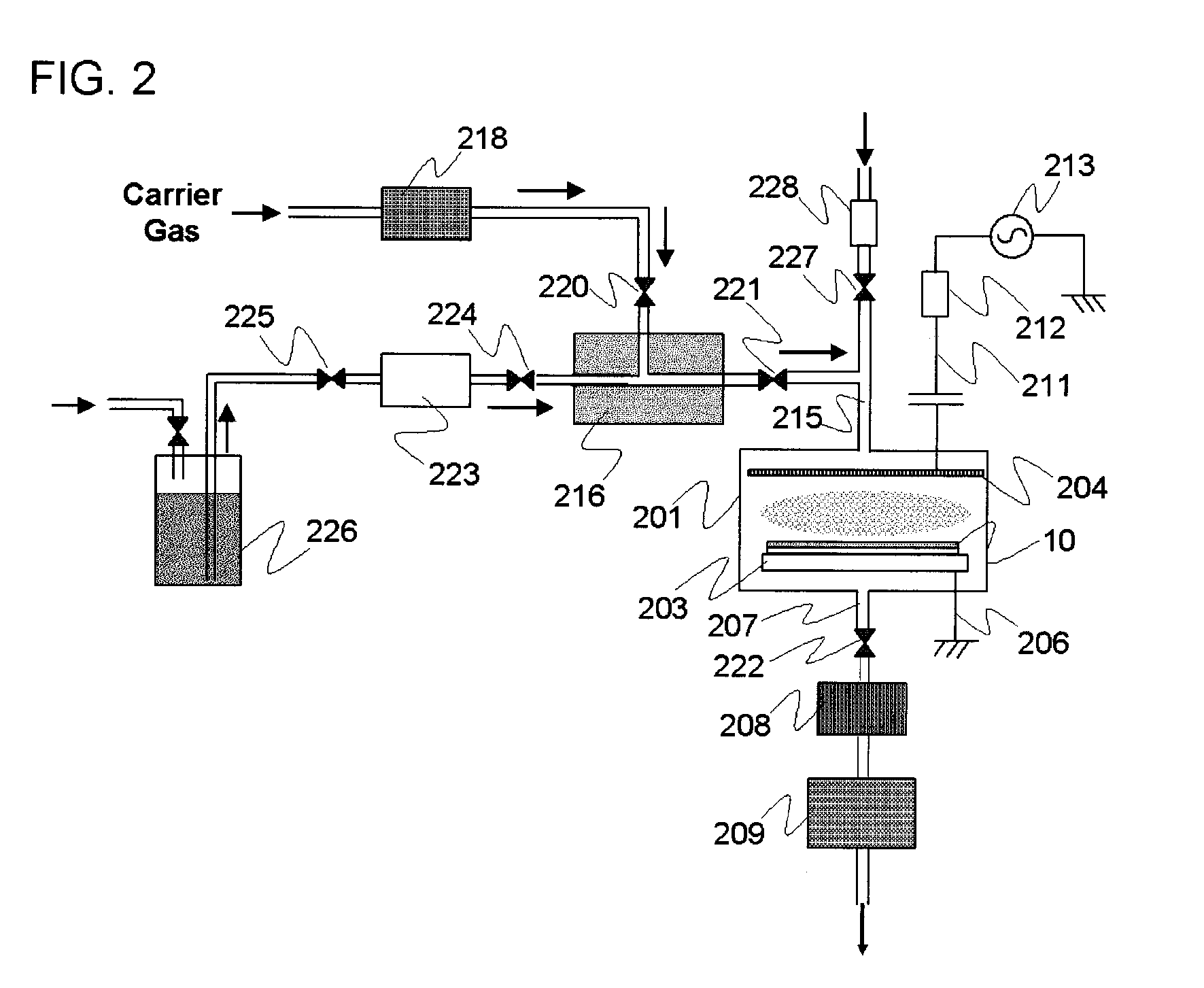

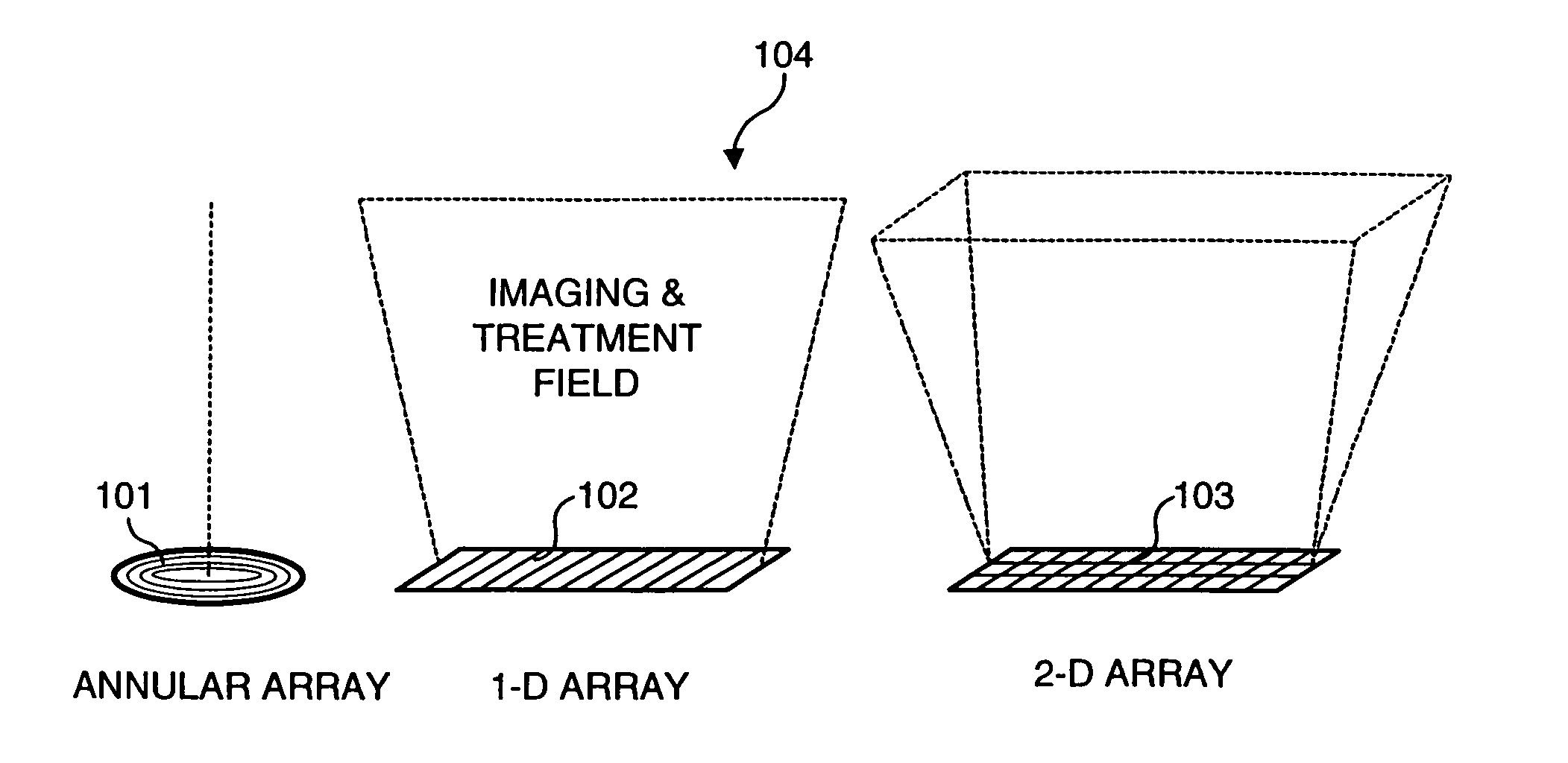

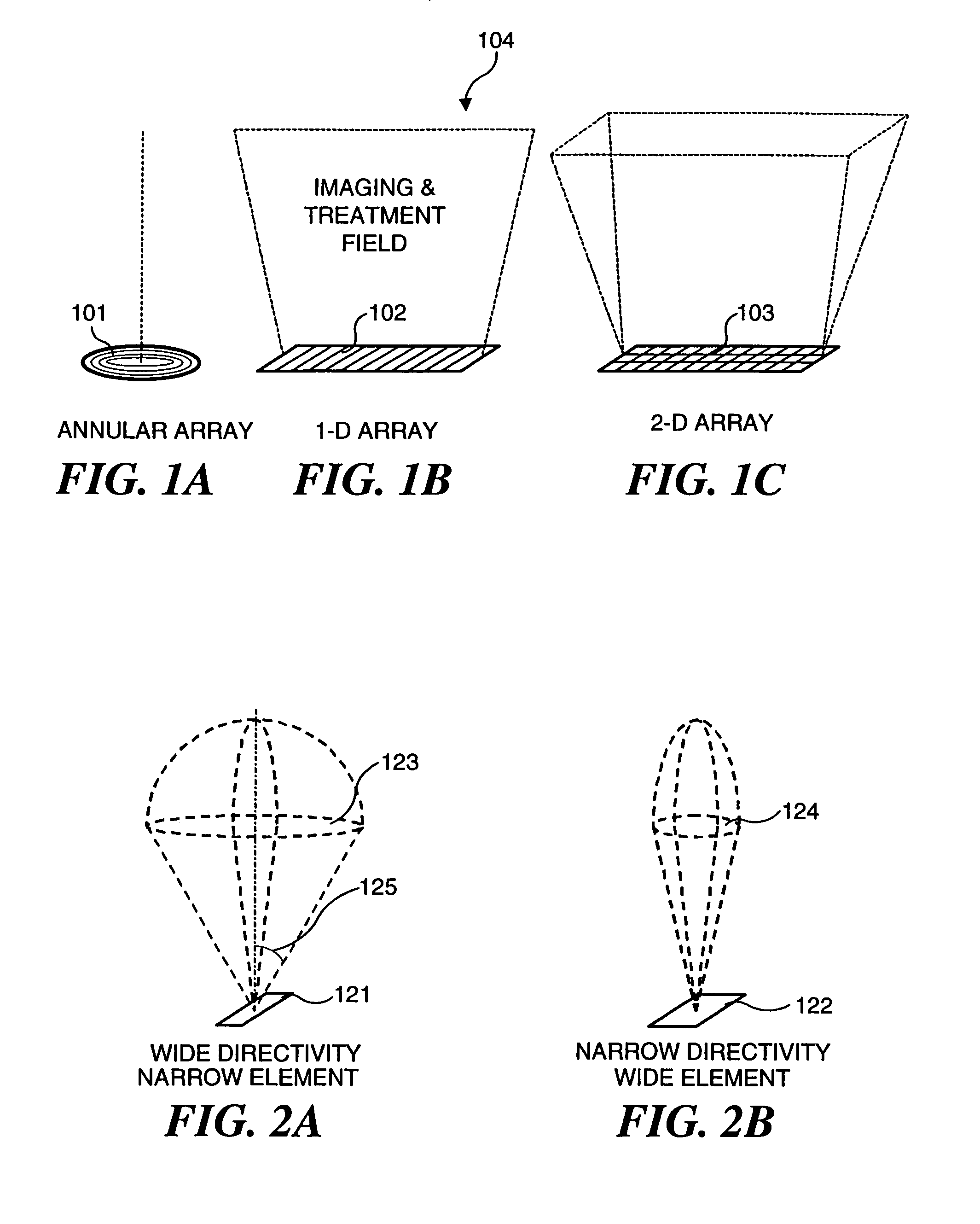

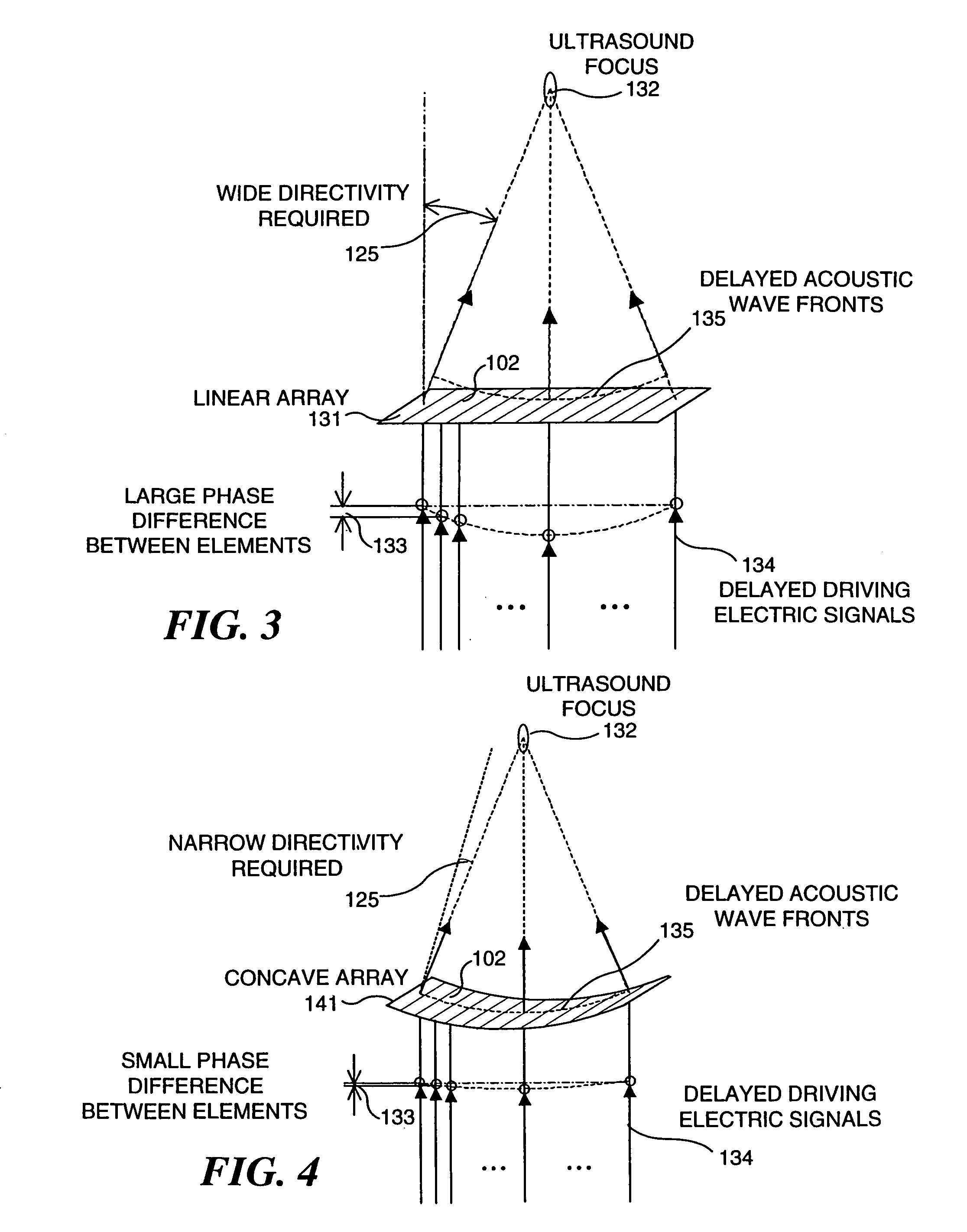

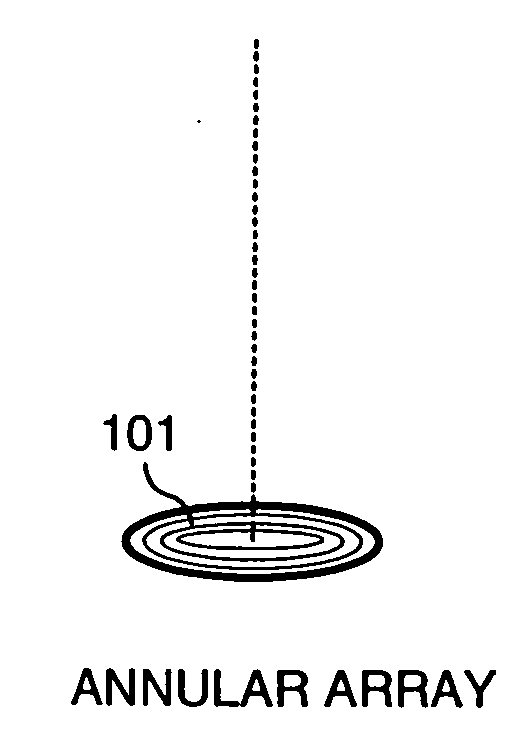

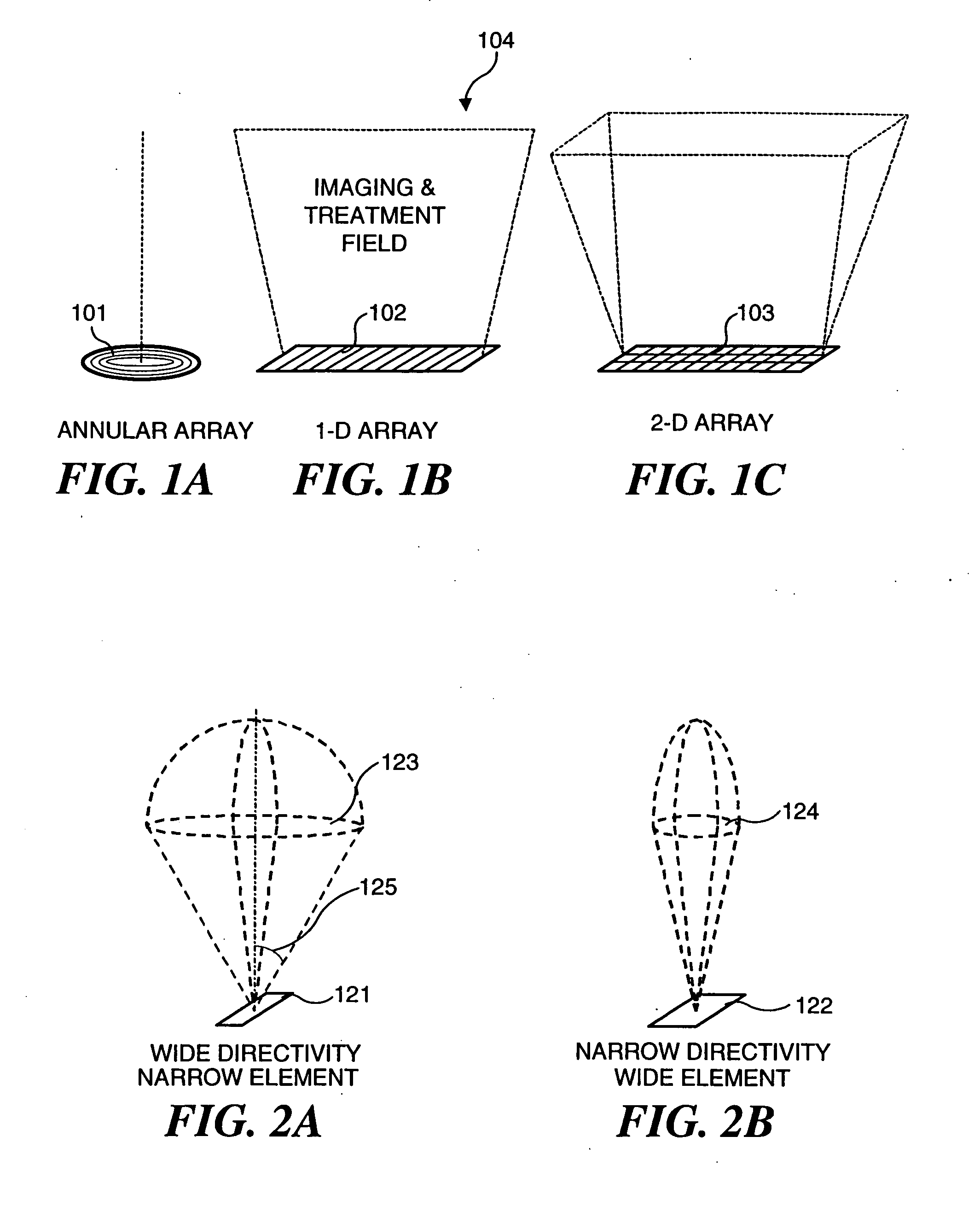

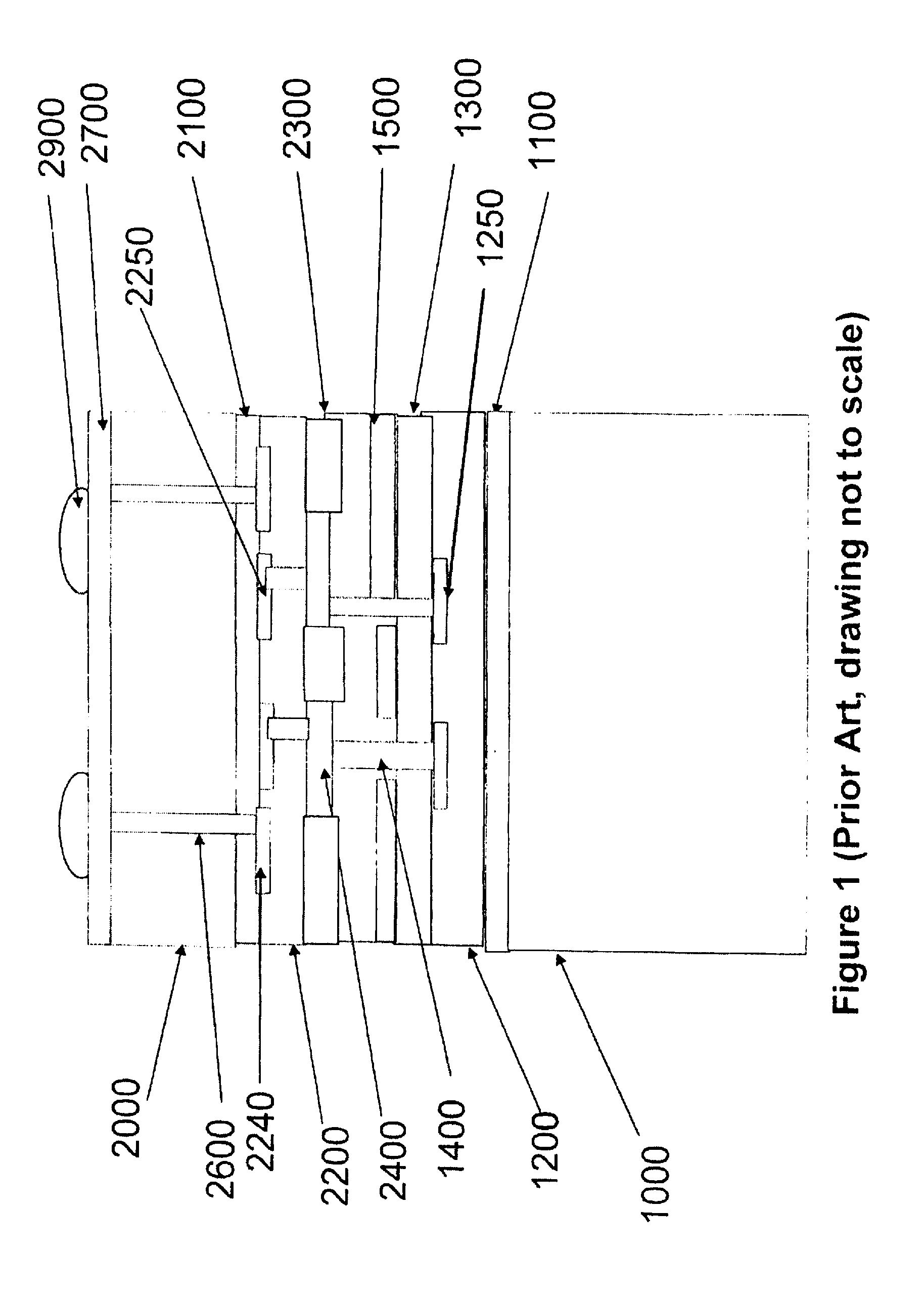

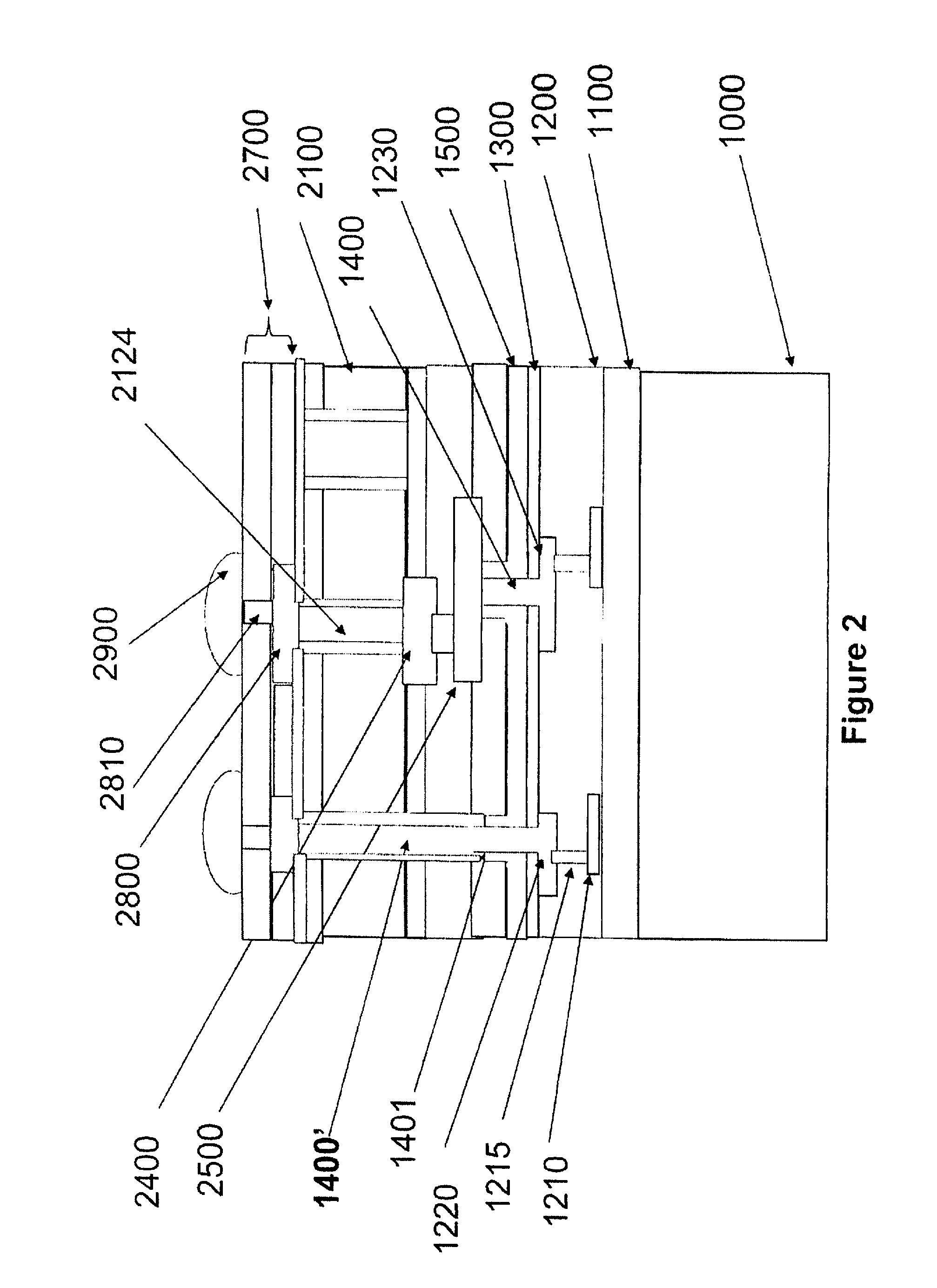

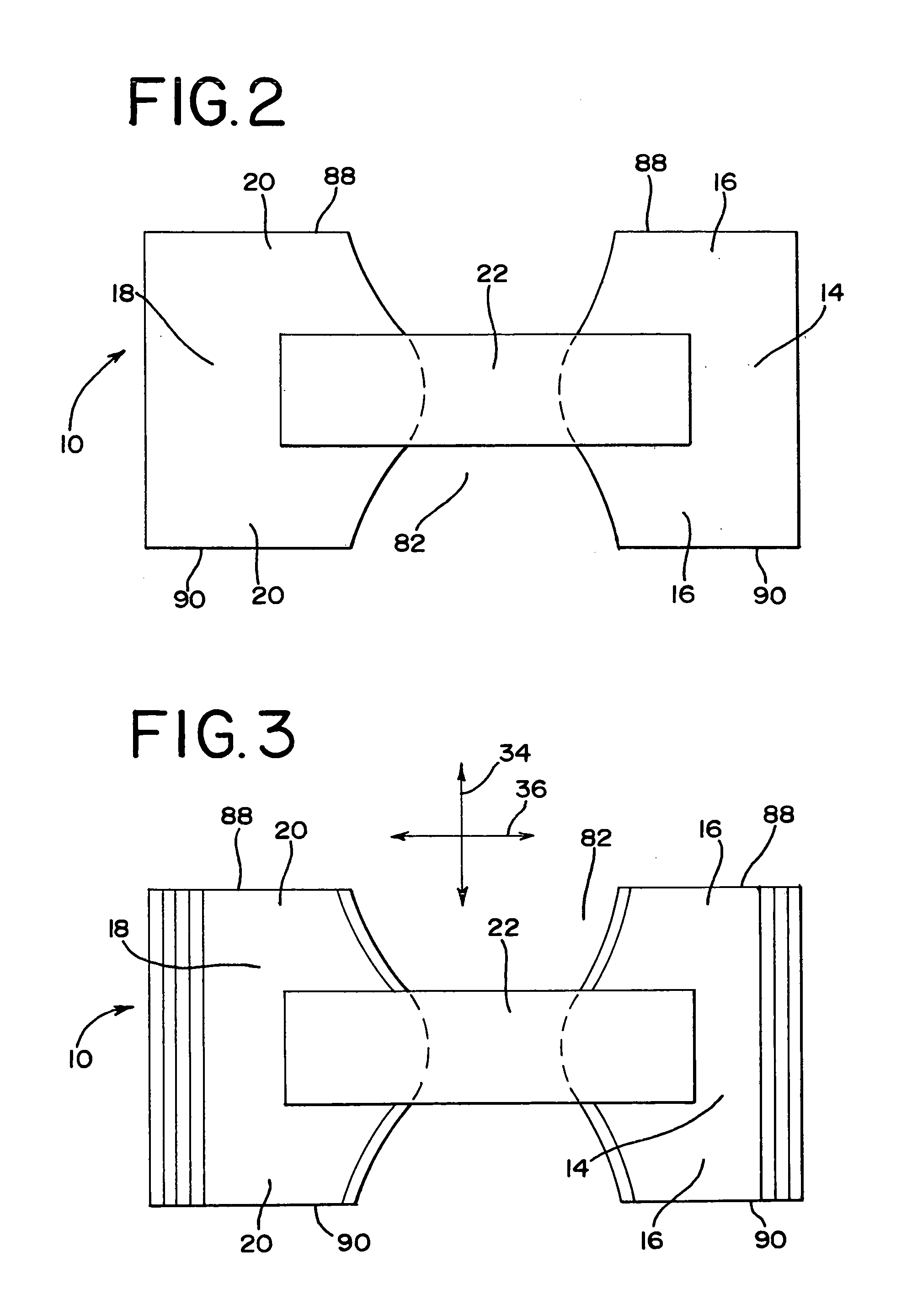

Ultrasound transducers for imaging and therapy

InactiveUS7063666B2Reduce in quantityReducing cross-talk and heatingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyElectrical resistance and conductanceSonification

Owner:OTSUKA MEDICAL DEVICES

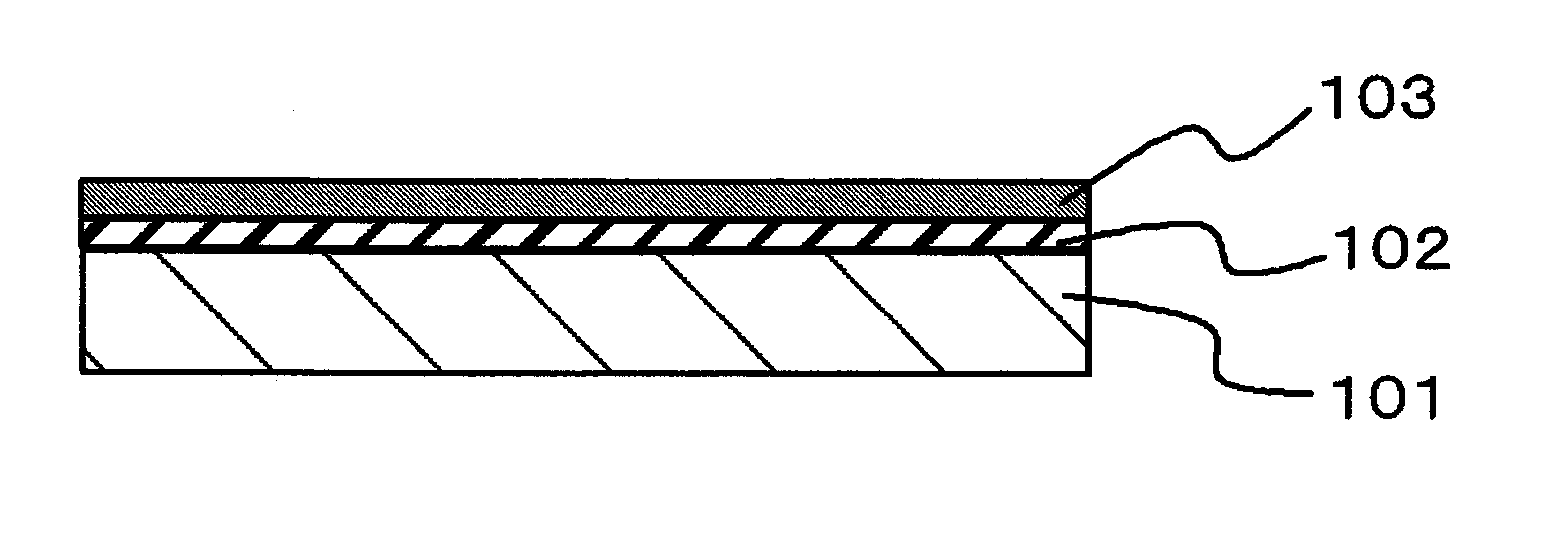

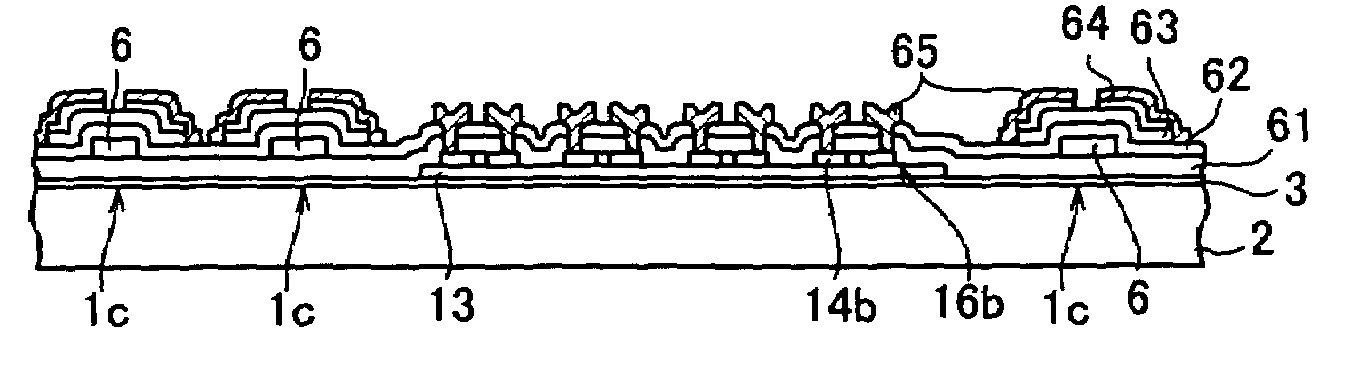

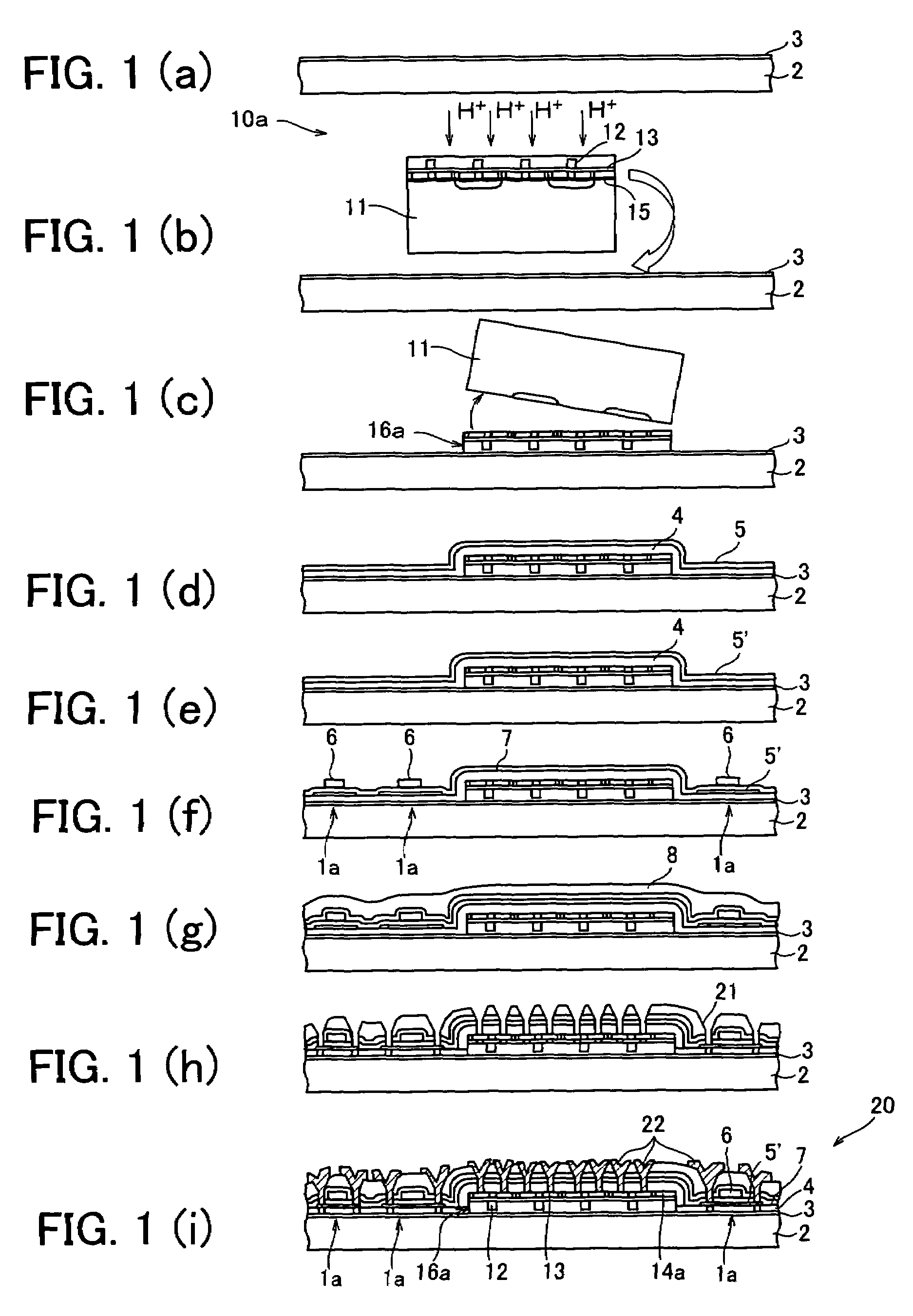

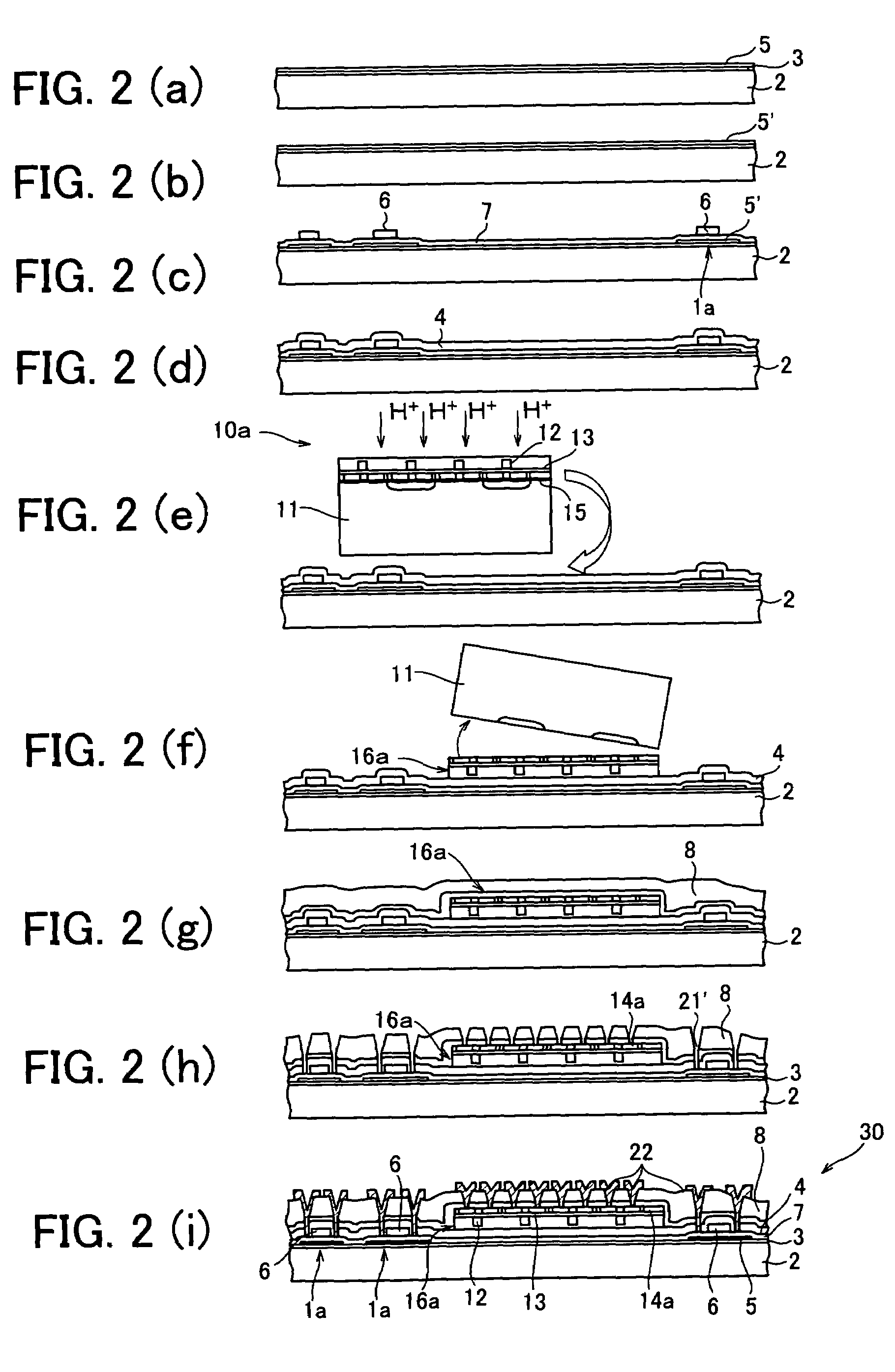

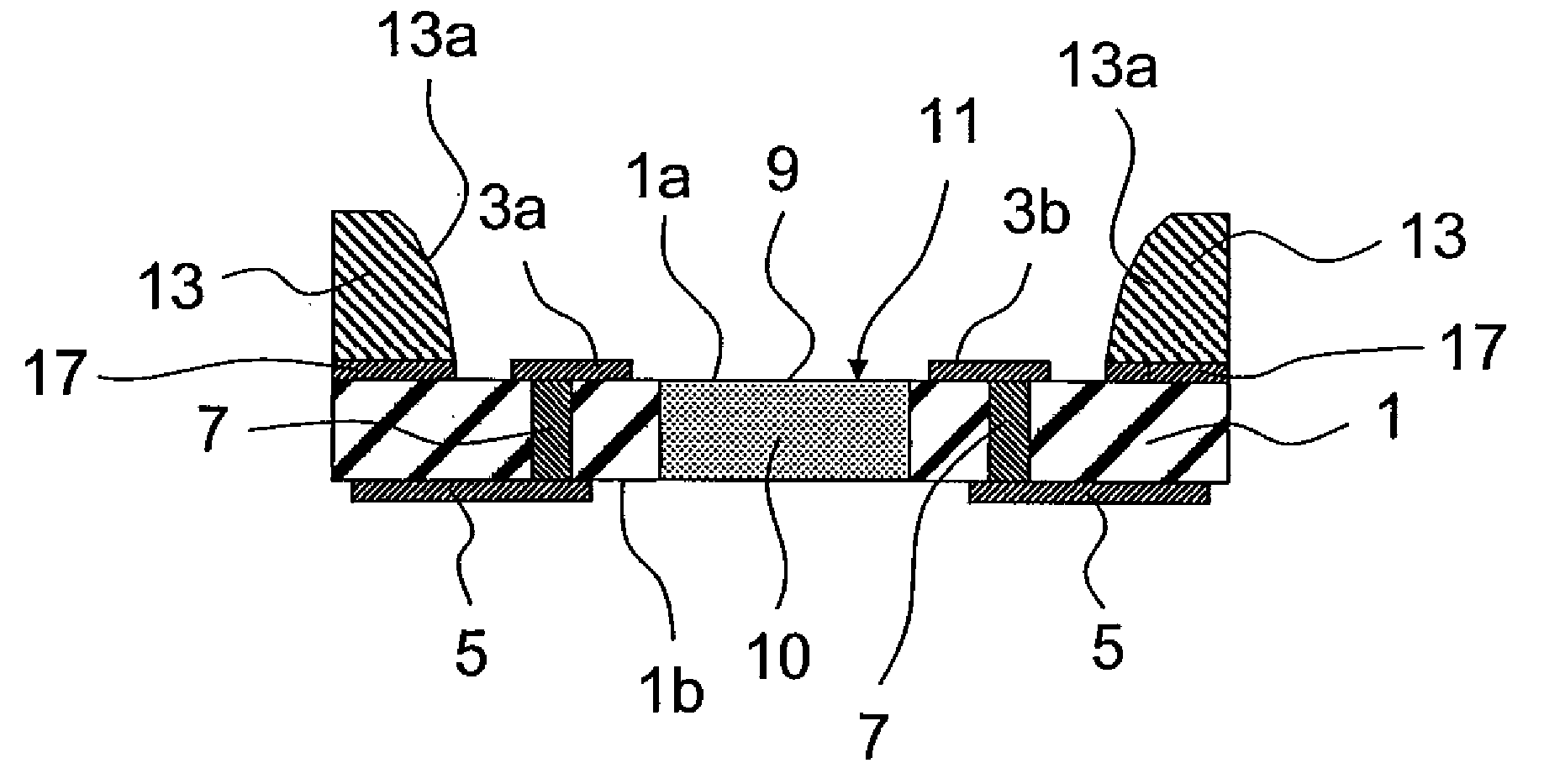

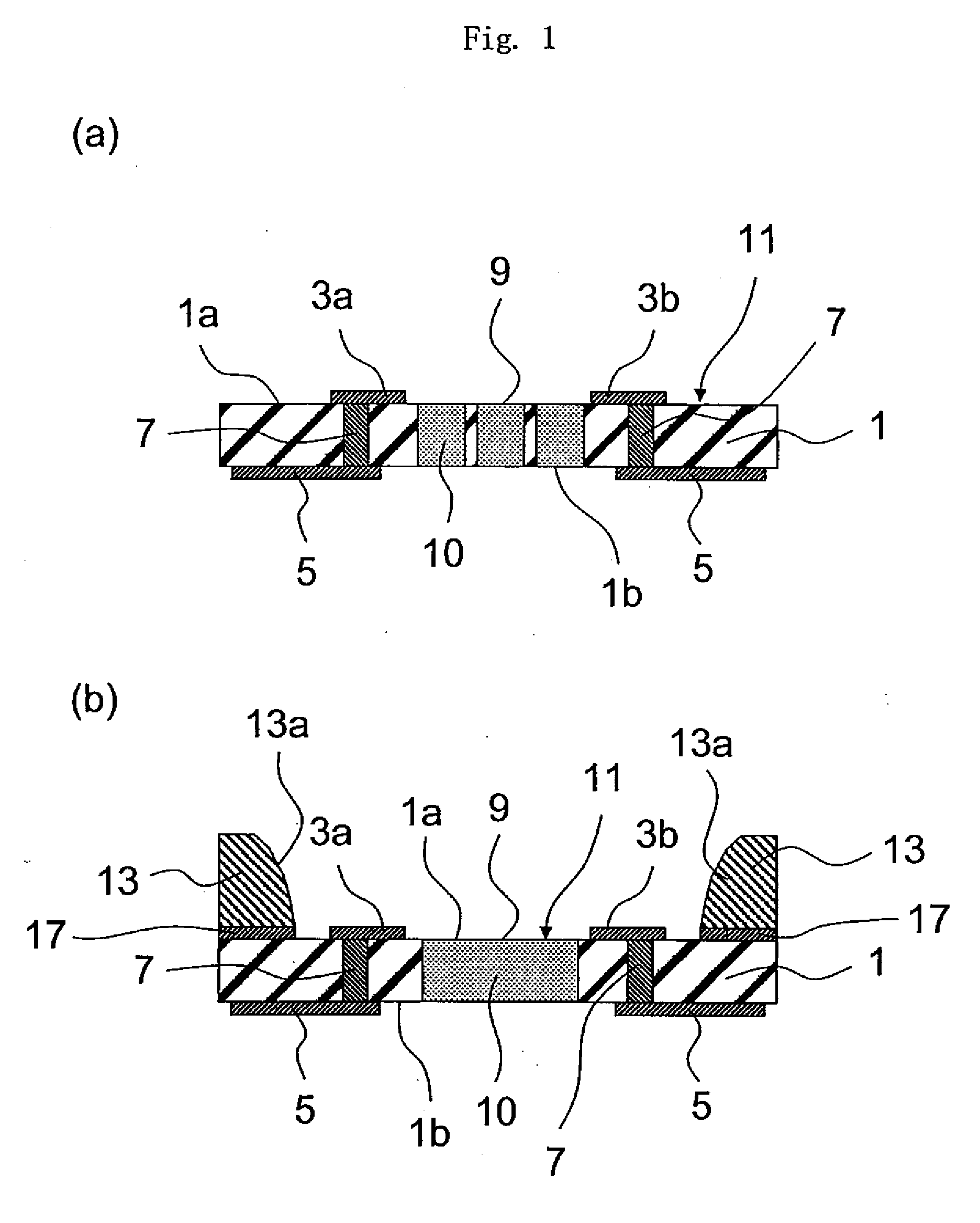

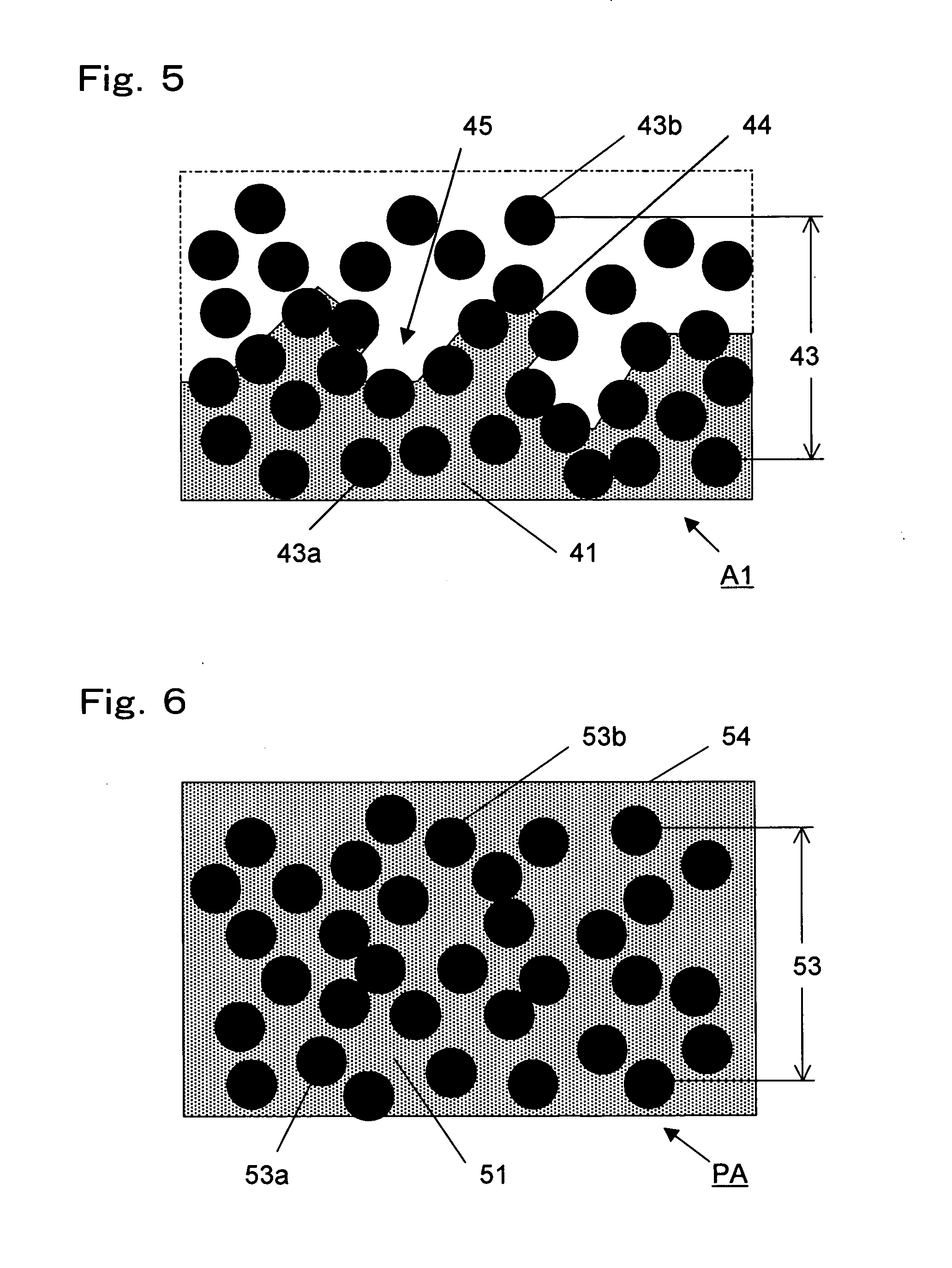

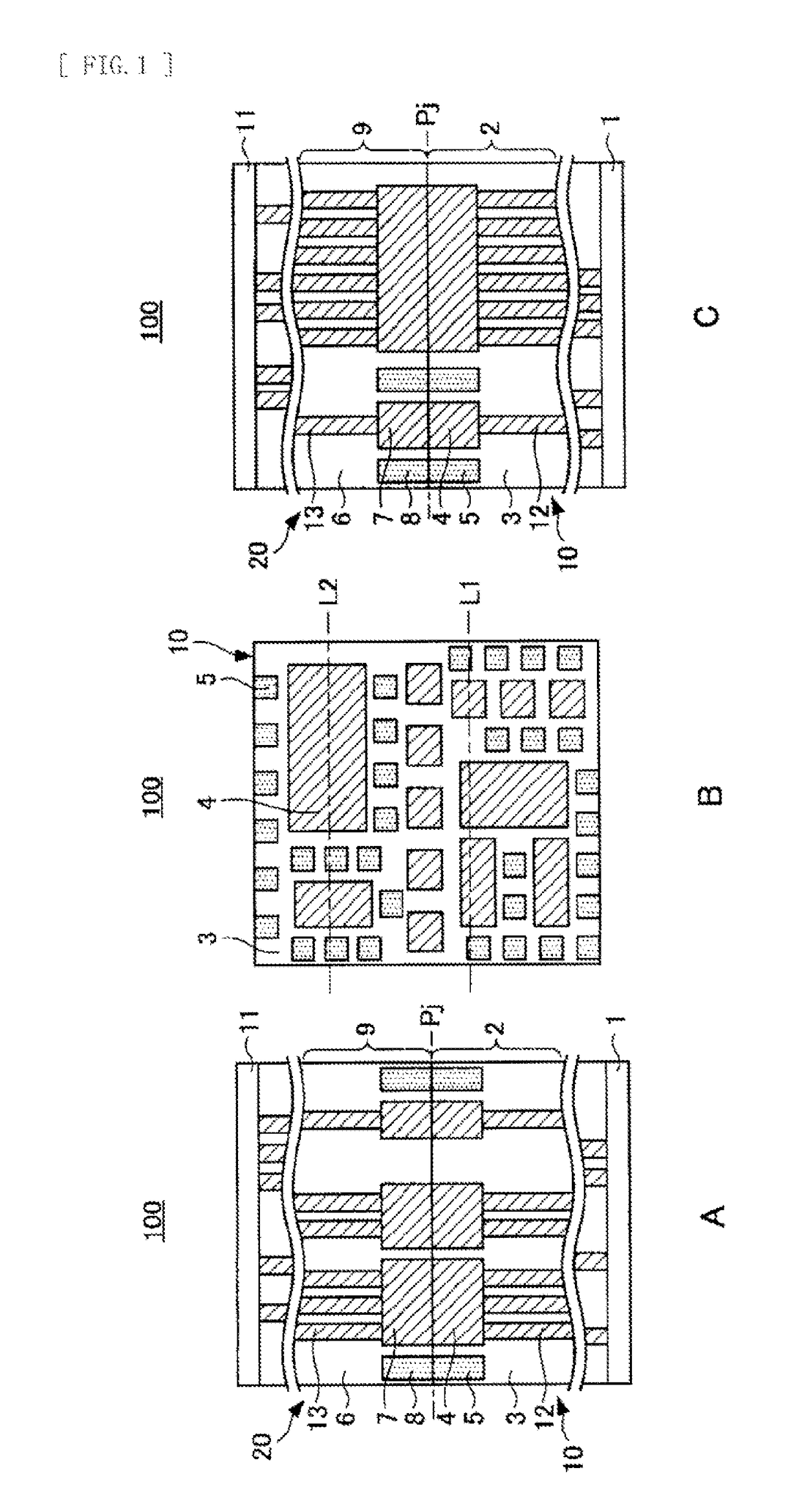

Single-crystal silicon substrate, SOI substrate, semiconductor device, display device, and manufacturing method of semiconductor device

InactiveUS7508034B2Well formedHigh bonding strengthTransistorSolid-state devicesDisplay deviceSoi substrate

A semiconductor device of the present invention is arranged in such a manner that a MOS non-single-crystal silicon thin-film transistor including a non-single-crystal silicon thin film made of polycrystalline silicon, a MOS single-crystal silicon thin-film transistor including a single-crystal silicon thin film, and a metal wiring are provided on an insulating substrate. With this arrangement, (i) a semiconductor device in which a non-single-crystal silicon thin film and a single-crystal silicon thin-film device are formed and high-performance systems are integrated, (ii) a method of manufacturing the semiconductor device, and (iii) a single-crystal silicon substrate for forming the single-crystal silicon thin-film device of the semiconductor device are obtained.

Owner:SHARP KK

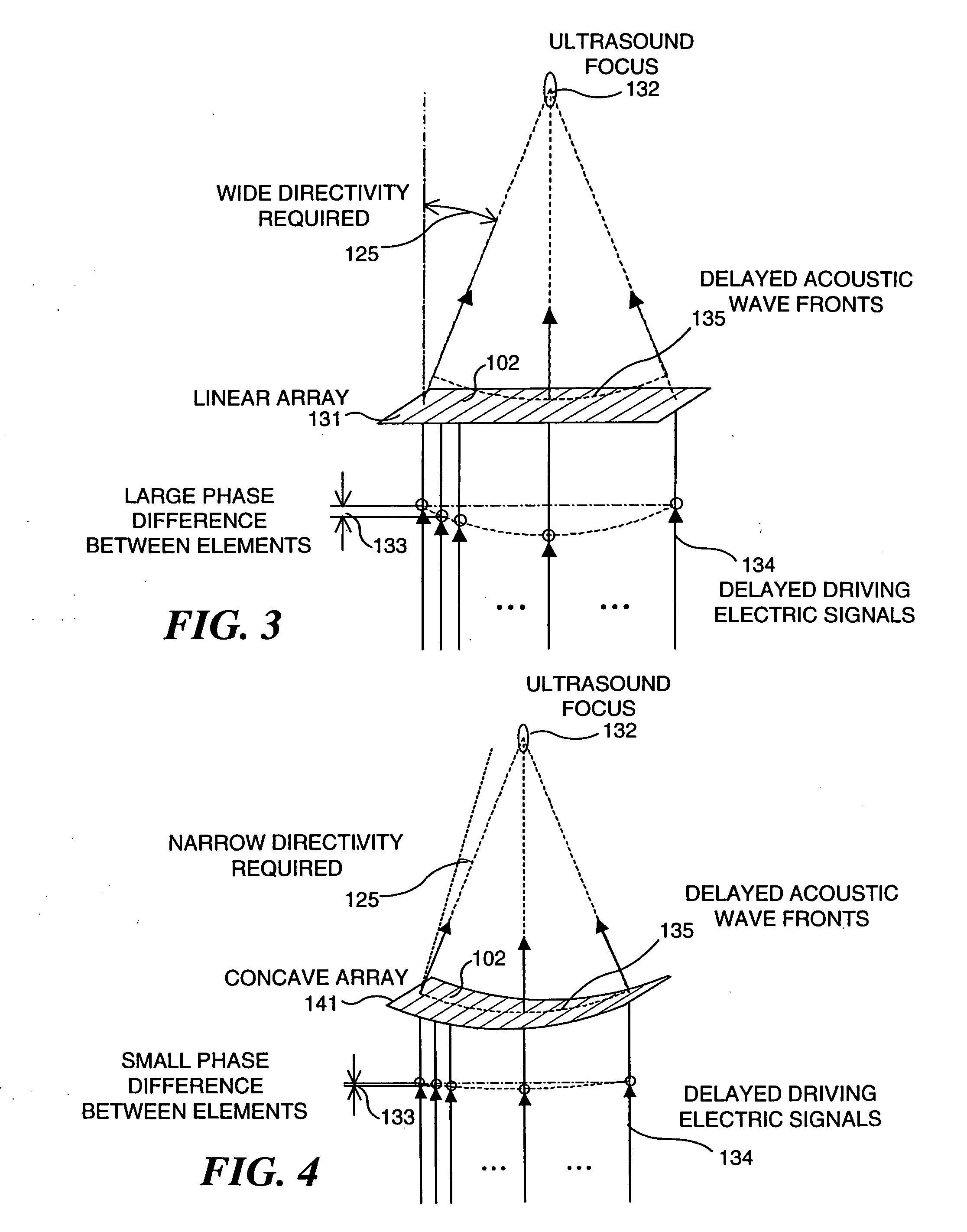

Ultrasound transducers for imaging and therapy

InactiveUS20050096542A1Improve likelihoodImprove bonding strengthUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationUltrasonic beam

Ultrasound applicators able to both image a treatment site and administer ultrasound therapy include an array of transducer elements that can be focused. In several embodiments, an electronically phased array is used for controlling the focal point of an ultrasound beam. The ultrasound beam produced thereby can also be electronically steered. To reduce the quality factor or Q of the array when the array is used for imaging, an electronic switch is selectively closed, placing a resistance in parallel with each of the array elements. A flexible array is employed in several embodiments and is selectively bent or flexed to vary its radius of curvature and thus control the focal point and / or a direction of focus of the array. In another embodiment, each of the transducer elements comprising the array are individually mechanically pivotable to steer the ultrasonic beam produced by the transducer elements.

Owner:OTSUKA MEDICAL DEVICES

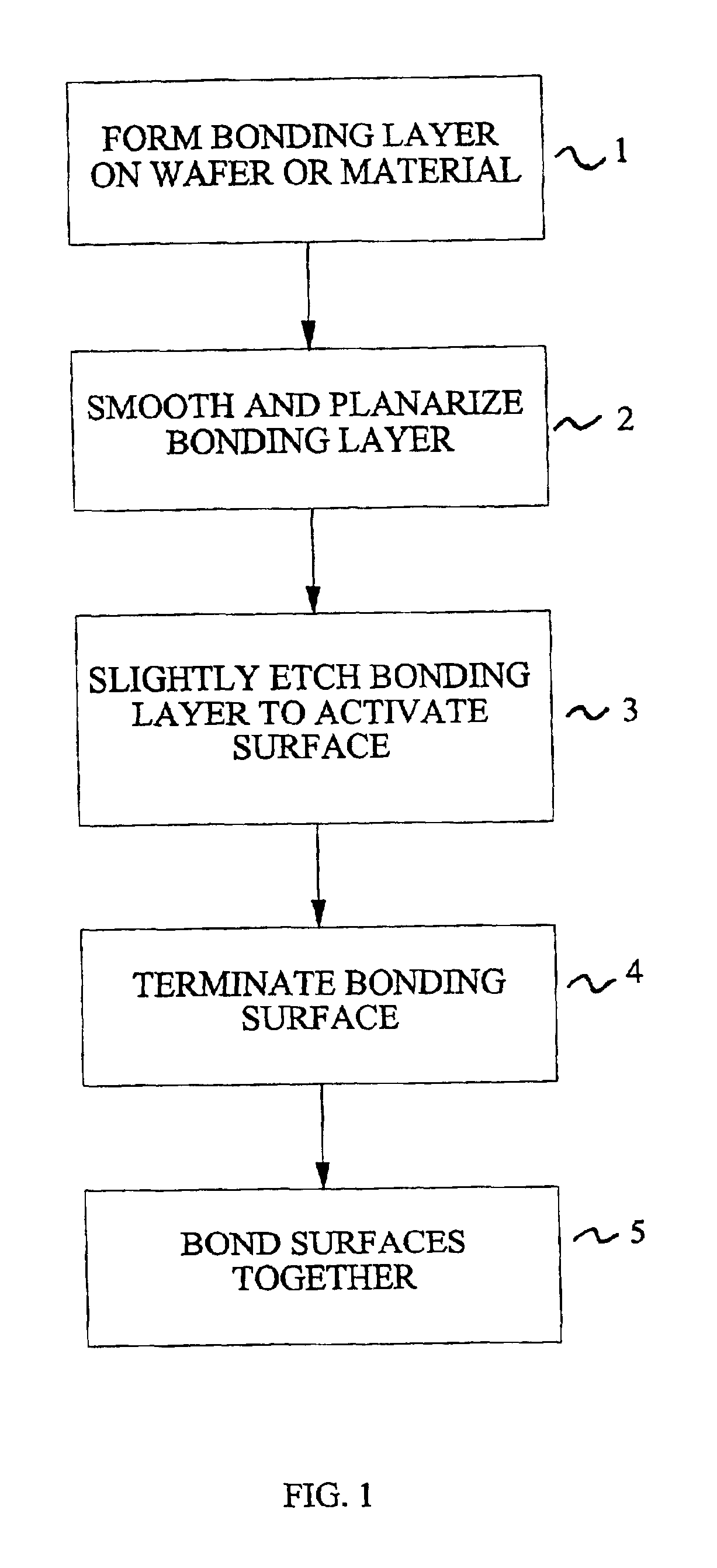

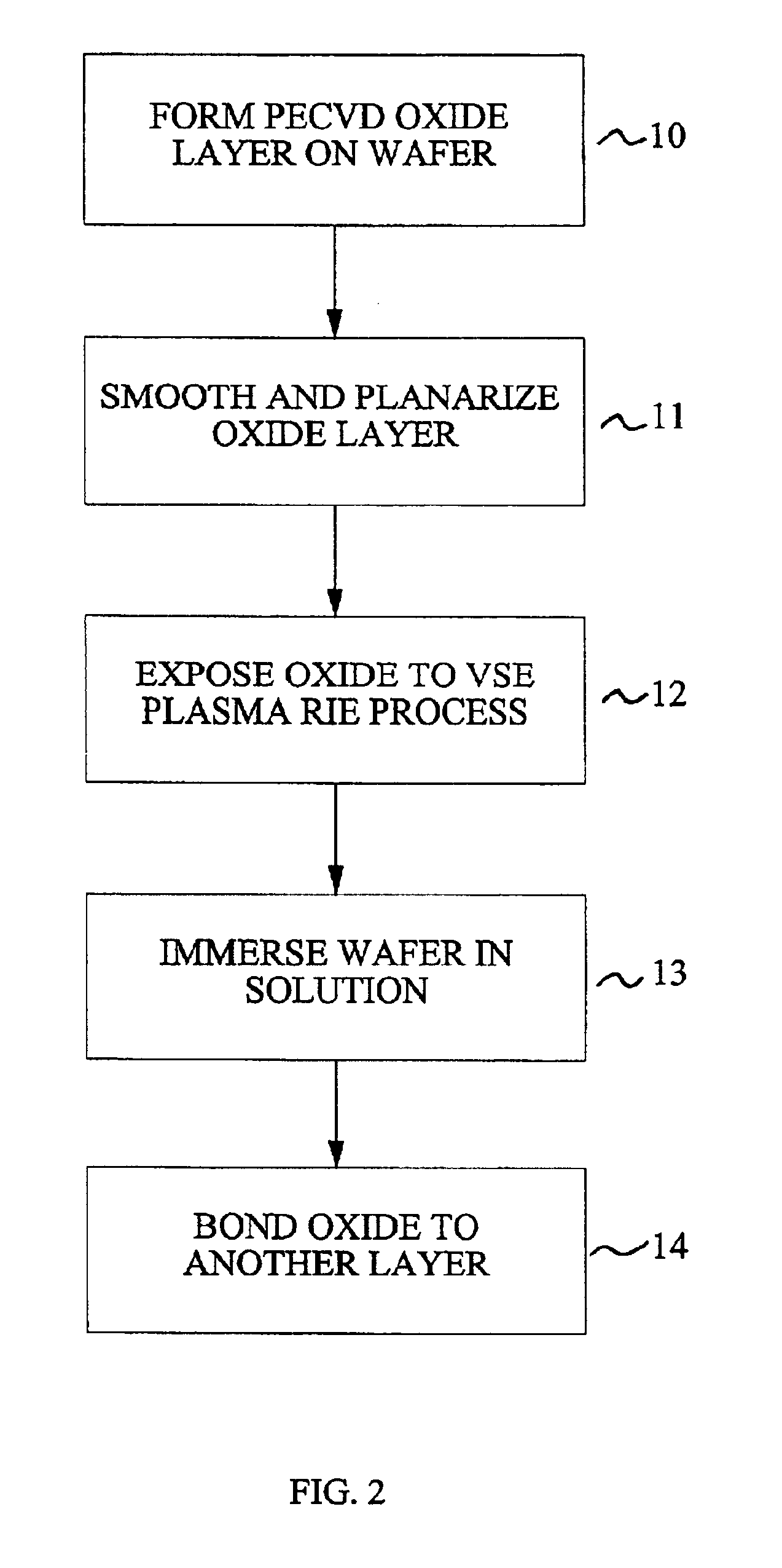

Method for low temperature bonding and bonded structure

InactiveUS6902987B1High bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSurface cleaningBiological activation

A method for bonding at low or room temperature includes steps of surface cleaning and activation by cleaning or etching. One etching process the method may also include removing by-products of interface polymerization to prevent a reverse polymerization reaction to allow room temperature chemical bonding of materials such as silicon, silicon nitride and SiO2. The surfaces to be bonded are polished to a high degree of smoothness and planarity. VSE may use reactive ion etching or wet etching to slightly etch the surfaces being bonded. The surface roughness and planarity are not degraded and may be enhanced by the VSE process. The etched surfaces may be rinsed in solutions such as ammonium hydroxide or ammonium fluoride to promote the formation of desired bonding species on the surfaces.

Owner:INVENSAS BONDING TECH INC

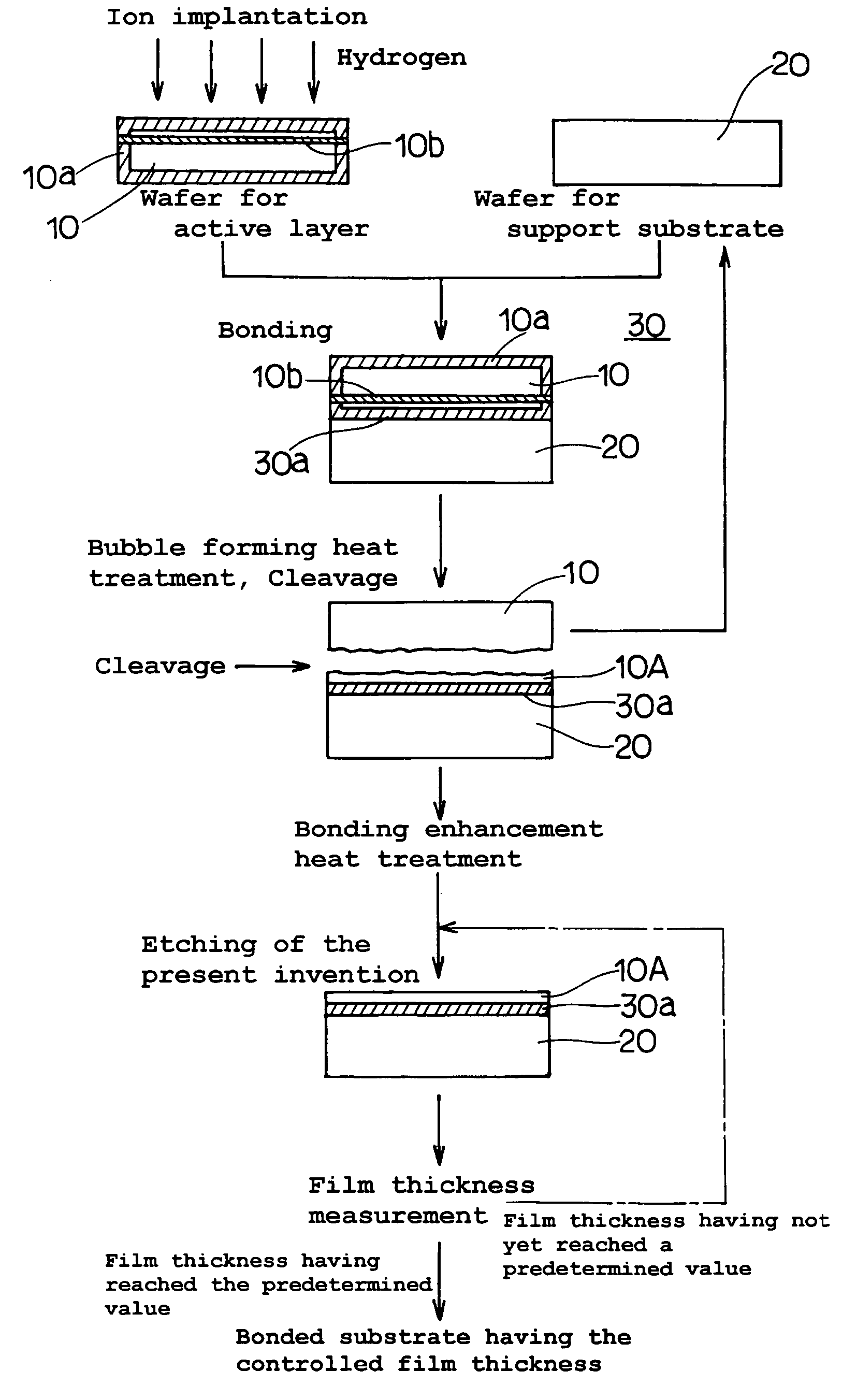

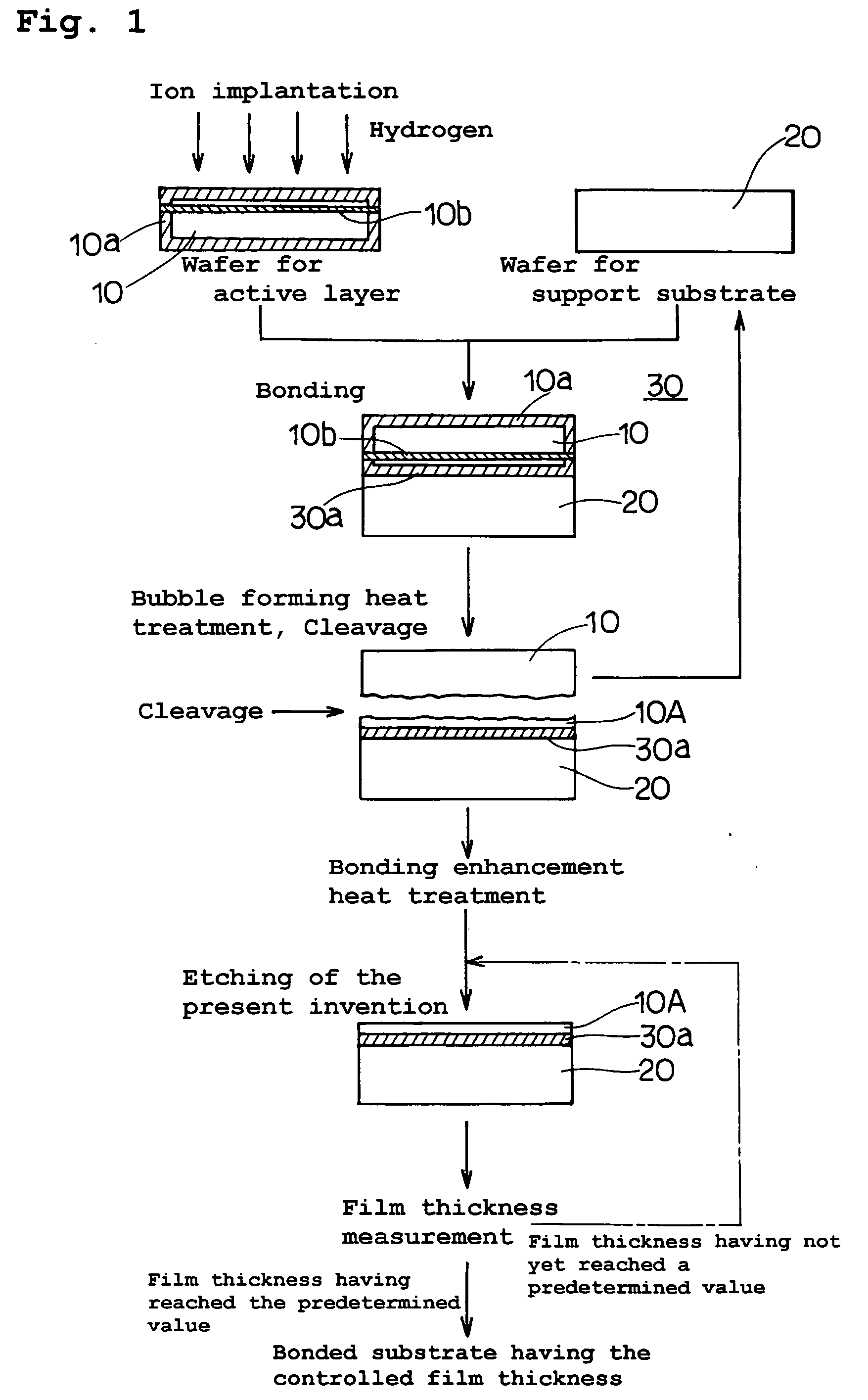

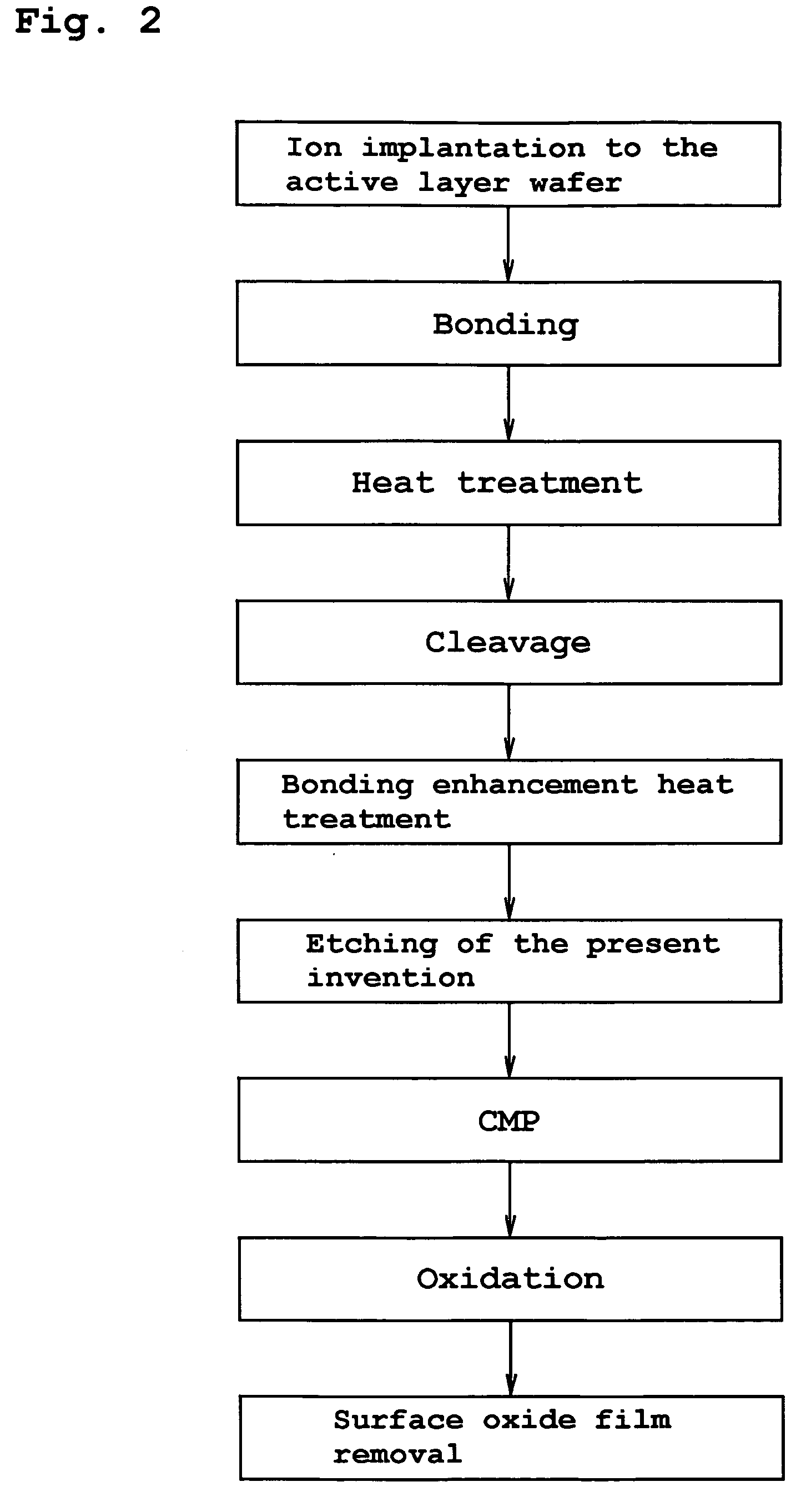

Laminated semiconductor substrate process for producing the same

InactiveUS20060118935A1Simple processReduce surface roughnessDecorative surface effectsSemiconductor/solid-state device detailsEtchingSurface roughness

The present invention provides a bonded substrate fabricated to have its final active layer thickness of 200 nm or lower by performing the etching by only 1 nm to 1 μm with a solution having an etching effect on a surface of an active layer of a bonded substrate which has been prepared by bonding two substrates after one of them having been ion-implanted and then cleaving off a portion thereof by heat treatment. SC-1 solution is used for performing the etching. A polishing, a hydrogen annealing and a sacrificial oxidation may be respectively applied to the active layer before and / or after the etching. The film thickness of this active layer can be made uniform over the entire surface area and the surface roughness of the active layer can be reduced as well.

Owner:SUMCO CORP +1

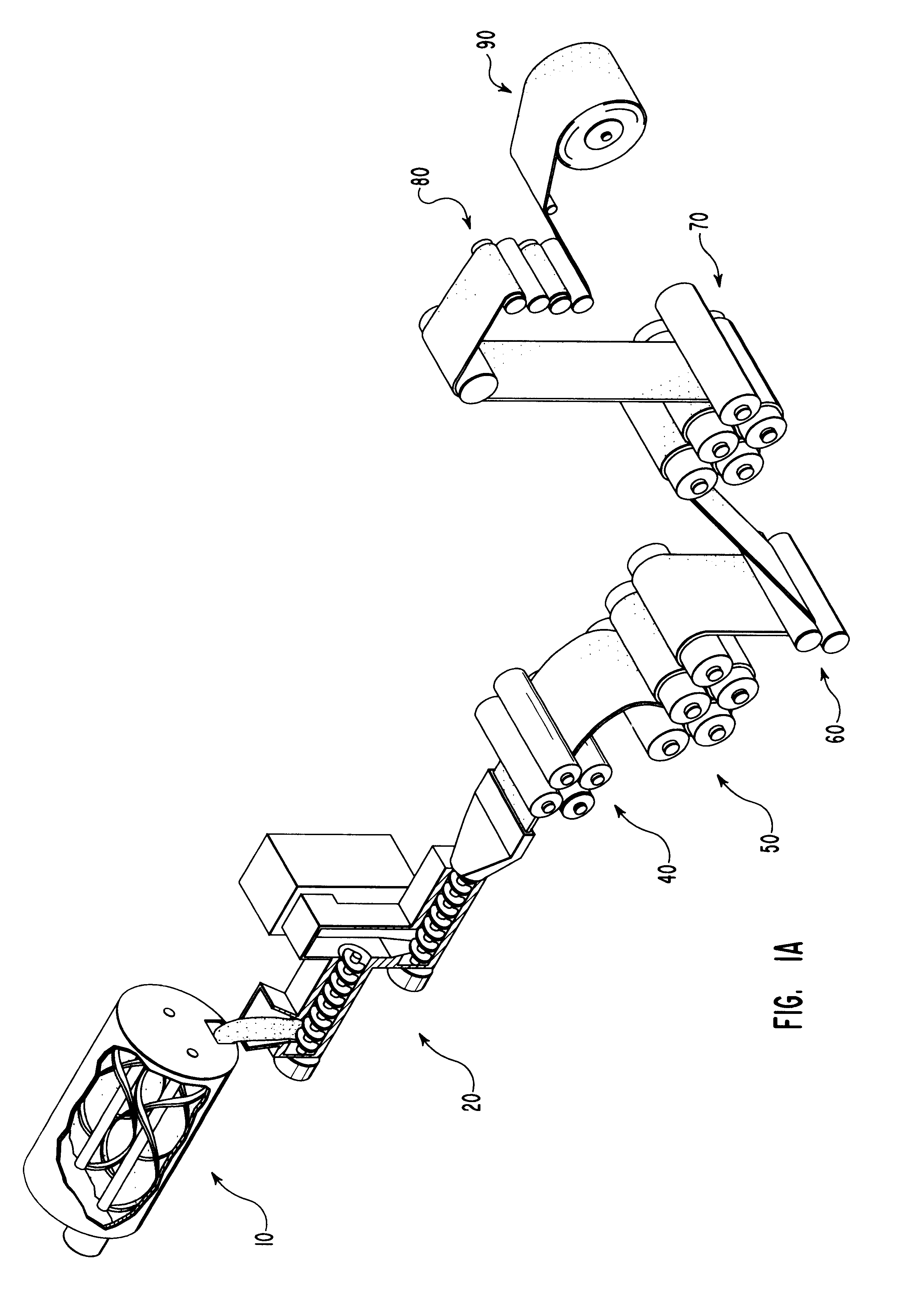

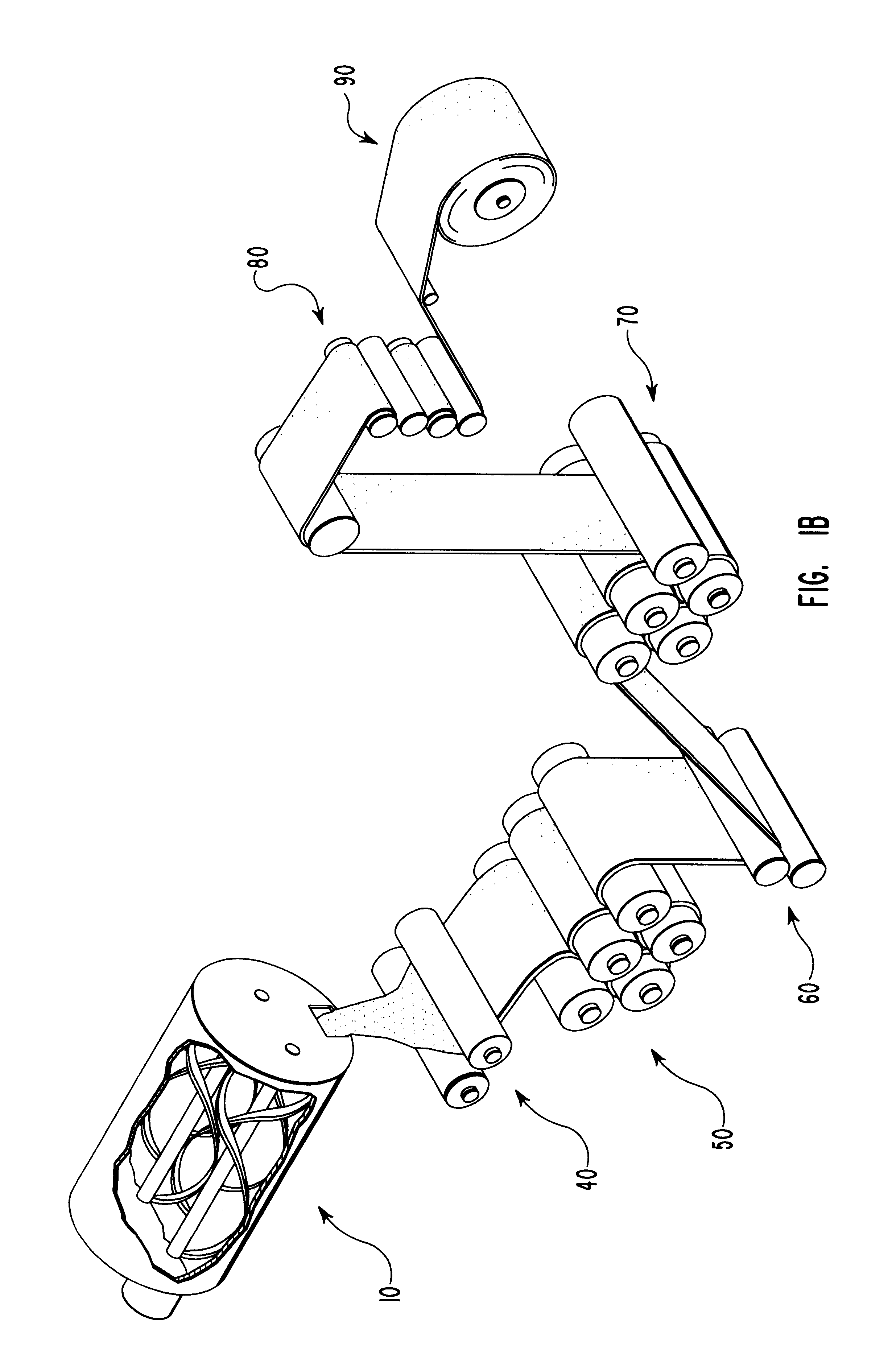

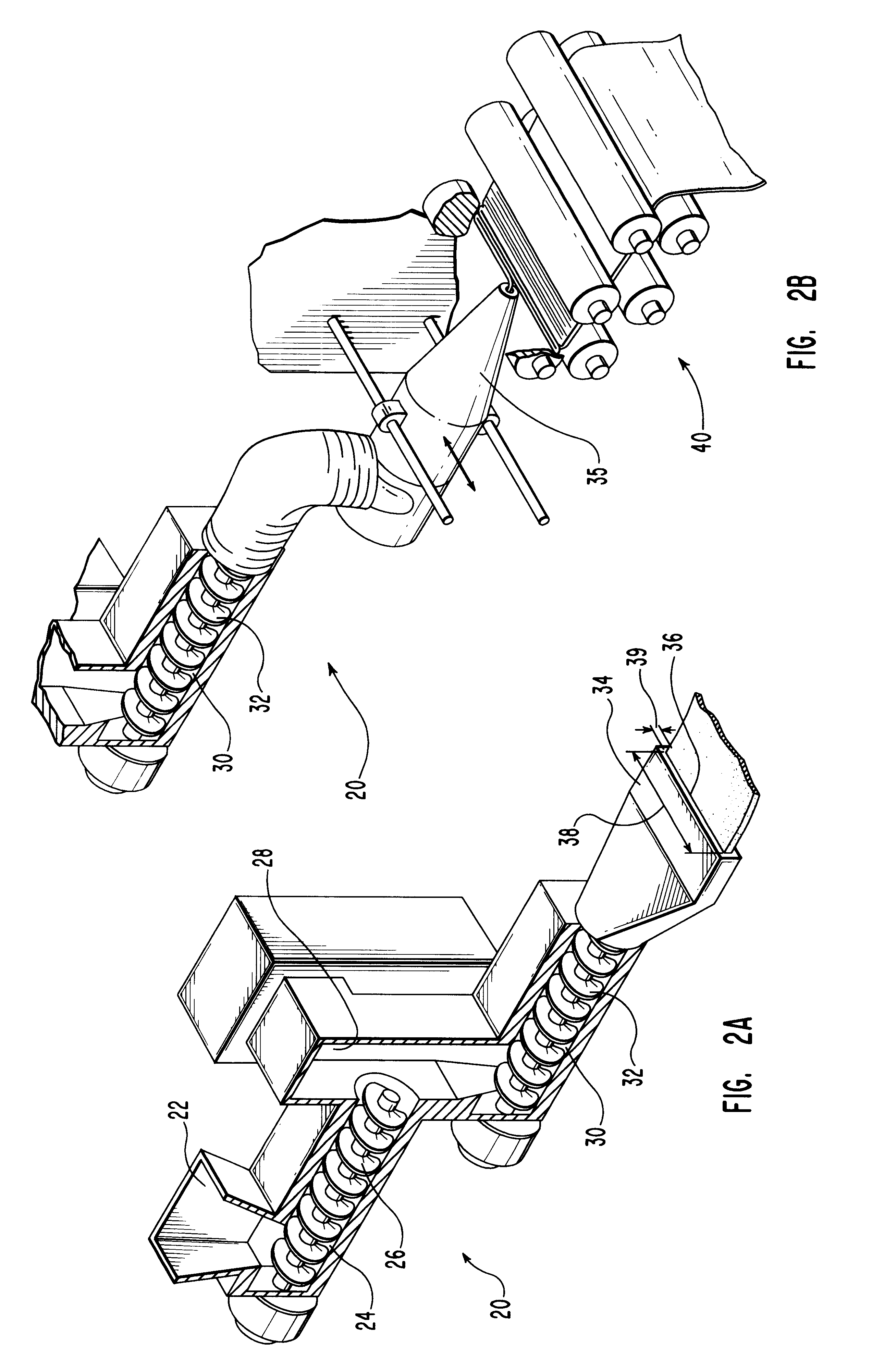

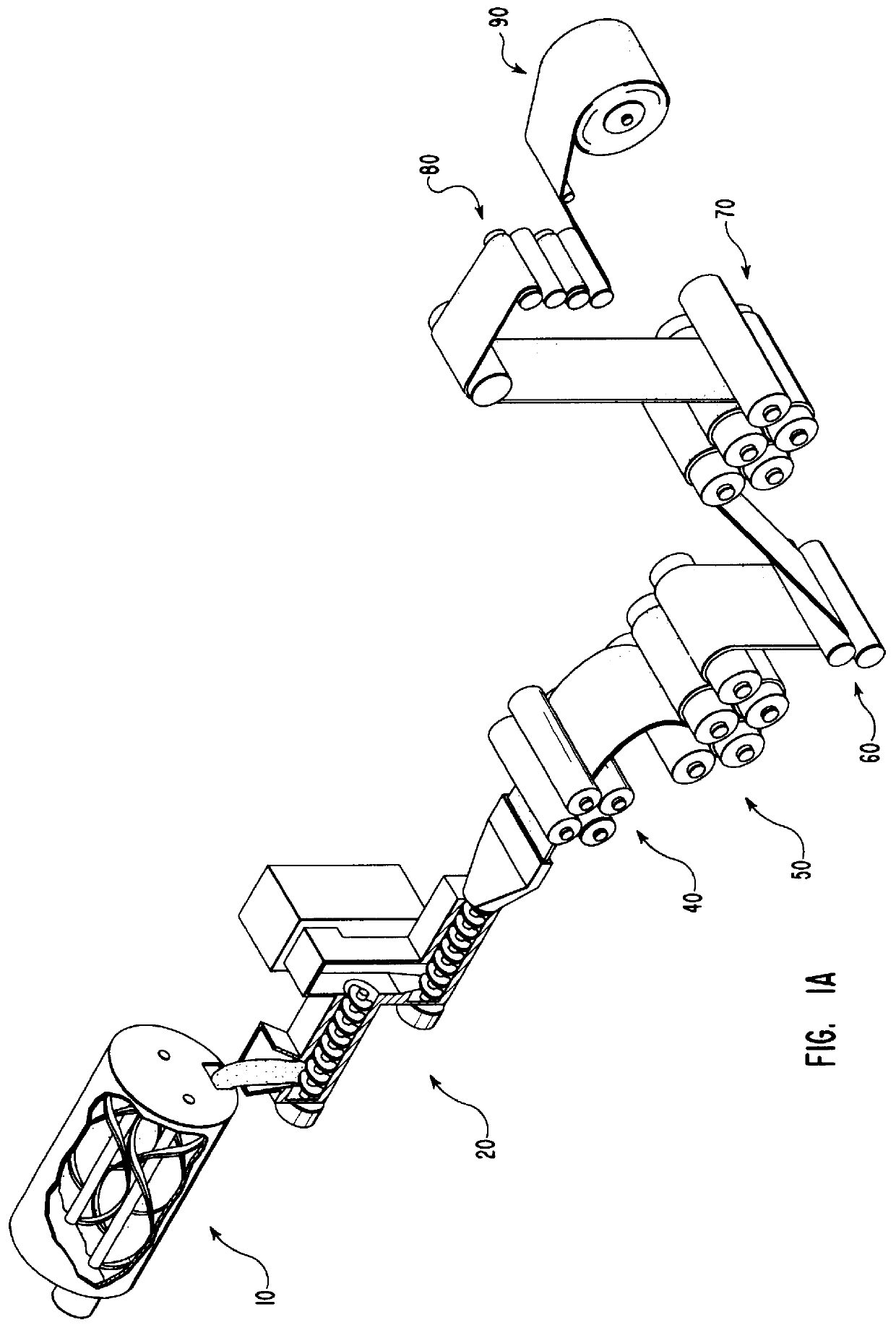

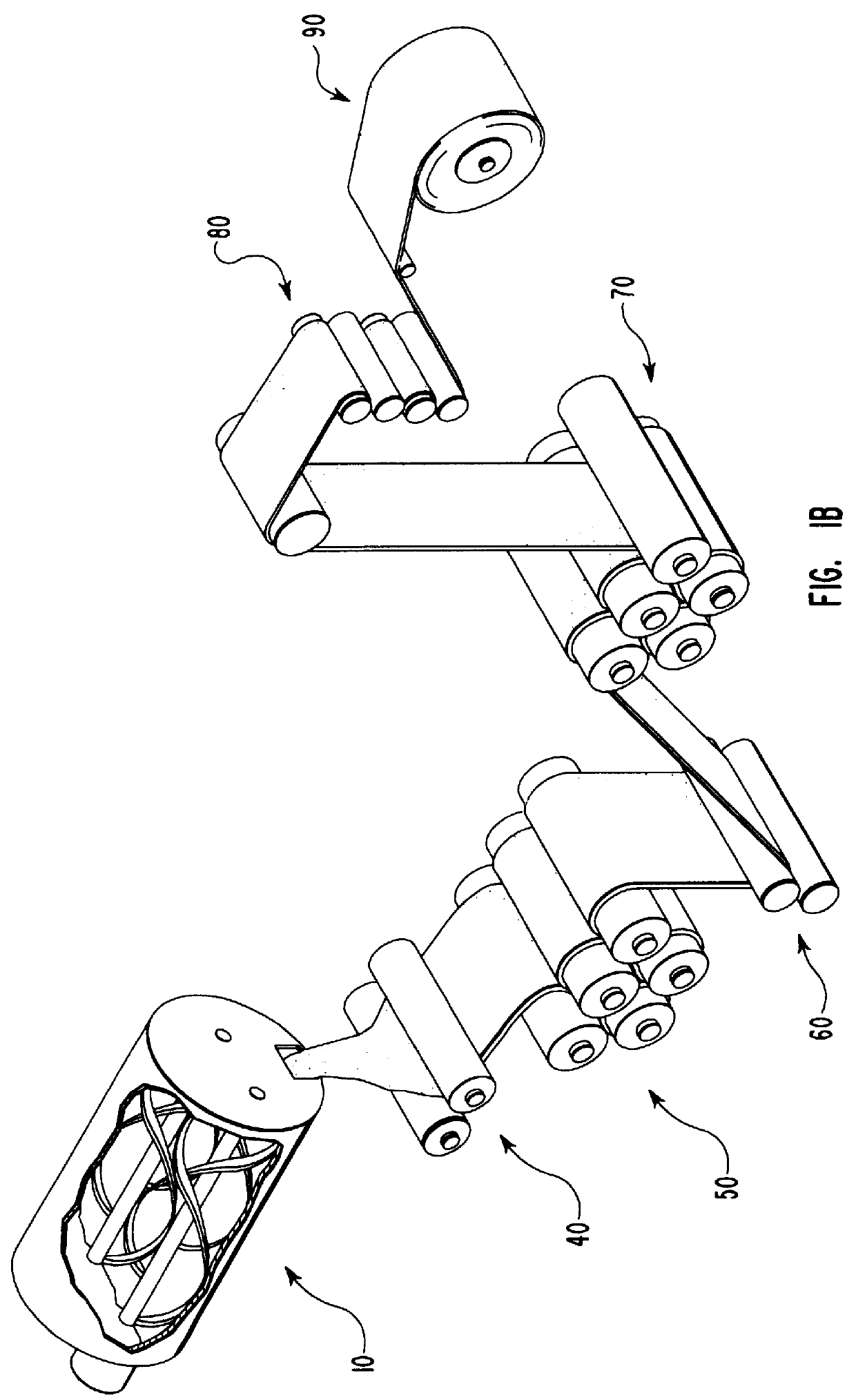

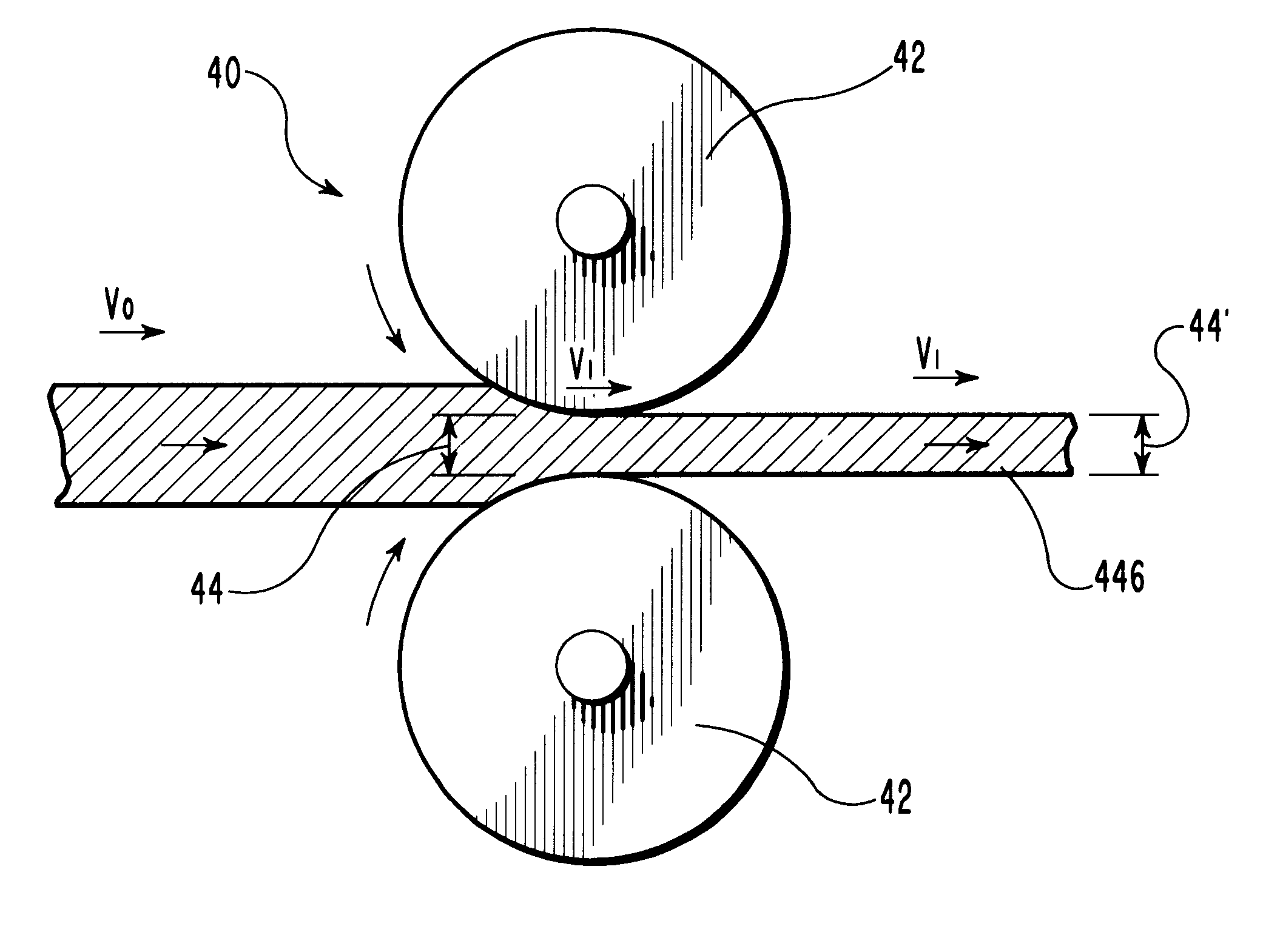

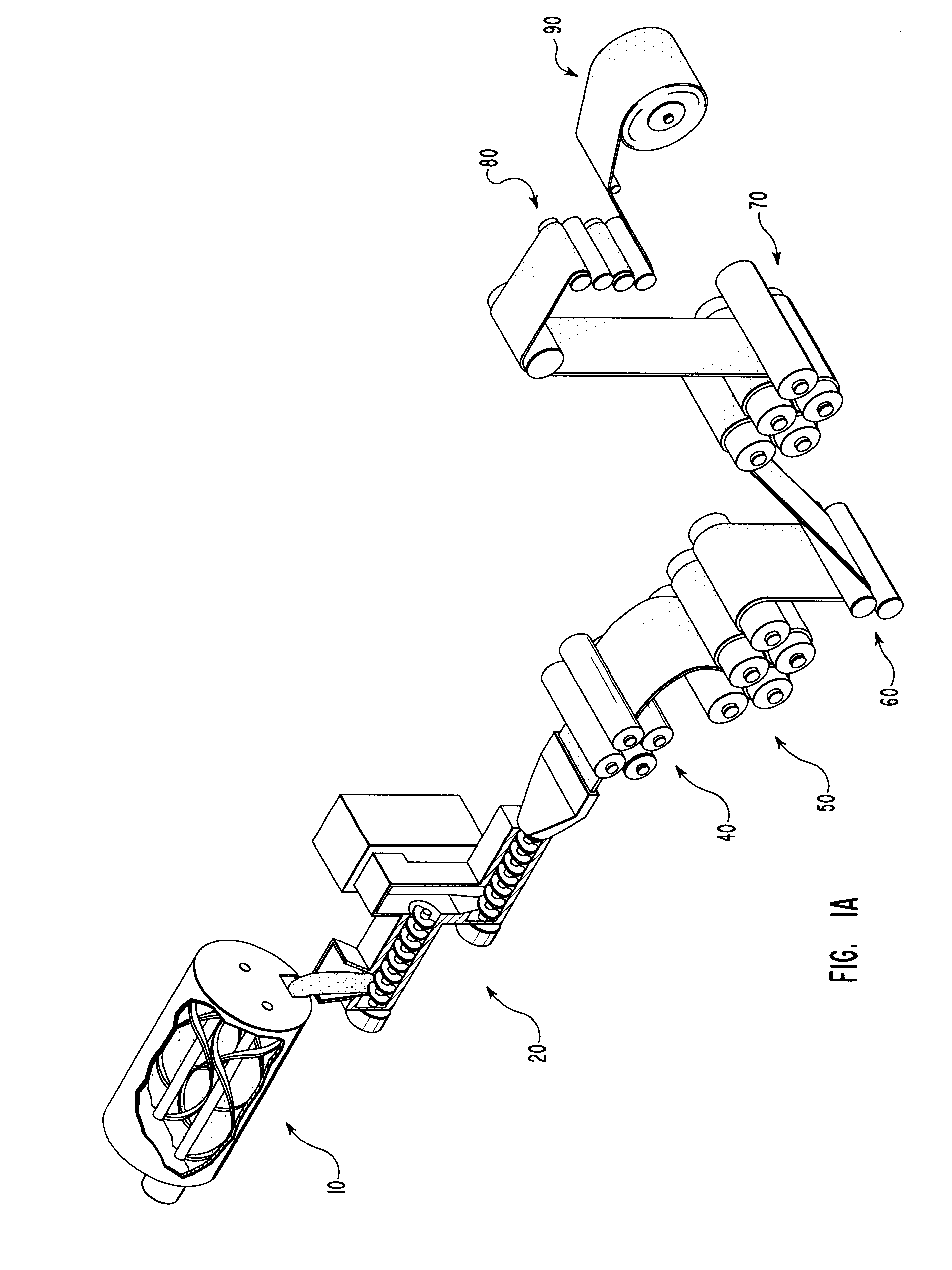

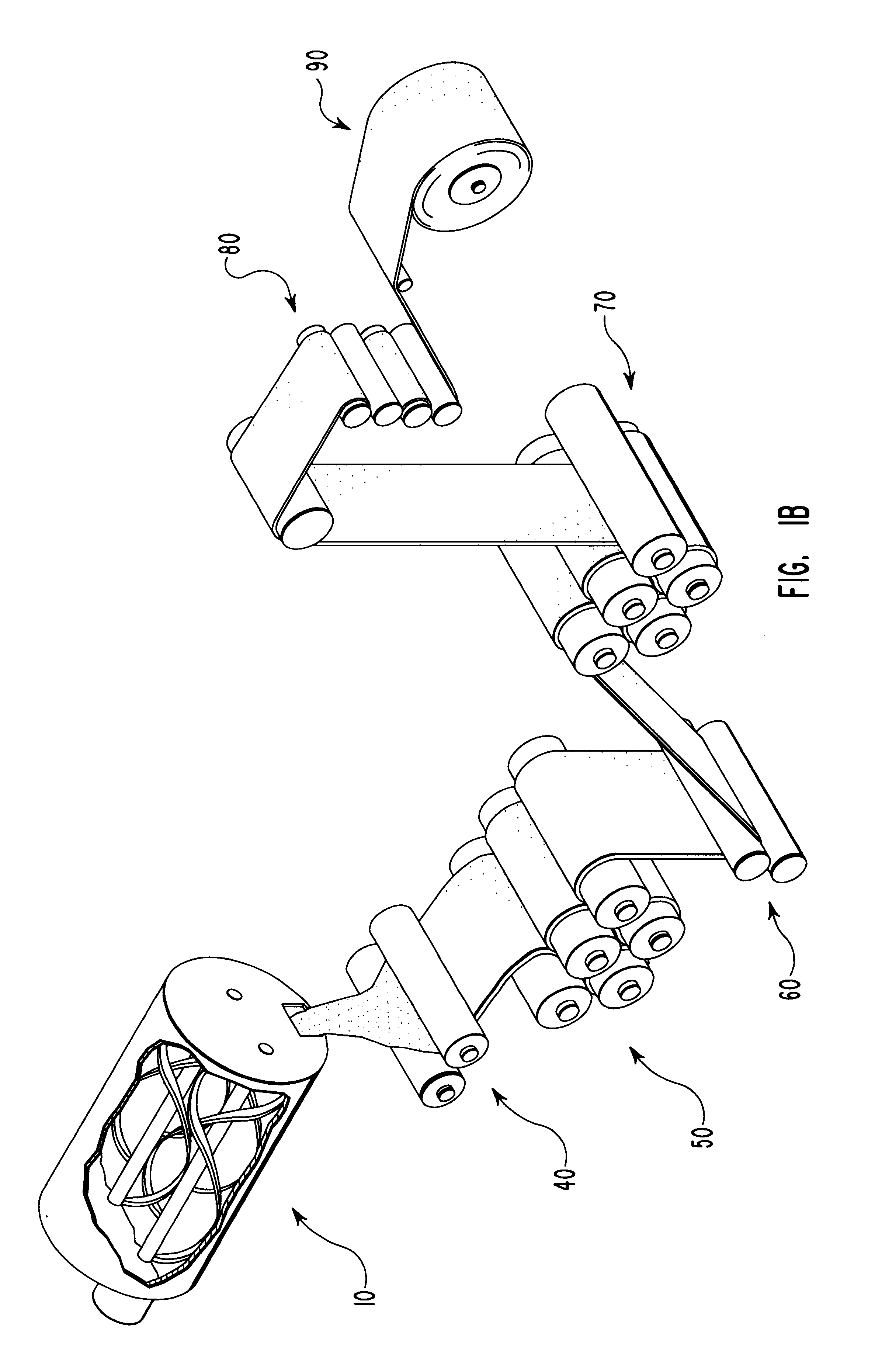

Compositions and methods for manufacturing starch-based compositions

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Lock and Key Through-Via Method for Wafer Level 3 D Integration and Structures Produced

InactiveUS20100078770A1High yieldFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesThinningActive devices

A three dimensional device stack structure comprises two or more active device and interconnect layers further connected together using through substrate vias. Methods of forming the three dimensional device stack structure comprise alignment, bonding by lamination, thinning and post thinning processing. The via features enable the retention of alignment through the lamination process and any subsequent process steps thus achieving a mechanically more robust stack structure compared to the prior art.

Owner:GLOBALFOUNDRIES US INC

Lock and Key Through-Via Method for Wafer Level 3D Integration and Structures Produced Thereby

ActiveUS20110111560A1High yieldFirmly connectedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringThinning

A three dimensional device stack structure comprises two or more active device and interconnect layers further connected together using through substrate vias. Methods of forming the three dimensional device stack structure comprise alignment, bonding by lamination, thinning and post thinning processing. The via features enable the retention of alignment through the lamination process and any subsequent process steps thus achieving a mechanically more robust stack structure compared to the prior art.

Owner:GLOBALFOUNDRIES US INC

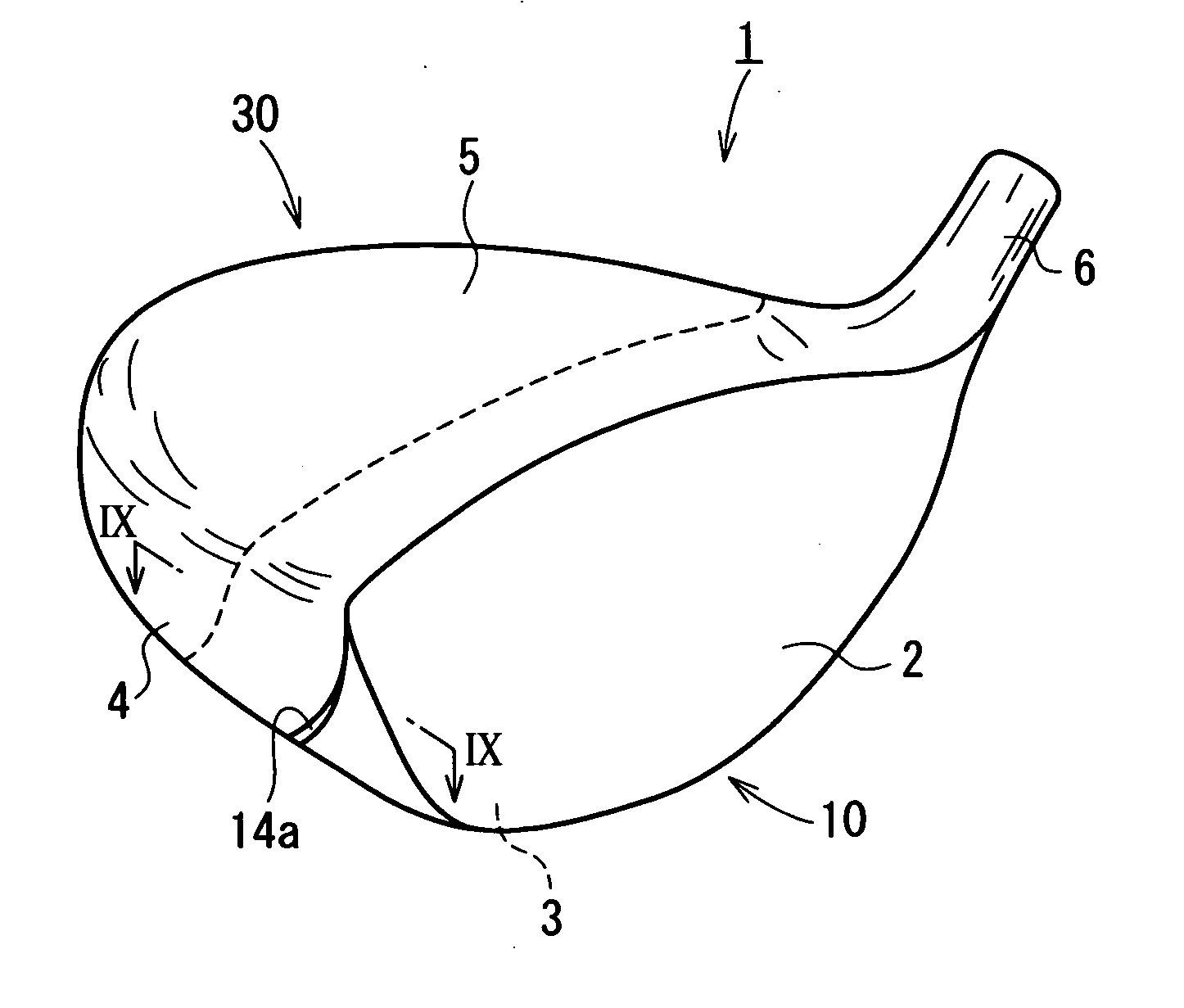

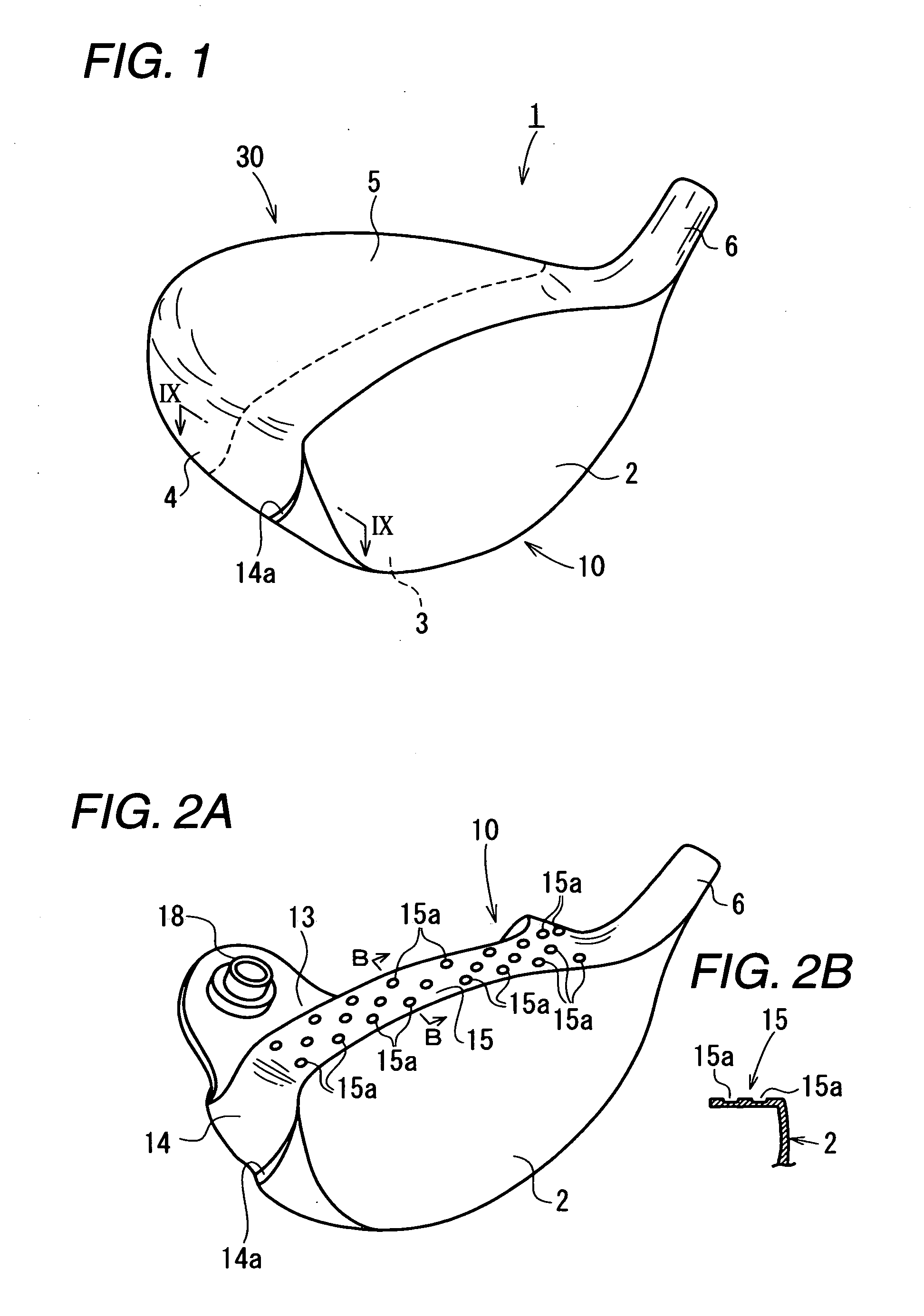

Golf club head

InactiveUS20060084525A1High bonding strengthIncreased durabilityGolf clubsRacket sportsFiberEngineering

A hollow golf club head includes a fiber-reinforced-plastic body and a metal body. The fiber-reinforced-plastic body includes a main portion of a crown portion. The metal body includes a face portion, a front edge portion of the crown portion continuous with the face portion, and a central portion of a sole portion in a toe-heel direction. The front edge portion of the crown portion made of a metal defines a recess portion in an upper surface thereof. A front edge portion of the fiber-reinforce-resin body overlaps and is joined to the front edge portion of the crown portion made of the metal.

Owner:BRIDGESTONE SPORTS

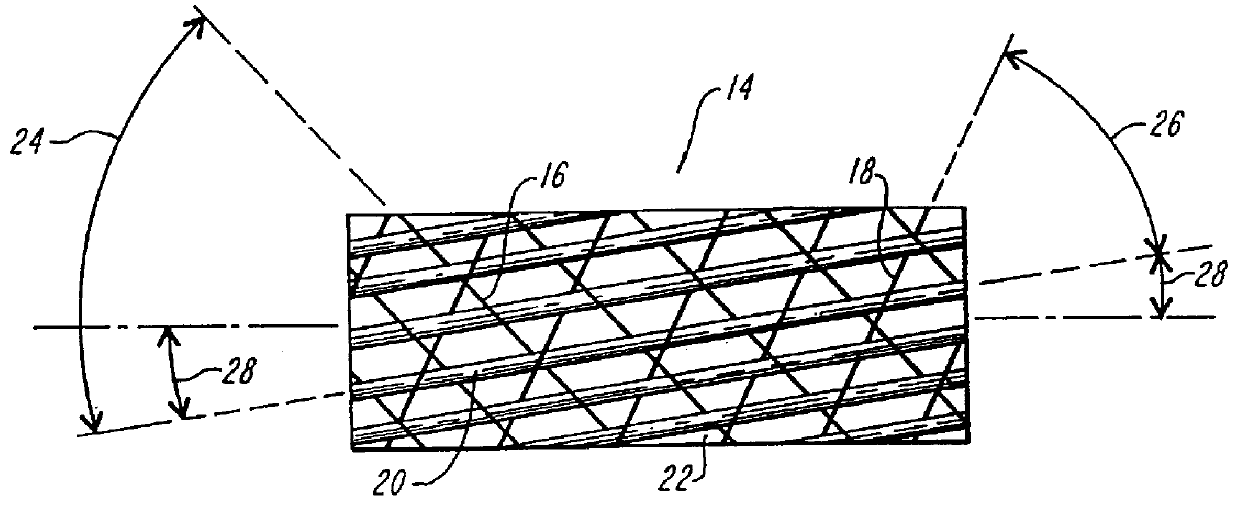

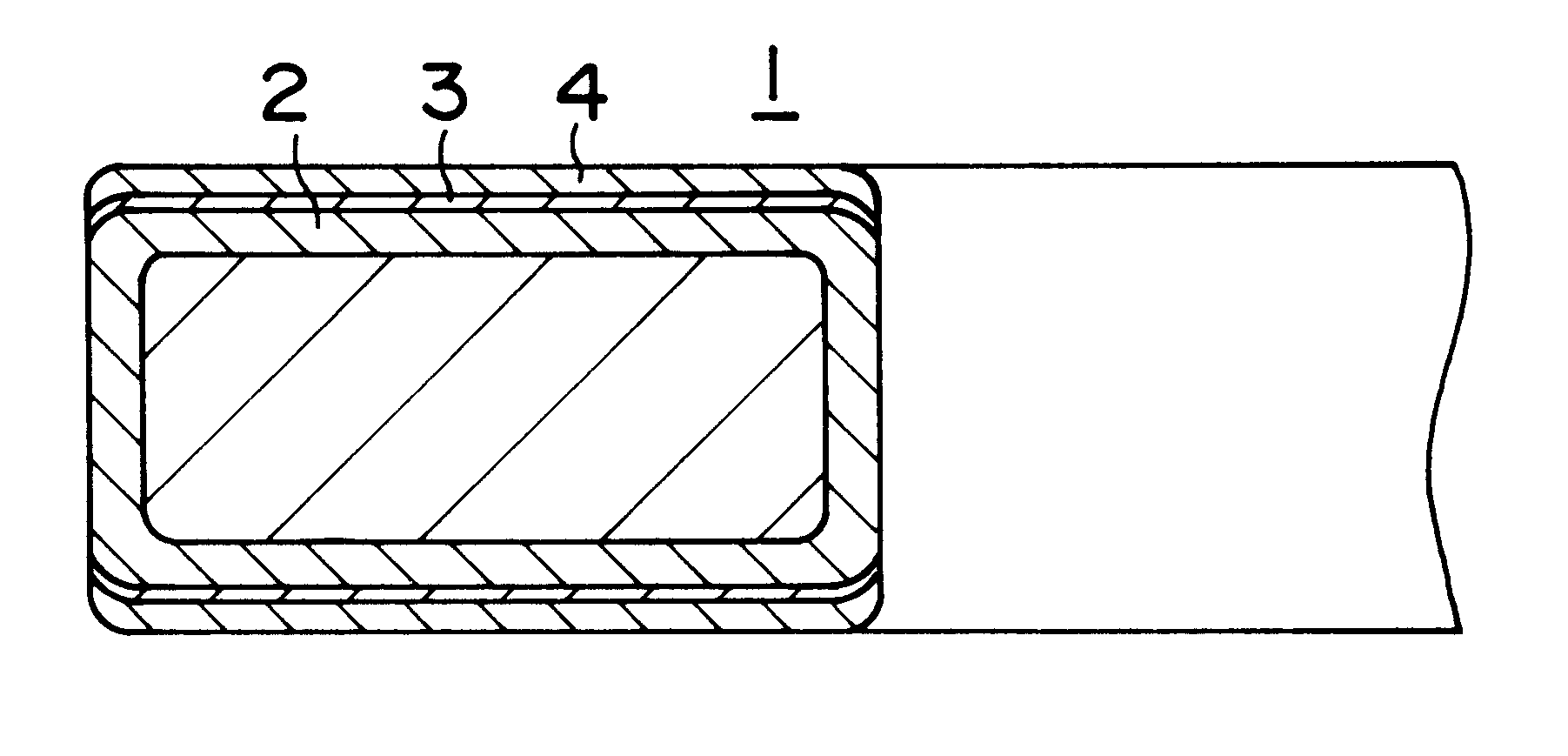

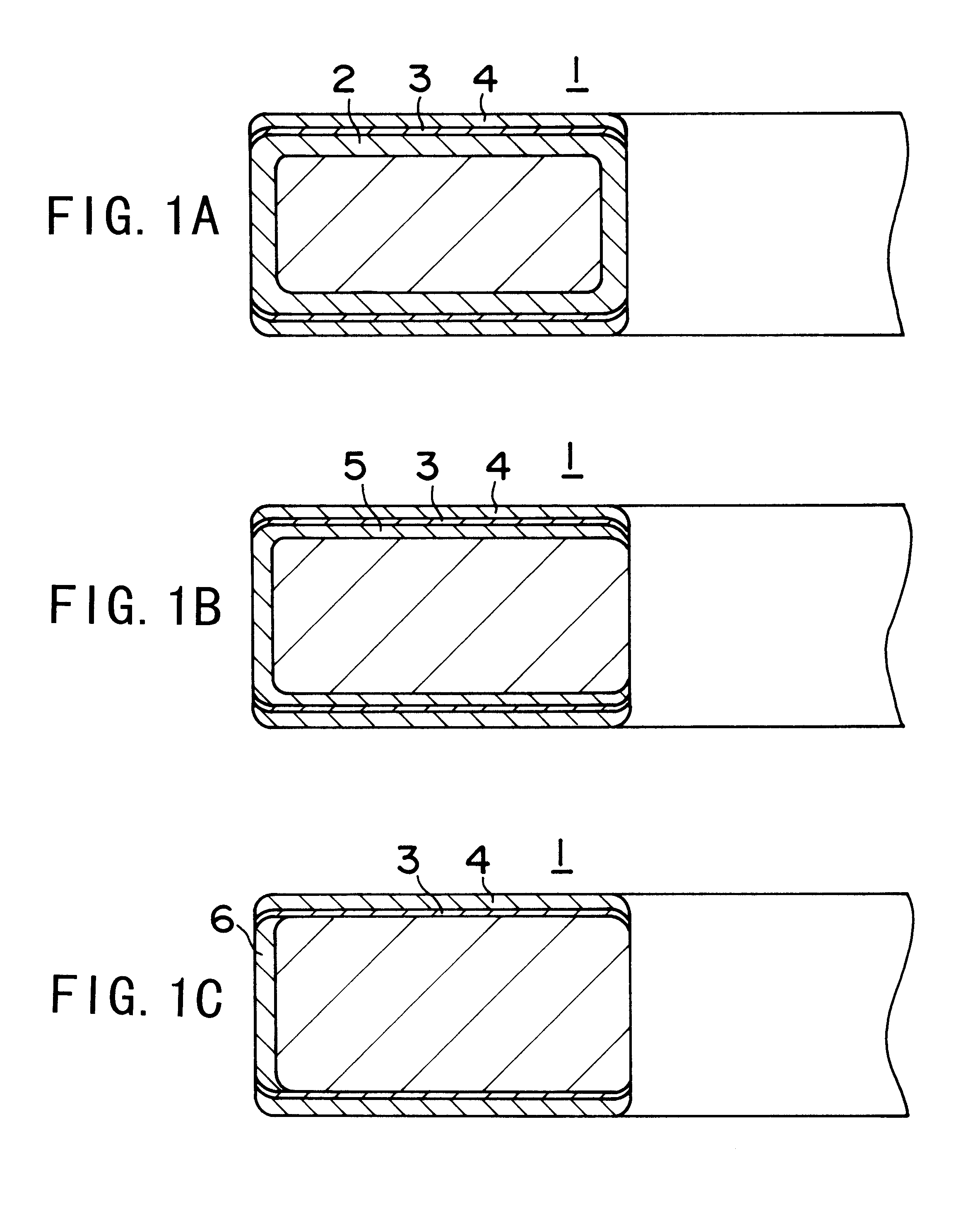

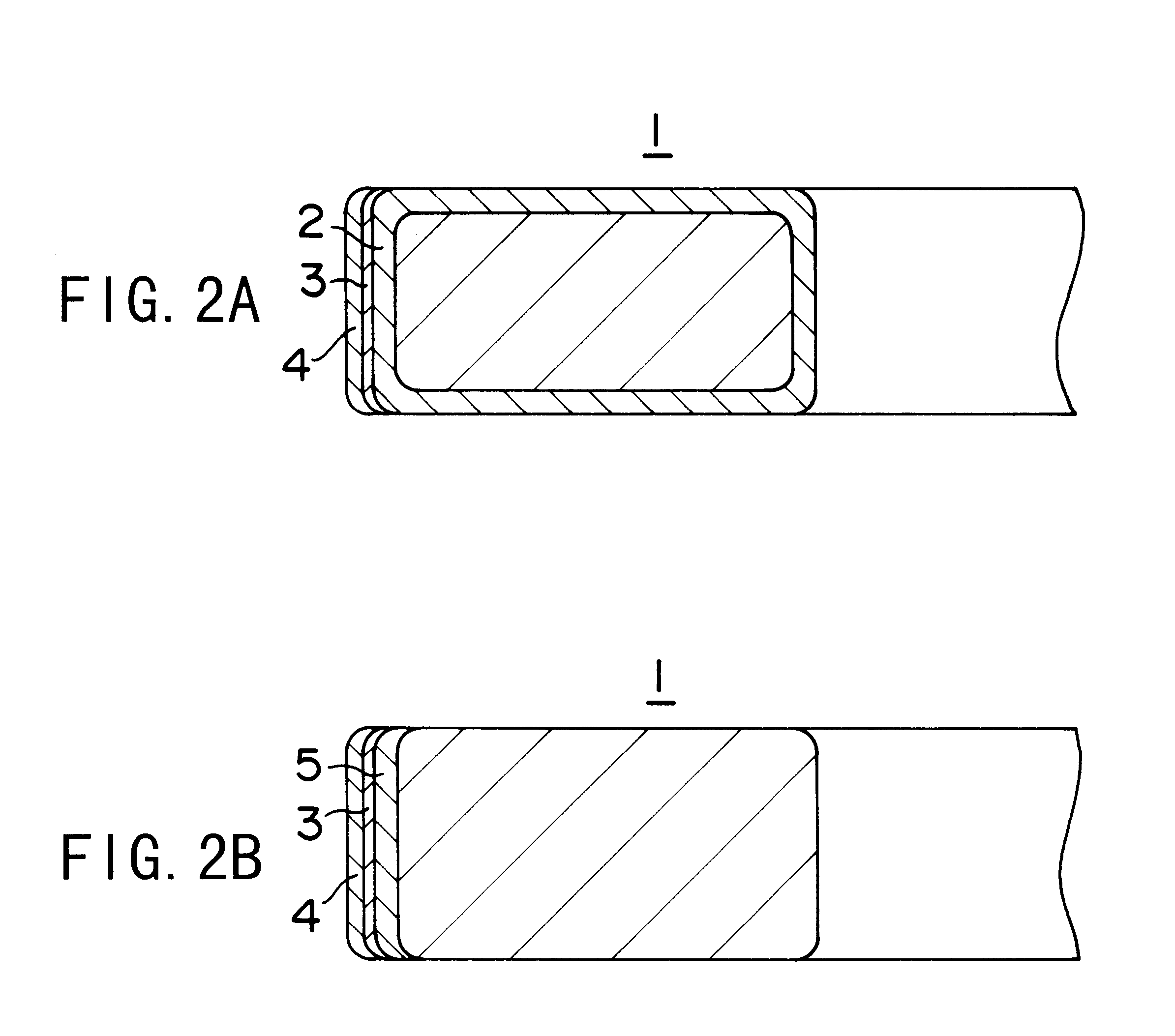

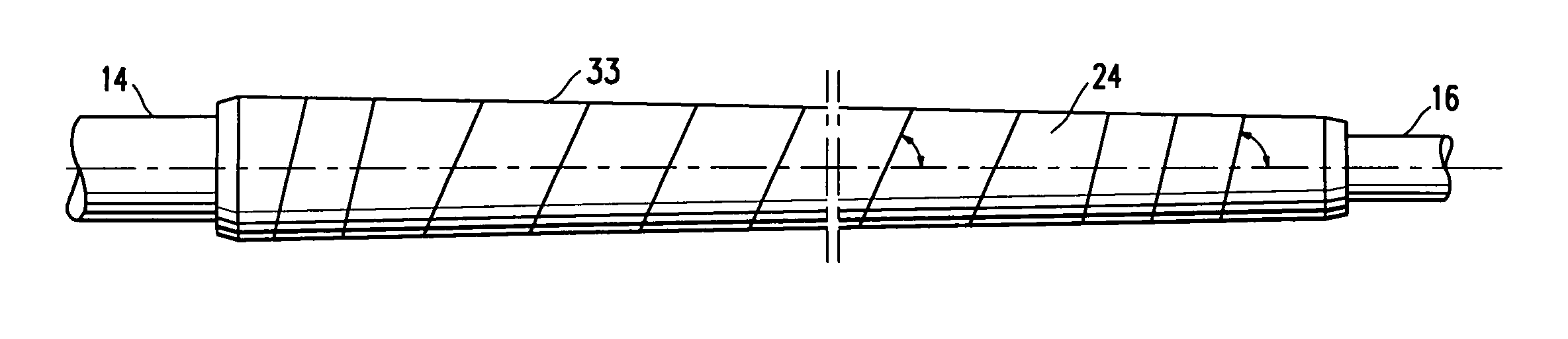

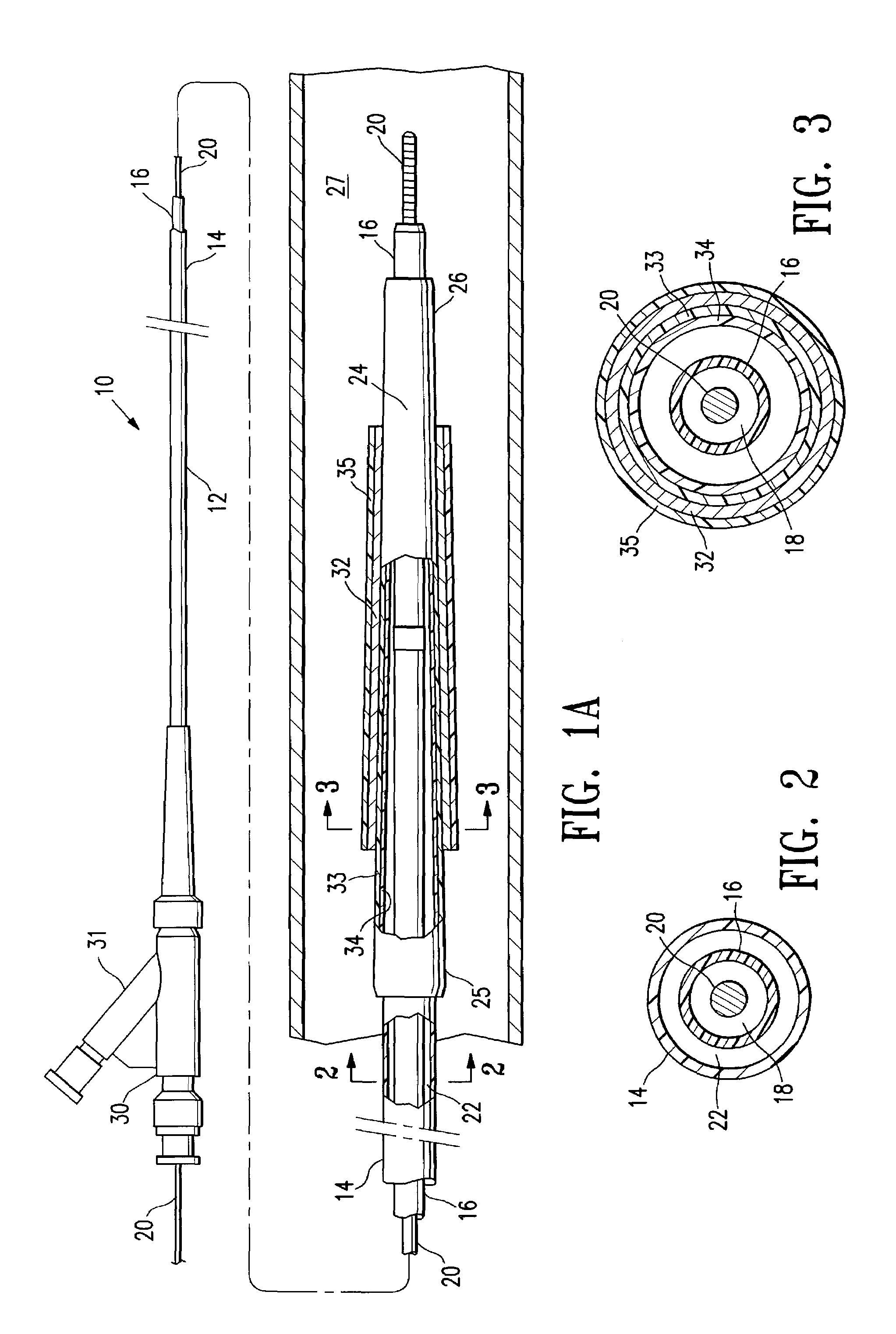

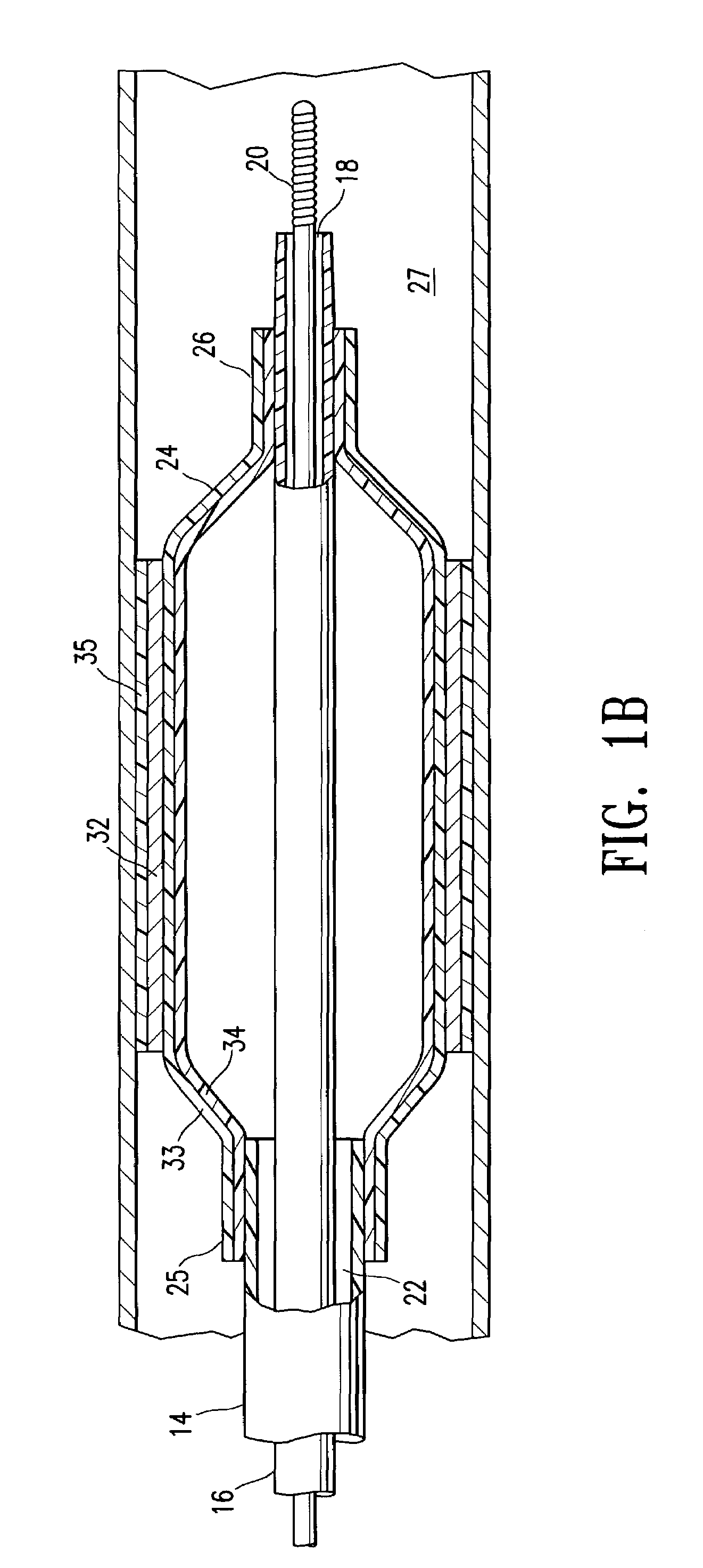

Composite spoolable tube

InactiveUS6016845AExtended service lifeExtending operational parameterDrilling rodsLayered productsInterface layerEngineering

A spoolable composite tube capable of being spooled onto a reel for storage and for use in oil field applications. The spoolable tube exhibits unique anistropic characteristics that provide improved burst and collapse pressures, increased tensile strength, compression strength, and load carrying capacity, while still remaining sufficiently bendable to be spooled onto a reel in an open bore configuration. The spoolable composite tube can include an inner liner, an interface layer, fiber composite layers, a pressure barrier layer, and an outer protective layer. The fiber composite layers can have a unique triaxial braid structure.

Owner:FIBERSPAR

Wiring Board for Light-Emitting Element

InactiveUS20080043444A1InhibitionHigh bonding strengthPrinted circuit aspectsSolid-state devicesElectrical conductorHeat conducting

A wiring board for light-emitting element, comprising a ceramic insulating substrate, and a conductor layer formed on the surface or in the inside of the insulating substrate, and having a mounting region mounting a light-emitting element on one surface of the insulating substrate; wherein the insulating substrate is provided with a heat-conducting pole-like conductor having a thermal conductivity higher than that of said insulating substrate; and the heat-conducting pole-like conductor is extending through the insulating substrate in the direction of thickness thereof from the light-emitting element mounting region of the insulating substrate, and is formed by the co-firing with the insulating substrate. The wiring board is produced inexpensively by co-firing, features excellent heat-radiating performance, is capable of quickly radiating the heat from the light-emitting element when the light-emitting element is mounted, and effectively prevents a decrease in the brightness of the light-emitting element caused by the heat.

Owner:KYOCERA CORP

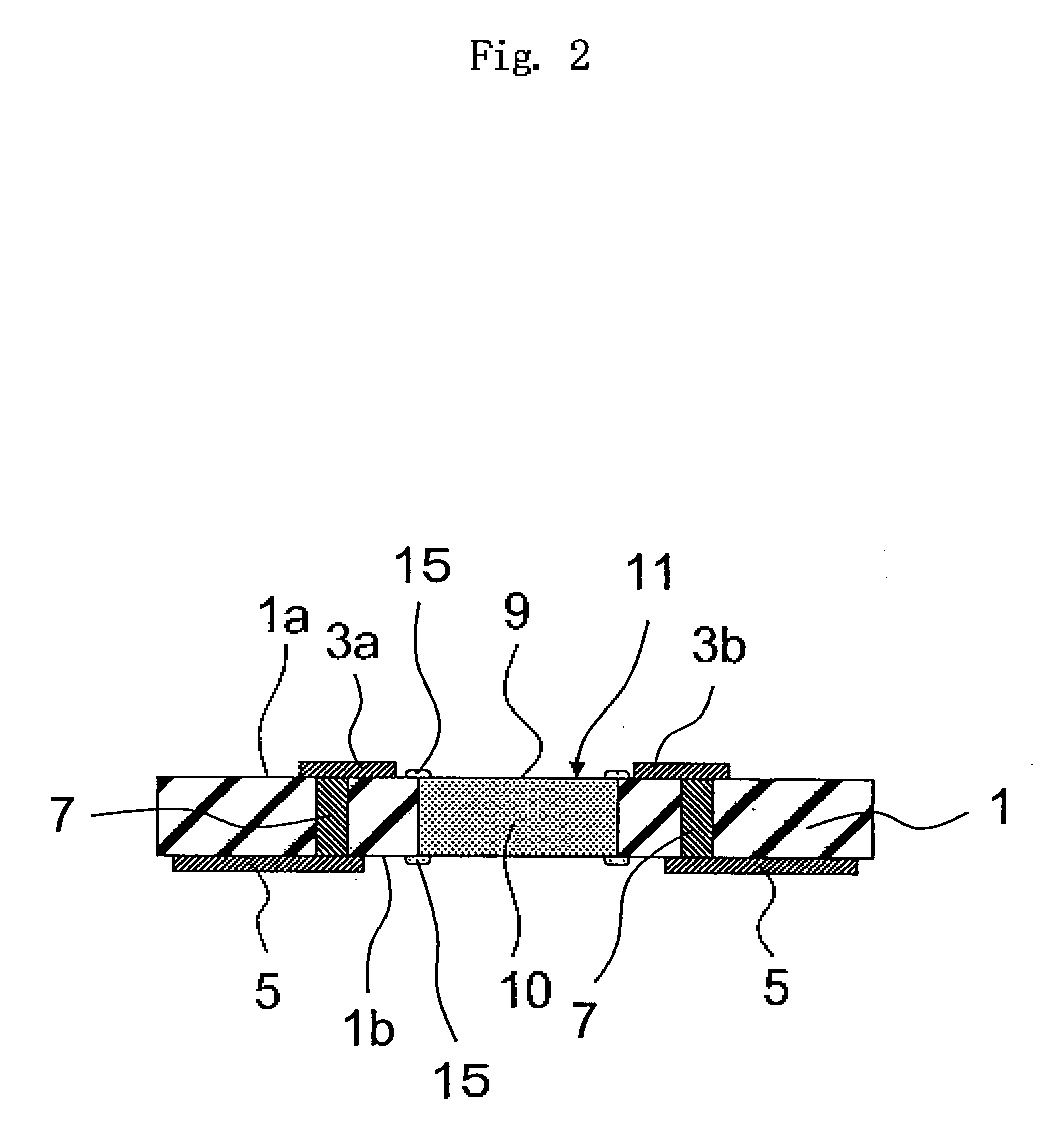

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

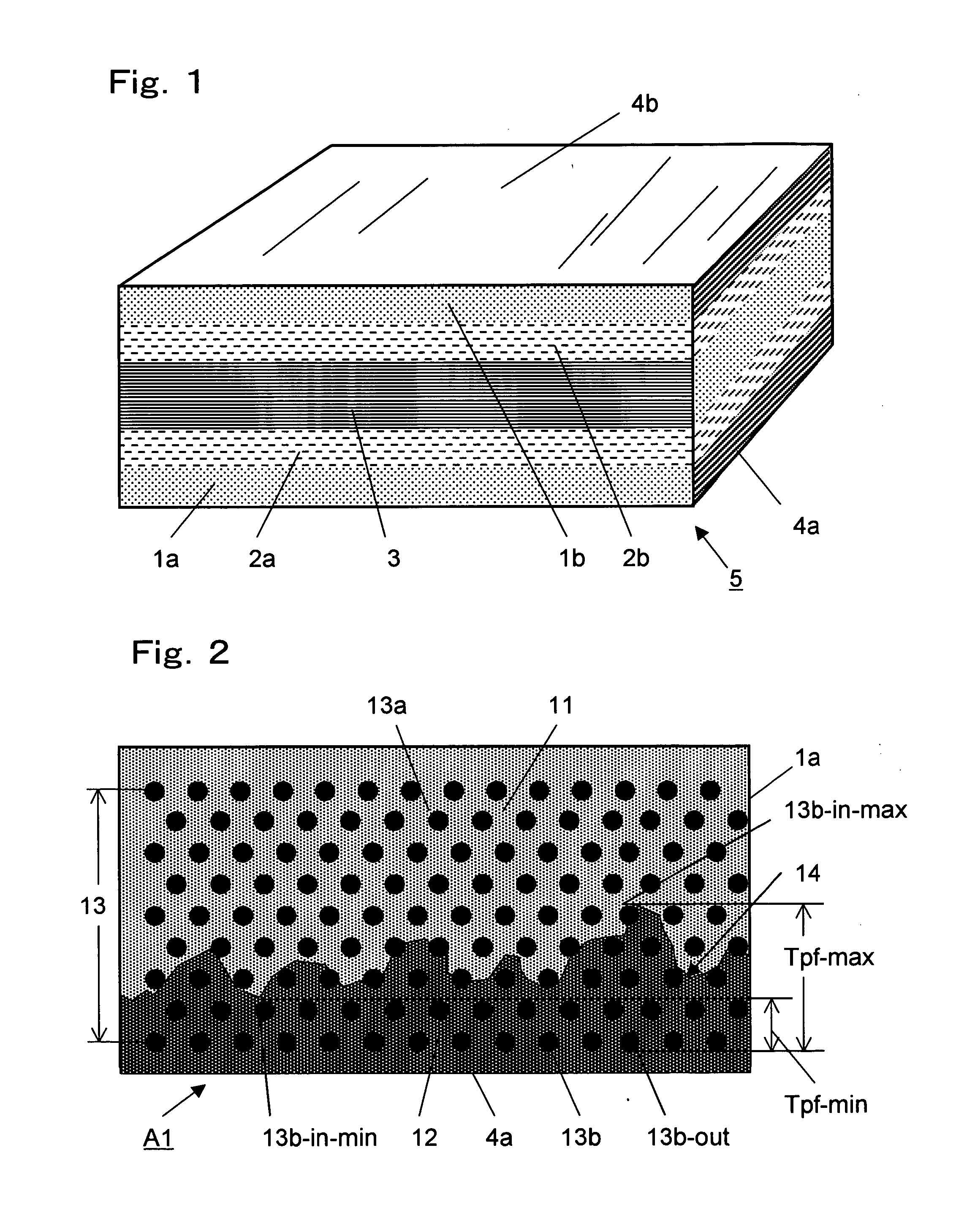

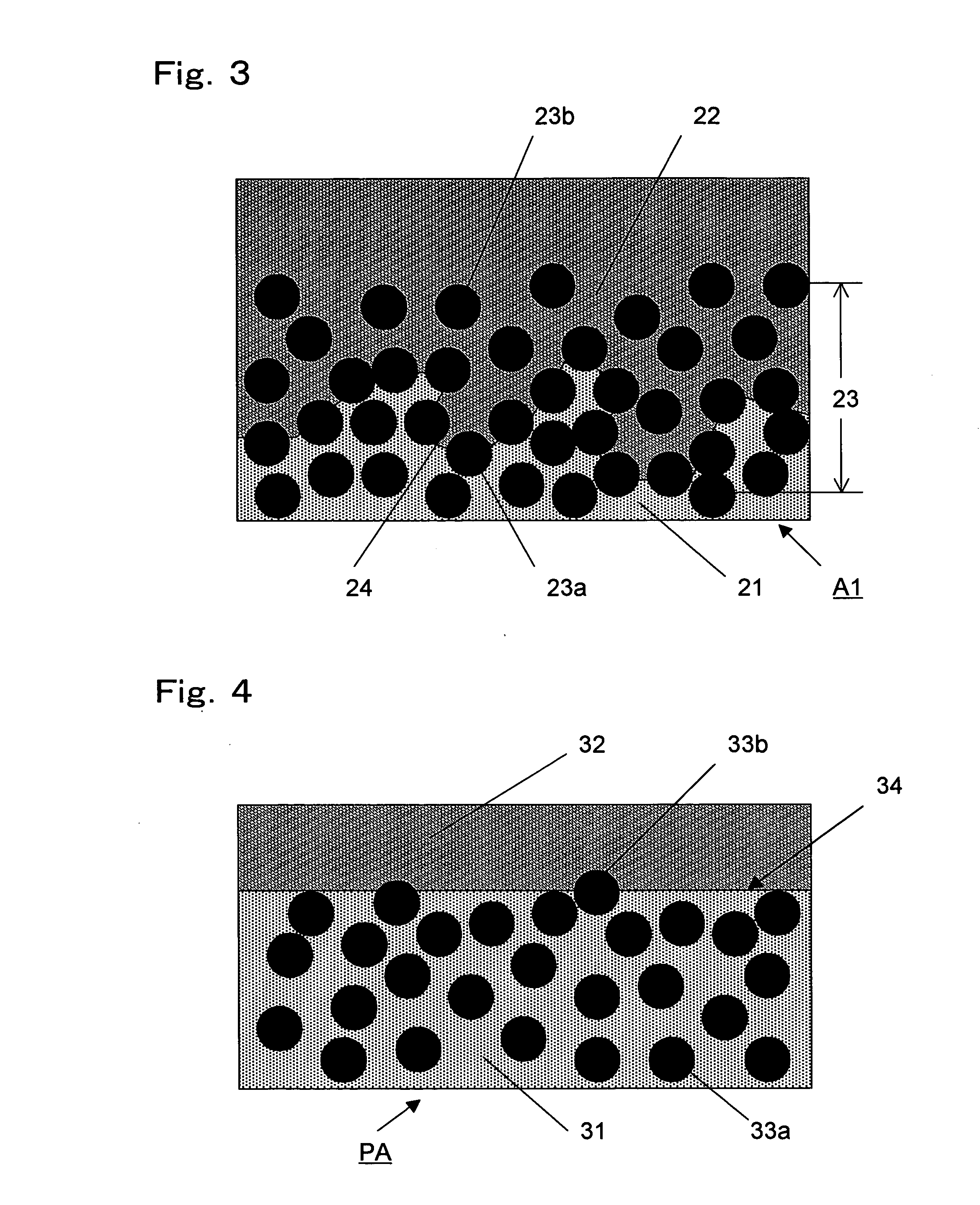

Layered product, electromagnetic-shielding molded object, and processes for producing these

ActiveUS20060110599A1Reduce thicknessReduce weightShielding materialsSynthetic resin layered productsFiberElectromagnetic shielding

A layered product which is a molded object comprising a thermoset resin layer, a thermoplastic resin layer, and reinforcing fibers comprising many continuous filaments, wherein the thremoset resin layer has been united with the thermoplastic resin layer at the interface between these layers, the resin of the thermoset resin layer and the resin of the thermoplastic resin layer each having an irregular surface shape at the interface, and a group of filaments among the reinforcing fibers are in contact with at least the resin of the thermoset resin layer and the other group of filaments among the reinforcing fibers are in contact with at least the resin of the thermoplastic resin layer, that side of the thermoplastic resin layer which is opposite to the interface being a surface of the molded object.

Owner:TORAY IND INC

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

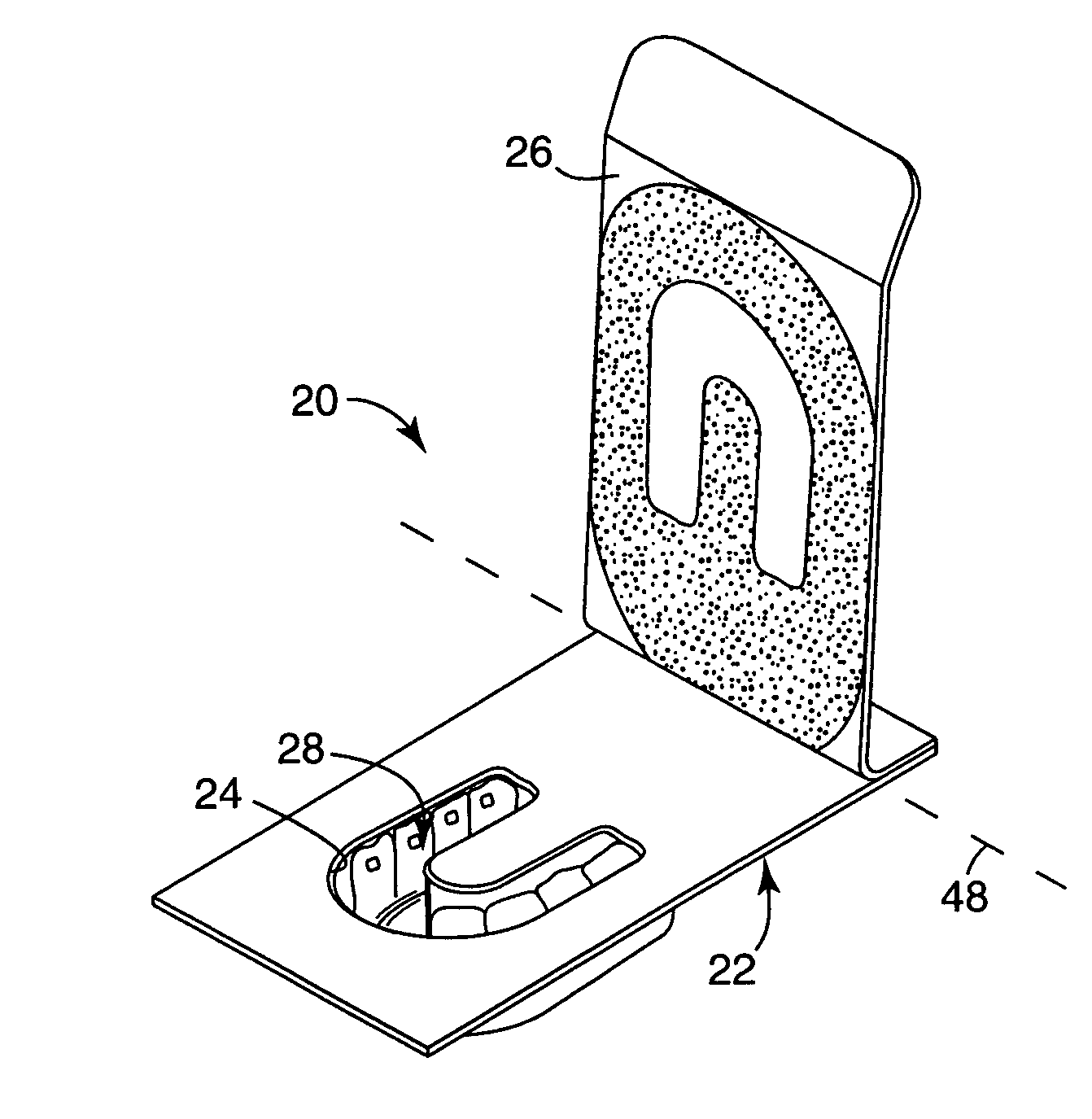

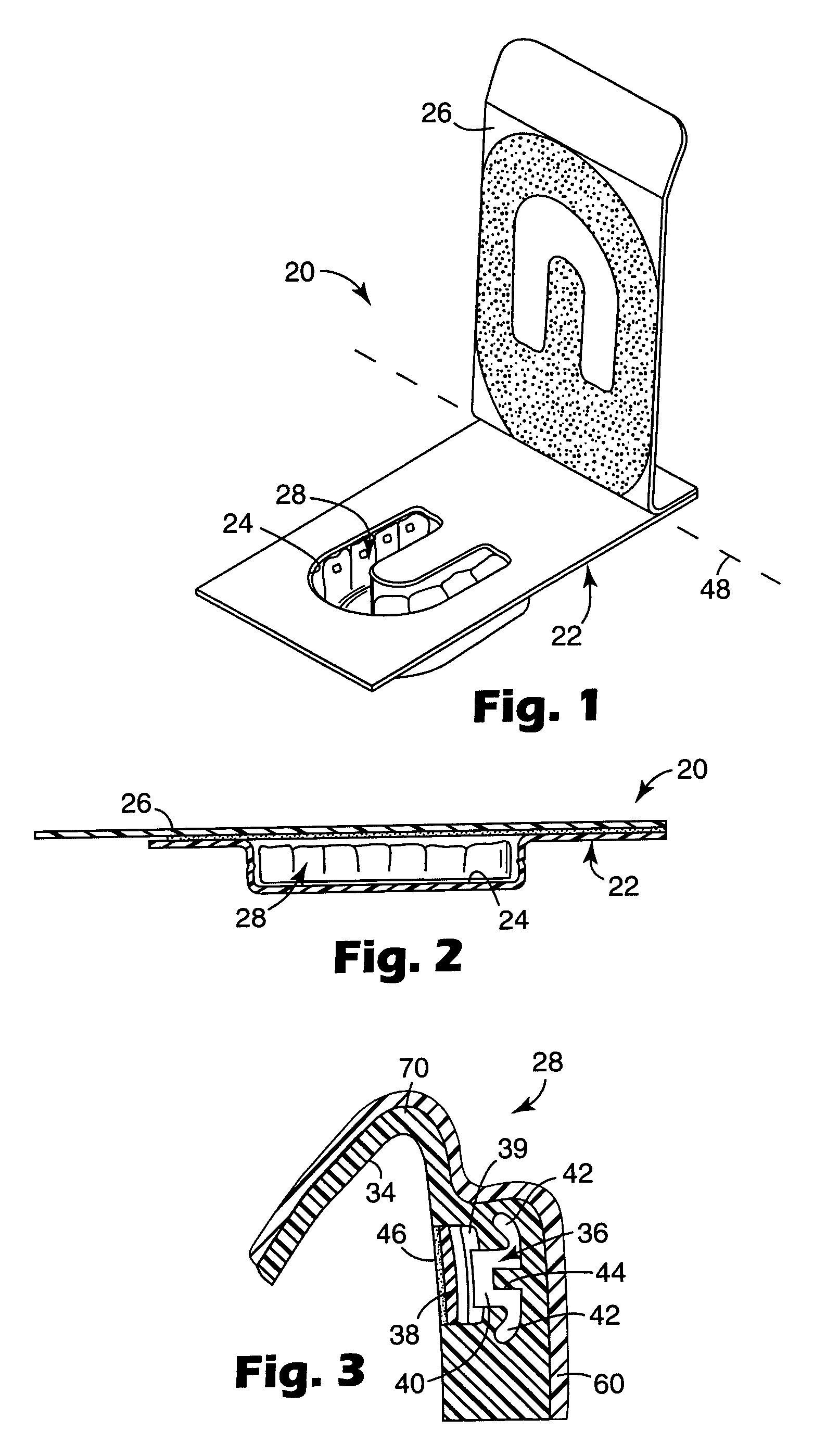

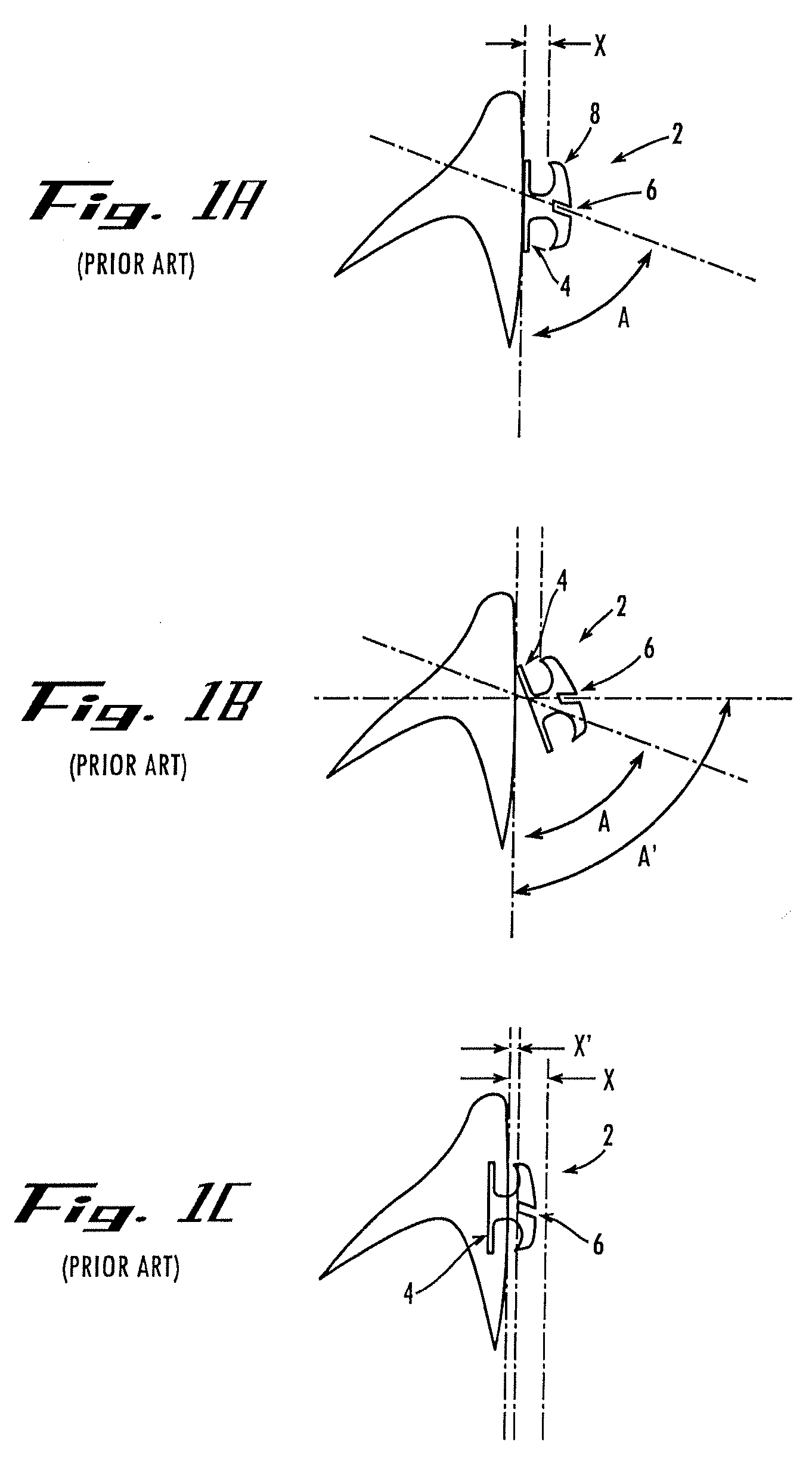

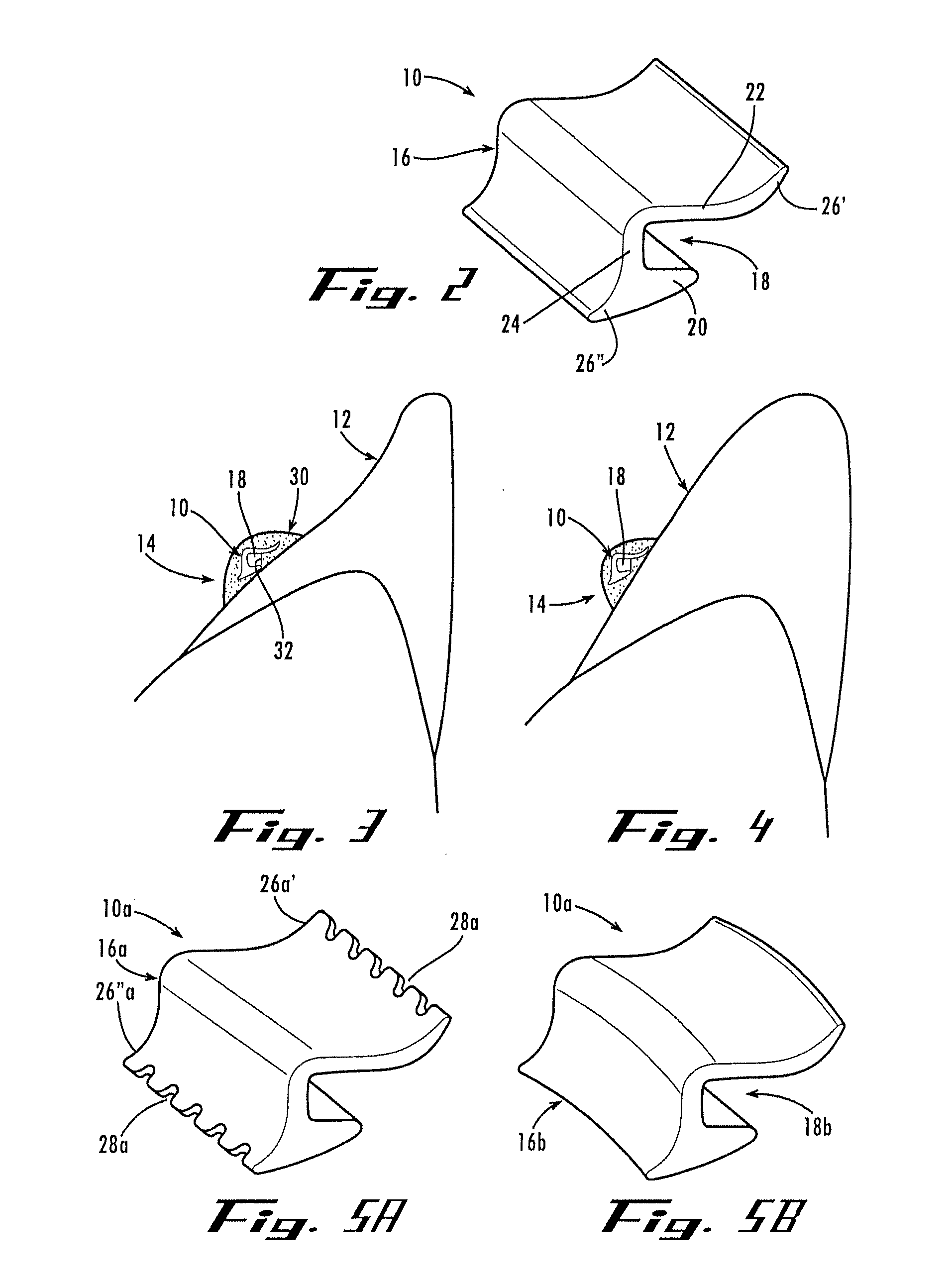

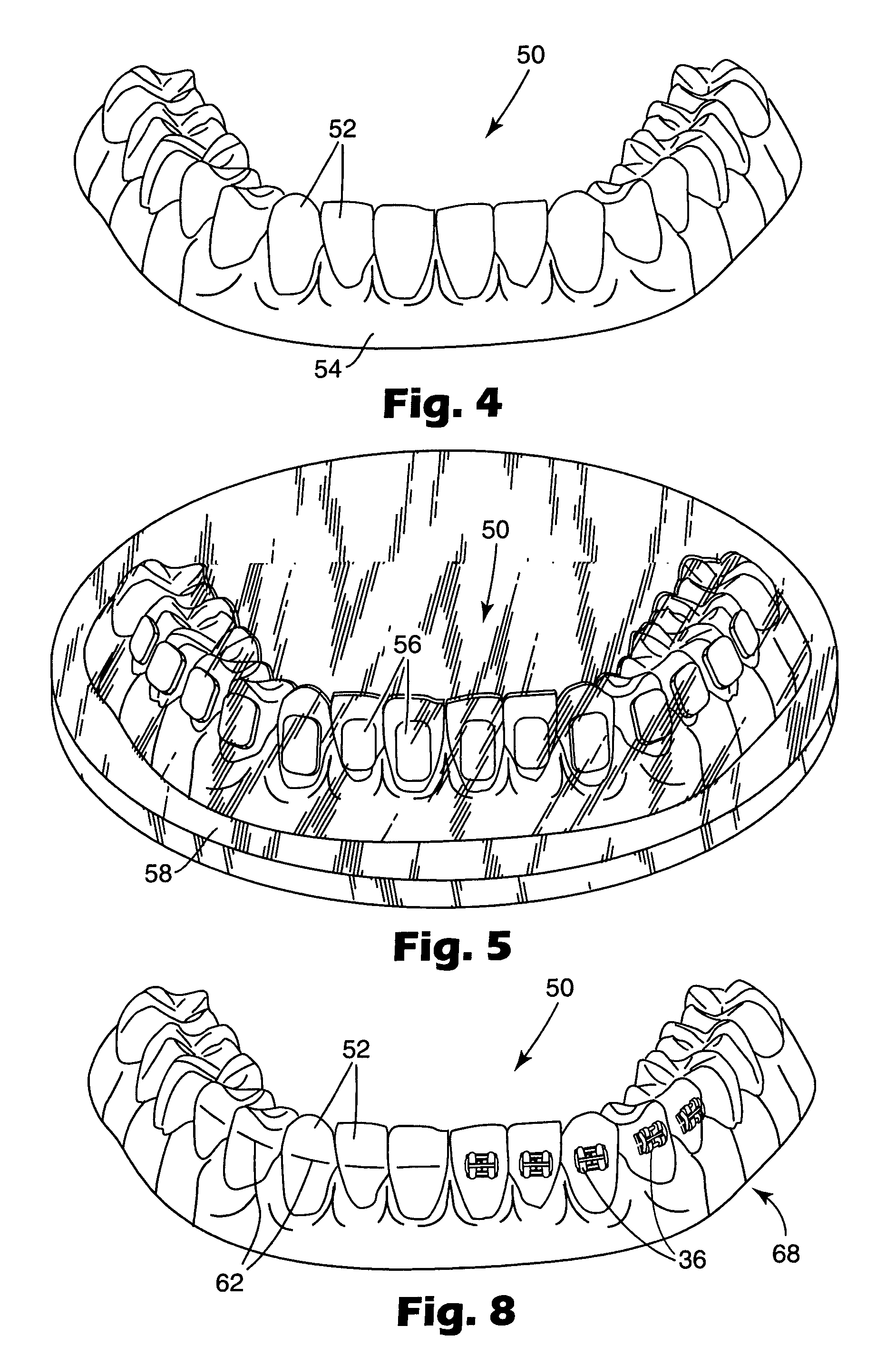

Apparatus for indirect bonding of orthodontic appliances and method of making the same

InactiveUS7137812B2Prepare the base of each appliance for bonding is eliminatedHigh bonding strengthImpression capsDispensing apparatusAnodic bondingDental structure

Owner:3M INNOVATIVE PROPERTIES CO

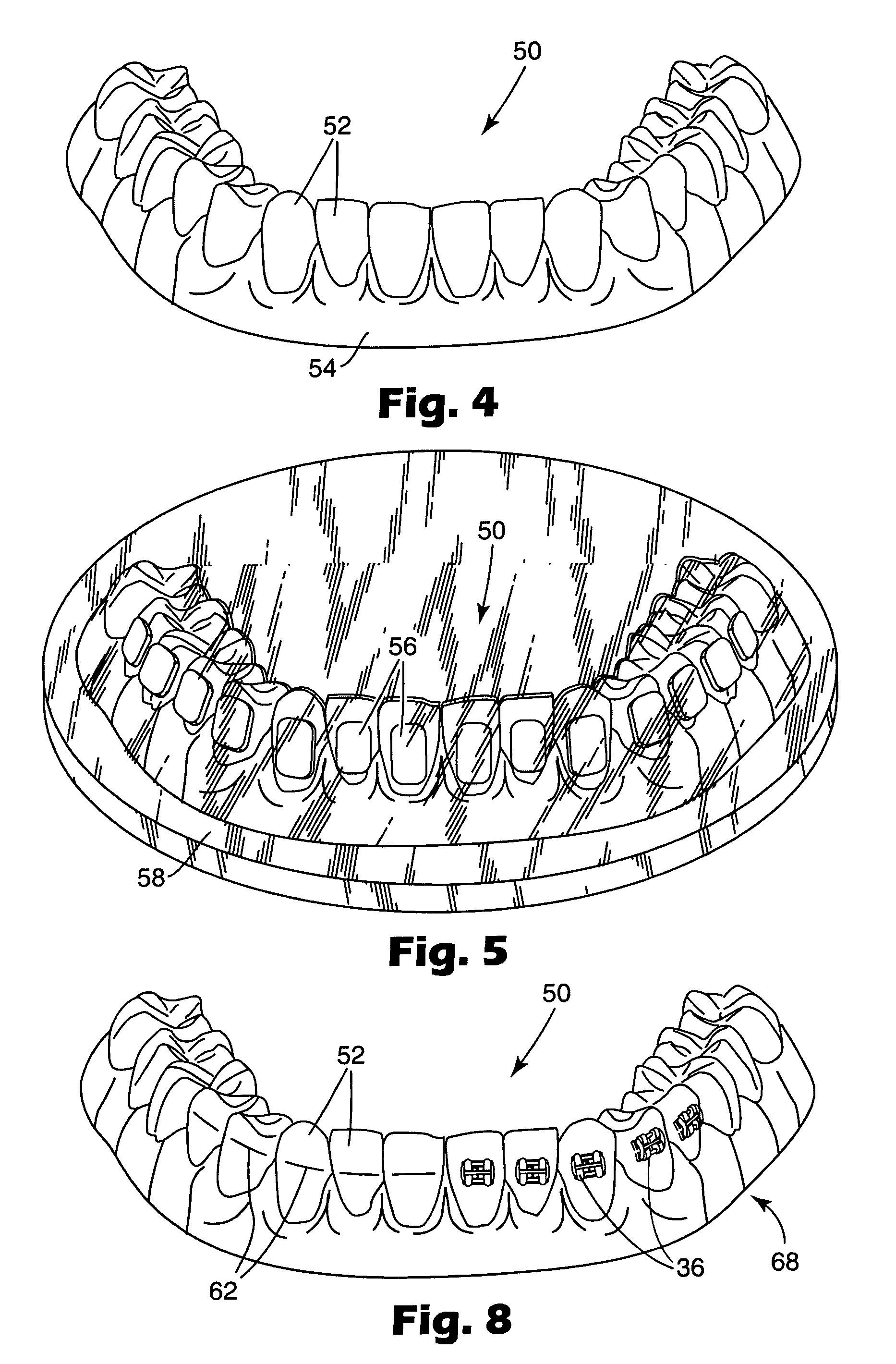

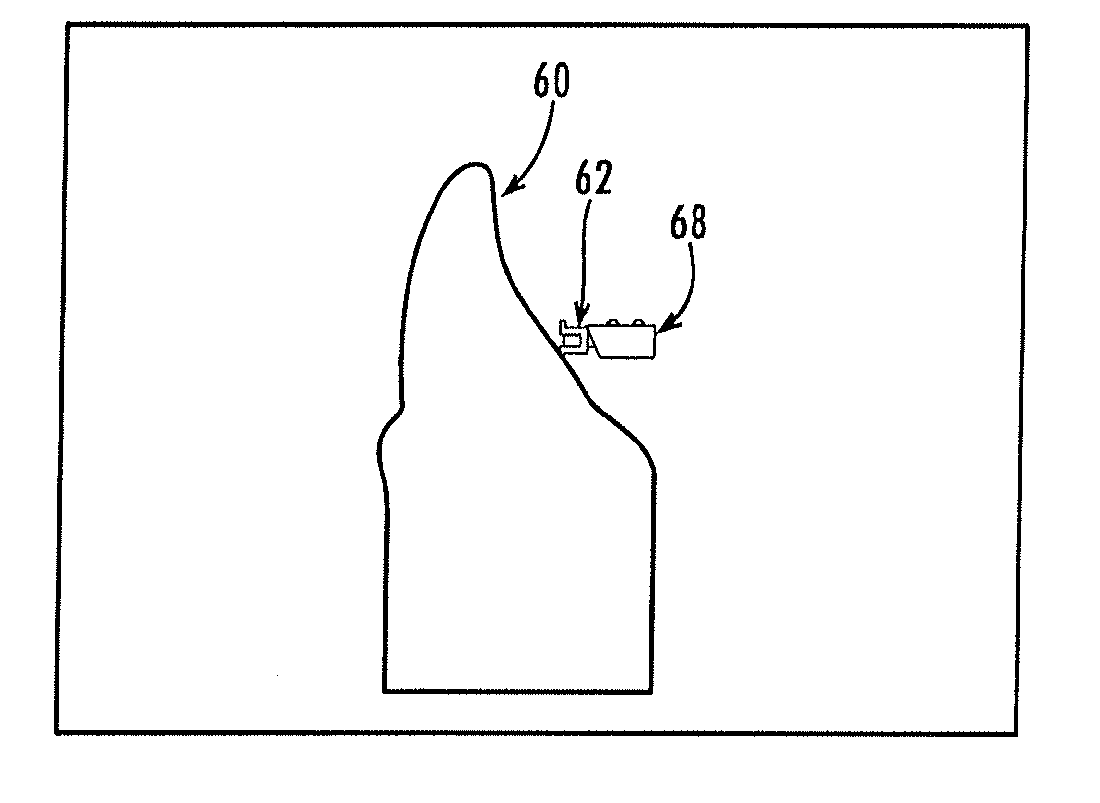

Orthodontic bracket and method of attaching orthodontic brackets to teeth

ActiveUS20070087302A1Minimal size profileEnhance patient comfortAdditive manufacturing apparatusBracketsIndirect MethodPhysical model

An orthodontic bracket having an opening for receiving a wire, but without a base to create a lever arm when the bracket is oriented in free space at a customized angle relative to a tooth surface. The bracket can be embedded into or encapsulated by an adhesive that is bonded to the tooth. A clip is provided for holding the bracket in position and occluding the opening while the adhesive is applied. And indirect methods of attaching the brackets to teeth are provided wherein the brackets can be attached to the lingual side of the teeth in a low-profile arrangement. A first method includes the step of positioning the brackets on a physical model of the teeth by using a positioning machine. A second method includes the step of positioning virtual brackets on a virtual model of the teeth using software, then generating a physical transfer try using rapid prototyping.

Owner:REISING BRIAN C

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

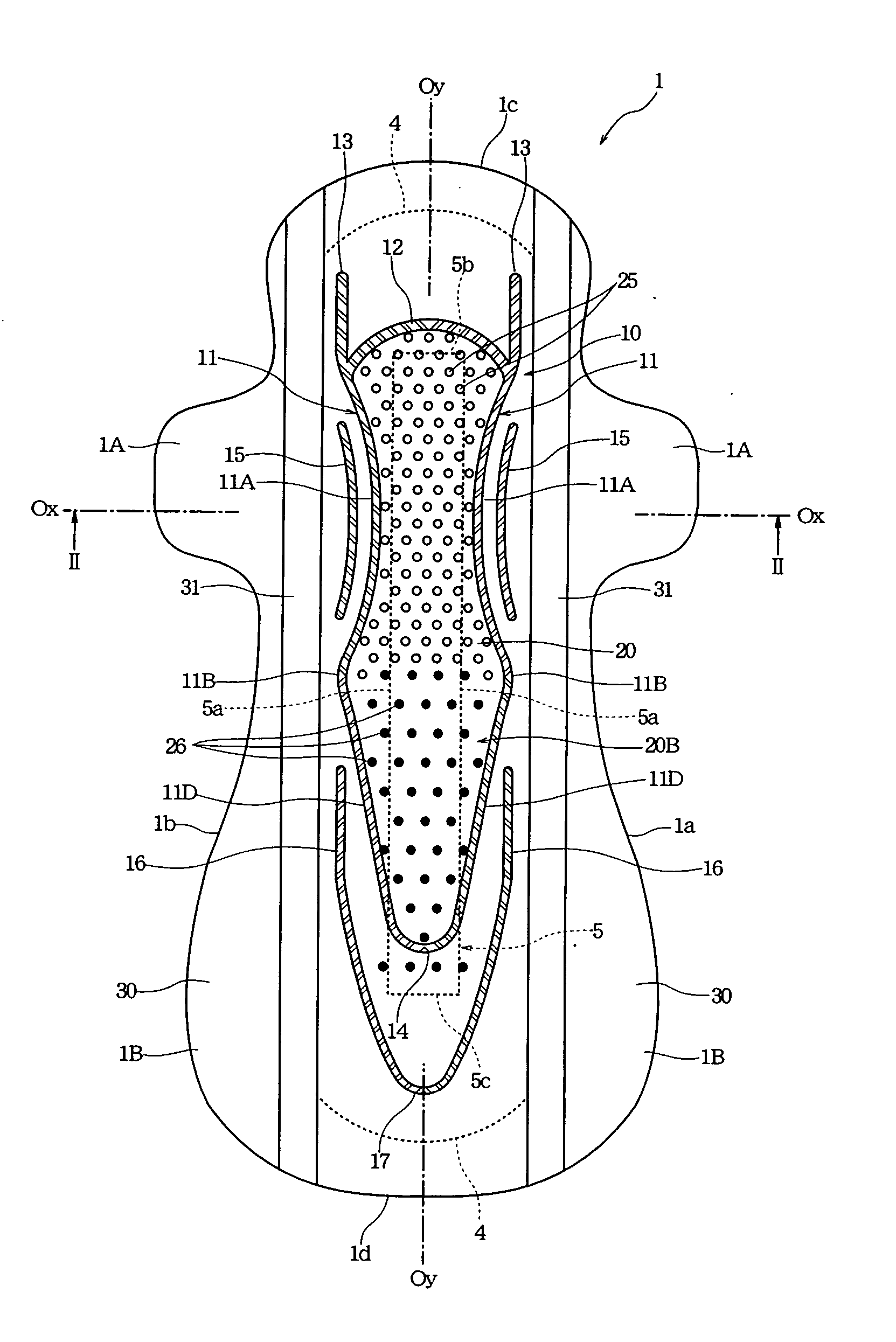

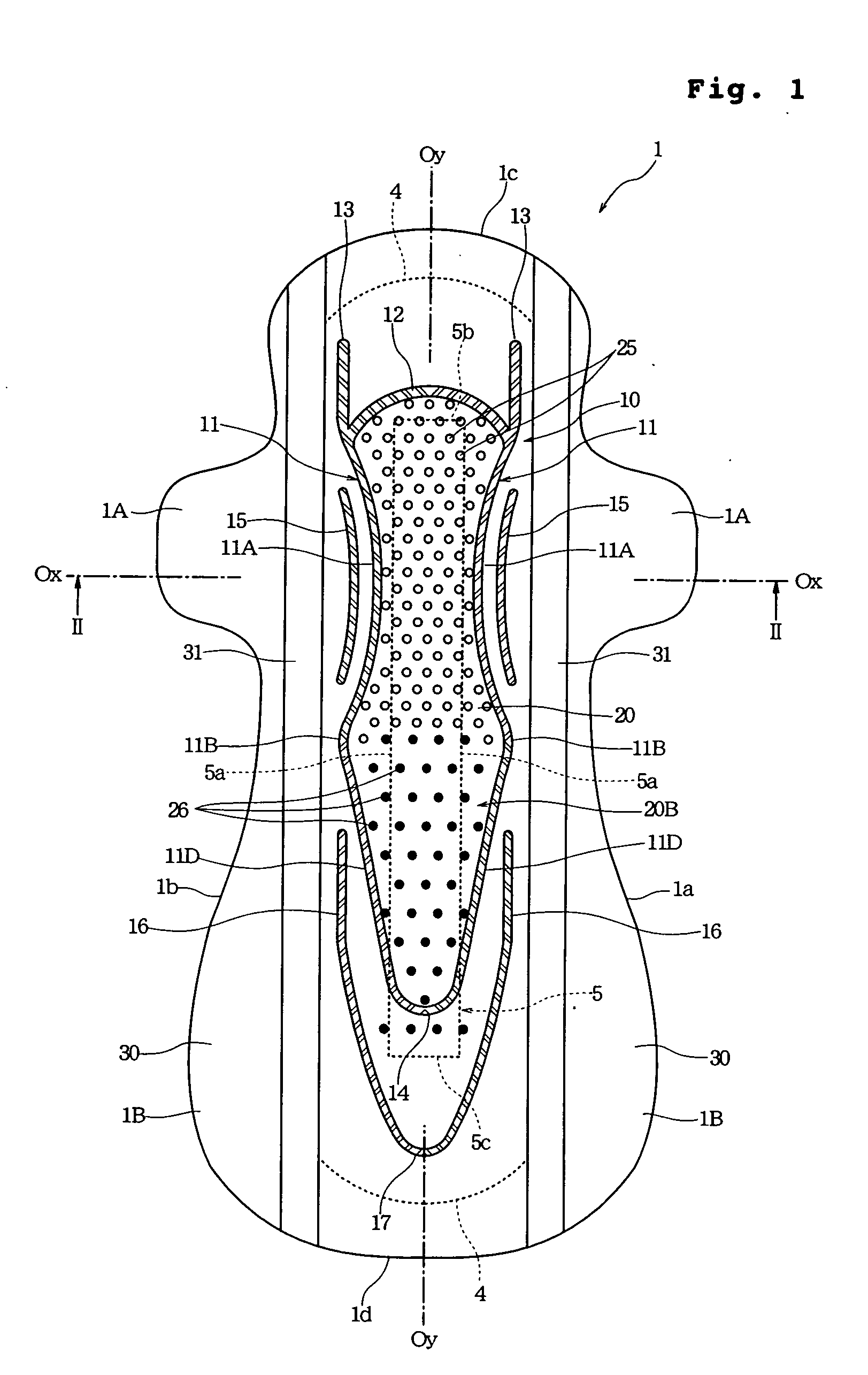

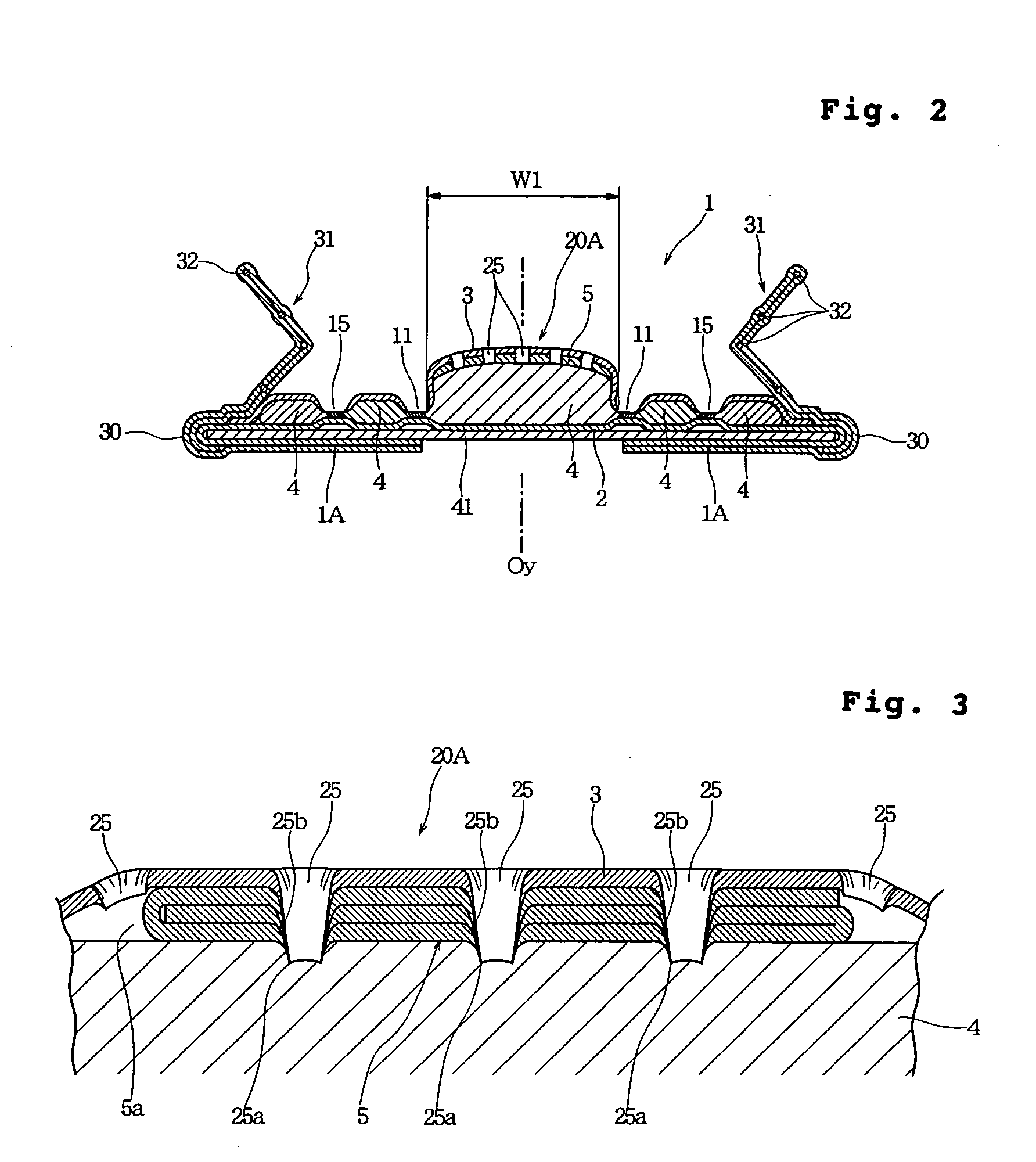

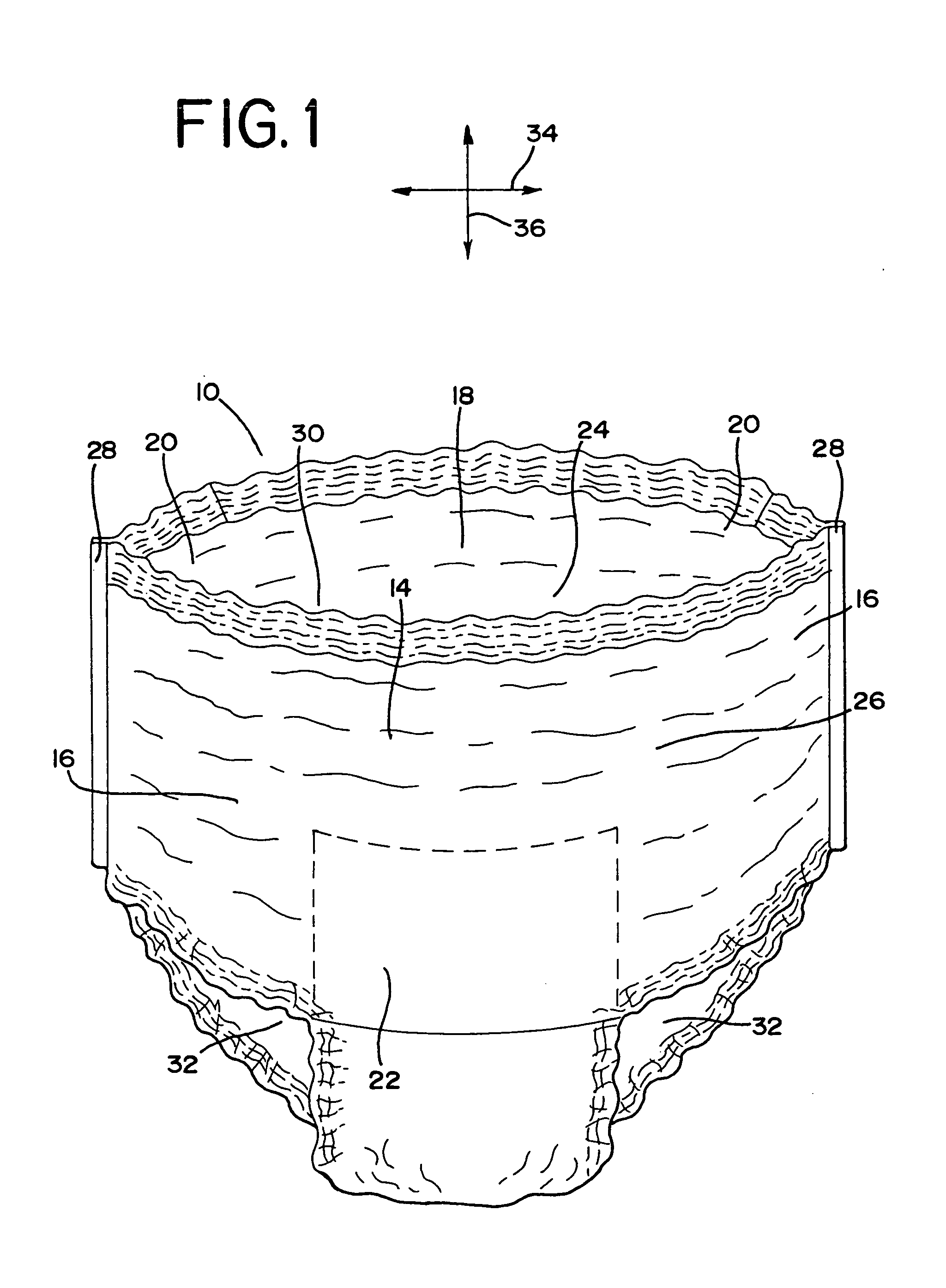

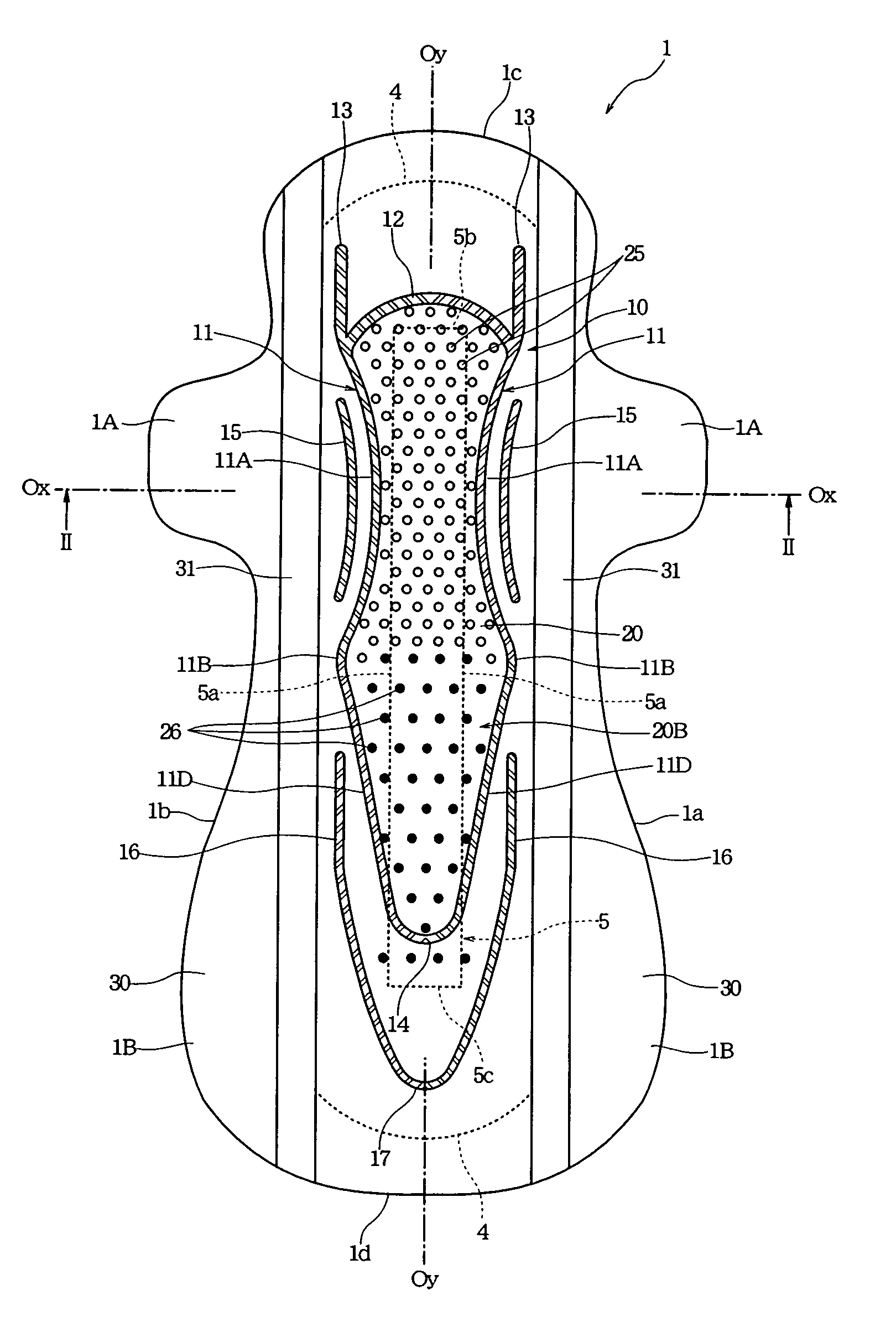

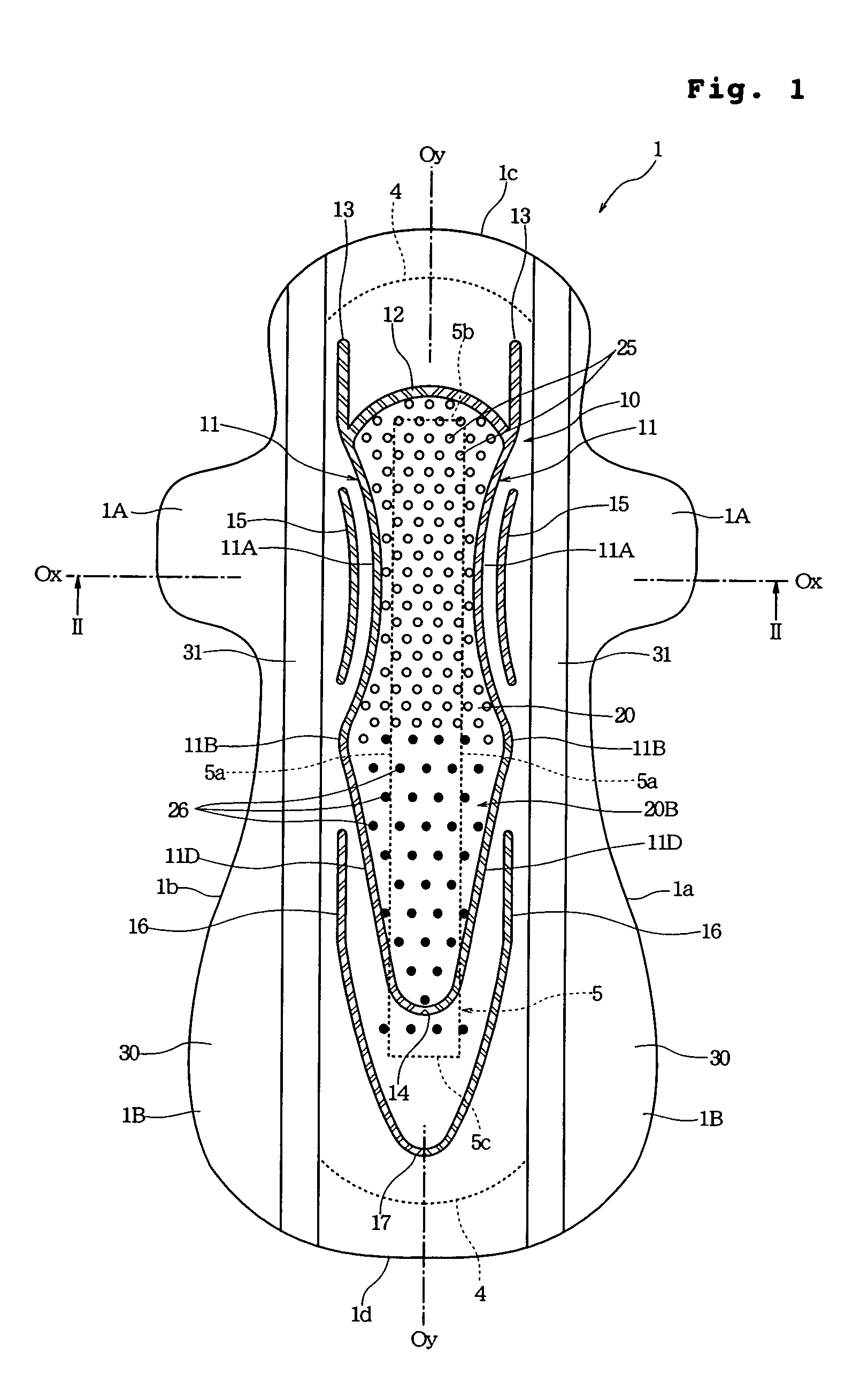

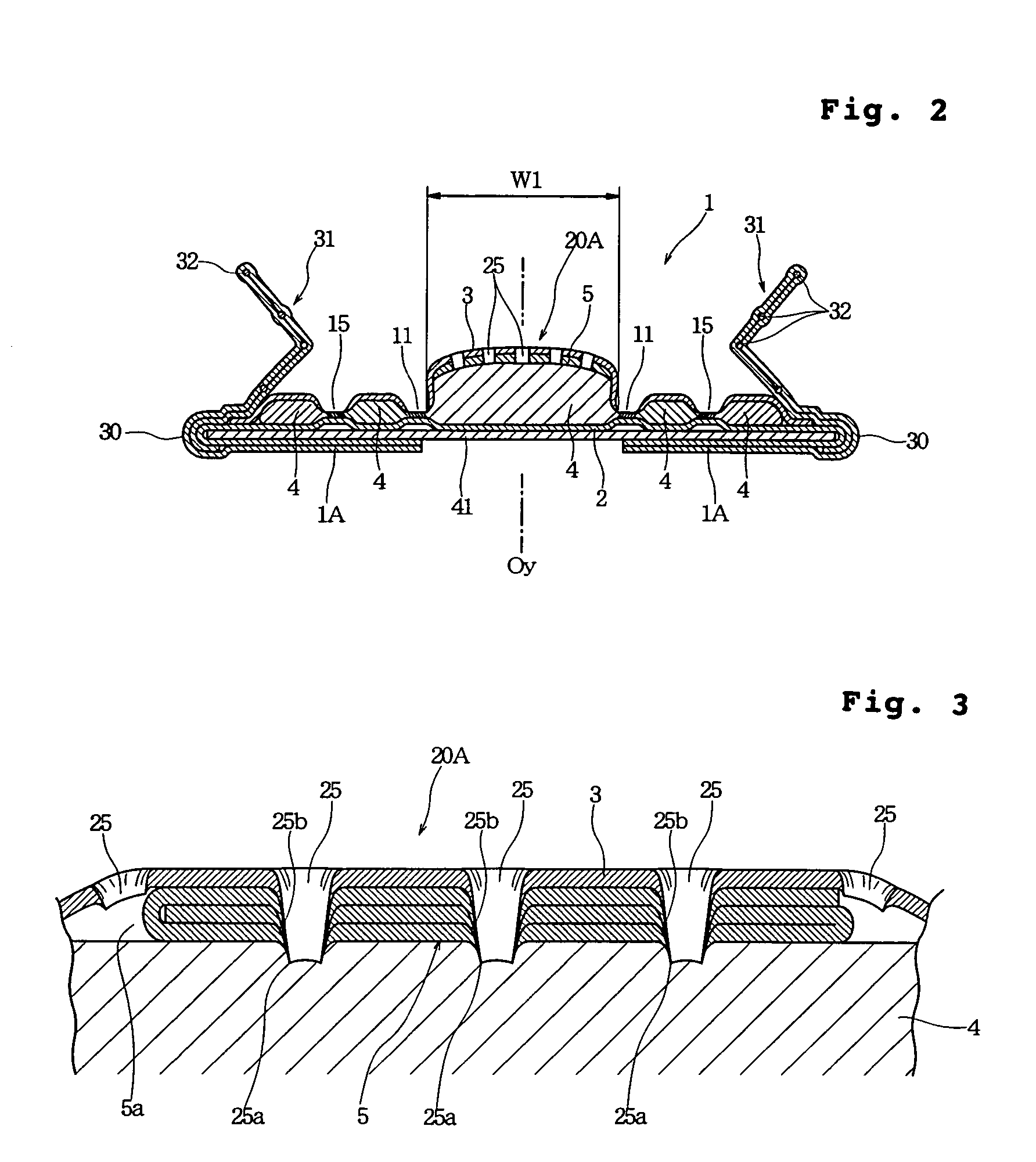

Elongated absorbent article

InactiveUS20050148971A1Penetrate fastSurface strengthBaby linensTamponsVolumetric Mass DensityMechanical engineering

Disclosed is an elongated absorbent article, in which liquid passage holes and embossments are dispersed in a central region including a front portion and a rear portion. Aperture density obtained by dividing (total of areas occupied by the liquid passage holes in the front portion) by (area of the front portion) is higher than aperture density obtained by dividing (total of areas occupied by the liquid passage holes in the rear portion) by (area of the rear portion), while embossment density obtained by dividing (total of areas occupied by the embossments in the rear portion) by (area of the rear portion) is higher than embossment density obtained by dividing (total of areas occupied by the embossments in the front portion) by (area of the front portion).

Owner:UNI CHARM CORP

Piston ring

InactiveUS6325385B1Good sliding propertiesRelieve pressurePiston ringsBraking action transmissionCarbon filmDiamond-like carbon

Owner:TEIKOKU PISTON RING CO LTD

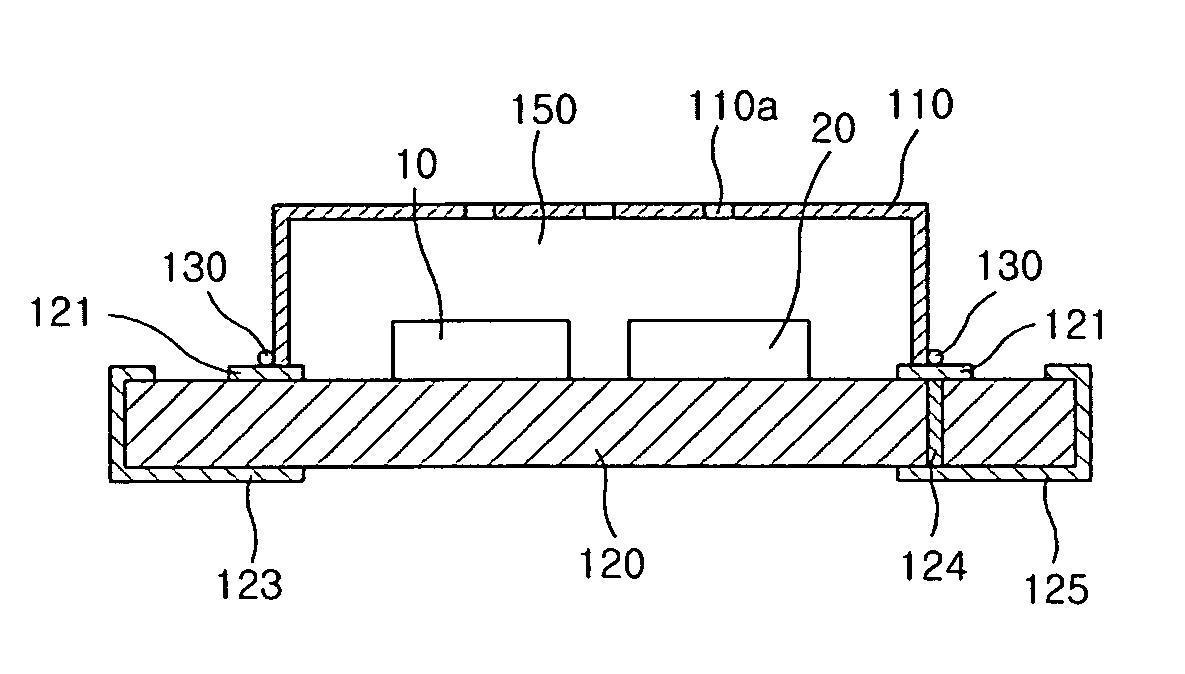

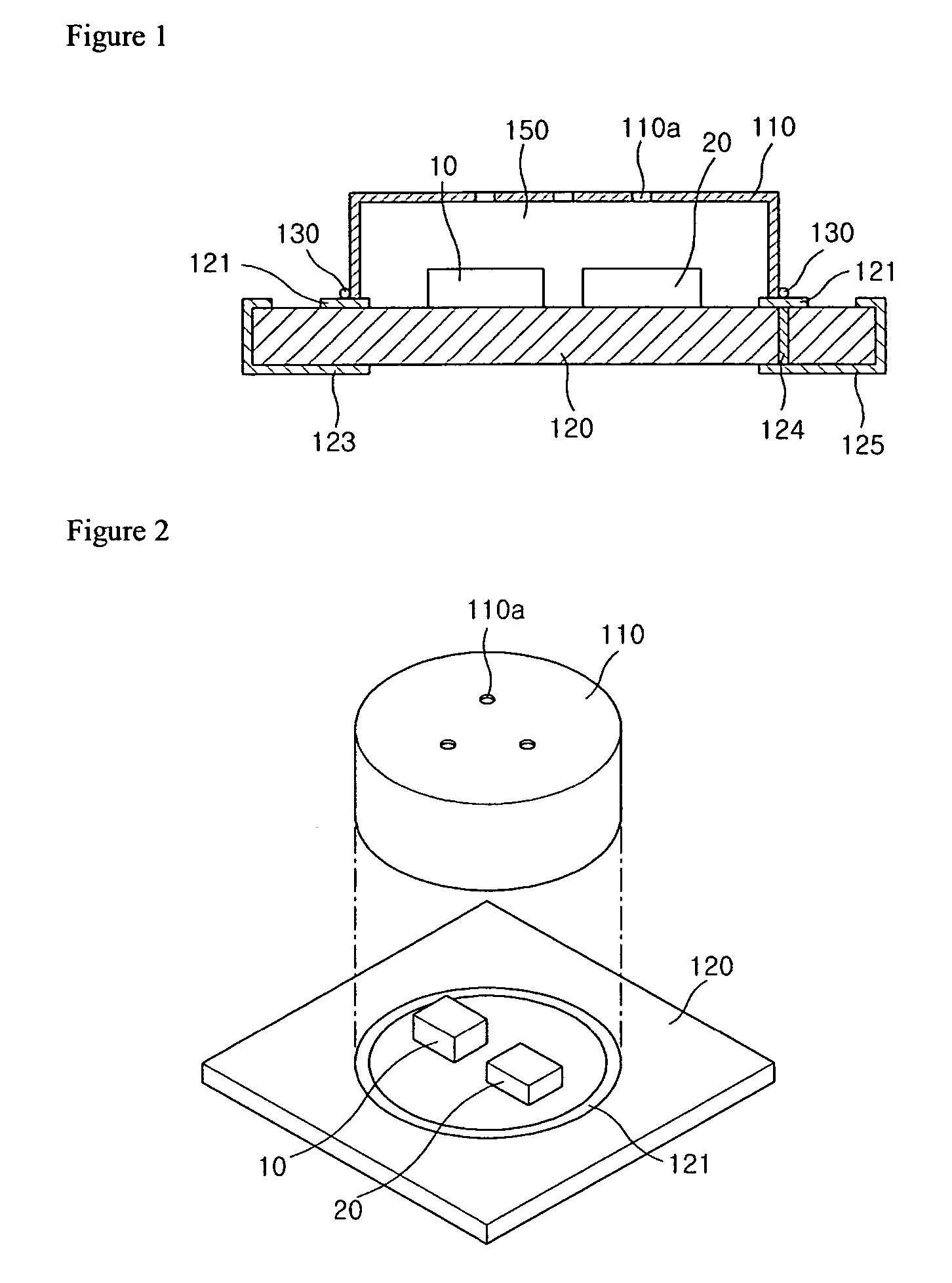

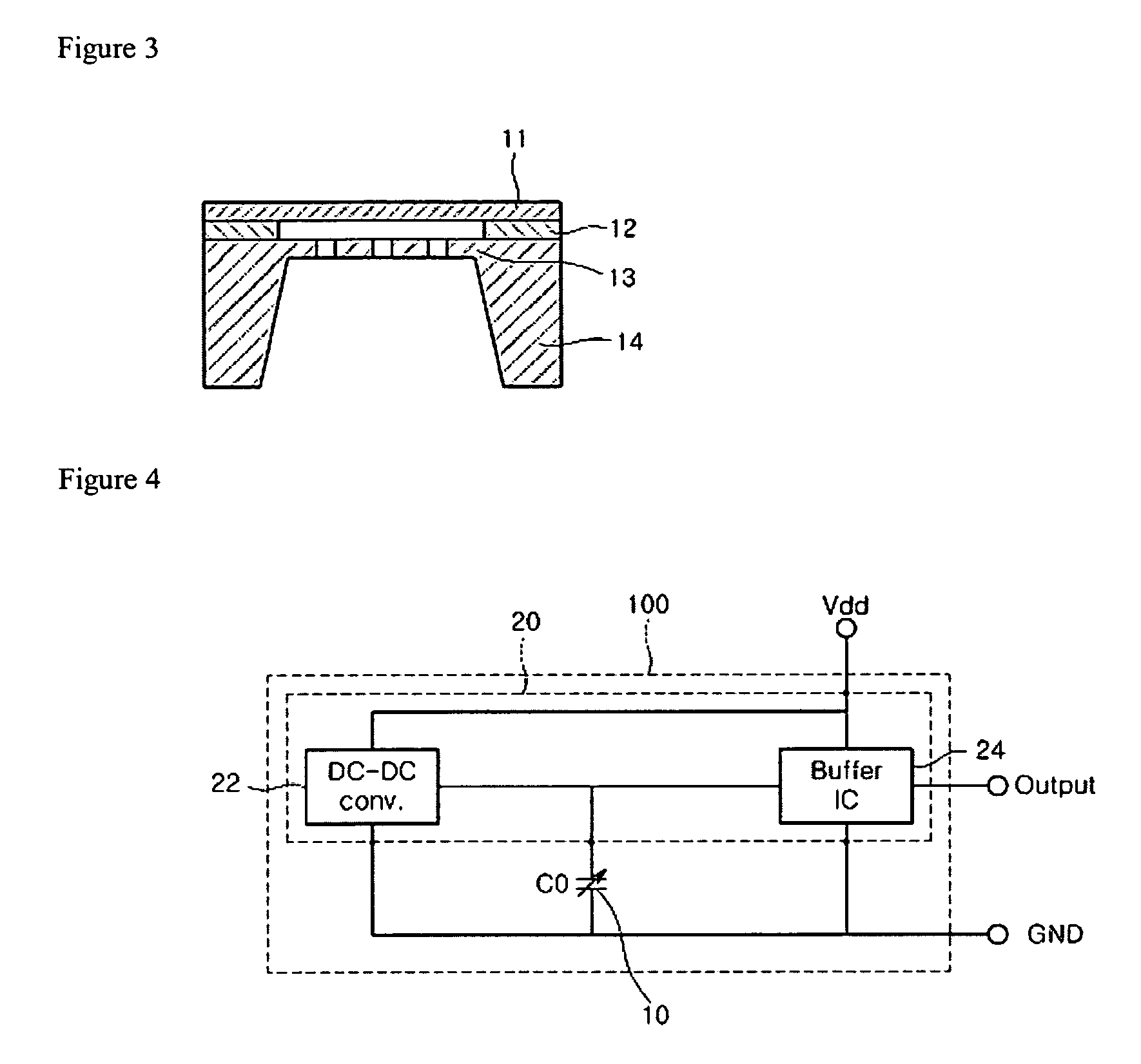

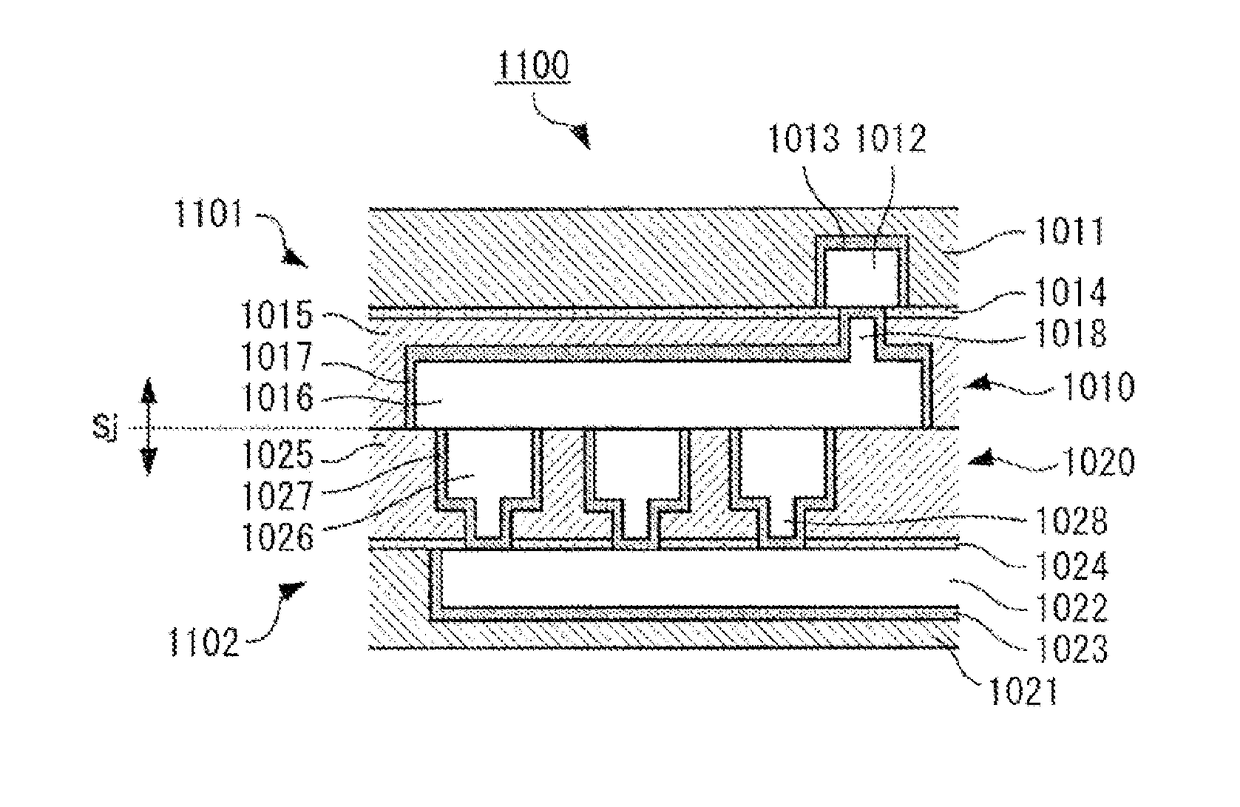

Silicon based condenser microphone and packaging method for the same

InactiveUS7903831B2High bonding strengthIncrease resistanceSolid-state devicesElectrostatic transducer microphonesMems microphoneCondenser microphone

Disclosed are a silicon based condenser microphone and a packaging method for the silicon based condenser microphone. The silicon based condenser microphone comprises a metal case, and a board which is mounted with a MEMS microphone chip and an ASIC chip having an electric voltage pump and a buffer IC and is formed with a connecting pattern for bonding with the metal case, wherein the connecting pattern is welded to the metal case. The method for packaging a silicon based condenser microphone includes the steps of inputting a board which is mounted with a MEMS chip and an ASIC chip and is formed with a connecting pattern; inputting a metal case, aligning the metal case on the connecting pattern of the board, and welding an opened end of the metal case to the connecting pattern of the board. Thus, the metal case is welded to the board by the laser.

Owner:BSE CO LTD

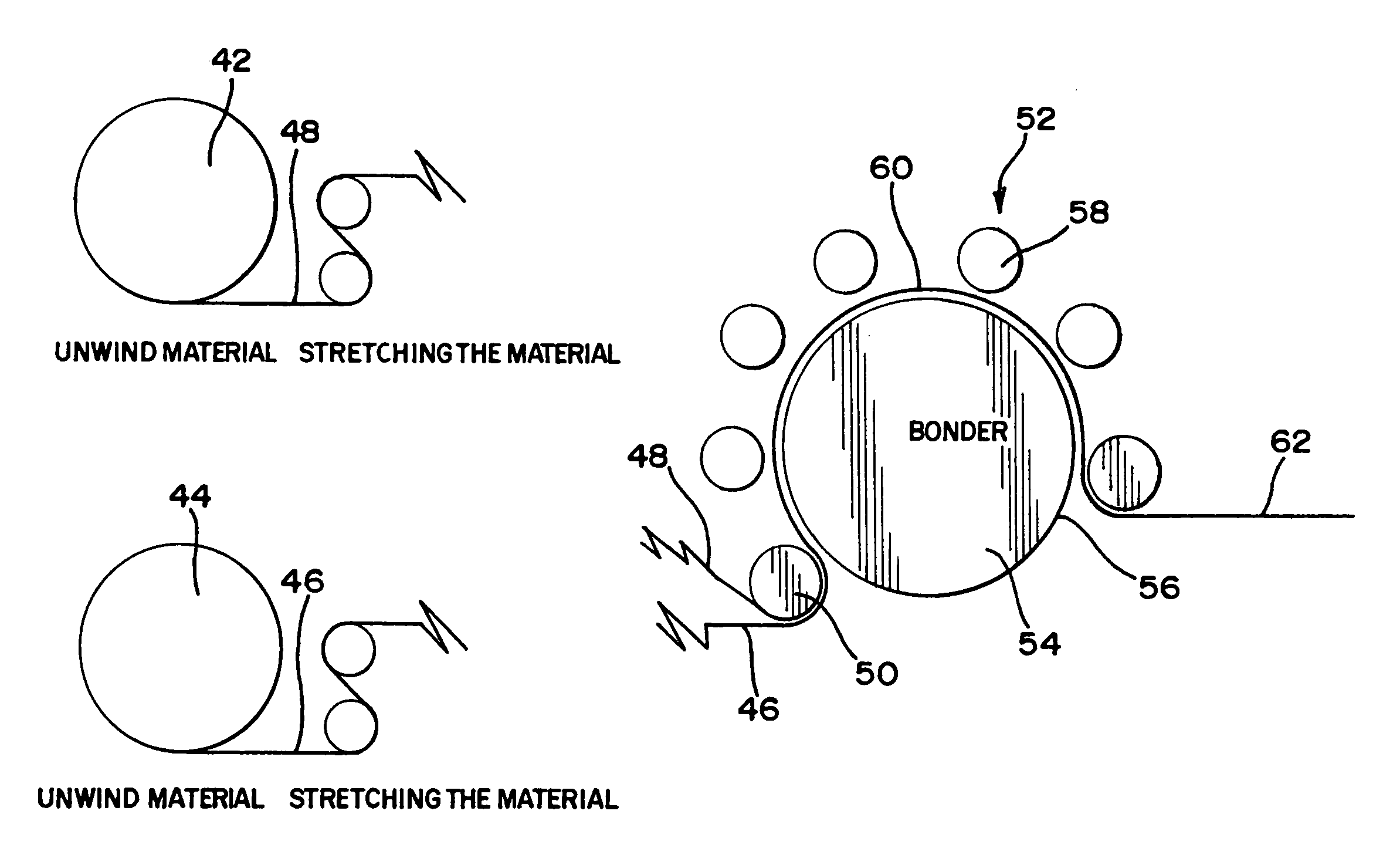

Method for improved bond strength in an elastomeric material

ActiveUS7108759B2High strengthIncreasing ultrasonic bond strengthPersonal careLayered product treatmentElastomerUltimate tensile strength

A method for increasing the bond strength of ultrasonic bonds in elastomeric materials comprising elongating the elastomeric materials prior to ultrasonically bonding the materials.

Owner:KIMBERLY-CLARK WORLDWIDE INC

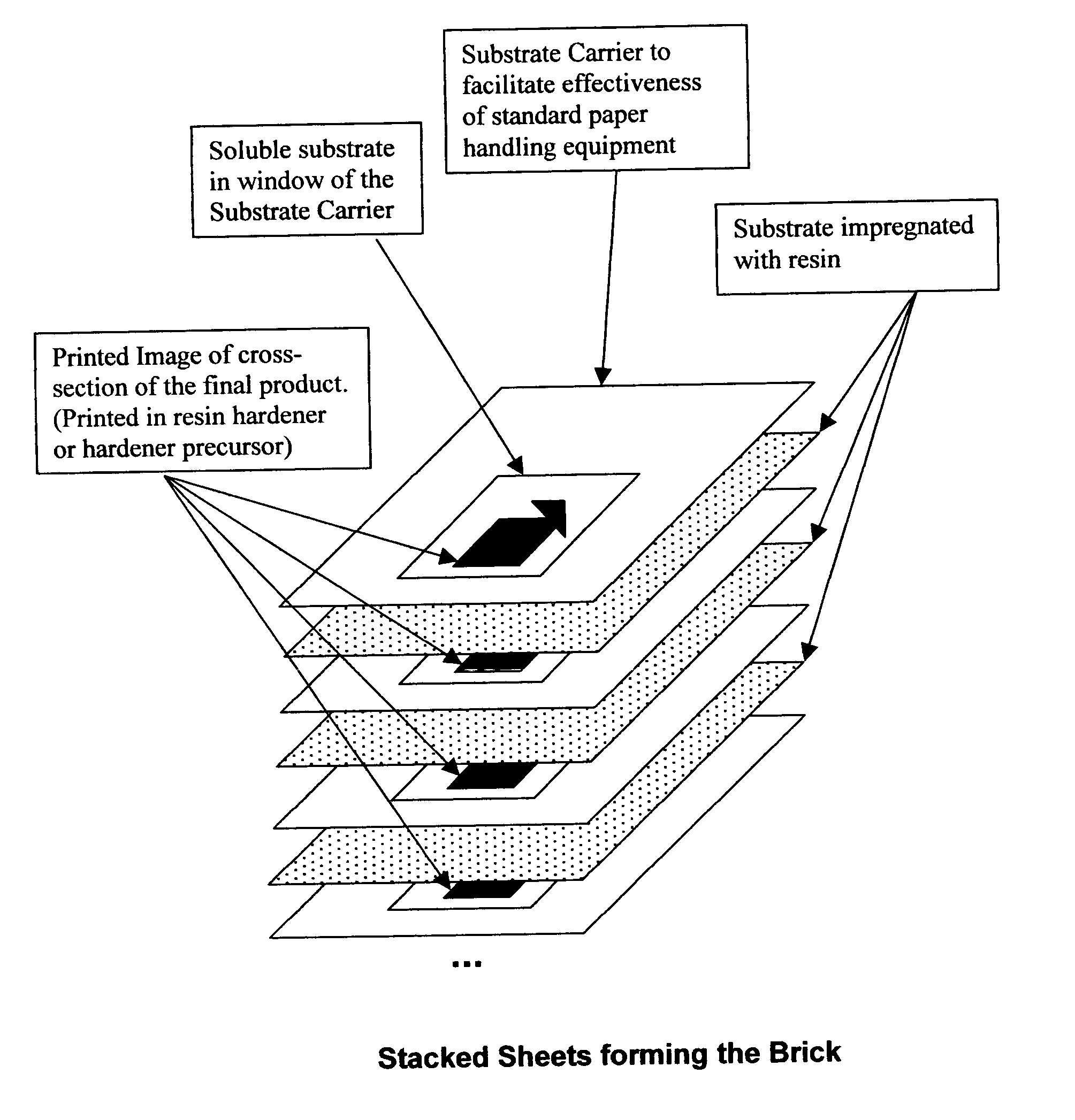

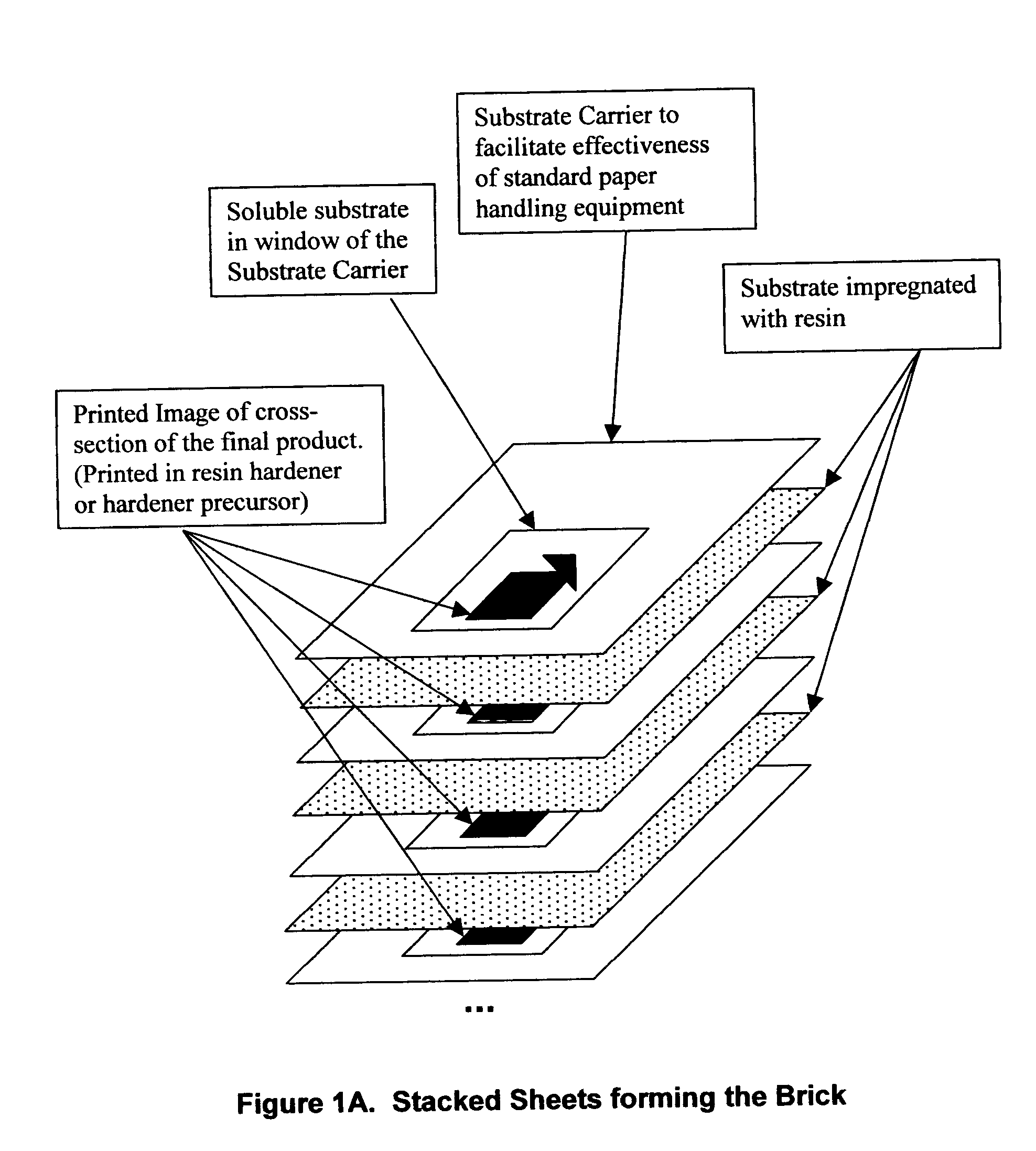

Three dimensional printing from two dimensional printing devices

InactiveUS20040112523A1Strength and quality be improveIncrease bonding strengthLamination ancillary operationsLaminationPaper sheetEngineering

A method of rapid prototyping a physical three-dimensional Product that can be preformed on readily available commercial 2D printing devices and paper handling equipment is presented. The method consists of using a 2D printing process to obtain a stack of sheets, each sheet printed with successive cross sectional areas of the desired product with ink (Hardener) that causes the sheet to become resistant to subsequent weakening and removal after the creation of the Brick. The Brick, containing both the positive (printed areas) and negative (unprinted areas), is then subjected to an agent(s) that weakens and removes the unwanted negative regions leaving only the desired Product.

Owner:CROM ELDEN WENDELL +1

Elongated absorbent article

InactiveUS7067711B2Penetrate fastSurface strengthBaby linensTamponsVolumetric Mass DensityEngineering

Disclosed is an elongated absorbent article, in which liquid passage holes and embossments are dispersed in a central region including a front portion and a rear portion. Aperture density obtained by dividing (total of areas occupied by the liquid passage holes in the front portion) by (area of the front portion) is higher than aperture density obtained by dividing (total of areas occupied by the liquid passage holes in the rear portion) by (area of the rear portion), while embossment density obtained by dividing (total of areas occupied by the embossments in the rear portion) by (area of the rear portion) is higher than embossment density obtained by dividing (total of areas occupied by the embossments in the front portion) by (area of the front portion).

Owner:UNI CHARM CORP

Apparatus for indirect bonding of orthodontic appliances and method of making the same

InactiveUS20050074716A1Prepare the base of each appliance for bonding is eliminatedHigh bonding strengthImpression capsDispensing apparatusOrthodonticsDental structure

Owner:3M INNOVATIVE PROPERTIES CO

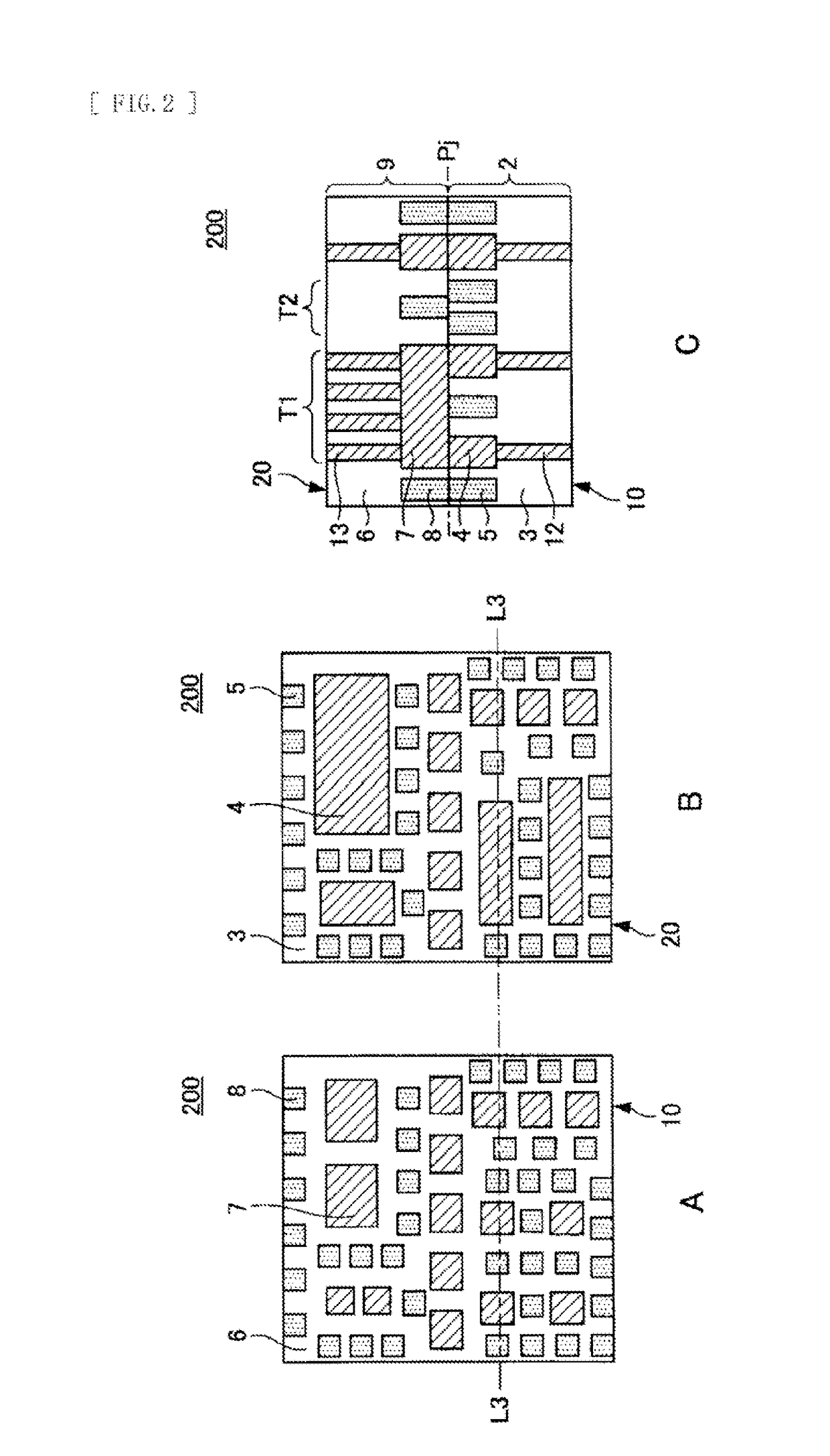

Semiconductor device

ActiveUS9799587B2Improve performanceReliable bonding surfaceSemiconductor/solid-state device detailsSolid-state devicesBond interfaceSemiconductor

A first semiconductor device includes: a first wiring layer including a first interlayer insulating film, a first electrode pad, and a first dummy electrode, the first electrode pad being embedded in the first interlayer insulating film and having one surface located on same plane as one surface of the first interlayer insulating film, and the first dummy electrode being embedded in the first interlayer insulating film, having one surface located on same plane as the one surface of the first interlayer insulating film, and being disposed around the first electrode pad; and a second wiring layer including a second interlayer insulating film, a second electrode pad, and a second dummy electrode, the second electrode pad being embedded in the second interlayer insulating film, having one surface located on same surface as one surface of the second interlayer insulating film, and being bonded to the first electrode pad, and the second dummy electrode having one surface located on same plane as the surface located closer to the first interlayer insulating film of the second interlayer insulating film, being disposed around the second electrode pad, and being bonded to the first dummy electrode. A second semiconductor device includes: a first semiconductor section including a first electrode, the first electrode being formed on a surface located closer to a bonding interface and extending in a first direction; and a second semiconductor section including a second electrode and disposed to be bonded to the first semiconductor section at the bonding interface, the second electrode being bonded to the first electrode and extending in a second direction that intersects with the first direction.

Owner:SONY CORP

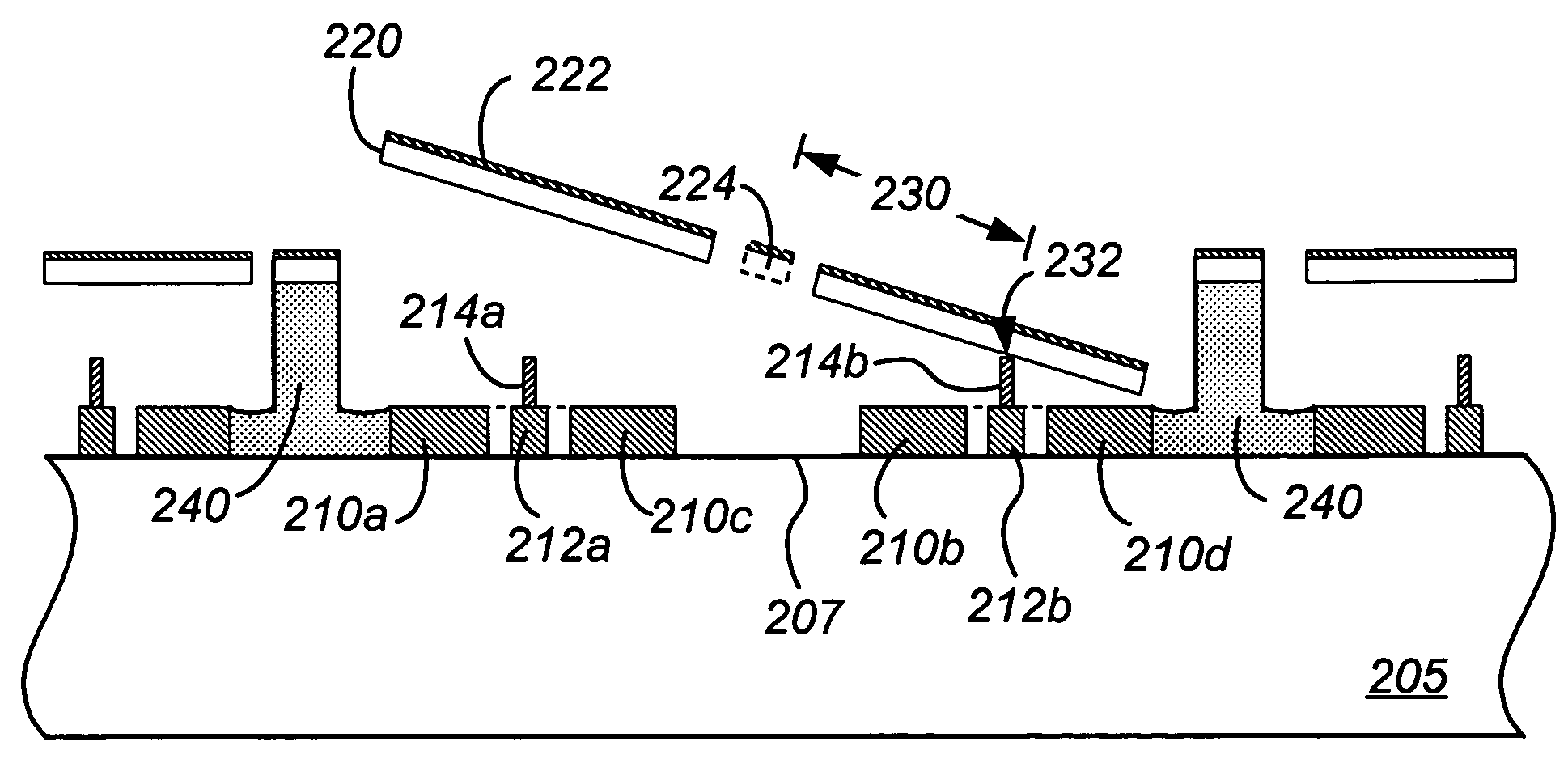

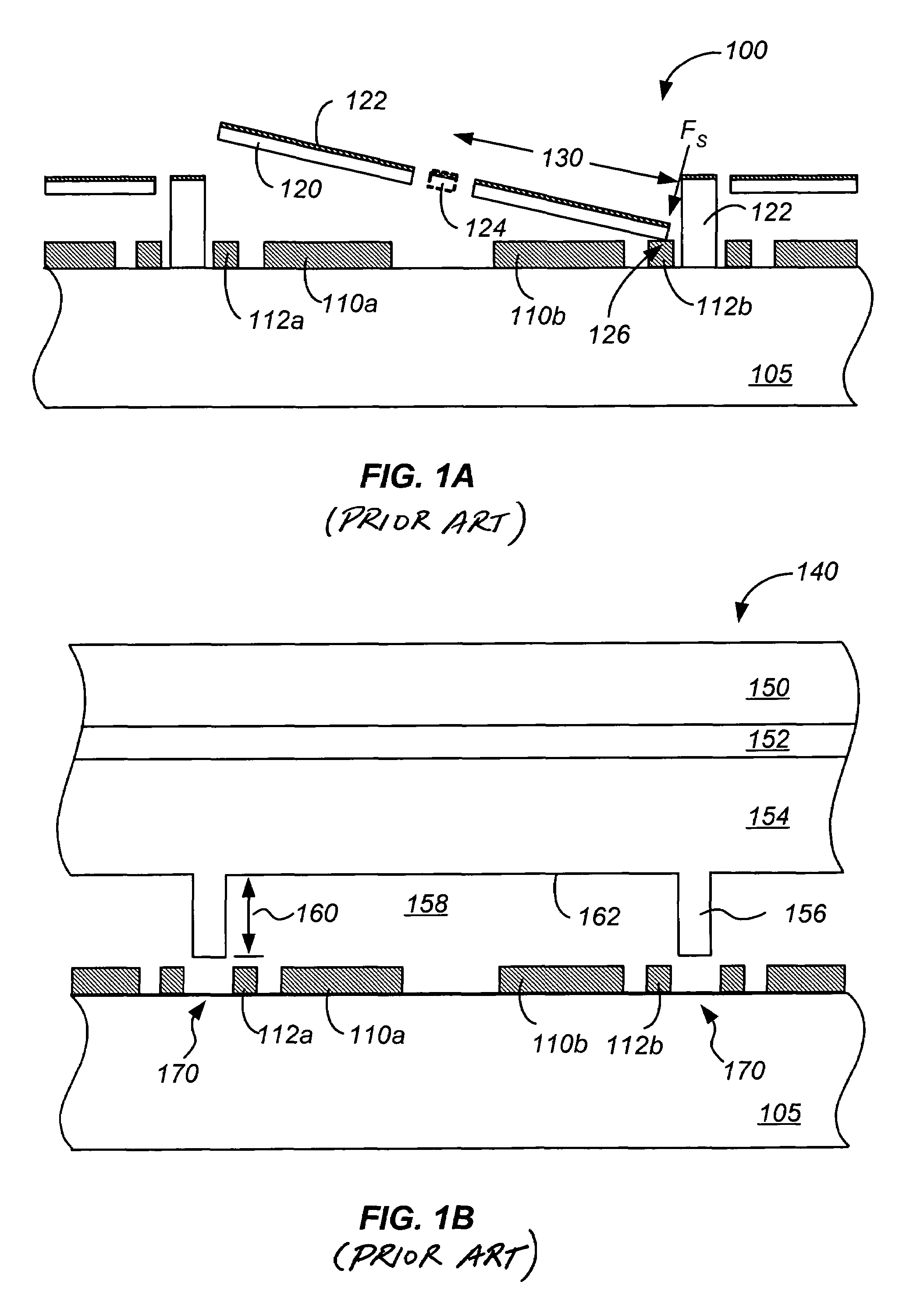

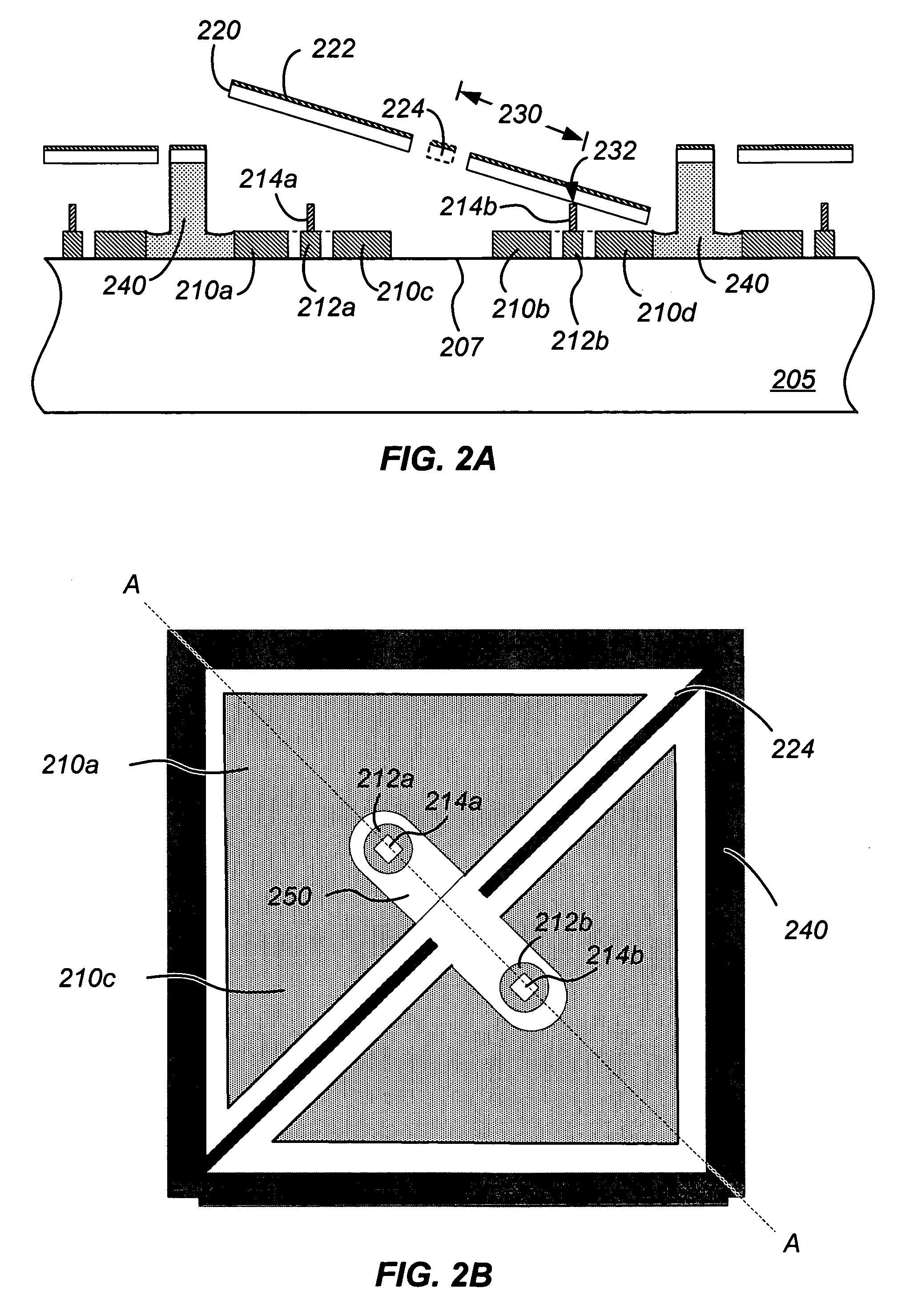

Method and structure reducing parasitic influences of deflection devices in an integrated spatial light modulator

ActiveUS7184195B2Reduce thicknessAlignment tolerances used during the substrate bonding process are greatly relaxedNon-linear opticsFlexible microstructural devicesSpatial light modulator

Owner:MIRADIA INC

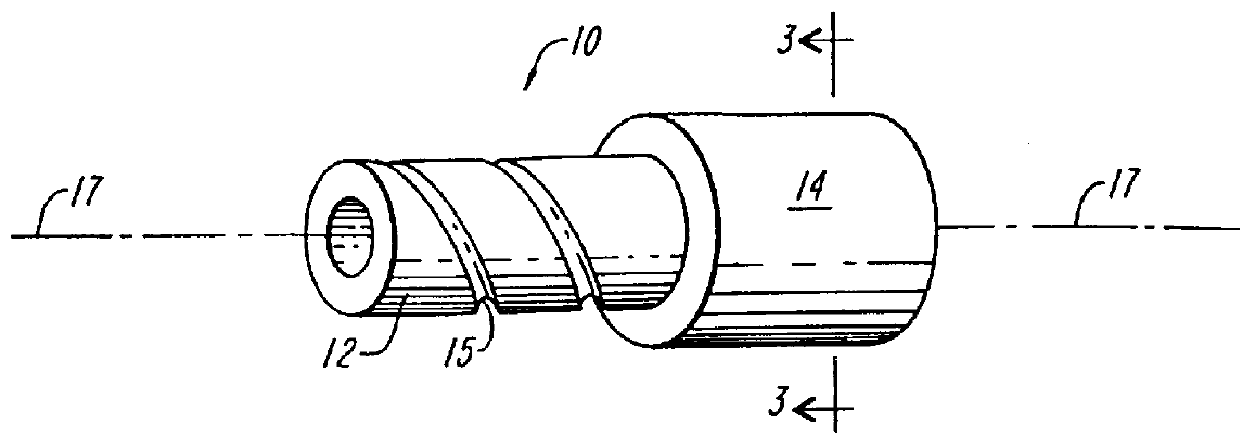

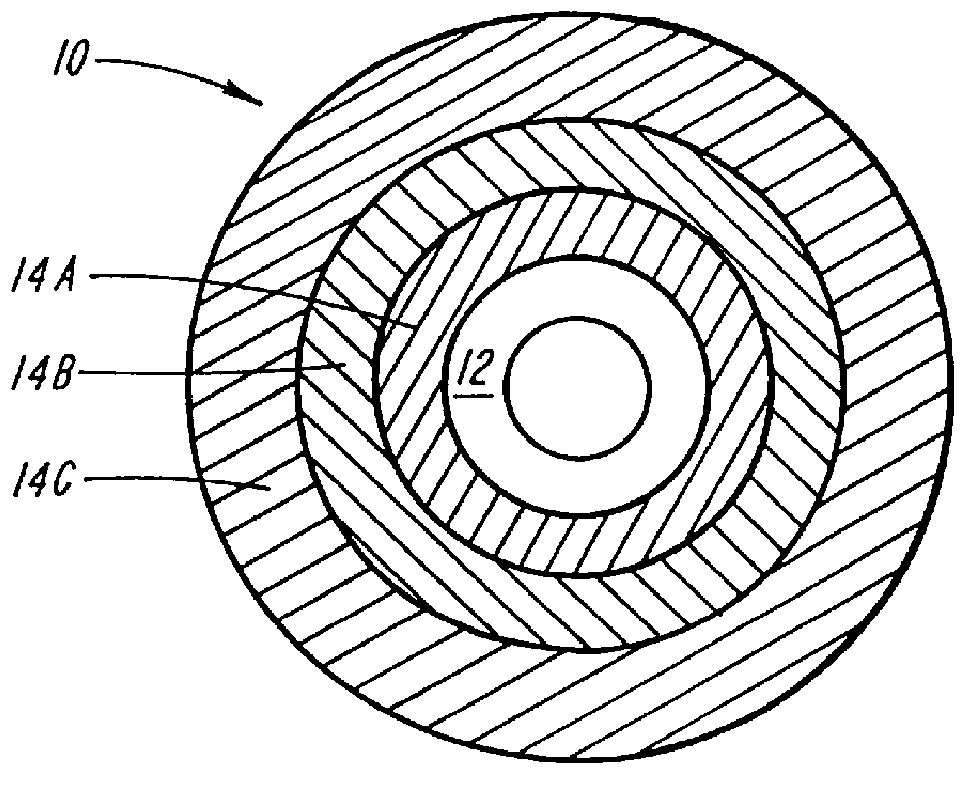

Catheter balloon

An expandable medical device or component thereof including a tubular body formed of a wrapped sheet of porous polymeric material fused together, the tubular body having a fused seam at an angle relative to the longitudinal axis of the tubular body which changes along the length of the tubular body from a first angle to a second angle greater than the first angle. The sheet of porous polymeric material is wound and then fused together such that the winding angle is less in a first longitudinal section of the tubular body compared with the winding angle in a second longitudinal section of the tubular body, in order to provide the second section with greater resistance to expansion (i.e., lower compliance) than the first section.

Owner:ABBOTT CARDIOVASCULAR

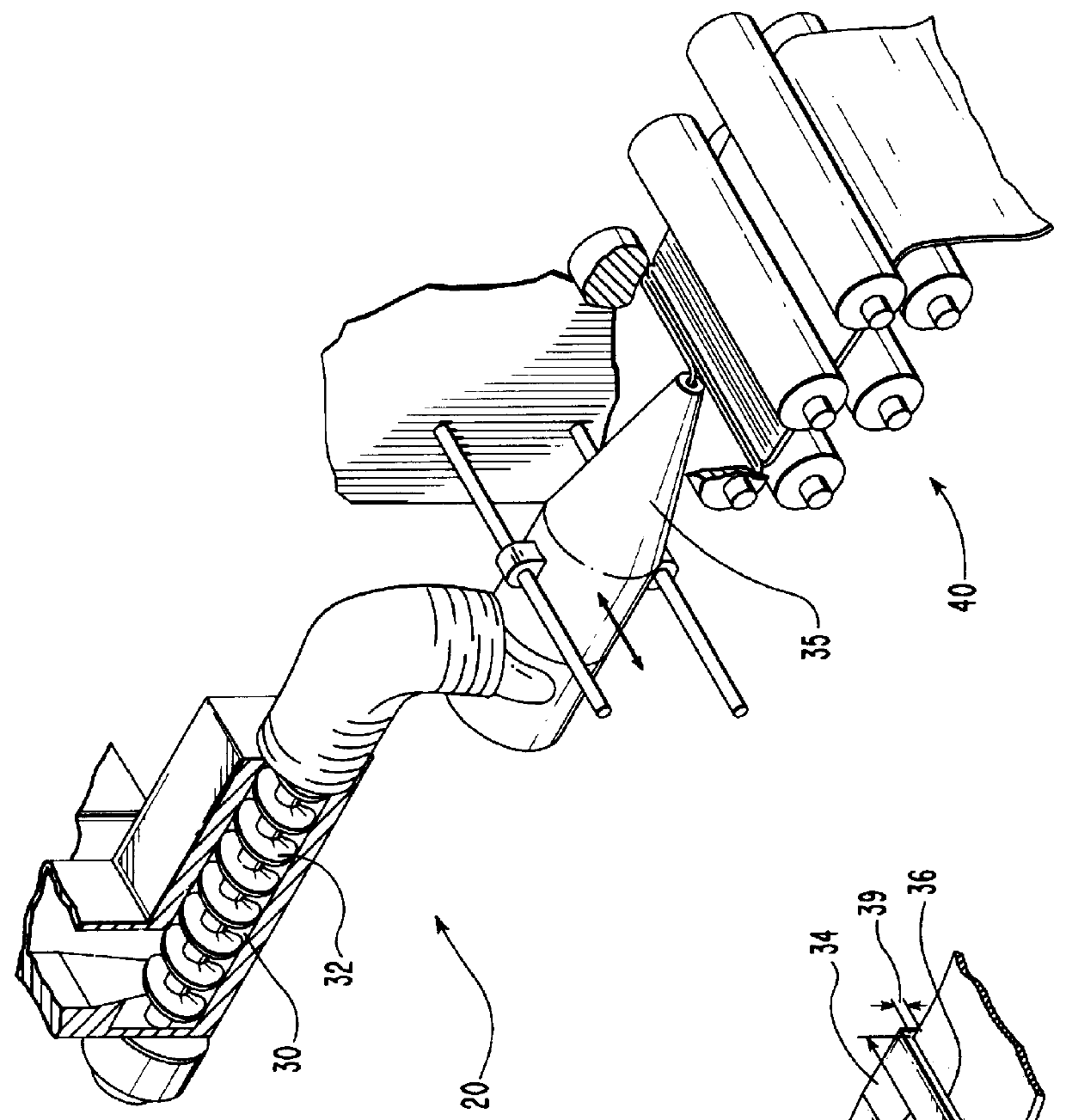

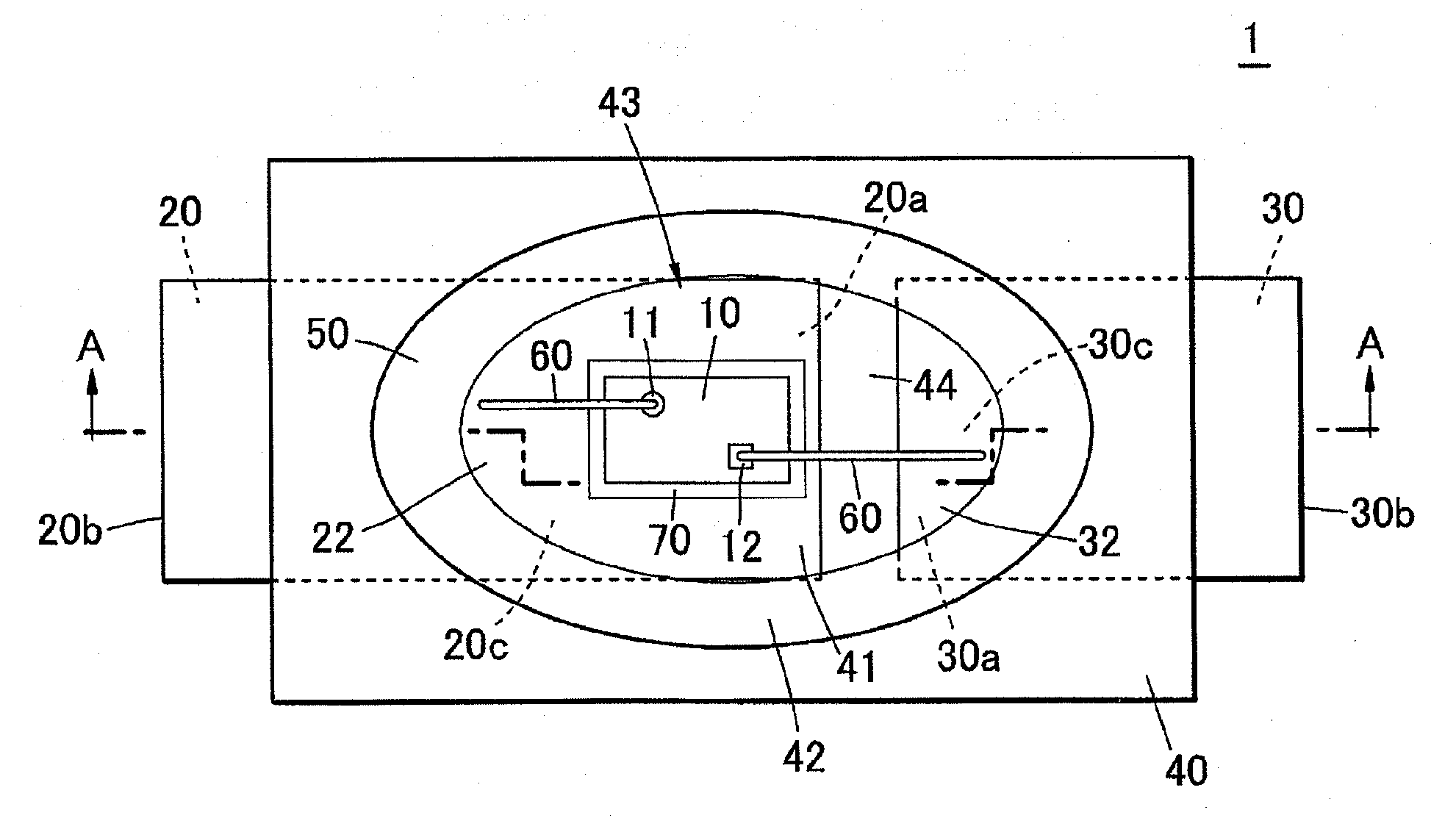

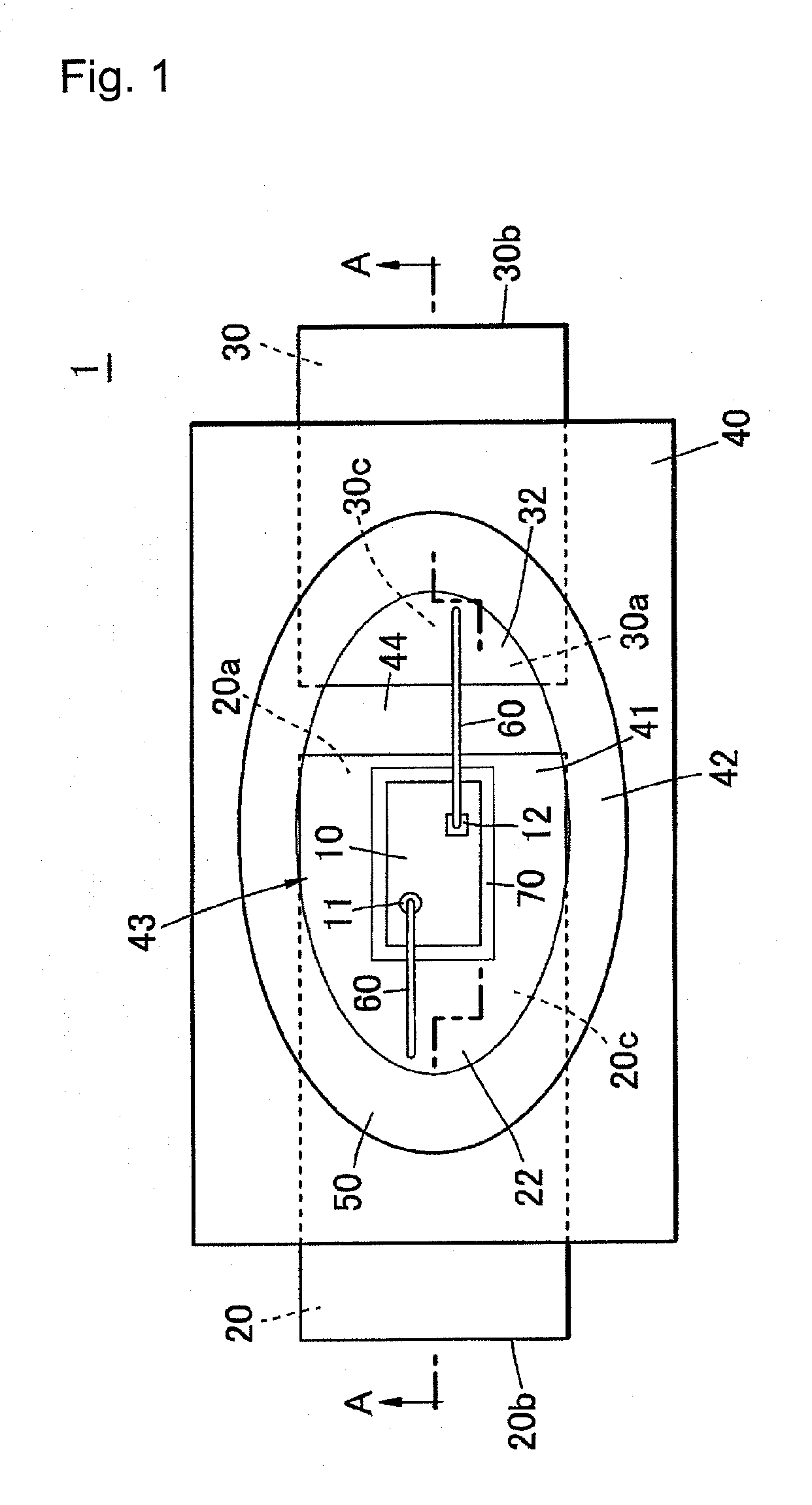

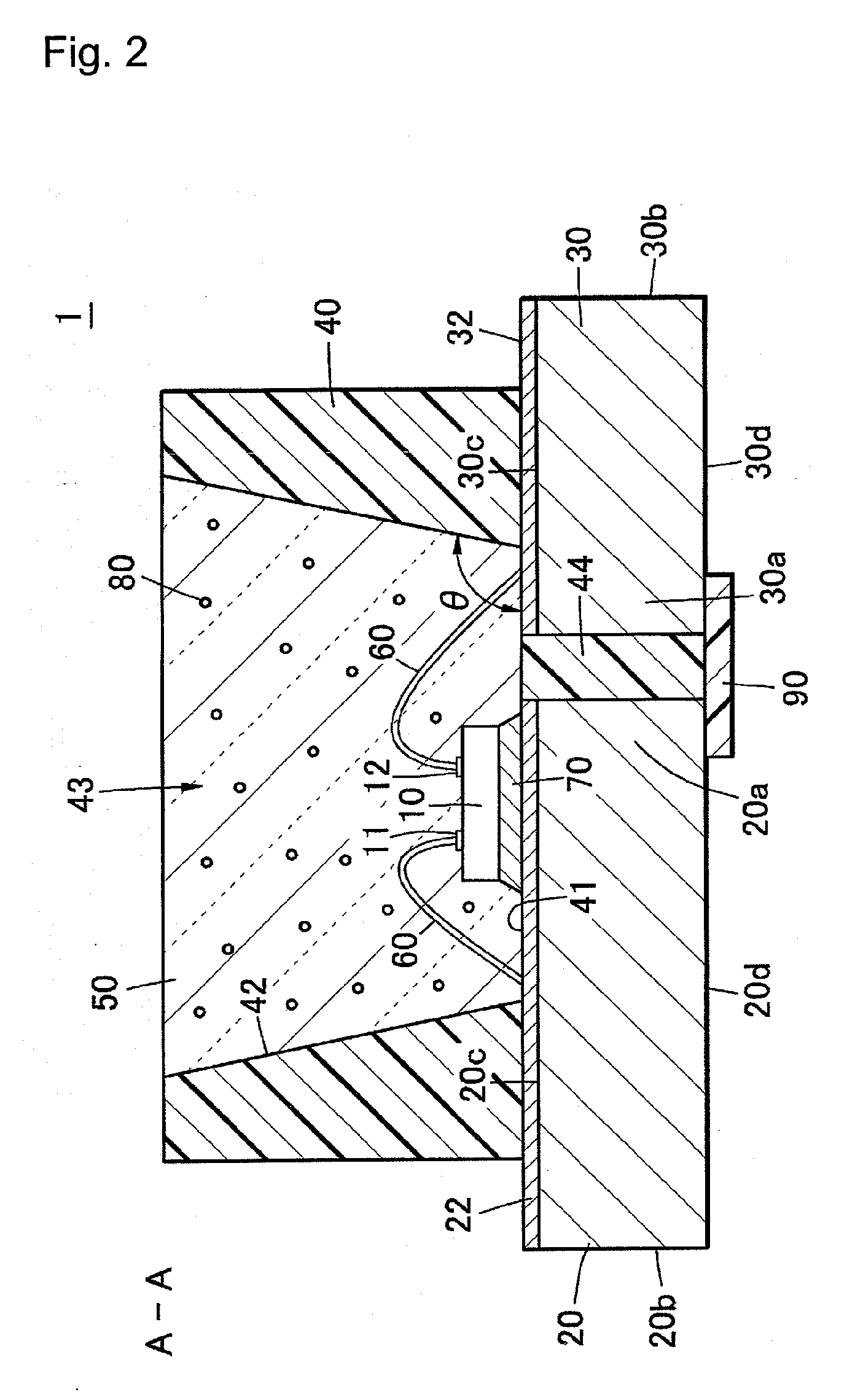

High output power light emitting device and packaged used therefor

ActiveUS20090261374A1Increase output powerEasy to useSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

An object of the present invention is to provide a light emitting device that has high output power and long service life where a package is suppressed from discoloring due to heat generation. The light emitting device 1 of the present invention contains a light emitting element 10, a package 40 formed of a thermosetting resin, the package having a recess 43 wherein the light emitting element 10 is mounted, a first lead electrode 20 which is exposed at the bottom of the recess 43 of the package 40 and whereon the light emitting element 10 is mounted, and a second lead electrode 30 which is exposed at the bottom of the recess 43 of the package 40 and is electrically connected to the light emitting element 10. The light emitting element 10 is bonded to the first lead electrode 20 through a eutectic layer 70, and at least a surface of the first electrode 20 is coated with an Ag film 22, a thickness of the Ag film 22 being in the range from 0.5 μm to 20 μm.

Owner:NICHIA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com